Patents

Literature

485 results about "Fiber drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

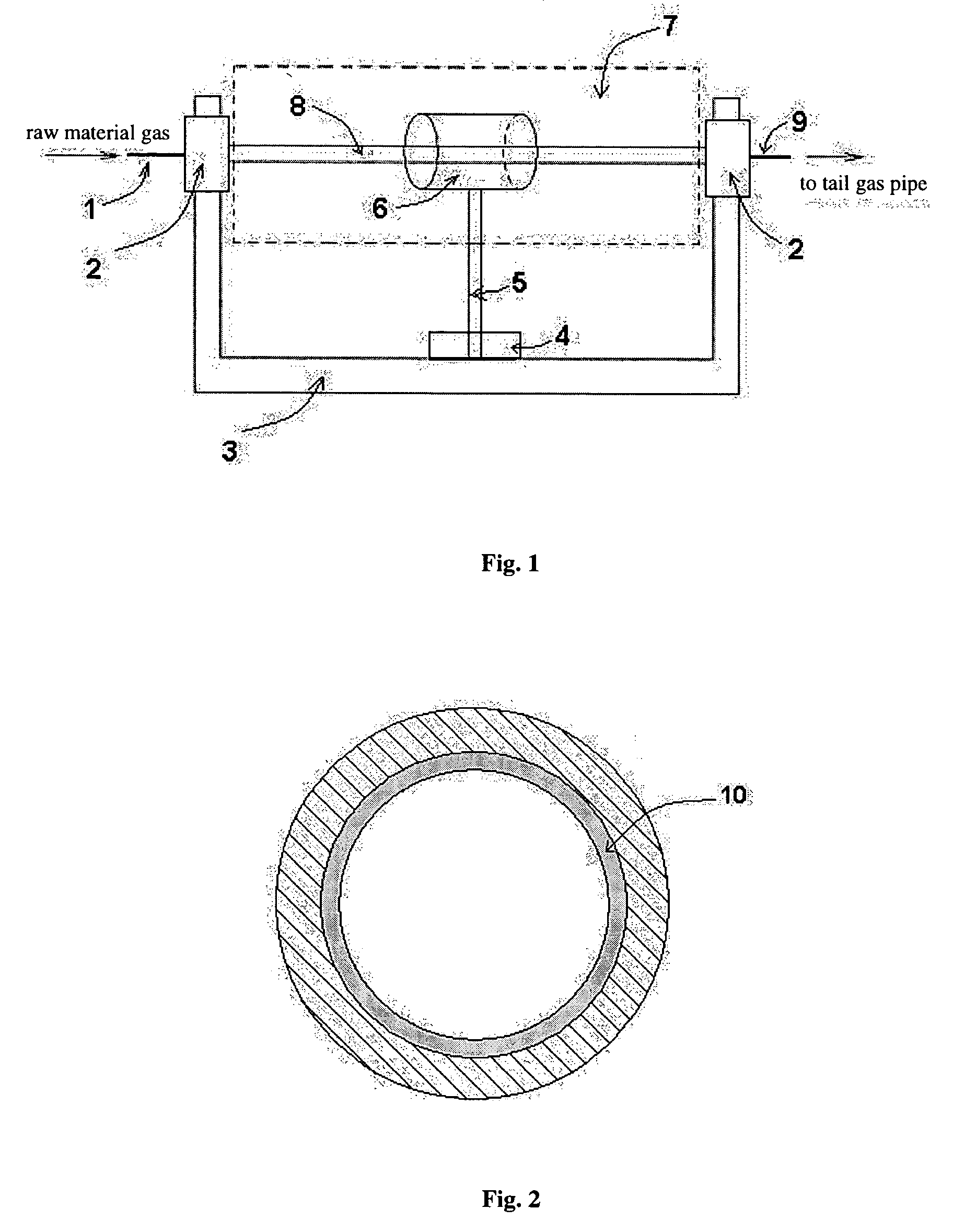

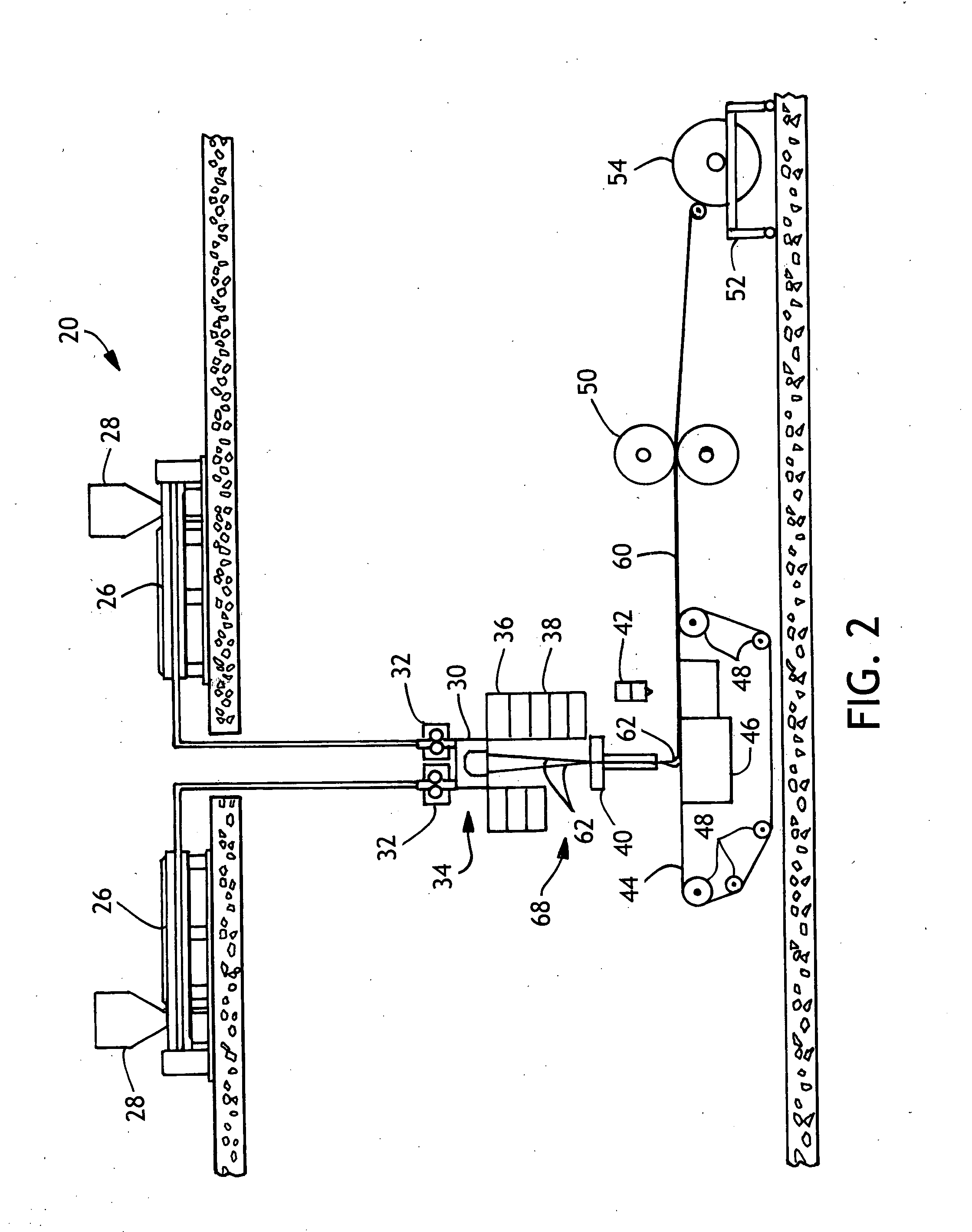

Method and apparatus for tensile testing and rethreading optical fiber during fiber draw

InactiveUS7832675B2Processing speedGlass fibre drawing apparatusFilament handlingFiber drawingTensile testing

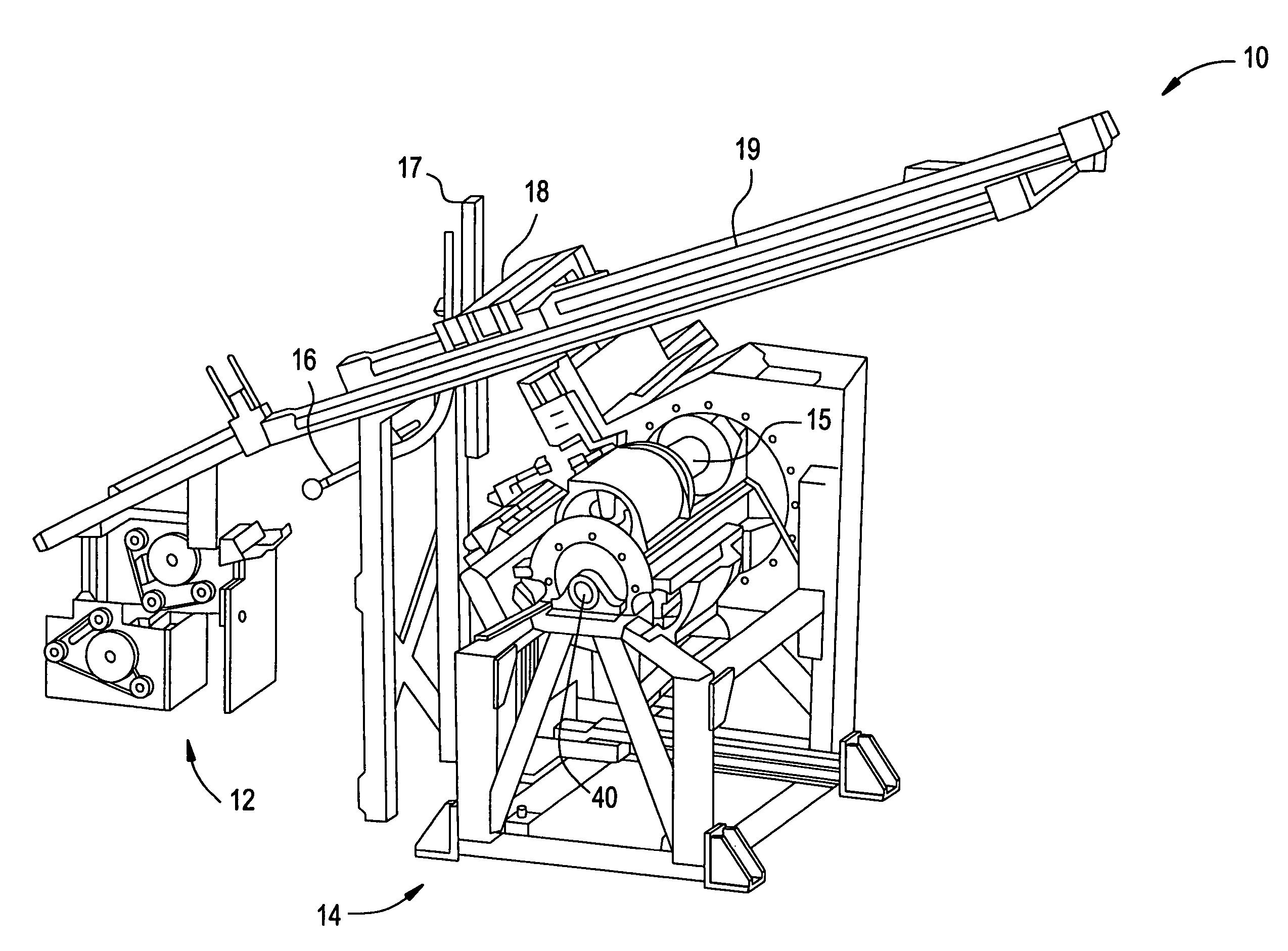

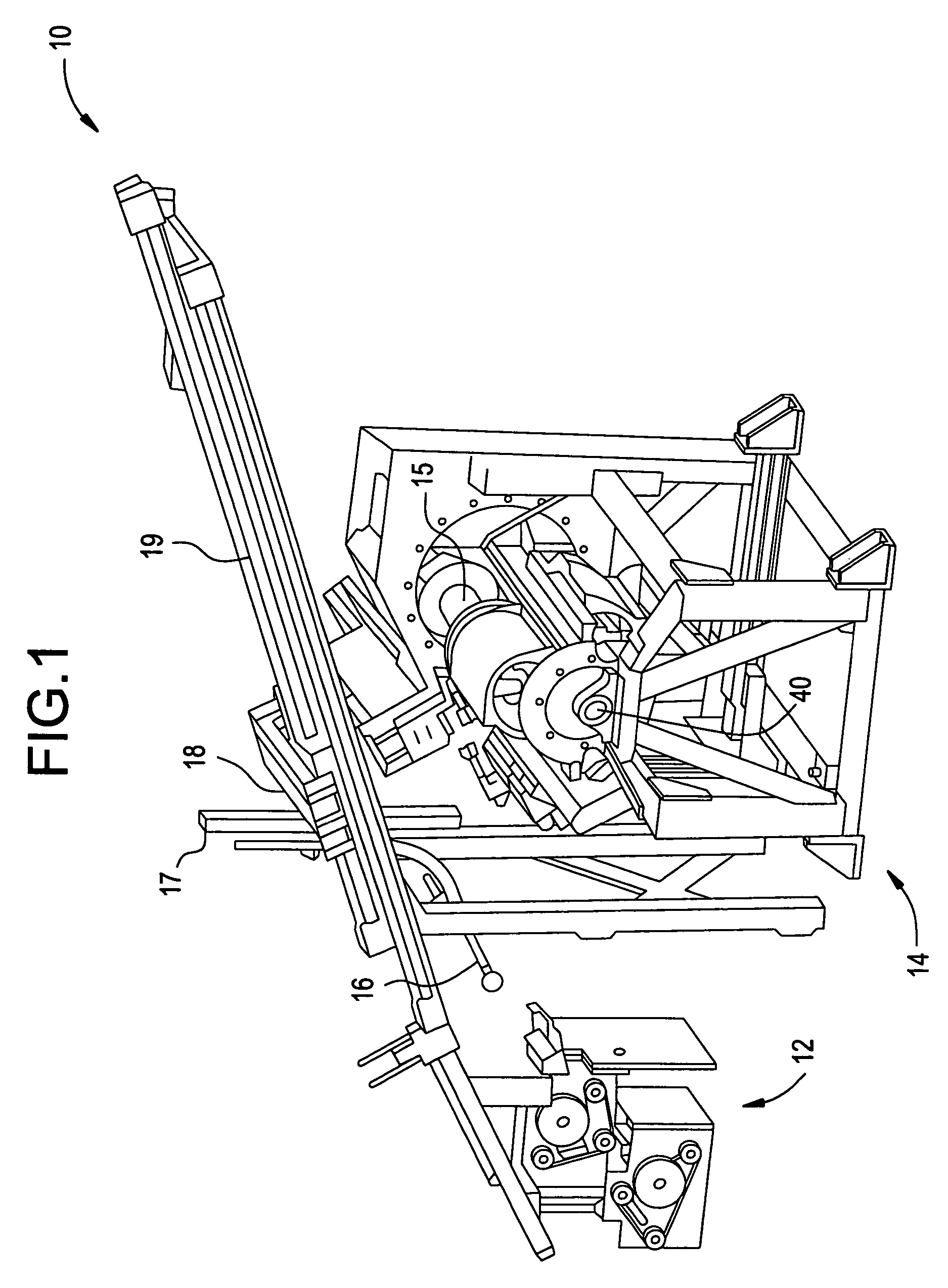

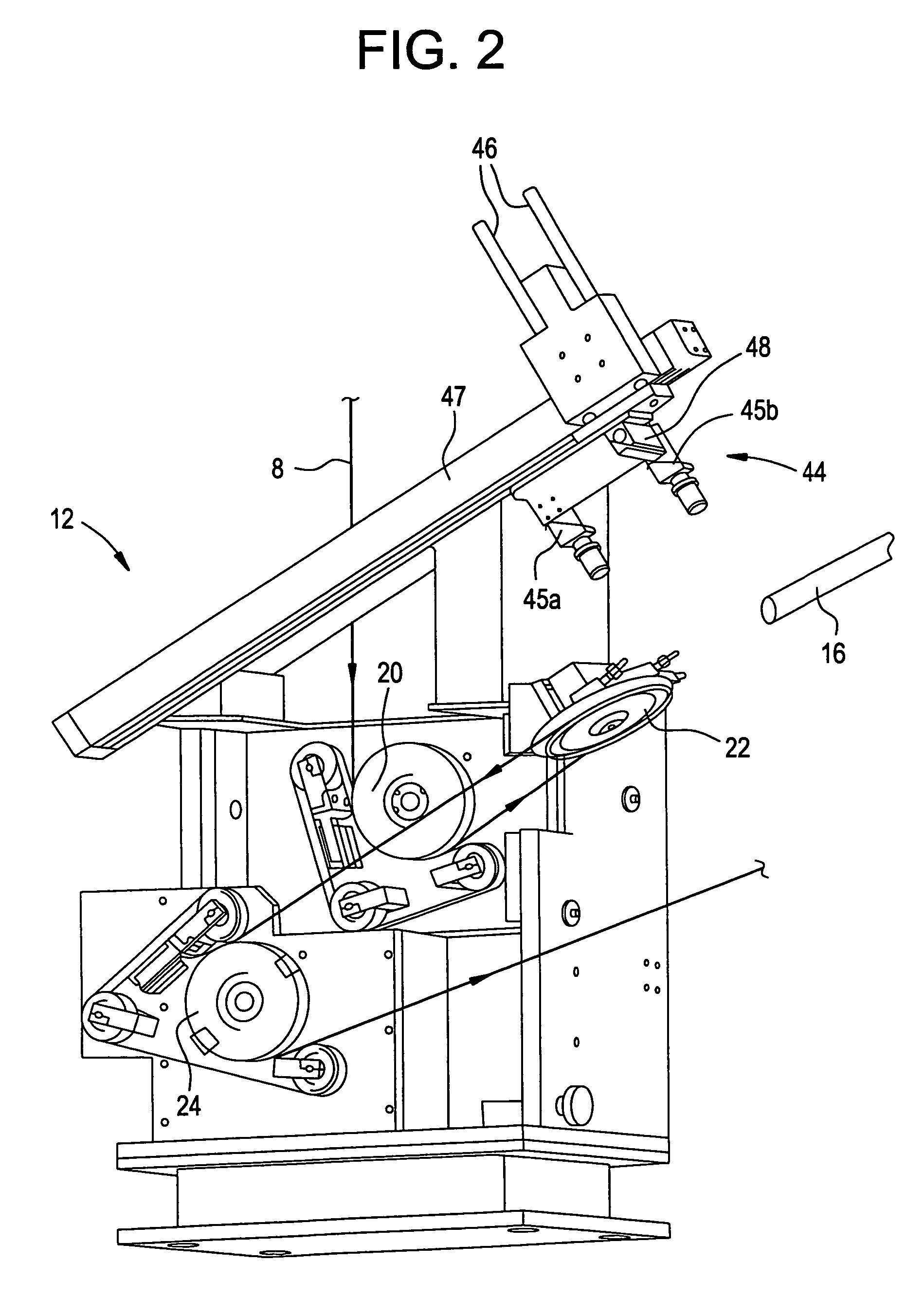

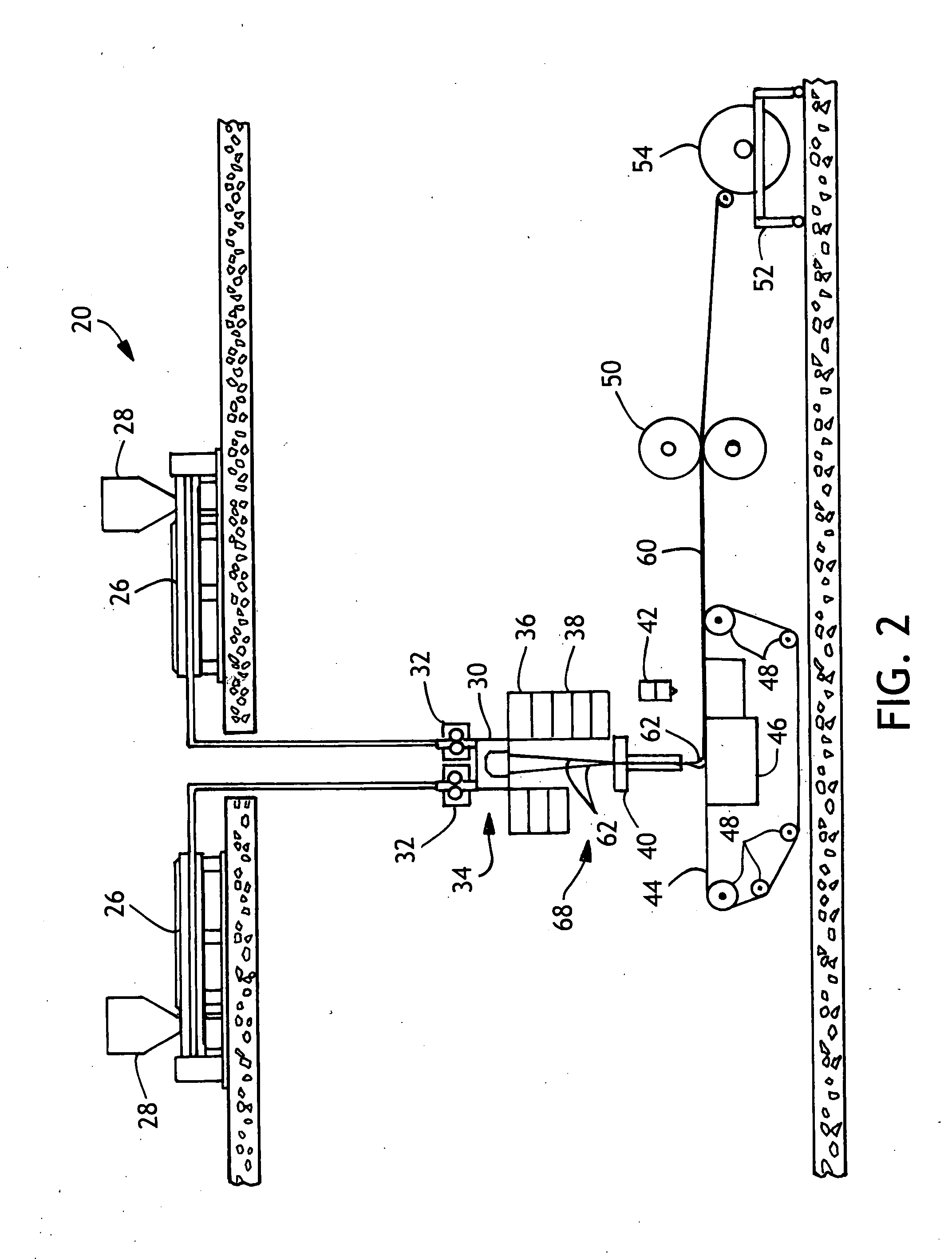

A method and apparatus for automatic threading and winding of optical fiber onto various components in a fiber draw system, as well as methods and apparatus for conducting online tensile screening of optical fiber at high speeds. In a preferred embodiment, the fiber is tensile tested during fiber draw and wound directly onto a shipping spool to be shipped to a customer. The tensile stress can be imparted to the fiber during the draw process by feeding the fiber through a screener capstan, which works in conjunction with another capstan to impart the desired tensile stress to the fiber during the draw process. Another aspect is a method and apparatus for threading or rethreading of a moving length of fiber through a fiber draw or fiber testing process, in which fiber is wound onto a spool, comprising activating an aspirator to obtain the fiber at a first location and moving said aspirator in at least two dimensions to thereby move the fiber to a second location and thread the fiber through or onto at least one component in the fiber draw or testing process.

Owner:CORNING INC

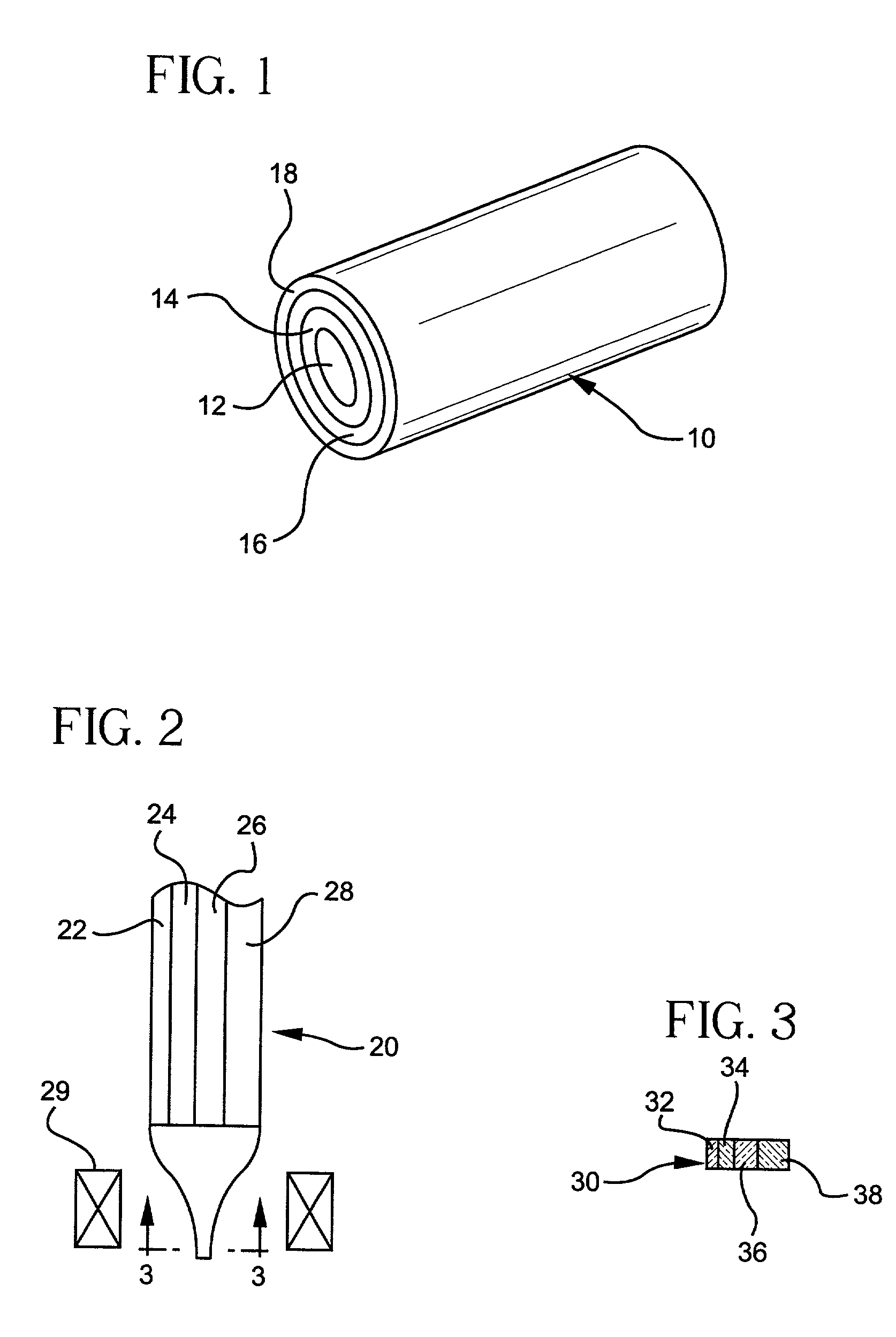

Side-emitting step index fiber

ActiveUS20110103757A1Produced economicallyImprove scalabilityOptical fibre with graded refractive index core/claddingGlass fibre drawing apparatusCouplingRefractive index

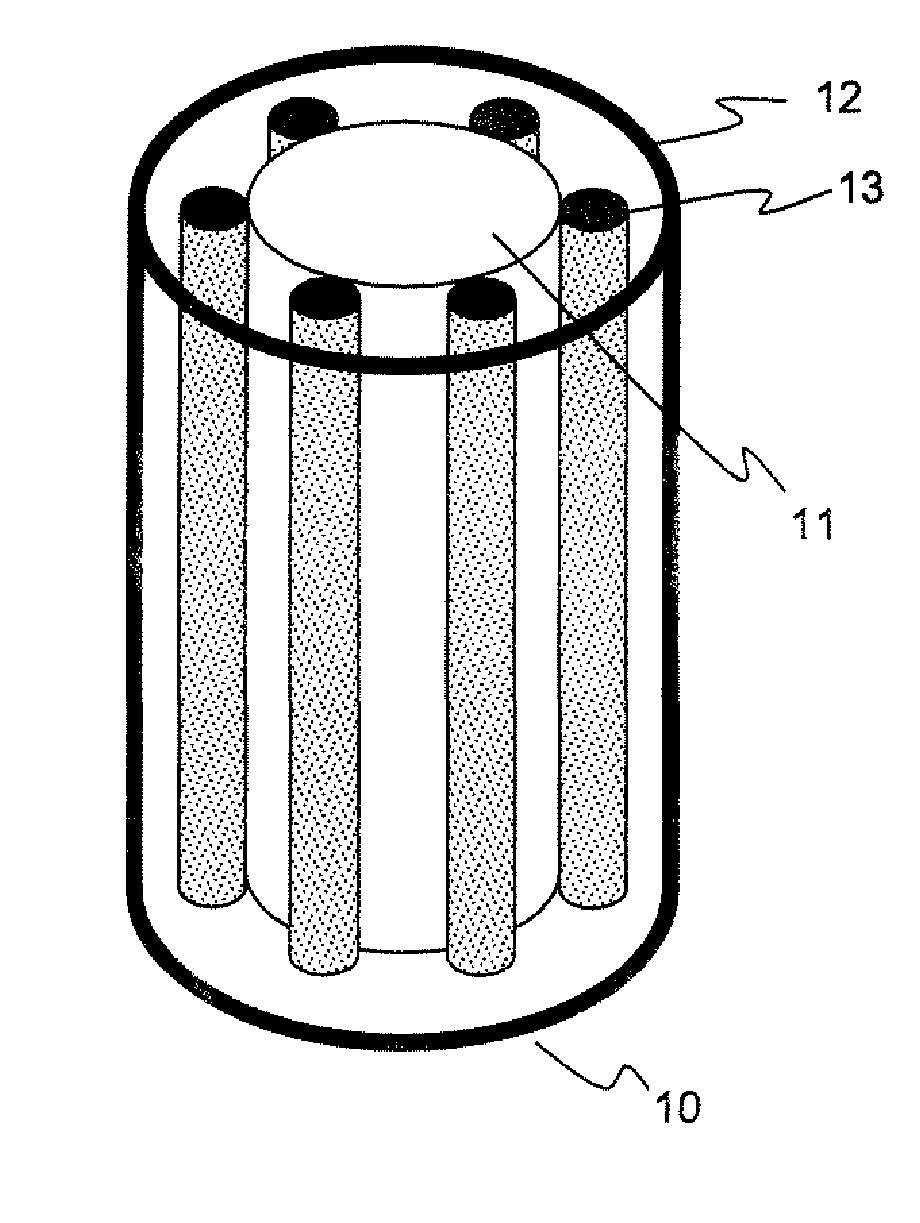

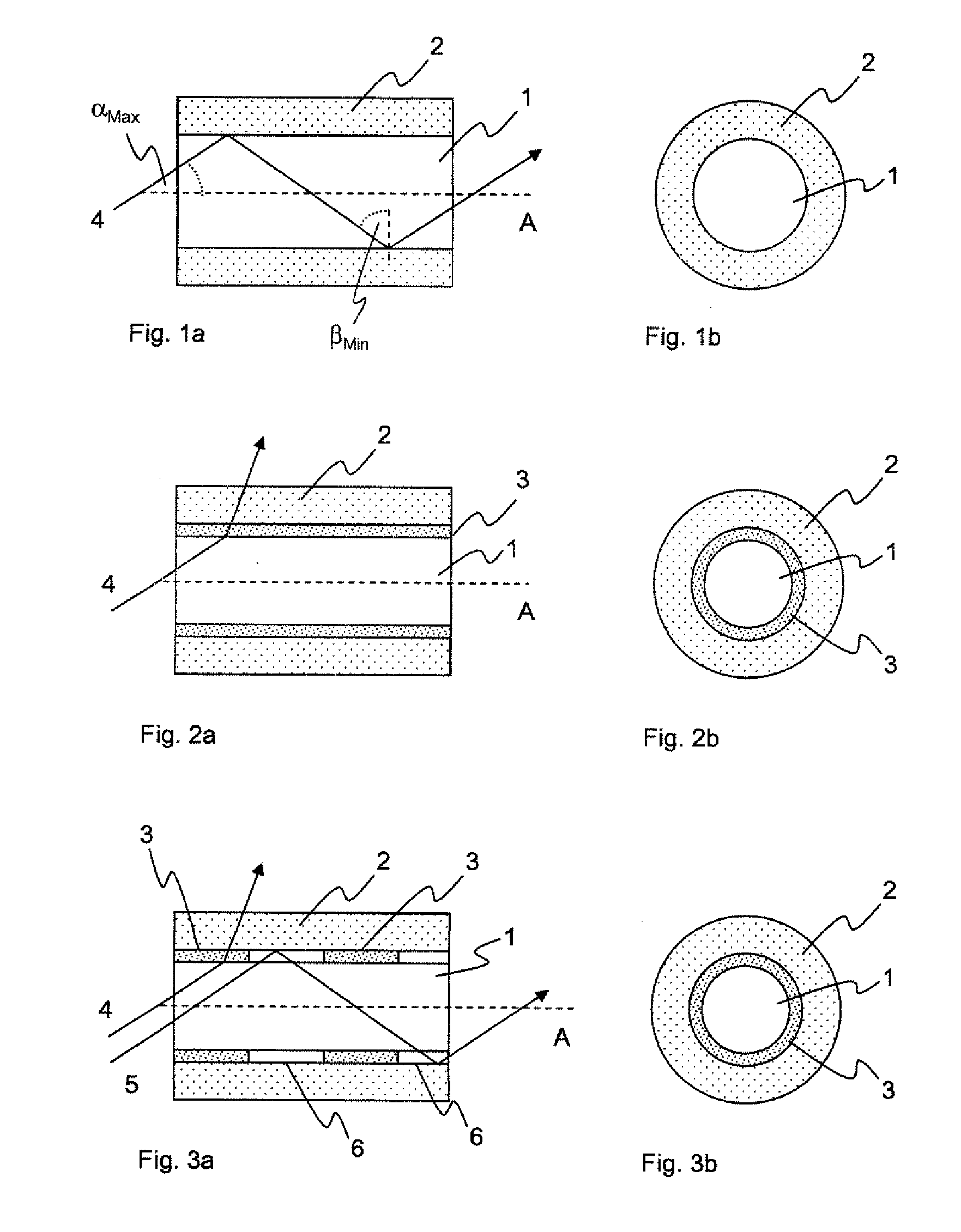

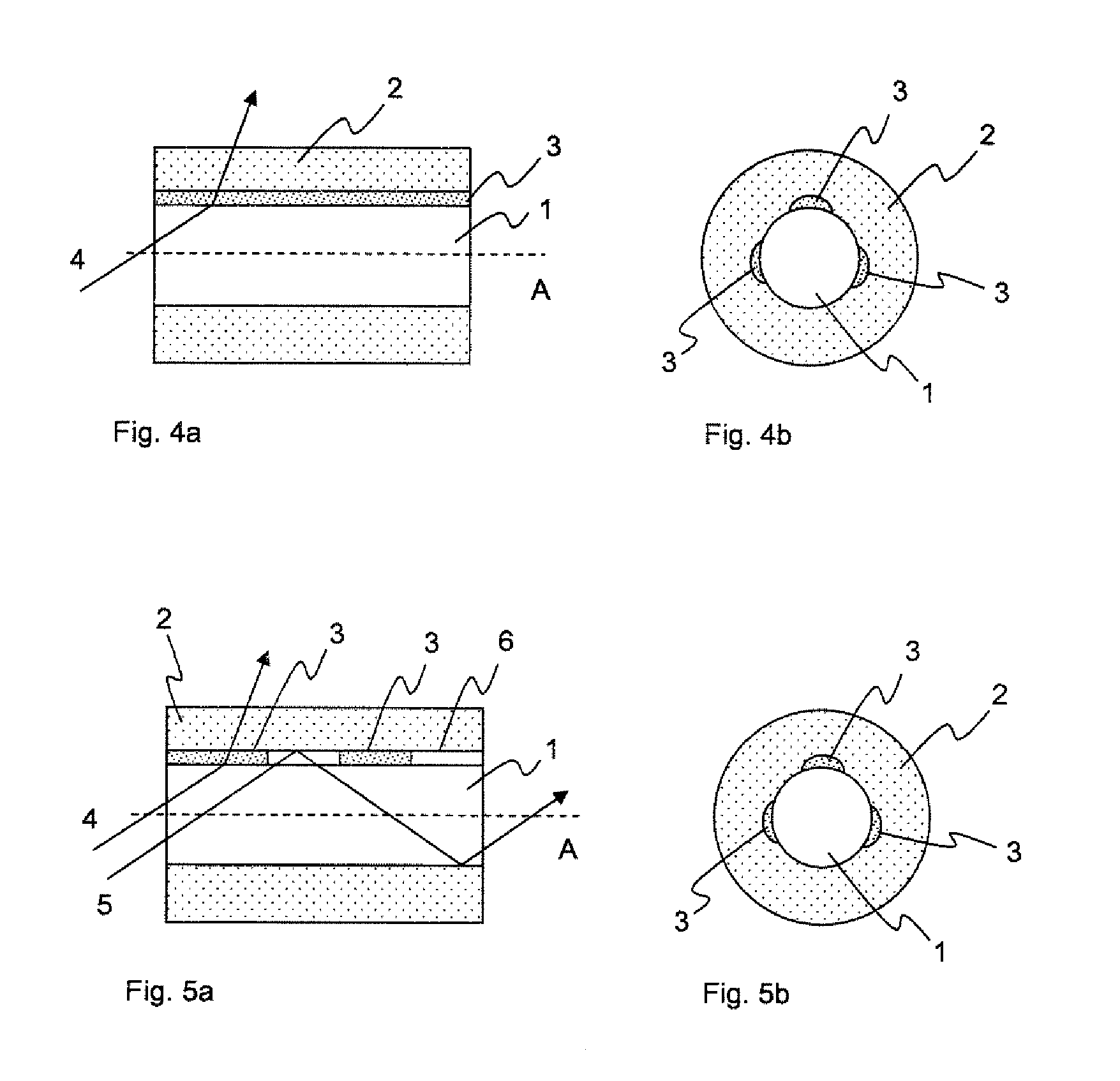

Side-emitting step index fibers. Between core and cladding, the side-emitting step index fibers have scattering centers that ensure the coupling out of light from the fiber. The side-emitting step index fibers are produced by preforms that contain inlay rods, in which the scattering centers are embedded and which are applied to the outer region of the fiber core during fiber drawing. Alternatively, at least one inlay tube can be used.

Owner:SCHOTT AG

Holey optical fiber with random pattern of holes and method for making same

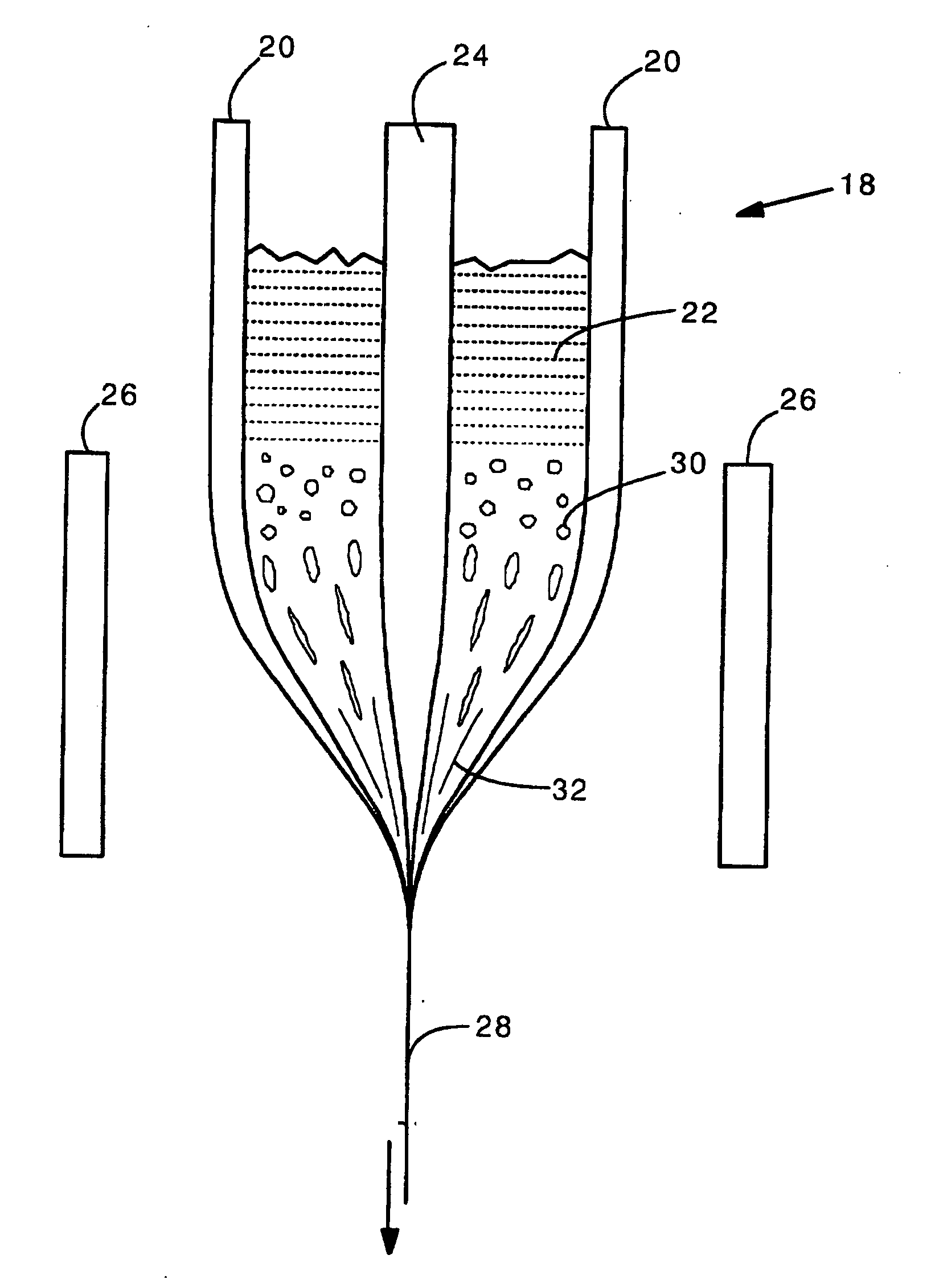

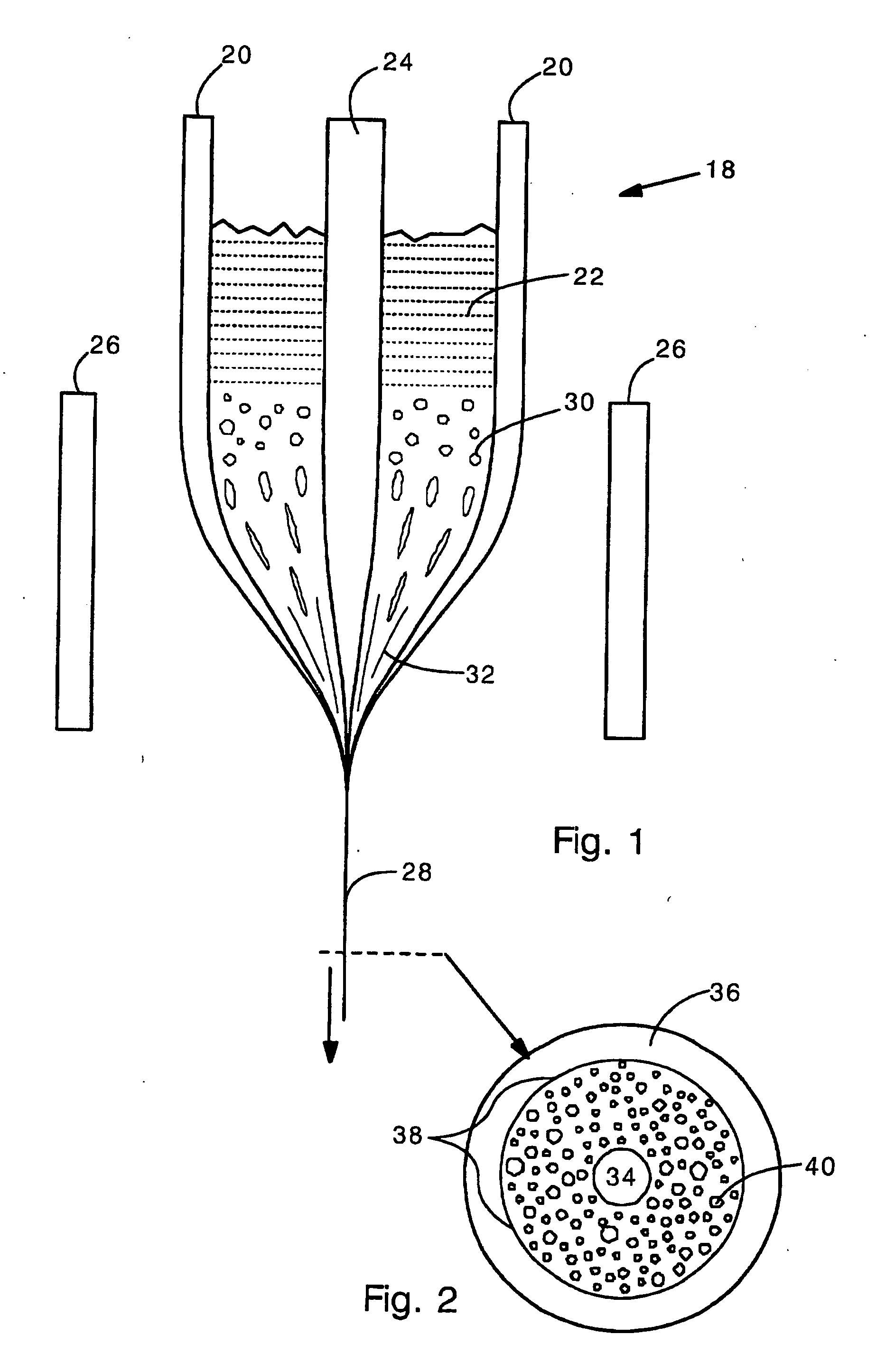

ActiveUS20050094954A1Glass making apparatusOptical fibre with multilayer core/claddingSilicon dioxideAir bubble

A random array of holes is created in an optical fiber by gas generated during fiber drawing. The gas forms bubbles which are drawn into long, microscopic holes. The gas is created by a gas generating material such as silicon nitride. Silicon nitride oxidizes to produce nitrogen oxides when heated. The gas generating material can alternatively be silicon carbide or other nitrides or carbides. The random holes can provide cladding for optical confinement when located around a fiber core. The random holes can also be present in the fiber core. The fibers can be made of silica. The present random hole fibers are particularly useful as pressure sensors since they experience a large wavelength dependant increase in optical loss when pressure or force is applied.

Owner:VIRGINIA TECH INTPROP INC

Coating composition for optical fiber

In the coating composition for a optical fiber of the present invention, a polyurethane (meth)acrylate oligomer (A), which is based on a urethane prepolymer having an equivalent ratio of NCO group in a polyisocyanate (a) to OH group in a polyol (b) of more than 3.0, is used and the oligomer (A) has a mixing weight ratio of an oligomer (d) having a number average molecular weight of 800 or less to an oligomer (e) having a number average molecular weight of 1,000 or more of 30 / 70-70 / 30. The coating composition of this invention has a low viscosity, and therefore, is suitable for a rapid fiber-drawing in a production of an optical fiber. Further, a cured material obtained from the coating composition of the present invention has both a high elastic modulus and a high elongation, which properties are required for a hard material, and has a slight change of elastic modulus with a change of temperature to improve a long-term reliability of an optical fiber.

Owner:MITSUI TAKEDA CHEM INC +1

Method of manufacture of low water peak single mode optical fiber

The present invention directs to a method of manufacturing low water peak single mode optical fiber, which comprises performing deposition in a substrate tube using PCVD technology, whereby a deposited layer of a certain construction design is formed on the inner wall of the substrate tube, melt contracting the substrate tube into a solid core rod according to melt contraction technology, producing an optical fiber preform by combining the core rod and a jacket tube of low hydroxyl content by means of RIT technology or by depositing an outer cladding on the outer surface of the core rod using OVD technology, sending the optical fiber preform into a fiber drawing furnace to draw it into an optical fiber, wherein: in the PCVD technology, the content of impurities in a gas mixture of raw materials, which is characterized by the infrared spectrum transmissivity thereof, is required to a transmissivity of 90% or greater, the water content in O2 is 100 ppb or less, the water content in C2F6 is 1000 ppb or less, the hydroxyl content of the substrate tube is 1000 ppb or less, the dynamic leak rate of a deposition machine is 1.0×10−5 mbar·l / s or less; during melt contraction of the substrate tube, the dynamic leak rate of a melt contraction machine is 1.0×10−5 mbar·l / s or less; the hydroxyl content of the jacket tube of low hydroxyl content is required to be 10 ppm or less; the relative humidity of environment during the process of manufacture is 25% or less; the ratio of the cladding diameter to the core layer diameter (b / a value) in the waveguide structure of the optical fiber is from 2.0 to 7.0.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

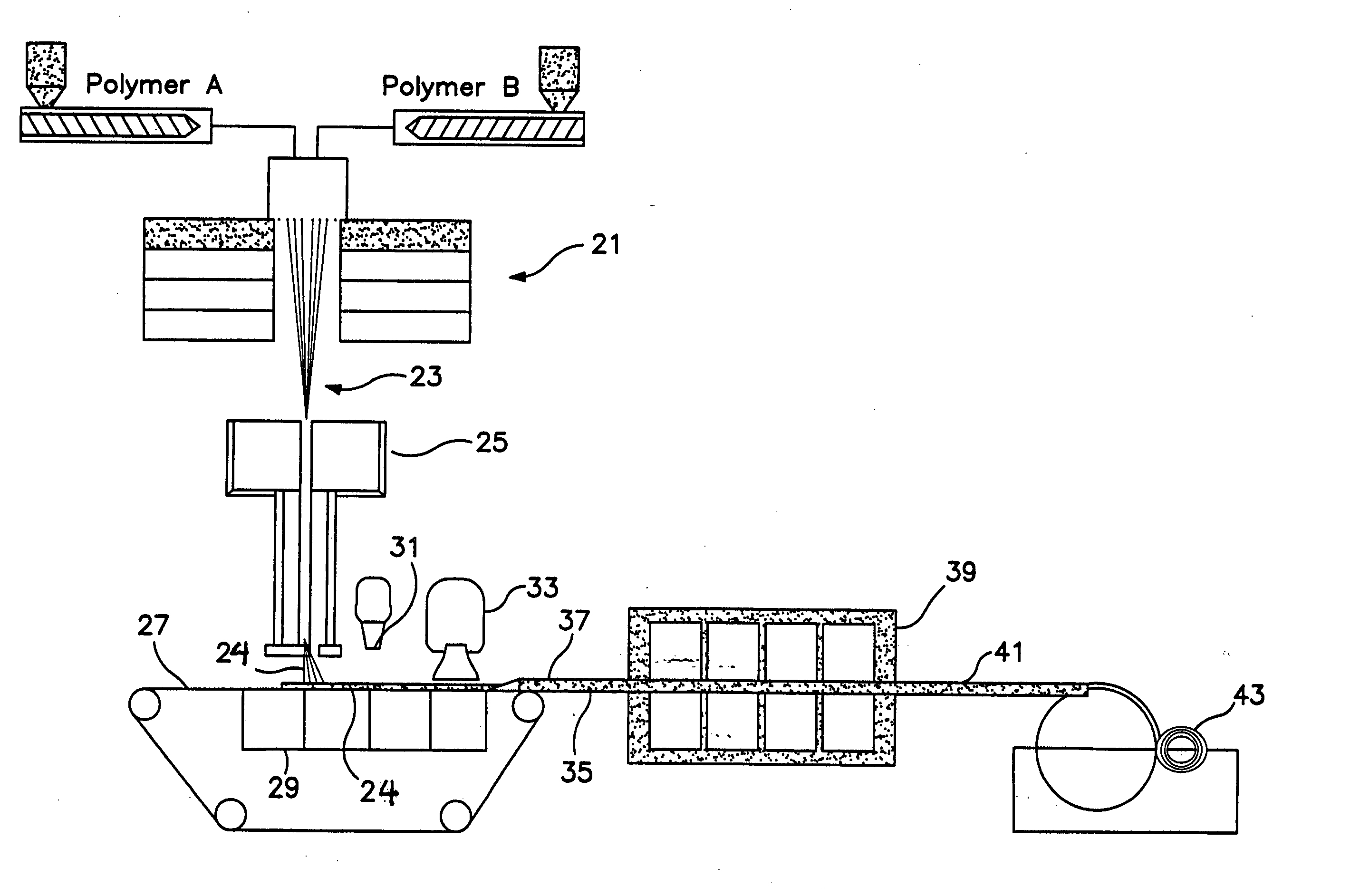

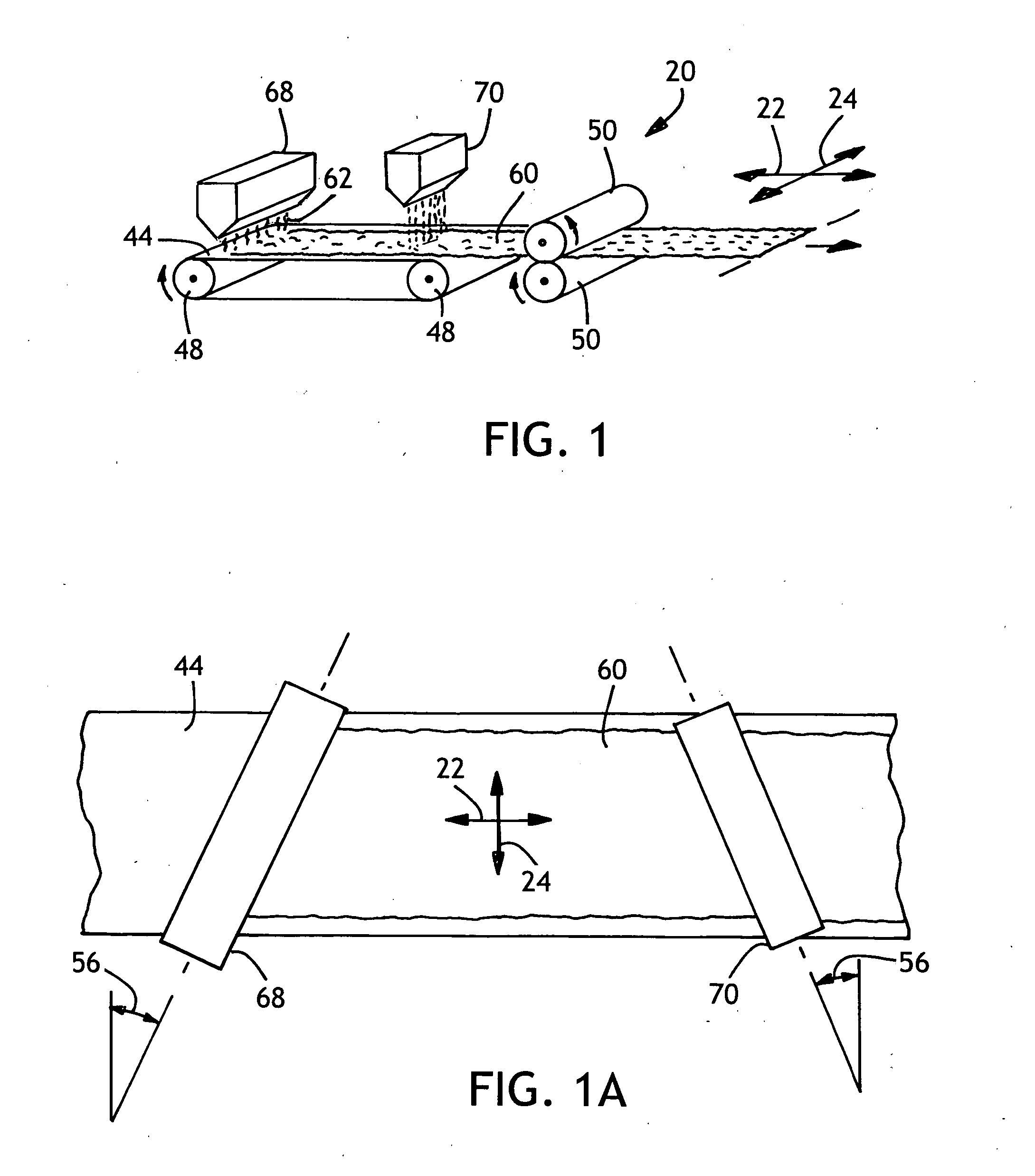

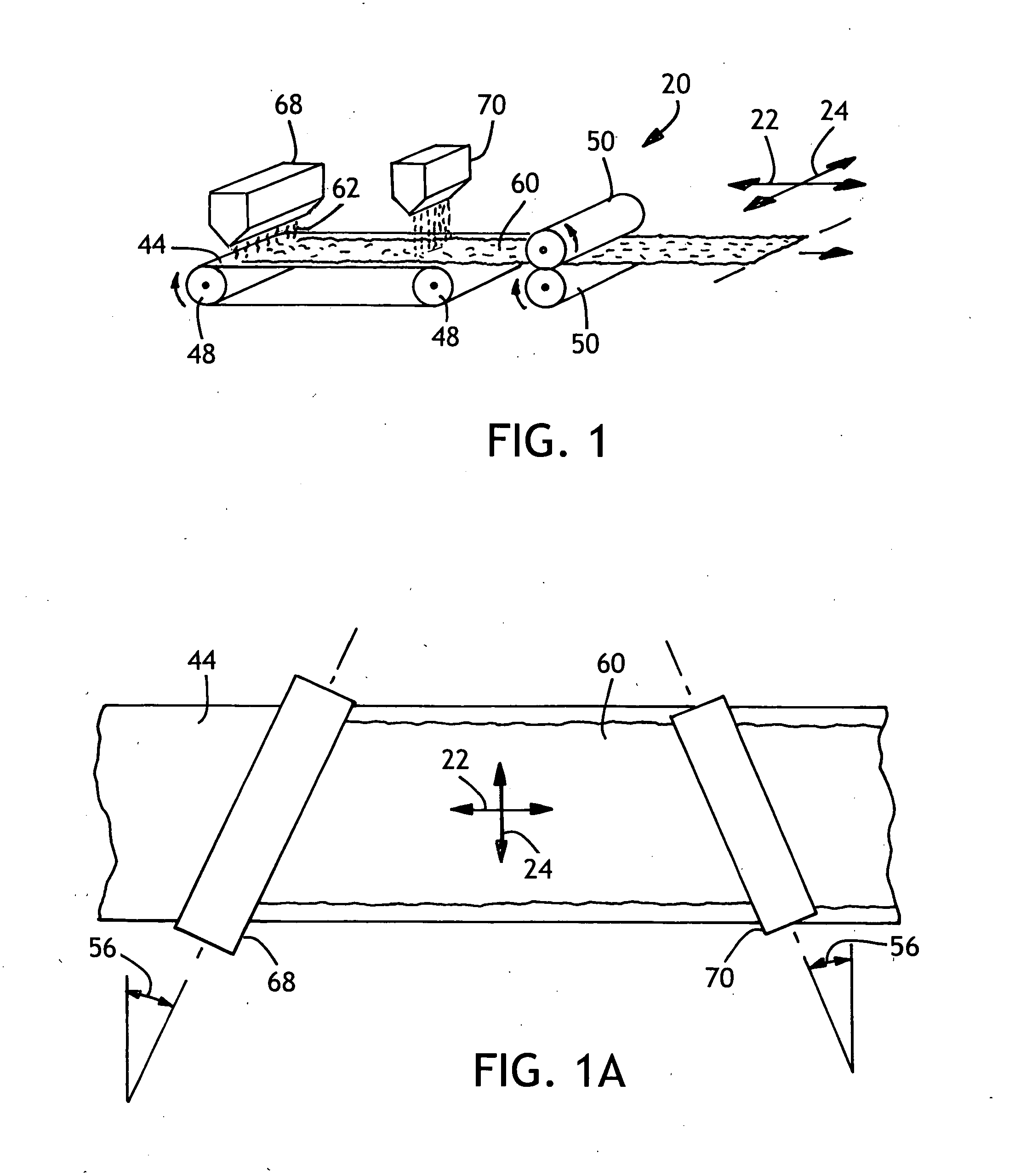

High loft low density nonwoven webs of crimped filaments and methods of making same

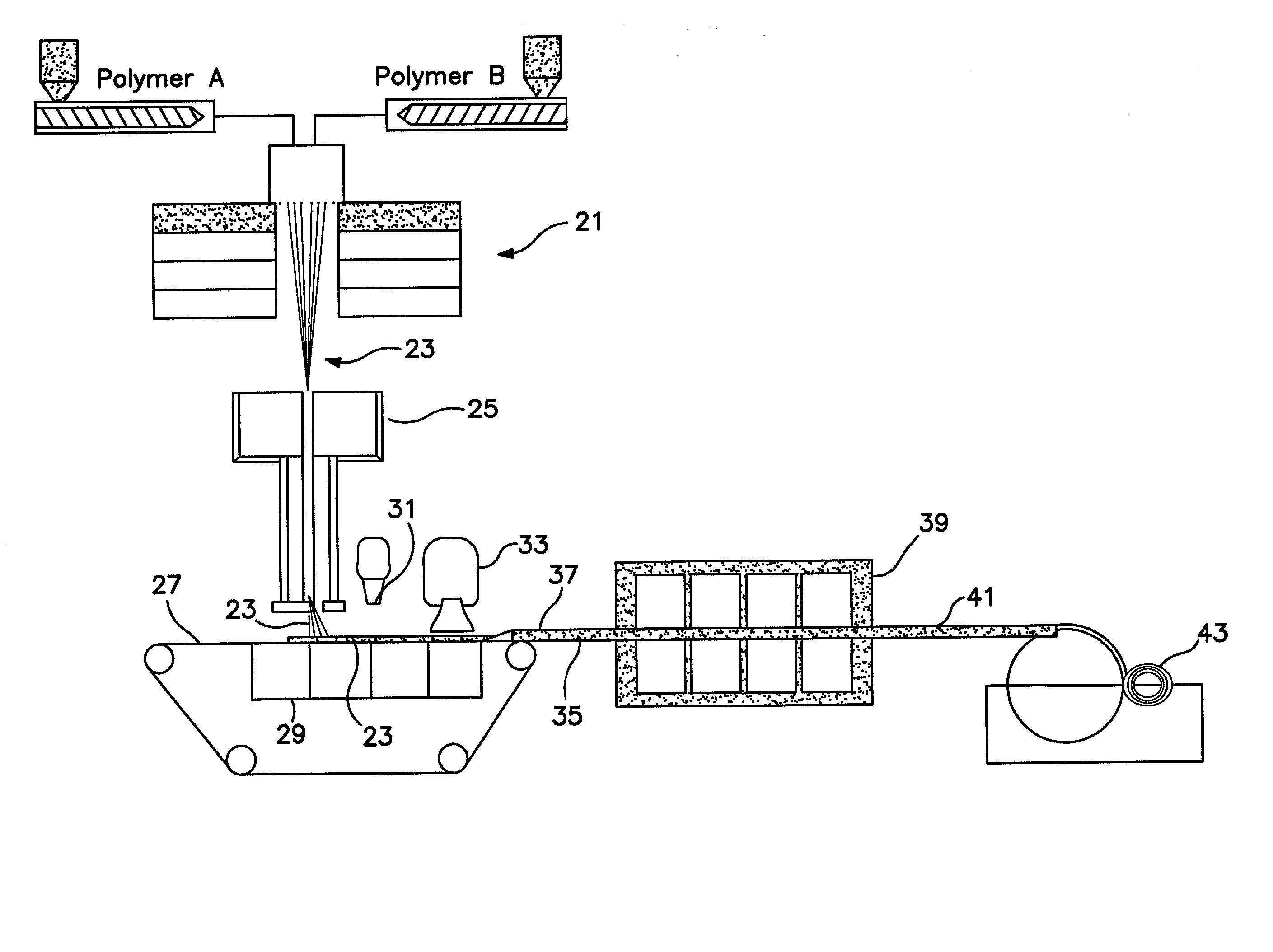

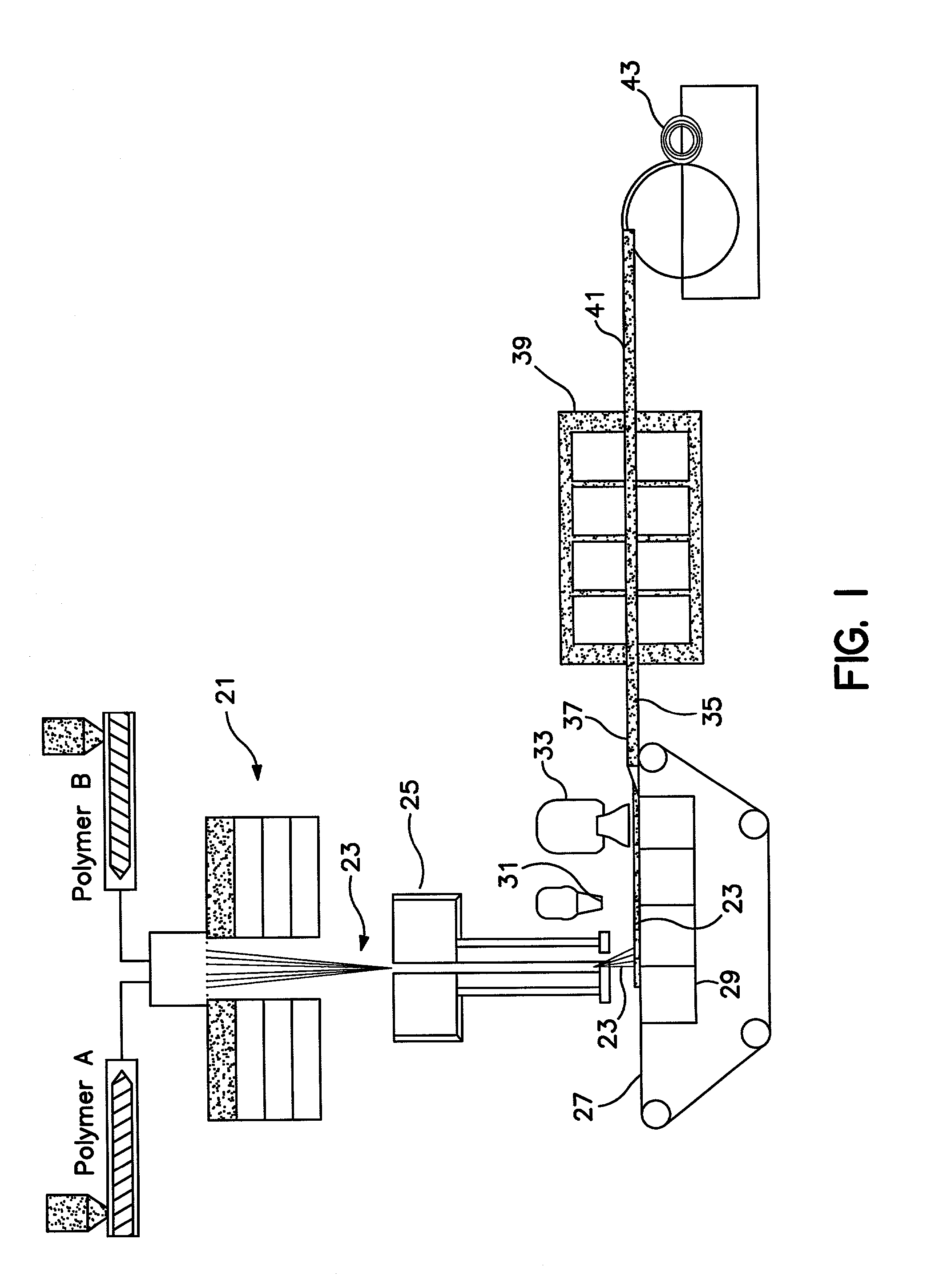

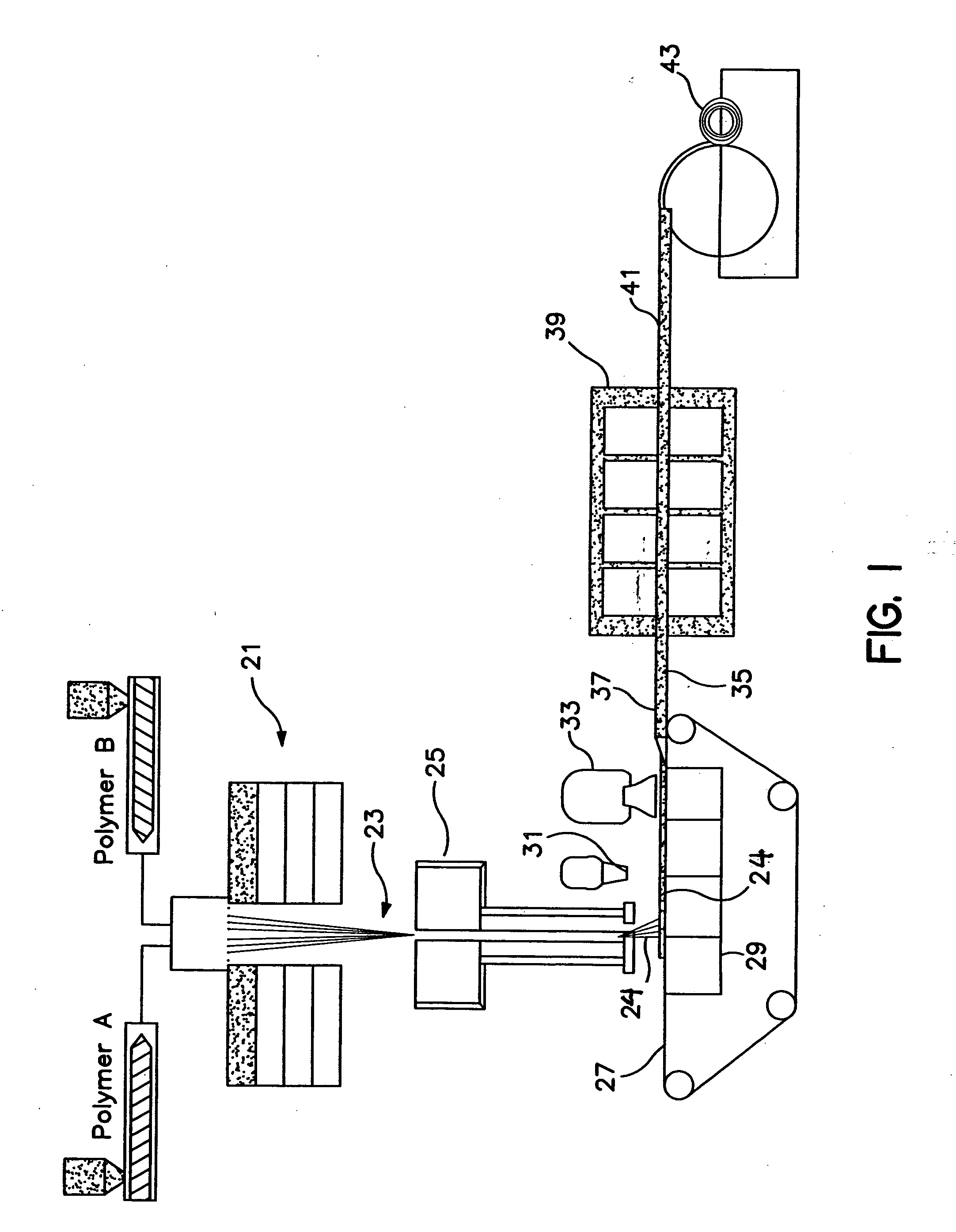

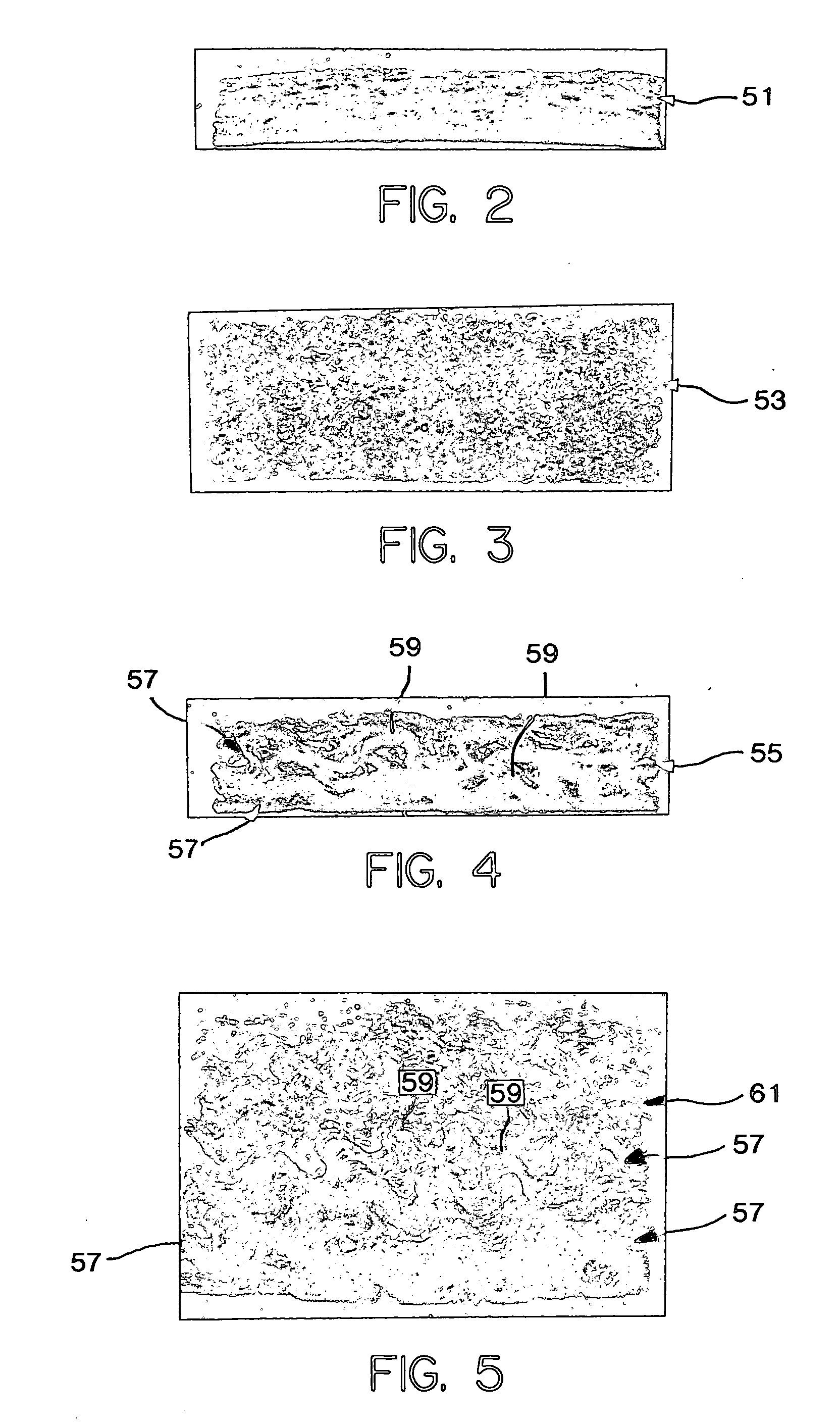

InactiveUS20030118816A1Maintain liquidityLow densityWoven fabricsNon-woven fabricsParticulatesPolymer science

High loft, low density nonwoven webs are produced by forming substantially continuous, spunbond, crimped, bicomponent fibers of A / B side by side morphology in an unheated fiber draw unit. The fibers are then heated and cooled in the absence of impeding forces to achieve maximum crimp in the z-direction and produce a web of lofted material. The resultant material is particularly suitable for use as an insulator. Particulates may be added to the webs if desired.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Detectable labels, methods of manufacture and use

InactiveUS20030119207A1Good adhesionAbsorption cross sectionPeptide librariesNanosensorsAnalyteReady to use

Owner:CORNING INC

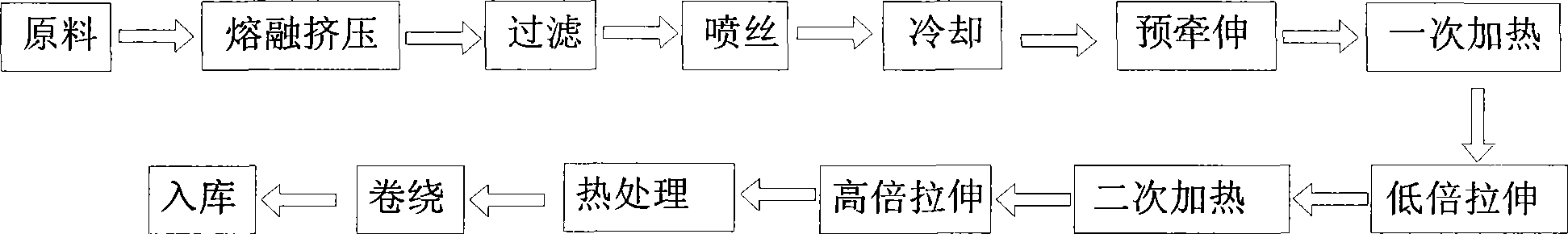

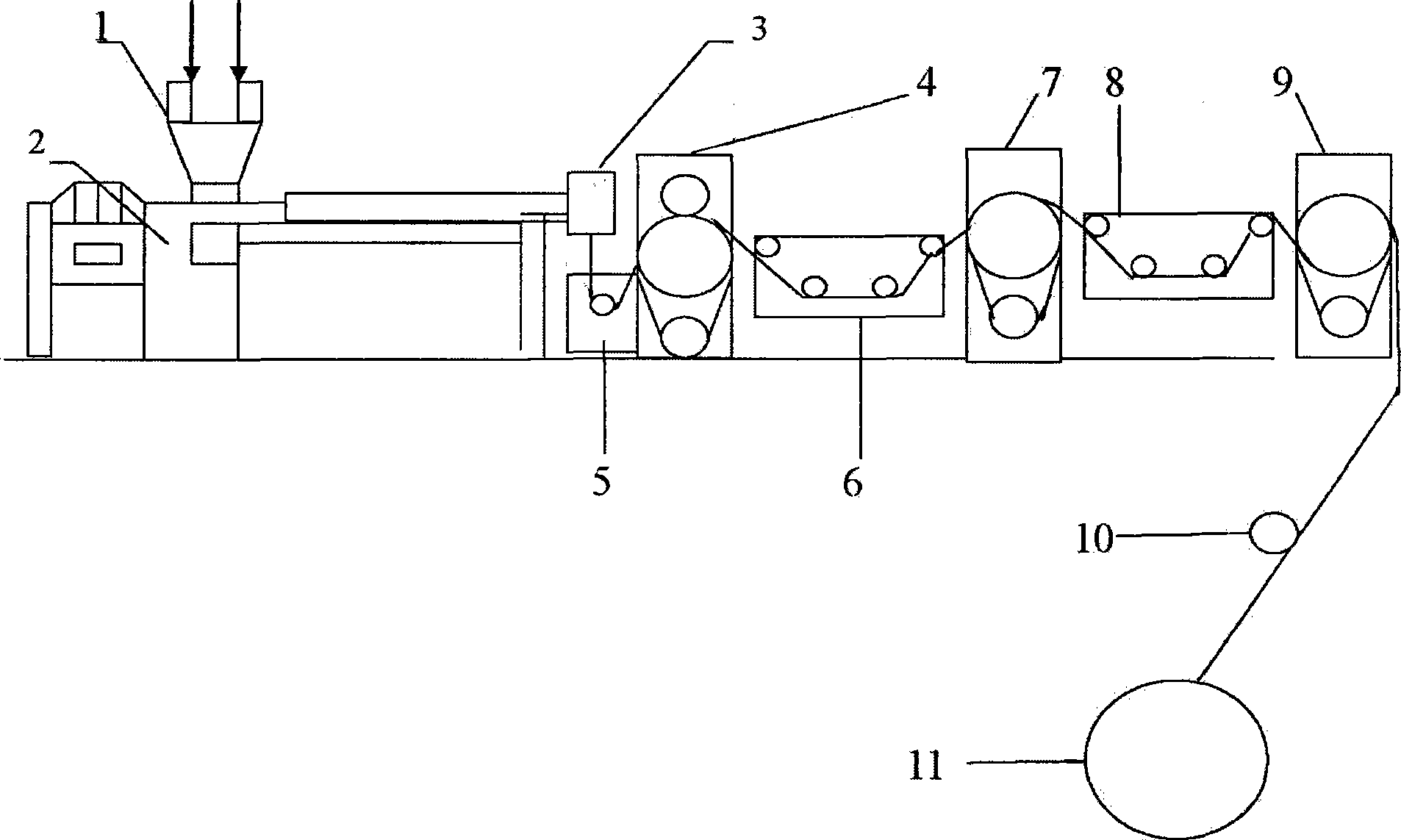

Method and apparatus for producing high strength, high modulus polyethylene filament by melt drawing

ActiveCN101476170AImprove featuresHigh strengthArtificial thread manufacturing machinesArtificial filament heat treatmentPolymer scienceHigh intensity

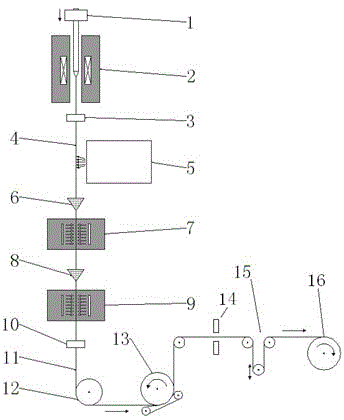

The invention discloses a method for producing polythene fiber with high strength and high modulus by melting fiber drawing and a device thereof. The method includes steps as follows: blend composition of polythene with super high molecular weight and three element blend composition of polythene with super high molecular weight are used as raw material, the raw material is spout fibre adobe after melted through a screw extruder, the fibre adobe is preset drafted after cooling, then low power drafted after once heating, then high power drafted after twice heating, finally is processed heat processing for obtaining polythene fiber with high strength and high modulus. The screw extruder, a cooling mechanism, a drafting machine processing preset drafting, an once heating mechanism, a low power drafting machine, a twice heating mechanism, a high power drafting machine, a heat processing mechanism, a winding reeling machine are arranged in the device orderly. The invention provides a producing method with simple technique, short producing flow, low cost and no pollution aiming at problem that UHMWPE melting spout fibre process has difficult to spin, and provides a device with compact equipment and easy to operate.

Owner:闫镇达

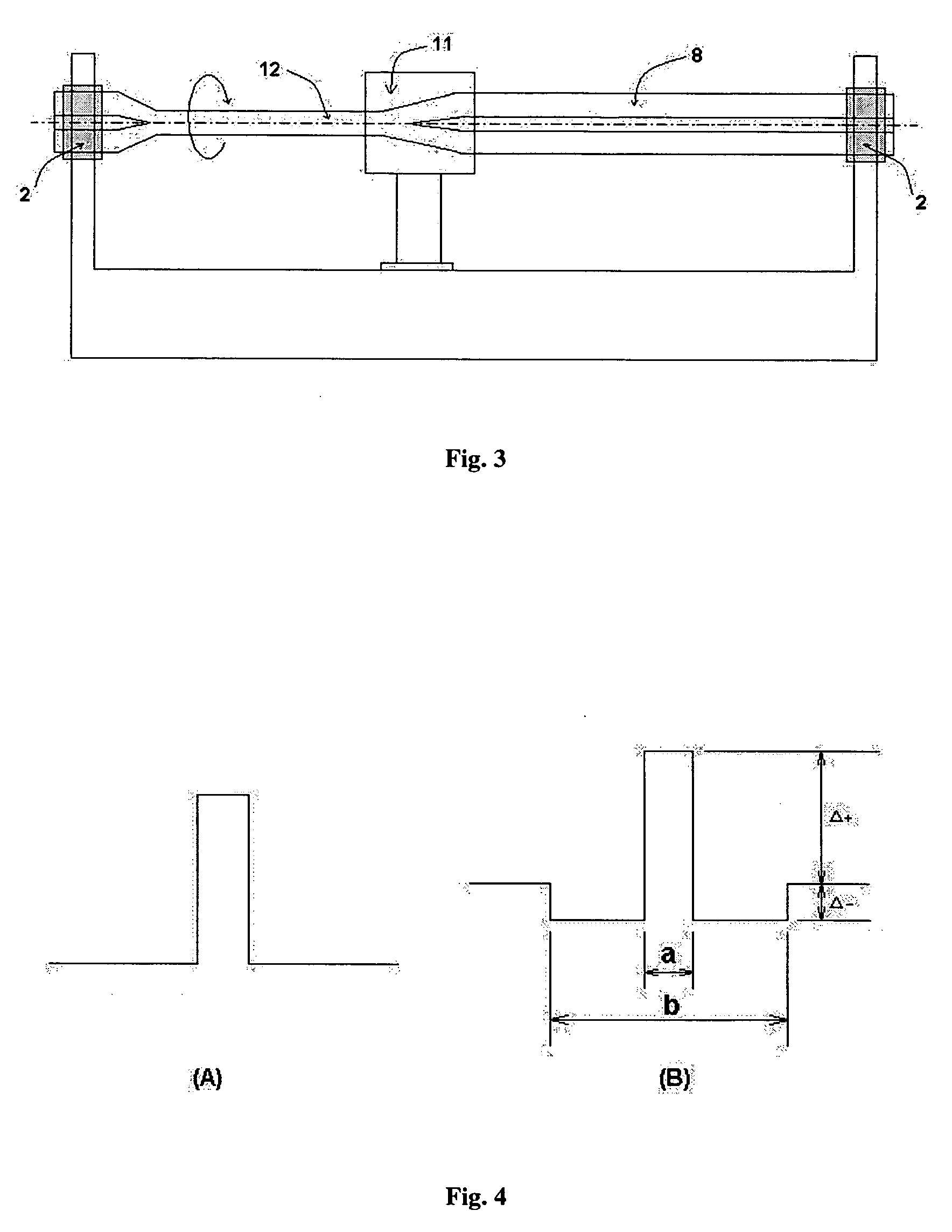

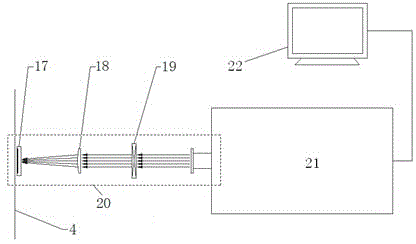

Preparation method of fiber grating

ActiveCN104678486AImprove consistencyThe process is reasonable and simpleCladded optical fibreOptical waveguide light guideGratingBare fiber

The invention relates to a preparation method of a fiber grating. The preparation method comprises the following steps: clamping a quartz glass matrix optical fiber performing bar on an optical fiber drawing tower to be molten and drawn, performing grating writing on the continuously descending bare fiber, coating the bare fiber with a coating, and performing ultraviolet curing, and at last reeling through a take-up reel, wherein the preparation method is characterized in that the grating writing adopts a phase-mask technique and uses a 193 nm excimer laser to perform monopulse exposure to write the bare fiber in the grating. The preparation method disclosed by the invention can be used for dynamically and continuously preparing the fiber grating array online, is simple, convenient and reasonable in process, and high in manufacturing efficiency; the grating written by the phase-mask technique and the 193 nm excimer laser is stable in central wavelength, good in spectral form, and high in consistency of grating reflectivity; the method can be used for preparing the high-quality grating array and solves the problems that the grating prepared by the fiber drawing tower online is poor in stability, low in reliability, poor in grating quality and low in efficiency; the prepared fiber grating array can be used for long-distance detection and signal transmission.

Owner:武汉烽理光电技术有限公司

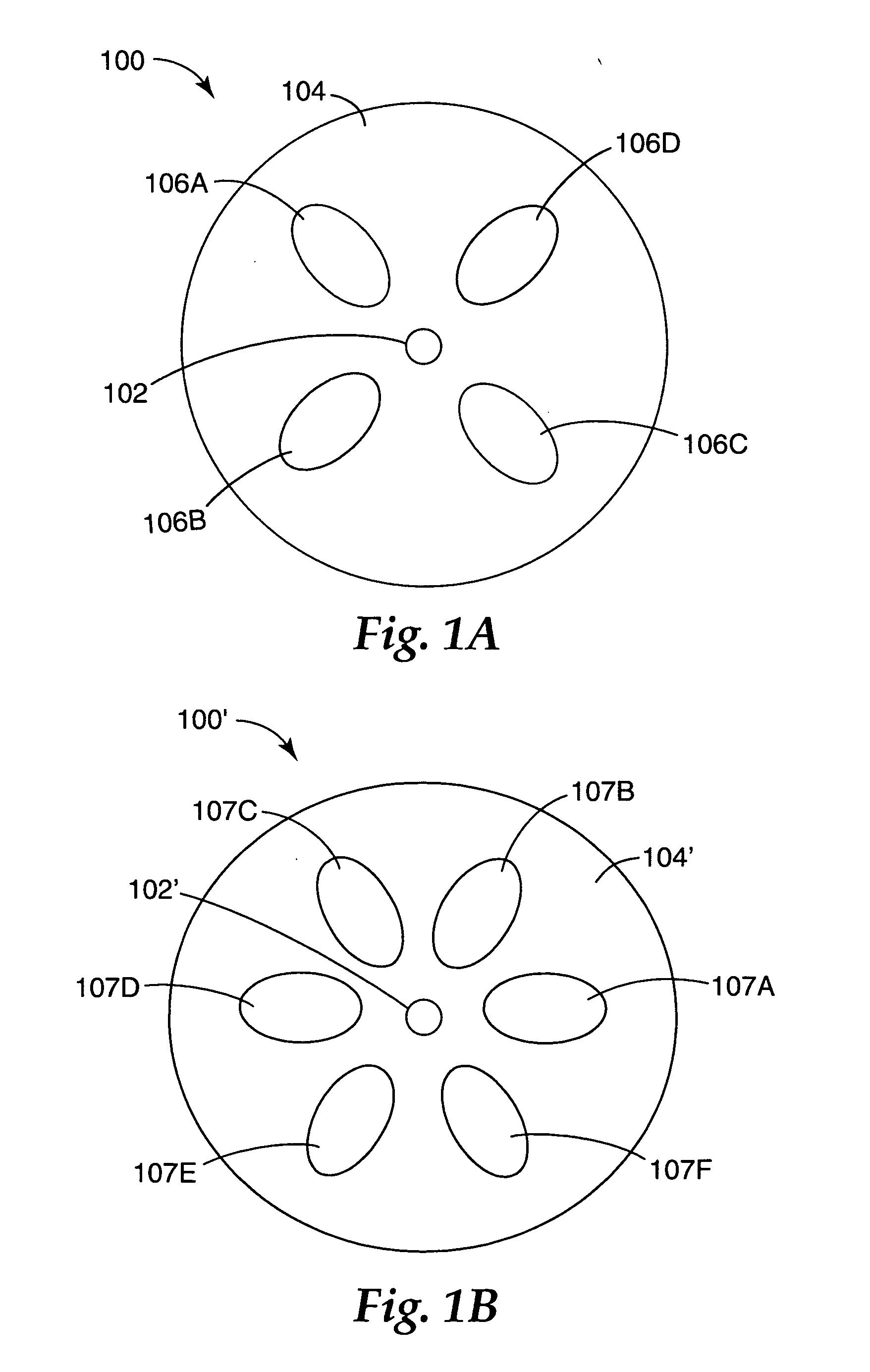

Method of making a hole assisted fiber device and fiber preform

InactiveUS20060130528A1Glass fibre drawing apparatusOptical light guidesInternal pressureEngineering

A method of fabricating a hole assisted fiber includes forming one or more slots in the perimeter of the cladding region. A tube is overcollapsed around the perimeter of the cladding region to form one or more channels, where the one or more channels bounded on one side by the overcollapsed tube. A fiber is drawn from the overcollapsed preform. An internal pressure is applied to the one or more channels during the fiber drawing step to form one or more holes of a pre-selected shape within the cladding region.

Owner:3M INNOVATIVE PROPERTIES CO

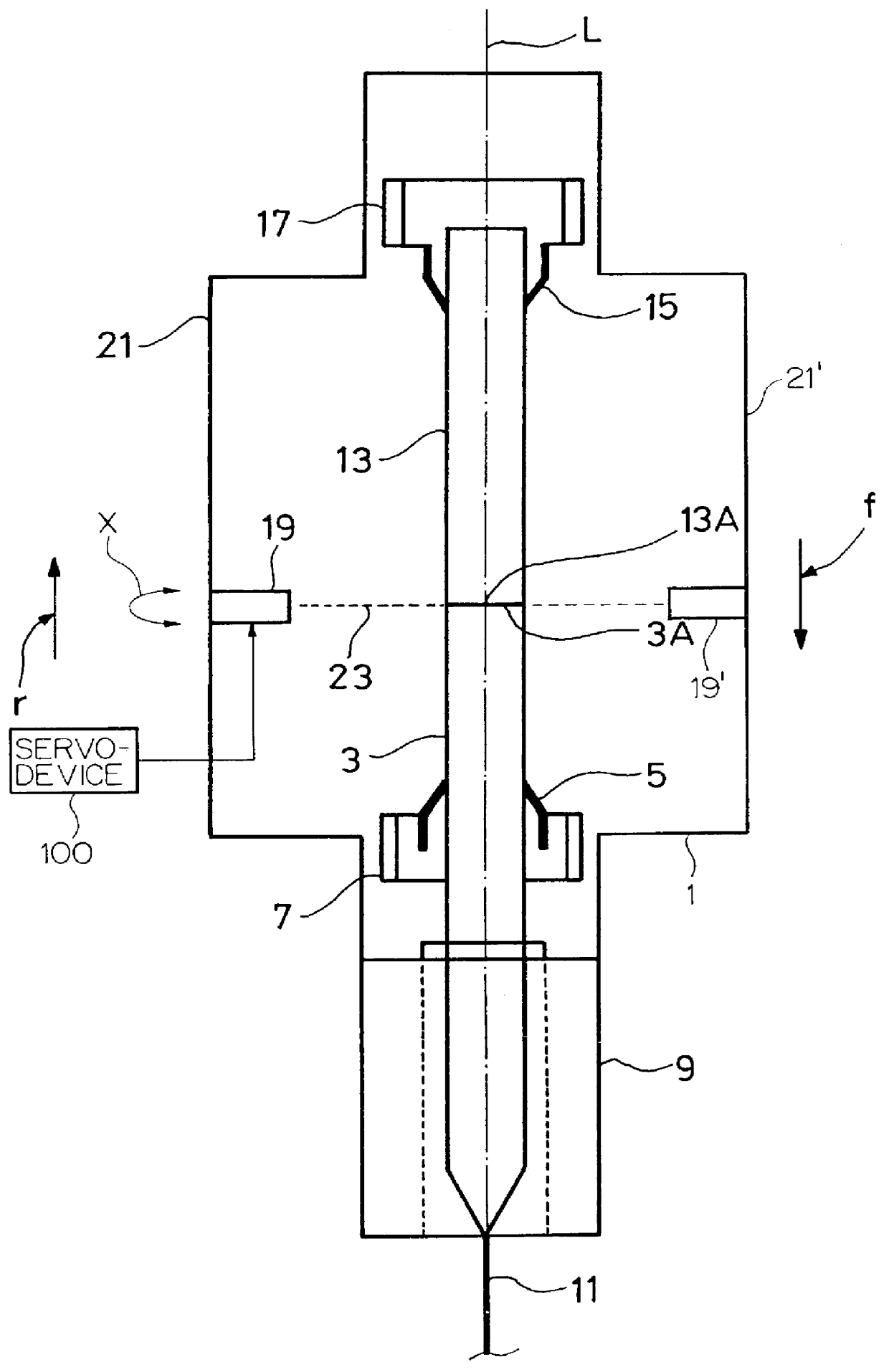

Method of drawing fiber continuously by butt welding optical fiber preforms

InactiveUS6098429AMitigates the above-described drawbacksSmall sizeCoupling light guidesGlass reforming apparatusButt weldingFiber drawing

In the method of drawing fiber continuously from preforms for manufacturing an optical fiber, a first preform is displaced along a fiber-drawing axis and is drawn into an optical fiber through a fiber-drawing furnace disposed on the fiber-drawing axis, and a second preform is displaced along the fiber-drawing axis, which second preform is butt welded to the first preform so as to be drawn into an optical fiber following on from the first fiber. The two preforms are butt welded, i.e. they are welded together end-to-end, by displacing at least one power laser along the fiber-drawing axis, and by servo-controlling the displacement of said laser to the displacement of the two preforms so as to maintain a laser beam emitted by the power laser at the same height as the two ends to be welded together, thereby making it possible to reduce considerably the size of the zone affected by the welding, and to avoid polluting the side surfaces of the two preforms upstream and downstream from the weld.

Owner:ALCATEL LUCENT SAS

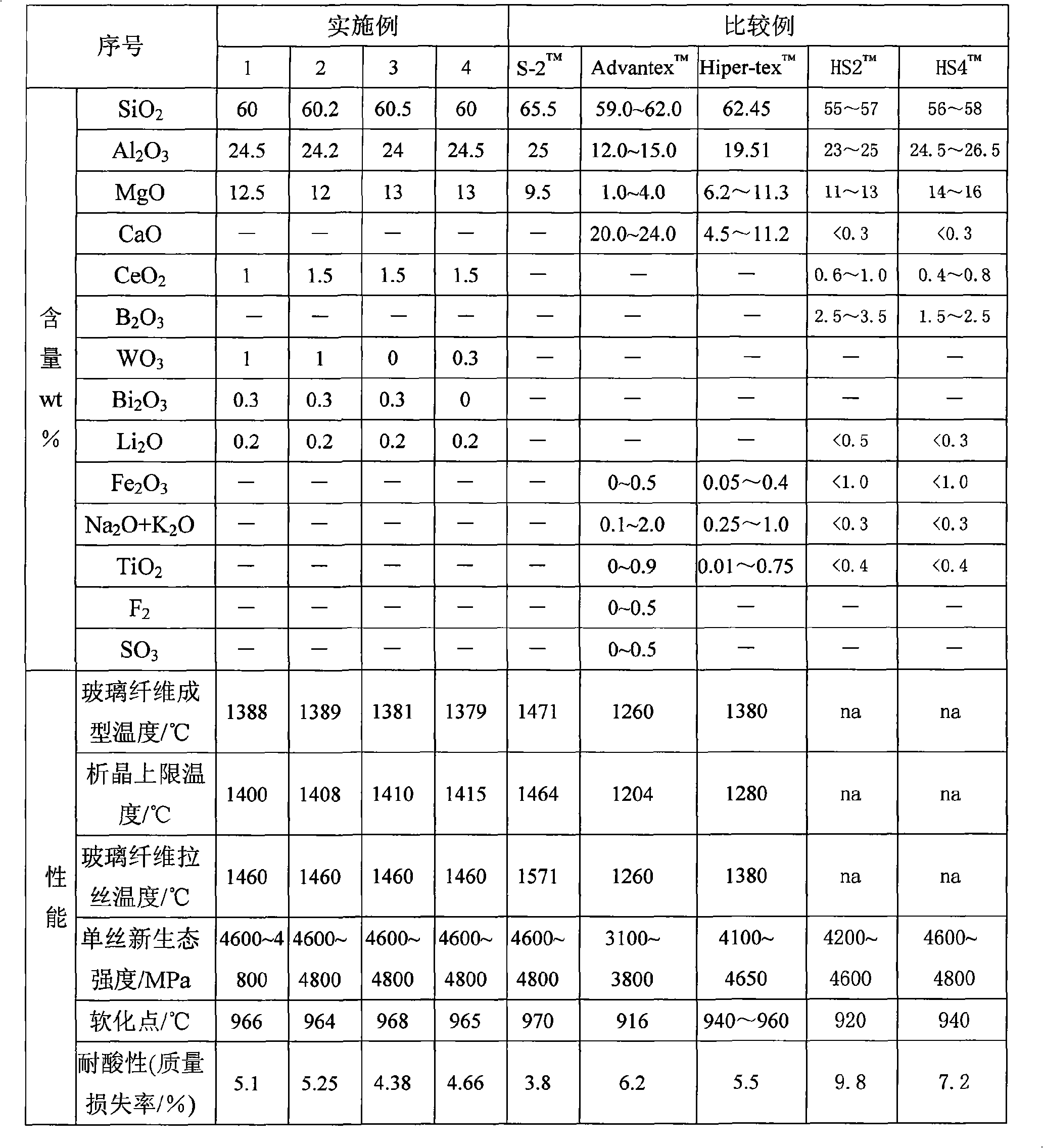

Composition for high-performance glass fiber

The invention relates to a composition for high-performance glass fiber, which comprises 55 to 63 wt percent of SiO2, 23 to 26 wt percent of Al2O3, 11.5 to 14.5 wt percent of MgO, 0.5 to 2.5 wt percent of CeO2, 0 to 0.5 wt percent of LiO2, 0 to 1.5 wt percent of Bi2O3, 0 to 1.5 wt percent of WO3, and the balance of unavoidable impurities; the contents of the Li2O, the Bi2O and the WO3 can not be zero simultaneously. By adopting the composition as a raw material, the high-performance glass fiber can be produced by using a melting furnace and a fiber drawing furnace which are made from the existing fire resisting materials to perform melting and wire drawing. With reduced production difficulty and low cost, the composition has good producibility, is suitable for industrial continuous production and can save energy source, and the produced high-performance glass fiber can be used as the reinforcing material of a resin base composite material and has the advantages of high strength, corrosion resistance, high temperature resistance and light weight.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Graphene modified polyvinyl acetate film forming agent preparation method

ActiveCN105085835AReduce surface resistanceEnhanced Static Dissipative Functional RequirementsFibre typesPolymer scienceCarbon fibers

The present invention provides a graphene modified polyvinyl acetate film forming agent preparation method which is as follows: graphene, graphene oxide or aminated graphene amide is modified by an olefinic unsaturated monomer to obtain functional graphene, the functional graphene is dispersed into a vinyl acetate, an acrylate or an unsaturated anhydride monomer bulk solution or aqueous solution, by emulsion polymerization, to obtain a graphene modified polyvinyl acetate emulsion film forming agent, the method has the advantages of low reaction temperature, simple process, low cost, and high conductivity efficiency, the film forming agent can be used as an antistatic film-forming agent or a conductive film-forming agent, can be used for the preparation of glass fiber drawing wetting agents, fabric sizing agents, leather finishing agents, carbon fiber sizing agents, binders or coatings, and the like, can effectively reduce the material surface resistance, and can be used in antistatic or electromagnetic field shielding material fields.

Owner:TAISHAN FIBERGLASS INC +1

Construction technique of fiber drawing archaized decoration coated by nitro lacquer for house

ActiveCN101468480AAchieve visual fullnessSolve surface lossPretreated surfacesWood working apparatusSolid woodLacquer

The invention relates to the technical field of home decoration, in particular to a construction process for home wiredrawing antique decoration. The invention discloses a construction process for home wiredrawing antique decoration, which comprises the following steps: material sanding, polyurethane ground paint coating, polyurethane ground paint sanding, nitryl true color ground paint coating, nitryl true color ground paint sanding, wiredrawing paint effect coating, nitryl transparent ground paint coating, nitryl glazing, nitryl transparent ground paint coating, cloth printing, lighting and shading, nitryl transparent ground paint coating, nitryl transparent ground paint sanding, nitryl glaze dry brushing, nitryl ground paint coating and nitryl transparent surface paint coating. The process can effectively achieve the paint film visual fullness and solve the problems of nitryl paint surface light loss and partial color change of antique furniture. At the same time, the process not only can ensure that solid wood furniture achieves wiredrawing antique coating effect, but also can ensure that a medium density fiber board or other composite materials are endowed with the wiredrawing antique coating effect, so that the wiredrawing antique effect can be achieved without adopting solid wood.

Owner:上海展辰涂料有限公司 +1

High loft low density nonwoven webs of crimped filaments and methods of making same

InactiveUS20040198124A1Take advantageDesired shapeWoven fabricsNon-woven fabricsParticulatesEngineering

High loft, low density nonwoven webs of increased uniformity are produced by forming substantially continuous, spunbond, crimped, bicomponent fibers of A / B side by side morphology in an unheated fiber draw unit. The fibers are then heated and cooled in the absence of impeding forces to achieve maximum crimp in the z-direction and produce a web of lofted material. The resultant material is particularly suitable for use as an insulator. Particulates may be added to the webs if desired.

Owner:KIMBERLY-CLARK WORLDWIDE INC

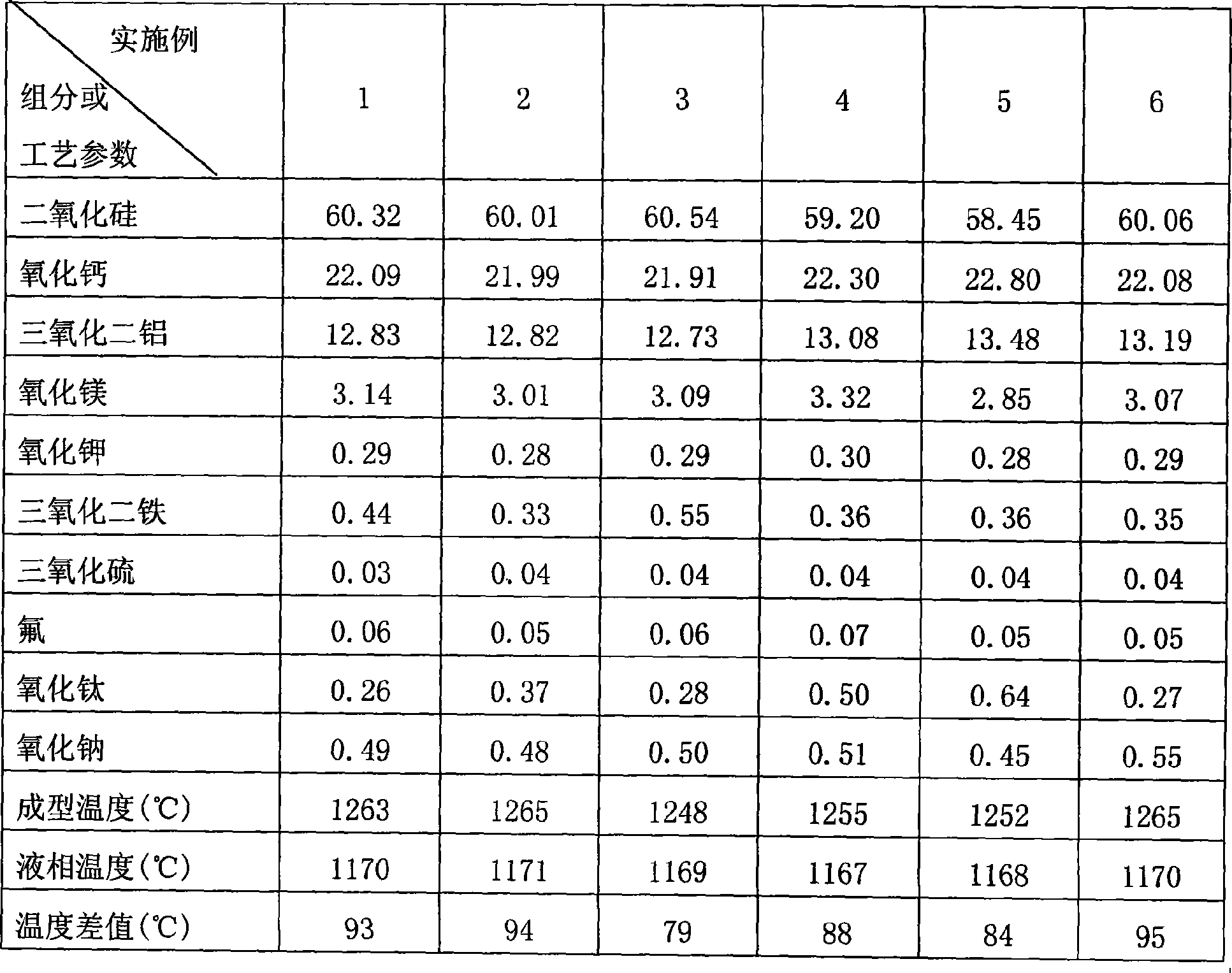

Alkali-free glass and manufacturing technique thereof

The invention relates to alkali-free glass for the production of continuous glass fiber product and production process thereof, pertaining to inorganic non-metallic material field. The main production raw materials of the alkali-free glass comprise quartz sand, limestone, pyrophyllite and dolomite; wherein, the production processes comprise proportioning, melting, fiber forming, fiber drawing and product processing; the temperature for fiber forming is 1160-1360 DEG C, the viscosity is 1000 poises and liquid phase temperature is at least 97 DEG C lower than that of the fiber forming; the weight proportions of compositions to the product are respectively that: silicon dioxide is 58-62 percent, calcium oxide 20-24 percent, aluminum oxide 12-14 percent, magnesium oxide 2-4 percent, fluorine 0-0.6 percent, potassium oxide and sodium oxide 0-2 percent in total, titanium oxide 0-2 percent, iron trioxide 0-0.6%, sulfur trioxide 0-0.6% and micro impurity 1%. By adjusting the variety and proportion thereof of glass raw materials, the invention removes fluoride materials such as fluorite and boride such as borocalcite from raw materials of glass, thereby controlling the origin of the waster gas pollutants.

Owner:JUSHI GRP CO

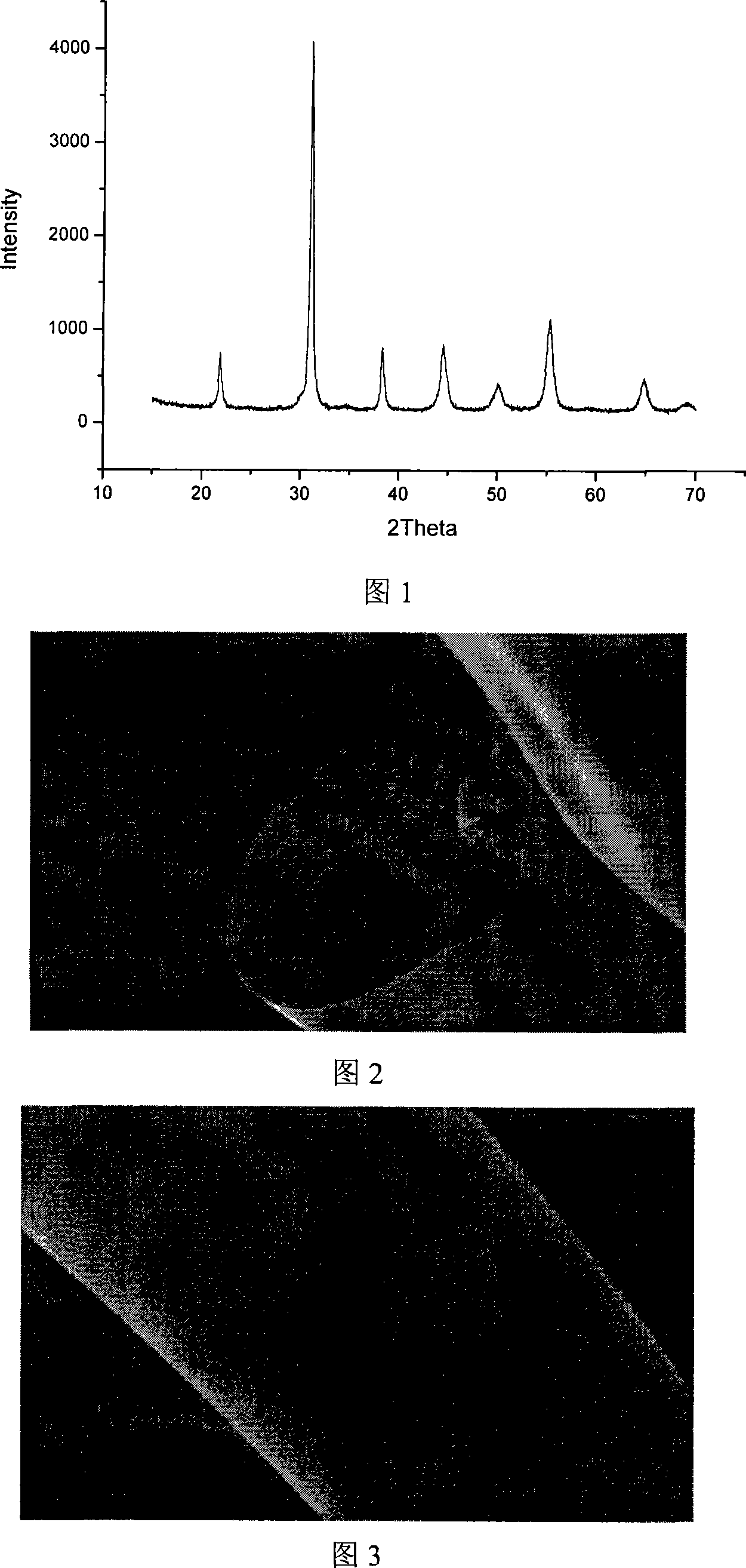

Method for preparing lead zirconate titanate ceramics fibre

The invention provides a preparation method of lead zirconate-titante ceramic fiber, which relates to a ceramic fiber. The fiber obtained with the diameter less than 30Mum and the length about 1cm has a single perovskite phase and comparatively high consistency and the invention can be a preparation method of lead zirconate-titante ceramic fiber of ceramic fiber for 1-3 piezoelectric composites. The preparation of lead zirconate-titante precursor solution is : lead acetate trihydrate is added into n-Butyl alcohol, complexing agent glacial acetic acid is added then; the mixture is heated, dissolved and cooled to obtain solution A; zirconium butoxide and titanium butoxide are poured into the n-Butyl alcohol in sequence to obtain the binary mixed solution of zirconium and titanium, and then acetyl acetone is added into the binary mixed solution and solution B is obtained after backflowing; the solution A and the solution B are mixed and the lead zirconate-titante precursor solution is obtained after backflowing. The preparation of lead zirconate-titante precursor sol is: the lead zirconate-titante precursor solution is steamed, concentrated and stirred, rod winding is carried out and the lead zirconate-titante precursor sol is obtained after concentration; lead zirconate-titante gel fiber is obtained through fiber drawing; after aging, the lead zirconate-titante gel fiber is dried and carried out by heat treatment.

Owner:XIAMEN UNIV

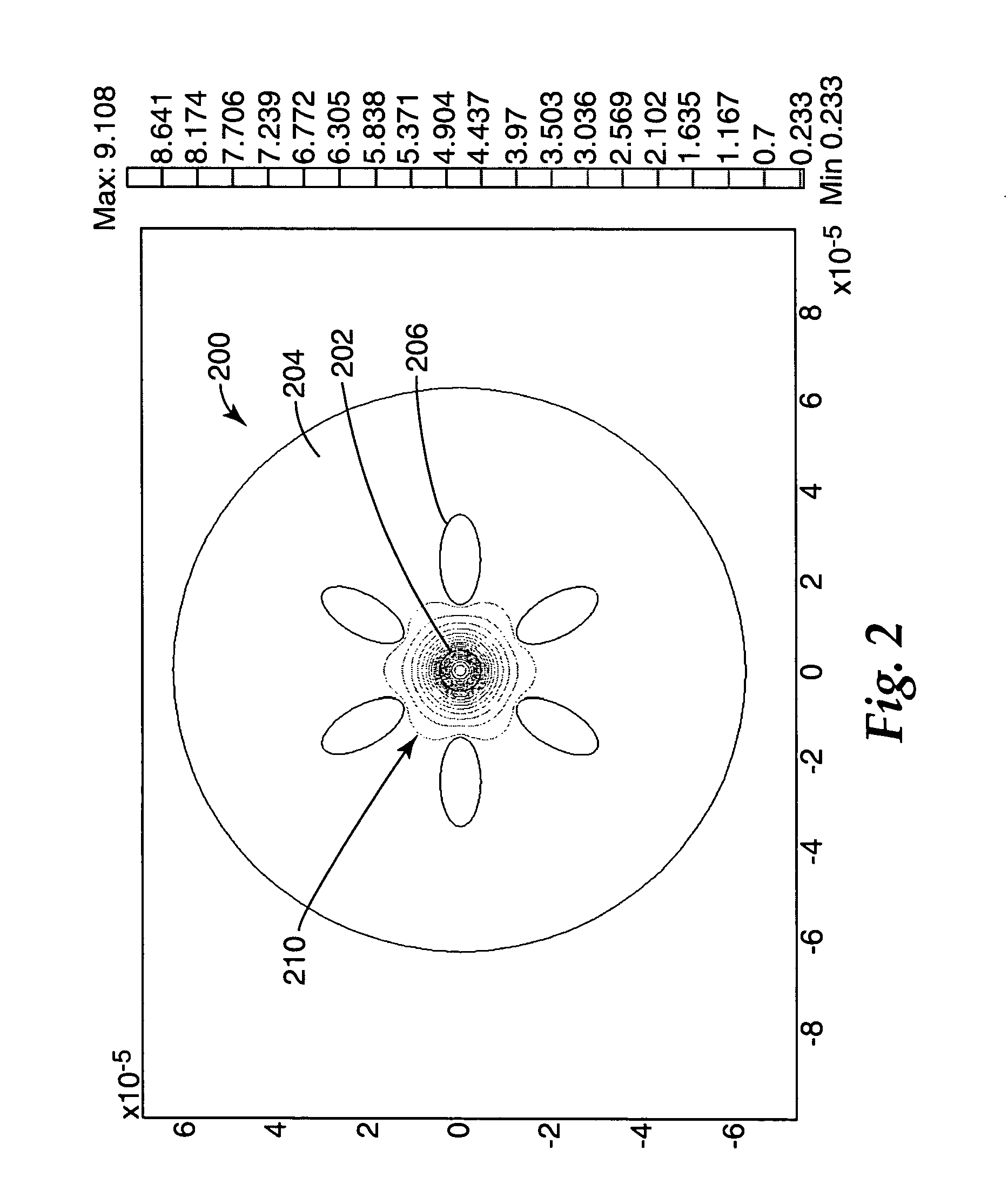

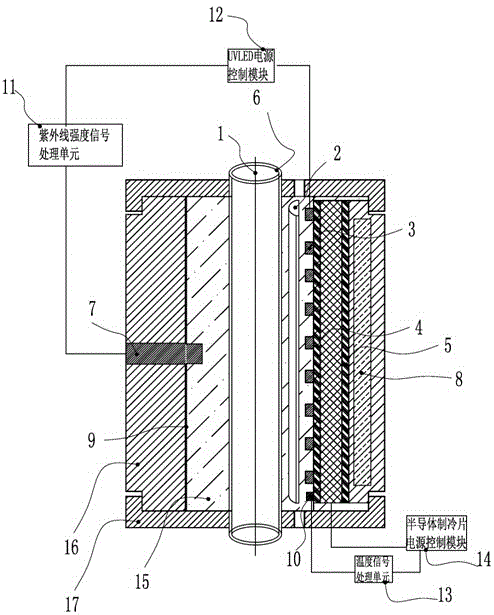

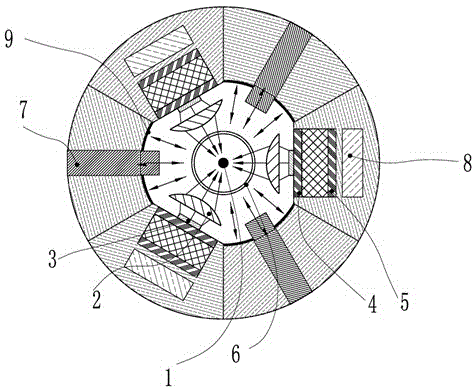

Light intensity-adjustable fiber coating layer ultraviolet curing apparatus

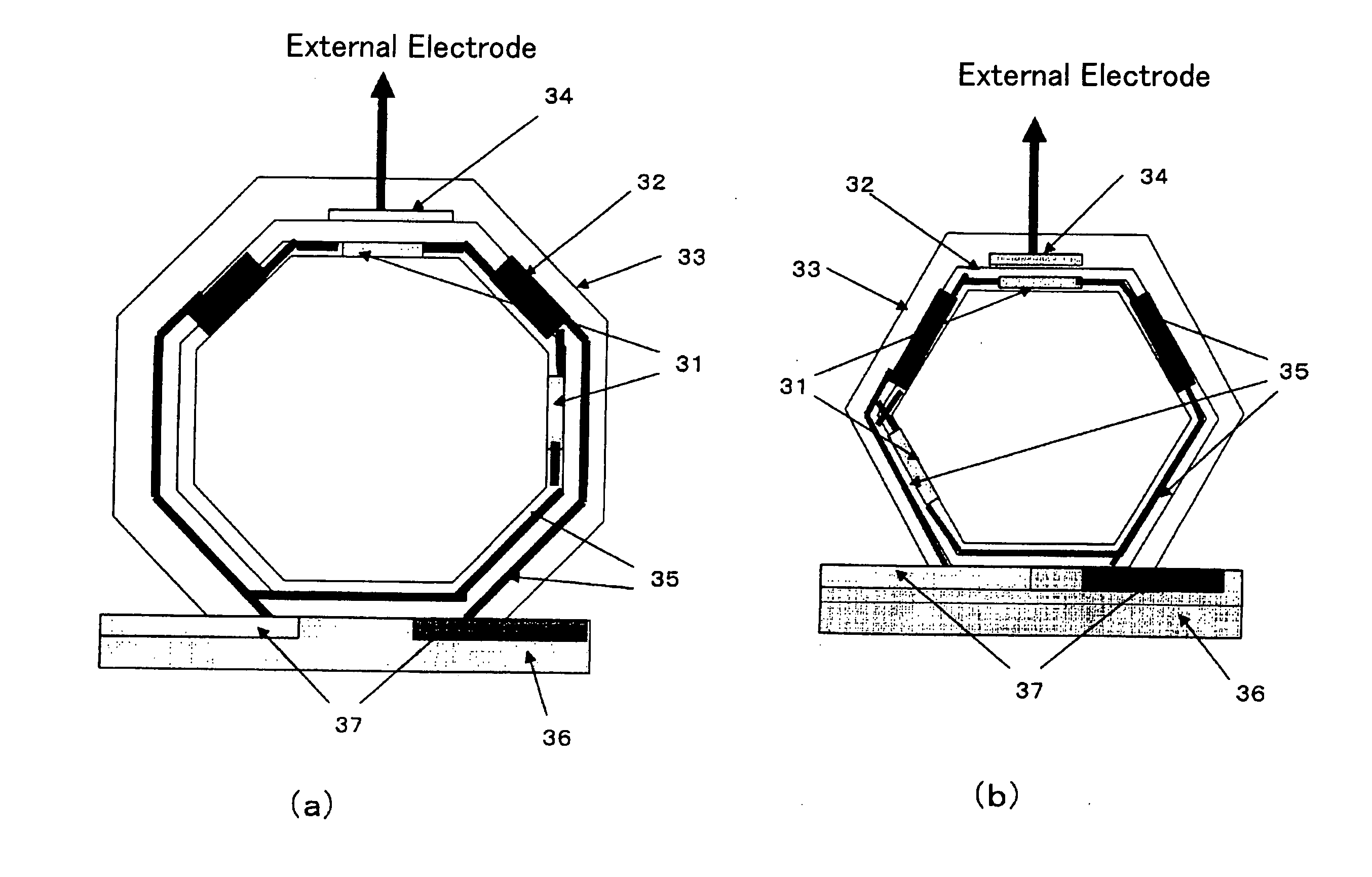

ActiveCN105060739AEfficient use ofSmall operating temperature fluctuationsElectrical apparatusElectroluminescent light sourcesClosed loopUltraviolet lights

The invention relates to a light intensity-adjustable fiber coating layer ultraviolet curing apparatus. The apparatus comprises a cylindrical mounting base, UVLED light source modules are circumferentially and axially arranged in the inner cavity of the cylindrical mounting base, a cylindrical focusing lens is arranged in front of the luminescence surfaces of the UVLED light source modules to make ultraviolet lights emitted by the UVLED light source modules focused on a curing axis, an ultraviolet sensor is arranged in the inner cavity of the cylindrical mounting base, the ultraviolet sensor is connected with an UVLED power supply control module through an ultraviolet intensity signal processing module, and the UVLED power supply control module is connected with the UVLED light source modules to make the fiber drawing speed and the ultraviolet intensity form a control closed loop. The apparatus allows the output of UVLED light sources and the fiber drawing speed to be adjusted and matched in real time in order to guarantee and improve the fiber coating layer curing quality, efficiently utilize the UVLED light sources and save electric energy; and the apparatus has the advantages of reasonable and simple structure, high curing efficiency, less energy consumption, high automation degree, good coating layer quality and simple use.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

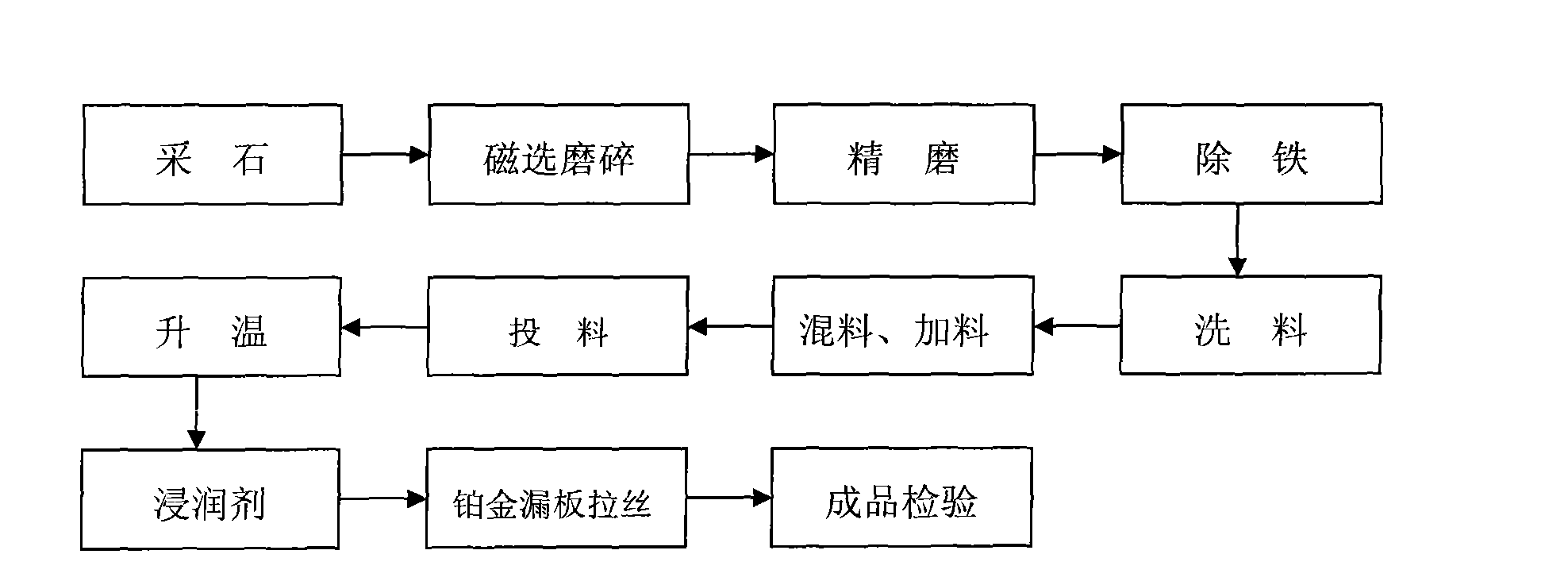

Method for producing ultra-fine basalt continuous filament

InactiveCN101492243AReasonable designOptimize layoutGlass making apparatusGlass productionUltra fineFiber drawing

The invention relates to a method for producing a superfine basalt continuous fiber, which comprises the following steps: breaking, smashing and screening a basalt ore raw material; removing iron from the basalt raw material powder; washing the raw material with clear water and mixing the raw material with a fusing assistant; and performing melting, soakage and fiber drawing on the mixed raw material in a tank furnace to finally obtain the superfine basalt continuous fiber. The production process provided by the invention has the characteristics of low cost, excellent product quality, and the like.

Owner:宋朋泽

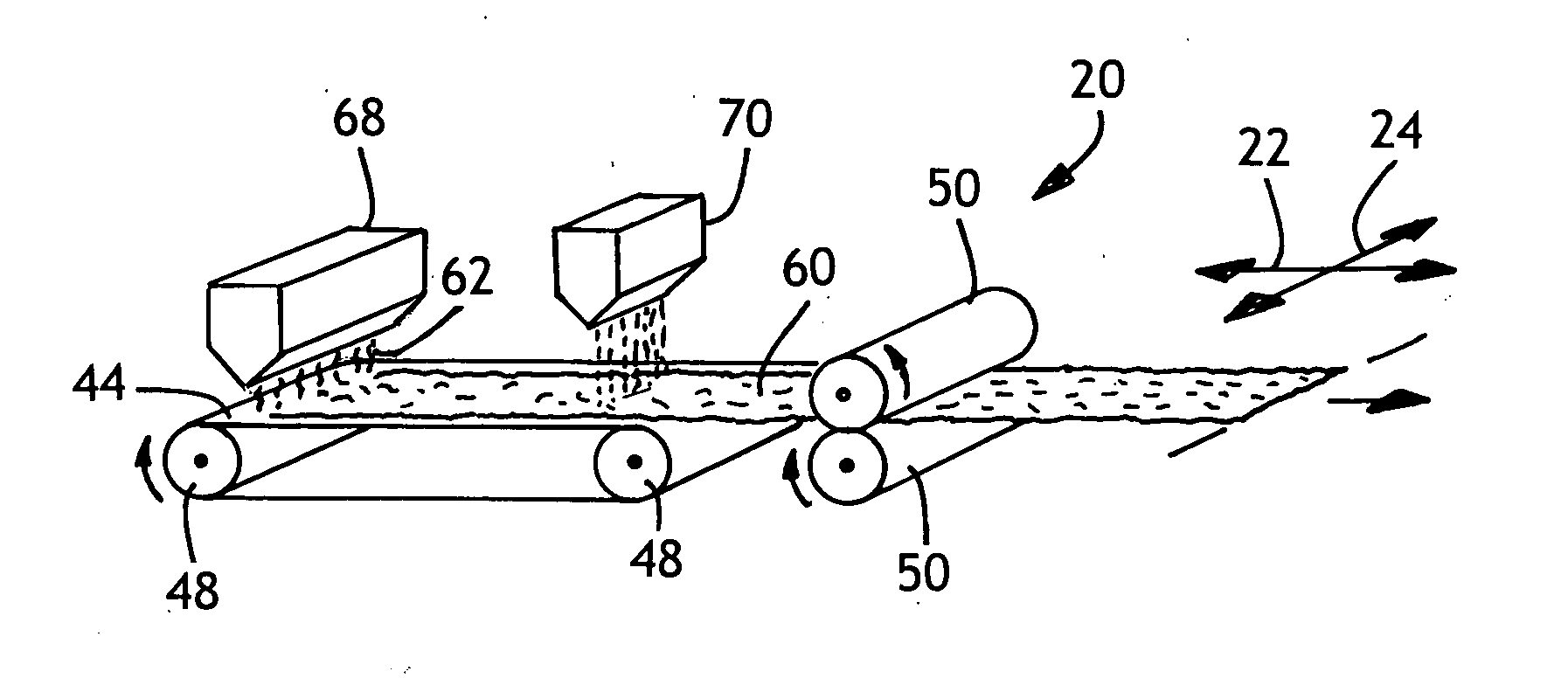

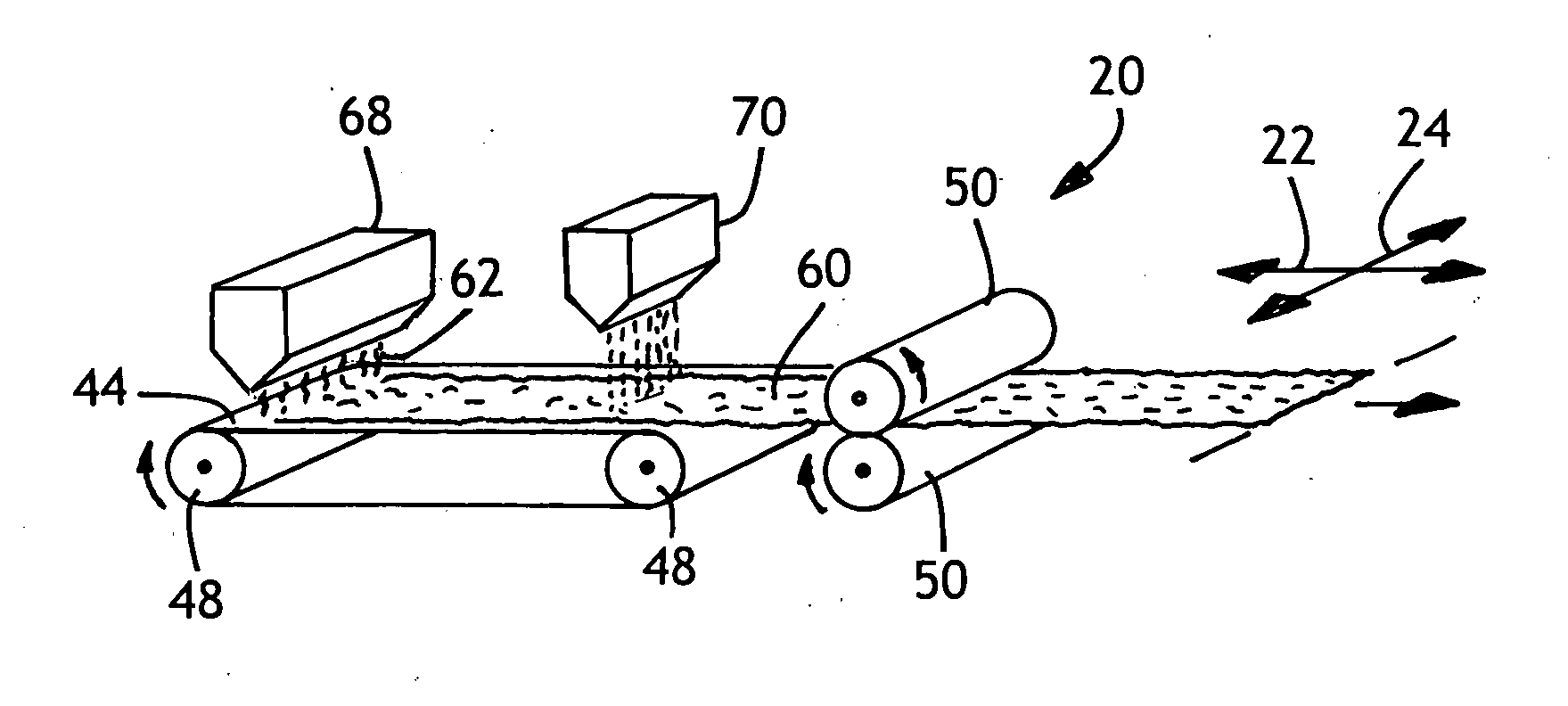

Fibers and nonwovens with improved properties

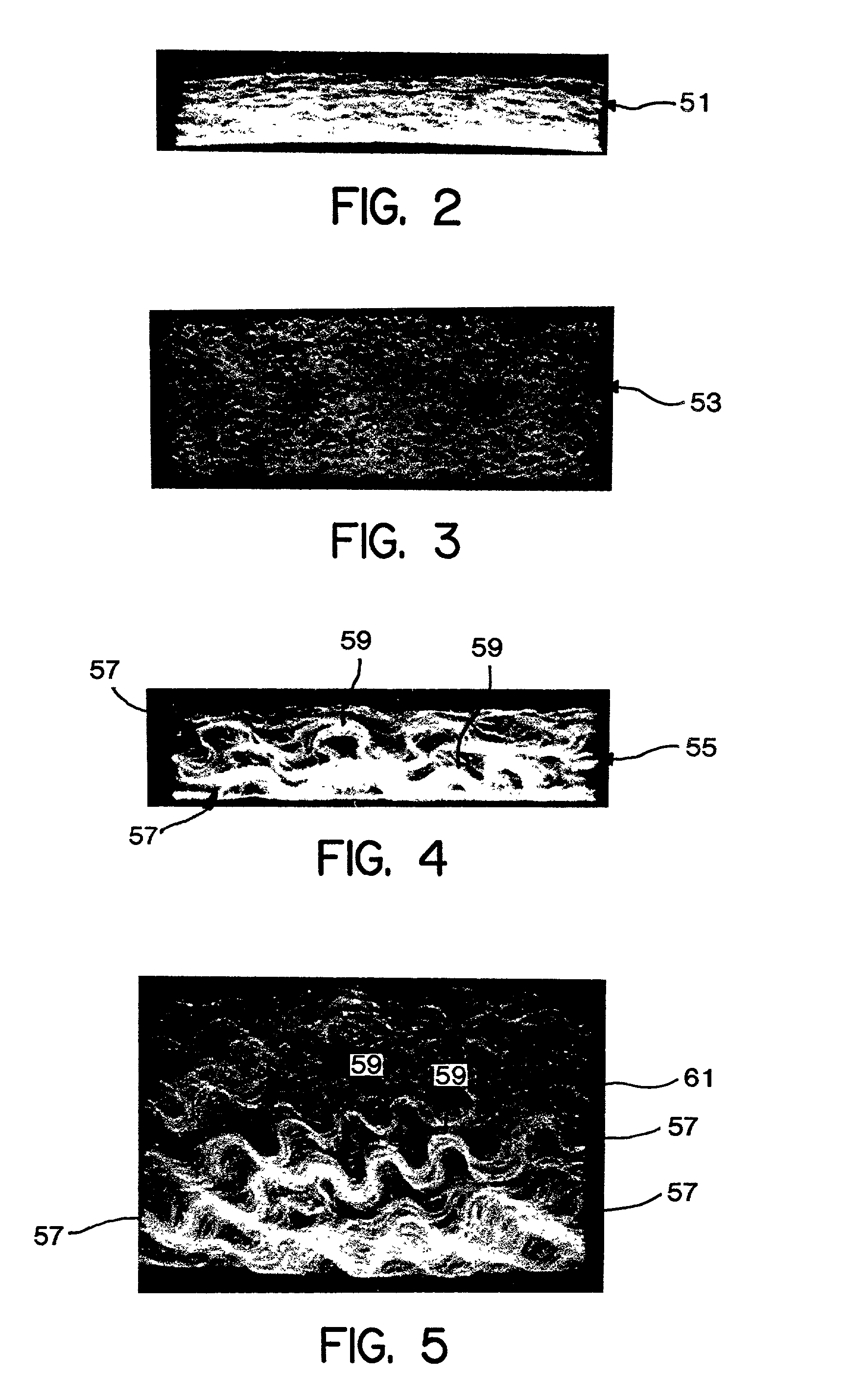

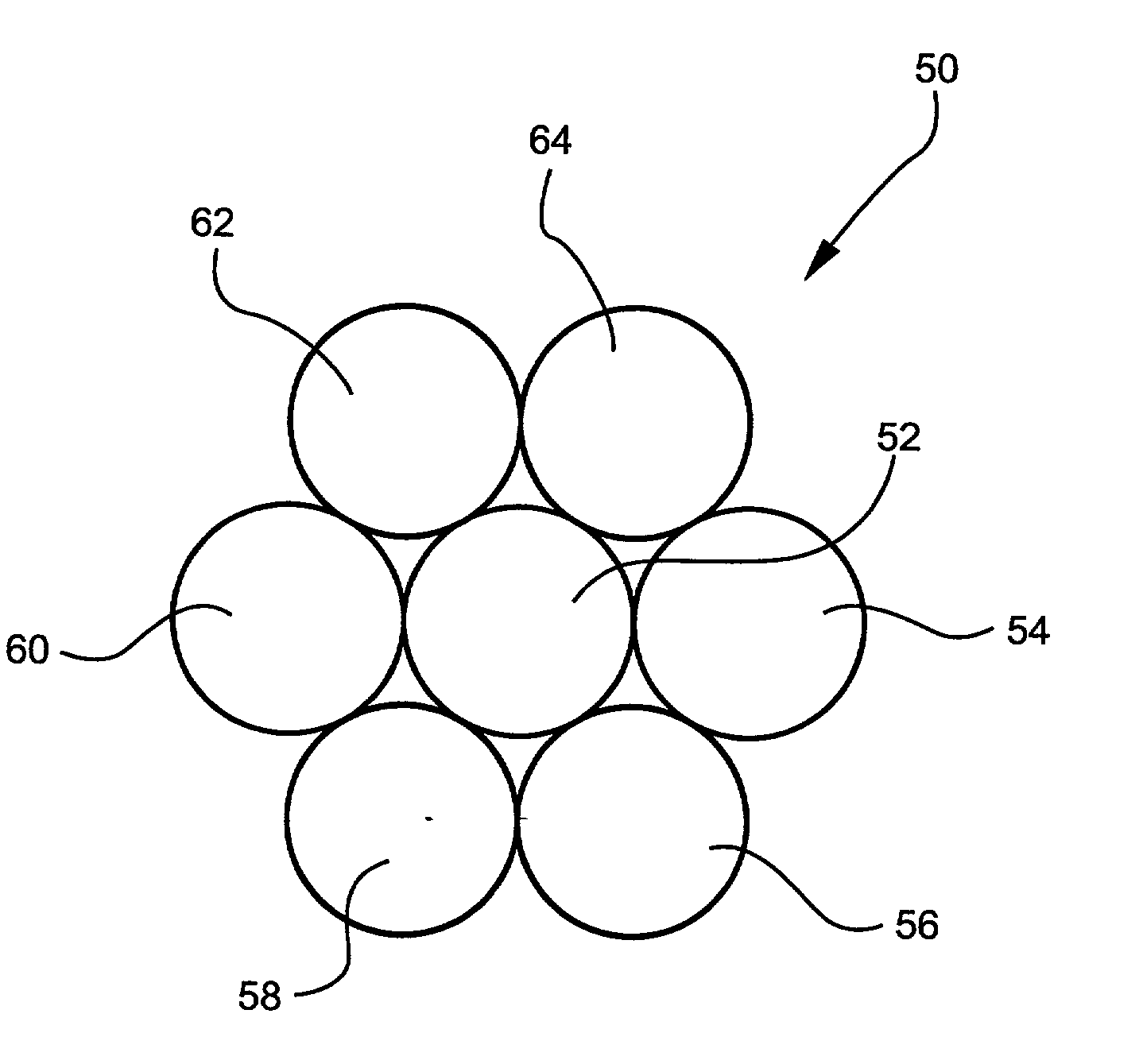

InactiveUS20060276092A1Slow crystallization rateHigh crystallinitySynthetic resin layered productsFilament/thread formingPolymer scienceCrystallinity

The present invention can provide a distinctive article which includes a plurality of fibers (62), wherein the fibers include a selected polymer, fiber material. In a particular aspect, the fiber material can exhibit a “low” crystallization rate. In other aspects, the fiber material has been subjected to a low fiber-draw percentage, and the polymer in the fibers can have a high crystallinity. Further aspects can include a fiber material which has been subjected to a low fiber-draw speed, and can include fibers which have a high tenacity. In still other aspects, the fibers can be configured to provide a fibrous web (60), and the fibrous web (60) can have a distinctive tensile strength quotient, with respect to tensile strengths along its machine-direction (22) and cross-direction (24).

Owner:KIMBERLY-CLARK WORLDWIDE INC

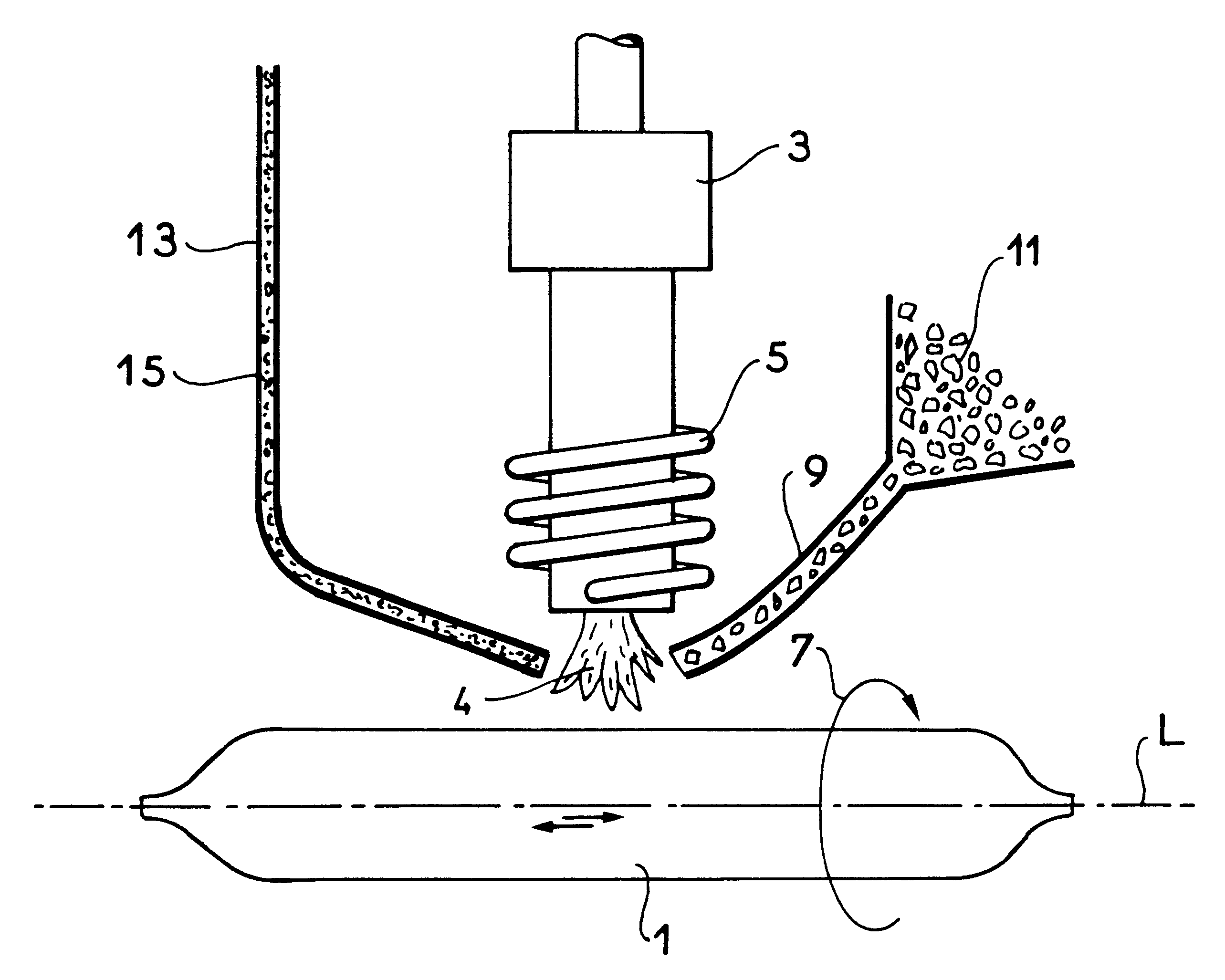

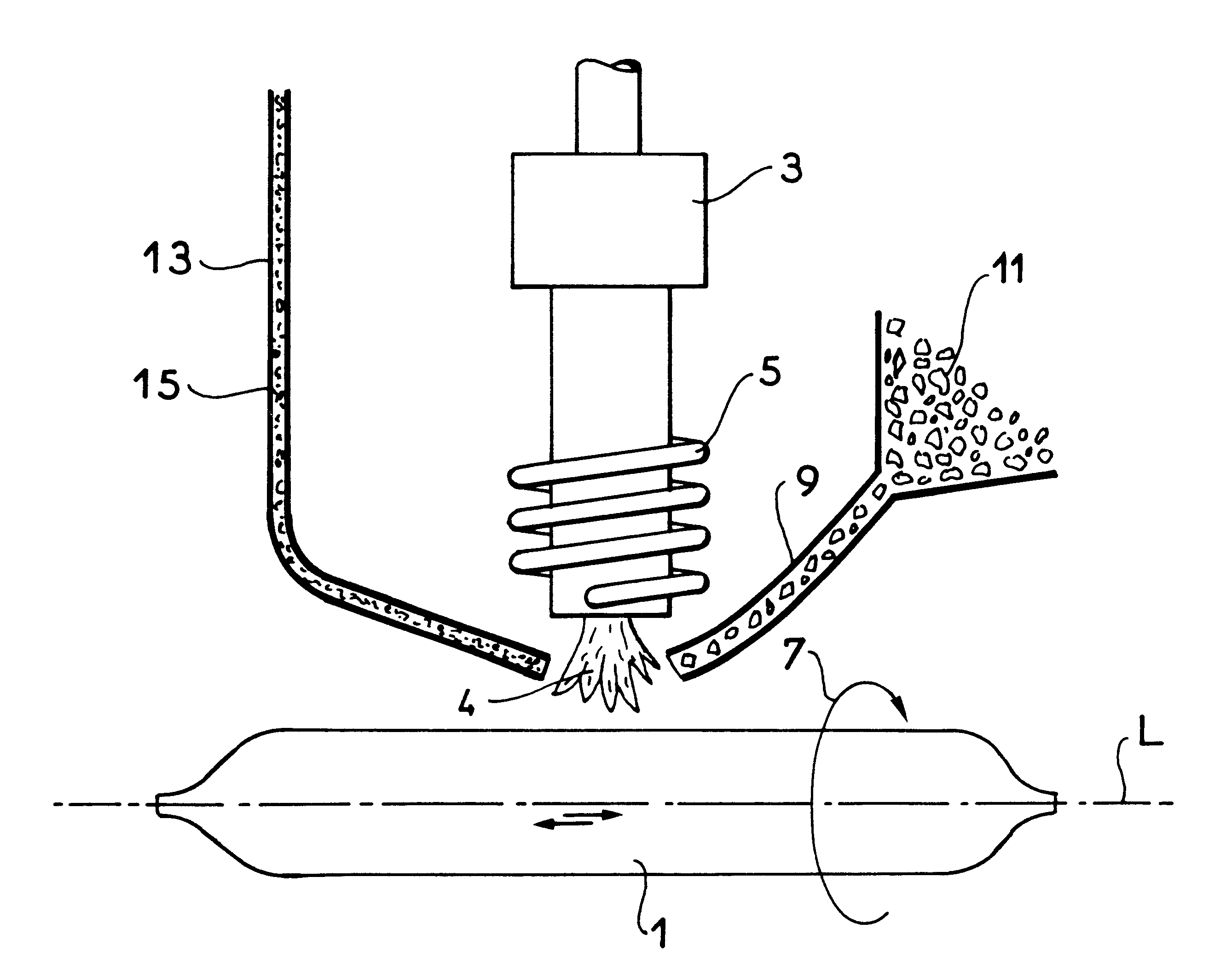

Method of purifying natural or synthetic silica, and application thereof to depositing purified natural or synthetic silica on an optical fiber preform

InactiveUS6477864B2Improve efficiencyIncrease feed rateLiquid surface applicatorsMolten spray coatingSilica particleLithium

Natural or synthetic silica is deposited on a preform set into rotation in front of a plasma torch which moves back and forth substantially parallel to a longitudinal direction of the preform, a first feed duct feeds the plasma with grains of natural or synthetic silica while a second feed duct feeds the plasma with a fluorine or chlorine compound, preferably a fluorine compound, mixed with a carrier gas. Any sodium or lithium contained in the grains of natural or synthetic silica react with the fluorine or chlorine of the fluorine or chlorine compound, thereby making it possible to improve the optical quality of fibers drawn from a preform built up with natural or synthetic silica, and to do so at reduced cost.

Owner:ALCATEL LUCENT SAS

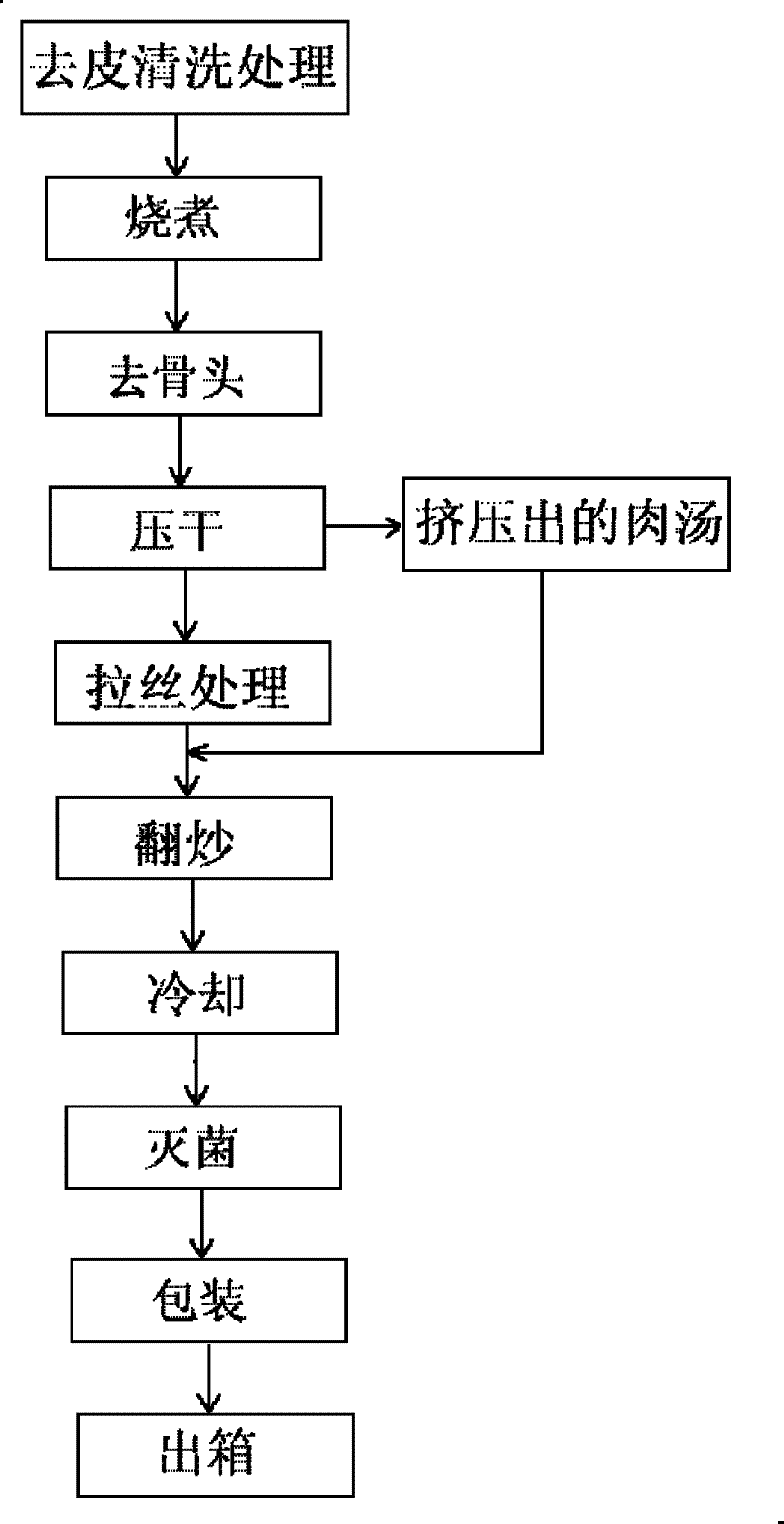

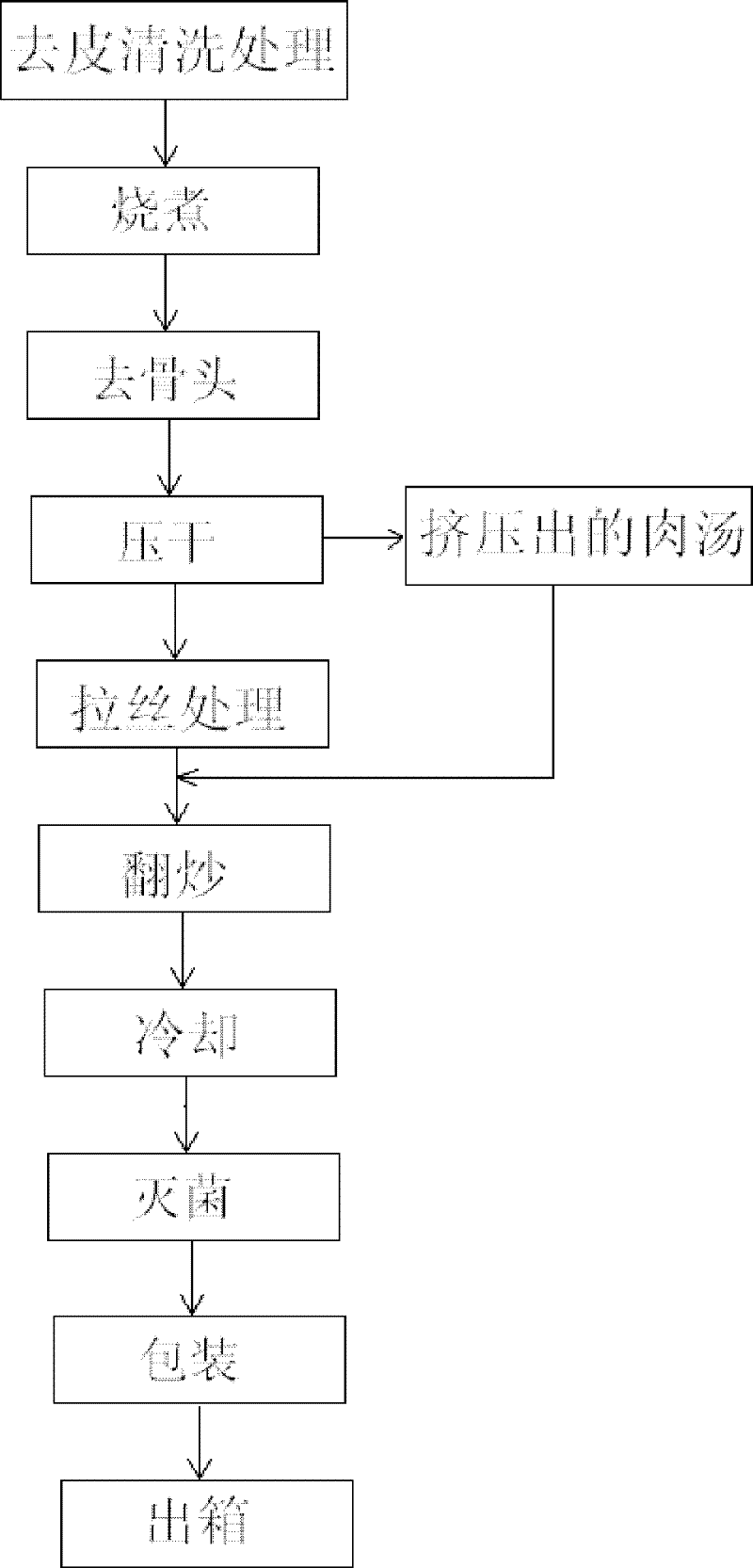

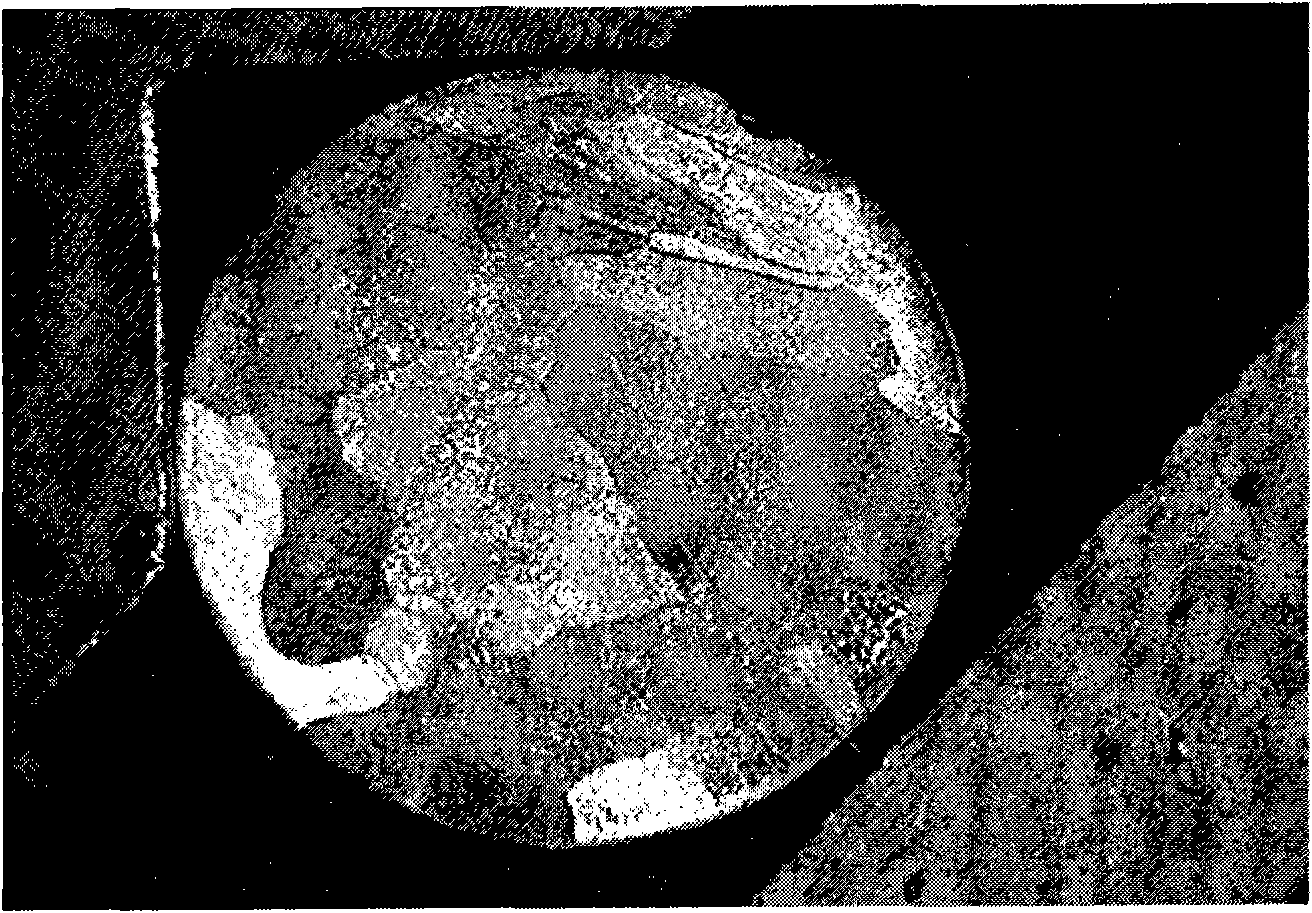

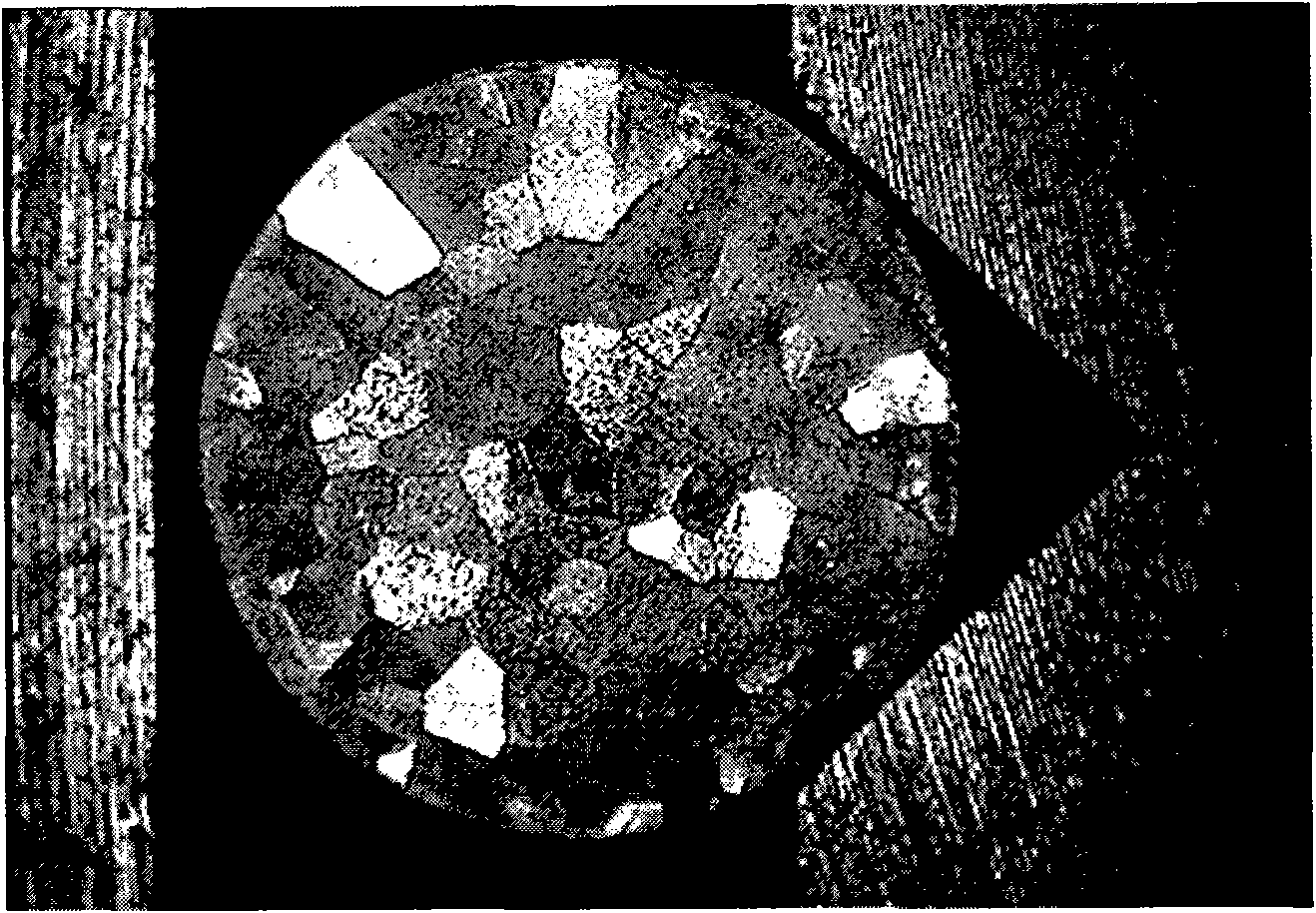

A kind of preparation method of meat floss

The invention discloses a method for making dried meat floss. The specific steps are as follows: take fresh pork leg meat and carry out peeling and cleaning treatment; add prepared soup material to the cleaned pork leg meat and stir for 2 to 3 hours; Pour the pork leg meat and soup into the pot, simmer for 8-10 hours, remove the bones; dry the boneless meat fibers until the water content is 20%-25%, and squeeze out the broth for use The dried meat fiber is drawn, and then the above-mentioned broth to be used is stirred evenly, and then stir-fried; the stir-fried meat floss is cooled, sterilized, packaged, and out of the box. Compared with the prior art, the present invention has the following advantages: the present invention uses fresh pork leg bones as raw materials, and braises with the bones, which not only reduces the damage to the meat fiber, but also presses out the bone oil to enhance the brightness of the meat floss , retain the nutritious flavor in the meat and bones, so that the produced meat floss keeps the original flavor, fresh and tender taste, rich in nutrition.

Owner:TAICANG FEIFENG FOOD

Mass production method for ultra-fine bonding gold wire

InactiveCN101607360AMeet the requirements of batch and large-scale productionSolid-state devicesFurnace typesExtensibilityMiniaturization

The invention discloses a mass production method for an ultra-fine bonding gold wire. The production method comprises the steps of a fusion casting process (alloy fusion casting), a fiber drawing process (coarse drawing, intermediate drawing, fine drawing and ultrafine drawing), an annealing process (final annealing and performance test), a winding process (fixed size compound winding) and the like. The method improves the alloy fusion casting process and the annealing process aiming at the mass production of the ultra-fine bonding gold wire, in the fusion casting process, by mainly utilizing the intermittent pull casting, and intermittently inhibiting the formation of columnar crystal, the small shaft diameter is formed conveniently, so that the extensibility of a cast ingot is ensured, and simultaneously certain strength can also be achieved, and the processing requirements of the ultra-fine bonding gold wire are better met. The product prepared by the method is suitable for the miniaturization packaging requirements of integrated circuits and large scale integrated circuits as well as low-cost requirements of packaging discrete devices and LEDs. The method has the characteristics of high yield of the ultrafine wire and good consistency among batch materials, and meets the requirements of batch and mass stable production.

Owner:北京达博有色金属焊料有限责任公司

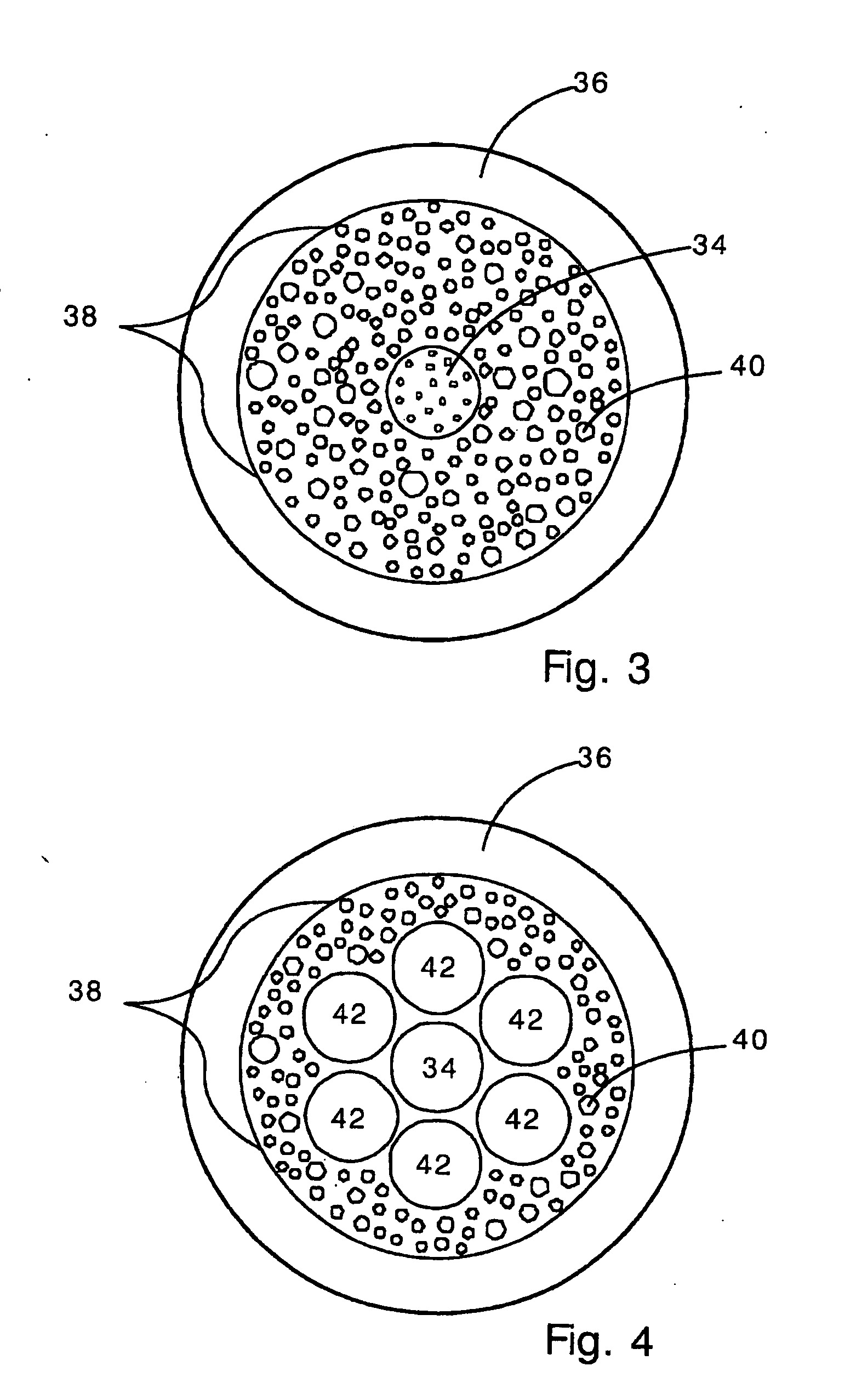

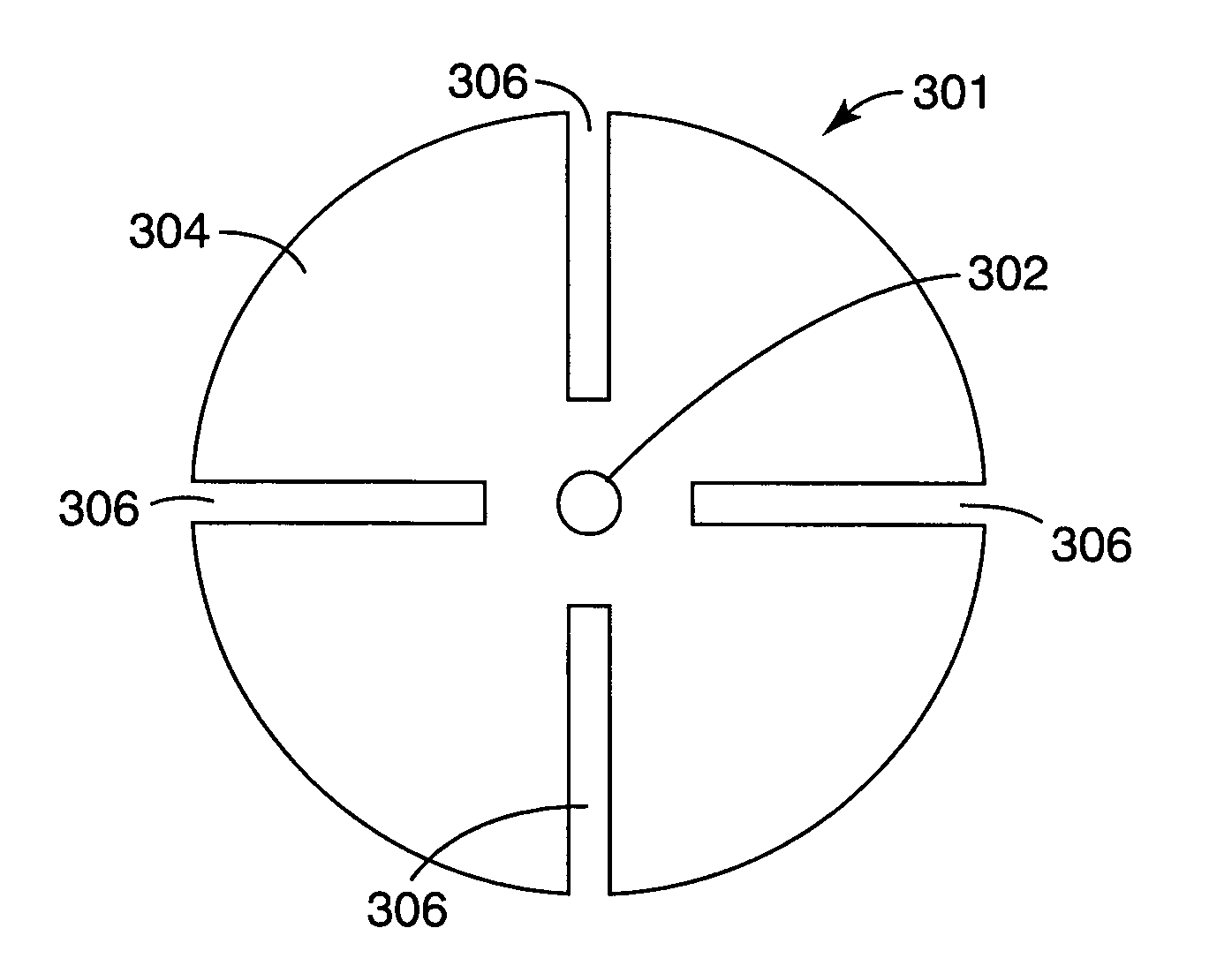

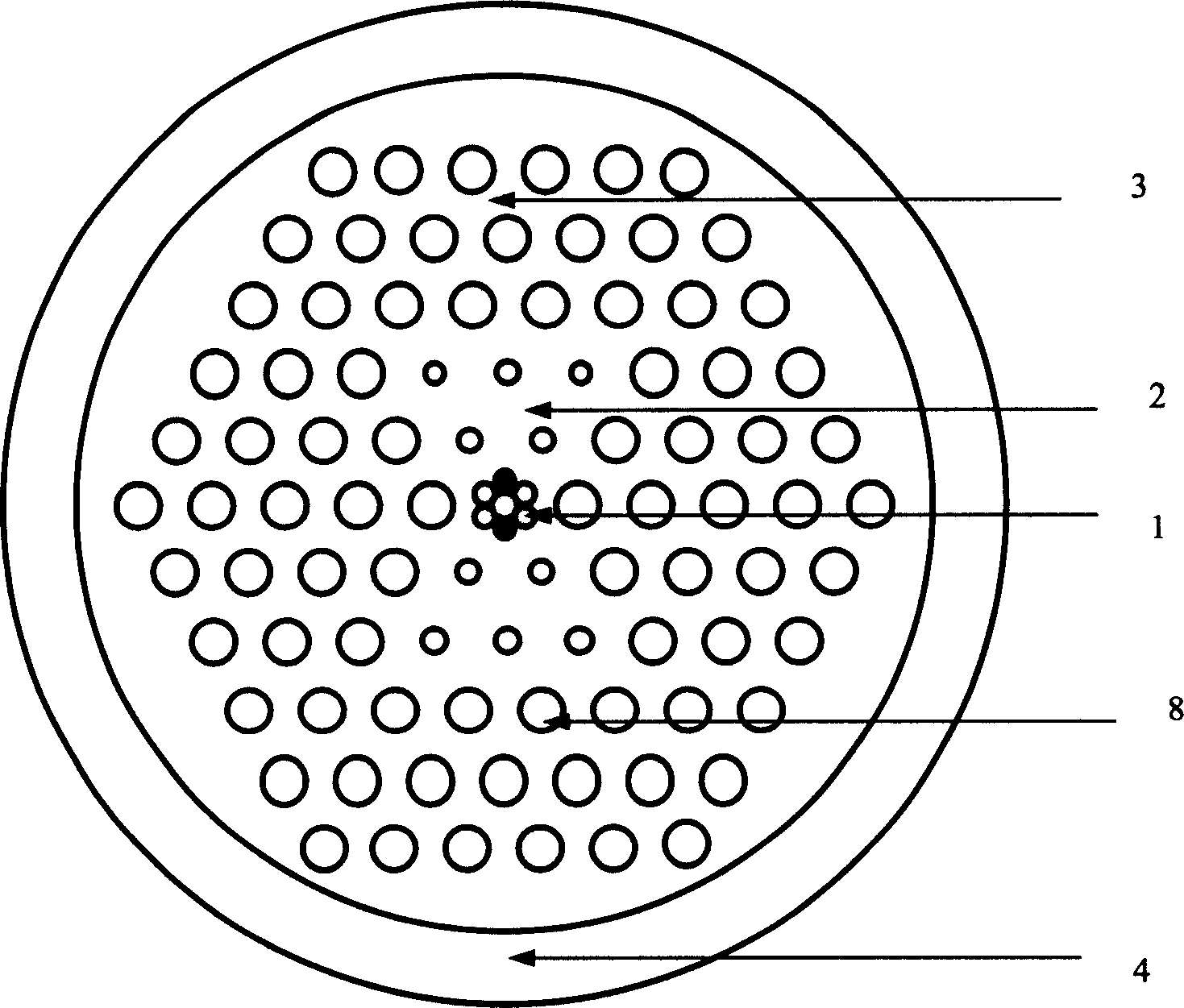

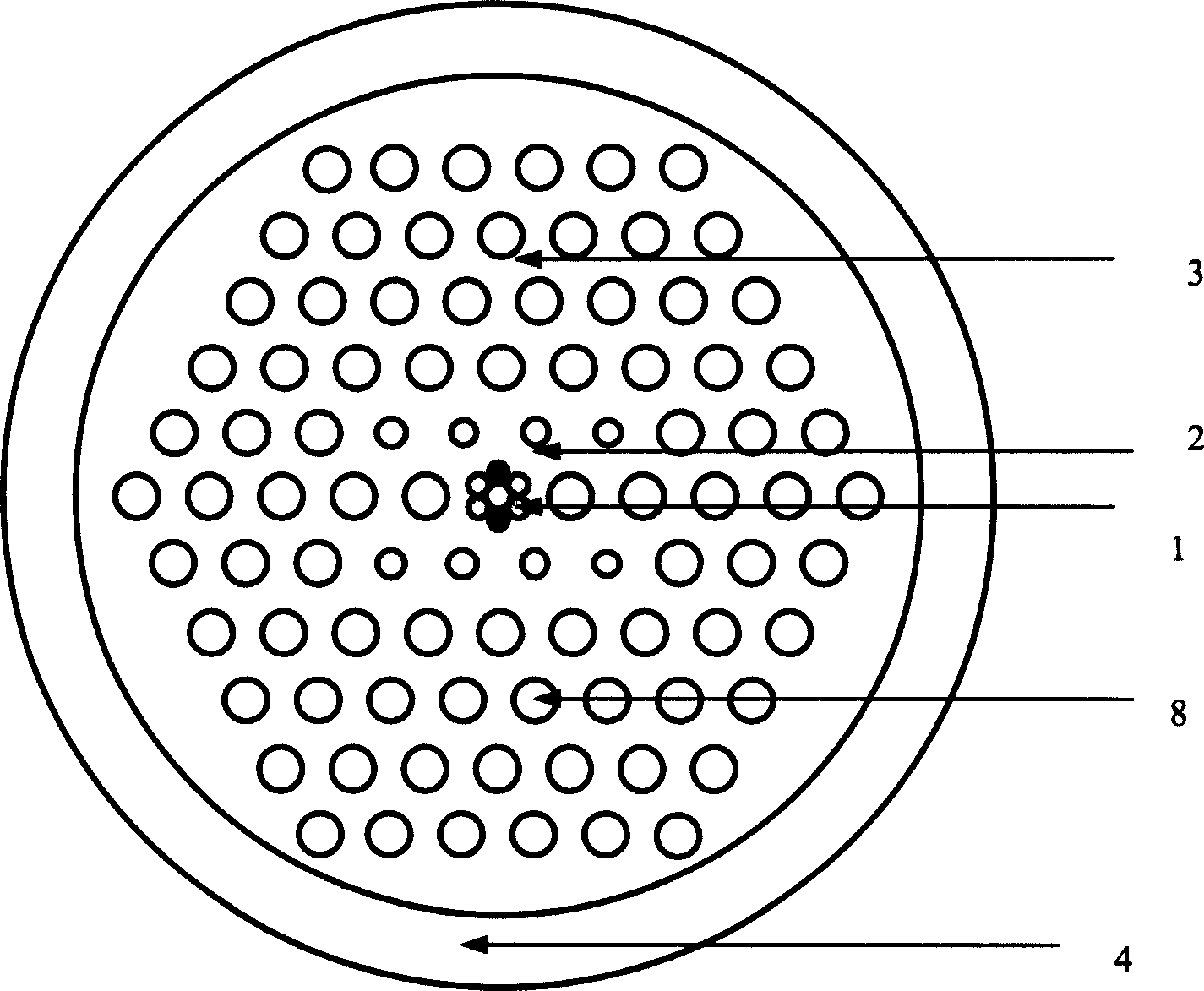

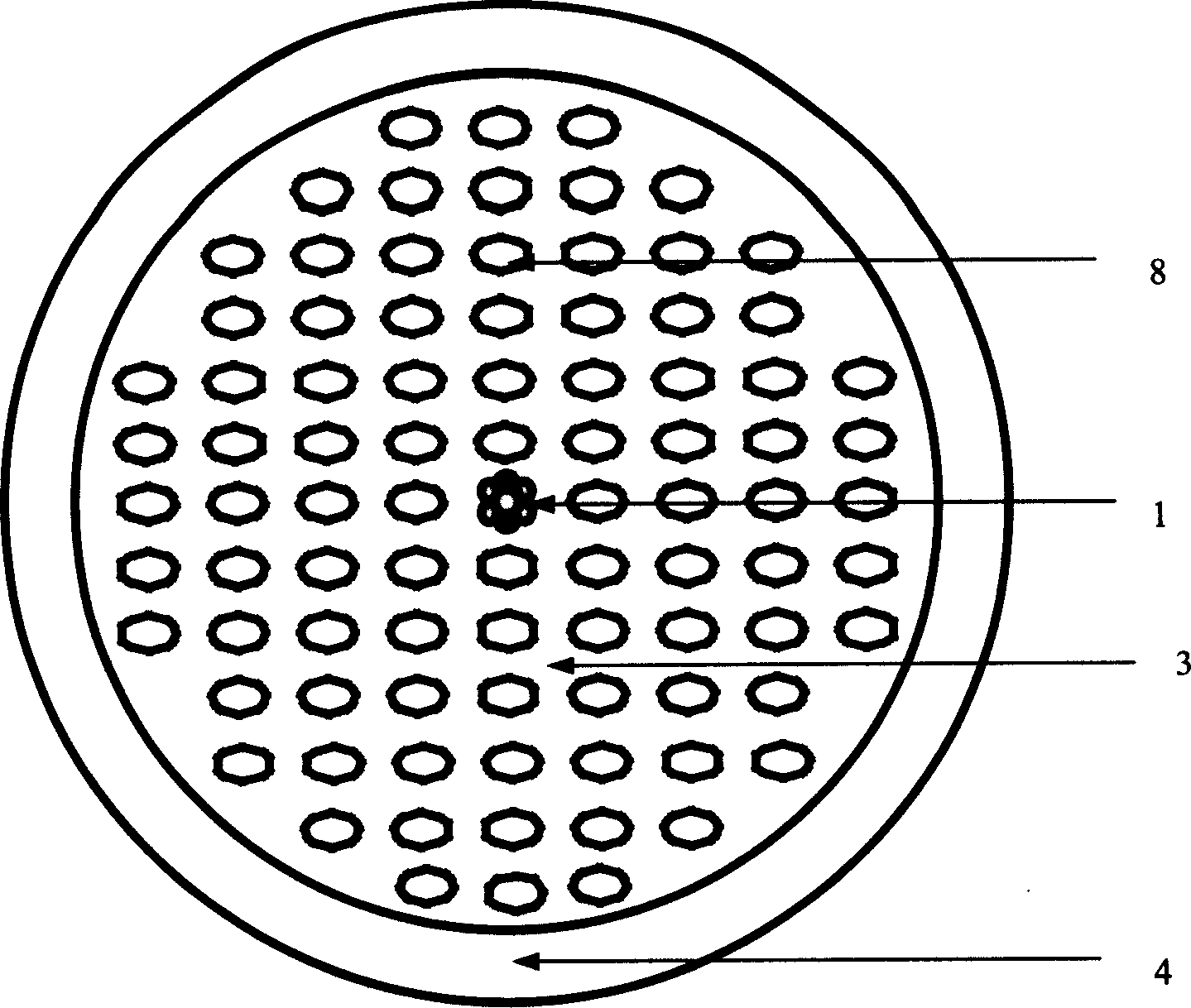

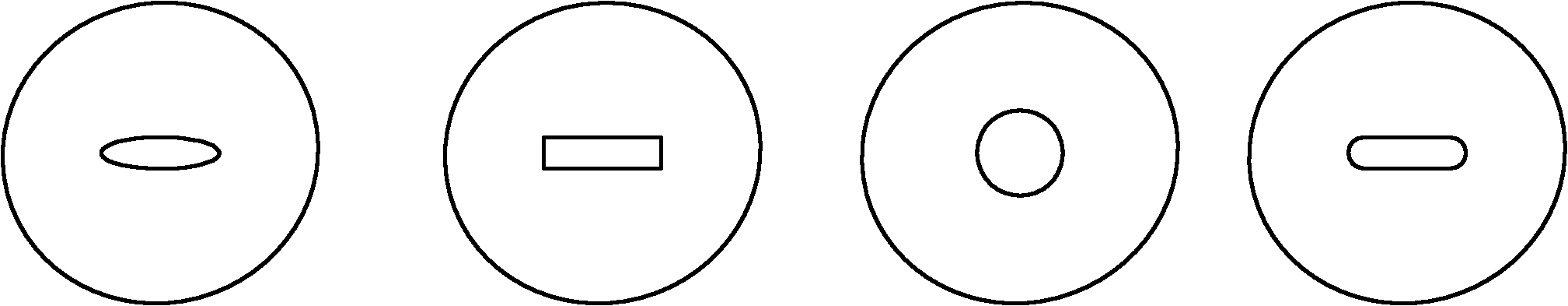

Double-refraction microstructure optical fiber and its mfg. method

ActiveCN1564034AHigh birefringence propertiesGood polarization temperature stabilityOptical light guidesFiber drawingPerpendicular direction

The fiber includes central core area, cladding area and coating area. Cladding area includes buried micropore array in axial direction surrounding the core area and coating area. Changing shapes, structures, size and quantity and arrangement etc. forms major effective refractivity between two perpendicular directions in fiber so as to fabricate birefringence microstructure optical fiber. Fabricating method includes steps: preparing pure or doping quartz tiny stick and pure quartz tiny tube with certain wall thickness; fabricating the said sticks and tubes to specific shape; assembling the said sticks and tubes to desired shape; bundling sticks and tubes in quartz sleeve; fiber drawing forms optical fiber.

Owner:FENGHUO COMM SCI & TECH CO LTD

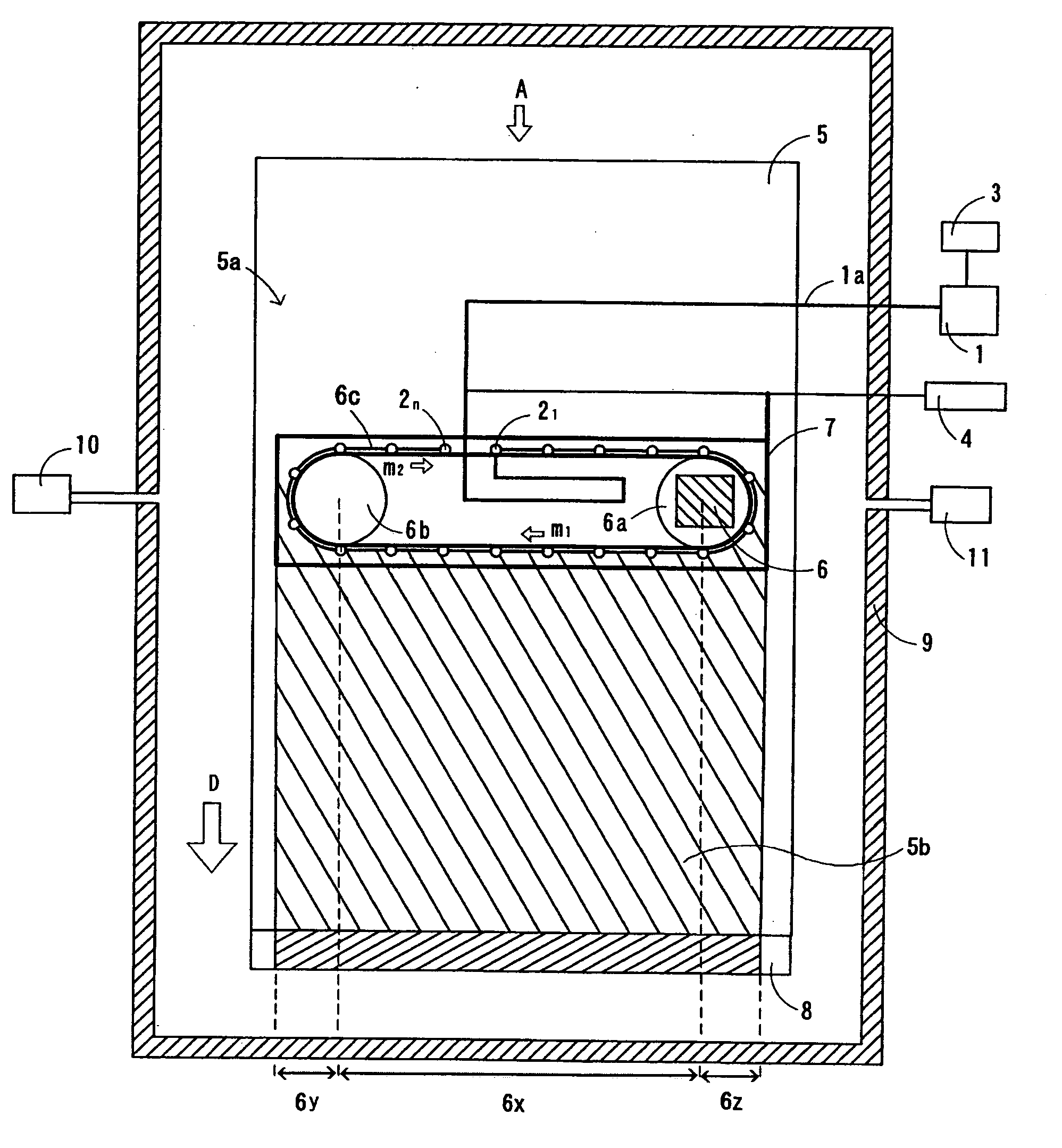

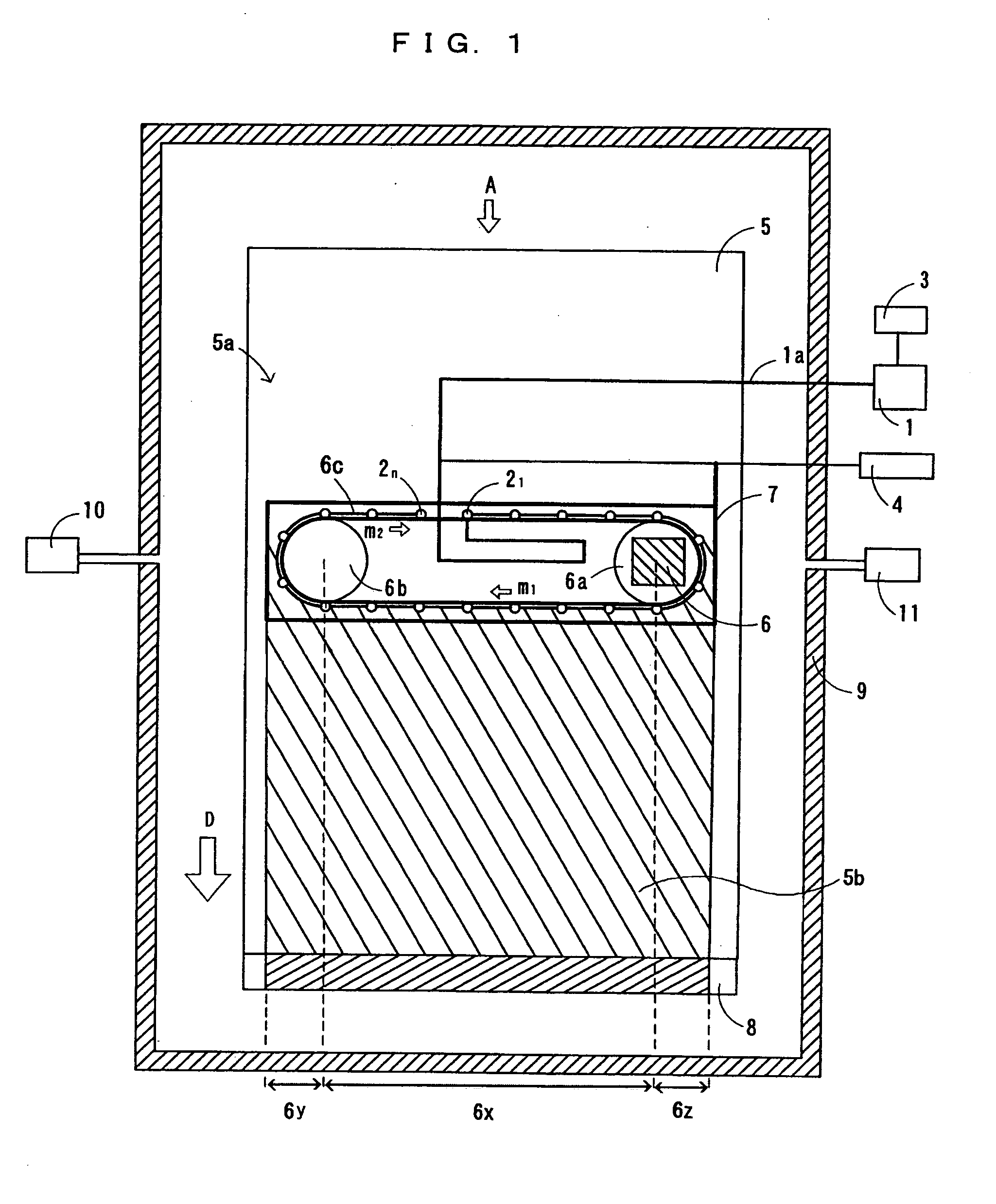

Method and apparatus of producing fibrous aggregate

InactiveUS20060060999A1Guaranteed smooth productionUniform mechanical strengthFilament/thread formingAuxillary shaping apparatusLinear motionEngineering

A method of producing fibrous aggregate, comprising: a supplying and discharging step in which a fiberizable liquid is supplied from a means for storing a fiberizable liquid to a means for discharging a fiberizable liquid via a supplying pipe, and the fiberizable liquid is discharged from the discharging means; and a fibers-collecting step in which fibers drawn and fiberized by applying an electrical field to the discharged fiberizable liquid are accumulated directly on a collecting surface of a collector while the collecting surface is unidirectionally conveyed to form the fibrous aggregate; wherein the discharging means is carried on a support capable of moving along an endless track capable of rotationally travelling between a pair of rotating shafts, and the fiberizable liquid is discharged from the discharging means while the support is revolved at a constant velocity under the condition that a moving direction of a linear motion area in the endless track conforms to a width direction of the collecting surface is disclosed.

Owner:NIPPON BAIRIIN

Method of making fibers and nonwovens with improved properties

ActiveUS20060273495A1Slow crystallization rateReduce speedWoven fabricsNon-woven fabricsPolymer scienceNonwoven fabric

The present invention can provide a distinctive method and process for making polymer fibers (62) and nonwoven fabric webs (60). The method can include providing a fiber material that exhibits a low crystallization rate. In a particular aspect, the fiber material can be subjected to an anneal-quench at an anneal-quench temperature that approximates a prime-temperature at which the polymer material most rapidly crystallizes. In another aspect, the fiber material can be subjected to a fiber-draw at a selected fiber-draw temperature, and in a further aspect, the fiber-draw temperature can be configured to approximate the prime-temperature of the polymer material. In still other aspects, the fiber material can be subjected to a relatively small amount of fiber-draw, and the fiber-draw can be provided at a relatively low fiber-draw speed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Linear semiconductor substrate, and device, device array and module, using the same

InactiveUS20060263921A1Reduce thicknessReduce manufacturing costNanoinformaticsSolid-state devicesFiber drawingSemiconductor

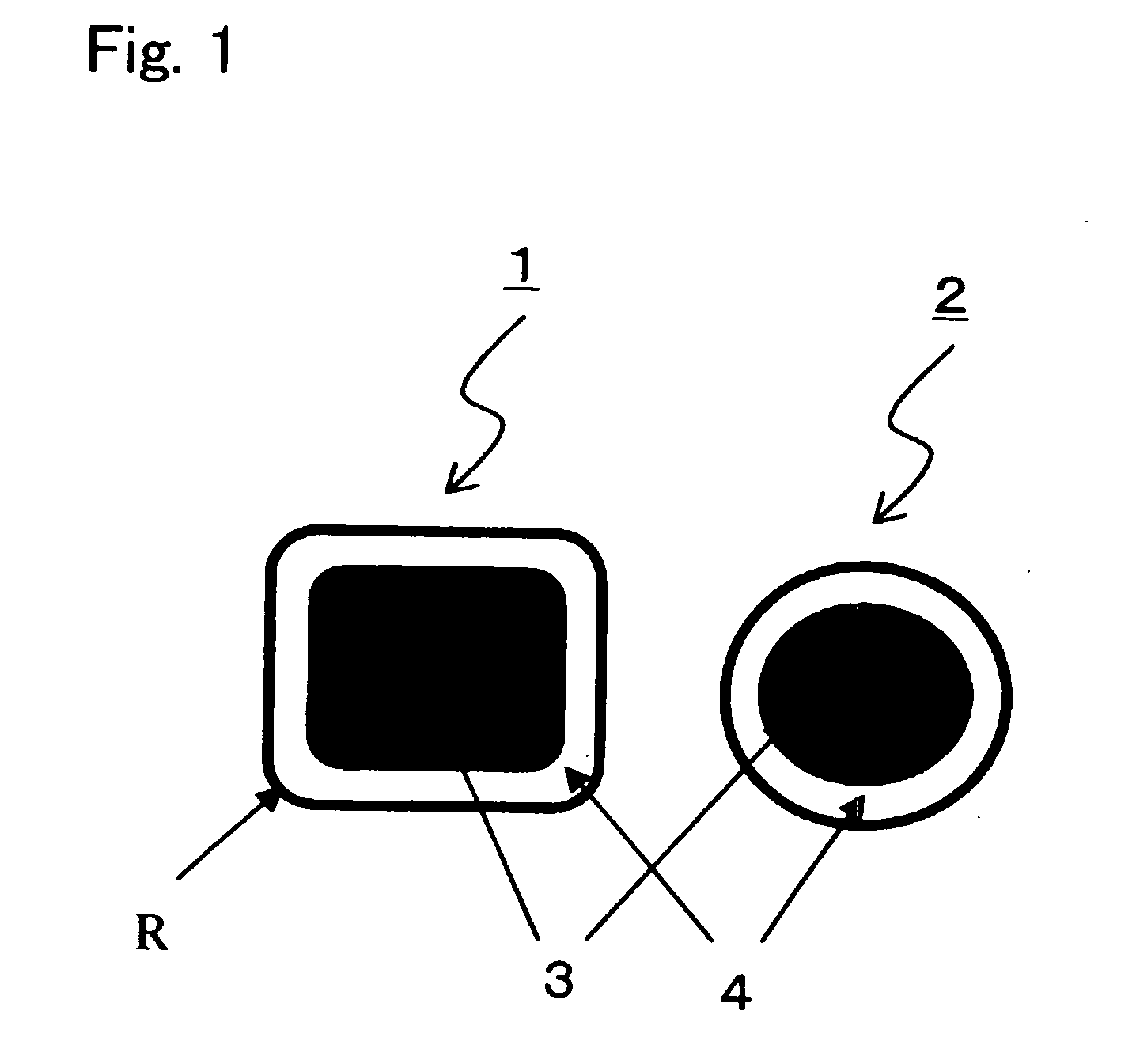

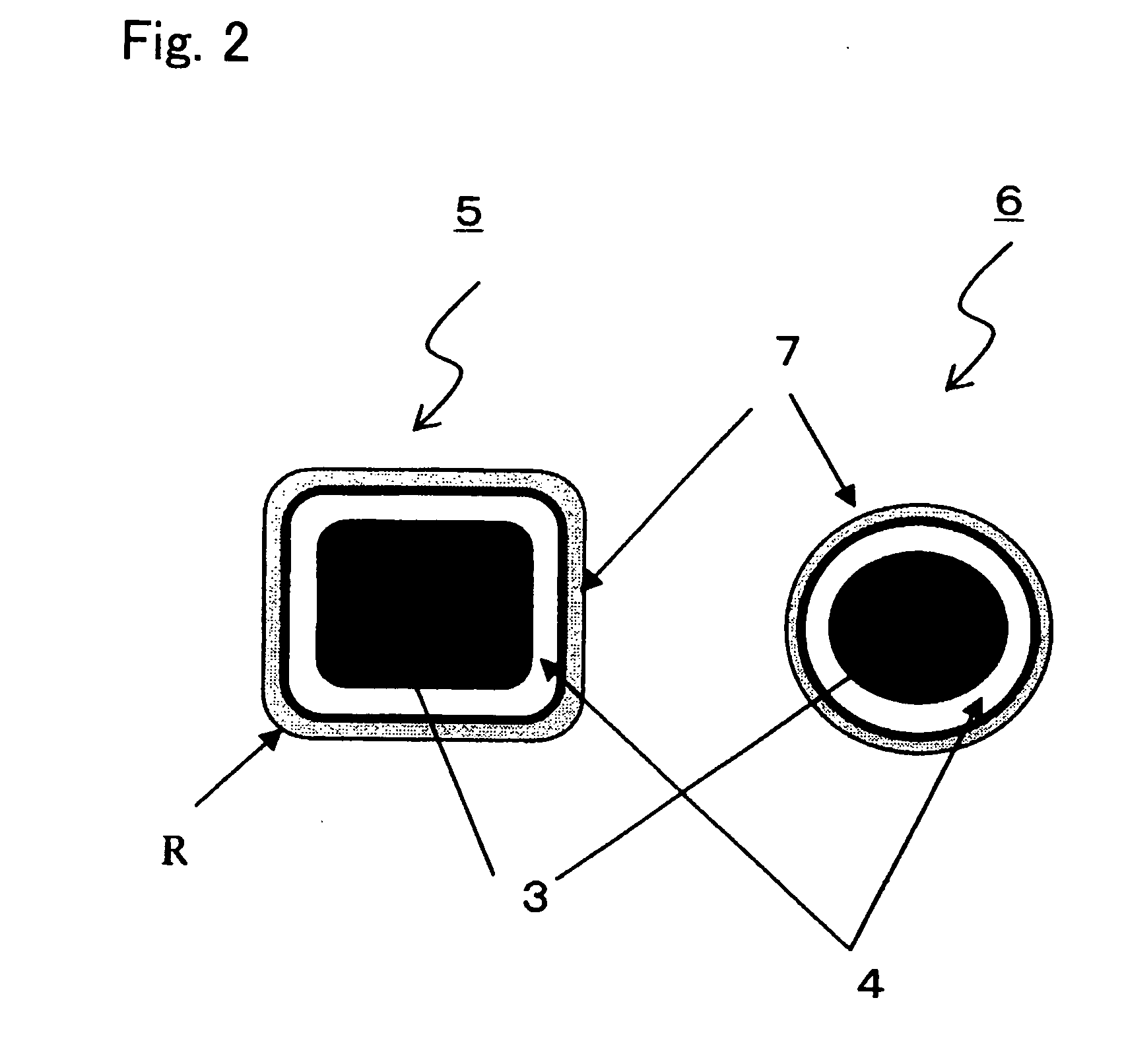

The linear semiconductor substrate 1 or 2 of the present invention comprises at least one desired thin film 4 formed on a linear substrate 3 having a length ten or more times greater than a width, thickness, or diameter of the linear substrate itself. Adopting semiconductor as the thin film 4 forms a linear semiconductor thin film. The linear semiconductor substrate 1 or 2 of the present invention is produced by utilizing a fiber-drawing technique which is a fabricating technique of optical fibers.

Owner:FURUKAWA ELECTRIC CO LTD

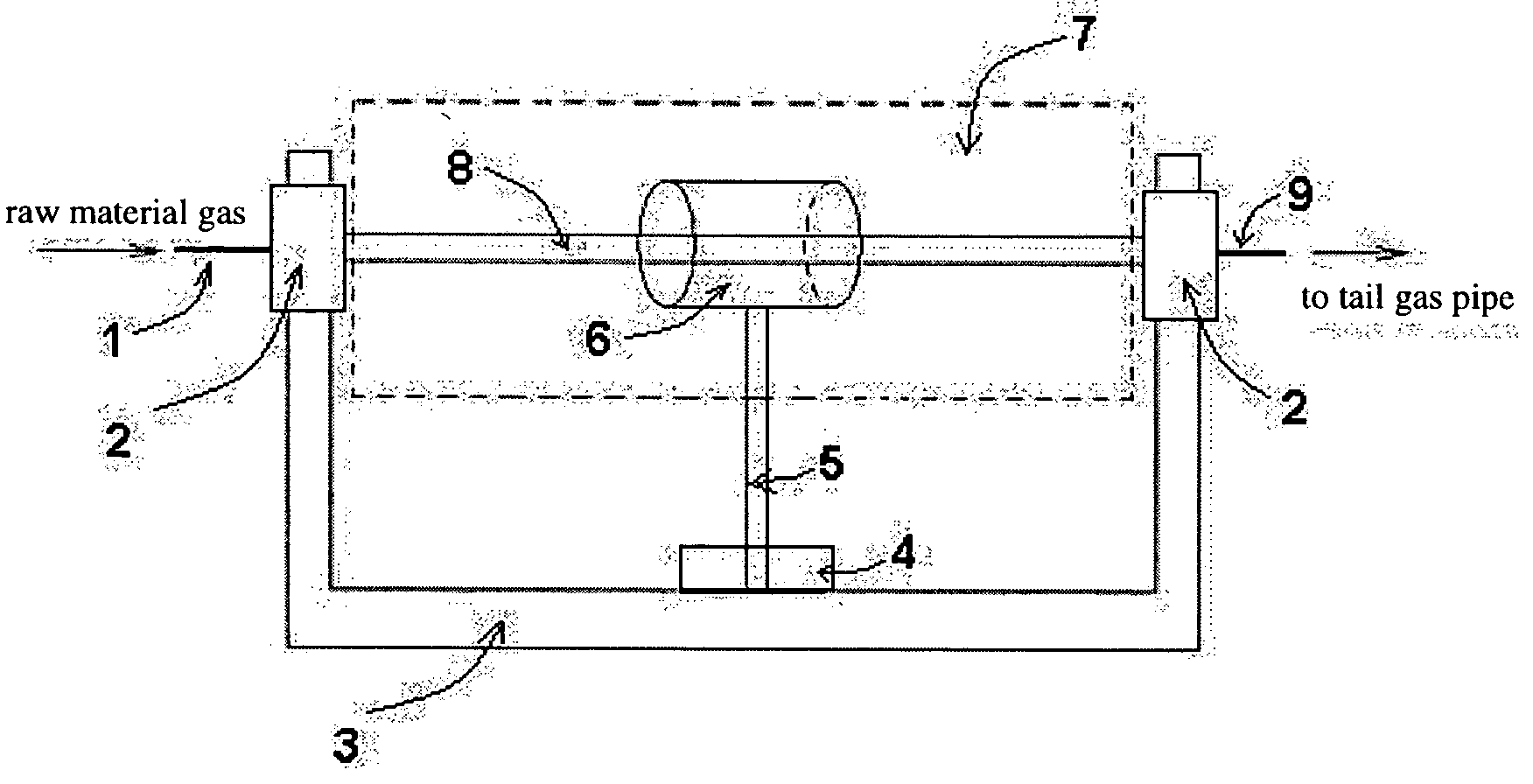

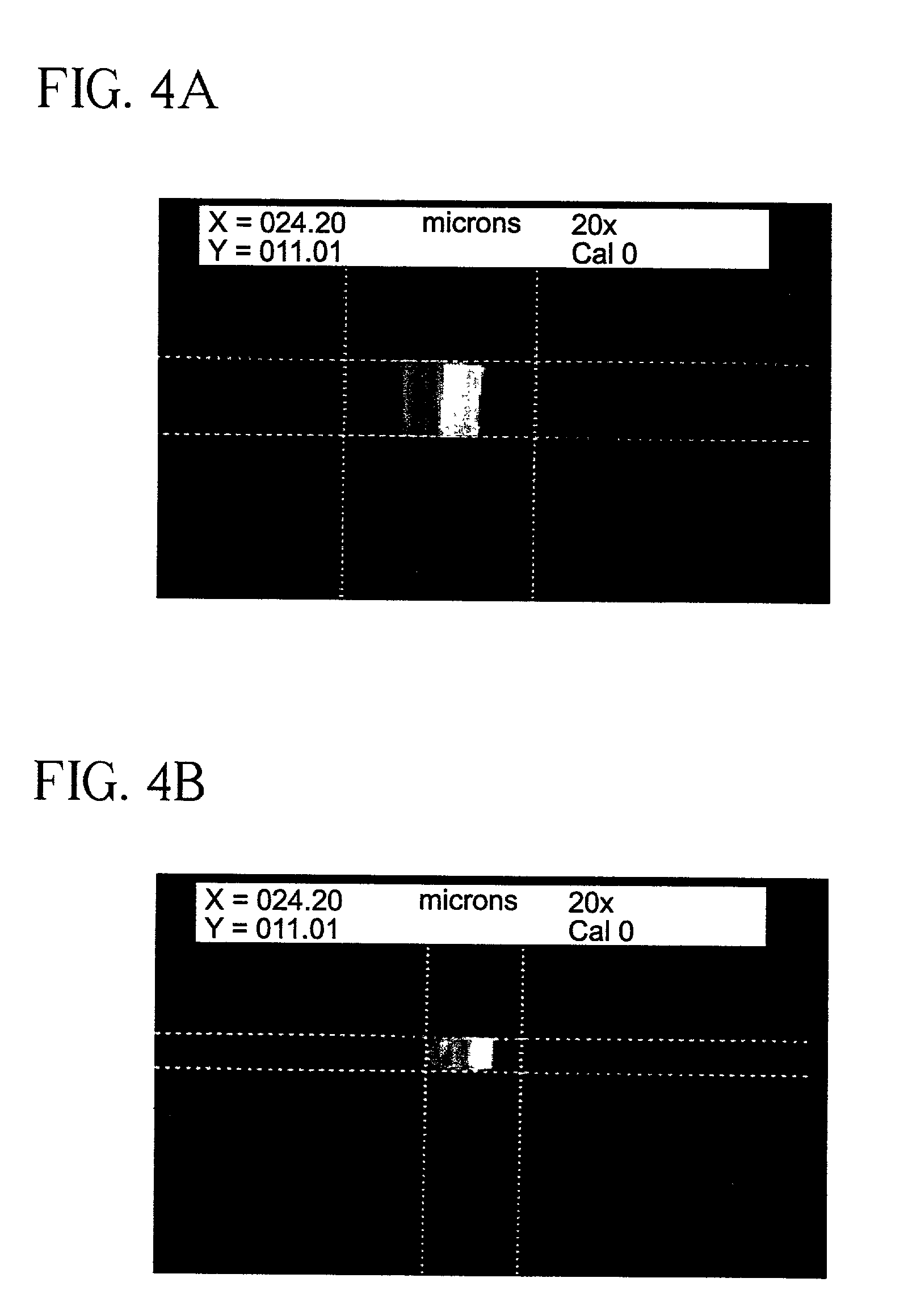

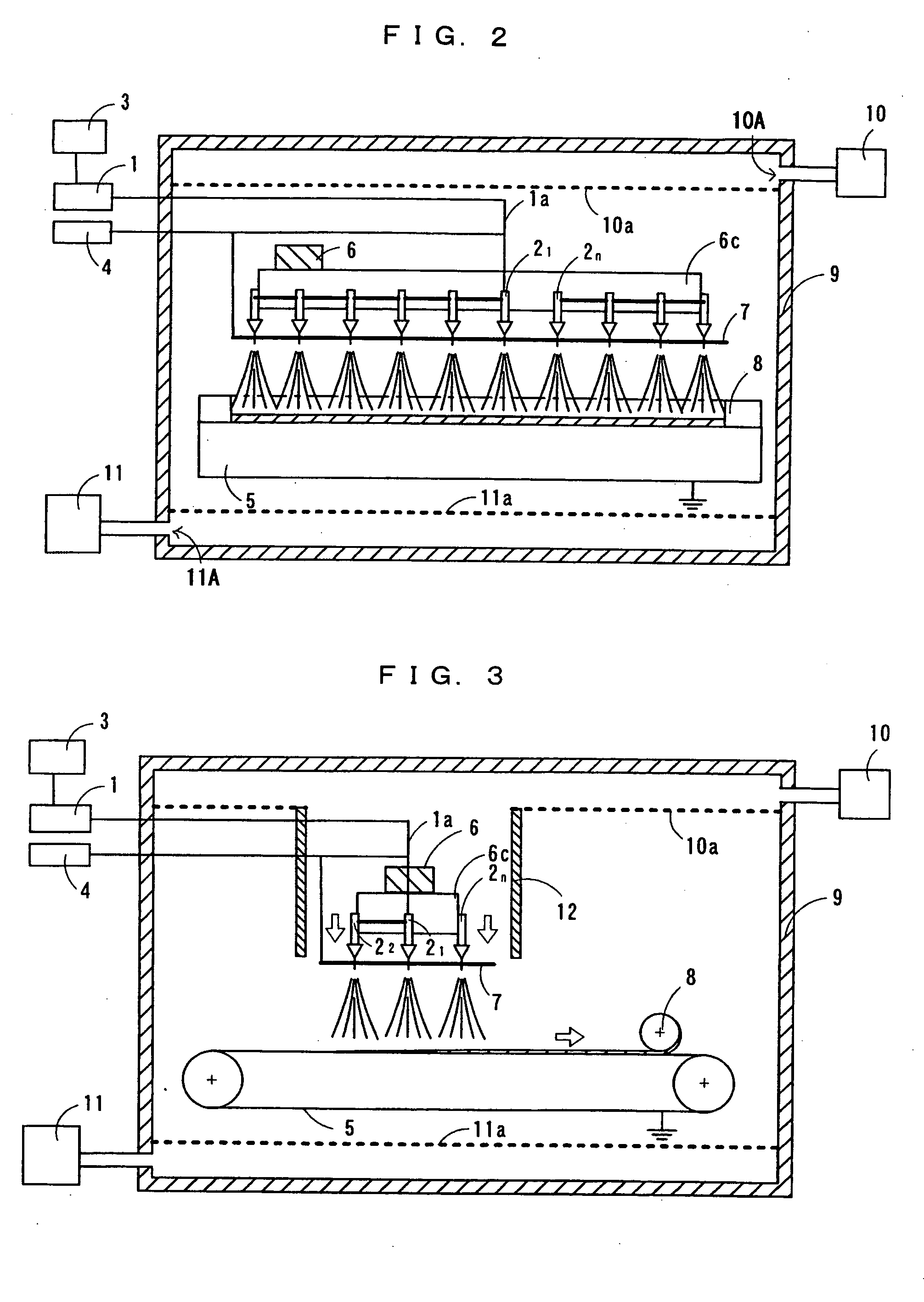

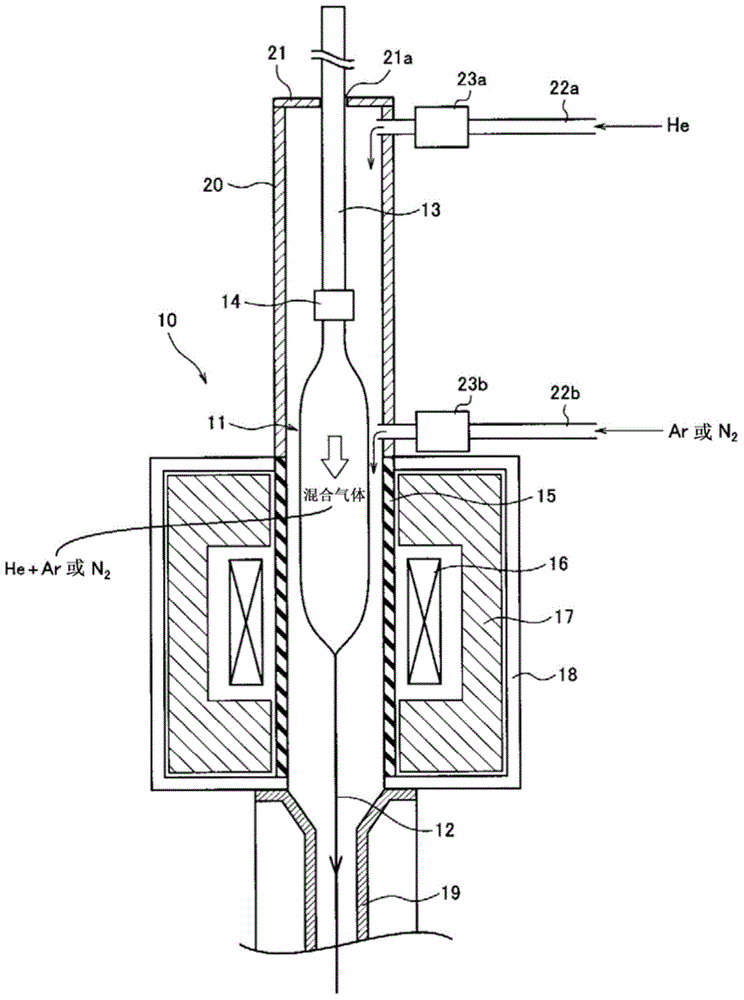

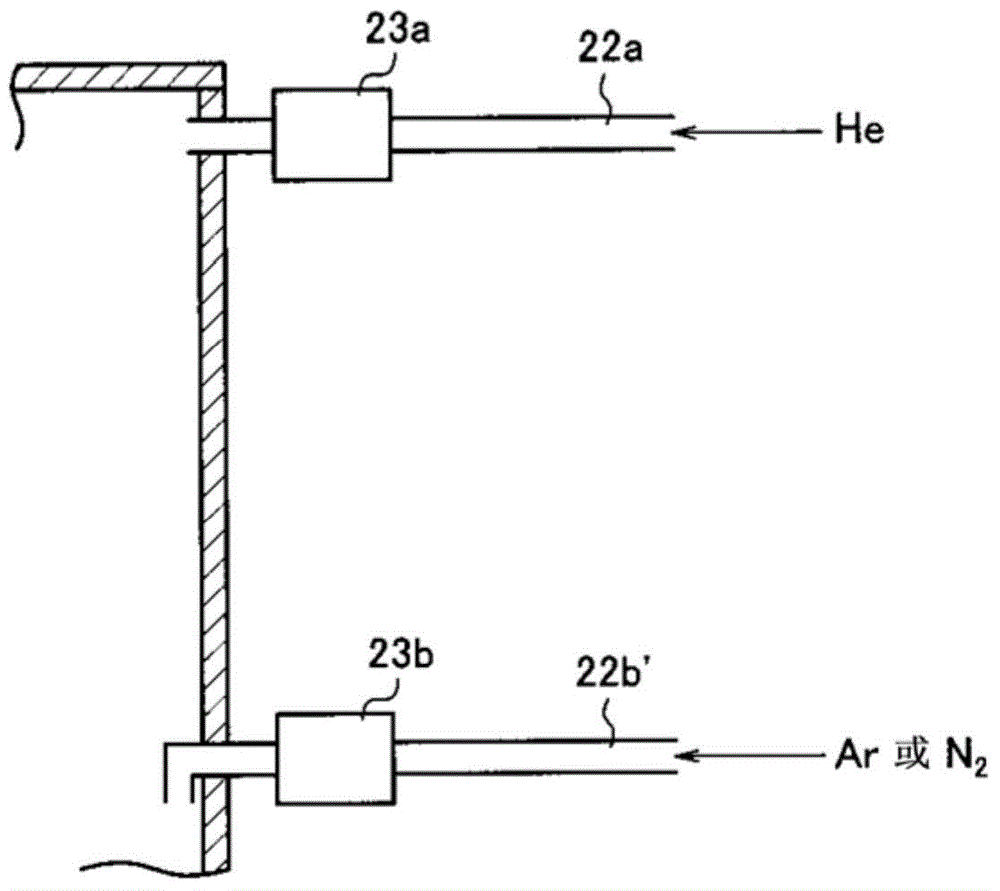

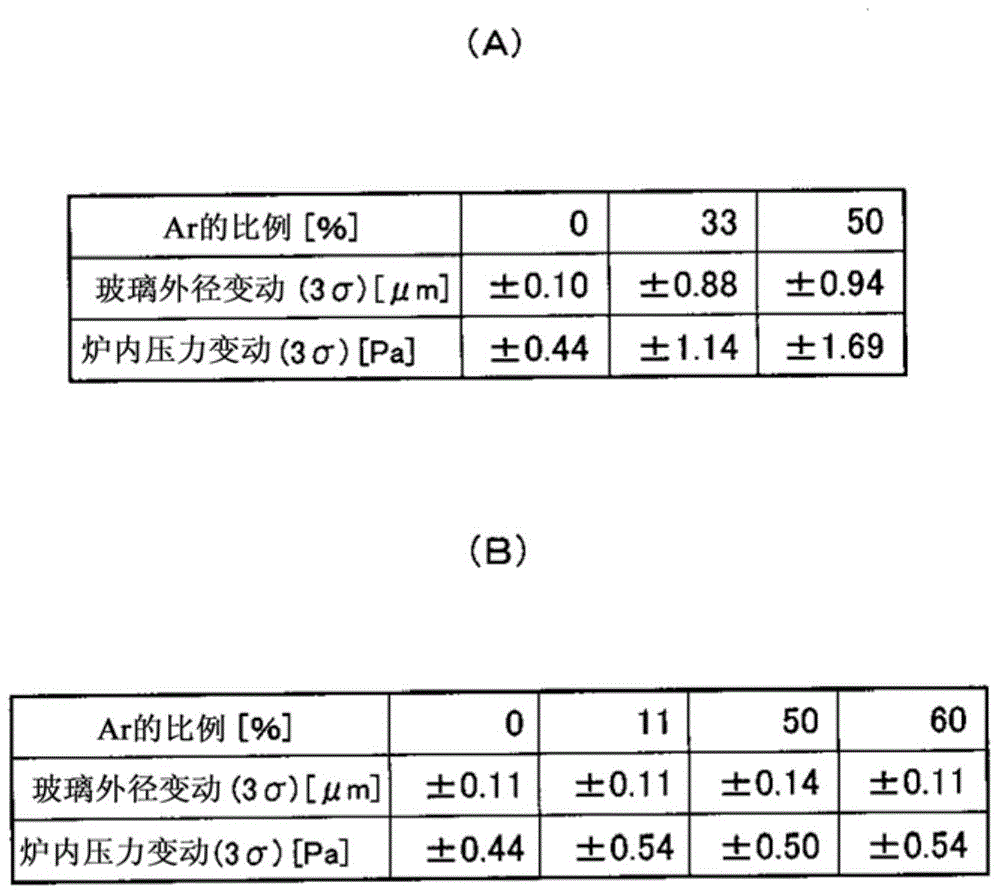

Fiber manufacturing method and fiber drawing furnace

The invention provides a fiber manufacturing method and a fiber drawing furnace, wherein the application amount of the helium gas is reduced and the pressure variation inside the furnace is lowered. Meanwhile, the gas is kept at a certain degree. The fiber drawing furnace (10) comprises a furnace tube (15) used for feeding glass parent material (11); a heater (16) arranged at the periphery of the furnace tube (15); and an upper chamber (20) connected with the upper part of the furnace tube (15) and used for accommodating the glass parent material (11).

Owner:SUMITOMO ELECTRIC IND LTD

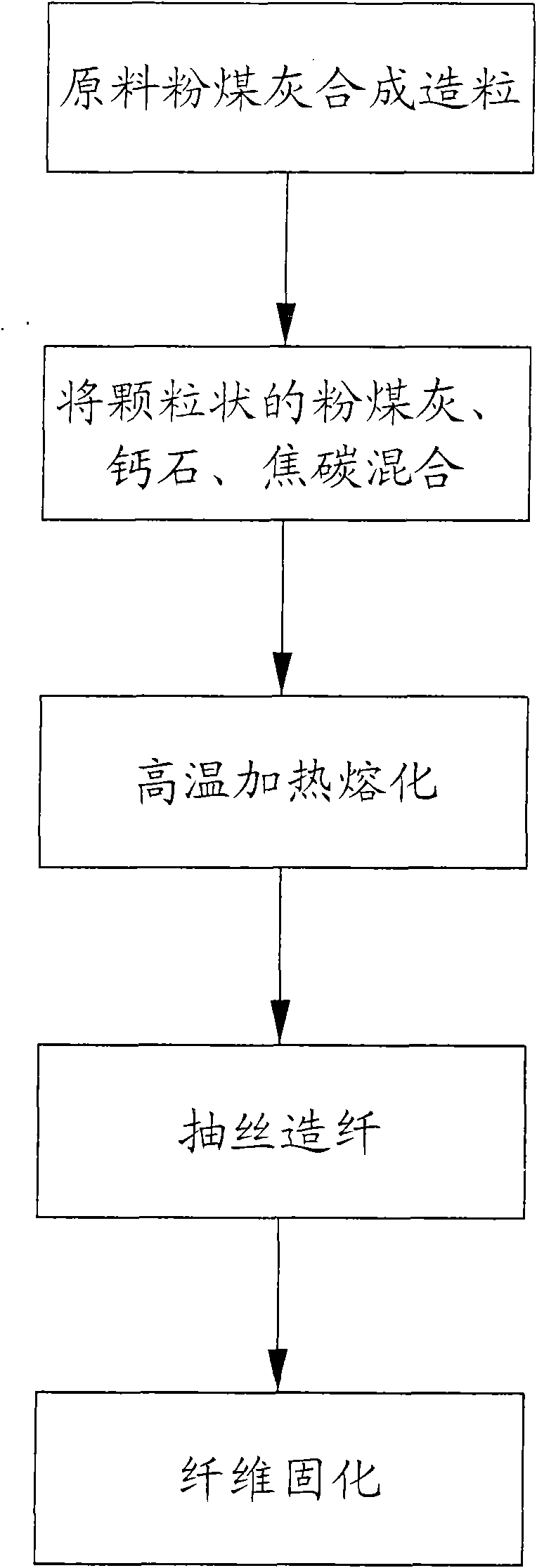

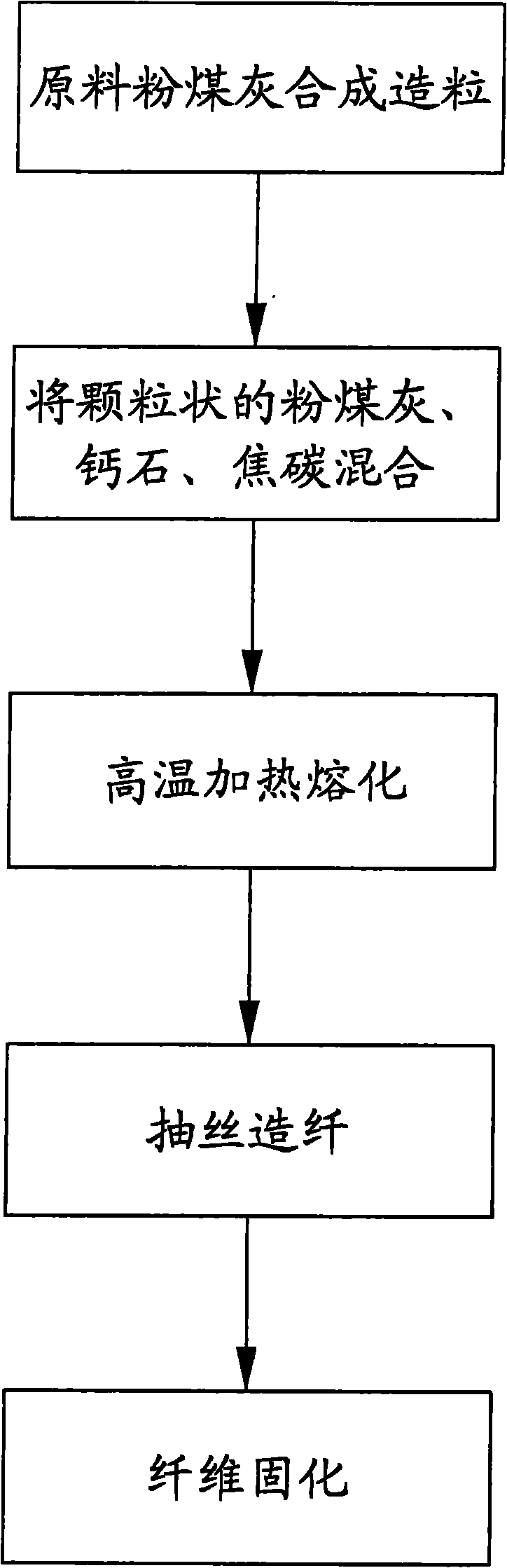

Method for producing cellucotton by using fly ash

InactiveCN101935159AQuality improvementHigh fiber rateGlass making apparatusClimate change adaptationSlagFiber drawing

The invention discloses a method for producing cellucotton by using fly ash, which comprises the following: 1) a step of synthesizing and granulating the fly ash serving as a raw material, in which the fly ash are formed into grains in a forming machine; 2), a step of mixing the raw materials, in which the calspar, white rock or basalt, the granular fly ash and coke; 3) a step of melting at high temperature, in which the raw materials are delivered to a high-temperature smelting furnace to be heated and melted; 4) a step of drawing fibers and producing cellucotton, in which the molten liquid is delivered to a high-speed centrifugal drawing machine to be drawn into fibers, and the fibers drawn out are gossypine cellucotton; and 5) a step of curing fibers, in which the gossypine fibers are stacked and added with curing agent to be cured into blocks and plates, which are blocky or platy cellucotton. The cellucotton manufactured by the method has fine fibers, high fiber yield and better heat-preservation, heat-insulation, sound-insulation, breathable performances and other performances than cellucotton manufactured by using mineral slag and steel slag as main raw materials.

Owner:厦门市榕薪环保设备有限公司

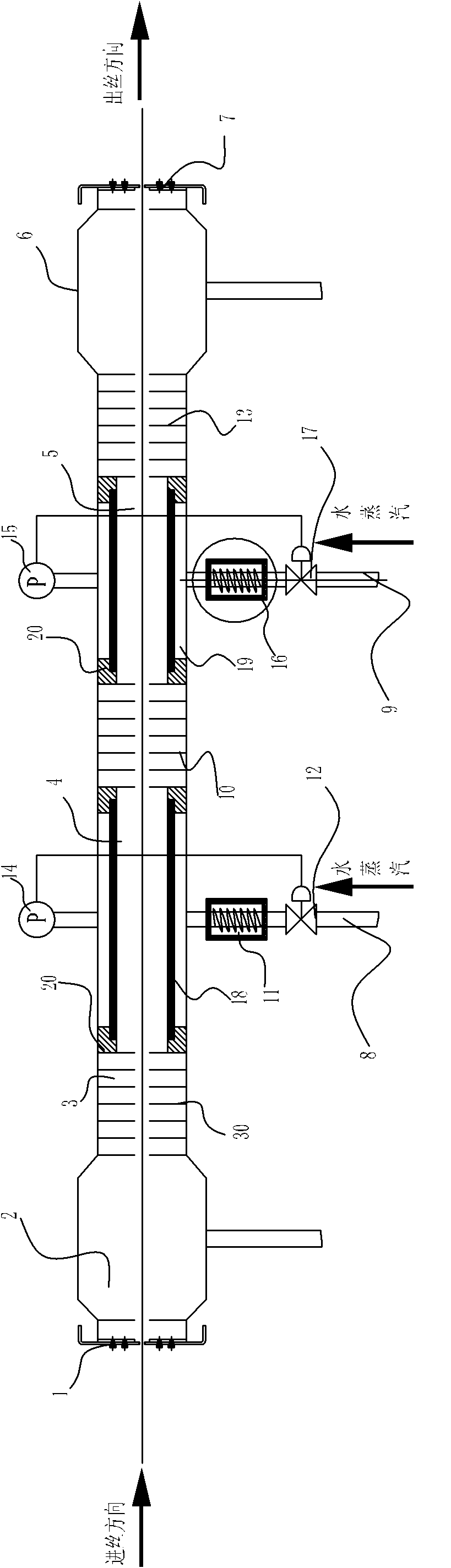

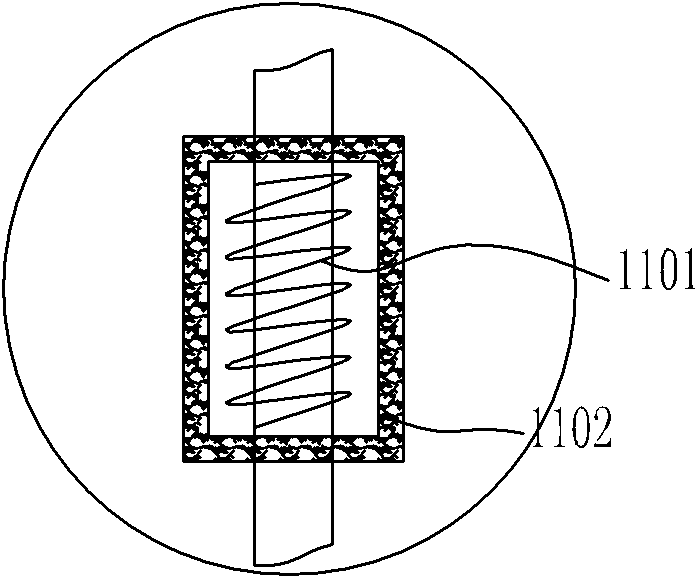

Fiber pressure-retaining drawing device under pressurized steam

InactiveCN102061531AAvoid it happening againGood heat conduction throughArtificial thread manufacturing machinesStretch-spinning methodsInternal pressureEngineering

The invention relates to a fiber pressure-retaining drawing device under pressurized steam. The drawing device comprises a drawing cavity, wherein, a feeding steam seal component, a preheating drawing cavity, a middle steam seal component, a heating drawing cavity and a discharging steam seal component are sequentially arranged in the drawing cavity along the advancing direction of filament bundle; the preheating drawing cavity is equipped with a steam preheating pipe for providing steam to the preheating drawing cavity; the heating drawing cavity is equipped with a steam heating pipe for providing steam to the heating drawing cavity; a steam preheating chamber is arranged in the middle part outside the preheating drawing cavity, the wall of the preheating drawing cavity is made of a porous material, and the steam preheating chamber is communicated with the steam preheating pipe; and a steam heating chamber is arranged in the middle part outside the heating drawing cavity, the wall of the heating drawing cavity is made of a porous material, and the steam heating chamber is communicated with the steam heating pipe. By utilizing the fiber pressure-retaining drawing device, the technical problem of the existing fiber drawing device under the pressurized steam that the internal pressure can not meet the technological requirement is solved, and broken filaments caused by up-down vibration of the filament bundle are avoided so that the internal pressure and temperature of the drawing cavity reach a constant state.

Owner:西安航科等离子体科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com