Patents

Literature

30241results about "Webs handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

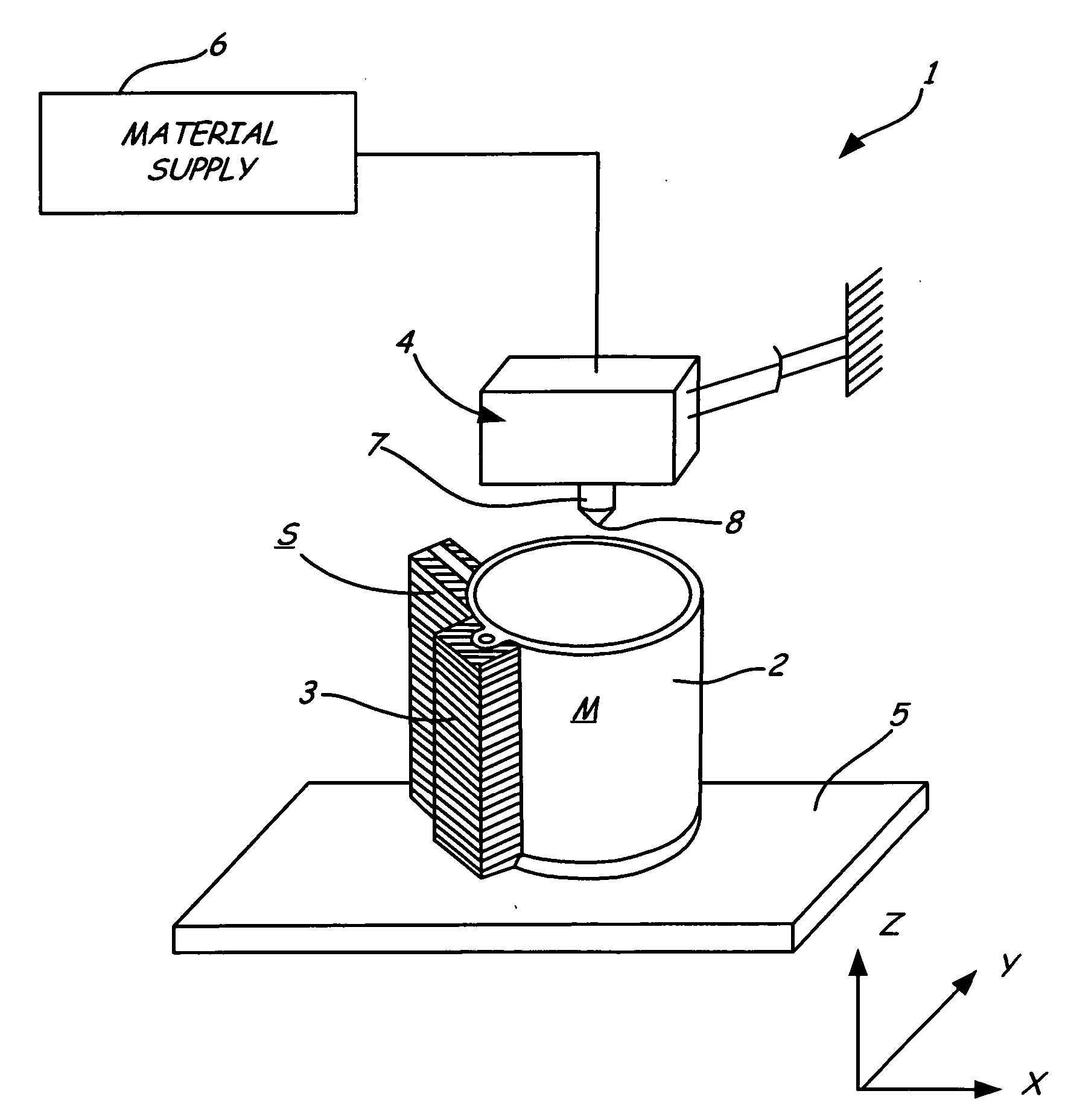

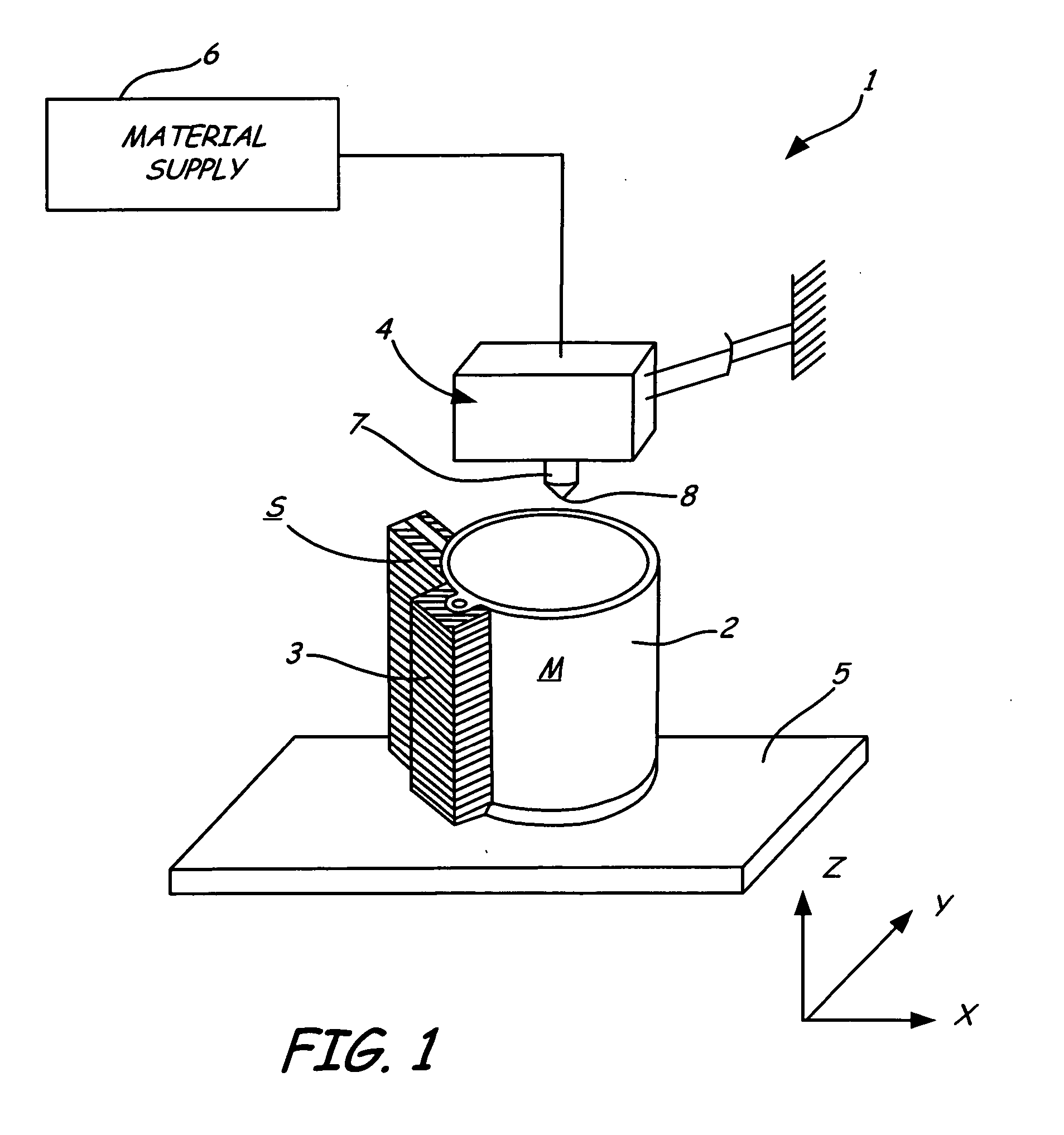

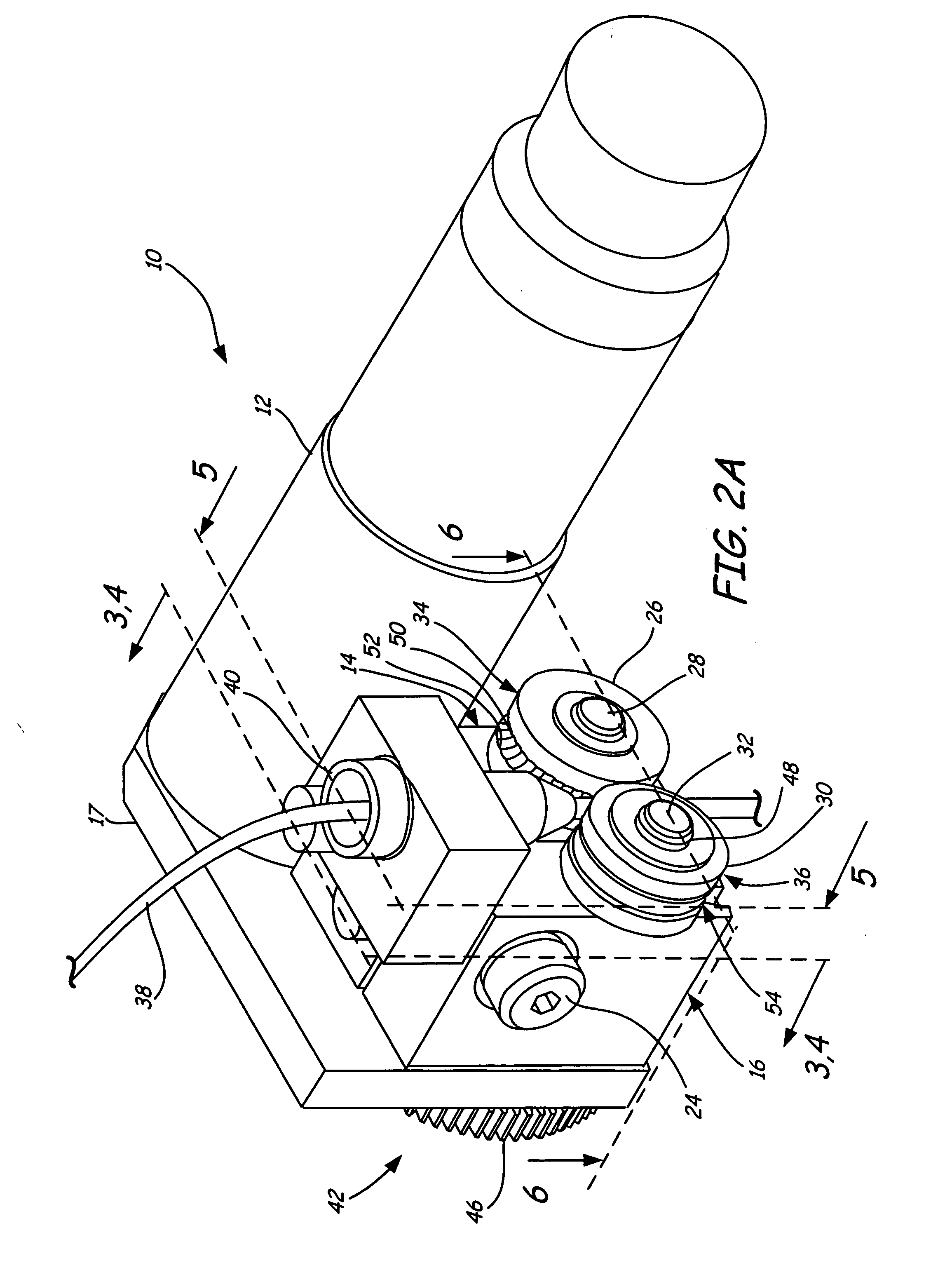

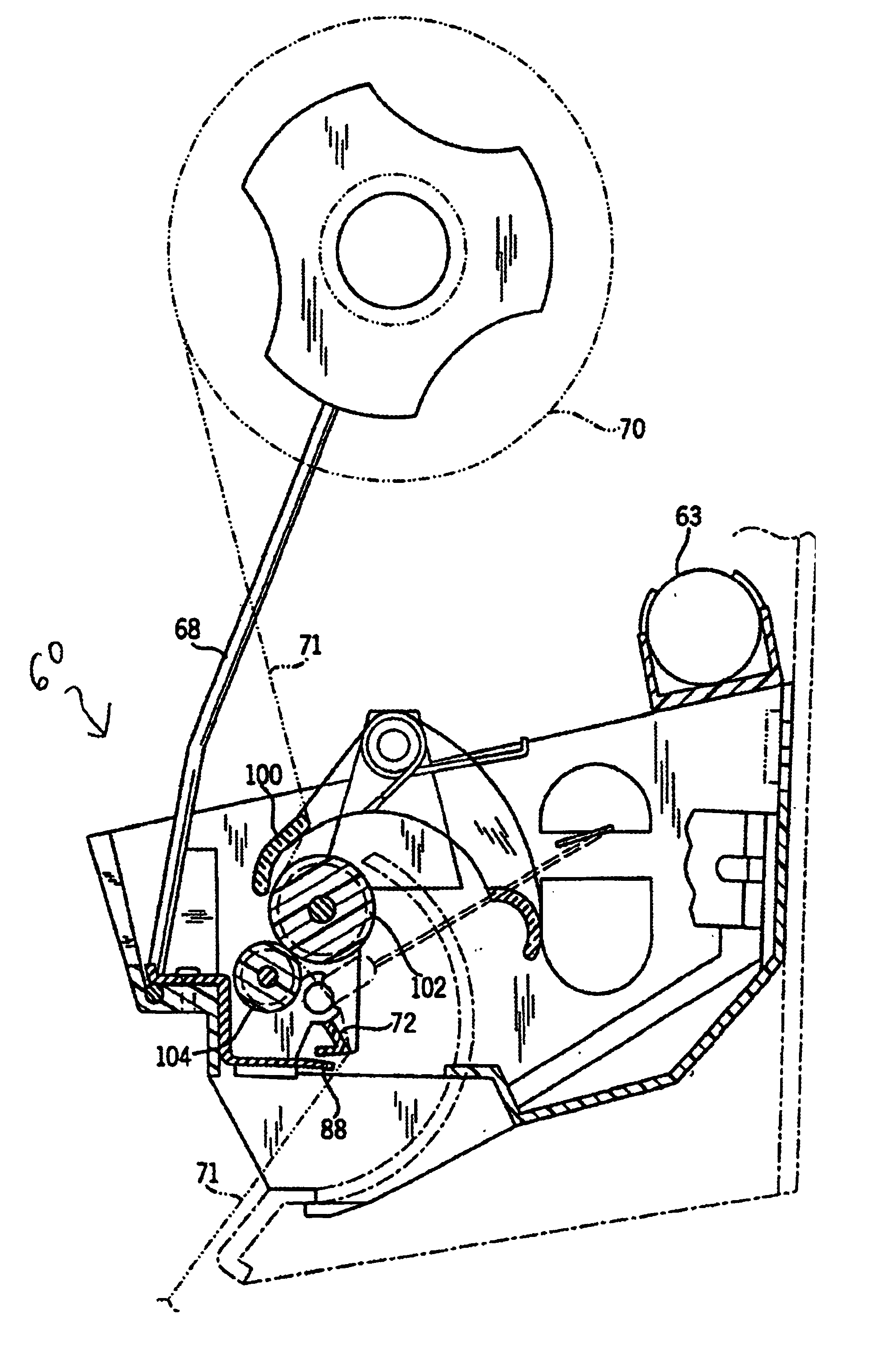

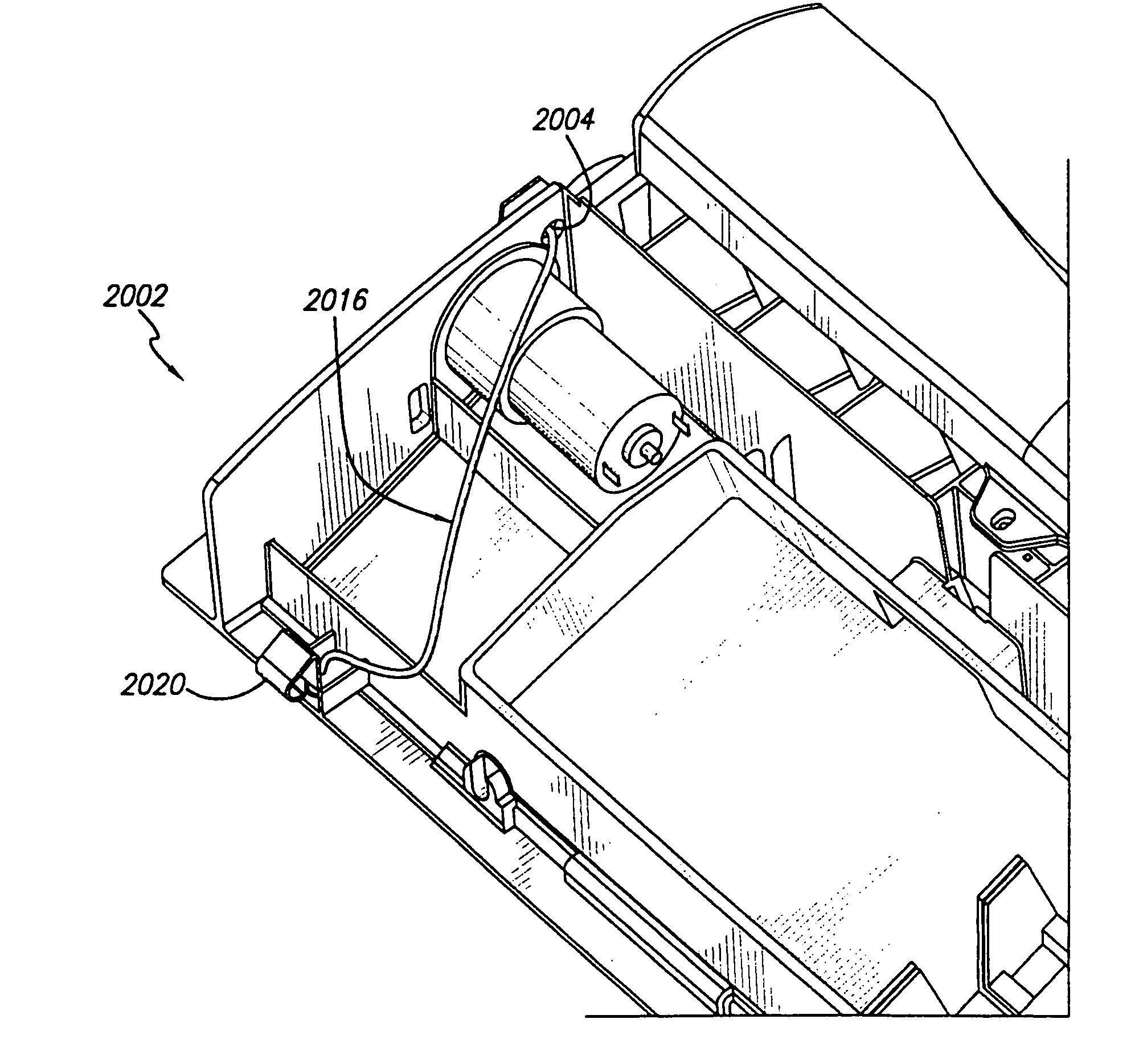

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

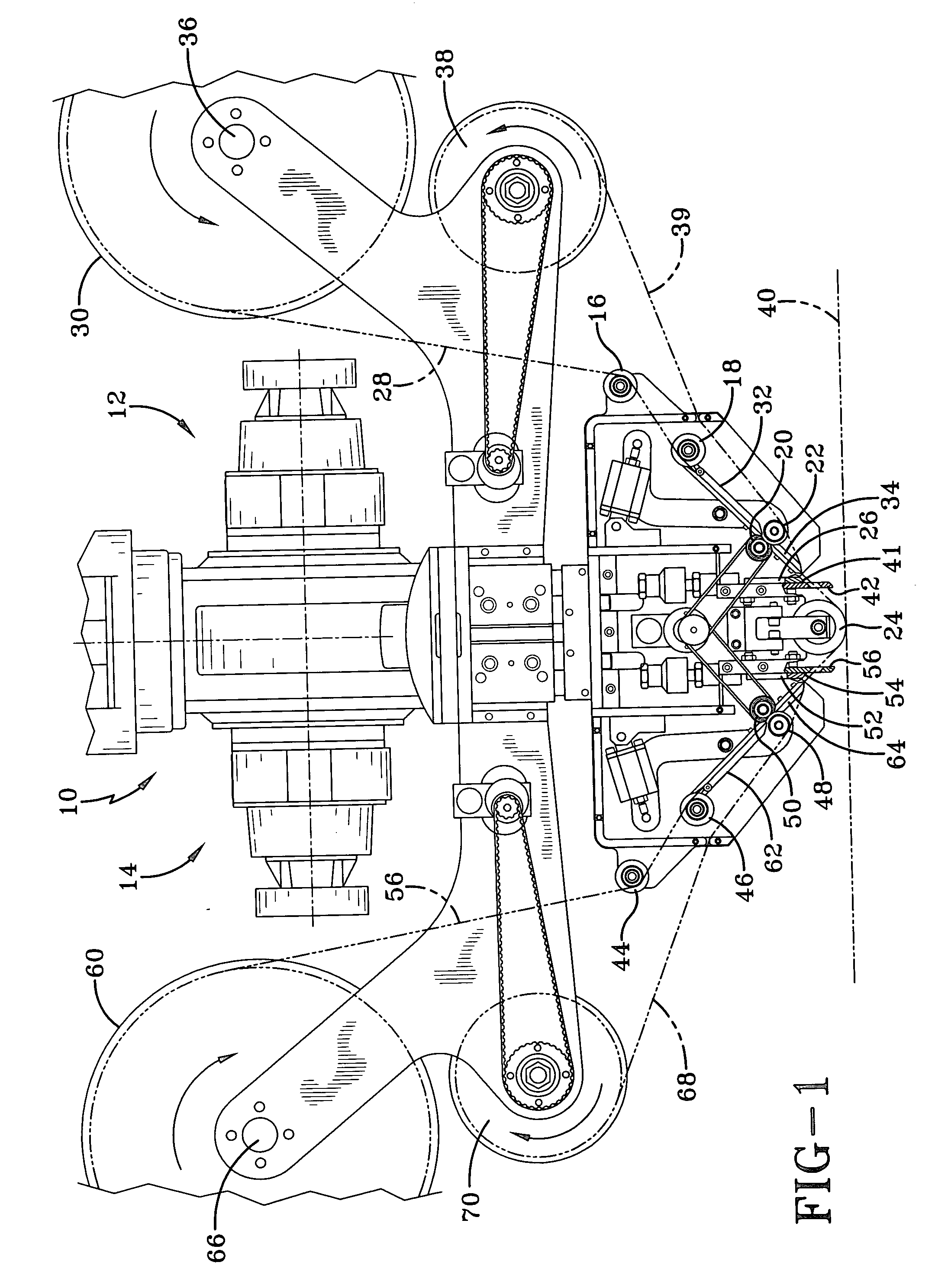

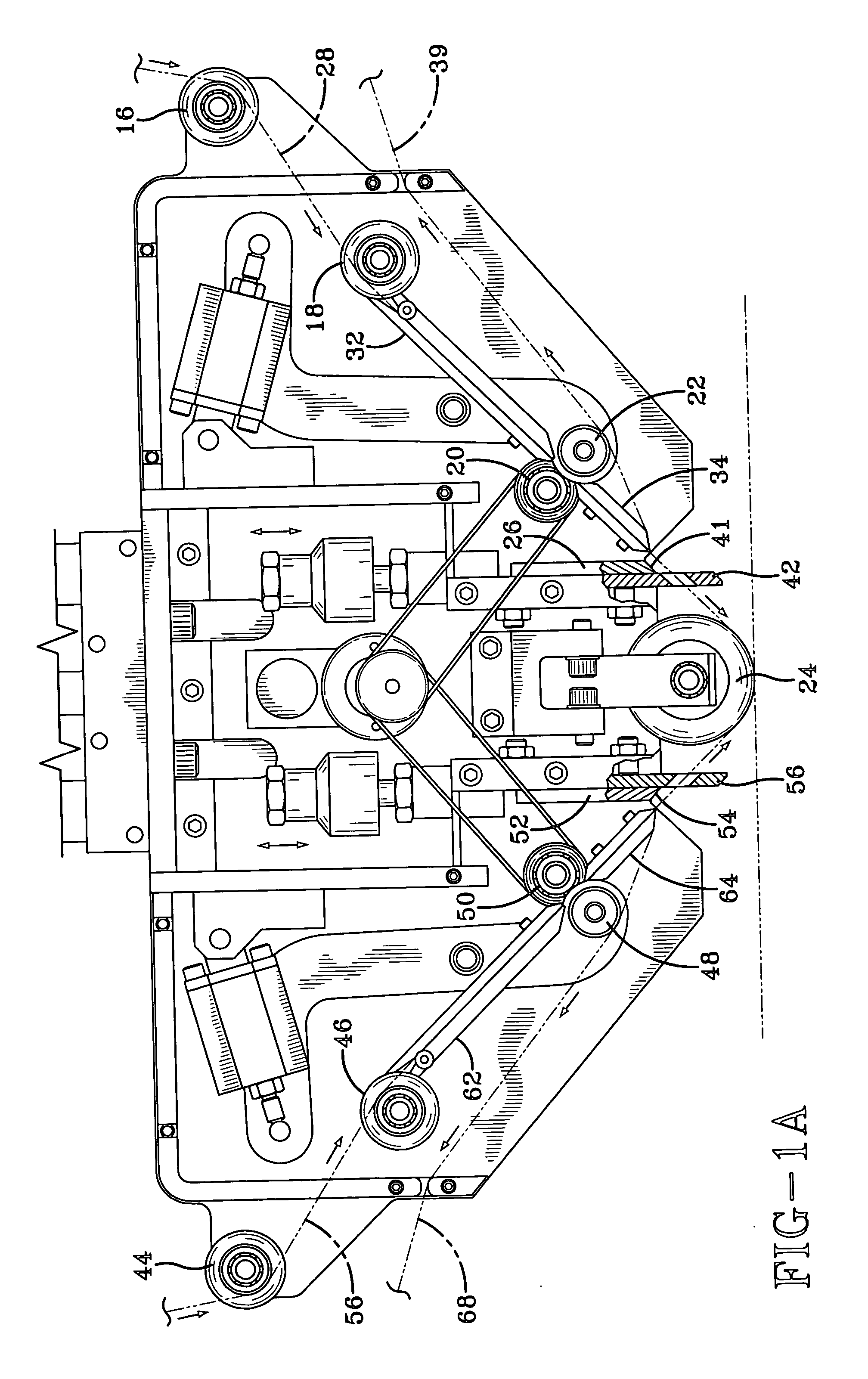

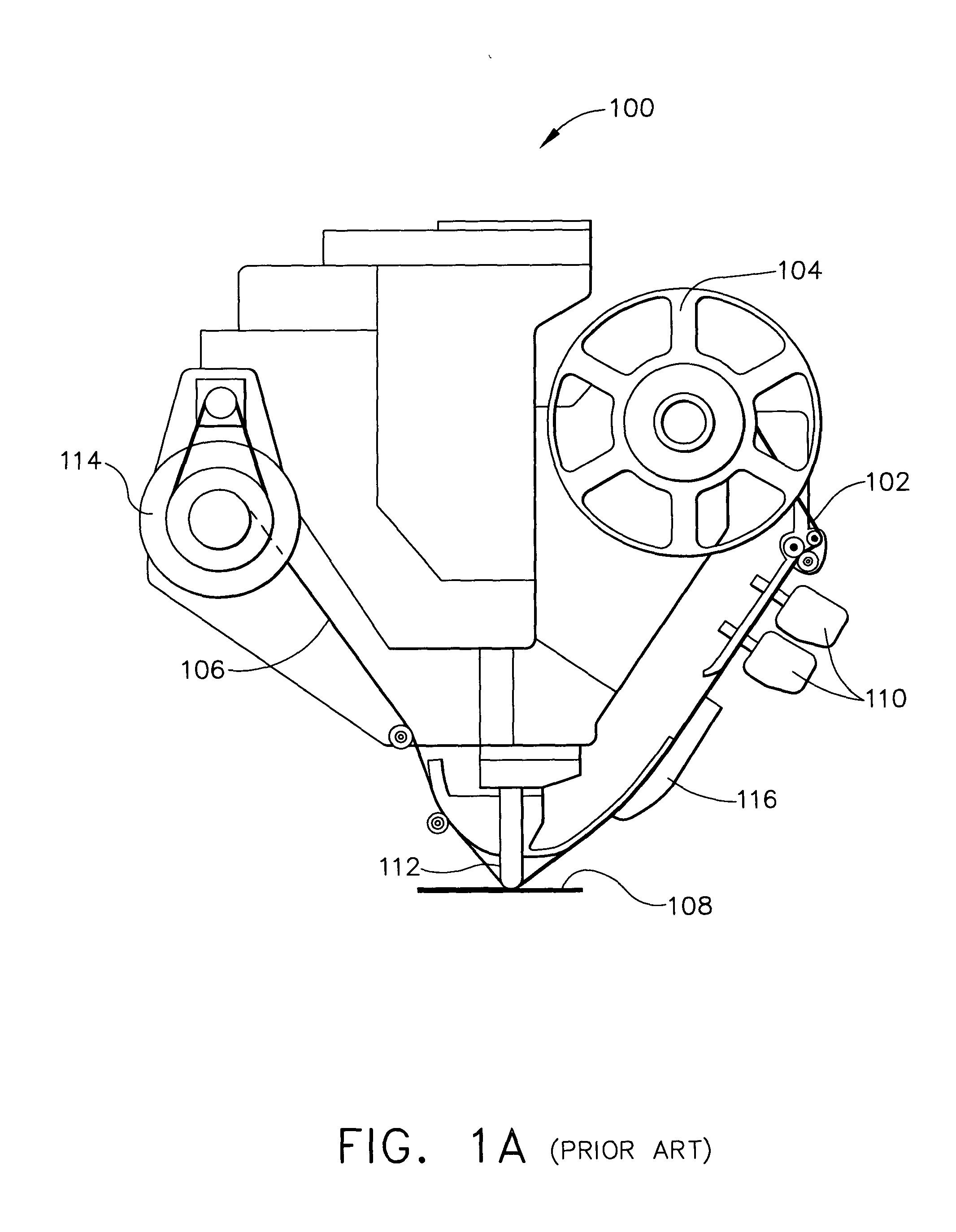

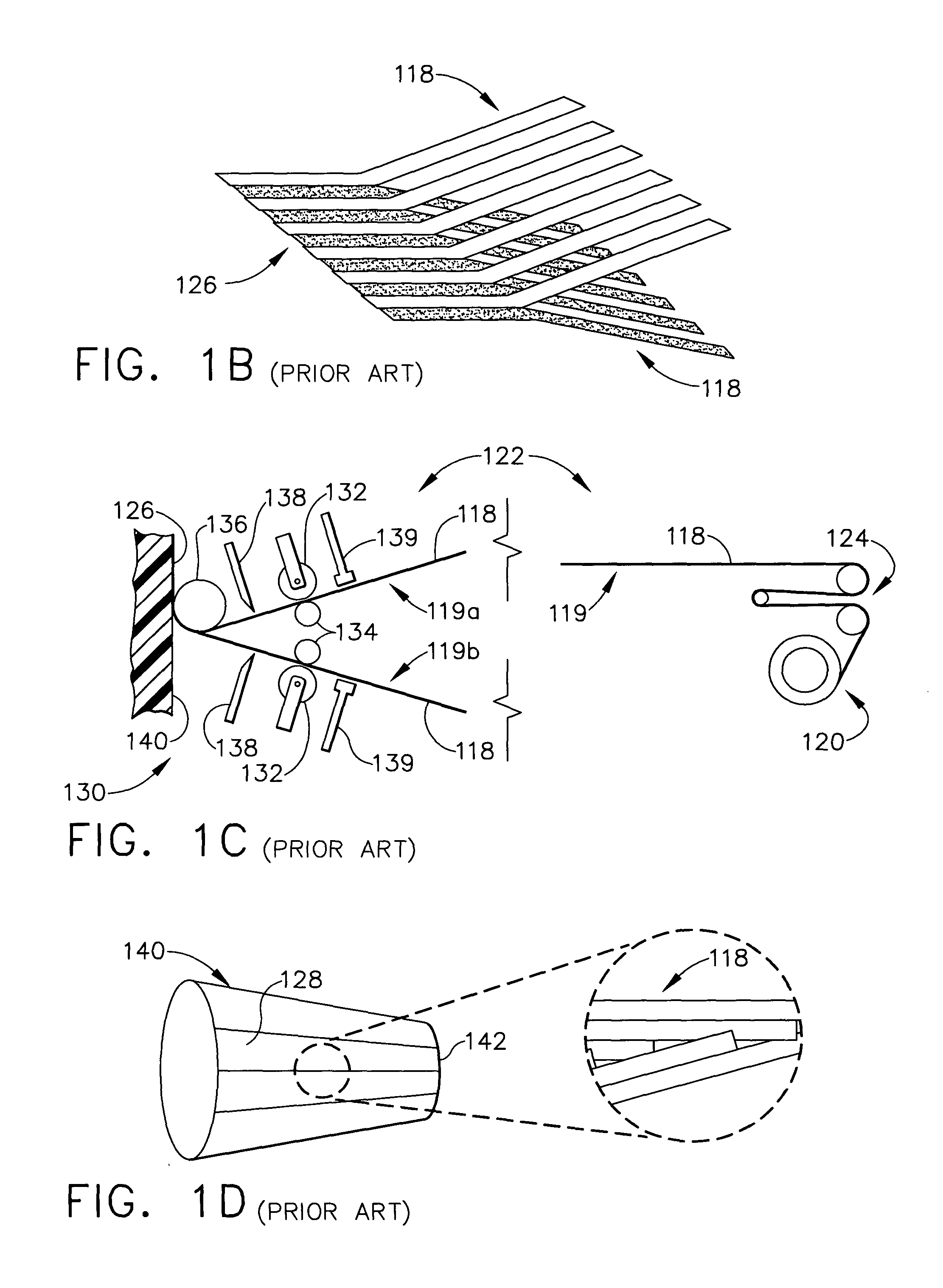

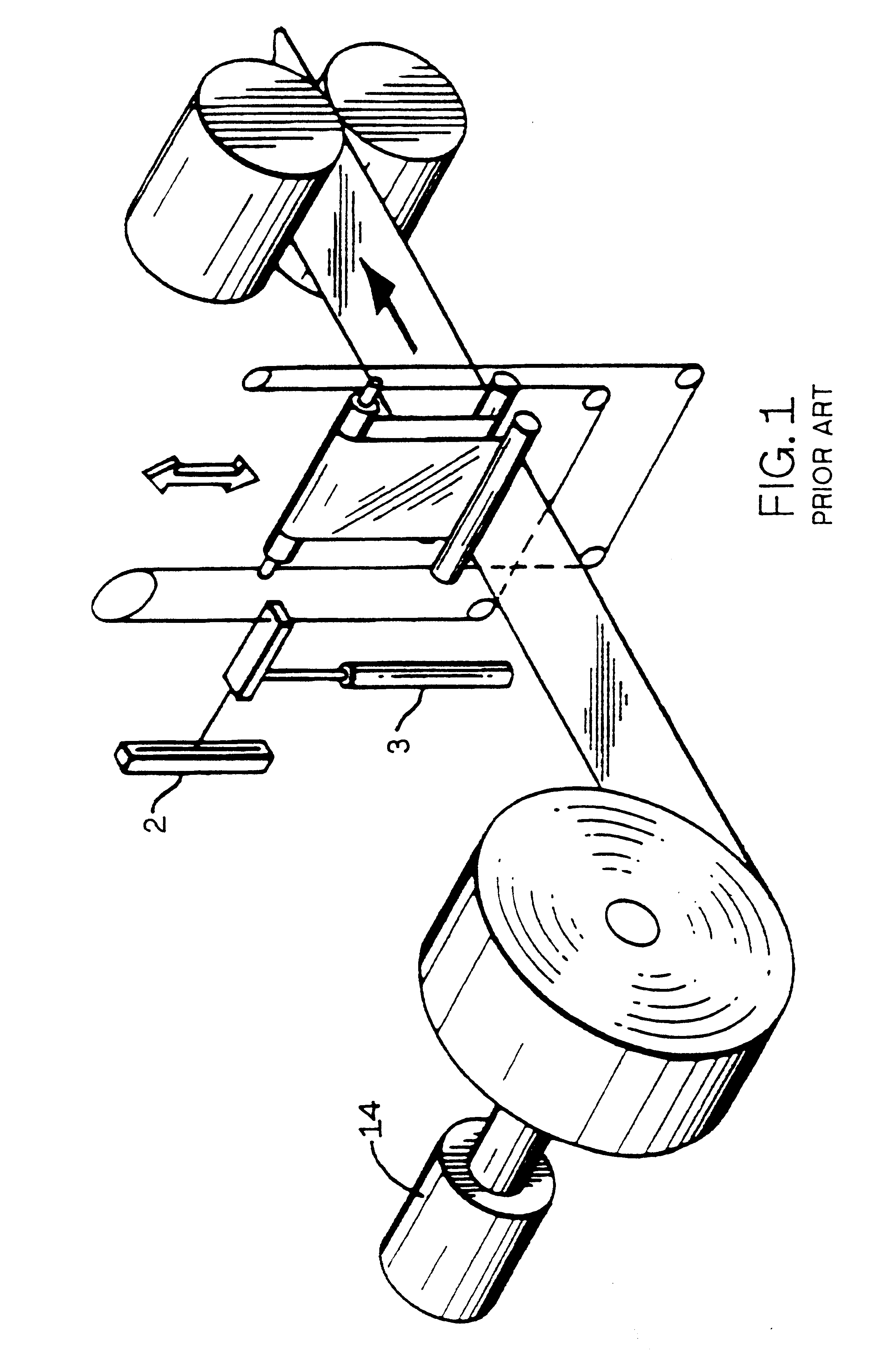

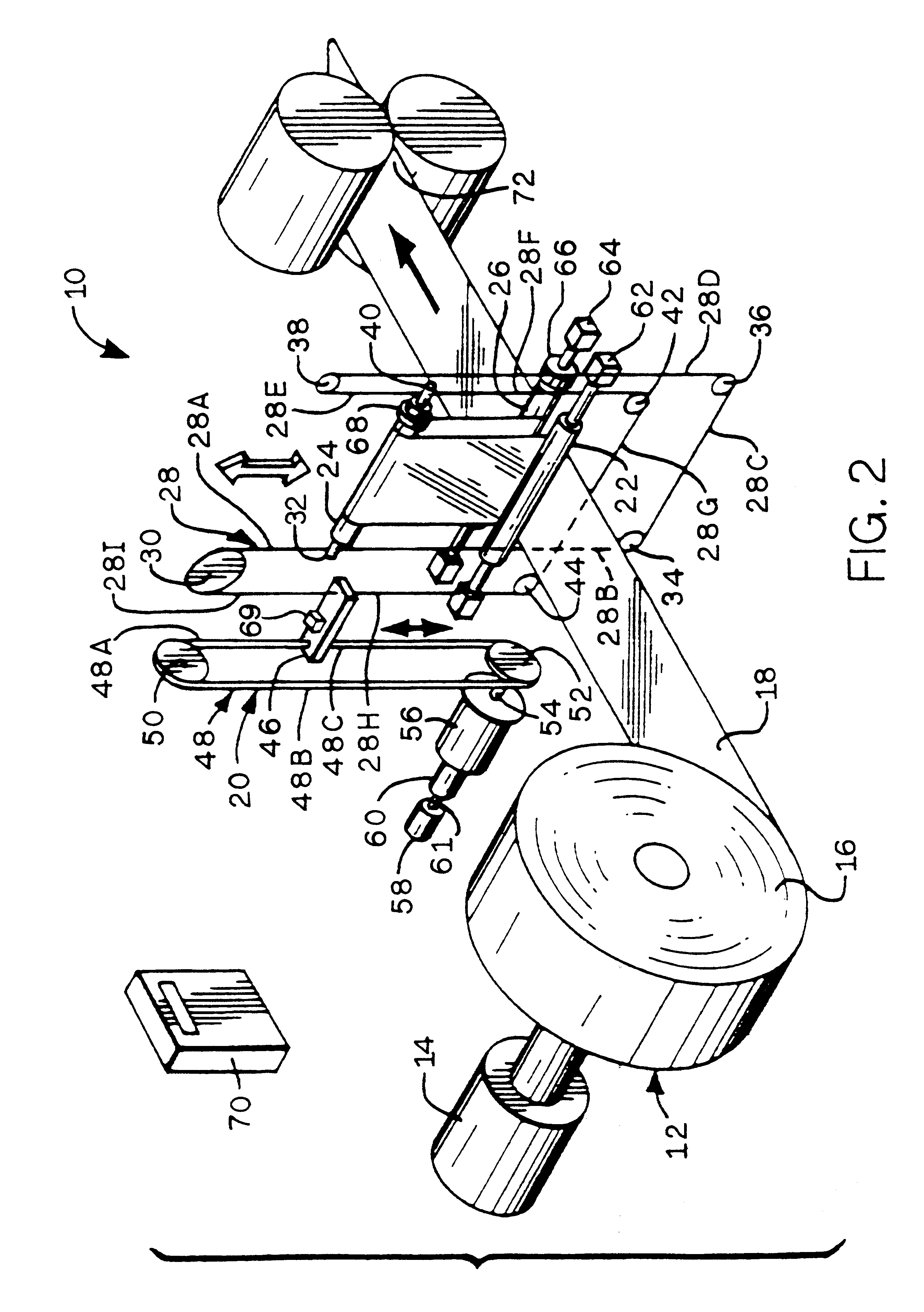

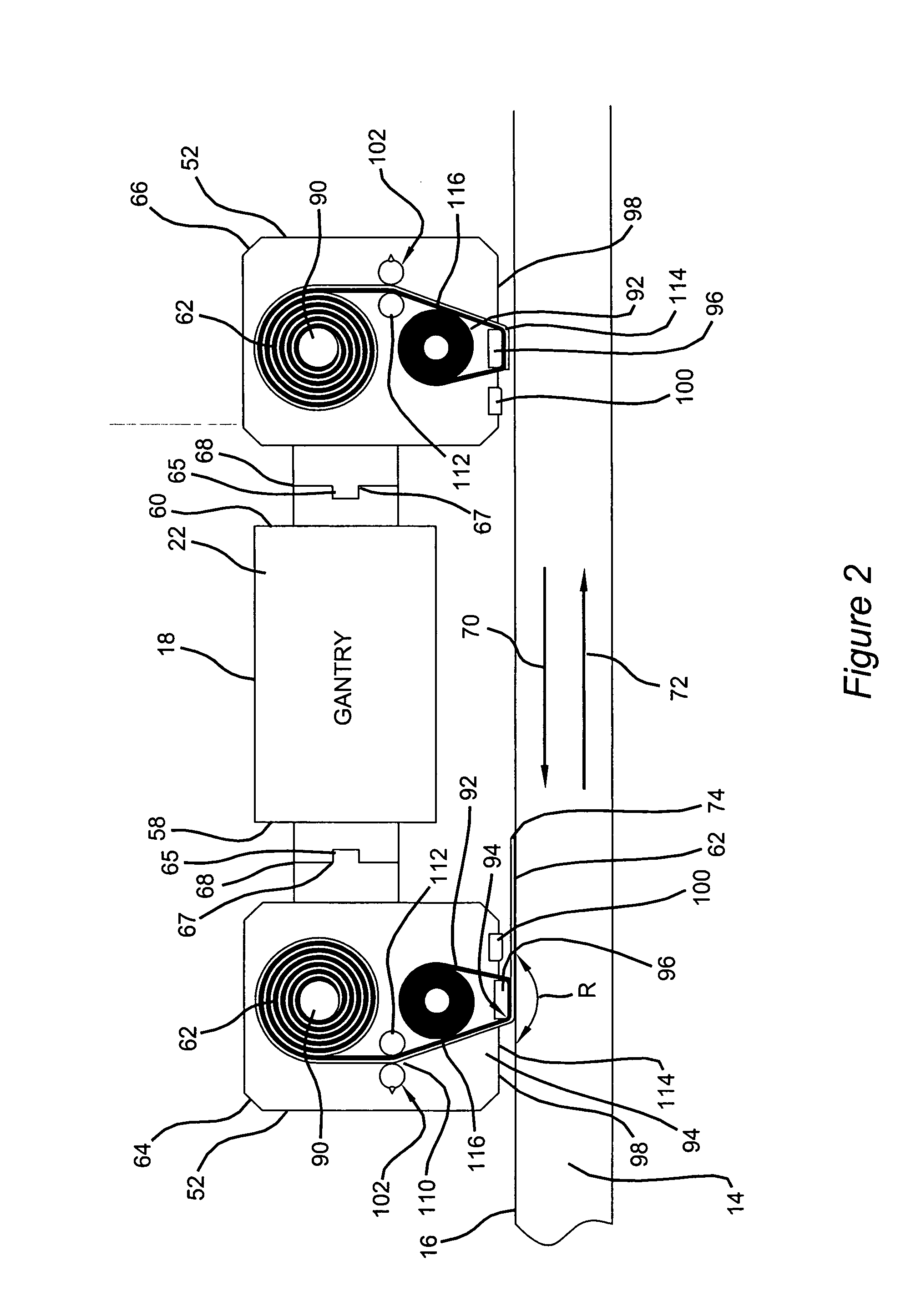

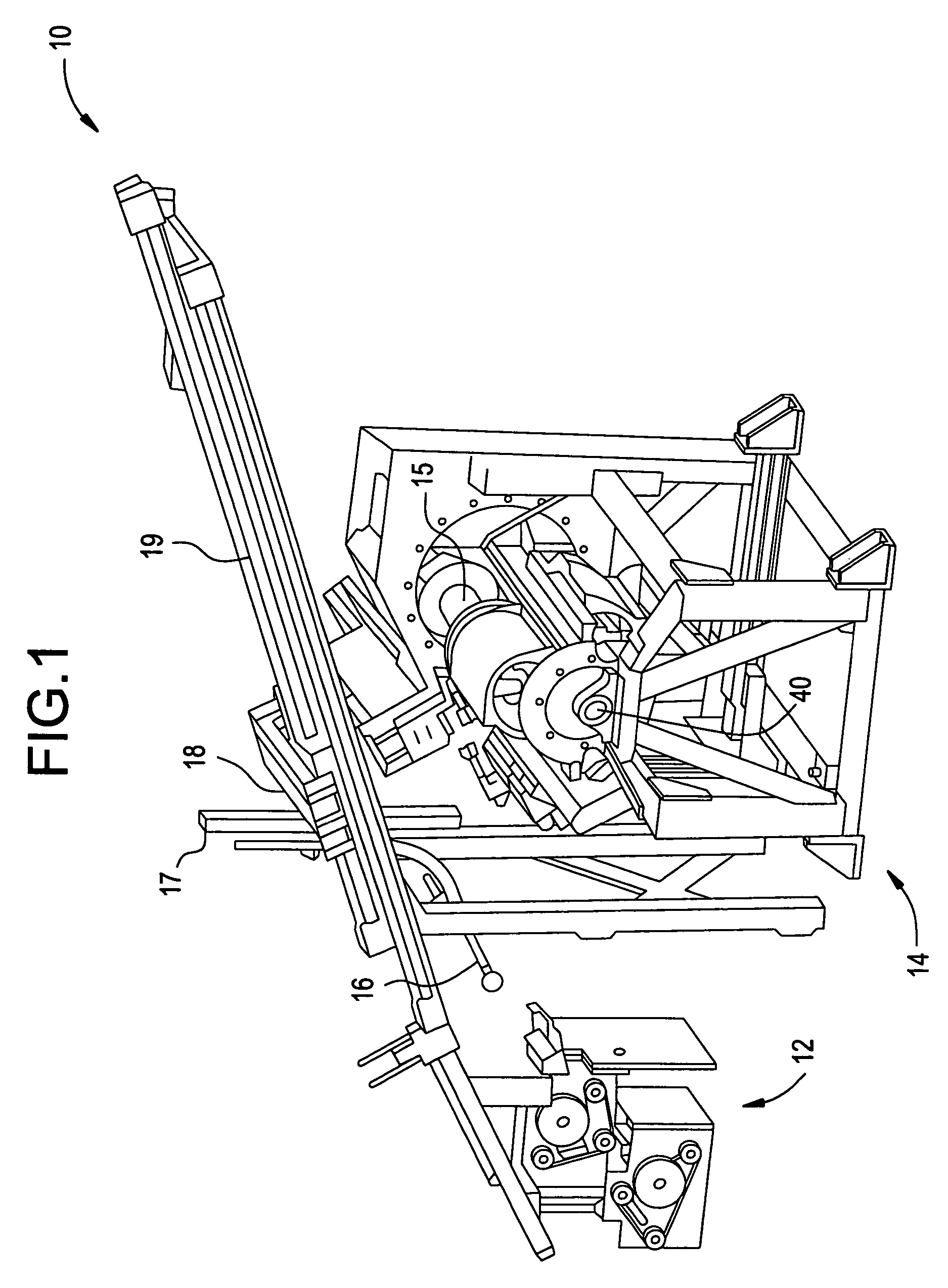

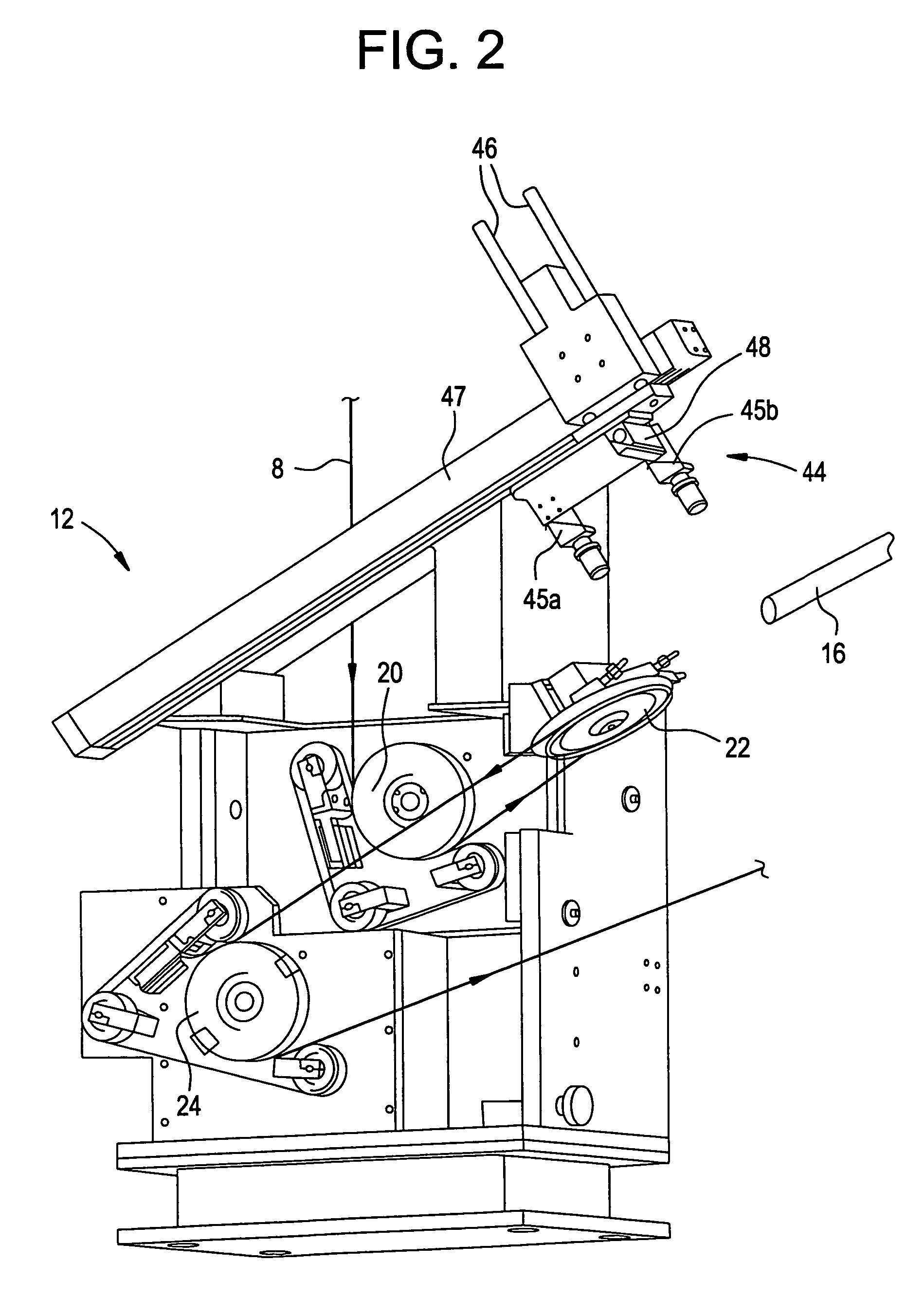

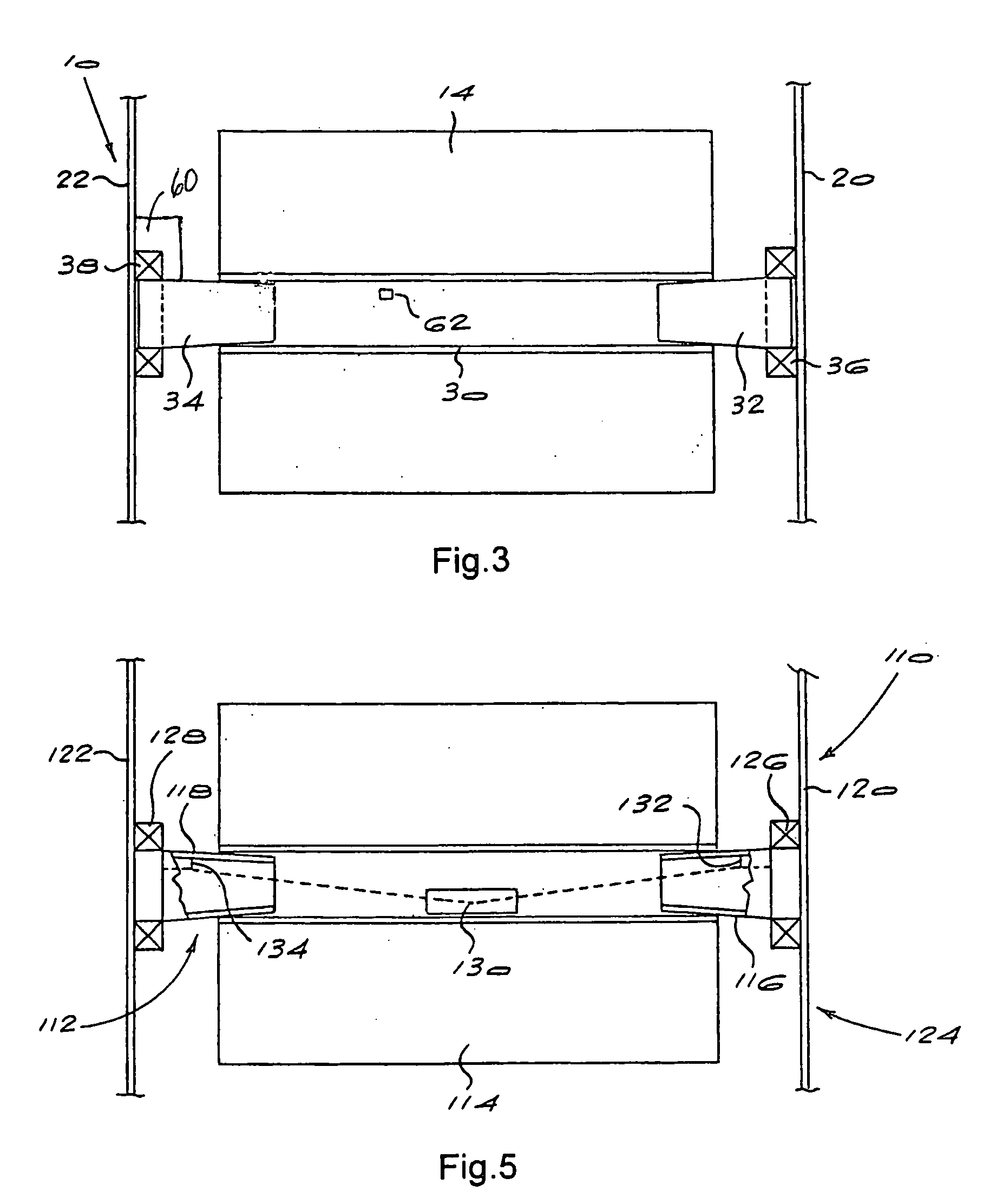

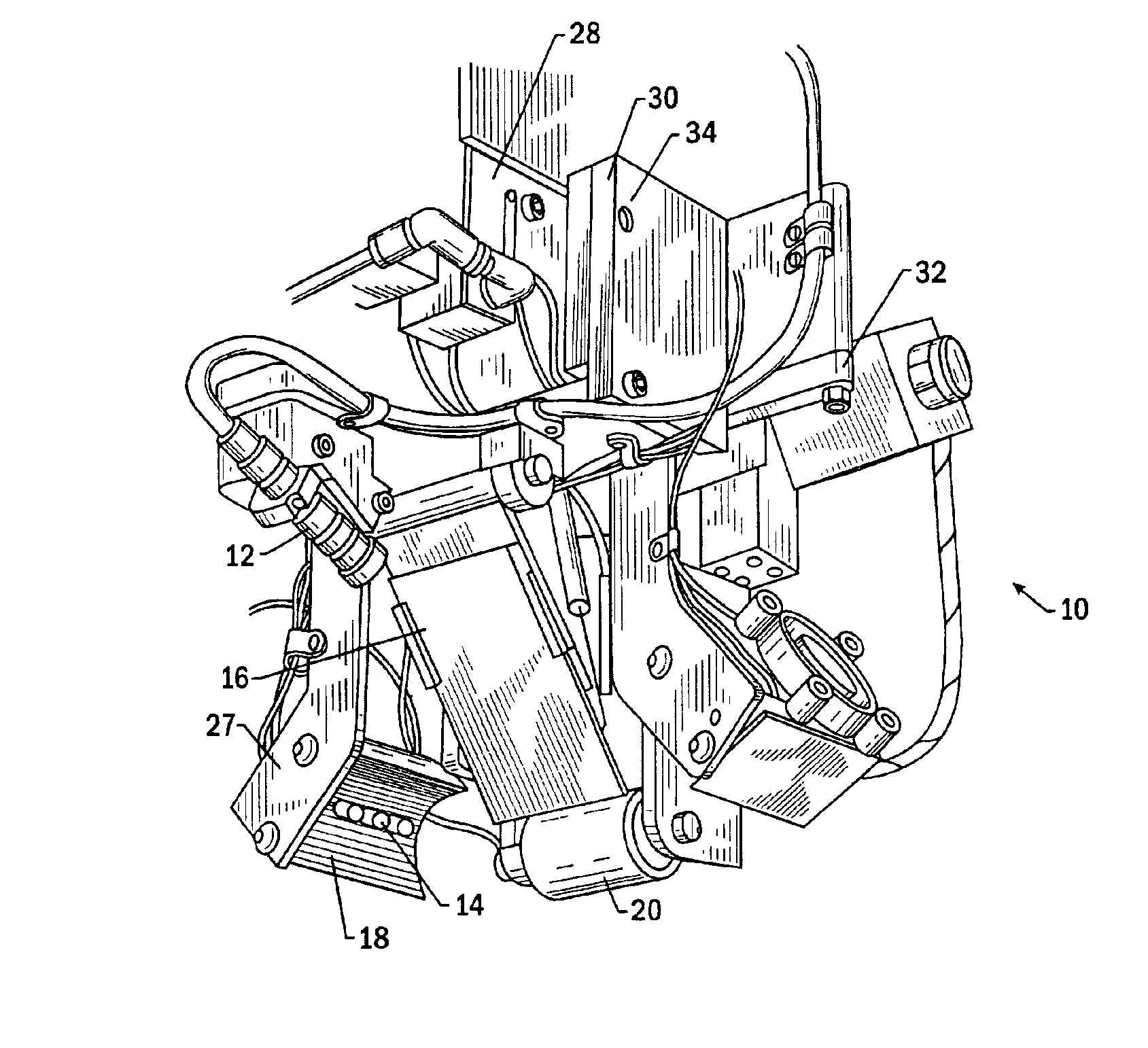

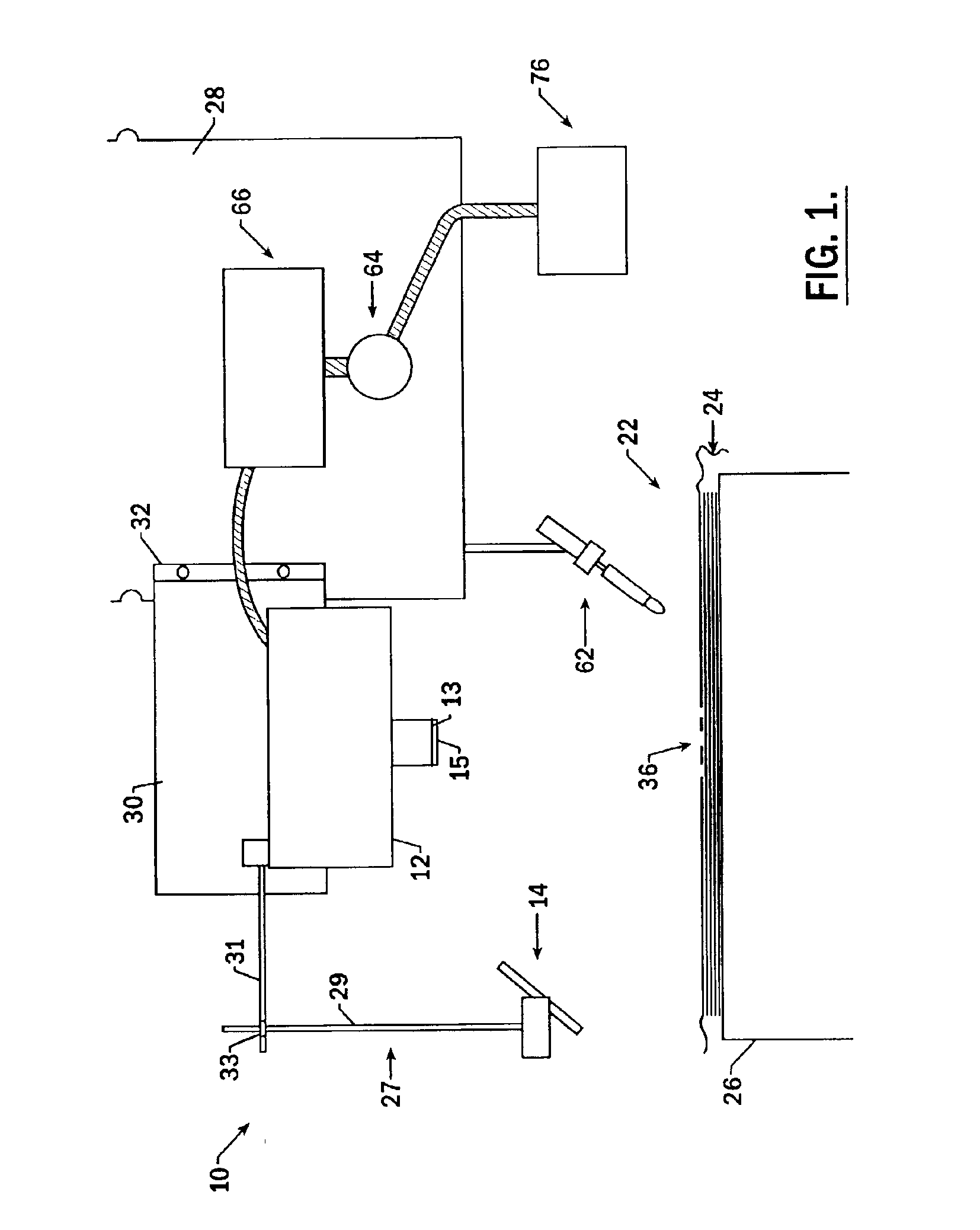

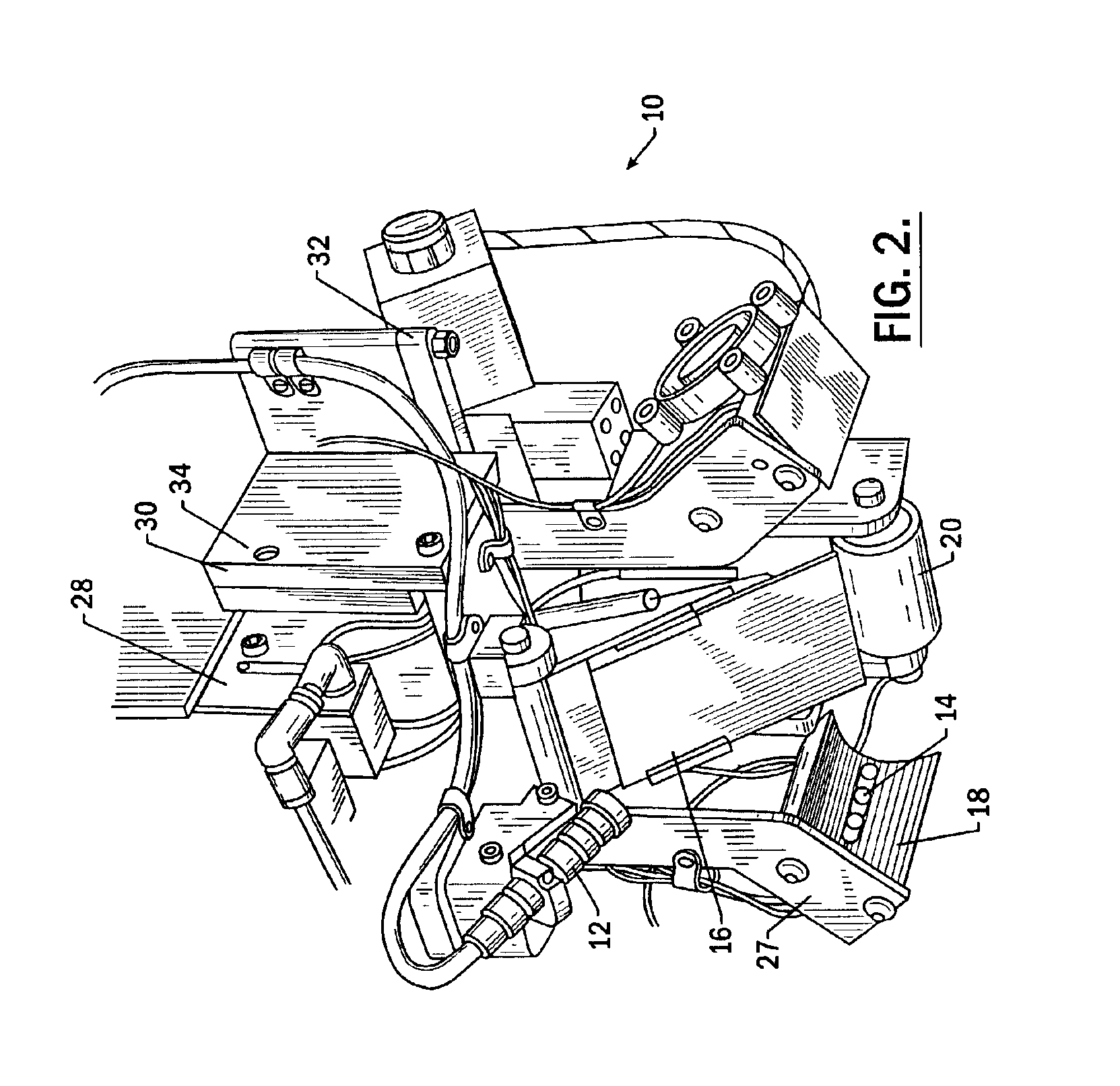

Multiple tape laying apparatus and method

ActiveUS20050061422A1Satisfactory depositionAvoid stickingLamination ancillary operationsPaper/cardboard articlesFiberMultiple layer

A fully automated method and apparatus is disclosed to laminate various structural articles with multiple layers of a resin impregnated fiber tape. The fiber tape is deposited with a tape laying member moving alternately in different travel directions. The tape laying member removes all backing layers from the tape being employed, then deposits the unbacked tape on the surface of the structural article and finally severs the end of the tape being deposited. An automated cut and restart procedure is employed in the present apparatus to increase throughput.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

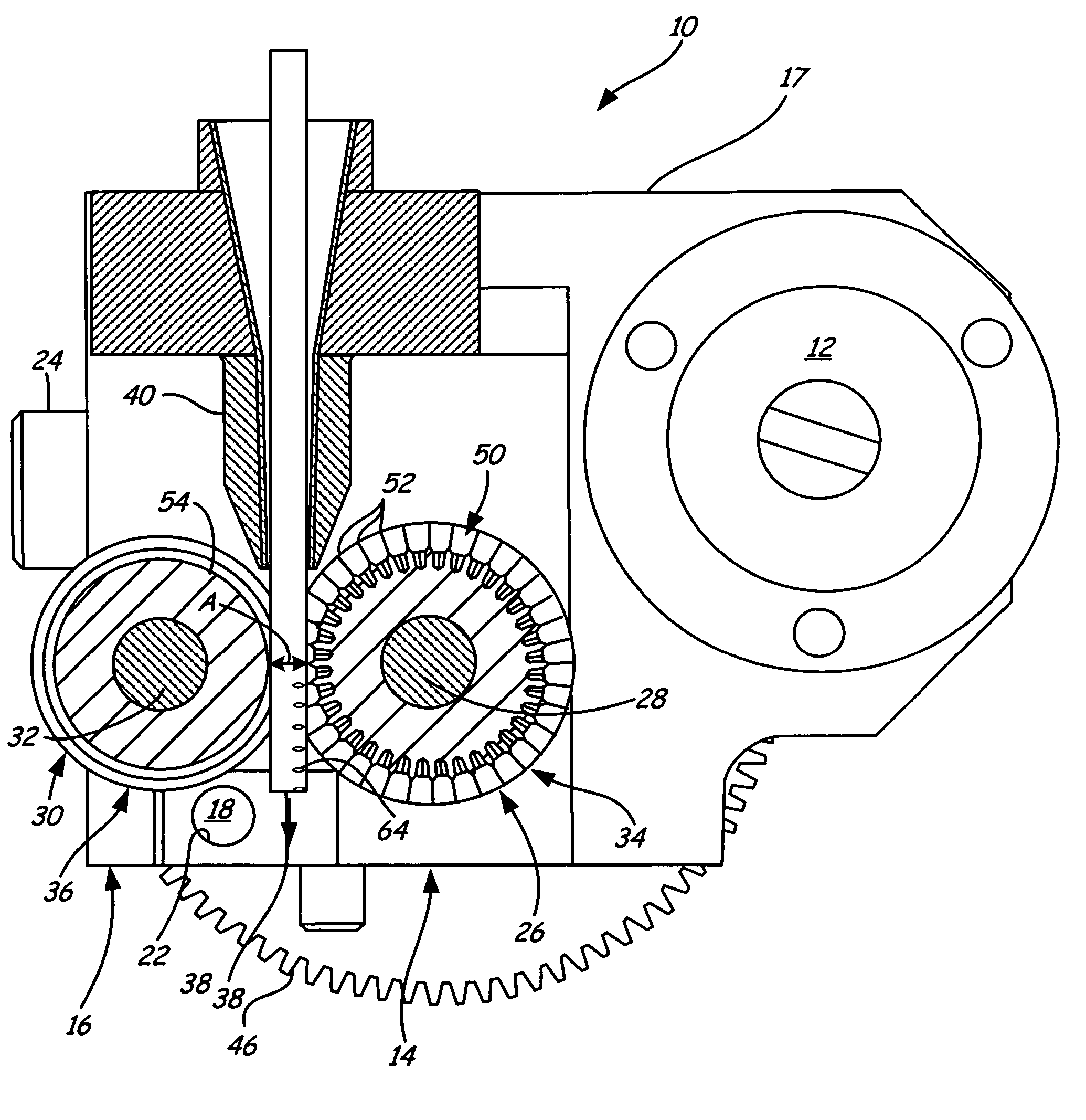

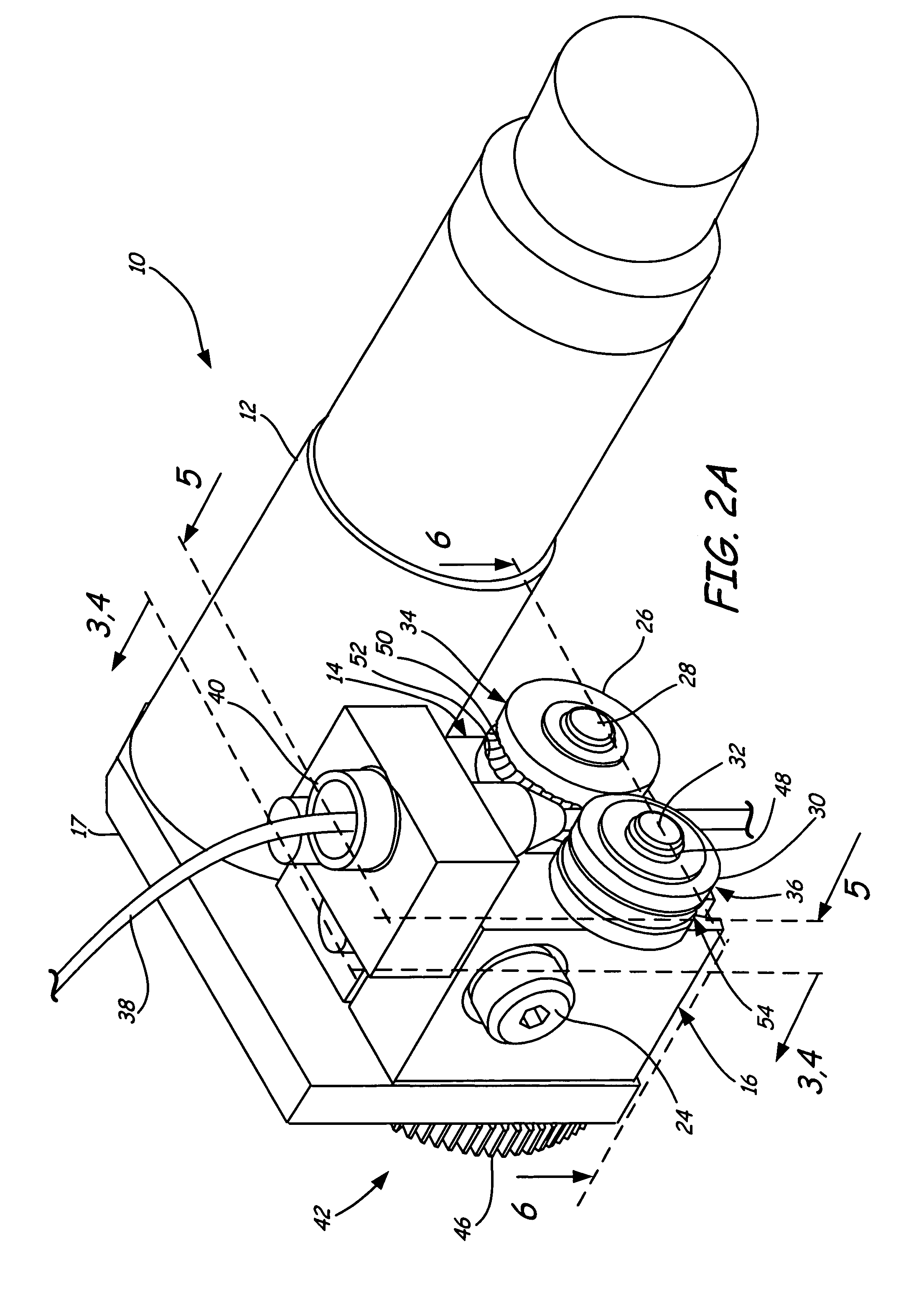

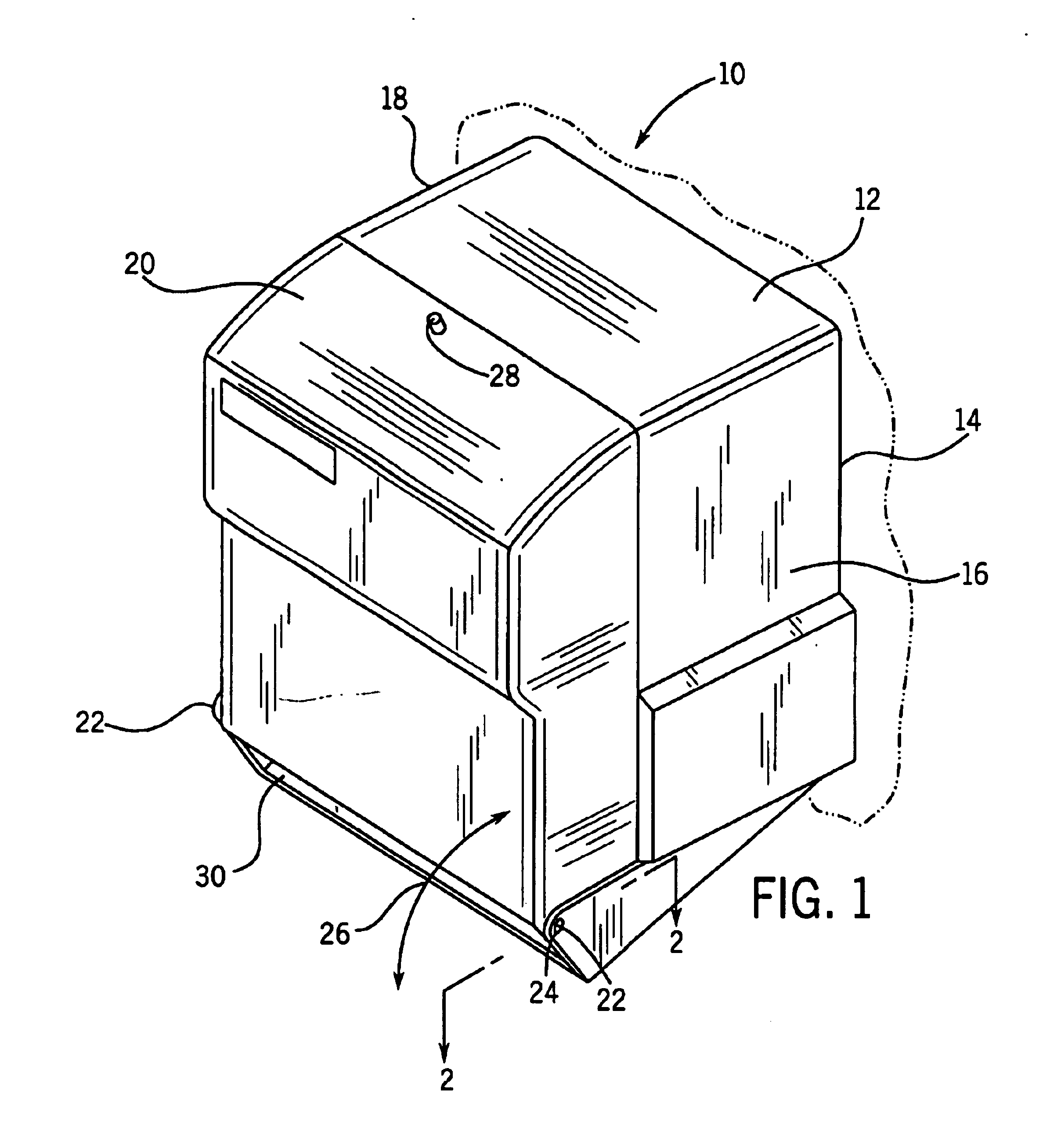

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

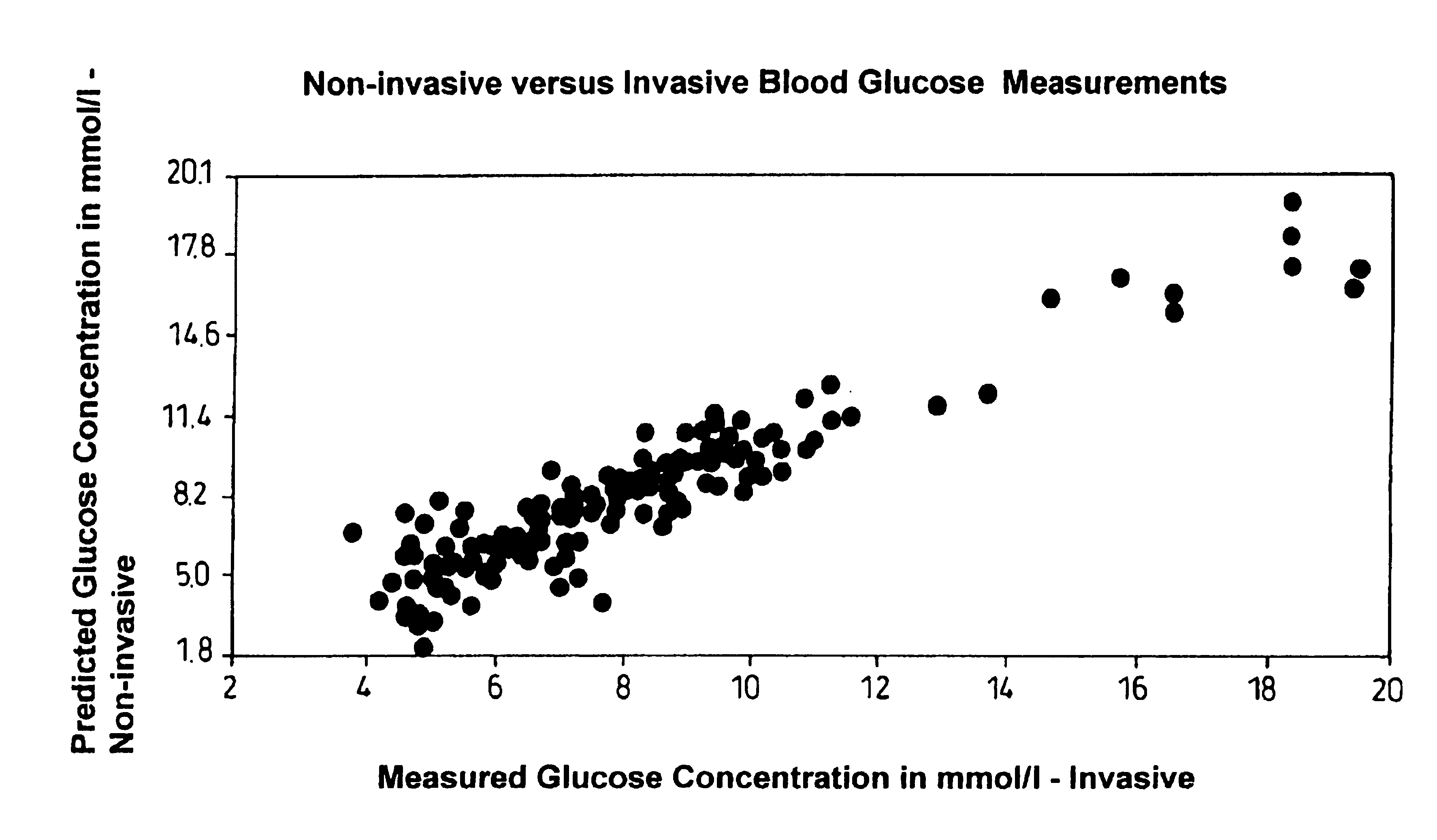

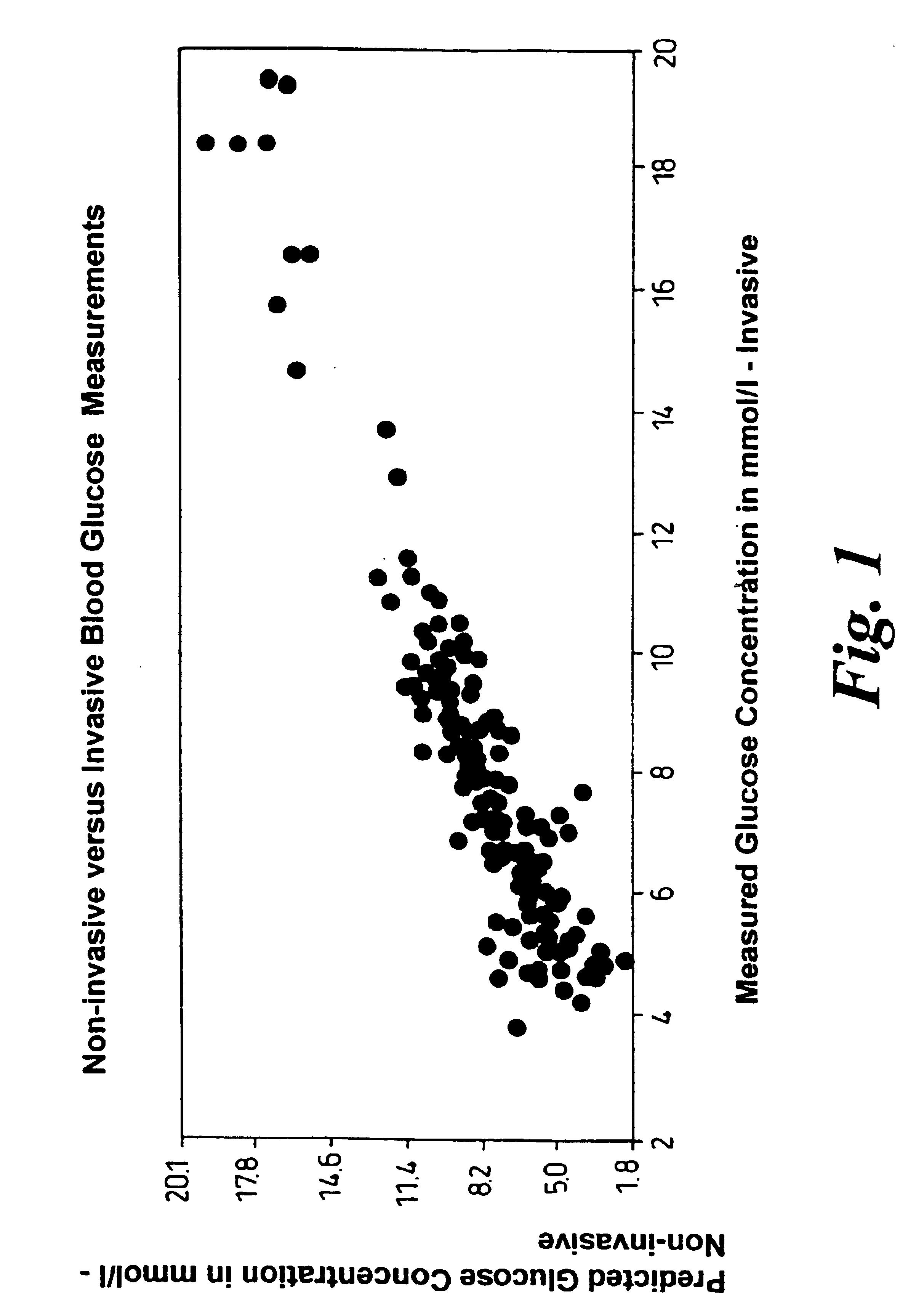

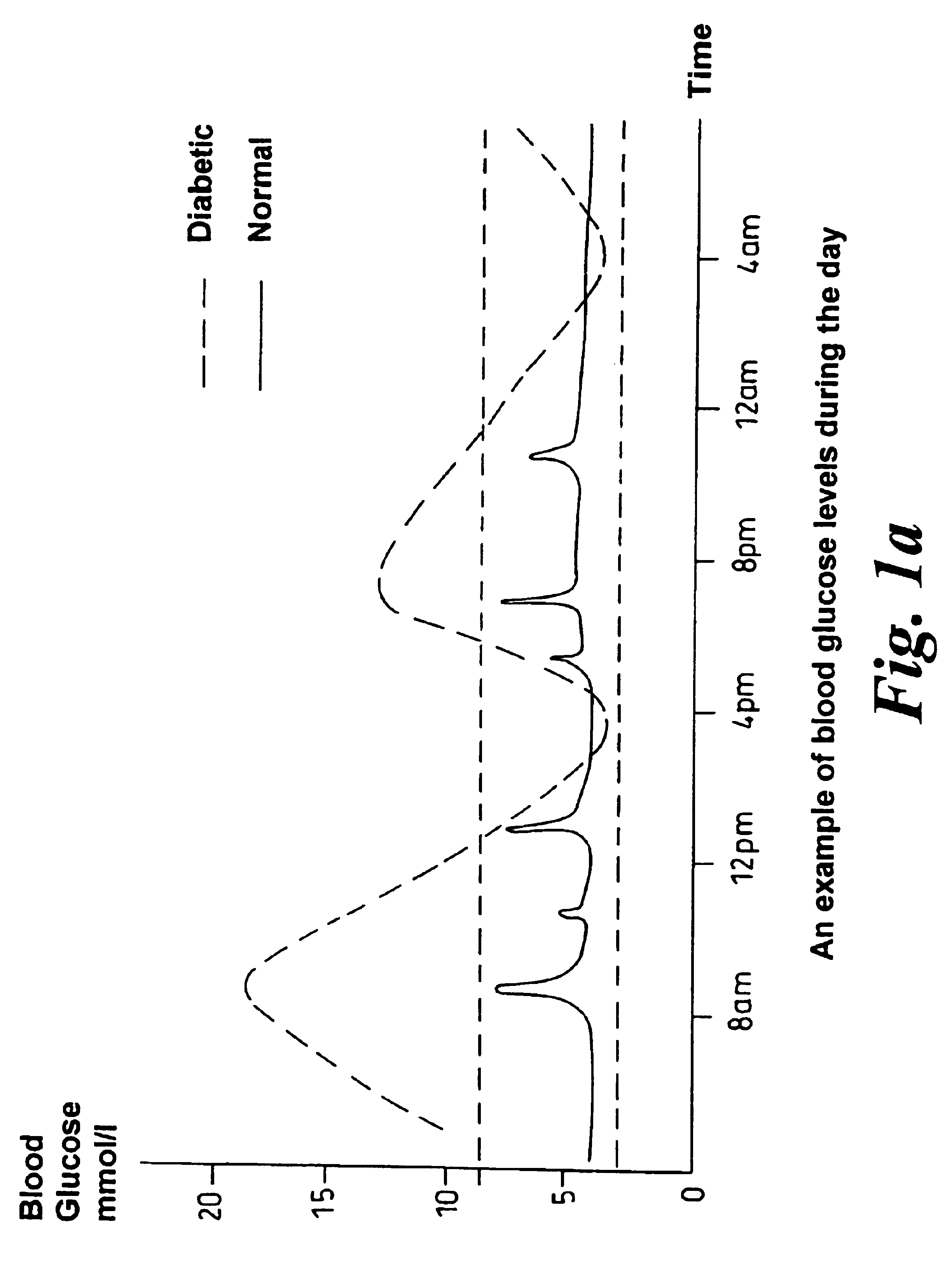

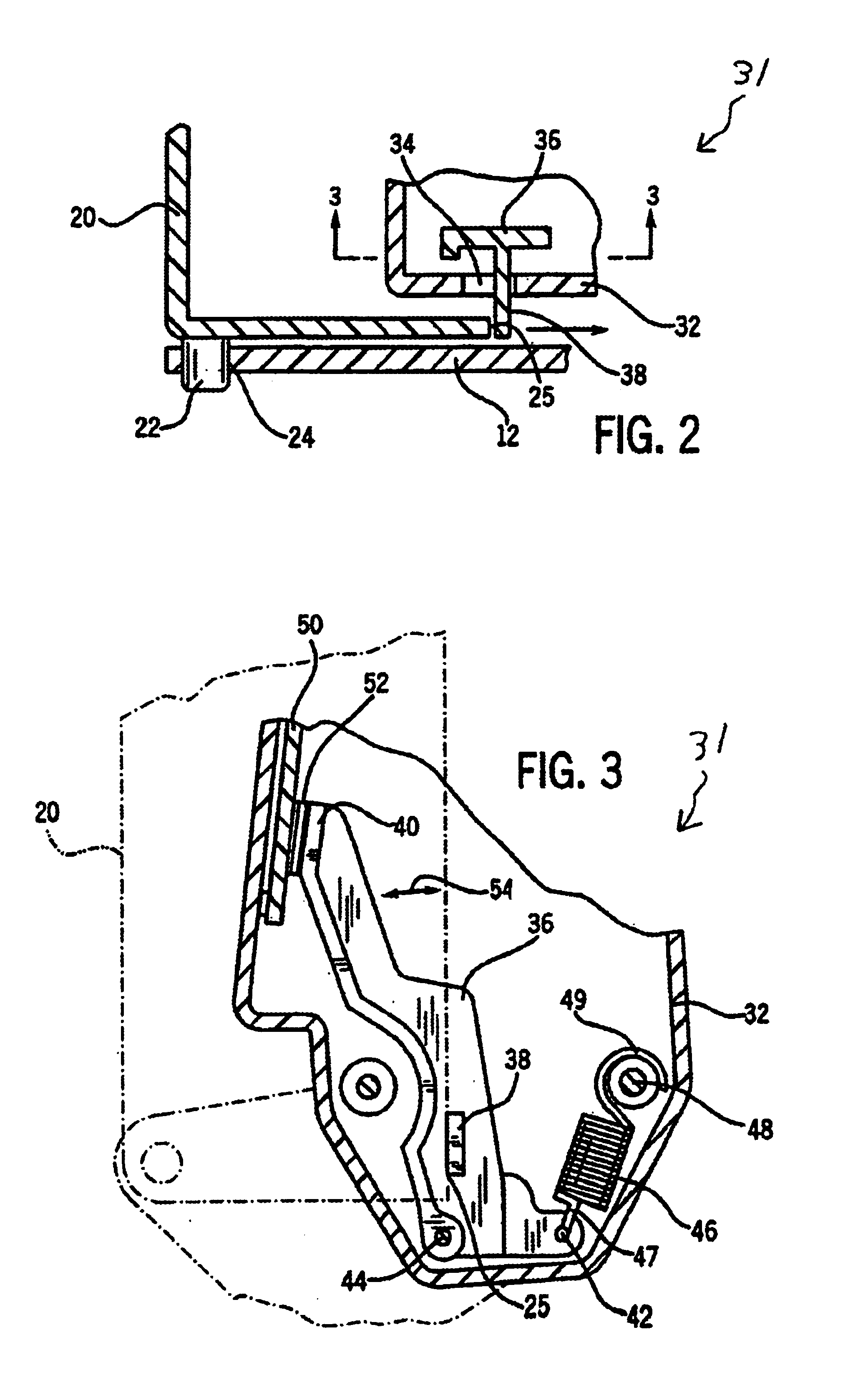

Apparatus for measurement of blood analytes

There is described a device for the non-invasive measurement of one or more analytes in blood in a patient's body part which comprises a light transmitter comprising a plurality of transmitting fibres positioned to transmit light to the body part and a light detector comprising a plurality of light detector fibres position to detect light transmitted through or reflected from the body part. The device especially utilises the non-pulsatile element of a patient's blood. There is also described a method of measuring blood glucose levels and a device programmed so as to calculate one or more of the haemoglobin index, the oxygen index and the blood oxygen saturation.

Owner:WHITLAND RES

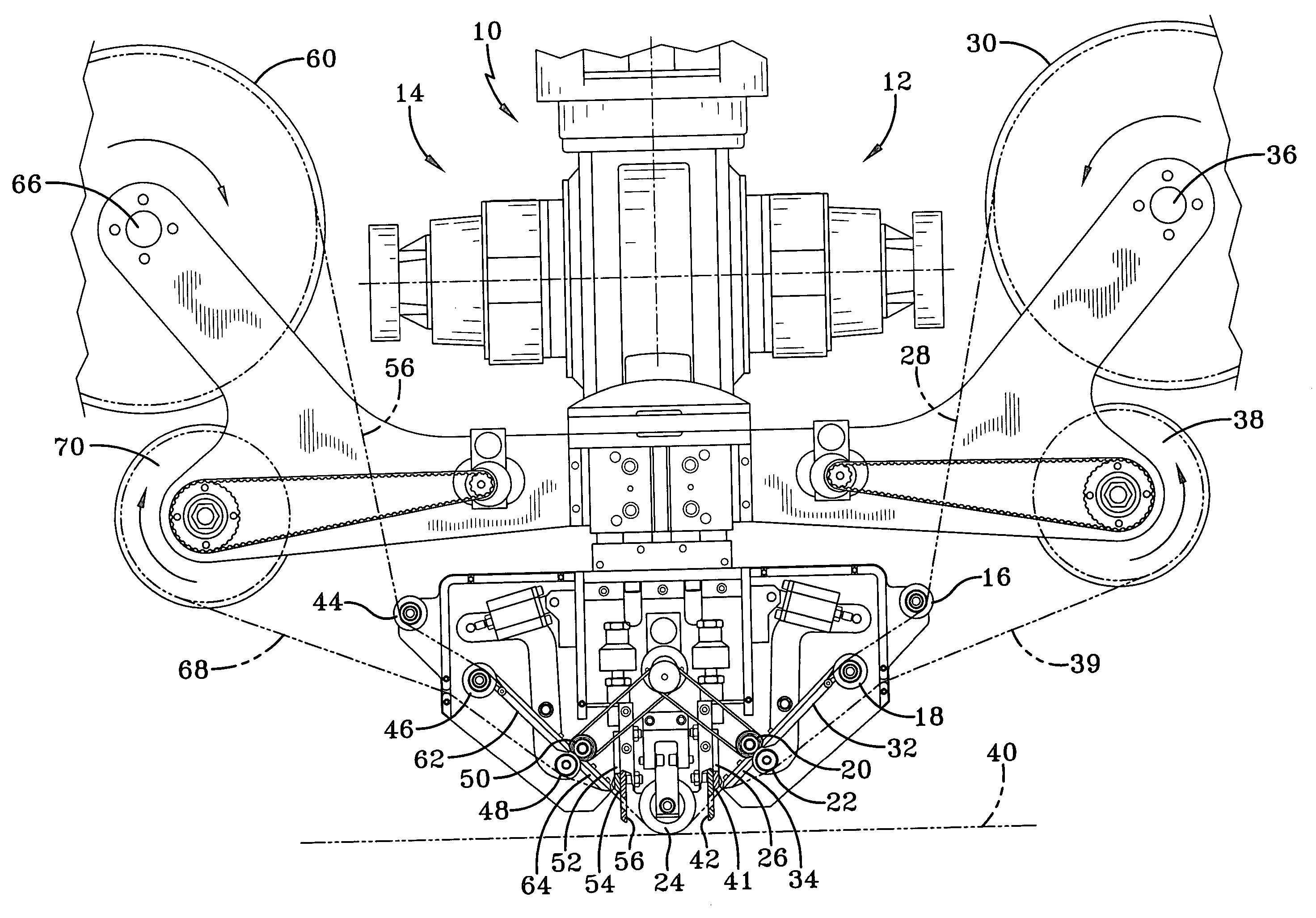

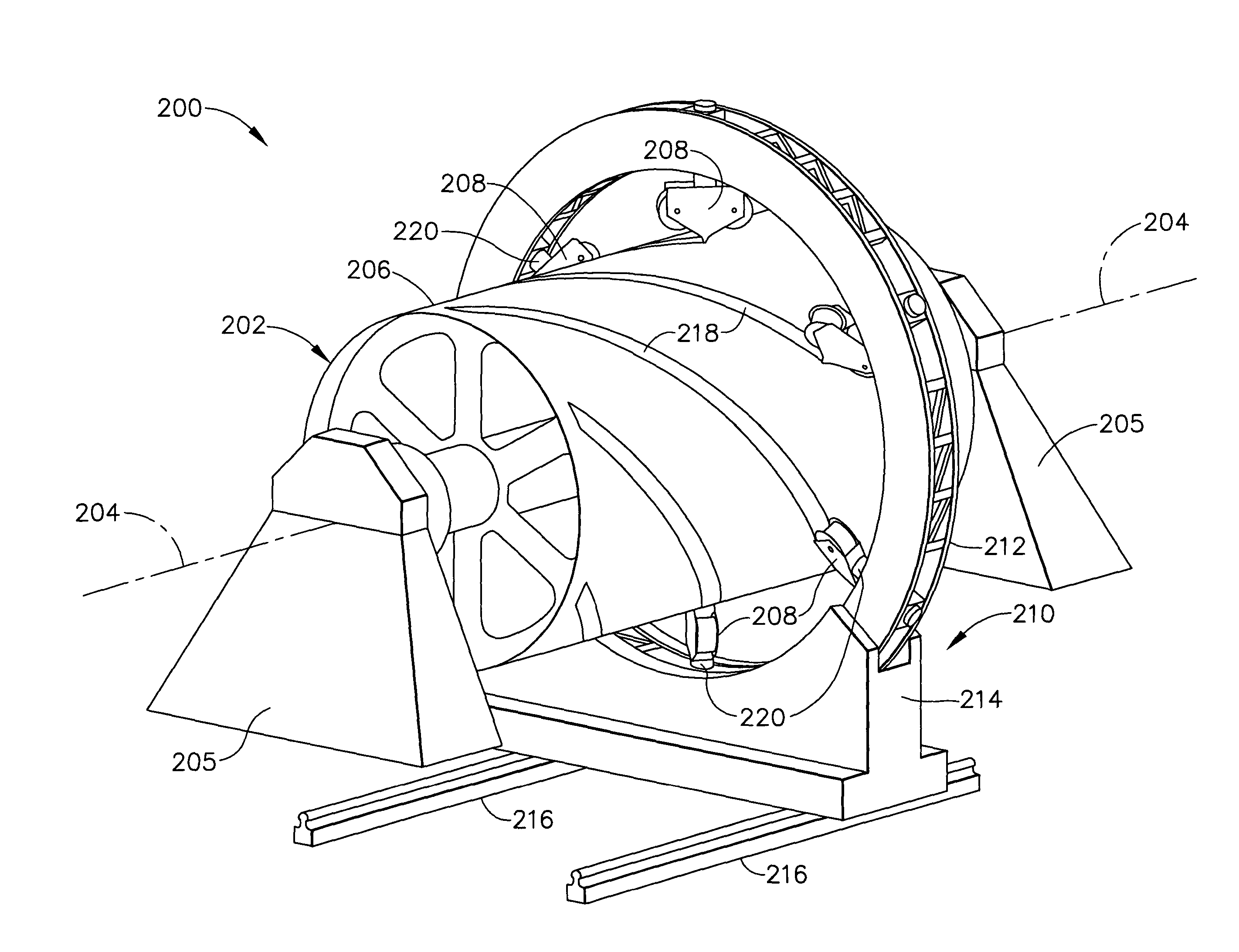

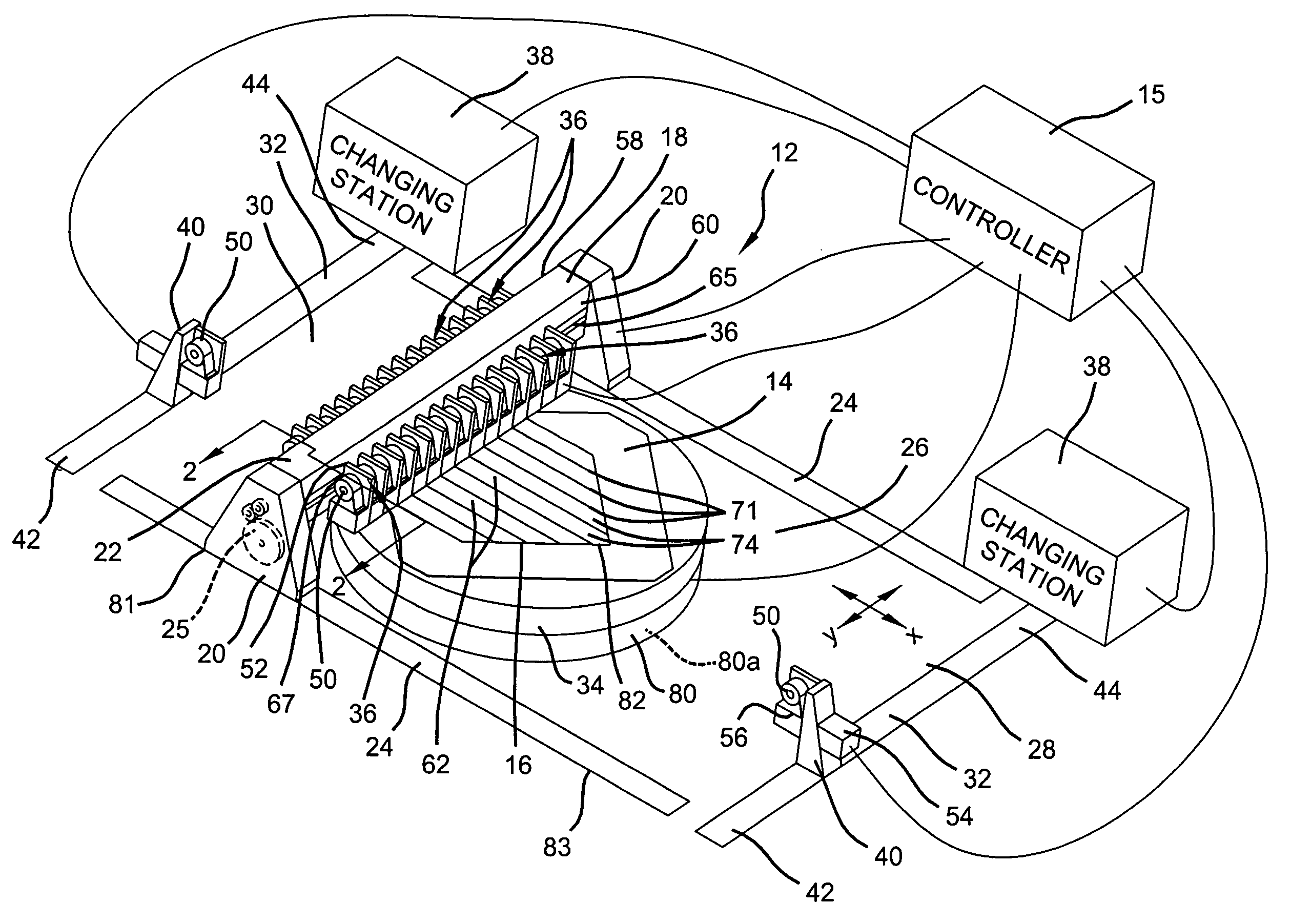

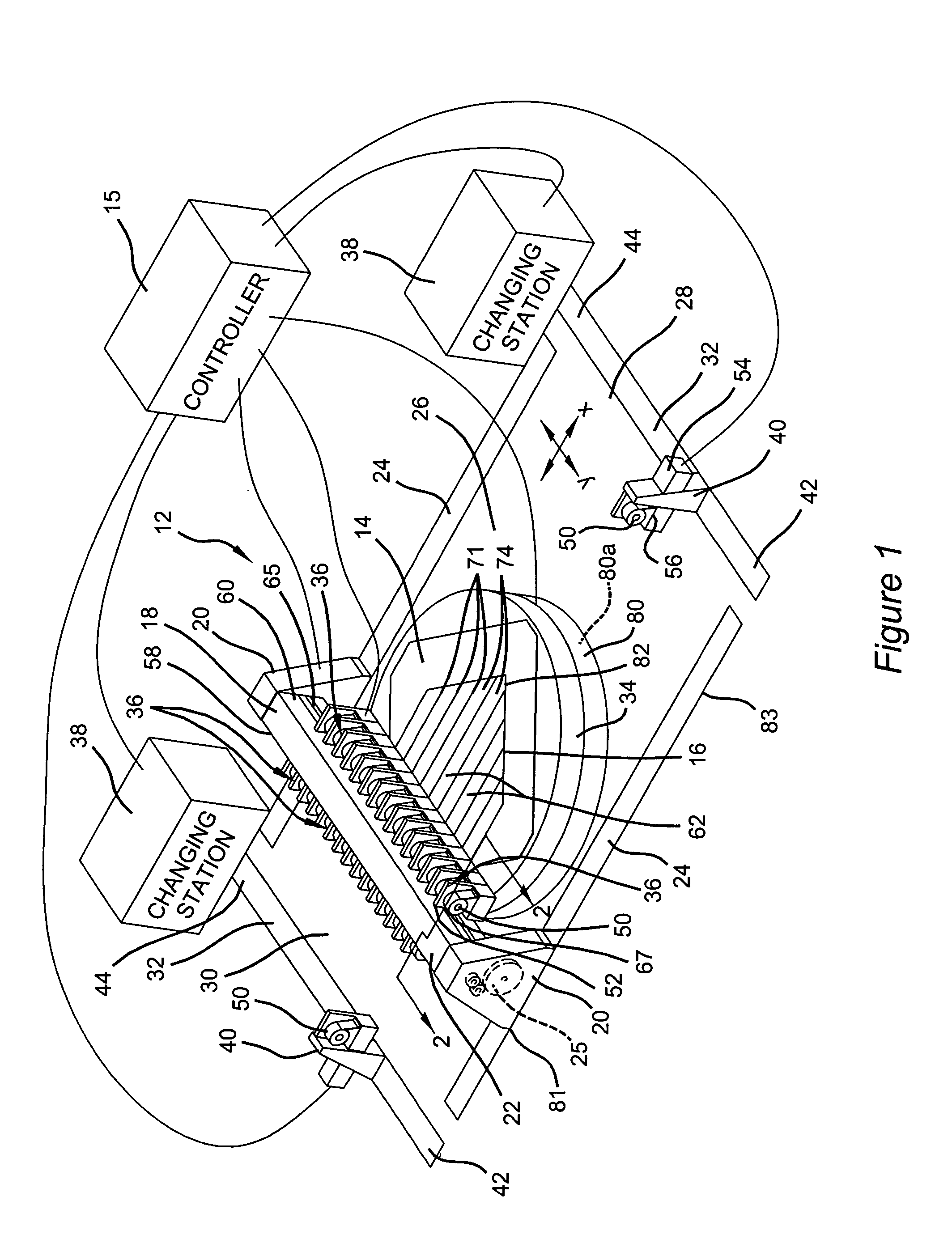

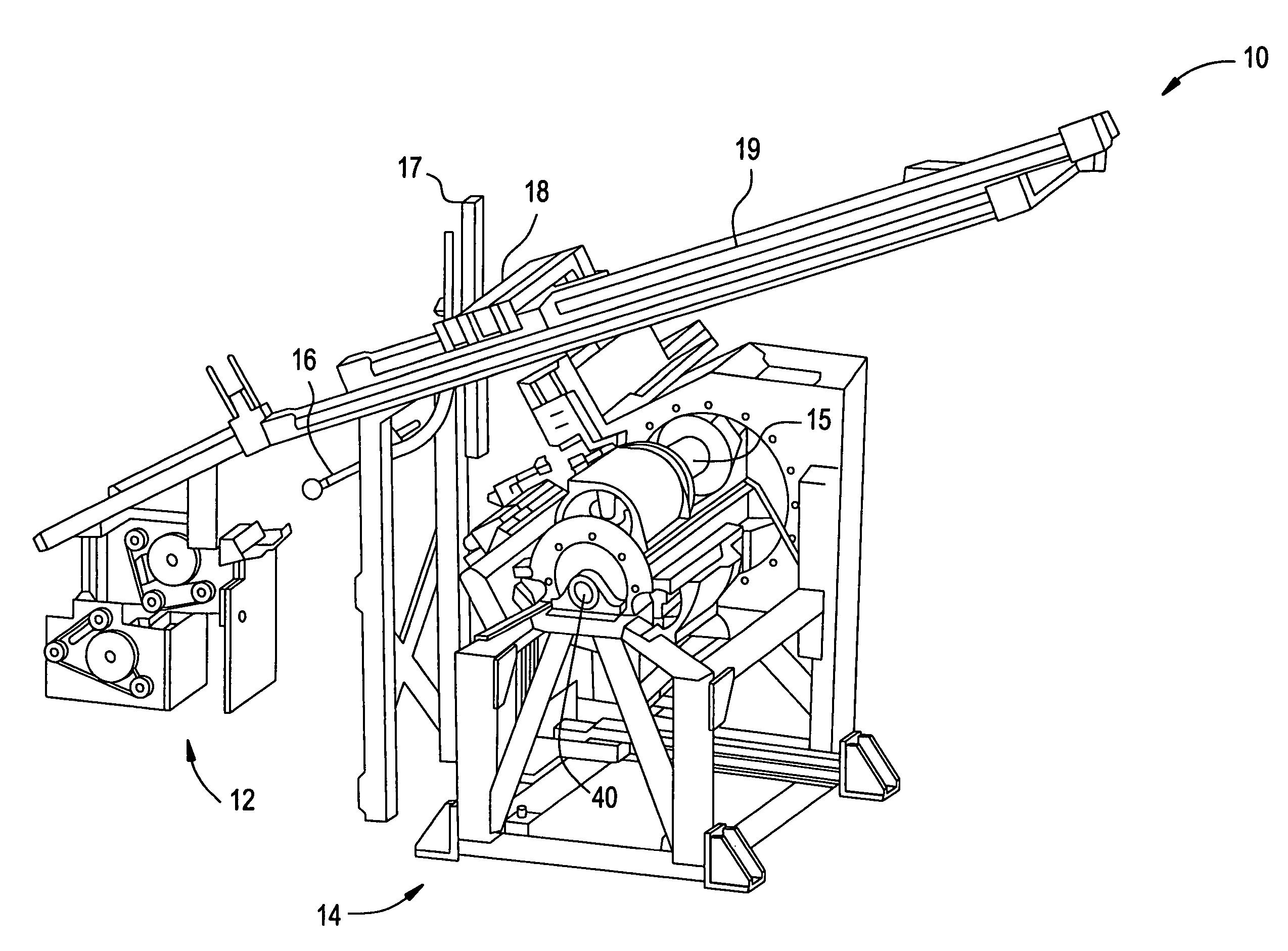

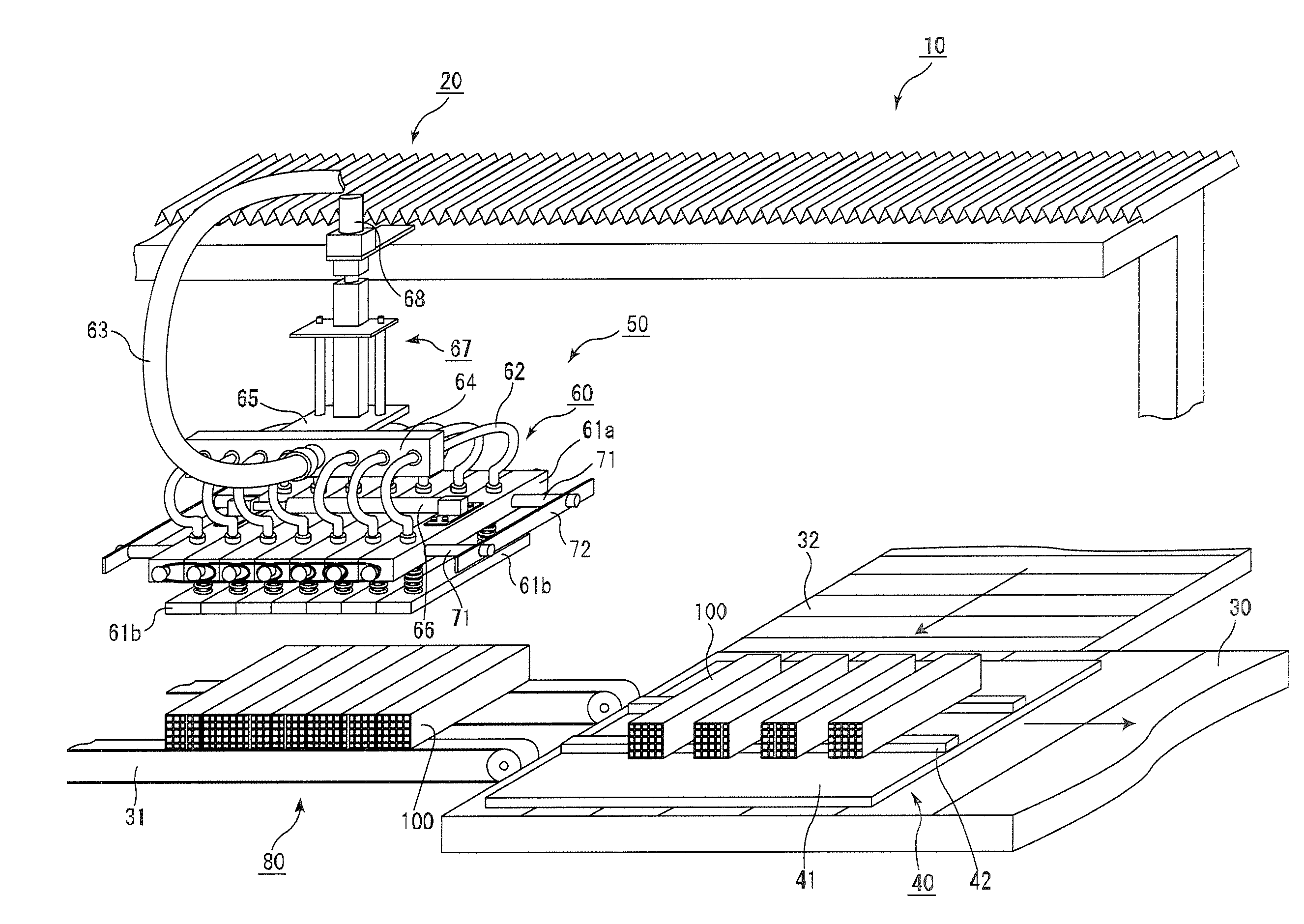

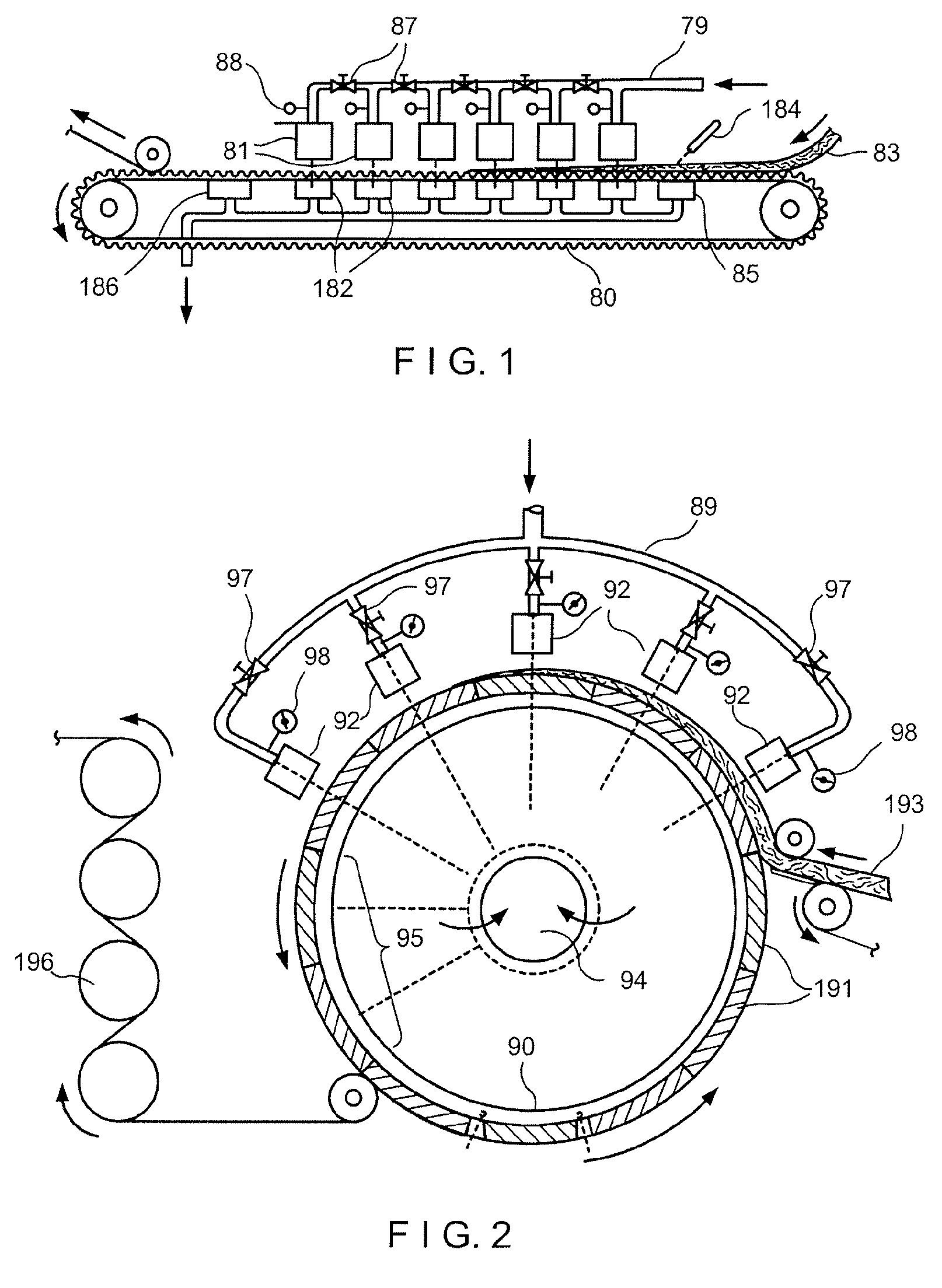

Multiple head automated composite laminating machine for the fabrication of large barrel section components

An aircraft part manufacturing device for automated composite lamination on a mandrel surface of a tool having a rotational axis includes a mechanical supporting structure that supports multiple material delivery heads. The tool is moveable and rotatable relative to the mechanical supporting structure. The mechanical supporting structure provides for axial translation of the material delivery heads relative to the mandrel surface while the mandrel surface is rotated for laying down courses of composite material over the entire mandrel surface of the tool. The position and movement of each of the plurality of material delivery heads is individually adjustable. Arm mechanisms provide motion of each material delivery head in a direction normal to the mandrel surface; rotation about an axis normal to the mandrel surface; circumferential position adjustment in a hoop direction relative to the mandrel surface; and axial position adjustment relative to the other material delivery heads.

Owner:THE BOEING CO

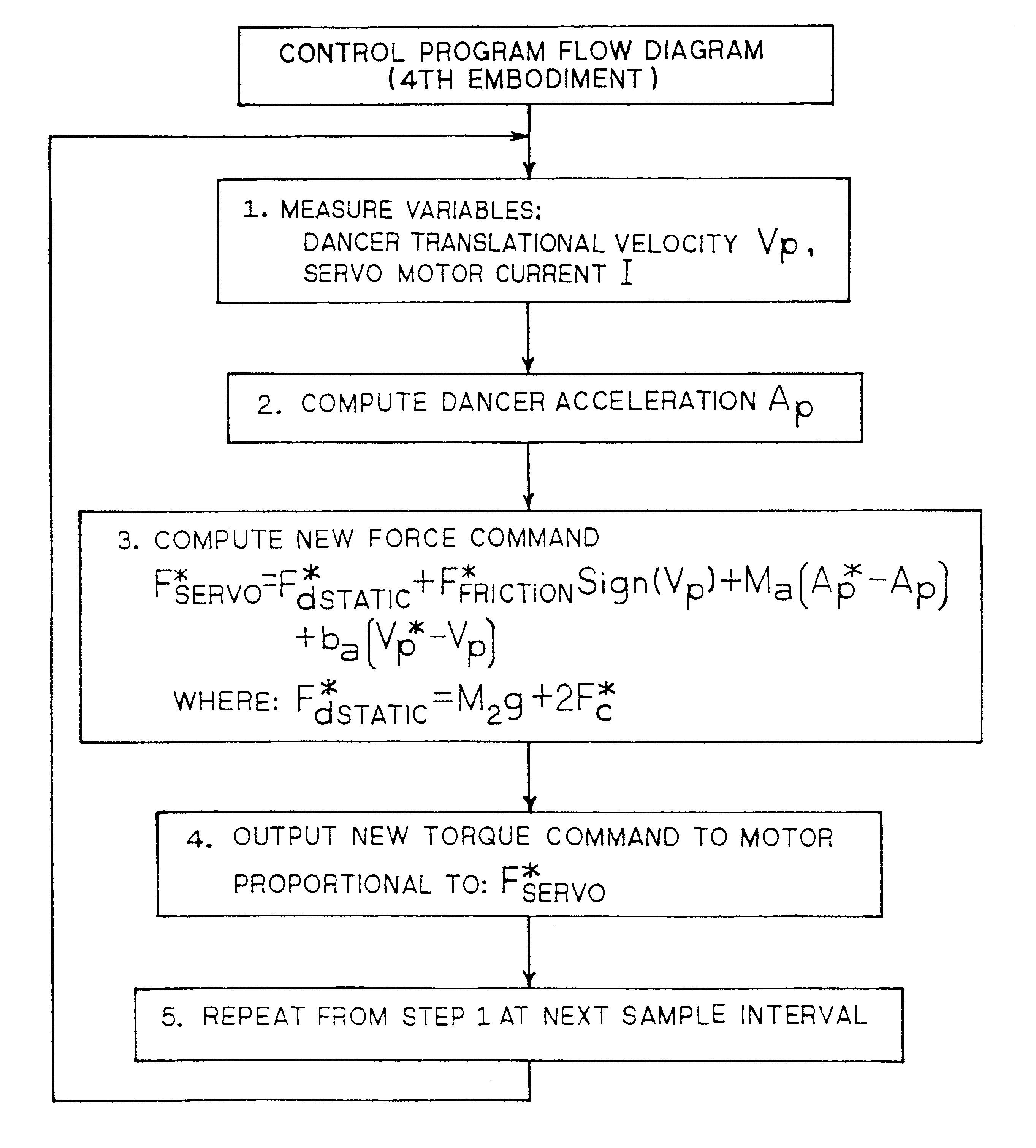

Method and apparatus for controlling web tension by actively controlling velocity and acceleration of a dancer roll

InactiveUS6314333B1The result is accurateAutomatic control devicesPrecision positioning equipmentControl systemEngineering

This invention pertains to processing continuous webs such as paper, film, composites, and the like, in dynamic continuous processing operations. More particularly, it relates to controlling tension in such continuous webs during the processing operation. Tension is controlled in a dancer control system by connecting a corresponding dancer roll to an actuator apparatus or the like, sensing variables such as position, tension, velocity, and acceleration parameters related to the web and the dancer roll, and providing active force commands, in response to the sensed variables, to cause translational movement, generally including a target acceleration, in the dancer roll to control tension disturbances in the web. In some applications of the invention, the dancer control system is used to attenuate tension disturbances. In other applications of the invention, the dancer control system is used to create tension disturbances.

Owner:KIMBERLY-CLARK WORLDWIDE INC

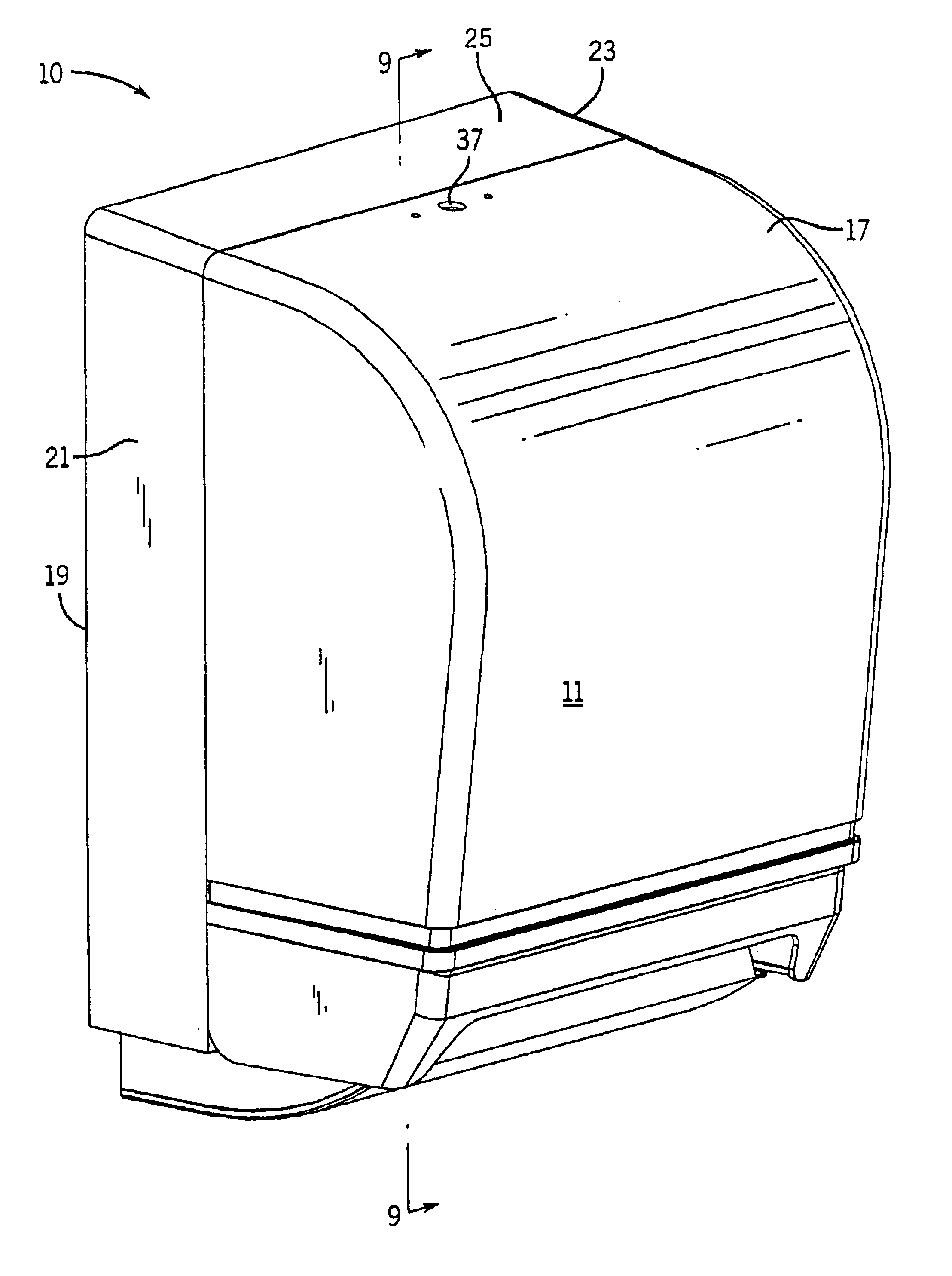

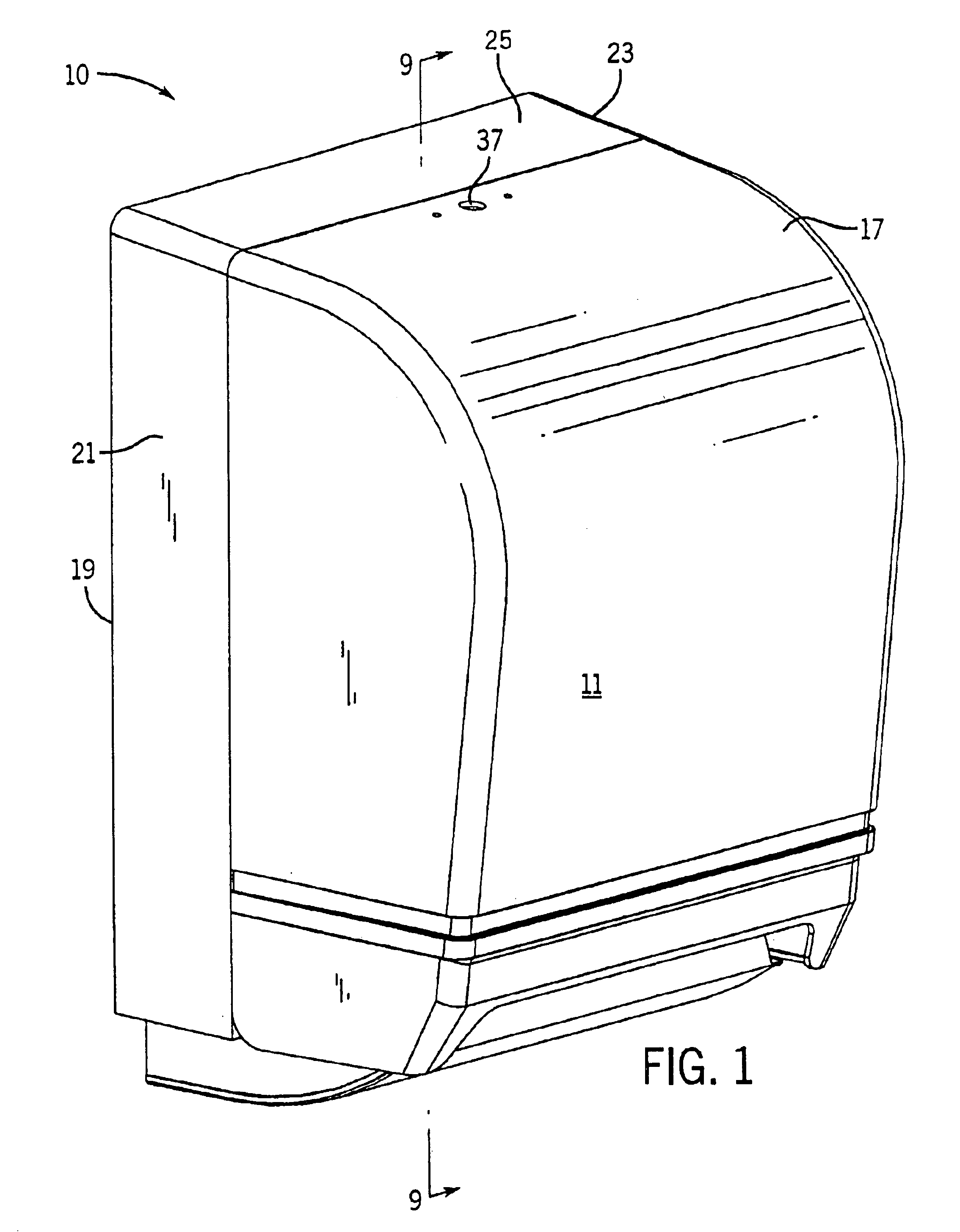

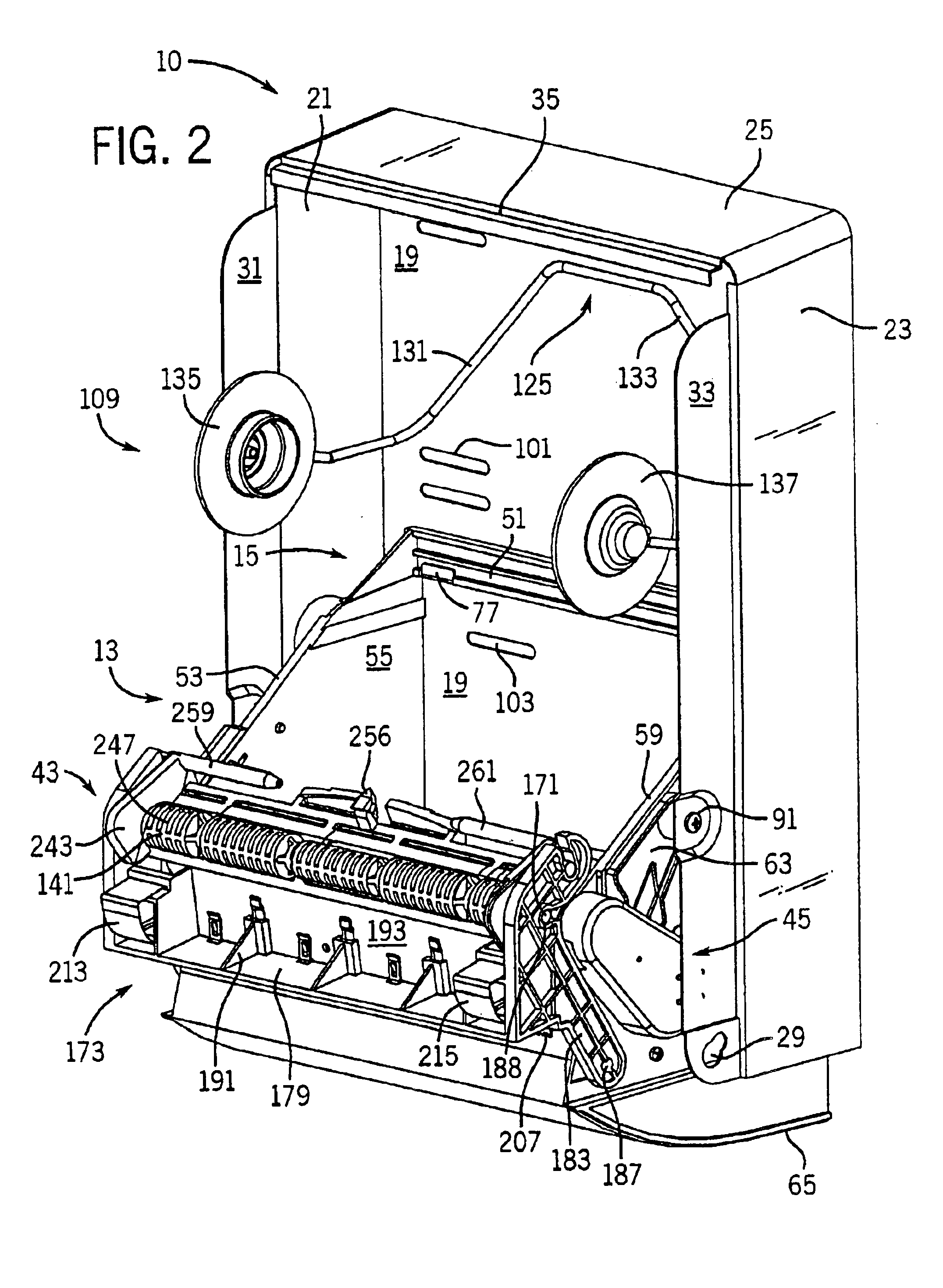

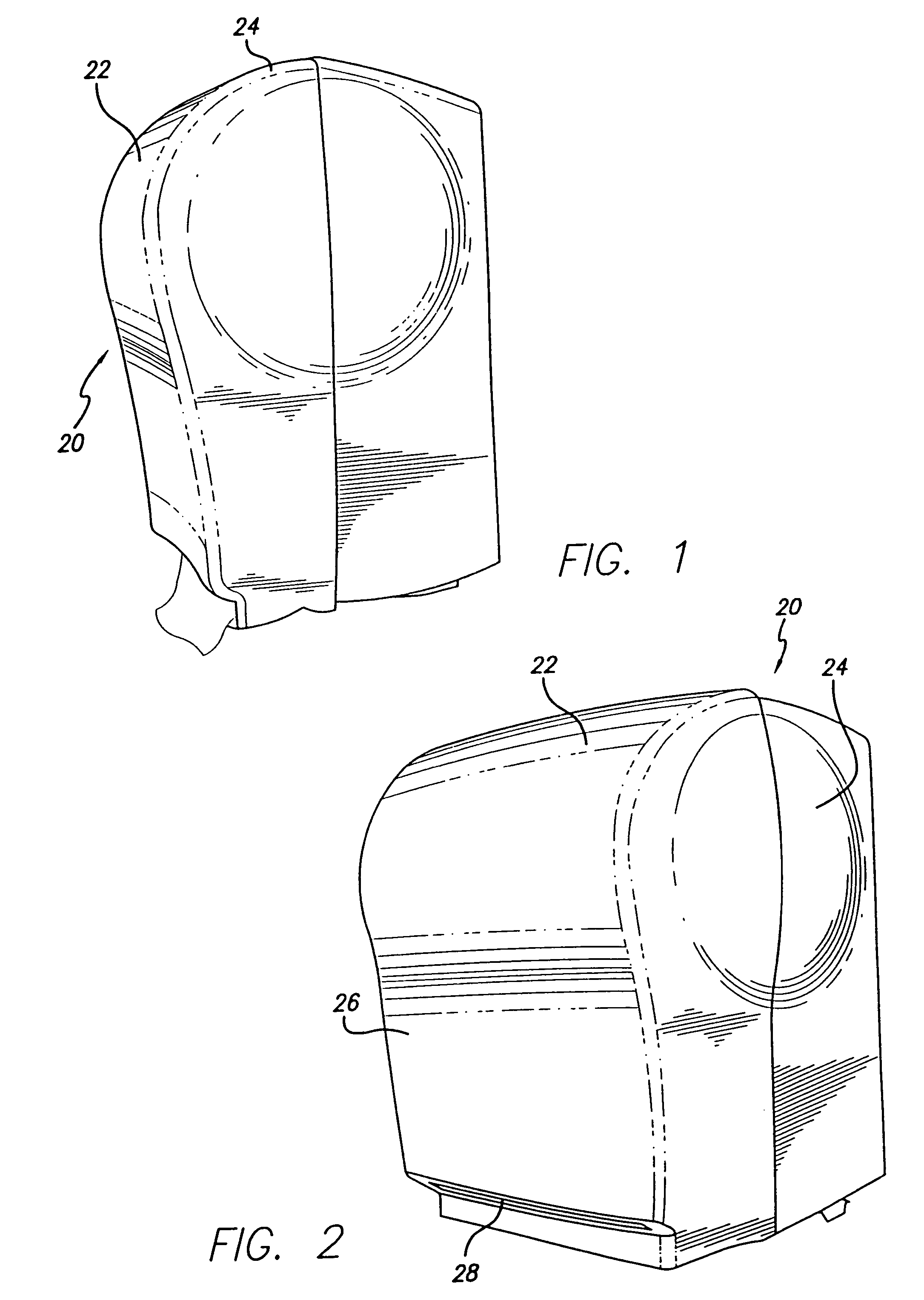

Static build up control in electronic dispensing systems

Apparatus for dispensing paper from rolls which feeds continuously, roll to roll, and does not require extra procedure to bring stub roll into position. The apparatus has device for holding and positioning at least first and second rolls of paper with respect to each other; device for dispensing paper from the first roll; device for dispensing paper from the first and second rolls simultaneously when the first roll reduces to a predetermined diameter of paper, device for positioning the depleted first roll for replacement without the necessity of removing the second roll; and device for dispensing from the second and replacement rolls simultaneously when the second roll reduces to a predetermined diameter of paper. The apparatus also has a proximity sensor, which senses when a hand is placed near the dispenser, and thereupon dispenses a set amount of towel. The dispenser incorporates device for dissipating static charges to a local ground.

Owner:GPCP IP HLDG LLC

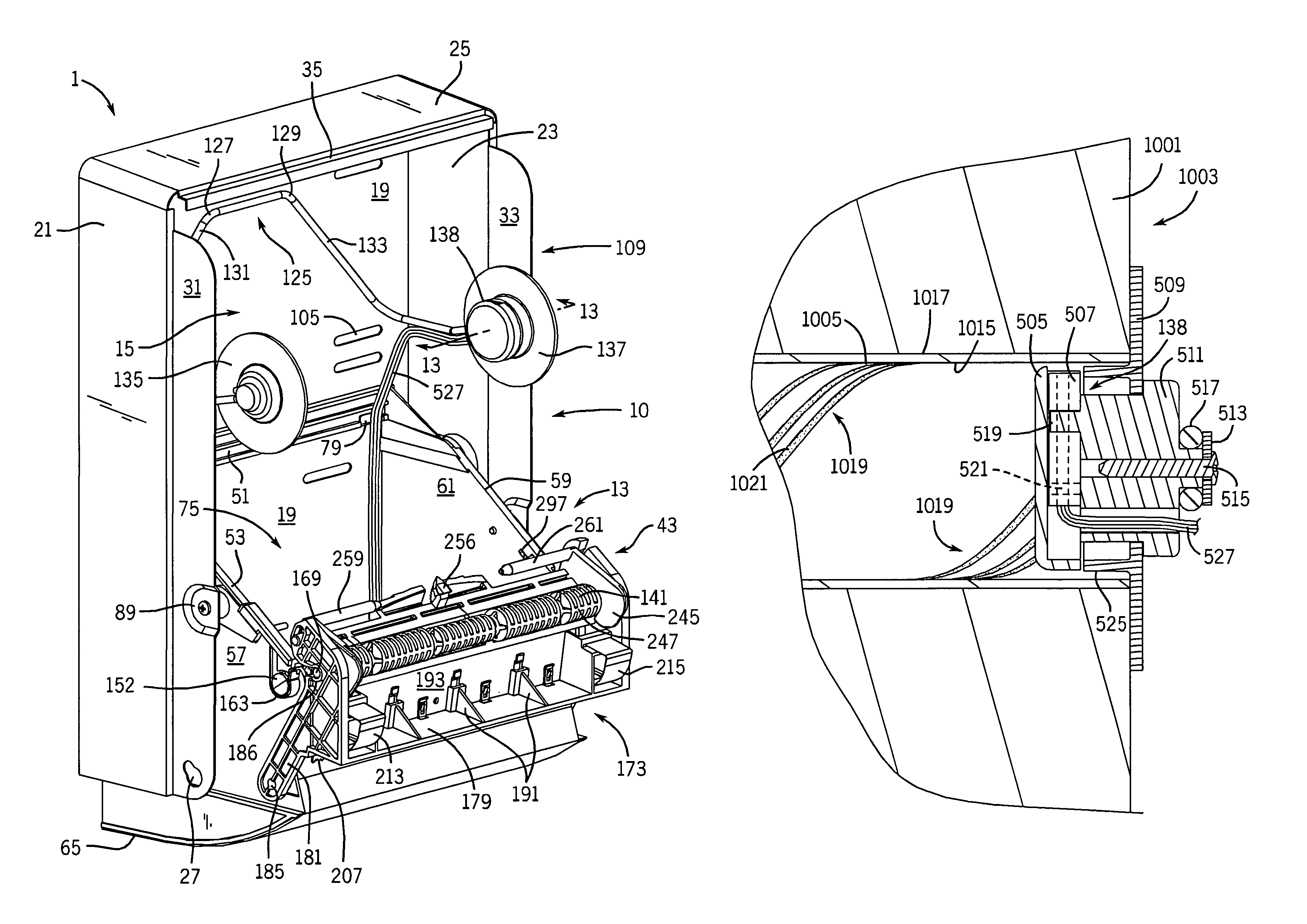

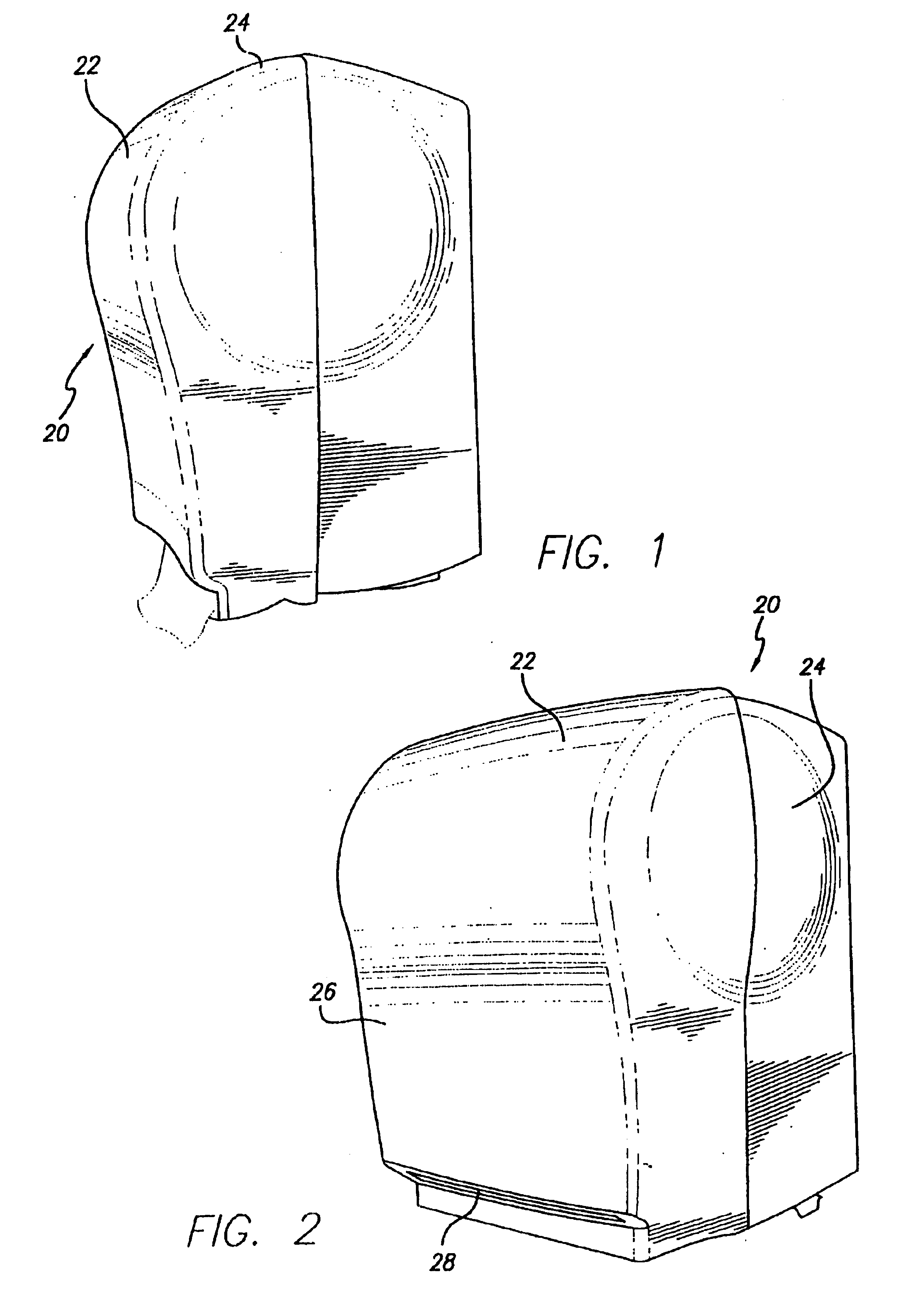

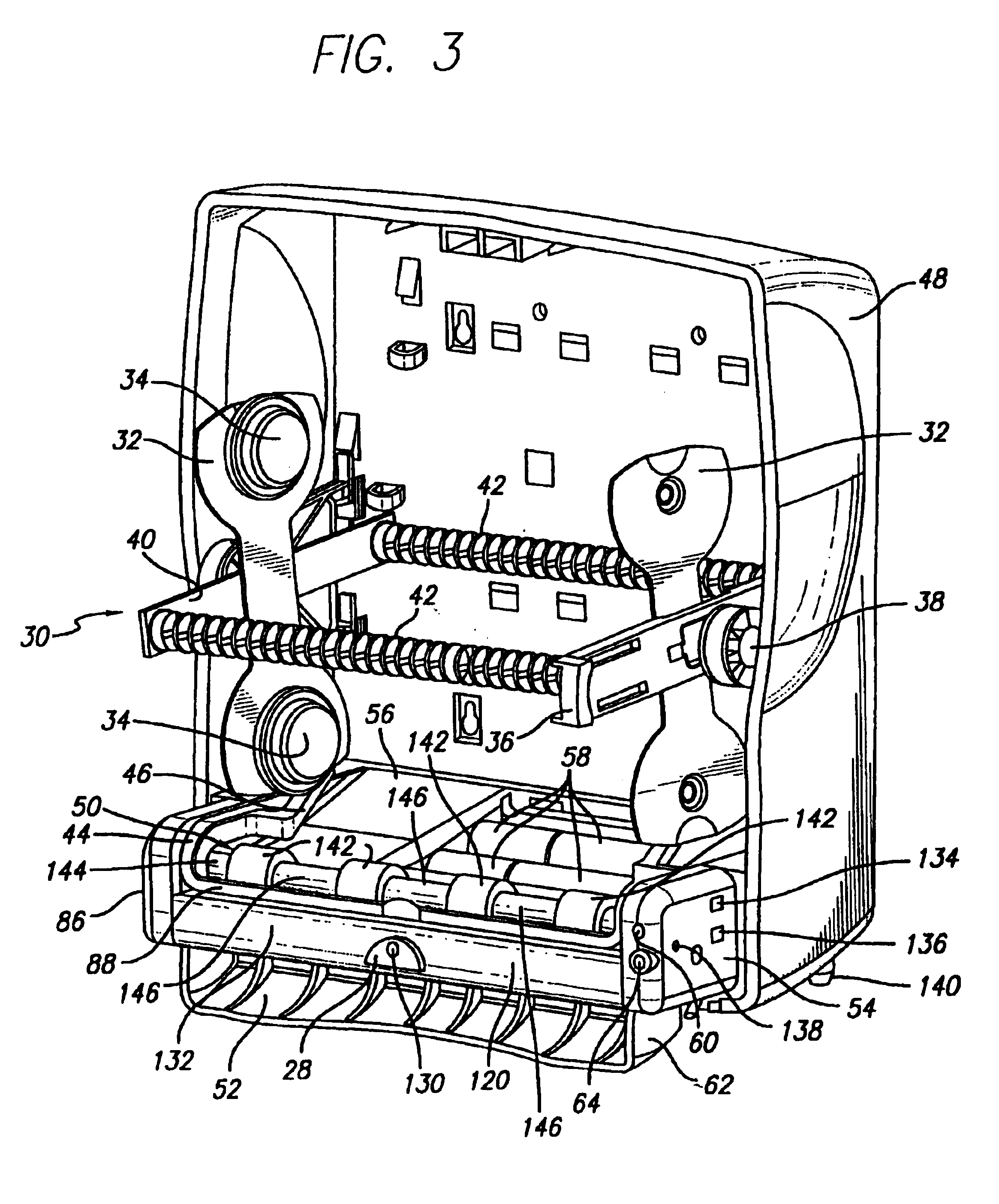

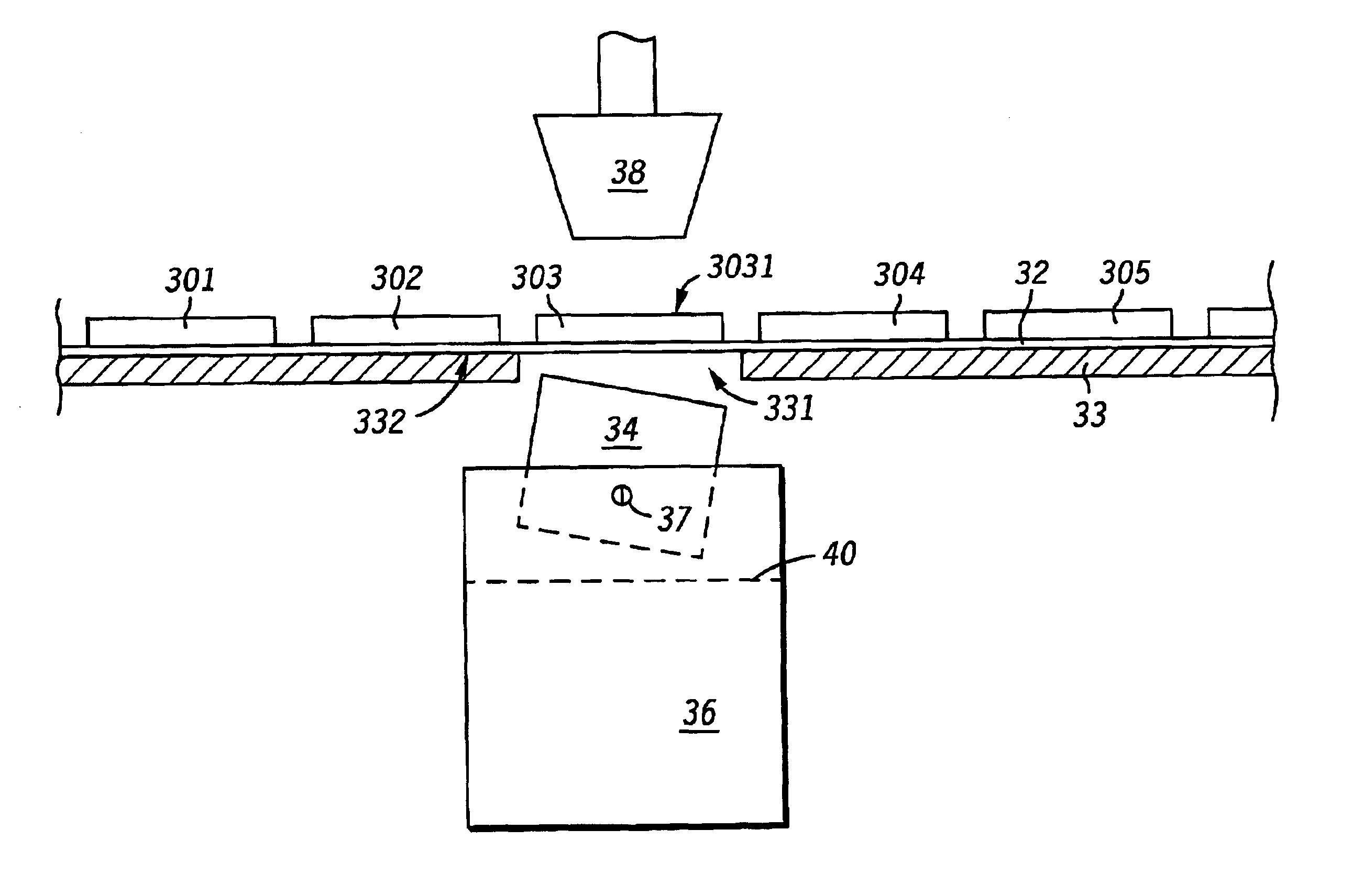

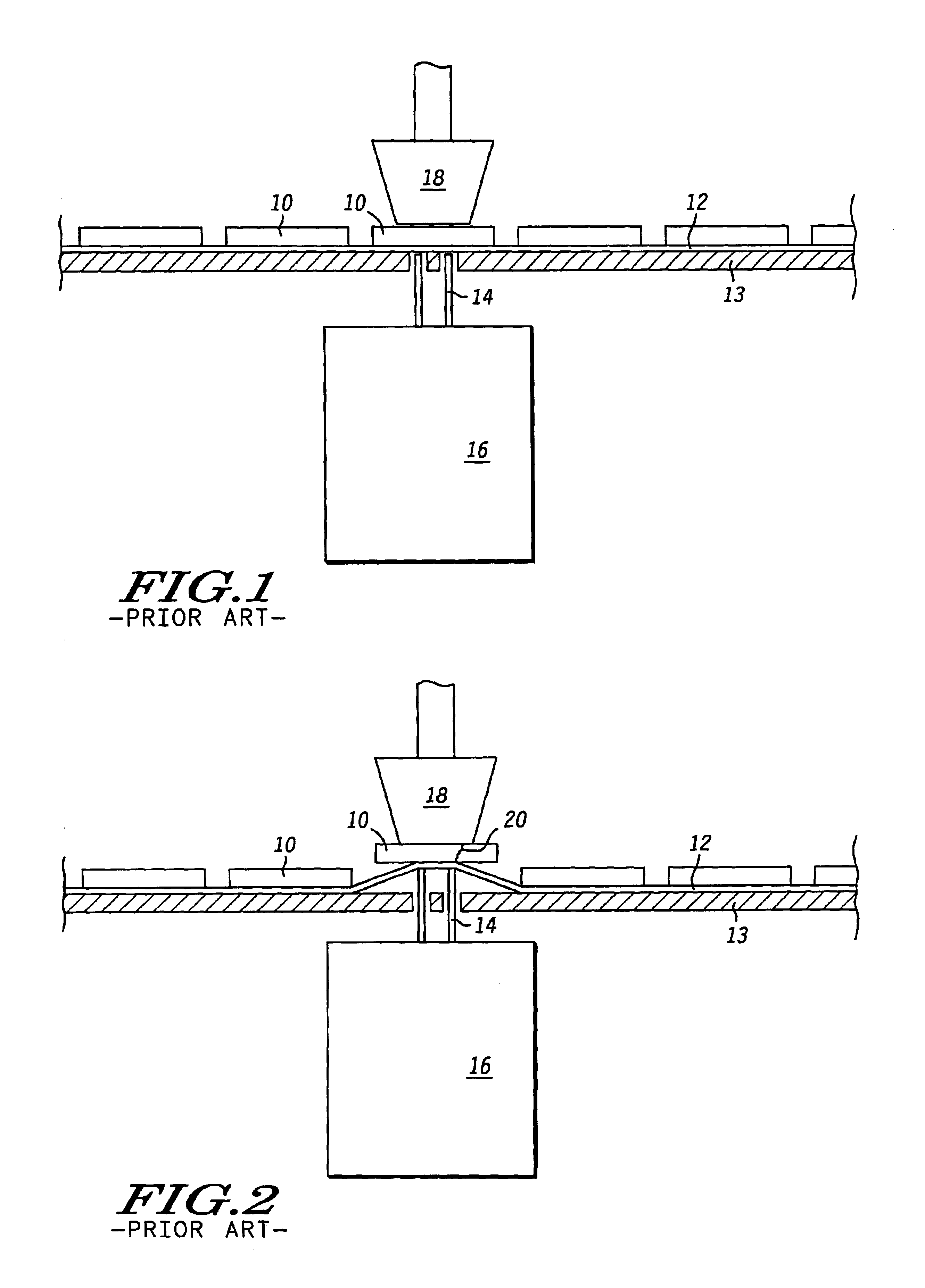

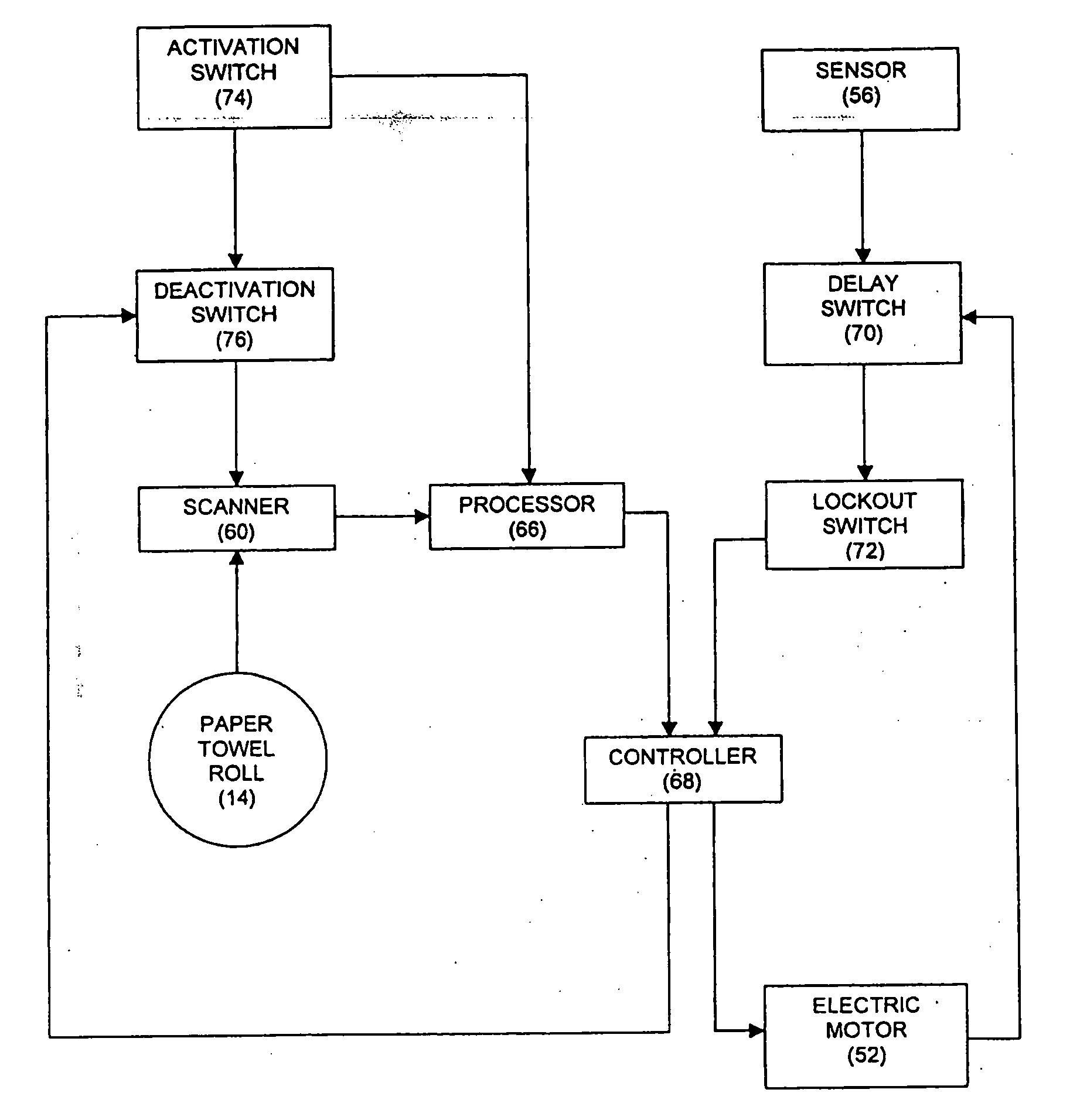

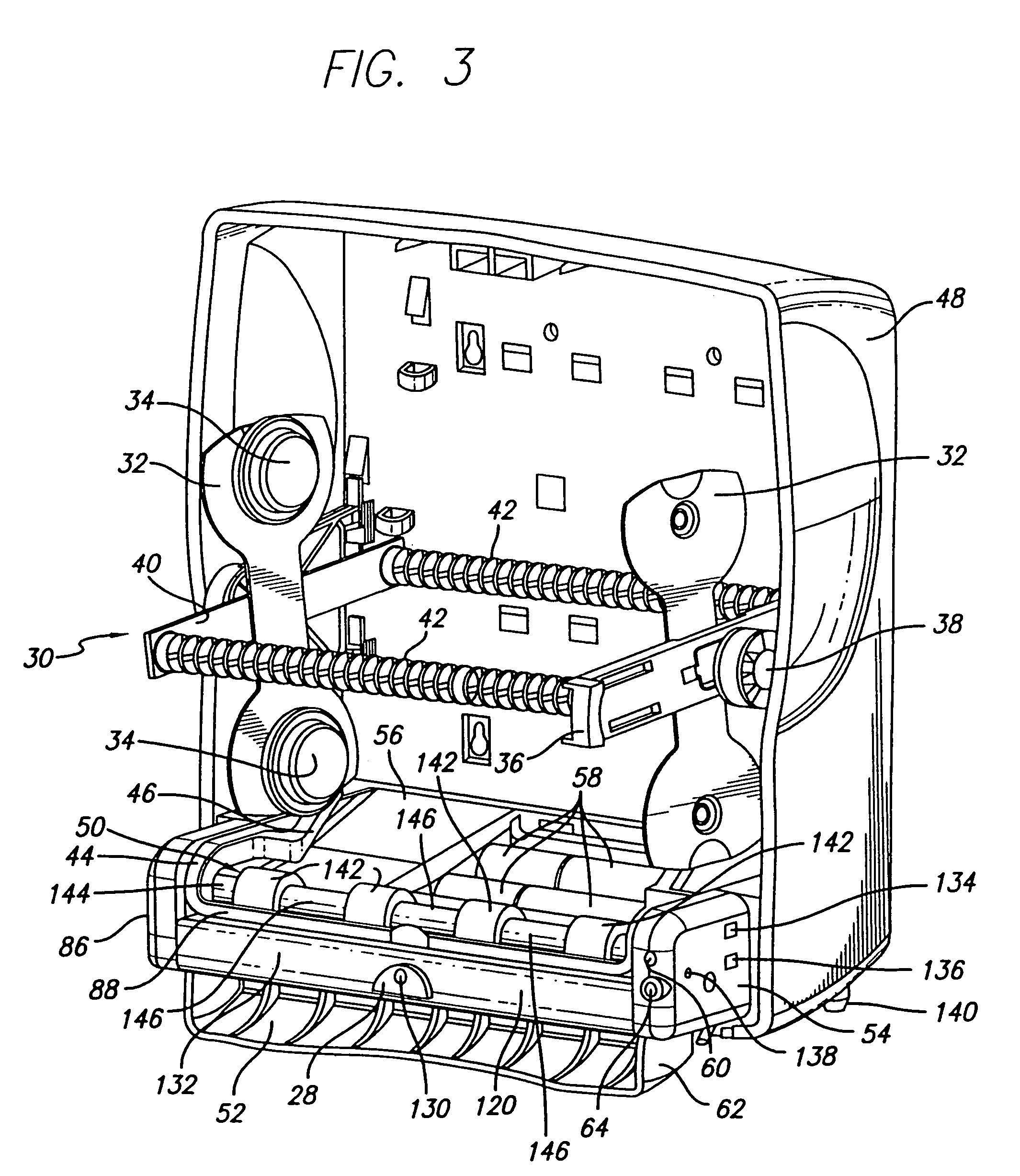

Dispenser with material-recognition apparatus and material-recognition method

InactiveUS7040566B1Risk minimizationEasy to operateFilament handlingDomestic applicationsMechanical componentsEngineering

Dispenser apparatus for dispensing flexible sheet material including material-recognition apparatus permitting the dispenser to recognize sheet material from an authorized source and to be enabled for operation with such material. The dispenser preferably includes standard mechanical components for dispensing sheet material from the dispenser including a housing, structure for supporting a roll of sheet material, drive and tension rollers forming a nip through which the sheet material is displaced as the drive roller rotates and drive apparatus in power-transmission relationship with the drive roller. The material-recognition apparatus includes a sensor mounted in the dispenser housing and in position to scan a code, preferably located on the core on which the sheet material is wound. The sensor generates a code signal corresponding to the code. A control circuit operatively connected to the sensor is adapted to receive the code signal and compare the code represented by said code signal to at least one code in a code database. The dispenser is placed in a dispenser-enabled state capable of dispensing sheet material corresponding to agreement between the codes and a dispenser-disabled state in which the dispenser is disabled when no such code agreement exists.

Owner:ALWIN MFG

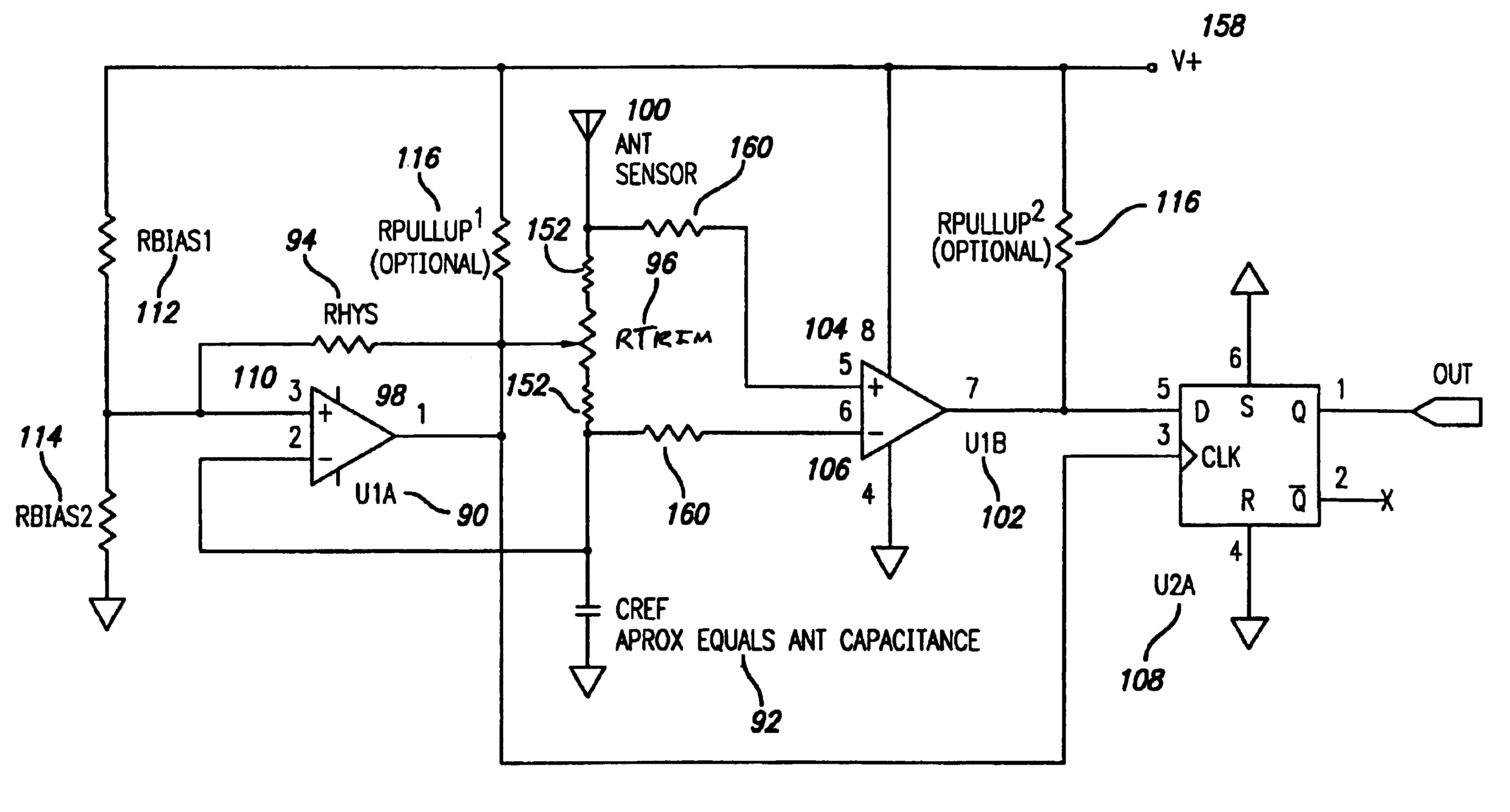

Proximity detection circuit and method of detecting small capacitance changes

InactiveUS6838887B2Guaranteed uptimeReduce wasteCurrent/voltage measurementResistance/reactance/impedenceCapacitanceProximity sensor

Apparatus for dispensing paper from rolls which feeds continuously, roll to roll, and does not require extra procedure to bring stub roll into position. The apparatus holds and positions at least first and second rolls of paper with respect to each other; dispenses paper from the first roll; dispenses paper from the first and second rolls simultaneously when the first roll reduces to a predetermined diameter of paper, positions the depleted first roll for replacement without the necessity of removing the second roll; and dispenses from the second and replacement rolls simultaneously when the second roll reduces to a predetermined diameter of paper. The apparatus also has a proximity sensor, which senses when a hand is placed near the dispenser, and thereupon dispenses a set amount of towel. The proximity sensor incorporates “static” and noise immunity circuitry.

Owner:GPCP IP HLDG LLC

Parallel configuration composite material fabricator

Owner:THE BOEING CO

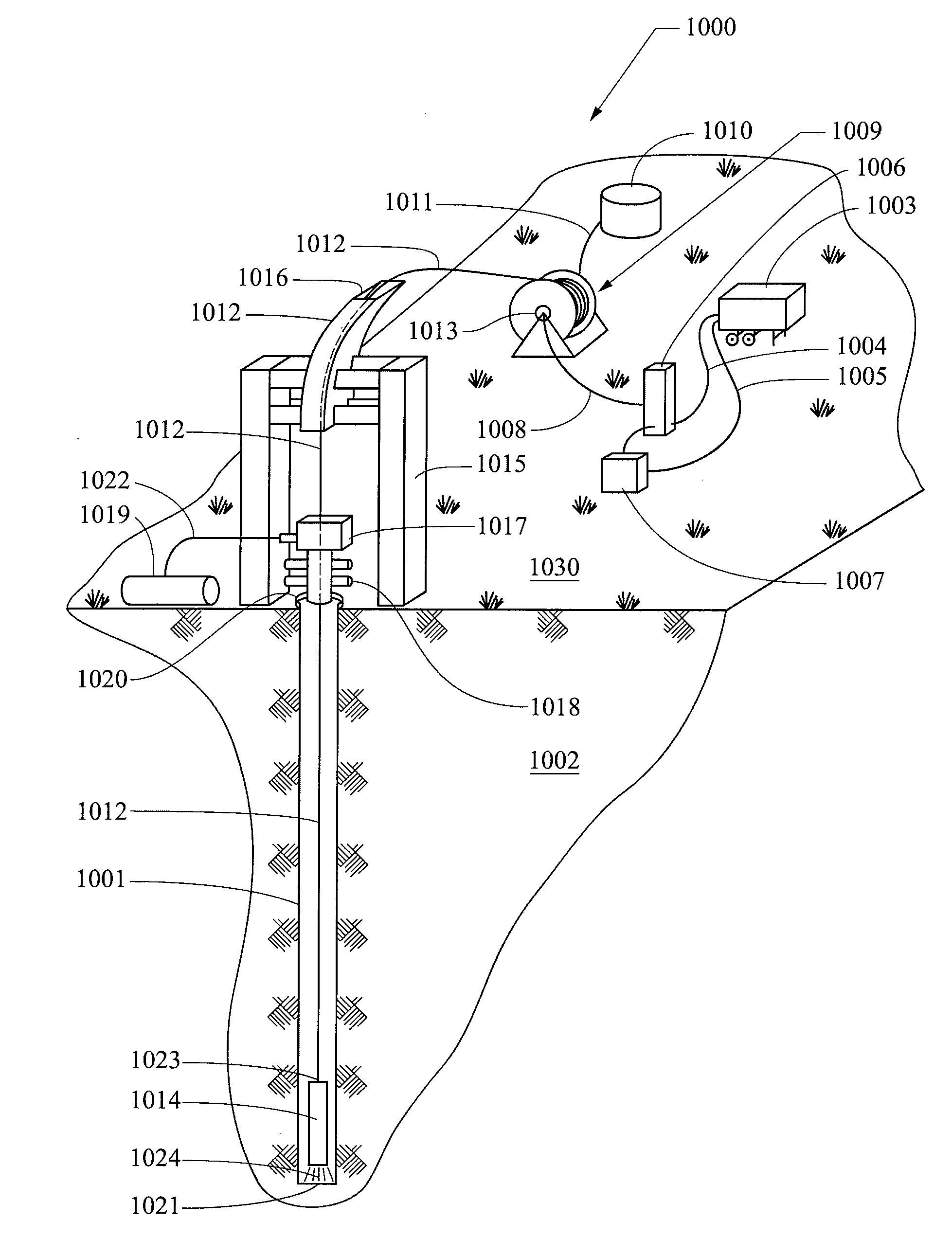

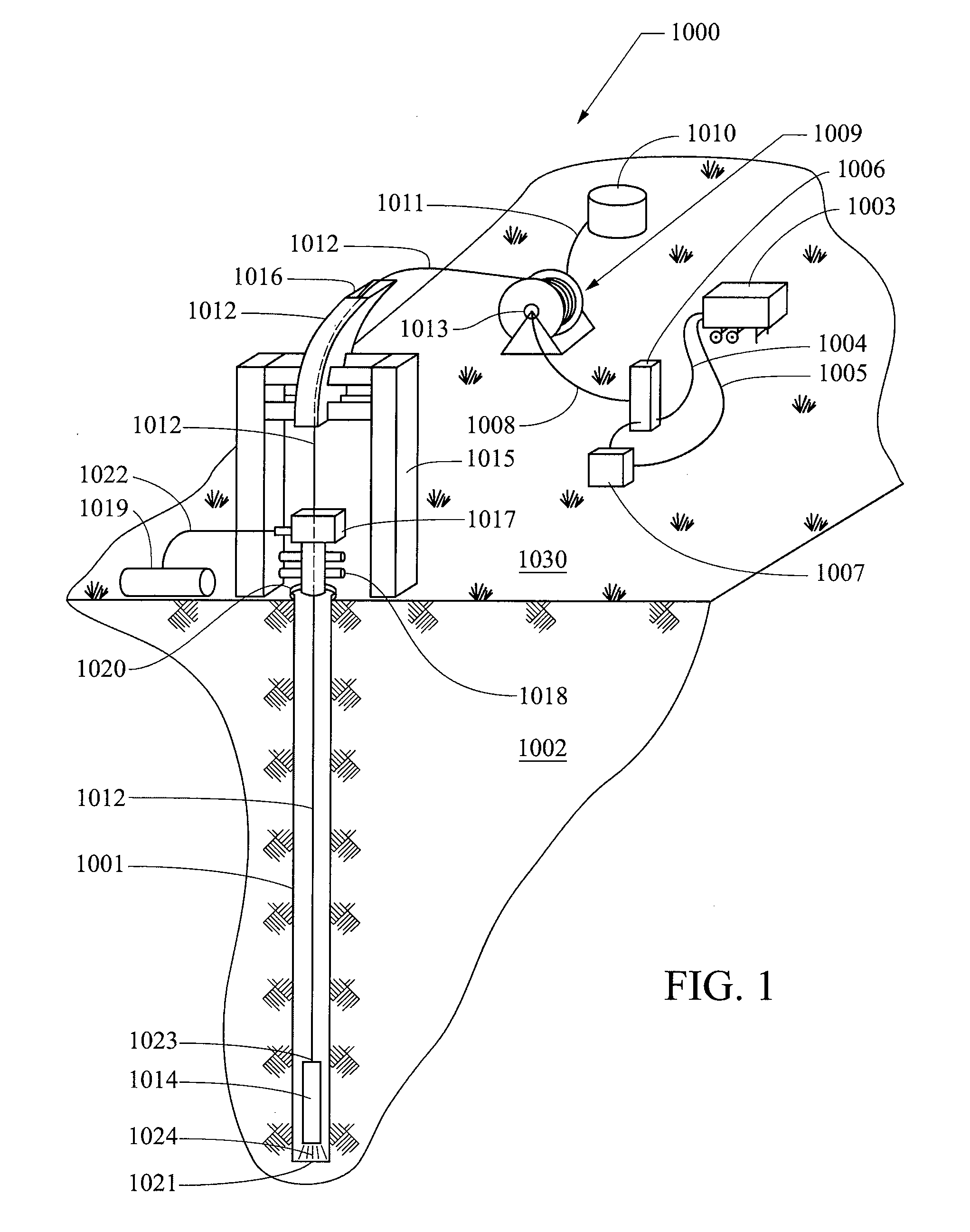

Method and apparatus for delivering high power laser energy over long distances

ActiveUS20100044106A1Suppressing nonlinear scattering phenomenonIncrease the lengthDrill bitsLaser using scattering effectsHigh power lasersOptoelectronics

There is provided a system, apparatus and methods for the laser drilling of a borehole in the earth. There is further provided with in the systems a means for delivering high power laser energy down a deep borehole, while maintaining the high power to advance such boreholes deep into the earth and at highly efficient advancement rates.

Owner:FORO ENERGY

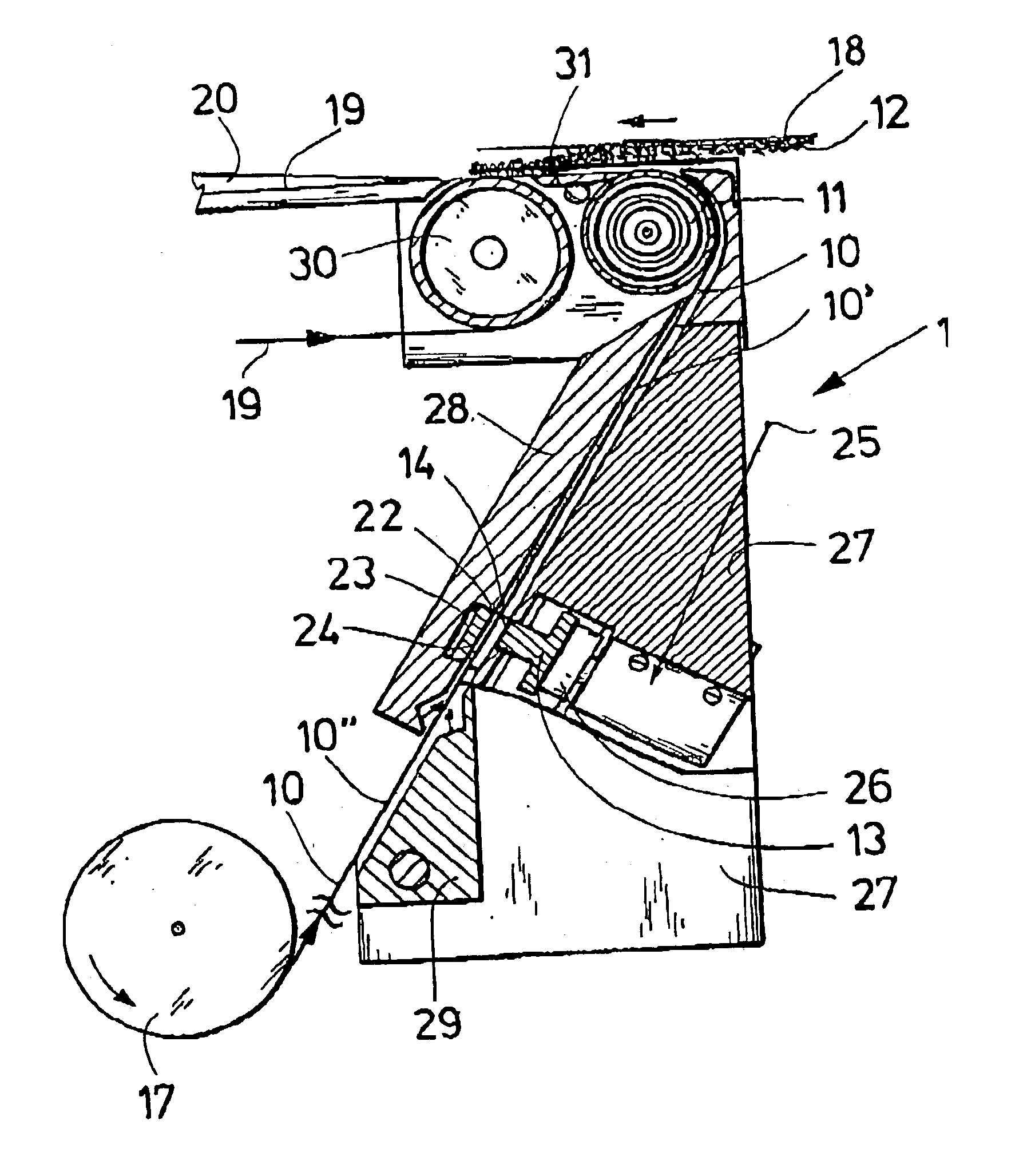

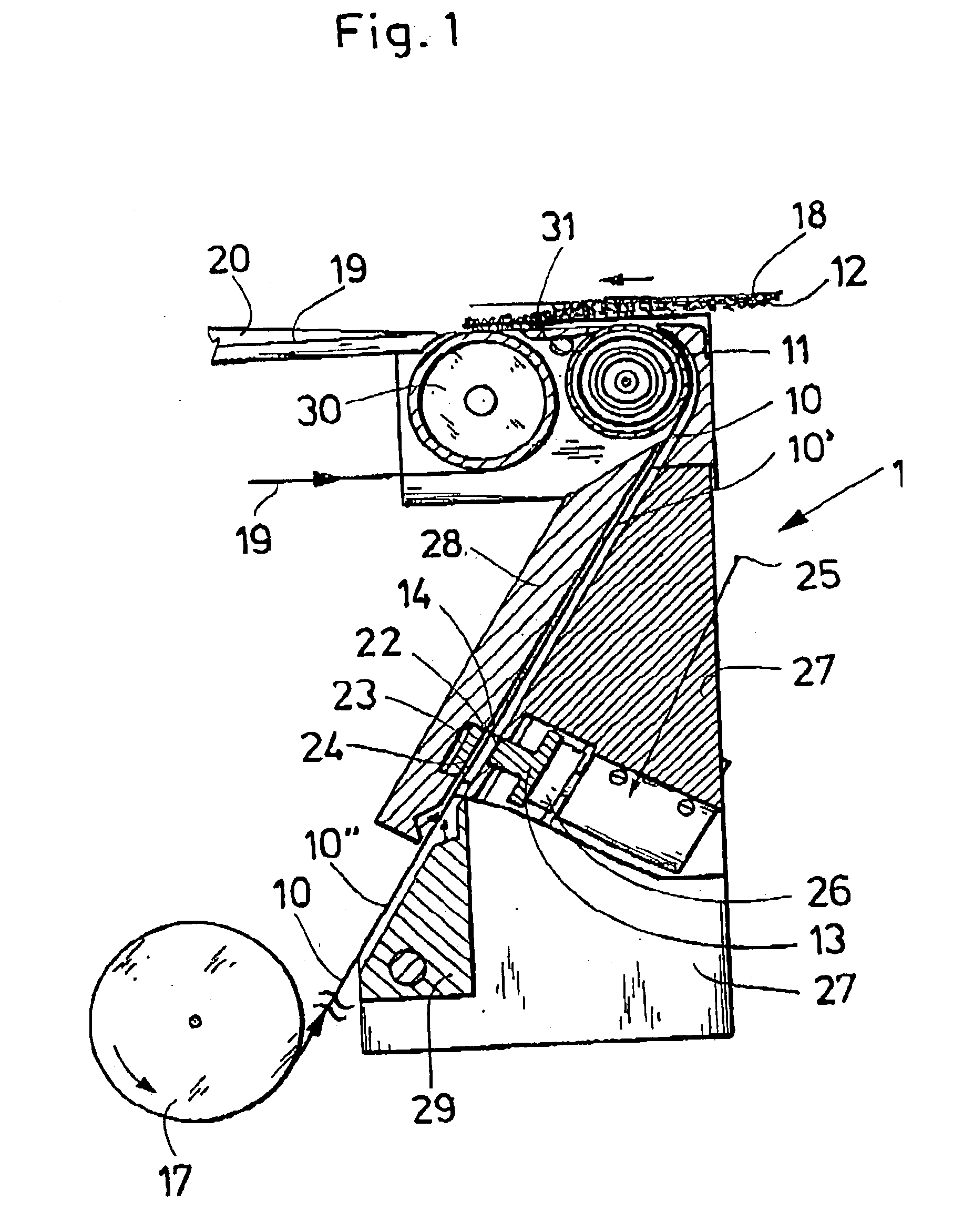

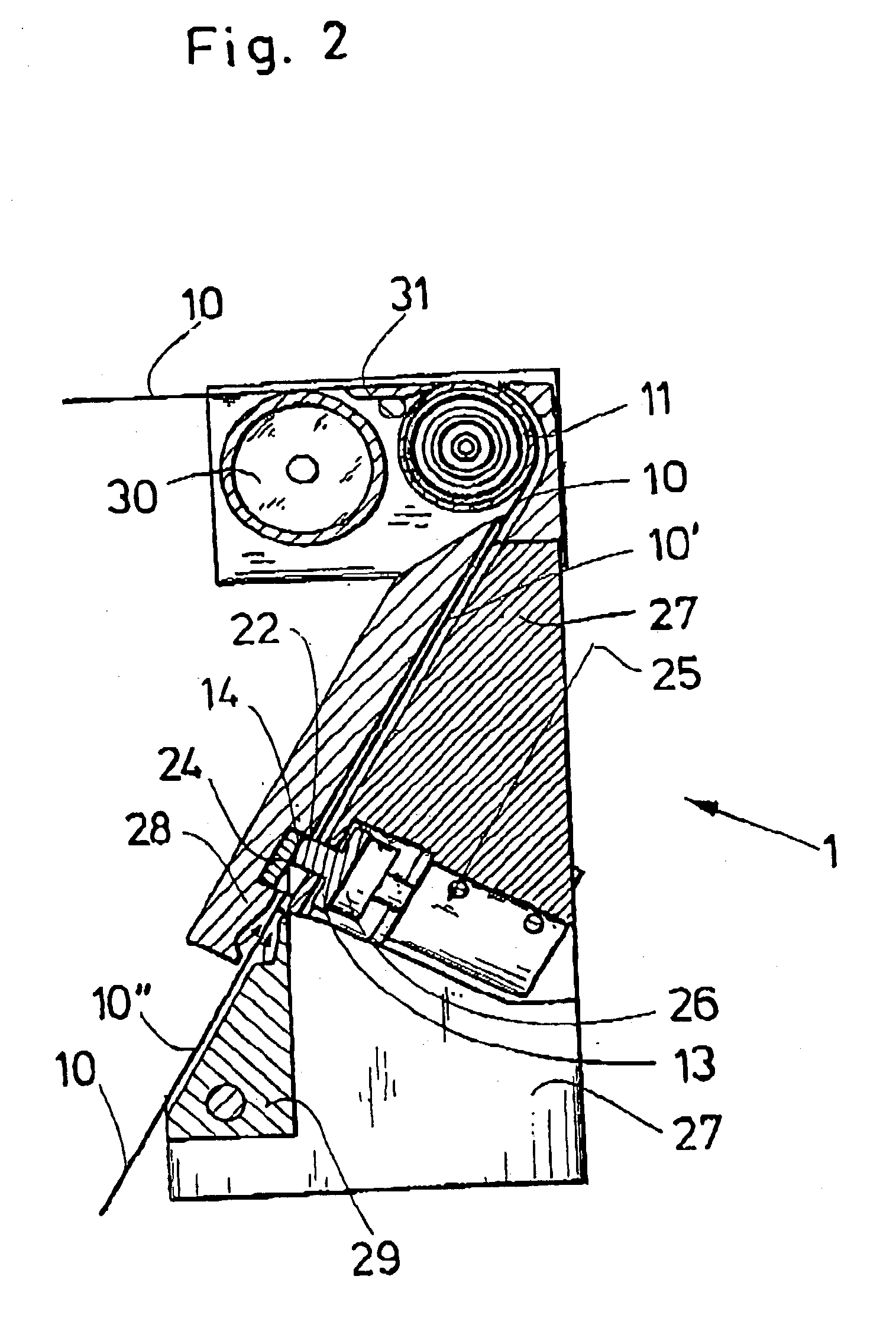

Process and device for conveying a wrapper strip in a machine of the tobacco processing industry

InactiveUS20030145866A1Little time takenGuaranteed uptimeCigar manufactureCigarette manufactureEngineeringMechanical engineering

Process and apparatus for operating a machine of the tobacco processing industry. The process includes guiding at least one wrapper strip along a conveyor path from a wrapping strip supply to a garniture device, and fixing the at least one wrapper strip in at least one preset position along the conveyor path The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:HAUNI MASCHINENBAU AG

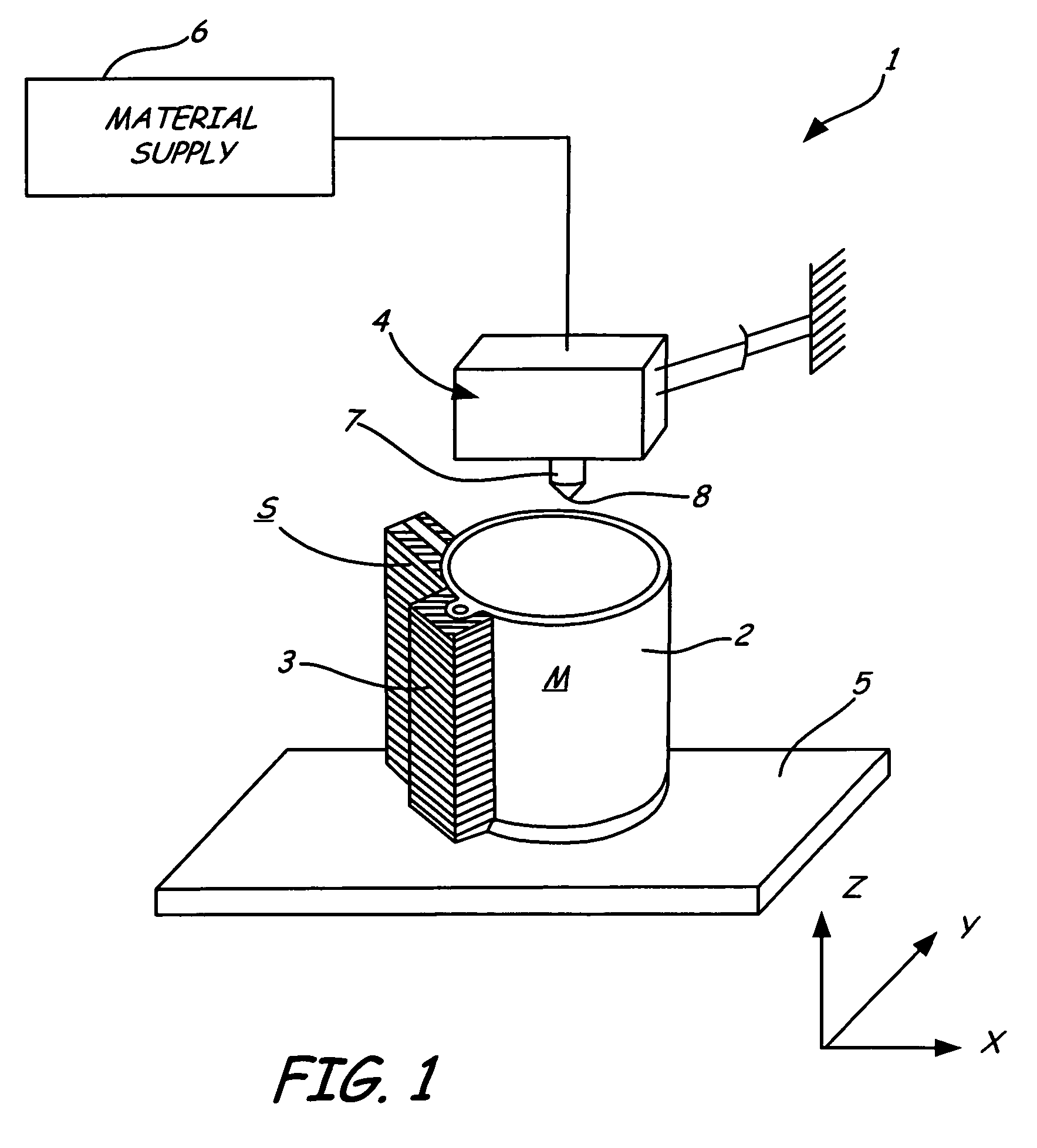

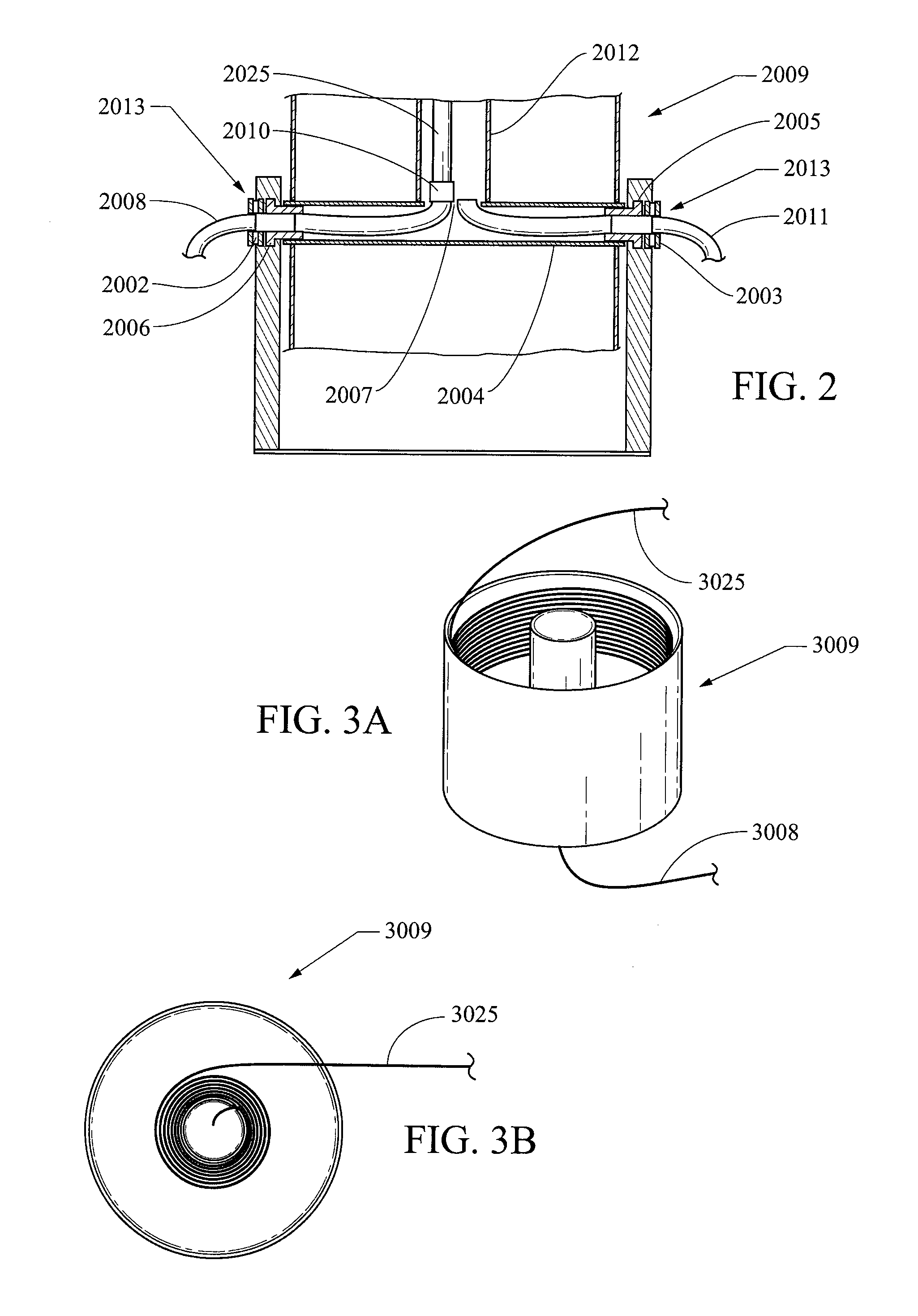

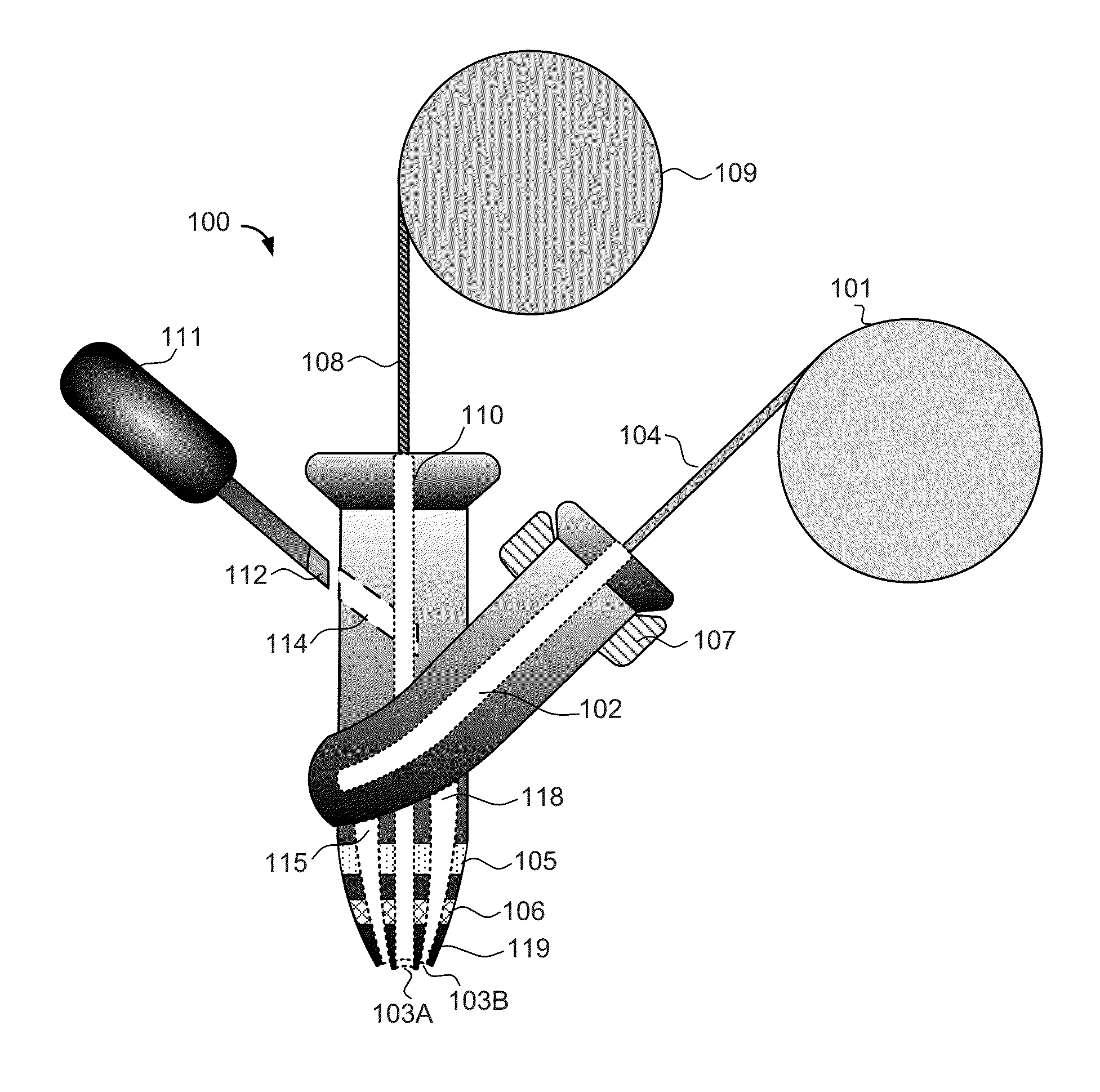

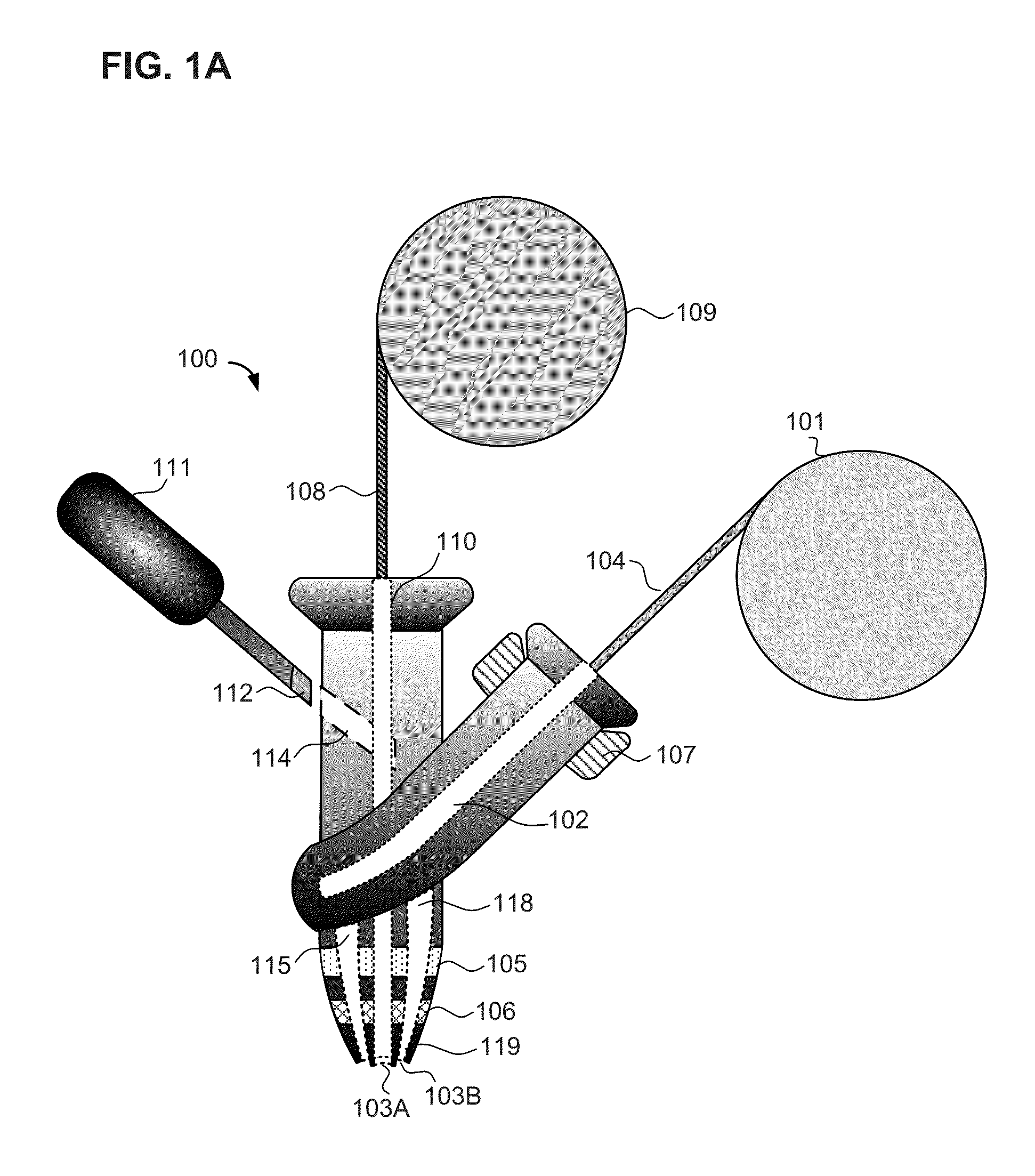

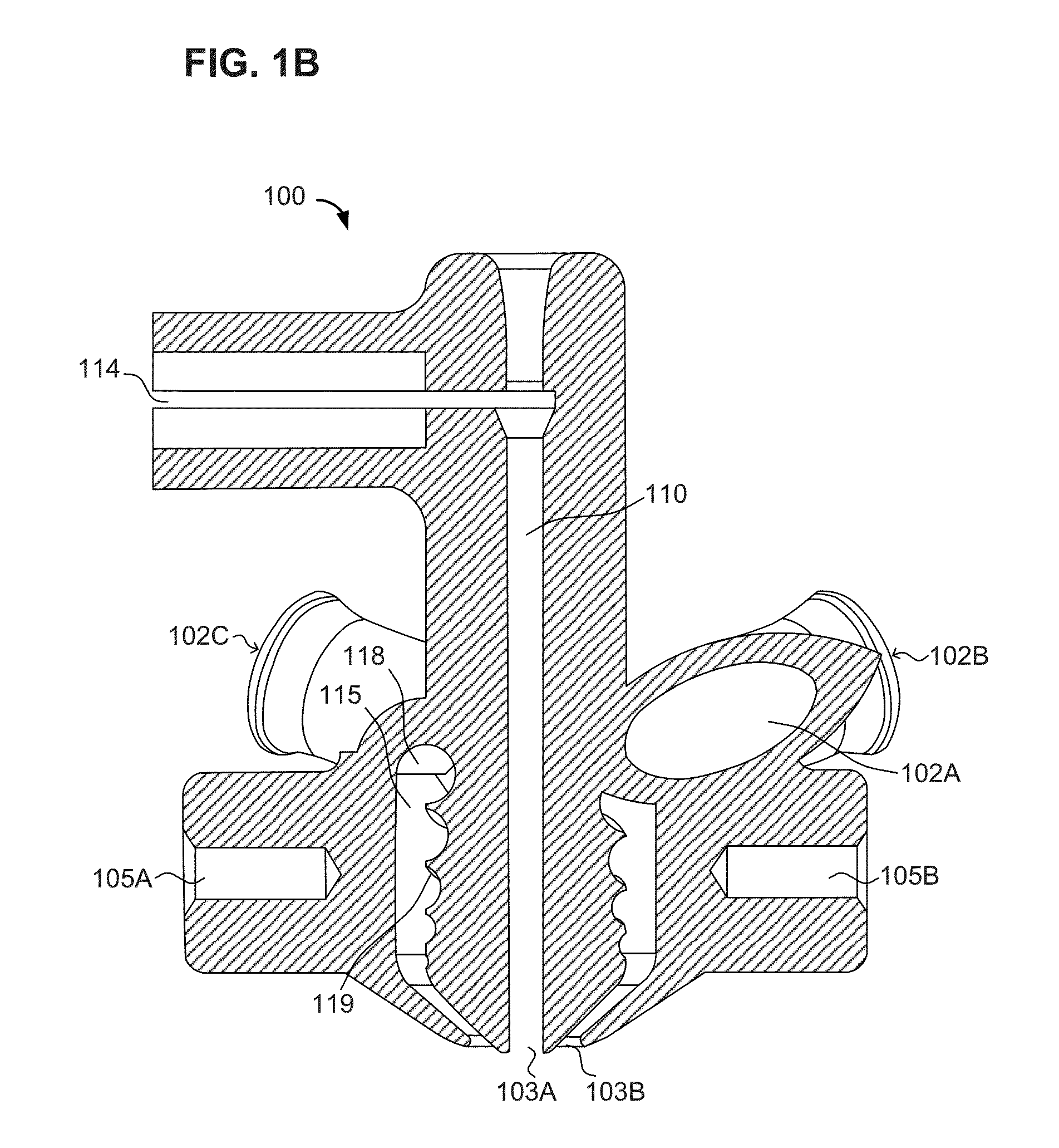

Additive manufacturing techniques and systems to form composite materials

InactiveUS20160136885A1Well formedConfectioneryCeramic shaping apparatusAdditive layer manufacturingHeating element

A printer system may include a coaxial extruder head that extrudes a core, a bulk, and / or a core and bulk cladding to form complex structures without retooling. The coaxial extruder head may include a distribution channel with an entrance and an exit, a priming chamber that surrounds the distribution channel. The priming chamber may include an outlet and a first inlet, a heating element thermally connected to the priming chamber, and a nozzle connected to the outlet of the priming chamber. Further, the nozzle may converge from the outlet of the priming chamber to an orifice of the nozzle. In addition, the exit of the distribution channel may be disposed at the orifice of the nozzle. This structure facilitates extruding a core and cladding type composite from the extruder head.

Owner:ORBITAL COMPOSITES INC

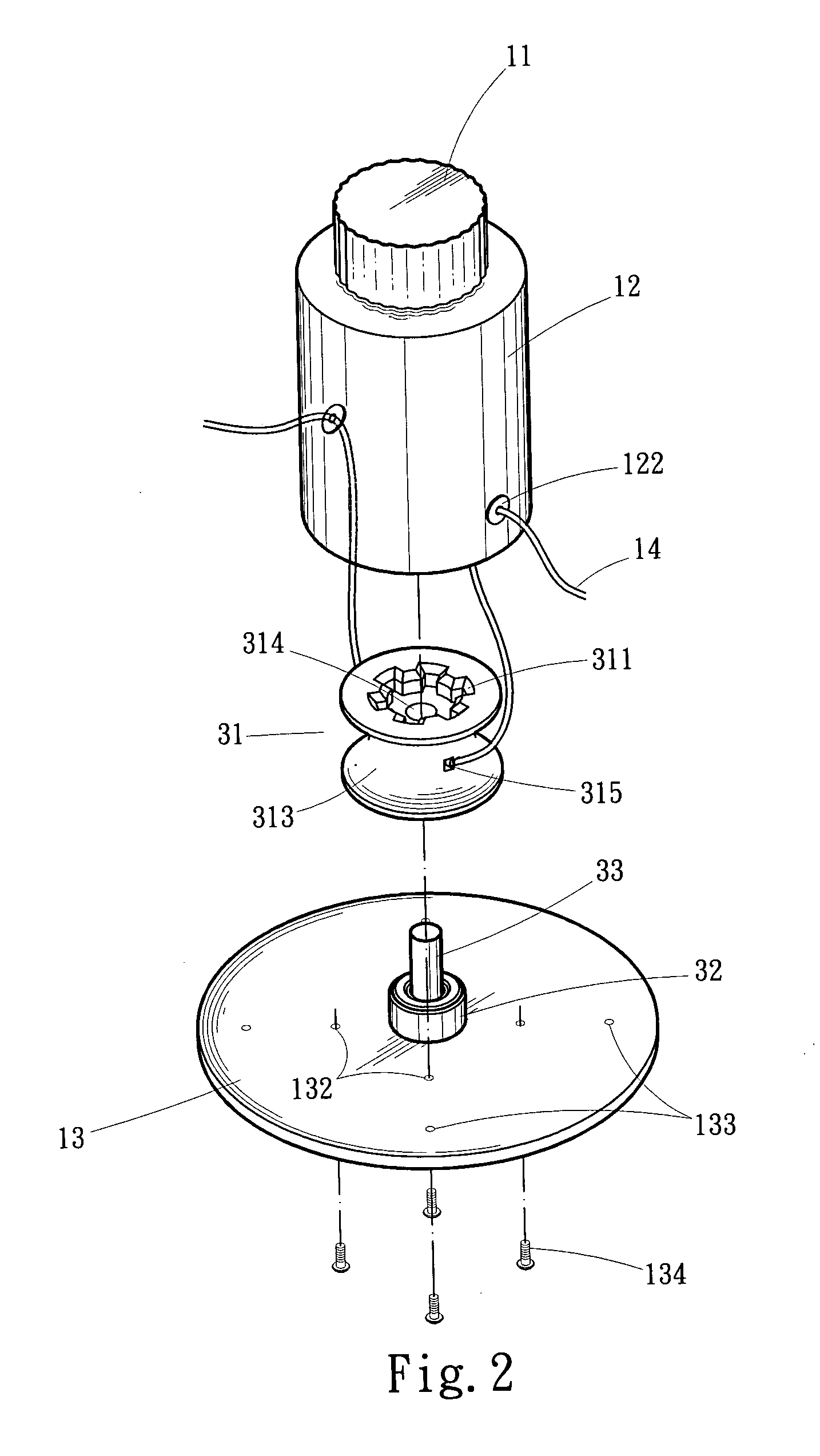

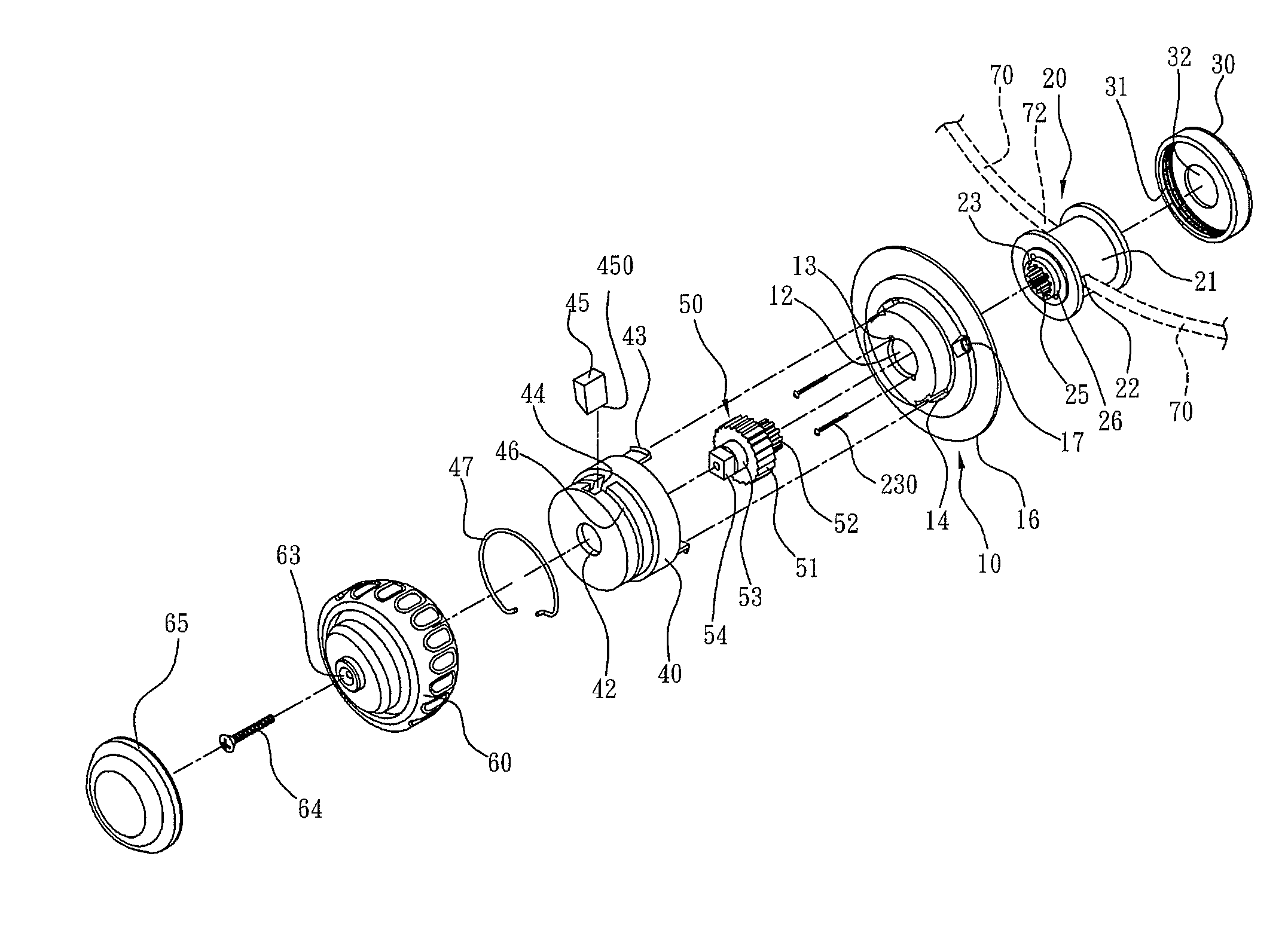

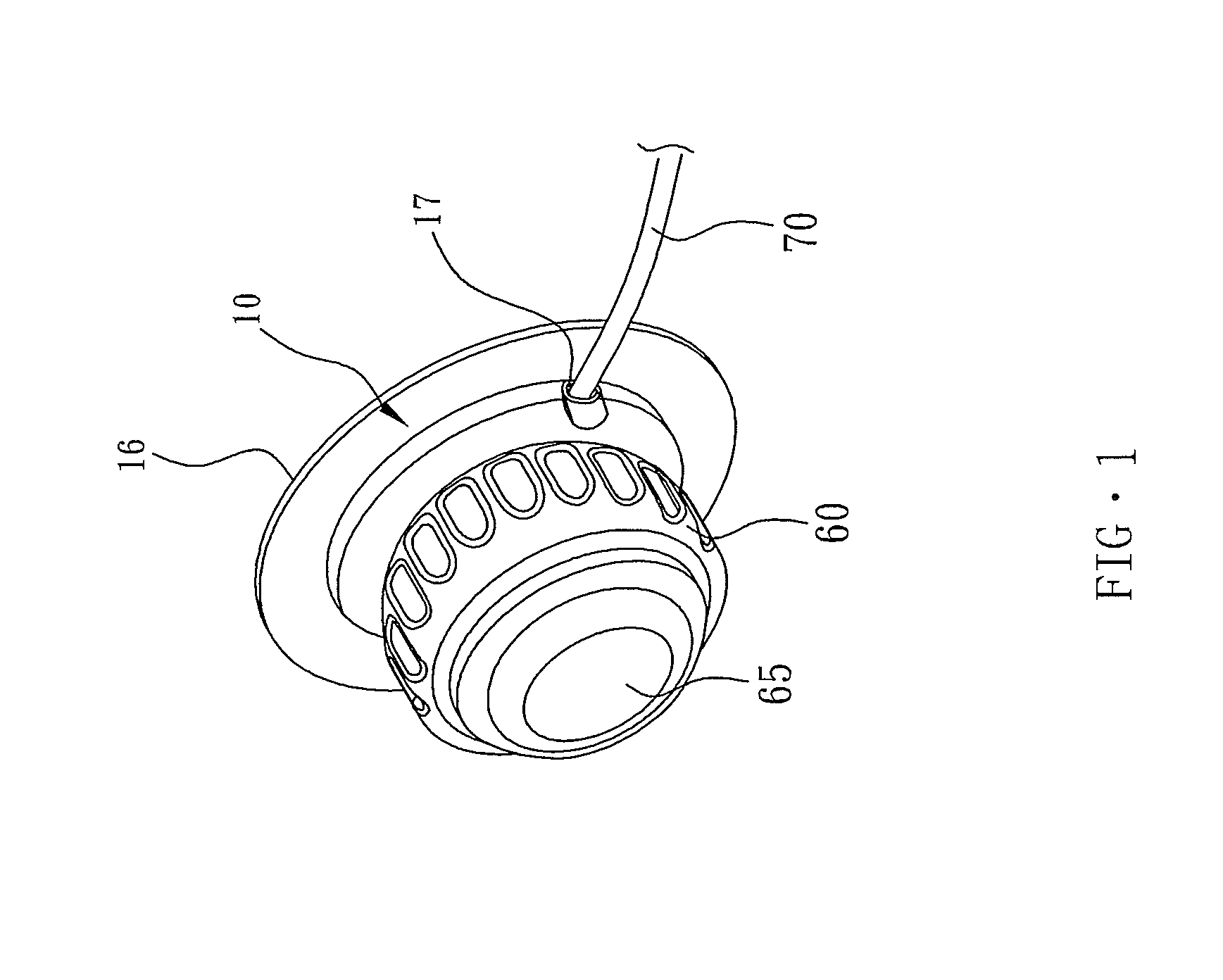

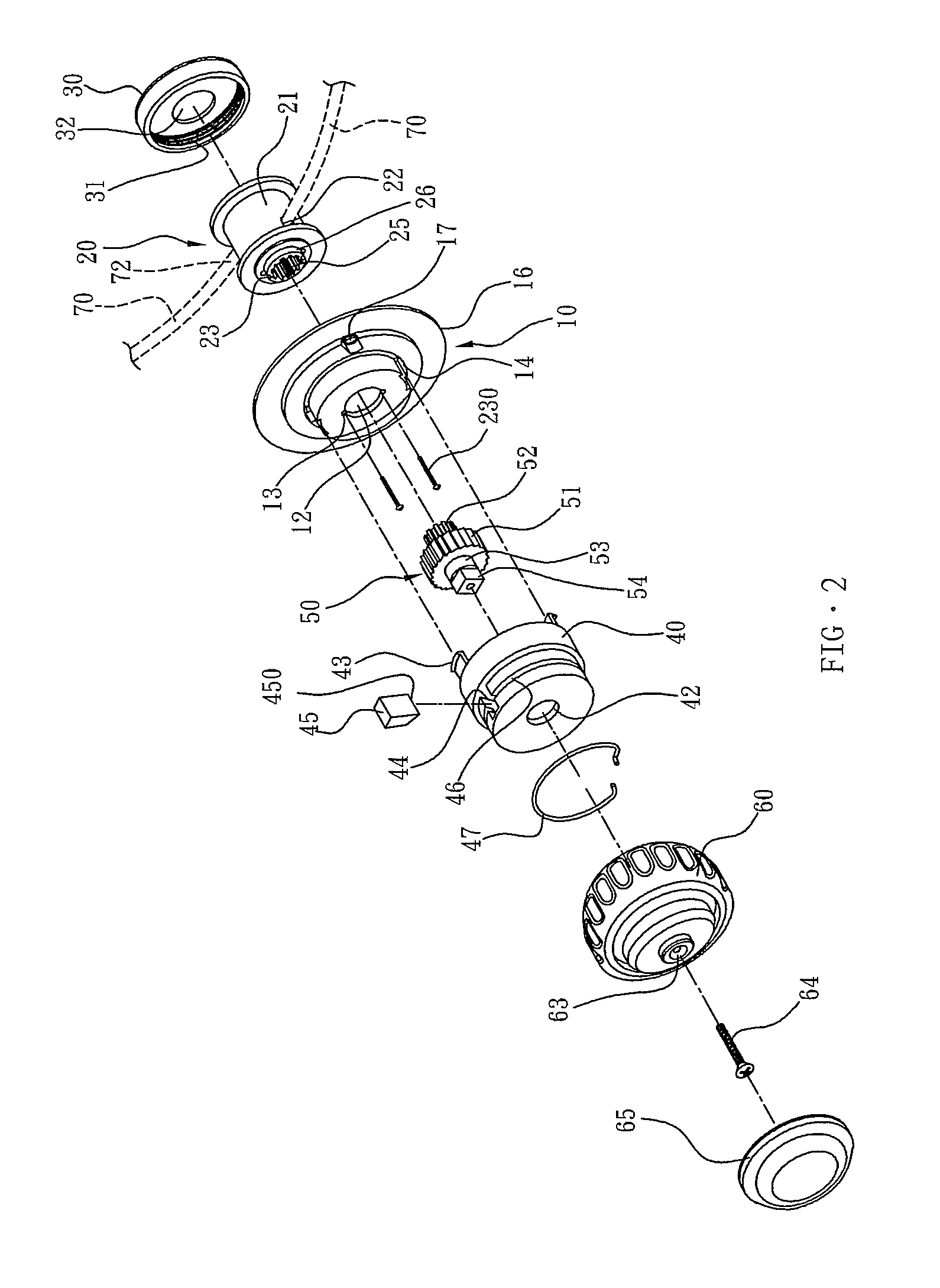

Cord taking-up and releasing device

InactiveUS20050098673A1Easy to operateFilament handlingShoe lace fasteningsEngineeringMechanical engineering

Owner:HUANG WEN SHENG

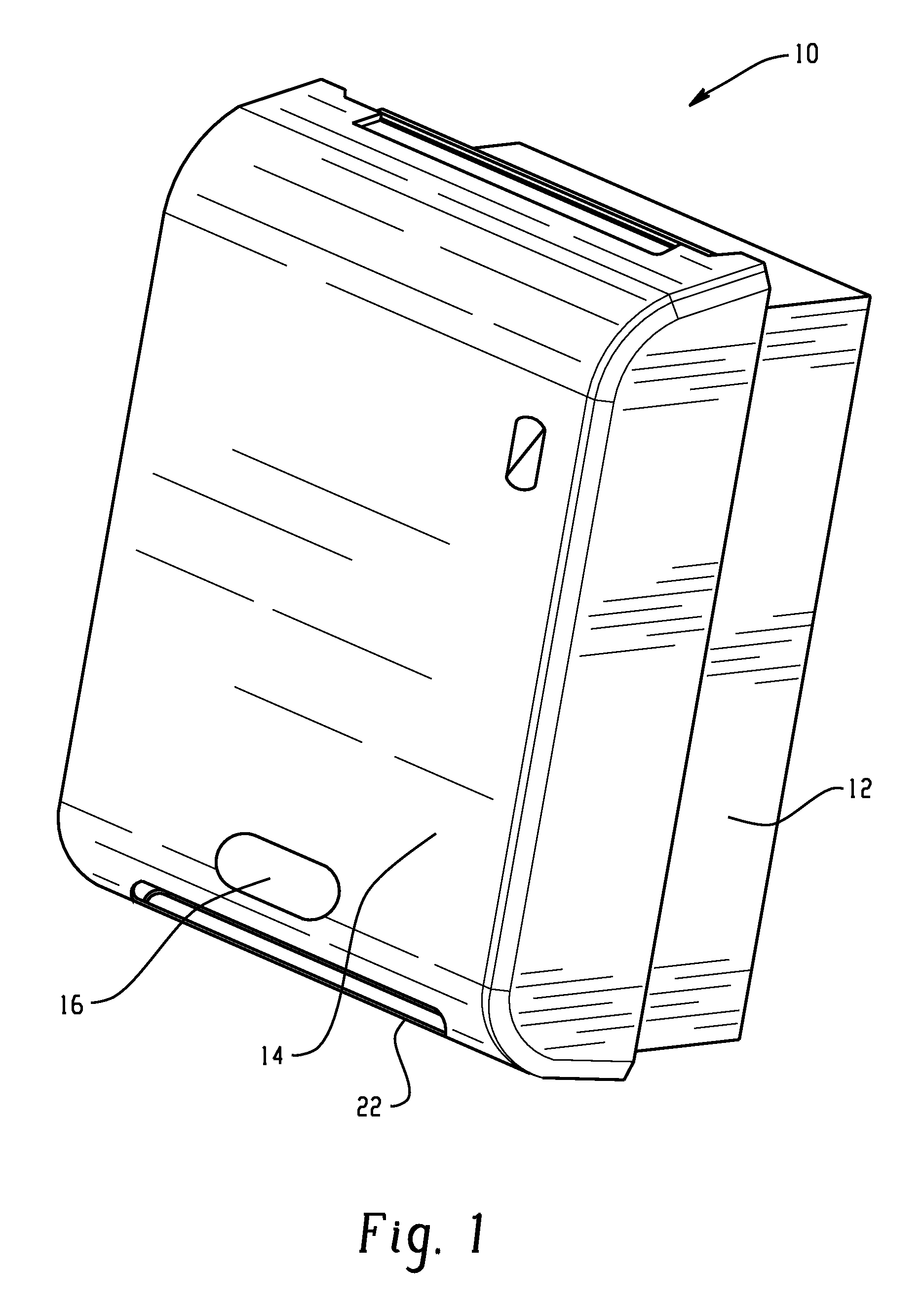

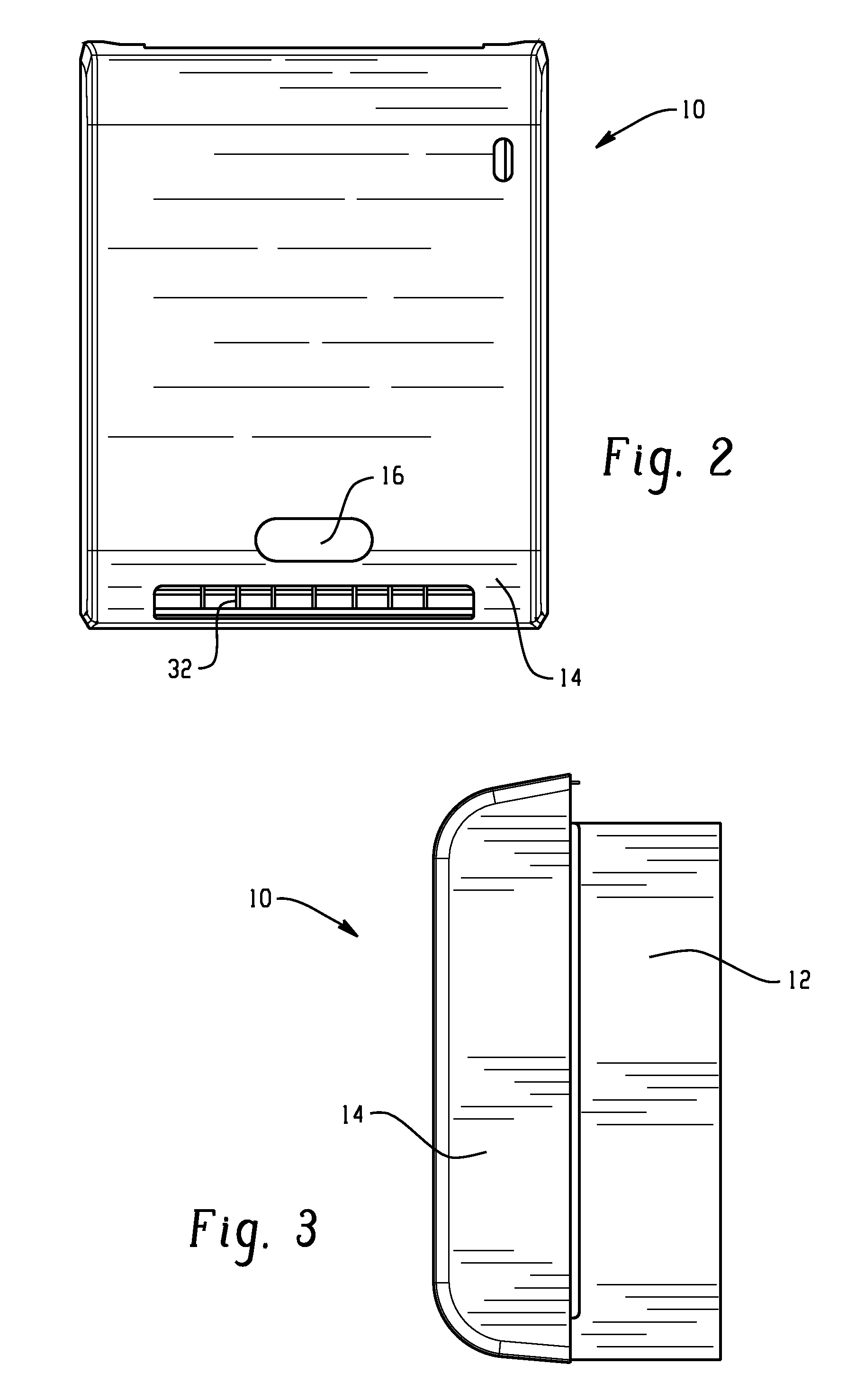

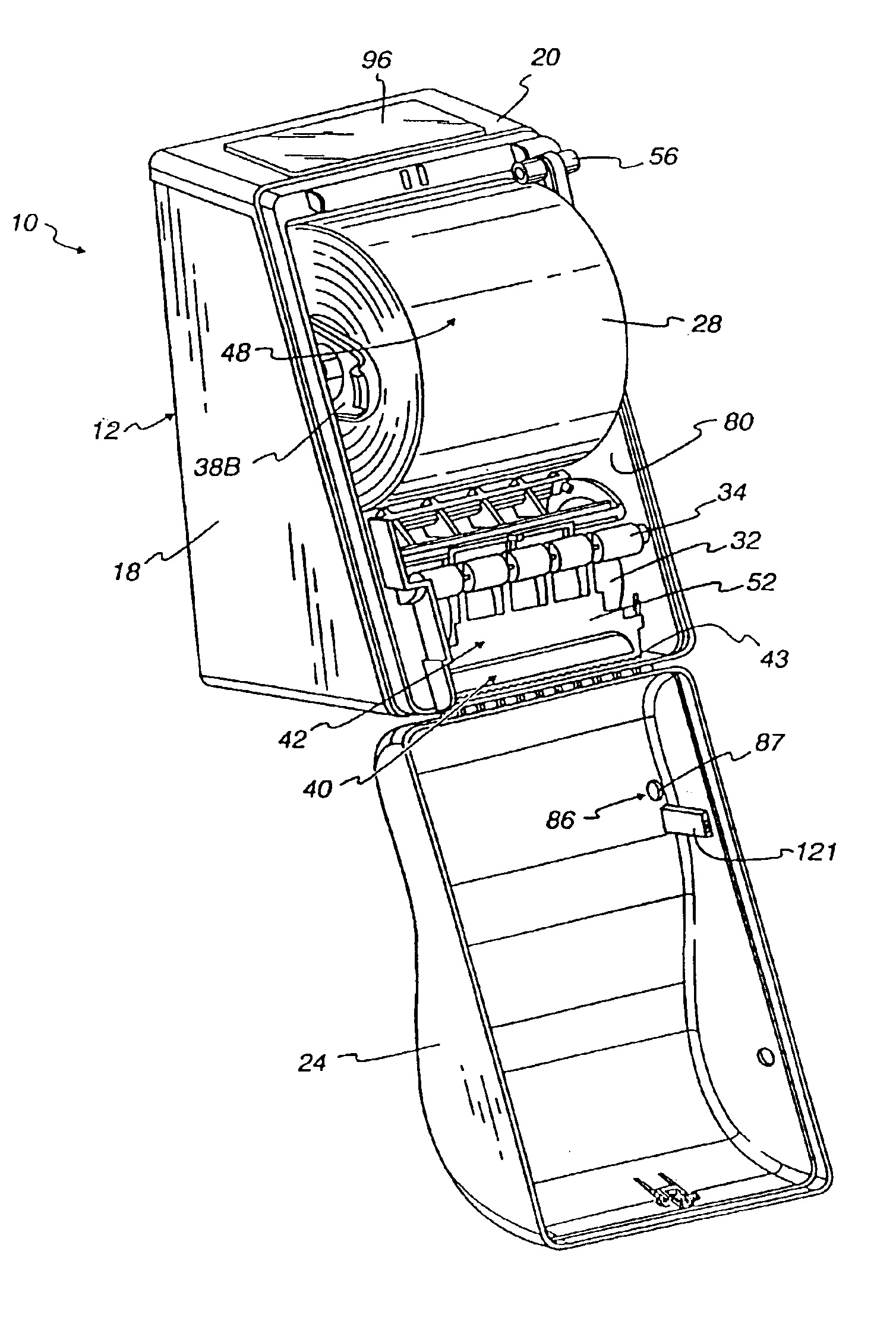

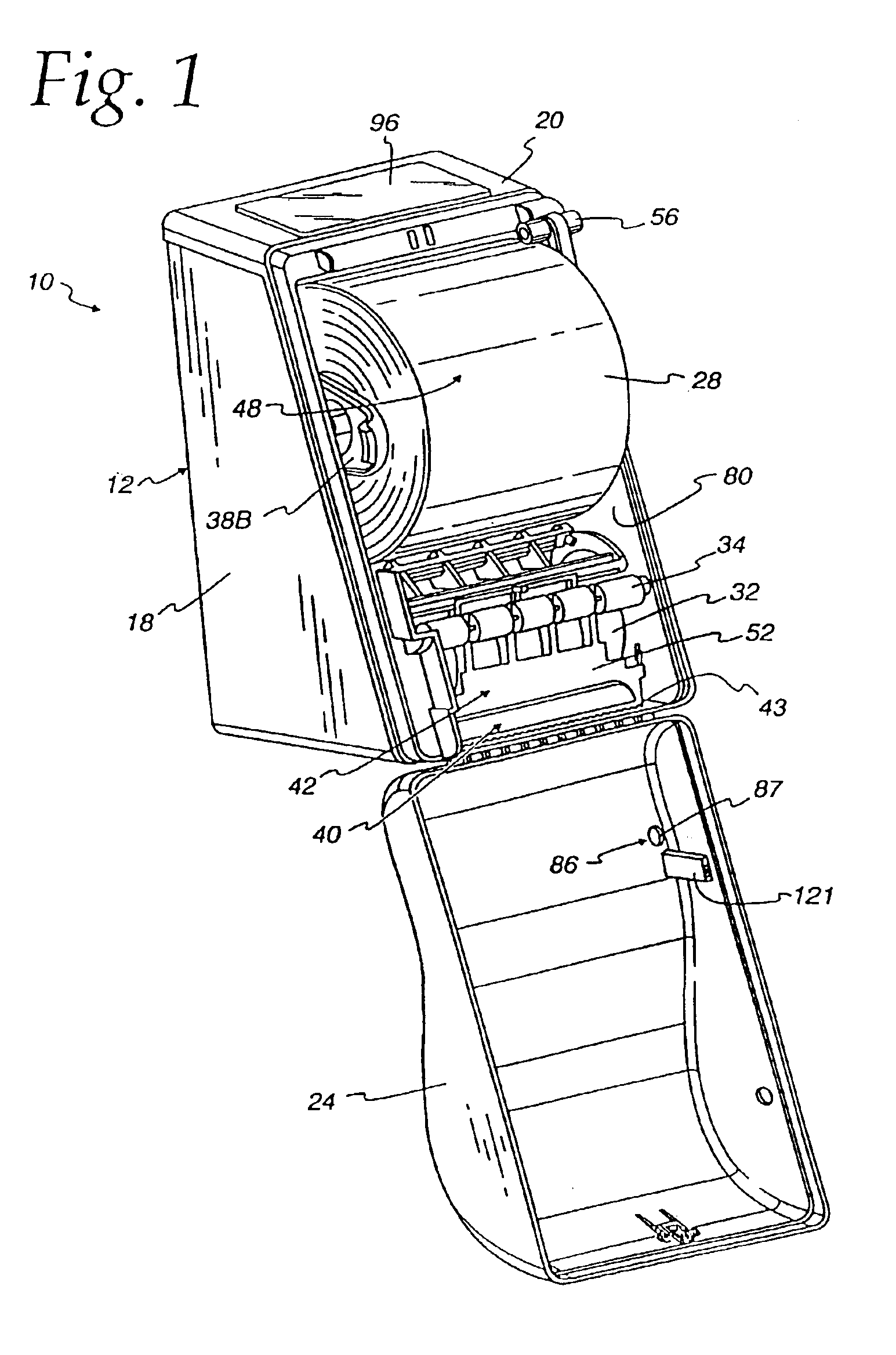

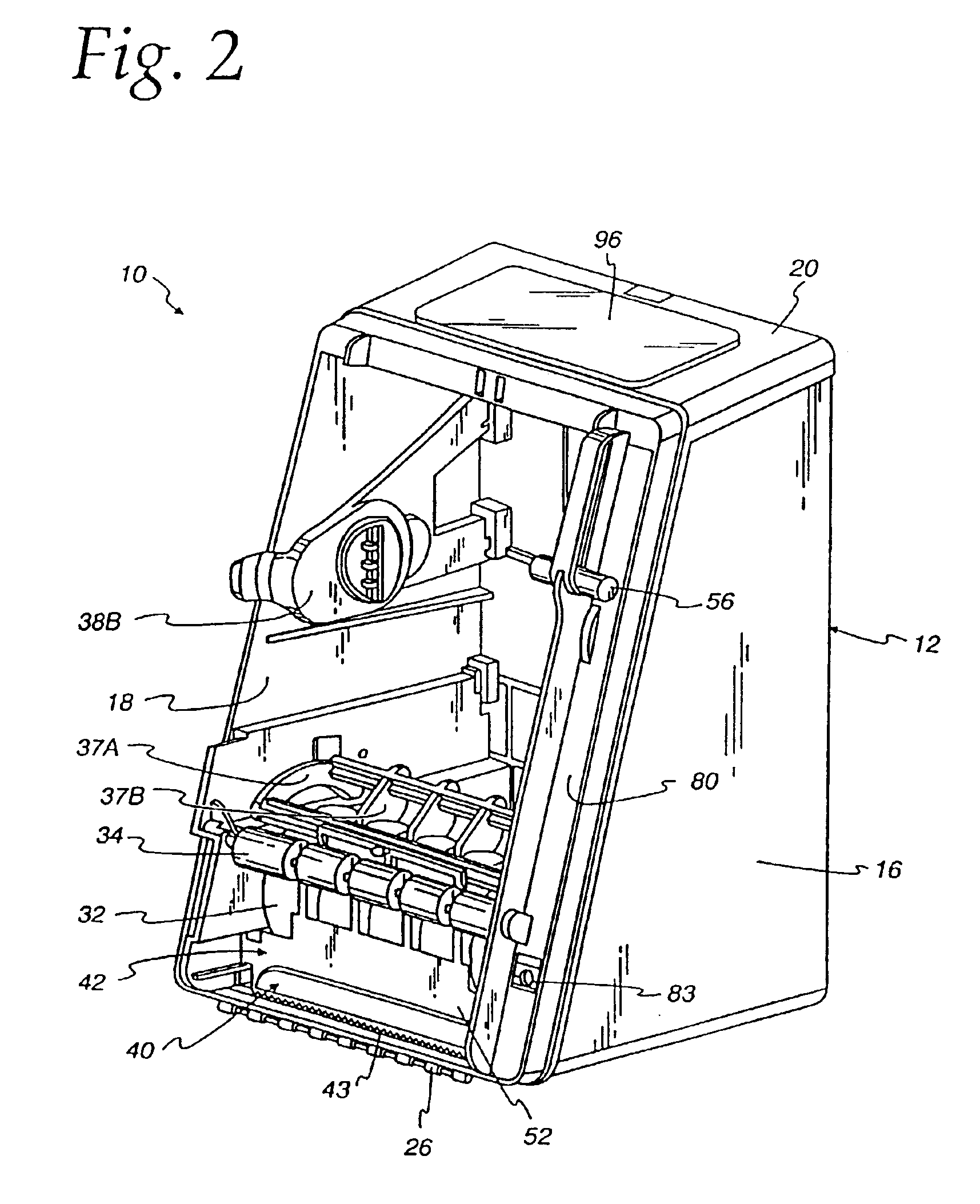

Automatic dispenser apparatus

InactiveUS6903654B2Easy to operateSame lengthCoin-freed apparatus detailsFilament handlingCapacitanceElectrical conductor

The invention is directed to improved automatic dispenser apparatus for dispensing sheet material and the like without contact between a user and the dispenser. Proximity detection apparatus is provided to detect the presence of a user in a detection zone generated outside the dispenser. Control apparatus controls actuation of the dispenser in response to the detected user. Preferred forms of the proximity detector include a sensor and a signal detection circuit operatively connected to the sensor. The sensor includes conductors configured to have a capacitance and positioned such that the capacitance is changed by the presence of a user within the detection zone. The signal detection circuit detects the change in capacitance and is provided with an oscillator having a frequency which is affected by the sensor capacitance and a differential frequency discriminator which detects changes in the oscillator frequency. The control apparatus receives the detected frequency change and generates a signal provided to actuate the dispenser to dispense the material. The dispenser control apparatus controls dispenser operation responsive to decreases in battery voltage which occur during the life cycle of the batteries and controls dispenser operation when the batteries near the end of such life cycle. Such control apparatus may be used with any type of battery powered dispenser, including hands-free dispensers and dispensers actuated by direct physical contact with the user.

Owner:ALWIN MFG

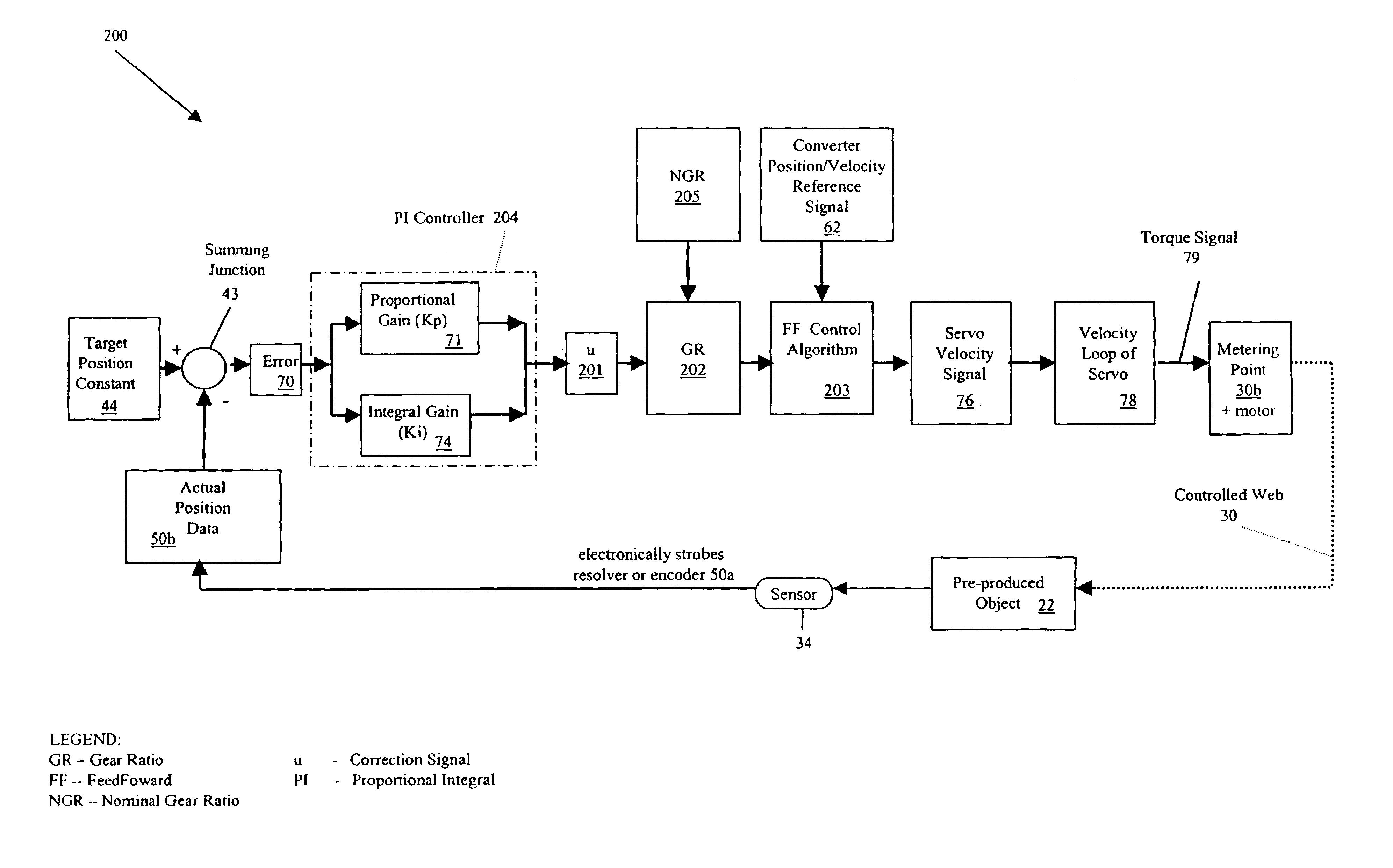

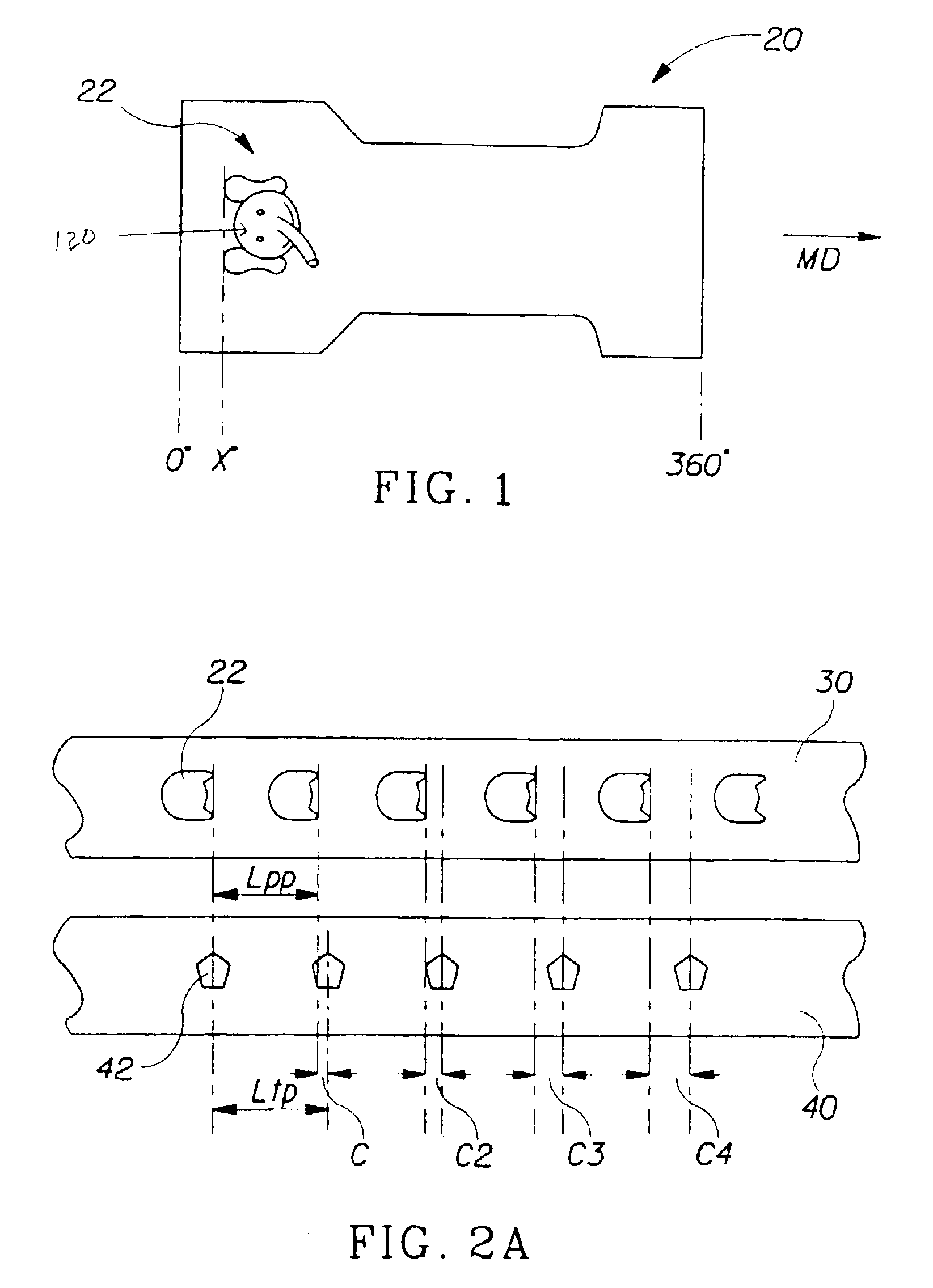

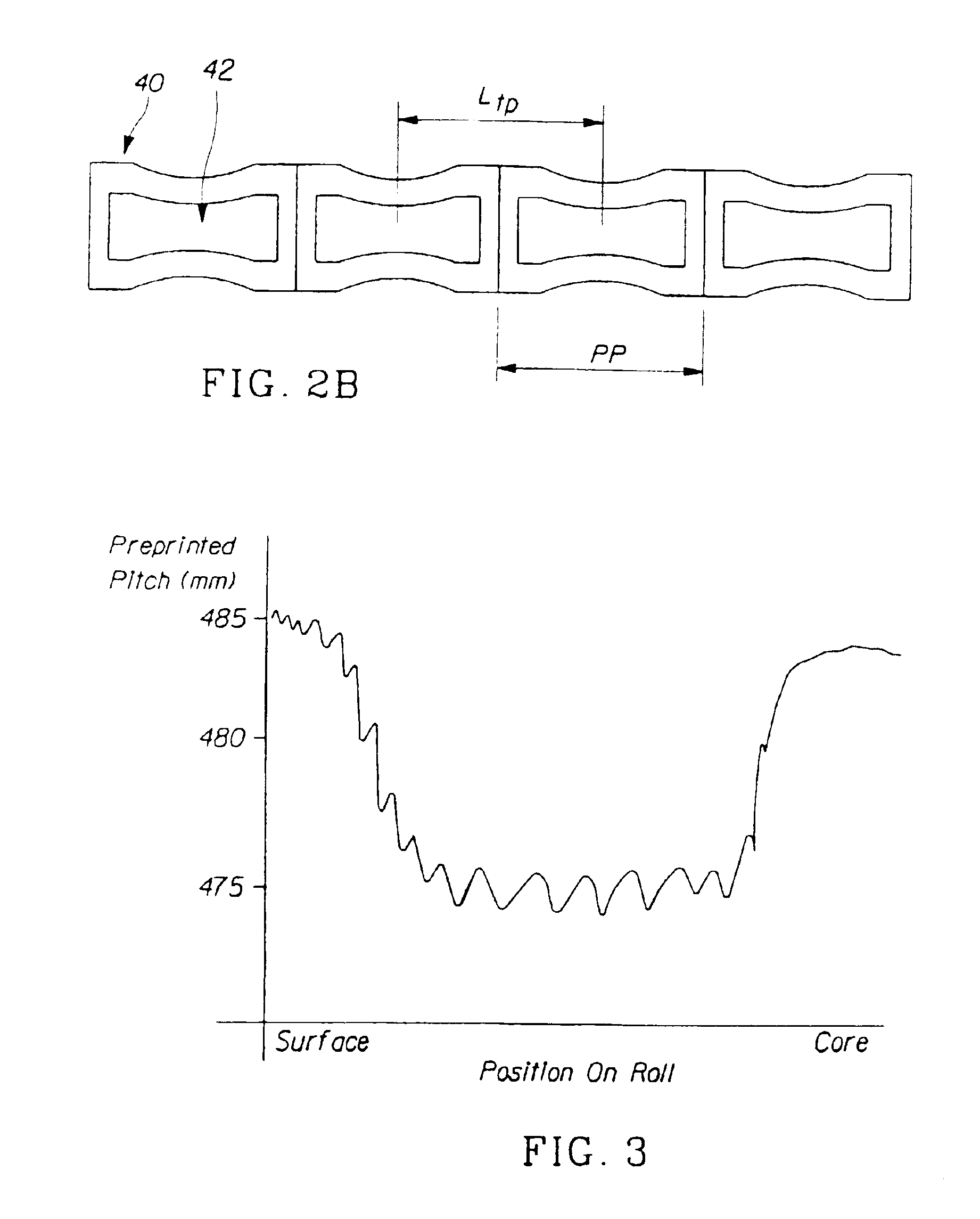

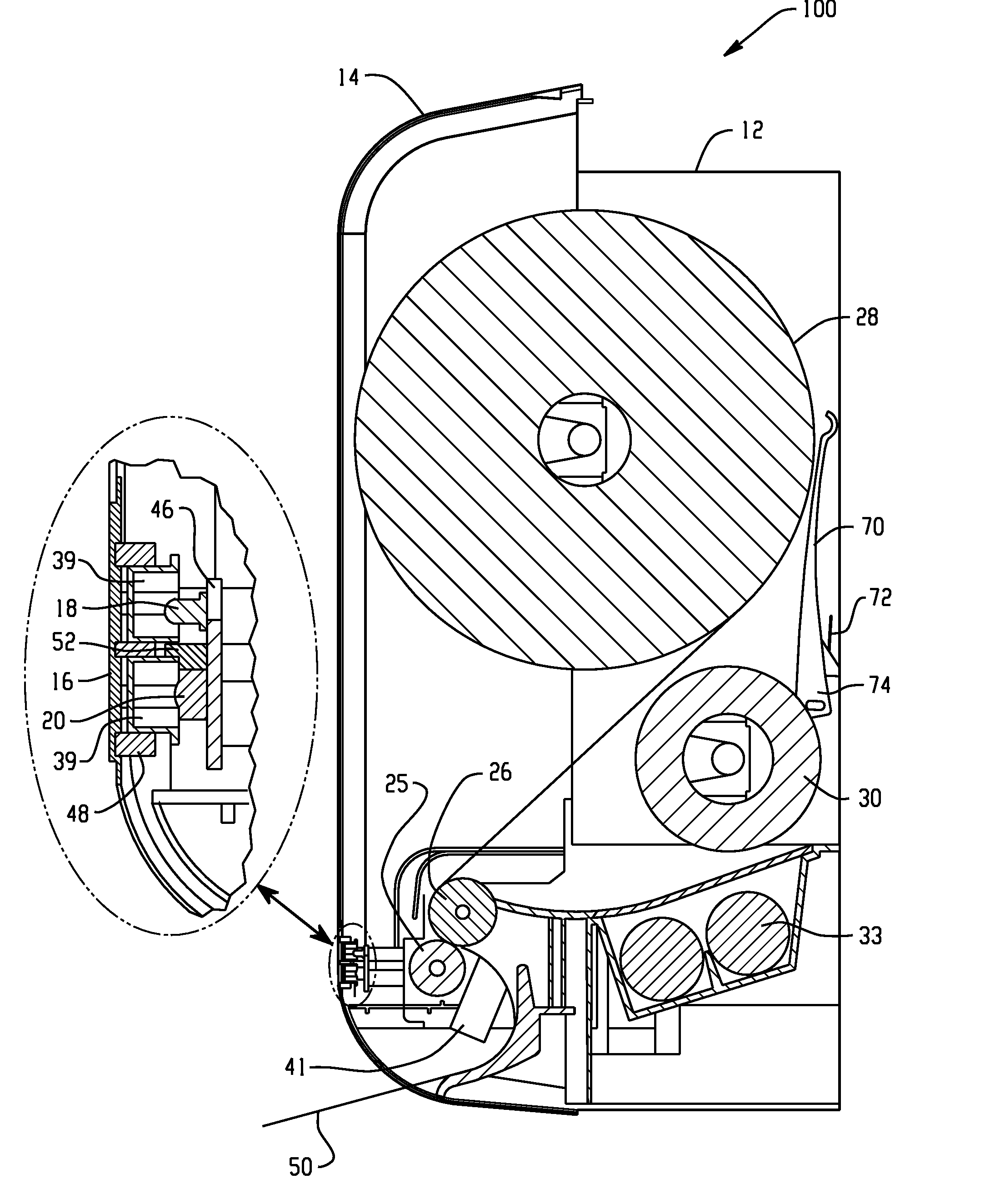

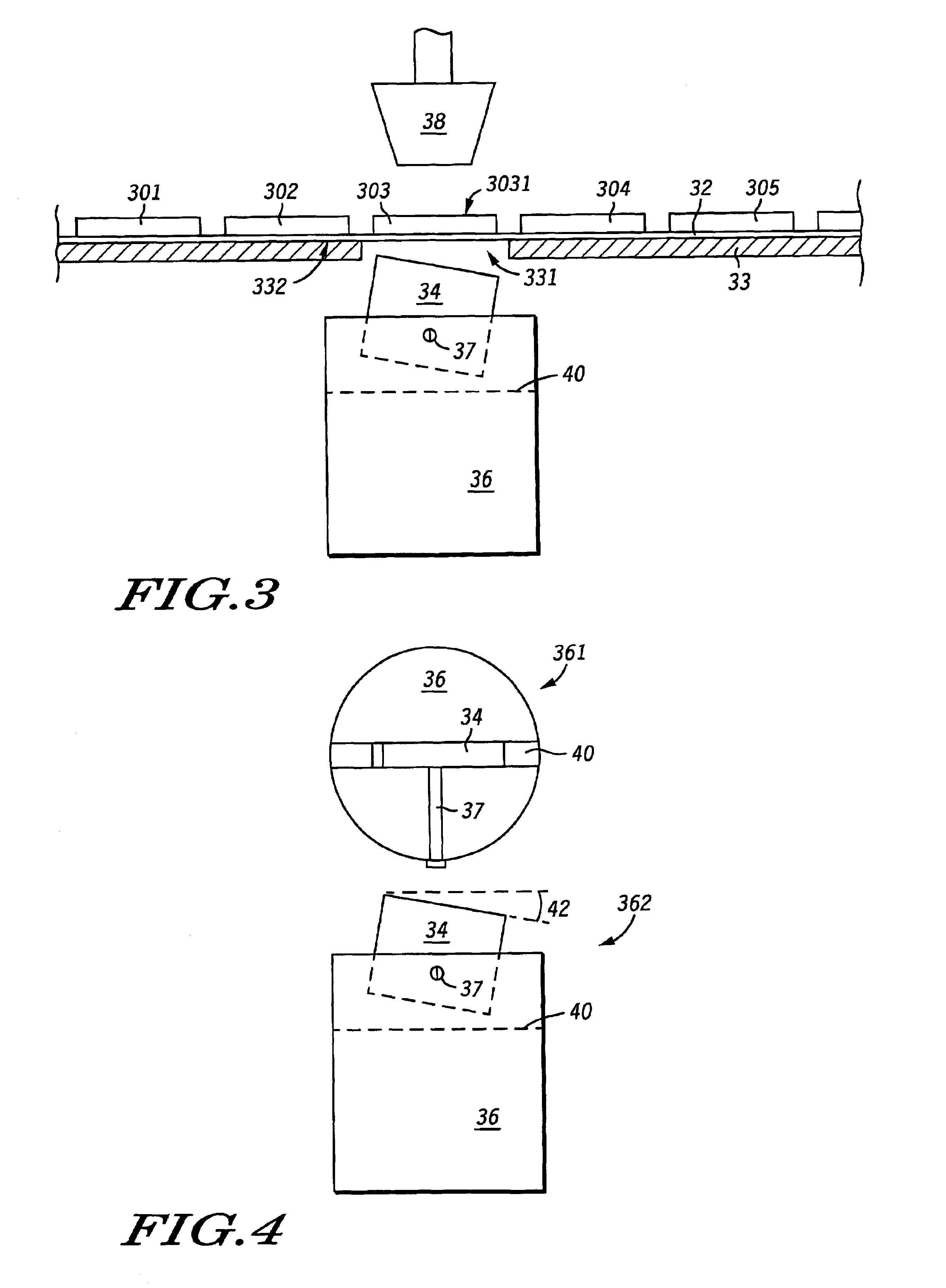

Method and system for registering pre-produced webs with variable pitch length

A new machine control method and system for registering pro-produced webs into a converting line producing disposable absorbent articles such as diapers, pants, feminine hygiene articles or a component thereof. The pre-produced web can include a multiplicity of pre-produced objects spaced on the web at a pitch interval in the web direction. The pre-produced web being manipulated in order for the pre-produced object of the web to be registered in relation to a target position constant. The present invention includes three embodiments, where the first embodiment is expressed as a generic claim. The first embodiment includes a closed-loop feedback registration system; the second and third embodiments, in addition, include an open-loop feedforward phasing system. In addition, the third embodiment uses a machine vision system to recognize any element of a complex pre-produced object (e.g., colorful graphics).

Owner:THE PROCTER & GAMBLE COMPANY

Electronic Dispenser for Dispensing Sheet Products

An electronic dispenser for dispensing sheet products includes an infrared proximity sensor operative to detect a presence of a user's hand at a predetermined location near the dispenser and a feed mechanism configured to engage a sheet product roll to cause a quantity of sheet product to be dispensed therethrough. The infrared proximity sensor is configured to have an adjustable sensitivity to vary a detection range of the infrared proximity sensor. The feed mechanism has a motor operative in response to the infrared proximity sensor to engage the feed mechanism.

Owner:GEORGIA PACIFIC CONSUMER PRODS LP

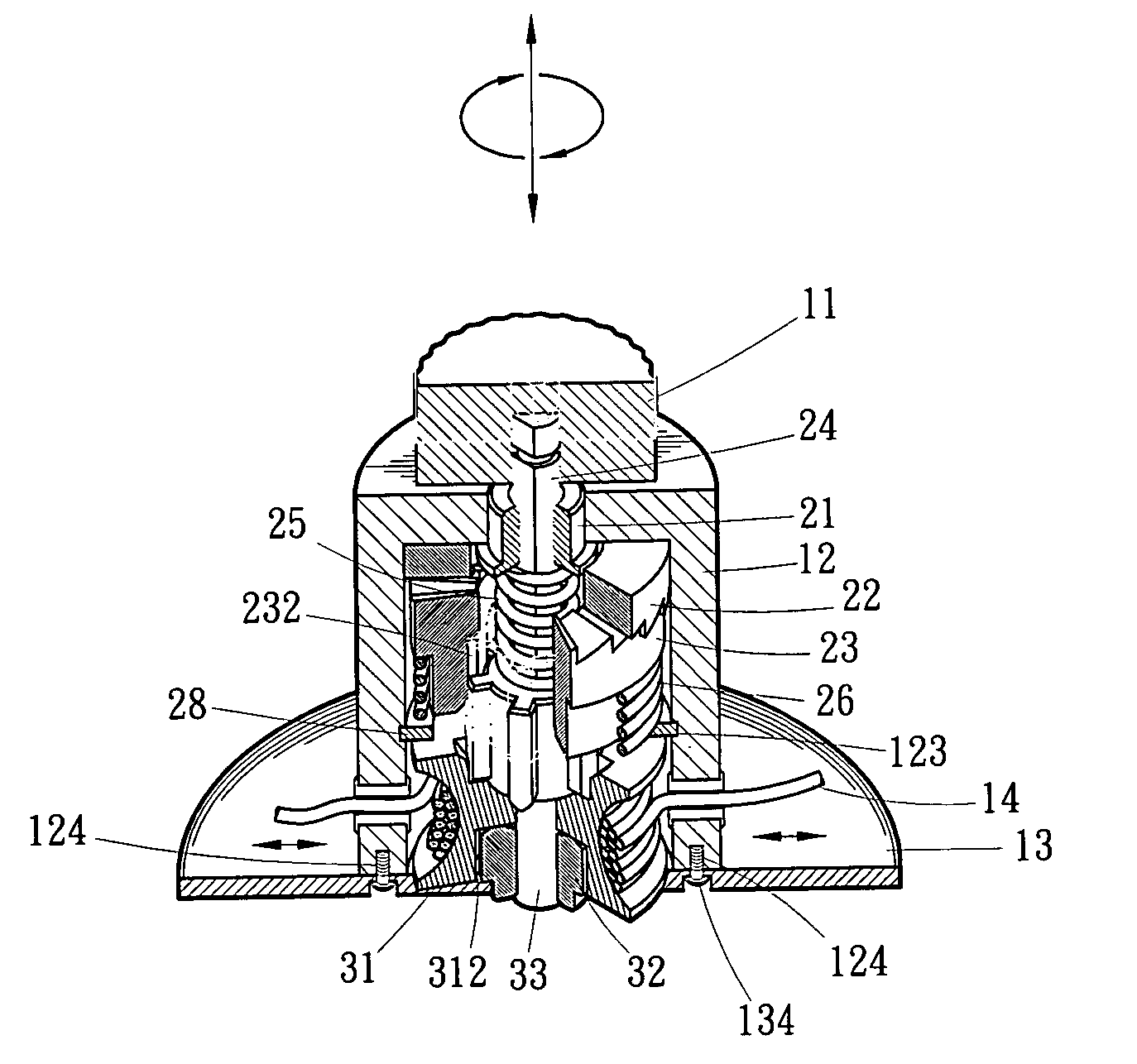

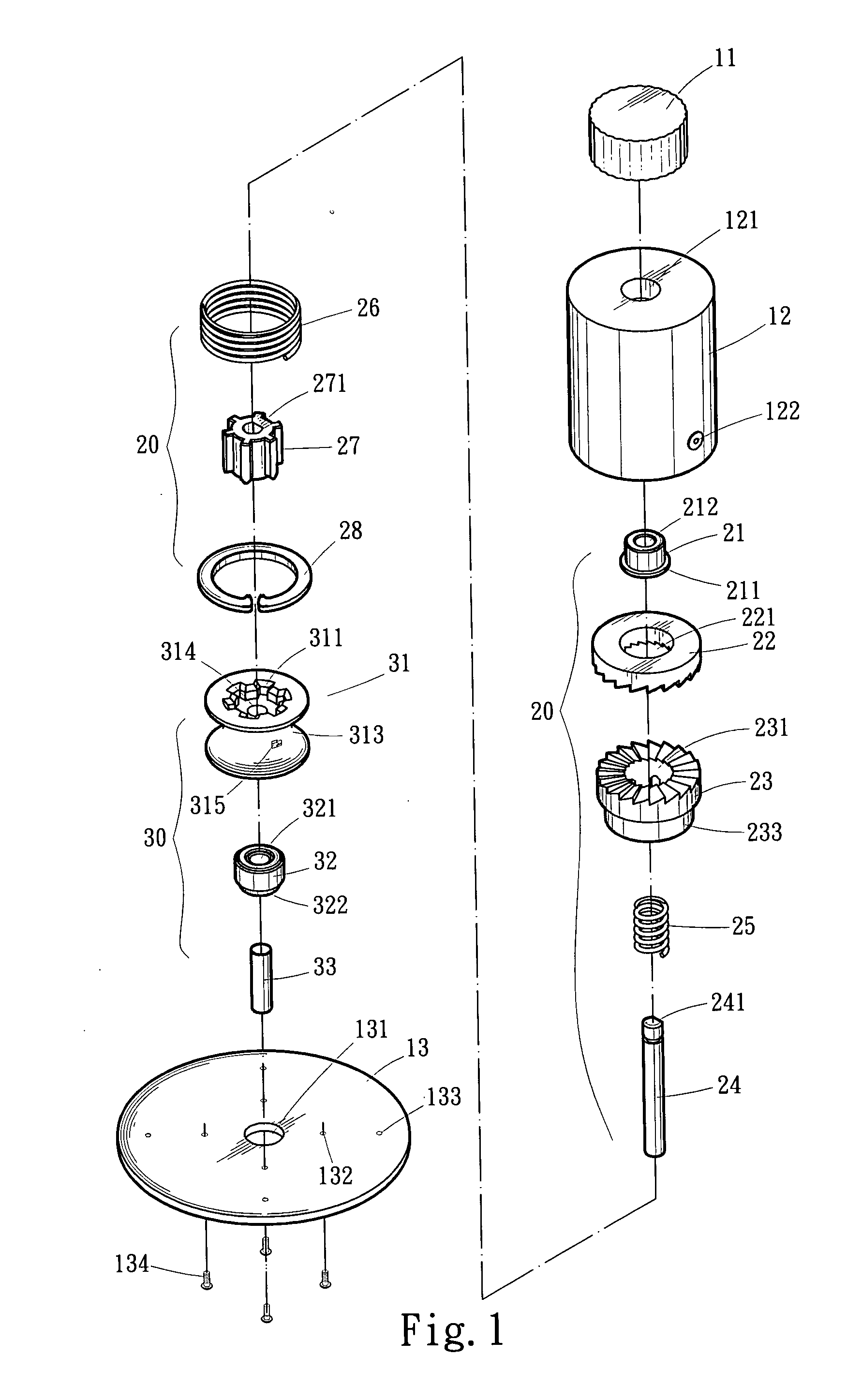

Lace winding device for shoes

InactiveUS8231074B2Stable and firmSmooth and stable windingSnap fastenersFilament handlingMechanical engineeringPositive direction

A lace winding device includes a base, a spool rotatably mounted in the base, a lace having two distal ends each extending through the base and each secured on the spool, a limit barrel mounted on the base, a drive member rotatably mounted in the limit barrel and connected with the spool to rotate the spool, and a ratchet block movably mounted on the limit barrel and engaging the drive member. Thus, the drive member is rotated in one direction only by limit of the ratchet block so that the spool is driven by the drive member to rotate in the positive direction only and cannot be rotated in the opposite direction so as to wind the lace easily and quickly.

Owner:HU RONG FU +1

Method and apparatus for tensile testing and rethreading optical fiber during fiber draw

InactiveUS7832675B2Processing speedGlass fibre drawing apparatusFilament handlingFiber drawingTensile testing

A method and apparatus for automatic threading and winding of optical fiber onto various components in a fiber draw system, as well as methods and apparatus for conducting online tensile screening of optical fiber at high speeds. In a preferred embodiment, the fiber is tensile tested during fiber draw and wound directly onto a shipping spool to be shipped to a customer. The tensile stress can be imparted to the fiber during the draw process by feeding the fiber through a screener capstan, which works in conjunction with another capstan to impart the desired tensile stress to the fiber during the draw process. Another aspect is a method and apparatus for threading or rethreading of a moving length of fiber through a fiber draw or fiber testing process, in which fiber is wound onto a spool, comprising activating an aspirator to obtain the fiber at a first location and moving said aspirator in at least two dimensions to thereby move the fiber to a second location and thread the fiber through or onto at least one component in the fiber draw or testing process.

Owner:CORNING INC

Process for disengaging semiconductor die from an adhesive film

Owner:NXP USA INC

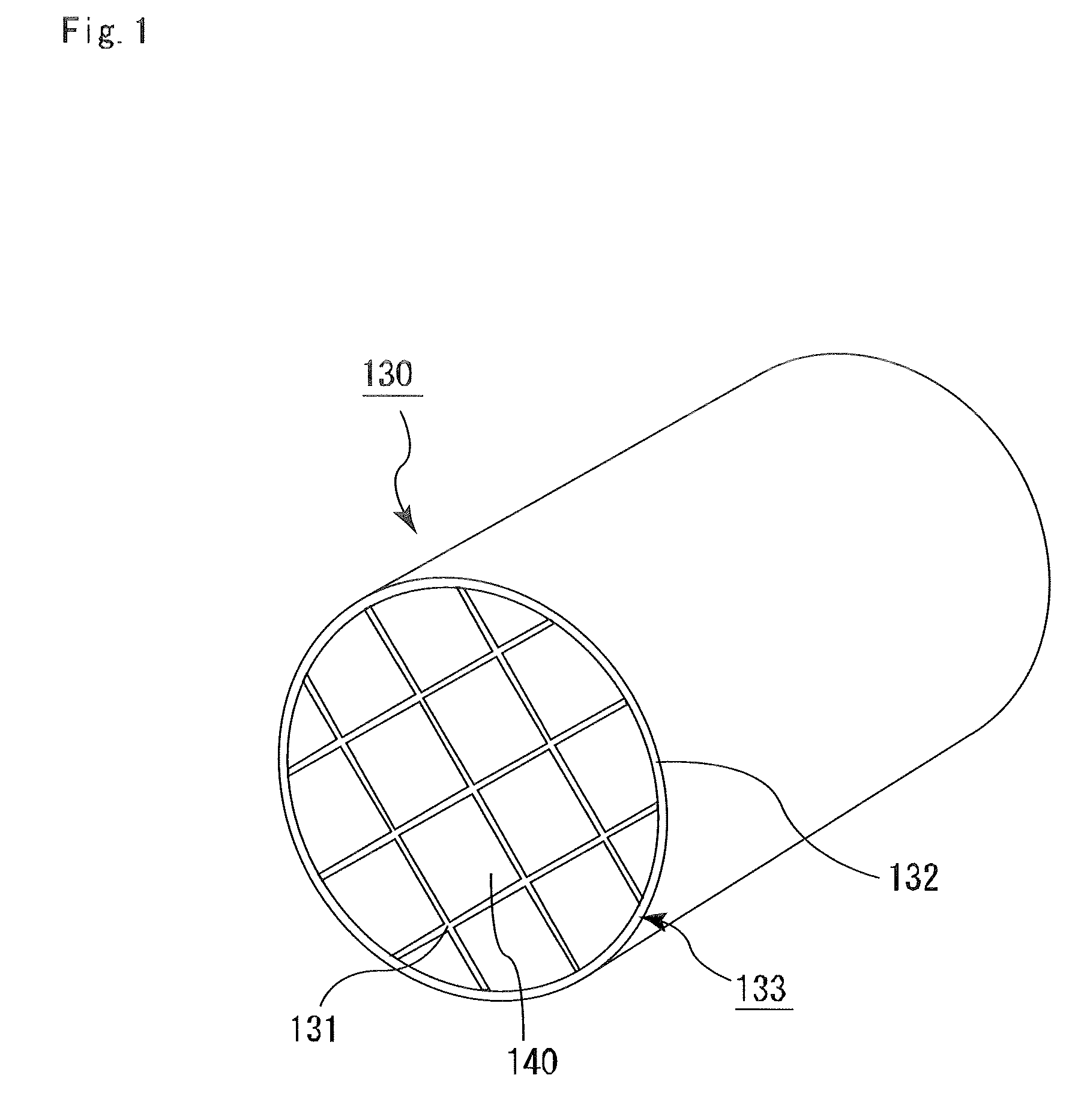

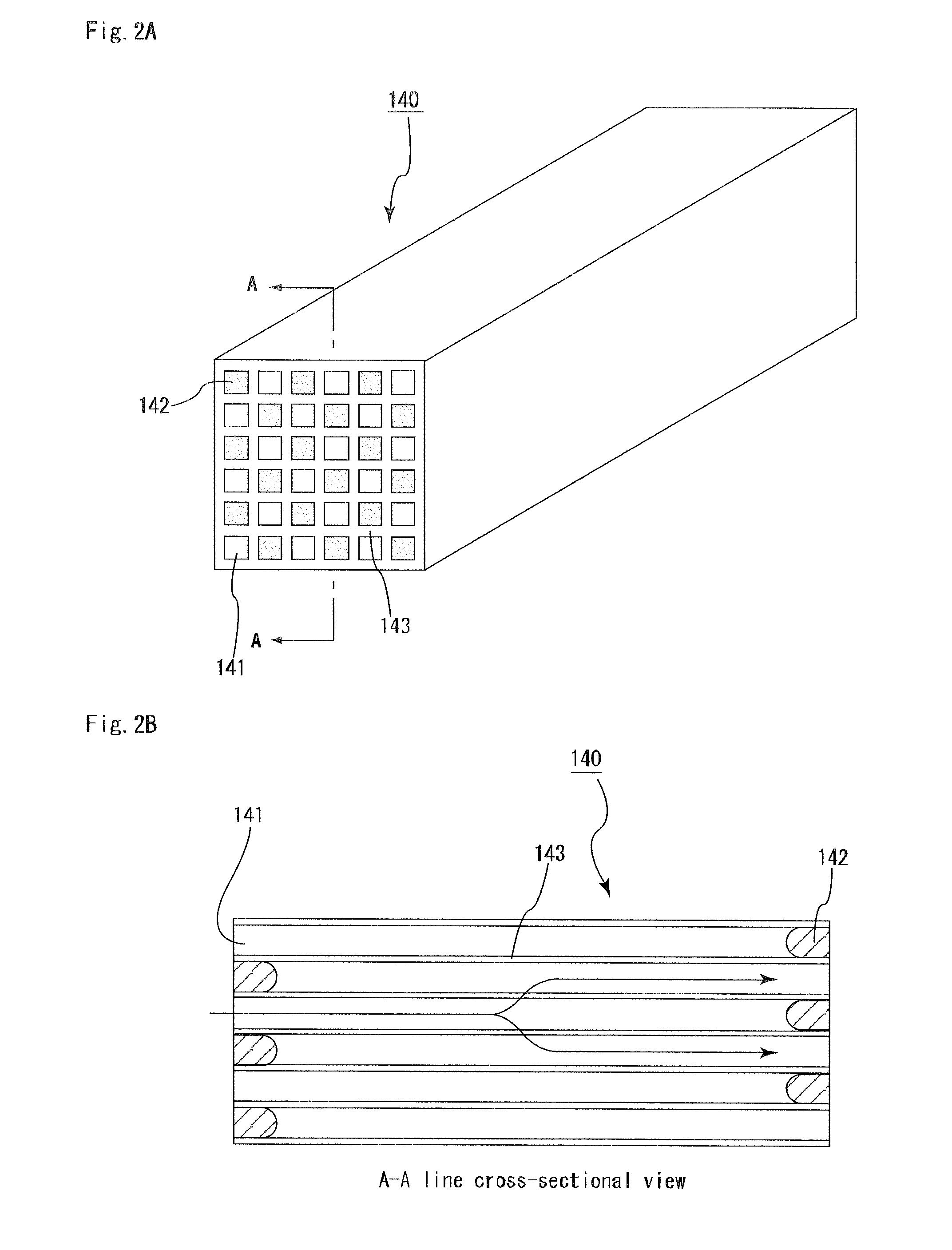

Degreasing furnace loading apparatus, and method for manufacturing honeycomb structure

A degreasing furnace loading apparatus including a molded body moving mechanism configured to move a plurality of ceramic molded bodies simultaneously, and a transporting table configured to transport a degreasing jig for mounting the ceramic molded bodies thereon to a degreasing furnace. The molded body moving mechanism is configured to simultaneously place the plurality of ceramic molded bodies on the degreasing jig, such that each of the ceramic molded bodies is placed to have predetermined intervals therebetween.

Owner:IBIDEN CO LTD

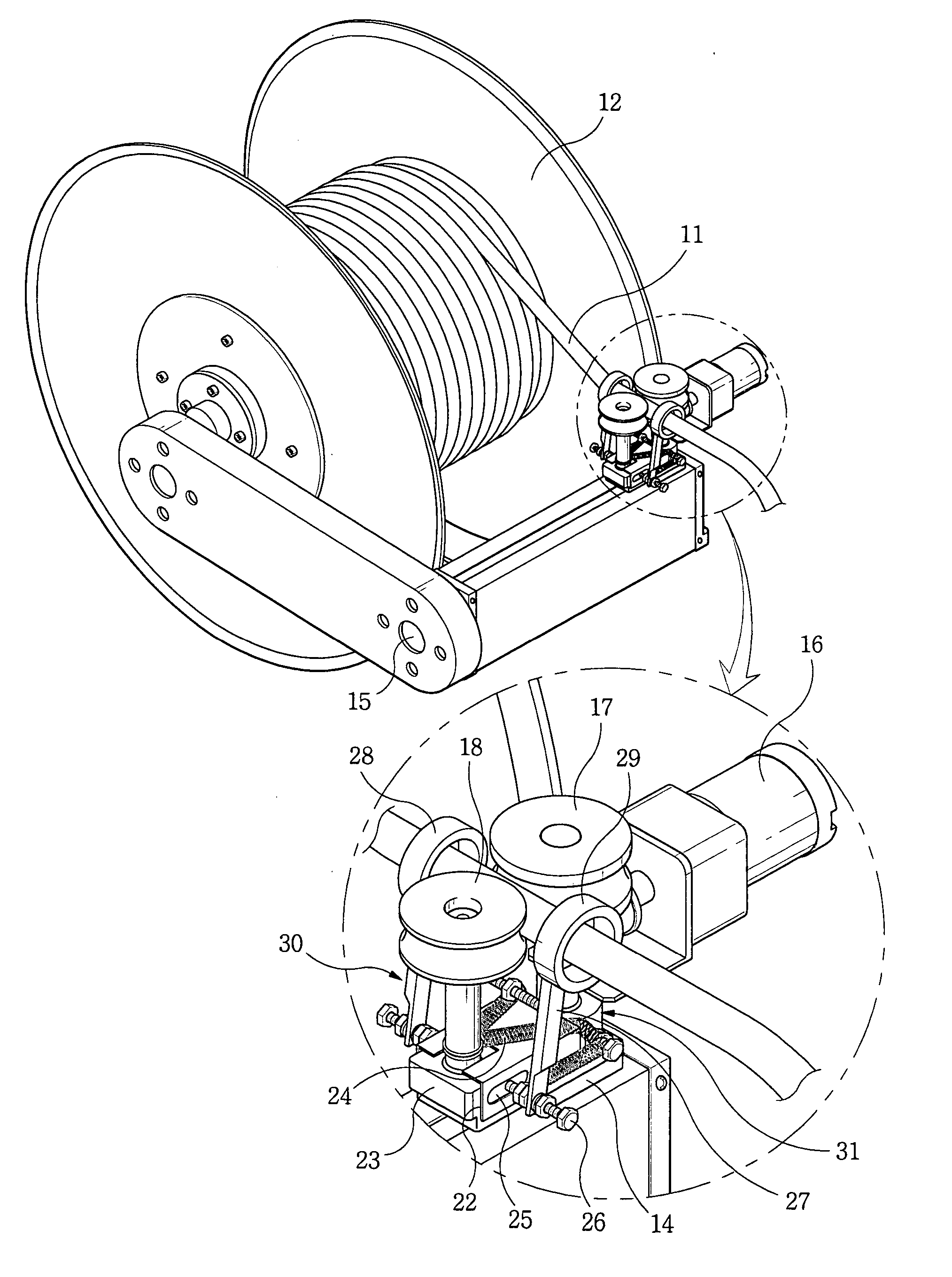

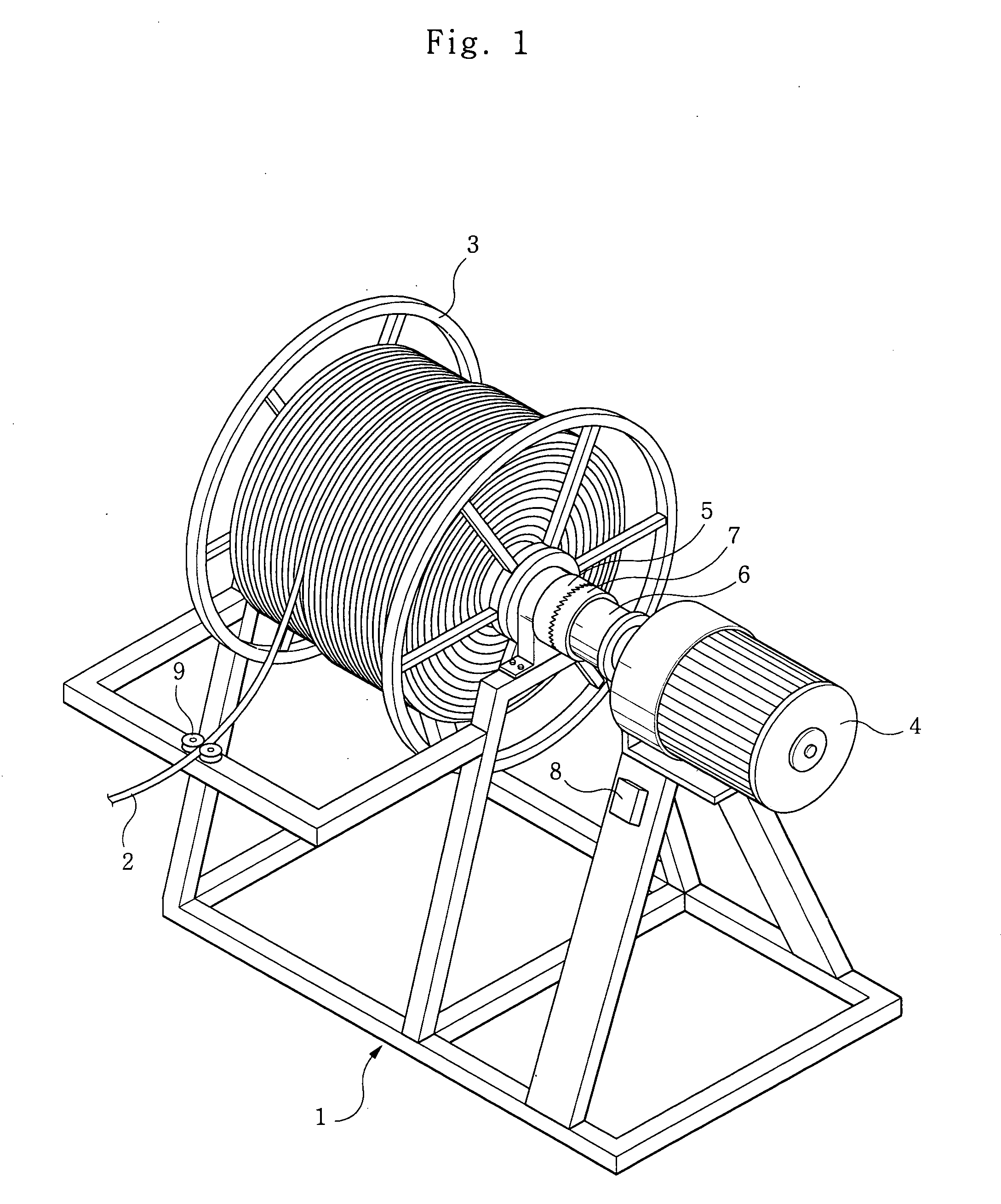

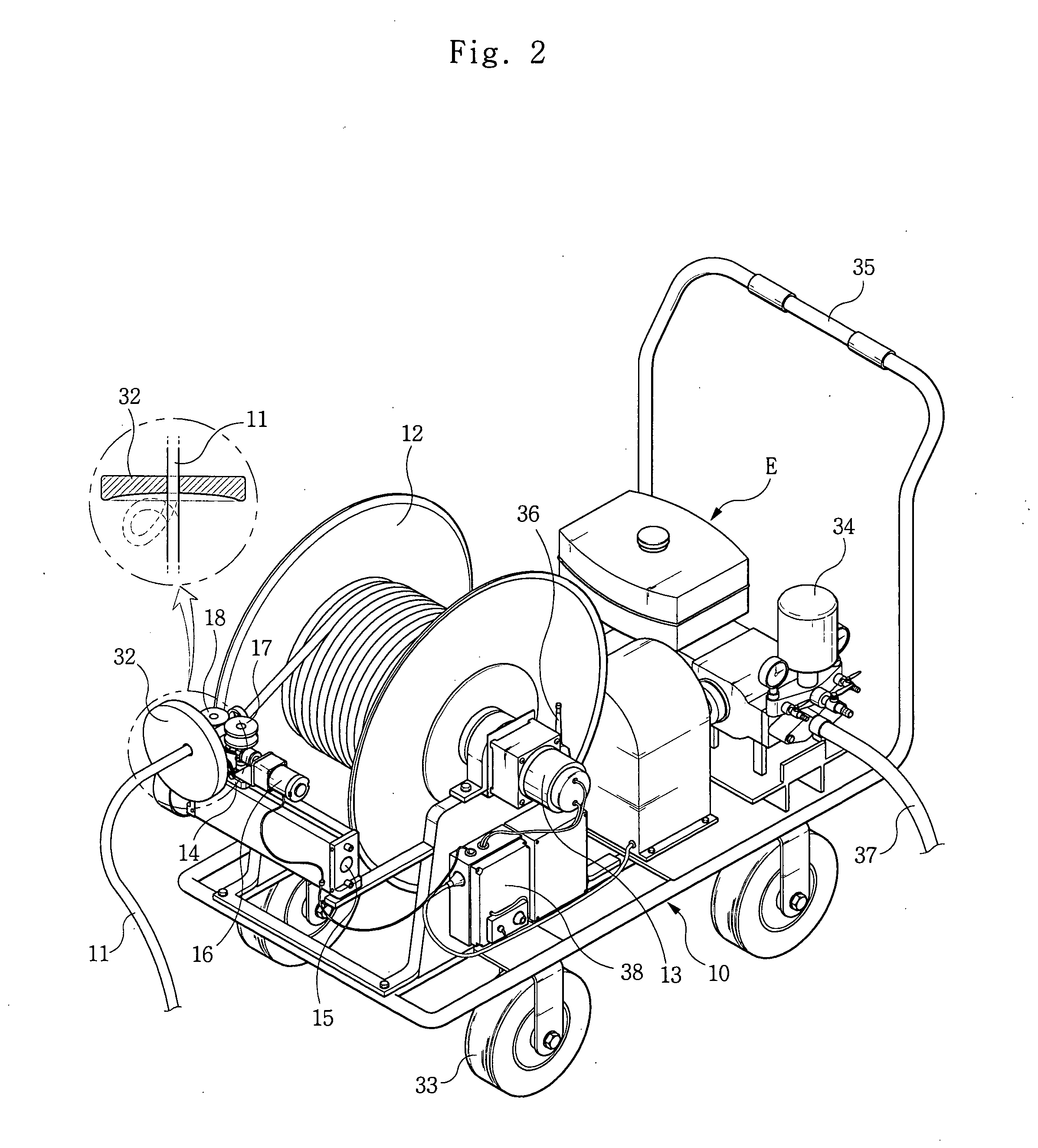

Labor reduction type agricultural chemical spraying system having automatic hose winding and unwinding apparatus

InactiveUS20050087644A1Avoid distortionLow costFilament handlingInsect catchers and killersMotor driveRemote control

The present invention relates to a labor reduction type agricultural chemical spraying system having an automatic hose winding and unwinding apparatus by which one worker is capable of spraying agricultural chemicals in such a manner that a hose is automatically wound and unwound from a reel based on a remotely controlled motor. The labor reduction type agricultural chemical spraying system having an automatic hose winding and unwinding apparatus comprises a frame in which a motored sprayer connected with an engine is installed; a reel rotatably installed in the frame wherein a hose is wound onto the reel; a first driving motor driven in both directions for rotating the reel in normal and reverse directions in accordance with a remote control signal; a rotary shaft rotating by a driving force from the rotary shaft of the reel and reciprocating a movable piece engaged to an upper side in the left and right directions with respect to the reel; a second driving motor installed on the movable piece in cooperation with the first driving motor and driven in the normal and reverse directions in accordance with a remote control signal; and a pair of rollers that are installed in the movable piece and are rotatably connected with the second driving motor and tension an outer surface of the hose, and unwind the hose from the reel.

Owner:HYUPWOO TRADING

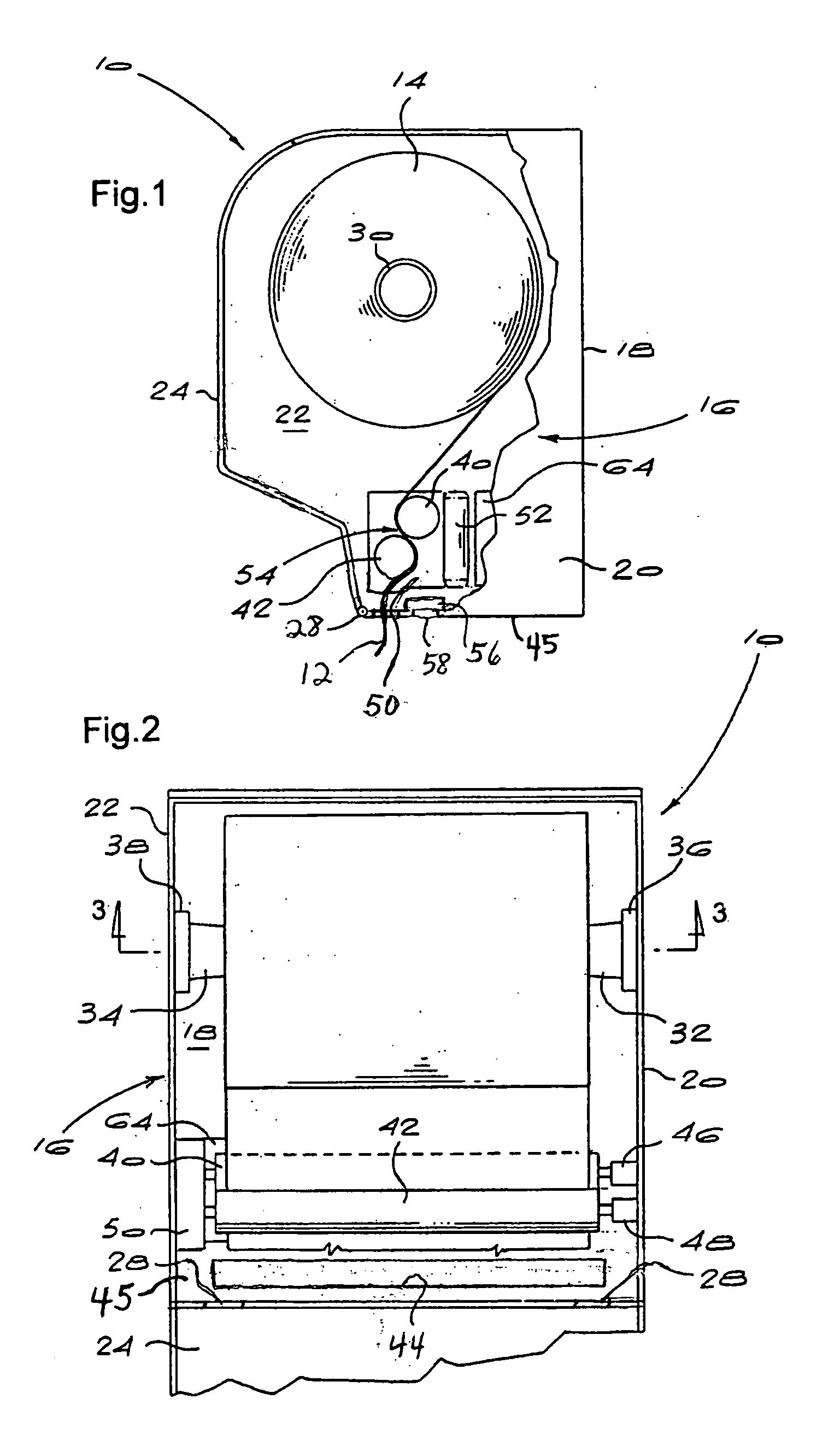

Apparatus and method for dispensing sheet material

A sheet material dispenser includes a controller for automatically controlling the lengths of sheet materials dispensed from a continuous roll by identifying the type of sheet materials on the roll and dispensing suitable lengths of the identified sheet material. The dispenser desirably has a support for rotatably supporting a roll of sheet material carrying identification relating to the type of sheet material on the roll, and an identifier positioned in or adjacent the dispenser for identifying the type of sheet material on the roll. A processor receives data from the identifier, processes the data and generates an output command, and a controller controls the lengths of sheet material dispensed from the roll in response to the output command. In this way, more absorbent products may be dispensed in shorter lengths and less absorbent products may be dispensed in longer lengths.

Owner:KIMBERLY-CLARK WORLDWIDE INC

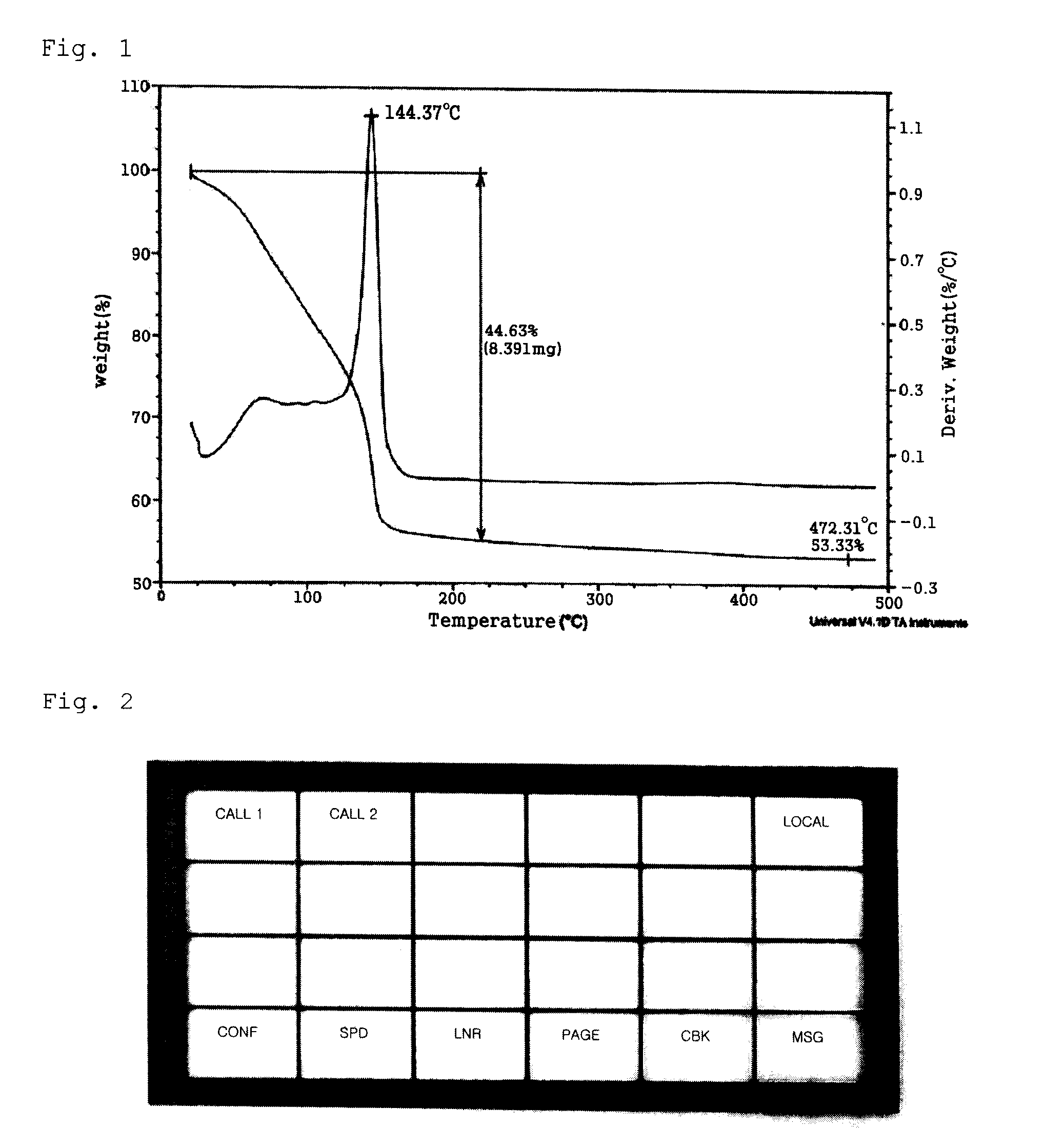

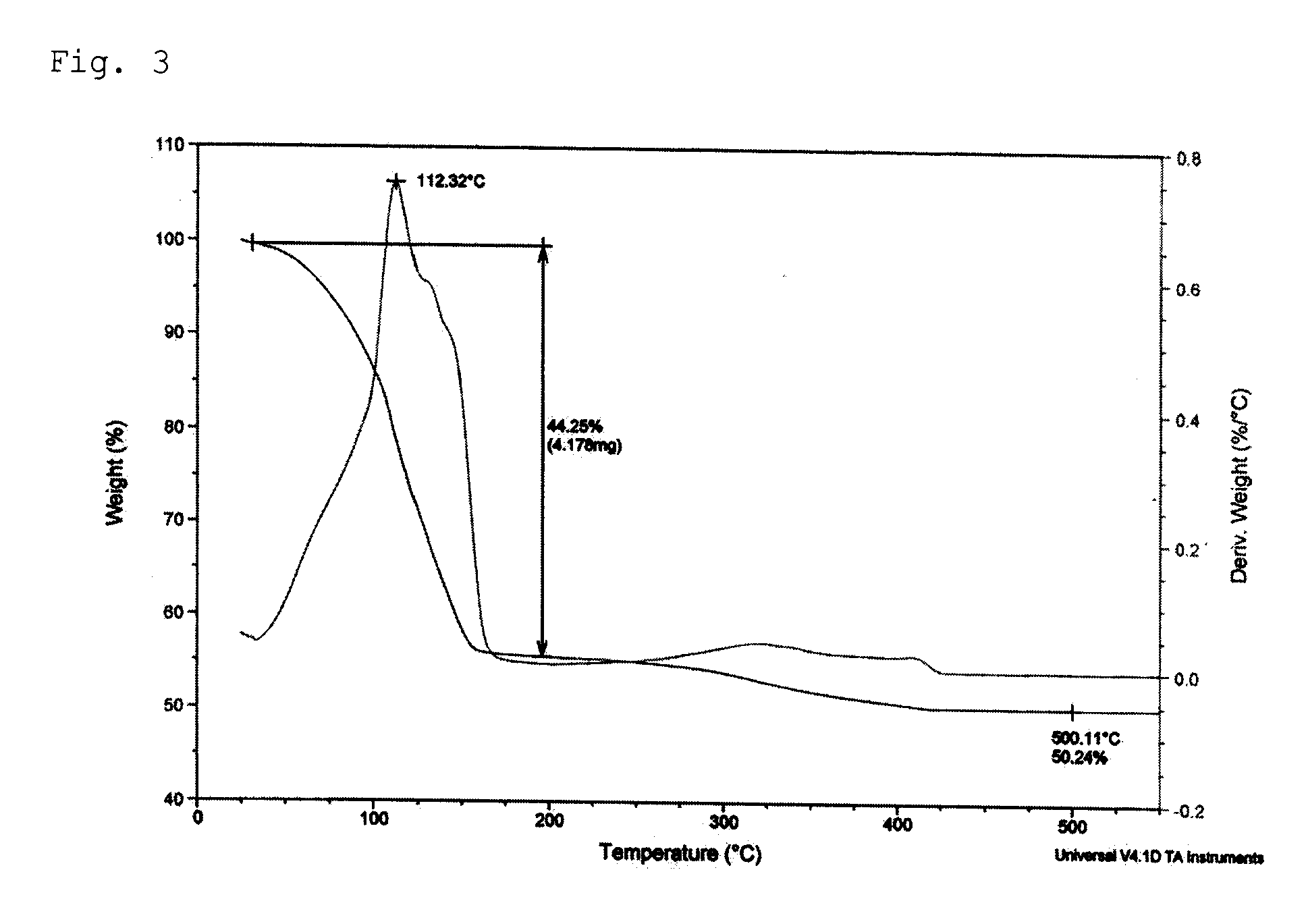

Conductive Inks and Manufacturing Method Thereof

ActiveUS20080206488A1Improve stabilityImprove solubilityElectric discharge heatingConductive materialAmmonium carbonateAmmonium carbamate

The present invention relates to a variety of conductive ink compositions comprising a metal complex compound having a special structure and an additive and a method for preparing the same, more particularly to conductive ink compositions comprising a metal complex compound obtained by reacting a metal or metal compound with an ammonium carbamate- or ammonium carbonate-based compound and an additive and a method for preparing the same.

Owner:INKTEC CO LTD

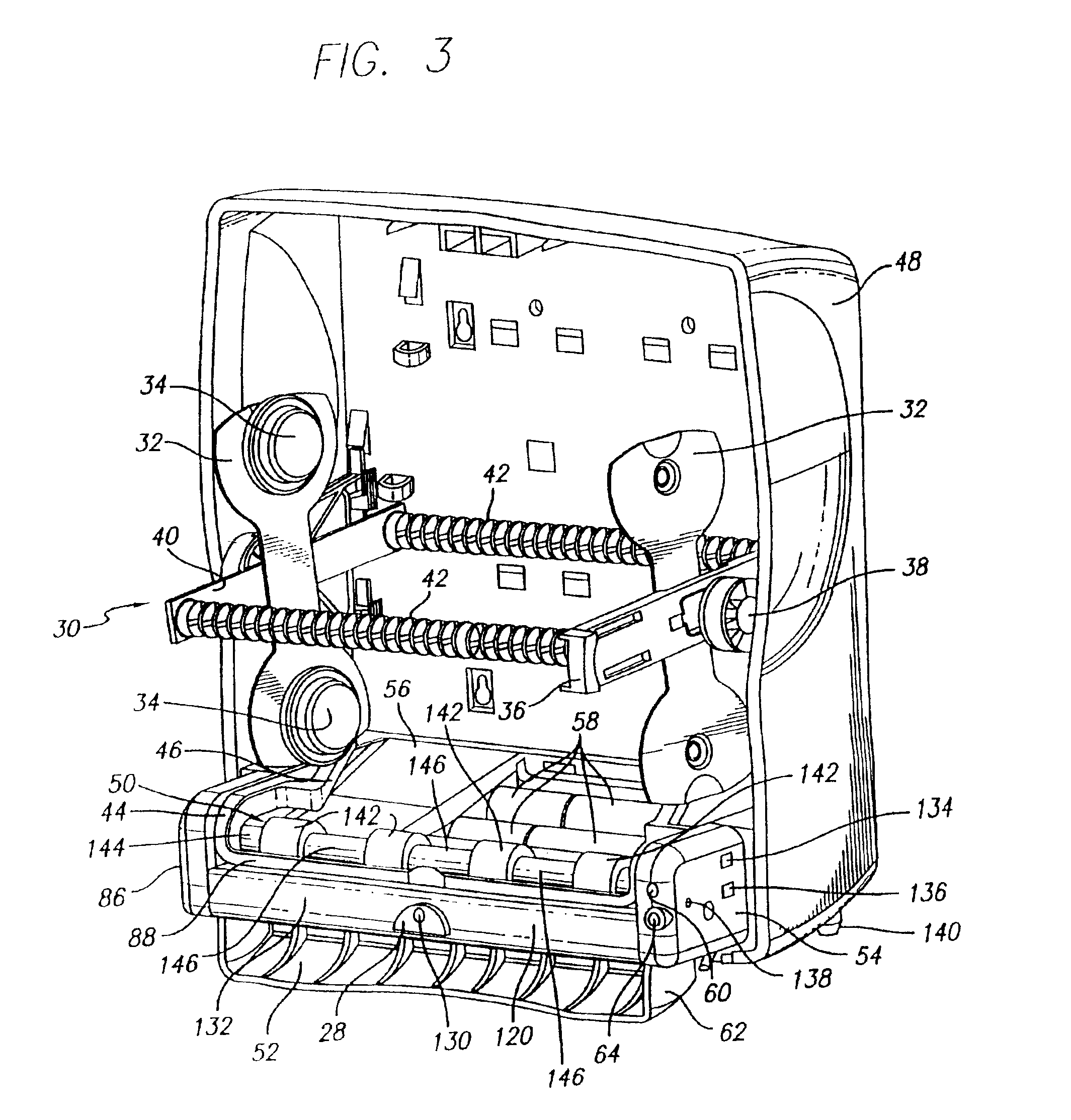

Electronically controlled roll towel dispenser with data communication system

InactiveUS7044421B1Easy to useLow costFilament handlingDomestic applicationsMicrocontrollerDigital data

An electronically controlled roll towel dispenser with a data communication system. The dispenser automatically dispenses a predetermined length of paper toweling from a supply roll after a length of toweling has been detached by a user pulling and tearing the protruding toweling against a stationary cutting blade. The dispenser is battery powered with an electric motor, an electromechanical dispensing mechanism, and an embedded microcontroller for controlling and monitoring operation of the dispenser. In addition to primary control functions, the microcontroller monitors parameters such as battery condition, towel usage, system status, system errors, and unsafe operating conditions. Pushbutton switches are also provided for programming towel length and the dispense delay. The dispenser further includes an optical transmitter for transmitting visual and infrared data to a receiving device. Useful information about the status of the dispenser can be visibly discerned by an operator through the use of primitive low-speed flash patterns, while high-speed infrared digital data can be simultaneously embedded in or multiplexed with the visible data.

Owner:SAN JAMAR INC +1

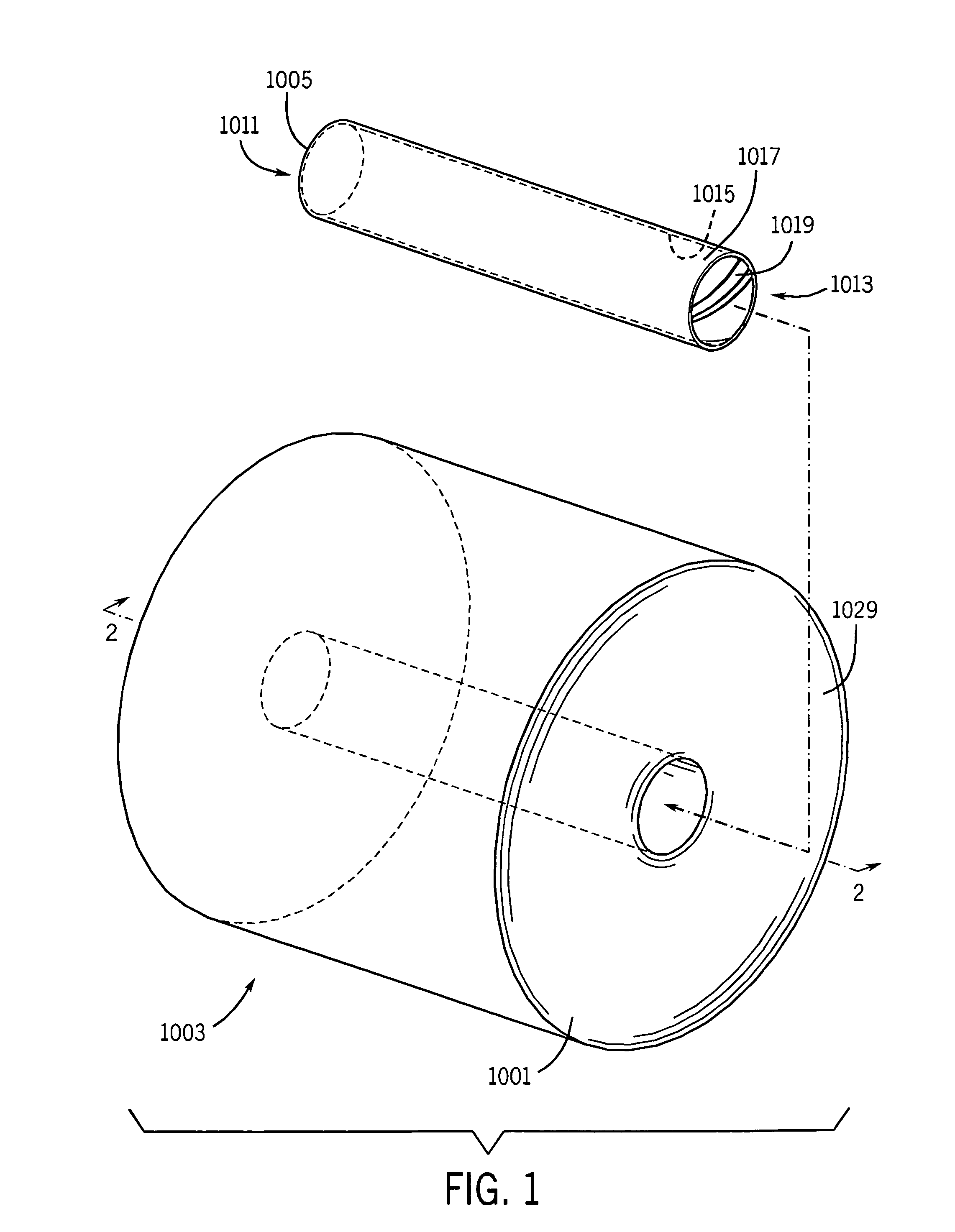

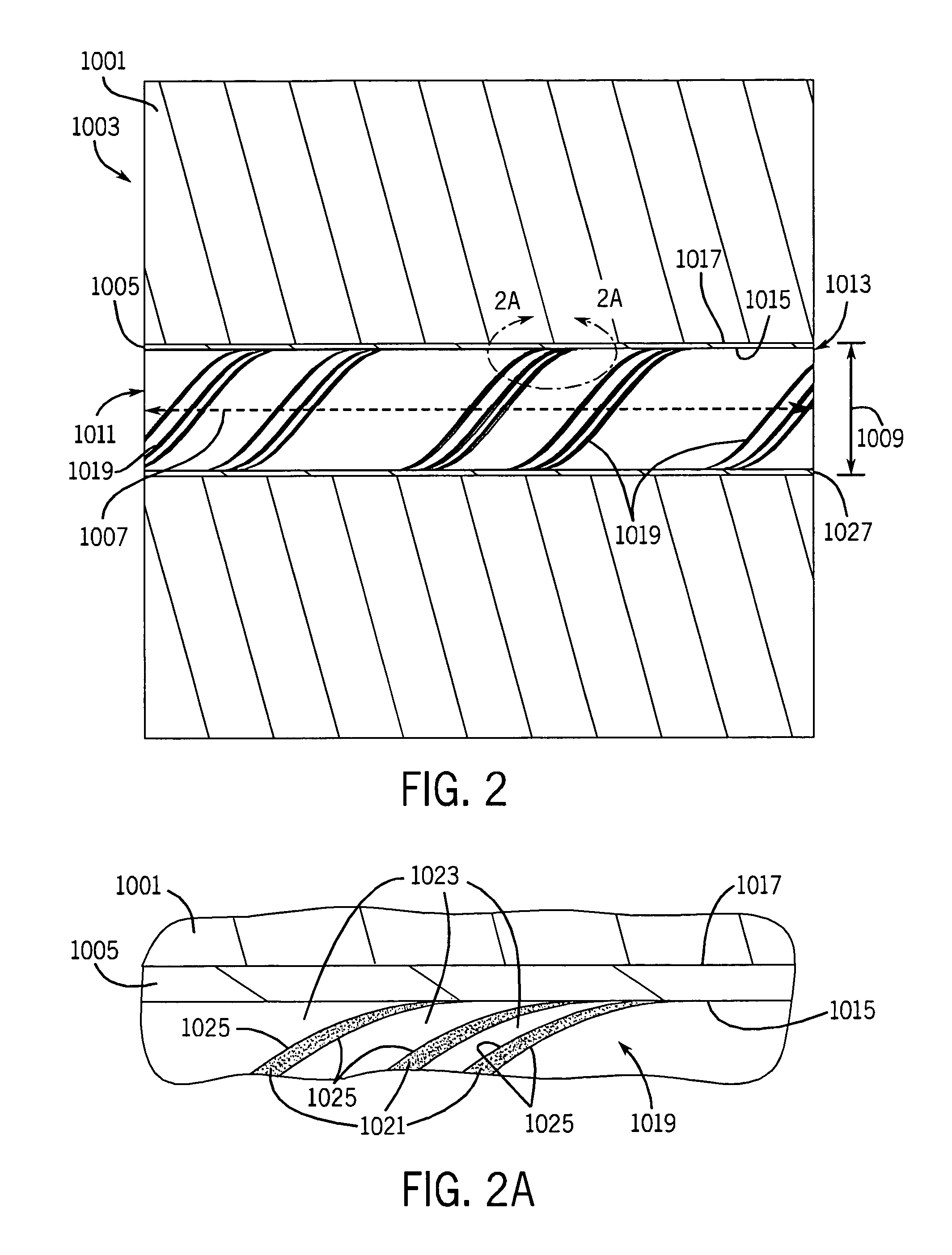

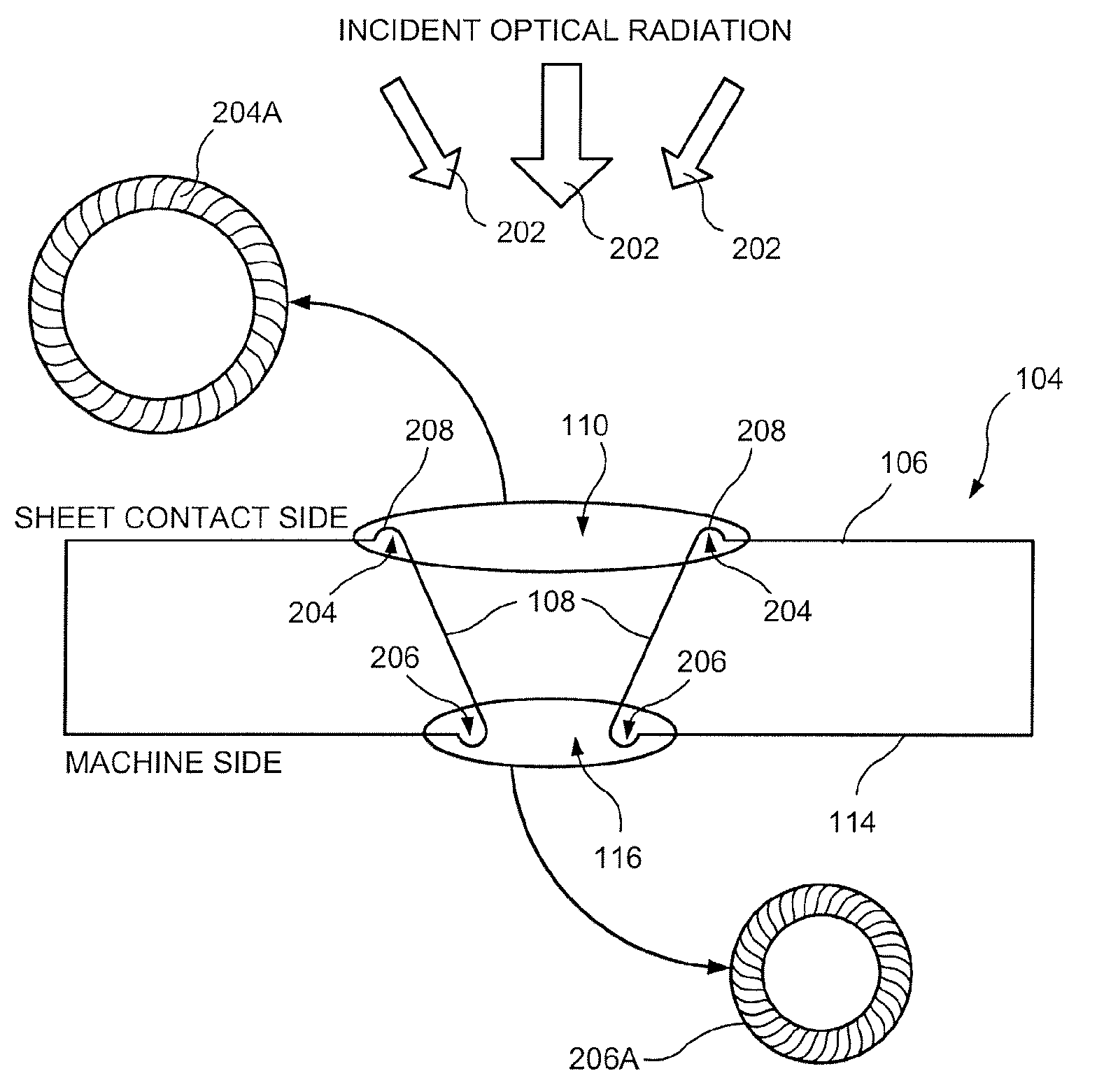

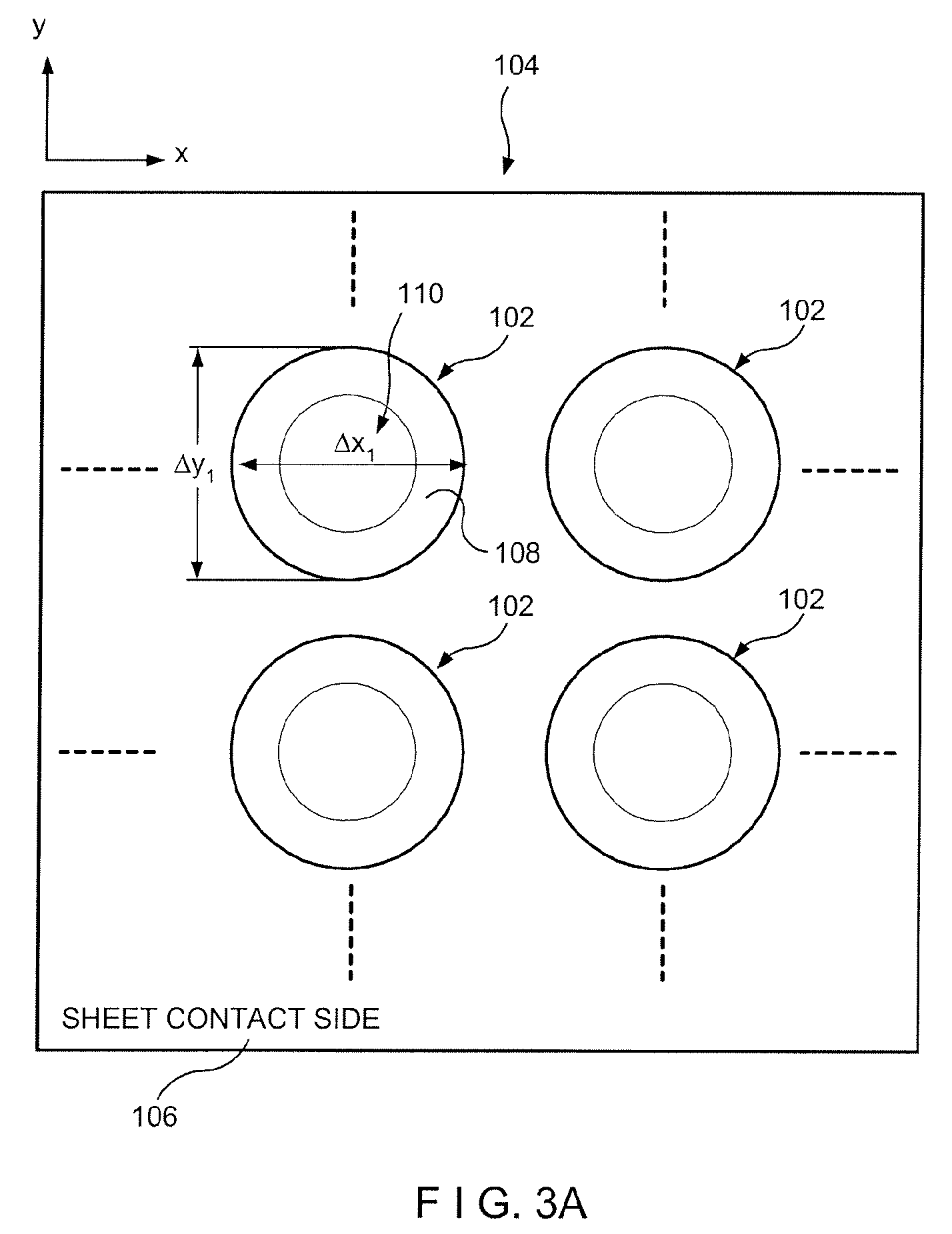

Industrial fabric, and method of making thereof

ActiveUS8822009B2Wet shapingEasy to cleanPattern makingSynthetic resin layered productsEngineeringMaterial Perforation

A support member such as a belt or sleeve includes a topographical pattern on its sheet contact side. A plurality of land areas, corresponding depressions, through voids, and / or groove areas are formed on the top surface of the support member to produce the topographical pattern. The land areas, corresponding depressions, through voids, and / or groove areas may be formed by graving, cutting, etching, embossing, mechanical perforation or a combination thereof. The improved belt or sleeve imparts desired physical characteristics, such as bulk, appearance, texture, absorbency, strength, and hand to a nonwoven product produced thereon.

Owner:ALBANY INT CORP

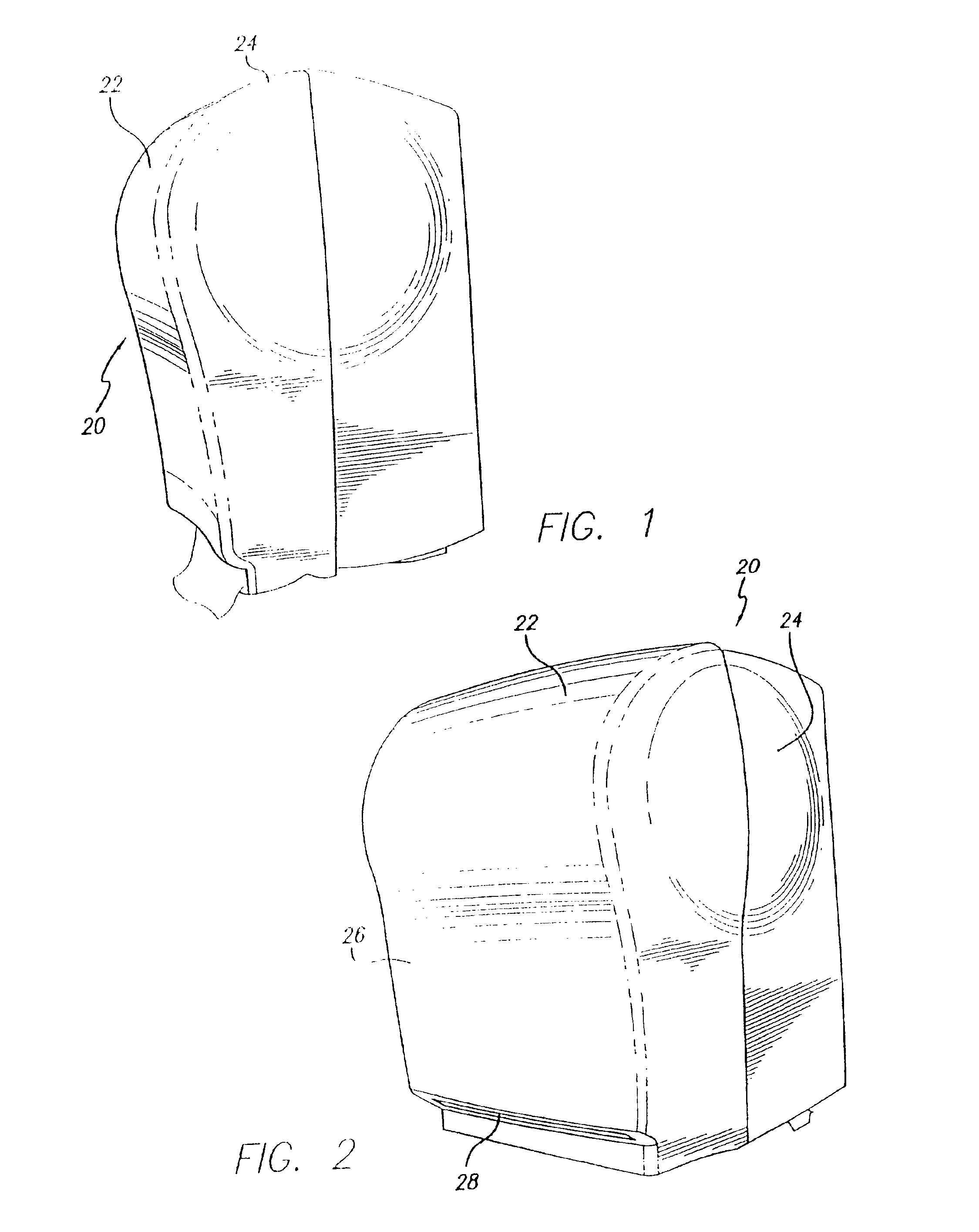

Hands-free paper towel dispensers

A hands-free paper towel dispenser including a housing with a front cover pivotally attached thereto. A sensor is disposed entirely within the housing, and mounted so that it is not attached to the front cover and oriented toward the front cover of the housing to detect an object adjacent the front cover of the housing without the object contacting the front cover. A dispensing mechanism is disposed within the housing for dispensing a length of towel, with the dispensing mechanism including a drive roller and a motor in driving engagement with the drive roller. Control circuitry controls operation of the sensor and the motor, with the control circuitry including a circuit to control the length of towel that is dispensed, and a circuit to provide a delay between dispensing cycles. The dispenser also includes an electric power source for powering operation of the dispenser.

Owner:WAUSAU PAPER TOWEL & TISSUE

System for identifying defects in a composite structure

InactiveUS6871684B2Accurate identificationShorten the timeRadiation pyrometryInvestigating composite materialsComputer scienceStructural integrity

The present invention provides an improved system for identifying defects in a composite structure by providing a light source such that defects, and in particular dark defects on a dark background and / or light defects on a light background, can be identified by capturing images of the illuminated composite structure. In particular, the improved system for identifying defects in a composite structure may provide a reflective surface, dispersion elements, and multiple and / or moveable light source(s) and / or camera(s) in order to ensure that the most accurate images of any area of the composite structure, even curved or contoured areas, are captured and processed. As a result, the system of the present invention permits the operator to quickly identify and correct defects which would otherwise create structural flaws or inconsistencies that may affect the integrity of the composite structure.

Owner:THE BOEING CO

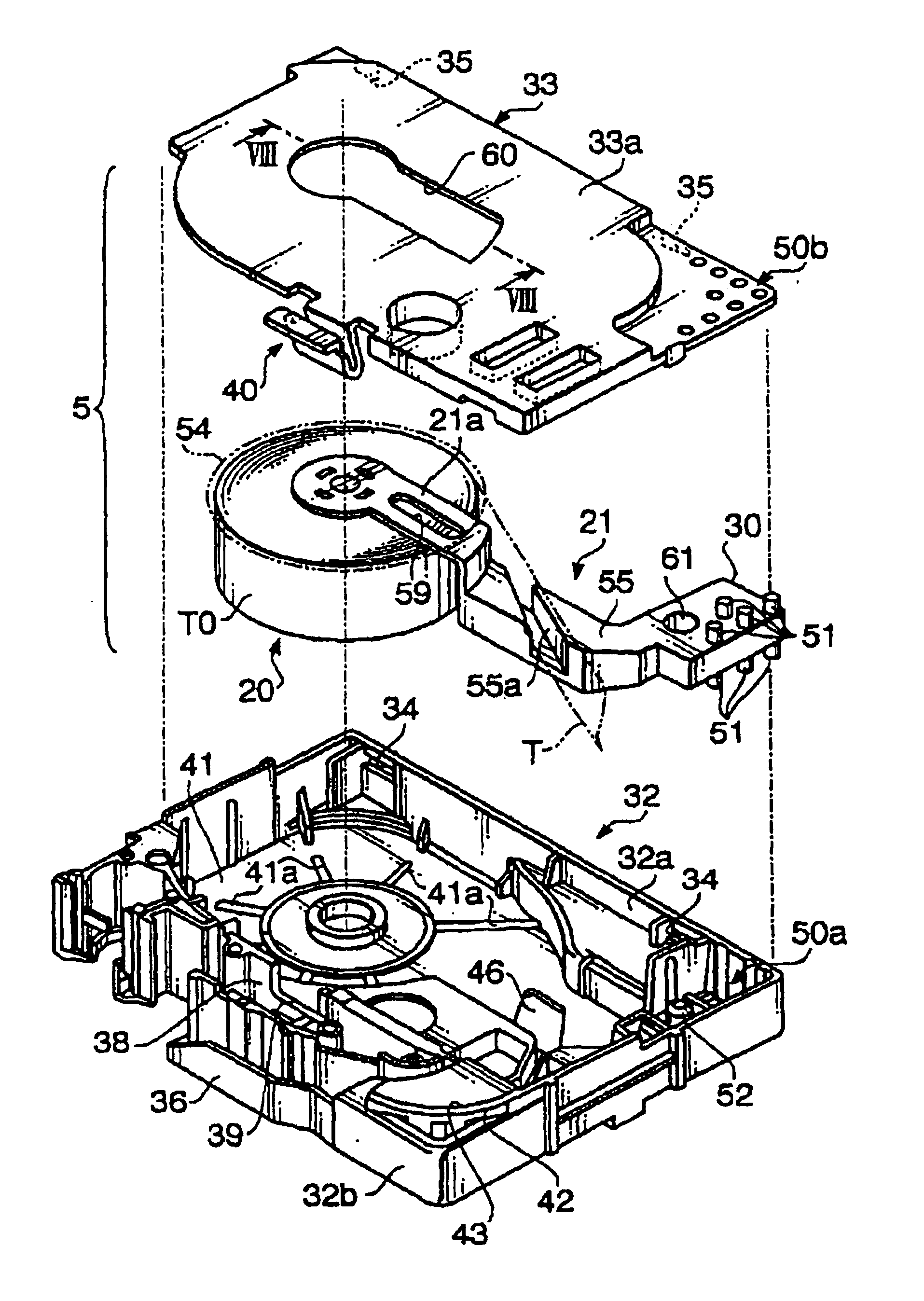

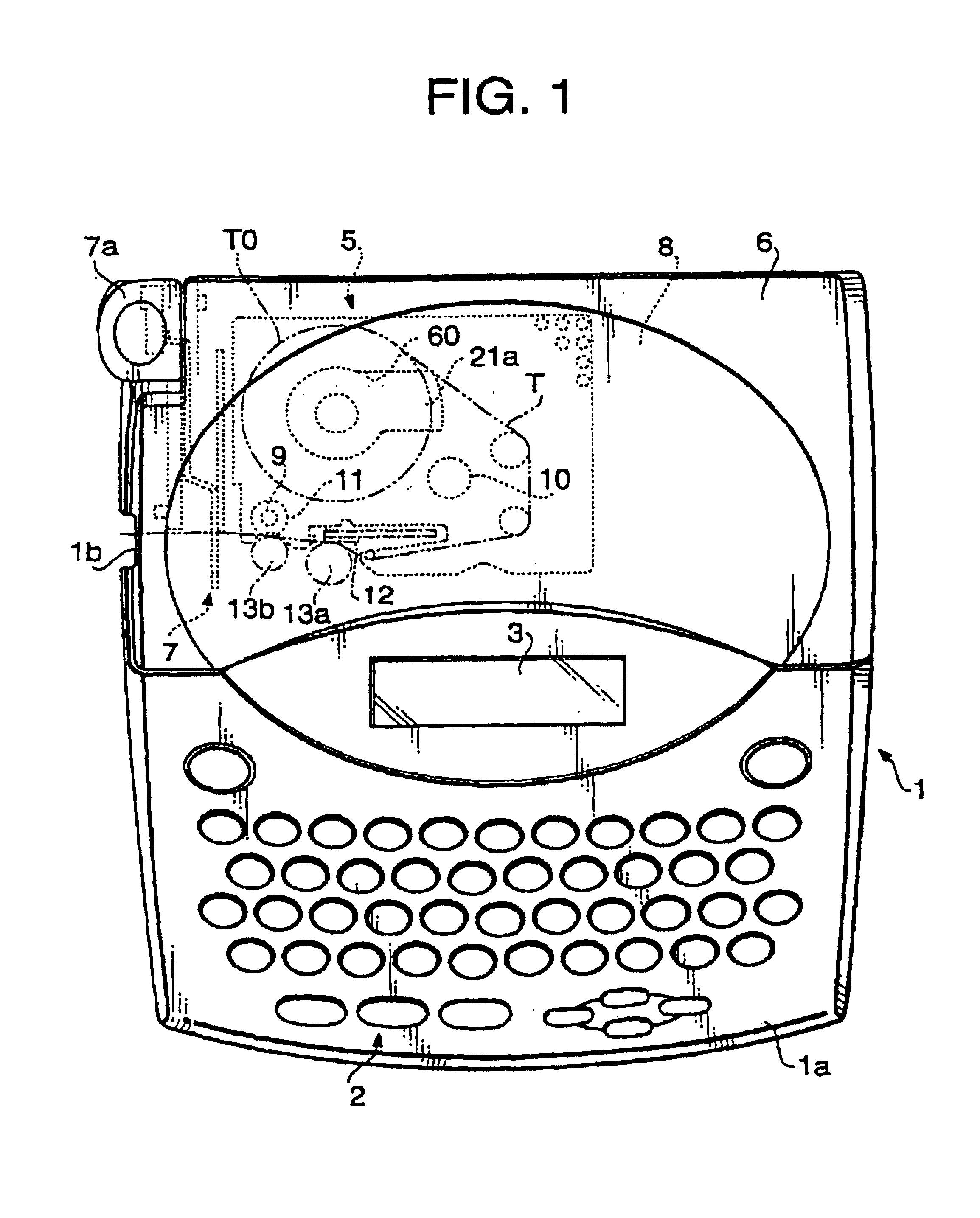

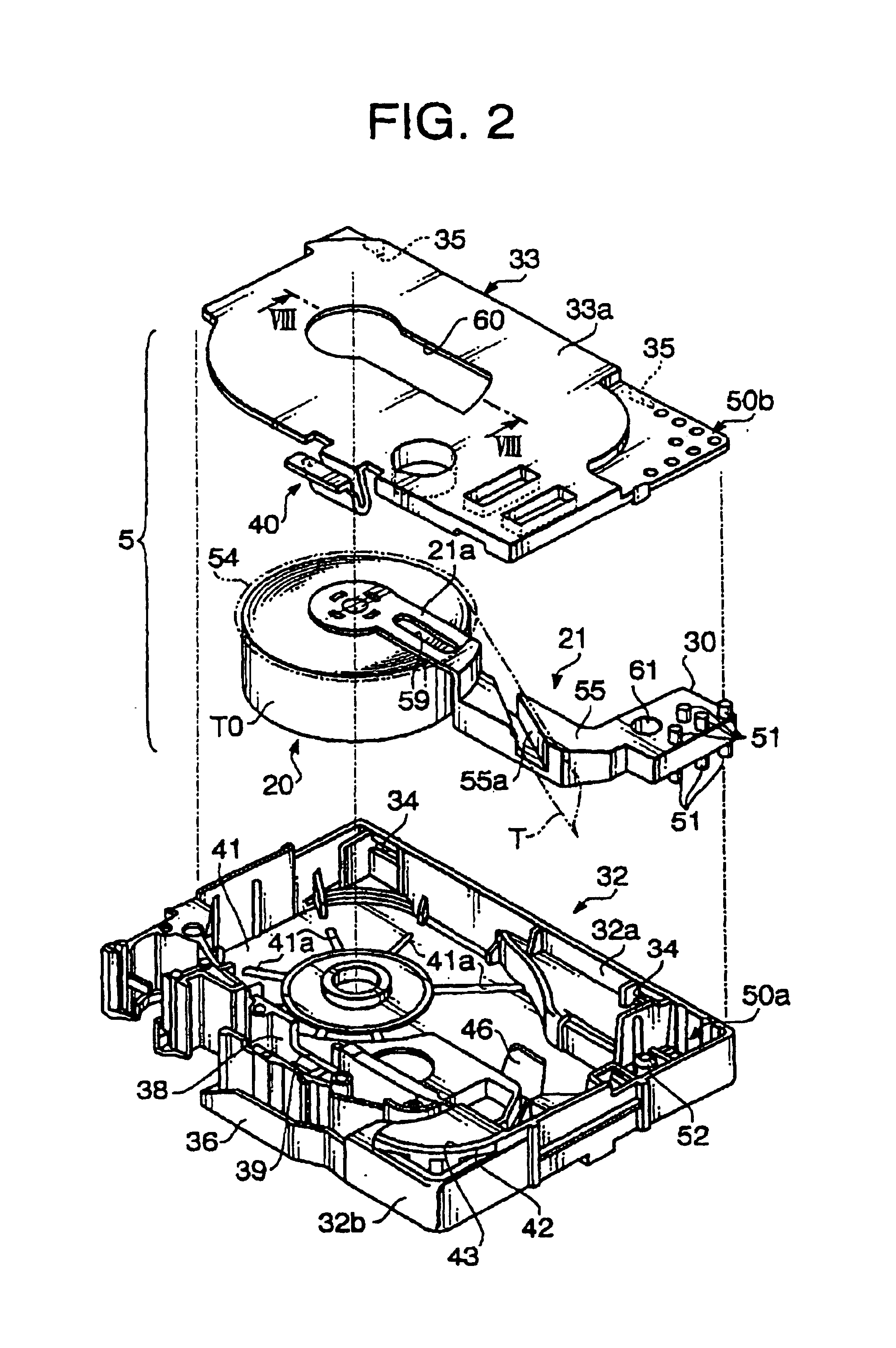

Tape cassette and tape unit

InactiveUS6955318B2Erroneous loadingPicture changing apparatusInking apparatusMagnetic tapeCassette tape

Owner:BROTHER KOGYO KK

Static build-up control in dispensing system

A method of grounding a dispenser. A low impedance path is connected to elements internal to the dispenser. The low impedance path is also connected to a surface contact spring which is adapted to contact an external mounting surface when the dispenser is affixed thereto. Static electrical charge accumulated on the elements is discharged through the low impedance path and the surface contact spring to the external mounting surface.

Owner:GPCP IP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com