Patents

Literature

3245results about How to "Improve labor productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

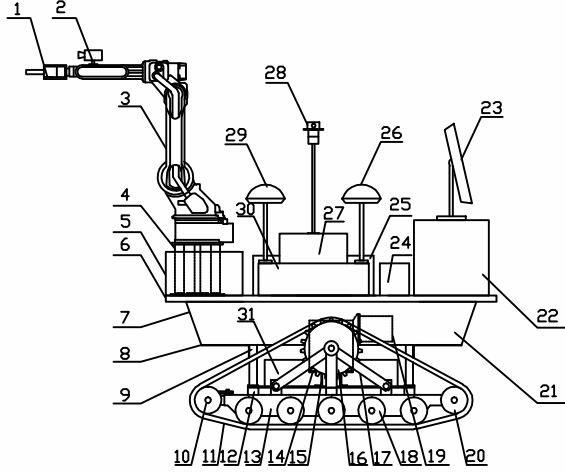

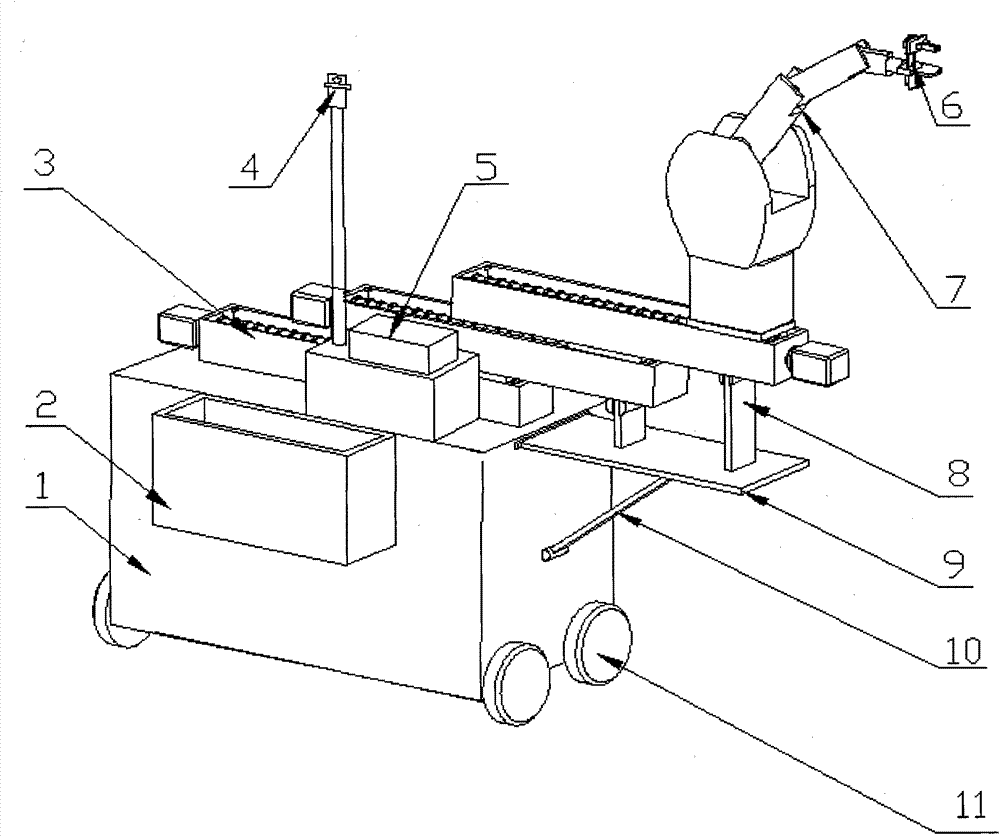

Automatic-navigation crawler-type mobile fruit picking robot and fruit picking method

InactiveCN102165880AFully automated pickingSimple structureProgramme-controlled manipulatorPicking devicesSimulationActuator

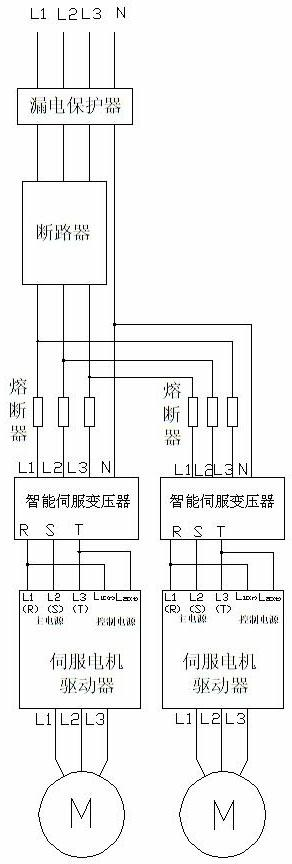

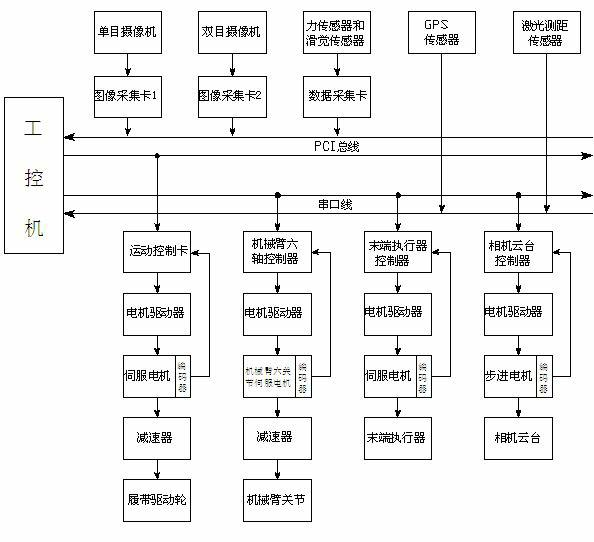

The invention discloses an automatic-navigation crawler-type mobile fruit picking robot which comprises a mechanical execution system and a control system and is characterized in that the mechanical execution system comprises an intelligent movable platform, a fruit picking mechanical arm and a two-finger type manipulator, wherein the intelligent movable platform comprises two crawler assemblies, an experimental facility fixing rack, a supporting stand column, a cross beam, a speed reducer and the like; and the control system comprises an industrial personal computer, a motion control card, a data collecting card, an image collecting card, an encoder, a GPS (global position system), a monocular zooming camera assembly, a binocular camera, a laser ranging sensor, a control circuit and the like. The automatic-navigation crawler-type mobile fruit picking robot integrates the fruit picking mechanical arm, the two-finger type manipulator, the intelligent movable platform and the sensor system, integrates multiple key technologies such as fruit identification, motion of the picking mechanical arm, grabbing of a tail-end executer, automatic navigation and obstacle avoidance of the movable platform, and the like, and really realizes automatic and humanized fruit picking.

Owner:NANJING AGRICULTURAL UNIVERSITY

Saline-sodic land reclamation and control method

InactiveCN101578935AIncrease the granular structureIncrease ventilationSoil lifting machinesClimate change adaptationHigh yieldingEuryhaline

The invention relates to a saline-sodic land reclamation and control method. Wide and deep research is long developed on the reclamation of saline-sodic land at home and abroad, and more focuses on engineering measures than applies biological techniques; although achievement has been made, some insurmountable difficulties still exist. The saline-sodic land reclamation and control method comprises the following steps: bulk deep loosening, applying soil deep loosening agents and saline-sodic soil improvement agents to deep loosening soil, purposefully and proportionally applying biologically organic fertilizer according to the composition of soil detected by adopting a nutrient balance method and a nitrogen phosphorus and potassium proportioning method which both comprise the following steps: subtracting soil nutrient-supplying amount from the fertilizer requirement of target yield, supplementing the balance through fertilizing, hathpace ridge forming, draining water and controlling salt, planting green manure-saline alkali tolerant high-yielding grass crop jerusalem artichoke to thoroughly improve the soil.

Owner:王彤

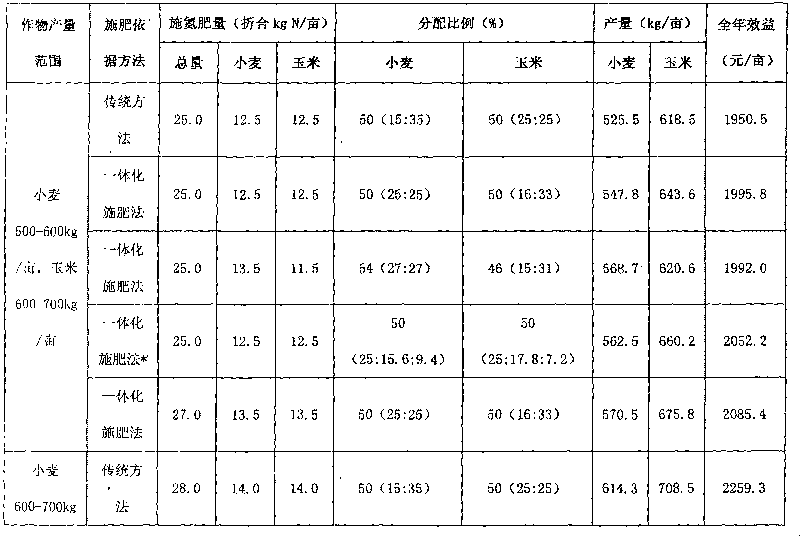

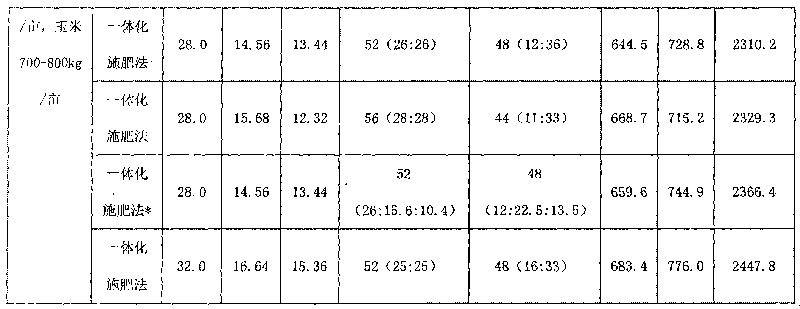

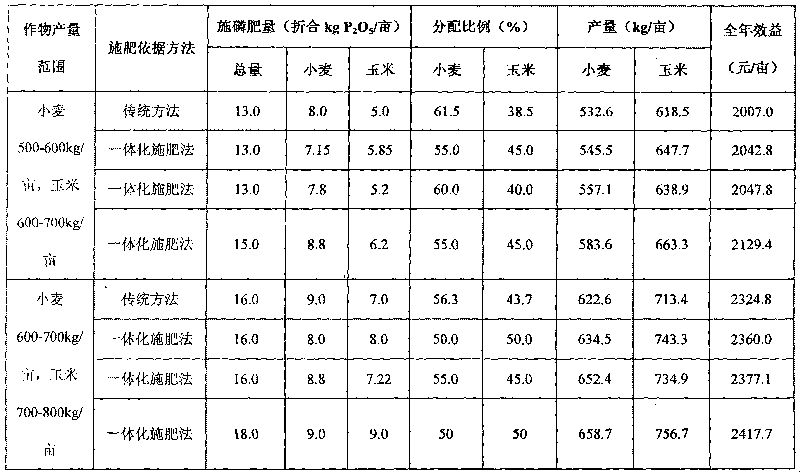

Integrated fertilization method under condition of NPKS of double-cropping crops of wheat and corn

ActiveCN101699961AHigh organic contentFixes and preserves nitrogen nutrientsHorticultureSoil-working methodsCorn stoverNitrogen fertilizer

The invention relates to an integrated fertilization method under the condition of NPKS of double-cropping crops of wheat and corn, comprising the NPKS of wheat to sow corn and the NPKS of corn to sow wheat. In the invention, under the conditions of NPKS of medium and high yield level of wheat and corn which can be harvested twice a year, the fertilization amount per mu is as follows: 25-32kg of N, 13-18kg of P2O5 and 13-18kg of K2O, the higher of the yield of the two crops, the greater of the application proportion of the nitrogen fertilizer therein on the wheat, while the allocation proportion of phosphorus and potassium is slightly different. The integrated fertilization method under the condition of NPKS can not only give consideration to complete and strong seedlings and high and stable yield of the two-cropping rotation crops of wheat and corn, but can also give full play to the positive influence of NPKS to increase soil organic matter and improve soil fertility, eliminating the negative influence, and can further reduce waste and environmental pollution caused by unreasonable input and allocation of chemical fertilizer.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Novel fast-set anticorrosion and wear-resistant epoxy powder coating and preparation process thereof

InactiveCN102492353AImprove anti-corrosion performanceSimple preparation processAnti-corrosive paintsPowdery paintsWear resistantWear resistance

The invention relates to the field of chemical coating, in particular to epoxy powder coating applied to material conveying steel belts in oilfield oil pumping pipelines or coal transportation in the oil industry. In a formula, the coating comprises the following components in percentage by weight: 32-56% of epoxy resin, 8-14% of curing agent, 30-50% of pigments and fillers, 2-10% of resin modifier and 2-6% of assistant, wherein the epoxy resin in the formula is bisphenol A type epoxy resin, a mixture of the bisphenol A type epoxy resin and phenolic aldehyde modified epoxy resin, and phenolic aldehyde modified epoxy resin, and the curing agent is phenolic hydroxyl resin. The epoxy powder coating disclosed by the invention belongs to fast-set anticorrosion and wear-resistant epoxy powder coating, has the granularity being 10-125 mu m, is applied under general curing conditions that the curing temperature is 180-200 DEG C and the curing time is 3-10min, can be regulated according to user needs and is superior to like products in anticorrosion performance, coating film mechanical performance and wear resistance, a preparation process is simple, the labour productivity can be obviously increased, and the epoxy powder coating is suitable for industrialized production.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

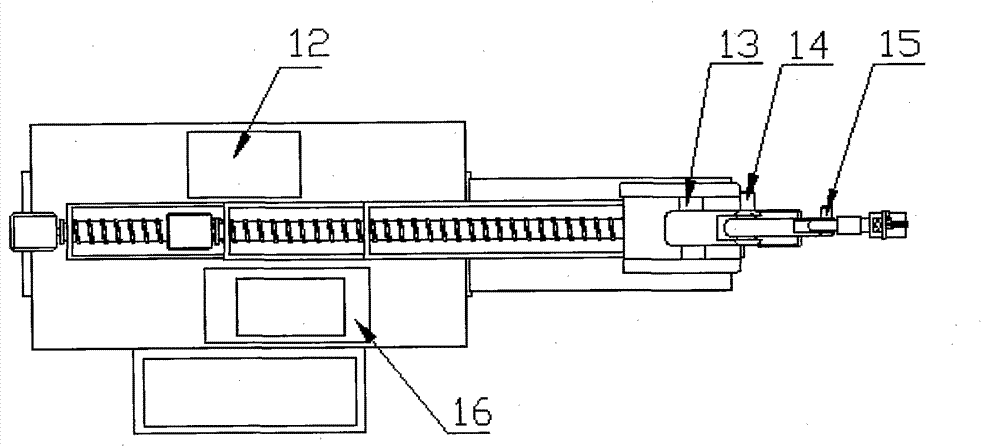

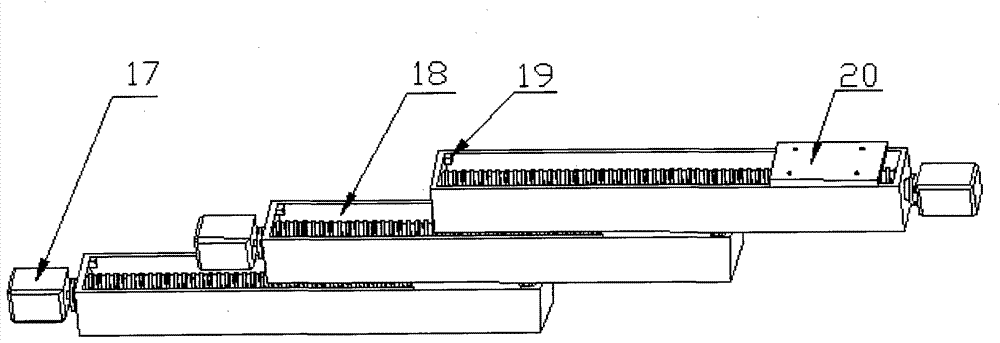

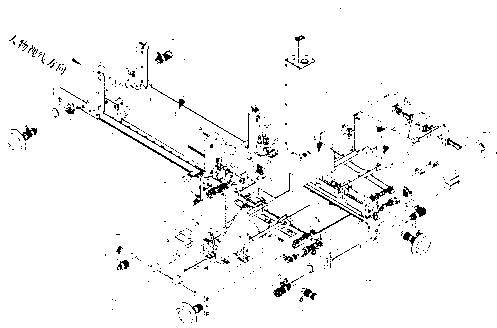

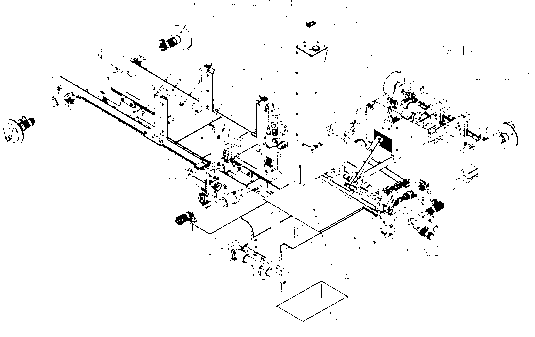

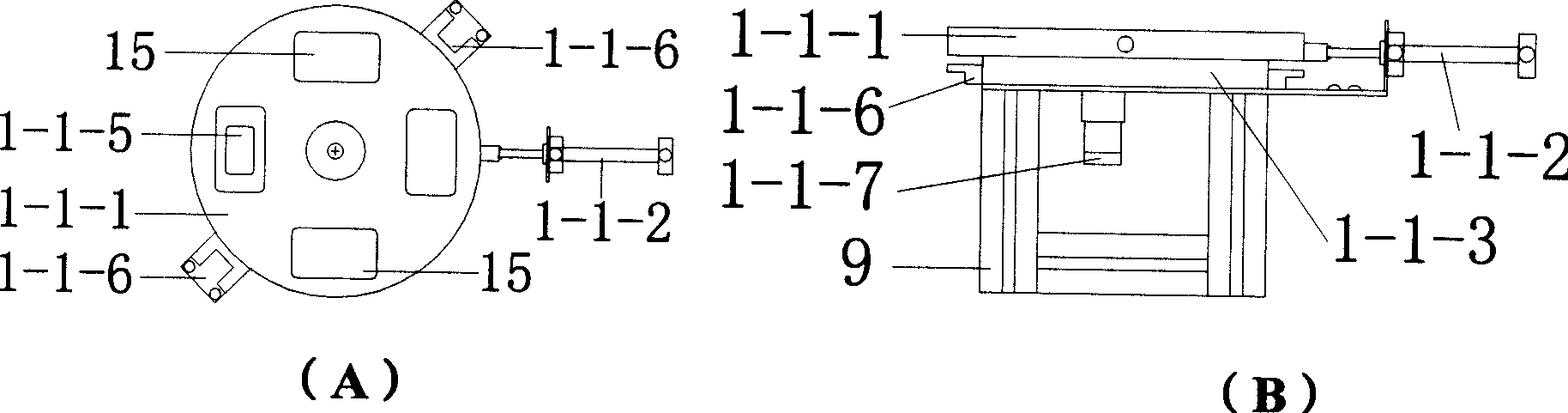

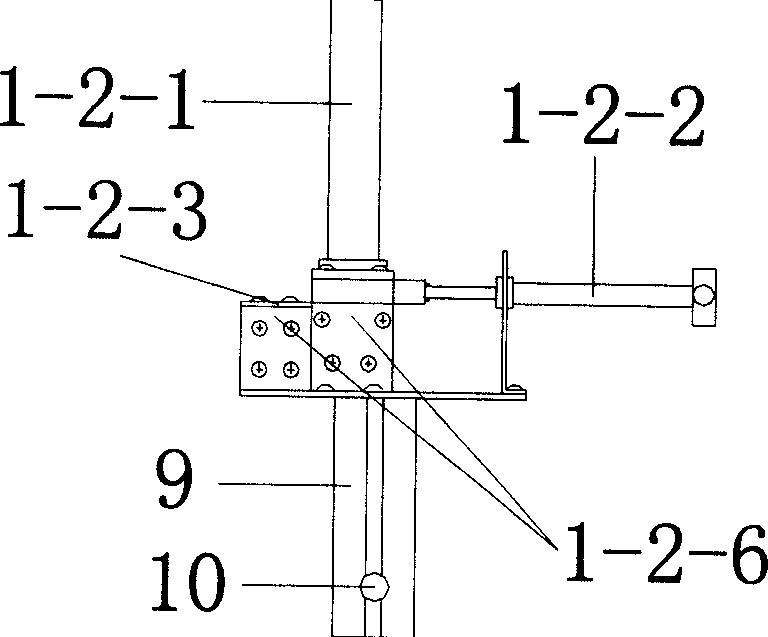

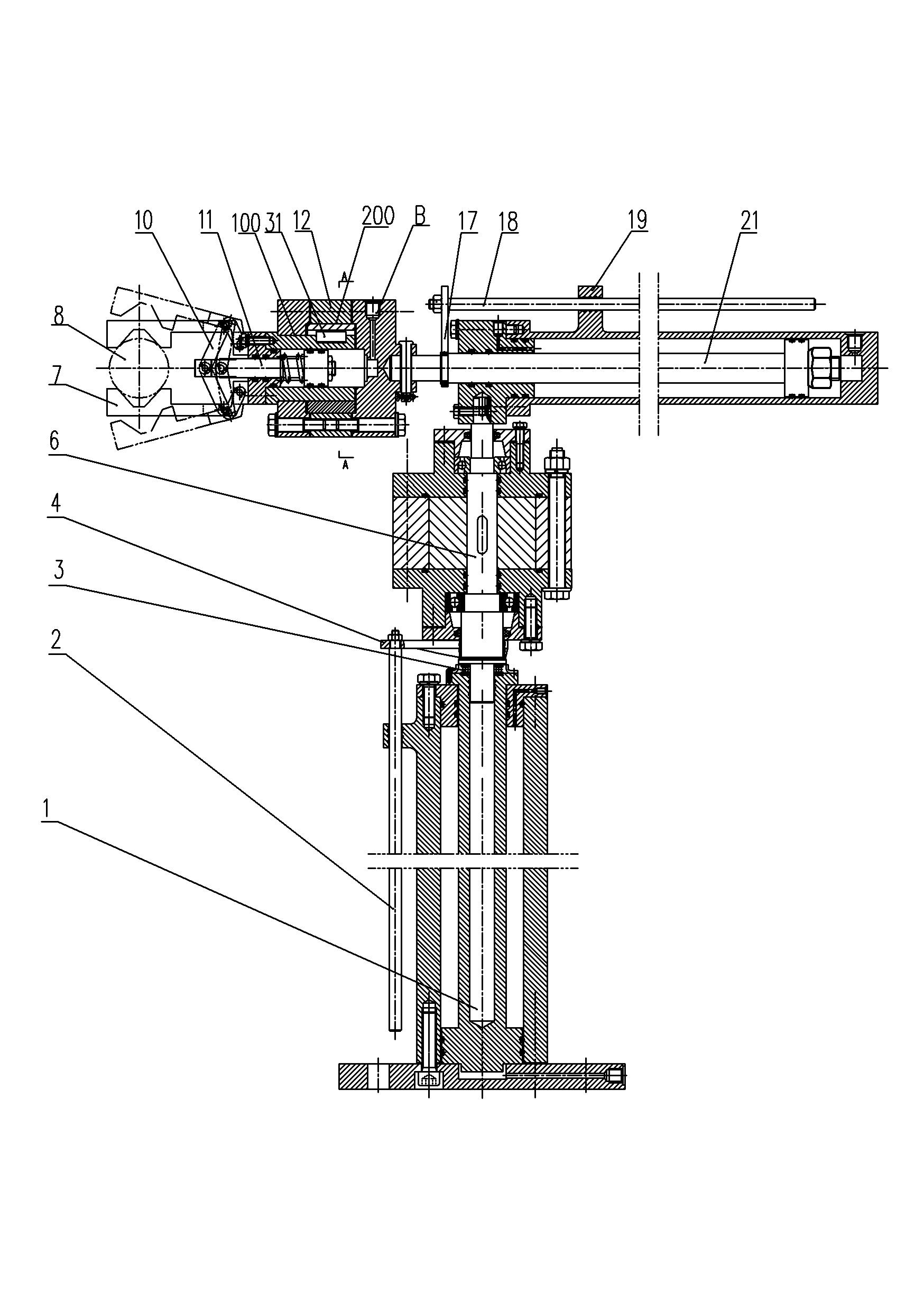

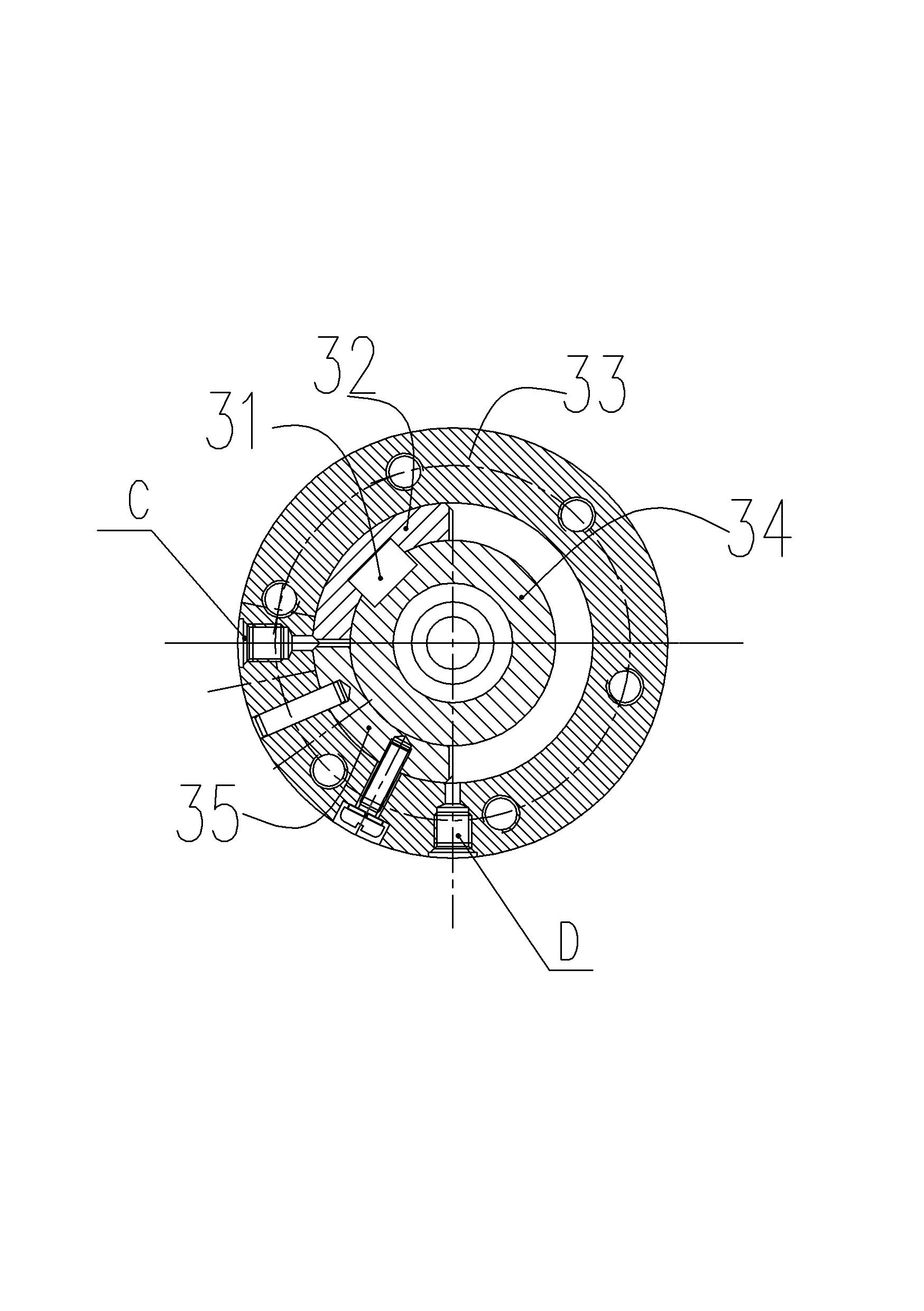

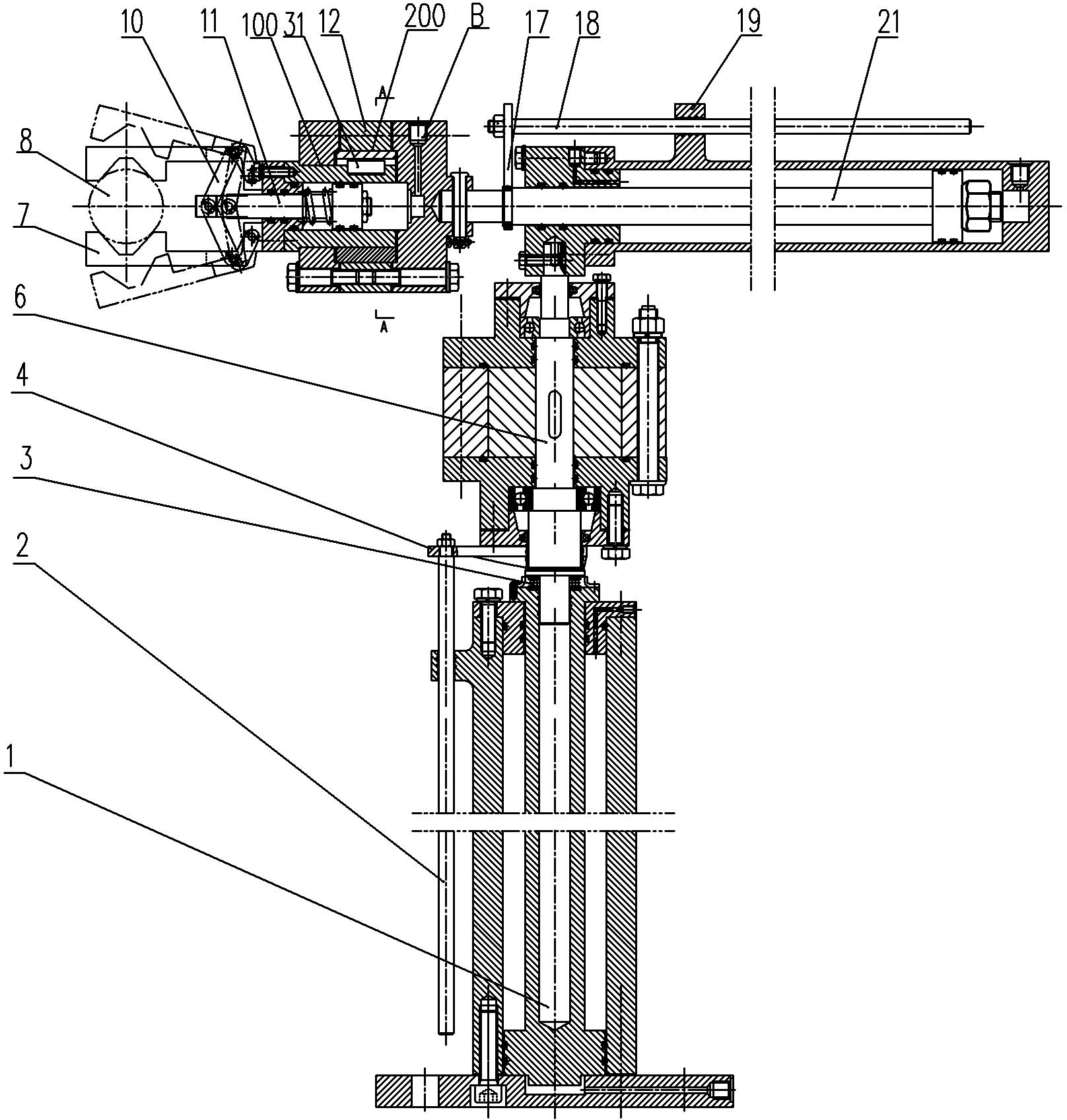

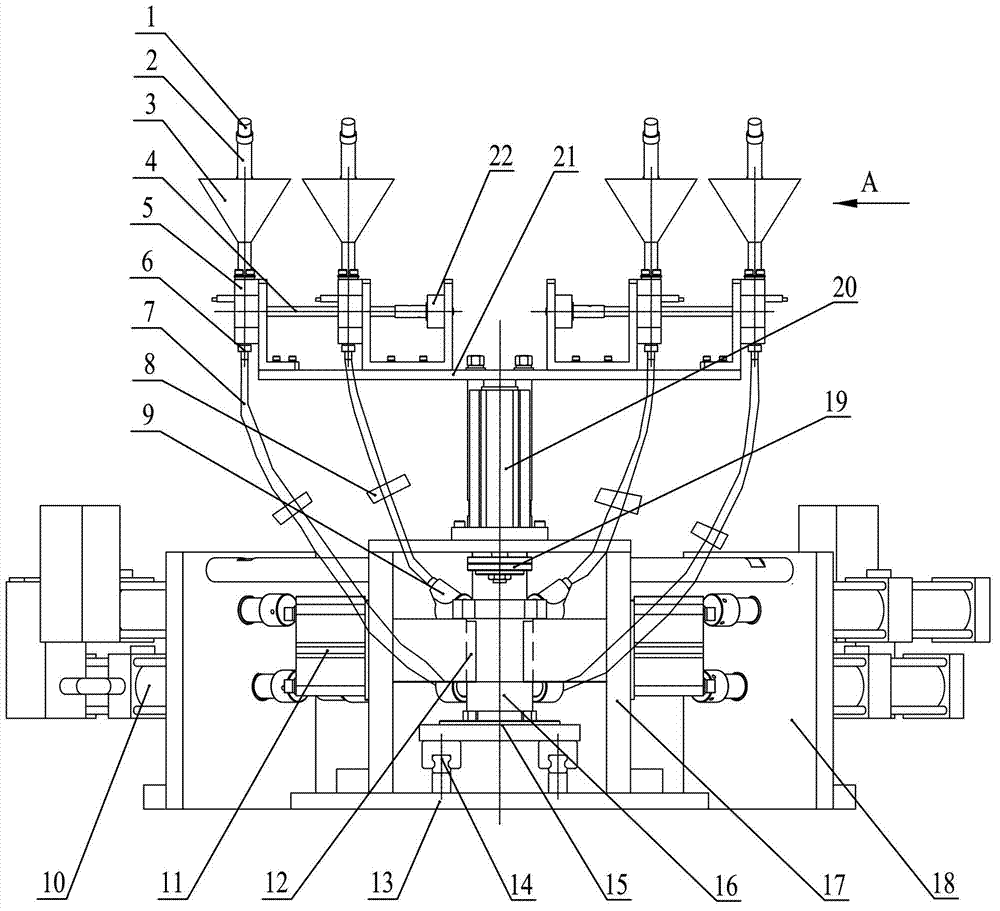

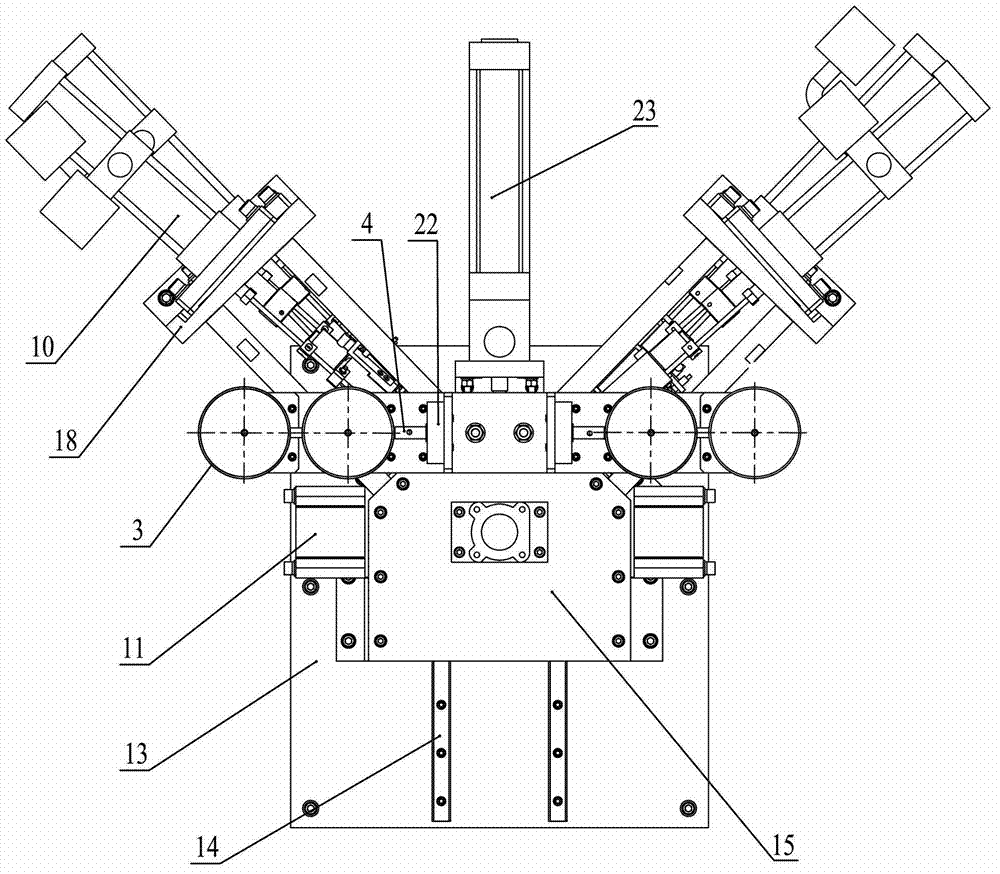

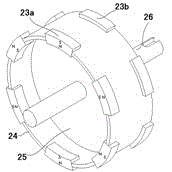

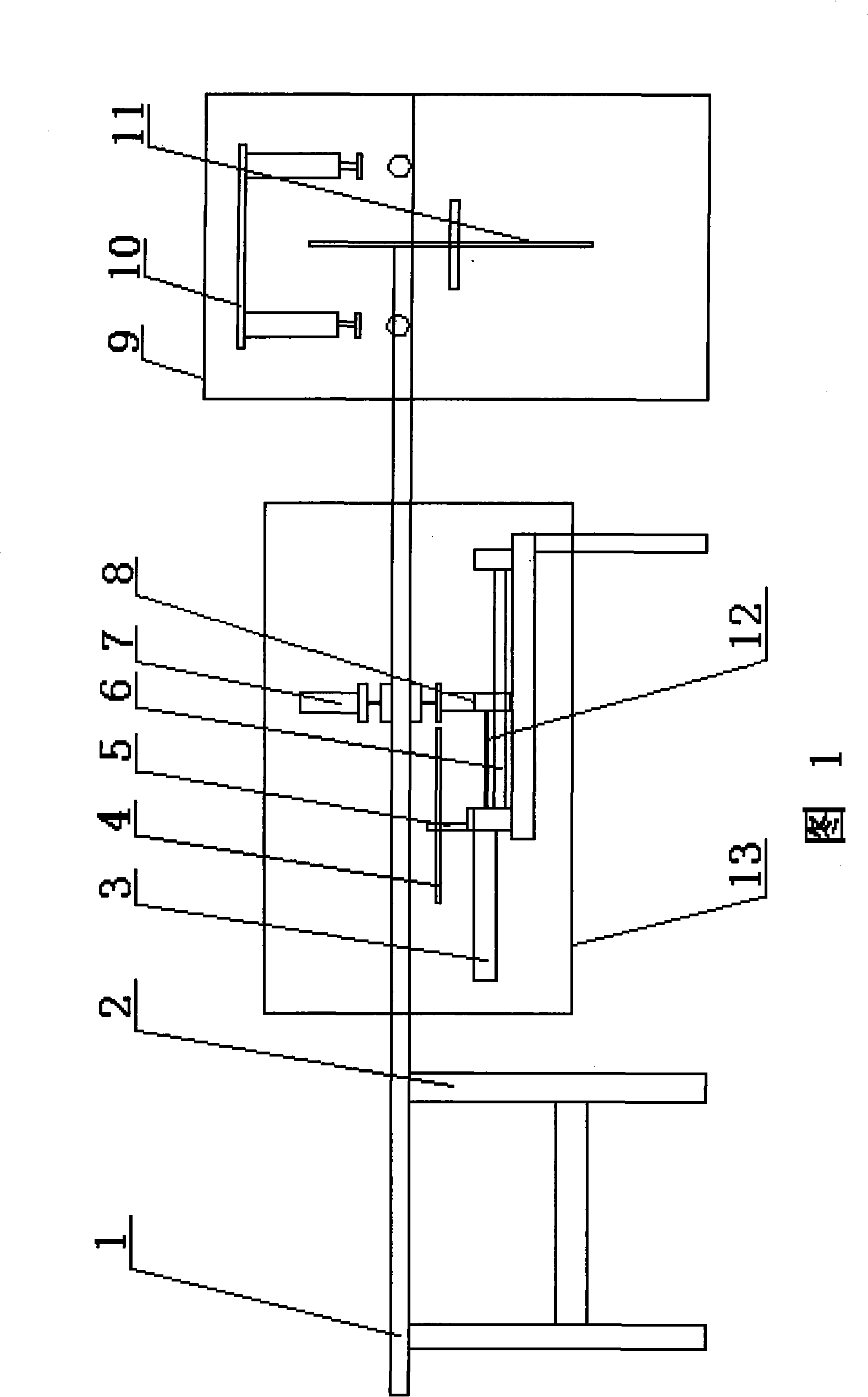

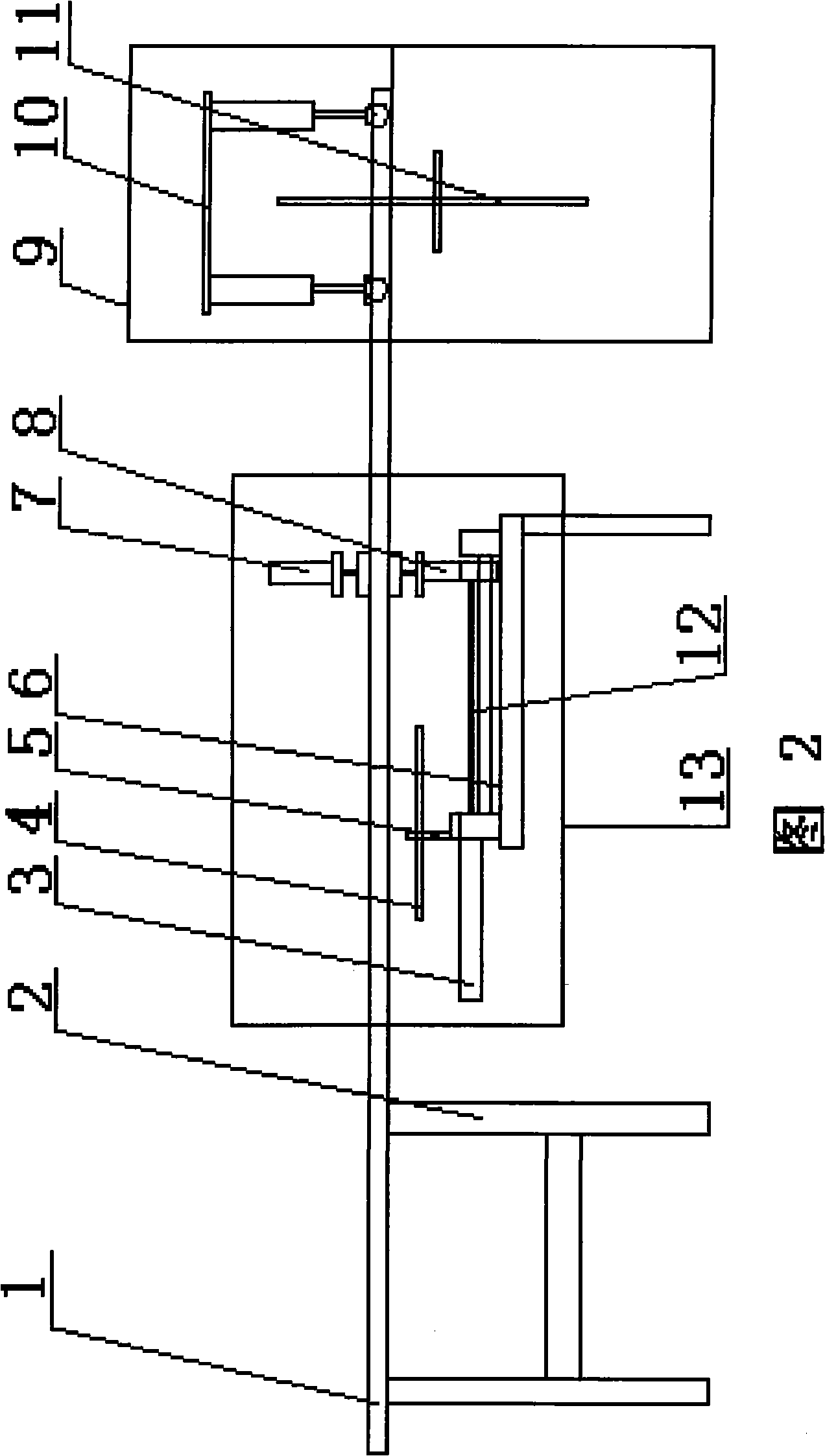

Picking robot and picking method for kiwi fruits

InactiveCN103749094AImprove environmental adaptabilityImprove work efficiencyPicking devicesActinidiaData acquisition

The invention discloses a picking robot and a picking method for kiwi fruits. The picking robot for the kiwi fruits comprises a machinery execution system and a control system, and is characterized in that the machinery execution system comprises a car body, a telescopic slide platform, a five freedom degree picking robot arm and a two finger type end actuator, and the control system comprises an industrial personal computer, a motion control card, a data acquisition card, an image acquisition card, a servo motor driver, a binocular video camera, an infrared sensor, a pressure sensor, an electric control cabinet and a control circuit. The picking robot and the picking method for the kiwi fruits use a building block design philosophy to integrate the two finger type end actuator, the five freedom degree picking robot arm, the telescopic slide platform and a sensor system together and integrate image acquisition and feature extraction of fruits and barriers, intelligent mobility of the telescopic slide platform, counterguard and fruit positioning of the five freedom degree picking robot arm and grab motions of the two finger type end actuator together, and therefore achieve mechanization and automation of picking of the kiwi fruits, improve labor productivity, reduce production cost, and guarantee harvest quality of the kiwi fruits.

Owner:NORTHWEST A & F UNIV

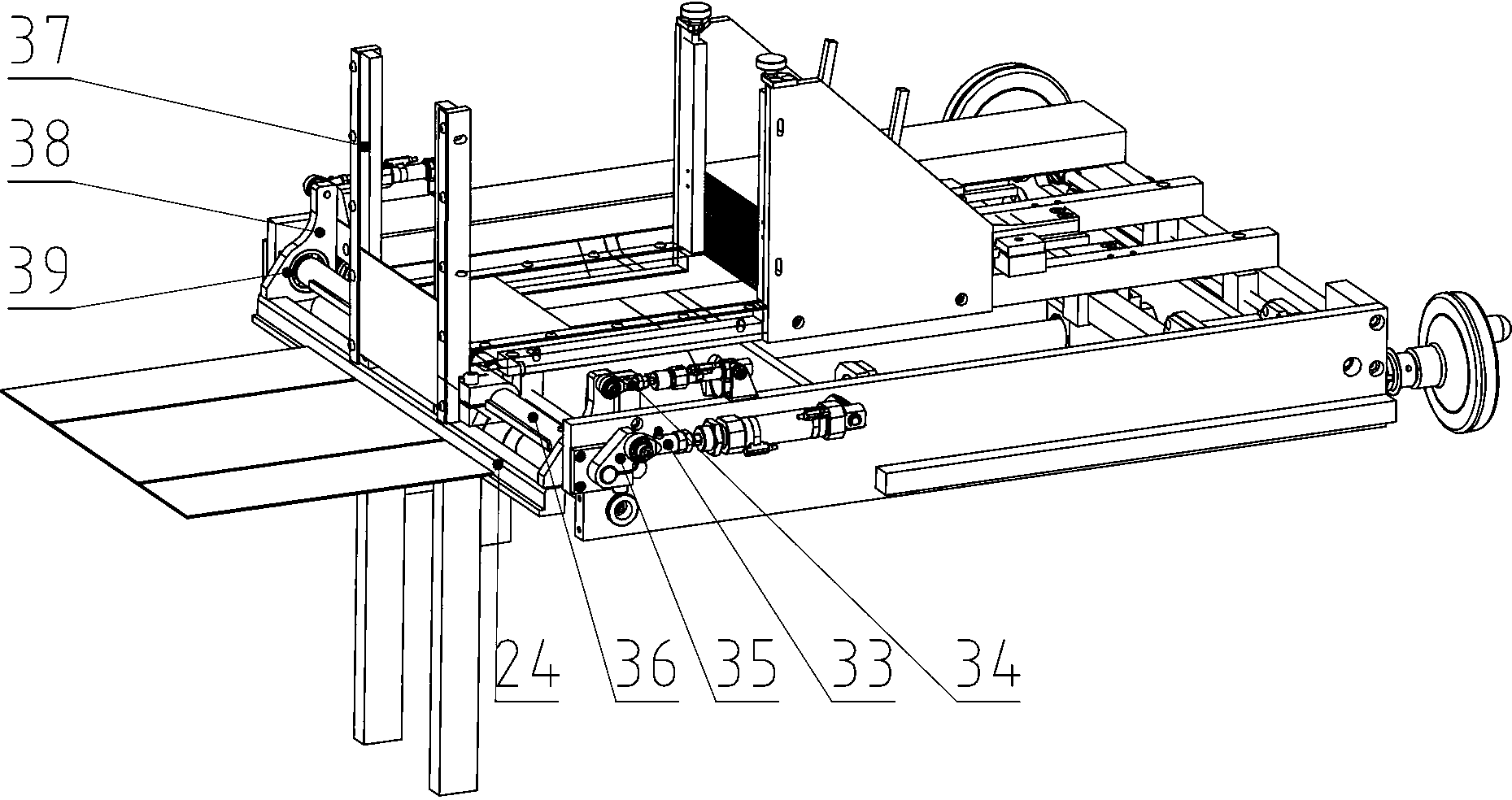

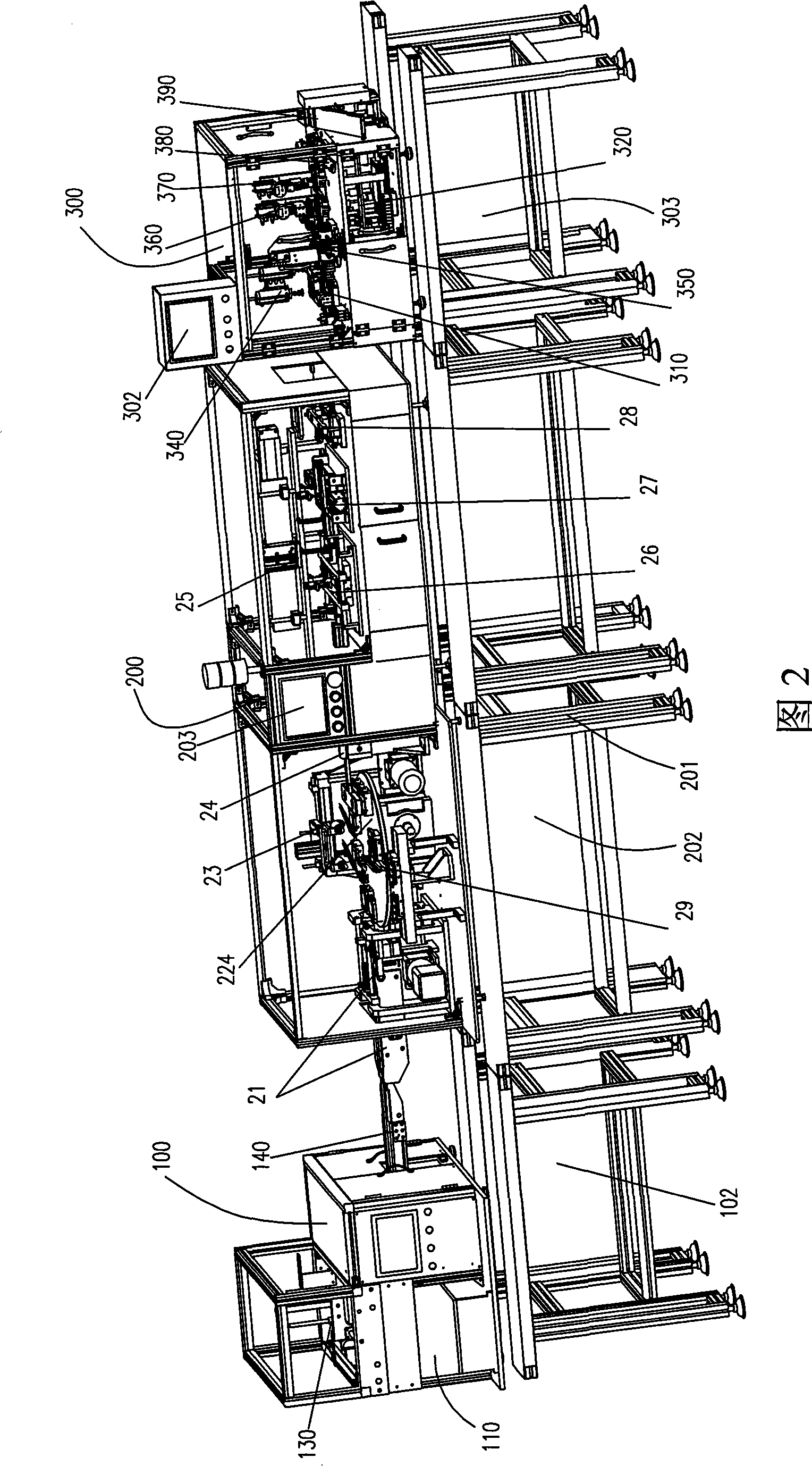

Full-automatic splicing type box machine and method for processing packing boxes

ActiveCN103317767ASolve the technical defect of insufficient firmnessRealize strong and beautifulBox making operationsPaper-makingEngineeringPackaging Case

The invention relates to a full-automatic splicing type box machine and a method for processing packing boxes. The full-automatic splicing type box machine comprises a bottom plate conveying and glue spraying station and a product forming station. The product forming station is connected with a left side plate conveying and erecting station and a right side plate conveying and erecting station, and a left plate erecting mechanism and a right plate erecting mechanism are respectively arranged at the two side plate conveying and erecting stations. The method for processing the packing boxes includes a technological procedure for conveying plates of the packing boxes, automatically spraying glue and forming and reinforcing the packing boxes by the aid of molds. The full-automatic splicing type box machine and the method have the advantages that a technological process is simple and feasible, effects of saving materials and reducing the cost are realized, the products are firm and attractive after being formed owing to an automatic glue spraying technology, a packing box processing procedure is automatic, and the full-automatic splicing type box machine and the method are favorable for organizing production and greatly improving the labor productivity.

Owner:WENZHOU GAOSHENG MACHINERY CO LTD

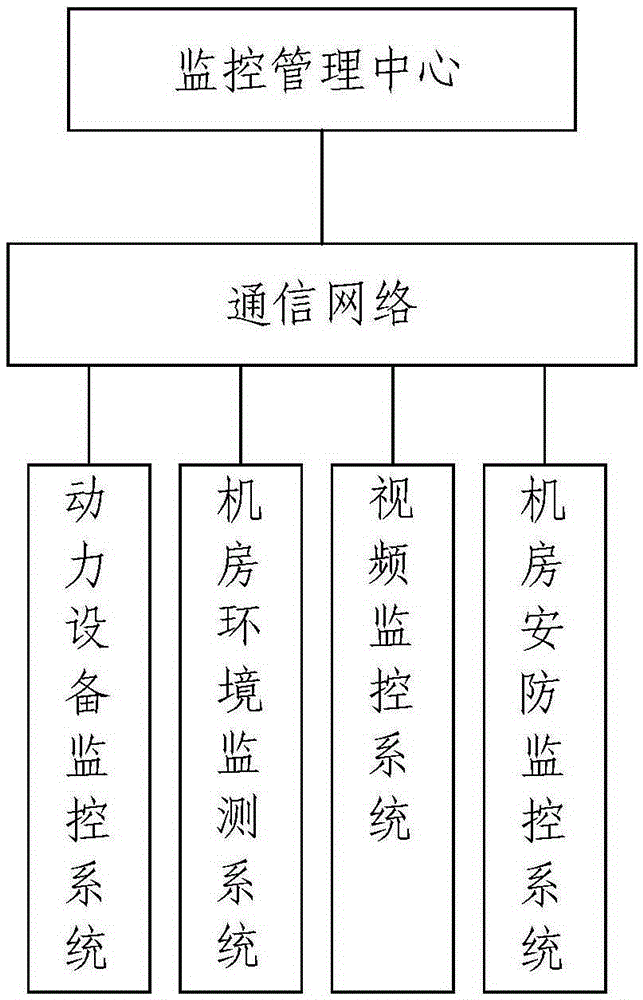

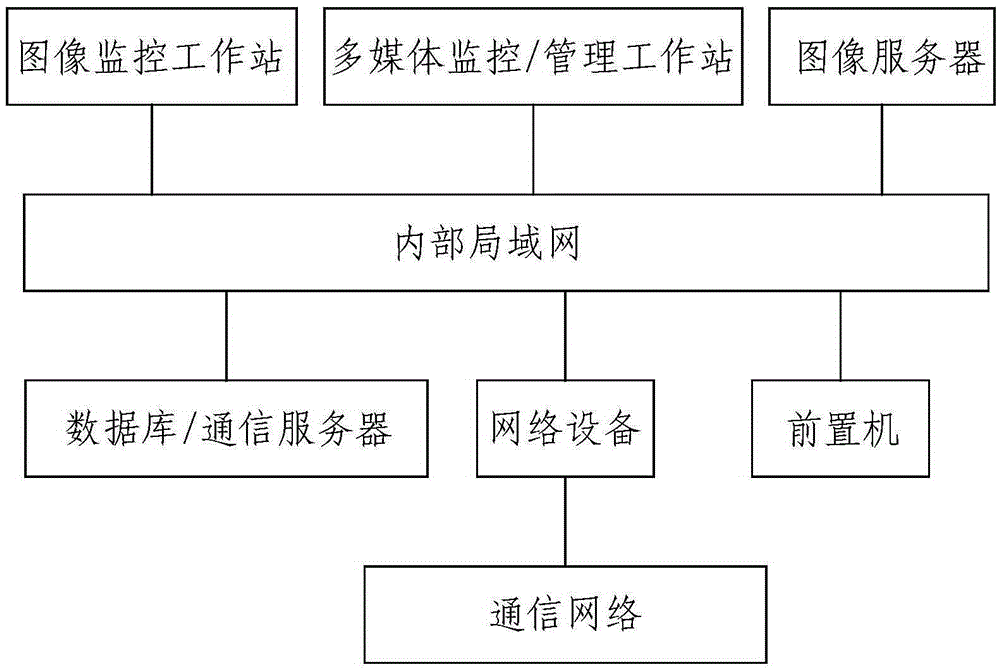

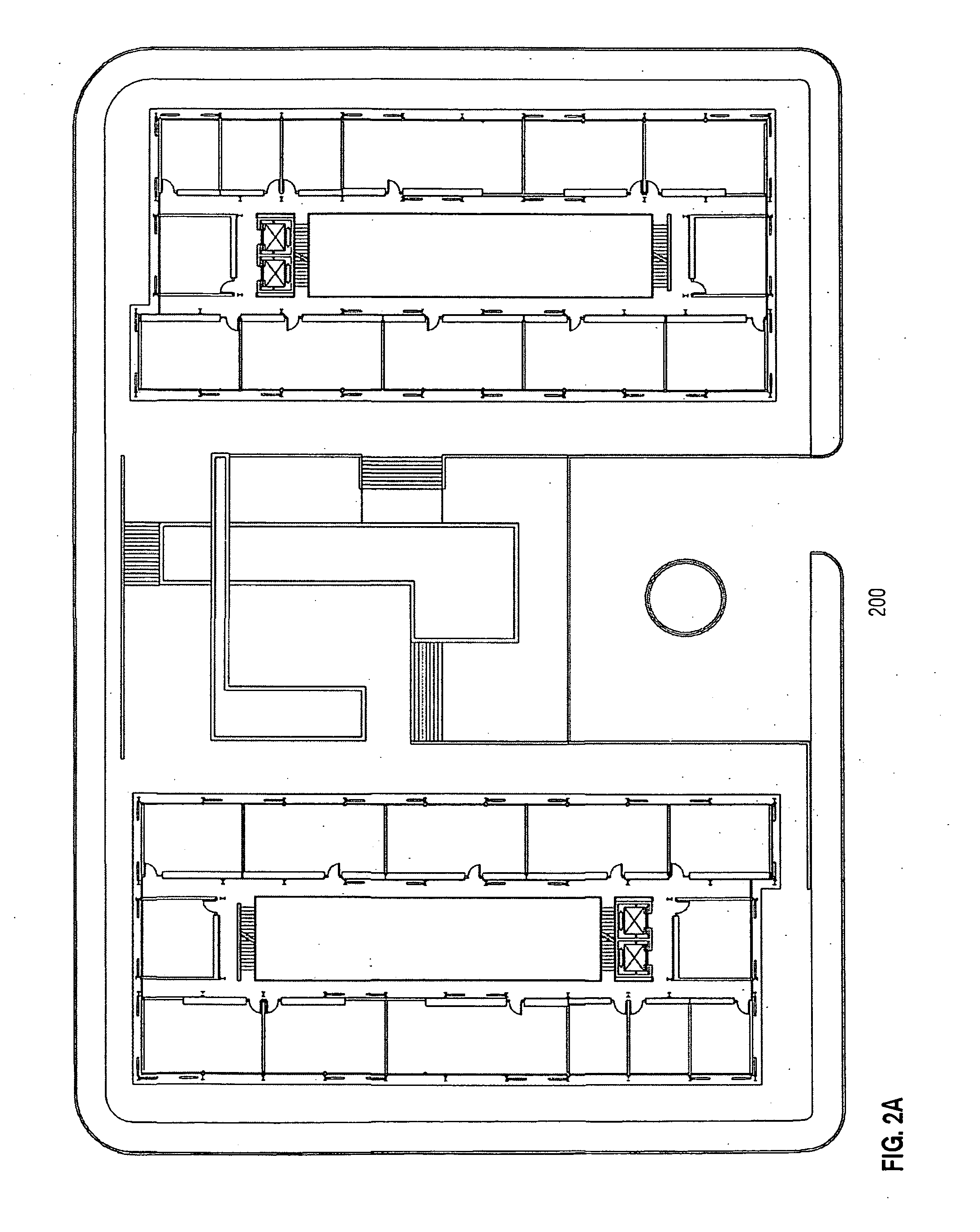

Machine room power environment centralized monitoring system

InactiveCN105425762AImprove reliabilityImprove securityProgramme total factory controlVideo monitoringReal-time data

Disclosed is a machine room power environment centralized monitoring system. The system comprises a monitoring management center, and a power equipment monitoring system, a machine room environment monitoring system, a video monitoring system and a machine room safety protection monitoring system which are connected with the monitoring management center through a communication network, wherein the monitoring management center is used for performing centralized monitoring management on the environment and power of a machine room, receiving various real-time data of the machine room, displaying a monitoring picture, realizing real-time processing analysis, storage, display and output functions of monitoring data, processing all alarm information, recording alarm events, outputting alarm content through telephone voice or mobile phone short messages and the like and sending control commands of management personnel to the power equipment monitoring system, the machine room environment monitoring system, the video monitoring system and the machine room safety protection monitoring system which are arranged in the machine room. The machine room power environment centralized monitoring system solves the problem of incapability of omni directional monitoring of the environment of the machine room by use of a conventional machine room monitoring device, ensures stable operation of machine room equipment and safety of the machine room, and has a positive promotion significance on modernization of maintenance of power supply equipment.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

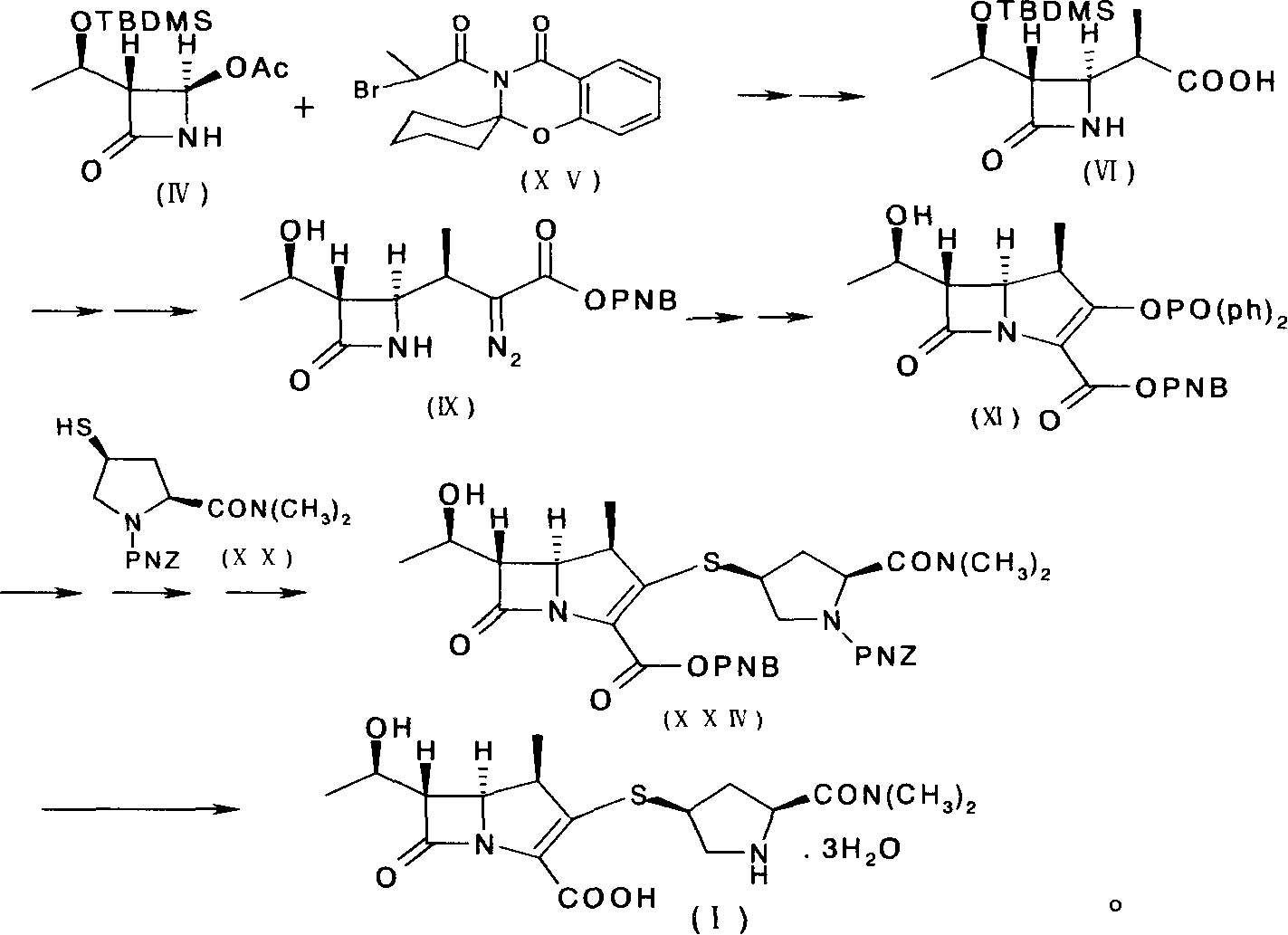

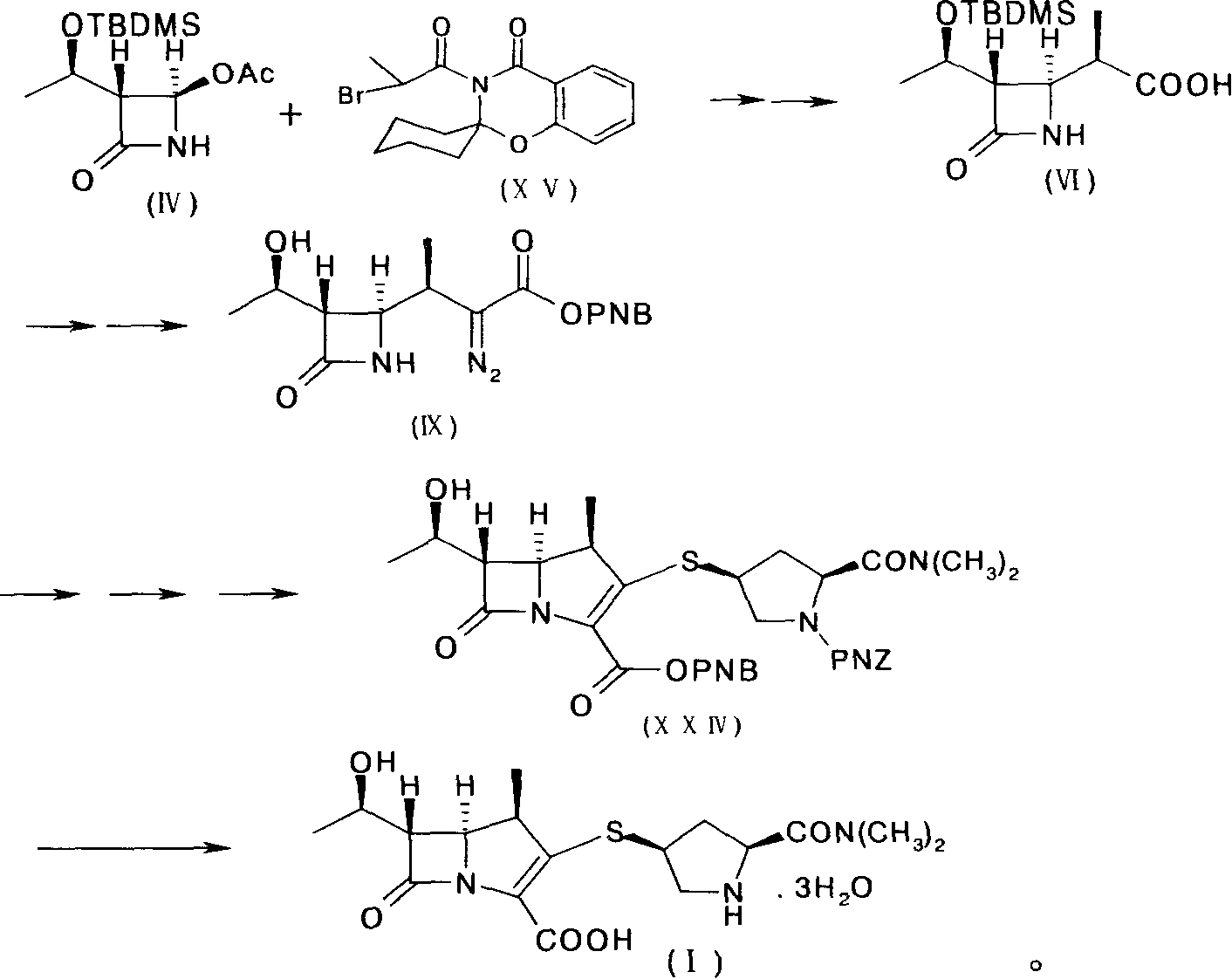

Preparation method of meluopeinan

InactiveCN1948312AReduce typesReduce the use effectAntibacterial agentsOrganic chemistryState of artChemical structure

The present invention relates to a preparation method of beta-methylcarbapenem antibiotic-meropenem. Said invention provides its chemical structure formula, and concrete steps of its preparation method.

Owner:SHENZHEN HAIBIN PHARMA +1

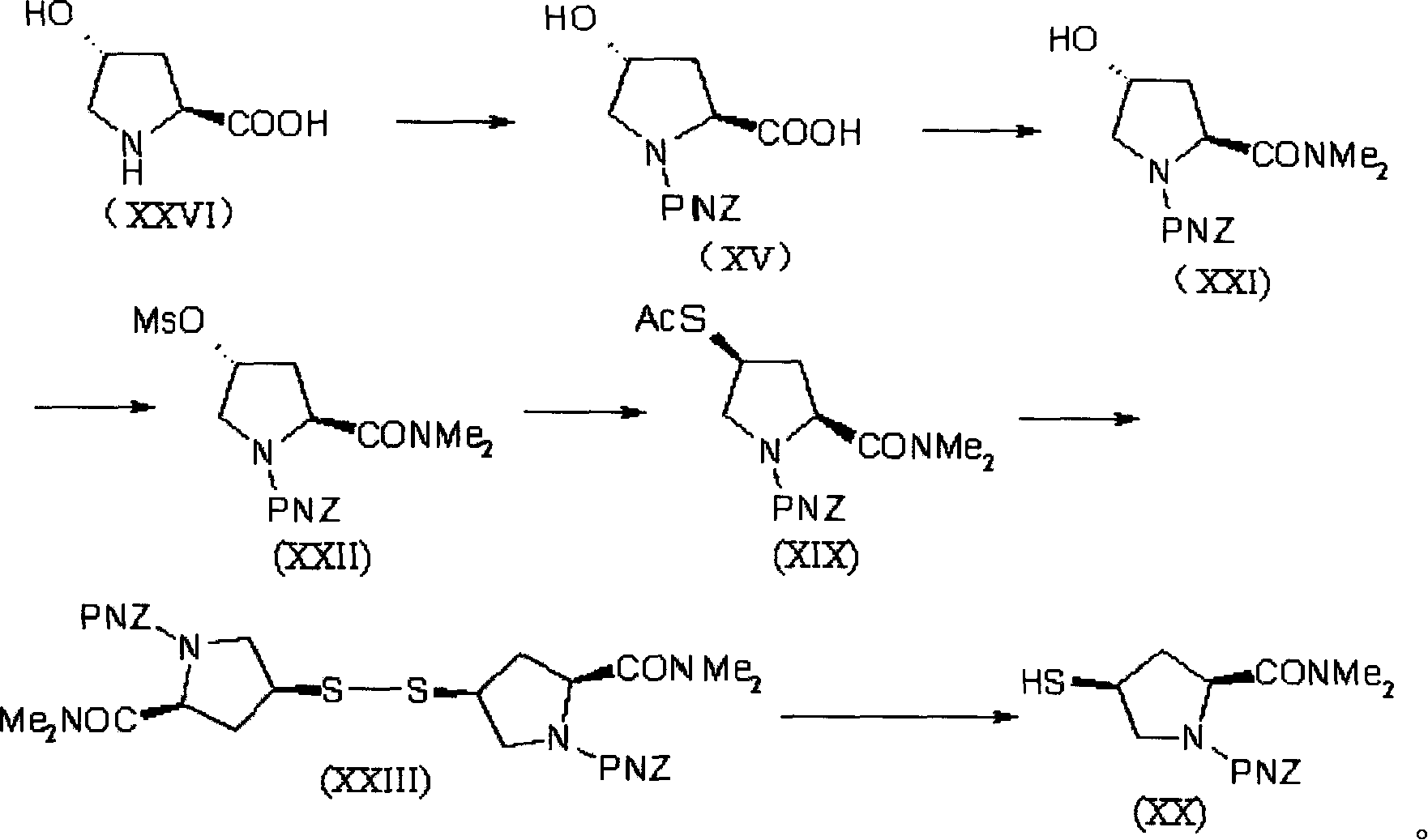

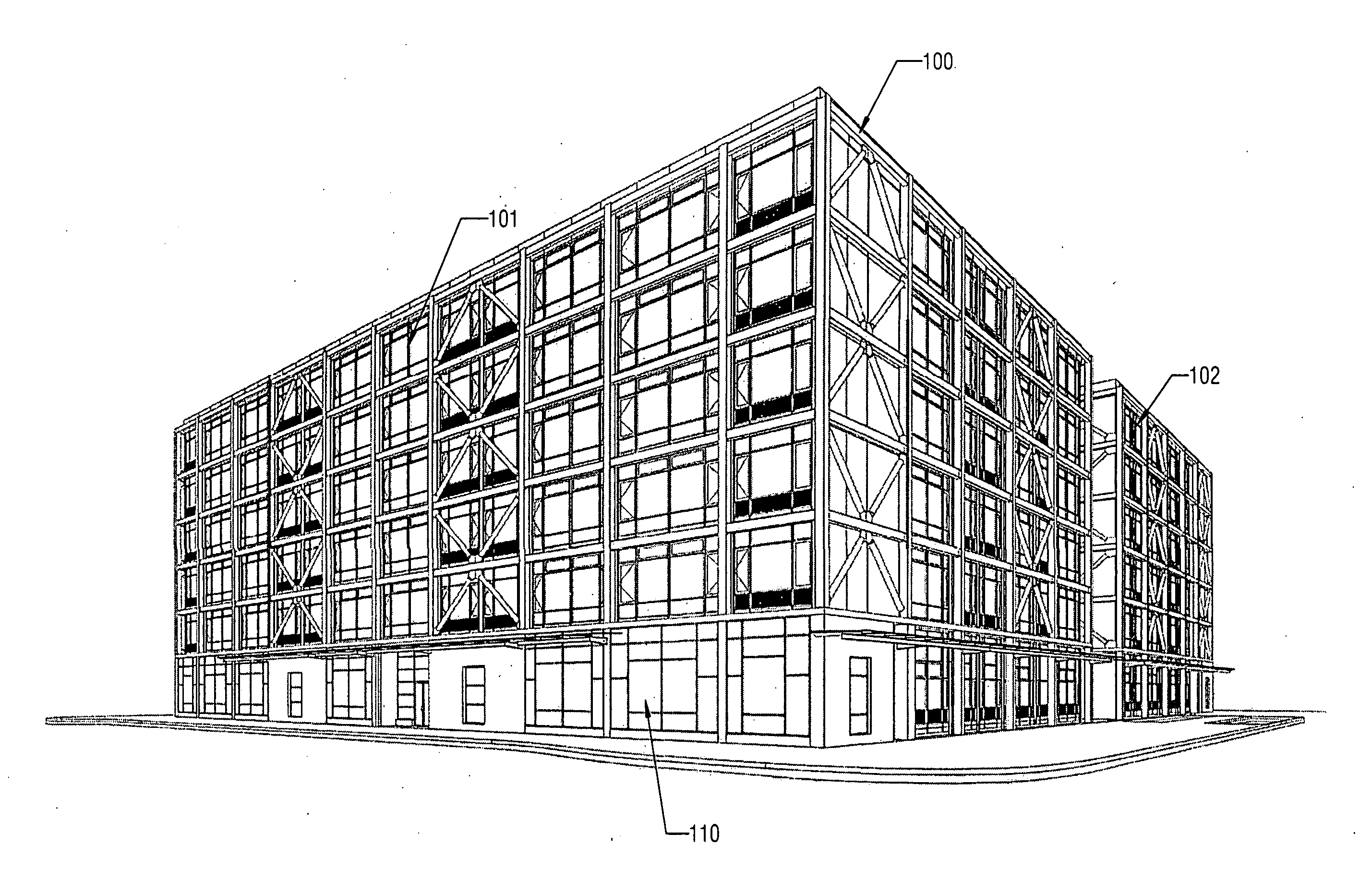

Lift-slab construction system and method for constructing multi-story buildings using pre-manufactured structures

ActiveUS20130067832A1Efficient and quick installation methodEliminates potential unsafeCovering/liningsWallsDesign planIntelligent design

The present invention integrates the use of pre-manufactured structures with minimal on-site installation and lift-slab construction to achieve the construction of multi-story buildings. The pre-manufactured structures are designed to be readily integrated with both horizontal and vertically adjacent building components, including lift-slab components, so that multiple building stories may be readily and securely stacked, one on top of the other. The present invention advantageously permits top- down lift-slab construction for multi-story buildings. The present invention also provides for the development of flexible design plans for institutional, residential, office and other types of buildings. The present invention advantageously provides for easier, more efficient, faster, cheaper, safer, higher quality and more consistent, environmentally advantaged, energy-efficient, easier to maintain, intelligently designed, and customizable multi-story building construction.

Owner:INNOVATIVE BUILDING TECH

Electroplating solution and electroplating method for electroplating through holes and blind holes of circuit boards

The invention discloses an electroplating solution for electroplating through holes and blind holes of circuit boards. The electroplating solution comprises the following components: 160-180g / L of copper sulfate pentahydrate, 20-50g / L of sulfuric acid, 0.05-0.07g / L of chloride ions, 0.5-1.5g / L of accelerant, 7-30g / L of inhibitor, 10-30g / L of leveling agent and the balance of water. The electroplating solution provided by the present invention is applicable to electroplate through holes and blinds holes of circuit boards, and in particular capable of realizing simultaneously hole-filling electroplating of a through hole and a blind hole in one groove of a circuit board; as a result, the electroplating steps are reduced and the production efficiency is improved.

Owner:苏州禾川化学技术服务有限公司

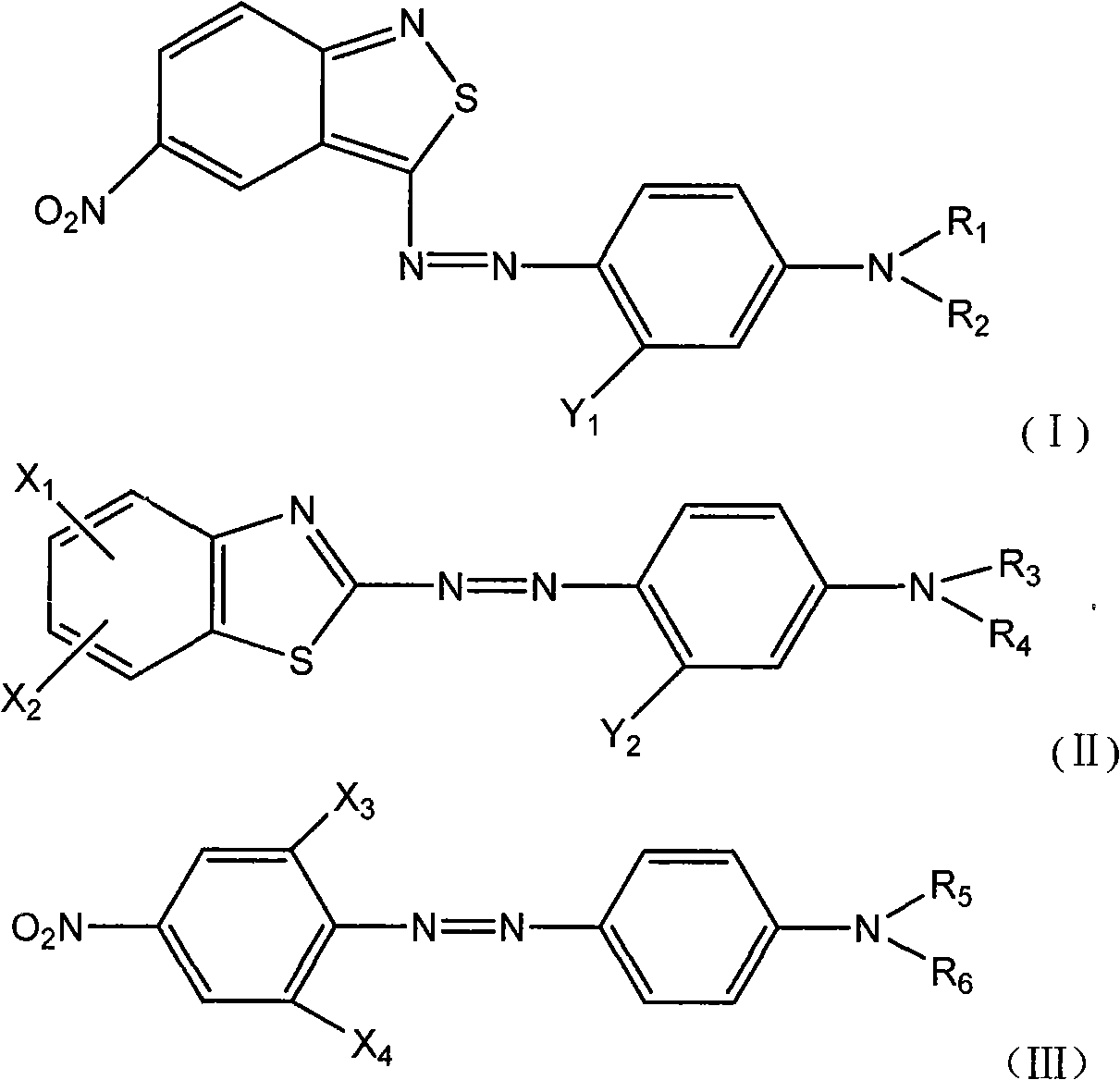

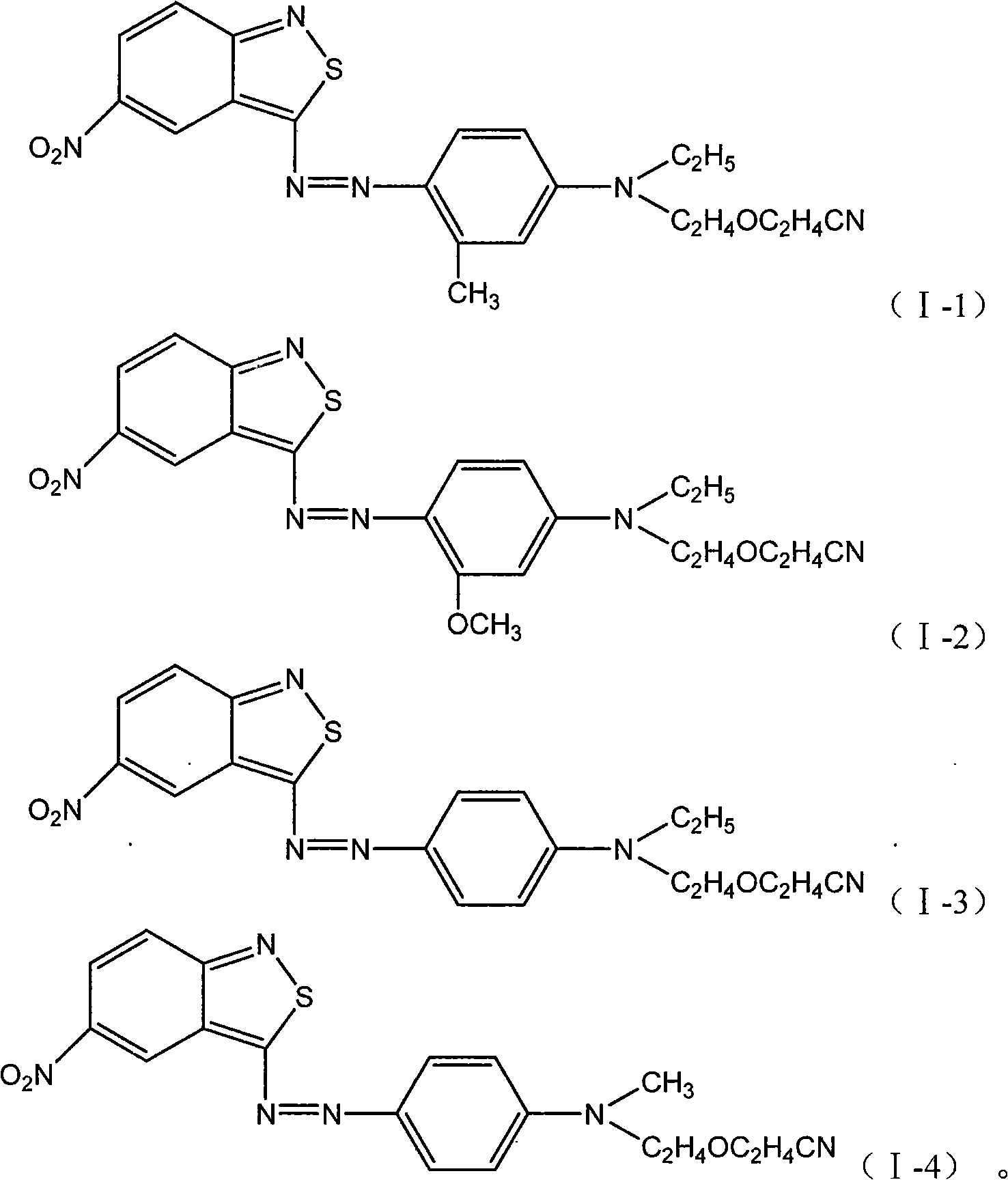

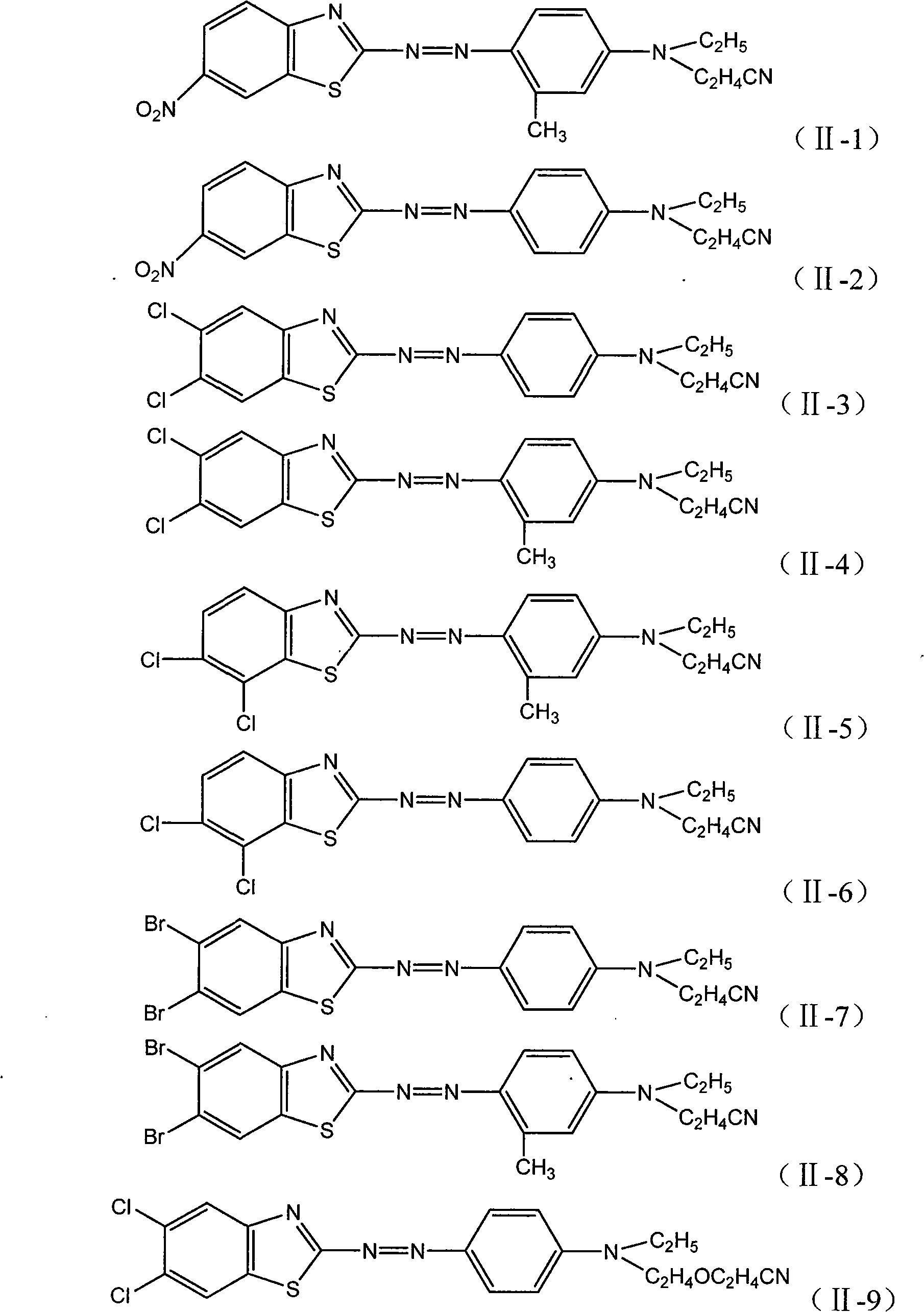

Disperse dye composition suitable for basic dyeing

ActiveCN101649129AAvoid problems such as contaminationGuaranteed stabilityOrganic dyesDyeing processDisperse dyeColour fastness

The invention provides a disperse dye composition suitable for basic dyeing, mainly comprising the following raw materials in percentage by weight: 40-95 percent of one or a plurality of blue dyeing components A with a structural formula (I), 1-25 percent of one or a plurality of red dyeing components B with a structural formula (II) and 4-50 percent of one or a plurality of orange dyeing components C with a structural formula (III). The disperse dye composition has a wide dependency range of pH values, and can dye in a pH value ranging from 4.0 to 10; dyed and woven fabrics with predominant color-fastness performance, such as full hues, washing fastness, and the like, can be obtained.

Owner:浙江龙盛染料化工有限公司

High temperature resistant economical electrostatic powder coating for electric room heater and preparation method thereof

InactiveCN101565587AImprove heat resistanceAvoid harmFireproof paintsPowdery paintsMetallurgyHigh pressure

The invention discloses a high temperature resistant economical electrostatic powder coating for an electric room heater and a preparation method thereof. The formulation of the powder coating comprises the following compositions in percentage by weight: 53 to 57 percent of thermosetting resin, 3 to 7 percent of curing agent, 1 to 30 percent of pigment, 5 to 34 percent of filler and 2 to 5 percent of auxiliary agent. The powder coating is produced by adopting the method of premixing, melt extrusion and mixing, tabletting, cooling and crushing, fine grinding and classification, sieving and separation, and product, wherein the average particle size of the powder coating is between 25 and 30 mu m, and the thickness requirement between 50 and 60 mu m of an economic coating is met. The powder coating is suitable for coating by a high voltage electrostatic powder coating method and simultaneously is suitable for coating by a frictional electrostatic powder coating method.

Owner:杨彬

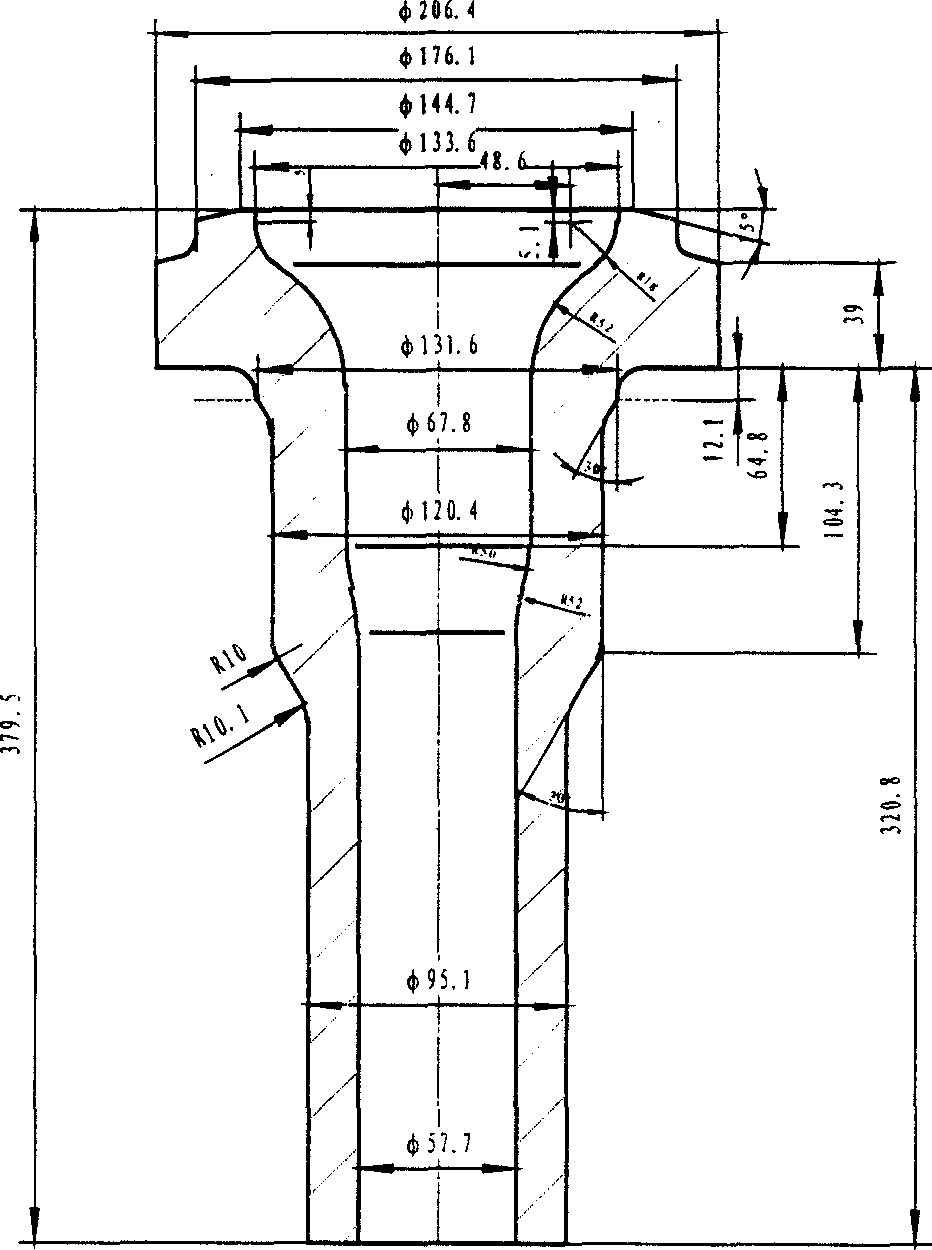

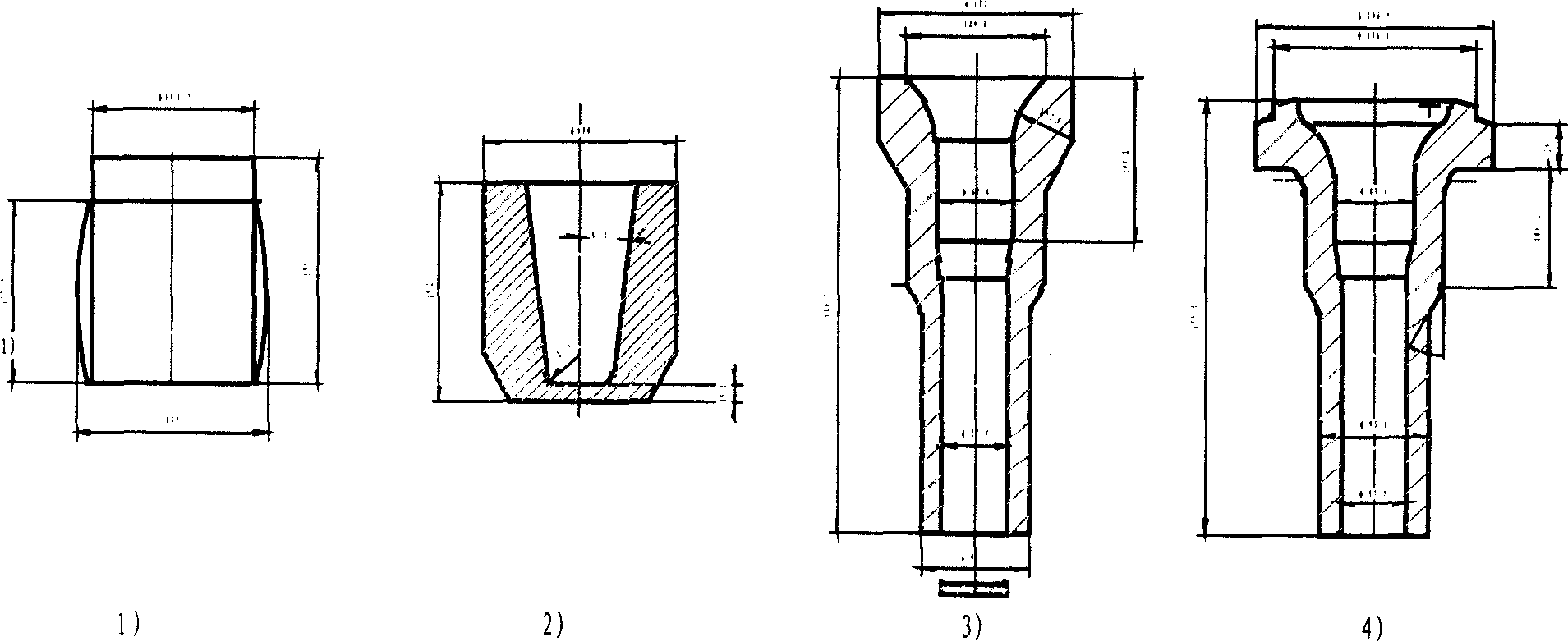

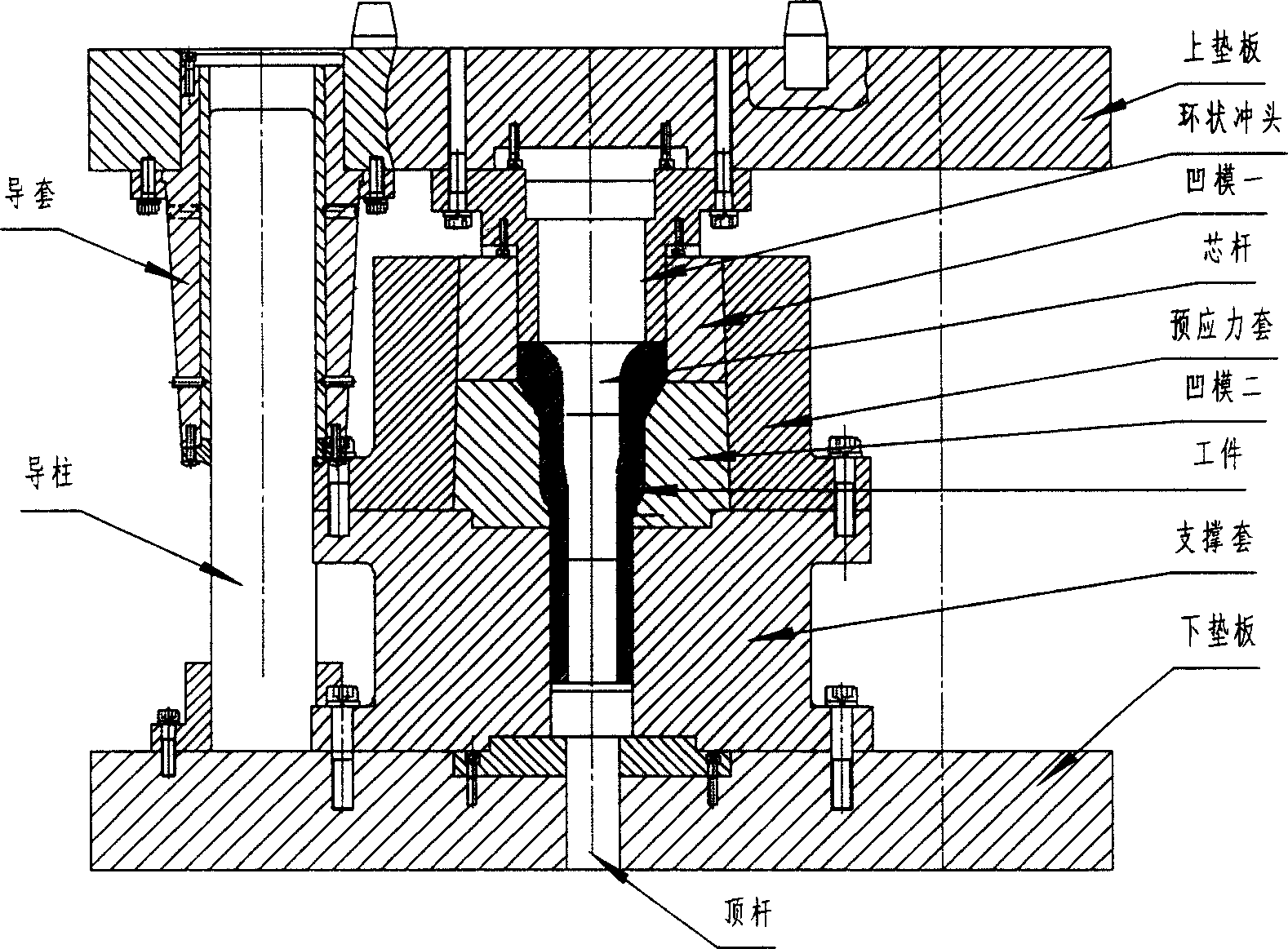

Fast precise semi-axle casing extruding formation process

InactiveCN1672863AImprove the state of stressGuaranteed dimensional accuracyMetal-working apparatusOther manufacturing equipments/toolsEngineeringMachining

The technological process of fast forming precise semi-axle casing with circular rod material heated to forging temperature includes four steps of upsetting, punching hole, perforating and positive extruding. The present invention realizes the fast formation of precise semi-axle casing in only four steps. Combined male die structure is adopted to simplify the technological process of extruding hollow rod, and the present invention has high production efficiency and raised material utilization.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

Logistics operation training system and making method

InactiveCN1716342AIncrease isolation protection functionEasy to set upEducational modelsMicrocontrollerLogistics management

The logistics operation training system includes manipulator assembling and conveying operation unit, automatic cargo distinguishing and buffering operation unit, stacking operation unit, automatic warehouse operation unit, visual detection operation unit, stacking operation unit, cargo flow direction controlling operation unit and container packing operation unit. Each of the operation units is provided with monolithic computer circuit and logic circuit with modular electric interface, and different units may be selected to form stepped configuration. The present invention is suitable for different teaching and training modes.

Owner:TIANJIN YUANFENG TECH DEV

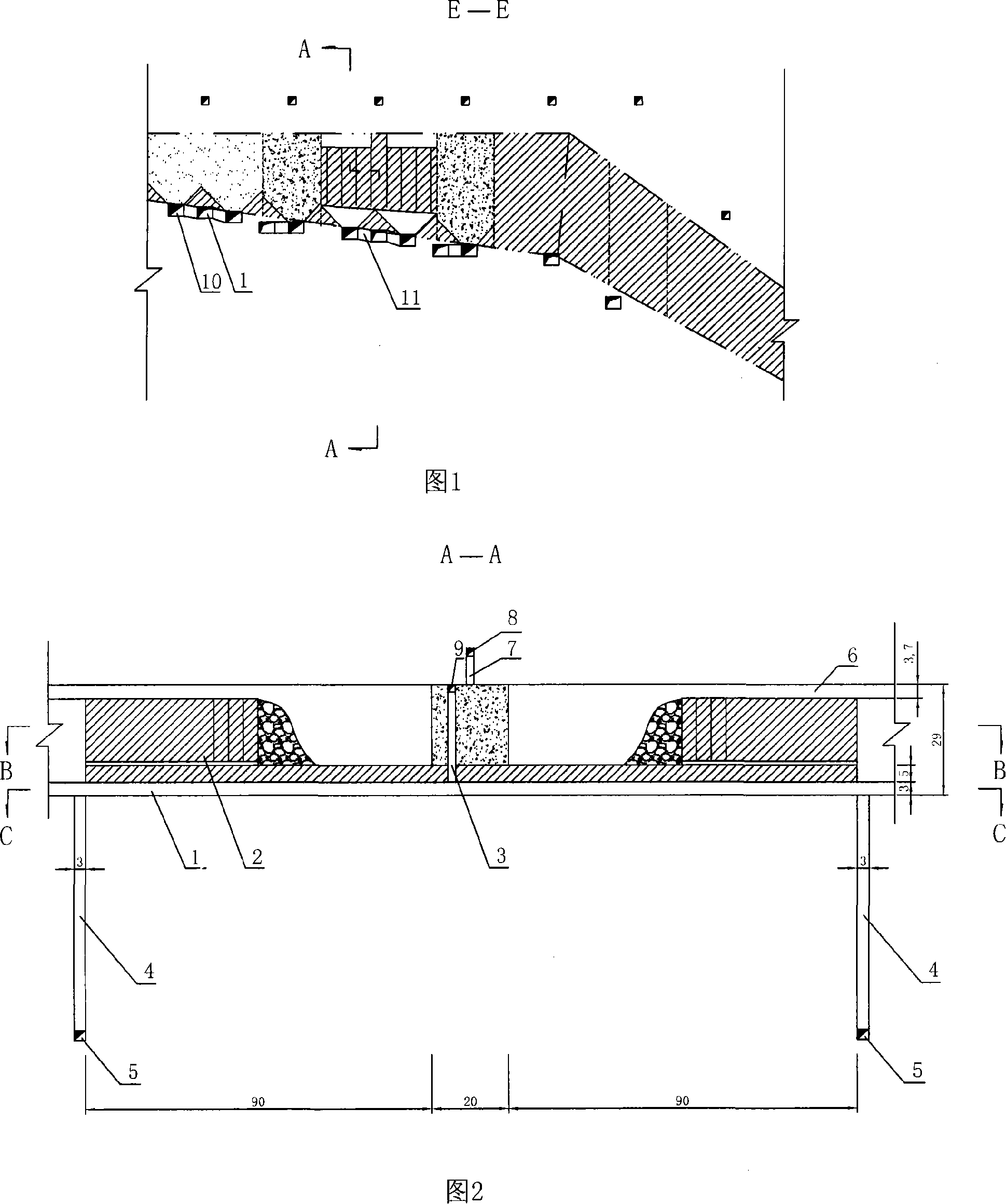

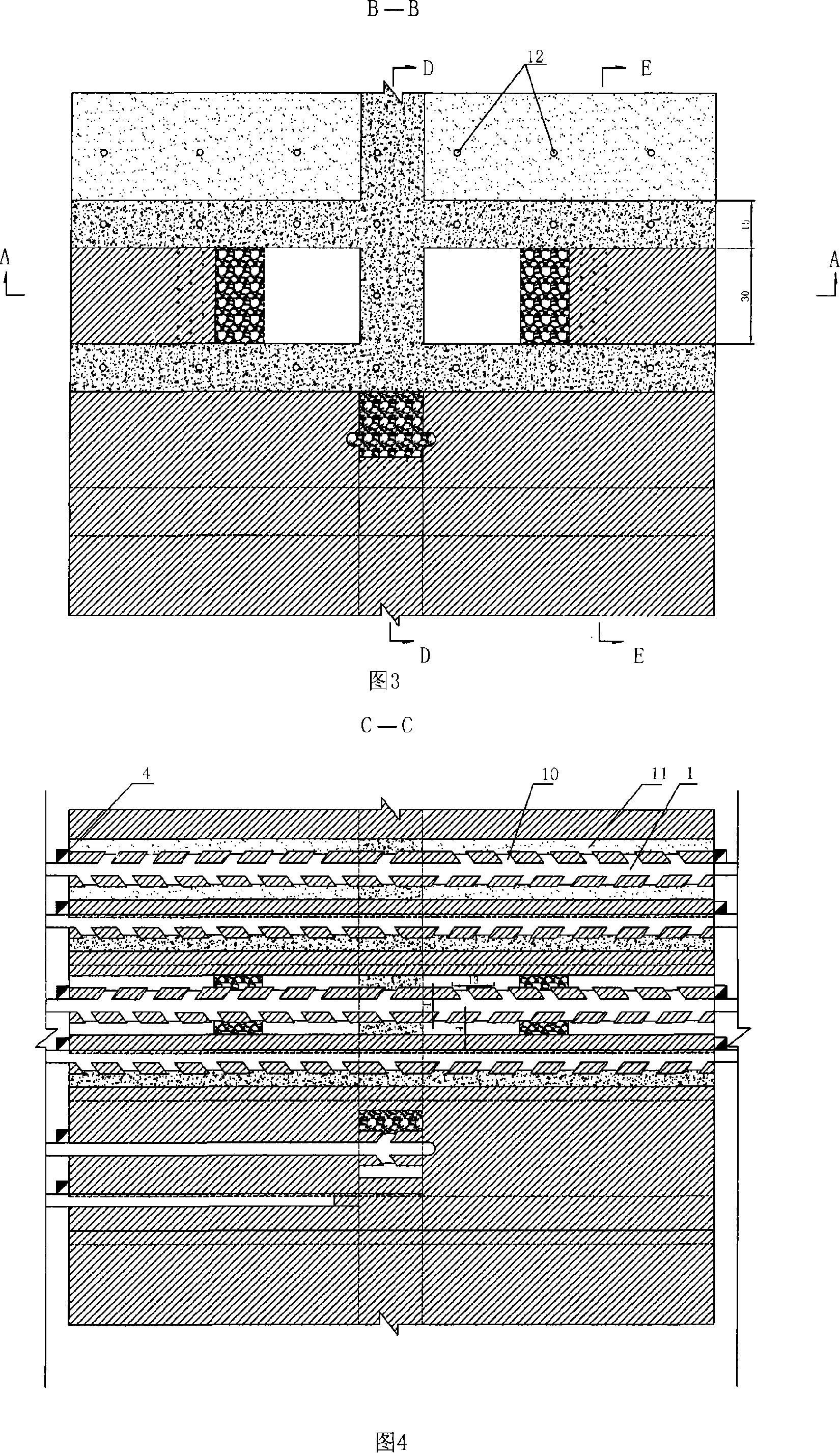

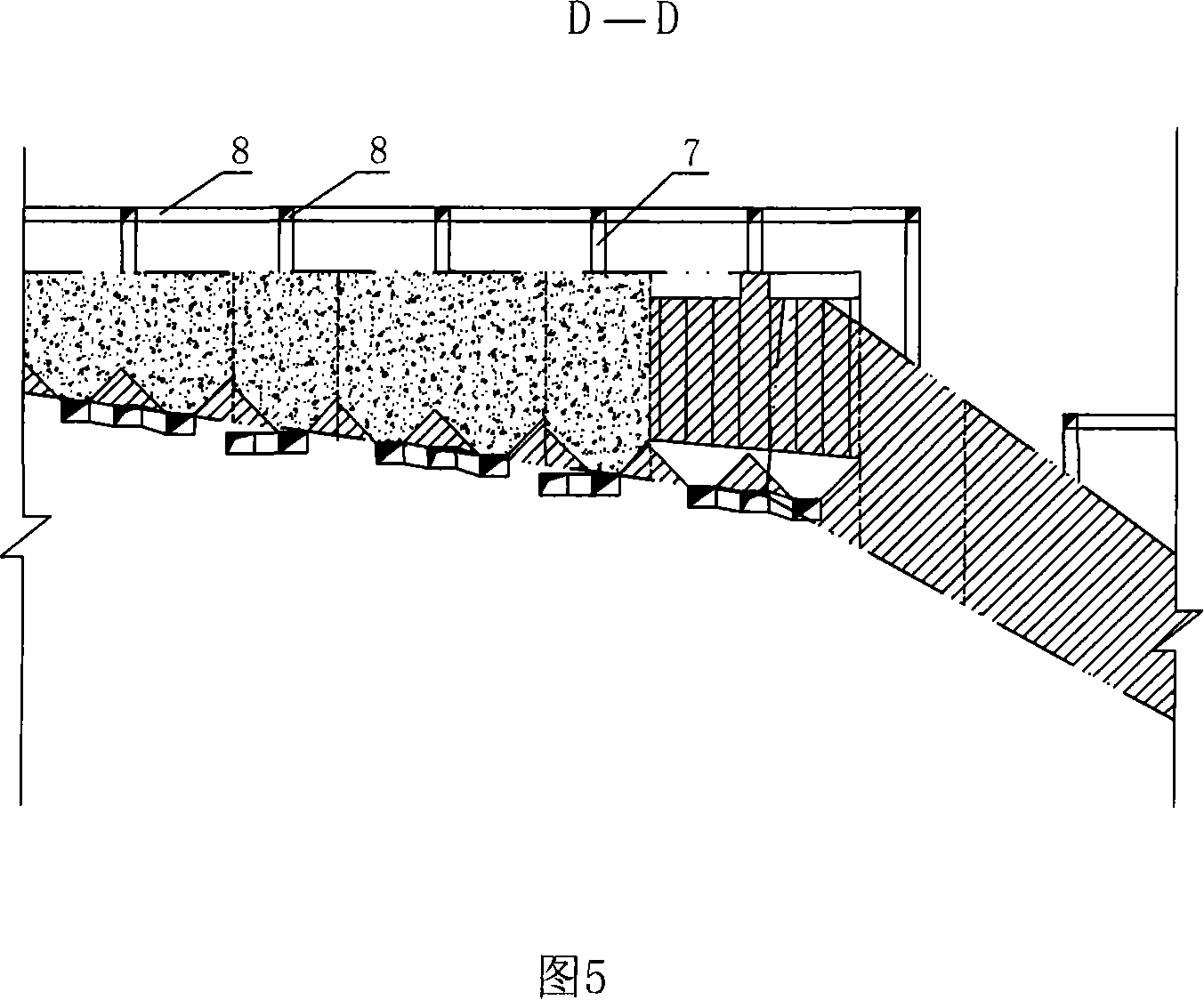

Mining environment reconstructed continuous mining afterwards filling mining method

InactiveCN101105129AHigh recovery rateImprove productivityUnderground miningSurface miningProduction rateMineralogy

The invention discloses a method of continuous mining followed by filling with mining environment reconstruction. The method comprises mining strip ore section in the middle part of the ore body, mining ore section with proper width extending towards two sides of the site that is perpendicular to and has proper distance far away the strip ore section followed by cementation filling to the mined-out area to form a continuous crisscross cementation filling top plate support frame structure. The frame structure meanwhile separates the ore body into several spaced and independent ore sections to reconstruct a new mining environment in the ore body. In such environment, performing spacedly or parallelly second mining with independent ore sections as second mining units followed by non-cementation filling to the mined-out area to realize continuous mining in the overall ore body, performing ore breaking in lateral direction with downward parallel and vertical deep holes, loading ore with double-trench or single-trench as bottom structure along ore blocks direction, landing down to the main gangway in the next stage through stage drop shaft, and transporting out of the mine by downhole locomotive. The invention has the advantages of safe and reliable mining environment, remarkably improved ore recovery rate and productivity, effectively controlled loss, and remarkably reduced production cost.

Owner:CENT SOUTH UNIV

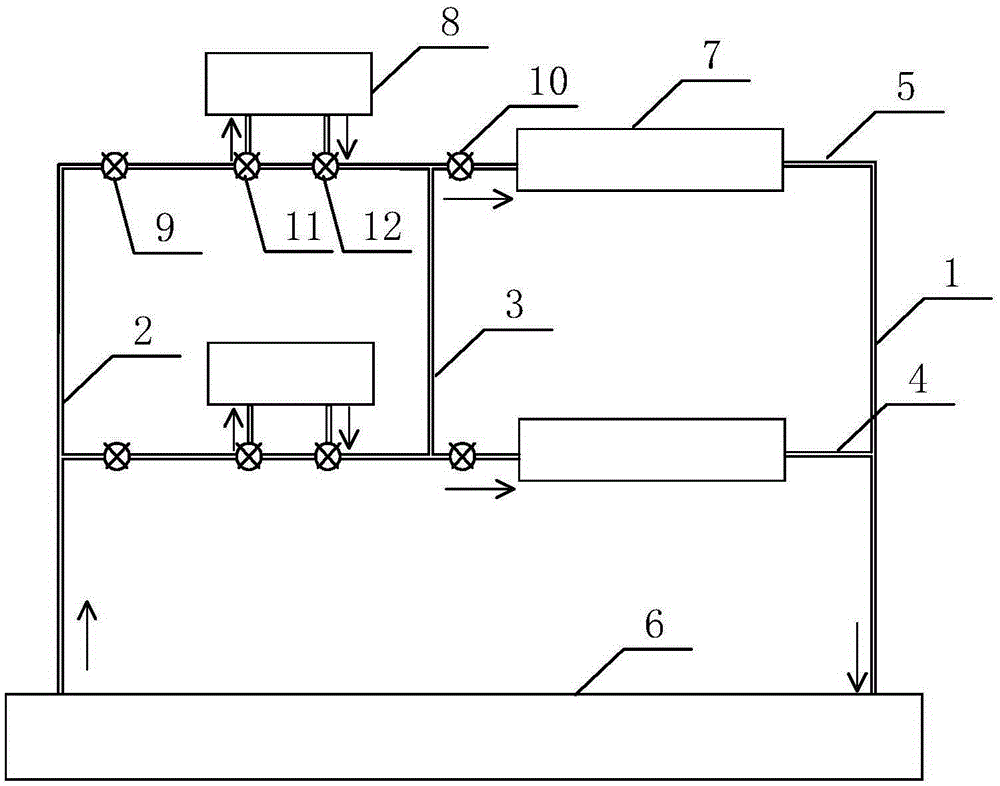

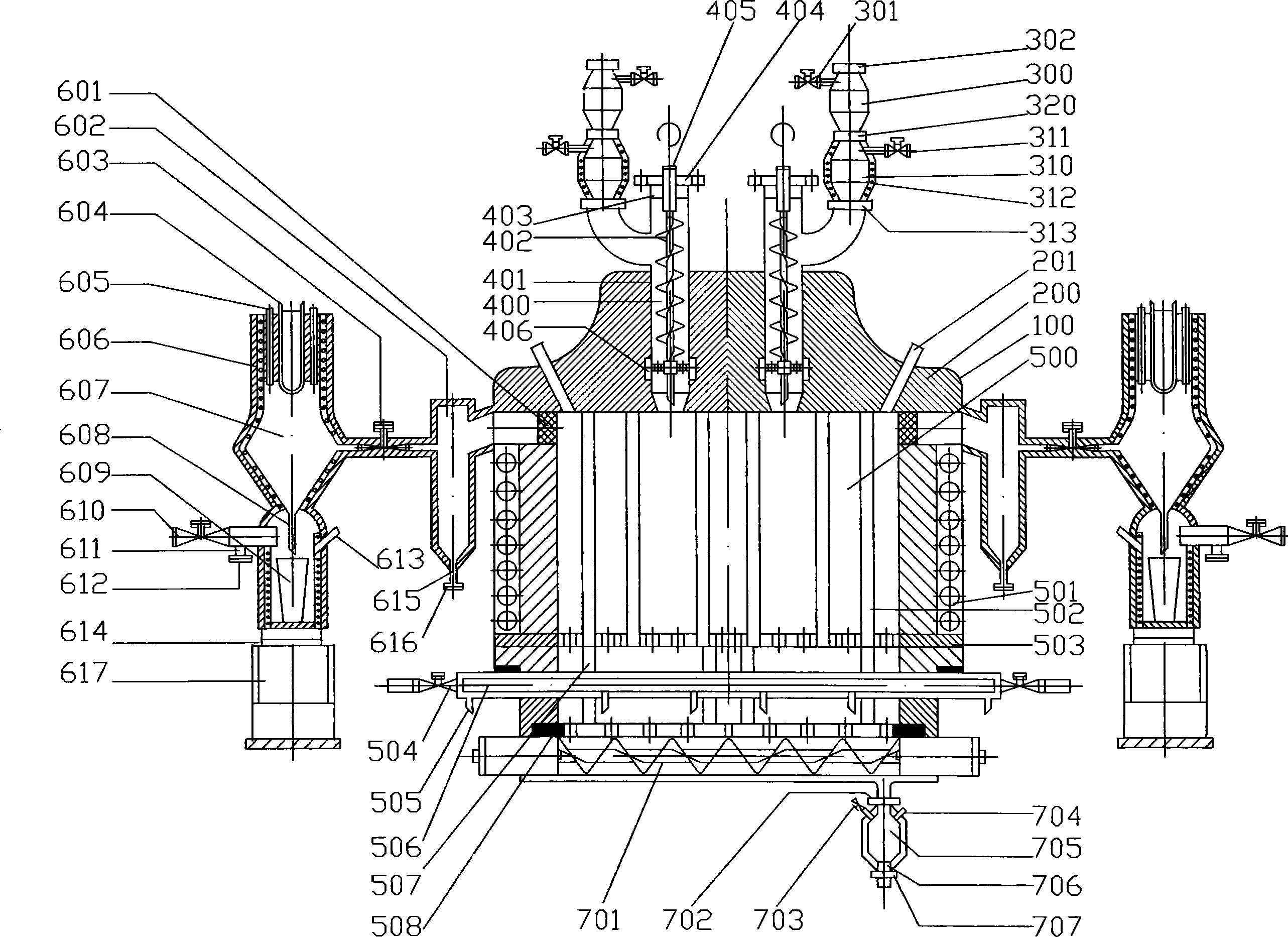

Induction heating continuous magnesium-smelting system and continuous magnesium-smelting technique

The invention discloses a system of inductive heating continuous magnesium smelting and a continuous magnesium smelting technique. The system comprises a continuous feeding device, an inductive heating reaction chamber, a magnesium steam condensing device and a continuous discharging device; wherein the feeding device consists of a feeding housing and a spiral feeding mechanism, the reaction chamber comprises an inductive heating winding, a heating element, a clapboard with holes and a slag cooling device, the condensing device consists of a mesh clapboard, a dust deposition chamber, the magnesium steam condensing chamber, the continuous discharging device comprises spiral slag discharging mechanism and slag housing. The continuous magnesium smelting technique consists of the processes of the continuous feeding of reacting burden into the reaction chamber, the continuous condensation of the magnesium steam and the discharge of liquid magnesium, and also comprises steps of the continuous feeding of reacting slag into the slag housing and slag discharging. The invention has high heat energy utilization rate, and can realize the low cost continuous production of the metal magnesium.

Owner:CENT SOUTH UNIV

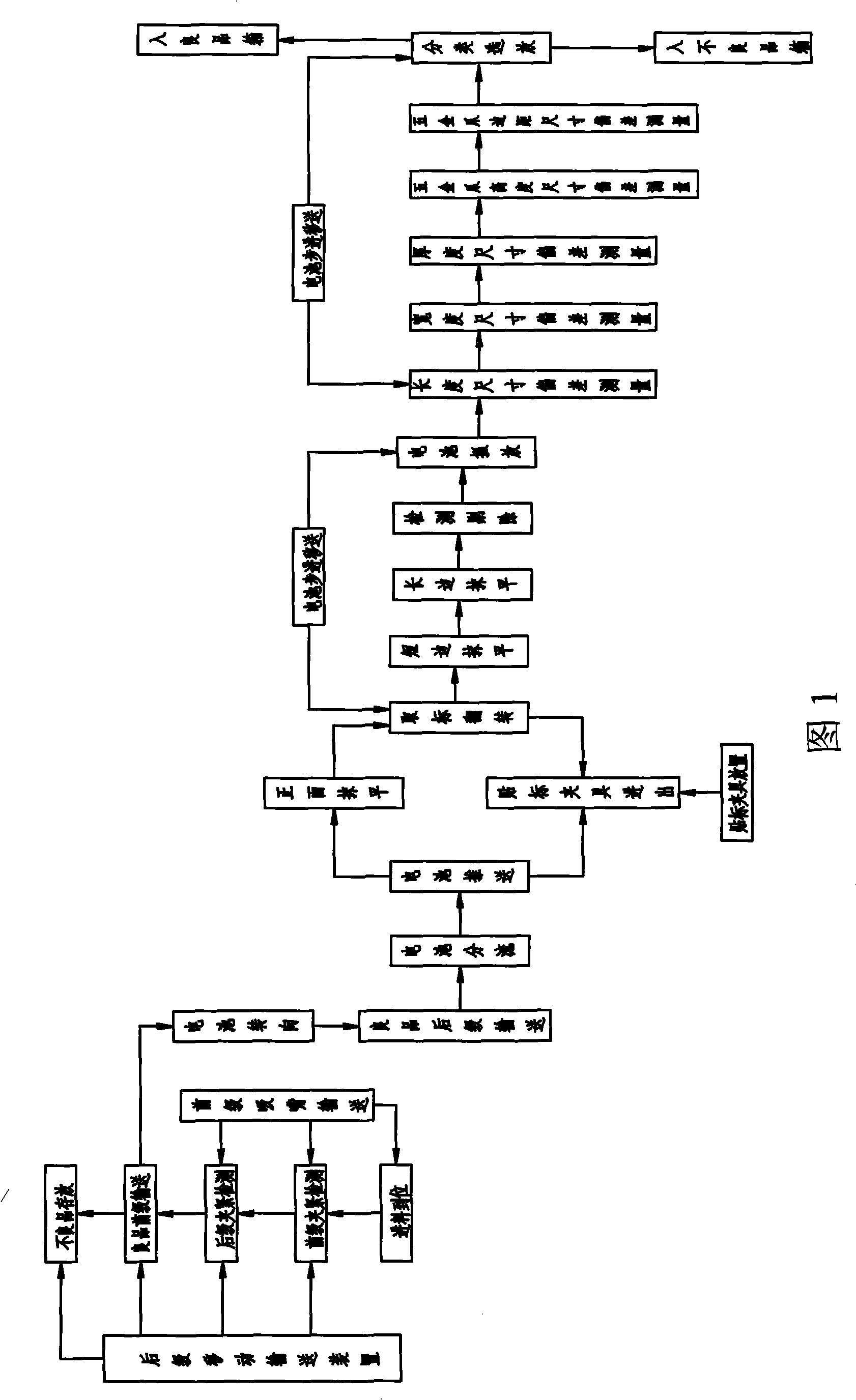

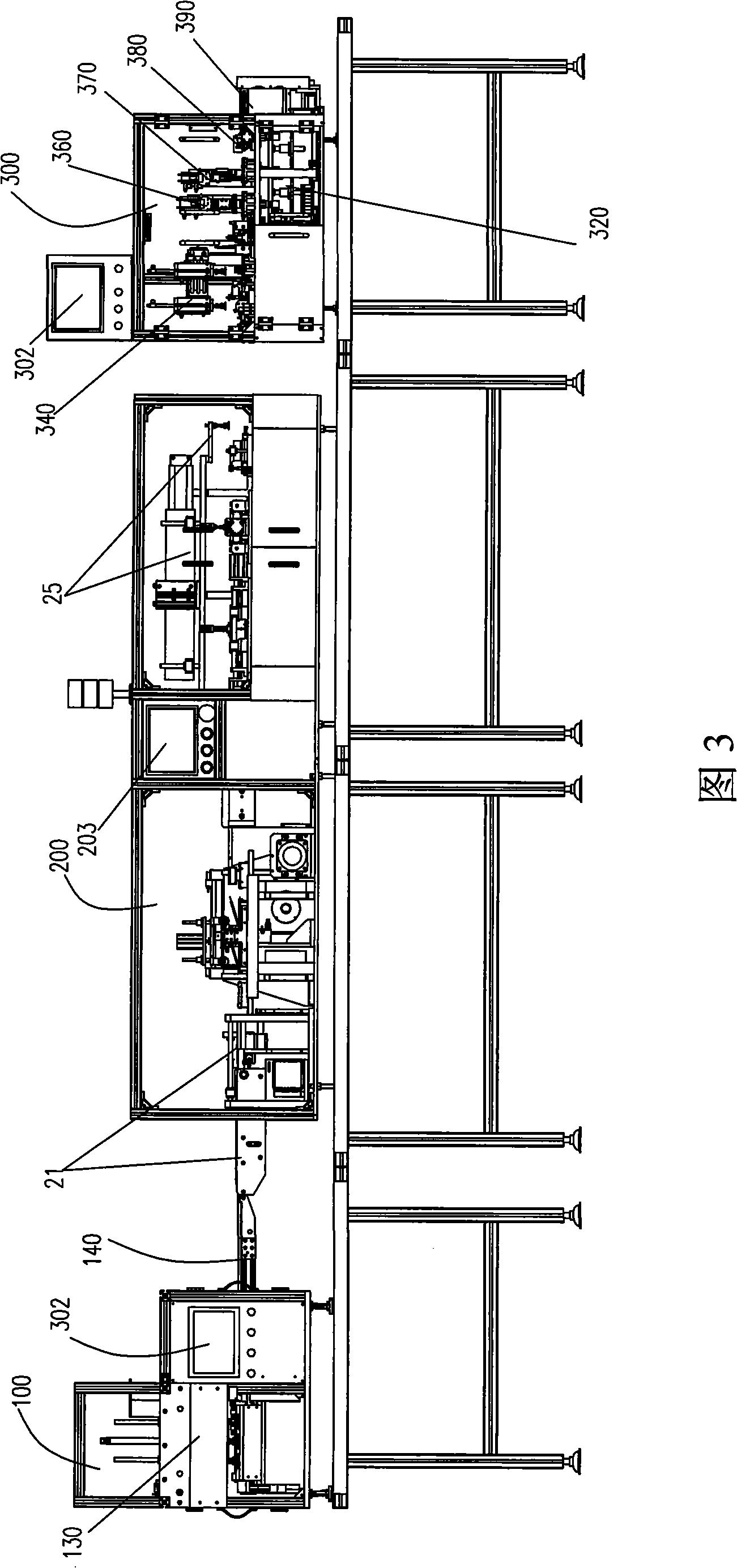

Detection, mark-wrapping, measurement automatic production line and process flow of mobile phone cell

InactiveCN101276929AReduce labor intensityImprove the wrapping effectFinal product manufacturePrimary cellsEngineeringAutonomation

The invention relates to a mobile phone detecting, mark wrapping, measuring automatic product line and technical flow. The product line comprises an orderly arranged mobile phone inside parameter automatic detector, a mobile phone automatic mark wrapper and a mobile phone cell size difference automatic measurer. A discharge port end of the mobile phone inside parameter automatic detector is connected with an inlet point end of the mobile phone automatic mark wrapper. A discharge port end of the mobile phone automatic mark wrapper is connected with an inlet point end of the mobile phone cell size difference automatic measurer that is connected electrically. In the invention, the cell feed in, position, clamp detection, mark wrapping and difference measurement after the mark wrapping are completed automatically. The mark wrapping effect is good, stable, and strongly reliable. The invention is simple in operation, high in efficiency and automatic level, which reduces the product manufacturing cost greatly and improves product quality and manufacturing speed, work efficiency as well as lightens labor intensity of the workers and improves labor capacity.

Owner:GRAND TECH SHENZHEN

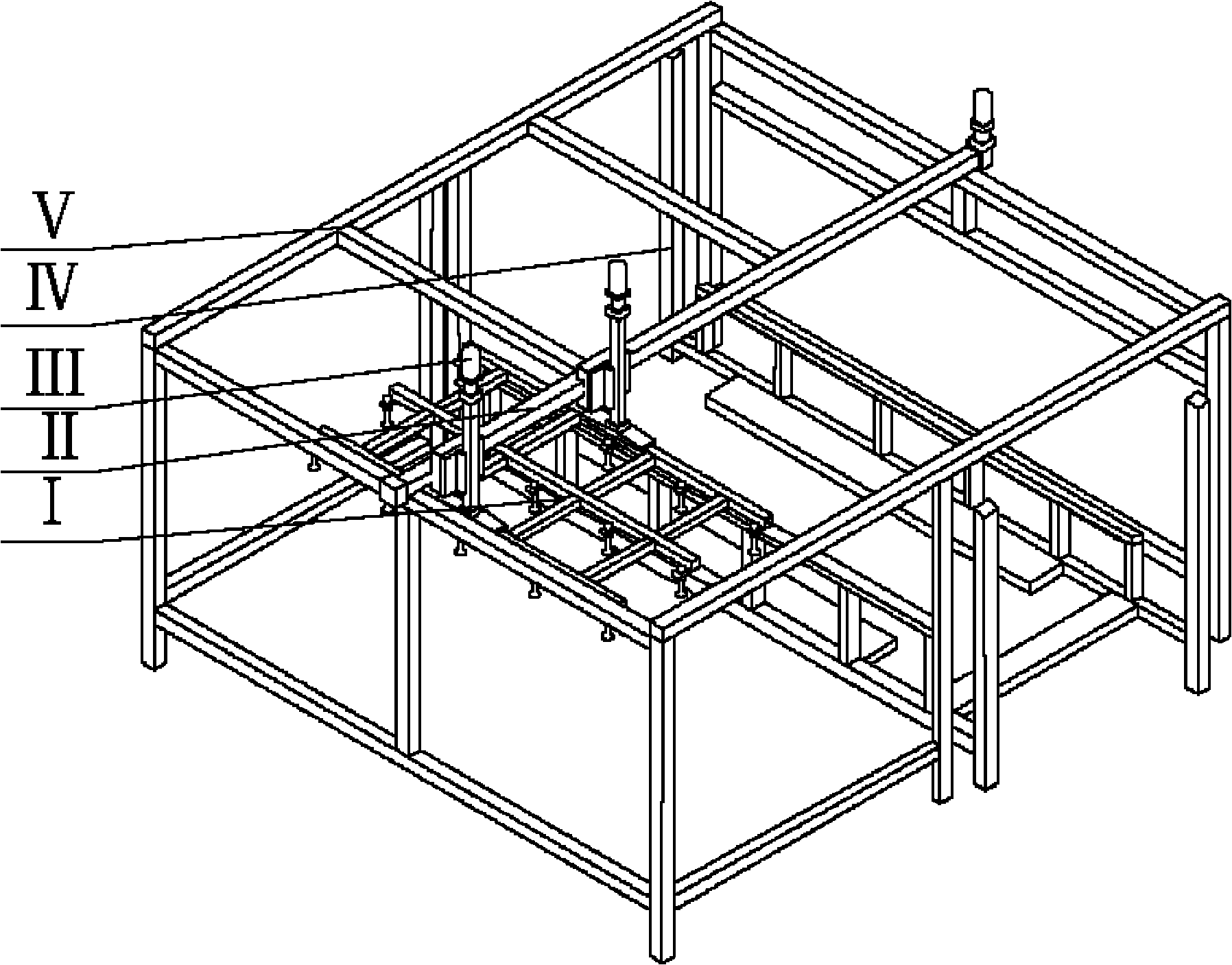

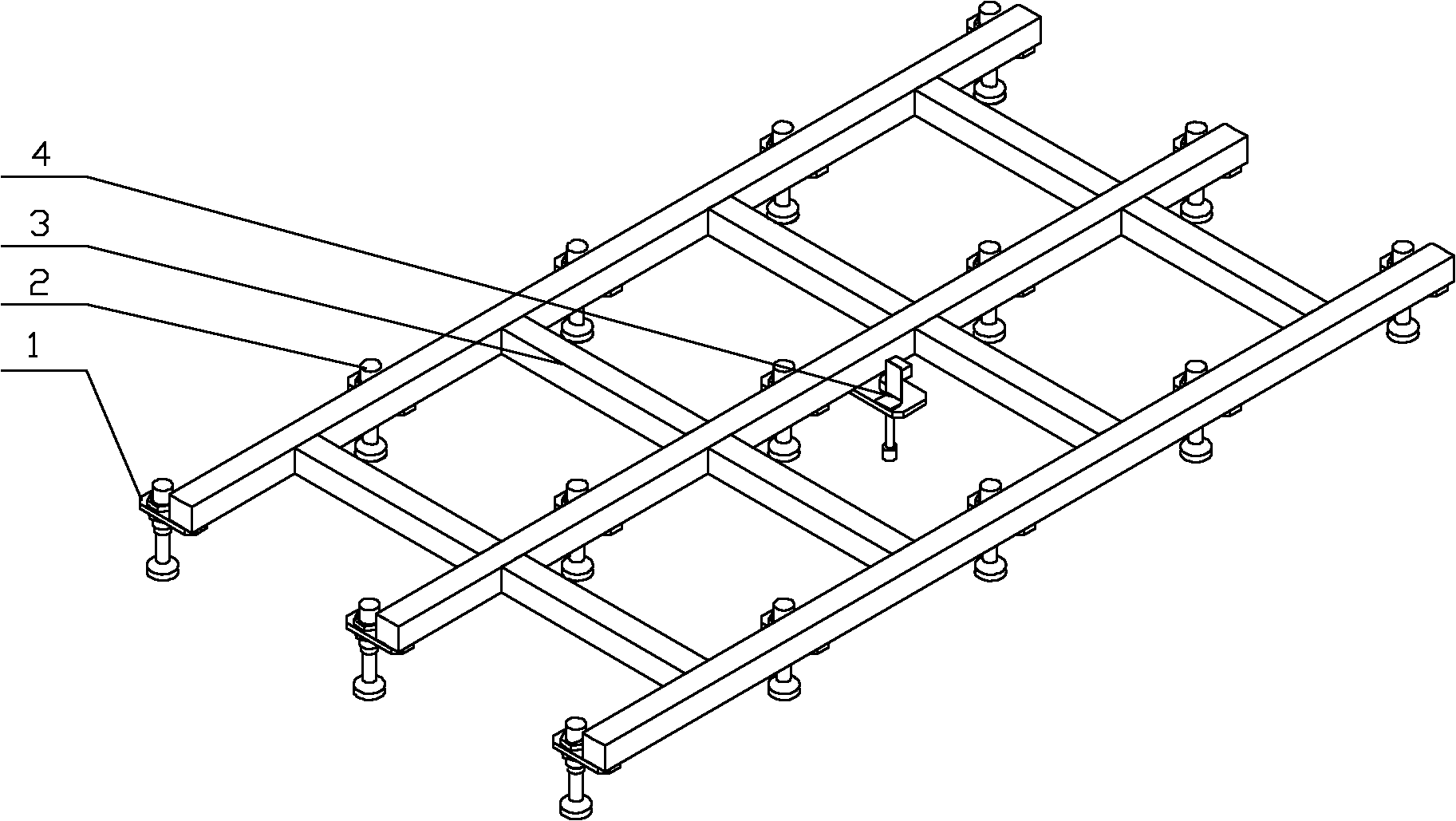

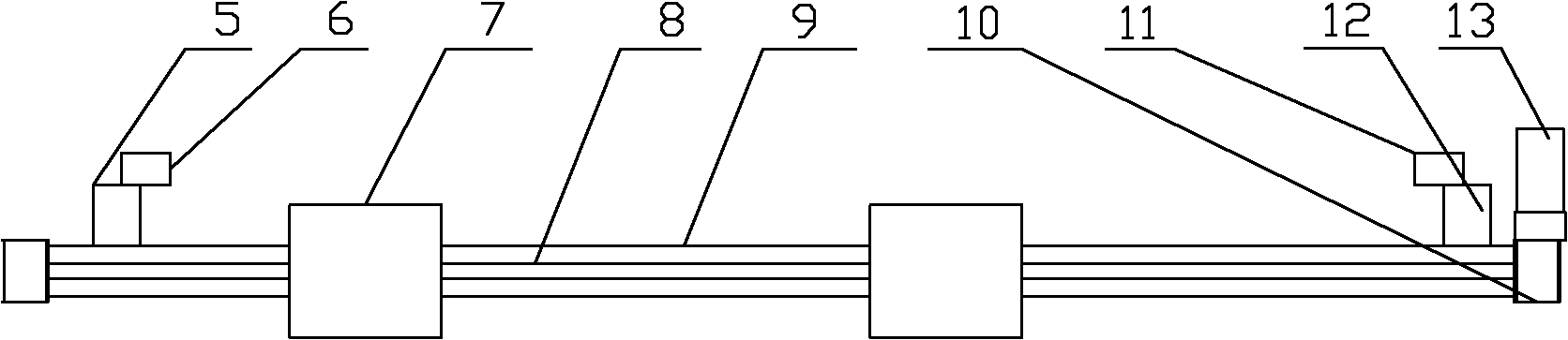

Loading and unloading handling mechanical arm for solar cell module

ActiveCN102107783AEven by forceAvoid bending momentCharge manipulationConveyor partsInteraction layerSolar cell

The invention provides a loading and unloading handling mechanical arm for a solar cell module, and the mechanical arm provided by the invention is used for realizing the functions of loading and unloading in a solar cell module producing process. The loading and unloading handling mechanical arm is characterized by consisting of a mechanical arm mechanism I, a horizontal motion unit II, two vertical motion units III, a pallet lift mechanism IV and a frame V, wherein the mechanical arm mechanism is of an aluminum alloy frame combined structure, and is provided with a plurality of groups of sucker modules so as to realize safe handling of solar cell modules in different specifications; and the horizontal motion unit and the vertical motion units adopt servo motors as drive, and drive the mechanical arm mechanism through a synchronous cog belt and a ball screw assembly respectively to realize accurate motion positioning in horizontal and vertical directions, and the motion units of two directions can independently or simultaneously move. A position servo control system is of a hierarchical control structure formed by a human-computer interaction layer, a motion control layer and a servo control layer. The handling mechanical arm has the advantages of large working space, high positioning accuracy, small motion inertia, reliable and smooth motion and suitability for handling large-sized fragile solar cell modules in different specifications.

Owner:YINGKOU JINCHEN AUTOMATION CO LTD

Bionic manipulator

InactiveCN102672713ASimple structureCompact structureProgramme-controlled manipulatorBionicsEngineering

The invention discloses a bionic manipulator, which comprises a main body lifting cylinder, which extends along a vertical direction, wherein a main body rotating cylinder capable of rotating around a central axis of the main body lifting cylinder is fixedly arranged on the output end of the main body lifting cylinder, an arm telescopic cylinder, which extends along a horizontal direction, is fixedly arranged on the output end of the main body rotating cylinder, an artifice rotating cylinder, which rotates around the central axis of the arm telescopic cylinder, is fixedly arranged on the arm telescopic cylinder, and a paw part used for grabbing articles is arranged on a rotating output part on the artifice rotating cylinder. When used, materials are grabbed by the paw part firstly, and then the paw part is moved and adjusted to a proper position through a telescopic action of the arm telescopic cylinder, a rotating action of the main body rotating cylinder and a lifting action of the main body lifting cylinder according to actual requirements, when the paw is moved in place, the materials are put down by the paw part, so that the materials can be conveyed without manual work.

Owner:HENAN UNIV OF SCI & TECH

Porous phosphorus removing ceramic granules with function of slowly releasing alkali and preparation method thereof

ActiveCN101935195AImprove plasticityLarge specific surface areaSilicon compoundsWater/sewage treatment by sorptionFiberPorosity

The invention discloses porous phosphorus removing ceramic granules with a function of slowly releasing an alkali and a preparation method thereof. The prepared ceramic granules are an environmental material for efficiently removing phosphorus from municipal sewage and industrial wastewater. Based on the basic chemical properties of the phosphorus in water and a phosphorus removing mechanism by chemical absorption, the preparation method of the ceramic granules comprises the following steps of: mixing 20 to 40 mass percent of ordinary portland cement (42.5 level), 10 to 20 mass percent of bentonite, 10 to 20 mass percent of fly ash, 10 to 15 mass percent of calcium oxide, 15 to 25 mass percent of nitrocellulose, 14 to 30 mass percent of xonotlite fiber particle and 0.1 to 0.5 mass percent of pore-creating agent; adding water for stirring the mixture according to a water-solid ratio of 0.35 to 0.45; granulating the mixture into granules with required grain sizes; and after the granules are foamed and solidified, curing the granules by using high-temperature steam to obtain the ceramic granules. The method has the advantages of simple preparation process, readily available raw materials, low cost and wide application prospect in the field of the removing of the phosphorus in water bodies. The prepared ceramic granules have the characteristics of capacity of slowly releasing the alkalis, silicic and calcareous textures, porosity, capacity of continuously and efficiently absorbing and removing the phosphorus and suitability for phosphorus removing systems of the municipal sewage and the industrial wastewater.

Owner:郑俊 +1

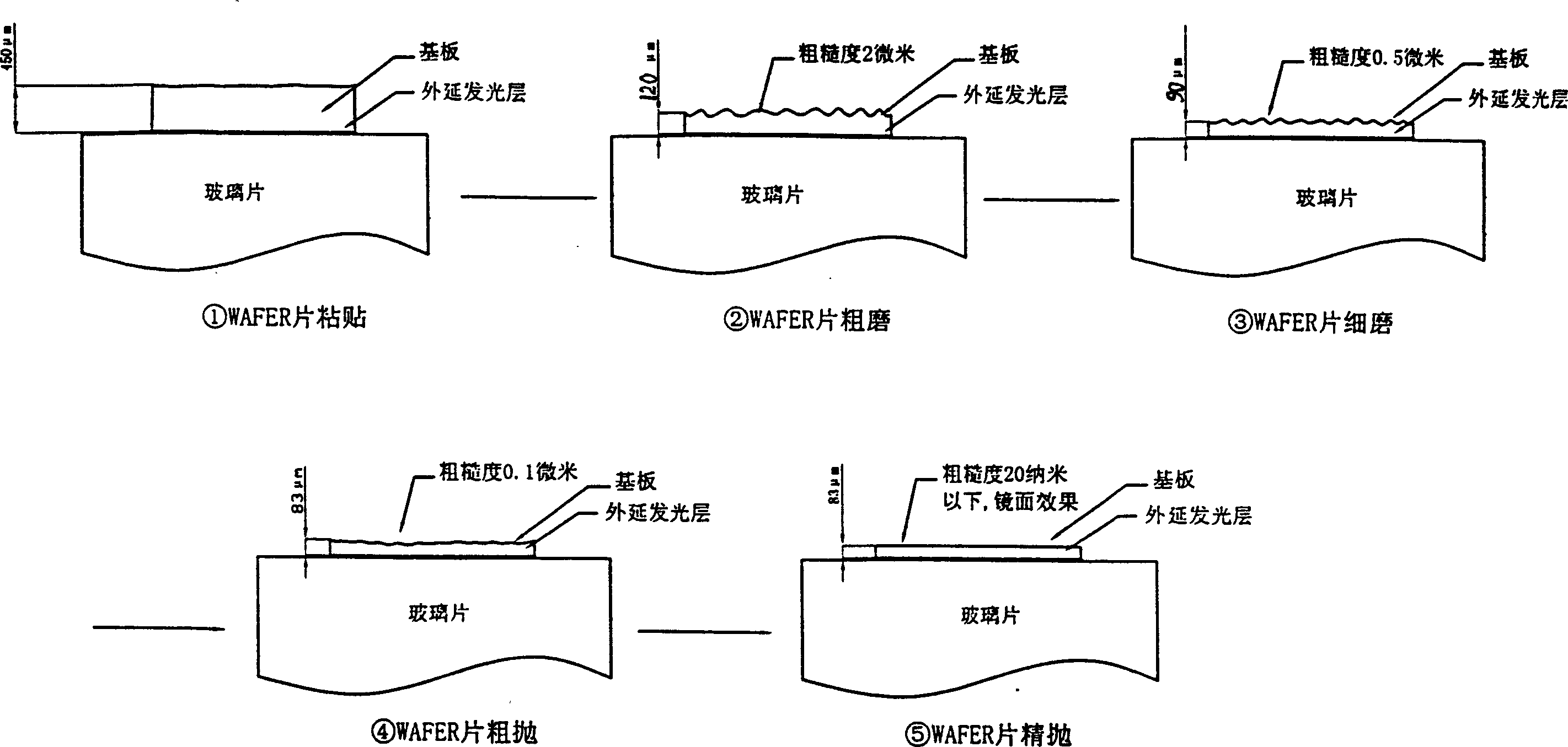

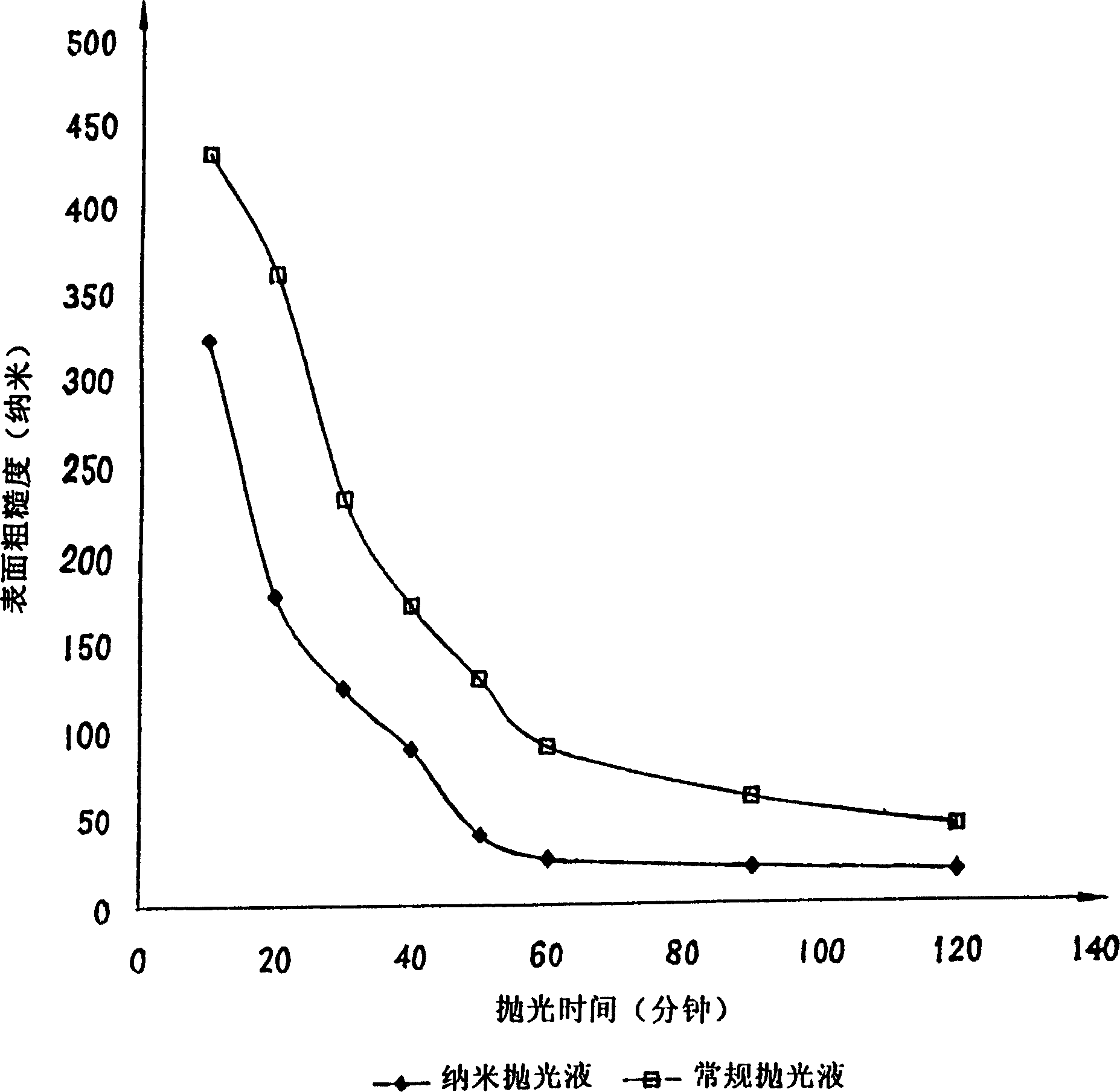

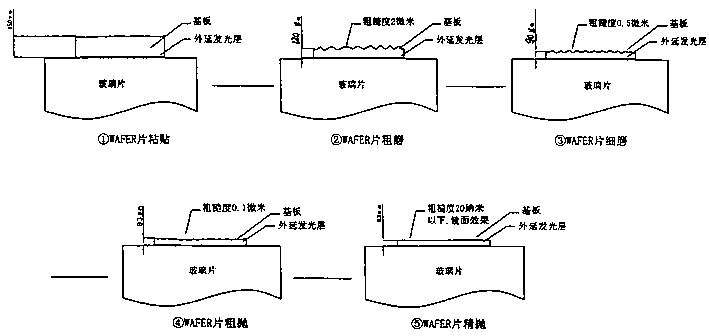

Processing method of nano level saphire substrate and its special polishing liquid

InactiveCN1469459AHigh surface finishExtended service lifeOther chemical processesSemiconductor/solid-state device manufacturingSurface finishNano silicon

The present invention relates to the processing technology of semiconductor device and is especially the processing method of sapphire substrate for HB-LED tube core and special polishing liquid. The processing method includes the steps of adhering, coarse grinding, fine grinding, coarse polishing and fine polishing. The nano polishing liquid consists of nano silicon powder, glycol, glycerine, ethanolamine and deionized water. The present invention can raise surface smoothness to obtain the mirror polishing effect, eliminate stress, lower loss of cutting tool, raise product quality and lower production cost. In addition, the polishing liquid can shorten polishing period greatly compared with micron level polishing liquid.

Owner:东莞市福地电子材料有限公司

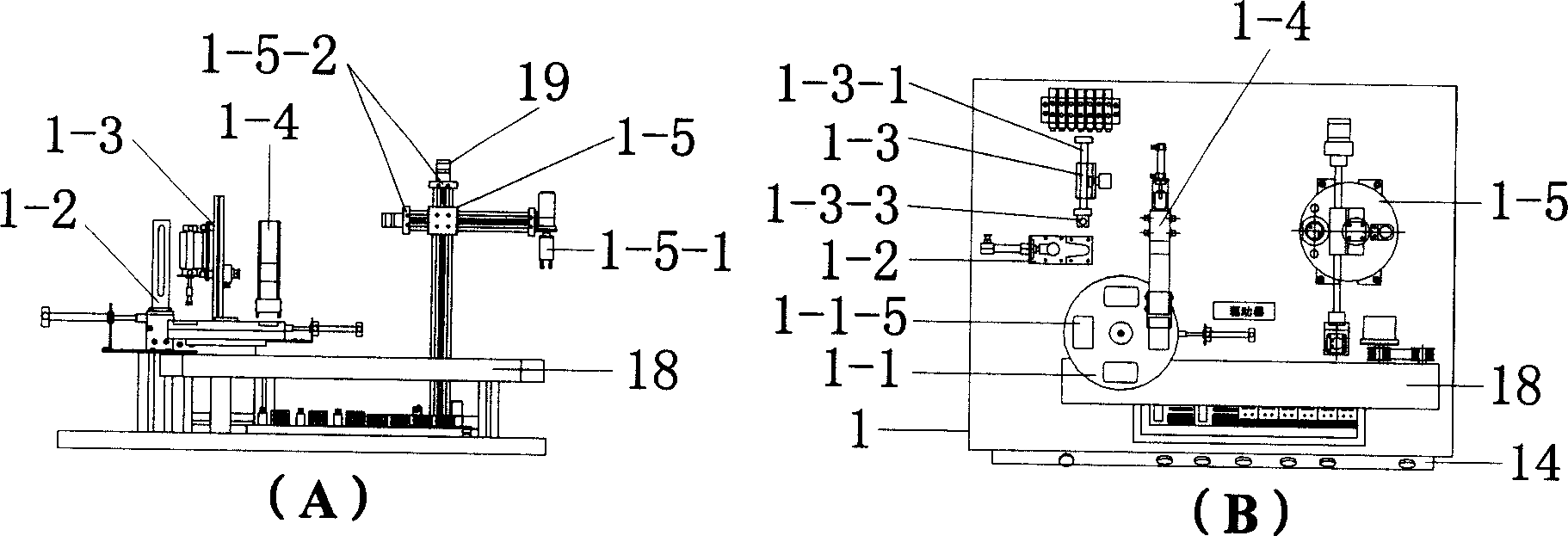

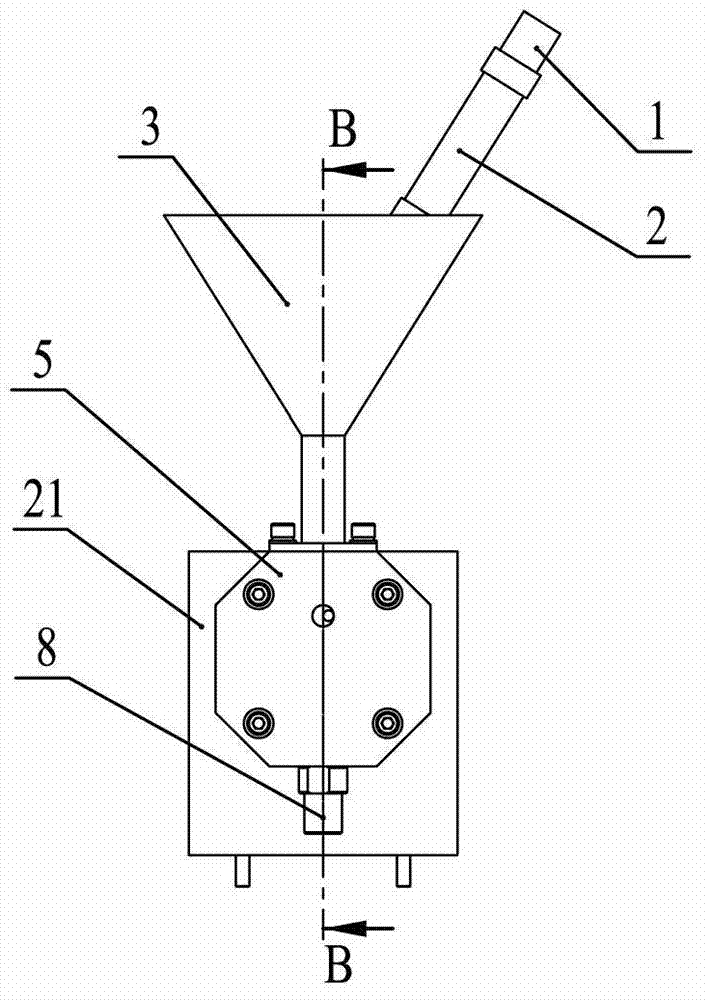

Automatic pressing-filling device for steel balls

ActiveCN102729035AImprove quality stabilityReduce work intensityAssembly machinesMetal working apparatusEngineeringSteel ball

The invention relates to an automatic pressing-filling device for steel balls. The automatic pressing-filling device is characterized by comprising a base and a support, wherein a workpiece conveying mechanism is installed on the base, and a workpiece clamping mechanism, a steel ball sorting and conveying mechanism and a steel ball pressing-in mechanism are installed on the support; the workpiece conveying mechanism is used for loading and conveying a workpiece, the workpiece clamping mechanism is used for fixing the workpiece which is conveyed in place, the steel ball sorting and conveying mechanism is used for conveying the steel balls to the workpiece, and the steel ball pressing-in mechanism is used for pressing the steel balls in the workpiece. The automatic pressing-filling device for steel balls disclosed by the invention is ingenious, compact and reasonable in structure, accurate in pressing-fitting and positioning, convenient in installation and maintenance, capable of automatically conveying the steel balls and accurately pressing-filling the steel balls in the workpiece of an oil pump shell, thus improving the quality stability of a positioning and pressing-filling process for the steel balls in the oil pump shell, lightening the working intensity of operating personnel, and improving the labour production efficiency; therefore, the quality of pressing-filling for the steel balls of the oil pump shell meets the requirements of a process assembly standard.

Owner:WUXI YAZHONG PNEUMATIC HYDRAULIC

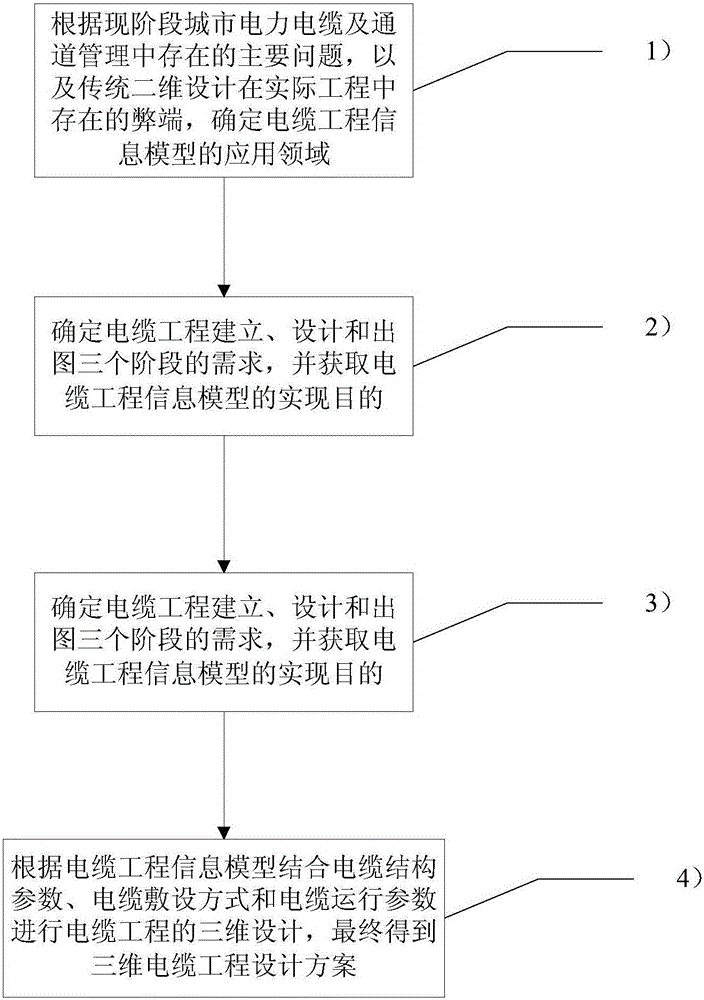

Three-dimension design method based on cable engineering information model

InactiveCN105005676ASolve the difficulty of quickly copyingSolve the problem of easy modificationSpecial data processing applicationsPower cableThree stage

The invention relates to a three-dimension design method based on a cable engineering information model. The three-dimension design method comprises the following steps: 1), according to main problems existing in city power cable and channel management at the present stage and defects of the conventional two-dimension design, which exist in actual engineering, determining an application field of the cable engineering information model; 2), determining demands in the three stages of cable engineering building, design and drawing and obtaining the achieving purpose of the cable engineering information model; 3), building the cable engineering information model by using a three-dimension design platform and according to a standard model base and regional digital model base; 4), carrying out three-dimension design on cable engineering according to the cable engineering information model and by combining cable structure parameters, a cable laying method and cable running parameters, and finally, obtaining a three-dimensional cable engineering designing scheme. Compared with the prior art, the three-dimension design method provided by the invention has the advantages of being intuitive and accurate, and advanced in platform and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

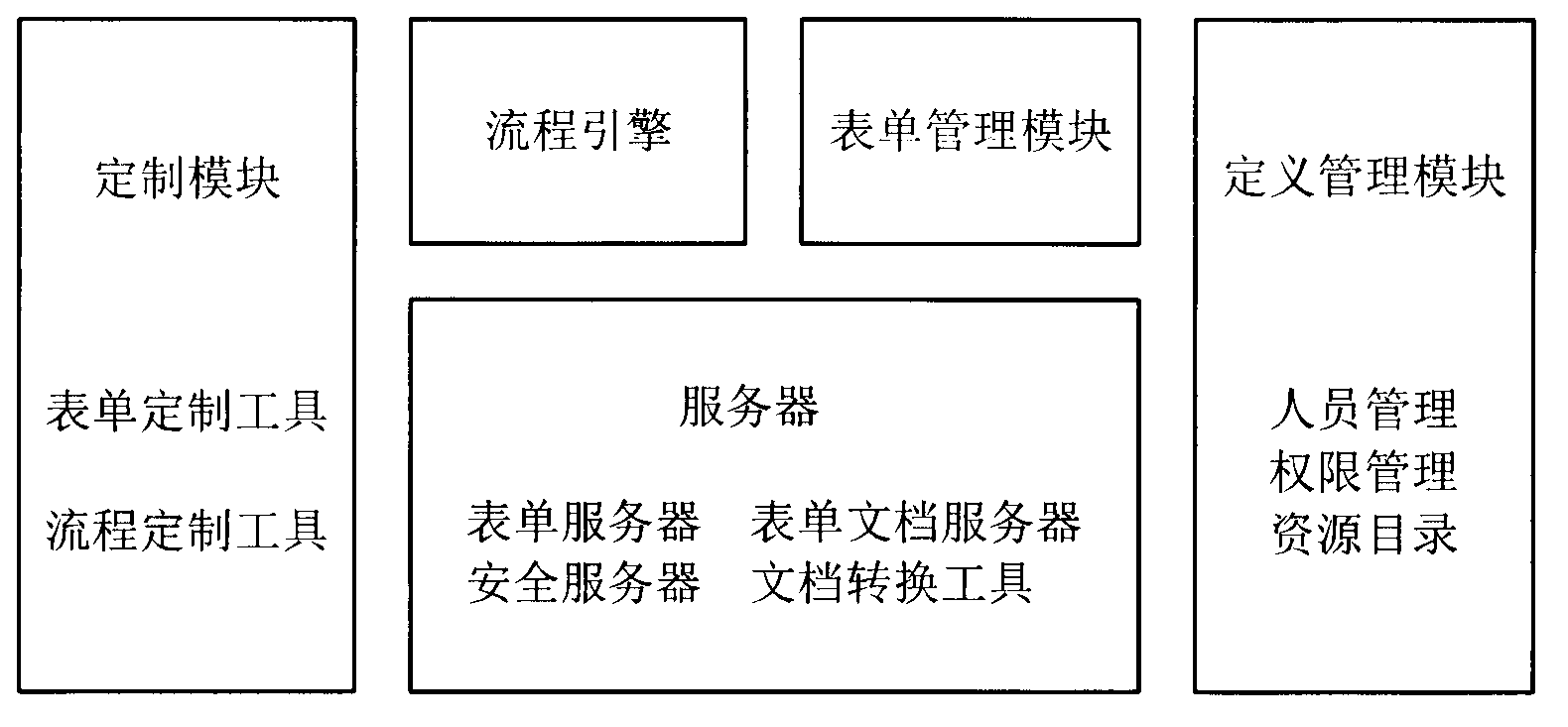

Flexible management information system with process and form customization function

InactiveCN103838706APromote reconstructionImplement triggerSpecial data processing applicationsPersonalizationBusiness Personnel

The invention discloses a flexible management information system with the process and form customization function. The flexible management information system comprises a customization module, a server, a process engine, a form management module and a definition management module, wherein the customization module is used for customizing the needed form style and the needed business process, the server is used for storing data, converting formats and ensuring safety, the process engine is used for analyzing and executing the business process designed by a designer, the form management module is used for managing various resources, such as form templates and process templates, in various application systems in a unified mode, and having control over the versions and the authority of the templates, and the definition management module is used for managing staff, the authority, the resource catalogues and the like. Real business personnel can customize the business process and the business forms according to the business requirements so as to configure the specific application system, then, operation is carried out according to the customized process through driving of the process engine, data are displayed according to customized forms, the capacity of management software for meeting the individual requirements of enterprises and supporting business process reengineering is greatly improved, the success rate of execution of the software is increased, and the degree of satisfaction of a client for the flexible management information system is improved.

Owner:JIANGSU MODERN SHIPBUILDING TECH

Method for producing copper alloy coil pipe

ActiveCN101698207AImprove yieldOptimize production methodsTemperature control deviceFurnace typesMetallurgyMethods of production

The invention relates to a method for producing a metal pipe, in particular to a method for producing a copper alloy coil pipe. According to the technical scheme provided by the invention, the method for producing the copper alloy coil pipe comprises the following steps: (a) melting, (b) horizontal and continuous casting, (c) face milling, (d) primary bright annealing, (e) planetary tube rolling, (f) stretching, (g) secondary bright annealing, (h) cleaning, and (i) third bright annealing. The method can improve the comprehensive finished product rate of a pipe material, the labor productivity and the grade of product quality.

Owner:江苏隆达超合金股份有限公司

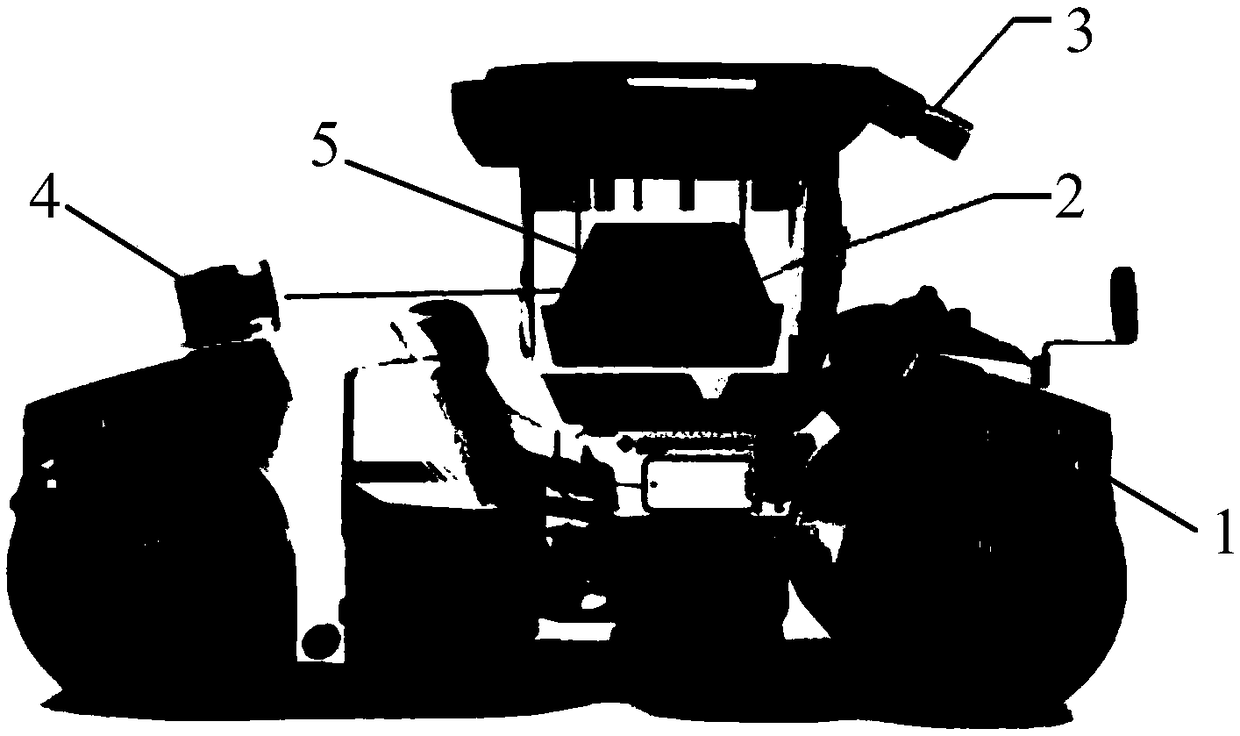

Full-automatic road roller location method based on multi-source data fusion

ActiveCN109099901AHigh positioning accuracySatisfy positioningPhotogrammetry/videogrammetryNavigation by speed/acceleration measurementsSignal voidMachine vision

The invention discloses a full-automatic road roller location method based on multi-source data fusion, comprising the following steps: setting a boundary marker at the boundary of a construction region, acquiring an image containing the boundary marker by a multichannel synchronous camera, acquiring point cloud data of the construction region by utilizing a laser radar, matching the image with laser point cloud data, identifying a construction region marker, and calculating a construction fence region; and calculating position and attitude information of a road roller in the construction region by utilizing fusion of the laser point cloud data and IMU output information, thus location of an unmanned road roller in the construction region is realized. By virtue of a machine vision locationmethod, vision data is fused with IMU data, a special construction environment of the road roller can be adapted, the problem of signal void due to pure dependence on GPS positioning is effectively avoided, and both location accuracy and speed can meet location and path planning requirements of the unmanned road roller in the construction environment, so that the method disclosed by the inventioncan be effectively applied to a construction site of the road roller, and the problem that the location accuracy of the road roller is poor is effectively solved.

Owner:中科微易(苏州)智能科技有限公司

Powder paint for plastic coating of firefighting pipelines and manufacturing method thereof

InactiveCN102101966AImprove labor productivityIncrease profitLiquid surface applicatorsPowdery paintsMetallurgyPowder coating

The invention discloses powder paint for the plastic coating of firefighting pipelines, which is characterized in that the powder paint consists of 30 to 60 mass percent of thermosetting resin, 4.5 to 30 mass percent of curing agent, 20 to 30 percent of paint and filler and 2 to 12 percent of assistant. The product disclosed by the invention can be used by electrostatic spraying, the film thickness reaches 300 to 400 mu m at one time of spraying, the performance of the film can reach requirements after one time of curing by baking, and the coating labor productivity is high. During spraying, the powder paint not sprayed can be recovered and reused, so the utilization rate of the paint is as high as over 98 percent. The powder paint can bear a high temperature of 300 DEG C and a low temperature of 30 DEG C below zero. After plastic coating, a high adhesive force is formed between the coating and the substrate. And compared with hot-galvanized firefighting pipelines, the firefighting pipe coated with the powder paint is more environmentally-friendly.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

Animal origin free flocks and herds frozen semen diluent and production method of flocks and herds frozen semen

InactiveCN101310729AReduce wasteEliminate the potential risk of spreading various diseasesMammal material medical ingredientsDead animal preservationAdditive ingredientSemen

A cattle and sheep non-animal-derived frozen semen diluent comprises at least one or the combination of the following ingredients: trehalose, propylene glycol, soybean lecithin, soluble soybean protein, nitrogen-trishydroxymethyl aminoethanesulfonic acid and dodecanoyl sodium sulfate. A production method of a cattle and sheet frozen semen by using the cattle and sheep non-animal-derived frozen semen diluent fully mixes the cattle or sheet semen and the dilutent, lowers the temperature and carries out the preservation. Compared with the prior art, the animal semen dilutent of the invention eliminates the animal-derived ingredients; the preservation method is more practical, the technical effects are better, thus thoroughly eliminating the potential risks of spreading various epidemic diseases between the animals and the people by the animal-derived ingredients in the dilutent. The cattle and sheep non-animal-derived frozen semen diluent can promote the popularization of animal artificial insemination technology to the utmost extent and improve the labor productivity and the economic benefits, thus having great economic and social values.

Owner:辽宁省重大动物疫病应急中心 +1

AC permanent magnet synergistic reluctance motor

ActiveCN103560633AIncrease magnetic intensityImprove reaction speedMagnetic circuit rotating partsMagnetic circuit stationary partsExcitation currentReluctance motor

The invention relates to an AC permanent magnet synergistic reluctance motor. The motor is characterized in that permanent magnets or permanent magnet components are combined with laminated cores in stator excitation salient pole pairs; when excitation coils do not have excitation current, the permanent magnets or the permanent magnet components and the laminated cores in the excitation salient pole pairs form locally closed magnetic circuits; when the excitation coils have the excitation current, the original closed permanent magnet magnetic circuits are opened and converged on the excitation magnetic circuits of the excitation salient pole pairs, and then compound excitation magnetic potential is produced on the two port surfaces of each salient pole of each excitation salient pole pair; when the magnetic port surfaces of the permanent magnets fixed to a rotor support are just opposite or coincide with the port surfaces of the stator excitation salient pole pairs, the shortest closed magnetic circuit with air gaps is formed. According to the AC permanent magnet synergistic reluctance motor, the magnetic induction intensity in the air gaps of the motor is greatly increased, the torque at the time of low rotation speed is increased, common magnetic circuit interference and flux leakage are reduced, electric energy is saved, and the power density of the motor and the use rate of equipment are further enhanced.

Owner:戴珊珊

Full automatic aluminium section bar cutter device

InactiveCN101352770AImprove accuracyReduce randomnessMetal sawing devicesMetal-working feeding devicesAssurance qualityEngineering

The invention discloses a full-automatic aluminum cutting device which aims at solving the problem of low manual feeding efficiency of the existing aluminum cutting device and provides a safe and convenient full-automatic aluminum cutting device which can ensure the quality. The device of the invention includes: a feed device, a bracket and a cutting saw arranged on the bracket; the feed device includes an upper clamping part, a lower clamping part, a horizontal feed part and a locating part. The device fully uses machines to replace manual operation, thus not only enhancing the accuracy, increasing the efficiency, reducing the cost, but also saving the human labor and materials as well as enhancing the safety performance.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com