Method for preparing graphene reinforced metal-based composite material through discharge plasma (SPS) sintering

A technology of discharge plasma and composite materials, which is applied in the field of preparation of dense metal matrix composite materials, can solve the problems of low reactivity, uneven distribution of graphene, large density difference, etc., and achieve simple and efficient preparation process and uniform performance. Isotropic, good interface binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Select 7055 aluminum alloy powder with a particle size of 50 μm and ball mill it for 45 minutes. After ball milling, put the powder into a graphite mold for SPS sintering. Sintering parameters: pressure 40MPa, sintering temperature 400°C, heating rate 50°C / min, 400°C, etc. Press and hold for 1 minute, the current on-off ratio is 4:1, and the heat preservation is completed with water cooling. Obtain a dense 7055 aluminum alloy block without graphene, numbered as 1# sample

Embodiment 2

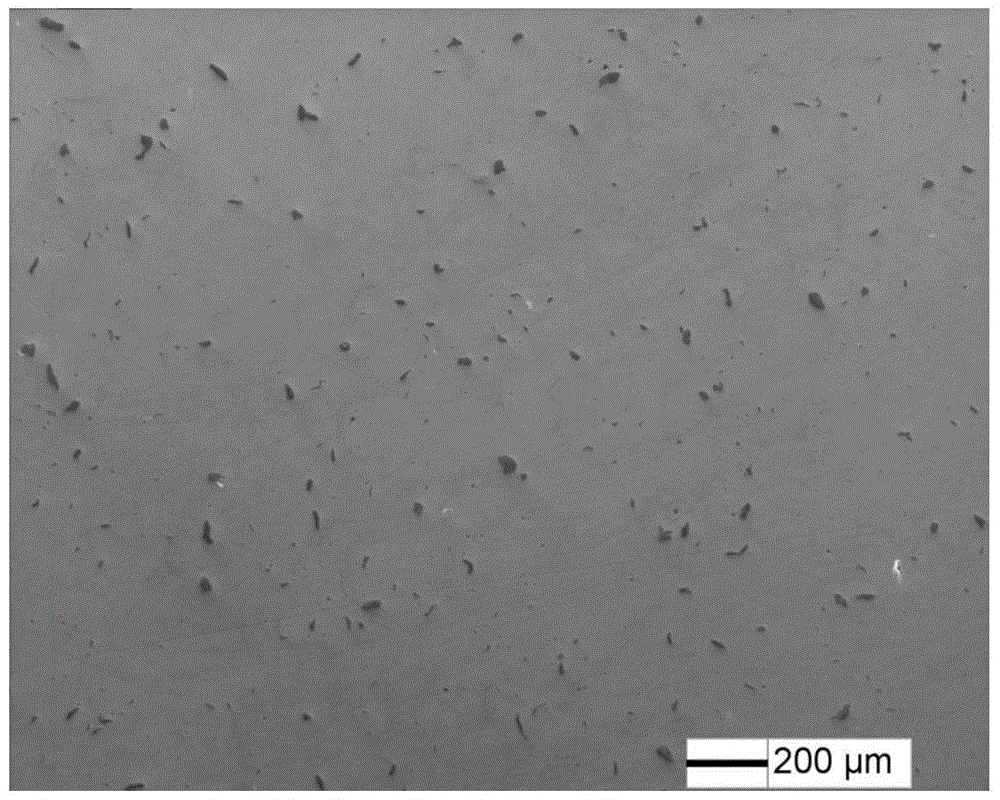

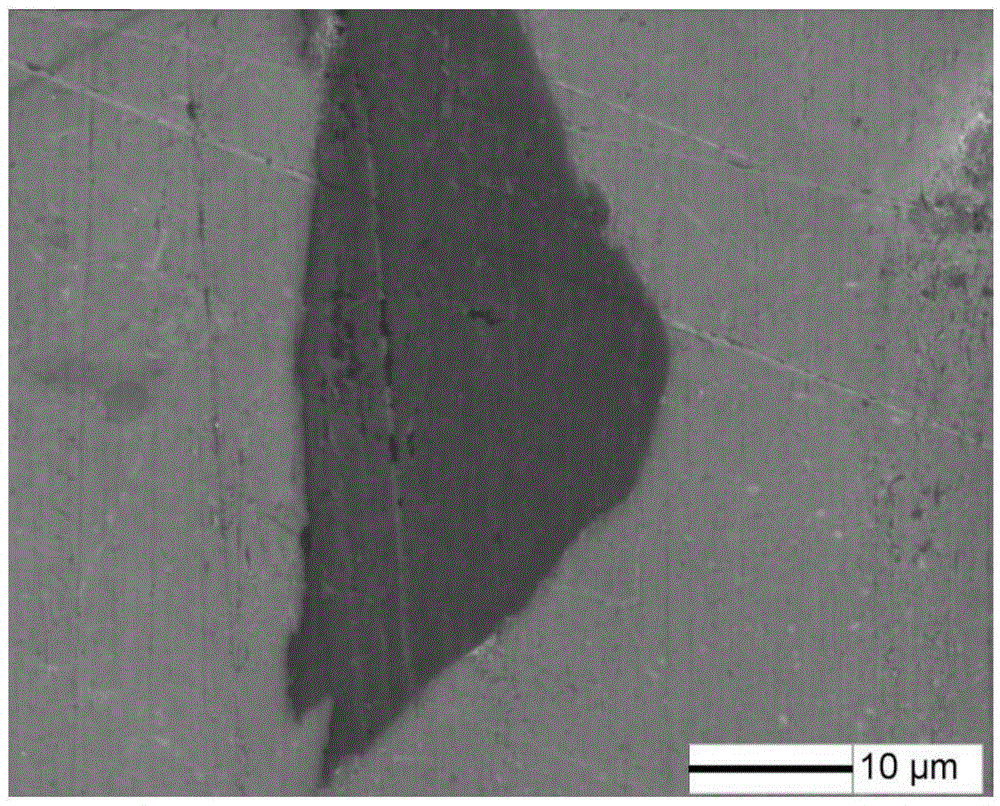

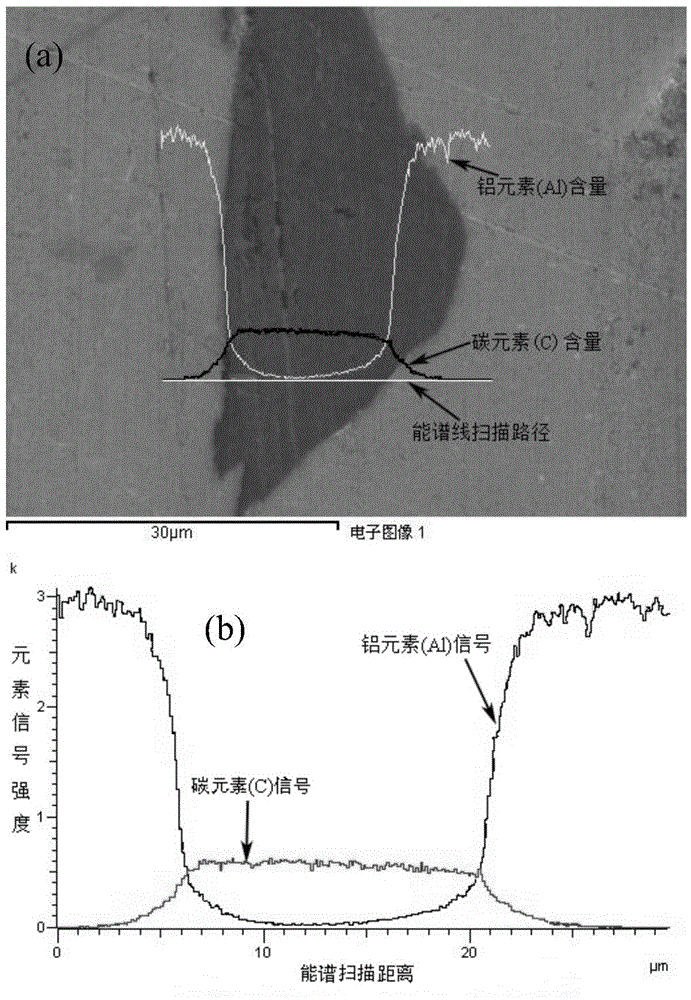

[0022] According to the mass ratio of 1:49, the graphene powder and the 7055 aluminum alloy powder with a particle size of 50 μm are evenly mixed, and ball milled for 45 minutes; the mixed composite powder is put into a graphite mold for SPS sintering, and the sintering parameters are: pressure 40MPa, sintering temperature The temperature is 400°C, the heating rate is 50°C / min, 400°C isobaric heat preservation for 1min, the current on-off ratio is 4:1, and water cooling is completed at the end of heat preservation. A dense 7055 aluminum alloy-based composite material with a mass fraction of graphene of 2% was obtained, numbered 2#.

Embodiment 3

[0024] According to the mass ratio of 1:24, the graphene powder and the 7055 aluminum alloy powder with a particle size of 50 μm are uniformly mixed, and ball milled for 45 minutes; the mixed composite powder is put into a graphite mold for SPS sintering, sintering parameters: pressure 40MPa, sintering temperature The temperature is 400°C, the heating rate is 50°C / min, 400°C isobaric heat preservation for 1min, the current on-off ratio is 4:1, and water cooling is completed at the end of heat preservation. A dense 7055 aluminum alloy-based composite material with a mass fraction of graphene of 4% was obtained, numbered 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com