Single-row multilayer winding machine for strip product

A multi-layer, winder technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc. Copper bar conductivity and other issues, to achieve the effect of low cost, improved winding efficiency and good winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

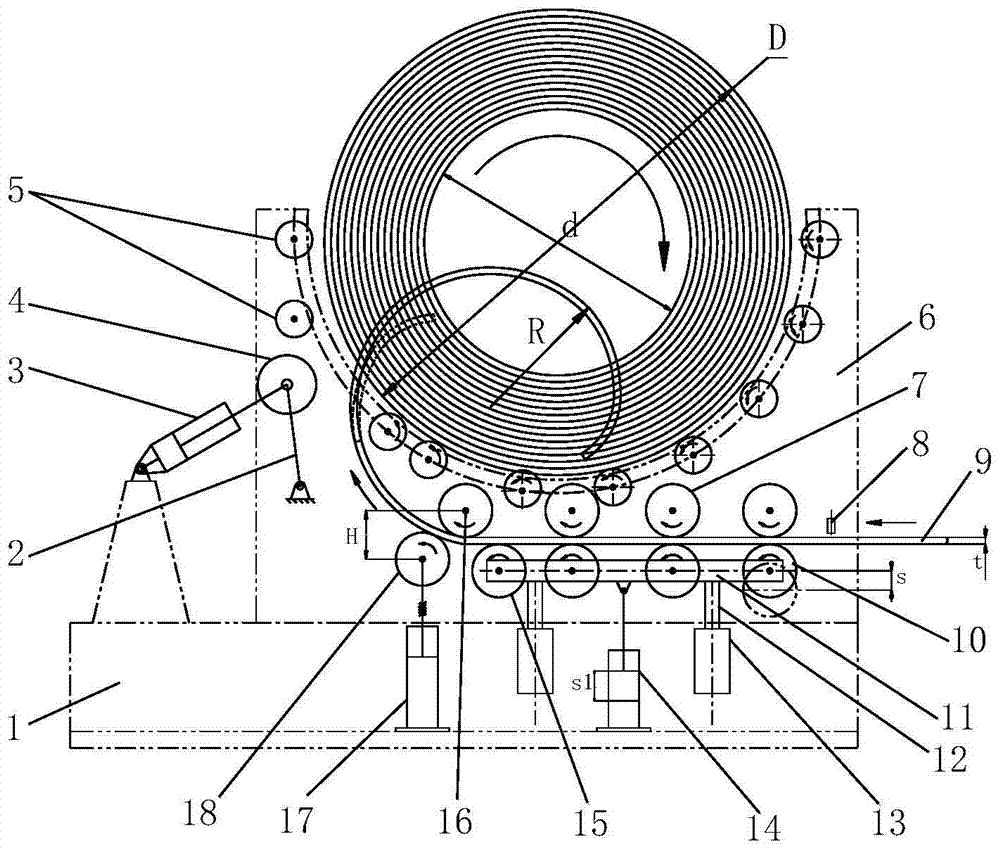

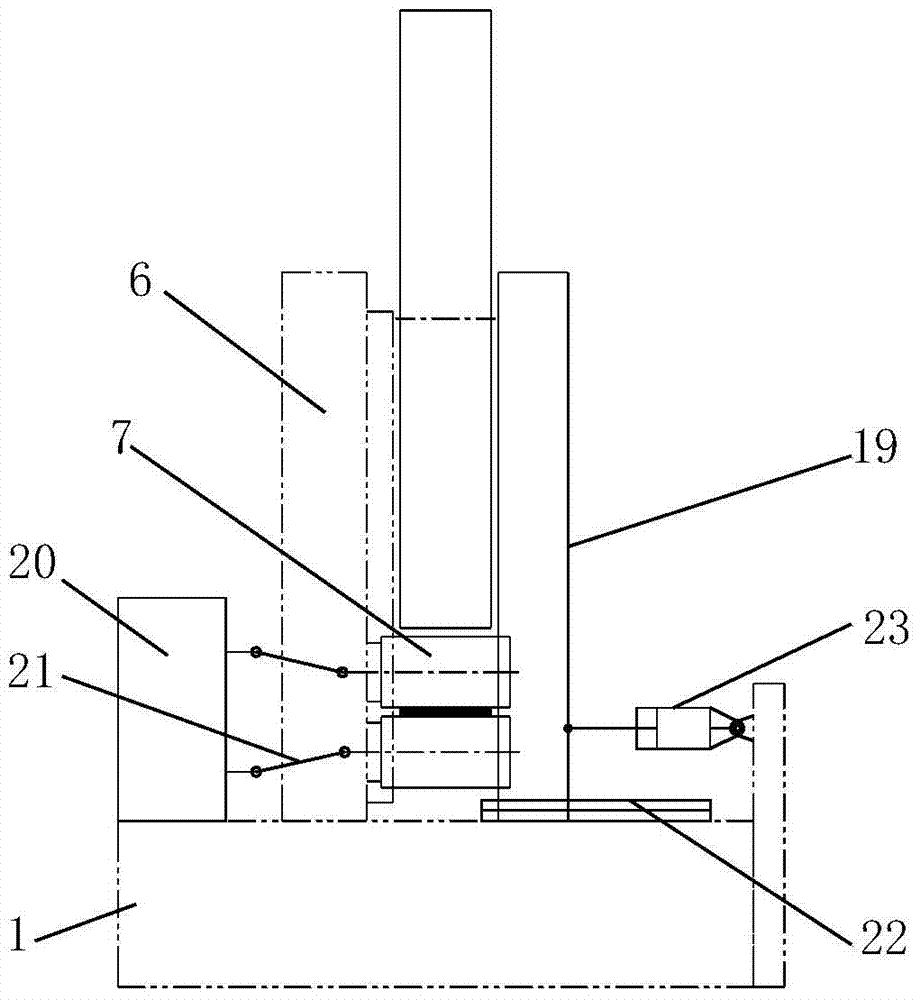

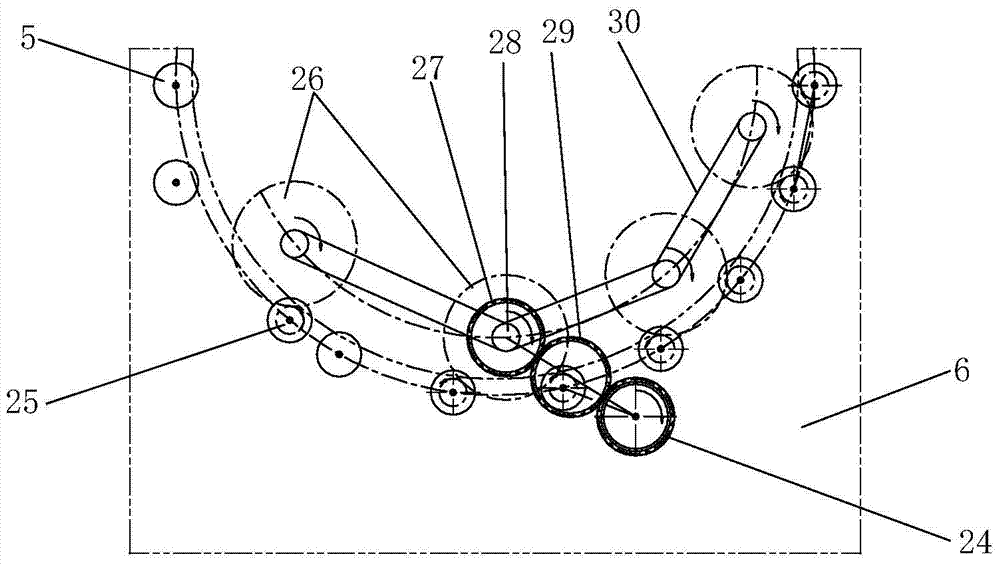

[0042] Such as figure 1 with figure 2 The single-row multi-layer winding machine for strip products shown includes a frame 1 and a first baffle plate 6 arranged on the frame 1. The first baffle plate 6 is on and along the product 9 A lower pinch roller 10, a bending support roller 15 and a bending roller 18 are arranged in the running direction in sequence. The upper pinch roller 10 is provided with an upper pinch that cooperates with the lower pinch roller 10 and is used to pinch products 9 The first baffle plate 6 is provided with a curved fixed roller 16 that cooperates with the curved support roller 15 and the curved roller 18 and makes the product 9 bend upwards. The curved fixed roller 16 is located on the curved support roller 15 and the curved Above the connecting line between the rollers 18, the frame 1 is provided with a power mechanism 20 for driving the upper pinch roller 7, the lower pinch roller 10, the bending support roller 15, the bending fixed roller 16 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com