Patents

Literature

1310 results about "Pure metals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

By definition, pure metals consist of a single element. Samples of these metals contain nothing but atoms of a single metallic substance.

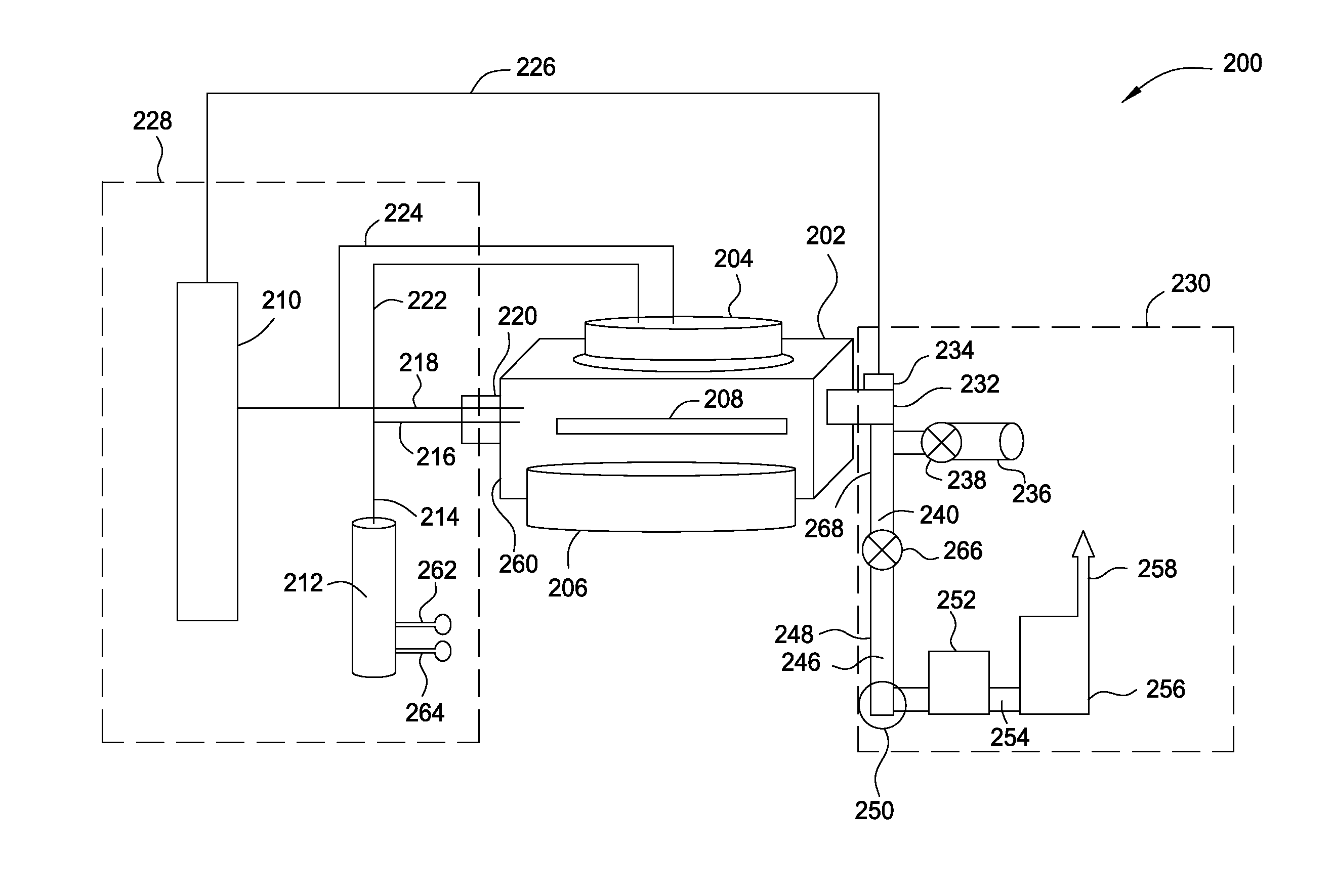

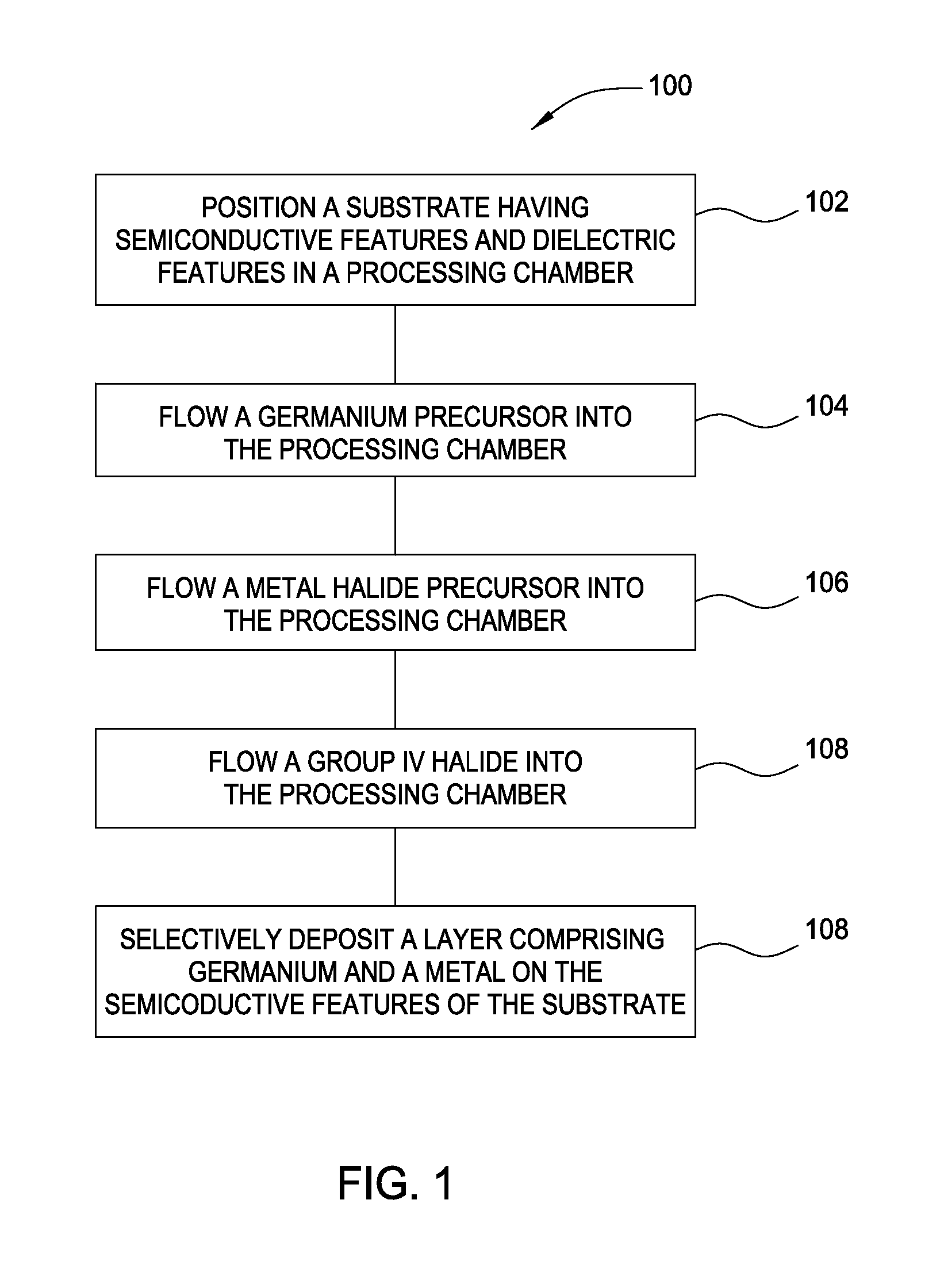

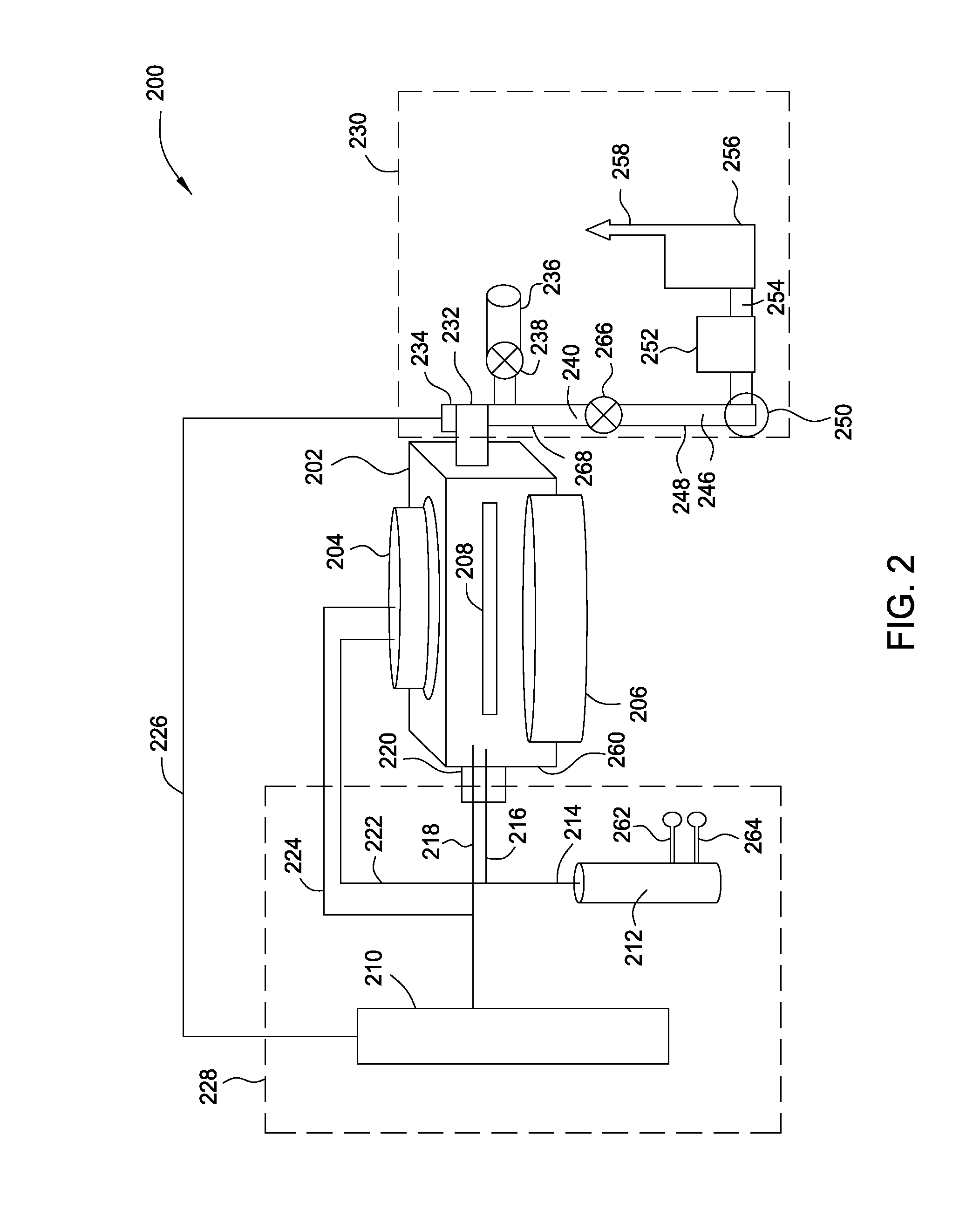

Method and apparatus for germanium tin alloy formation by thermal CVD

InactiveUS20130280891A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSelective depositionLiquid metal

A method and apparatus for forming semiconductive semiconductor-metal alloy layers is described. A germanium precursor and a metal precursor are provided to a chamber, and an epitaxial layer of germanium-metal alloy, optionally including silicon, is formed on the substrate. The metal precursor is typically a metal halide, which may be provided by evaporating a liquid metal halide, subliming a solid metal halide, or by contacting a pure metal with a halogen gas. A group IV halide deposition control agent is used to provide selective deposition on semiconductive regions of the substrate relative to dielectric regions. The semiconductive semiconductor-metal alloy layers may be doped, for example with boron, phosphorus, and / or arsenic. The precursors may be provided through a showerhead or through a side entry point, and an exhaust system coupled to the chamber may be separately heated to manage condensation of exhaust components.

Owner:APPLIED MATERIALS INC

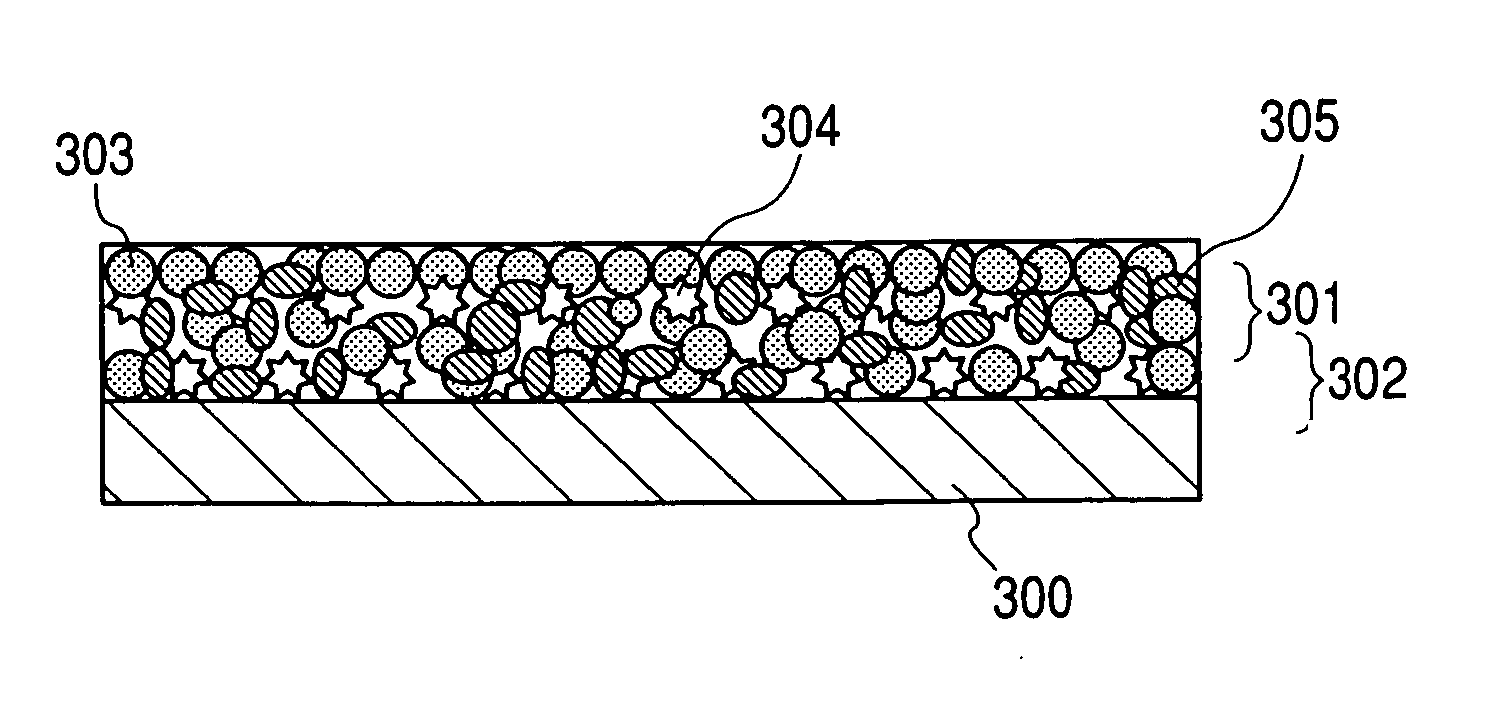

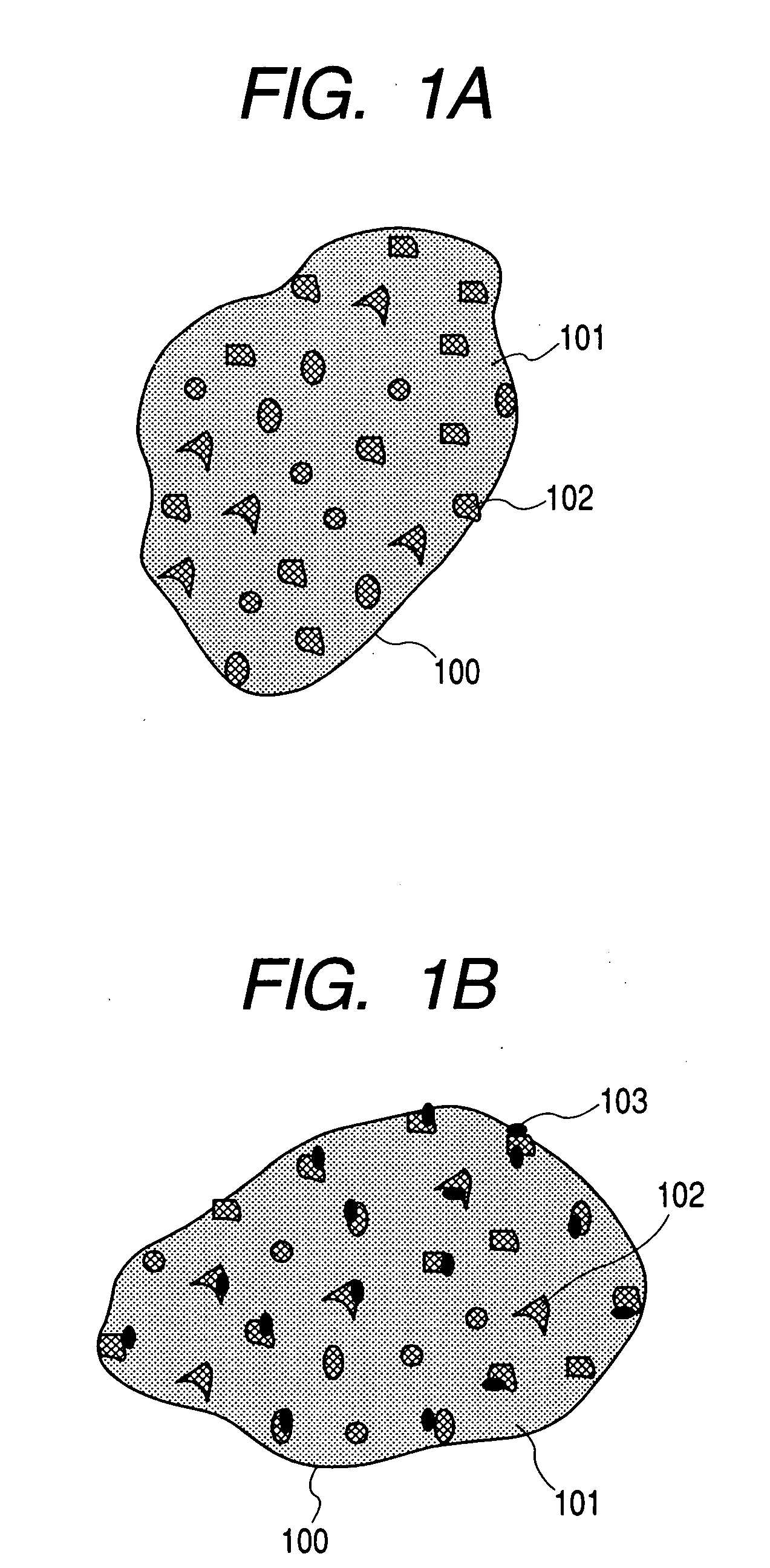

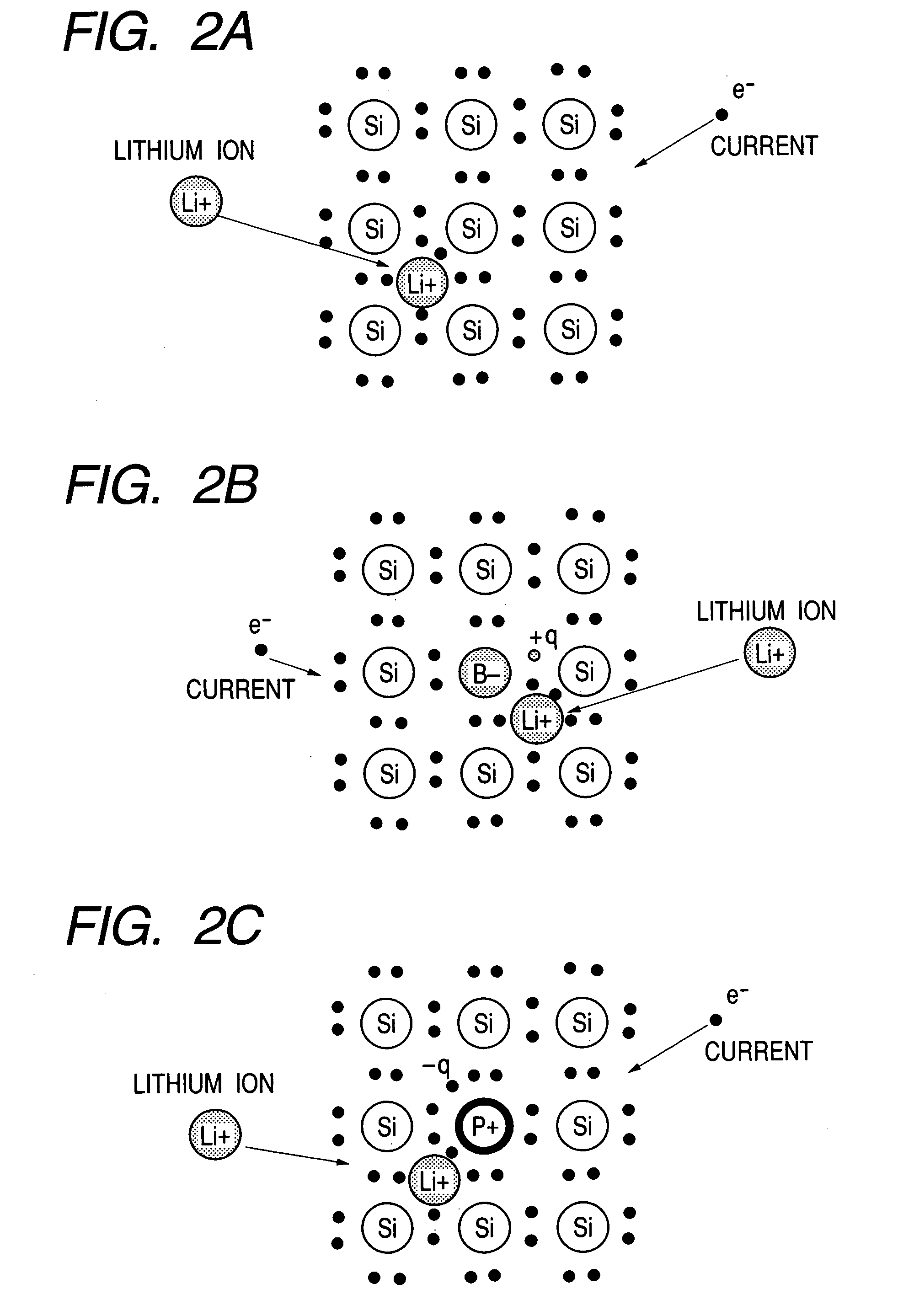

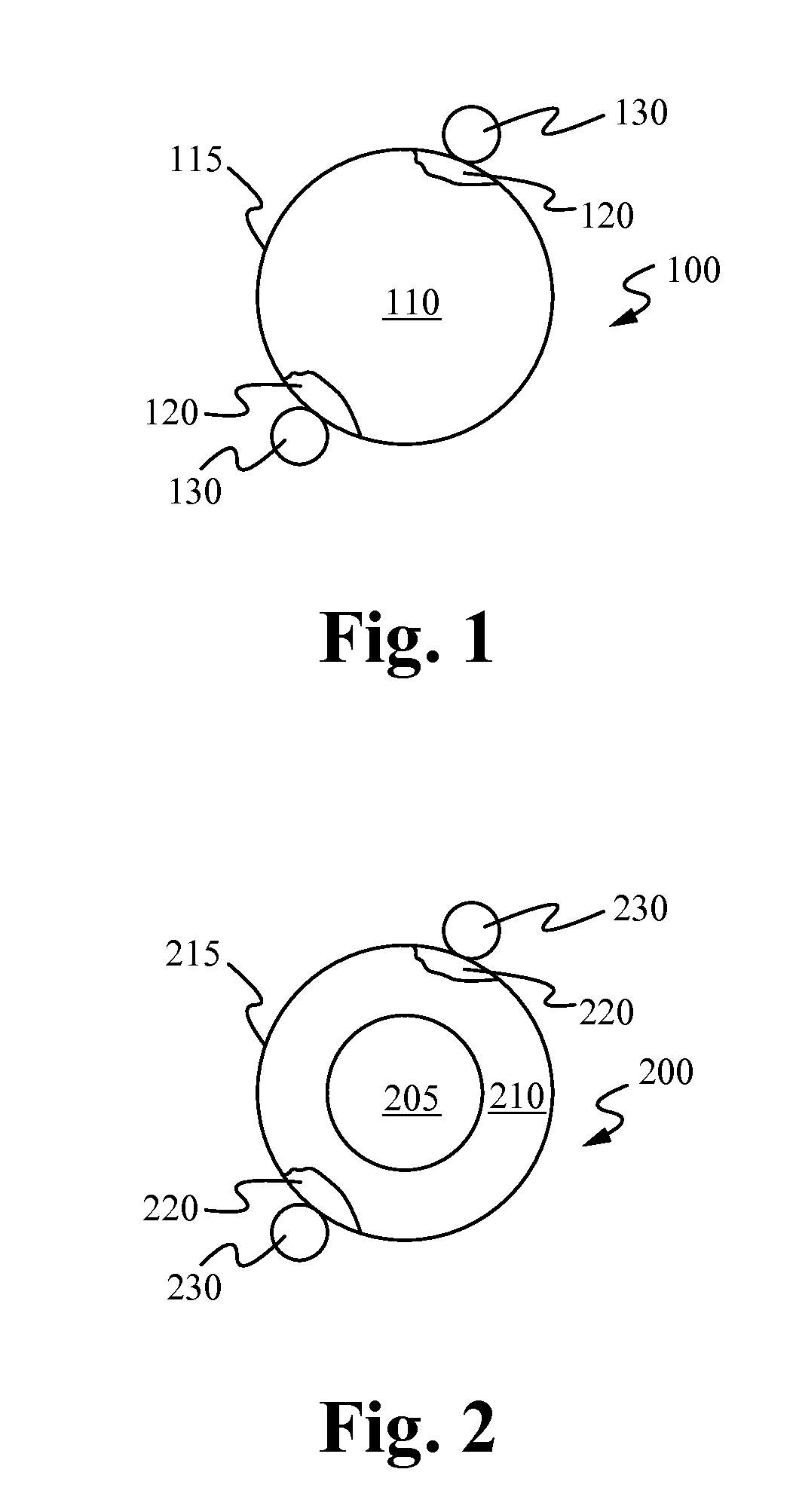

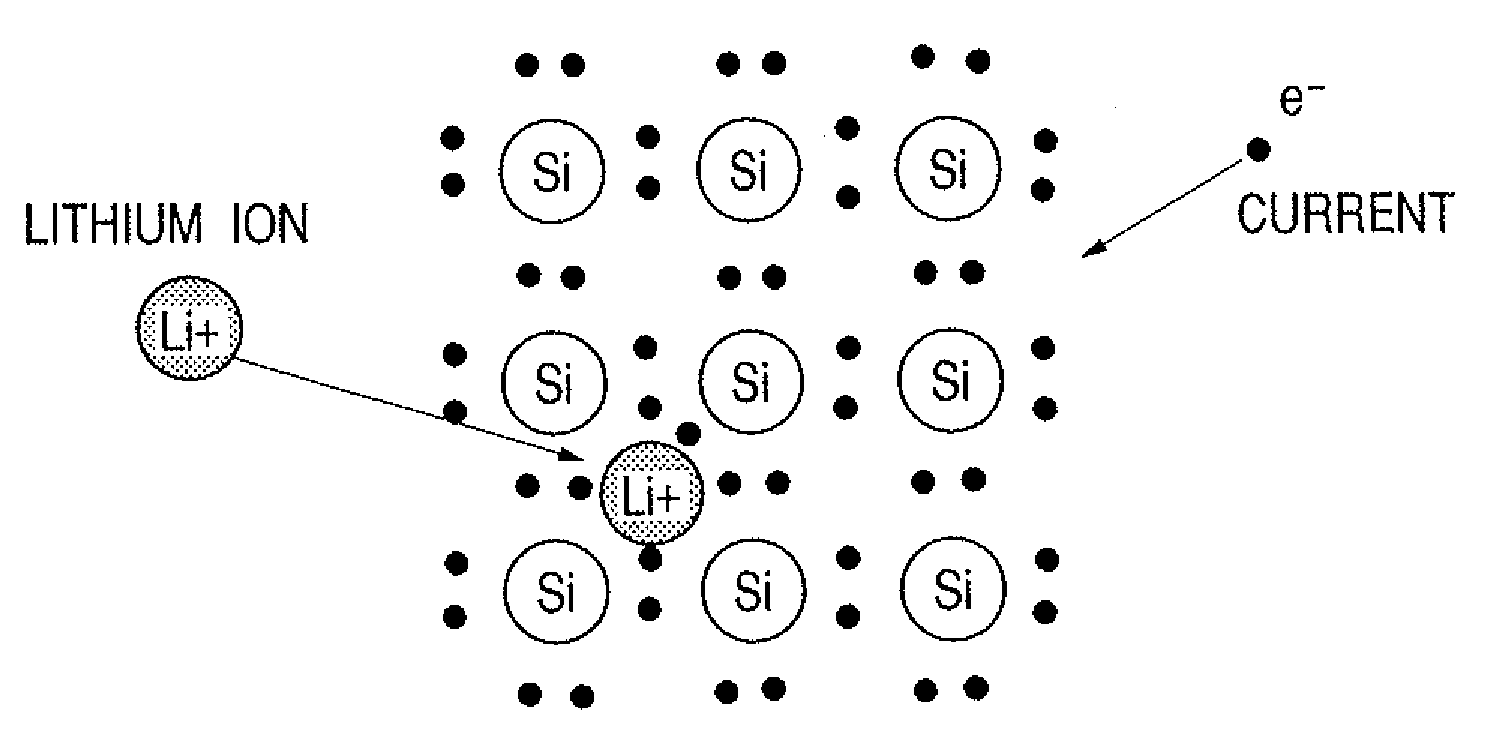

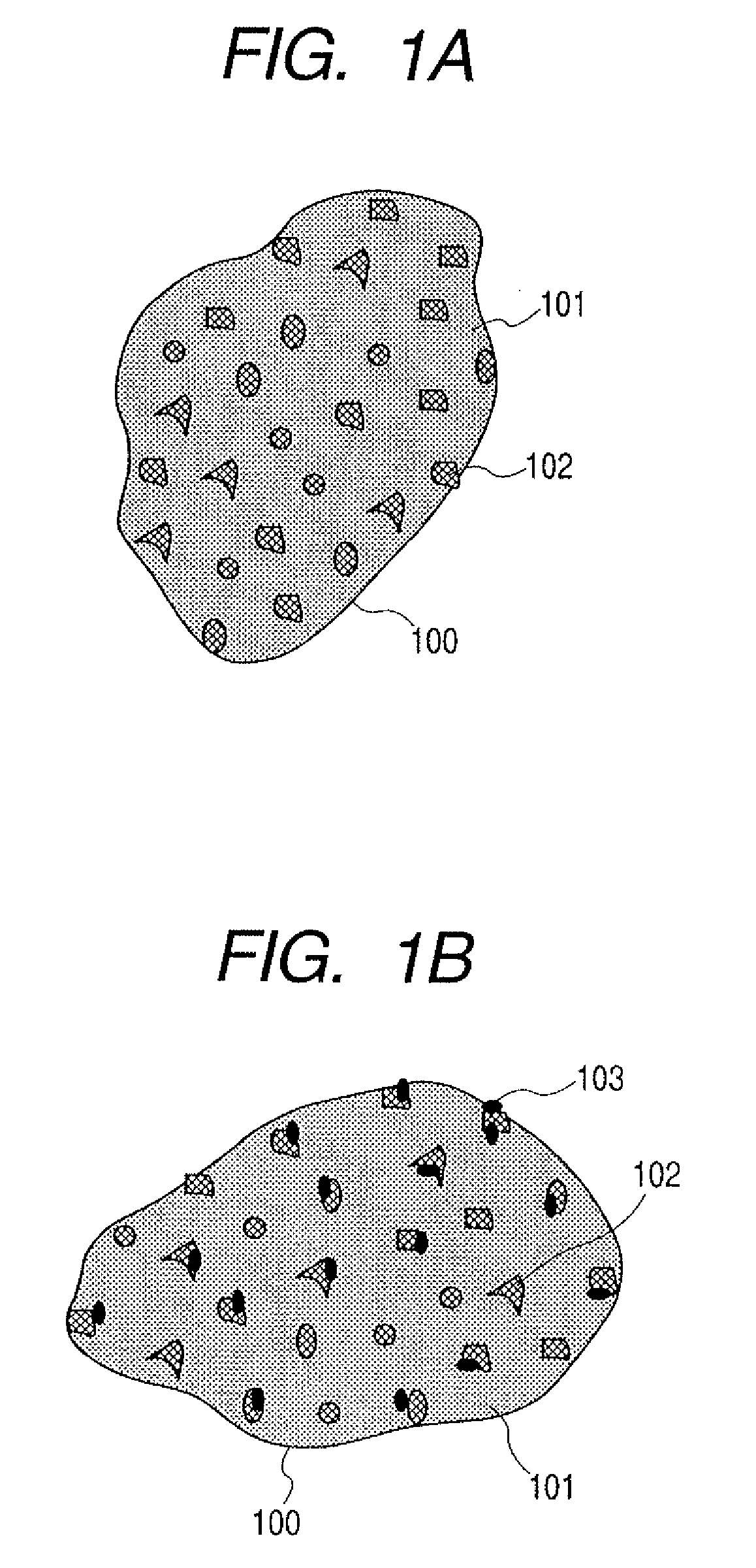

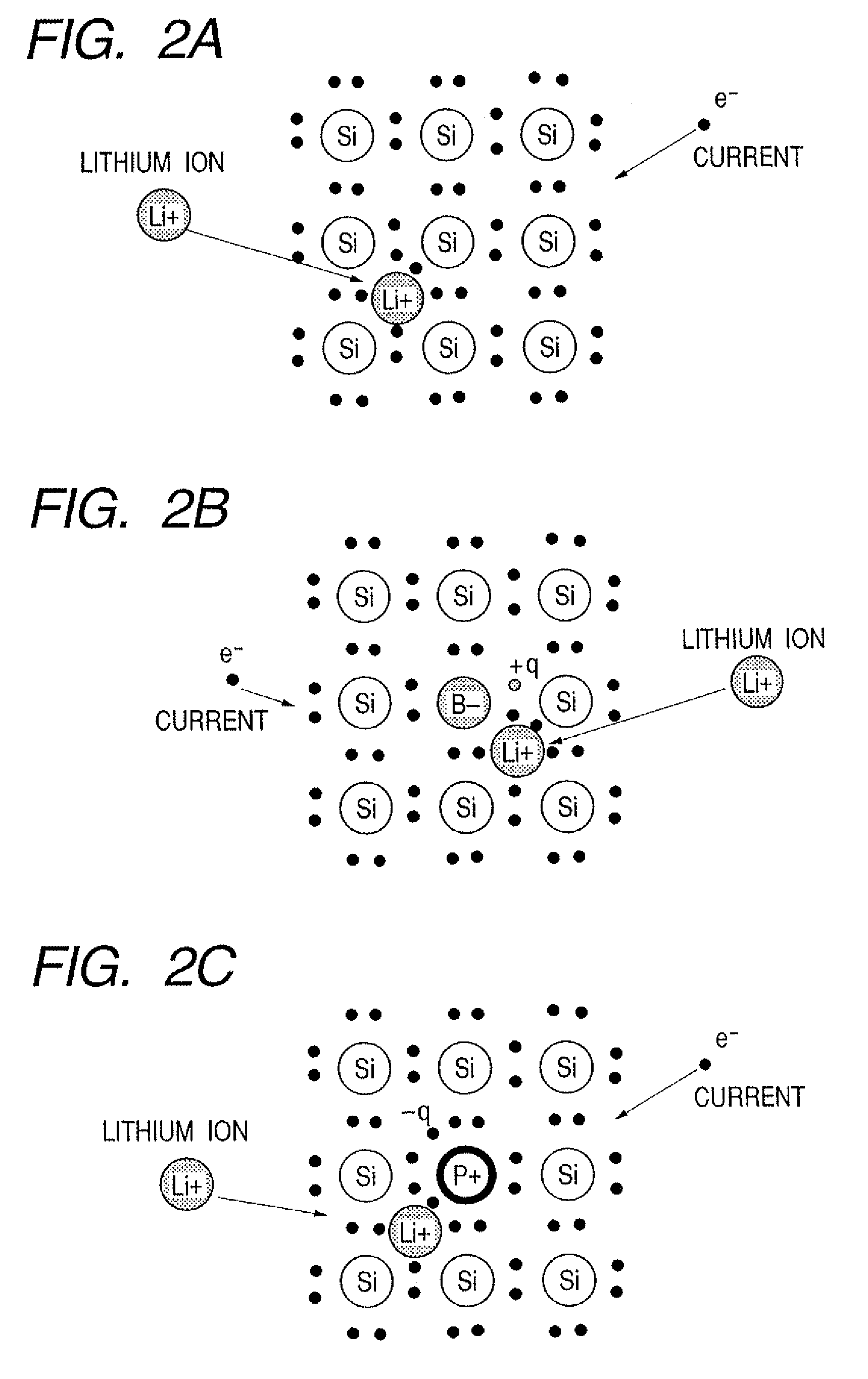

Electrode material for lithium secondary battery and electrode structure having the electrode material

InactiveUS20060040182A1Reduce conductivityImprove conductivityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumLiquid state

The electrode material for a lithium secondary battery according to the present invention includes particles of a solid state alloy having silicon as a main component, wherein the particles of the solid state alloy have a microcrystal or amorphous material including an element other than silicon, dispersed in microcrystalline silicon or amorphized silicon. The solid state alloy preferably contains a pure metal or a solid solution. The composition of the alloy preferably has an element composition in which the alloy is completely mixed in a melted liquid state, whereby the alloy has a single phase in a melted liquid state without presence of two or more phases. The element composition can be determined by the kind of elements constituting the alloy and an atomic ratio of the elements.

Owner:CANON KK

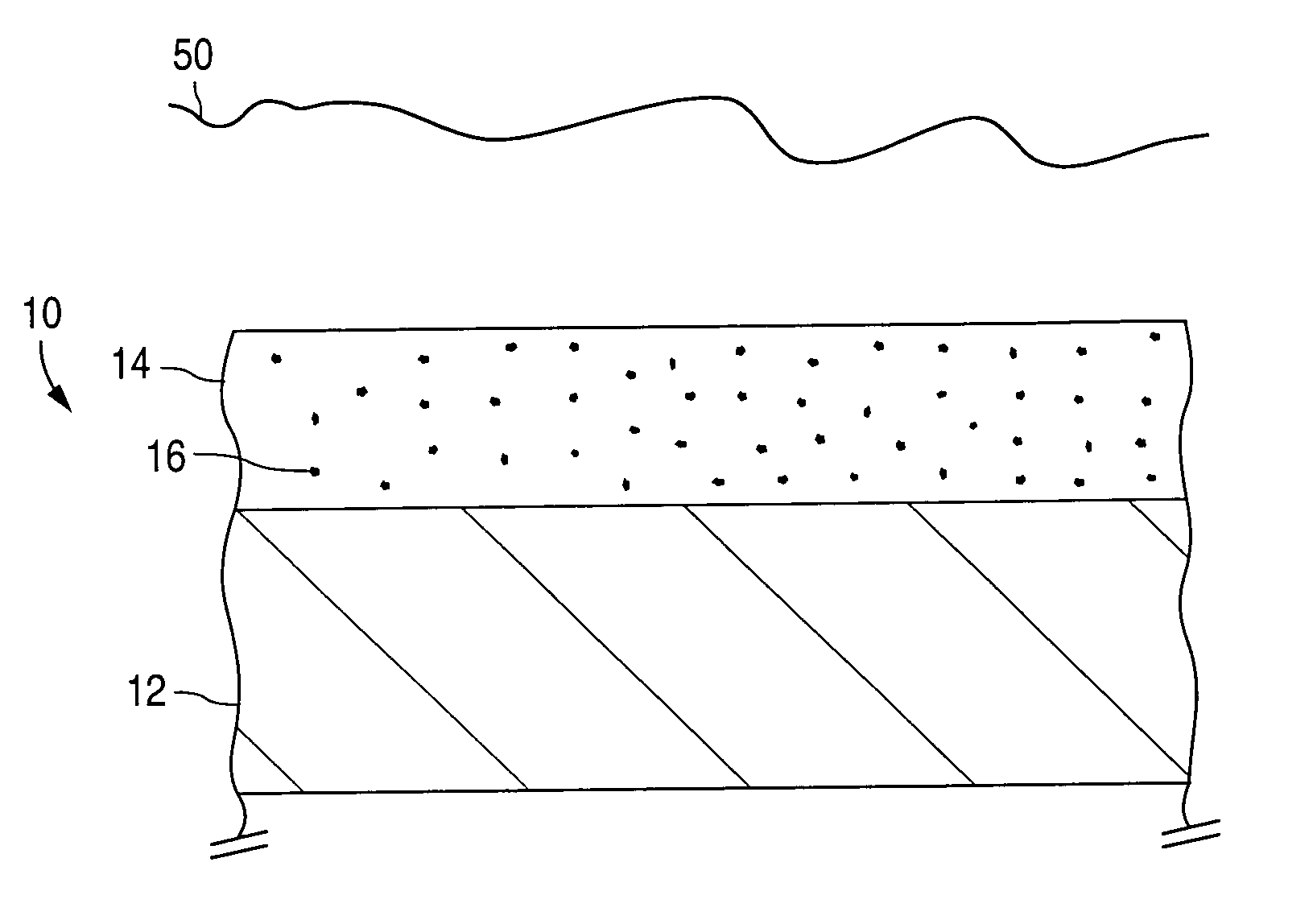

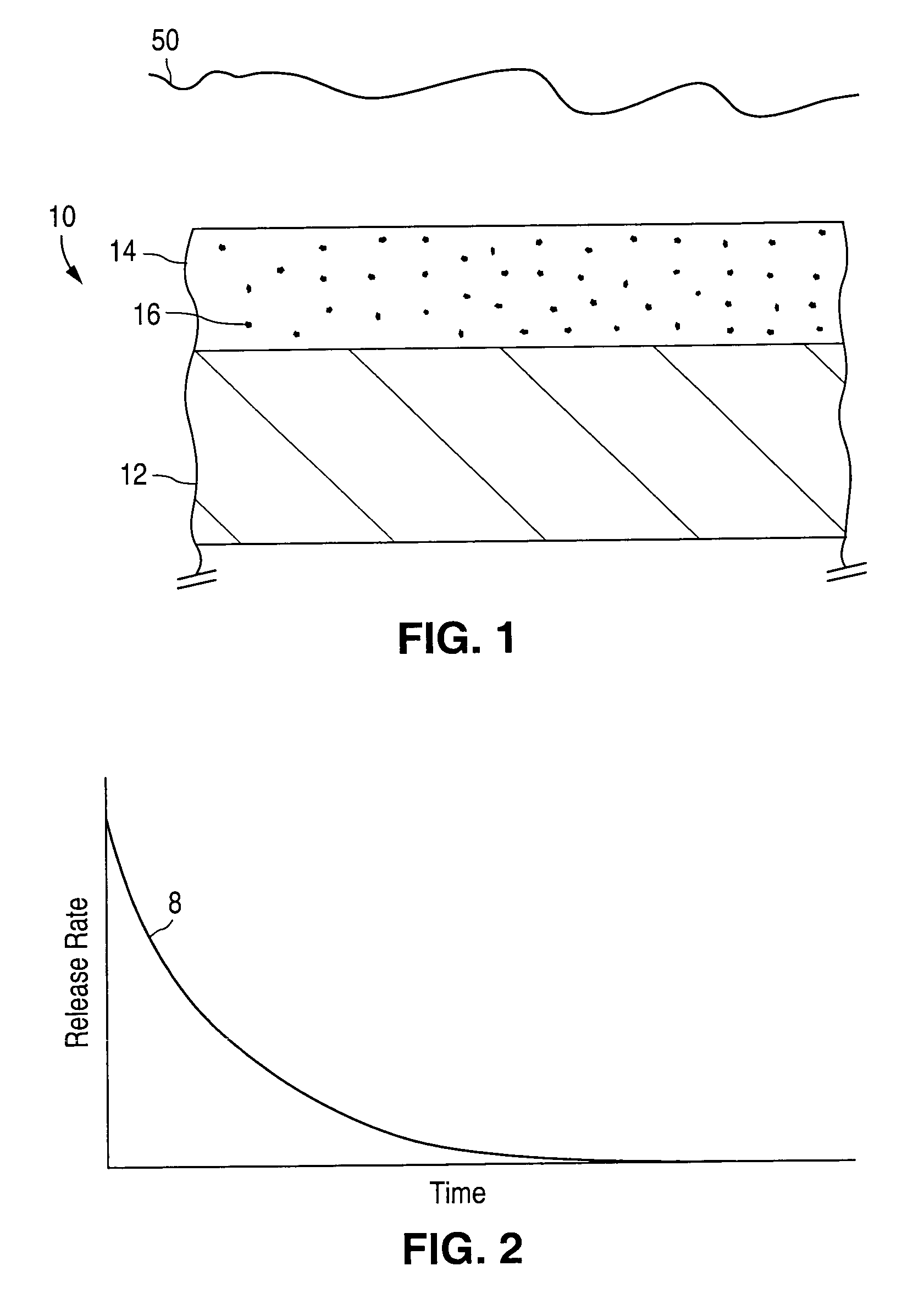

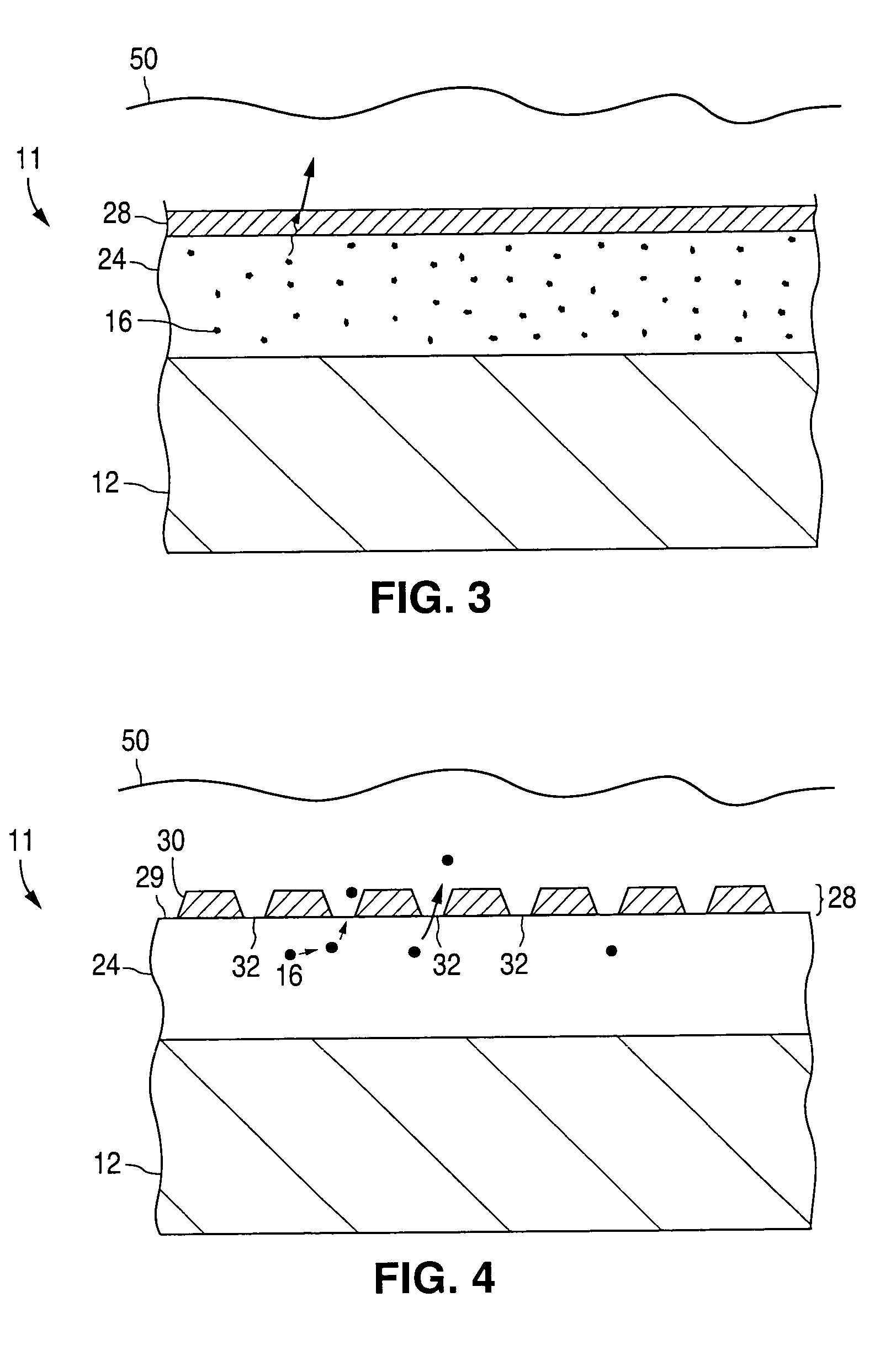

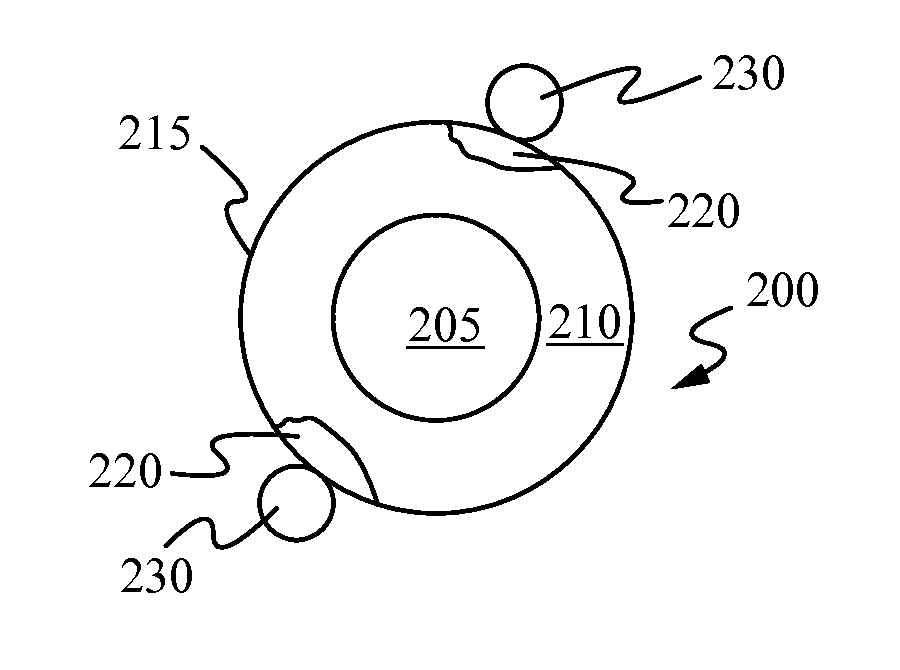

Barriers for polymer-coated implantable medical devices and methods for making the same

InactiveUS6953560B1Reduce and prevent and inflammationReduce and prevent proliferationStentsSurgeryHafniumPt element

An implantable medical device and methods for making the implantable medical device are disclosed. The implantable medical device includes a substrate. At least a portion of the substrate is coated with a first layer including a polymer containing a drug. A barrier overlies the first layer. The barrier significantly reduces the rate of release of the drug from the polymer, thereby sustaining release of the drug from the medical device for a longer time.The barrier may be a homogeneous layer overlying the first layer, or a number of discrete deposits over the first layer. Alternatively, the barrier may be intermixed with an outer portion of the first layer. The barrier material is biocompatible, and typically has a thickness ranging from about 50 angstroms to about 20,000 microns. Suitable materials for the barrier include, but are not limited to, inorganic compounds, such as inorganic silicides, oxides, nitrides, carbides, as well as pure metals such as aluminum, chromium, gold, hafnium, iridium, niobium, palladium, platinum, tantalum, titanium, tungsten, zirconium, and alloys of these metals. The barriers disclosed may be applied to the first layer by several techniques, depending on the material being applied. Exemplary deposition techniques include physical vapor deposition, alkoxide hydrolysis, and electroless plating.The implantable device may be a stent or a graft, among other possibilities.

Owner:ABBOTT CARDIOVASCULAR

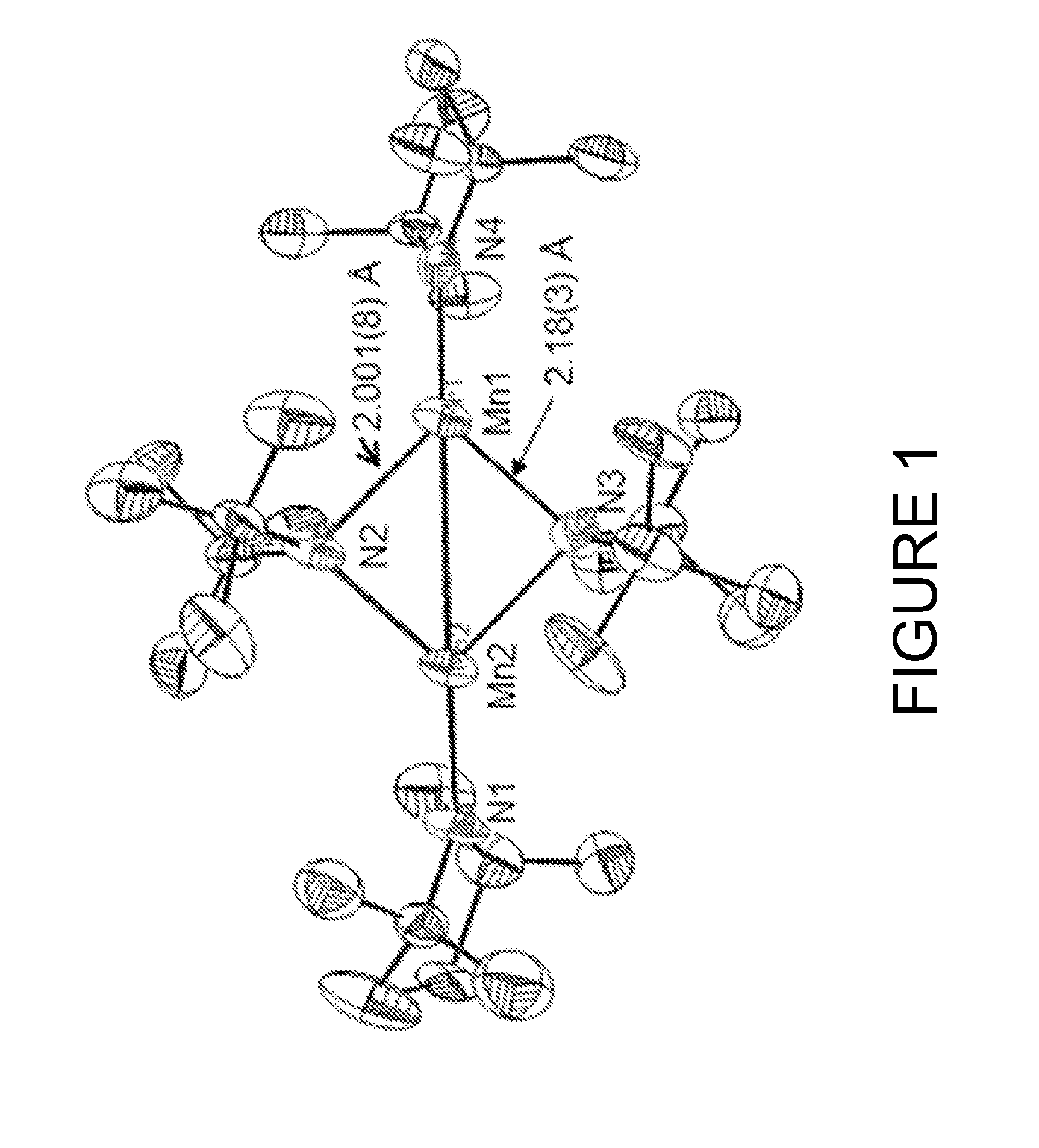

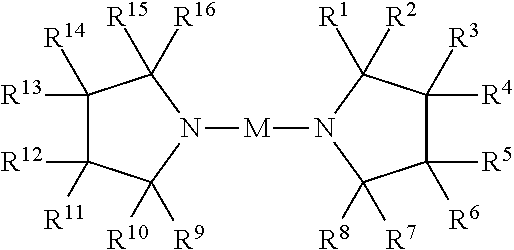

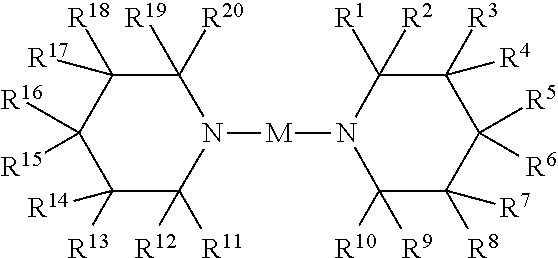

Metal amides of cyclic amines

ActiveUS20160152649A1Improve thermal stabilityImprove conductivityIron group organic compounds without C-metal linkagesNickel organic compoundsGermanideMetal silicide

Compounds, and oligomers of the compounds, are synthesized with cyclic amine ligands attached to a metal atom. These compounds are useful for the synthesis of materials containing metals. Examples include pure metals, metal alloys, metal oxides, metal nitrides, metal phosphides, metal sulfides, metal selenides, metal tellurides, metal borides, metal carbides, metal silicides and metal germanides. Techniques for materials synthesis include vapor deposition (chemical vapor deposition and atomic layer deposition), liquid solution methods (sol-gel and precipitation) and solid-state pyrolysis. Suitable applications include electrical interconnects in microelectronics and magnetoresistant layers in magnetic information storage devices. The films have very uniform thickness and high step coverage in narrow holes.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

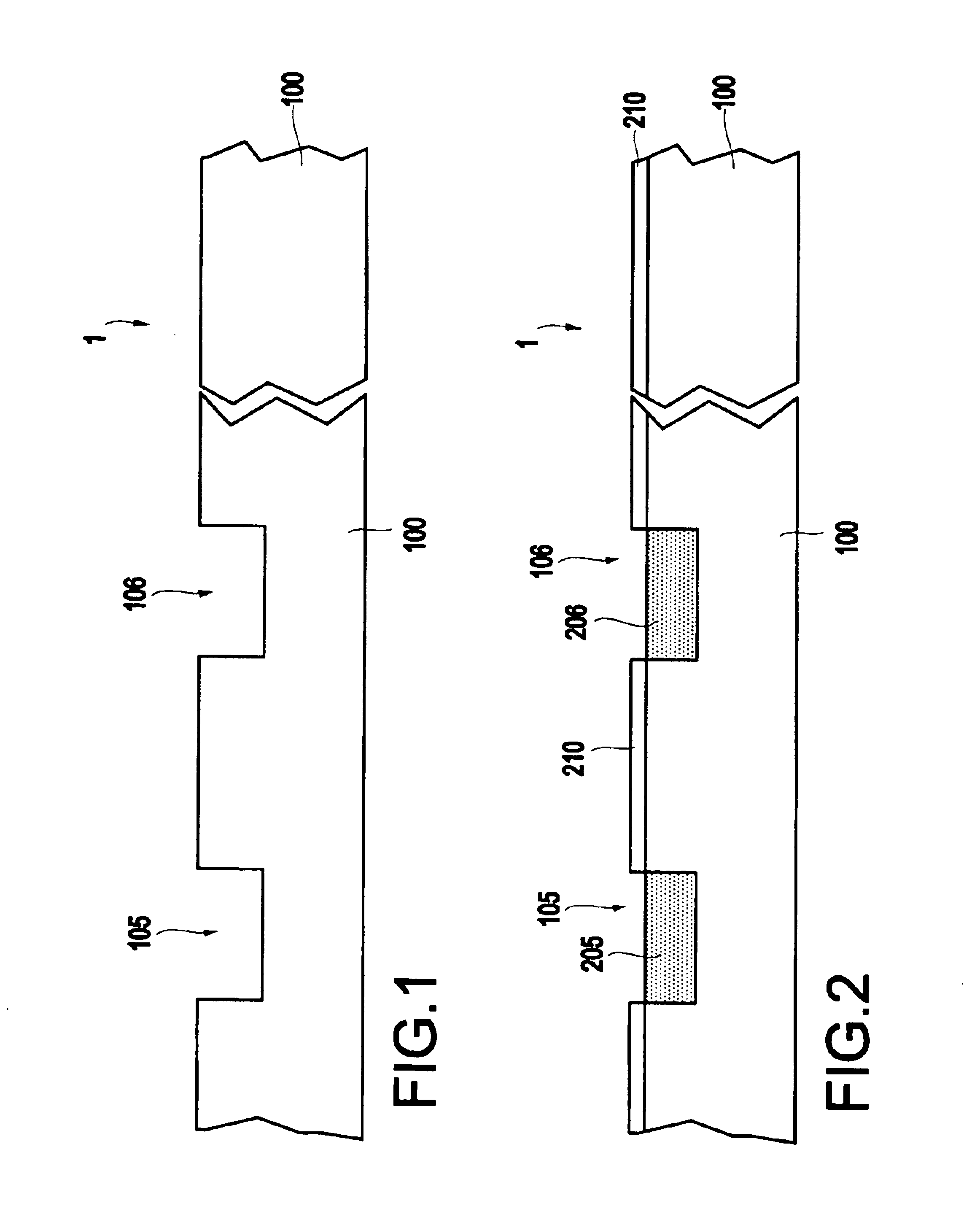

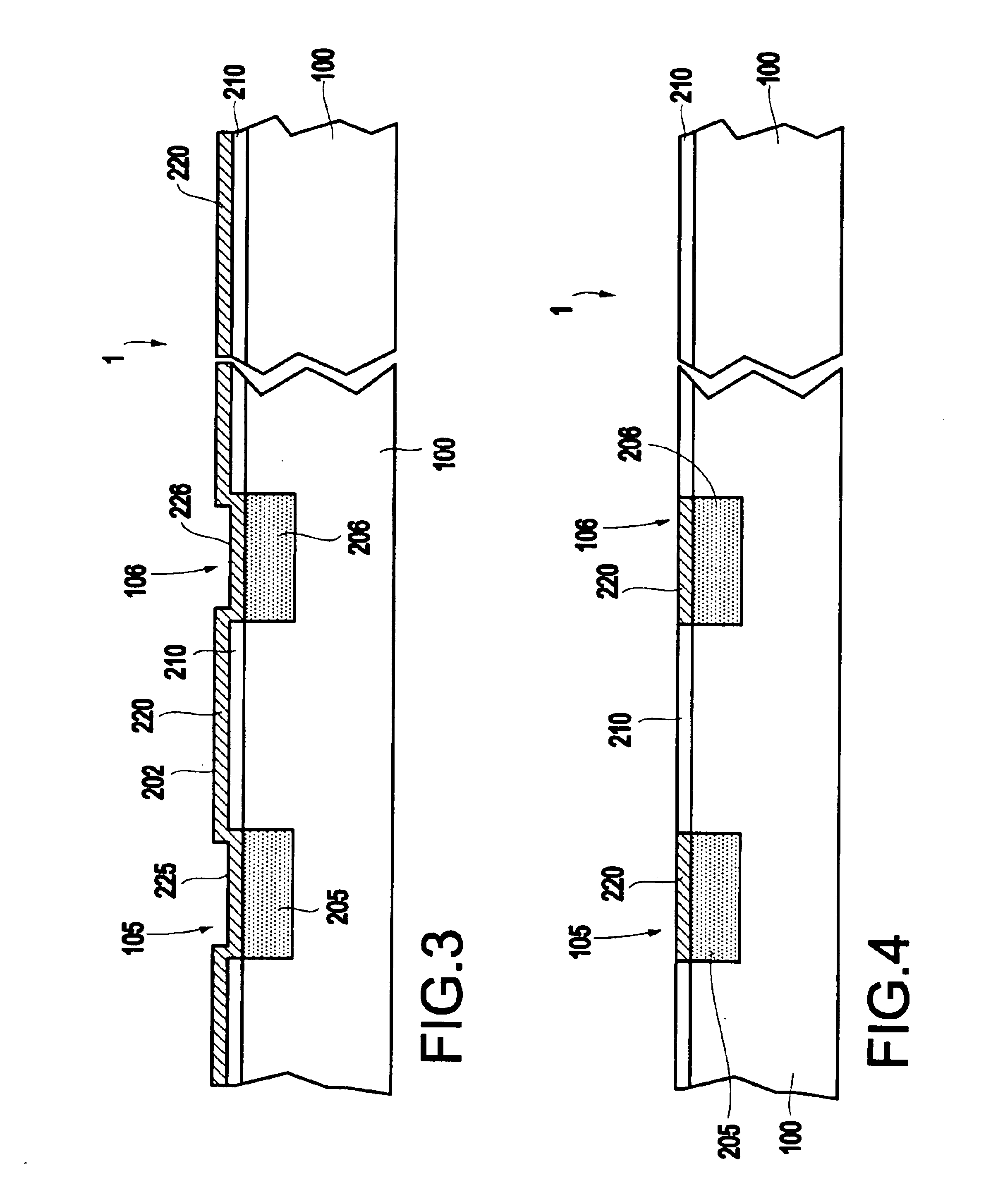

Printing of electronic circuits and components

InactiveUS6855378B1Reduce the content of particulate matterCell electrodesFinal product manufactureParticulatesHigh concentration

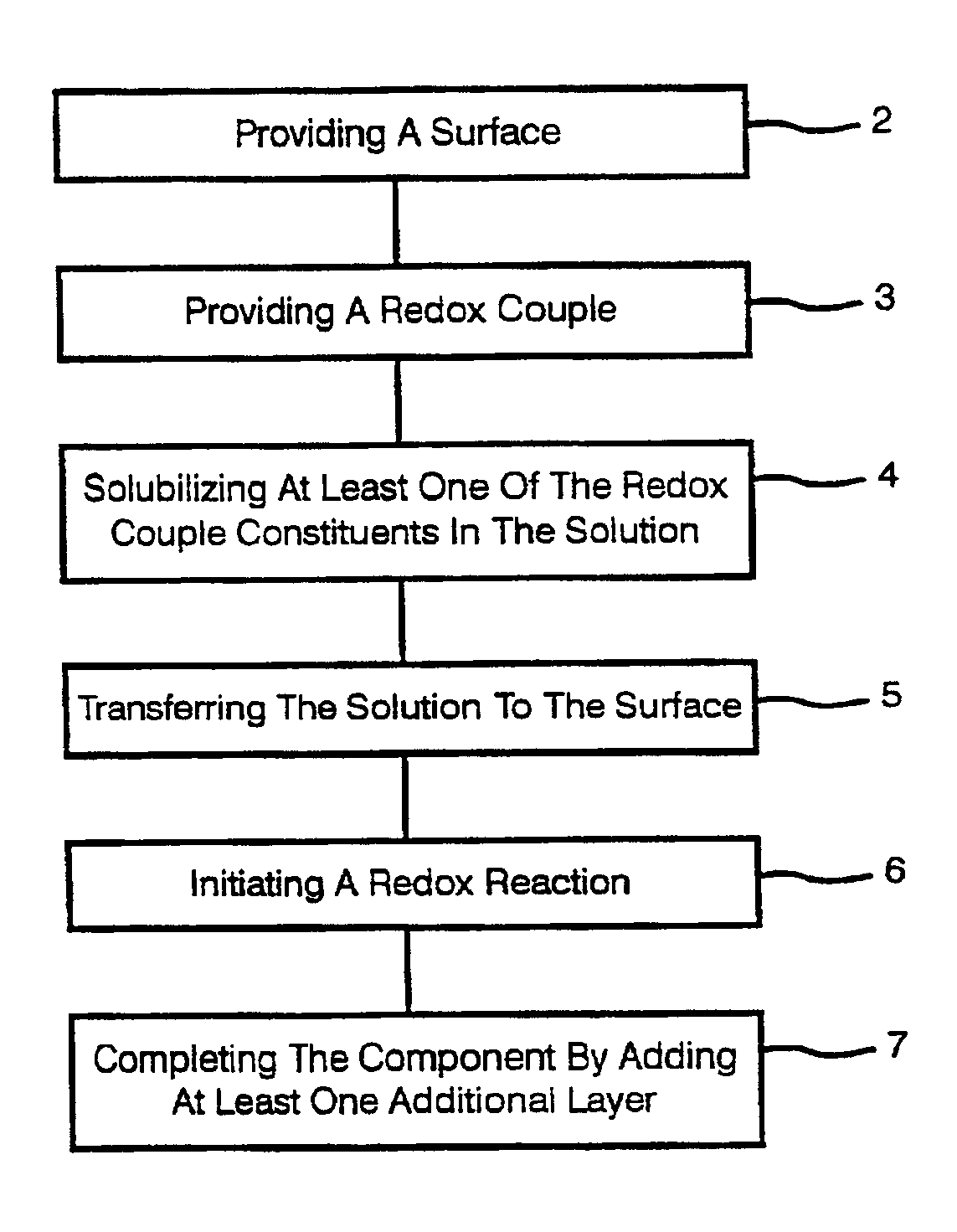

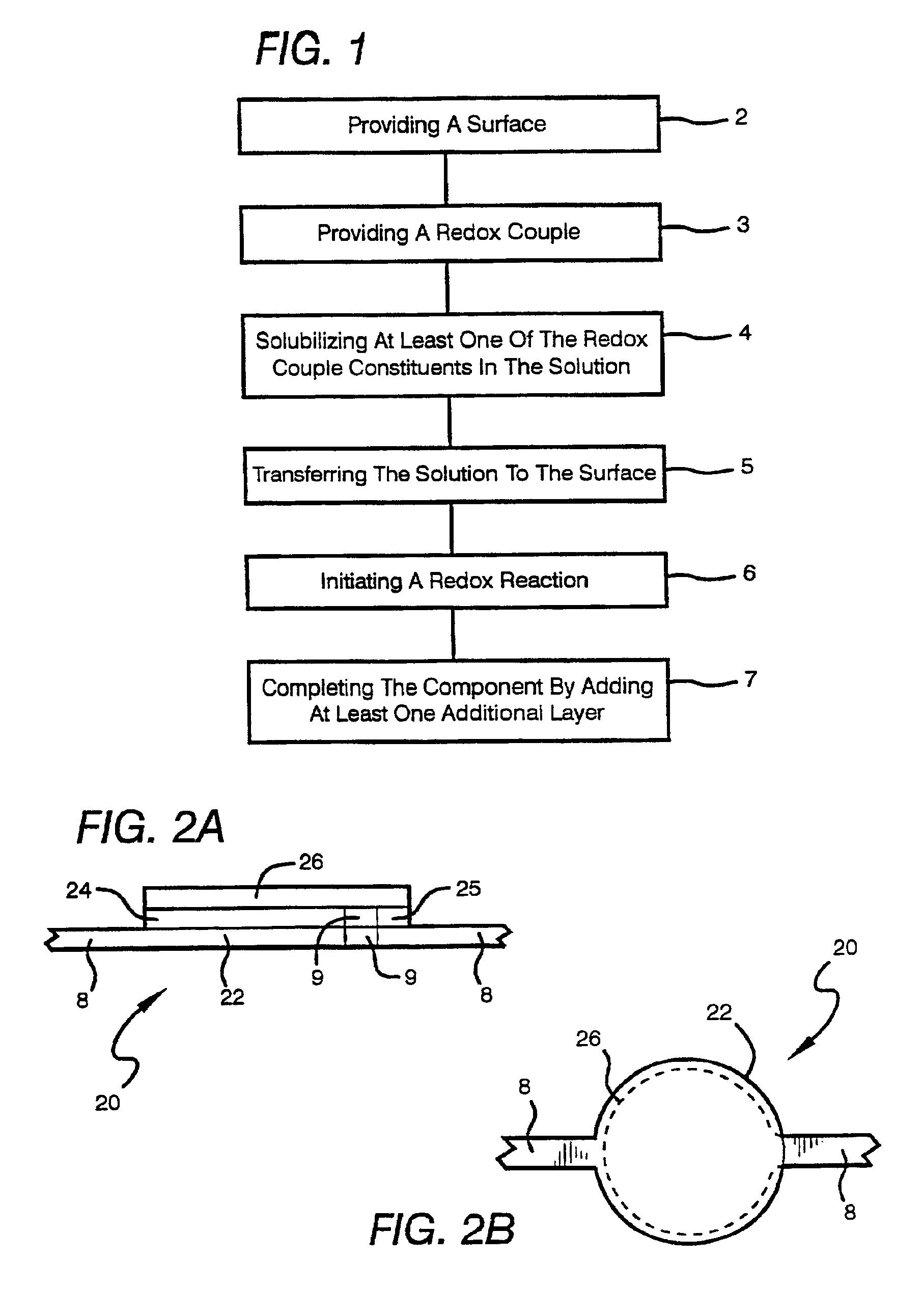

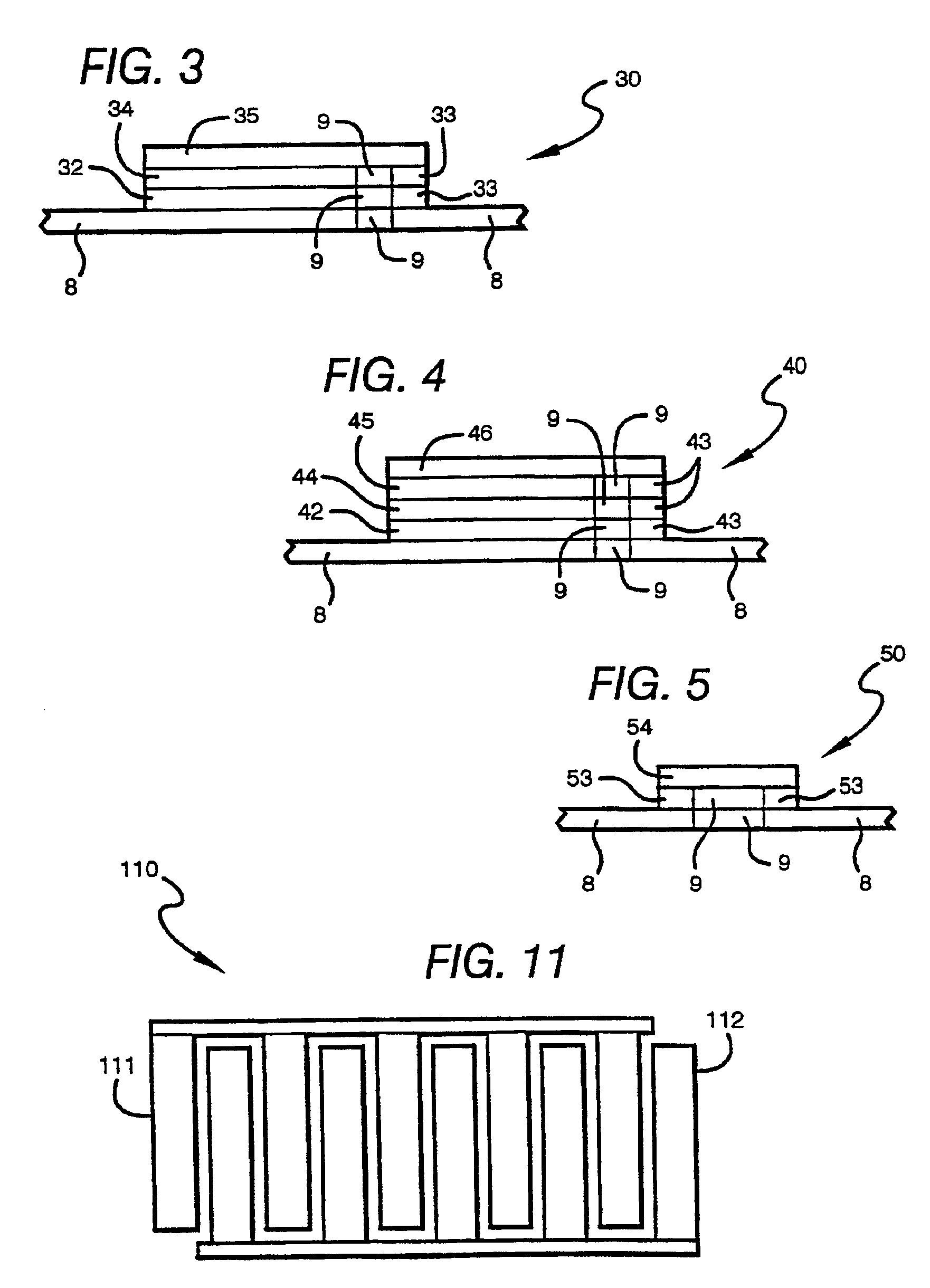

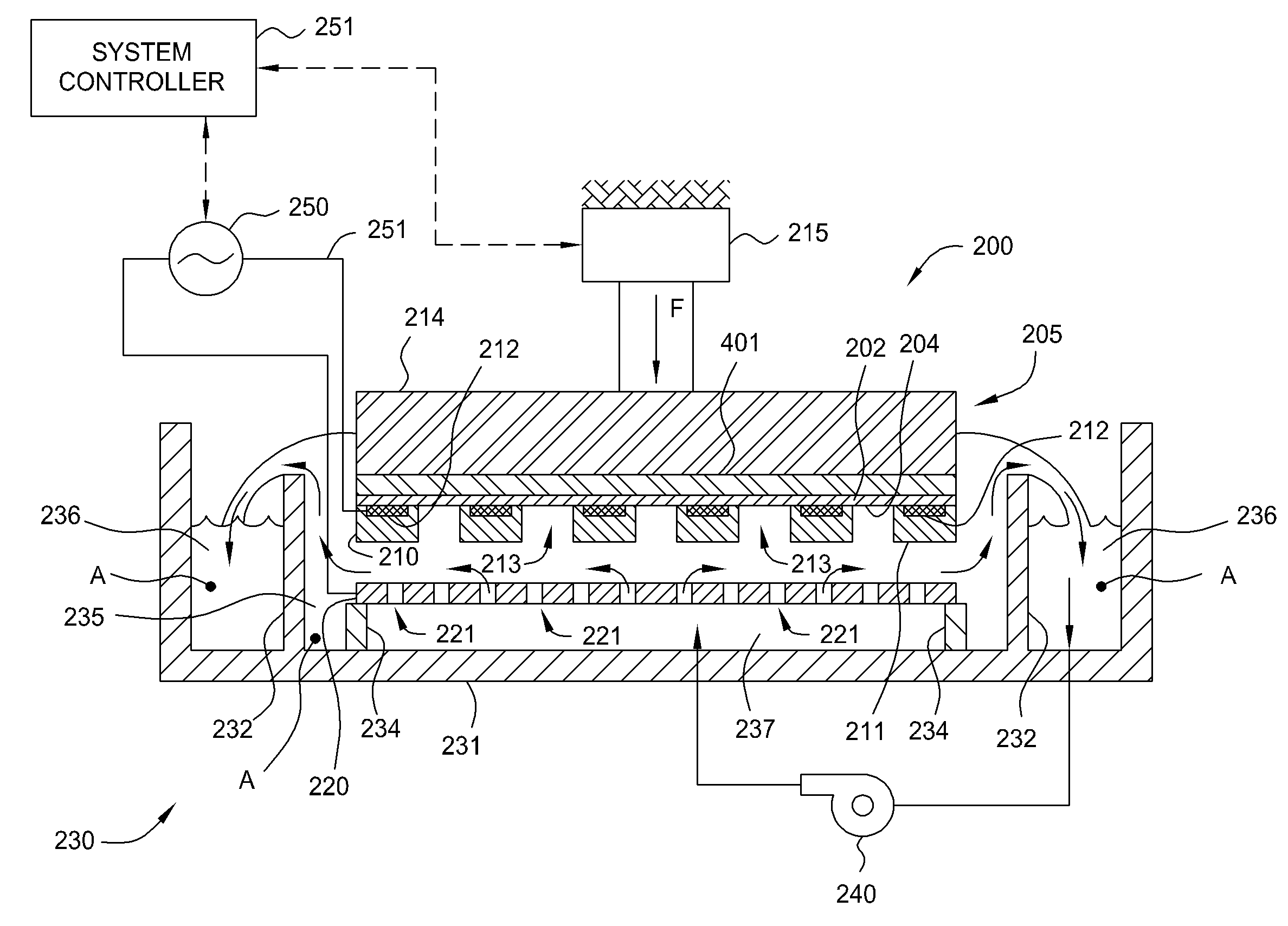

Methods are disclosed for printing (2-7) multilayer electronic components, and circuits on a surface (2), where at least one of the layers is formed by a redox reaction (6) occurring in a deposited solution (4, 5). Electronic components may comprise semiconductors such as in transistors or diode, or metal oxide or electrolyte such as in batteries or fuel cells, or are capacitors, inductors, and resistors. Preferably, the oxidizer of the redox reaction is a strong oxidizer, and the reducer is a strong reducer (3). Reactions are preferably sufficiently exothermic that they can be initiated (6), rather than driven to completion, by microwave or other suitable energy sources, and may yield substantially pure metal or metal oxide layers. The solution being deposited (5) may have either high concentrations of particulates, such as 60-80 wt. % of dry weight, or low concentrations of particulates, such as ≦5 wt. % or ≦2 wt. %. Low particulate content provides printing of structures having lateral resolution of ≦10 μm, ≦5 μm, or ≦1 μm.

Owner:SRI INTERNATIONAL

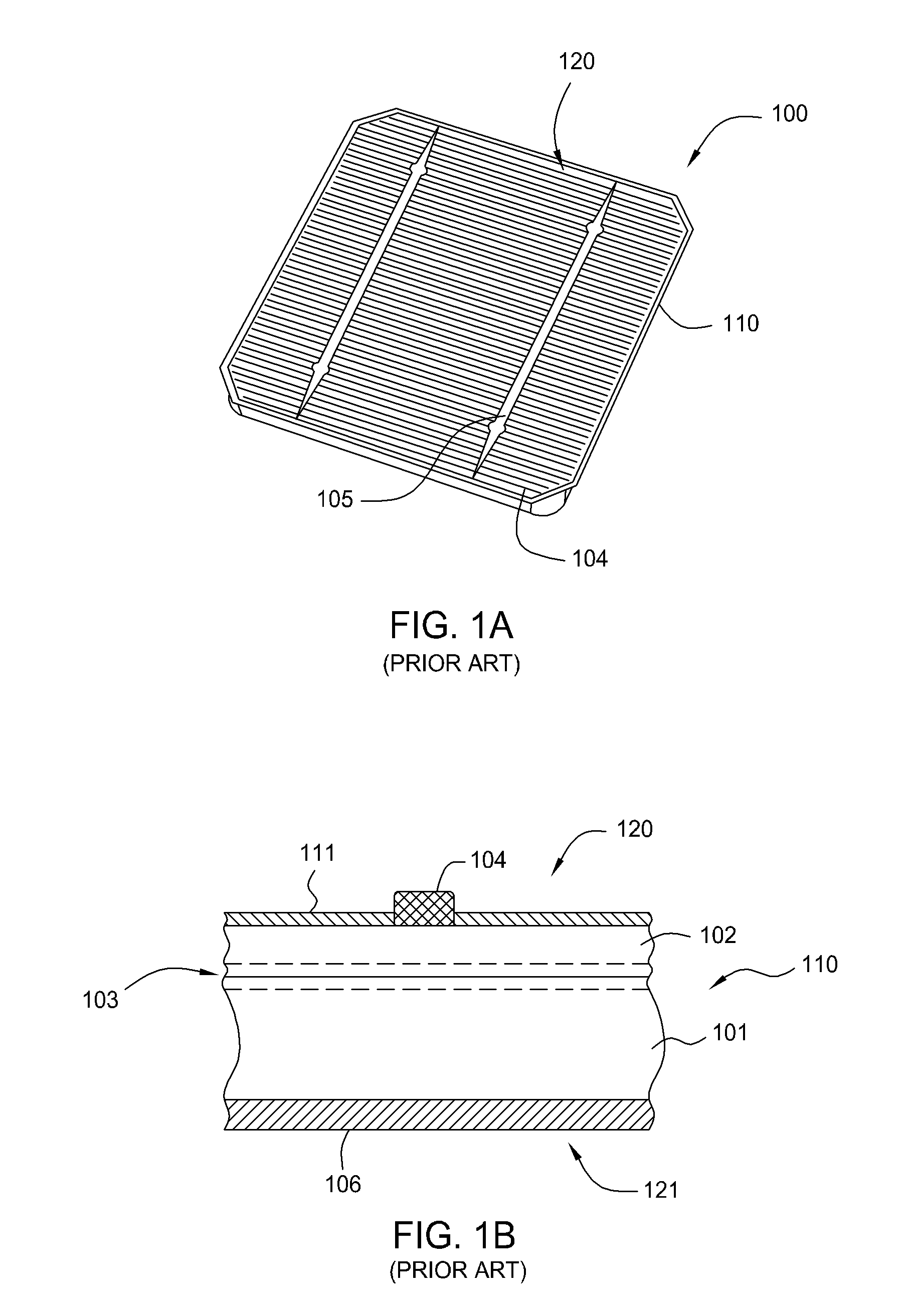

Pulse plating of a low stress film on a solar cell substrate

InactiveUS20080092947A1Photovoltaic energy generationSemiconductor devicesMetal interconnectEngineering

Embodiments of the invention contemplate the formation of a low cost solar cell metal contact structure that has improved electrical and mechanical properties through the use of an electrochemical plating process. The resistance of interconnects formed in a solar cell device greatly affects the efficiency of the solar cell. It is thus desirable to form a solar cell device that has a low resistance connections that is reliable and cost effective. One or more embodiments of the invention described herein are adapted to form a low cost and reliable interconnecting layer using an electrochemical plating process containing common metal, such as copper. However, generally the electroplated portions of the interconnecting layer may contain a substantially pure metal or a metal alloy layer. Methods are discussed herein that are used to form a solar cell containing conductive metal interconnect layer(s) that have a low intrinsic stress.

Owner:APPLIED MATERIALS INC

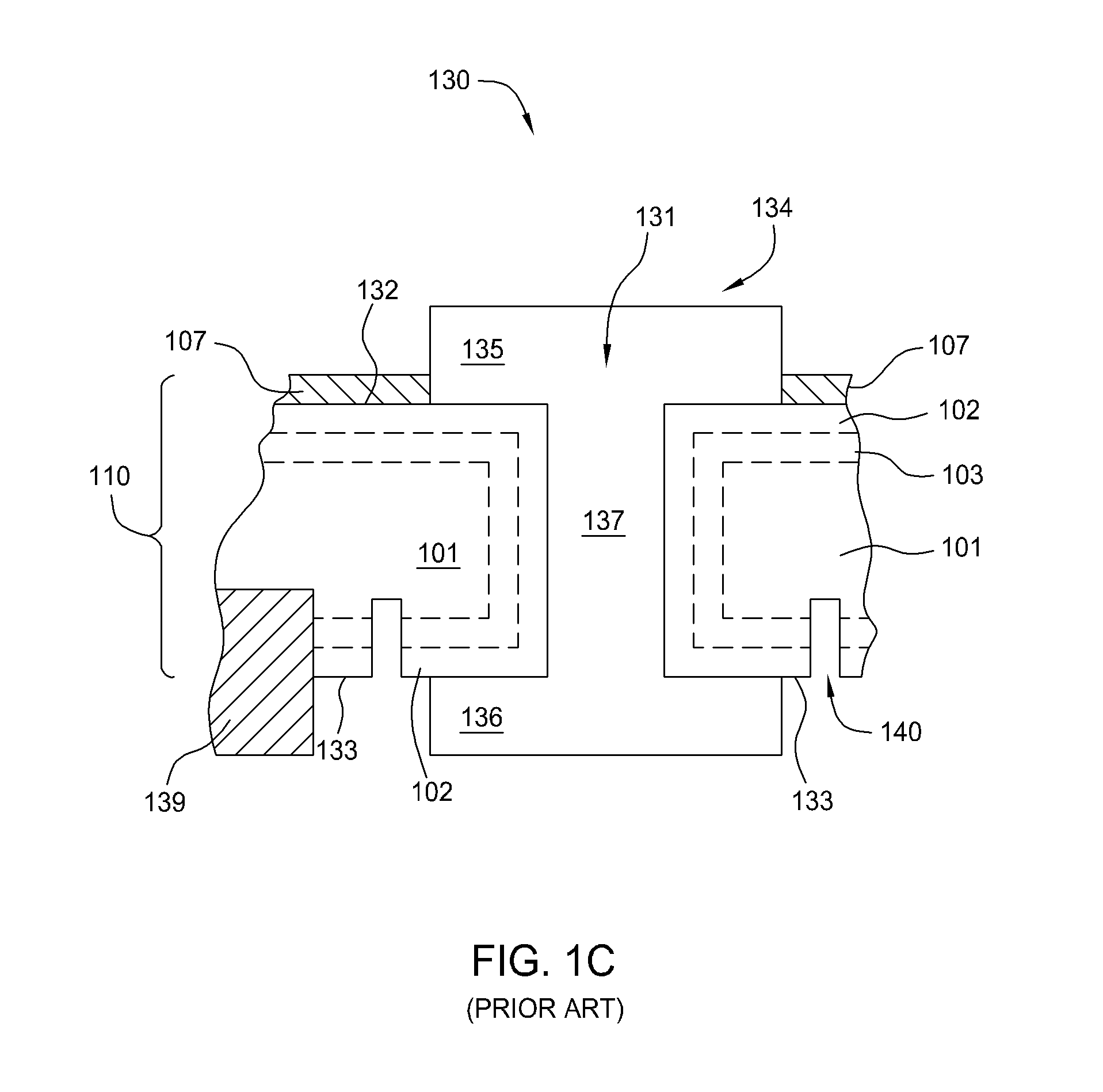

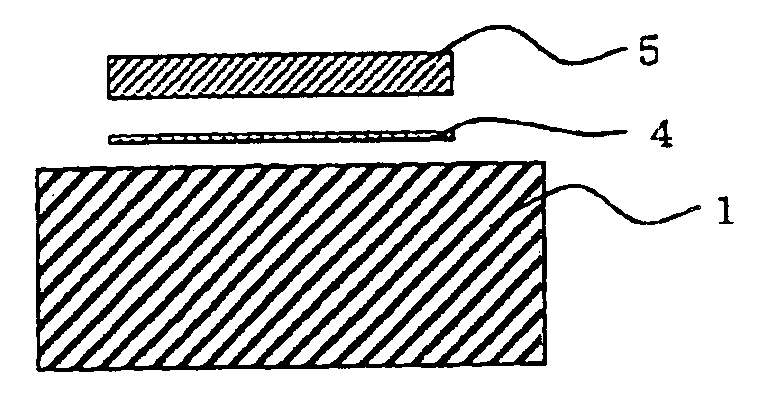

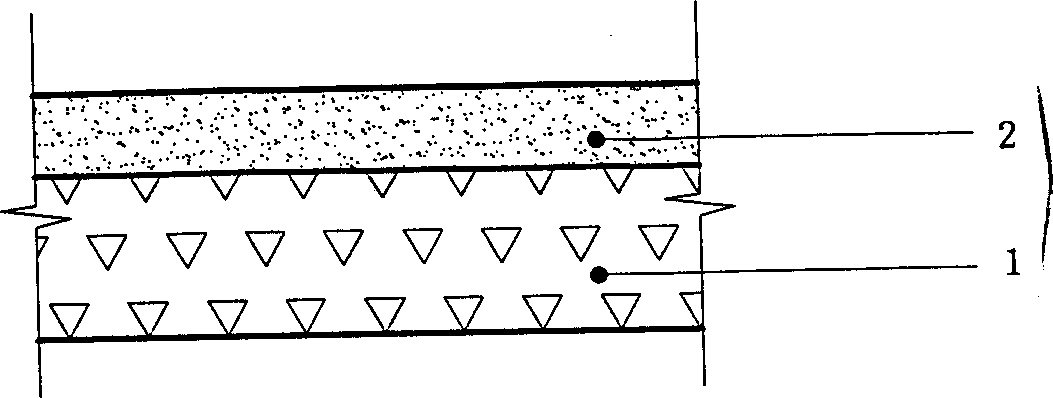

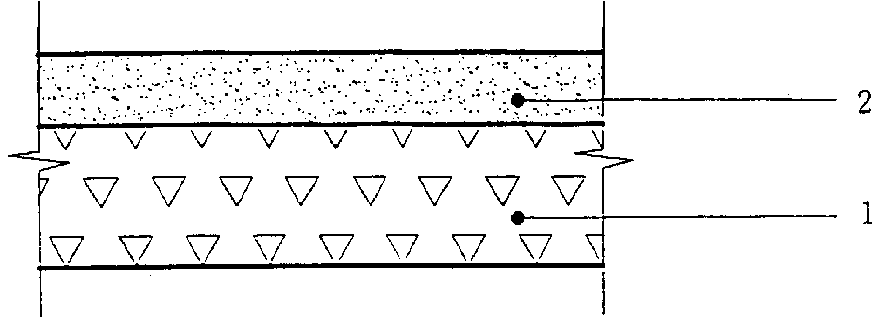

Bonded member comprising different materials, and production method thereof

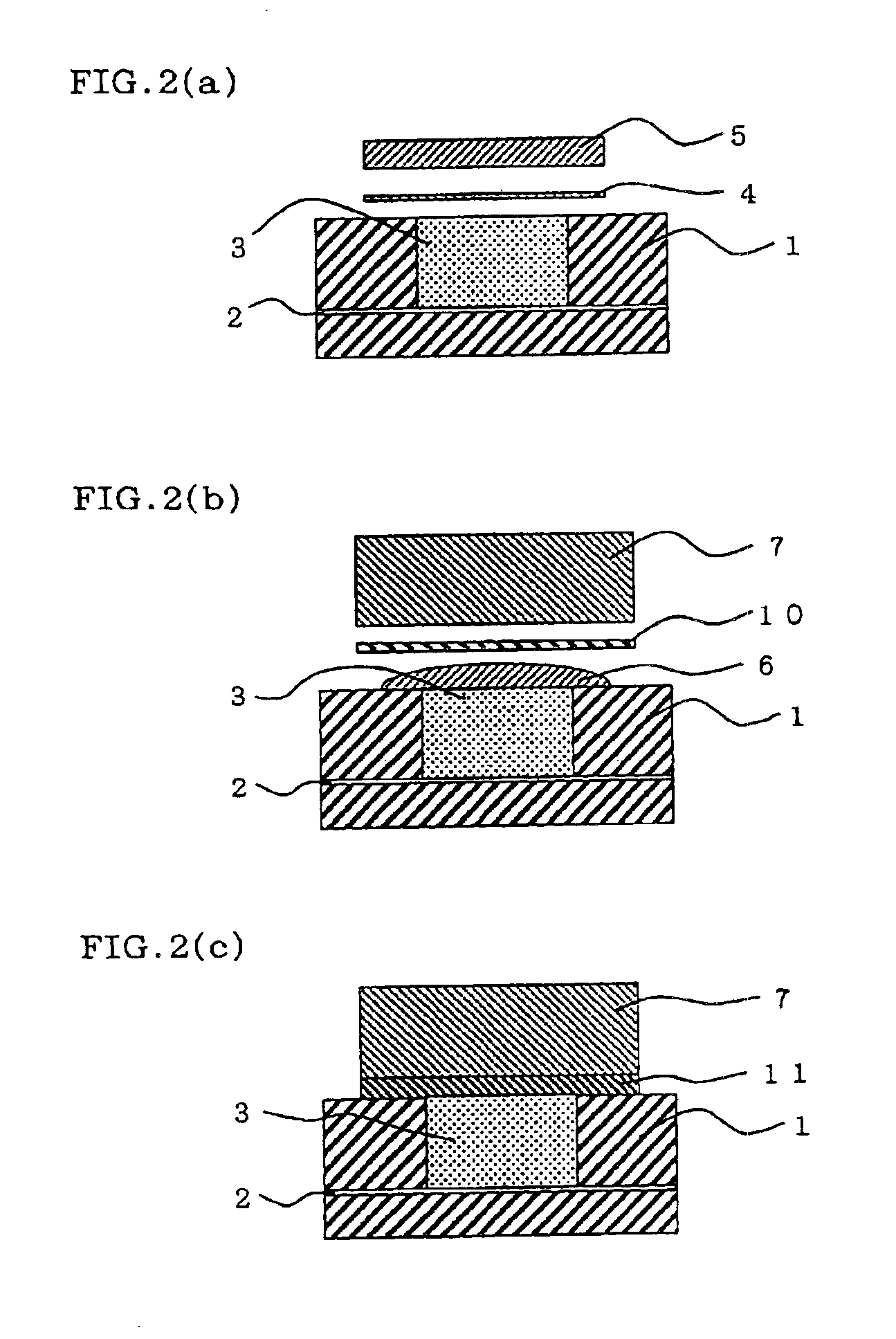

InactiveUS6918530B2Easy to operateHigh bonding strengthLayered product treatmentSoldered/welded conductive connectionsAlloyLow melting point

A bonded member including a ceramic base material 1 and a metallic member 7 which are bonded together, wherein a solder material 5 comprising Au is disposed on the surface of the ceramic base material 1 via an active metal layer, the active metal layer and the solder material 5 are molten by heating so as to form a precoat layer 6, the metallic member 7 is disposed on the surface of the precoat layer 6 via an insertion metal layer comprising pure metal which may form an alloy having a lower melting point than Au with Au or an alloy of the pure metal and Au, and the insertion metal layer and at least a portion in the vicinity of the interface between the insertion metal layer and the precoat layer 6 are molten by heating to bond the metallic member 7 and the precoat layer 6.

Owner:NGK INSULATORS LTD

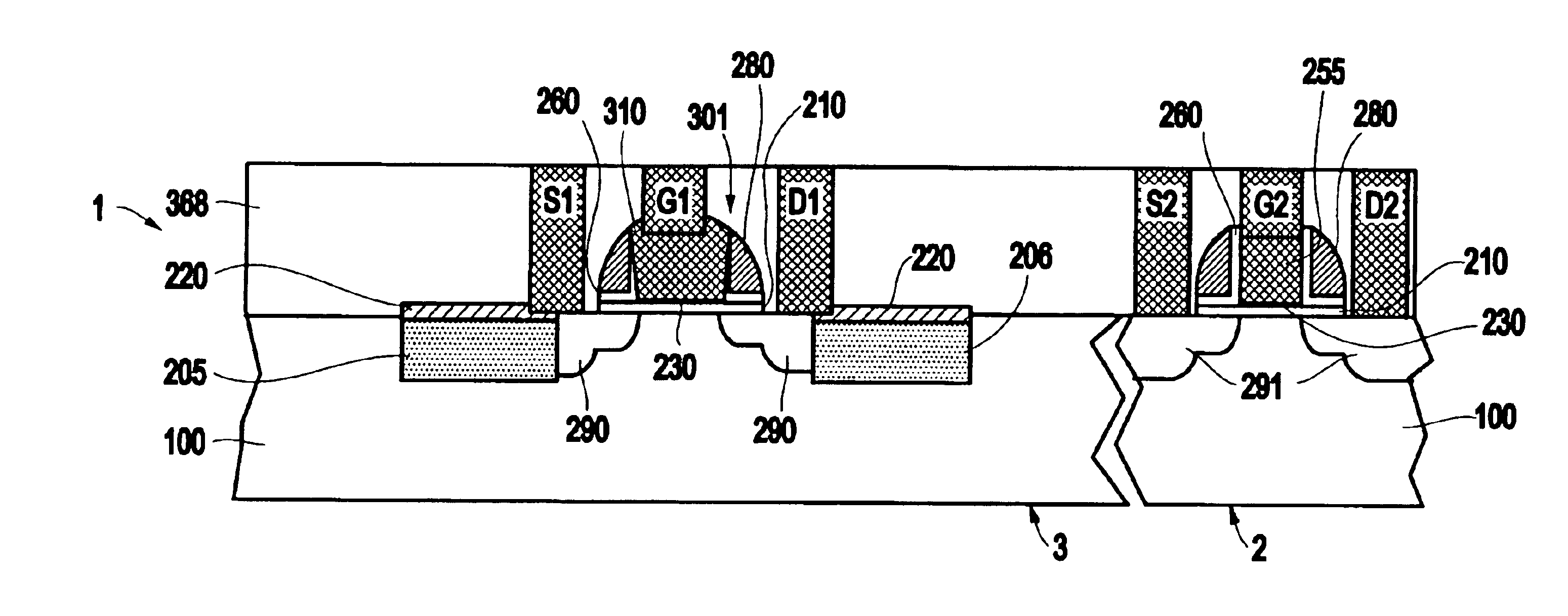

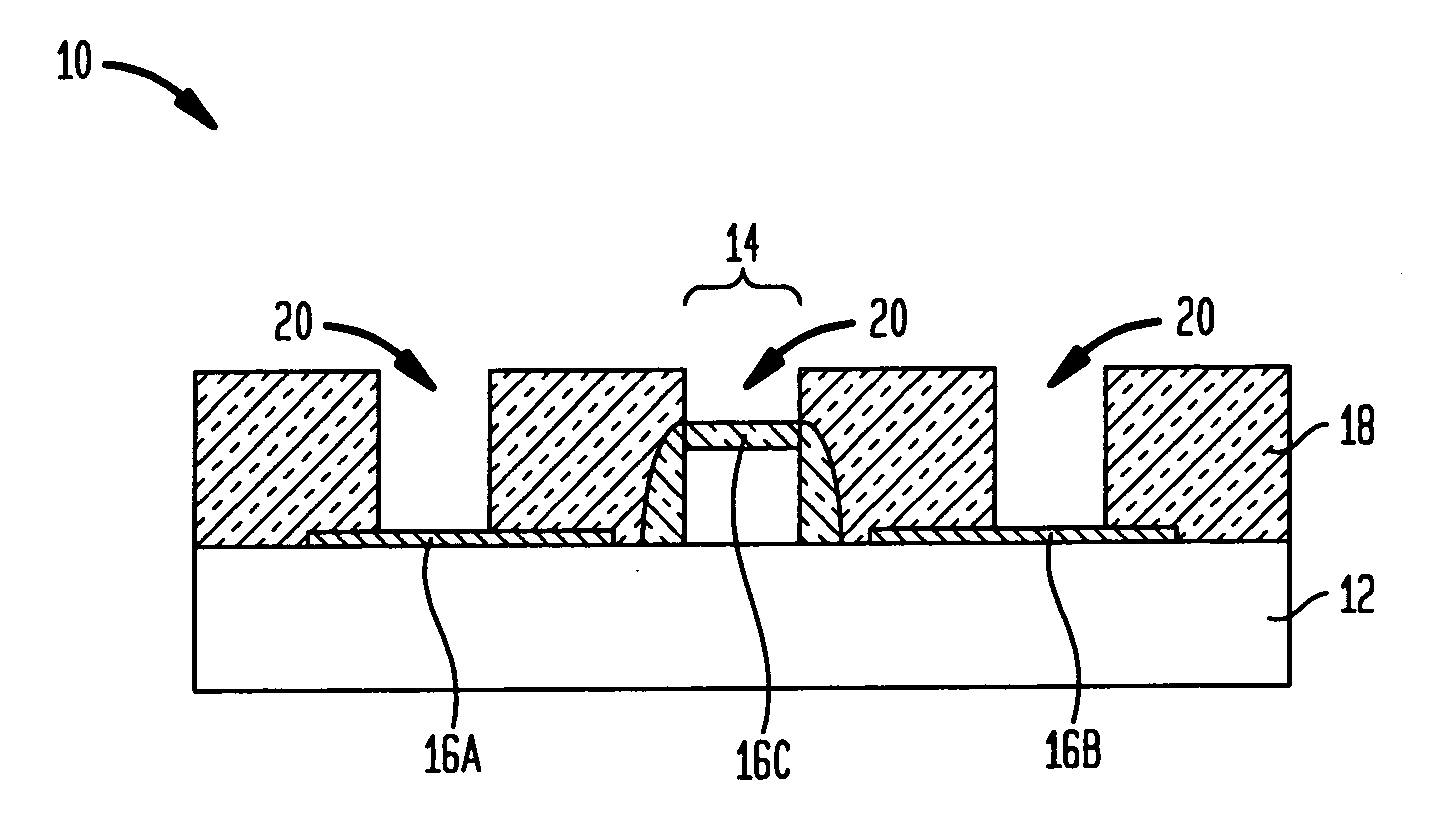

Semiconductor chip using both polysilicon and metal gate devices

InactiveUS6777761B2Improve reliabilityReduce leakage currentTransistorSolid-state devicesSingle processGate dielectric

A semiconductor structure (and method for forming) having transistors having both metal gates and polysilicon gates on a single substrate in a single process is disclosed. The method forms a gate dielectric layer on the substrate and forms the metal seed layer on the gate oxide layer. The method patterns the metal seed layer to leave metal seed material in metal gate seed areas above the substrate. Next, the method patterns a polysilicon layer into polysilicon structures above the substrate. Some of the polysilicon structures comprise sacrificial polysilicon structures on the metal gate seed areas and the remaining ones of the polysilicon structures comprise the polysilicon gates. The patterning of the polysilicon gates forms the sacrificial gates above all the metal gate seed areas. Following that, the invention forms sidewall spacers, and source and drain regions adjacent the polysilicon structures. Then, the invention protects the polysilicon gates, removes the sacrificial polysilicon structures, and plates the metal gate seed areas to form the metal gates. The sidewall spacers self-align the metal gates. The plating process forms the metal gates of pure metal. All thermal processing that raises the temperature above a damage threshold for the metal is performed before the plating process.

Owner:ELPIS TECH INC

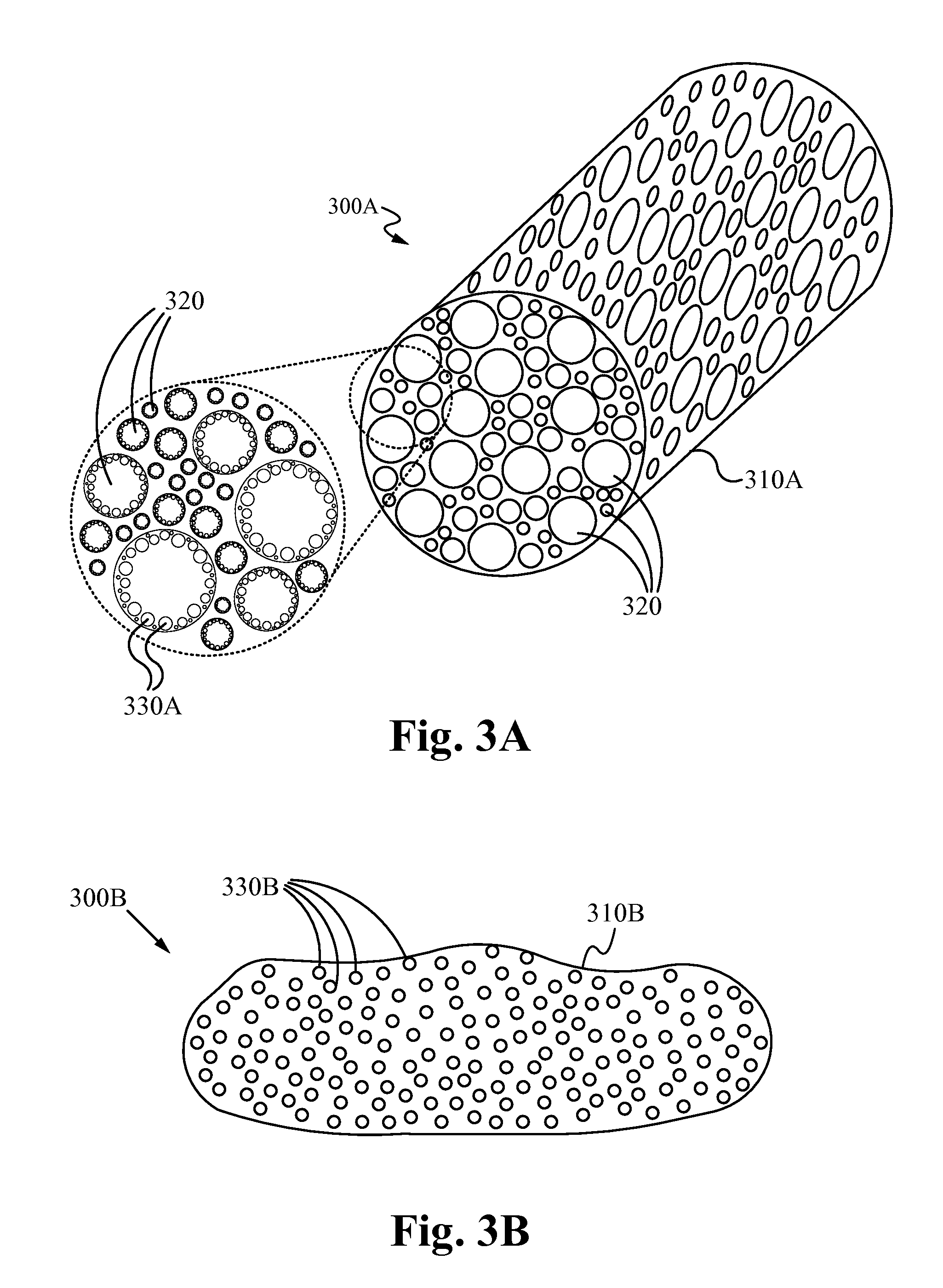

Nanotube coatings for implantable electrodes

ActiveUS7162308B2Reduce polarizationIncrease surface areaSpinal electrodesMaterial nanotechnologyImplantable ElectrodesBoron nitride

Coatings for implantable electrodes consisting of single- or multi-walled nanotubes, nanotube ropes, carbon whiskers, and a combination of these are described. The nanotubes can be carbon or other conductive nanotube-forming materials such as a carbon-doped boron nitride. The nanotube coatings are grown “in situ” on a catalytic substrate surface from thermal decomposition, or they are bonded to the substrate using a metal or conductive metal oxide thin film binder deposited by means of a metal compound precursor in liquid form. In the latter case, the precursor / nanotube coating is then converted to a pure metal or conductive metal oxide, resulting in the desired surface coating with imbedded nanotubes.

Owner:WILSON GREATBATCH LTD

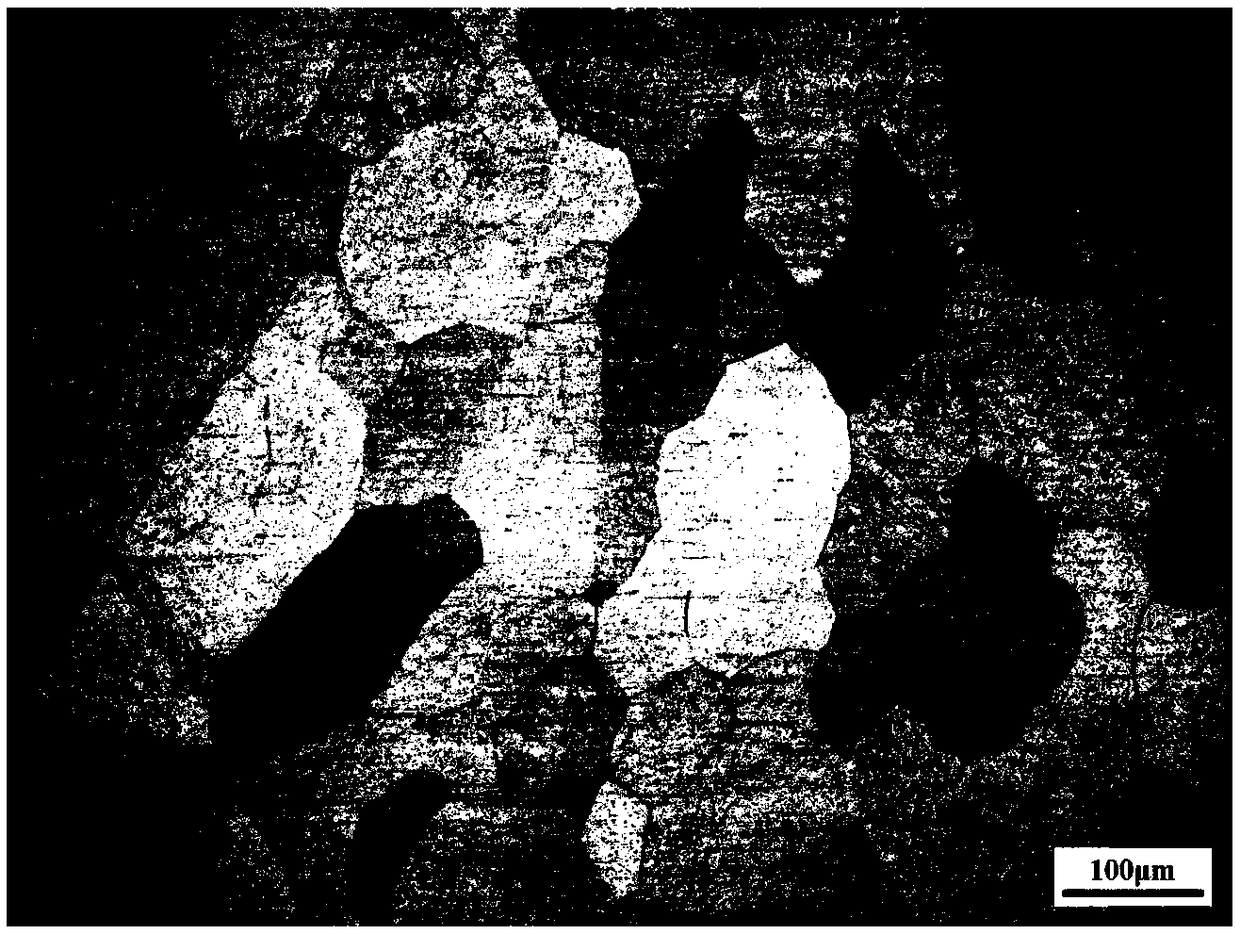

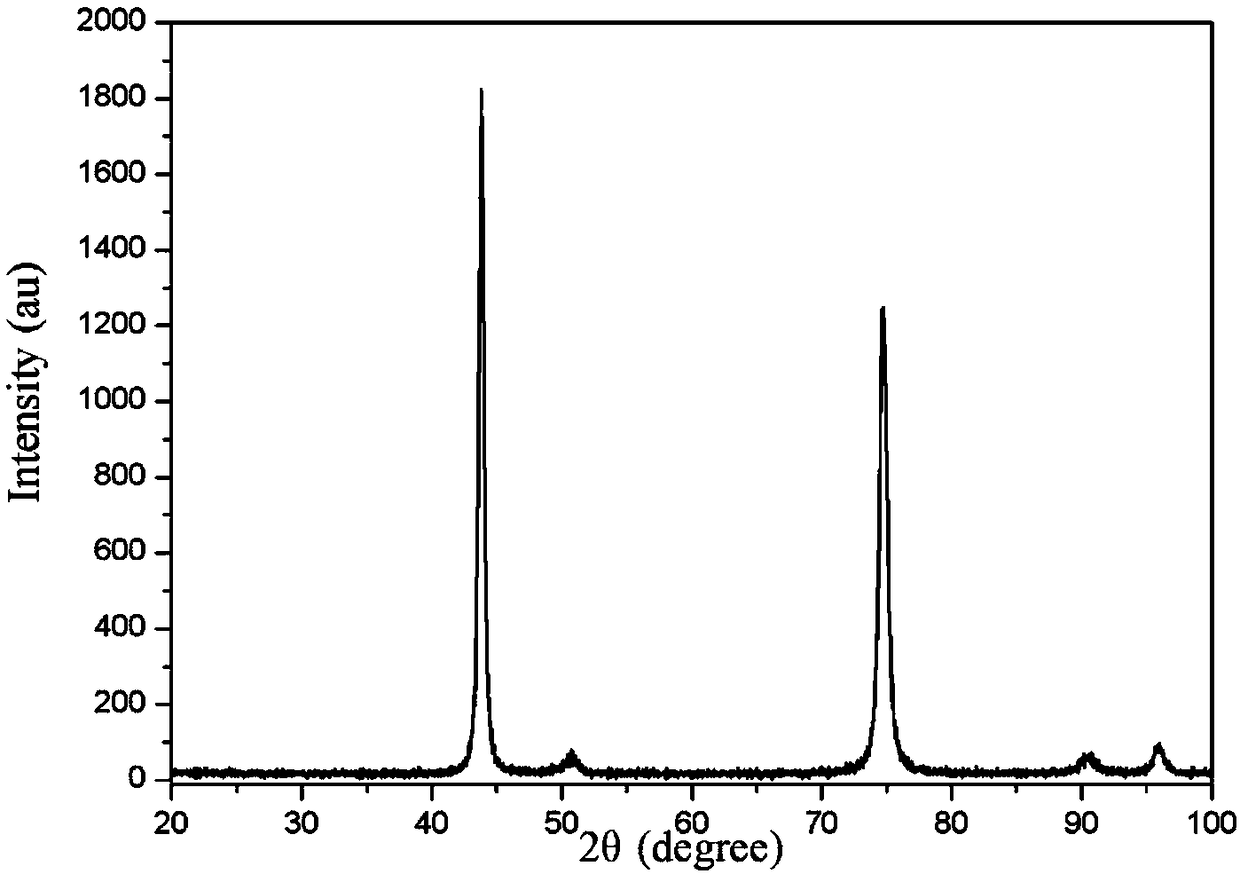

Preparation method of ultra-fine grain high-entropy alloy

The invention belongs to the technical field of metal materials and machining and relates to a preparation method of an ultra-fine grain high-entropy alloy. Firstly, smelting is conducted, an FeCoCrNiMn series high-entropy alloy is compounded to be an intermediate alloy composed of pure metal with the purity being higher than 99.5% or alloy elements, a vacuum furnace is adopted for smelting, and the furnace casting temperature is 1550-1600 DEG C; then after cast ingots are subjected to homogenization heat treatment at the temperature of 1000-1350 DEG C, strong deformation asynchronous and synchronous mixed cold rolling treatment is conducted, continuous rolling is conducted through single-pass large percent reduction, the total rolling quantity is no smaller than 85%, and alloy structure nanocrystallization is achieved; and the rolled alloy is subjected to annealing treatment under the temperature of 450-800 DEG C, and the high-entropy alloy of an ultra-fine grain structure is obtained. Compared with the prior art, the preparation method is simple in technique, easy to achieve on a plate rolling production line, high in production efficiency and low in cost; and the size of the prepared ultra-fine grain high-entropy alloy is large, the comprehensive mechanical performance is excellent, and the preparation method can be applied to the fields of engineering machinery, aeronauticsand astronautics, military industry, electronics, instruments and the like.

Owner:SHANGHAI JIAO TONG UNIV

WET CHEMICAL METHOD OF FORMING STABLE PiPd DIESEL OXIDATION

InactiveUS20120214666A1Minimizing and eliminating mobilityMinimizing and eliminating and agglomerationMaterial nanotechnologyCatalyst activation/preparationNanoparticleCopper

A nano-particle comprising: an interior region comprising a mixed-metal oxide; and an exterior surface comprising a pure metal. In some embodiments, the mixed-metal oxide comprises aluminum oxide and a metallic pinning agent, such as palladium, copper, molybdenum, or cobalt. In some embodiments, the pure metal at the exterior surface is the same as the metallic pinning agent in the mixed-metal oxide in the interior region. In some embodiments, a catalytic nano-particle is bonded to the pure metal at the exterior surface. In some embodiments, the interior region and the exterior surface are formed using a plasma gun. In some embodiments, the interior region and the exterior surface are formed using a wet chemistry process. In some embodiments, the catalytic nano-particle is bonded to the pure metal using a plasma gun. In some embodiments, the catalytic nano-particle is bonded to the pure metal using a wet chemistry process.

Owner:UMICORE AG & CO KG +1

Electrode material for lithium secondary battery and electrode structure having the electrode material

InactiveUS20090061322A1Increase capacityImprove efficiencyNon-aqueous electrolyte accumulator electrodesLi-accumulatorsAlloyMicrocrystalline silicon

The electrode material for a lithium secondary battery according to the present invention includes particles of a solid state alloy having silicon as a main component, wherein the particles of the solid state alloy have a microcrystal or amorphous material including an element other than silicon, dispersed in microcrystalline silicon or amorphized silicon. The solid state alloy preferably contains a pure metal or a solid solution. The composition of the alloy preferably has an element composition in which the alloy is completely mixed in a melted liquid state, whereby the alloy has a single phase in a melted liquid state without presence of two or more phases. The element composition can be determined by the kind of elements constituting the alloy and an atomic ratio of the elements.

Owner:CANON KK

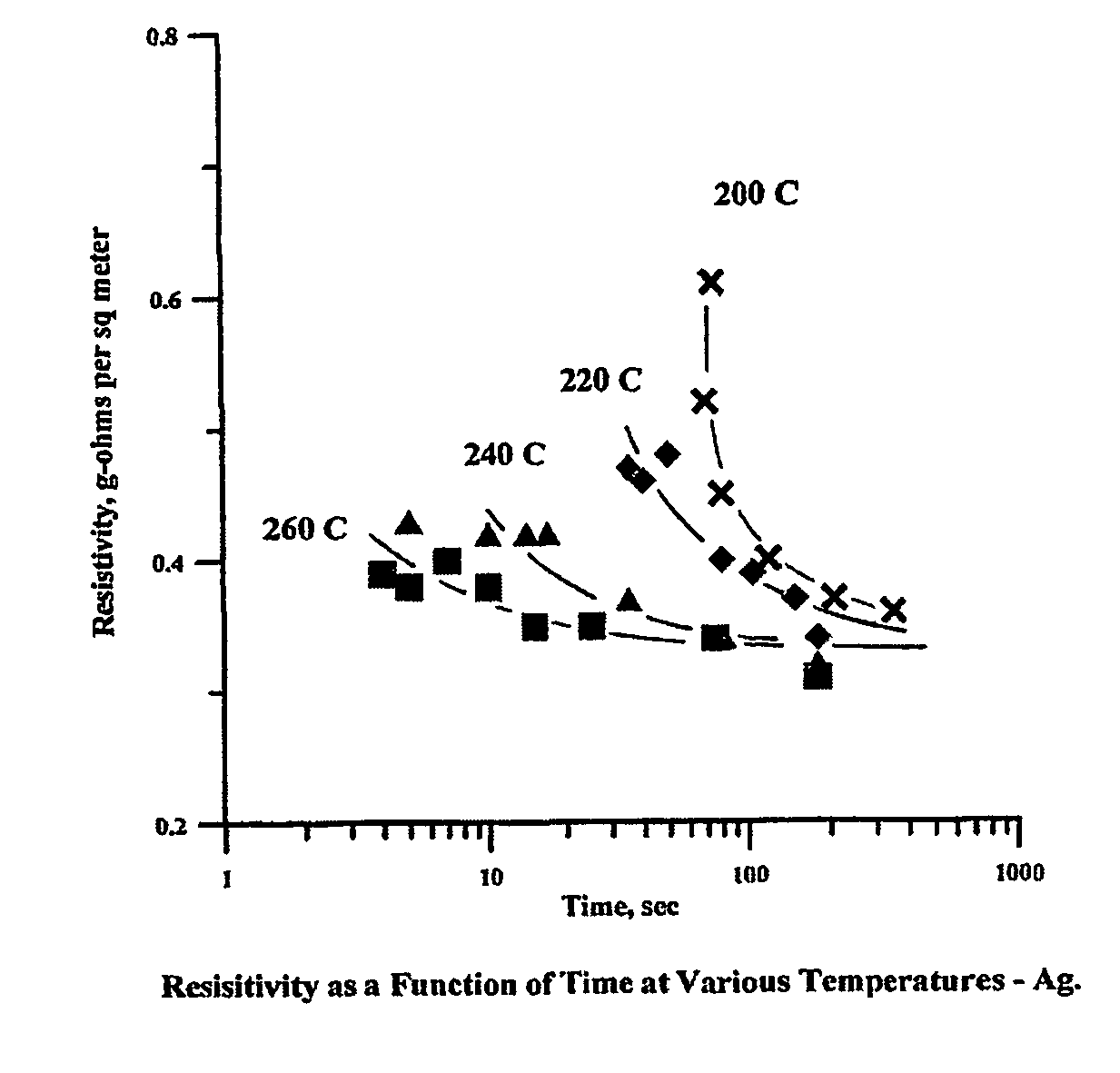

Low temperature method and composition for producing electrical conductors

InactiveUS7115218B2Increase speedLow costLayered productsSemiconductor/solid-state device detailsElectrical conductorOrganic media

A composition of matter having a metal powder or powders of specified characteristics in a Reactive Organic Medium (ROM). These compositions can be applied by any convenient printing process to produce patterns of electrical conductors on temperature-sensitive electronic substrates. The pattern can be thermally cured in seconds to form pure metal conductors at a temperature low enough to avoid damaging the substrate.

Owner:PARELEC

Method of producing aluminium scandium alloy by electrolysis

The invention relates to the method for producing the alloy of aluminium and scandium by using oxides of aluminium and scandium as the raw materials. Fused salt electrolysis process is adopted to electrolyze and separate out aluminium and scandium so as to form the alloy. The weight ratio of the electrolyte of fused cryolite is as following: alumina 1%-10%, scandium oxide 0.1%-10%, cryolite as the rest and the unavoidable impurities. The ratio between sodium fluoride and aluminium fluoride is 2-3. The relevant parameters are as following: temperature of electrolysis 900-990 deg.C, operating voltage of the electrobath 3.0V-6.5V and the electrode distance 2.0cm-7.0 cm. The invention possesses the features of no need of high pure metal scandium, shortened technological flow and high metal yield so as to reduce the cost of the alloy greatly.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Wet chemical and plasma methods of forming stable PtPd catalysts

InactiveUS8669202B2Minimizing and eliminating mobility and agglomerationArea maximizationMaterial nanotechnologyOther chemical processesCobaltInterior design

A nano-particle comprising: an interior region comprising a mixed-metal oxide; and an exterior surface comprising a pure metal. In some embodiments, the mixed-metal oxide comprises aluminum oxide and a metallic pinning agent, such as palladium, copper, molybdenum, or cobalt. In some embodiments, the pure metal at the exterior surface is the same as the metallic pinning agent in the mixed-metal oxide in the interior region. In some embodiments, a catalytic nano-particle is bonded to the pure metal at the exterior surface. In some embodiments, the interior region and the exterior surface are formed using a plasma gun. In some embodiments, the interior region and the exterior surface are formed using a wet chemistry process. In some embodiments, the catalytic nano-particle is bonded to the pure metal using a plasma gun. In some embodiments, the catalytic nano-particle is bonded to the pure metal using a wet chemistry process.

Owner:UMICORE AG & CO KG +1

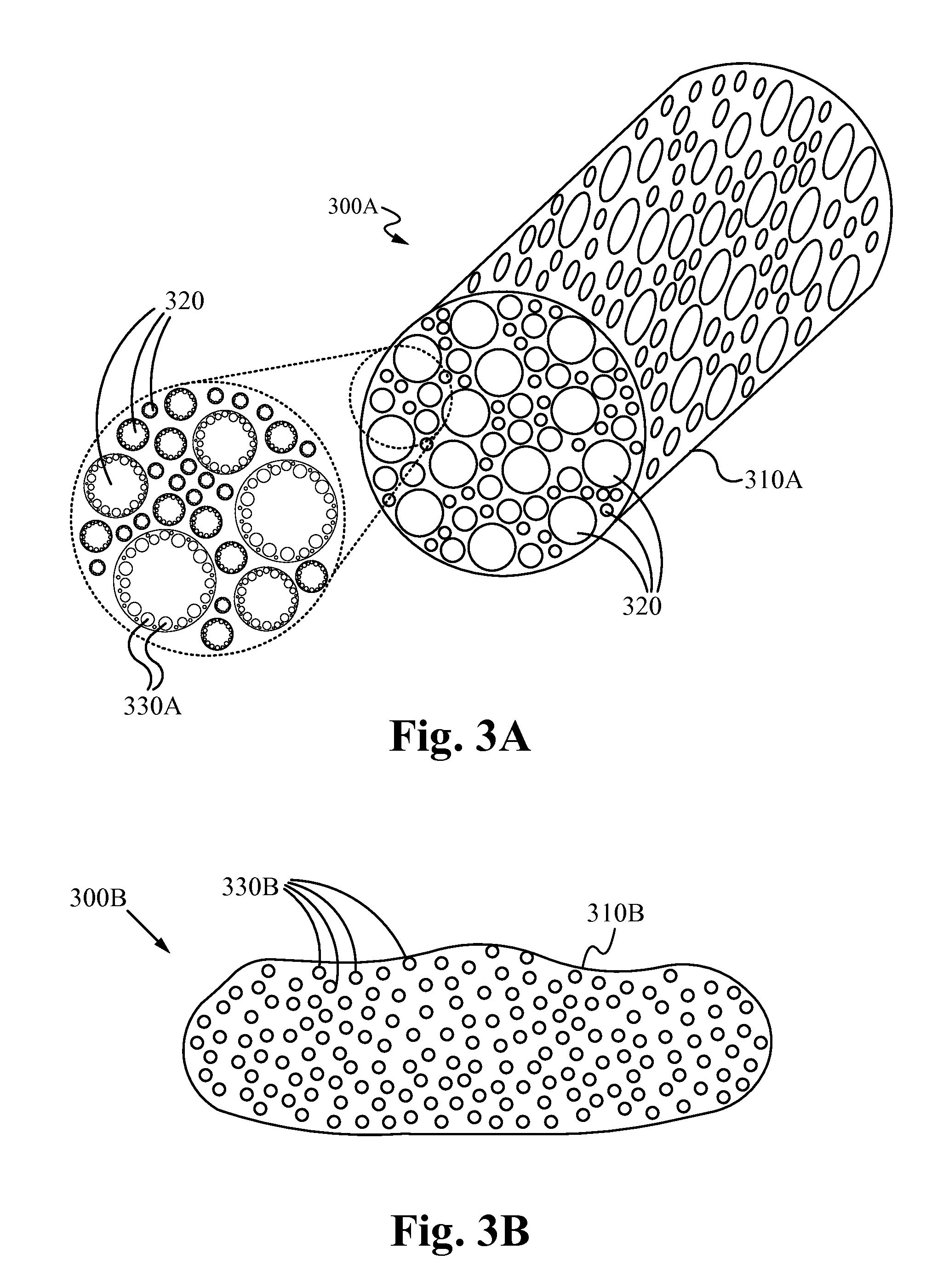

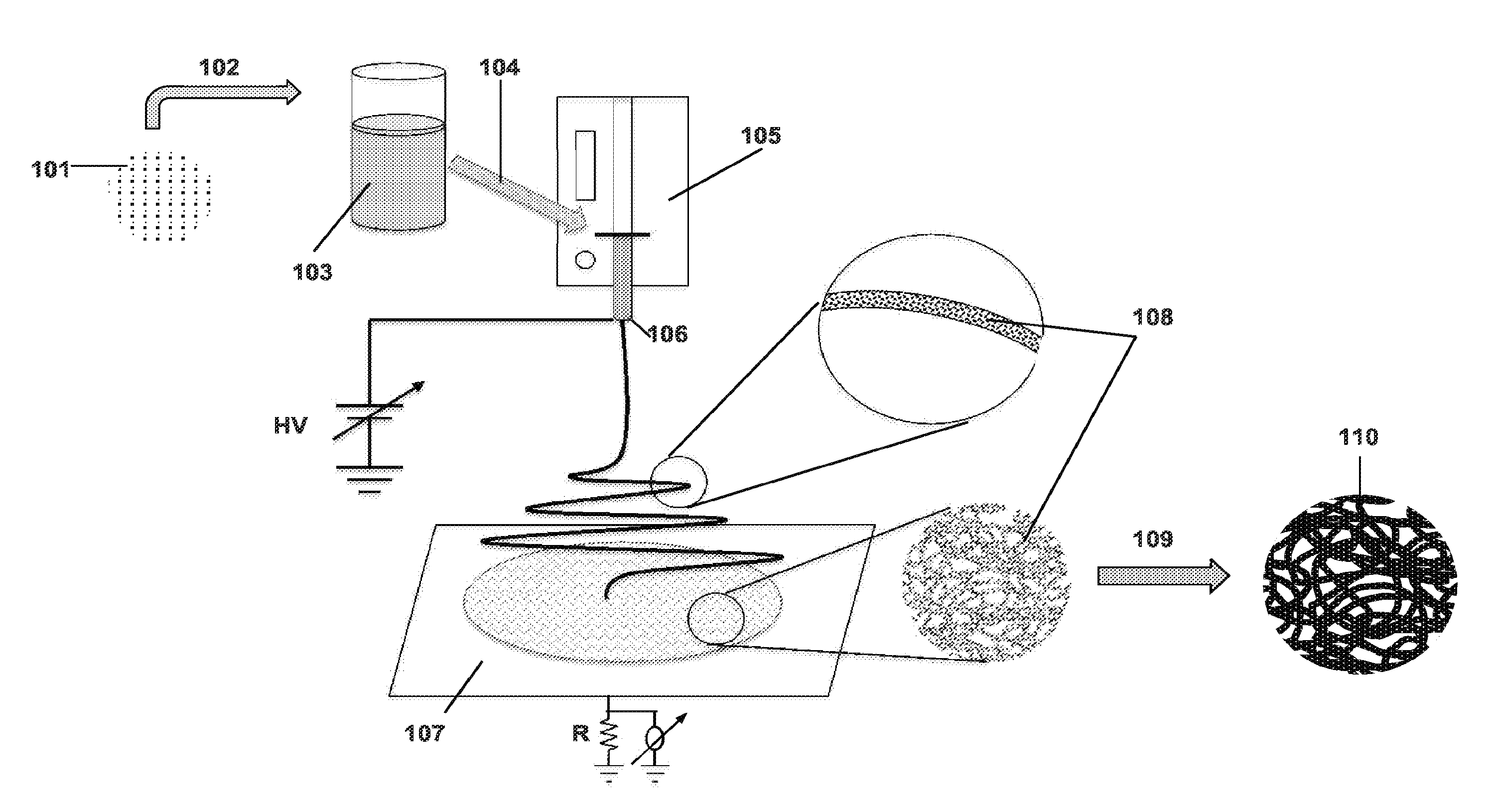

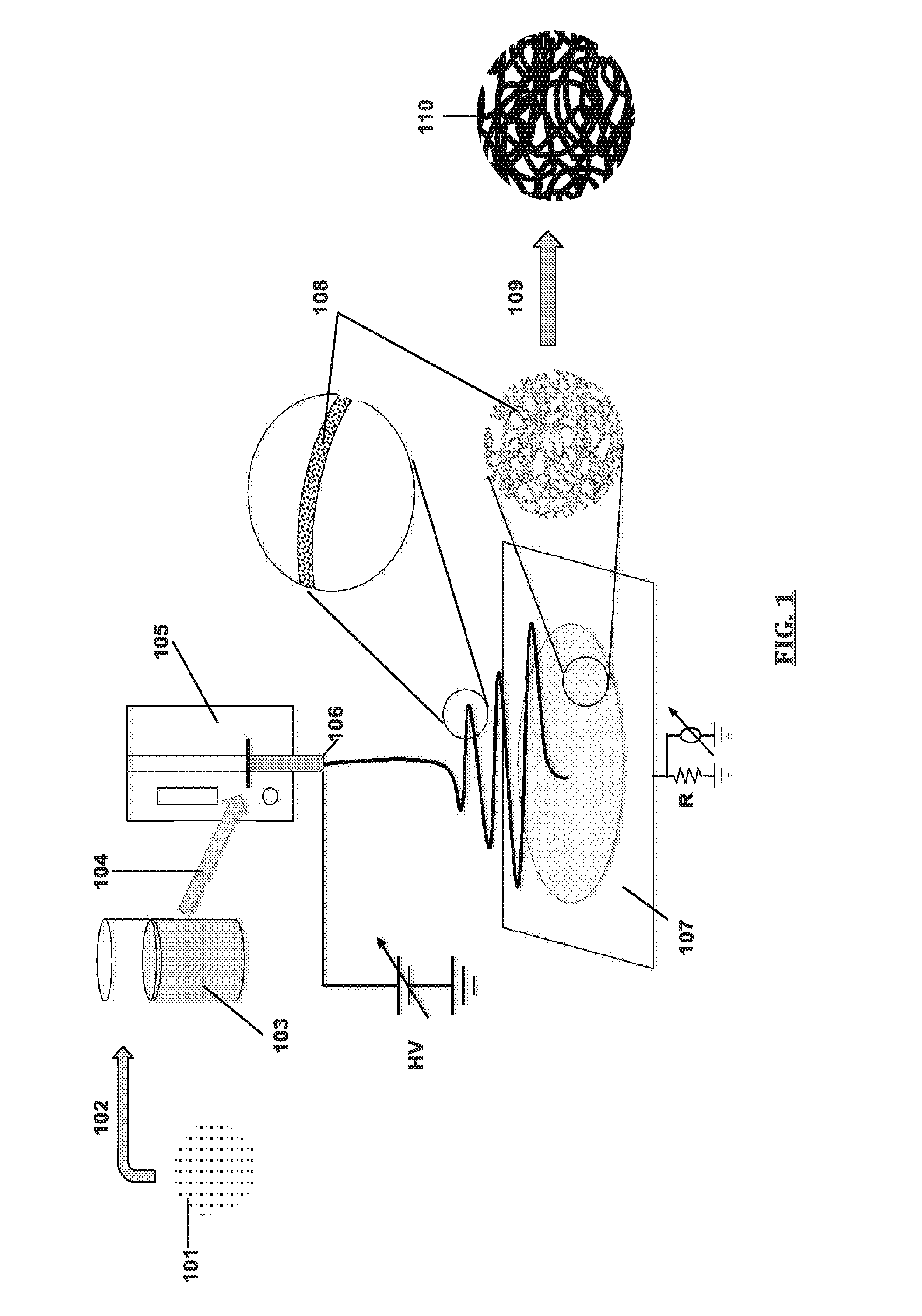

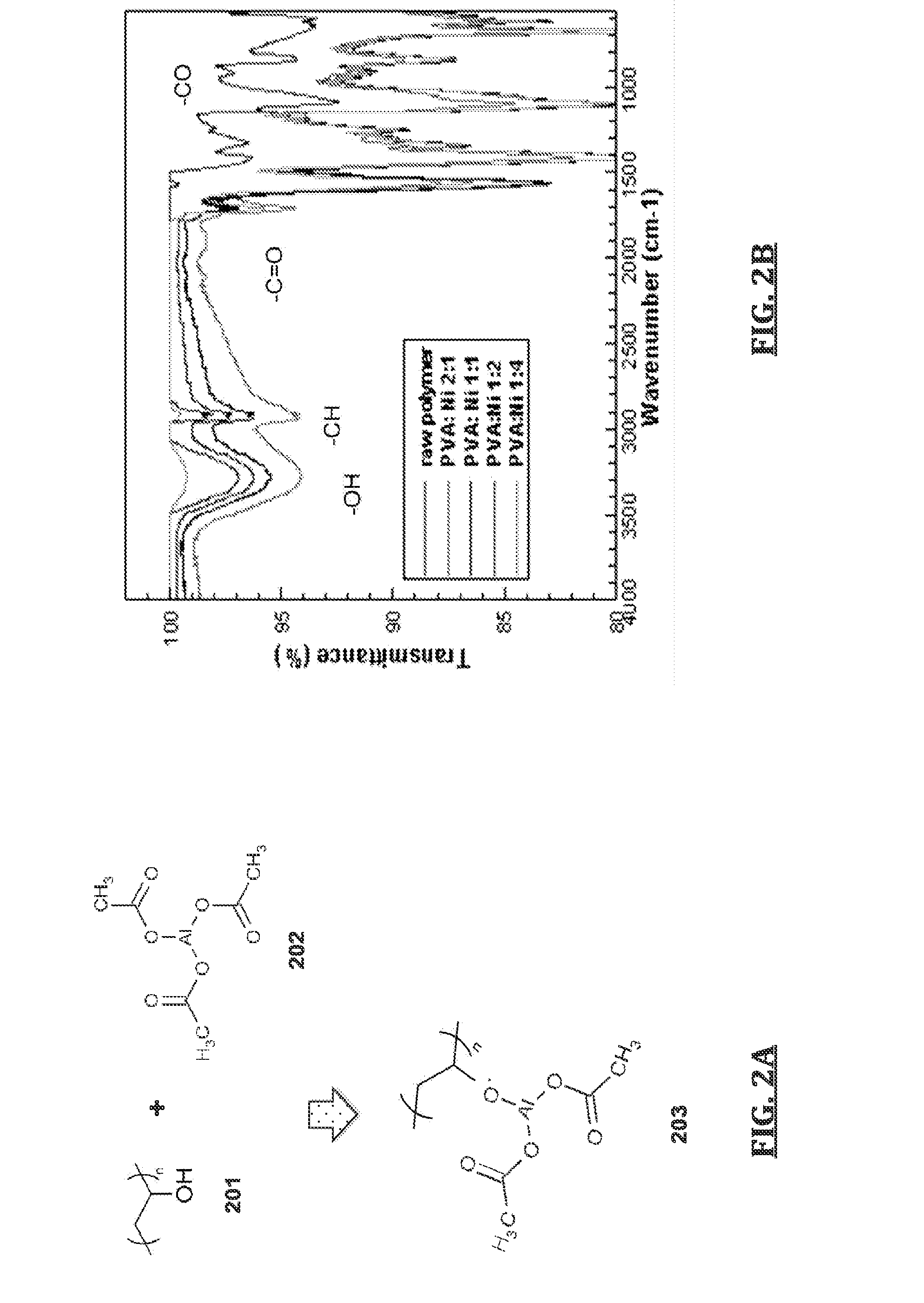

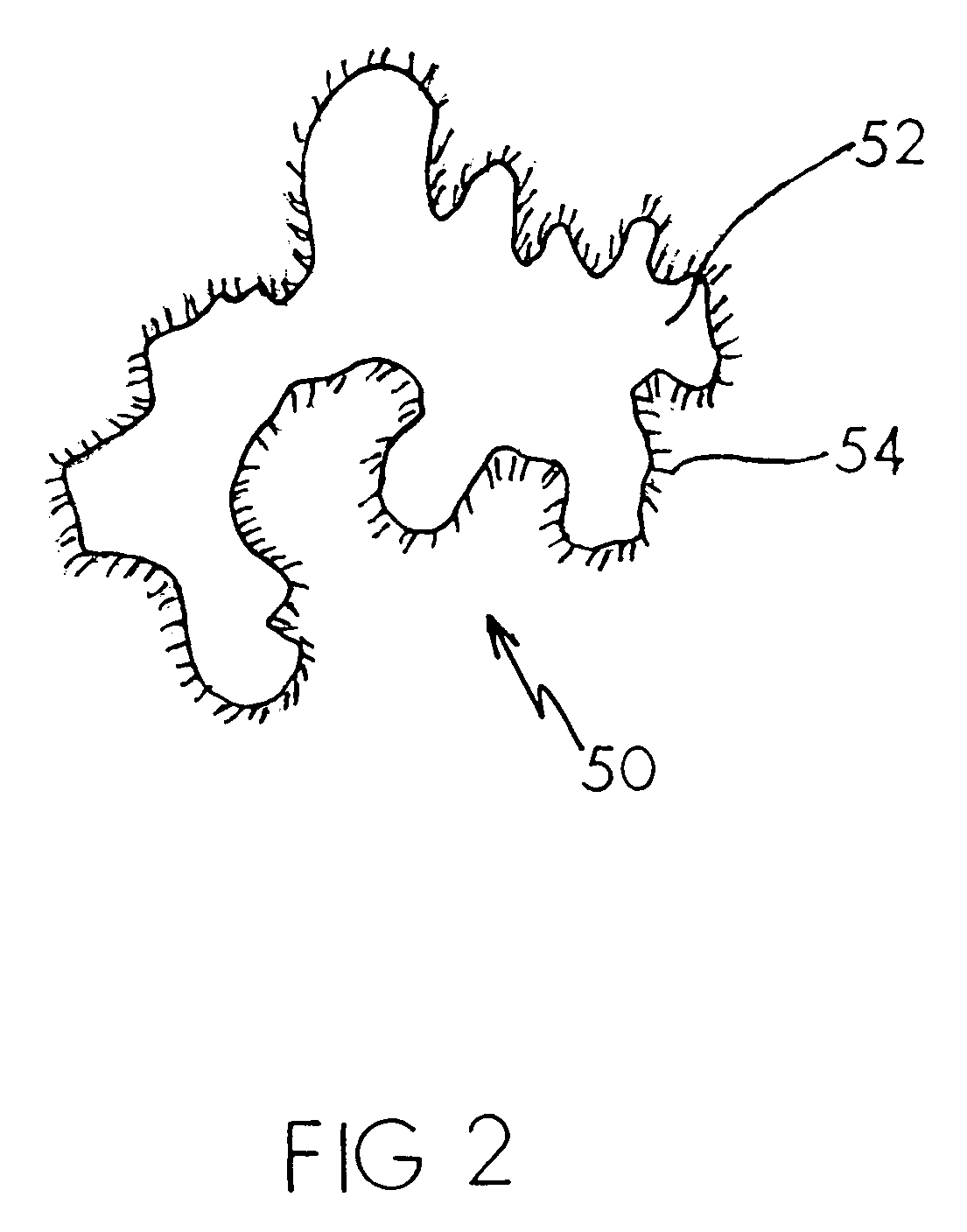

Pure metal and ceramic nanofibers

InactiveUS20140332733A1Few voidFew defectOrganic active ingredientsGold compoundsFiberElectrospinning

Provided herein are nanofibers and processes of preparing nanofibers. In some instances, the nanofibers are metal and / or ceramic nanofibers. In some embodiments, the nanofibers are high quality, high performance nanofibers, highly coherent nanofibers, highly continuous nanofibers, or the like. In some embodiments, the nanofibers have increased coherence, increased length, few voids and / or defects, and / or other advantageous characteristics. In some instances, the nanofibers are produced by electrospinning a fluid stock having a high loading of nanofiber precursor in the fluid stock. In some instances, the fluid stock comprises well mixed and / or uniformly distributed precursor in the fluid stock. In some instances, the fluid stock is converted into a nanofiber comprising few voids, few defects, long or tunable length, and the like.

Owner:CORNELL UNIVERSITY

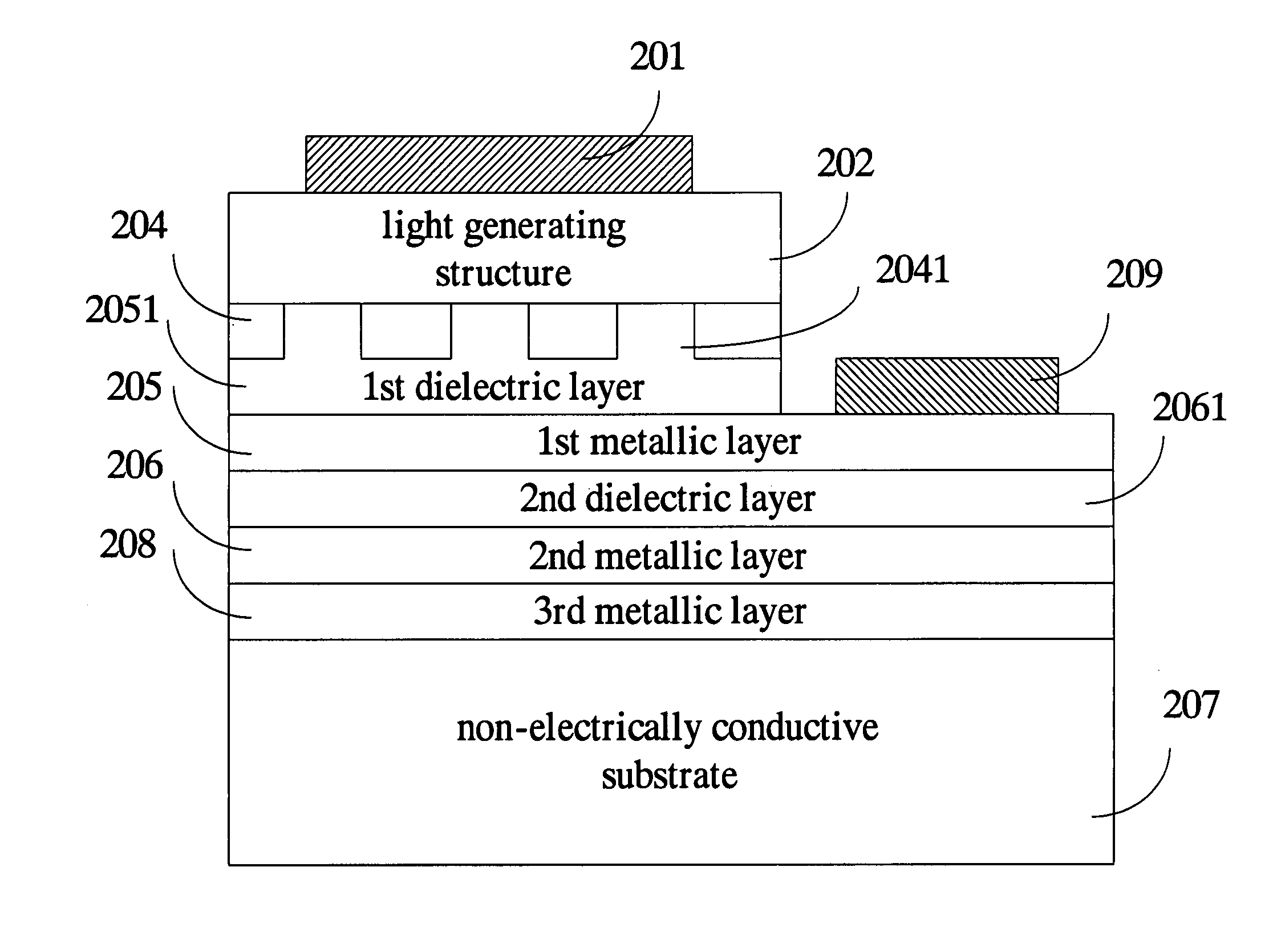

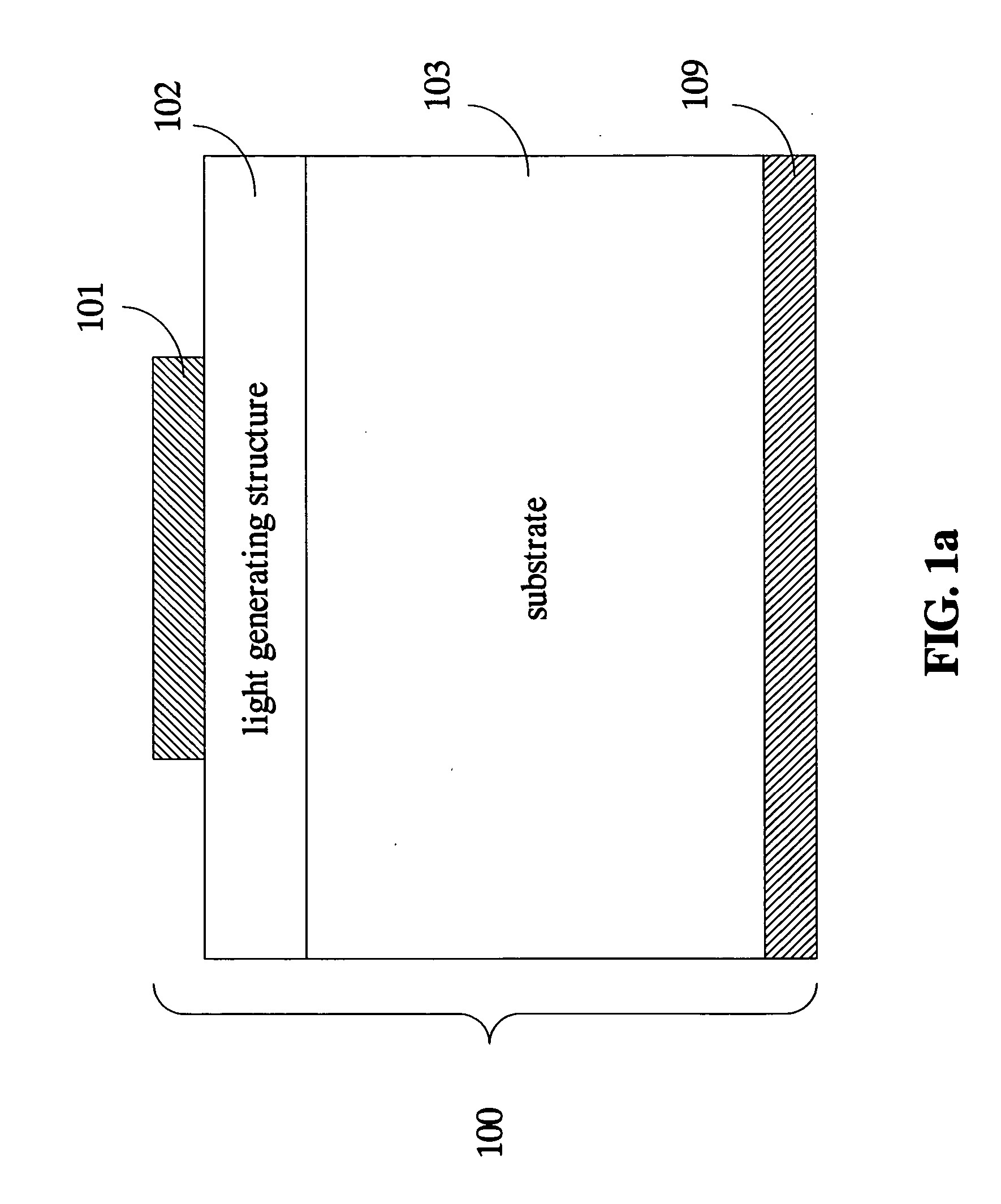

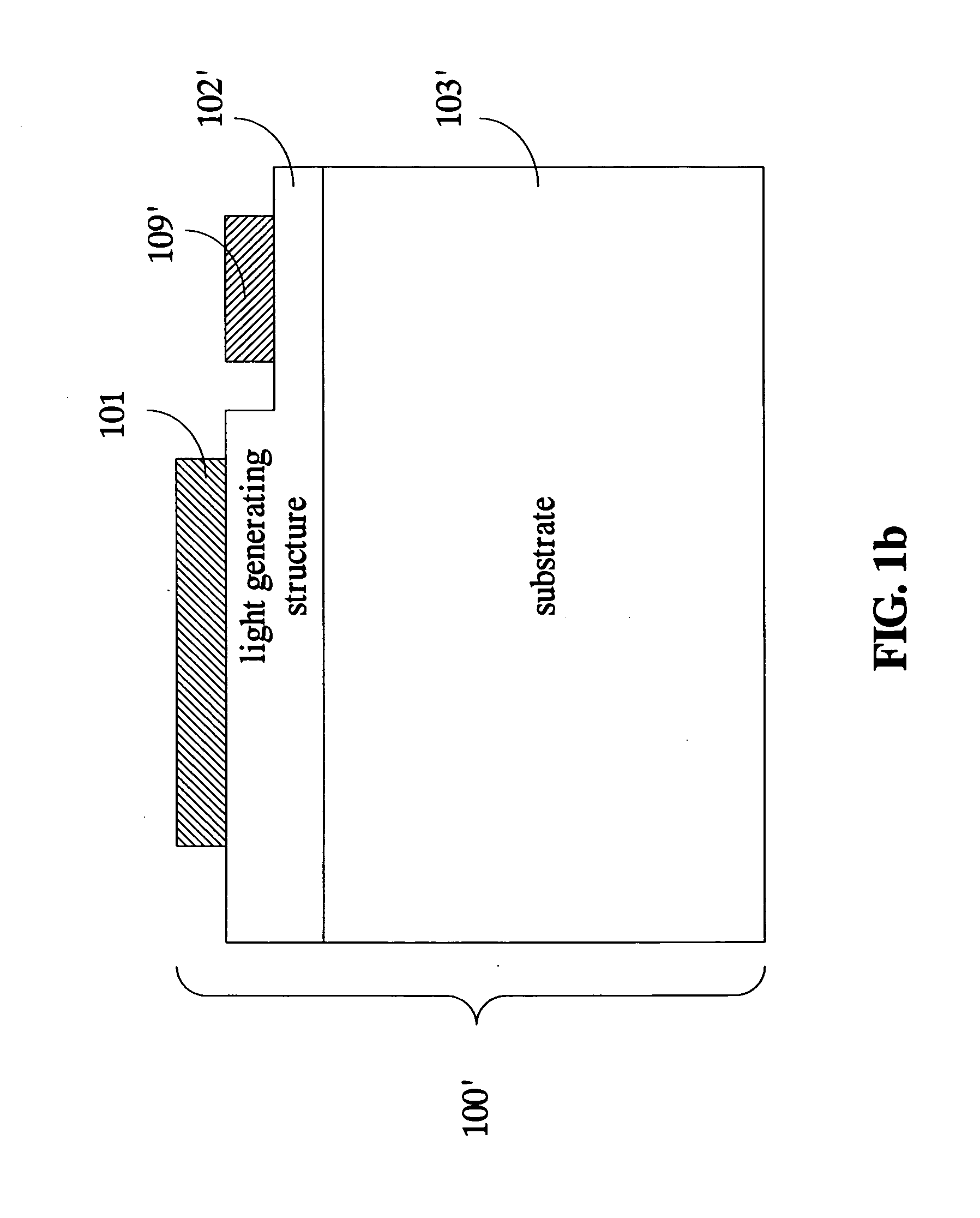

High-brightness light emitting diode having reflective layer

ActiveUS20070012937A1Increase brightnessImprove insulation performanceSemiconductor/solid-state device detailsSolid-state devicesOhmic contactAlloy

An LED structure is disclosed herein, which comprises, sequentially arranged in the following order, a light generating structure, a non-alloy ohmic contact layer, a metallic layer, and a substrate. As a reflecting mirror, the metallic layer is made of a pure metal or a metal nitride for achieving superior reflectivity. The non-alloy ohmic contact layer is interposed between the metallic layer and the light generating structure so as to achieve the required ohmic contact. To prevent the metallic layer from intermixing with the non-alloy ohmic contact layer and to maintain the flatness of the reflective surface of the first metallic layer, an optional dielectric layer is interposed between the metallic layer and the non-alloy ohmic contact layer.

Owner:EPISTAR CORP

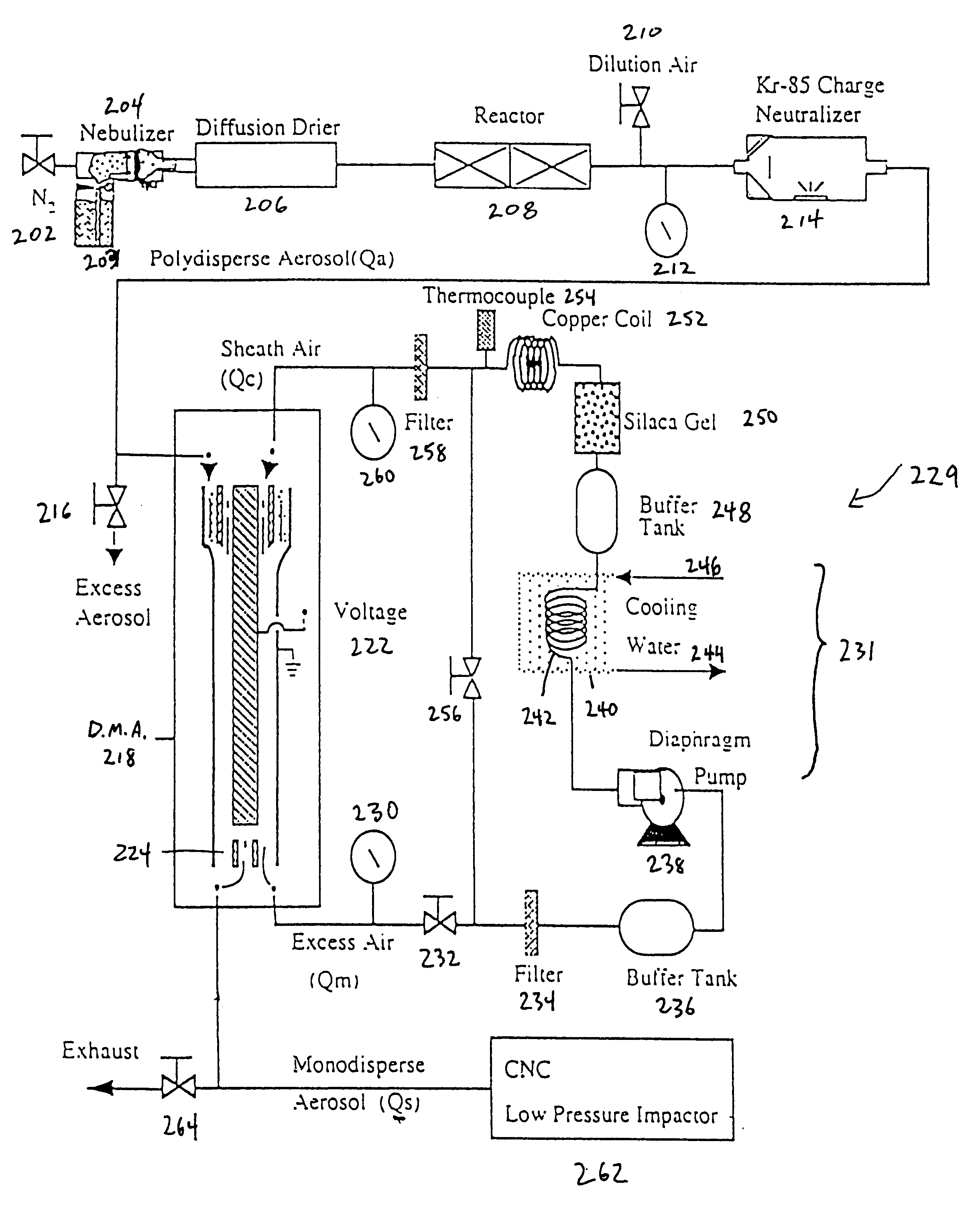

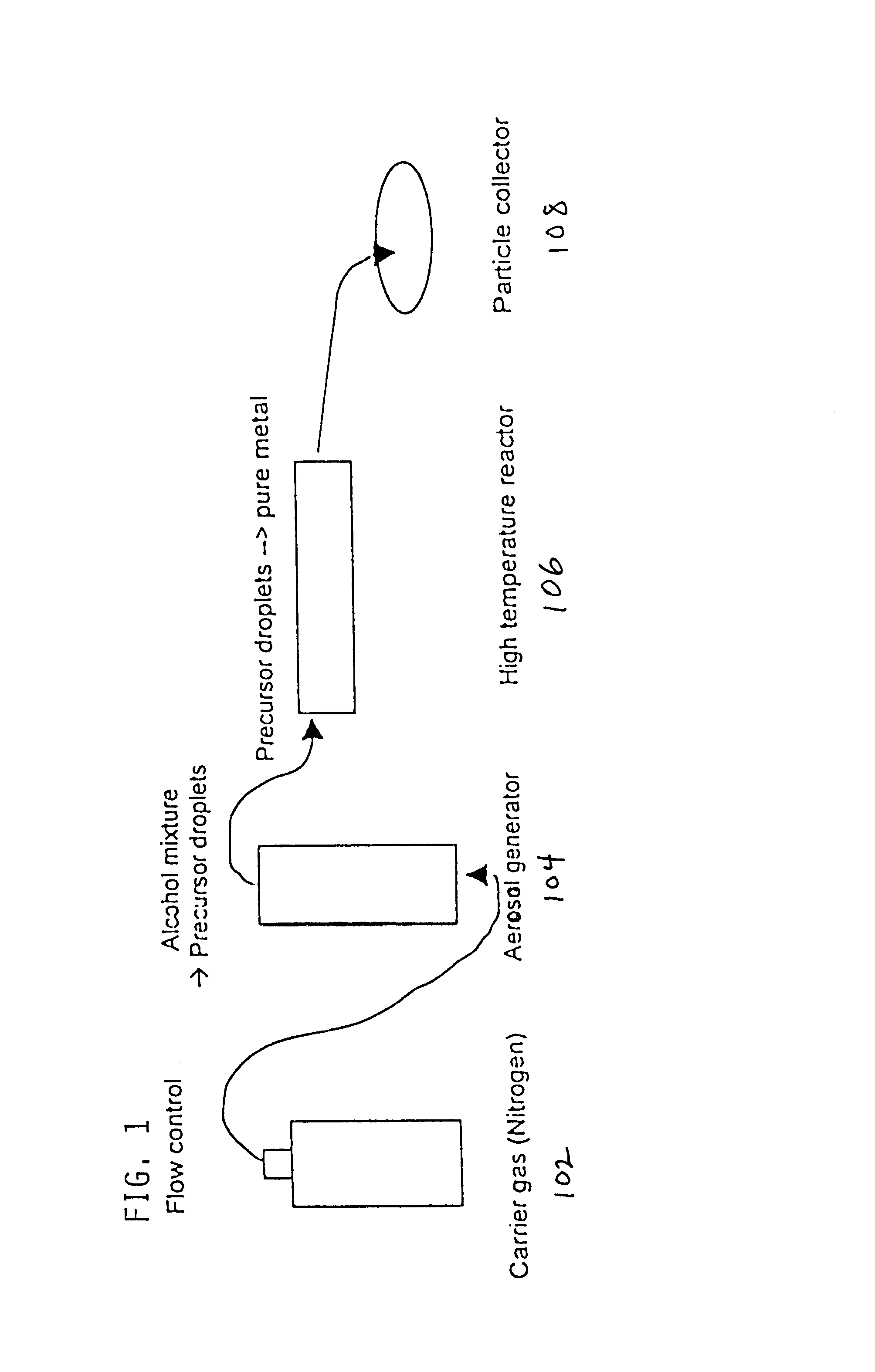

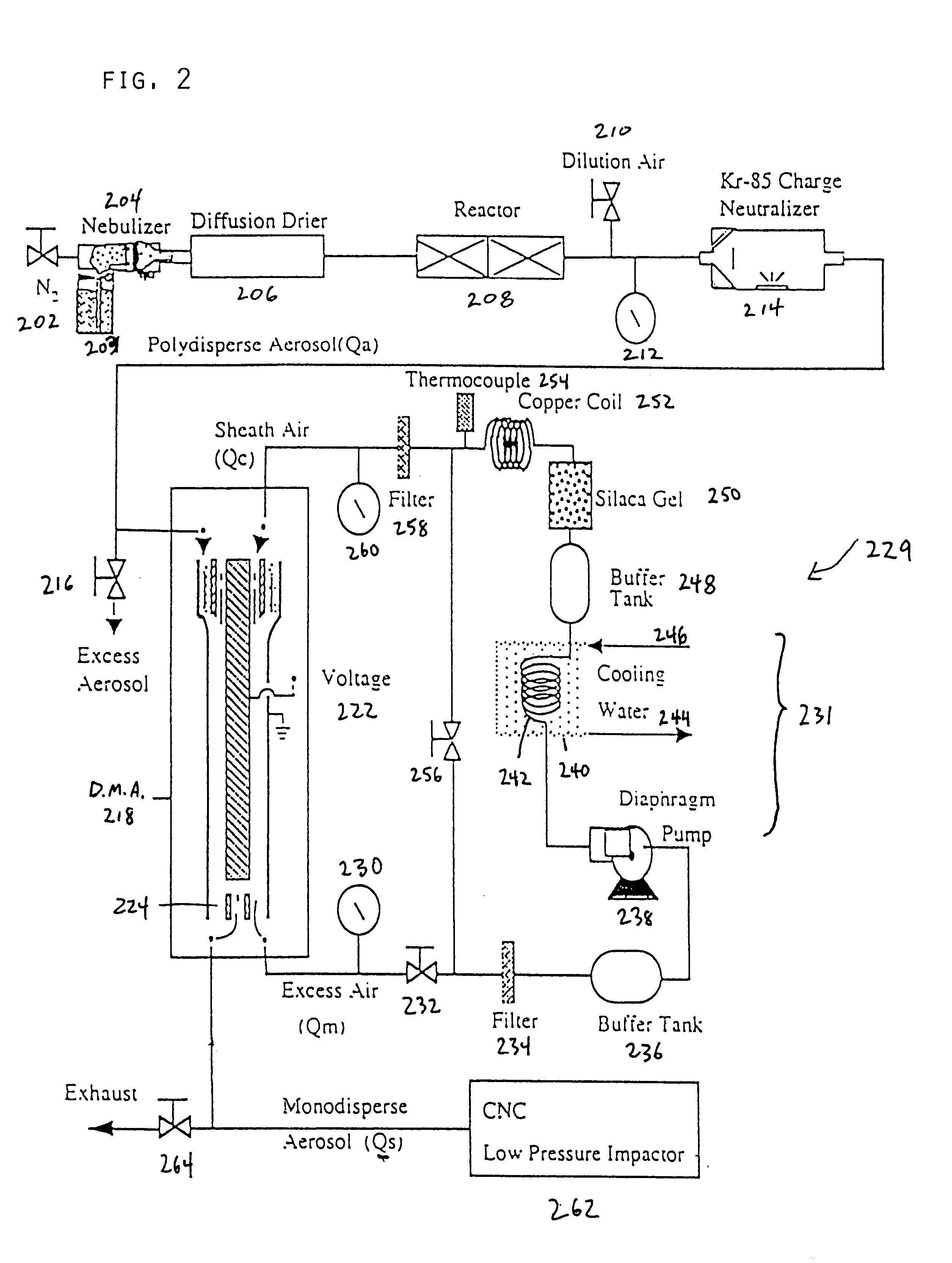

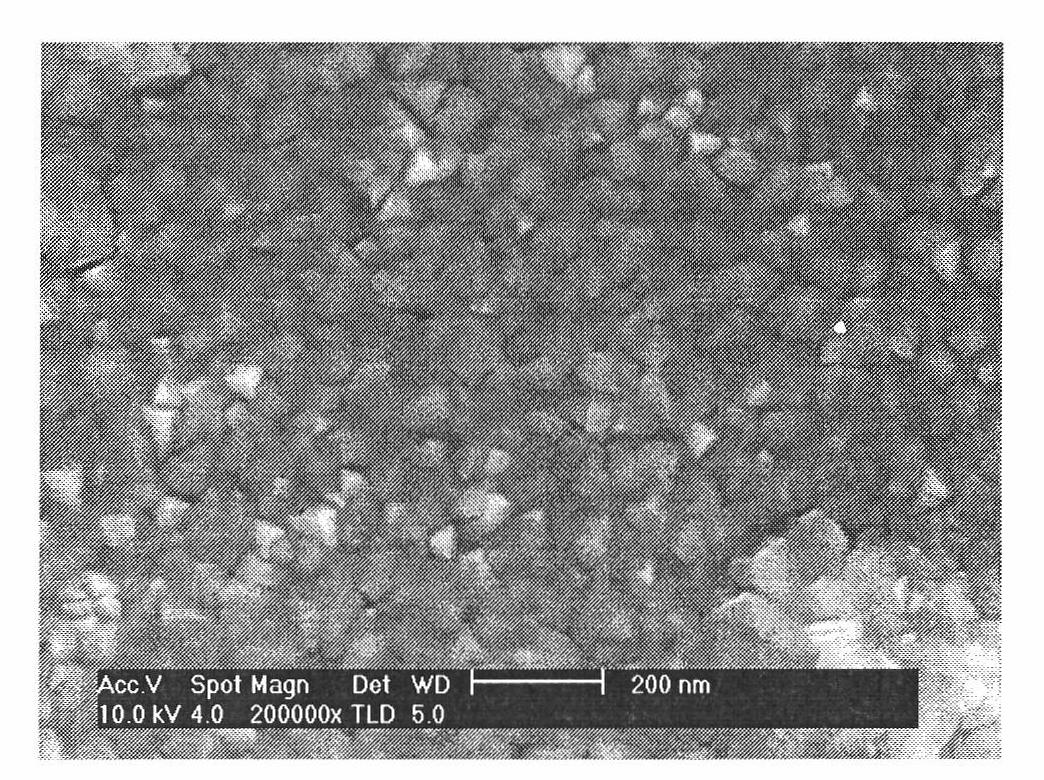

Method of producing metal particles by spray pyrolysis using a co-solvent and apparatus therefor

InactiveUS6679938B1Efficiently provideNanotechTransportation and packagingCarbon numberMetal particle

A spray pyrolysis method for producing pure metal and / or metal oxide particles uses a mixture of a carrier gas and a solution of a metal salt precursor, water and a co-solvent reducing agent. The metal salt precursors preferably comprise metals from the group consisting of Fe, Co, Ni, Cu, Zn, Pd, Ag and Au, whereas the salt anions preferably comprise nitrates, acetates, oxalates and chlorides. The co-solvents are those that act as a reducing agent, are vaporizable, are inert with respect to the carrier gas, and are hydrophilic, such as alcohols, in particular, low-carbon numbered alcohols such as methanol or ethanol.

Owner:GOVERNMENT OF THE US SEC COMMERCE THE +1

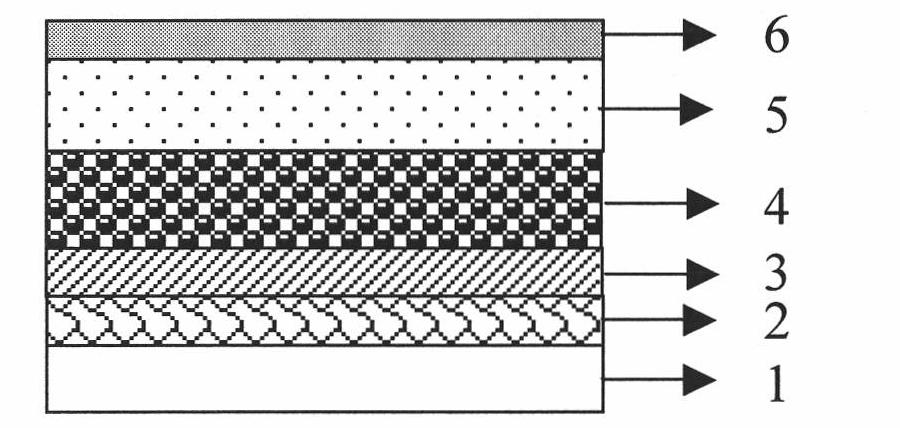

Non-vacuum solar spectrum selective absorption coating and preparation method thereof

ActiveCN102121757ASolve high temperature oxidationImprove absorption rateSolar heat devicesLayered productsIr reflectionLow emissivity

The invention relates to a non-vacuum solar spectrum selective absorption coating and a preparation method thereof. The preparation method comprises the following steps: (1) selecting copper or stainless steel with low infrared emissivity as a base material; (2) selecting oxide resistant to high-temperature oxidation, nitride and complex or doped oxide as a film material, wherein a metal or an alloy serves as a bonding force increased layer, metal nitride or pure metal serves as a high infrared reflecting layer, an absorption layer is composed of two conducting particle ceramic layers with different metal nitride conducting particle volume fractions, and aluminium nitride and aluminium oxide serve as an antireflection layer; (3) controlling the components and contents of different film materials by controlling gas flow and sputtering power; (4) cleaning the base material before the base material is placed into a vacuum chamber, and carrying out argon ion bombarding on the surface of the base material before sputtering is carried out; and (5) obtaining a multilayer coating, wherein the thickness of the coating is less than 500nm, and the coating has high absorption rate alpha (0.9-0.97) in the solar spectrum range (0.3-2.5microns) and has extremely low emissivity epsilon (0.02-0.18) in the infrared region (2.5-50microns).

Owner:GRIMAT ENG INST CO LTD

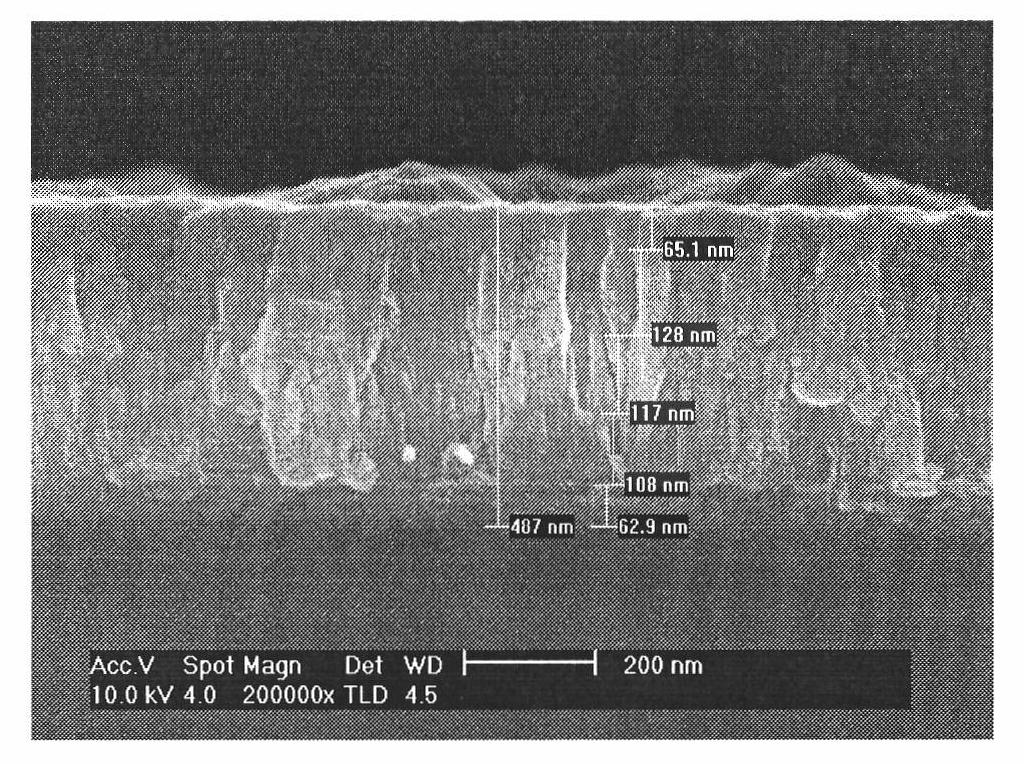

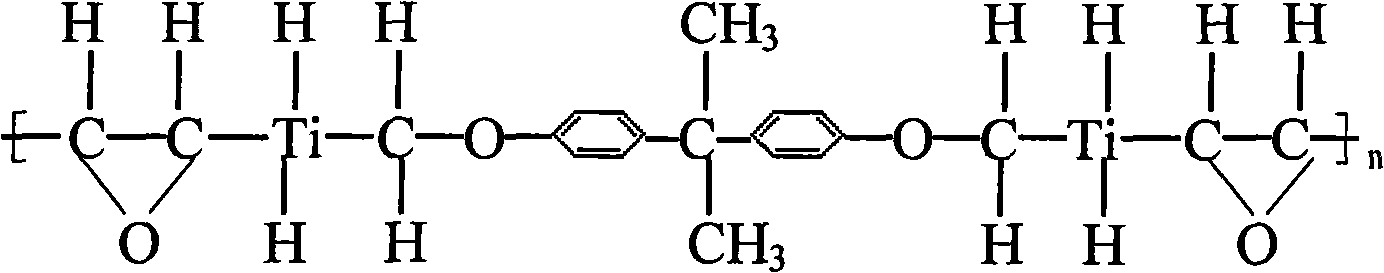

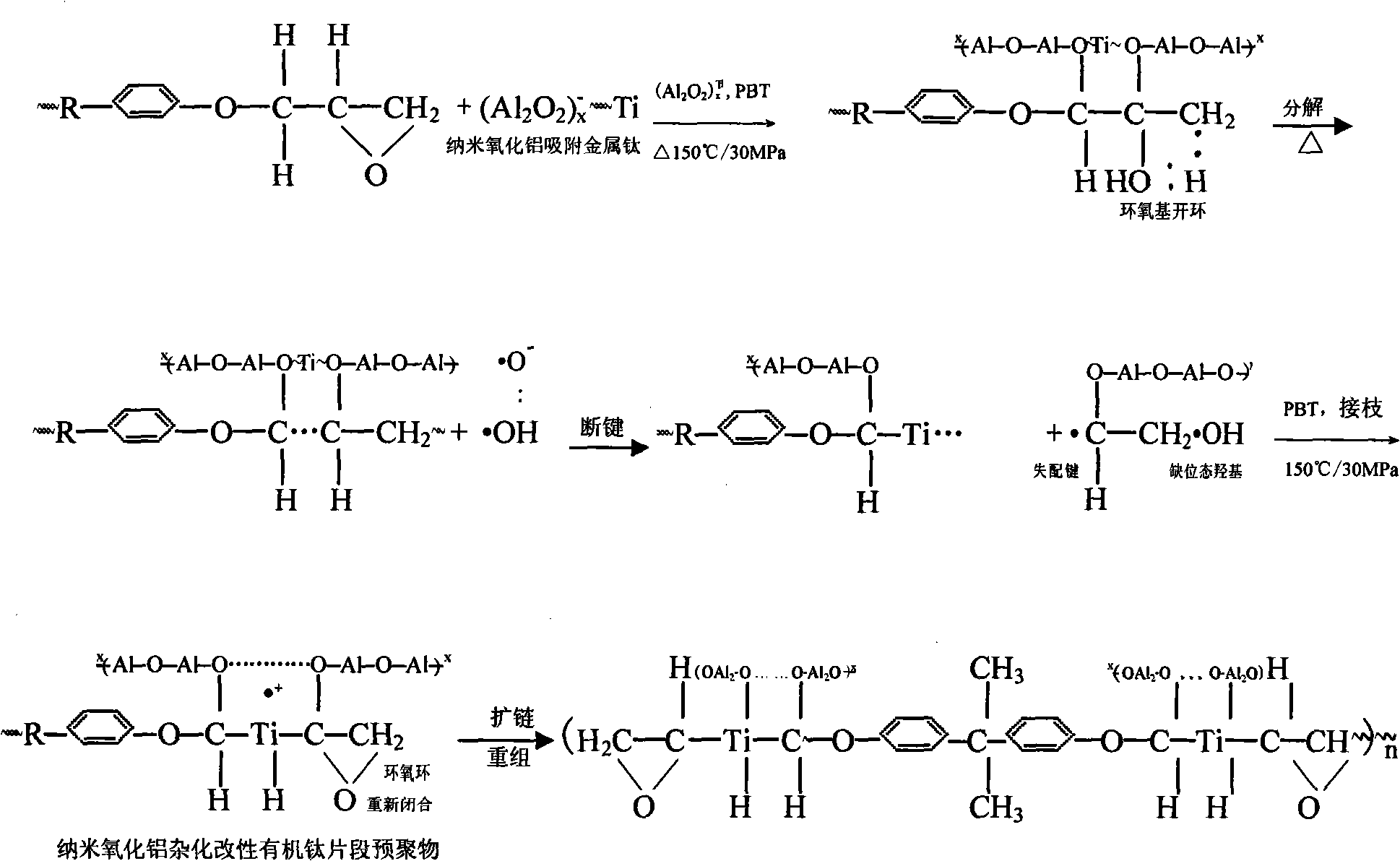

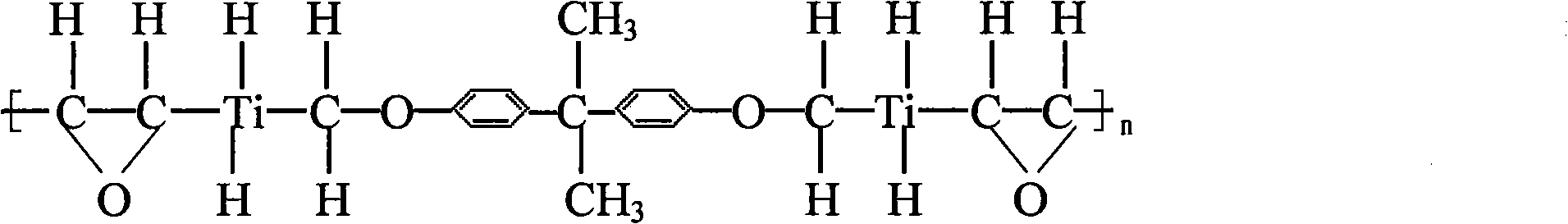

Nano organic titanium polymer, coating thereof and manufacturing method thereof

The invention relates to a nano organic titanium polymer, a coating thereof and a manufacturing method thereof. A polymerization reaction product is named as a nano organic titanium macromolecular alloy hybrid polymer, which is manufactured by the following steps: mixing pure metal titanium powder as raw material, film-forming resin, solvent medium and the like according to a formulation proportion, filling the mixture into a special closed planetary ball-milling reactor, grinding the mixture at high speed, and thinning the grinded pure metal titanium powder to nano grain diameter to produce nano effect so as to initiate a polymerization reaction under the action of a catalyst along with heat energy accumulation produced by grinding and high pressure produced by vaporization of a solvent.The polymer is an intermediate for preparing the special nano organic titanium painting. Multi-purpose high-performance anticorrosion coatings can be manufactured by compounding of the intermediate polymer and a plurality of film-forming resins.

Owner:陕西至强重防材料技术有限公司

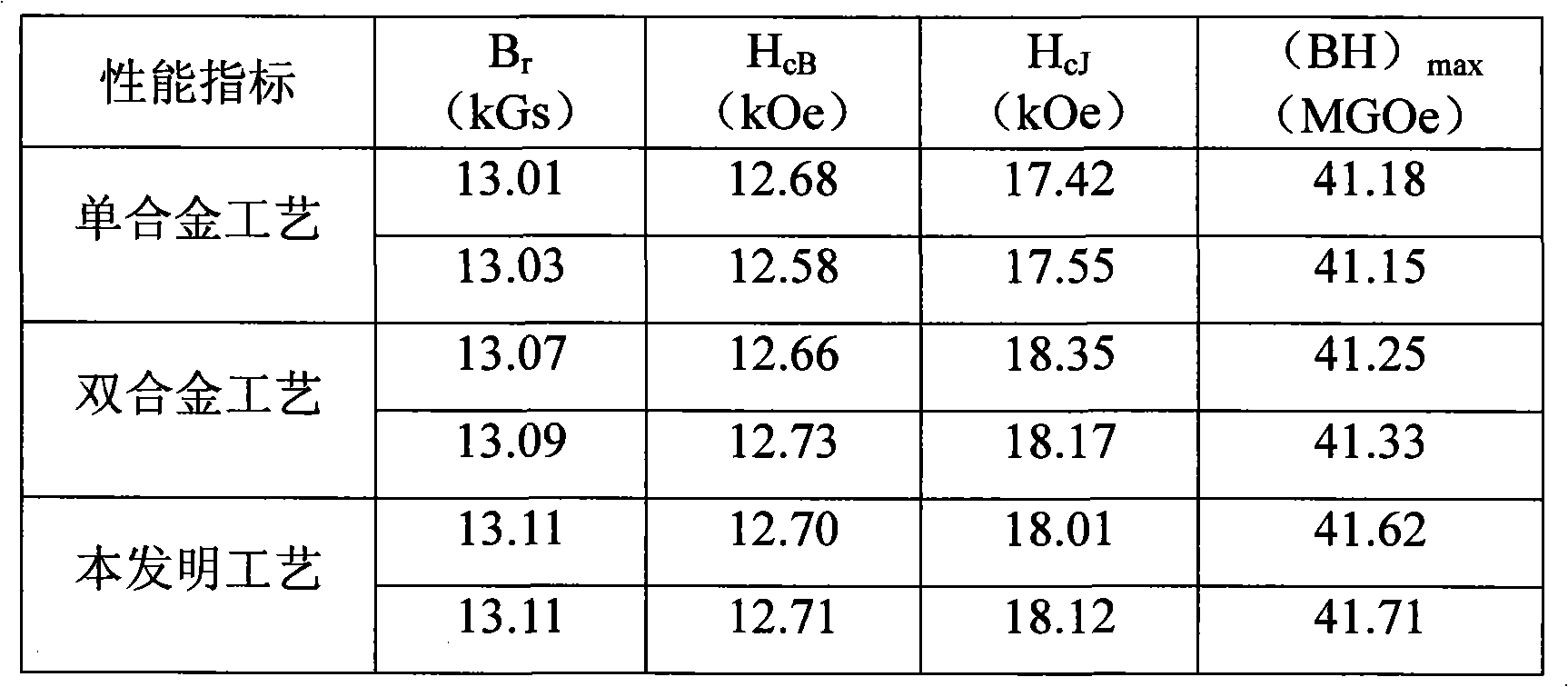

Rare earth permanent magnetism material and its making method

ActiveCN101266855AReduce manufacturing costImprove magnetic propertiesMagnetic materialsHydrogenAdditive ingredient

The invention relates to a rare earth permanent magnet and a manufacturing method thereof, more particularly a neodymium ferroboron permanent magnet material and a manufacturing method thereof. The rare earth permanent magnet comprises a rapid hardening alloy and a crystal boundary object, the crystal boundary object is one or more of metal Nd, Pr, Sm, Eu, Gd, Tb, Dy, Ho, Al, Cu, Sn, Zn, the crystal boundary mixture is 0.3-2% of the total weight. The crystal boundary object, without melting, directly crushes pure metals or the metal mixture with hydrogen and adds gas stream to mill into powder, then mixes with main phase rapid hardening alloy powder to form and sinter, the performance of magnet is more improved than the magnet with the same ingredients in traditional procedure. The invention omits a melting procedure of the crystal boundary object, directly adds the powder and saves the production cost of the magnet.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Method for high temperature mercury capture from gas streams

ActiveUS7033419B1Maintain thermal efficiencyIncrease temperatureGas treatmentOther chemical processesIridiumSorbent

A process to facilitate mercury extraction from high temperature flue / fuel gas via the use of metal sorbents which capture mercury at ambient and high temperatures. The spent sorbents can be regenerated after exposure to mercury. The metal sorbents can be used as pure metals (or combinations of metals) or dispersed on an inert support to increase surface area per gram of metal sorbent. Iridium and ruthenium are effective for mercury removal from flue and smelter gases. Palladium and platinum are effective for mercury removal from fuel gas (syngas). An iridium-platinum alloy is suitable for metal capture in many industrial effluent gas streams including highly corrosive gas streams.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

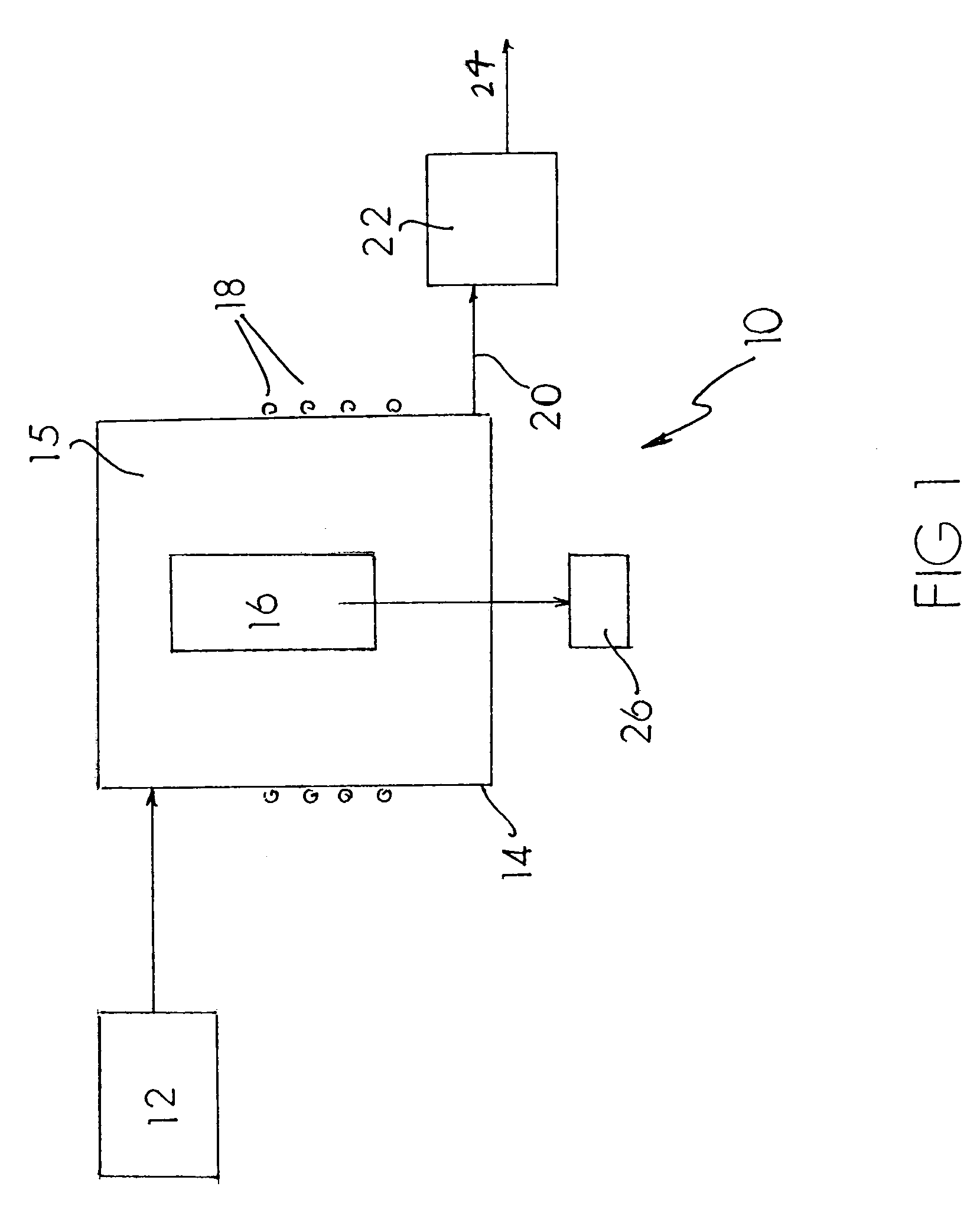

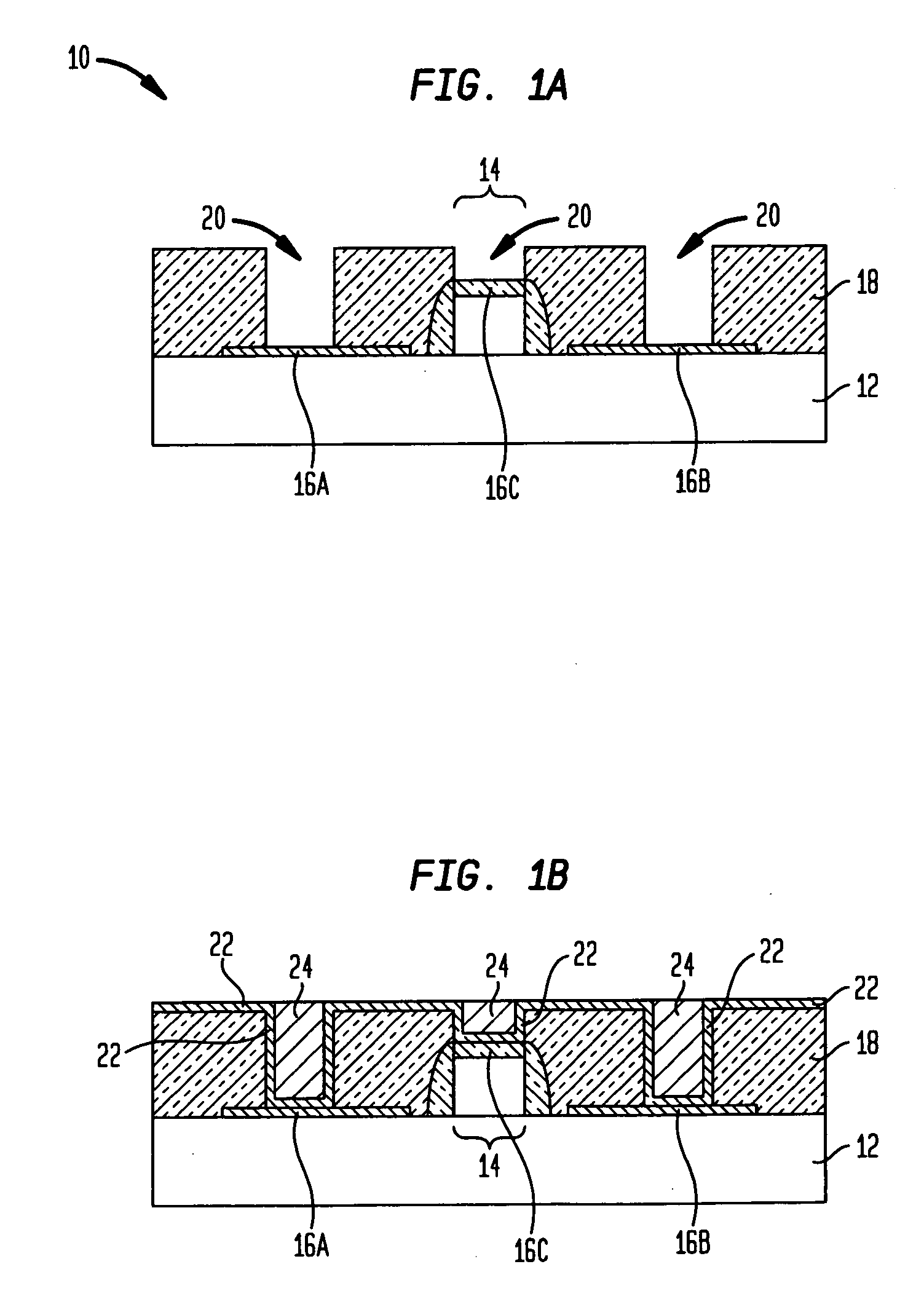

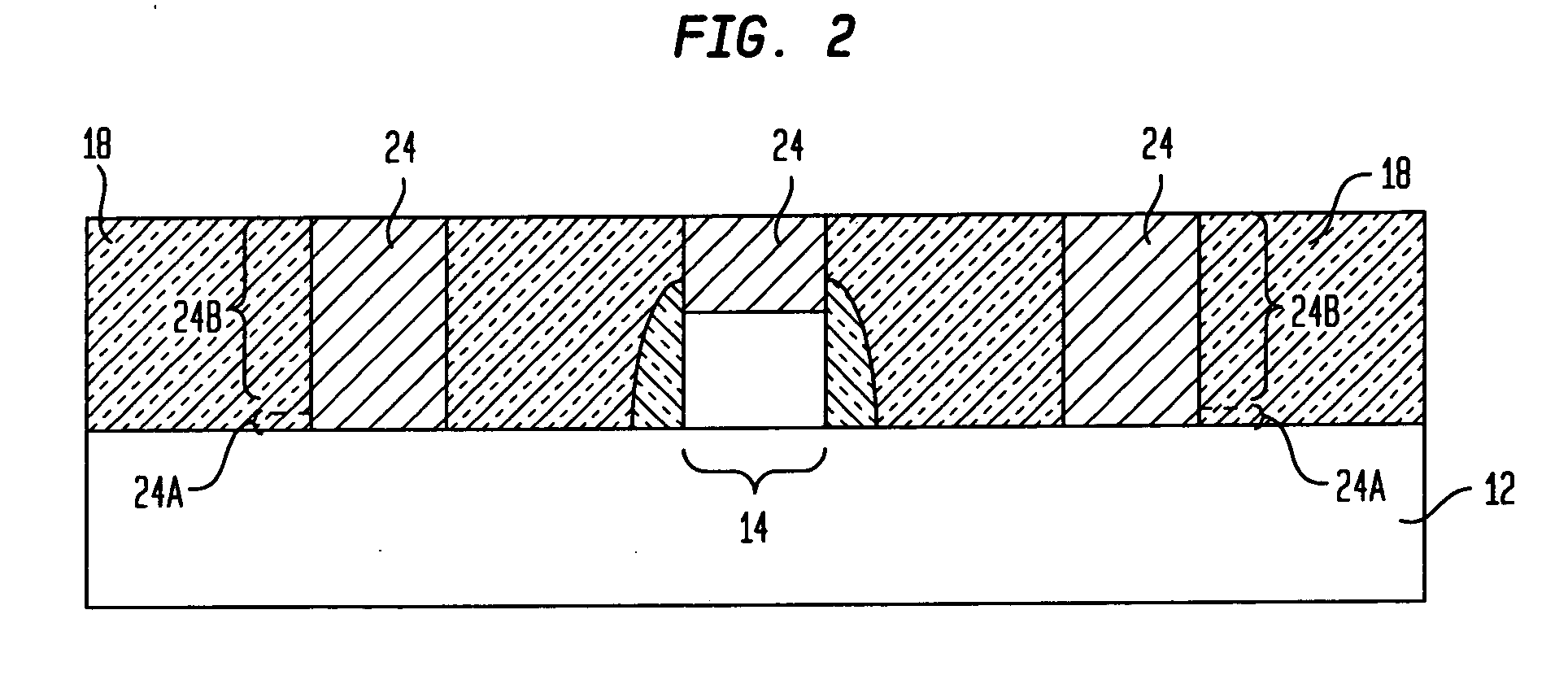

Method and structure for reducing contact resistance between silicide contact and overlying metallization

InactiveUS20070275548A1Lower resistance contactReduce contact resistanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureMetal silicide

A semiconductor structure in which the contact resistance in the contact opening is reduced as well as a method of forming the same are provided. This is achieved in the present invention by replacing conventional contact metallurgy, such as tungsten, or a metal silicide, such as Ni silicide or Cu silicide, with a metal germanide-containing contact material. The term “metal germanide-containing” is used in the present application to denote a pure metal germanide (i.e., MGe alloy) or a metal germanide that includes Si (i.e., MSiGe alloy).

Owner:GLOBALFOUNDRIES INC

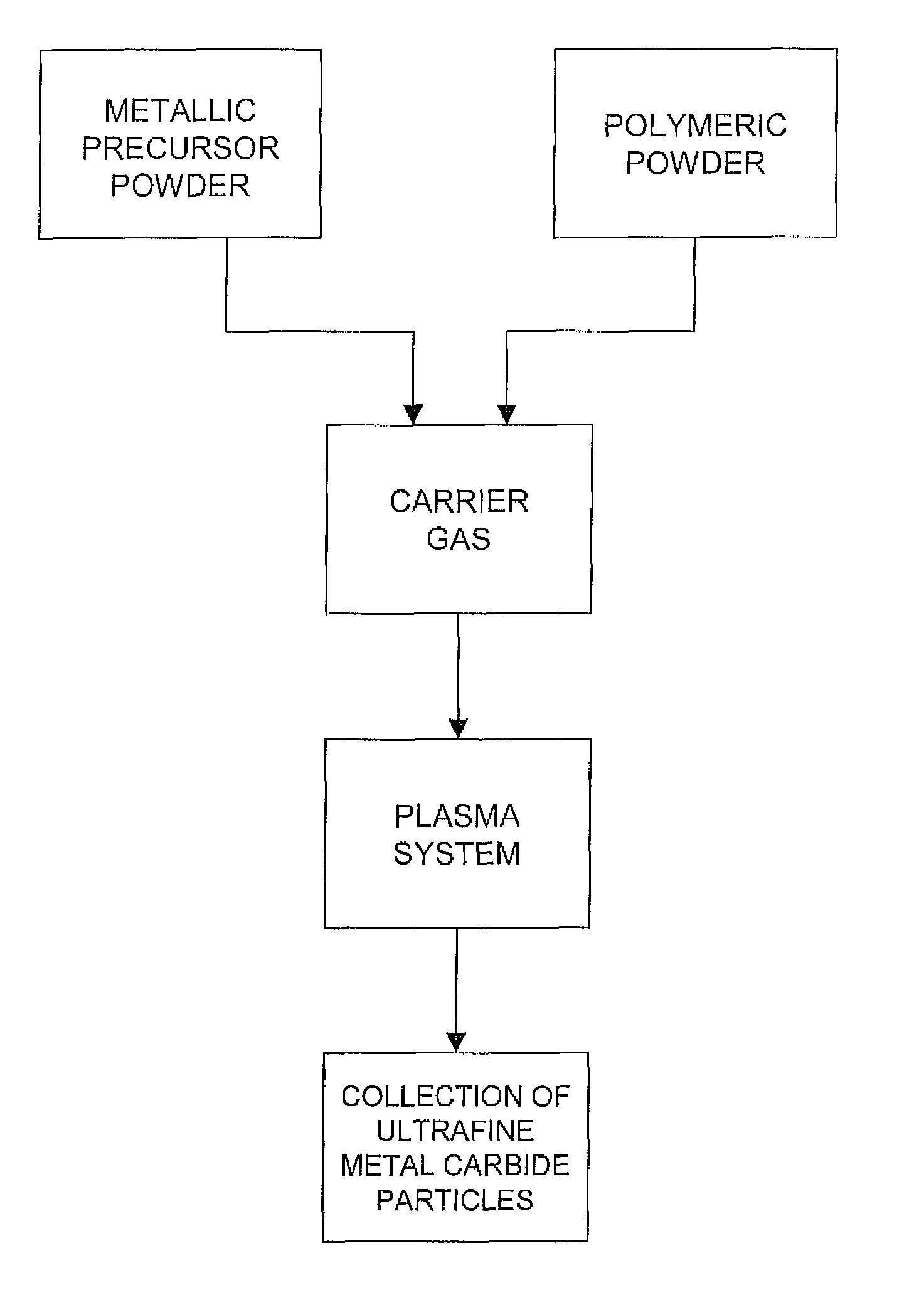

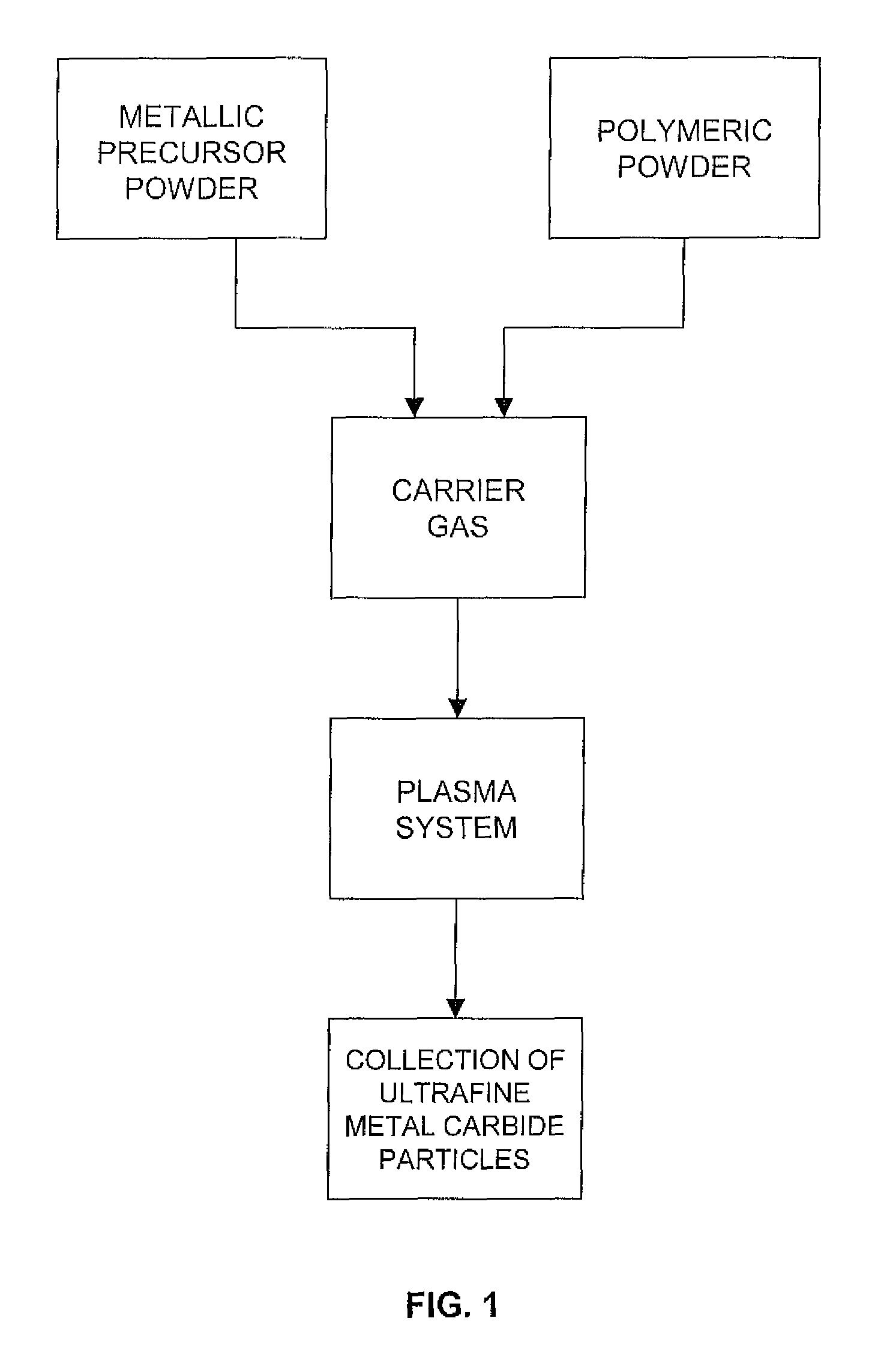

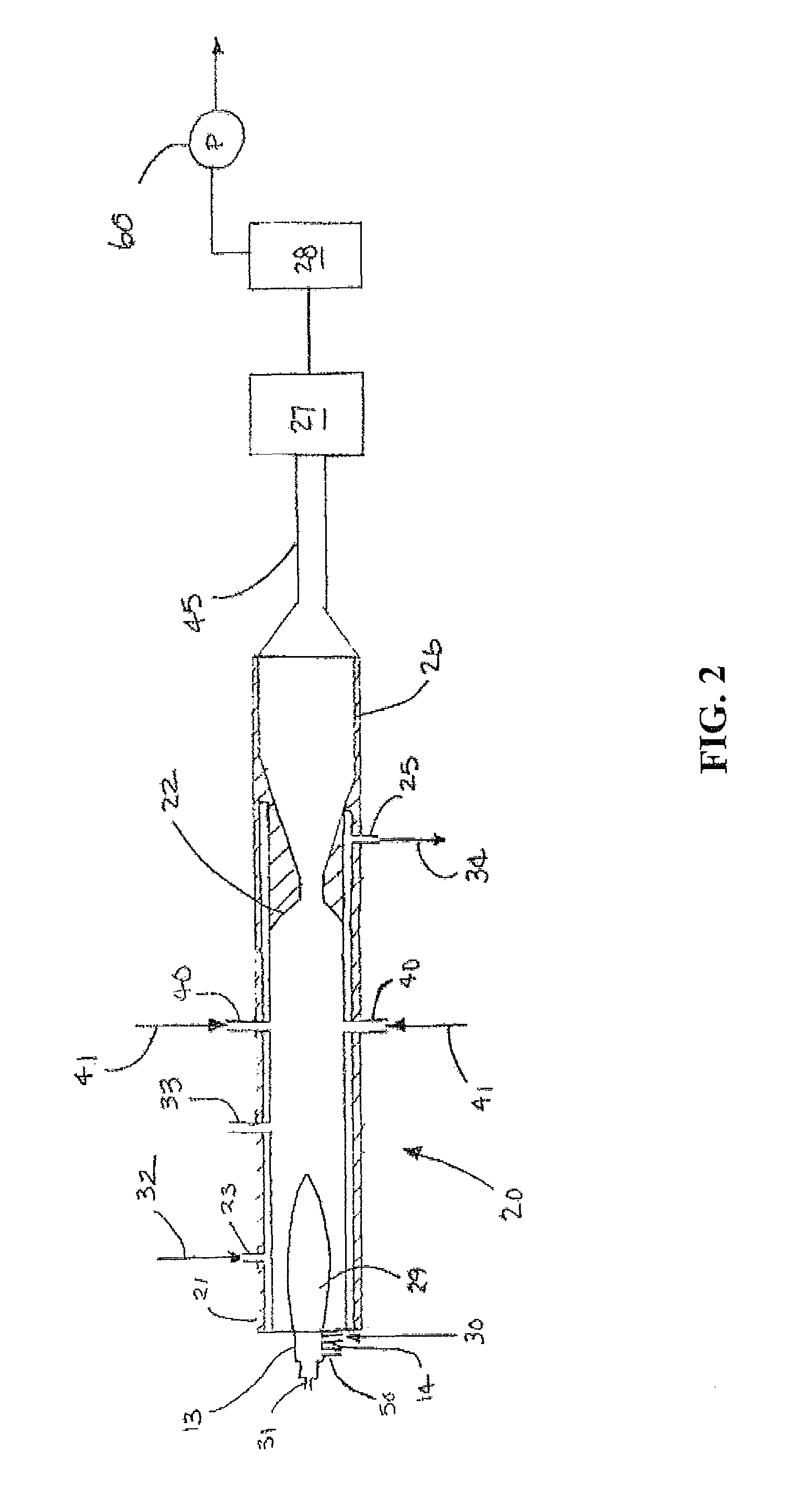

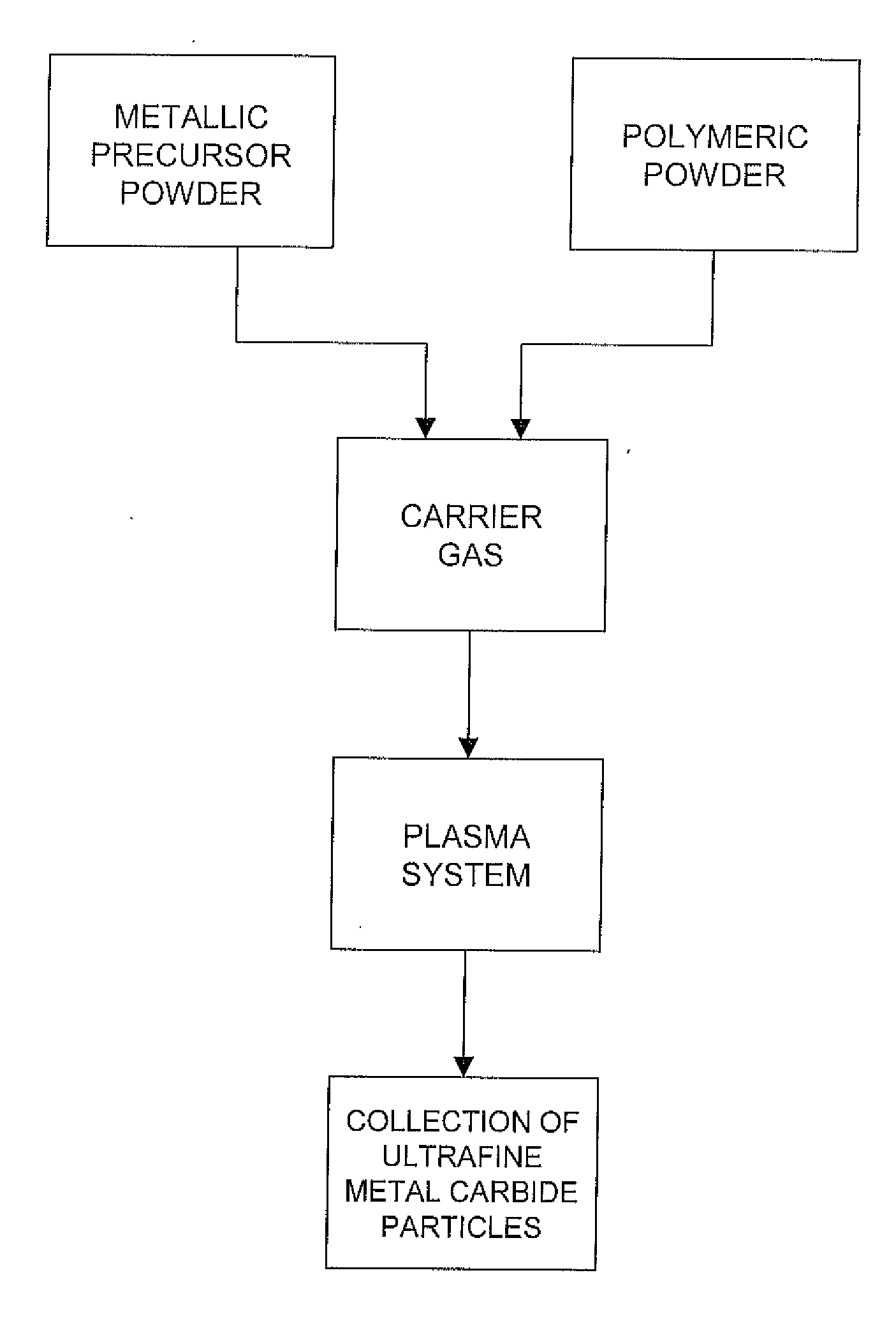

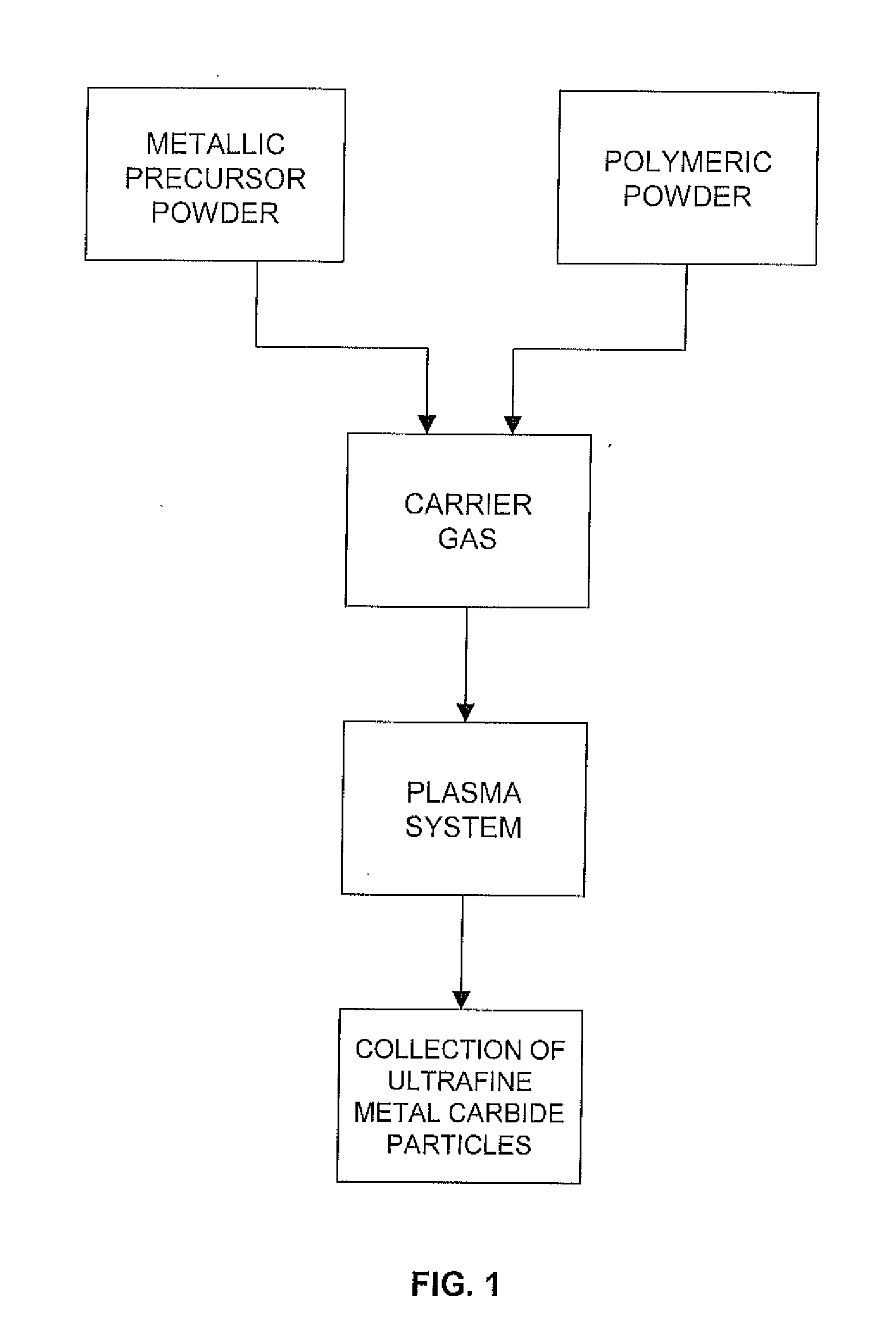

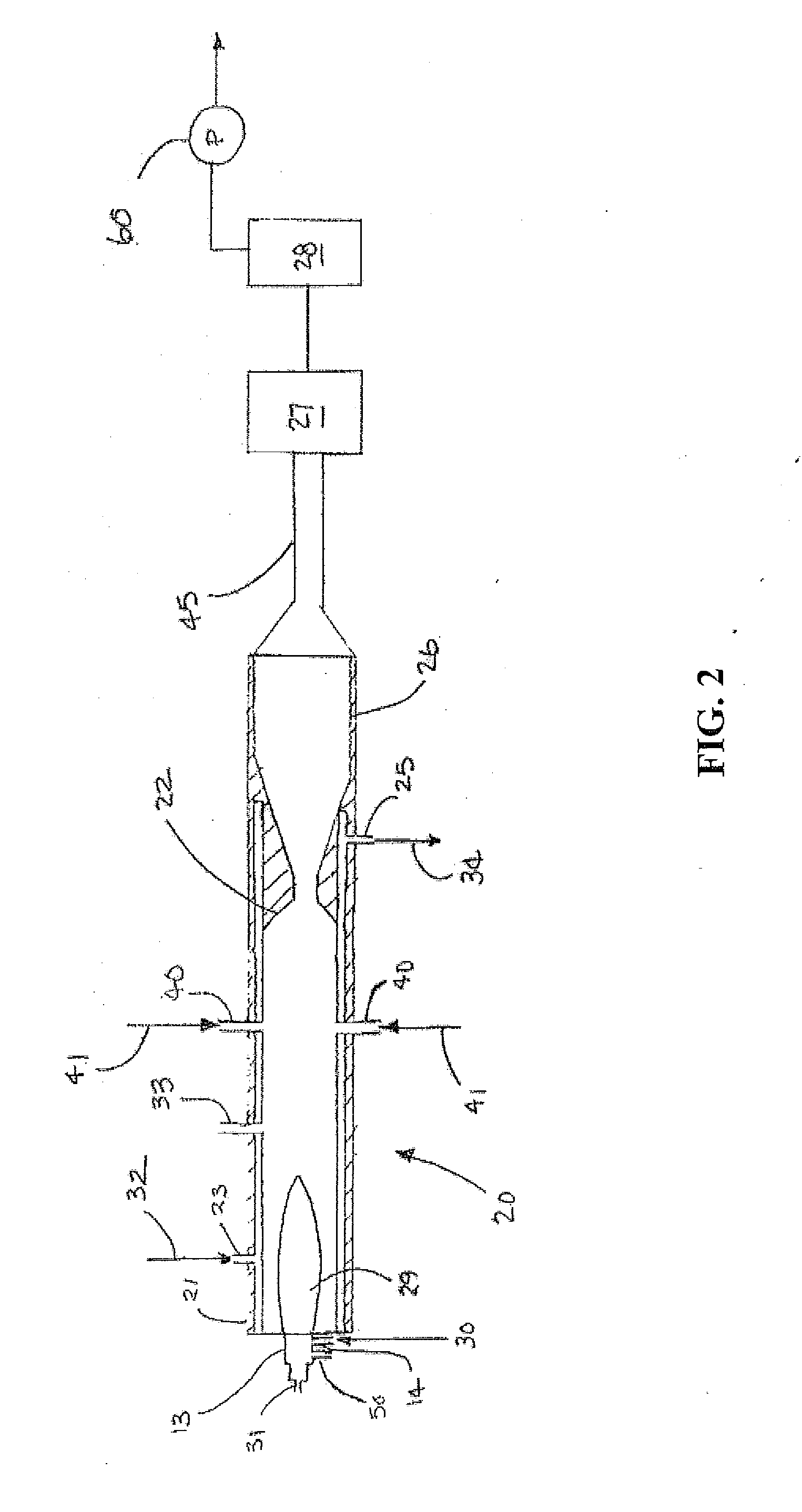

Production of ultrafine metal carbide particles utilizing polymeric feed materials

The production of ultrafine metal carbide powders from polymeric powder and metallic precursor powder starting materials is disclosed. In certain embodiments, the polymeric powder may comprise polypropylene, polyethylene, polystyrene, polyester, polybutylene, nylon, polymethylpentene and the like. The metal precursor powder may comprise pure metals, metal alloys, intermetallics and / or metal-containing compounds such as metal oxides and nitrides. In one embodiment, the metal precursor powder comprises a silicon-containing material, and the ultrafine powders comprise SiC. The polymeric and metal precursor powders are fed together or separately to a plasma system where the feed materials react to form metal carbides in the form of ultrafine particles.

Owner:PPG IND OHIO INC

Production of ultrafine metal carbide particles utilizing polymeric feed materials

The production of ultrafine metal carbide powders from polymeric powder and metallic precursor powder starting materials is disclosed. In certain embodiments, the polymeric powder may comprise polypropylene, polyethylene, polystyrene, polyester, polybutylene, nylon, polymethylpentene and the like. The metal precursor powder may comprise pure metals, metal alloys, intermetallics and / or metal-containing compounds such as metal oxides and nitrides. In one embodiment, the metal precursor powder comprises a silicon-containing material, and the ultrafine powders comprise SiC. The polymeric and metal precursor powders are fed together or separately to a plasma system where the feed materials react to form metal carbides in the form of ultrafine particles.

Owner:PPG IND OHIO INC

Preparation method of whole continuous nano-porous copper

The invention relates to a preparation method of whole continuous nano-porous copper, comprising the following steps: (1) heating the pure metallic aluminum and copper to the molten state, stirring and mixing the mixture to form Cu-Al alloy liquid; (2) fast blowing the alloy liquid out with inert gas to solidify the molten liquid metal on the copper rollers which rotate in high speed and prepare alloy strips, or solidify the molten liquid metal in copper molds to prepare alloy plates or alloy bars; and (3) performing dealloying process to the obtained alloy, cleaning the alloy in the distilled water to be neutral and airing the alloy to obtain nano-porous copper. The beneficial effects of the invention are as follows: (1) the produced nano-porous copper is whole continuous and whole continuous nanosize bulk materials can also be prepared; (2) low concentration of corrosion solution is used to prepare nano-porous copper in the method of the invention, and the operation process is simple and the method is suitable for large-scale industrialized production; and (3) according to the components of the mother alloy and the types of corrosion solution, the structure and size of nanoporous copper can be regulated.

Owner:UNIV OF JINAN

Nanotube coatings for implantable electrodes

ActiveUS20050075708A1Reduce polarizationIncrease surface areaSpinal electrodesMaterial nanotechnologyImplantable ElectrodesBoron nitride

Coatings for implantable electrodes consisting of single- or multi-walled nanotubes, nanotube ropes, carbon whiskers, and a combination of these are described. The nanotubes can be carbon or other conductive nanotube-forming materials such as a carbon-doped boron nitride. The nanotube coatings are grown “in situ” on a catalytic substrate surface from thermal decomposition, or they are bonded to the substrate using a metal or conductive metal oxide thin film binder deposited by means of a metal compound precursor in liquid form. In the latter case, the precursor / nanotube coating is then converted to a pure metal or conductive metal oxide, resulting in the desired surface coating with imbedded nanotubes.

Owner:WILSON GREATBATCH LTD

Method for melting titanium alloy containing high-melting point alloy element

The invention relates to an industrial preparation method for a high-melting point alloy element titanium alloy ingot. The invention is characterized in that an alloy raw material is selected, an electrode block which is specially assembled and spliced is employed, a routine vacuum self-consumption arc melting technology is used, three times melted current and voltage can be adjusted, so that thetitanium alloy ingot containing high-melting point alloy element with uniform chemical components and no impurities can be prepared. The high melting point metal has the advantages of uniform distribution in the self-consumption electrode, convenient self-consumption electrode preparation and low cost, the current and the voltage parameter are reasonable during the melting process, based on the traditional technical route, according to the specific self-consumption assembling mode, a pure metal plate with low cost is used for substituting a mode of adding an intermediate alloy with expensive cost and adding other pure metals in titanium alloy, a multi-time vacuum self-consumption arc melting furnace is used for carrying out melting to obtain the titanium alloy ingot containing high-melting point alloy element and possessing uniform ingredients. The method for melting titanium alloy containing high-melting point alloy element is adapted to industrial application.

Owner:CENT SOUTH UNIV

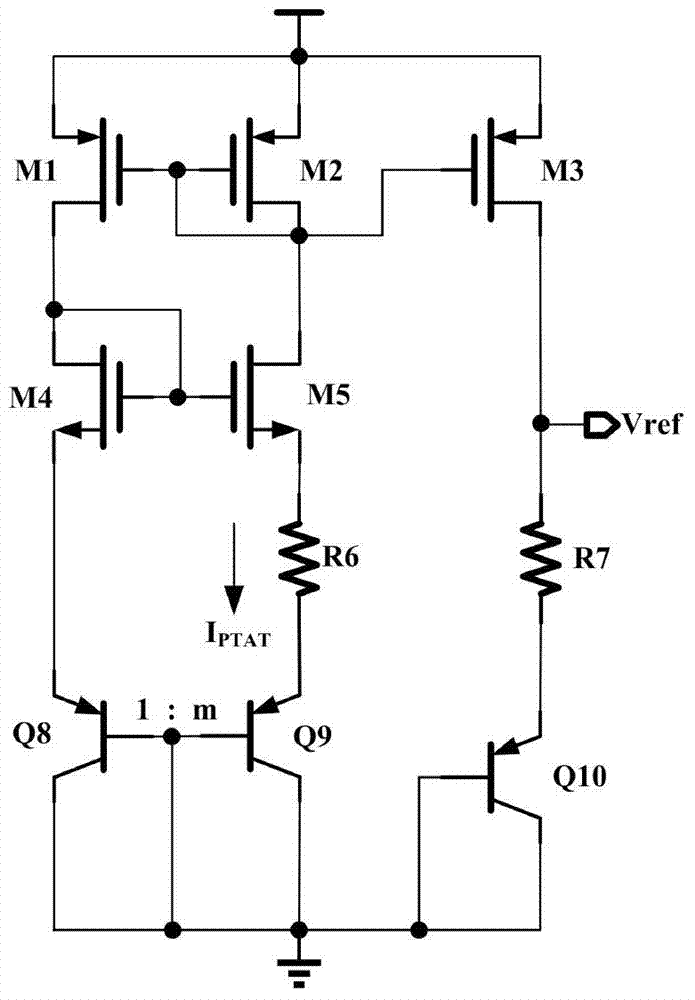

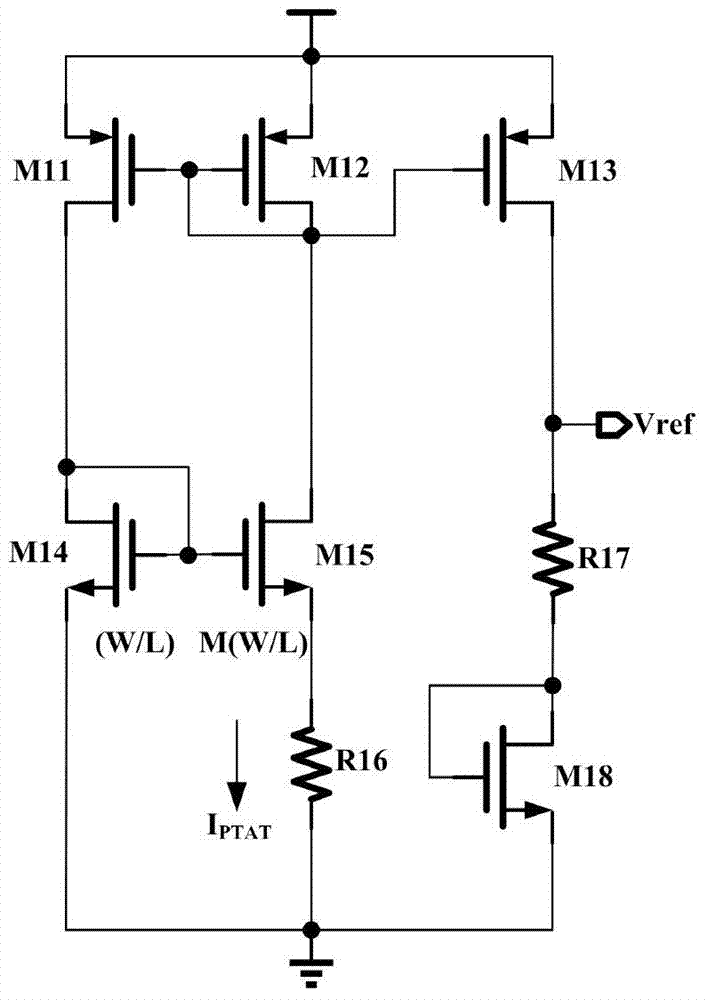

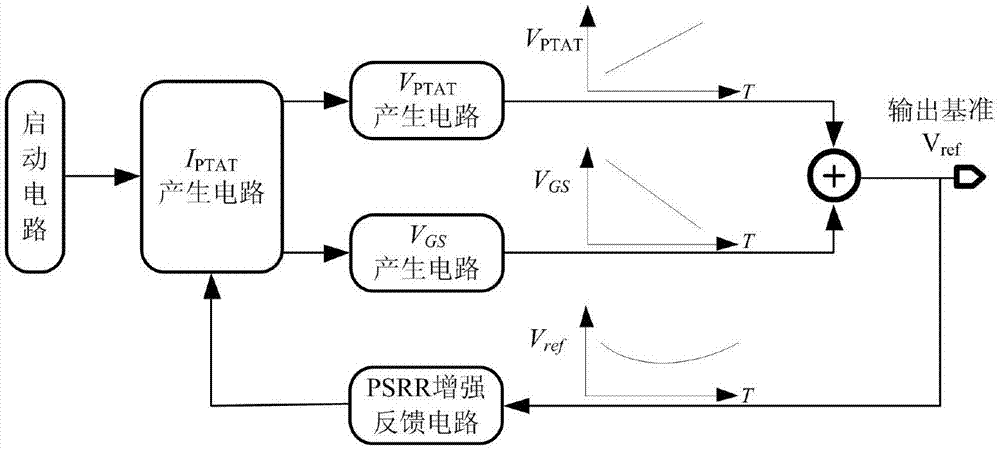

Pure metal oxide semiconductor (MOS) structure voltage reference source with high power supply rejection ratio

ActiveCN103529897AImprove voltage suppression performanceReduce design difficultyElectric variable regulationVoltage referenceFeedback circuits

A pure metal oxide semiconductor (MOS) structure voltage reference source with high power supply rejection ratio (PSRR) comprises a starting circuit, an IPTAT generation circuit, a VPTAT generation circuit, a VGS generation circuit and a PSRR reinforcing feedback circuit. The starting circuit is connected with the IPTAT generation circuit, the output of the IPTAT generation circuit is connected with the VPTAT generation circuit and the VGS generation circuit, the output of the VPTAT generation circuit and the output of the VGS generation circuit are overlapped to form Vref reference voltage output, and the output reference voltage is fed back to the IPTAT generation circuit through the PSRR reinforcing feedback circuit to generate a circuit to form a closed feedback loop.

Owner:SOUTHEAST UNIV

Titanium dioxide photocatalysis air-cleaning film and its preparation method

The present invention relates to a titanium dioxide photocatalysis air-cleaning film and its preparation method. It is characterized by that it utilizes the megnetron sputtering to form titanium dioxide photocatalysis air-cleaning film on the carriers of glass, metal and ceramics. It uses the direct synthesis of pure metal titanium target material and oxygen gas and utilzies are controlling power supply to prevent pure metal target material from poisoning, in which the crystal grains formed by titanium dioxide film can be grown along the vertical direction or horizontal direction of carrier. The grain size is 10-100 nano, and the thickness of the film is 20-100 nano. Said titanium dioxide film is formed from single anatase phase or single rutile phase or their mixed phase, in which the anatase content is 50%-98% and rutile phase content is 2%-50%. Said film can effectively degrade harmful gases of formaldehyde and phenol, etc.

Owner:TSINGHUA UNIV +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com