Patents

Literature

264415results about How to "Improve work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric power tool

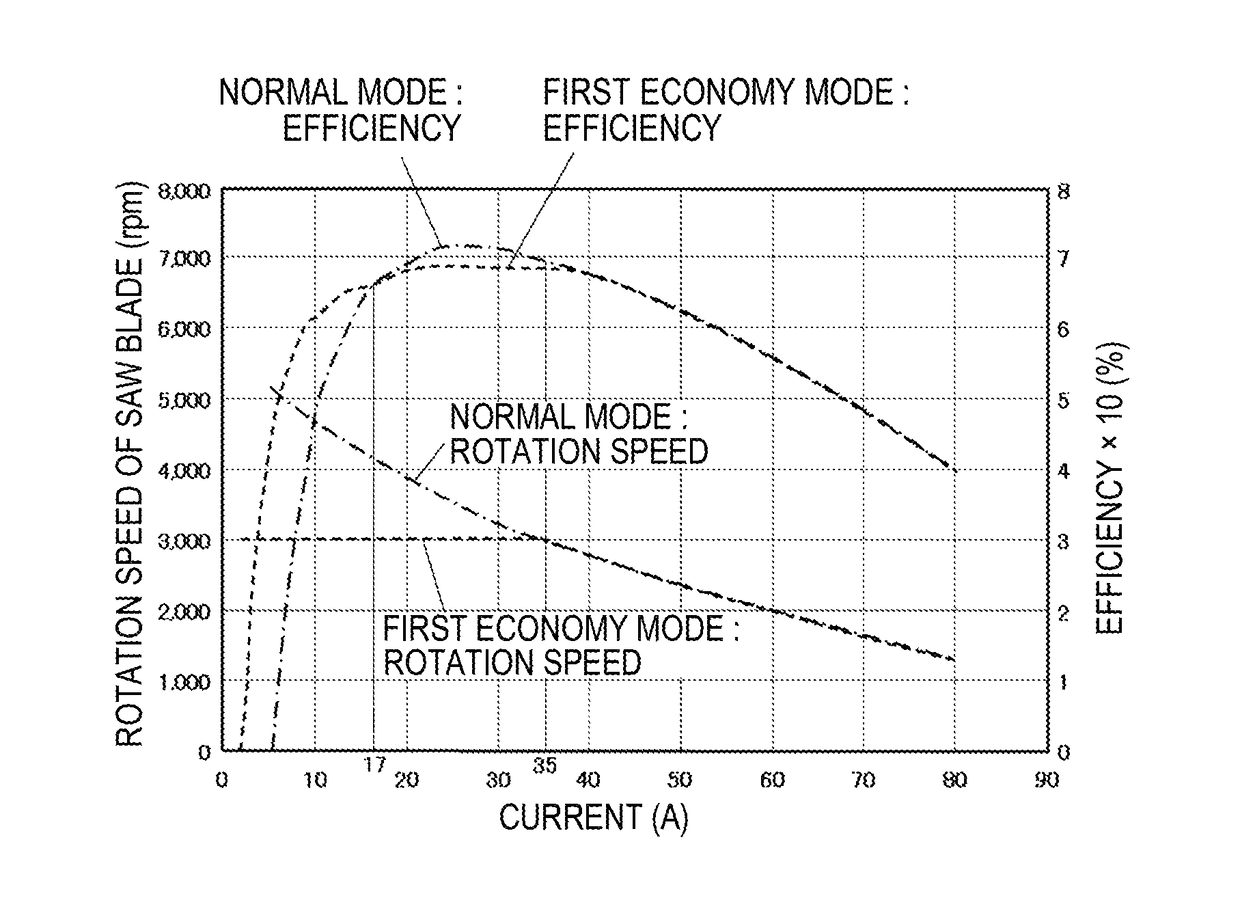

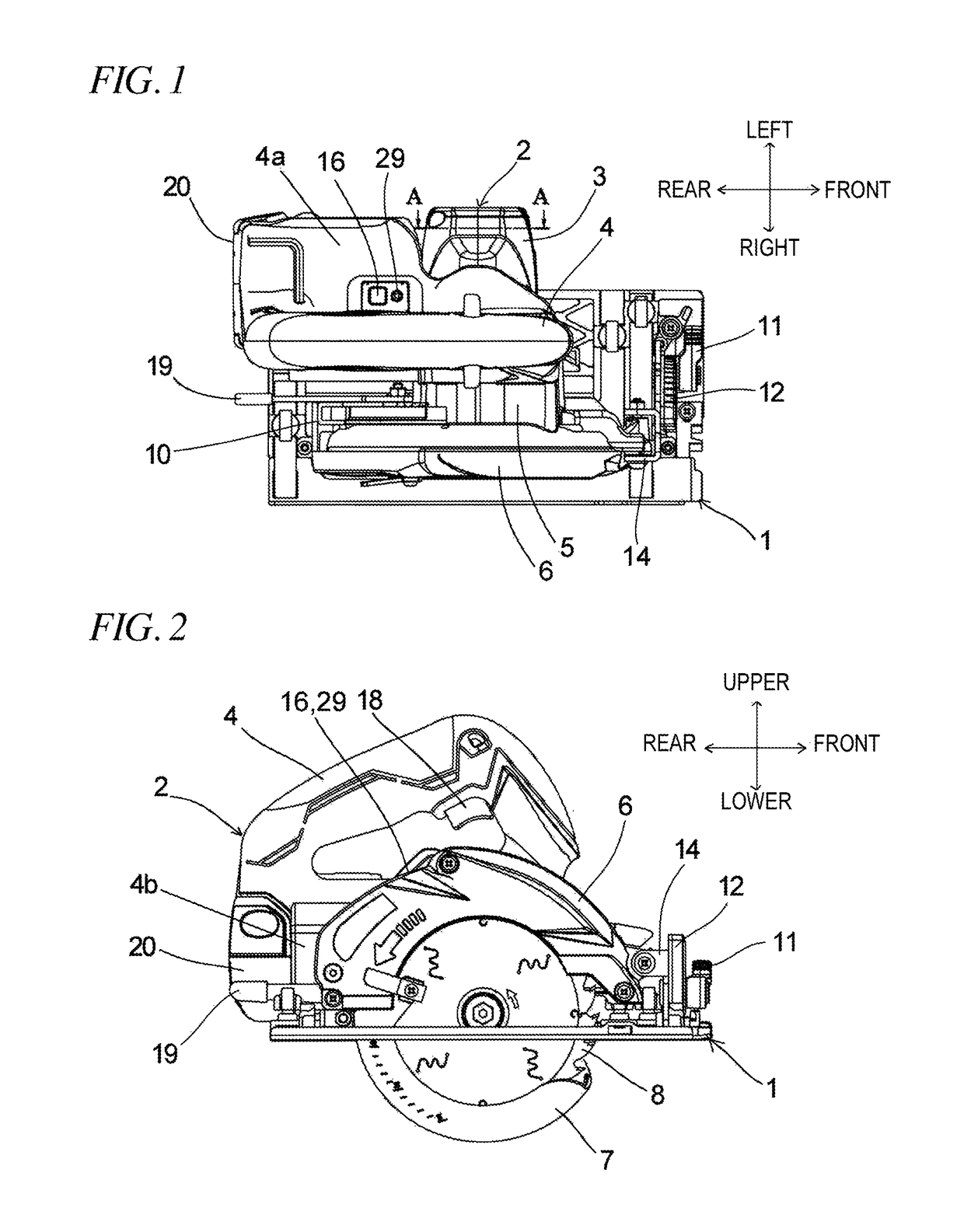

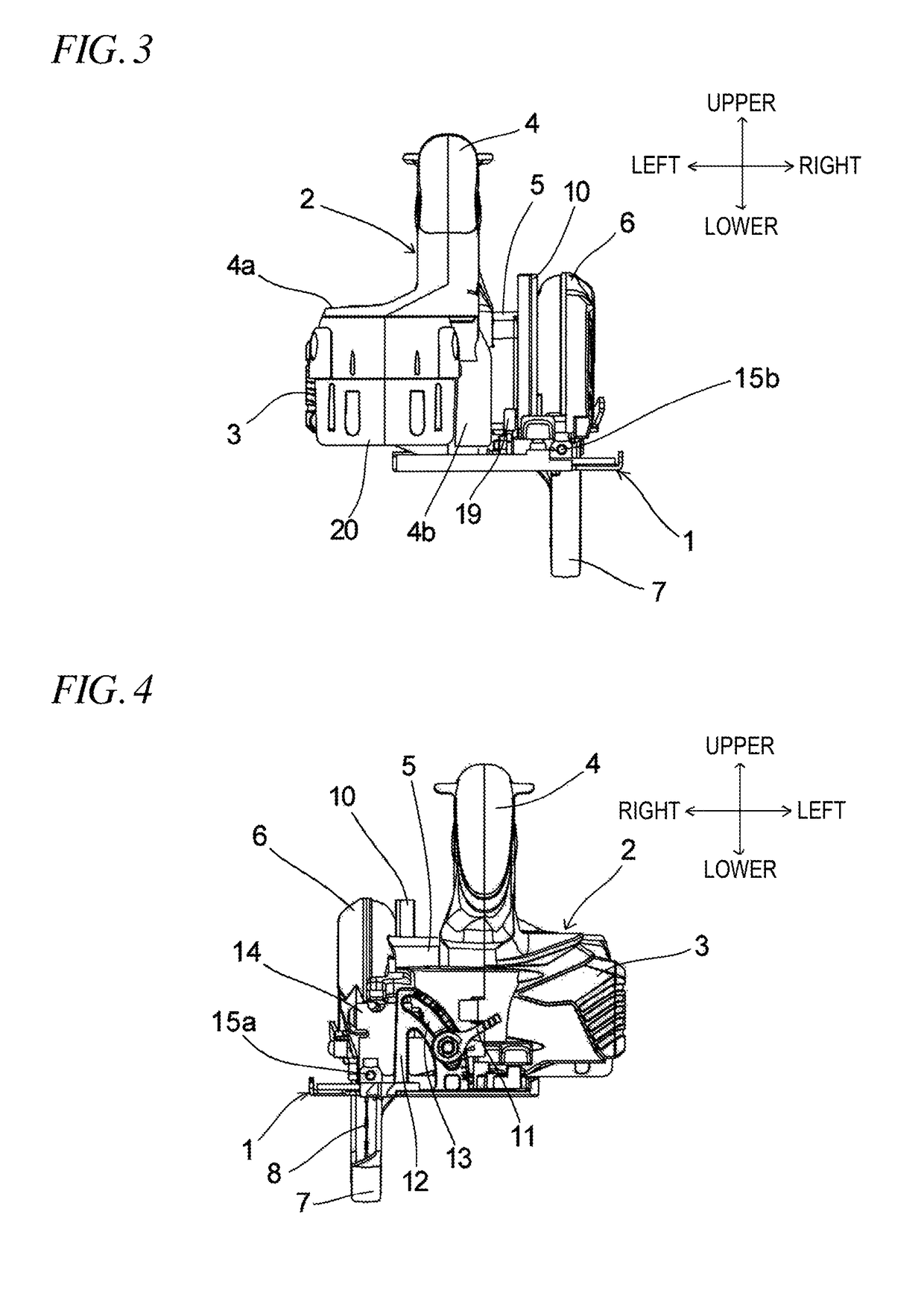

ActiveUS10099303B2Improve work efficiencyConvenience to workMetal sawing devicesMetal sawing accessoriesBrushless motorsLow speed

Owner:KOKI HLDG CO LTD

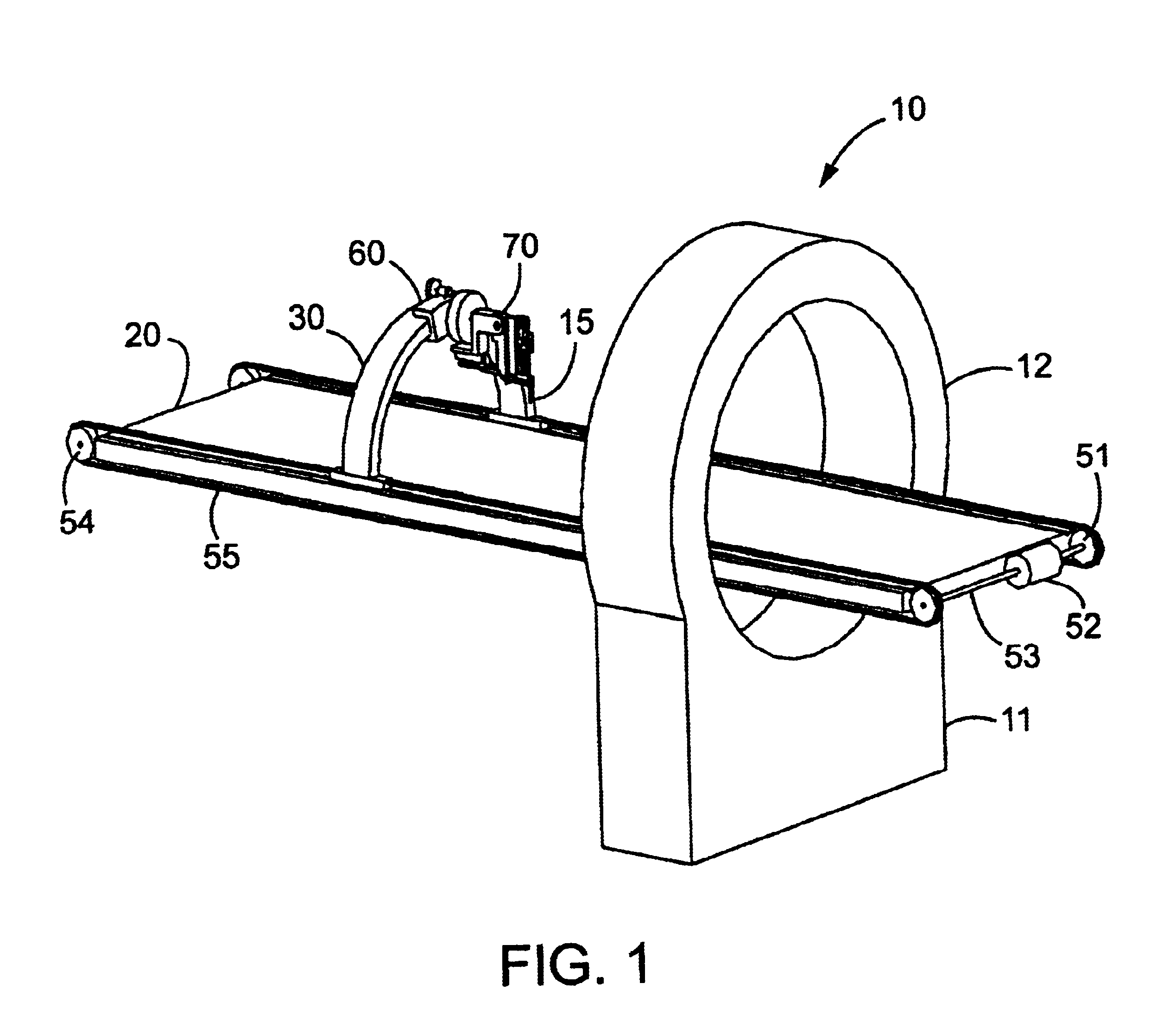

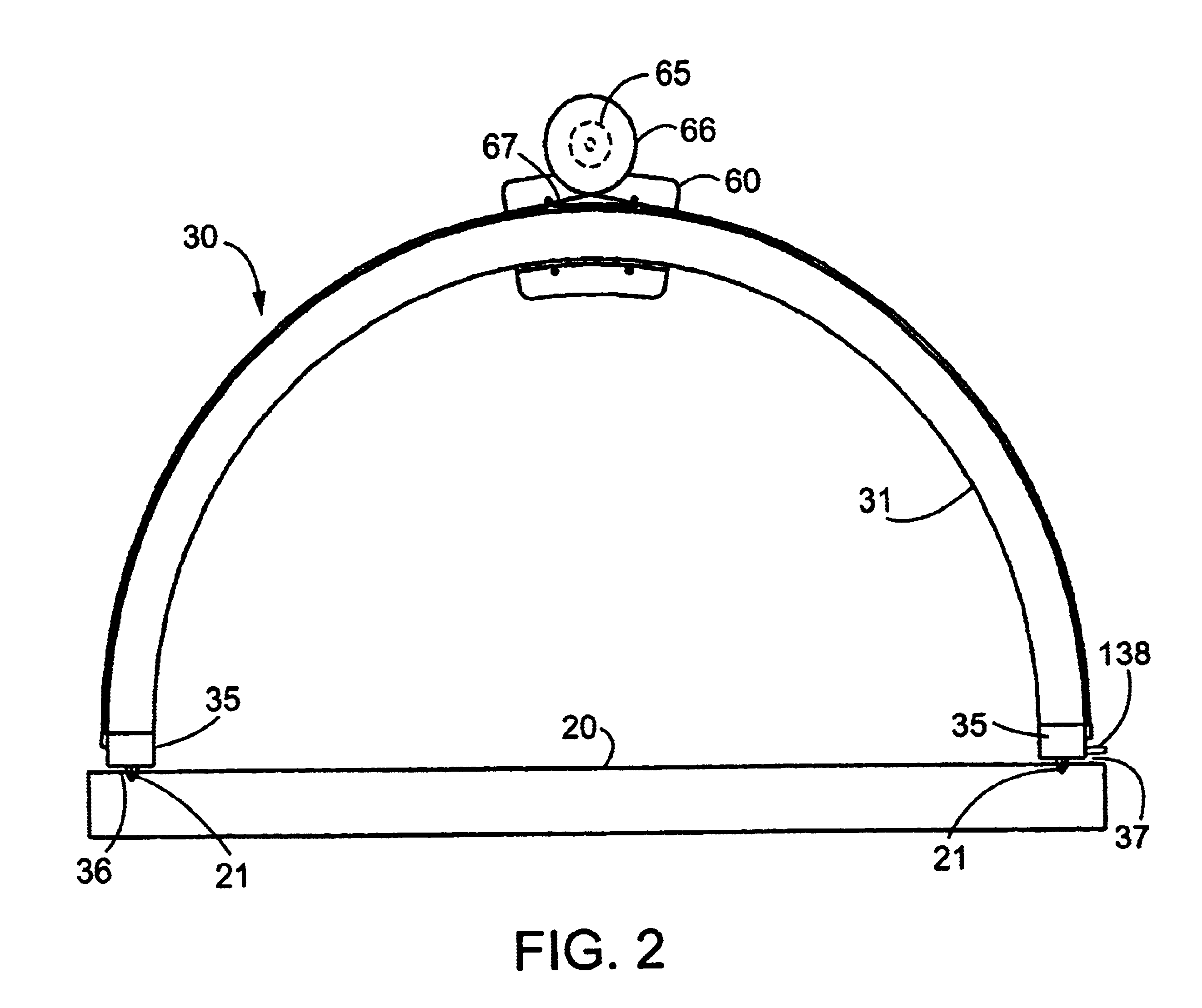

Medical manipulator for use with an imaging device

InactiveUS6665554B1Easy to insertLess stressSurgical needlesVaccination/ovulation diagnosticsDegrees of freedomEngineering

A manipulator for use in medical procedures can manipulate a medical tool with one or more degrees of freedom with respect to a patient. The manipulator is particularly useful for positioning a medical tool with respect to a patient disposed inside an imaging device such as a computer tomography machine.

Owner:MICRODEXTERITY SYST

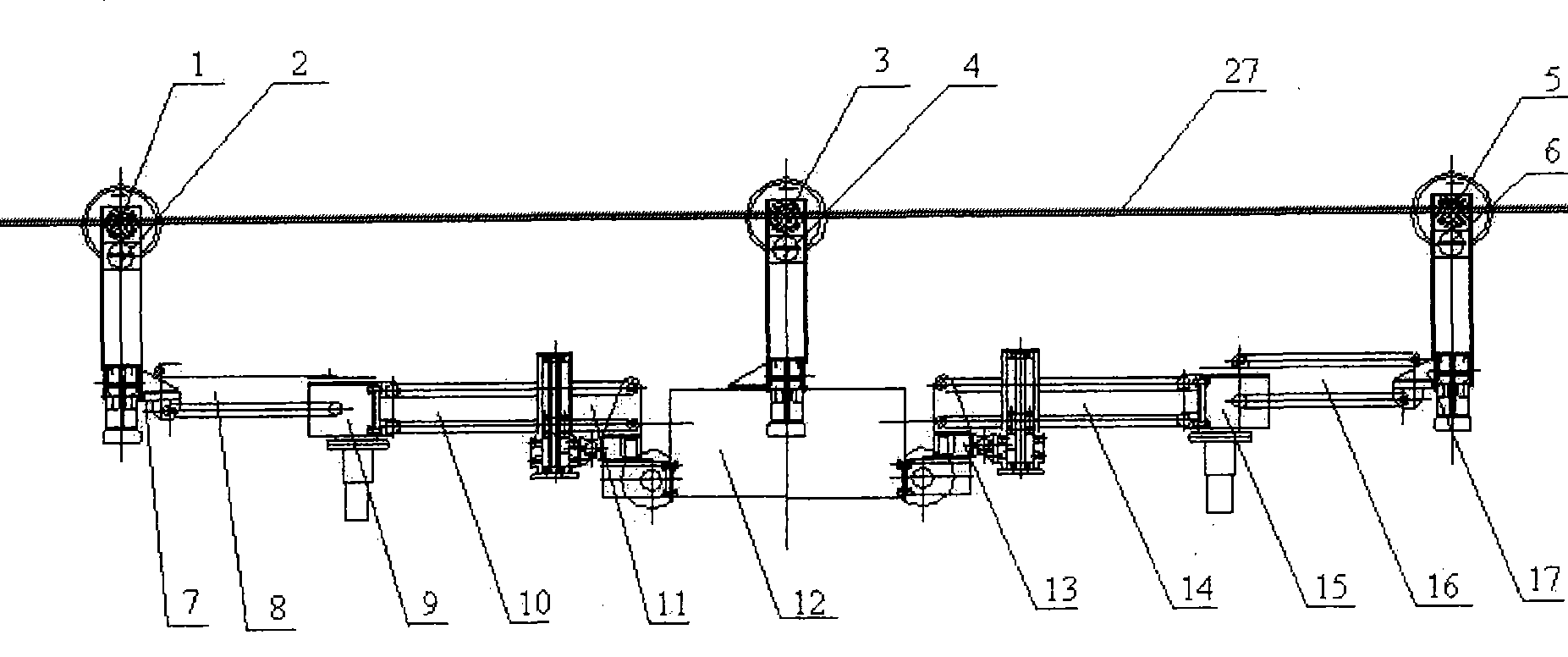

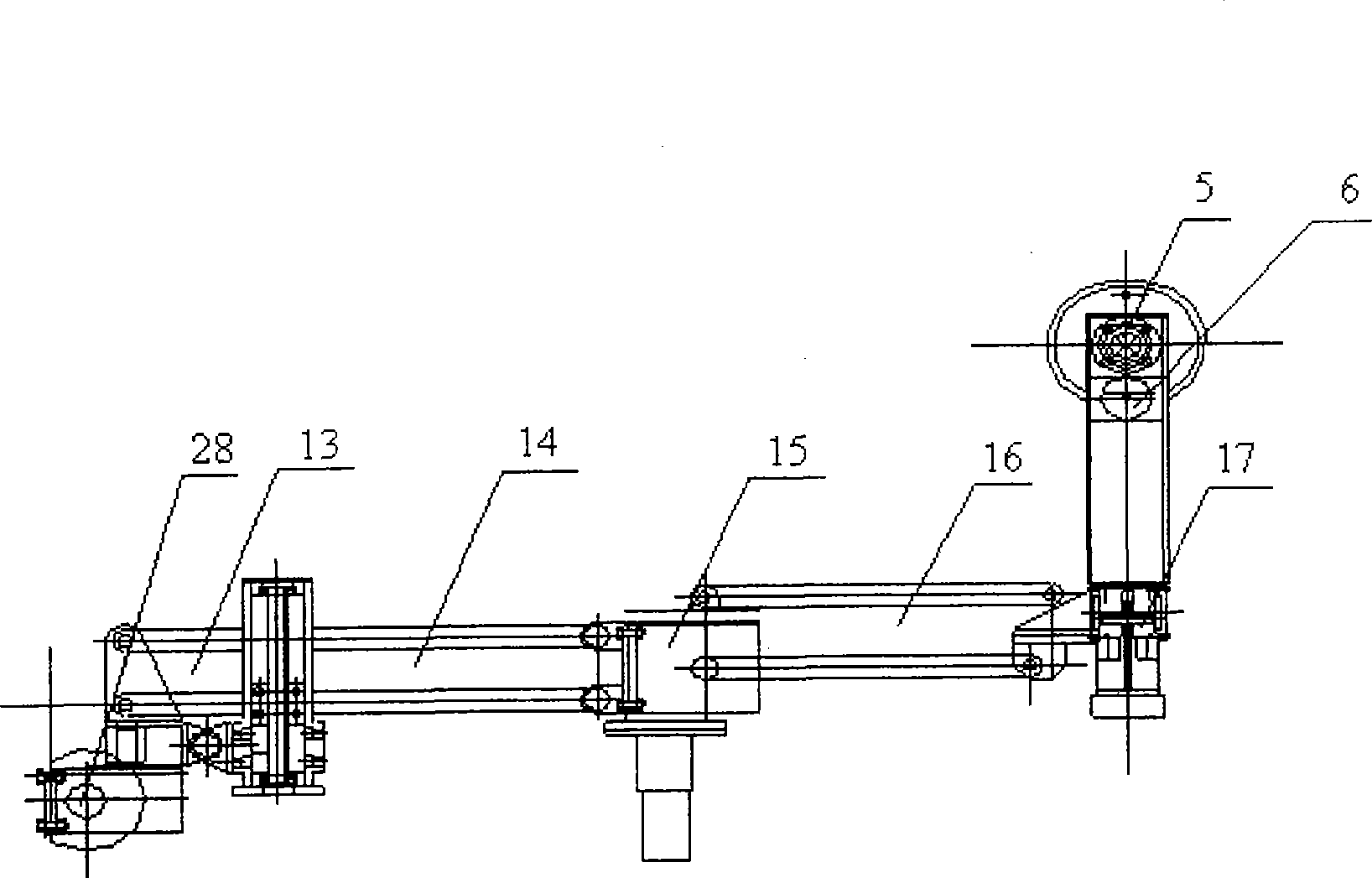

Robot of autonomous moving along 110KV transmission line and its working method

InactiveCN100502181CReduce workloadGuaranteed safe operationManipulatorApparatus for overhead lines/cablesWireless image transmissionSimulation

This invention is a robot walking automatically along 110kV transmitting wire and its operational method. It is composed of the robot reality, the control device, the sensor, the detecting device and wireless image transmitting device; the control device and the wireless image transmitting device are set in the control box in the middle of the robot reality, the position sensors are equipped at the terminals of every joint, the visual sensor CCD measuring the distance of sensors and obstacle is equipped in the front of every hand, the detecting device includes high speed vidicon and the hot imaging device connected to the robot reality through the platform. It can walk stably on the 110kV transmitting wire and automatically span all kinds of obstacles on the wire, and it replaces the human to patrol the transmitting wire and reduces the working amount of patrolling, and improves the working efficiency and detecting precision to assure the safe operation of the electric wire.

Owner:SHANDONG UNIV

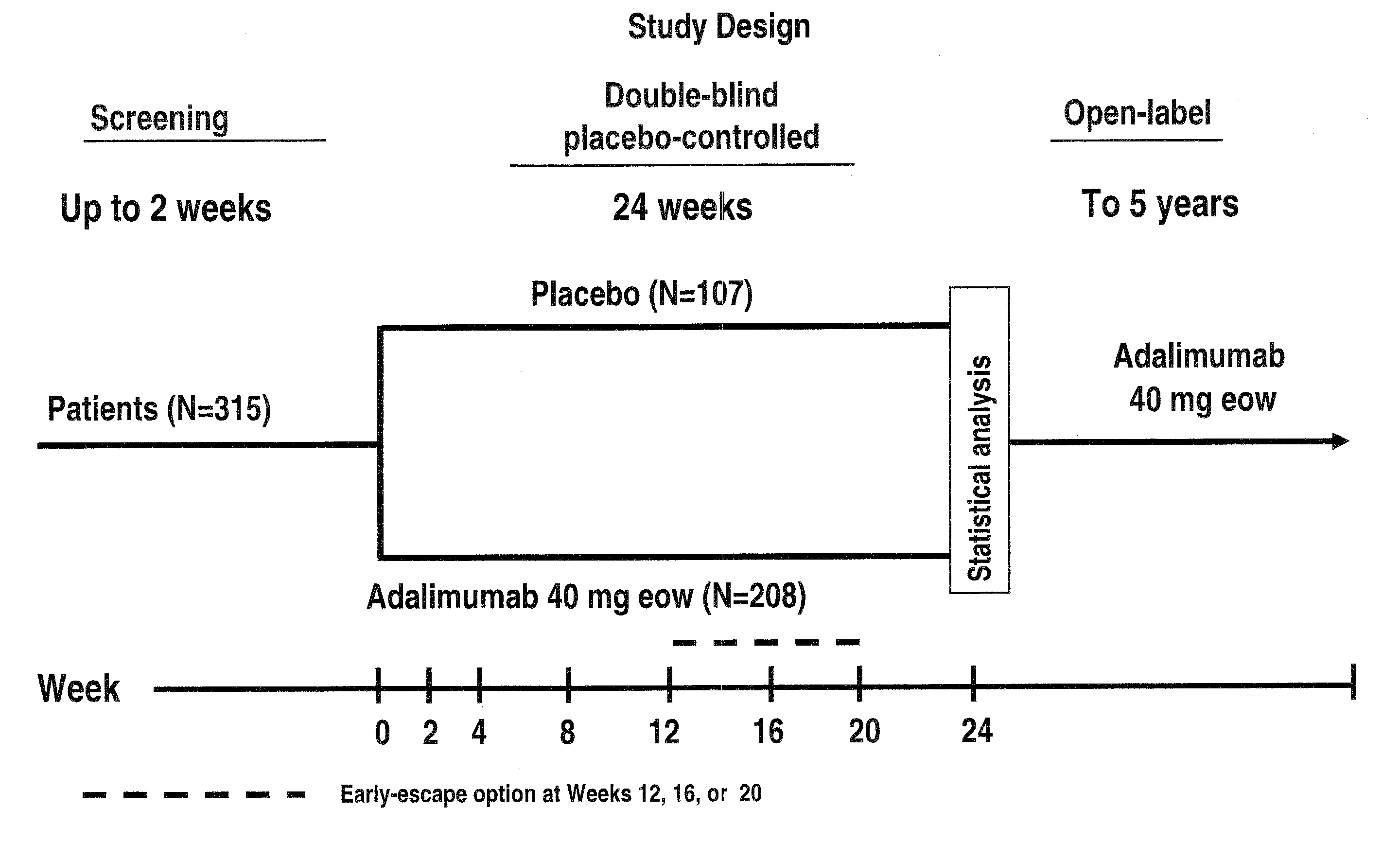

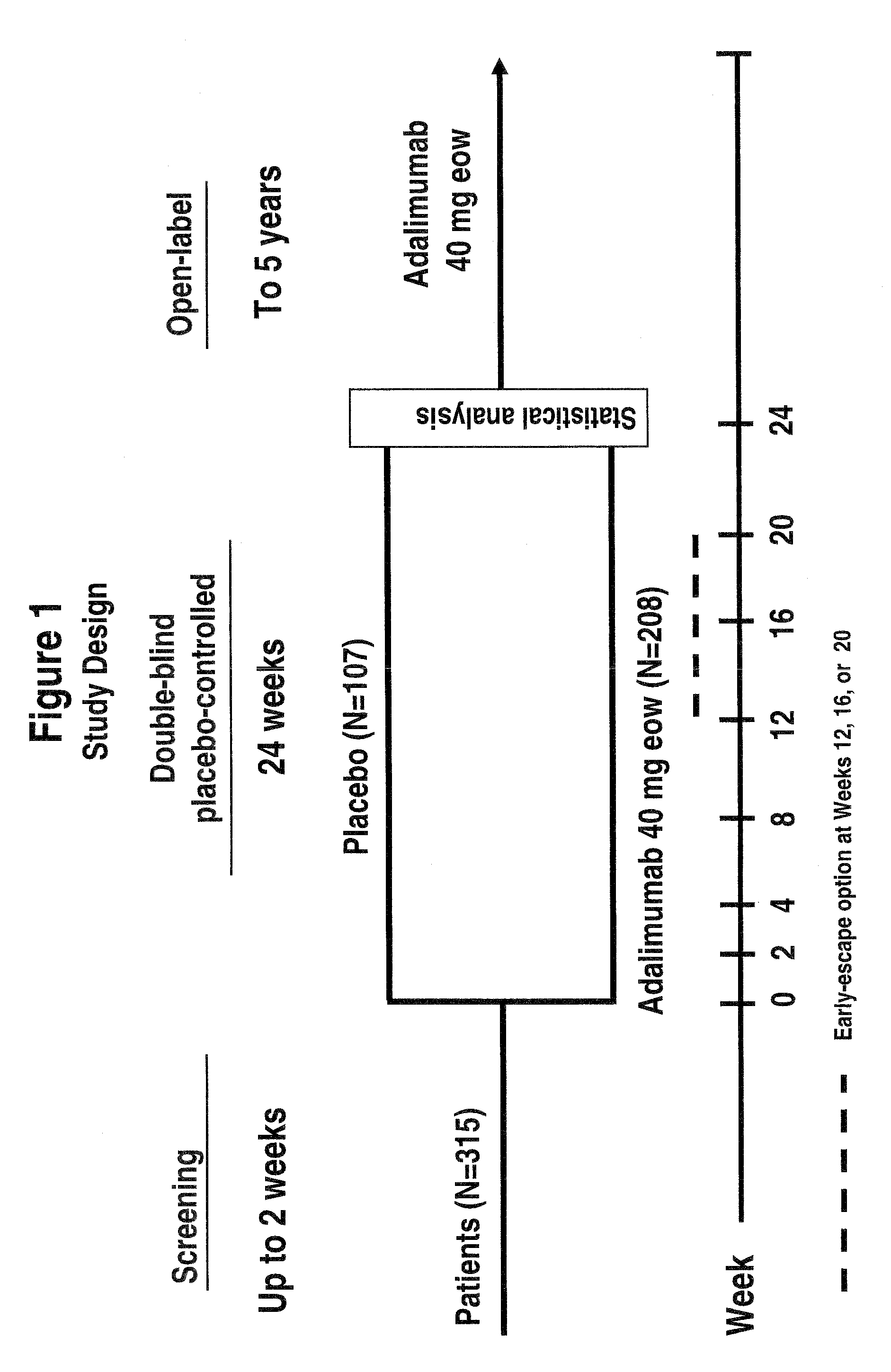

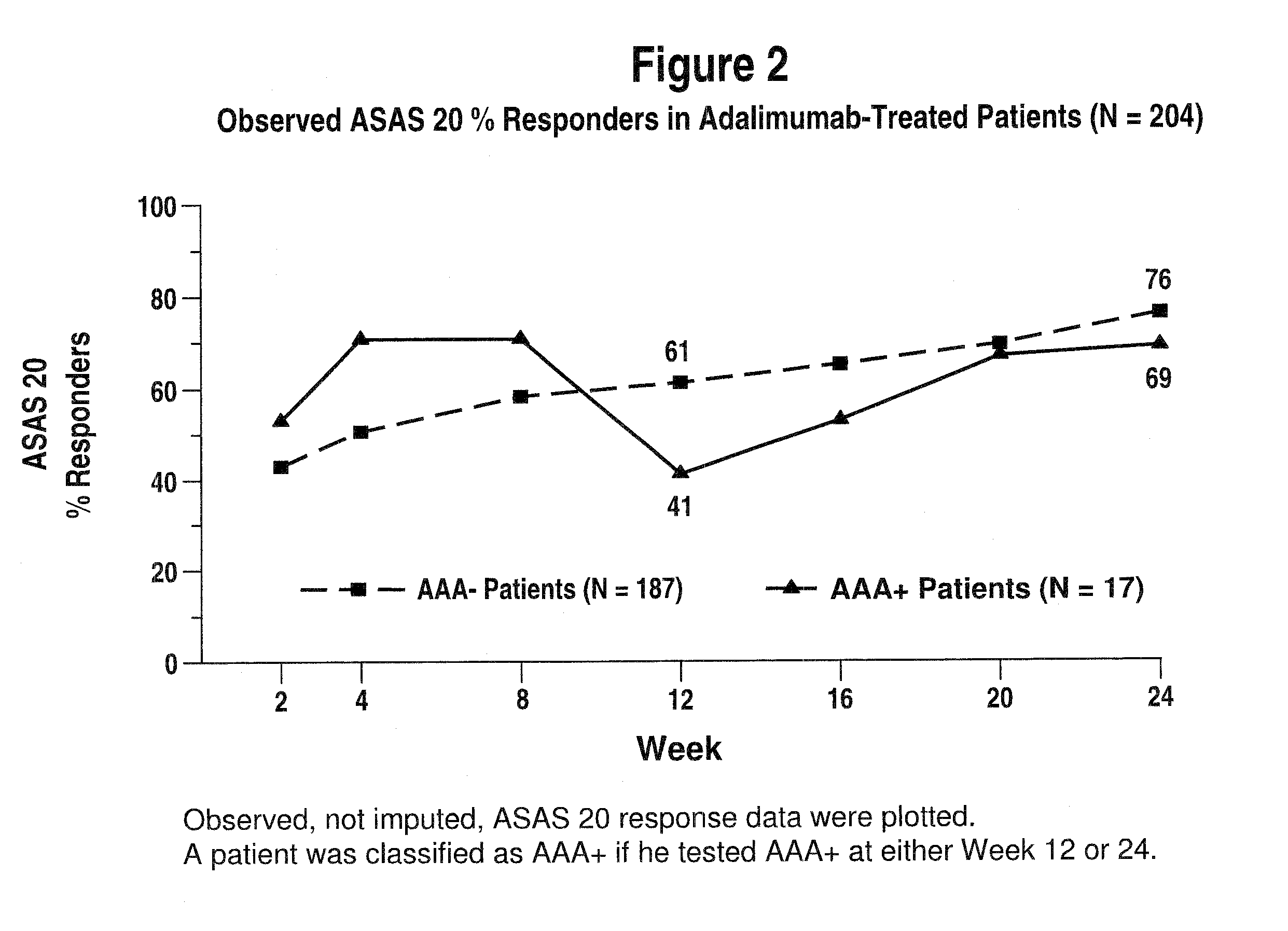

Uses and compositions for treatment of ankylosing spondylitis

ActiveUS20090123378A1Treatment safetyImprove fatigueCompounds screening/testingAntibody ingredientsMedicineAnkylosing spondylitis

The invention provides methods, uses and compositions for the treatment of ankylosing spondylitis (AS). The invention describes methods and uses for treating ankylosing spondylitis, wherein a TNFα inhibitor, such as a human TNFα antibody, or antigen-binding portion thereof, is used to reduce signs and symptoms of ankylosing spondylitis in a subject. Also described are methods for determining the efficacy of a TNFα inhibitor for treatment of ankylosing spondylitis in a subject.

Owner:ABBVIE BIOTECHNOLOGY LTD

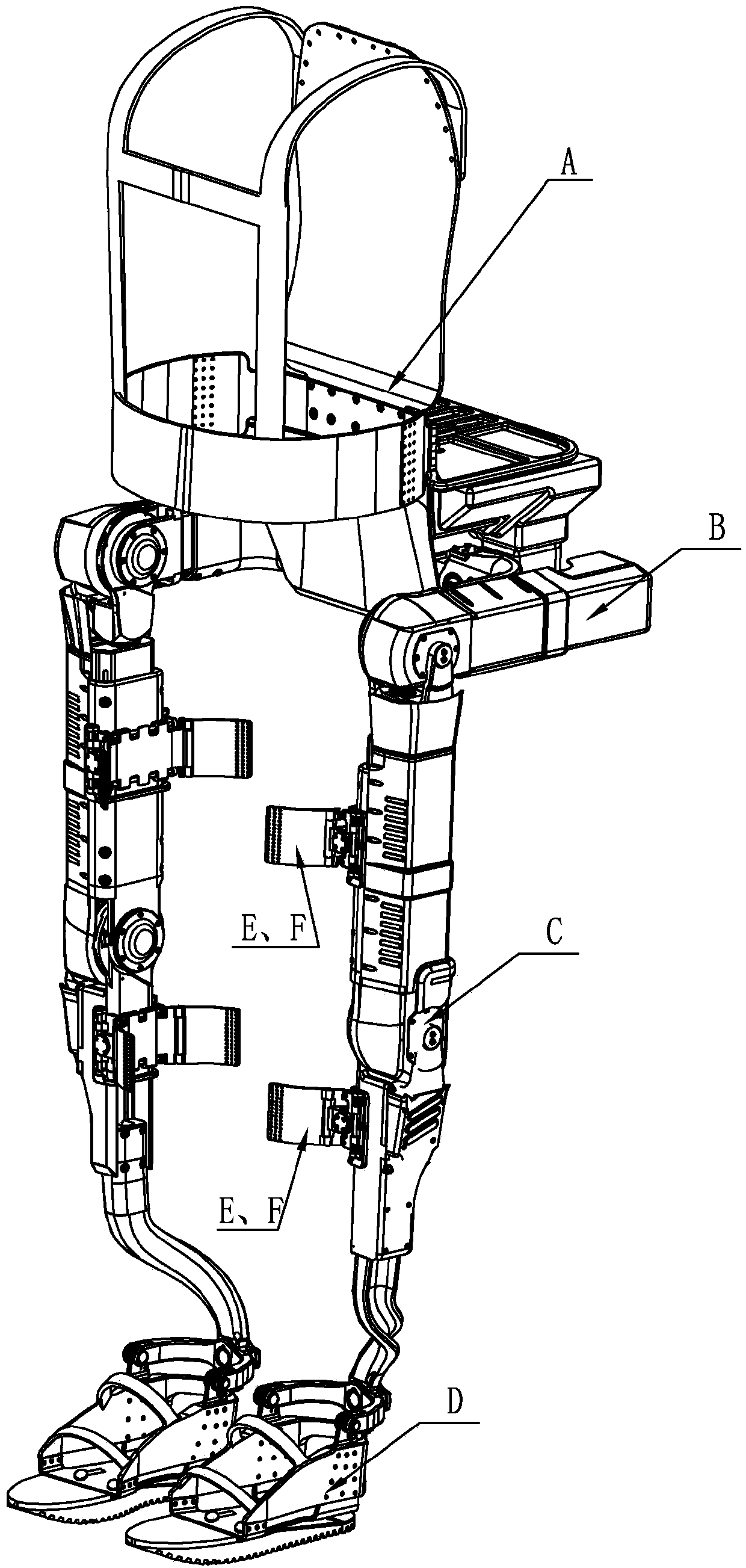

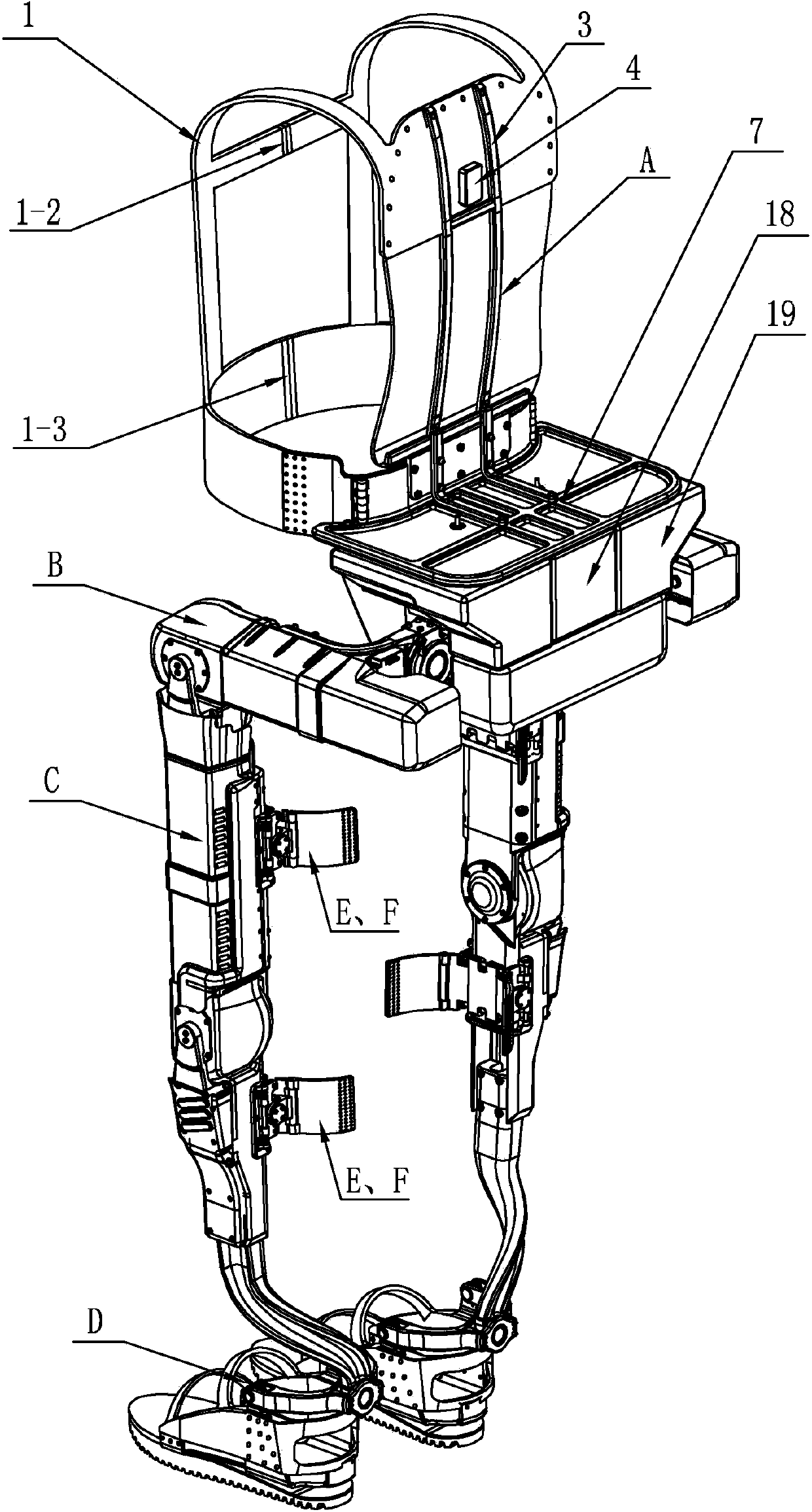

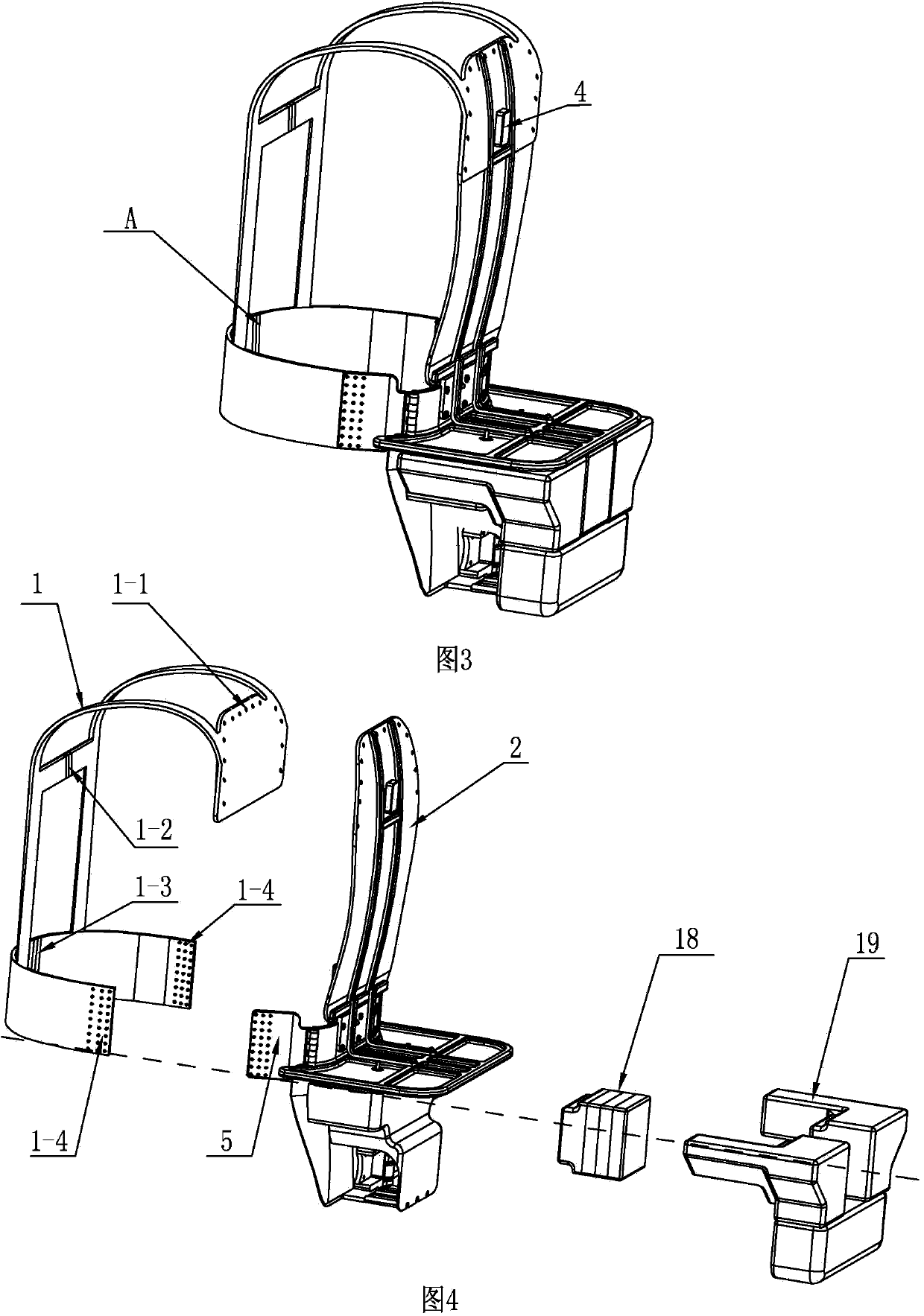

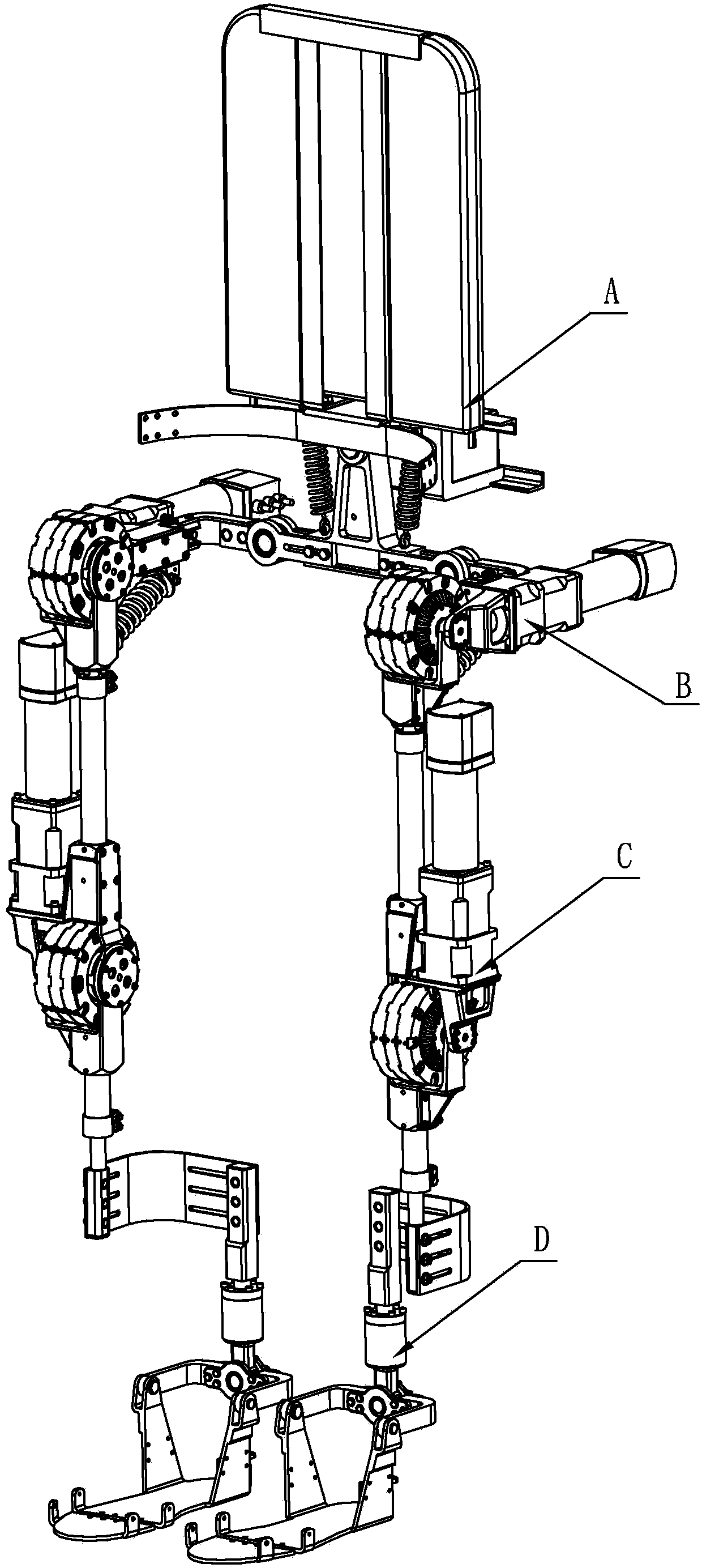

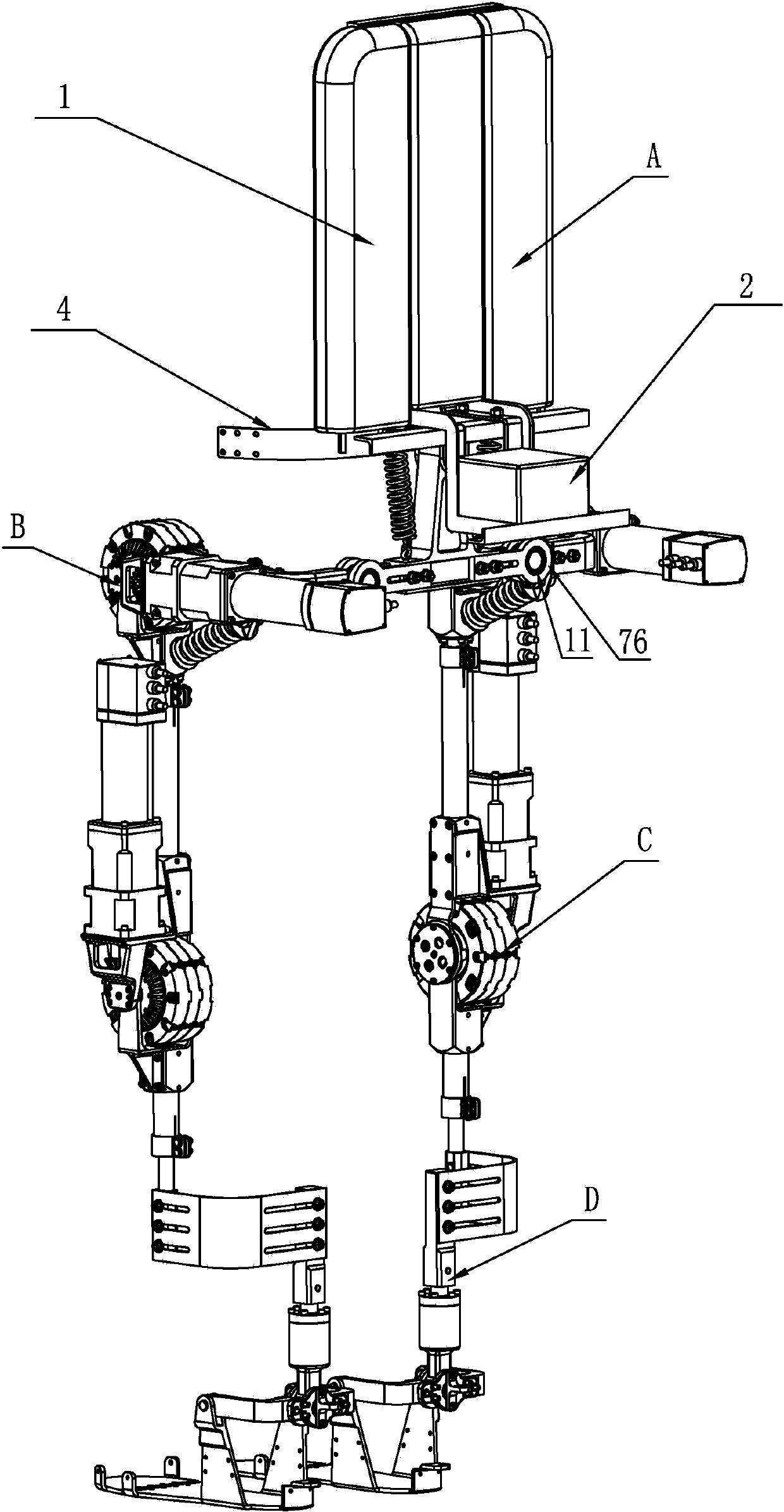

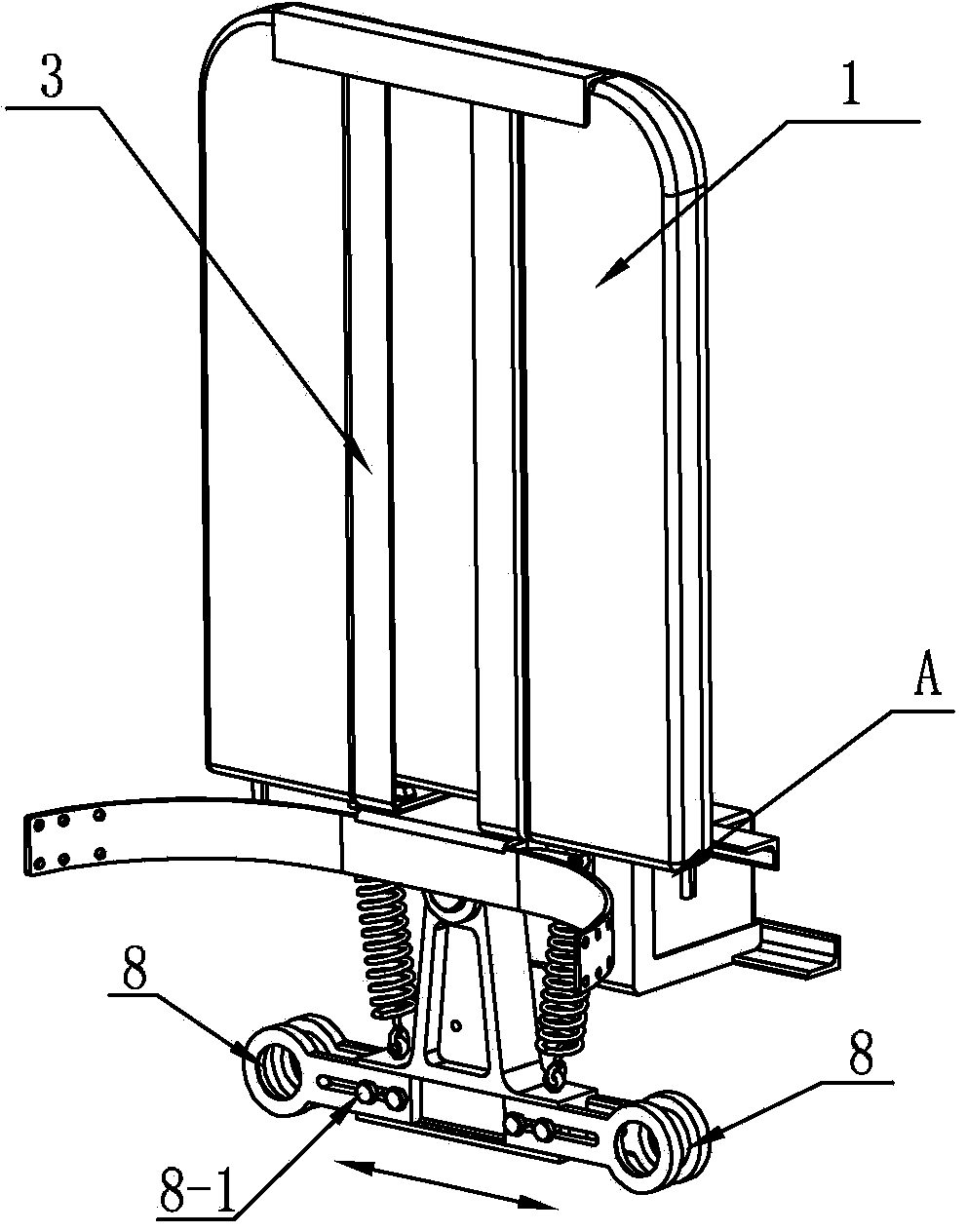

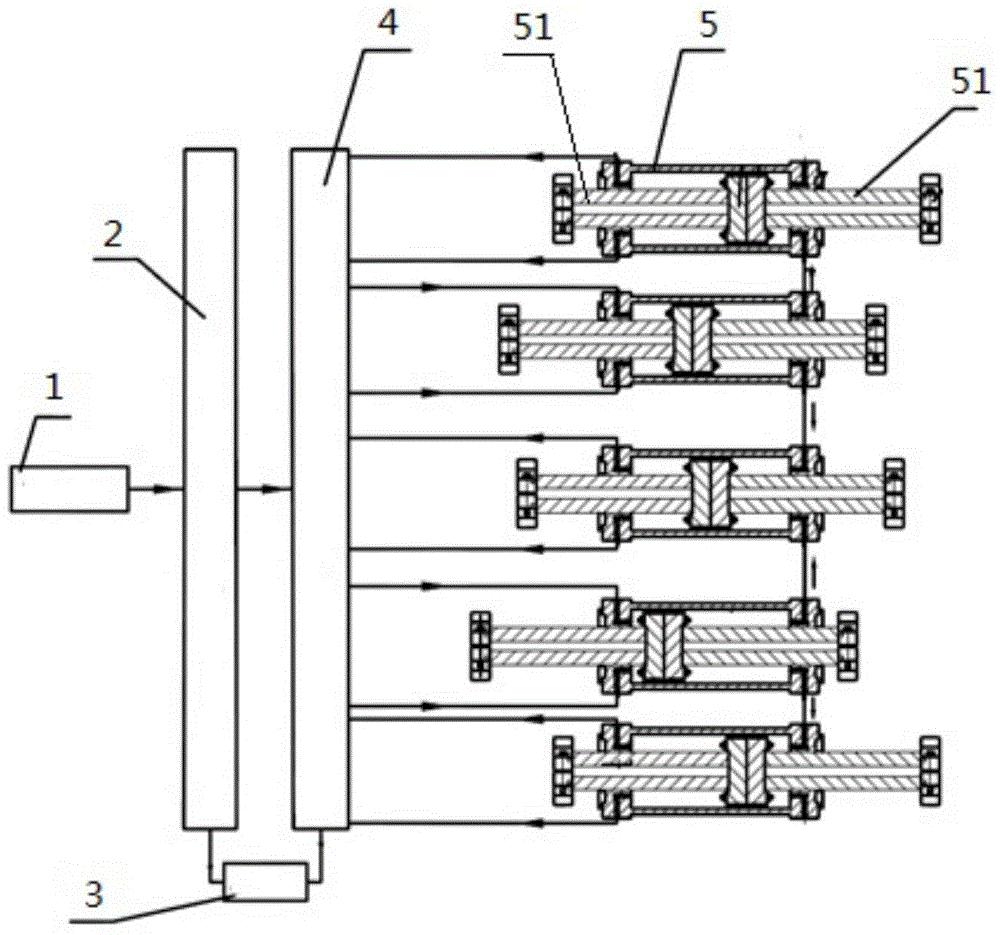

Human-simulated external skeleton robot assisting lower limbs

ActiveCN103610568ARealize the safety requirements of mechanical limitConvenient and accurate adjustment of telescopic lengthChiropractic devicesWalking aidsThighExoskeleton robot

The invention relates to an external skeleton robot, in particular to a human-simulated external skeleton robot assisting the lower limbs. The human-simulated external skeleton robot assisting the lower limbs aims to solve the problems that an existing external skeleton robot is low in coupling degree of motion space and poor in wearing comfort, reliability and adaptation, and power needed by a motor is large. The human-simulated external skeleton robot assisting the lower limbs comprises an upper body back part, a left leg and a right leg. The left leg and the right leg respectively comprise a hip drive system, a knee drive system and a foot wearing system. A rear side connection board of the waist is in rotating connection with a load installation board. Each hip joint supporting board is provided with a first motor and a first reducer, wherein the first motor is provided with an encoder, and the output end of the first motor provided with the encoder is connected with the input end of the first reducer. Each hip joint connecting board can rotate in the vertical plane. Each thigh stretching board is in detachable connection with the corresponding hip joint connecting board. The output end of a main drive mechanism is connected with each crus connecting board. The lower surfaces of elastic boards are bonded with the upper surfaces of the rubber soles of the feet. The human-simulated external skeleton robot assisting the lower limbs can assist in walking.

Owner:HARBIN INST OF TECH

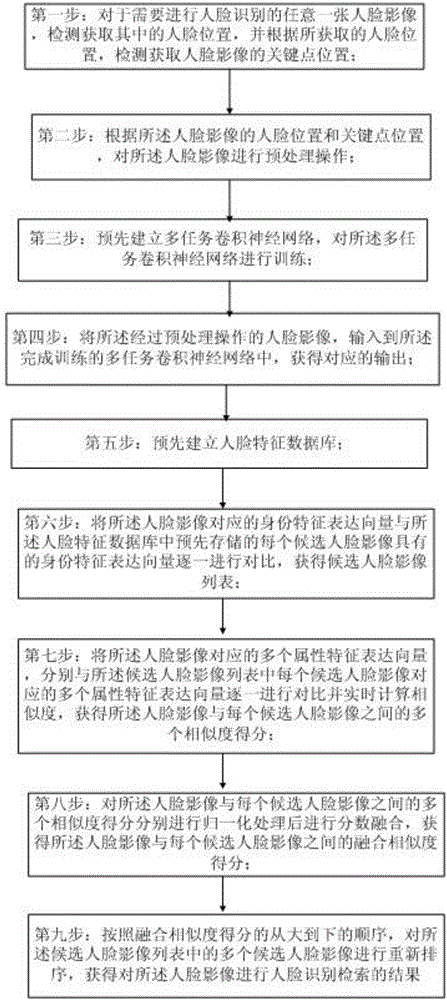

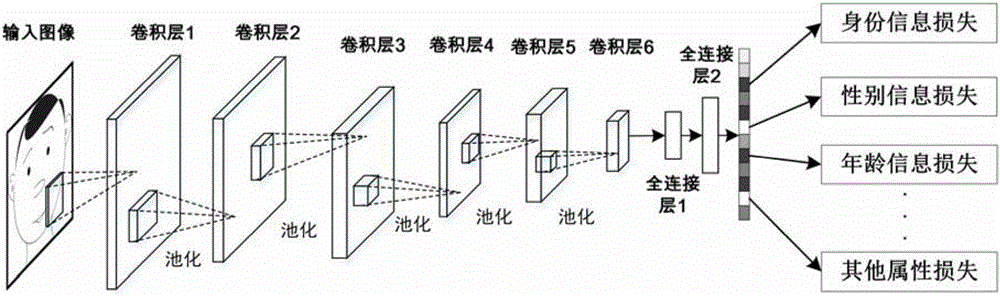

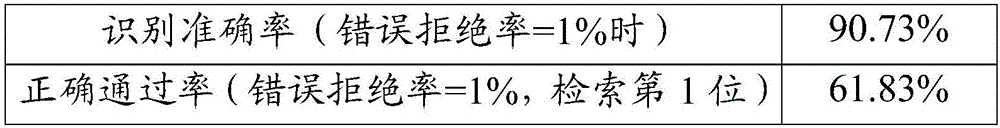

Face retrieval method based on multitask convolution nerve network

ActiveCN106815566AHigh quality recognitionImprove work efficiency and work qualityCharacter and pattern recognitionCrucial pointConvolution

The invention discloses a face retrieval method based on a multitask convolution nerve network; the method comprises the following steps: detecting a random face image so as to obtain face position and key point positions; preprocessing the face image; pre-building the multitask convolution nerve network, and training the same; inputting the preprocessed face image into the trained multitask convolution nerve network; pre-building a face feature database; calculating identity feature similarity for the face image and the face feature database, thus obtaining a candidate face image list; calculating a plurality of attribute feature expression vector similarities between the face image and the candidate face images; carrying out normalization and fusing; ranking the images according to the fuse similarity scores, thus obtaining a retrieval result. The method can realize face image high quality identification, thus fast and effectively determining user IDs corresponding to mass face images, and satisfying people demands on the face identification function.

Owner:天津中科智能识别有限公司

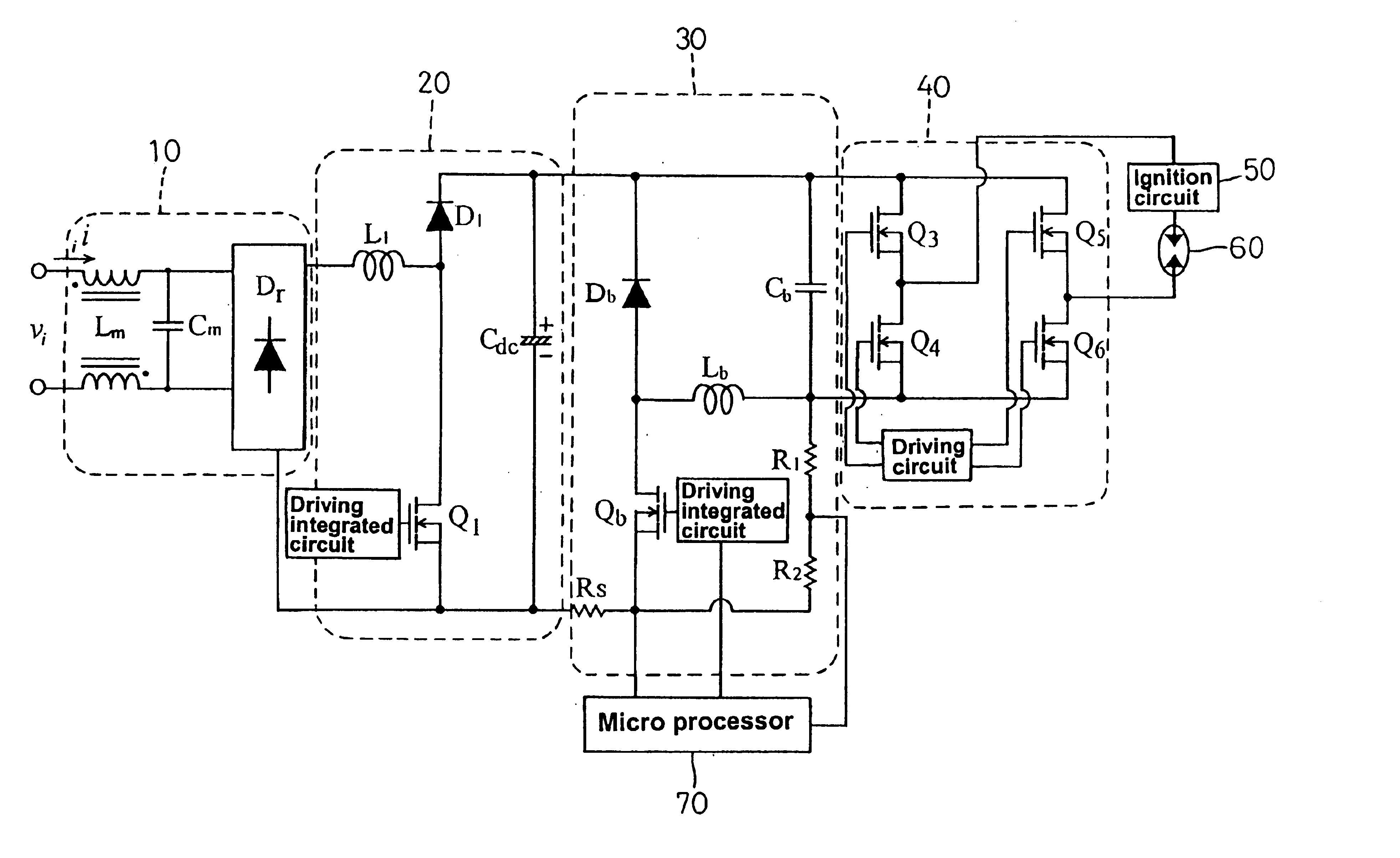

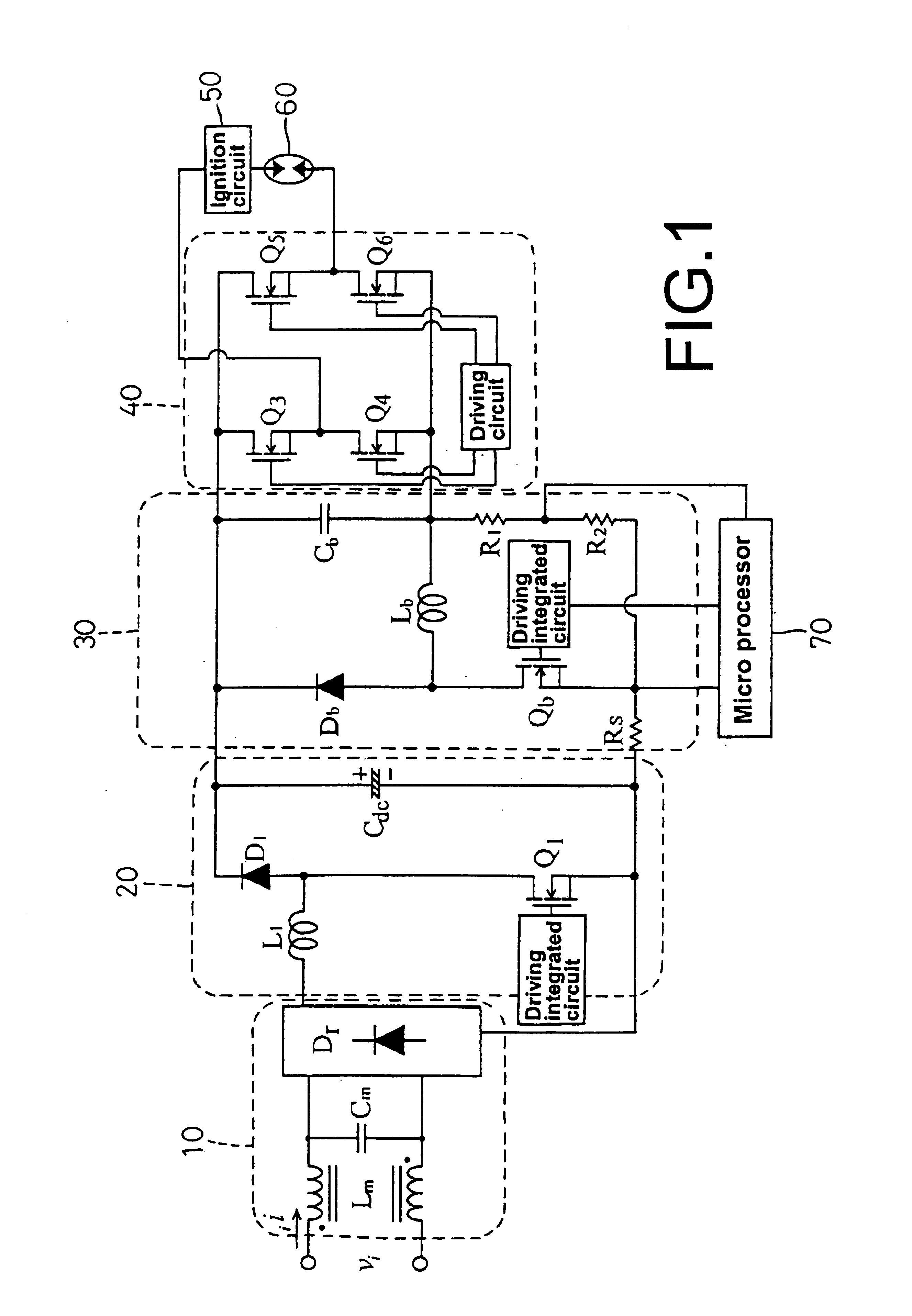

Three-stage electronic ballast for metal halide lamps

InactiveUS6856102B1Reduce power lossImprove efficiencyElectrical apparatusElectric light circuit arrangementFull bridgeThree stage

A three-stage electronic ballast for metal halide lamps mainly comprises a step-up converter, a step-down converter and a full-bridge DC-AC converter, wherein the step-down converter operates an inductor in a continuous boundary current mode to achieve reducing power loss and enhancing efficiency. Equipped with a micro processor, the electronic ballast further possesses the function of power regulation. The electronic ballast can be added with various protective functions without complex control circuits and sensing elements, thereby becoming a high-quality and low-cost electronic ballast for metal halide lamps.

Owner:LIGTEK ELECTRONICS

Path control system used for hydraulic digger operating device and its method

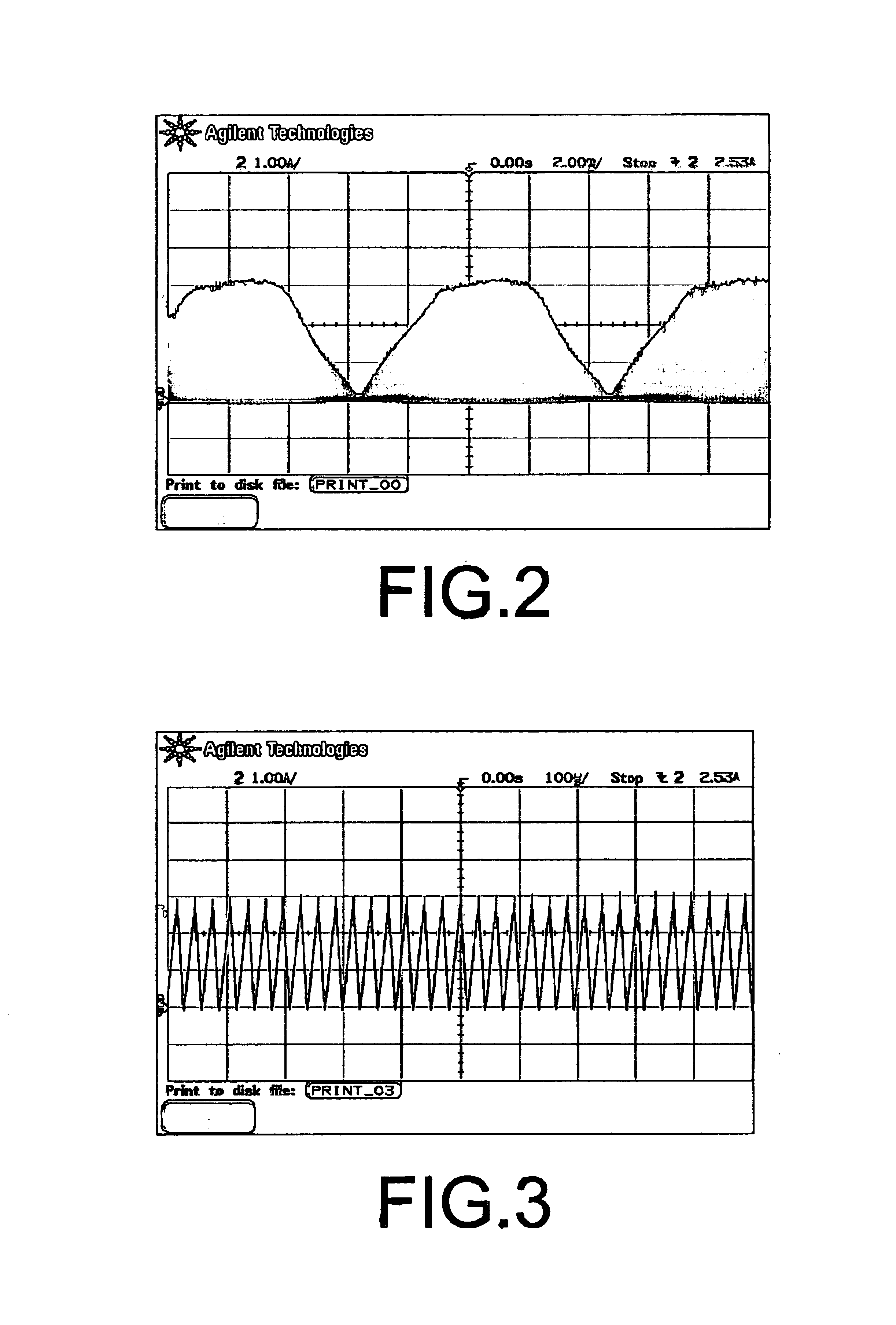

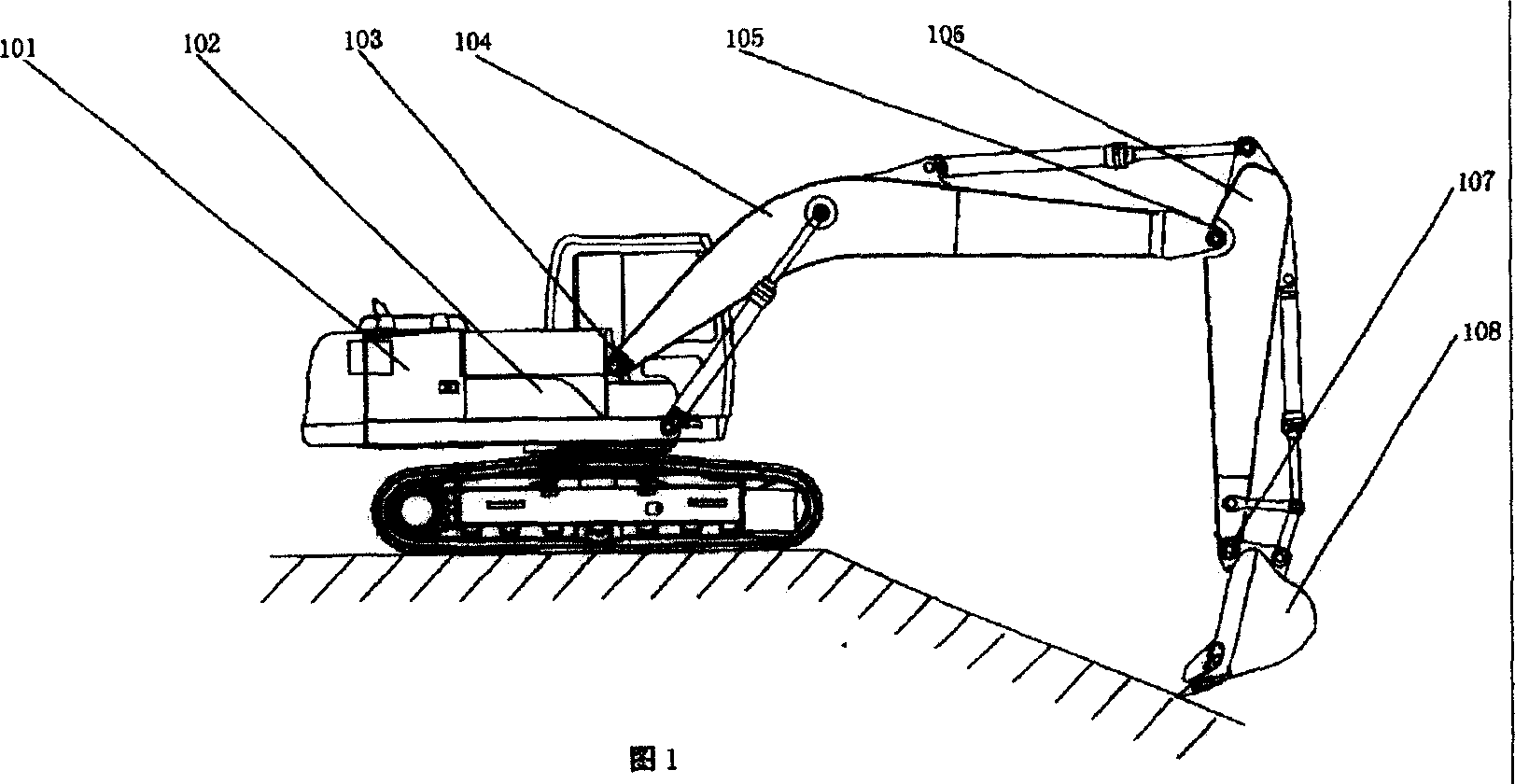

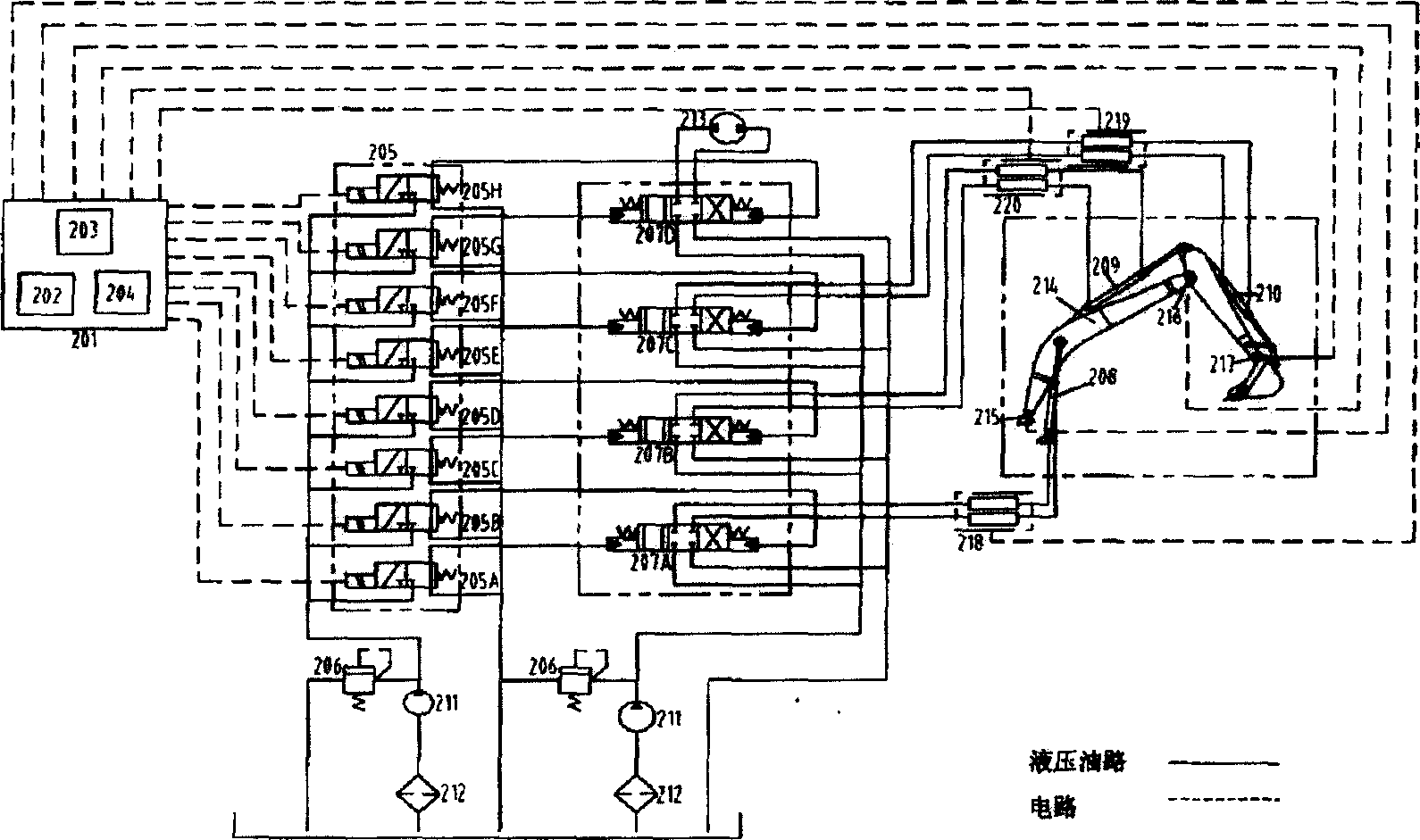

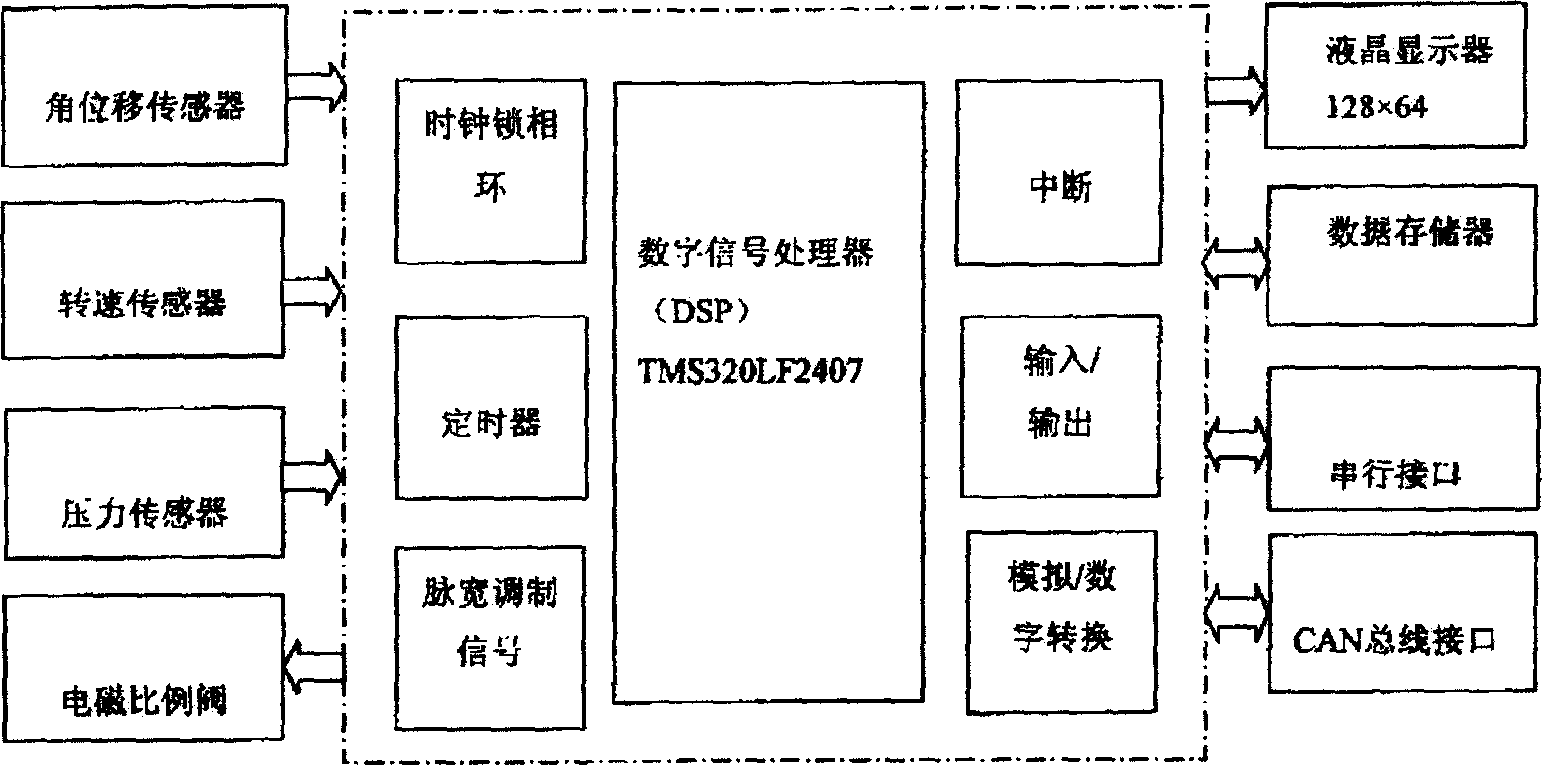

InactiveCN1651666ARealize automatic manipulationPrecise and stable positionSoil-shifting machines/dredgersPosition/direction controlHydraulic cylinderAutomatic control

The present invention relates to a track control system for hydraulic excavator working equipment and its method. Said system includes the following main components: DSP, moving arm angle detection mechanism, bucket arm angle detection mechanism, bucket angle detection mechanism, hydraulic cylinder, engine, working equipment and its driving cylinder and CAN bus. Said invention also provides the concrete steps of said control method. It can implement automatic control of hydraulic excavator working equipment, and can accurately and stably control the position and attitute of said hydraulic excavator working equipment so as to raise its working efficiency.

Owner:GUANGXI LIUGONG MASCH CO LTD

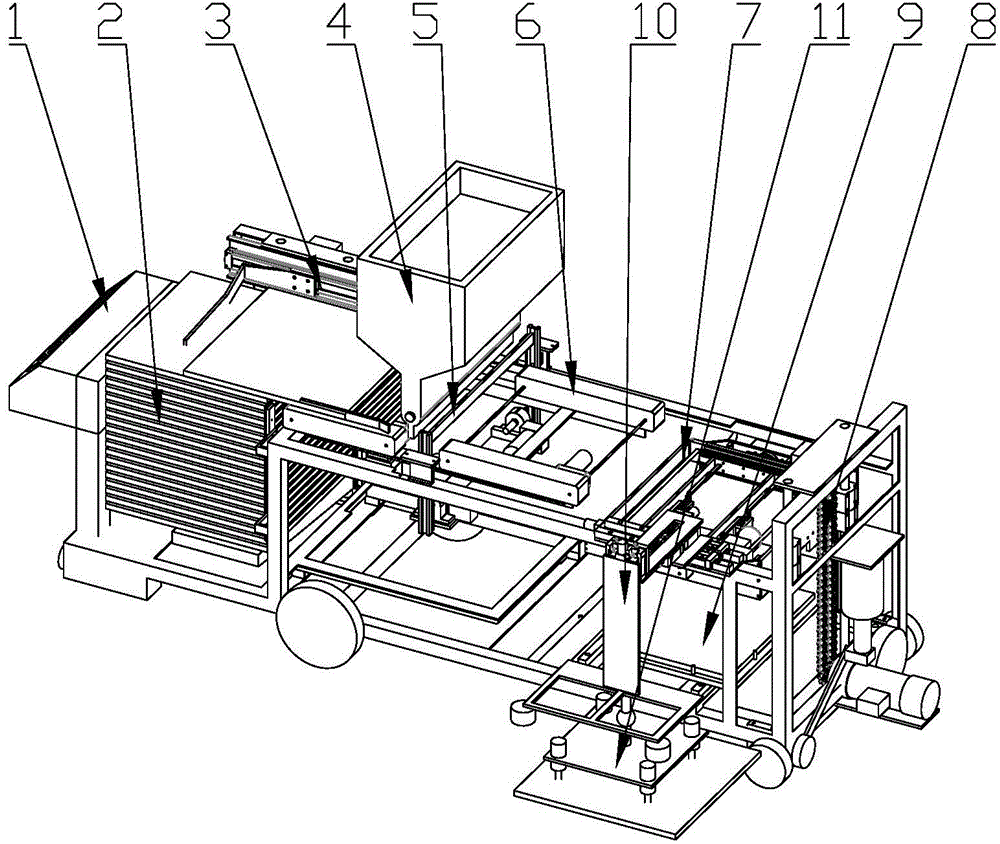

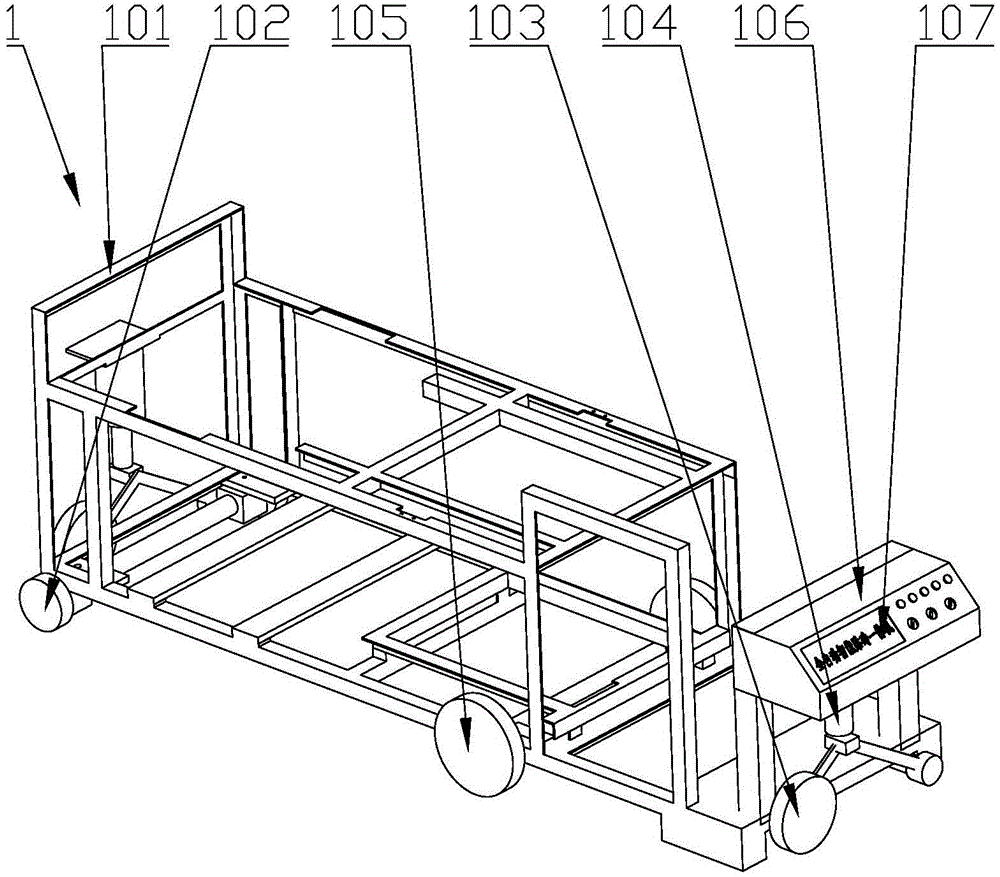

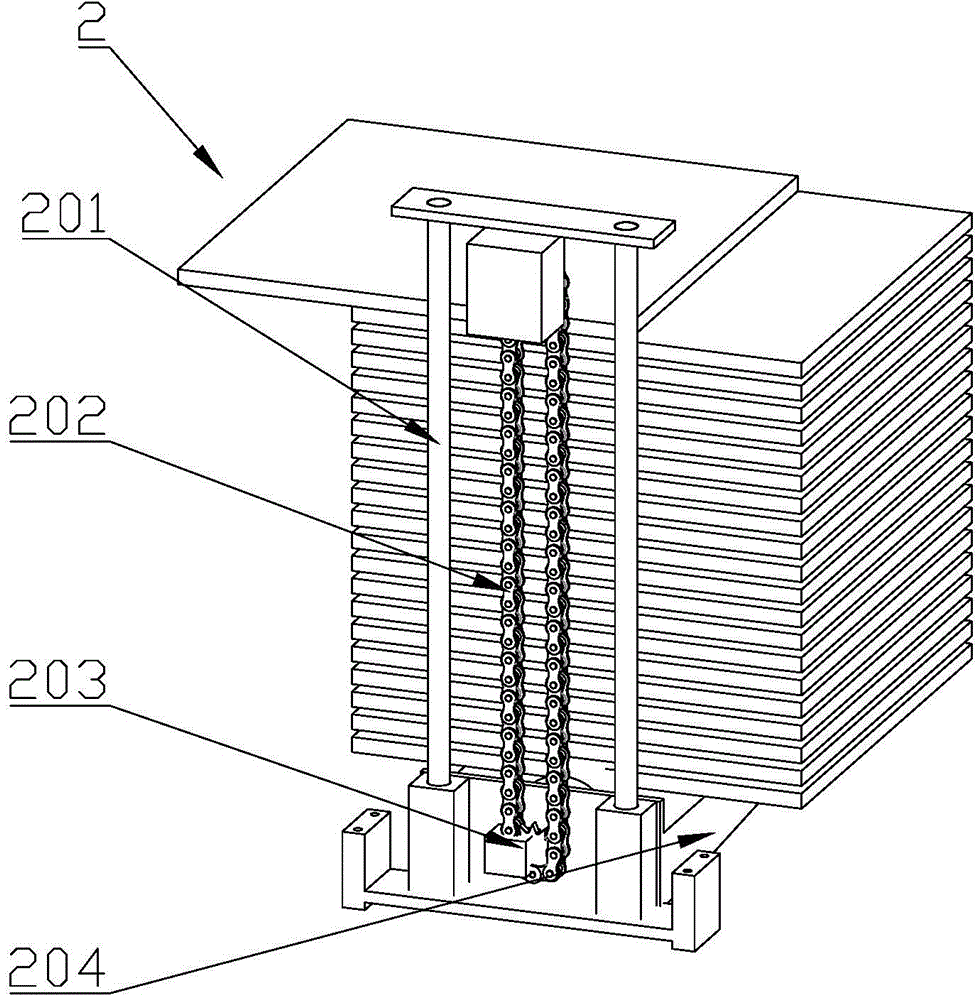

Full-automatic intelligent tiling machine

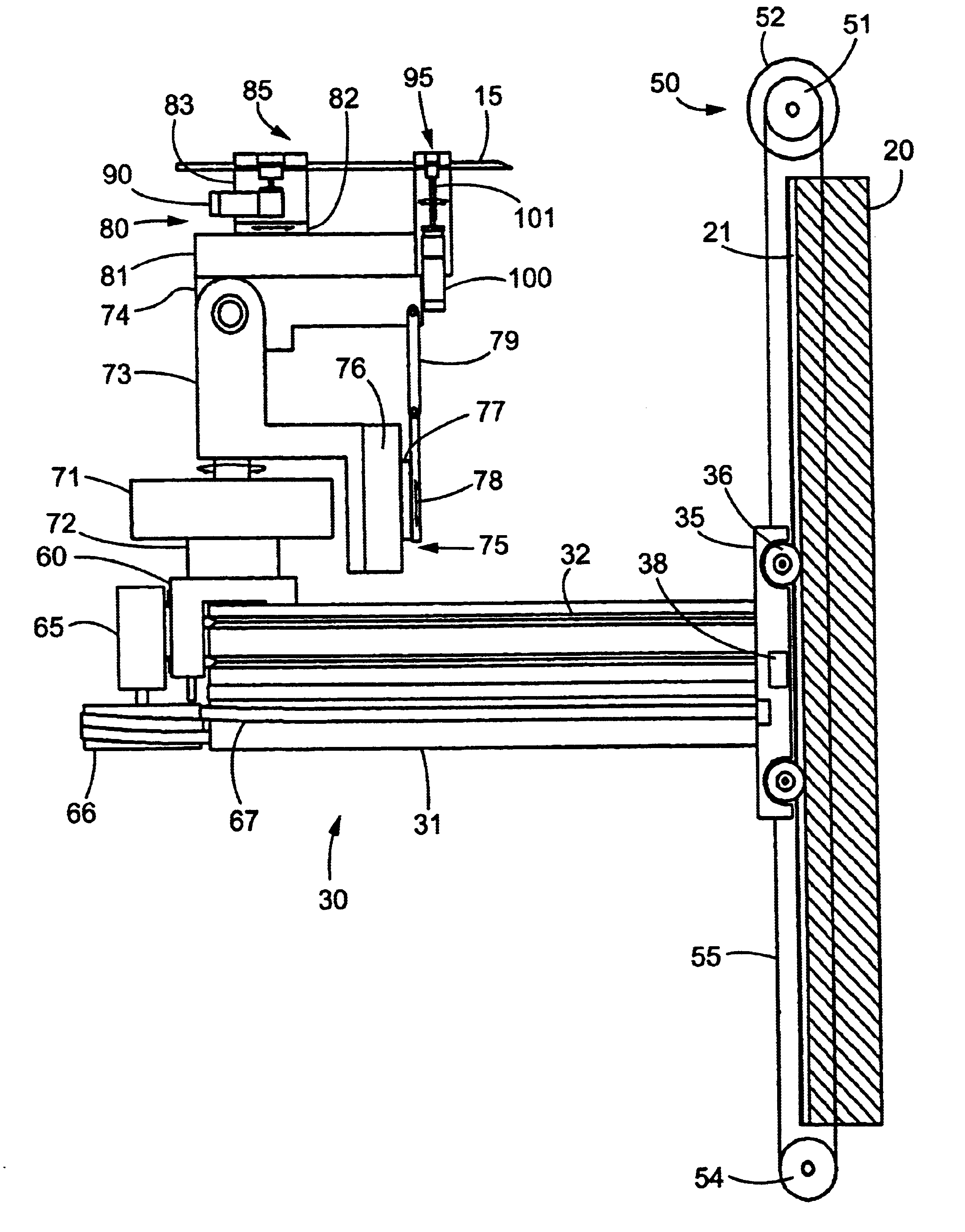

InactiveCN104060808ARealize fully automatic mechanized operationImprove work efficiencyBuilding constructionsEngineeringPositioning system

The invention discloses a full-automatic intelligent tiling machine, which comprises a rack, a feeding lifting system, an automatic pulling system, an automatic plastering hopper, an automatic mortar scraping mechanism, a material transportation mechanism, a feeding automatic turnover mechanism, a feeding automatic lifting platform, a second-time positioning system, a four-axis positioning system for floor tile tiling, and a measurement and vibration tiling mechanism. The tiling machine is also provided with a wall tiling system and a ground and wall tiling pouring system. The full-automatic intelligent tiling machine has the advantages that due to the adoption of the tiling machine which enables that ground tiles and wall tiles can be tiled simultaneously, manpower can be replaced completely and a full-automatic machinery operation in tiling is realized, so that working efficiency is greatly improved and labor intensity is reduced; besides, the wall tiles and the ground tiles tiled by the intelligent tiling machine are superior in quality in consideration of good tidiness, sound smoothness and aesthetic appearances, so that the intelligent tiling machine is particularly suitable for large-area ground or wall tiling; the craft of plastering first and then tile paving, and that of tile paving first and then mortar pouring can be adopted by the intelligent tiling machine simultaneously, and a suitable tiling craft can be chosen according to the smoothness degree of ground surfaces and wall surfaces, so that tiling efficiency is better improved.

Owner:王越

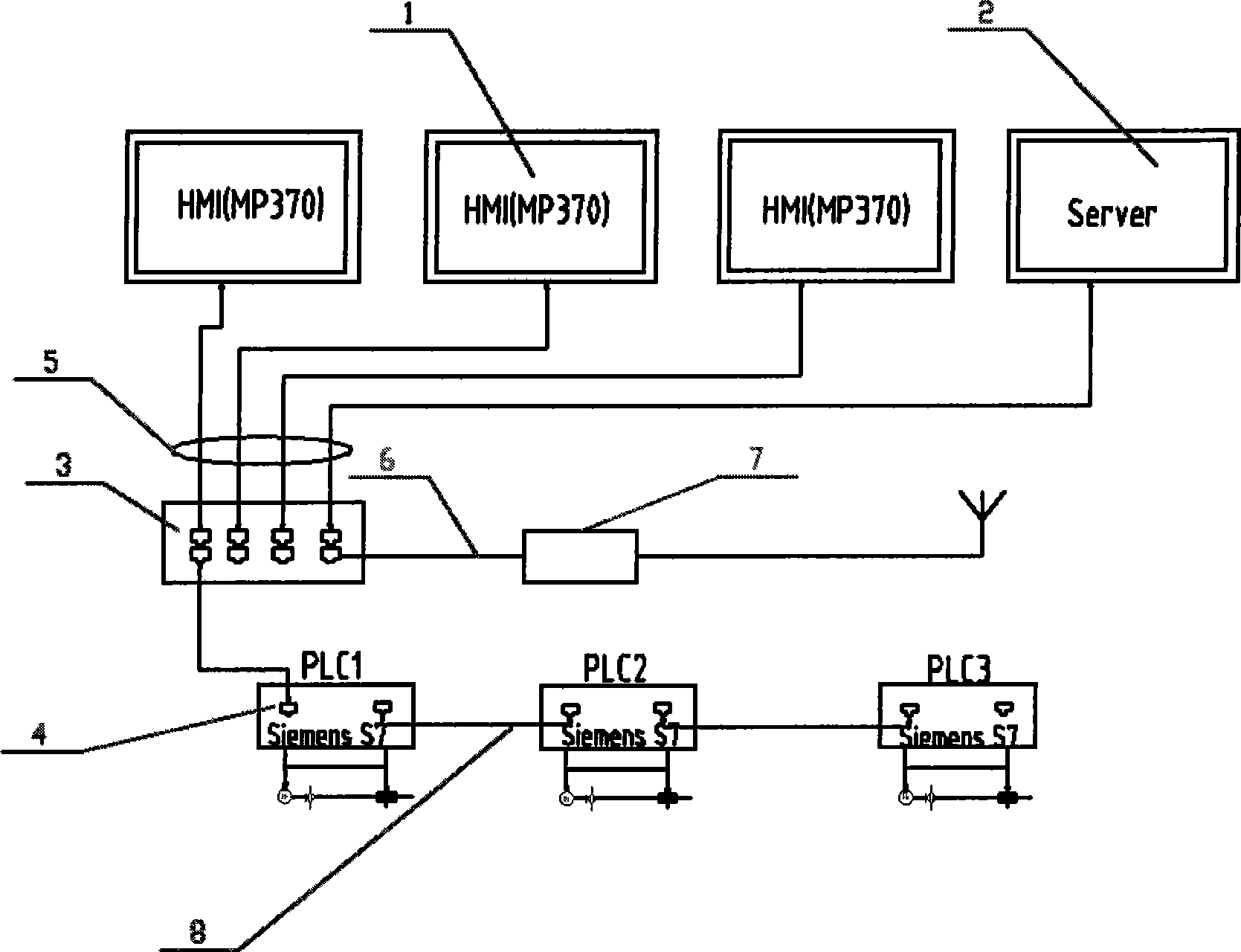

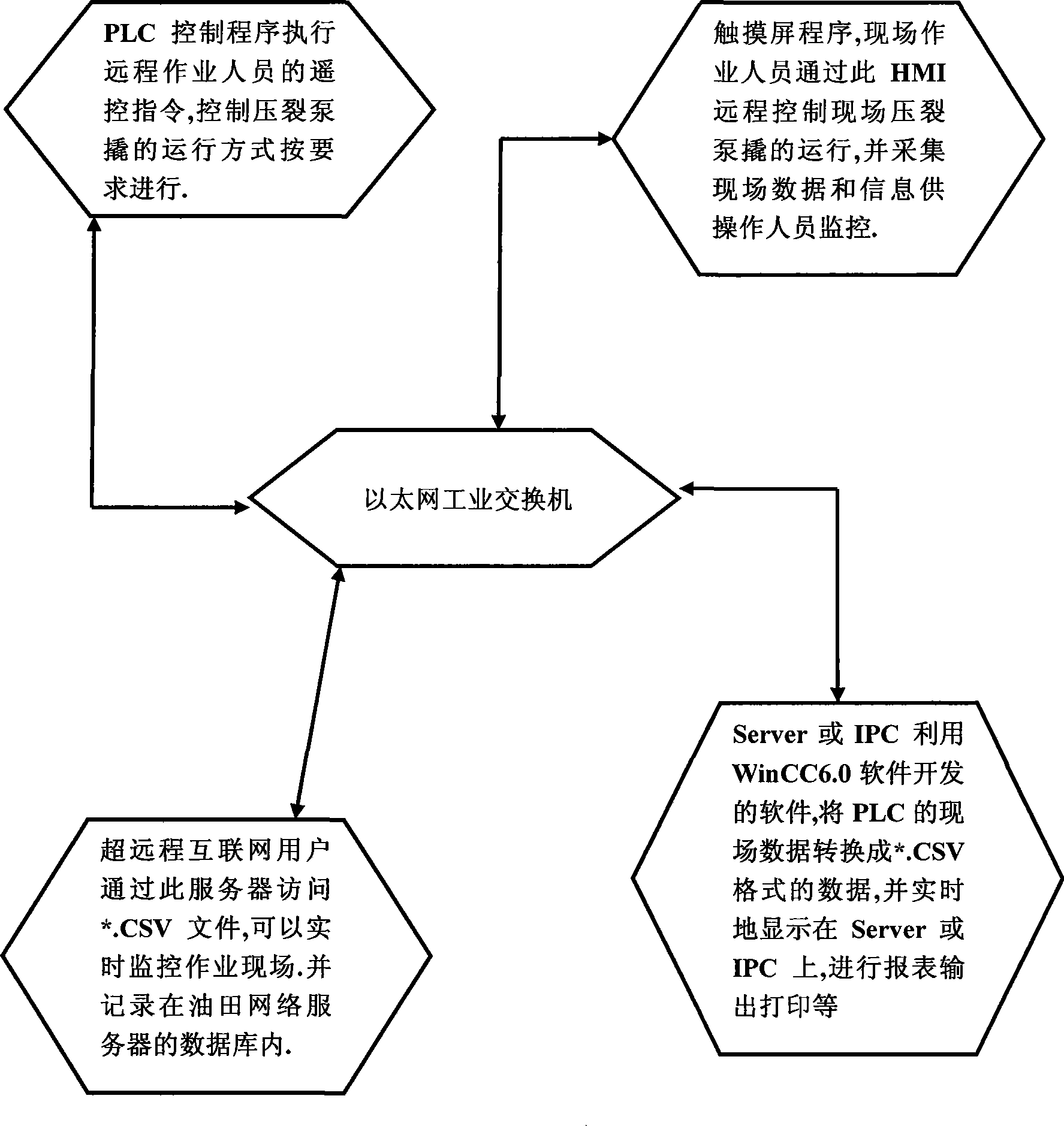

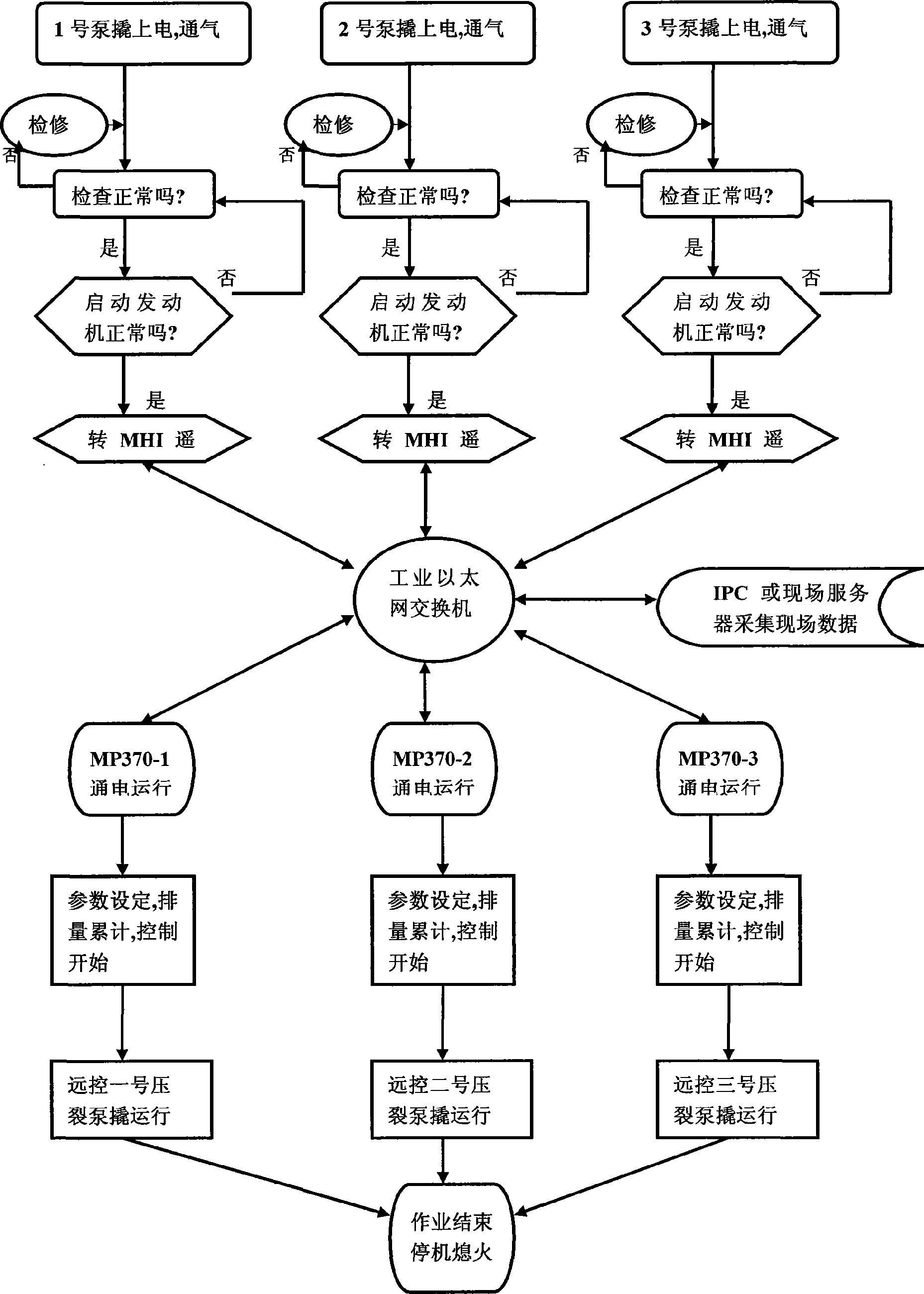

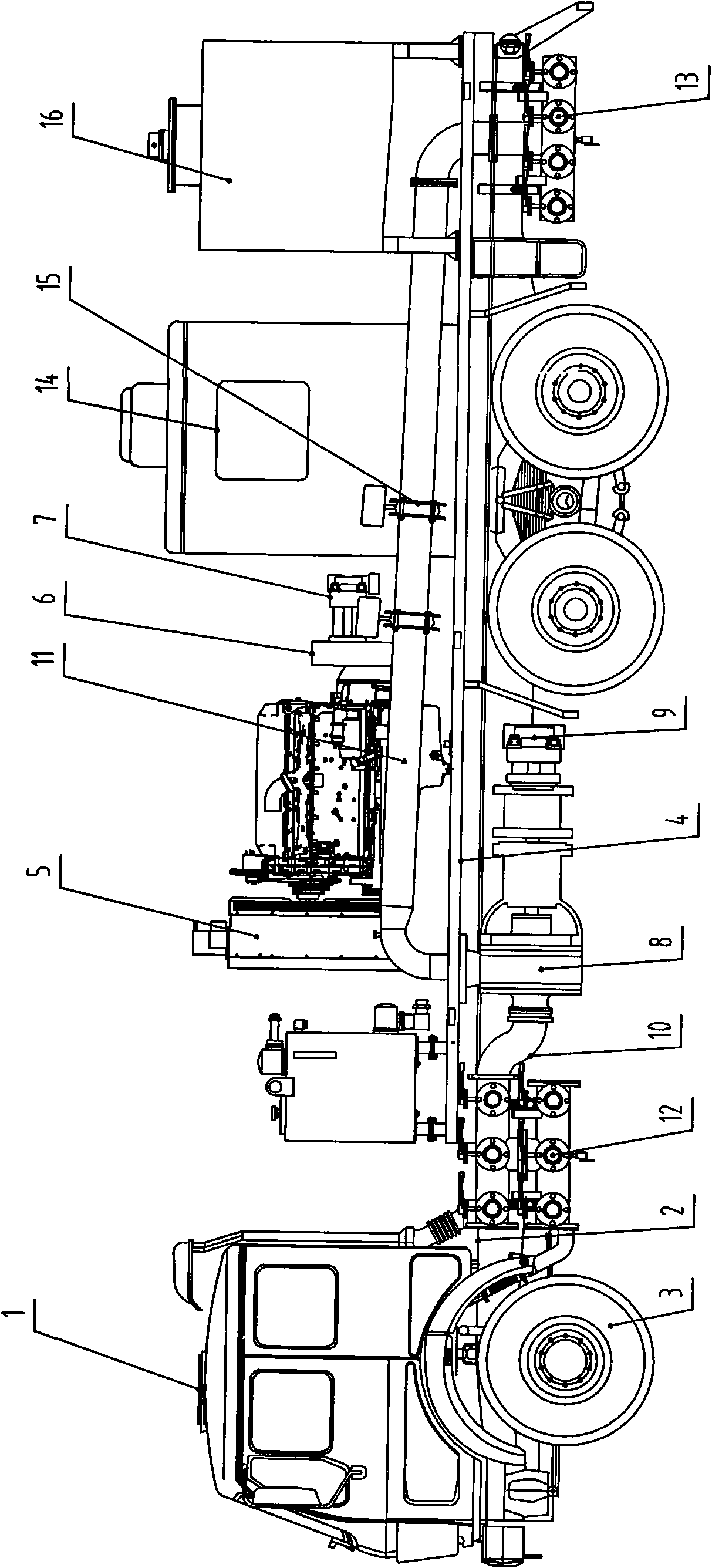

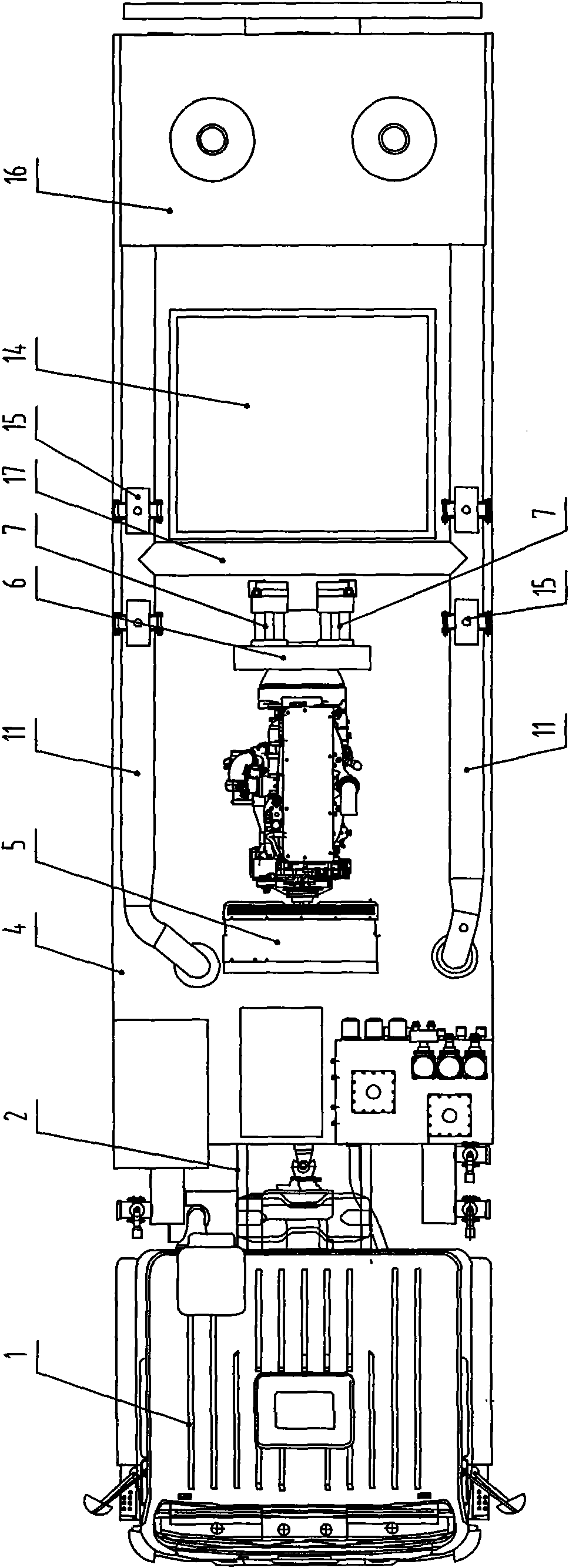

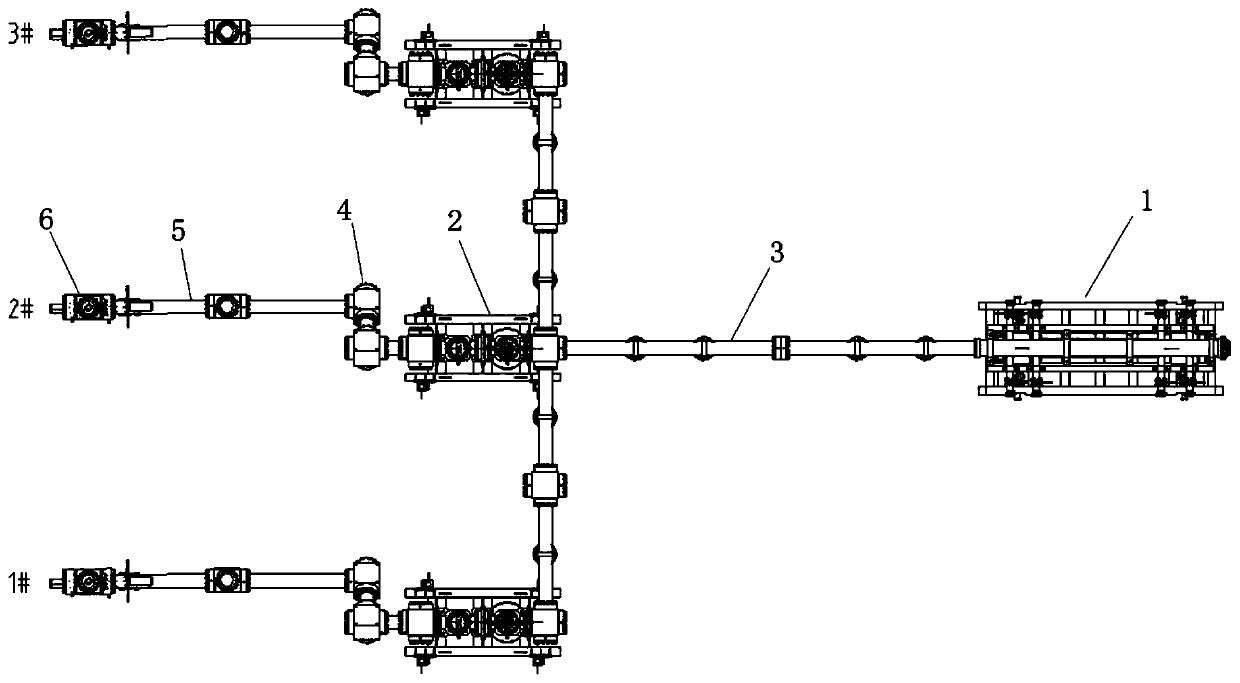

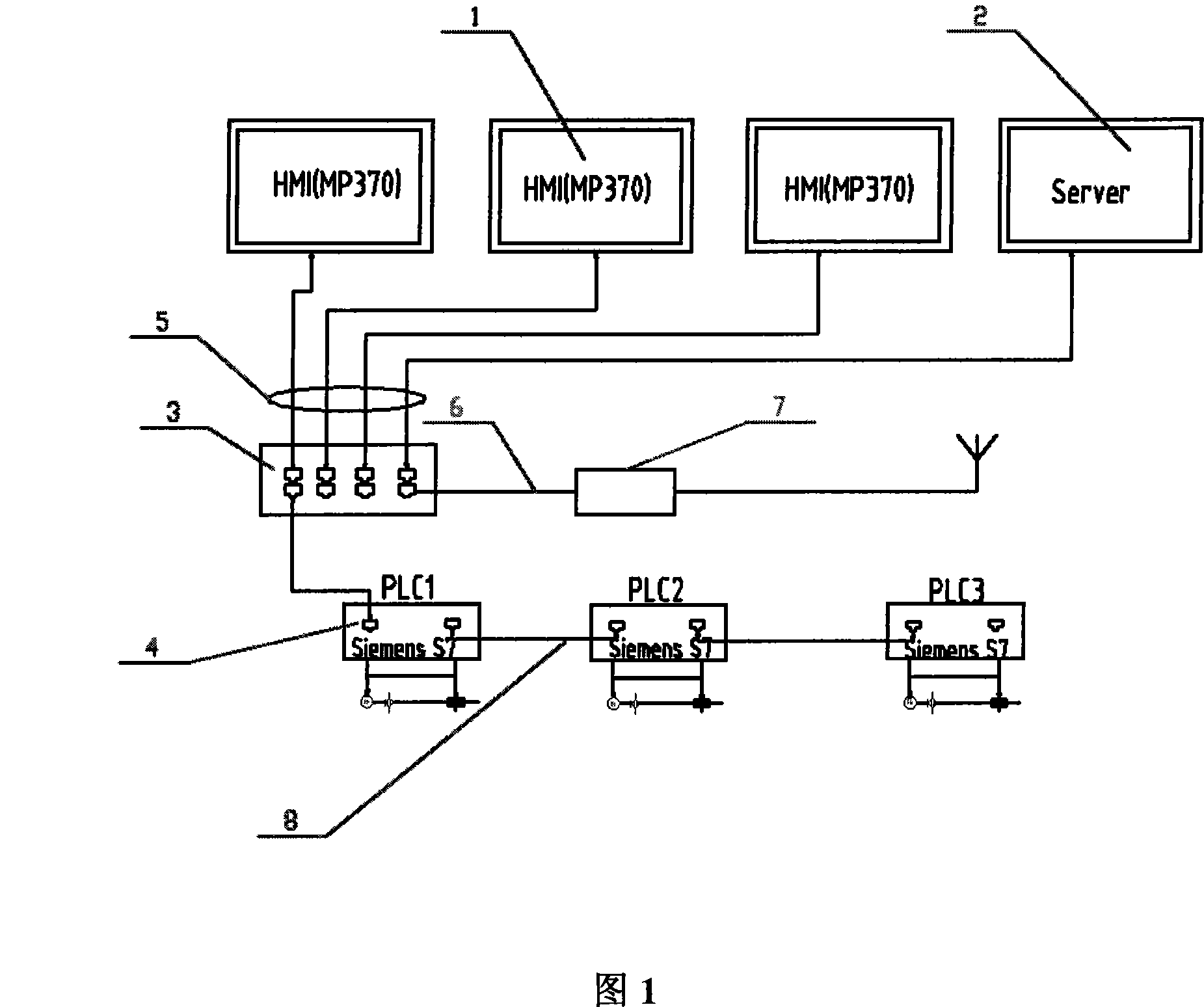

Oil field fracturing pumping remote automatic control system

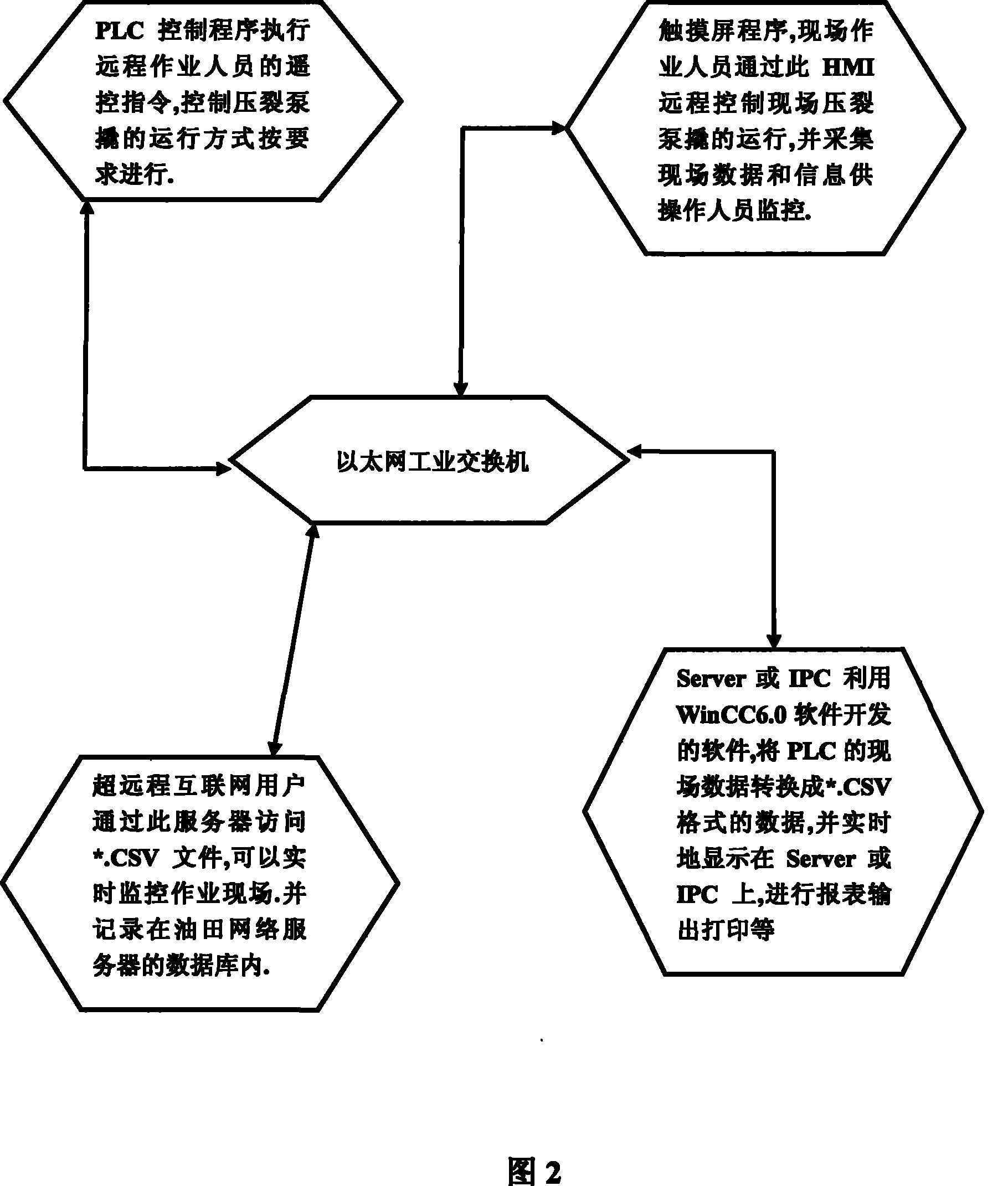

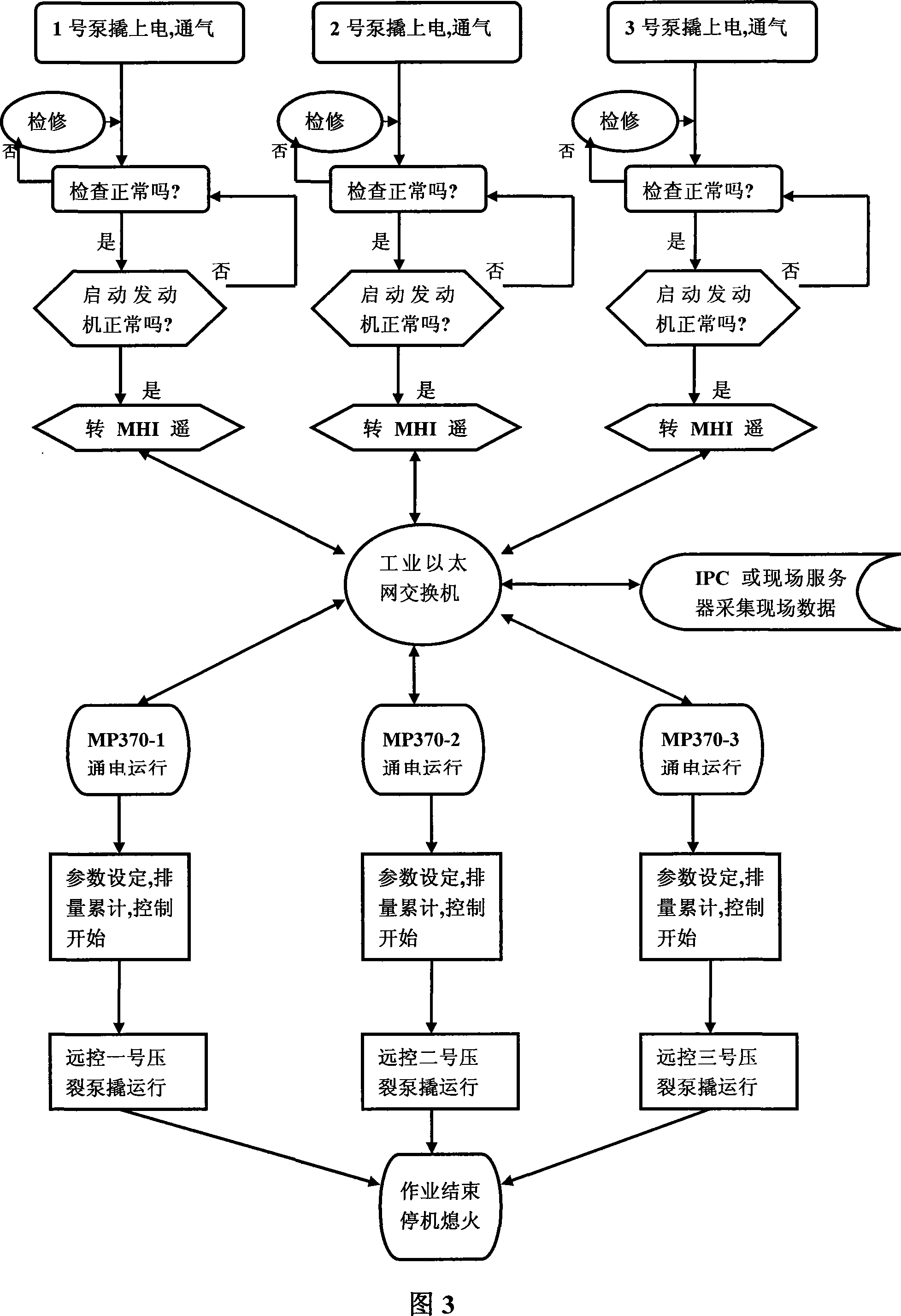

ActiveCN101414171AMonitor and control operationsOrderly and stable operationTotal factory controlProgramme total factory controlAutomatic controlHuman–machine interface

The invention discloses a remote automatic control system of a fracturing pump skid used in an oil field. The system is used for remote automatic control of a well service pump skid and a truck-mounted skid used in the oil field; the remote automatic control system consists of a field control system which consists of Siemens S7-315 series PLCs which are taken as a core, a Siemens MP370 which is taken as a remote control human-machine interface, and Ethernet which is taken as a transmission media; the system can achieve remote control functions such as start, stop and emergency stop of an engine, gear shifting, braking, turning back to a neutral position and idle speed of a gearbox and the like, and the system can modify field running parameters in a remote manner, thus realizing bidirectional transmission between the pump skid and the human-machine interface (HMI); the Ethernet is taken for communication so that the pump skid can transmit the field data to a remote controller or a server at the speed of 100MB / S; an industrial exchanger is taken to connect the devices such as the PLC, the HMI and the like to achieve more group controls; the exchanger can convert the field data into the data formats such as a standard *.CSV format and the like, and directly transmit the data to the server for data processing.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

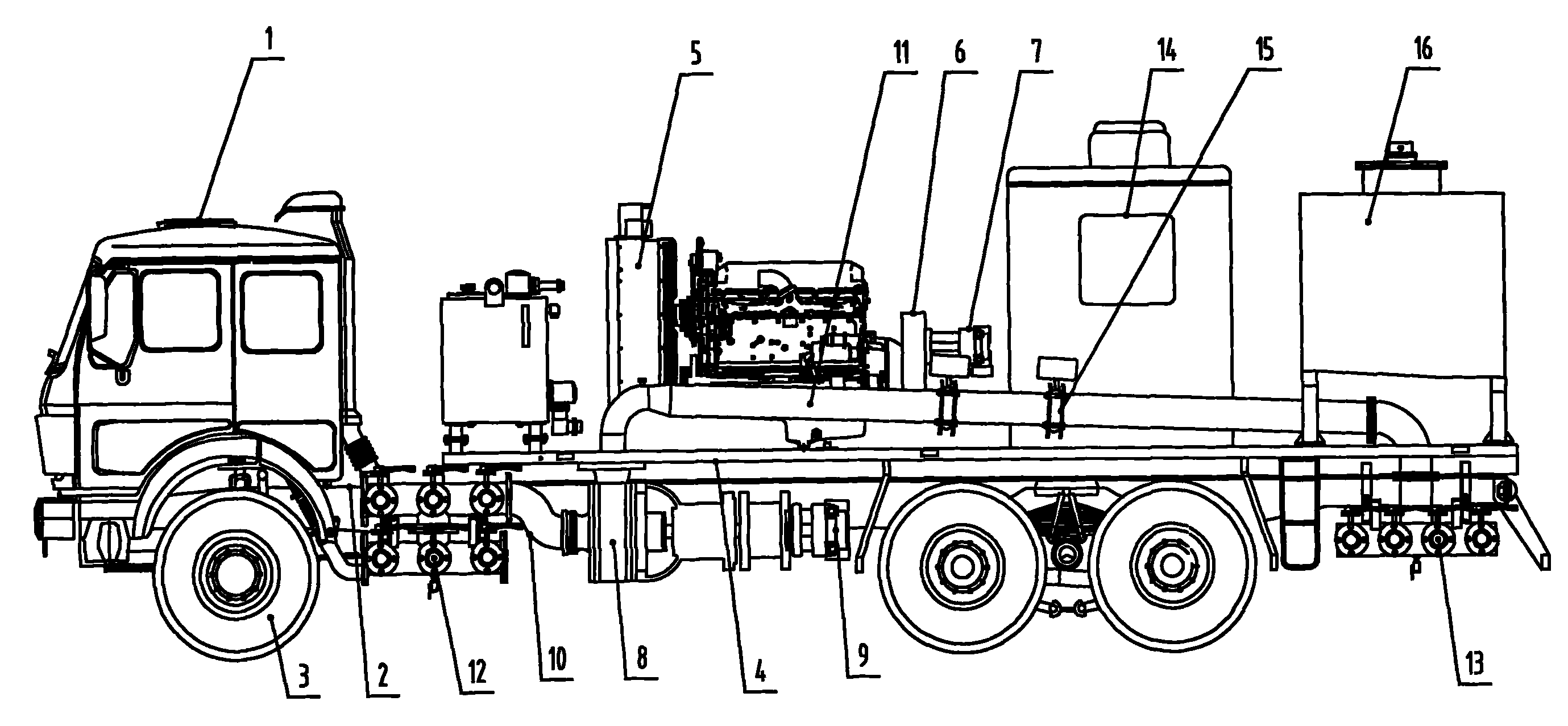

Liquid supply vehicle

ActiveCN101885307ALower suction heightImprove inhalation performanceFluid removalItem transportation vehiclesVehicle frameSewage

The invention discloses a liquid supply vehicle, which comprises a frame with a cab. The lower part of the frame is provided with wheels, the rear upper part of the frame is provided with a bedplate, a power driving device is arranged on the bedplate, a centrifugal pump is arranged below the bedplate, the power driving device is in transmission connection with the centrifugal pump, and an inlet and an outlet of the centrifugal pump are connected with a suction pipe and a discharge pipe respectively. The liquid supply vehicle has the advantages of improving the self-sucking effect of a fracturing truck, improving the operation efficiency of the fracturing truck and shortening the operation time, along with reasonable design, simple structure, easy assembly and manufacture, and also can be used for liquid delivery in other industries of flood drainage, sewage clearing and the like.

Owner:ZYT GASOLINEEUM EQUIP

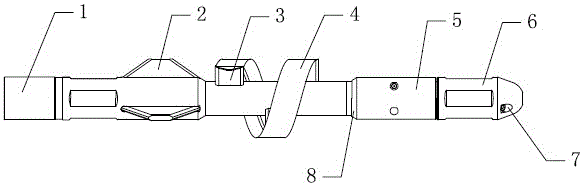

Oil and gas field coiled tubing paraffin removal and contaminant release process and tool thereof

PendingCN106761561AWill not artificially cause blockageImprove cleanlinessCleaning apparatusWaxCoiled tubing

The invention relates to an oil and gas field coiled tubing paraffin removal and contaminant release process and a tool thereof. Paraffin removal is performed by using coiled tubing, and removed paraffin can be recycled to the ground, and therefore a wellbore cannot be blocked due to human factors. A flushing port is designed at the upper end of a flushing tool, and then paraffin remaining on mechanical scraping portions can be cleared. The coiled tubing is connected with the paraffin removal and contaminant release tool for paraffin removal and contaminant release. The flushing tool at the front end of a pipe string can first perform 360 degree hydraulic cleaning on the wellbore, and then along with descending of the pipe string, a paraffin remover in the pipe string performs mechanical cleaning on the wellbore, and therefore dual cleaning mode combining the hydraulic cleaning with mechanical scraping is achieved, removal effects are greatly improved, cost is saved, and work efficiency is improved.

Owner:JEREH ENERGY SERVICES

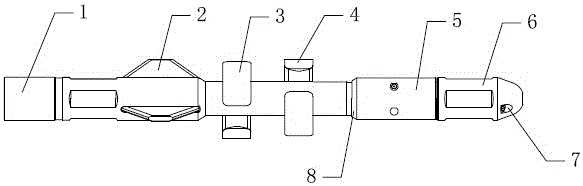

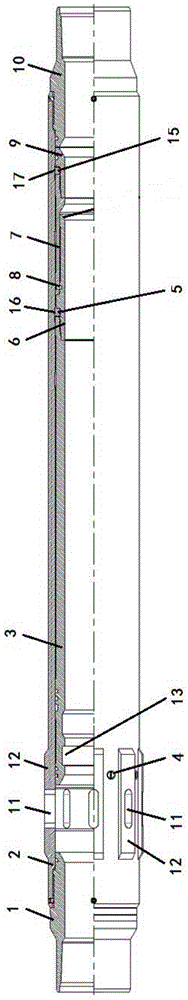

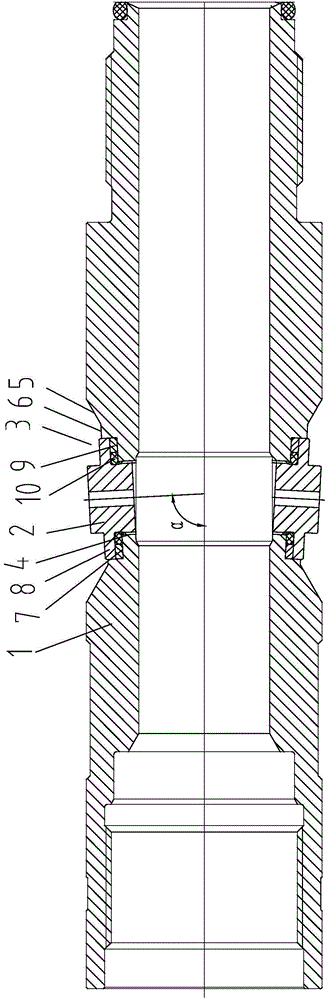

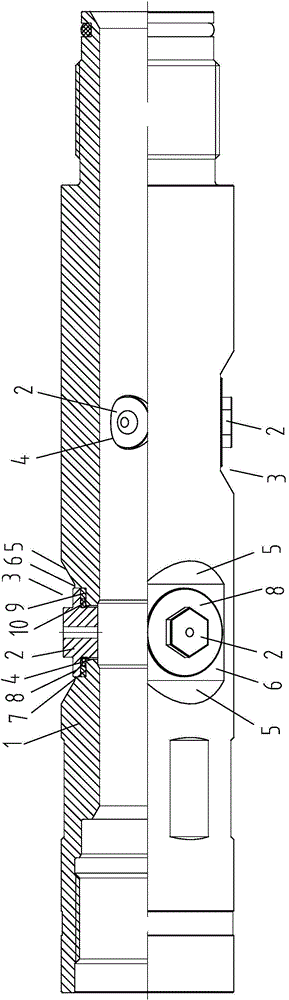

Switchable well cementation sliding sleeve based on fracturing of separate layers and construction method thereof

A switchable well cementation sliding sleeve based on fracturing of separate layers comprises an outer barrel, an upper joint and a lower joint are installed at the upper end and the lower end of the barrel respectively, a fracturing port is formed in the side wall of the upper portion of the outer barrel, and an upper center pipe, an upper connection sleeve, a lower center pipe and a lower connection sleeve are installed inside the outer barrel. The switchable well cementation sliding sleeve based on fracturing of the separate layers is not provided with a ball seat, so a full bore of the inner wall can be maintained, fracturing fluid can flow back in time, and the construction period is shortened. The well cementation sliding sleeve is set in the upper center pipe through a bottom packer, downward pushing force big enough can be generated in the process of annular or continuous tubing pressing, so the upper center pipe can overcome shearing force of corresponding shearing dowels and move downwards, and therefore the fracturing port of the well cementation sliding sleeve can be opened.

Owner:JEREH ENERGY SERVICES

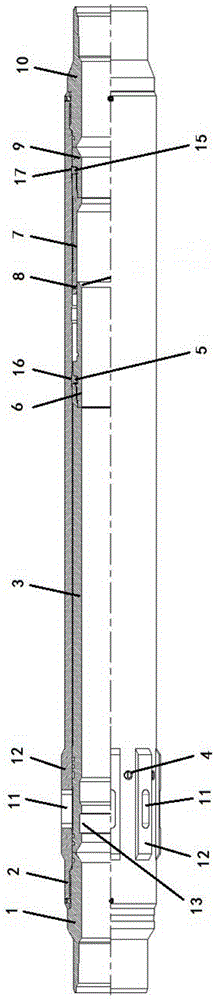

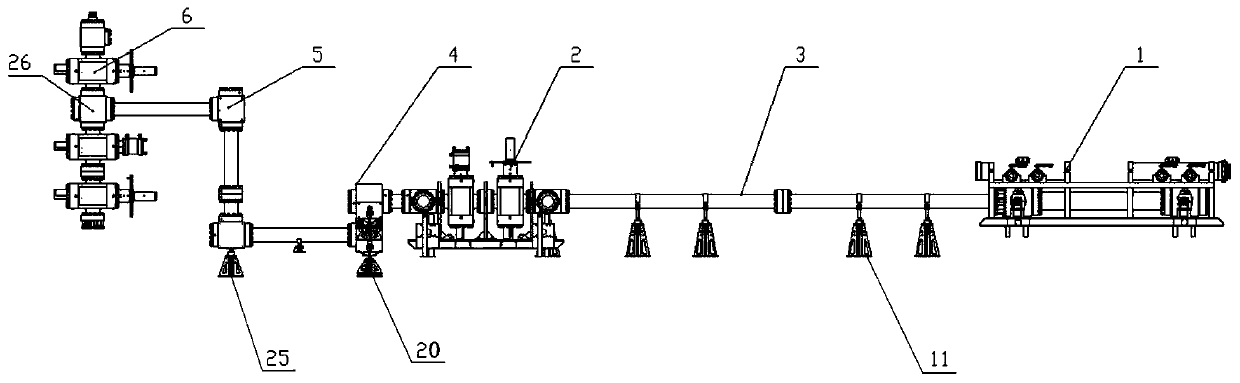

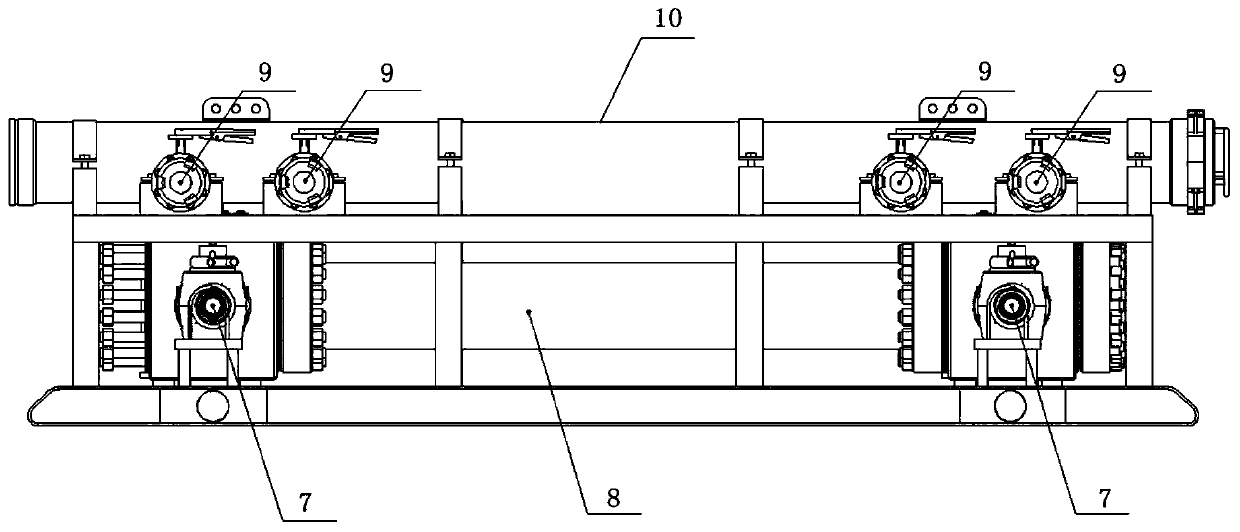

Fracturing conveying ground manifold system

PendingCN111503517AImprove work efficiencyOptimize layoutFluid removalPipeline systemsLine tubingEngineering

The invention discloses a fracturing conveying ground manifold system. The fracturing conveying ground manifold system comprises a fracturing tree, a high-low pressure manifold device, a high-pressureflange conveying pipeline, a ground fracturing control manifold device, an offset flange mechanism and a corner pipeline, wherein the high-low pressure manifold device is linearly connected with theground fracturing control manifold device through the high-pressure flange conveying pipeline; the ground fracturing control manifold device is connected with the fracturing tree through the offset flange mechanism and the corner pipeline; and the offset flange mechanism and the corner pipeline can realize adjustment of different heights and directions between the ground fracturing control manifold device and the fracturing tree. The fracturing conveying ground manifold system has the advantages that the whole manifold system is large in displacement, simple in structure, simple in layout, fewin pipelines, few in joints, linear in conveying, relatively low in kinetic energy loss and capable of being separated from the ground, effectively prolonging the service life of the manifold, realizing multi-wellhead zipper type operation and improving the operation efficiency of a fracturing well factory.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

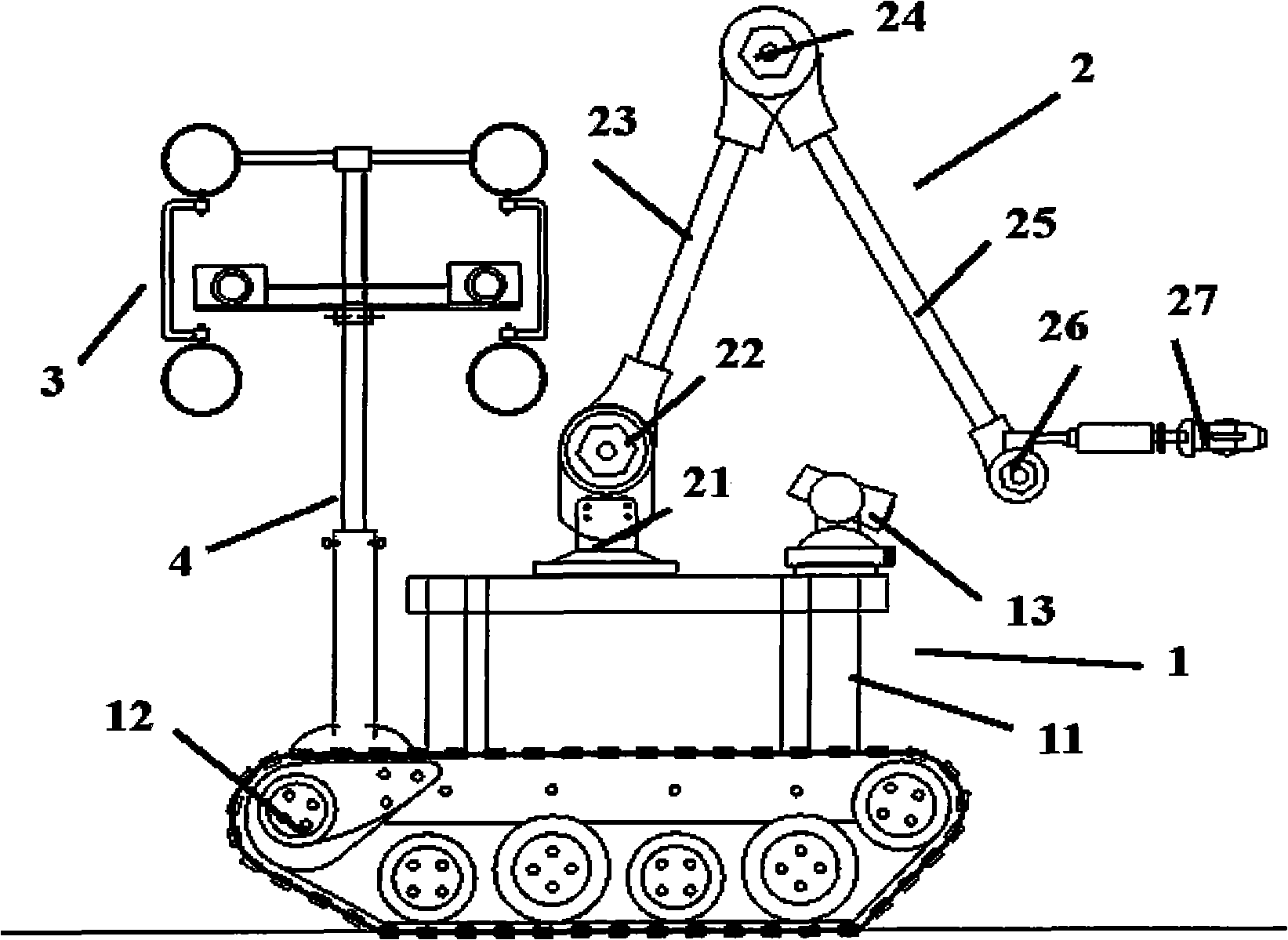

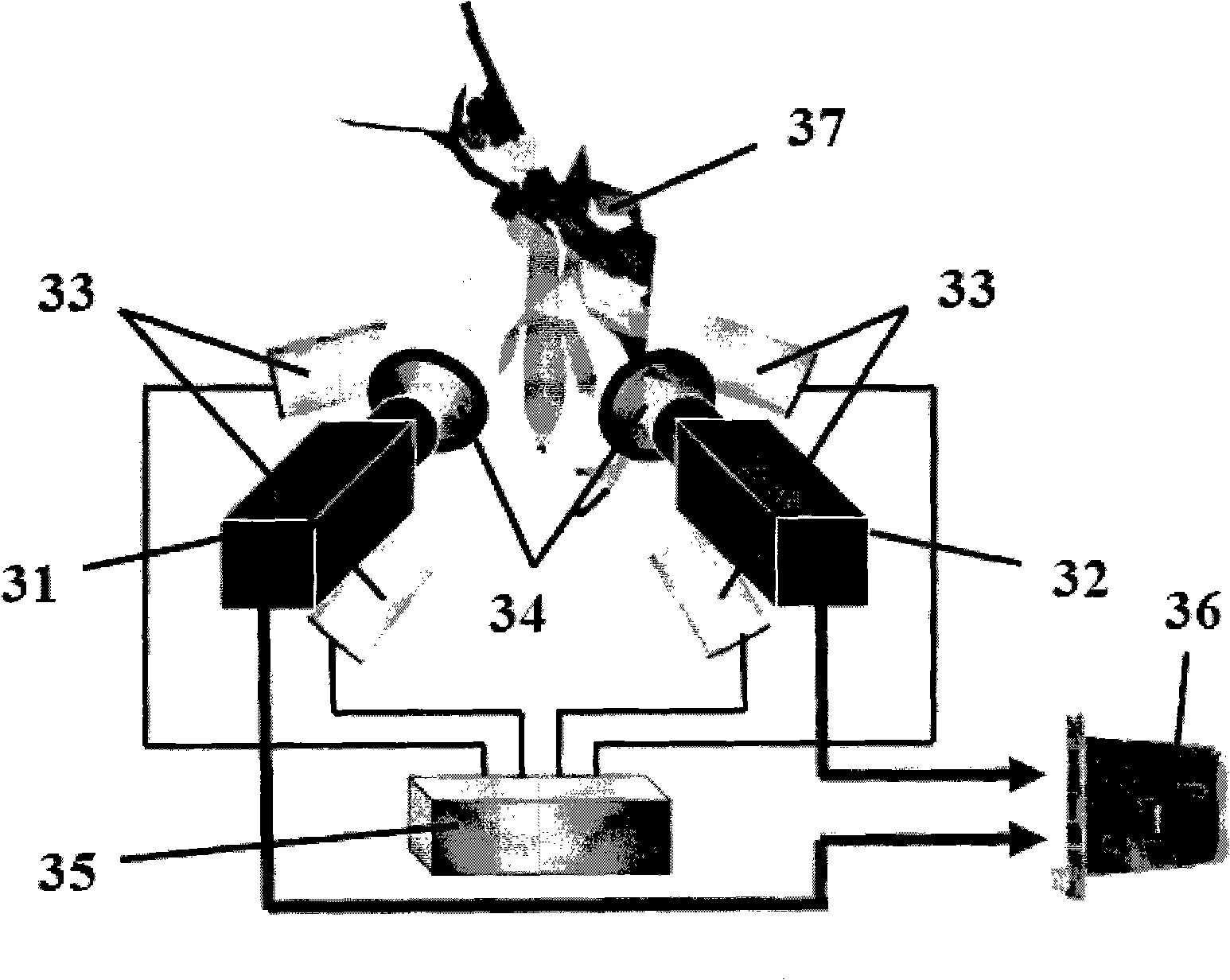

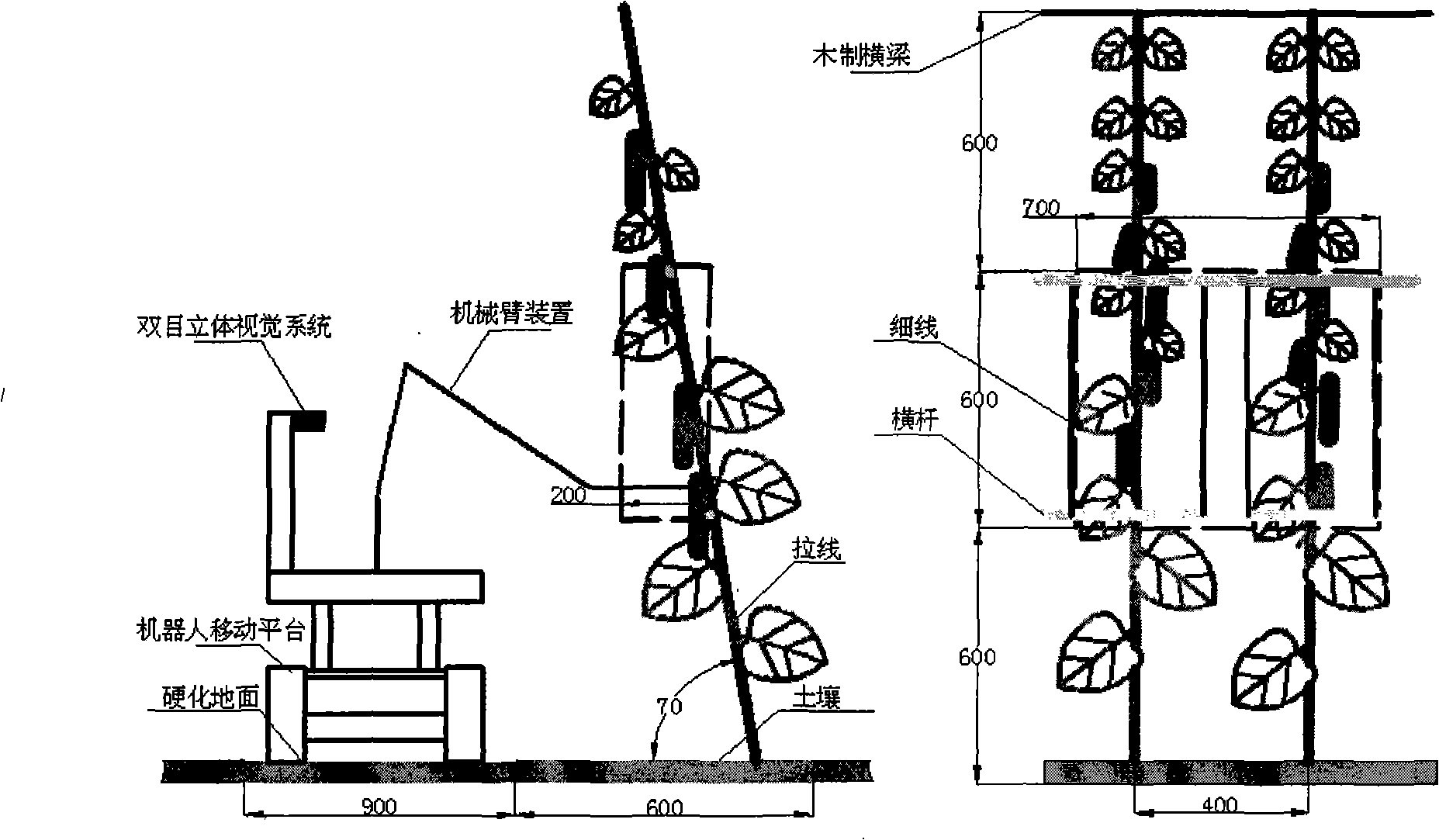

Cucumber picking robot system and picking method in greenhouse

The invention discloses a cucumber picking robot system in a greenhouse environment. The robot system comprises a binocular stereo vision system, a mechanical arm device and a robot mobile platform; the binocular stereo vision system is used for acquiring cucumber images, processing the images in real time and acquiring the position information of the acquired targets; the mechanical arm device is used for capturing and separating the acquired targets according to the position information of the acquired targets; and the robot mobile platform is used for independently moving in the greenhouse environment; wherein, the binocular stereo vision system comprises two black and white cameras, a dual-channel vision real-time processor, a lighting device and an optical filtering device; the mechanical arm device comprises an actuator, a motion control card and a joint actuator; and the robot mobile platform comprises a running mechanism, a motor actuator, a tripod head camera, a processor and a motion controller. The invention also discloses a cucumber picking method in the greenhouse environment. The method of combining machine vision and agricultural machinery is adopted to construct the cucumber picking robot system which is suitable for the greenhouse environment, thus realizing automatic robot navigation and automatic cucumber reaping, and reducing the human labor intensity.

Owner:SUZHOU AGRIBOT AUTOMATION TECH

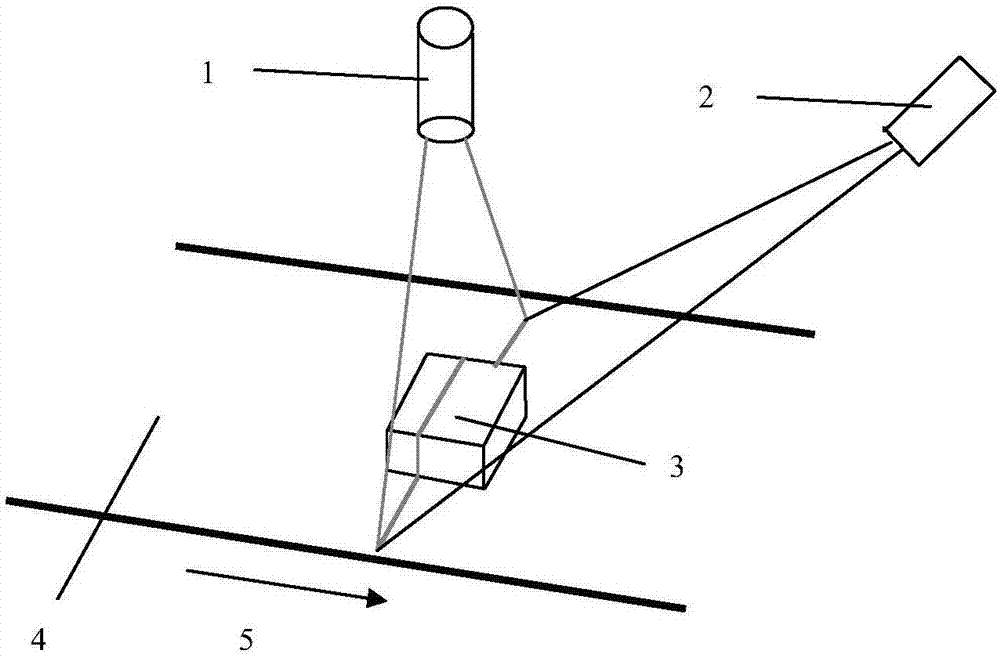

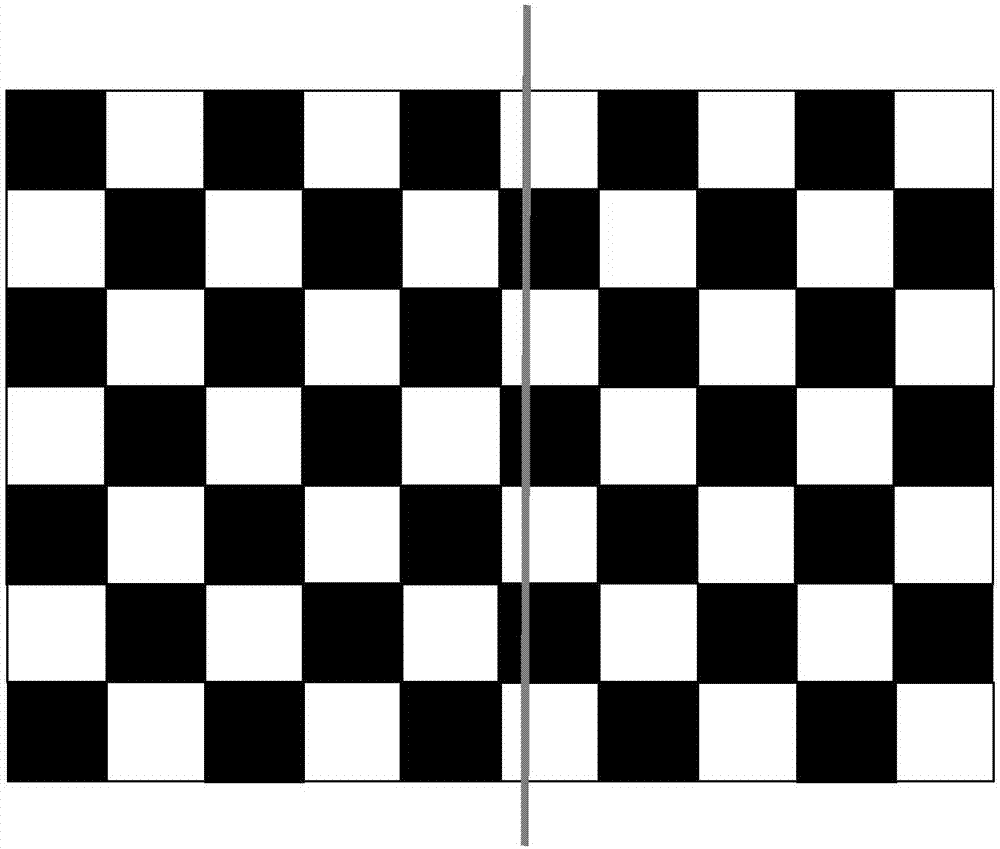

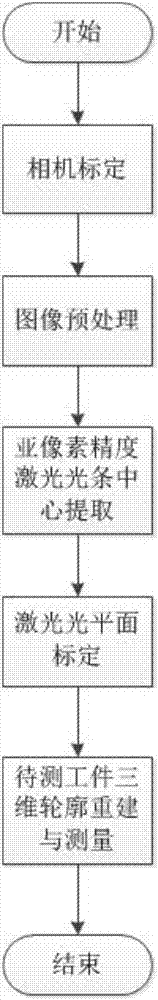

A method of 3D contour measurement of a workpiece on a conveyor belt based on line laser scanning

ActiveCN107578464AHigh measurement accuracyAccurate measurementImage analysisUsing optical meansMobile laser scanningLaser light

The invention discloses a method of 3D contour measurement of a workpiece on a conveyor belt based on line laser scanning. The method comprises the following steps of obtaining camera internal and external parameters through camera calibration, carrying out filtering and laser light strip center position initial extraction through an image preprocessing step, carrying out sub-pixel precision refinement on the center coordinates of a light bar, obtaining a light plane equation through the laser light plane calibration and finally carrying out reconstruction and measurement of the three-dimensional contour information of a workpiece to be measured. The workpiece 3D contour measurement brought forward by the invention has the following advantages: a high measurement precision which means thethree-dimensional contour information of the workpiece to be measured can be accurately obtained through the laser light bar extraction with sub-pixel precision and 3D reconstruction; a fast measurement speed which means real-time measurement of 3D contour information of the workpiece to be tested can be realized to improve the efficiency of industrial production site operations; and low hardwarecosts which is realized in a hardware implementation mode in which laser is combined with a monocular camera. Accordingly, the technical method of the application has advantages such as being in a non-contact mode, high in measurement precision, fast in speed and low in cost, and can be applied to an industrial automation production process to realize accurate measurement of the 3D contour information of the workpiece on the conveyor belt.

Owner:CHANGSHA XIANGJI HAIDUN TECH CO LTD

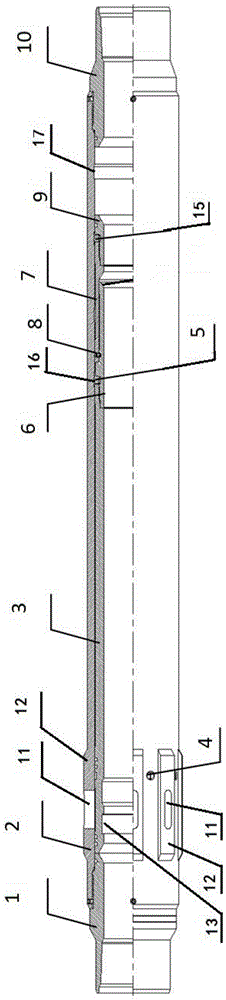

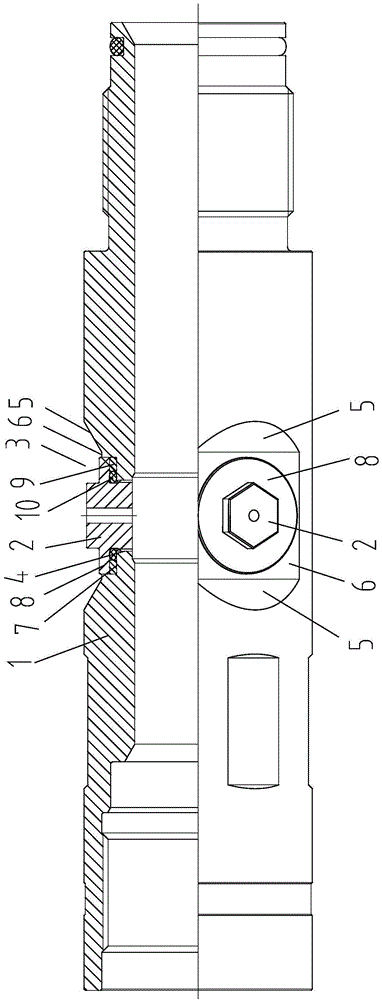

Anti-back-splash sand blasting perforator

The invention relates to an anti-back-splash sand blasting perforator, which comprises a body and a nozzle, wherein a groove is formed in the outer wall of the body; an installation hole is formed in the middle of the groove; the side wall of the groove is inclined; the nozzle is installed in the installation hole; the outer end of the nozzle stretches out from the bottom surface of the groove. The anti-back-splash sand blasting perforator is simple in structure, less in parts, and easy to process and assemble; through the arranged groove and a bulge on the outer end of the nozzle, a flow guide structure is formed around the nozzle, so that back-splash liquid can be timely and uniformly flown when back splashing on the perforator, can be prevented from forming vortex in the groove, and can be prevented from flowing in the groove for a long time; the erosion of the back-splash liquid on the perforator is reduced, and the service life of the perforator is improved.

Owner:JEREH ENERGY SERVICES

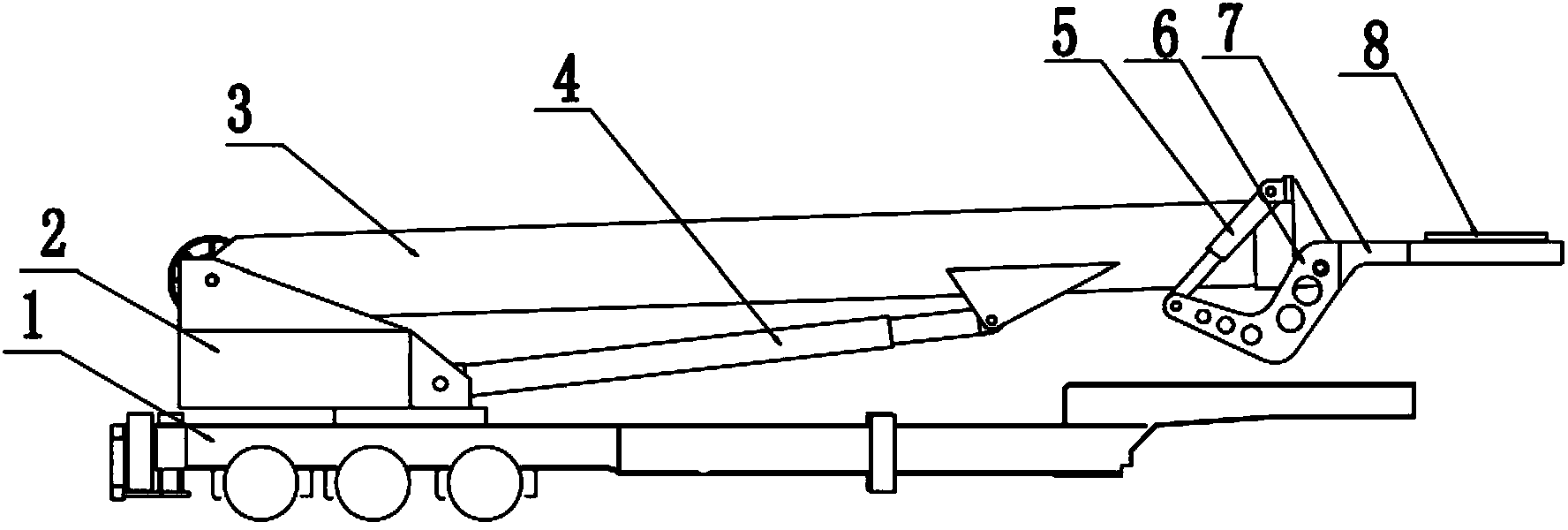

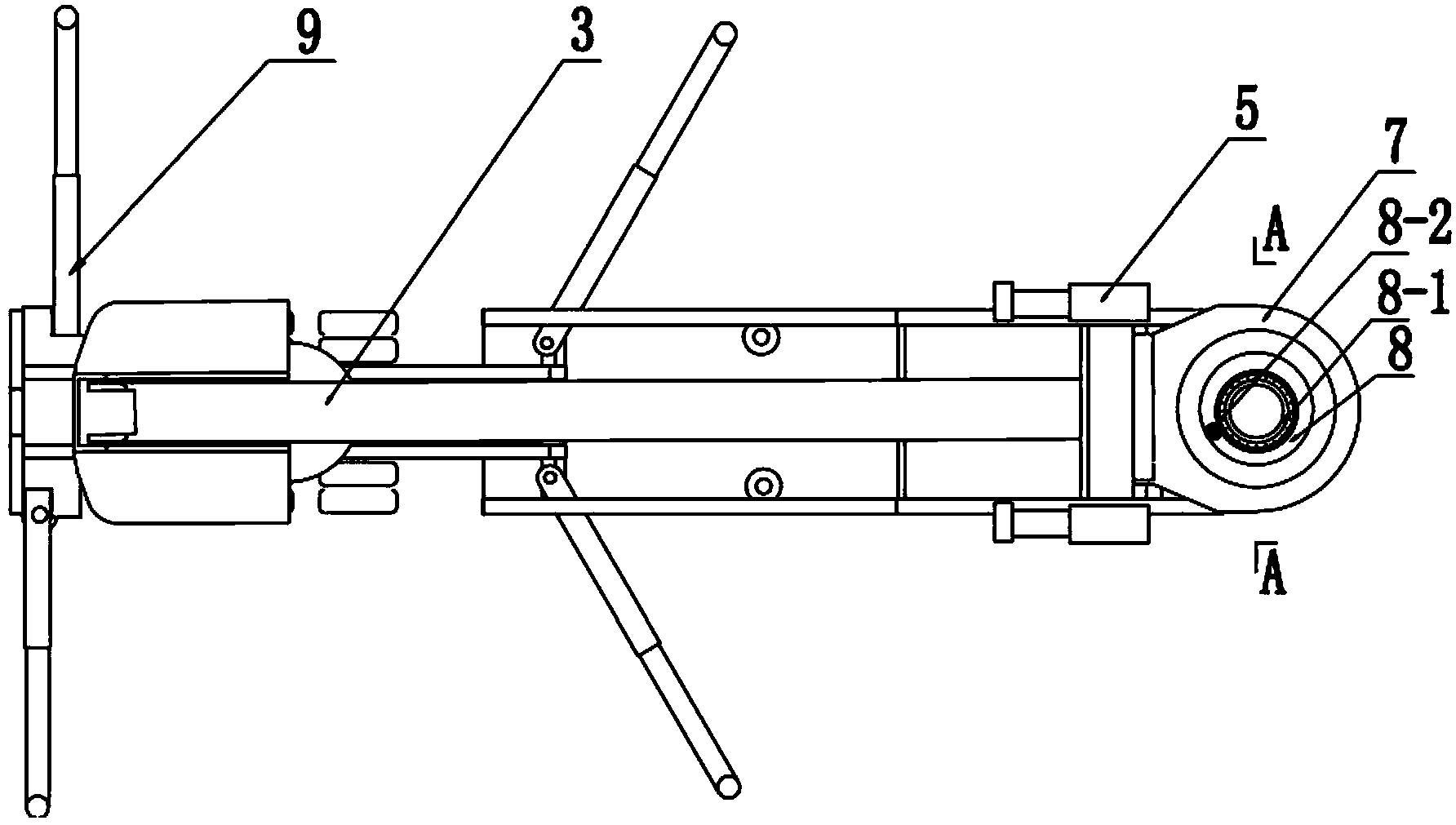

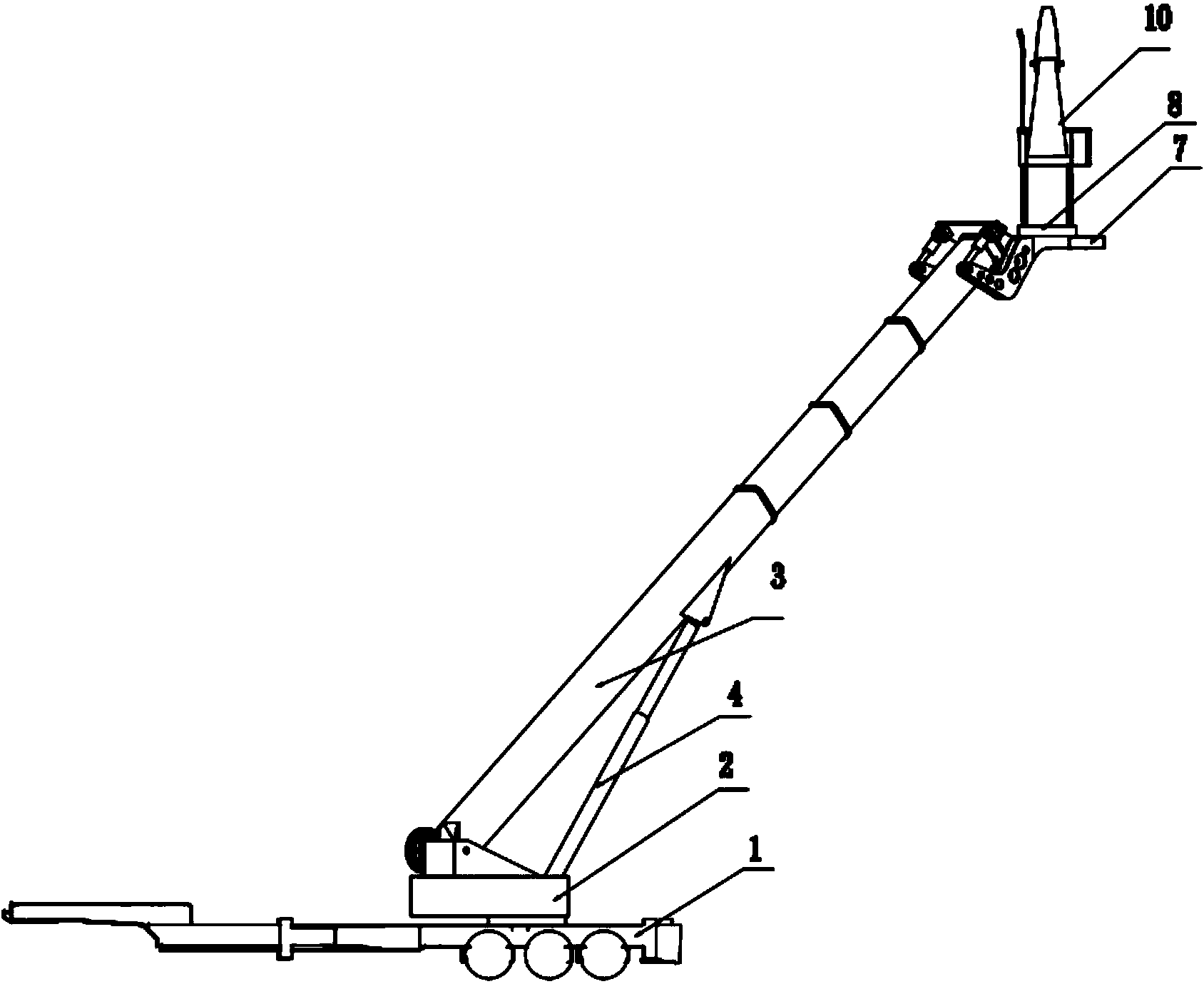

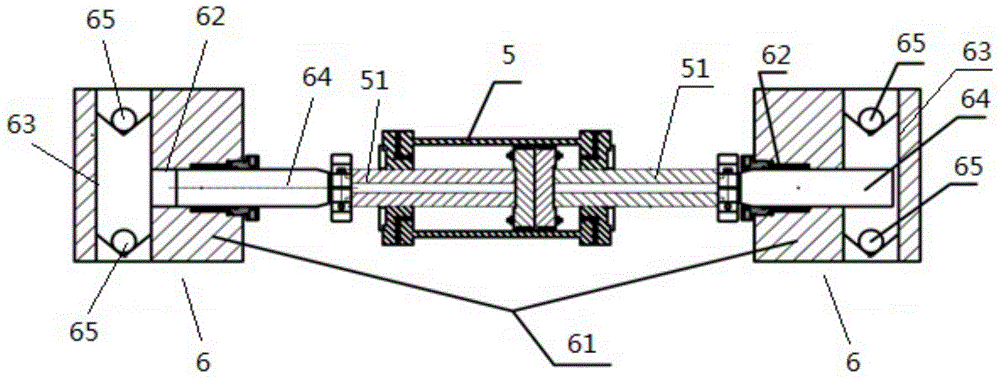

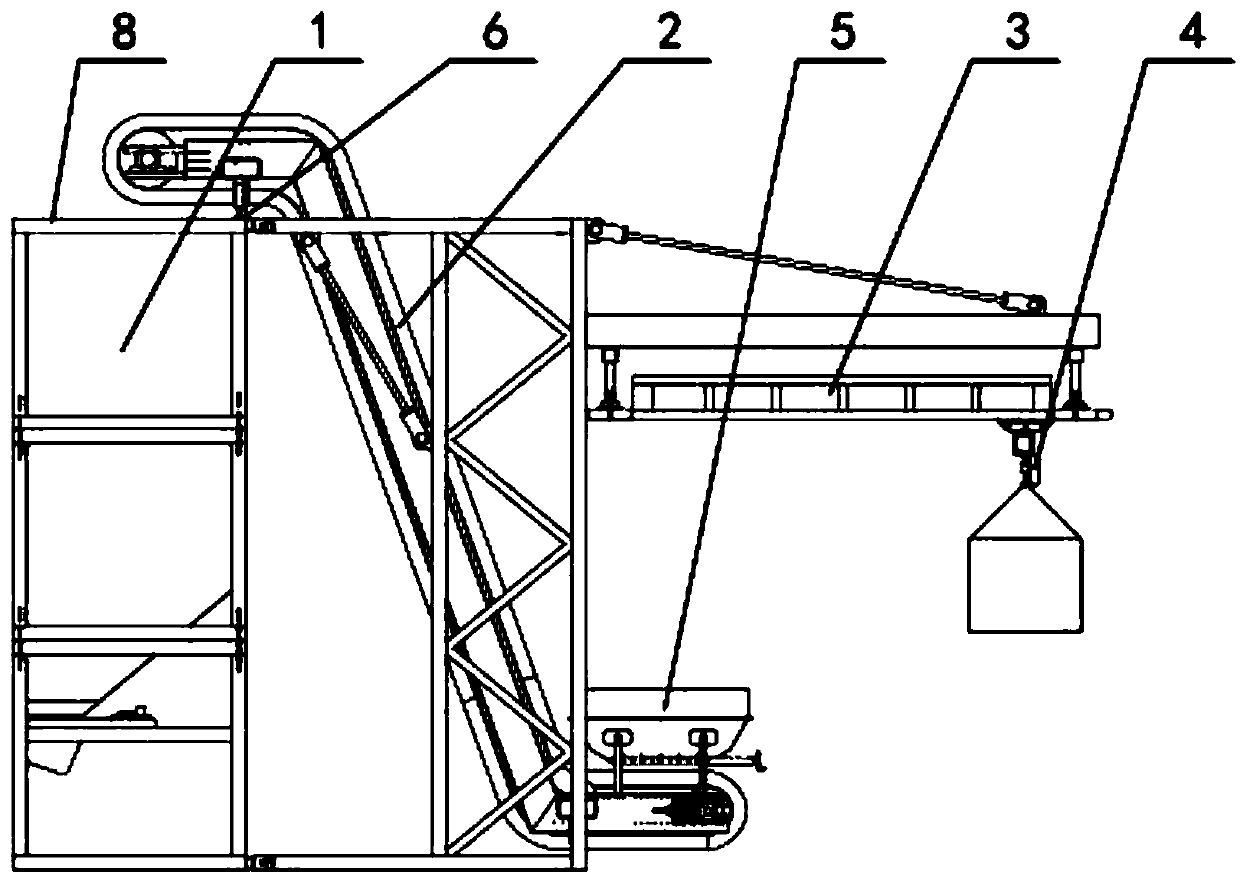

Hoisting derrick specially for coiled tubing equipment

The invention relates to a hoisting derrick specially for coiled tubing equipment. The hoisting derrick comprises a derrick transportation supporting platform, a derrick swinging base, a derrick telescopic boom, a first telescoping cylinder and second telescoping cylinders, which are connected with one another through rotation and articulation; the hoisting derrick is characterized by also comprising an injection head mounting platform, wherein lever arms are arranged on the injection head mounting platform, one ends of the level arms are fixedly connected with the injection head mounting platform, the other ends of the level arms are articulated with the plunger piston ends of the second telescoping cylinders, the cylinder body ends of the second telescoping cylinders are articulated with the derrick telescopic boom, and the level arms and the second telescoping cylinders are arranged in pairs and are arranged on two sides of the derrick telescopic boom respectively. The hoisting derrick has the beneficial effects that the injection head and an oil well can be centered rapidly, the labor intensity of workers is reduced and the mounting cost is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

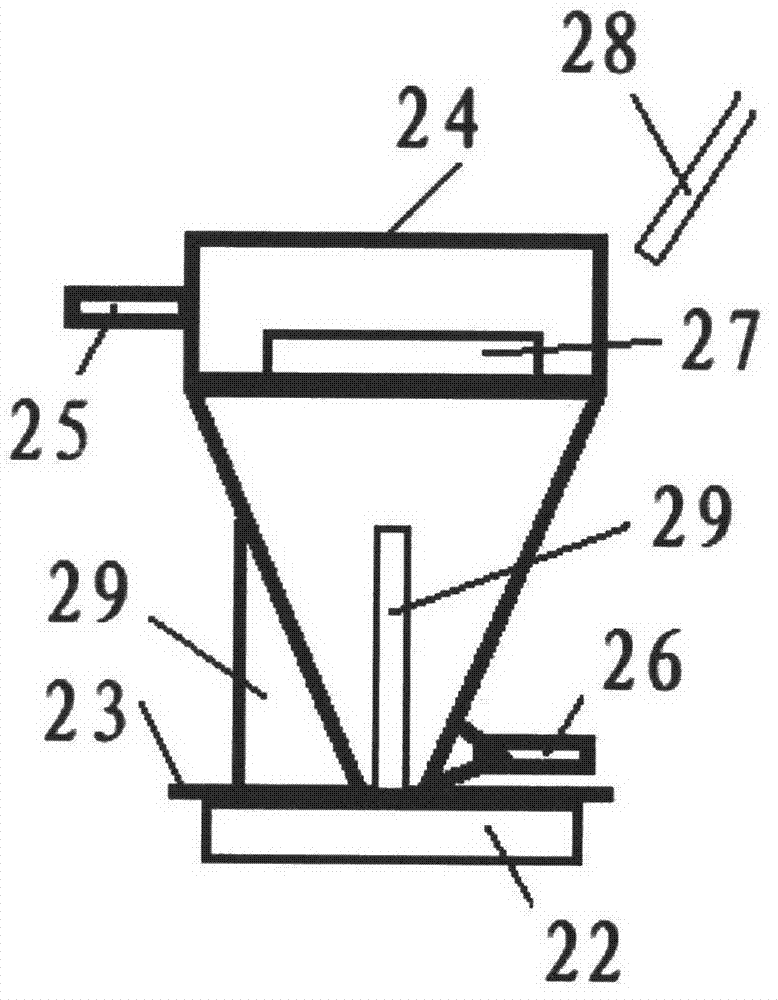

Down filling machine

ActiveCN102808245AStable outputHighly stable suedeUpholstery manufactureOakum treatmentEngineeringUltimate tensile strength

The invention discloses a down filling machine, which comprises a down storage box, weighing cabinets, down filling pipes and a programmable controller, wherein the down storage box is provided with at least two weighing cabinets; at least two weighing boxes are arranged in each weighing cabinet; the total number of the weighing boxes is equal to the total number of down outlets of the down storage box; each weighing cabinet is provided with at least one down filling pipe; the total number of the weighing boxes in each weighing cabinet is dual, and the number of the down filling pipes is a half of the total number of the weighing boxes. According to the down filling machine, the close full-automatic down filling can be carried out, the labor intensity is reduced, the production efficiency is improved, and the production cost is decreased. The down filling machine has the advantages of reasonable design, simple structure, low cost and good practicability. The down storage box of the down filling machine has stable down output, so that the down filling consistence and the down filling precision are ensured; a weighing process of the weighing boxes is independent, precise and effective; the down filling pipes cannot fill the down to airtight cutting pieces; working conditions of the multiple weighing boxes are alternatively changed and one down filling pipe is used for outputting, so that the down filling efficiency is further improved.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

Portable energy-storage type external skeleton assisting robot

ActiveCN103610524AIntrusion Length AdjustmentEasy to disassemble and assembleArtificial legsThighExoskeleton robot

The invention relates to an external skeleton assisting robot, in particular to a portable energy-storage type external skeleton assisting robot. The problems that an existing lower limb external skeleton assisting robot worn on the human body is poor in assisting effect so that the loading capacity of the human body can be reduced, the wearing comfort for the human body is poor, the universality is poor, and the field environmental suitability is poor are solved. The portable energy-storage type external skeleton assisting robot comprises the upper body back, the left leg and the right leg, and the left leg and the right leg respectively comprise a hip driving system, a thigh driving system and a shank wearing system. A hip joint energy-storage mechanism comprises a connecting base, a stretching rod, a second spring and a stopping sheet, and a first bevel gear is meshed with a second bevel gear. Each hip driving system comprises a second motor with a coder, a second reducer, a third bevel gear, a fourth bevel gear, a thigh connecting rod, a knee joint support, a knee joint connecting plate, an angle sensor, a series connection elastic combination body, a knee joint gearbox body, a knee joint shaft and an end cover. The portable energy-storage type external skeleton assisting robot is suitable for being worn outdoors for walking assisting.

Owner:HARBIN INST OF TECH

Hydraulic bidirectional pumping device

ActiveCN104612928AExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

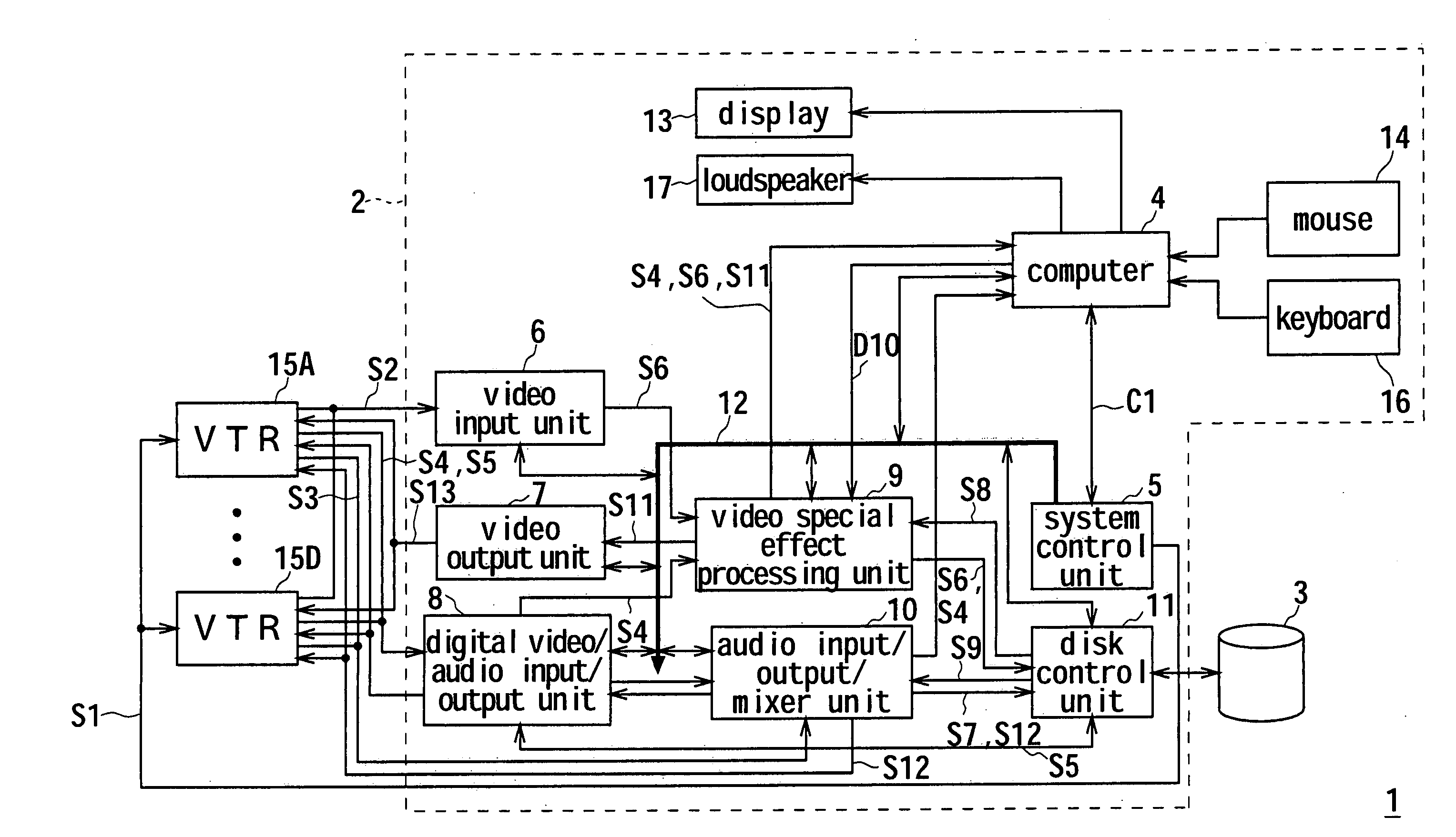

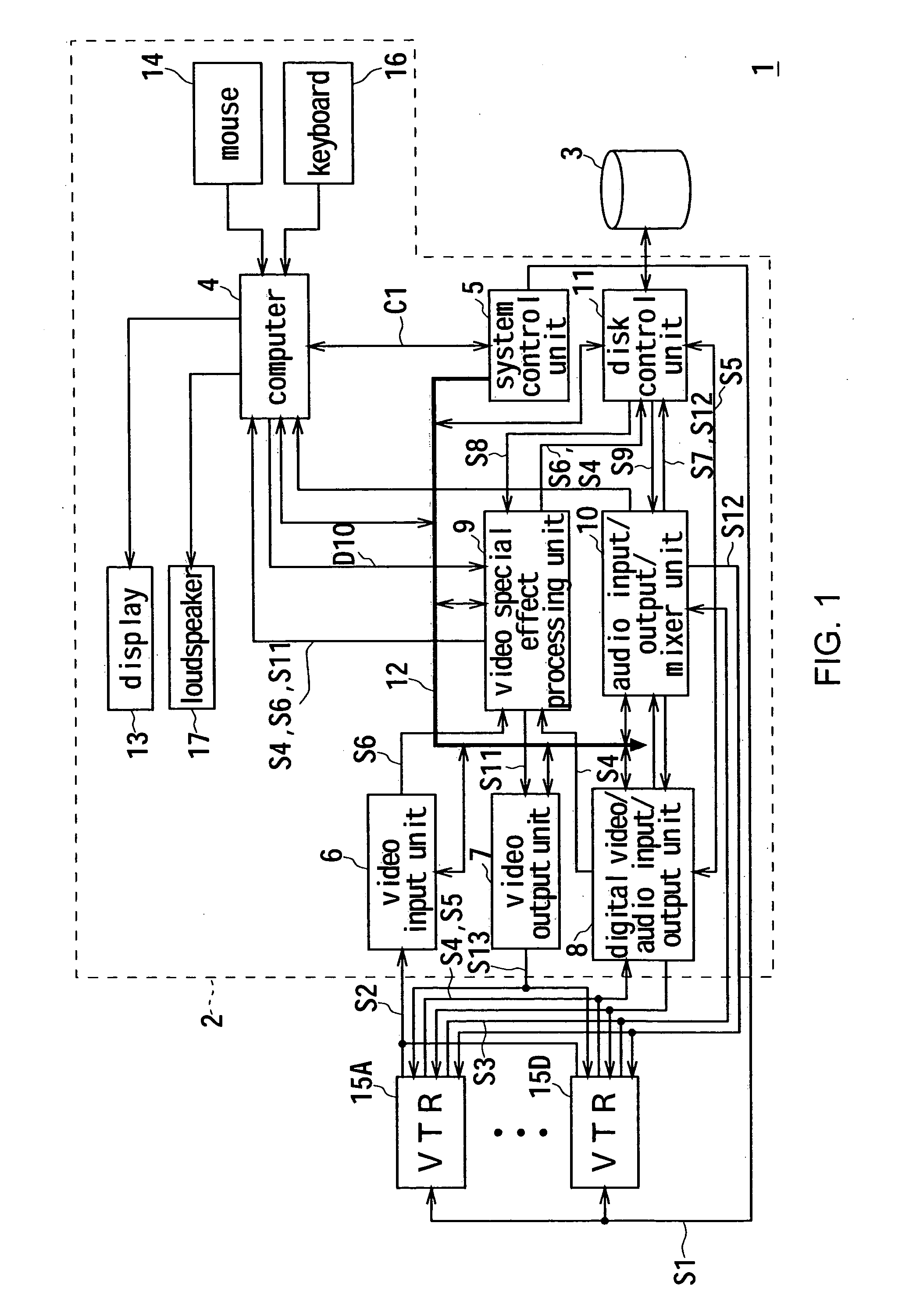

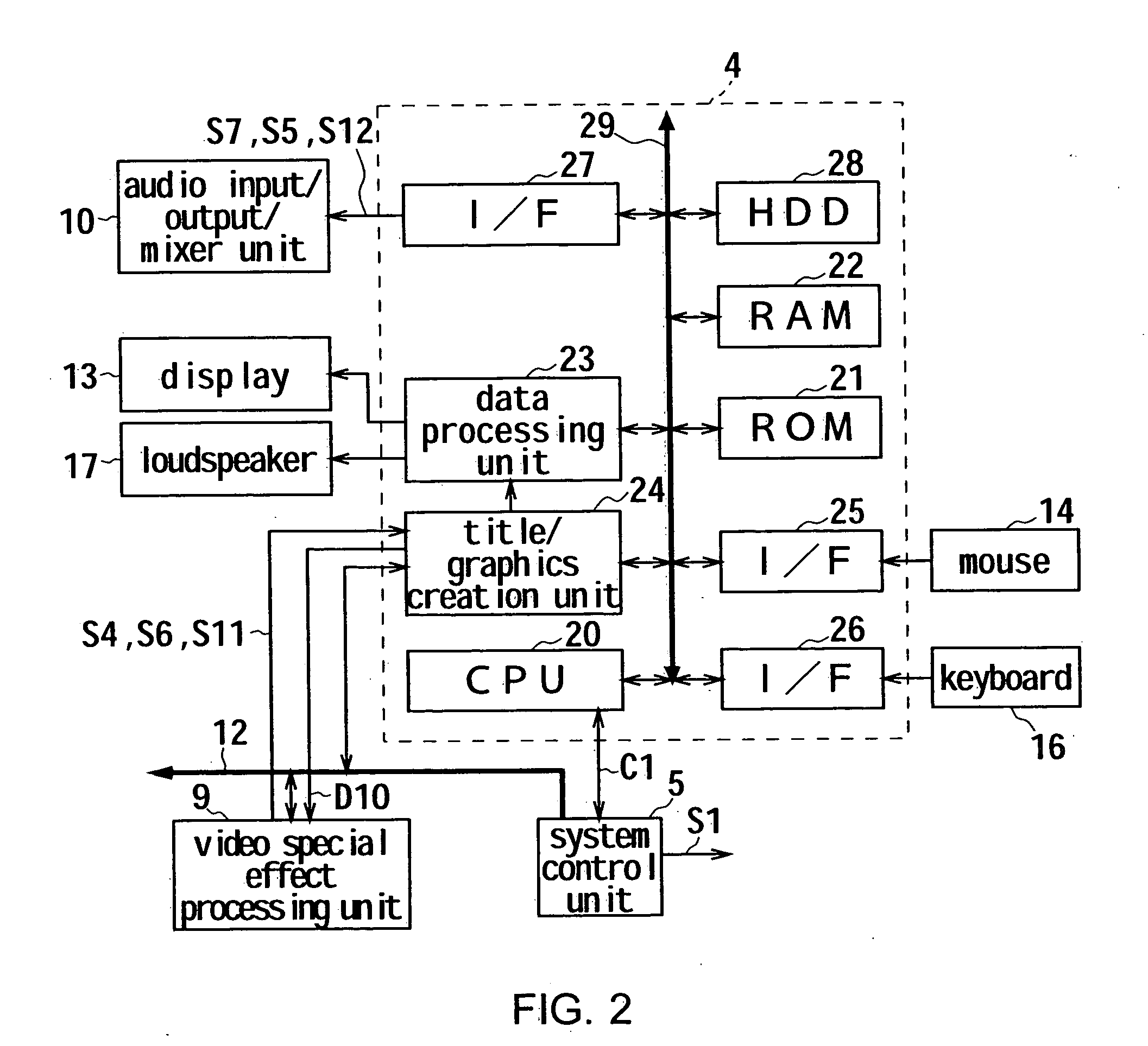

Editing apparatus and control method thereof, and program and recording medium

InactiveUS20060008247A1Excellent visibility and operabilityImprove editing efficiencyTelevision system detailsElectronic editing digitised analogue information signalsSpecial effectsGraphical user interface

A plurality of video materials specified out of video materials is managed as one group, information on each video material belonging to the group is displayed on a graphical user interface according to first operation, and according to second operation, a process to add a video material to the group or delete a video material specified out of the video materials belonging to the group is performed and the contents of a special effect set to a video material specified out of the video materials belonging to the group are managed in correspondence with only the video material.

Owner:SONY CORP

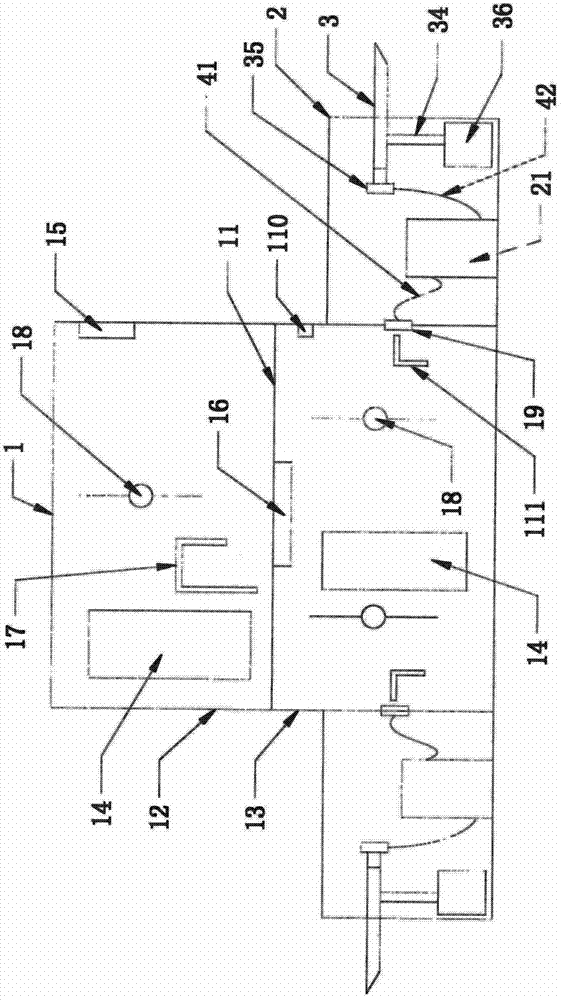

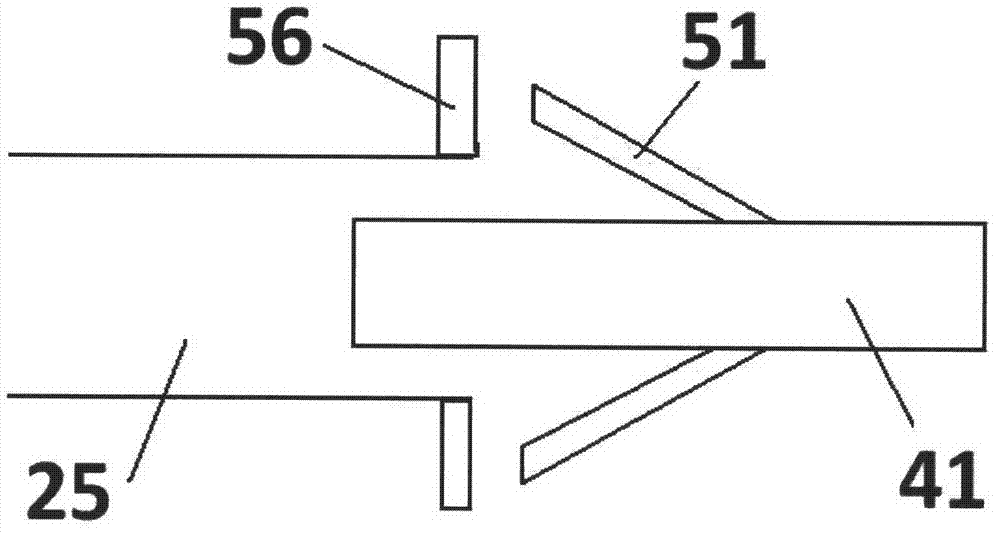

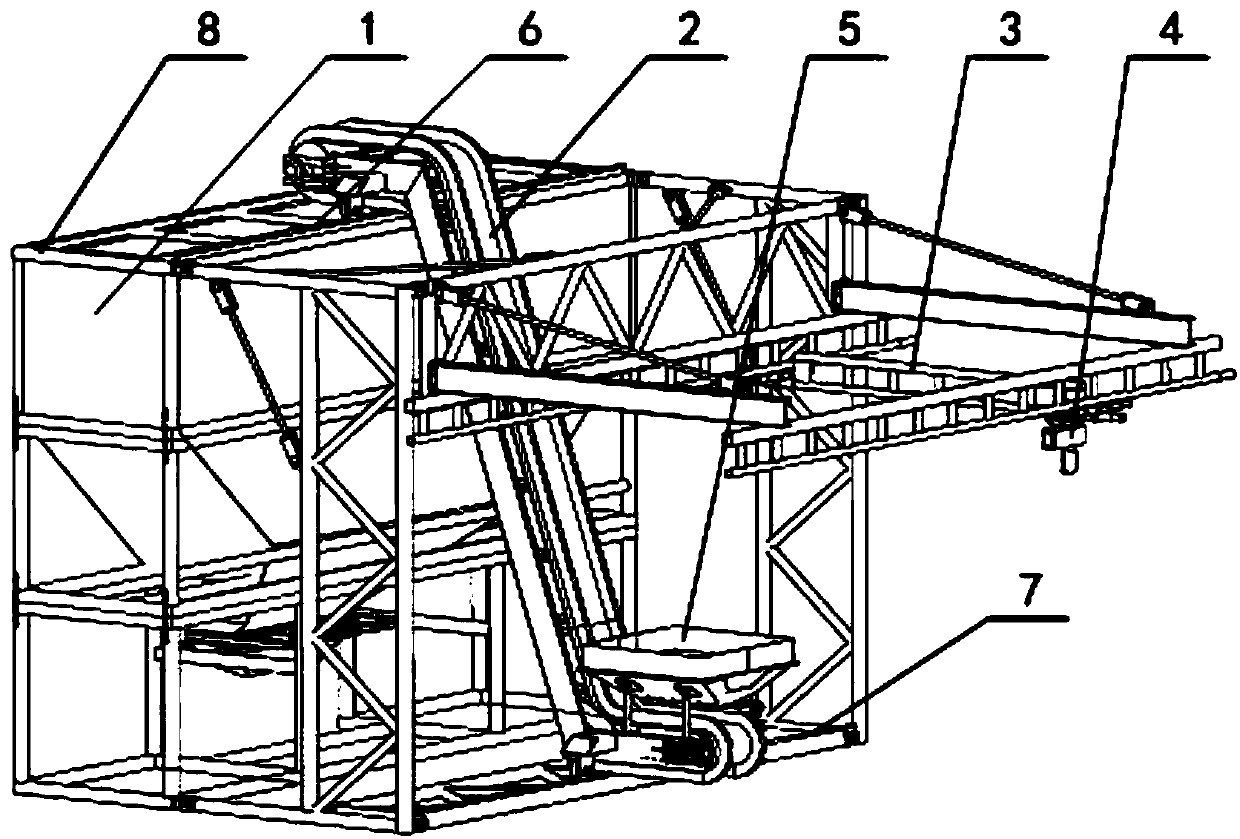

Material hoisting and transportation device

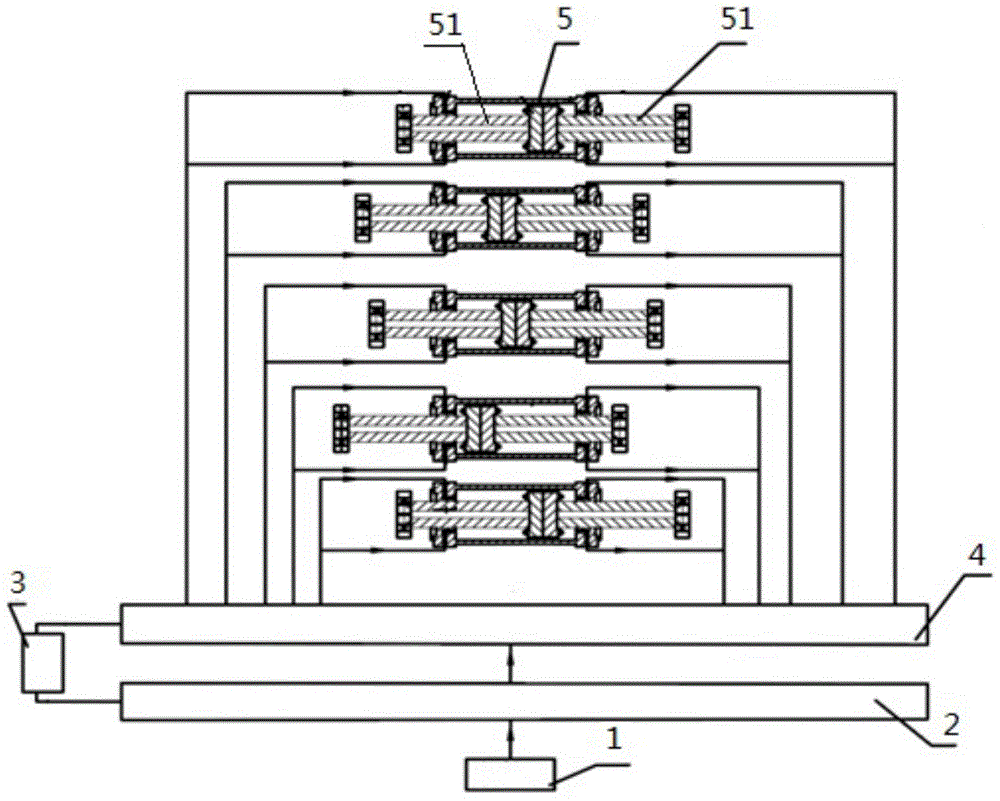

PendingCN107902427ASave on high costsEliminate potential safety hazardsStorage devicesEngineeringOrbit

The invention relates to the oil gas industry, particularly to a material hoisting and transportation device utilized in oil and gas field fracturing operation. The material hoisting and transportation device is characterized in that a material storage tank is mounted on the left of a frame body; an upper orbit is mounted at the upper part of the frame body; a lower orbit is mounted at the right end of the lower part of the frame body; a belt conveying device is mounted on the upper orbit and the lower orbit; a feeding hopper is mounted at the bottom of the belt conveying device; a hoisting device is mounted at the right end of the upper part of the frame body; the hoisting device is mounted in an operation orbit; a hook is mounted on the hoisting device; during operation, the belt conveying device can longitudinally move on the upper orbit and the lower orbit; and during operation, the hoisting device can longitudinally and transversely move in a horizontal plane. The material hoisting and transportation device has a one-key locating function, and automatic operation and locating of the belt conveying device and the hoisting device can be achieved through the function.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Remote, automatic control system for oil field fracturing pumping

ActiveCN101414171BMonitor and control operationsOrderly and stable operationTotal factory controlProgramme total factory controlAutomatic controlHuman–machine interface

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

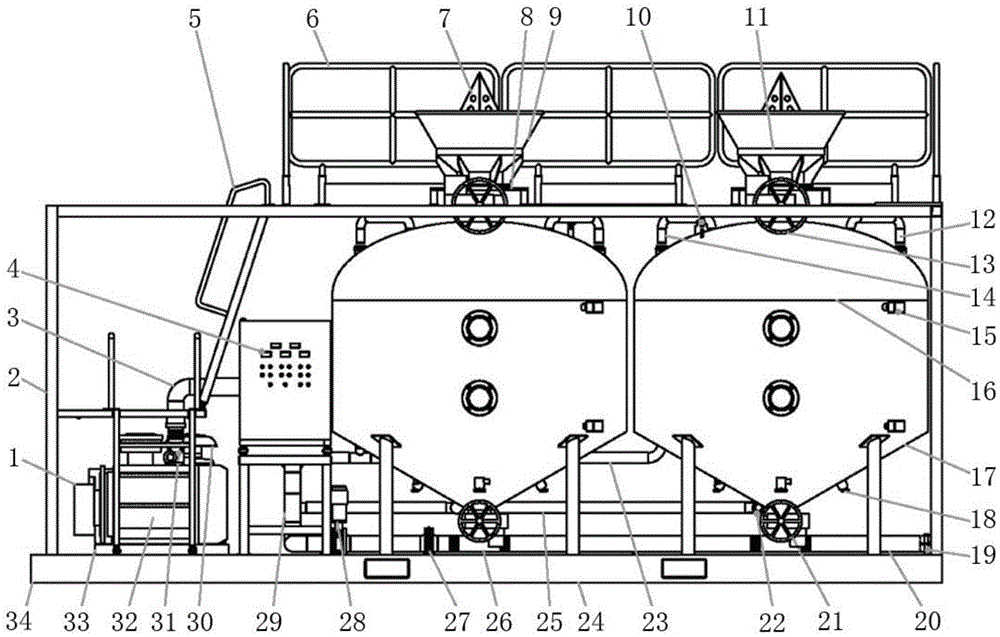

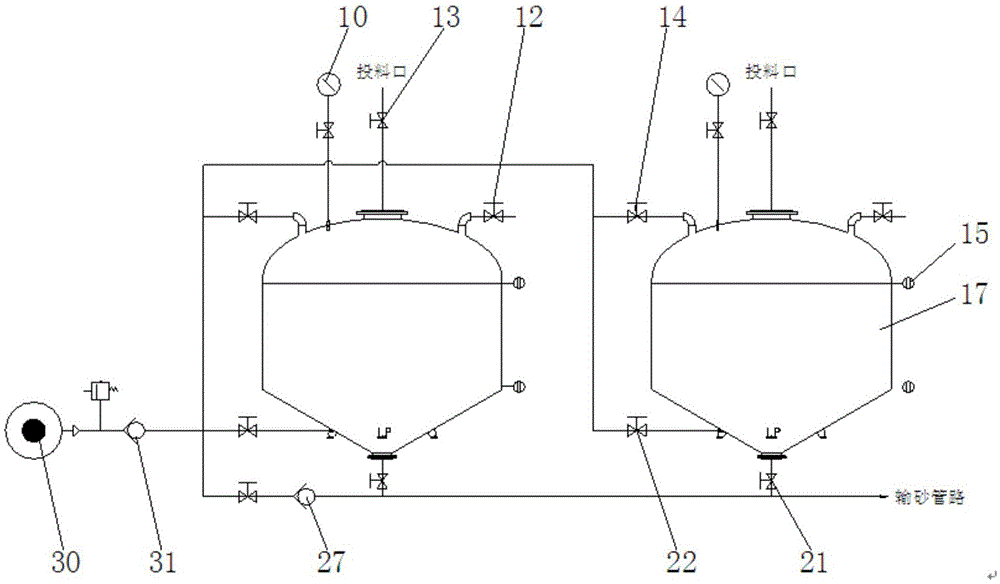

A positive pressure pneumatic conveying skid for oil field fracturing proppant

ActiveCN104340682BImprove securityReduce the difficulty of homeworkBulk conveyorsPositive pressureControl system

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

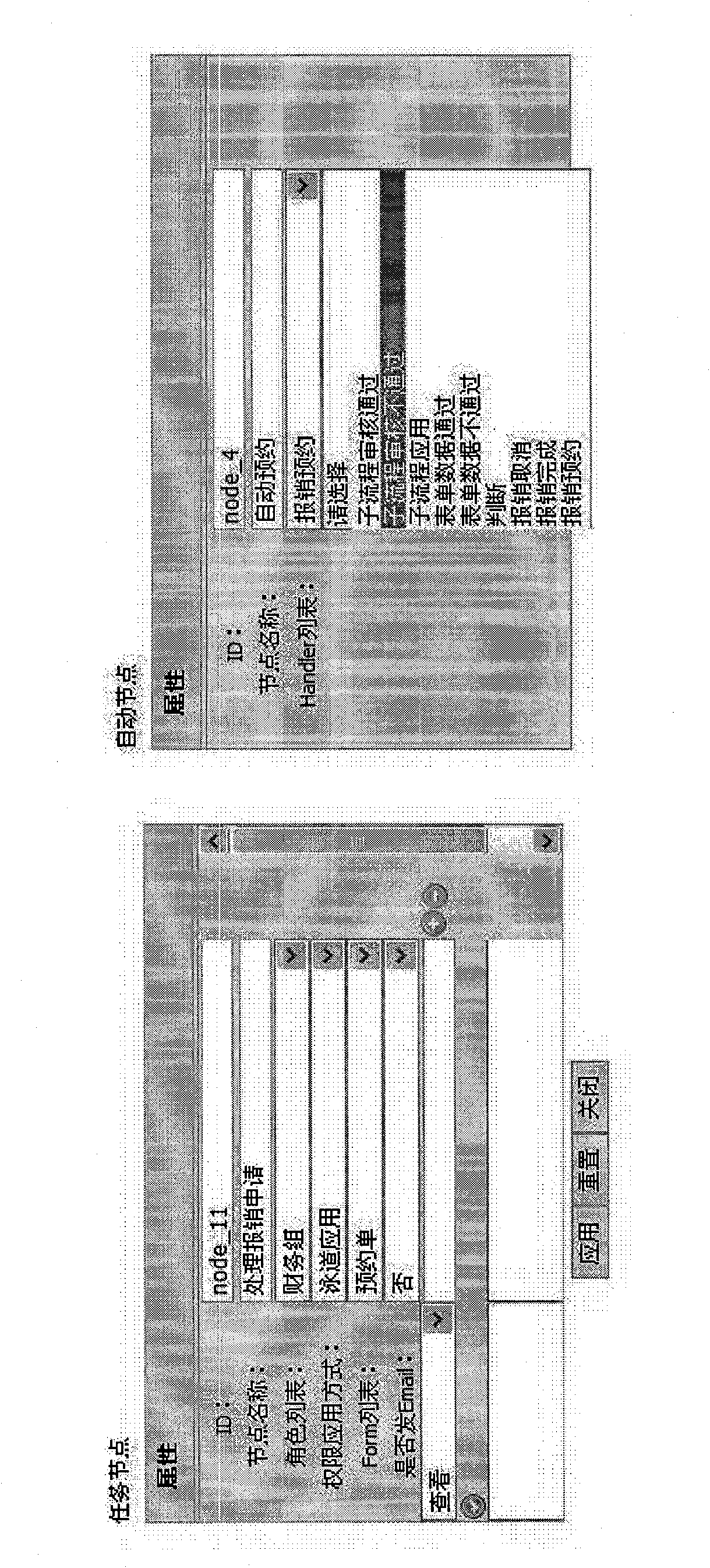

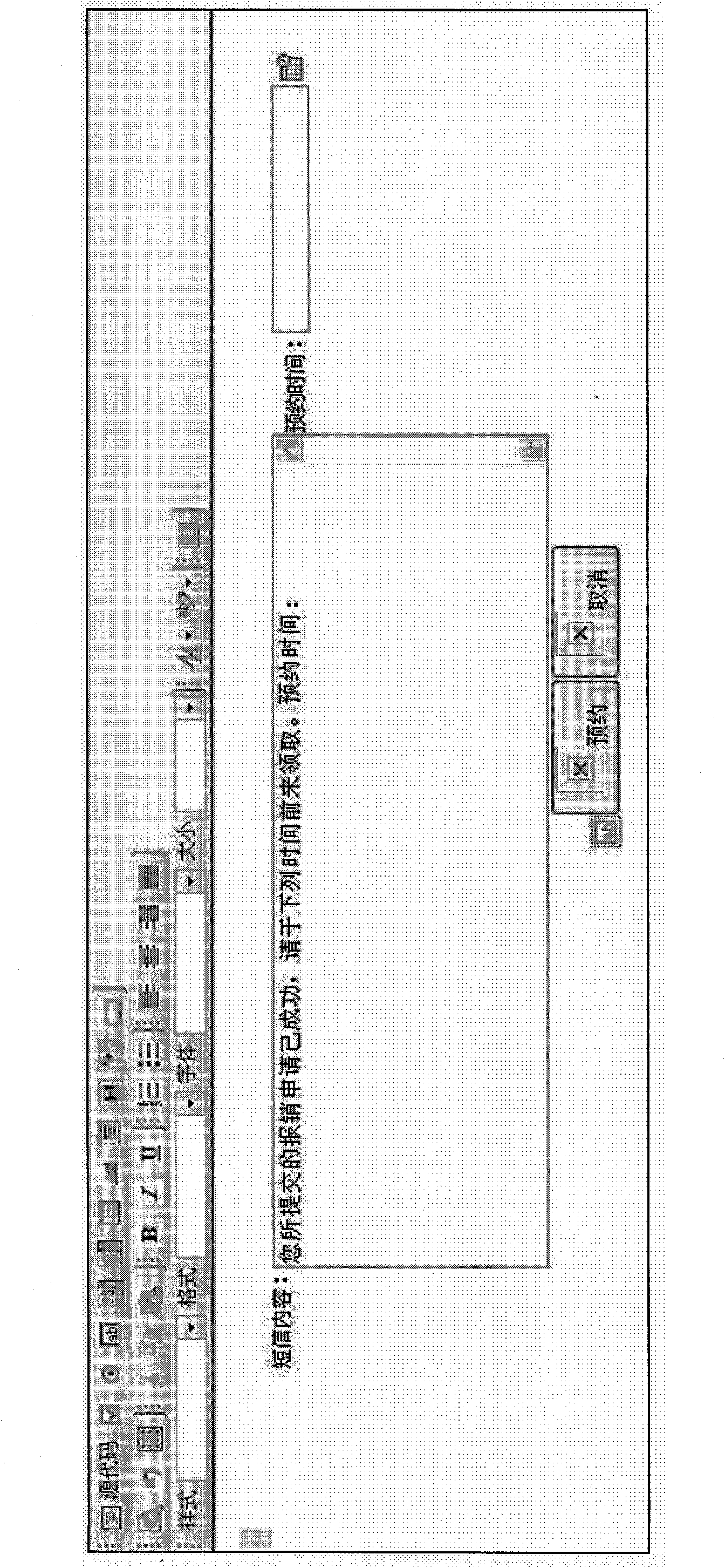

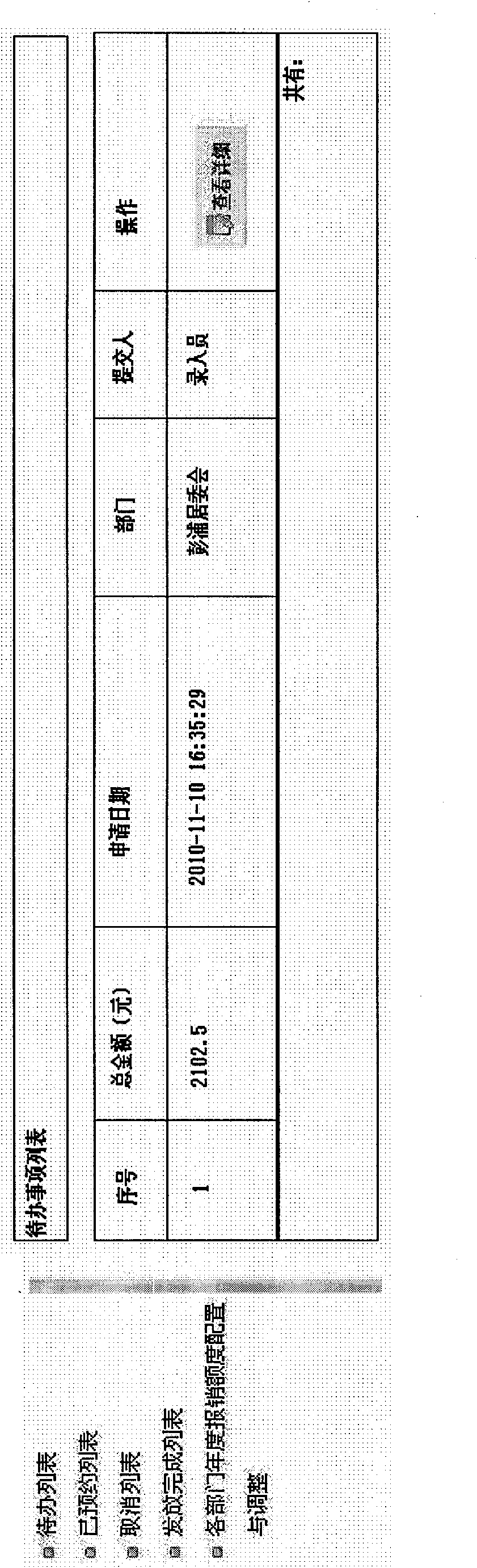

Workflow realization method and workflow system capable of customizing flow in user-defined manner

InactiveCN102486730AImprove and optimize business processesImprove work efficiencyResourcesSpecific program execution arrangementsSystem administratorFilling-in

The invention provides a workflow realization method capable of customizing a flow in a user-defined manner. The method comprises the following steps of: establishing a WYSIWYG (What You See Is What You Get) webpage flow editor; drawing a flow diagram by a system manager; starting a platform program and generating an operation code so as to generate a corresponding workflow operation program; filling in a system by a terminal user, submitting a form, and triggering and starting the workflow working program; and sequentially operating all the flows by the system until the flows are finished. The invention further provides a workflow system capable of customizing the flow in the user-defined manner and the workflow system comprises a defining module, an analyzing module, a workflow engine module, a flow execution module and a database module. According to the invention, the problem that the existing workflows need to be modified by programmers or a modification tool is separated from a user is solved; and the workflow realization method and the workflow system have the advantages of easiness of modification and maintenance, time conservation and cost conservation.

Owner:SHANGHAI XIEXUN SOFTWARE

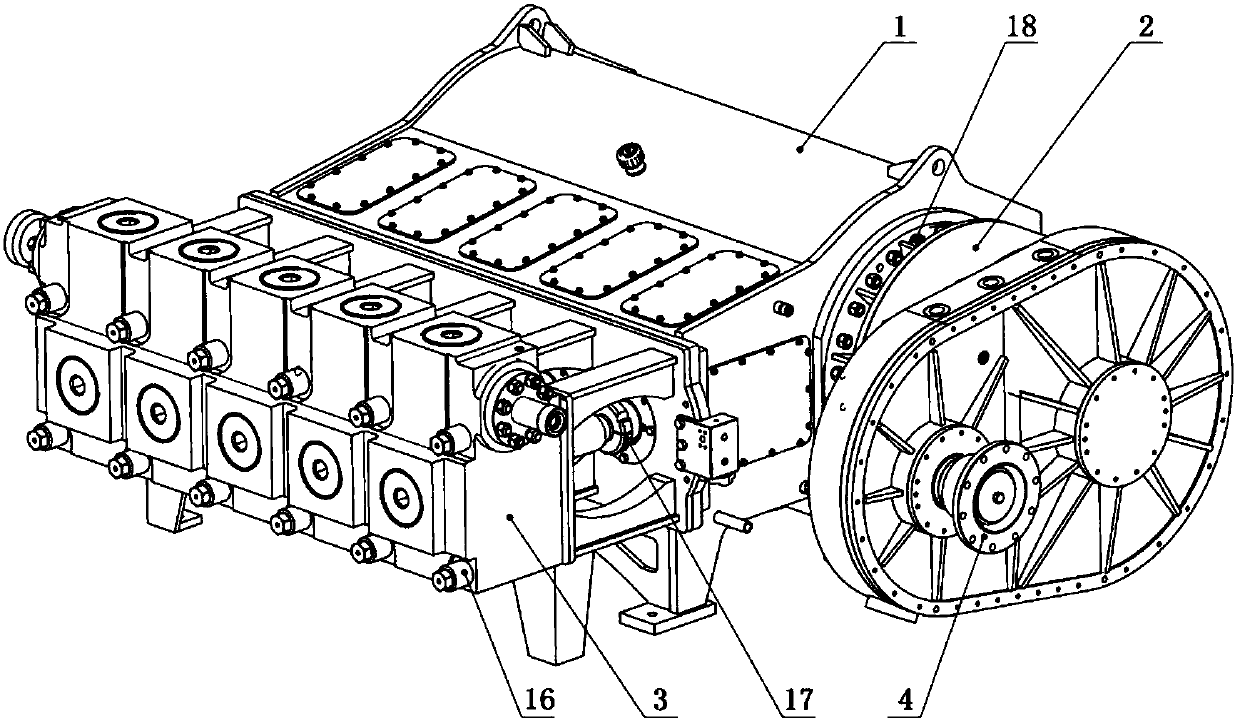

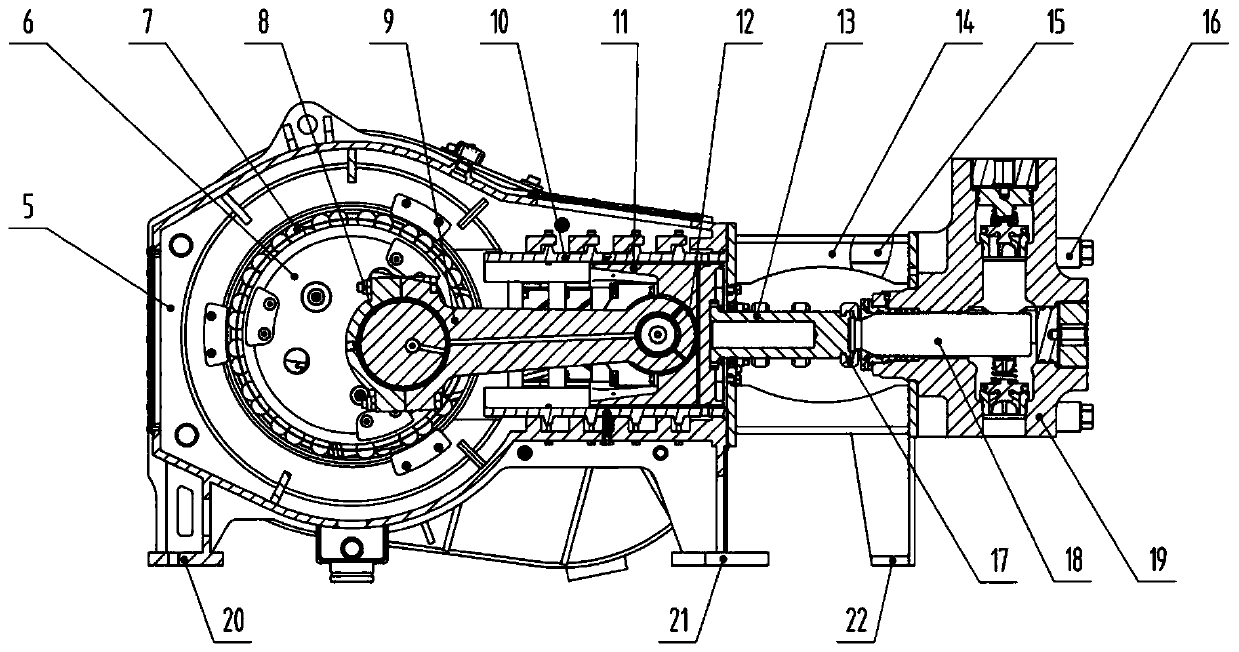

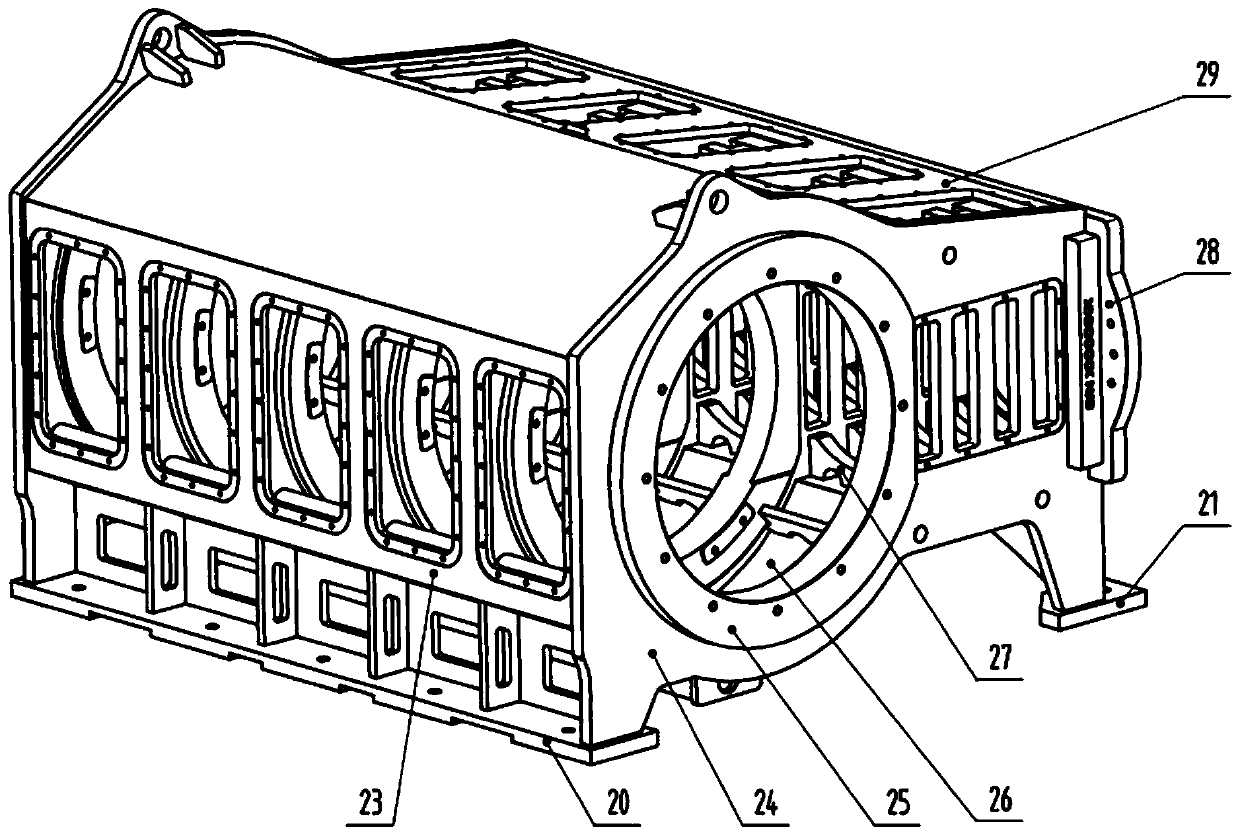

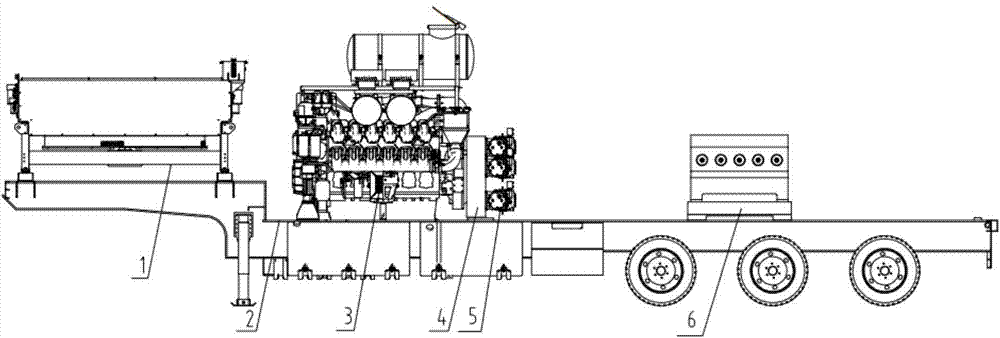

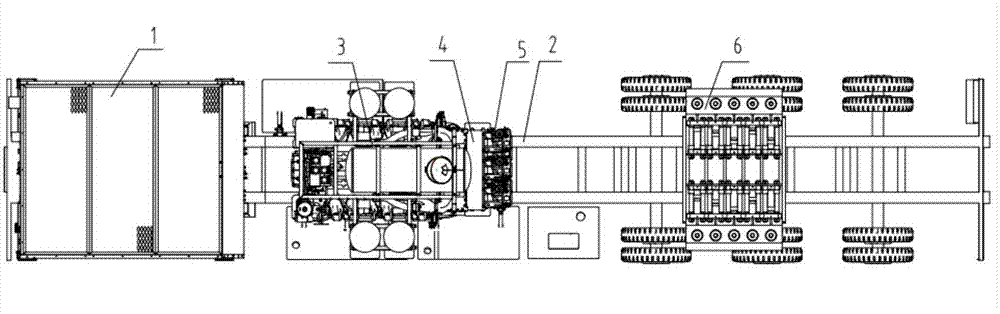

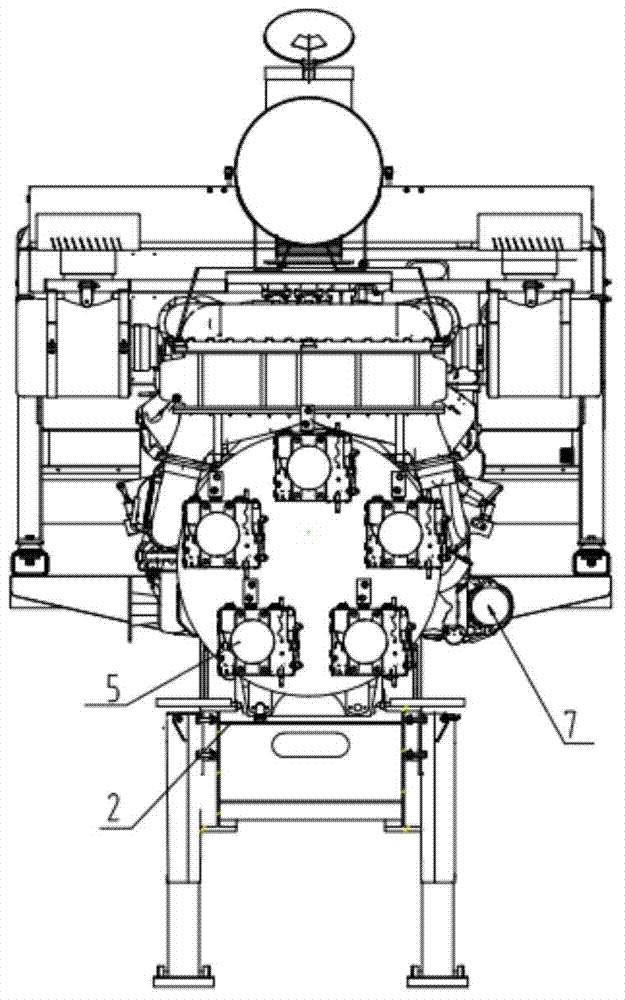

High-power five-cylinder plunger pump

PendingCN110617187AIncrease the carrying areaOptimize layoutPositive displacement pump componentsFluid removalEngineeringMechanical engineering

The invention discloses a high-power five-cylinder plunger pump. The plunger pump comprises a power end assembly, a hydraulic end assembly and a reduction gearbox assembly, wherein the power end assembly comprises a crankshaft box body, a crosshead box body and a spacer frame; the crankshaft box body, the crosshead box body and the spacer frame are sequentially connected; the hydraulic end assembly is fixed on the spacer frame; the reduction gearbox assembly is fixed on the crankshaft box body; and the cylinder spacing of the five-cylinder plunger pump is 13-14 inches, so that a guarantee is provided for the output of high power of the five-cylinder plunger pump. According to the high-power five-cylinder plunger pump, the problems that the area of a shale gas fracturing well site is narrowand the number of required fracturing equipment is relatively large are effectively solved, thus reducing the use of equipment, and facilitating the arrangement of the well site.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Fracturing transmission and high-pressure discharging system

InactiveCN104727797AExpand the range of selectionSave layout spaceFluid removalTransfer caseEngineering

The invention relates to a fracturing transmission and high-pressure discharging system. The fracturing transmission and high-pressure discharging system comprises a chassis and is characterized in that a high-power engine, a transfer case, a plurality of variable displacement plunger pumps and a double-acting fracturing pump are arranged on the chassis, the output end of the high-power engine is connected with the input end of the transfer case, the output end of the transfer case comprises a plurality of power take-off ports, and each power take-off port is connected with one variable displacement plunger pump; the variable displacement plunger pumps drive the double-acting fracturing pump through a hydraulic system. The fracturing transmission and high-pressure discharging system further comprises a system radiator and a heat dissipation plunger pump used for driving the system radiator, and the heat dissipation plunger pump is connected with one power take-off port of the transfer case. The power take-off ports of the transfer case and the variable displacement plunger pumps are arranged annularly. The fracturing transmission and high-pressure discharging system has the advantages that hydraulic driving replaces mechanical transmission, and working vibration is reduced; the layout space of a whole vehicle is saved, and meanwhile, operating efficiency and the stability of the whole vehicle are improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

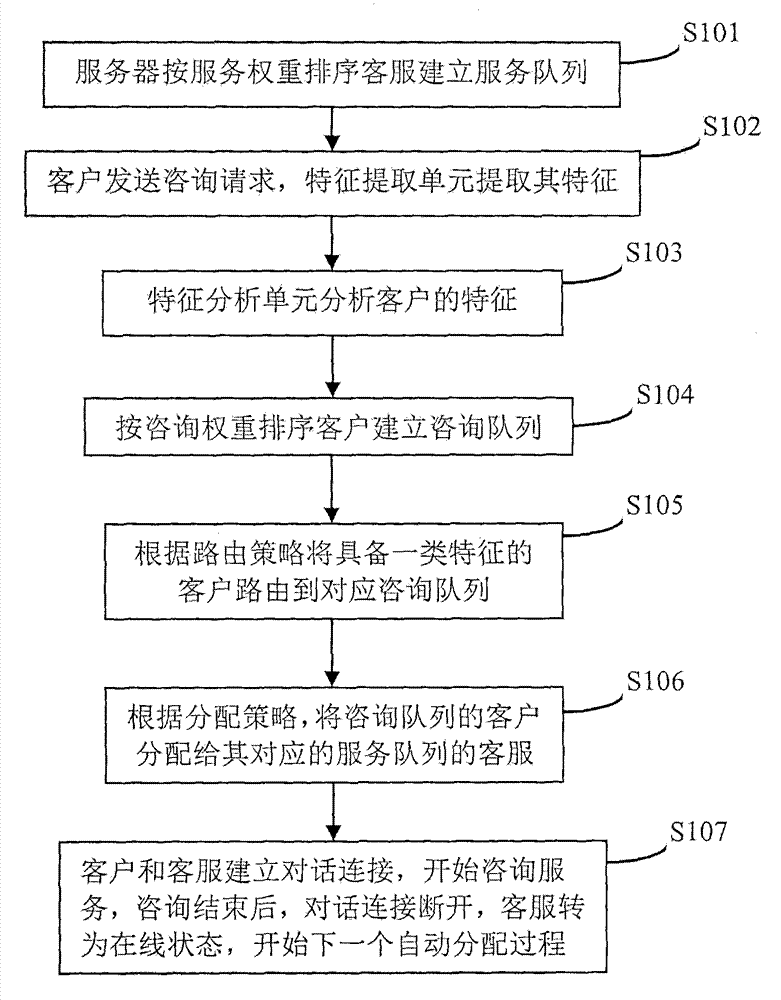

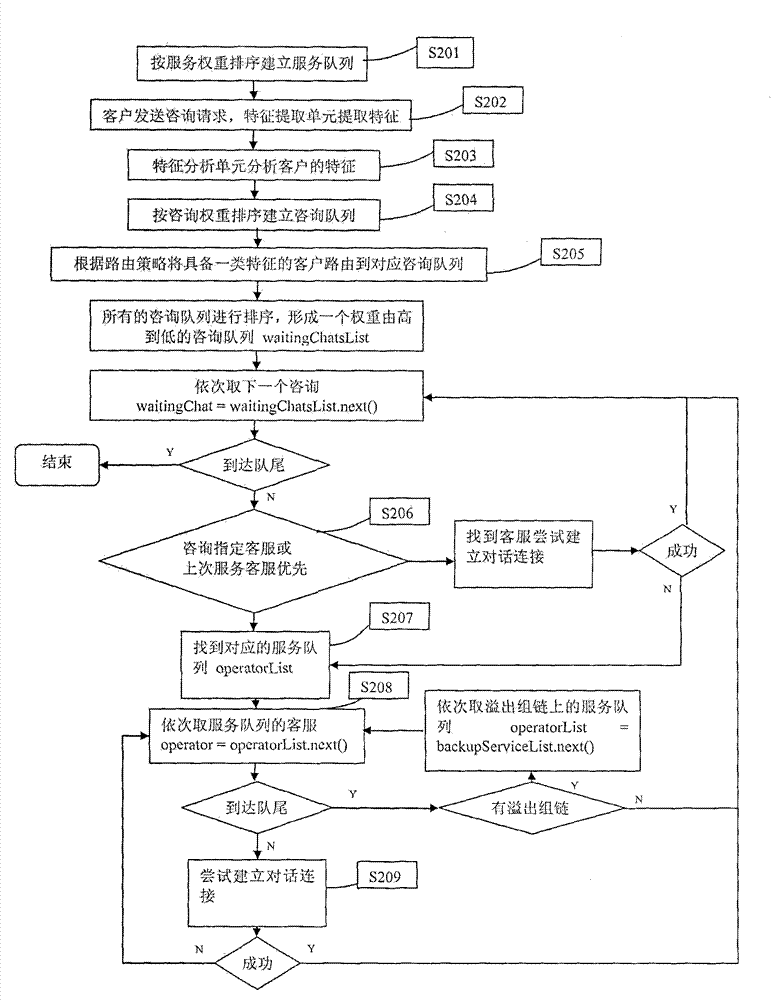

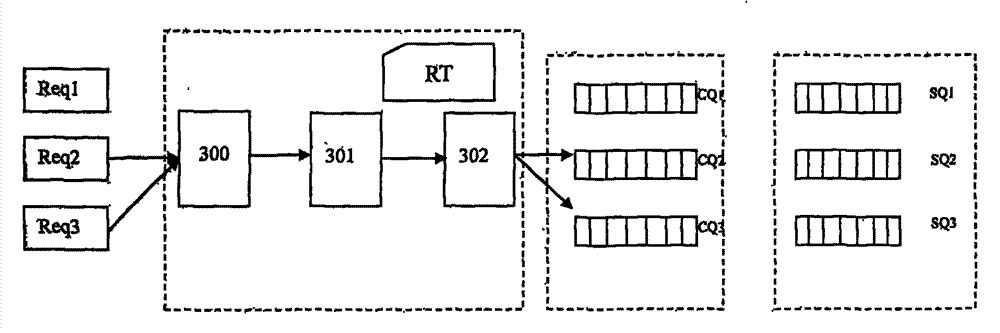

Method and device for automatically distributing online customer service executives to conduct customer service

ActiveCN103684874AImprove targetingImprove work efficiencyData switching networksClient-sideInstant messaging

The invention relates to a method and a device for automatically distributing online customer service executives to conduct customer service. The method includes that a service queue formed by the customer service executives is built; a client consultation request is sent to a server; the server transmits characteristic information of clients, the consultation request and characteristic information of the consultation request to a routing selection unit of the server; the server builds at least one consultation queue formed by the clients; the server distributes the consultation to the corresponding service queue according to a preset distribution strategy and then sequentially and automatically distributes the clients of the consultation queue to specific customer service executives of the service queue, and a conversation connection request is sent to a client side instant communication terminal through the server; the client side instant communication terminal receives and responds to the conservation connection request, and builds direct conversation connection with the customer service executives to enable the customer service executives to conduct client consultation service; after the consultation service is finished, conservation connection between the clients and the customer executives is broken, then the server recalculates customer service executive weights and rearranges the service queue.

Owner:成都天润金铠甲科技有限公司

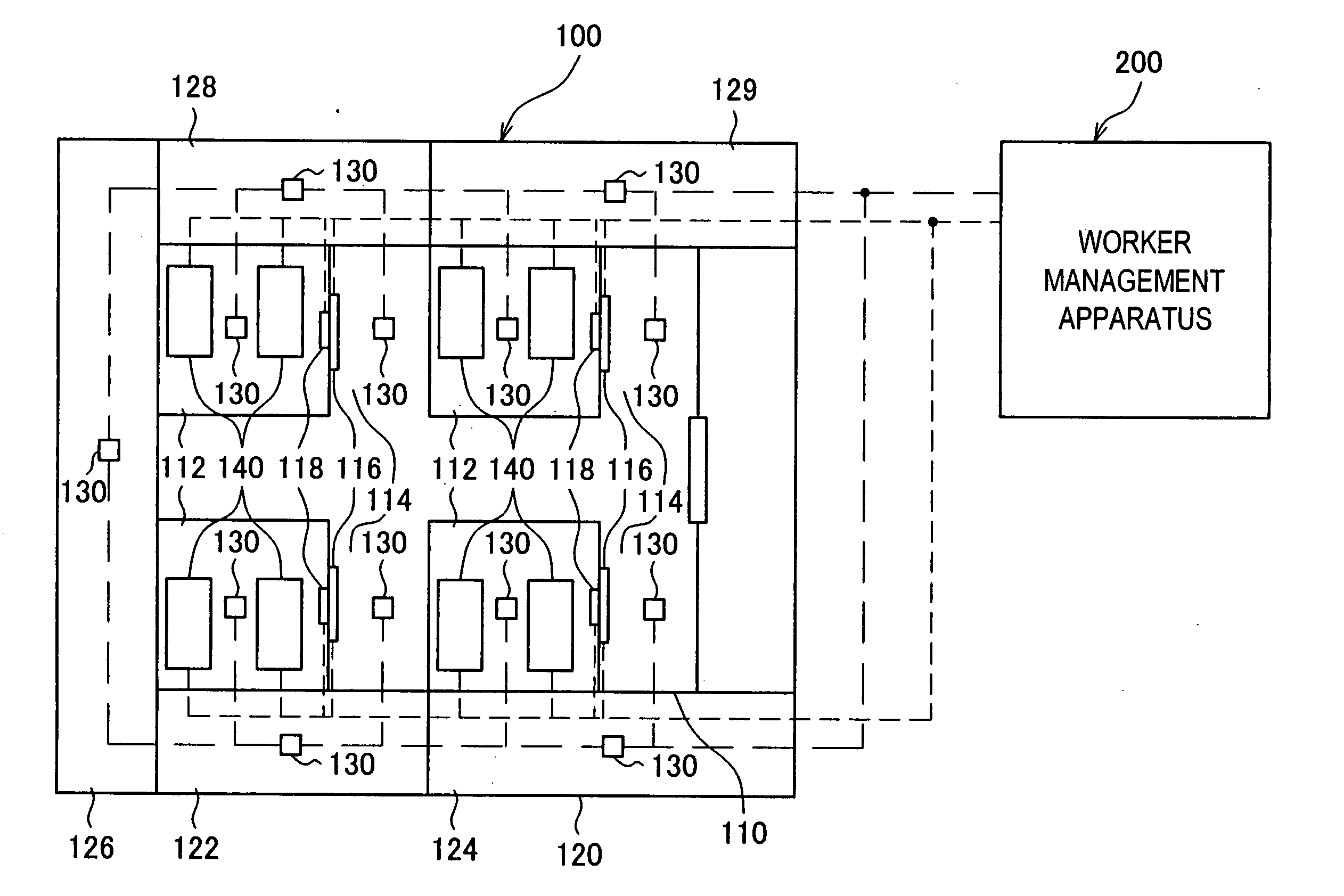

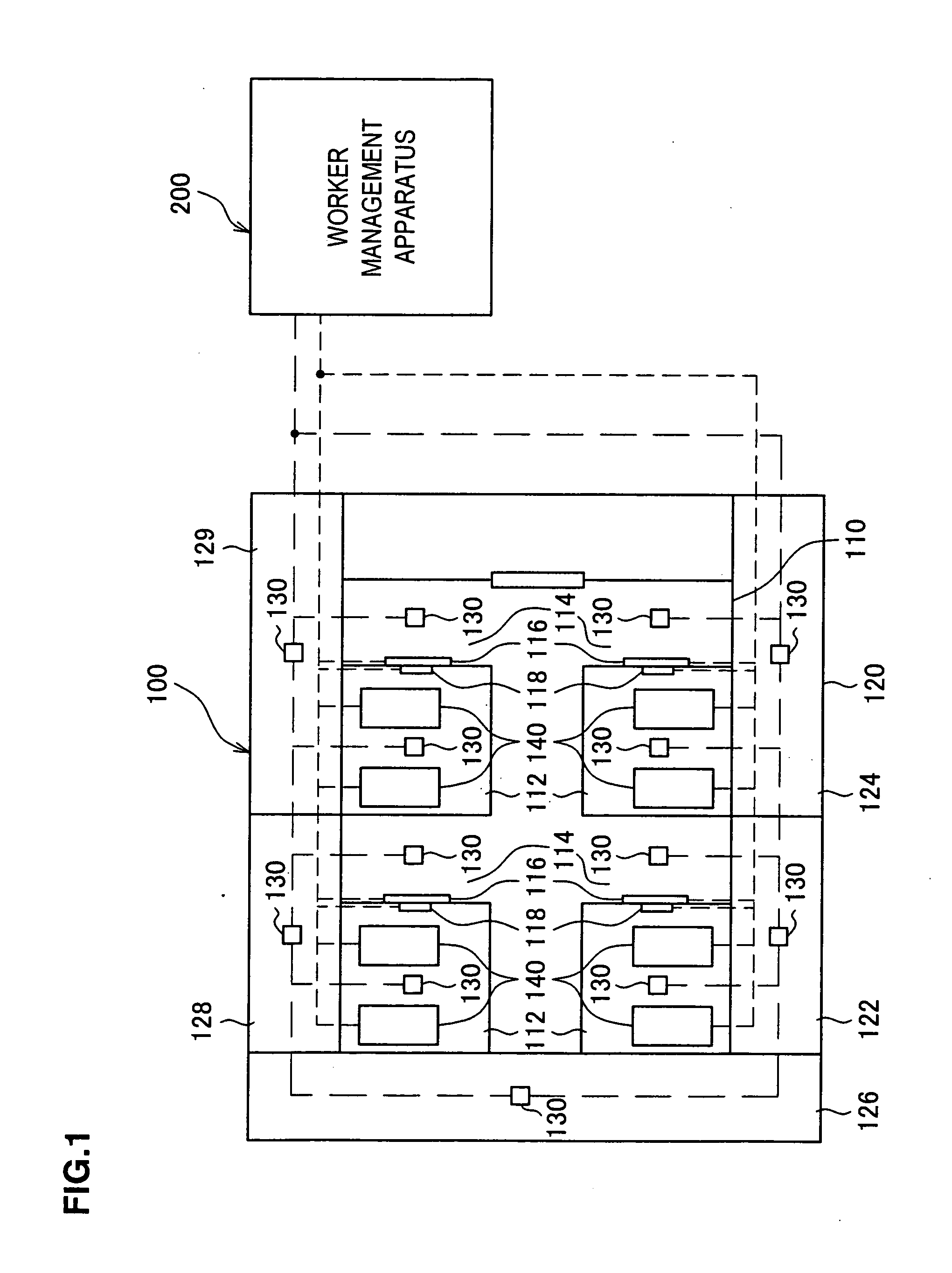

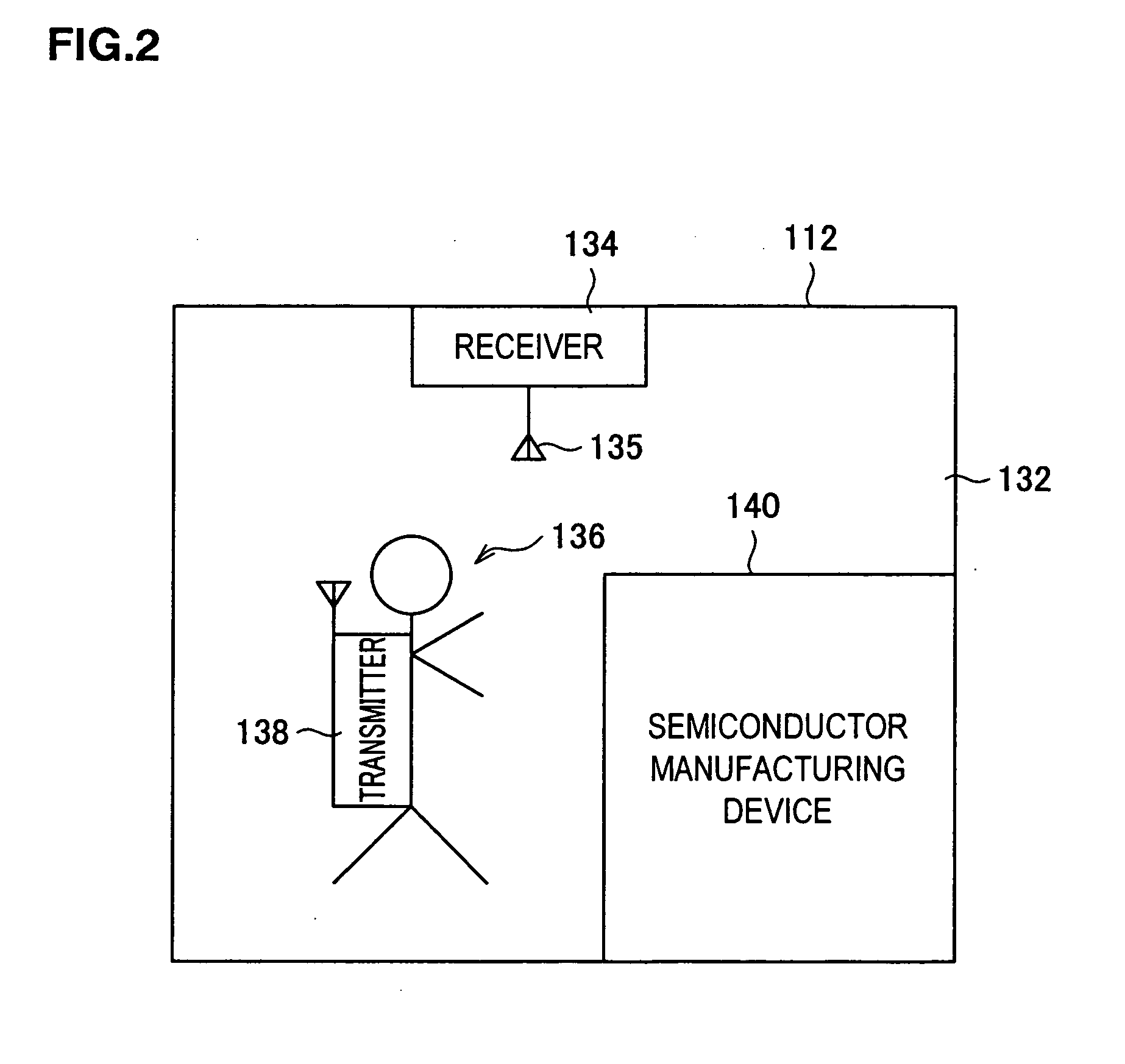

Worker management system, worker management apparatus and worker management method

InactiveUS20050209902A1Easy to detectDelay detectionFrequency-division multiplex detailsTime-division multiplexComputer scienceManagement system

A worker management system, which includes a plant 100 divided into a plurality of work areas each in correspondence to specific task contents, a database 220 having stored therein task identification information correlating each work area 112 with contents of tasks performed therein and worker detection sensors 130 installed in each work area, identifies the specific work area where a worker is currently located based upon outputs from the worker detection means and then identifies the task currently performed by the worker based upon the task identification information. Based upon the current task thus identified, a decision is made as to whether the worker should continue the current task or be assigned a new task and an instruction for task execution is issued to the worker. Therefore the identification of current tasks, the assignment of a new task and the task reassignment are facilitated to improve the work efficiency.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com