Patents

Literature

882 results about "Artificial bone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial bone refers to bone-like material created in a laboratory that can be used in bone grafts, to replace human bone that was lost due to severe fractures, disease, etc. Bone fracture, which is a complete or partial break in the bone, is a very common condition that has more than three million US cases per year. Human bones have the ability to regenerate themselves by cycle of bone resorption and bone formation. The cell responsible for bone resorption is osteoclast, while the cell responsible for bone formation is osteoblast. That being said, the human body can regenerate fractured bone. However, if damage to bone is caused by a disease or severe injury, it becomes difficult for the body to repair itself. When the human body is unable to regenerate the lost bone tissue, surgeons come in and replace the missing bone using autografts, allografts, and synthetic grafts (artificial bone). When compare artificial bone to autograft and allograft, it is less invasive and more biocompatible since it avoids the risk of unknown viral infections.

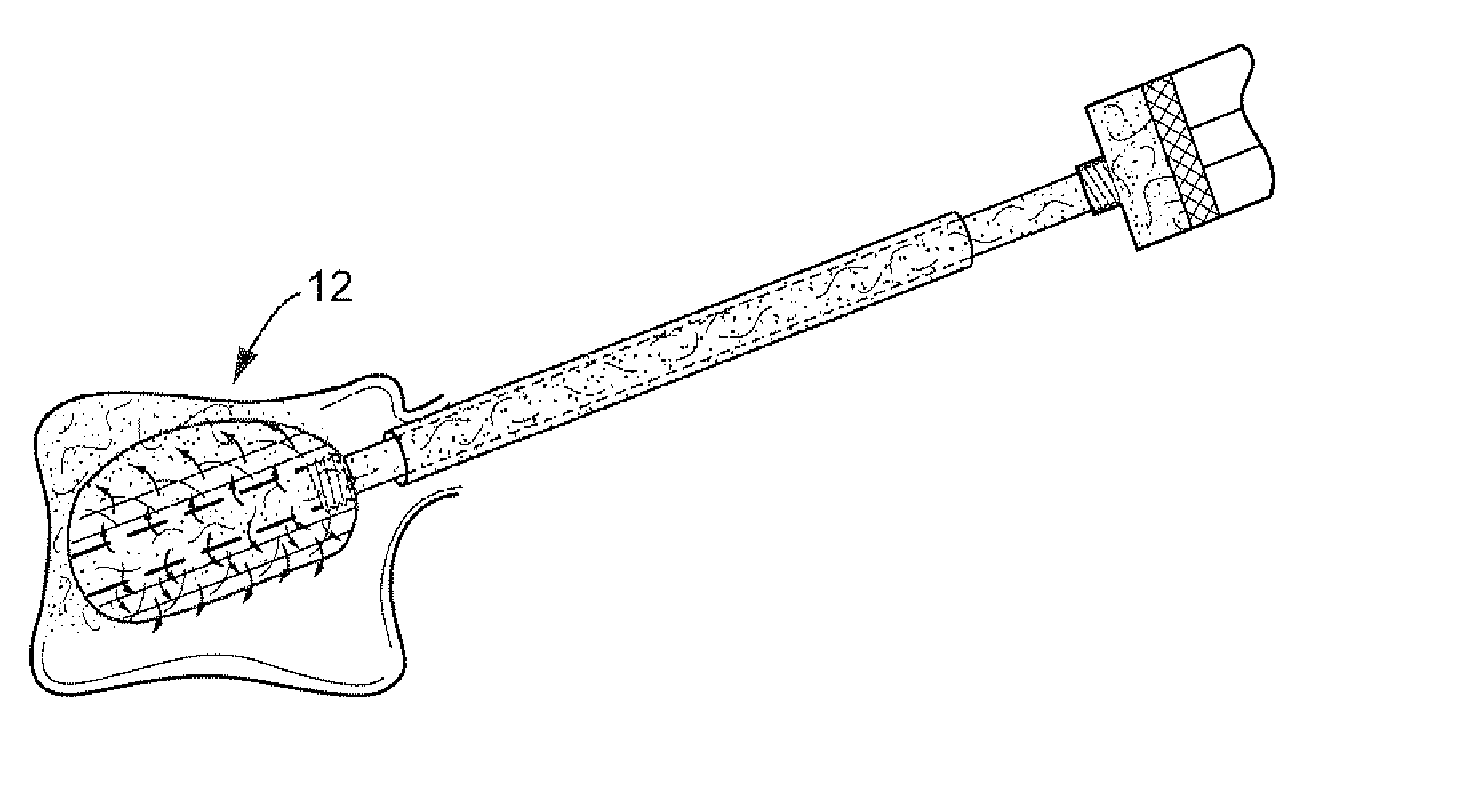

Biologic Vertebral Reconstruction

ActiveUS20090187249A1Minimize extrusionConvenience to mergeInternal osteosythesisBone implantBiomechanicsHost bone

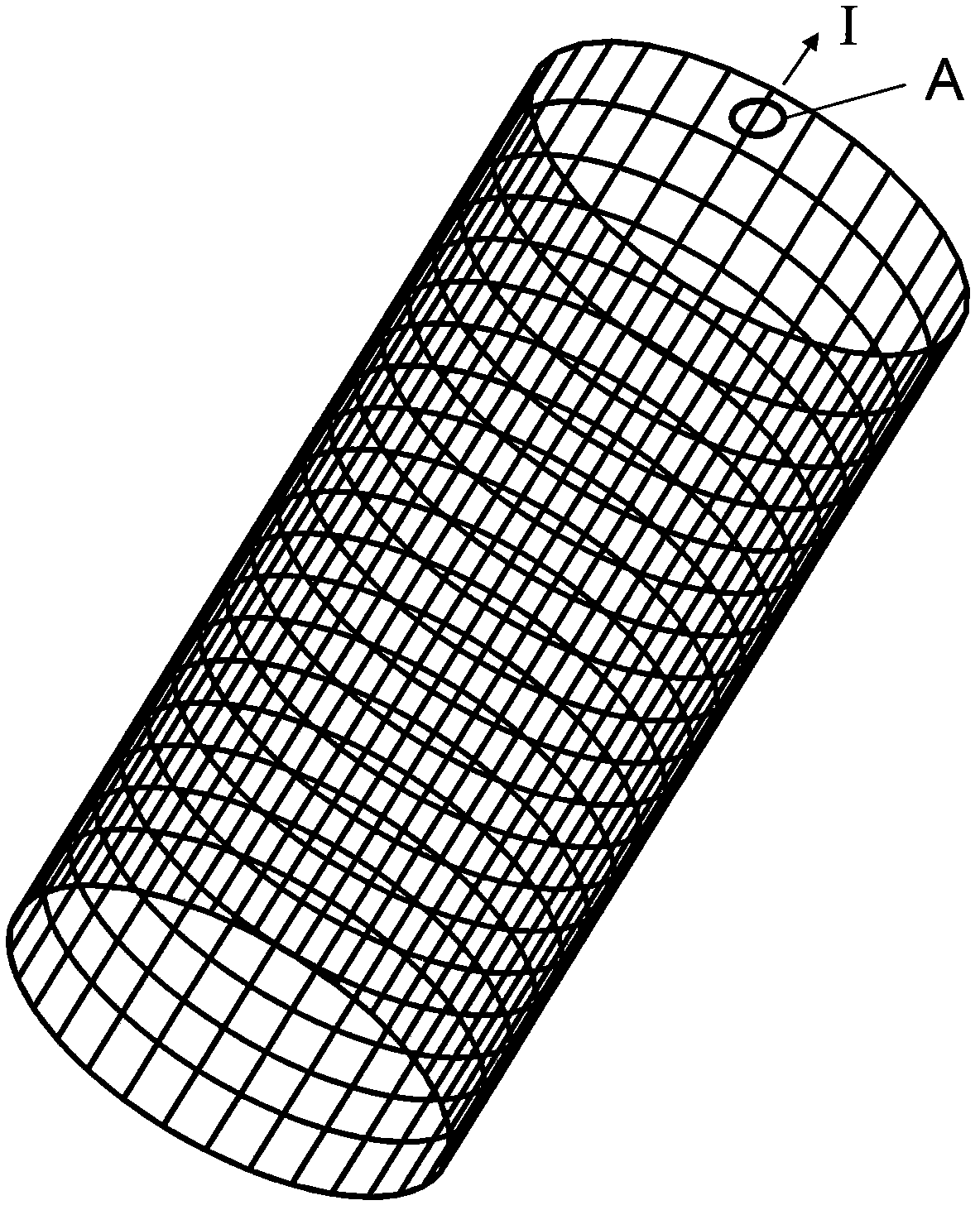

A device and method for biologic vertebral reconstruction utilizes a biologically active jacket inserted into a cavity formed in a vertebra to be reconstructed. An artificial bone material is inserted into the biologically active jacket and allowed to set. The structure and method described herein provide for effective biologic vertebral reconstruction. The use of a biological material and artificial bone enables the host bone to replace the artificial bone over a period of time. Additionally, the structure of the biologically active jacket minimizes any impact into the spinal canal and the paravertebral spaces. Moreover, because of its biomechanical characteristics, which approximate the host bone, there is relative protection of the neighboring vertebral against fracture. Still further, the materials of the biologically active jacket may be impregnated with various substances to achieve various advantageous tasks.

Owner:SPINAL ELEMENTS INC

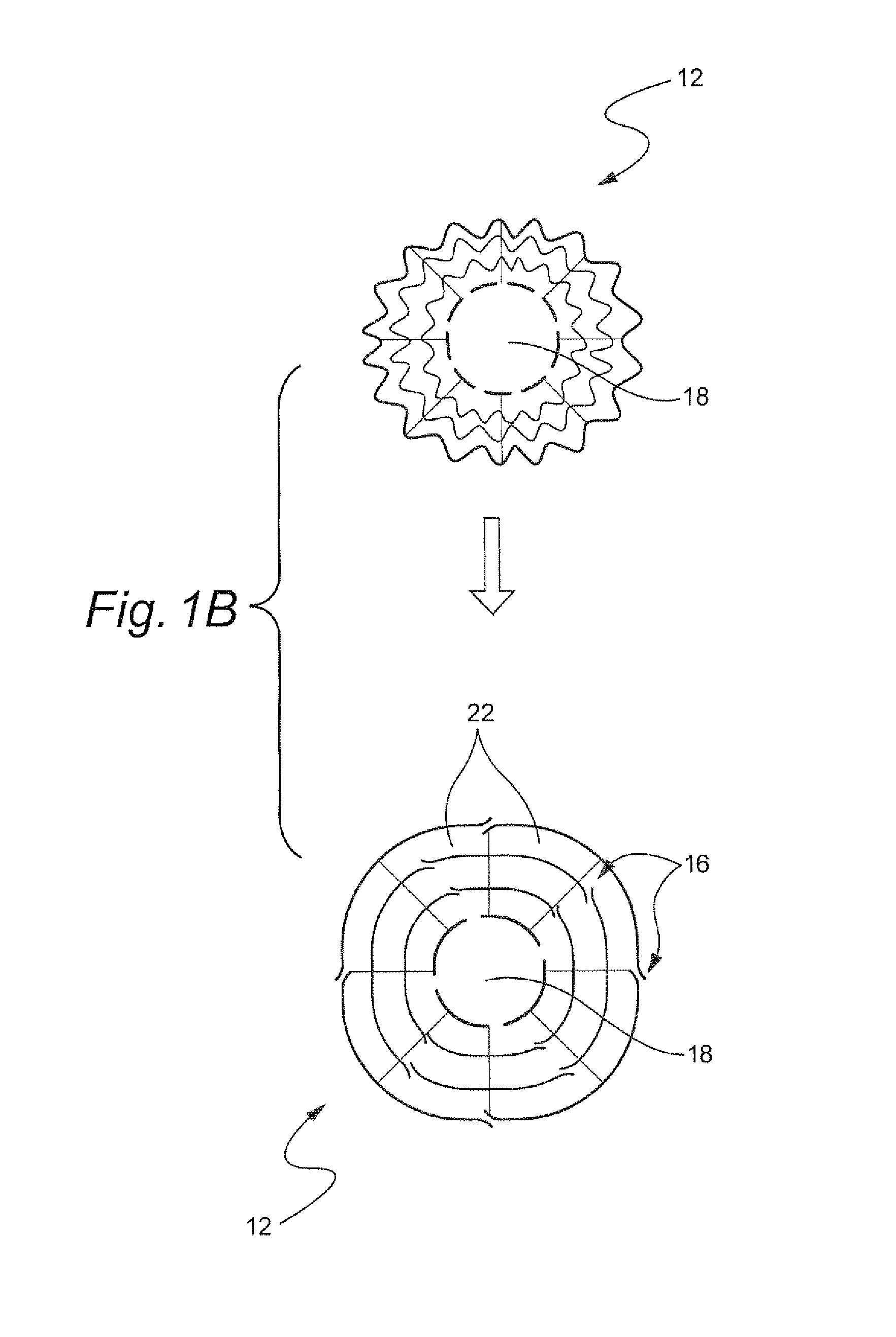

Process for producing an artificial bone model and an artificial bone model produced by the process

ActiveUS6932610B2Improve skillsEasy to getAdditive manufacturing apparatusPharmaceutical delivery mechanismHuman bodySurgical operation

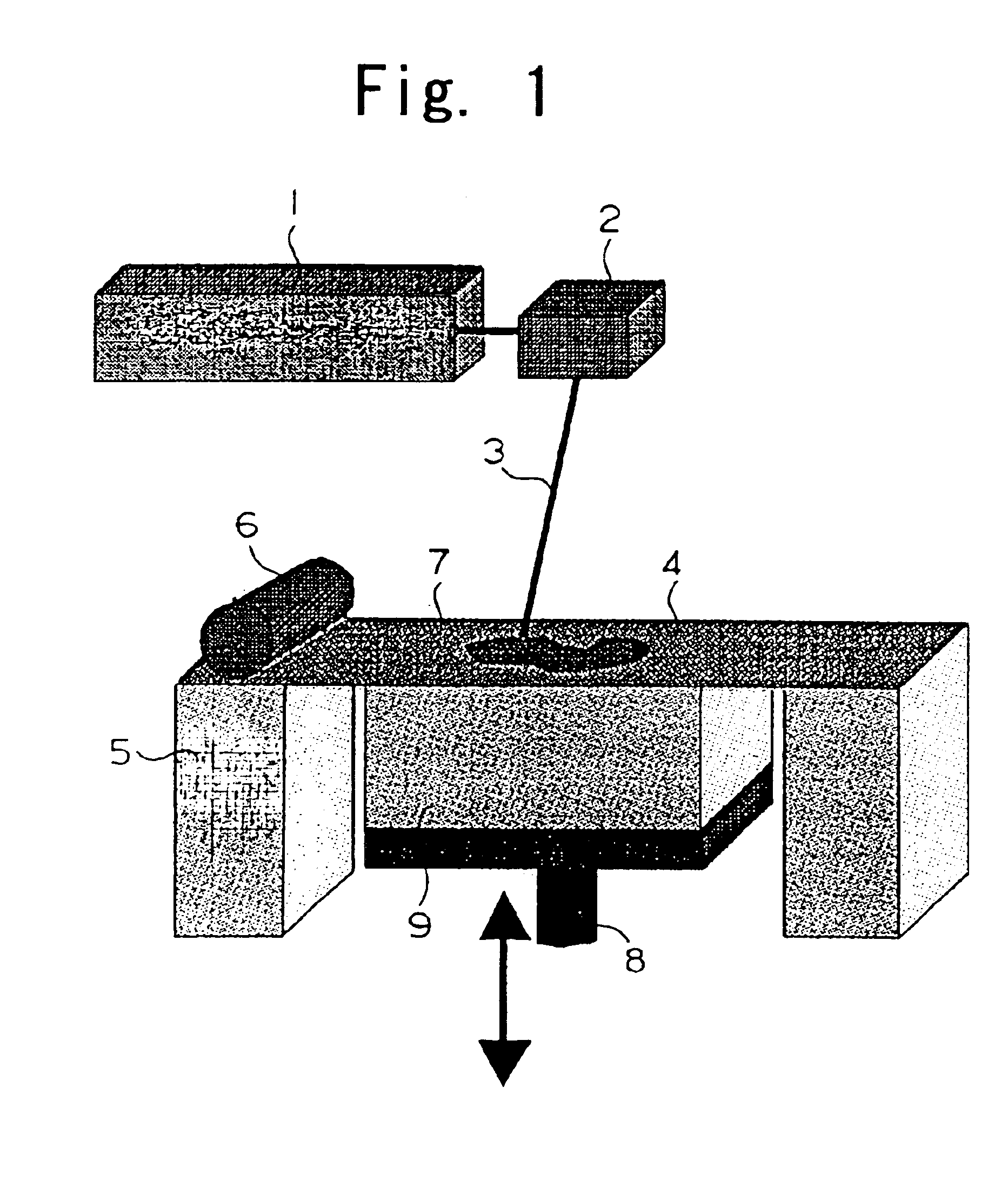

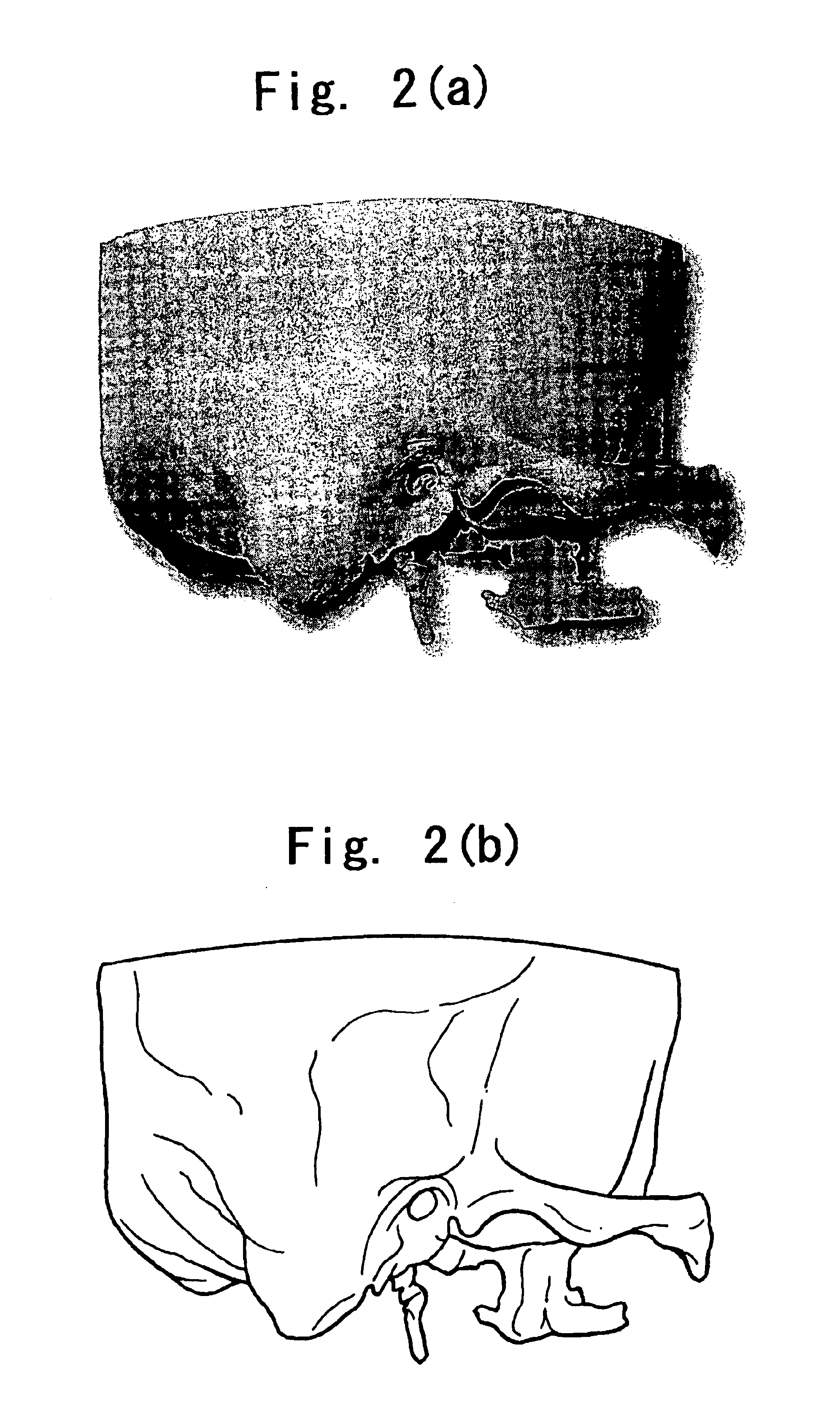

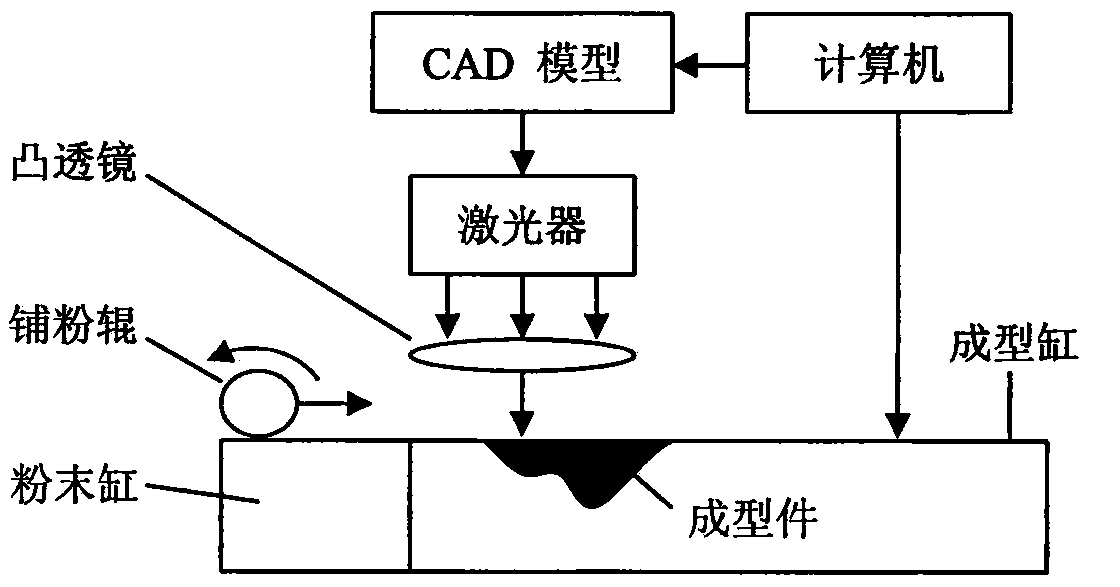

A process for producing an artificial bone model in accordance with the selective laser sintering process which comprises extending a powder material for sintering comprising 30 to 90 parts by weight of powder of a synthetic resin and 10 to 70% by weight of an inorganic filler to form a thin layer and irradiating a portion of the thin layer having the shape formed based on tomograpic information of a natural bone with laser light so that the irradiated portion of the thin layer is sintered. The extension of the powder material for sintering to form the thin layer and the irradiation of the thin layer with laser light for sintering are conducted repeatedly. The artificial bone model can three-dimensionally reproduce steric shapes of natural bones such as bones in the human body precisely and accurately and exhibits the property for cutting closely similar to that of natural bones. The artificial bone model can be used for educational training or for studying a plan for curing before a surgical operation.

Owner:ONO +1

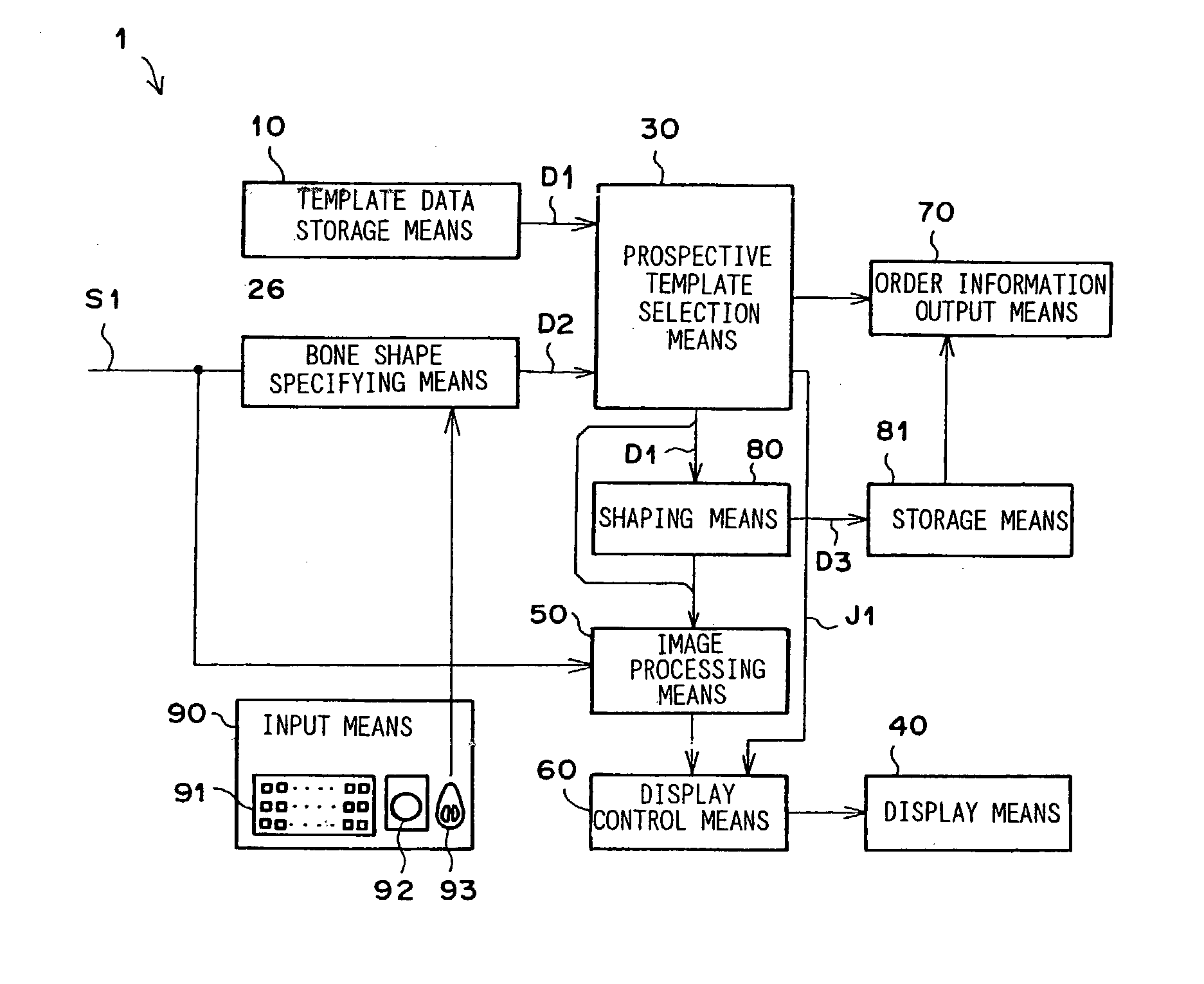

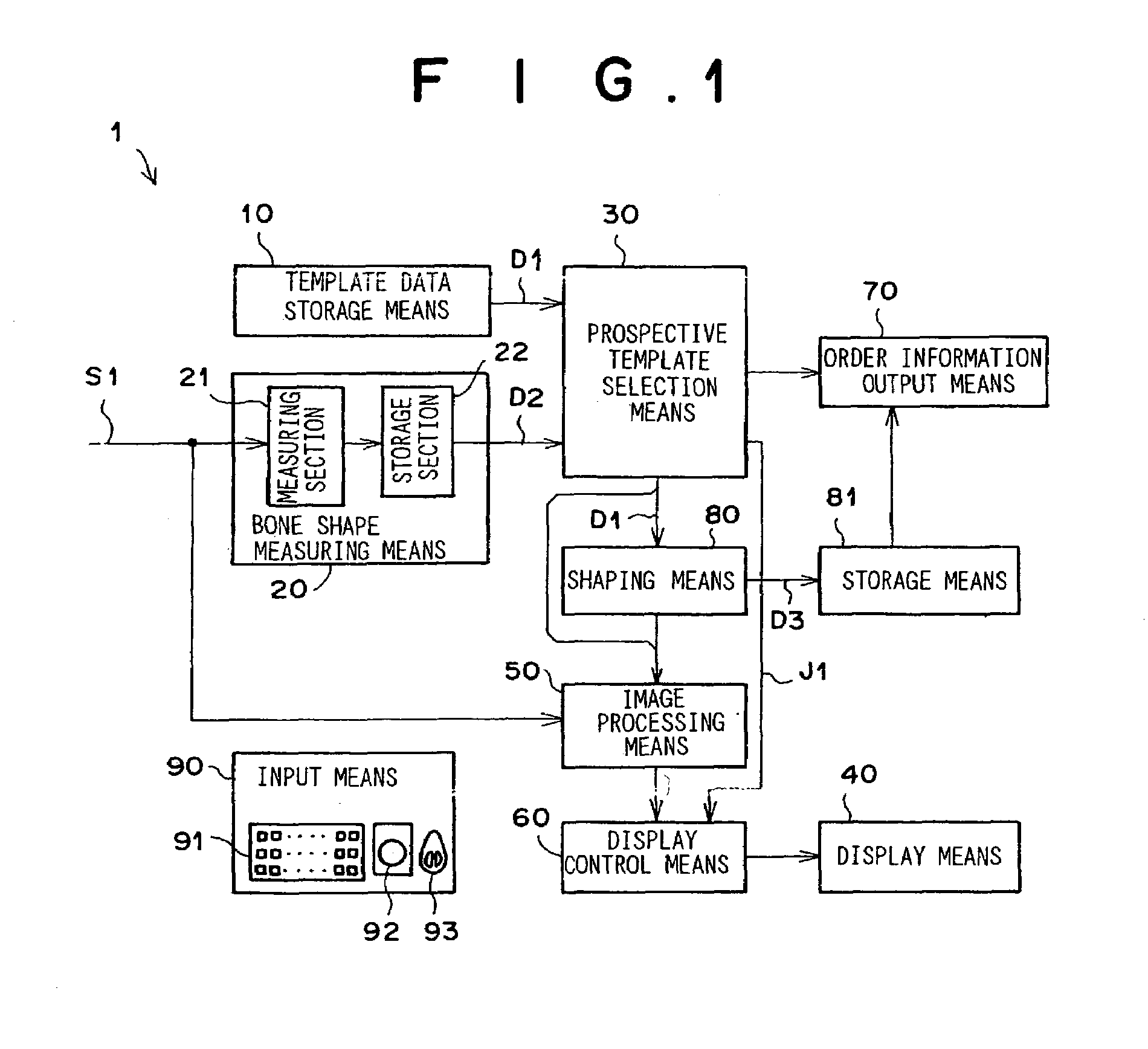

Artificial bone template selection system, artificial bone template display system, artificial bone template storage system and artificial bone template recording medium

InactiveUS7039225B2Valid choiceShort timePerson identificationCharacter and pattern recognitionSelection systemArtificial bone

An artificial bone template selection system includes a template data storage system in which template data representing a plurality of templates representing a plurality of artificial bones of different shapes is stored. A bone shape measuring system measures the shape of bone to be supplemented by artificial bone on the basis of bone image data representing an image including the bone to be supplemented by artificial bone. A prospective template selection system selects at least one template the shape of which substantially conforms to the shape of the bone to be supplemented by artificial bone as measured by the bone shape measuring system out of the plurality of templates represented by the template data.

Owner:FUJIFILM CORP

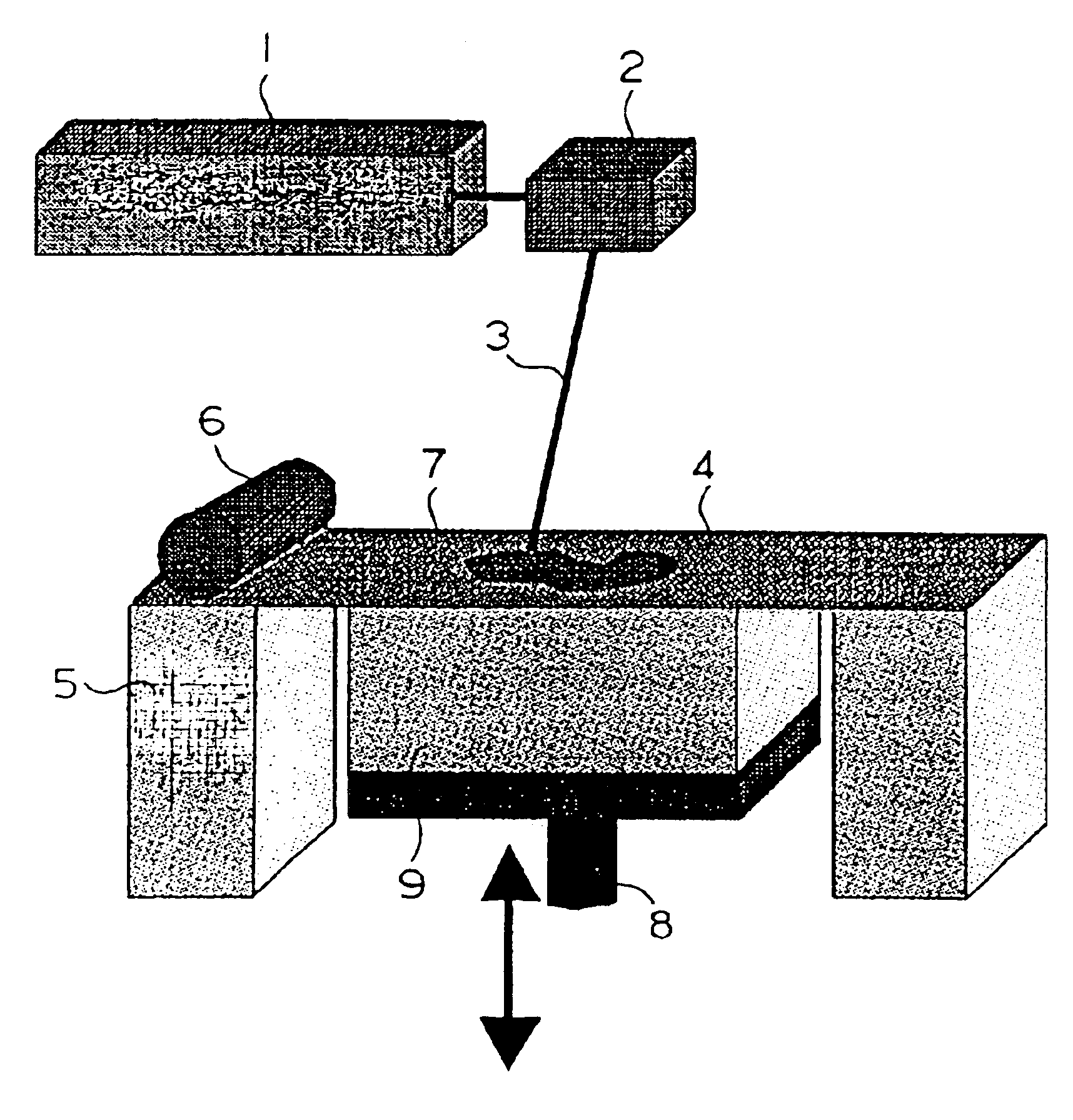

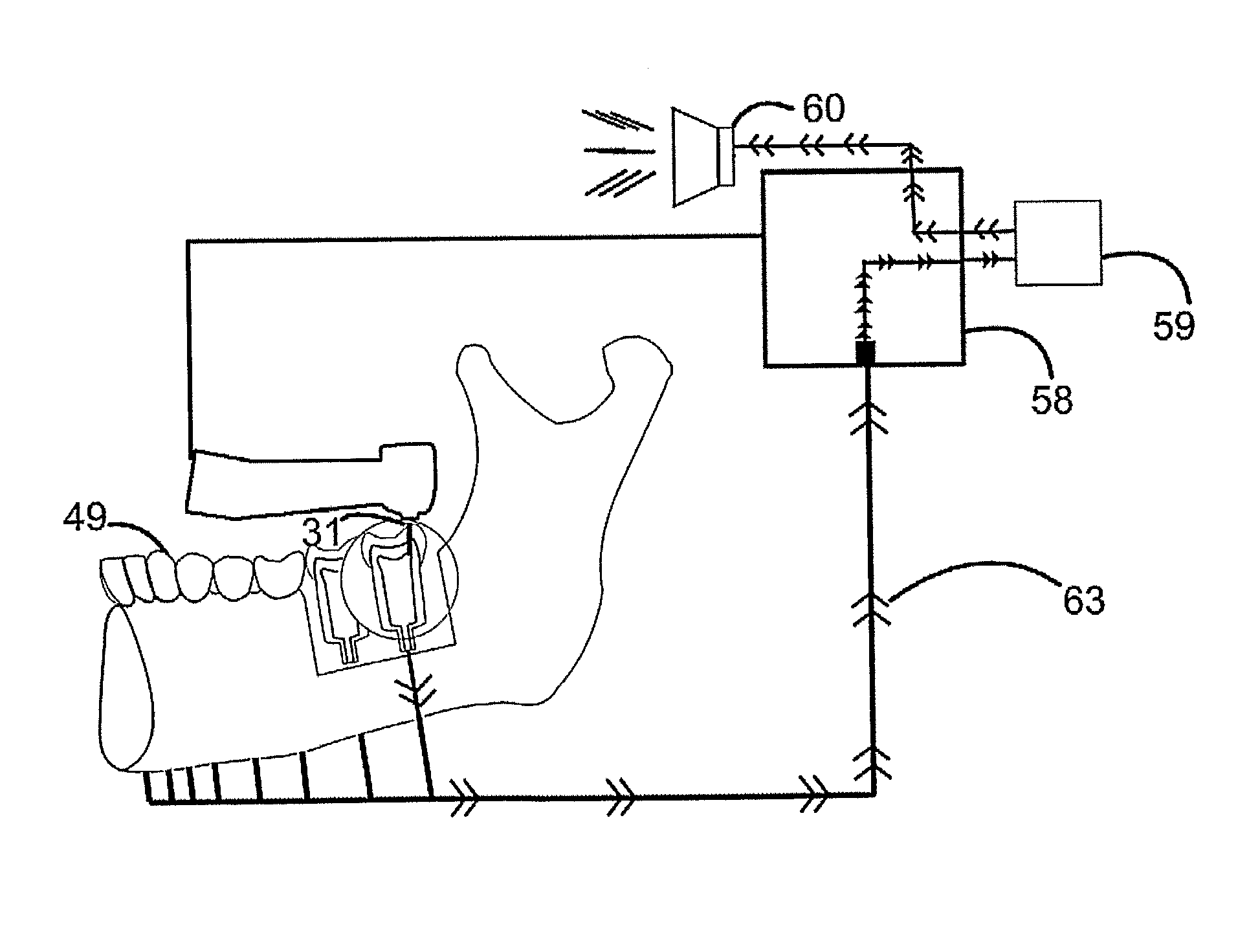

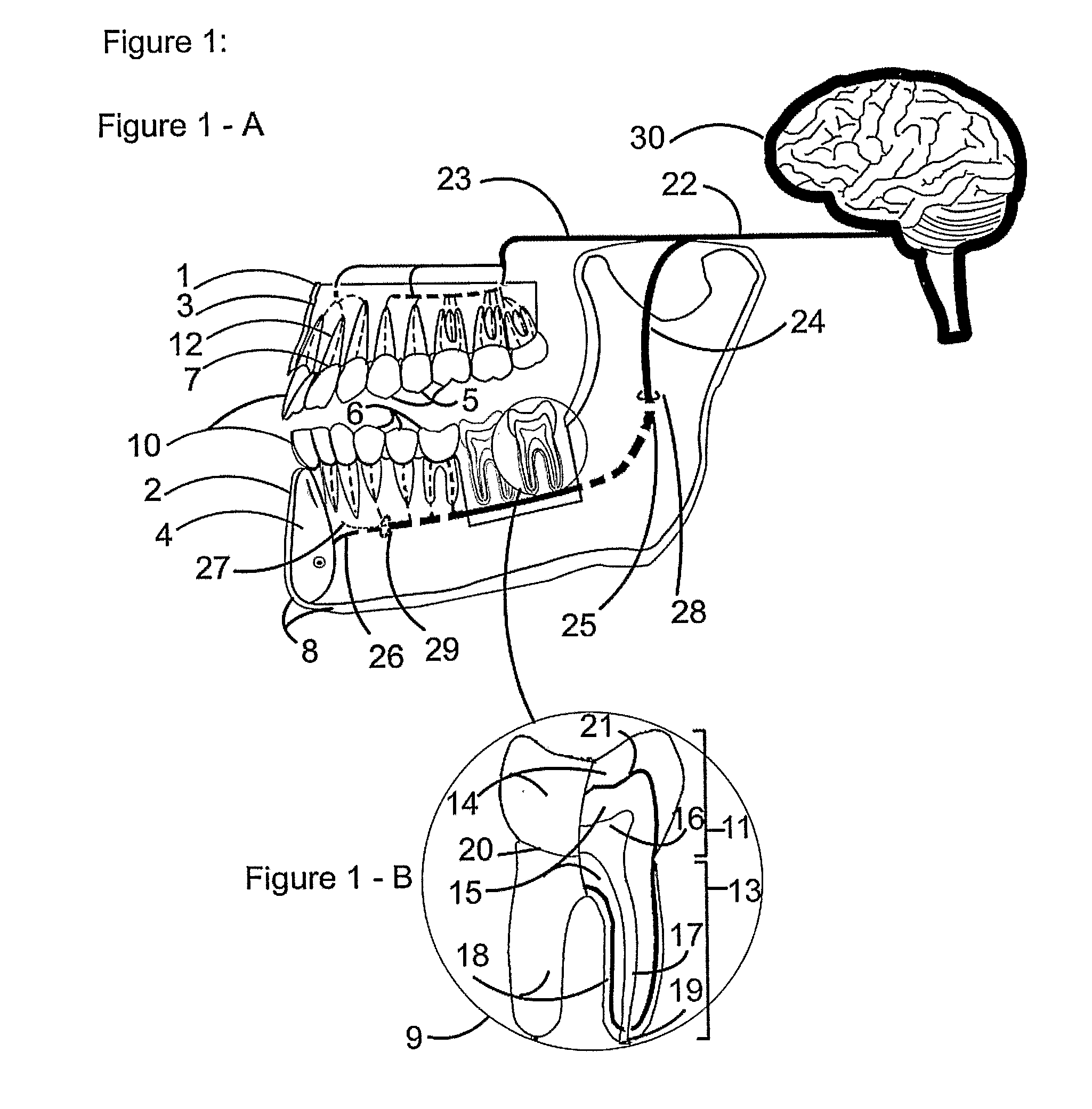

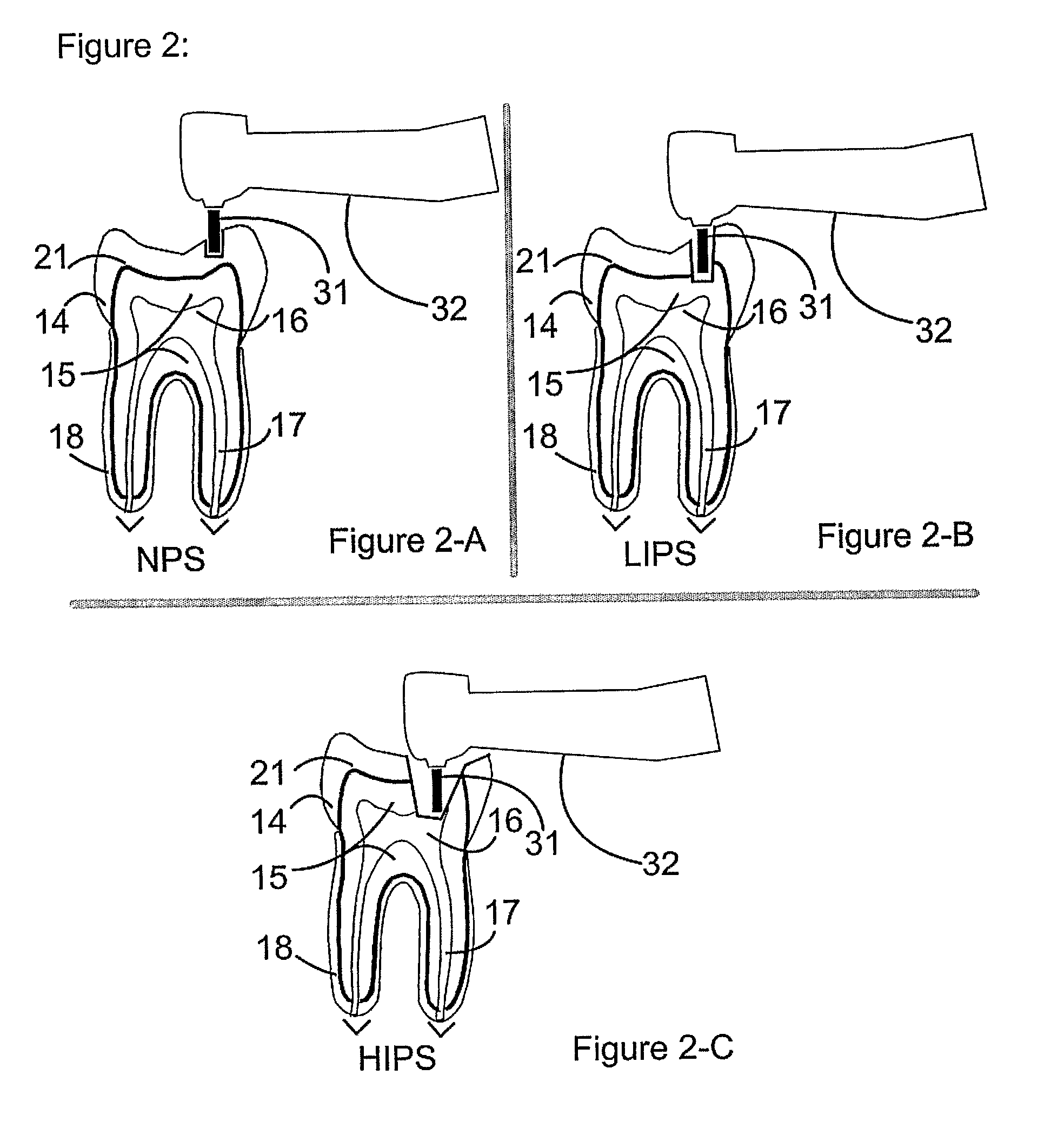

Method and a device for practicing dental treatments

A method, system, device and an artificial tooth is disclosed for simulating both pain and anesthesia in a model of jaws. The tooth is equipped with sensors and connected to a data processing unit, memory unit and audiovisual display unit. The system is for teaching and practicing in the field of dentistry according to which removing artificial tooth or artificial bone substances by a dental drill, generates signals of pseudo pain with different intensities. Signals are fed to the data processing unit which simulates perception of the simulated pain and accordingly to said audio-visual display unit which simulates reaction to the different intensities of generated pseudo pain signals by playing different sounds which are stored in said memory unit. Furthermore, the system is able to simulate anesthesia by generating block signals as a result of applying different anesthetic techniques by means of a dental syringe connected to the system.

Owner:DRSK DEV

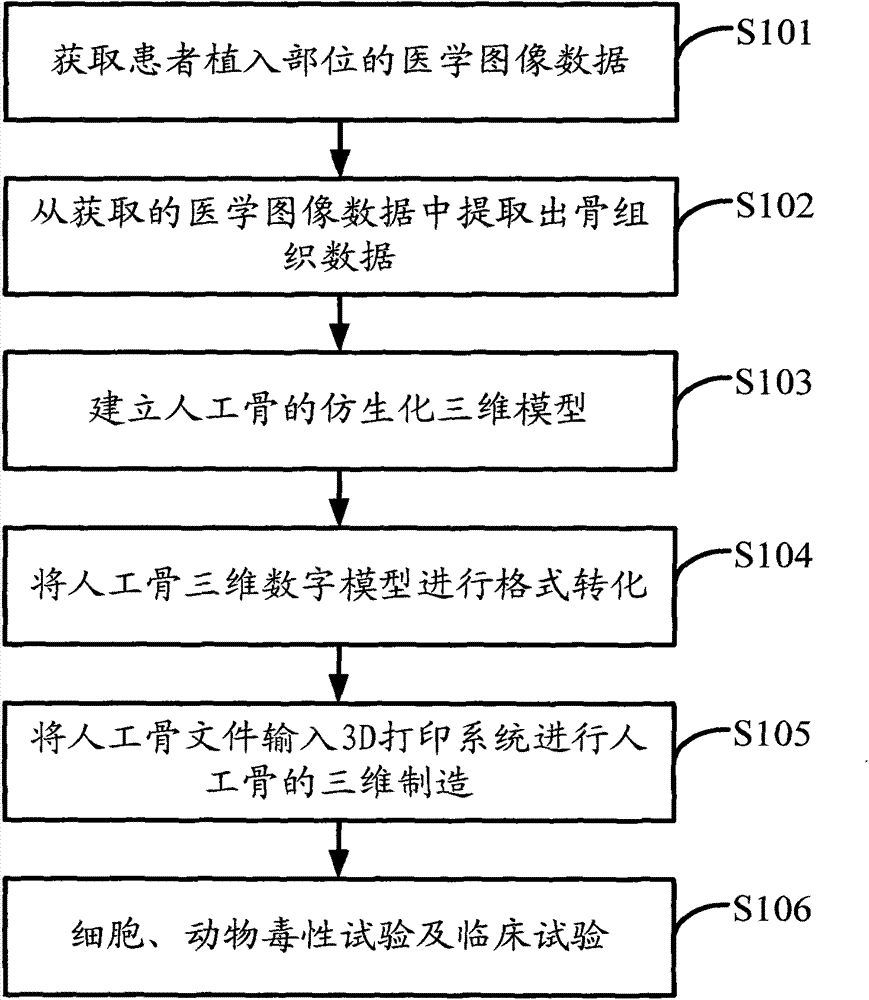

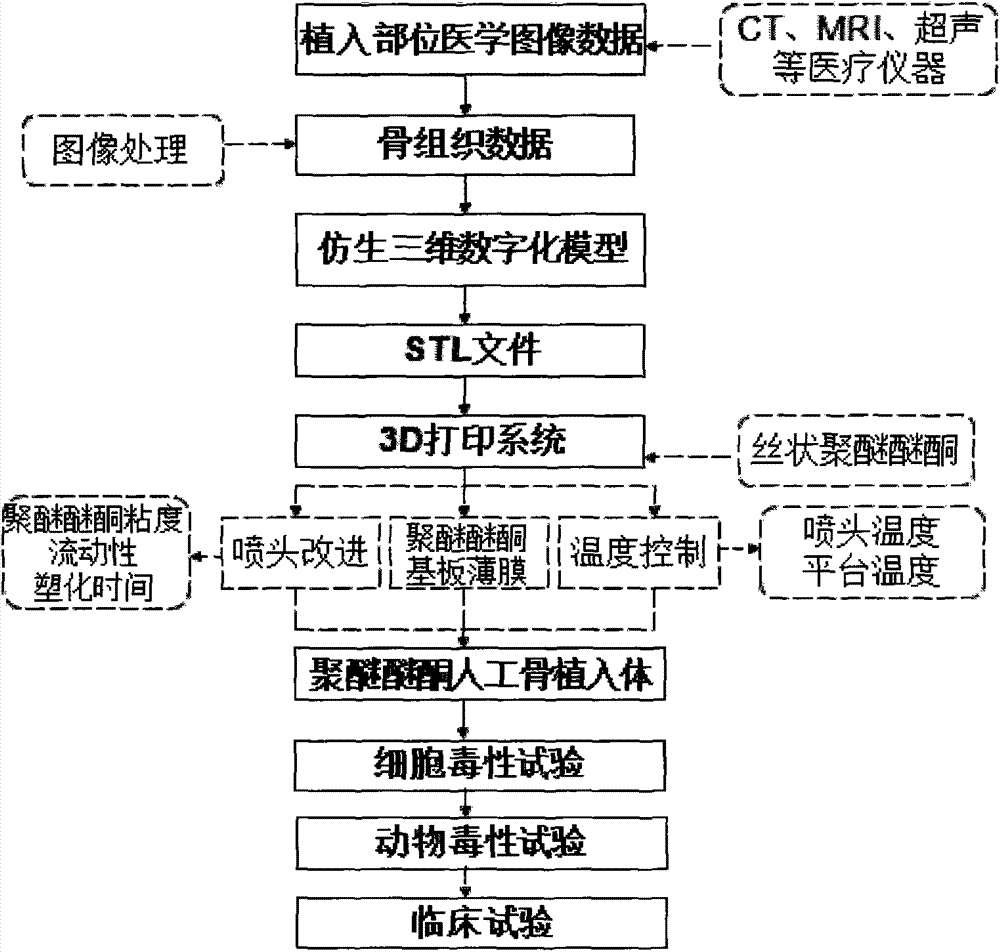

Polyether-ether-ketone biomimetic artificial bone 3D printing manufacturing method

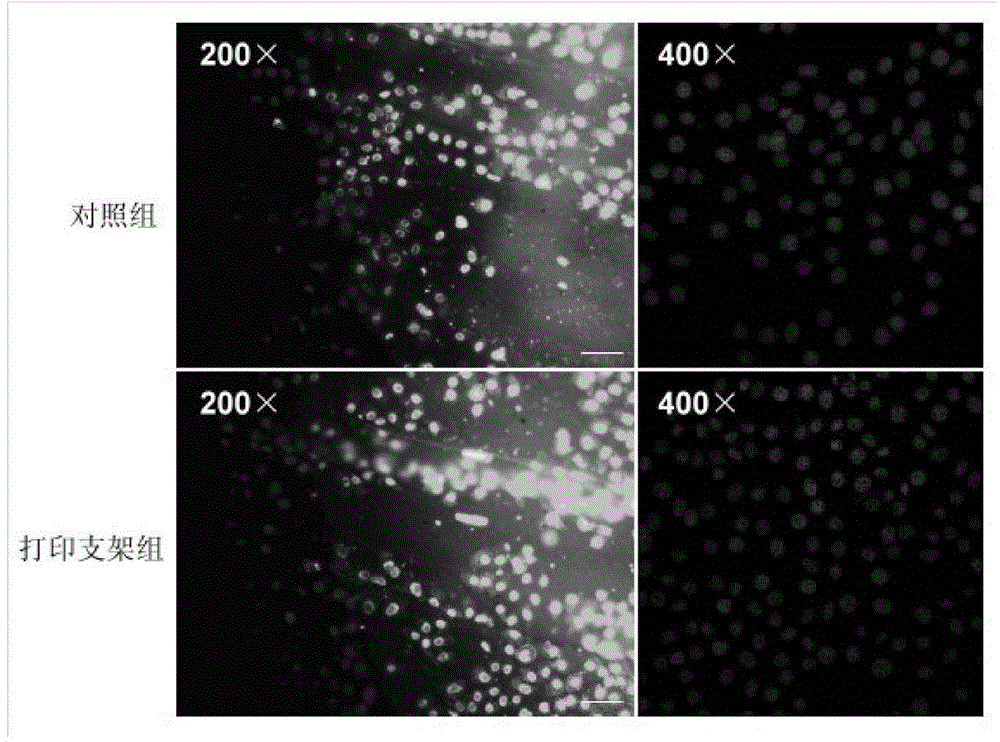

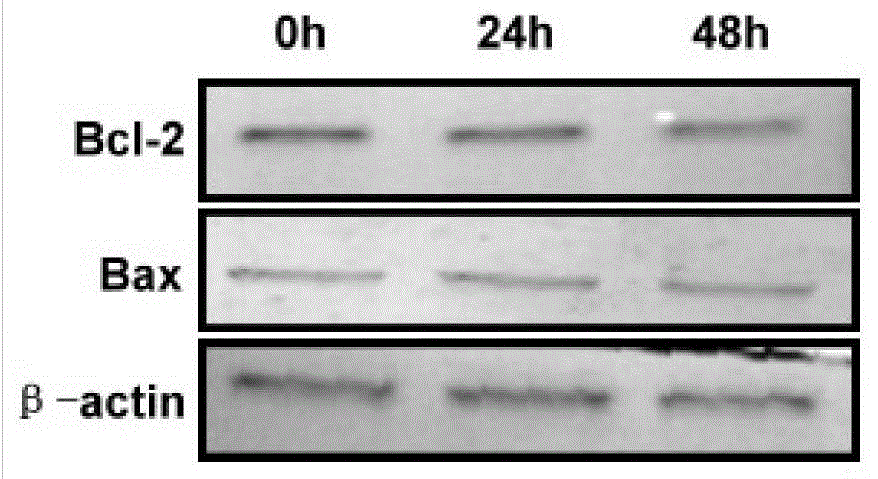

ActiveCN103707507ASave timeSave costSpecial data processing applications3D modellingBiocompatibility TestingArtificial bone

The invention discloses a polyether-ether-ketone biomimetic artificial bone 3D printing manufacturing method, wherein the artificial bone can replace metal and has an excellent biocompatibility. The method comprises the following steps: first, collecting the bone tissue image data of the part, which is about to be implanted with an artificial bone, of a patient by using a medical instrument; secondly, establishing a three-dimensional digital model of the artificial bone on the basis of the collected data; thirdly, carrying out a format conversion on the three-dimensional digital model of artificial bone, inputting the converted file into a 3D printing system to manufacture the artificial bone; and finally carrying out cell toxicity tests, animal tests, and clinical tests. The invention utilizes a self-made polyether-ether-ketone 3D printing system to manufacture artificial bones, thus the time and cost for manufacturing moulds are saved, the manufacture period is shortened; at the same time, the shape of parts can be adjusted at any time according to the setting of the forming software; so that an crystalline polymer polyether-ether-ketone artificial bone, which has excellent biocompatibility, can be implanted into the human body, and has the advantages of high melting point, large viscosity, and bad fluidity, can be manufactured through the 3D printing method.

Owner:JILIN UNIV

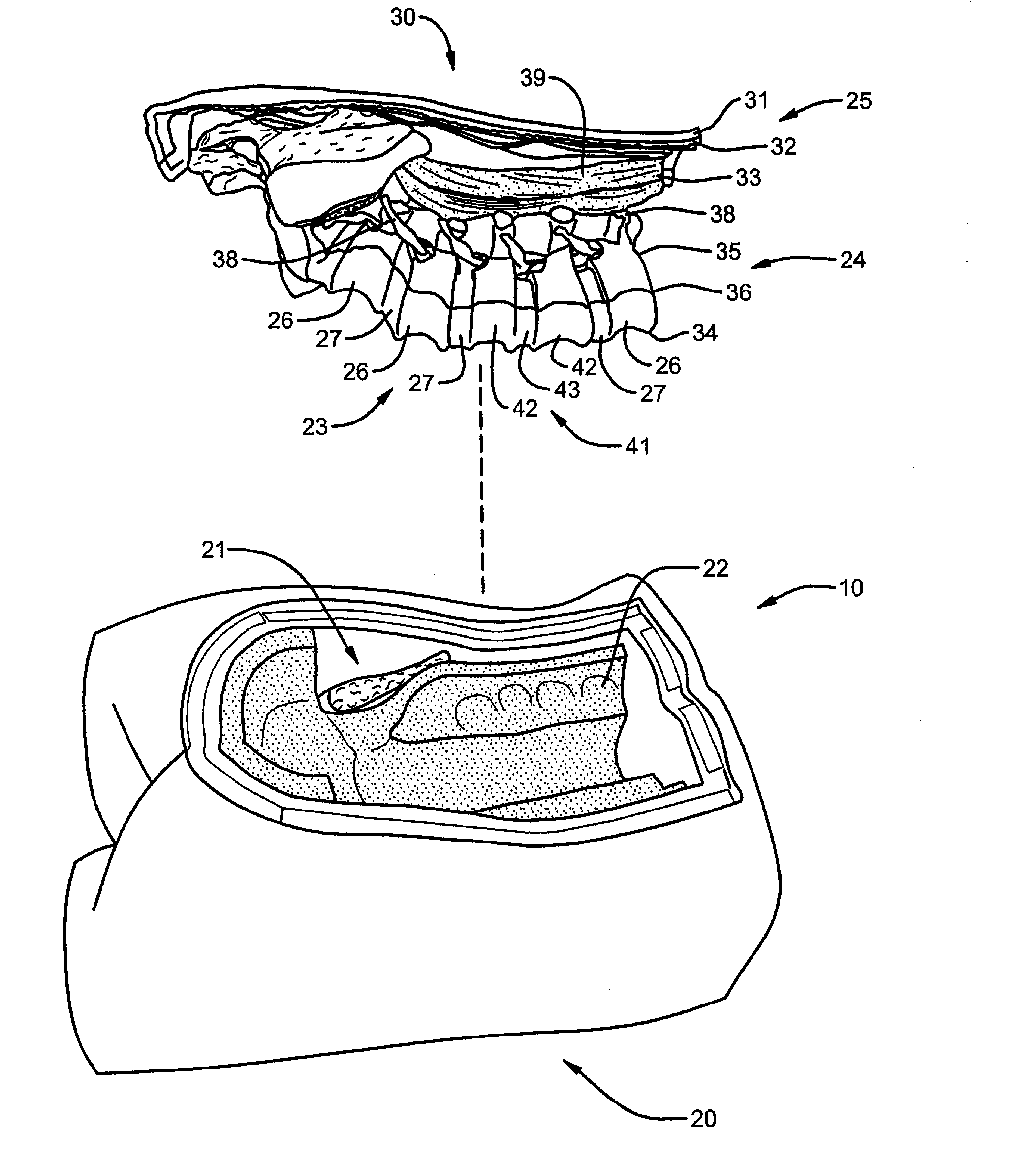

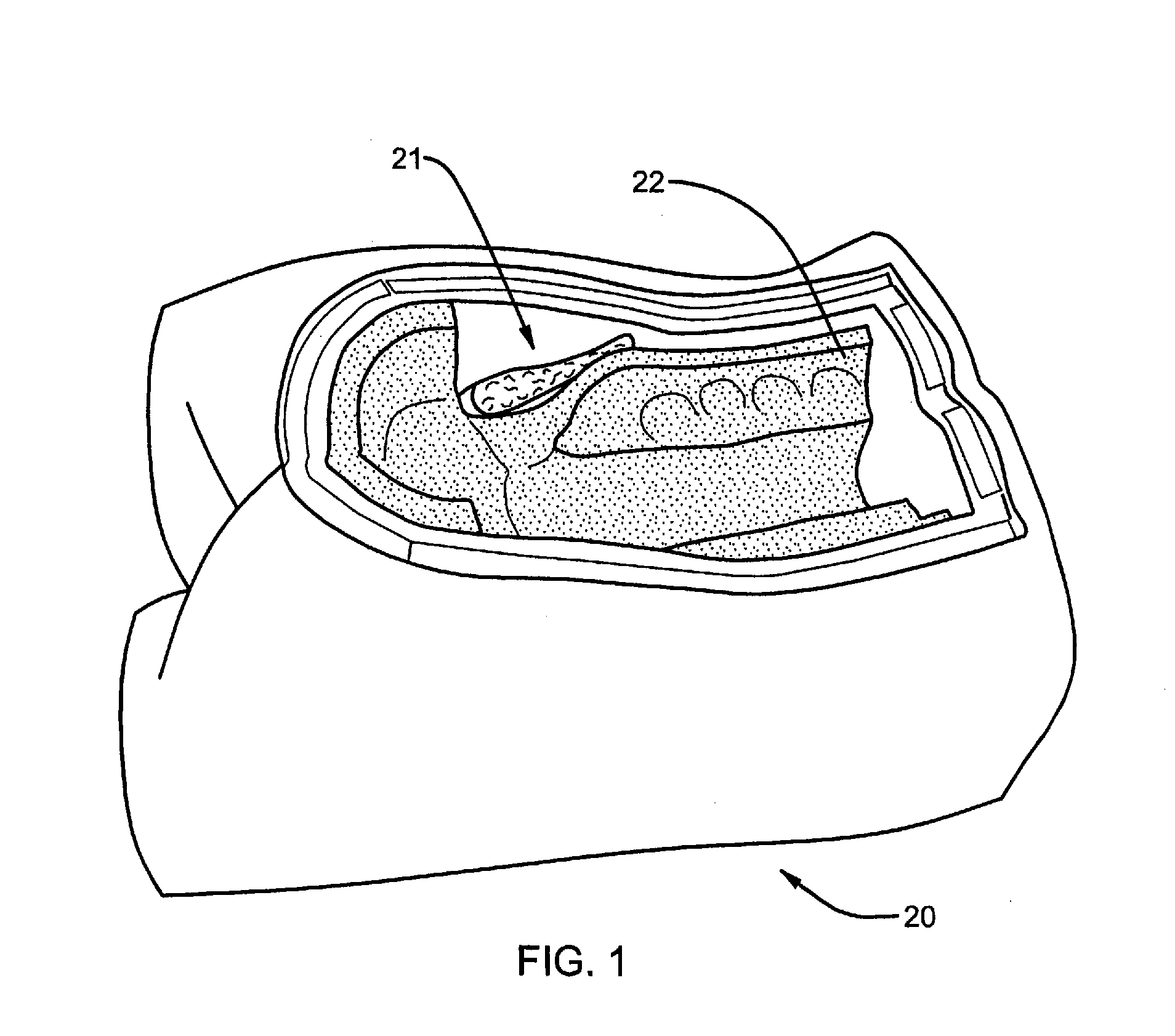

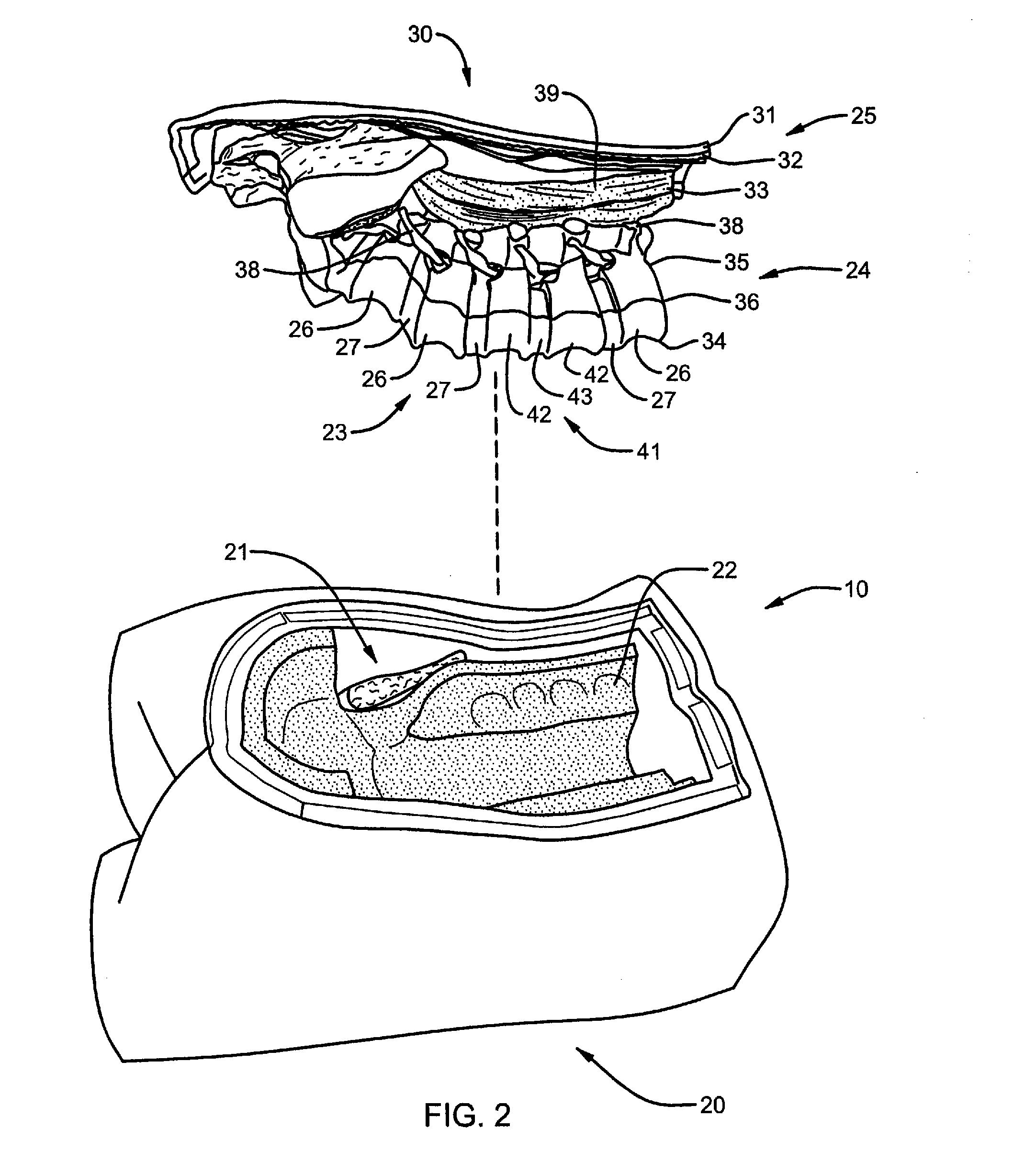

Surgical training model and method for use in facilitating training of a surgical procedure

InactiveUS20080138781A1Reduce use costIncrease flexibilityEducational modelsDiagnostic Radiology ModalityDisease

A surgical training model for use in facilitating training a user of a surgical procedure. The model includes a holder member with a receptacle and an insert member configured for placement within the receptacle of the holder member. The insert member is modular relative to the holder member, thereby allowing a user of the model to dispose of the insert member following the performance of a surgical procedure. The insert member includes a portion of a human vertebral column, with the human vertebral column having an artificial bone portion and artificial soft tissue portion. The artificial bone portion and the artificial soft tissue portion are positioned proximate relative to each other to substantially mimic resistance of human vertebral bone and surrounding soft tissue. The insert member also includes a pathology structure that replicates certain disease or structural modalities. A method for manufacturing a surgical training model is also disclosed.

Owner:WARSAW ORTHOPEDIC INC

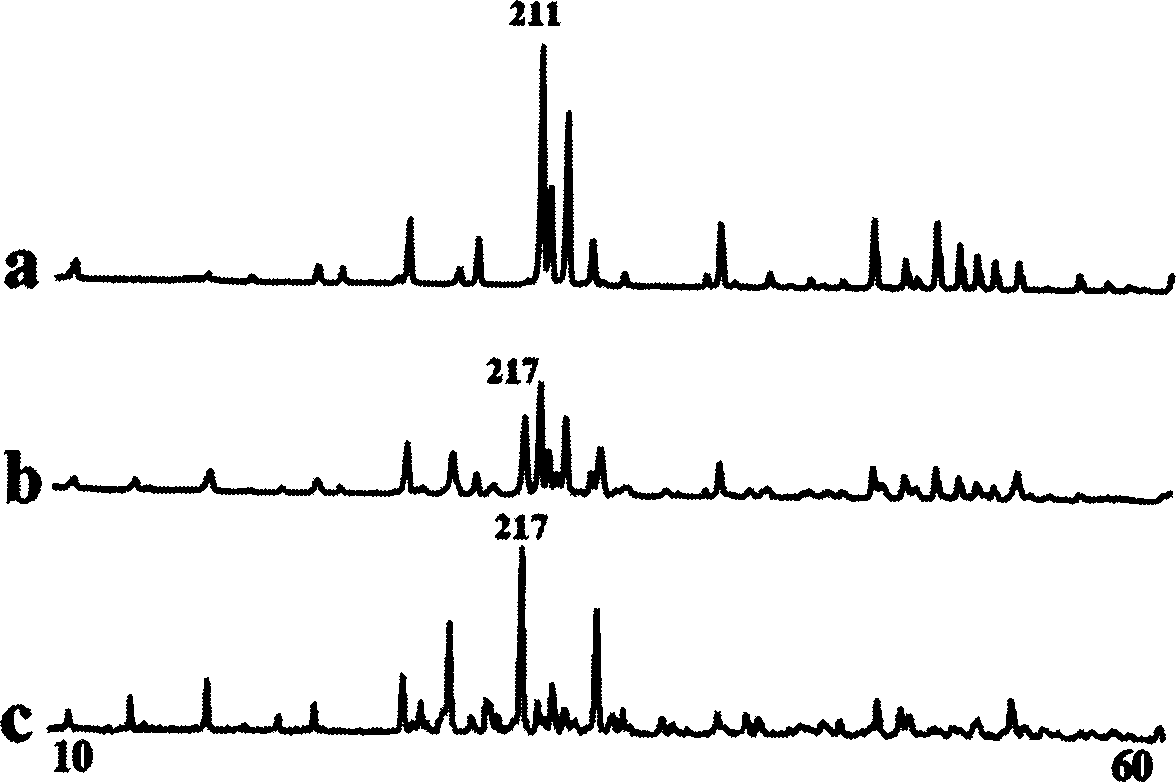

Composite material for porous material and gel use thereof

InactiveCN1644221AImprove stabilityGood adhesionProsthesisCalcium biphosphateAlpha-tricalcium phosphate

A composition of porous material and gel for preparing artificial bone is prepared from collagen and porous material chosen from alpha-tricalcium phosphate / hydroxy apatite, beta-tricalcium phosphate / hydroxy apatite-coral, calcium phosphate / hydroxy apatite, calcium carbonatel tricalcium phosphate, etc.

Owner:徐小良

Composite material and methods of making the same

A method of making artificial bone comprises providing a membrane of collagen with solutions of calcium ions and of phosphate ions on opposite sides of the membrane. The calcium ions and phosphate ions diffuse through the membrane and precipitate as a hydroxyapatite material. Control of ionic concentrations ensures that precipitation takes place within the fibrils of the membrane. The result is an artificial bone material comprising a matrix of collagen and a hydroxyapatite material deposited within the matrix.

Owner:ISIS INNOVATION LTD

Biodegradable stent composite material and preparation method thereof

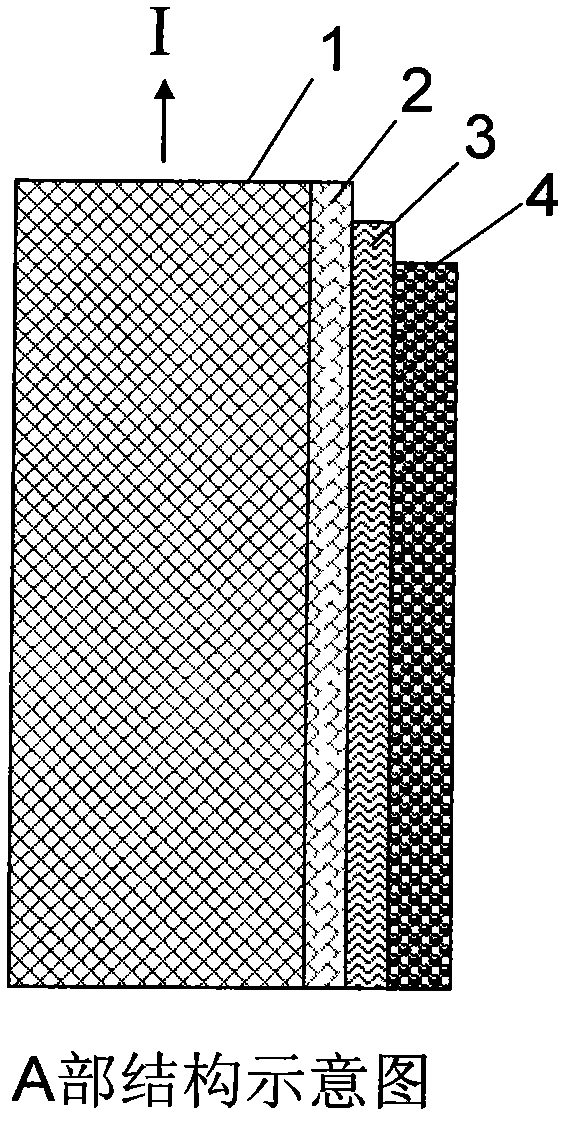

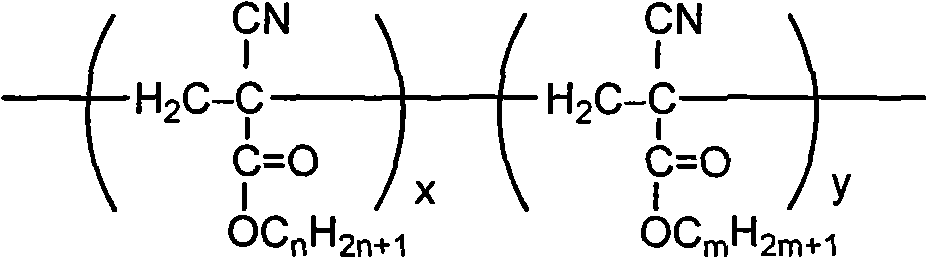

ActiveCN102008751AGood mechanical propertiesPromote degradationSuture equipmentsSurgical adhesivesBiocompatibility TestingAlloy

The invention relates to a biodegradable stent composite material and a preparation method thereof. The degradable material has a multi-gradient composite structure, and comprises a matrix made of a medical metal or an alloy thereof, a chemical coupling layer attached to the surface of the matrix, a high polymer transition layer attached to the surface of the chemical coupling layer and a degradable high polymer functional layer fixed on the surface of the high polymer transition layer. The stent composite material has high mechanical property, degradation property and biocompatibility, also can absorb and carry needed therapeutic medicaments, and meets the requirement on clinical treatment. The degradable composite material can be used as stent materials of esophagi, biliary ducts, intestinal tracts, urethrae, tracheae and other non-vessel lumens and blood vessels, and also can be used for manufacturing artificial bones, bone nails, bone connectors, bone sutures, anchors for suture, intervertebral discs, hemostatic clamps, hemostatic forceps, hemostatic plates, hemostatic screws, tissue adhesives, sealants and other medical devices and products.

Owner:清北高科(北京)科技有限公司

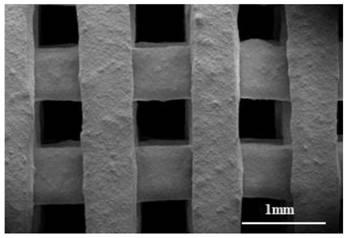

3D printing manufacturing method for tantalum-coated hierarchical pore polyether-ether-ketone artificial bone scaffold

The invention discloses a 3D printing manufacturing method for a tantalum-coated hierarchical pore polyether-ether-ketone artificial bone scaffold. The method comprises the steps of scanning bone tissues of a human injured part through CT (computed tomography) to ensure that the tissue structure of symmetrical parts can be scanned at the bone tissues of the deficient part, acquiring injured bone image data, importing the data into Mimics software, and establishing a three-dimensional bone model of a human specified part; controlling the software through a 3D printing system to generate a motion locus code; printing a polyether-ether-ketone artificial bone scaffold by using the 3D printing system till the manufacturing process of the whole artificial bone scaffold is completed, putting the dried artificial bone scaffold into the cavity of a sputtering chamber of a magnetron sputtering instrument, bonding the artificial bone scaffold to an objective table by using silver colloid, and plating a tantalum coating on the artificial bone scaffold by adopting a magnetron sputtering technology; discharging gas from the sputtering chamber after the tantalum coating is plated, taking the artificial bone scaffold out, and disinfecting the tantalum-coated hierarchical pore polyether-ether-ketone scaffold to complete all the steps. The artificial bone scaffold is manufactured through 3D printing, so that the method disclosed by the invention has the advantage that the manufactured scaffold is harmless to the human body.

Owner:JILIN UNIV

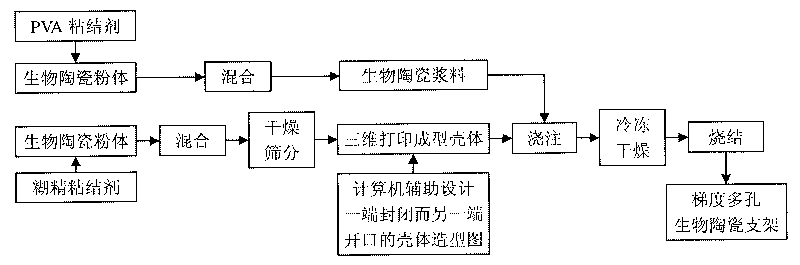

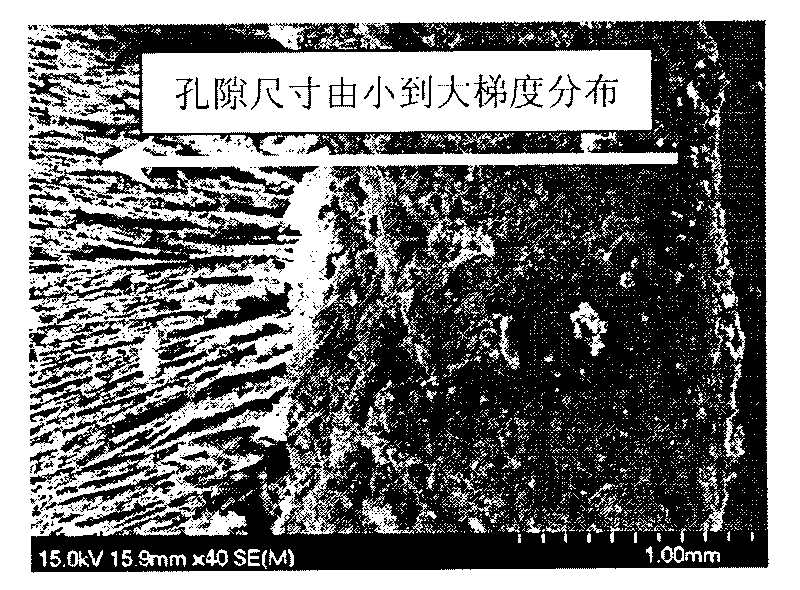

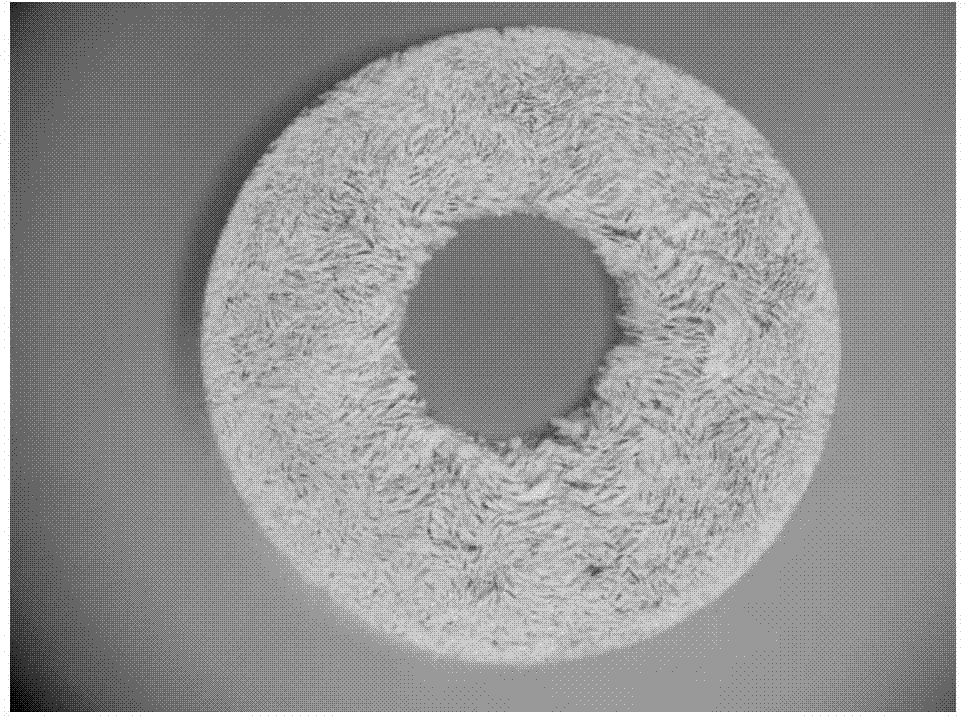

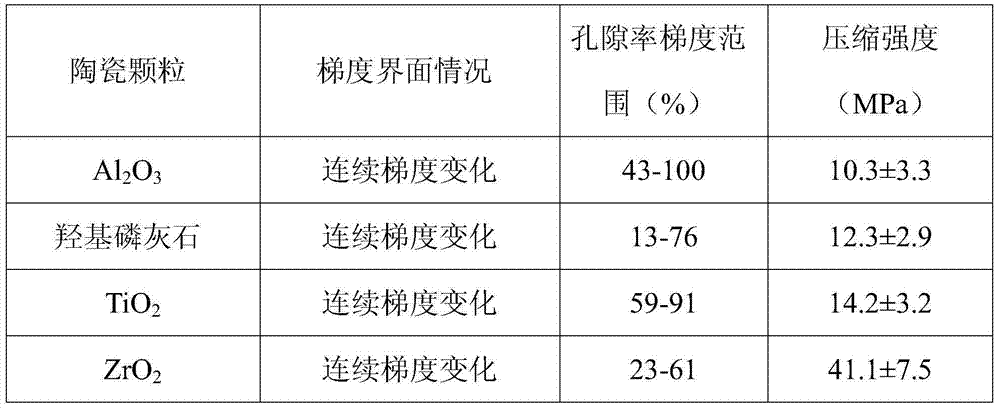

Preparation method of gradient porous bioceramic scaffold

ActiveCN101690828AGuaranteed normal transportationImprove carrying capacityProsthesisBioceramicArtificial bone

The invention discloses a preparation method of gradient porous bioceramic scaffold. The method adopts the steps of preparing three-dimensional shells, pouring bioceramic slurry, freeze-drying and sintering to prepare porous bioceramic scaffold with relatively dense structure in the exterior and directional layered porous structure in the interior. The average flexural strength of the shell material reaches 28.5-35.6MPa; in addition, the porous bioceramic scaffold prepared by the method of the invention can be customized according to the individual differences of patients without relying on moulds for shaping and the invention is characterized by fast production; and the gradient porous bioceramic scaffold can be used in the field that artificial bone is used to repair pathological or injured bone tissues.

Owner:西安点云生物科技有限公司

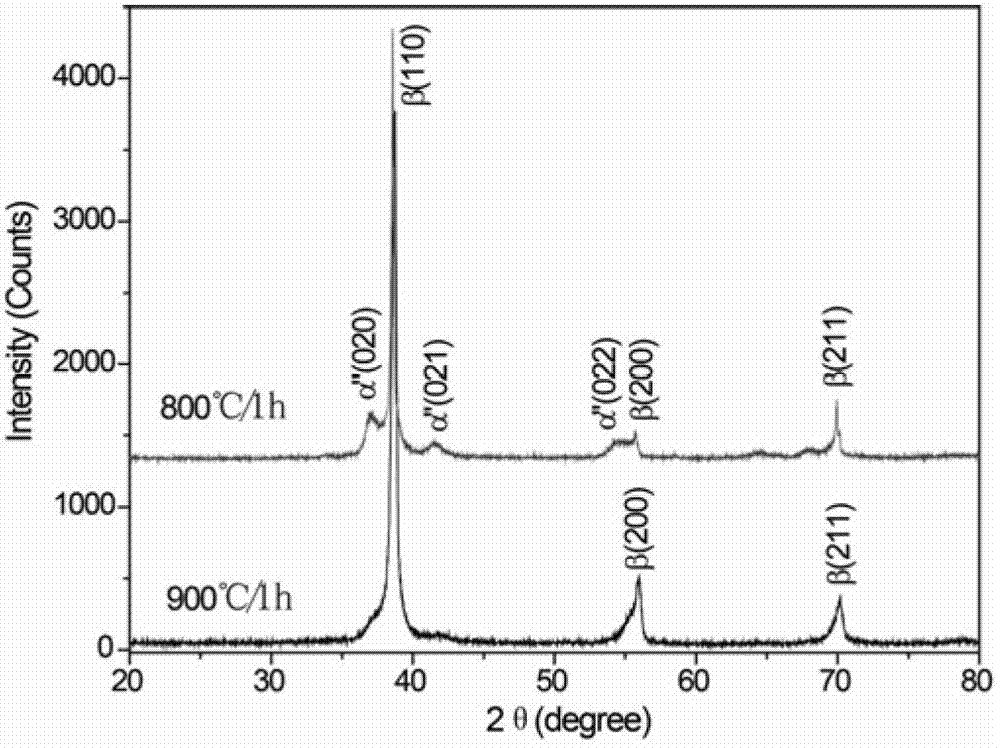

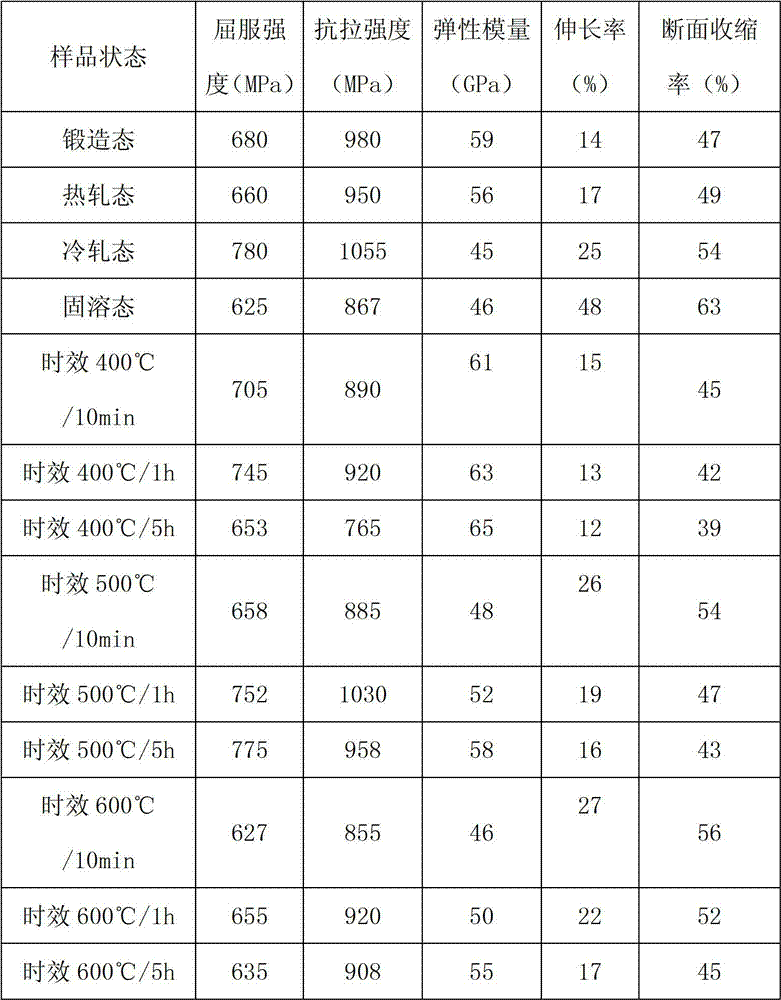

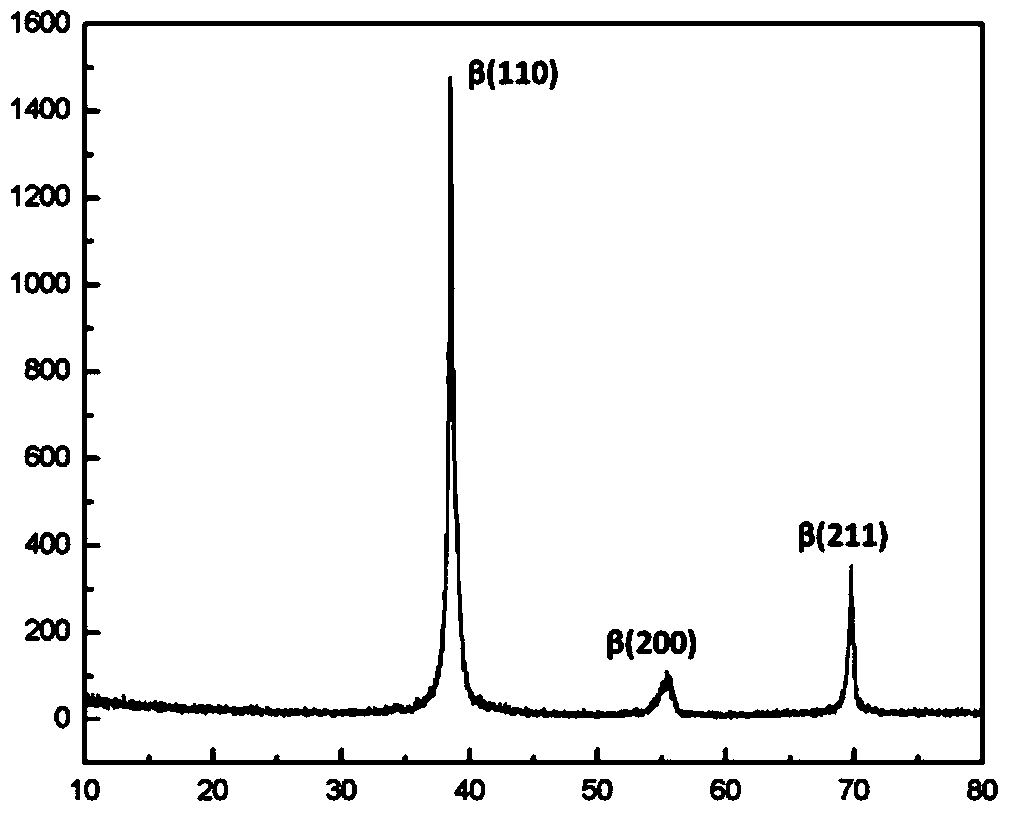

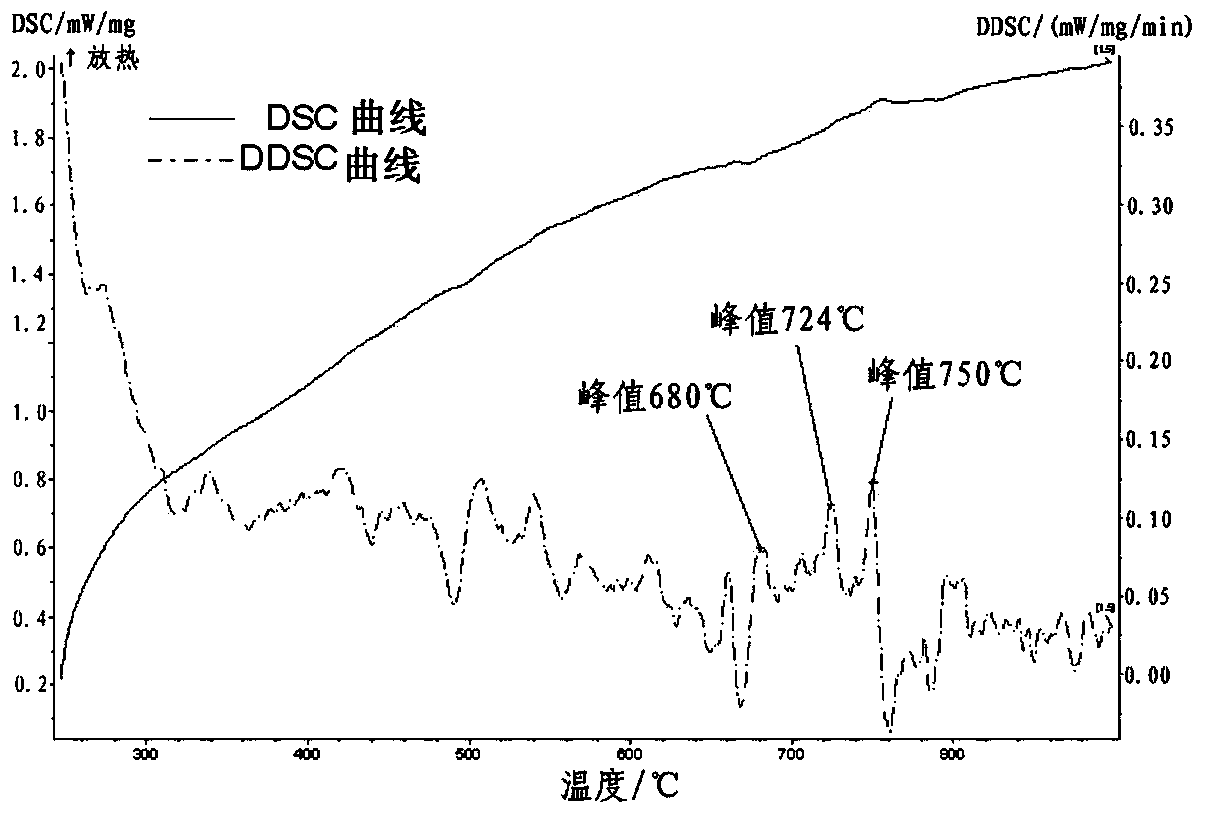

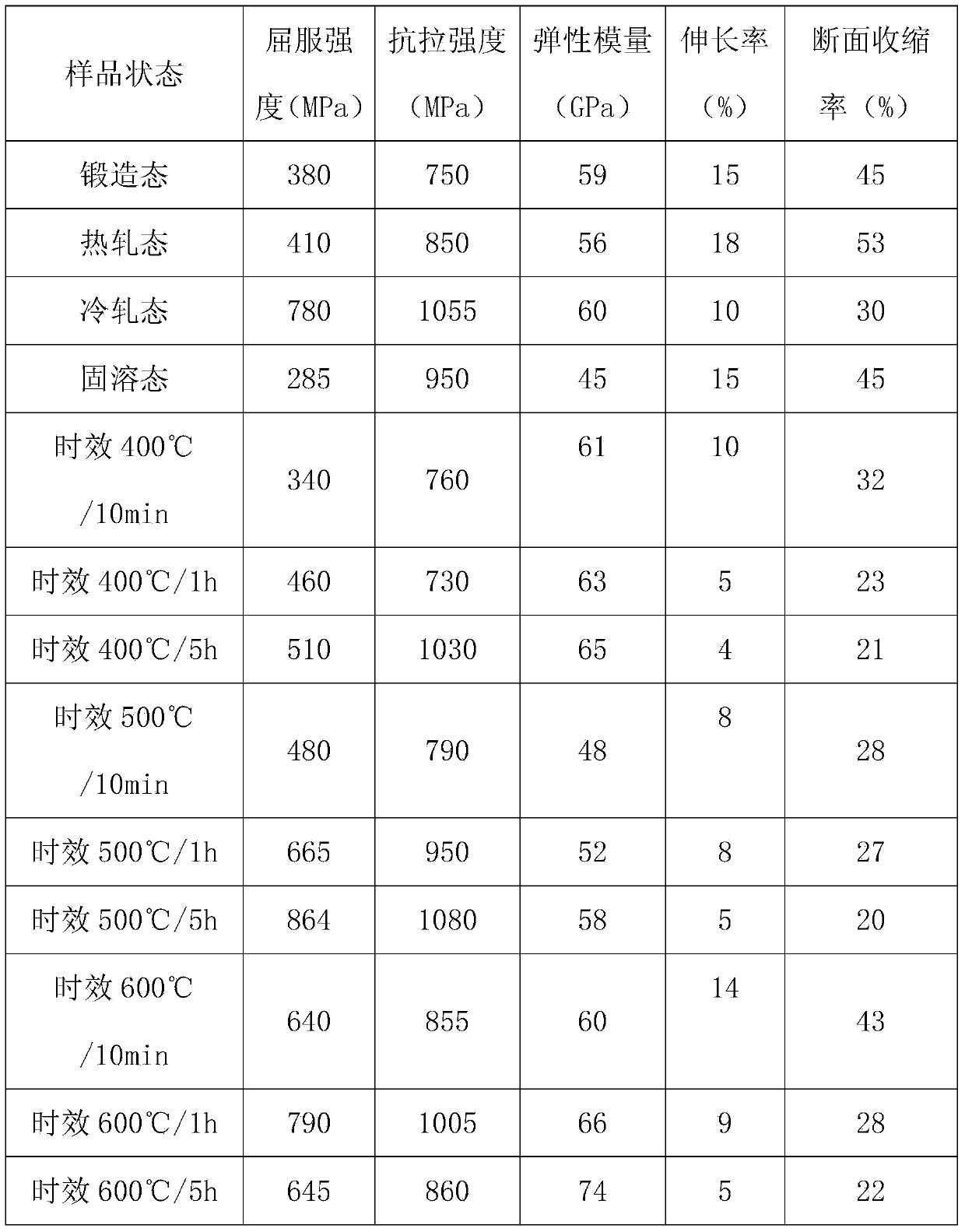

Biomedical beta-titanium alloy material and preparation method

The invention relates to a biomedical beta-titanium alloy material and a preparation method, and belongs to the technical field of preparation of titanium alloy materials with high niobium content. The alloy comprises the following components in percentage by mass: 30-40 percent of Nb, 5-15 percent of Zr, 1-10 percent of Sn, 0.1 and 0.3 percent of O and the balance of Ti. The titanium alloy has high comprehensive performance, and the strength and the elastic modulus of the alloy can be modulated and controlled by different heat treatment processes; the elastic modulus E of the alloy is 40-68GPa; the yield strength sigma 0.2 is 580-800MPa; the tensile strength sigma b is 750-1120MPa; the elongation ratio epsilon is 12-48 percent; and the section shrinking percentage is 36-65 percent. The titanium alloy does not contain toxic elements, has excellent corrosion resistance, biocompatibility and cold treating performance, and can perform cold rolling in a large deformation amount. The titanium alloy is wide in use, so that the titanium alloy can be used for manufacturing tissue recovery or replacement materials of a human body of mouth rehabilitation, artificial bone, joint prosthesis and the like, and also can be used for manufacturing machines in sports and industry.

Owner:BAOJI TITANIUM IND +1

Artificial bone and tissue engineering carrier

An artificial bone comprising a calcium phosphate-based ceramic porous body having a plurality of pores which are three-dimensionally distributed throughout an entire region of the porous body including a surface thereof and have a diameter ranging from 0.01 μm to 2000 μm, and interconnecting portions which are formed between neighboring pores, interconnect a plurality of pores existing on a surface of the porous body.

Owner:OLYMPUS CORP

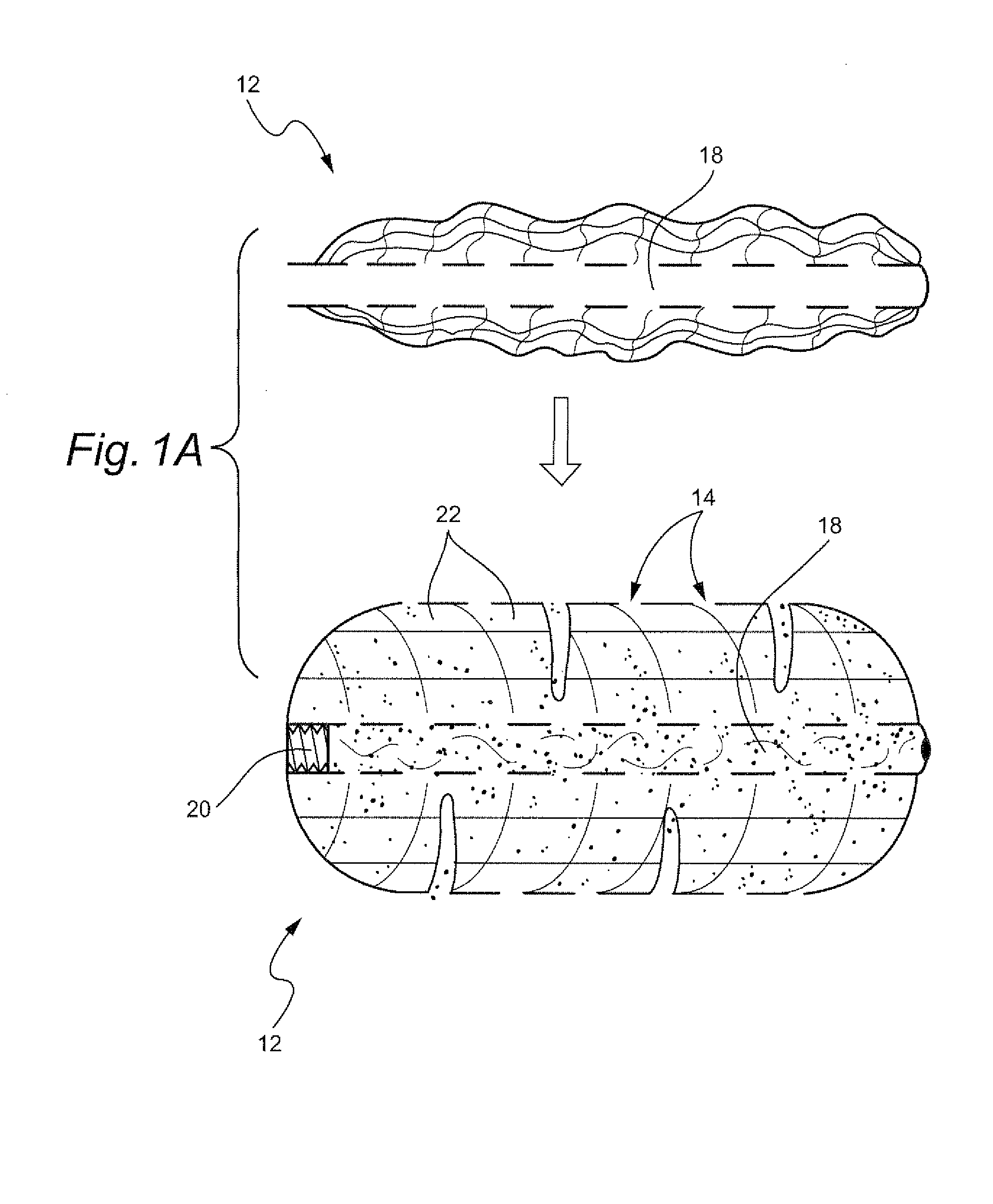

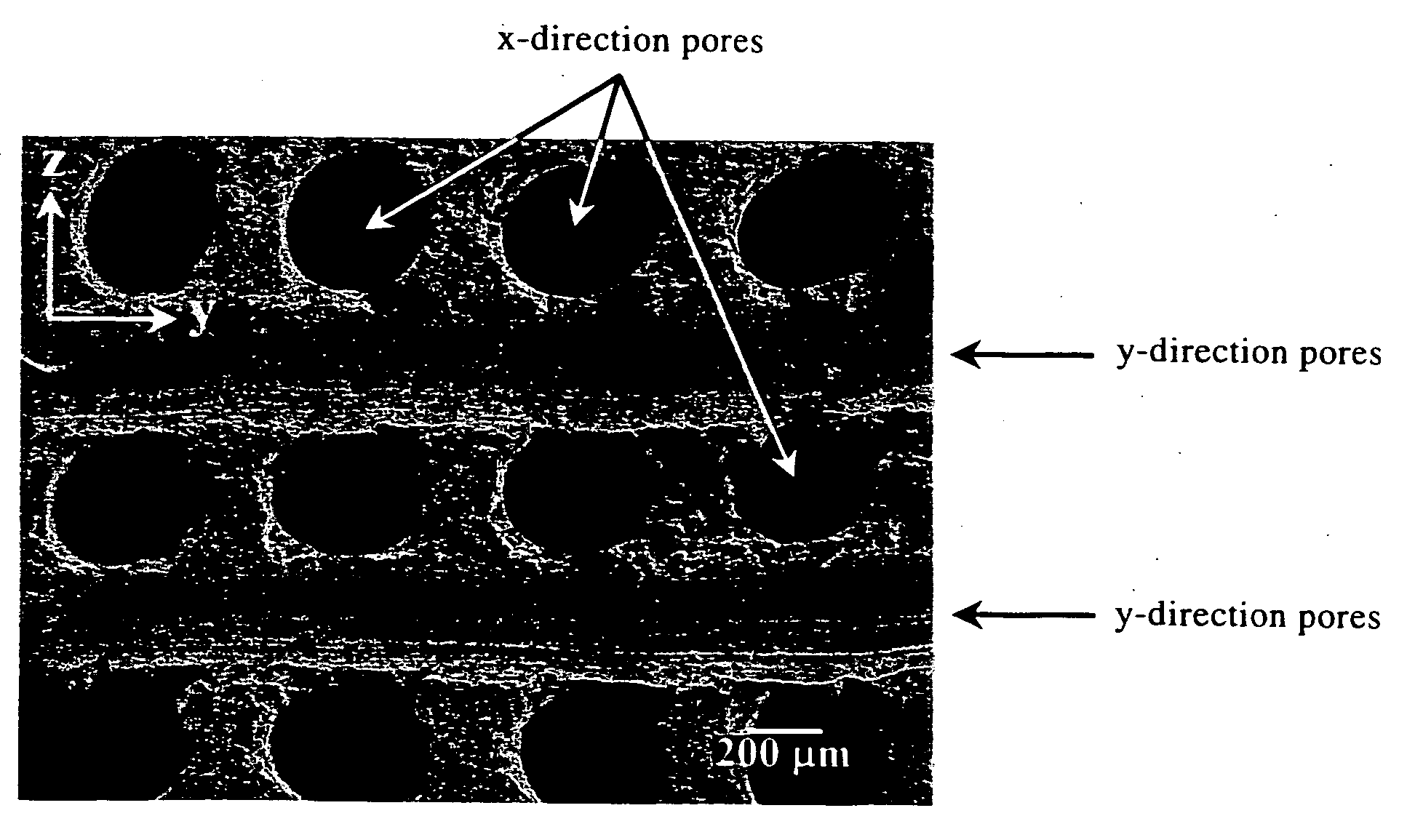

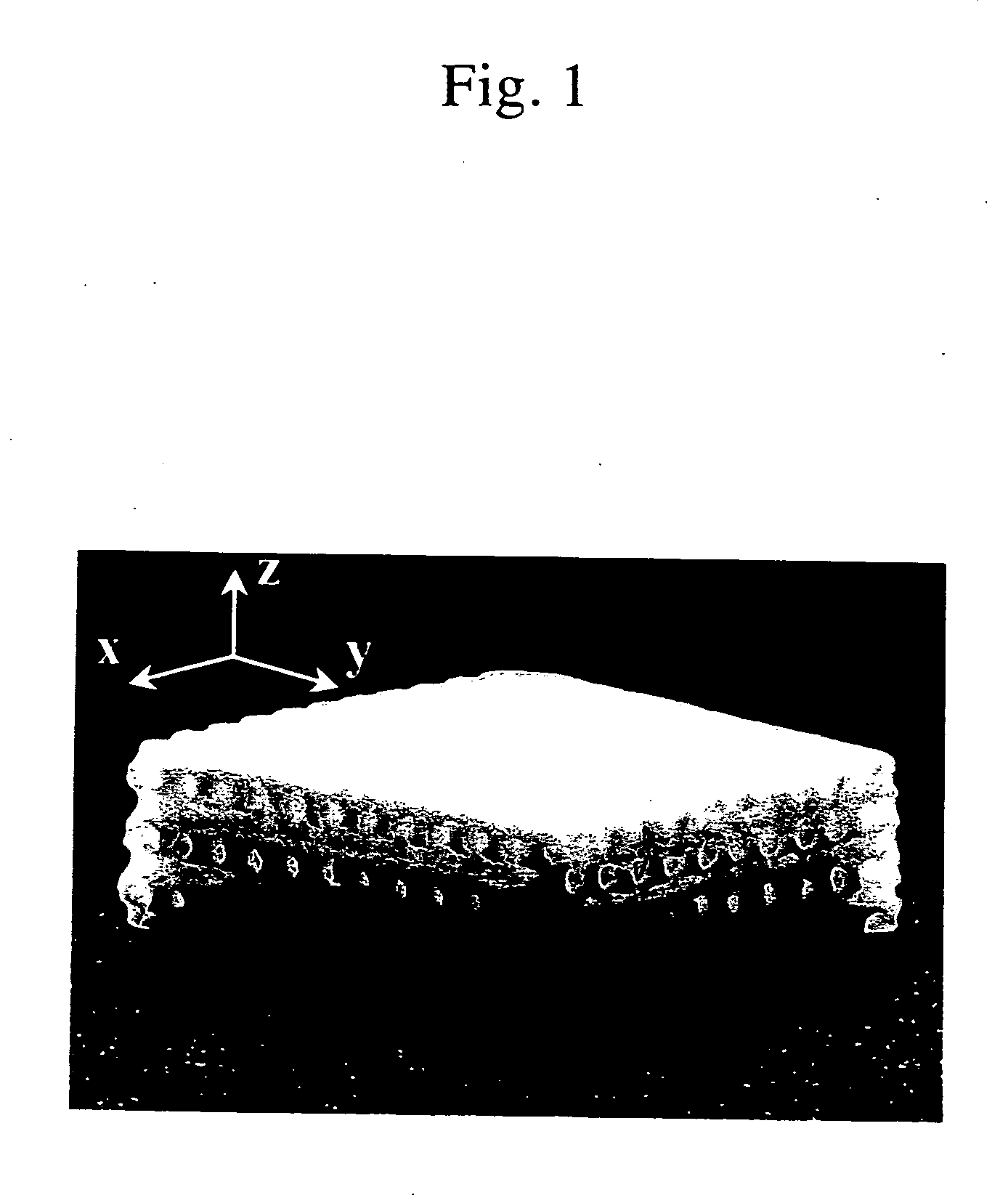

Biomaterial, method of constructing the same and use thereof

InactiveUS20100075419A1Precise positioningLow costDischarging arrangementMouldsArtificial jointsArtificial bone

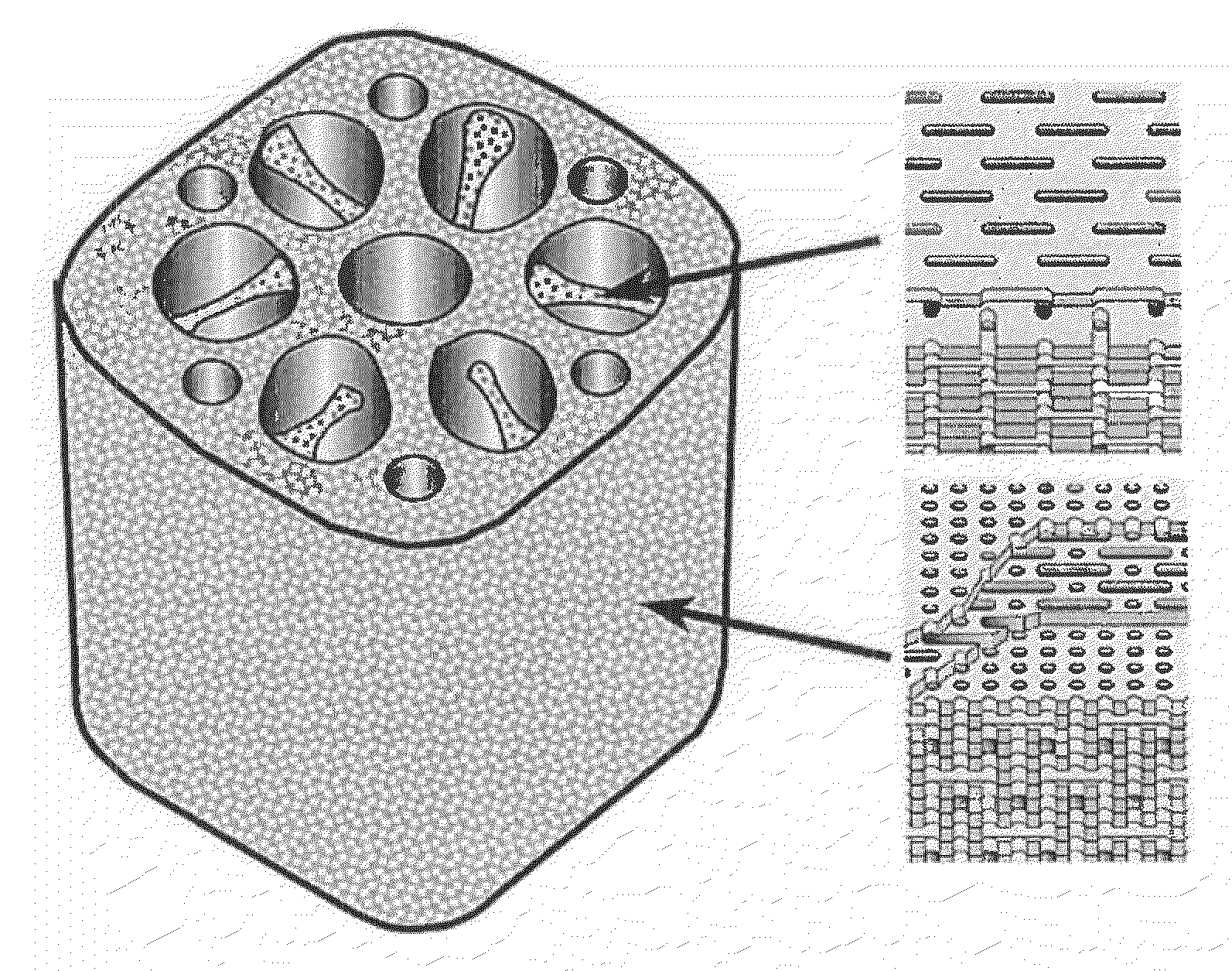

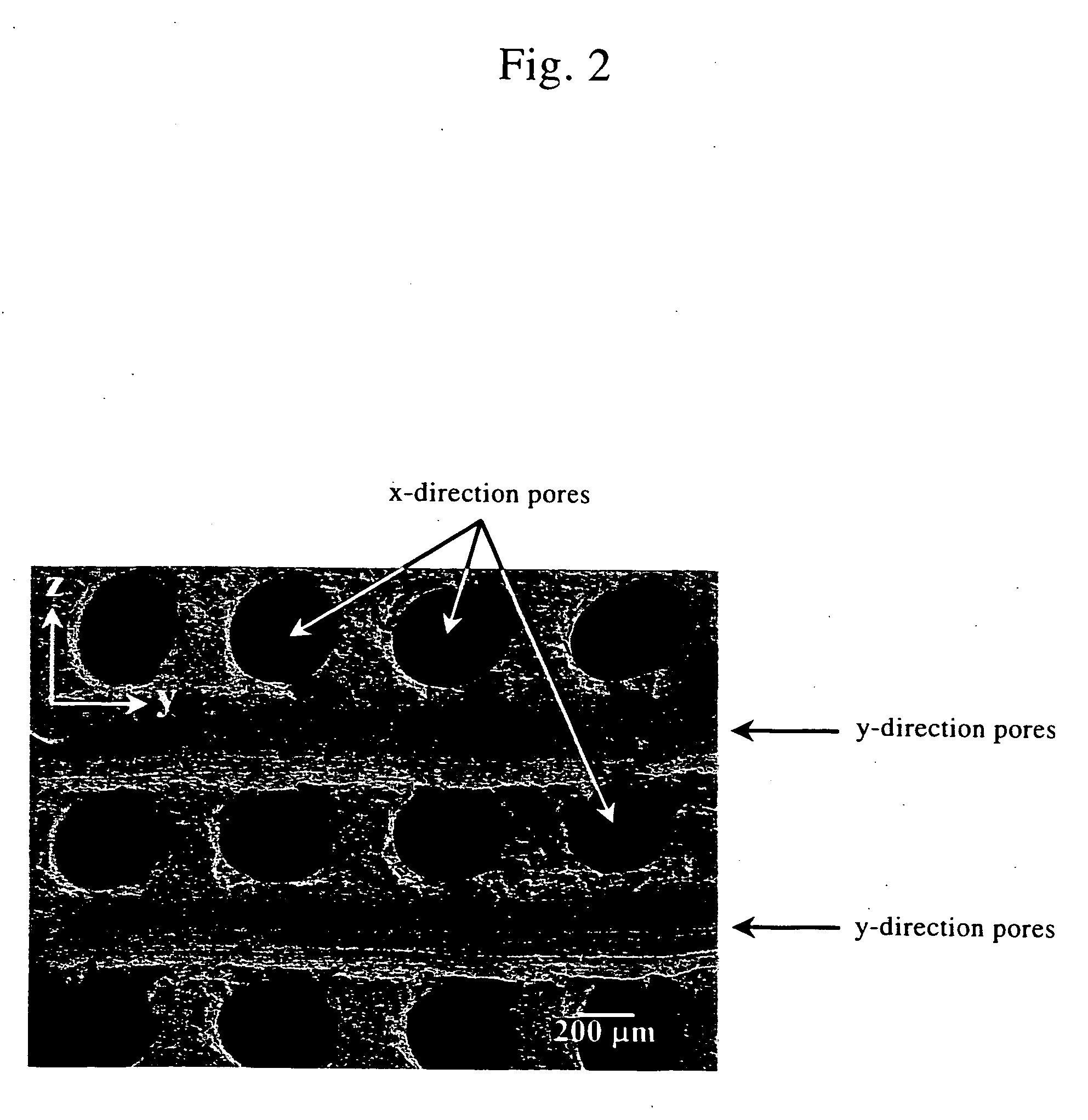

The present provides a biomaterial composed in part of a porous material having an internal structure that has been completely controlled so as to optimize living tissue infiltration or cell introduction, a method of manufacturing, and uses thereof, including bio-implant materials for artificial bones, artificial joints and artificial tooth roots, and cell culture supports; the biomaterial undergoes increased infiltration by living tissues and the like owing to the formation of a porous region in at least a portion of the material, wherein the porous region is a porous body having therein a group of oriented pores that has an orientation and is made up of pores whose size, shape and direction have been controlled to optimize living tissue infiltration or cell introduction, and also having formed therein connecting pores that link together the primary pores and enable the passage of bodily fluids and gas bubbles, and formed with a spatial configuration in which the oriented pores are not directly connected to other oriented pores and the connecting pores which link together the oriented pores are not directly connected to other connecting pores.

Owner:INAGAKI MASAHIKO +2

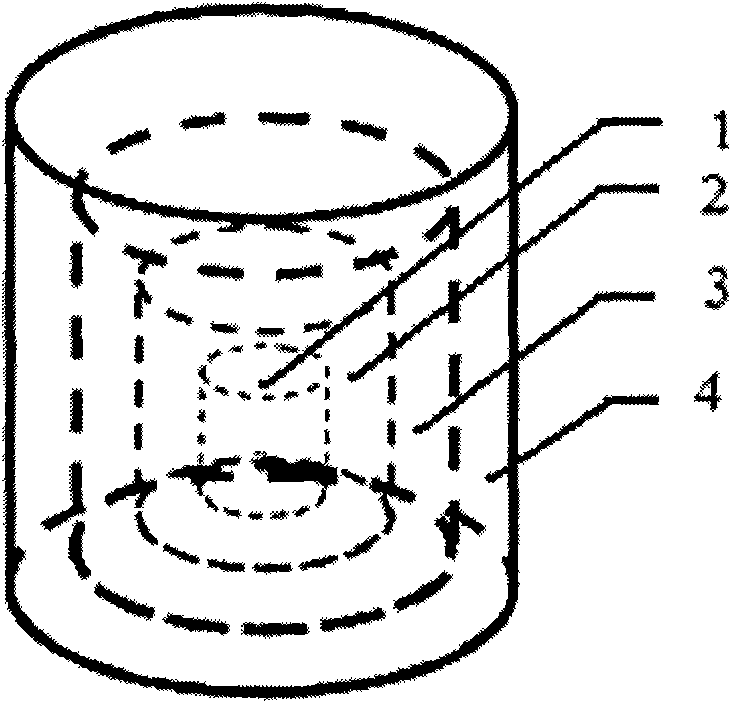

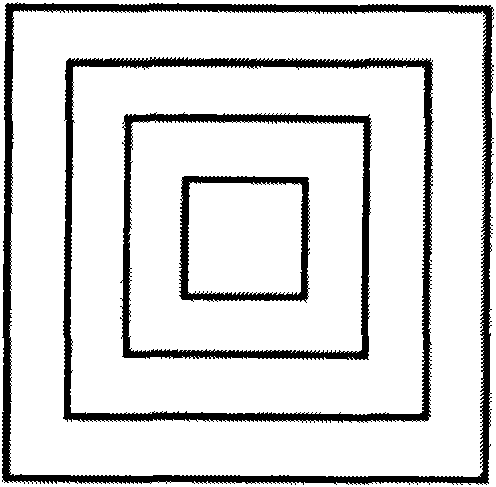

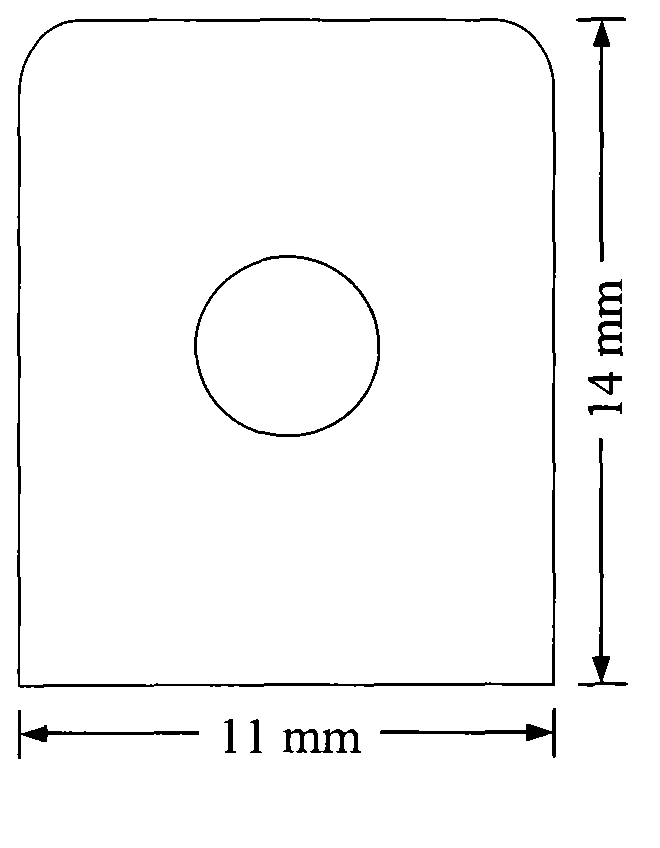

Controlled-release multilayer drug-loaded artificial bone and preparation method thereof

InactiveCN101862230AIncrease concentrationProlong the action timeBone implantMedical devicesControlled releaseIndividualized treatment

The invention discloses a controlled-release multilayer drug-loaded artificial bone and a preparation method thereof. The controlled-release multilayer drug-loaded artificial bone is a multilayer structure which is coated layer by layer and is composed of artificial bone carrier materials loaded with drugs or a multilayer structure which is coated layer by layer and is formed by alternately arranging the artificial bone carrier materials loaded with the drugs and artificial bone carrier materials loaded with no drugs; the outline of the controlled-release multilayer drug-loaded artificial bone can be cylindrical, cuboid, square or irregular; and the artificial bone carrier materials loaded with the drugs at different layers comprise the same or different drugs. The controlled-release multilayer drug-loaded artificial bone is prepared by adopting a three-dimensional stereoscopic printing rapid prototyping technology, and the drugs distributed at the different layers are released from outside to inside layer by layer, thereby being capable of realizing multidrug combined action, regulating the releasing sequence and time of the drugs and selecting appropriate drugs to load so as to achieve the individualized treatment goal. The invention can be applied to carrying out local chemotherapy and filling and repairing bone coloboma after eradication focuses of various infections, concretions, tumours and the like of the orthopedics department.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

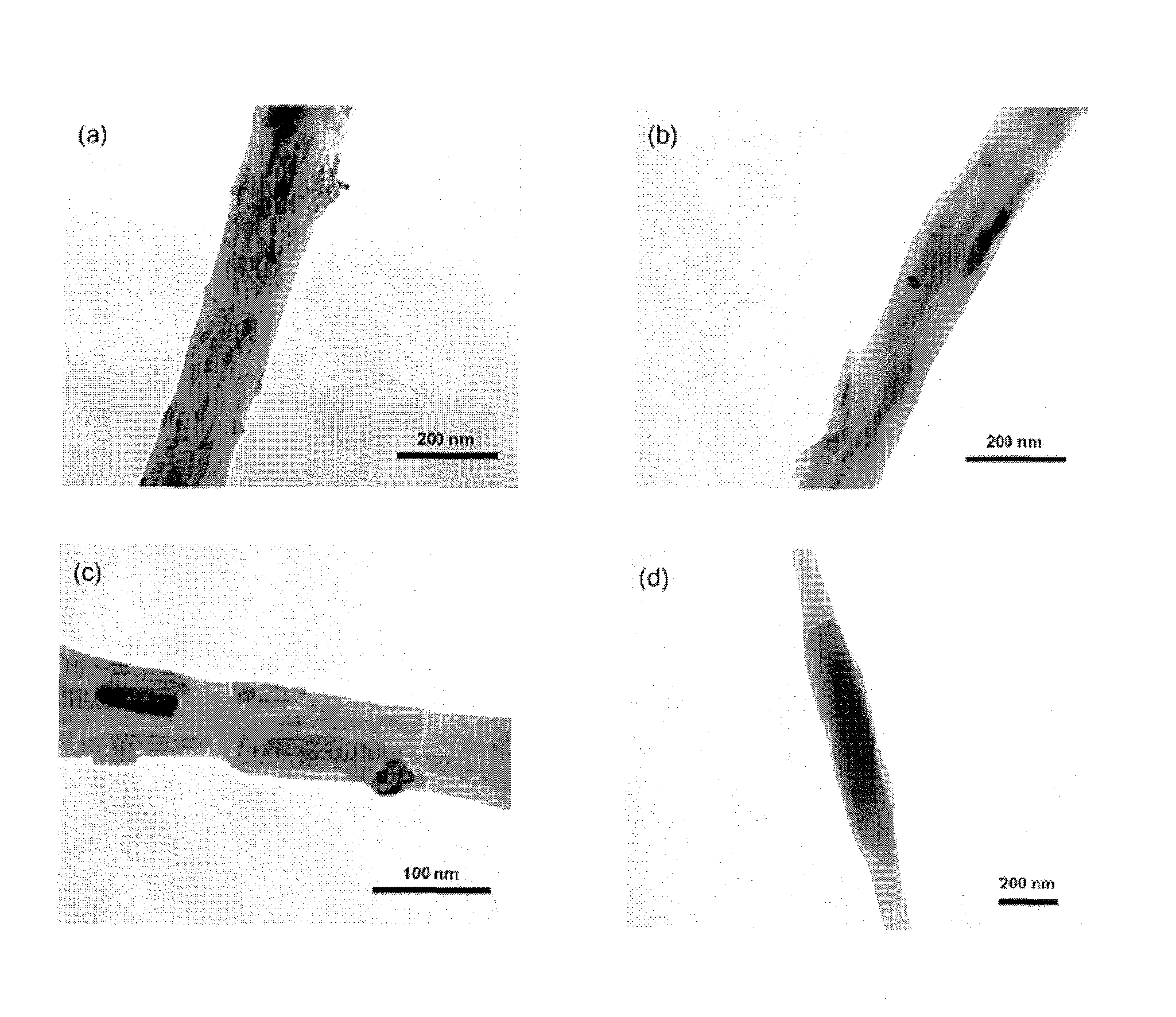

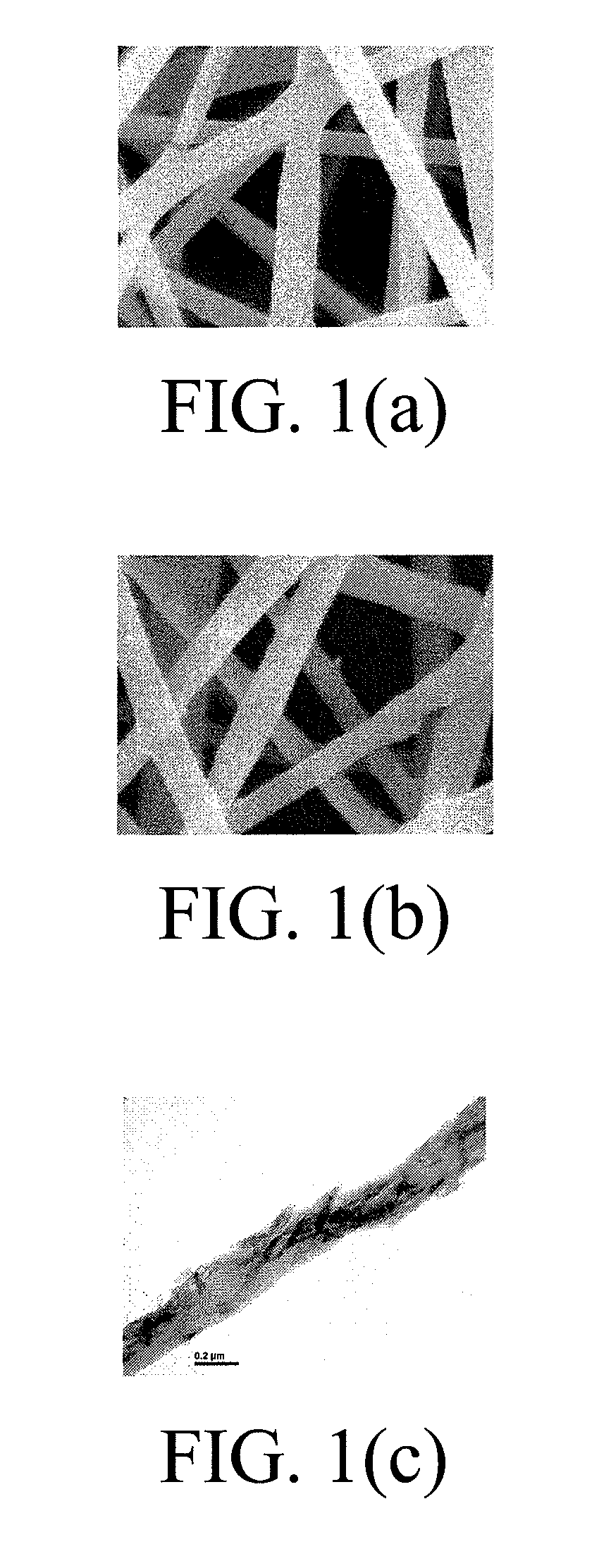

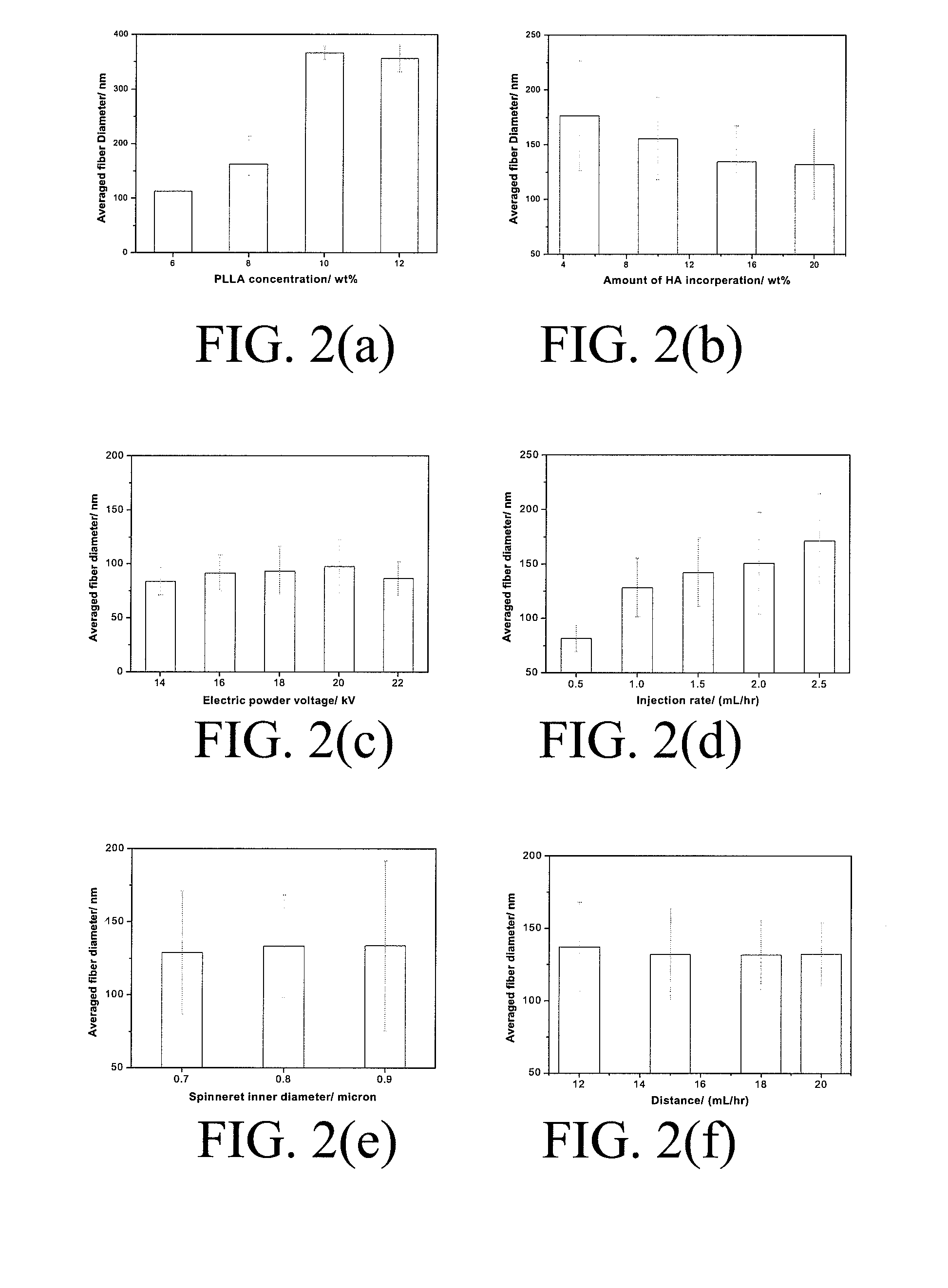

Electrospun apatite/polymer nano-composite scaffolds

InactiveUS7879093B2Convenient and versatile fabrication techniqueElectric discharge heatingBone implantFiberApatite

Owner:UNIV OF CONNECTICUT

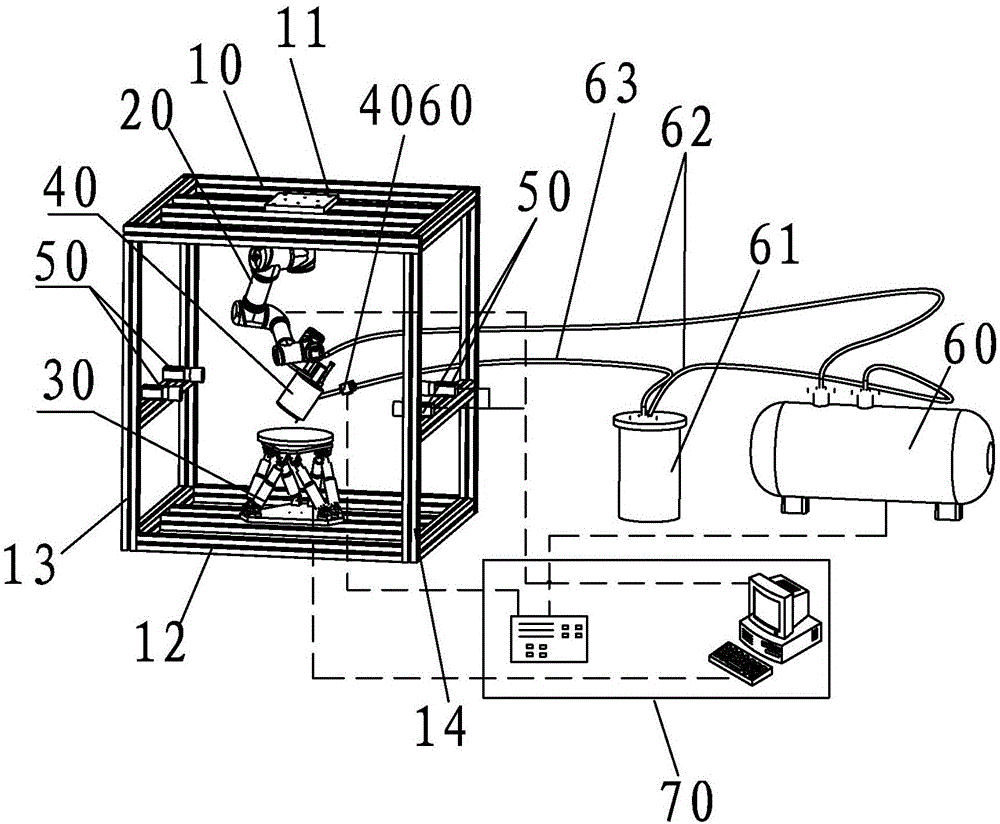

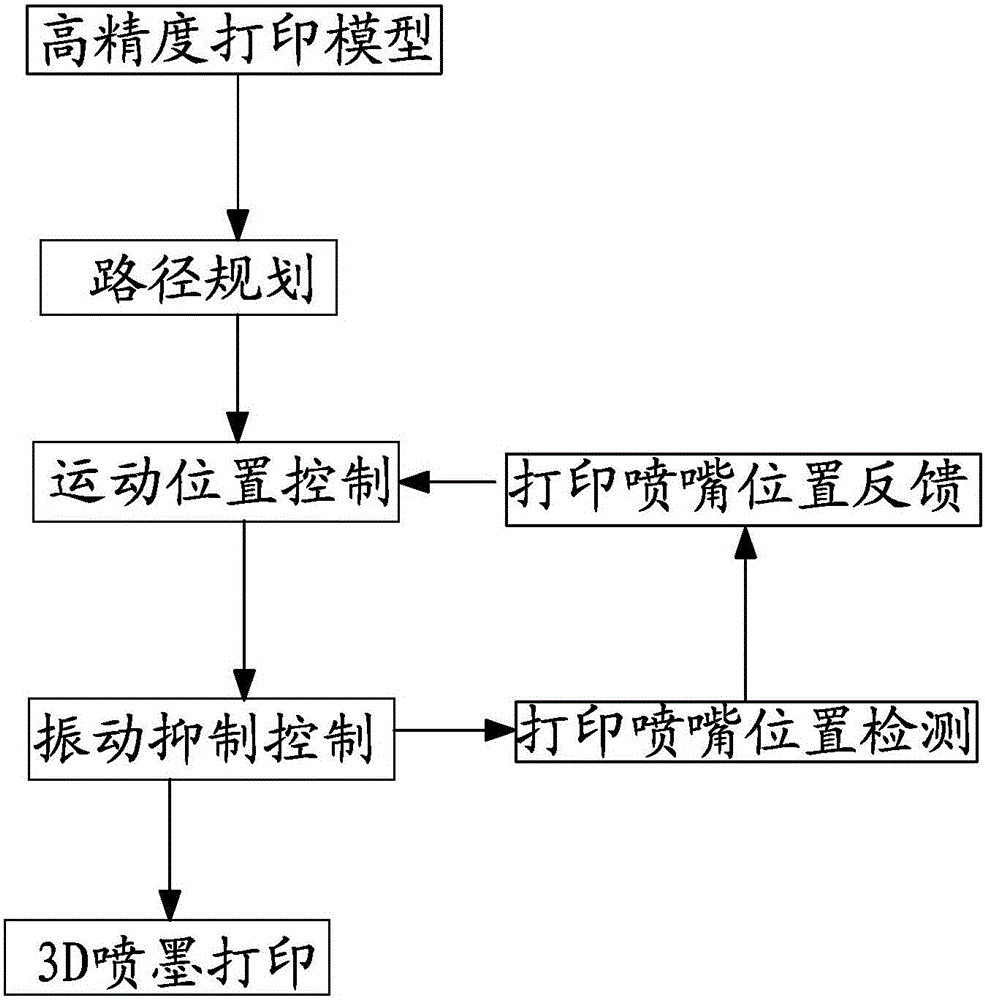

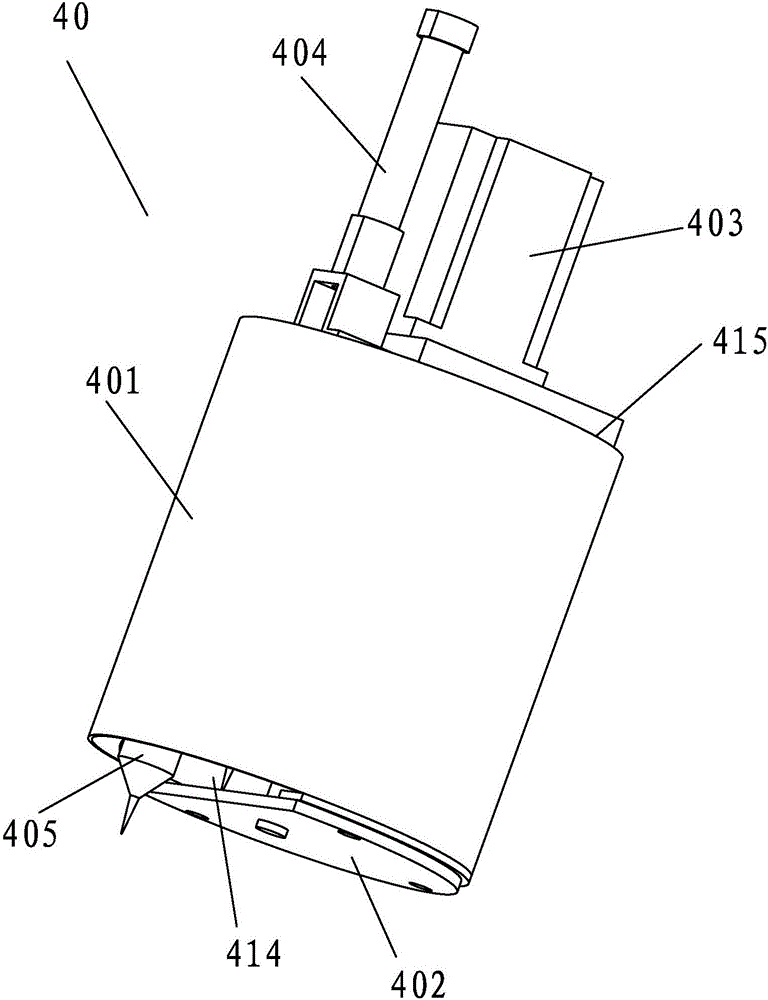

3D printing system based on multi-axis linkage control and machine vision measurement

ActiveCN106264796ARealize 3D patterned printingSimple structureManufacturing driving meansBone implantMachine visionControl system

The invention relates to a 3D printing system based on multi-axis linkage control and machine vision measurement. The 3D printing system comprises a rack, a workbench for placing an artificial bone scaffold, a printing device arranged above the workbench, a material conveying device for conveying a printing material, an image collection camera, a drive mechanism for adjusting the direction of the printing device and a control system, wherein the printing device, the material conveying device, the image collection device and the drive mechanism are all connected with the control system; the workbench is a six-degree-of-freedom parallel platform connected with the rack; the drive mechanism is a six-axis mechanical arm; and the printing device is connected with the six-axis mechanical arm. When in use, the artificial bone scaffold is put on the six-degree-of-freedom parallel platform, and the position of the printing device is controlled by the six-axis mechanical arm; and through the cooperation between the six-degree-of-freedom parallel platform and the six-axis mechanical arm, accurate control on the spatial position of a printing nozzle of the printing device is realized, and three-dimensional pattern printing is realized on a complicated tiny artificial bone surface and the internal surface of a porous structure.

Owner:QUANZHOU INST OF EQUIP MFG

Porous article of sintered calclium phosphate, process for producing the same and artificial bone and histomorphological scaffold using the same

InactiveUS20050049715A1Good fluidity of powderPoor adhesionBone implantJoint implantsPorosityCalcium biphosphate

The present invention provides porous material of calcium phosphate of high strength whose open pores penetrate the porous body and have a size of 70 μm or more, preferably 100 μm or more, and are arranged in a three-dimensional network, whose porosity is sufficiently high for blood vessels to invade and perforate itself or for cells to infiltrate itself, whose chemical composition, in particular, Ca / P molar ratio can be freely changed within the range of 0.75 to 2.1, to which elements important for facilitating osteogenesis and producing resorbable effect can be added, and whose phase composition can be relatively easily changed. The invention is porous sintered compact of calcium phosphate which has artificially formed, penetrated open pores 70 μm to 4 mm in diameter, whose porosity is from 20% to 80%, and whose chief ingredient is calcium phosphate having a Ca / P molar ratio of from 0.75 to 2.1.

Owner:NAT INST OF ADVANCED IND SCI & TECH

High-strength collagen base artificial bone repair material

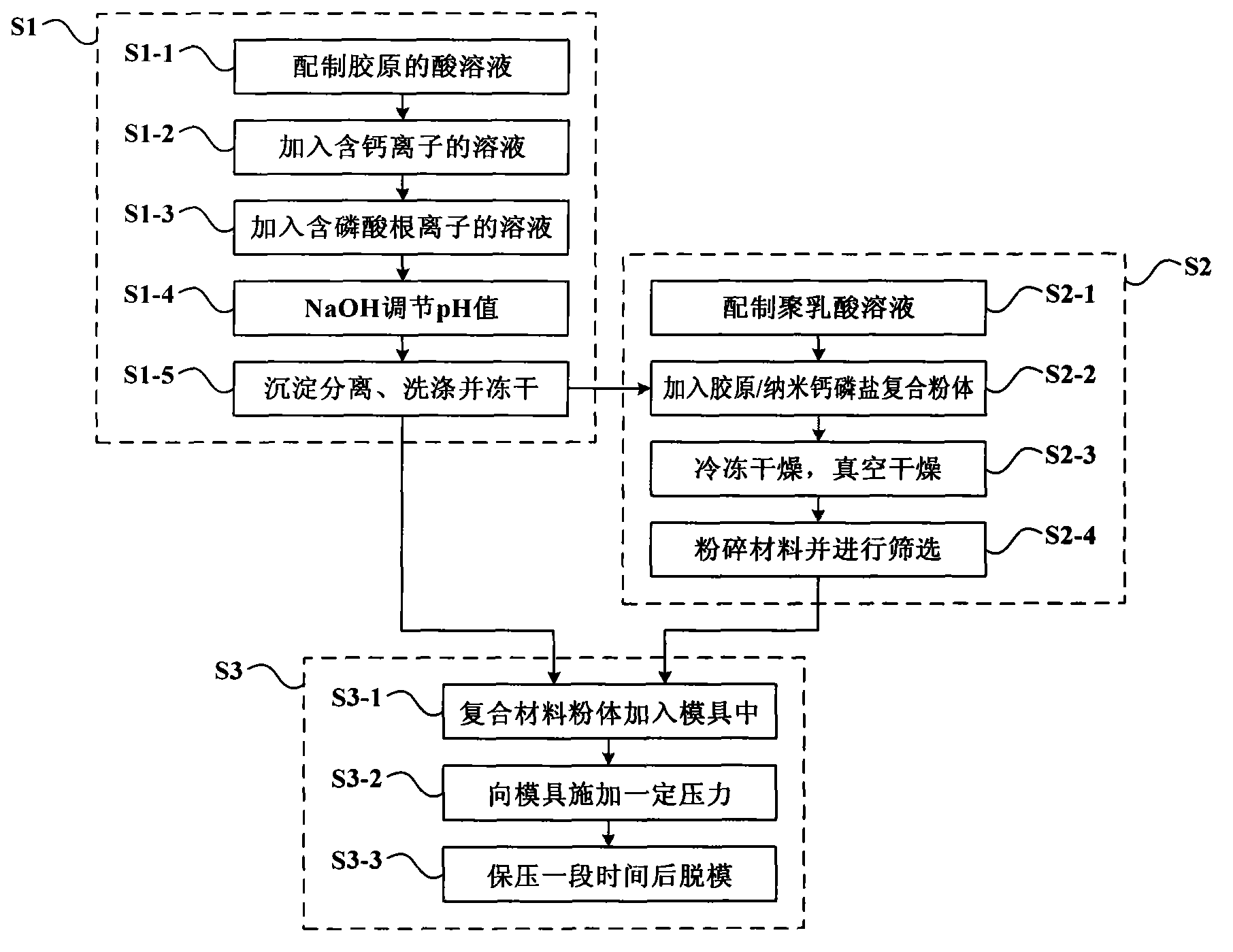

ActiveCN103830775AImprove mechanical propertiesImprove biological activityProsthesisHuman bodyBone Cortex

The invention provides a high-strength collagen base artificial bone repair material which can be used for repairing the bone defect of bearing parts of a human body. The high-strength collagen base artificial bone repair material has chemical composition and structure formed by self-assembly of nanometer calcium phosphate and collagen molecules, so that the high-strength collagen base artificial bone repair material has a biomimetic mineralization structure similar to the natural bone tissue of the human body. In terms of mechanical properties, the material has the mechanical strength similar to that of the cortical bone of the human body and can be used for repairing the bone defect of the bearing parts of the human body. The invention also provides a preparation method of the high-strength collagen base artificial bone repair material.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

New-type of inorganic bone grafting material and its prepn and use

InactiveCN101020085AGood biocompatibilityPromote degradationProsthesisSulfateBiocompatibility Testing

The present invention is one kind of new inorganic bone grafting material and belongs to the field of medical material. The inorganic bone grafting material consists of beta-tricalcium phosphate grain in 20-80 wt% and alpha-calcium sulfate semihydrate powder in 20-80 wt%, and the alpha-calcium sulfate semihydrate powder form layered structure in the surface and / or pores of beta-tricalcium phosphate grain. Both beta-tricalcium phosphate and alpha-calcium sulfate semihydrate have excellent biocompatibility and excellent in vivo degrading performance, and the composite artificial bone grain may be used in repairing bone defect of different shapes. The composite artificial bone grain has wide material source, convenient use, excellent performance, simple preparation process, low cost and other advantages.

Owner:GENERAL HOSPITAL OF PLA

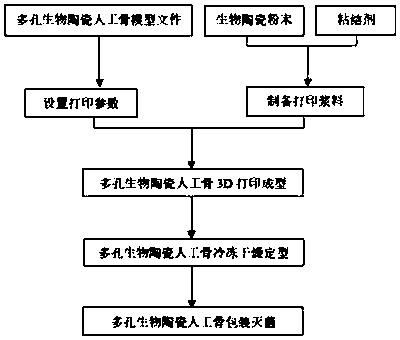

3D printing bionic porous biological ceramic artificial bone and preparation method thereof

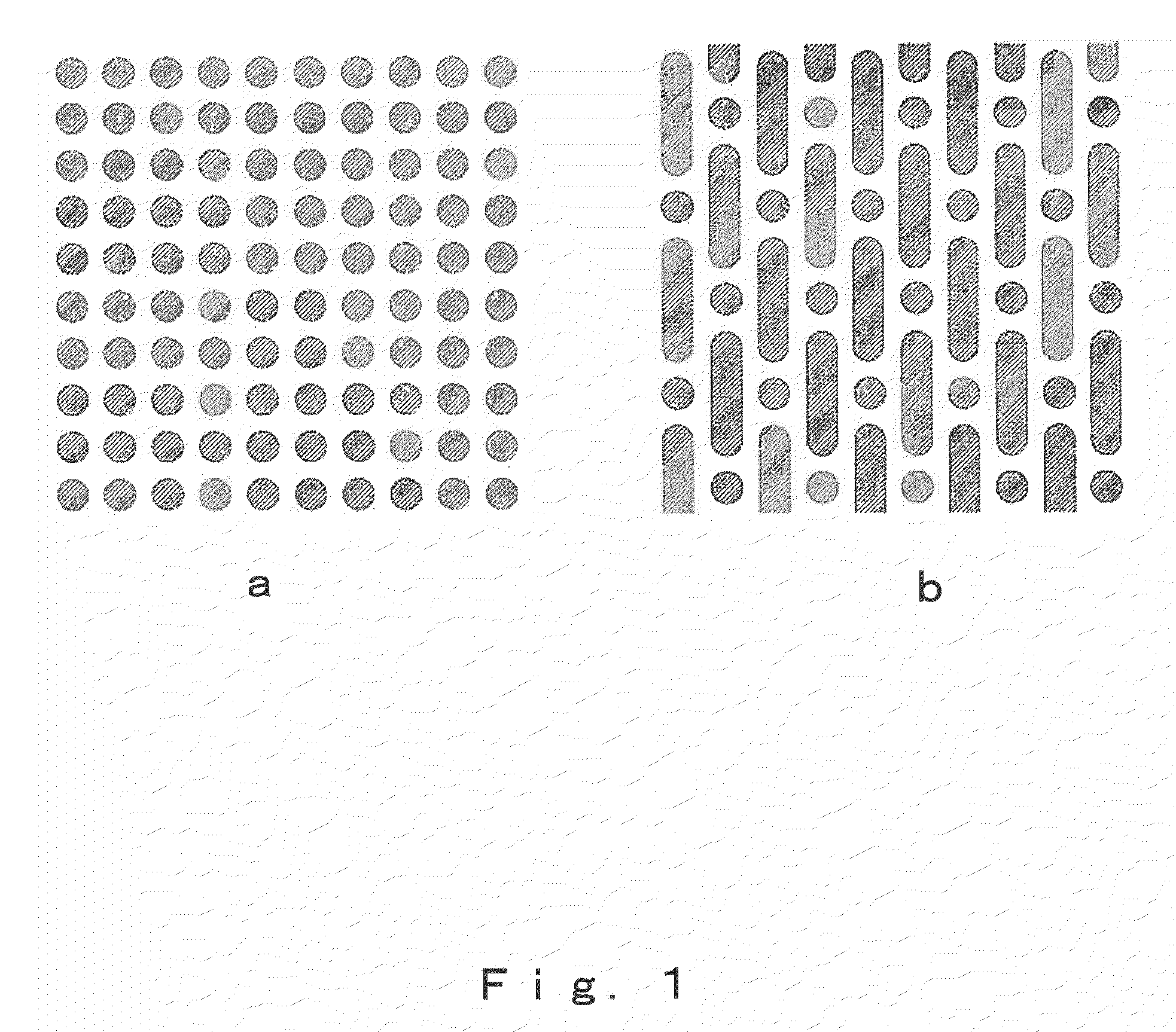

ActiveCN111070376APrecise porosity controlGood molding propertiesAdditive manufacturing apparatusBone implantHuman bodyTissue fluid

The invention discloses a 3D printing bionic porous biological ceramic artificial bone and a preparation method thereof. A porous biological ceramic artificial bone model is designed through a TPMS and CSG combined method, slurry capable of being used for printing is prepared through biological ceramic powder and a binding agent, macropores and micropores are distributed in the porous biological ceramic artificial bone prepared through the combination with the 3D filament-free printing process, the pore diameter of the micropores is smaller than 100 micrometers, the pore diameter of the macropores is 200-800 micrometers, the total porosity is 20% to 80%, the communicating rate between the macropores is not lower than 99%, precise design of porosity, communication and homogeneity in the artificial bone is achieved, and meanwhile good pore communication is ensured. Adopted raw materials have good biocompatibility, entry passageways of cells and tissue fluid are provided by the macropores, the micropores can better adsorb tissue fluid nearby for cell growth, the cell growth speed and the new bone generation speed can be increased by combining the micropores with the marcropores, and application of the porous biological ceramic artificial bone in human body large bone defect repair clinic treatment is facilitated.

Owner:西安点云生物科技有限公司

Composite technique of preparing lacunaris titanium coating by using cold spraying and vacuum sintering

InactiveCN101032633AGood pore uniformityHigh bonding strengthImpression capsSurgeryArtificial boneTitanium alloy

The present invention discloses composite cold spraying and vacuum sintering process for preparing porous titanium coating. Mixed titanium-magnesium powder is first sprayed onto the roughened titanium or titanium alloy substrate to form composite titanium-magnesium coating, which is then sintered at high vacuum and high temperature to obtain porous titanium coating. Thus produced porous titanium coating has no oxide, thickness greater than 0.5 mm, opened and communicated pore structure, pores of 30-200 microns, porosity of 30-65 %, and metallurgical combination with the substrate with combination strength higher than 60MPa and elastic modulus adjustable in 30-50 GPa. The present invention is suitable for making bearing hard tissue implant, such as artificial joint, artificial bone, artificial tooth root, etc. with improved long term stability.

Owner:XI AN JIAOTONG UNIV

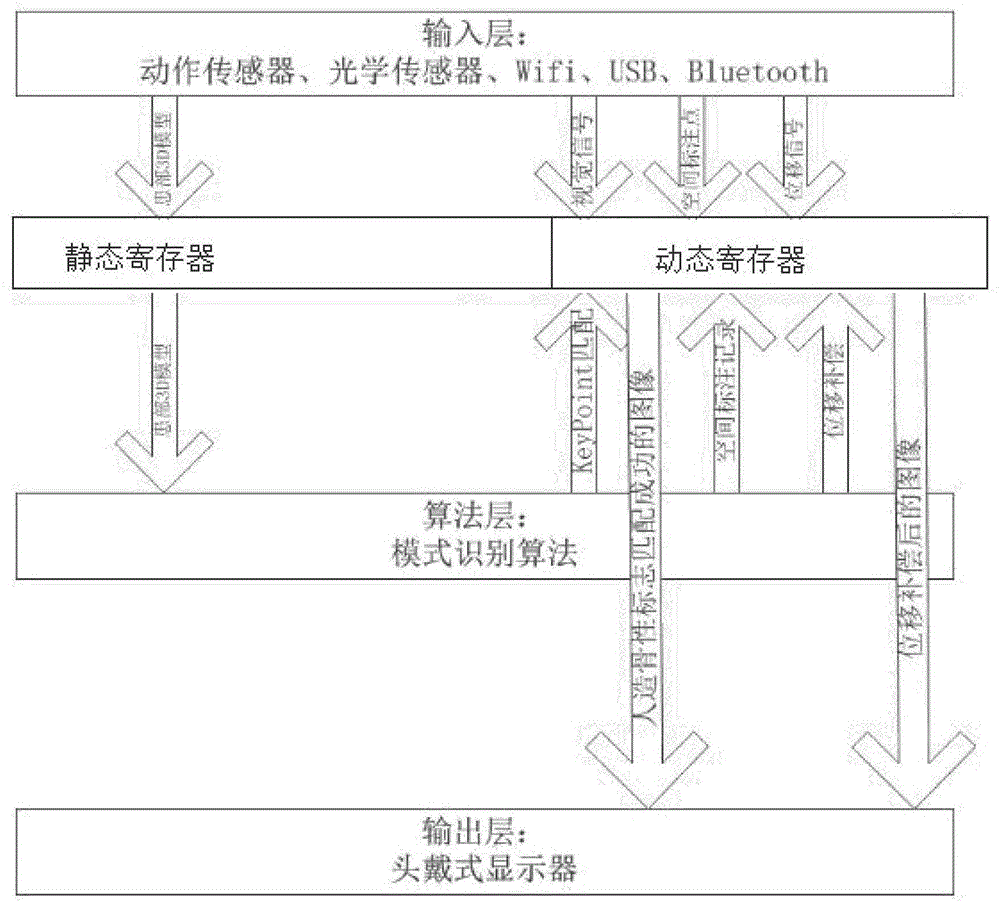

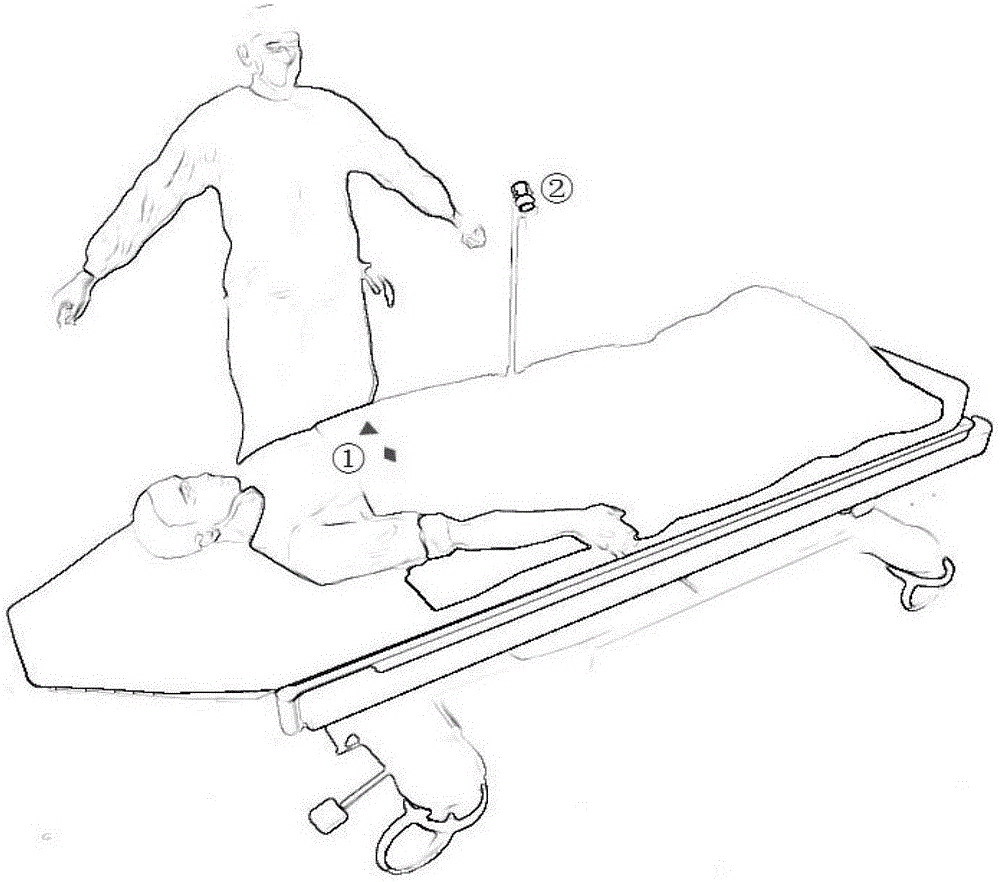

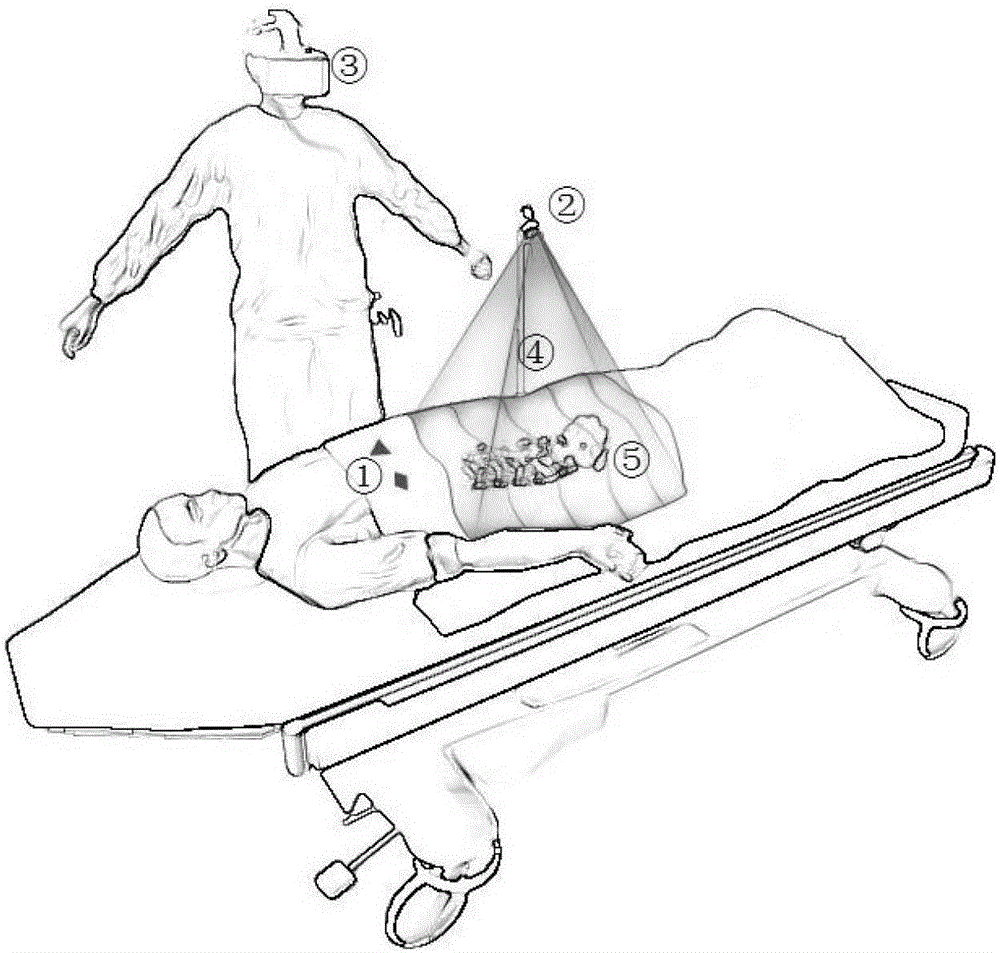

Head-mounted medical system and operation method thereof

InactiveCN106109015AImprove securityFunctionalDiagnosticsComputer-aided planning/modellingComputed tomographyDisplay device

The invention discloses a head-mounted medical system and an operation method thereof; the head-mounted medical system comprises an AR / MR head-mounted display device and a laser generator; the operation method comprises the following steps: wearing the AR / MR head-mounted display device on a doctor head; erecting the laser generator above an operating table; making artificial bone marks on a patient body surface; allowing the laser generator to irradiate on the body surface of the patient disease portion; inputting a CT scanned disease portion 3D model into the AR / MR head-mounted display device; allowing the doctor to wear and start the AR / MR head-mounted display device, to aim the visual line at the artificial bone mark, and to wear a camera in the AR / MR head-mounted display device to observe and identify the artificial bone mark; displaying the disease portion 3D model on the corresponding position of the patient body; allowing the doctor wearing the AR / MR head-mounted display device to randomly walk around the operating table, thus observing the disease portion 3D model, and guiding the operation. Compared with the prior art, the head-mounted medical system and the operation method thereof are more effective and direct, higher in safety, and stronger in functionality.

Owner:上海瓴舸网络科技有限公司

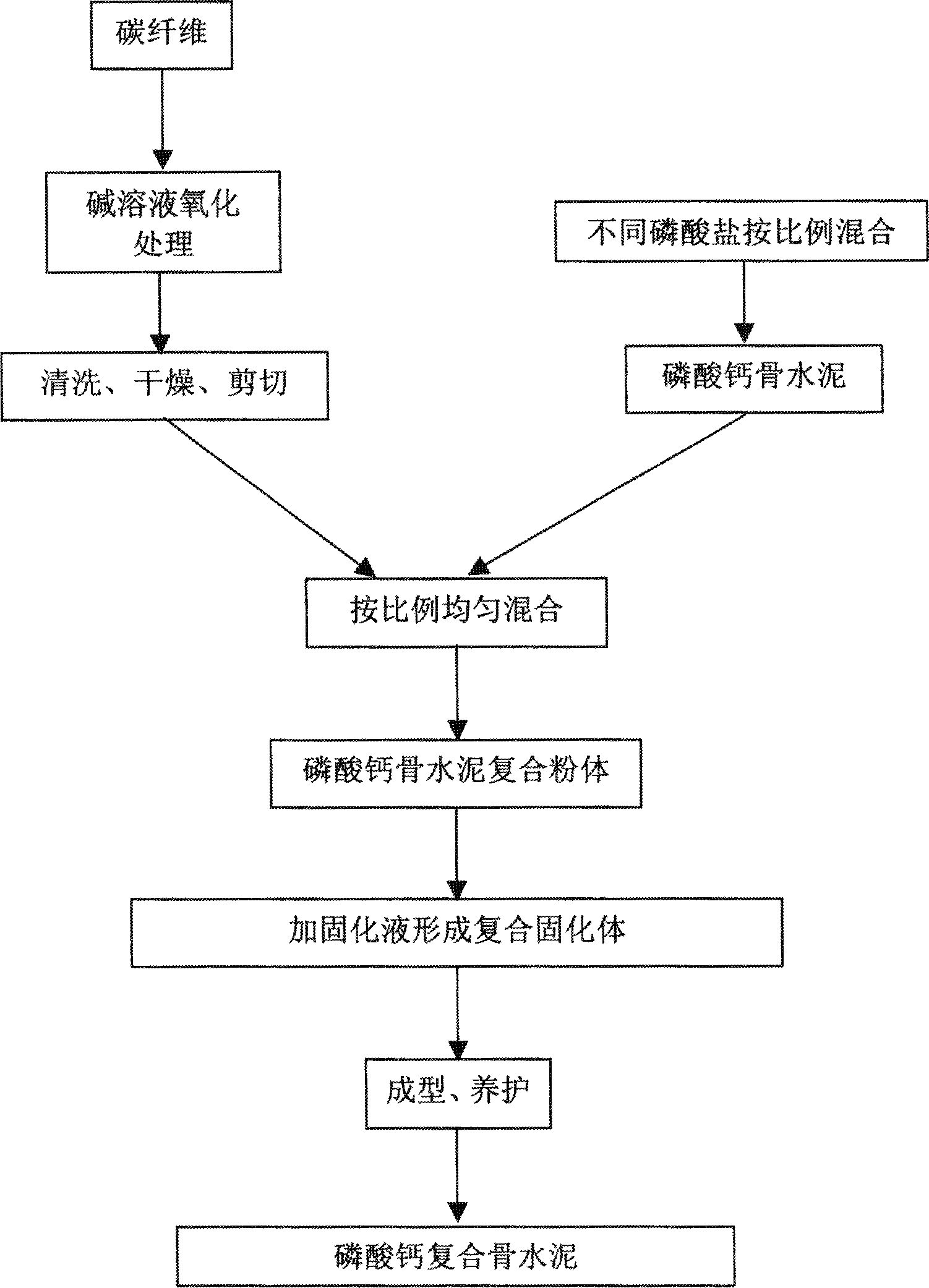

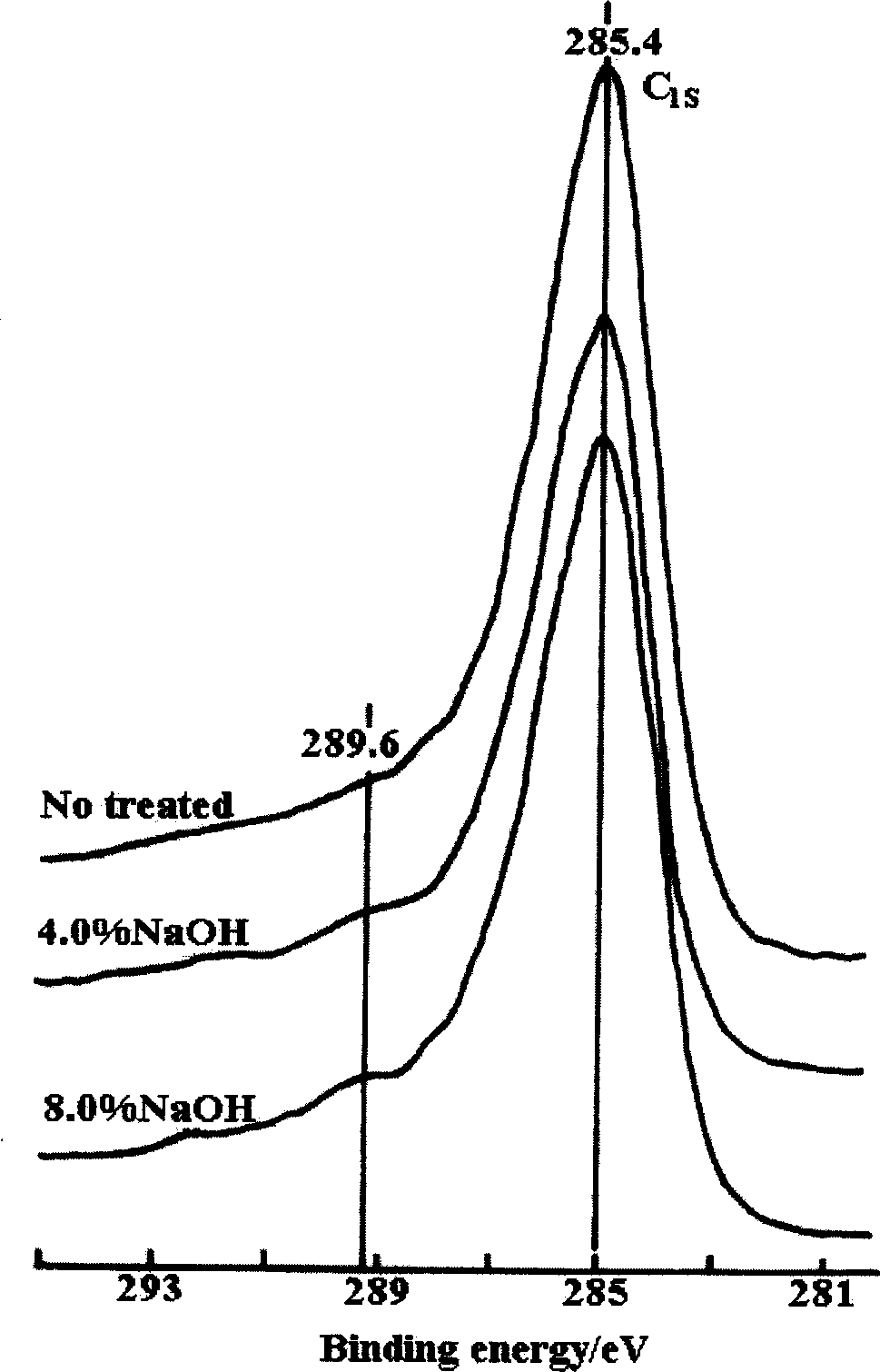

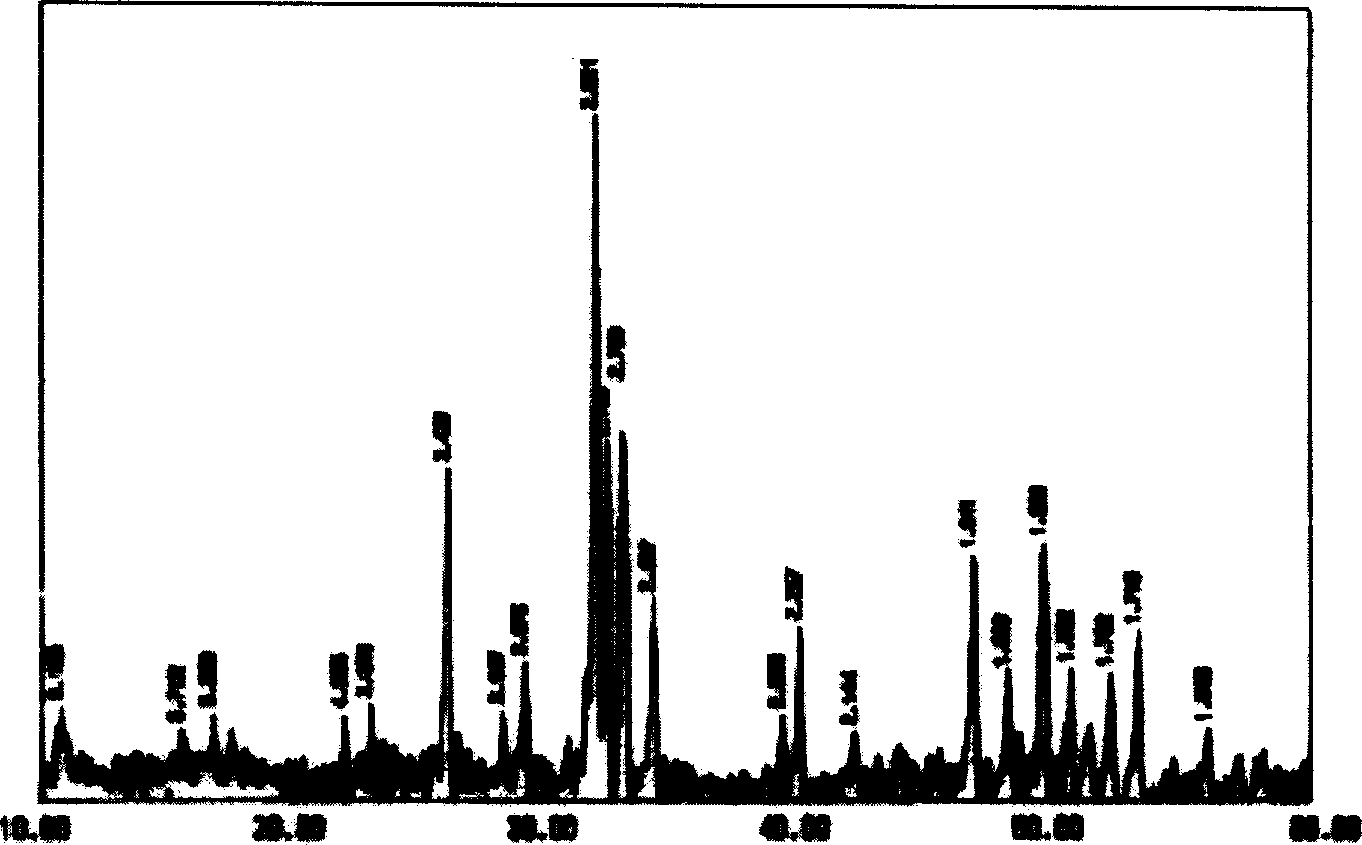

Preparation method of calcium phosphate composite bone cement

A composite calcium phosphate cement for preparing artificial bone is prepared through immersing carbon fibres in NaOH solution, heating at 70-90 deg.C for 2-3 hr, flushing, drying, shearing short, proportionally mixing it with calcium phosphate cement, stirring to obtain composite powder, proportionally mixing it with solidifying liquid, stirring, moulding and curing.

Owner:WUHAN UNIV OF TECH

Method for preparing gradient porous ceramic by using centrifugal freeze drying technology

ActiveCN103896624AReduce residual stressImprove mechanical propertiesCeramicwareFreeze-dryingAdhesive

The invention discloses a method for preparing a gradient porous ceramic by using centrifugal freeze drying technology. The method comprises the following steps: firstly, preparing ceramic slurry by using ceramic powder, distilled water, a dispersing agent and an adhesive, injecting the ceramic slurry into a mold, centrifugally rotating, directionally freezing, drying under low pressure and sintering to obtain a porous ceramic of which the porosity shows continuous gradient change. The gradient porous ceramic prepared by the method is of an 'inner sparse, outer dense' bionic structure; the porosity shows continuous gradient change from inside to outside; the gradient porous ceramic has small residue stress, good mechanical property and good stability, can be widely applied to fields such as filtering materials, catalyzer carriers, vibration-absorptive materials, fuel cells, artificial bone substitute materials and drug release carriers.

Owner:XIAN UNIV OF TECH

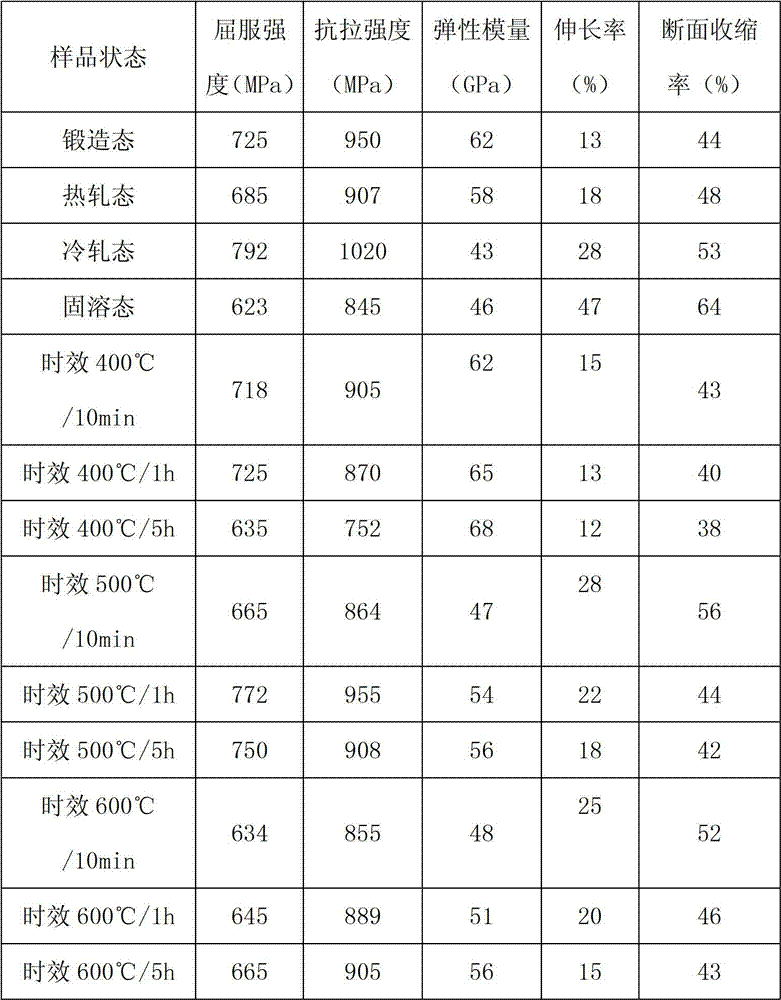

Metastable beta titanium alloy with low elastic modulus and preparing method thereof

The invention relates to a titanium alloy material, in particular to a multi-functional biomedical metastable beta titanium alloy material with excellent processing performance, and belongs to the technical field of titanium alloy material preparation. The alloy contains the following ingredients by mass: 18-27% of Nb, 0.5-2% of Mo, 3-5% of Zr, 7-9% of Sn, 0.1-0.3% of O and the balance of Ti. The titanium alloy has excellent comprehensive performance, and the strength and the elastic modulus of the alloy can be regulated through different thermal treatments. The elastic modulus E of the alloy is 40-7 3GPa, the yield strength sigma 0.2 is 260-864 MPa, the tensile strength sigma b is 686-1094 MPa, the elongation rate epsilon = 4-20%, and the facture surface shrinkage rate is 20-52%. The titanium alloy does not contain toxic elements, such as Al and V, and has excellent corrosion resistance, biocompatibility and cold processing performance. The titanium alloy can be used for manufacturing tissue repairing or substituting materials, such as artificial bones, artificial joints and bone plates.

Owner:BAOJI TITANIUM IND +1

Method for strengthening and toughening biological ceramic material by use of graphene and preparing artificial bone prepared from material

InactiveCN103656752AHigh strengthImprove toughnessProsthesisCalcium silicateSelective laser sintering

Aiming at the problems of low strength and low toughness of bioactive ceramics, the invention provides a method for strengthening and toughening a bioactive ceramic material by use of graphene and preparing graphene / biological ceramic artificial bone by a selective laser sintering (SLS) technology. The method has the advantages that graphene is added into the bioactive ceramic (hydroxylapatite, calcium phosphate, bioglass, calcium silicate and the like) as a nano enhanced phase, and the strength and toughness of the ceramic can be remarkably improved by use of the excellent mechanical property of graphene; the SLS technology is applied to the preparation process of graphene / biological ceramic artificial bone, and the sintering time can be shortened to the second level and even millisecond level by use of the characteristic of quick heating and cooling of laser so as to avoid structural injury of graphene caused by long-time high-temperature effect. The method for strengthening and toughening the ceramic material by use of graphene provided by the invention is of great significance to the application of bioactive ceramic to the load bearing parts of the human body.

Owner:CENT SOUTH UNIV

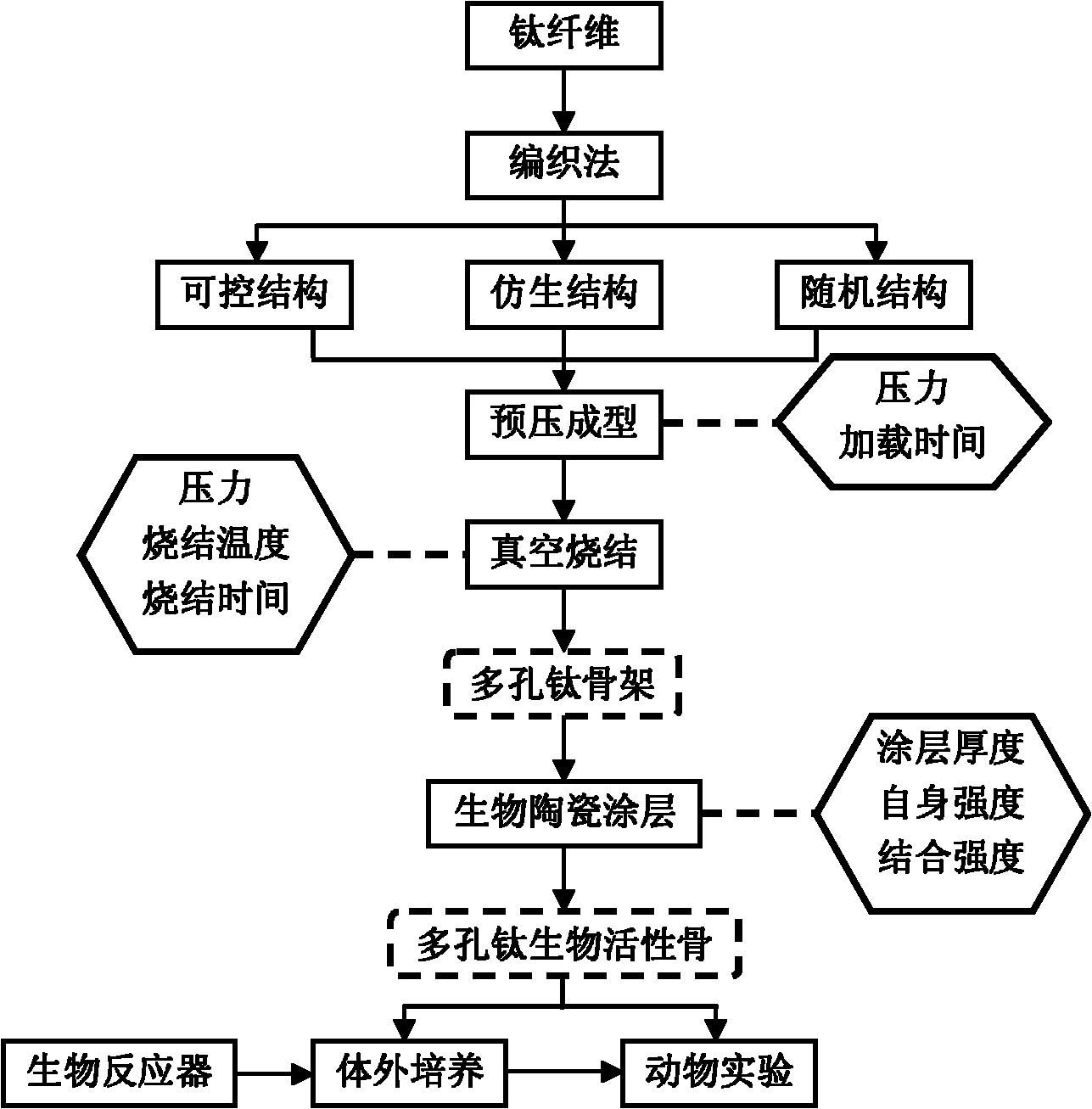

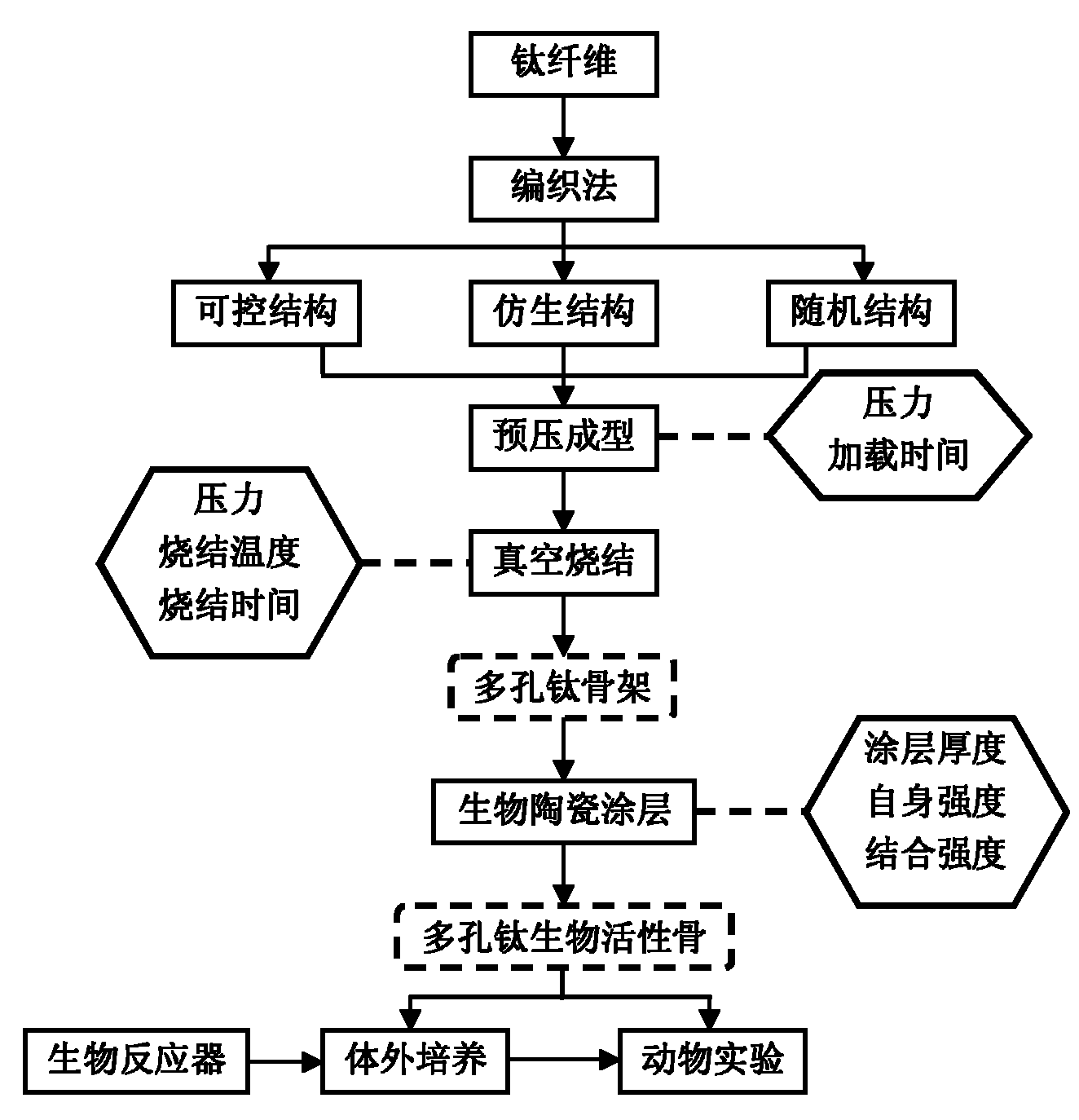

Preparation method of bio-ceramic coating titanium-wire sintering porous titanium artificial bone

InactiveCN101889912AHave biological propertiesBiologically activeBone implantCoatingsFiberPrincipal stress

The invention discloses a preparation method of a bio-ceramic coating titanium-wire sintering porous titanium artificial bone, belonging to the biomedical engineering field. In the invention, a three-dimensional weaving method is utilized, a titanium metal fiber wire is constructed into a controllable structure model, a random structure model and a bionic structure model which can stimulate the bone trabecula and principal stress line of a human bone, and then is prepared into the porous titanium artificial bone through prepressing molding and vacuum sintering, after that, a sol-gel method is utilized to manufacture a gradient coating or a complex coating on the surface of the porous titanium artificial bone, so that the gradient coating transiting from titanium dioxide to bio-ceramics or the bio-ceramics-titanium dioxide complex coating is formed on the surface of the porous titanium artificial bone to obtain the bio-ceramic coating titanium-wire sintering porous titanium artificial bone. The preparation method not only can protect the titanium metal skeleton and prevent titanium ions from dissociating to enter a human body, but also can ensure that the titanium metal skeleton the surface of which is coated with the bio-ceramics has the biological characteristics, therefore, the bio-ceramic coating titanium-wire sintering porous titanium artificial bone can be applied to repairing clinical segmental defect of long bones.

Owner:SHANGHAI JIAO TONG UNIV

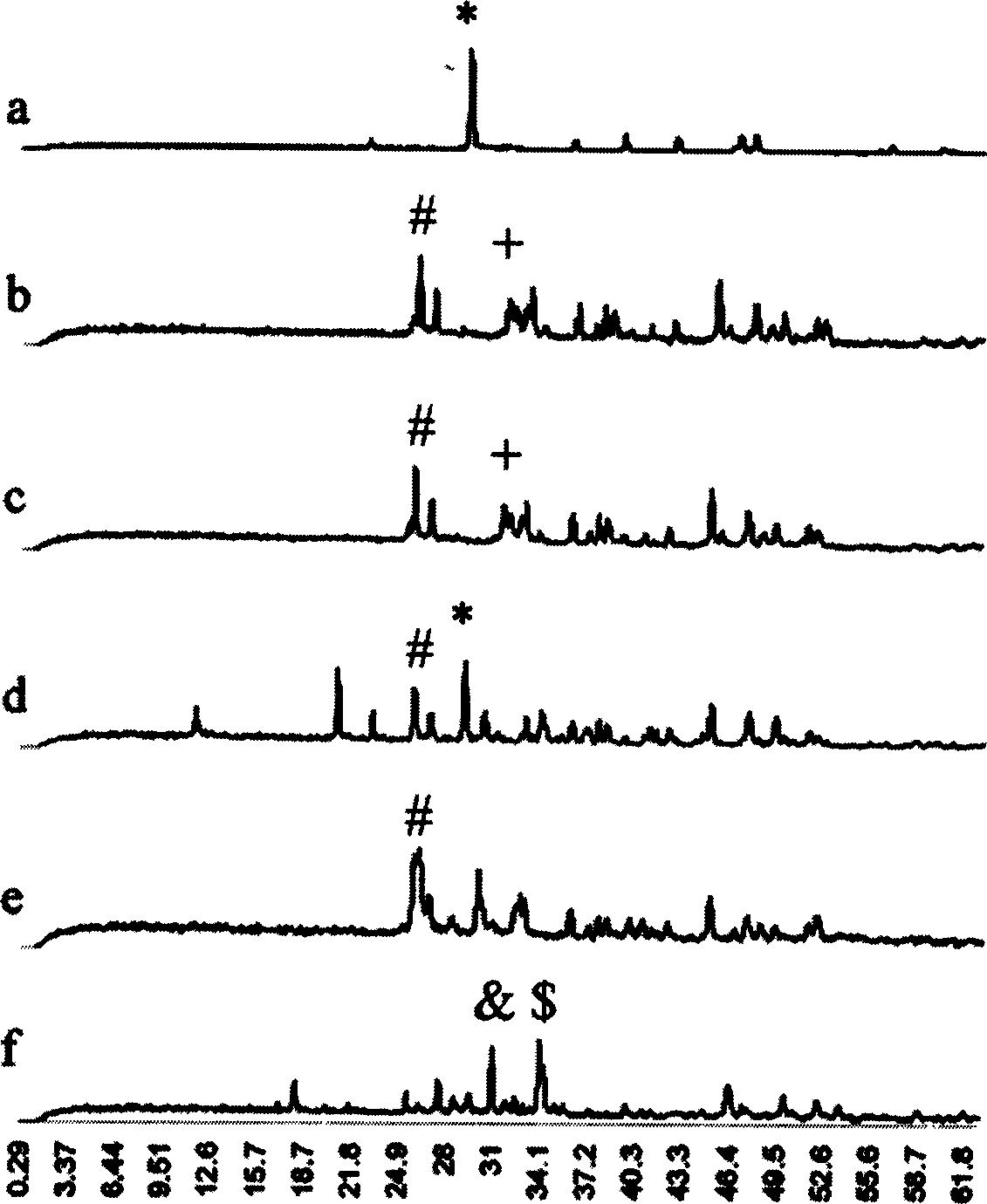

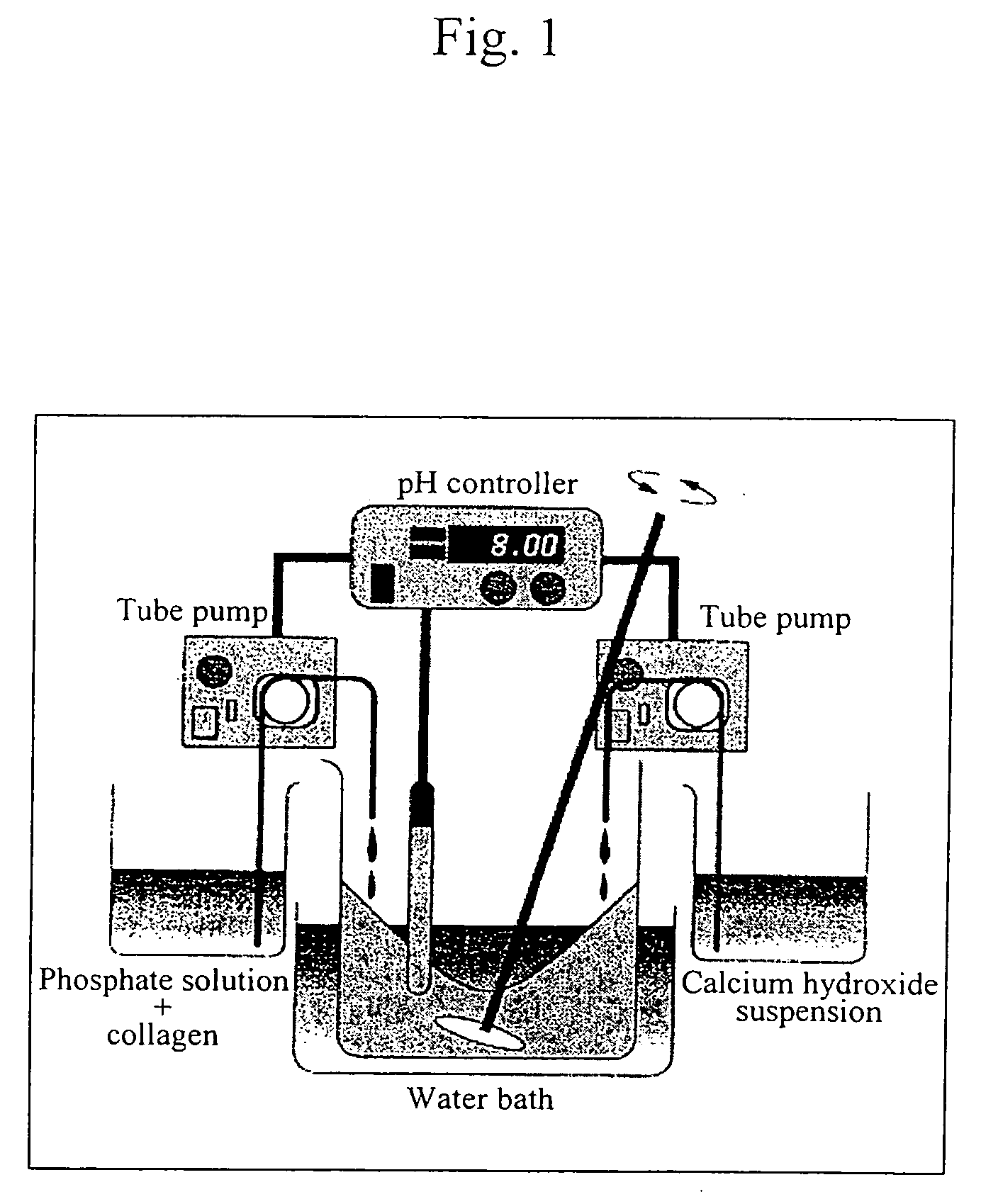

Organic/inorganic composite biomaterials and process for producing the same

This invention provides organic / inorganic composite biomaterials constituted by composites of hydroxyapatite and collagen and having an average fiber length of 60 μm or longer, and a process for producing the same in which the calcium ion and phosphate ion concentrations in the reaction vessel are optimized through regulation of the concentration of a starting material and the flow rate. The organic / inorganic composite biomaterials have mechanical strength and a biodegradation rate suitable for artificial bones through the introduction of crosslinking therein.

Owner:JAPAN SCI & TECH CORP +2

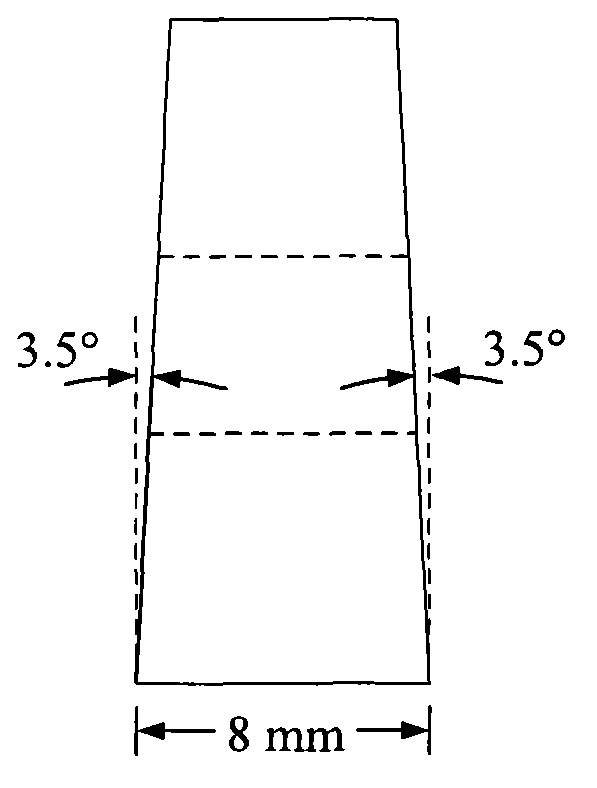

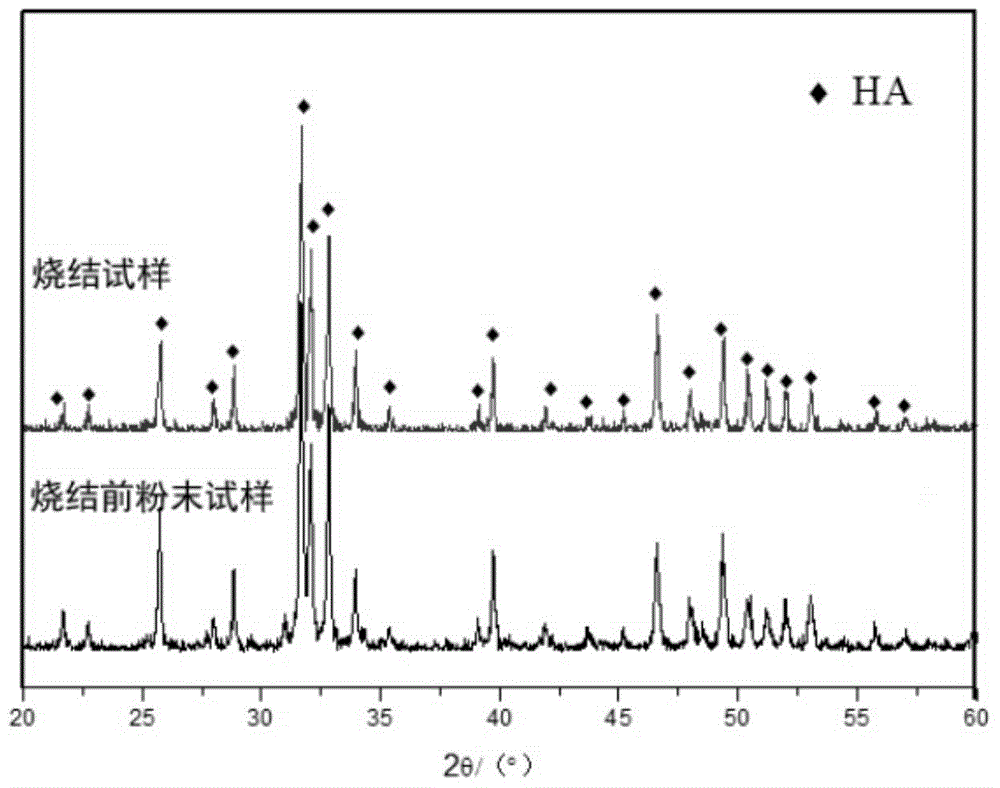

Method for preparation of bone hydroxyapatite-imitating bone repair material

The invention discloses a method for preparation of a bone hydroxyapatite-imitating bone repair material, nano hydroxyapatite ceramic powder and NH4HCO3 powder are mixed proportionally, after mixing, the powder is loaded into a gradient mold for mechanical pressing into a block pressed blank, the block pressed blank is put into a discharge plasma sintering furnace, heated to 950 DEG C and 1050 DEG C in the heating rate of 100 DEG / min, and then kept warm for 10-20min, and after demoulding, a nano scale bone gradient-imitating porous hydroxyapatite bone repair material is obtained. The nano scale bone gradient-imitating porous hydroxyapatite bone repair material is prepared by the method comprises outer and inner two layers, the porosity is 34% to 80%, and the pore scale is controllable in the range of 100-500mum, and the nano scale bone gradient-imitating porous hydroxyapatite bone repair material has the advantages of fine grain size, composition purity, no residual pore former, controllable mechanical properties and degradation rate and the like, and can be used as a good artificial bone tissue repair material.

Owner:FIRST PEOPLES HOSPITAL OF YUNNAN PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com