Patents

Literature

370 results about "Titanium surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium boride coatings on titanium surfaces and associated methods

InactiveUS7264682B2High wear and corrosion and oxidation resistanceResistance to galling and seizureSolid state diffusion coatingMetal boridesBorideTitanium surface

Owner:UNIV OF UTAH RES FOUND

Preparation method of ultrasonic microarc oxidation silver-carrying antibiotic bioactive coating on magnesium and titanium surface

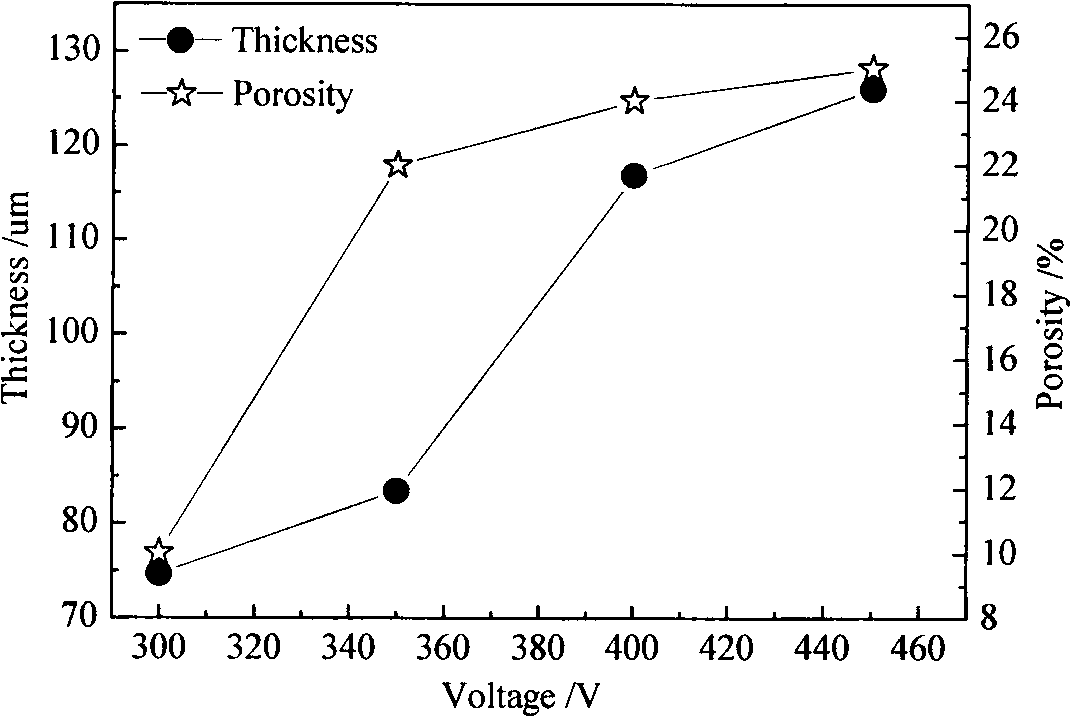

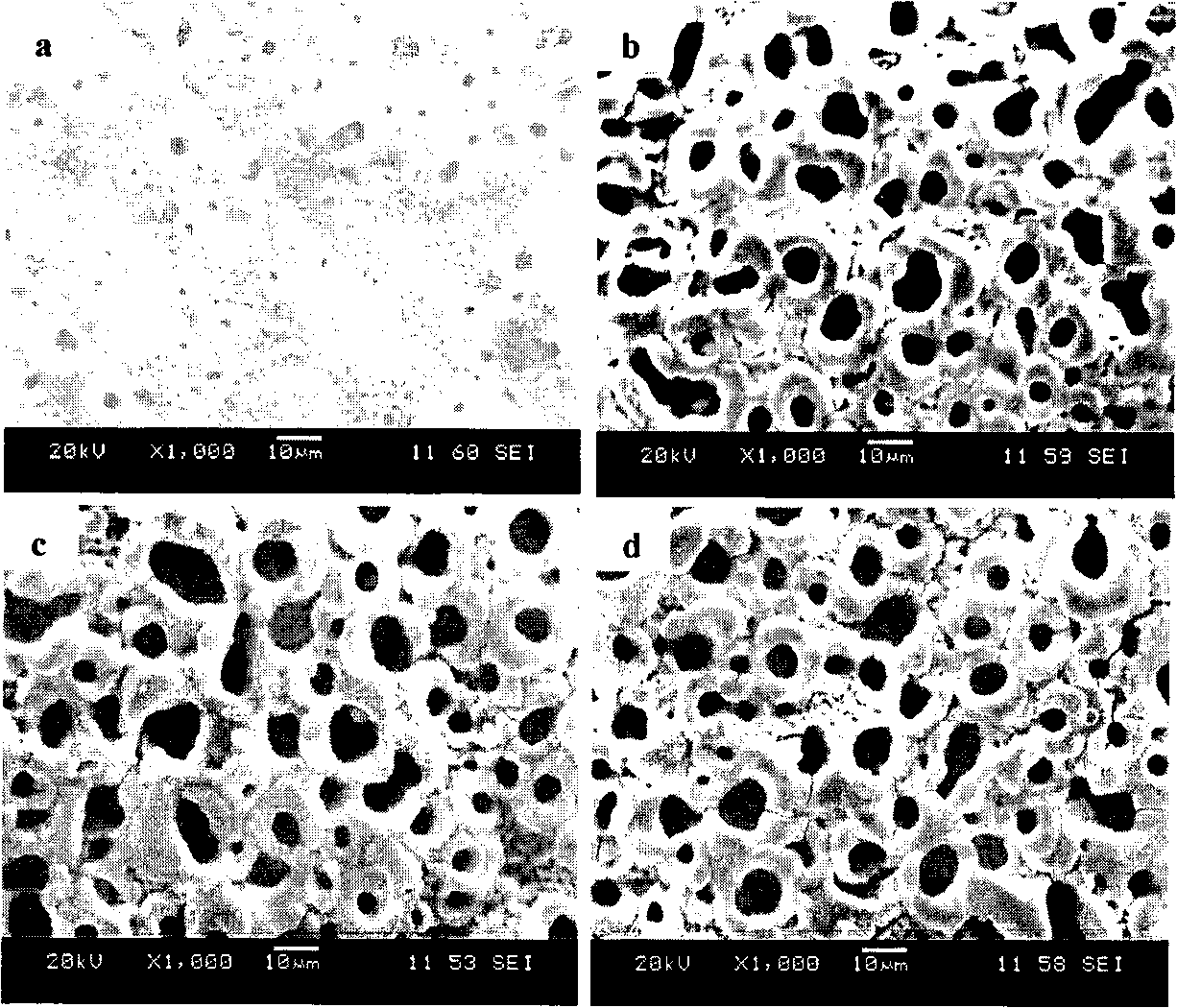

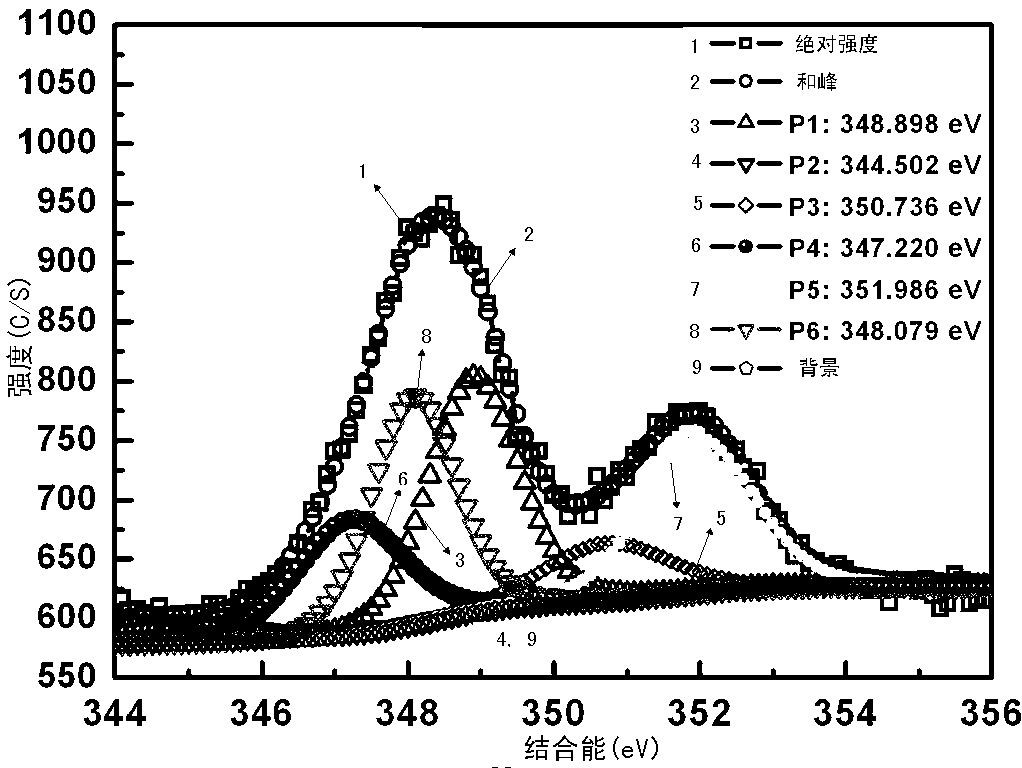

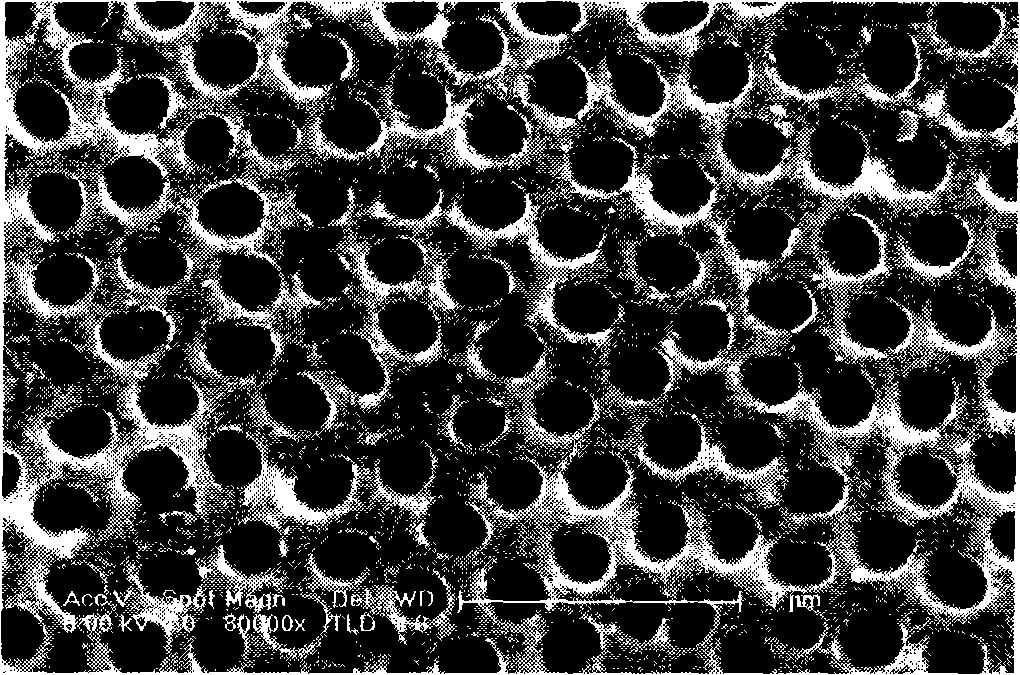

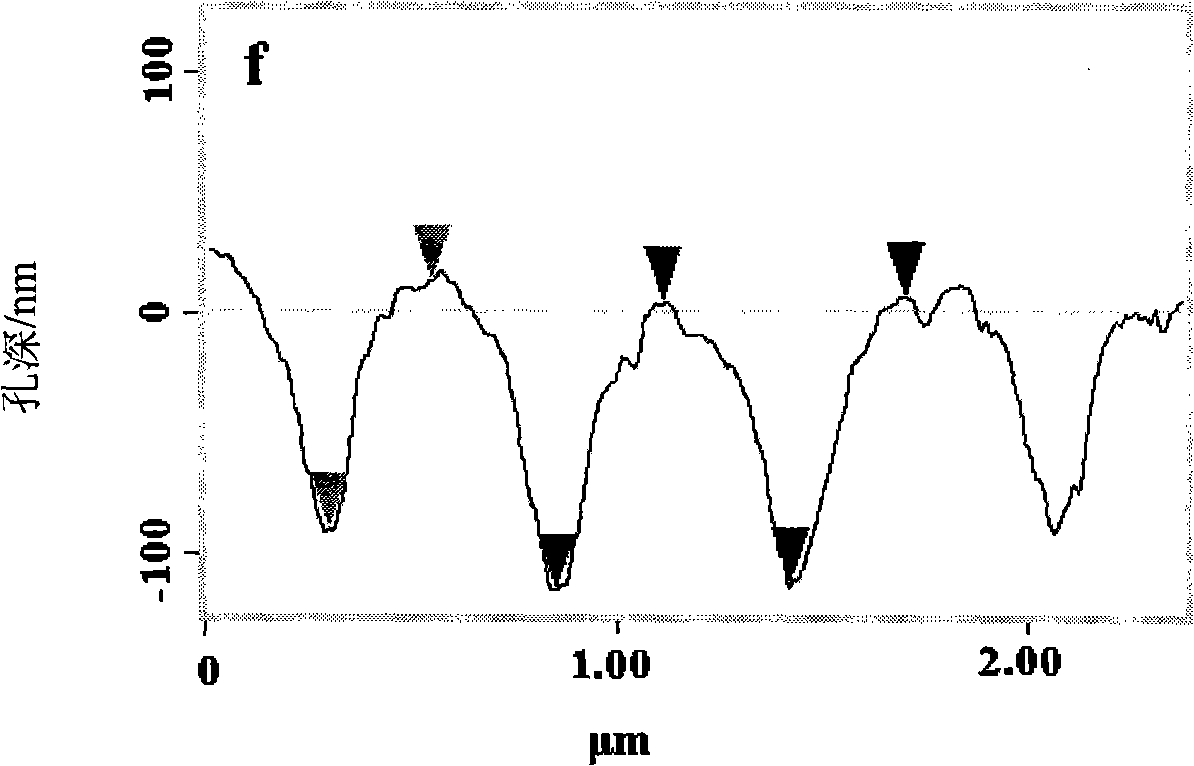

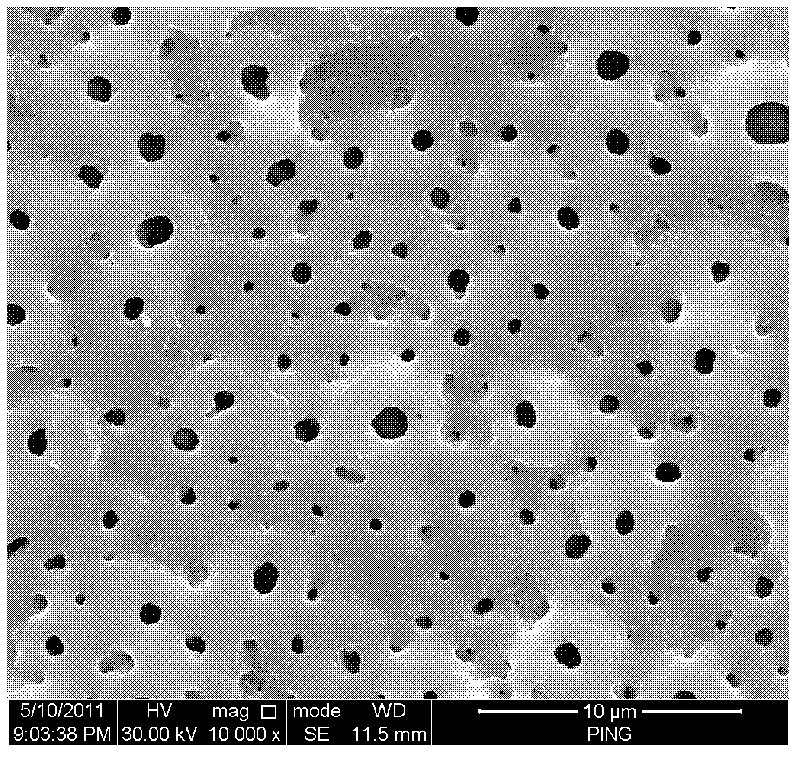

InactiveCN101899700AImprove corrosion resistanceGood resistance to friction and wear in human environmentAnodisationProsthesisPorosityPlasma electrolytic oxidation

The invention relates to a new method for preparing an antibiotic bioactive coating material on the surface of titanium alloy and magnesium alloy by ultrasonic-microarc oxidation composite technology, which can be used for obtaining a biological coating material which is compact at the bottom layer and is porous at the surface layer, wherein Ca, P and Ag contained in the coating can improve the bioactivity and the corrosion resistance of magnesium and titanium, and reduce bacterial infection caused by implantation. The invention can meet the requirements of bearing bones of human beings for mechanical properties of implanted materials, and can overcome disadvantages of the traditional surface modification method for biologic materials. In the coating composite material, the coating thickness of titanium alloy is 50-85 mu m, the surface hole diameter is 4-25 mu m, the porosity is 20-30%, and the bonding strength between the coating and the matrix is 23-40 MPa. The coating thickness of magnesium alloy is 16-22 mu m, the surface hole diameter is 5-28 mu m, the porosity is 21-30%, and the bonding strength between the coating and the matrix is 8-20 MPa.

Owner:JIAMUSI UNIVERSITY

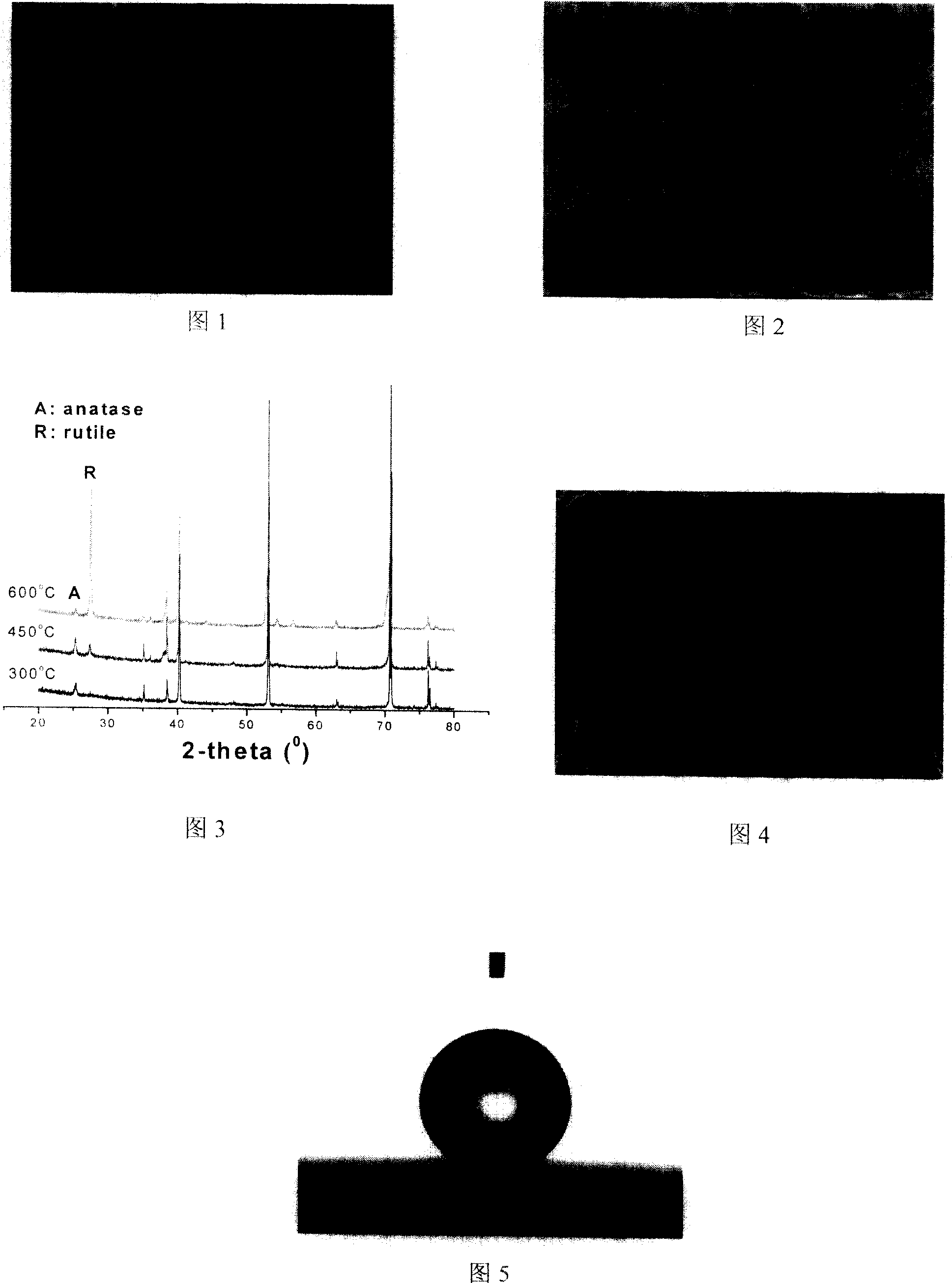

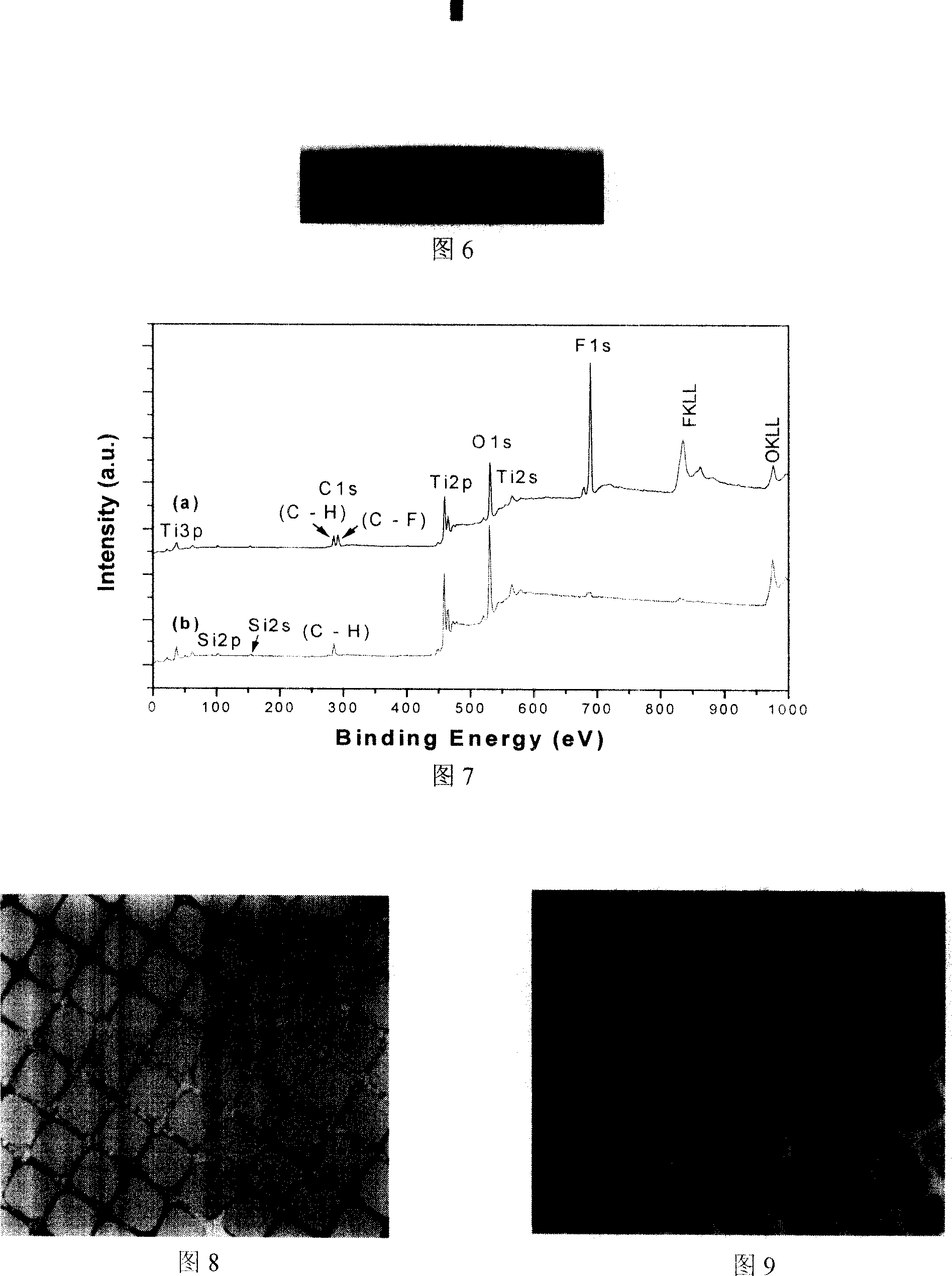

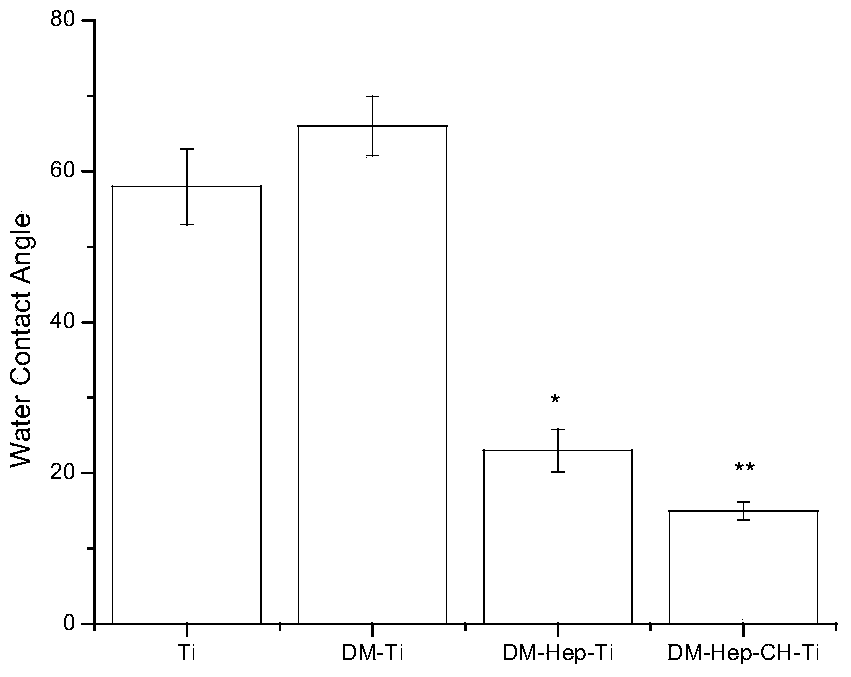

Construction method of titanium surface micrometre-grade pattern based on ultra-hydrophilic/ultra-hydrophobic characteristic

InactiveCN101016642APracticalImprove controllabilitySurface reaction electrolytic coatingElectrochemical anodizationUltraviolet lights

The invention discloses a construction method of titanium surface micron-size picture based on super hydrophilic / super hydrophobic peculiarity, which comprises the following steps: pre-processing the surface of base material; allocating electrolytic solution; controlling voltage and temperature; proceeding electro chemical anodic oxidation; getting titanium oxide nanometer structure array film layer; proceeding heat treatment; getting example; soaking in fluorine silicane methanol solution at 10-240 min; getting out; drying at 120-160 deg.c; getting super hydrophobic TiO2 nanometer structure array film layer; covering photomask; irradiating with ultraviolet light; getting the final picture.

Owner:XIAMEN UNIV

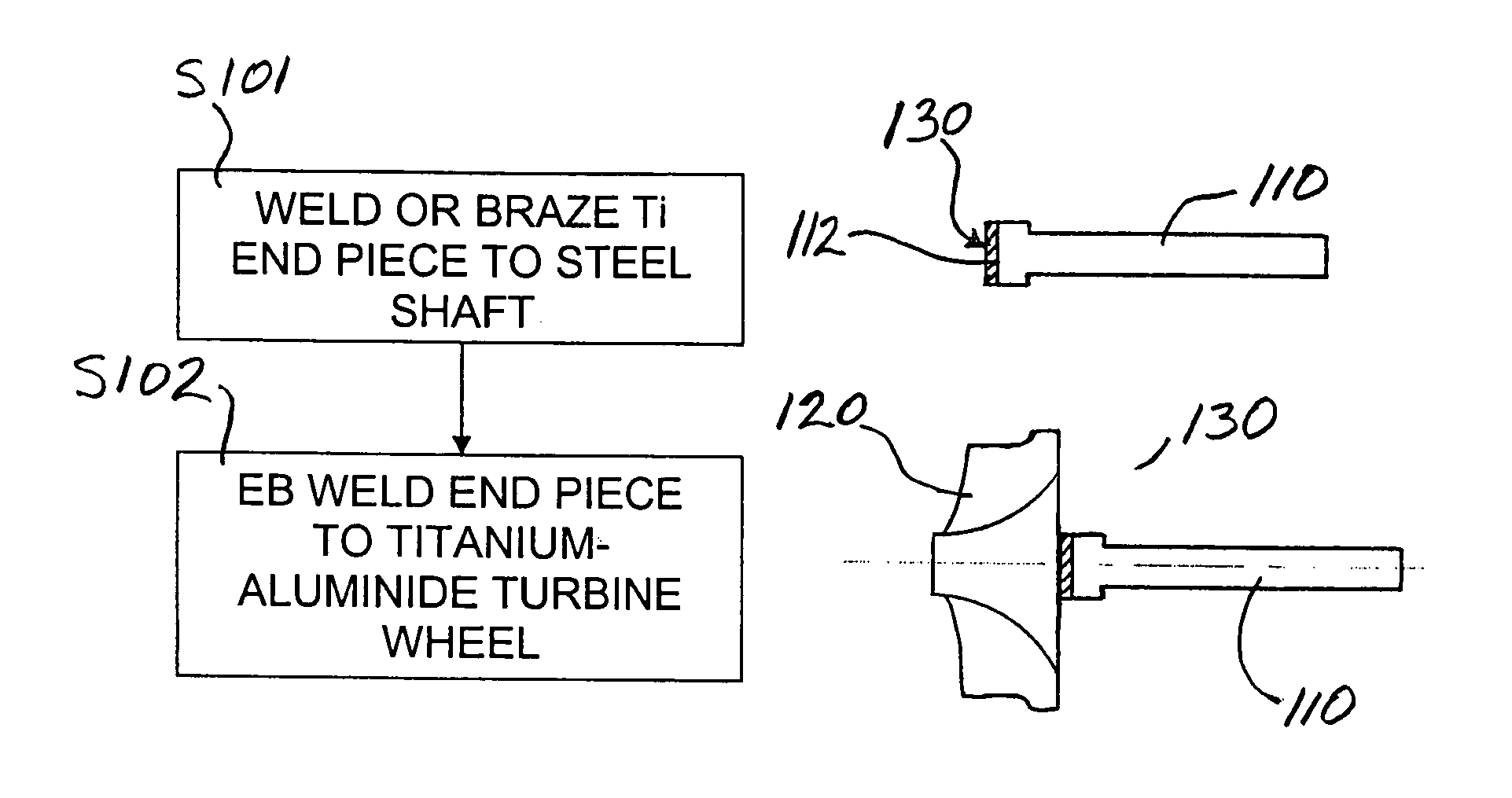

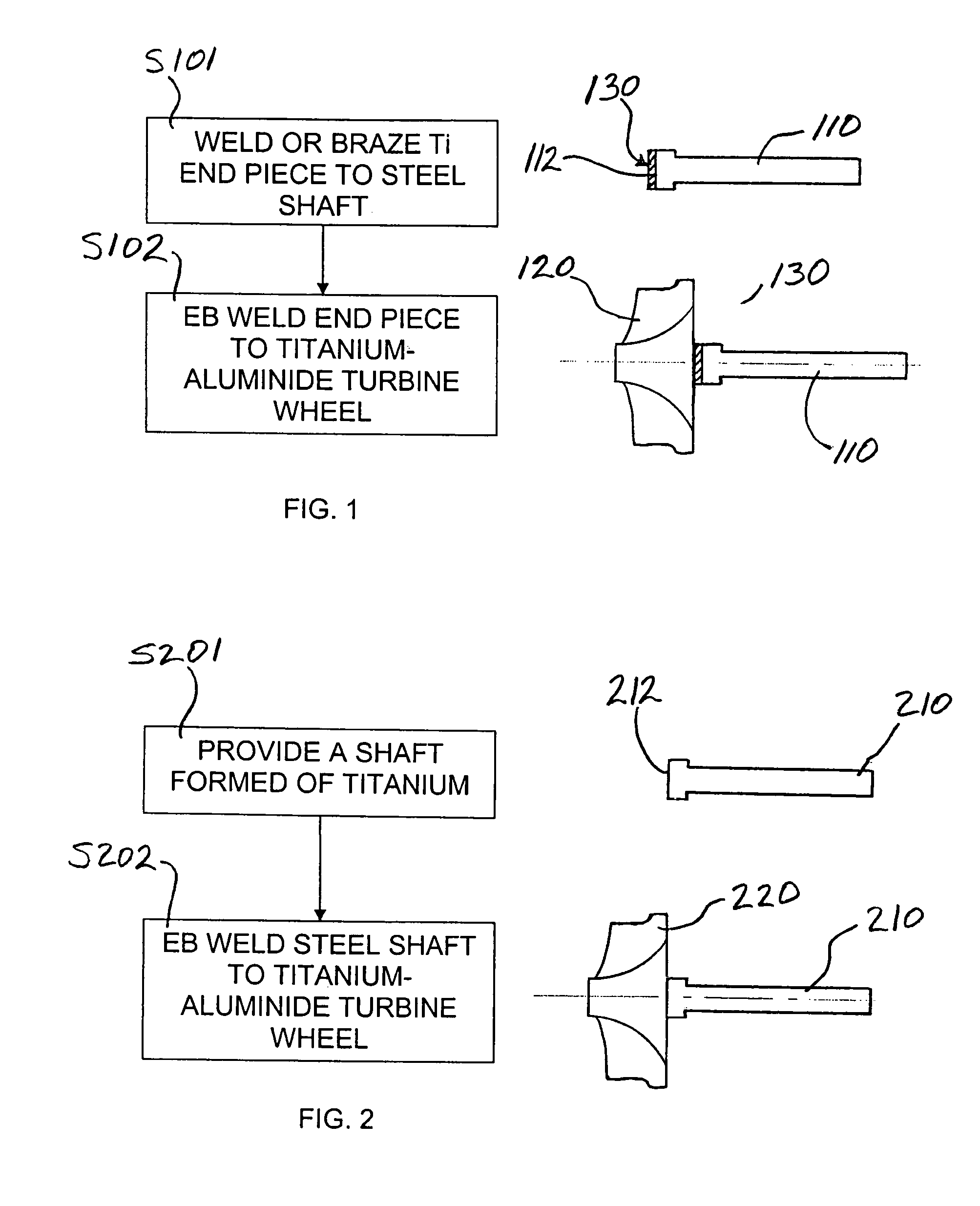

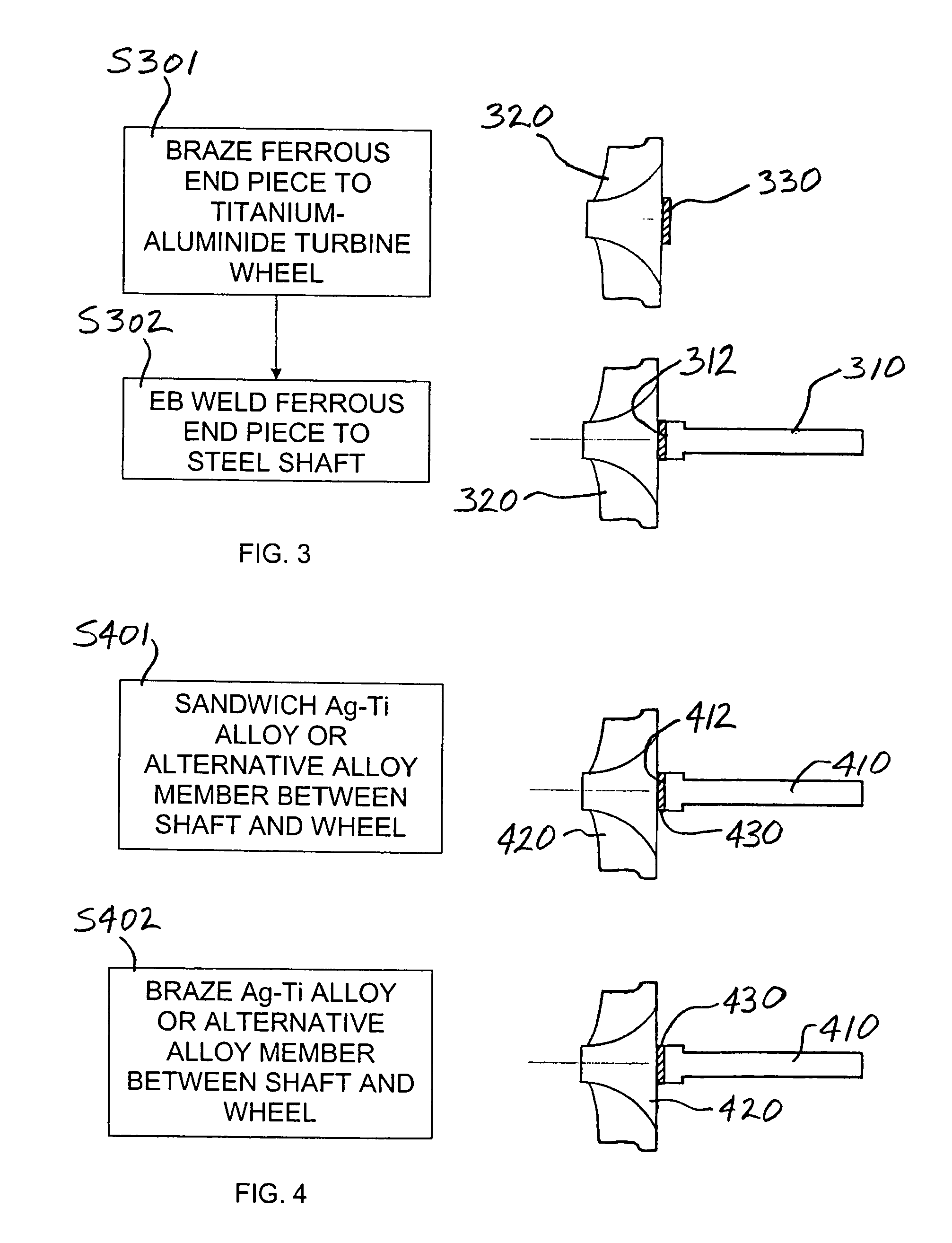

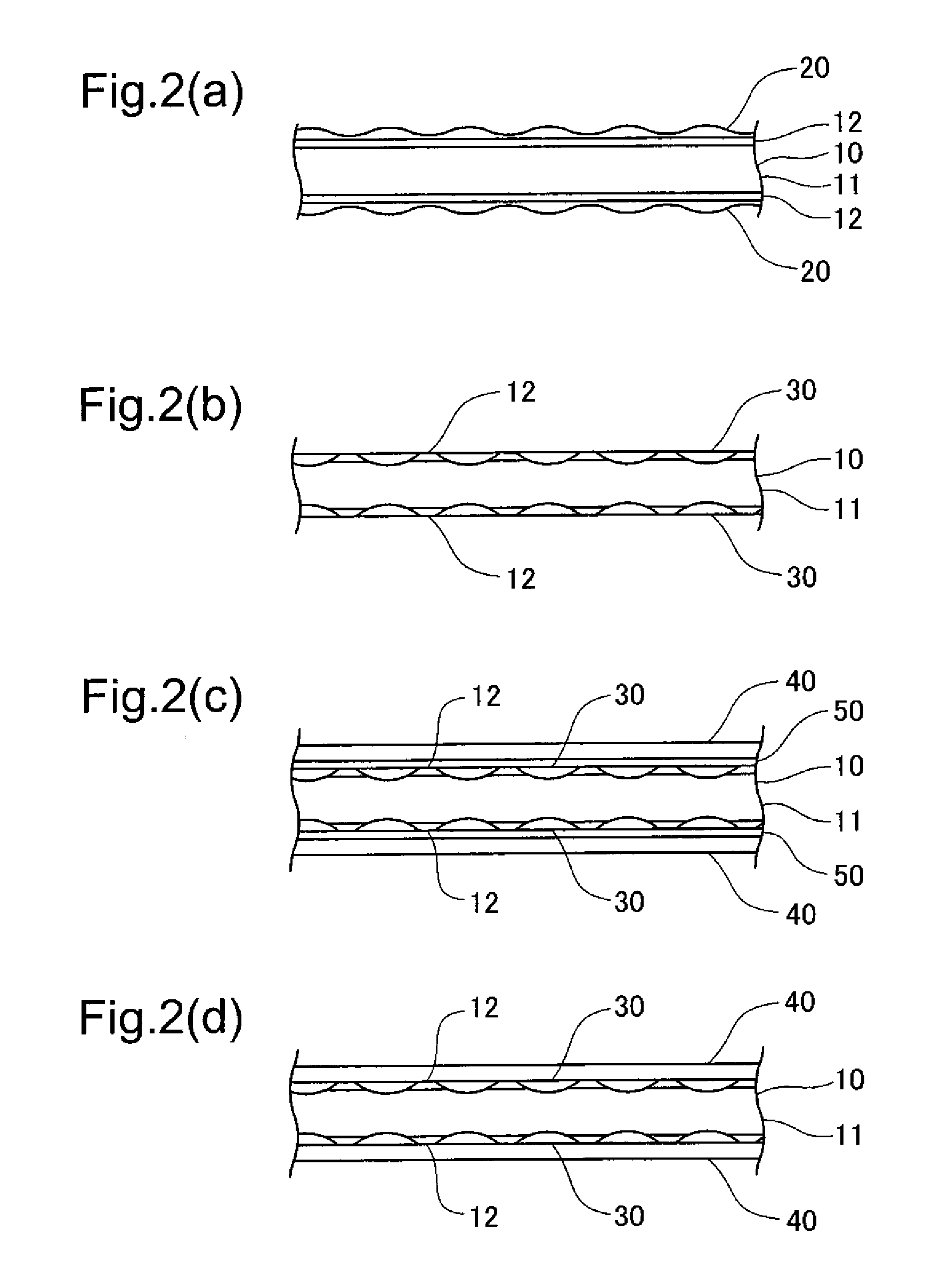

Titanium-aluminide turbine wheel and shaft assembly, and method for making same

A titanium-aluminide turbine wheel (120, 220, 320, 420) is joined to the end of a shaft (110, 210, 310, 410) by utilizing a titanium surface on the end of the shaft to be joined to the wheel, and electron-beam welding the wheel onto the titanium surface on the shaft. A steel shaft (110, 310, 410) can have a titanium-containing end piece (130, 330, 430) mechanically joined (by brazing, bonding, or welding) to the end of the shaft, and the end piece can be directly electron-beam welded to the wheel. Alternatively, the shaft (210) can be formed as a titanium member and the end (212) of the shaft can be directly electron-beam welded to the wheel (220). In another embodiment, a ferrous end piece (330) is mechanically joined to the titanium-aluminide turbine wheel (320) and then the end piece is directly electron-beam welded to the end of a steel shaft (310). Alternatively, a silver-titanium alloy member (430) is sandwiched between the wheel (420) and a steel shaft (410) and is melted to join the parts together.

Owner:GARRETT TRANSPORATION I INC

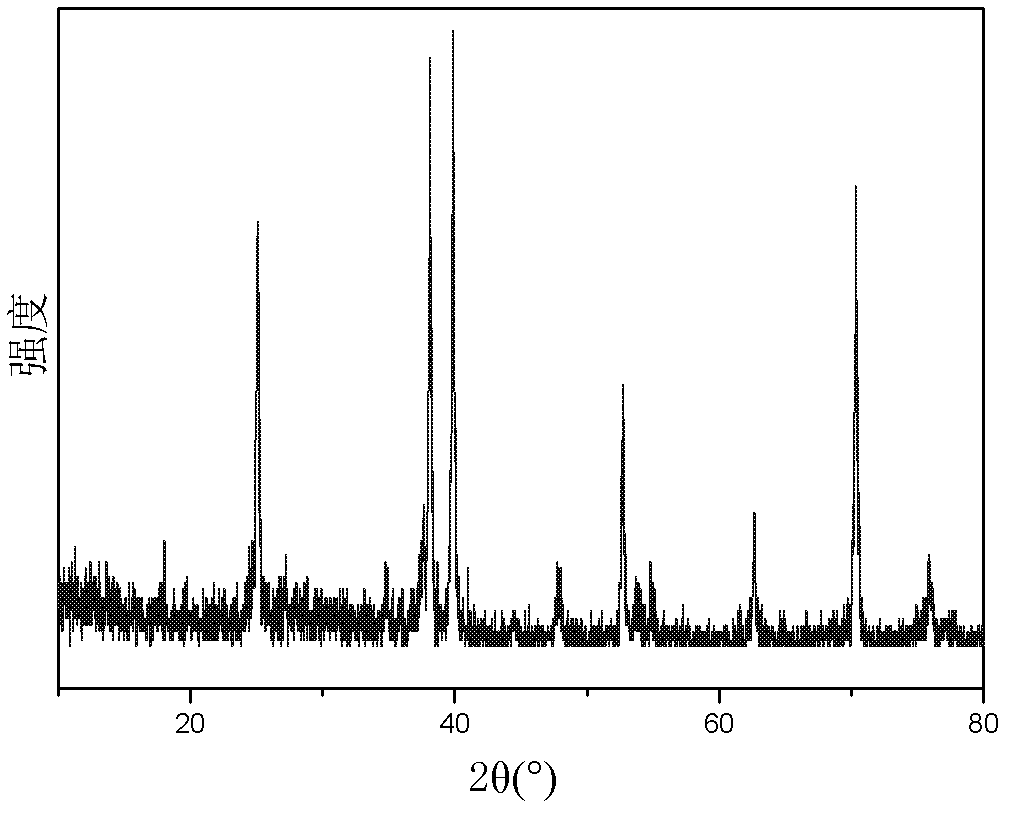

Titanium boride coatings on titanium surfaces and associated methods

InactiveUS20050208213A1High wear and corrosion and oxidation resistanceResistance to galling and seizureLiquid surface applicatorsSolid state diffusion coatingParticulatesSolid particle

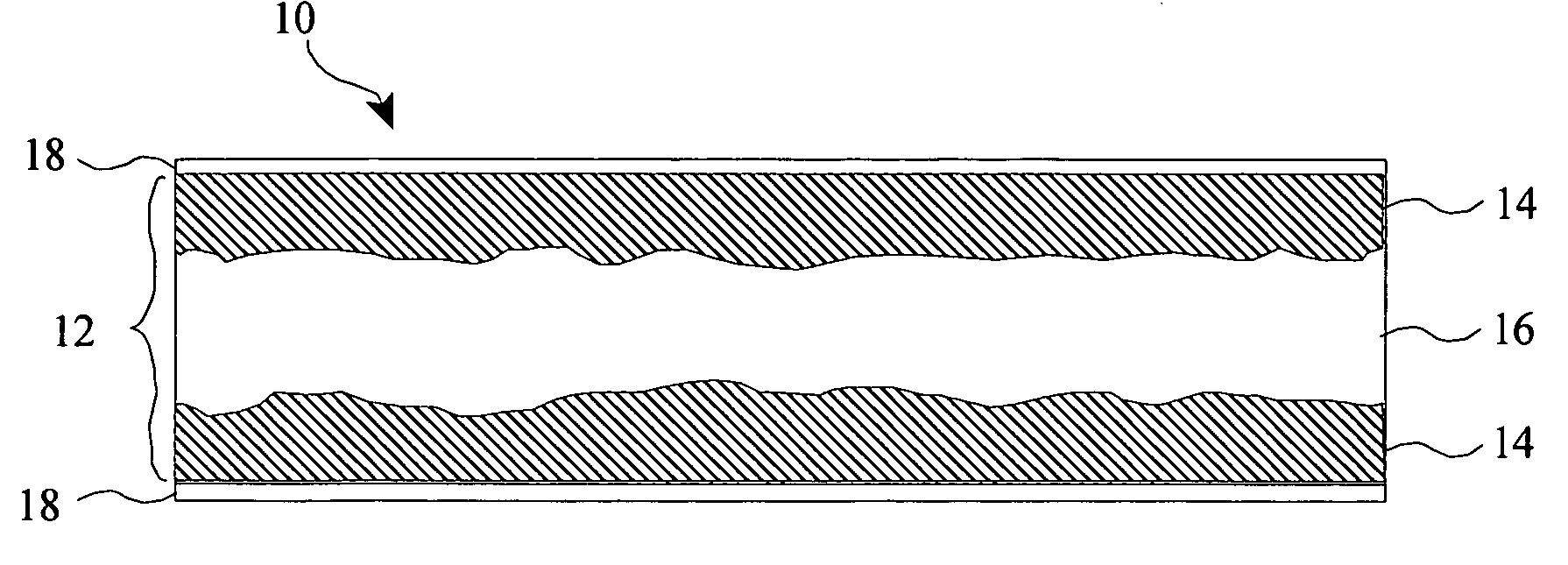

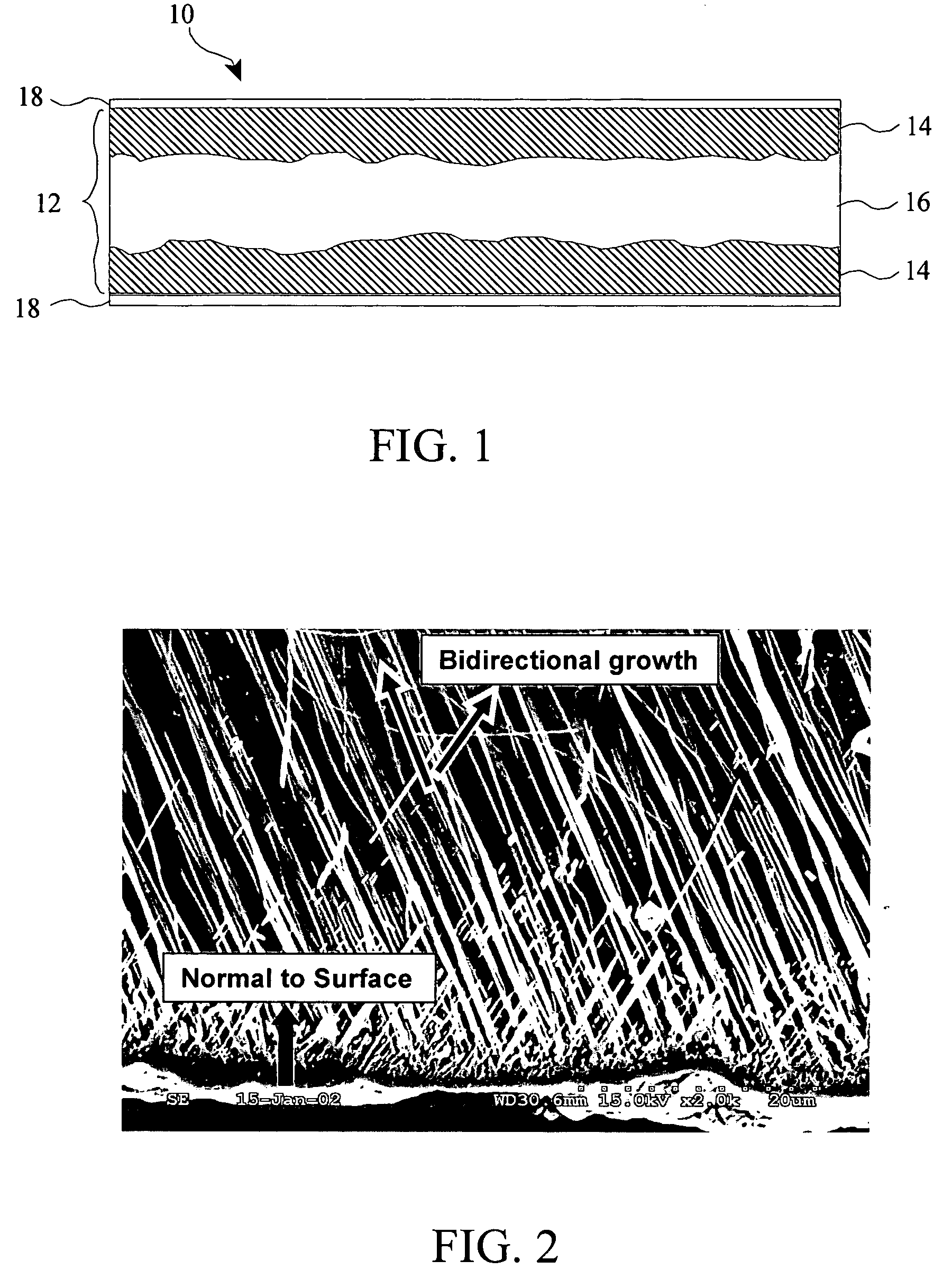

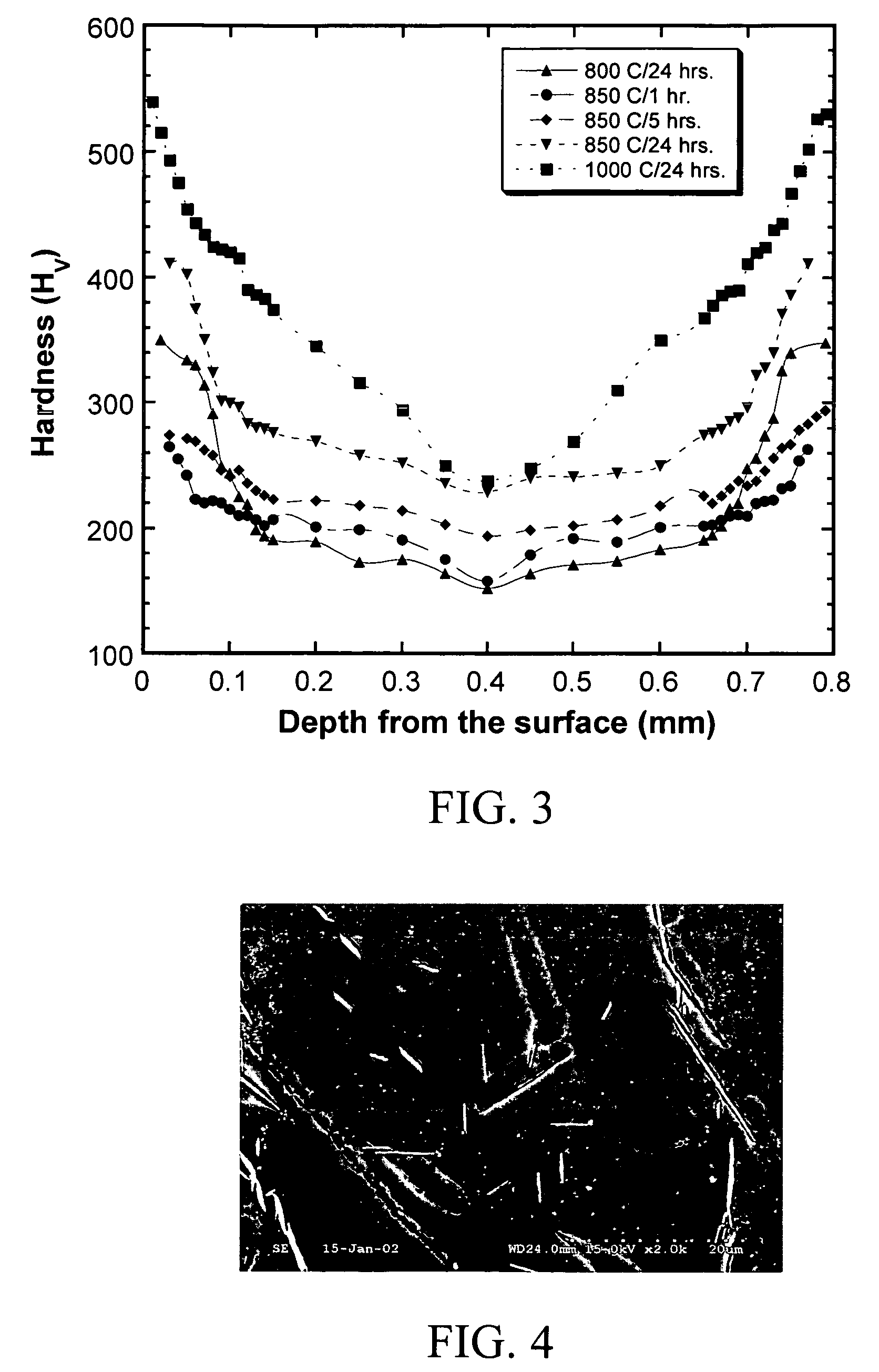

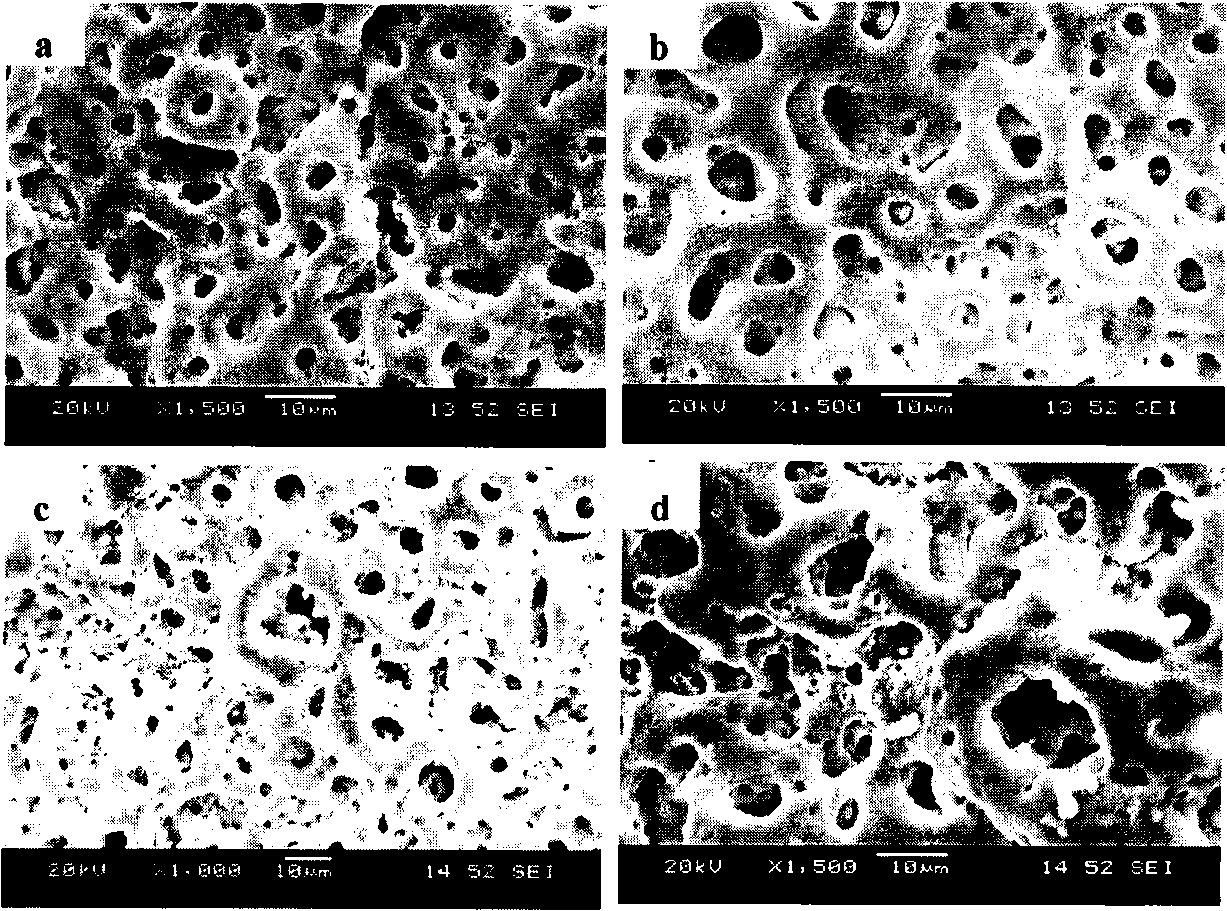

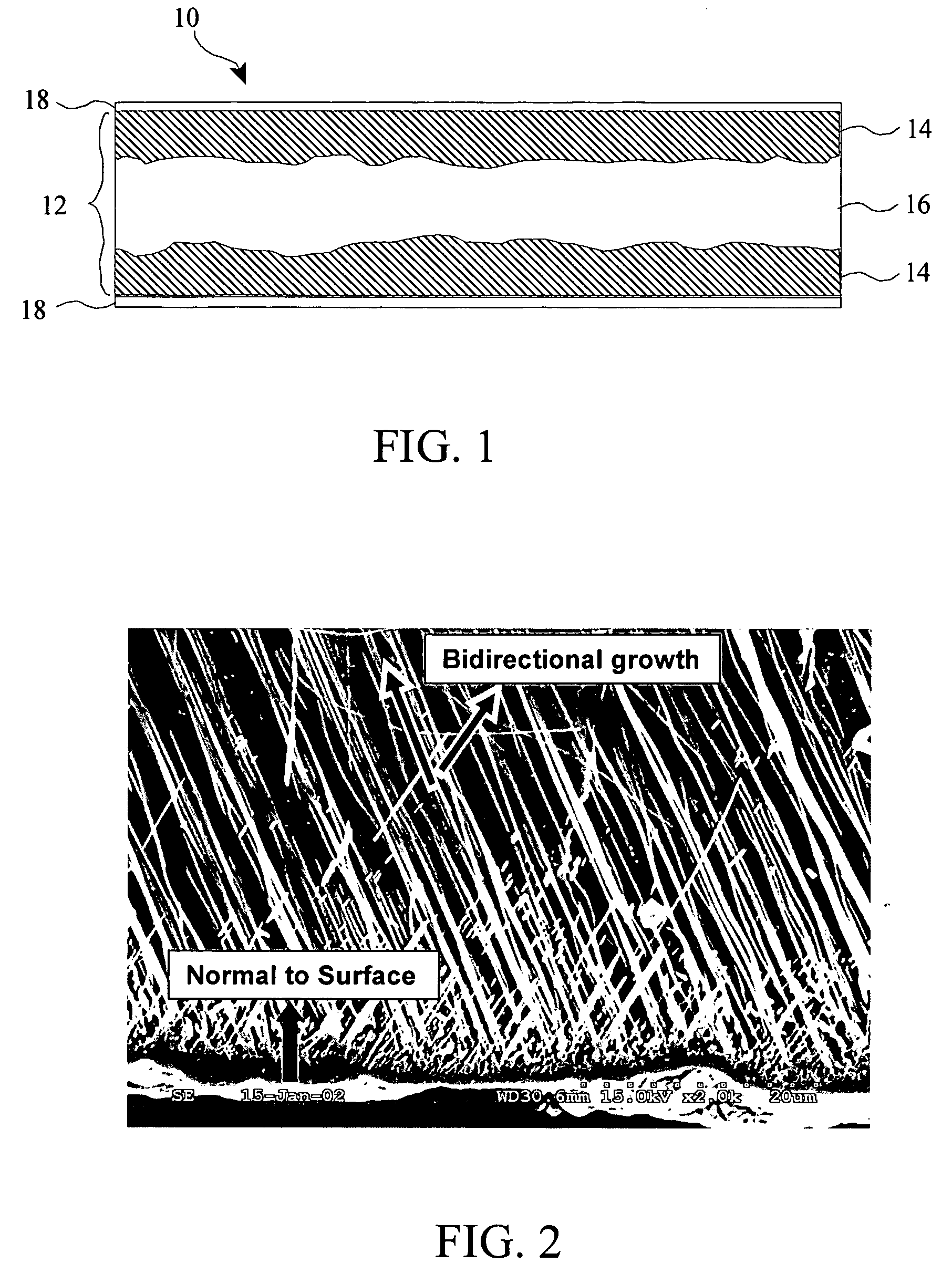

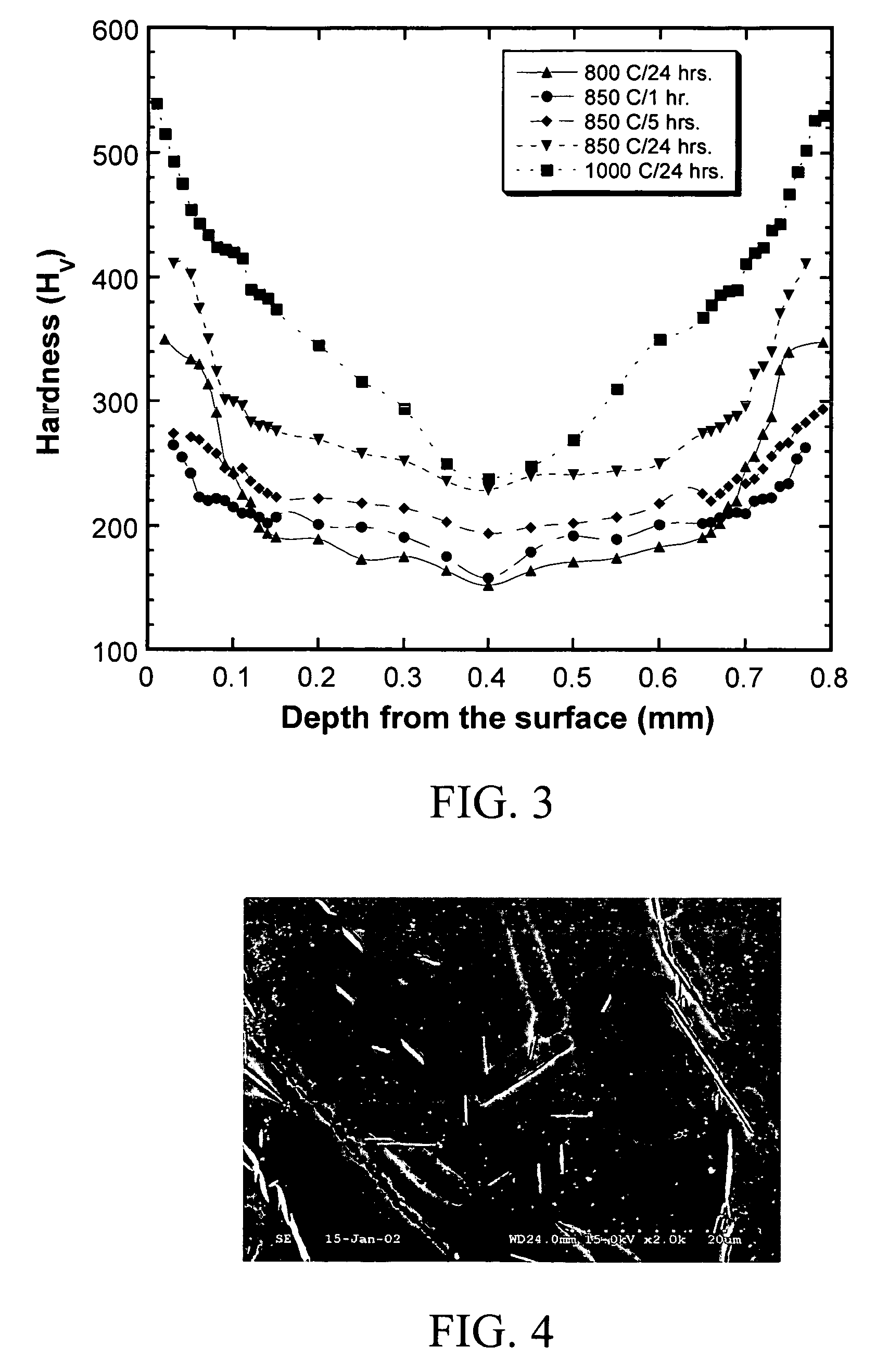

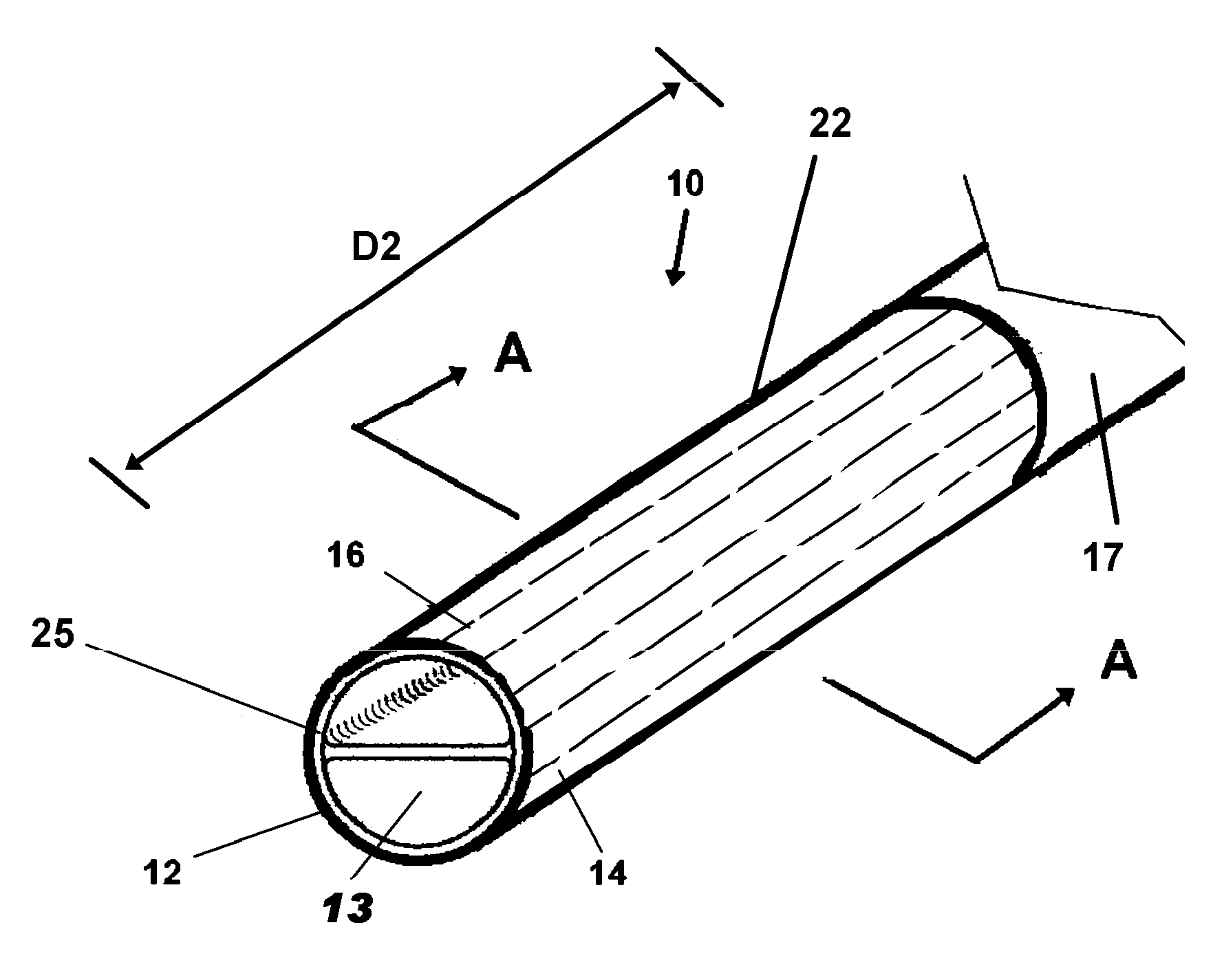

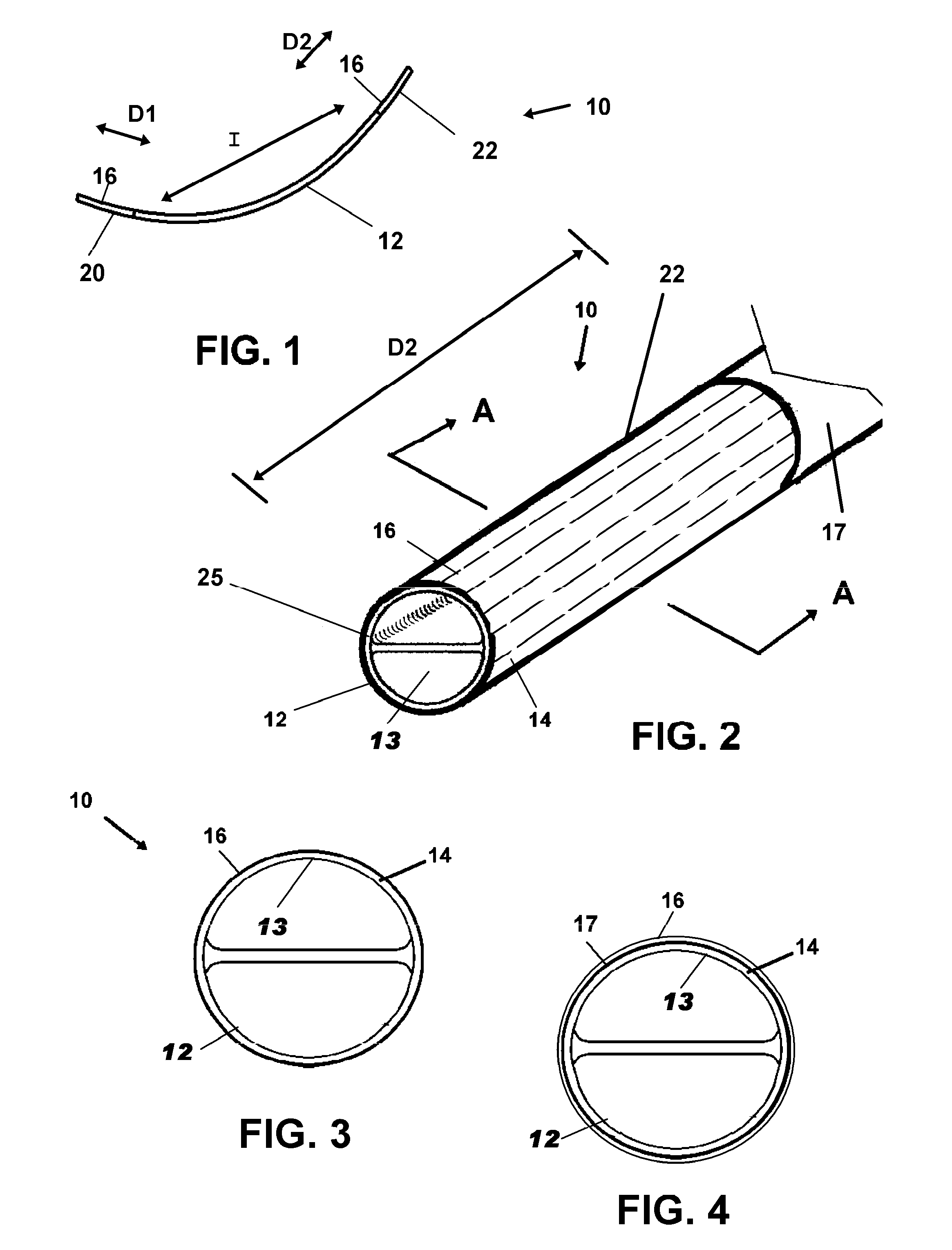

A borided titanium article can include a titanium mass having titanium monoboride whiskers infiltrating inward from a surface of the titanium mass to form an integral surface hardened region. The titanium mass can be almost any titanium based metal or alloy such as high purity titanium, commercial grade titanium, α-titanium alloy, α+β titanium alloy, β-titanium alloy, titanium composite, and combinations thereof. Borided titanium articles can be formed by methods which include providing a titanium mass, contacting a surface of the titanium mass with a boron source medium, and heating the titanium mass and boron source medium to a temperature from about 700° C. to about 1600° C. The boron source medium can include a boron source and an activator selected to provide growth of titanium monoboride whiskers. The boron source medium can be provided as a solid particulate mixture, liquid mixture, or as a gaseous mixture. During heating, boron from the boron source infiltrates into the titanium mass and forms titanium monoboride whiskers which improve the surface hardness, wear resistance, oxidation resistance, and corrosion resistance of the treated surface. The titanium monoboride whiskers can be controlled to have the desired dimensions, depending on the application requirements. Boriding titanium surfaces using these methods, provides a relatively inexpensive and effective process for improving the surface properties of titanium which are then useful in a wide variety of applications.

Owner:UNIV OF UTAH RES FOUND

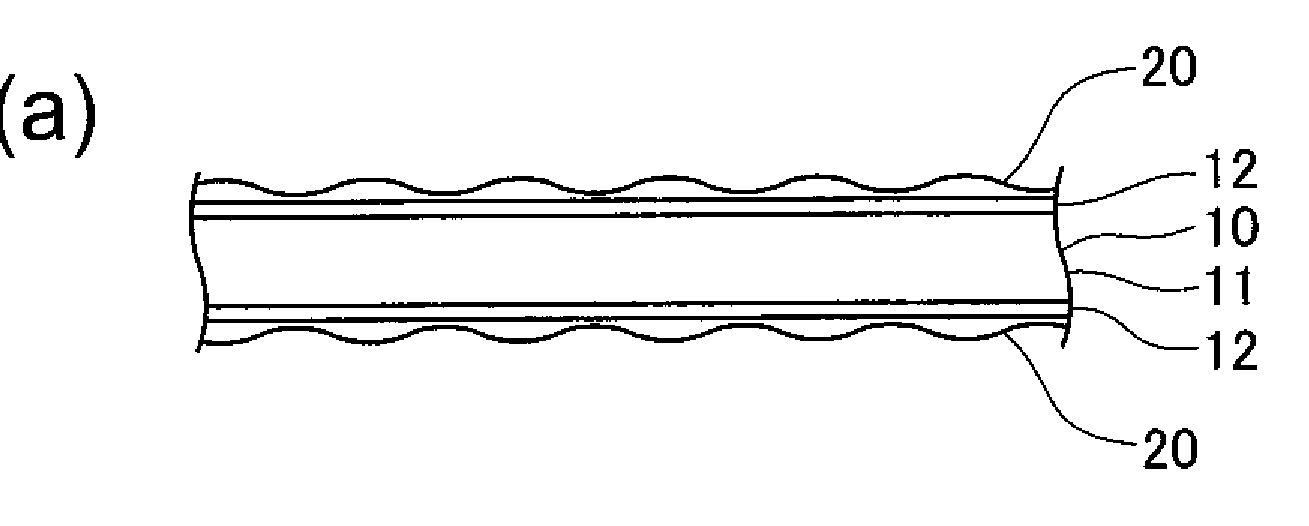

Catheter having antimicrobial coating

InactiveUS20130245568A1Good biocompatibilityAvoid introducingPharmaceutical delivery mechanismCatheterTitanium surfaceCatheter

A catheter for human or animal vascular engagement is provided. The catheter has at least one interior lumen defined by a sidewall having an exterior circumferential. A titanium surface area is positioned along the circumferential surface entirely or at one or both ends to enhance lubricity. Additionally included may be an anti pathogenic and / or anti microbial surface area positioned adjacent to the titanium surface area of the circumferential surface.

Owner:PFM MEDICAL

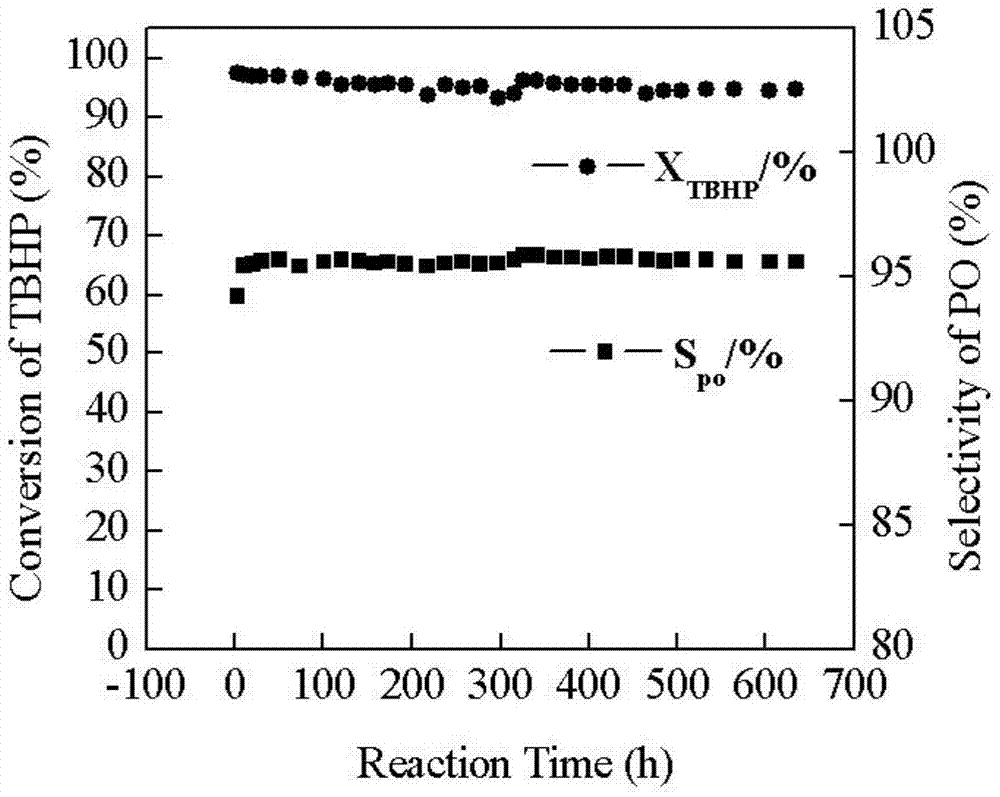

Epoxidation catalyst preparation method and prepared epoxidation catalyst thereof, and applications of epoxidation catalyst

ActiveCN106964337AHigh hydrothermal stabilityImprove stabilityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsTitanium surfaceGas phase

The present invention relates to an epoxidation catalyst preparation method and a prepared epoxidation catalyst thereof, and applications of the epoxidation catalyst. According to the present invention, titanium is loaded onto a silica gel by using a chemical vapor deposition method, silanization treatment and hydrolysis are performed, and molybdenum is loaded onto the titanium surface by using a liquid phase ion exchange compounding method so as to achieve the directional loading of molybdenum; the epoxidation catalyst has excellent molybdenum stability; and with the application of the epoxidation catalyst in oxidation of olefins to produce the corresponding epoxy compound, the catalytic activity and the selectivity are high.

Owner:WANHUA CHEM GRP CO LTD

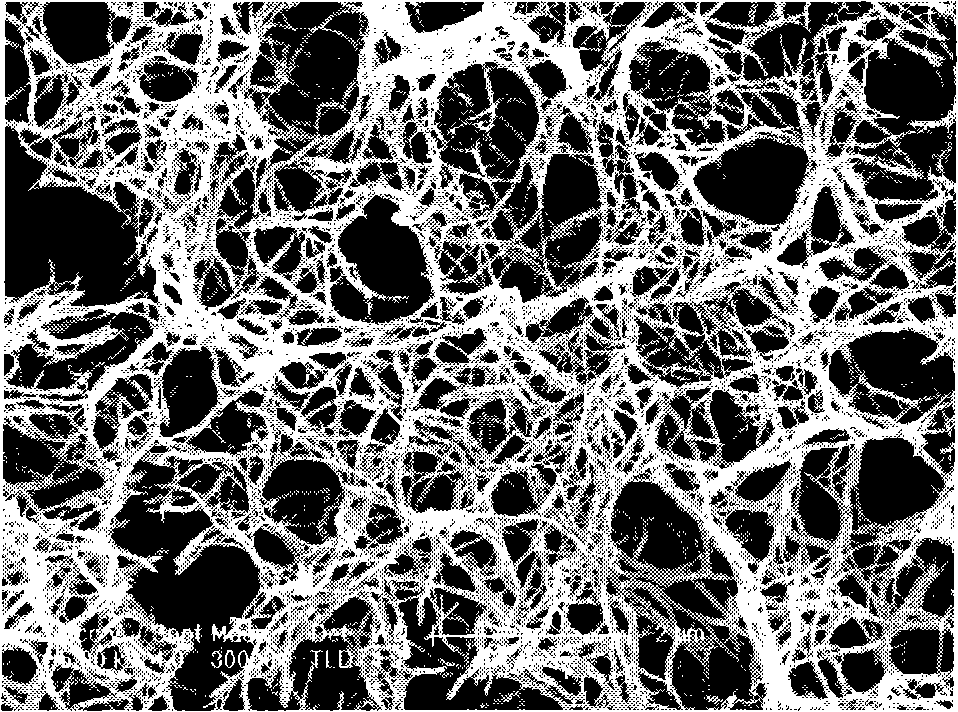

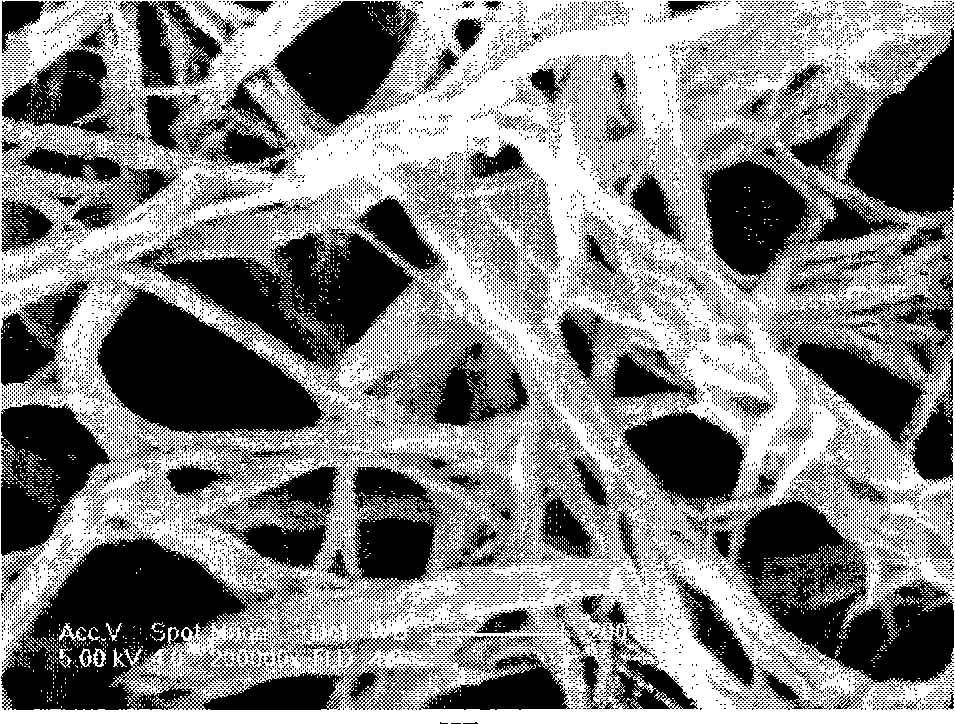

Titanium oxide nano wire film on metallic titanium surface and manufacture method thereof

InactiveCN101343746ALarge specific surface areaImprove bindingMetallic material coating processesTitanium surfaceNanowire

The invention relates to a metal titanium surface titanium oxide nanowire film and the preparation method. The component of the prepared film can be titanate, titanic acid or titanium dioxide, the diameter of the nanowire is between 10nm to 100nm, the nanowires are interlaced and winded to form a great amount of large holes and mesopore networks, and the pore space is between 20nm to 500nm. The main procedures of the preparation method are: firstly, pickling cleaning of the metal titanium surface; secondly, mixed oxidizing solution of strong alkali and oxydol is used to oxidize the metal titanium surface and to form the titanate nanowire film; thirdly, acid soaking is adopted to exchange alkaline metal ions to form the titanic acid nanowire film; fourthly, the titanium dioxide nanowire film is formed through high temperature torrefying. The preparation method of the metal titanium surface titanium oxide nanowire film of the invention is simple, the cost is low, the method is suitable for large-scale industrial production, and the prepared titanium oxide has the application prospect in photochemical catalysis related field and the electrochemistry sensing related field.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing titanium surface black oxidation titanium film

InactiveCN101177773ASimple preparation processLow costSurface reaction electrolytic coatingSolid state diffusion coatingTitanium surfaceMicro arc oxidation

The invention discloses the preparation method of black titanium oxide film at titanium surface. The preparation process is: after atmospheric oxidation, anodized or micro-arc oxidation, a titanium oxide film with more than 0.01Mum thickness is generated at the surface of a clean titanium or titanium alloy specimen. After washing and drying, the specimen which generates the titanium oxide film at surface is arranged in vacuum or non-oxidizing atmosphere for heat treatment, and then a black titanium oxide film is formed at the surface of the titanium. The invention is characterized by simple preparation method of generating black titanium oxide film at titanium surface, low cost and no pollution.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Micro-arc oxidation process for reducing surface friction coefficient of titanium alloy

InactiveCN101280450AImprove bindingHigh hardnessSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

Disclosed is micro-arc oxidation process to reduce the friction coefficient of titanium alloy surface, which has the process steps of (1) the chemical degreasing, (2) the micro-arc oxidation that the basic parameters are trisodium phosphate of 1-30g / L, tungsten sodium of 0-10g / L, sodium silicate of 0-50g / L, tartaric acid of 0-20g / L, glycerol of 0-10g / L and sodium hydroxide of 5-10g / L, (3) the post-processing that the hot oil immersion treatment is proceeded for the film after the oxidation. Through the invention, the high-performance ceramic membrane with strong cementing property, high hardness and low coefficient friction can be obtained on the titanium surface. Through the testing of a high-temperature friction and wear testing machine of MM-U5G screen material end surface, the friction coefficient of the titanium micro-arc oxidation film is 0.1 to 0.5. During the observation of the oxidation film after the experiment, the shedding and wear phenomenon is not found.

Owner:NANCHANG HANGKONG UNIVERSITY

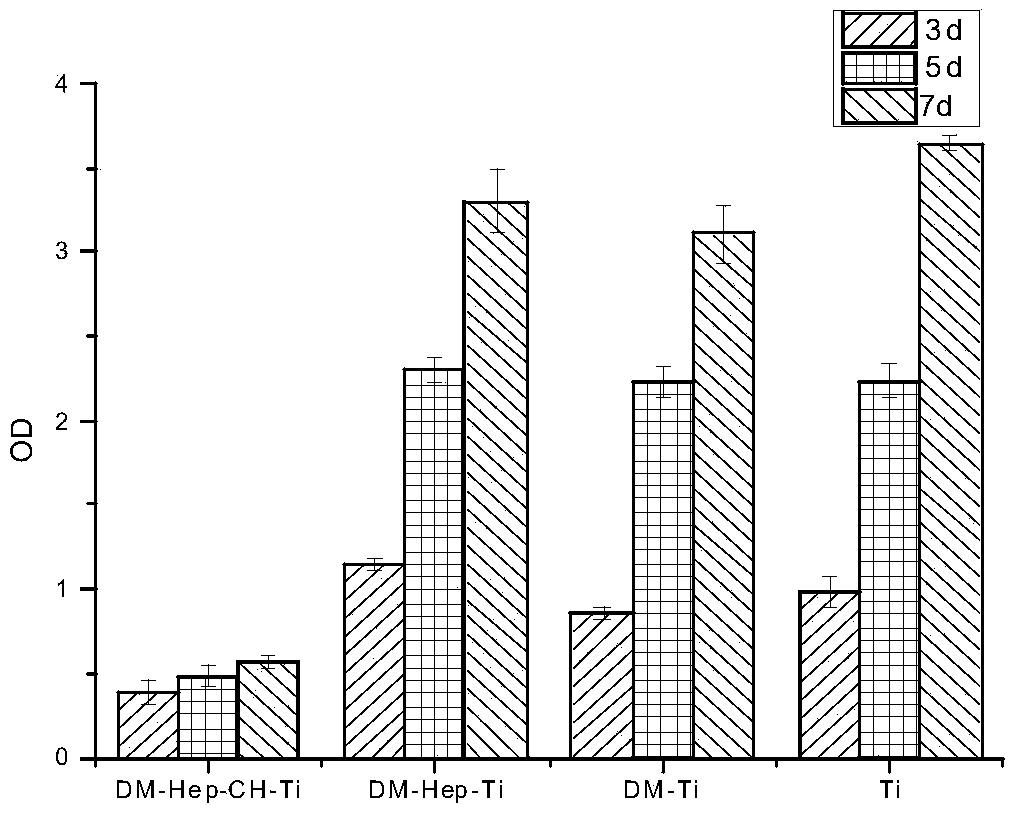

Antibacterial and antitumor orthopaedic implantation material and preparation method thereof

The invention discloses an antibacterial and antitumor orthopaedic implantation material and a preparation method thereof. The implantation material is a medical pure titanium sheet with the surface modified by chitosan, methotrexate, heparin sodium, polylysine and dopamine. According to the material, dopamine serves as a bridge to allow polylysine and a heparin sodium particle to be bonded on the surface of titanium; heparin, as a good anticoagulant, can improve biocompatibility between the material and blood, and is bonded with chitosan and methotrexate with antibacterial and antitumor effects through an electrostatic effect. Physiological-biochemical characteristics of drugs are utilized ingeniously to form an orderly and uniform antibacterial and antitumor coating with high biocompatibility on the surface of the titanium, and the prepared implantation material has good antibacterial and antitumor activity, and can effectively prevent bacterial adhesion and reproduction, as well as recurrence and transfer of a cancer.

Owner:GUANGZHOU GENERAL HOSPITAL OF GUANGZHOU MILITARY COMMAND

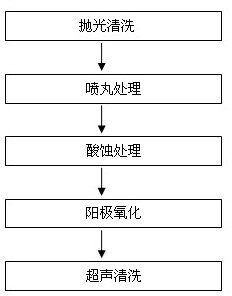

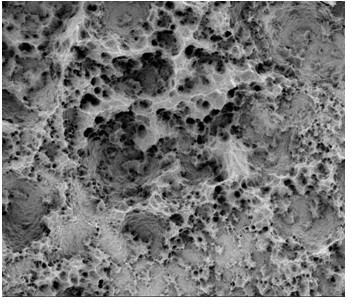

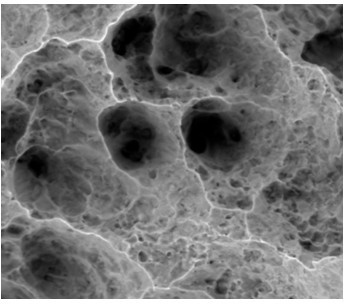

Method for forming graded multi-hole shape on titanium surface

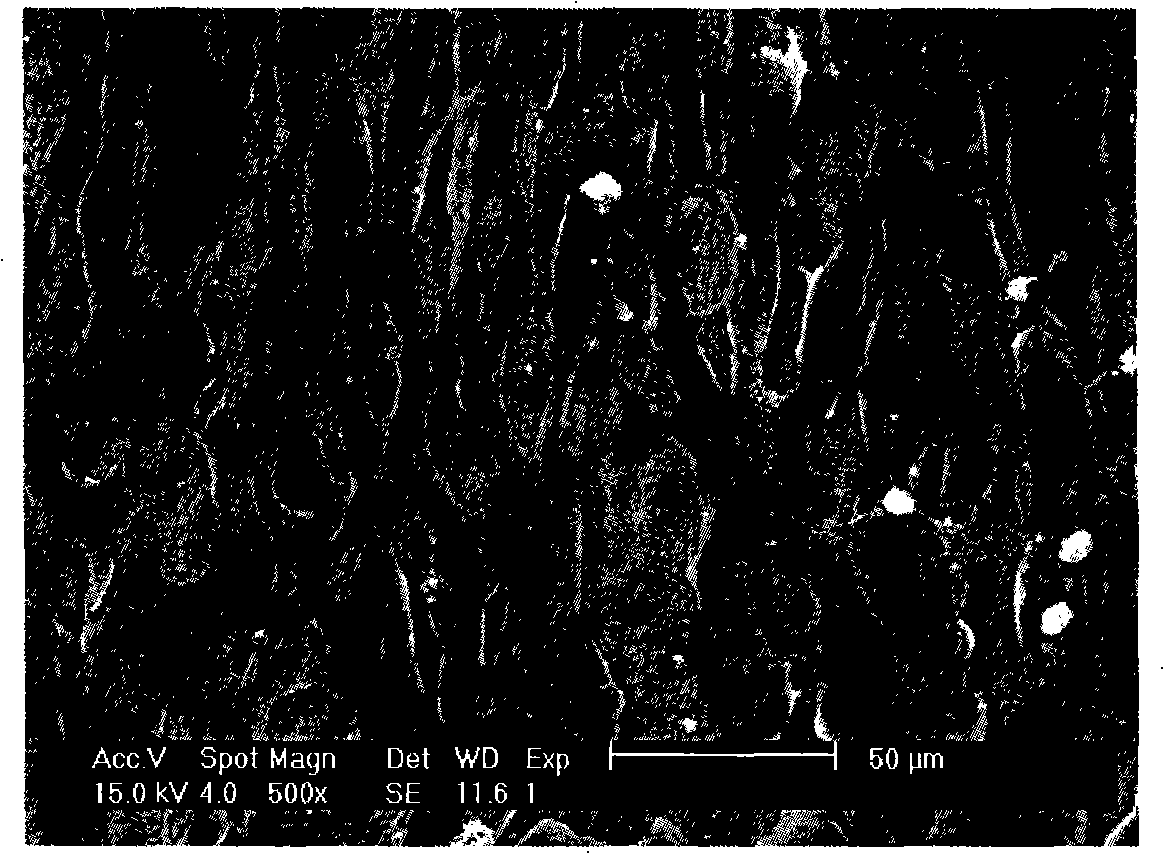

The invention discloses a method for forming a graded multi-hole shape on the titanium surface, which is used for surface treatment of a pure titanium biological material and comprises the steps of titanium sample polishing and cleaning, shot blasting treatment, acid etching, anodic oxidation and ultrasonic cleaning. The graded multi-hole shape with biological activity and a thick ionic compound TiO2 layer formed by combining ionic bonds and with high biological chemical stability are formed on the pure titanium surface. The method combines the acid etching and anodic oxidation, wherein micron-sized holes and sporadic micron-sized holes are formed through shot blasting treatment, many evenly-distributed micron-sized holes are produced through anodic oxidation reaction, and the thick ionic compound TiO2 layer is formed. The method for forming the graded multi-hole shape on the titanium surface greatly improves the biological activity of the pure titanium surface and the stability of pure titanium.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +2

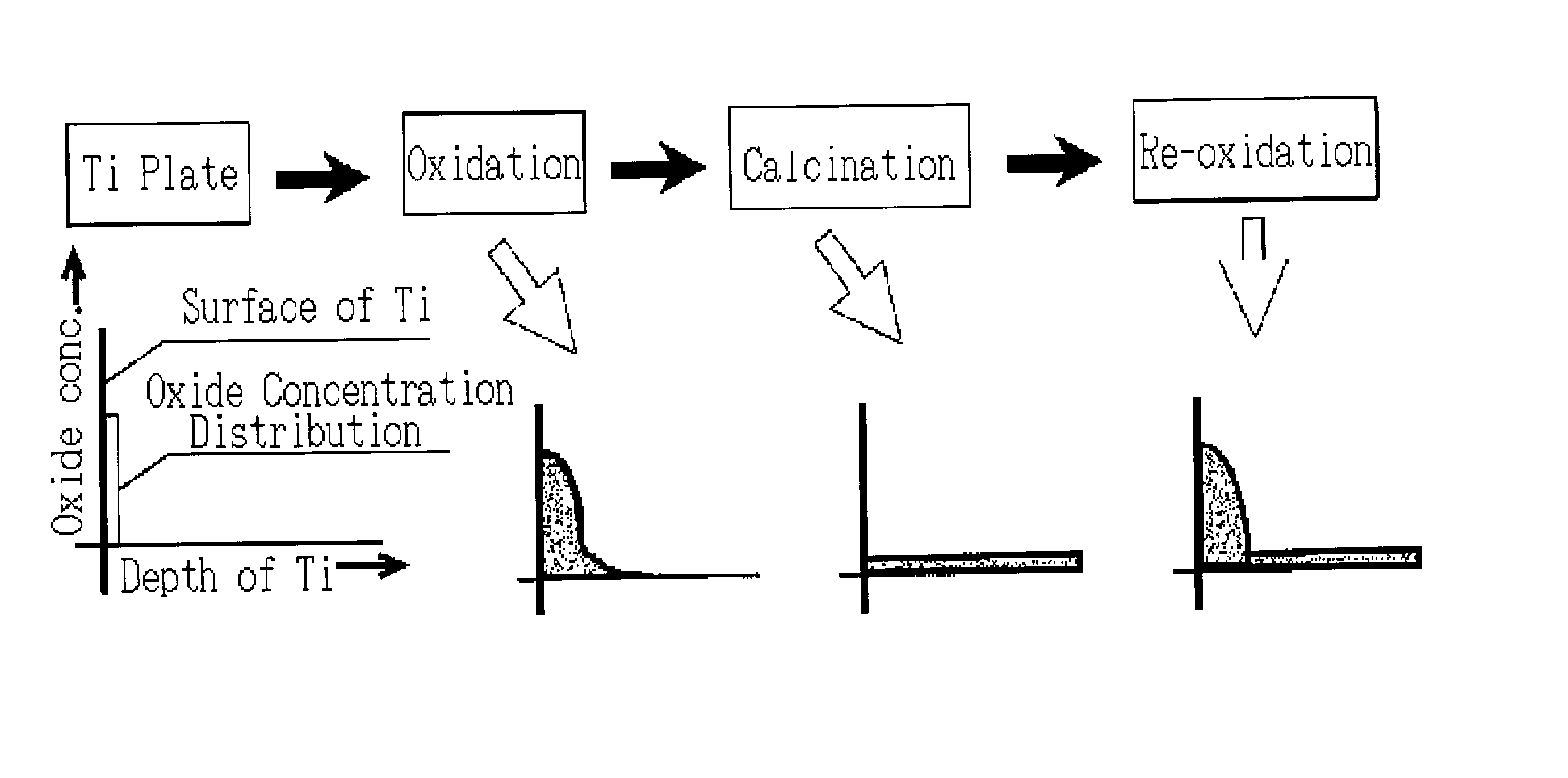

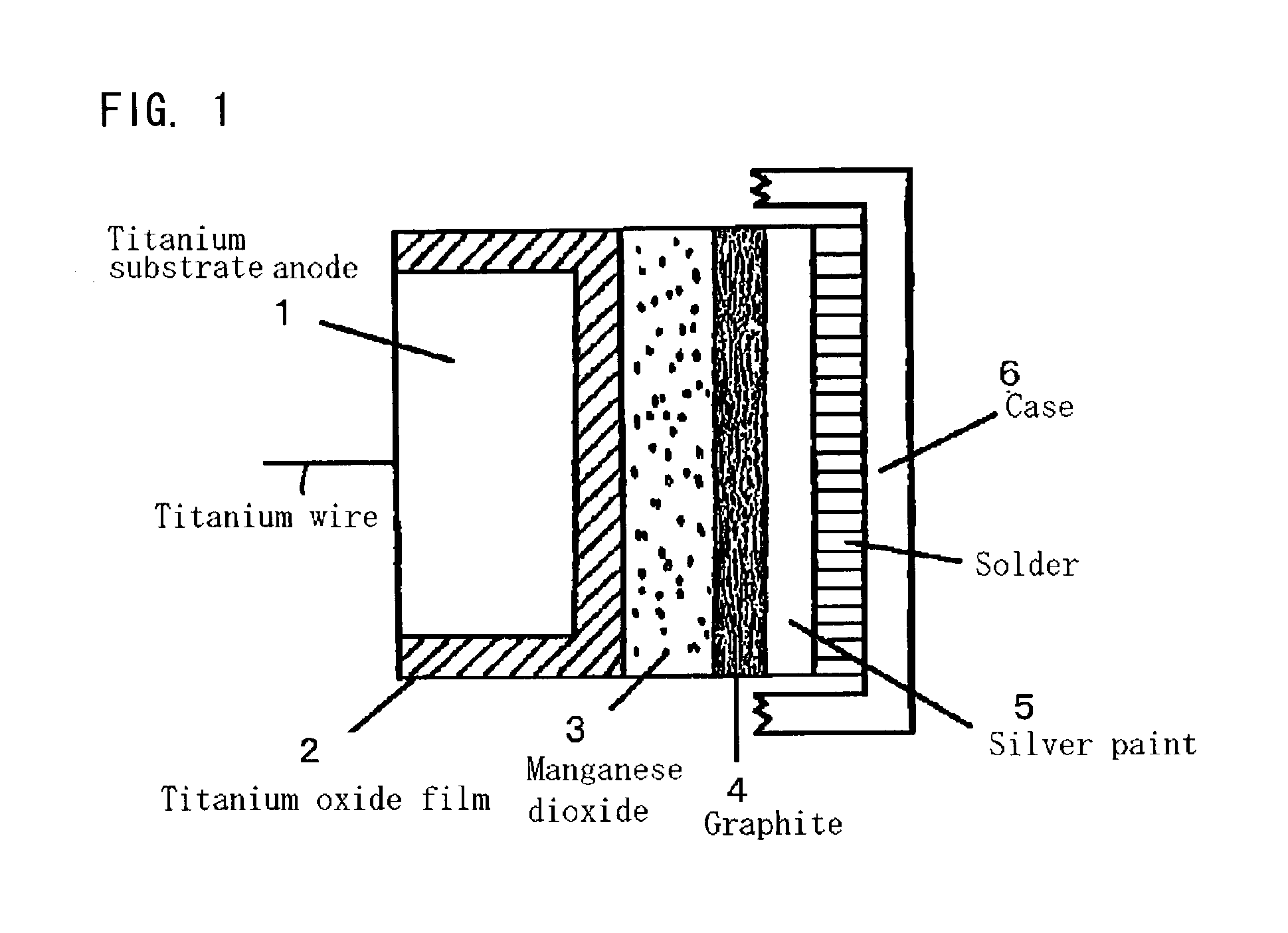

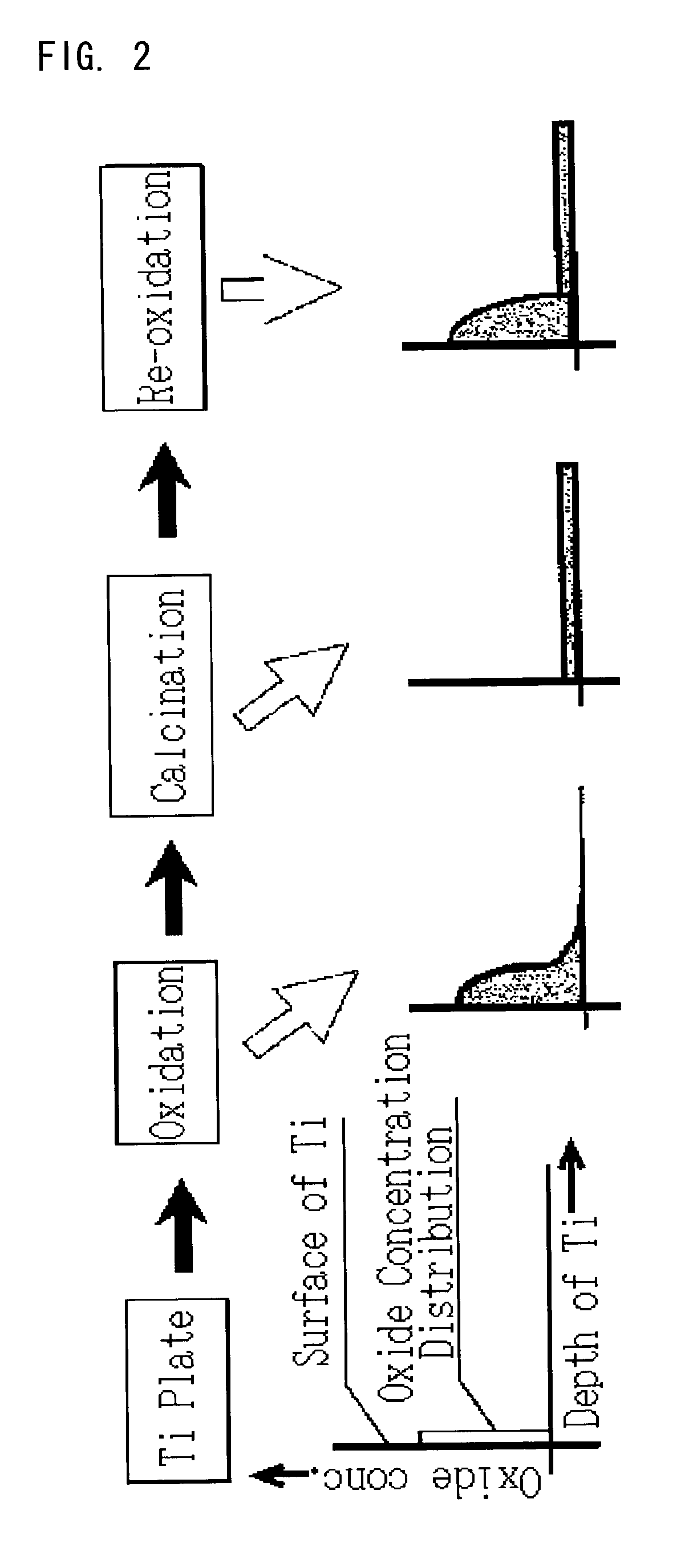

Method for forming titanium oxide film and titanium electrolytic capacitor

InactiveUS20030010407A1Capacitor electrodesSolid state diffusion coatingTitanium surfaceElectrolysis

A compact type large capacity titanium electrolytic capacitor having minimized leakage current is provided by forming a stable oxide film having a large dielectric constant on a titanium surface, wherein a titanium substrate having a titanium oxide film thereon having a thickness of 50 nm or more is subjected to calcination in vacuum or an inert gas atmosphere, thereby reducing the thickness of said oxide film to less than 50 nm and the calcined surface of said metal titanium substrate is subjected to oxidation, thereby re-forming an oxide film on the surface of said metal titanium substrate. The metal titanium substrate having the re-formed oxide film obtained by such method can be used as an anode for a titanium electrolytic capacitor.

Owner:TOHO TITANIUM CO LTD

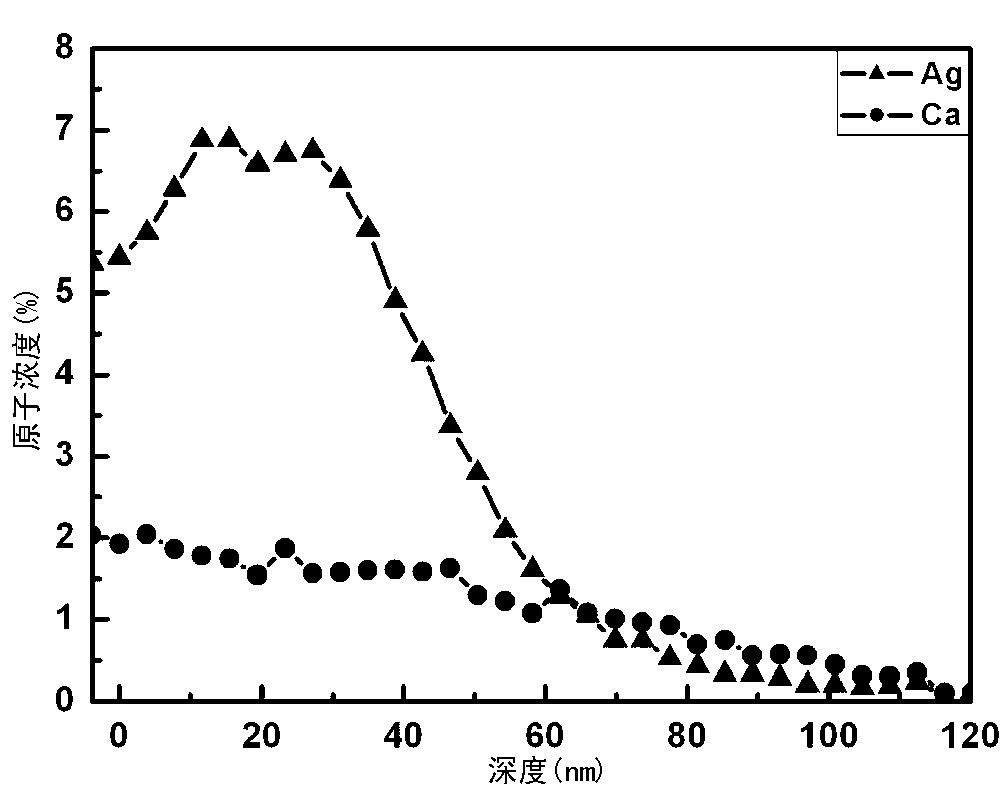

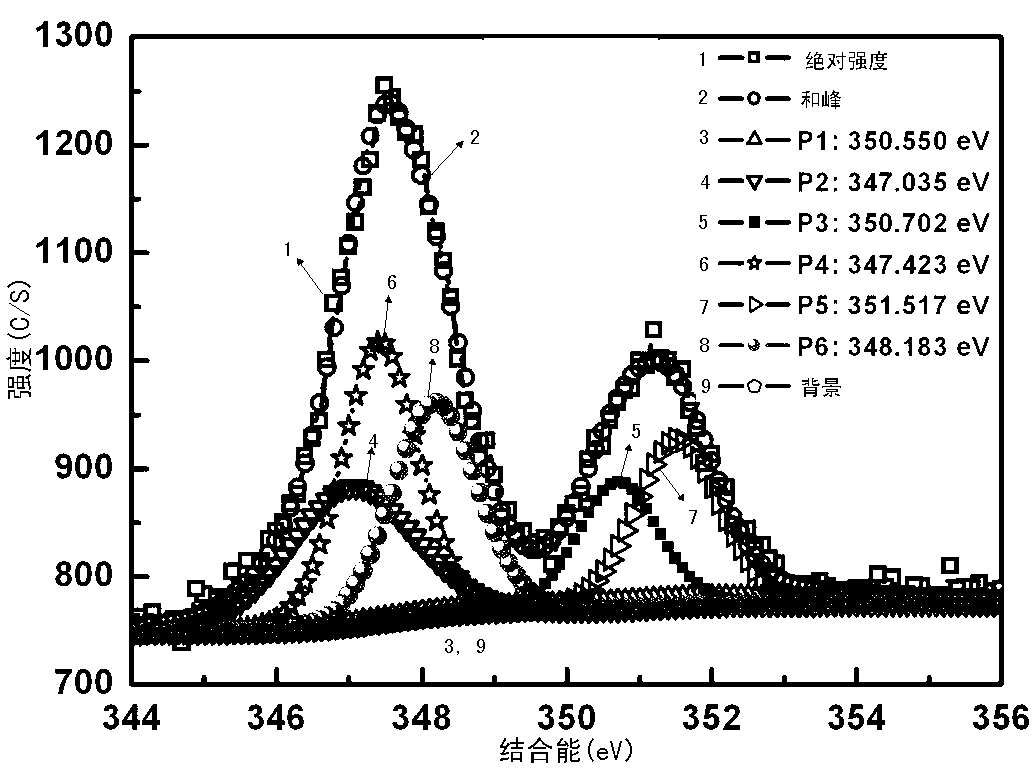

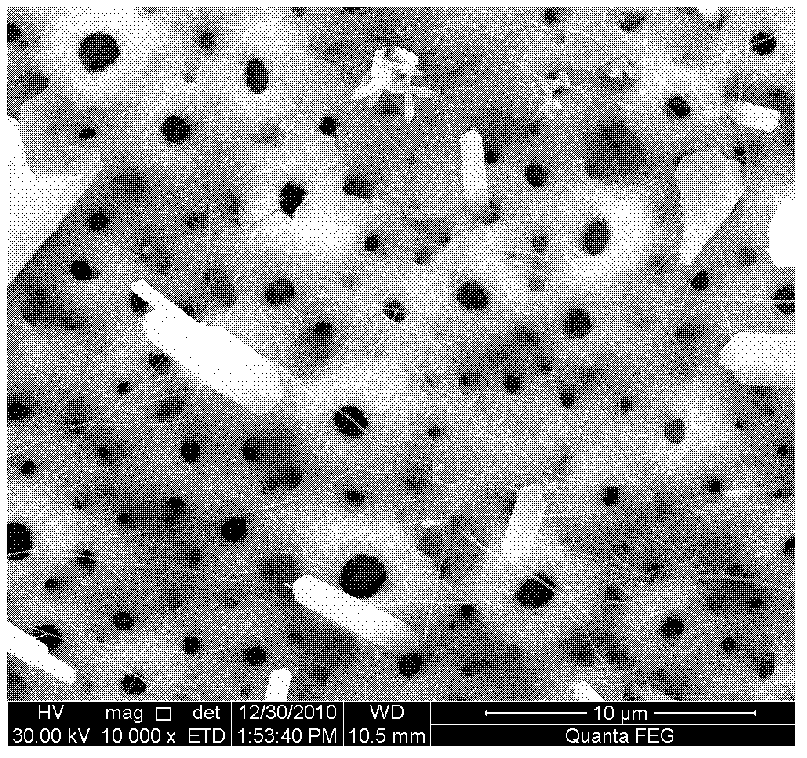

Modification method for titanium surface with osteogenic performance and antibacterial performance

ActiveCN103014646AEnhanced inhibitory effectPromote osteogenesisVacuum evaporation coatingSputtering coatingEscherichia coliMedical equipment

The invention relates to a modification method for a titanium surface with osteogenic performance and antibacterial performance. The modification method adopts a plasma-immersion ion implantation treatment process to co-implant silver ion and calcium ion to the surface of a titanium base material, wherein the co-implantation simultaneously arouse two cathode impulse arc sources, which respectively adopt pure silver and pure calcium as a cathode, to carry out plasma-immersion ion implantation treatment process. The silver-calcium co-implantation method provided by the invention can be used for improving the osteogenic performance and antibacterial performance of the surface (for example an artificial bone, an artificial joint and a dental implant) which can be implanted to medical equipment. The prepared modified material has a remarkable inhibitory effect to the escherichia coli and staphylococcus aureus, and a remarkable promotion to adhesion and proliferation of relevant osteoblast (BMSCs, MG63 cells).

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

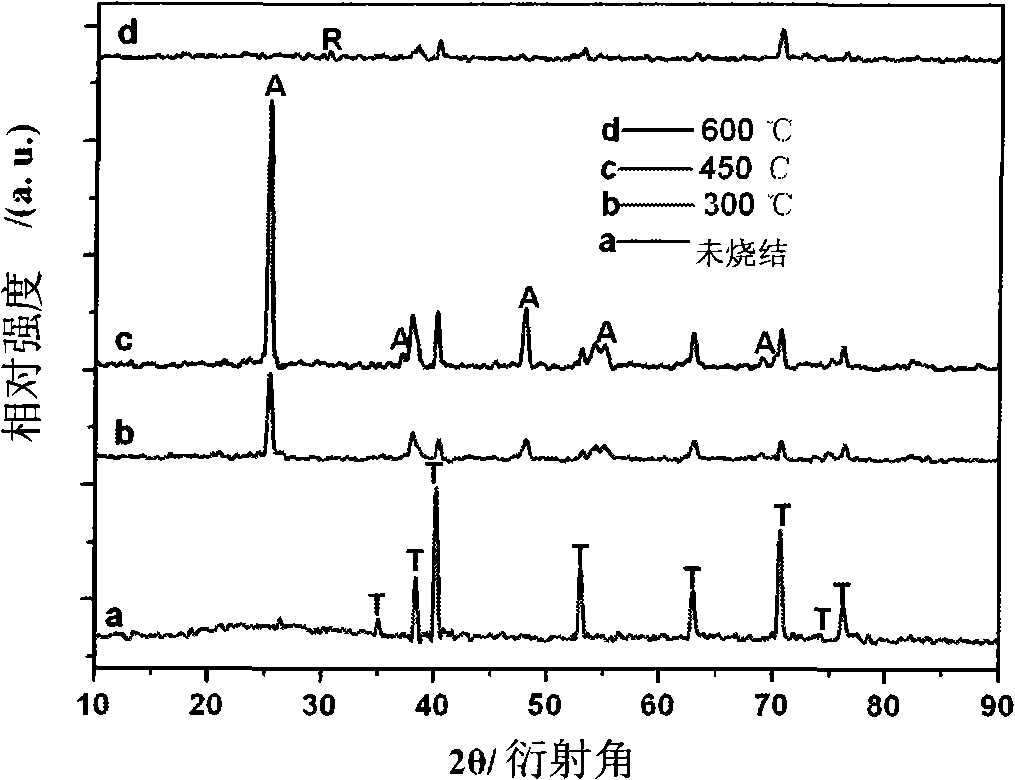

TiO2 nanometer pore array material preparation method and uses thereof

InactiveCN101307479AImprove bindingShorten the migration pathPolycrystalline material growthSurface reaction electrolytic coatingChemical oxygen demandTitanium oxide

Owner:SHANGHAI JIAO TONG UNIV

Application of femtosecond laser in pure titanium implantation material surface treatment

InactiveCN101264551AGood biocompatibilityReduce the impactTeeth fillingBone implantTitanium surfaceLaser processing

The invention relates to an application of femto-second laser in the surface treatment of the pure titanium implanting material, belonging to the technical field of application of laser in the material surface treatment. The application method comprises the following steps: in the air, the femto-laser impulse is in normal incidence and focused right on the top of the lump pure titanium implanting material which is ground and dried, a light spot with a radius of 5um is formed at the surface of the pure titanium implanting material, the femto-laser processing parameters are defined as follows: the impulse repeat frequency is 1 kHz, the single impulse power is from 5 to 200 micro joule, the impulse width is 50 femtosecond, the impulse center wavelength is 800 nanometer, the line interval of the laser processing is between 10 to 100 micron, the laser scanning speed is between 0.5 to 1.2 mm / sec, the laser polarization direction is regulated to be parallel to the laser scanning direction, the femto-laser scans the whole surface of the pure titanium implanting material, a titanium based biomedical material with an oxide layer generated on the titanium surface, even roughness, and a pattern of strips, holes, grooves or the combined pattern thereof formed on the pure titanium implanting material is made.

Owner:HEBEI UNIV OF TECH +2

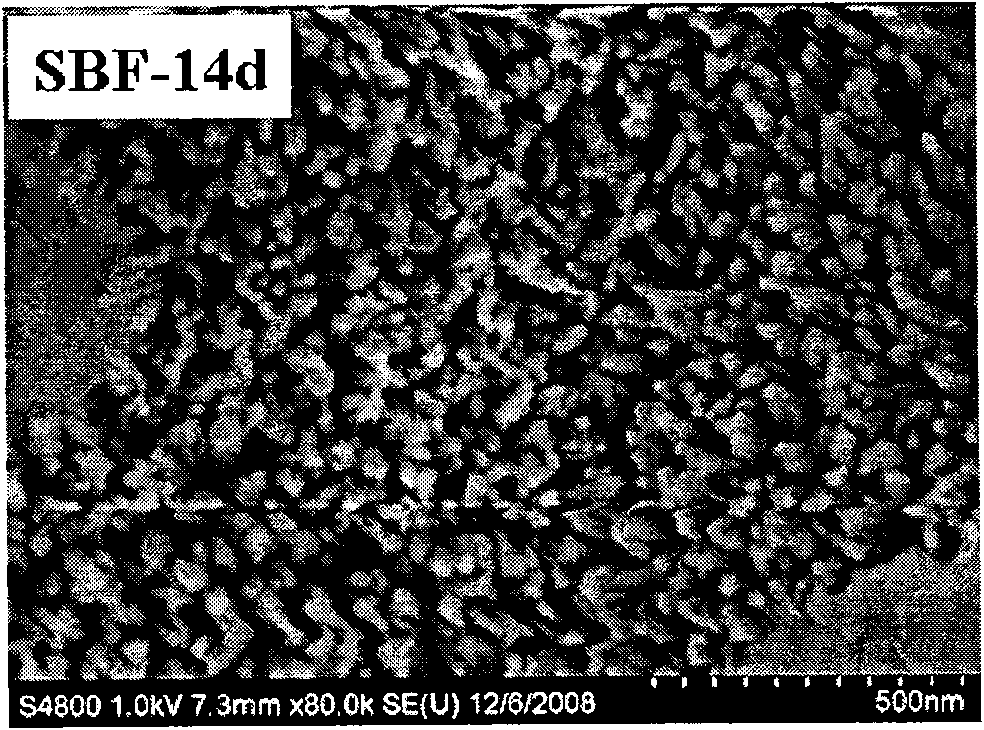

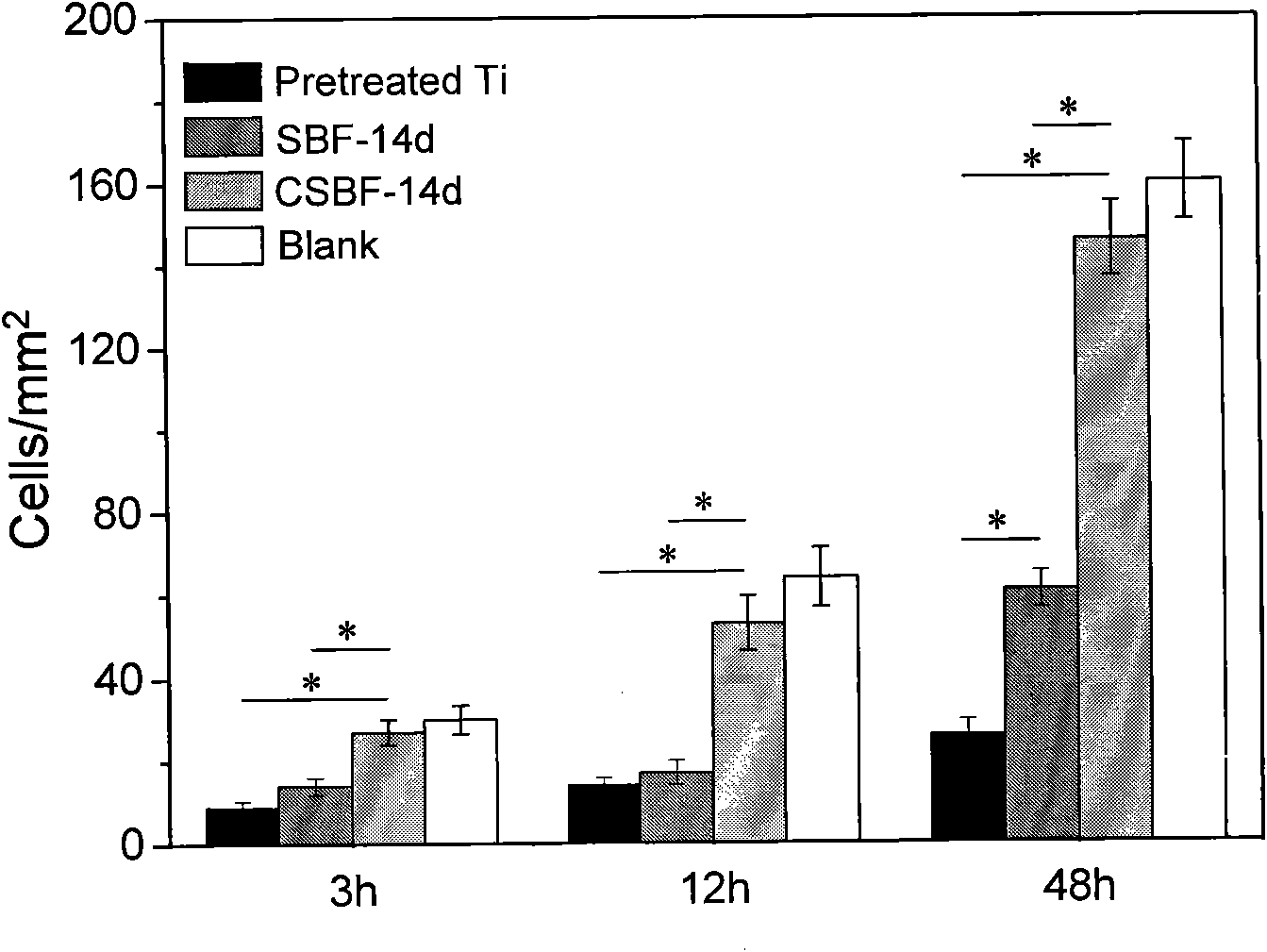

Method for coating surface of titanium materials and application of coating composite materials

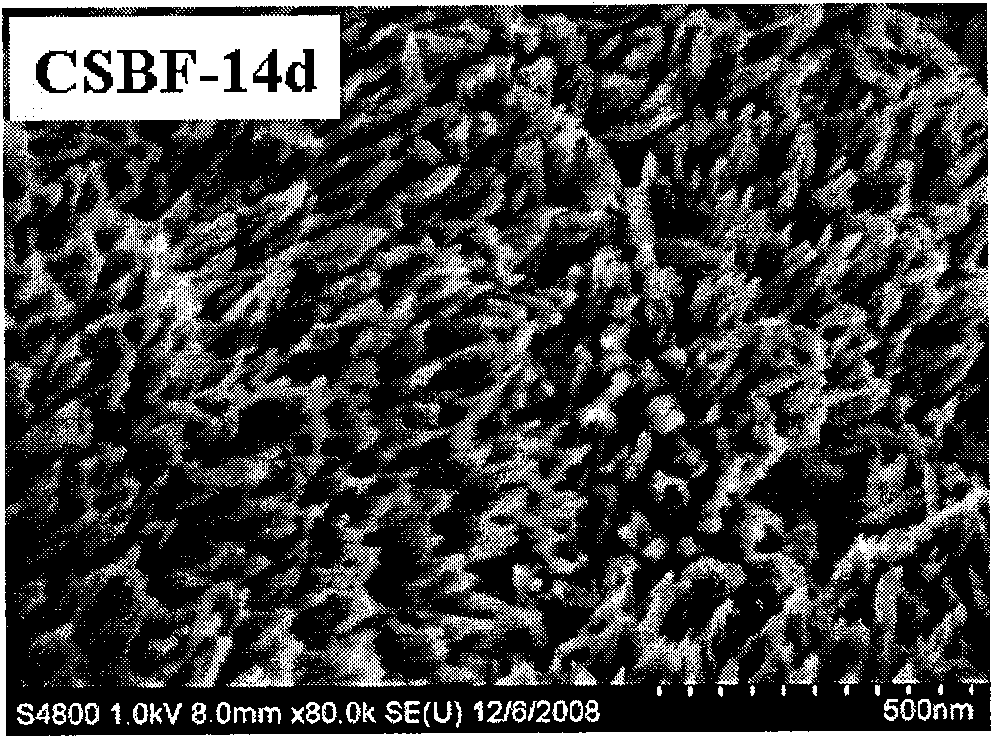

The invention discloses a method for coating the surface of titanium materials, which comprises the following steps: cooling an alkali heat treated titanium disc, putting the titanium disc in a 12-hole plate, respectively adding 5ml of 1.5 times of bionic liquid to each hole, standing the bionic liquid for 2 to 14 days at a temperature of 37 DEG C, and changing 1.5*CSBF liquid every 12h; taking out the titanium disc for washing with deionized water, and naturally drying the titanium disc to acquire a bioactive coating on the titanium surface. The coating is a composite coating of recombined collagen and hydroxyapatite. The coating formed by the method is a composite of nano-hydroxyapatite crystals and the recombined collagen, has two key components of a natural bone, and has the function of promoting cell adhesion, proliferation and differentiation. The prepared titanium composite materials can be applied in bone tissue engineering as bone repair or substitute materials.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing antibacterial coating on surface of titanium implant

ActiveCN105688278AGood biocompatibilityImprove antibacterial propertiesPharmaceutical delivery mechanismLiquid/solution decomposition chemical coatingBiocompatibilityBiology

The invention provides a method for preparing an antibacterial coating on the surface of a titanium implant. A silver-loaded polyelectrolyte multilayer film is prepared on the titanium surface with a layer-layer self-assembly method, so that the titanium surface has good biocompatibility and antibacterial performance. The method is simple and particularly suitable for implants in complex shapes; the surface coating adopts natural polymers with good biocompatibility, so that the coating has bacterium killing and inhibiting properties and causes no toxic effect to cells.

Owner:WUHAN UNIV

Preparation method and application of metal surface-etched nanoporous array

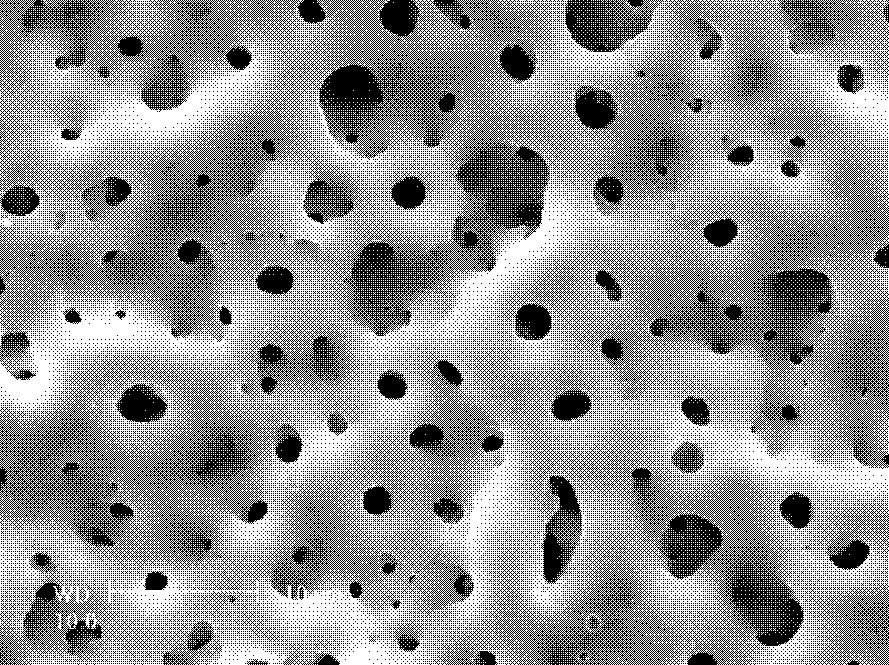

InactiveCN102552977AThe method is simpleEasy to operatePolycrystalline material growthSurgeryTitanium surfaceInternal bone fixation

The invention relates to application of pure titanium and titanium alloy (hereinafter called titanium) surface-etched TiO2 nano-porous array appearance in preparing human metal implant which can be a dental implant, a bone implant, a fixing plate and a fixing nail, wherein the appearance is to prepare a TiO2 nano-porous array structure on the titanium surface. The invention also provides an optimal preparation method of the appearance. The preparation method has the advantages that: the preparation can be performed at normal temperature and normal pressure; the prepared TiO2 nano-porous array is regular; and the method is relatively simple in process, convenient for operation, low in cost and short in process flow. The prepared titanium surface nano-porous array structure has selective effect to different types of cells, so that the success rate of implant can be greatly increased; the nano-porous array structure can inhibit fibroblast from adhering or multiplying on the surface of the structure, so that the success rate of bone and dental implant operation and bone internal fixation can be greatly improved; and therefore, the preparation method is a bone implant material and bone fixation material surface appearance modification method with clinical application prospect.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Process for preparing composite coating of hydroxyapatite and porous titanium dioxide on biomedical titanium metal surface

InactiveCN102560595AImprove bindingImprove biological activitySurface reaction electrolytic coatingProsthesisMicro arc oxidationPlasma electrolytic oxidation

A process for preparing a composite coating of hydroxyapatite and porous titanium dioxide on the biomedical titanium metal surface belongs to the technical field of metal surface modification. Compared with other technologies of coating titanium surface bioactive coating, the process prepares the a composite coating of hydroxyapatite and porous titanium dioxide on the biomedical titanium matrix surface in situ, thereby the adhesion of titanium matrix substitutes implanted into the body and bone tissues is remarkably improved. The process includes the following steps of, firstly, placing titanium or titanium alloy into a stainless steel groove containing an alkaline electrolyte, using a bipolar impulsing power source, controlling micro-arc oxidation electrical parameters and micro-arc oxidation time, enabling the titanium surface to form a porous titanium dioxide coating by a disruptive discharge of the titanium surface; secondly, putting the coating into a reactor containing liquid through a hydro-thermal method, thereby the hydroxyapatite can grow in situ of the biomedical titanium matrix surface in situ. The process for preparing a composite coating of hydroxyapatite and porous titanium dioxide on the biomedical titanium metal surface is simple in operation, high in controllability and low in manufacturing cost, and can introduce non-toxic substances into the coating.

Owner:HARBIN INST OF TECH

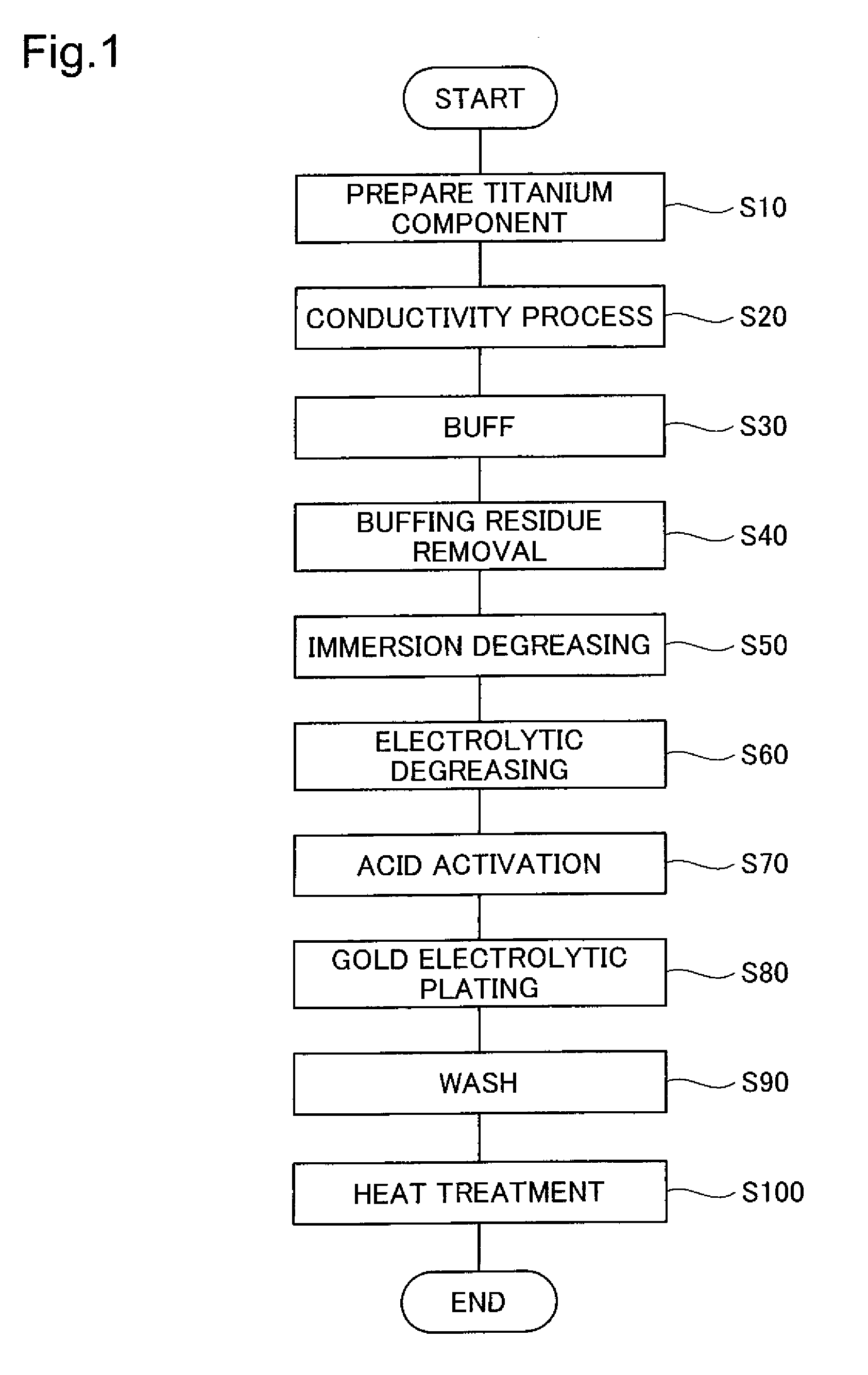

Rare Metal Plating Of Titanium Components

InactiveUS20090087558A1Strong adhesionFinal product manufacturePretreated surfacesTitanium surfaceFuel cells

The present invention provides technology for rare metal plating of titanium surfaces. A process such as the following would be carried out when manufacturing a partially gold-plated separator for a fuel cell, for example. First, a titanium component made of titanium or titanium alloy is prepared for use as the fuel cell separator (S10). This titanium component is a titanium component whose surfaces are coated with carbon-containing substance. This titanium component is then subjected to a first heat treatment at a prescribed first temperature of between 300 and 700 degrees Celsius (S20). Gold plating of the surfaces of the heat-treated titanium component is then carried out (S80). In this way it is possible to more easily carry out gold electrolytic plating of titanium surfaces.

Owner:TOYOTA JIDOSHA KK

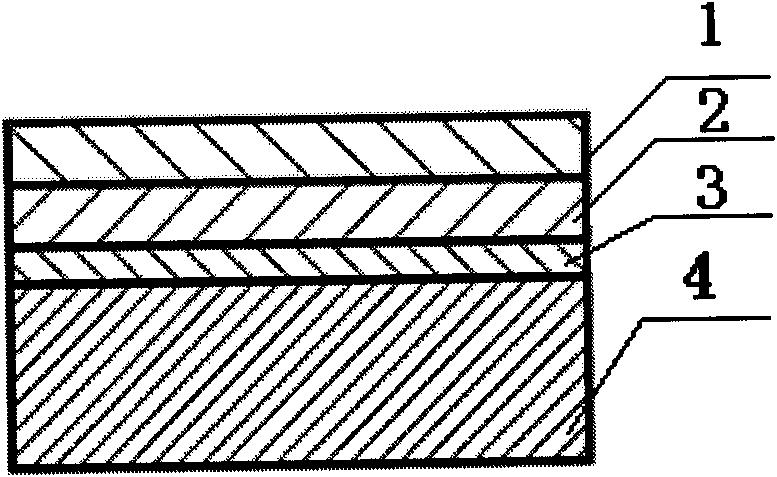

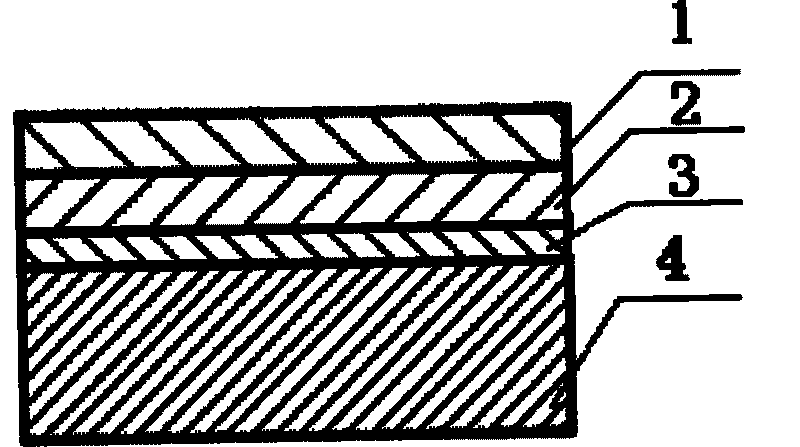

Titanium or titanium alloy having TiO2-HA surface coating and preparation method thereof

InactiveCN101757689AReduce sheddingFast depositionLiquid surface applicatorsCoatingsTitanium surfacePre treatment

The invention discloses titanium or a titanium alloy having a TiO2-HA surface coating and a preparation method thereof. The titanium or the titanium alloy having the TiO2-HA surface coating comprises a TiO2-HA gradient coating and a titanium substrate or a titanium alloy substrate, wherein the TiO2-HA gradient coating is coated on the titanium alloy substrate or the titanium alloy substrate and comprises an HA layer, a TiO2-HA layer and a TiO2 layer sequentially from outside to inside. The preparation method comprises the following steps of: firstly, performing alkali thermal treatment on a titanium surface or a titanium alloy surface subjected to surface pretreatment, and secondly, coating sol of titanium dioxide, compound sol of titanium dioxide and hydroxyapatite, and sol of hydroxyapatite on the titanium surface or the titanium alloy surface. Residual stress caused by the thermal mismatching between the substrate and the coating can be reduced by using the gradient coating, so that the substrate and the coating have high bonding strength; and the preparation method provided by the invention has the advantages of simple operation, easy implementation, low treatment temperature, no damage to the mechanical properties of the titanium or the titanium alloy, and low cost.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Process for glow ion hydrogen-free carbonizing titanium surface

A non-hydrogen glow ion process for carbonizing the surface of titanium (or Ti alloy) is characterized by that under the action of electric bias field and inert energy, the carbon ions (or atoms) sputted out from graphite electrode in glow plasmas reach to the surface of hot titanium workpiece, and under the action of thermal diffusion and ion bombardment the carbon ions (or atoms) come in the surface of titanium to form titanium carbide. Its advantages are high surface hardness (3000 HV) and antiwear nature, and deep carbonized layer.

Owner:太原理工大学表面工程研究所 +1

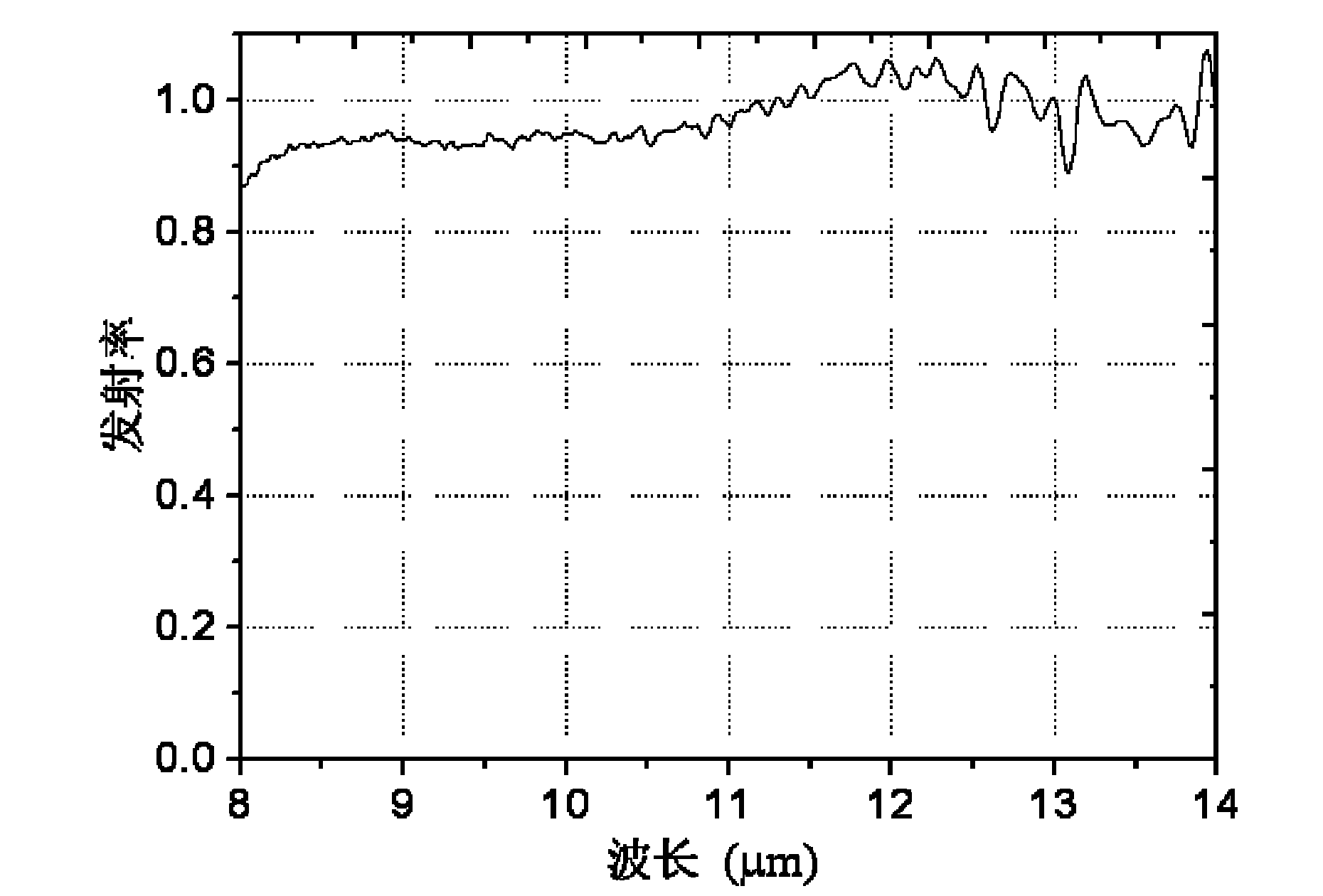

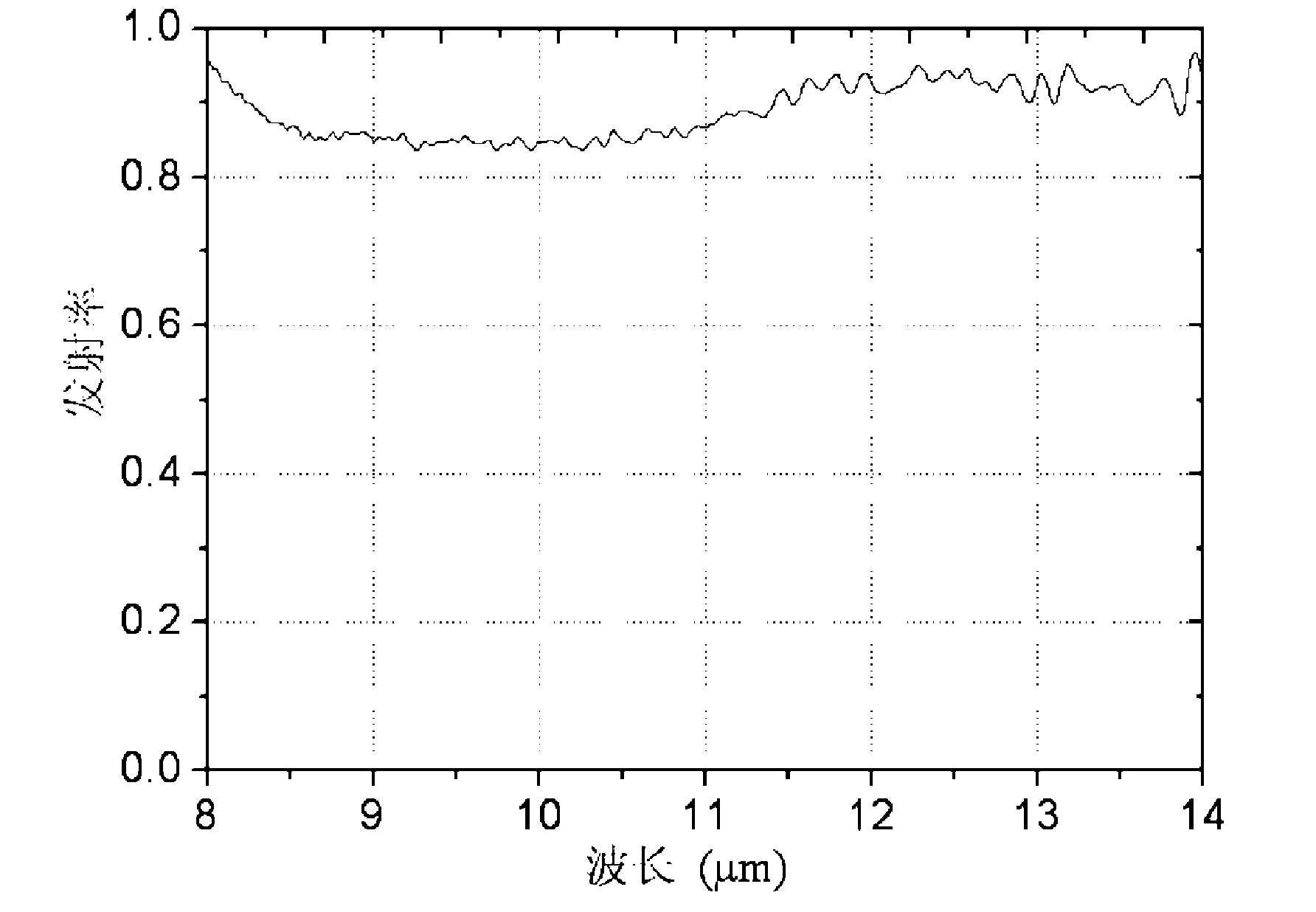

Method for preparing black titanium oxide coating on titanium surface

InactiveCN101775633AUniform surfaceHigh blacknessSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a method for preparing a black titanium oxide coating on a titanium surface, which relates to a method for preparing a micro-arc oxidation coating on a titanium surface. The invention solves the problems of complexity, high energy consumption and high cost of the traditional preparation process of forming a black titanium oxide film on the titanium surface. The method is characterized in that a titanium part is taken as the anode after being degreased, stainless steel is taken as the cathode, the anode and the cathode are soaked in an electrolyte, and micro-arc oxidation is carried out after electrical parameters are regulated, thereby the black titanium oxide coating on the titanium surface is obtained. The invention simplifies the process and has simple operation, energy and time saving and low cost by adopting a single-step micro-arc oxidation process; the obtained black titanium oxide coating is even and has high blackness, and the emission coefficient is 0.85 to 1.0 within the infrared wavelength range of 8 to 14mum; and the reflection coefficient of the wavelength of the black titanium oxide coating is 0.02 to 0.15, and thereby, the black titanium oxide coating is used for the field of military thermal control and civil decorative coatings. The invention is not limited by the shape and the dimension of the part, thereby being suitable for industrial mass production.

Owner:HARBIN INST OF TECH

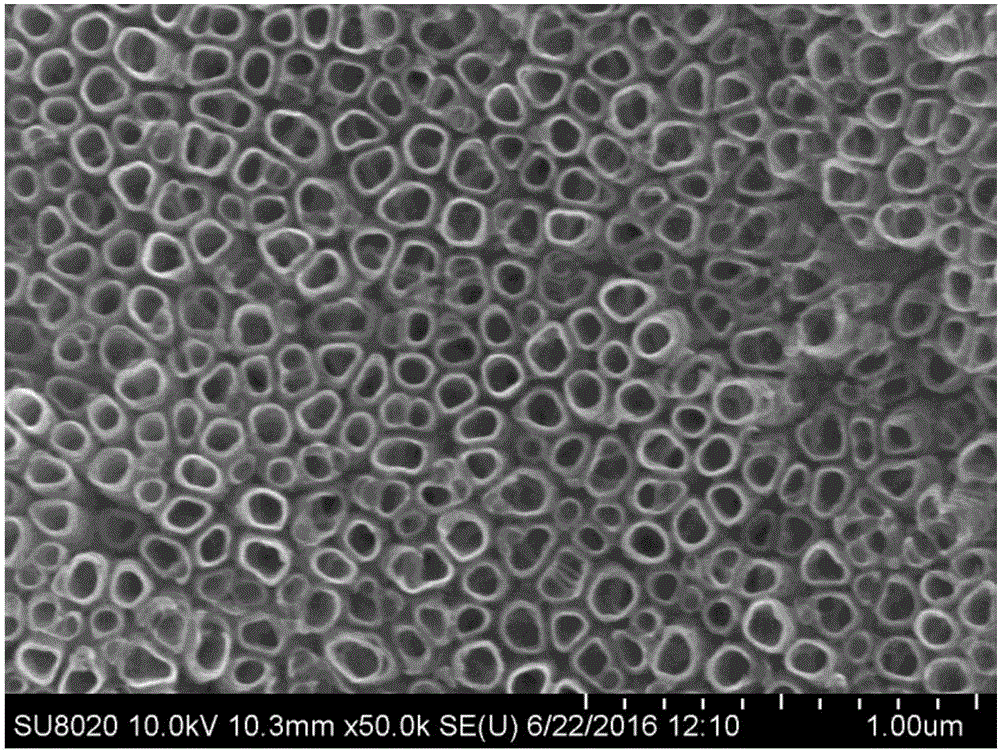

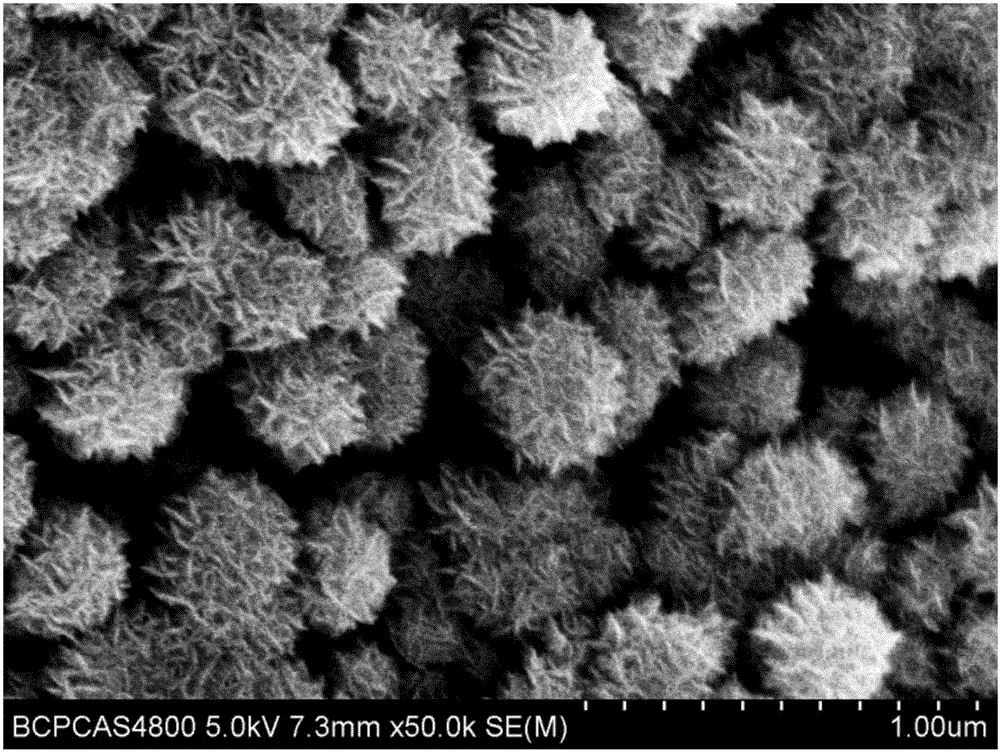

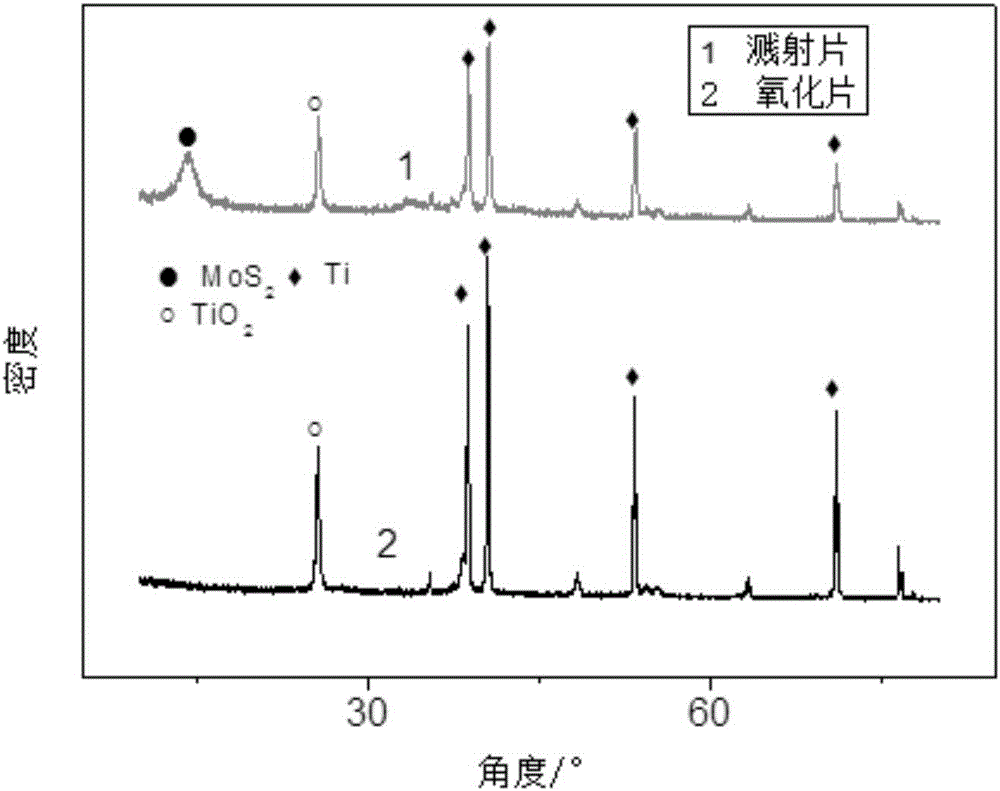

Method for solidly supporting molybdenum disulfide through porous titanium oxide film

ActiveCN106086990AReduce coefficient of frictionNot easy to fall offSurface reaction electrolytic coatingVacuum evaporation coatingFrictional coefficientTitanium alloy

The invention provides a method for solidly supporting molybdenum disulfide through a porous titanium oxide film, and belongs to the technical field of surface modification of metal materials. The method comprises the following steps: performing in-situ assembling on a porous titanium dioxide film on the metal surface of metallic titanium by an anodizing method; and then introducing a solid lubricant into the porous titanium dioxide film by a magnetron sputtering technology, wherein the minimum frictional coefficient of the titanium surface can reach 0.20 and is far less than the frictional coefficient of 0.46 of pure titanium; the solid lubricant can deposit on the surface of the porous titanium dioxide film and can be recycled in 4305 times; if the porous titanium dioxide film is not used, the lubricant falls off after being recycled in 15 times. According to the method, the technology of solidly supporting a solid lubricant in the porous titanium dioxide film is provided and can greatly decrease the frictional coefficients of the metallic titanium surface, and a novel effective measure is provided to solve the problem of meshing, caused by adhering, of a titanium alloy fastener.

Owner:BEIJING UNIV OF TECH

Preparation method for Ag/SnO2/TiO2 composite membrane photoanode used for photogenerated cathodic protection

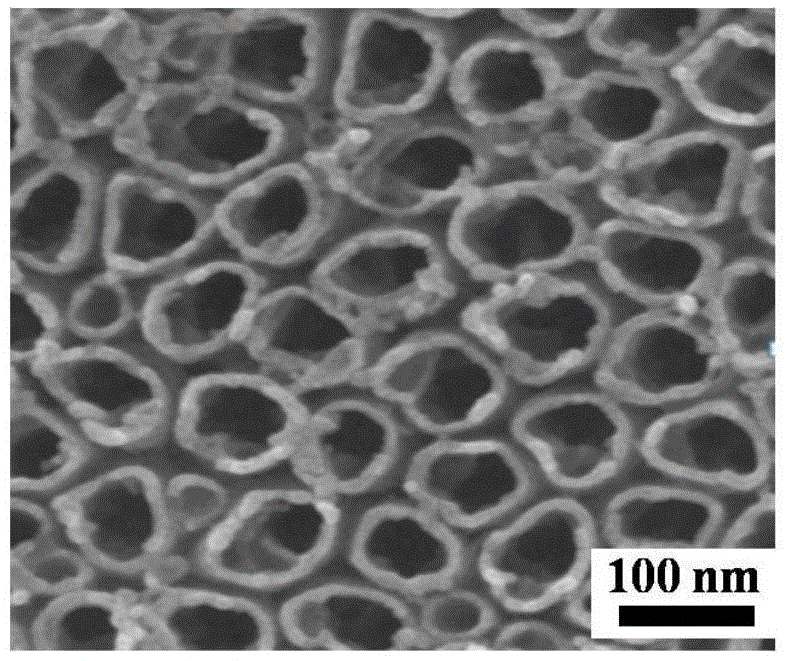

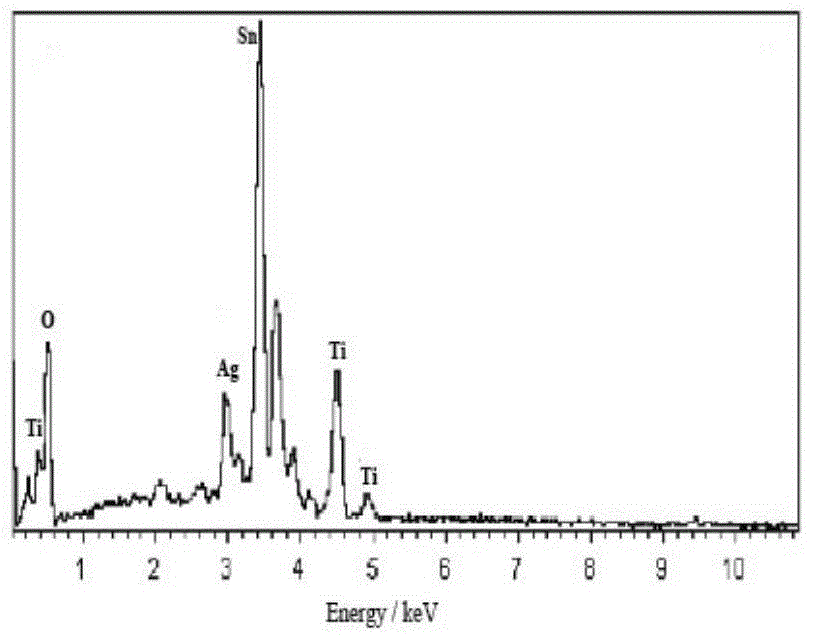

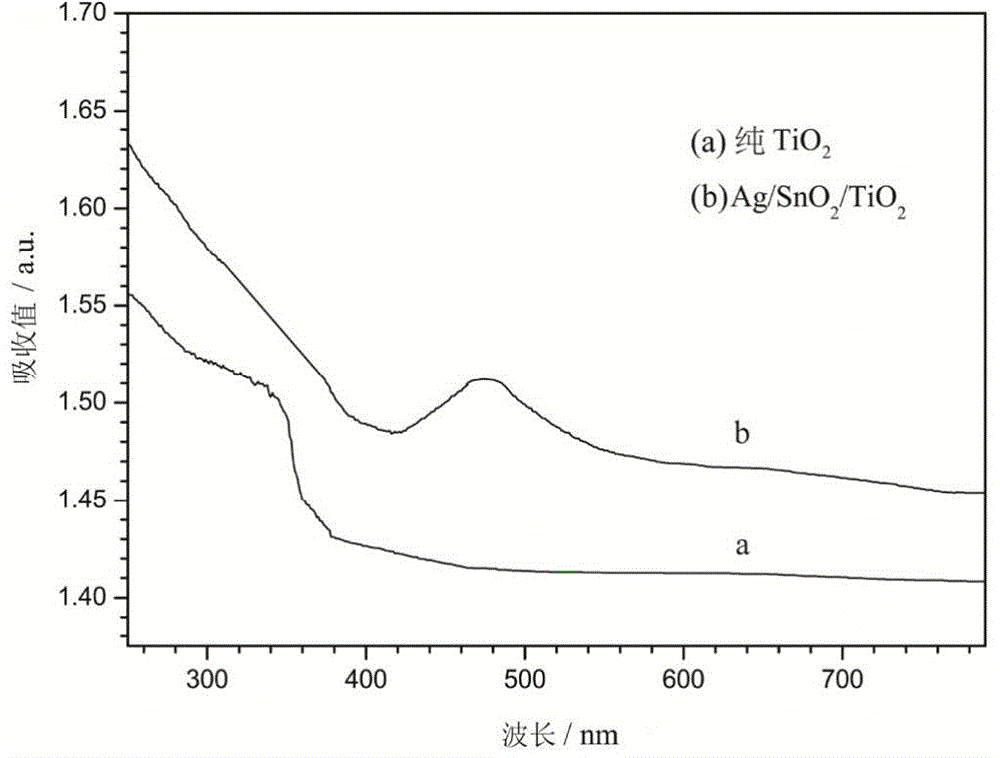

ActiveCN103952708AUniform and complete coatingLower electrode potentialSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingTio2 nanotubeAcetone

The invention relates to preparation methods for an Ag / SnO2 / TiO2 composite membrane photoanode used for photogenerated cathodic protection, and relates to a composite membrane photoanode, and provides a preparation method for the efficient stable Ag / SnO2 / TiO2 composite membrane photoanode used for photogenerated cathodic protection. The preparation method comprises: 1) preparing a titanium substrate sample, specifically taking titanium foil as a substrate, and performing ultrasonic cleaning successively in acetone, absolute ethanol and deionized water to obtain a titanium substrate sample; 2) preparing a titanium-surface TiO2 nanotube array membrane, specifically dissolving NH4 in deionized water, adding glycol, mixing uniformly, taking platinum as a counter electrode, performing anodization, calcining the titanium substrate sample, and cooling to room temperature along the furnace, so as to obtain the TiO2 nanotube array membrane on the surface of titanium; and 3) preparing the Ag / SnO2 / TiO2 composite membrane, specifically preparing Ag and SnO2 nanometer particles on the surface of the TiO2 nanotube array membrane, so as to obtain the Ag / SnO2 / TiO2 photoanode used for photogenerated cathodic protection.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

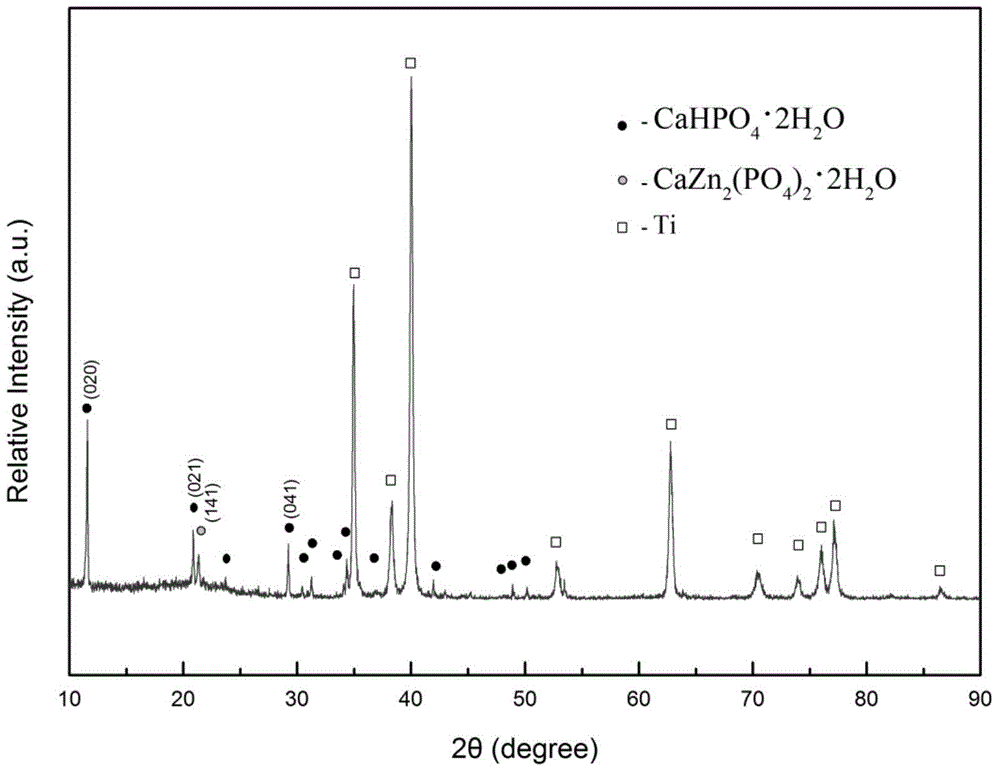

Method for preparing calcium hydrophosphate micro-nanofiber conversion coating on pure-titanium surface

Owner:SHANDONG UNIV

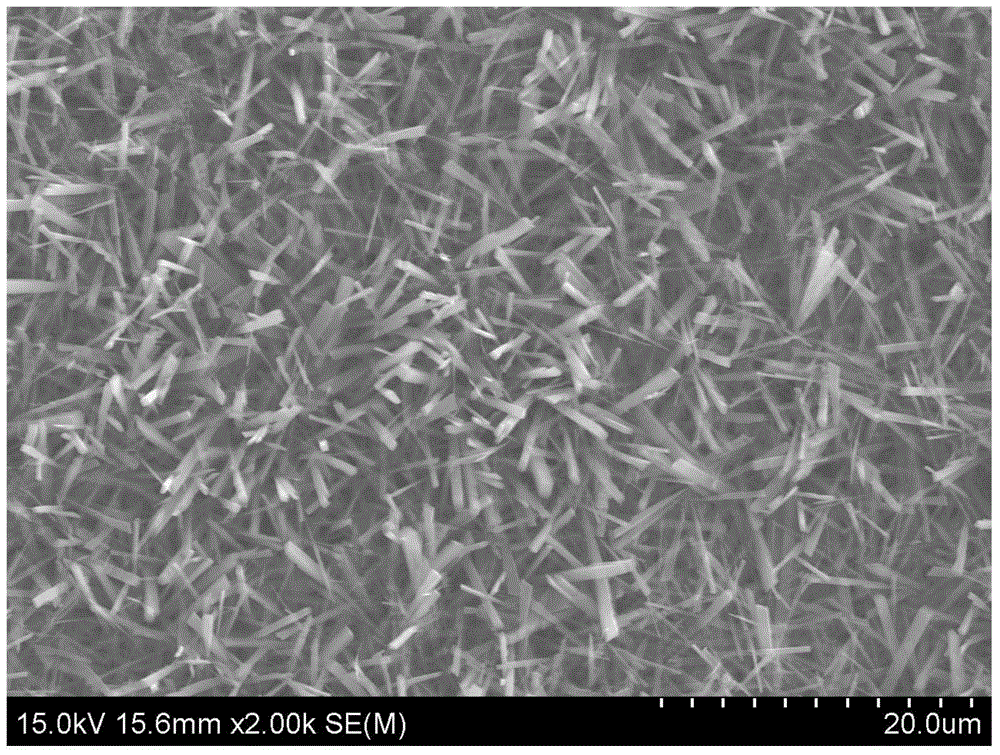

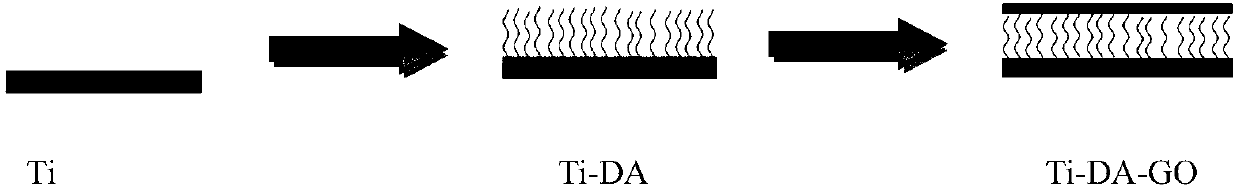

Method for improving biological activity of pure titanium surface by using dopamine to be bonded with graphene oxide

InactiveCN104141124ANo toxicityFacilitate depositionMetallic material coating processesProsthesisDrug biological activityPollution

The invention relates to a method for improving biological activity of a pure titanium surface by using dopamine to be bonded with graphene oxide. The method comprises the following steps: successively carrying out ultrasonic cleaning on a pure titanium sheet of which the surface roughness Ra is not greater than 1micron by adopting acetone and deionized water; carrying out acid treatment by using a nitric acid, cleaning the pure titanium sheet by the deionized water, and then carrying out alkali treatment on a sample by using sodium hydroxide at 40-80 DEG C; preparing a dopamine-trihydroxymethyl aminomethane solution of which the pH is 8.5; soaking the processed pure titanium sample into the prepared dopamine solution, and standing the sample at room temperature for 12-24 hours; taking out the sample, cleaning the sample by using the deionized water, and drying the sample at room temperature, so as to prepare a titanium / dopamine sample; soaking the titanium / dopamine sample into a graphene oxide water solution and standing the sample at room temperature for 12-24 hours; and cleaning the sample by using the deionized water after taking out the sample, drying the sample at room temperature, so as to prepare a titanium / dopamine / graphene oxide sample. The method is simple to operate, green and pollution-free, mass production can be achieved, and a channel is expanded for surface modification of the titanium material.

Owner:TIANJIN UNIV

Preparation method of titanium surface porous structure layer bioactive ceramic membrane with low elasticity modulus

InactiveCN103088348AImprove stress distributionIncrease pressureCoatingsProsthesisMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a preparation method of a titanium surface porous structure layer bioactive ceramic membrane with low elasticity modulus, and relates to the field of biomedical implant, especially the preparation technology of a biomedical implant made of a titanium or titanium alloy material. The method comprises steps of: first preparing a porous structure layer on a matrix structure of a pure titanium or titanium alloy implant with a solid structure by using a powder metallurgy method; then forming a titanium dioxide membrane containing calcium and phosphorus on a hole surface of the porous structure layer by a micro-arc oxidation method; and finally, preparing a hydroxyl apatite layer on a hole external surface of the porous structure layer by an electrodeposition method. The invention can realize formation of porous structure layer on the surface of the pure titanium or titanium alloy implant with solid structure, and reduce elastic modulus on the implant surface; meanwhile, the implant is endowed with high biological activity through implantation of a hydroxyapatite layer, and can be used in the field of biological medicine.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

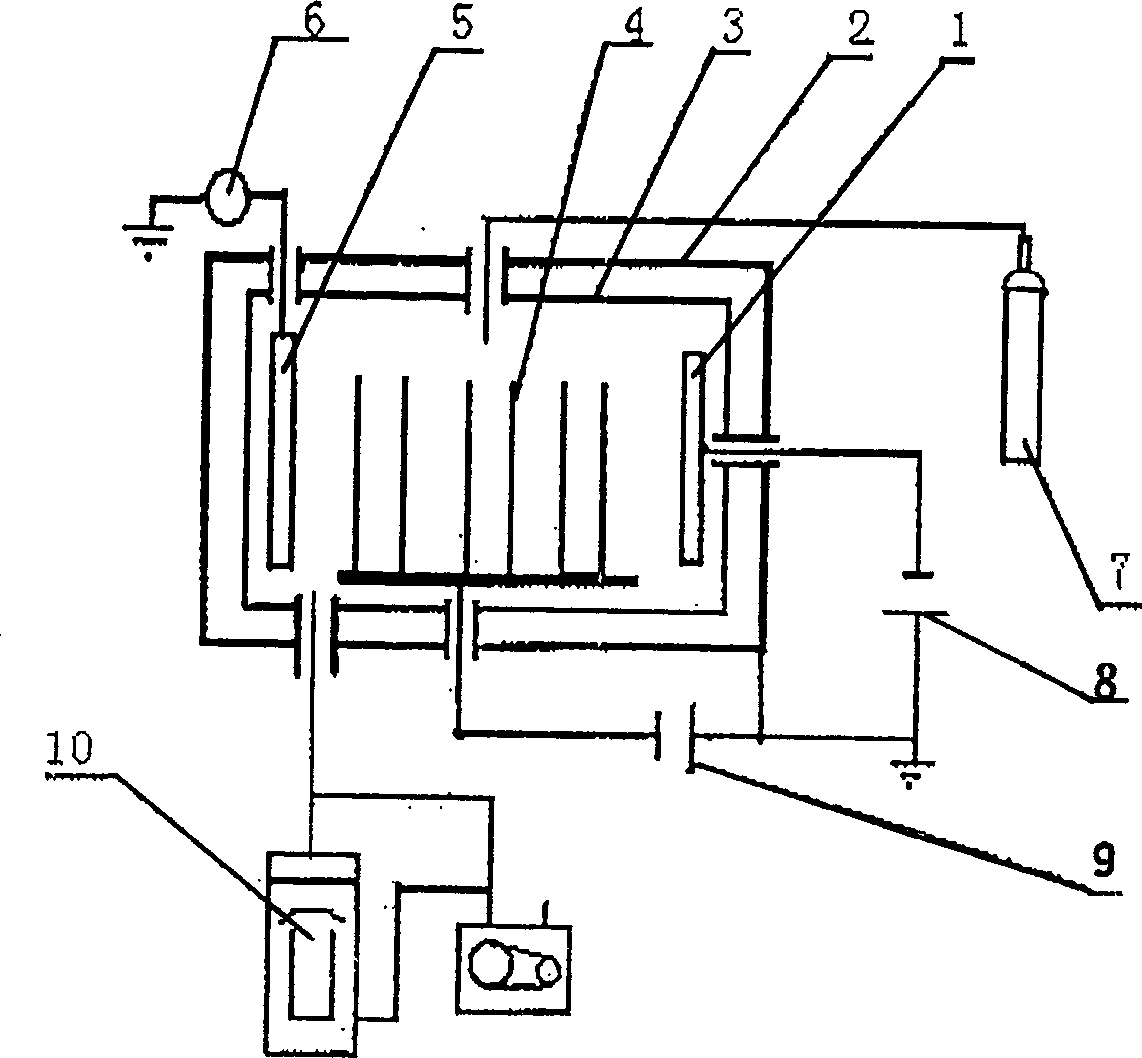

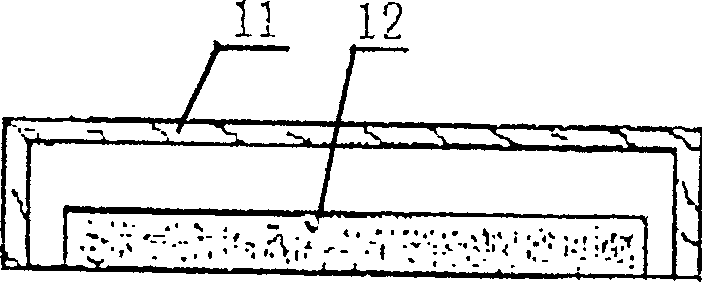

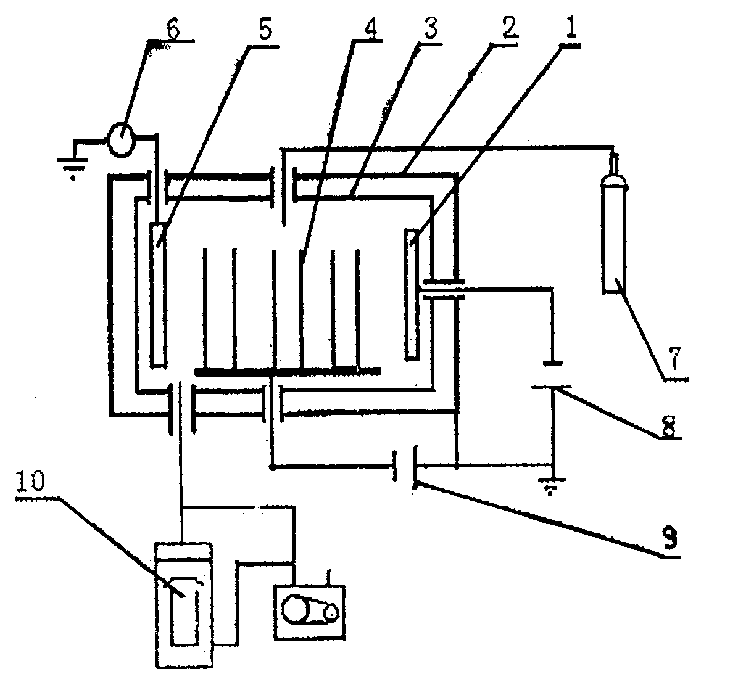

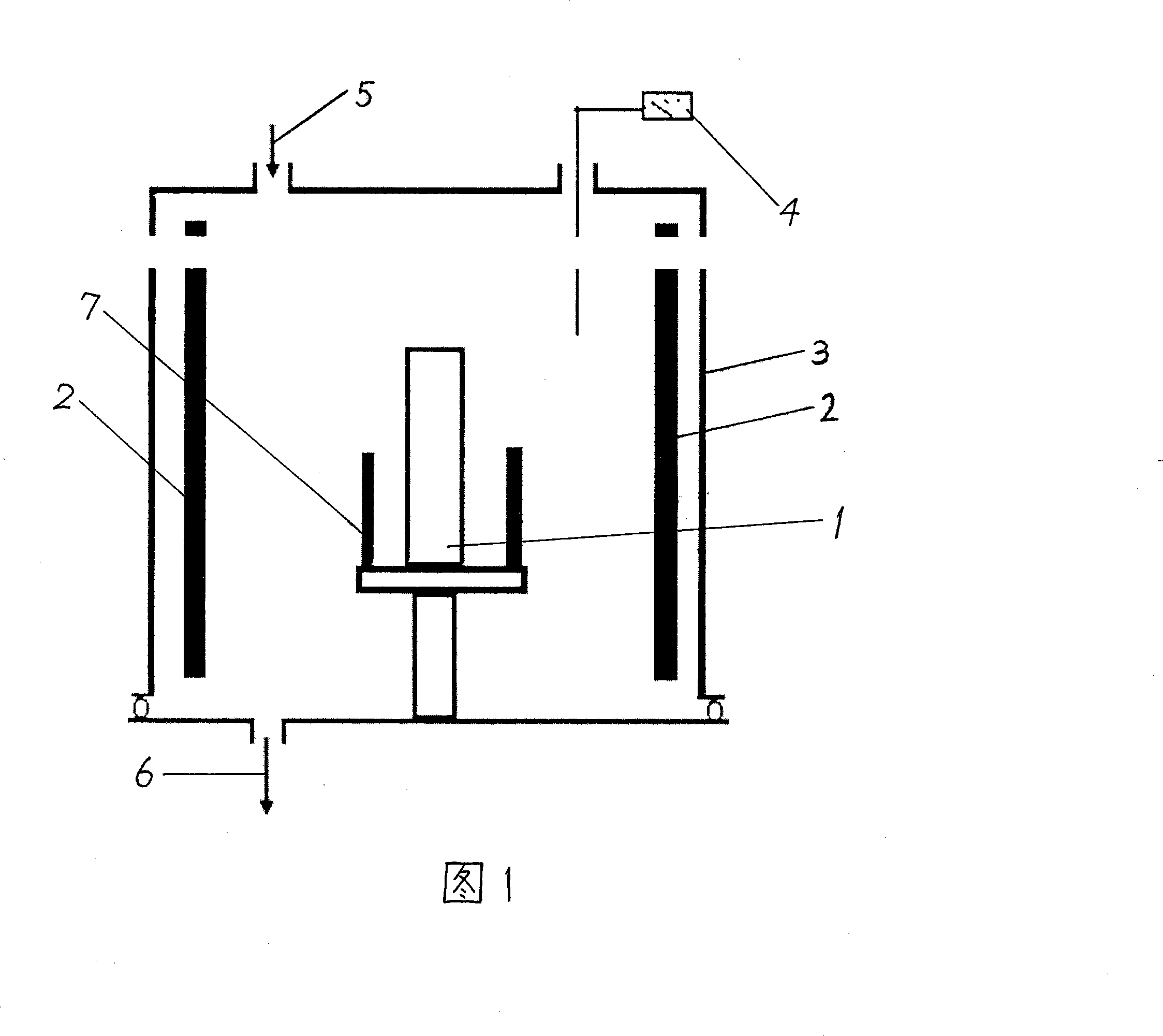

Apparatus and method for titanium and titanium alloy surface oxygen-carbon co-cementation

ActiveCN101177774AAchieve hydrogen-free hardeningSolid state diffusion coatingTitanium surfaceCarbide

The invention discloses a titanium and titanium alloy surface carbonitriding device and a method thereof. In a vacuum state, the temperature of titanium and titanium alloy reaches to 700 DEG C to 1100 DEG C, a high purity CO 2 gas with 0.1 Pa to 1000 Pa of pressure is inlet, and after 0.5 hour to 200 hours of processing, a 30Mum to 1000Mum thick of hard coat is formed at the surface of the titanium alloy; the compositions of the hard coat are the oxide and carbide of titanium, with a hardness reaching to 700 to HV 1100. The inexistence of H element which results in the hydrogen embrittlement of titanium in preparation process realizes the non-hydrogen hardening of the titanium surface.

Owner:西安赛福斯材料防护有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com