Patents

Literature

24498 results about "Autonomation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Autonomation describes a feature of machine design to effect the principle of jidoka (自働化) used in the Toyota Production System (TPS) and Lean manufacturing. It may be described as "intelligent automation" or "Automation with a human touch". This type of automation implements some supervisory functions rather than production functions. At Toyota, this usually means that if an abnormal situation arises; the machine stops and the worker will stop the production line. It is a quality control process that applies the following four principles...

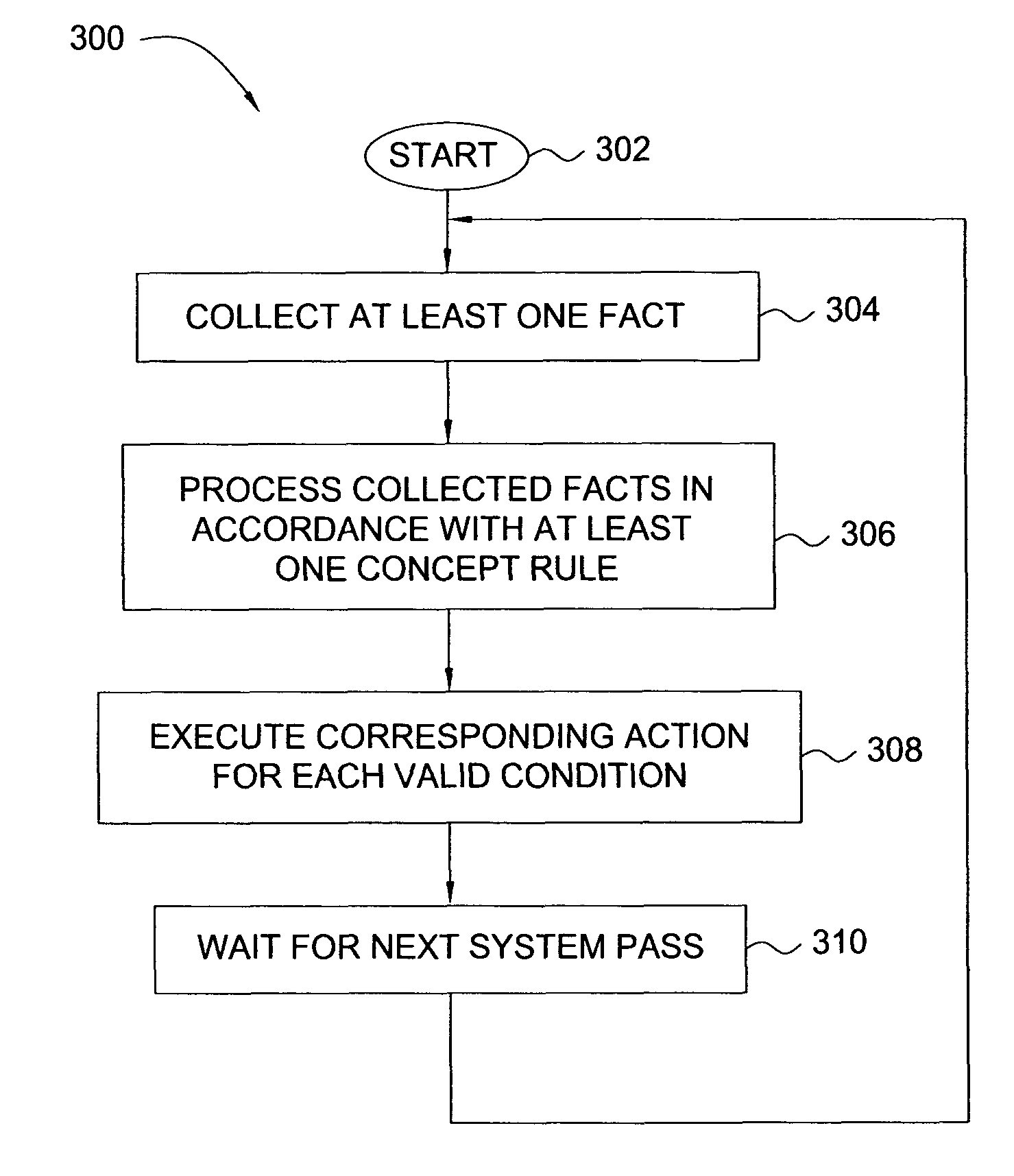

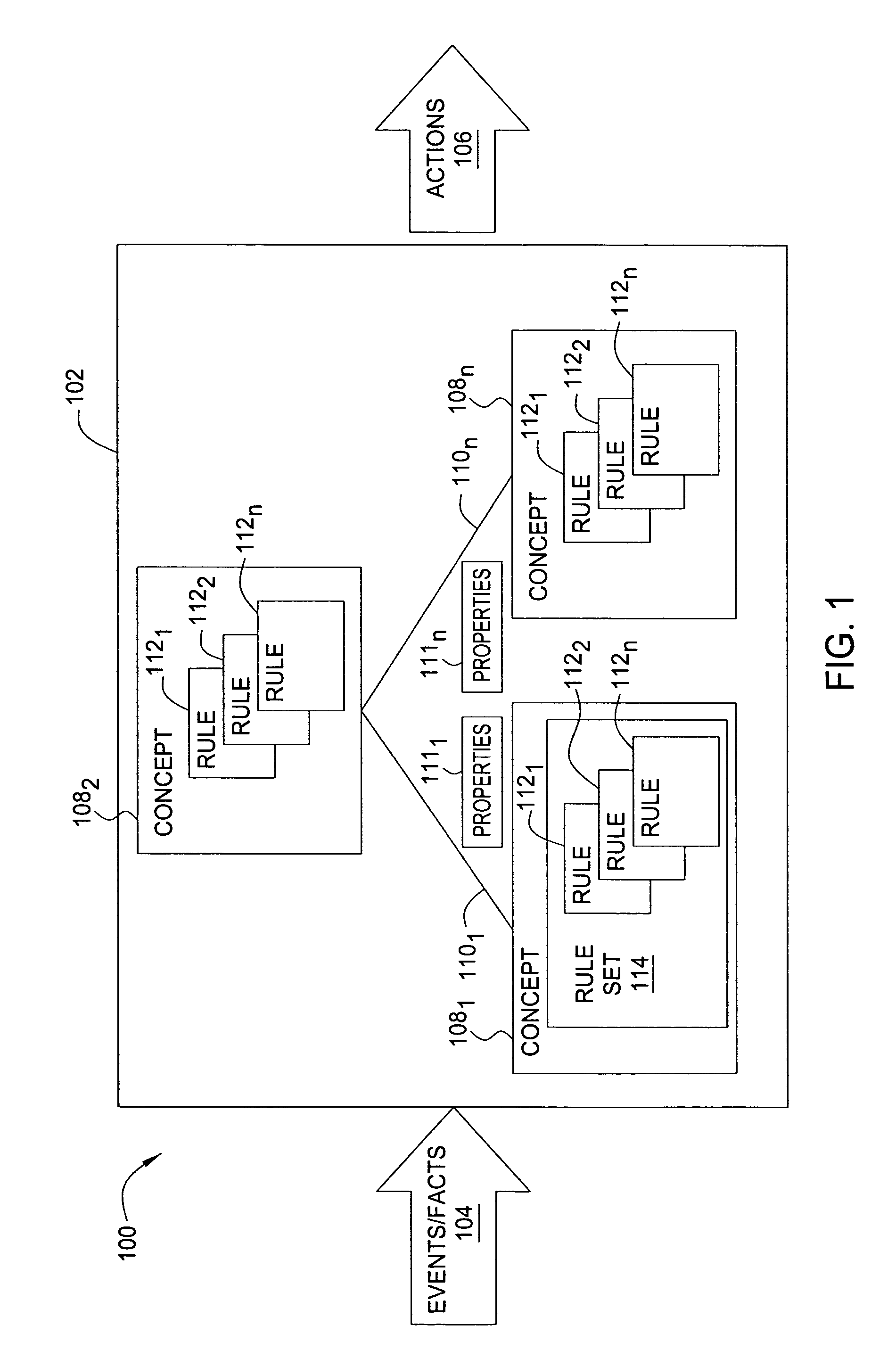

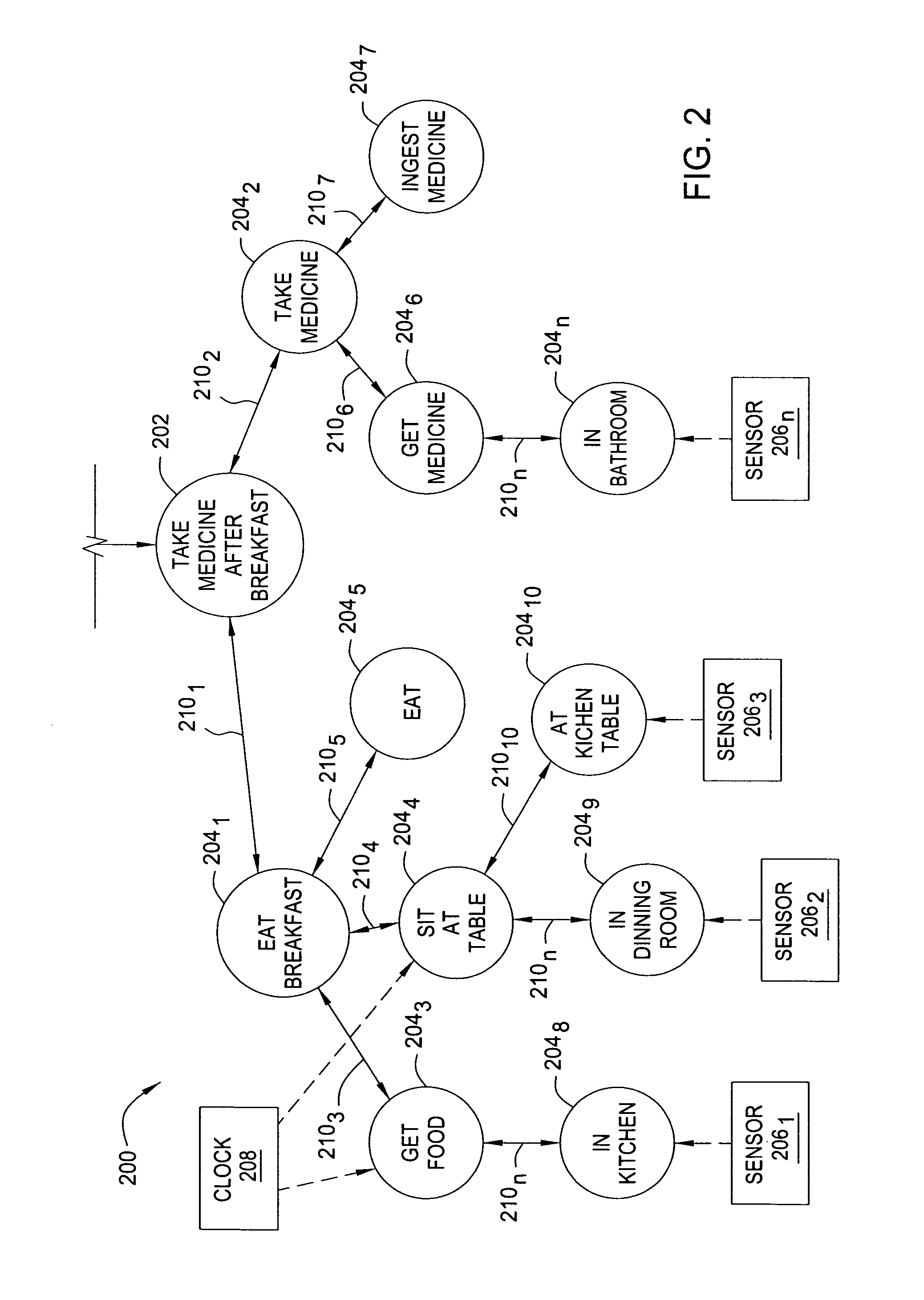

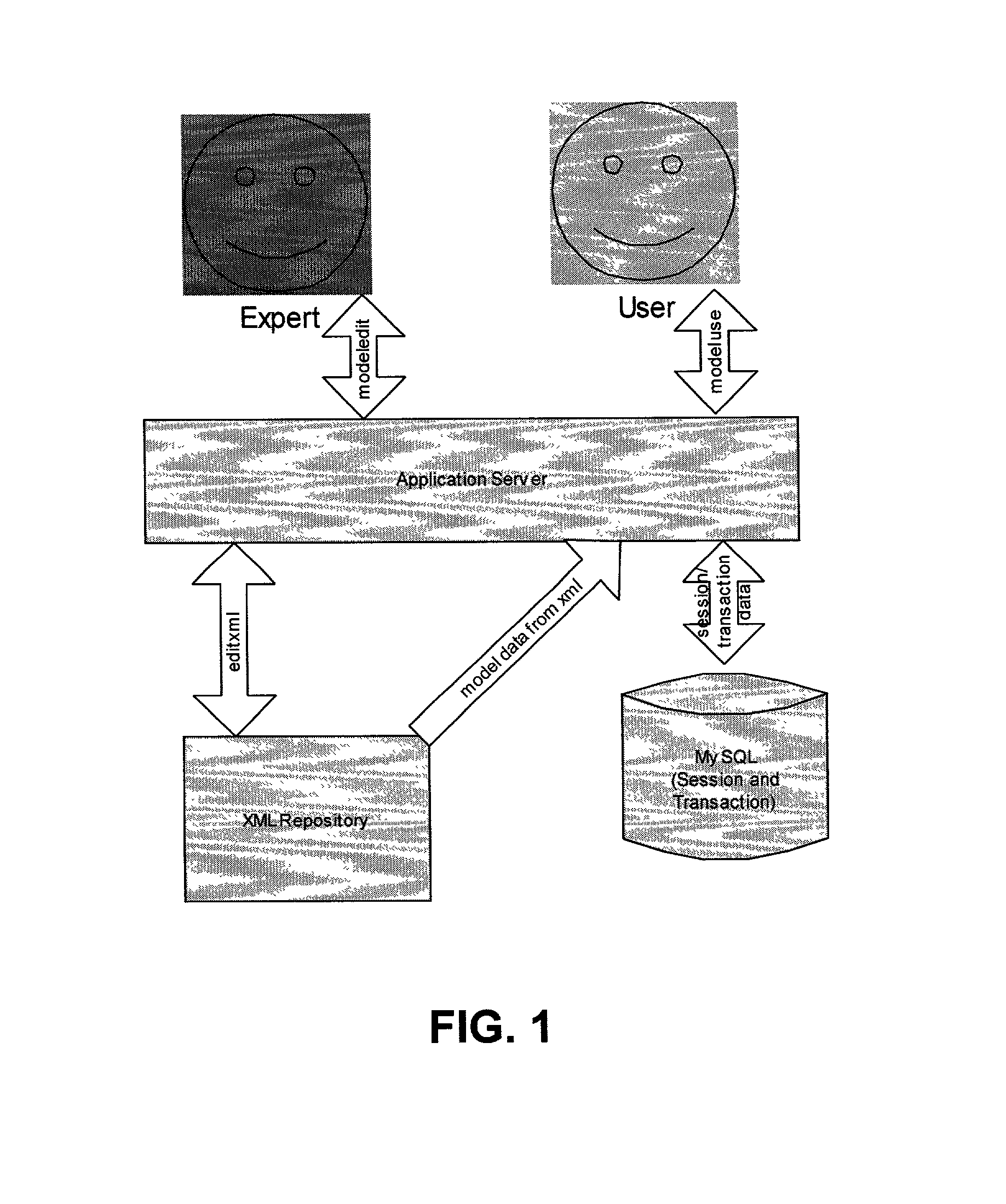

Method and apparatus for building an intelligent automated assistant

A method and apparatus are provided for building an intelligent automated assistant. Embodiments of the present invention rely on the concept of “active ontologies” (e.g., execution environments constructed in an ontology-like manner) to build and run applications for use by intelligent automated assistants. In one specific embodiment, a method for building an automated assistant includes interfacing a service-oriented architecture that includes a plurality of remote services to an active ontology, where the active ontology includes at least one active processing element that models a domain. At least one of the remote services is then registered for use in the domain.

Owner:APPLE INC

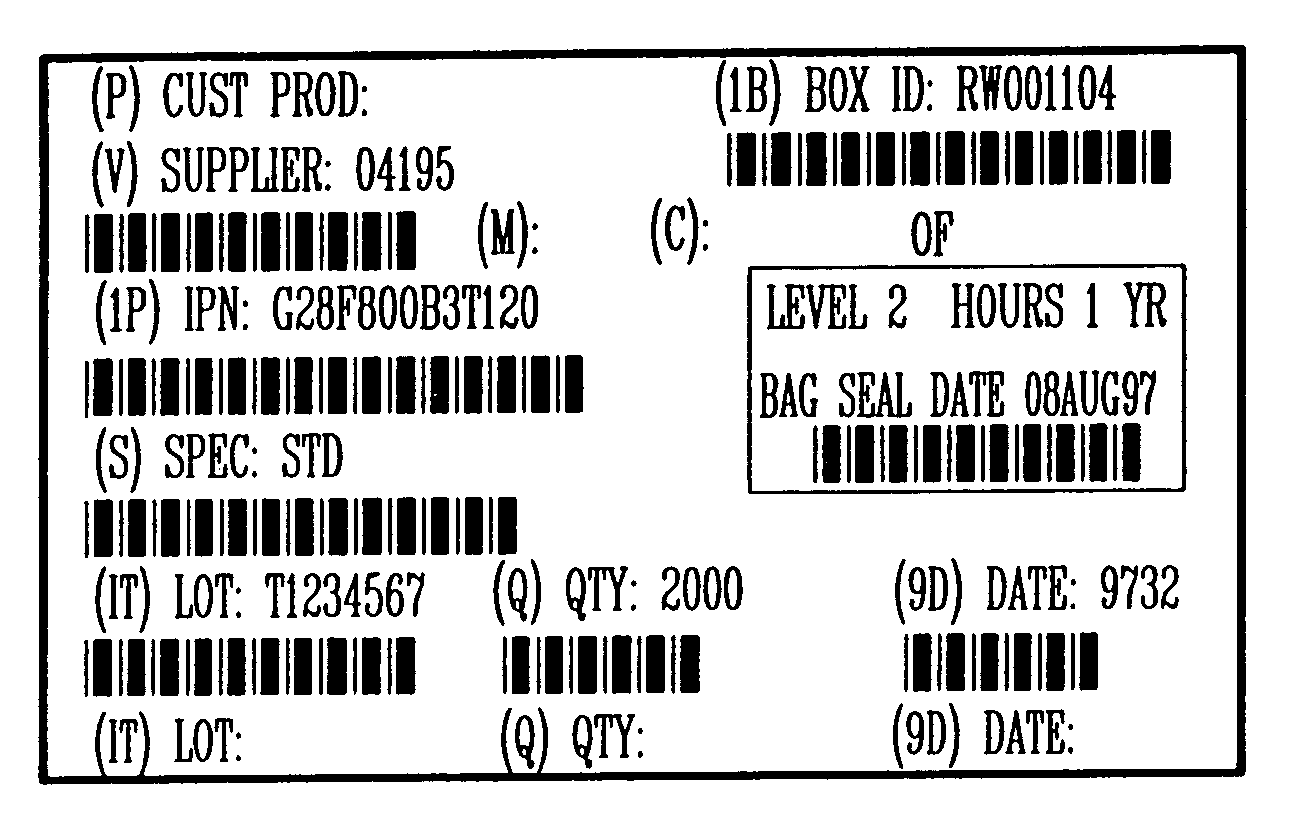

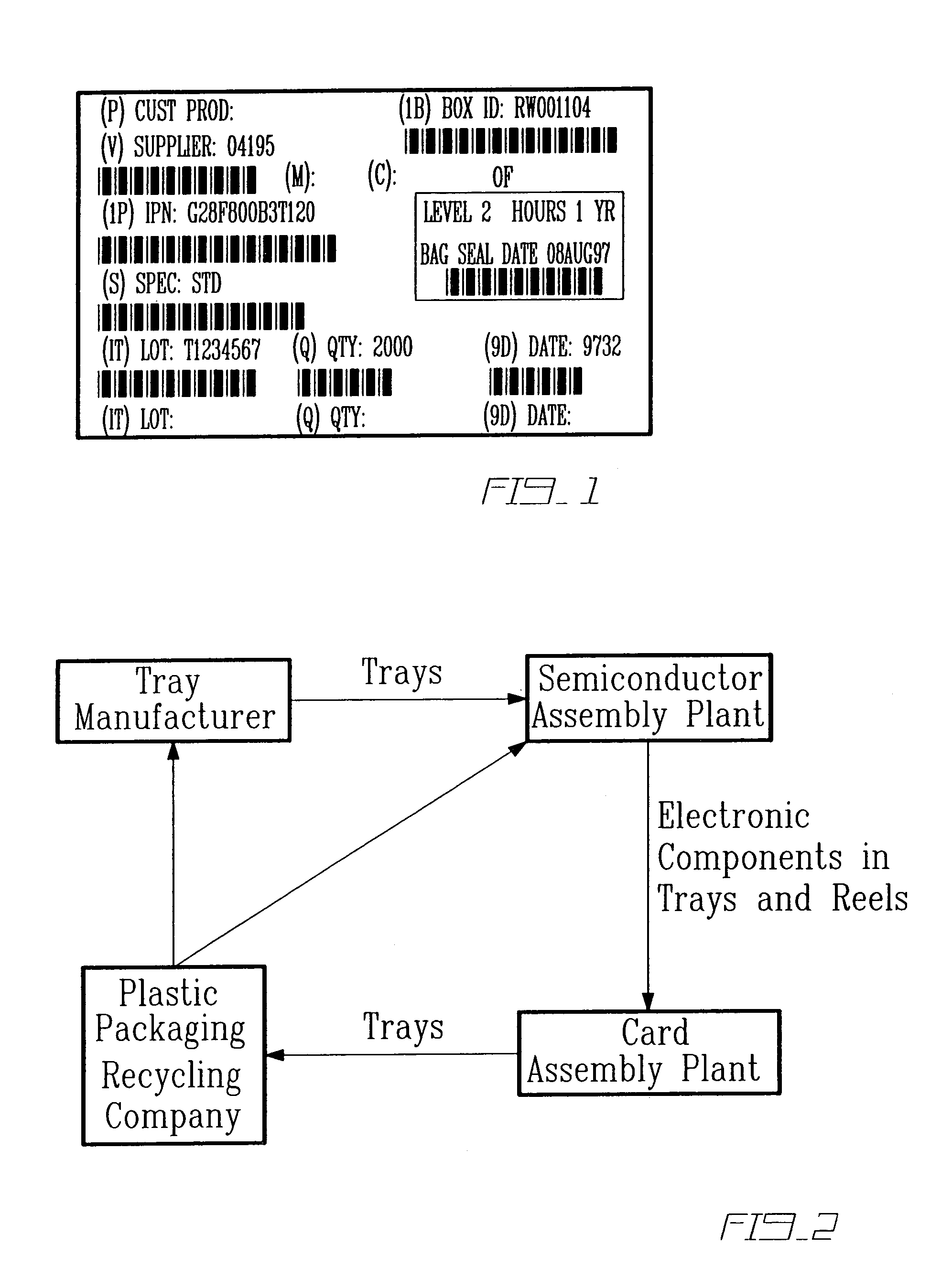

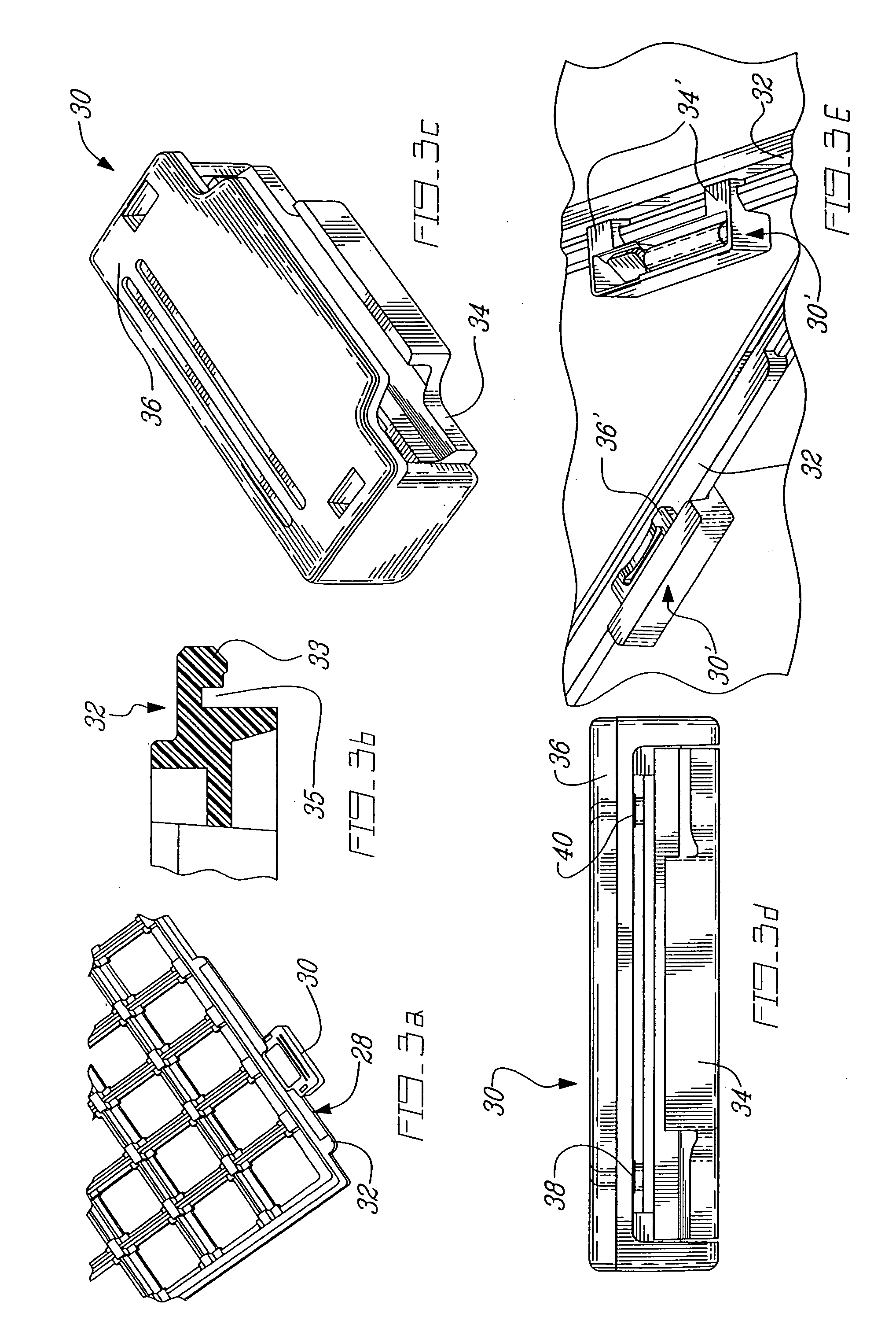

Automated manufacturing control system

InactiveUS7069100B2Reduce human interactionDigital data processing detailsTotal factory controlHuman interactionMachine

An automated manufacturing control system is proposed to greatly reduce the human interaction relative to the data transfer, physical verification and process control associated with the movement of components, tooling and operators in a manufacturing system. This is achieved by the use of data carriers which are attached to the object(s) to be traced. These data carriers (12) can store all the relevant identification, material and production data to required by the various elements, e.g. stations, of the manufacturing system. Various readers, integrated with controllers and application software, are located at strategic points of the production area, including production machines and storage areas, to enable automatic data transfer and physical verification that the right material is at the right place at the right time, using the right tooling.

Owner:COGISCAN

Programmable tactile touch screen displays and man-machine interfaces for improved vehicle instrumentation and telematics

InactiveUS8482535B2Transmission systemsDashboard fitting arrangementsDashboardHuman–machine interface

Disclosed are new methods and apparatus particularly suited for applications in a vehicle, to provide a wide range of information, and the safe input of data to a computer controlling the vehicle subsystems or “Telematic” communication using for example GM's “ONSTAR” or cellular based data sources. Preferred embodiments utilize new programmable forms of tactile touch screens and displays employing tactile physical selection or adjustment means which utilize direct optical data input. A revolutionary form of dashboard or instrument panel results which is stylistically attractive, lower in cost, customizable by the user, programmable in both the tactile and visual sense, and with the potential of enhancing interior safety and vehicle operation. Non-automotive applications of the invention are also disclosed, for example means for general computer input using touch screens and home automation systems.

Owner:APPLE INC

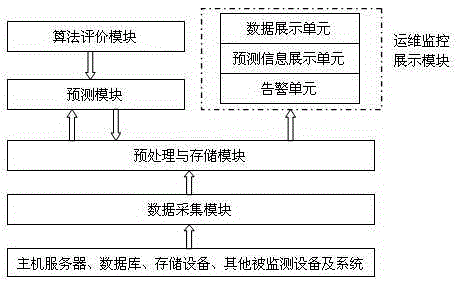

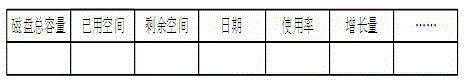

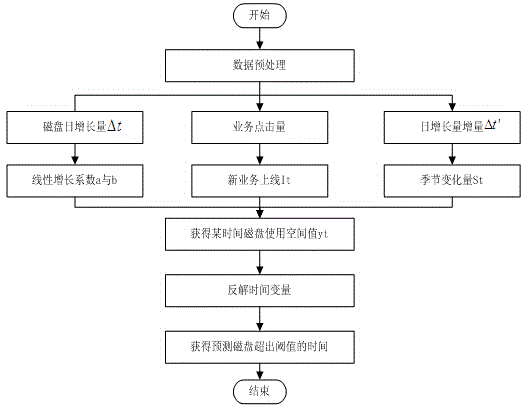

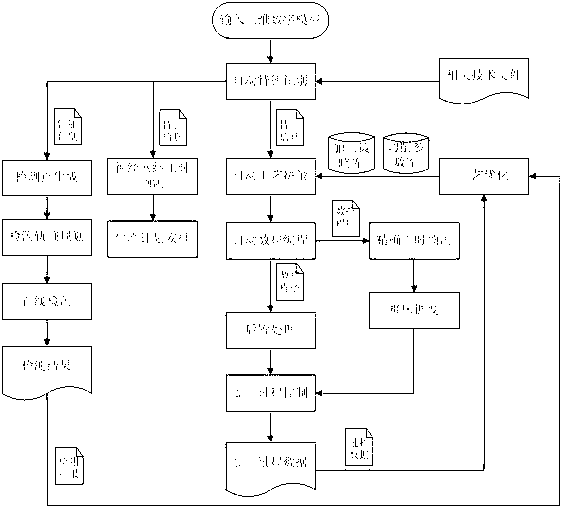

Operation and maintenance automation system and method

ActiveCN105323111AEasy to viewImprove the difficulty of operation and maintenanceData switching networksPrediction algorithmsData acquisition

The invention discloses an operation and maintenance automation system and method. The system comprises a data acquisition module, a pre-processing and storing module, a prediction module, an algorithm evaluation module and an operation and maintenance monitoring management module, wherein the data acquisition module is used for acquiring key performance indexes and running states of monitored units in an operation and maintenance system through a network management protocol or a log file; the pre-processing and storing module is used for performing pre-processing work and sorted storing on data acquired by the data acquisition module; the prediction module is used for performing predictions, including a CPU (Central Processing Unit) load prediction and a disk load prediction according to the data processed by the pre-processing and storing module; the algorithm evaluation module is used for establishing an evaluation criterion of a prediction algorithm and the prediction module, comparing an actual value with a predicted value of the prediction algorithm, and establishing a self-learning process; and the operation and maintenance monitoring management module is used for interacting with operation and maintenance management personnel. A load prediction mechanism and an algorithm prediction model are established in order to finish predictions specific to resource use situations of CPUs, memories, disks and the like. Alarm information is analyzed by further referring to a load prediction result in order to give a relevant auxiliary decision. Resource expansion and fault handling are realized in a way of using scripts, an API (Application Programming Interface) interface and the like.

Owner:NANJING NARI GROUP CORP

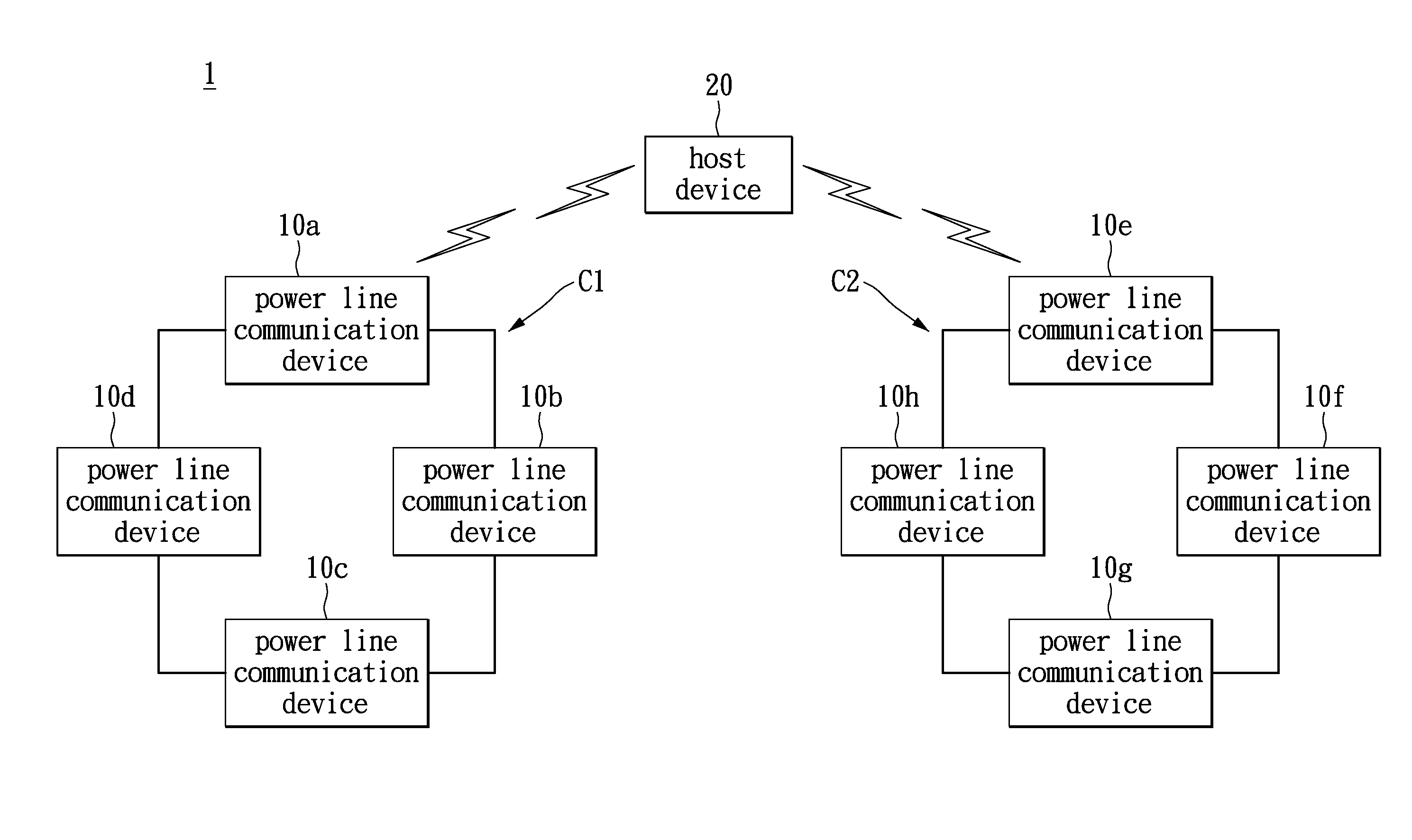

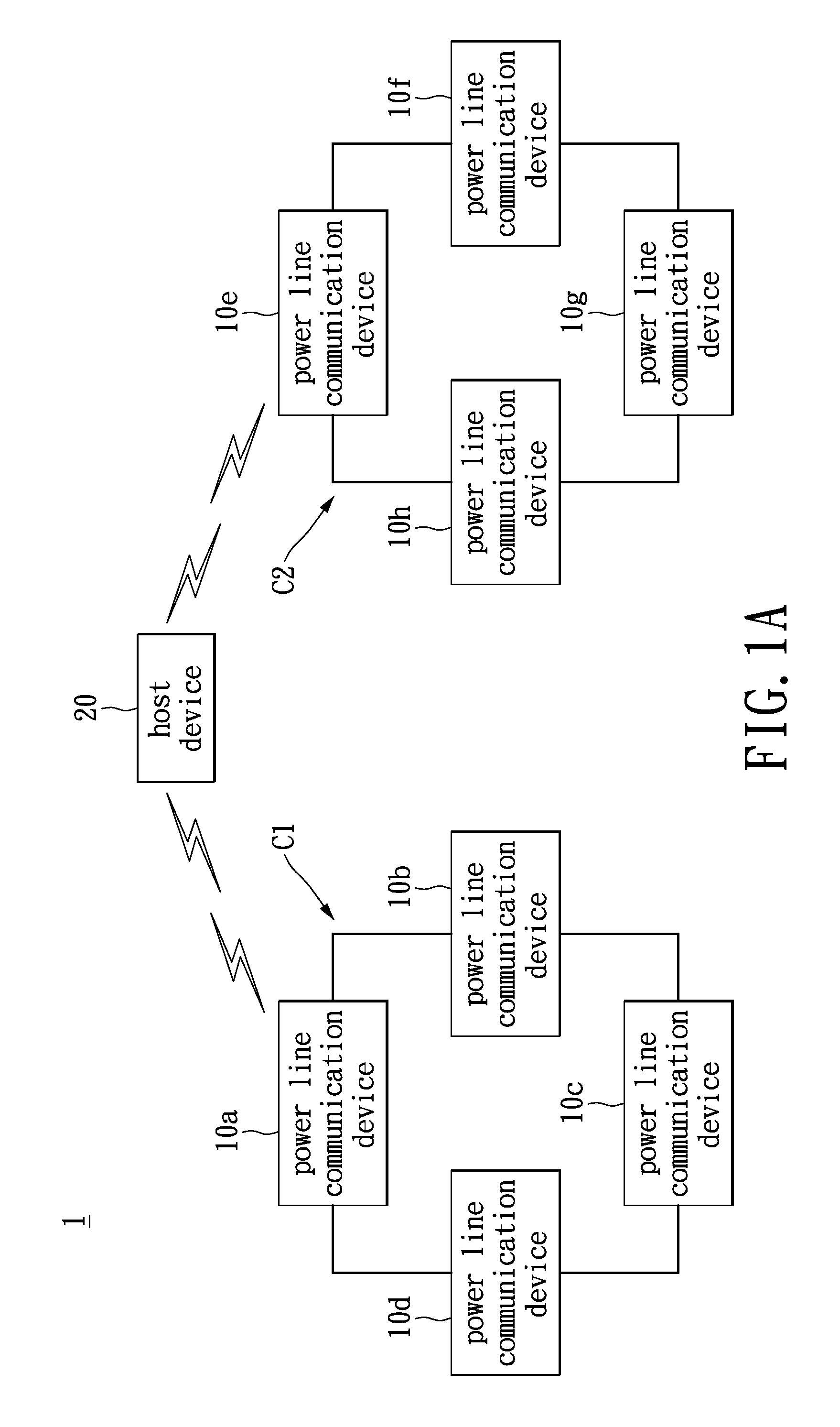

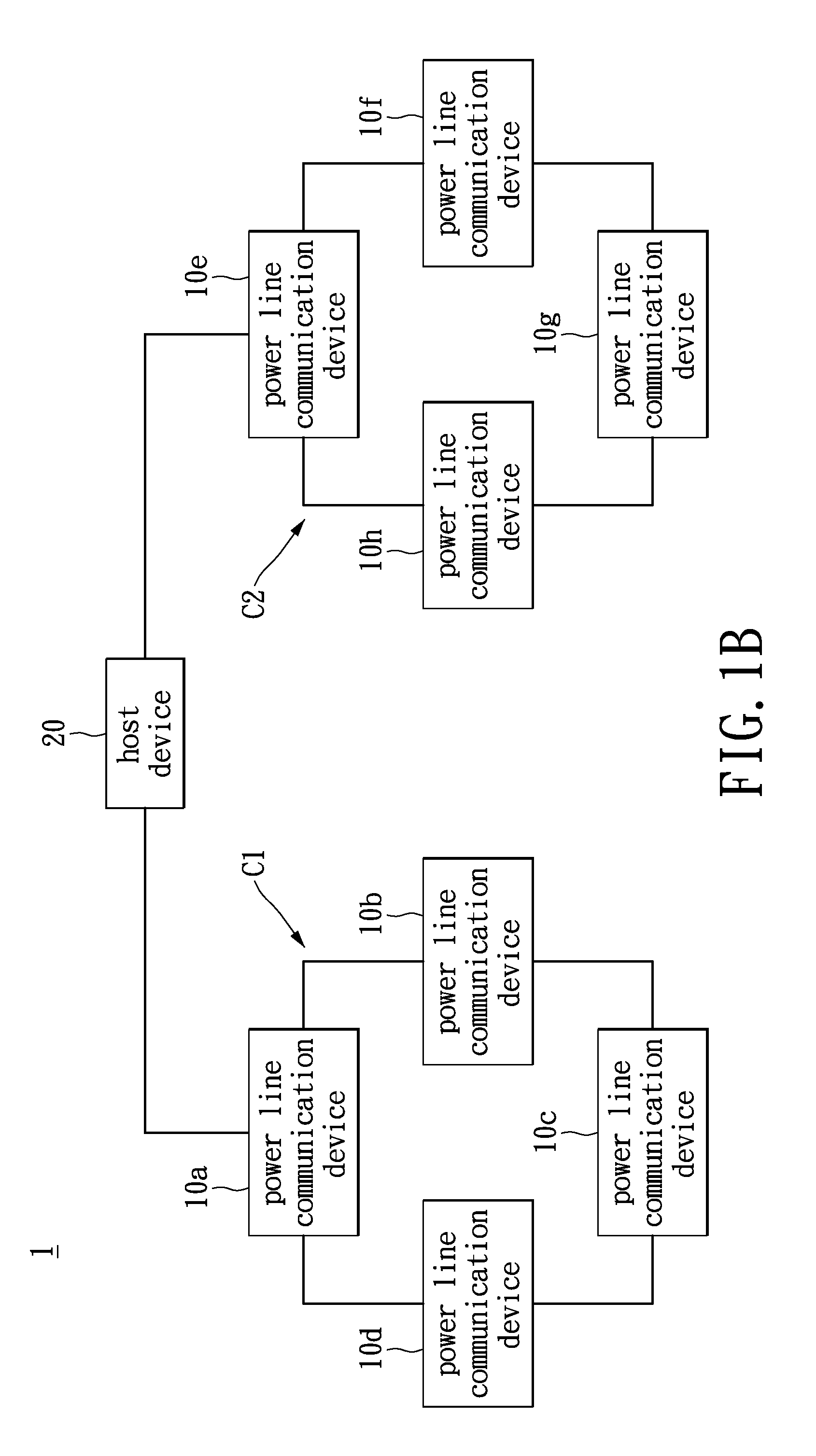

Hybrid power line/wireless appliance automation system, device, and power monitoring method utilzing the same

ActiveUS20140177692A1Effectively reducing/removing connectivity dead zoneOperational securityTransmission control/equlisationSystems with measurements/testing channelsElectric power distributionEngineering

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

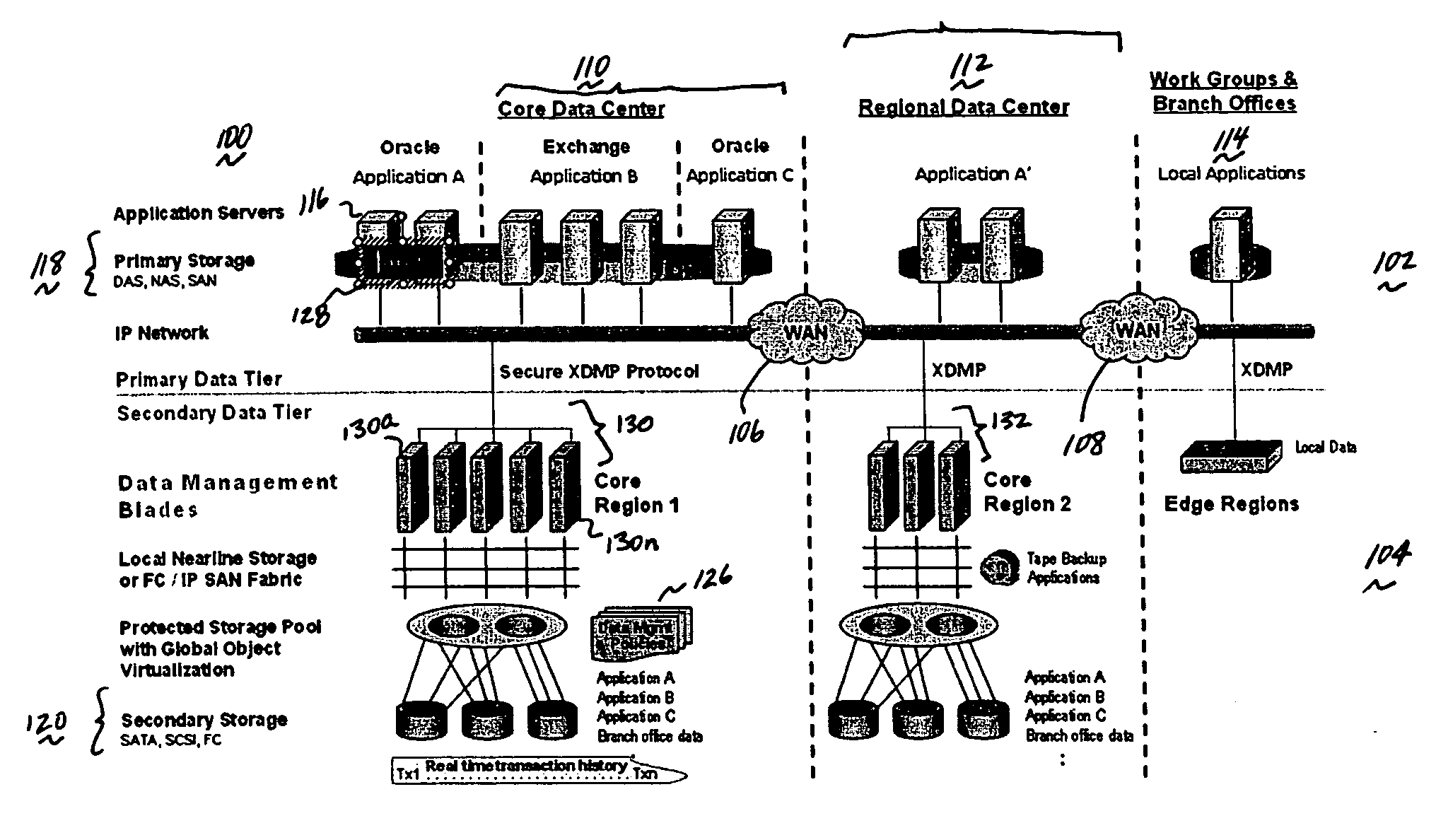

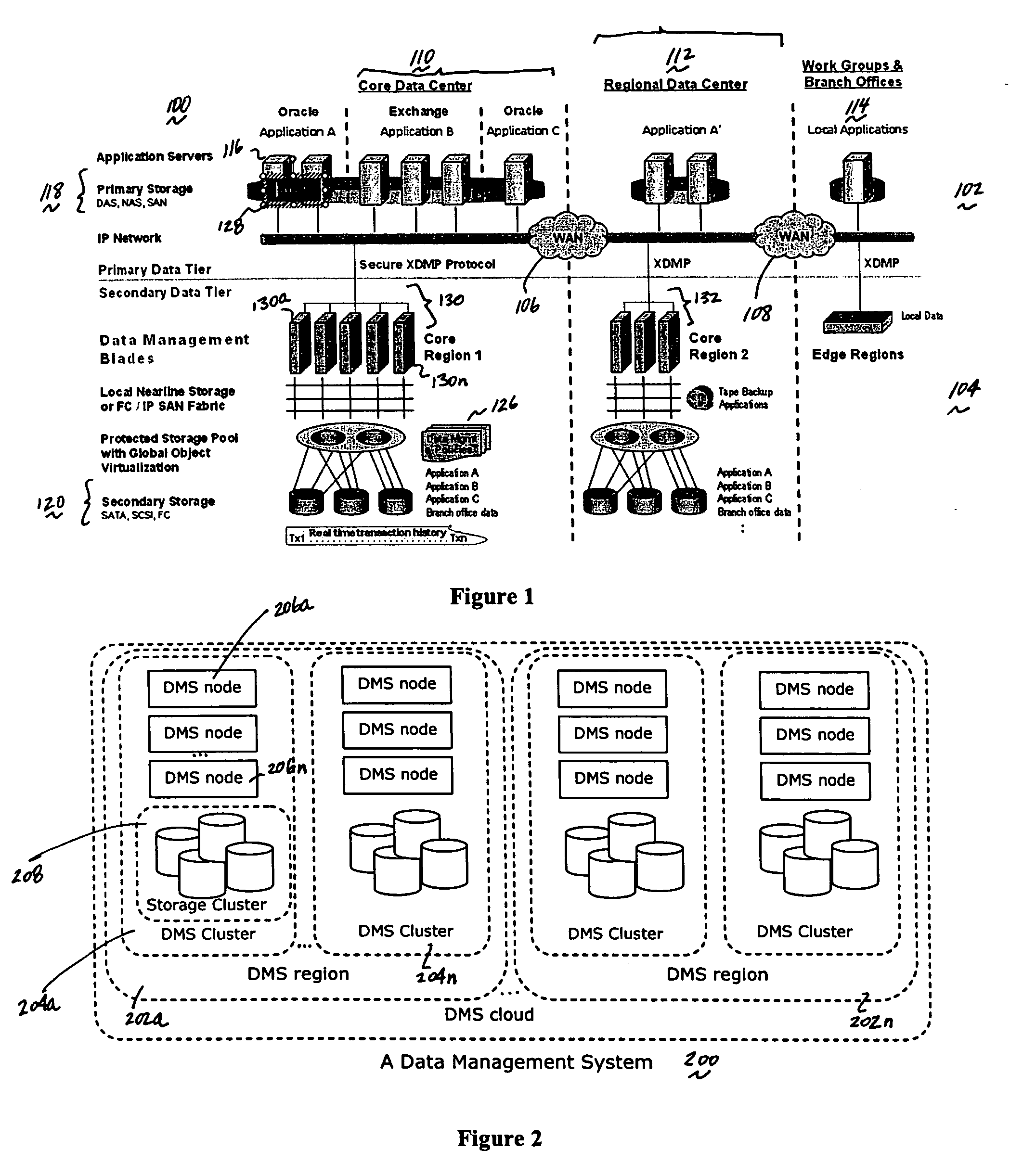

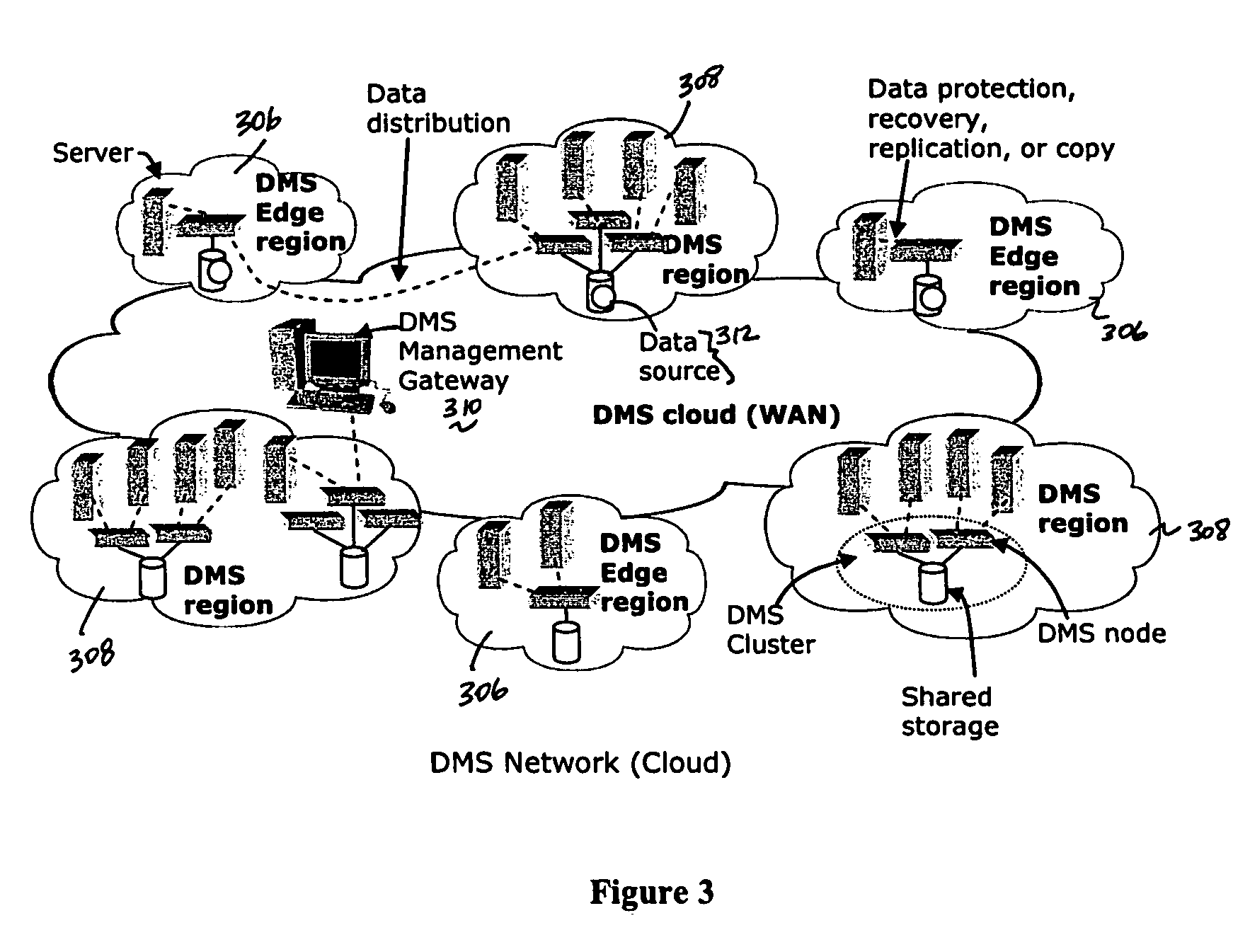

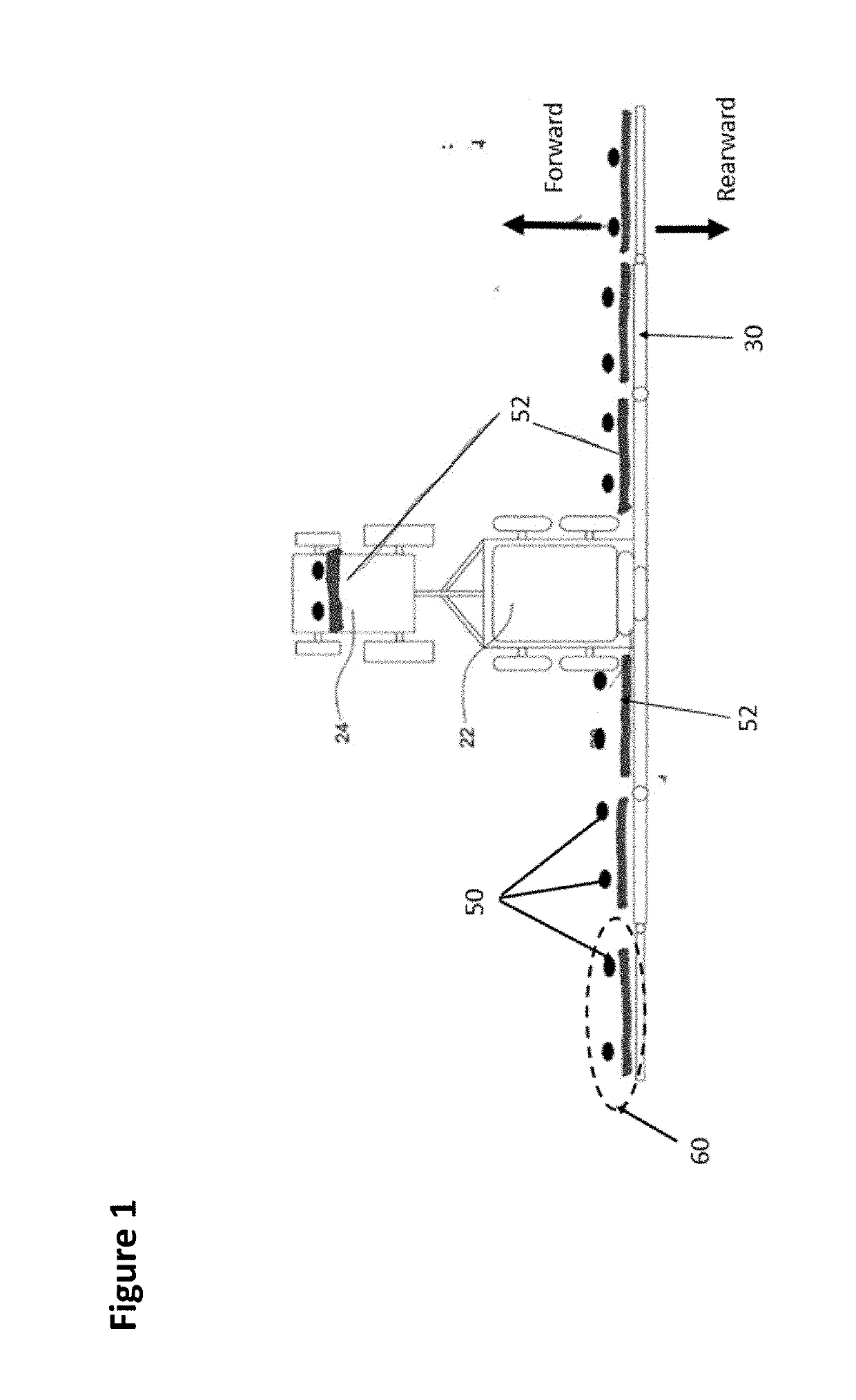

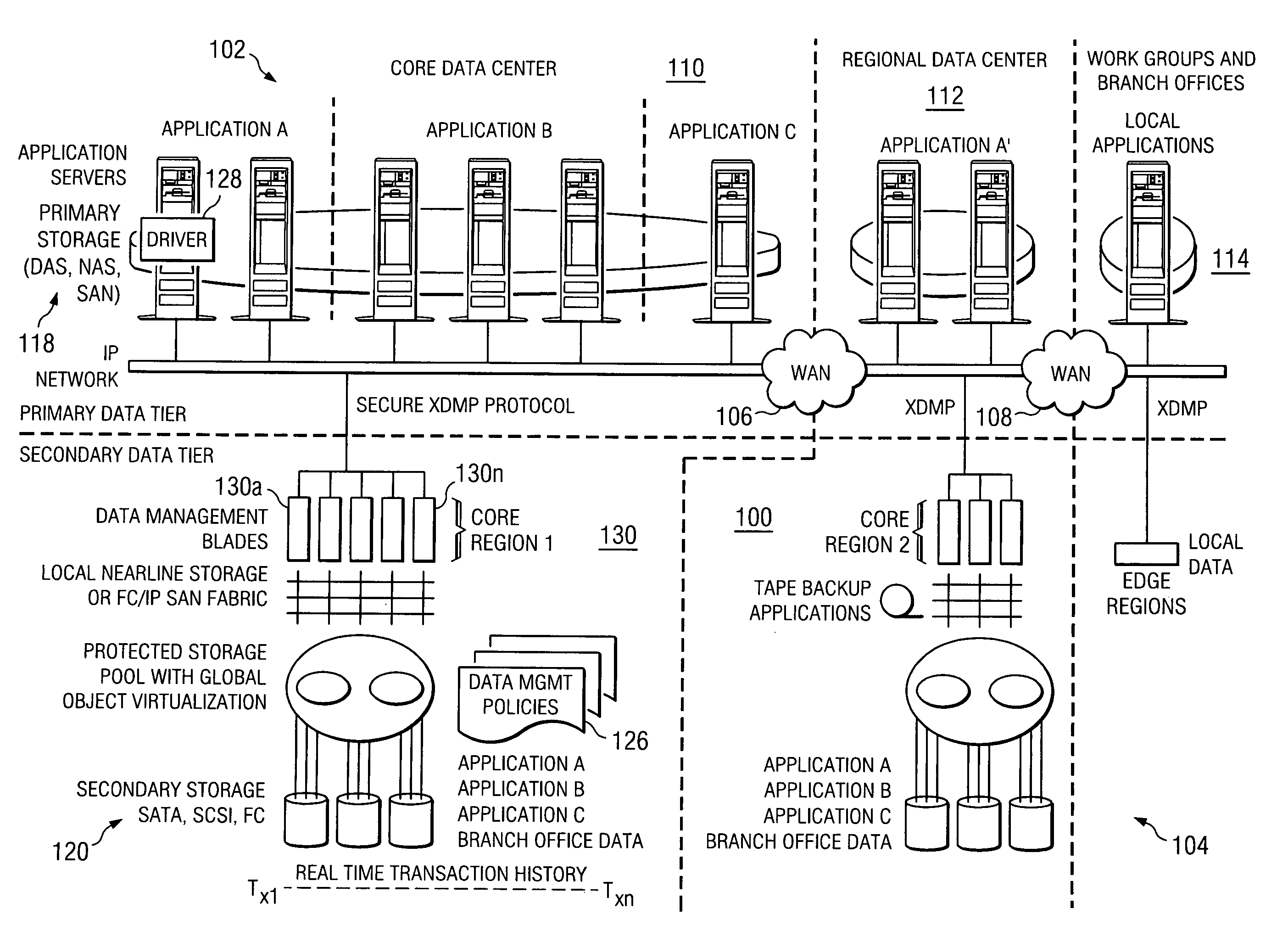

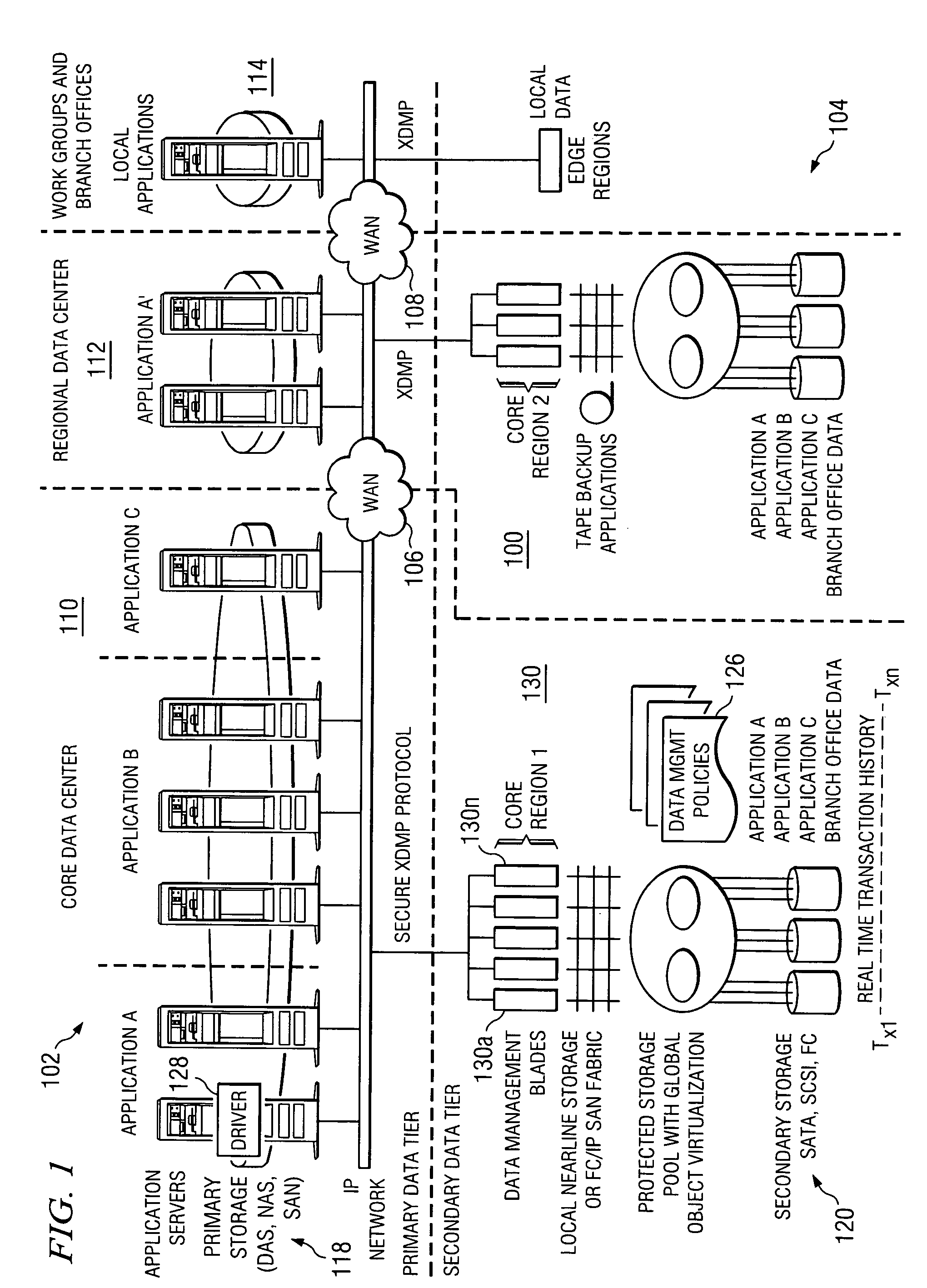

Method and system for automated, no downtime, real-time, continuous data protection

ActiveUS20050262377A1Easy to optimizeError detection/correctionGroup 6/16 element organic compoundsData streamFinite-state machine

A data management system or “DMS” provides an automated, continuous, real-time, substantially no downtime data protection service to one or more data sources associated with a set of application host servers. To facilitate the data protection service, a host driver embedded in an application server captures real-time data transactions, preferably in the form of an event journal that is provided to other DMS components. The driver functions to translate traditional file / database / block I / O and the like into a continuous, application-aware, output data stream. The host driver includes an event processor that provides the data protection service, preferably by implementing a finite state machine (FSM). In particular, the data protection is provided to a given data source in the host server by taking advantage of the continuous, real-time data that the host driver is capturing and providing to other DMS components. The state of the most current data in DMS matches the state of the data in the host server; as a consequence, the data protection is provided under the control of the finite state machine as a set of interconnected phases or “states.” The otherwise separate processes (initial data upload, continuous backup, blackout and data resynchronization, and recovery) are simply phases of the overall data protection cycle. As implemented by the finite state machine, this data protection cycle preferably loops around indefinitely until, for example, a user terminates the service. A given data protection phase (a given state) changes only as the state of the data and the environment change (a given incident).

Owner:QUEST SOFTWARE INC

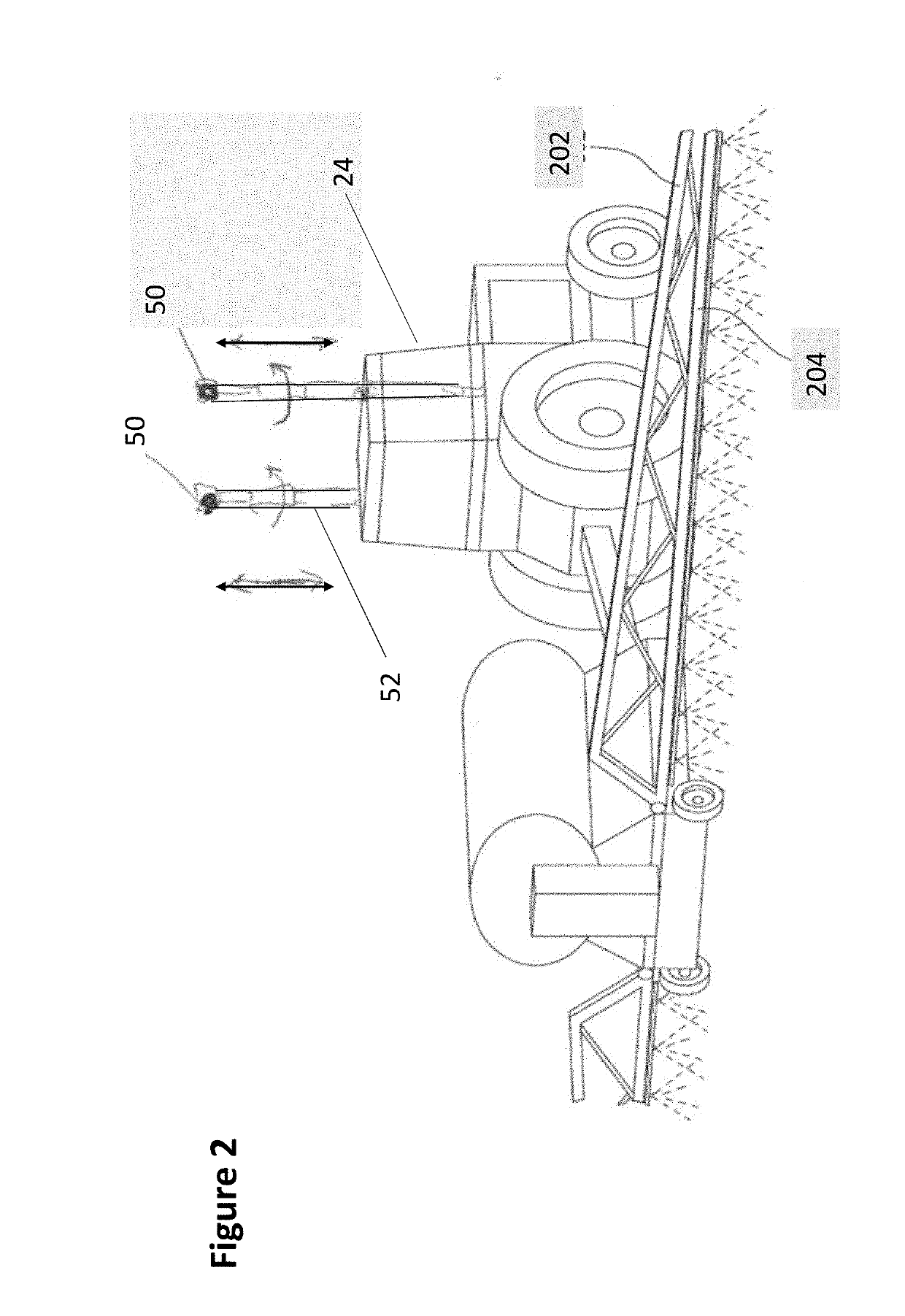

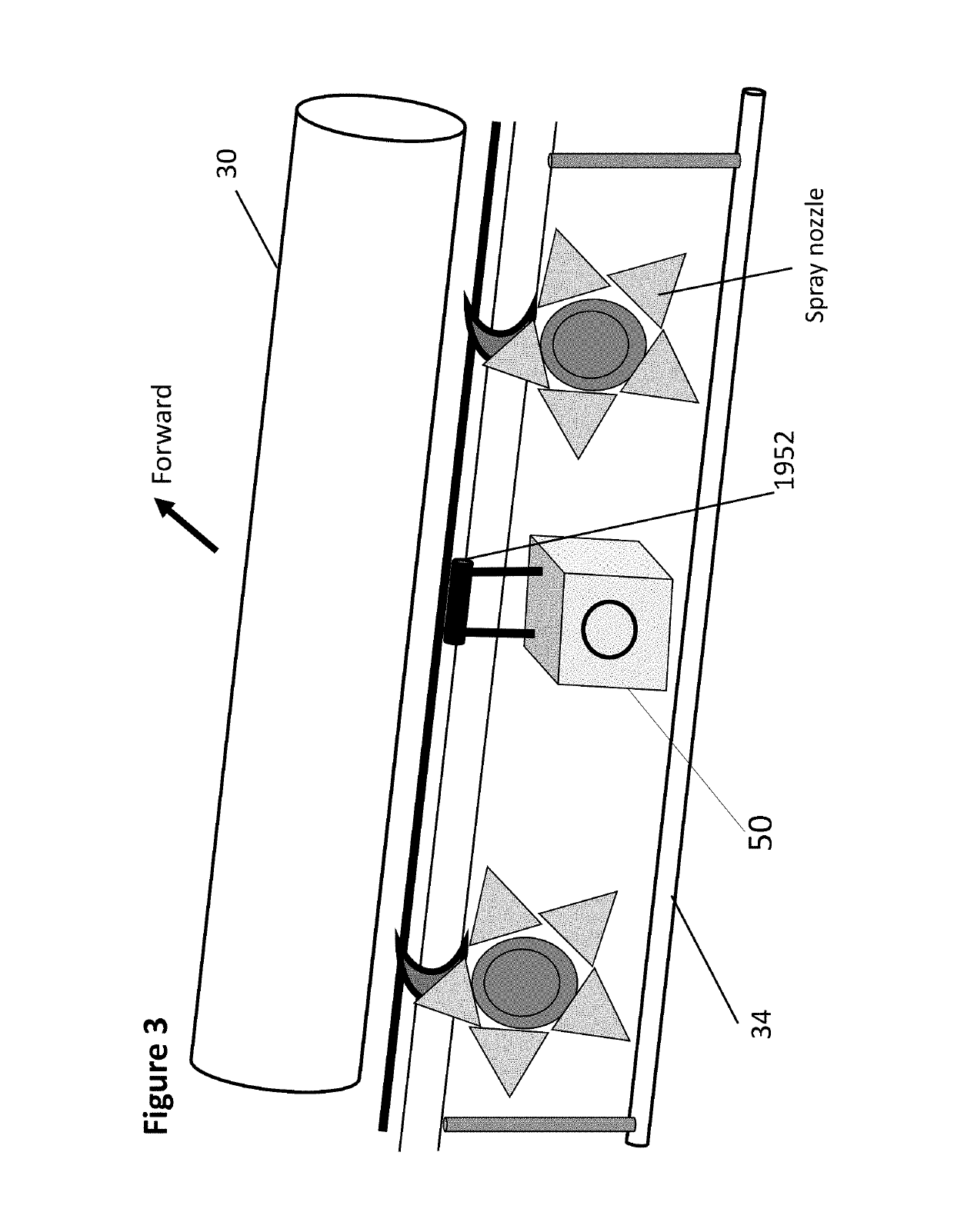

Monitoring and control implement for crop improvement

ActiveUS20190150357A1Increase crop yieldPreserve landImage enhancementImage analysisReal time analysisEngineering

An example machinery includes an automated crop management motorized vehicle having an intelligent, modularized image sensor (e.g. camera or video) system that is portable to other crop management vehicles such as a combine, planter or a tillage machine. The image sensor system includes a framework having a bank of procedures for monitoring and control of navigation, spray application, weeding, seeding, machine configuration, in real time as the machines go through a crop field throughout a crop cycle. One example implementation includes electronic circuits, with more than one set mounted on a platform that facilitates moving the setup to other agricultural machines. The framework captures, preserves and corrects the captured images for real time analysis and response, and for spray management to improve crop yield that is correlated with the machine settings and crop management practices.

Owner:DOLLY Y WU PLLC

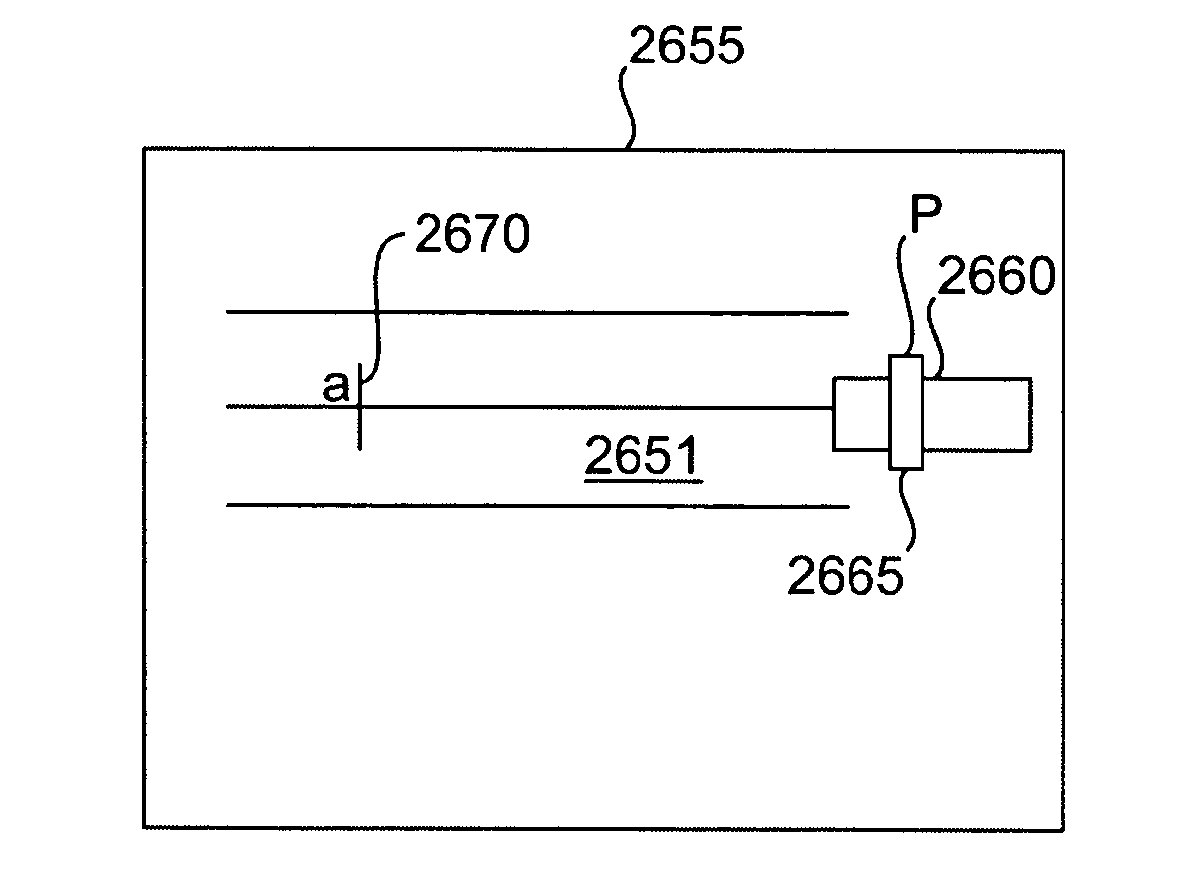

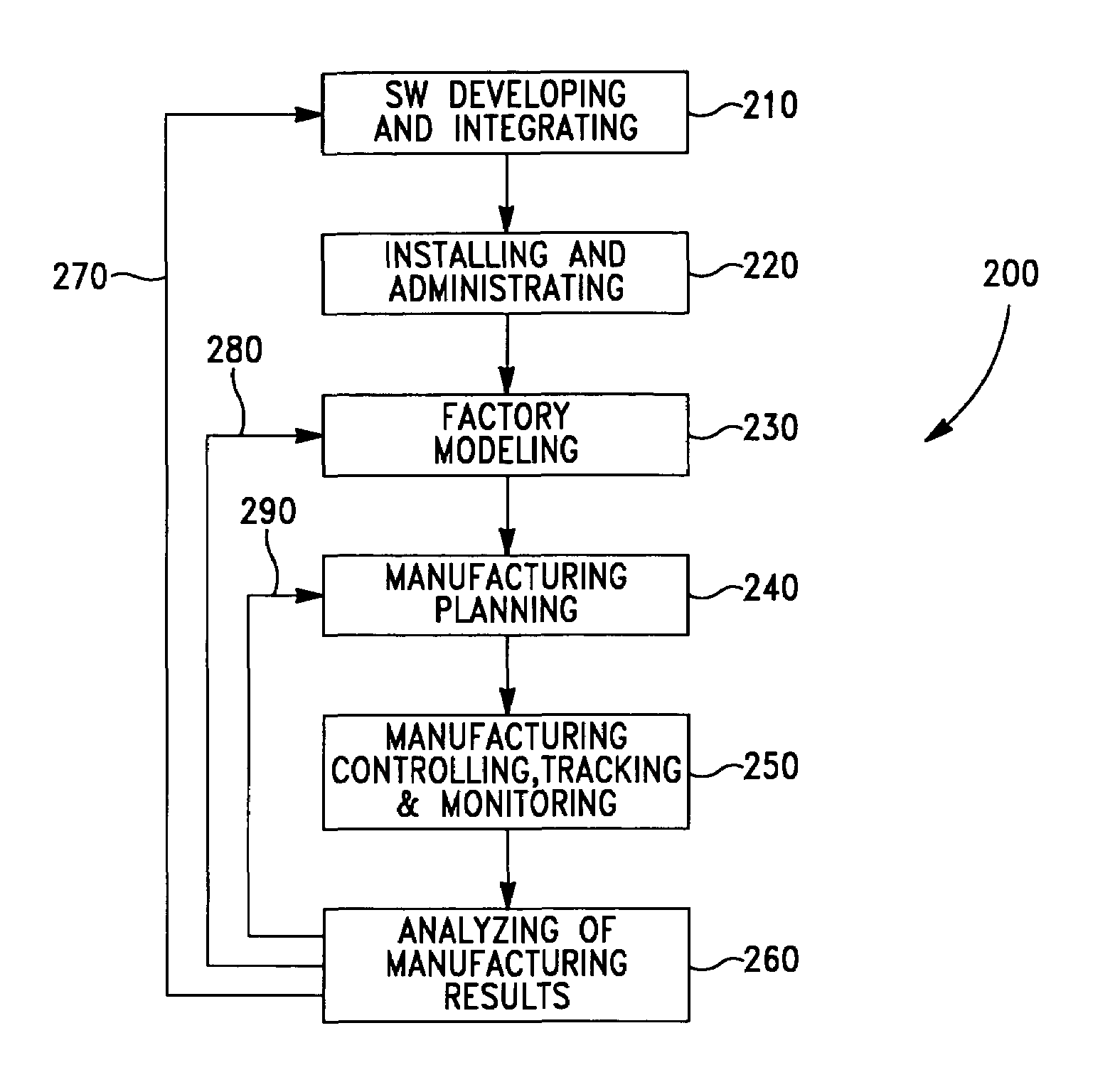

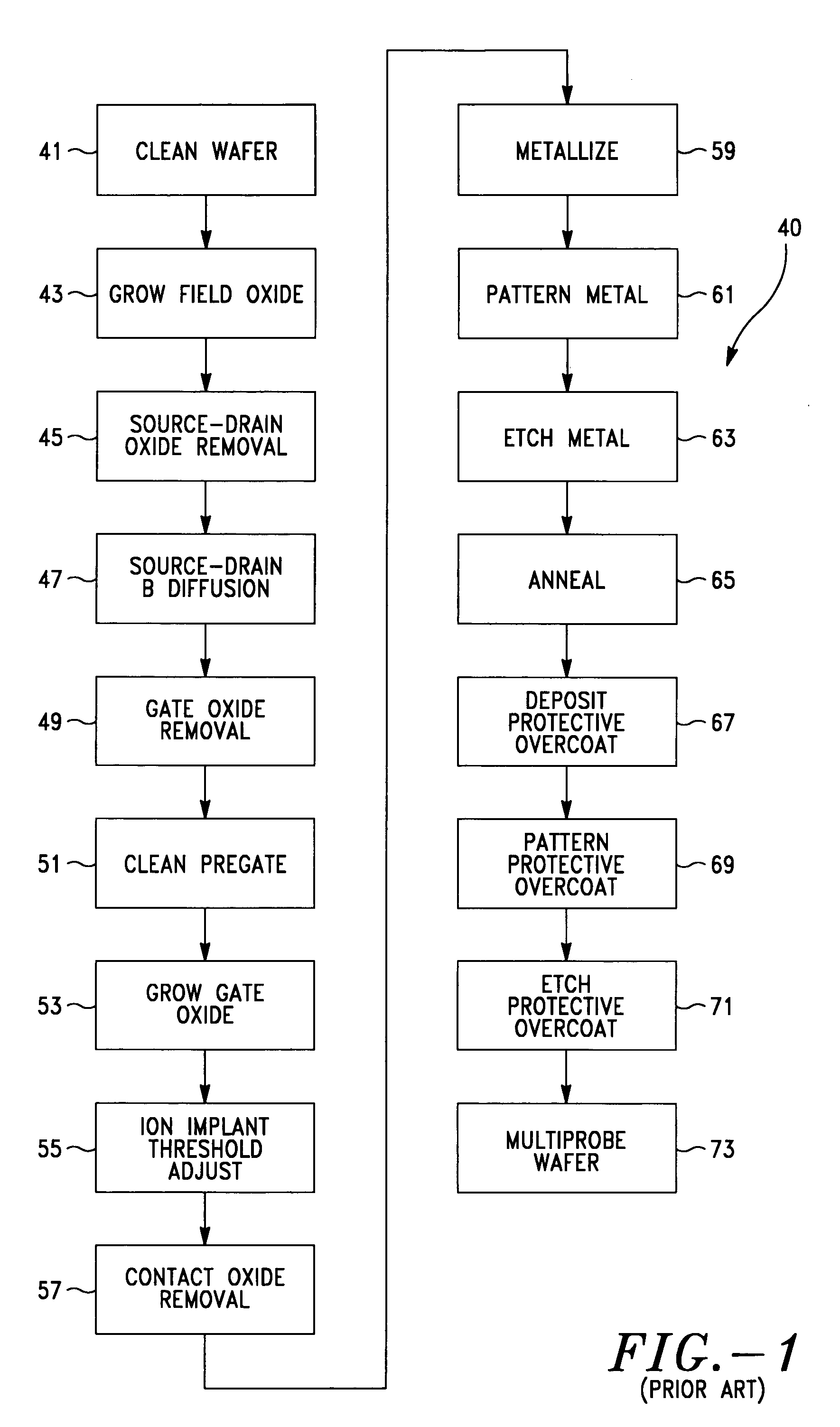

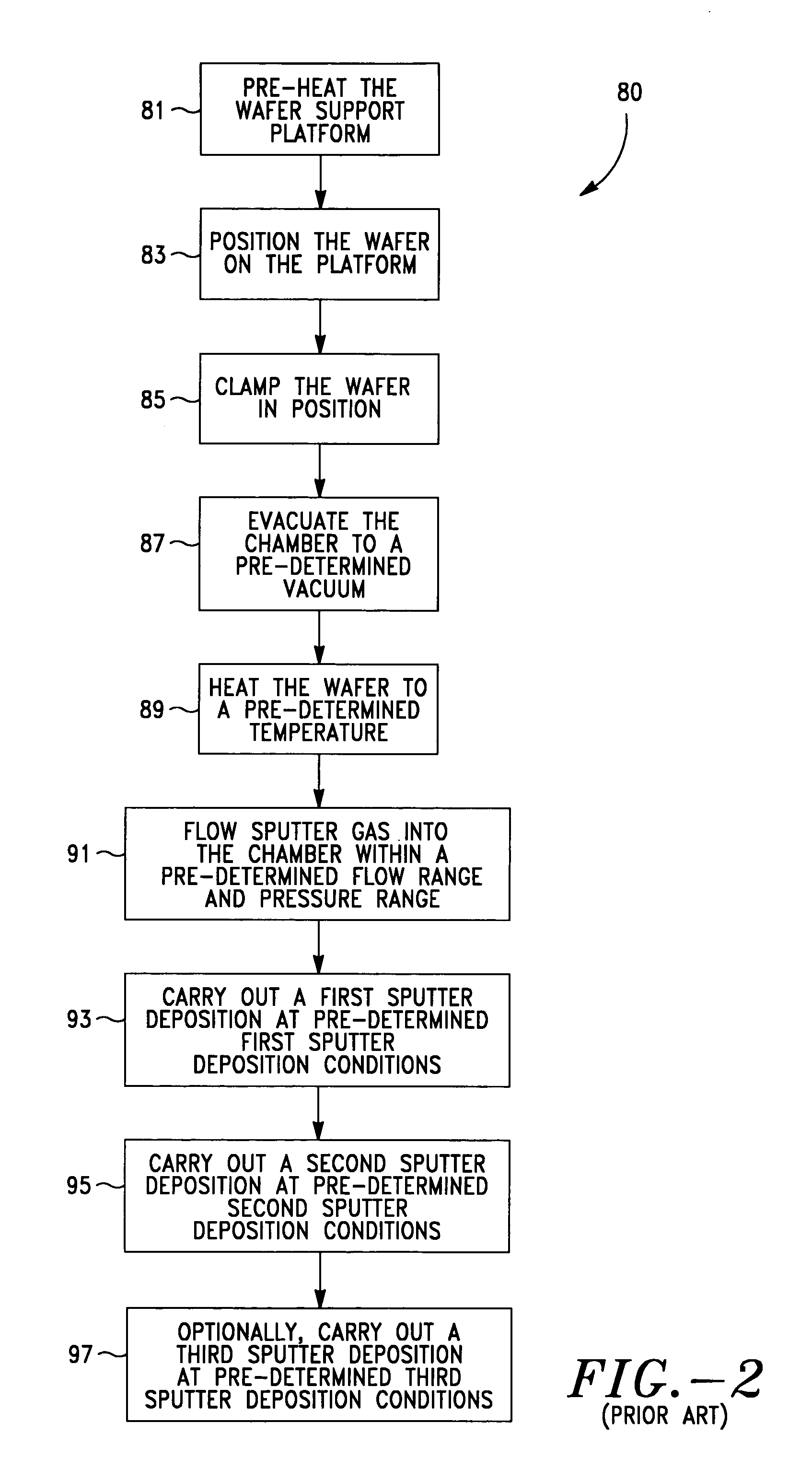

Computer integrated manufacturing techniques

InactiveUS7069101B1Process Control OptimizationQuality improvementData processing applicationsSemiconductor/solid-state device manufacturingConsequence analysisManufacturing technology

The present invention provides a novel distributed factory system framework including a novel factory automation lifecycle (200) having lifecycle activities for SW developing and integrating (210), installing and administrating (220), factory modeling (230), manufacturing planning (240), manufacturing controlling, monitoring and tracking (250) and analyzing of manufacturing results (260). The factory lifecycle comprises framework components. The distributed factory system framework also includes application components and software building blocks. The framework components are adapted for managing the application components, while the application components are utilized to provide instructions for managing a process such as a wafer fab. The building blocks are adapted for forming or modifying framework and application components. The distributed factory system framework provides computer implemented methods for integrating processing systems and facilitates process and equipment changes.

Owner:APPLIED MATERIALS INC

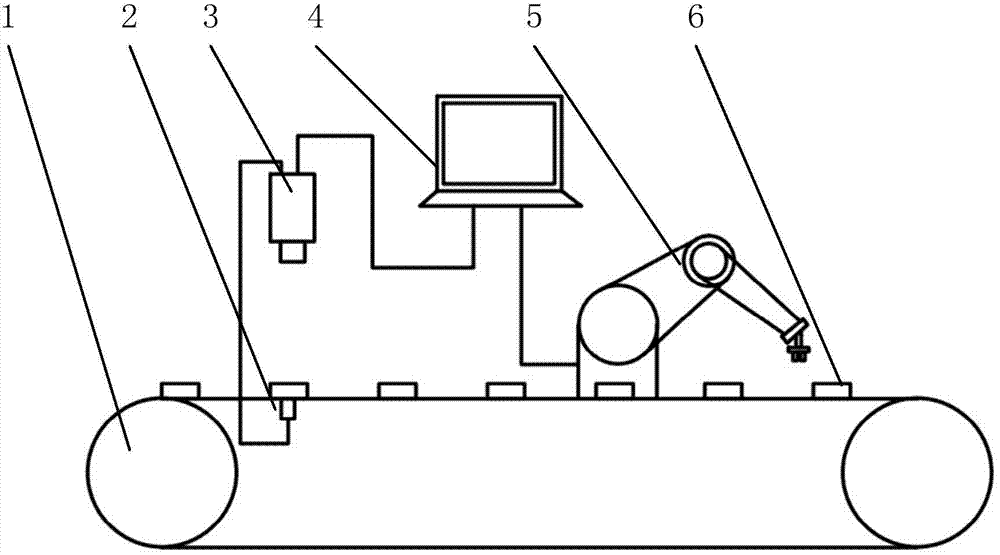

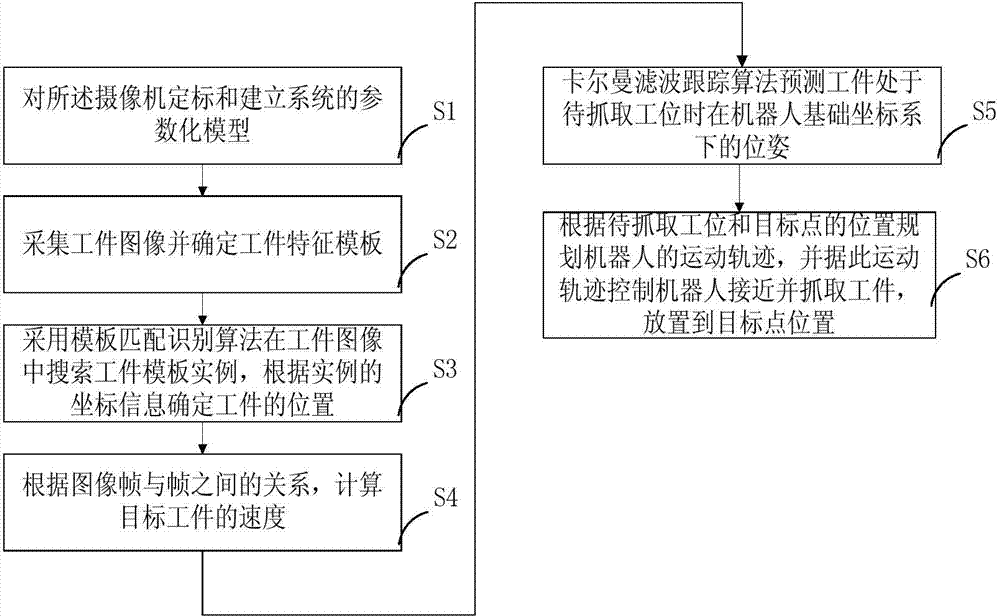

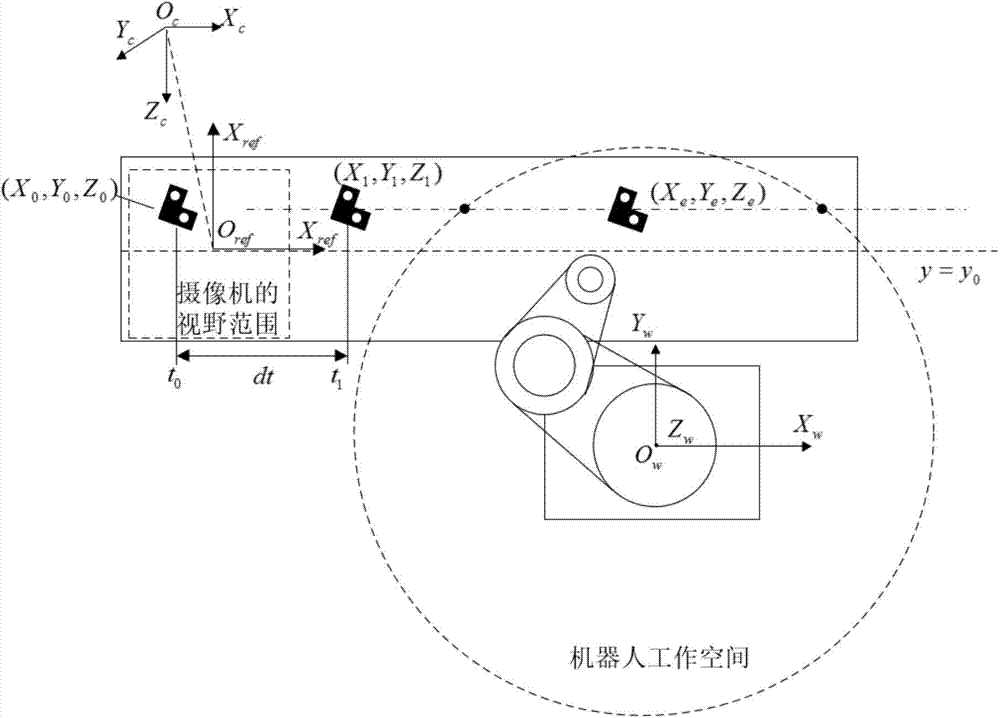

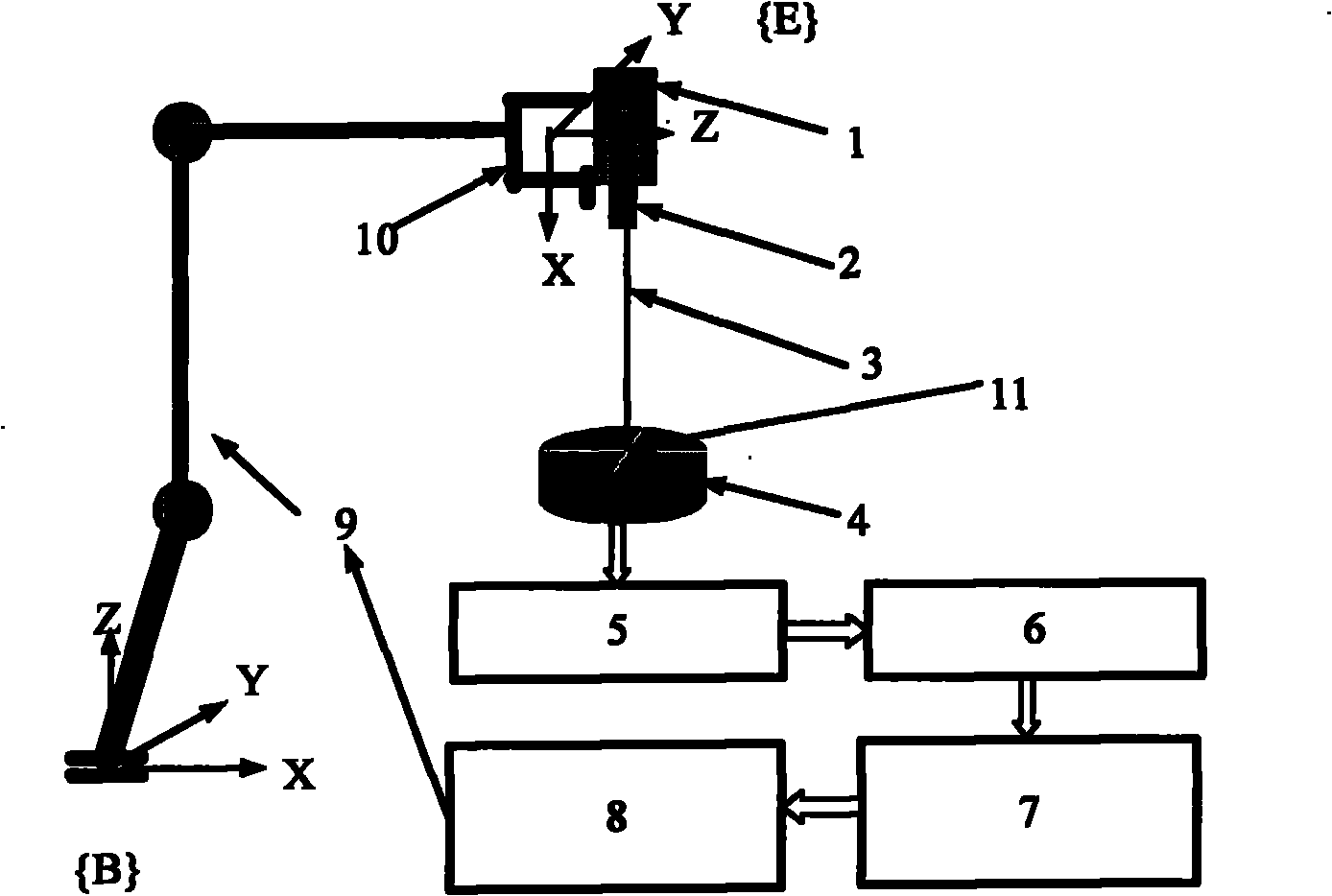

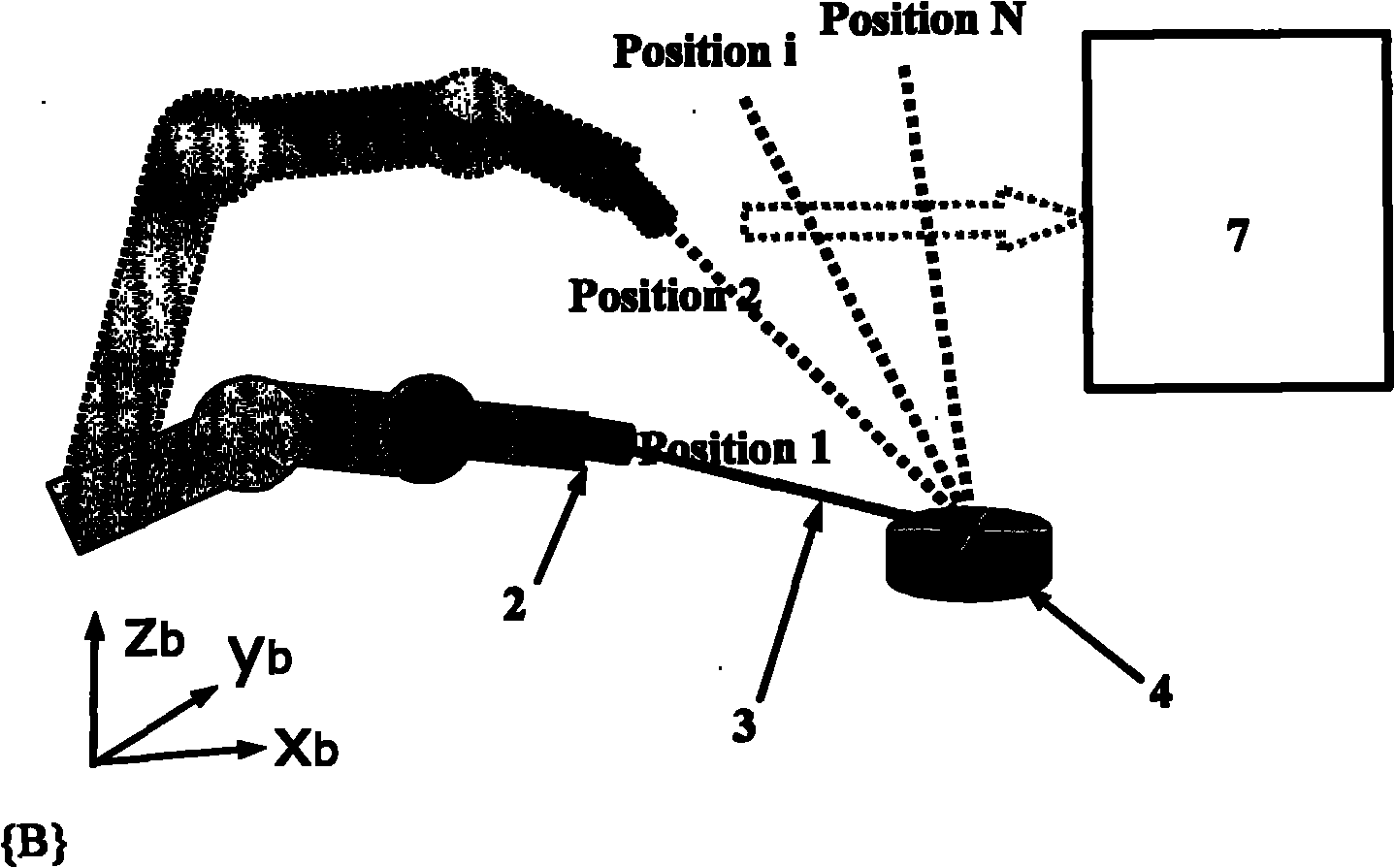

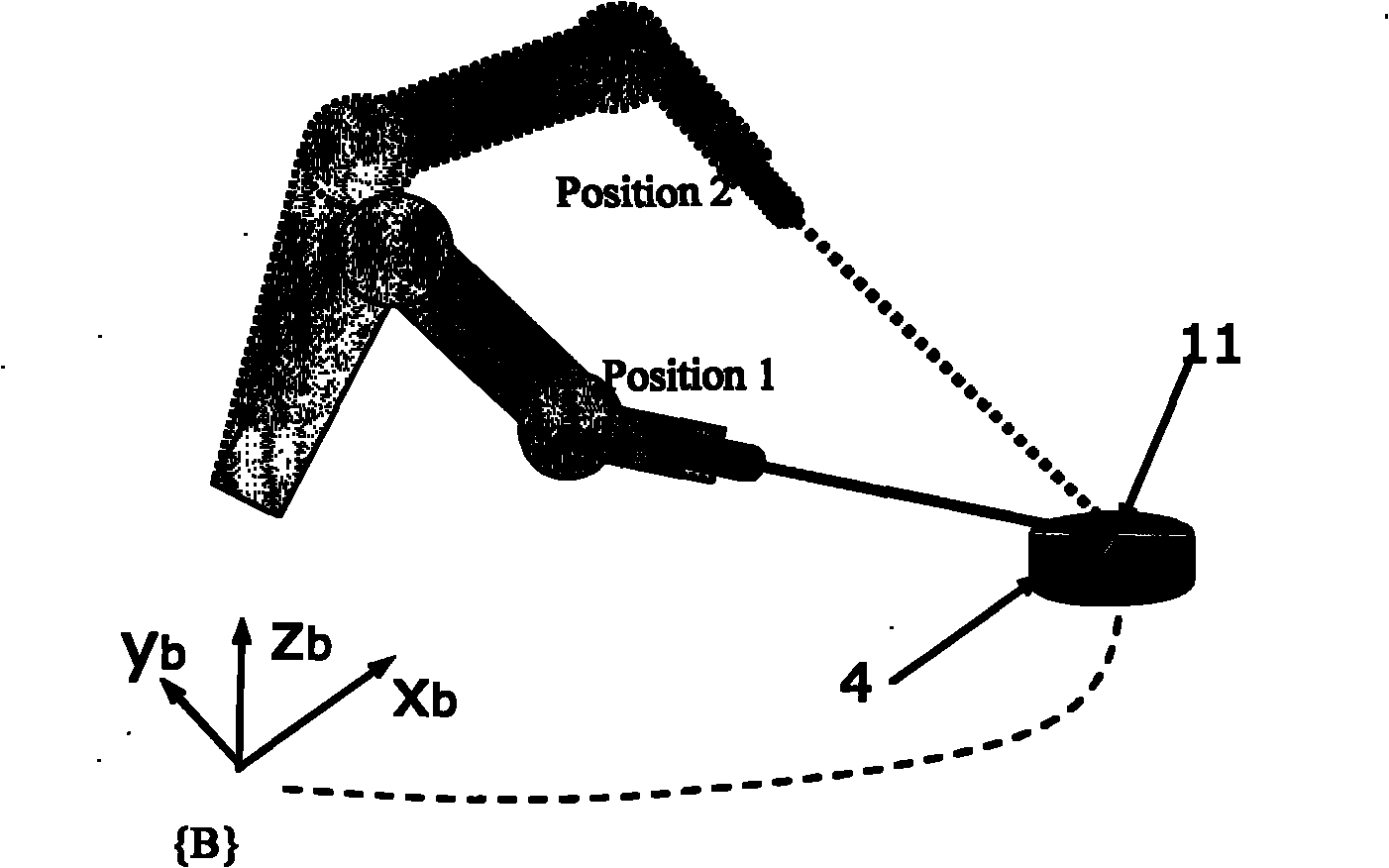

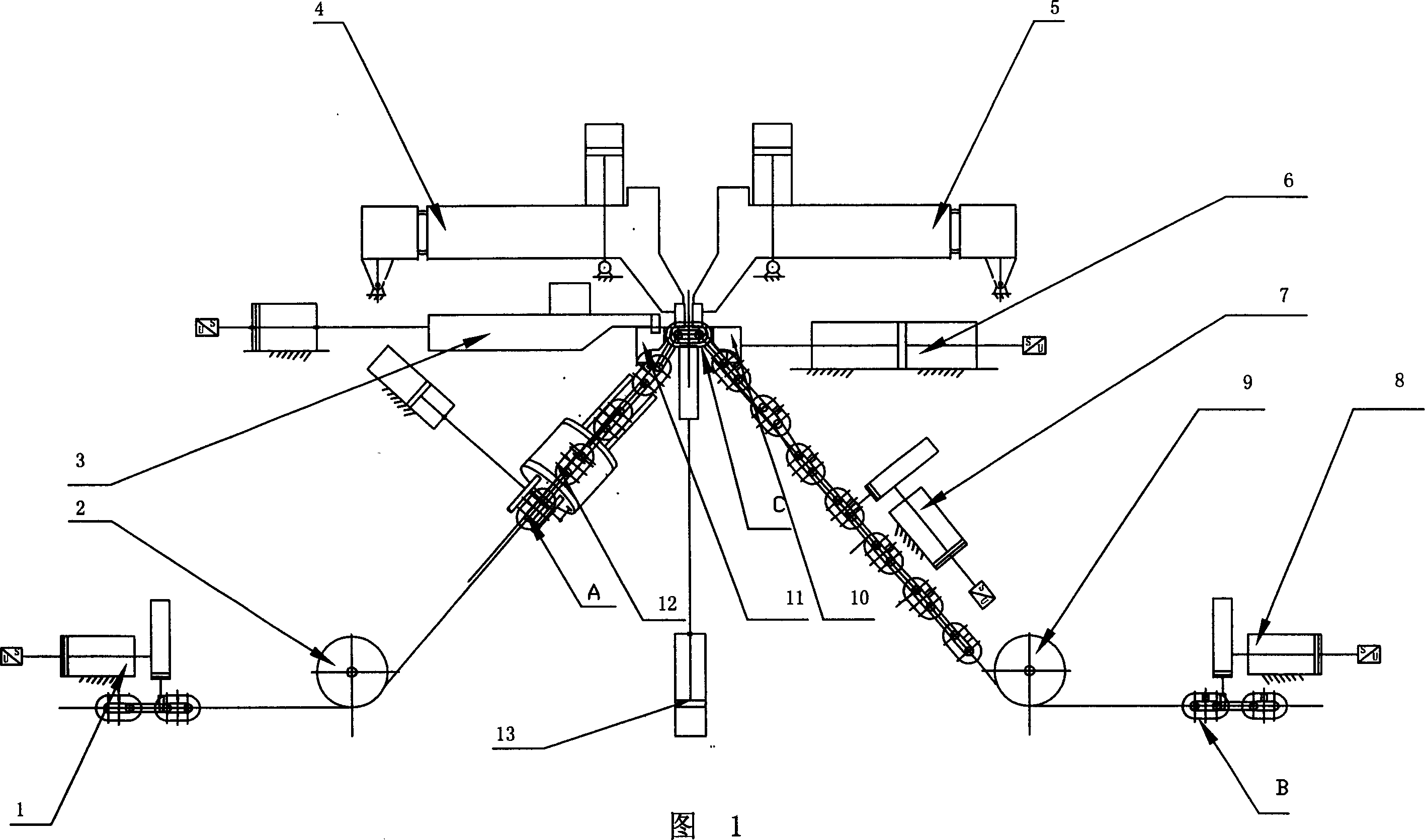

Industrial robot workpiece positioning grabbing method and system based on visual guidance

InactiveCN103895042AAccurate calculationHigh positioning accuracyManipulatorVisual perceptionComputer science

The invention discloses an industrial robot workpiece positioning grabbing method based on visual guidance. The method includes the following steps that 1, a system parametric model is established, and calibration of a camera is conducted; 2, a workpiece feature template is determined; 3, workpiece template living examples are sought for, and the positions of workpieces are determined according to coordinate information of the living examples; 4, the speed of a target workpiece is calculated; 5, the pose, in a robot basic coordinate system, of the workpiece is predicted when the workpiece is located at a station to be grabbed; 6, a robot moves according to a planned path to approach and grab the workpiece and place the workpiece at the position of a target point. The invention further discloses a system for implementing the industrial robot workpiece positioning grabbing method based on visual guidance in the patent claim 1. The system comprises a conveying belt, an optoelectronic switch, a camera, an industrial control computer, the robot and the target workpiece. The system has the advantages of being high in positioning accuracy, high in working efficiency, high in automation degree and the like.

Owner:SOUTH CHINA UNIV OF TECH

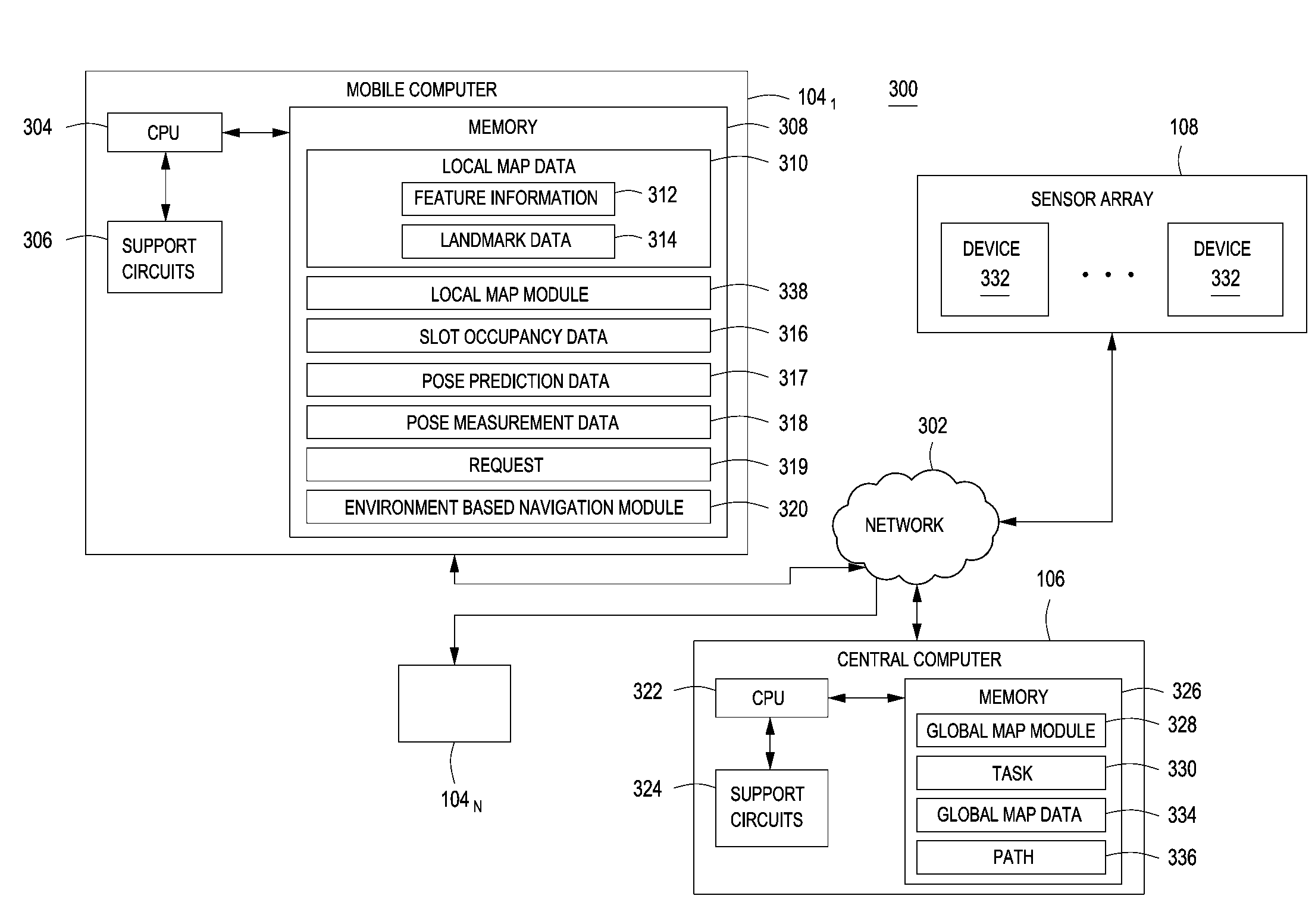

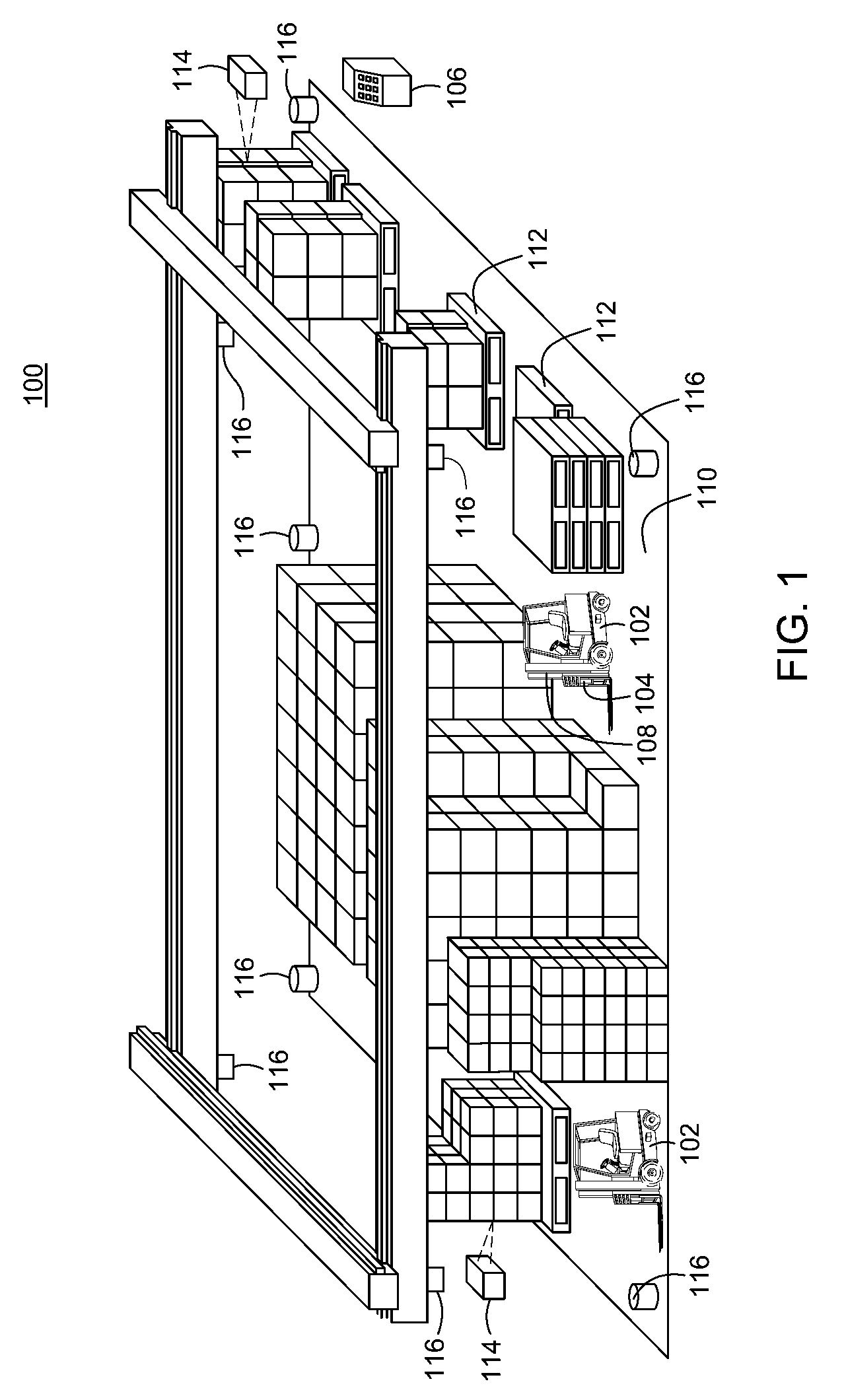

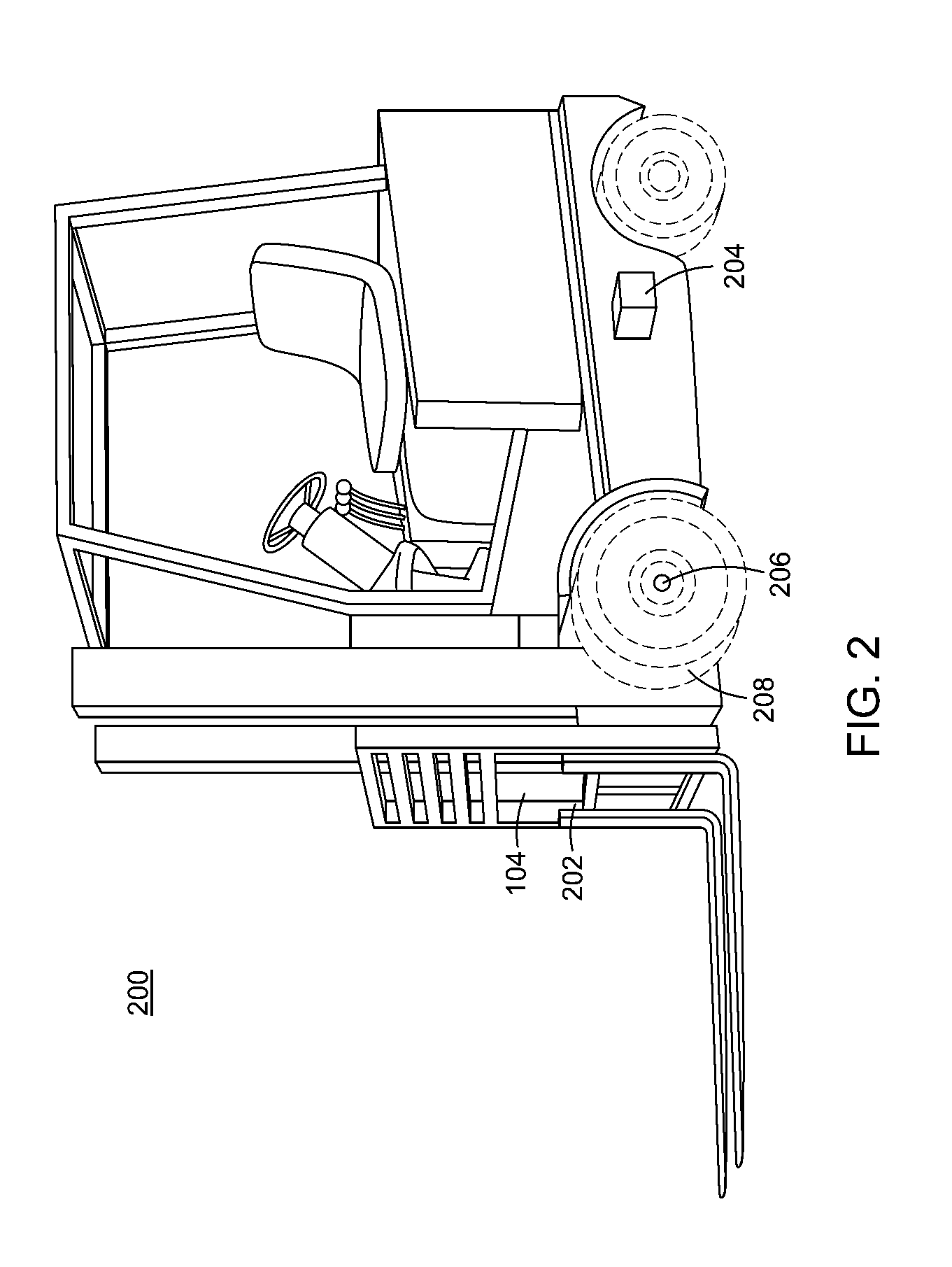

Method and apparatus for sharing map data associated with automated industrial vehicles

ActiveUS20120323431A1Instruments for road network navigationLifting devicesComputer sciencePhysical context

A method and apparatus for sharing map data between industrial vehicles in a physical environment is described. In one embodiments, the method includes processing local map data associated with a plurality of industrial vehicles, wherein the local map data comprises feature information generated by the plurality of industrial vehicles regarding features observed by industrial vehicles in the plurality of vehicles; combining the feature information associated with local map data to generate global map data for the physical environment; and navigating an industrial vehicle of the plurality of industrial vehicles using at least a portion of the global map data.

Owner:CROWN EQUIP CORP

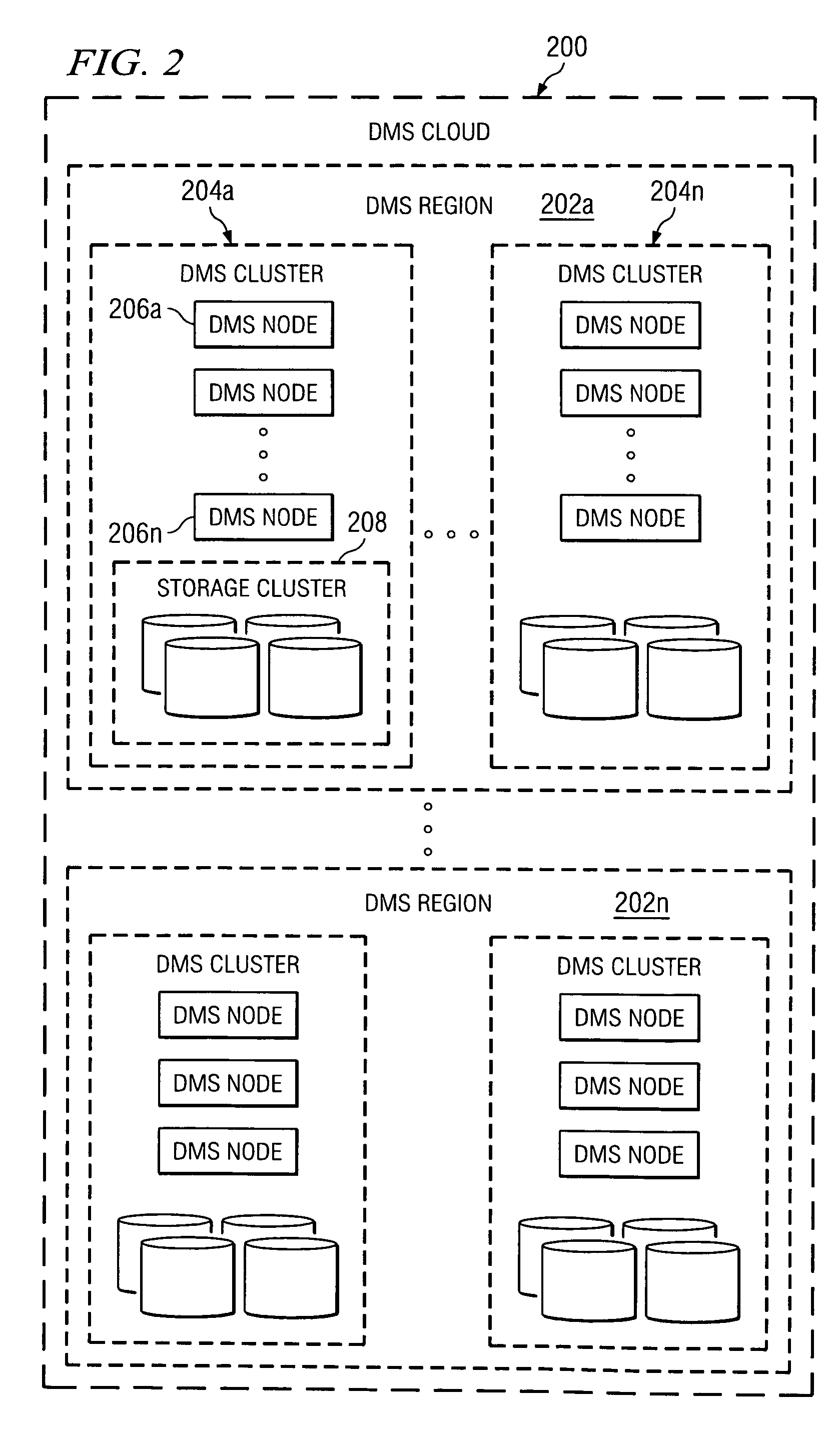

Method and system for automated, no downtime, real-time, continuous data protection

ActiveUS7096392B2Error detection/correctionGroup 6/16 element organic compoundsData streamFinite-state machine

A data management system or “DMS” provides an automated, continuous, real-time, substantially no downtime data protection service to one or more data sources associated with a set of application host servers. To facilitate the data protection service, a host driver embedded in an application server captures real-time data transactions, preferably in the form of an event journal that is provided to other DMS components. The driver functions to translate traditional file / database / block I / O and the like into a continuous, application-aware, output data stream. The host driver includes an event processor that provides the data protection service, preferably by implementing a finite state machine (FSM). In particular, the data protection is provided to a given data source in the host server by taking advantage of the continuous, real-time data that the host driver is capturing and providing to other DMS components. The state of the most current data in DMS matches the state of the data in the host server; as a consequence, the data protection is provided under the control of the finite state machine as a set of interconnected phases or “states.” The otherwise separate processes (initial data upload, continuous backup, blackout and data resynchronization, and recovery) are simply phases of the overall data protection cycle. As implemented by the finite state machine, this data protection cycle preferably loops around indefinitely until, for example, a user terminates the service. A given data protection phase (a given state) changes only as the state of the data and the environment change (a given incident).

Owner:QUEST SOFTWARE INC

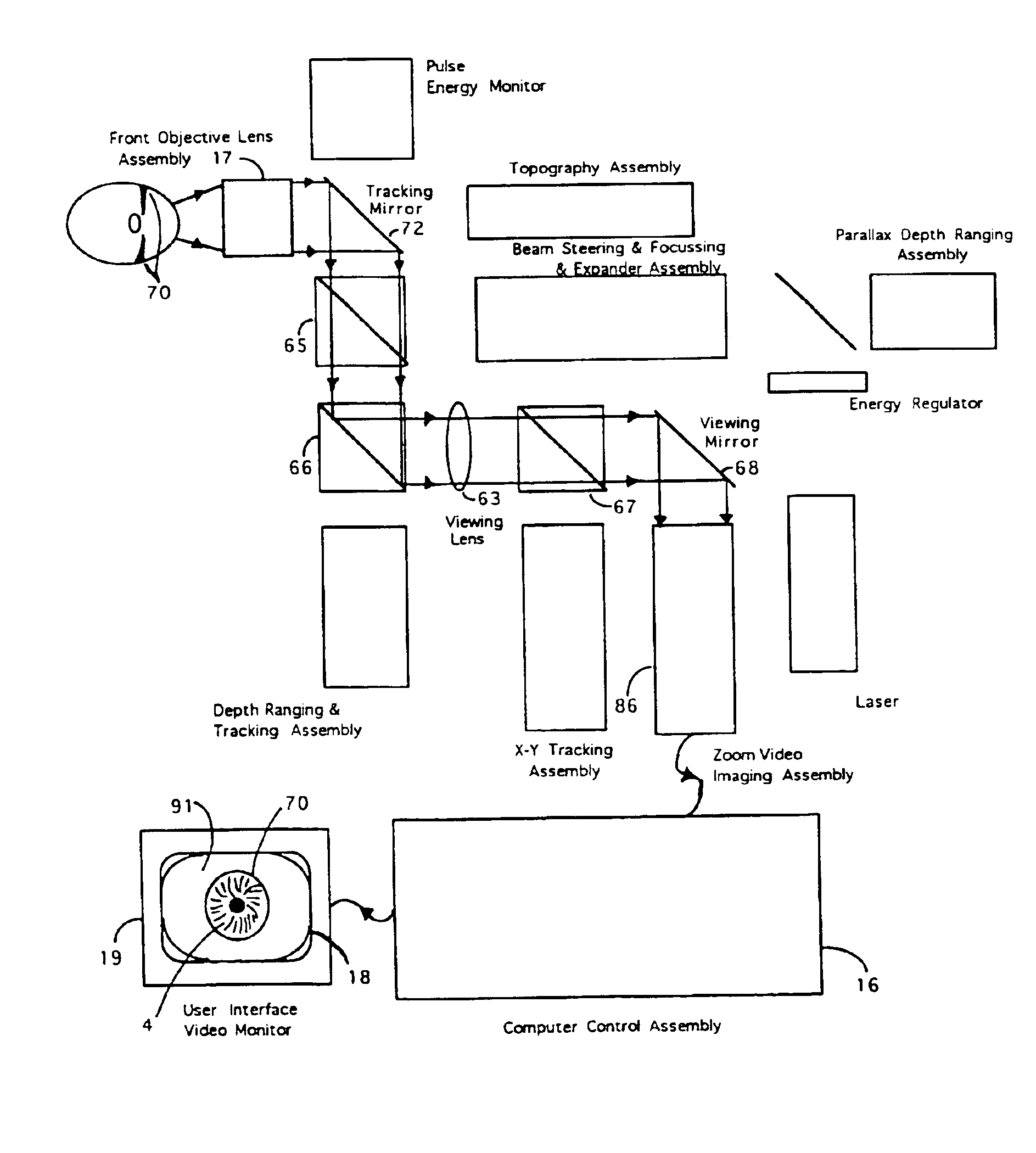

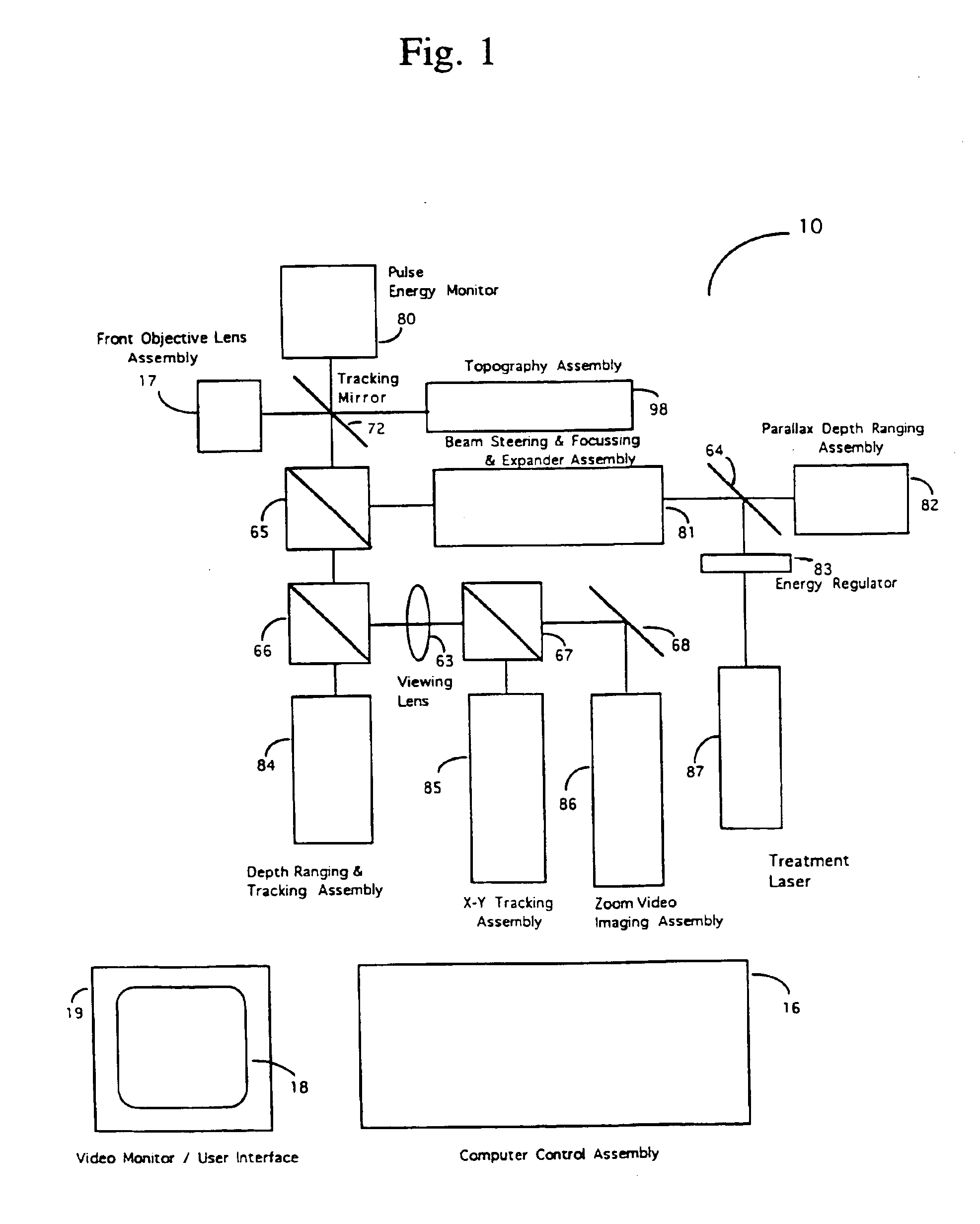

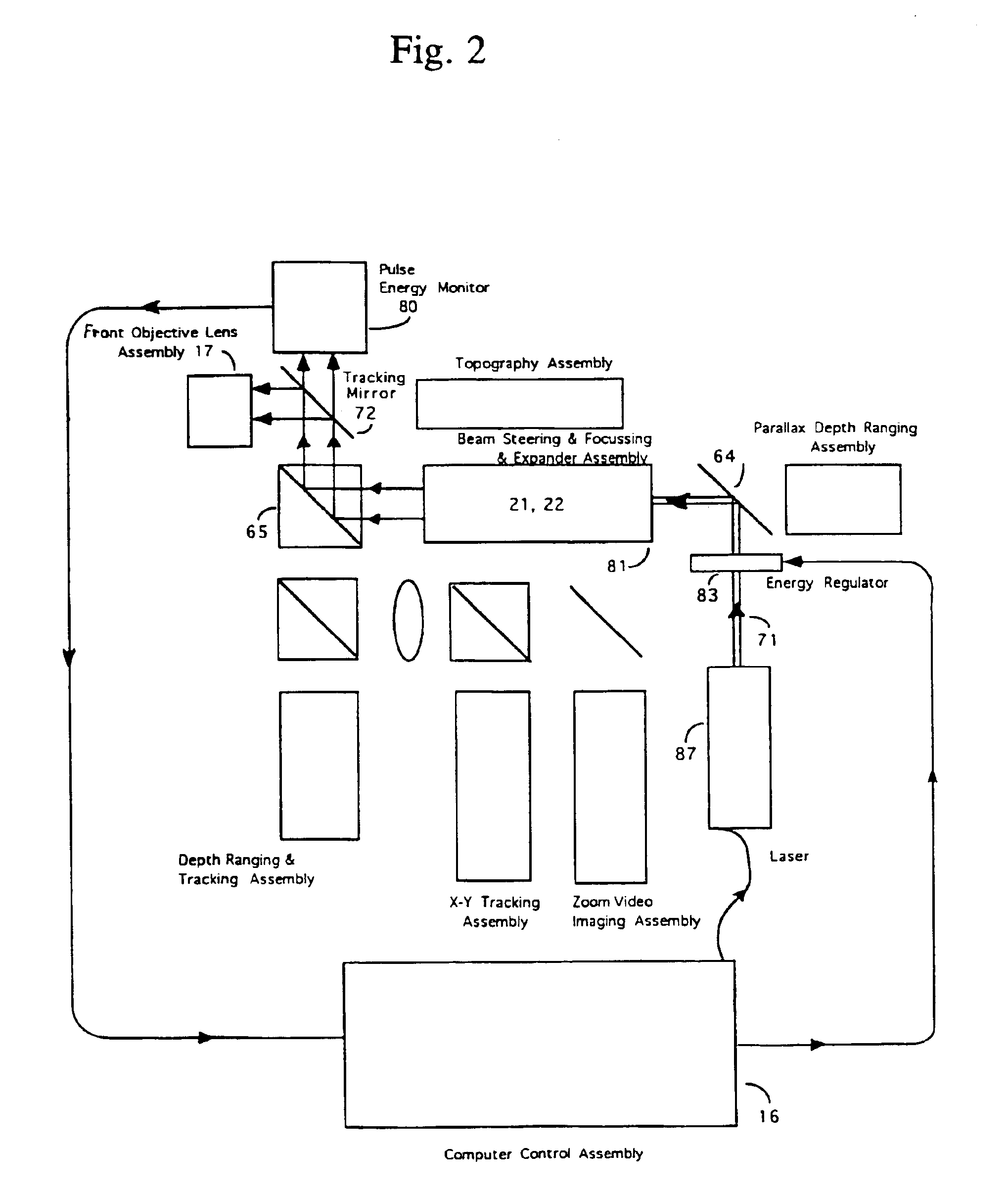

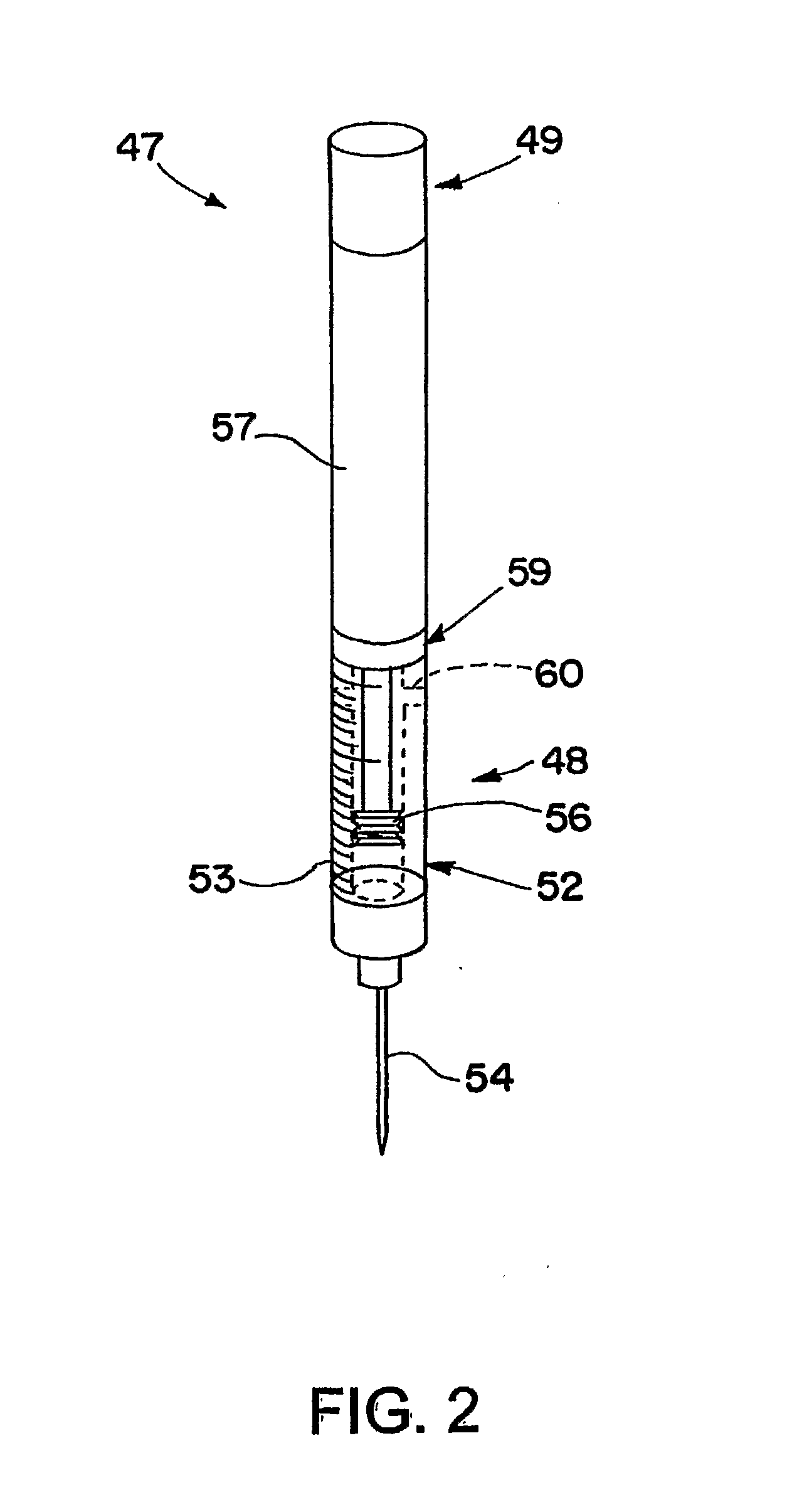

Automated laser workstation for high precision surgical and industrial interventions

InactiveUS6913603B2Speed of surgeryAvoid injuryLaser surgerySurgical instrument detailsEye laser surgerySurgical microscope

A method and system is described that greatly improves the safety and efficacy of ophthalmic laser surgery. The method and system are applicable to precise operations on a target subject to movement during the procedure. The system may comprise the following elements: (1) a user interface, (2) an imaging system, which may include a surgical microscope, (3) an automated tracking system that can follow the movements of an eye, (4) a laser, (5) a diagnostic system, and (6) a fast reliable safety means, for automatically interrupting the laser firing.

Owner:AMO MFG USA INC

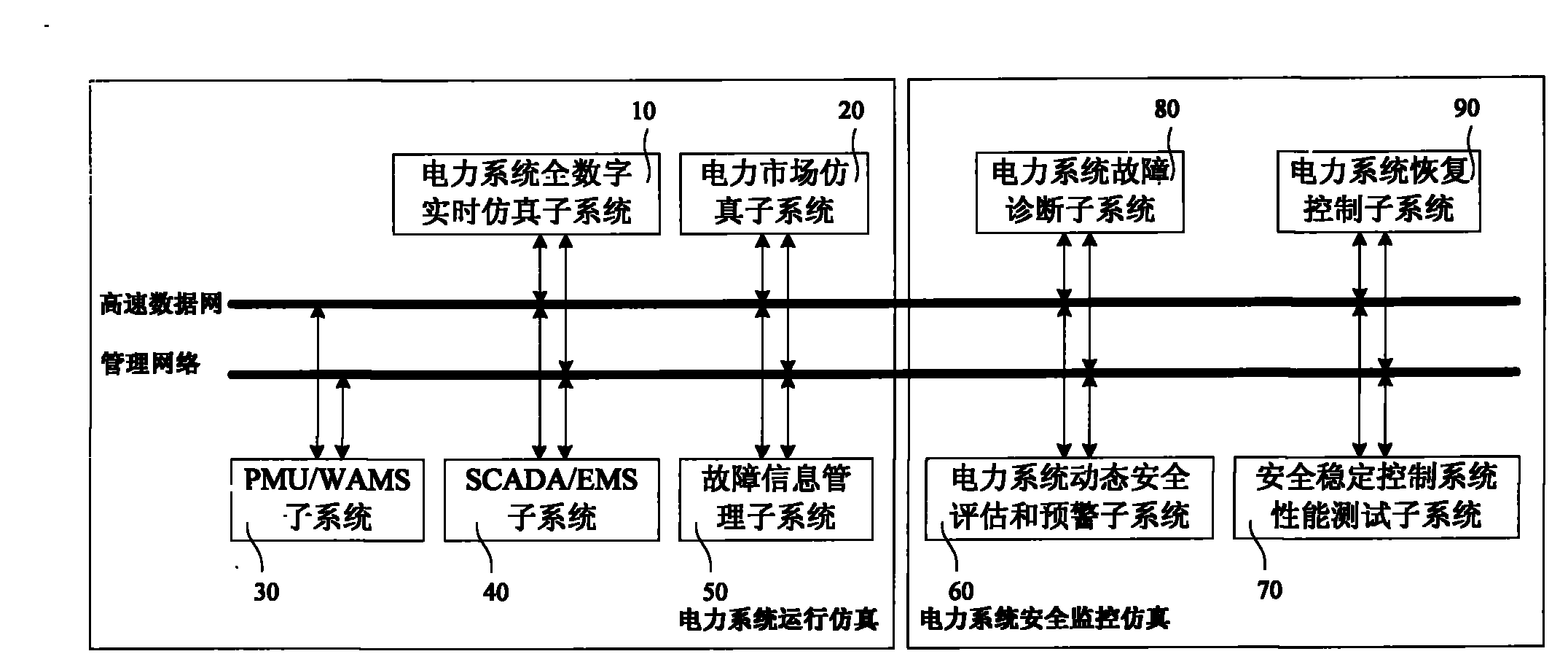

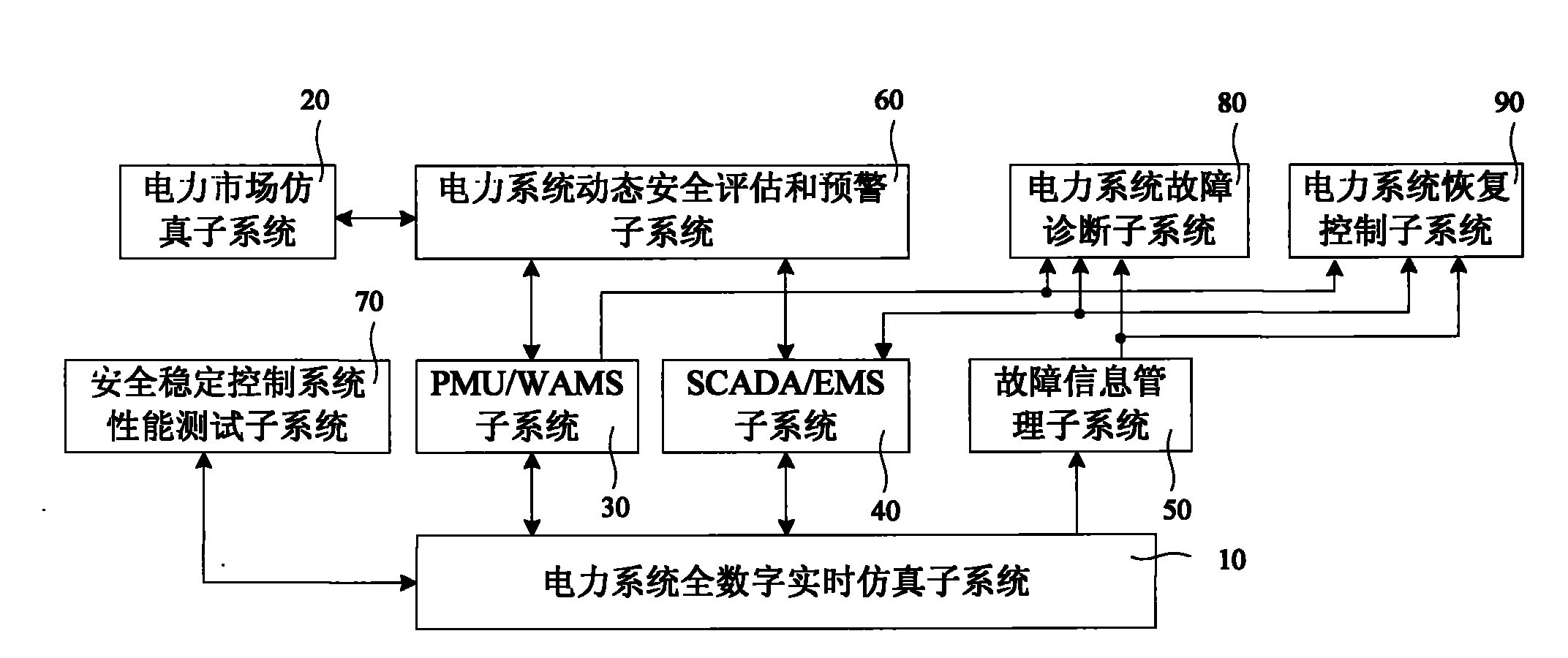

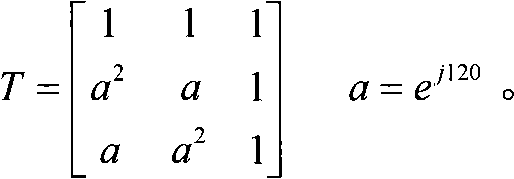

Operation and safety monitoring simulation system for power system

ActiveCN101944766AComprehensive effectComprehensive performance testingCircuit arrangementsSpecial data processing applicationsElectricity marketPower system scheduling

The invention relates to an operation and safety monitoring simulation system for a power system, which comprises a power system full digital real-time simulation subsystem used for simulating the operation of a large-scale power system in real time and providing simulation data to other subsystems, a power market simulation subsystem used for simulating and training power market transaction, a PMU / WAMS subsystem used for carrying out real-time dynamic monitoring and analysis on a simulated power system, an SCADA / EMS subsystem used for monitoring and analyzing the simulated power system, a fault information management subsystem used for managing and comprehensively utilizing fault information, a power system dynamic safety assessment and early warning subsystem used for carrying out safety assessment and early warning on the current power system and carrying out safety verification on the operation mode of a future plan, a safety and stability control system performance test subsystem used for testing the performance of a protective relay device, a power system stabilizer (PSS) and other automated equipment as well as a safety and stability control system and equipment, a power system fault diagnosis subsystem used for carrying out on-line diagnosis and intelligent safety alarming on the fault of the simulated power system and providing a dispatching control decision under the fault condition, and a power system recovery control subsystem used for recognizing the state of the fault of the simulated power system, searching and inferring the power supply path of an outage region and providing a power grid recovery control strategy. The system can simulate the operation of a large-scale power grid in real time, and can be used for searching and comprehensively testing the technology and software of various power systems in dispatching, operation, control and other aspects.

Owner:CHINA ELECTRIC POWER RES INST +1

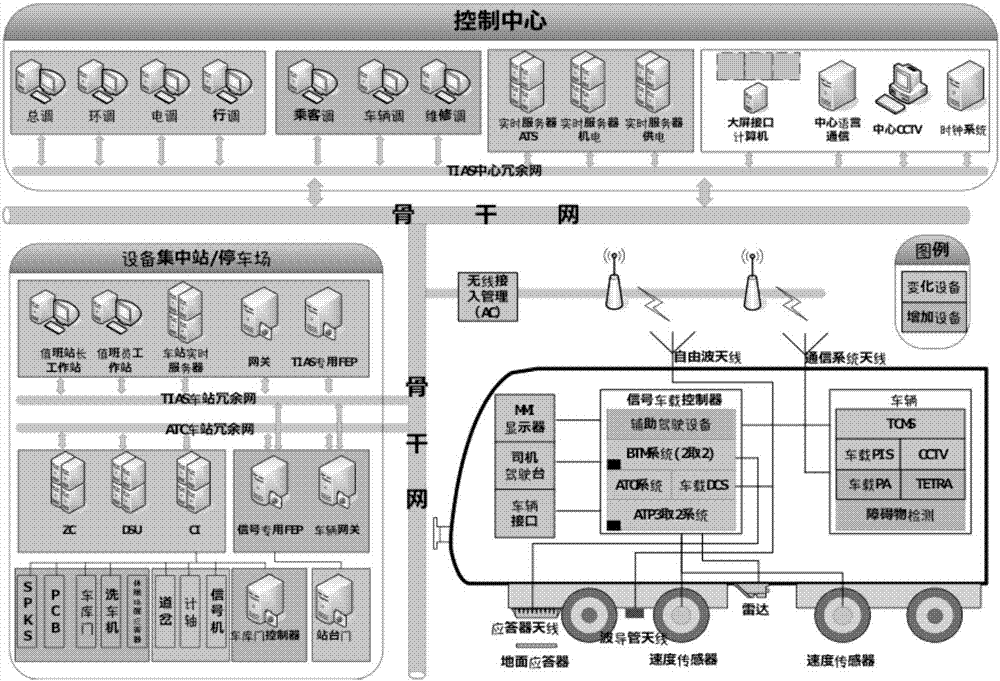

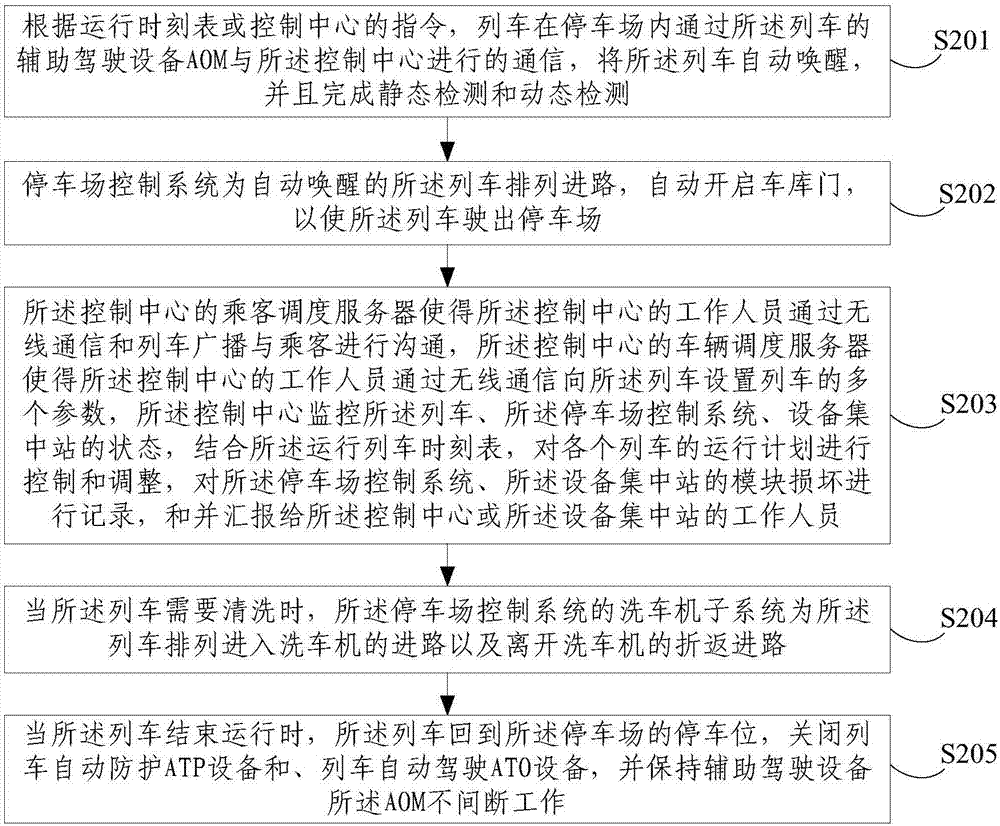

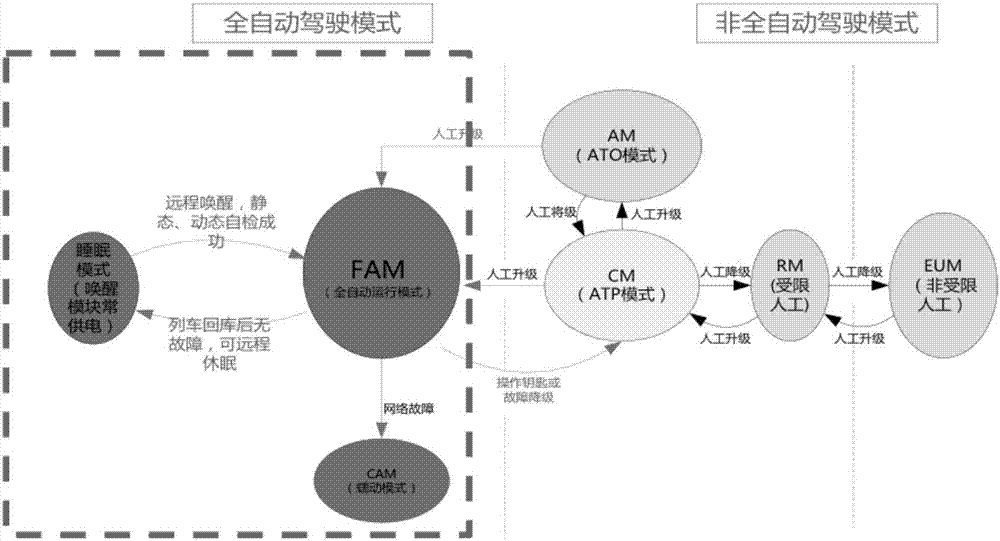

Train full-automatic running method and system

ActiveCN107226099ARealize fully automatic operationImprove reliabilityAutomatic systemsLocomotivesAutomatic train protectionProgram planning

The invention provides a train full-automatic running method and system. The train full-automatic running method comprises the following steps that according to a running schedule or a command of a control center, trains are automatically awakened, and static detection and dynamic detection are completed; a parking lot control system performs route arrangement on the trains which are automatically awakened; the control center monitors the condition of the trains, the condition of the parking lot control system and the condition of an equipment centralization station, and controls and adjusts the running plan of each train combining the running schedule; when the trains need cleaning, a train washing machine sub system of the parking lot control system arranges a route for the trains to enter the train washing machine and a reentrant route for the trains to leave from the train washing machine; and when the trains stop running, automatic train protection ATP equipment and automatic train operation ATO equipment are closed, and AOM is kept working continuously. Compared with a conventional CBTC system, the train full-automatic running method disclosed by the invention realizes full-automatic running, the reliability, the safety, the availability and the maintainability of the train full-automatic running system are further improved, the operating emergency handling level is improved, the automation level is improved, and the labor strength is reduced.

Owner:TRAFFIC CONTROL TECH CO LTD

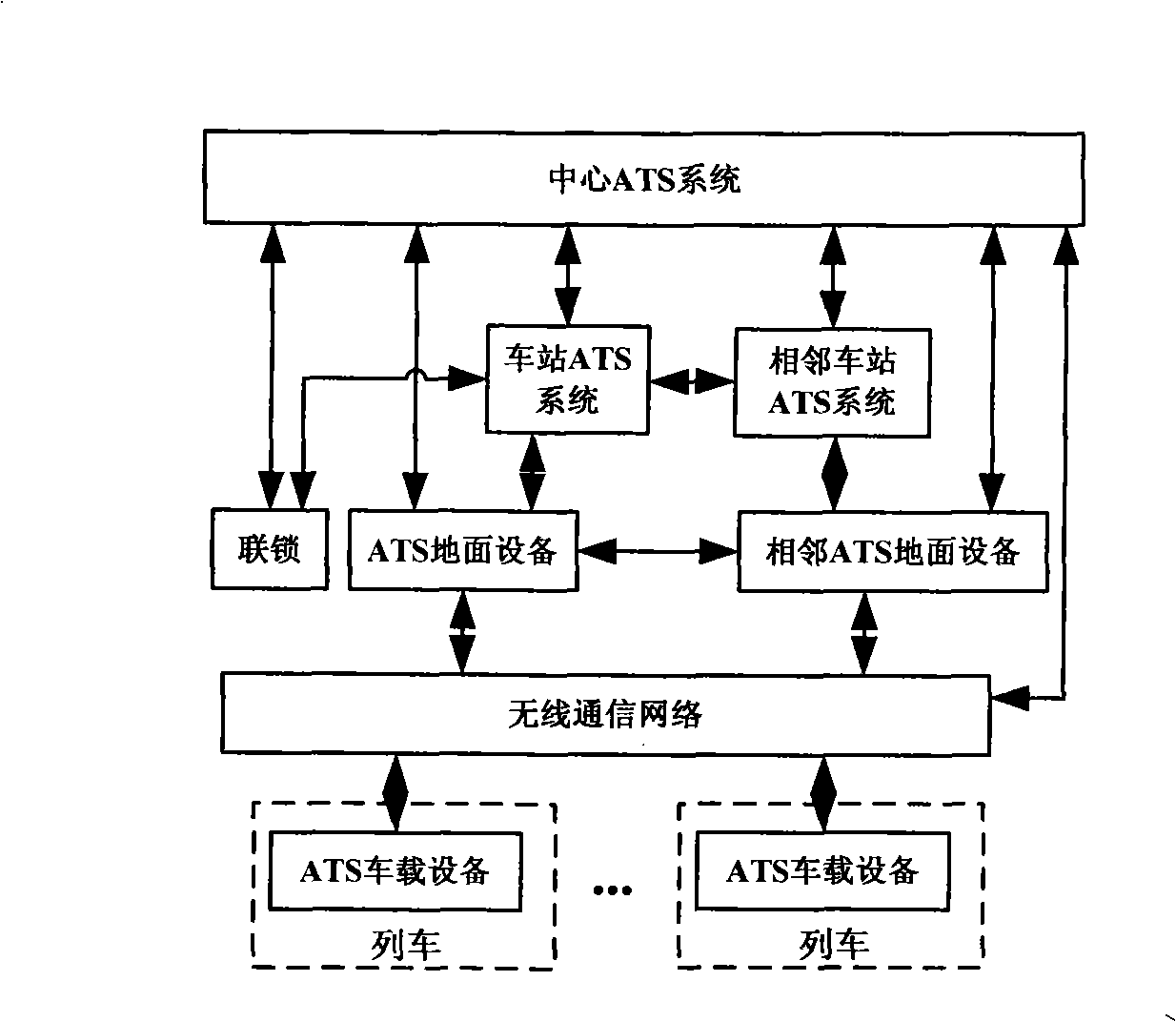

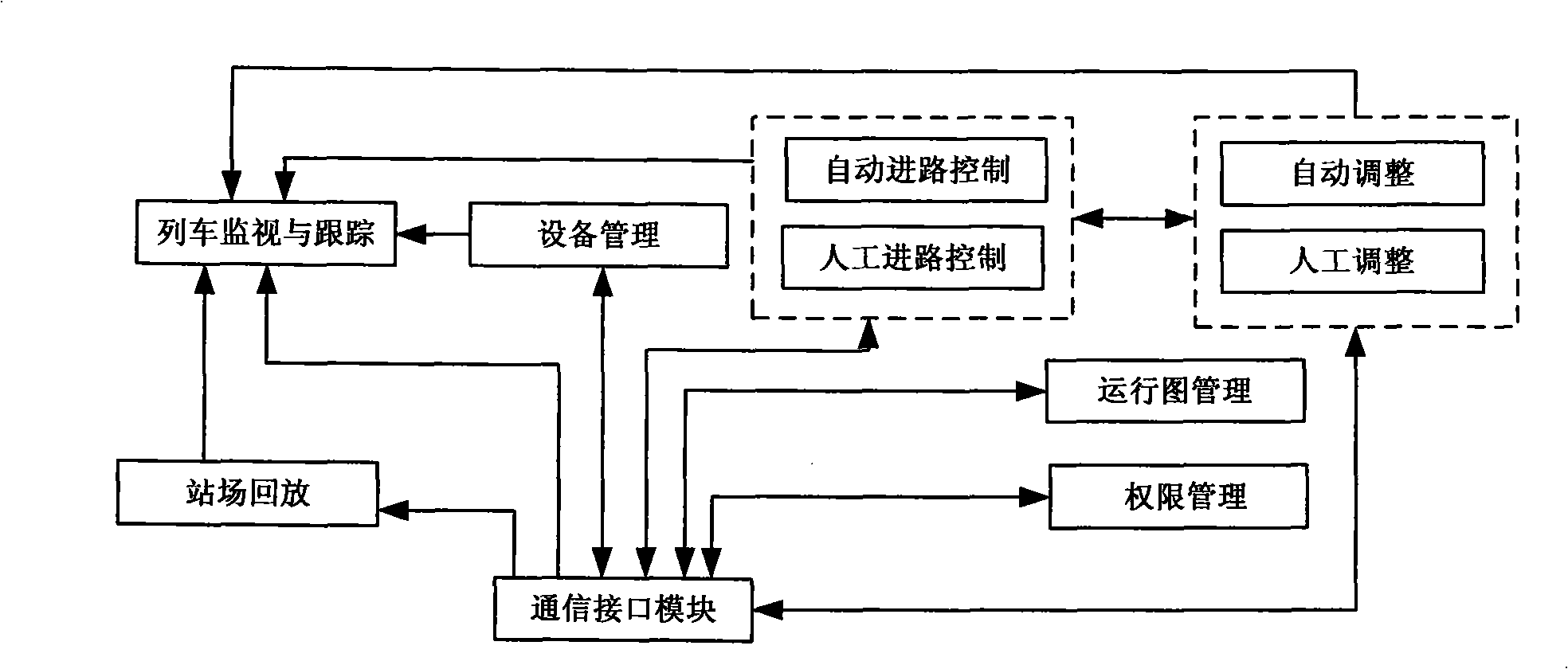

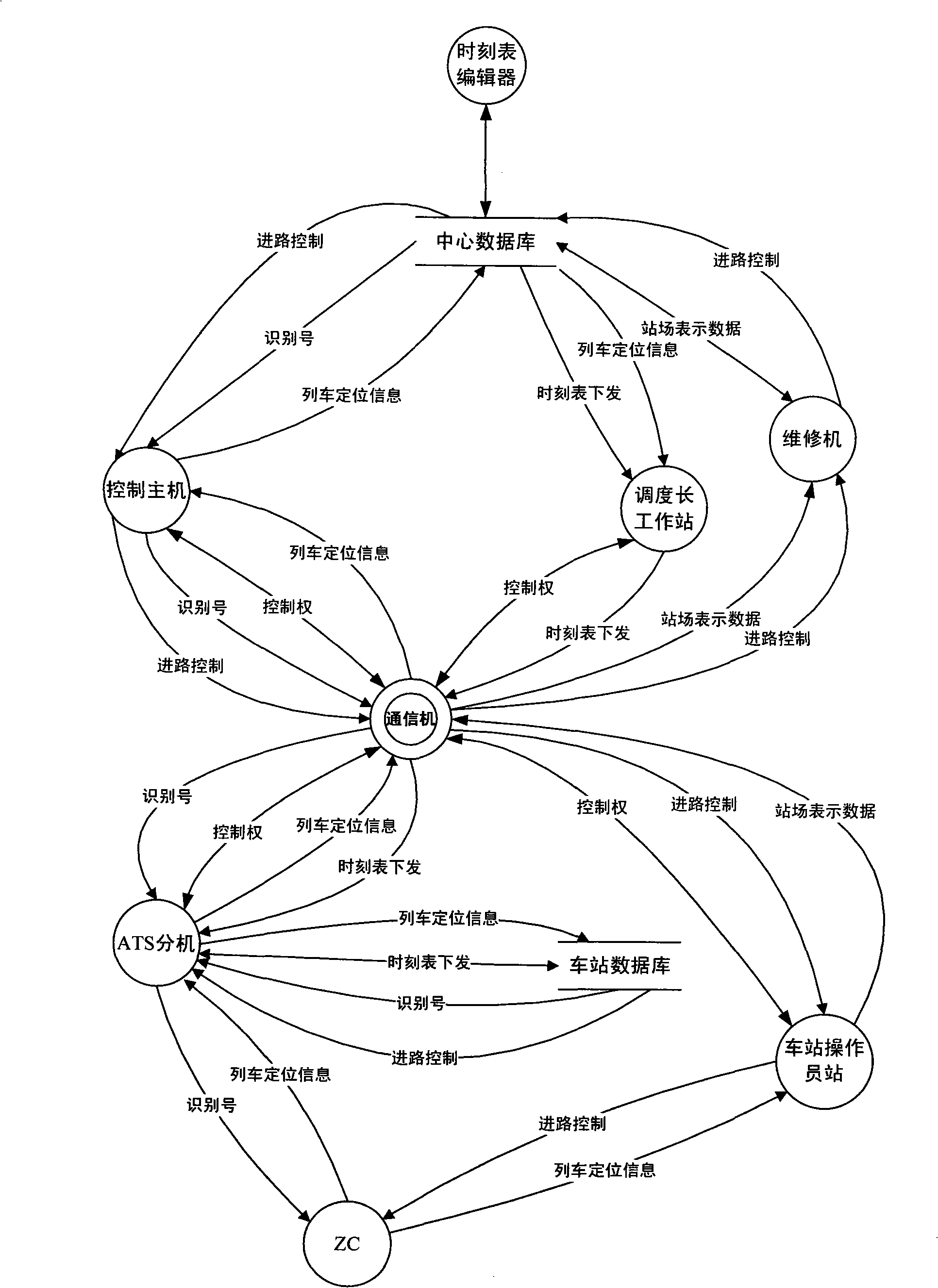

Rail transit train automatic monitoring system based on communication

The invention discloses a rail transportation train automatic monitoring system based on communication, which comprises on-board equipment and a ground automatic monitoring system. The on-board equipment arranged on the train is used for collecting train information and sending to the ground automatic monitoring system through a wireless network, and is also used for receiving and executing dispatching commands sent by the ground automatic monitoring system. The ground automatic monitoring system is used for receiving the train information from the on-board equipment, interlocking calculating according to the train information to generate dispatching commands and sending the commands to the on-board equipment through the wireless network. The invention realizes the closed loop control to the train through the train-ground bidirectional information transmission, greatly lowers the effect of human error, and raises the system reliability; ATS system real-timely knows various operation parameters of the train such as the position, the speed, etc. thereby improving the operation efficiency and the automation of the system; moving block is realized through wireless communication, thereby facilitating the improvement of traffic density; and the train can timely respond the dispatching and the adjusting commands of the ATS system.

Owner:北京和利时系统集成有限公司

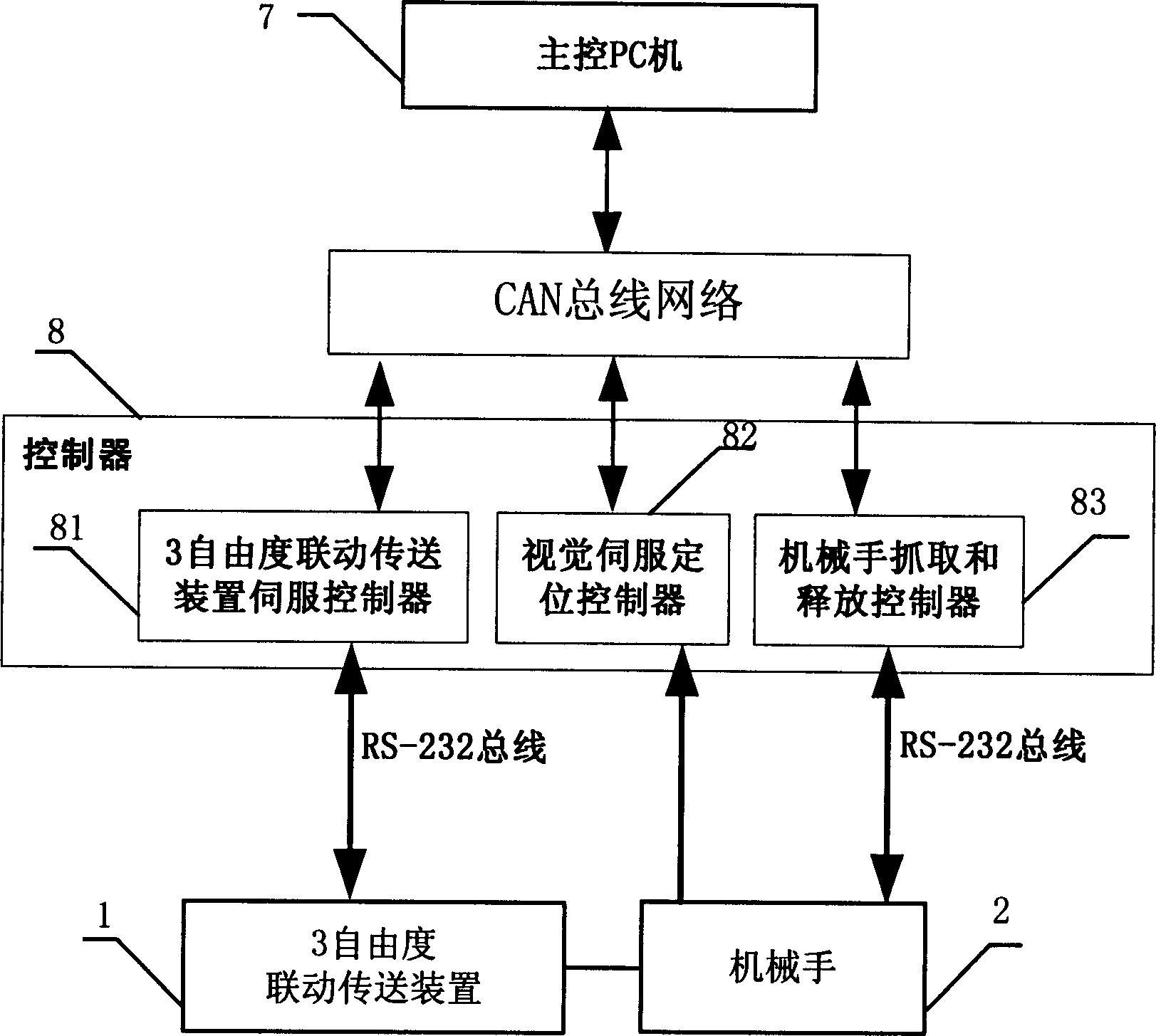

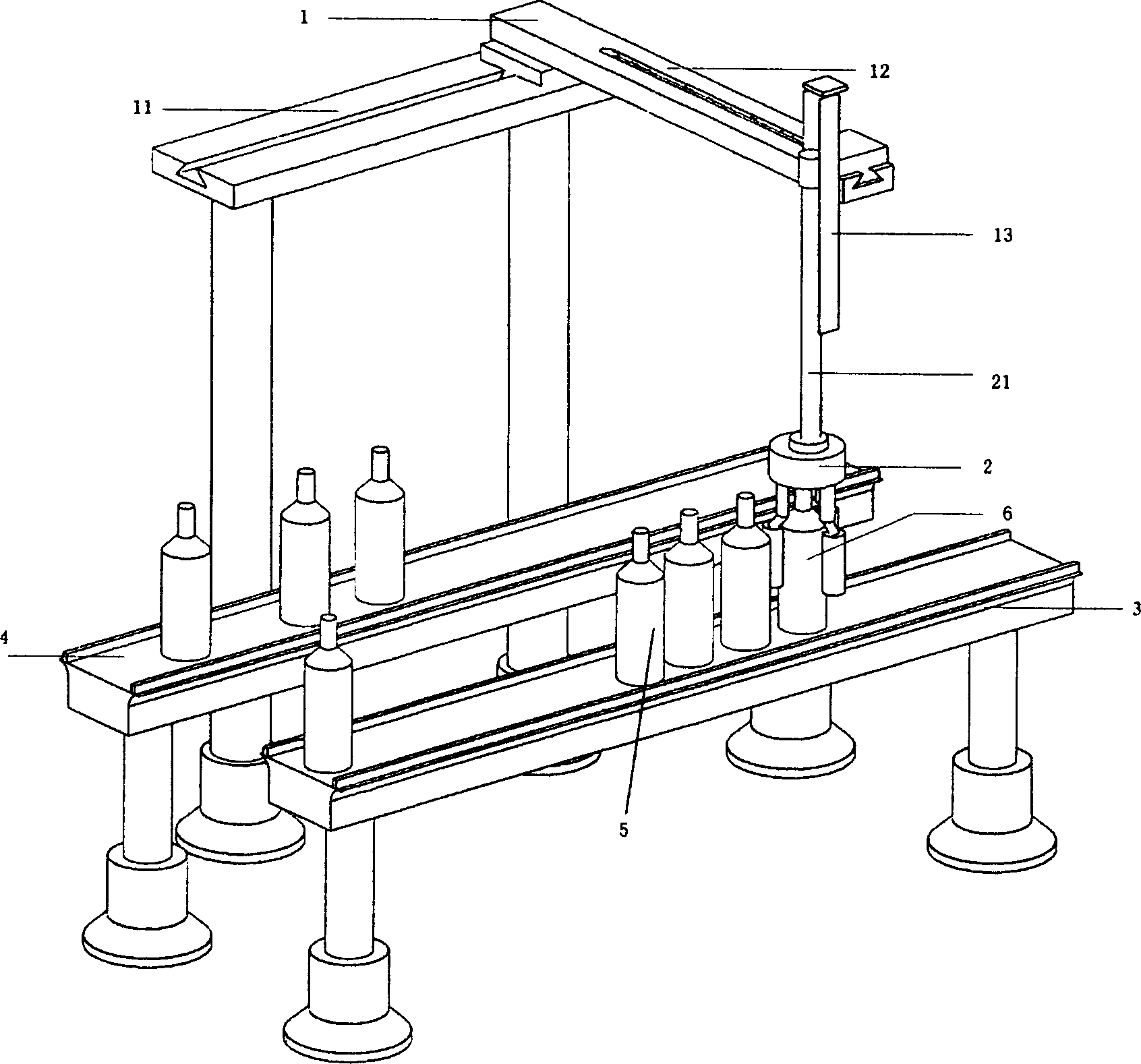

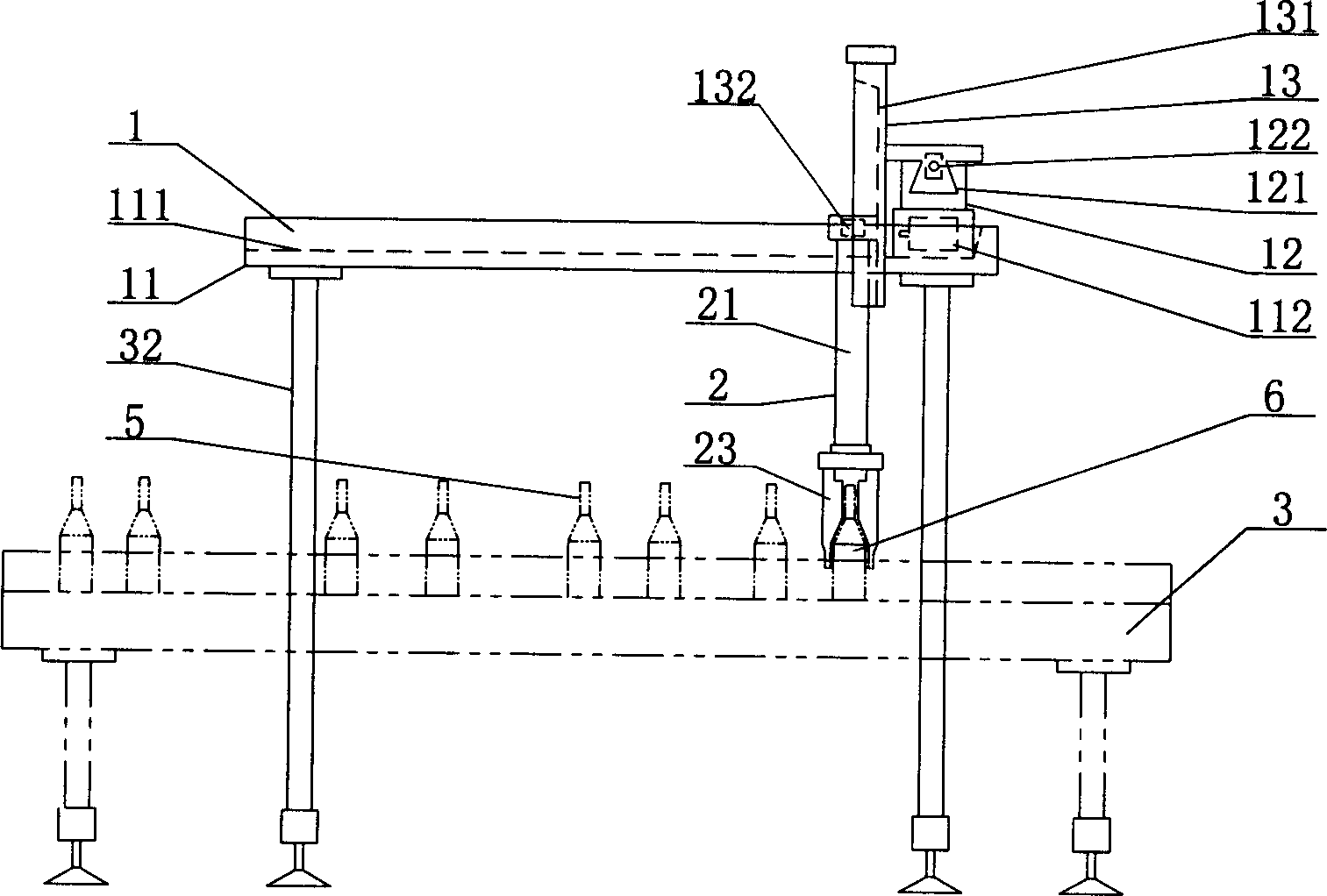

Defective goods automatic sorting method and equipment for high-speed automated production line

InactiveCN1806940AHigh-speed grabbing and sorting processingHigh-speed sorting processProgramme-controlled manipulatorGripping headsProduction lineRobotic arm

The invention relates the auto sorting faulty goods method on the high-speed automatic production line and unit. The method comprises the following steps: sorting faulty goods system receiving the sorting signal, starting the freedom degree linked conveying device 3, then positioning the mechanical arm connected with 3 on the faulty goods, the mechanical arm keeping the same speed with conveyer belt, gripping the faulty goods, lifting it and releasing it to appointed position. The unit comprises electrical control and mechanical part. The mechanical part comprises 3 and mechanical arm which comprises arm and hand. In the center of the mechanical hand there is camera, and the electrical control is connected with 3 and mechanical arm. The invention possesses high accuracy, low cost, good versatility, and no environmental pollution.

Owner:HUNAN UNIV

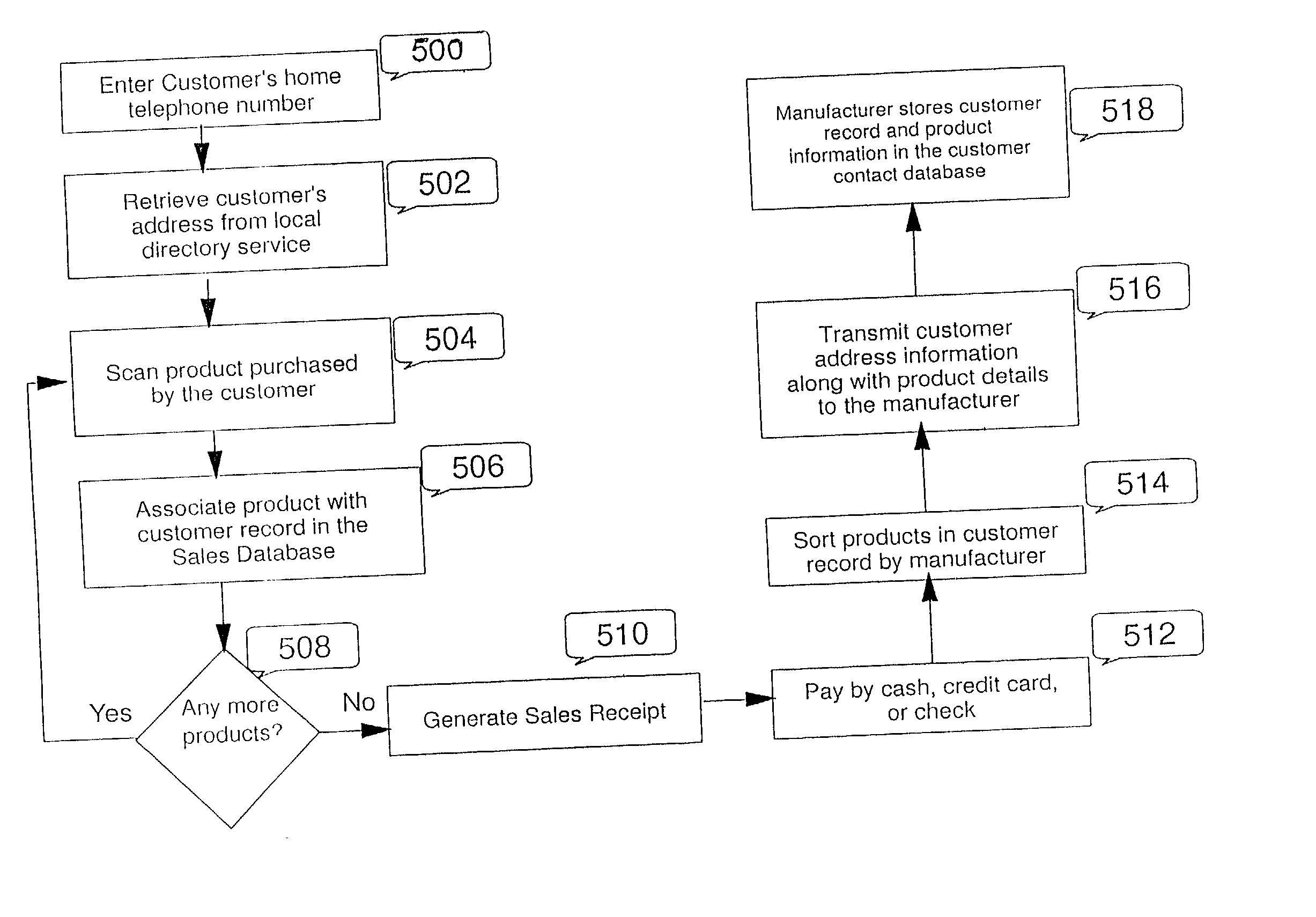

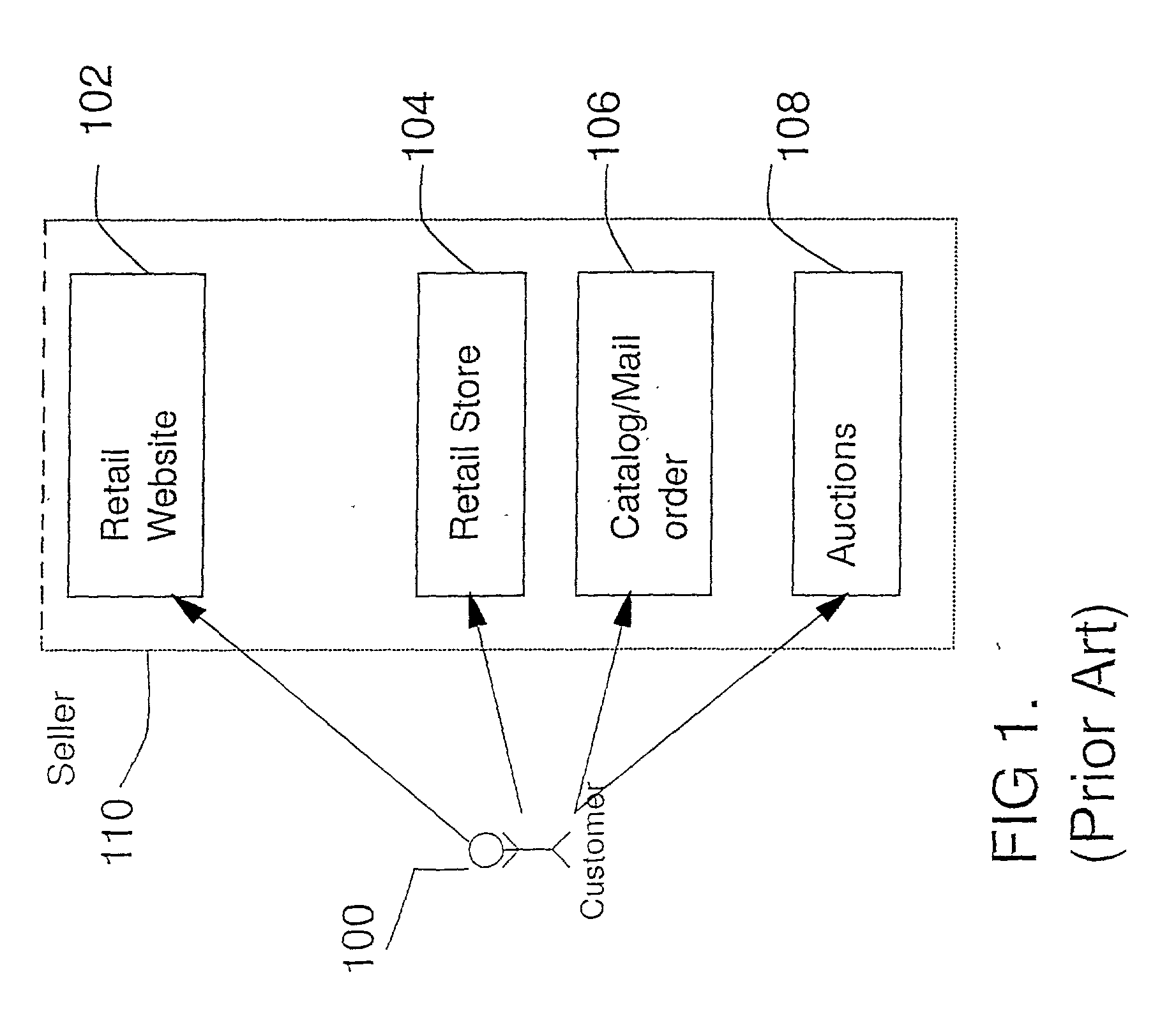

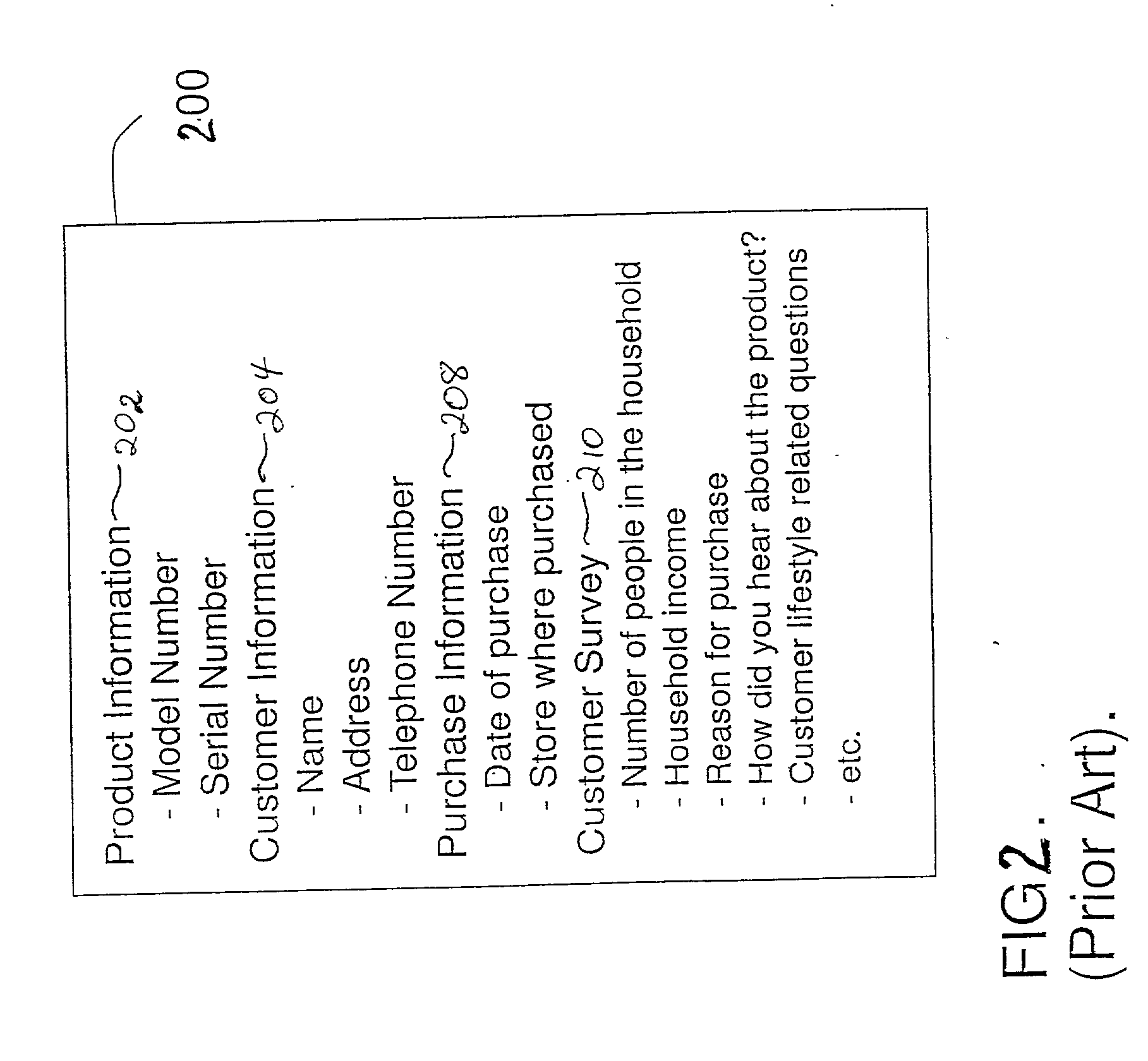

Method and system for automating product registration

InactiveUS20020128851A1Raise the possibilityFinanceOffice automationComputer scienceProcess engineering

The present invention provides a method and system for automating product registration of one or more products by transmitting product registration information generated at the time of purchase respectively to one or more manufacturers for subsequent completion of the registration of the one or more products automatically by the one or more manufacturers or by the customer.

Owner:IBM CORP

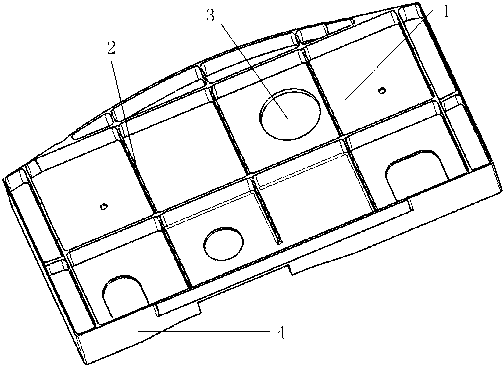

Feature-based numerical-control method for processing and manufacturing complicated parts

ActiveCN103235556AAchieve integrationAchieve deliveryProgramme controlComputer controlNumerical controlClosed loop

Disclosed is a feature-based numerical-control method for processing and manufacturing complicated parts. The feature-based numerical-control method includes expressing features on the basis of a body and an object-oriented process; expressing geometrical and technological information of a part in an integral manufacturing procedure on the basis of the features; utilizing the features as carriers of manufacturing knowledge and experience to implement effective integration and closed-loop control for information of manufacturing stages of designing, processing, detecting and the like; and carrying out automatic technological decision, automatic numerical-control programming, post-processing, control for a processing procedure, online detection, technology optimization and working hour prediction on the basis of automatic feature identification and the features. The feature-based numerical-control method has the advantages that information links are effectively connected with one another in the processing procedure, the manufacturing procedure is automatic and intelligent, dependence on manual experience is reduced in the manufacturing procedure, production management for the manufacturing procedure is facilitated, the manufacturing efficiency is improved, and the production cost is reduced.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

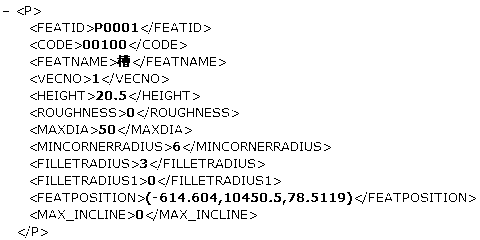

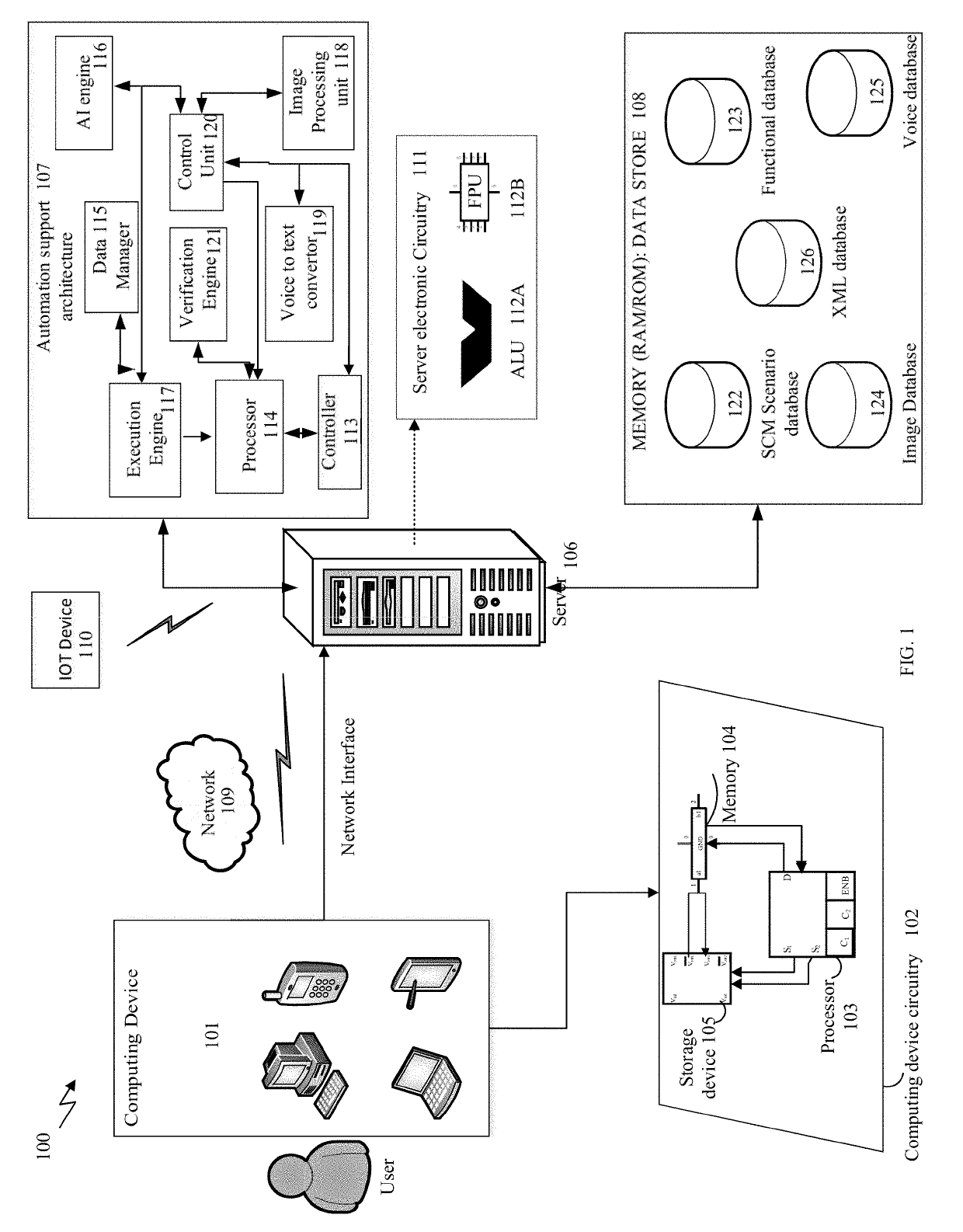

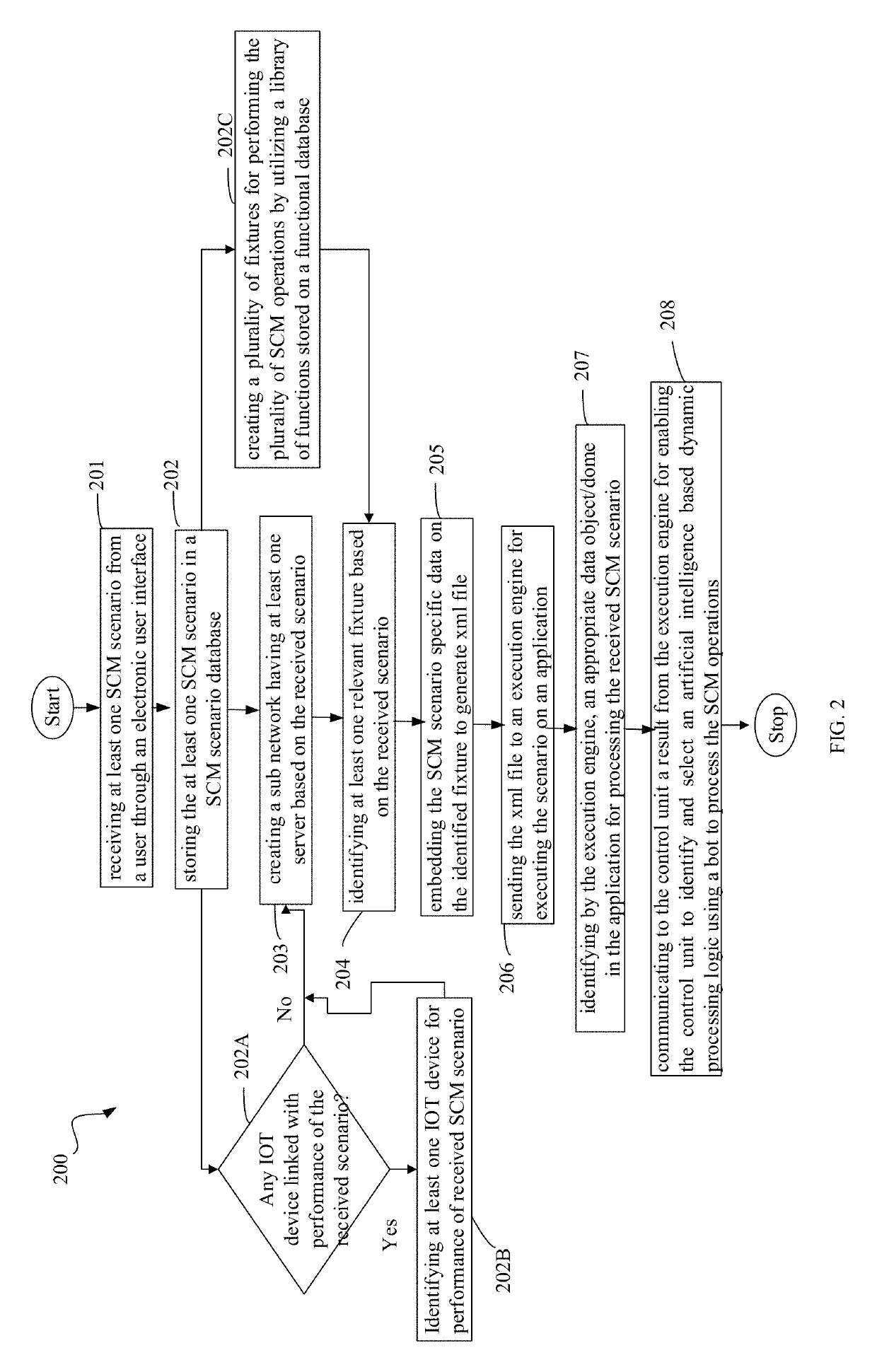

Robotic process automation for supply chain management operations

ActiveUS10324457B2Reduce processing timeMinimize process stepProgramme-controlled manipulatorArtificial lifeComputer scienceAutomation

Owner:GLOBAL EPROCURE

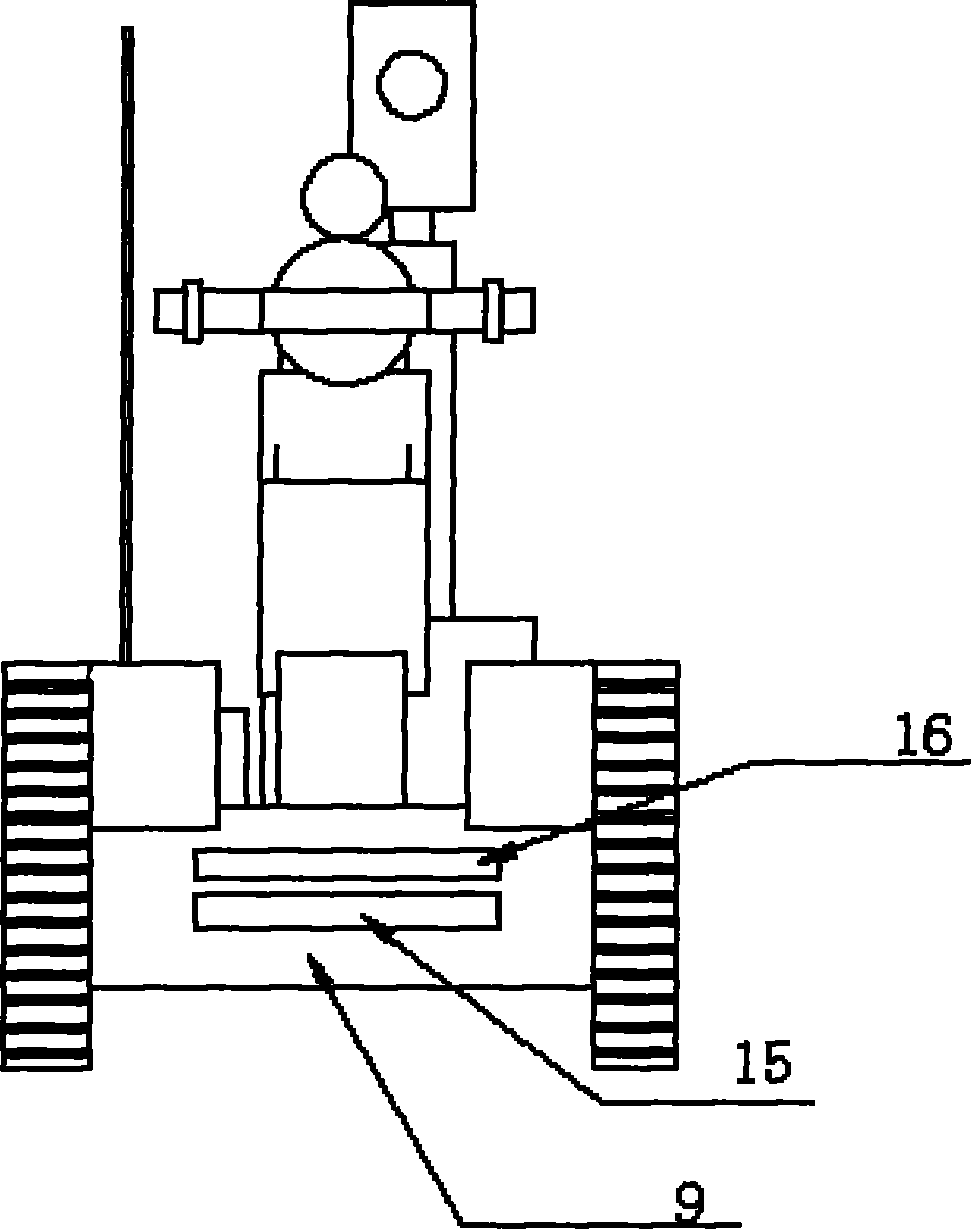

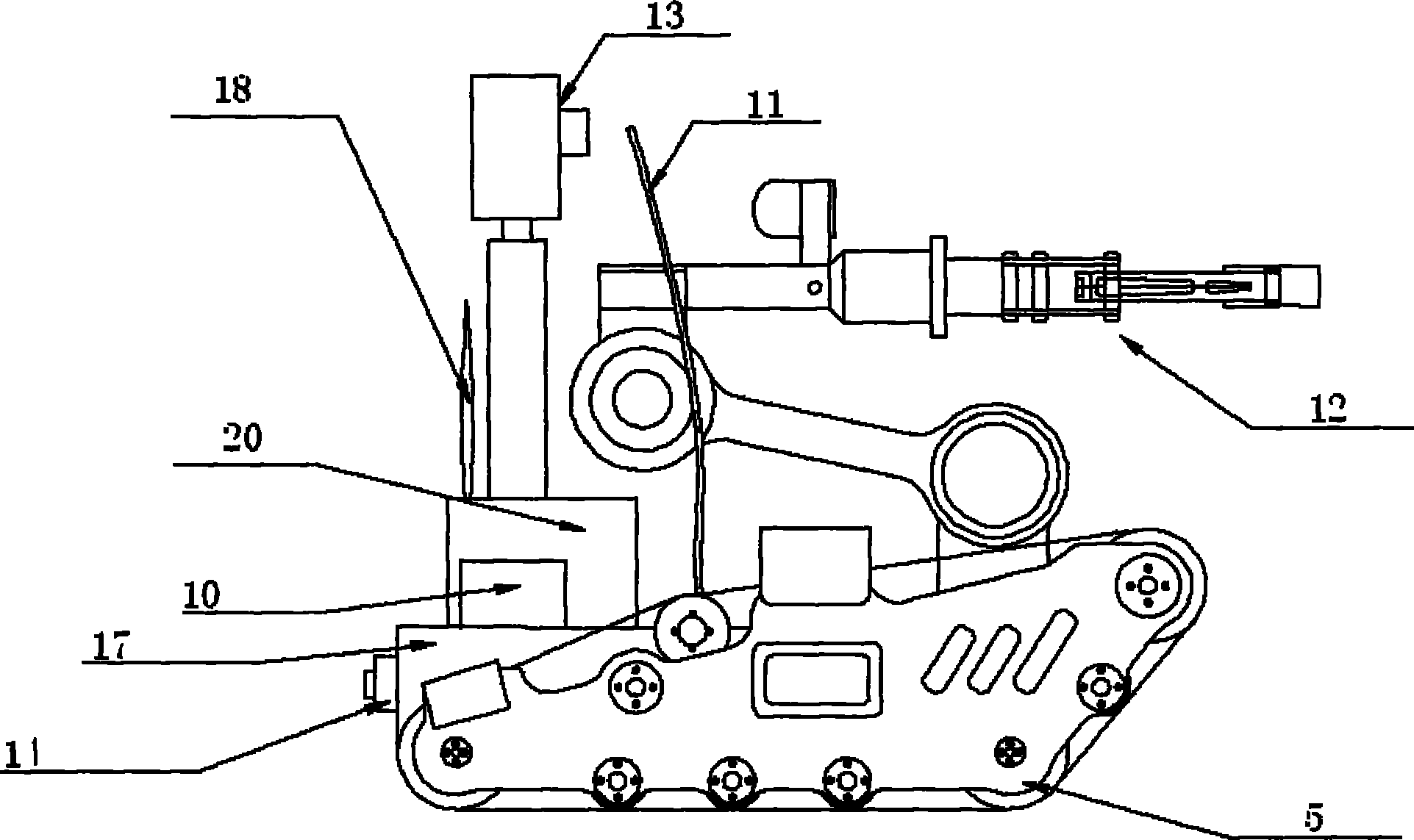

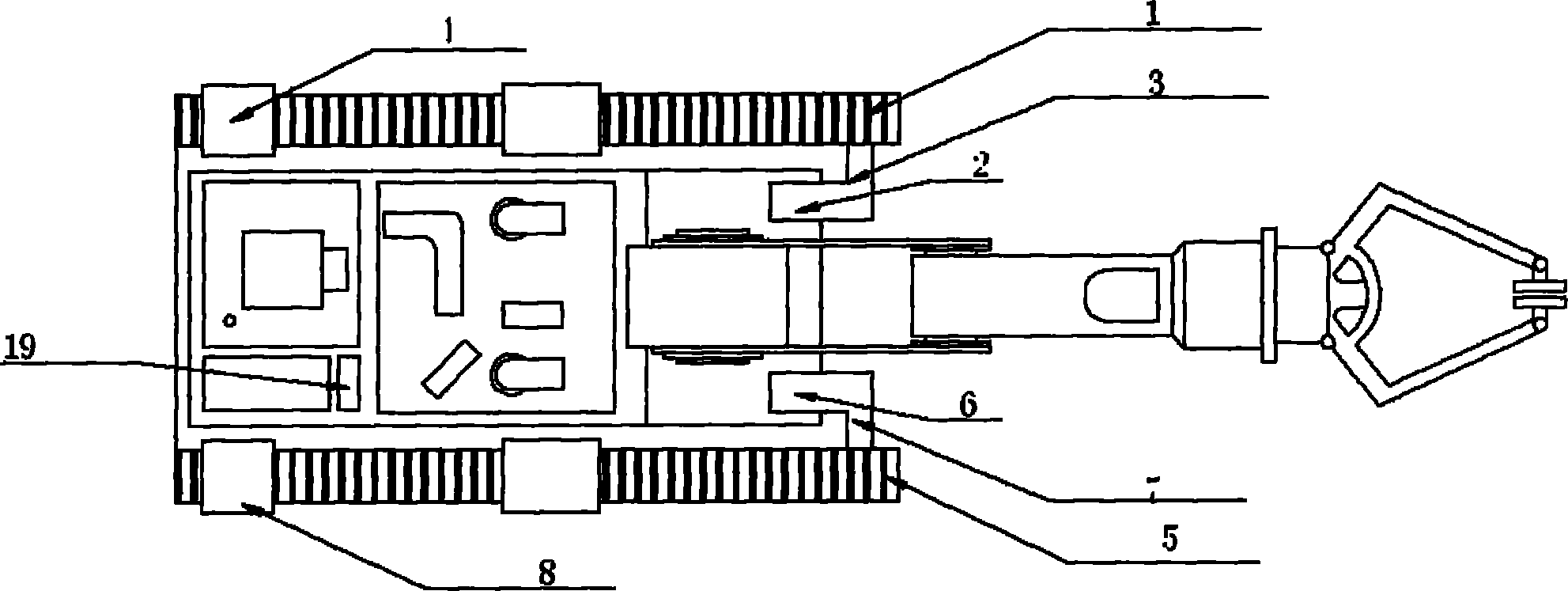

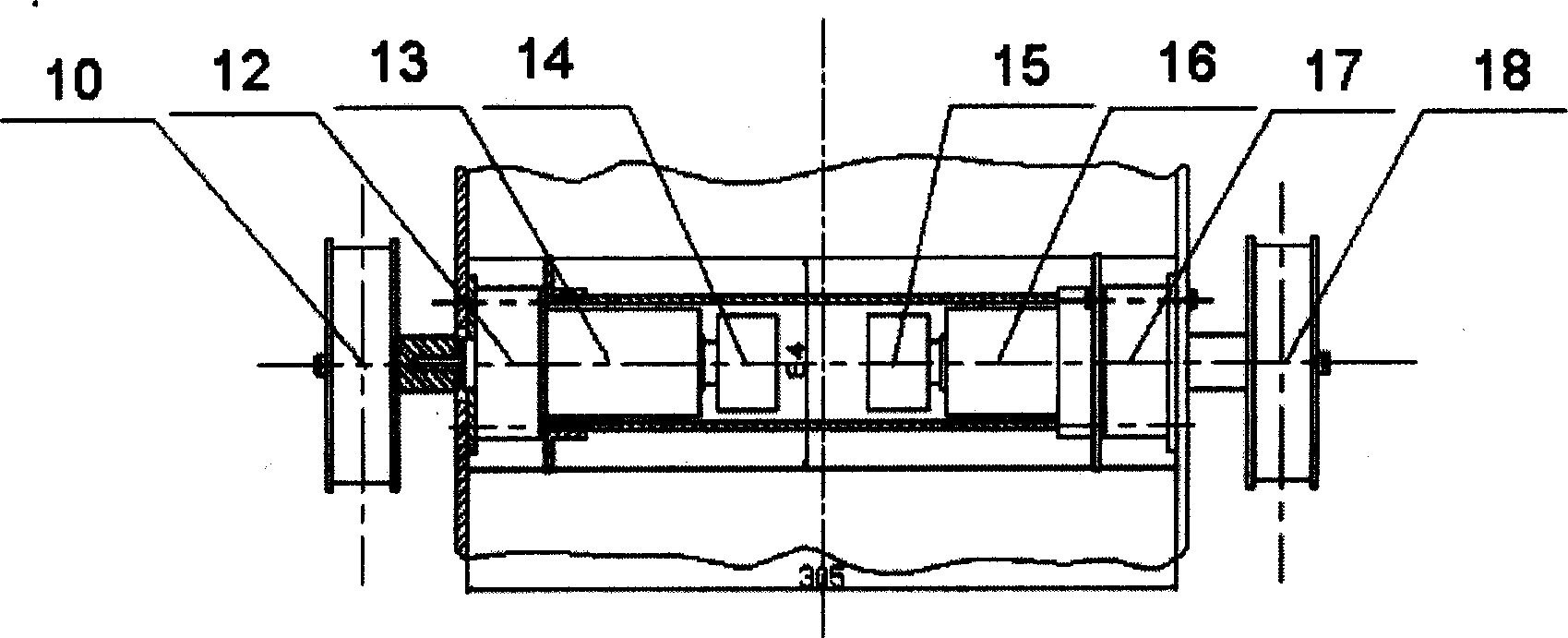

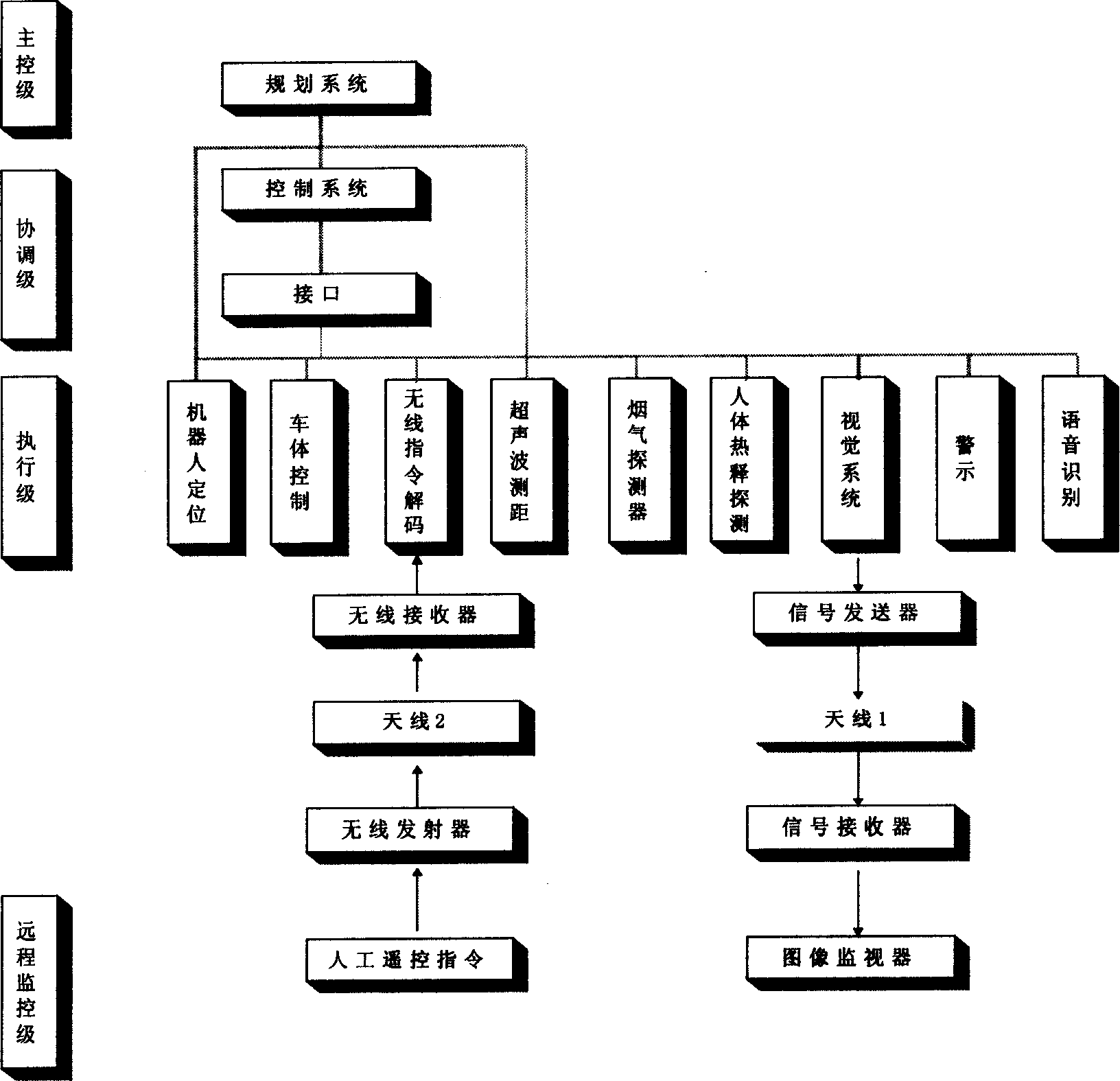

Nuclear power plant working robot and control system thereof

InactiveCN101774170ACapable of autonomous navigationRealize online monitoringEndless track vehiclesManipulatorTerrainOperational costs

The invention relates to a nuclear power plant working robot and a control system thereof, which belong to the fields of robots and automation equipment. The nuclear power plant working robot is a crawler-type mobile manipulator and is composed of a mobile platform driven by double crawlers and a four freedom degree manipulator carried on the mobile platform. The nuclear power plant working robot can move inside a nuclear power plant, has two control modes of manual remote control and autonomous control, and is remotely controlled by a wireless or wired mode. The control system of the nuclear power plant working robot includes a host monitoring and planning control system and a robot control system which are matched to control the operation of the robot. The robot operates autonomously, is safe and reliable, can complete certain dangerous tasks in high radioactivity environment; the robot has small size, stable performance, great maneuverability and low operation cost; a crawler-type chassis has strong gripping force as well as certain climbing and obstacle clearing ability, and is suitable to walking over complex terrains; and the robot has high intelligence degree and can realize autonomous control and manual remote control.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Security ensuring and patrolling robot

InactiveCN1593859AReliable completionStabilize security patrol tasksManipulatorControl systemPatrolBot

The invention relates to a kind of patrolling robot. It consists of robot body, the movable controlling unit and the bearing rack of which is fixed firmly to the outer shell; anti- stakeout system, which consists of infrared temperature sensor, smoking sensor, hot releasing infrared sensor, mini CCD camera eye, signal lamp, buffer, and graphic message wireless conveying module; the controlling system that sends message to control the robot to patrol, move to control and give an alarm automatically within the circumstance; multi-sensor system. The robot can patrol along the scheduled path, and judge the location is at according to the messages from the sensors to avoid the impediment and change the moving path. The invention is more suitable to increasing onerous security task, and improves the atomicity of security work.

Owner:SOUTH CHINA UNIV OF TECH

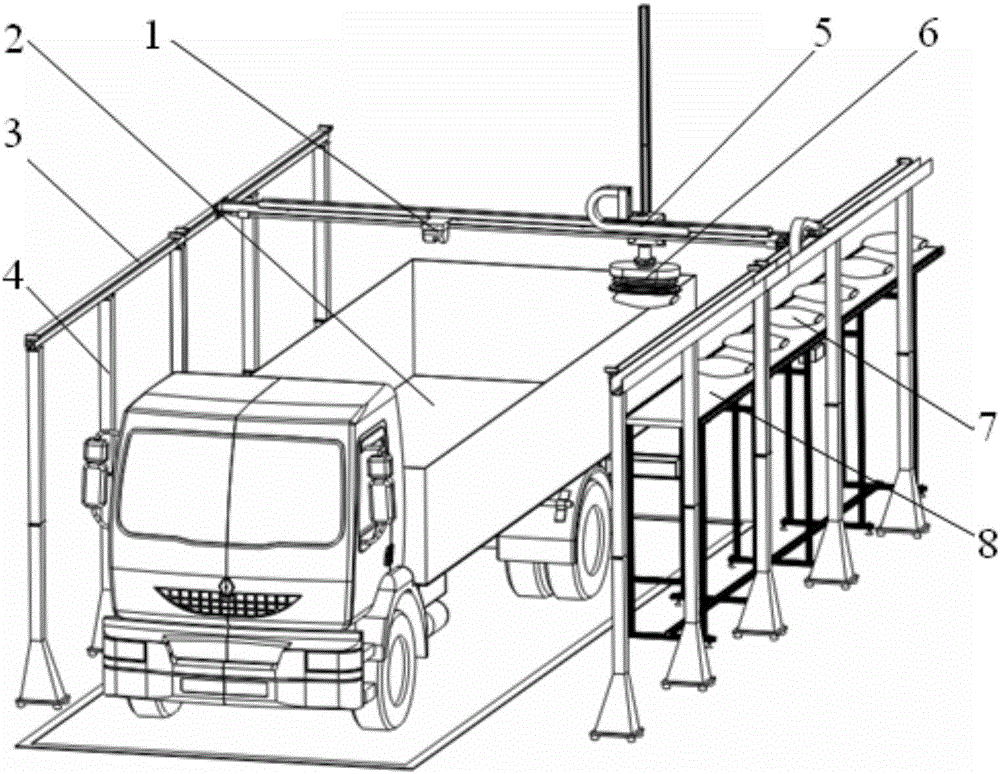

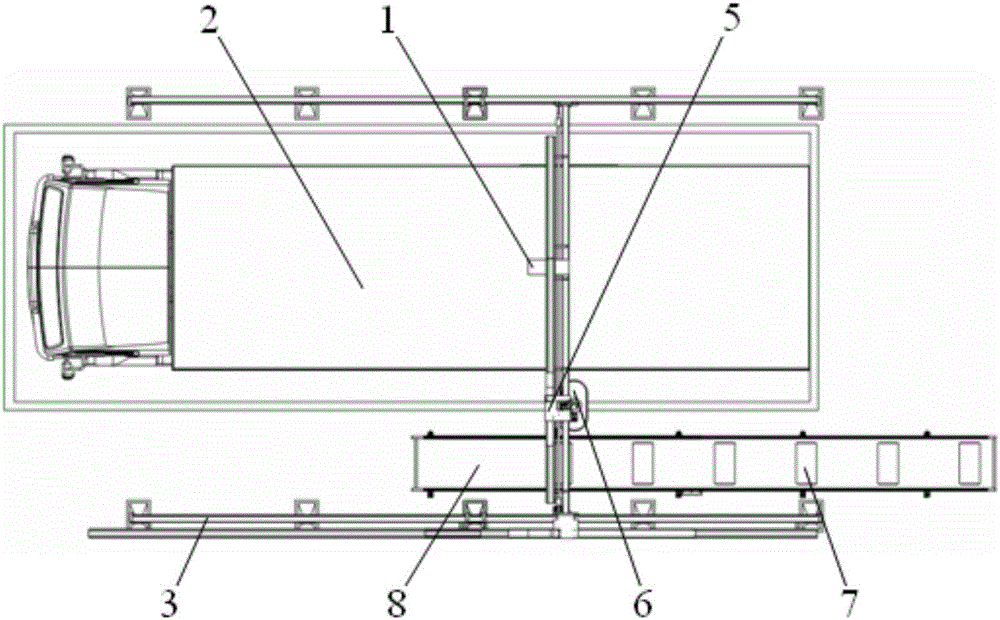

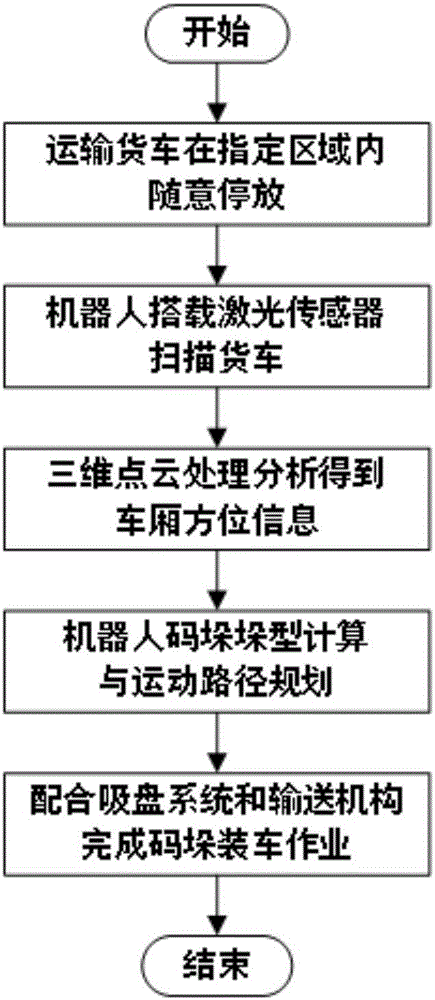

Automatic stacking and truck-loading system and truck-loading method thereof

InactiveCN106429483AReduce labor intensityReduce complexityStacking articlesDe-stacking articlesTruckLaser sensor

The invention discloses an automatic stacking and truck-loading system. According to the technical scheme of the automatic stacking and truck-loading system, goods (7) are loaded onto and unloaded from a transportation truck (2) through a robot, and the robot is a four-axis gantry type robot (5); a sucking disc device (6) used for delivering the goods (7) is arranged on the four-axis gantry type robot (5); and the four-axis gantry type robot (5) is further provided with a laser sensor (1). The invention further discloses a truck-loading method of the truck-loading system. By means of the automatic stacking and truck-loading system and the truck-loading method thereof, the goods stacking and truck-loading technology based on the laser sensor is adopted; real full automatization of the whole process including positioning inspection of the transportation truck and goods stacking and truck-loading is achieved; intelligentized positioning of a compartment of the truck is achieved, and scientific planning can be conducted on the stacking process; human cost and labor intensity of operators are lowered, and safety and reliability of truck-loading operation are enhanced; and meanwhile, equipment cost is lowered.

Owner:WUHU HIT ROBOT TECH RES INST

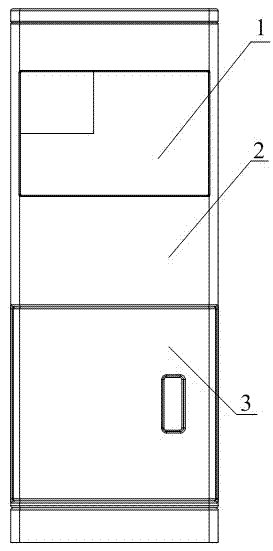

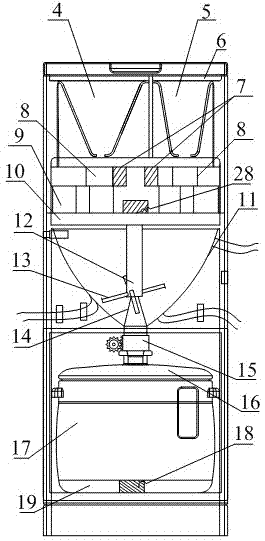

Internet of things full-automatic self-learning electric cooker and implementation method thereof

InactiveCN102824099ARemote control and monitoring of cookingRealize the function of automatic rice washing and cookingCooking vesselsTotal factory controlControl systemThe Internet

The invention discloses an internet of things full-automatic self-learning electric cooker and an implementation method thereof, and belongs to the field of household appliances. The internet of things full-automatic self-learning electric cooker comprises a storage system (1), a rice washing device (2), a cooking pan (3) and an embedded measurement control system for controlling the storage system (1), the rice washing device (2) and the cooking pan (3), wherein the embedded measurement control system is also connected with a communication module, an input module and an output module. Due to the configuration, by the internet of things full-automatic self-learning electric cooker, the shortcomings that the conventional electric cooker cannot automatically wash rice and cook through remotely and precisely configuring a rice type, rice amount and water amount in the prior art are overcome; furthermore, the internet of things full-automatic self-learning electric cooker can also remotely or in site interact with a user on real-time state information such as residual rice amount, water failure and power failure in real time; moreover, the internet of things full-automatic self-learning electric cooker has a self-learning function, so that the electric cooker can be used for cooking according to general favors of the user; and the internet of things full-automatic self-learning electric cooker is relatively humanized, high in automation degree and suitable for popularization and use.

Owner:张捷

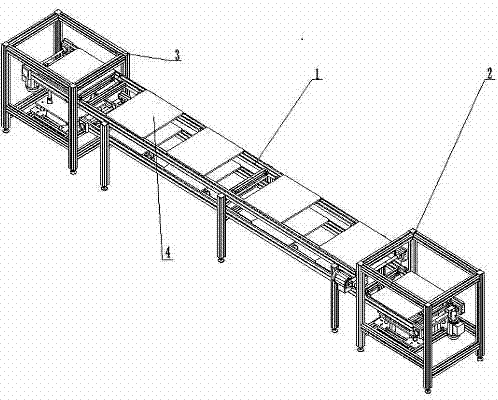

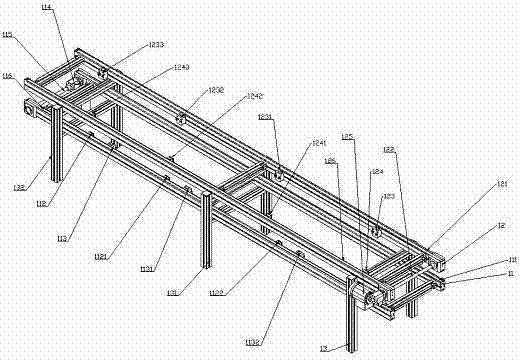

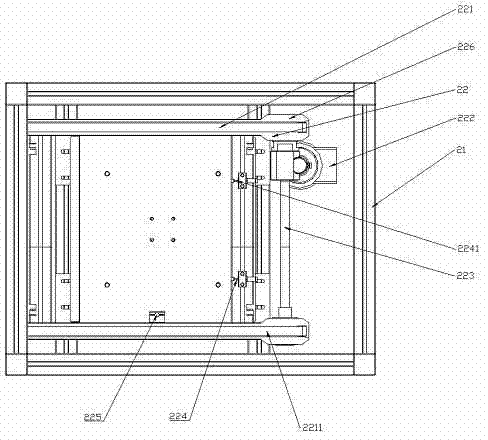

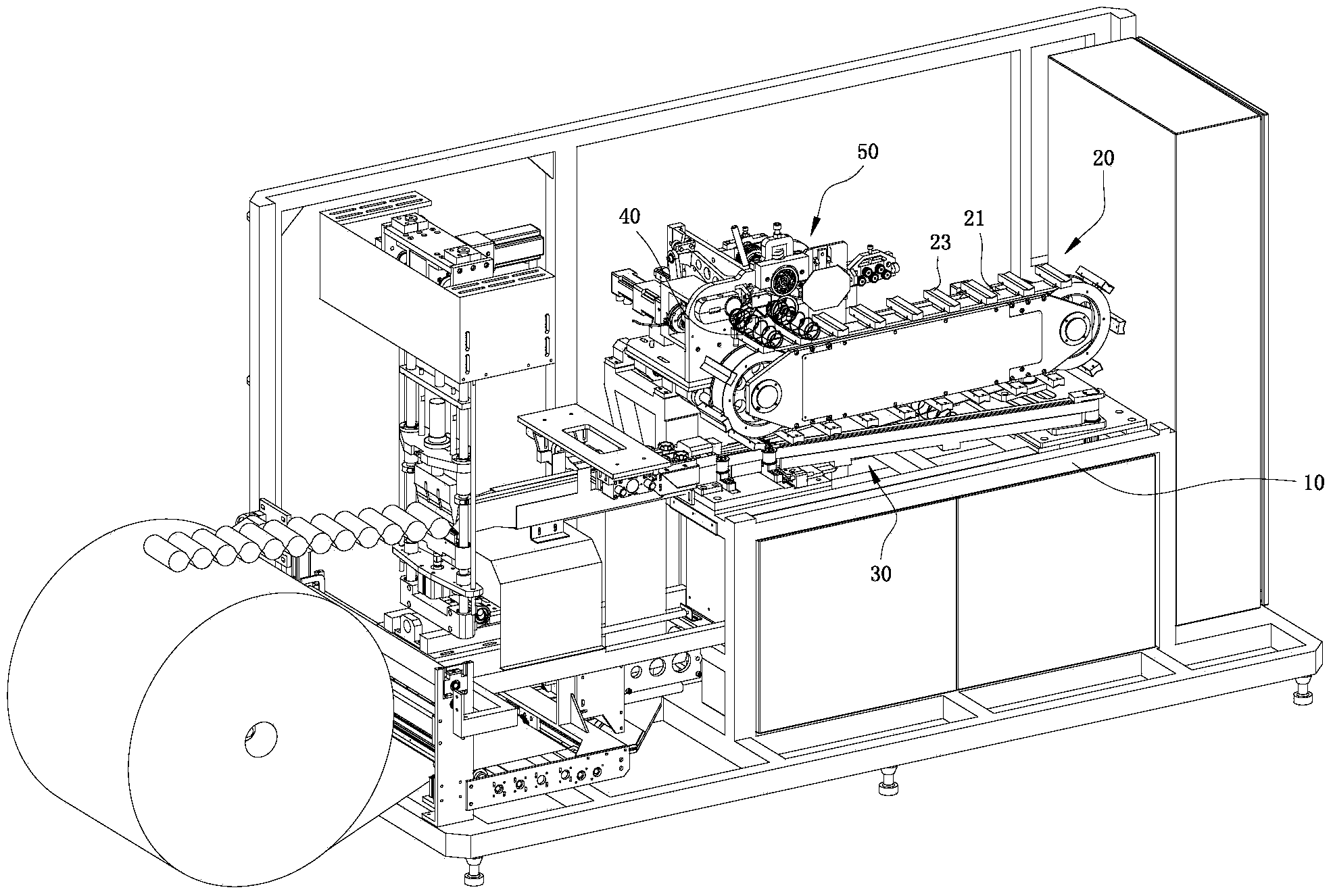

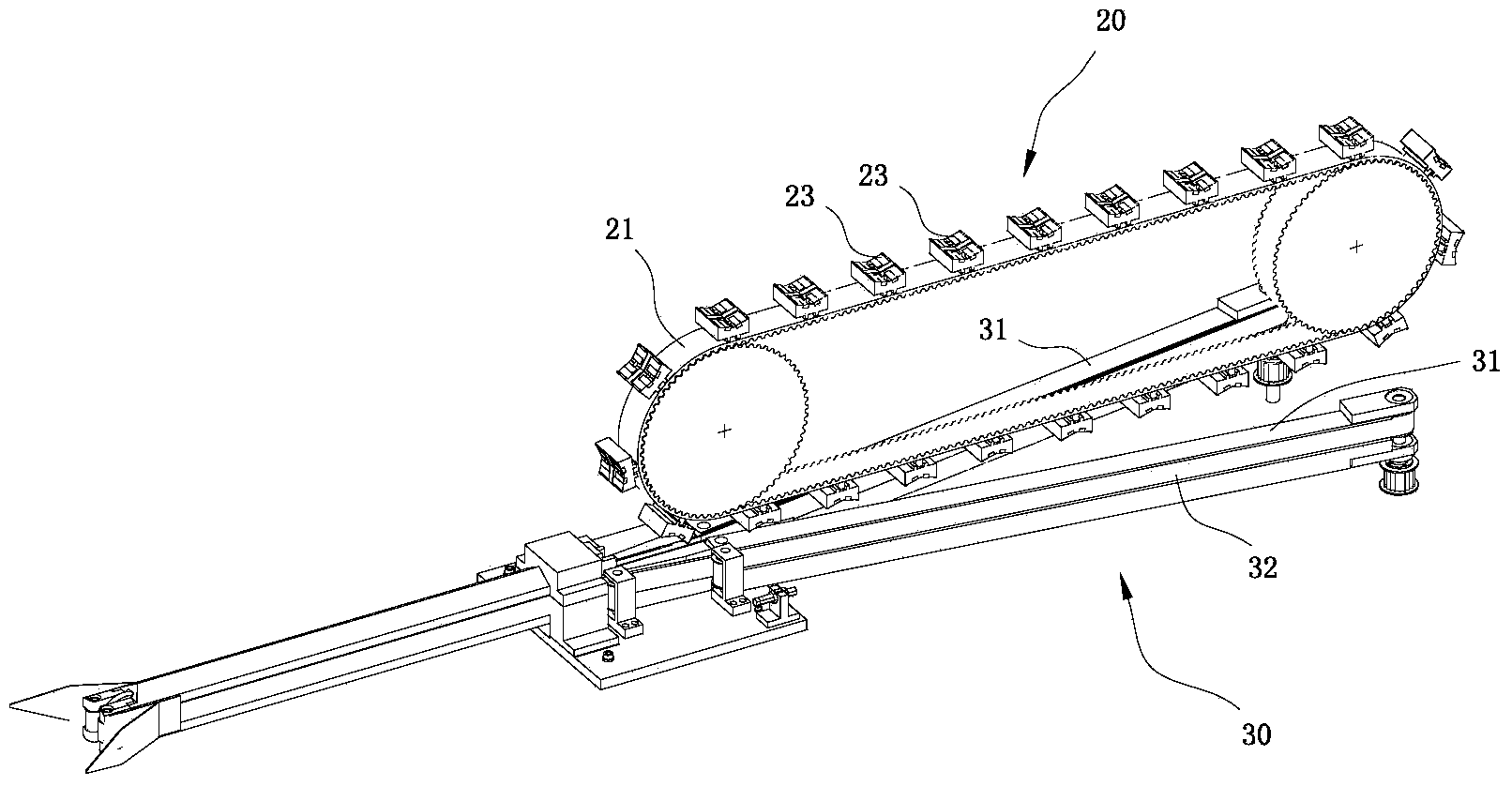

Method and conveying system for intelligently and circularly conveying products in vertical lift manner

InactiveCN104724455ARealize intelligenceFully automatedControl devices for conveyorsMechanical conveyorsProcess engineeringData management

The invention discloses a method and a conveying system for intelligently and circularly conveying products in a vertical lift manner. The method includes: subjecting product trays on a conveying line to reverse circular conveying between an upper tier and a lower tier, allowing vertical lift circular conveying at two ends of the double-tier conveying line, and setting RFID (radio frequency identification) passive reader-writers on the conveying line. The conveying system comprises the double-tier conveying line, lift conveyers mounted at two ends of the double-tier conveying line and a product tray assembly operating on the double-tier conveying line. The method and the conveying system have the advantages that products are under intelligent conveying control during conveying, multi-point operation with different spans is achieved for a production site, less space is used, conveying efficiency is high, input cost is low, the products can be subjected to data management during line production, the produced products are traceable, and automatic productivity of the whole process can be comprehensively improved.

Owner:KEN DAYSTAR SHANGHAI AUTOMATION SYST

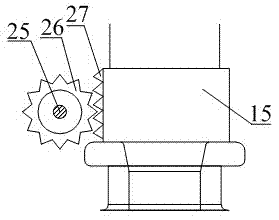

Compression conveying mechanism for bagged spring production

ActiveCN103879604AHigh degree of automationIncrease productivityPackagingMechanical conveyorsMachineAutonomation

The invention discloses a compression conveying mechanism for bagged spring production. The compression conveying mechanism for bagged spring production comprises a machine frame, a spring conveying mechanism and a spring compression conveying mechanism. The spring compression conveying mechanism comprises two baffles which are oppositely arranged on the machine frame and a conveying belt which is arranged on the outer sides of the baffles in a winding mode, the distance between the two baffles is decreased gradually from one end to the other end, and the spring conveying mechanism conveys a spring to the position between the two baffles and drives the spring to move so that the spring can be moved to the other end where the distance between the two baffles is small from the end where the distance between the two baffles is large. The spring is compressed gradually in the horizontal moving process along with the gradually-decreased distance between the two baffles, and after the spring is compressed to a certain degree, the spring is disengaged from the spring conveying mechanism and is conveyed by the spring compression conveying mechanism. Due to the spring conveying mechanism and the spring compression conveying mechanism, compressing and conveying of the spring are integrated, the structural style of a traditional bagged spring production machine is abandoned, the degree of automation is high, the structure is simple, production efficiency is high, and compressing and conveying are more smooth and steady.

Owner:GUANGZHOU LIANROU MACHINERY & EQUIP

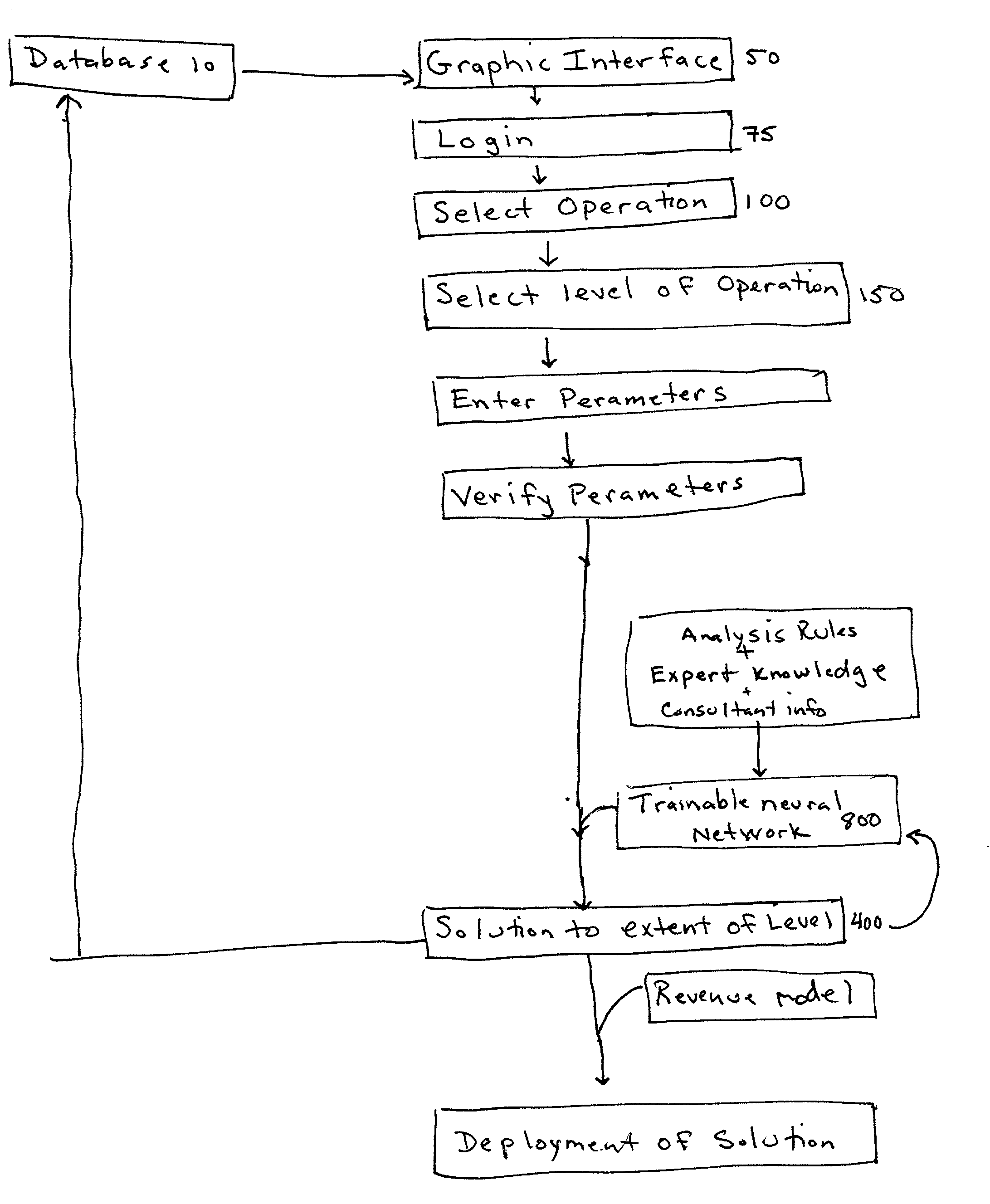

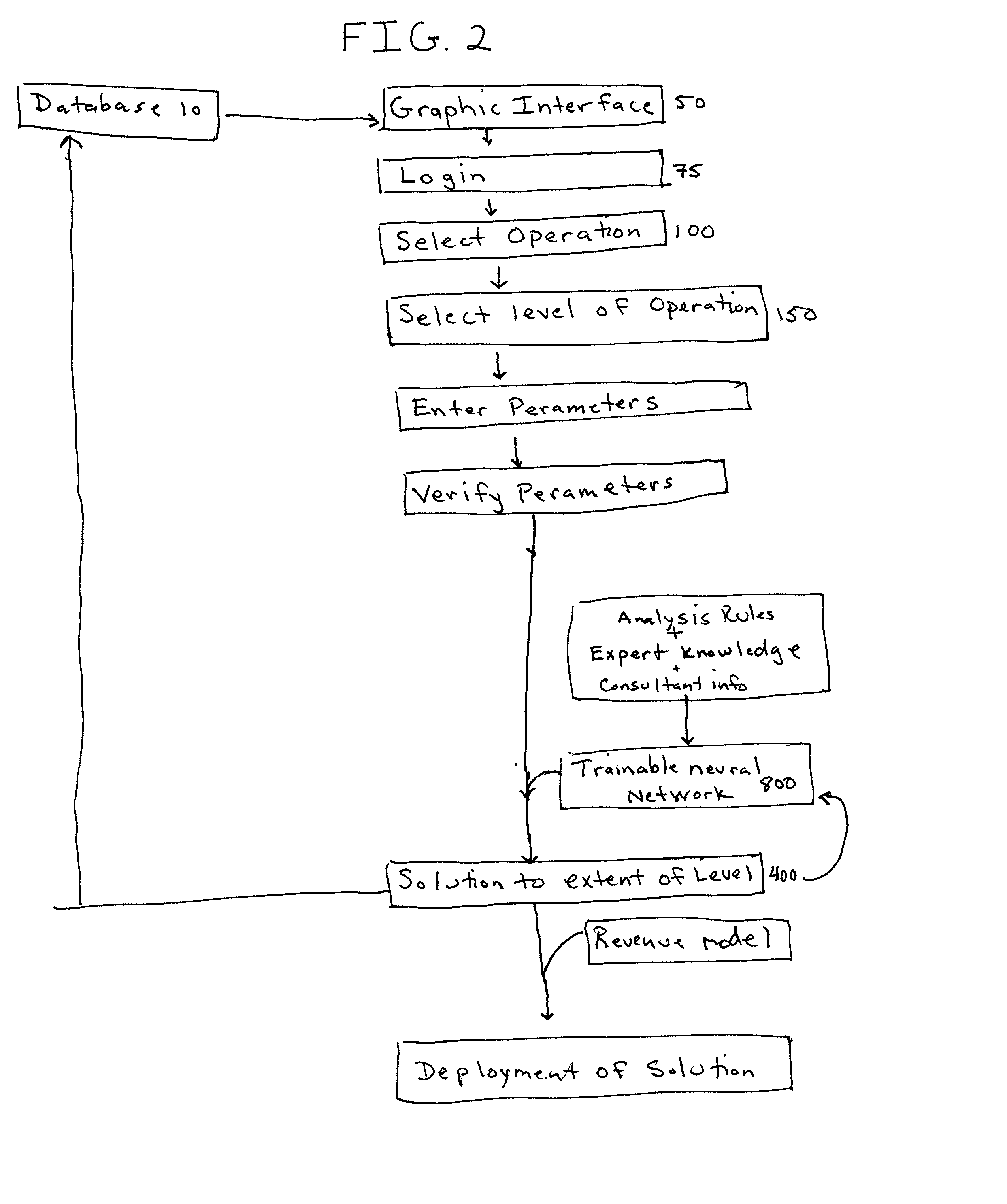

Artificial intelligence manufacturing and design

InactiveUS20020049625A1Digital computer detailsCAD network environmentSmart manufacturingSystems engineering

An automated artificial intelligence method and system for the design and implementation of engineering and manufacturing design services.

Owner:KILAMBI SRINIVAS +1

Industrial robot zero-position self-calibration method and device

InactiveCN101968341ASolving Zero Calibration ProblemsHigh precisionUsing optical meansSimulationObject function

The invention discloses a novel industrial robot zero-position self-calibration method and a novel industrial robot zero-position self-calibration device. In the method, a PSD device is optionally arranged in a robot-reachable working space first, and then a central point projected on the PSD is automatically positioned by depending on a beam of laser passing through the tail end of the robot so as to realize a calibration task of the robot. Accurate positioning and control of the robot is realized through high-precision PSD feedback; the position of the PSD central point is calculated by a wire-based method; and the zero error of the robot is obtained through an iterative algorithm by establishing a target function based on point constraint. The method does not need the position of the PSD central point or actual physical contact measurement, and has the obvious advantages of low cost, automation, portability, high efficiency, high precision and the like.

Owner:NANJING UNIV OF SCI & TECH

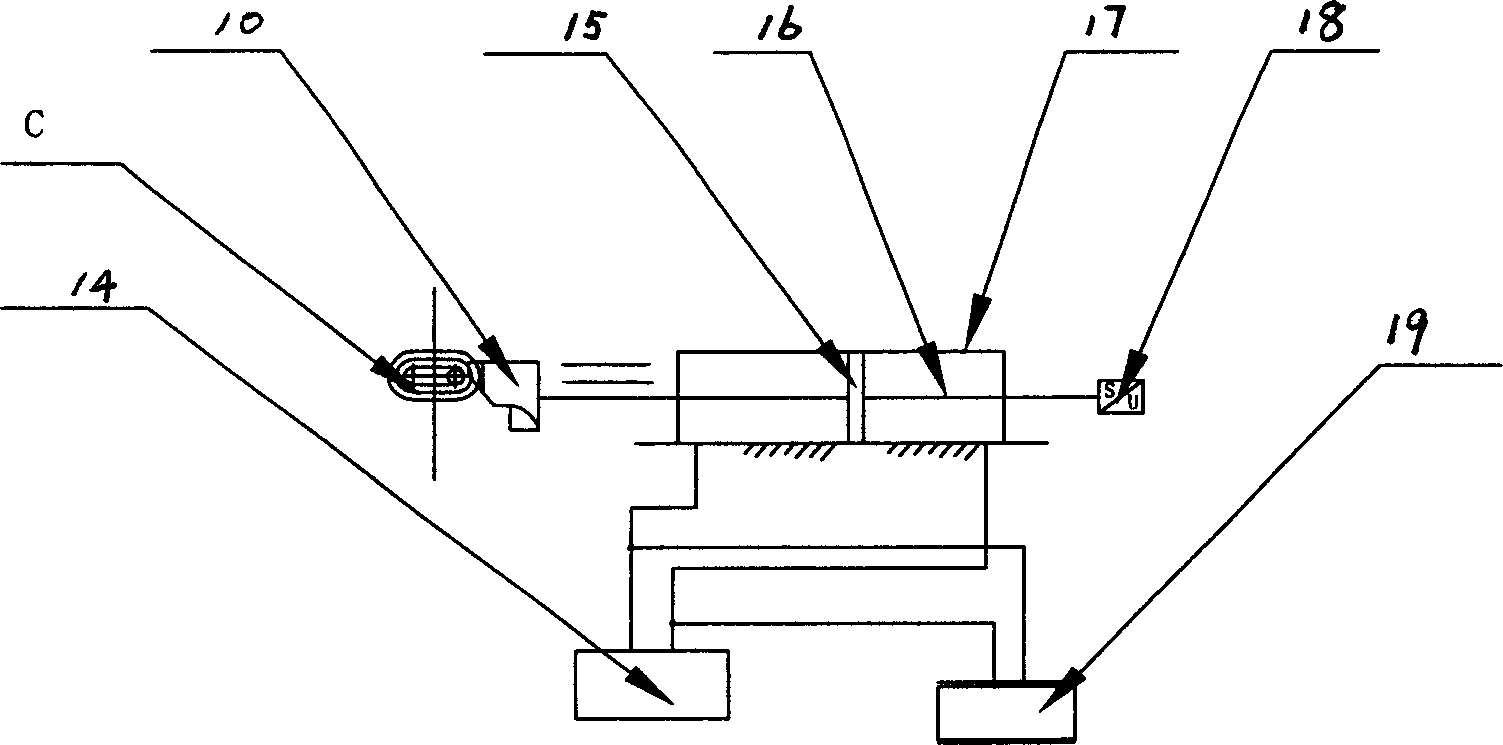

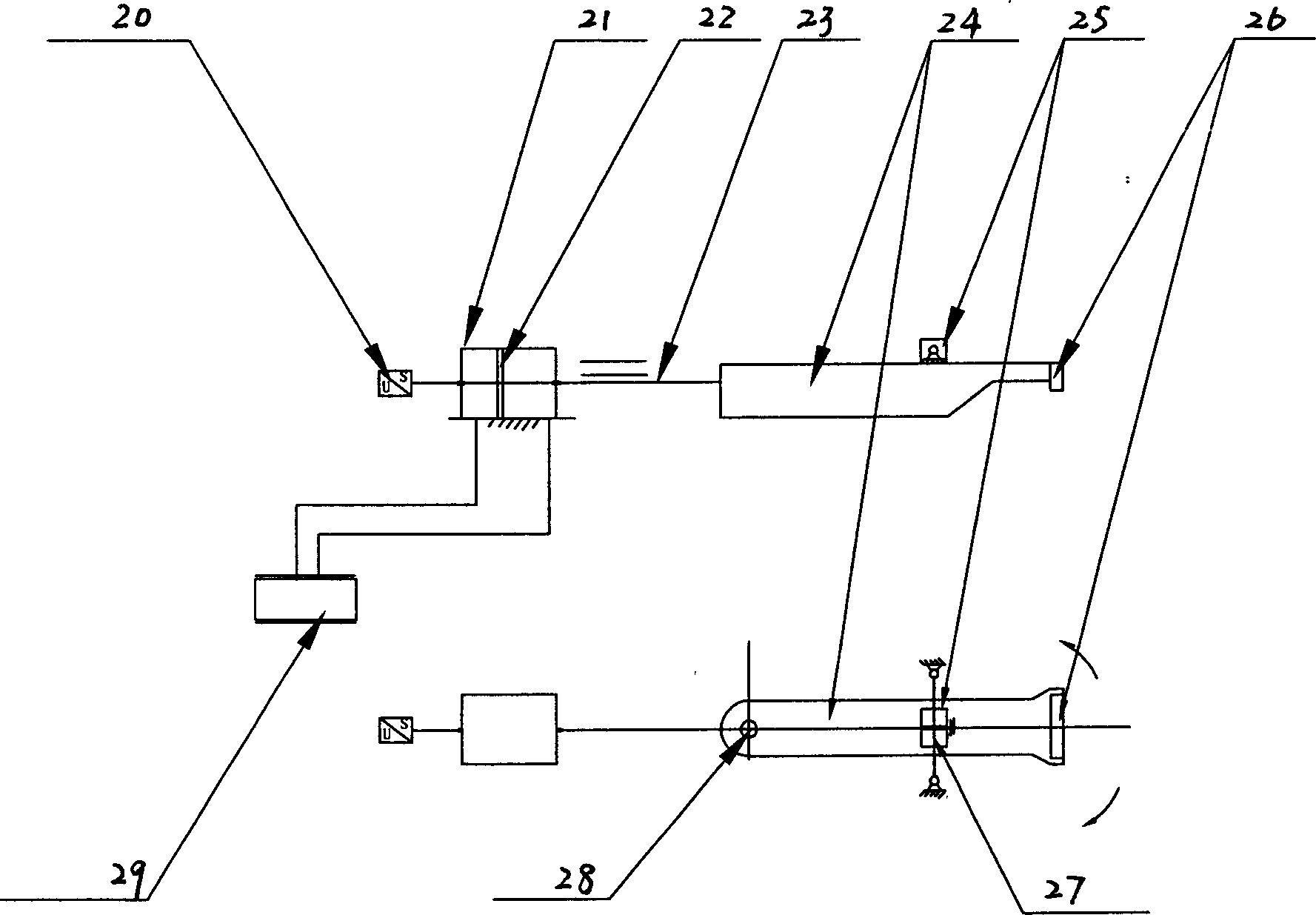

Full automatic hydraulic flash butt welding method of metal circular ring chain and apparatus thereof

ActiveCN1806992AHigh quality excisionFully automaticWelding/cutting auxillary devicesAuxillary welding devicesButt weldingTransducer

The invention relates the metallic bond full-automatic all-hydraulic flash butt welding method and device. The method is that the open of each chain link is automatically welded after the metallic bond is knitted to chain. The method comprises the following step: sending the chain link from left end of machine to position of welding under the combined action of main conveyer and subsidiary conveyer, controlling the hydraulic heading equipment with displacement transducer, servo valve and heading valve, preheating, burning, flashing and heading welding, auto removing the burrs, and exporting the finished chain link from the right end of machine. The whole process is the full-automatic all-hydraulic flash butt welding method. The invention possesses the characters of high automation level, high production efficiency, high product quality and high safe reliability. The said method and device will replace the national current fall behind electric milling cam type FBW method and device.

Owner:王洪军

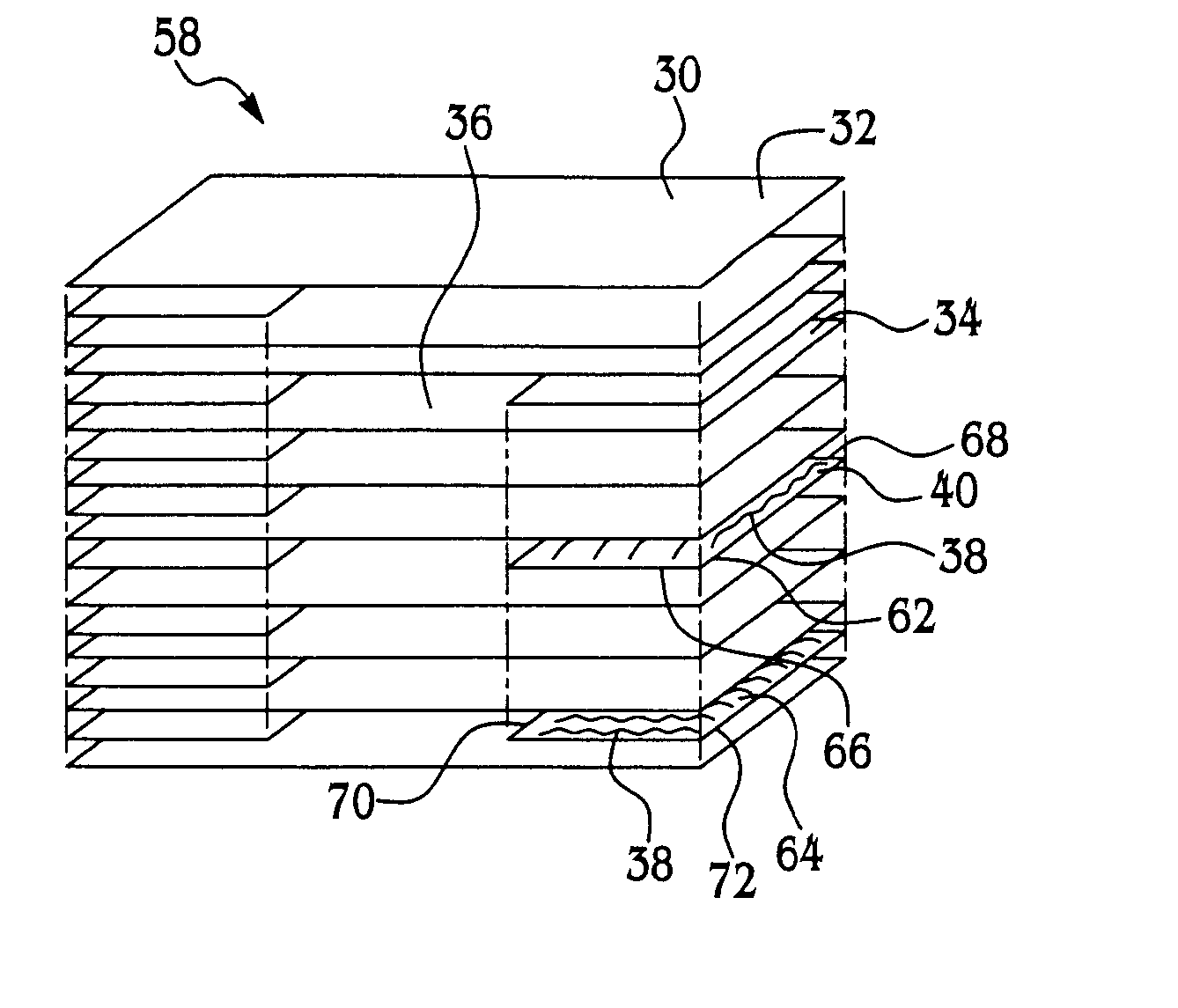

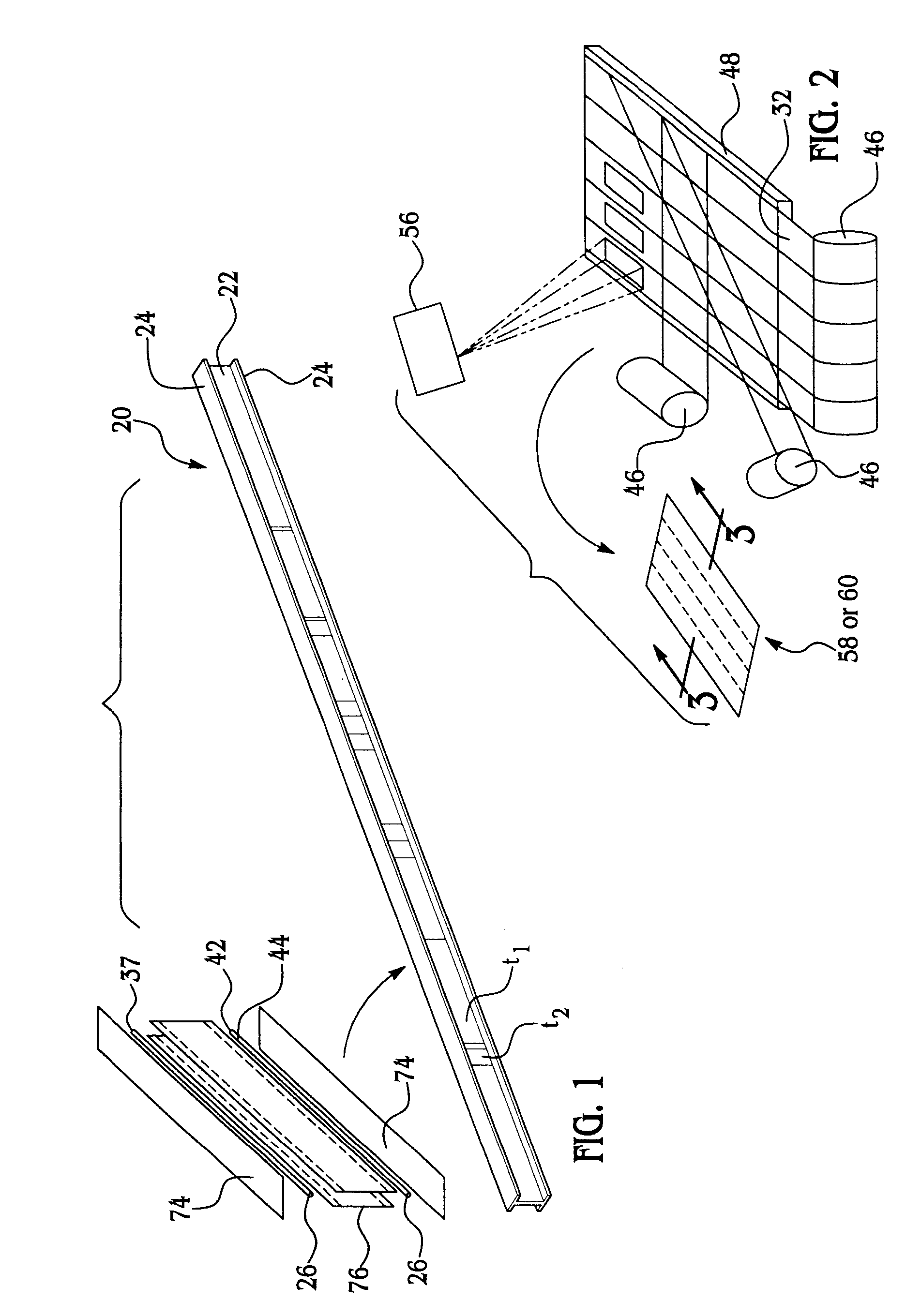

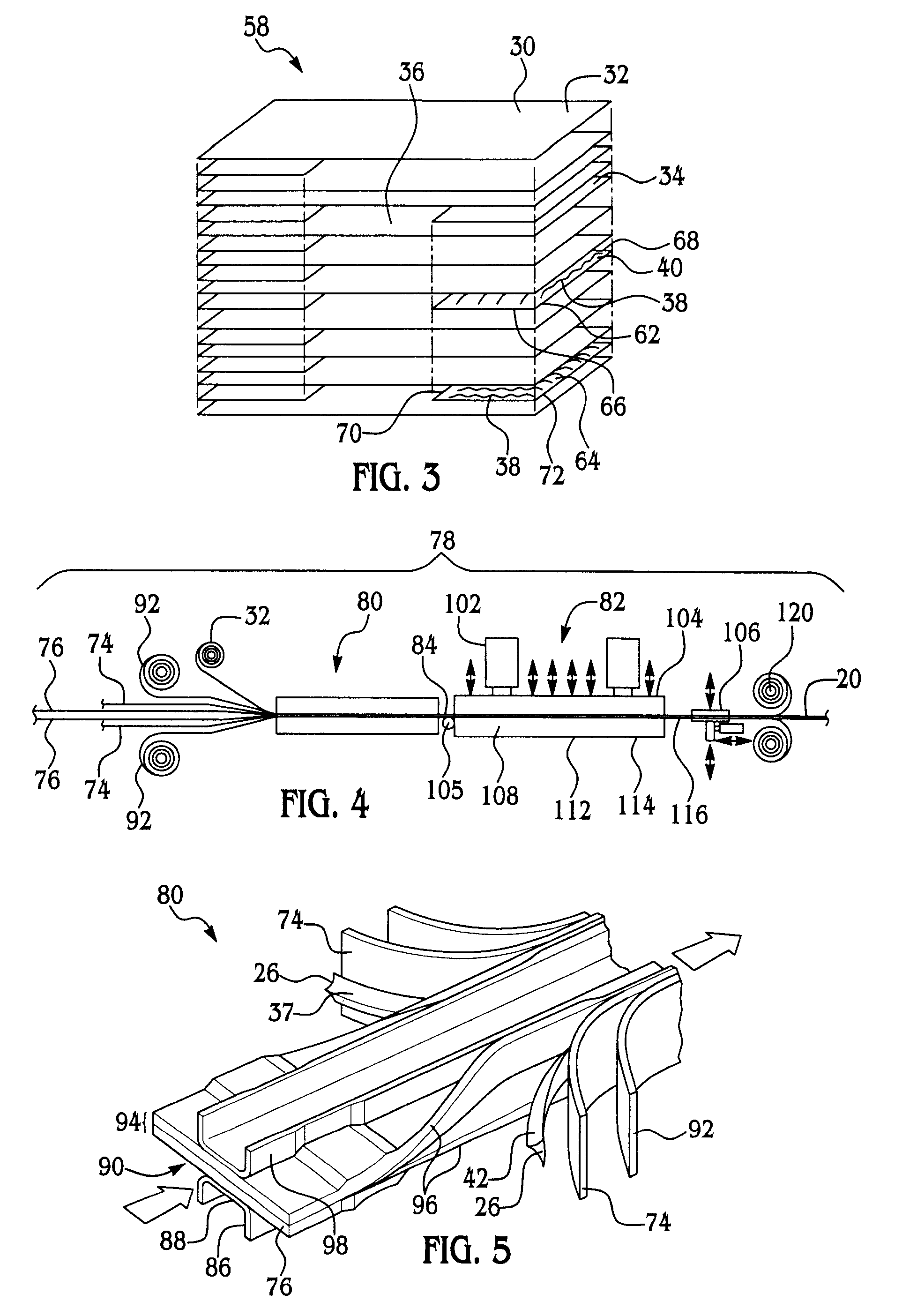

Continuous Fabrication of Parts Using In-Feed Spools of Fiber Reinforced Thermoplastic

ActiveUS20070175572A1Automate processingNeed can be reduced eliminatedWood veneer joiningBaby linensEngineeringVarying thickness

Thermoplastic composite laminate parts with tailored and varying thickness and / or curved sections are manufactured in a continuous process. Automated equipment or hand lay-up is used to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. Some or all of the plies may be continuously fed from spools of single or multiply ply material. Ply consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from the multiple ply stacks.

Owner:THE BOEING CO

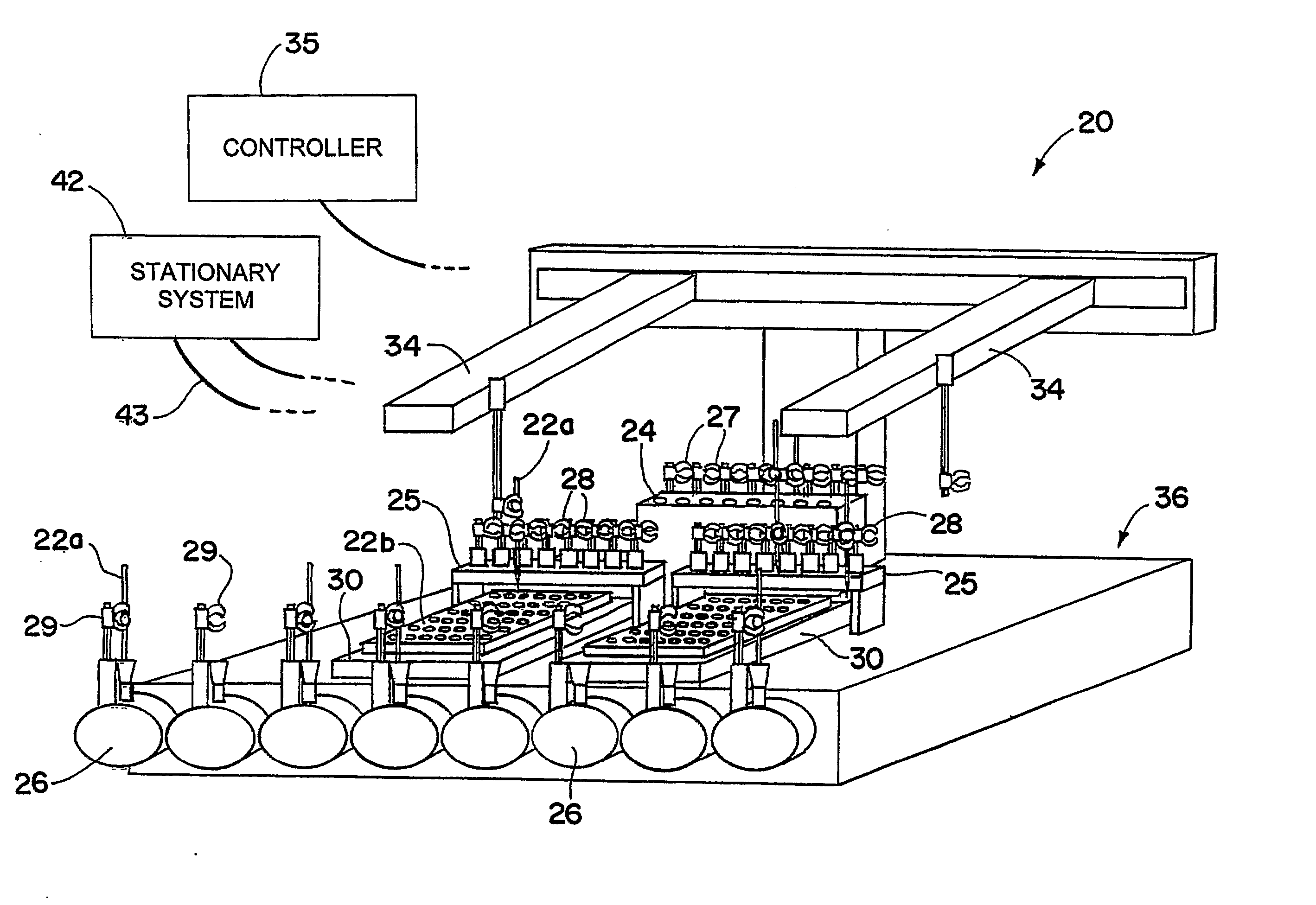

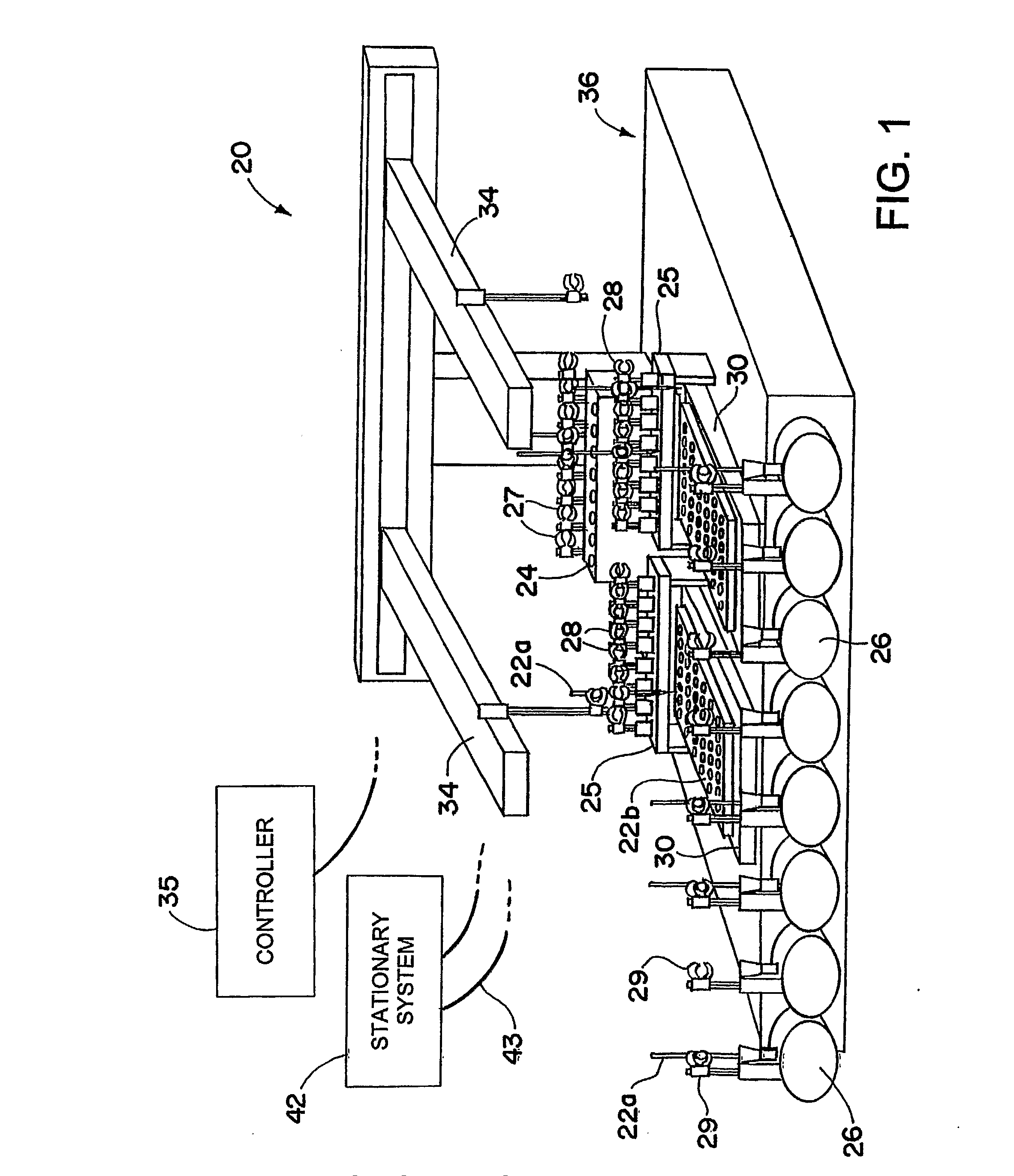

Robotic Handling System and Method with Independently Operable Detachable Tools

InactiveUS20070295113A1Reduce complexityEliminate needWithdrawing sample devicesMaterial analysis by optical meansManagement processEngineering

An analytical system and method that enables more efficient transport of movable devices (22) among stations (24, 25, 26). According to one aspect of the invention, the system and method permit operational timesharing of a transport mechanism (34) for the movable devices. According to another aspect of the invention, control of the transport mechanism is effected on an event-driven basis. The invention has particular application to an adaptive, motion and fluids system for automating the sample handling / management process associated with analytical processes and especially bioanalytical processes such as introducing samples into LC and HPLC systems.

Owner:PARKER HANNIFIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com