Patents

Literature

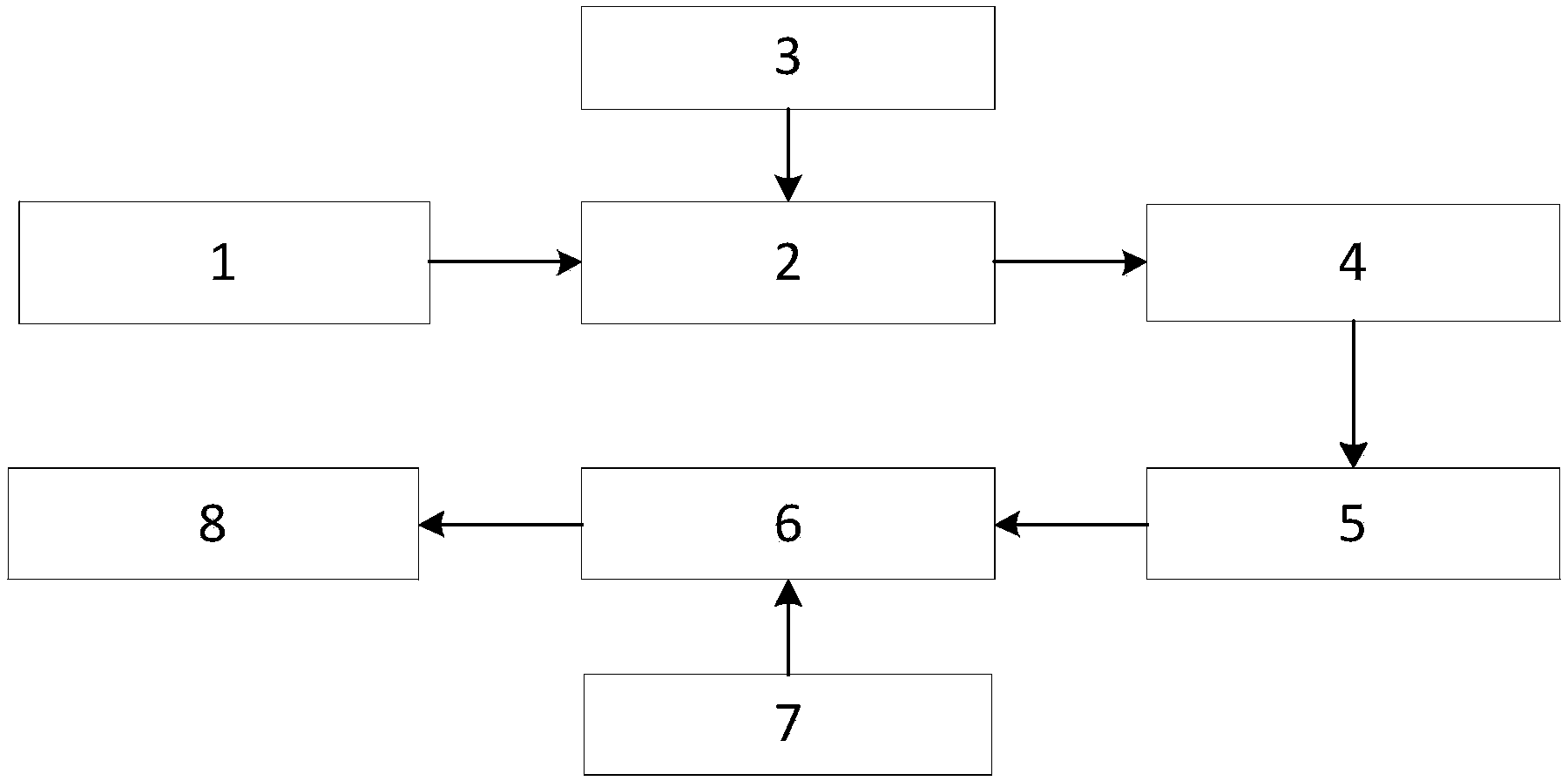

547 results about "Scale structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-interface enhanced reactor bubble scale structure-activity regulation and control model building method

ActiveCN107563051AReduce mistakesImprove versatilitySpecial data processing applicationsActivity regulationScale structure

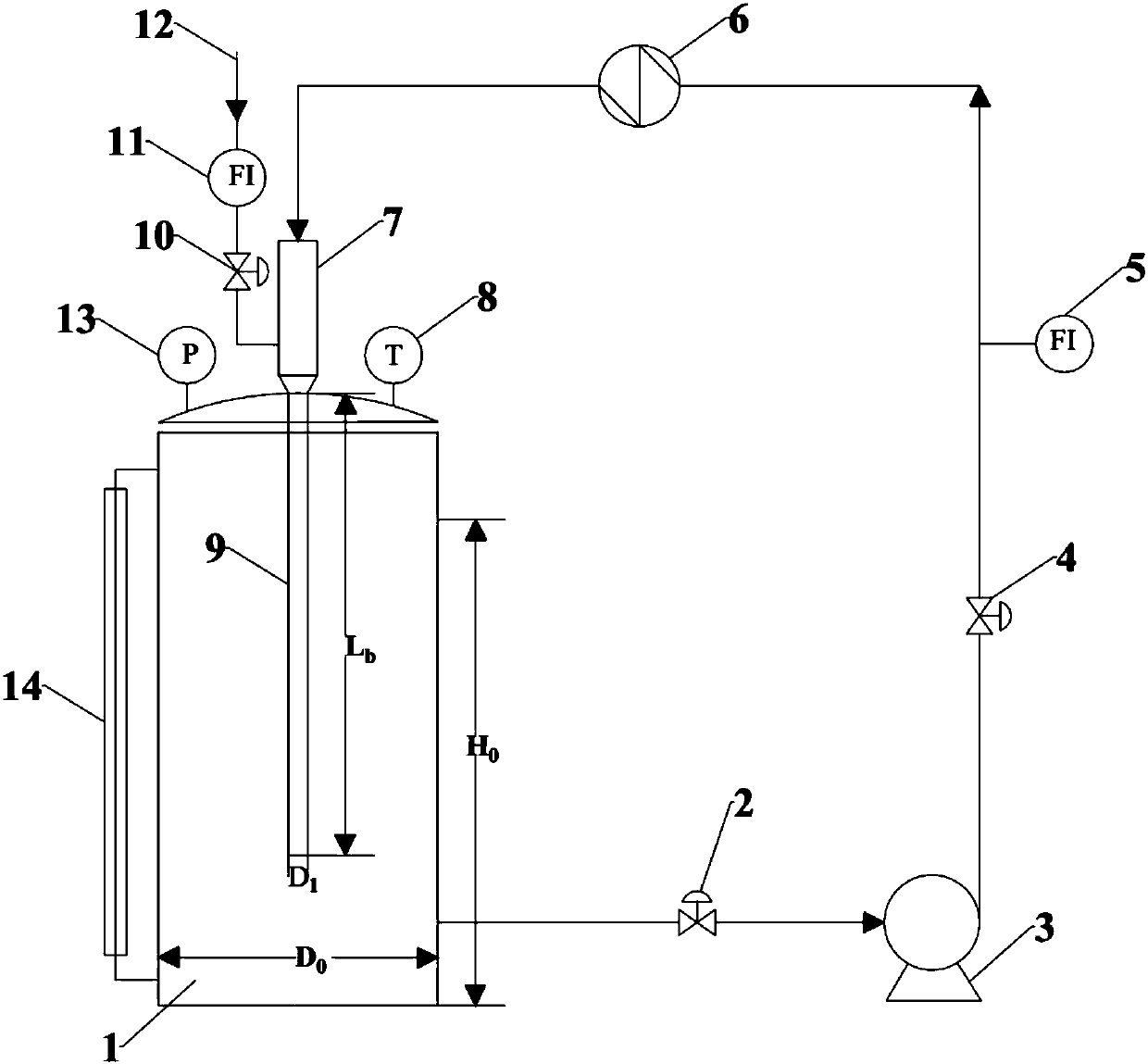

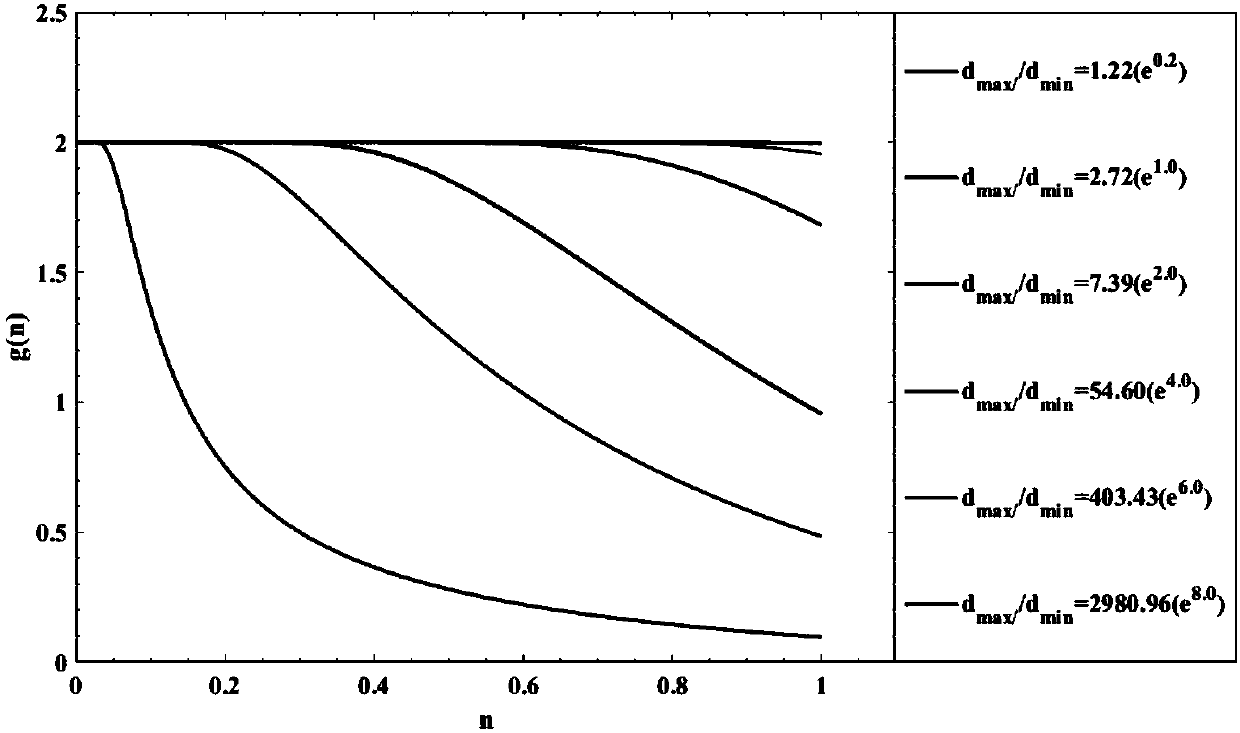

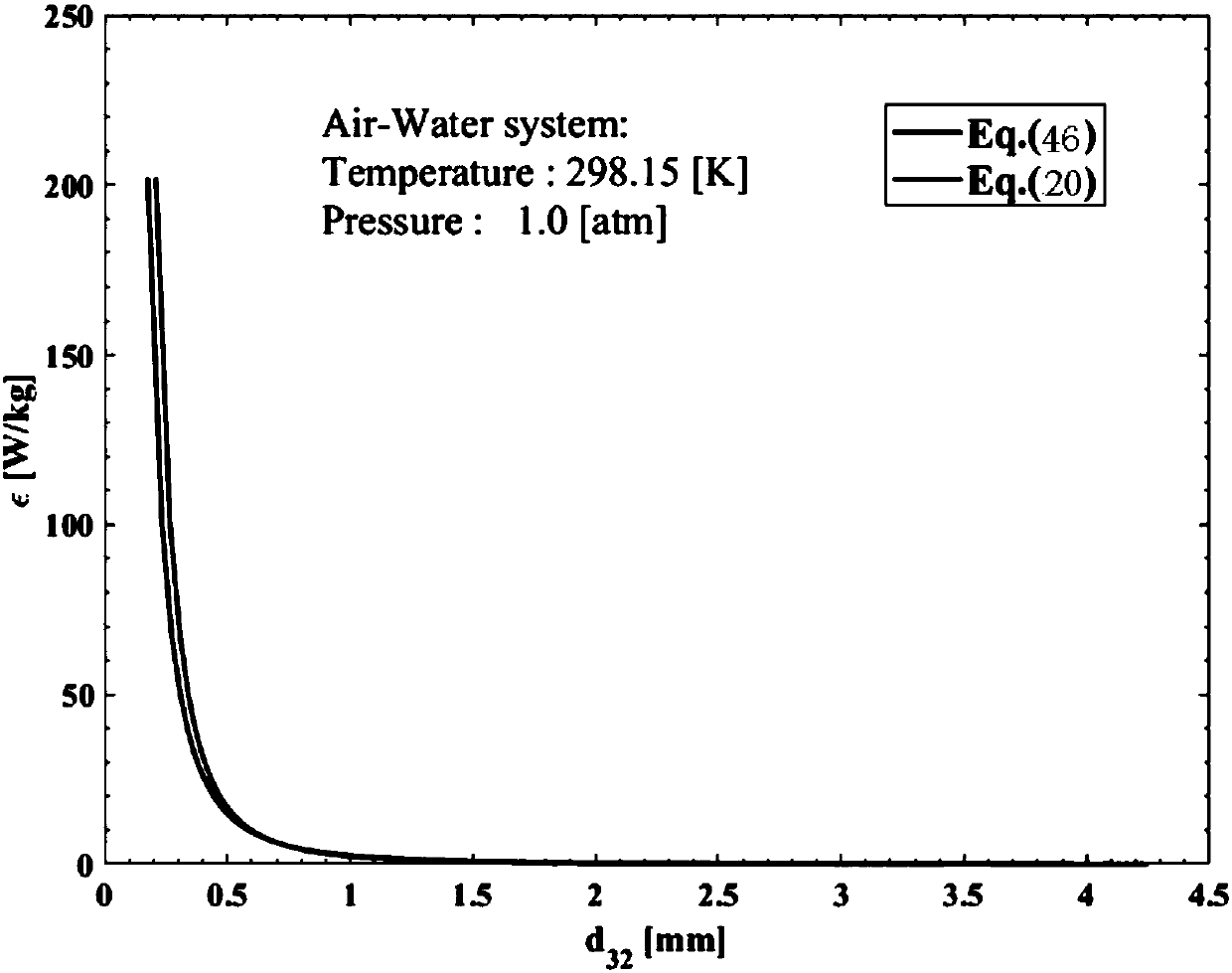

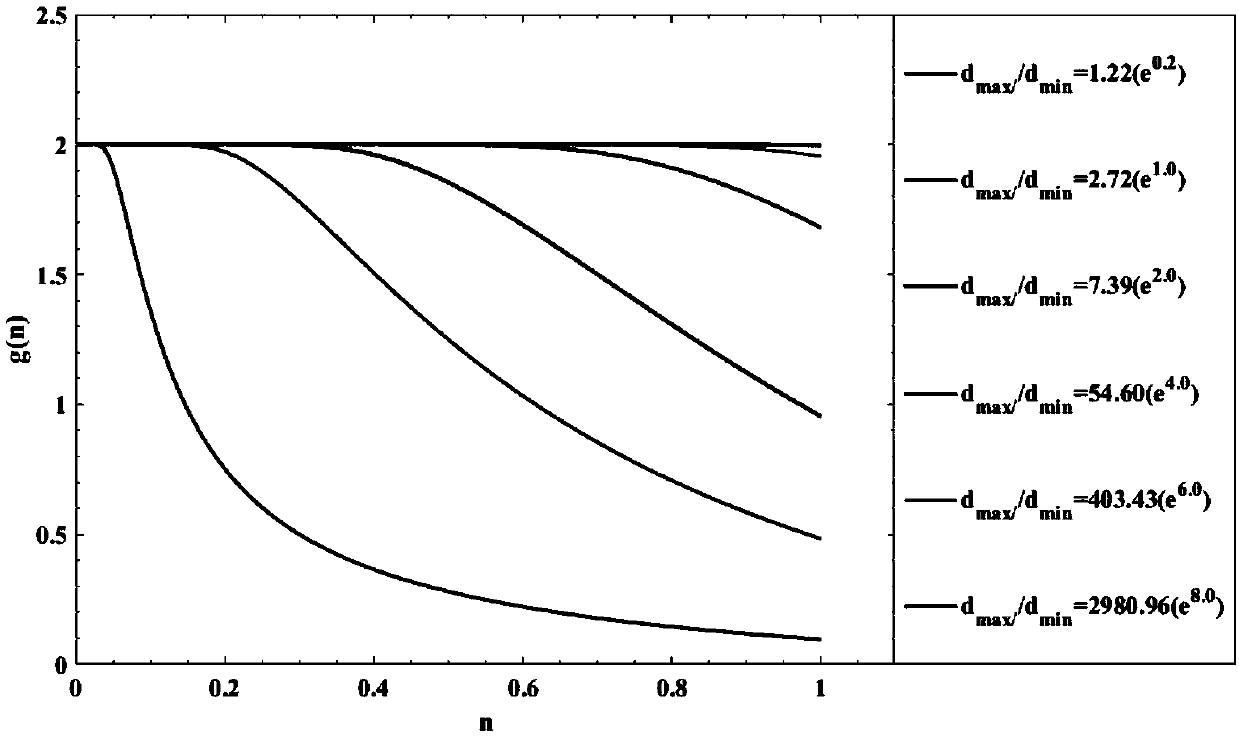

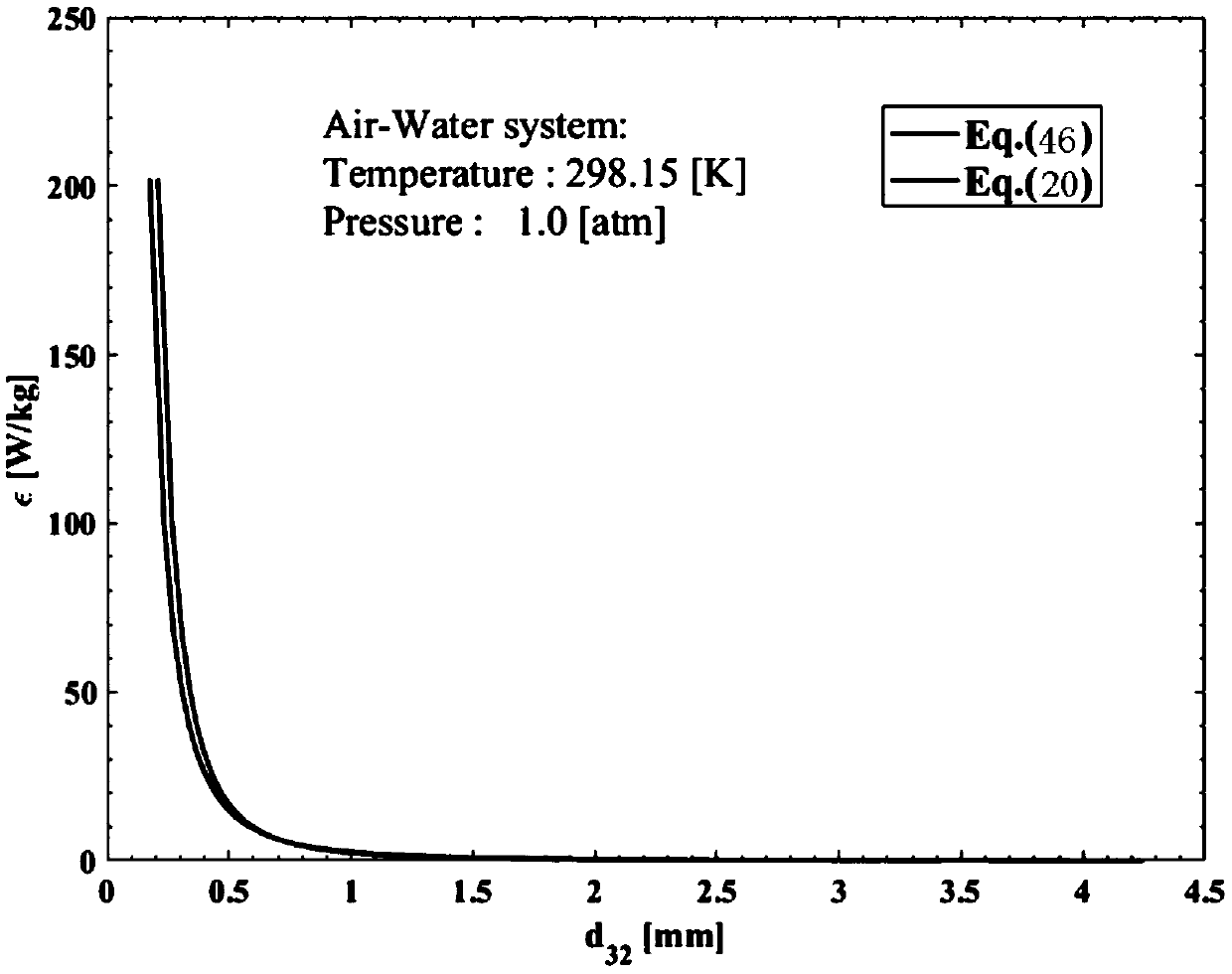

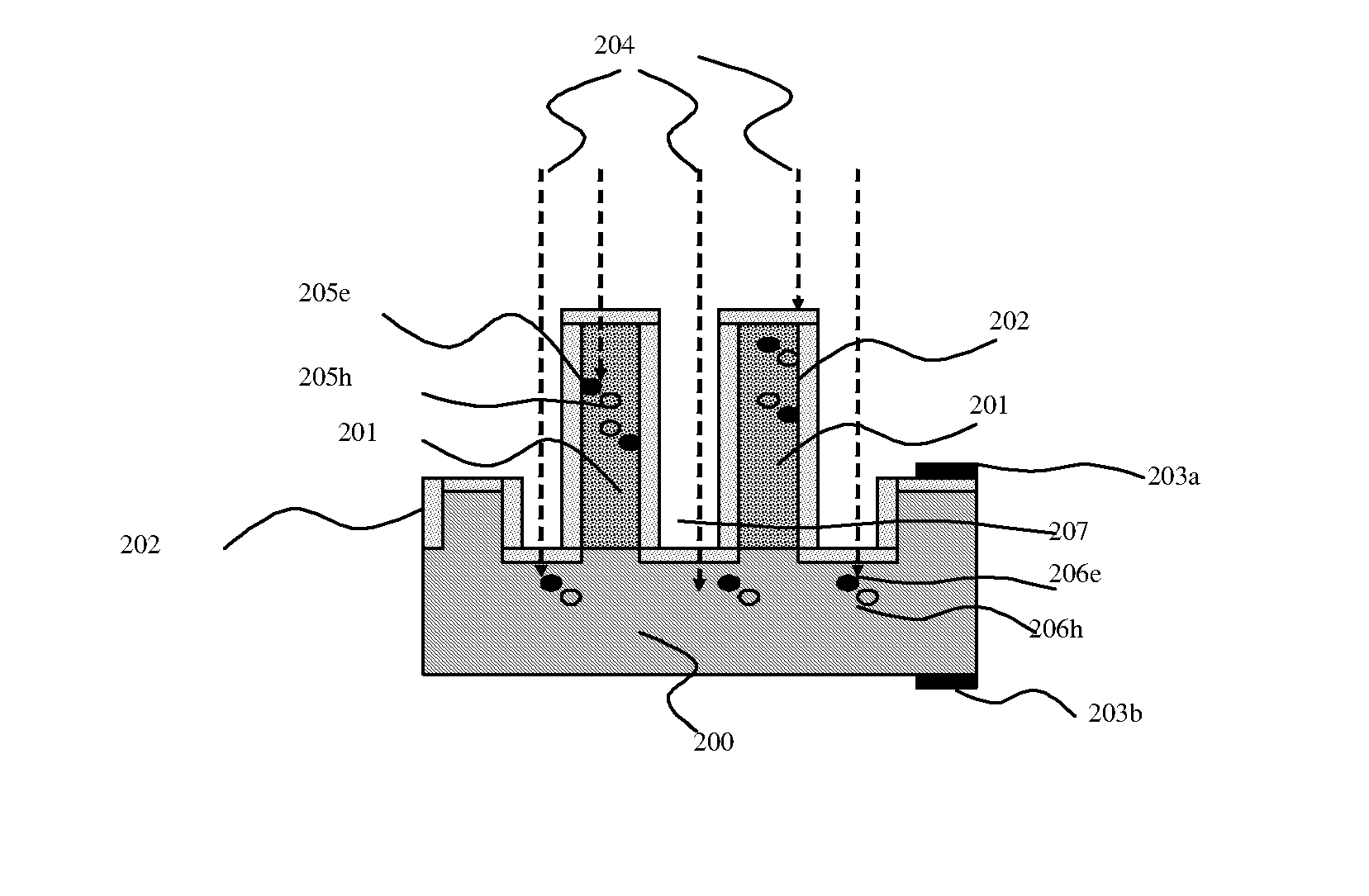

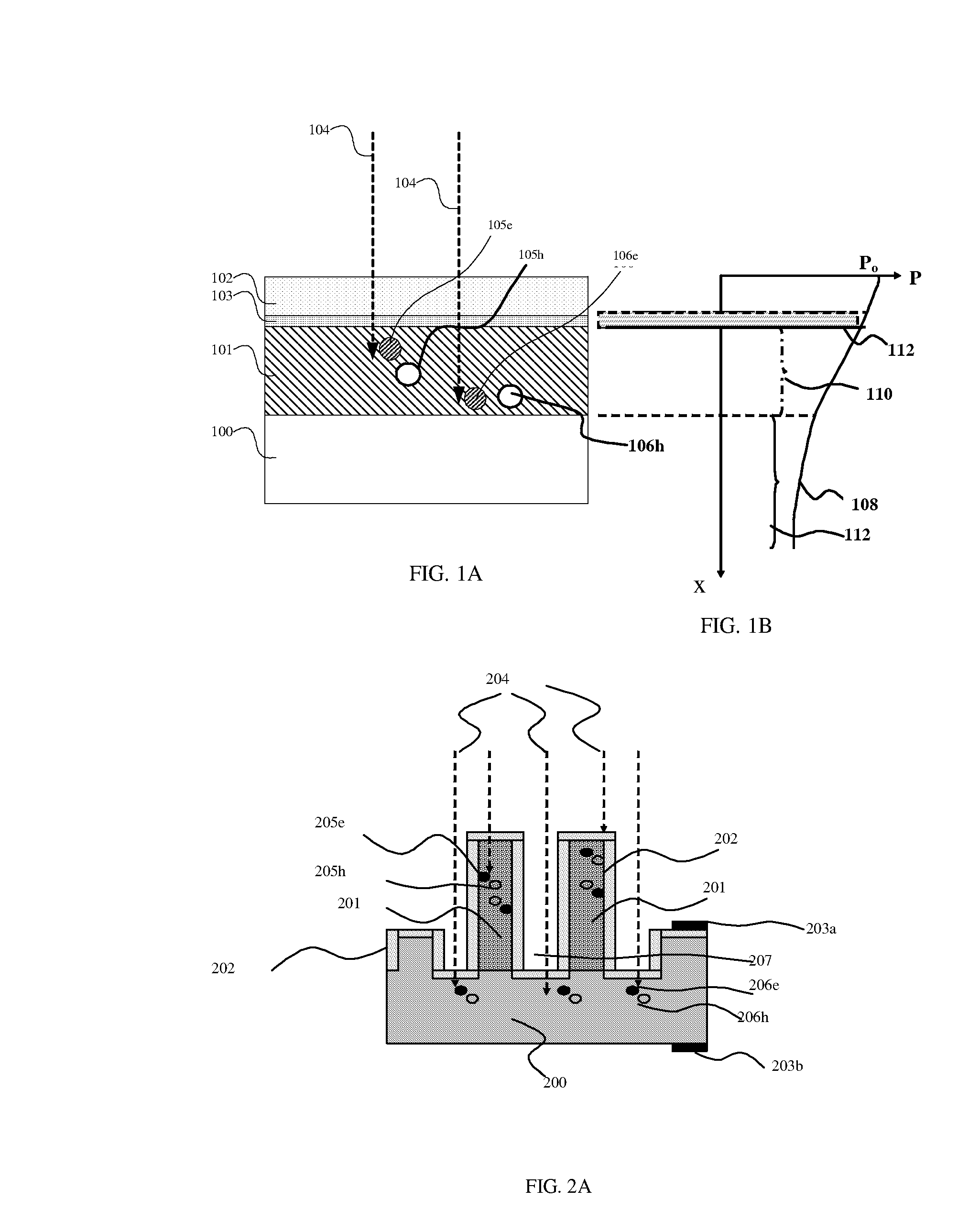

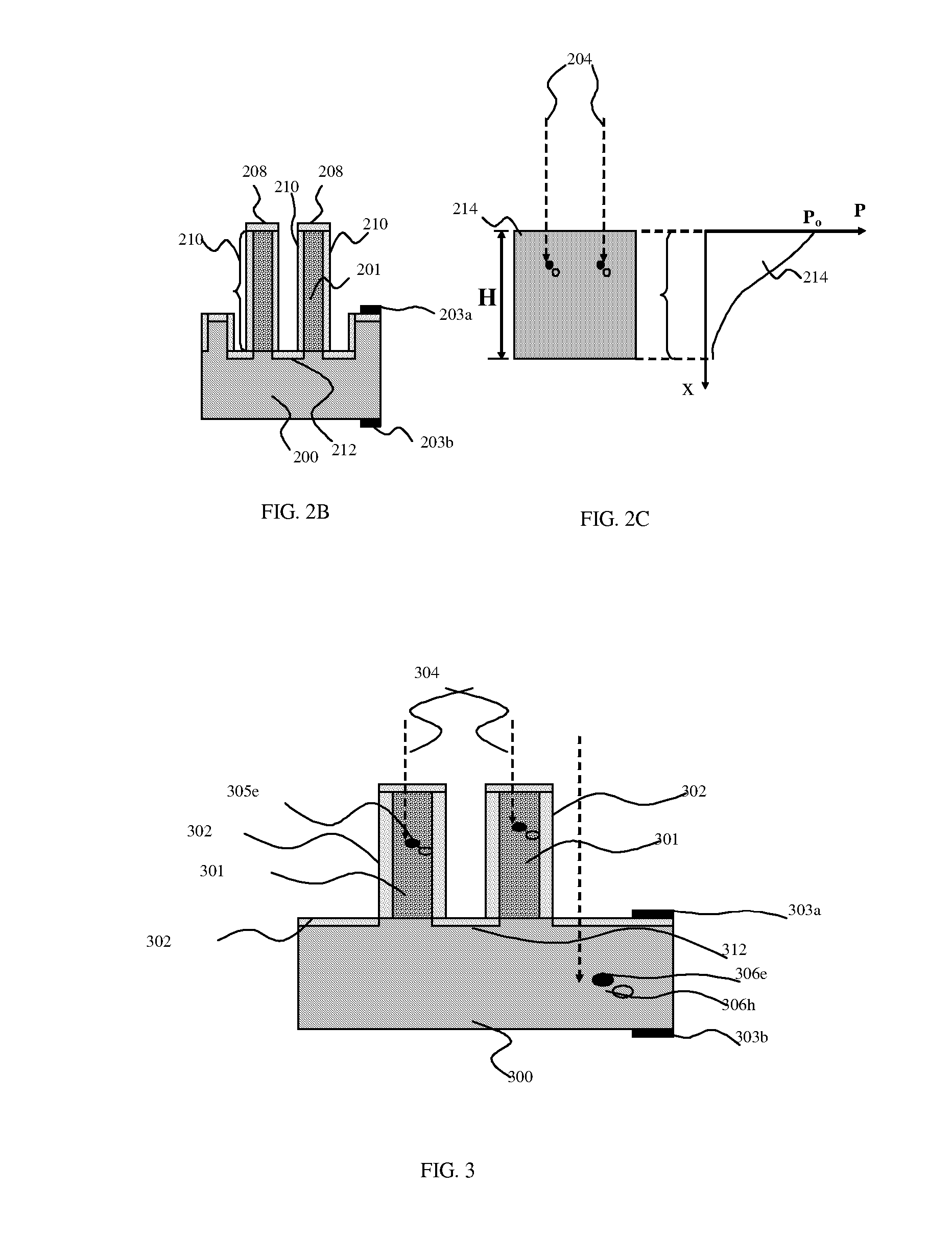

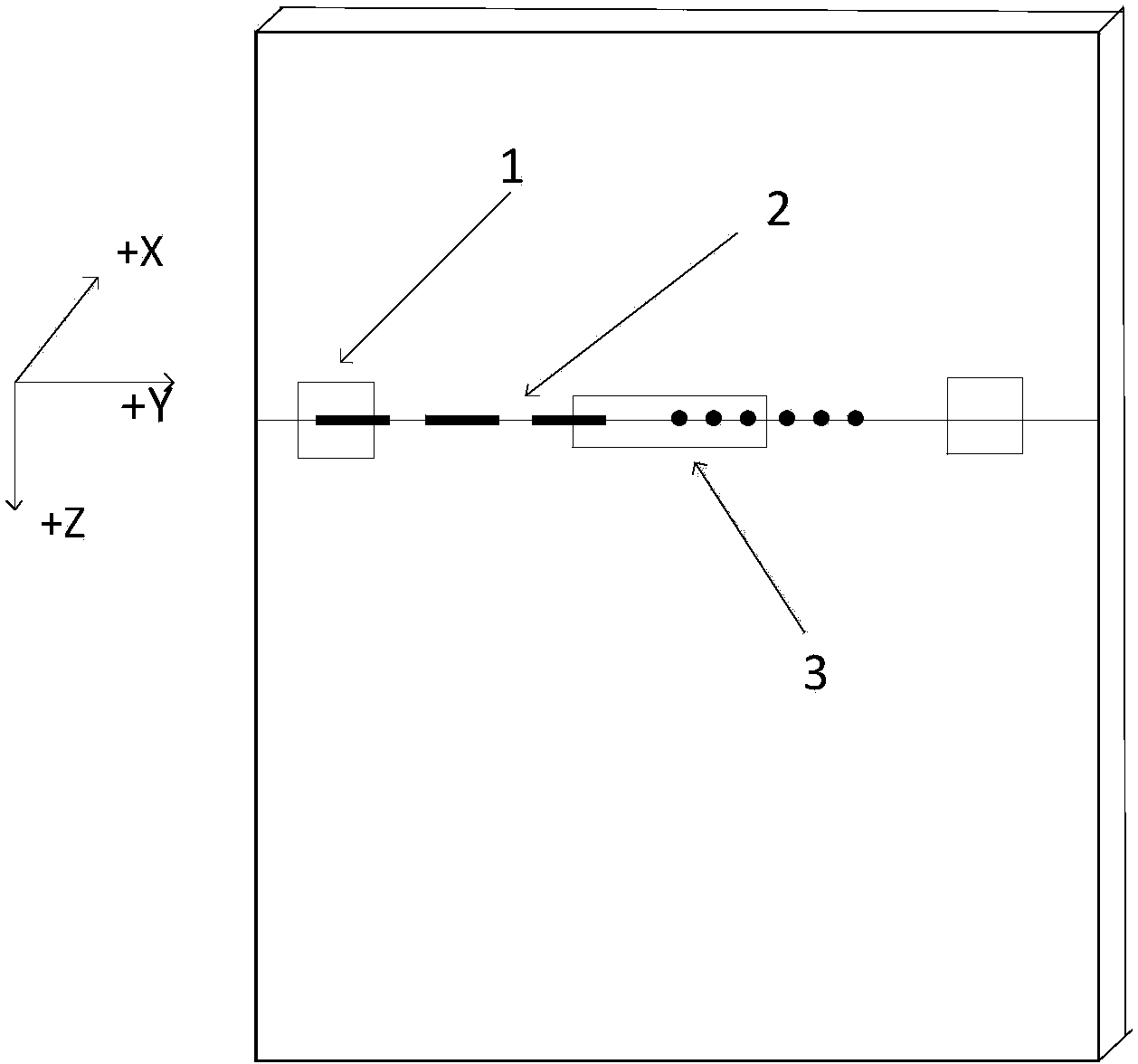

The invention relates to a micro-interface enhanced reactor bubble scale structure-activity regulation and control model building method. The diameter dmax of the largest bubble of a micro-interface enhanced reactor and the diameter dmin of the smallest bubble of the micro-interface enhanced reactor serve as independent variables, the average diameter d32 of the bubble Sauter serve as a dependentvariable, and a numerical relationship is built; based on the Kolmogorov-Hinze theory, the relationship between the diameter dmax of the largest bubble of the micro-interface enhanced reactor, the diameter dmin of the smallest bubble and the parameters of the reactor is built. According to the method, the reactor bubble scale is associated with the structural parameter, the operation parameter andthe physical property parameter of the reactor by using specific numerical relationship, the numerical relationship has the guiding significance for the design of the reactor and can be applied to avariety of reactors, the versatility is good, by means of a bubble scale regulation and control model built through the method, by adjusting the structural parameter and the operation parameter of thereactor, and the maximization of energy efficiency and material efficiency in the reaction process can be achieved, or under the condition that reaction targets, energy consumption and material consumption are given, a high-efficiency reactor structure is designed.

Owner:NANJING UNIV

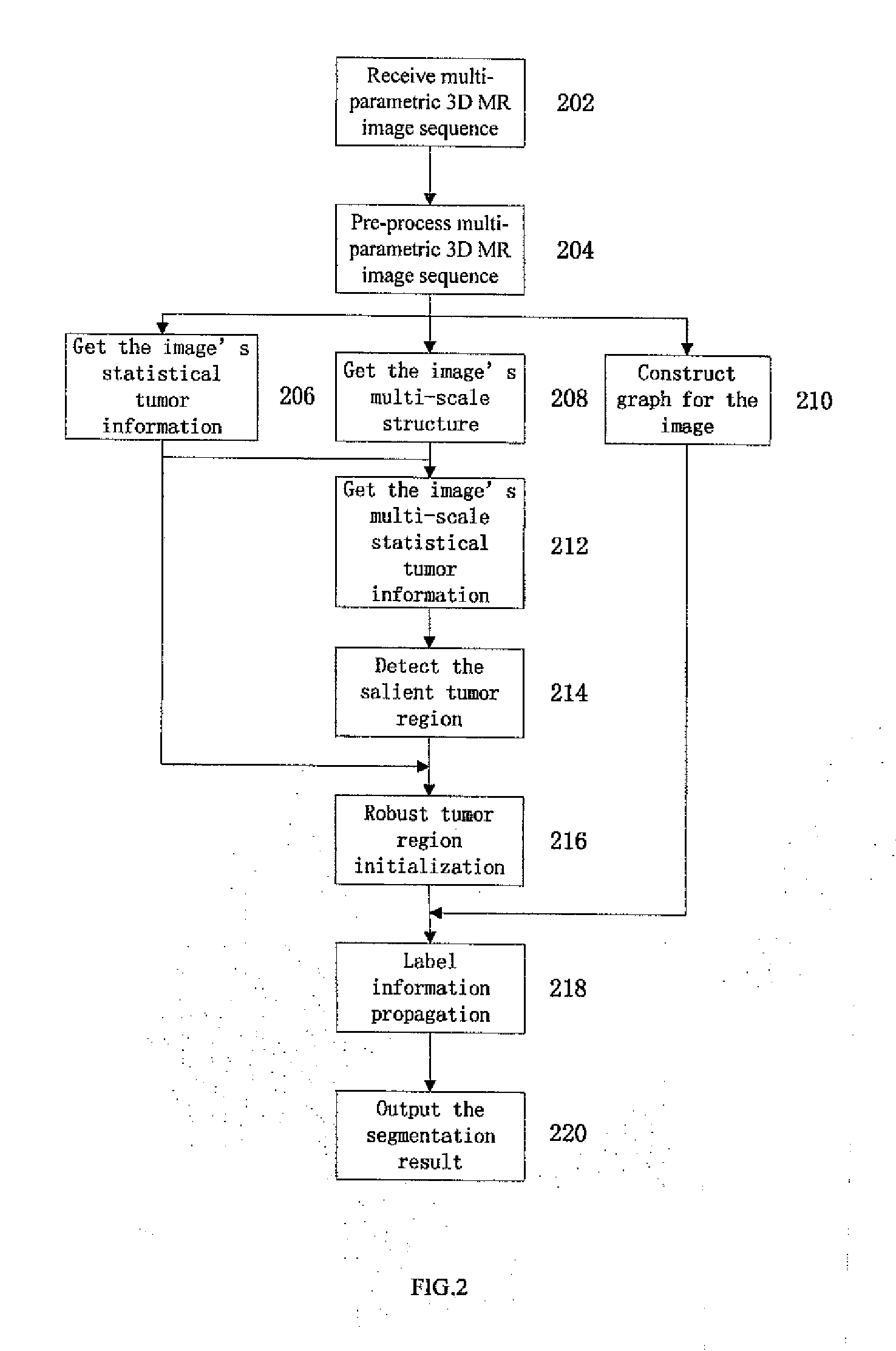

Method for brain tumor segmentation in multi-parametric image based on statistical information and multi-scale struture information

InactiveUS20130182931A1Accurate and reliable tumor segmentationPerformance degradation can be reducedImage enhancementImage analysisPattern recognitionVoxel

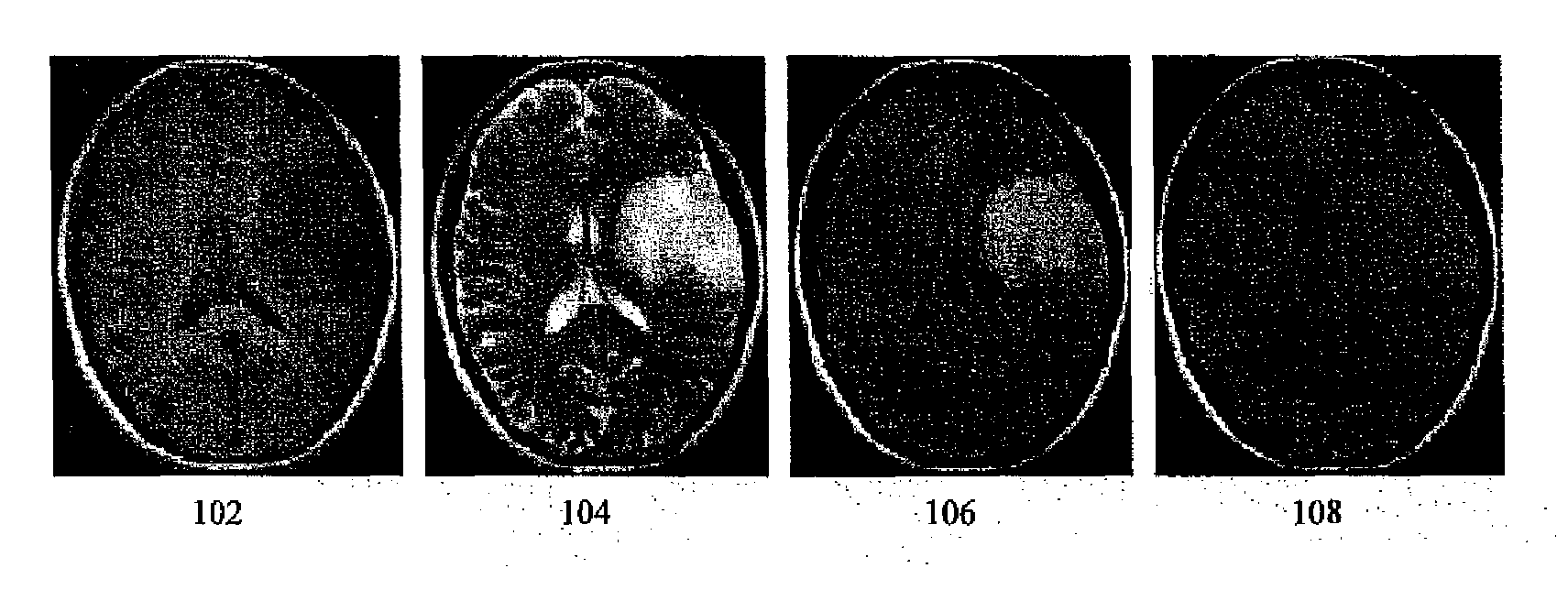

A method for brain tumor segmentation in multi-parametric 3D magnetic resonance (MR) images, comprising: determining, for each voxel in the multi-parametric 3D MR image sequence, a probability that the voxel is part of brain tumor; extracting multi-scale structure information of the image; generating multi-scale tumor probability map based on initial tumor probability at voxel level and multi-scale structure information; determining salient tumor region based on multi-scale tumor probability map; obtaining robust initial tumor and non-tumor label based on tumor probability map at voxel level and salient tumor region; and generating a segmented brain tumor image using graph based label information propagation. The present invention is capable of achieving statistical reliable, spatially compact, and robust tumor label initialization, which is helpful to the accurate and reliable tumor segmentation. And the label information propagation framework could partially alleviate the performance degradation caused by image inconsistency between images to be segmented and training images.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

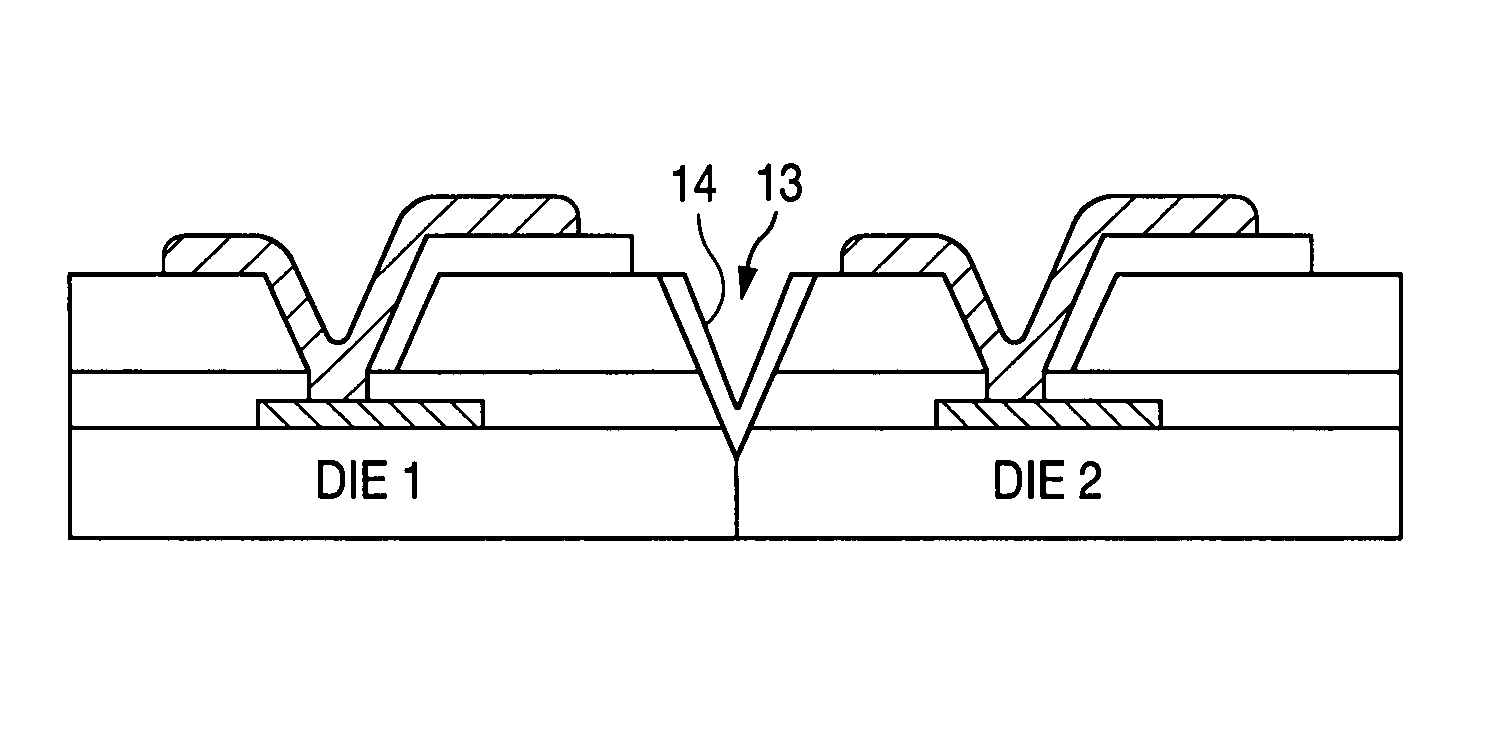

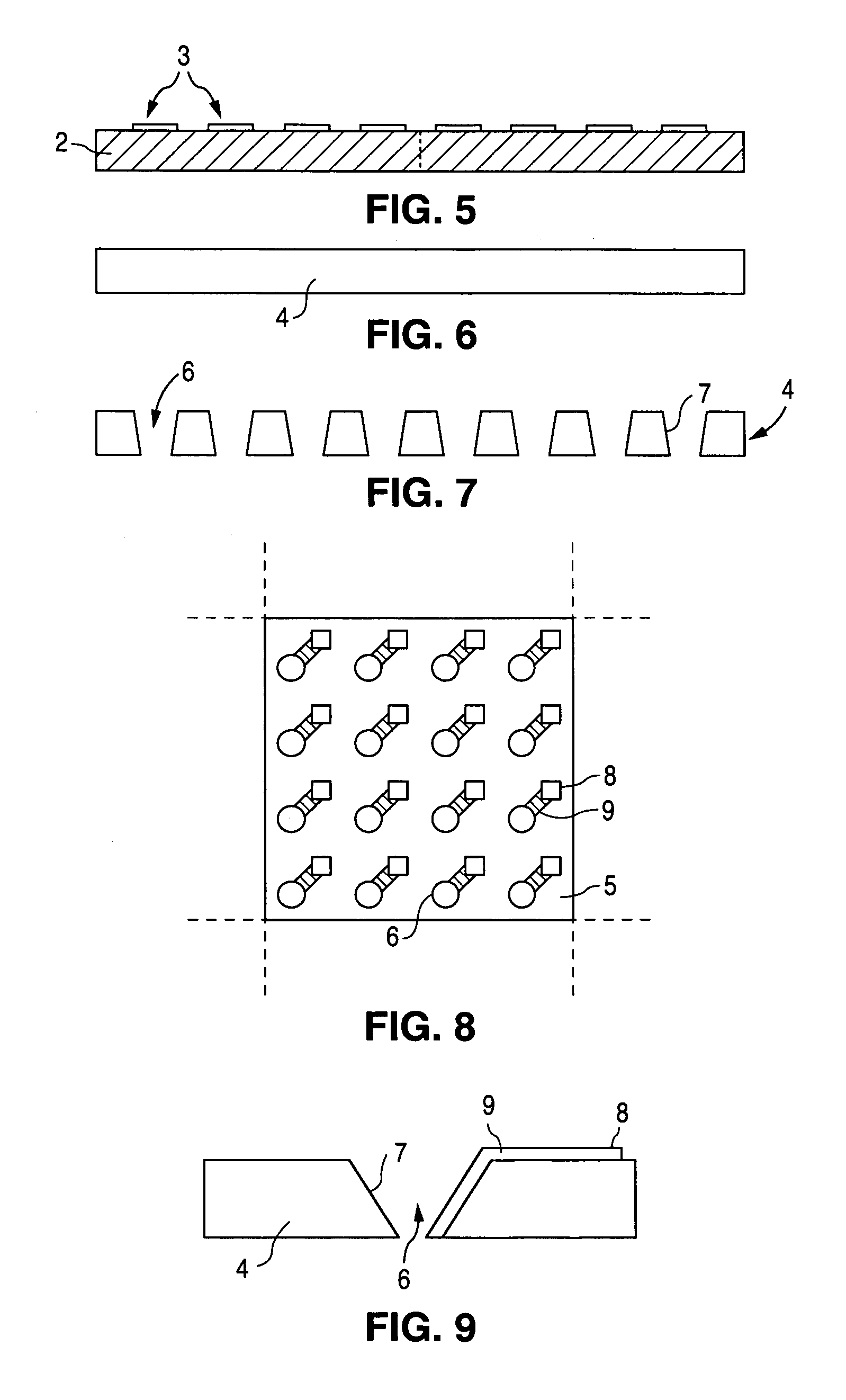

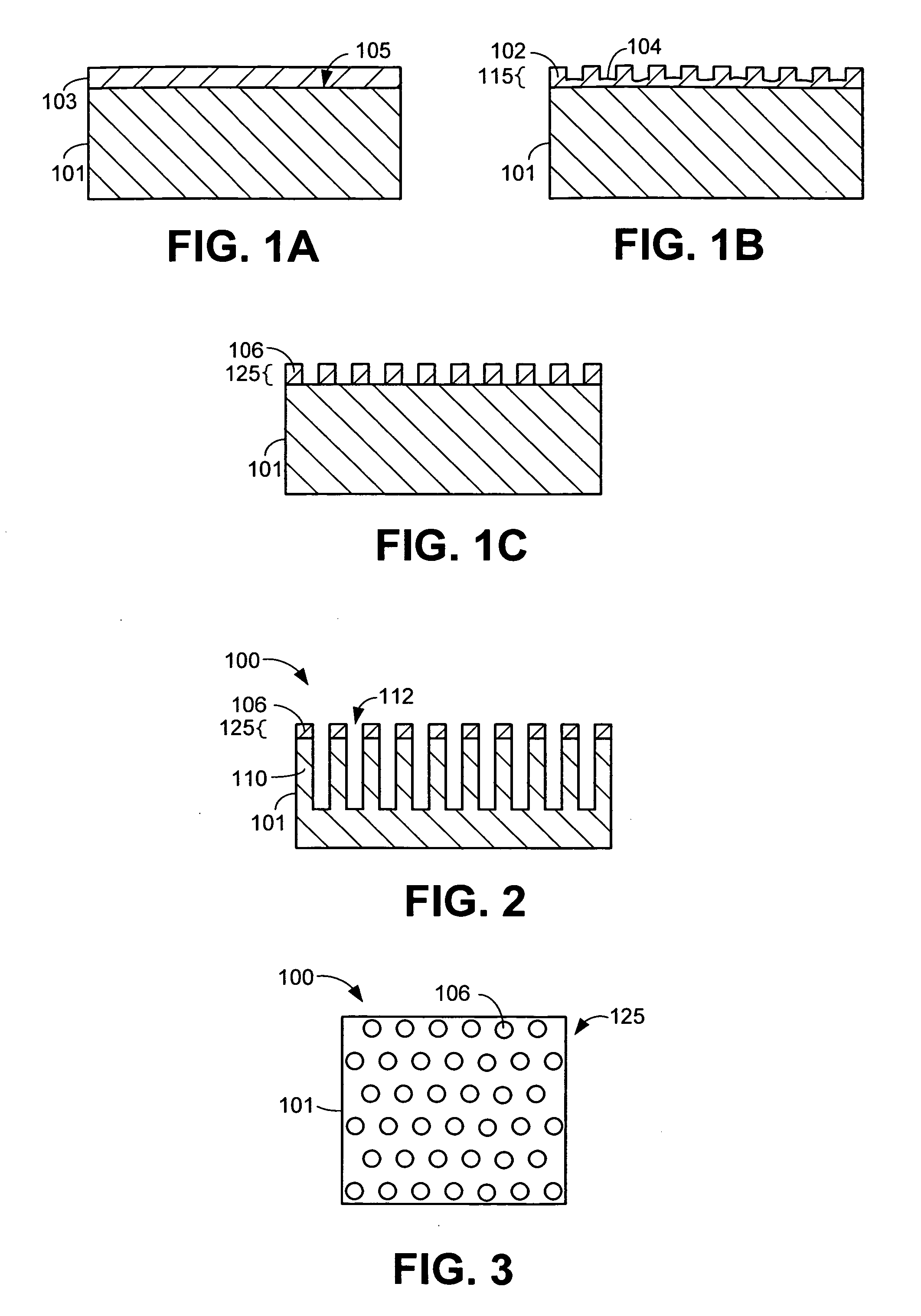

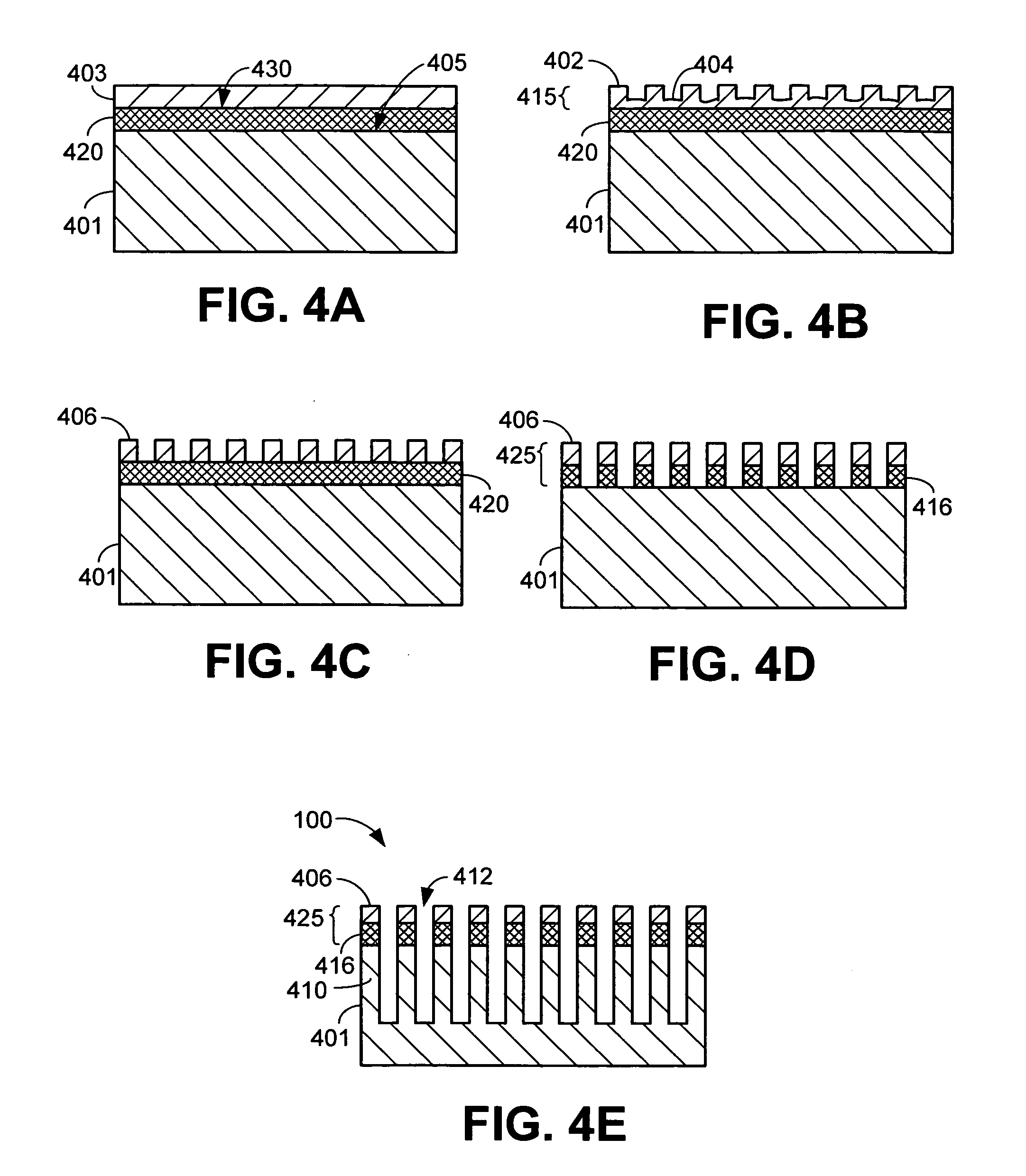

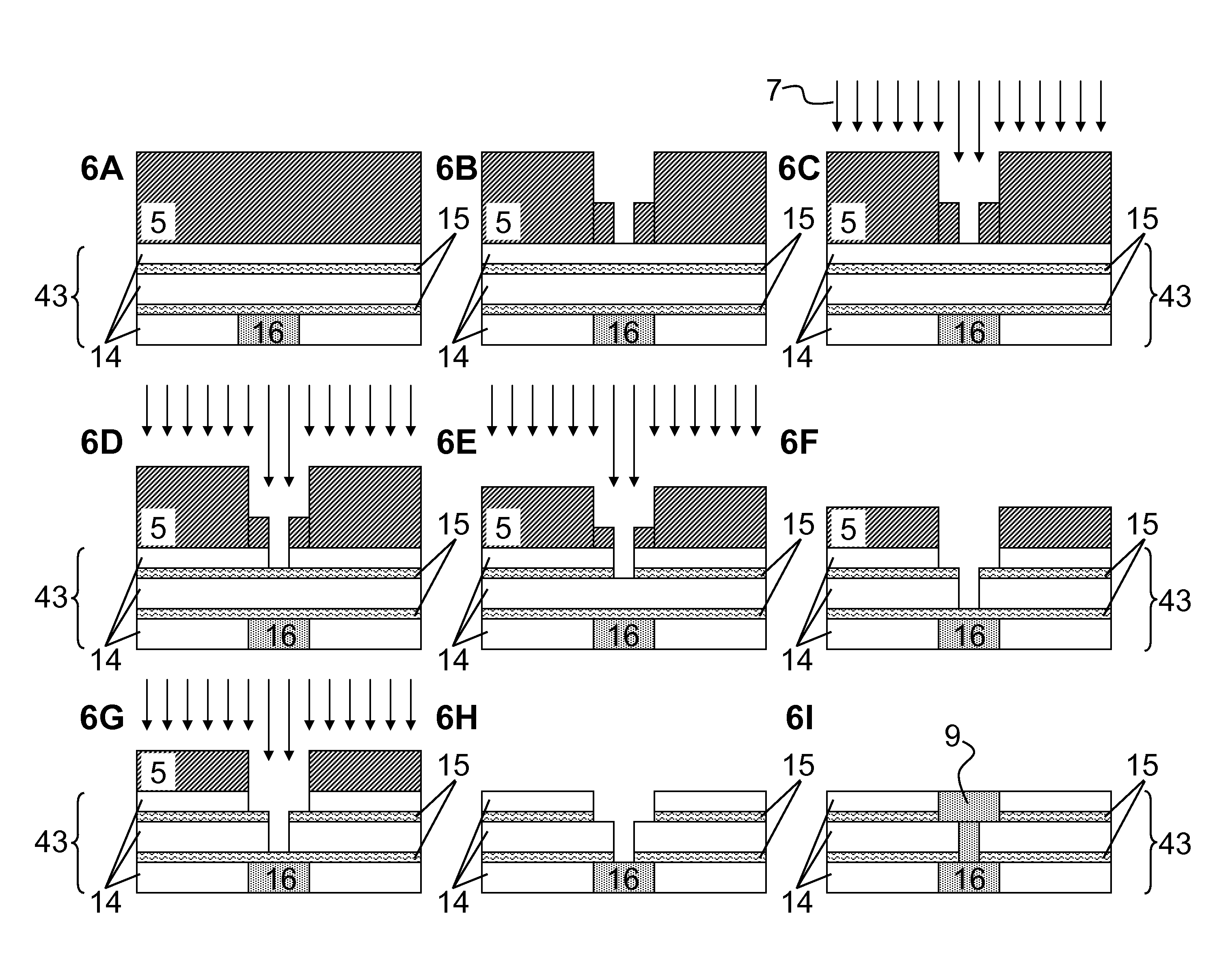

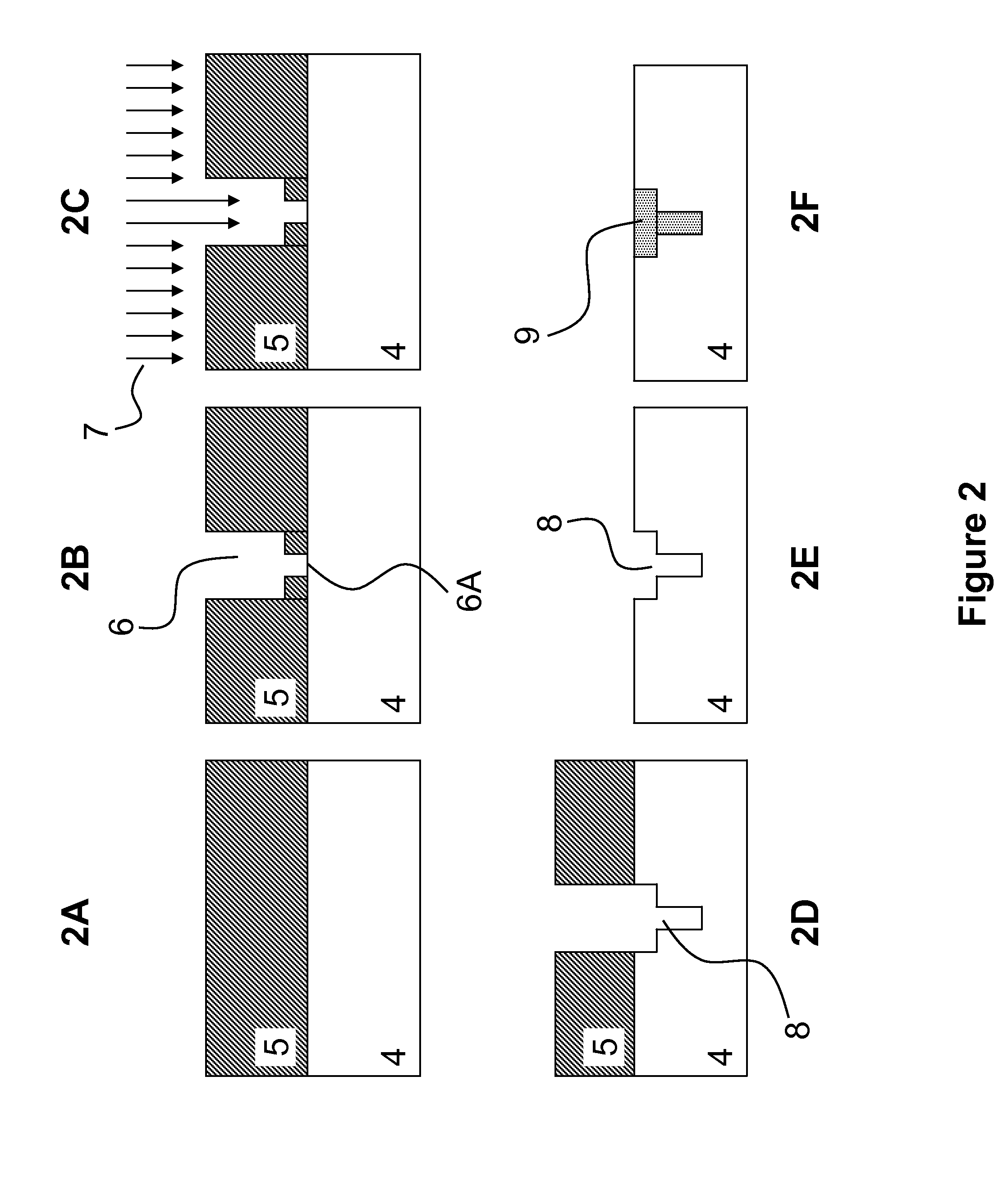

Hermetic wafer scale integrated circuit structure

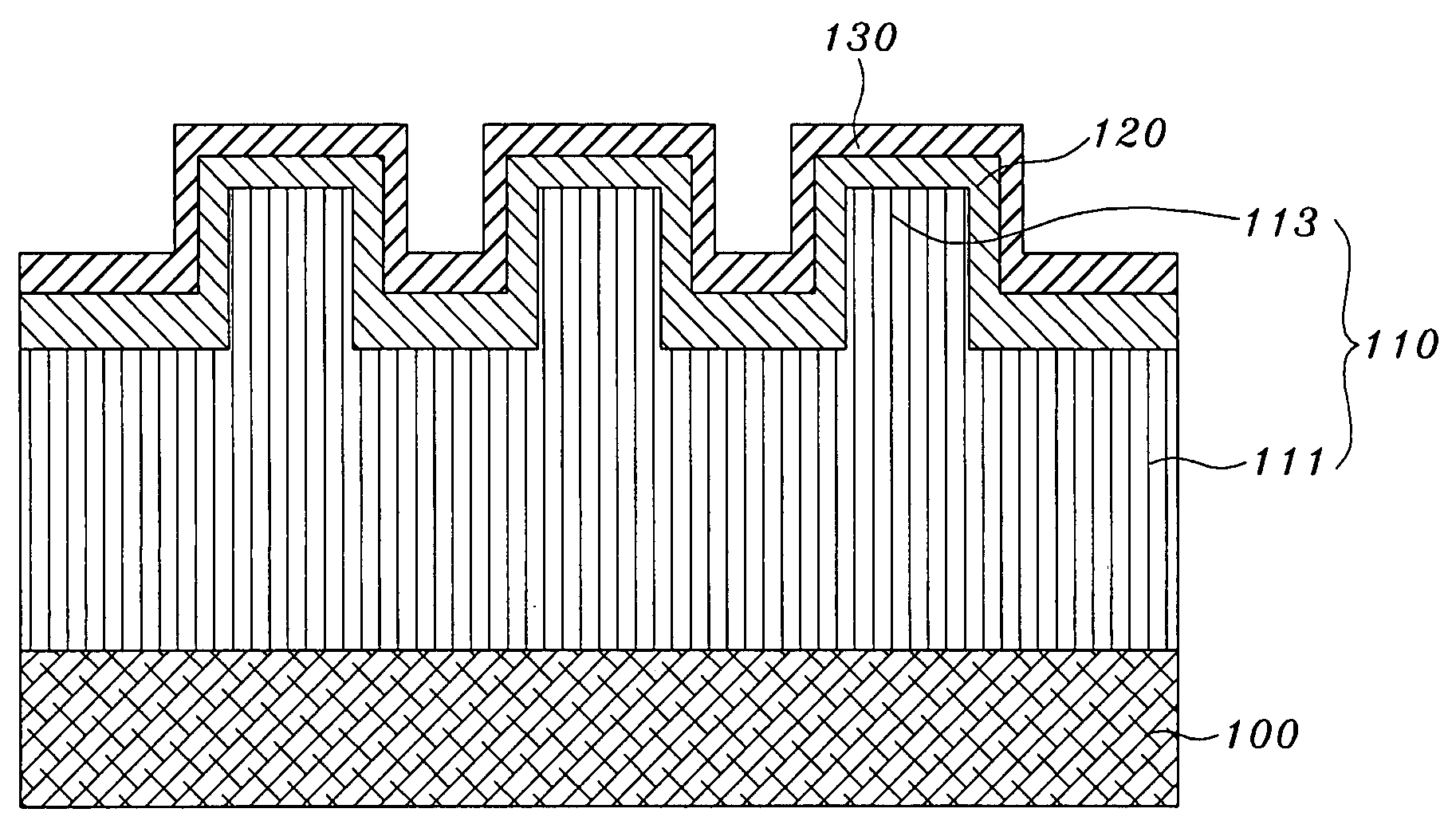

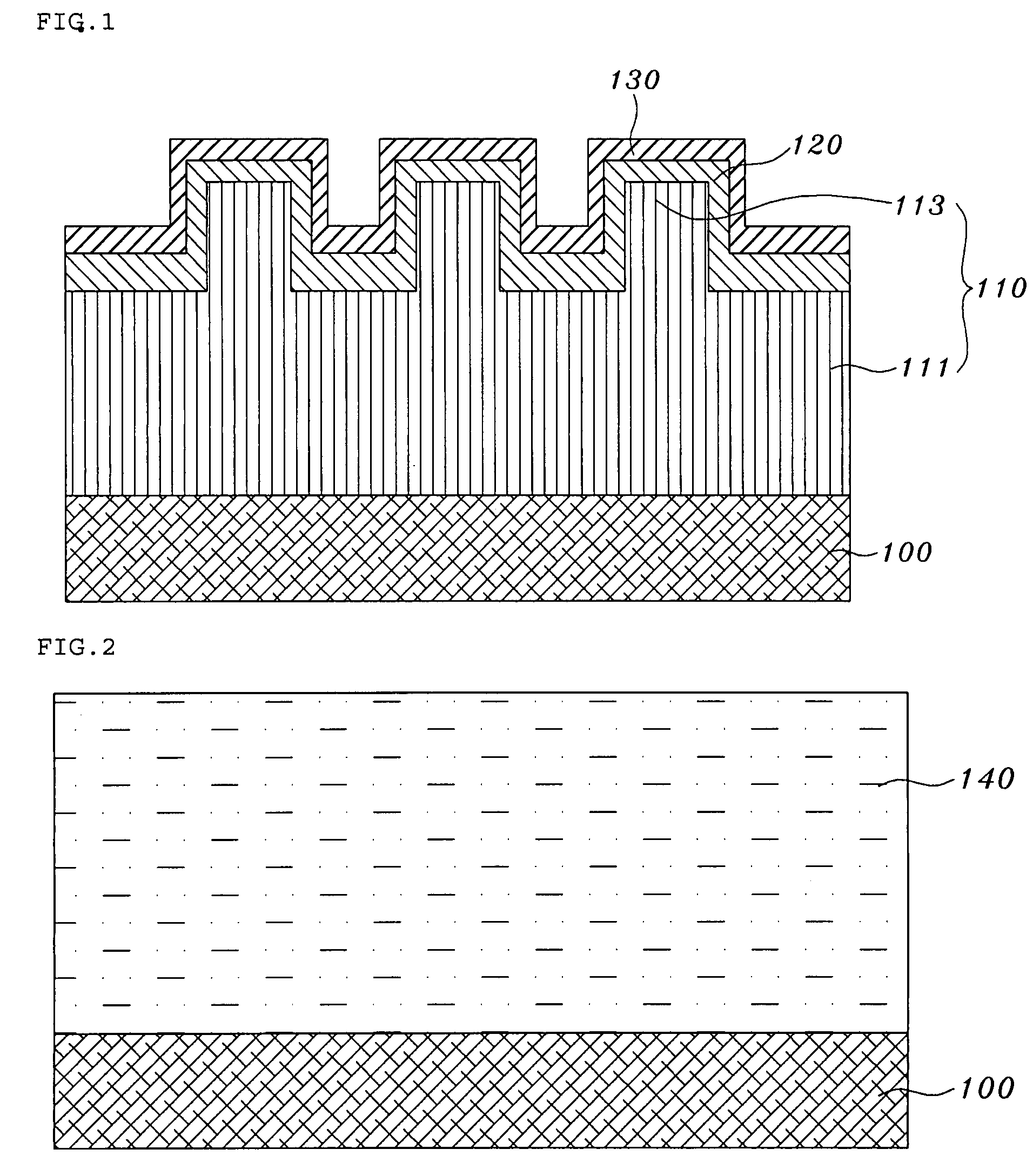

InactiveUS6982475B1Prevent surfaceDamaged and destroyedSemiconductor/solid-state device detailsSolid-state devicesScale structureHermetic seal

A wafer scale semiconductor integrated circuit packaging technique provides a hermetic seal for the individual integrated circuit die formed as part of the wafer scale structure. A semiconductor wafer is manufactured to include a number of individual semiconductor die. Each individual die formed on the wafer includes a number of bond pads that are exposed on the die surface in various locations to provide electrical connections to the circuitry created on the die. The wafer further includes a planar glass sheet that is substantially the same size as the wafer, the glass sheet being adhered to the wafer using a suitable adhesive. The glass sheet has a number of pre-formed holes in it, the arrangement of the pre-formed holes corresponding to the location of the bond pads at each of the individual semiconductor die formed as part of the wafer structure. Following adherence of the glass sheet to the semiconductor wafer utilizing the intermediate adhesive material, metal connections are made between pads formed on the glass sheet and the bond pads formed on the integrated circuit die. Solder balls are then attached to the pads on the glass sheet to provide a conductive flow between the solder balls and the bond pads. After the solder balls are attached, trenches are cut around each of the individual die on the wafer. The trenches are cut at an angle and extend through the glass sheet and the intermediate adhesive material and into the semiconductor substrate in which the integrated circuits are formed. After the trenches are cut around each individual semiconductor die, a noble metal is deposited on the sidewalls of the trench to extend over the interface between the glass sheet, the adhesive material and the semiconductor die. The wafer is then cut along the noble metal lined trenches to provide individual, hermetically sealed packaged integrated circuit die.

Owner:MICRO CHIP SCALE PACKAGING

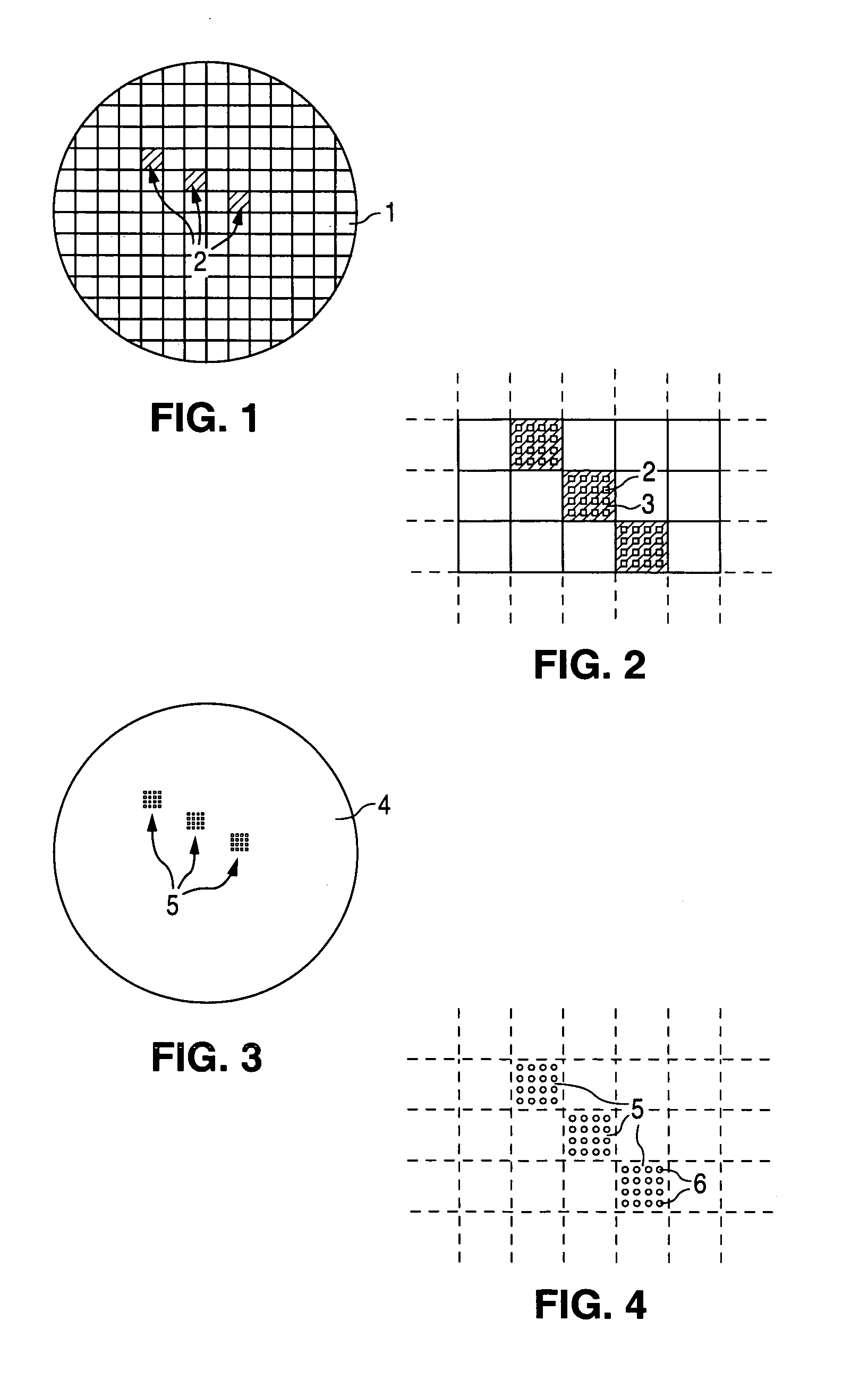

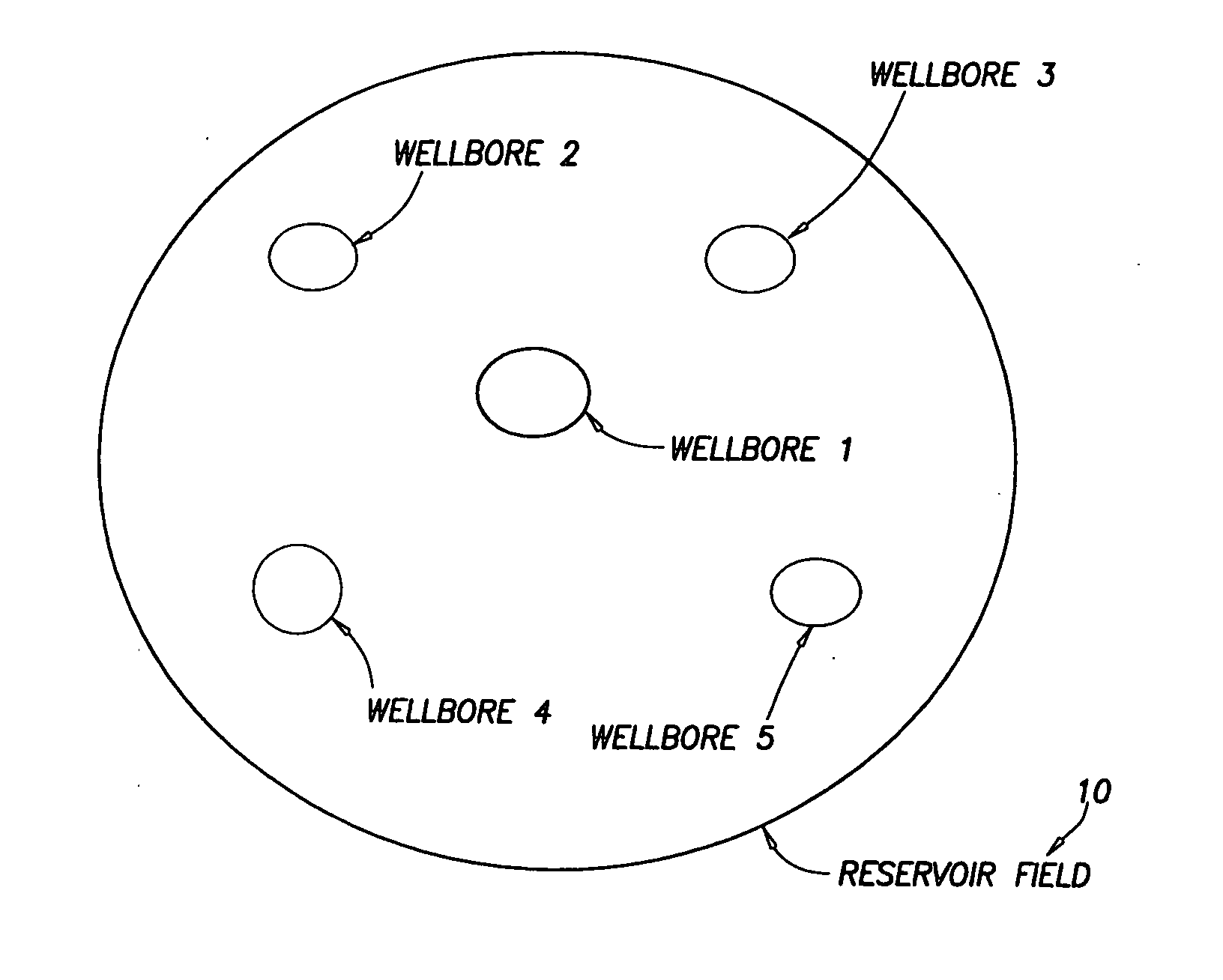

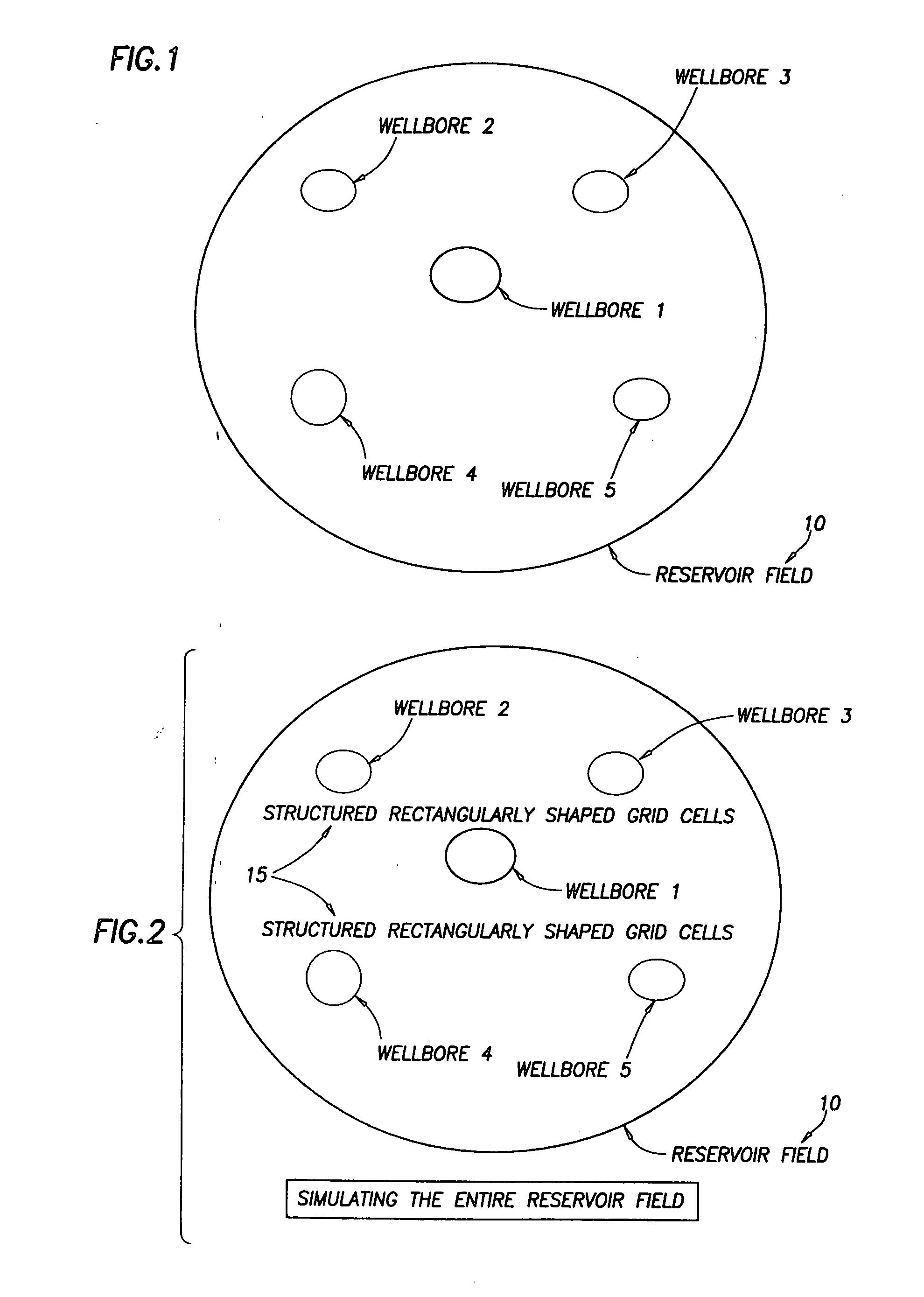

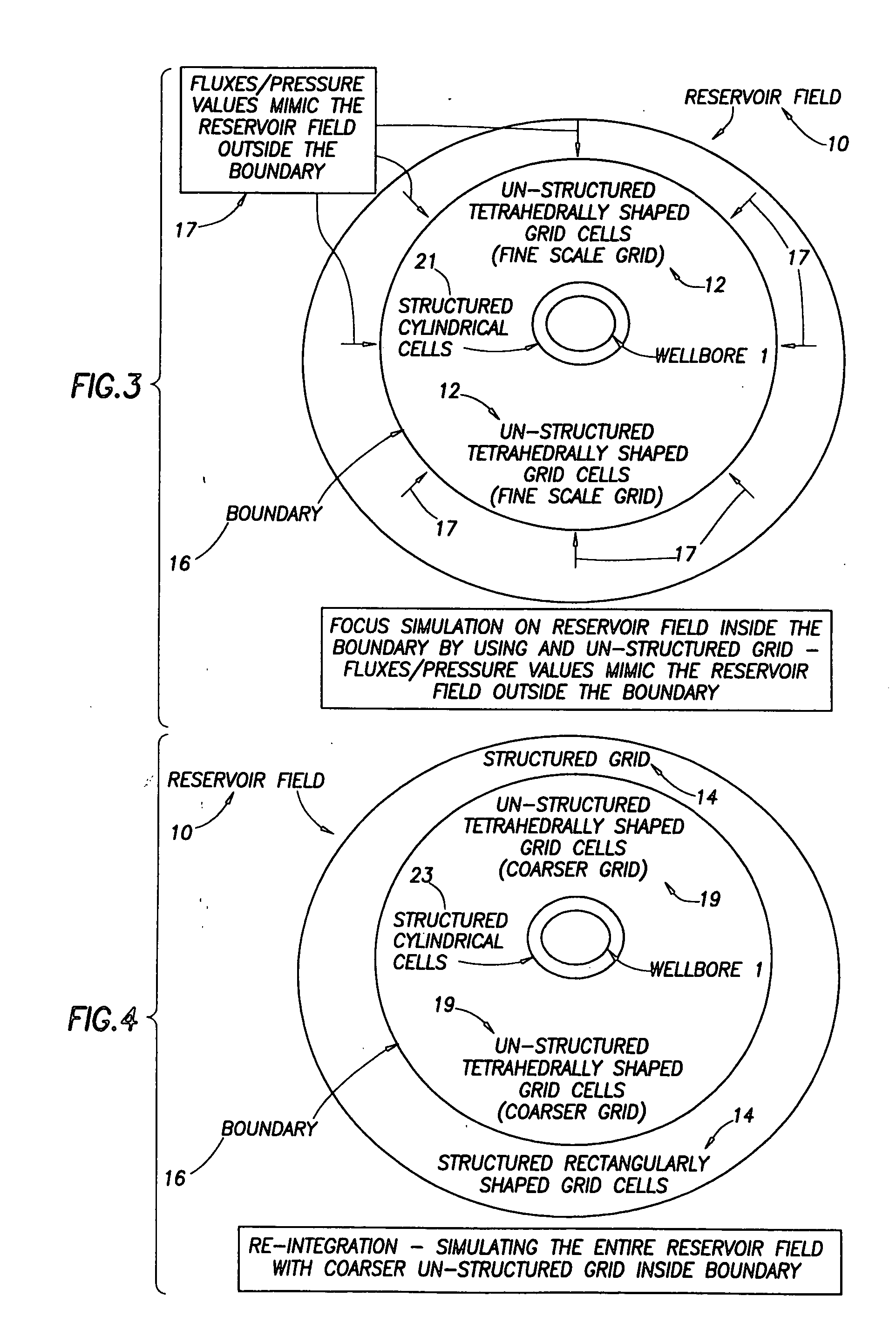

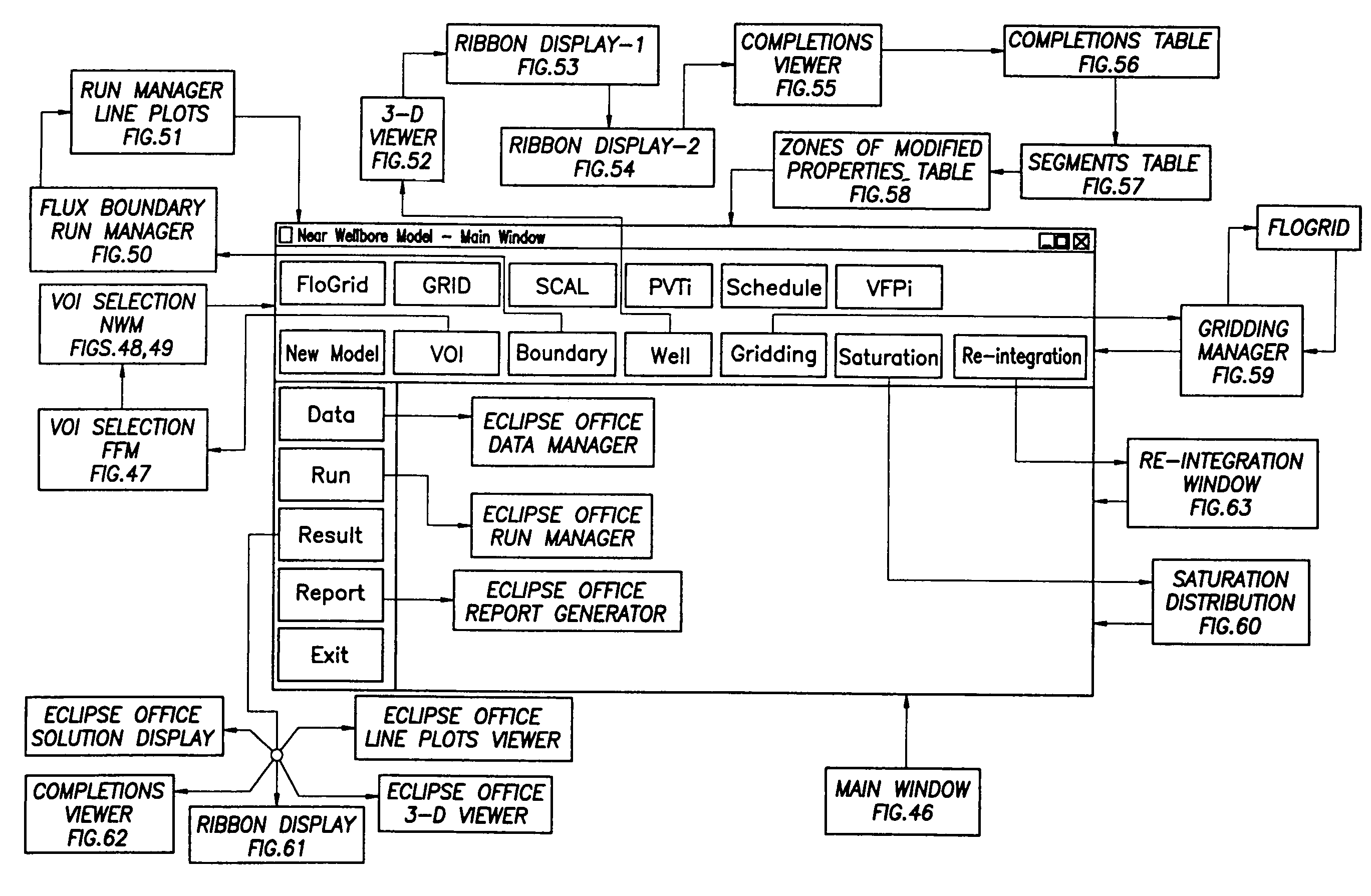

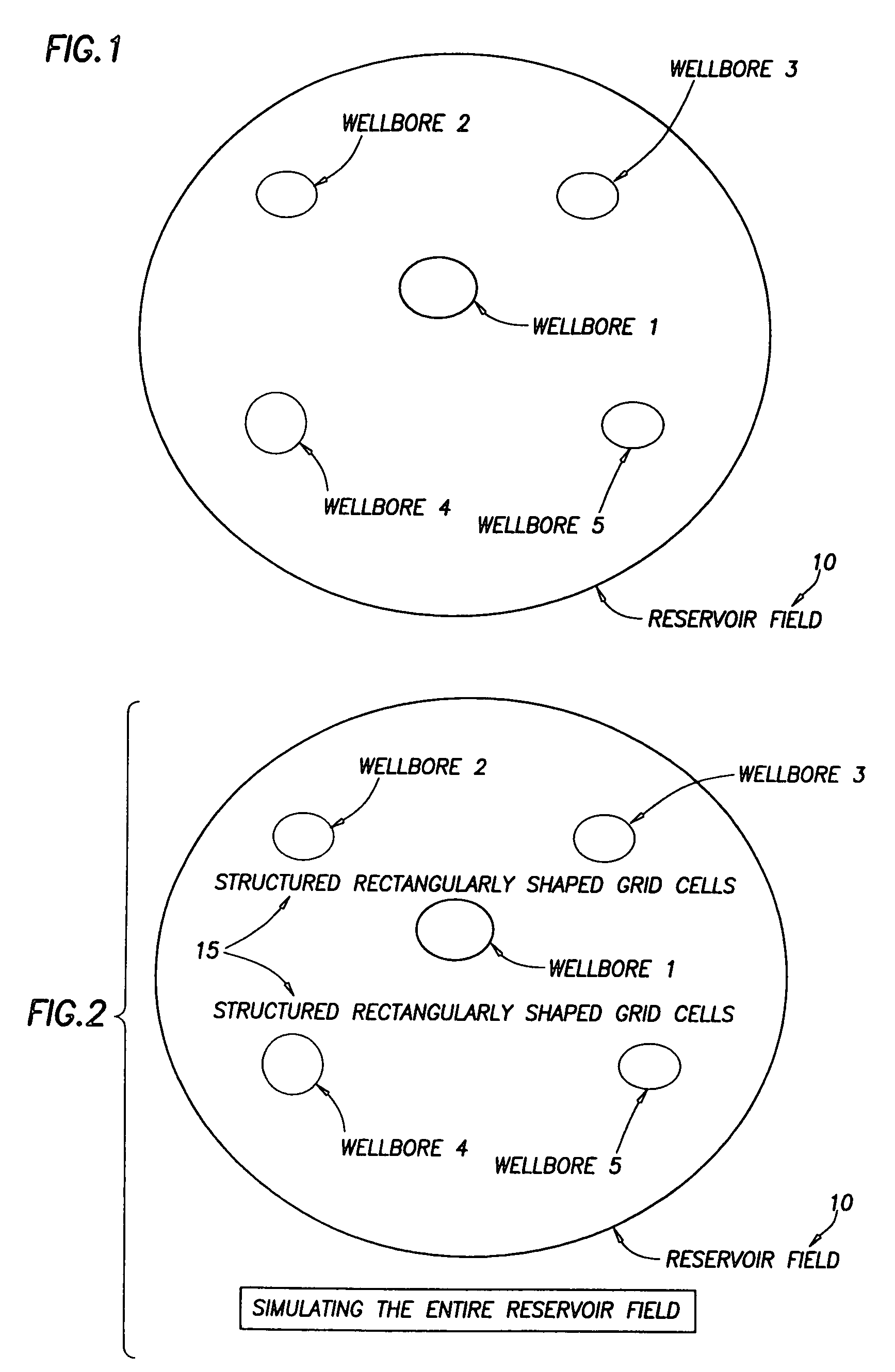

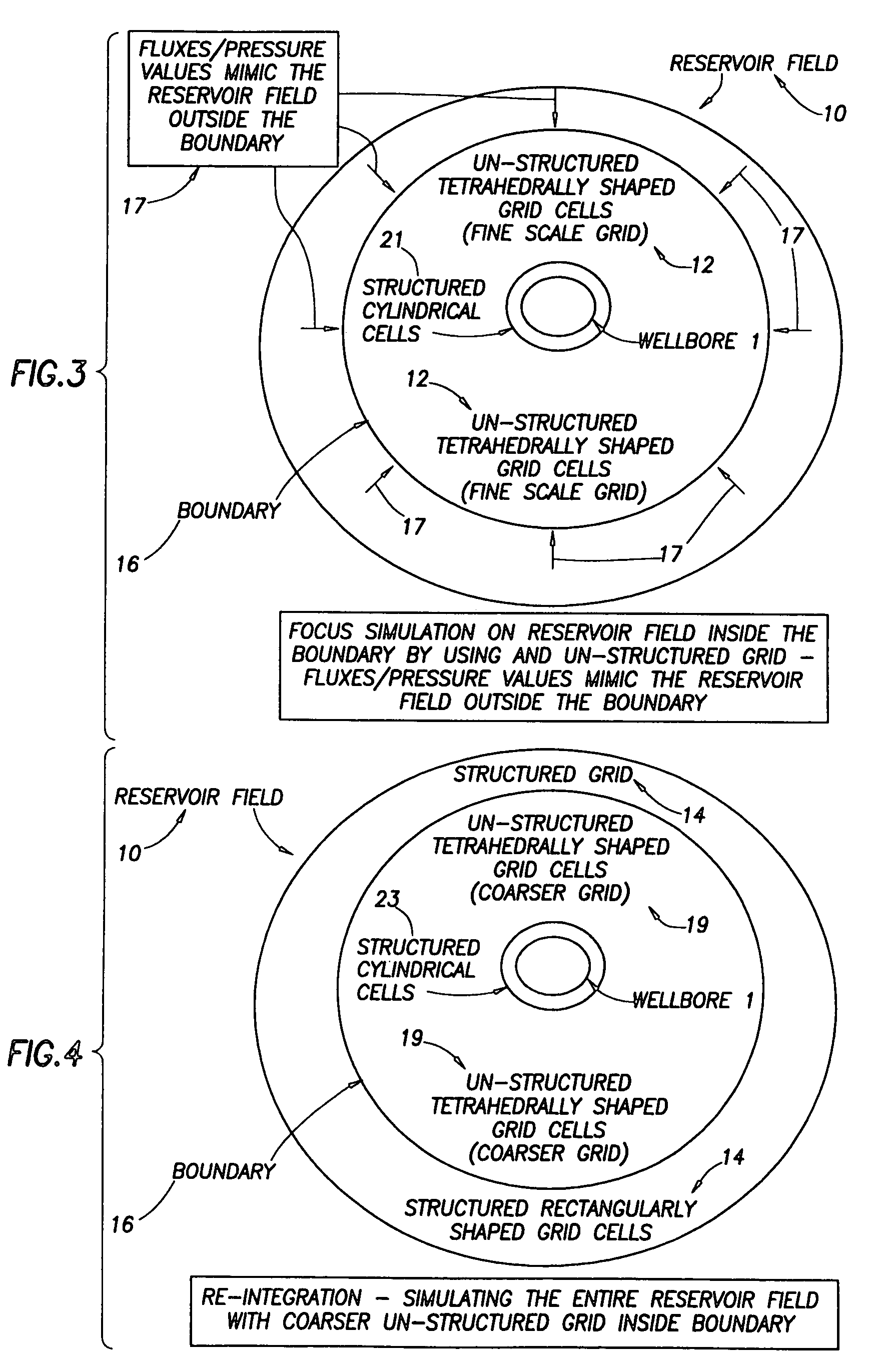

Near wellbore modeling method and apparatus

ActiveUS20050015231A1Electric/magnetic detection for well-loggingComputation using non-denominational number representationModel methodScale structure

A “near wellbore modeling” software will, when executed by a processor of a computer, model a localized area of a reservoir field which surrounds and is located near a specific wellbore in the reservoir field by performing the following functions: (1) receive input data representative of a reservoir field containing a plurality of wellbores, (2) establish a boundary around one specific wellbore in the reservoir field which will be individually modeled and simulated, (3) impose an “fine scale” unstructured grid inside the boundary consisting of a plurality of tetrahedrally shaped grid cells and further impose a fine scale structured grid about the perforated sections of the specific wellbore, (4) determine a plurality of fluxes / pressure values at the boundary, the fluxes / pressure values representing characteristics of the reservoir field located outside the boundary, (5) establish one or more properties for each tetrahedral cell of the unstructured grid and each cylindrical grid cell of the structured grid, (6) run a simulation, using the fluxes / pressure values at the boundary to mimic the reservoir field outside the boundary and using the fine scale grid inside the boundary, to thereby determine a plurality of simulation results corresponding, respectively, to the plurality of grid cells located inside the boundary, the plurality of simulation results being representative of a set of characteristics of the reservoir field located inside the boundary, (7) display the plurality of simulation results which characterize the reservoir field located inside the boundary, and (8) reintegrate by coarsening the grid inside the boundary, imposing a structured grid outside the boundary, and re-running a simulation of the entire reservoir field.

Owner:SCHLUMBERGER TECH CORP

Near wellbore modeling method and apparatus

ActiveUS7451066B2Electric/magnetic detection for well-loggingSeismic signal receiversModel methodScale structure

Owner:SCHLUMBERGER TECH CORP

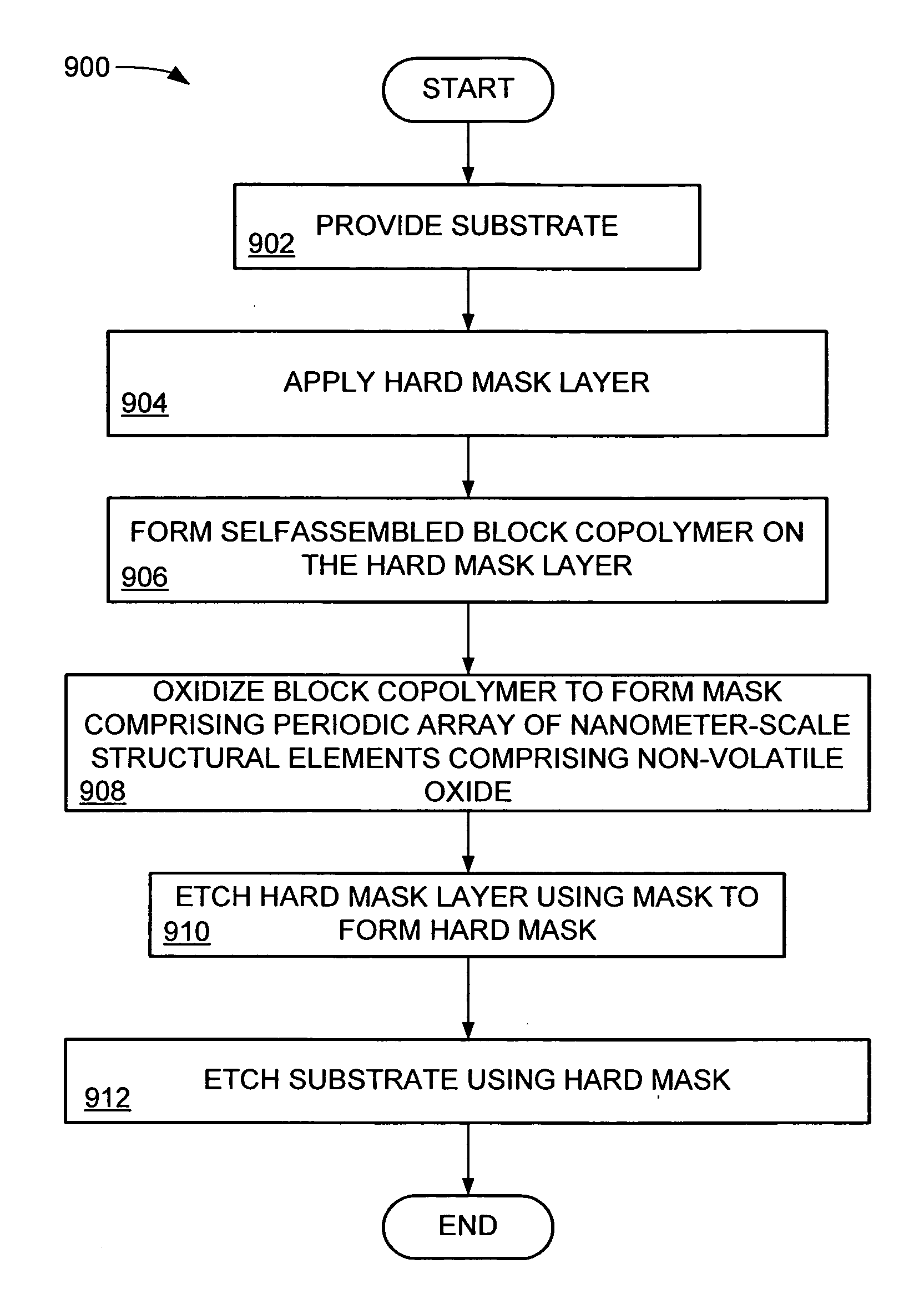

Block copolymer mask for defining nanometer-scale structures

InactiveUS20070289943A1High aspect ratioMaterial nanotechnologyComponent separationScale structureEngineering

A nanometer-scale mask includes a periodic array of nanometer-scale structural elements comprising an inorganic oxide.

Owner:AGILENT TECH INC

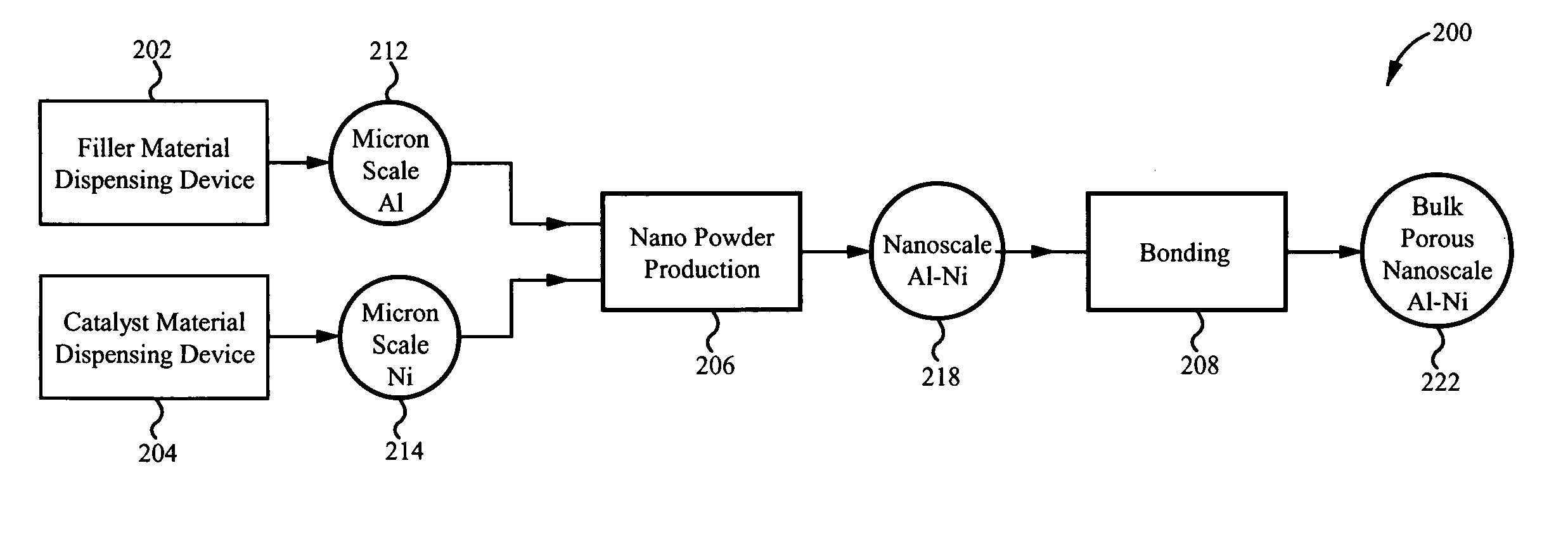

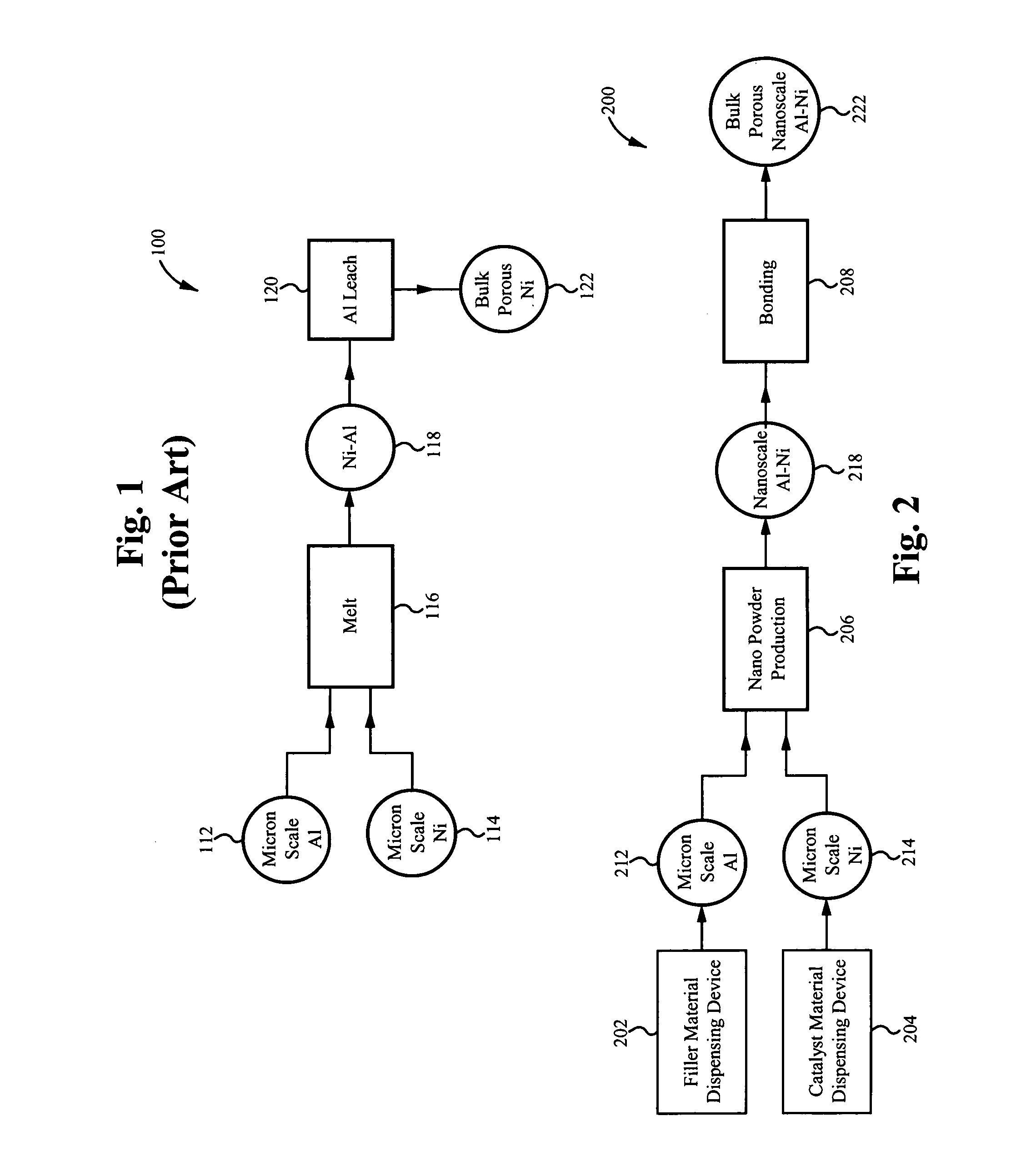

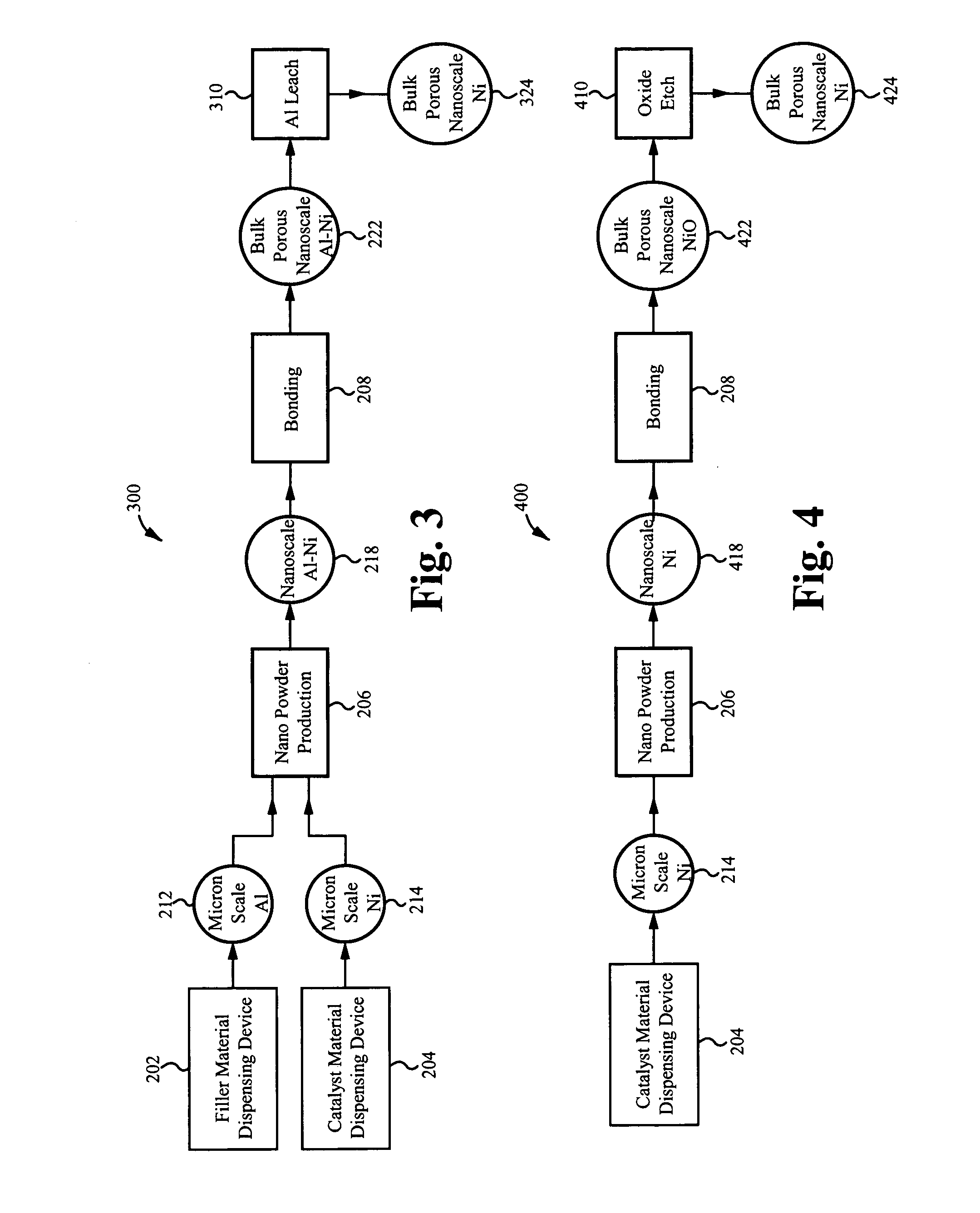

Nano-skeletal catalyst

ActiveUS20080280756A1Increase surface areaMassive costMechanical working/deformationSemiconductor/solid-state device manufacturingPolymer scienceScale structure

A method of producing a catalyst material with nano-scale structure, the method comprising: introducing a starting powder into a nano-powder production reactor, the starting powder comprising a catalyst material; the nano-powder production reactor nano-sizing the starting powder, thereby producing a nano-powder from the starting powder, the nano-powder comprising a plurality of nano-particles, each nano-particle comprising the catalyst material; and forming a catalyst precursor material from the nano-powder, wherein the catalyst precursor material is a densified bulk porous structure comprising the catalyst material, the catalyst material having a nano-scale structure.

Owner:SDC MATERIALS +1

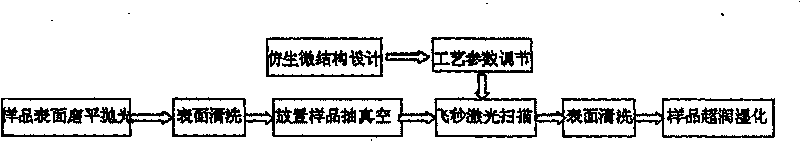

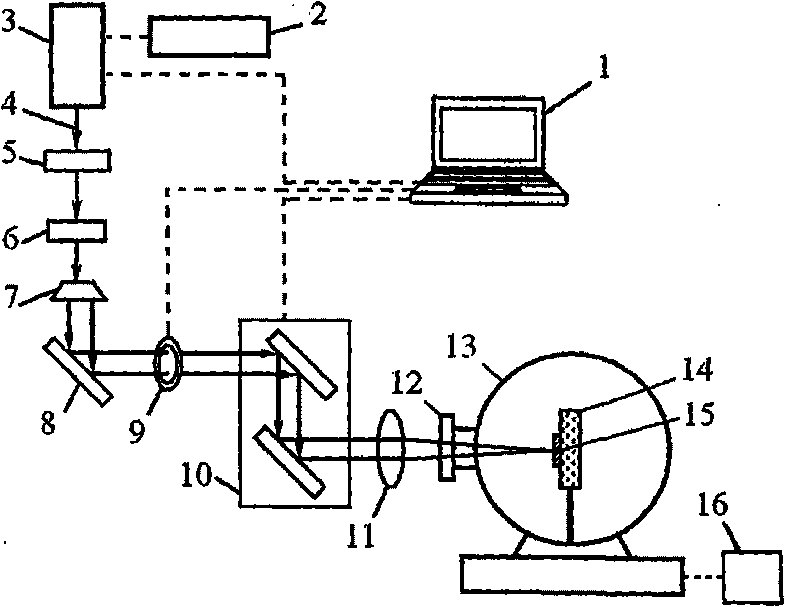

Bionic metal ultra-wetting trans-scale structure design method and preparation method

InactiveCN101712102AEasy to analyze and calculateIdeal wettability structureLaser beam welding apparatusMacroscopic scaleScale structure

The invention relates to the technical field of laser microprocessing, in particular to a method for obtaining a metal-based ultra-wetting surface by designing the trans-scale structure of a metal surface, preparing a laser microstructure on the metal surface and carrying out necessary ultra-wetting decoration to the metal surface. The method comprises the following steps: firstly, designing a macroscopical large-area superficial periodical mastoid structure which simulates a locus leaf surface; constructing a micronano periodical structure on the microstructure of the mastoid structure to obtain a macroscopical-micronano trans-scale geometric model; adjusting laser parameters and a laser scanning path according to geometric parameters acquired after the bionic metal ultra-wetting trans-scale structure is designed; scanning the plane first time; rotating a sample 90 degrees; and scanning the plane again with low-energy laser. The trans-scale microstructure approaches to the surface appearance of a natural organism, is easy to calculate and analyze a contact angle and has a simple and controllable preparation process.

Owner:JIANGSU UNIV

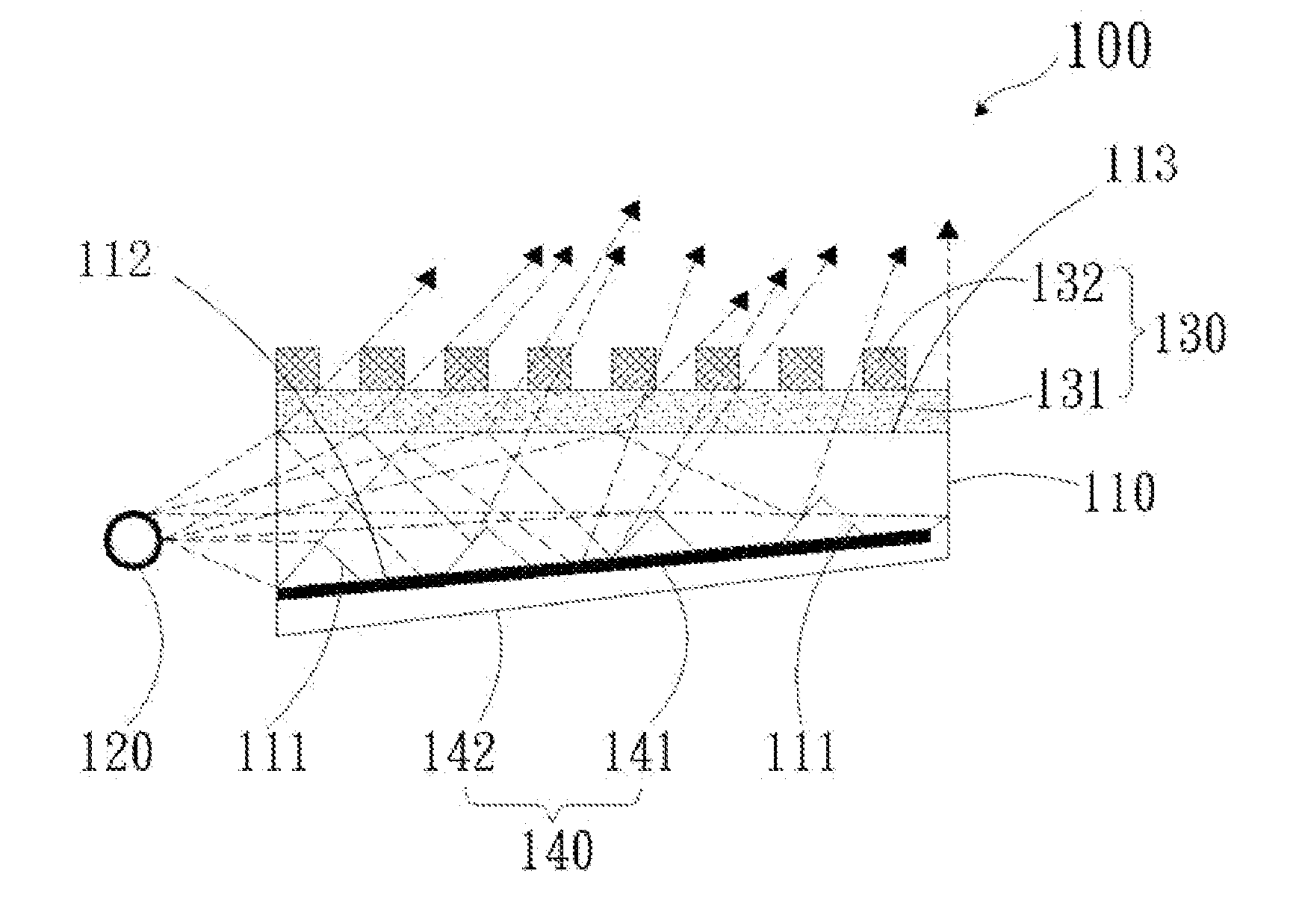

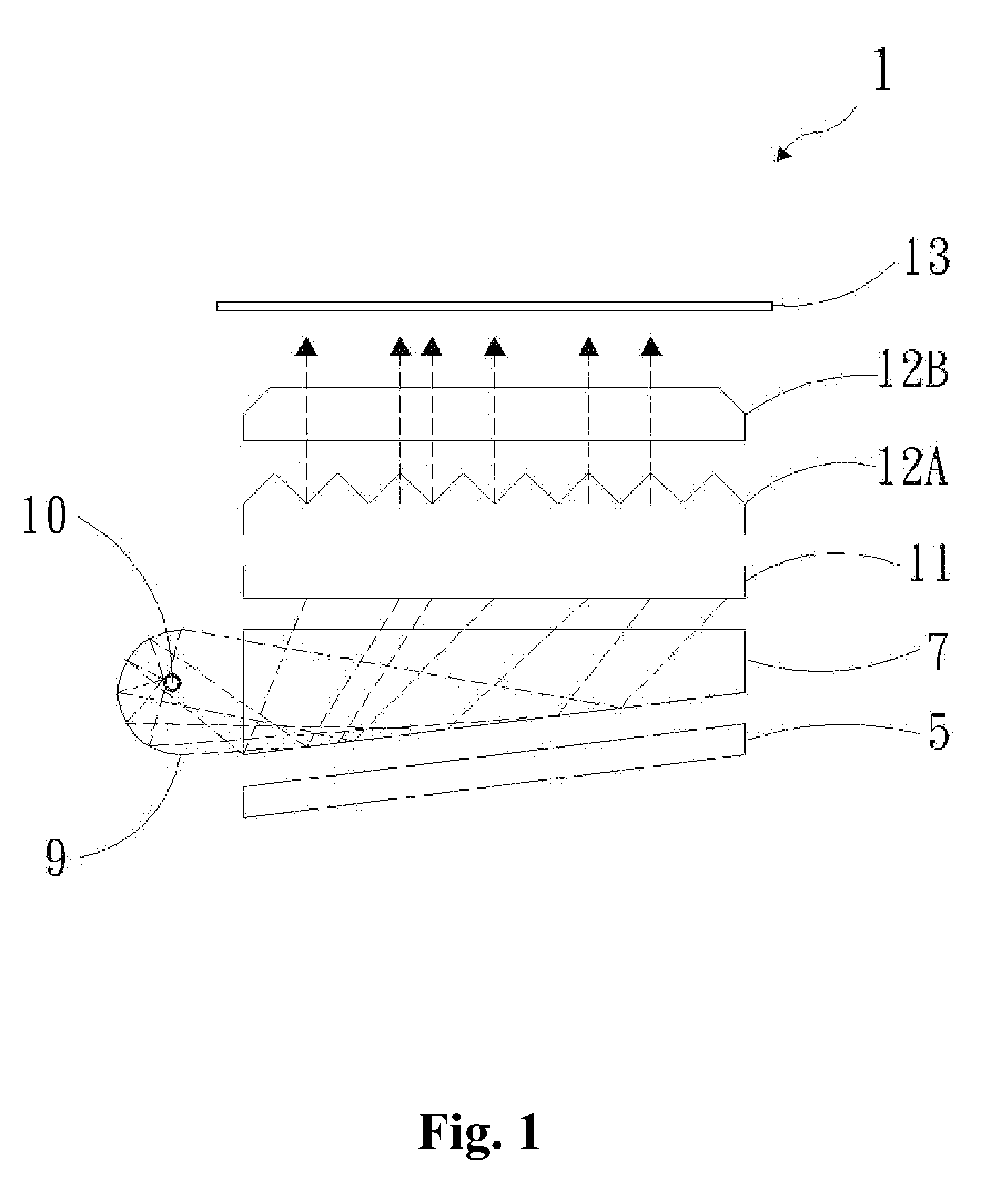

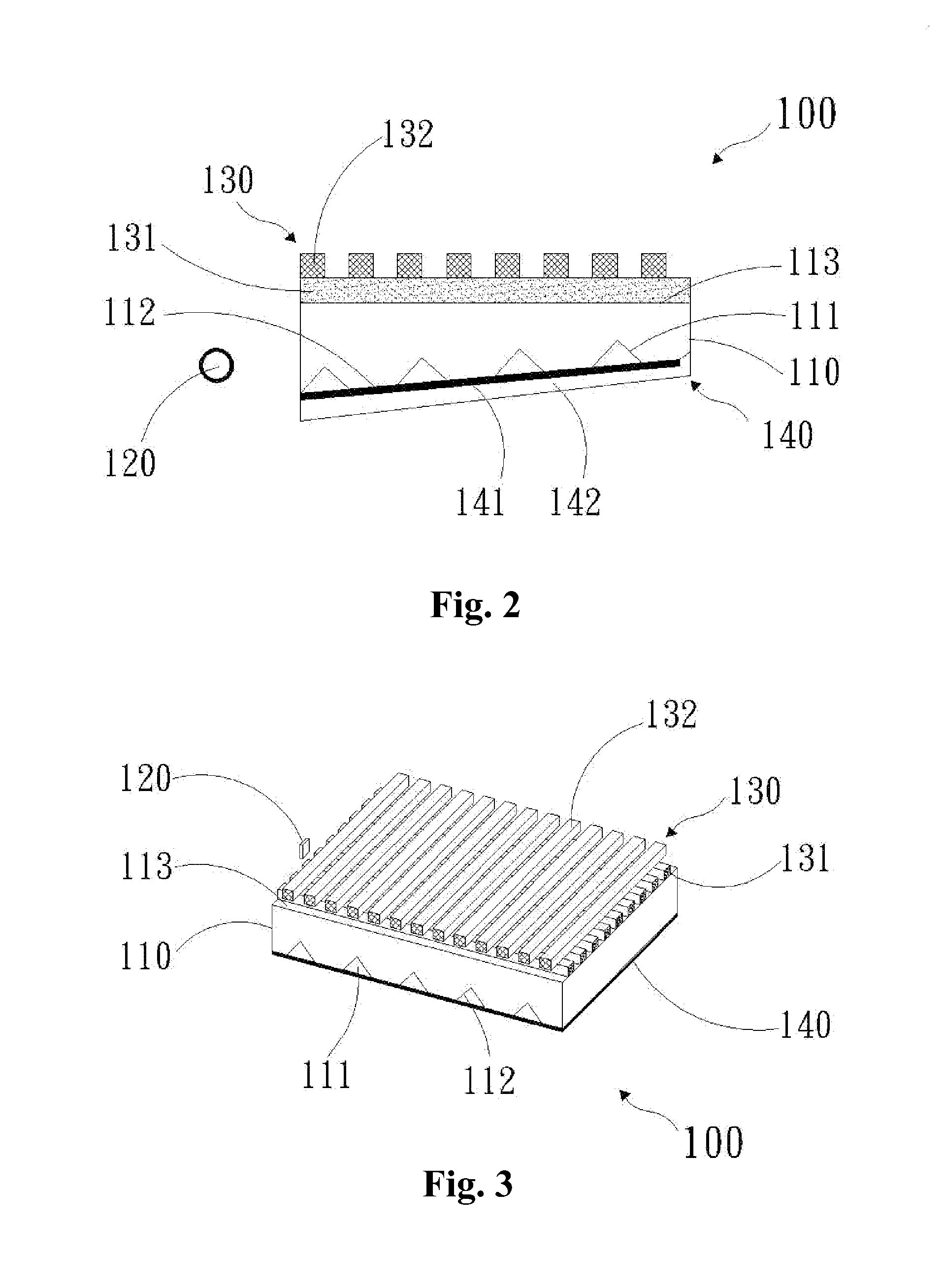

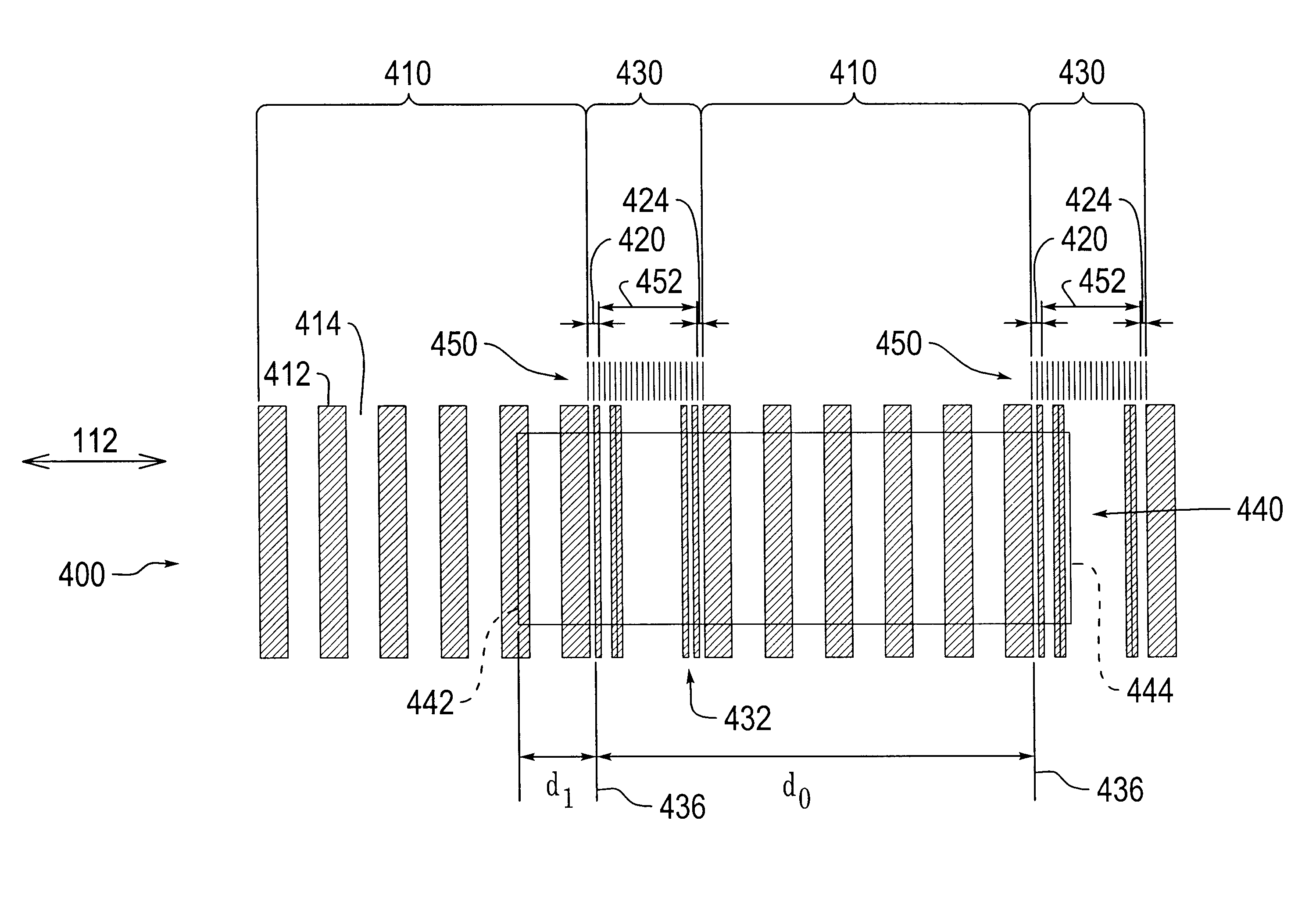

Microstructural polarized light-guide device

A microstructural polarized light-guide device comprises an unpolarized light source module, a subwavelength polarization beam splitter structure and a polarization conversion module, the unpolarized light source module comprises a light-guide plate and a light source at the edge of the light-guide plate, the material of the light-guide plate is PMMA with the characteristic of high transparency, the surface of the light-guide plate has a plurality of extraction patterns, the polarization beam splitter structure is a nano-scale structure and comprises a dielectric nanograting layer and a metallic nanograting layer, and the dielectric nanograting layer and the metallic nanograting layer are vertically stacked with each other, the dielectric nanograting layer is integrated with a surface opposite to the surface with the plurality of extraction patterns, the polarization conversion module is disposed on the surface with the plurality of extraction patterns of the light-guide plate.

Owner:NATIONAL TSING HUA UNIVERSITY

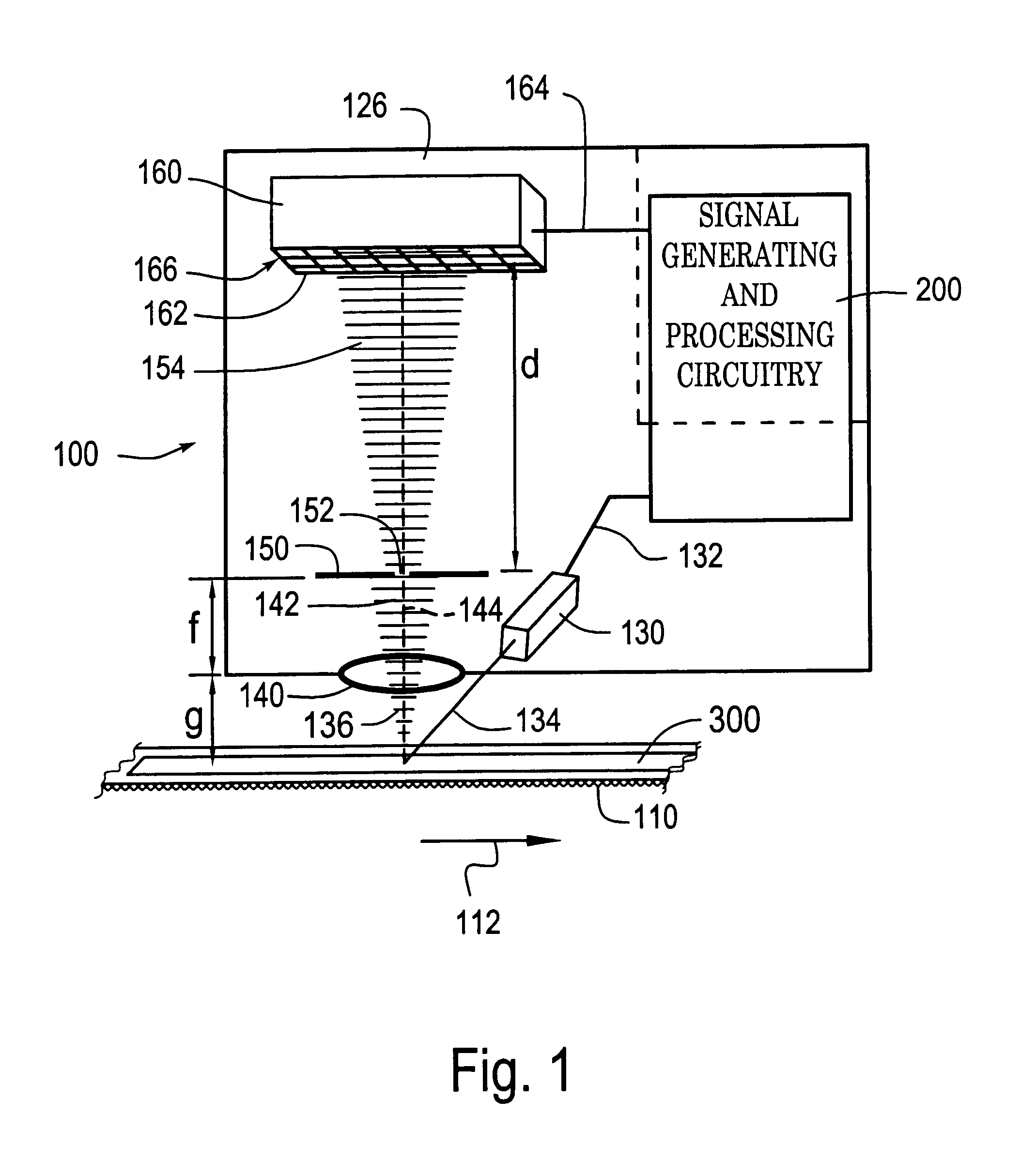

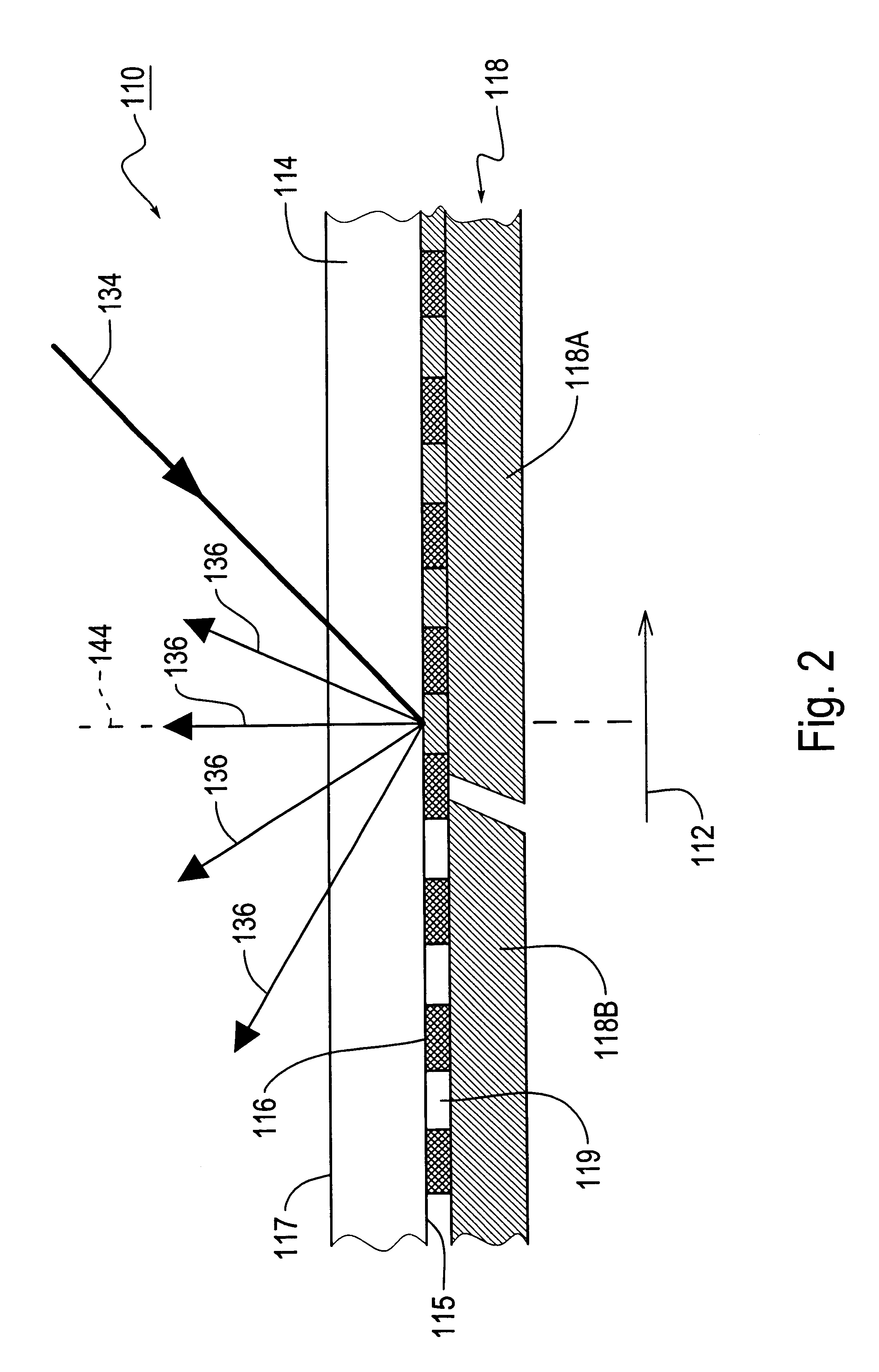

Scale structures and methods usable in an absolute position transducer

InactiveUS6664535B1Small sizeReduce widthMaterial analysis by optical meansPhotoelectric discharge tubesScale structureTransducer

An absolute position-sensing device is usable to measure the relative position of two elements. An absolute scale includes an integrated track extending along a measuring axis of the scale. The integrated track includes a plurality of periodic portions interleaved with a plurality of non-periodic portions. Each periodic portion includes a plurality of periodically-placed scale elements. Each non-periodic portion includes a plurality of code elements indicative of an absolute measurement value. The code elements may have a length that is narrower along the measuring axis than the length of the periodic scale elements. The offset of the periodic-placed elements relative to a readhead of the device is combined with the absolute measurement value to determine an absolute position.

Owner:MITUTOYO CORP

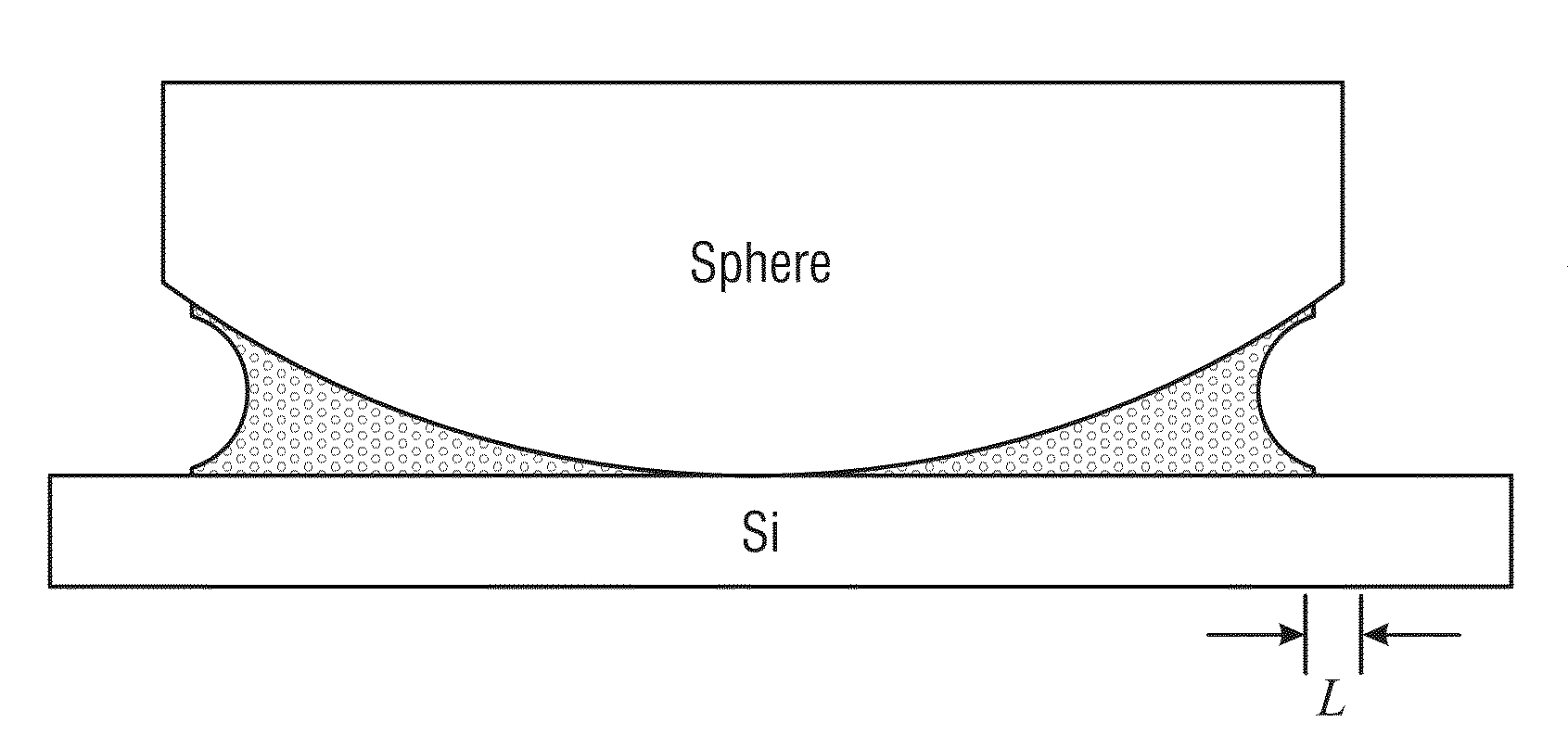

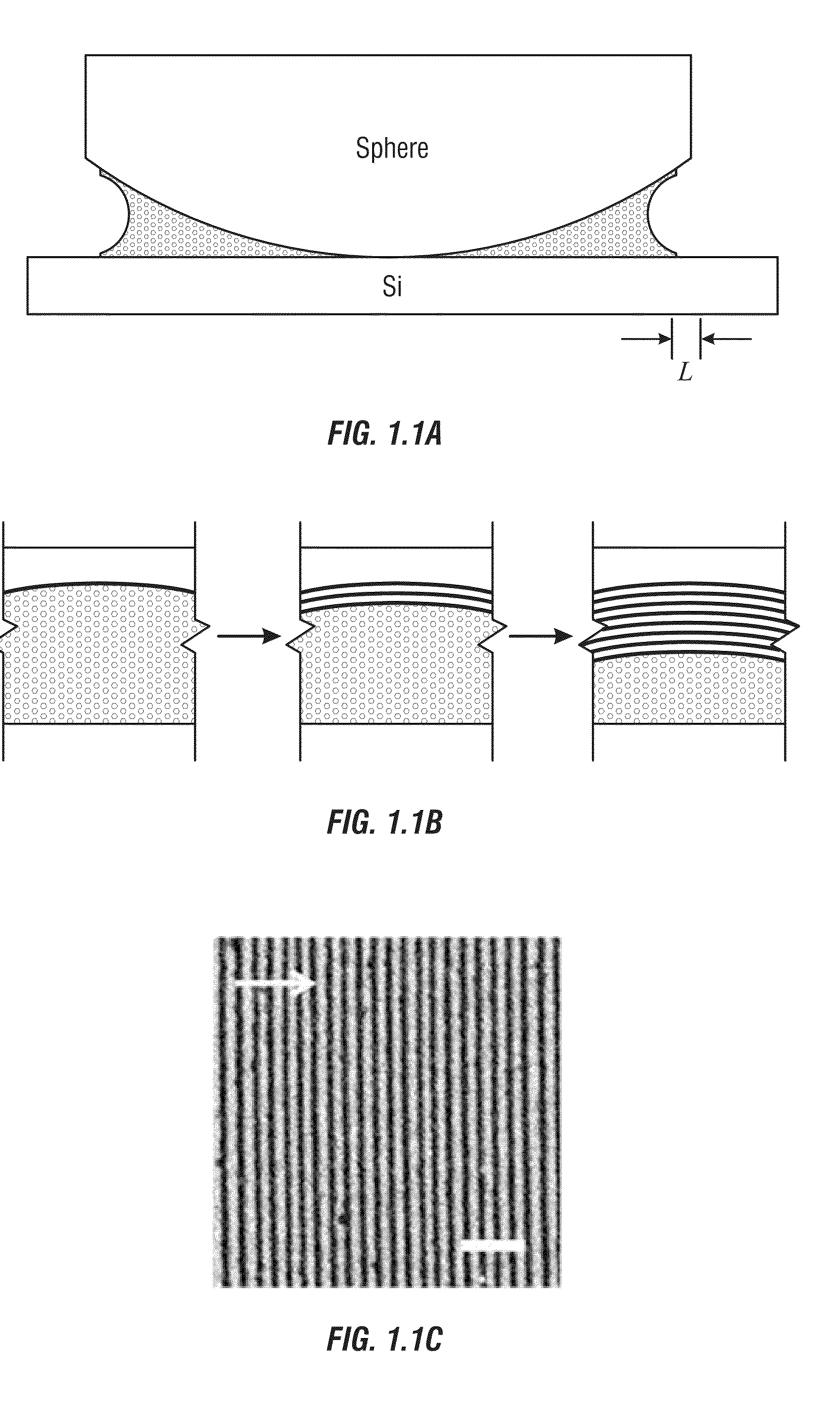

Drying-mediated self-assembly of ordered or hierarchically ordered micro- and sub-micro scale structures and their uses as multifunctional materials

Methods, apparatus, and systems of fabricating ordered or hierarchically ordered small-scale structures (e.g. micro- or sub-micro size) without the need for lithographic techniques or external fields. The methods use irreversible solvent evaporation to deposit the solute on a surface. A spherical lens is brought down into contact with the droplet. By selection and control of one or more relevant parameters, various characteristics or features of the resulting structures can be controlled. Nano-scale structures or materials can be formed or included in the micro- or sub-micro-scale formed structures. The nano-scale structures or materials can self-assembly in hierarchical order by selection and control of certain process parameters.

Owner:IOWA STATE UNIV RES FOUND

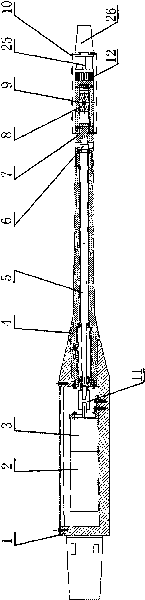

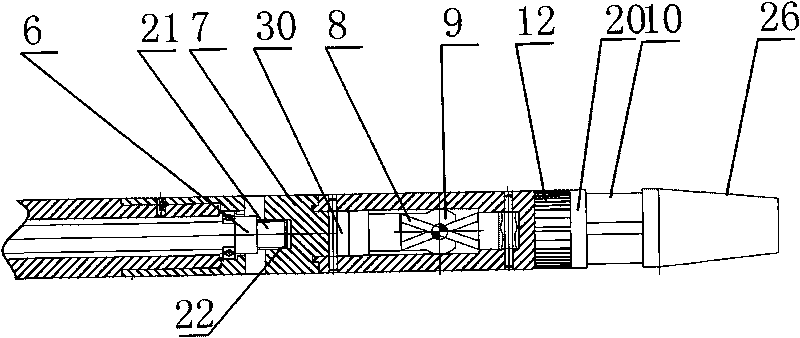

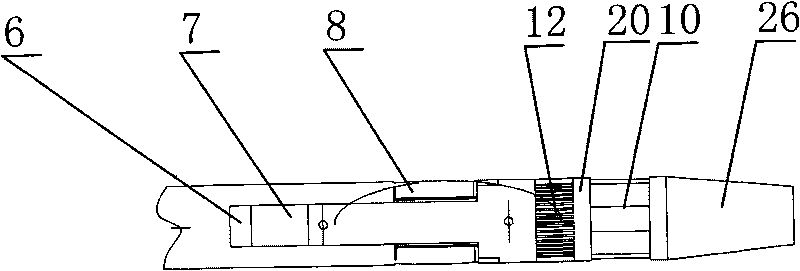

Scale measuring device for pitching dynamic derivative experiment

InactiveCN101726401AAccurate detectionDesign scienceSubsonic/sonic/ultrasonic wave measurementAerodynamic testingMeasurement deviceDrive shaft

The invention provides a scale measuring device for a pitching dynamic derivative experiment. An electric motor is arranged in a motor support rod; a motor output shaft is connected with a transmission shaft via a speed reducer and a shaft coupling; the transmission shaft is rotationally connected with a scale support rod; the rear end of the scale support rod is fixedly connected with the front end of the motor support rod; the front end of the transmission shaft is provided with an eccentric wheel which is provided with a lug; the lug is inserted into a sliding chute of a slide block; upper and lower cross springs of a cross spring scale have a crisscross structure respectively, and the front and rear ends thereof are fixedly connected with a scale frame via a front seat; and central positions of the upper and lower cross springs are provided with supporting cylinders. The scale measuring device for the pitching dynamic derivative experiment is a novel pitching dynamic derivative scale device. A pitching direct derivative of an aerial craft and a rolling crossover derivative induced by yaw oscillation can be measured under a big attack angle by designing a special vibrating mechanism, the cross spring scale and a pitching five-component scale structure. The scale measuring device for the pitching dynamic derivative experiment can meet the requirement of a wind tunnel trial.

Owner:SHENGYANG AERODYNAMIC INST AVIATION IND CORP OF CHINA

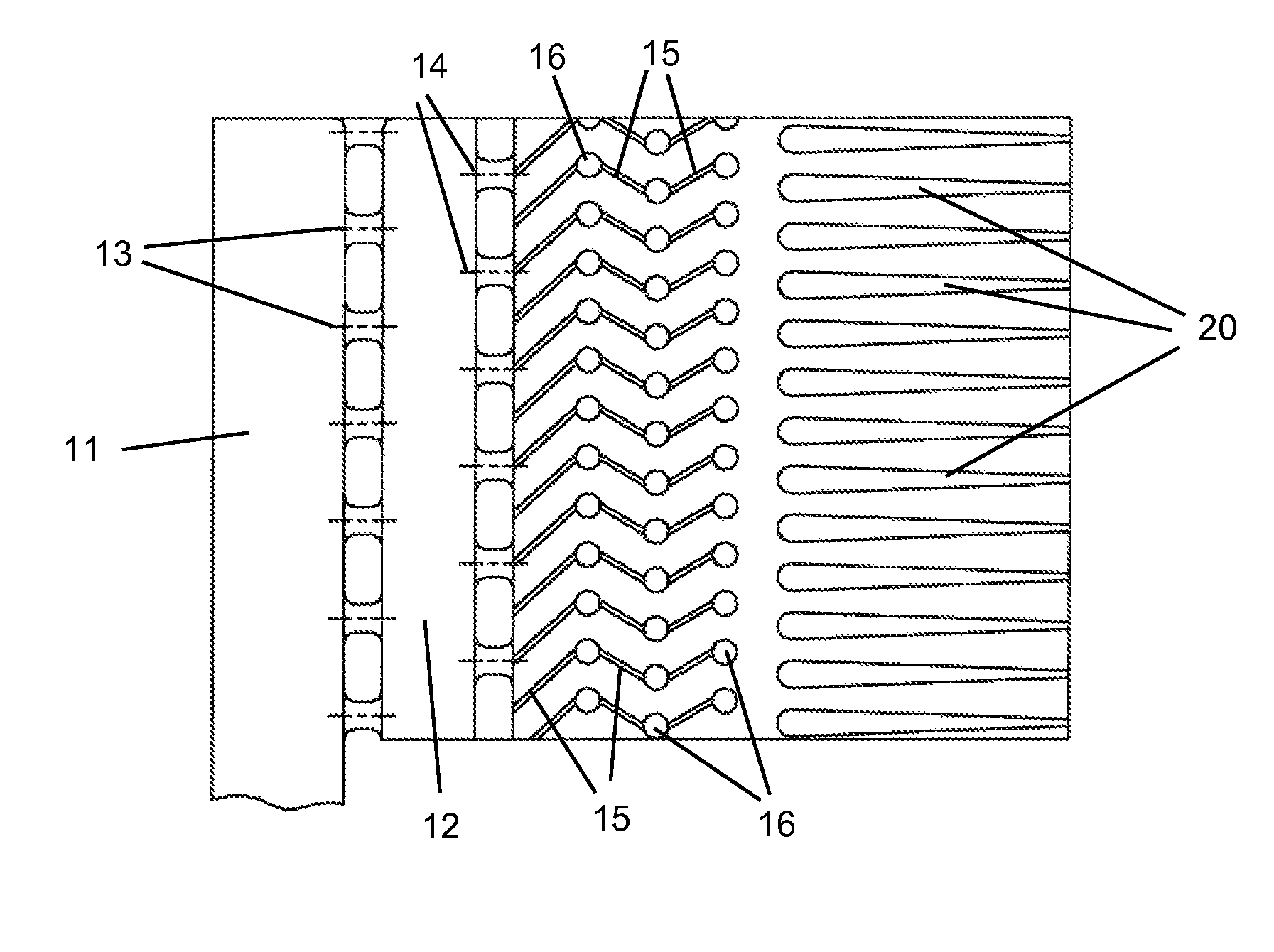

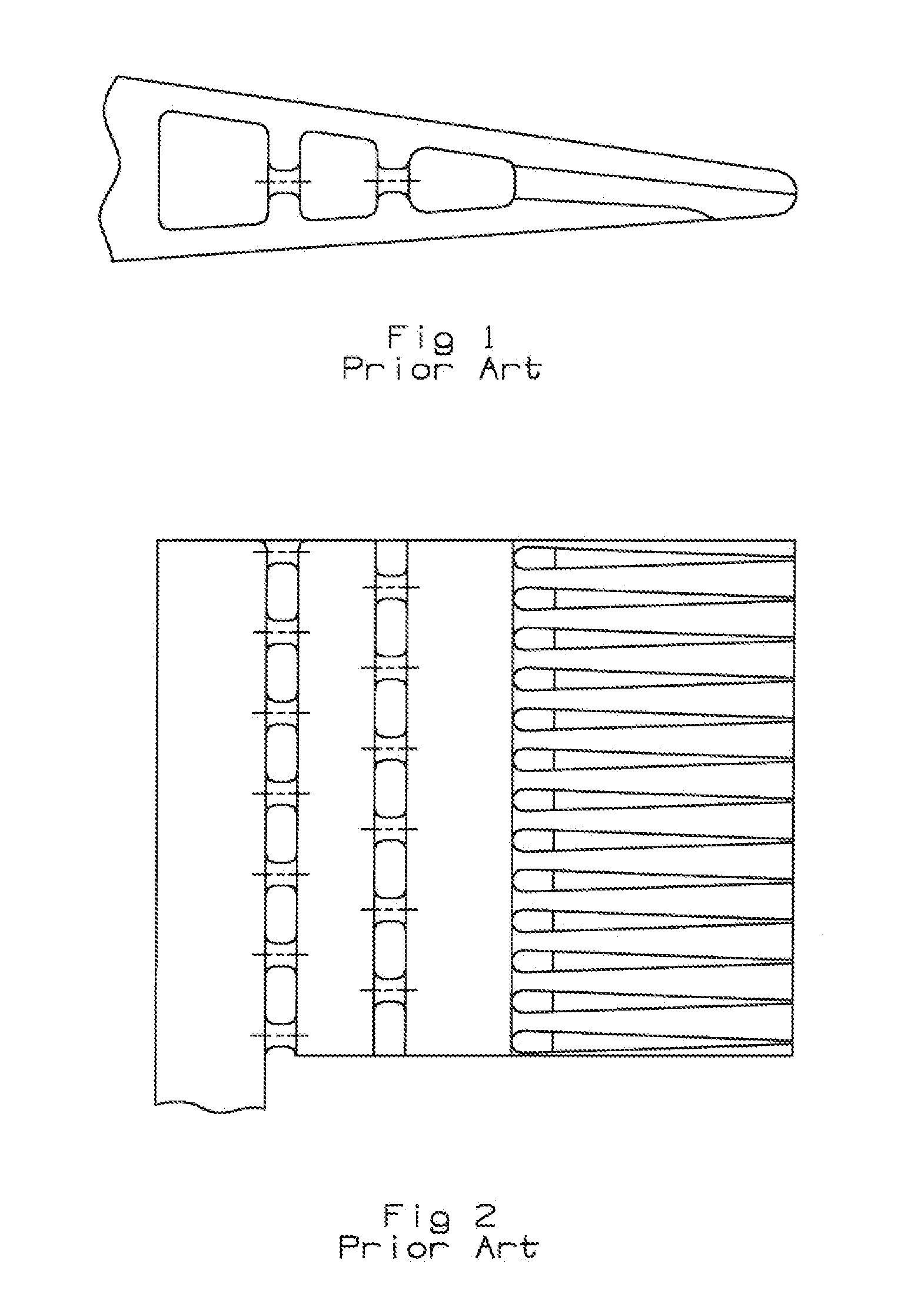

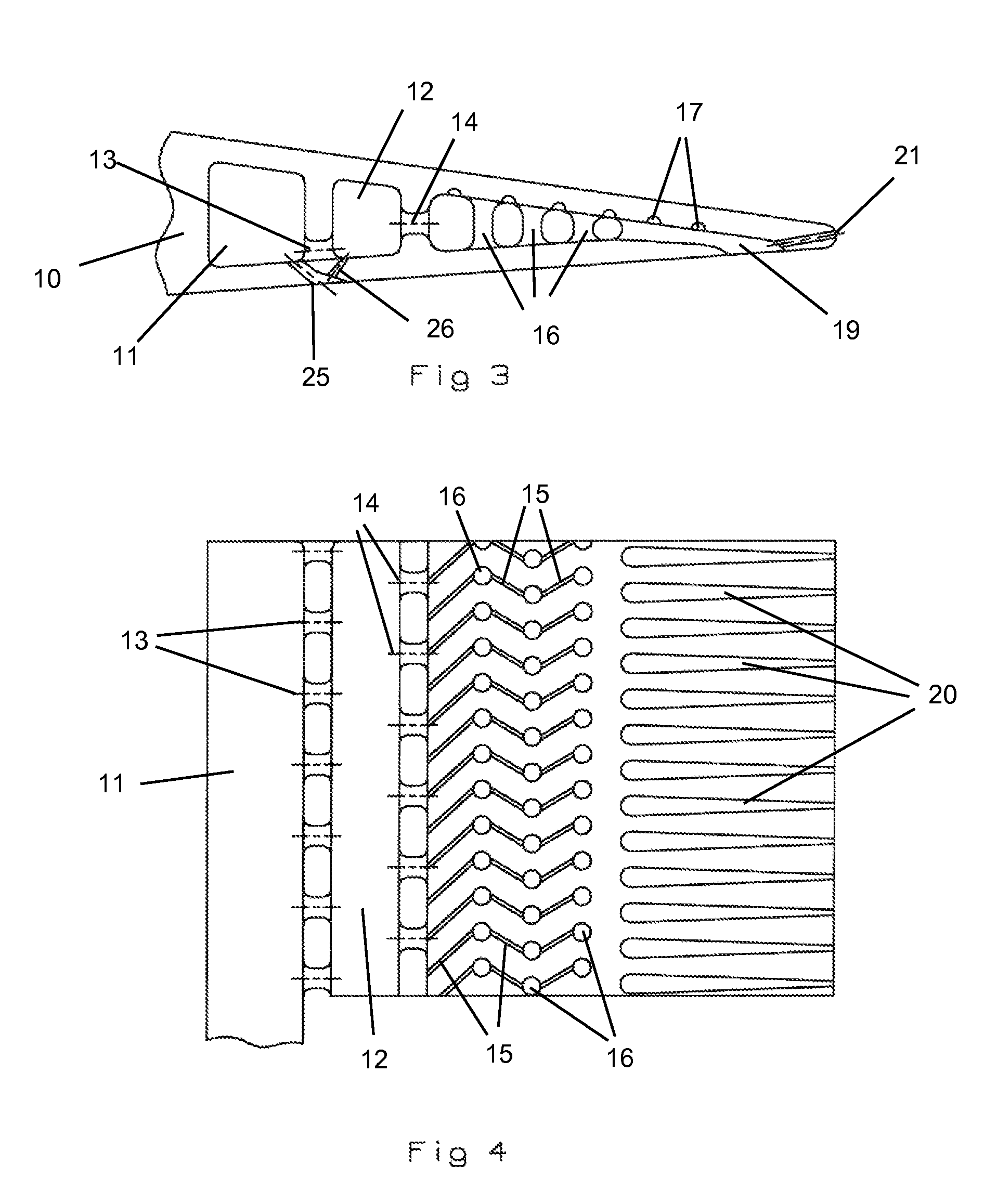

Turbine airfoil with micro cooling channels

Owner:SIEMENS ENERGY INC +1

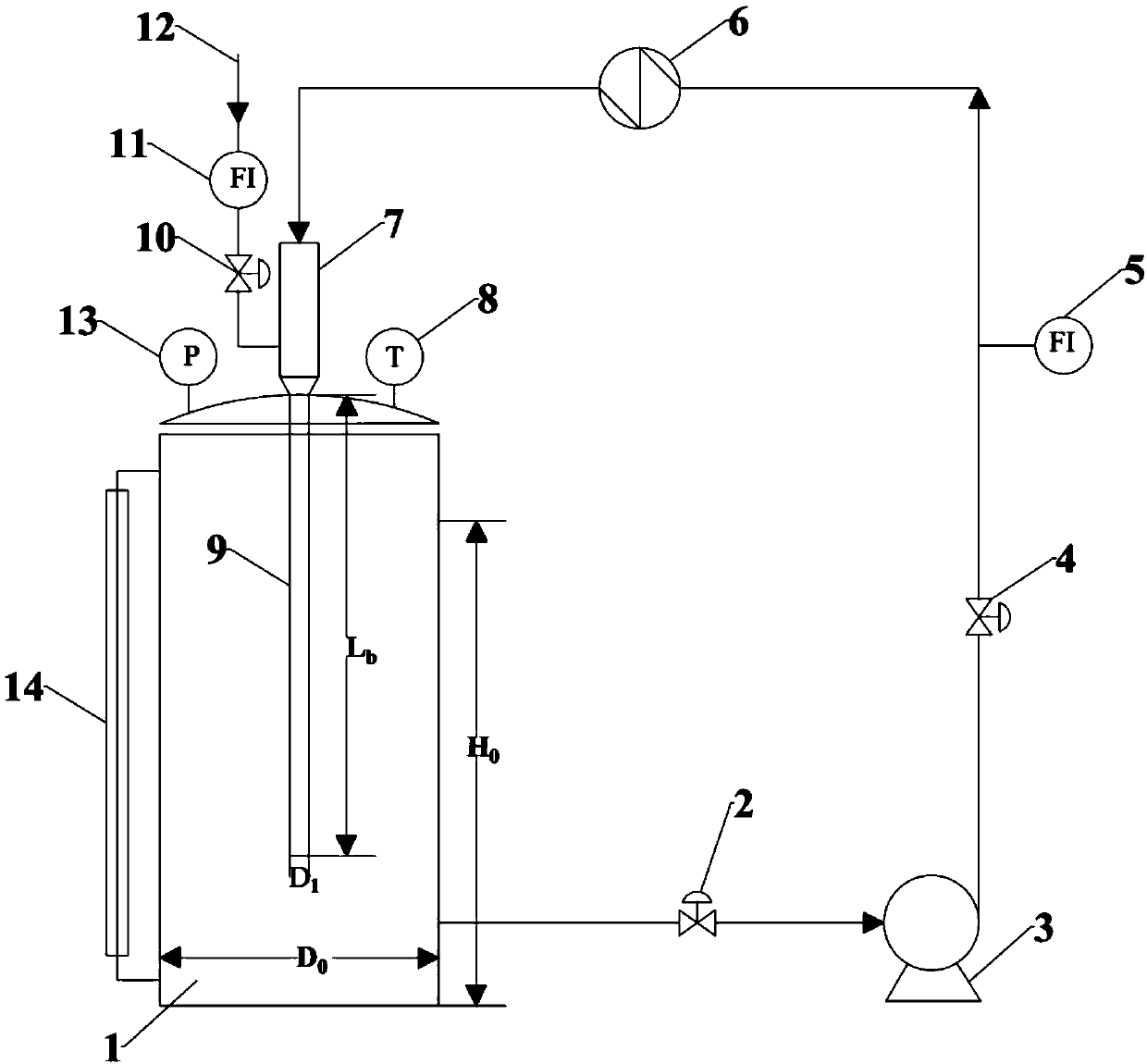

Bubble-scale structure-effect control model modeling method for micro-interface strengthening reactor

ActiveCN107563051BReduce mistakesImprove versatilitySpecial data processing applicationsActivity regulationScale structure

The invention relates to a micro-interface enhanced reactor bubble scale structure-activity regulation and control model building method. The diameter dmax of the largest bubble of a micro-interface enhanced reactor and the diameter dmin of the smallest bubble of the micro-interface enhanced reactor serve as independent variables, the average diameter d32 of the bubble Sauter serve as a dependentvariable, and a numerical relationship is built; based on the Kolmogorov-Hinze theory, the relationship between the diameter dmax of the largest bubble of the micro-interface enhanced reactor, the diameter dmin of the smallest bubble and the parameters of the reactor is built. According to the method, the reactor bubble scale is associated with the structural parameter, the operation parameter andthe physical property parameter of the reactor by using specific numerical relationship, the numerical relationship has the guiding significance for the design of the reactor and can be applied to avariety of reactors, the versatility is good, by means of a bubble scale regulation and control model built through the method, by adjusting the structural parameter and the operation parameter of thereactor, and the maximization of energy efficiency and material efficiency in the reaction process can be achieved, or under the condition that reaction targets, energy consumption and material consumption are given, a high-efficiency reactor structure is designed.

Owner:NANJING UNIV

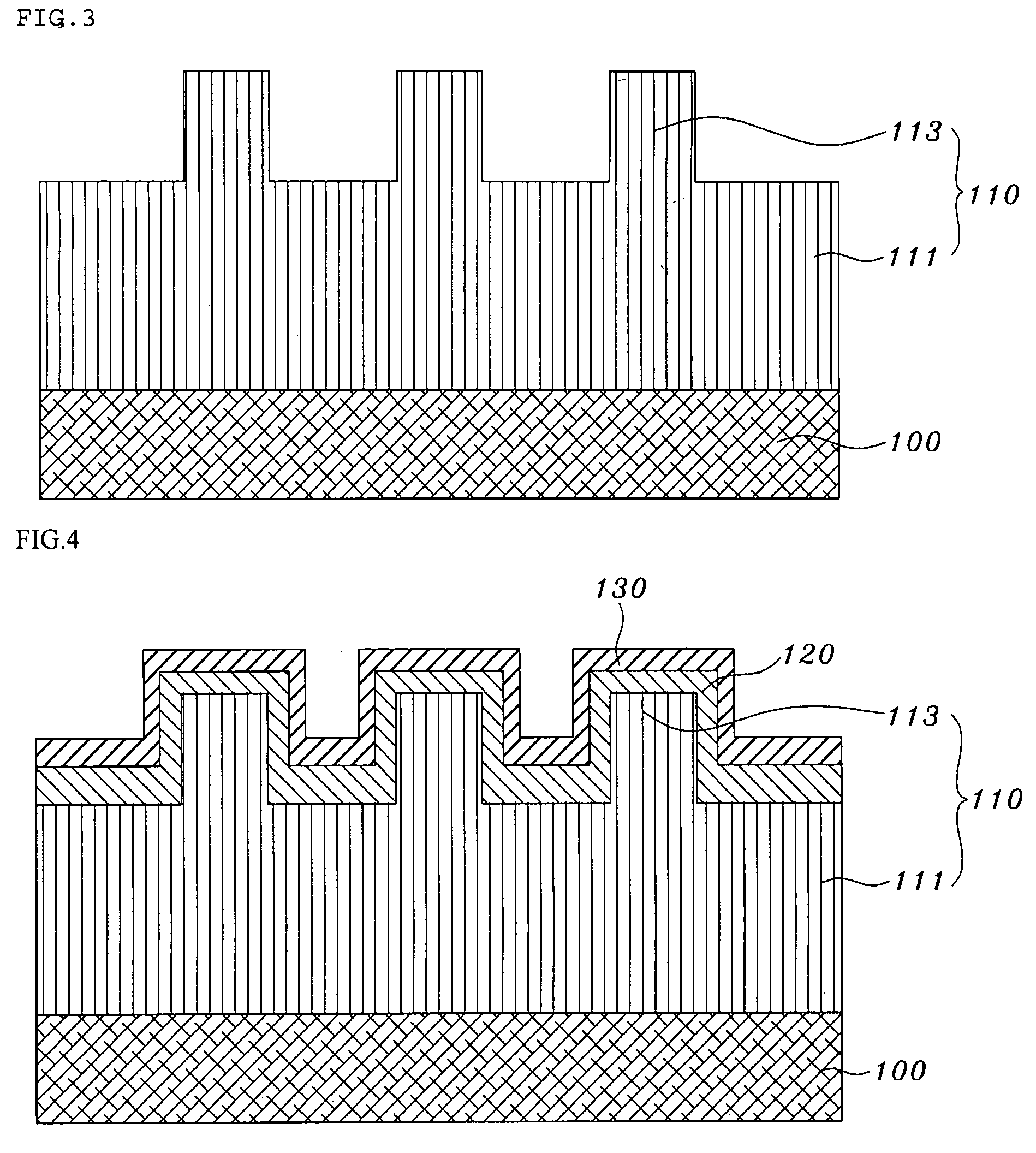

Mold for nano-imprinting and method of manufacturing the same

InactiveUS20080061214A1Increased durabilityAvoid damageNanostructure manufactureConfectioneryScale structureOptoelectronics

A nano-imprint mold and a method of manufacturing the same are provided, which can be used for replicating a nano-scaled structure to a polymer layer. The nano-imprint mold comprises: a substrate; a pattern portion having a prominence and depression pattern formed on the substrate; a hard layer formed of a material with a hardness higher than the pattern portion on a surface of the pattern portion; and a separation layer formed on a surface of the hard layer. In the nano-imprint mold of the present invention, an original pattern can be uniformly replicated even on a substrate with an irregular surface. Further, the pattern can be prevented from being damaged by pressure and being contaminated by synthetic resin, resulting in better accuracy and durability of the pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

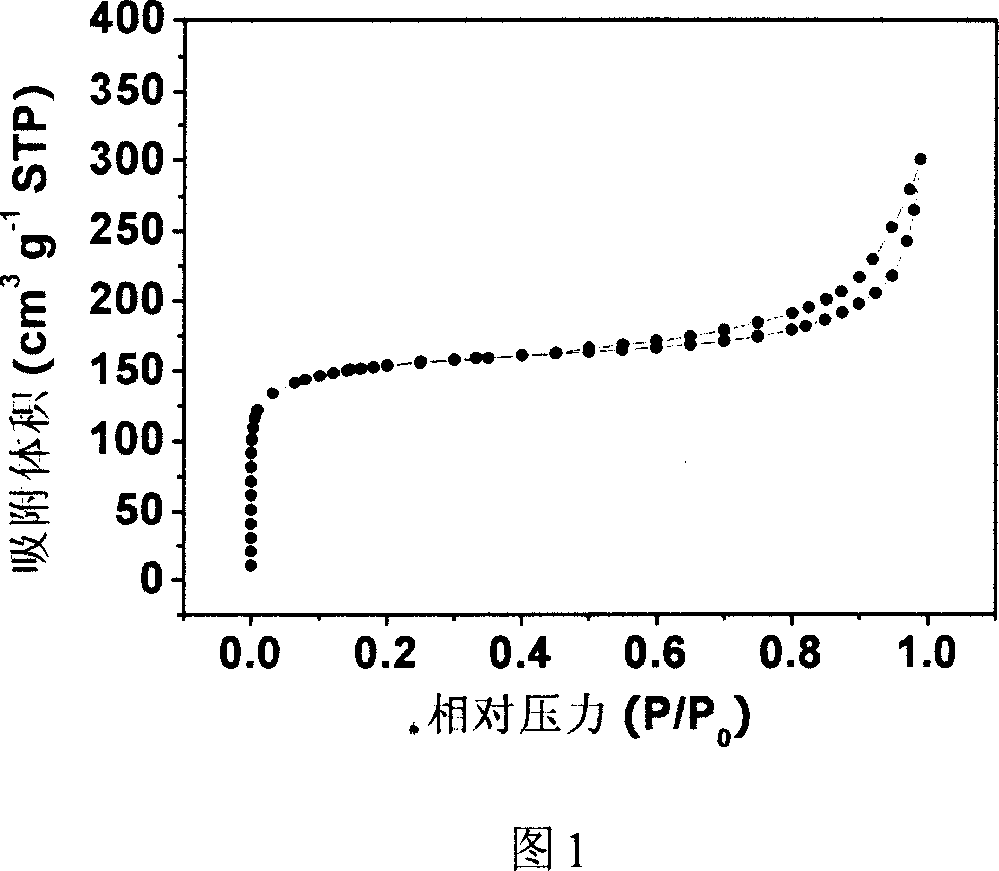

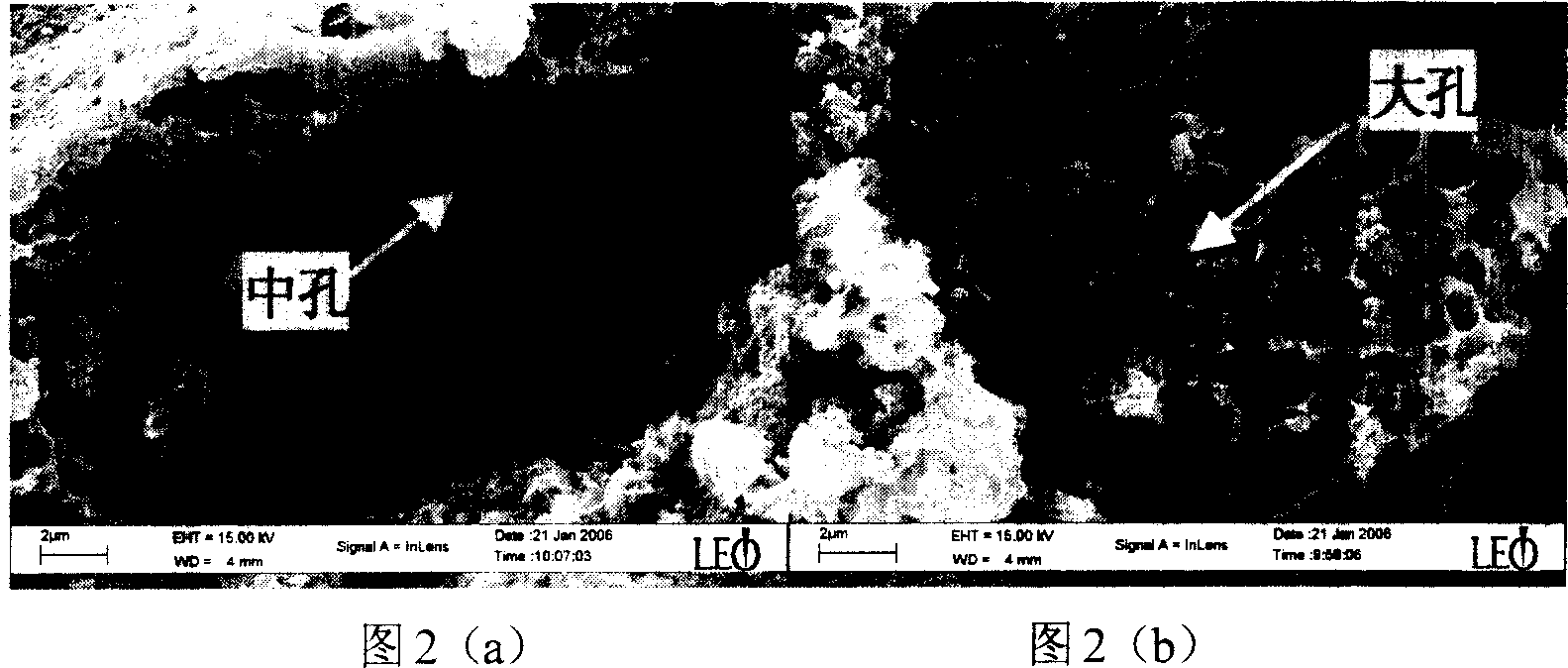

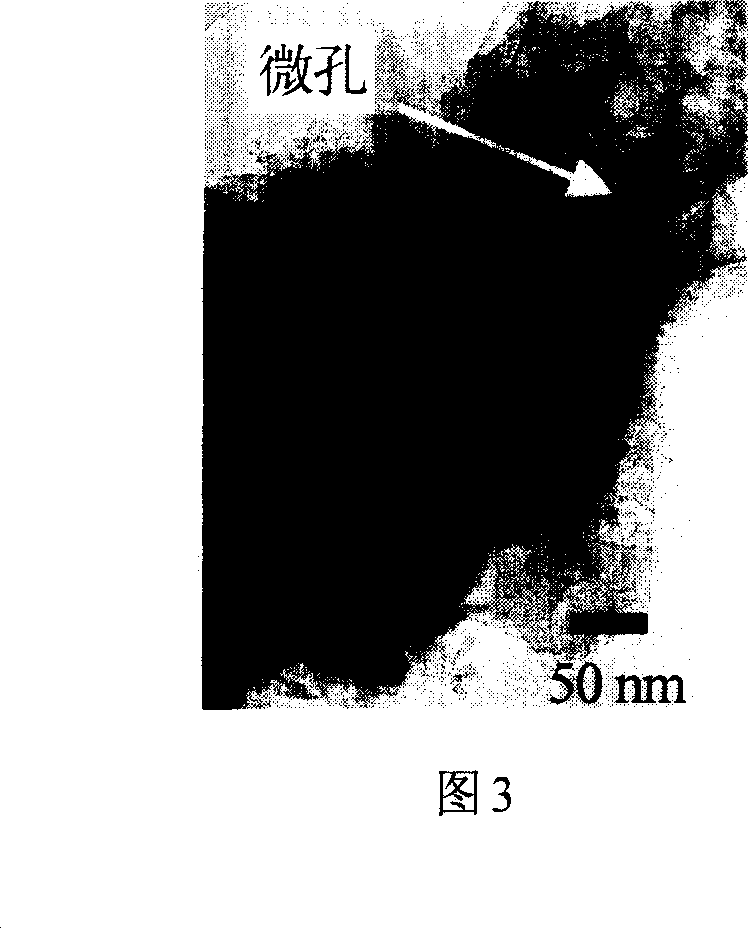

Layer combination controllable carbon material with nano pole of different scale, preparation method and application

The invention relates to a method for design advanced materials with nano-scaled structure and techniques for preparing same. In particular, the invention relates to a carbon material capable of controllable laminated combination with the nano-holes of variable sizes and preparation and application thereof. The method comprises the steps of: preparing metal oxide sol in the alkali solution system, which is then mixed with an alcohol solution of an alcohol-soluble resin; the oxide sol being used as the template and water being the resin precipitation agent during the process to directly prepare resin / oxide sol composite system. After solvent removal, carbonization, activation and template removal processes, the carbon material with laminated nano-holes combination is prepared which is of controllable micro-holes proportion, controllable medium-holes aperture and proportion, controllable big-holes aperture and propotion and concentrated distribution of medium-holes and big-holes apertures. The carbon material capable of controllable laminated combination with the nano-holes of variable sizes prepared in the invention is characterized in laminated holes structure, excellent ion transfer performances and high electrochemical active specific surface area and the material is expected to be used as high energy density high power density electrochemical capacitor used electrode material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Photovoltaic cells based on NANO or micro-scale structures

ActiveUS20070204901A1Electric power generatedLarge power generation capabilitySolid-state devicesSemiconductor/solid-state device manufacturingScale structureEngineering

Novel structures of photovoltaic cells (also treated as solar cells) are provided. The cells are based on nanometer-scaled wires, tubes, and / or rods, which are made of electronic materials covering semiconductors, insulators or metallic in structure. These photovoltaic cells have large power generation capability per unit physical area over the conventional cells. These cells will have enormous applications in space, commercial, residential, and industrial applications.

Owner:BANPIL PHOTONICS

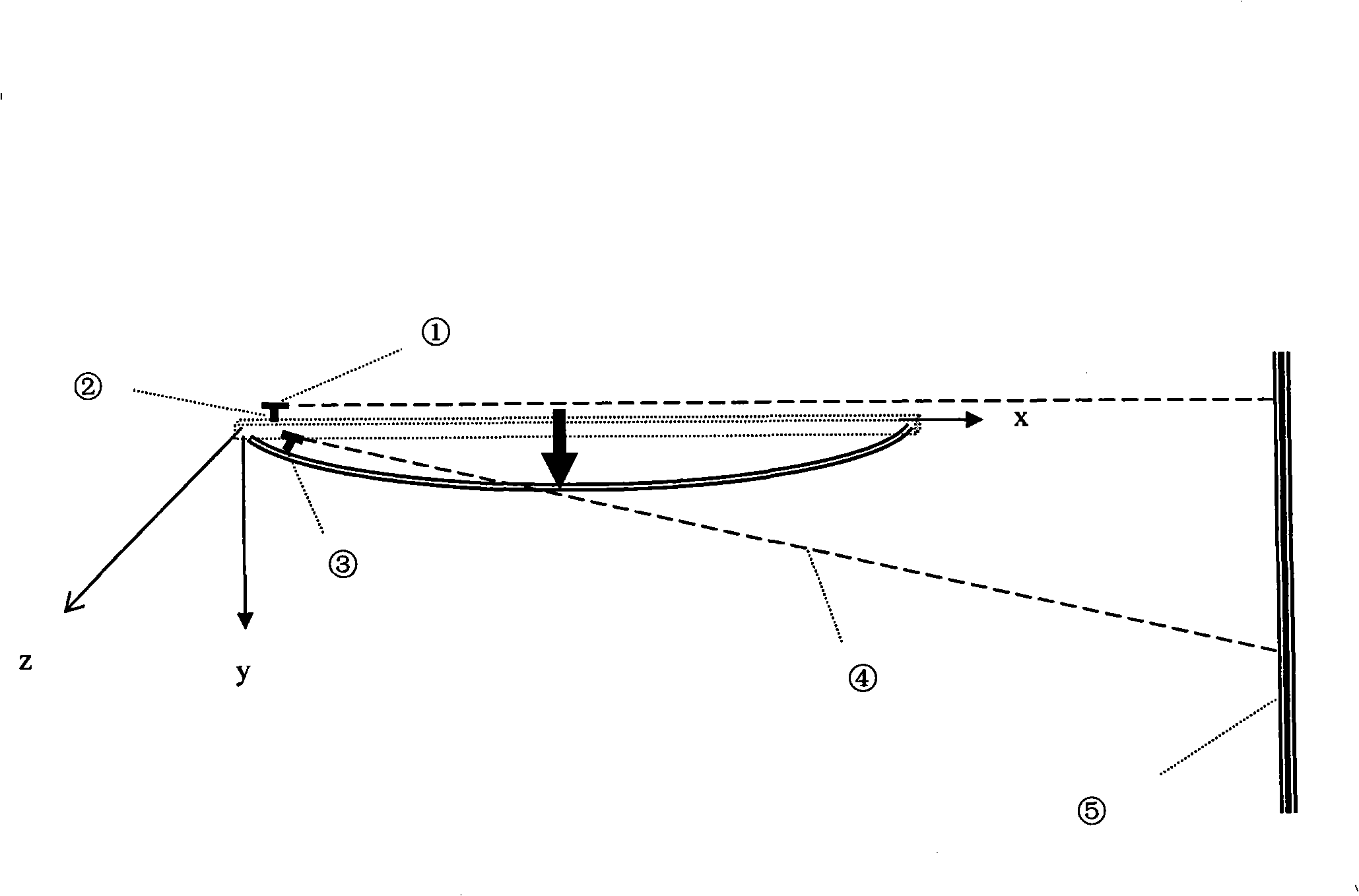

Laser amplifying measurement method for bending structure deformation

InactiveCN101344383AAccurate measurementAccurate small deformationUsing optical meansMeasurement pointMeasuring instrument

The invention relates to a laser amplification measurement method of the deformation of a twisted structure by utilizing laser. The technical proposal of the invention is as follows: a support is arranged on a rotation angle part to be measured of the twisted structure to be measured, a laser beam transmitter is arranged on the support, a scale optical target is set, when the twisted structure to be measured is displaced or twisted, a laser beam which is transmitted by the laser beam transmitter is displaced at a projection point on the optical target, a deformation valve of the rotation angle or a twist angle of a measurement point of the twisted structure to be measured is obtained according to the formula that Theta is equal to arctg (Delta divided by L), and the stiffness parameters of the twisted structure to be measured is calculated, thereby obtaining the tiny rotation deformation amount of the point to be measured. The shortcoming that the non-contact measurement instruments are always lack of precision on the long-distance measurement of the tiny deformation of large-scale structures is solved. The laser amplification measurement method of the invention arranges the measurement instrument on a measured object to allow the measurement instrument to move together with the deformed part of the measured object, thereby having the advantage that the tiny displacement to be measured is fully amplified by utilizing the optical lever principle.

Owner:YANGZHOU UNIV

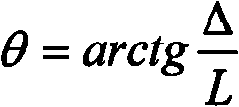

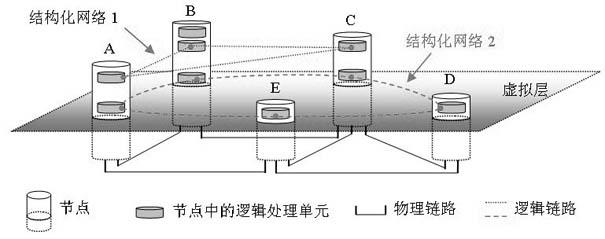

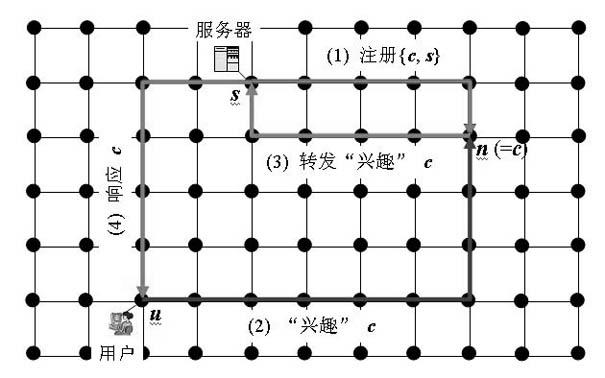

Structured network system applicable to future internet

InactiveCN102523166AEliminate blockingLoad balancingData switching networksContent distributionScale structure

The invention provides a structured network system applicable to the future internet, which constructs and maintains a plurality of concomitant structured networks (SNs) on a physical network through a virtual layer. The system can construct the structured future internet on a large-scale structure-free network, adopt globally unified and simple addressing, route and inquiring mechanisms, and enable route inquiring time, network interoperability or interconnection, content distribution efficiency and service obligation to be greatly improved. Practical examples of the structured network comprise hypercube networks, artificial neural networks and Batcher networks. Achieved functions comprise content / service addressing, semanteme searching, and mobile supporting, safe service based on positions, multicast, intrusion detection, network measurement, data fusion, webpage grading and flow load balancing.

Owner:SUN YAT SEN UNIV

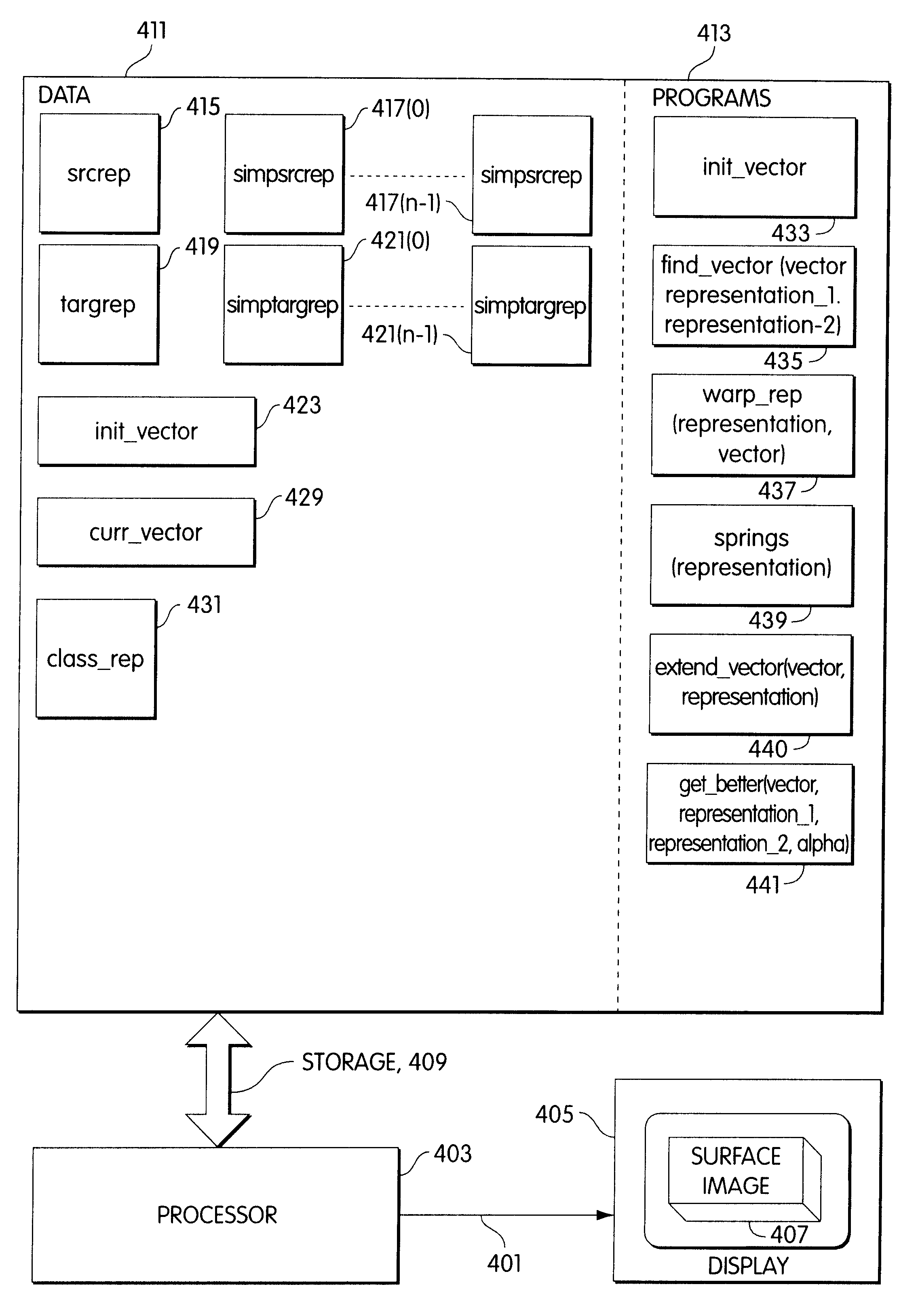

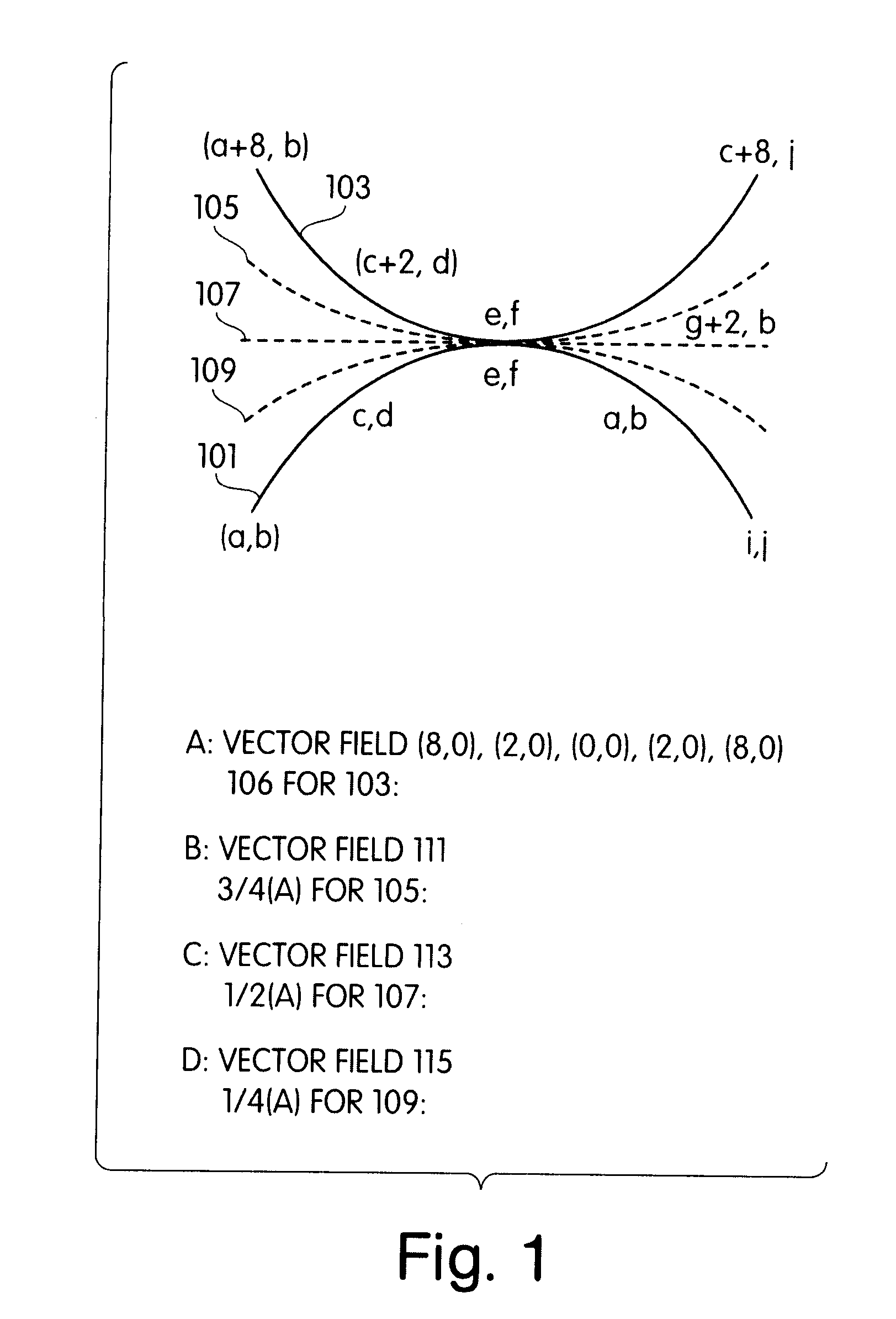

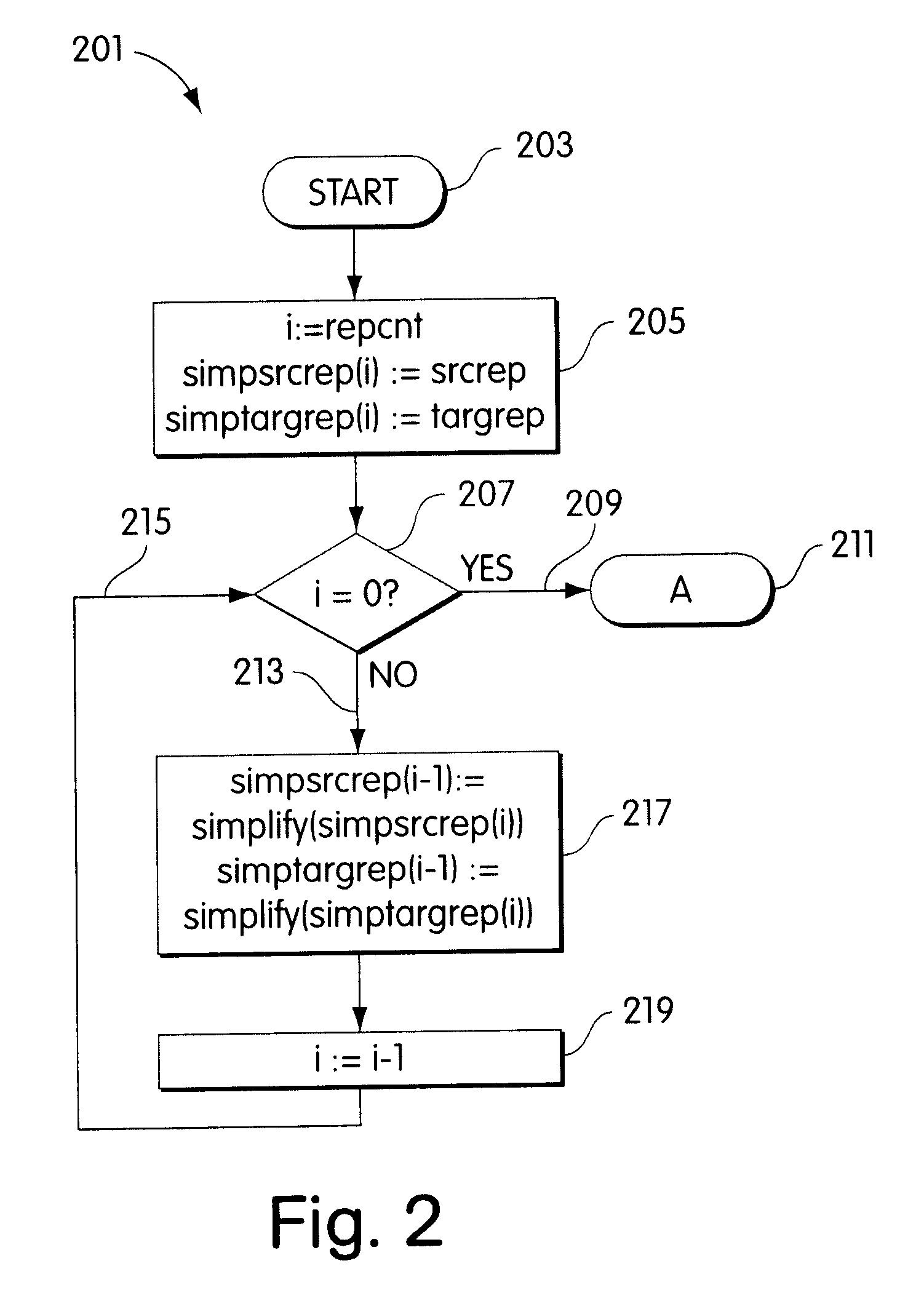

Correspondence between n-dimensional surface: vector fields that are defined by surfaces and that generate surfaces which preserve characteristics of the defining surfaces

Techniques for finding a correspondence between a source object and a target object, the objects having n>2 dimensions, such that a vector field based on the correspondence generates objects which tend to preserve the characteristics of both the source object and the target object. The techniques result in vector fields which maximize the generated object's similarity to the target object while minimizing structural changes to the source object. Minimization of structural changes is done by associating directional spring functions with points in the source object and finding a vector which generates an object for which changes in the directional spring functions are minimized. Further included are techniques for reducing the computational cost of finding a correspondence by making a set of pairs of increasingly-simplified representations of the source object and the target object and then finding pair vector fields for the pairs, beginning with the most simplified pair and ending with the original representations of the source object and the target object. The increasingly-simplified representations have the property that they preserve the large-scale structure of the original representations of the source object and the target object. The pair vector field for a given pair is found by extending the pair vector field found for the next simpler pair so that it applies to the pair's source object and then using the extended pair vector field as the initial vector field in finding the pair vector field. The techniques may be applied to images and to surfaces in which color is represented by means of additional dimensions. Vector fields found using the techniques may be used to generate objects belonging to a class of objects defined by the source object and at least the target object.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

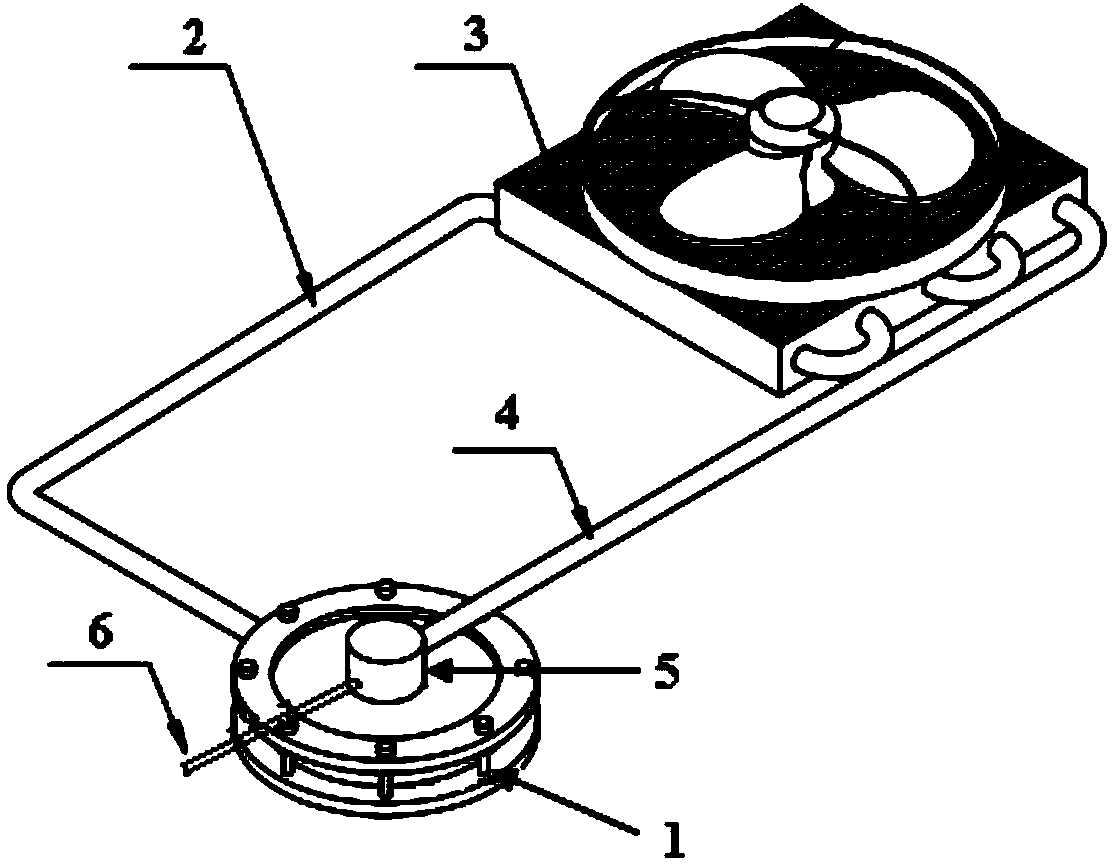

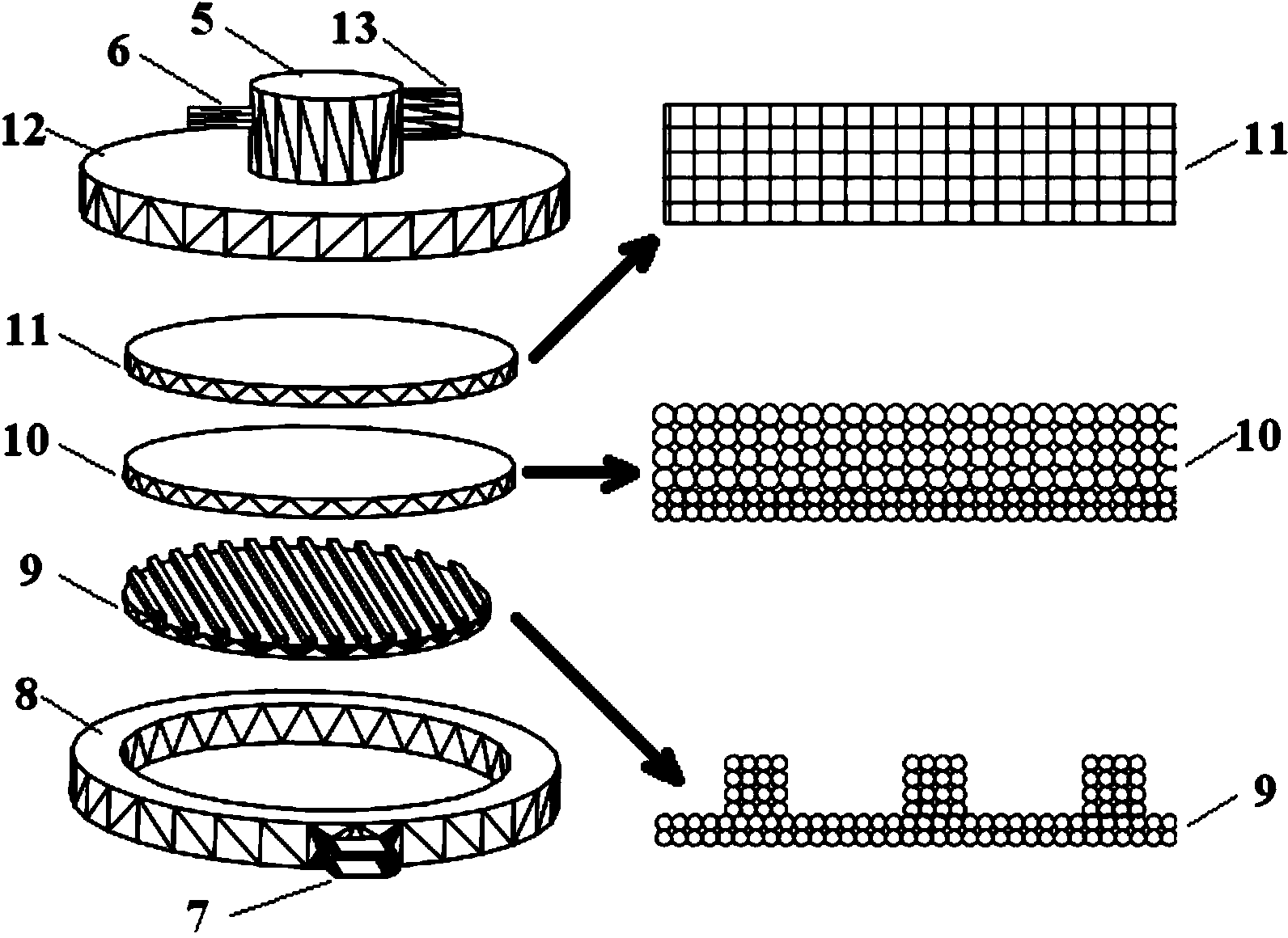

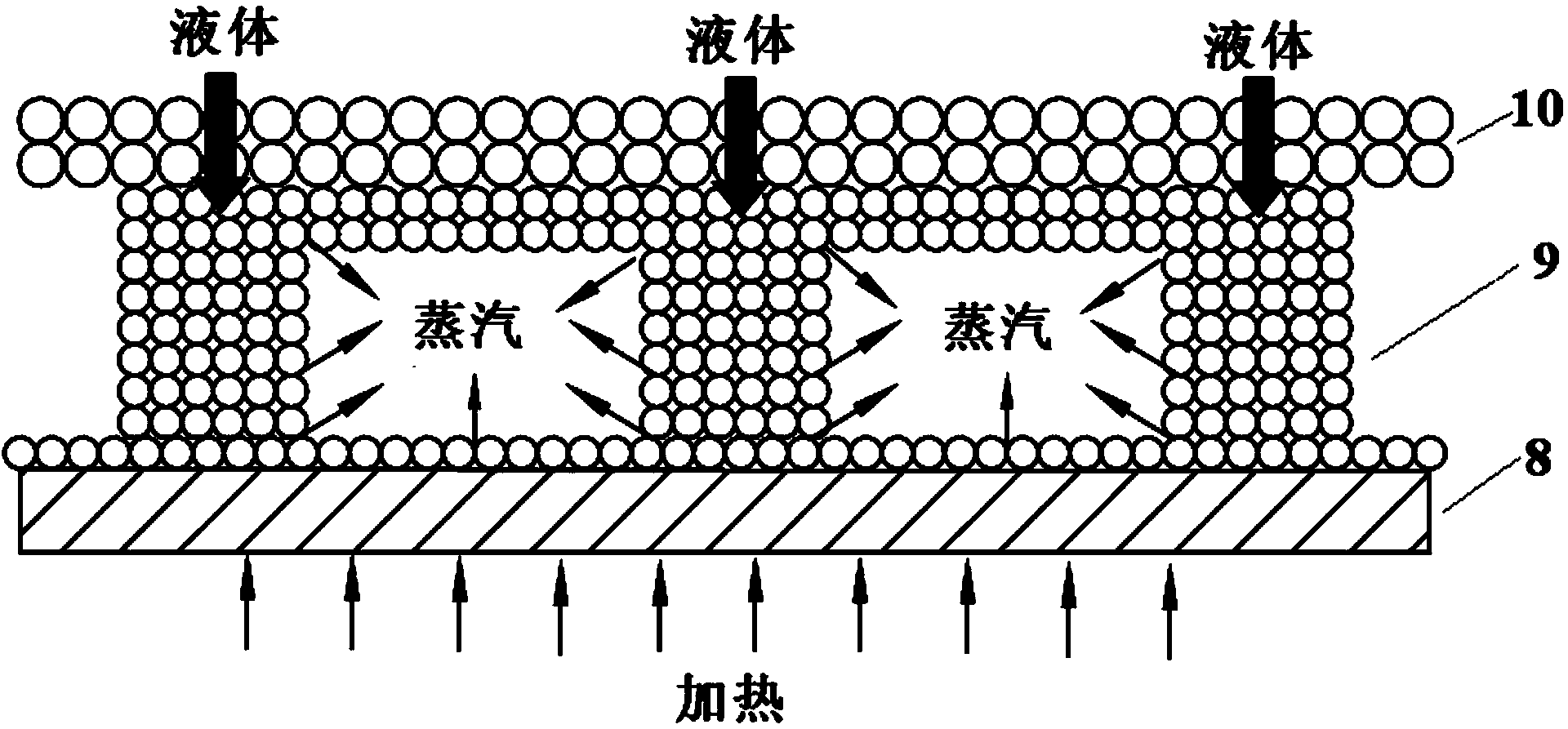

Multi-scale capillary core flat plate loop heat pipe type heat-dissipation device

InactiveCN103629963ASolve flow resistanceSolve the paradoxical relationship between capillary suctionSemiconductor/solid-state device detailsSolid-state devicesVapor liquidSuction force

The invention relates to a multi-scale capillary core flat plate loop heat pipe type heat-dissipation device, and belongs to the technical field of phase transition heat dissipation. The heat-dissipation device comprises an evaporating part, a condensing part, a compensating cavity, a gas phase pipeline and a liquid phase pipeline, wherein the gas phase pipeline is connected with the evaporating part and the condensing part, and the liquid phase pipeline is connected with the condensing part and the compensating cavity; a base plate of the evaporating part is in a flat plate shape, metal powder is sintered to form two layers of multi-scale capillary cores at the upper surface of the base plate, and a steam channel is constructed between the two layers of capillary cores; a layer of water absorption cotton tightly covers a second layer of capillary cores and is taken as a third layer of capillary cores, and the three layers of capillary cores form a multi-scale structure. By utilizing the multiple layers of multi-scale capillary cores and the constructed steam channel, the problem of the contradictoriness between the vapor-liquid flow resistance and the capillary suction force is solved, the starting temperature of a loop heat pipe is lowered, the high heating flux bearing capacity of the heat-dissipation device is improved, and the instability in heat transfer is reduced; the multi-scale capillary core flat plate loop heat pipe type heat-dissipation device has the advantages of high cooling capacity, large heat flux bearing capacity, low starting temperature, small temperature fluctuation, good antigravity performance and long transmission distance.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

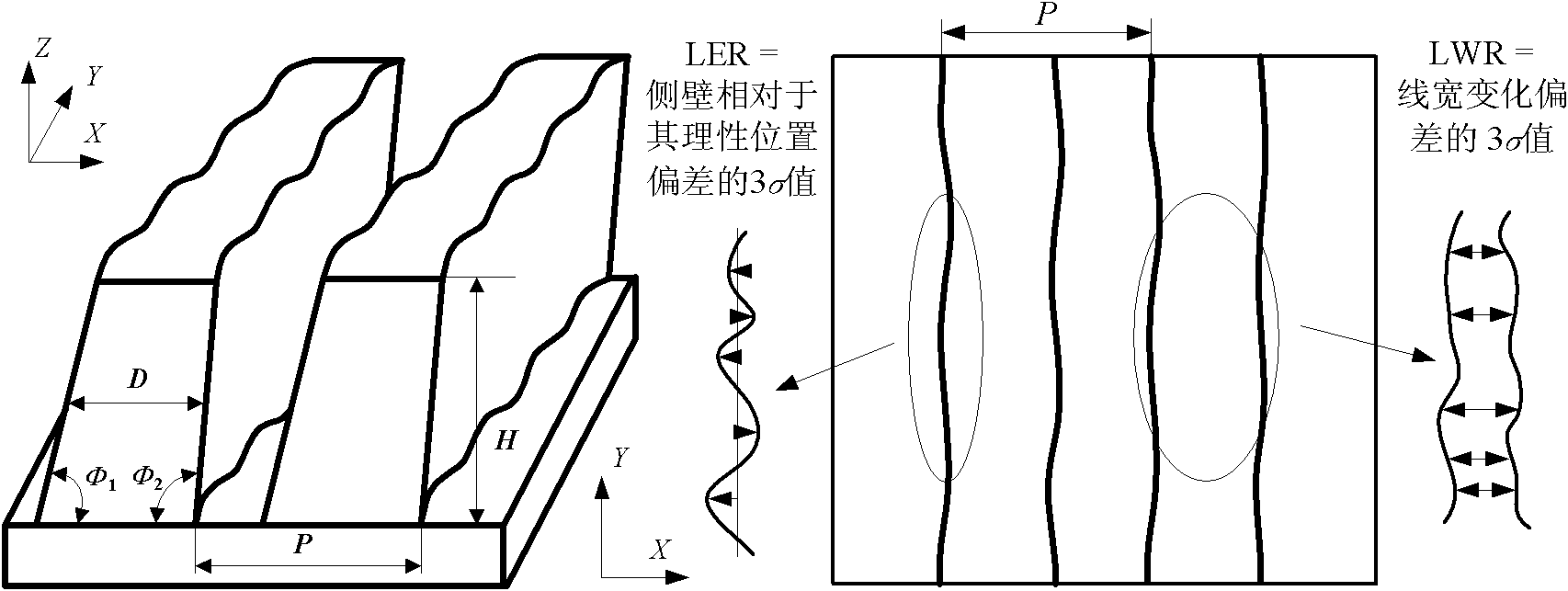

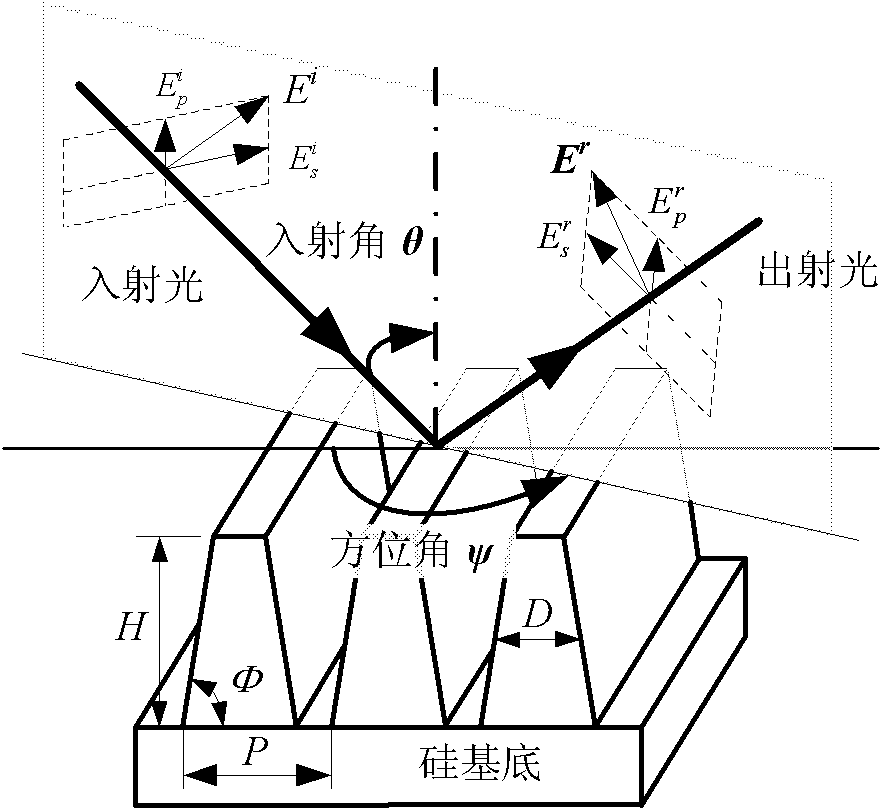

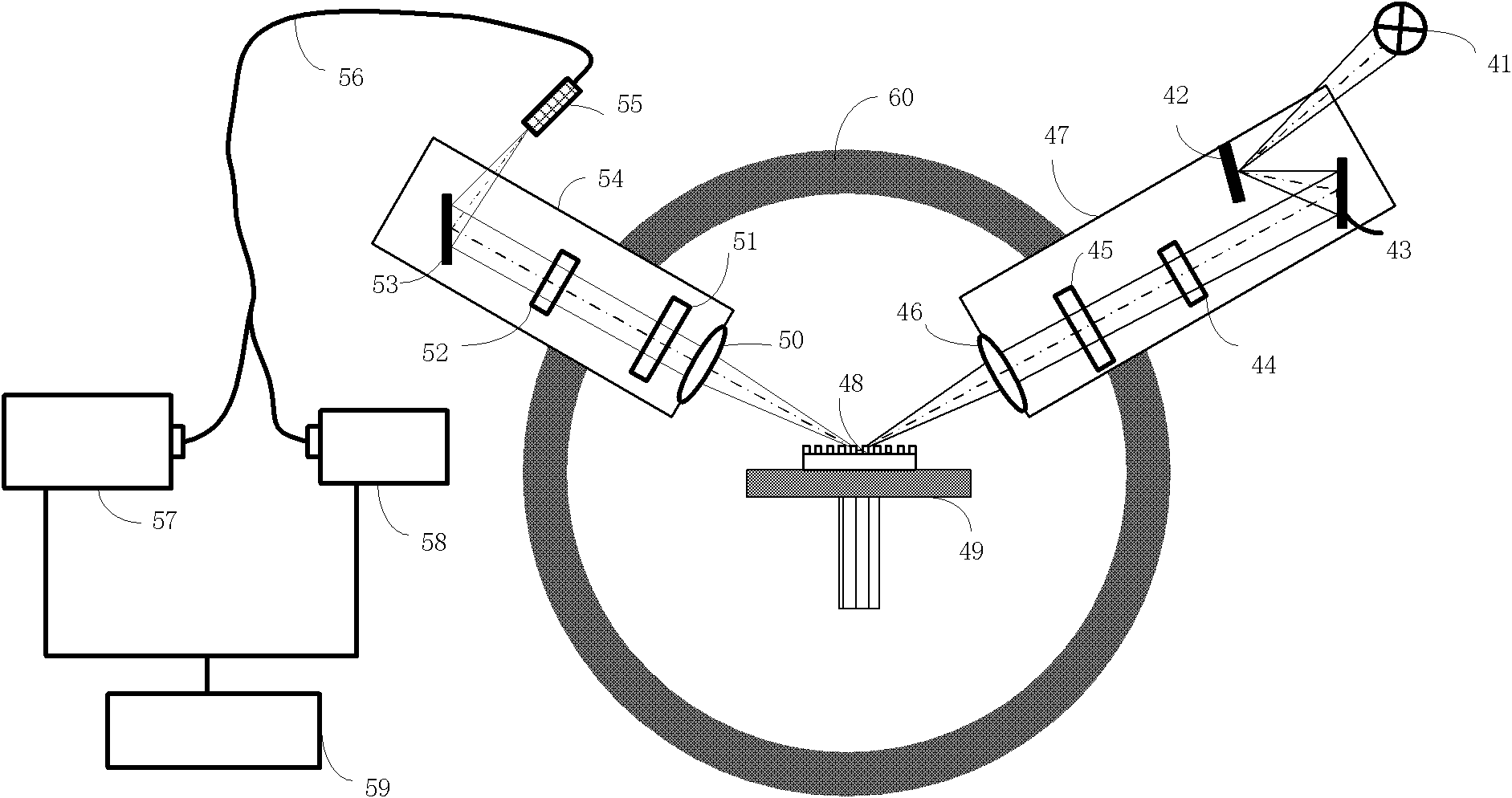

Method and device for measuring three-dimensional topography of nano structure

ActiveCN101881599AMeet measurement needsHigh spectral sensitivityUsing optical meansEtchingImage transfer

The invention discloses a method and a device thereof for measuring three-dimensional topography of a nano structure, which can simultaneously measure three-dimensional topography parameters such as line width, depth, side corner, line edge roughness, line width roughness and the like of the nano structure. The method comprises the following steps of: performing splitting, polarization and front and back phase compensation on light beams with wavelengths in ultraviolet to near-infrared wave band to obtain elliptical polarized light and projecting the elliptical polarized light for later measurement; acquiring surface reflected zero-level diffraction signals of the to-be-measured structure, and obtaining a measurement Mueller matrix of the nano structure by calculation; and matching the measurement Mueller matrix and a theoretical Mueller matrix, and obtaining a three-dimensional topography parameter value of the to-be-measured nano-scale structure. The device provided by the invention for measuring the three-dimensional topography parameter of the nano structure can provide a non-contact, nondestructive, low-cost and quick measurement means for one-dimensional and two-dimensional sub-wavelength periodic structures in processes of photo-etching, nano impressing and the like of an image transfer-based batch manufacturing method.

Owner:WUHAN EOPTICS TECH CO LTD

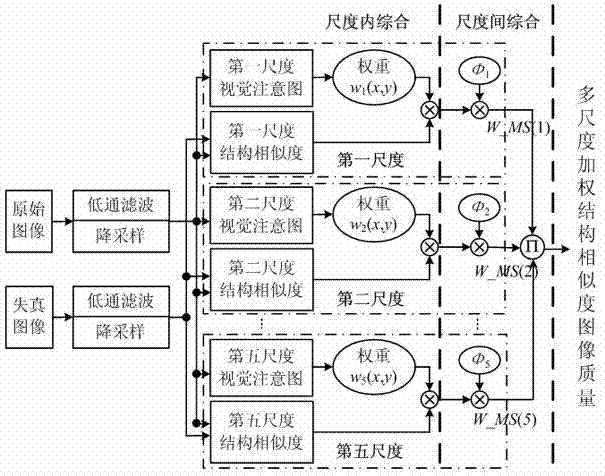

Image quality evaluating method based on multi-scale structure similarity weighted aggregate

InactiveCN102421007AImprove the problem of low prediction accuracyImprove performanceTelevision systemsPattern recognitionImaging quality

The invention discloses an image quality evaluating method based on multi-scale structure similarity weighted aggregate. The traditional method based on structure similarity has defects in many aspects, in the method disclosed by the invention, the visual attention characteristics and multilayer visual characteristics of a human visual system are fully considered to realize the weighted aggregatefor the structure similarity in intra-scale and inter-scale manners, and the objective evaluation to a full reference image is carried out. The image quality evaluating method mainly comprises the steps of: in the scales, generating a weight coefficient of a corresponding image block based on visual saliency, and performing weighted aggregate on the structural similarity in the intra-scale manner; and among the scales, performing the weighted aggregate on the structure similarity in the inter-scale manner by using the weighted coefficient obtained through training or from experience.

Owner:ZHEJIANG UNIV

Method of regulating and controlling light absorption property of metal surface by picosecond pulse laser

The invention discloses a method of regulating and controlling light absorption property of a metal surface by picosecond pulse laser. The method comprises the following steps: irradiating the metal surface by picosecond pulse laser; carrying out laser ablation for removal and self-assembly of the metal surface induced by picosecond pulse laser to obtain a micro-nano dual-scale structure on the metal surface thus realizing regulation and control of the light absorption property of the metal surface. The method disclosed by the invention fully exerts a picosecond laser preparation rule or the micron structure in random distribution as well as capacity of forming the self-assembled nanostructure, and is agile and controllable in processing process, low in processing cost and high in efficiency, so that the method is an economical and practical method of regulating and controlling the light absorption property of the metal surface.

Owner:TSINGHUA UNIV

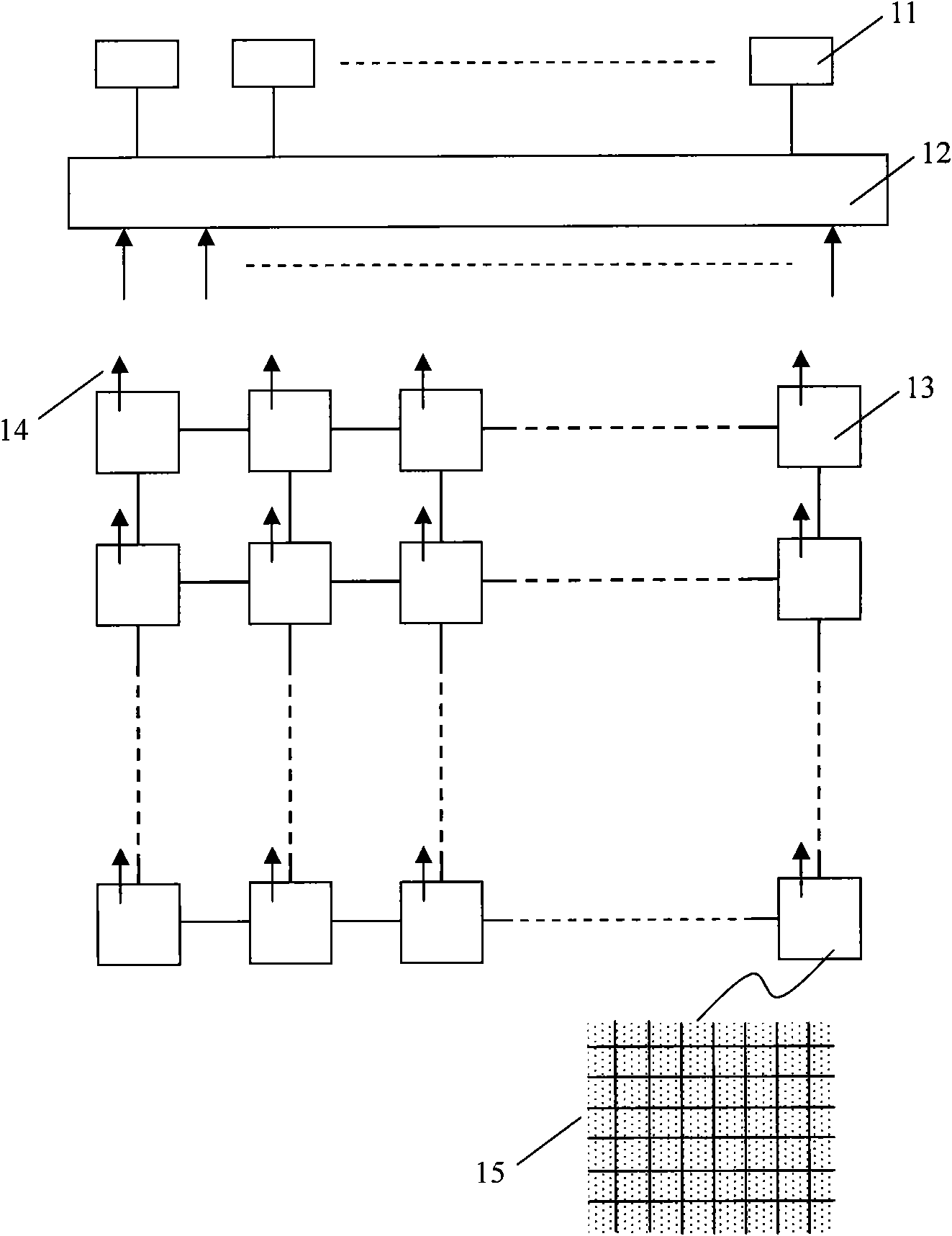

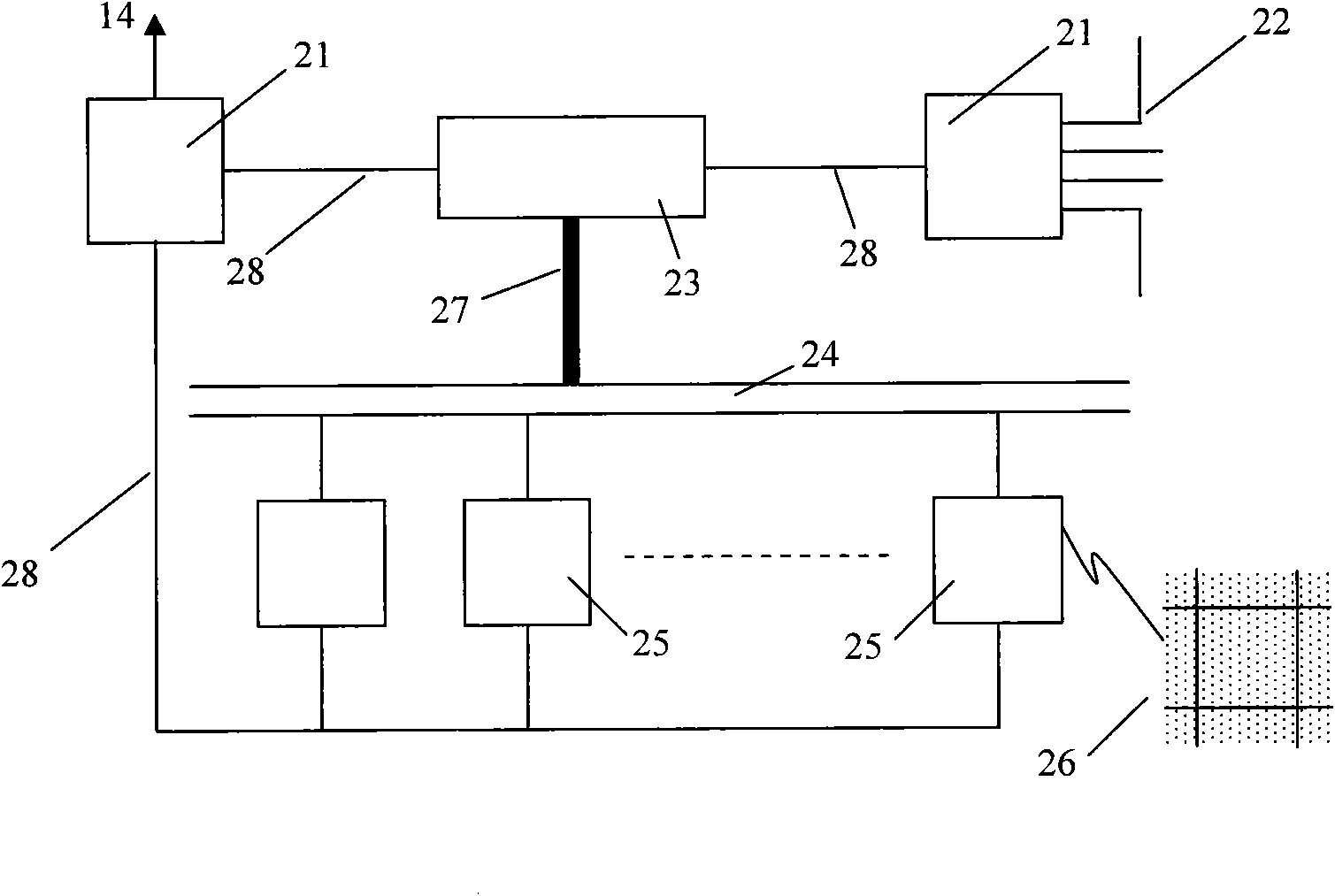

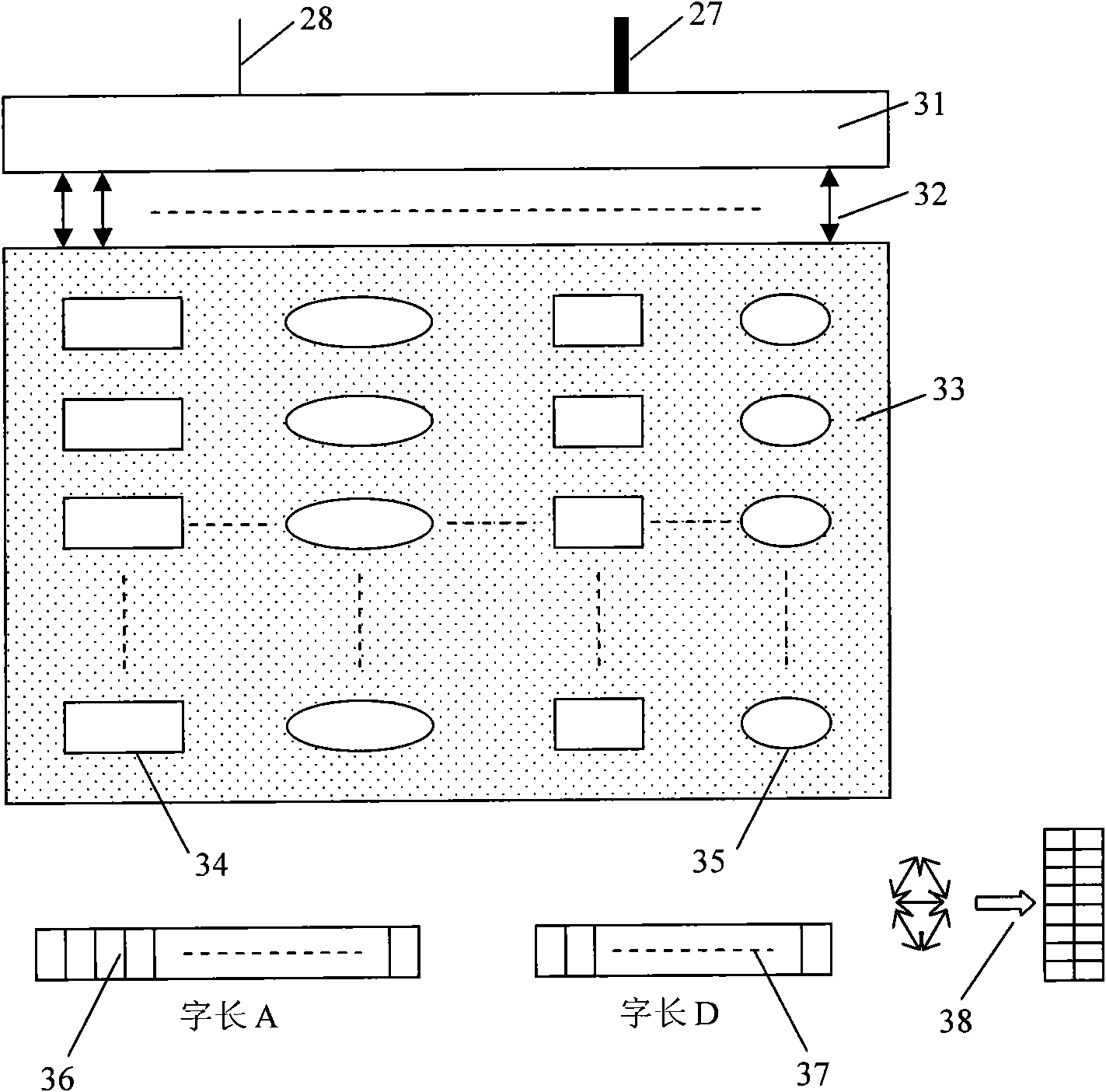

Concurrent computational system for multi-scale discrete simulation

ActiveCN102053945AImprove general performanceSimple designDigital computer detailsElectric digital data processingScale structureComplex system

The invention relates to the technical field of high-performance computers, and discloses a concurrent computational system for multi-scale discrete simulation. In respect to the multi-scale structure and discrete characteristics of the complex system in the real world, the system maintains the consistency and similarity among simulation object, computation model, frame of algorithm and computer architecture. The system describes the local behavior of the systems in different layers with a large number of adjacent discrete units and describes the collective behavior of the systems in different layers with long-range restraint and correlation, and two-way feedback is applied between the upper layer unit and the lower layer unit. Correspondingly, the special reconfigurable vectorized accelerator group is used as the bottom layer computation hardware, the universal processor array is used as the upper layer computation hardware, and the adjacent processors or accelerators in the same layer can directly communicate or share memory with the processors or accelerators in the part of adjacent layers. Therefore, the system can efficiently and truly simulate complex process and system.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for fabricating dual damascene profiles using sub pixel-voting lithography and devices made by same

ActiveUS20090023098A1Reduce complexityLow costElectric discharge tubesSolid-state devicesScale structureIntegrated electronics

This invention provides processing steps, methods and materials strategies for making patterns of structures for integrated electronic devices and systems. Processing methods of the present invention are capable of making micro-and nano-scale structures, such as Dual Damascene profiles, recessed features and interconnect structures, having non-uniform cross-sectional geometries useful for establishing electrical contact between device components of an electronic device. The present invention provides device fabrication methods and processing strategies using sub pixel-voting lithographic patterning of a single layer of photoresist useful for fabricating and integrating multilevel interconnect structures for high performance electronic or opto-electronic devices, particularly useful for Very Large Scale Integrated (VLSI) and Ultra large Scale Integrated (ULSI) devices. Processing methods of the present invention are complementary to conventional microfabrication and nanofabrication methods for making integrated electronics, and can be effectively integrated into existing photolithographic, etching, and thin film deposition patterning systems, processes and infrastructure.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Production method of black steel for 510L automobile frame

InactiveCN102172622AFulfil requirementsImprove performanceWork treatment devicesMetal rolling arrangementsHeating timeMetallurgy

The invention discloses a production method of black steel for a 510L automobile frame, belonging to the technical field of sheet rolling. Through control over components and a rolling process, the ratio of Fe3O4 in a surface iron scale structure of a coiled sheet is over 80 percent, and the thicknesses of the iron scales are less than 10 mum. The black steel comprises the following components in percentage by weight 0.06-0.14 percent of C, less than 0.2 percent of Si, 1.2-1.6 percent of Mn, less than 0.02 percent of P, less than 0.010 percent of S, 0.01-0.05 percent of Nb, 0.02-0.06 percent of Alt, less than 0.2 percent of Si and the balance of Fe. The rolling process is controlled as follows: the plate blank heating temperature is controlled at 1,230-1,270 DEG C, the heating time is 3-3.5 hours, the rough descaling temperature is over 1,173 DEG C, the pressure of a descaling system is controlled over 18 MPa, a double-row descaling process is adopted, the RT2 temperature is controlled at 1,040-1,080 DEG C, the final rolling temperature is controlled at 860-880 DEG C, a pre-cooling mode is adopted for laminar flow, and the coiling temperature is controlled at 540-580 DEG C.

Owner:SHOUGANG CORPORATION

Automatic collimation surveying apparatus having image pick-up device

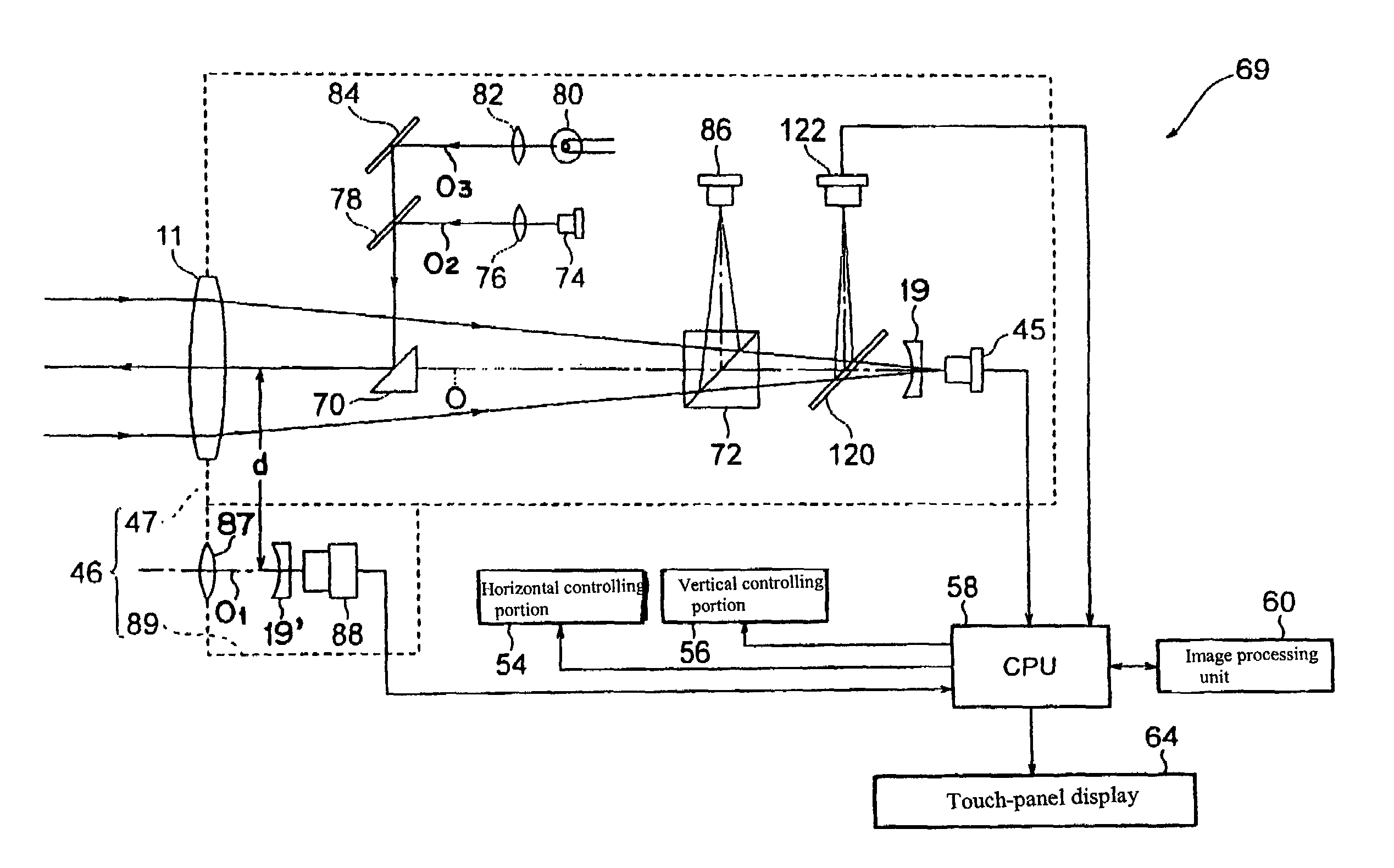

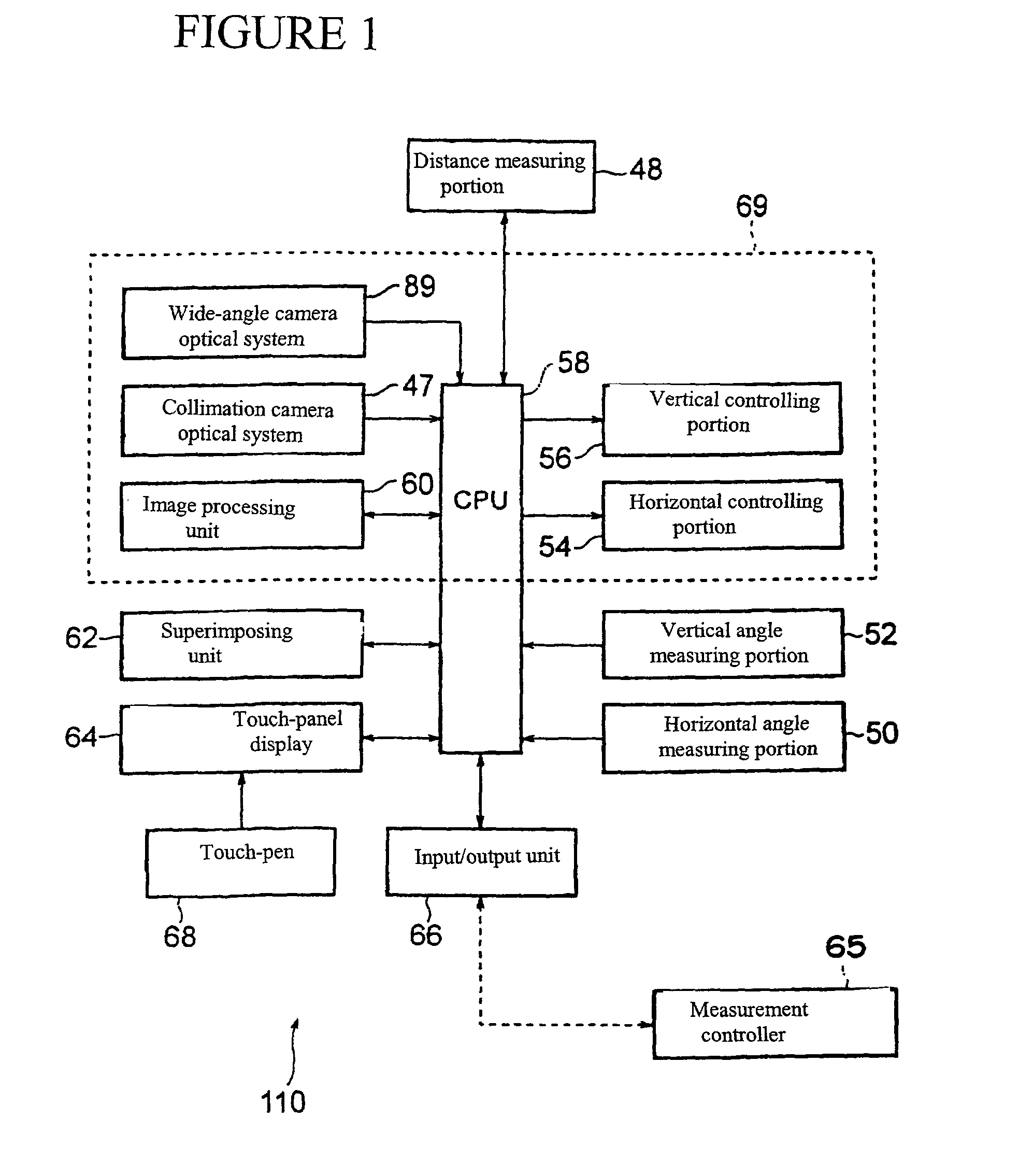

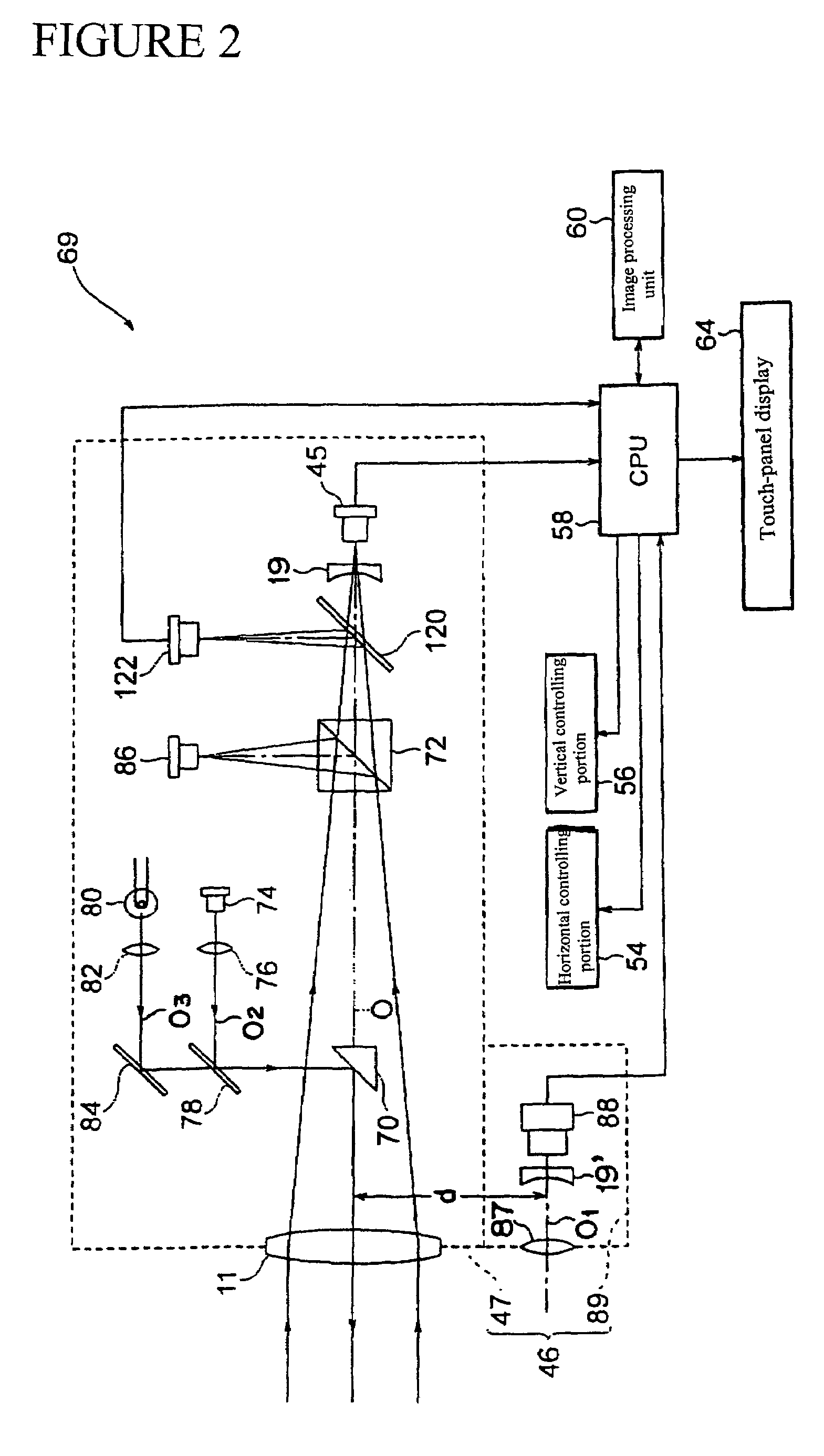

InactiveUS7081917B2Reduce loadEfficient measurementSurveying instrumentsColor television detailsImaging processingWide field

An automatic collimation surveying apparatus is provided with a collimation camera optical system (47) of a high magnification ratio; a wide-angle CCD camera optical system (89) having a wide field of view; a touch-panel display (64) for displaying an image picked up by both CCD camera optical systems; an image processing unit (60) for discriminating points of measurement from the above-described image; a touch-pen for pointing out points of measurement on the above-described image; and an automatic collimation unit (69) for automatically collimating the pointed-out points of measurement. In addition, illumination light from light source (80) is concurrently used as collimation light and is aligned so as to be emitted along the collimation axis (O) of a collimation camera optical system. The surveying apparatus can be remotely controlled from a measurement controller such as a peripheral personal computer. The surveying apparatus allows a number of point-of-measurement positions to be efficiently measured on a large-scaled structure by a single operator.

Owner:SOKKOIA COMPANY LIMITED

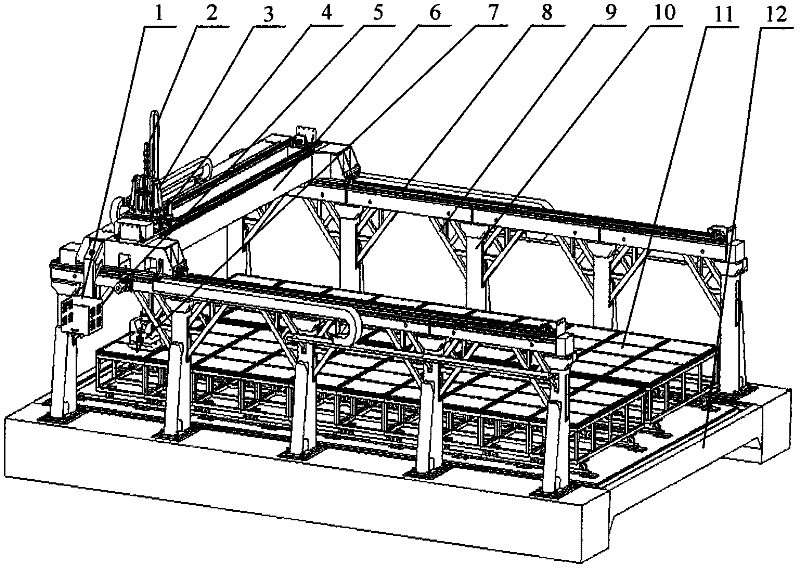

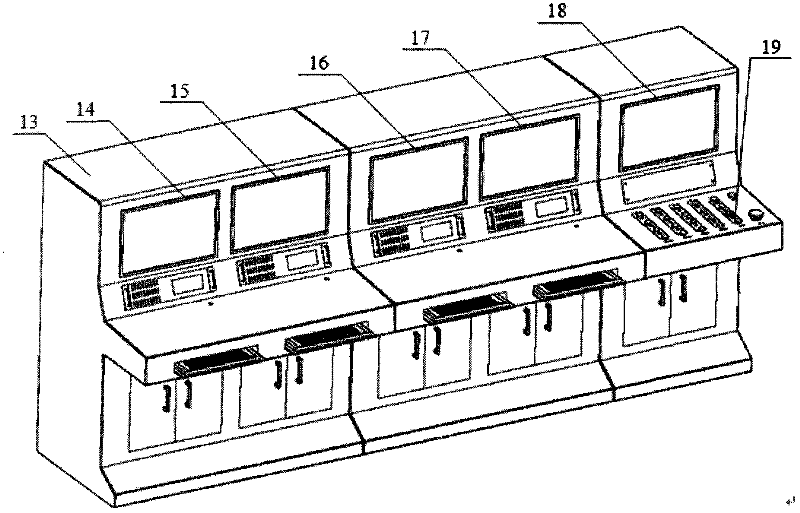

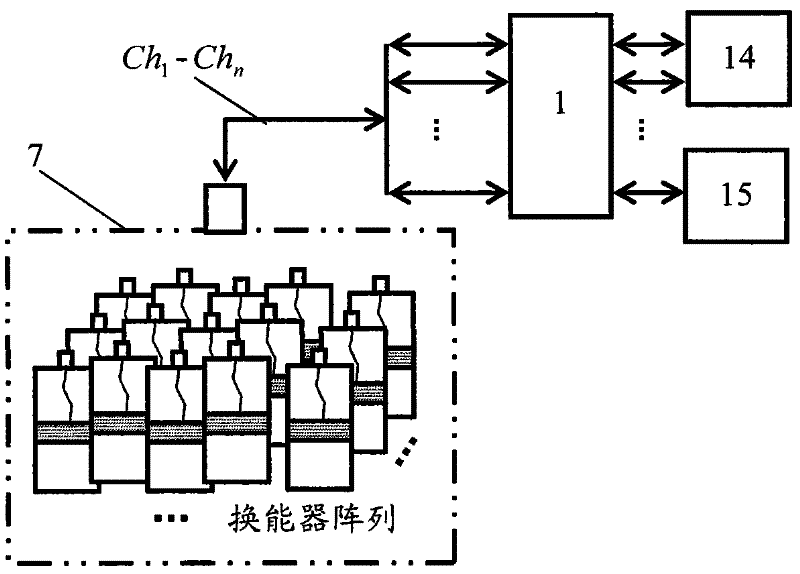

Industrial scale ultrasonic automatic scanning and imaging detection device

ActiveCN102411032AAuto scanReduce complexityMaterial analysis using sonic/ultrasonic/infrasonic wavesAviationBlind zone

The invention belongs to a nondestructive detection technology and relates to an industrial scale ultrasonic automatic scanning and imaging detection device used for large-scale structures made of composite materials and metal materials in the fields of aviation, aerospace, electronics, weapons, ships, metallurgy, iron and steel, transportation, construction and the like. The detection device comprises an ultrasonic automatic scanning system, an ultrasonic automatic scanning control and imaging system and a multi-channel ultrasonic system. The design according to the invention adopts a multi-axis parallel numeric control upward floating type super-static steady scanning mechanism and an ultrasonic flexible self-adaptive tracking array acoustic scanning technology, thereby greatly improving the ultrasonic automatic scanning and imaging detection efficiency and the imaging quality of the large-scale structures, realizing the industrial scale high-efficient ultrasonic automatic scanning and imaging detection of the large-scale structures made of the composite materials and the like in different specifications and enabling the detection resolution and a surface blind zone to achieve 0.13mm; and when 20 channels are detected, the efficiency is improved by at least 50 times compared with the manual scanning detection efficiency, and is improved by 20 times compared with the traditional single-channel ultrasonic automatic scanning detection.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

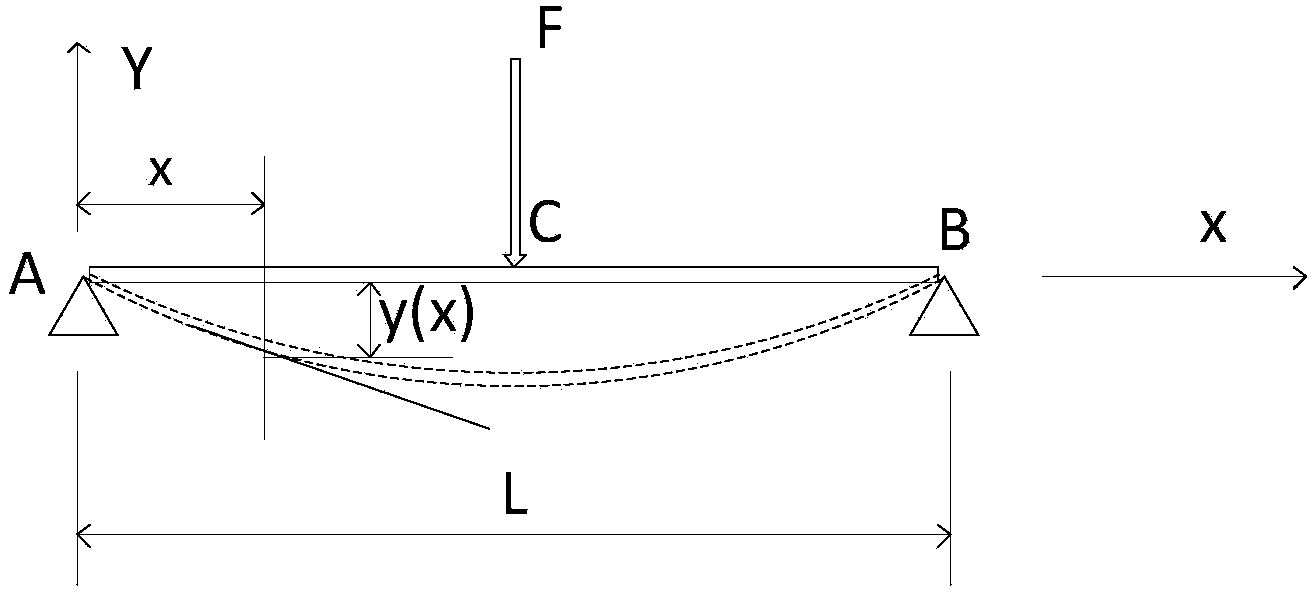

Fiber bragg grating sensor network based large-scale structure body deformation measurement method

ActiveCN104111032AOvercome the disadvantages of difficulty in networking and susceptibility to electromagnetic interferenceConcise fitUsing optical meansSpecial data processing applicationsFiberShielded cable

The invention provides a fiber bragg grating sensor network based large-scale structure body deformation measurement method which aims to detect the condition of deformation of a large-scale structure body which is stressed by an external force or an internal force and real-timely monitors health conditions of the large-scale structure body. The fiber bragg grating sensor network based large-scale structure body deformation measurement method includes arranging a fiber bragg grating sensor network on a structure body to be detected, using a fiber bragg grating strain sensor to detect strain borne by the structure body, using a fiber bragg grating temperature sensor as temperature compensation of the strain sensor, interpolating detected disperse strain data into polynomials, performing twice integration, and bringing in initial conditions to obtain a deformation curve of the structure body. The fiber bragg grating sensor network based large-scale structure body deformation measurement method is mainly used for monitoring health conditions of the large-scale structure body and is suitable for large-scale networking; compared with traditional resistance strain gages for measuring strain of the structure body, the fiber bragg grating sensor network based large-scale structure body deformation measurement method has the advantages that defects that resistance strain gages are difficult to network and prone to be interfered by electromagnets and many shield cables are heavy are overcome.

Owner:山东双测安全信息技术产业研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com