Method of regulating and controlling light absorption property of metal surface by picosecond pulse laser

A metal surface and picosecond pulse technology, which is applied in the field of regulating the light absorption performance of metal surfaces, can solve the problems of effective regulation, strict environmental requirements, and low processing efficiency, and achieve the effects of good processing adaptability, simple process, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

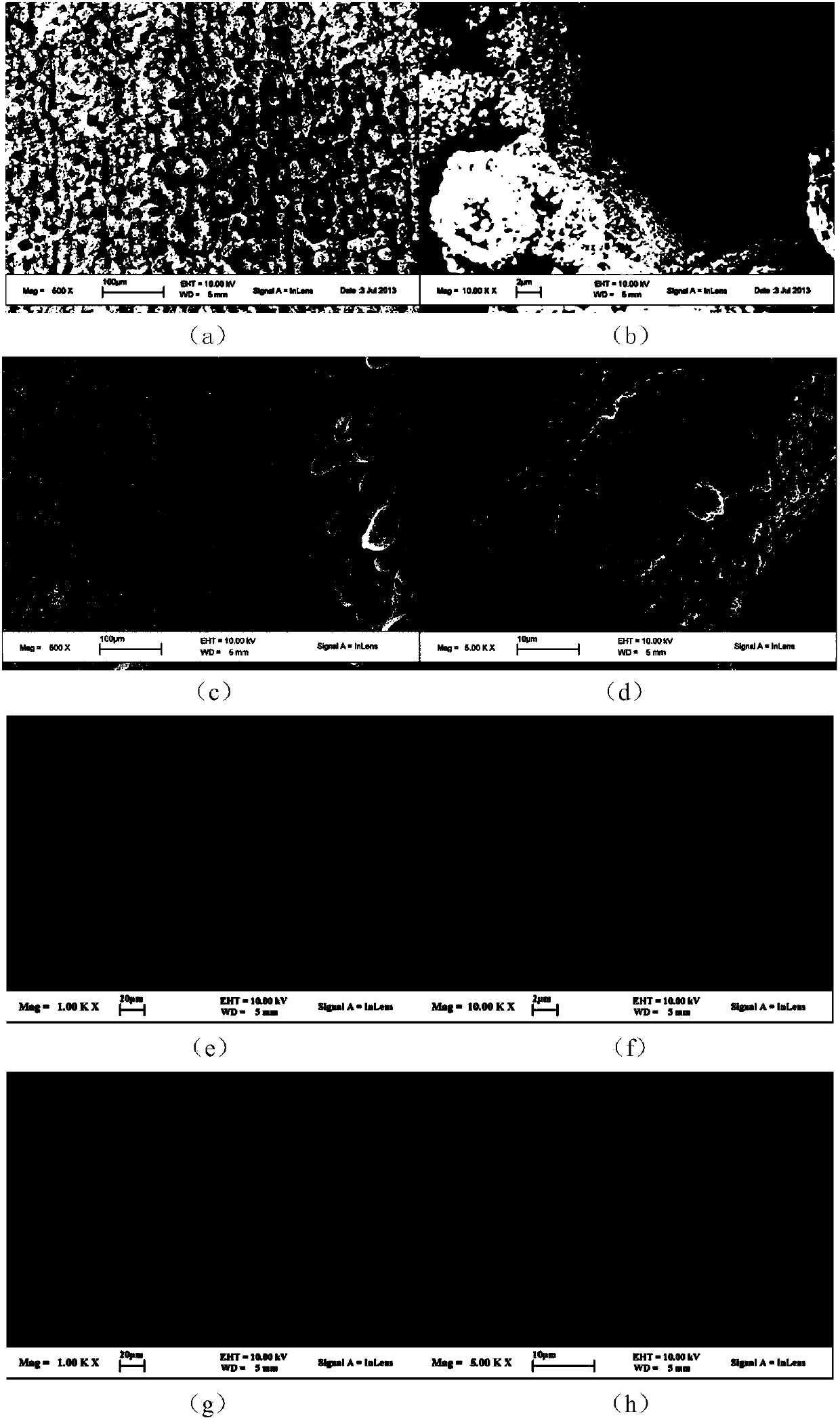

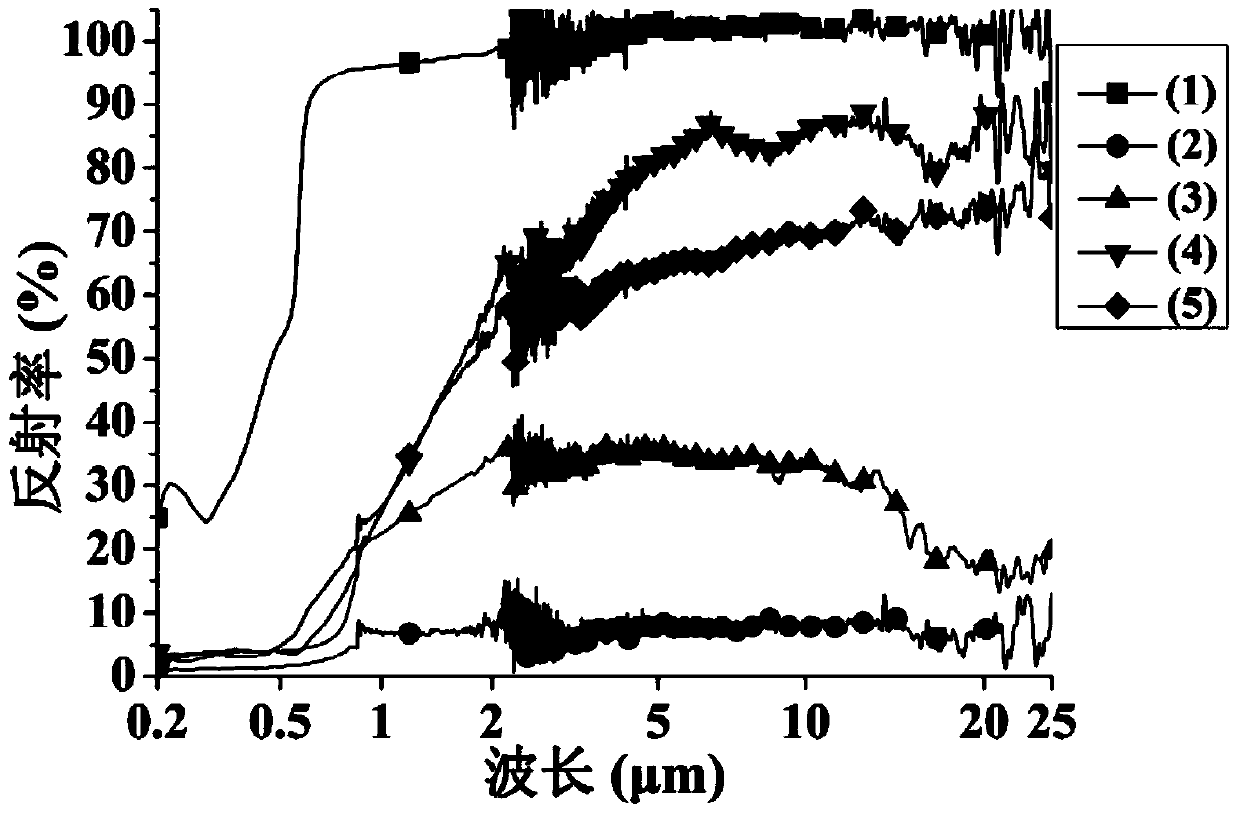

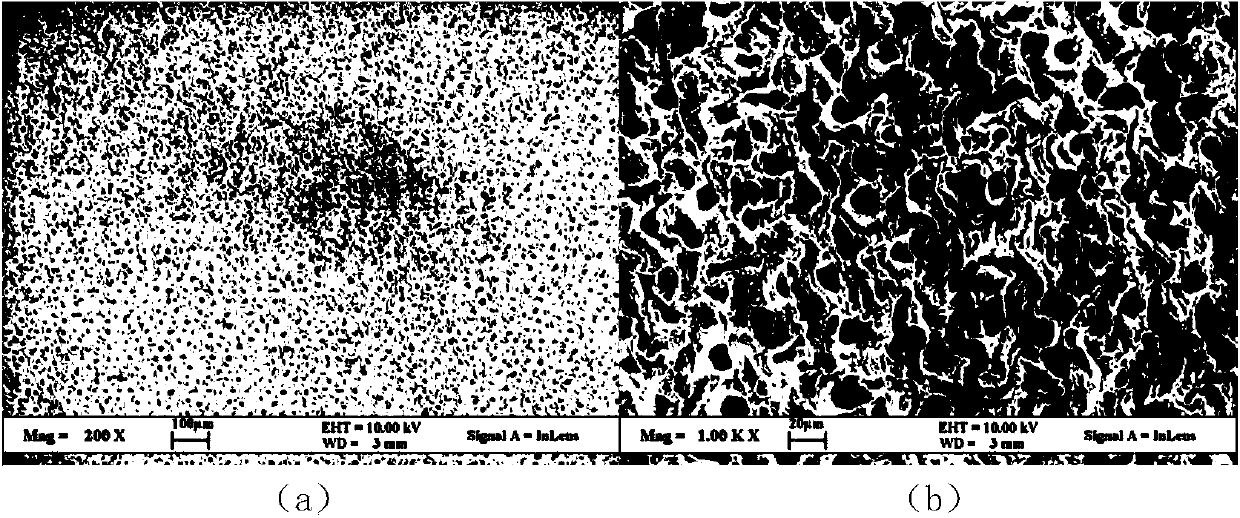

[0061] Example 1, picosecond pulse laser regulation of copper surface light absorption performance

[0062] Copper is an excellent functional material, especially has good electrical and thermal conductivity, and has broad application prospects in the fields of solar photoelectric conversion, solar photothermal conversion, sensors, etc. In this embodiment, the copper surface is treated, including the following steps:

[0063] First, remove the oxide layer on the copper surface by mechanical grinding, then polish it with sandpaper and polishing cloth, and finally clean the copper surface with alcohol.

[0064] The central wavelength of the picosecond pulsed laser selected in this embodiment is 1064 nm, and the pulse width is 10 picoseconds. The laser beam is deflected by the galvanometer, and the deflection trajectory and deflection speed are controlled by the computer, and then focused on a rectangular metal copper surface with a thickness of 3mm through a scene with a focal l...

Embodiment 2

[0073] Example 2. Picosecond pulsed laser regulating the light absorption performance of aluminum surface

[0074] Aluminum is an excellent light metal material, which is widely used in aerospace, construction, automobile and other fields. In this embodiment, the aluminum surface is treated, including the following steps:

[0075] Use grinding to remove the oxide layer on the aluminum surface and make the surface to a certain degree of smoothness, then clean the aluminum surface with alcohol.

[0076] The central wavelength of the picosecond pulsed laser selected in this embodiment is 1064 nm, and the pulse width is 10 picoseconds. The laser beam is deflected by the galvanometer, and the deflection trajectory and deflection speed are controlled by the computer, and then focused on a rectangular aluminum surface with a thickness of 2mm through a scene with a focal length of 100mm, and the diameter of the focal spot is 30μm. During the laser beam deflection process, the laser ...

Embodiment 3

[0079] Example 3. Picosecond pulsed laser regulating the light absorption performance of titanium surface

[0080] Titanium is an excellent light metal functional material, which is widely used in aerospace and national defense. In this embodiment, the titanium surface is treated, including the following steps:

[0081] The oxide layer on the titanium surface is removed by grinding, and the surface reaches a certain level of smoothness, and then the titanium surface is cleaned with alcohol.

[0082]The central wavelength of the picosecond pulsed laser selected in this embodiment is 1064 nm, and the pulse width is 10 picoseconds. The laser beam is deflected by the galvanometer, and the deflection trajectory and deflection speed are controlled by the computer, and then focused on a rectangular titanium surface with a thickness of 2mm through a scene with a focal length of 100mm, and the diameter of the focal spot is 30μm. During the laser beam deflection process, the laser irr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com