Method for strengthening and toughening biological ceramic material by use of graphene and preparing artificial bone prepared from material

A technology of bioceramics and bioactive ceramics, applied in medical science, prosthesis, etc., can solve problems such as low strength and poor toughness, achieve good product performance, improve strength and toughness, and avoid structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention is set forth below by an example:

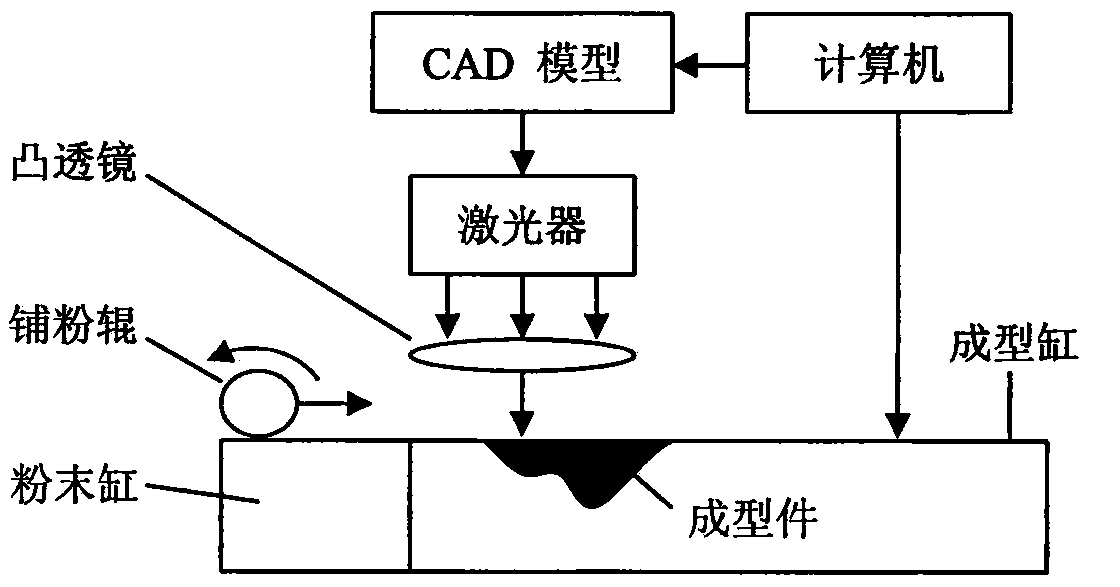

[0018] Using single-layer graphene and β-tricalcium phosphate (β-TCP) ceramic powder as raw materials, the single-layer graphene (JCG-2, Nanjing Jicang Nano Technology Co., Ltd.) has a diameter of 0.8-3 μm and a thickness of 0.8-1.2 nm, purity 99.8%; β-TCP (Kunshan Overseas Chinese Technology New Material Co., Ltd.) has a calcium-phosphorus ratio of 1.50±0.03, an average particle size of 200nm, and a purity of 98%. A uniformly mixed graphene / β-TCP mixed powder was obtained after grinding for 30 min by mechanical mixing, wherein the mass fraction of graphene was 1 wt%. Using the self-developed selective laser sintering system, the graphene / β-TCP mixed powder was sintered and formed under the process conditions of laser power 10W, scanning speed 100mm / min, spot diameter 1mm, and powder coating thickness 0.2mm. After the sintering is completed, the artificial bone is taken out from the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com