Patents

Literature

1417results about How to "Guaranteed smooth production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

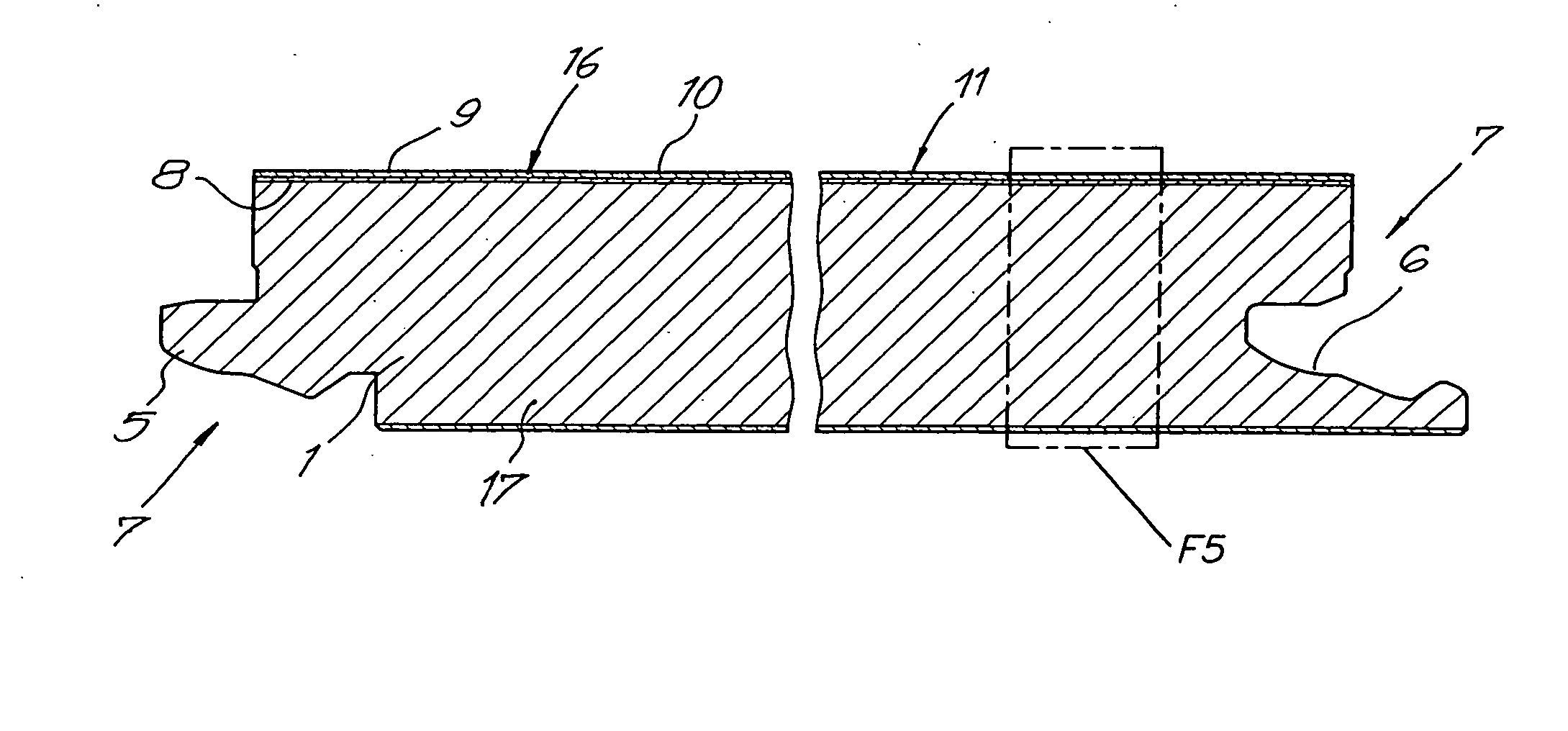

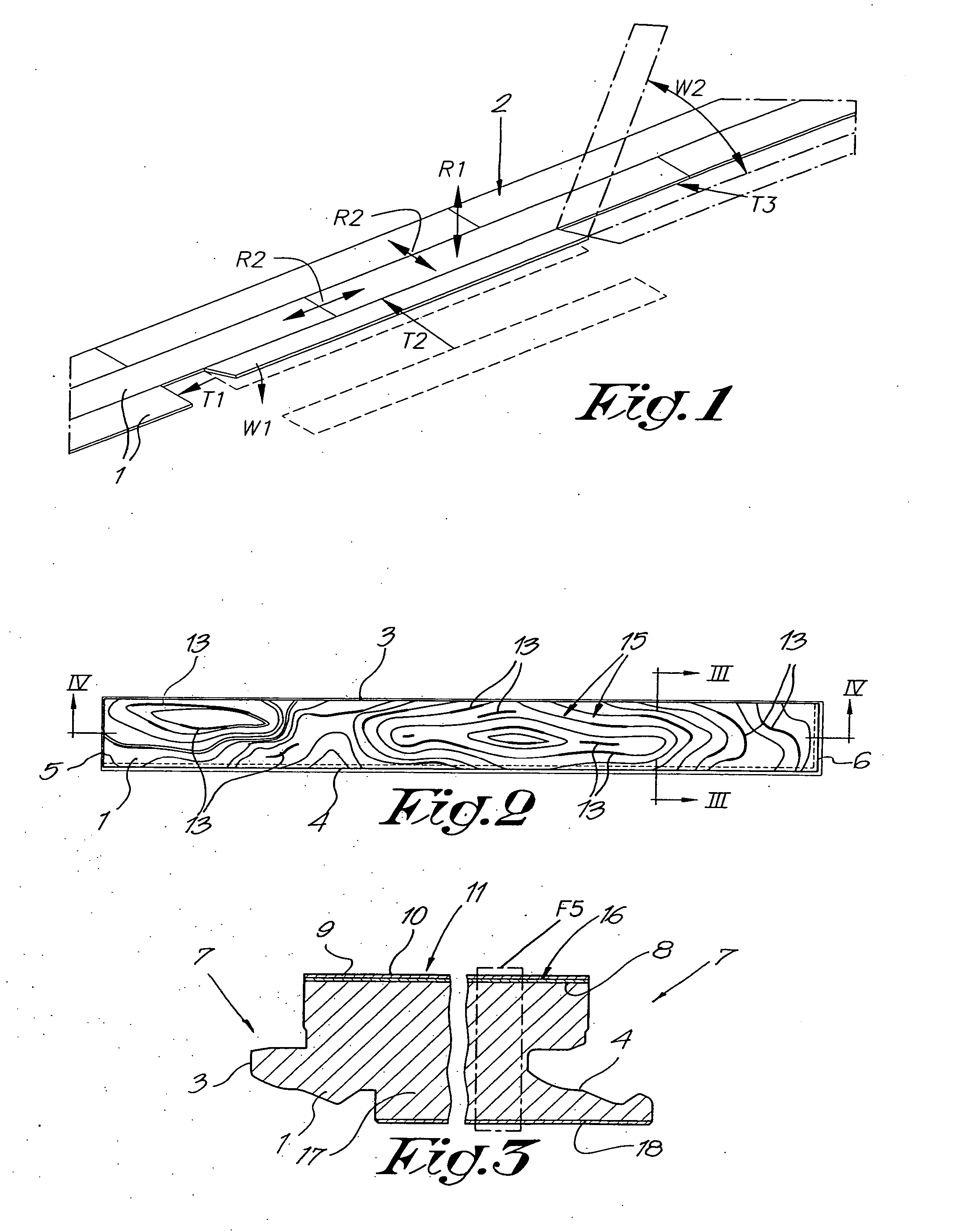

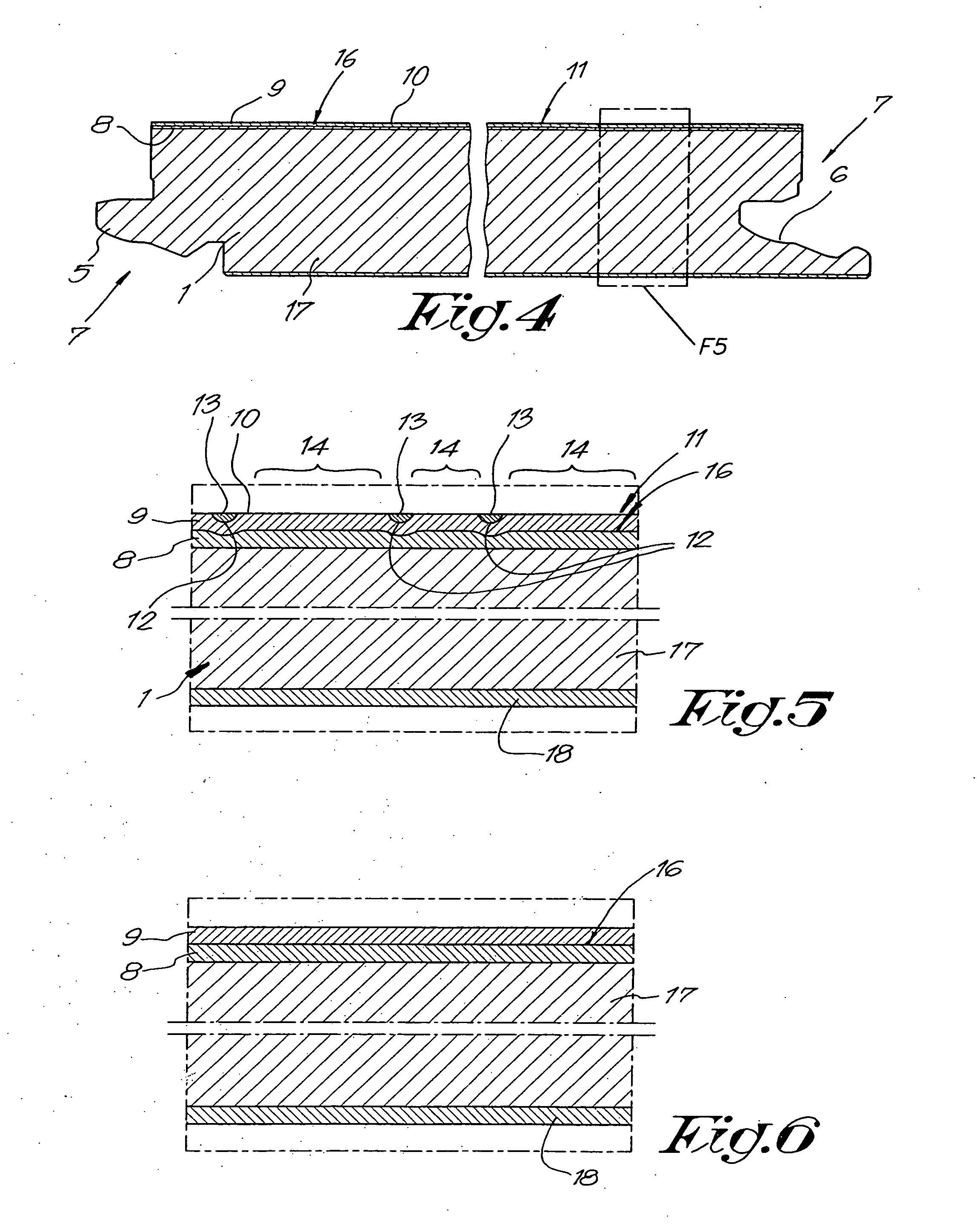

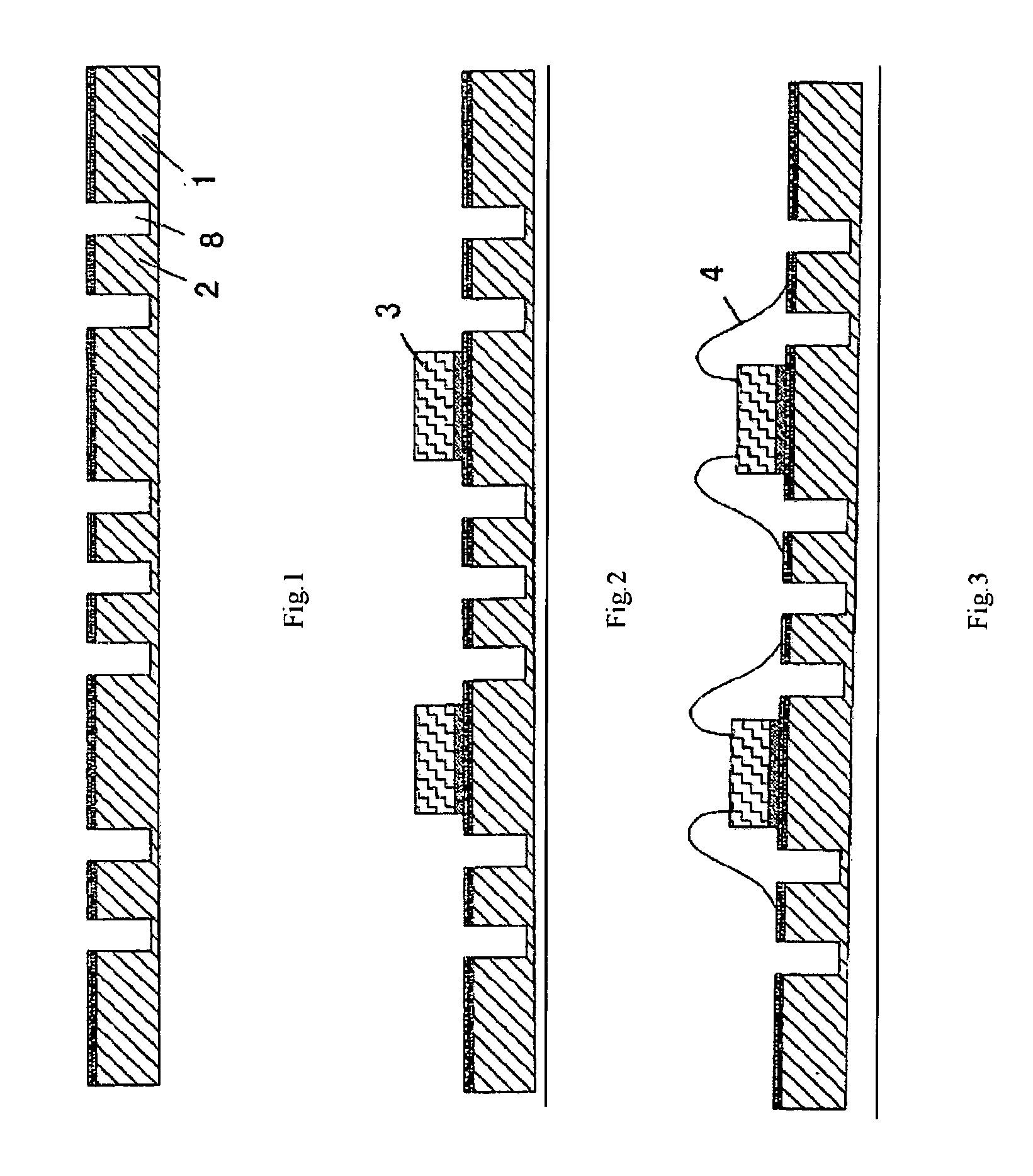

Floor panel and method for manufacturing such floor panels

Floor panel, of the type consisting of a laminate panel which comprises at least a printed decorative layer (8) and a top layer (9) forming the upper surface (10) of the floor panel (1), more particularly a so-called overlay, whereby this top layer (9), or, thus, overlay, is realized on the basis of a thermosetting resin, characterized in that in the upper side (11) of the floor panel (1), indentations (12) are formed and in that at last in a number of these indentations (12), a component (13) is provided, which is obtained in that it has been provided in those indentations (12) after the provision of the indentations (12).

Owner:FLOORING IND LTD

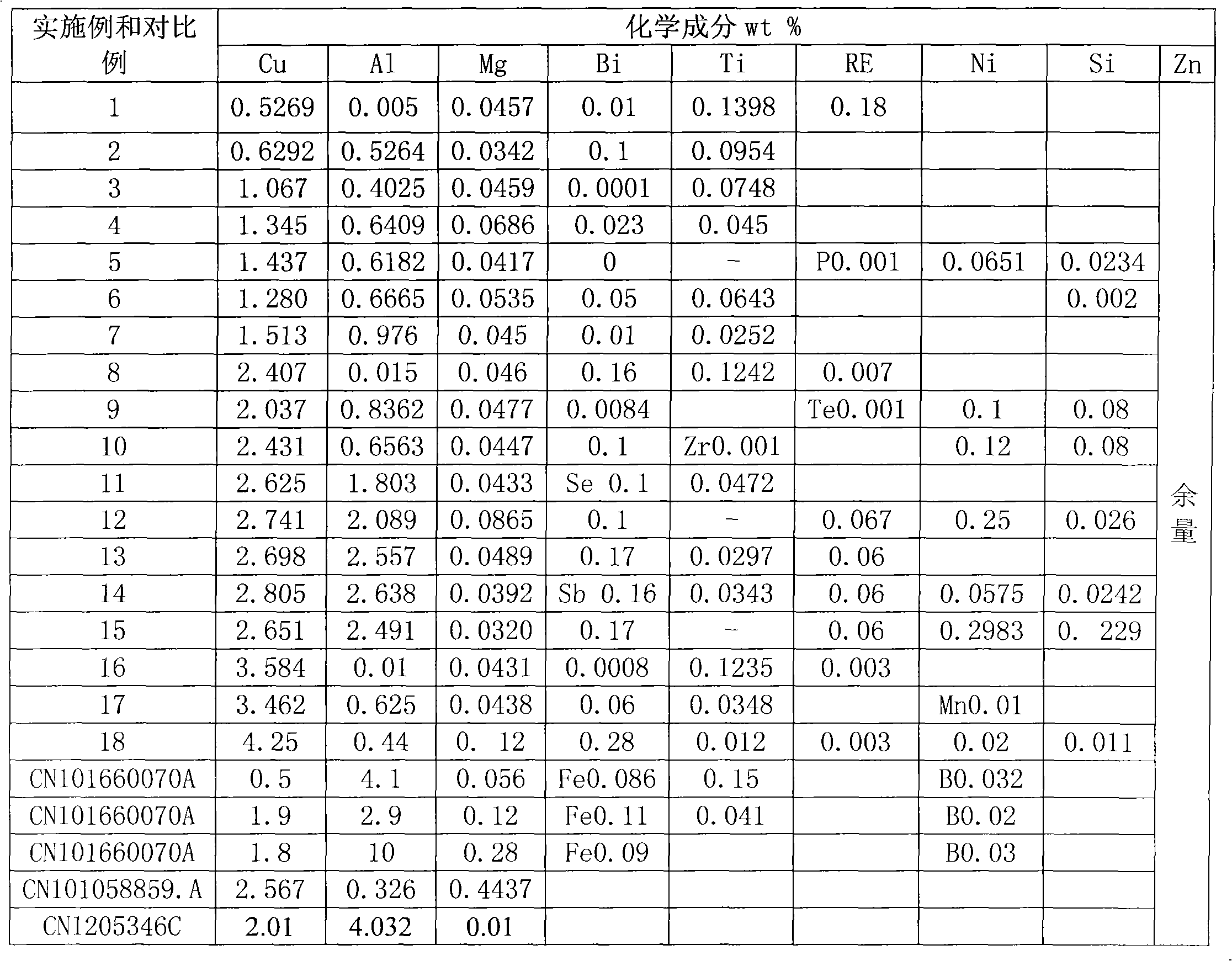

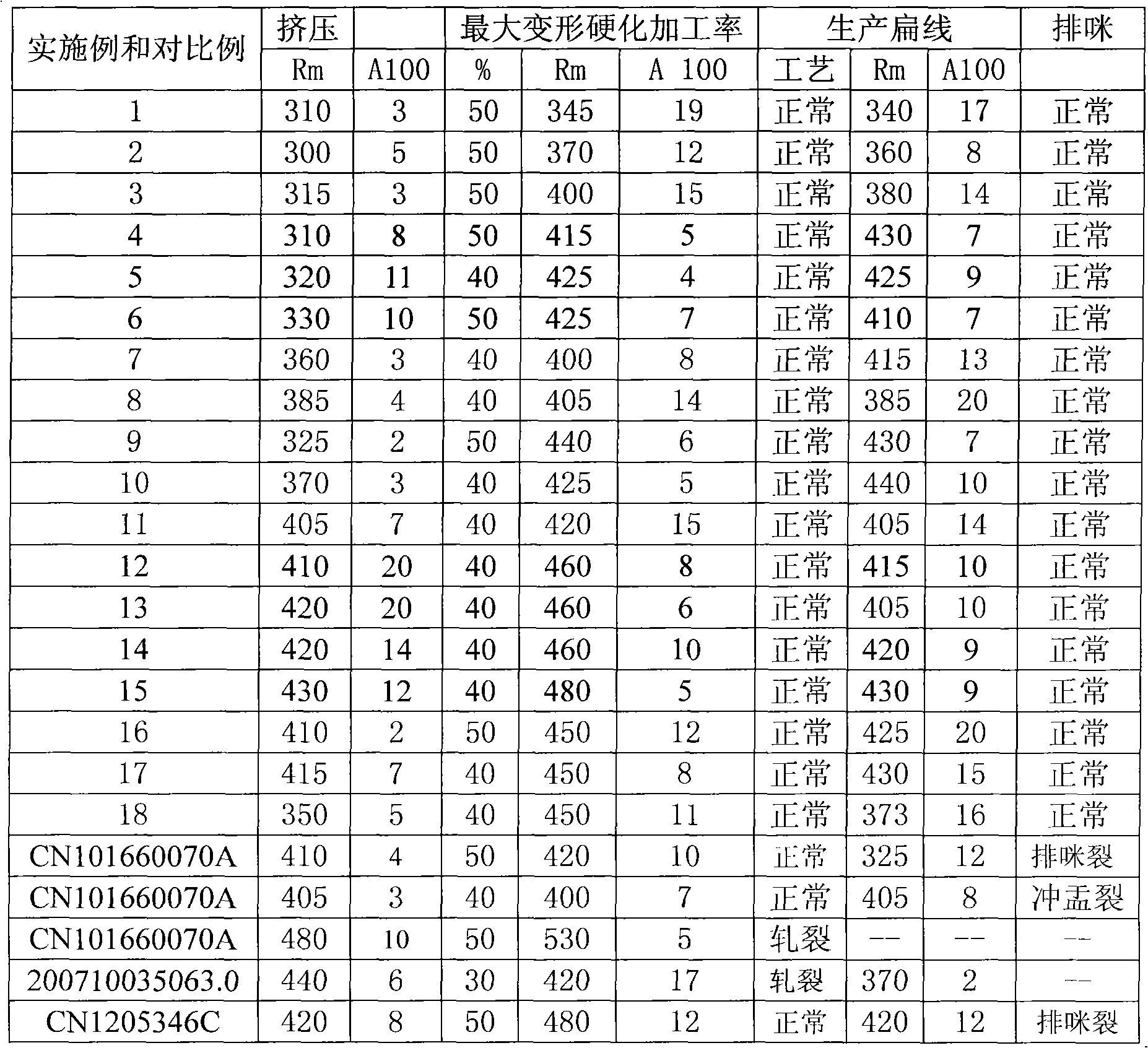

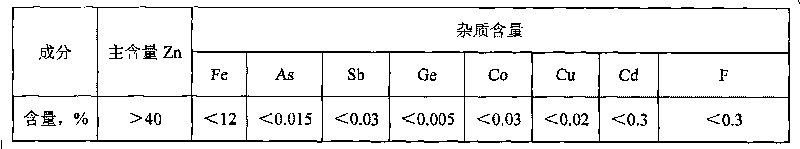

Zinc alloy for zipper tooth belt and preparation method of zipper tooth belt

ActiveCN102011029AOvercoming difficult deformationMeet the mechanical performance requirementsSlide fastenersZinc alloysImpurity

The invention discloses a zinc-alloy zipper tooth belt produced by a row microphone method, in particular to zinc alloy for a zipper tooth belt and a preparation method of the zipper tooth belt. The alloy comprises the following components by weight percent: 0.5-5% of Cu, 10-4.5% of Al, 0.01-0.2% of Mg and the balance of X, Y, Zn and unavoidable impurities, wherein the sum of the percentages of the components is 100%; the X is selected from at least one of 0.0001-0.5% of Bi, 0.01-0.19% of Ti, 0.001-0.3% of RE, 0.001-1% of Ni and 0.001-1% of Si; and Y is selected from at least one of Mn, Co, Nb, Zr, Cr, Ca, P, Sb, Te and Se. By adopting the deformed zinc alloy and the alloy producing method disclosed in the invention, the production of the zipper line can be met, and the zipper tooth belt can be produced smoothly by the row microphone method; and the produced zipper can be processed into different colors.

Owner:NINGBO POWERWAY ALLOY MATERIAL

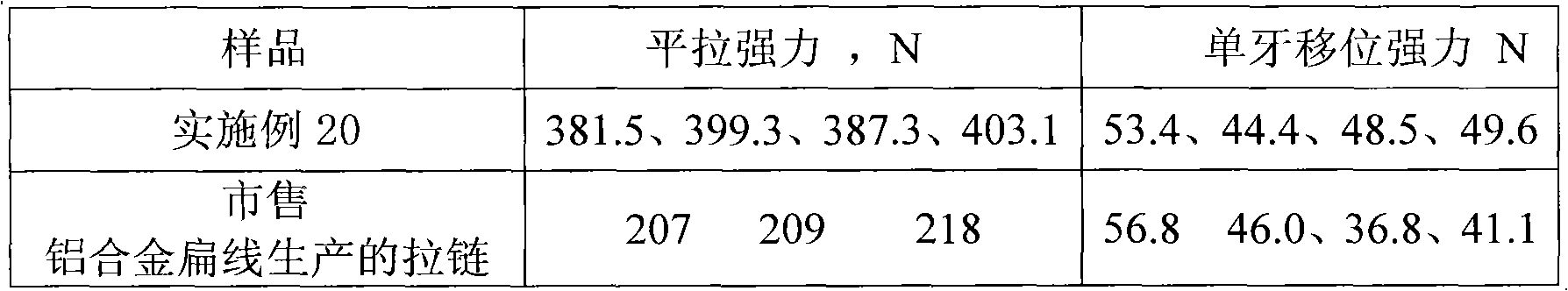

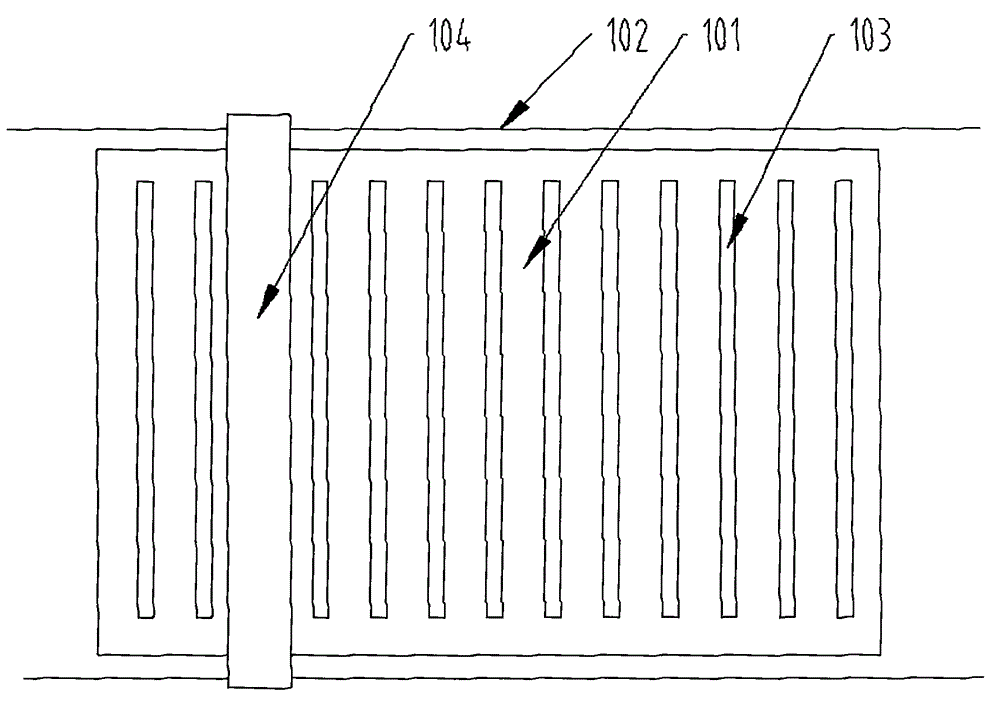

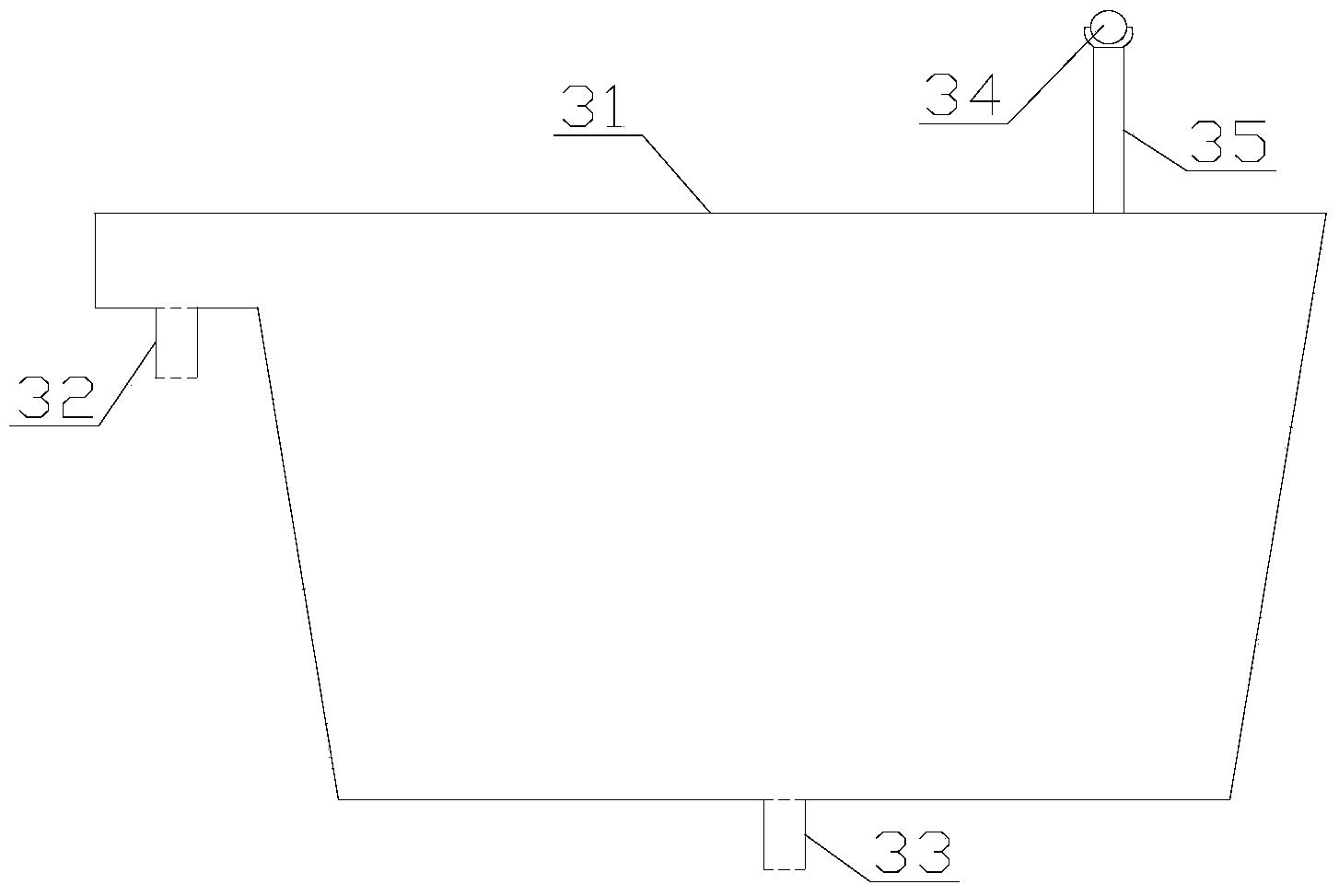

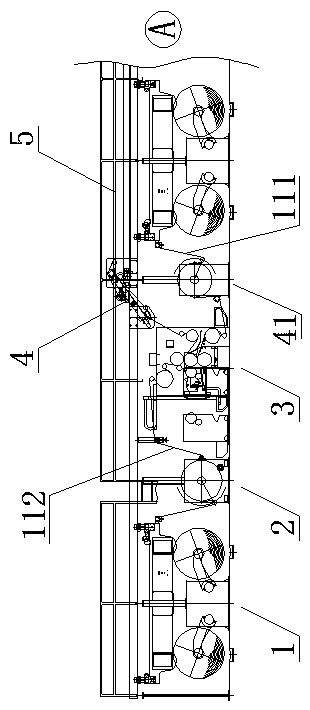

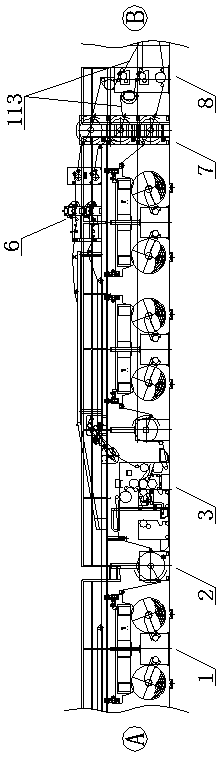

Induction heating continuous magnesium-smelting system and continuous magnesium-smelting technique

The invention discloses a system of inductive heating continuous magnesium smelting and a continuous magnesium smelting technique. The system comprises a continuous feeding device, an inductive heating reaction chamber, a magnesium steam condensing device and a continuous discharging device; wherein the feeding device consists of a feeding housing and a spiral feeding mechanism, the reaction chamber comprises an inductive heating winding, a heating element, a clapboard with holes and a slag cooling device, the condensing device consists of a mesh clapboard, a dust deposition chamber, the magnesium steam condensing chamber, the continuous discharging device comprises spiral slag discharging mechanism and slag housing. The continuous magnesium smelting technique consists of the processes of the continuous feeding of reacting burden into the reaction chamber, the continuous condensation of the magnesium steam and the discharge of liquid magnesium, and also comprises steps of the continuous feeding of reacting slag into the slag housing and slag discharging. The invention has high heat energy utilization rate, and can realize the low cost continuous production of the metal magnesium.

Owner:CENT SOUTH UNIV

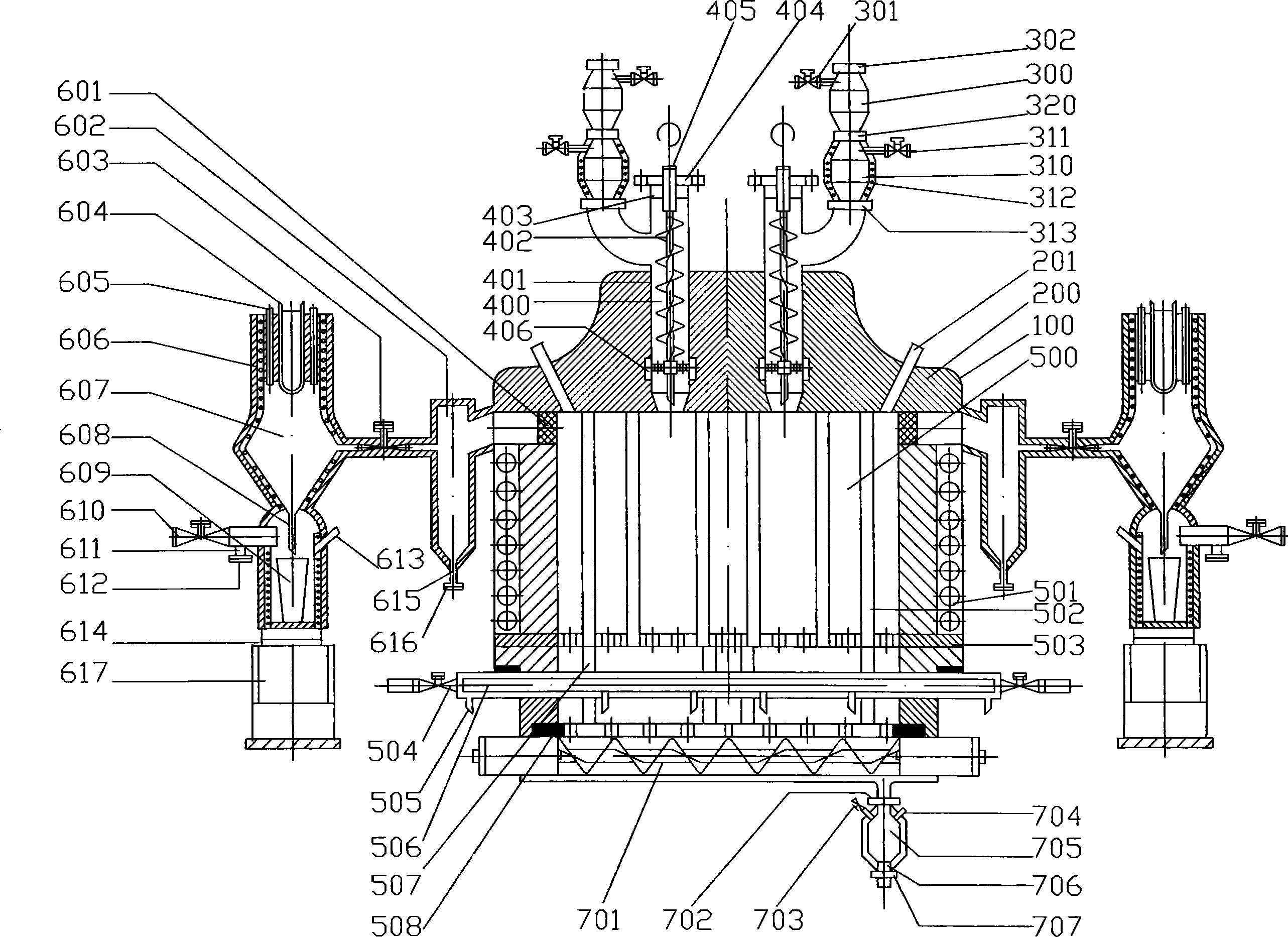

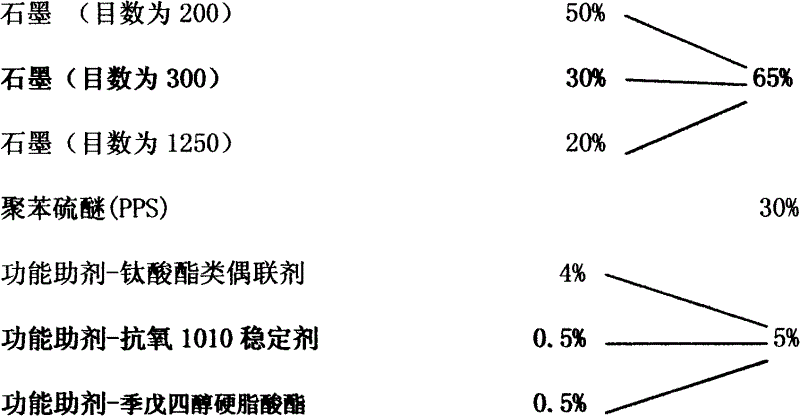

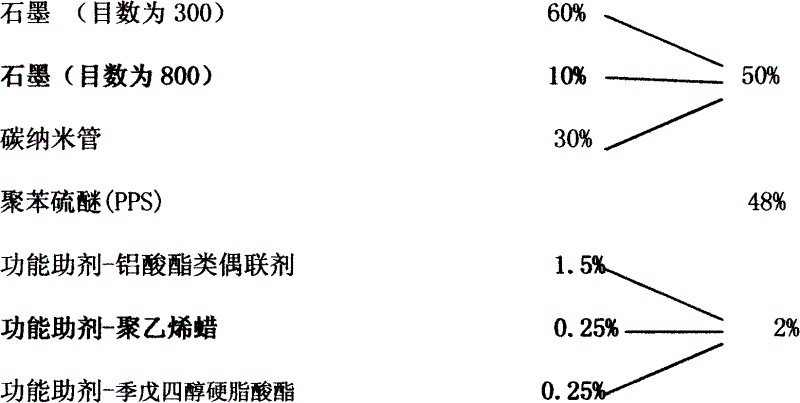

Preparation method of high-heat-conduction thermal-plasticizing inorganic substance composition and heat-dissipation part manufactured by method

ActiveCN102604219AImprove thermal conductivityLow injection molding processabilitySemiconductor devicesWork performanceElectron

The invention discloses a preparation method of a high-heat-conduction thermal-plasticizing inorganic substance composition and a heat-dissipation part manufactured by the method. The high-heat-conduction thermal-plasticizing inorganic substance composition is prepared by a component A, a component B and a component C, wherein the component A consists of 51wt%-88wt% of one or more inorganic substances with high heat conduction performance, the component B consists of 10wt% to 38wt% of one or more plastics with good processing properties, and the component C consists of 2wt% to 20wt% of a function additive. The preparation method comprises the following steps that: firstly, the configured component A and the configured component B are dried; secondly, the dried components A, B and C are mixed or internally mixed and then are preprocessed to manufacture raw materials; the manufactured raw materials are fed into an extruder, and fibrous heat-conduction inorganic substances are added from a side feeding part to perform modified processing and then are extruded into strips through a multiple-hole die; and fourthly, the materials extruded into strips are subjected to die-surface sized dicing or brace cooling sized dicing, thereby manufacturing the high-heat-conduction thermal-plasticizing inorganic substance composition. According to the invention, the normal service life and work performance of a chip of an electronic product are ensured, and the production cost is reduced.

Owner:东莞市兆科电子材料科技有限公司

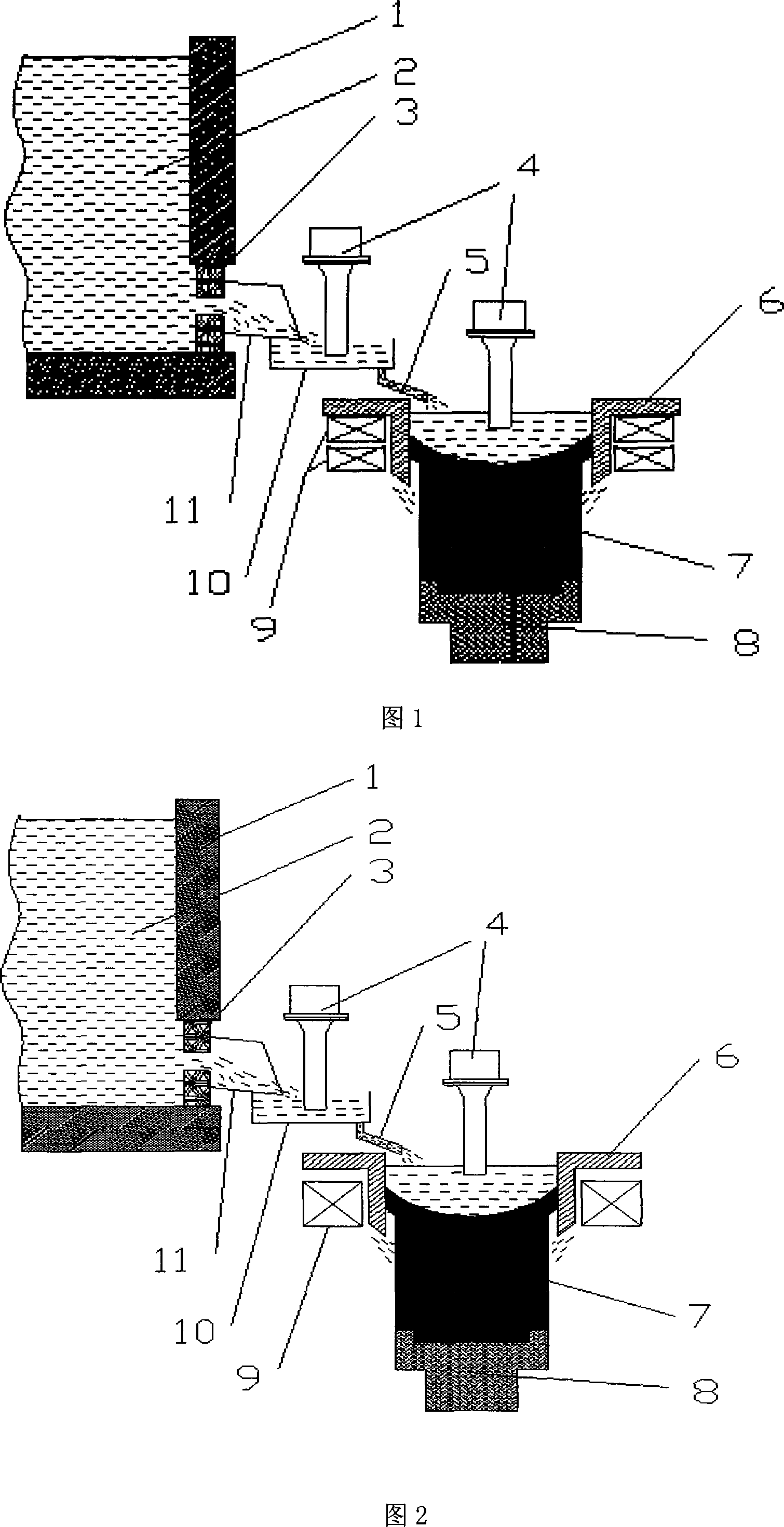

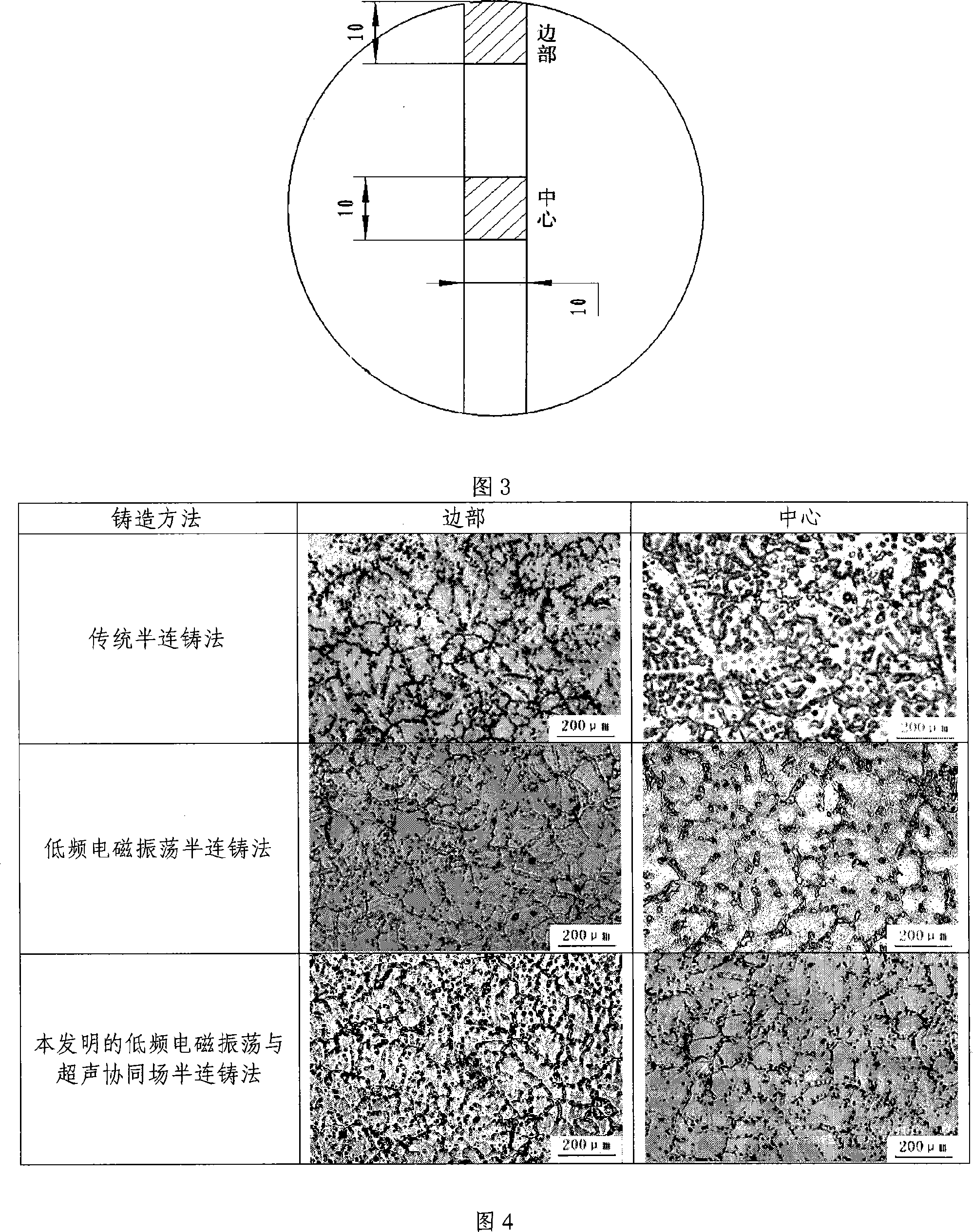

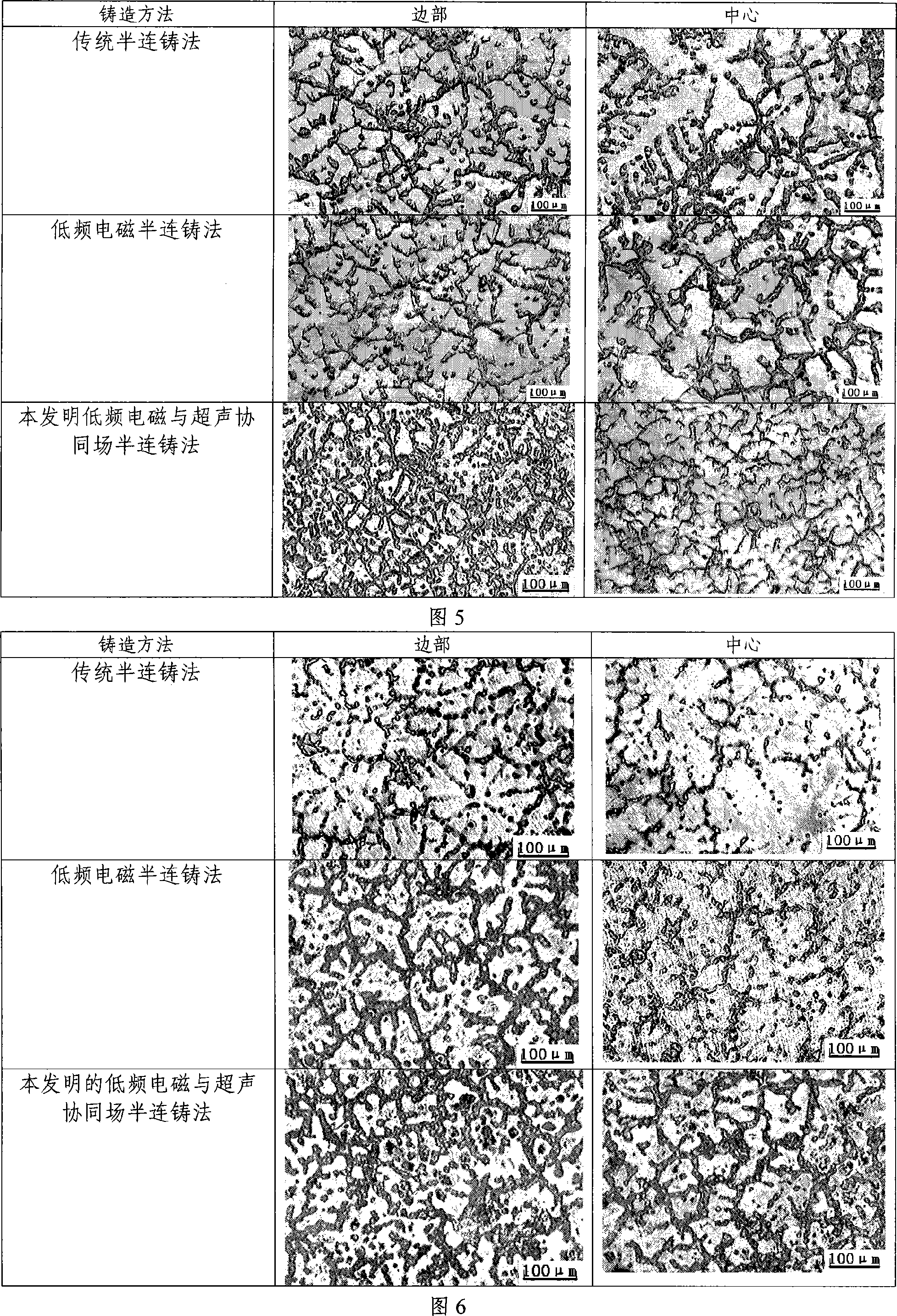

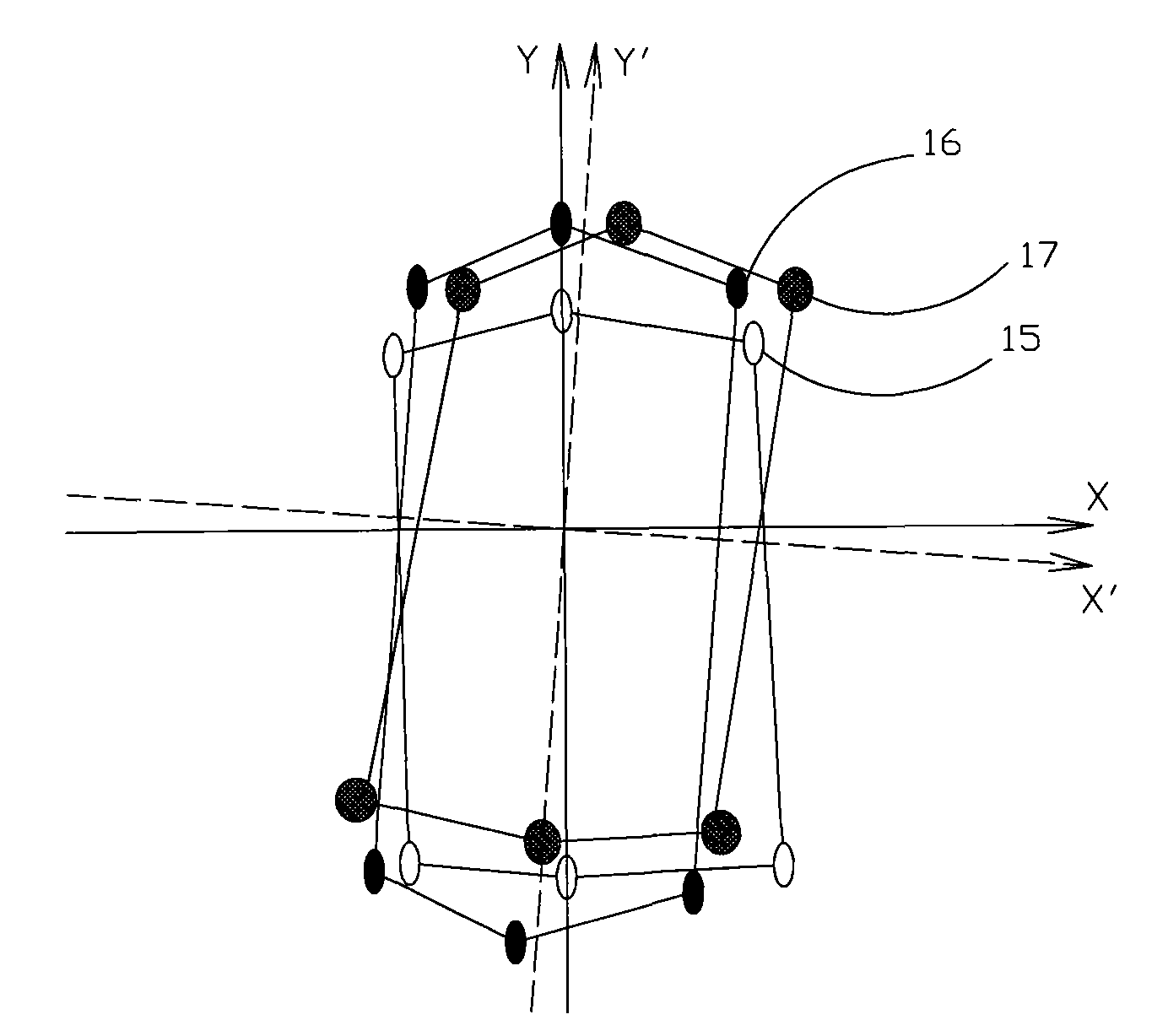

Vertical semi-continuous light alloy ingot casting process and apparatus with cooperation of power ultrasound wave and low frequency electromagnetic wave

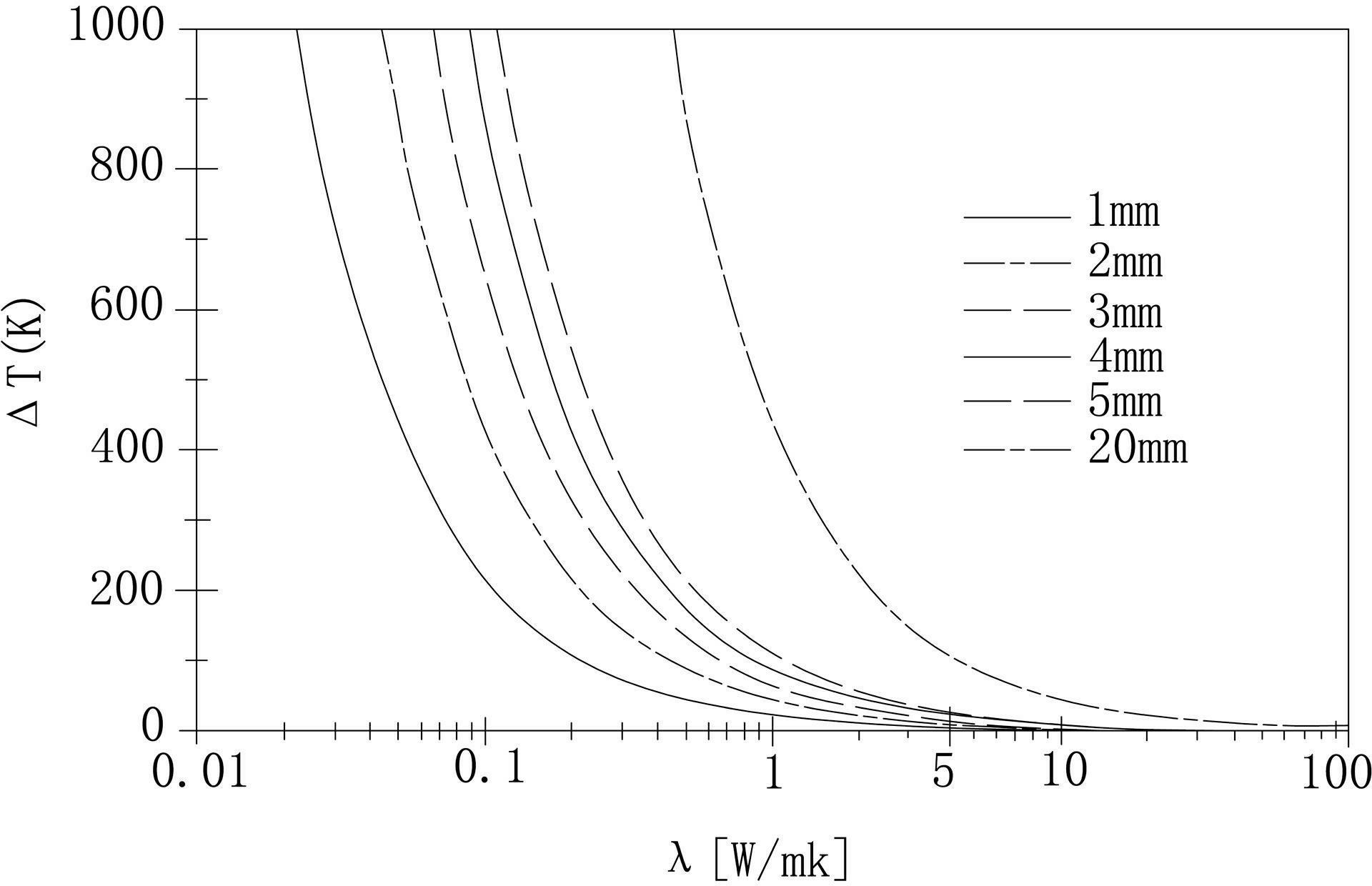

InactiveCN101020229AReduced lateral temperature gradientImprove uniformityElectromagnetic fieldIngot casting

The present invention is vertical semi-continuous light alloy casting process and apparatus with cooperation of power ultrasonic field and low frequency electromagnetic field. During casting, one low frequency electromagnetic field acting on the surface of metal molt and one power ultrasonic field acting on the crystallizer axis part are applied simultaneously. The present invention can reduce the transverse temperature gradient in casting blank solidification, alter liquid hole shape, raise the homogeneity of the casting blank and raise casting blank quality.

Owner:NORTHEASTERN UNIV

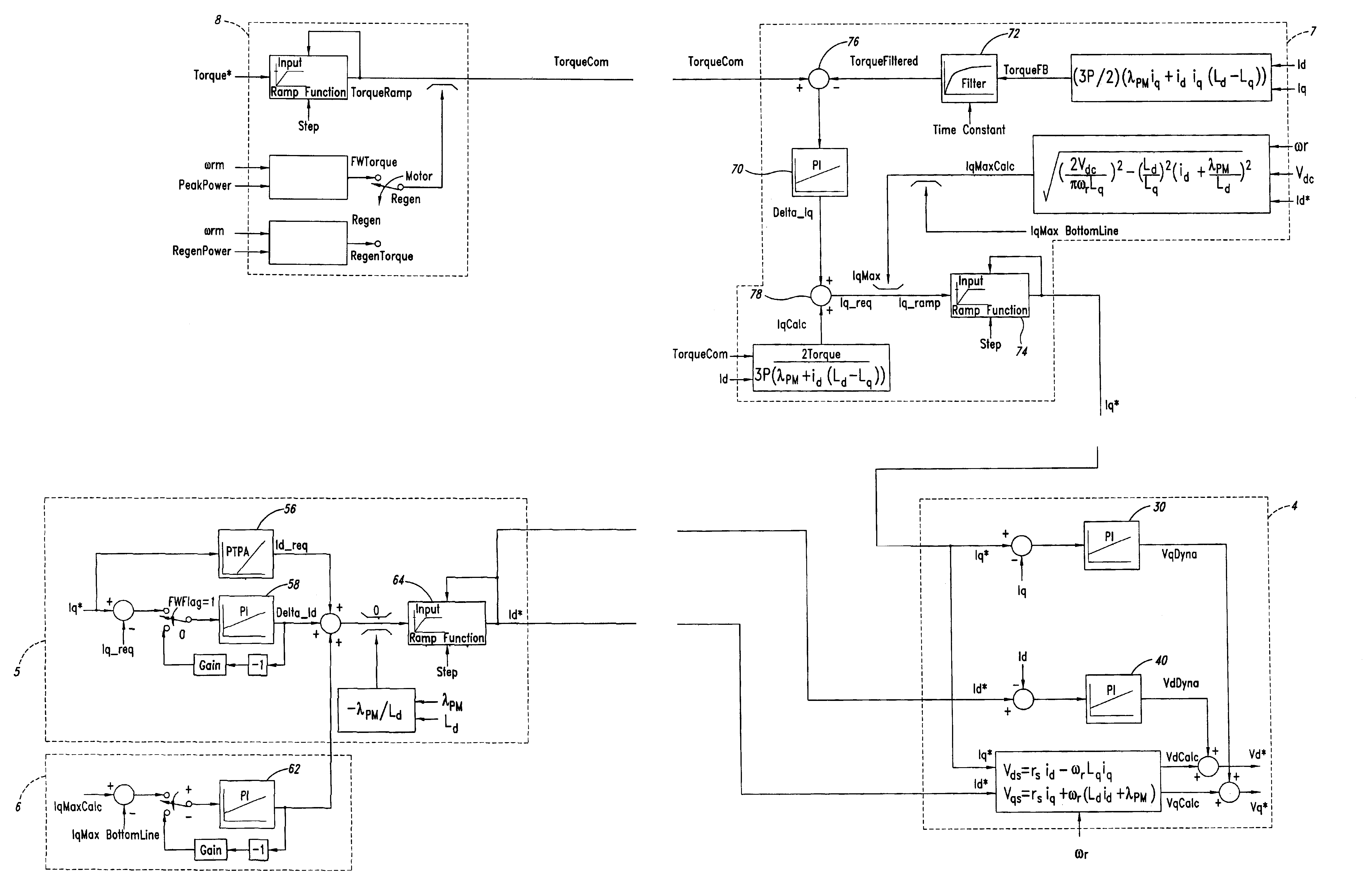

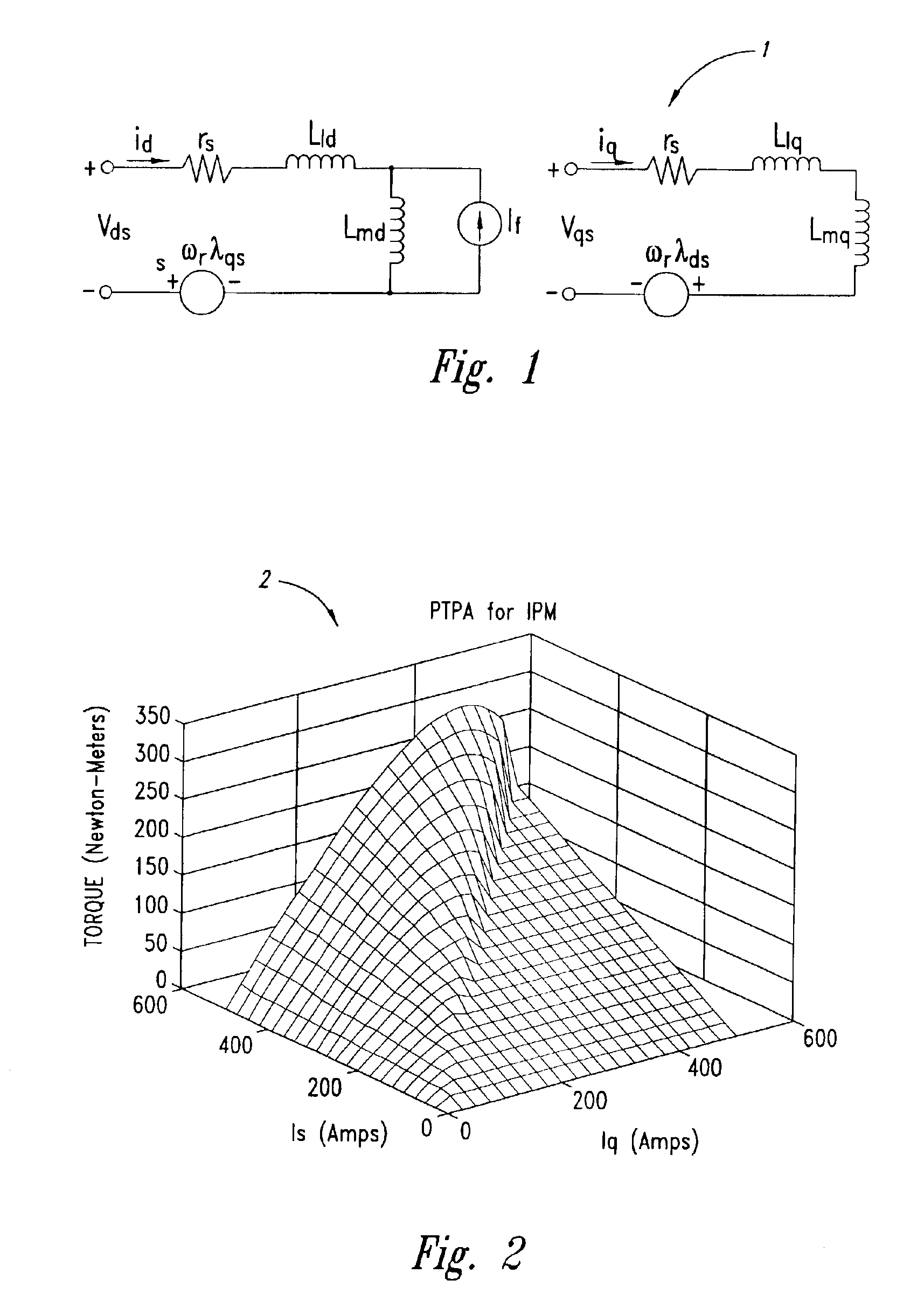

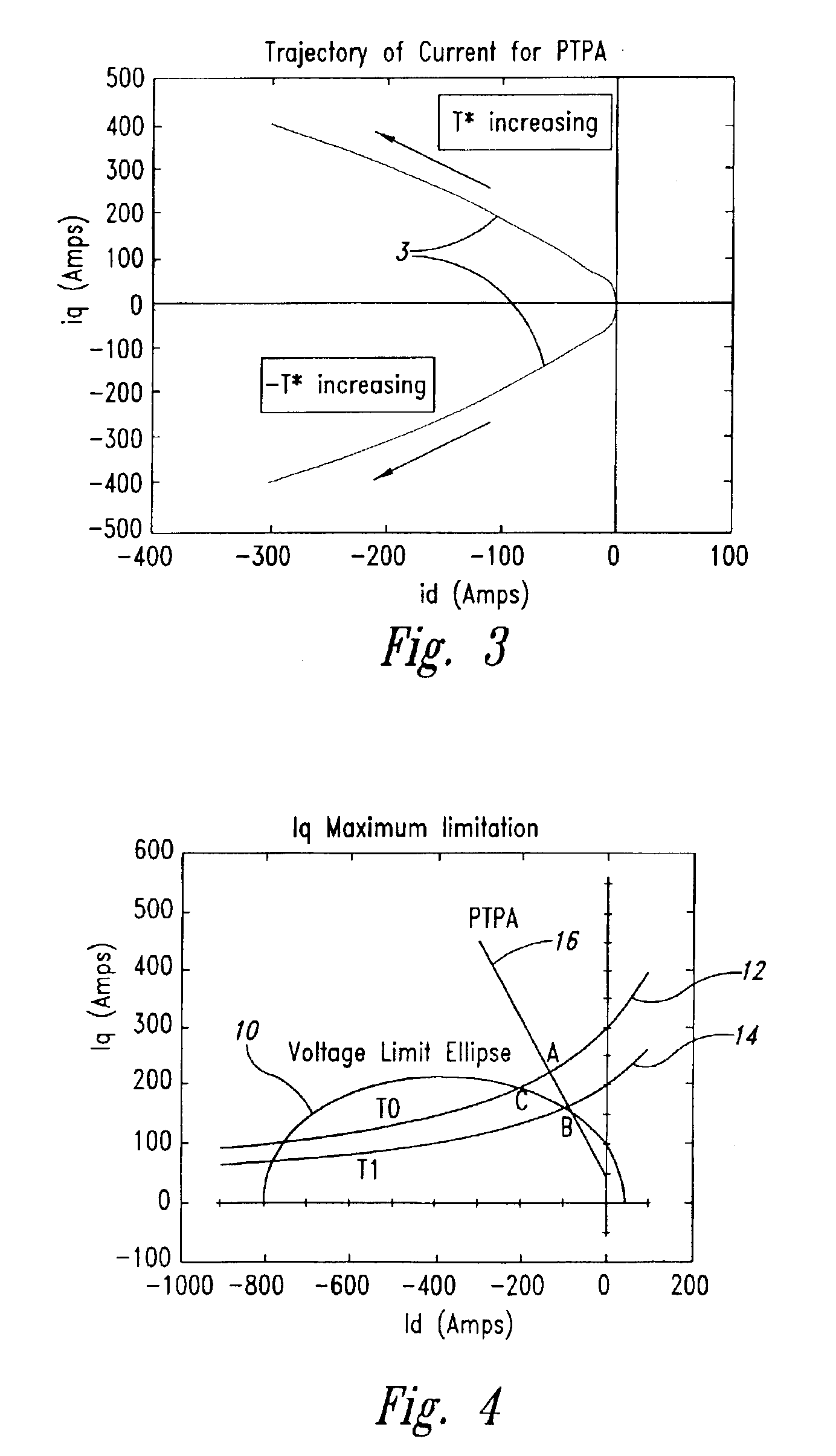

Method and apparatus for motor control

ActiveUS6936991B2Exceeds capabilityImprove stabilityMotor/generator/converter stoppersAC motor controlMaximum torqueCurrent limiting

A closed-loop permanent magnet motor control method and system optimally partitions torque and flux-weakening currents to produce a desired torque without exceeding the capability of the DC source. A maximum limit for allowable torque current and a minimum threshold for the maximum torque current are determined, and the flux current is varied based at least in part on whether the maximum torque current limit is above or below the minimum threshold while operating in a flux-weakening region to compensate for the variability of the DC source voltage.

Owner:VITESCO TECH USA LLC

New material for reducing LED junction temperature and preparation method thereof

InactiveCN102617927AEasy to passEnhanced transfer processPoint-like light sourceLighting heating/cooling arrangementsJunction temperatureInjection moulding

The invention relates to an inorganic material with high heat transfer and radiation characteristics in the technical field of LED (light-emitting diode) heat radiation. The technical scheme is as follows: a new material for reducing LED junction temperature comprises the following components in percent by weight: 50-90% of one or more inorganic material components A with high heat transfer and radiation characteristics, 5-48% of one or more plastic components B, and 2-20% of functional auxiliary agent component C. The preparing process of the new material for reducing the LED junction temperature comprises the following working steps: (1) heating and drying main materials; (2) respectively mixing organic materials and inorganic materials, and then metering and adding according to a proportion in sequence or adding after full mixing, banbury compounding, plastication and adhesion; (3) uniformly plasticizing and dispersing by a screw extruder; (4) extruding by a porous mold head to obtain strips; (5) carrying out mold head hot pelleting or strip cold pelleting; and (6) carrying out injection molding.

Owner:许永信

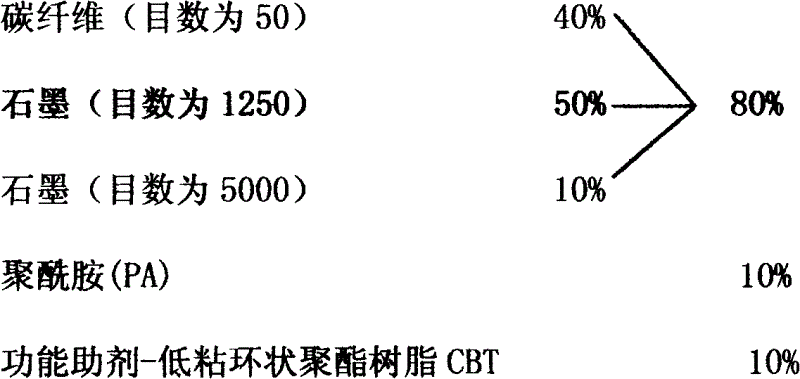

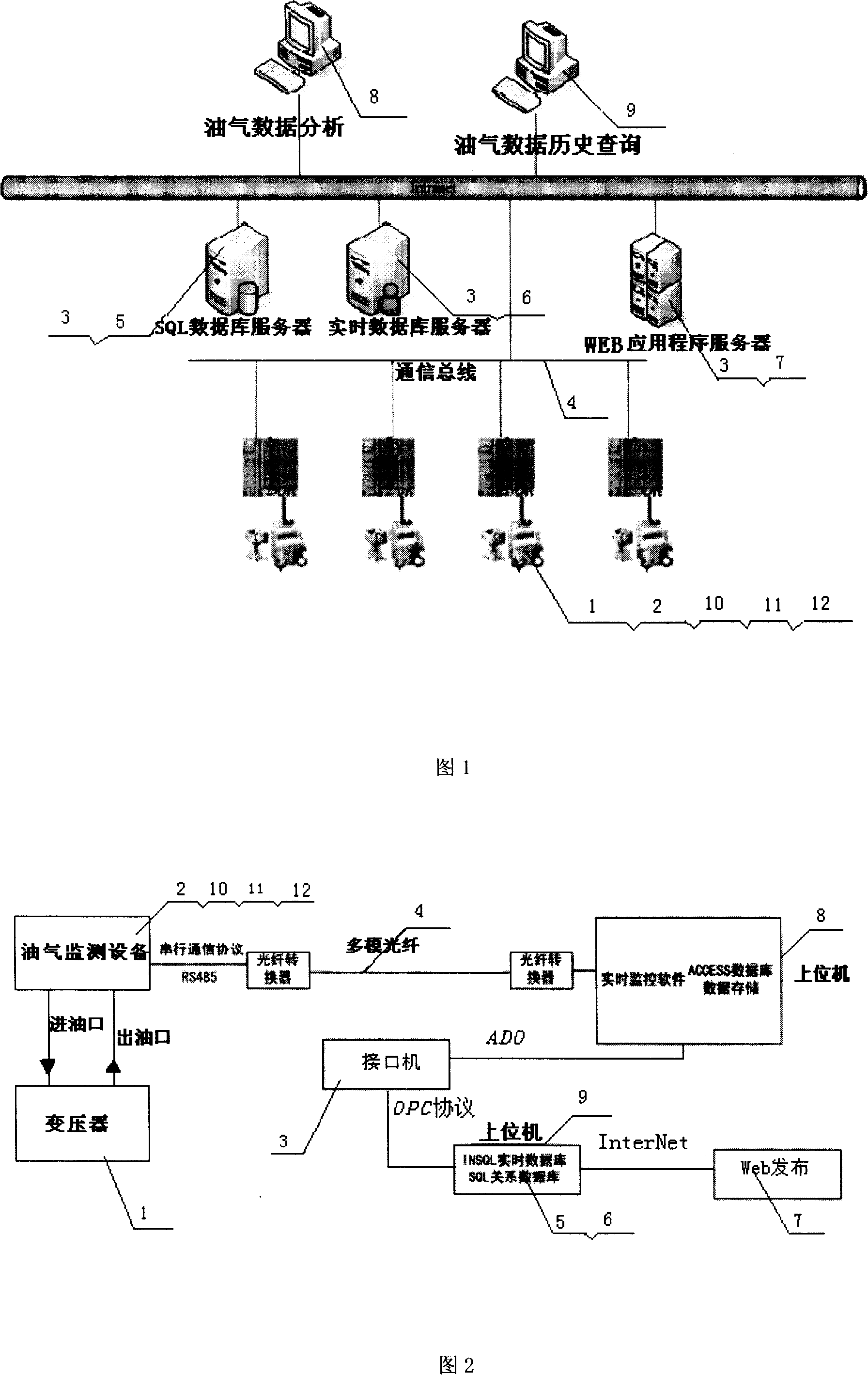

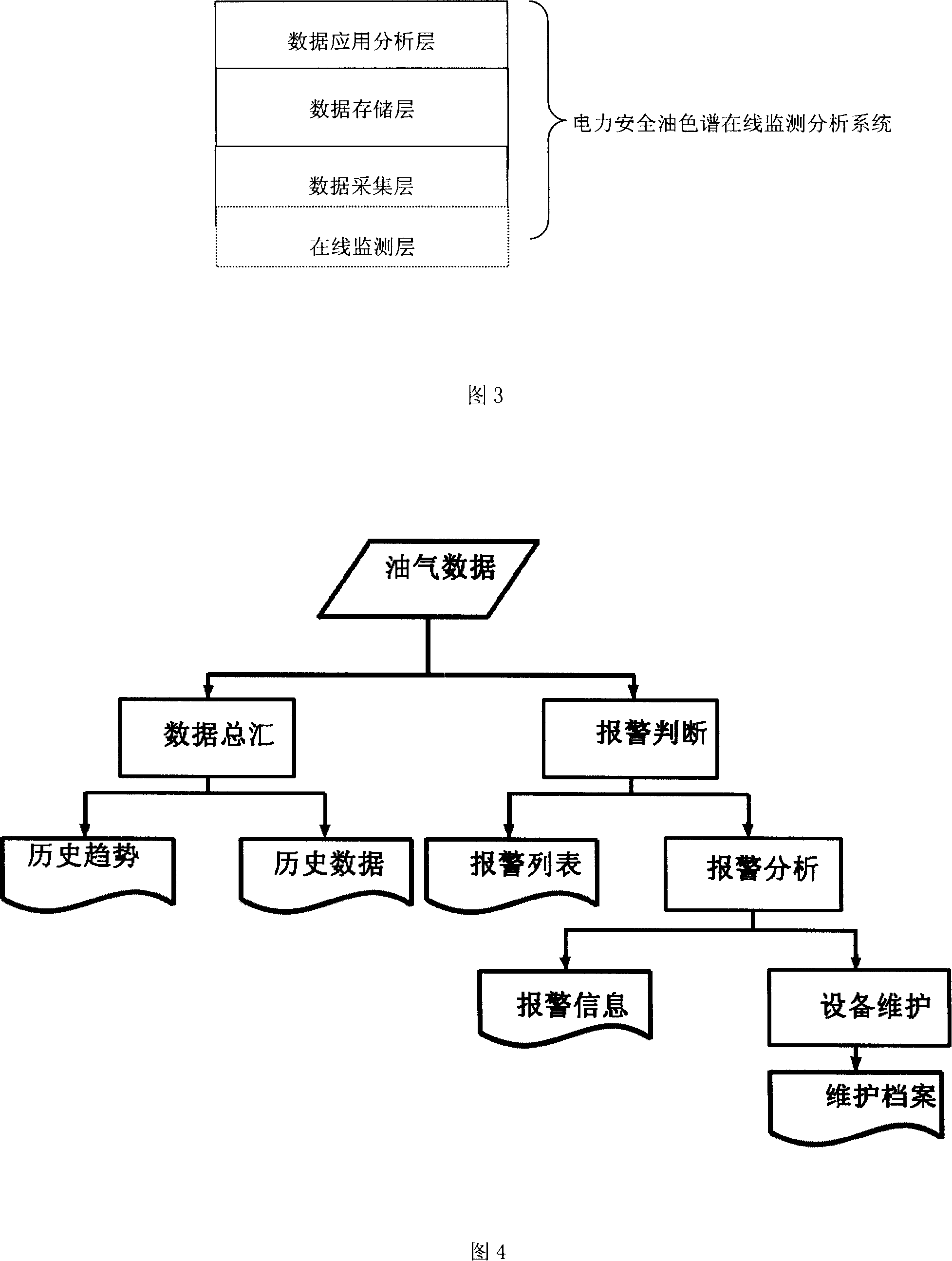

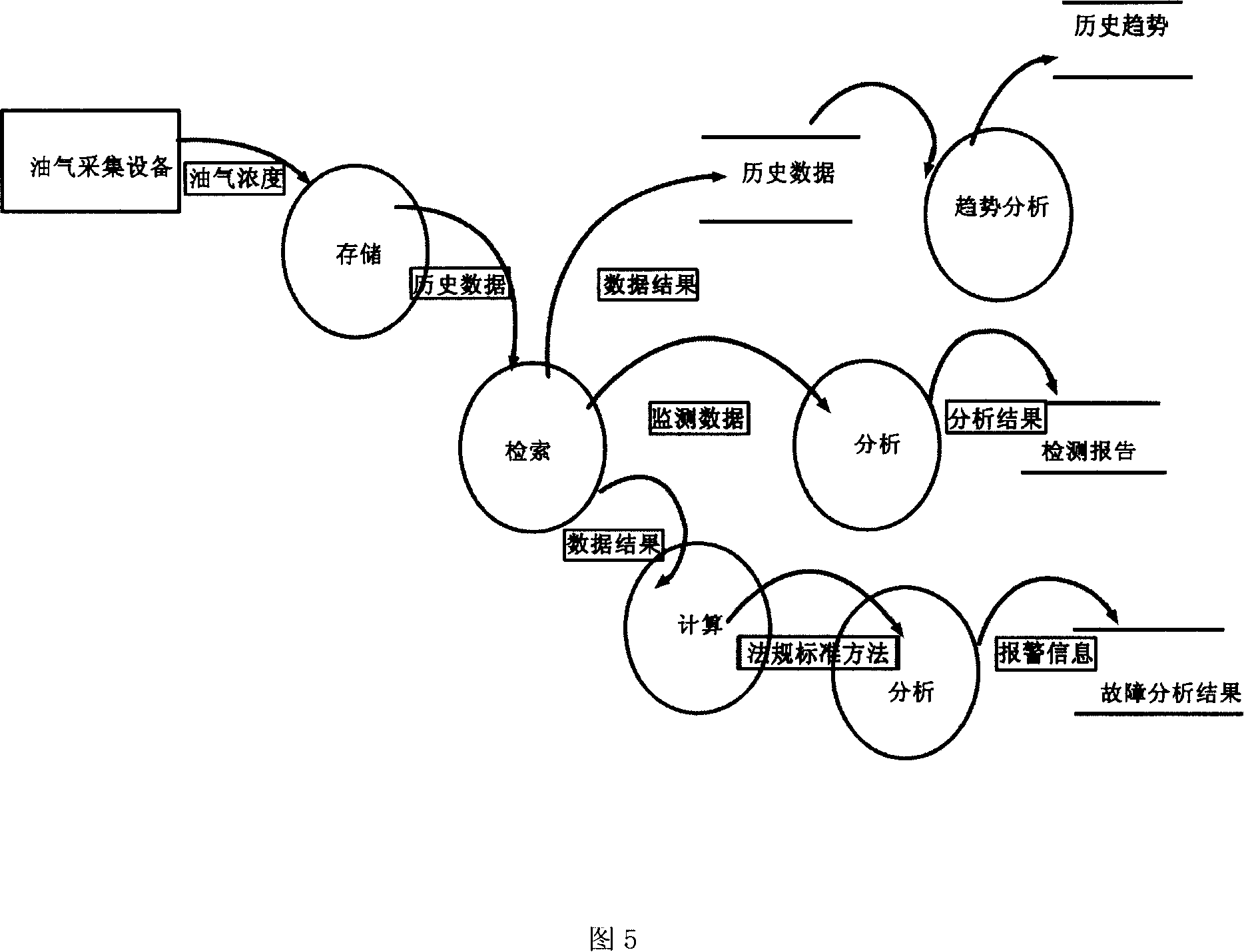

On-line detection method for transformer insulation oil temperature and characteristic gas in oil and oil chromatography

ActiveCN101122523AReal-time acquisitionRealize analysisComponent separationThermometers using electric/magnetic elementsAutomatic controlEnvironmental geology

The invention relates to a hydrocarbon detection system for a power supply system transformer of an electrolytic aluminum enterprise, in particular to an on-line detecting method for the insulation oil temperature of the transformer, characteristic gas in the oil and oil chromatogram. The analyze methods of the invention include an on-line monitoring layer, a data collecting layer, a data concentration layer and a data application analysis layer. The steps of the methods include a data monitoring step, a data collecting step, a data concentration step and a data application analysis step. The beneficial effects of the invention are that the data collection of the invention can realize the automatic collection and the protocol conversion of various data on the transformer operation site. The collected data are processed, treated, analyzed, stored and published by the data storing. An application system relative to the management of the transformer operation status is constructed by the data application analysis to supply an information platform for scientific organization, commandment, decision and monitoring production process. The invention is applied to the automatic control system of the electric power supply system.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

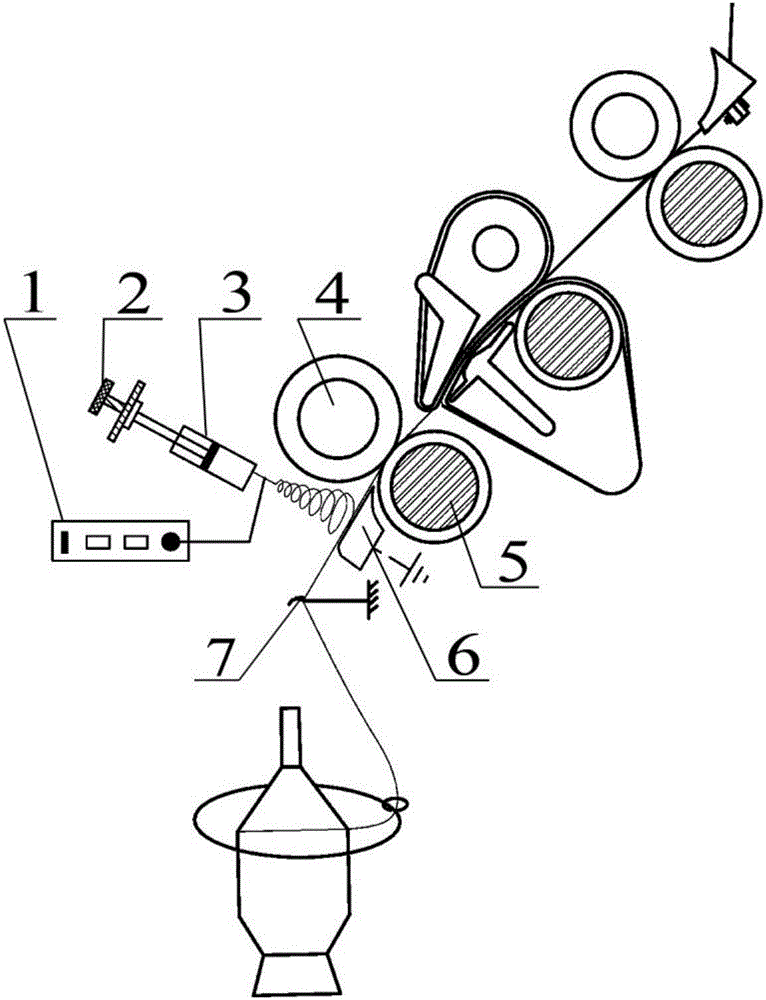

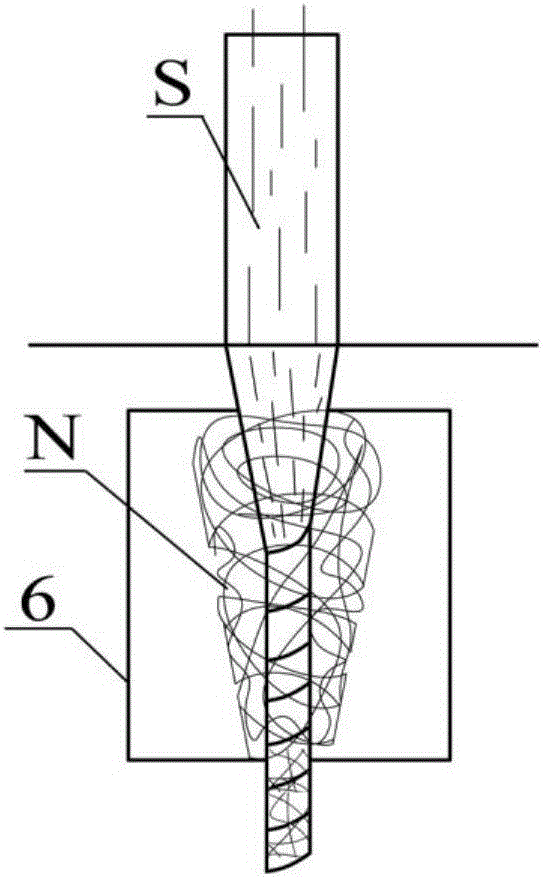

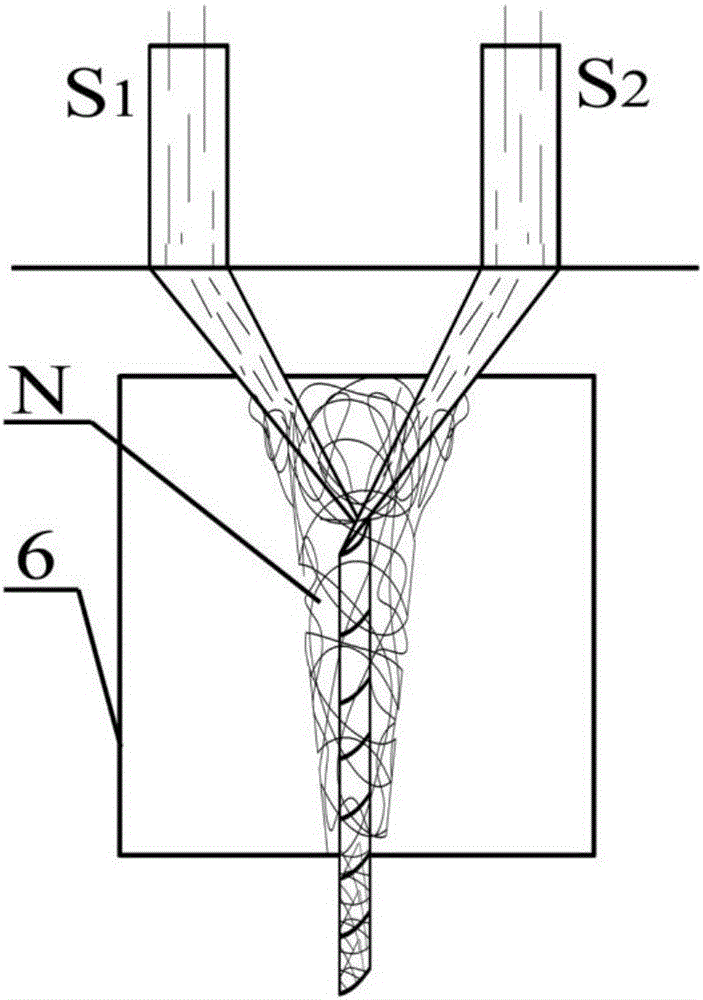

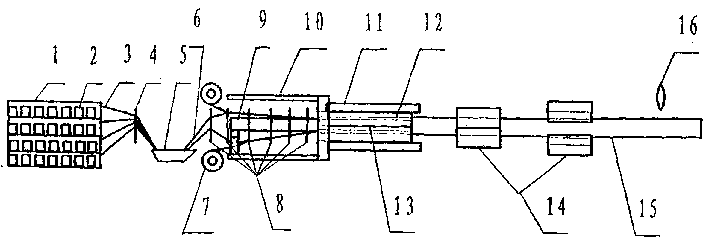

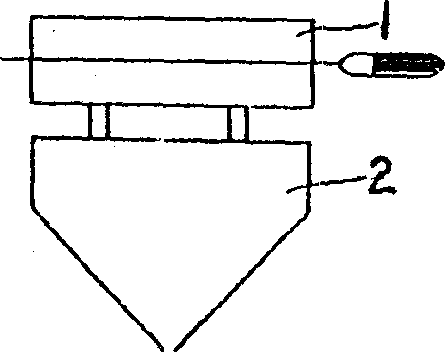

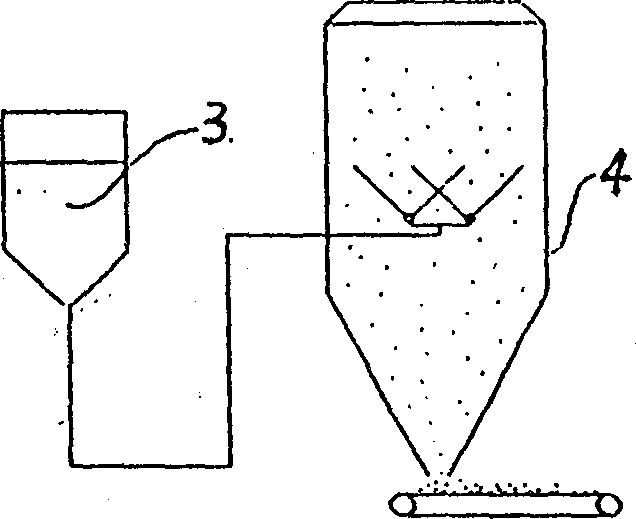

Nano electrostatic spinning and staple fiber ring spinning integrated yarn forming method

The invention relates to a nano electrostatic spinning and staple fiber ring spinning integrated yarn forming method, and belongs to the technical field of textile processing. The method comprises the following steps: arranging an electrostatic spinning apparatus between each yarn guide hook of a ring spinning frame and a front roller jaw formed by a front roller corresponding to the yarn guide hook and a front rubber roll, enabling a receiving surface of the electrostatic spinning apparatus to stay on a same plane with a public tangential surface of a front leather roll and the front roller at the front roller jaw, forming an electrostatic spinning area between an electrostatic spray head and a receiving surface of a receiving plate, and combining and twisting a nano fiber net spun out from the electrostatic spray head and staple fiber strands passing by the receiving surface of the receiving plate. According to the method, the electrostatic spinning and a conventional ring spinning are reasonably integrated, so that the high-speed successful production of nano fiber yarns is guaranteed, the naon fiber net effectively captures exposed fibers and improves the winding tightness, and the yarn forming structure and performance quality of the nano fiber wrapped blended yarns can be greatly improved. Equipment involved in the method is universal, and the operation and the use are convenient.

Owner:WUHAN TEXTILE UNIV

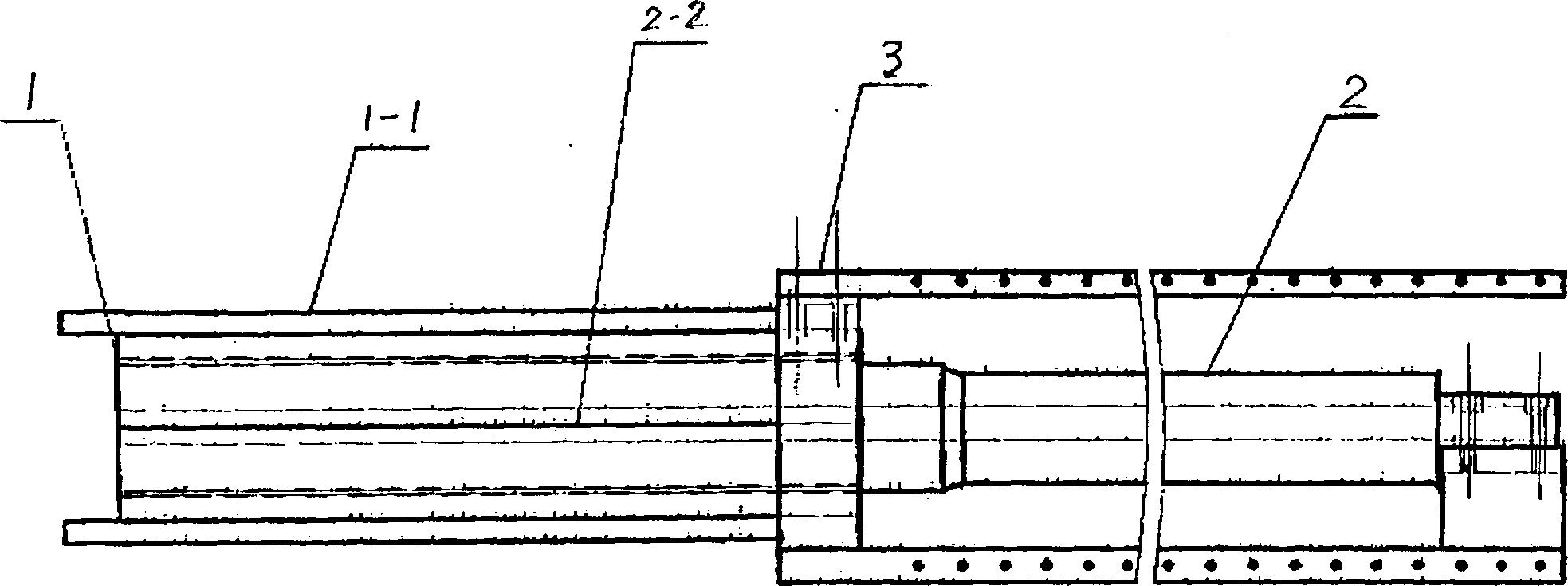

Technological method for pultrusion of glass fibre reinforced plastics pipe and die thereof

The present invention relates to a pultrusion process for making glass fibre reinforced plastics tube and its special-purpose die equipment. Said process includes the steps of soaking yarn, felt-yarncombination, preforming, solidfying and forming and tube-discharging and coaling. Its special-purpose die equipment includes a die cavity whose internal diameter is equal to the external diameter of formed glass fibre reinforced plastic tube, the periphery of said die cavity is equipped with heating device, a die core whose external diameter is equal to the internal diameter of formed glass fibrereinforced plastic tube is cover-mounted in the interior of die cavity, the centre of said die core is hoelow, and its interior is equipped with heating device. Said invention adopts common heating method in exterior and interior of said die cavity, so that the interior and exterior of glass fibre reinforced plastic tube are solidified well, and its surface is smooth.

Owner:柳惠平

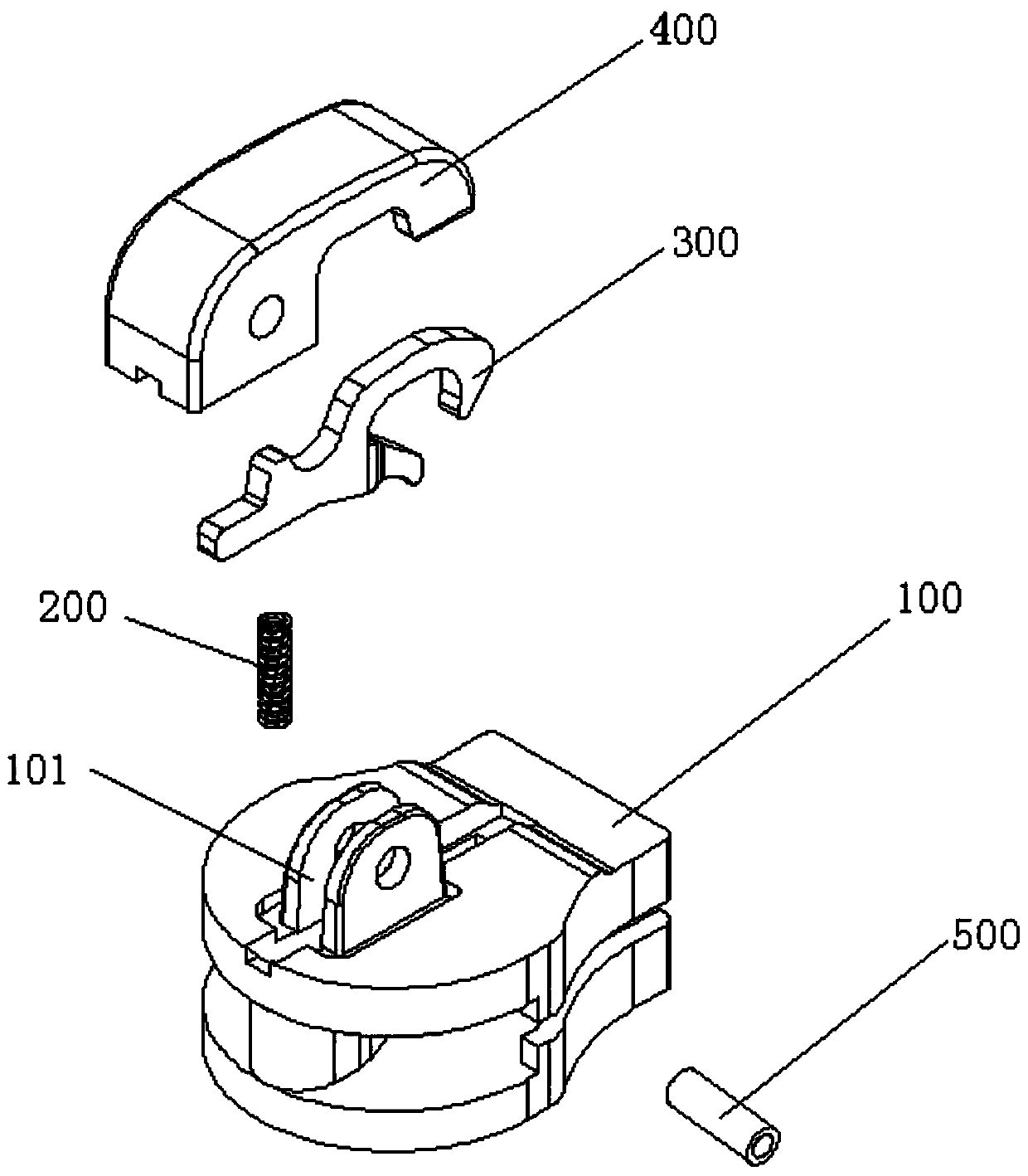

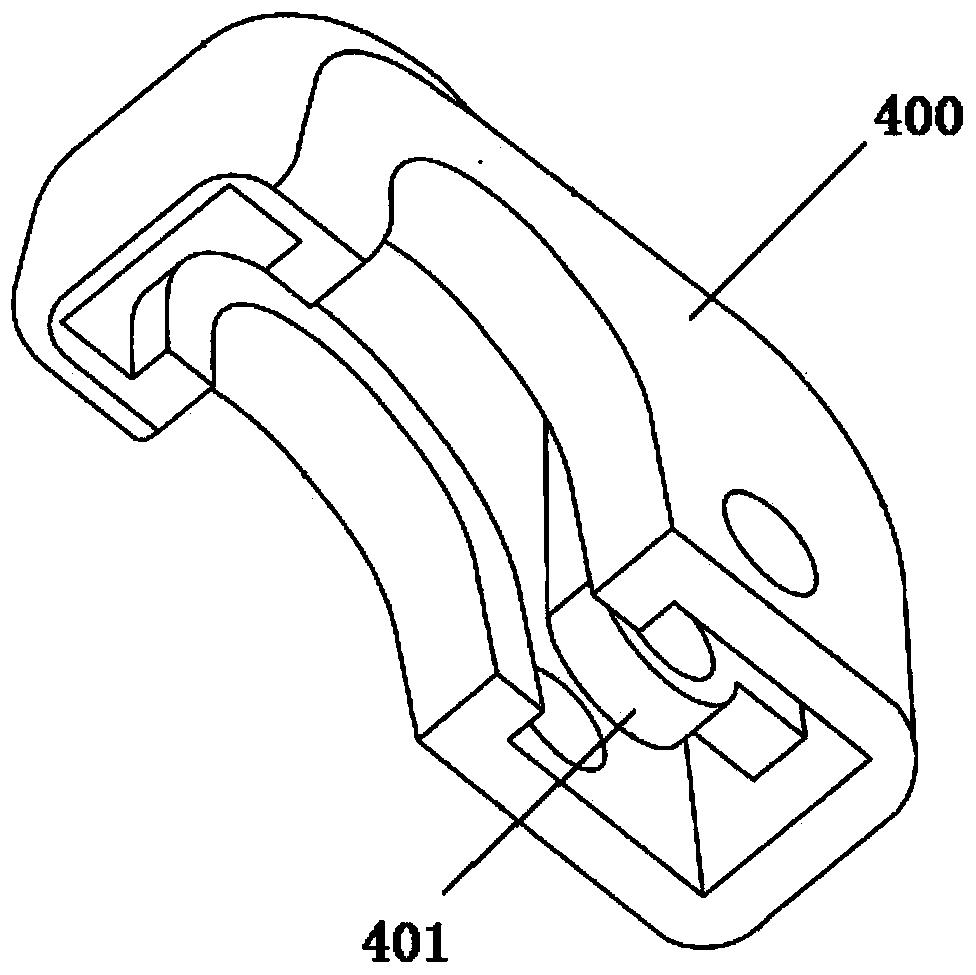

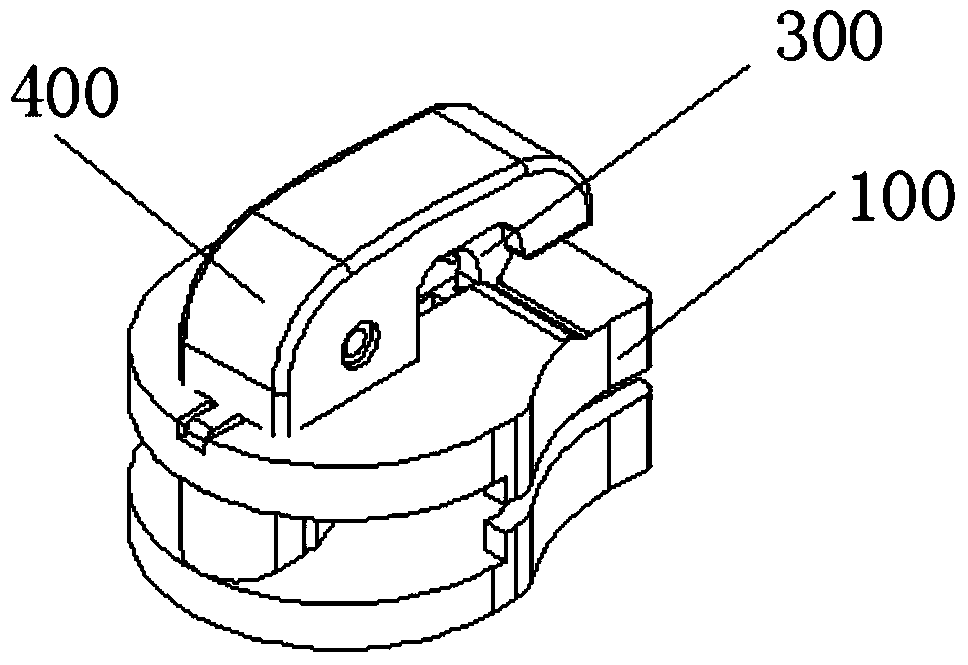

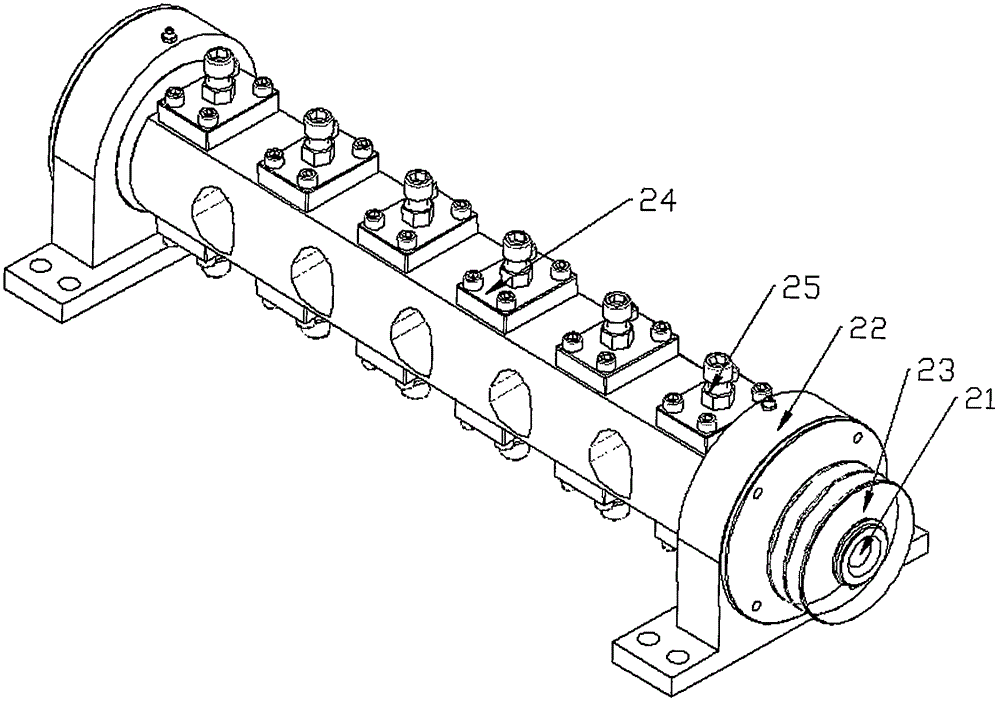

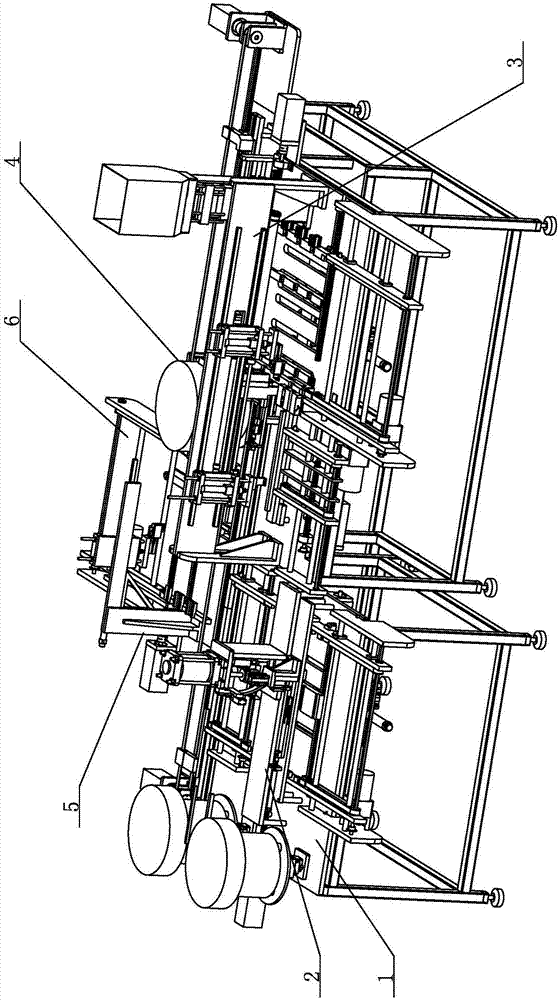

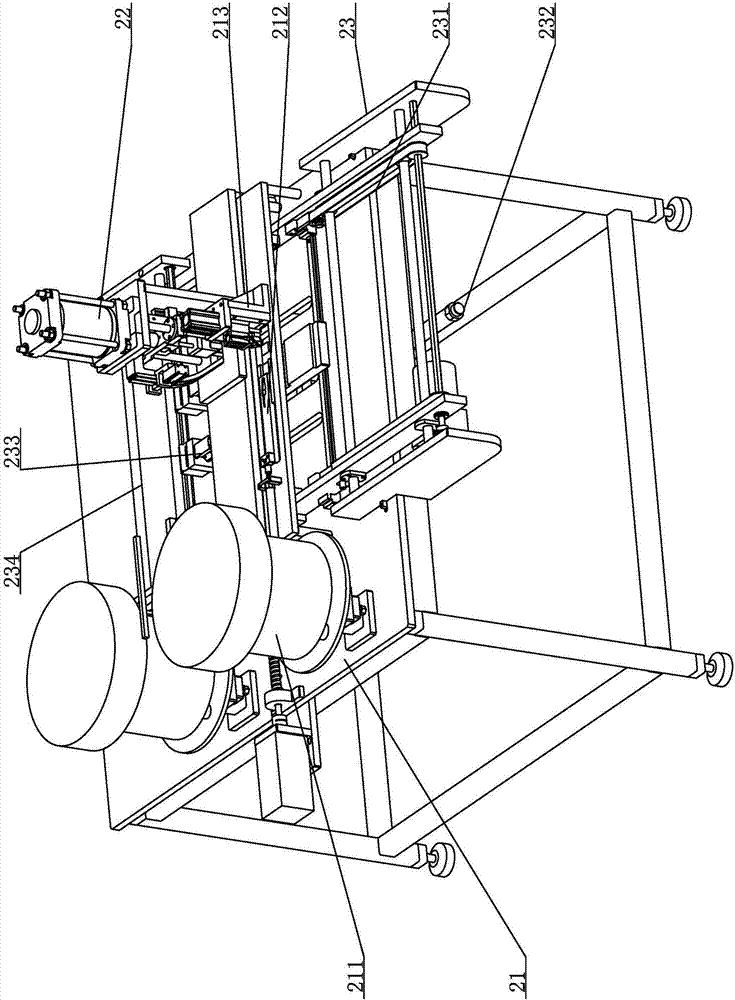

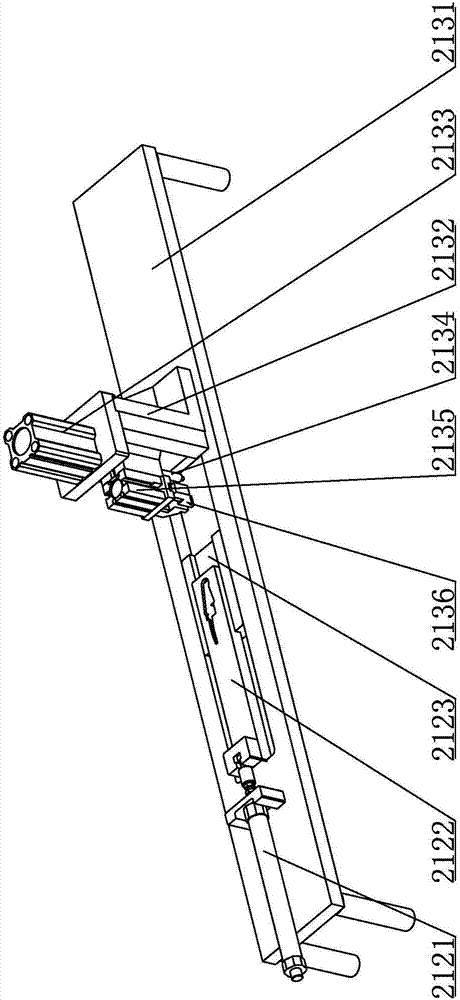

Automatic all-purpose zipper head assembly machine

ActiveCN103445407AGuaranteed smooth assemblyGuaranteed smooth productionSlide fastenersPunchingEngineering

The invention provides an automatic all-purpose zipper head assembly machine. The automatic all-purpose zipper head assembly machine comprises a machine base, wherein a power transmission device is arranged in the machine base; a rotary disc and a pressure disc are mounted above the machine base; the power transmission device not only enables the rotary disc to perform graduation intermittent rotation, but also enables the pressure disc to perform lifting movement; molds for placing a pull head are uniformly distributed on the periphery of the rotary disc; work station devices corresponding to the stop positions of the molds are fixed on the pressure disc or the table surface of the machine base; the work station devices include a feeding device, a detection device, a riveting device and a material returning device. The automatic all-purpose zipper head assembly machine is characterized by further comprising a burr removing device in front of the copper tube feeding device, and the burr removing device is formed by a cap cover pressing and fixing device mounted on the pressure disc and a punching device mounted on the table surface of the machine base. The automatic all-purpose zipper head assembly machine can automatically complete multi-wall pin penetrating all-purpose zipper head assembly, and is reliable in movement and high in production efficiency; in addition, the automatic all-purpose zipper head assembly machine is simple in structure and easy to debug and maintain, and lowers equipment cost.

Owner:FUJIAN ZIPPER SCI & TECH CO LTD

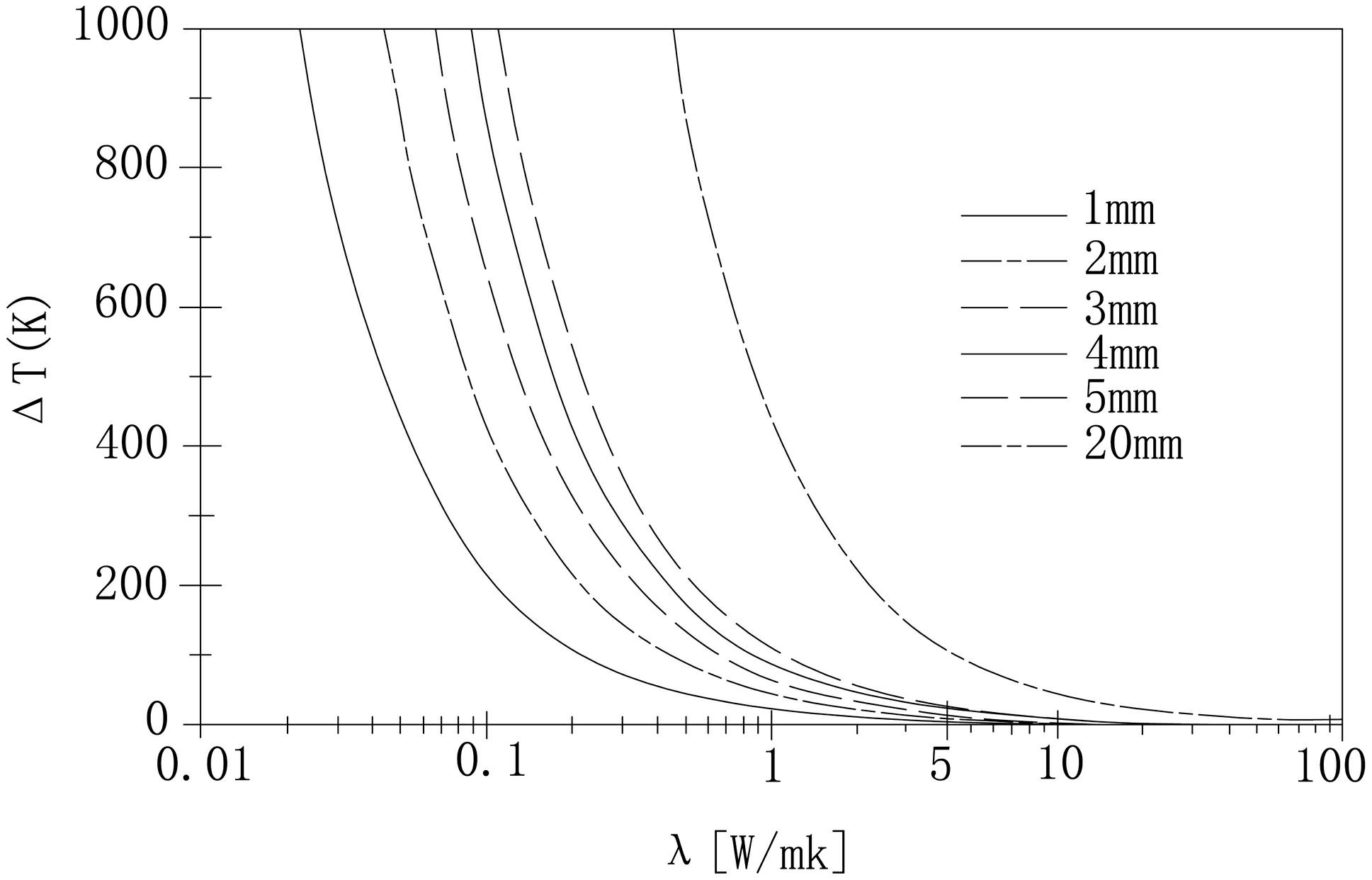

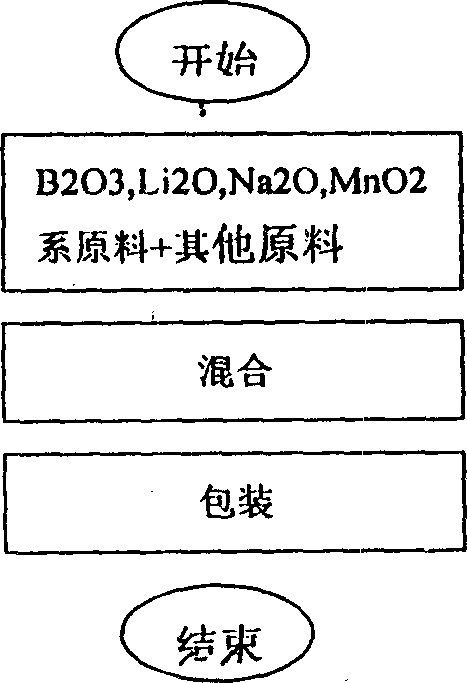

Fluorine free protecting slag for steelmaking and continuous casting and method for manufacturing same

A fruorine-free mold flux for the continuous casting of steel and method for producing the same relates to a mold flux for the continuous casting of new steel grade, which accord with the requirement of protecting natural environment. The characteristic is in that the mold flux contains the fellowing compositions and performance range: 23-40% SiO2, 20-4-% CaO, 0.5-10% MgO, 0.5-10% Al2O3, 0.5-10% MnO2, 2-15% Na2O, 5-15% B2O3, and 0.5-10% C; the melting point is 800-1200 DEG C, the viscosity is 0.2-5 pt, and the crystallizer rate is 0.1-30%. The advantages of the invention are in that the fruorine-free mold flux can alternatively act the role of the fluorine component, according with the continuous casting conditions (steel grade, casting speed, and the like). In this way, uniform fusing characteristic, fluidity and viscosity are improved or promoted, and the mold flux is contributed to the improvement of the operational stability and the product quality with the smooth workability in the continuous casting process by singly or in combination use.

Owner:SANYI METALLURGICAL MATERIAL

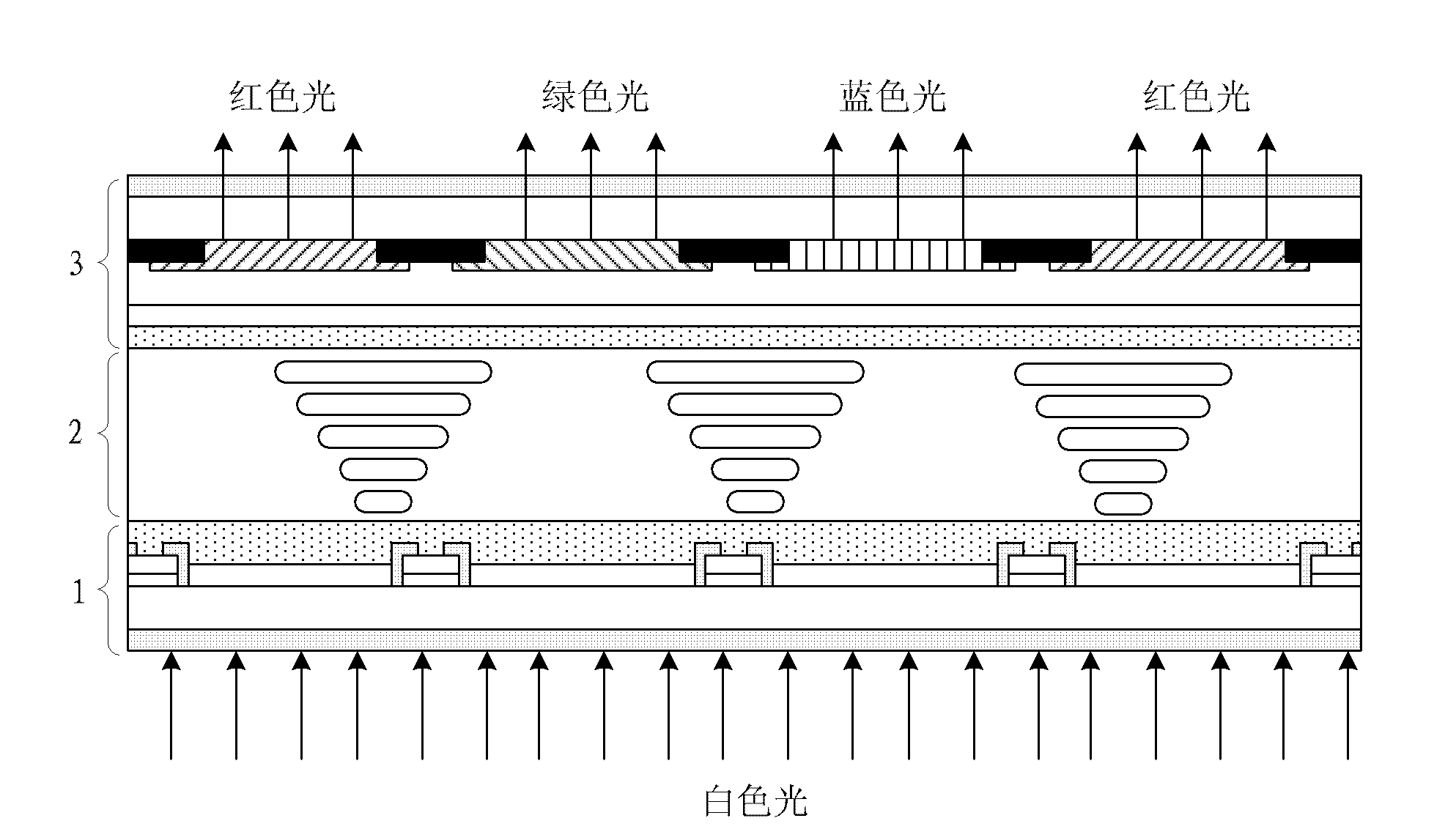

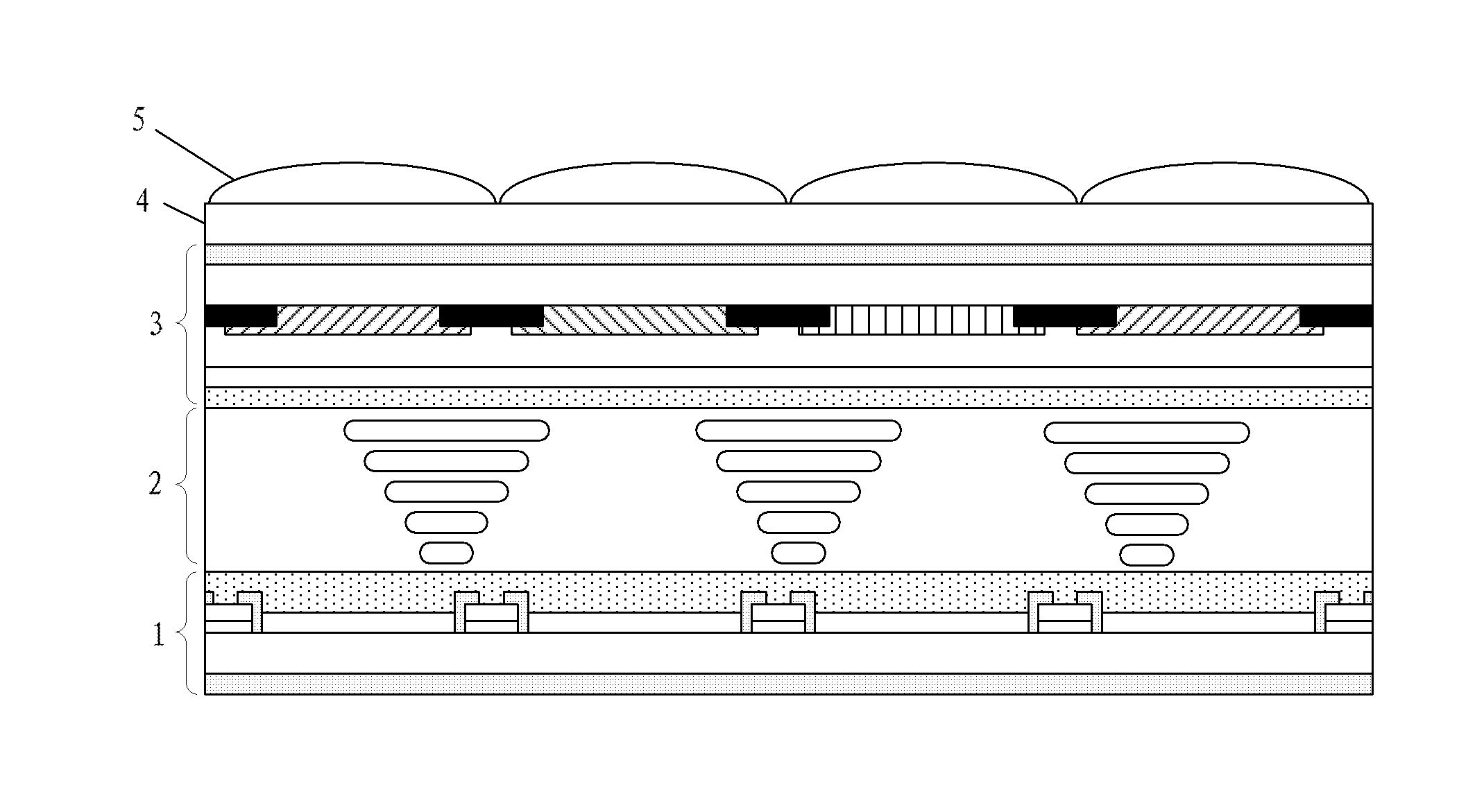

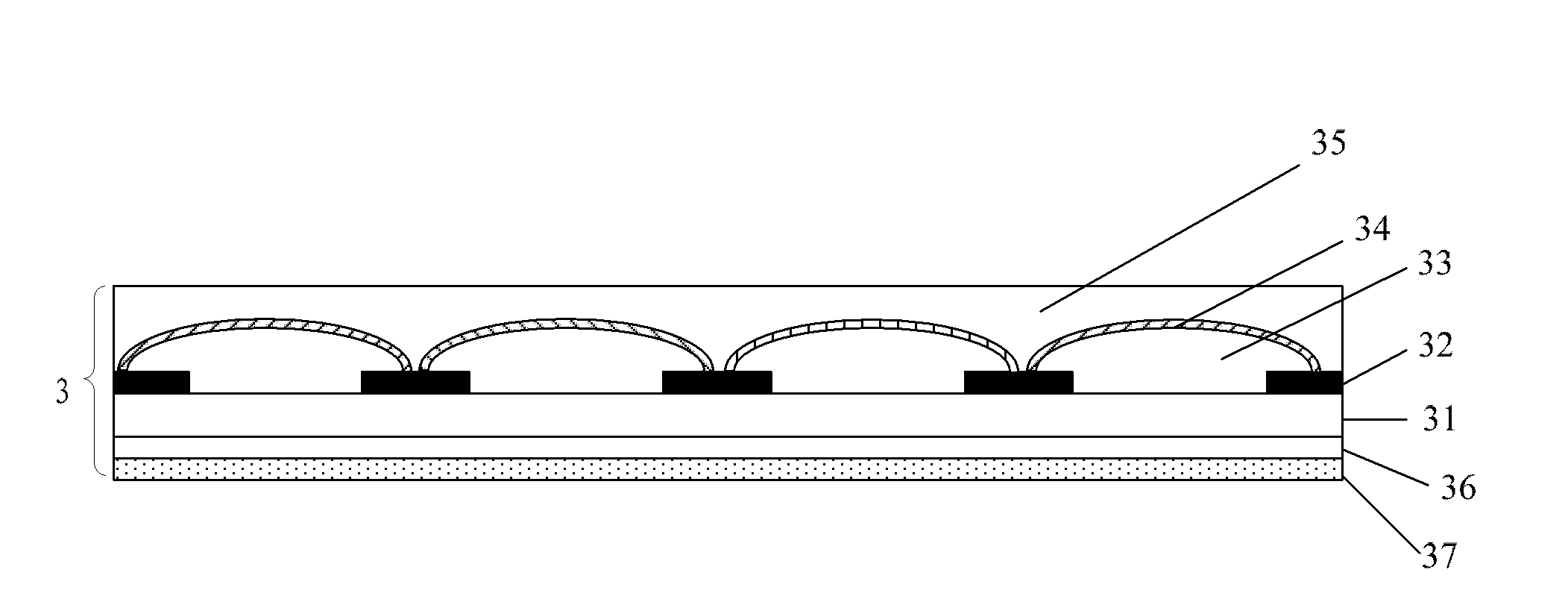

Display device, liquid crystal panel, color filter and manufacturing method thereof

InactiveCN102289016ASmooth productionImprove product yieldOptical filtersNon-linear opticsColor filter arrayLiquid crystal

The invention provides a display device, a liquid crystal panel, a color filter and a manufacturing method thereof. The color filter includes: a substrate; a black matrix formed on one side of the substrate; and a colored lenticular lens formed between the black matrices. By directly forming a lenticular lens in the color filter, the present invention can integrate the production process of naked-eye 3D display products, reduce process difficulty, and improve product quality.

Owner:SHENZHEN SUPER PERFECT OPTICS LTD

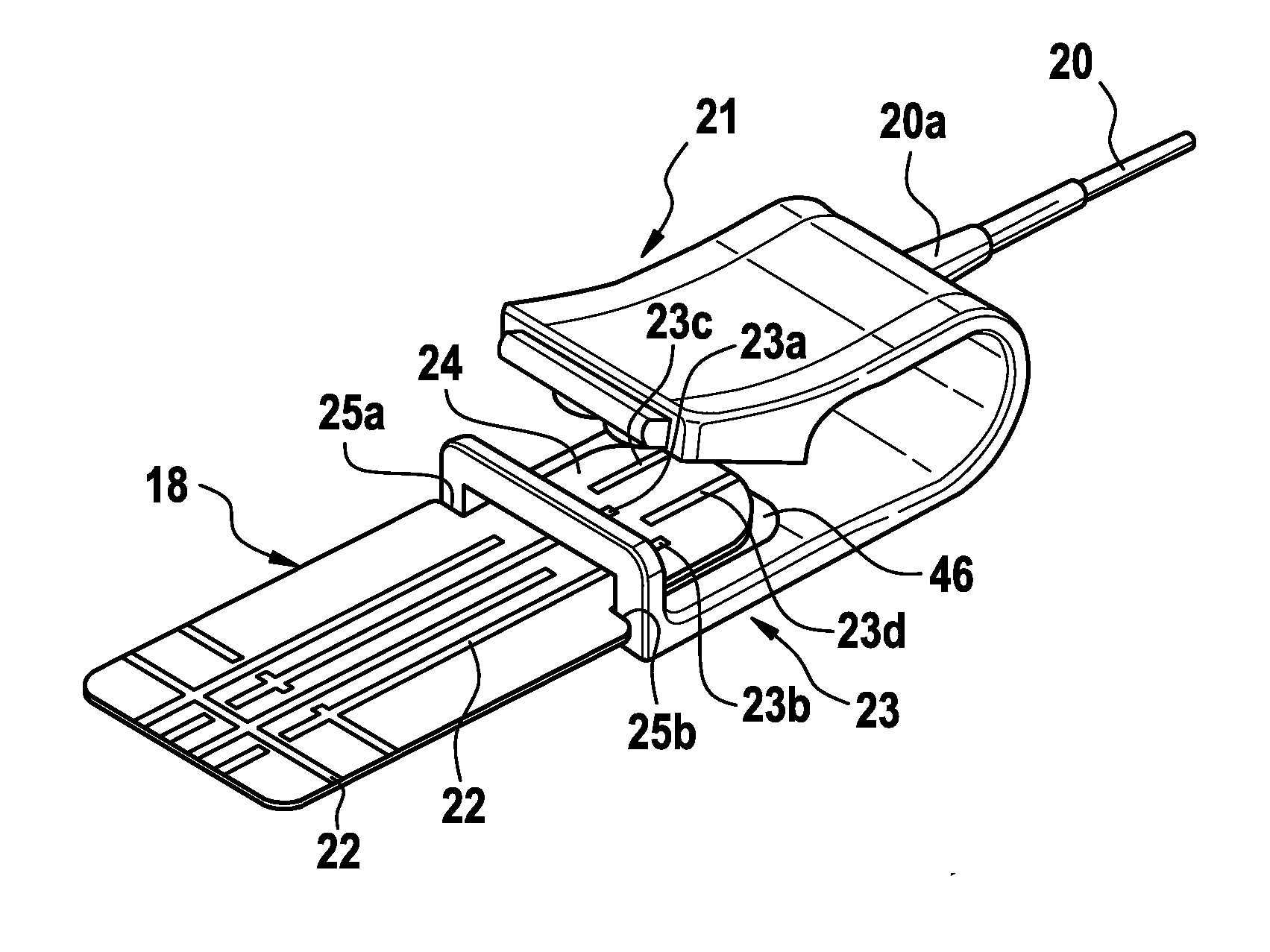

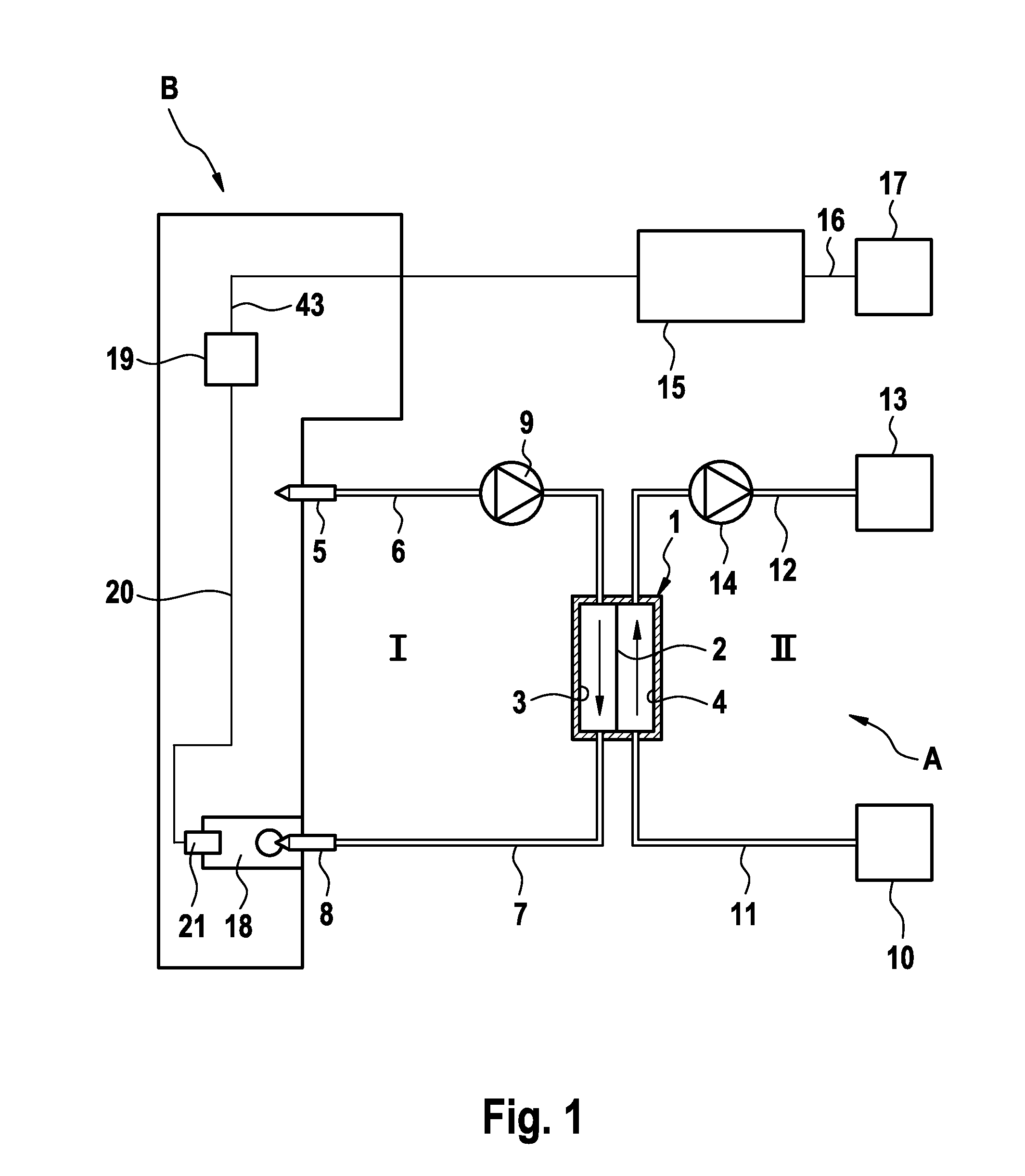

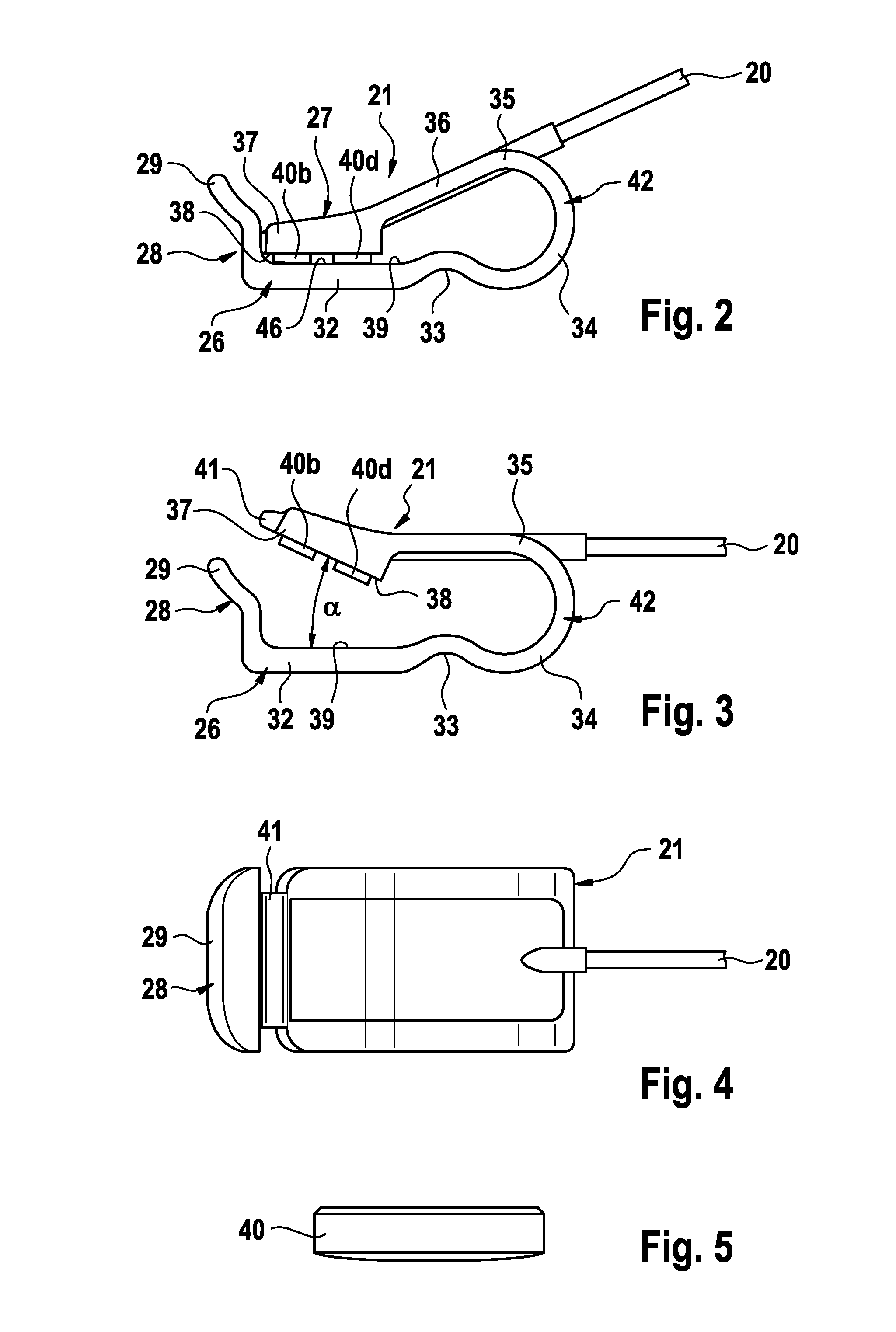

Terminal clamp for a moisture sensor for monitoring a vascular access

ActiveUS20130072870A1Produced cost-effectivelyReliable electrical contactDialysis systemsMedical devicesMoisture sensorBiomedical engineering

A terminal clamp for a moisture sensor to be placed on a patient's skin in order to monitor a vascular access to a patient includes first, lower and second, upper legs for clamped fixing of terminal tab of moisture sensor, rear end pieces of the legs being connected. The terminal clamp includes terminal contacts for contacting electrical contact points of terminal tab, and a guide piece having a slot-shaped cutout for receiving terminal tab. Slot-shaped cutout of guide piece is bounded laterally by two stop elements so that terminal tab is held in terminal clamp in a predetermined position, in which terminal contacts of terminal clamp contact the electrical contact points of terminal tab. Upper leg comprises a latching device, which is fixed in slot-shaped cutout in a snap-in manner when terminal clamp is closed to lock upper leg in position on lower leg.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

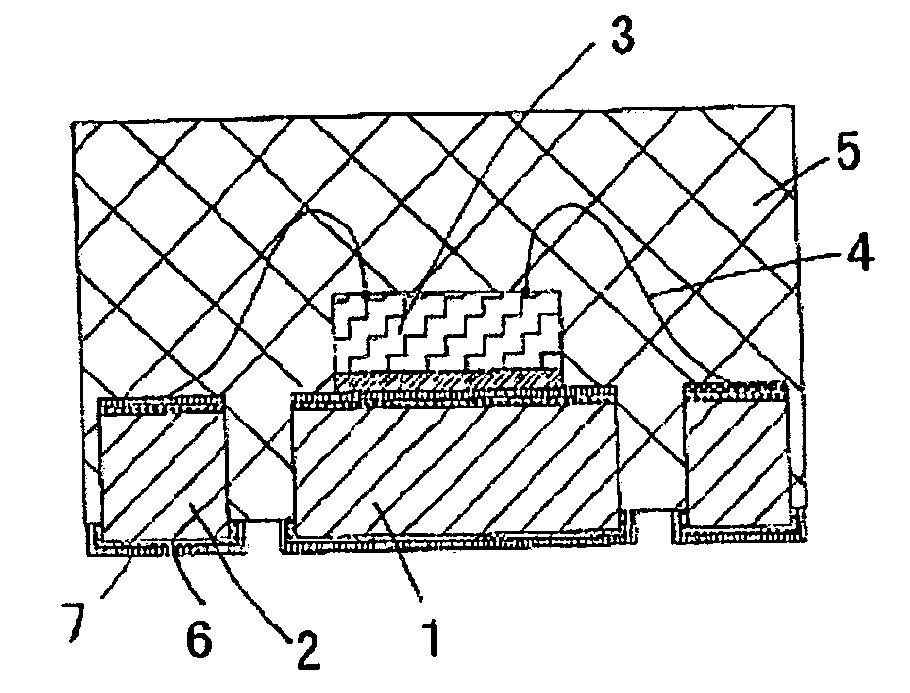

Package Structure With Flat Bumps For Electronic Device and Method of Manufacture the Same

InactiveUS20080258273A1High melting pointImprove product qualitySemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

The invention discloses an ultra thin package structure of leadless electronic device and the packaging method, and includes lead support base adjacent to the chip support base; chip mounted on the chip support base; wires bonded between chip and lead support base; the molded body encapsulating the top surface and side surface of the chip support base, small protrusions of the chip support base and lead support base below the molded body; in the individual package, the number of the chip support base island can be one or more, the lead pins can be arrayed at one side of the island, also can be arrayed at two sides or three sides of the island, one or two rows of lead pins can be located around the island.

Owner:JCET GROUP CO LTD

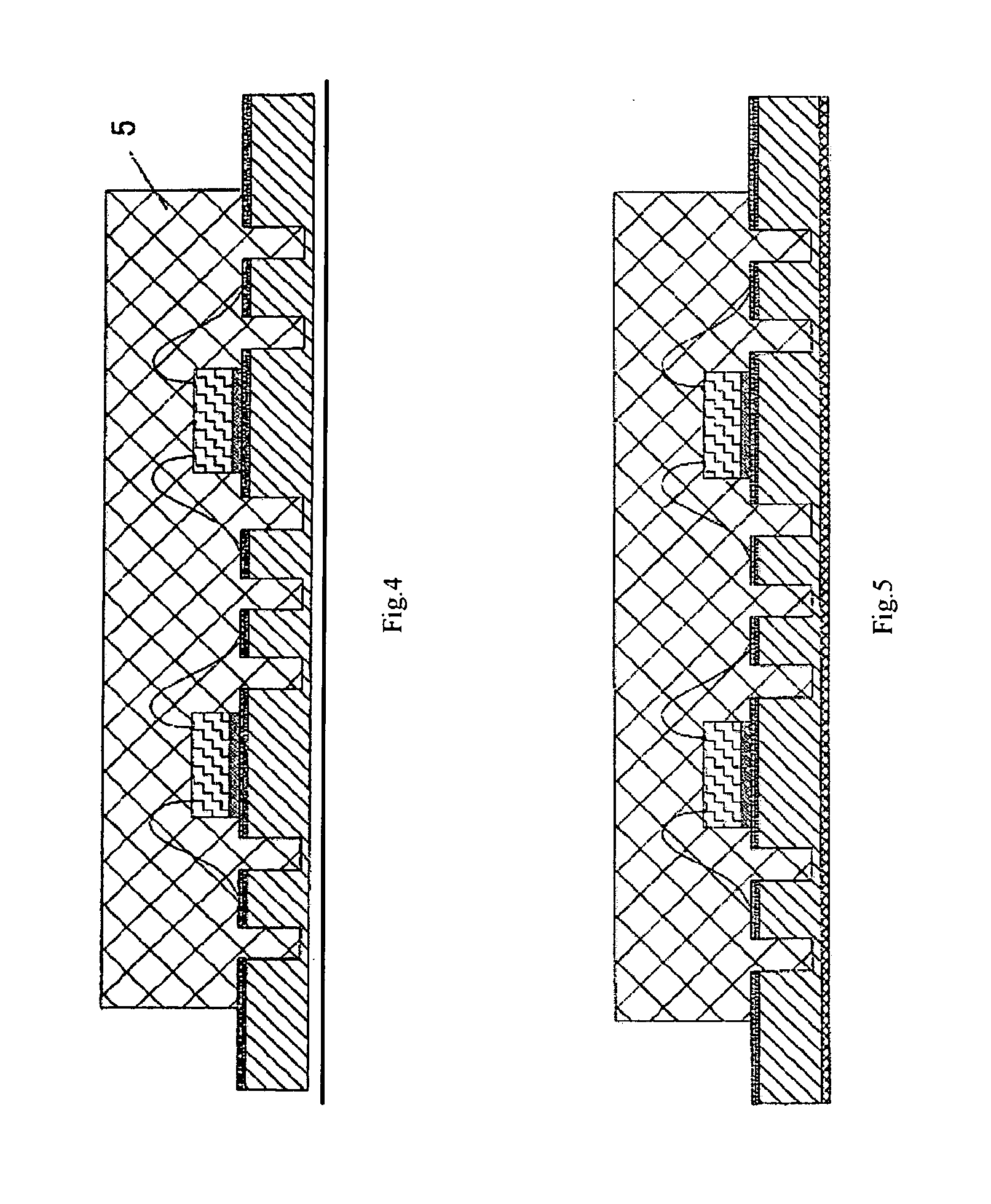

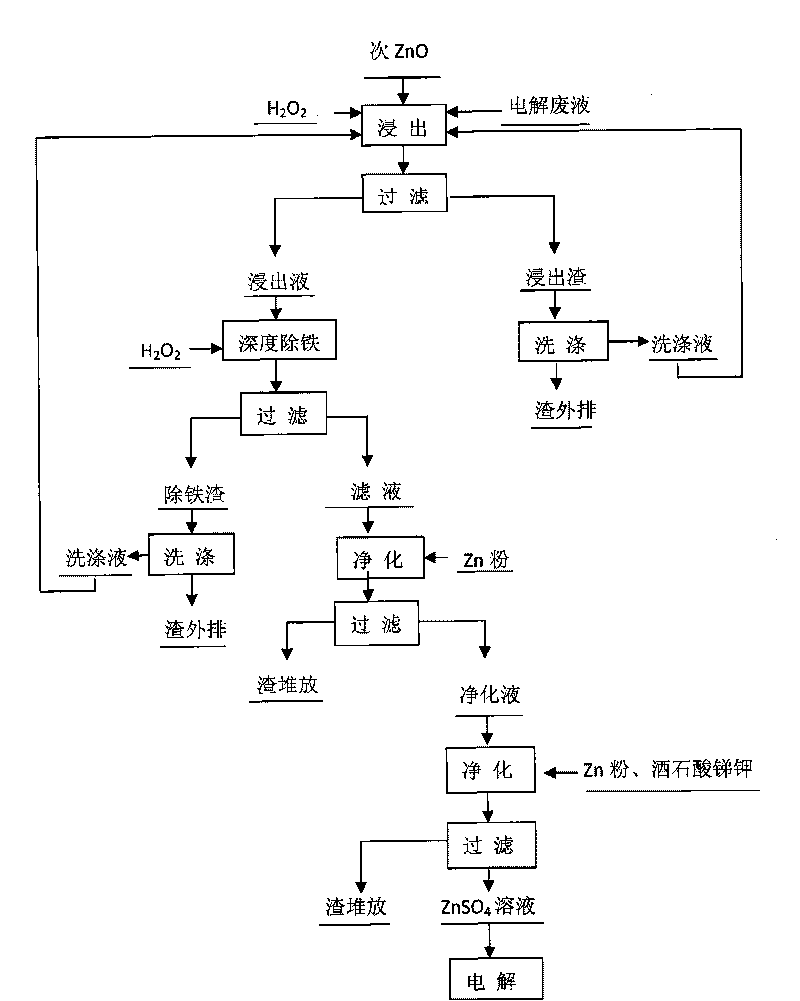

Method for removing impurities by oxidation in process of zinc hydrometallurgy

A method for removing impurities by oxidation in the process of zinc hydrometallurgy with sub-zinc oxide high in iron content as the raw material specifically comprises the following five procedures: A. primary impurity removal during leaching of sub-zinc oxide; B. deep impurity removal of ZnSO4 solution; C. first-stage purification of ZnSO4 solution; D. second-stage purification of ZnSO4 solution; and E. filtration to finally obtain the ZnSO4 solution in accordance with the requirement for producing zinc by electrolysis. The method better solves the problem of impurity removal in the process of producing electrolytic zinc with sub-zinc oxide as the raw material, especially the removal of As, Sb, Ge, F and Fe, and ensures the electrolytic zinc to be produced smoothly and ensures high product quality. In the method, the industrial grade H2O2 is used as the oxidant to remove the impurities from the leachate of zinc oxide and can not bring in the impurities harmful to the electrolytic zinc, thus ensuring smooth production, improving the product quality and the production yield and lowering the cost, in addition, the industrial grade H2O2 is relatively cheap and easy to purchase, thus the method is suitable for popularization and application in large scale.

Owner:孙位成

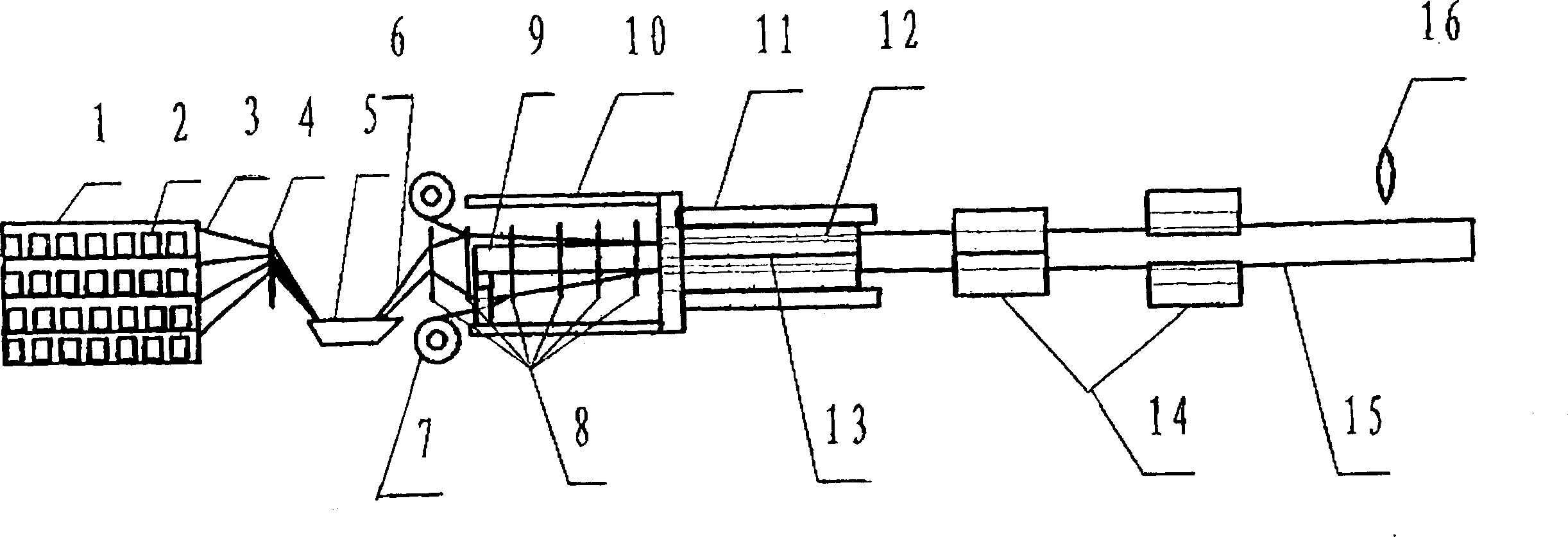

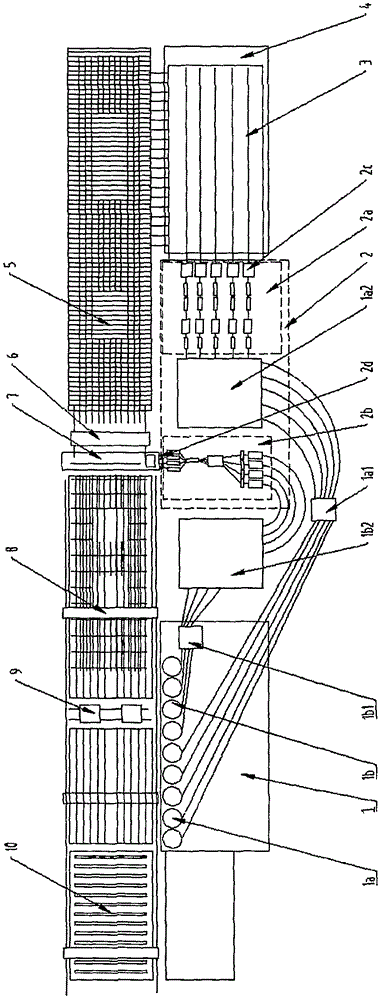

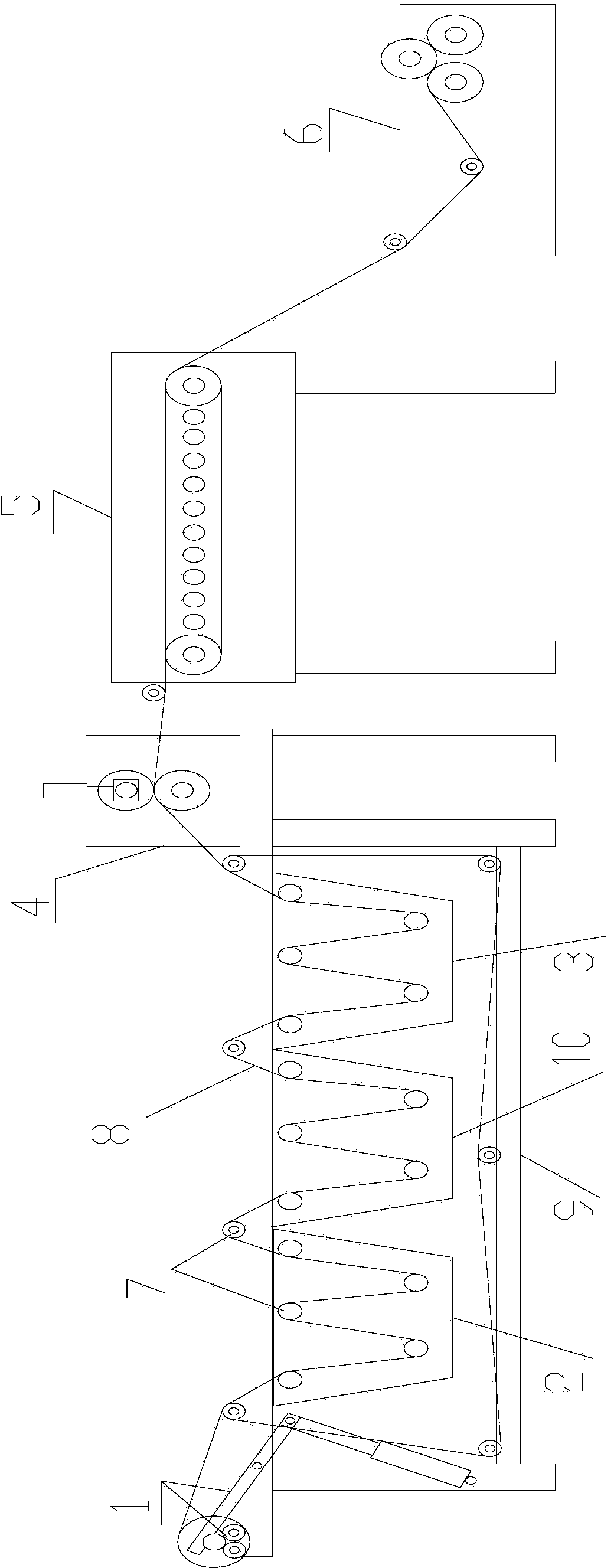

Welding protection line for reinforcing mesh

ActiveCN105215237AFirmly connectedStrong design compatibilityWire networkProduction lineNumerical control

The invention discloses a welding production line for a reinforcing mesh. The welding production line comprises a wire feeding part, a straightening part, a wire collecting frame, a longitudinal bar reinforcement machine, a longitudinal bar distribution machine, a longitudinal bar traction and alignment machine, a welding machine, a traction arching machine, a bending machine and a discharging machine. The welding production line is characterized in that the wire feeding part, the straightening part, the wire collecting frame, the longitudinal bar reinforcement machine, the longitudinal bar distribution machine, the longitudinal bar traction and alignment machine, the welding machine, the traction arching machine, the bending machine and the discharging machine are connected in sequence. The welding production line has the beneficial effects that smooth production is achieved from raw materials to finished products, all production technologies are joined smoothly, a numerical control assembly and a control device are conveniently connected in equipment, and the design compatibility of a control system is high. Functions are rich, and opposite side bending, four side bending, multi-power net welding and other technologies can be completed.

Owner:TIANJIN YINFENG MACHINERY SYST ENG CO LTD

Method for preparing antistatic polyacrylonitrile fibers from double-component nano electroconductive agent

InactiveCN102409422AImprove fill factorImprove conductivityElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentCarbon nanotubeSolvent

The invention discloses a method for preparing antistatic polyacrylonitrile fibers from a double-component nano electroconductive agent. The method comprises the following steps of: (1) compounding nano ATO (antimony tin oxide) with carbon nanotubes at a mass ratio of 1: (1-100) to obtain the double-component nano electroconductive agent, placing the double-component nano electroconductive agent,polyacrylonitrile and a dispersant in a spinning solvent, sufficiently stirring for dissolving polyacrylonitrile to obtain a blend solution, and treating in an ultrasonic dispersion device to prepare a blend spinning stock solution; and (2) passing through the blend spinning stock solution through a filtering and metering pump, and intruding to a coagulation bath composed of the spinning solvent and water through spinneret orifices to prepare the polyacrylonitrile fibers. The method has a simple process and high production efficiency, and can easily realize fiber production by adopting a conventional wet spinning process. By reasonable matching of different features and properties of nano ATO and carbon nanotubes, an electroconductive channel is formed in a polyacrylonitrile matrix, thus the electric conductivity of the polyacrylonitrile fiber is greatly improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Non-woven fabric dying production line

InactiveCN103820962AAvoid shakingPrevent fallingSucessive textile treatmentsTextile treatment machine arrangementsEngineeringNonwoven fabric

The invention discloses a non-woven fabric dying production line which comprises an uncoiling device, a dying cylinder, a cleaning cylinder, dry-rolling device, a drying device, a coiling device, a plurality of guide rollers, net belts and a first frame body. The uncoiling device, the dying cylinder, the cleaning cylinder and the dry-rolling device are arranged on the first frame body in sequence. The coiling device is arranged in rear of the drying device, and the dying cylinder, the cleaning cylinder and the first frame body are provided with the guide rollers. The net belts are arranged on the guide rollers in a tensioning mode. Compared with the prior art, the good cleaning effect can be achieved, the dying quality of a product is not affected, the size of an exhaust opening can be adjusted, the normal temperature in drying non-woven fabric in a drying oven and the coherence of the whole production process are guaranteed, production efficiency is not affected, crimples are avoided, the overall attractiveness and the coiling quality of the non-woven fabric are ensured, slippage in transmission can also be avoided, the transmission rate is guaranteed, the uncoiling speed can be prevented from being higher than the belt supporting speed of the net belts, water removing is even, the normal water removing effect is achieved, and the drying effect is not affected.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

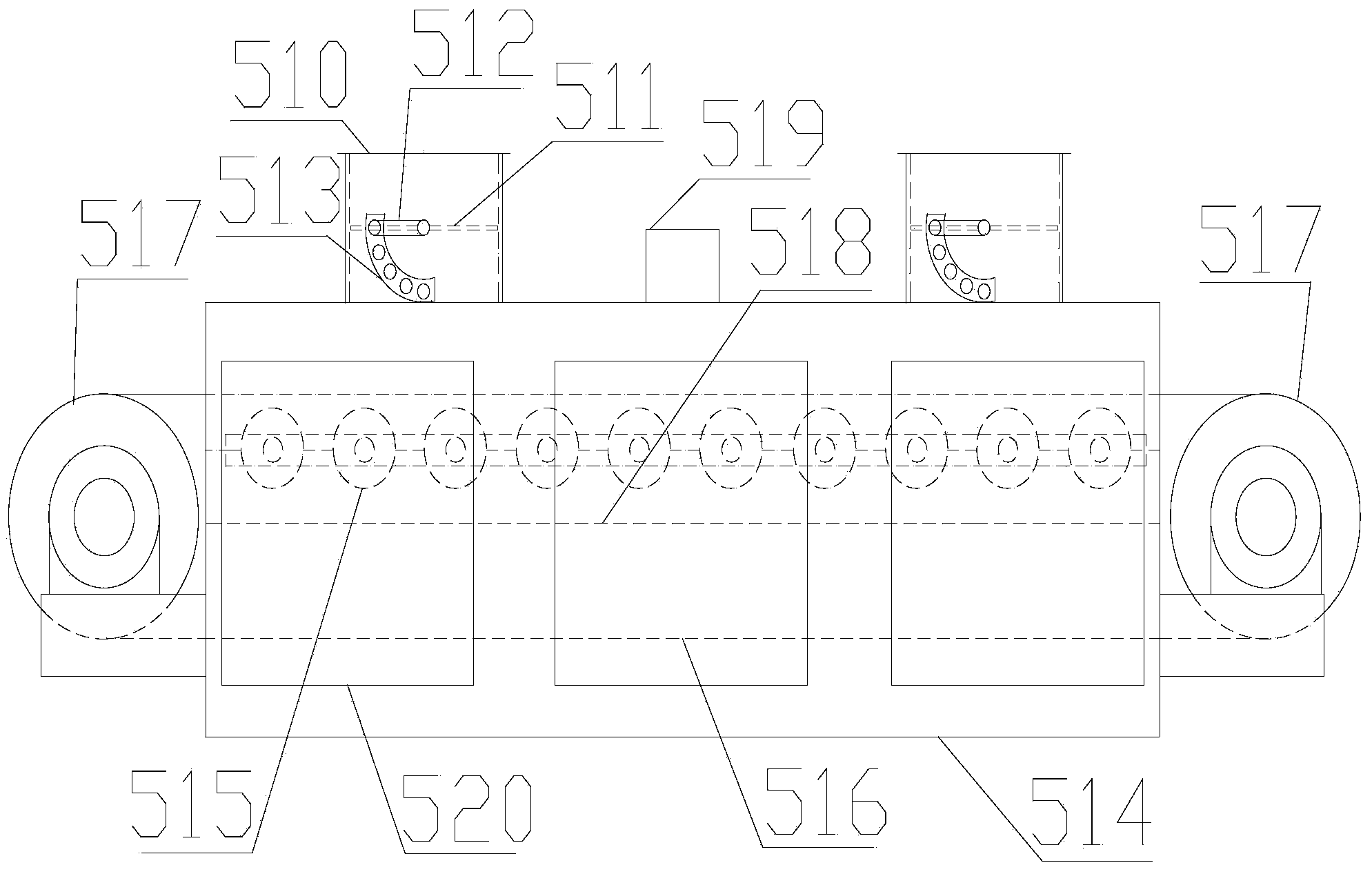

Automatic assembly machine of slide rail

ActiveCN107225381AReasonable layoutSave spaceFinal product manufactureMetal working apparatusAssembly machineAutomation

The invention discloses an automatic assembly machine of a slide rail. The automatic assembly machine comprises a rack provided with an assembly station, a circuit controller arranged on the rack, and an inner rail moving glue mounting mechanism, a middle rail bead nest mounting and oil smearing mechanism, a middle rail check block mounting and inner rail sleeving mechanism, a middle rail assembly outer bead strip mounting and outer rail sleeving mechanism and a slide rail outputting mechanism which are arranged on the rack and are electrically connected with the circuit controller. Compared with the prior art, the automatic assembly machine has the advantages that integrated layout is reasonable, the space is saved, automation degree is high, production process is coherent, and production efficiency can be improved.

Owner:GUANGDONG SACA PRECISION MFG CO LTD

Preparation method of water-based coating for lost foam casting

The invention discloses a preparation method of a water-based coating for lost foam casting. A coating prepared by the preparation method has excellent performances, good suspensibility, thixotropy and permeability, and high surface strength. The preparation method overcomes the defects that refractory powder adopted by the conventional casting coating preparation technology is very expensive and a coating production cost of the conventional casting coating preparation technology is high. A casting coating obtained by the preparation method is smooth and has appropriate viscosity. Through the preparation method, a high-quality casting coating can be prepared from cheap raw materials through simple production processes. Therefore, the preparation method reduces a coating production cost and realizes good finished product quality.

Owner:南通江海港建设工程有限公司

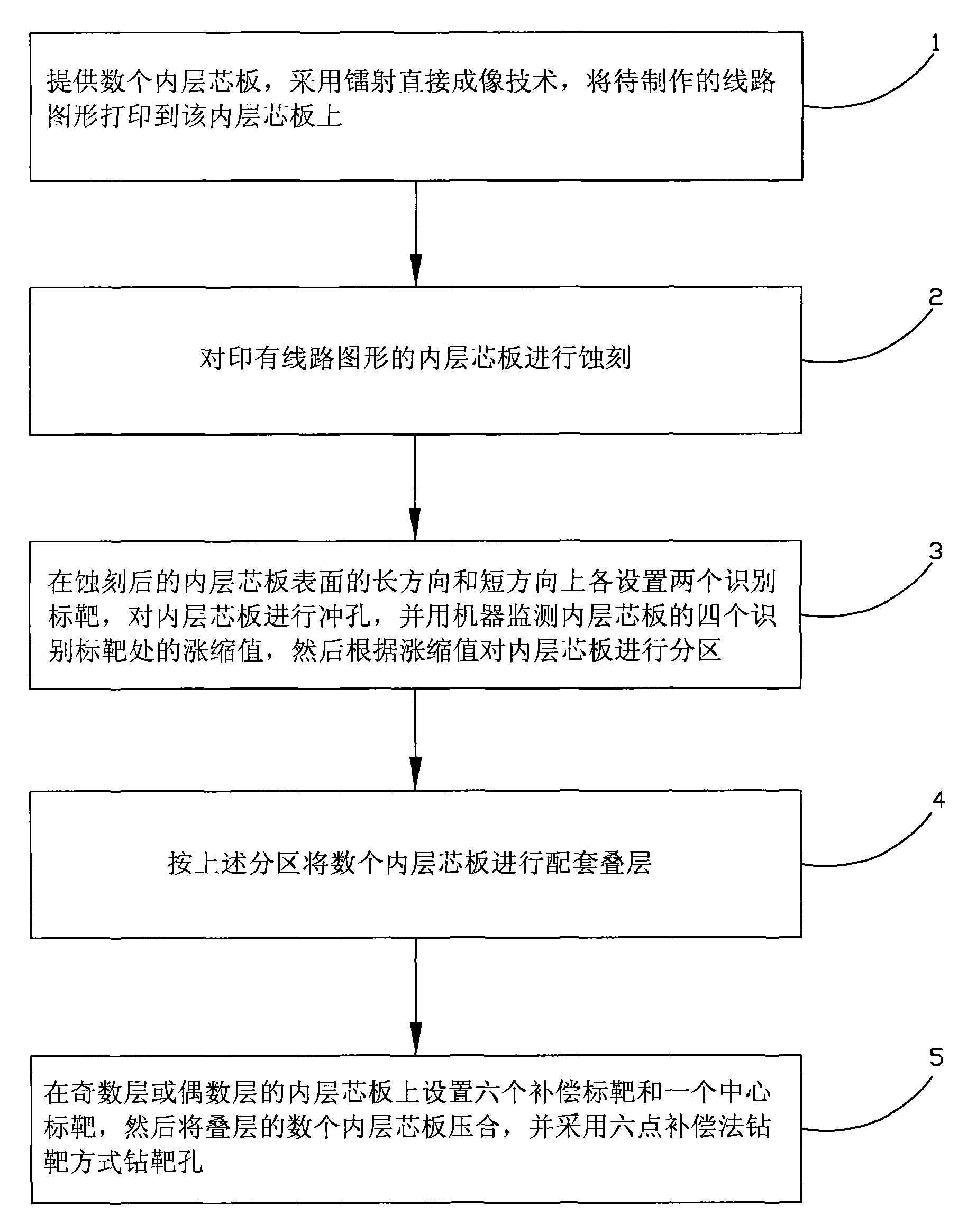

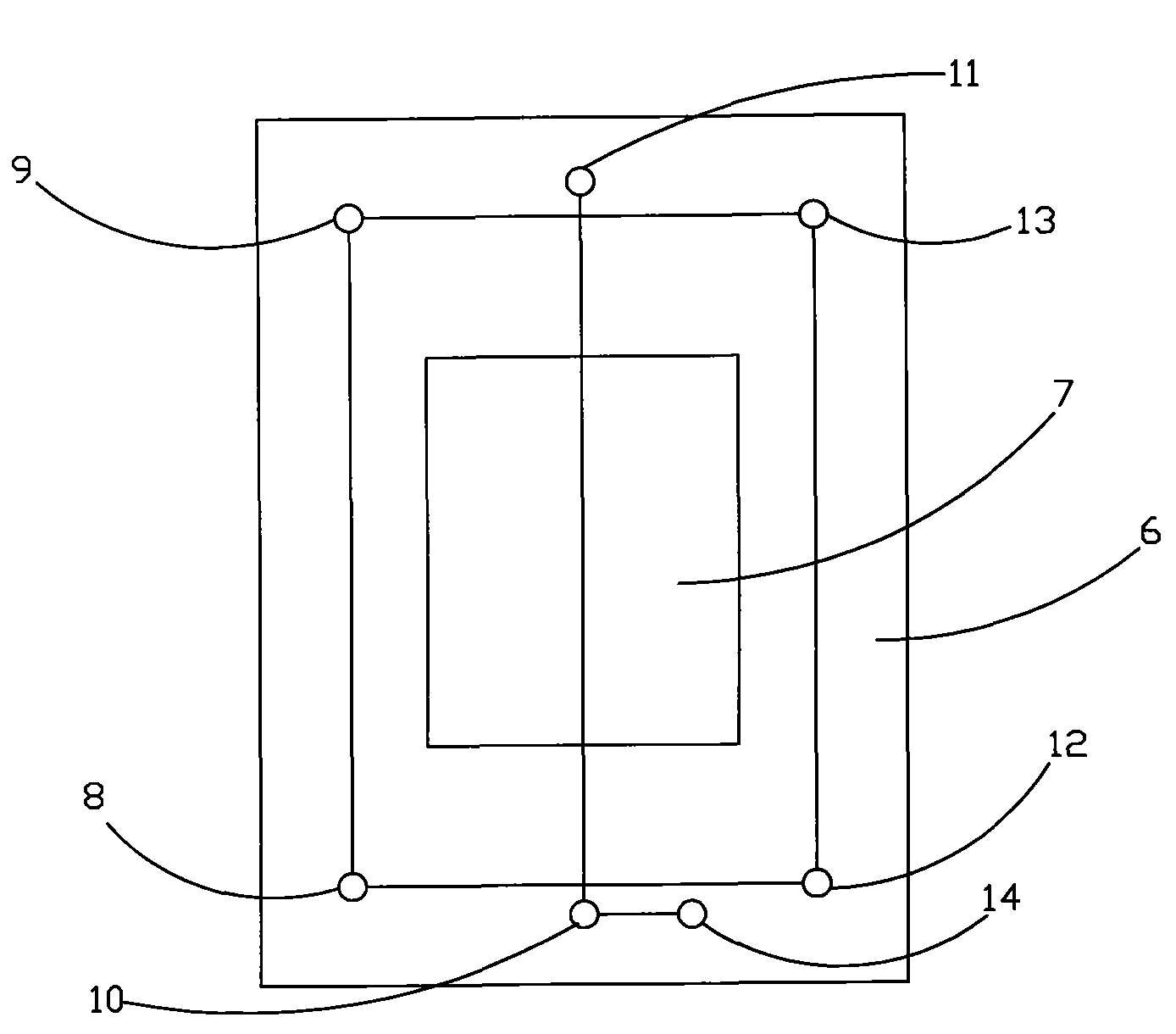

Method for making high alignment printed circuit board

ActiveCN101668389AHigh control precisionEasy alignmentConductive material chemical/electrolytical removalMultilayer circuit manufactureDirect imagingEngineering

The invention relates to a method for making a high collimation printed circuit board, comprising the following steps: step 1. providing a plurality of internal layer core plates, and printing circuitpatterns to be made onto the internal layer core plates by adopting a laser direct imaging technique; step 2. etching the internal layer core plates printed with the circuit patterns; step 3. respectively arranging two identifying targets for punching holes on the internal layer core plates in the long direction and short direction of the surfaces of the etched internal layer core plates, monitoring the expansion and shrinkage values of four identifying targets of the internal layer core plates by using a machine, and then partitioning the internal layer core plates according to the expansionand shrinkage values; step 4. matching and overlaying the plurality of internal layer core plates according to the partitions; and step 5. arranging six compensation targets and a central target on the internal layer core plates of odd layers or even layers, then pressing the plurality of overlaid internal layer core plates and drilling target holes by adopting a target drilling mode of six-pointcompensation method. With the method, the quality of the printed circuit board products can be effectively monitored, so that the invention is propitious to the improvement of the alignment of the printed circuit boards.

Owner:DONGGUAN MEADVILLE CIRCUITS

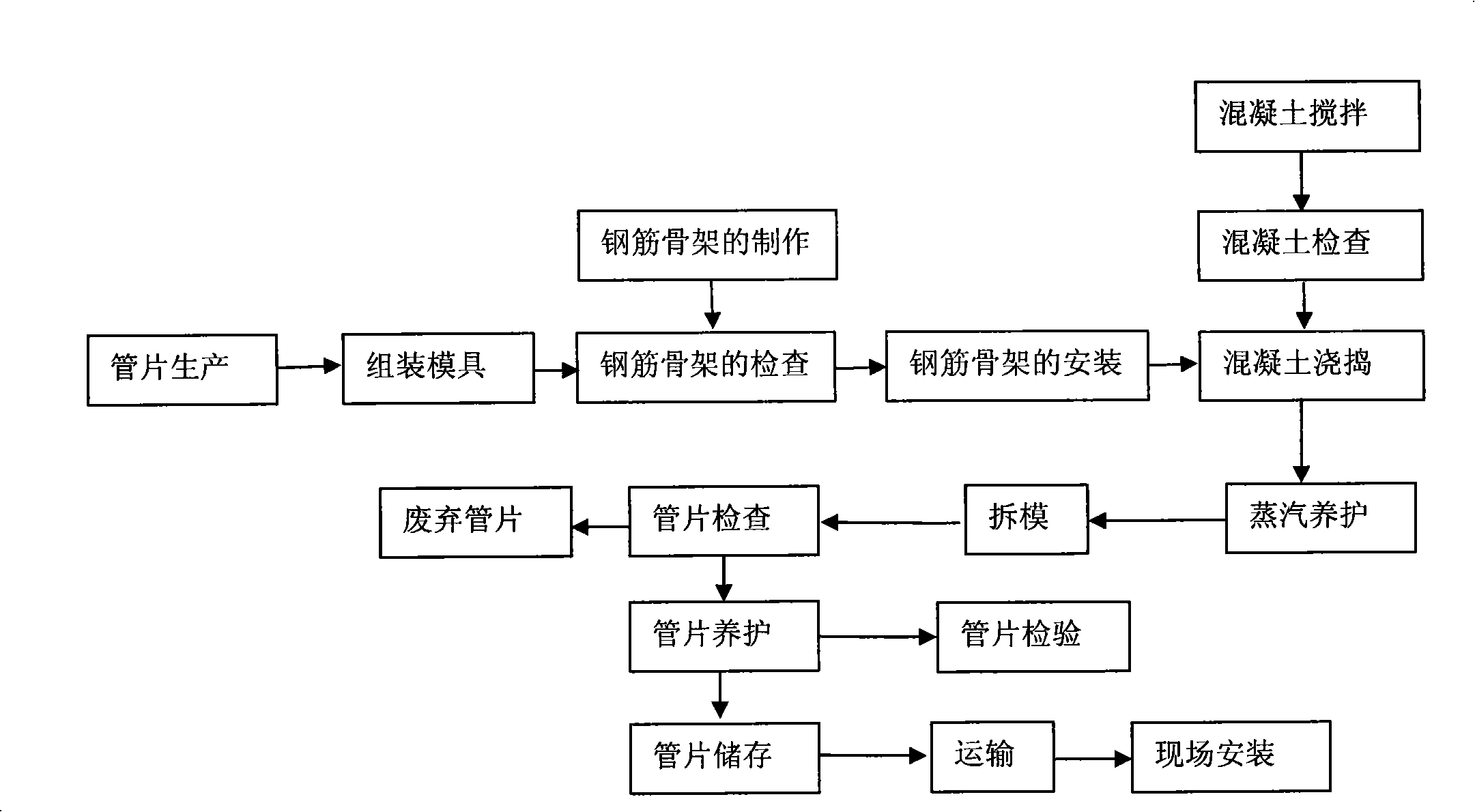

Subway dedicated shield tunneling segment prefabricated construction method

ActiveCN101338682AReasonable process layoutGuaranteed smooth productionUnderground chambersTunnel liningProduction lineEngineering

The present invention relates to a shield segment prefabrication construction method special for subway. The method comprises the steps of manufacturing and installing a reinforcement cage, assembling a mould, stirring, transporting and casting concrete, carring out segment surface, steam maintenance, removing the mould and segment maintenance. The segment is allowed to stand for one hour after the segment surface is finished. Firstly, the segment is covered with a maintaining cover and then is processed for non-pressure steam maintenance. The segment maintenance comprises pool maintenance and spray maintenance. The segment is allowed to stand for 30 to 60 minutes after the mould is removed, the pool maintenance is not less than seven days, and then the segment is transferred to a spray maintenance field. The concrete ring segment prefabrication construction used for an underground large-caliber pipeline shield can also refer to the shield segment prefabrication construction method which has reasonable technical distribution, smooth production, less resource investment, large production capacity, high production efficiency and high automatization degree and is good for forming a segment production line on a large scale.

Owner:GUANGZHOU JISHI CONSTR GRP +1

Process of rolling stainless steel coil in conventional hot continuous rolling production line

InactiveCN103157658AReduce manufacturing costSmooth productionTemperature control deviceWork treatment devicesLaminar coolingEngineering

The invention discloses a process of rolling a stainless steel coil in a conventional hot continuous rolling production line. A stainless steel slab with the thickness of 150-250mm is placed in a heating furnace, the tapping temperature of the slab is 1200 DEG C-1300 DEG C, the time when the slab is in the furnace is 150-400min, the slab is taken out of the furnace and continuously rolled for 5-7 times after being descaled through a rough rolling descaling machine, and a medium slab is manufactured. The medium slab enters a hot coiling box through a middle roller way for uncoiling, is cropped through a flying shear, and enters a fine continuous rolling mill composed of seven machine frames after being descaled through a fine rolling descaling machine so as to be manufactured into strip steel with the thickness of 2.2-3.5mm. The strip steel enters a coiling machine after being cooled through laminar flow and is coiled to form a steel coil. The rolling process does not need increasing of equipment investment, is stable in rolling, high in comprehensive yield and good in quality of the surface of the strip steel, and has application and popularization value.

Owner:湖南华菱涟源钢铁有限公司

Five-layered corrugated paper production line

ActiveCN109130329AMeet functional needsPrecise position of fixed-point machiningMechanical working/deformationBox making operationsCardboardPaper production

The invention discloses a five-layered corrugated paper production line. The five-layered corrugated paper production line comprises a plurality of body paper racks used for unreeling body paper, facepaper preheating wheels, core paper preheating wheels, a single corrugated paper machine, an upward leading device, a double-layered paper rack, a conveying device, a triple preheating wheel, a pasting machine, a paper board forming machine, a driving device and an N.C. cutting and line pressing edge trimmer, wherein the face paper preheating wheels and the core paper preheating wheels are arranged between every two body paper racks; the single corrugated paper machine is used for roller forming of core paper and further compounding the core paper and face paper into single corrugated paper boards; the upward leading device and the double-layered paper rack are arranged above the single corrugated paper machine; the conveying device is used for conveying the single corrugated paper boards; the triple preheating wheel is used for preheating the single corrugated paper boards and the face paper; the pasting machine is used for pasting the face paper and two layers of the single corrugated paper boards; the paper board forming machine is used for compounding the face paper and the two layers of the single corrugated paper boards into a five-layered corrugated paper board; the drivingdevice is used for conveying the five-layered corrugated paper board; and the N.C. cutting and line pressing edge trimmer is used for shaping the five-layered corrugated paper board. By adoption of the five-layered corrugated paper production line, the corrugated paper board of a five-layered structure can be produced, and fixed-point notching treatment of the five-layered corrugated paper boardcan be conducted; and the automatic detecting and waste discharging functions are further achieved, and the number of discarded products in finished corrugated paper board products is decreased.

Owner:晋江市新达纸箱包装有限公司

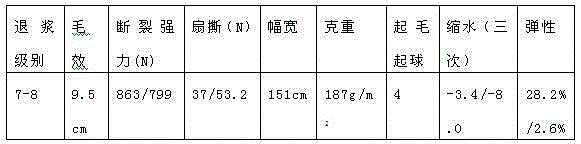

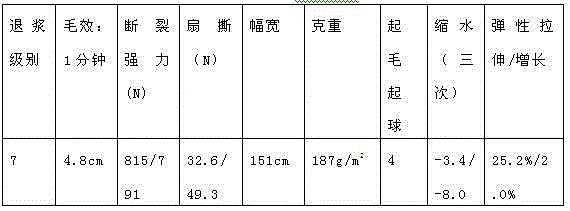

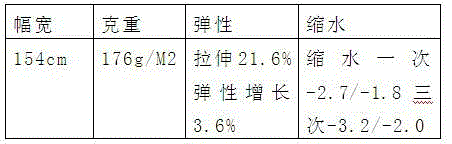

Method for printing and dyeing dacron/chinlon/cotton/spandex multi-component fiber fabric

ActiveCN104532611AEliminate potential wrinklesGuaranteed smooth productionBleaching apparatusDyeing processFiberPolymer science

The invention belongs to the technical field of printing and dyeing of textiles and in particular relates to a method for printing and dyeing a dacron / chinlon / cotton / spandex multi-component fiber fabric. The method comprises the following sequential steps: preparing gray fabric, turning seams, rolling enzyme and carrying out cold stacking, bleaching and washing at low temperature, sizing, mercerizing, dyeing and after-finishing. After dyeing, finishing and functional after-finishing, the fabric has fluffy style, and is stiff and smooth and elastic, is capable of absorbing moisture and releasing sweat, and is comfortable and has a close fitting effect; the fabric is integrated with the advantages of a plurality of advantages; the effect of adopting advantages while overcoming disadvantages is exerted; the requirements of superior-quality fabric can be met; meanwhile, the fabric is hydrophilic, and is easy to decontaminate and due to after-finish, the fabric has the characteristic of easiness in cleaning; the quality of the fabric is improved; the enterprise competitiveness is improved.

Owner:HUAFANG

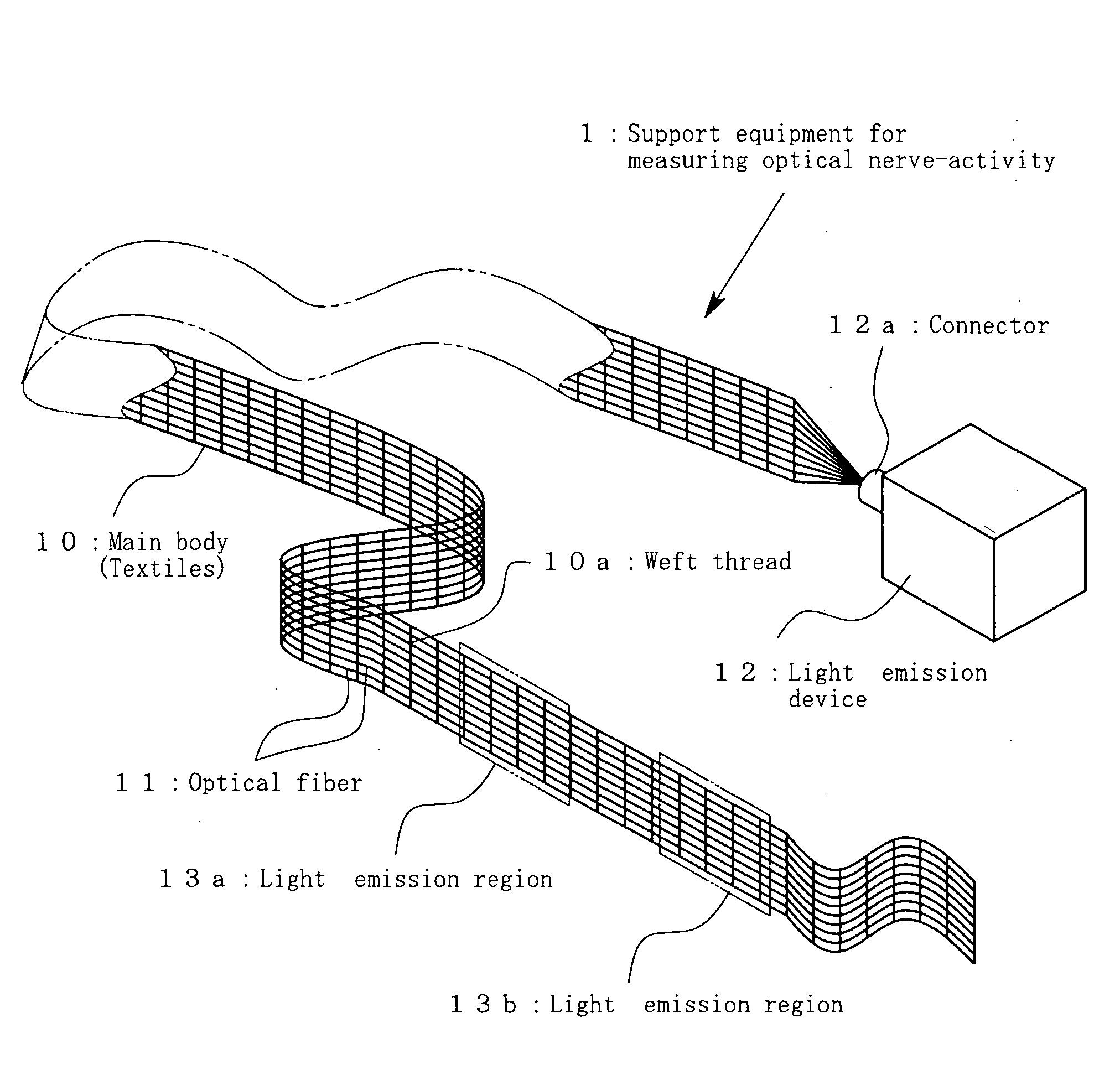

Support equipment for measurement of the activity of the optic nerve

InactiveUS20110077549A1Sufficient light intensityAvoid obstaclesElectroencephalographySensorsEngineeringOptic nerve

The invention provides easy handling and low cost-support equipment for measuring optical nerve-activity which is less stressful for subjects or doctors and the like. The support equipment, which provides light stimulation for subject eyes with its main body 10 fixed to the subject-head region and measures the subject optical nerve-activity, comprises a thin walled-main body 10 with a plurality of optical fibers 11 joined in the width direction; light emission regions 13a, 13b at least one of which is positioned in the main body aligned to the subject eye-position(s) and composed of a plurality of light leak parts 11c formed in peripheral surfaces of the optical fibers 11; and a connector 12a for connecting with a light emission device 12 providing light for each of the plurality of optical fibers.

Owner:UNIVERSITY OF FUKUI

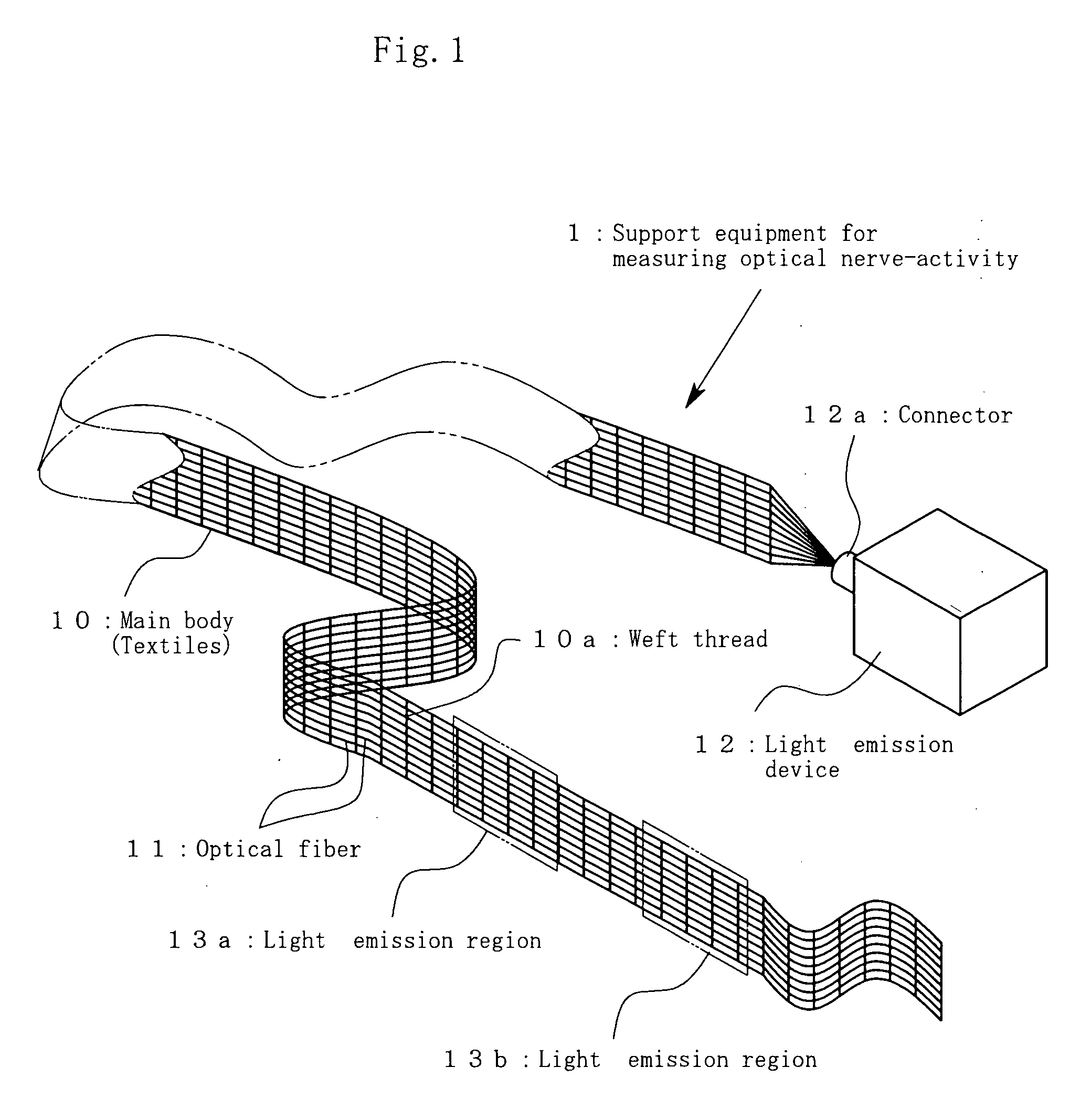

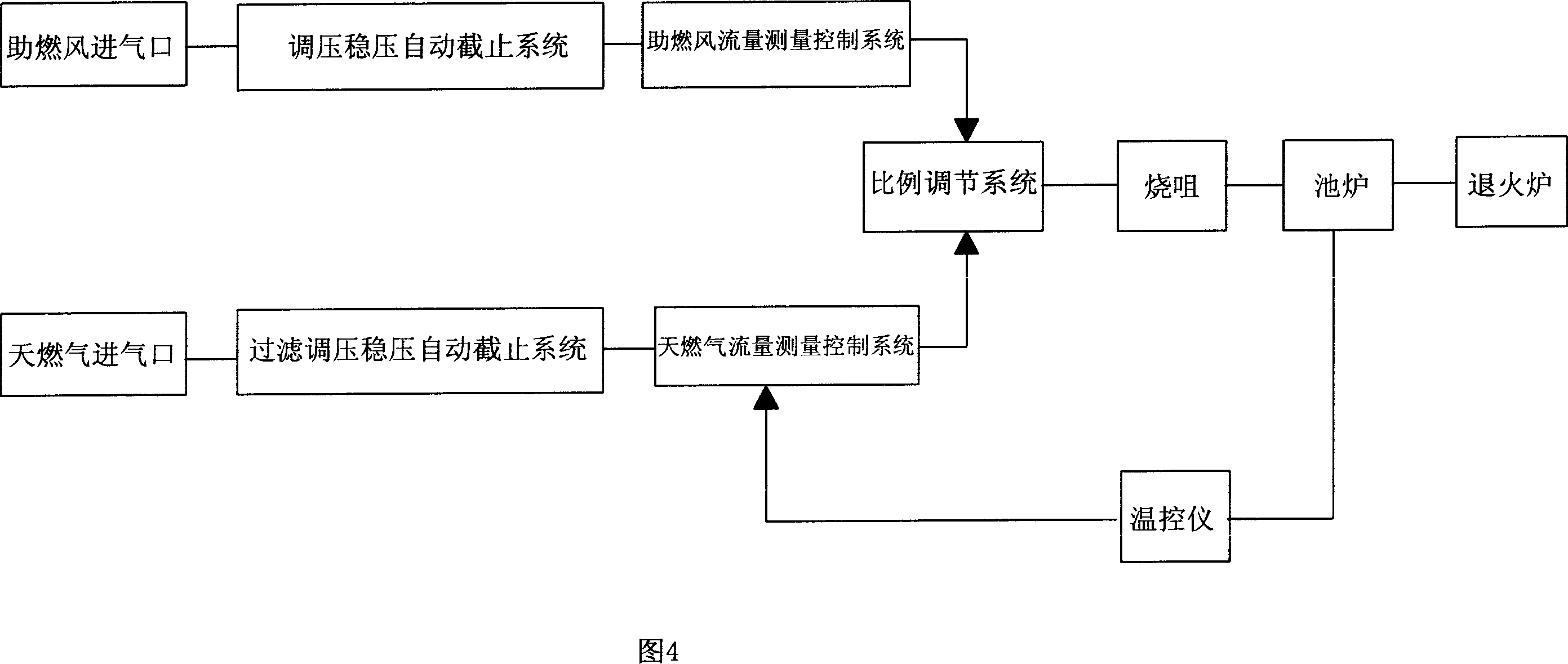

Environmental protective flint optical glass with heavy lanthanum, production method and equipment

ActiveCN101003417AGuaranteed smooth productionEasy to produceGlass furnace apparatusRefractive indexLanthanum

This invention provides environmentally friendly heavy lanthanum flint optical glass with high refractive index and medium optical dispersion. The optical glass is composed of: SiO2 20-40 wt.%, B2O3 5-20 wt.%, TiO2 5-20 wt.%, Nb2O5 5-20 wt.%, ZrO2 0-3 wt.%, Sb2O3 0-0.5 wt.%, La2O3 10-30 wt.%, K2O + Na2O 0-5 wt.%, and BaO + CaO + SrO 12-40 wt.%. The optical glass does not contain pollutive components such as PbO, As2O3 or GdO2. Its Nd is 1.74-1.83, and Nf-Nc is 32-47. This invention adopts one-step material melting in a tank furnace to produce the optical glass, and has such advantages as simple process, short production time.

Owner:CDGM OPTICAL GLASS

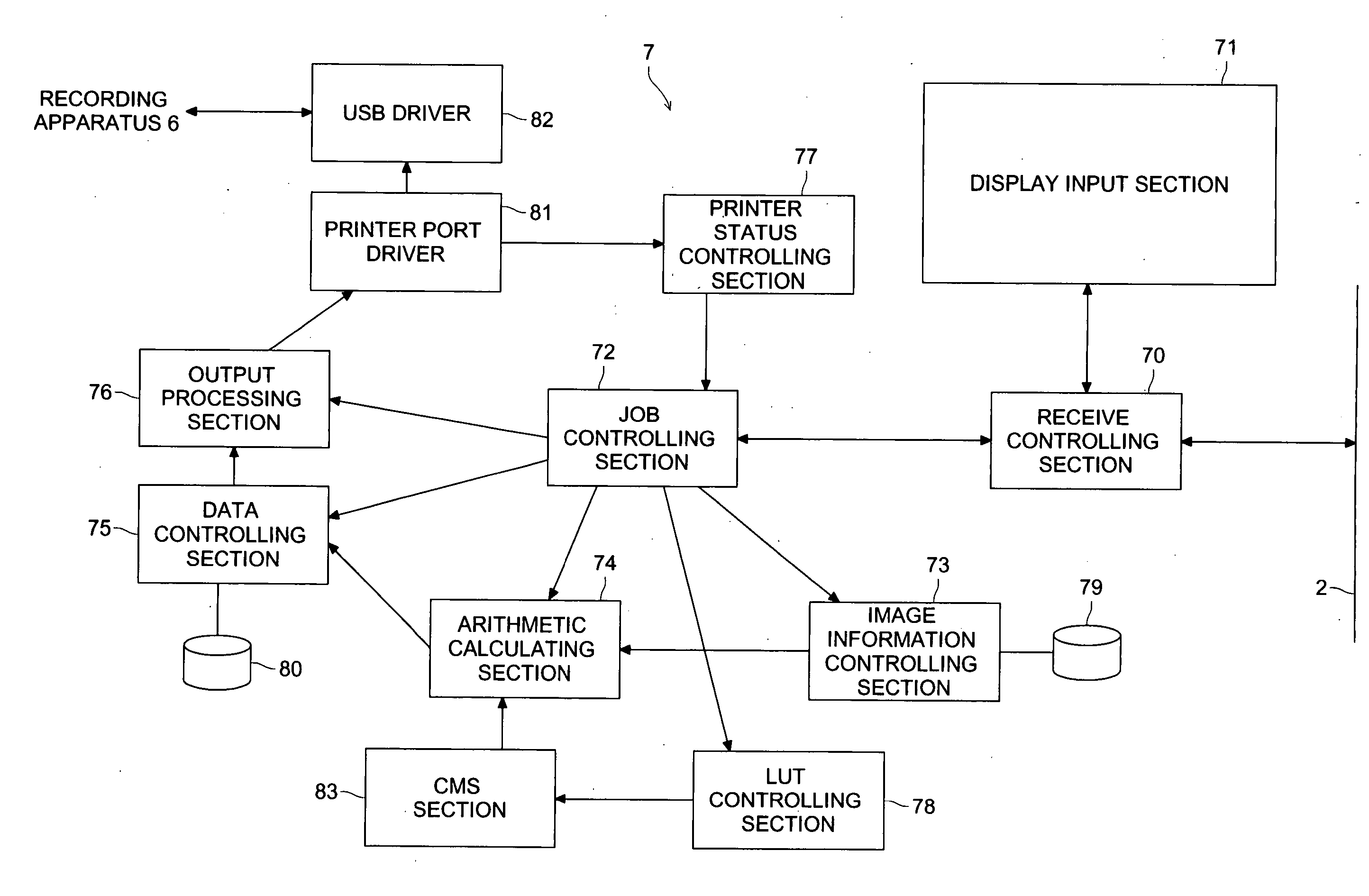

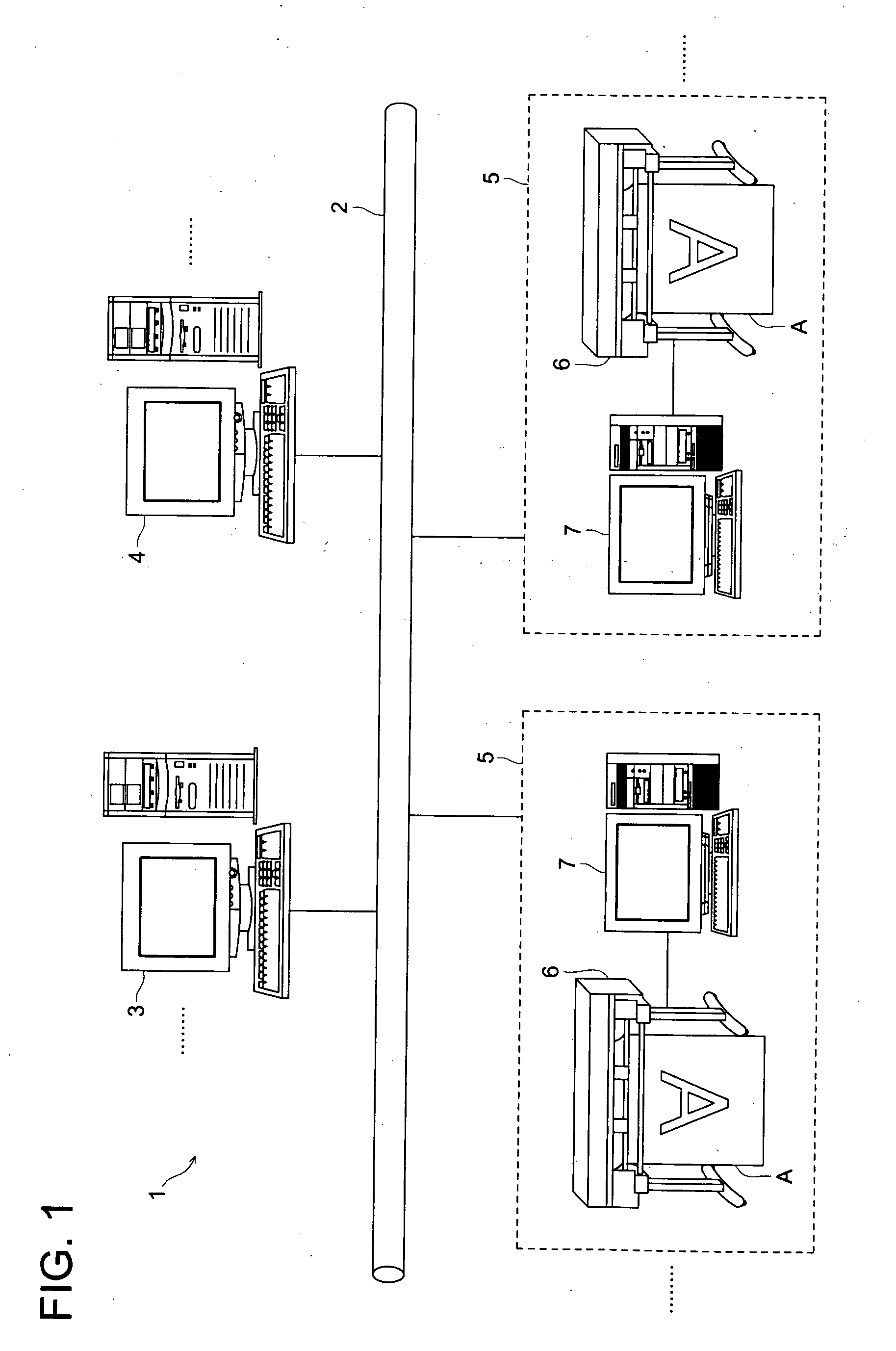

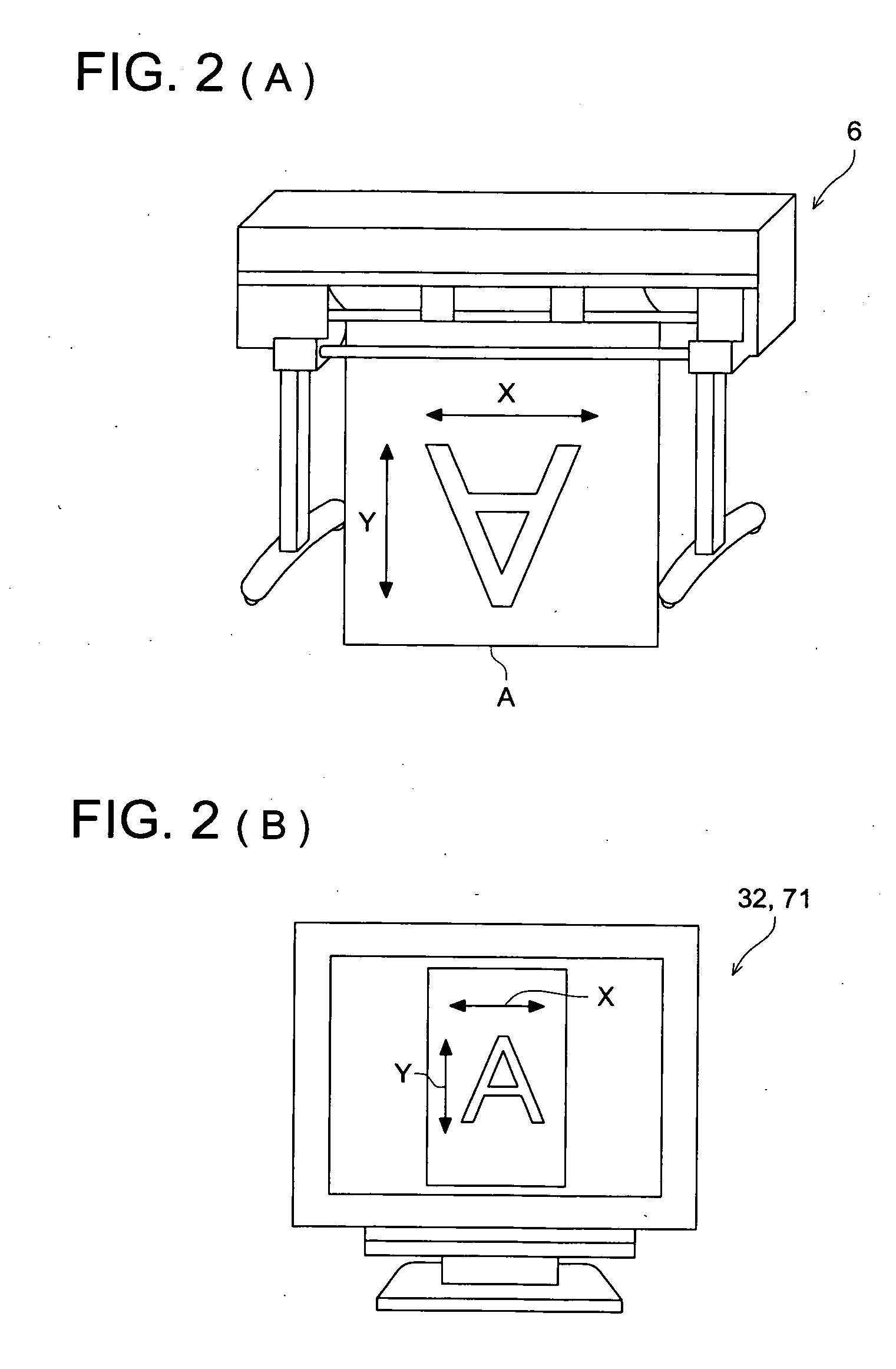

Image-processing apparatus, image-recording apparatus and image-recording system

InactiveUS20050168765A1Guaranteed smooth productionDigital computer detailsVisual presentationImaging processingImage recording

There is described an image-processing apparatus that is provided with a receiving section to receive jobs, each of which includes image data; an arithmetic calculating section to convert the image data to print data for every job; a storage section to store the jobs received by the receiving section and the print data converted by the arithmetic calculating section for every job; an outputting section to output the print data to a printing section for every job; and a controlling section to control a receiving processing applied for the jobs in the receiving section, a conversion processing applied for each of the jobs in the arithmetic calculating section and an output processing applied for each of the jobs in the outputting section. Accordingly, the image-processing apparatus can separately control a receiving state of each of the jobs, a converting state of each of the jobs and an outputting state of each of the jobs.

Owner:KONICA MINOLTA INC

Low-acidity acidic etching regenerant and acidic etching mother liquor thereof

The invention relates to the technical field of circuit board printing, particularly a low-acidity acidic etching regenerant and an acidic etching mother liquor thereof. The regenerant provided by the invention comprises the following components in percentage by weight: 10-12% of sodium chlorate, 15-17% of sodium chloride, 0.15-1.17% of ammonium chloride, 0.5-0.7% of urea, 1-1.5% of additive and 70-74% of water. The invention can perform the acidic etching under low acid equivalent, thereby ensuring the smoothness of the production, improving the working environment and prolonging the equipment life.

Owner:广州广合科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com