Patents

Literature

2119 results about "Fast measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

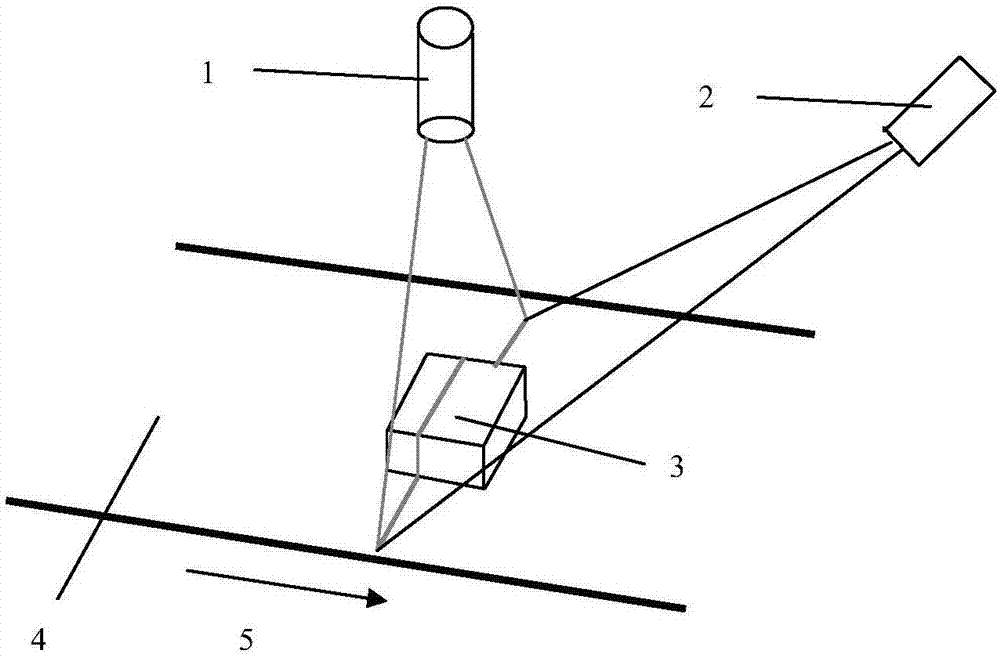

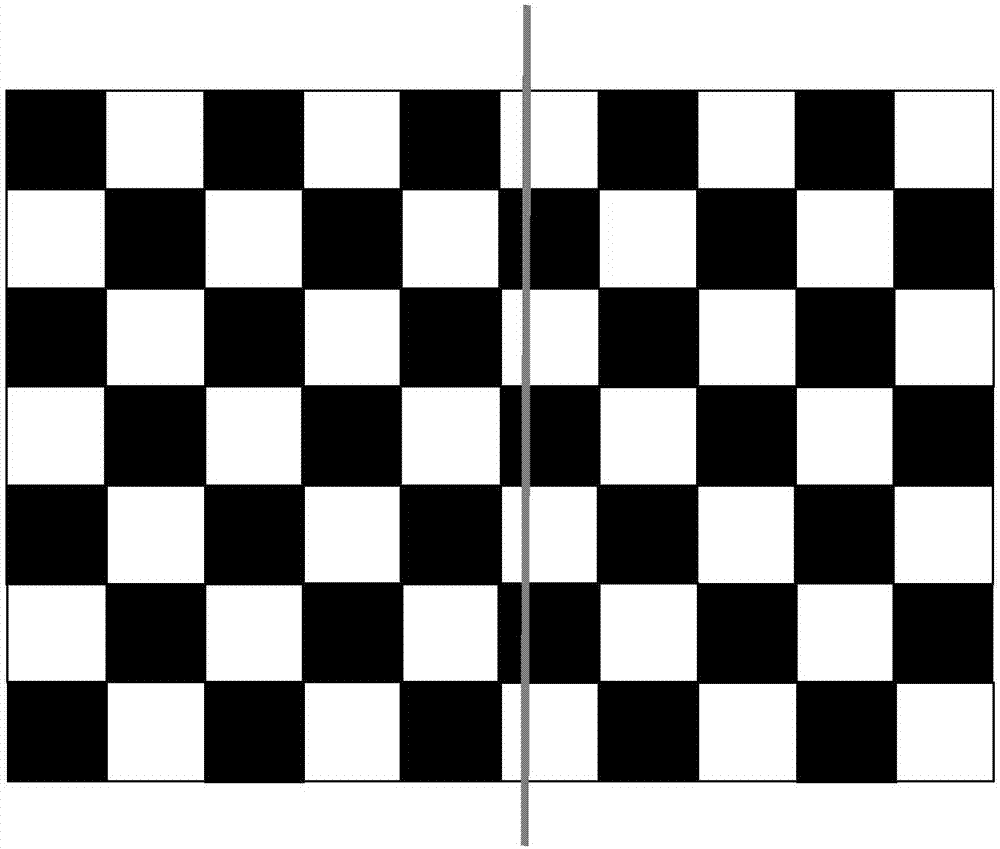

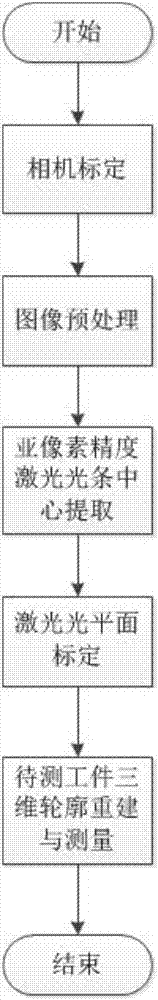

A method of 3D contour measurement of a workpiece on a conveyor belt based on line laser scanning

ActiveCN107578464AHigh measurement accuracyAccurate measurementImage analysisUsing optical meansMobile laser scanningLaser light

The invention discloses a method of 3D contour measurement of a workpiece on a conveyor belt based on line laser scanning. The method comprises the following steps of obtaining camera internal and external parameters through camera calibration, carrying out filtering and laser light strip center position initial extraction through an image preprocessing step, carrying out sub-pixel precision refinement on the center coordinates of a light bar, obtaining a light plane equation through the laser light plane calibration and finally carrying out reconstruction and measurement of the three-dimensional contour information of a workpiece to be measured. The workpiece 3D contour measurement brought forward by the invention has the following advantages: a high measurement precision which means thethree-dimensional contour information of the workpiece to be measured can be accurately obtained through the laser light bar extraction with sub-pixel precision and 3D reconstruction; a fast measurement speed which means real-time measurement of 3D contour information of the workpiece to be tested can be realized to improve the efficiency of industrial production site operations; and low hardwarecosts which is realized in a hardware implementation mode in which laser is combined with a monocular camera. Accordingly, the technical method of the application has advantages such as being in a non-contact mode, high in measurement precision, fast in speed and low in cost, and can be applied to an industrial automation production process to realize accurate measurement of the 3D contour information of the workpiece on the conveyor belt.

Owner:CHANGSHA XIANGJI HAIDUN TECH CO LTD

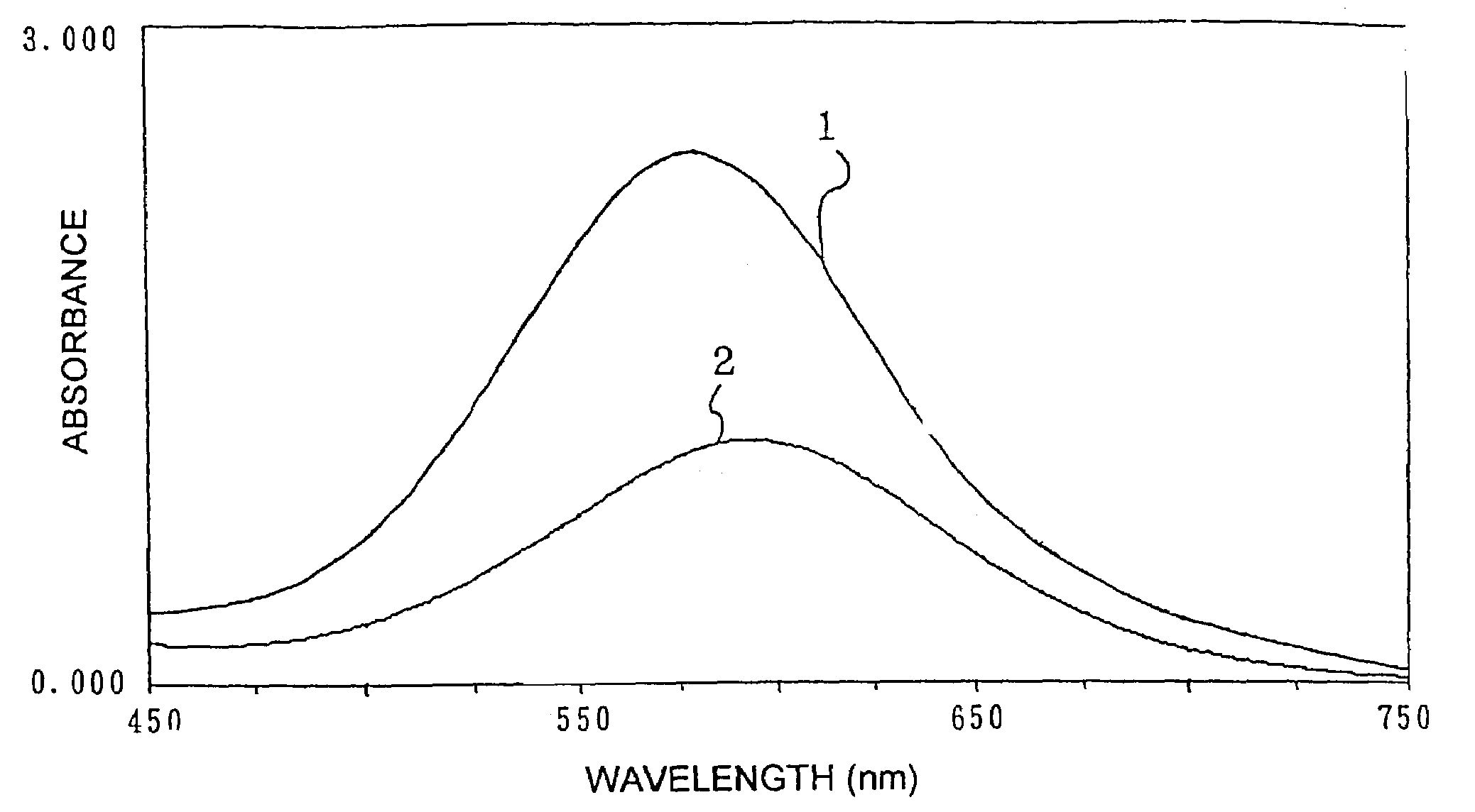

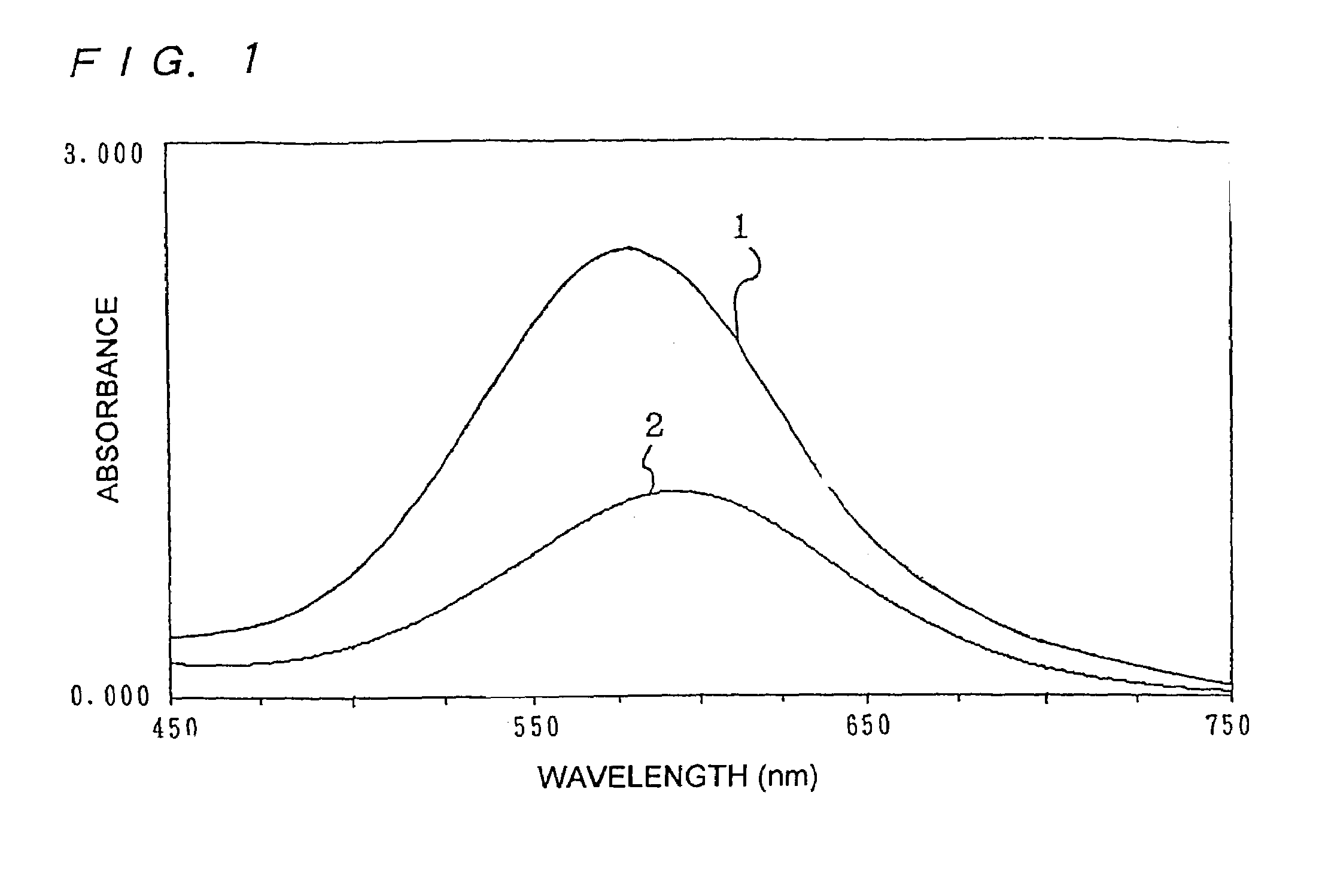

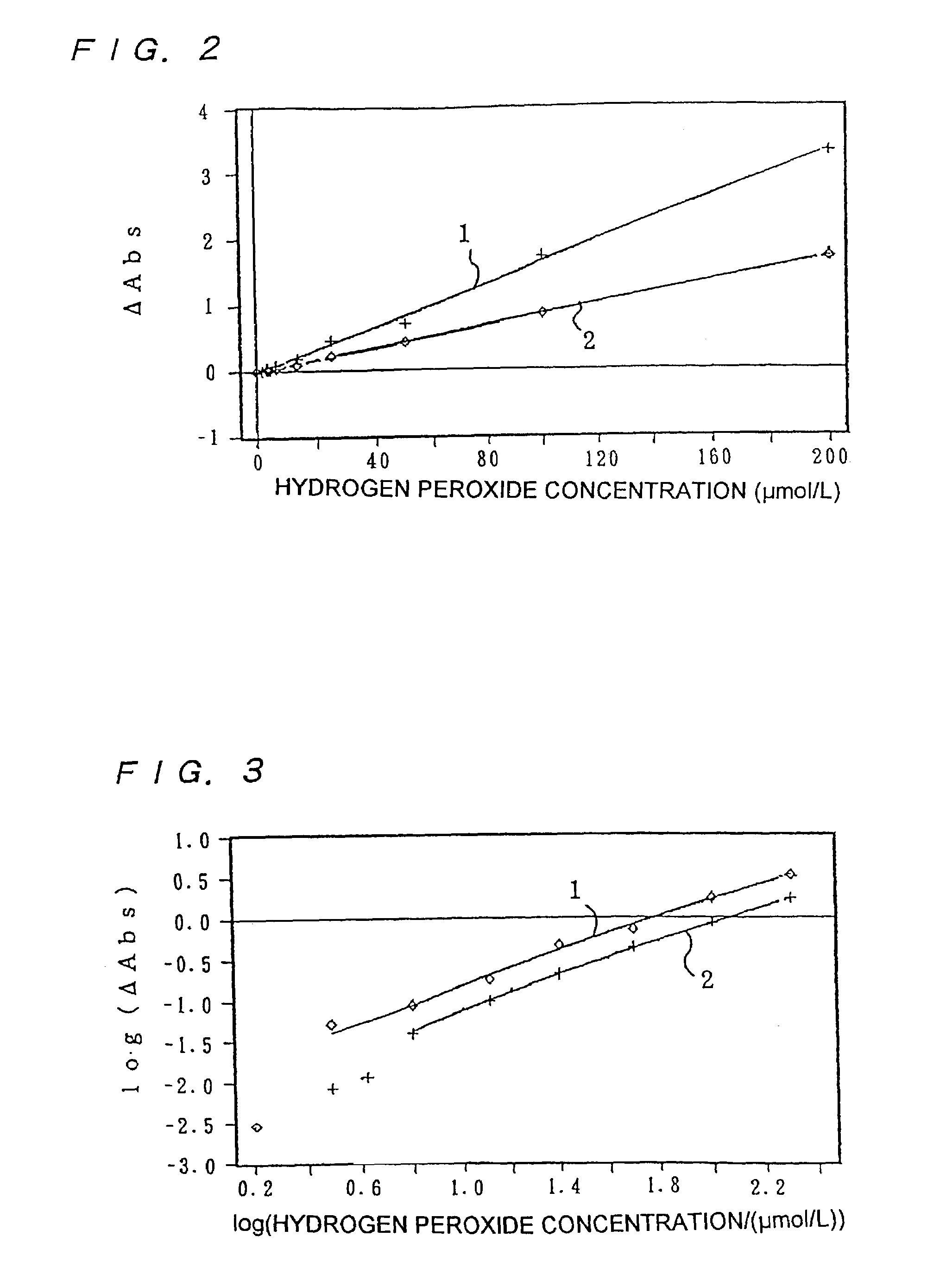

Method for measuring substance and testing piece

InactiveUS7153696B2High measurement accuracyHigh measurement sensitivityAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorDiffusionChemical reaction

A method of measuring an analyte, comprising a step of measuring a detectable substance by using a reaction system including a formation reaction of the detectable substance based on a chemical reaction of the analyte contained in a sample, wherein a layered inorganic compound is caused to exist in the reaction system including the formation reaction of the detectable substance, whereby high-sensitivity measurement is made possible, the detectable substance can be stabilized to improve accuracy of the measurement, a rate of a chemical reaction is increased to enable quick measurement, and high-sensitivity measurement is made possible even in a reaction system which forms an insoluble substance. Also, it can be provided an analytical testing piece for measuring an analyte, by measuring a detectable substance by using a reaction system including a formation reaction of the detectable substance based on a chemical reaction of the analyte contained in a sample, wherein the testing piece comprises at least one test portion having a detection portion for detecting the detectable substance and contains a layered inorganic compound at least in the test portion, whereby diffusion and elution of a dyestuff or the like is prevented, more sensitive and accurate simple analysis is made possible, and easy handling is possible.

Owner:ARKRAY INC

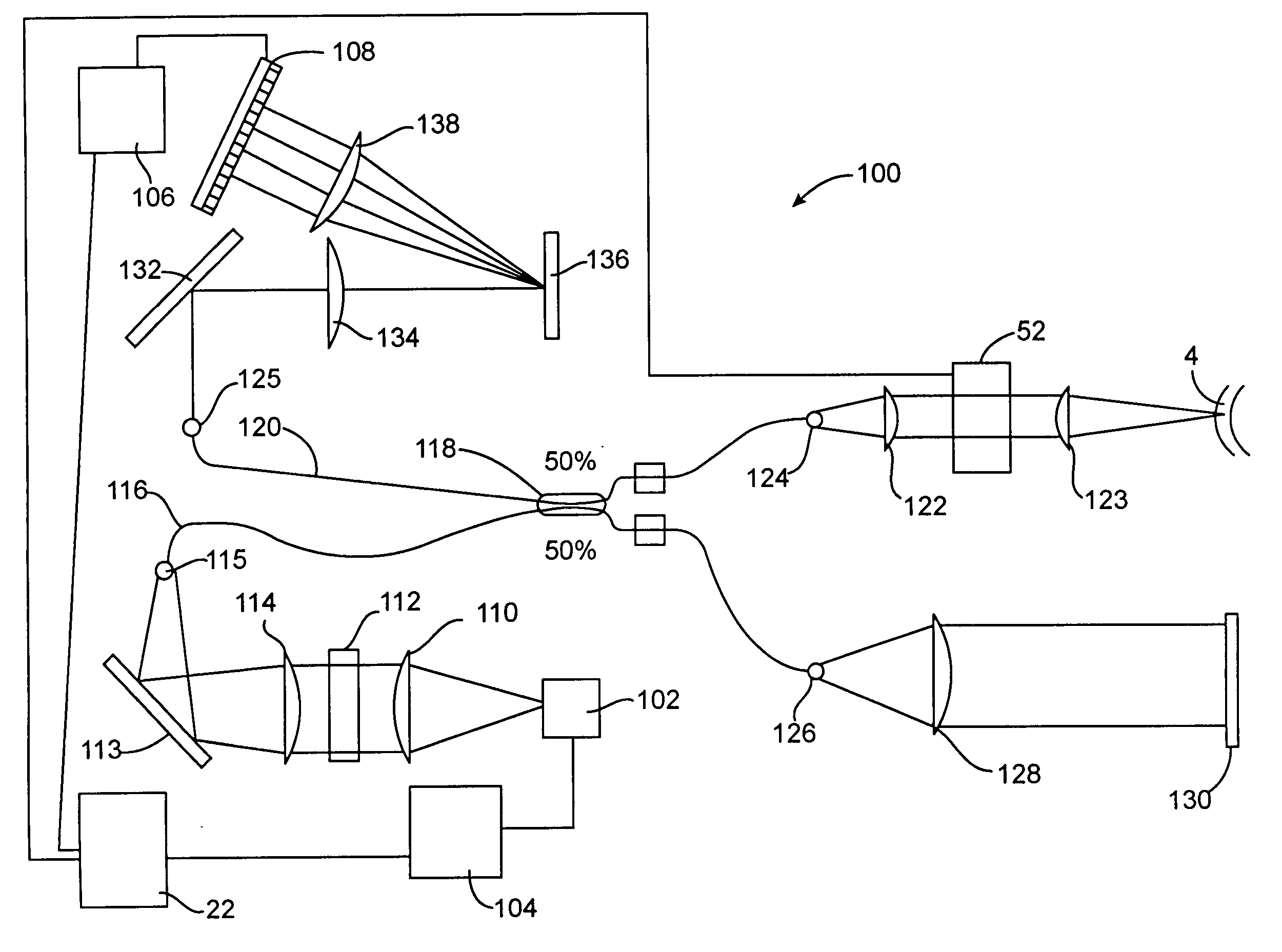

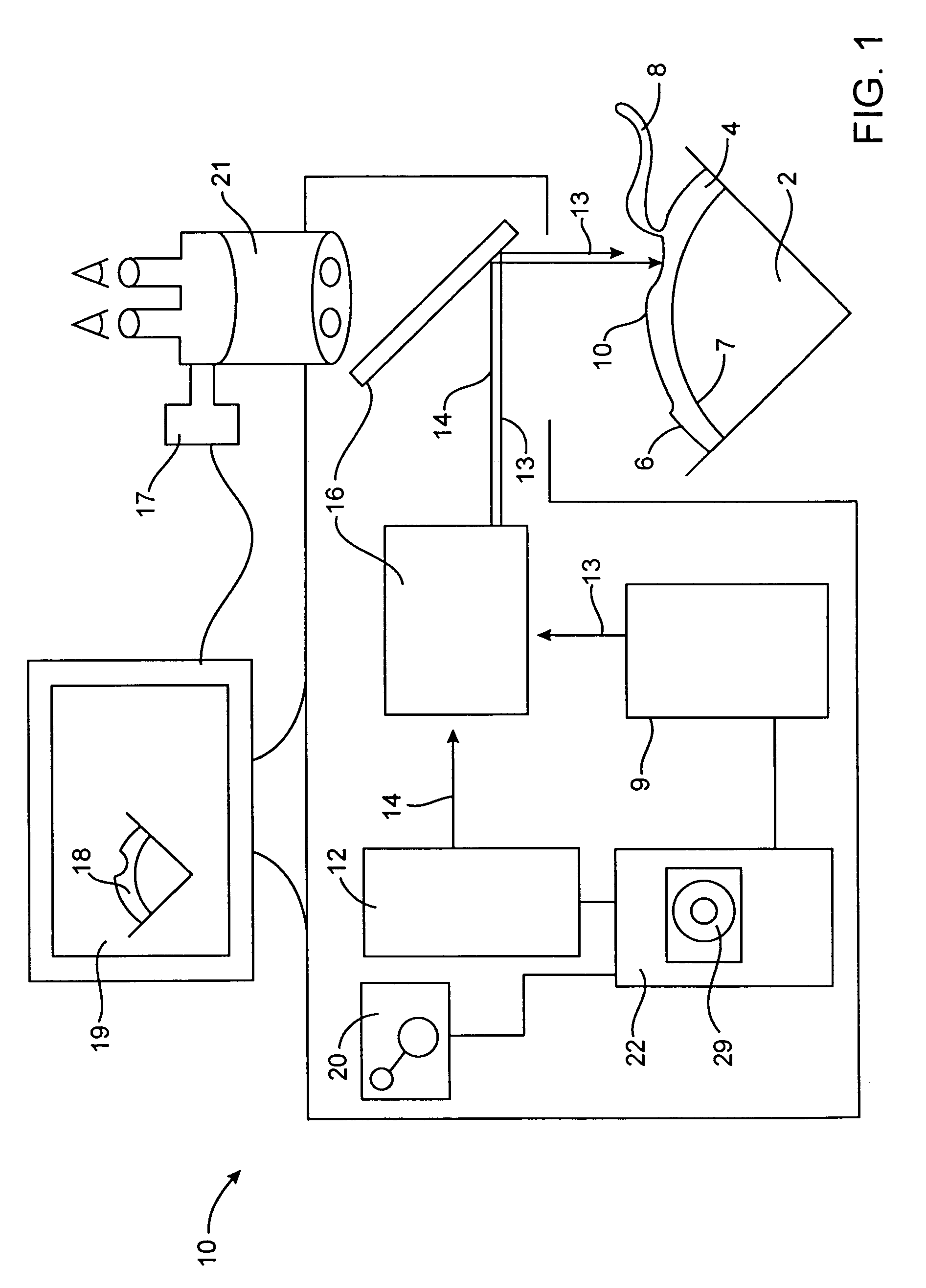

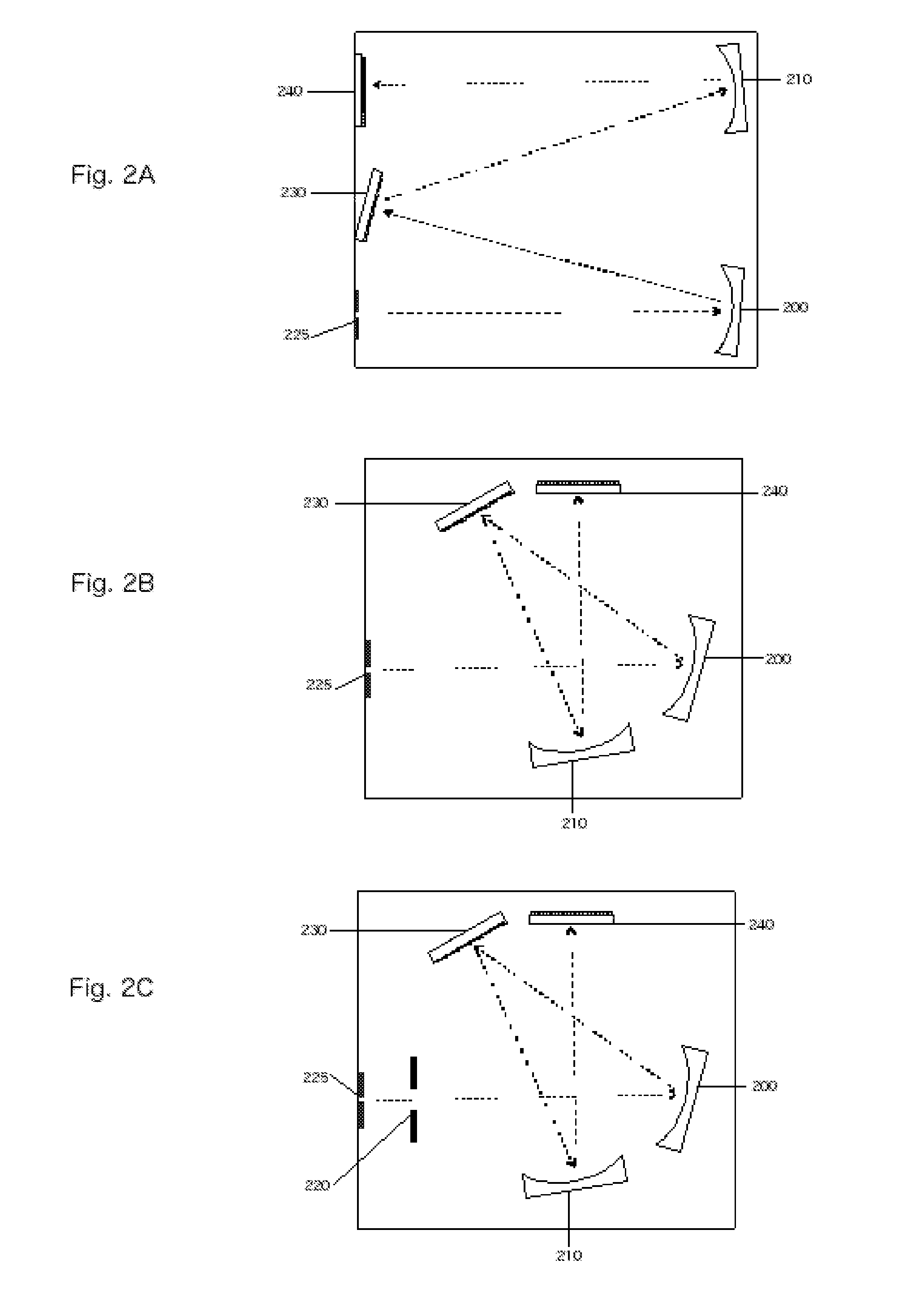

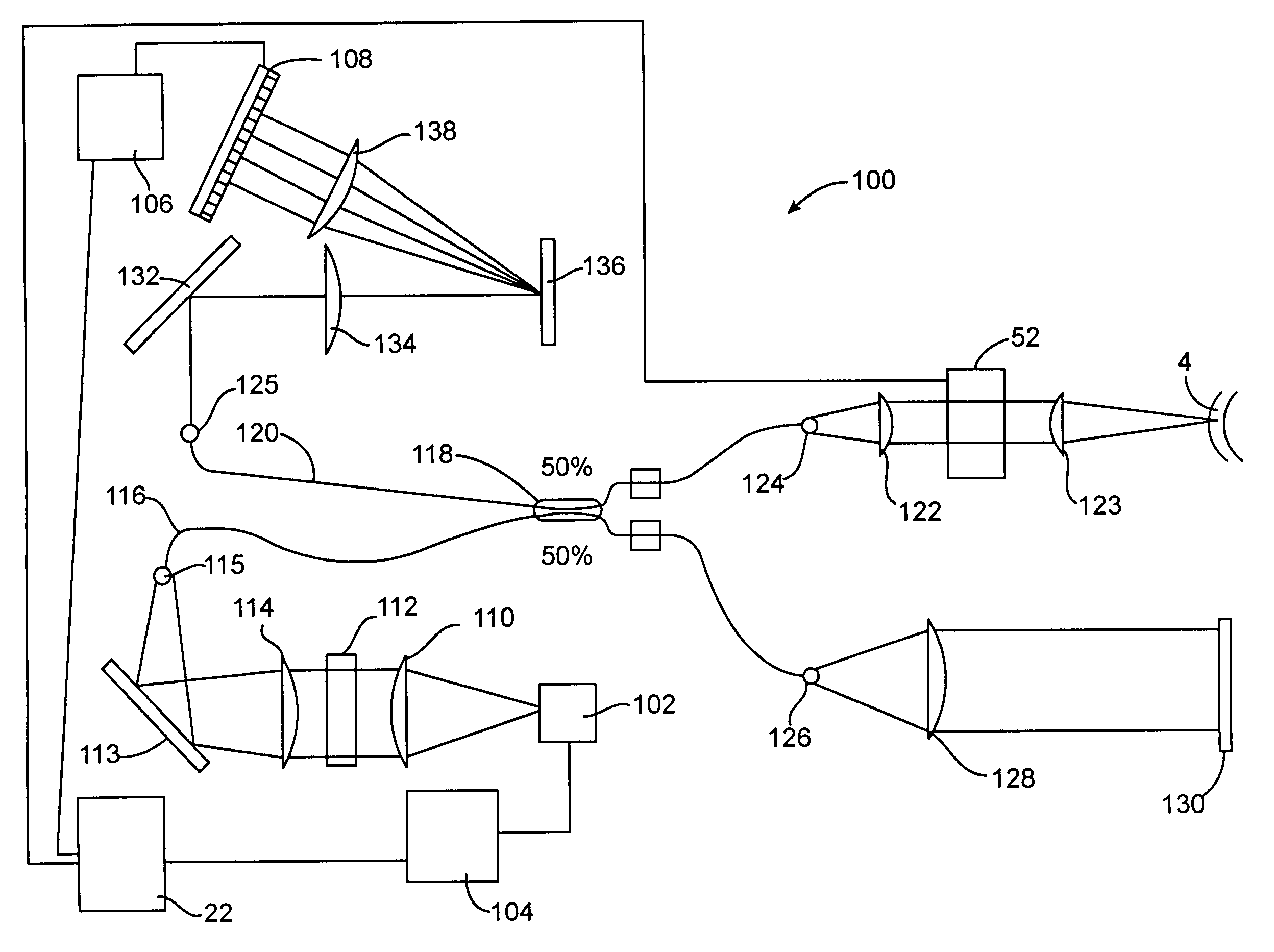

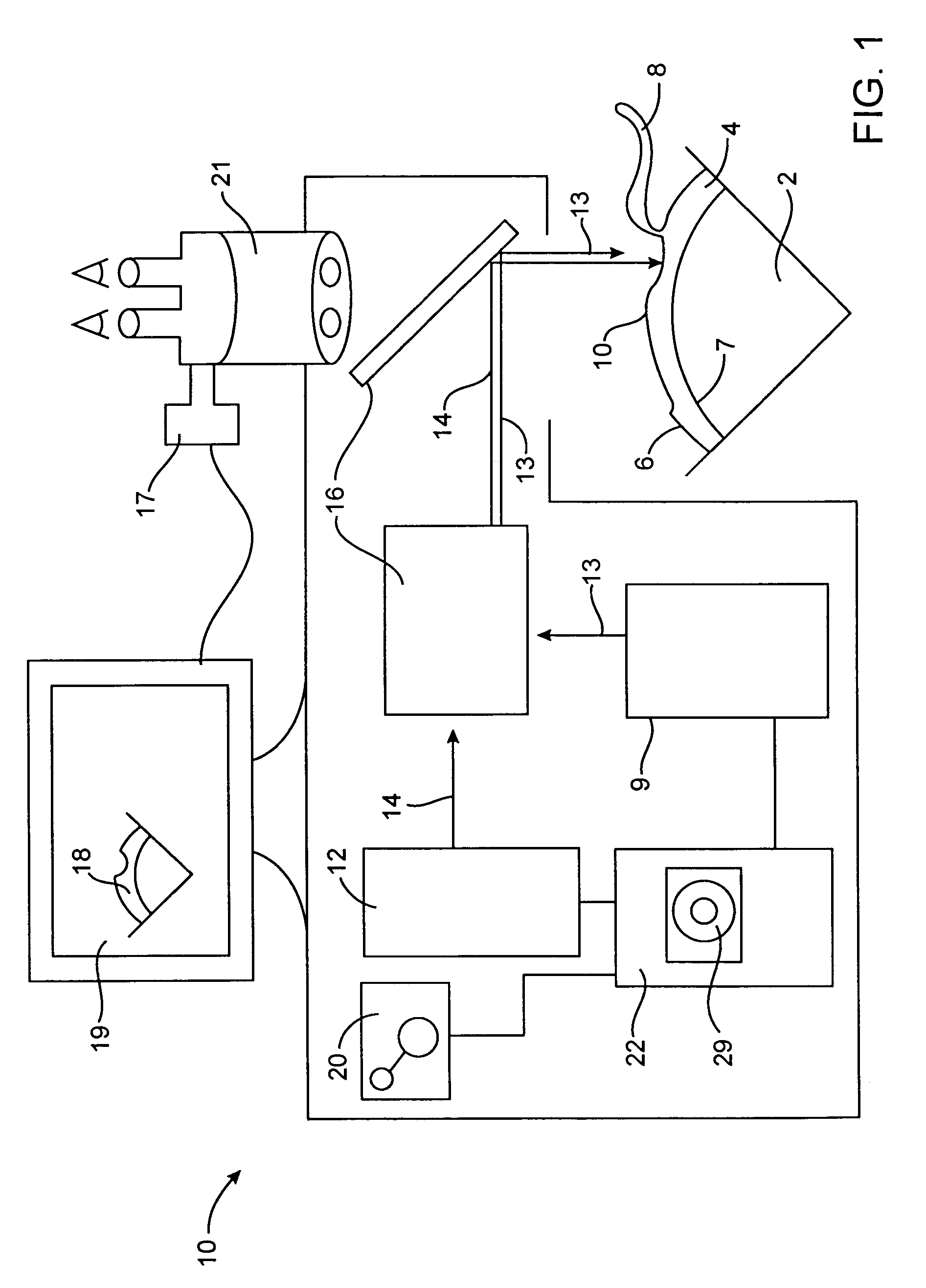

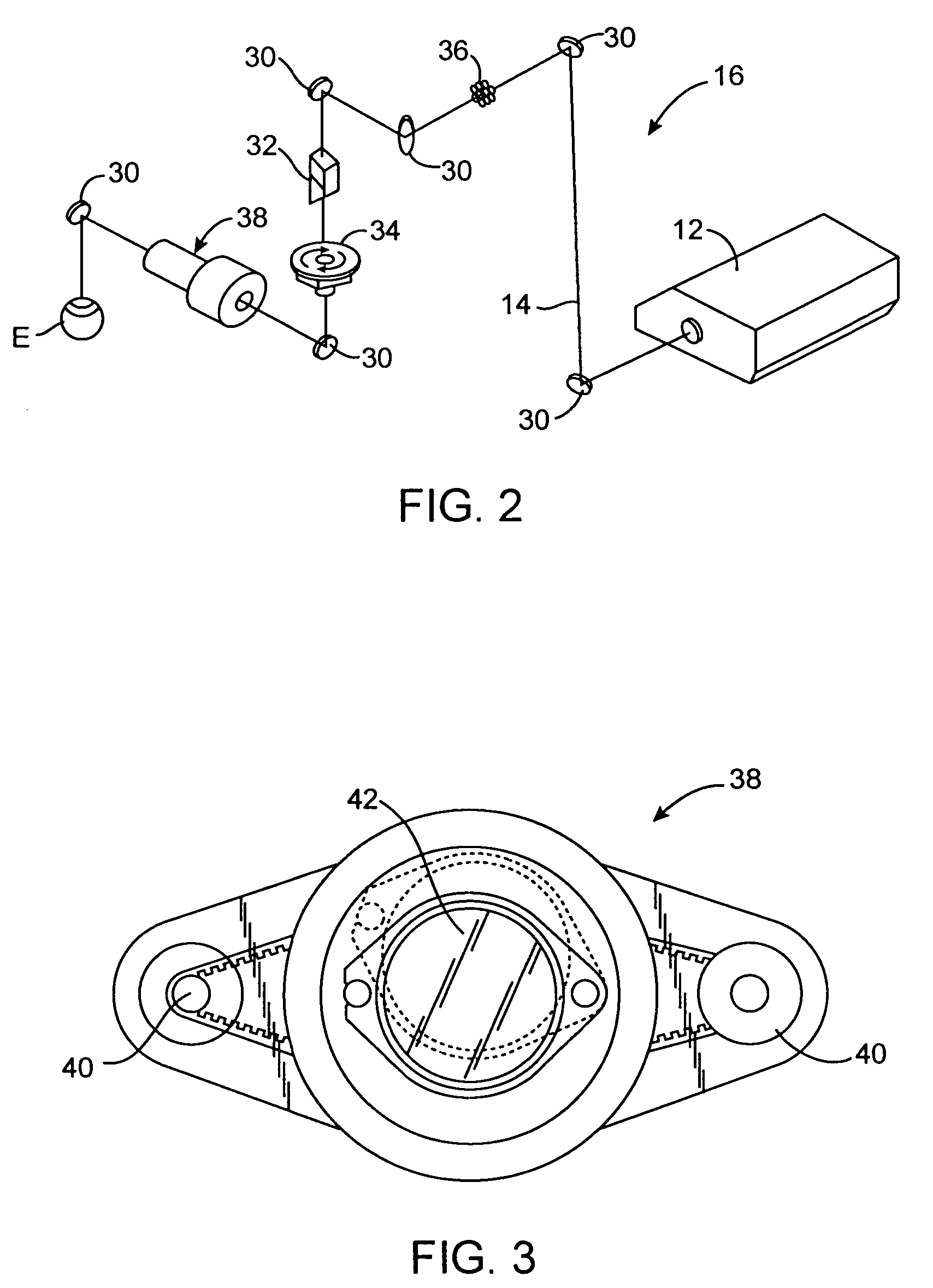

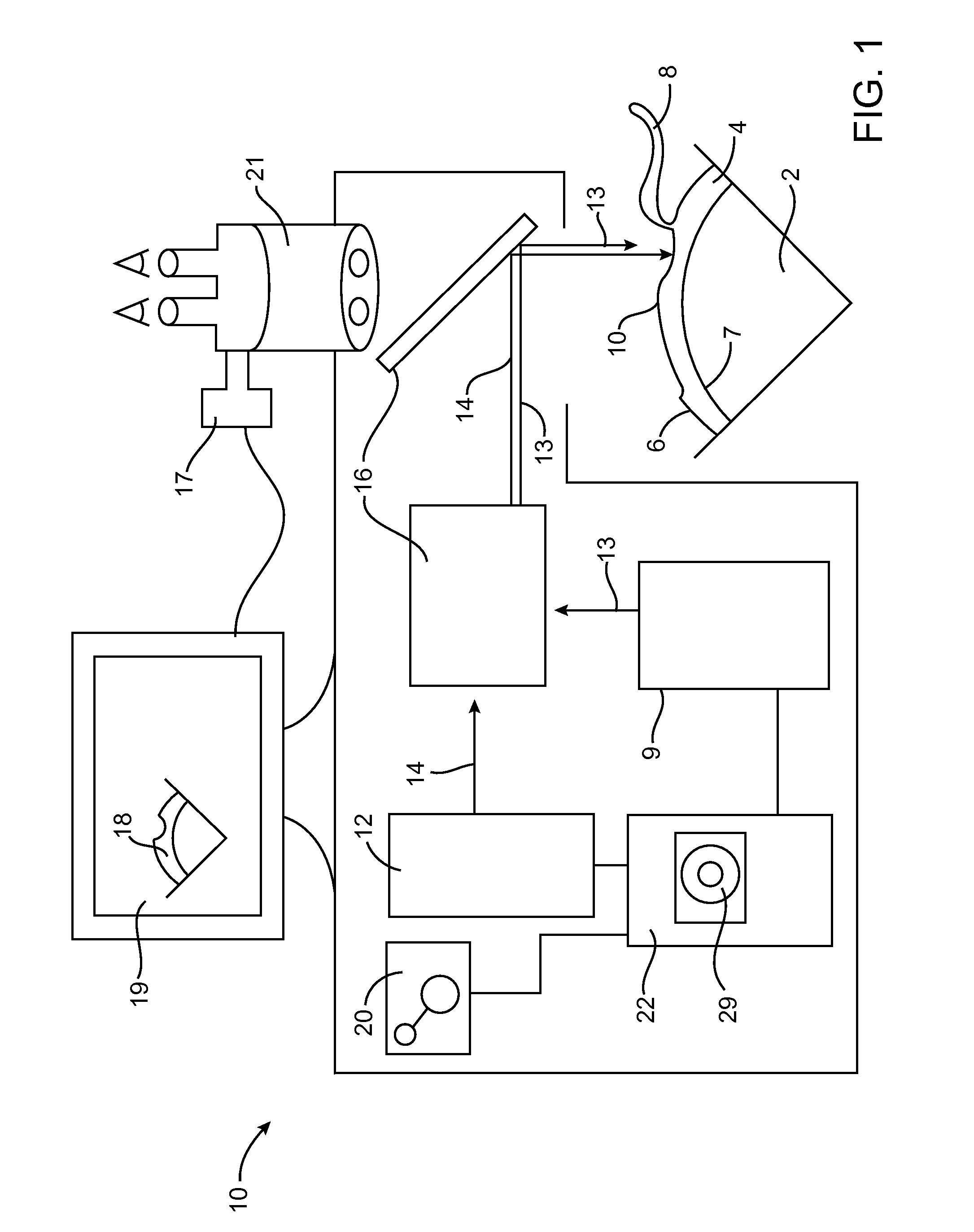

Integrated scanning and ocular tomography system and method

InactiveUS20040021874A1Quick measurementQuick monitoringLaser surgerySurgeryMeasurement deviceFast measurement

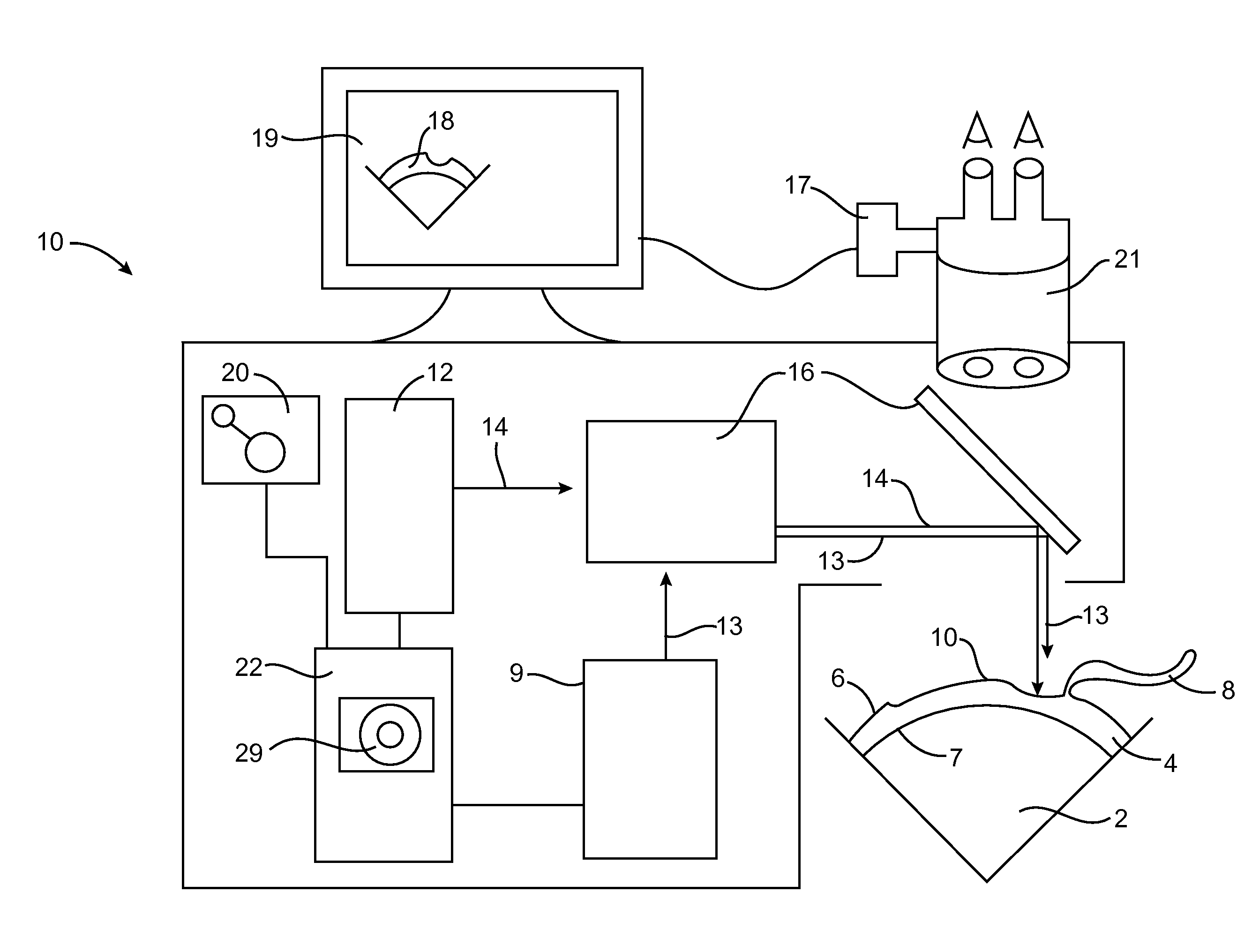

Systems and methods of the present invention measure at least one reflecting surface of an object disposed along an optical path. In some embodiments a measured optical interference signal for each of at least three wavelengths of reflected light may be used to determine a modulation of frequency components of a Fourier series. Frequency components of a Fourier series may be transformed to spatial components that describe intensities and positions of light reflected along an optical path. Systems and methods of the present invention permit rapid measuring and may monitor corneal thickness during surgery. The invention may do so by integrating an ablation device and a measurement apparatus into a single system. An integrated scanning and monitoring system may include an ablative light source producing an ablative beam and a measurement light source producing a measurement beam.

Owner:AMO MFG USA INC

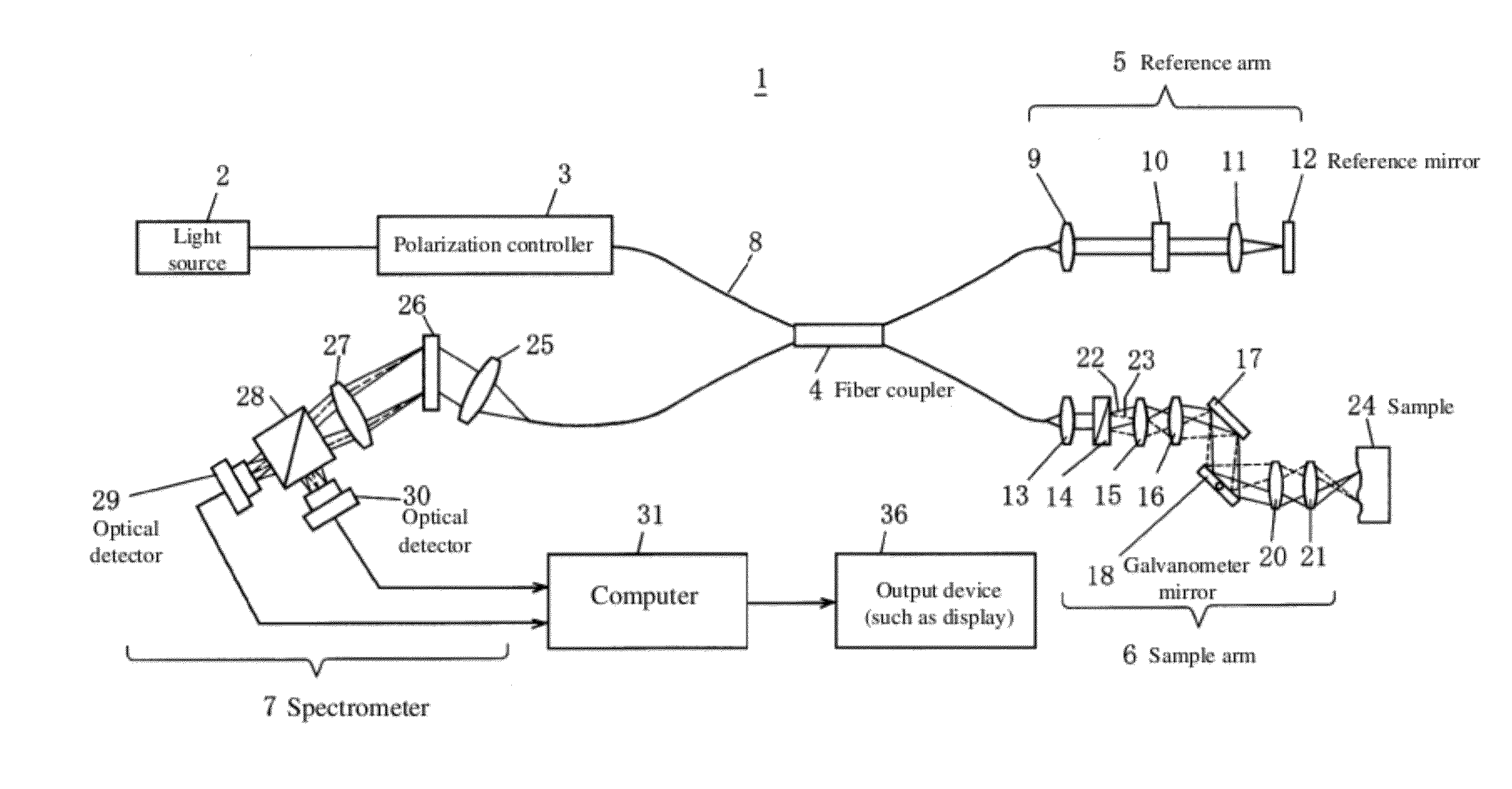

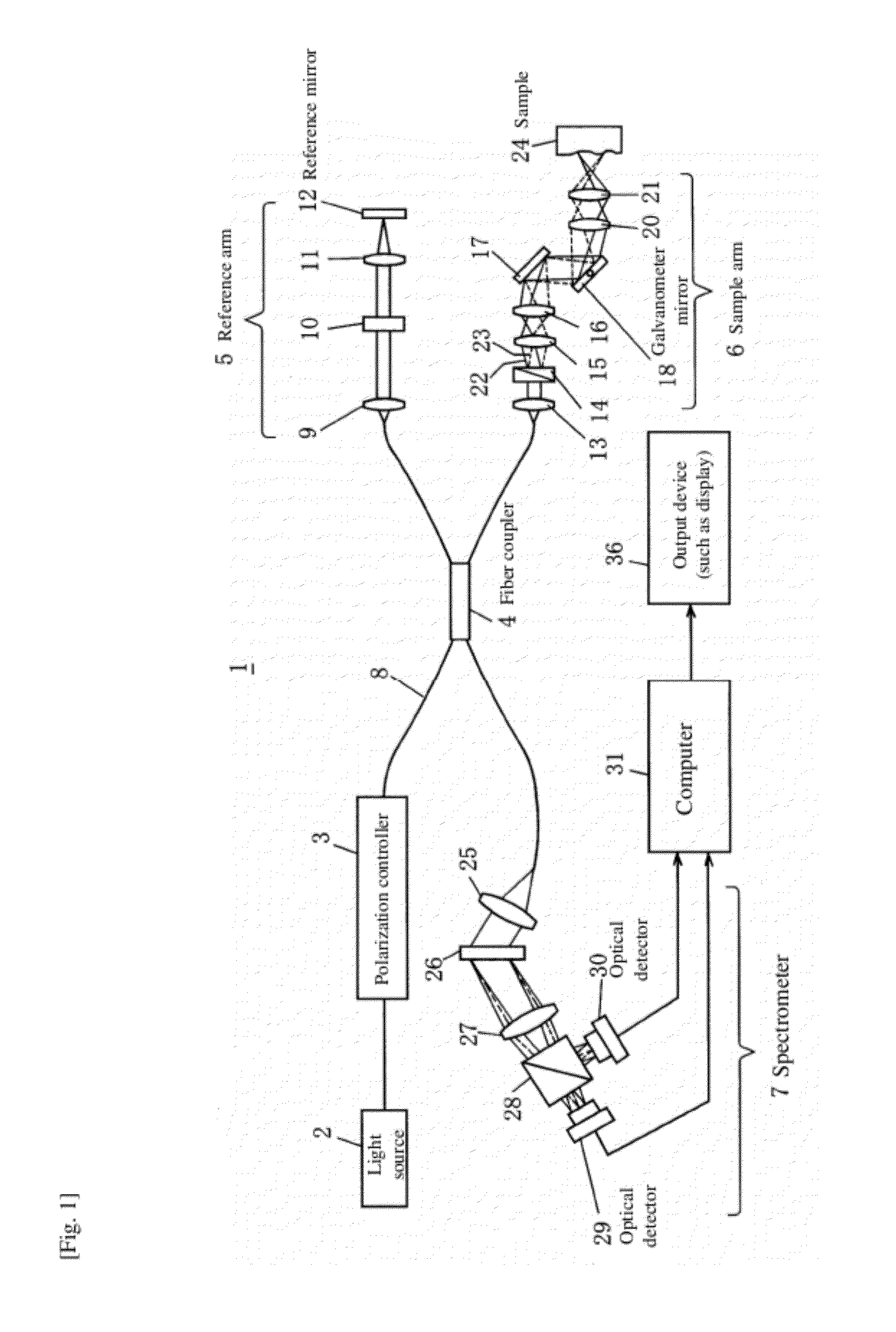

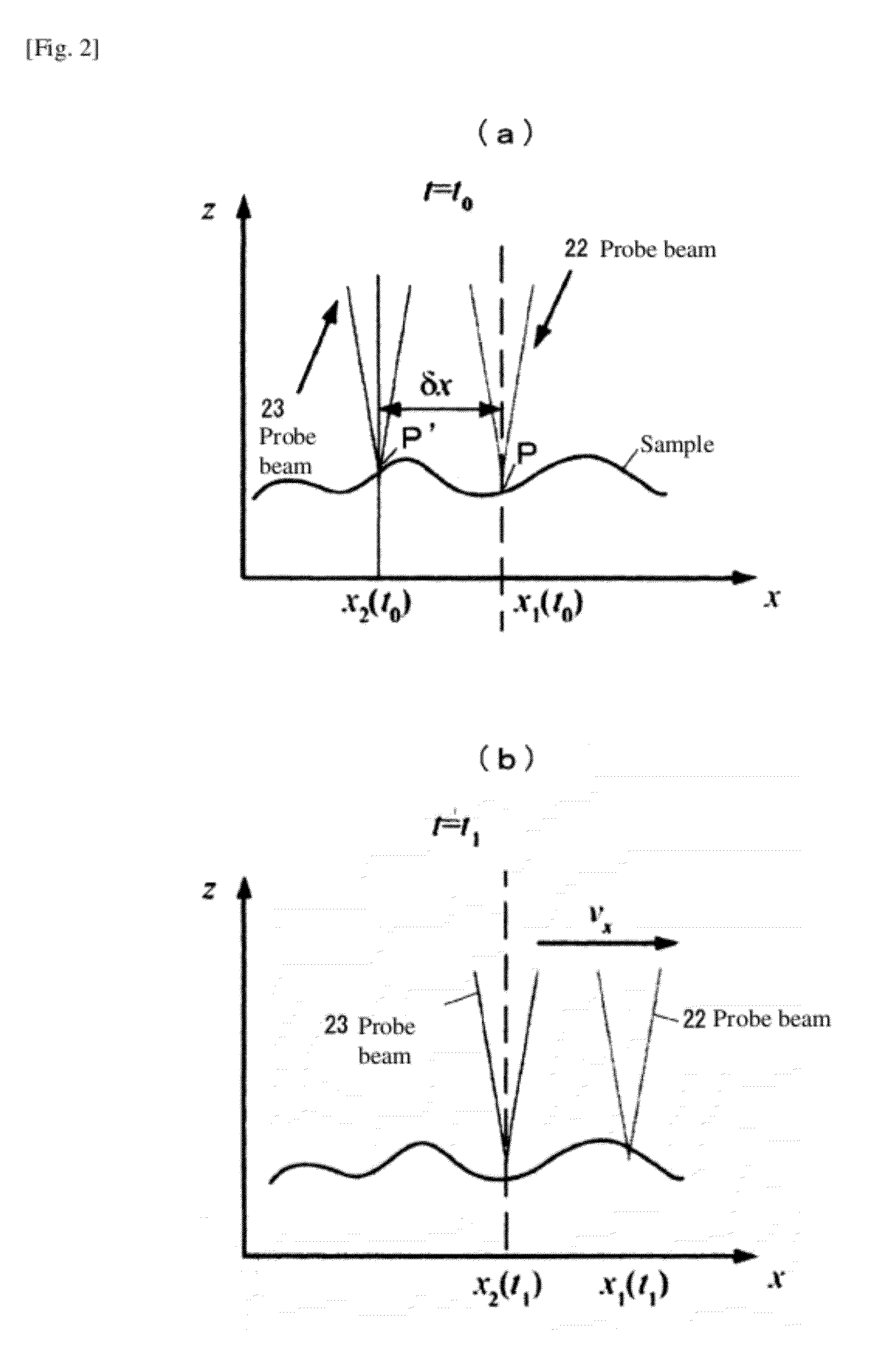

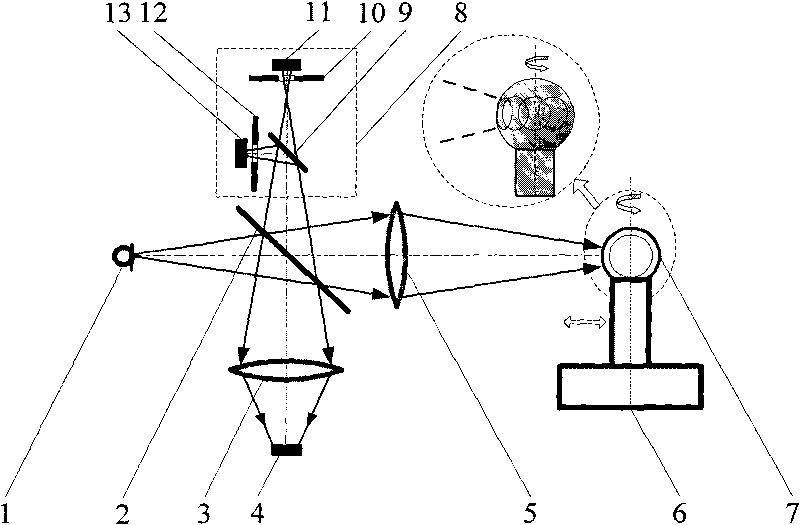

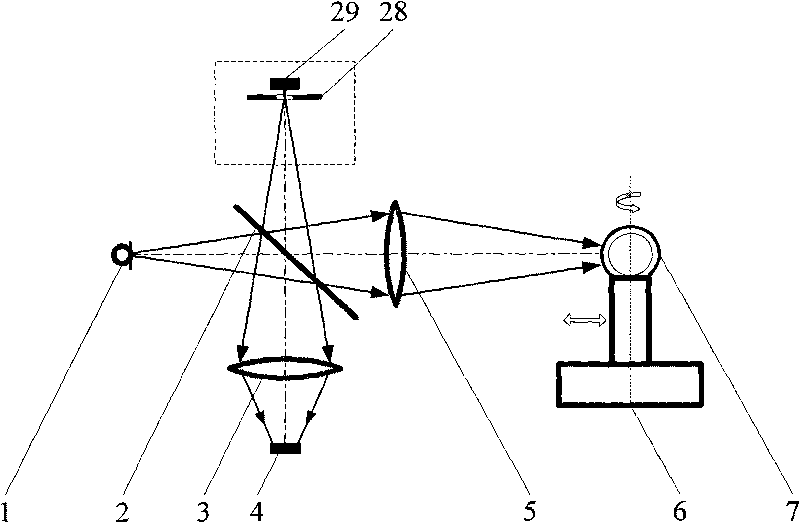

Two-beam optical coherence tomography apparatus

ActiveUS20120120408A1Solve the slow scanning speedHigh measurement sensitivityMaterial analysis by optical meansDiagnostic recording/measuringBeam splitterSpectroscopy

The scanning speed of a sample in Doppler OCT, etc., is increased to enable quick measurement of blood flow rate, blood flow volume, etc. Wideband light from a light source 2 is linearly polarized by a polarization controller 3 and this linearly polarized beam is split into vertically polarized light and horizontally polarized light using a Wollaston prism 14 at a sample arm, which are then irradiated simultaneously onto two different locations of the sample in the scanning direction using a galvanometer mirror18, and reference light from a reference arm 5 and object light from a sample arm 6 are merged and caused to interfere with each other, with the resulting interference signal light passed through a diffraction grating 26 for spectroscopy, while the horizontal component and vertical component are separated by a polarized beam splitter 28, to simultaneously measure the components with two polarization-sensitive optical detectors 29, 30 and thereby obtain two tomography images of the same location at different times by one mechanical scan, thus allowing the amount of temporal change in phase to be measured using the two tomography images.

Owner:UNIV OF TSUKUBA

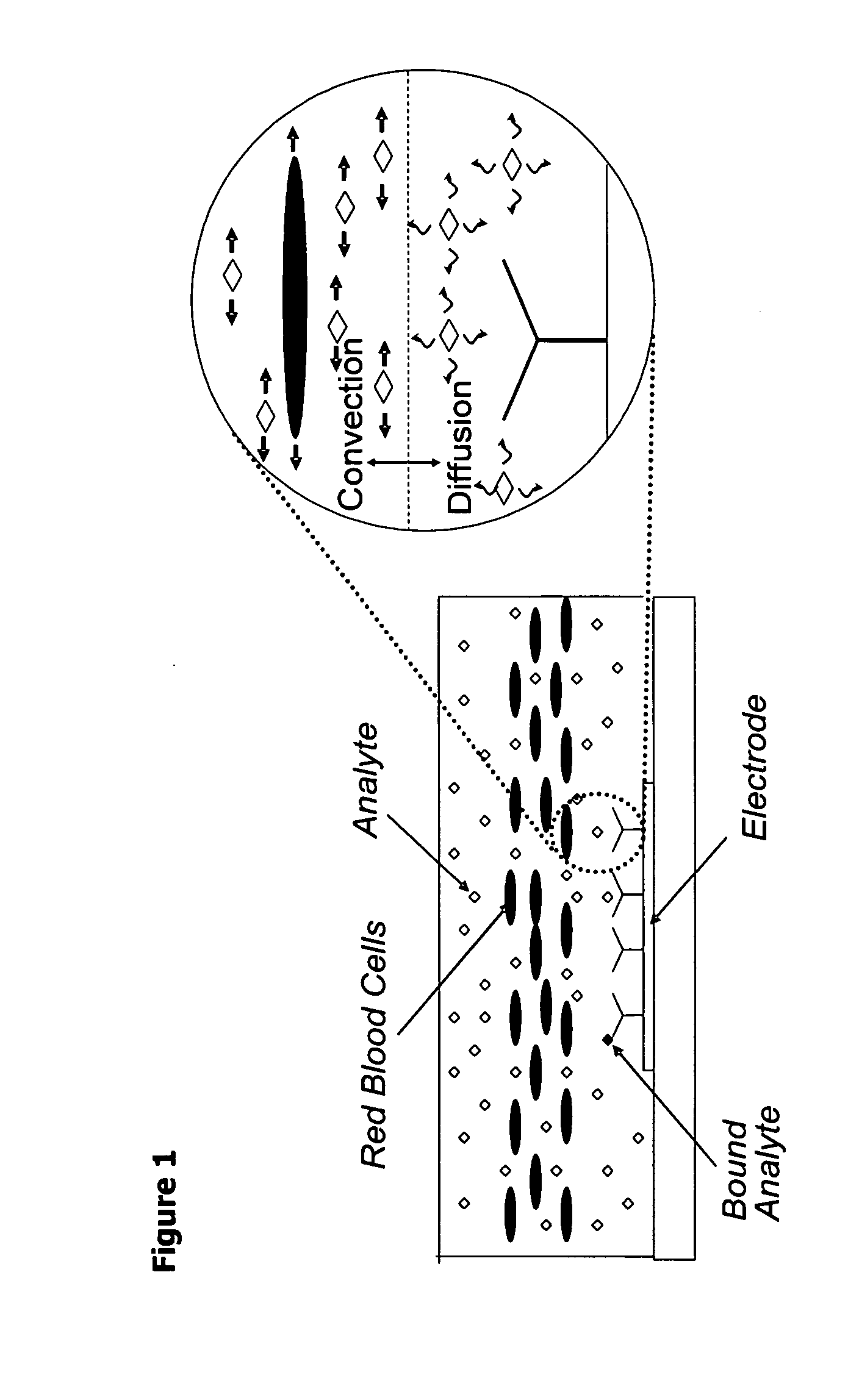

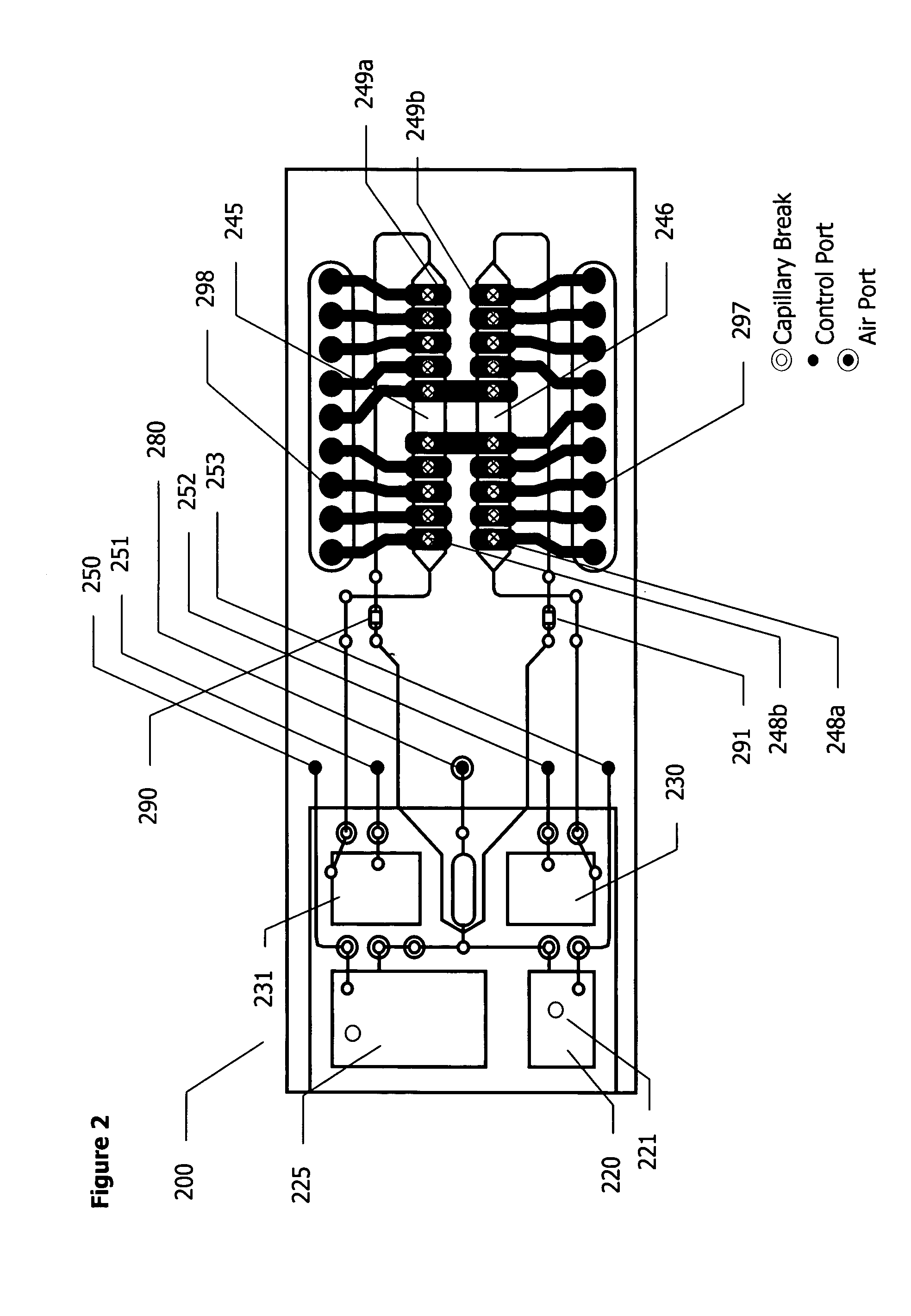

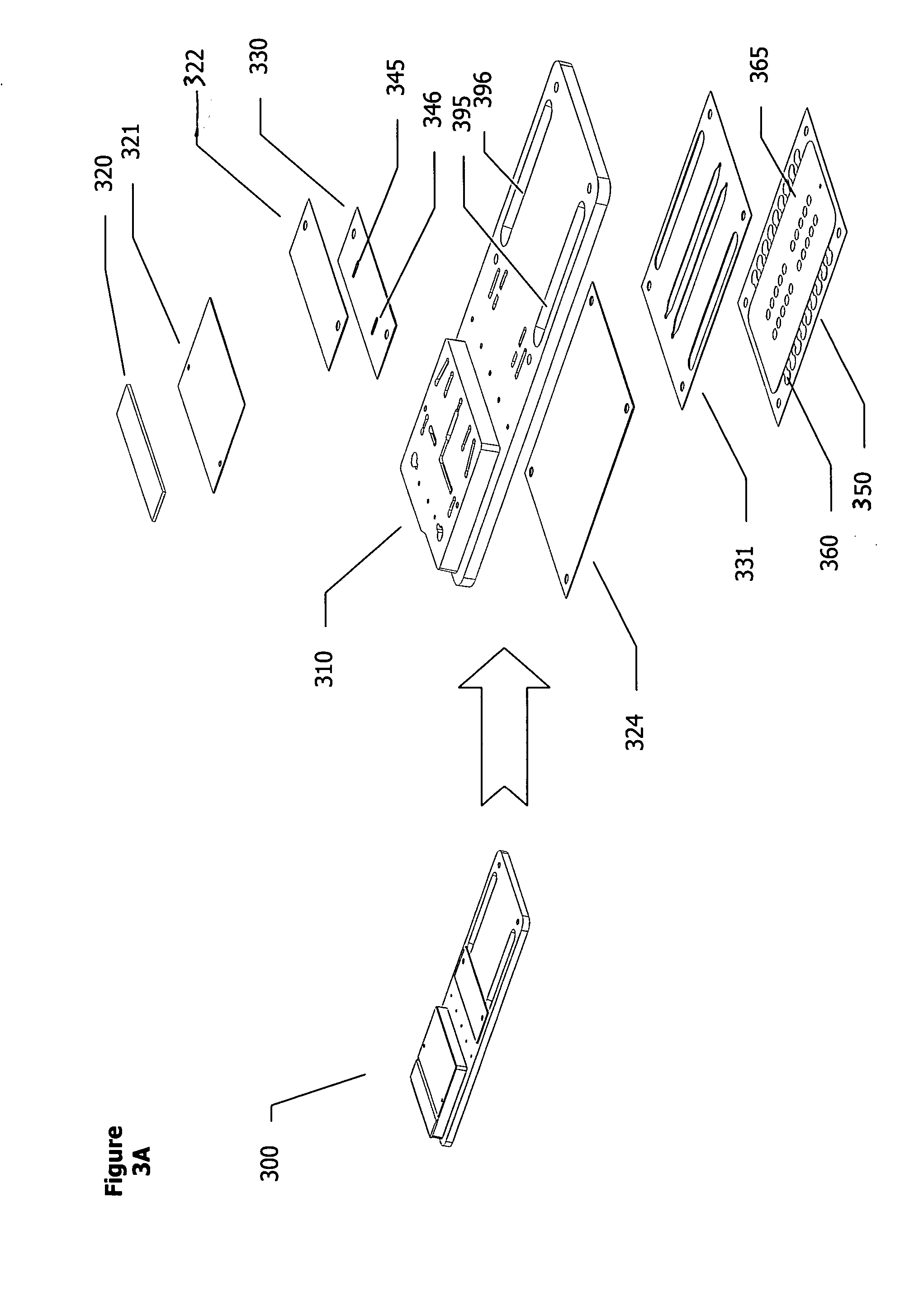

Methods and apparatuses for conducting assays

ActiveUS20060019319A1Bioreactor/fermenter combinationsBiological substance pretreatmentsParticulatesAnalyte

Disclosed are methods for conducting assays of samples, such as whole blood, that may contain cells or other particulate matter. Also disclosed are systems, devices, equipment, kits and reagents for use in such methods. One advantage of certain disclosed methods and systems is the ability to rapidly measure the concentration of an analyte of interest in blood plasma from a whole blood sample without blood separation and hematocrit correction.

Owner:MESO SCALE TECH LLC

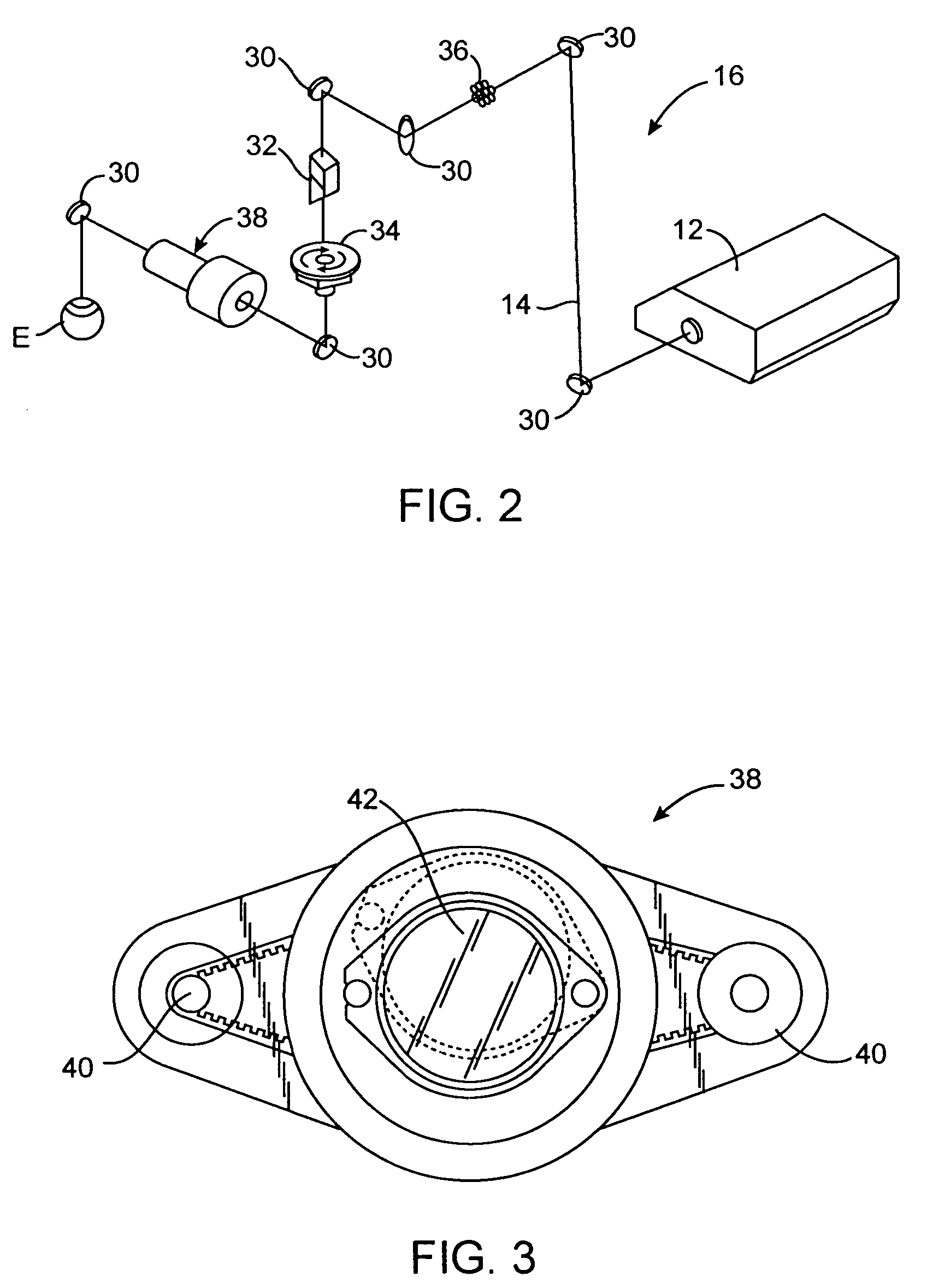

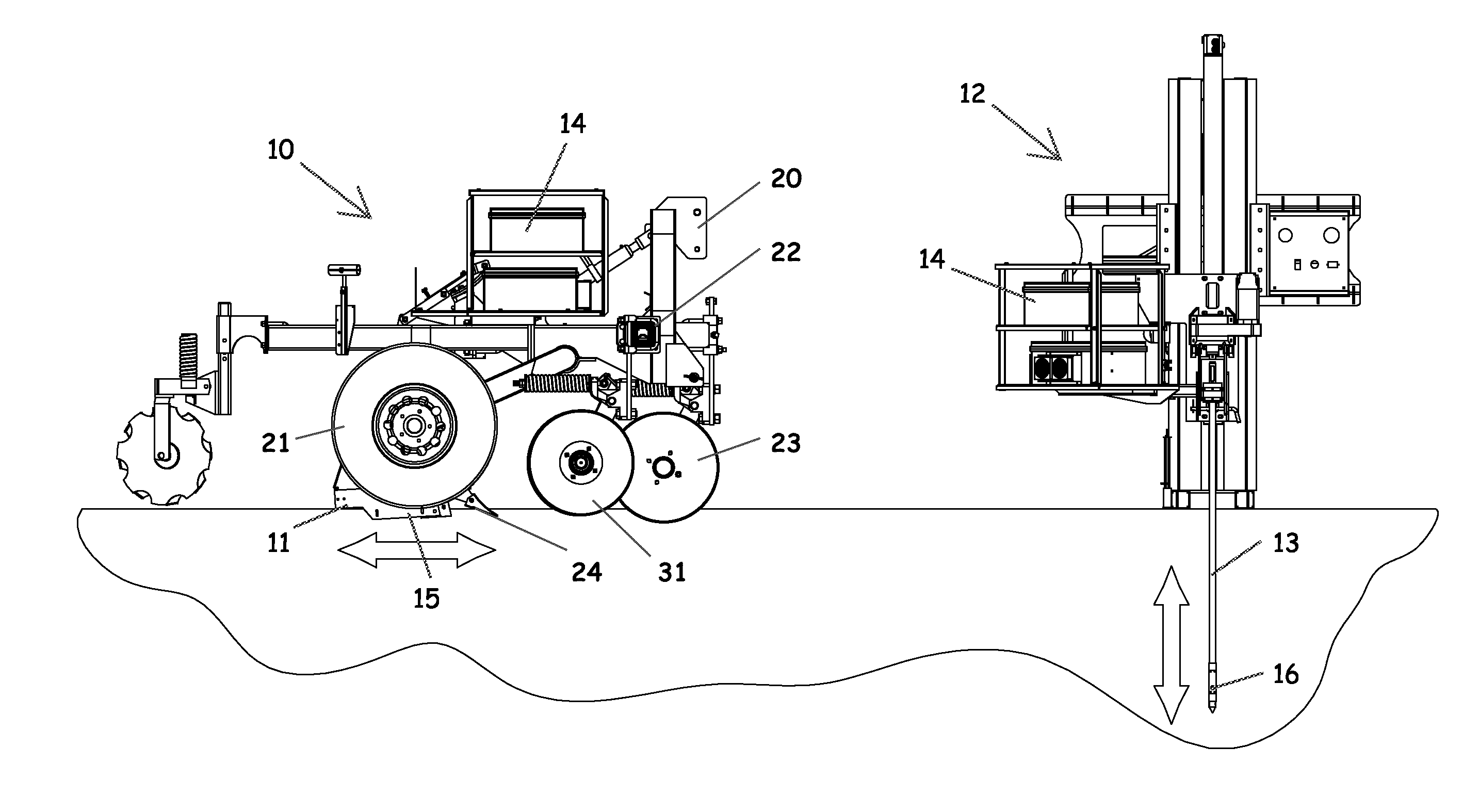

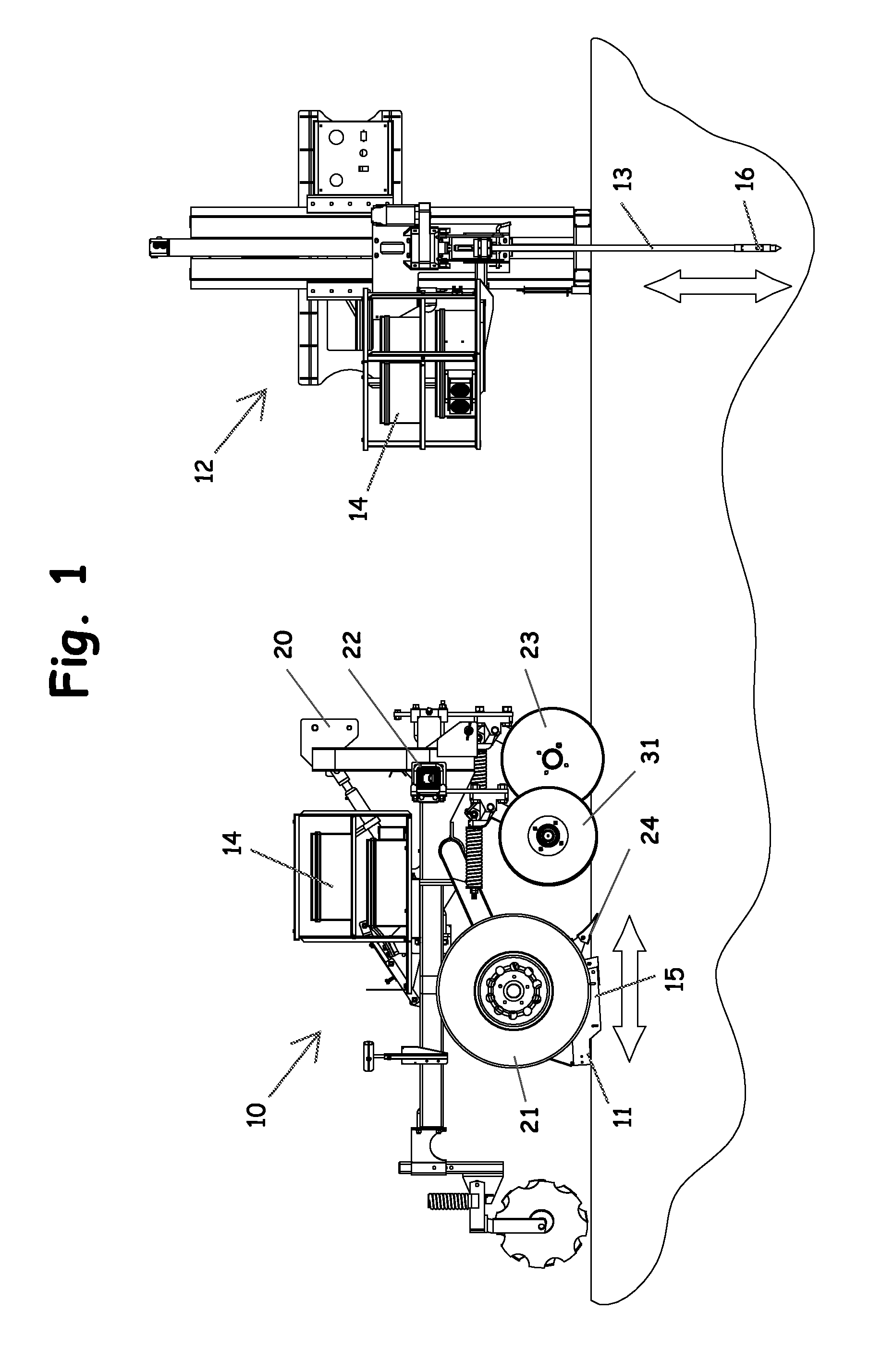

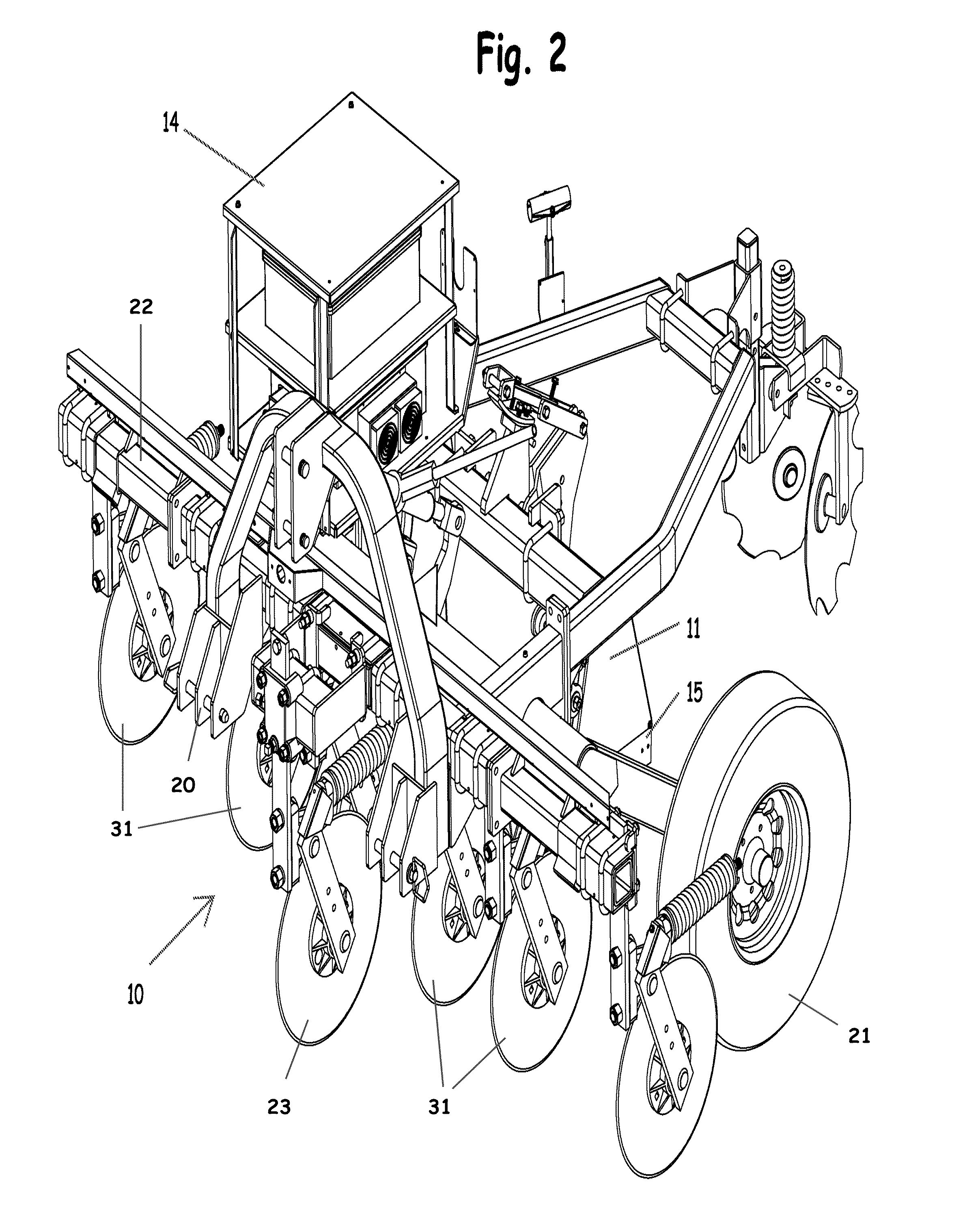

Multiple sensor system and method for mapping soil in three dimensions

ActiveUS20110106451A1Material analysis by optical meansSpecial data processing applicationsSoil propertiesMultiple sensor

A multi-sensor system rapidly measures diffuse reflectance of soil, soil conductivity, and other soil properties in situ, in three dimensions. The system includes a tractor-drawn implement containing a sensor shank used for X-Y axis measurements, a hydraulic probe implement containing a sensor probe for −Z axis measurements, and a set of visible and near-infrared spectrometers, controls, and firmware that are shared by each implement. Both implements include optical sensors and soil electrical conductivity sensors. The probe implement incorporates a sensor that measures insertion force, and the shank implement includes a soil temperature sensor. These combinations of sensors are used to calibrate the system and to characterize the soil properties within a field or area. Geo-referenced soil measurements are collected with the shank implement to identify optimal locations for conducting sensor probe insertions. The probe implement is then used for sensor probing and for collecting soil core samples for lab analysis.

Owner:VERIS TECH

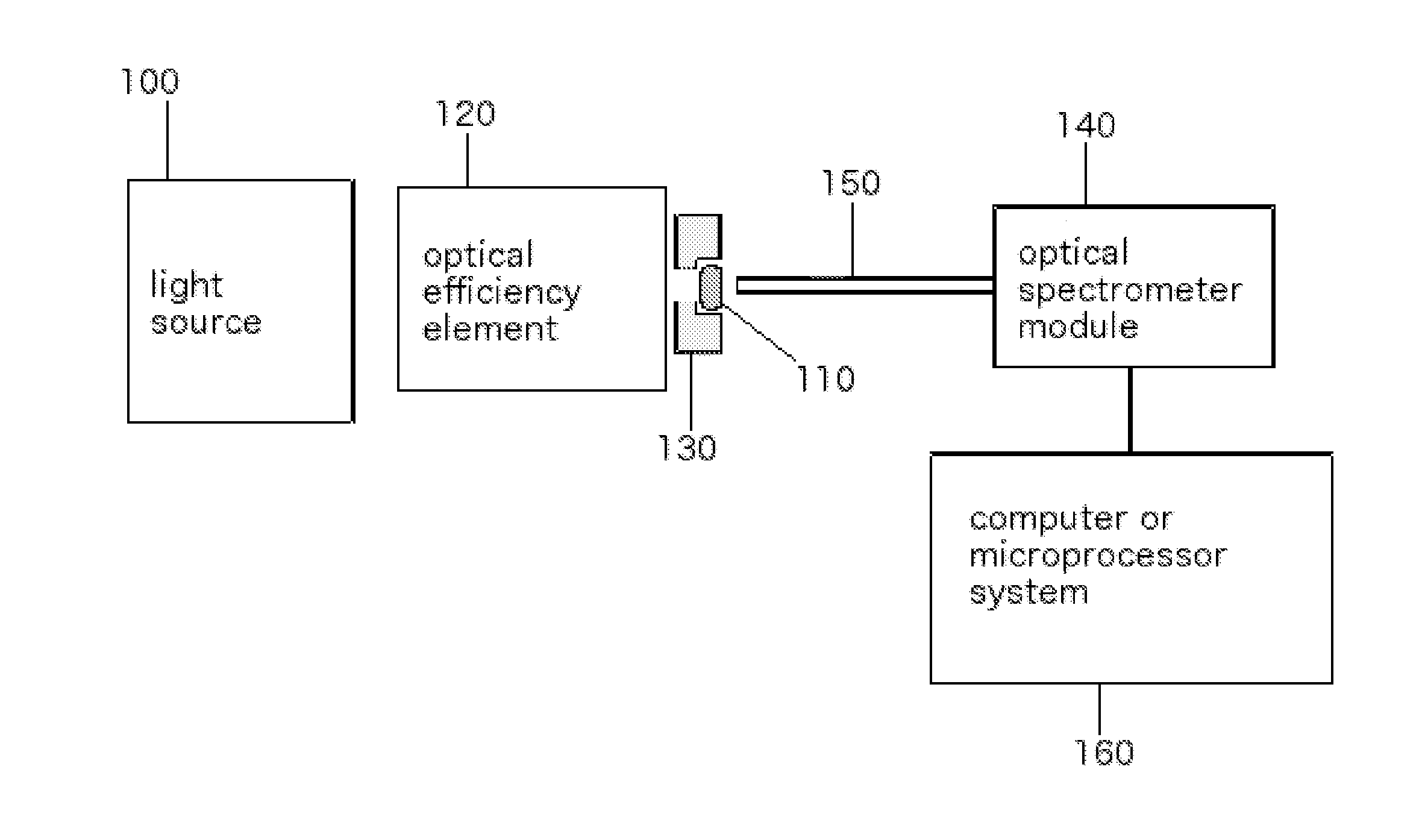

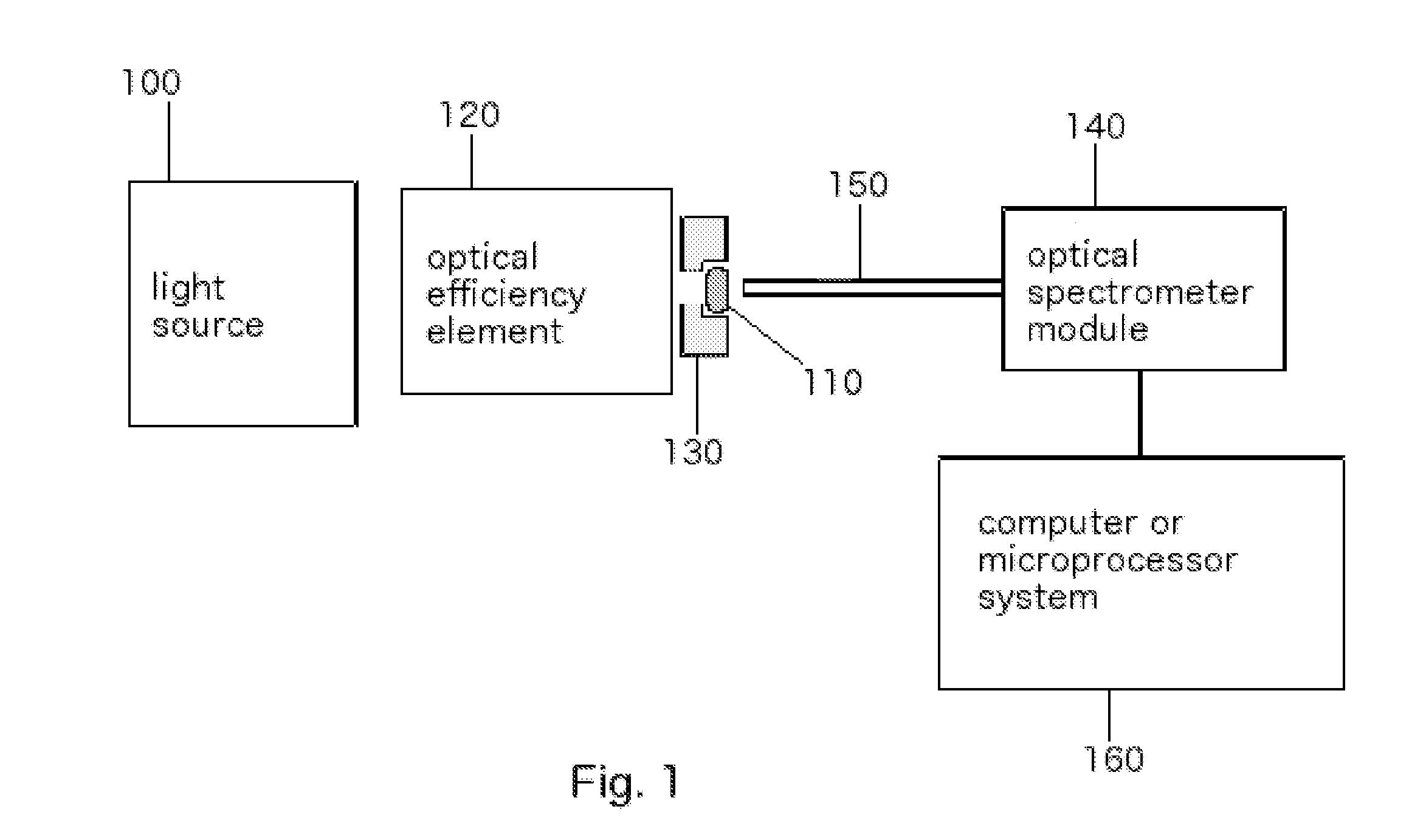

Optical analyzer for identification of materials using reflectance spectroscopy

ActiveUS20130256534A1Reduce manufacturing costSmall sizeRadiation pyrometrySpectrum generation using diffraction elementsFast measurementChemical composition

Owner:INNOVATIVE SCI TOOLS

Integrated scanning and ocular tomography system and method

InactiveUS7133137B2Rapid measuring and monitoringSimple and efficientLaser surgeryInterferometersMeasurement deviceFast measurement

Owner:AMO MFG USA INC

Method for quickly measuring blade of large-sized water turbine

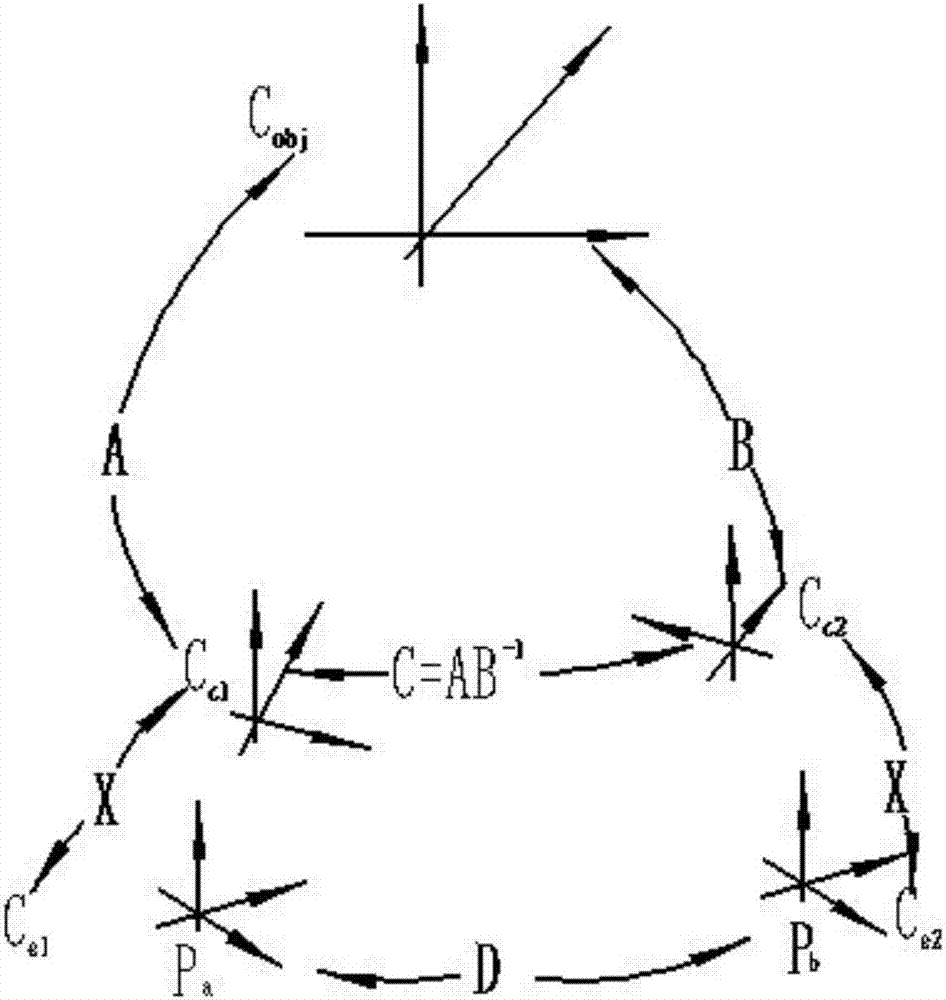

The invention discloses a method for quickly measuring a blade of a large-sized water turbine, which is characterized by comprising the following steps: firstly, sticking a mark point to the surface of the blade, then shooting a group of photos from different angles as measured primary data, and inputting the data to a computer to carry out analytic processing; by carrying out image detection for the group of photos in a measurement software, identifying the mark point in each photo and positioning the center of the mark point, and matching the mark points with the same name; finally, reconstructing a three-dimensional coordinate of corresponding object points according to a plurality of two-dimensional coordinates of the mark points, fitting a sparse framework model of a target by the reconstructed three-dimensional mark points, then scanning the surface of the blade block by block by using a binocular grating scanning method to acquire a local dense point cloud, and aligning the dense point cloud to an overall coordinate system according to the local mark points to acquire a dense point model of the blade; and by comparing the dense point model with a CAD designed model after aligning, calculating a three-dimensional processing error of the surface of a workpiece.

Owner:XI AN JIAOTONG UNIV

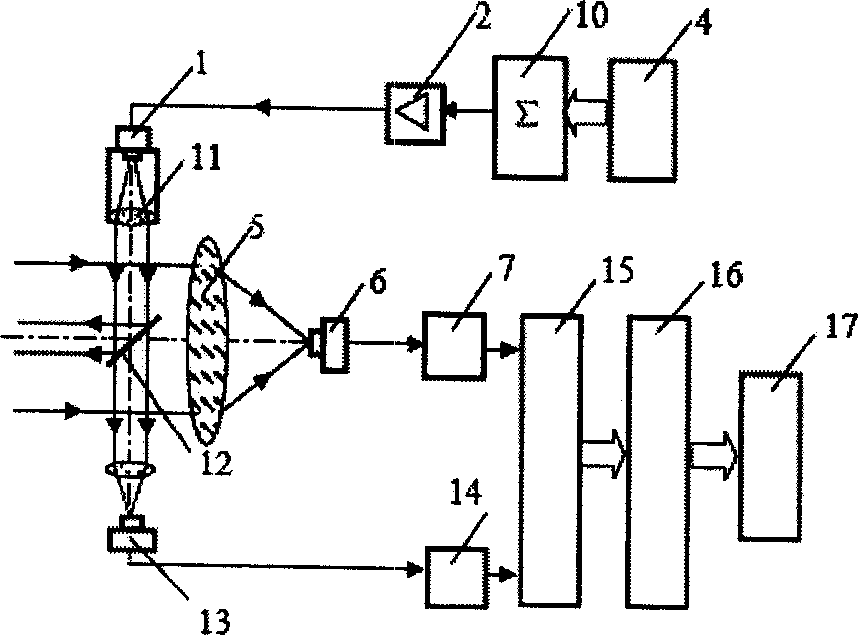

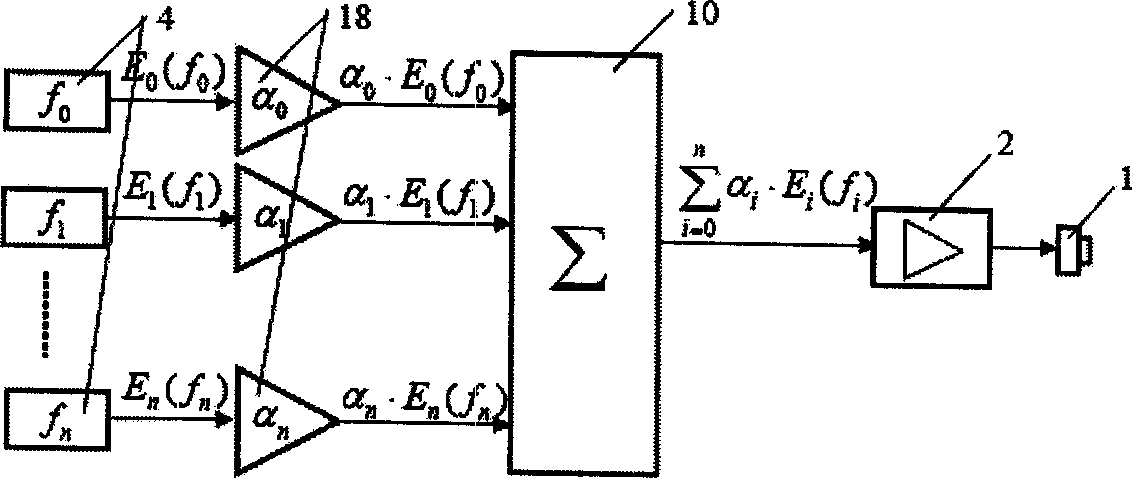

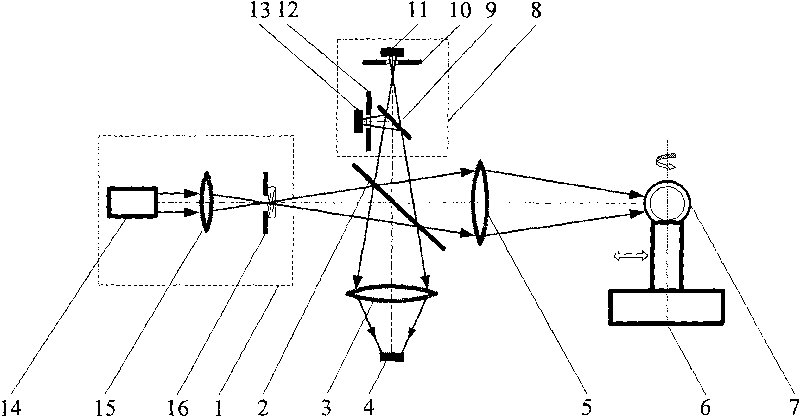

Multi-frequency synchronous modified large range high precision fast laser ranging method and apparatus

InactiveCN1825138AGood effectGuaranteed speedElectromagnetic wave reradiationLaser rangingFast measurement

The invention relates to a wide range high accuracy fast laser distance measuring method and device based on multiple frequency synchronous condenser. The multiple frequency modulating signals are taken characteristic pre-compensation weight summarizing at laser emitting unit. After compounding, the laser power is modulated to take distance measuring. Synchronous band pass filter frequency selection and phase determination method is used to taken signal process. The method could gain the distance measuring result of distance measuring frequency in multiple frequency modulating distance measuring, and gain the final distance result. The distance measuring speed and real time is ensured. It also avoids measuring error coursed by the location movement of the target.'

Owner:HARBIN INST OF TECH

Method and device for measuring appearance and wall thickness of sphere by combining differential confocal and point-diffraction interference

The invention belongs to the field of optical precision measurement and relates to a method and a device for measuring the appearance and the wall thickness of a sphere by combining a differential confocal confocal technology and point-diffraction interference. The method realizes the high-precision rapid measurement on the appearance of the outer surface of the sphere by using the point-diffraction interference, the rotation of the measured sphere and the splice of a measuring sub-aperture; and the appearance and wall thickness of the inner surface and the outer surface of a key area of a transparent or semitransparent sphere can be scanned and measured point by point by using the differentia confocal technology. The invention organically integrates a point-diffraction interference technology and the differentia confocal technology so as to realize the synchronous measurement on the appearance and the wall thickness of the inner surface and the outer surface of the sphere, and aims to solve the difficult problems that the traditional AFM or a single confocal sensor and the other scanning methods have low measuring speed, low efficiency, easy leakage in measurement and the like during measuring the surface of the sphere. The invention has broad application prospect in the fields of testing the appearance and the wall thickness of a laser fusion pellet, the appearance and the outline of a spherical surface and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

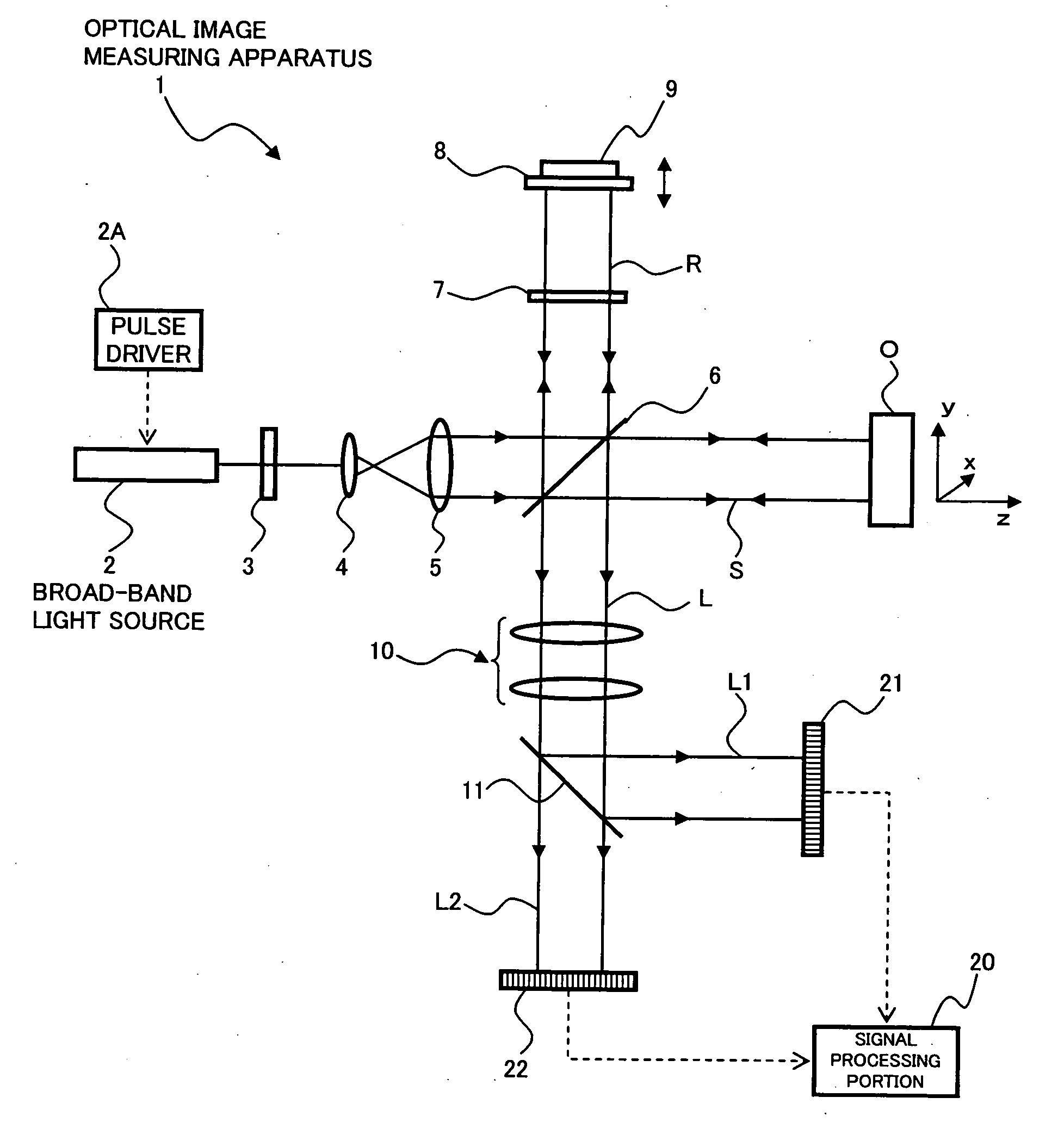

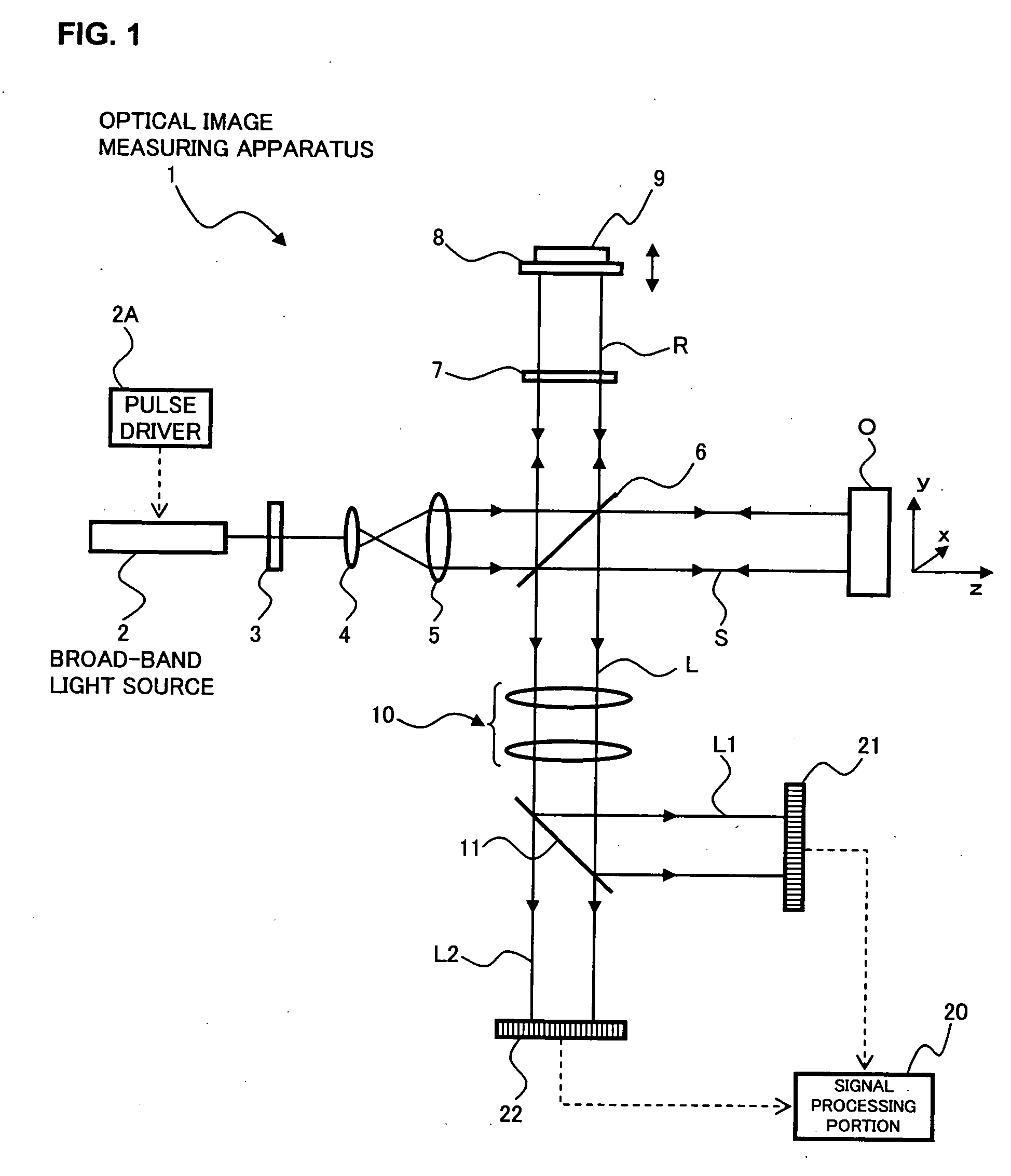

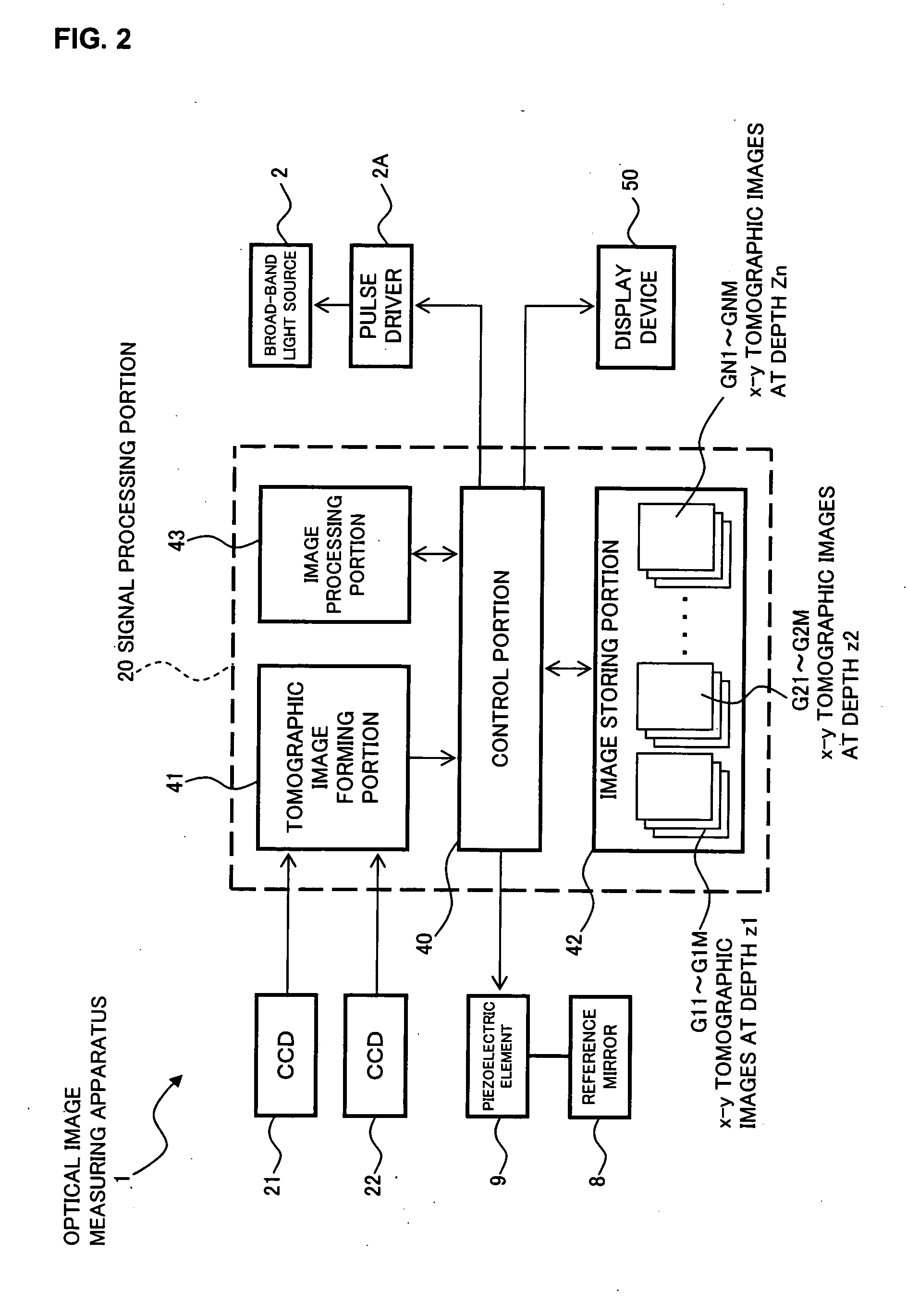

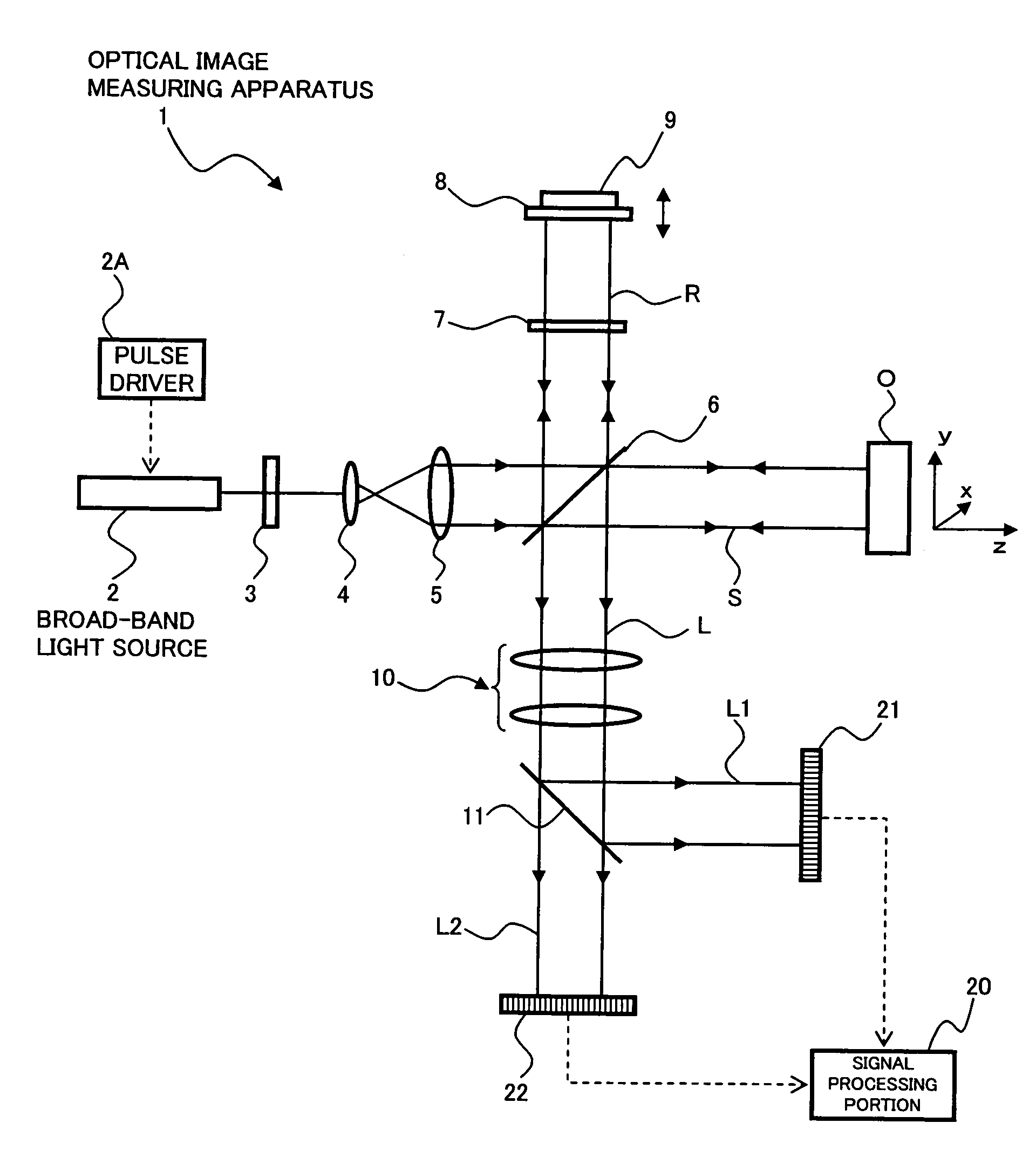

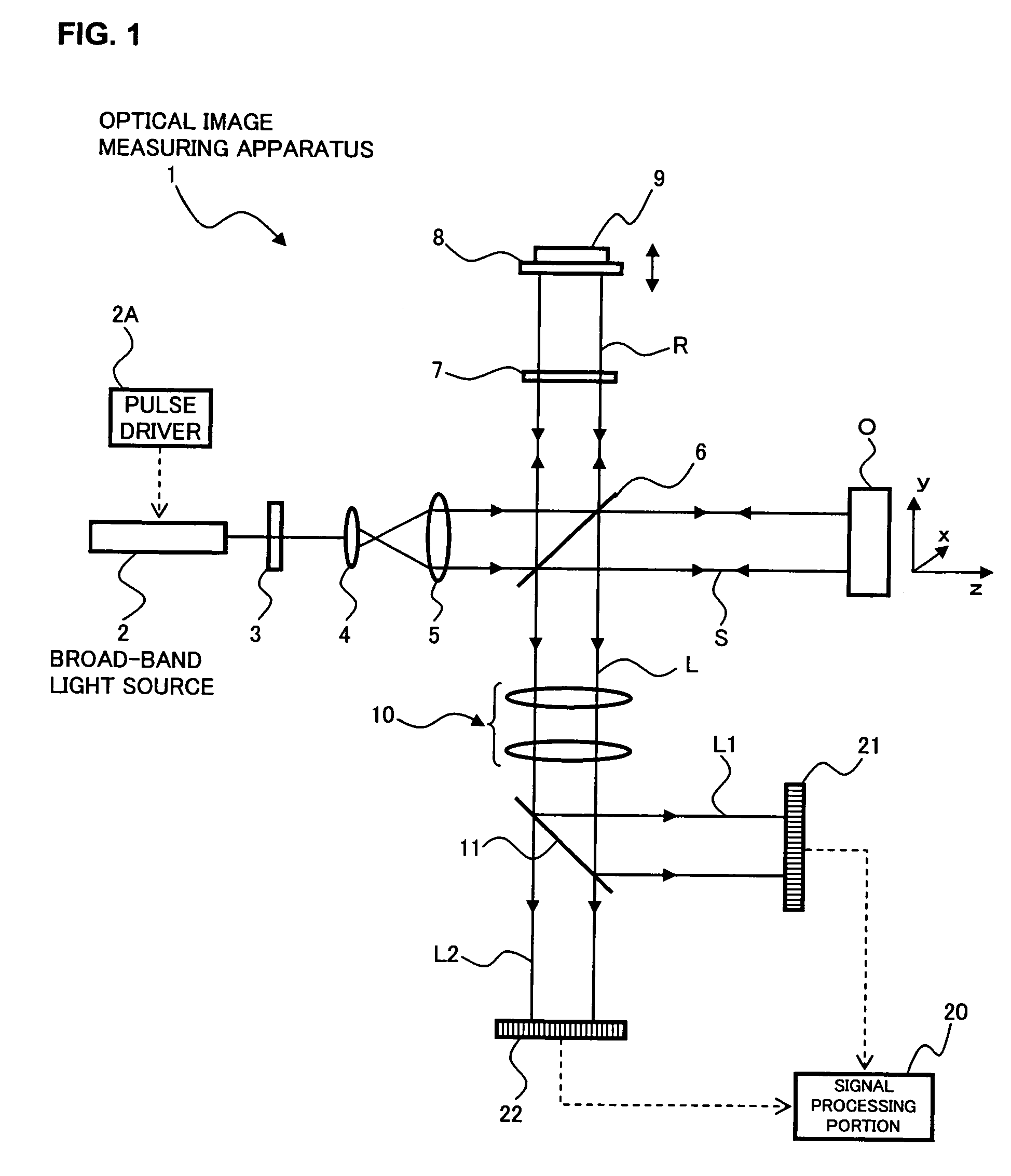

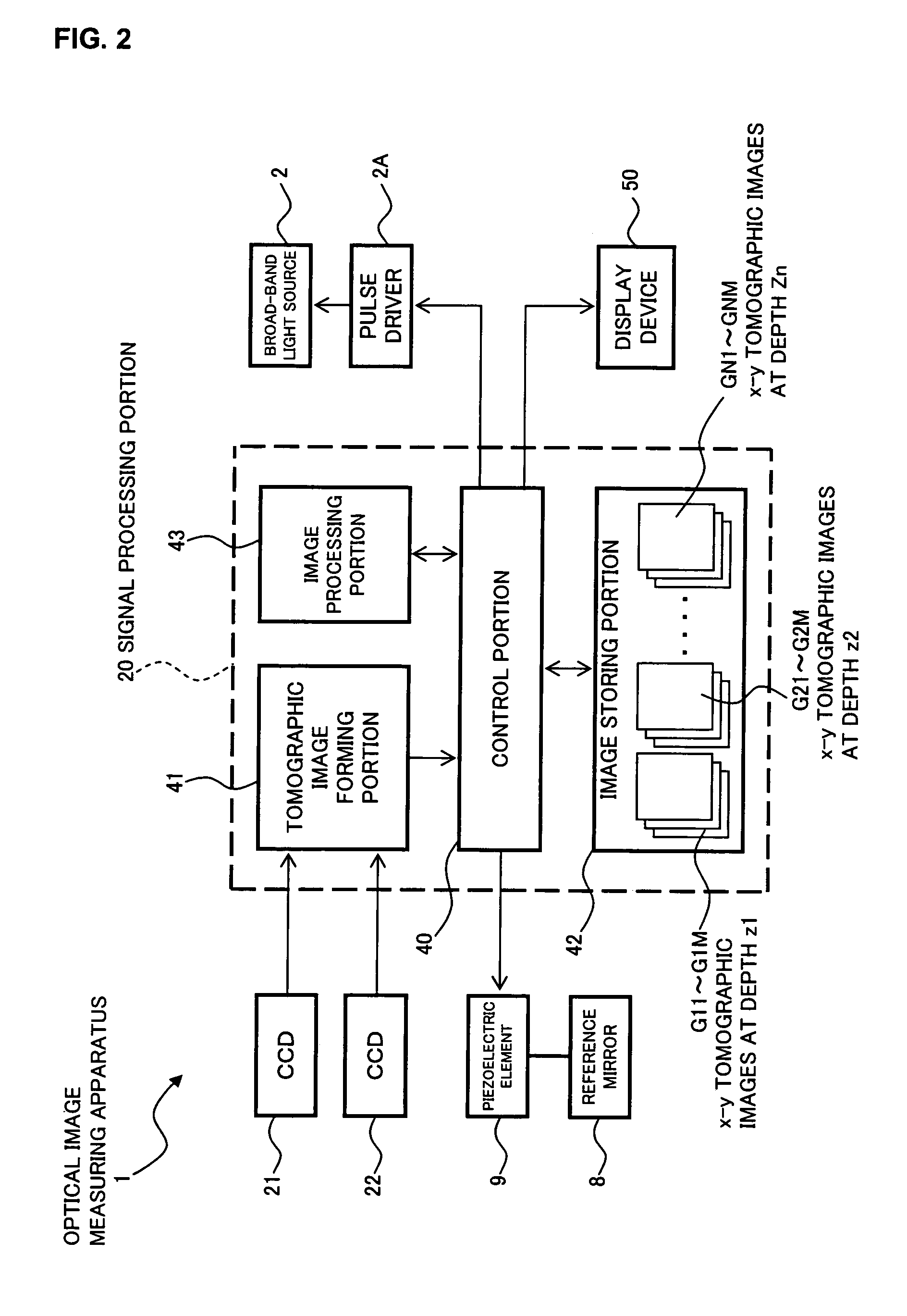

Optical image measuring apparatus and optical image measuring method

InactiveUS20060100528A1Efficient measurementDiagnostics using lightInterferometersSignal lightIntensity modulation

Provided is an optical image measuring apparatus capable of speedily measuring a velocity distribution image of a moving matter. Including a broad-band light source, means for increasing a beam diameter, a polarizing plate converting the light beam to linearly polarized light, and a half mirror, a wavelength plate converting the reference light to circularly polarized light, the half mirror superimposing the signal light whose frequency is partially shifted by the moving matter in the object and the reference light is circularly polarized light to produce superimposed light including interference light, CCDs for receiving different polarized light components of the interference light, and outputting detection signals including interference frequency components corresponding to beat frequencies of the interference light, and a signal processing portion for forming the velocity distribution image based on interference frequency component corresponding to a beat frequency equal to an intensity modulation frequency of the light beam.

Owner:KK TOPCON

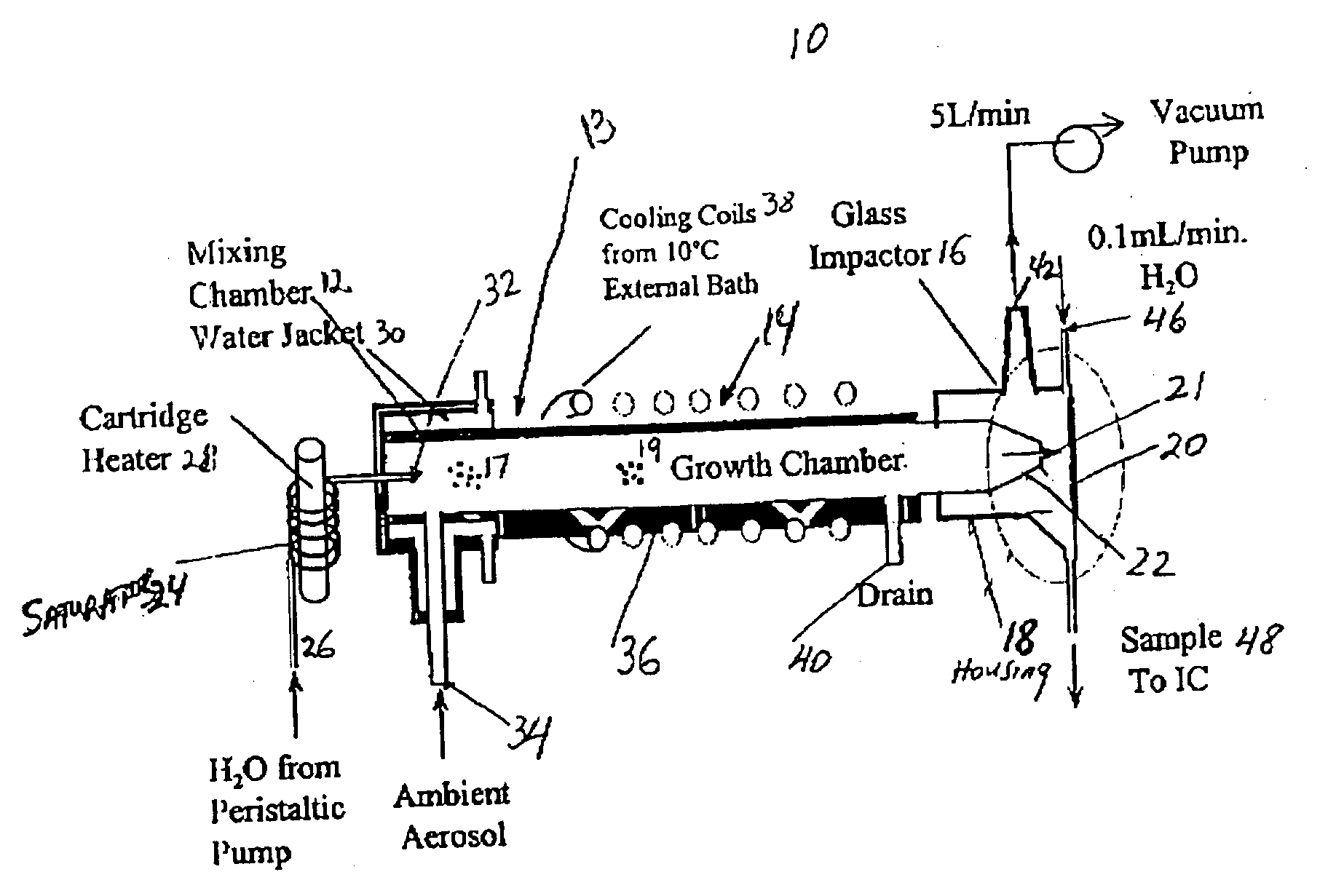

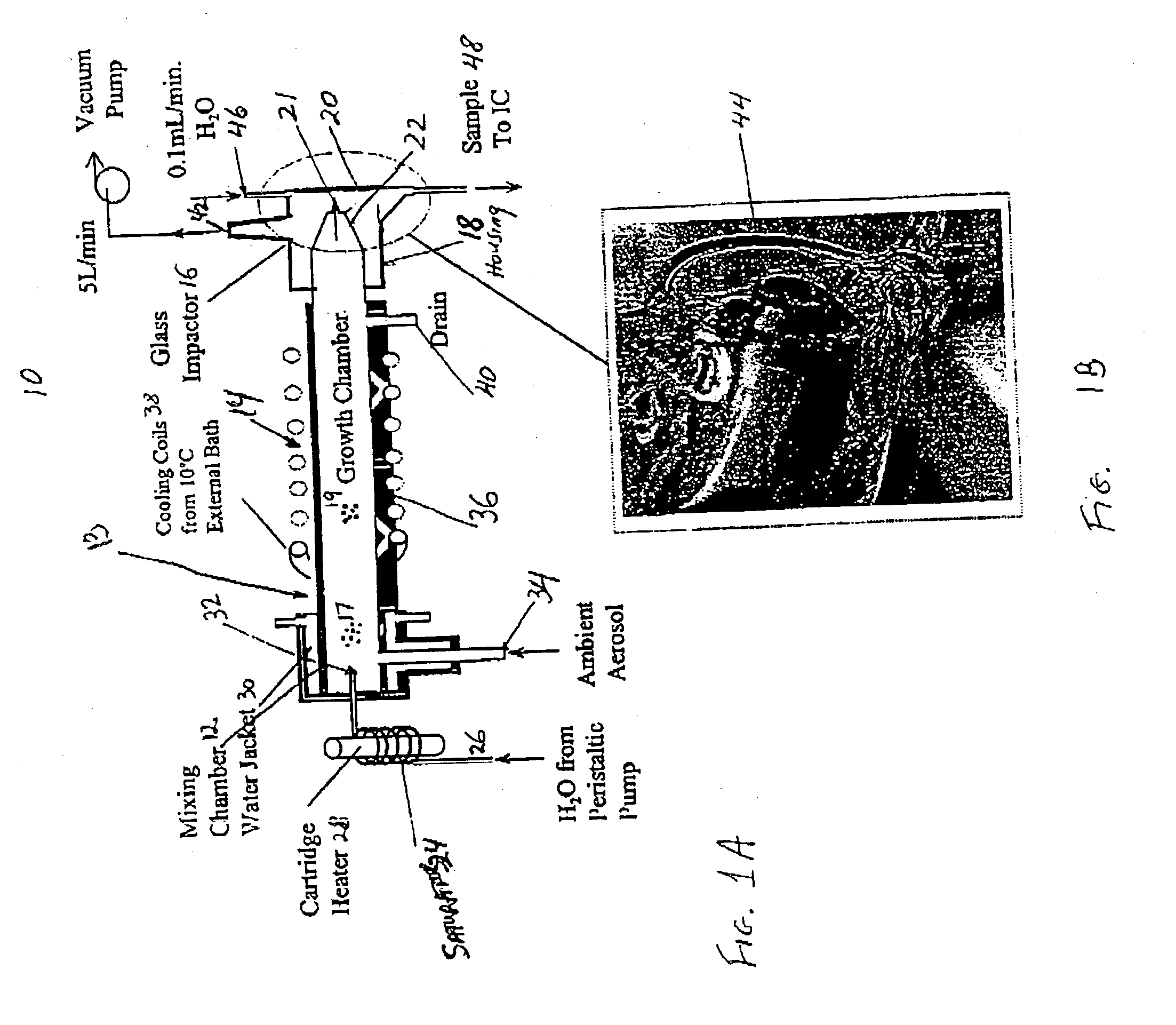

Apparatus for rapid measurement of aerosol bulk chemical composition

InactiveUS20030082825A1Improvement in droplet collectionMinimizing contributionComponent separationWithdrawing sample devicesAir exposureFast measurement

An apparatus for continuous on-line measurement of chemical composition of aerosol particles with a fast time resolution is provided. The apparatus includes an enhanced particle size magnifier for producing activated aerosol particles and an enhanced collection device which collects the activated aerosol particles into a liquid stream for quantitative analysis by analytical means. Methods for on-line measurement of chemical composition of aerosol particles are also provided, the method including exposing aerosol carrying sample air to hot saturated steam thereby forming activated aerosol particles; collecting the activated aerosol particles by a collection device for delivery as a jet stream onto an impaction surface; and flushing off the activated aerosol particles from the impaction surface into a liquid stream for delivery of the collected liquid stream to an analytical instrument for quantitative measurement.

Owner:BROOKHAVEN SCI ASSOCS +1

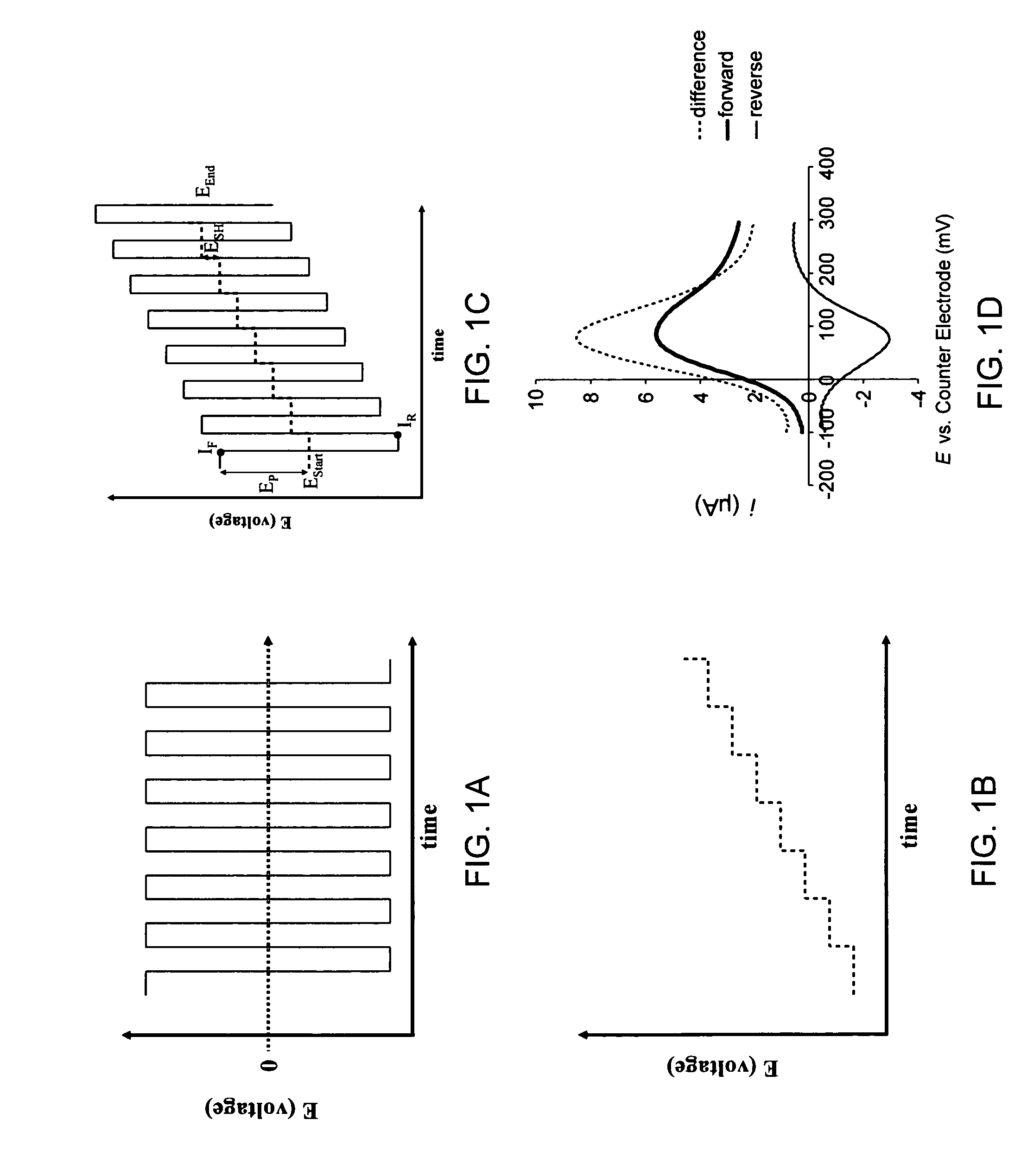

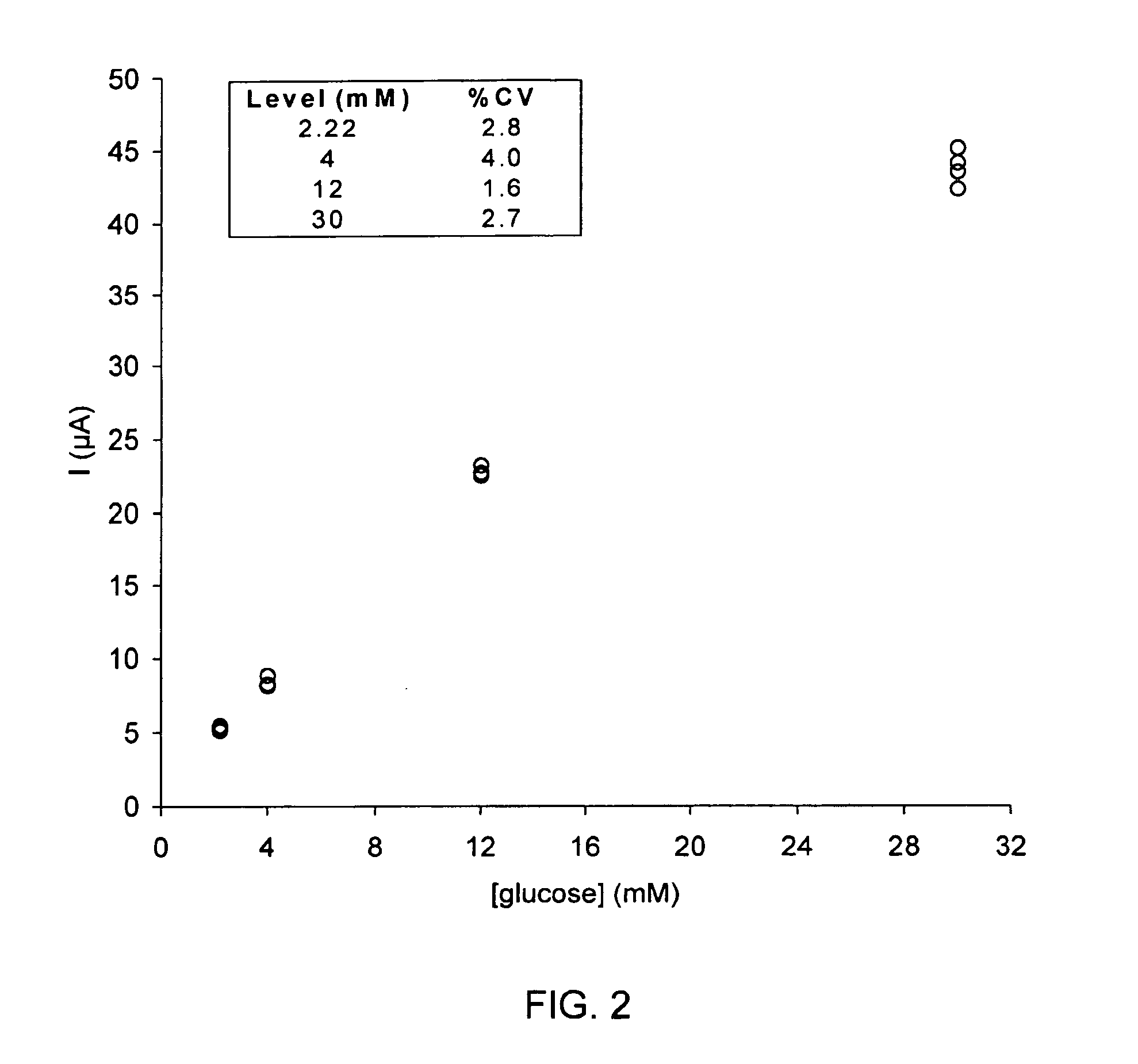

Rapid analyte measurement assay

ActiveUS20080000780A1Shorten the timeImmobilised enzymesBioreactor/fermenter combinationsFast measurementAnalyte

Owner:ABBOTT DIABETES CARE INC

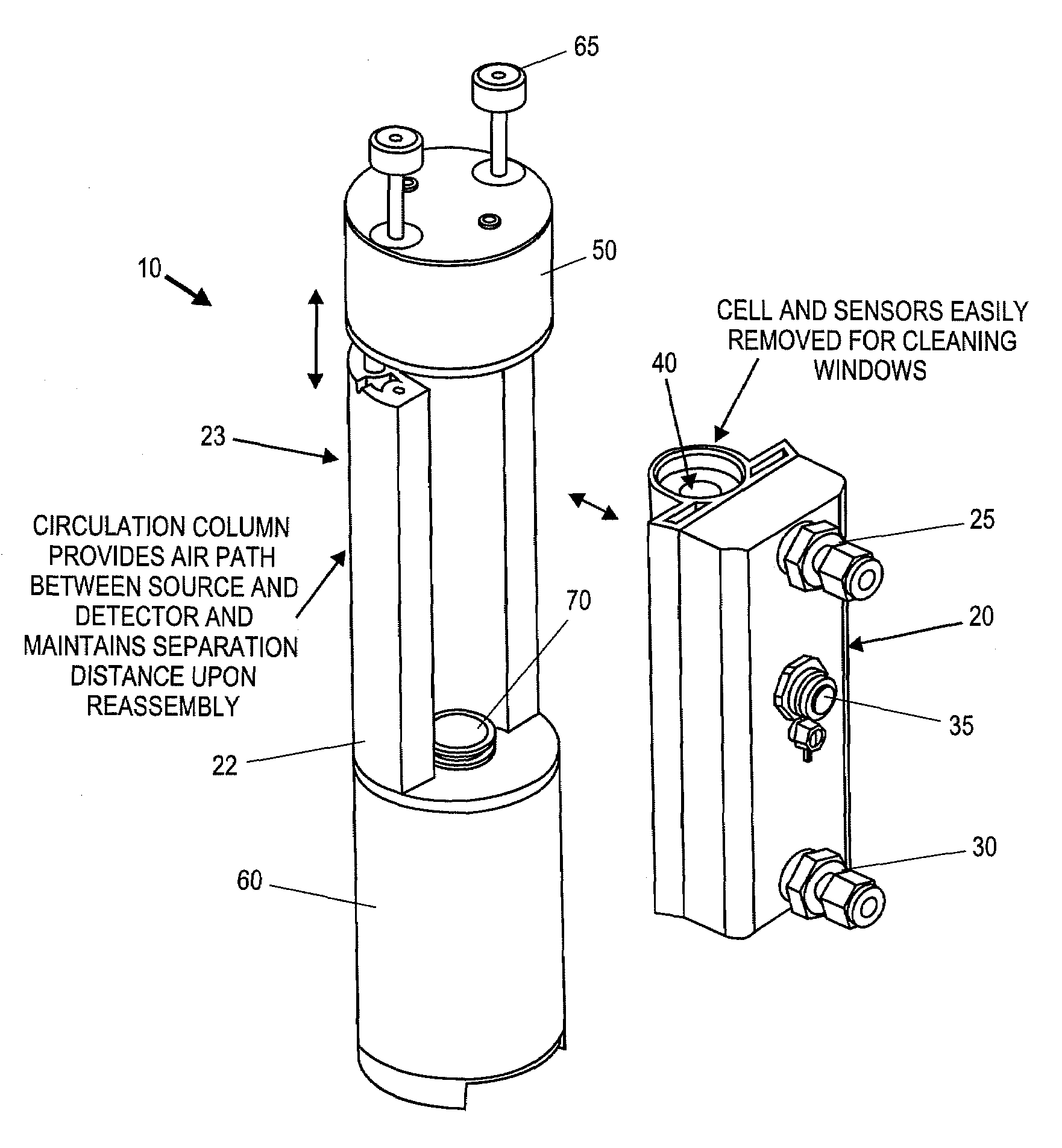

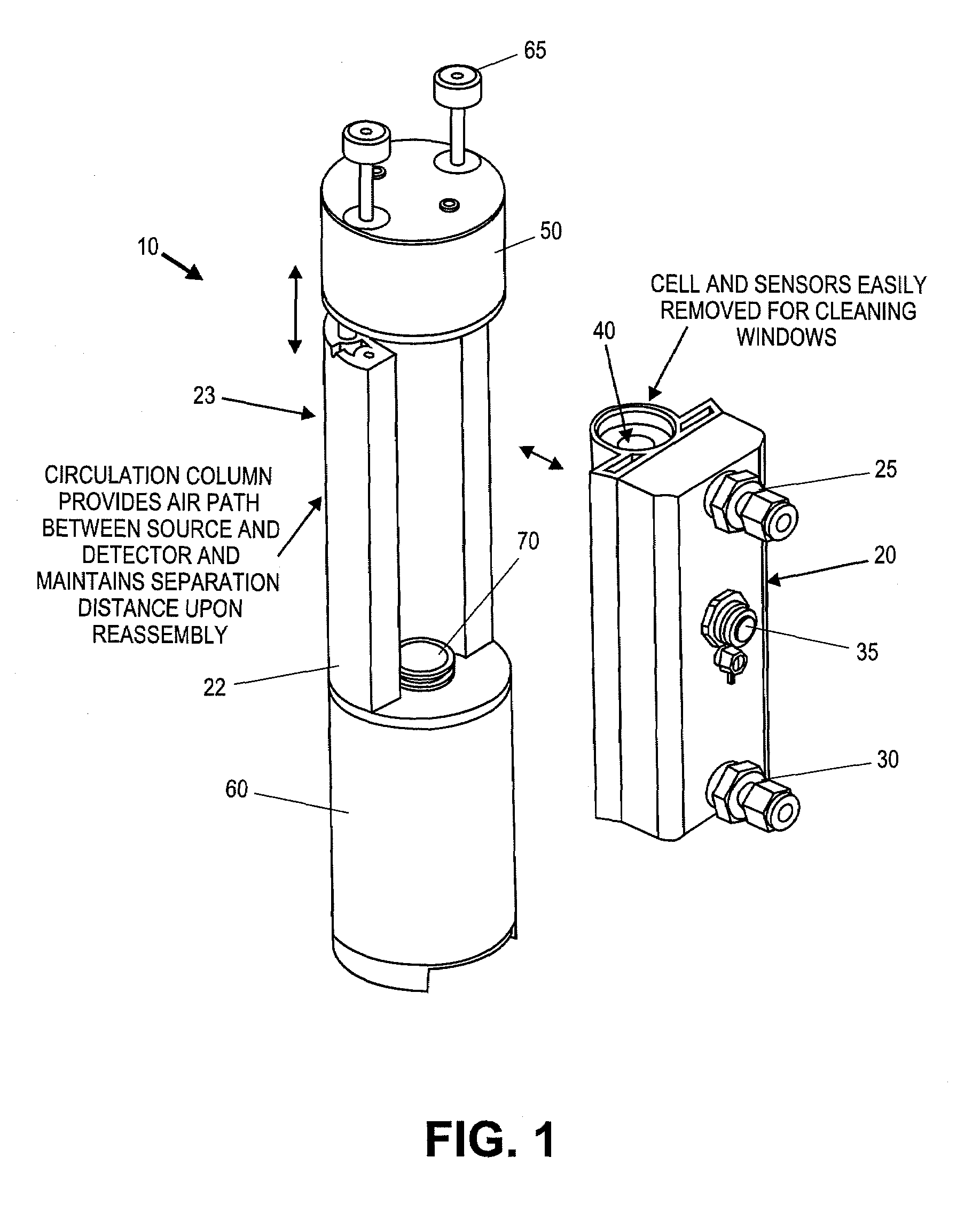

Gas analyzer

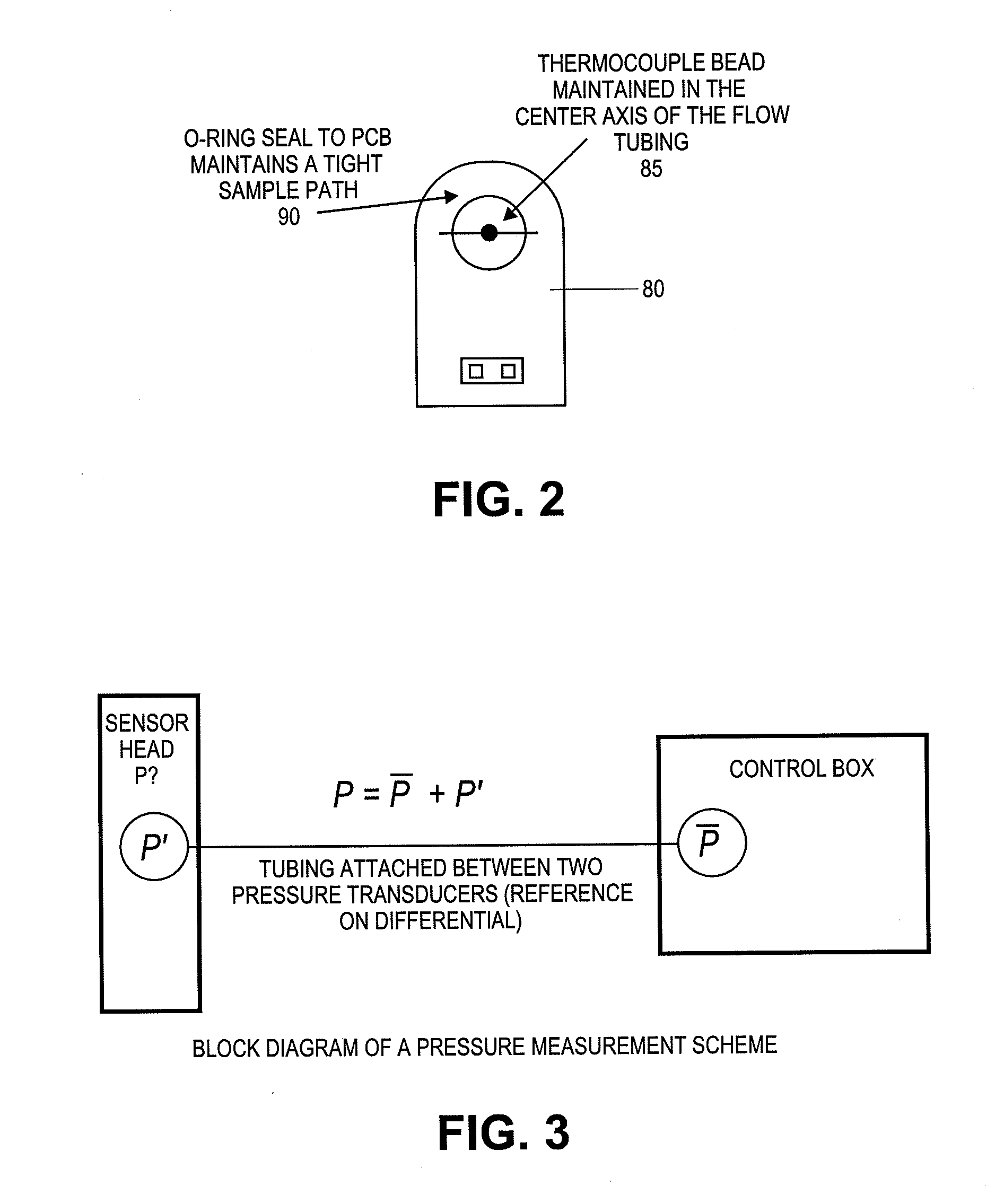

ActiveUS20100110437A1Quick measurementShort intake tubeThermometer detailsSamplingFast measurementCoupling

Gas analyzer systems and methods for measuring concentrations of gasses and in particular dry mole fraction of components of a gas. The systems and method allow for rapid measurement of the gas density and / or dry mole fraction of gases for a number of environmental monitoring applications, including high speed flux measurements. A novel coupling design allows for tool-free removal of a cell enclosing a flow path to enable in field cleaning of optical components.

Owner:LI COR

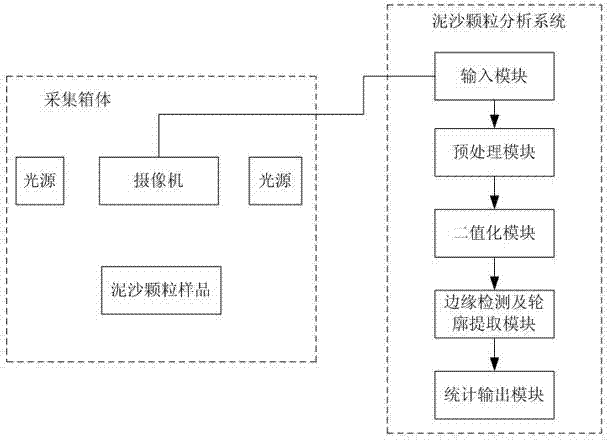

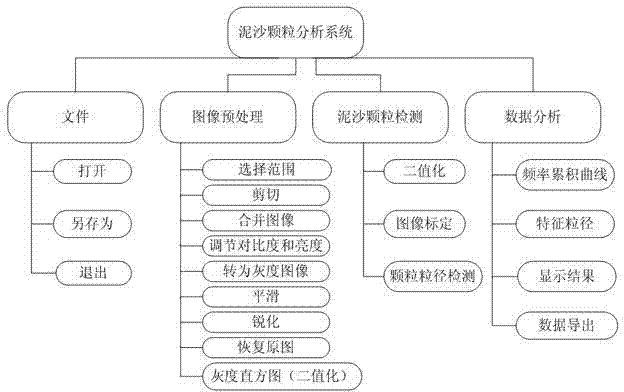

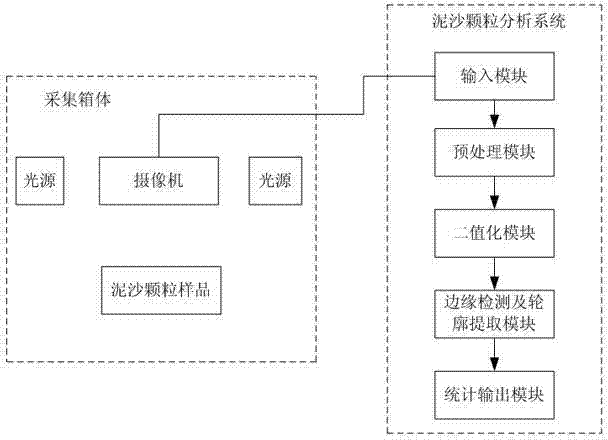

Sediment particle analysis device and analysis method based on digital image technology

The invention discloses a sediment particle analysis device based on digital image technology, which includes a collection box, an image acquisition unit, and a sediment particle analysis system; wherein the image collection unit is arranged in the collection box for collecting sediment samples. Image; the sediment particle analysis system includes an input module, an image preprocessing module, an image binarization module, an edge detection and contour extraction module, and a statistical output module. The invention also discloses a sediment particle analysis method based on digital image technology. The image of the sediment particle sample is collected by a camera, and then the image is preprocessed, binarized, and edge contour is extracted, and the projected area of each particle is calculated. According to the equivalent projected area, the particle size of each particle is obtained, and then a series of particle information is obtained, which realizes the rapid measurement of the characteristic parameters of sediment particles.

Owner:HOHAI UNIV

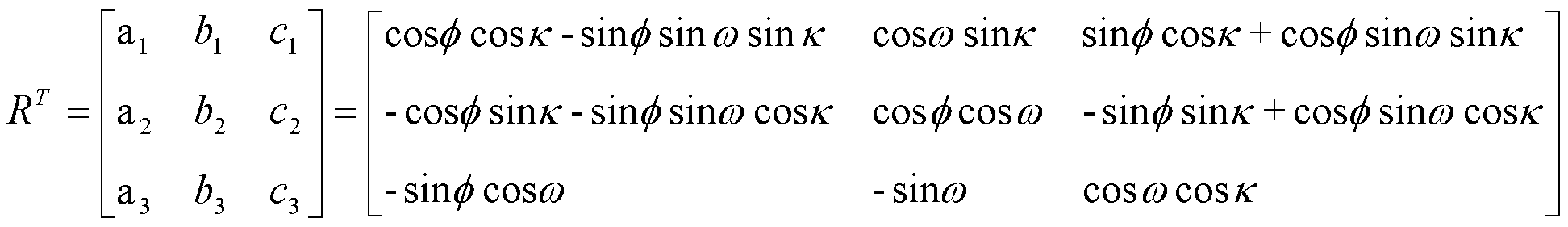

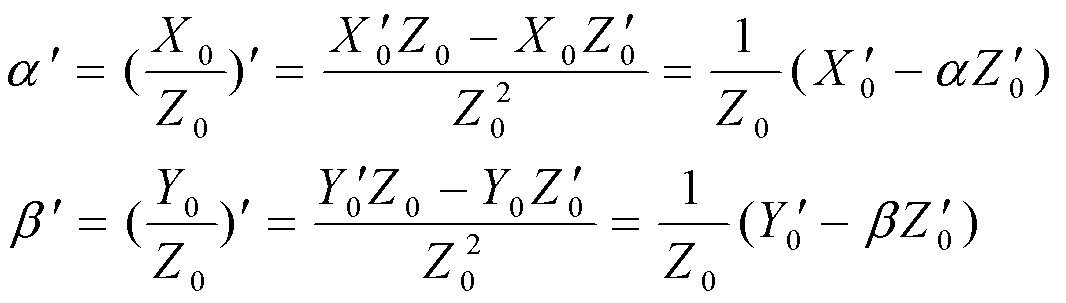

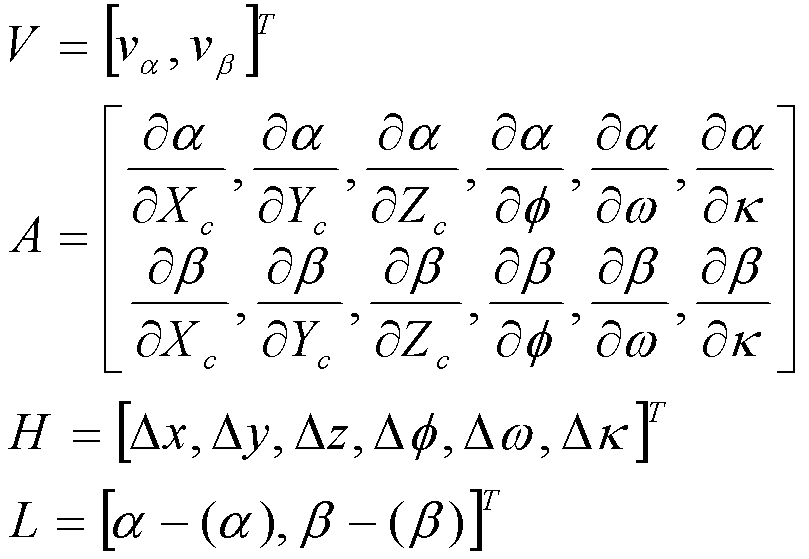

Registration and measurement method of spherical panoramic image and three-dimensional laser scanning point cloud

ActiveCN103017653AReduce data volumeQuick measurementImage analysisUsing optical meansPoint cloudFast measurement

The invention provides a registration and measurement method of a spherical panoramic image and a three-dimensional laser scanning point cloud. The method comprises the following steps: firstly, using a three-dimensional structure simulation spherical panoramic image of a unit sphere, converting a pixel coordinate of the spherical panoramic image into a three-dimensional rectangular coordinate, then calculating an attitude parameter of the spherical panoramic image in point cloud data and a position coordinate of the optical center of the spherical panoramic image in the point cloud data to carry out the registration to the spherical panoramic image in the point cloud data; obtaining a depth map of the spherical panoramic image through the calculation; and finally moving a mouse to a target point position to be measured when the measurement is required to be carried out on the spherical panoramic image to calculate a three-dimensional coordinate of the target point. The registration and measurement method provided by the invention not only can carry out the height registration on the spherical panoramic image and the three-dimensional laser scanning point cloud, and also can realize fast measurement on a target point simultaneously.

Owner:WUHAN HI TARGET DIGITAL CLOUD TECH CO LTD

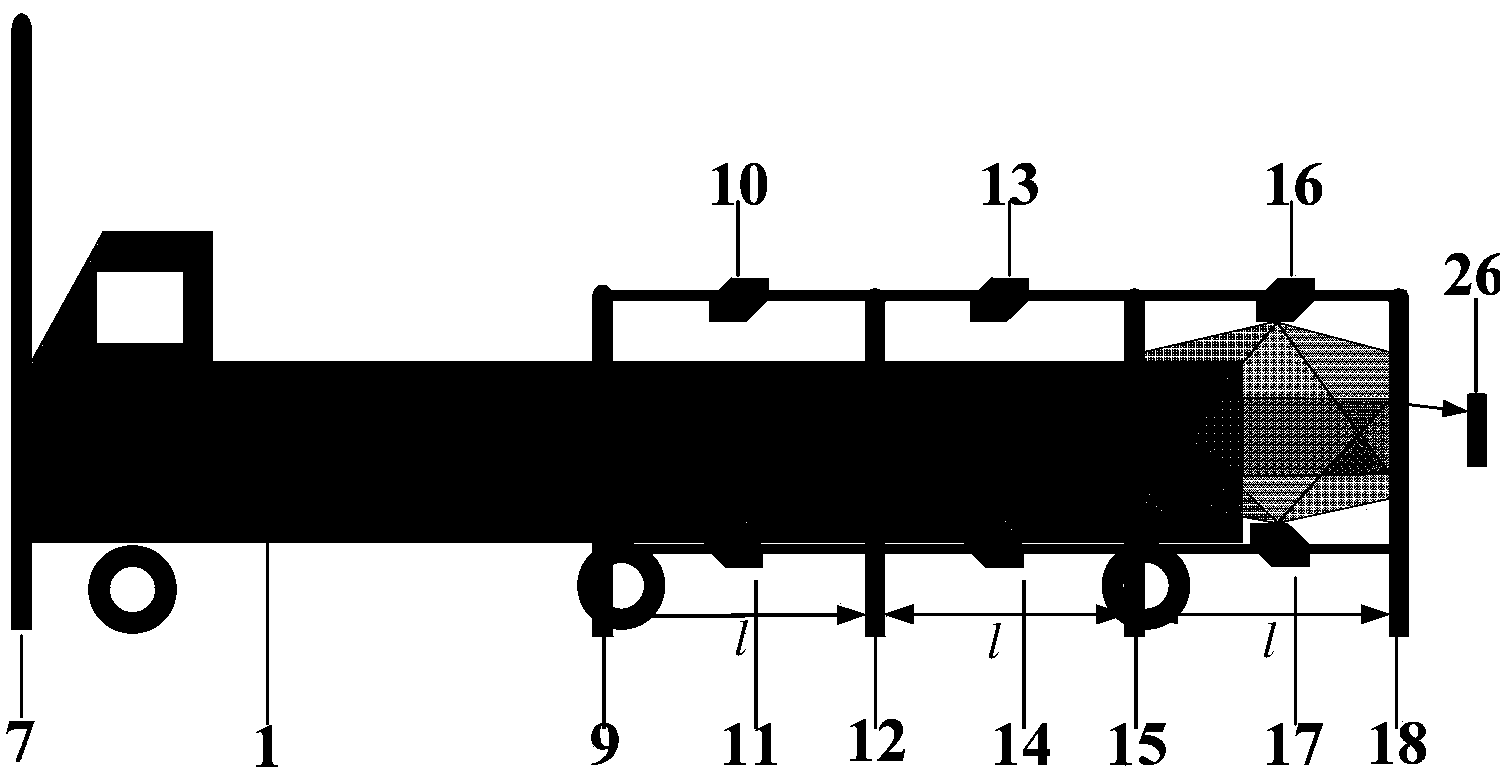

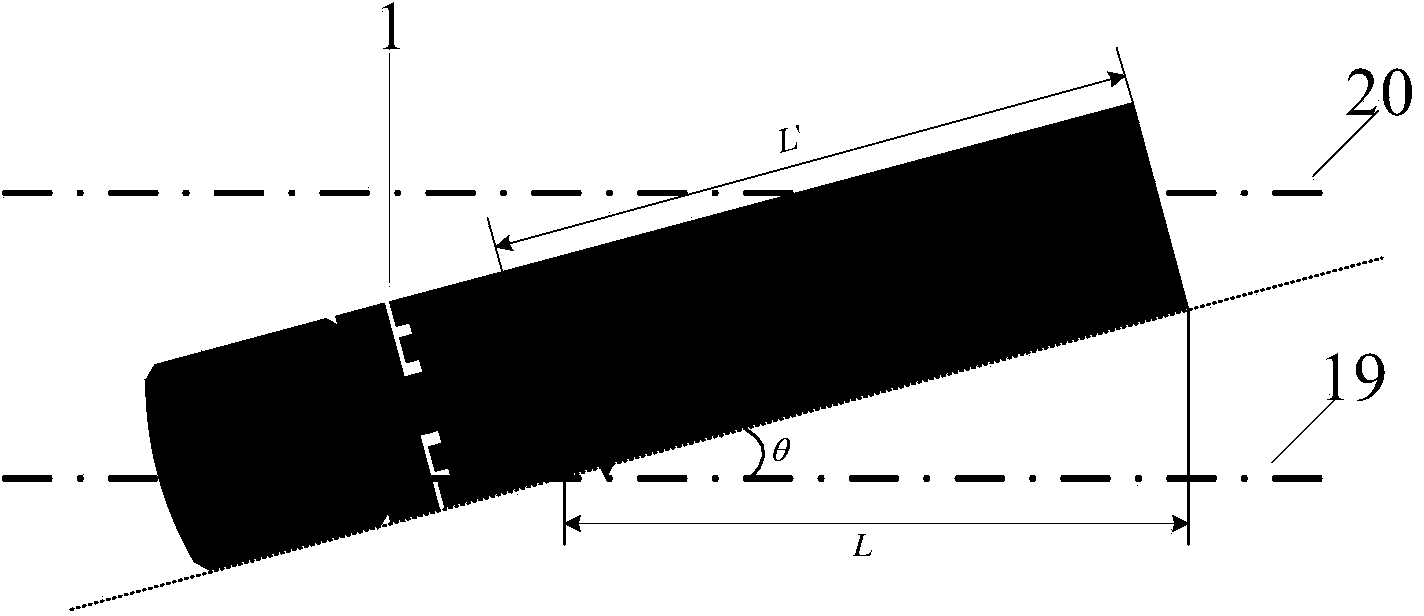

System and method for measuring vehicle outline dimensions based on machine vision and laser light curtain

The invention belongs to the technical field of test and measurement, provides a system and method for measuring vehicle outline dimensions based on machine vision and a laser light curtain, and high-precision, real-time and rapid measurement for feature sizes such as the length, width and height of a vehicle can be achieved on the premise of not influencing the normal running state of the vehicle. According to the technical scheme, the system for measuring the vehicle outline dimensions comprises a vehicle outline length dimension measuring module, a vehicle outline width dimension measuring module and a vehicle outline height dimension measuring module. Furthermore, a group of one-dimensional laser detector arrays are installed on a position, relative to the same height of the transverse laser light curtain, of the other side of a running measuring area of a vehicle to be measured, and the one-dimensional laser detector arrays are used for detecting laser beams output by the transverse laser light curtain sheltered by a vehicle which is not tested. The system and method for measuring vehicle outline dimensions based on machine vision and the laser light curtain are mainly applied to vehicle detection.

Owner:善测(天津)科技有限公司

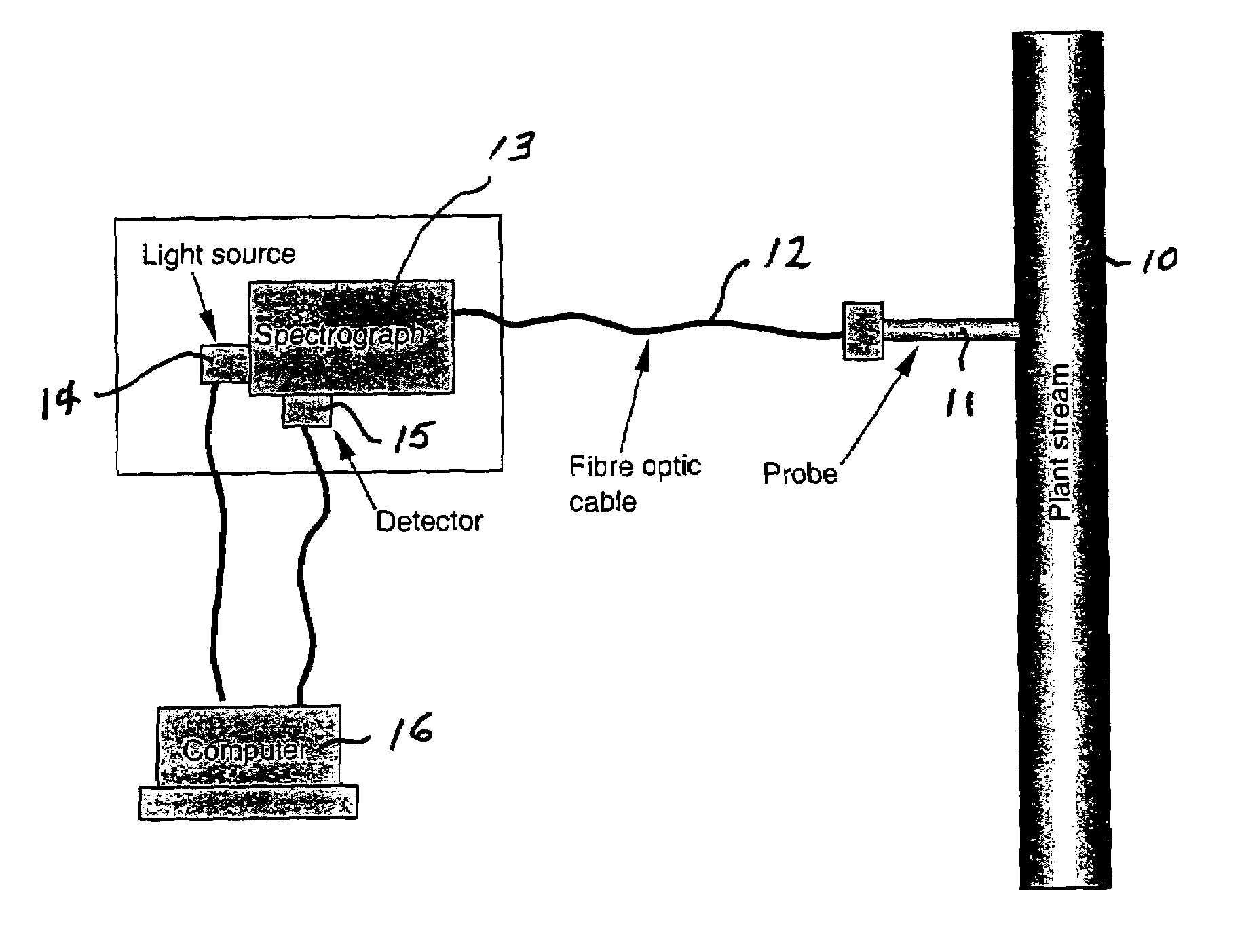

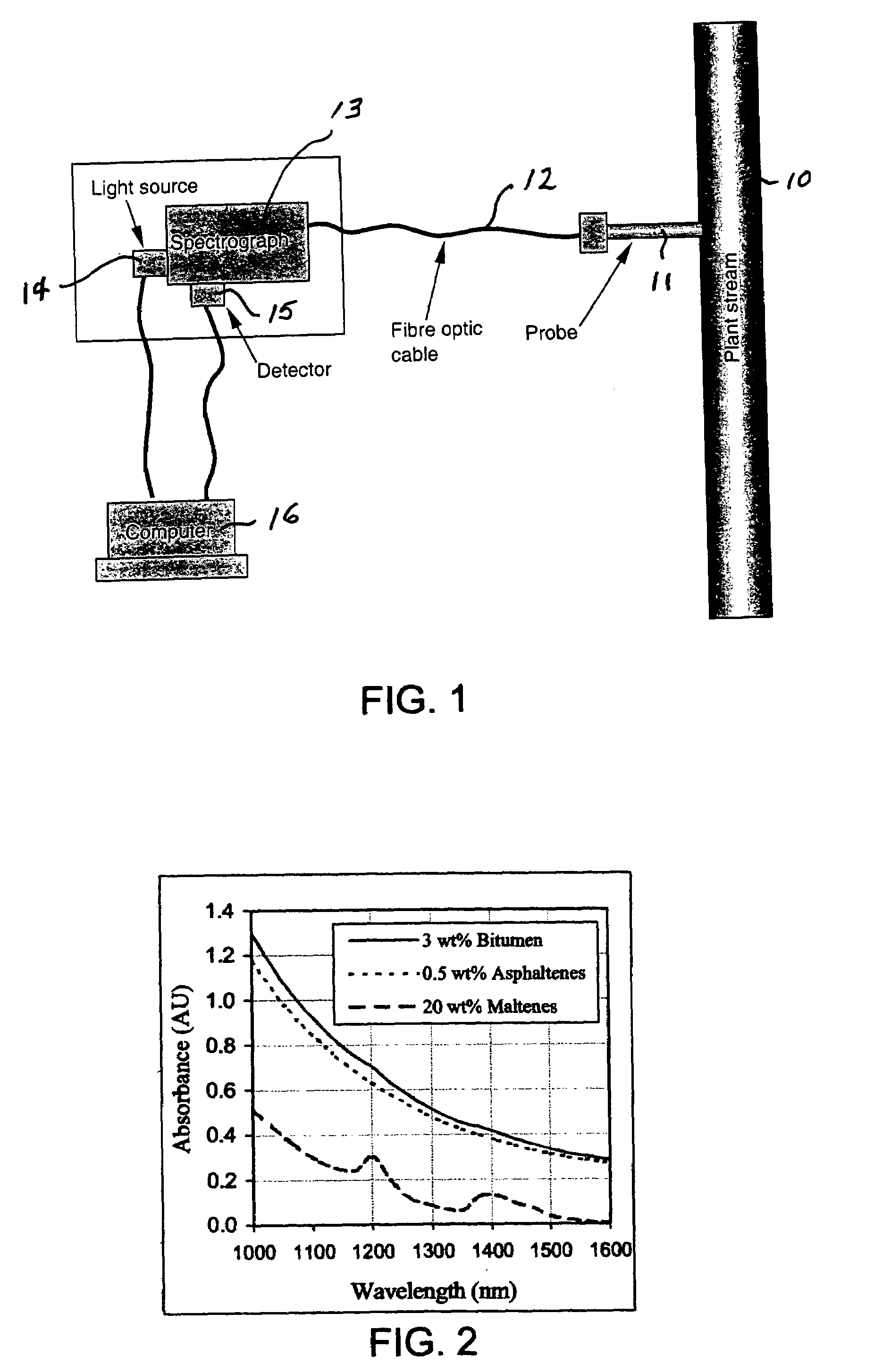

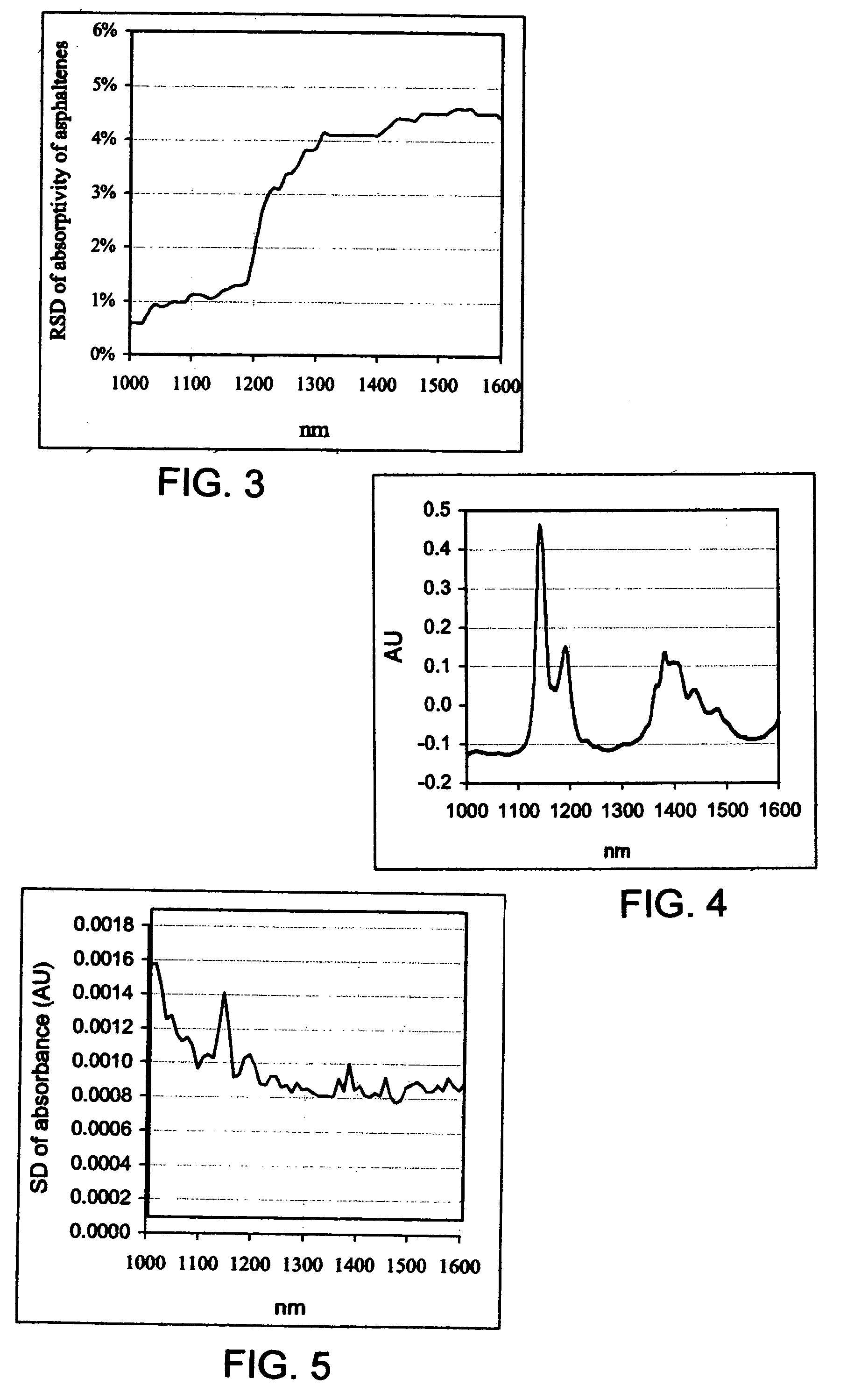

NIR spectroscopy method for analyzing chemical process components

ActiveUS7067811B2Minimize temperature effectRadiation pyrometryInvestigating moving fluids/granular solidsInfraredFiber

A method is described for providing rapid on-line analyses of chemical compositions such as chemical process streams, utilizing near-infrared (NIR) spectroscopy in combination with chemometrics. In the method, for each type of analysis to be conducted, a database is provided by analyzing a series of samples using standard laboratory analytical procedures, utilizing the results as reference values to establish quantitative calibration models from NIR spectroscopy using chemometric techniques and storing this information in a computer database. An NIR spectroscopic system is also provided comprising a transflectance or a transmittance probe coupled via fiber-optic cables to a stable white light source and a spectrograph. The probe is inserted into a test sample or chemical process stream to be analyzed, a stable white light of selected wavelength range is beamed to the probe and the spectra obtained on the spectrograph are recorded. Finally the spectra obtained are correlated to the reference data stored in the computer to obtain a rapid measurement of the analysis desired.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

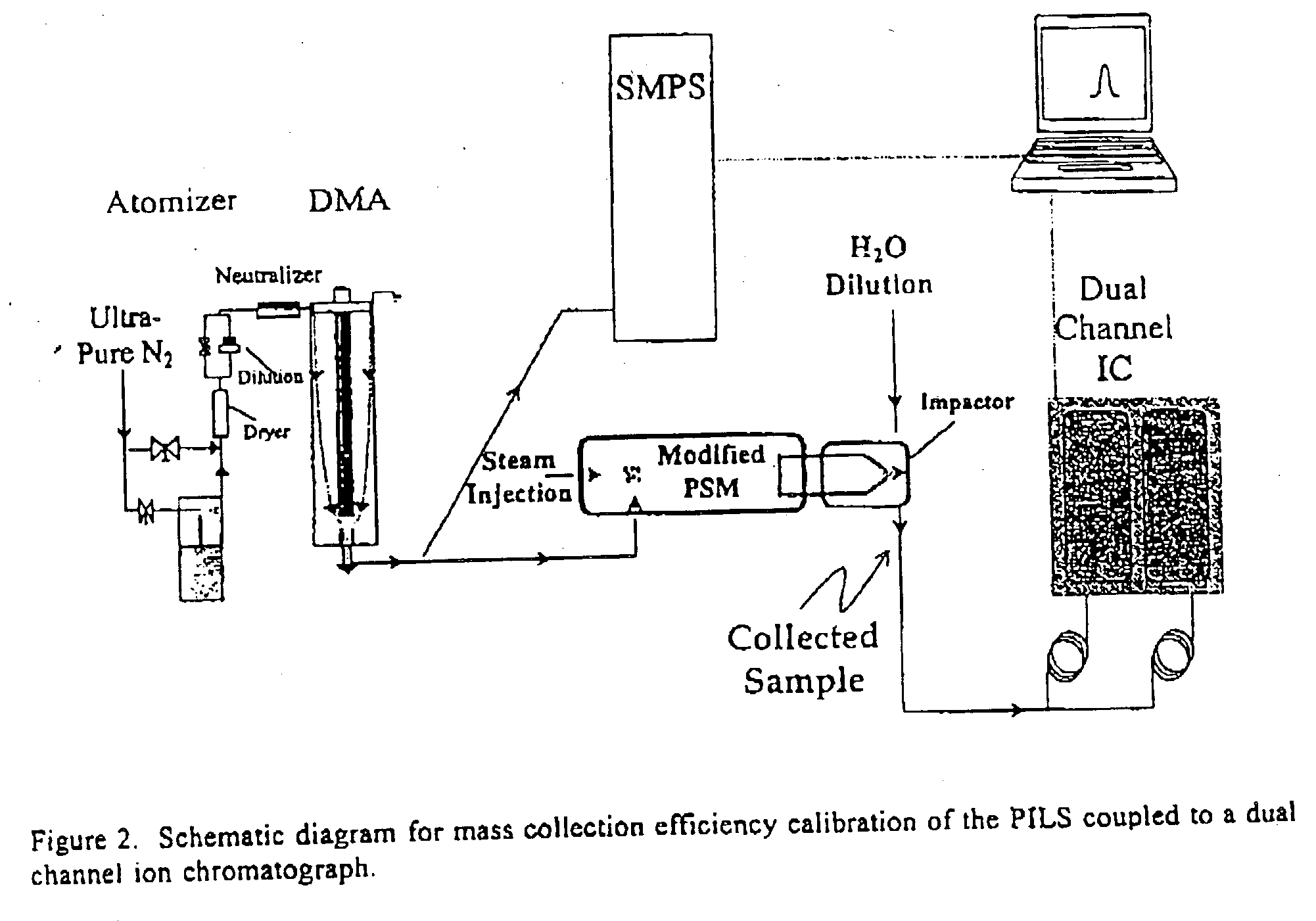

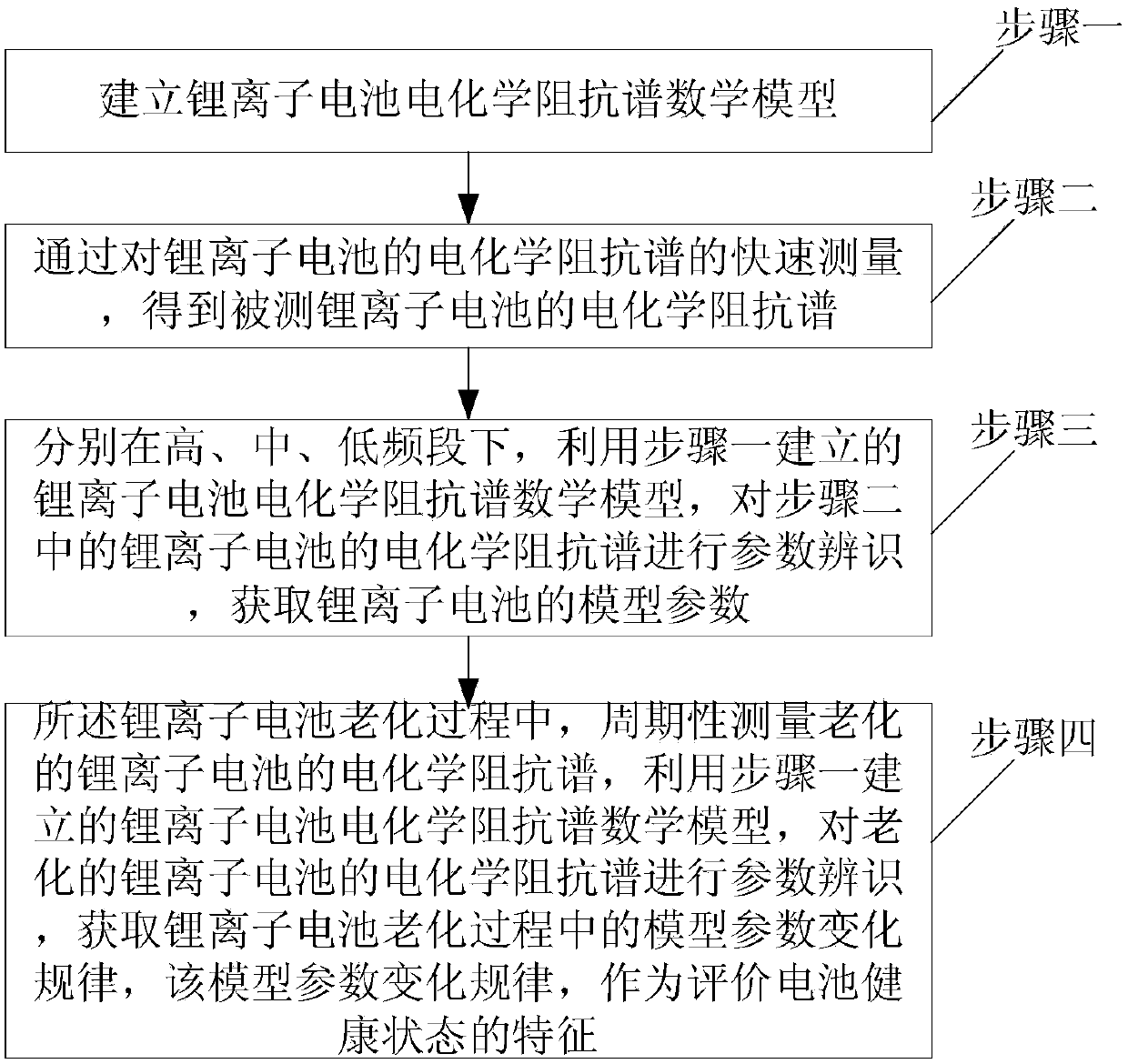

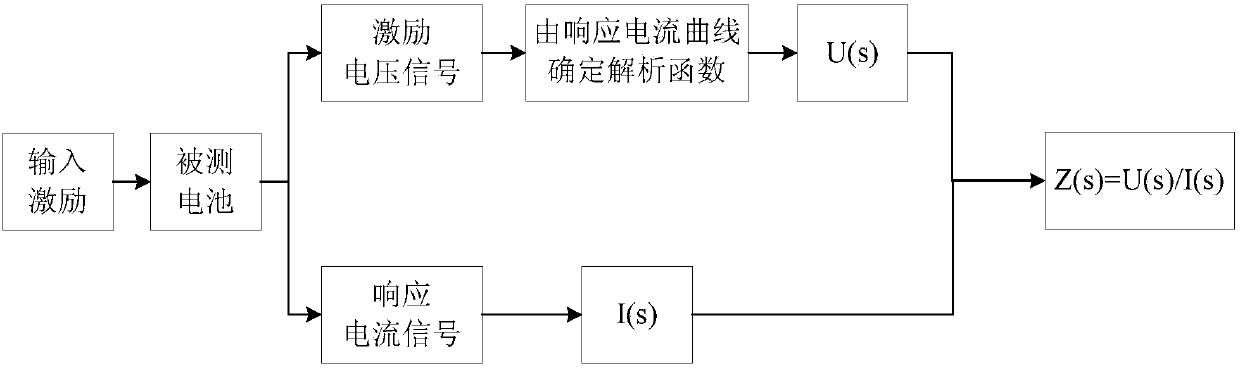

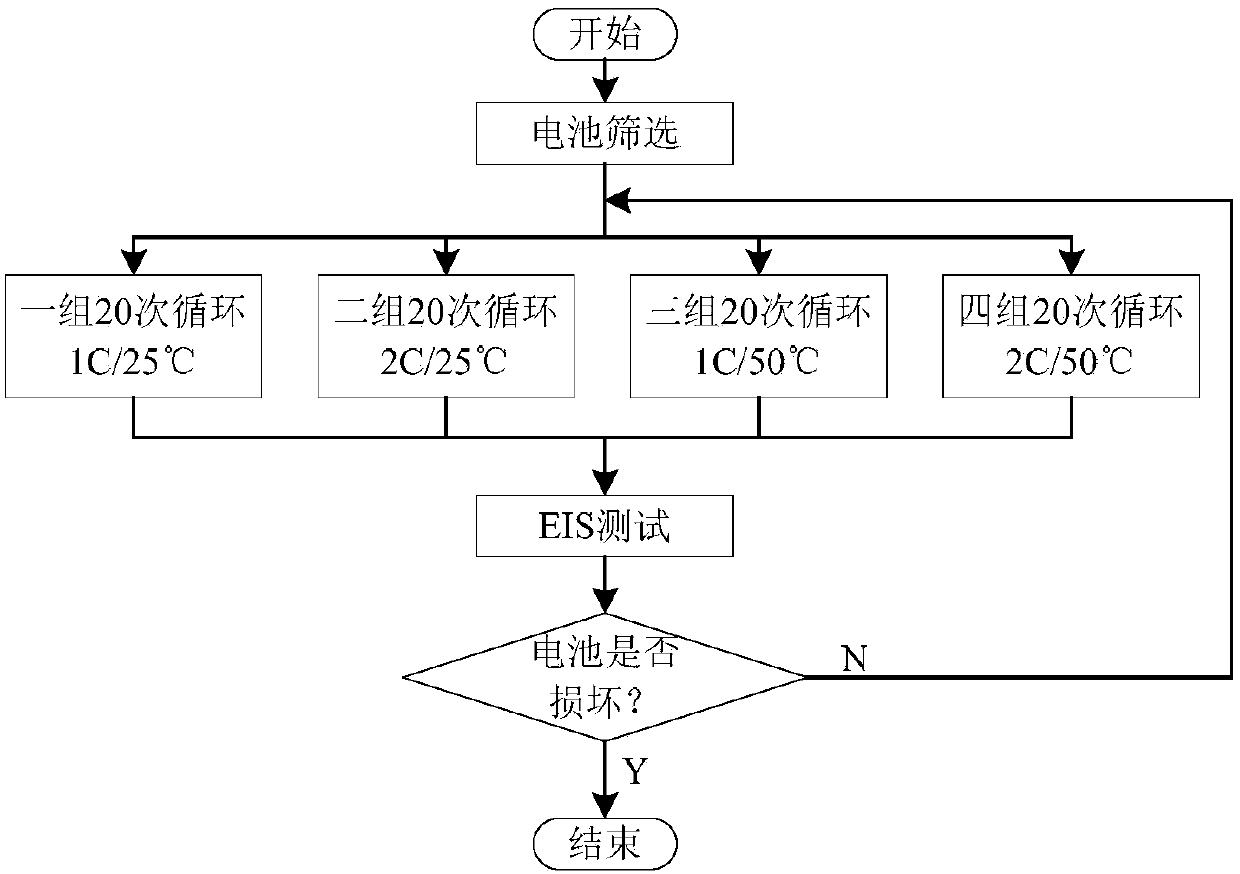

Lithium ion battery internal health feature extraction method based on impedance spectrum

A lithium ion battery internal health feature extraction method based on an impedance spectrum, and relates to the new energy research field; an existing method uses an EIS to analyze and estimate a SOH, wherein the EIS is long in measuring time, and cannot realize online measurements; the lithium ion battery internal health feature extraction method comprises the following steps: building a lithium ion battery electrochemistry impedance spectrum mathematics model; fast measuring a lithium ion battery electrochemistry impedance spectrum, and obtaining the lithium ion battery electrochemistry impedance spectrum; using the lithium ion battery electrochemistry impedance spectrum mathematics model to identify the lithium ion battery electrochemistry impedance spectrum parameters respectively under high, medium and low frequency stages, thus obtaining the lithium ion battery model parameters; periodically measuring the electrochemistry impedance spectrum of the aged lithium ion battery, using the lithium ion battery electrochemistry impedance spectrum mathematics model to identify the lithium ion battery electrochemistry impedance spectrum parameters of the aged lithium ion battery, thus obtaining the model parameter changing rules in the lithium ion battery aging process, and serving as the features that evaluate the battery health states. The lithium ion battery internal health feature extraction method is used for evaluating the battery health states.

Owner:HARBIN INST OF TECH

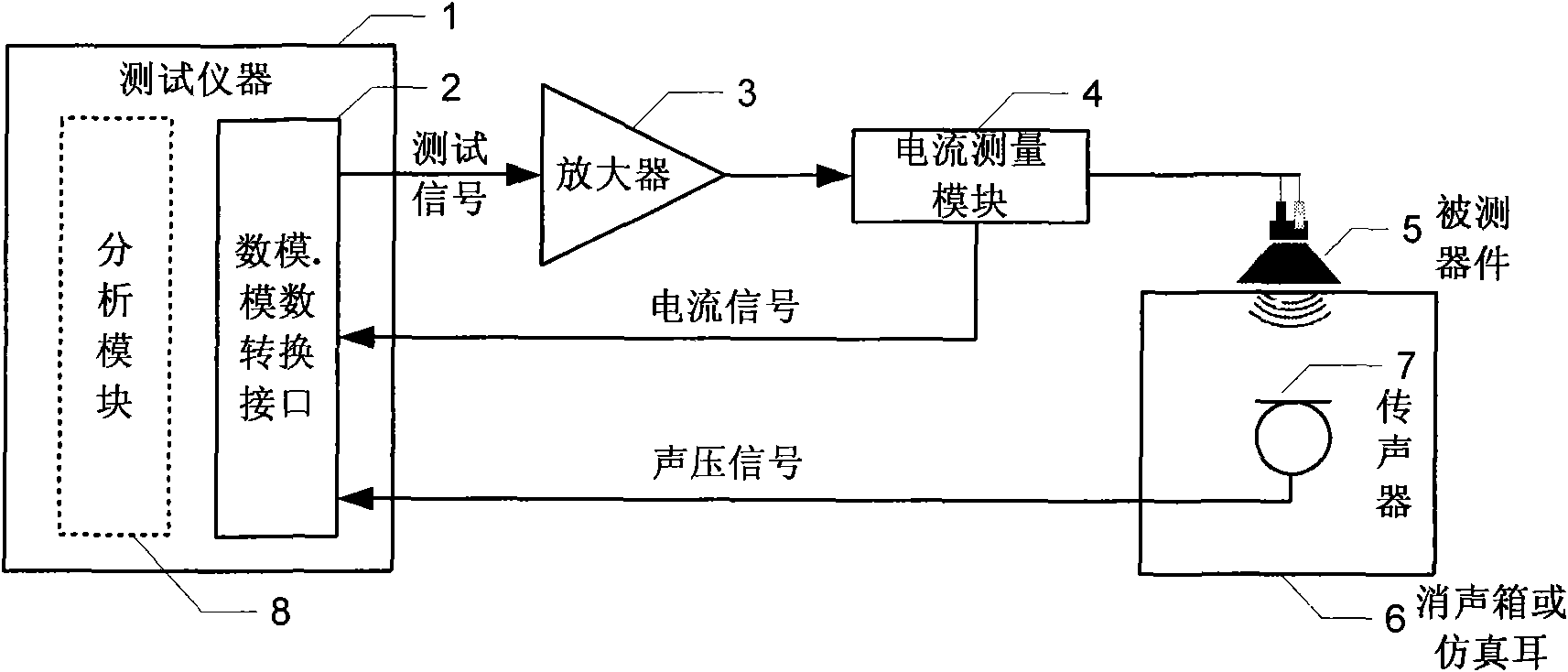

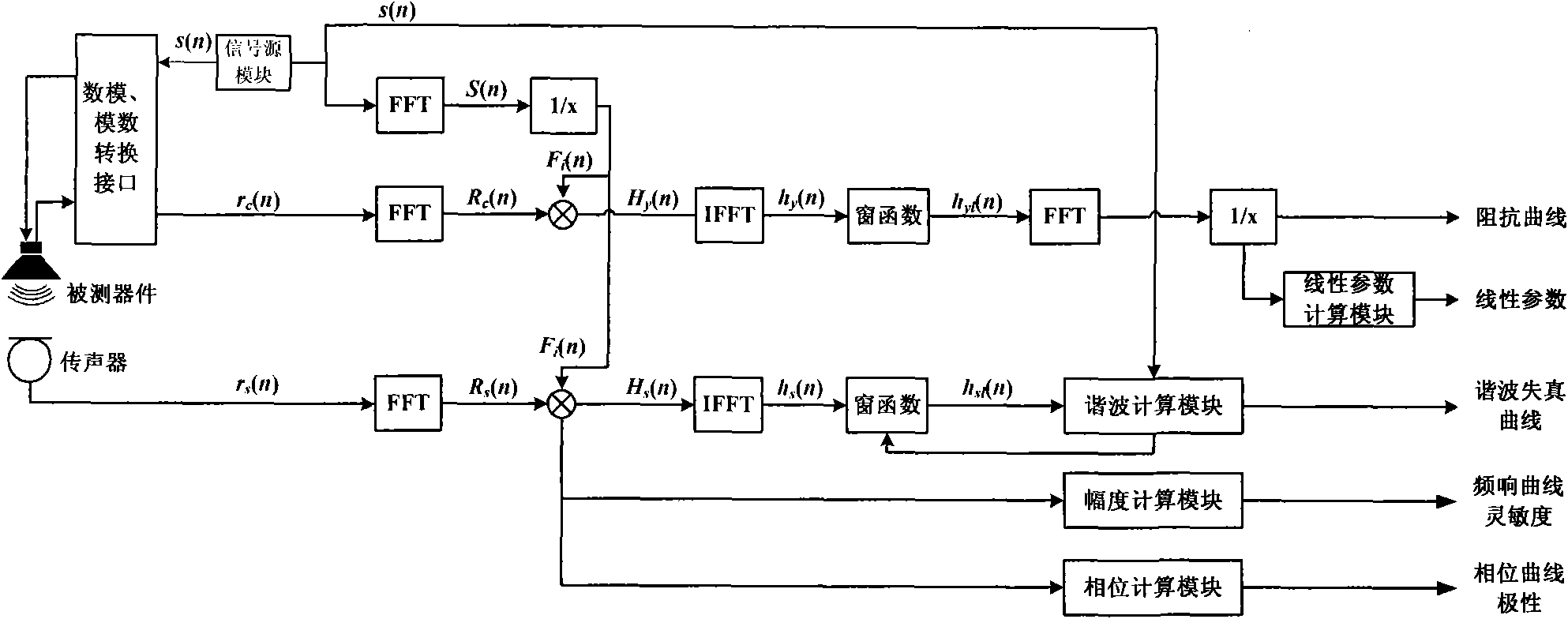

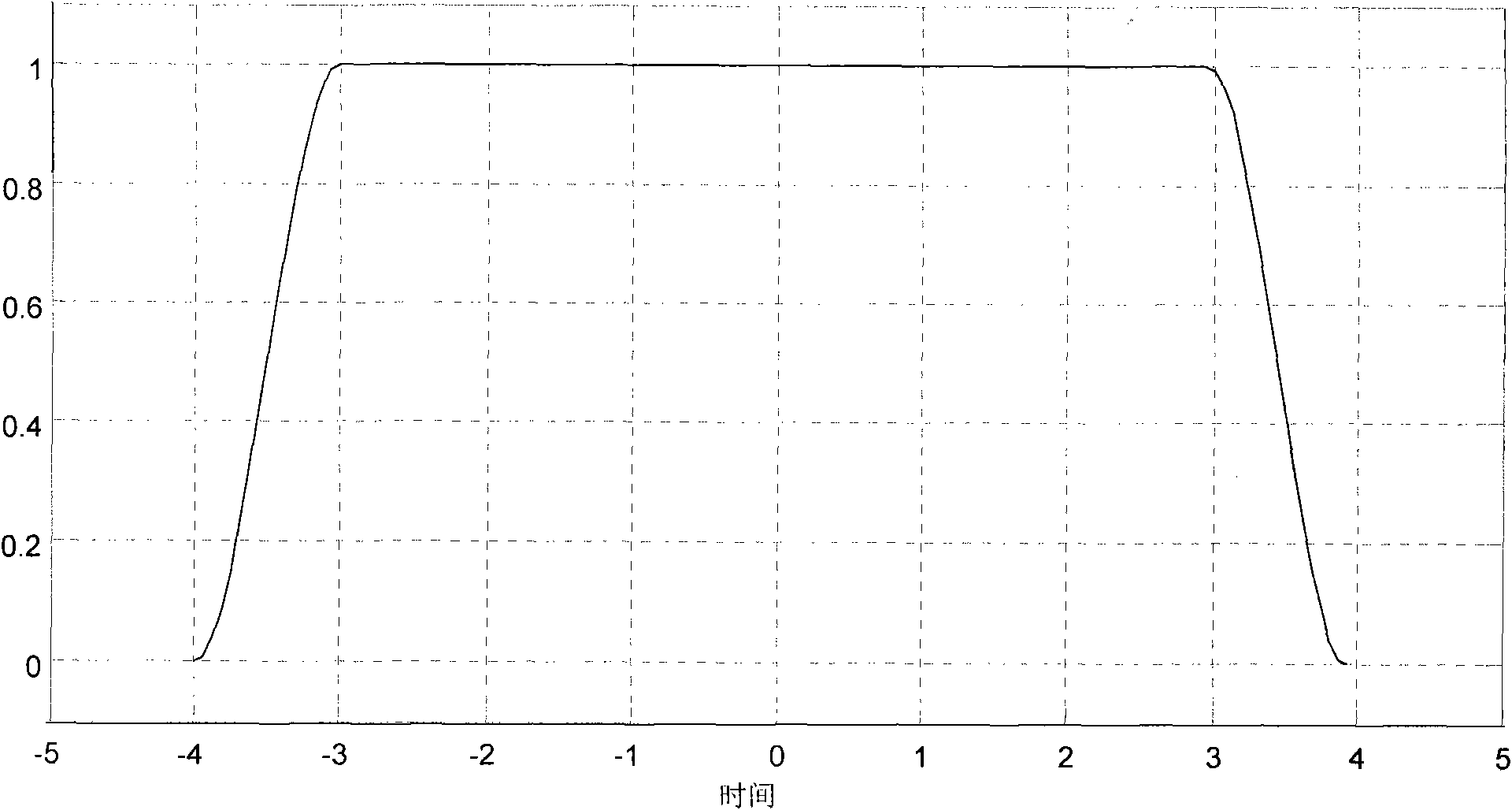

Method and system for obtaining a plurality of parameters of electro-acoustic product by adopting continuous logarithmic swept-frequency signal

The invention provides a method for rapidly measuring a plurality of parameters of an electro-acoustic product and also provides a test system realizing the method. The method comprises the following steps: adopting a continuous logarithmic swept-frequency signal to stimulate an electro-acoustic component and collecting an acoustic response signal transmitted by the electro-acoustic component to be tested and a current response signal flowing through the electro-acoustic component to be tested; obtaining a frequency response curve and a phase curve after the acoustic response signal is filtered by an inverse filter, and calculating and obtaining a harmonic distortion curve after time domain processing is carried out on the frequency response curve; calculating and obtaining an impedance curve after inverse filter and time domain processing are carried out on the current response signal; and further analyzing a result curve and obtaining results, such as sensitivity, polarity, rated impedance, linear parameters and the like. The test system comprises a test instrument, an amplifier, a current measurement module and a microphone.

Owner:嘉兴中科声学科技有限公司

Optical image measuring apparatus and optical image measuring method for forming a velocity distribution image expressing a moving velocity distribution of the moving matter

InactiveUS7345770B2Efficient measurementDiagnostics using lightInterferometersSignal lightIntensity modulation

Owner:KK TOPCON

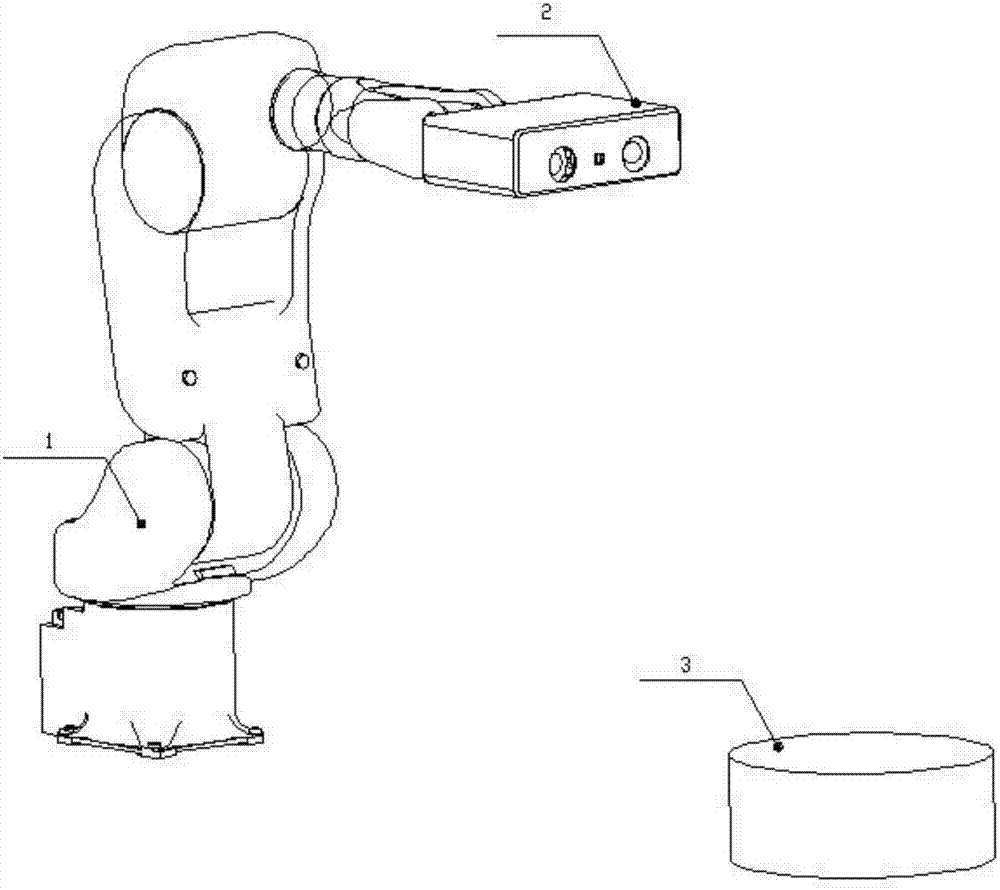

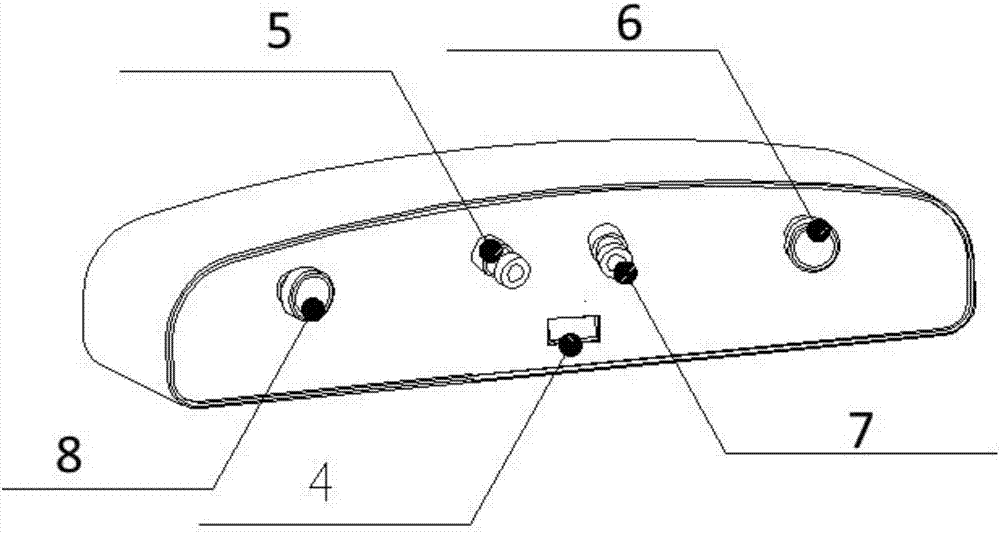

Robot automatic scanner and scanning method thereof

PendingCN107144236AOvercoming the defect of low precisionRealization of high-precision scanningUsing optical meansFast measurementPoint cloud

The present invention discloses a robot automatic scanner through combination of multi-scanning modes and a scanning method thereof. The device comprises a six-axis manipulator arm, an MEMS scanning galvanometer laser three-dimensional measuring head, and a rotary table; and the MEMS scanning galvanometer laser three-dimensional measuring head mainly comprises a remote scanning camera and a close-range scanning camera, and the scanning measuring head is installed at the tail end of the six-axis manipulator arm. The remote scanning camera is configured to perform rapid measurement of the surface of an object to obtain whole point cloud data of the object and perform scanning path planning of the point cloud data. The close-range scanning camera is configured to perform high-precision measurement of the surface of the object along the planned measurement path.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

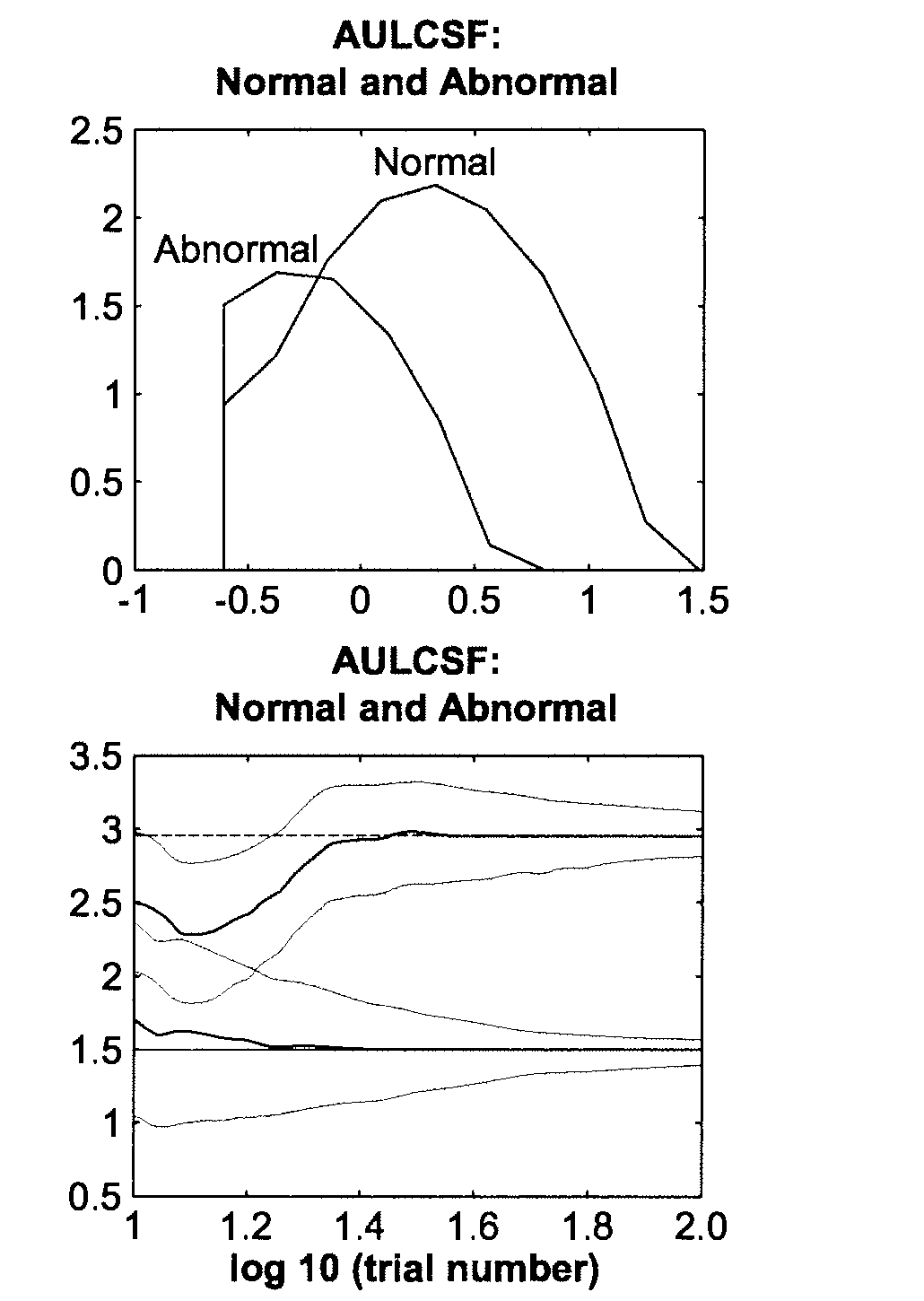

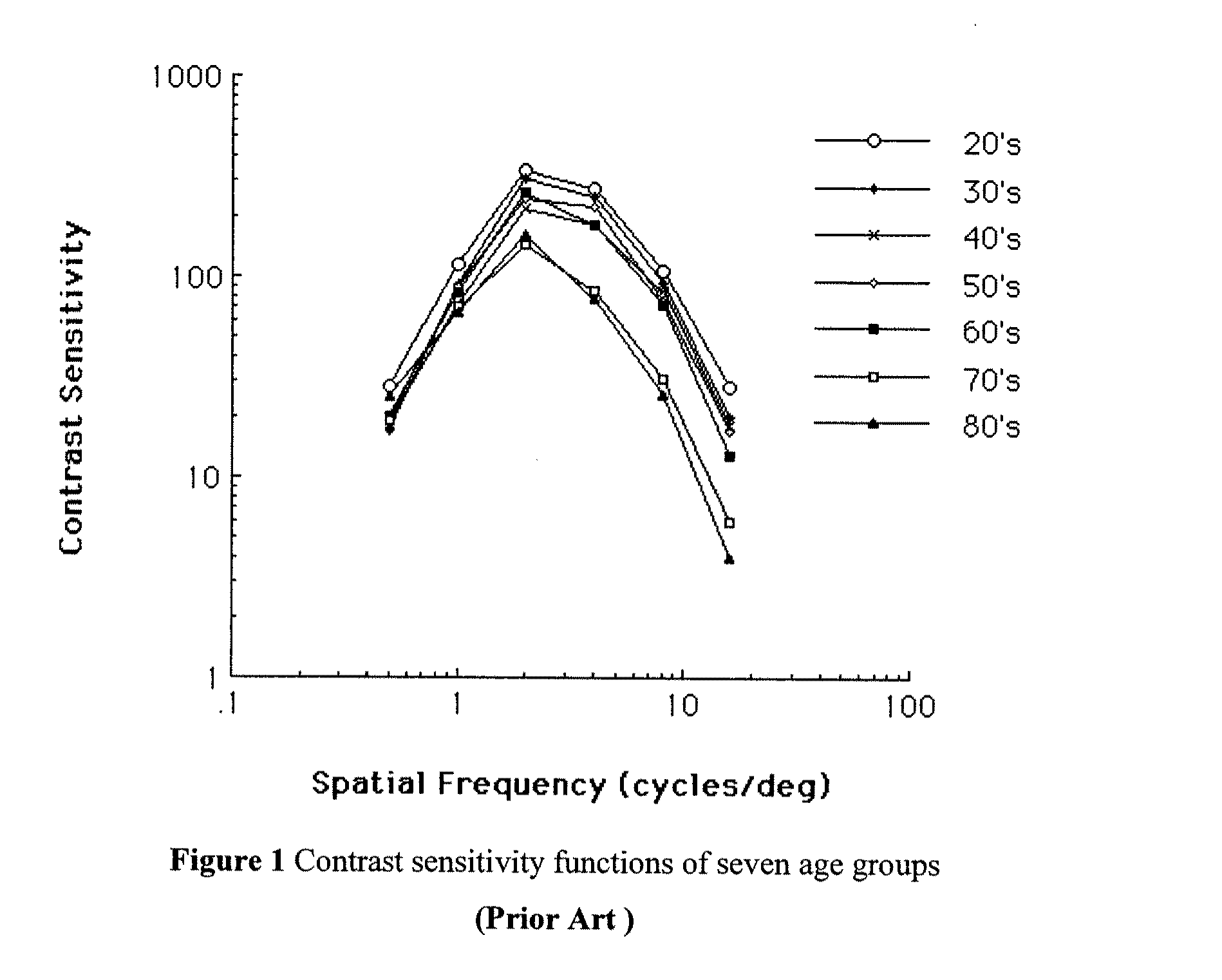

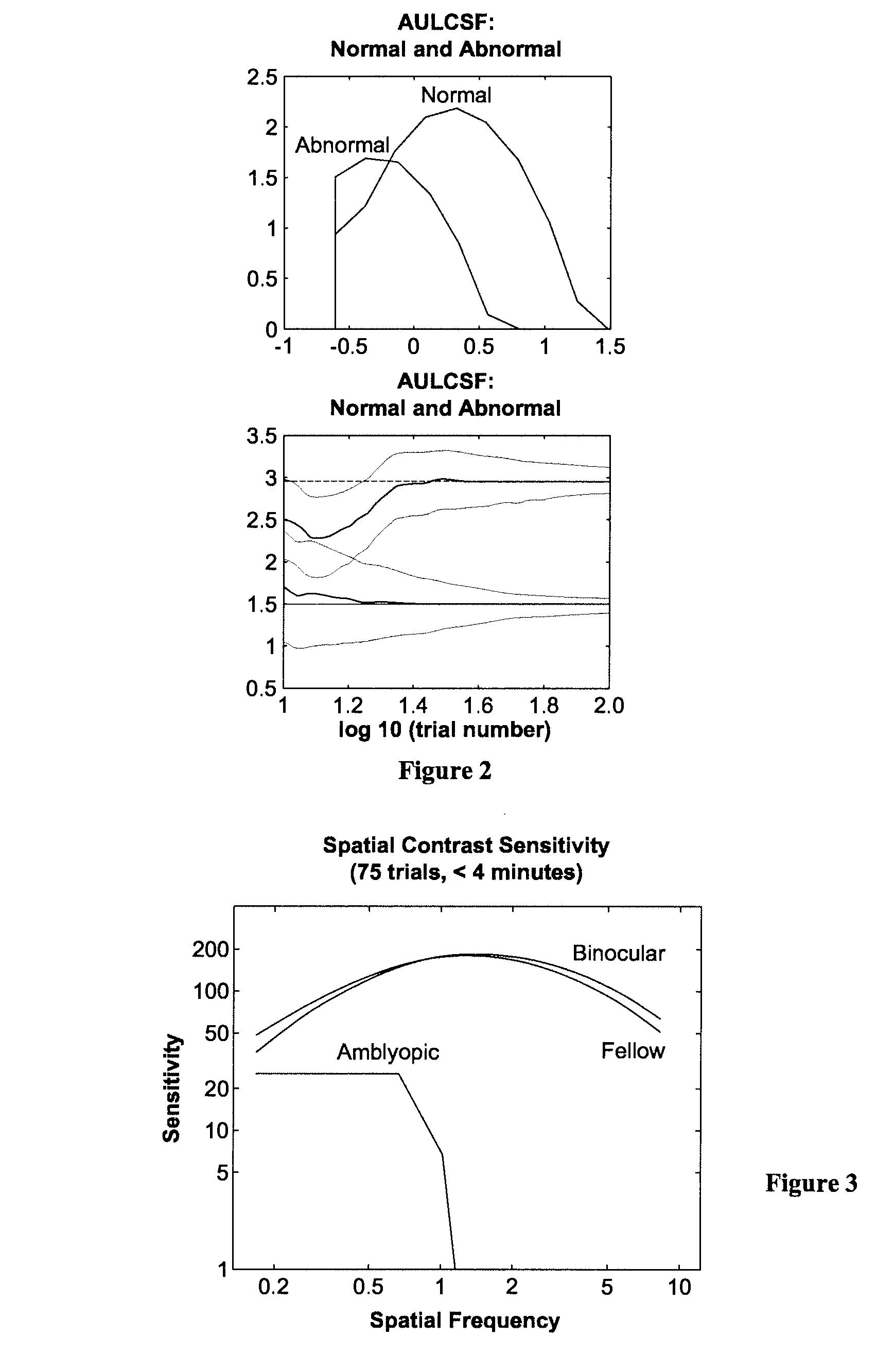

Methods and Devices for Rapid Measurement of Visual Sensitivity

ActiveUS20100007851A1Quick measurementMaximizes expected information gainPhoroptersFast measurementVisual sensitivity

Owner:UNIV OF SOUTHERN CALIFORNIA

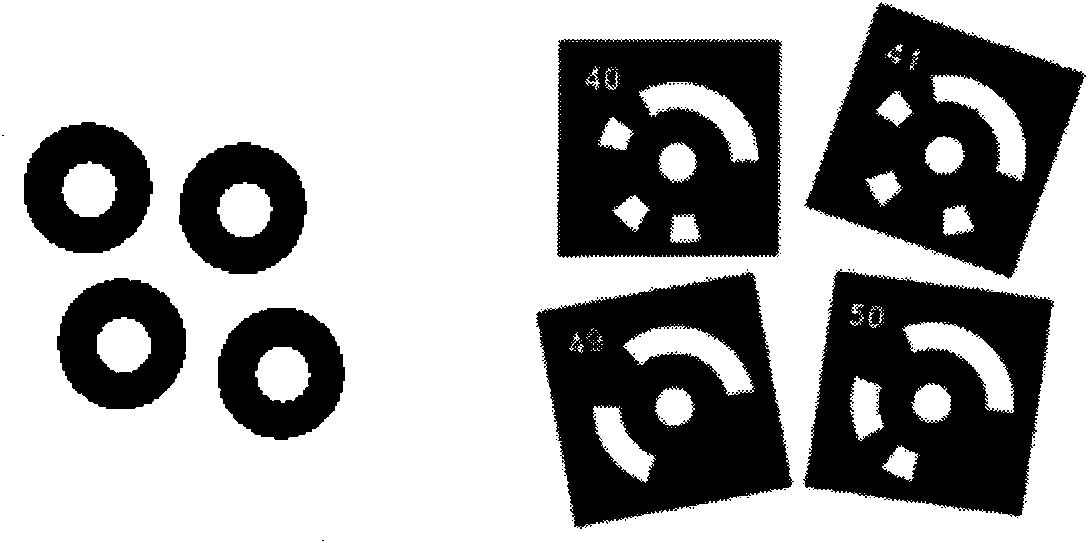

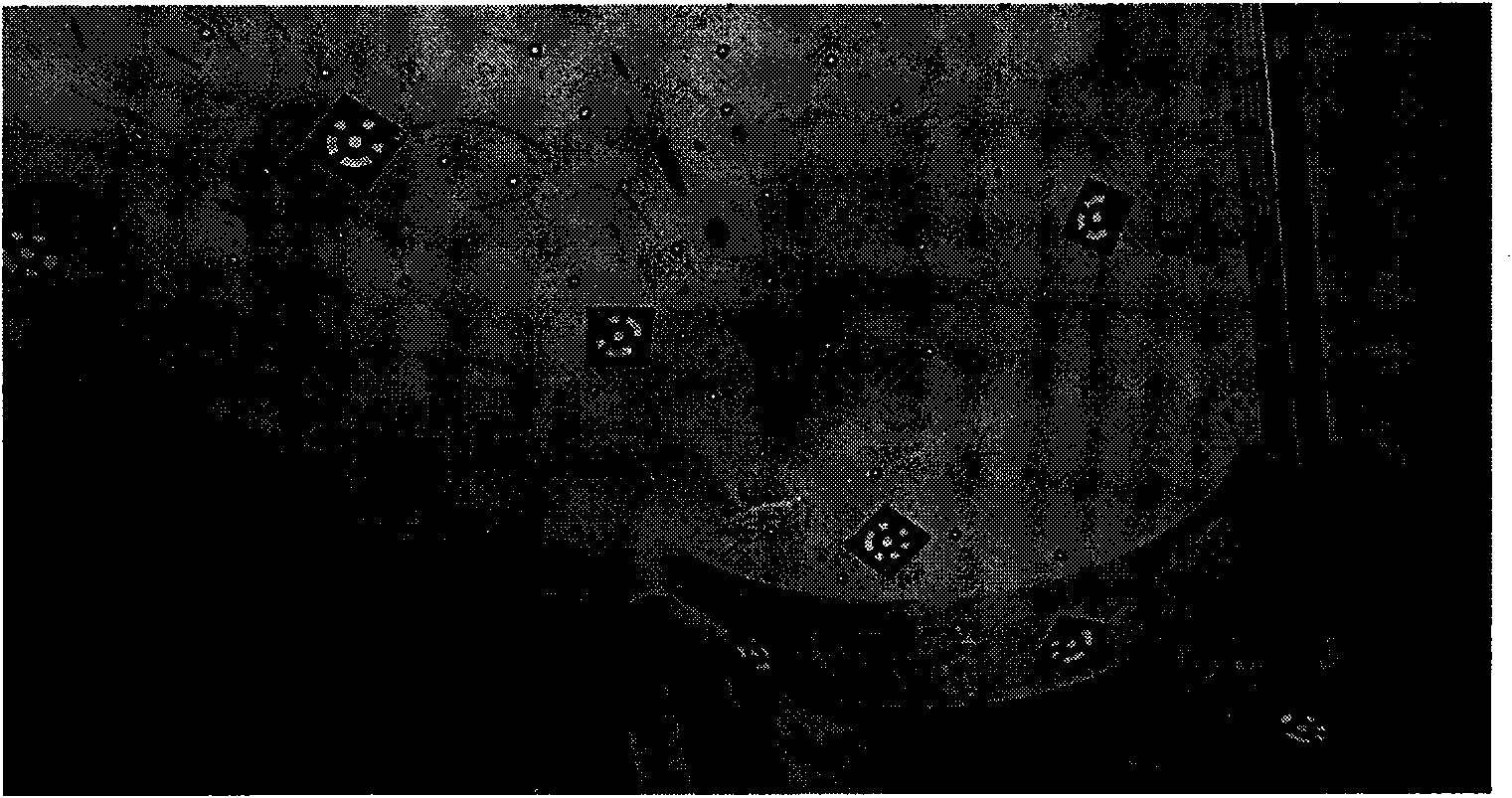

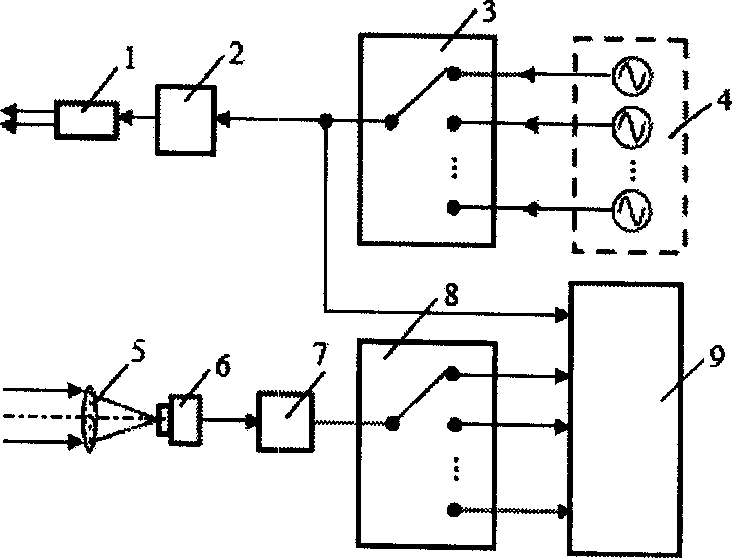

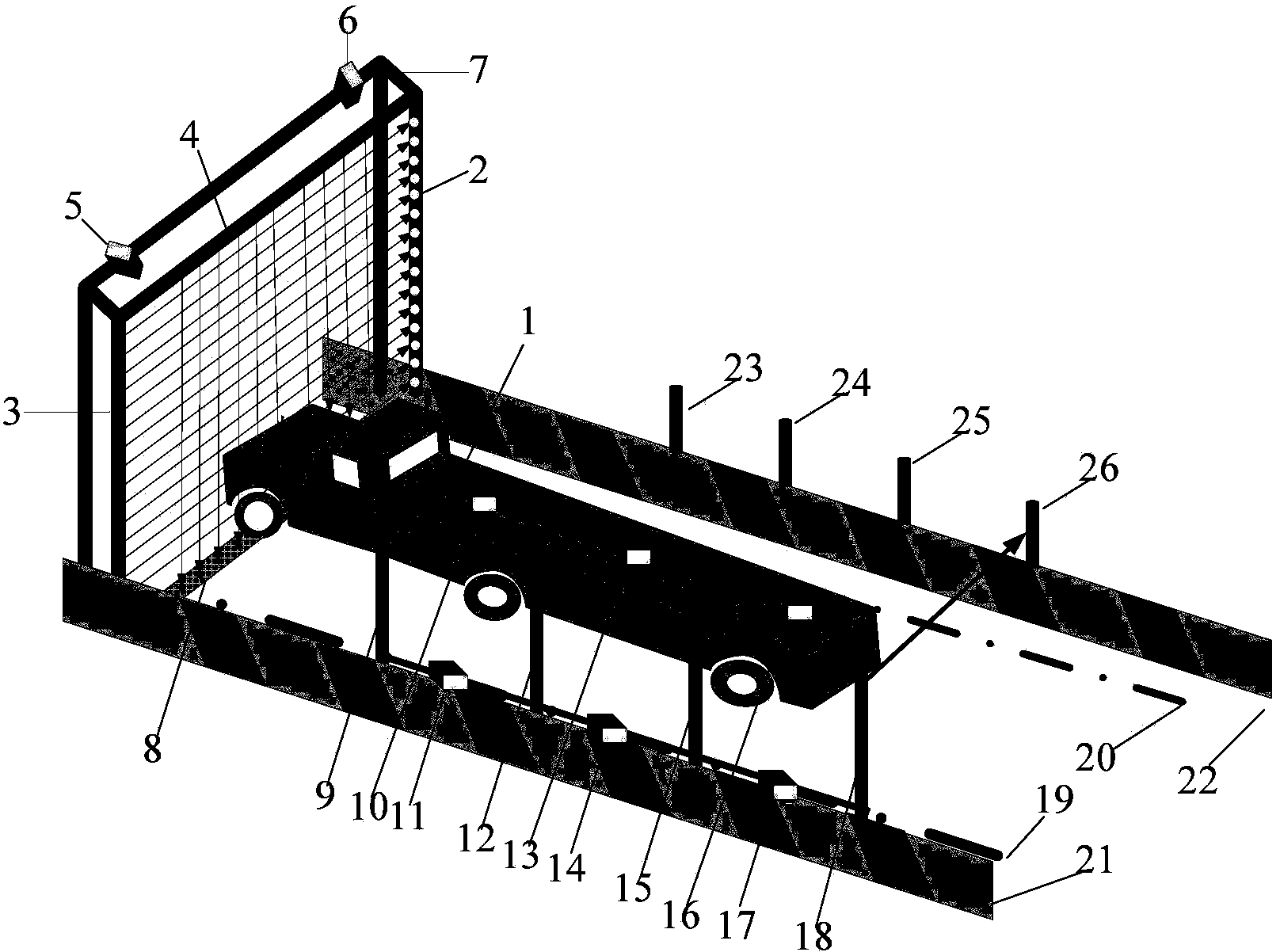

Method for rapidly measuring foundation pile control net (CPIII) of rapid transit railway

InactiveCN101914881AReduced measurement timeSimplify your measurement workSurveying instrumentsMeasuring apparatusFast measurementRelative precision

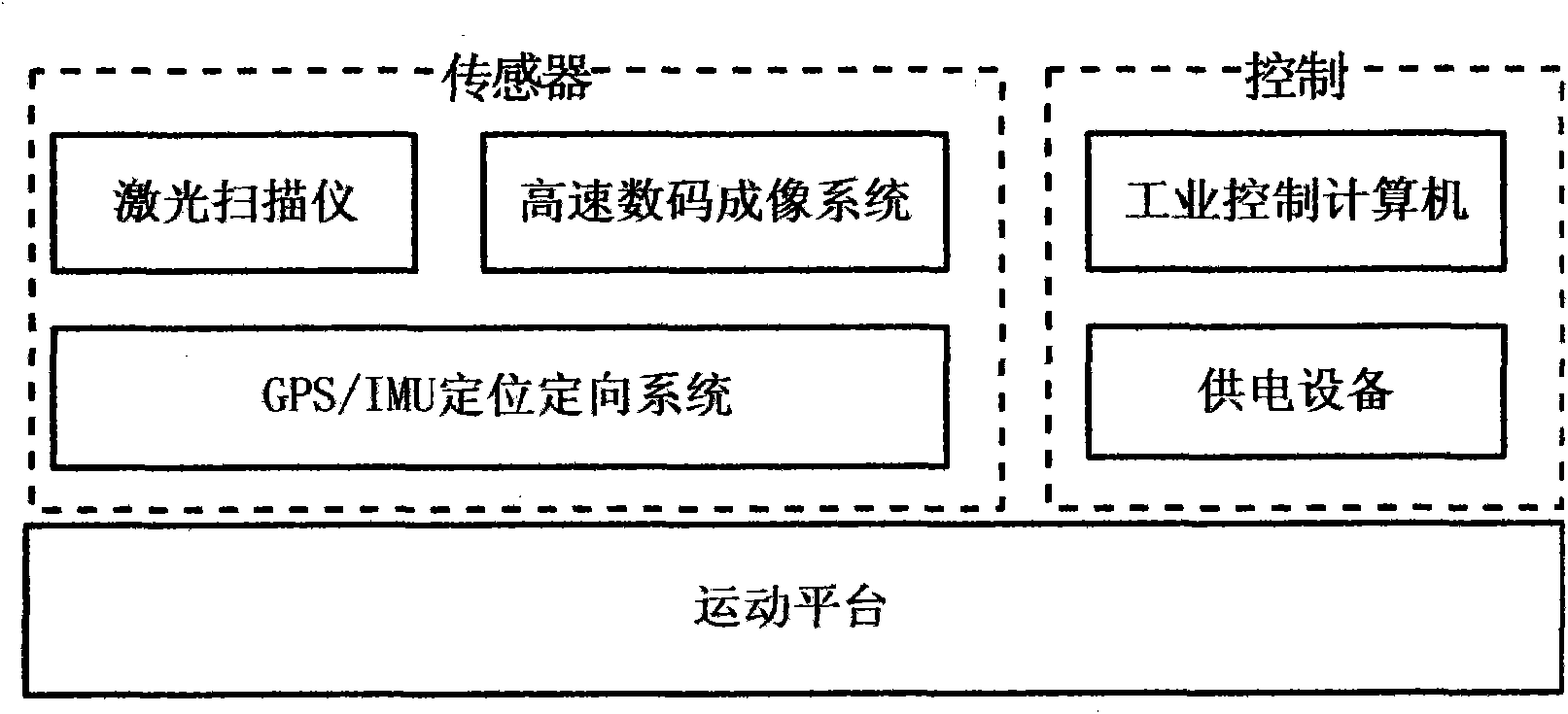

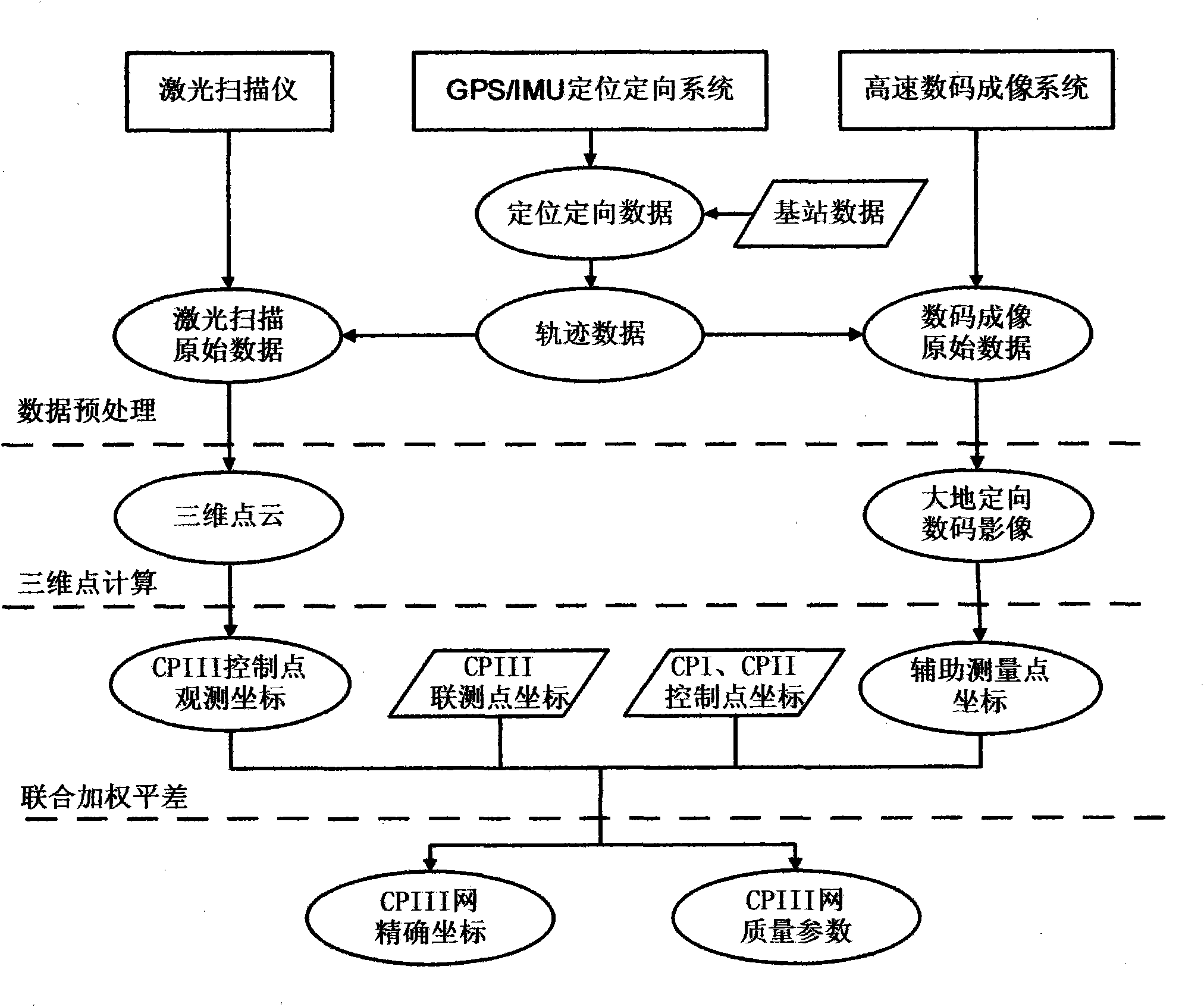

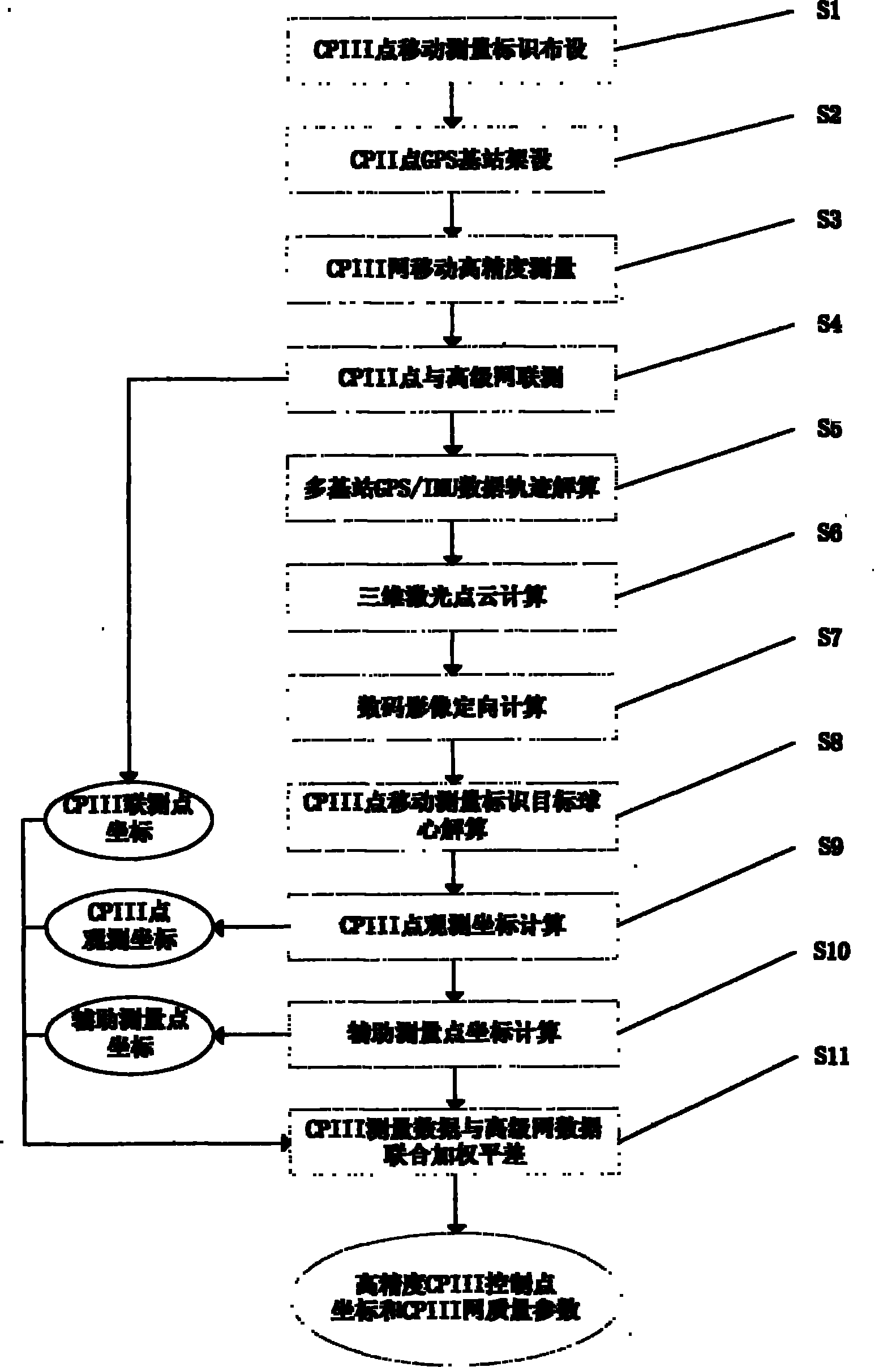

The invention relates to the field of precise engineering survey, in particular to a method for rapidly measuring a foundation pile control net (CPIII) of a rapid transit railway on the basis of movable laser radar measuring technology and high-speed digital imaging technology. control net (CPIII) measurement data is obtained by using a movable high-precision measurement system comprising a laser scanner (1), a GPS / IMU positioning and orientating system (2), a high-speed digital imaging system (3), an industrial computer (4) and a power supply device (5); and united weighted adjustment is carried out on advanced net data, united measured data and auxiliary measurement points extracted from images to obtain high-precision control net (CPIII) control point coordinates. The invention can greatly shorten the measurement time of the control net (CPIII), overcomes the defect of little total correlation of discrete single-point measurement, carries out integral adjustment on all control points, has good closing property and high relative precision, obtains plane and elevation coordinates of all control points, and greatly simplifies the measurement work of the control net (CPIII).

Owner:扬州德可达科技有限公司

Integrated Scanning and Ocular Tomography System and Method

InactiveUS20060206102A1Rapid measuring and monitoringSimple and efficientLaser surgeryInterferometersMeasurement deviceWavelength

Systems and methods of the present invention measure at least one reflecting surface of an object disposed along an optical path. In some embodiments a measured optical interference signal for each of at least three wavelengths of reflected light may be used to determine a modulation of frequency components of a Fourier series. Frequency components of a Fourier series may be transformed to spatial components that describe intensities and positions of light reflected along an optical path. Systems and methods of the present invention permit rapid measuring and may monitor corneal thickness during surgery. The invention may do so by integrating an ablation device and a measurement apparatus into a single system. An integrated scanning and monitoring system may include an ablative light source producing an ablative beam and a measurement light source producing a measurement beam.

Owner:AMO MFG USA INC

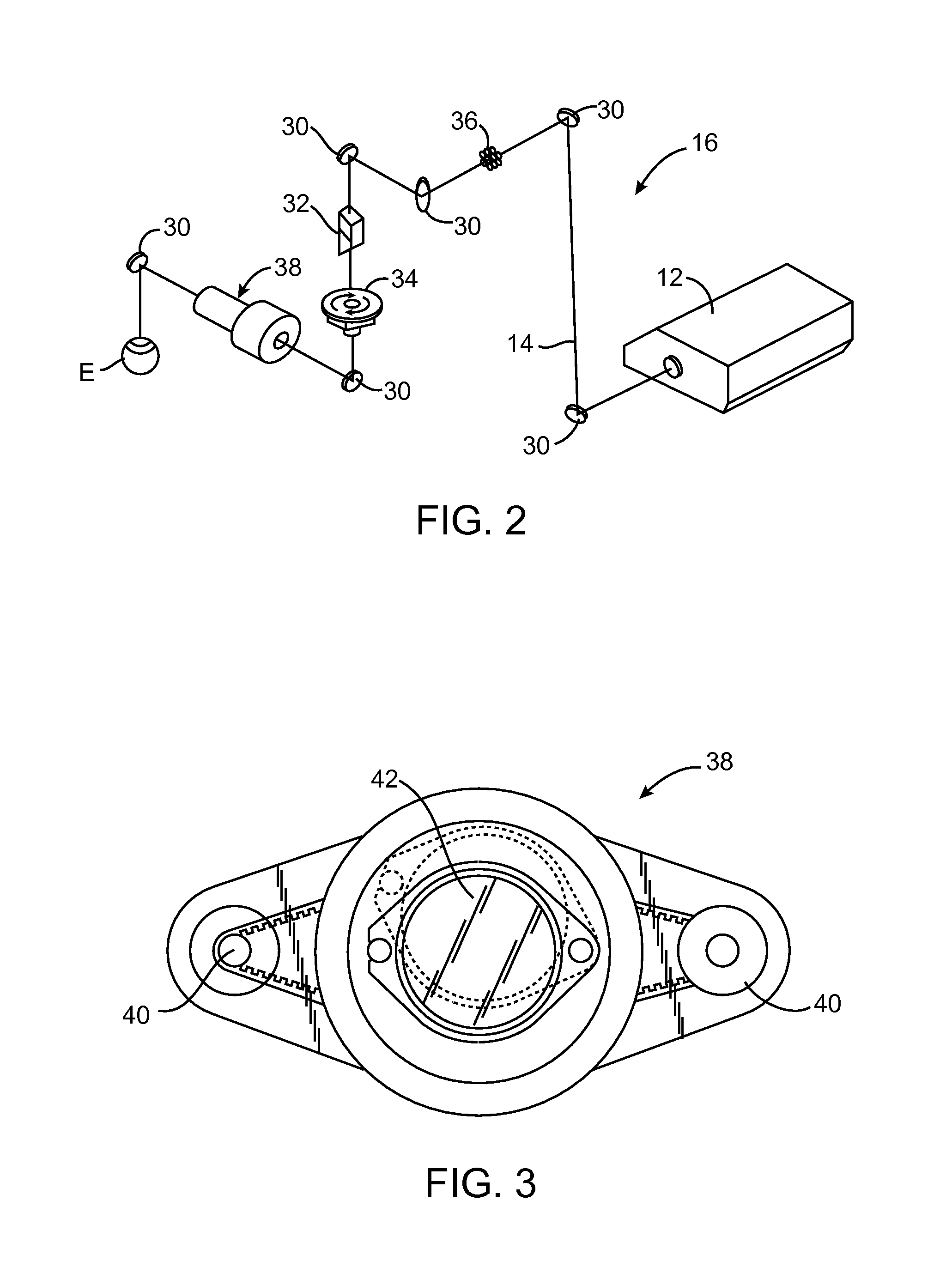

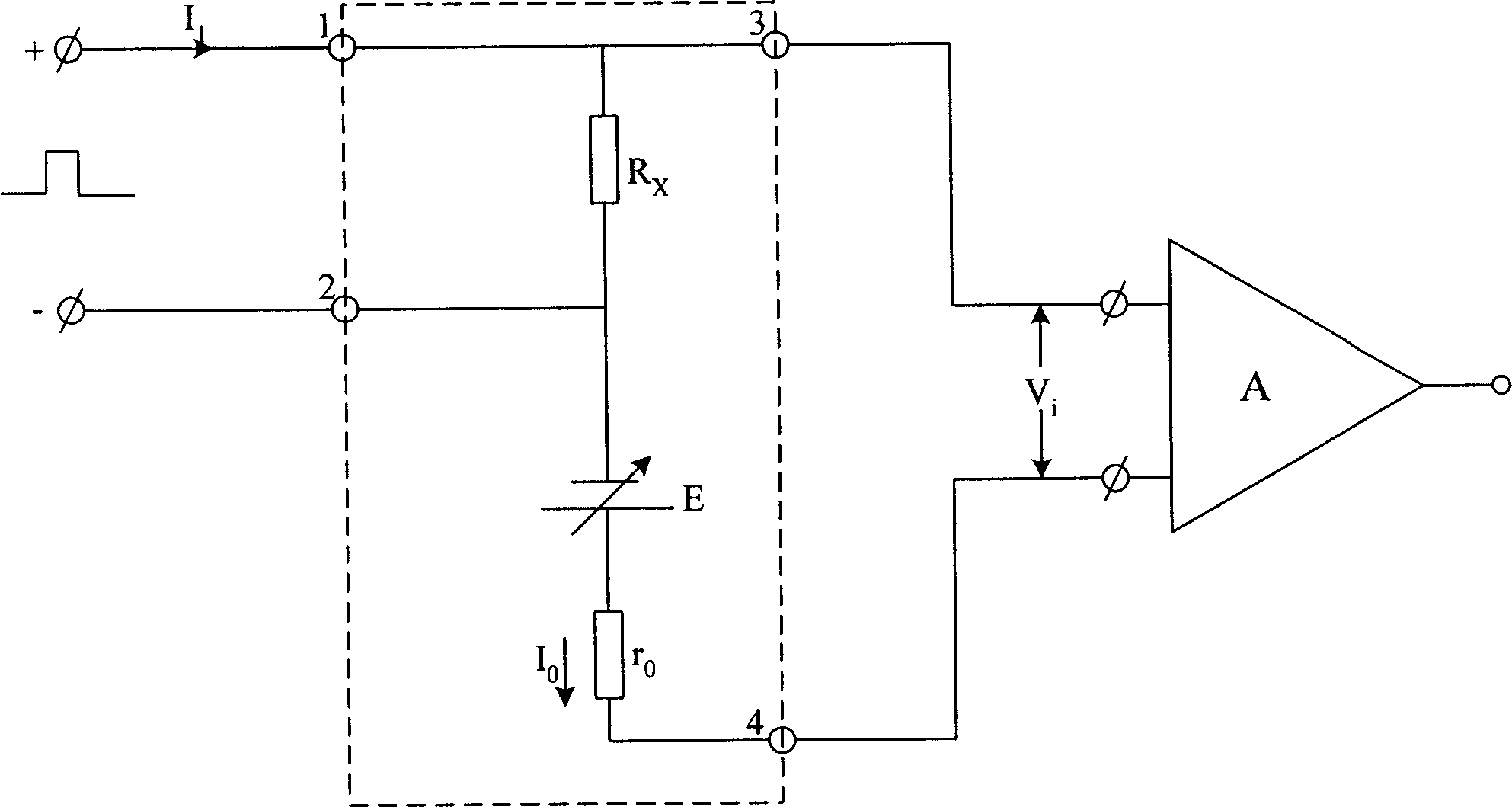

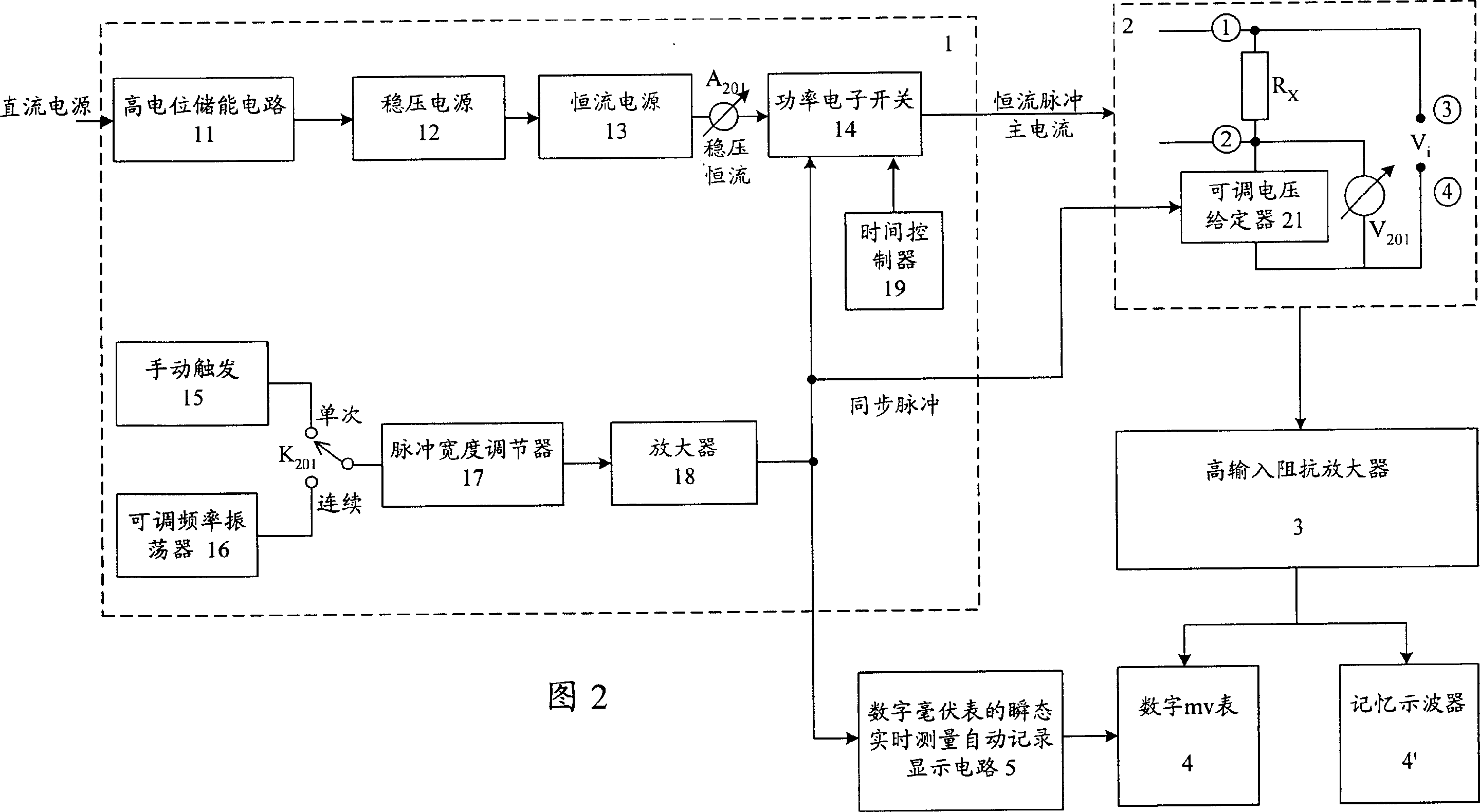

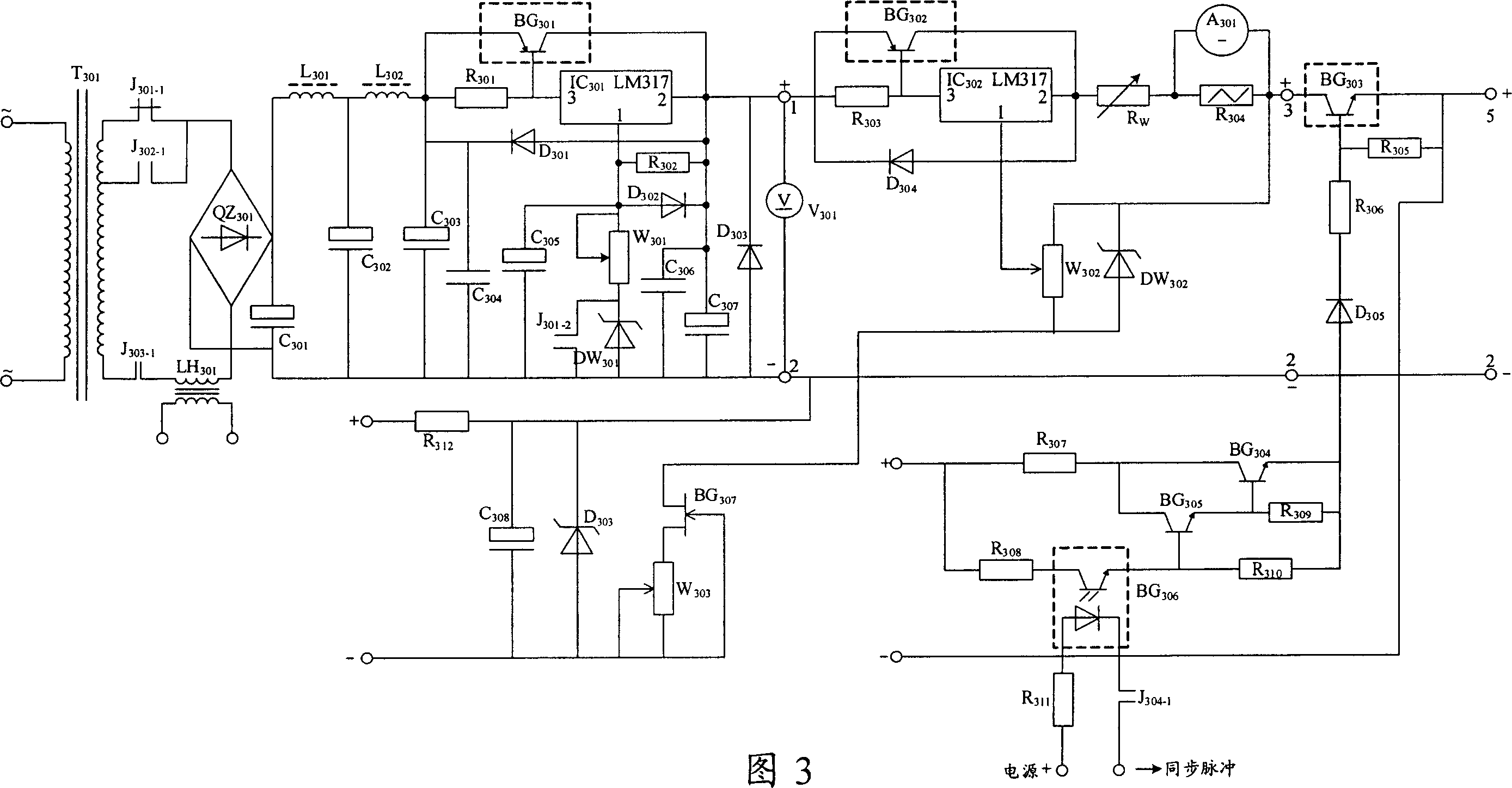

Method and device for detecting resistance

InactiveCN1749763APrecise processResistance/reactance/impedenceElectrical resistance and conductanceMeasurement device

The resistance measuring method and device is especially suitable for quickly measuring small resistance and varying resistance according with Ohmí»s law. The resistance measuring device includes constant-current pulse source, four-end network containing the measured resistance, high input impedance amplifier, real-time measuring and automatic recording display circuit for voltmeter, and digital millivoltmeter. It measures resistance through generating constant-current pulse, producing voltage drop on the measured resistance, amplifying the voltage drop, automatic conversion between reading state and holding memory state and recording and displaying voltage drop. During measuring resistance change, given voltage synchronous with the constant-current pulse is added into the four-end network, and the varying voltage drop the constant-current pulse produces on the measured resistance is measured by means of potential approaching method and further differential method.

Owner:UNIV OF SCI & TECH BEIJING

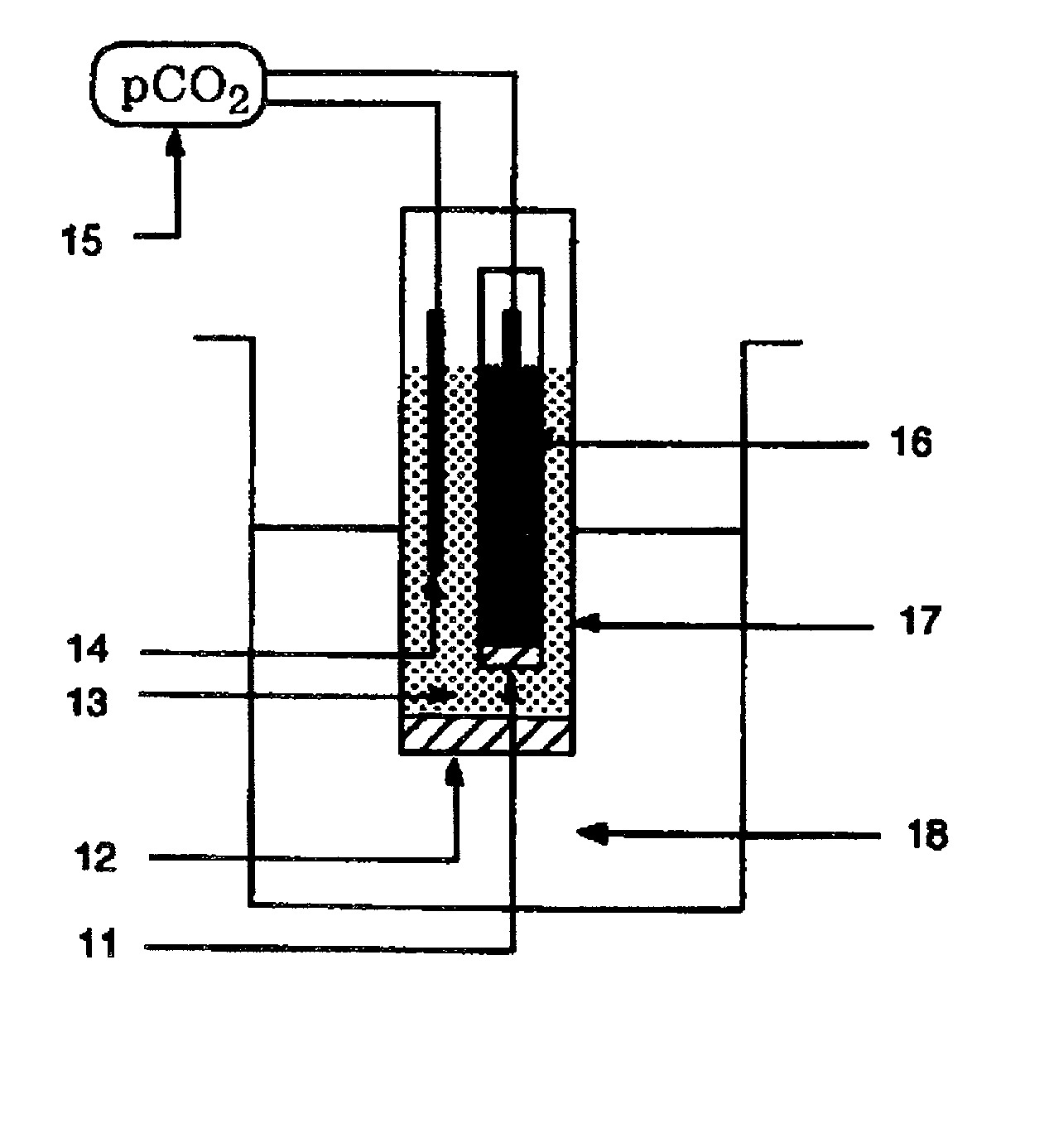

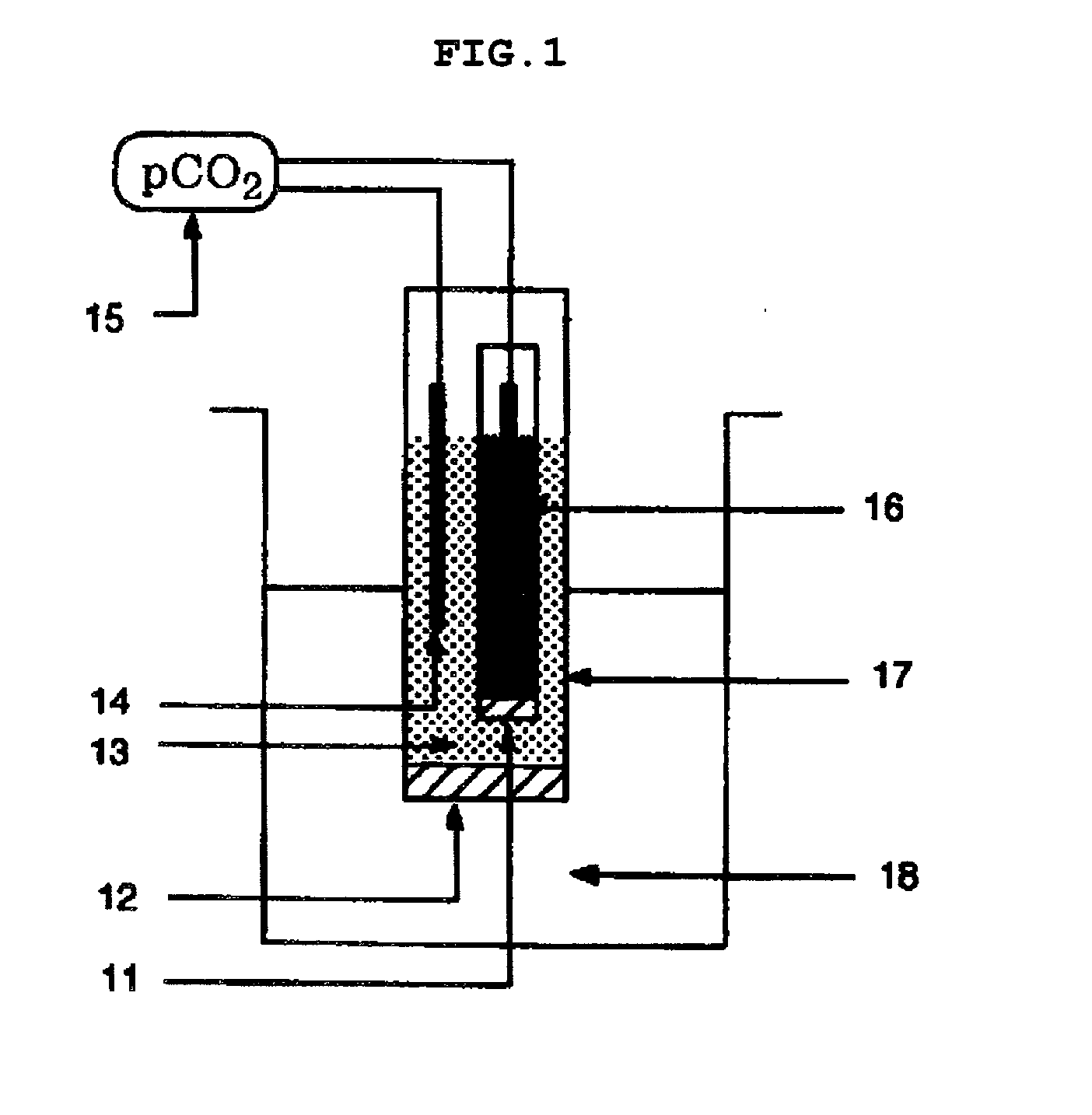

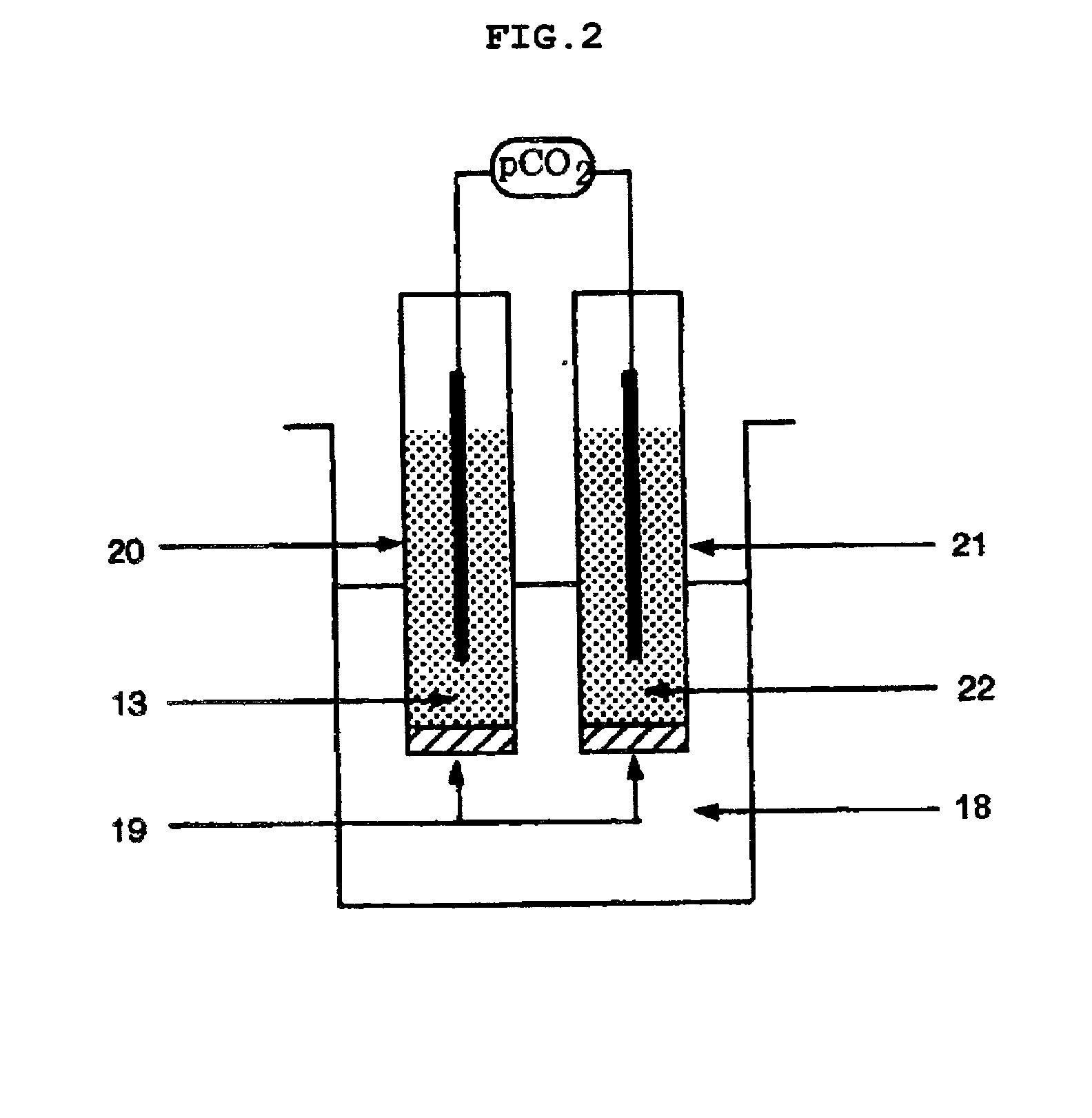

Microchip-based carbon dioxide gas sensor

InactiveUS20020011408A1Facilitate the micro-fabrication of potentiometric carbon dioxide electrodesReduced measurement timeImmobilised enzymesBioreactor/fermenter combinationsSodium bicarbonateFast measurement

There is provided a microchip-based differential-type carbon dioxide gas sensor for detecting dissolved carbon dioxide levels. It functions with at least one working electrode composed of an unbuffered hydrogel membrane containing a certain amount of sodium bicarbonate and a pH-sensitive gas-permeable membrane; and a reference electrode composed of a buffered hydrogel membrane and a pH-sensitive gas-permeable membrane. The unbuffered hydrogel membrane contains carbonic anhydrase, which reduces the time period for the hydration of carbon dioxide, thereby allowing the quick measurement of the level of carbon dioxide. In addition to being significantly improved in stabilization, sensing, and recovering time periods, the differential-type carbon dioxide gas sensor can be fabricated in small sizes and quickly measure levels of carbon dioxide dissolved in sample solution.

Owner:I SENS INC

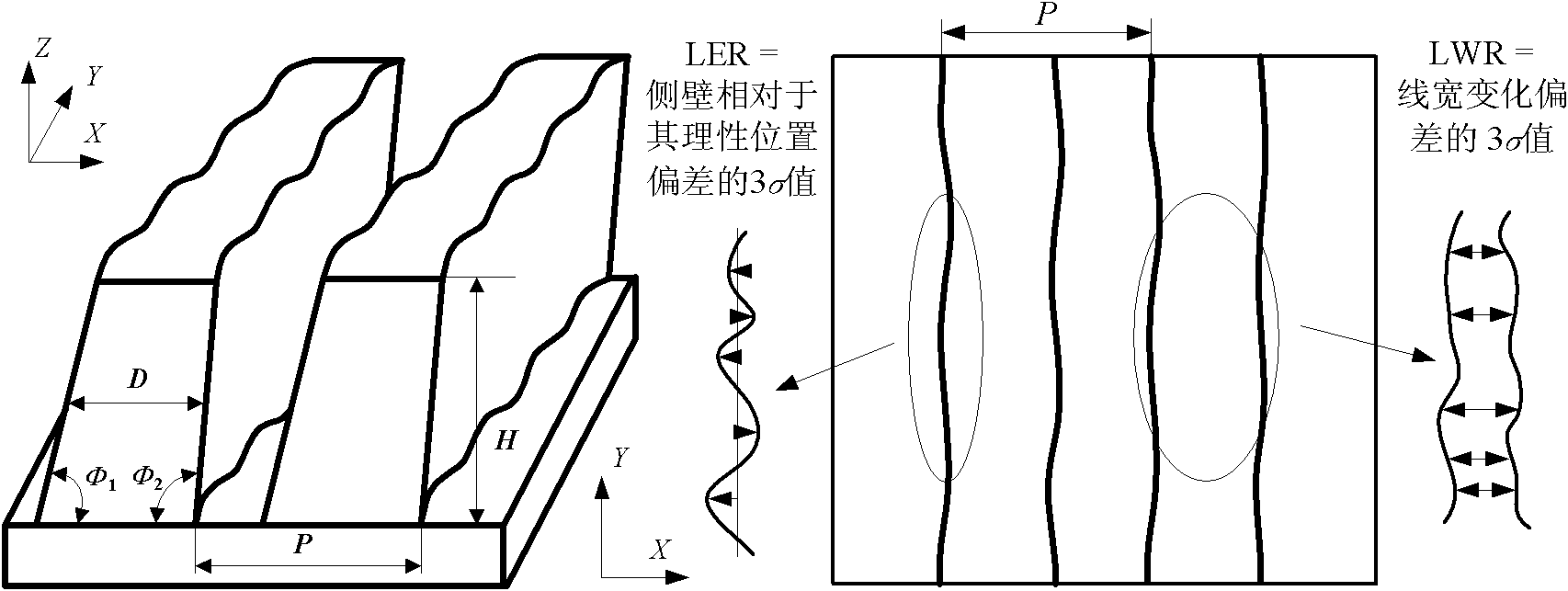

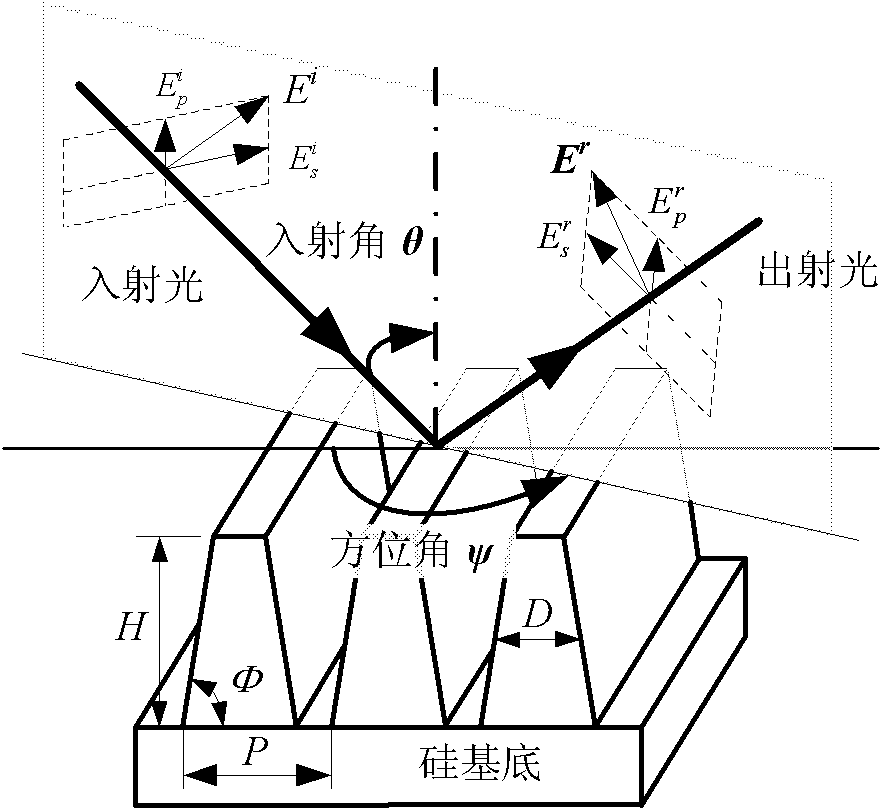

Method and device for measuring three-dimensional topography of nano structure

ActiveCN101881599AMeet measurement needsHigh spectral sensitivityUsing optical meansEtchingImage transfer

The invention discloses a method and a device thereof for measuring three-dimensional topography of a nano structure, which can simultaneously measure three-dimensional topography parameters such as line width, depth, side corner, line edge roughness, line width roughness and the like of the nano structure. The method comprises the following steps of: performing splitting, polarization and front and back phase compensation on light beams with wavelengths in ultraviolet to near-infrared wave band to obtain elliptical polarized light and projecting the elliptical polarized light for later measurement; acquiring surface reflected zero-level diffraction signals of the to-be-measured structure, and obtaining a measurement Mueller matrix of the nano structure by calculation; and matching the measurement Mueller matrix and a theoretical Mueller matrix, and obtaining a three-dimensional topography parameter value of the to-be-measured nano-scale structure. The device provided by the invention for measuring the three-dimensional topography parameter of the nano structure can provide a non-contact, nondestructive, low-cost and quick measurement means for one-dimensional and two-dimensional sub-wavelength periodic structures in processes of photo-etching, nano impressing and the like of an image transfer-based batch manufacturing method.

Owner:WUHAN EOPTICS TECH CO LTD

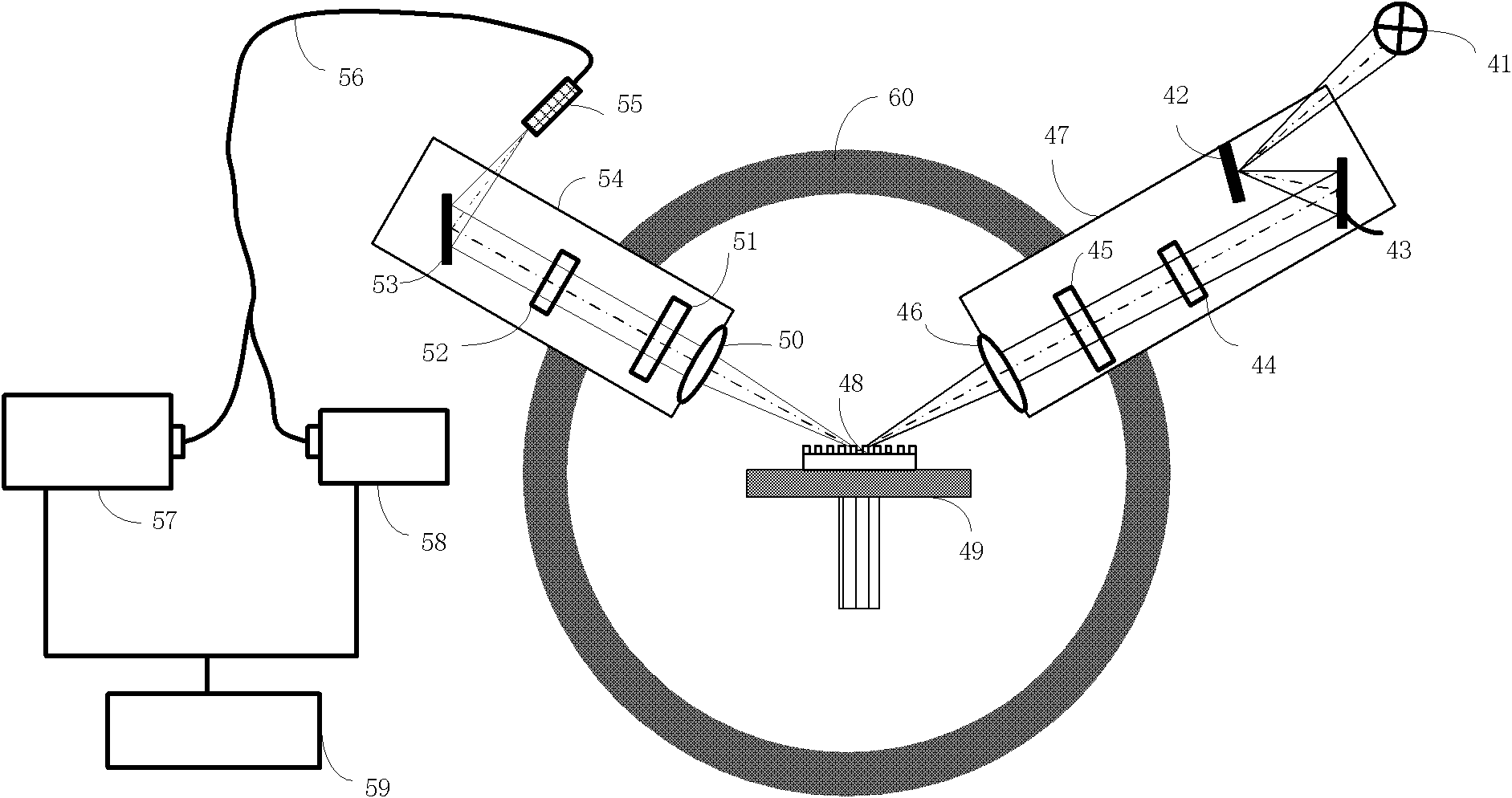

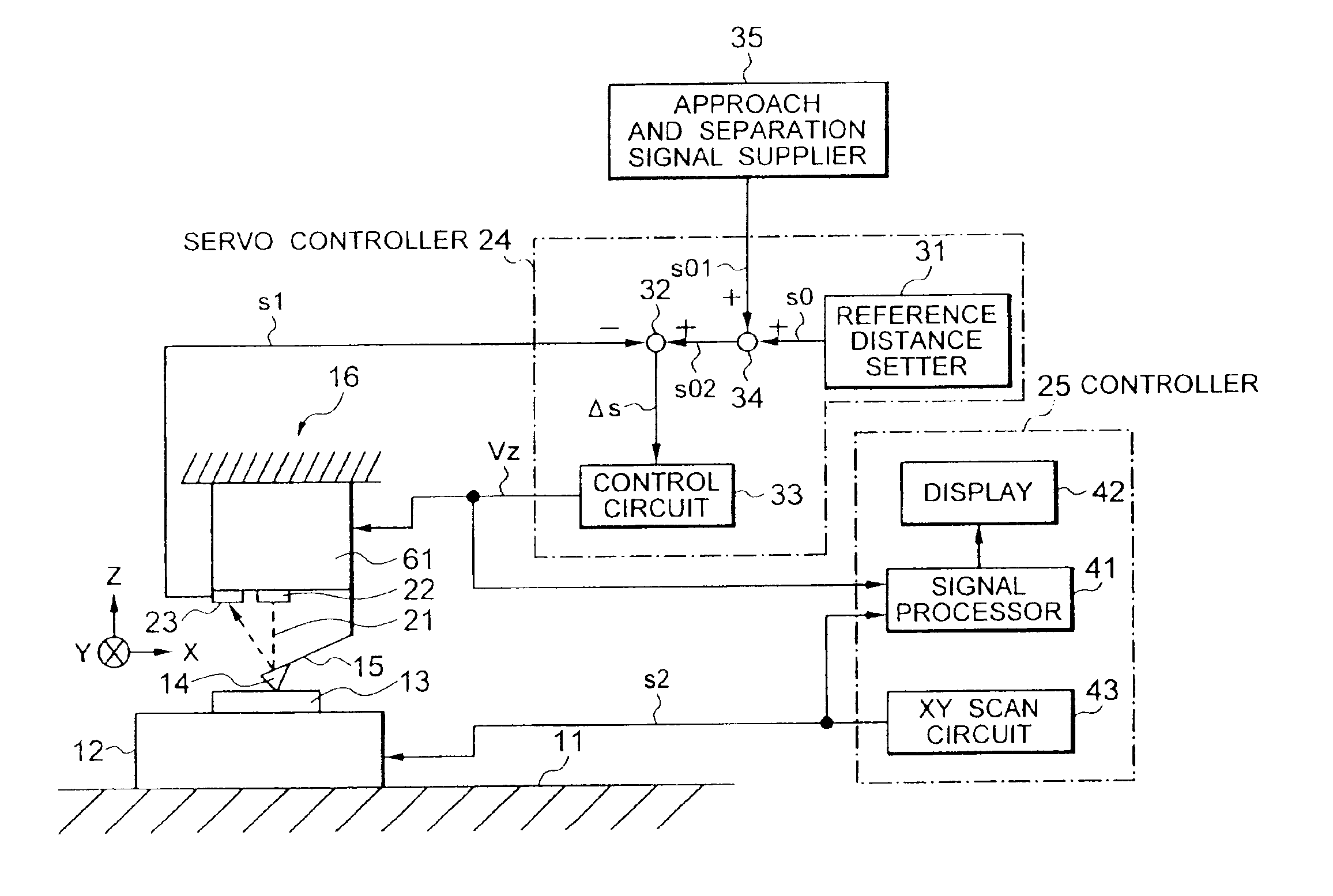

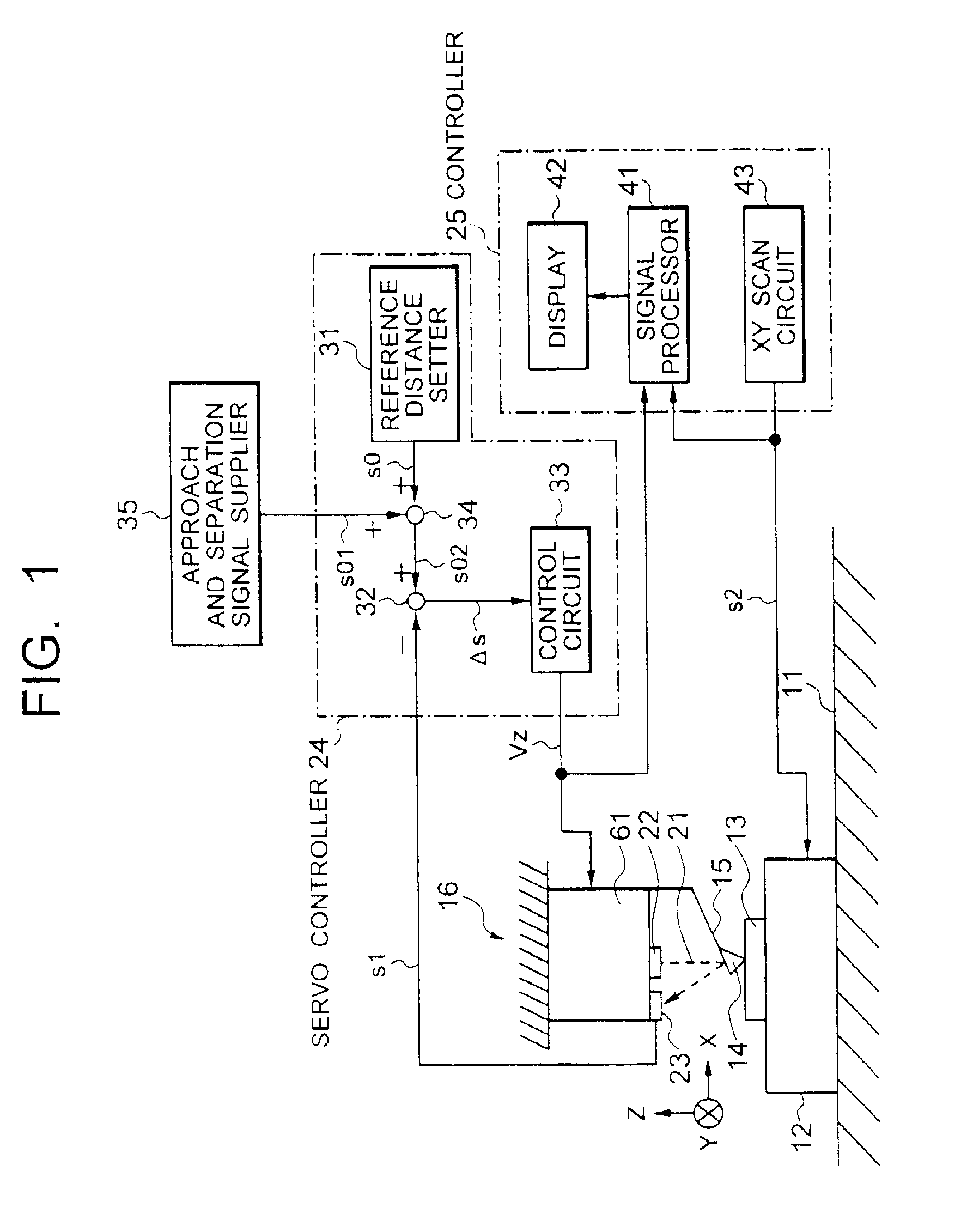

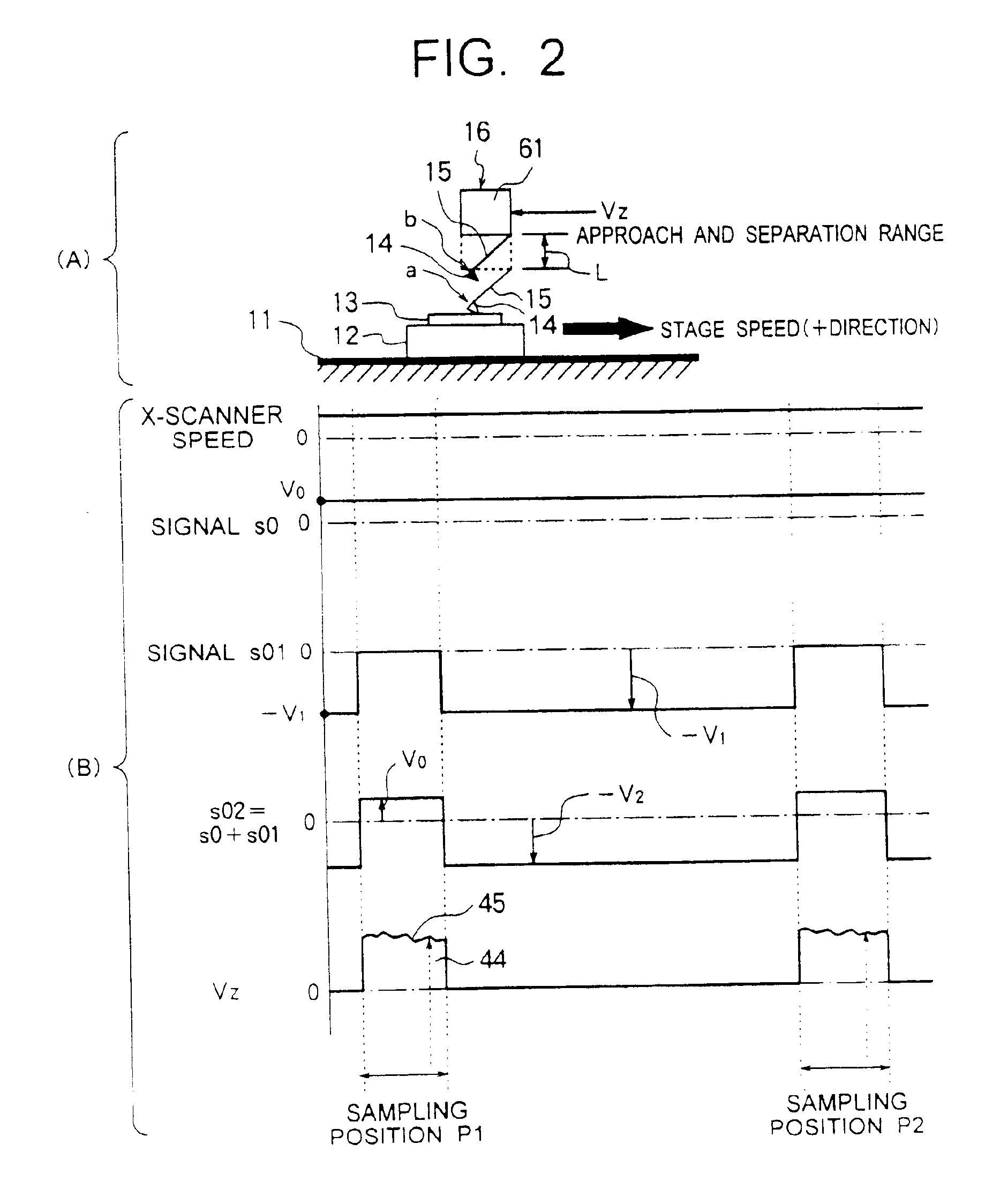

Scanning probe microscope and method of measurement

InactiveUS6881954B1Easy to controlShort timeNanotechMaterial analysis using wave/particle radiationFast measurementScanning Hall probe microscope

A scanning probe microscope has an XY scanner for making a probe scan a sample surface, an approach and separate drive element for making the probe approach to the sample surface at a sampling position and separate the probe from the sample surface during movement between the sampling positions, and a servo controller for holding the distance between the probe and the sample surface at a reference distance during measurement at the sampling position. A plurality of scattered measurement locations are set away from each other as sampling positions. The approach and separation movements are performed at each sampling position. When measuring the surface by the probe at a sampling position and while making the probe move between sampling positions, servo control by the servo controller is continued. This makes it possible to quickly measure the surface by a simple controller and possible to measure a wide area or measure a high aspect ratio. When making the probe approach to the sample surface for measurement at the sampling position, it is also possible to cause a scan motion for tandem movement at an equal speed and in the same direction as the scan motion by the XY scanner.

Owner:NIHON KENKI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com