Patents

Literature

1166results about How to "Short sintering time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of fine-grained WC-based cemented carbide material and preparation method thereof

A fine-grained WC-based cemented carbide material and a preparation method thereof. The fine-grained WC-based cemented carbide material uses fine-grained WC as a matrix, Mo or Ni as a binder, and TaC, VC, One or more types of TiC are grain inhibitors, Cr3C2 is used as a hardener, and C, SiC or rare earth metals are used as a toughener. The size of fine-grained WC is 0.8-1μm. WC of this size can It brings about an increase in hardness and flexural strength. This cemented carbide material provides an alternative to Co and has high hardness, good toughness, and excellent comprehensive wear resistance.

Owner:四川欧曼机械有限公司

Method for preparing graphene reinforced metal-based composite material through discharge plasma (SPS) sintering

The present invention relates to a method for preparing a graphene reinforced metal-based composite material through discharge plasma (SPS) sintering. The method is characterized in that the graphene reinforced metal-based block material is prepared through SPS sintering and has the following advantages that: the preparation method is simple, the material is compact and does not have pores, the graphene mass fraction can be arbitrarily regulated, the distribution is uniform, no aggregation is generated, the material mechanical property isotropy is provided, and the wettability of the metal and the graphene interface is good. The method comprises: (1) reducing graphene oxide through a chemical method or a hydrothermal method to obtain graphene sheets with a sheet layer thickness of not more than 4 nm and sheet layer diameter of not more than 50 [mu]m; and (2) preparing metal powder with a particle size of not more than 200 [mu]m through a rotating electrode atomization method, mechanical crushing or a high-speed ball milling method; (3) carrying out mechanical or ball milling mixing on the graphene powder and the metal powder according to the required mass ratio; and (4) carrying out SPS sintering forming on the mixed powder, wherein the obtained material has characteristics of improved mechanical property, decreased density, good heat conduction capability, and good electric conduction capability, and the performance customizing can be achieved by adjusting the preparation parameters.

Owner:BEIHANG UNIV

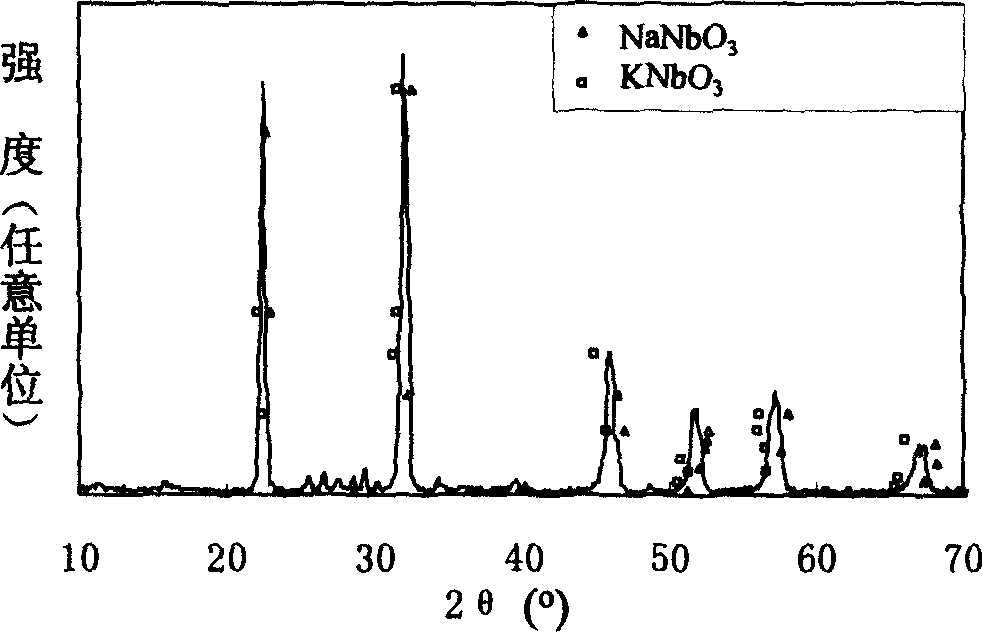

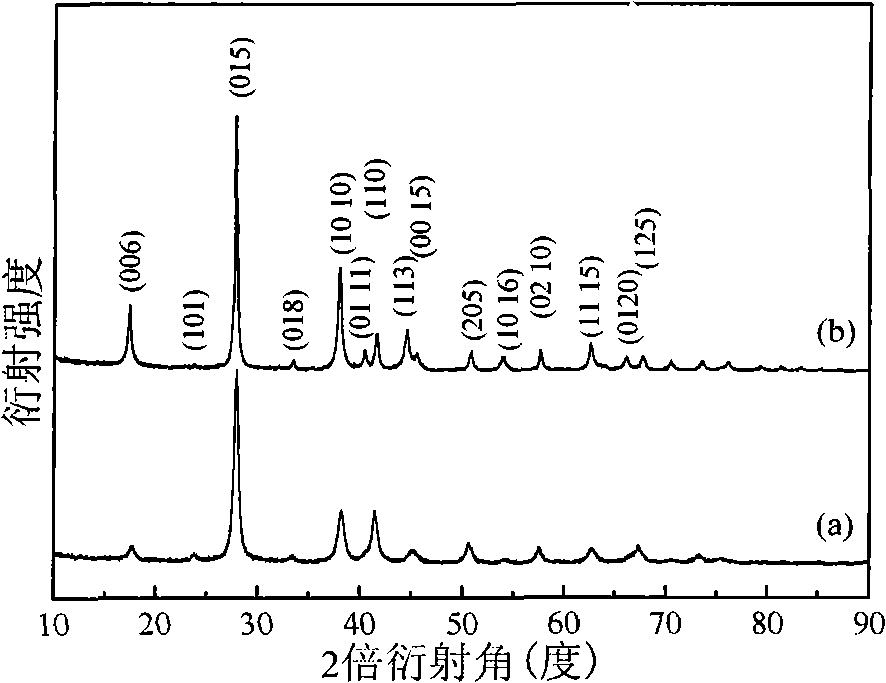

Lead free piezoelectric ceramics of potassium sodium niobate and preparation thereof

ActiveCN1644562ALower sintering temperatureShort sintering timePiezoelectric/electrostrictive/magnetostrictive devicesElectric fieldNatural state

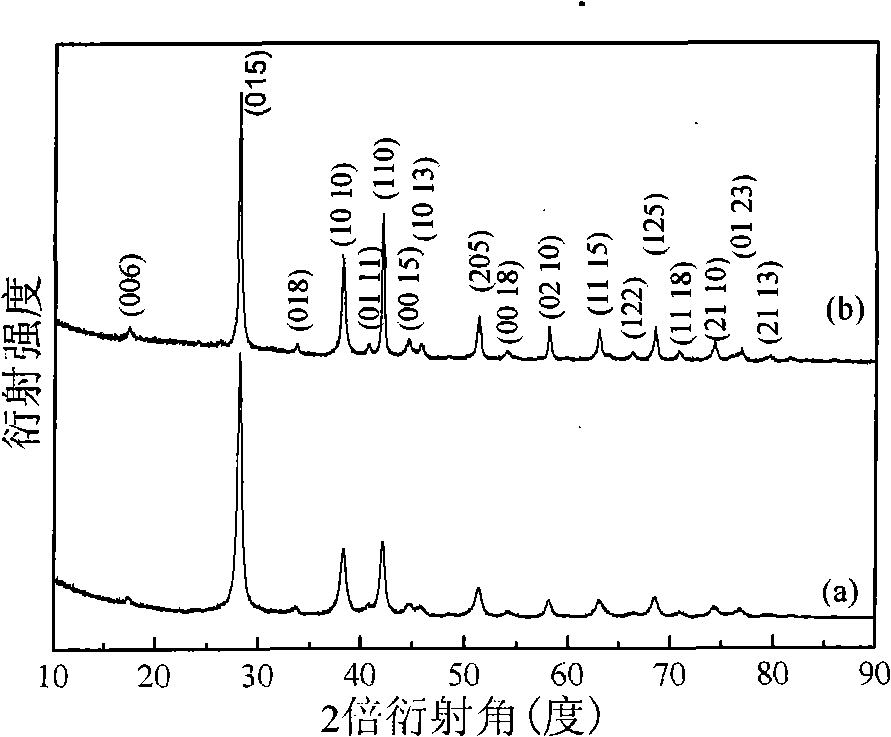

A niobic acid potassium sodium system lead-free piezoelectric ceramic and its production are disclosed. The components of the niobic acid potassium sodium system lead-free piezoelectric ceramic are (1-n)KxNa1-xNbO3.nMH, it is prepared by SPS process. The production is carried out by grinding mixing raw materials, calcining synthesizing niobate, using SPS process for the obtained powdery material, annealing treating under oxygen atmosphere, and obtaining piezoelectric / ferroelectric ceramic materials. Its advantages include lead-free composition, good piezoelectric performance, low calcining temperature, short calcining time and fine tissue.

Owner:TSINGHUA UNIV +2

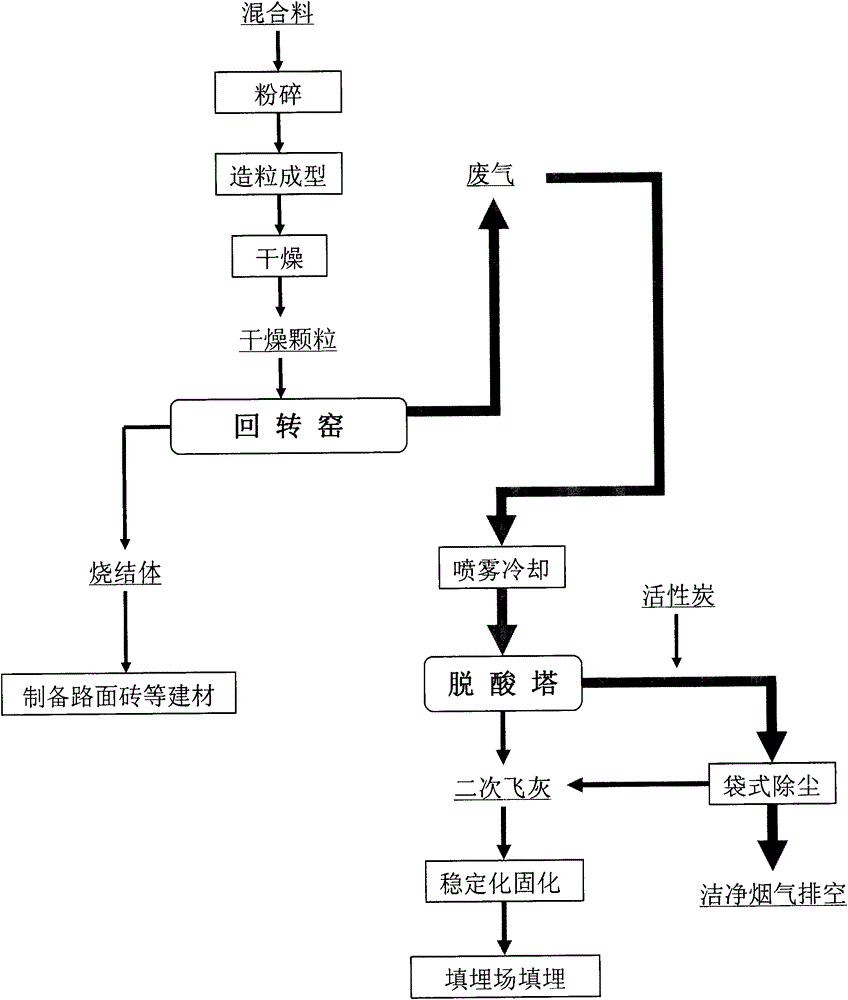

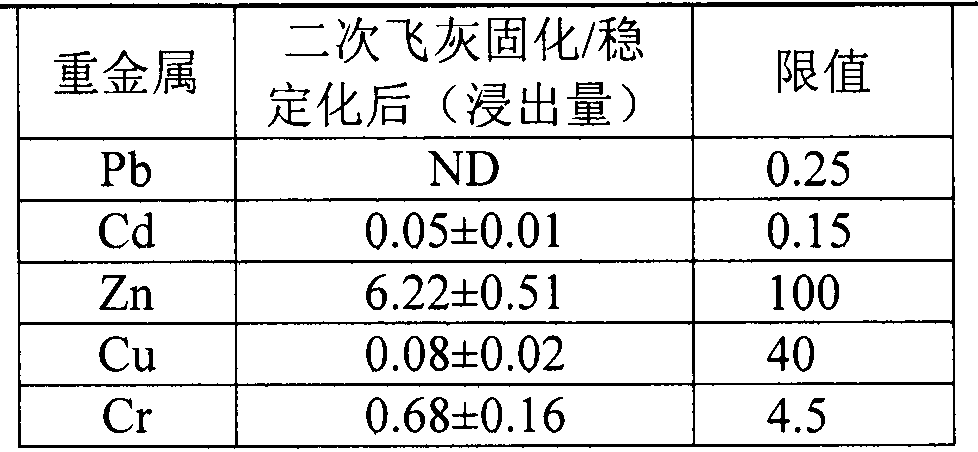

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

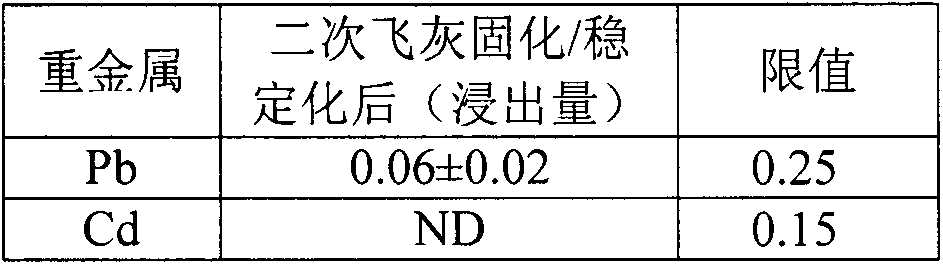

The invention relates to a garbage burning fly ash sintering harm-eliminating resource-utilization treatment technology. According to the invention, garbage burning fly ash is mixed with premixed coal and auxiliary materials; the mixture is granulated and shaped; and the material is dried and is sintered in a rotary kiln. During the sintering process, when the temperature is increased and a coal ignition point is reached, the premixed coal is spontaneously combusted. Therefore, external coal dose can be reduced. Initial combustion of the premixed coal can provide a reductive atmosphere, such that dechlorination and detoxification of dioxin in fly ash can be benefited. Large amount of gas is produced by subsequent combustion, such that dust pores and holes are produced on inner and outer parts of the sintered body, and heavy metal volatilization can be promoted, and fly ash sintered body with low heavy metal content and leaching amount can be obtained. The sintered body has no potential harm to the environment, such that fly ash harm-eliminating and resource-utilization are sufficiently realized. During the processing process, smoke and secondary fly ash production amounts are low, and heavy metal and acidic component contents are high. In deacidification and heavy metal stabilization processes, agent utilization rate is improved. Compared with a traditional original fly ash curing / stabilizing process, a landfill amount can be reduced by 80-90%, such that pressure caused by serious landfill space shortage can be effectively relieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

High-ore-matching-ratio brown iron ore sintering technology

The invention relates to a high-ore-matching-ratio brown iron ore sintering technology. The weight ratio of brown iron ore and powdered iron in raw material proportion is (5-19):1, the moisture content of the first mixing is controlled to be 7%-8%, the mixing time lasts for 2-3minutes, and the temperature of the mixture is 50-62 DEG C; the moisture content of second mixing pelletizing is controlled to be 7-9%, the pelletizing time lasts for 2-3.5minutes, and the temperature of materials is 52-65 DEG C; the thickness of grate-layer materials in distribution is 20mm, and a sintering material layer is 780-900mm thick; the ignition temperature for sintering is1050-1150 DEG C, and the ignition time lasts for 1.8-2.2minutes; and the negative pressure for sintering is 12-15kpa, the machine speed is 0.9-1.2m / min, the vertical sintering speed is 29-34mm / min, the air leakage rate is no more than 40%, the cooling negative pressure is 11-14kpa, the temperature of a cooling section of a sintering machine is reduced to 250 DEG C below. By using the high-ore-matching-ratio brown iron ore sintering technology, energy is saved, consumption is reduced, cost is decreased and benefit is increased.

Owner:唐山瑞丰钢铁(集团)有限公司

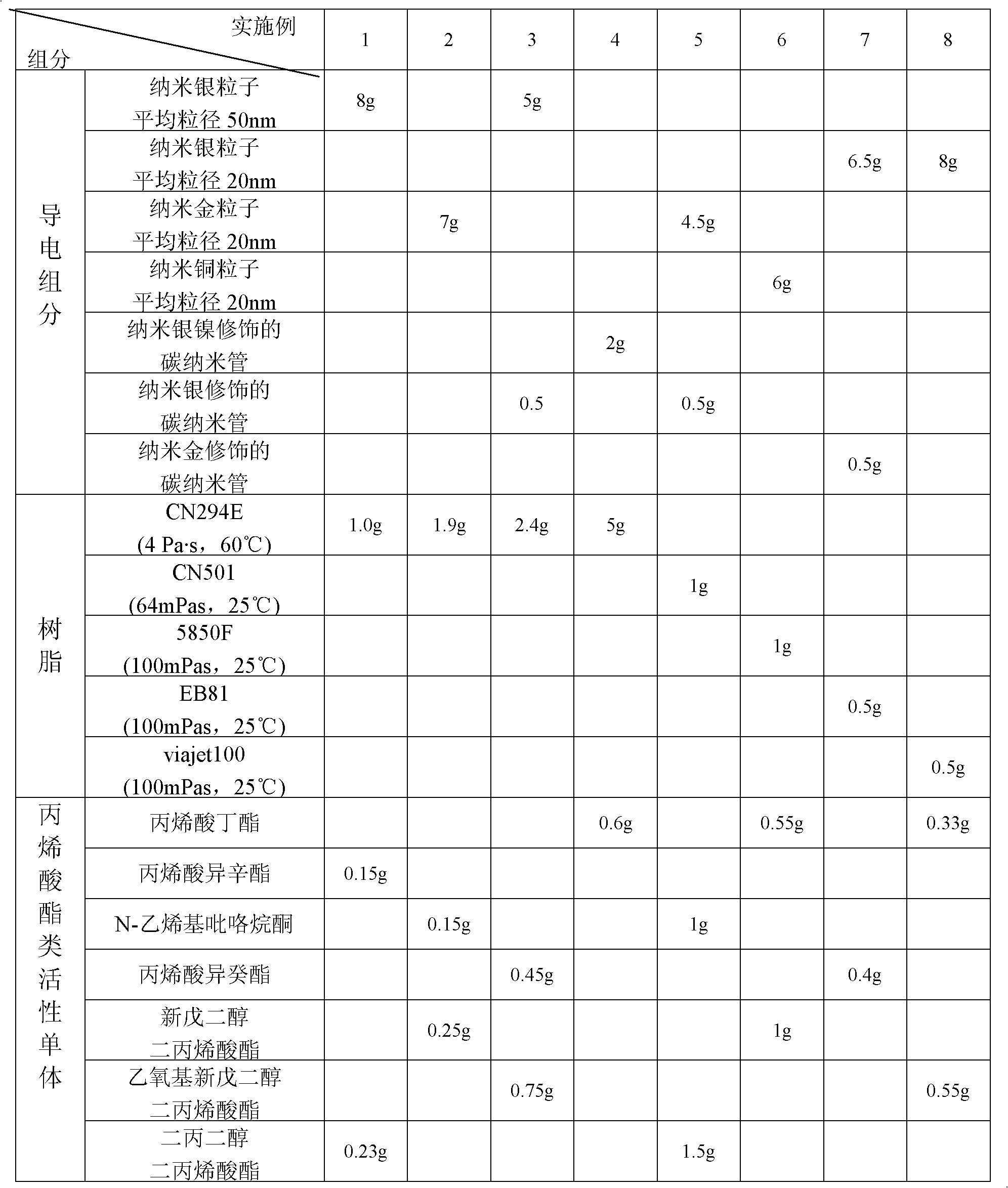

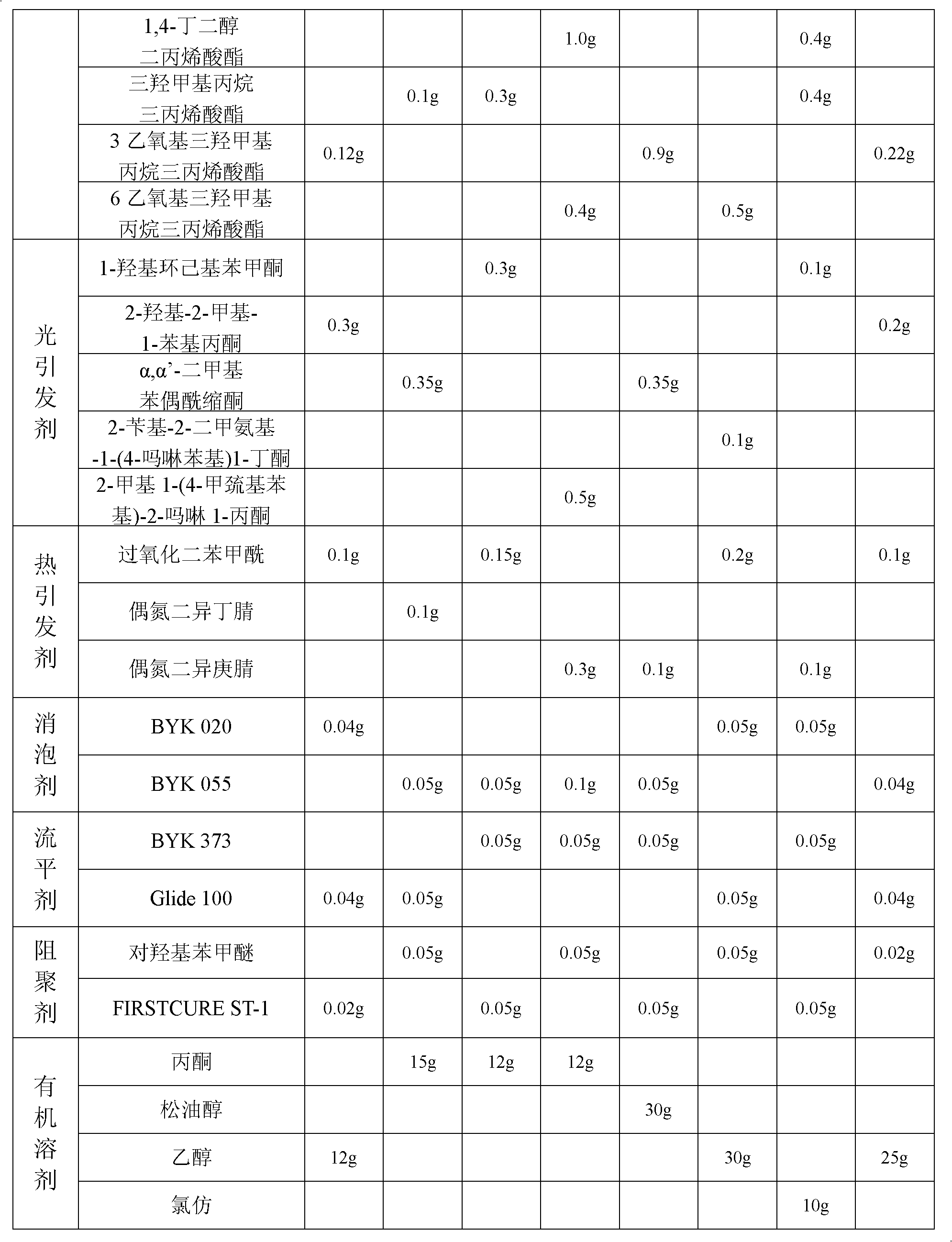

Flexible circuit conductive composition, preparation method and using method thereof

ActiveCN102212304AGuaranteed resistivityGuaranteed adhesionPhotomechanical apparatusPolyurea/polyurethane coatingsFlexible circuitsFlexible electronics

The invention relates to a flexible circuit conductive composition for a flexible printed circuit board (FPC), a preparation method and a using method thereof. The preparation method comprises the following steps of: adding photocurable resin and an optical activity monomer into a conductive nanometer material dispersion liquid and then preparing the composition by adopting a double-curing mode such as firstly photocuring and then thermal treatment. The photocuring leads the surface coating to be rapidly cured so as to achieve good mechanical property; and the thermal curing leads the coatingto be cured completely so as to reach the deep curing requirements. The thermal treatment leads nanometer metals to be sintered together so as to achieve good conductive performance. The prepared conductive system obtains a predesigned pattern in the specific area of a base material in a screen printing or nanometer impressing mode; the conductive pathway is obtained after the double curing and has the advantages of short curing time, low curing temperature, good electrical conductivity, high resolution ratio; and the prepared conductive film has the advantages of good adhesiveness, high hardness and good flexibility.

Owner:BEIJING UNIV OF CHEM TECH

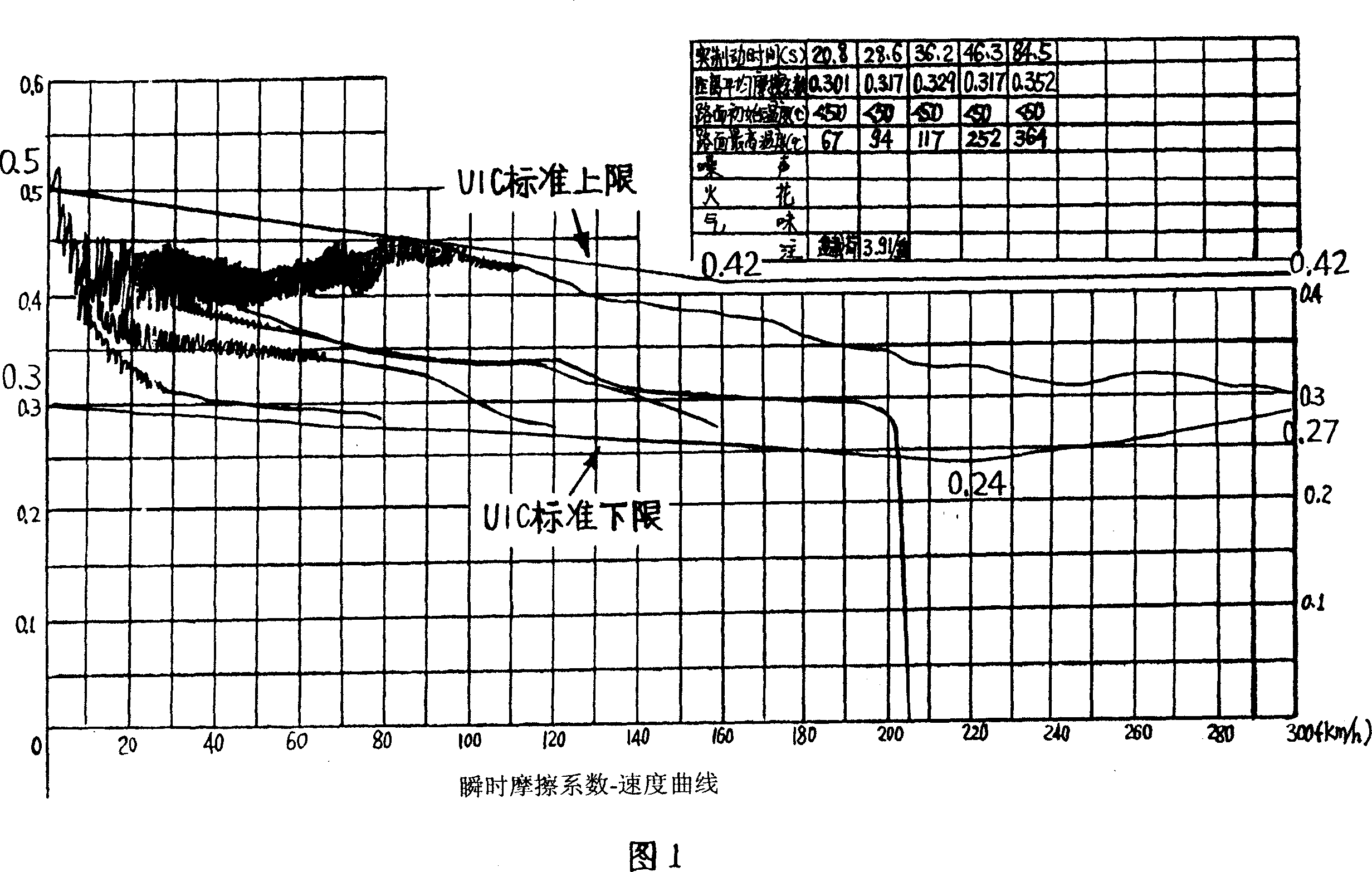

Copper base particle reinforced friction material

InactiveCN1995436AHigh degree of alloyingHigh strengthFriction liningManufacturing cost reductionGraphite

The invention discloses a reinforced friction material of copper-based particle in the friction material making domain, which comprises the following parts: 30-70% Cu, 4-11% Sn, 1-15% Al, 5-18% Fe, 2-15% Al2O3, 2-15% SiO2, 0-15% ferrochrome and 5-20% graphite.

Owner:大连远通制动制品有限公司

NbMoTaW high-entropy alloy, and preparation method thereof

InactiveCN106167870AImprove performanceEliminate composition segregationHigh entropy alloysSolid solution

The invention belongs to the technical field of high-entropy alloy, and discloses a NbMoTaW high-entropy alloy, and a preparation method thereof. According to the preparation method, mechanical alloying and spark plasma sintering are combined for forming, alloying of Nb, Mo, Ta, and W which are high in melting points is realized at solid states, heating to the melting points is not necessary, block materials with excellent performance can be obtained via only one time of solid phase sintering ( the sintering temperature is 1600 DEG C or lower), a difficult problem that the melting temperature (>2900 DEG C) of smelting method is high is solved, processing temperature is reduced greatly, and technology is simplified. According to the microscopic structure of the NbMoTaW high-entropy alloy, dispersion distribution of a granular second phase in an isometric crystal substrate is observed, both the substrate phase and the second phase are BCC solid solution, the substrate average particle size is smaller than 6<mu>m, the second phase average particle size is smaller than 4<mu>m, the material crystal particles are small, the structure is uniform, no dendritic segregation is caused, and strength and hardness are high.

Owner:SOUTH CHINA UNIV OF TECH

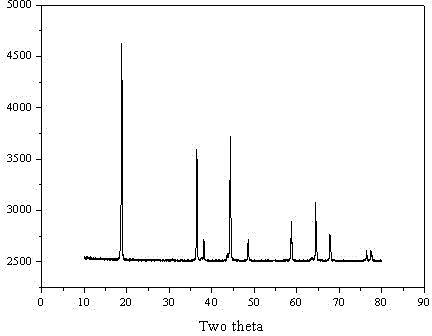

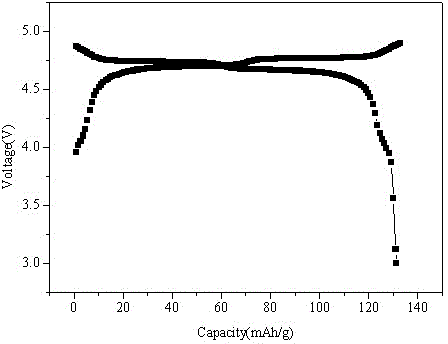

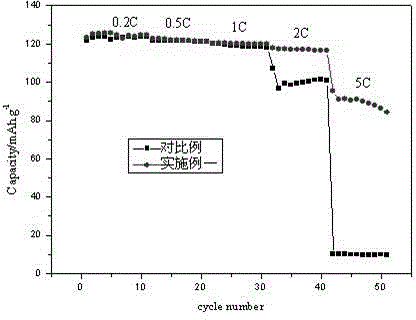

High voltage lithium ion battery cathode material and preparation method thereof

InactiveCN103332754AImprove uniformityImprove electrochemical performanceCell electrodesNickel compoundsNickel saltManganese

The invention provides a high voltage lithium ion secondary battery cathode material, which is represented by a general formula LiNi0.5-xMn1.5-yMx+yFzO4-z. Specifically, M is one or several elements of Mg, Cr, Ti, Co, Al, Fe, Zn and Cu, x is greater than or equal to 0 and smaller than or equal to 0.1, y is greater than or equal to 0 and smaller than or equal to 0.2, Z is greater than or equal to 0 and smaller than or equal to 0.2. The invention also provides a preparation method of the cathode material. The method includes: firstly employing a coprecipitation technique to generate a carbonate precursor of a nickel salt, a manganese salt and an M salt, then mixing the precursor with a lithium salt and LiF, performing ball milling, and carrying out fast microwave sintering to obtain the sample LiNi0.5-xMn1.5-yMx+yFzO4-z. The preparation method has the advantages of simple and controllable production process, short heating time, and low energy consumption, thus being suitable for large-scale industrial production. In the invention, an anion-cation composite doping way is adopted, the advantages of anions and cations are utilized comprehensively, and simultaneously their disadvantages can mutually offset, and the generated synergistic effect can improve the battery performance. The material prepared by the invention has completely developed crystal grains with moderate and uniform size, and has the advantages of high voltage, high capacity, excellent rate performance and high temperature cycle performance, etc.

Owner:WHOLE WIN BEIJING MATERIALS SCI & TECH

Method for strengthening and toughening biological ceramic material by use of graphene and preparing artificial bone prepared from material

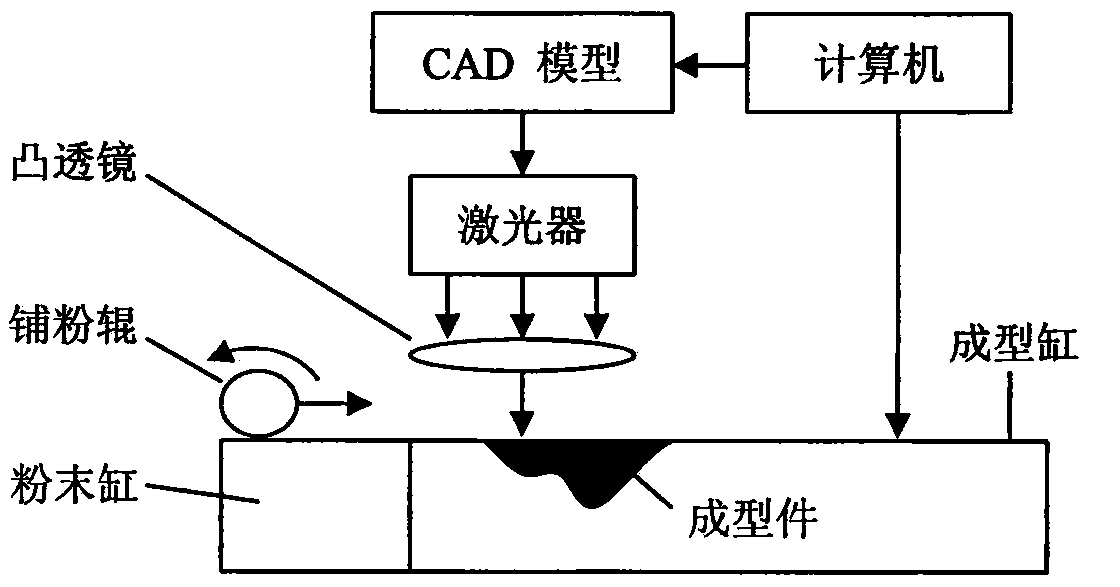

InactiveCN103656752AHigh strengthImprove toughnessProsthesisCalcium silicateSelective laser sintering

Aiming at the problems of low strength and low toughness of bioactive ceramics, the invention provides a method for strengthening and toughening a bioactive ceramic material by use of graphene and preparing graphene / biological ceramic artificial bone by a selective laser sintering (SLS) technology. The method has the advantages that graphene is added into the bioactive ceramic (hydroxylapatite, calcium phosphate, bioglass, calcium silicate and the like) as a nano enhanced phase, and the strength and toughness of the ceramic can be remarkably improved by use of the excellent mechanical property of graphene; the SLS technology is applied to the preparation process of graphene / biological ceramic artificial bone, and the sintering time can be shortened to the second level and even millisecond level by use of the characteristic of quick heating and cooling of laser so as to avoid structural injury of graphene caused by long-time high-temperature effect. The method for strengthening and toughening the ceramic material by use of graphene provided by the invention is of great significance to the application of bioactive ceramic to the load bearing parts of the human body.

Owner:CENT SOUTH UNIV

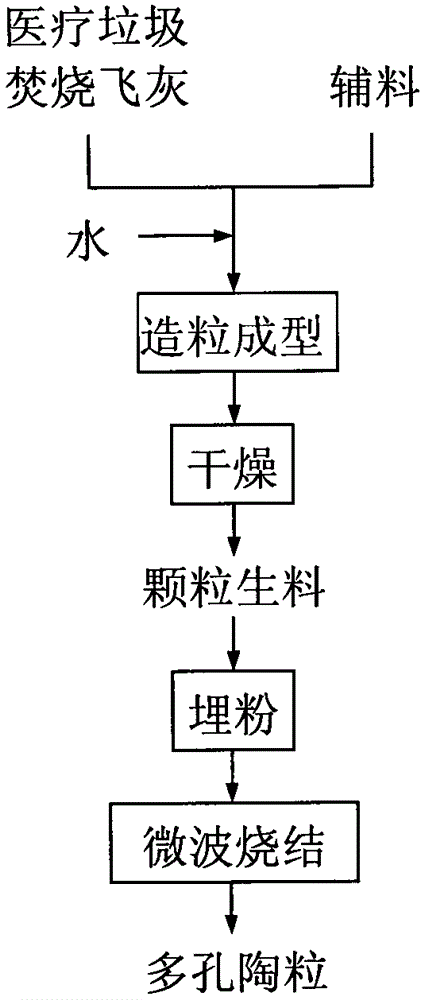

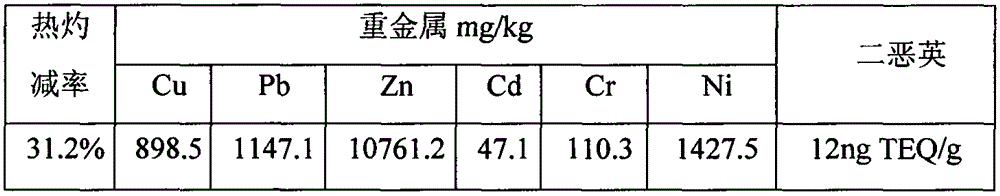

Method for microwave firing of porous ceramsites by adopting medical waste incineration fly ash

The invention discloses a method for microwave sintering of porous ceramsites by adopting medical waste incineration fly ash. The method comprises the following steps: (1) fully mixing the medical waste incineration fly ash with an auxiliary material, adding a small amount of water into the mixture, and carrying out granulation molding by a molding machine; (2) carrying out granulation molding, drying to obtain a particle raw material, filling the periphery of the particle raw material with a microwave coupling agent powder; and (3) carrying out microwave sintering of the particle raw material filled with the powder, and after sintering, cooling to the room temperature to obtain the porous ceramsites. The method can utilize a 'hot spot' effect of fly ash high-content active carbon in a microwave field to instantly completely decompose dioxins in the fly ash, at the same time, allows most heavy metals to be wrapped and cured in grids of the sintered product, and rapidly sinters the fly ash into the porous ceramsites; and the ceramsites can be used for building aggregates or wastewater filter materials, achieves further resource utilization while achieving harmlessness treatment of the medical waste incineration fly ash, and achieves many things at one stroke.

Owner:TIANJIN CHENGJIAN UNIV

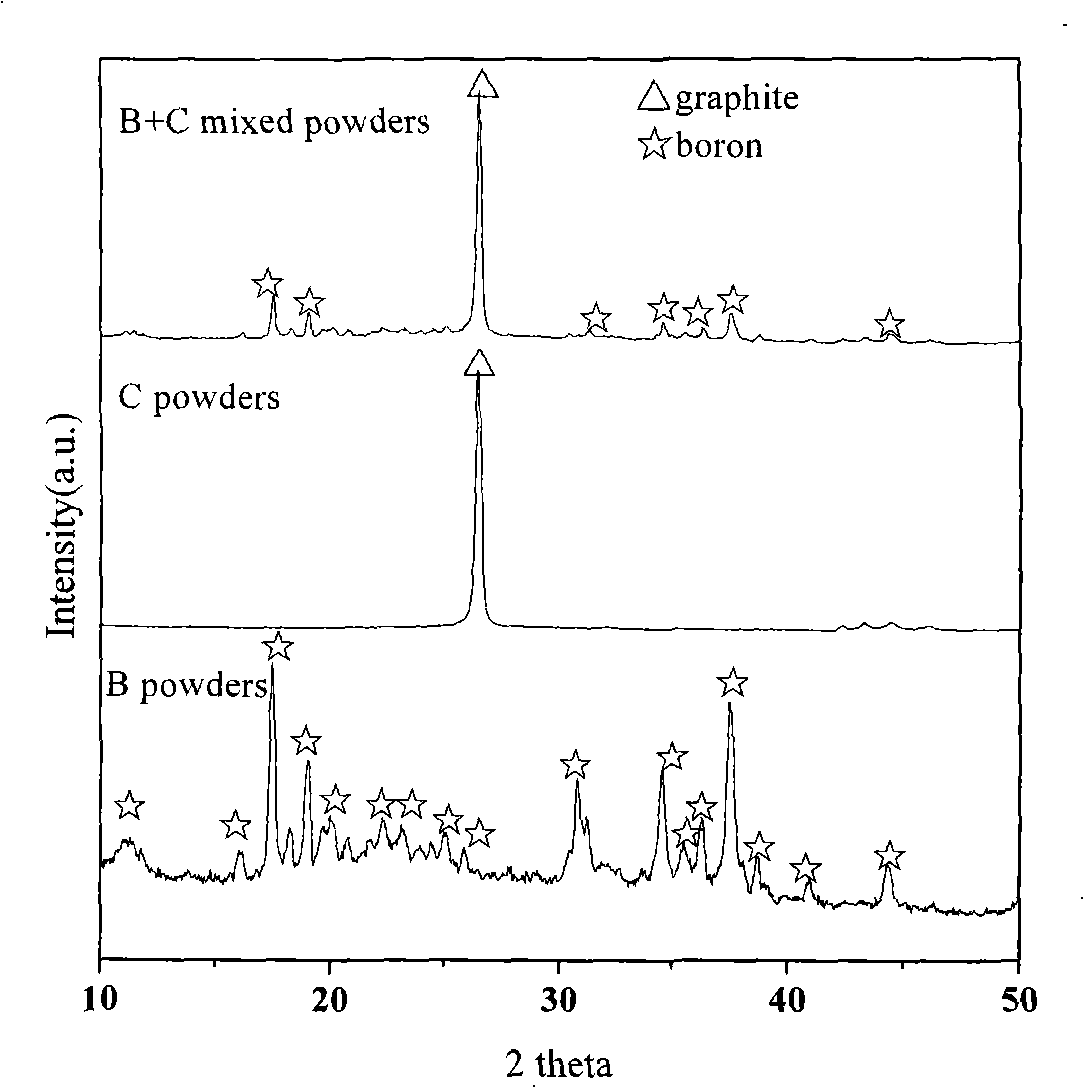

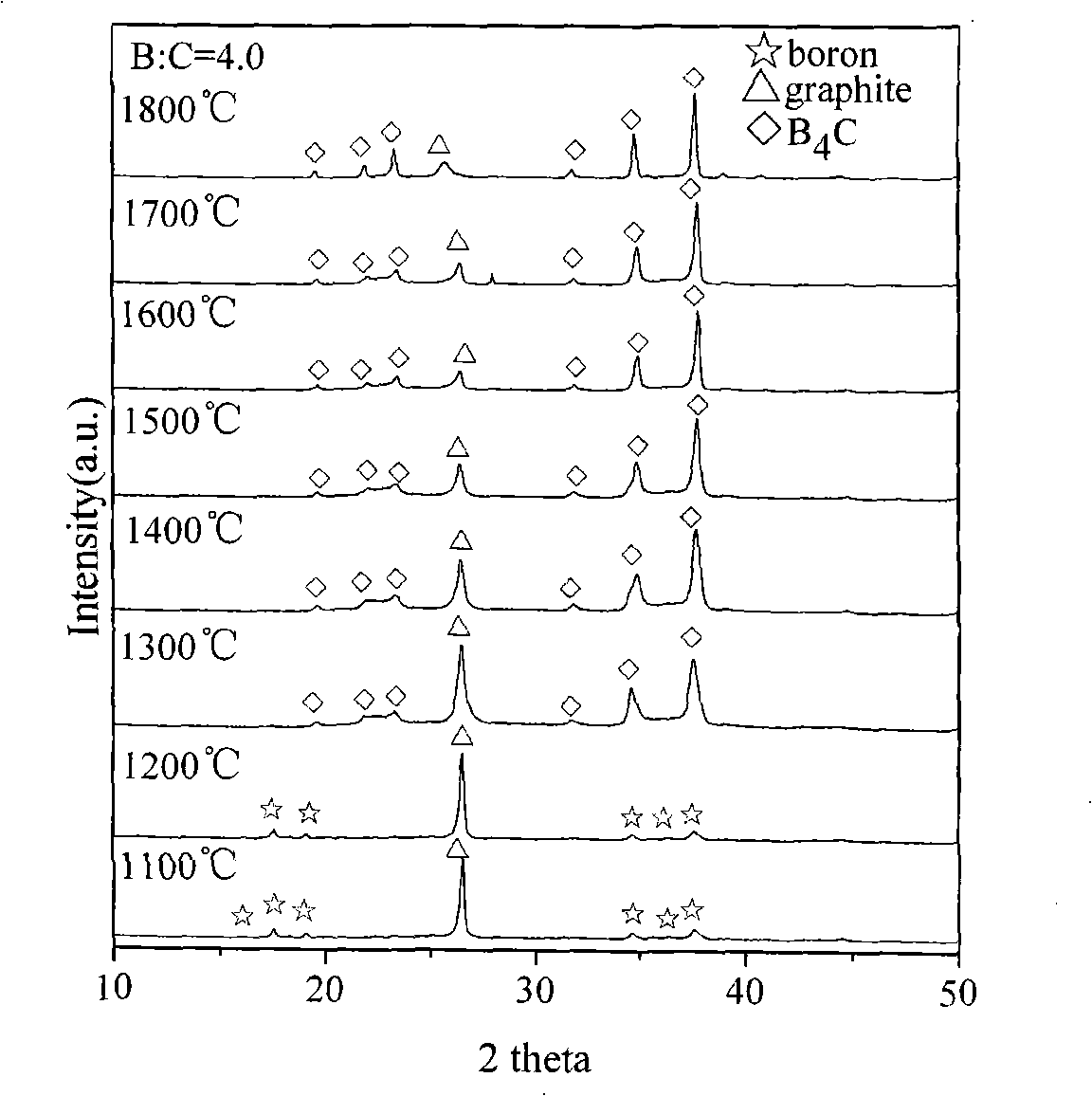

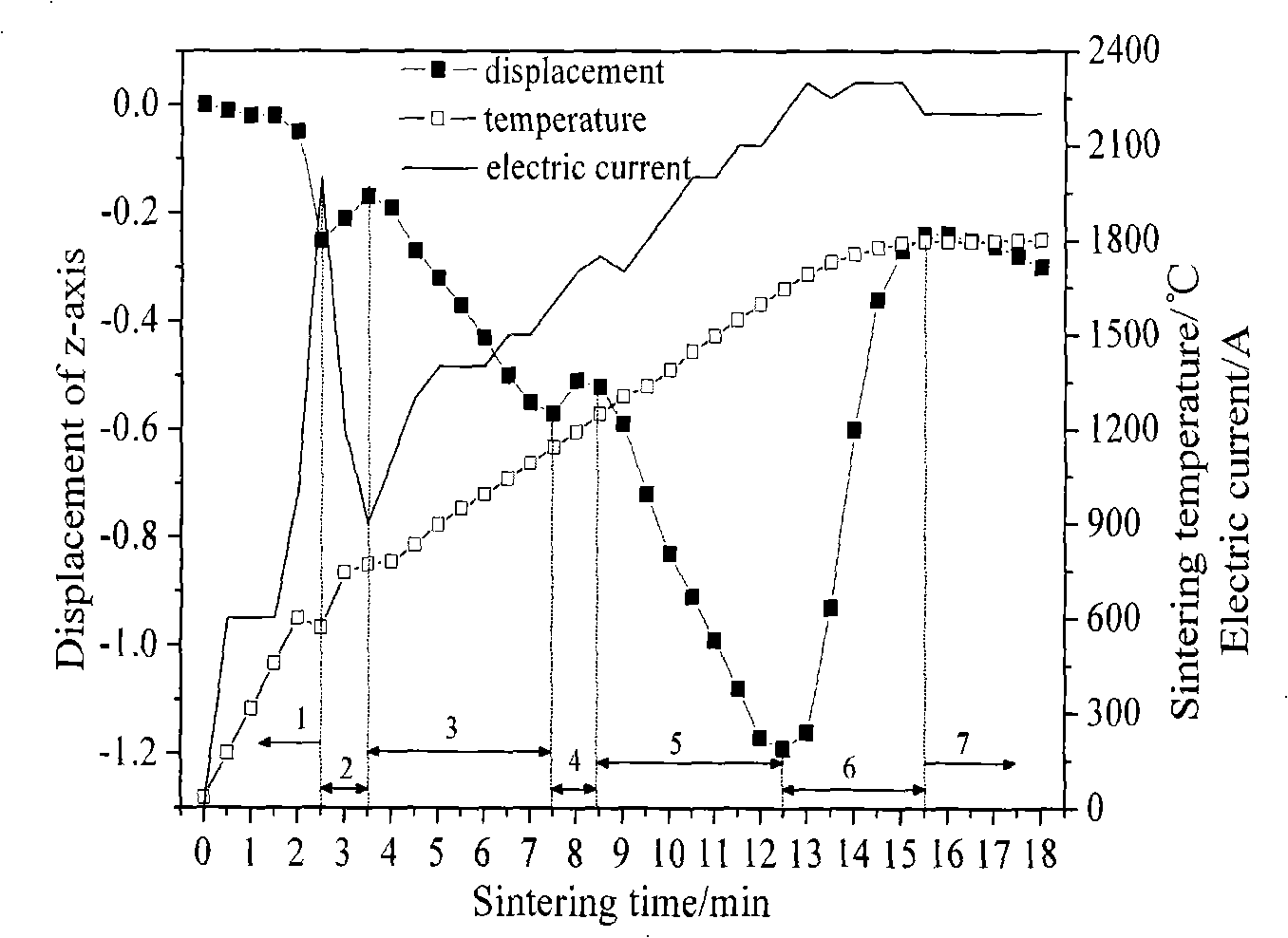

Method for preparing boron carbide ceramic

The present invention relates to a preparation method of boron carbide ceramics. In particular, the preparation method comprises the following steps: first, boron powder and carbon powder are weighed and mixed with the molar ratio of boron and carbon equal to 0.5 to 22.5; secondly, the powder prepared in the first step is arranged in a die and transmitted to discharging plasma sintering equipment for sintering, and the temperature is raised to be between 1300 and 2200 DEG C under the vacuum conditions; thirdly, the die is taken out from the discharging plasma sintering equipment and cooled to be at the room temperature; then the die is drawn away and thus the final product is prepared. In the preparation method, the direct synthesis and densification of boron carbide are completed in one step; the powder is sintered under the vacuum conditions; and the prepared boron carbide ceramics has the advantages of high purity, variety in the ratio of boron and carbon, and high hardness.

Owner:WUHAN UNIV OF TECH

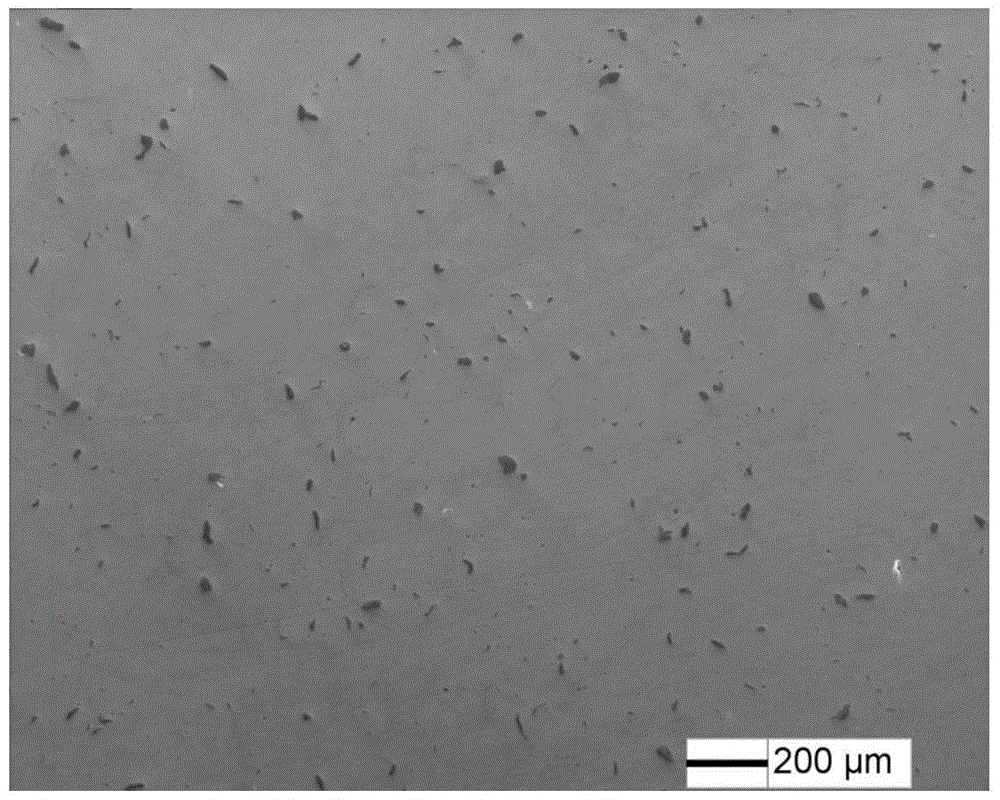

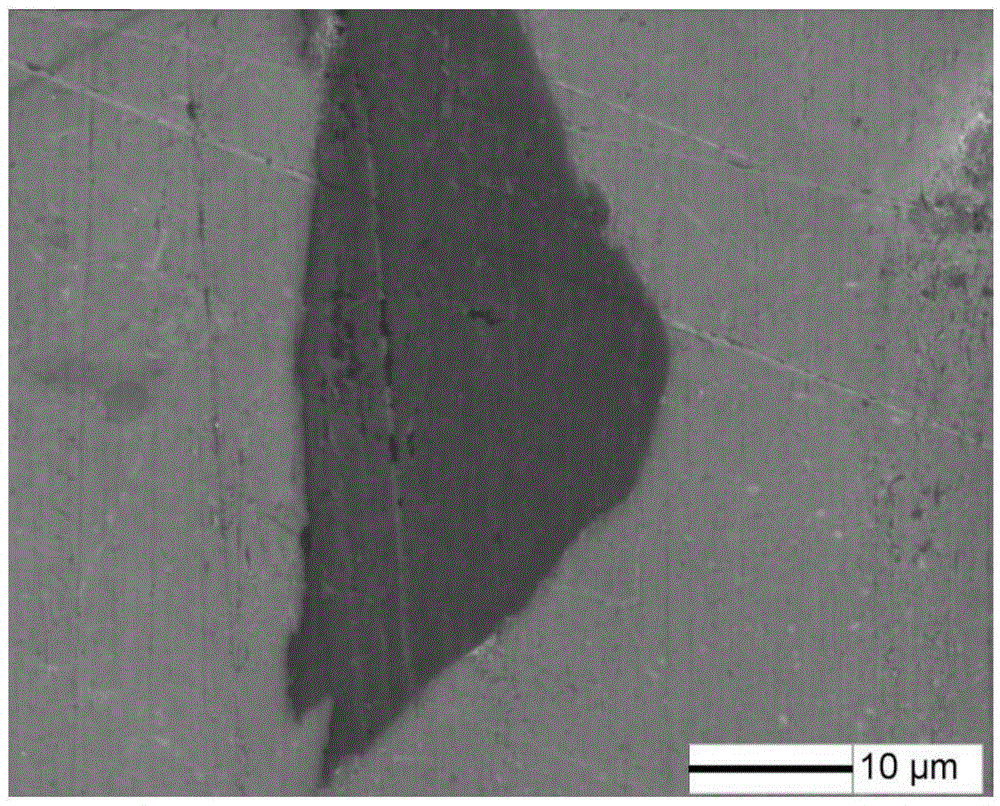

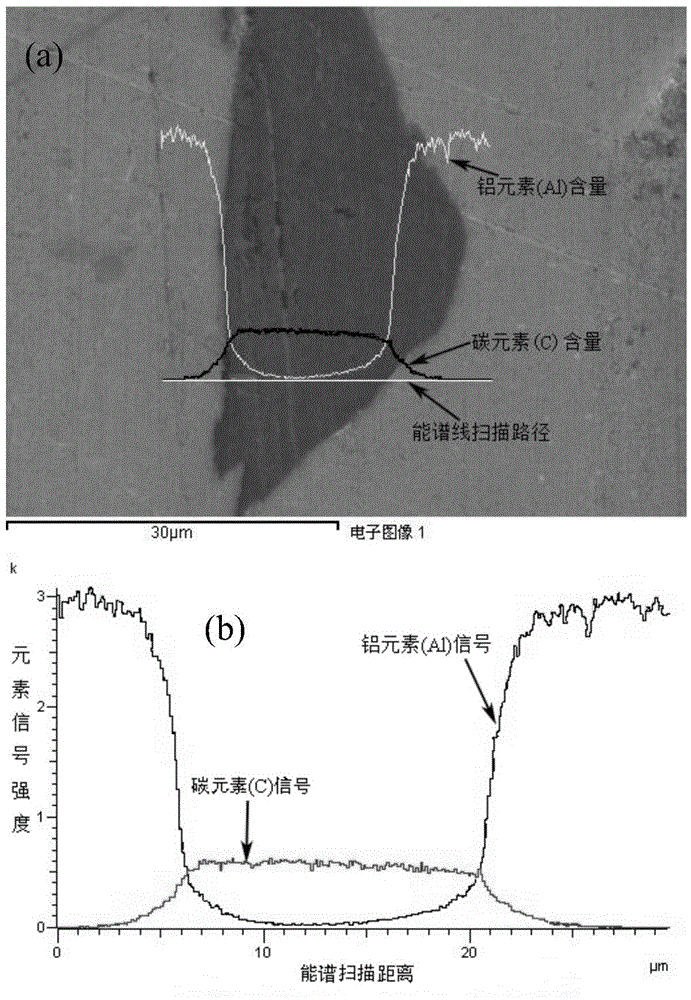

Method of preparing compact Ti3AlC2 ceramic by low-temperature non-pressure sintering

This invention relates to a low temperature pressless sintering preparation method for TiAL carbide ceramic, which takes pure Ti, Al and C as the raw materials to weigh and mix them in the mol ration of 3:1:2, then takes the mol volume of Al as the primary standard to add Sn, Si or Al powder of 0.3-0.6mol as the sinter aids, putting the mixed material in a ball mill kettle to be milled for 10-60h, in which, stainless steel balls or horniness alloy balls are applied in the kettle, the weight ratio of the ball material is 10:1-30:1, Ar or N inert gas is filled to the vacuumed kettle and the rate of the ball mill is 200-350rpm to get nanometer level super fine powder then to be ball-milled in ethanol medium for 3h to be dried and added with suitable PVB adhesive to granulate the powder and put into a steel model and pressed to an ingot on a cold equal static press to be sintered in vacuum, Ar or N protection atmosphere for 2-6h under 1250-1500deg.C to get a densed Ti3AlC2 ceramic.

Owner:SHANGHAI UNIV

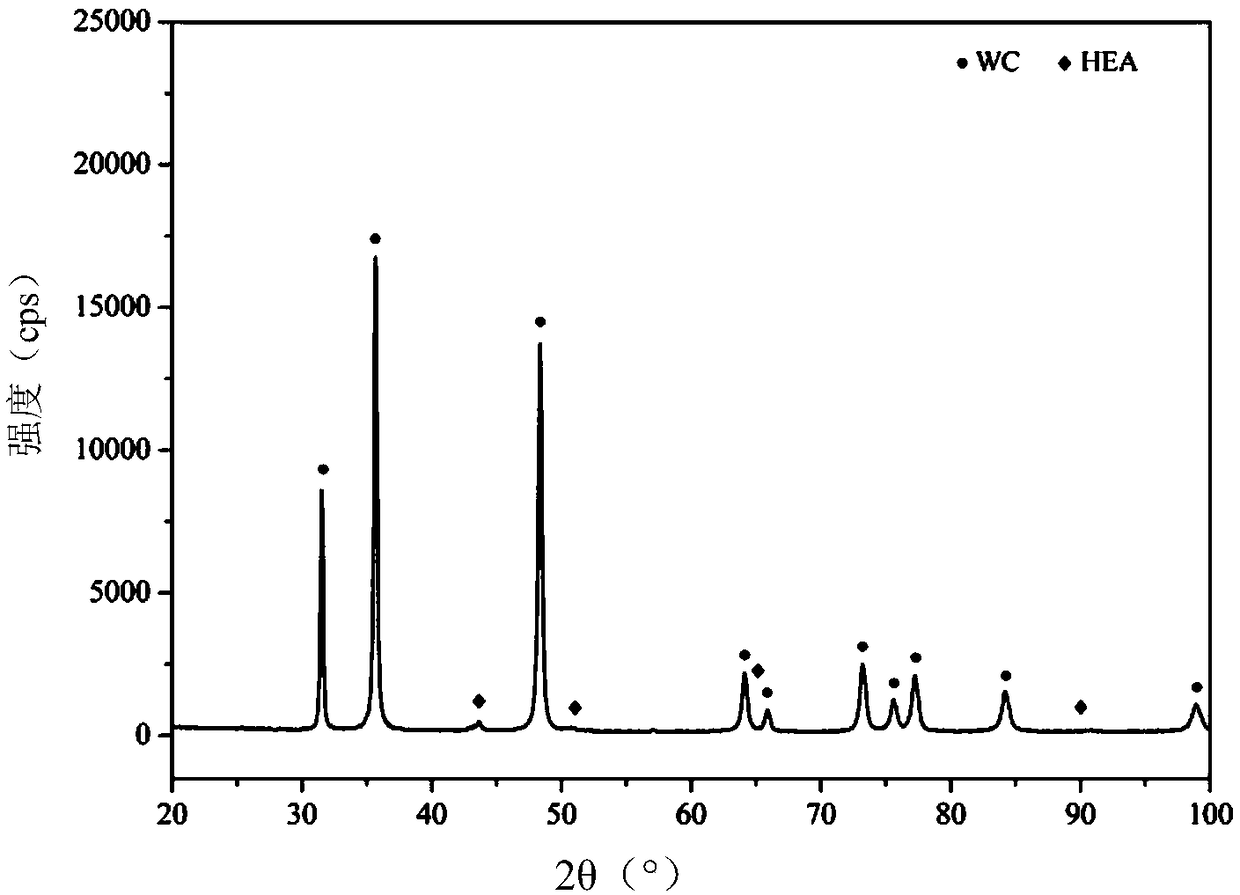

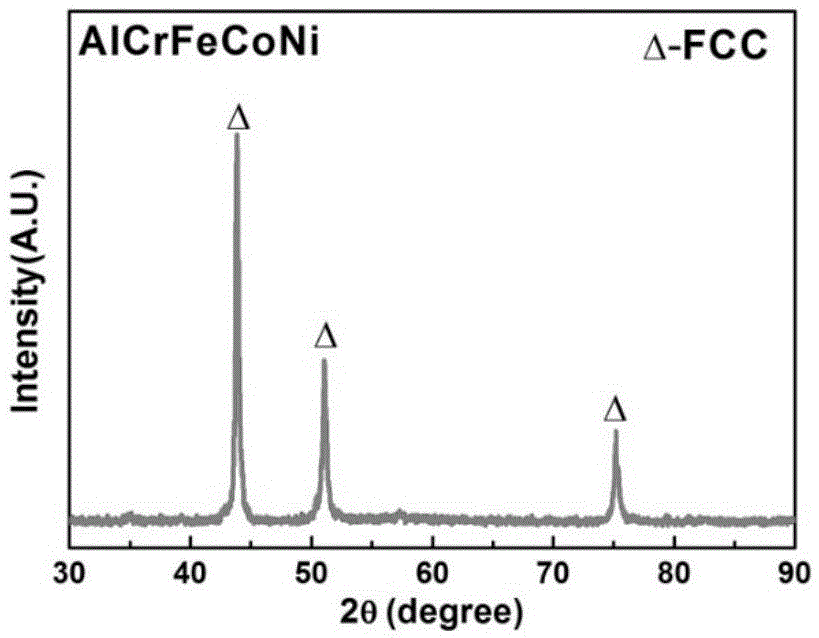

High-entropy alloy binding phase ultrafine tungsten carbide hard alloy and preparation method thereof

The invention belongs to the technical field of hard alloy, and discloses high-entropy alloy binding phase ultrafine tungsten carbide hard alloy and a preparation method thereof. According to the high-entropy alloy binding phase ultrafine tungsten carbide hard alloy, high-entropy alloy is used as a binding phase, and tungsten carbide is used as a hard phase; the high-entropy alloy is prepared fromthe components of five or more of Al, Co, Cr, Cu, Fe and Ni, and an atomic percentage of each element is 5-35%. The method comprises the steps that after high-entropy alloy powder and WC powder are mixed, spark plasma sintering forming is conducted to obtain the high-entropy alloy binding phase ultrafine tungsten carbide hard alloy. The tungsten carbide hard alloy is fine and small in crystal grain, and is good in comprehensive mechanical performance; adding a crystal growth inhibitor is not needed; consumption of the Co is significantly reduced, so that the raw material cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

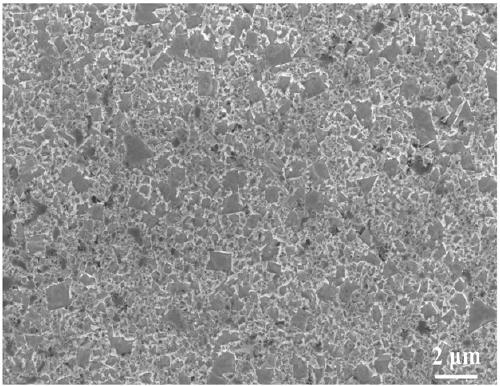

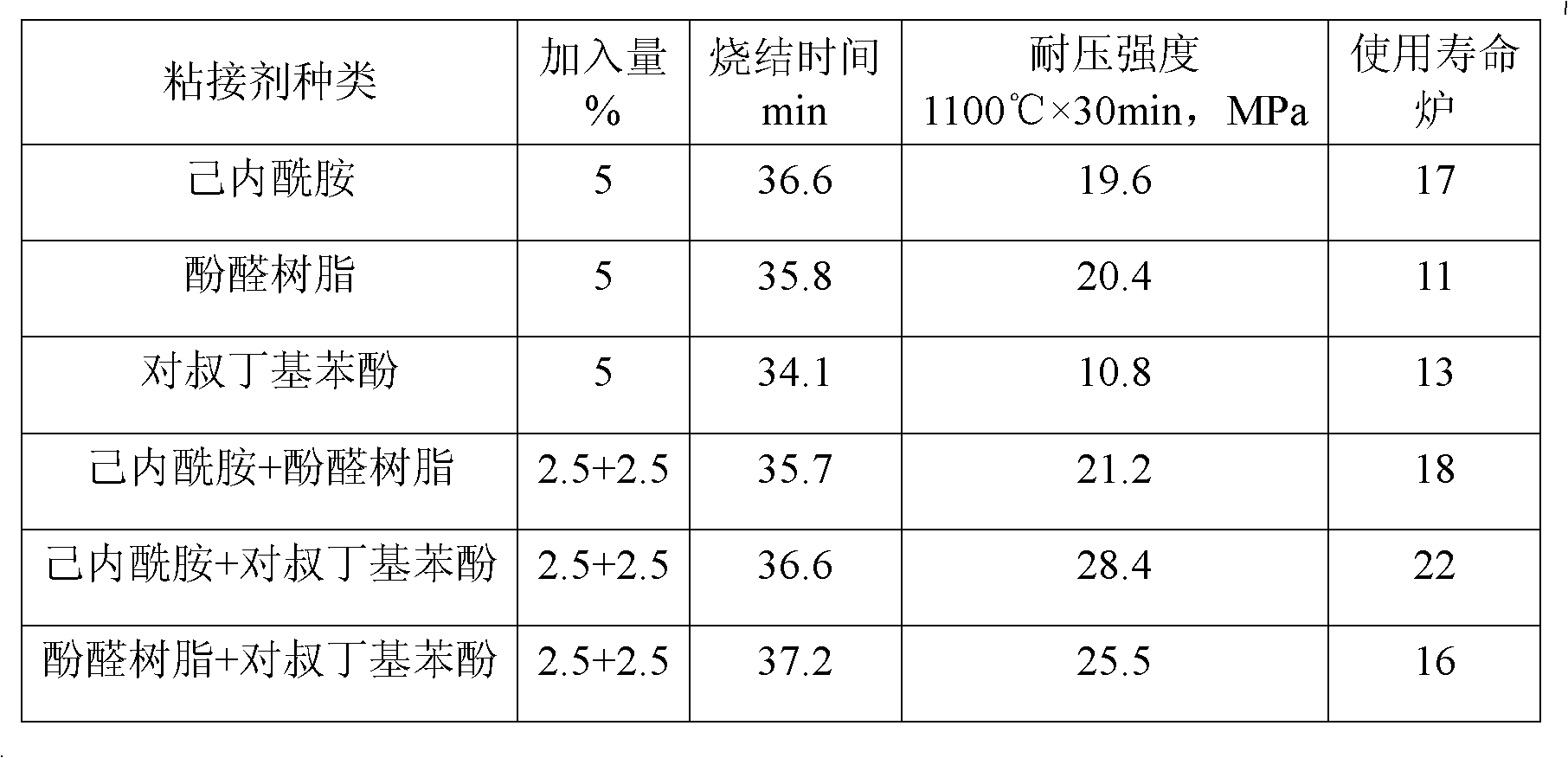

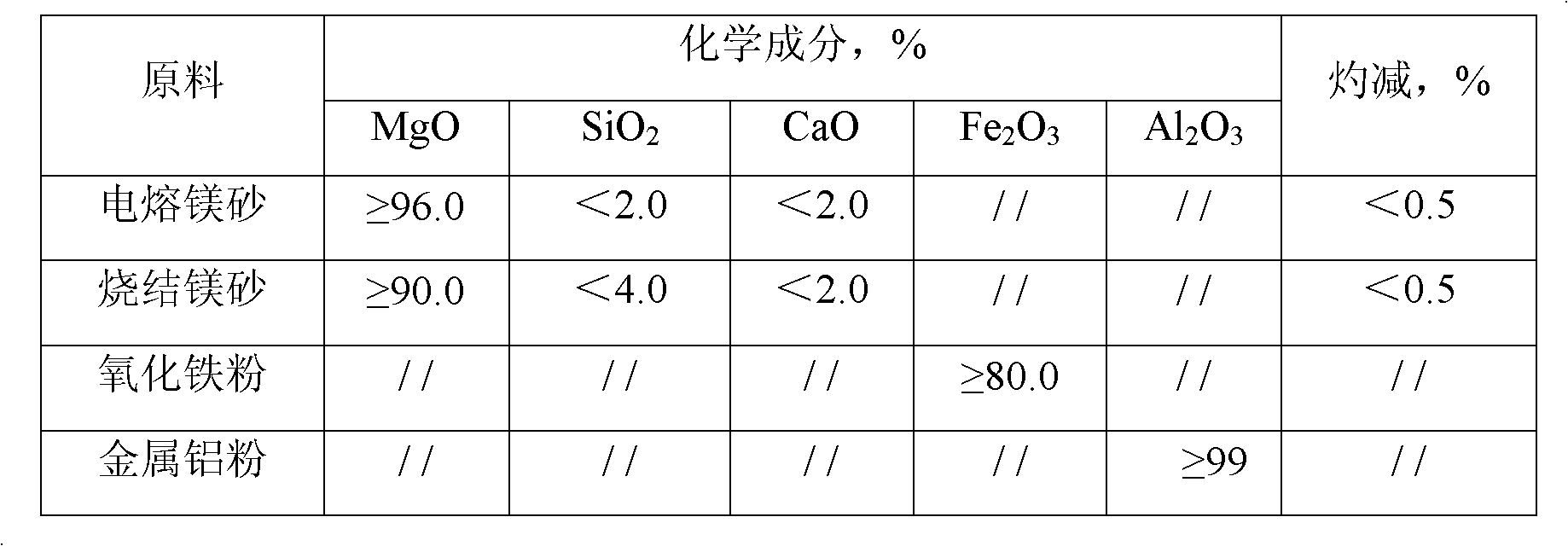

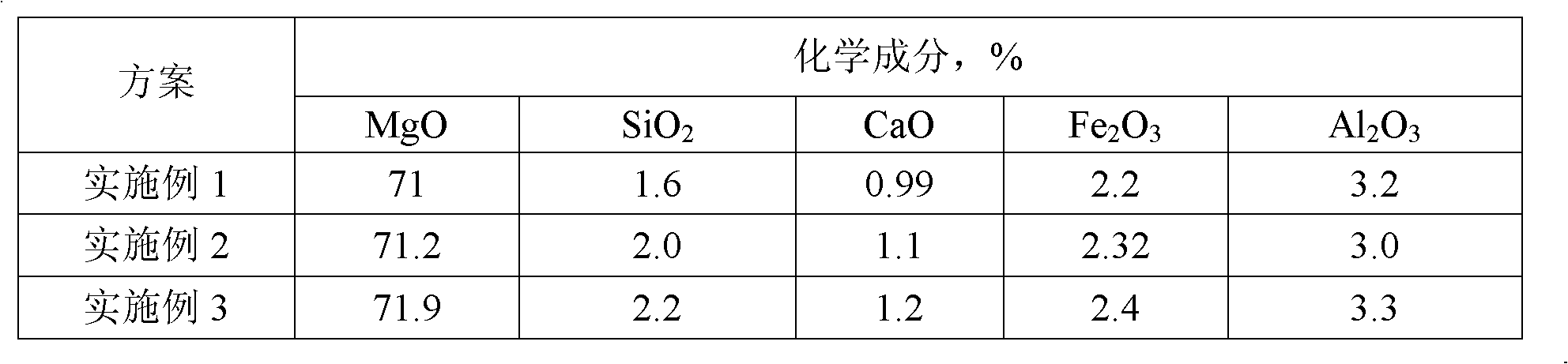

Repairing mass and preparation method thereof

The invention relates to a repairing mass for repairing in the converter production process of steel making and vanadium extracting of steel enterprises, in particular to a repairing mass used for a converter lining made of magnesia carbon bricks and a preparation method thereof, and provides a repairing mass having the advantages of short sintering time and long service life for meeting the requirement of production. The repairing mass per 100 weight parts comprises the following raw materials in parts by weight: 48-60 parts of fused magnesia, 22-28 parts of magnesite clinker, 10-16 parts ofmodified asphalt, 1-5 parts of metallic aluminum powder, 1-4 parts of ferric oxide powder and 2-10 parts of adhesive. The preparation method of the repairing mass is simple and convenient, i.e. all the raw materials are mixed. In the fettling production process of the vanadium extracting converter, when a local breakage appears on the converter lining, the repairing mass is coated on the part to be repaired; the repairing mass is sintered by utilizing the wall temperature of the converter, and production by blending with iron can be carried out after sintering; and under the conditions of lowsmelting temperature (1,360-1,400 DEG C) of the vanadium extracting converter and shorter smelting period (5-10 minutes), the repairing mass still can be quickly sintered with a working lining to form an organic combination with higher strength so as to prolong the service life of the repairing mass.

Owner:攀枝花钢城集团瑞矿工业有限公司

Metal-ceramic bond diamond grinding wheel and production method thereof

ActiveCN103692371AGood self-sharpeningImprove gripAbrasion apparatusGrinding devicesPowder mixtureCopper plating

The invention discloses a novel metal-ceramic bond diamond grinding wheel having the high strength and form-holding property in metal bond grinding wheels and the high self-sharpening property in ceramic bond grinding wheels, and a production method thereof. The metal-ceramic bond diamond grinding wheel is produced by: 1, preparing powder mixture out of 60-70% of copper-plated diamond powder, 15-20% of (W, Ti)C powder, 5-10% of tin powder, and 5-15% of iron group powders; mixing according to the above components and ratio to obtain the powder mixture; 2, forming, namely pressing the powder mixture into blanks by pressure forming; 3, sintering, namely subjecting the blanks to inert atmosphere low-pressure sintering, heating the blanks to 850-1050DEG C during sintering, and holding the temperature for 10-30 minutes. The copper-plated diamond powder is composed of particles with average particle size of 5-80 micrometers, and the particles are composed of diamond cores and copper coatings covering the diamond cores. Inert atmosphere during sintering is 5-10Mpa.

Owner:长沙市萨普新材料有限公司

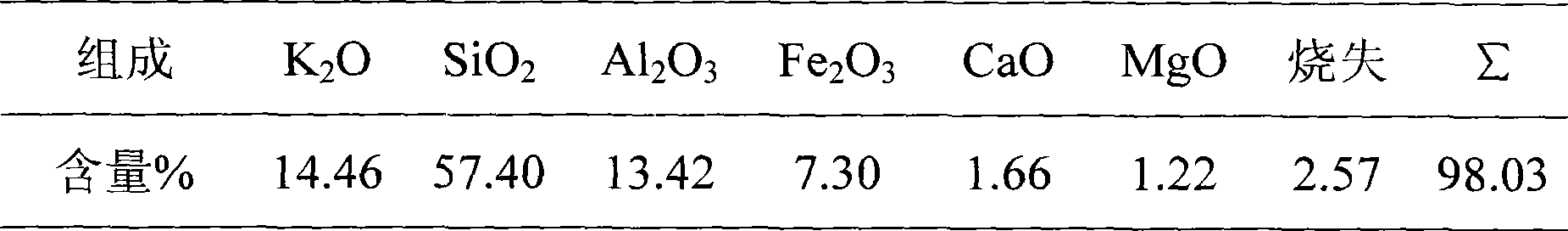

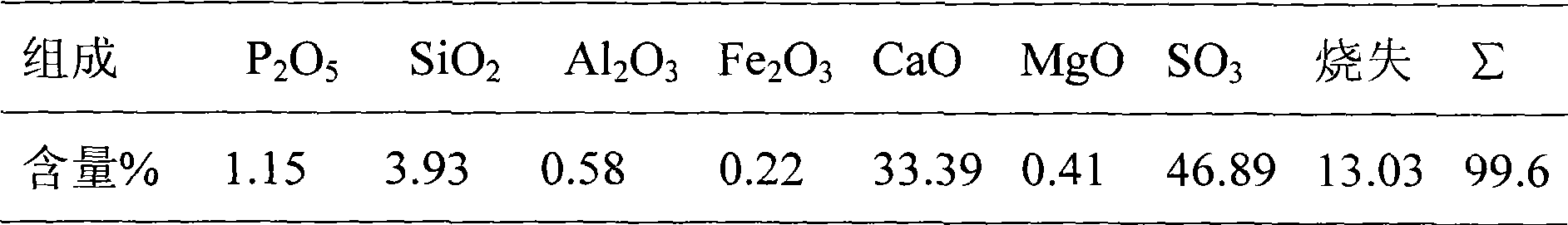

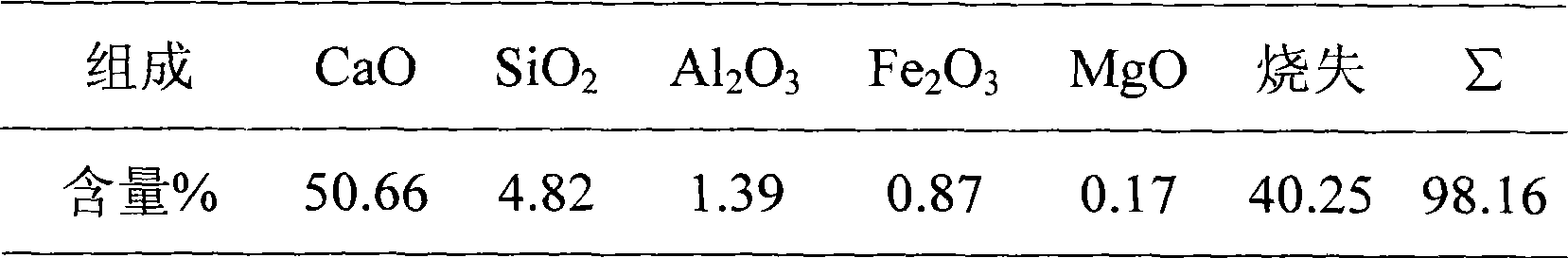

Method for producing potassium-calcium fertilizer by using potassium feldspar, limestone and phosphogypsum

InactiveCN101544518ALow melting pointLower sintering temperatureCalcareous fertilisersPotassium fertilisersTunnel kilnPotassium

The invention relates to a method for producing potassium-calcium fertilizer by using potassium feldspar, limestone and phosphogypsum, and belongs to the technical fields of three-waste treatment and chemical engineering technical field. The method comprises that: the feldspar, the limestone and the phosphogypsum are mixed in certain proportion, subjected to grinding, ball forming or block forming and then baked in a rotary kiln, vertical kiln or tunnel kiln, and the sintered grog is crushed and packaged into products of the potassium-calcium fertilizer. One of main raw materials for producing the potassium-calcium fertilizer is industrial waste residue phosphogypsum, and the method has more advantages than the prior methods for producing the potassium-calcium fertilizer.

Owner:GUIZHOU XIYANG FERTILIZER IND

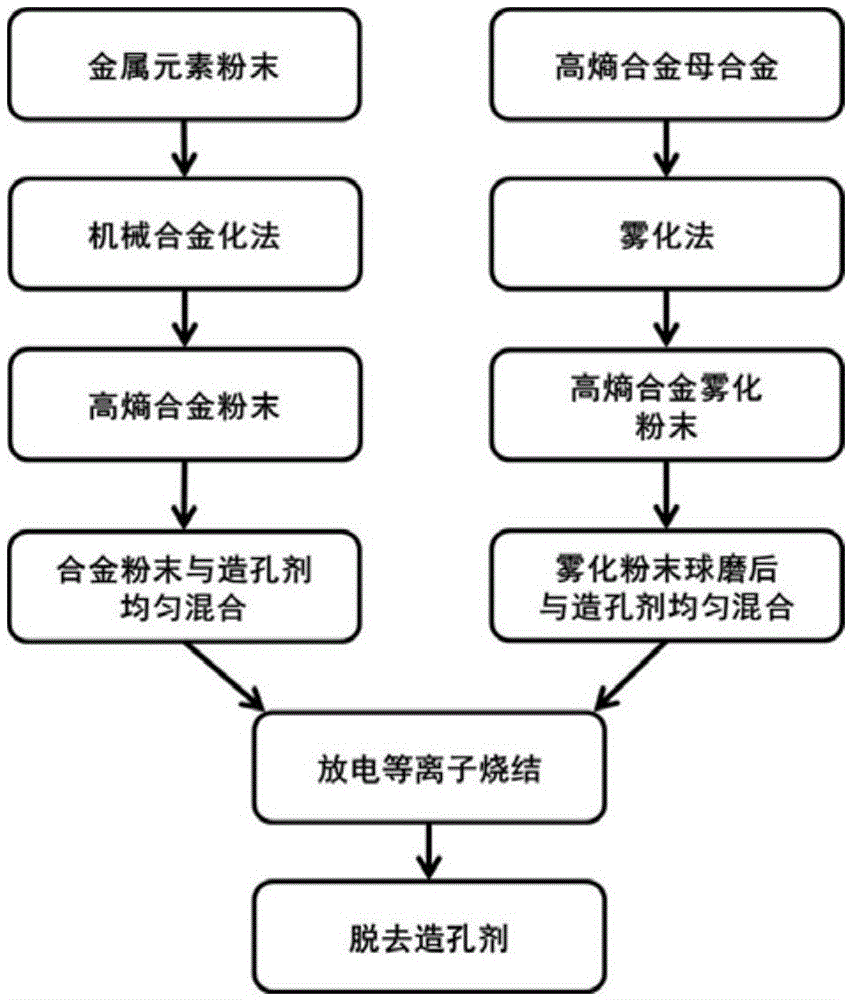

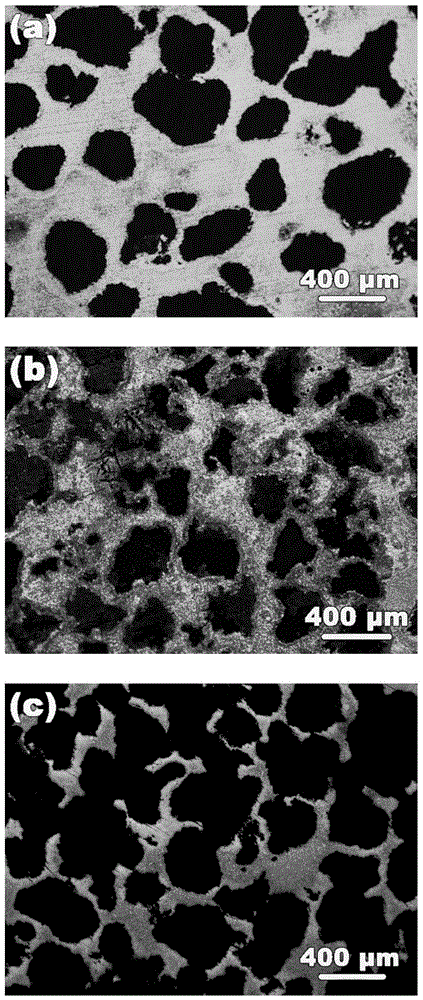

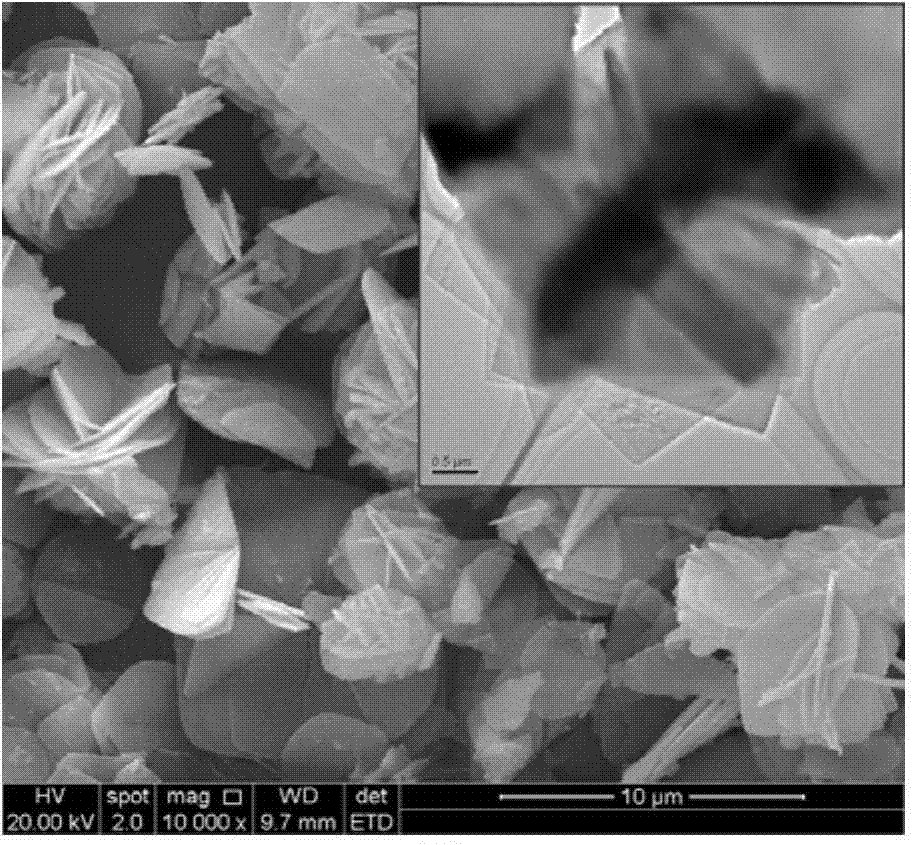

Porous high-entropy alloy and preparation method thereof

The invention discloses porous high-entropy alloy and a preparation method thereof and belongs to the field of porous foam metal. The preparation method of the porous high-entropy alloy specifically comprises the steps that high-entropy alloy powder and screened pore-forming agents are mixed proportionally according to the requirements for the porosity and the pore size, and the high-entropy alloy powder and the screened pore-forming agents are sintered through spark plasma sintering (SPS) directly after being uniformly mixed by a blender mixer; after sintering is completed, a sintered sample is put into deionized water to be subjected to ultrasonic cleaning, and particles of the pore-forming agents are removed by using the characteristic that the pore-forming agents are soluble in water; and finally the porous high-entropy alloy is obtained. The preparation method is simple in process, particularly, the preparation time is shortened greatly through the SPS method, and the efficiency is improved. The prepared porous high-entropy alloy has the characteristics of being high in porosity, uniform in pore size distribution, controllable in porosity and pore size and the like and has potential application prospects in the fields of biology, petroleum, metallurgy, chemical industry and the like.

Owner:UNIV OF SCI & TECH BEIJING

Manganese slag-solid waste mixed sintering brick making method

The invention discloses a manganese slag-solid waste mixed sintering brick making method, which includes that manganese slag, shale and fly ash which are dried to have constant weight are mixed and ground together or are respectively ground and then mixed in certain ratio, and are sieved according to a certain gradation requirement to obtain preparation materials of solid waste mixed sintering brick, then a certain amount of sodium humate stabilizer is added and uniformly stirred with clear water and is aged for a period of time, then is produced to be samples by an extruder, at last the finished products of solid waste mixed sintering bricks are obtained by the heat treatment processes of drying, roasting, cooling and the like. The invention uses electrolytic manganese dioxide slag as the main material, adopts the shale to replace clay as supplementary raw material, and adds the fly ash to adjust the components on the basis, the manganese slag-solid waste sintering brick is prepared through the processes of proportioning, preprocessing, patternmaking, drying, roasting and cooling, and the utilization of a large amount of solid waste resource is realized.

Owner:CENT SOUTH UNIV

High strength and toughness 3Y-TZP composite ceramic and preparation method thereof

The invention discloses a high strength and toughness 3Y-TZP composite ceramic and a preparation method thereof. The 3Y-TZP composite ceramic consists of 3Y-TZP, a SiC crystal whisker and Sr2Nb2O7; and the preparation method of the 3Y-TZP composite ceramic comprises the steps of preparing and mixing Sr2Nb2O7 powder, ball milling, profiling, degumming and sintering. The composite ceramic is obtained by sintering the SiC crystal whisker and a Sr2Nb2O7 ferroelectric material second-phase addictive which are introduced into the 3Y-TZP. The ceramic material with high strength and toughness can be obtained by adjusting the contents of the SiC crystal whisker and the Sr2Nb2O7 and optimizing a microwave sintering process under the synergistic effect of reinforcing by the SiC crystal whisker and toughening by the Sr2Nb2O7 piezoelectric second phase. The invention has reasonable components and simple preparation process and simultaneously achieves the effects of strengthening and toughening by adopting a synergistic technology of reinforcing by the SiC crystal whisker and toughening by the Sr2Nb2O7 piezoelectric second phase. In addition, the invention is applicable for industrial production, effectively improves the mechanical property of the 3Y-TZP ceramic and widens the application field of the 3Y-TZP ceramic.

Owner:CENT SOUTH UNIV

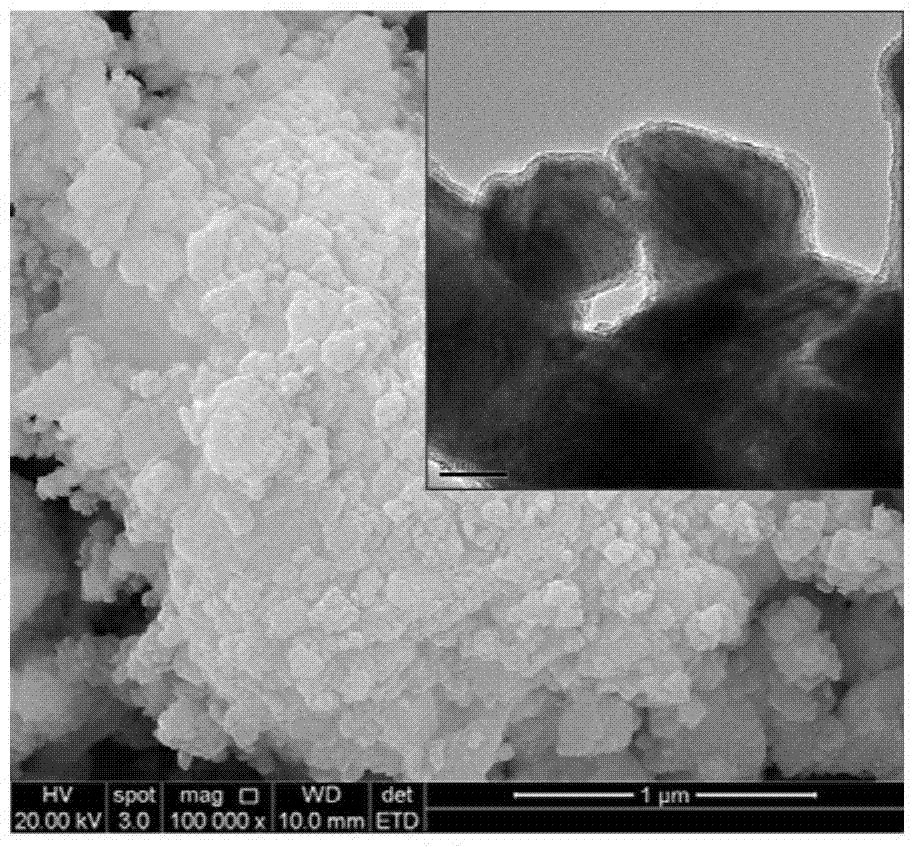

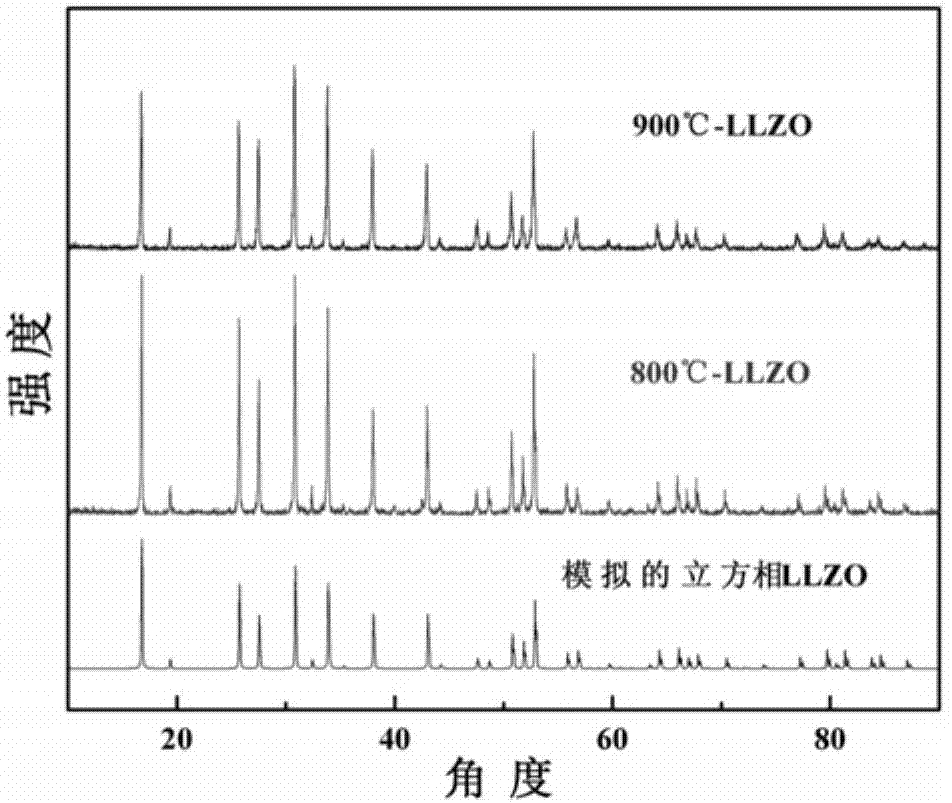

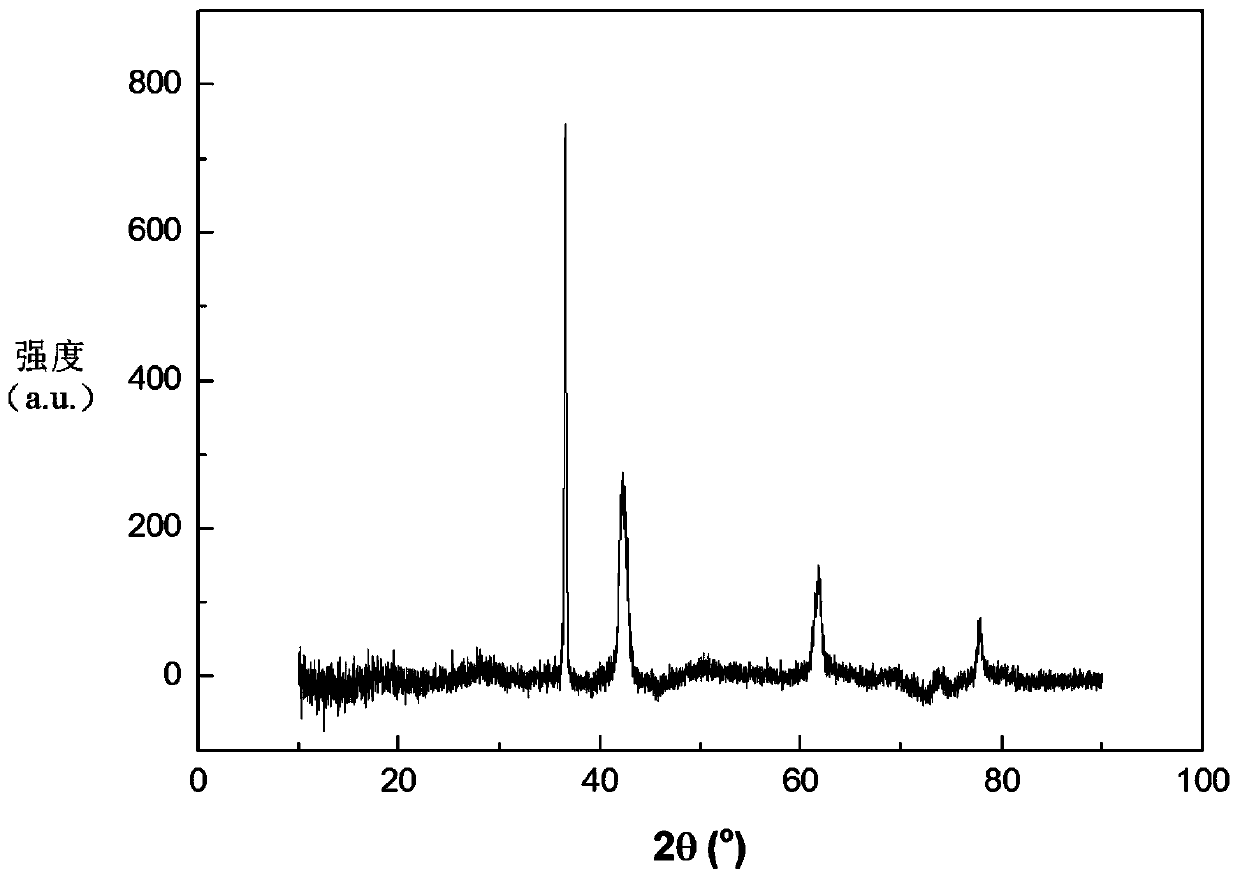

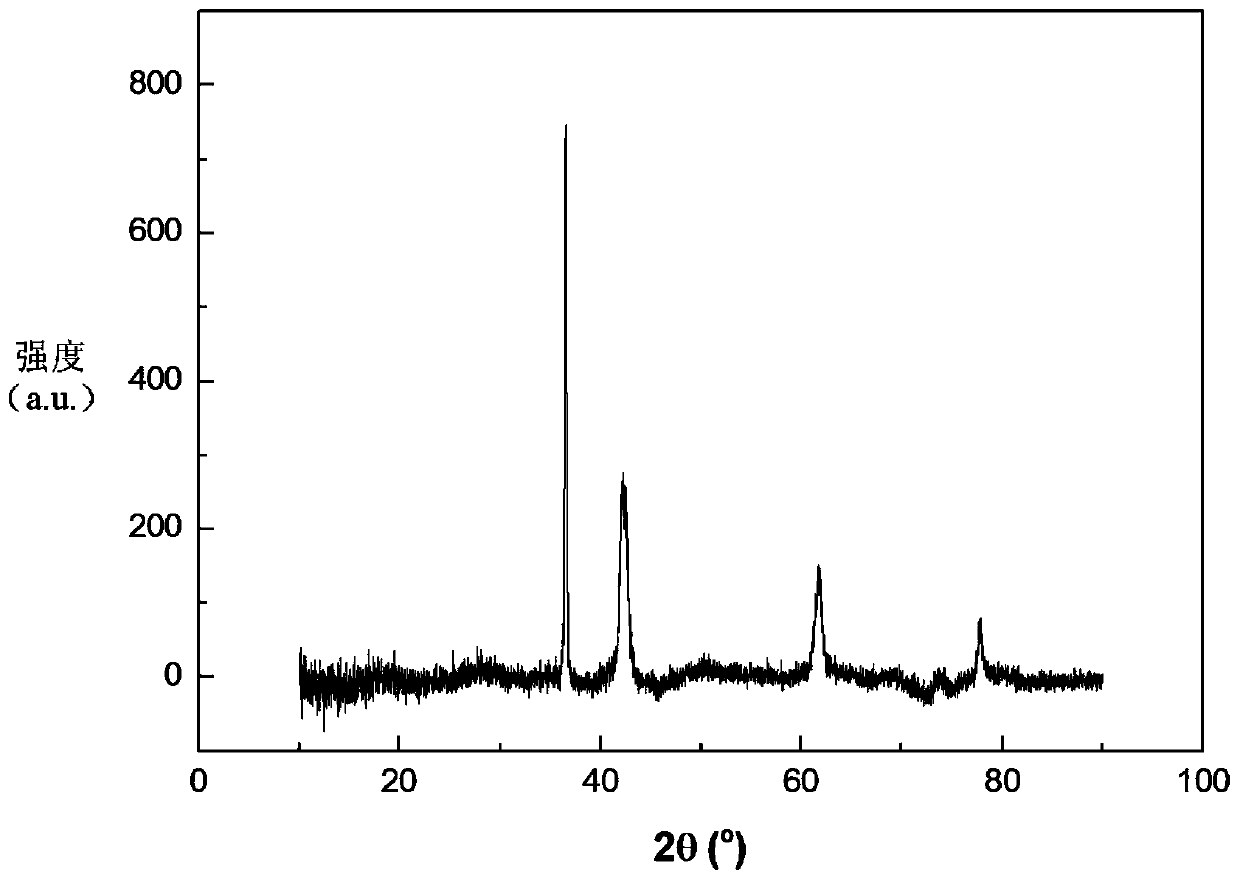

Method for preparing solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder

ActiveCN104124467ACalcination temperature is lowHigh sintering activitySecondary cellsElectrical batteryElectrochemistry

The invention discloses a method for preparing a solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder. The method specifically comprises the steps of dissolving a certain amount of lanthanum nitrate and zirconium nitrate into water, adding a precipitator, namely ammonium carbonate, controlling the pH value to ensure that La<3+> and Zr<4+> ions are simultaneously precipitated, and filtering and washing the precipitate; weighing a certain amount of lithium oxalate, dissolving lithium oxalate into water, adding the precipitate into the lithium oxalate solution, stirring, evaporating, crystallizing, and separating out lithium oxalate crystal on the surface of the precipitate to form precursor powder with a coated structure. The prepared powder has the advantages of uniform mixing, fine grains, high purity and the like; through the formed specific coated structure, the calcination temperature of the powder is low, the sintering time of the powder is short, and the room-temperature lithium ion electric conductivity of the sintered lithium lanthanum zirconium oxide is more than 2.2*10<-4>S / cm. According to the method, the process is simple, the cost is low, the preparation conditions are easy to control, and the prepared solid electrolyte is good in electrochemical stability and high in electric conductivity and can be used for preparing all-solid-state lithium ion batteries.

Owner:WUHAN UNIV OF TECH

Nanocrystalline tungsten-based alloy block body material and preparation method thereof

The invention relates to a plastic forming technique and a powder metallurgical technique, in particular to a nano crystal tungsten based alloy block material and a method for preparing the same. The block material comprises the following components in weight percentage: 86 to 88 percent of W, 6.5 to 7.5 percent of Ni, 2.5 to 3.5 percent of Fe, 2 to 4 percent of Mo and 1 to 2 percent of Co. The preparation method comprises the following steps: Fe-Co-Ni and W-Mo after dry mixing are ball milled in advance respectively until the Fe, Co and Ni completely form solid solution, and tungsten phase crystal grain is thinned to below 100nm; the Fe-Co-Ni and W-Mo are subjected to high energy ball milling until the Fe-Co-Ni is evenly distributed around the W-Mo crystal grain; and the discharge plasma rapid sintering is adopted. The nano crystal tungsten based alloy block material has the advantages of reasonable formula, even and thin microstructure, nearly full compact, higher hardness and tensile strength and good specific elongation, and the method for preparing the block material effectively improves the mechanical performances of the sintering material.

Owner:SOUTH CHINA UNIV OF TECH

Trace cobalt-containing tungsten carbide without bonding phase and preparation method thereof

The invention belongs to the field of powder metallurgy sintering, in particular refers to a trace cobalt-containing tungsten carbide without bonding phase and preparation method thereof. A hard alloy comprises components, by weight, as follows: 0.20-1.00% of Co, 0.01-0.50% of Cr3C2, 0.01-0.50% of VC and the balance of WC with grain size of 0.2-0.8 mum. The preparation method comprises the steps of: carrying out feeding and high energy ball milling according to the above raw material powder ratio, until WC powder in the ball milling powder has an average grain size refined to less than 200nm; then sintering the cemented carbide powder rapidly after the high energy ball milling by discharge plasma. The tungsten carbide base cemented carbide powder of the invention has reasonably designed components and a simple preparation method; the powder gives out heat uniformly and has fast heating and cooling speed, low sintering temperature and short sintering time to save the energy greatly; and the obtained ultrafine-grained WC cemented carbide has excellent integrated properties.

Owner:江西长裕硬质新材料有限公司

Preparation method of high-entropy oxide ceramic

The invention discloses a preparation method of high-entropy oxide ceramic. The method comprises the following steps that 1, according to metal atom mole ratio being 1:1:1:1 or 1:1:1:1:1, four or fiveor less kinds of metal oxide powder are weighed; the oxide powder includes MgO, ZnO, NiO, CuO, CaO, CoO, ZrO2, CeO2, Al2O3, Gd2O3, La2O3, Er2O3, Y2O3, Fe2O3, Co3O4 and CaCO3; 2, powder weighed in step 1 is subjected to ball milling, drying and granulation; 3, granulated powder is pressed and molded to form a green body; 4, the green body obtained in step 3 is subjected to thermal treatment; 5, the green body obtained after thermal treatment in step 4 is heated to the preset temperature, an electric field of the preset electric field intensity is applied to a sample, after flash-burning appears, a power source is converted from the constant voltage state to the constant current state, the temperature is kept constant for 1-60 min under the preset current density, and then quenching is performed to obtain the needed high-entropy oxide ceramic. The flash-burning is adopted for preparing the high-entropy oxide ceramic, the sintering temperature is remarkably lowered, and the sintering time is remarkably shortened.

Owner:SOUTHWEST JIAOTONG UNIV

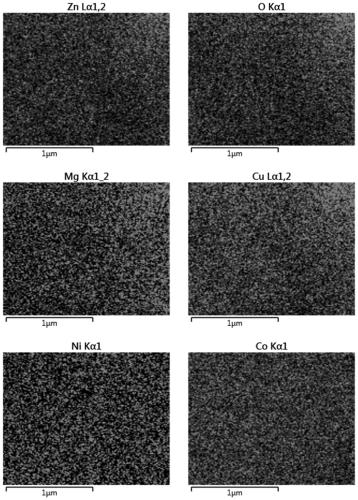

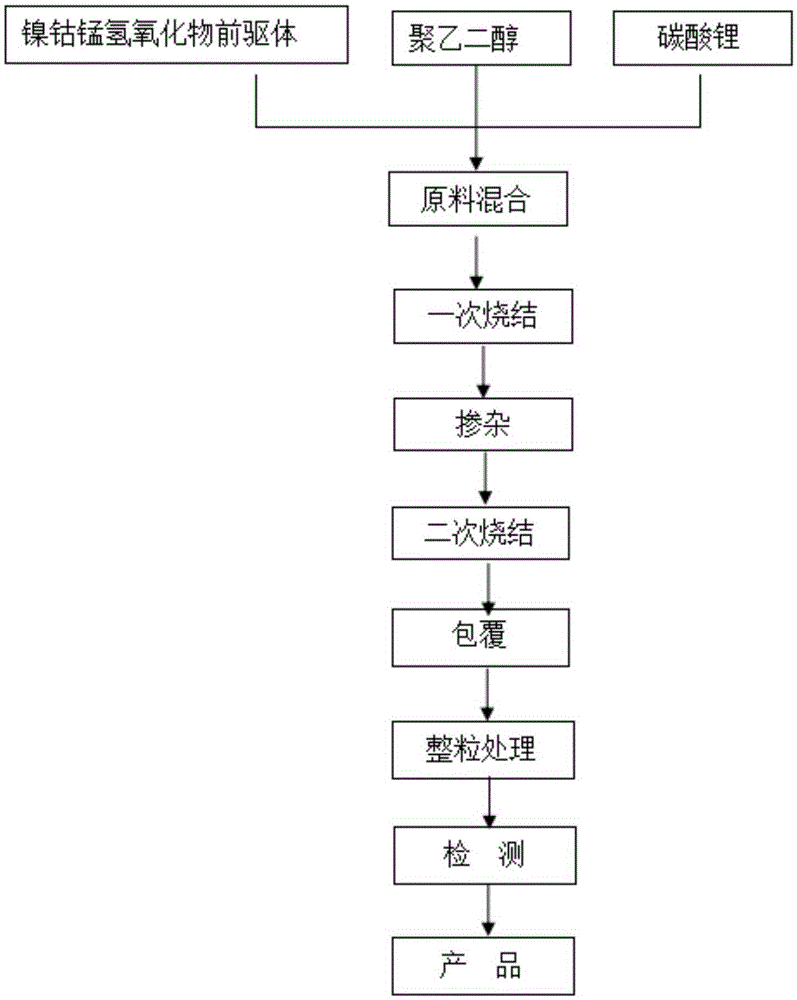

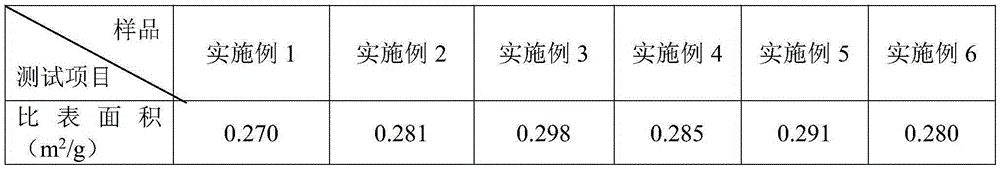

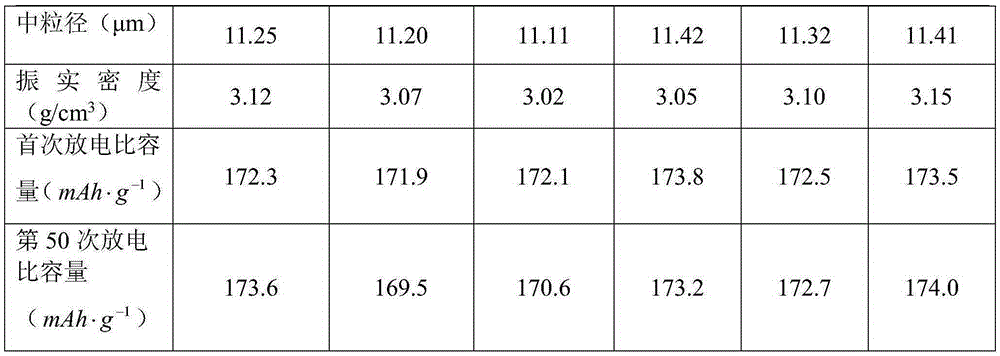

Preparation method of aluminum oxide coated lithium nickel manganese cobalt cathode material

ActiveCN105355911ASimple structureImprove electrochemical cycle performanceCell electrodesSecondary cellsManganesePolyethylene glycol

The invention belongs to the technical field of battery materials, and discloses a preparation method of an aluminum oxide coated lithium nickel manganese cobalt cathode material. The method comprises the steps of raw material mixing, primary sintering, doping, secondary sintering, coating and size stabilization treatment, wherein the step of raw material mixing comprises the steps that a three-dimensional efficient titled mixer is adopted, polyurethane balls serve as a mixing medium, dispersing, even mixing and smashing are conducted on lithium carbonate, a nanometer spherical nickel cobalt manganese hydroxide precursor and polyethylene glycol, and a uniform intermediate mixture is formed. The preparation method of the aluminum oxide coated lithium nickel manganese cobalt cathode material is low in primary sintering temperature, short in sintering time, simple in technology, large in specific capacity and good in cycling performance. The preparation method further has the advantages of being low in investment, reliable in technology, low in operating cost and the like, and the good economic benefit and market promotion value are achieved.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

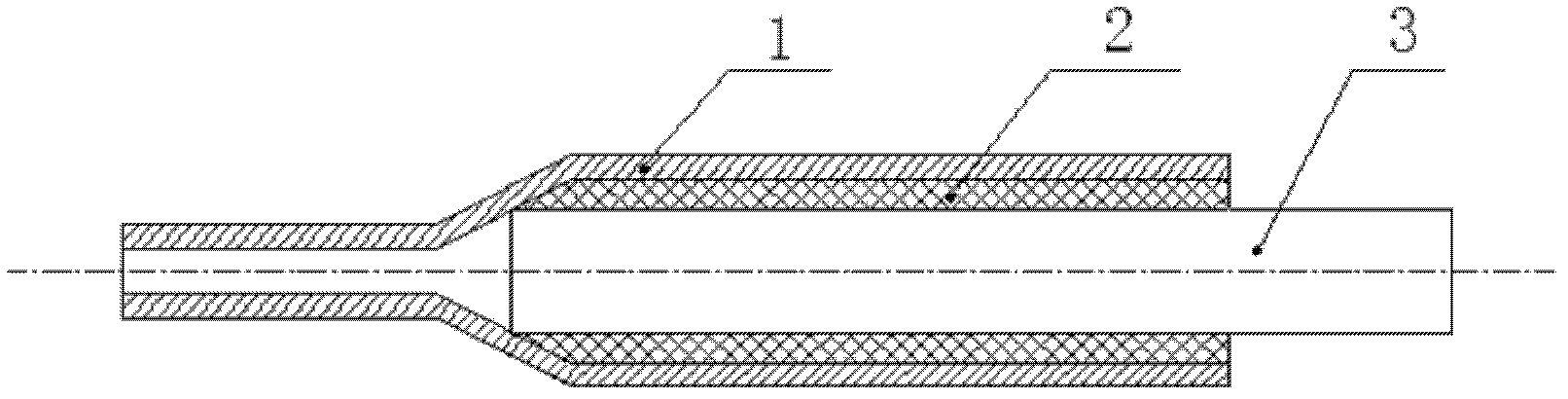

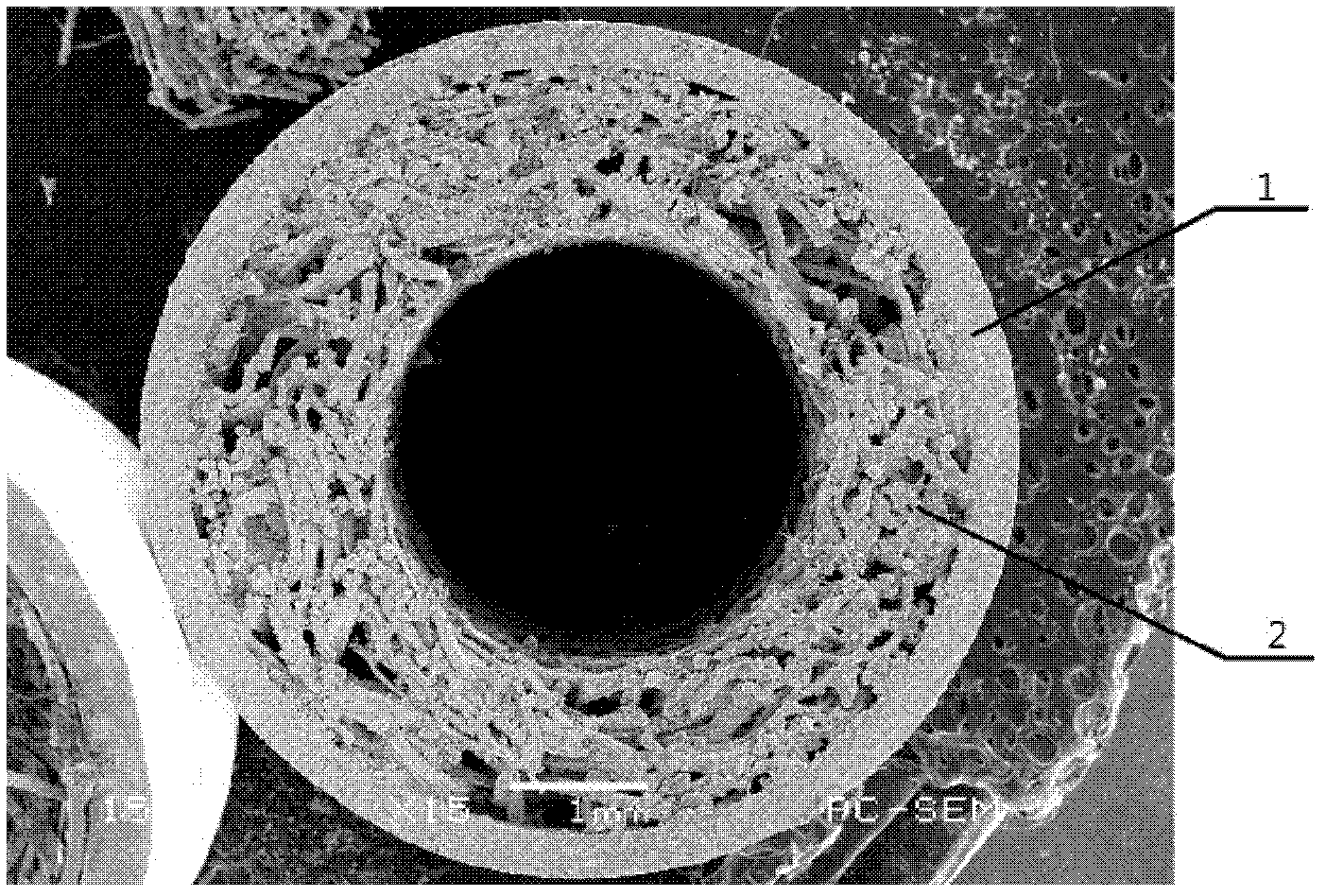

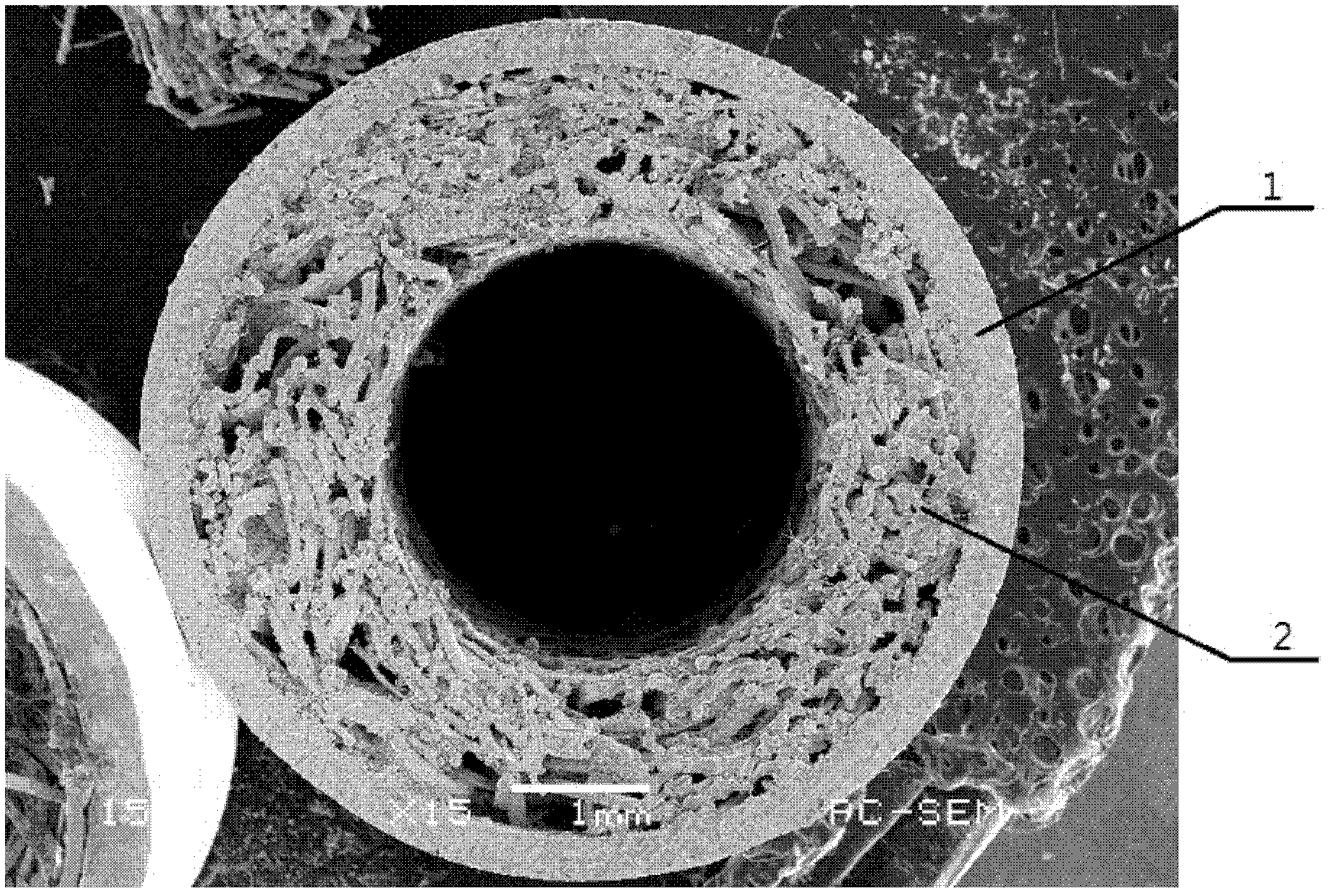

Fiber sintering type micro heat pipe and manufacturing method thereof

InactiveCN102305564ARich multi/microscale surface structuresIncrease contact areaIndirect heat exchangersPorosityMetal fiber

The invention discloses a fiber sintering type micro heat pipe and a manufacturing method thereof. The fiber sintering type micro heat pipe consists of a base pipe, a liquid suction core and a liquid working medium, wherein the liquid suction core is formed by solid-phase sintering for metal fibers. The manufacturing method for the fiber sintering type micro heat pipe mainly comprises four steps, namely preparation for the base pipe, processing of the metal fibers, manufacturing of the liquid suction core and precise encapsulation for the liquid suction core. After the metal fibers are sintered, metallurgical bonding is realized among the fibers and a large quantity of multi-scale pore structures are formed. The fiber sintering type micro heat pipe manufactured by using the method has the advantages of simple process, low cost, high porosity and controllability of the liquid suction core, high permeability, small liquid reflux resistance, large specific surface area of a metal fiber sintering layer, high capillary force and the like, and a stable three-dimensional meshed porous structure is formed among the fibers, so the fiber sintering type micro heat pipe is difficult to damage.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing radioactive waste solidified body

InactiveCN102930915AImprove performanceEasy to excludeRadioactive decontaminationHigh densityPolyvinyl alcohol

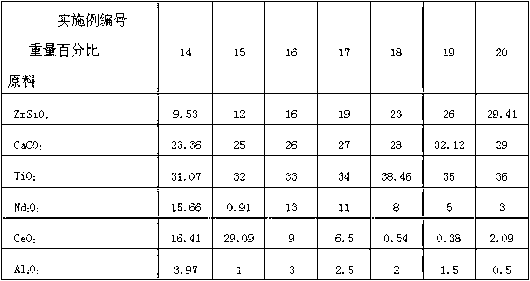

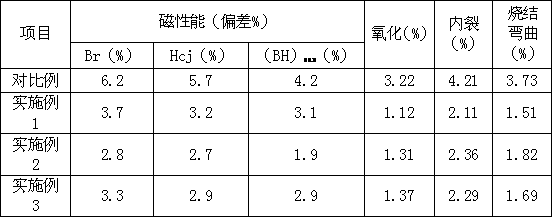

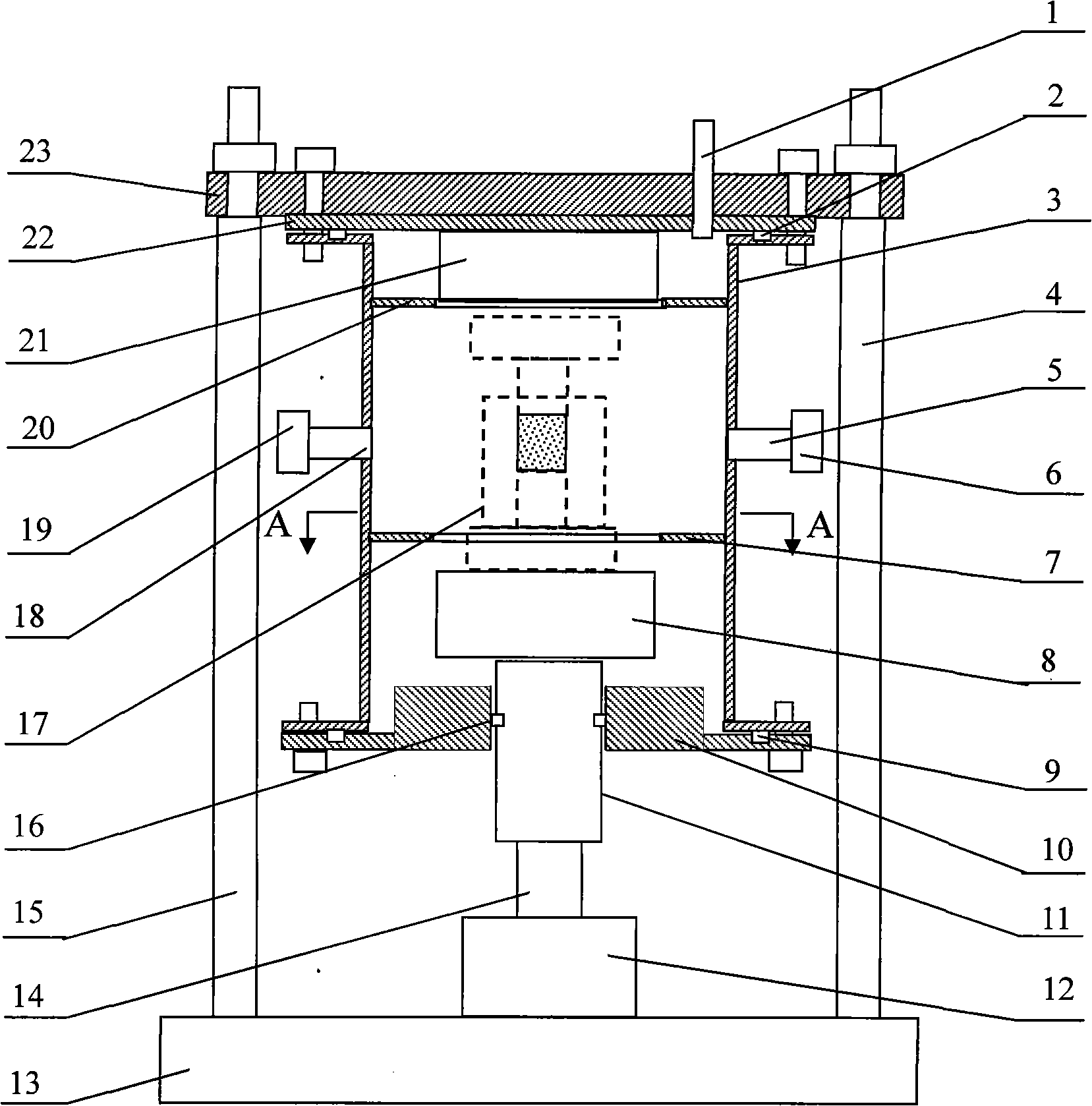

The invention discloses a method for preparing a radioactive waste solidified body. The method is characterized by comprising the following steps of: finely grinding a raw material which comprises 9.53 to 29.41 weight percent of ZrSiO4, 23.36 to 32.12 weight percent of CaCO3, 31.07 to 38.46 weight percent of TiO2, 0 to 15.66 weight percent of Nd2O3, 0 to 29.09 weight percent of CeO2 and 0 to 3.97 weight percent of Al2O3; drying the raw material; and adding polyvinyl alcohol sol, granulating, screening, molding, discharging the sol, performing vacuum hot-pressing sintering, and thus obtaining the radioactive waste solidified body. By adoption of the method, the raw material is low in cost, a high-purity and high-density perovskite acorite and titanite combined mineral solidified body is prepared at low temperature by using a simple and practical hot-pressing sintering technology, and foundation is laid for engineering application to artificial rock solidification treatment of high-level waste.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Partial pressure sintering method for sintering neodymium-iron-boron magnet

ActiveCN103000363AEnsure consistencyGuaranteed uniformityInductances/transformers/magnets manufactureMagnetic materialsMetallurgyVacuum pump

The invention relates to a partial pressure sintering method for sintering a neodymium-iron-boron magnet. Certain inert gases Ar are filled into various deflation sections in the sintering process, the pressure of the Ar gases inside a furnace is regulated according to blank deflation velocity and vacuum pump system exhaust velocity through vacuum degree control, so that heating sintering is carried out by uniformly deflating under different partial pressures of the Ar gases, and negative pressure is still kept. The partial pressure sintering method disclosed by the invention ensures the consistency and uniformity of magnetic property and saves the sintering time.

Owner:宁波永久磁业有限公司

Preparation method of bismuth telluride based bulk nano crystalline thermoelectric material

InactiveCN101786162ASimple processLess investmentThermoelectric device manufacture/treatmentMicrowaveBismuth telluride

The invention relates to a bismuth telluride based bulk nano crystalline thermoelectric material and preparation method thereof. The technical scheme includes that: firstly simple substance powder with mass percent more than 99.99% is taken as raw material, burdening is carried out according to the chemical formula (SbxBi1-x)2Te3 or Bi2(SeyTe1-y)3, wherein x is more than or equal to 0.75 and less than or equal to 0.85, y is more than or equal to 0.04 and less than or equal to 0.06, mixing to be uniform is carried out, and then ball milling is carried out by a ball mill, thus obtaining bismuth telluride base alloy nano powder; secondly, the bismuth telluride base alloy obtained in the first step is loaded into a graphite mould or ceramic mould to be sintered in a micro wave irradiation pressure sintering device; temperature rises to 300-550 DEG C by heating under the condition that the pressure applied to the powder is 10-40MPa, and then heat preservation is carried out for 10-60min under the condition that the pressure applied to the powder is 30-60MPa, thus obtaining the bismuth telluride based bulk nano crystalline thermoelectric material. The invention has the characteristics of less investment, low production cost, simple technology and short period; and the obtained bismuth telluride based bulk nano crystalline thermoelectric material has high performance.

Owner:WUHAN UNIV OF SCI & TECH

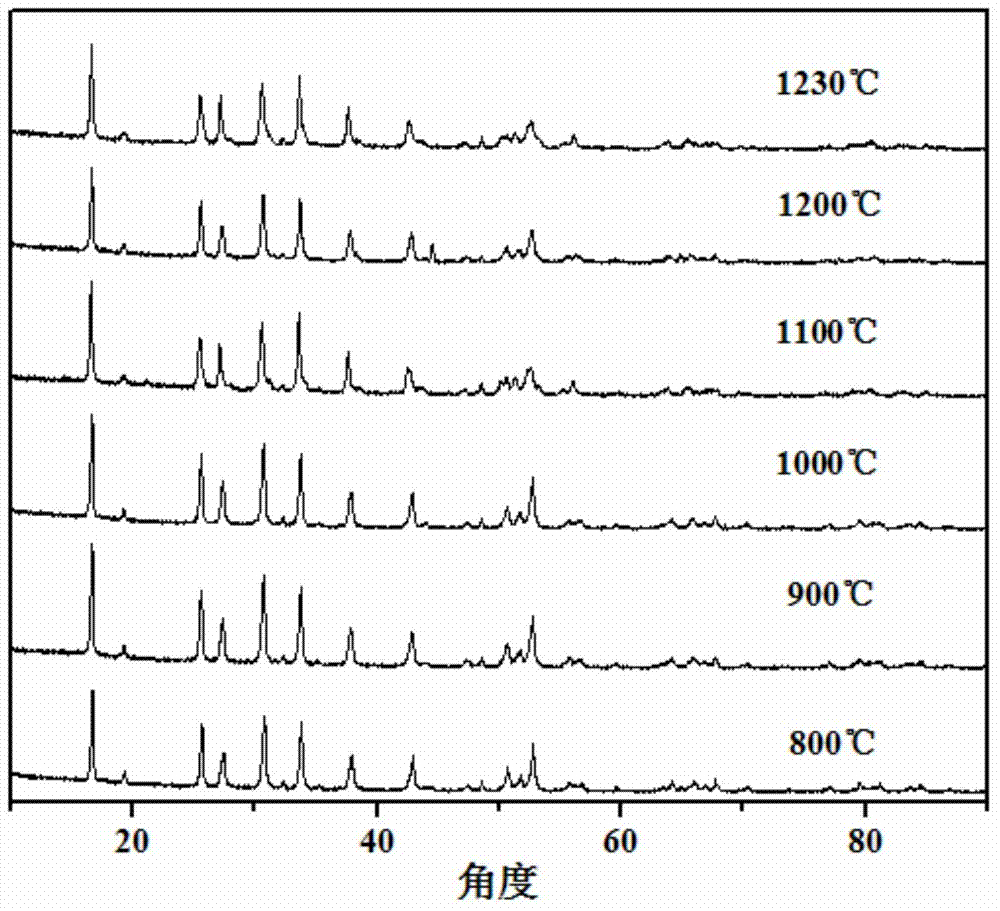

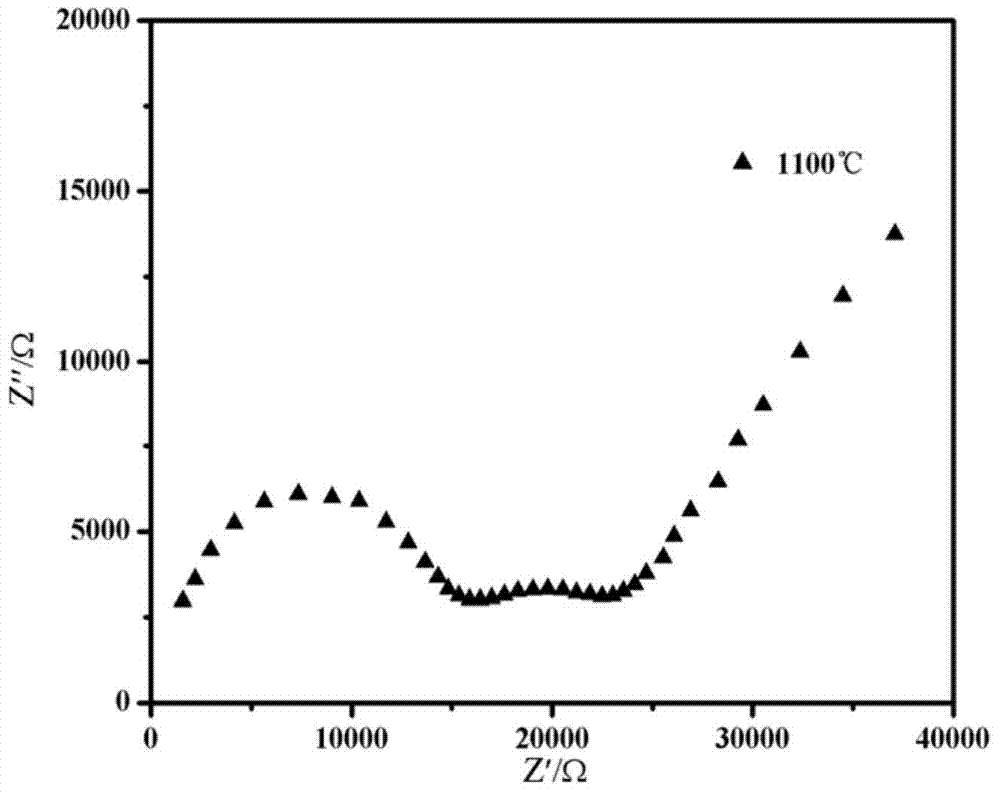

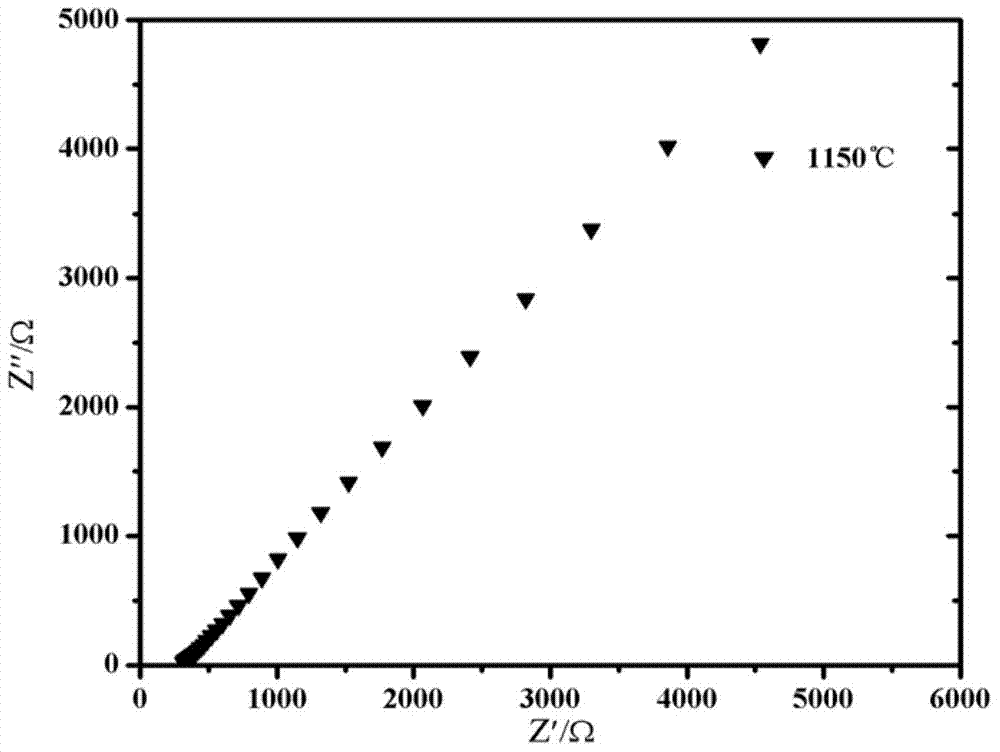

Electric field activated sintering method of solid electrolyte material

The invention provides an electric field activated sintering method of a solid electrolyte material Li7La3Zr2O12 (LLZO). The electric field activated sintering method comprises the following specific steps: ball-milling with a ball and mixing Li2O, La2O3 and ZrO2 powder, the mass percents of which are respectively 9.2-15.5%, 56.2-60.4% and 28.3-30.4%, wherein a zirconium oxide ball is used as a ball-milling medium, isopropanol is used as a solvent, and the ball-milling time is 12-36 hours; carrying out vacuum drying on ball-milling milled powder for 6-12 hours at the temperature of 80 DEG C; and carrying out electric field activated sintering, wherein the temperature is in the range from 800 to 1230 DEG C, the pressure is 0-100 MpaMPa, and a sintered sample has the room-temperature lithium-ion conductivity greater than 6*10<-4S>S / cm. Compared with a conventional solid-phase synthesis method, the electric field activated sintering method has the advantages that the synthesis reaction and the sintering compact process are completed in one step, the synthetic efficiency is improved to a large extent, the preparation technology is simplified, and the LLZO with the high lithium-ion conductivity is obtained.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com