Patents

Literature

149results about How to "Reliable completion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor-processing apparatus provided with self-cleaning device

InactiveUS20060228473A1Reliable completionImprove throughputLiquid surface applicatorsVacuum gauge using ionisation effectsSemiconductorOptics

A CVD apparatus comprising an optical unit detecting the mass of contaminants adhering to an inner surface of a CVD reactor by irradiating an inner surface of the reactor with light having monochromaticity through an optical window provided on an inner wall of the reactor and receiving its reflected light is provided.

Owner:ASM JAPAN

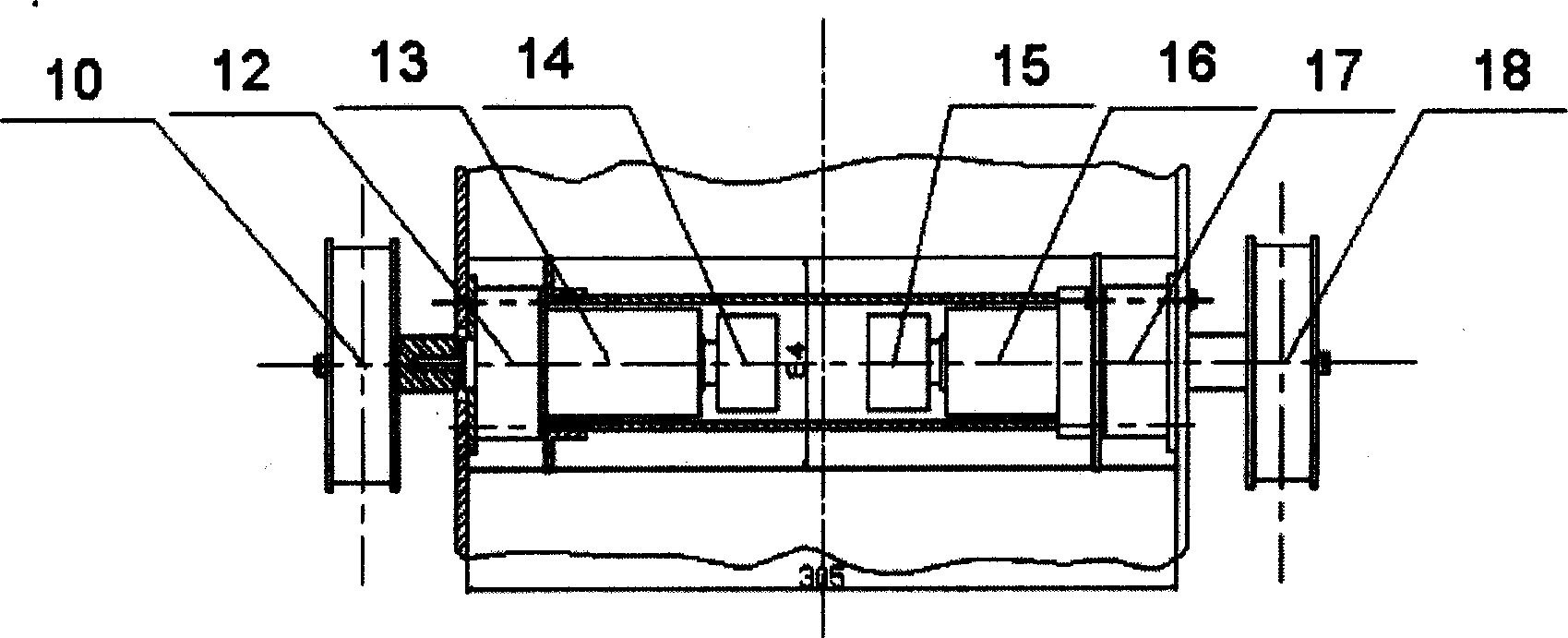

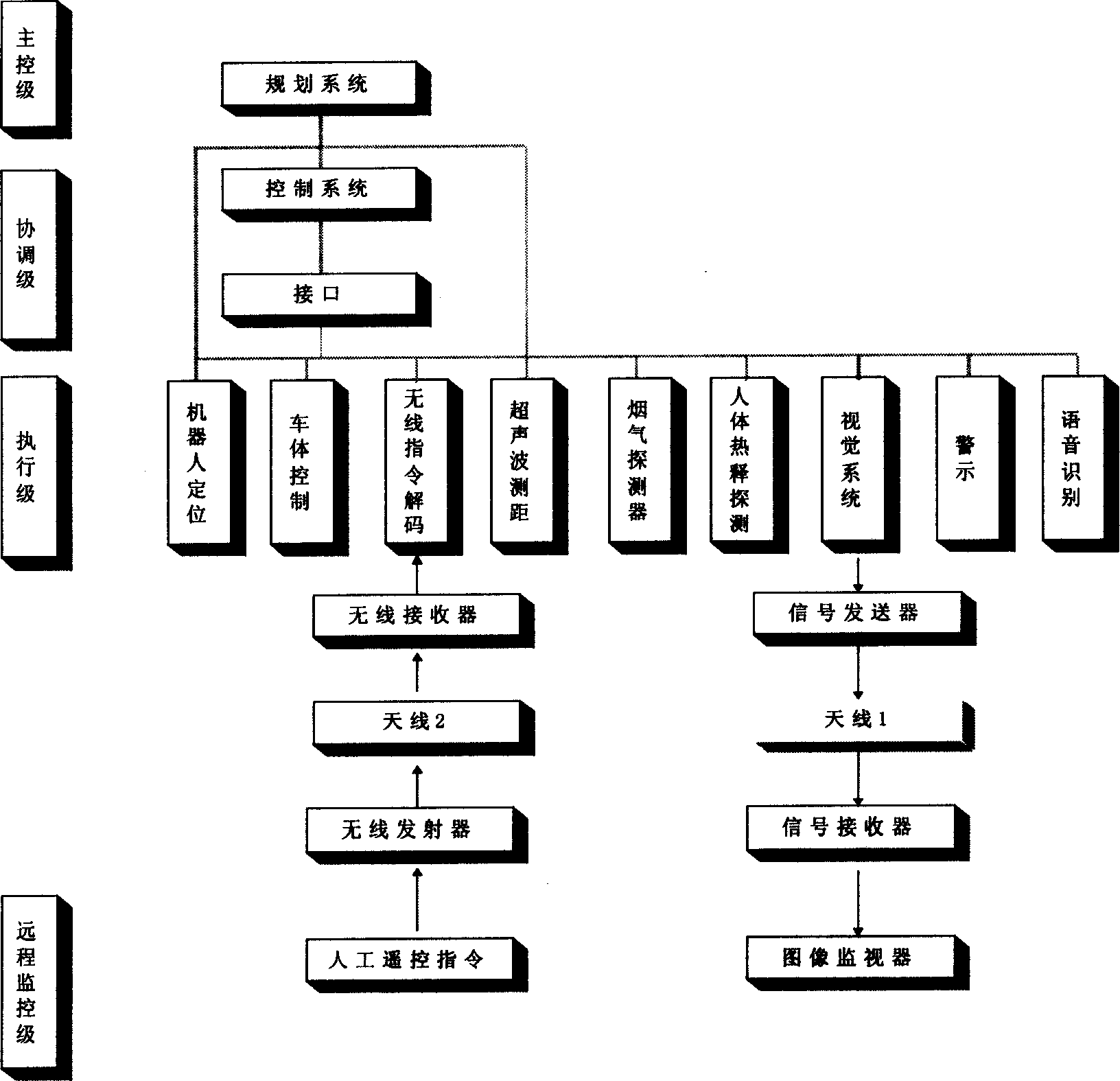

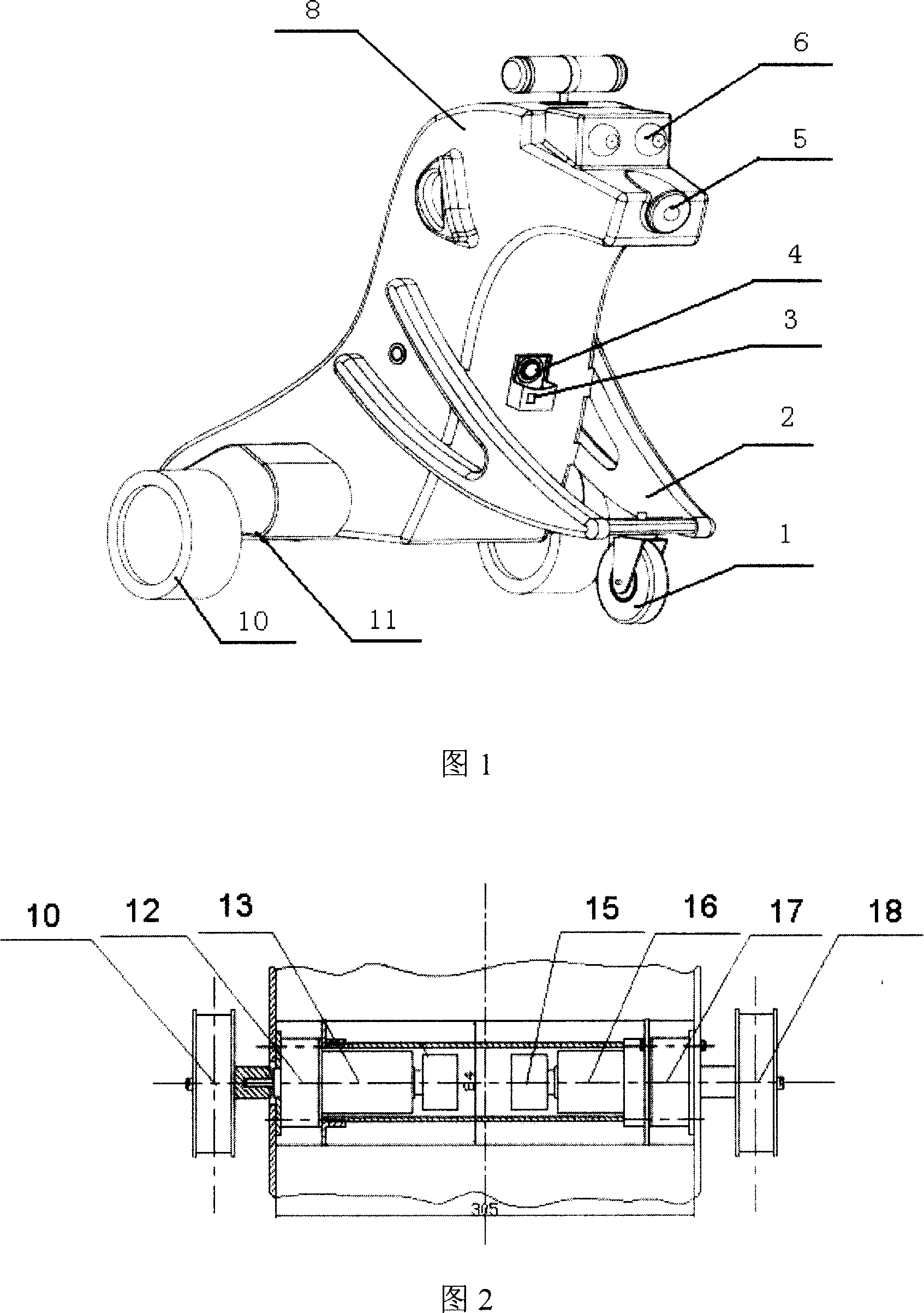

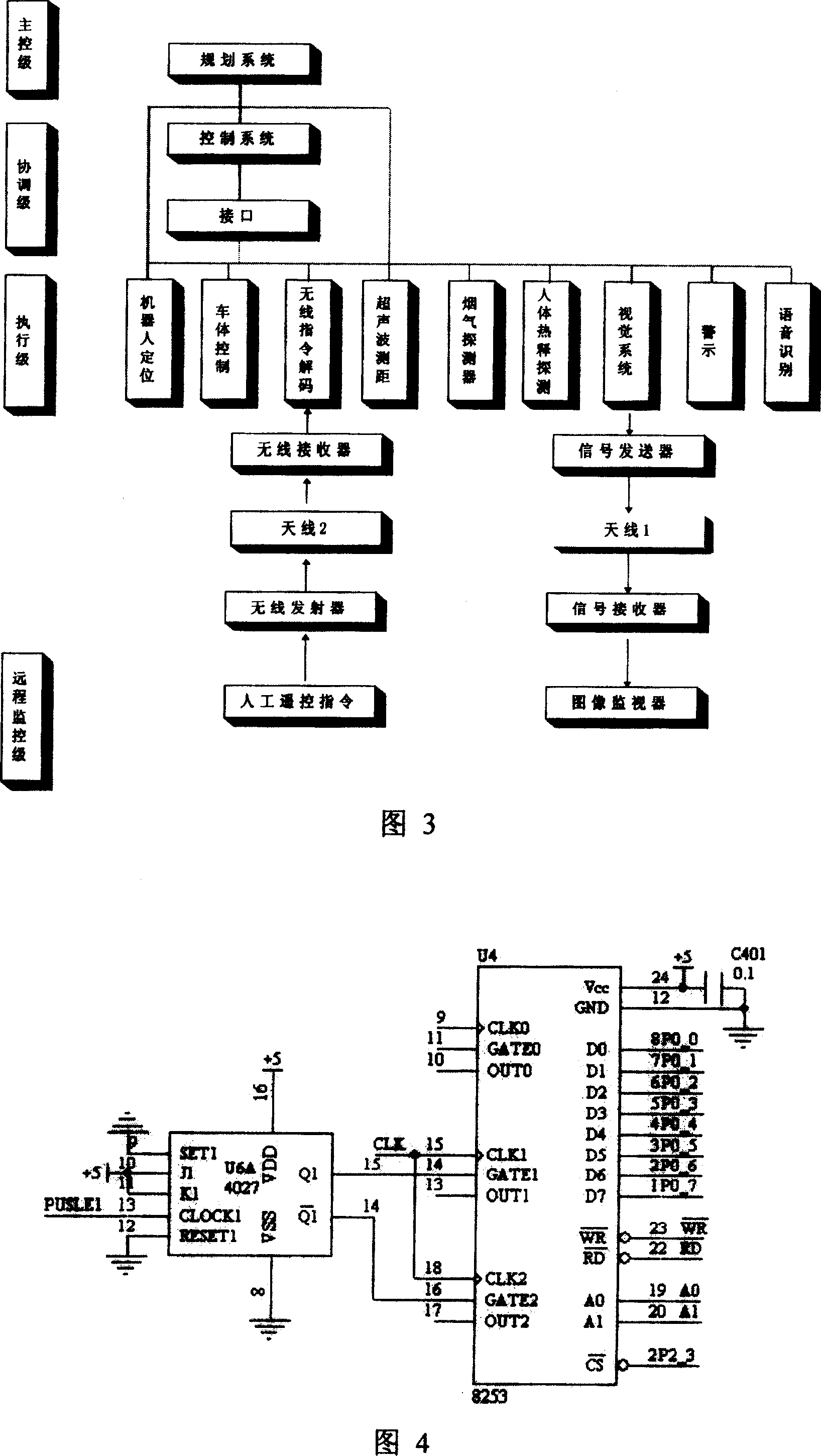

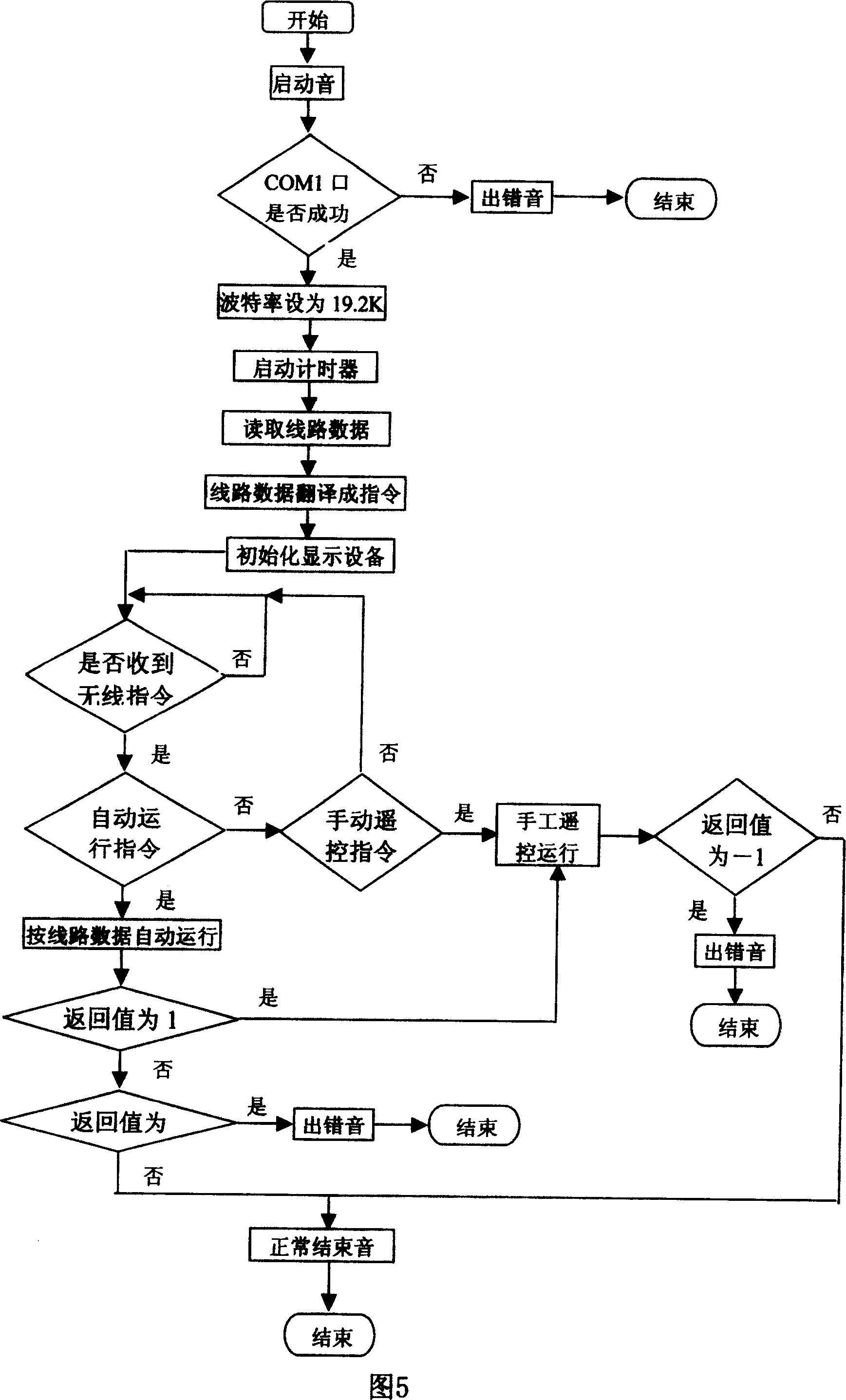

Security ensuring and patrolling robot

InactiveCN1593859AReliable completionStabilize security patrol tasksManipulatorControl systemPatrolBot

The invention relates to a kind of patrolling robot. It consists of robot body, the movable controlling unit and the bearing rack of which is fixed firmly to the outer shell; anti- stakeout system, which consists of infrared temperature sensor, smoking sensor, hot releasing infrared sensor, mini CCD camera eye, signal lamp, buffer, and graphic message wireless conveying module; the controlling system that sends message to control the robot to patrol, move to control and give an alarm automatically within the circumstance; multi-sensor system. The robot can patrol along the scheduled path, and judge the location is at according to the messages from the sensors to avoid the impediment and change the moving path. The invention is more suitable to increasing onerous security task, and improves the atomicity of security work.

Owner:SOUTH CHINA UNIV OF TECH

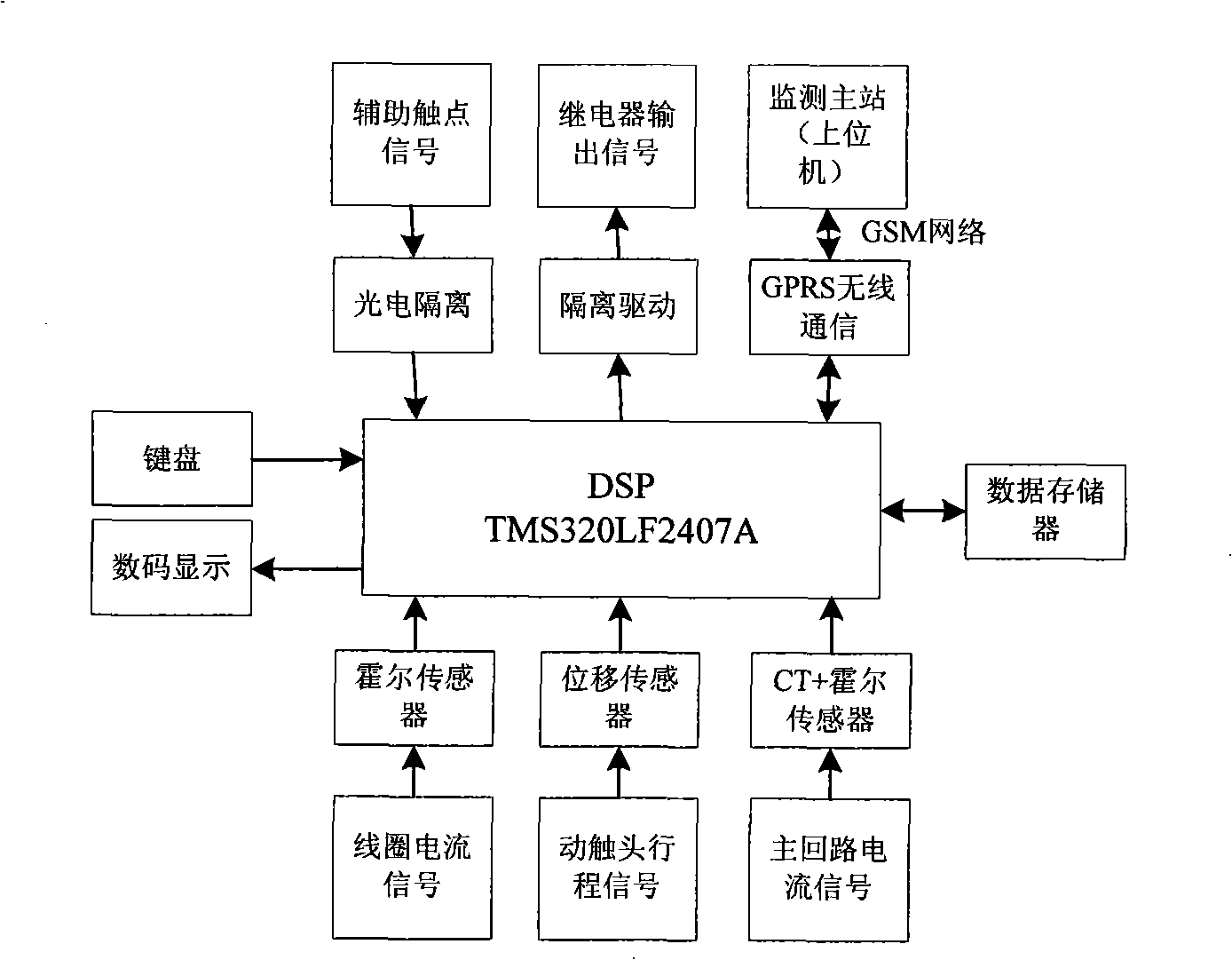

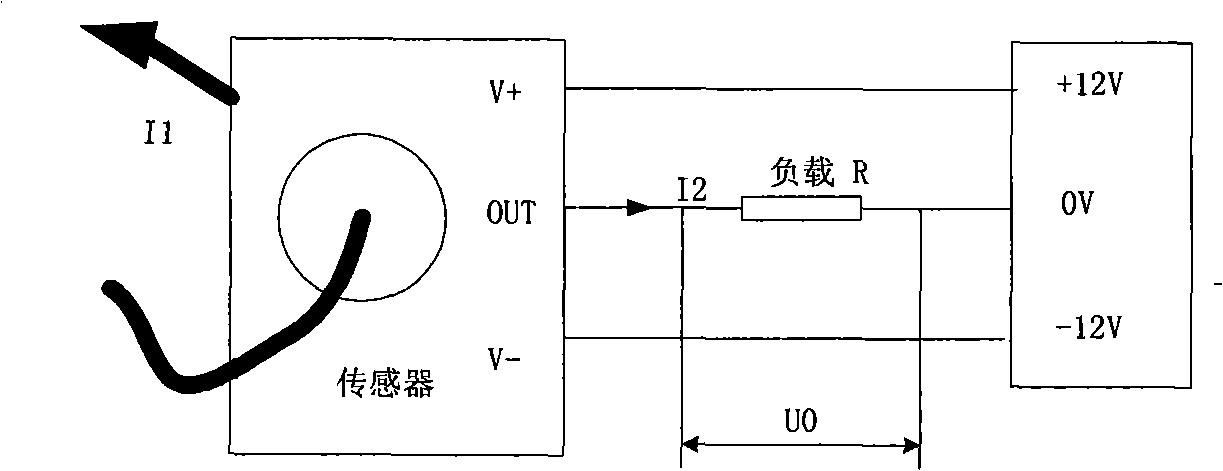

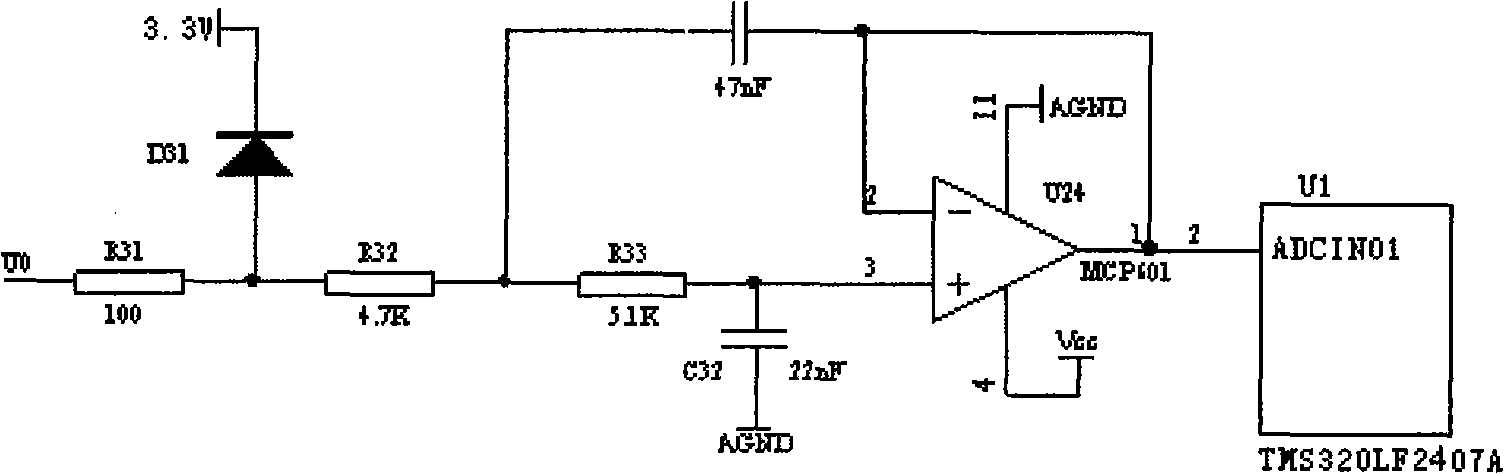

24KV high-voltage vacuum breaker mechanical features on-line monitoring method and monitoring device

InactiveCN101261192AEasy to analyzeSpeed upStructural/machines measurementHigh pressureSingle chip

The invention provides a 24kV high-voltage vacuum circuit breaker mechanical characteristic online monitoring method in which the mechanical characteristic parameters of the vacuum circuit breaker are gained by monitoring the closing and opening switch coil current characteristic curve and the stroke characteristic curve of a moving contact when the vacuum circuit breaker acts; a corresponding monitoring device comprises a DSP single chip microprocessor, a circuit breaker coil current monitoring module, a circuit breaker movable contact stroke monitoring module, a circuit breaker main circuit current monitoring module, and a GPRS communication module. Compared with the existing circuit breaker mechanical characteristic online monitoring method and the device, the online monitoring method and the device of the invention adopt advanced sensing technique, signal processing technique, wireless communication technique, and computer technique, etc., realizes outdoor high voltage vacuum circuit breaker online monitoring; the online monitoring method and the device also display the real-time opening and closing coil current characteristic curve and the stroke characteristic curve of the moving contact by monitoring data when the vacuum circuit breaker acts, and calculates the mechanical characteristic parameters such as the closing and opening switch time of the vacuum circuit breaker, action speed, stroke of movable contact, and opening distance, etc., and can conveniently analyze the monitoring results.

Owner:NANJING INTELLIGENT DISTRIBUTION AUTOMATION EQUIP

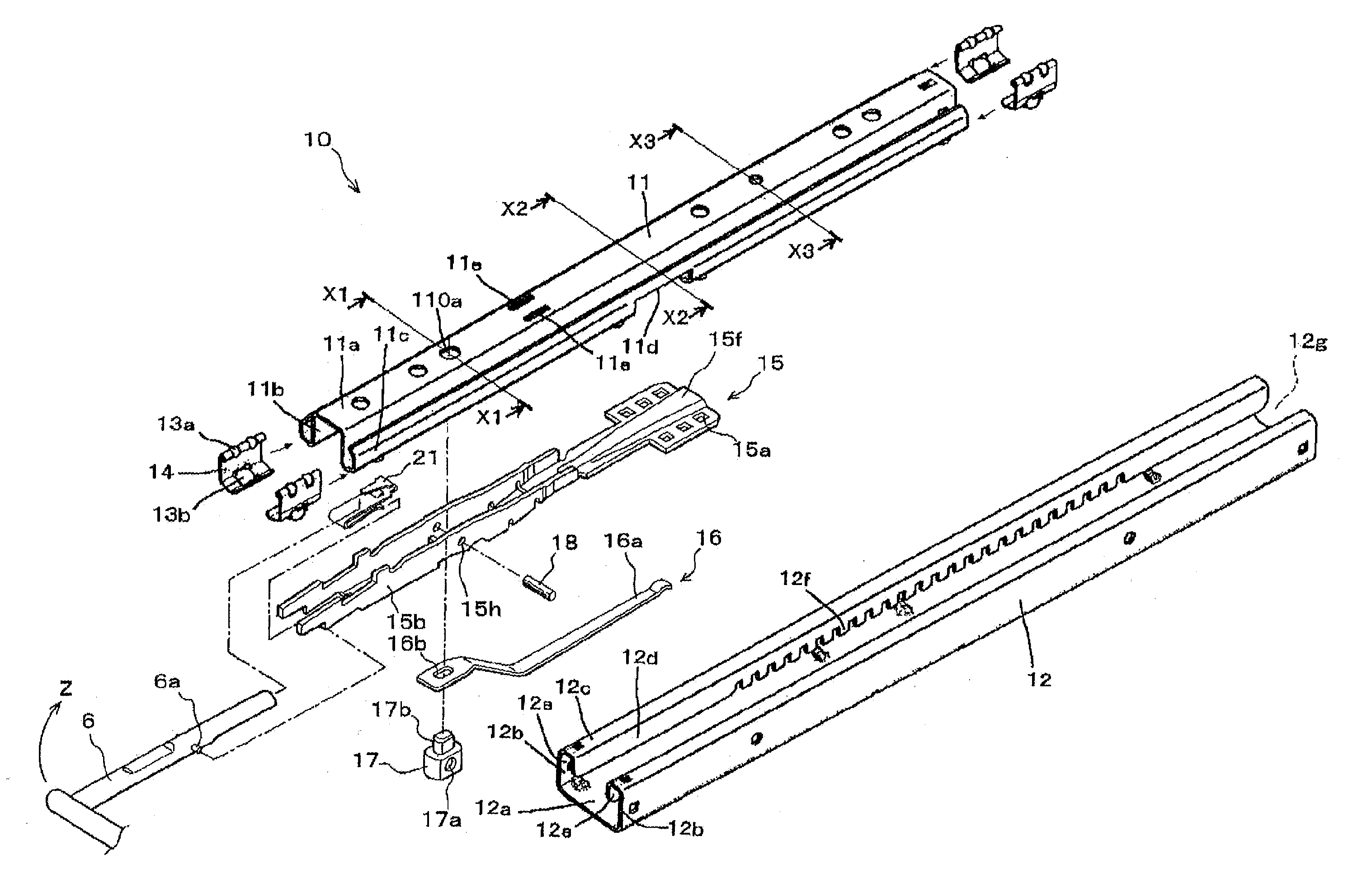

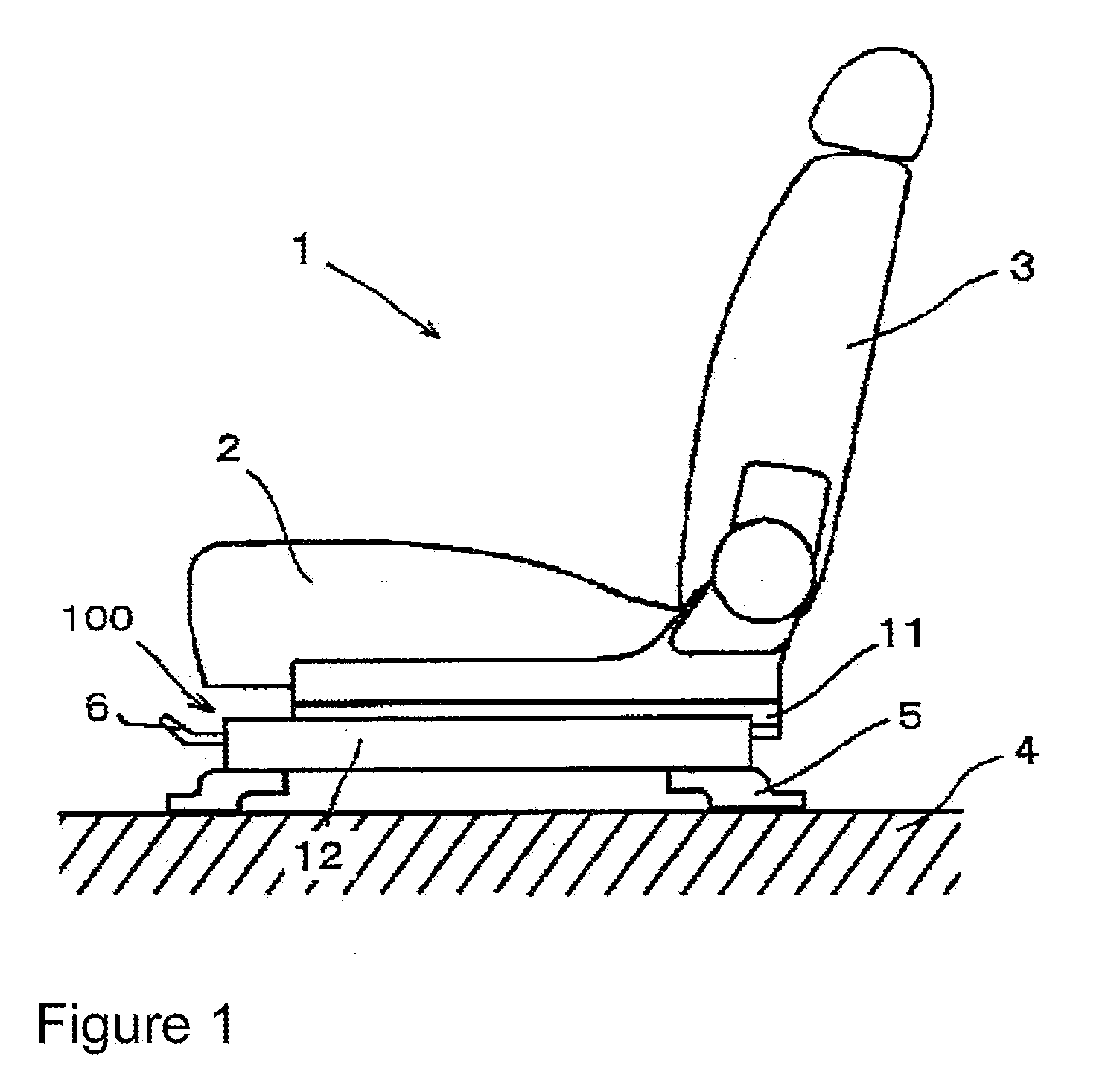

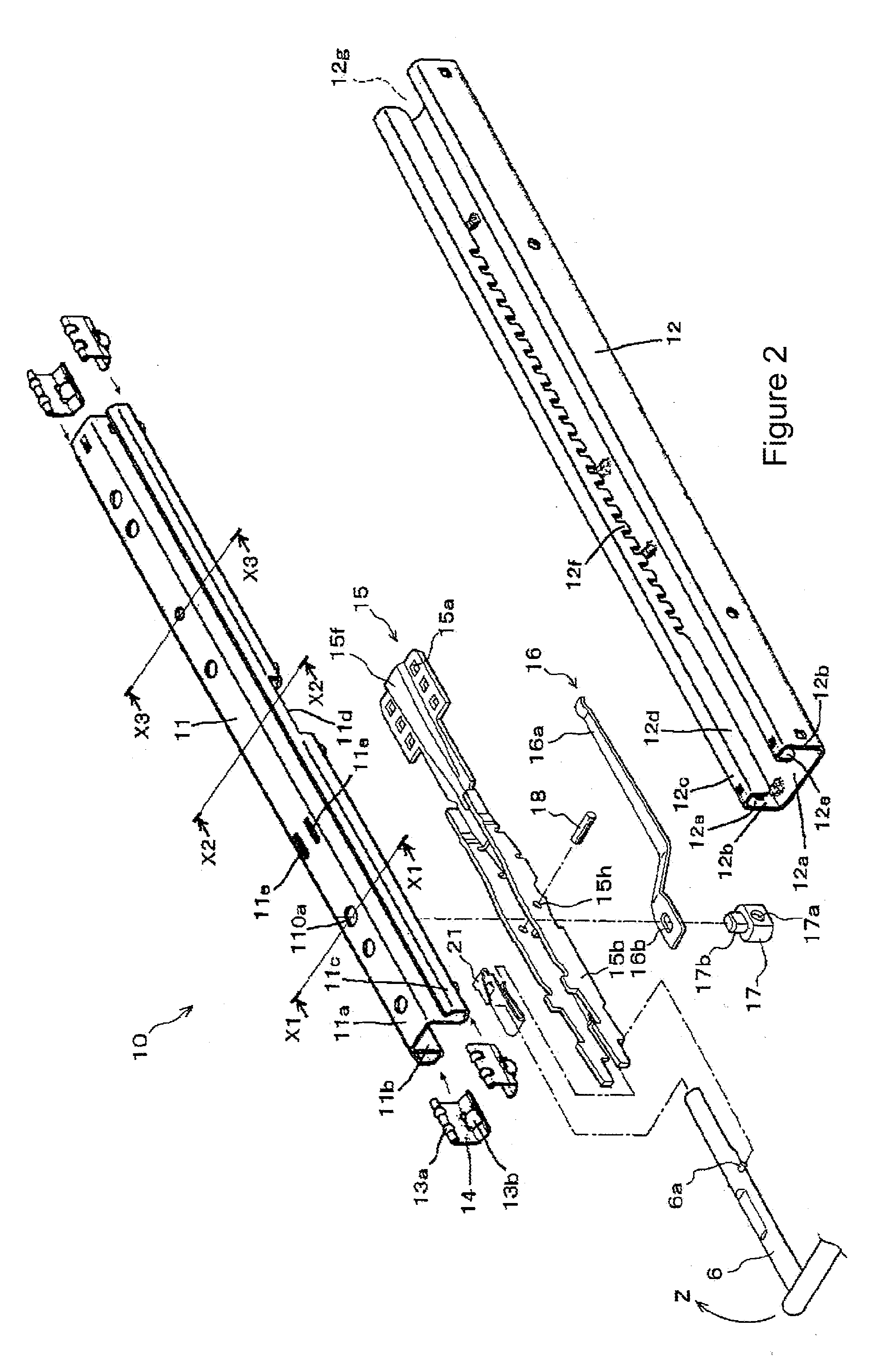

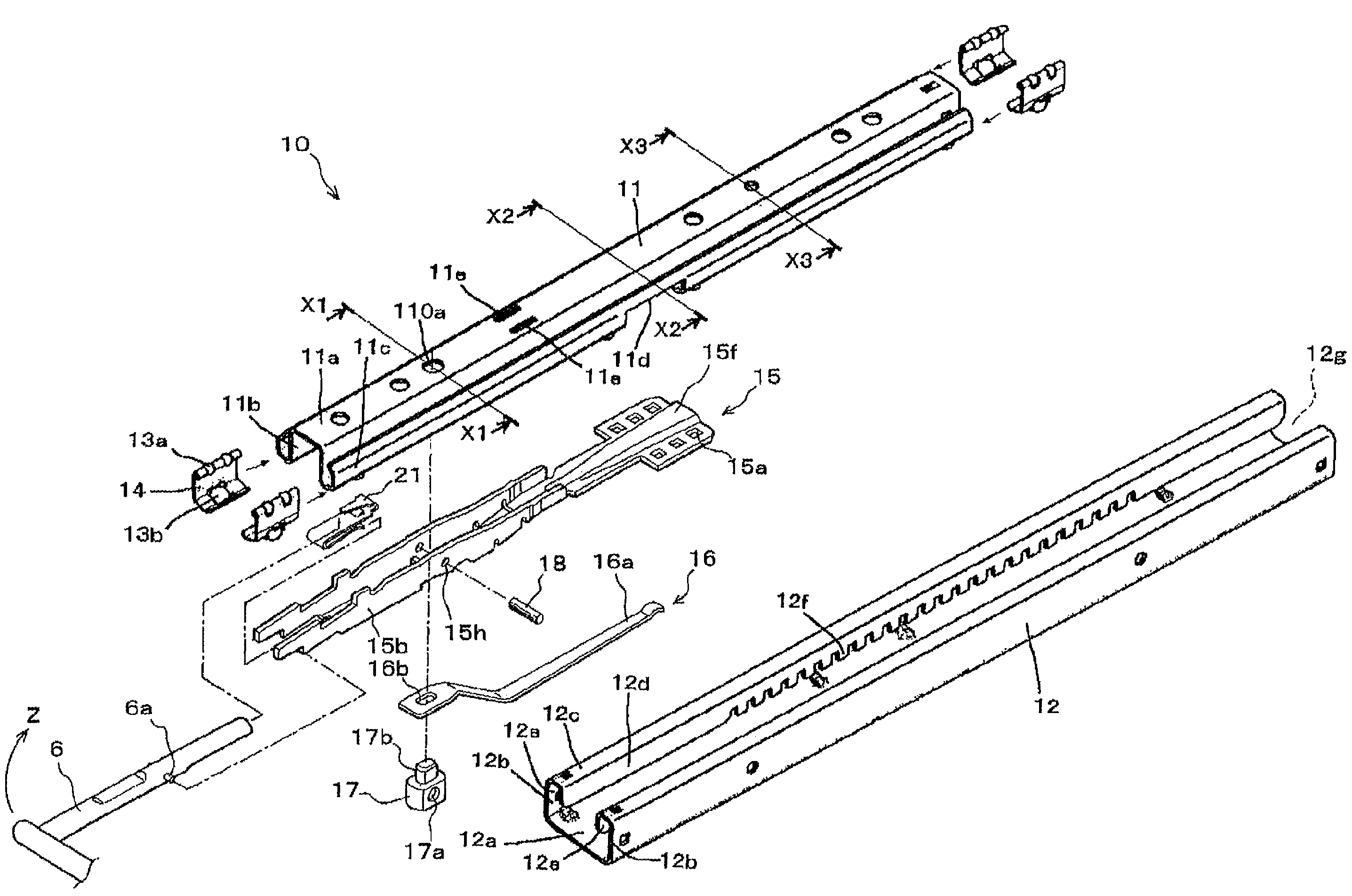

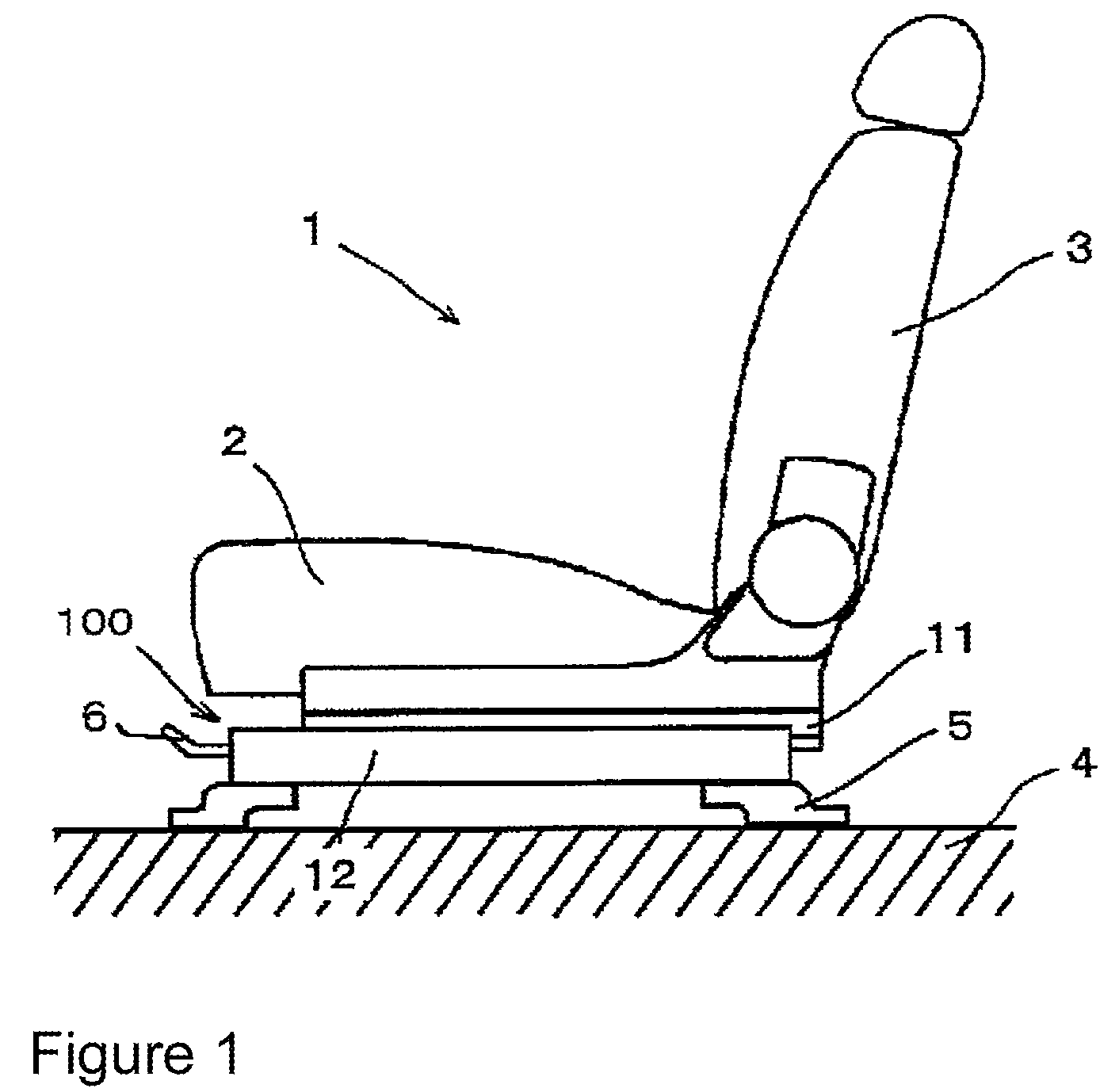

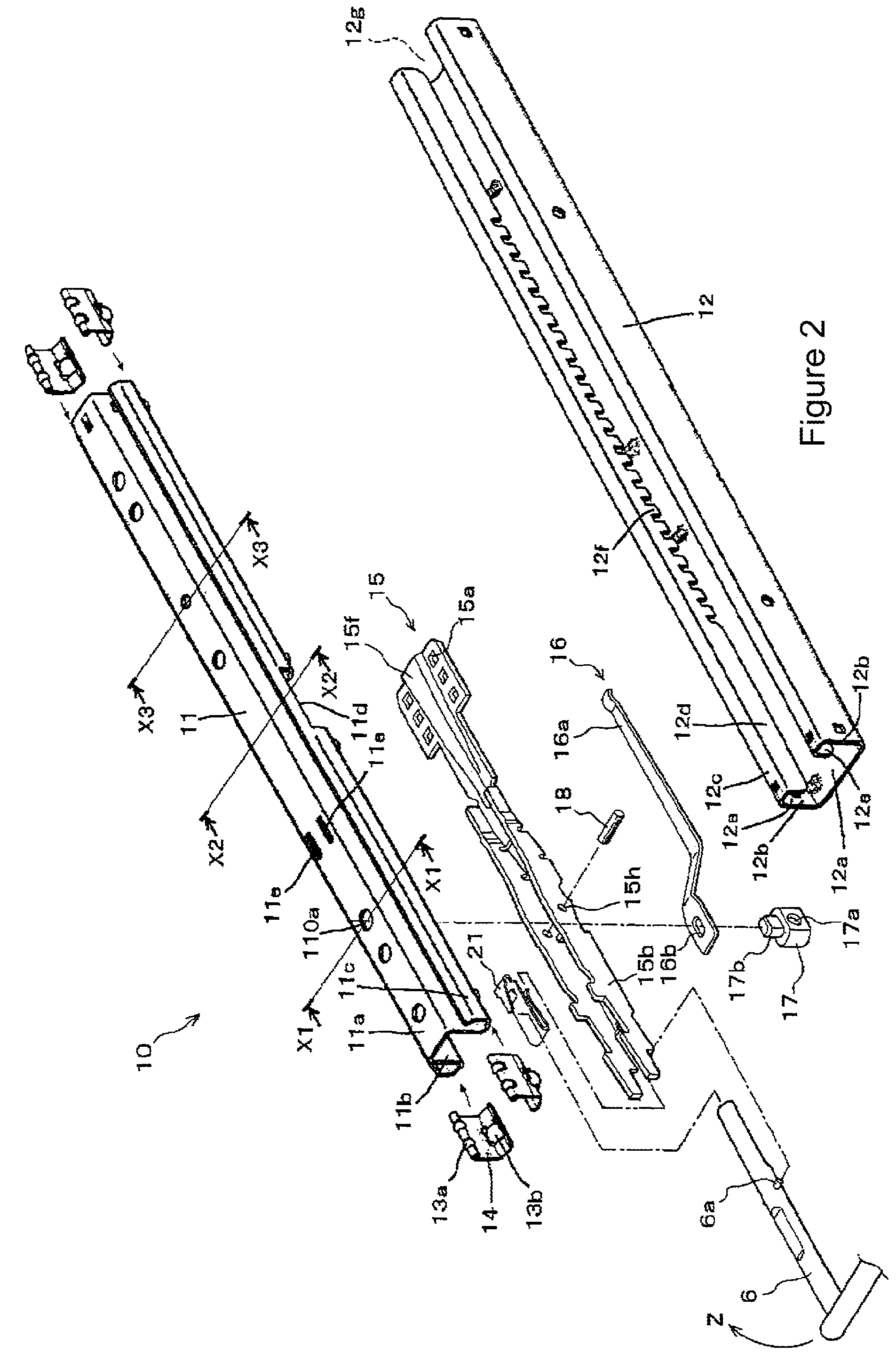

Slide rail unit

ActiveUS20080231101A1Prevent displacementReliably completeSafety beltsPedestrian/occupant safety arrangementLeaf springEngineering

A simple, compact and easy-to-assemble slide rail unit is provided. The slide rail unit reliably restrains right and left rails from sliding even when the right and left rails are installed onto the vehicle floor at an inclination angle different from each other in a longitudinal direction thereof. The slide rail unit includes a slide rail member having an upper rail member and an upper rail member slidably engaged with each other and a lock lever rotatably pivoted to the upper rail member so as to engage with / disengage from an engagement portion formed on the lower rail member. The slide rail unit also includes an operation lever connected to the lock lever within the slide rail member. Between the lock lever and the operation lever, a leaf spring member is disposed for connecting the lock lever and the operation lever therebetween.

Owner:IMASEN ELECTRIC IND

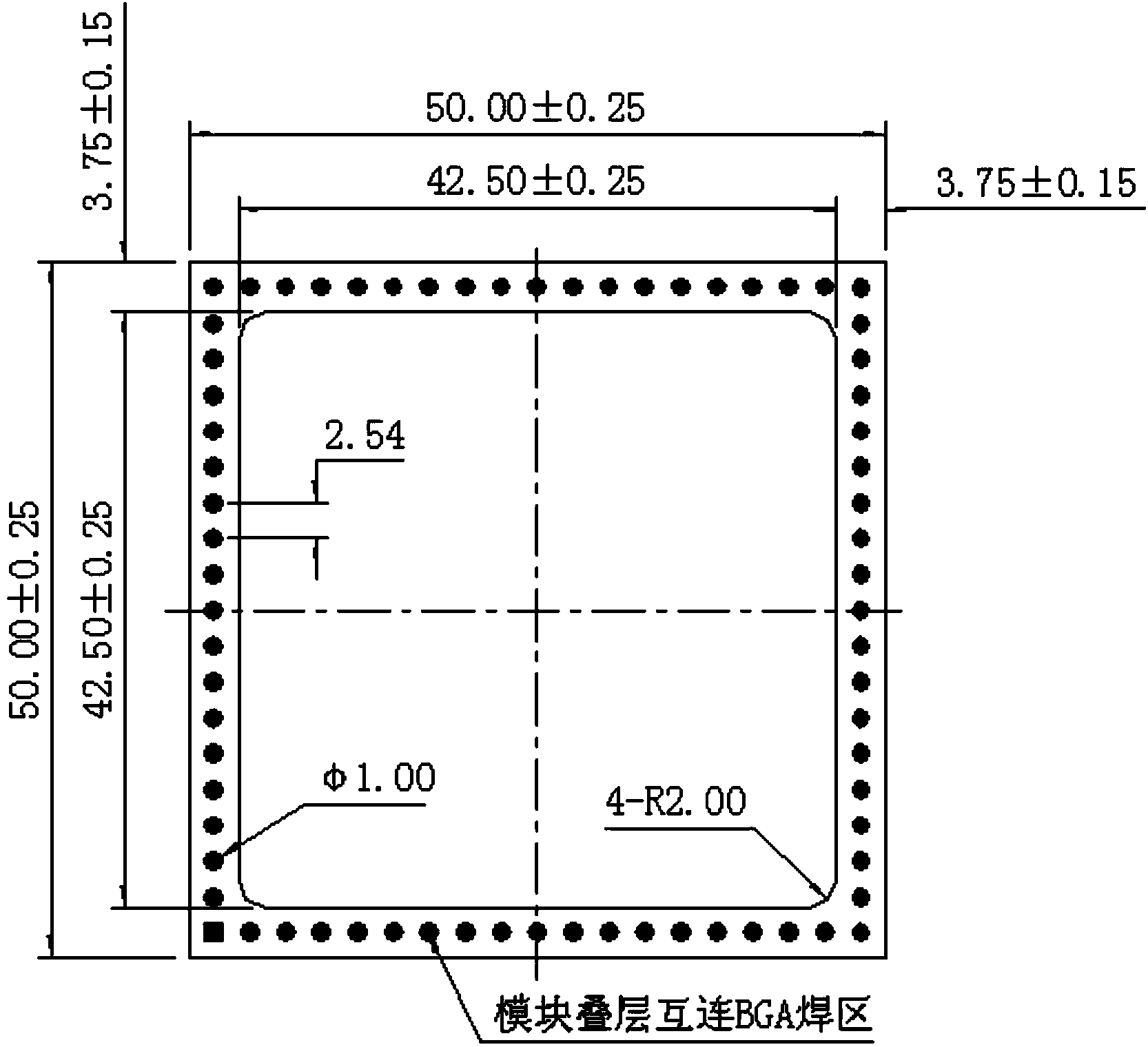

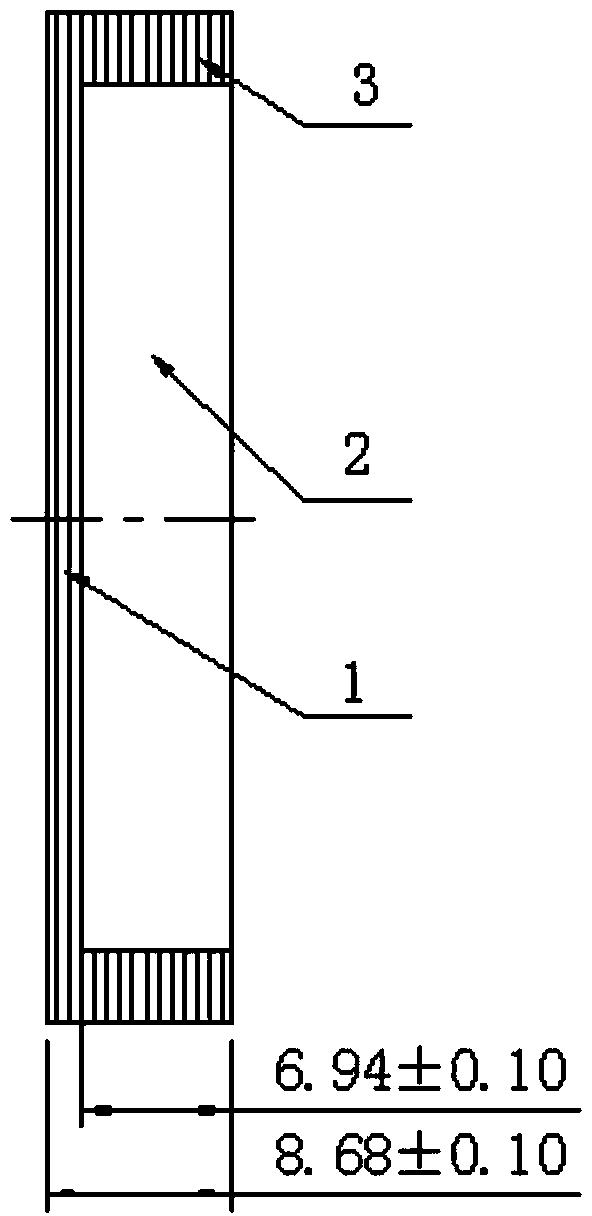

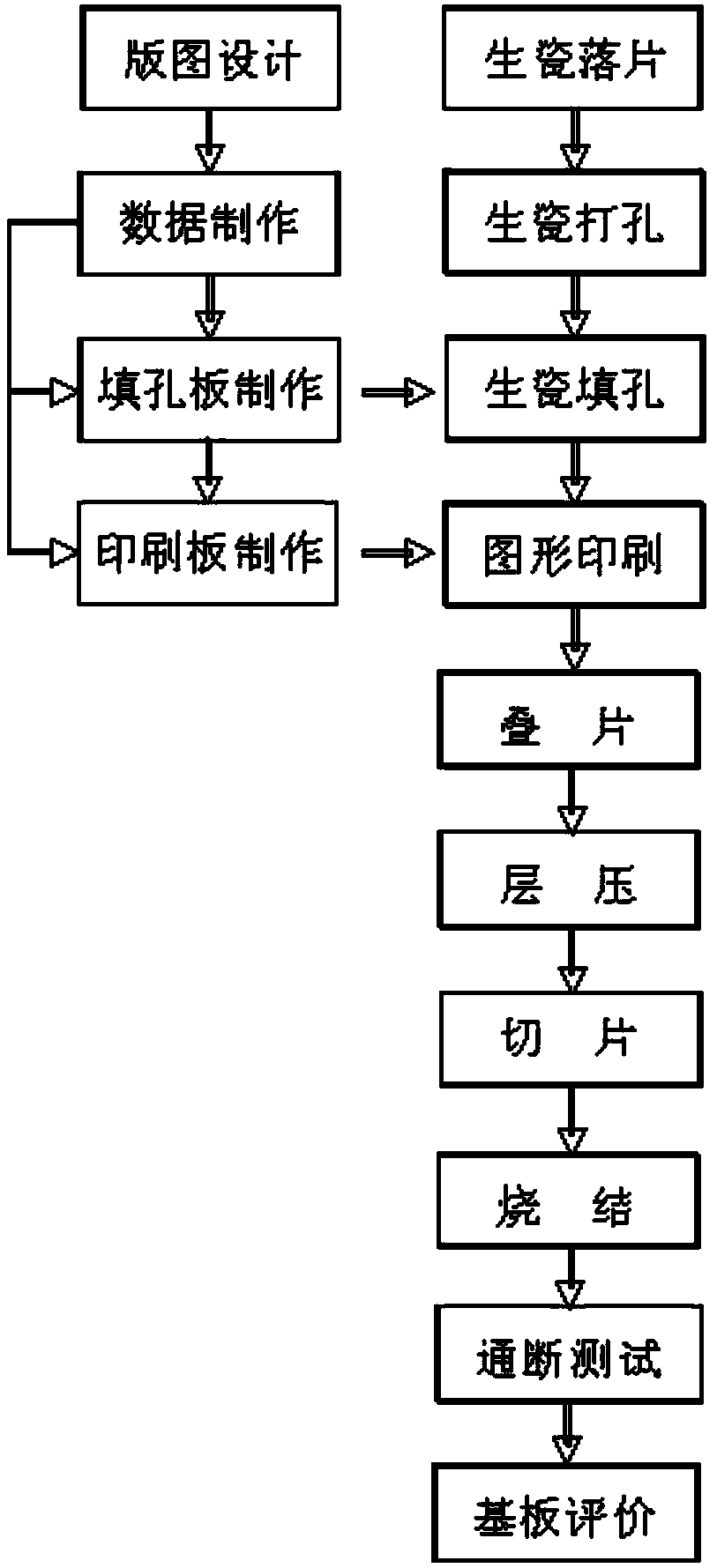

Ultra-multi-layer ultra-deep-cavity LTCC substrate manufacturing technology

ActiveCN104284534AAchieve preparationEasy to operateMultilayer circuit manufacturePrinted element electric connection formationScreen printingManufacturing technology

The invention discloses an ultra-multi-layer ultra-deep-cavity LTCC substrate manufacturing technology. A conventional solid flat plate LTCC substrate machining technology is broken through, after hole filling and screen printing, a cavity window in an unglazed porcelain layer is formed in a laser-cutting-up mode, the non-operability problem of hole filling and screen printing technologies on a large-size window unglazed porcelain piece is avoided, and the contraction amount and the unevenness of an unglazed porcelain piece obtained after filling and printing before piece stacking are lowered. After cofiring, an abrasive wheel cuts a ripe porcelain plate in a rotating mode, and the fact that an LTCC substrate which is regular in shape, accurate in size, thin in wall and ultra-deep in cavity is machined is guaranteed. Network multi-through-hole connecting is used in an ultra-deep-cavity ultra-multi-layer unglazed porcelain side wall, and the connecting pass rate is guaranteed through redundancy. Through a lamination tool set and an optimized overlying technology method, the lamination and stacking technology of the deep-large-cavity ultra-thick LTCC substrate is guaranteed. An abrasive wheel dicing saw is used for opposite cutting of a ripe porcelain body LTCC substrate from the bottom face and the top face of the ultra-thick substrate, and the problem that the maximum thickness can only reach 5 mm during blade unglazed porcelain hot cutting and abrasive wheel ripe porcelain rotating cutting is solved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

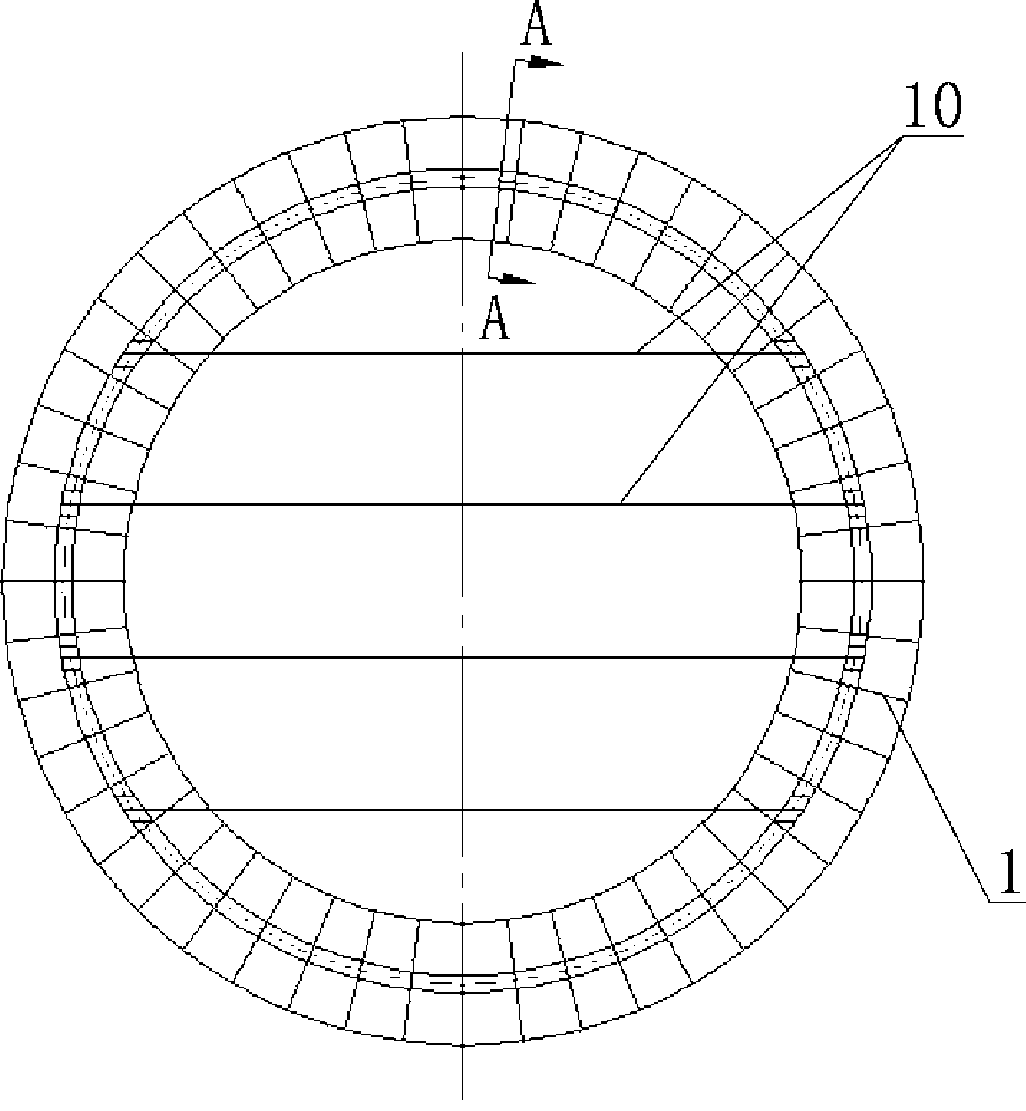

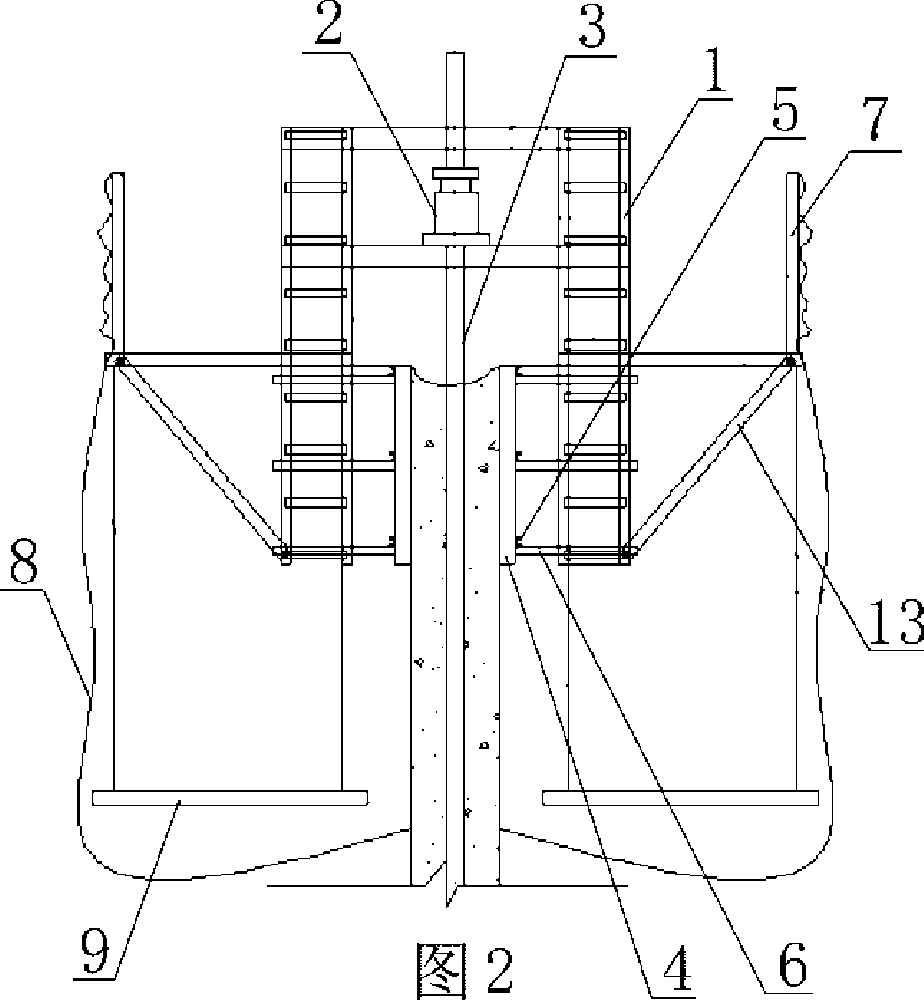

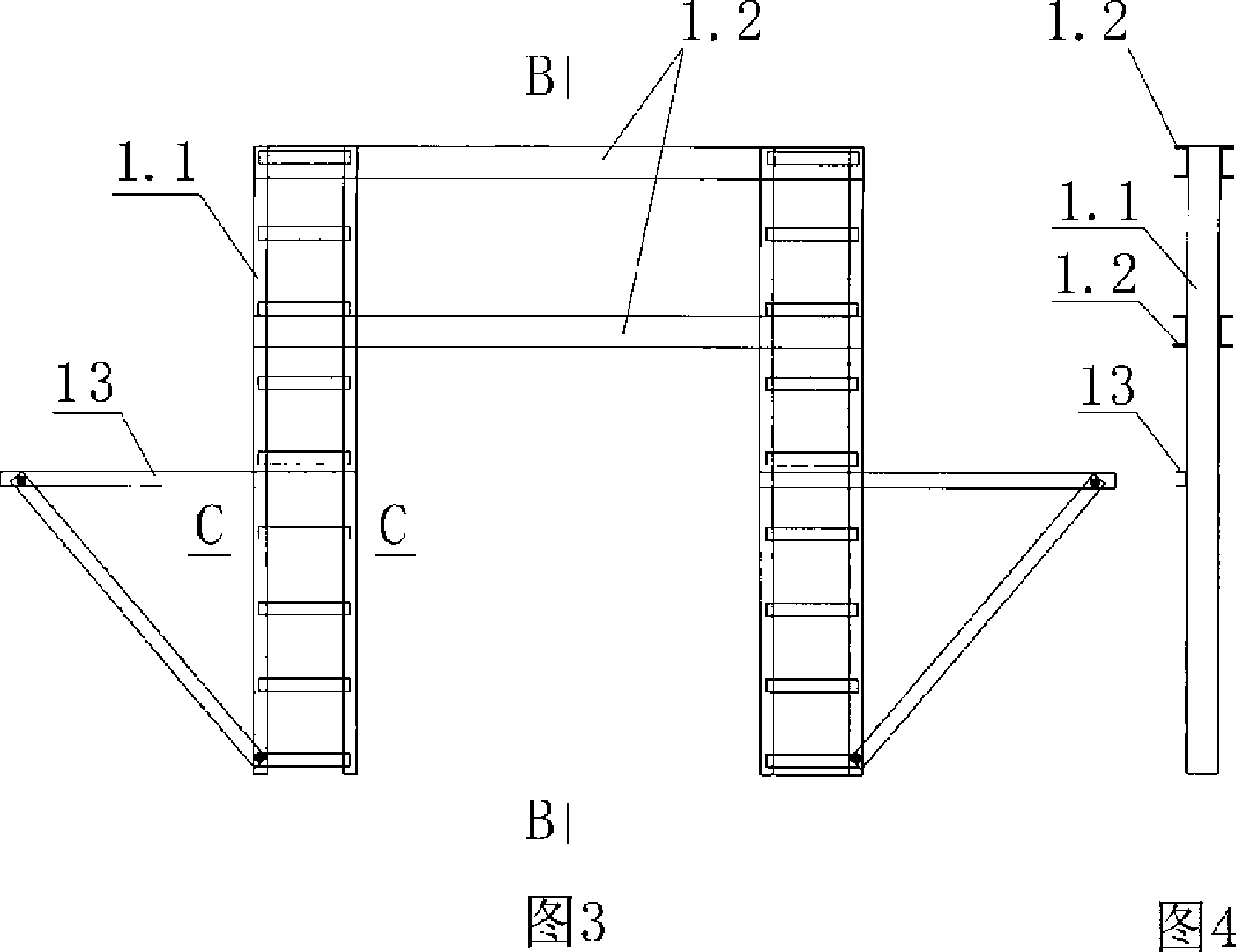

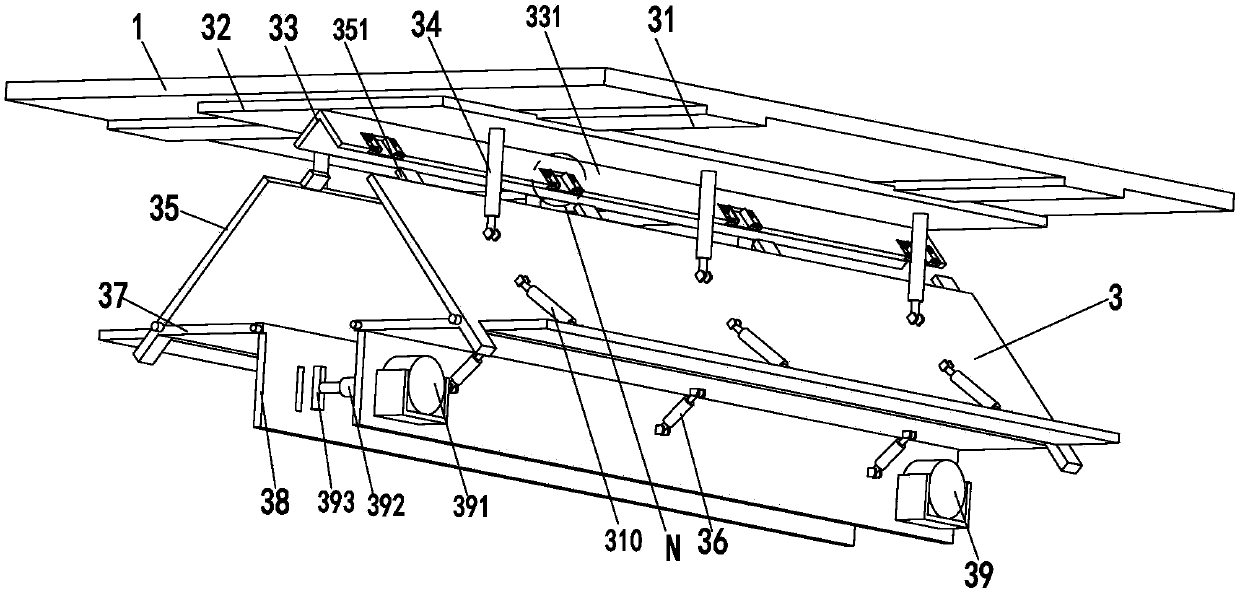

Cabin top steel beam hydraulic hoisting and positioning apparatus of cylinder cabin structure building and construction method thereof

Disclosed is a steel beam hydraulic lifting emplacing device on the top of silo structure building, which comprises a sliding formwork device and a hydraulic lifting system, and is characterized in that the sliding formwork lifting frames of the sliding formwork device are connected with an inside formwork, an outside formwork, and an operating platform, a scissors support is connected between two lifting frame upright columns, the sliding formwork lifting frame is also connected with a steel beam supporting frame, the steel beam support frame is connected with the steel beam on the top of the silo to form a lifting integration, the hydraulic lifting system is utilized to be the lifting power system for the lifting integration, and the hydraulic lifting system is composed of a hydraulic jack, a support rod, a hydraulic console, and an oil circuit. The invention can rapidly, conveniently, reliably, and safely complete the construction task of mounting the steel beam on the top of the silo, without using large scale hoisting equipment, thereby avoiding the problems of difficult emplacement and lower efficiency of large scale hoisting equipment. The device of the invention can be widely applied to the hoisting and emplacement construction for the steel frame on the top of silo buildings.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU +1

Slide rail unit

ActiveUS7717392B2Simple and compact structureEasy to assembleSafety beltsPedestrian/occupant safety arrangementEngineeringLeaf spring

A simple, compact and easy-to-assemble slide rail unit is provided. The slide rail unit reliably restrains right and left rails from sliding even when the right and left rails are installed onto the vehicle floor at an inclination angle different from each other in a longitudinal direction thereof. The slide rail unit includes a slide rail member having an upper rail member and an upper rail member slidably engaged with each other and a lock lever rotatably pivoted to the upper rail member so as to engage with / disengage from an engagement portion formed on the lower rail member. The slide rail unit also includes an operation lever connected to the lock lever within the slide rail member. Between the lock lever and the operation lever, a leaf spring member is disposed for connecting the lock lever and the operation lever therebetween.

Owner:IMASEN ELECTRIC IND

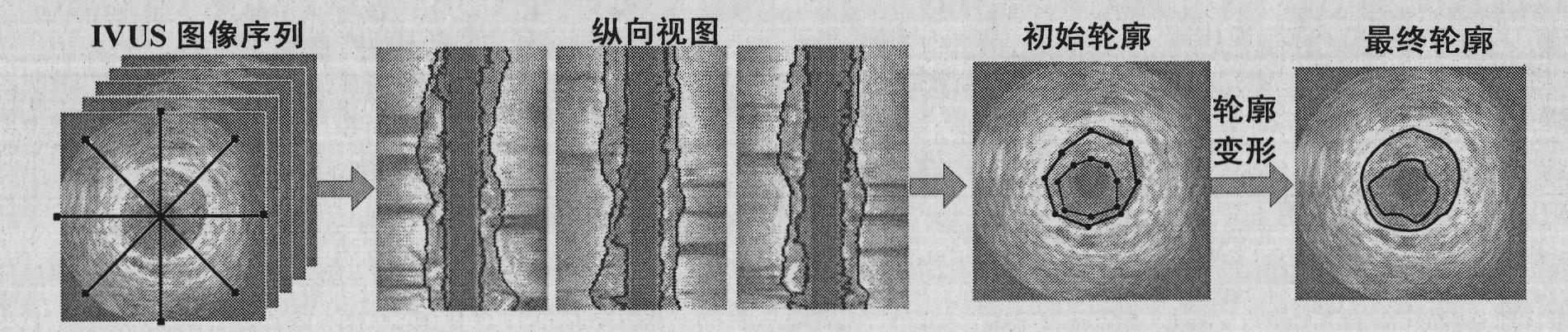

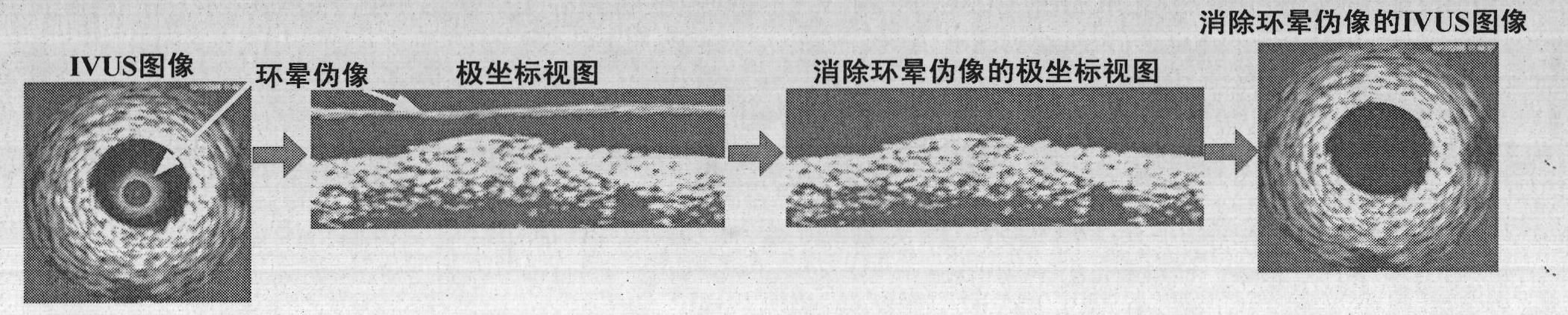

Three-dimensional segmentation method for intravascular ultrasound image sequence

InactiveCN101964118ASplit automaticallyQuick splitImage enhancement3D modellingSonificationUltrasound angiography

The invention discloses a three-dimensional segmentation method for an intravascular ultrasound (IVUS) image sequence, which is used for improving the segmentation processing efficiency of an image sequence. The technical scheme comprises the following steps of: first, performing preprocessing of filtering noise and inhibiting a ring halo pseudomorphism on an original image; then, acquiring four longitudinal views of the IVUS image sequence and extracting intravascular cavity boundaries and intermediate-outer film boundaries from the longitudinal views; next, acquiring initial boundaries in transverse views by mapping boundary curves to IVUS images of each frame; and finally, acquiring the intravascular cavity boundaries and the intermediate-outer film boundaries in the IVUS images of the each frame finally by maximizing an energy function and discontinuously deforming the initial boundaries. Compared with a conventional method, the three-dimensional segmentation method has the following advantages of: first, capacity of utilizing the information of an overall image sequence; and second, capacity of finishing segmenting images of the each frame at the same time and realizing parallel processing of the overall image sequence, so as to greatly improve processing efficiency and shorten processing time.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

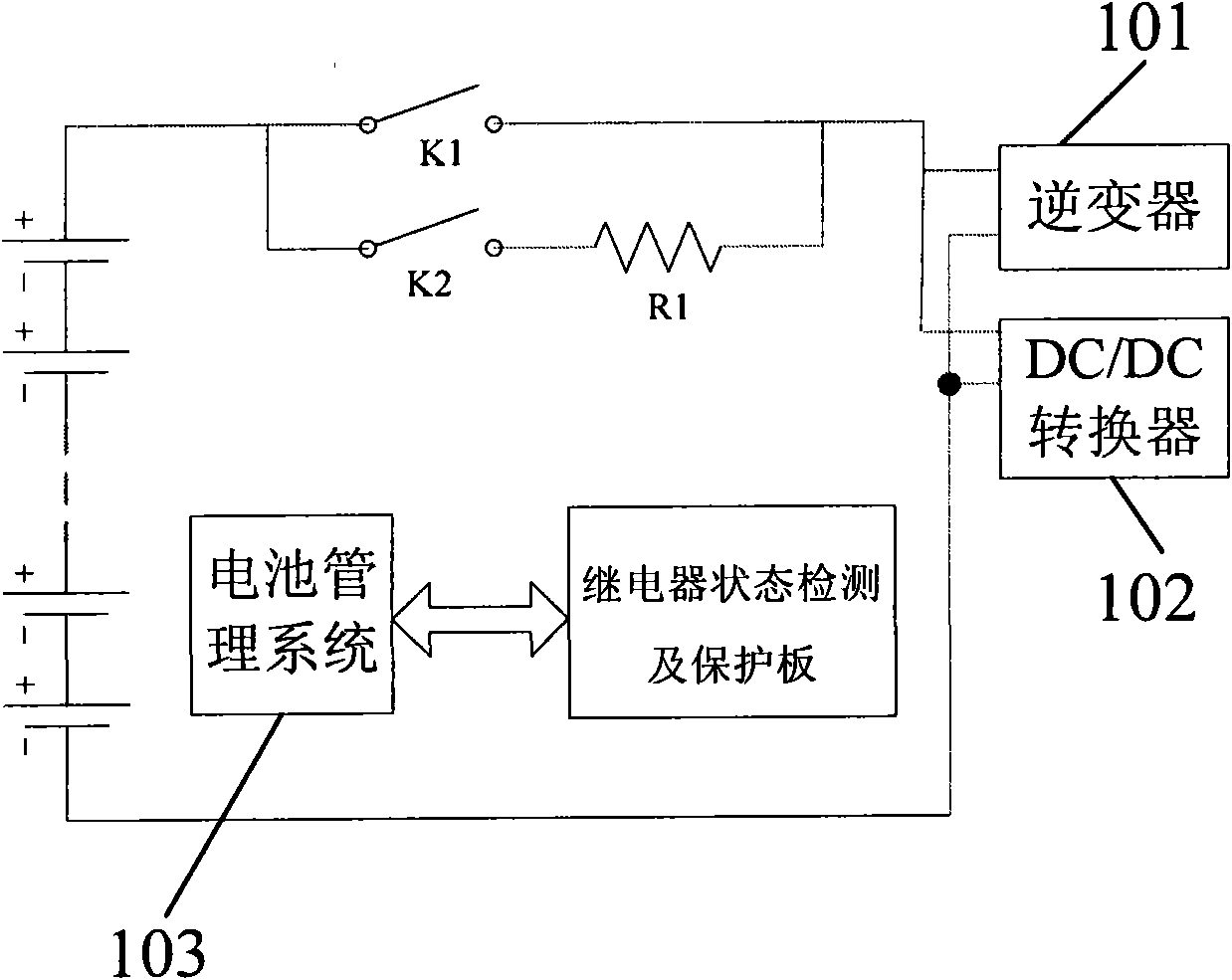

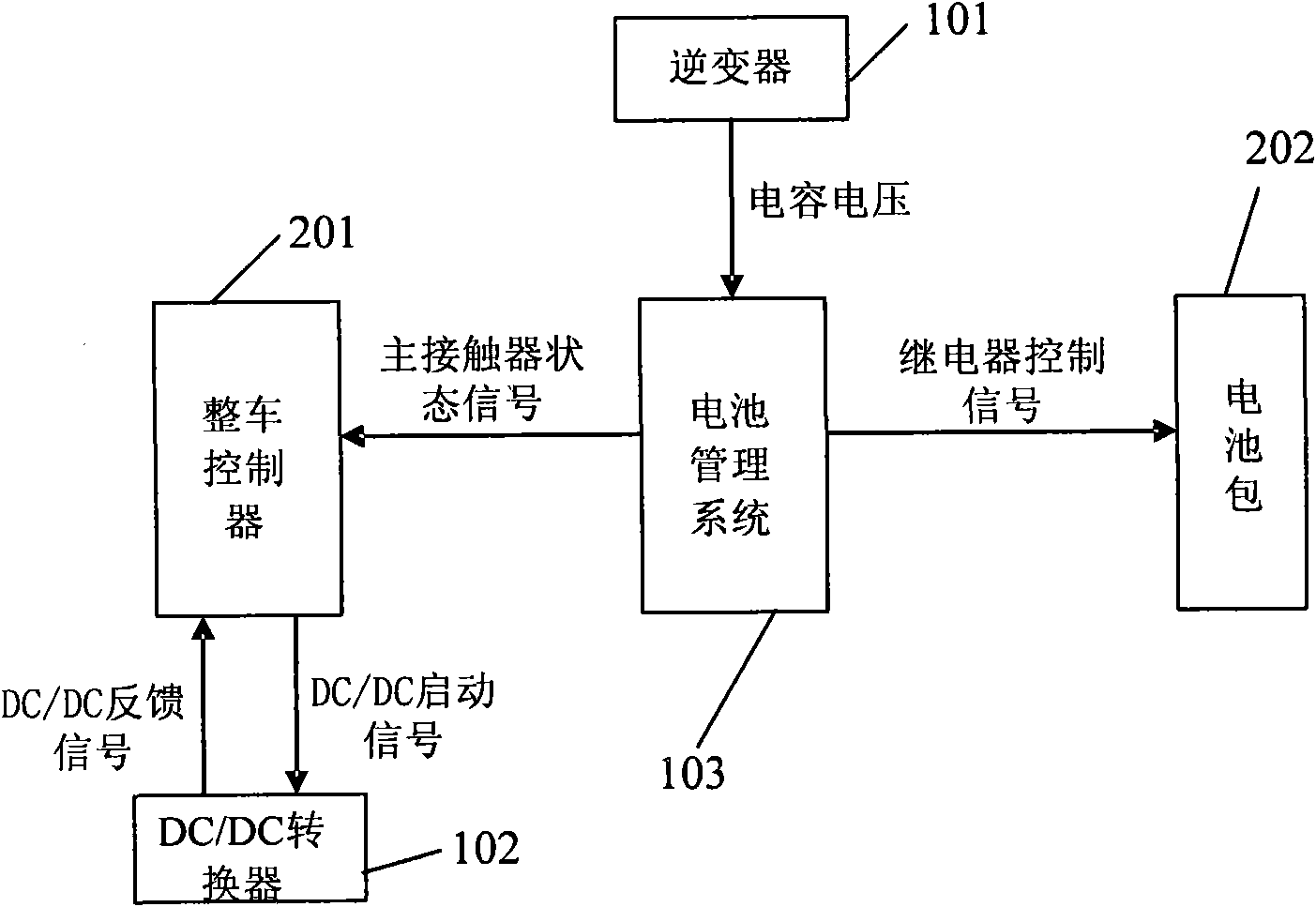

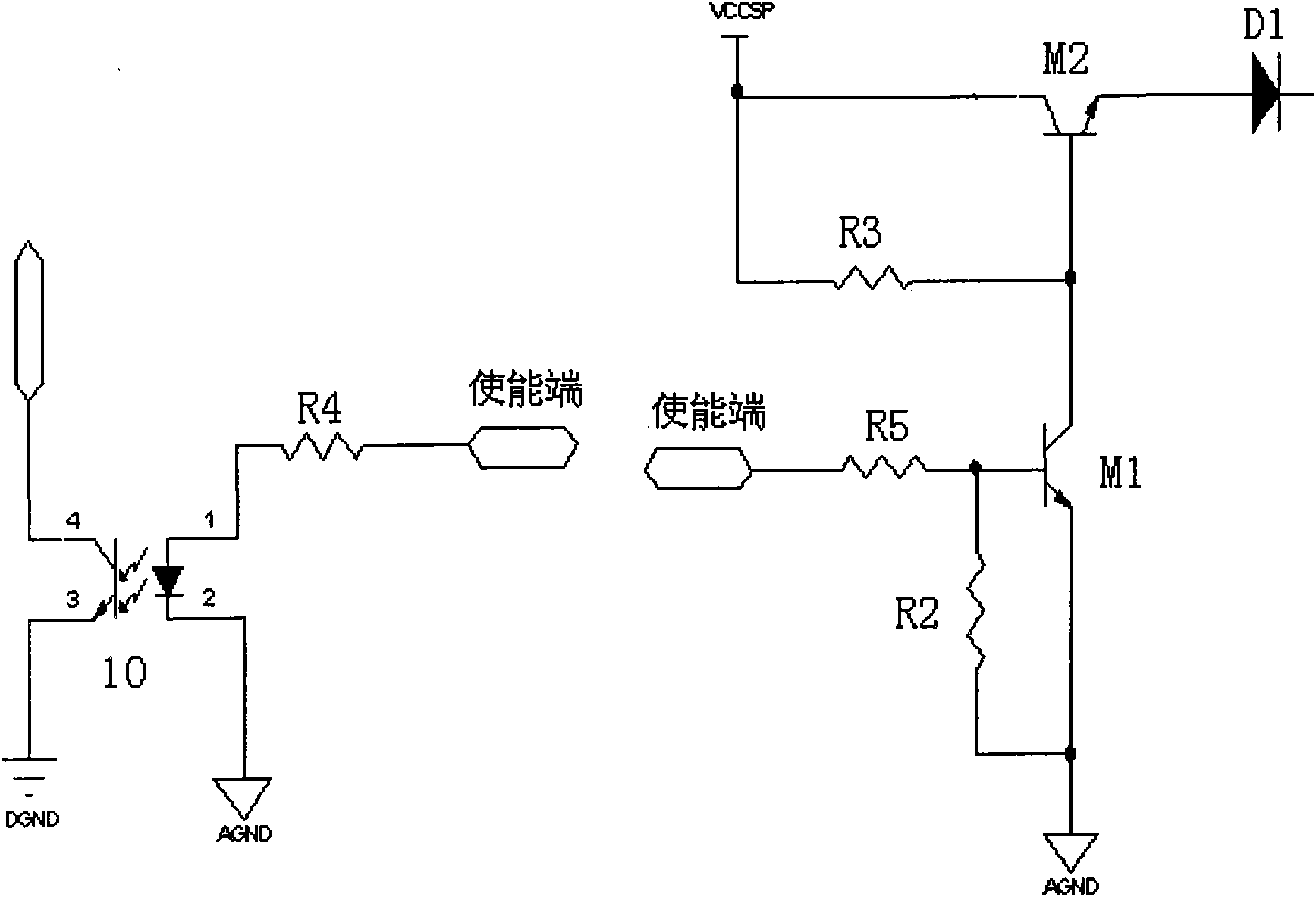

Method and system for protecting electric vehicle pre-charging circuit

ActiveCN101841177AAvoid startingAvoid the risk of being burned outBatteries circuit arrangementsElectric powerConvertersElectrical battery

The invention provides a method and a system for protecting an electric vehicle pre-charging circuit, which can solve the problem of pre-charging resistor damage. The method for protecting the electric vehicle pre-charging circuit comprises the following steps that: when a pre-charging process is started, a DC / DC converter remains off, and a battery management system BMS turns off a pre-charging relay so as to start the charging to an inverter capacitor; and when the pre-charging process is over, the BMS disconnects the pre-charging relay and turns off a main contactor; and the DC / DC converter is started. The system for protecting the electric vehicle pre-charging circuit comprises the battery management system BMS which is used for turning off the charging relay when the pre-charging process is started so as to start the charging to the inverter capacitor and disconnecting the pre-charging relay and turning off the main contactor when the pre-charging process is over, and the DC / DC converter which is off when the pre-charging process is started and on when the pre-charging process is over.

Owner:BEIQI FOTON MOTOR CO LTD

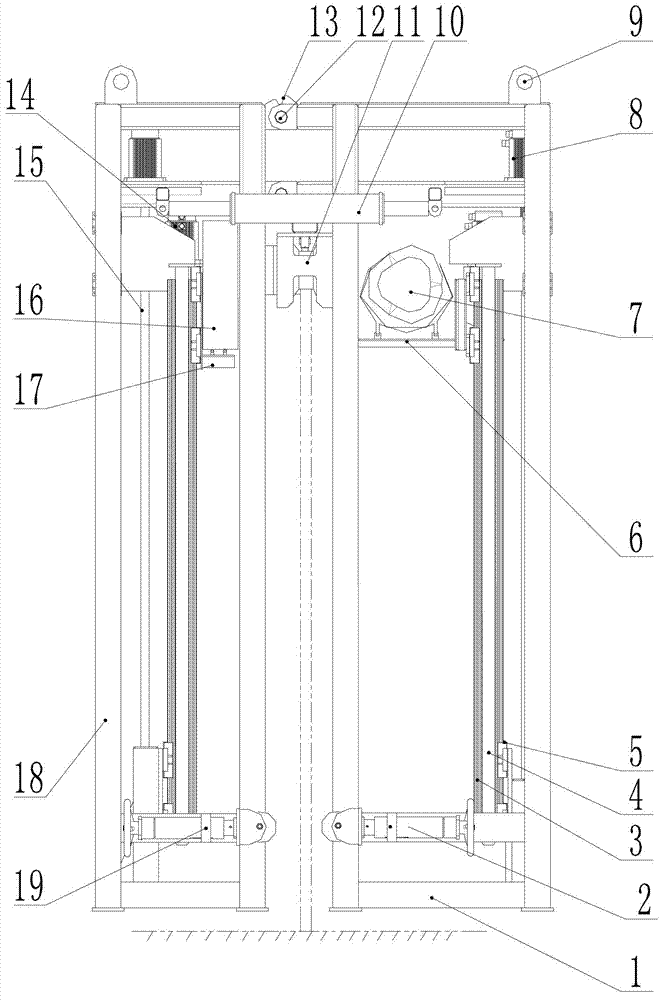

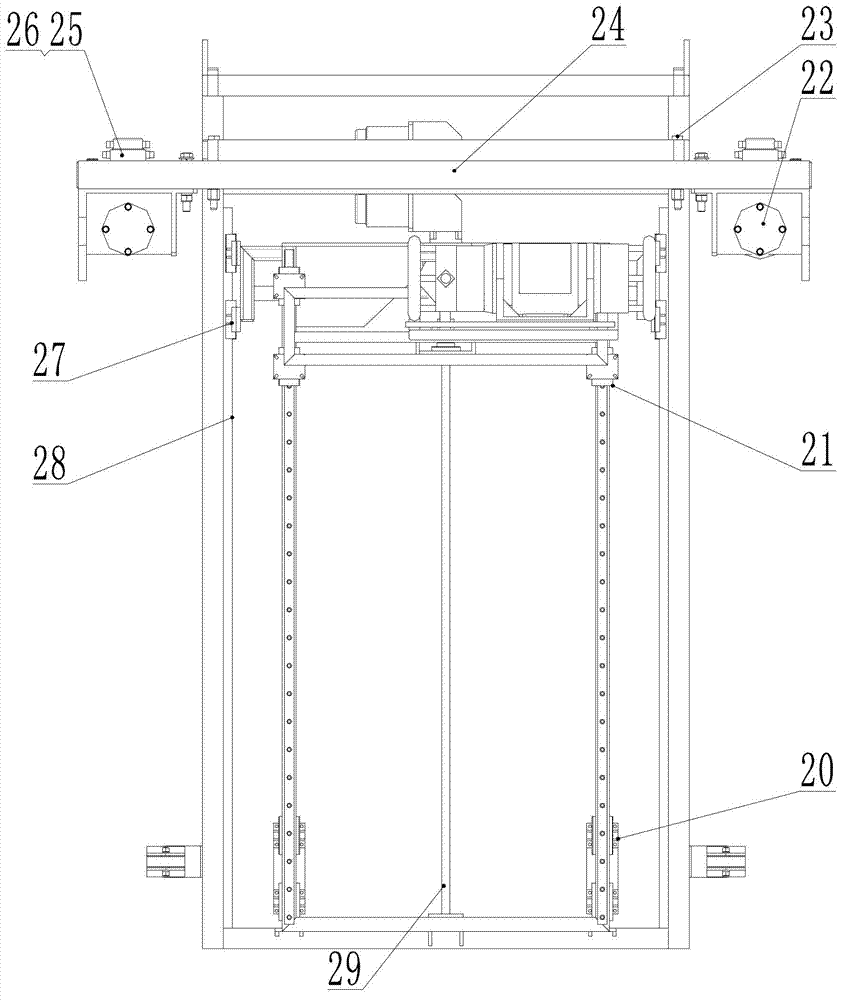

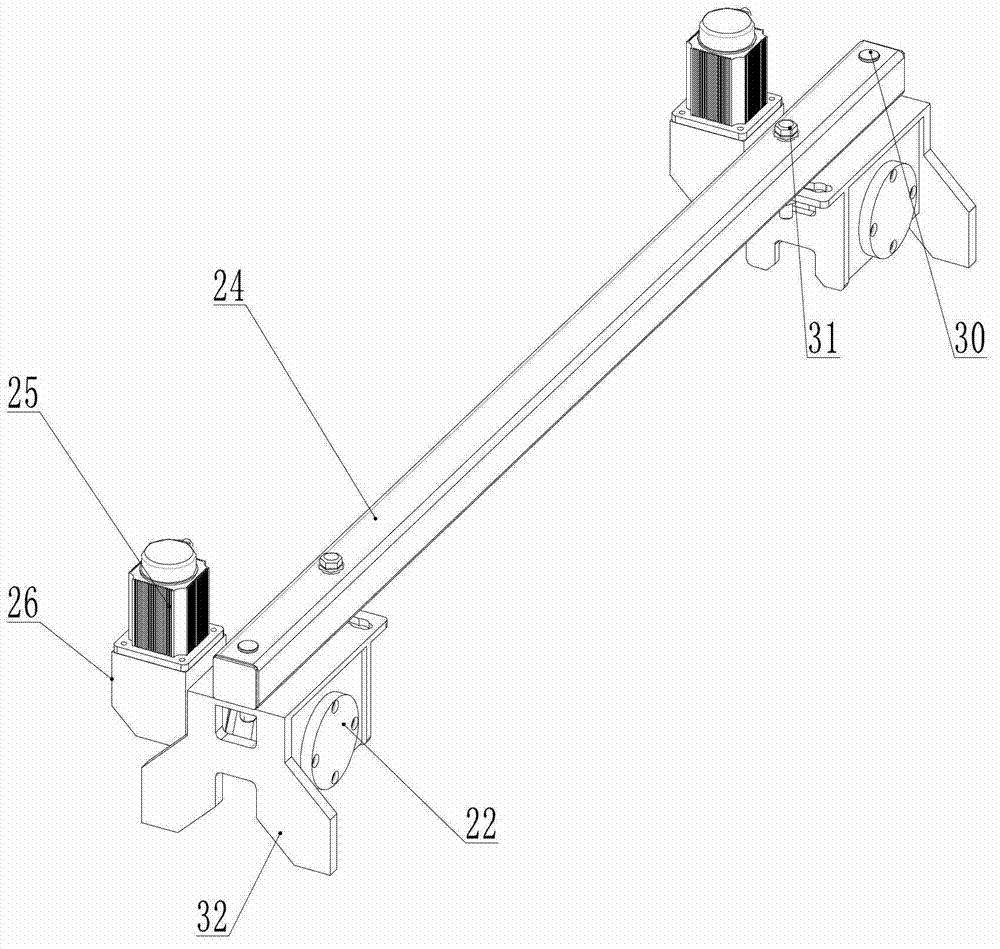

X-ray digital nondestructive detection device and method of welding seam of storage tank

ActiveCN103196928AReliable completionObjective completionMaterial analysis by transmitting radiationDigital imagingStructural engineering

The invention relates to an X-ray digital nondestructive detection device of a welding seam of a storage tank, and a detection method using the same, and mainly solves the problems of high flaw detection cost and influence on detection quality in the conventional X-ray film method. The device comprises a riding seat type gantry rack, movement guide mechanisms, a transverse movement mechanism, longitudinal movement mechanisms and a digital imaging system, wherein the riding seat type gantry rack consists of an outer rack and an inner rack; a mechanical buffer is arranged between the inner rack and the outer rack; the transverse movement mechanism is arranged at the upper end of the outer rack; two movement guide mechanisms are respectively arranged on the lower parts of the outer rack and the inner rack; and a longitudinal movement mechanism is respectively arranged on the opposite inner sides of the inner rack and the outer rack. The digital nondestructive detection on the welding seam of 0 to 3m through a digital imaging device and an X-ray flaw detector is realized by using each mechanism in the device and using a synchronization telescoping driving control method. The method is high in degree of automation, high in positioning accuracy and high in imaging speed; and the x-ray digital nondestructive detection on the welding seam of the storage tank can be reliably, objectively and accurately accomplished.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

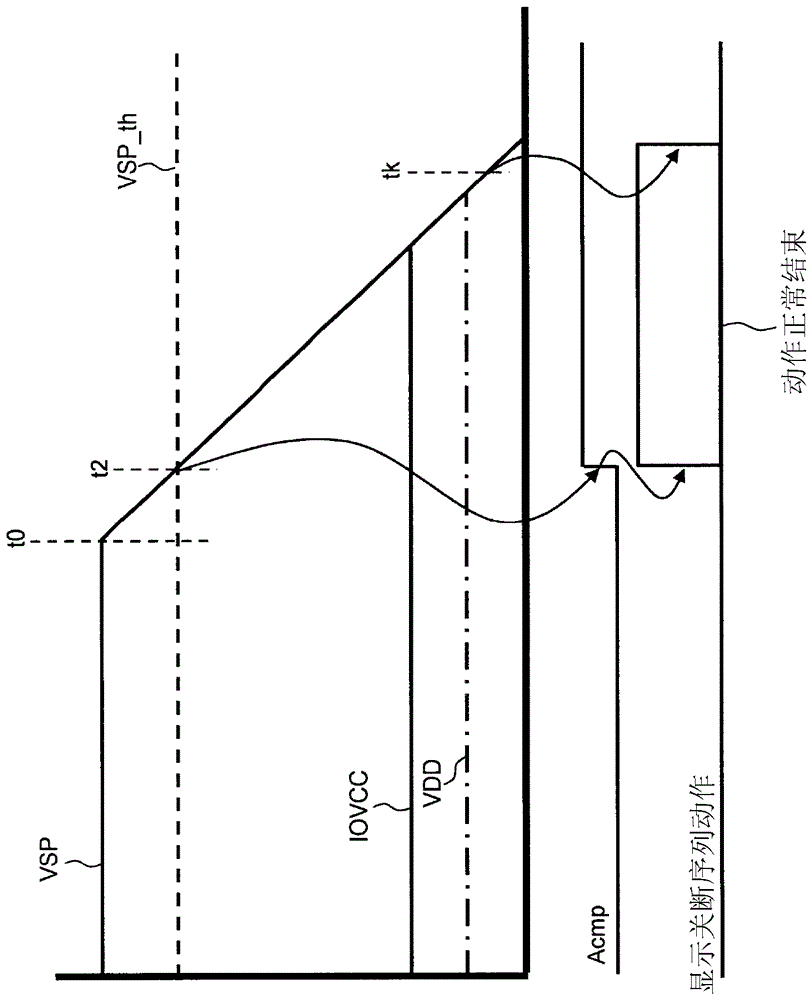

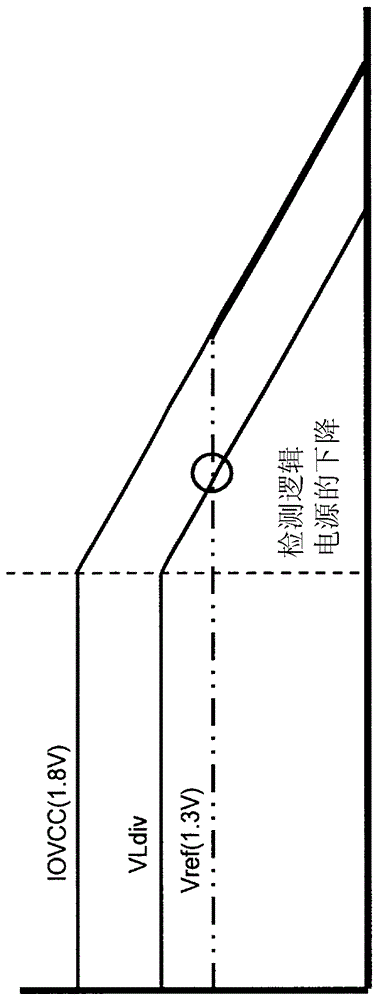

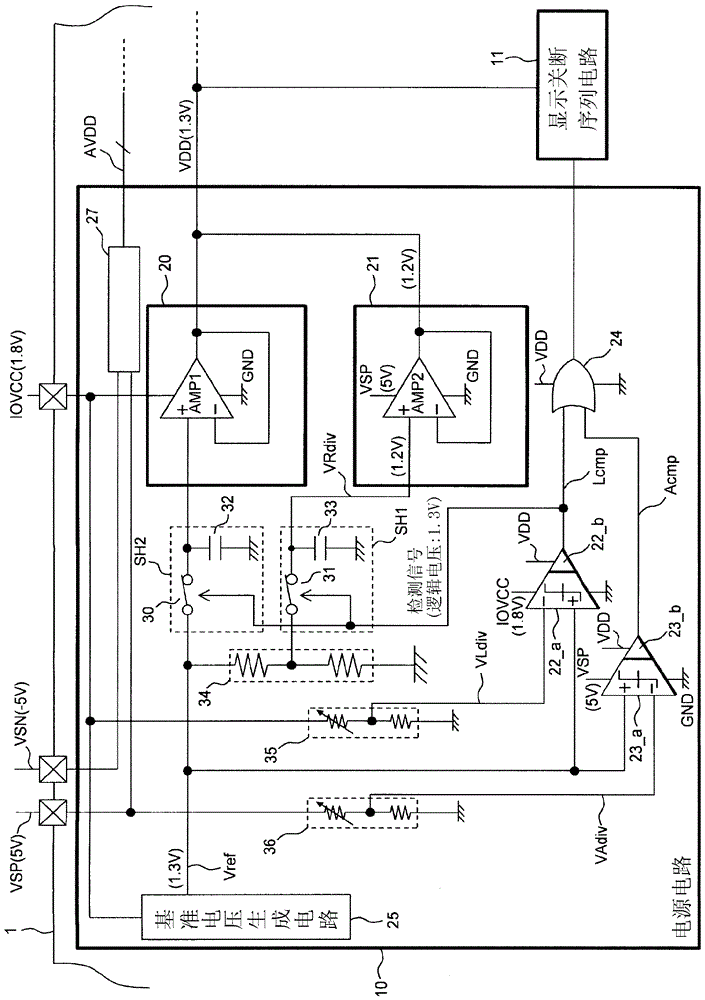

Semiconductor device and electronic apparatus

InactiveCN105976773AReliable completionStatic indicating devicesElectric variable regulationPower semiconductor deviceAudio power amplifier

The invention can ensure an external power supply not to be cut off by using initialization of a drive unit, so the control can be finished without being cut off in the process; the solving method comprises the following steps: forming a first internal power supply voltage (VDD) from the first external power supply voltage (IOVCC); forming a second internal power supply voltage (AVDD) from the second external power supply voltage (VSP) with higher voltage absolute value than the first external power supply, setting detection circuits (22, 23) capable of checking abnormal conditions of the external power supply being cut in the power supply circuit, wherein the detection circuits can start the initialization sequence; when the detection circuits detect the first external power supply is abnormal, using the second external power supply as the work power supply and to compensate a dropping auxiliary amplifier (21) and a sample keeping circuit (SH1) of the reference voltage (VRdiv) of the auxiliary amplifier under the first internal power supply voltage, wherein the sample keeping circuit is in the keeping state according to the abnormal detection of the first external power supply voltage.

Owner:SYNAPTICS JAPAN GK

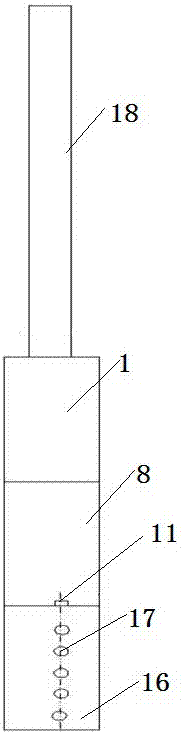

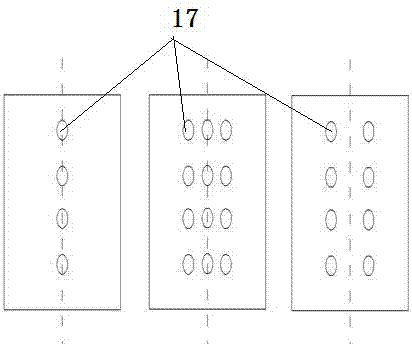

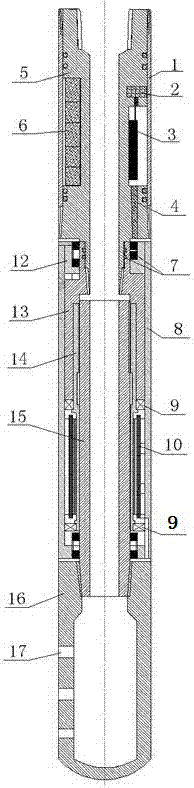

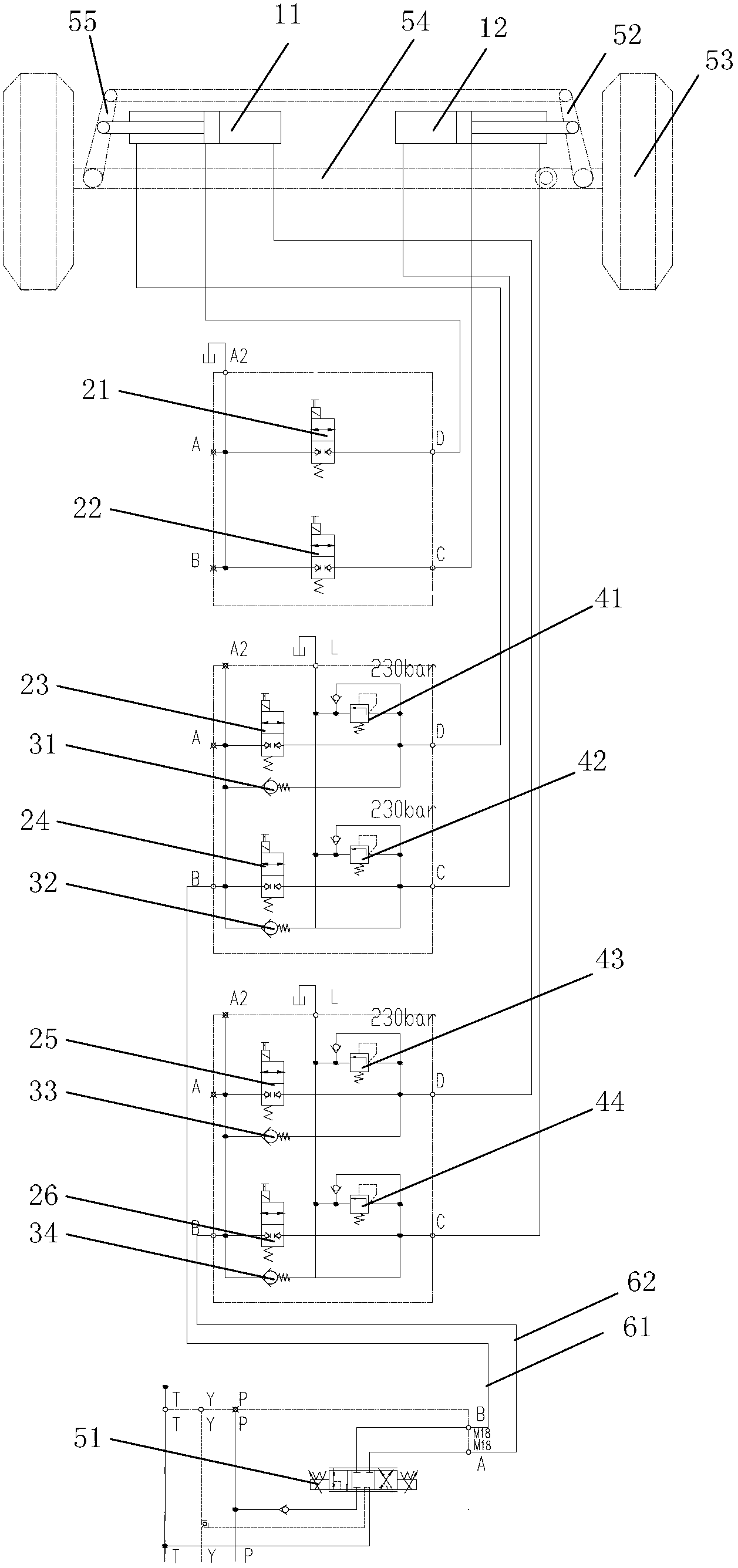

Downhole directional hydraulic jetting tool ground control method

InactiveCN107227948AAvoid misuseHigh torqueLiquid/gas jet drillingDirectional drillingEngineeringMaterial Perforation

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

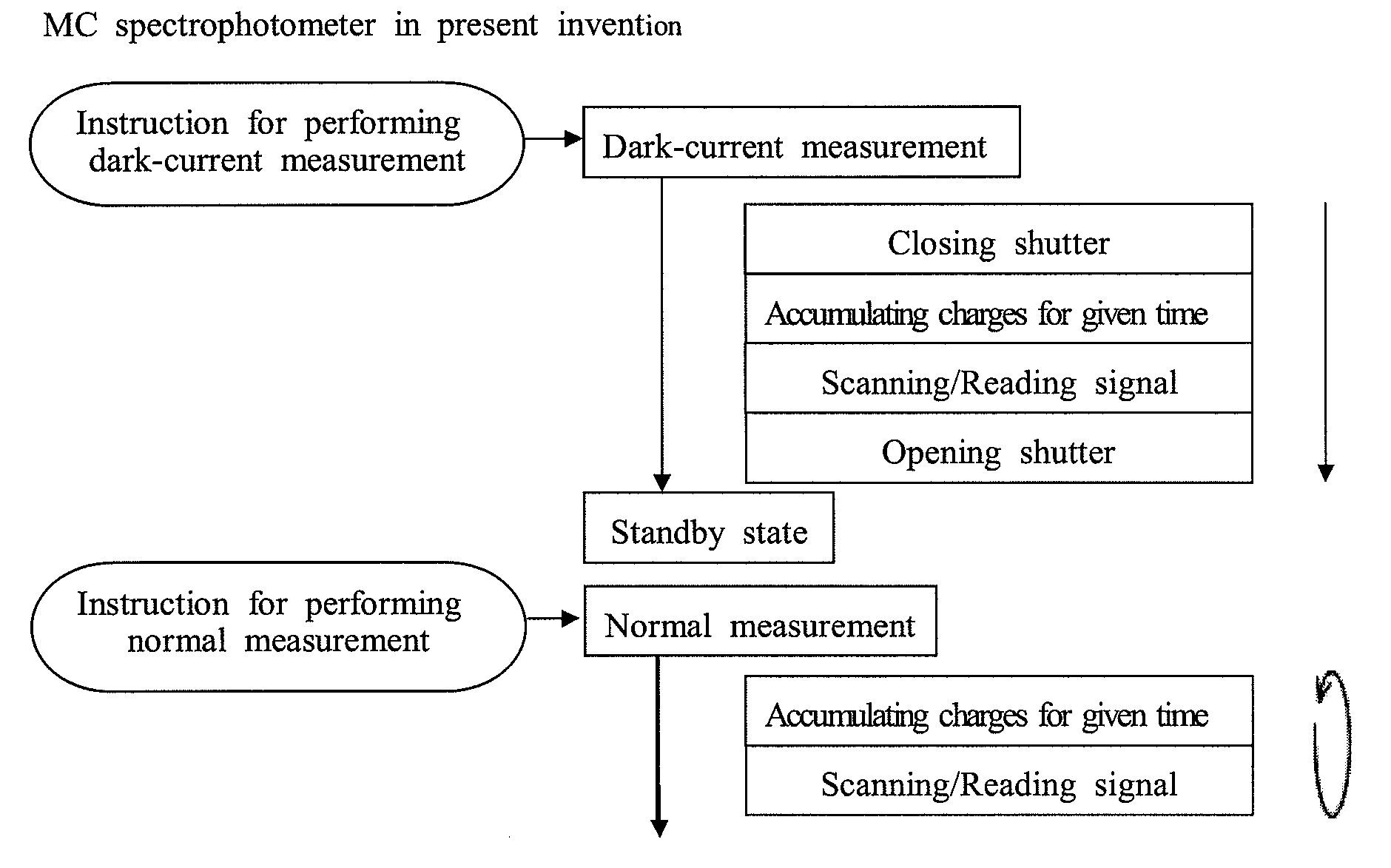

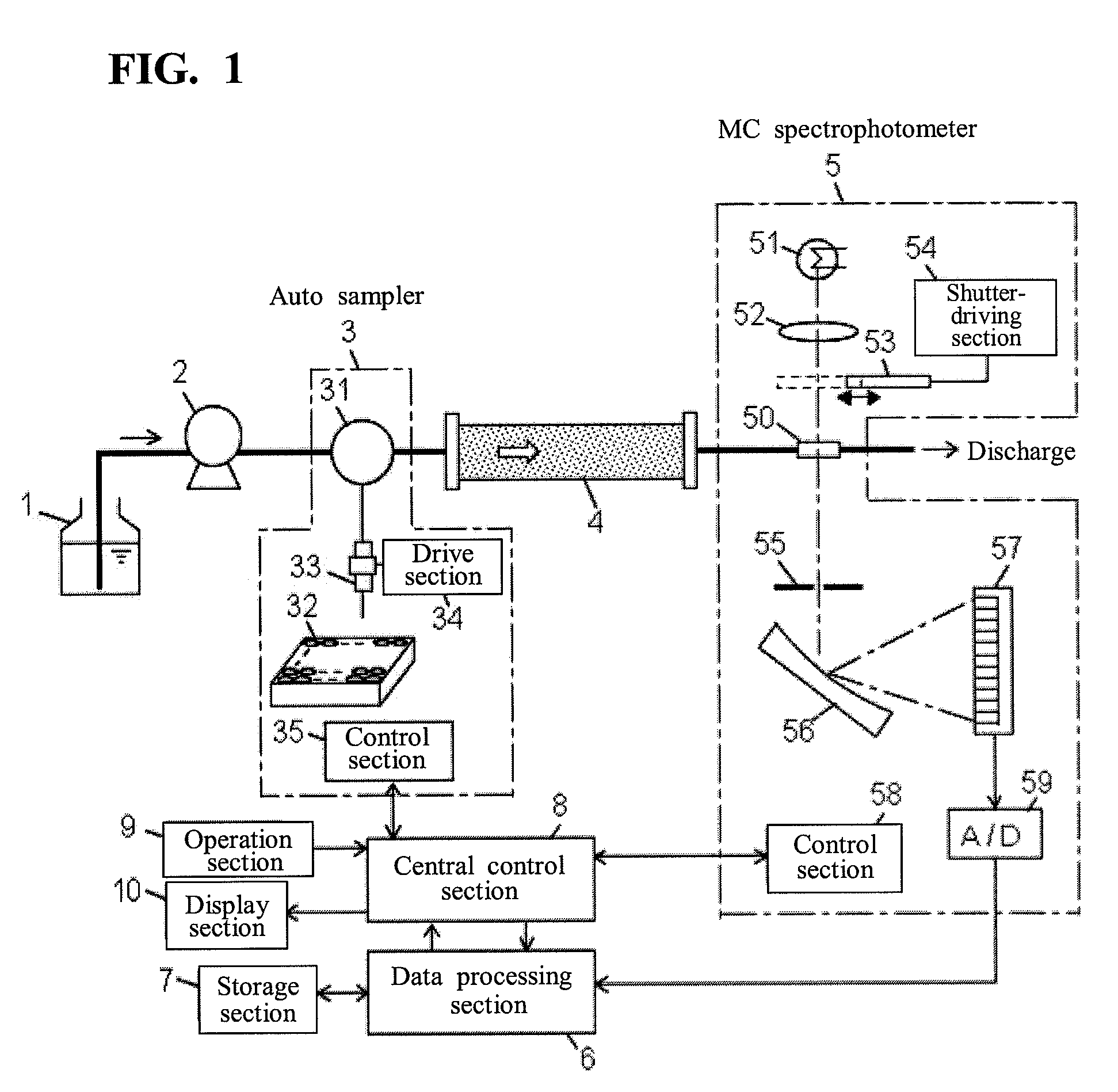

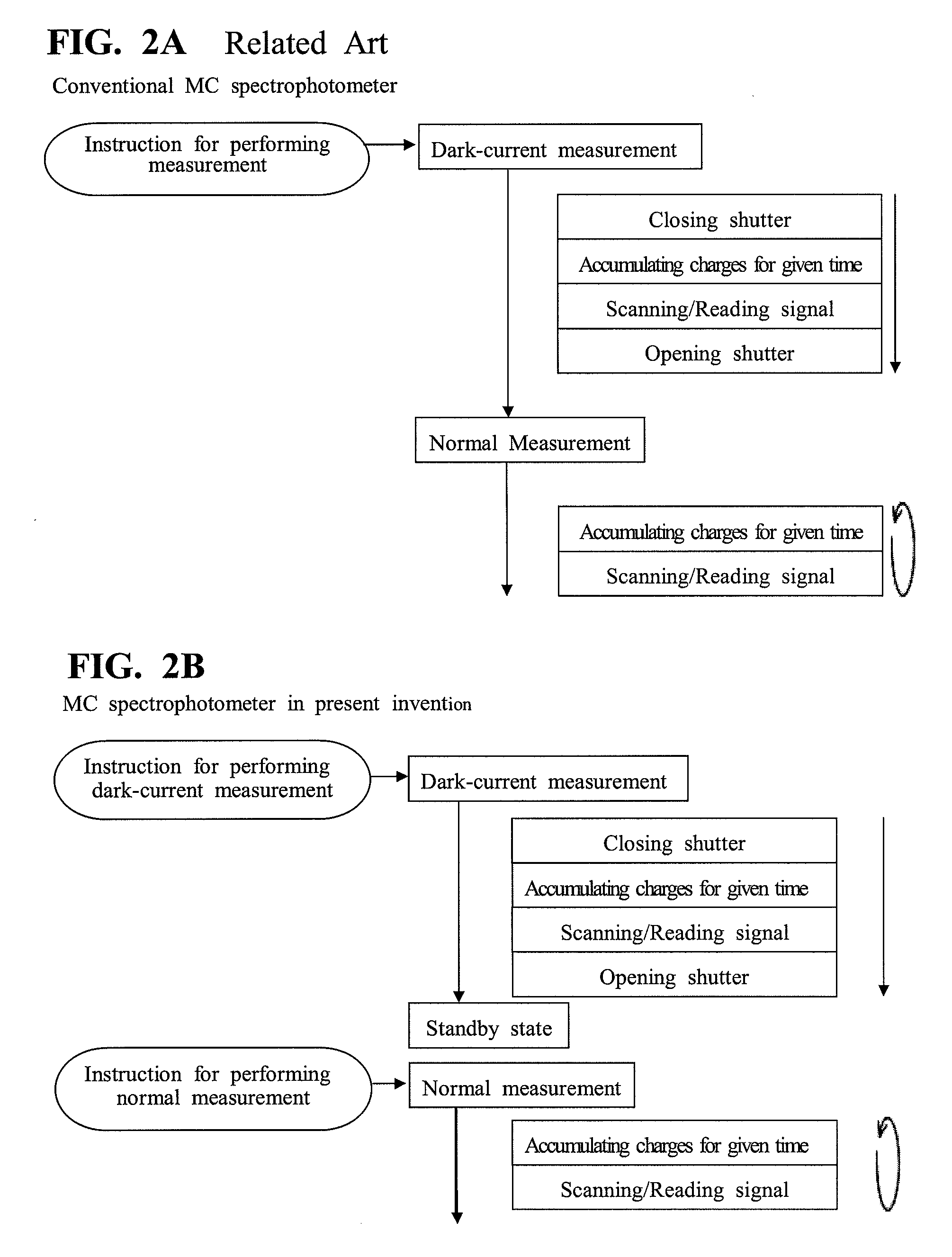

Analysis system

ActiveUS20090153865A1Reliable detectionAccurate dark currentRadiation pyrometrySpectrum investigationAutosamplerComputer science

Analysis system including a central control section for generally controlling the analysis that sends a command to perform a pre-injection operation, to an automatic sampler together with information designating a sample to be selected, such as an identification number, and simultaneously sends a command to perform an operation of measuring a dark current in a photodiode array (PDA) detector, to a multi-channel spectrophotometer. Thus, the automatic sampler performs the pre-injection operation, such as an operation of moving a needle to a position of a designated vial container to suck a sample, and the spectrophotometer performs the dark-current measurement operation during a time period of the pre-injection operation. After the sample is actually introduced into the column, in response to a command to perform a normal measurement operation, an operation of acquiring absorption data of an eluate from the column is started without performing the dark-current measurement operation.

Owner:SHIMADZU CORP

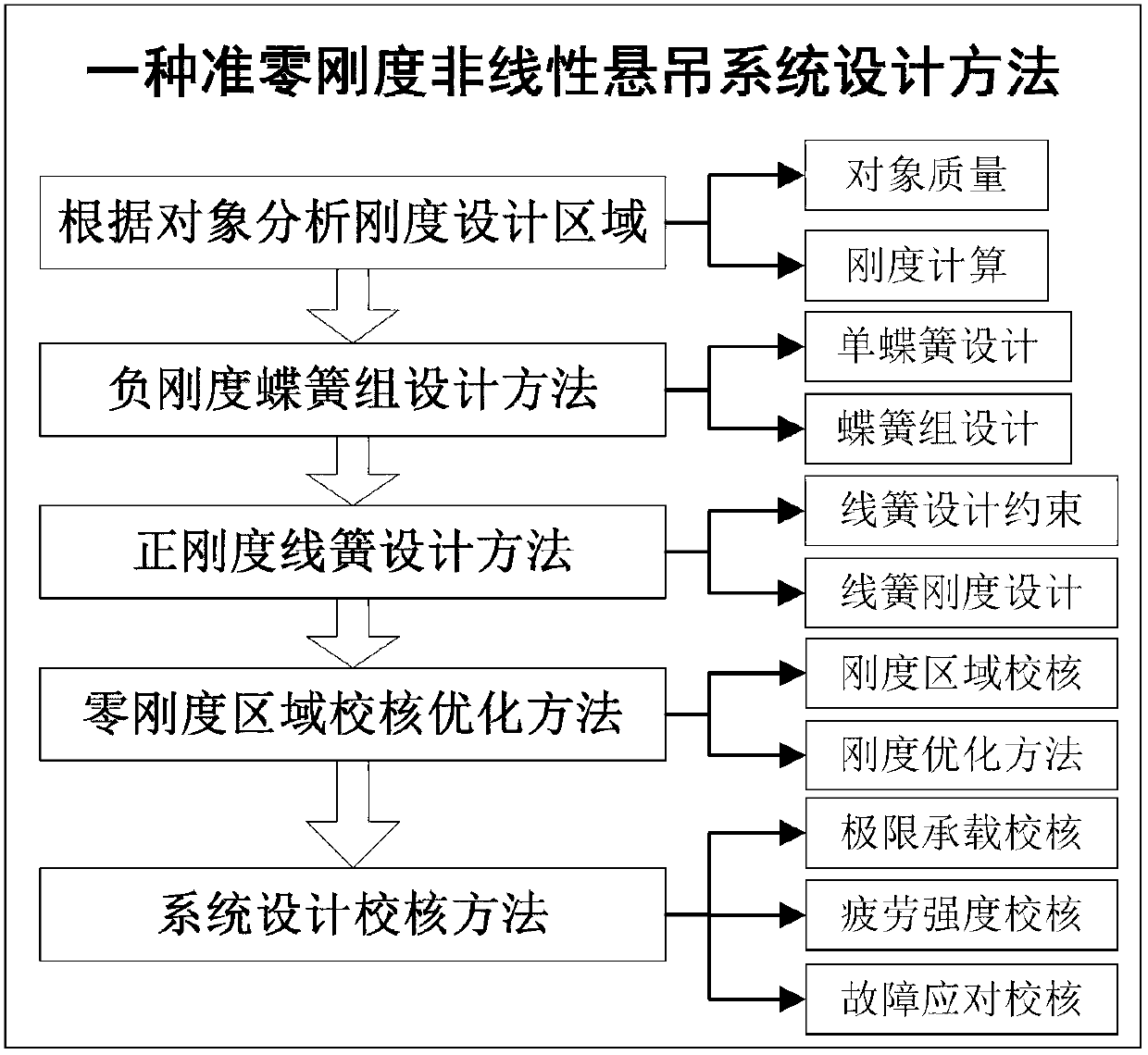

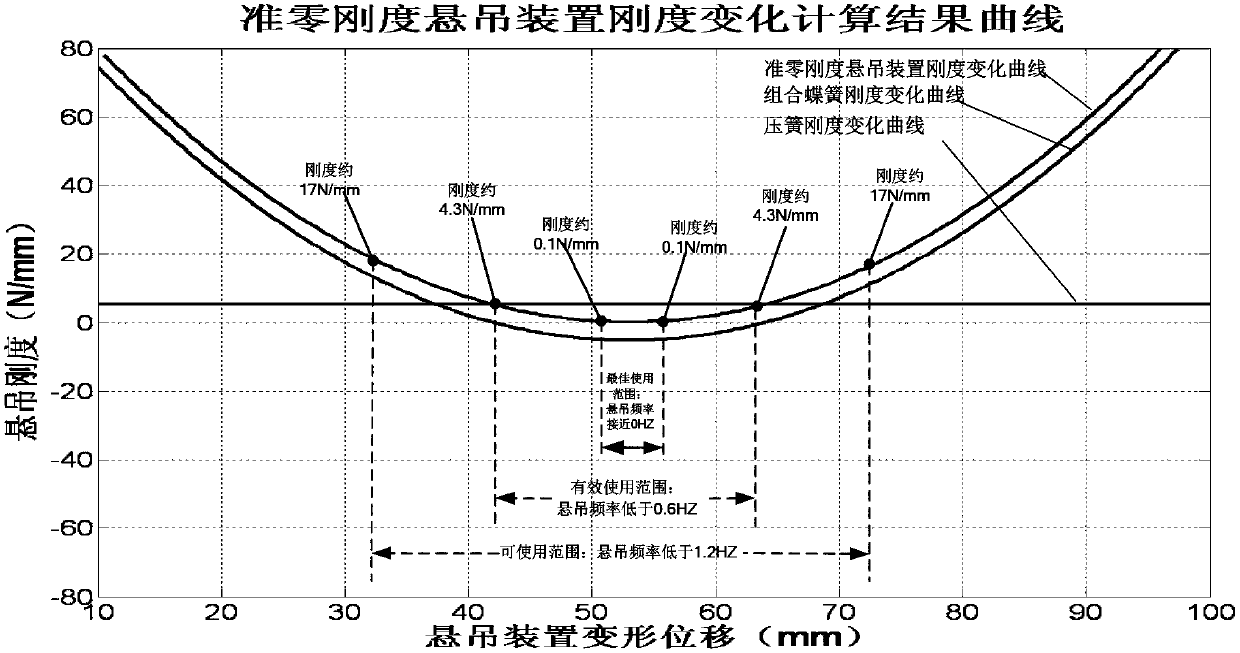

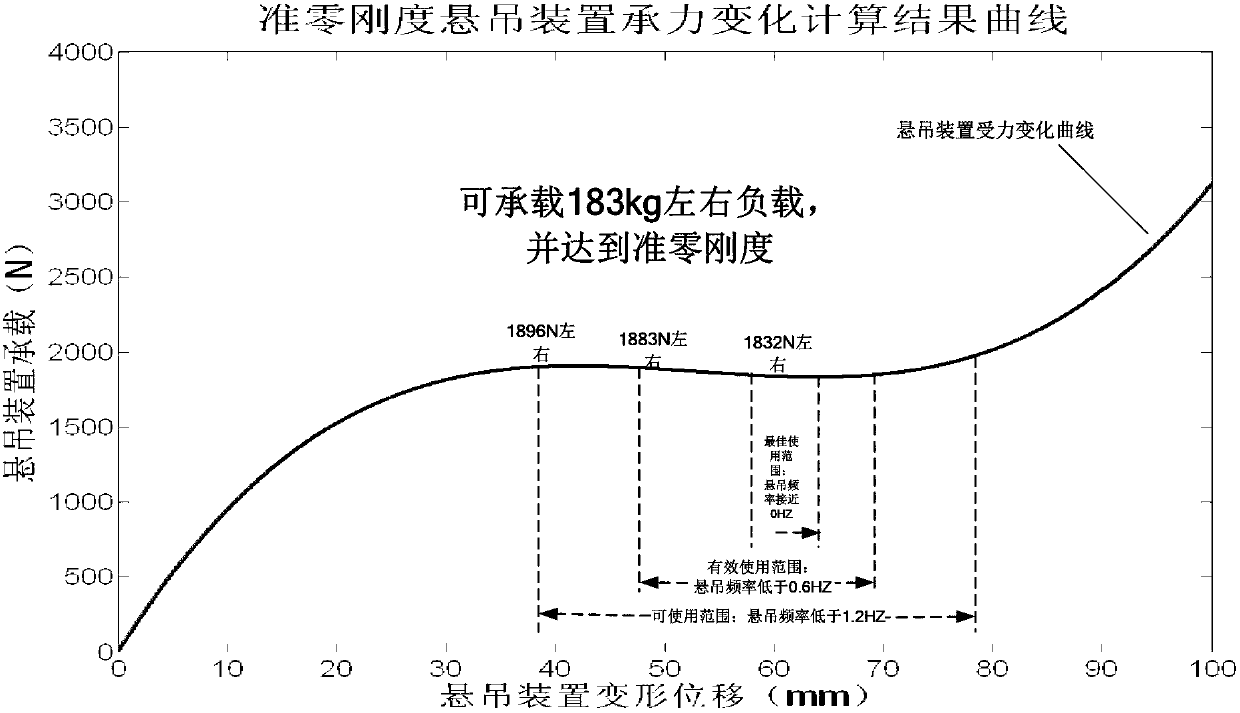

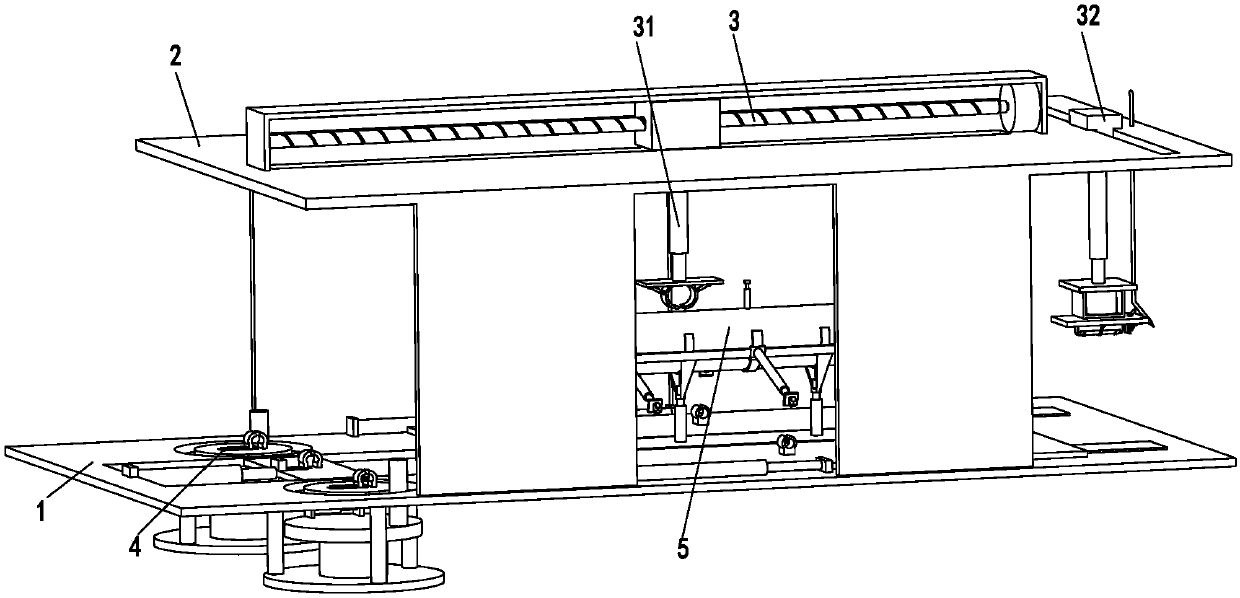

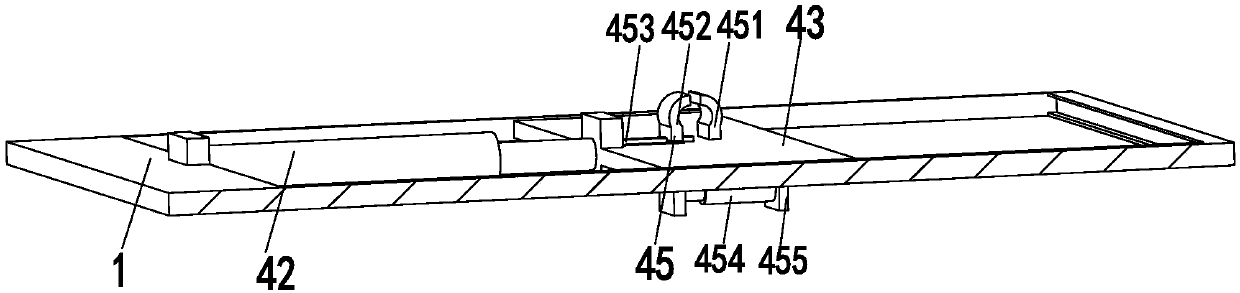

Method for designing quasi-zero stiffness nonlinear suspension system

ActiveCN103279595AGood design guidanceEfficient Design ImplementationSpecial data processing applicationsSpace environmentSystems design

The invention provides a method for designing a quasi-zero stiffness nonlinear suspension system. The method includes the following steps that step one, a zero stiffness area of the quasi-zero stiffness nonlinear suspension system is determined according to the quality of a suspended object and the frequency range of suspension; step two, the stiffness of a negative stiffness disc spring set is designed according to a space environment and a test environment; step three, the stiffness of a positive stiffness wire spring is designed; step four, the zero stiffness area of the suspension system is verified and optimized; step five, ultimate bearing strength and fatigue life of the suspension system are verified; step six, a failure analysis and a failure handling are carried out on the suspension system, and design of the suspension system is completed. Under the limit conditions of the suspended object and an application environment, the design of the suspension system can be achieved rapidly and reliably, implementation is high in efficiency, reliability, safety and expandability are high, the application prospects are broad and applicable economic value is high.

Owner:SHANGHAI SATELLITE ENG INST

Building decoration machine capable of automatically building reinforced concrete triangle coping reinforcement cage

InactiveCN108031777AReduce labor intensityImprove work efficiencyWire networkBuilding material handlingReinforced concreteArchitectural engineering

The invention relates to a building decoration machine capable of automatically building a reinforced concrete triangle coping reinforcement cage. The building decoration machine comprises a base plate, an installing support, an auxiliary device, a bending device and a constructing device, the base plate is provided with the installing support, the installing support is provided with the auxiliarydevice, the lower end of the auxiliary device is provided with the bending device and the constructing device, the bending device and the constructing device are sequentially installed on the base plate from left to right, and the constructing device comprises a linear sliding rail, a base plate, a limiting groove, a connecting plate, a pushing air cylinder, a fixing plate, a linear guide rail, an electric sliding plate and a supporting mechanism. By means of the building decoration machine the problems that in the existing triangle coping reinforcement cage constructing process, potential safety hazards exist, the labor intensity is large, the labor cost is high, the working efficiency is low and the application condition is single are solved, the triangle coping reinforcement cage bending and constructing automation function can be achieved, and the beneficial effects of being free of potential safety hazards, low in labor intensity, low in labor cost, high in working efficiency, wide in using scope and the like are achieved.

Owner:胡红建

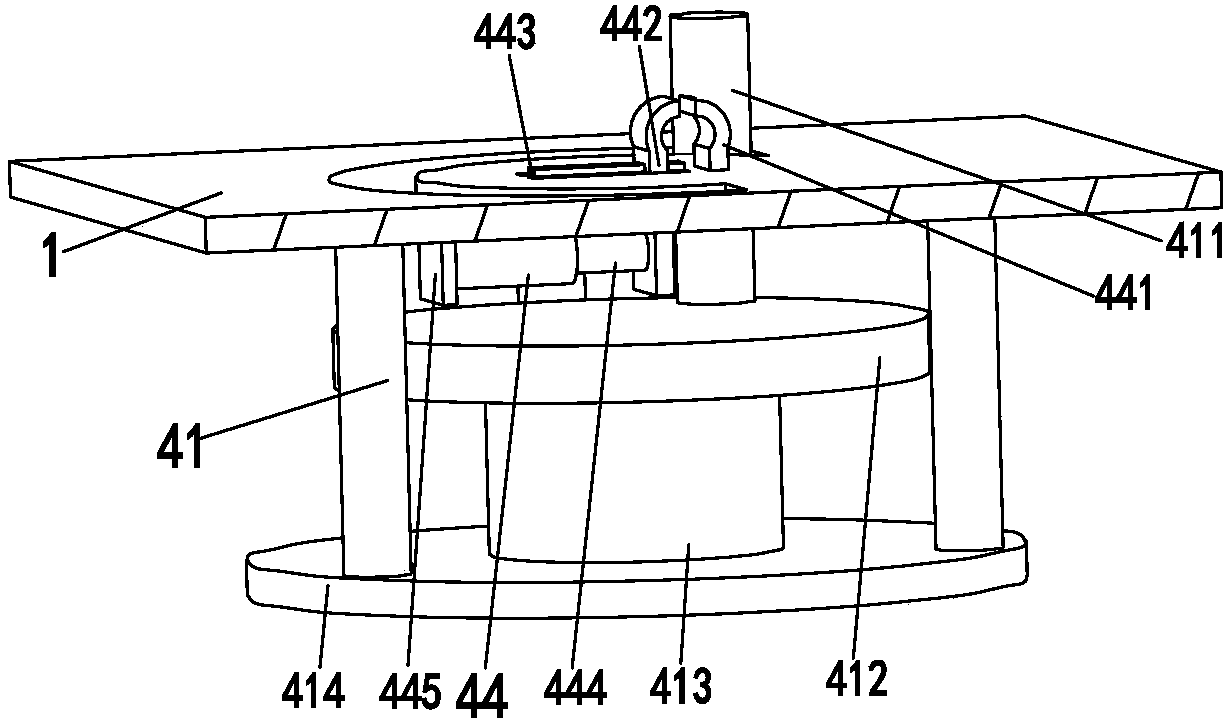

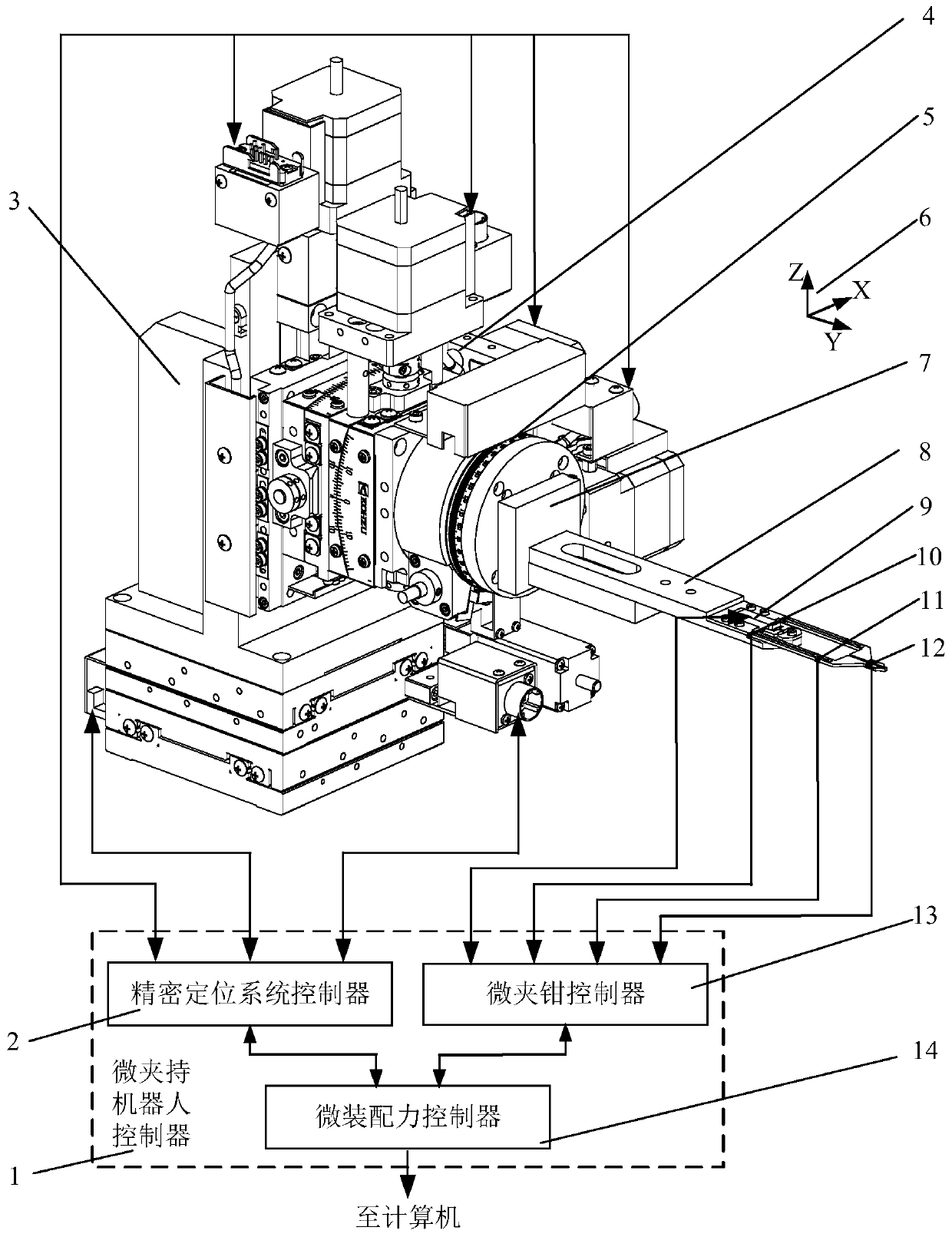

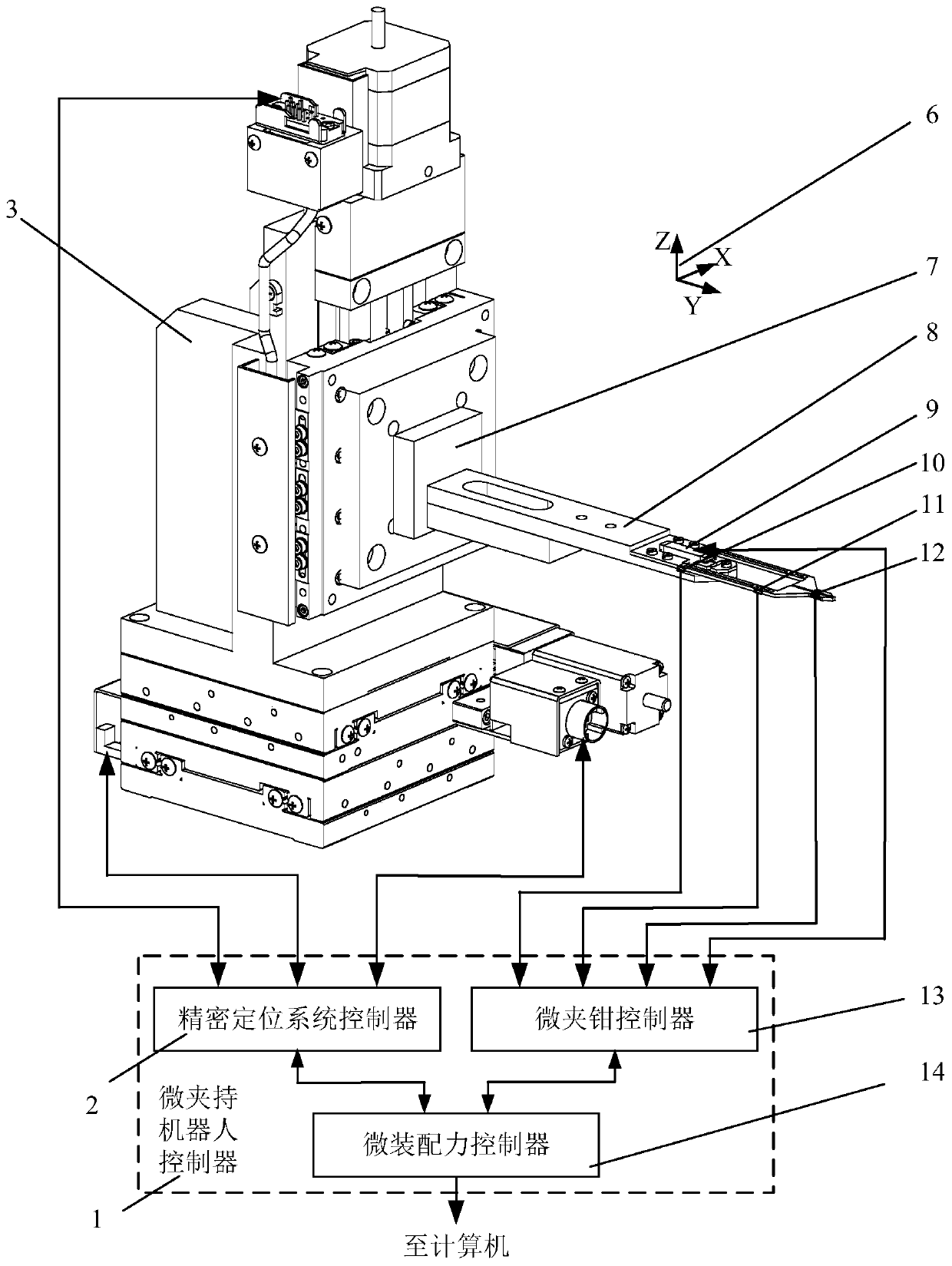

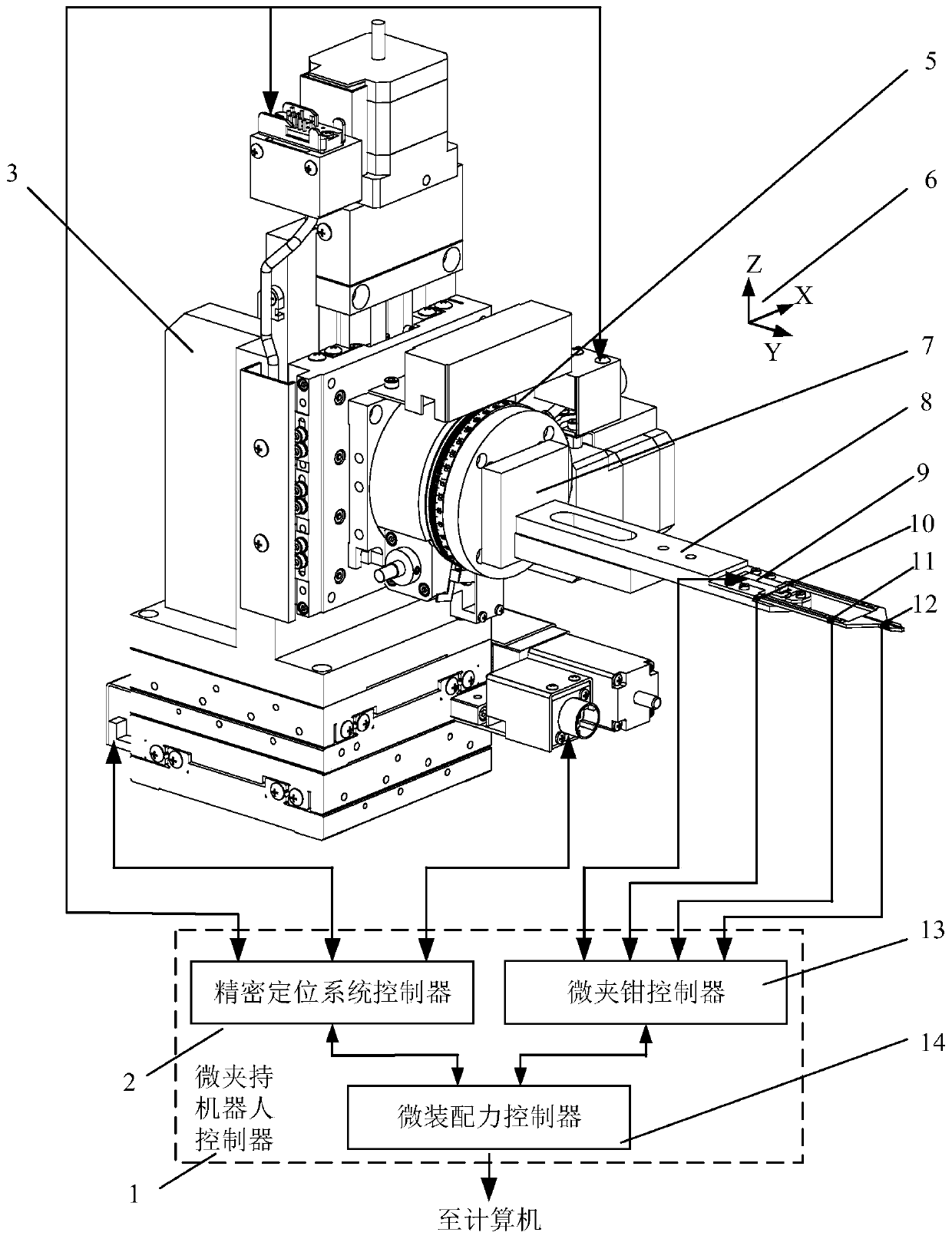

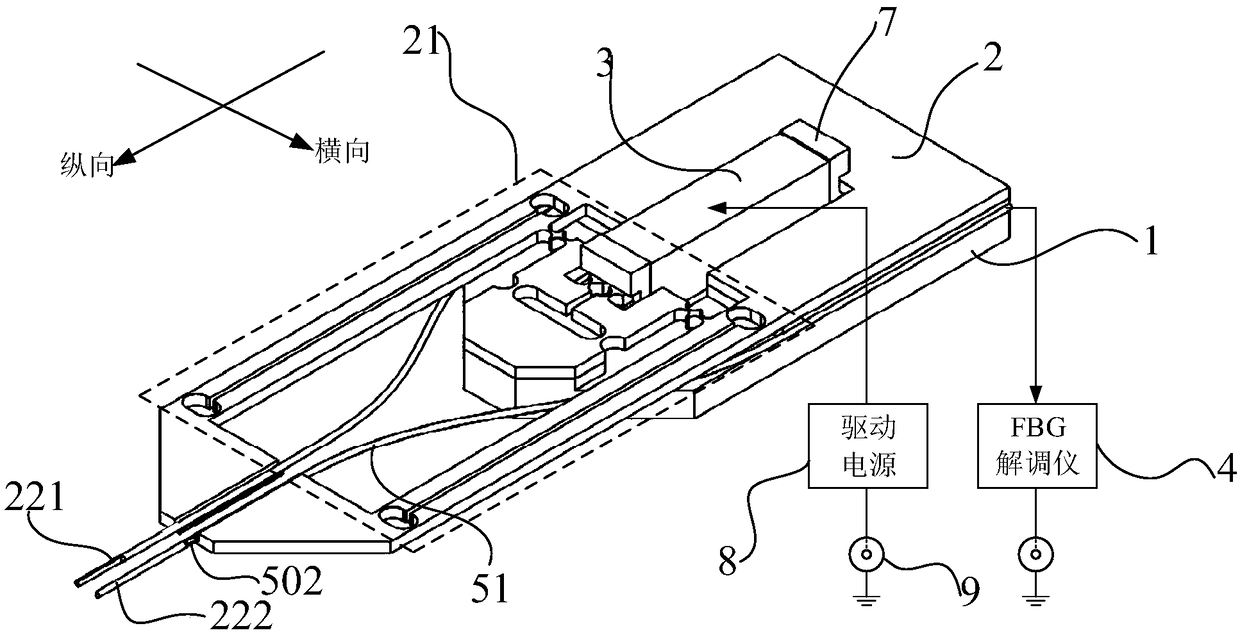

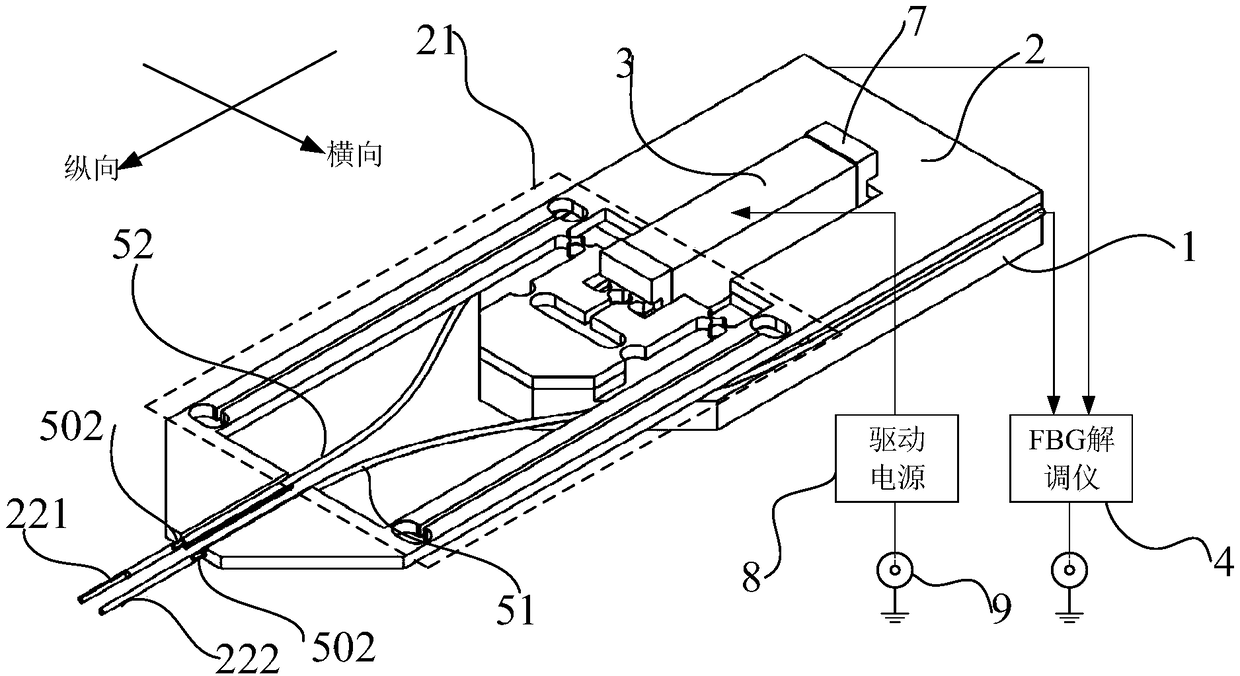

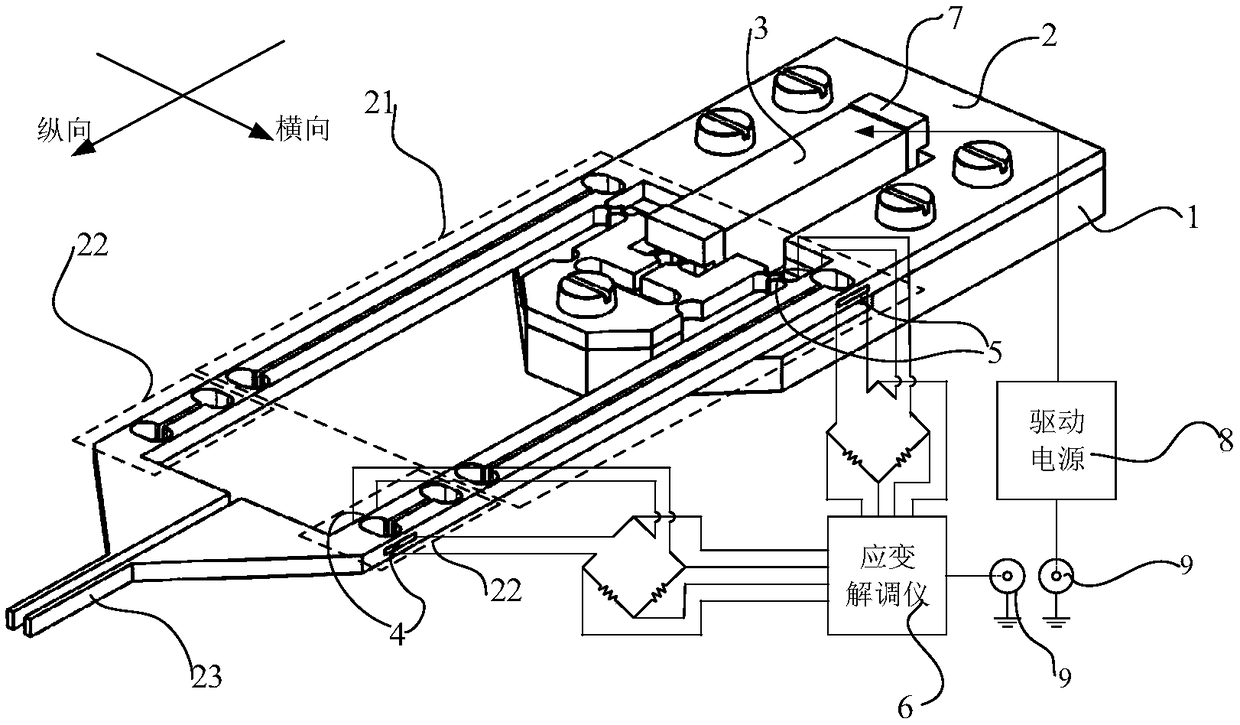

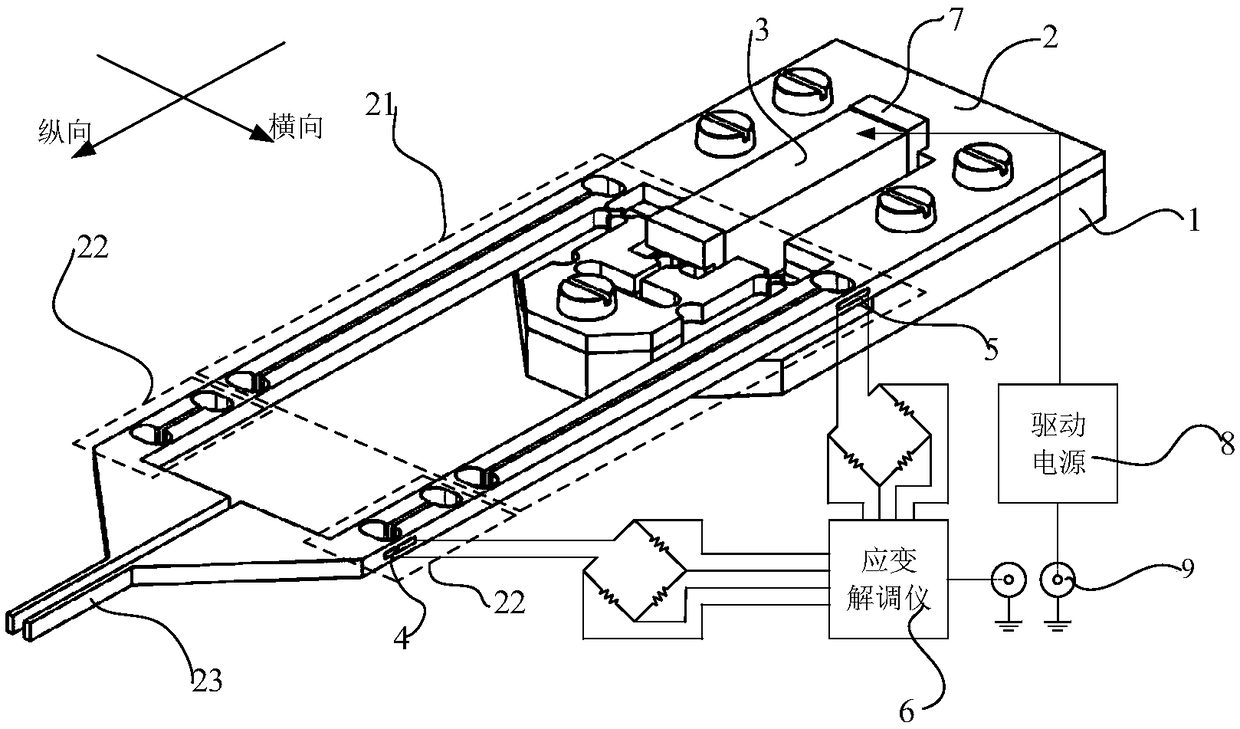

Micro-clamping robot

ActiveCN111299996ARealize high precision positioningRealize large-scale spatial positioningProgramme-controlled manipulatorMicromanipulatorCompliant mechanismLinear motion

The invention relates to a micro-clamping robot. According to the robot, micro parts can be clamped, high-precision motion positioning can be achieved, and meanwhile, the detection and feedback control over clamping jaw displacement, clamping force and micro-assembly force can be achieved. The micro-clamping robot is composed of a micro-clamp which can achieve clamping jaw displacement detection,clamping force detection and micro-assembly force detection at the same time, a precision positioning system and a micro-clamping robot controller, linear motion and rotary motion along X axis, Y axisand Z axis are achieved, and meanwhile, detection, sense and feedback of clamping jaw displacement, clamping force and micro-assembly force can be achieved at the same time; the micro-clamp is composed of a base, a single-piece compliant mechanism fixed on the base, an actuator and a micro-clamp controller; and first-stage lever mechanisms which are symmetrically arranged, third-stage series parallelogram mechanisms which are symmetrically arranged and clamping jaws which are symmetrically arranged are arranged on the single-piece compliant mechanism.

Owner:CHONGQING UNIV

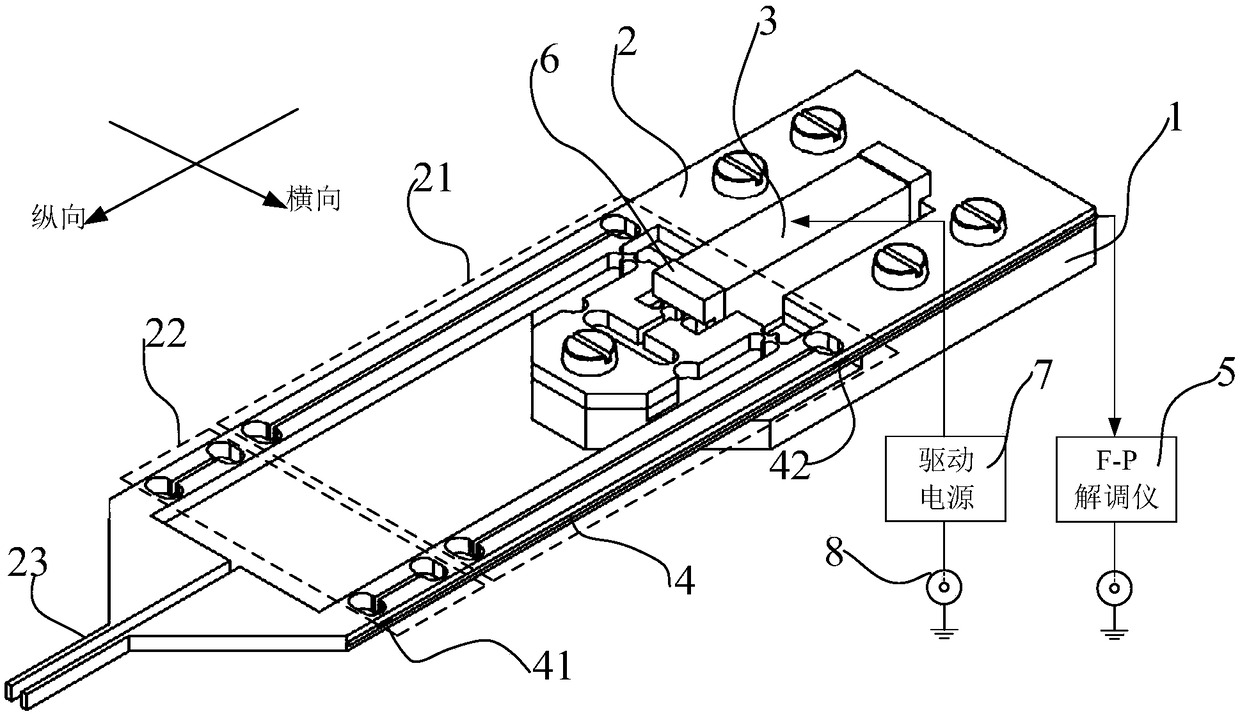

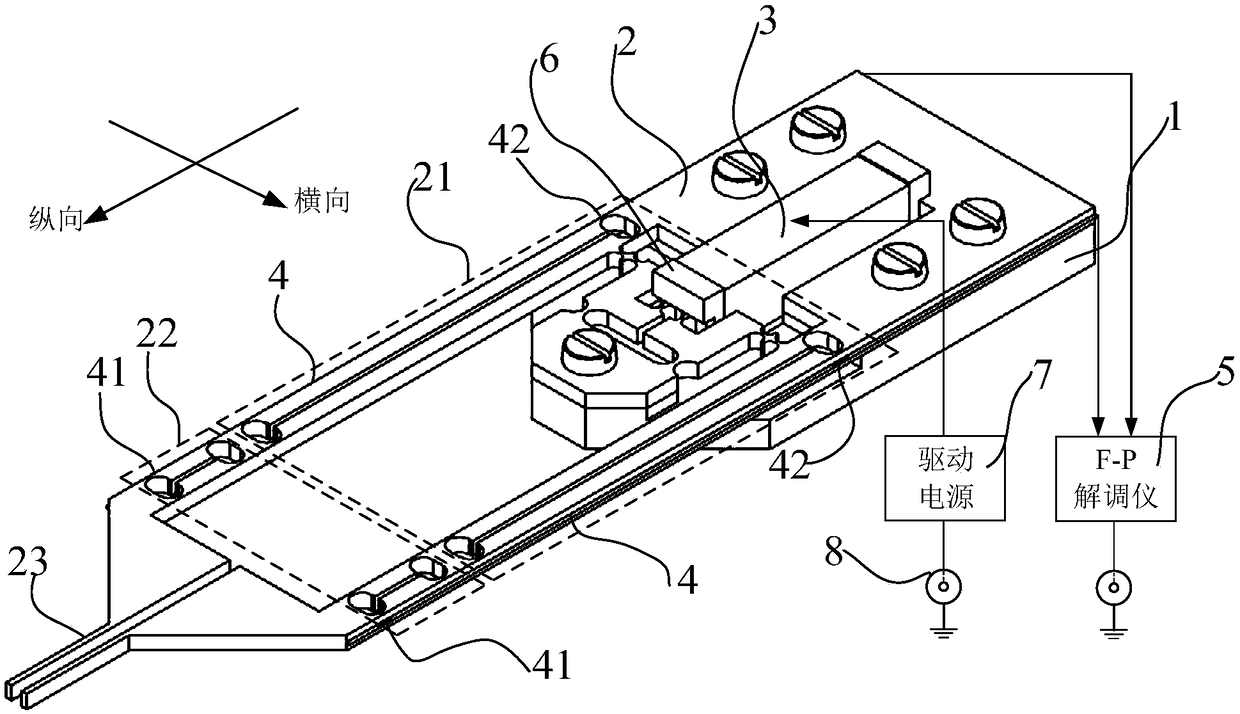

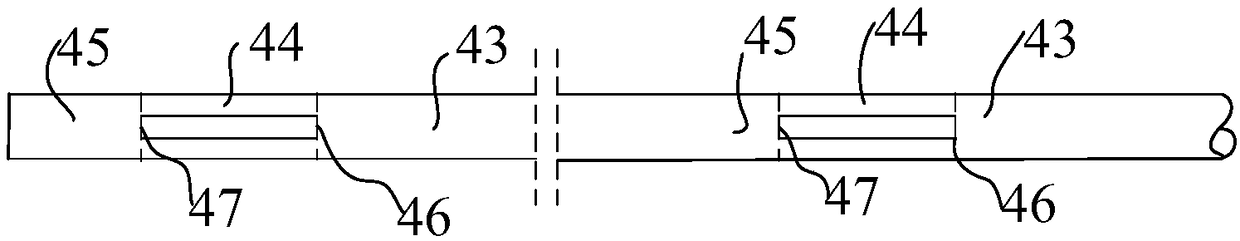

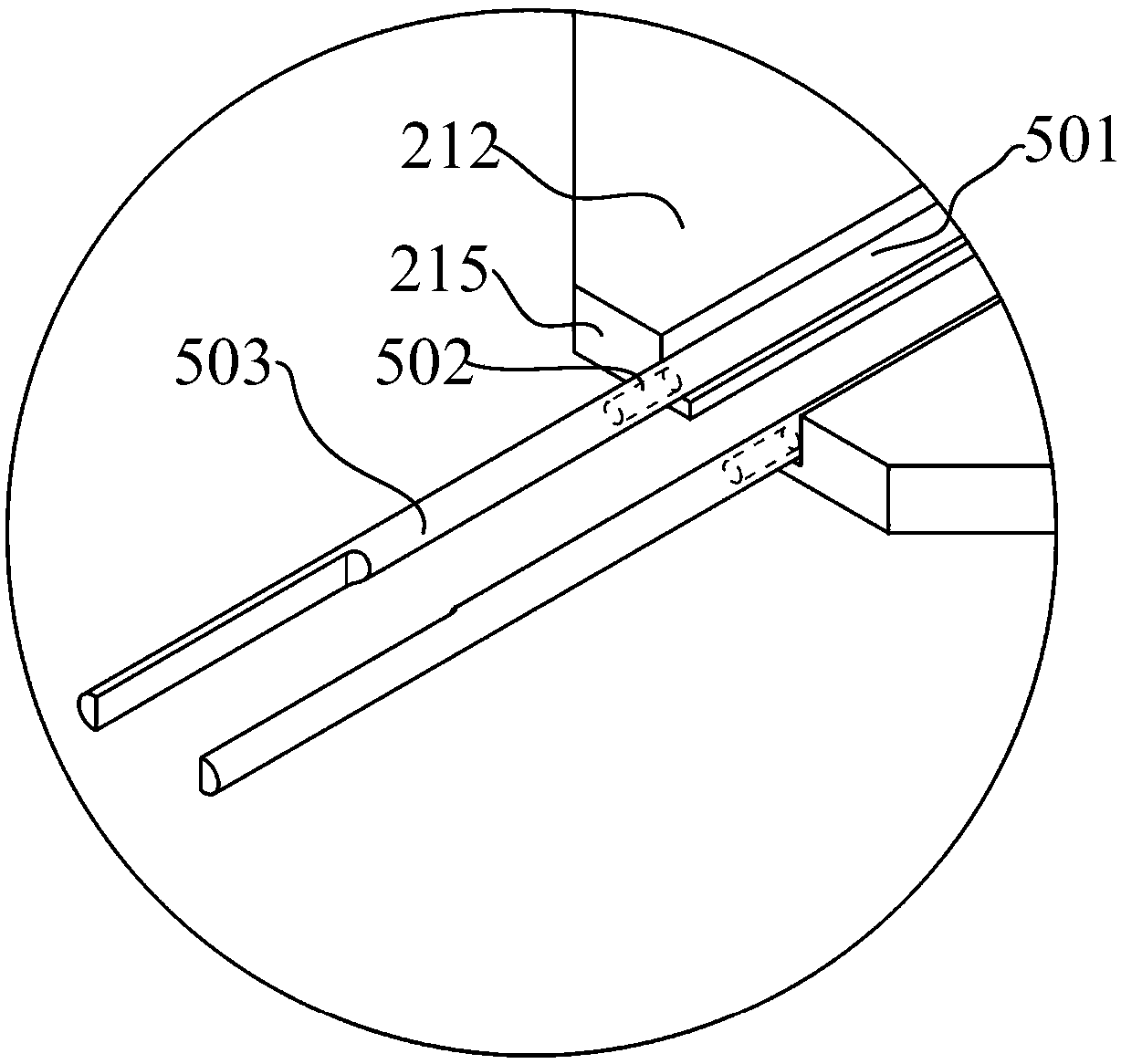

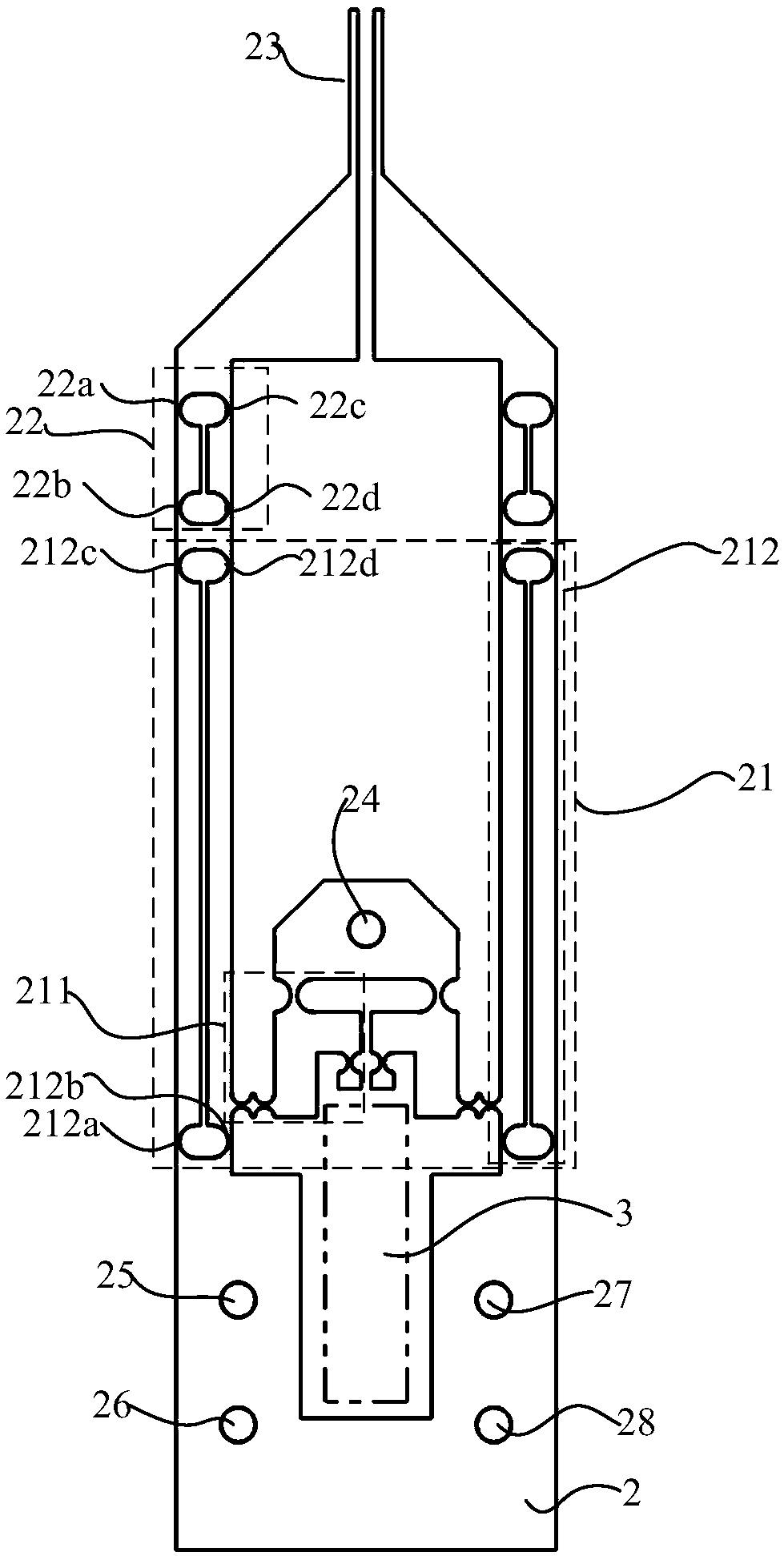

Micro-gripper for measuring clamping force and jaw displacement by optical fiber Fabry-Perot interferometer

ActiveCN109231152AAccurate measurementSimple structureTelevision system detailsMeasurement devicesEngineeringActuator

The invention relates to a micro-gripper for measuring the clamping force and the jaw displacement by an optical fiber Fabry-Perot interferometer to solve the problem that the micro-gripper in the prior art cannot measure the clamping force and the jaw displacement accurately at the same time. The technical scheme is that the micro-gripper comprises a base, a monolithic flexible mechanism fixed onthe base, an actuator installed in a cavity provided on the monolithic flexible mechanism, a controller, an F-P demodulator connected with the controller, and an optical fiber Fabry-Perot multiplexedsensor connected with the F-P demodulator. The monolithic flexible mechanism comprises: a displacement amplifier mechanism, two clamping force sensing mechanisms symmetrically arranged and two clamping jaws symmetrically arranged, the input stage of the displacement amplifying mechanism is in contact with the actuator, the two output stages of the displacement amplifying mechanism, the two clamping force sensing mechanisms and the two clamping jaws correspond one by one, and the output stage of the displacement amplifying mechanism, the clamping force sensing mechanism and the clamping jaws are sequentially connected.

Owner:CHONGQING UNIV

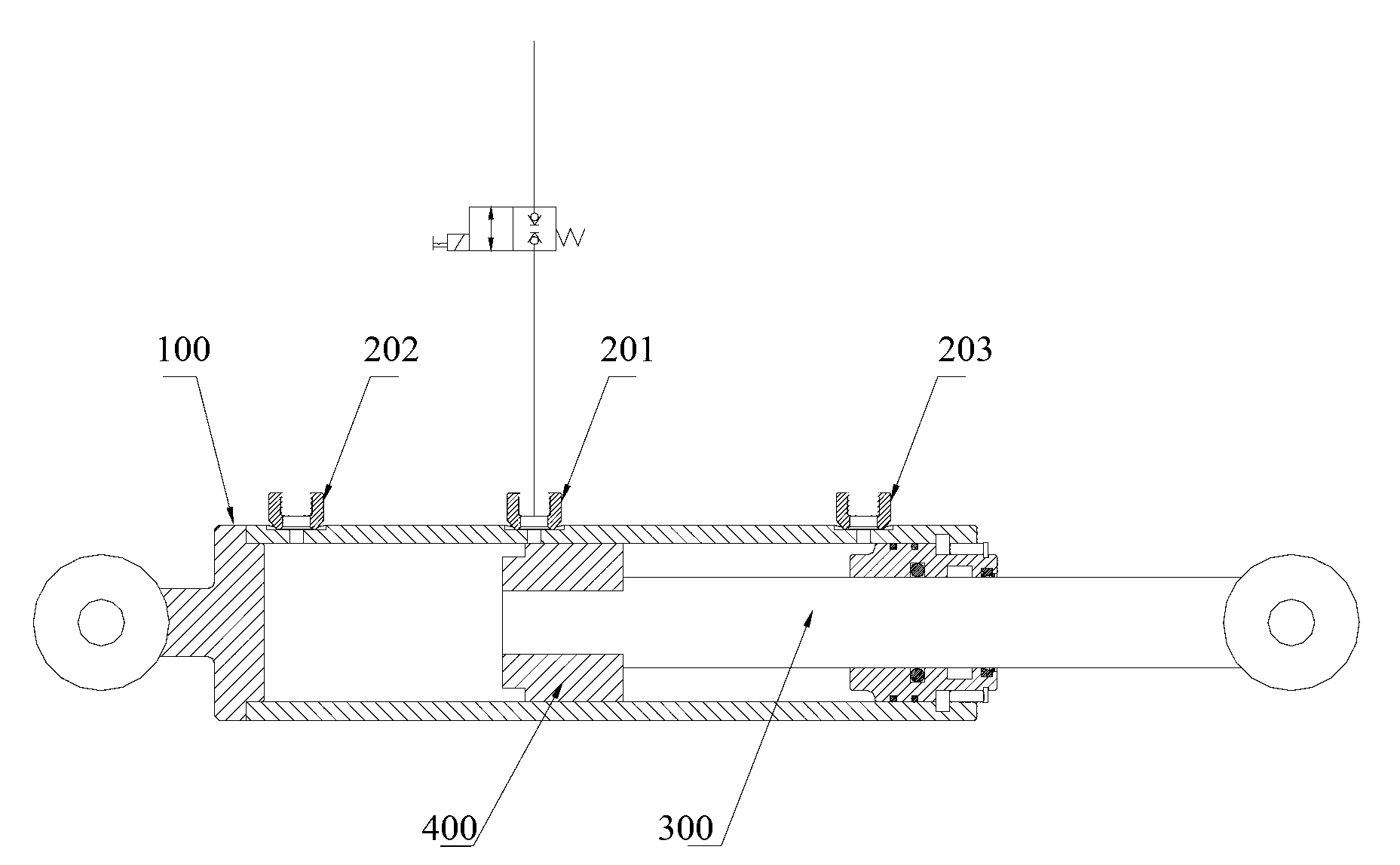

Steering oil cylinder structure, steering device and electric control steering axle

InactiveCN102700604AReliable completionReliable centering limit functionFluid steeringElectric controlPiston rod

The invention provides a steering oil cylinder structure which comprises a first oil port, at least one second oil port, at least one third oil port, a piston and a piston rod, wherein the piston rod is connected to the piston; the cavity of an oil cylinder is divided into a rod cavity and a rodless cavity by the piston; the second oil port is arranged on a cylinder barrel corresponding to the rodless cavity; the third oil port is arranged on a cylinder barrel corresponding to the rod cavity; and the first oil port is arranged between the second oil port and the third oil port. The invention also provides a steering device provided with the steering oil cylinder structure and an electric control steering axle provided with the steering device. According to the steering device provided by the invention, the structure is simple, the weight of the whole vehicle is reduced, and the reliable centering function is realized.

Owner:SANY HEAVY IND CO LTD (CN)

Microgripper with claws of fiber Bragg gratings and gripping force self-sensing function

The invention relates to a microgripper with jaws of fiber Bragg gratings and a gripping force self-sensing function and is intended to solve the problem that jaws of a microgripper of the prior art cannot provide component gripping and gripping force self-sensing at the same time. The microgripper comprises: a base, a single-sheet flexible mechanism fixed to the base, an actuator mounted in a cavity in the single-sheet flexible mechanism, an FBG (fiber Bragg grating) demodulator, and a controller connected with the actuator and the FBG demodulator. The single-sheet flexible mechanism includes: a displacement amplifying mechanism; an input stage of the displacement amplifying mechanism is abutted to the actuator; two output stages of the displacement amplifying mechanism are connected withtwo jaws respectively. The microgripper also includes one or two first fiber Bragg gratings each corresponding to one jaw; each first fiber Bragg grating includes a clamping portion for forming the jaws and a clamping force sensing portion for sensing deformation which occurs when the jaws clamp a part to be clamped; the first fiber Bragg gratings are connected with the FBG demodulator.

Owner:CHONGQING UNIV

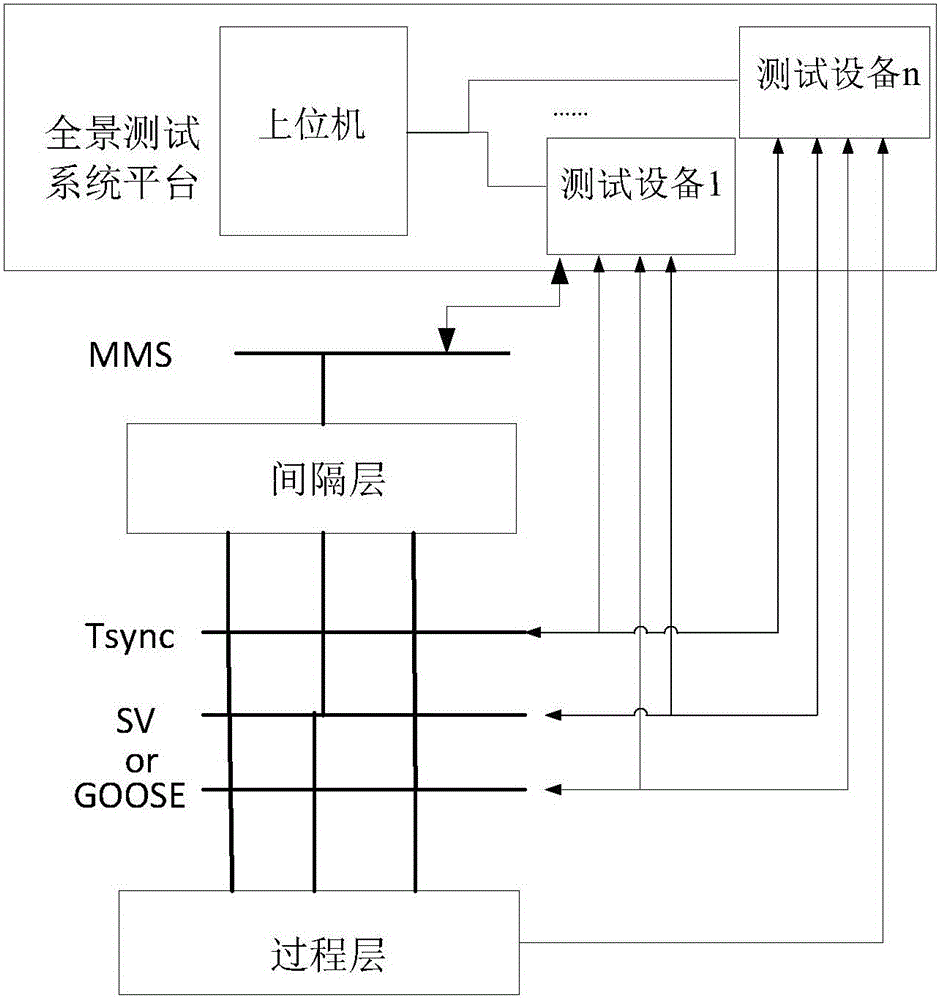

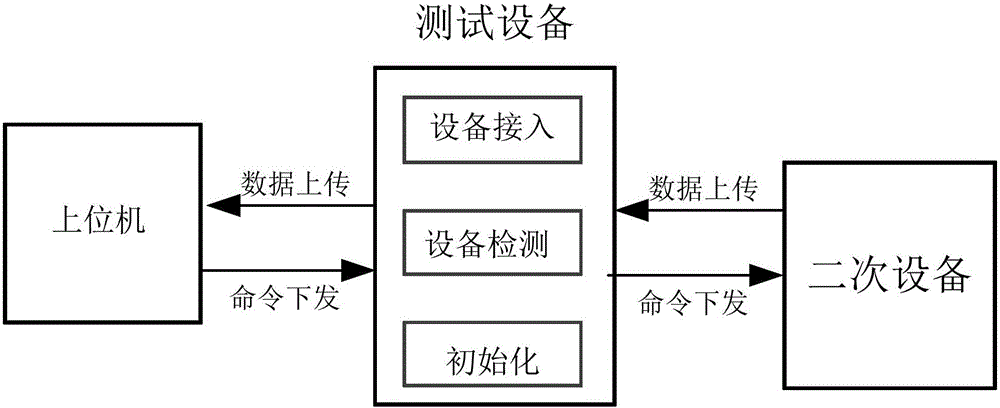

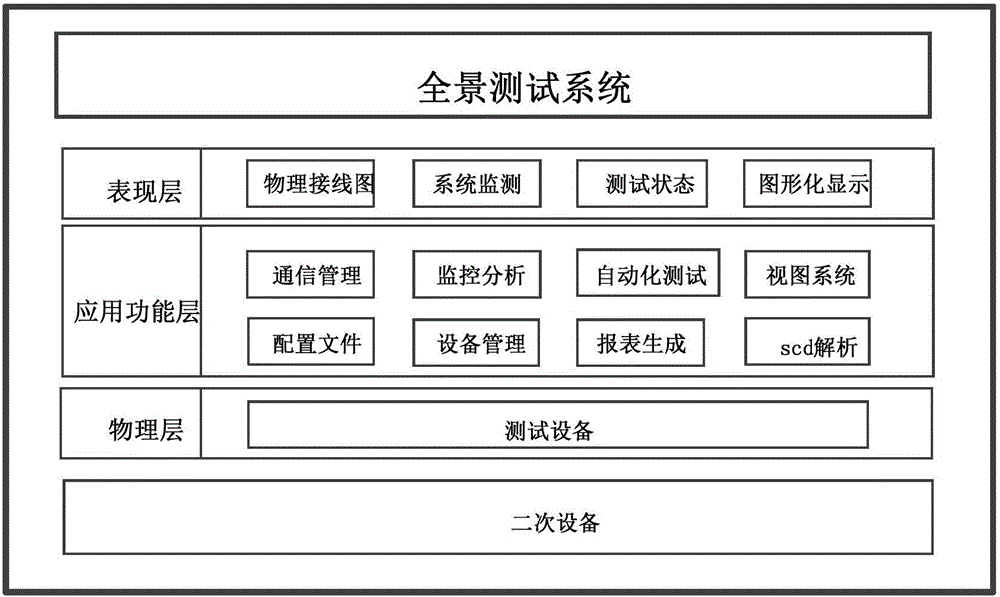

Intelligent transformer substation secondary equipment panorama test system and construction and test method thereof

ActiveCN105738736AComplete efficientlyEfficient debuggingElectrical testingVirtual terminalSmart substation

The embodiment of the present invention discloses an intelligent transformer substation secondary equipment panorama test system and a construction and test method thereof. According to the present invention, by analyzing a transformer substation database configuration file, all intelligent electronic devices and the configuration information of the intelligent electronic devices can be obtained, and by the virtual terminal input and output of the acquisition and control modules between the intelligent electronic devices, the connection between the intelligent electronic devices is realized; a secondary equipment panorama diagram is drawn by taking the intervals as units, the intelligent electronic devices in the panorama diagram are monitored real-timely, and the states and the data flow directions of the intelligent electronic device virtual terminals can be visualized; the connection states of the input and output virtual terminals of the intelligent electronic devices and the correlated devices are displayed, and the connection states of the virtual terminals and the information and the data flow directions of the devices of a transformer substation can be changed directly under the panorama diagram. The test system and the test method provided by the embodiment of the present invention can carry out the integration and visualization test on the functions of a plurality of intelligent electronic devices of the whole transformer substation simultaneously, thereby finishing the overall debugging and verification of the intelligent transformer substation secondary equipment efficiently and reliably.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

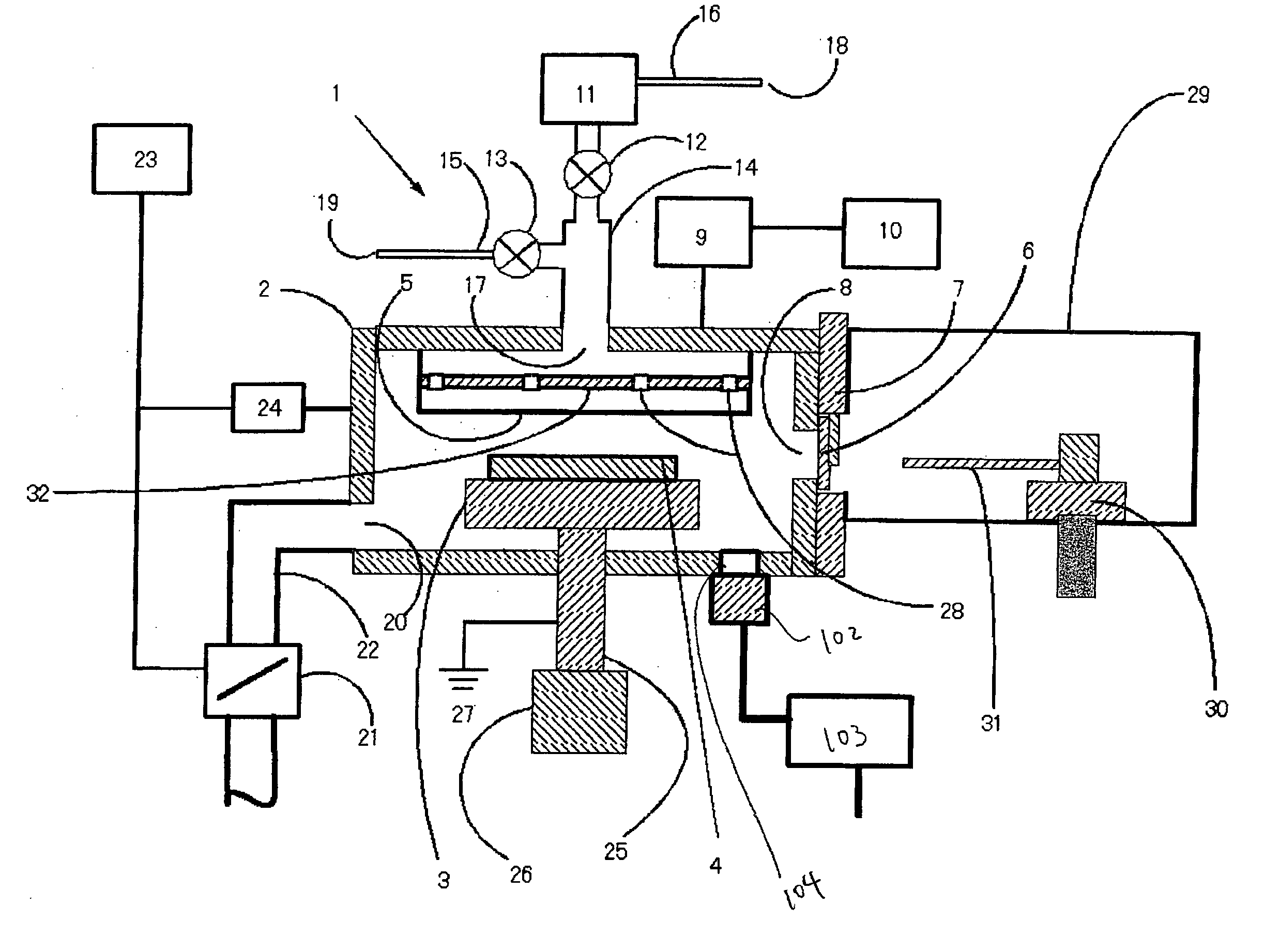

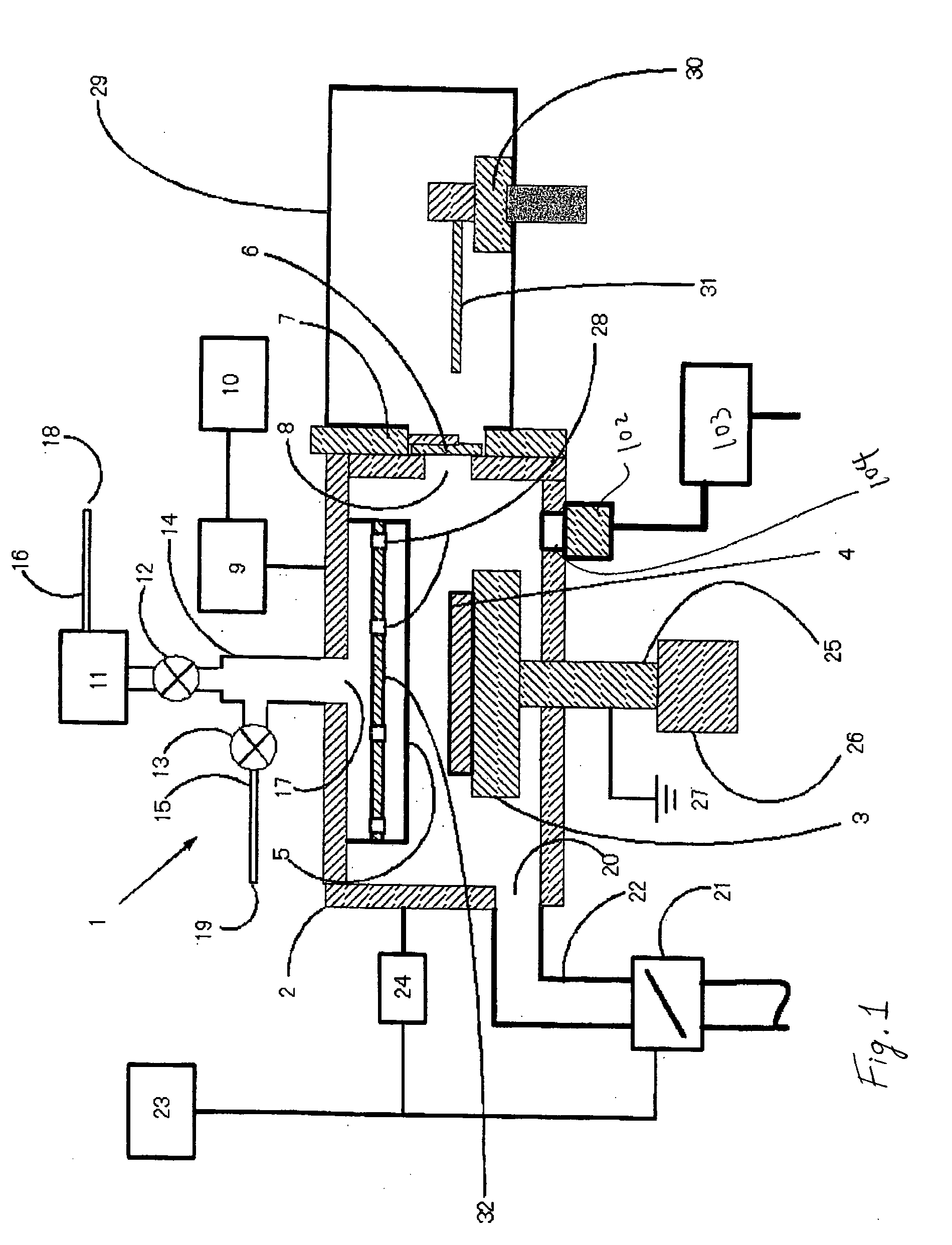

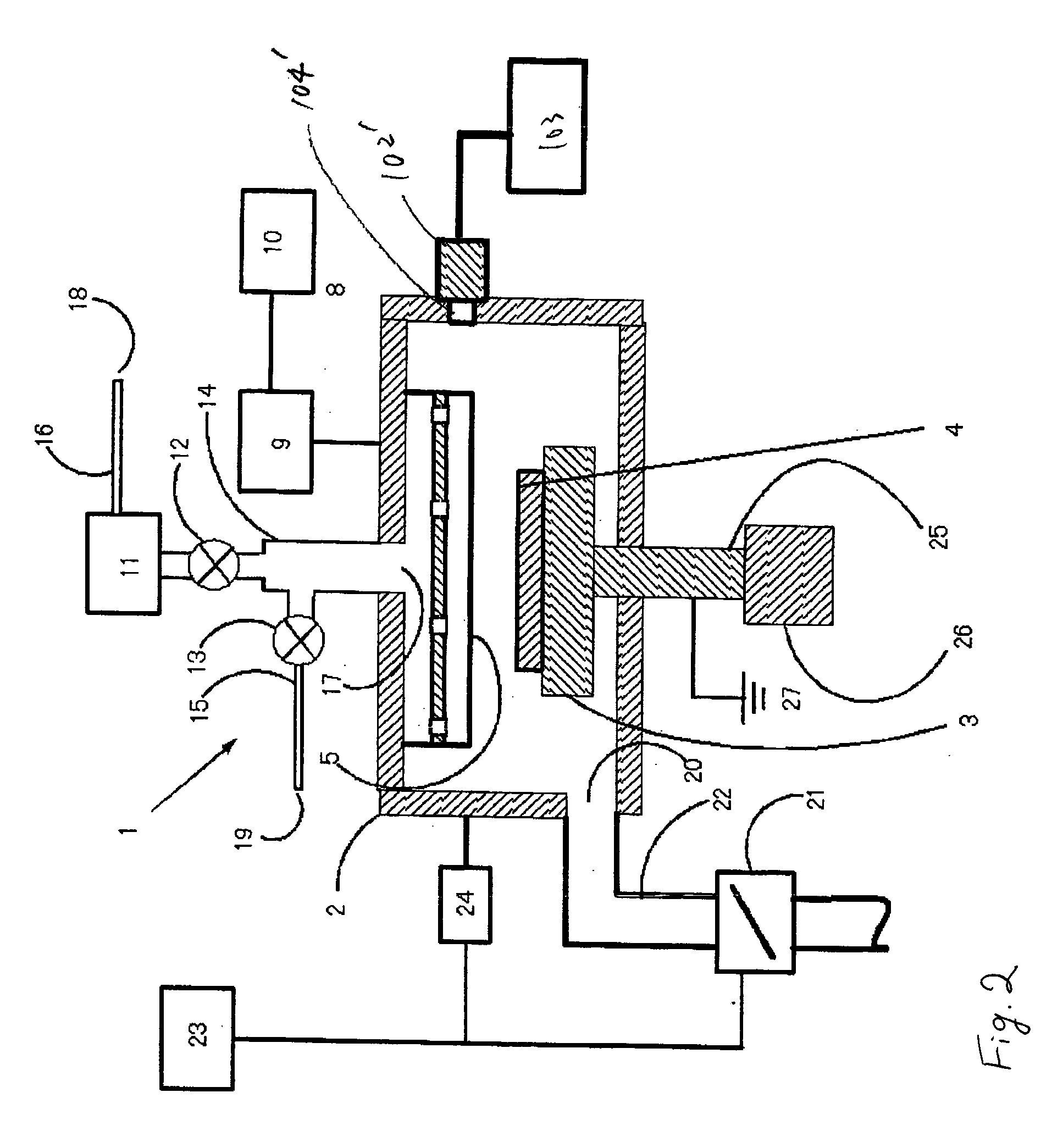

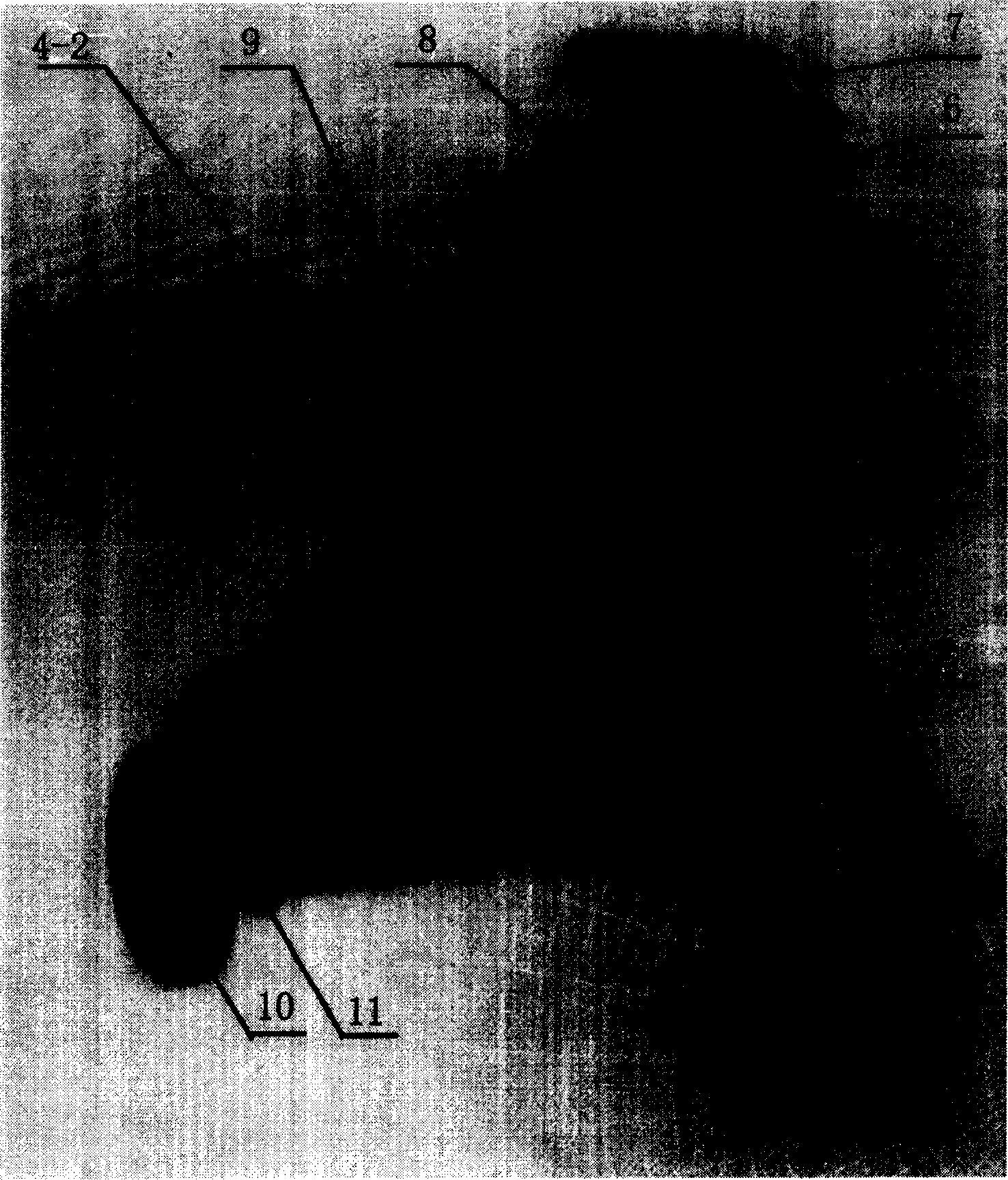

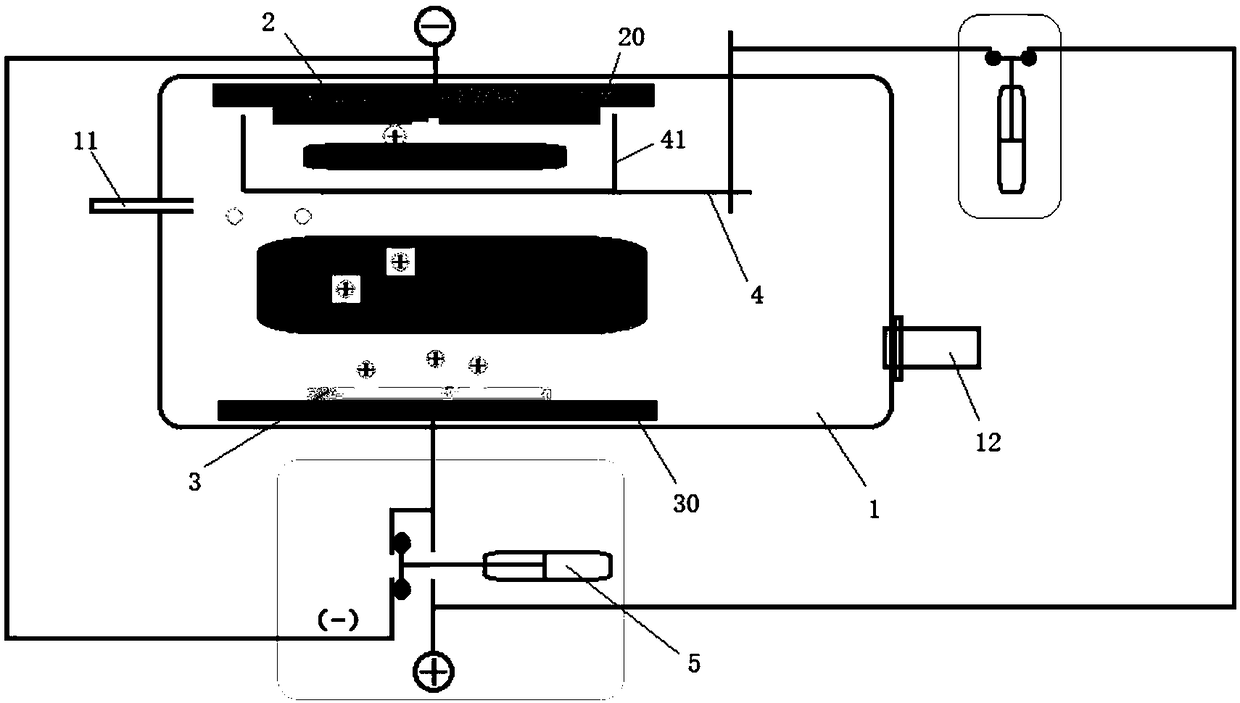

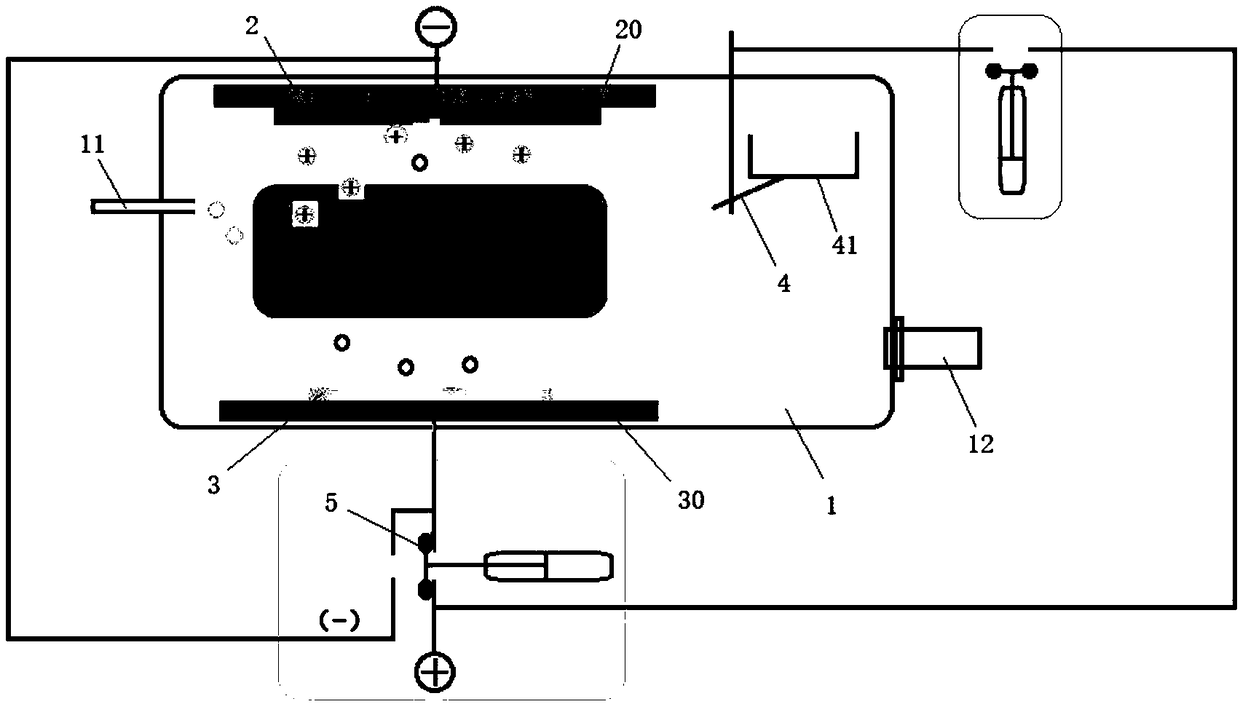

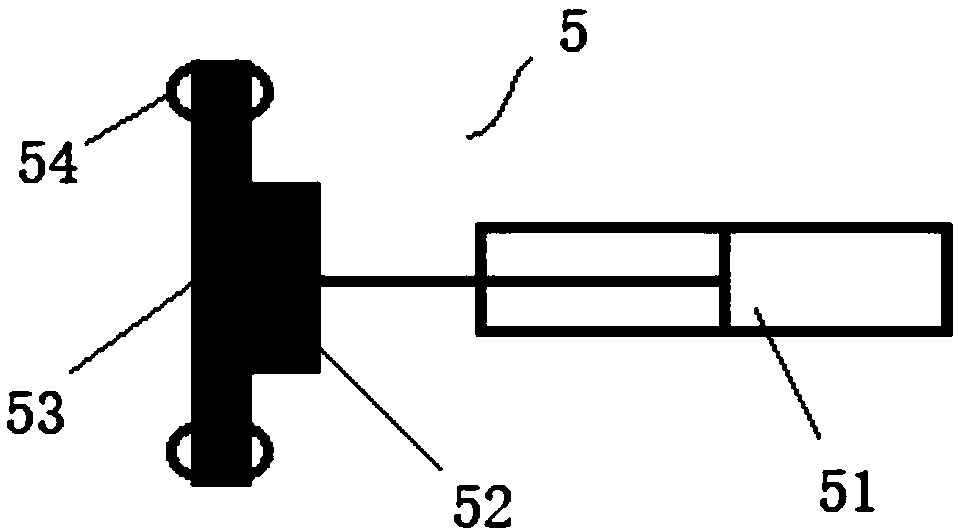

Ion cleaning magnetron sputtering system

ActiveCN108165946ALess equipmentReliable Coating ProcessVacuum evaporation coatingSputtering coatingIonElectrical and Electronics engineering

The invention provides an ion cleaning magnetron sputtering system. The ion cleaning magnetron sputtering system comprises a vacuum cavity, a target material substrate and a wafer tray, wherein the target material substrate and the wafer tray are arranged in the vacuum cavity, the target material substrate and the wafer tray are connected with a negative electrode of a power supply or the ground,target materials are arranged on the target material substrate, a wafer is arranged on the wafer tray, and the vacuum cavity is provided with a gas inlet and an exhaust system; the ion cleaning magnetron sputtering system further comprises a shutter device and switching devices, wherein the shutter device is provided with a shutter cover capable of covering or exposing the target materials, one ofthe two switching devices is arranged in a power supply circuit of the wafer tray, and the other one of the switching devices is arranged in a power supply circuit of the target material substrate and the shutter device. The two processes of plasma cleaning and magnetron sputtering are performed through the same set of devices through the switching devices (power switching systems), the purpose of simultaneously achieving wafer ion cleaning and magnetron sputtering is achieved through a shutter device and the two functional switching devices, the coating process is conveniently and reliably completed through the control of the program, and equipment is saved.

Owner:ZHEJIANG HUAYUAN MICRO ELECTRONICS TECH CO LTD

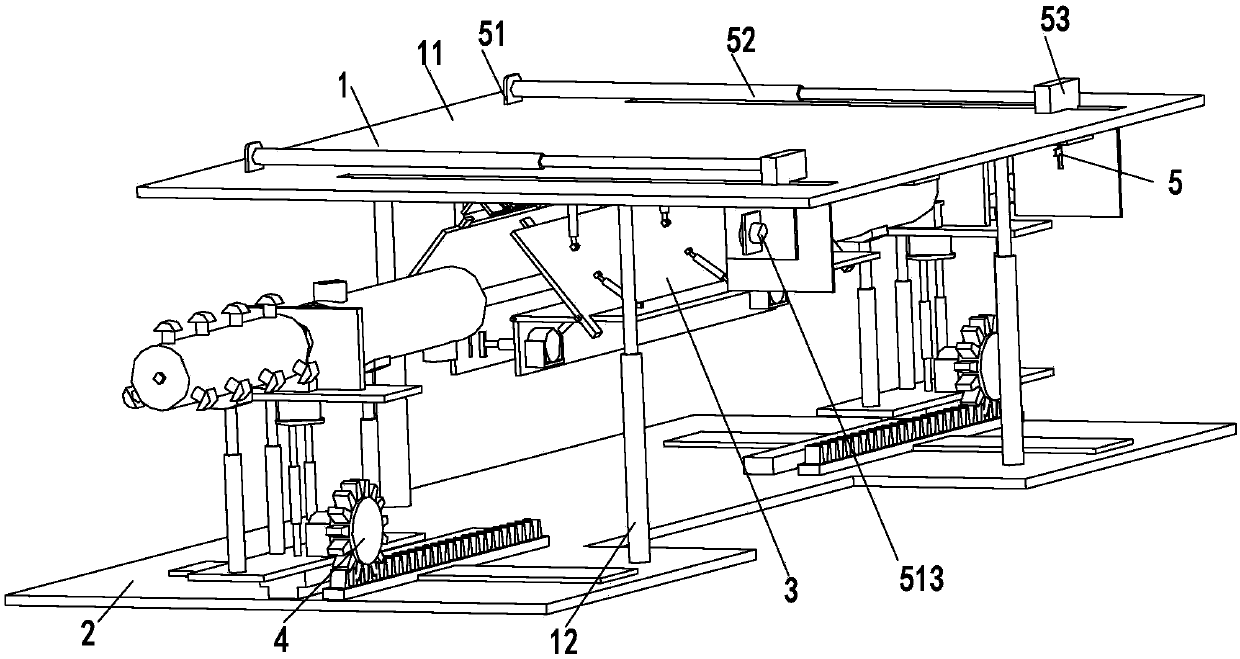

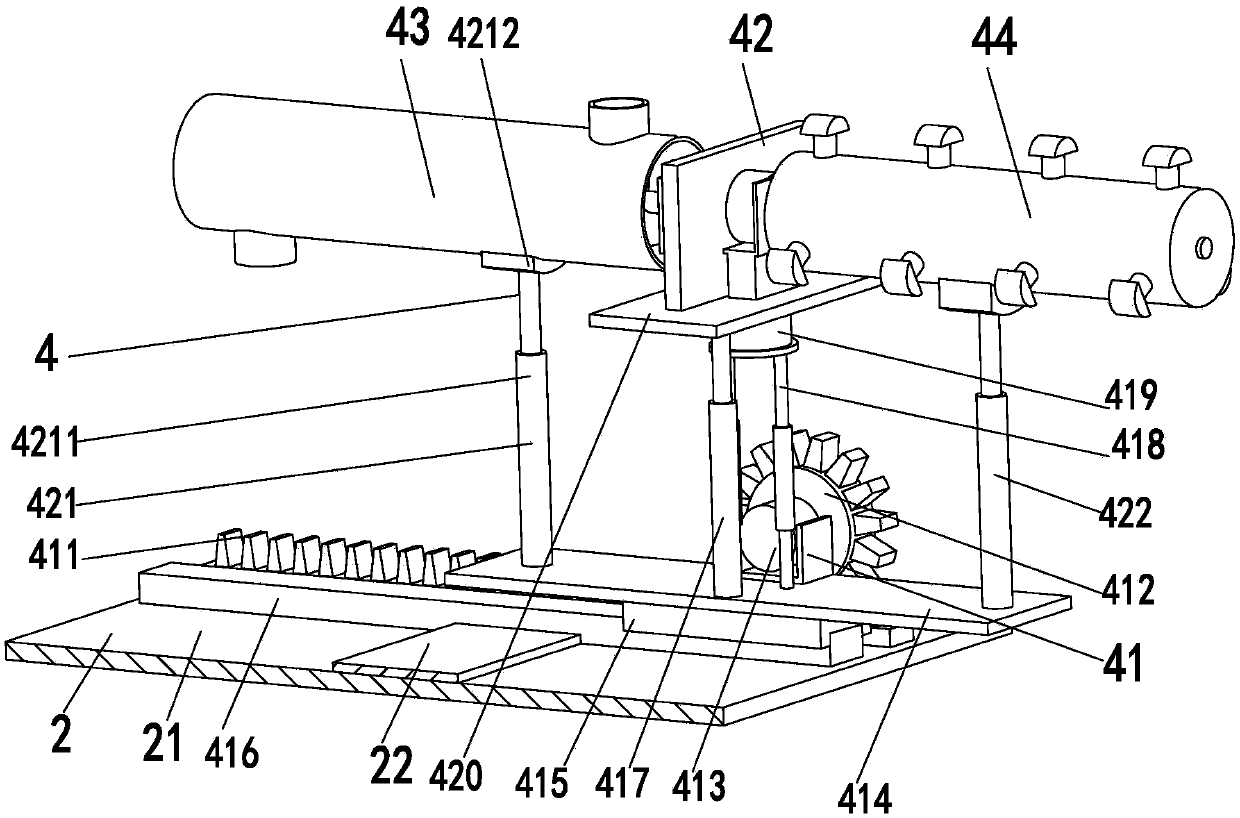

Building construction equipment capable of automatically constructing coping of masonry wall of floor house

InactiveCN107829562AEasy to operateFlexible adjustmentBuilding material handlingArchitectural engineeringUltimate tensile strength

The invention relates to a kind of building construction equipment that can be automatically constructed by masonry wall pressing of a storey house. It includes a mounting frame, a bottom plate, a formwork support device, a concrete pouring device and an extrusion device. A formwork support device is installed, and an extrusion device is installed on the upper end of the installation frame. The number of extrusion devices is two. The two extrusion devices are symmetrically installed at the left and right ends of the installation frame. A concrete pouring device is installed on the bottom plate. The number of concrete pouring devices is two. , two concrete pouring devices are installed symmetrically at the left and right ends of the bottom plate. The invention can solve the problems of high labor intensity, low work efficiency, uneven compaction, large safety hazards and easy mixing of impurities in the process of concrete conveying existing in the existing wall construction process, and can realize the function of automatic construction of the top. It has the advantages of low labor intensity, high work efficiency, uniform vibration, no safety hazard and no impurity mixing.

Owner:吴秋敏

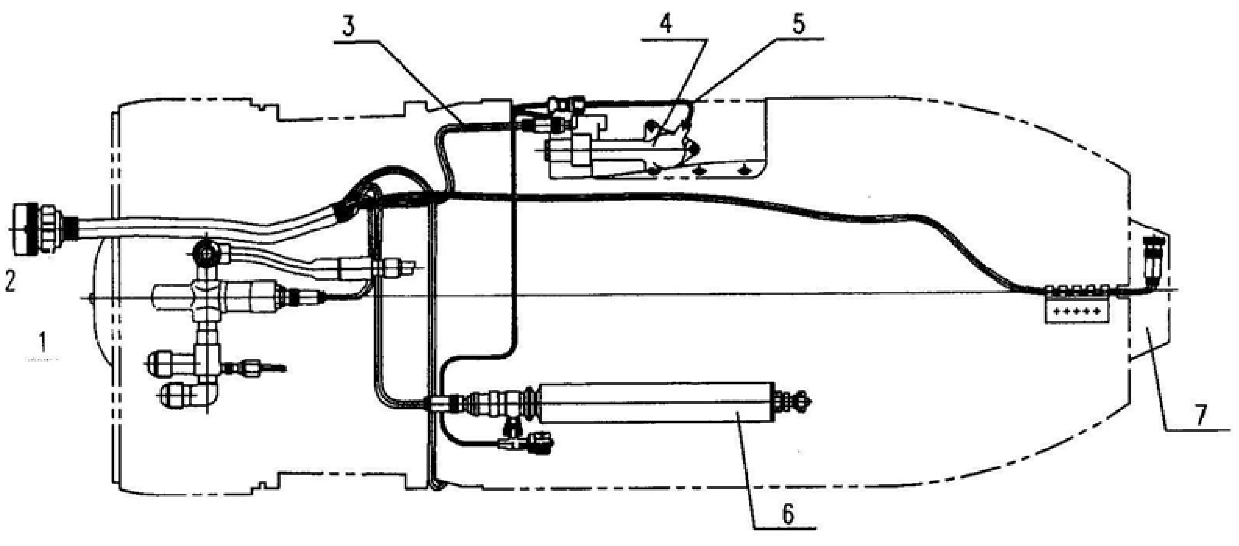

Engine pyrotechnics starting system

InactiveCN106342115BImprove sealingReliable completionGas turbine plantsJet propulsion plantsDetonatorCombustion chamber

The invention relates to an engine pyrotechnic starting system, which includes an engine oil supply pipe, an oxygen bottle, a pyrotechnic igniter, and a pyrotechnic starter. The pyrotechnic igniter is installed on the combustion chamber, and the pyrotechnic starter is installed at the tail of the engine. , the fuel supply pipe of the engine, the pyrotechnic igniter, the pyrotechnic starter and the gas outlet of the oxygen cylinder are equipped with electric detonators and are all connected to the external integrated controller, and one end of the fuel supply pipe is connected to the external fuel oil The other end is connected with the nozzle of the combustion chamber of the engine, and the oxygen cylinder is connected with the pyrotechnic igniter through the oxygen supplement pipe. Valves are also arranged at the electric initiator at the inside and at the gas outlet of the oxygen cylinder. The invention has the characteristics of simple structure, high starting success rate and reduced engine weight, can directly ignite the auxiliary fuel oil of the engine, and at the same time use an oxygen bottle to ignite and replenish oxygen, thereby shortening the ignition time of the engine.

Owner:HARBIN DONGAN ENGINE GRP

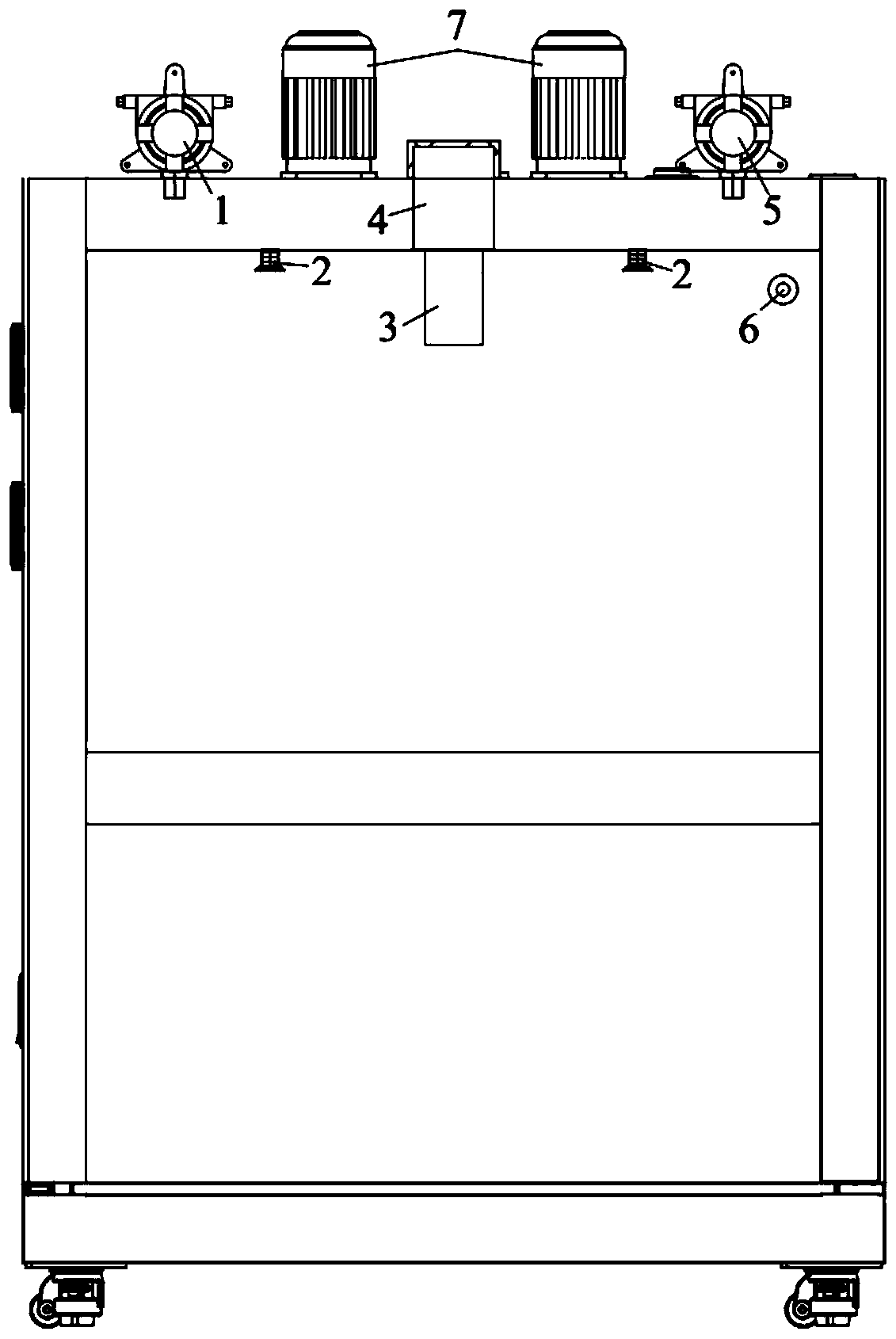

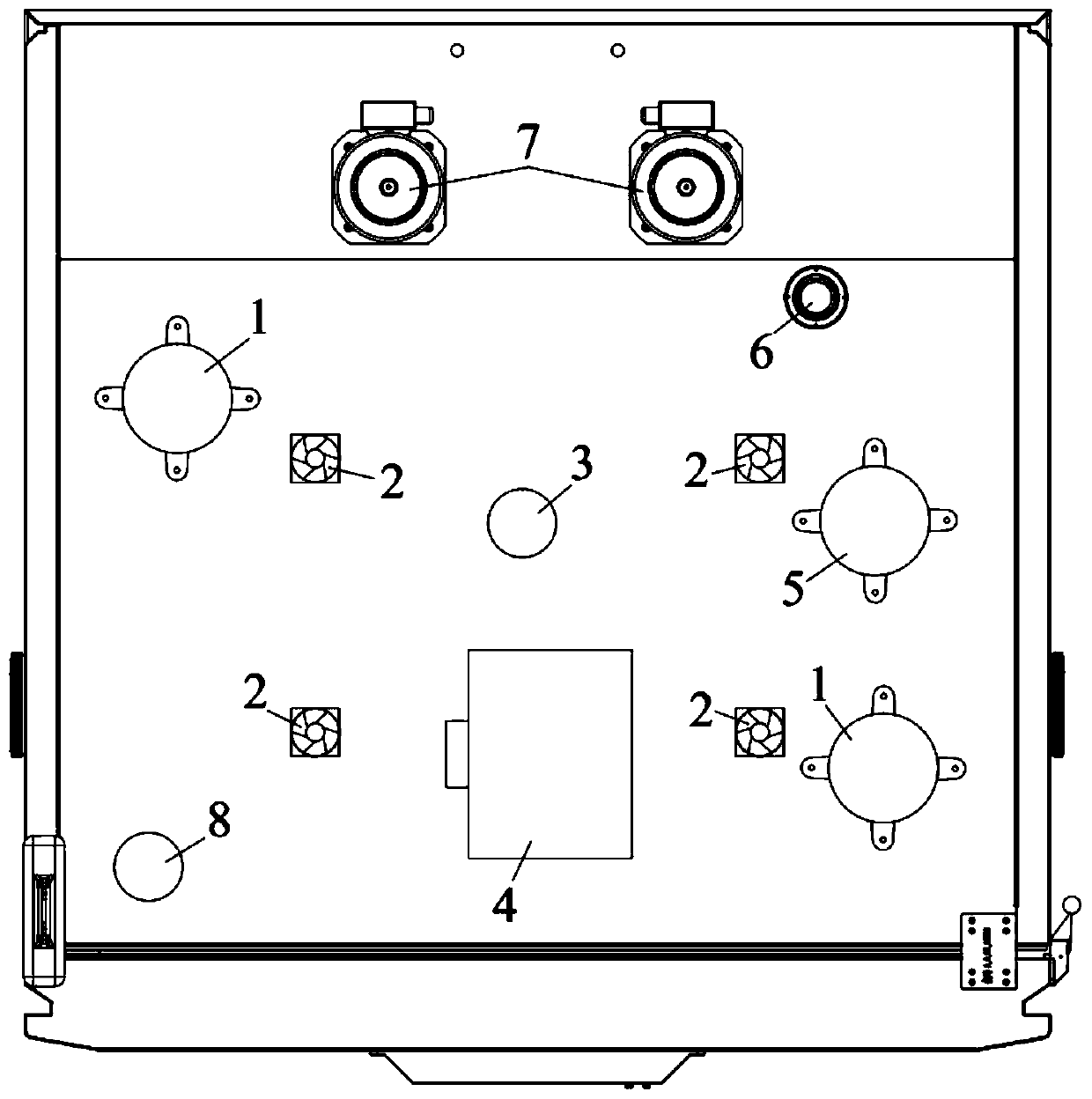

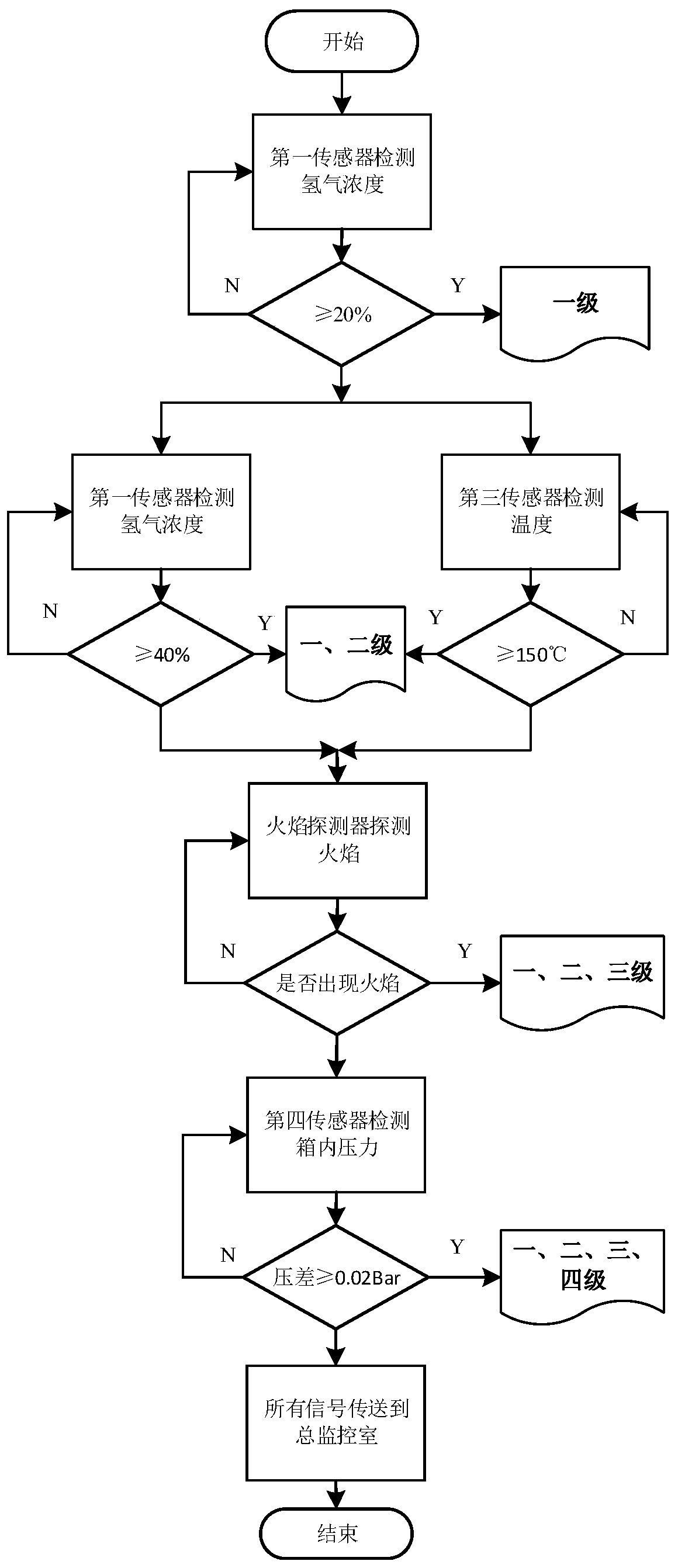

Safety system for fuel cell engine test and control method thereof

InactiveCN111103141AWith explosion-proof functionEasy dischargeEngine testingTemperature controlFuel cells

The invention discloses a safety system for a fuel cell engine test and a control method thereof, and belongs to the technical field of engine tests. The safety system for the fuel cell engine test comprises an environment box used for placing a fuel cell engine, and a pressure relief device and an exhaust outlet being arranged at the top end of the environment box and used for exhausting gas; a spiral finned tube heater, arranged in the environment box and used for heating the temperature in the environment box; a control system, used for receiving the signal and sending a control signal; a monitoring system, in signal connection with the control system and used for charging nitrogen into the environment box or starting the air outlet; and a fire extinguishing system, in signal connectionwith the control system and used for starting the high-pressure water mist spray head at the top end of the environment box so as to spray water into the environment box to extinguish fire. The safety system has the advantage that the fuel cell engine can safely and reliably complete test items in various simulation environments in the environment box.

Owner:CHINA FIRST AUTOMOBILE

Tiny clamp capable of integrating clamping force sensor and clamping jaw displacement sensor

The invention relates to a tiny clamp capable of integrating a clamping force sensor and a clamping jaw displacement sensor and aims to solve the problems in the prior art that the tiny clamp cannot simultaneously measure the clamping force and the displacement of a clamping jaw and cannot ensure that the clamping jaw moves in parallel. According to the technical scheme, the tiny clamp comprises abase, a single-piece flexible mechanism fixed on the base, an actuator mounted in a cavity formed in the single-piece flexible mechanism, a controller, a strain demodulator connected with the controller, and the clamping force sensor and the clamping jaw displacement sensor connected with the strain demodulator, wherein the single-piece flexible mechanism comprises a displacement amplifying mechanism, two symmetrical clamping force sensing mechanisms and two symmetrical clamping jaws; the input stage of the displacement amplifying mechanism is connected with the actuator in a propped manner;the two output stages of the displacement amplifying mechanism, the two clamping force sensing mechanisms and the two clamping jaws are in one-to-one correspondence; and the output stages of the displacement amplifying mechanism, the clamping force sensing mechanisms and the clamping jaws are sequentially connected.

Owner:CHONGQING UNIV

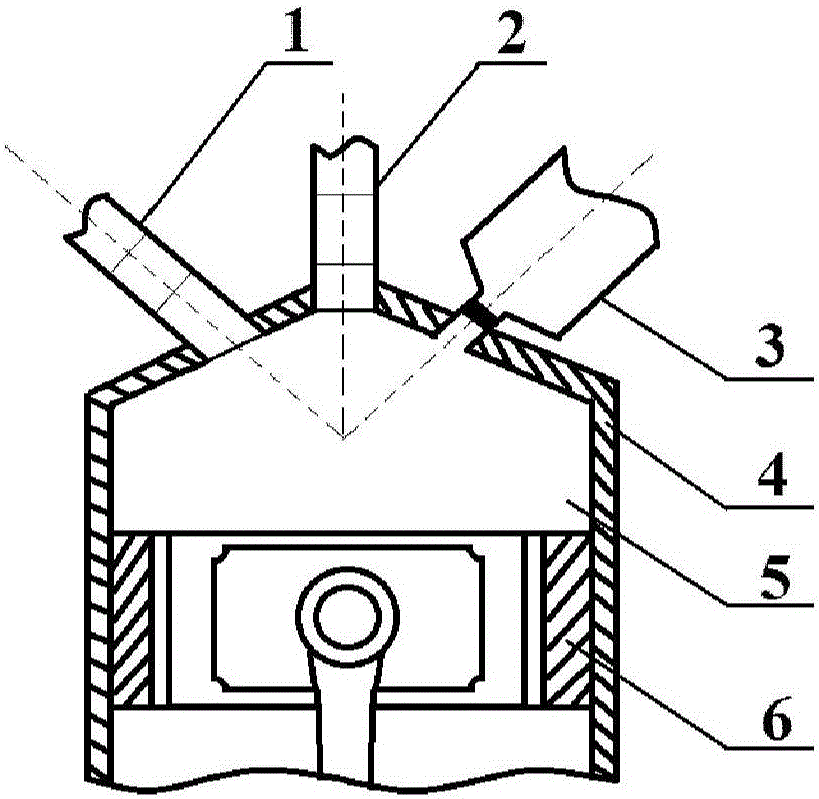

Device and method for ignition through dual-mode lasers in gas breakdown manner

ActiveCN105134453AIncreased ignition path/rangeFast ignitionMachines/enginesEngine ignitionPistonCombustion chamber

The invention provides a device and method for ignition by generating plasma sparks through continuous and pulsed dual-mode lasers in a gas breakdown manner. The device is mainly provided with a continuous laser transmitting end, a pulsed laser transmitting end, a fuel injection device, a cylinder cover, a combustion chamber, a piston and the like. The laser transmitting ends do not stretch into the combustion chamber. According to the device and method for ignition through the continuous and pulsed dual-mode lasers in the gas breakdown manner, the plasma sparks can always be reliably generated to ignite a fuel-air mixture in the combustion chamber; and the ignition path / range can be effectively increased, the ignition speed can be increased, the combustion area can be increased, combustion efficiency can be improved, and fuel can be saved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

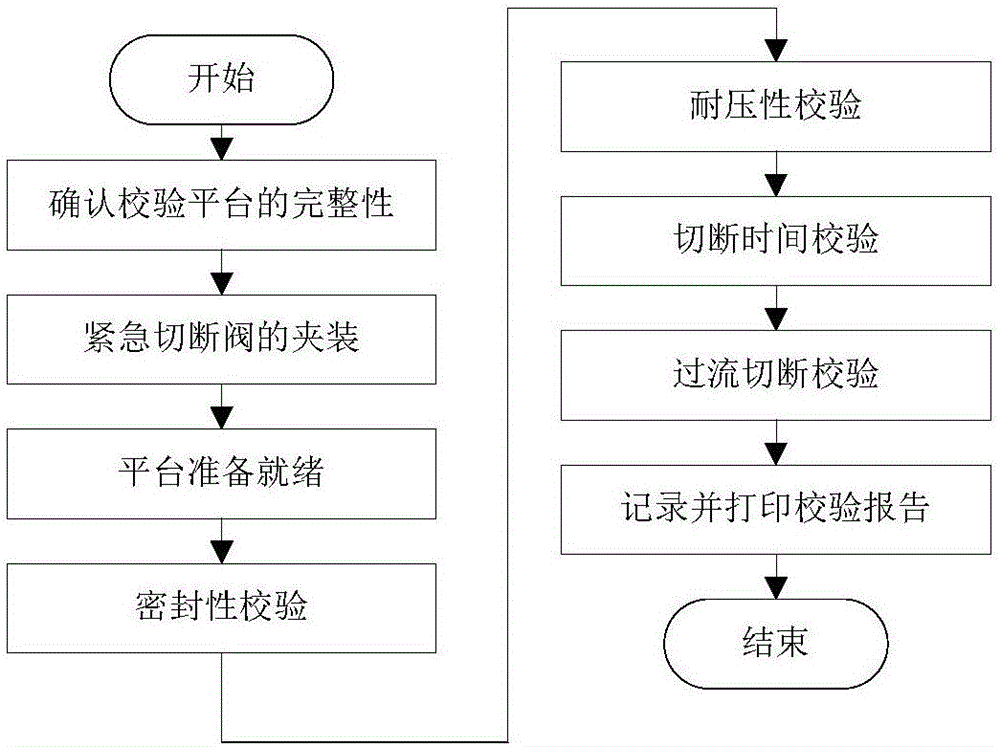

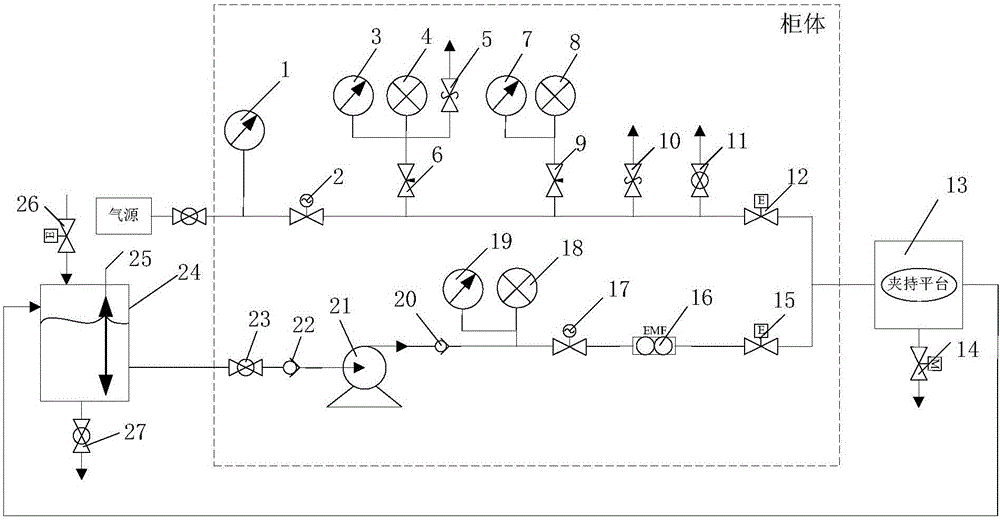

Integrated check system for emergency cut-off valve

InactiveCN106840552AReduce mistakesSmall footprintMachine part testingMeasurement of fluid loss/gain rateEngineeringPressure resistance

The invention relates to an integrated check system for an emergency cut-off valve. The integrated check system comprises a pipe system, a clamping platform, a check operation platform and a control system, wherein the pipe system comprises a gas path pipe and a waterway pipe; a gas path DN15 and a waterway DN50 flange interface is arranged at an inlet of the check operation platform; one DN50 outlet is shared by an outlet gas path and an outlet waterway in a mixed manner and is connected with the camping platform; the clamping platform is used for clamping the to-be-checked emergency cut-off valve, wherein a gas path part is used for checking the air-tightness and the pressure resistance of the emergency cut-off valve; a waterway part is used for checking cut-off time and overcurrent cut-off of the emergency cut-off valve and circulating water is adopted; and the control system is used for completing operation control by adopting a PLC; all check work is completed on the operation platform, so that automatic check work can be achieved, the check work can be manually controlled through components on the operation platform, and a monitoring management center can record and display all check operation states in real time.

Owner:TIANJIN UNIV

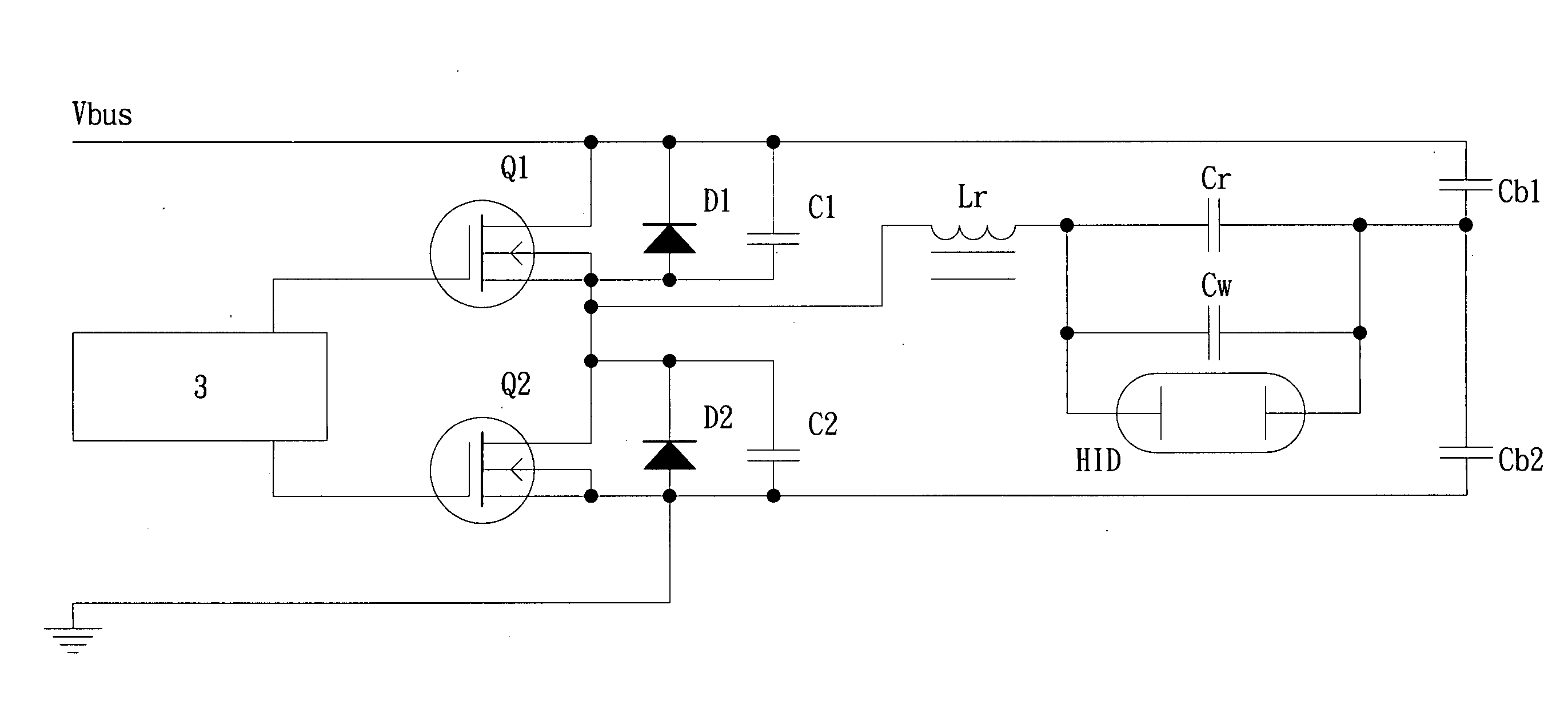

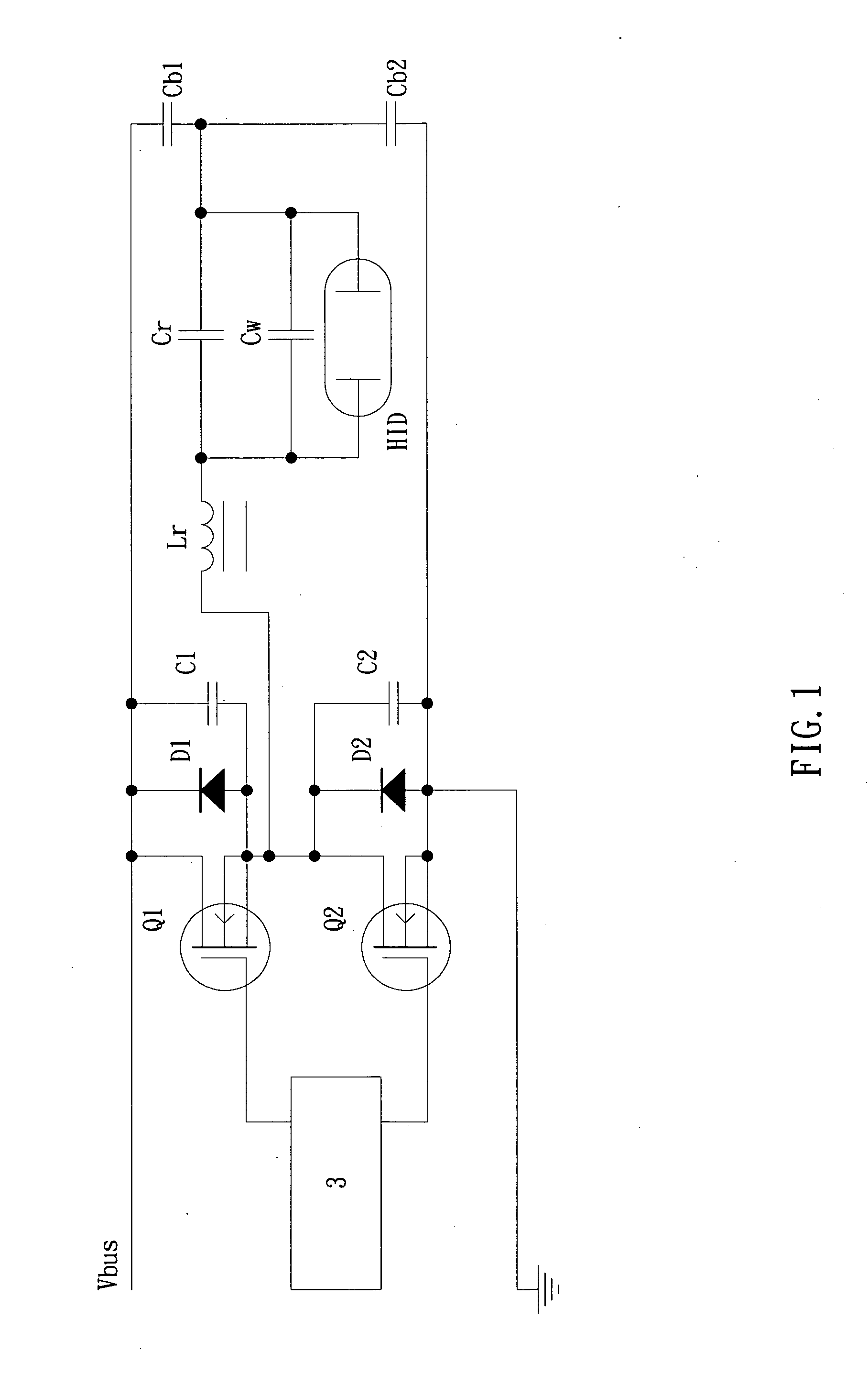

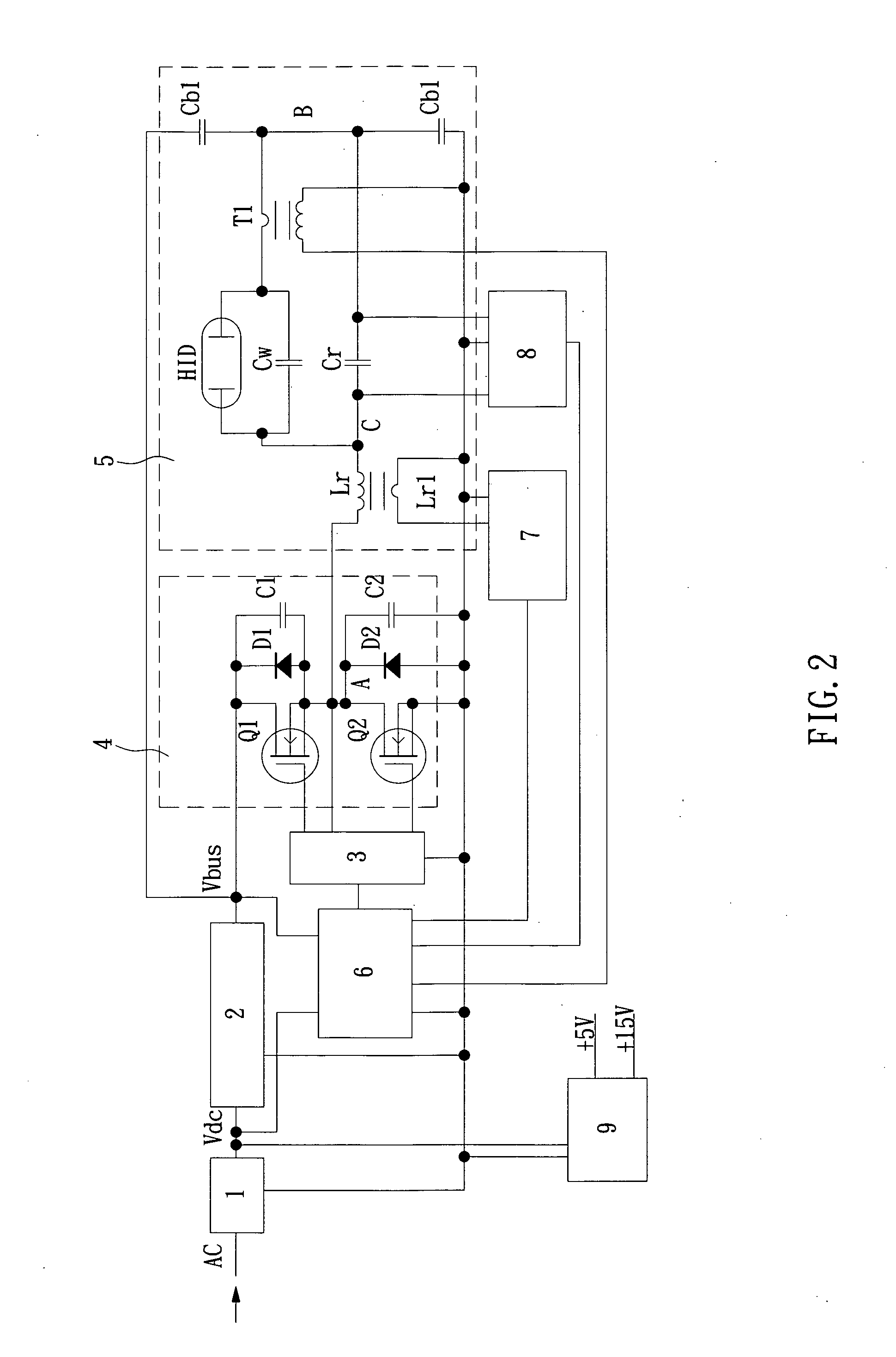

Adaptive sliding-frequency triggering ignition method for electronic ballast of high pressure gas discharge lamp

InactiveUS20110115393A1Safely and reliably completeImprove quality and life and other parameterElectrical apparatusElectric lighting sourcesEngineeringHigh pressure

An adaptive sliding-frequency triggering ignition method for electronic ballast of high pressure gas discharge lamp includes the steps of: measuring an accurate value of free oscillation frequency of the ballast load loop by using a single-chip before sliding-frequency triggering ignition, implementing safe and reliable sliding-frequency triggering ignition after calculating the initial frequency and ending frequency of sliding-frequency triggering ignition according to the accurate value. The method can safely and reliably finish sliding-frequency triggering ignition course, thus improving the parameters such as the quality, life of the high pressure gas discharge lamp electronic ballast.

Owner:FOSHAN METROPOLIS LIGHTING

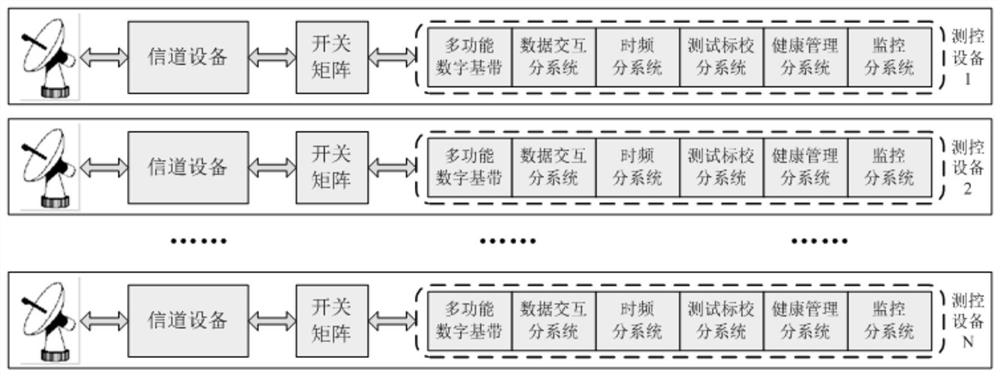

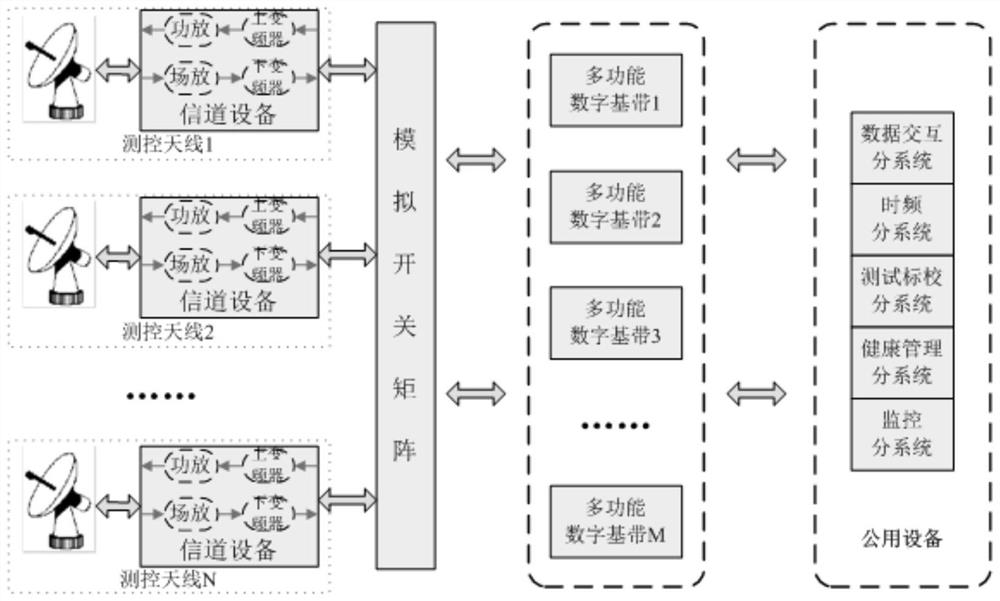

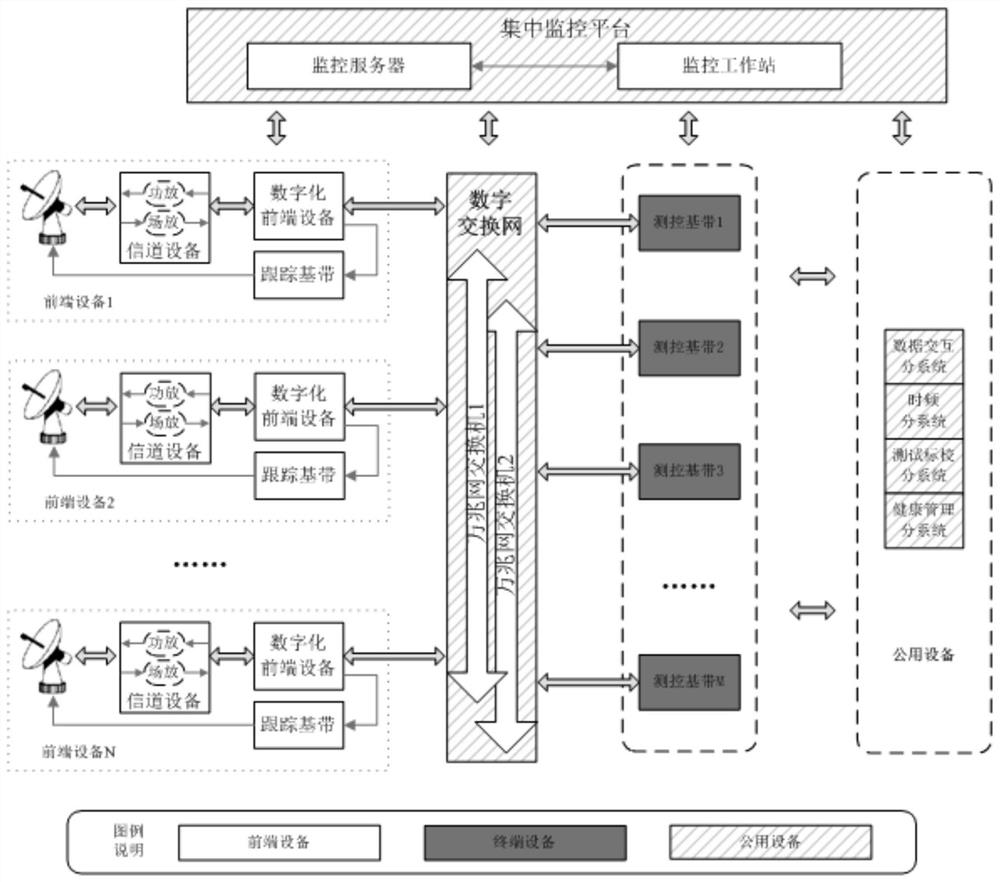

Spaceflight ground measurement and control station all-digital resource pool architecture

ActiveCN112290994AFlexible and Efficient Realization of ReorganizationOvercome self-jitterRadio transmissionHigh level techniquesRadio frequencyTransmission delay

The invention relates to a spaceflight ground measurement and control station all-digital resource pool architecture, which comprises front-end equipment, terminal equipment and public equipment, andis characterized in that the front-end equipment and the terminal equipment carry out resource recombination through a digital exchange network and are recombined into a measurement and control systemwith specific measurement and control capability under the cooperation of the public equipment. The full-digital resource pool architecture of the spaceflight ground measurement and control station is based on the designed resource pool architecture with front-end equipment solidification combination, terminal equipment flexible recombination and public equipment unified configuration, and corresponding digital implementation technologies such as radio frequency direct acquisition, network reliable transmission, time delay real-time correction and full-link hot backup are adopted. It is guaranteed that different measurement and control devices in the same station address stably and reliably complete tasks, recombination is flexibly and efficiently achieved, the construction mode that a traditional large measurement and control station guarantees tasks through quantity is changed, and a foundation is laid for intensive, efficient and on-demand configured construction routes in the future.

Owner:NO 63921 UNIT OF PLA +1

Security ensuring and patrolling robot

InactiveCN1331641CReliable completionStabilize security patrol tasksManipulatorControl systemEngineering

The invention relates to a kind of patrolling robot. It consists of robot body, the movable controlling unit and the bearing rack of which is fixed firmly to the outer shell; anti- stakeout system, which consists of infrared temperature sensor, smoking sensor, hot releasing infrared sensor, mini CCD camera eye, signal lamp, buffer, and graphic message wireless conveying module; the controlling system that sends message to control the robot to patrol, move to control and give an alarm automatically within the circumstance; multi-sensor system. The robot can patrol along the scheduled path, and judge the location is at according to the messages from the sensors to avoid the impediment and change the moving path. The invention is more suitable to increasing onerous security task, and improves the atomicity of security work.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com