Patents

Literature

485 results about "Spray pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spray pyrolysis is a process in which a thin film is deposited by spraying a solution on a heated surface, where the constituent react to form a chemical compound. The chemical reactants are selected such that the products other than the desired compound are volatile a t the temperature of deposition.

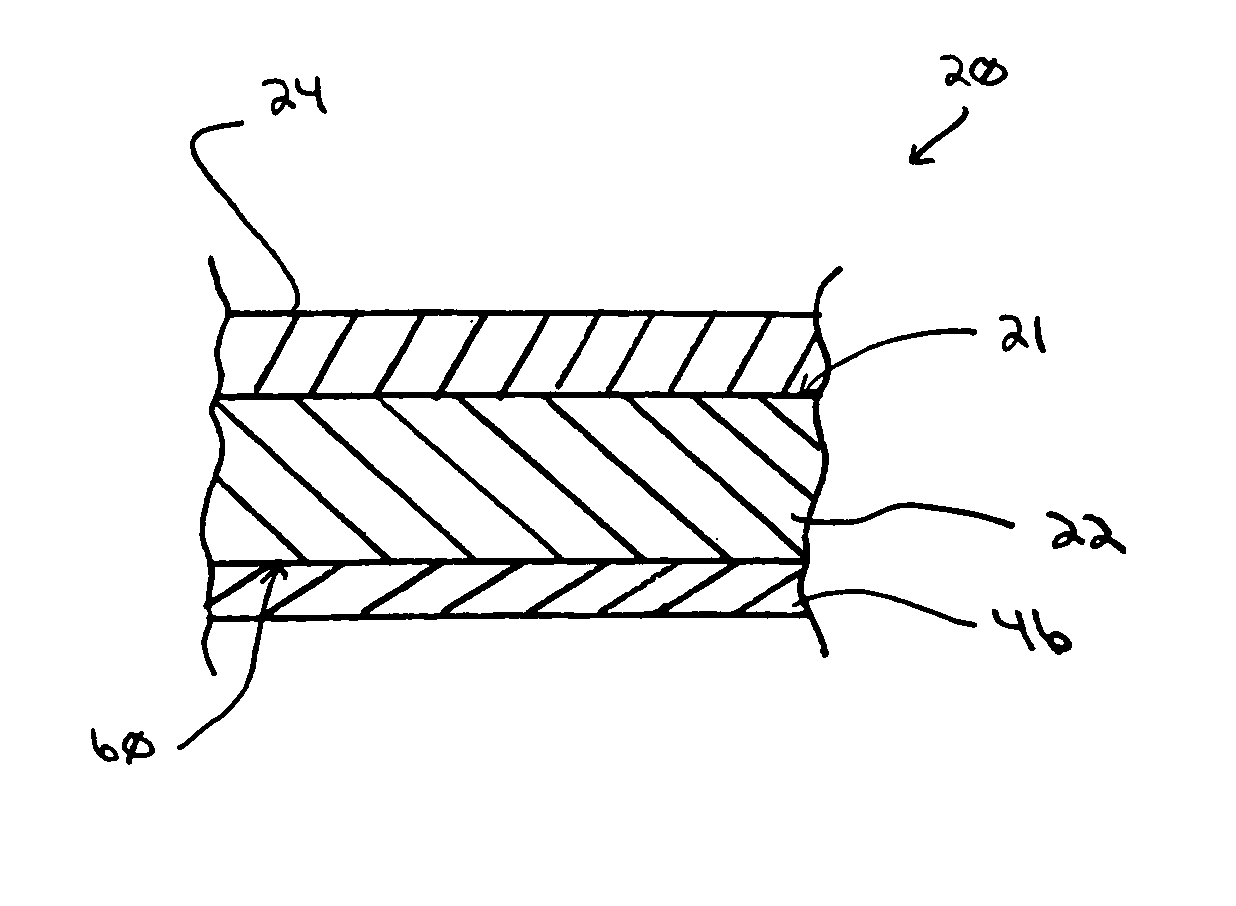

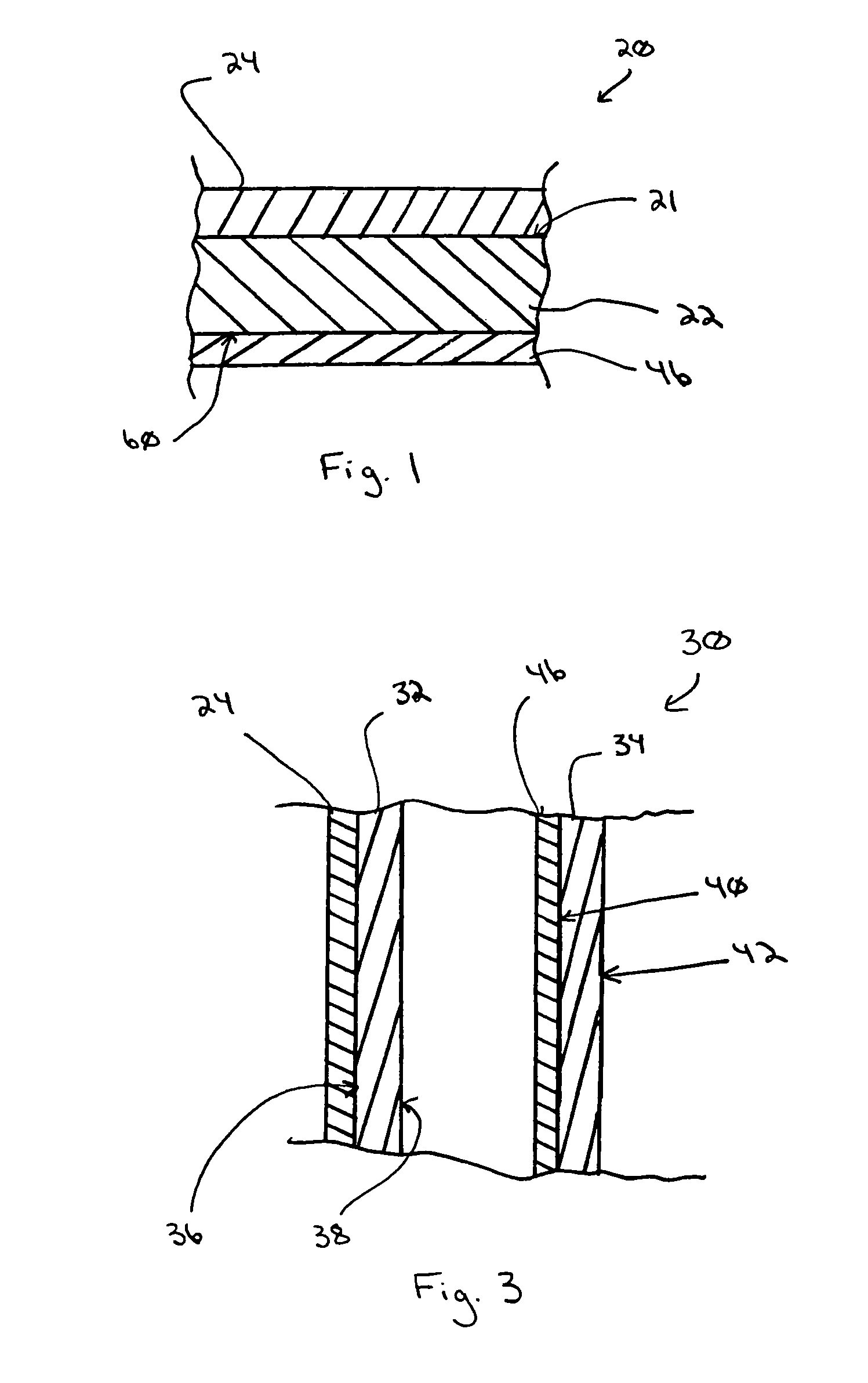

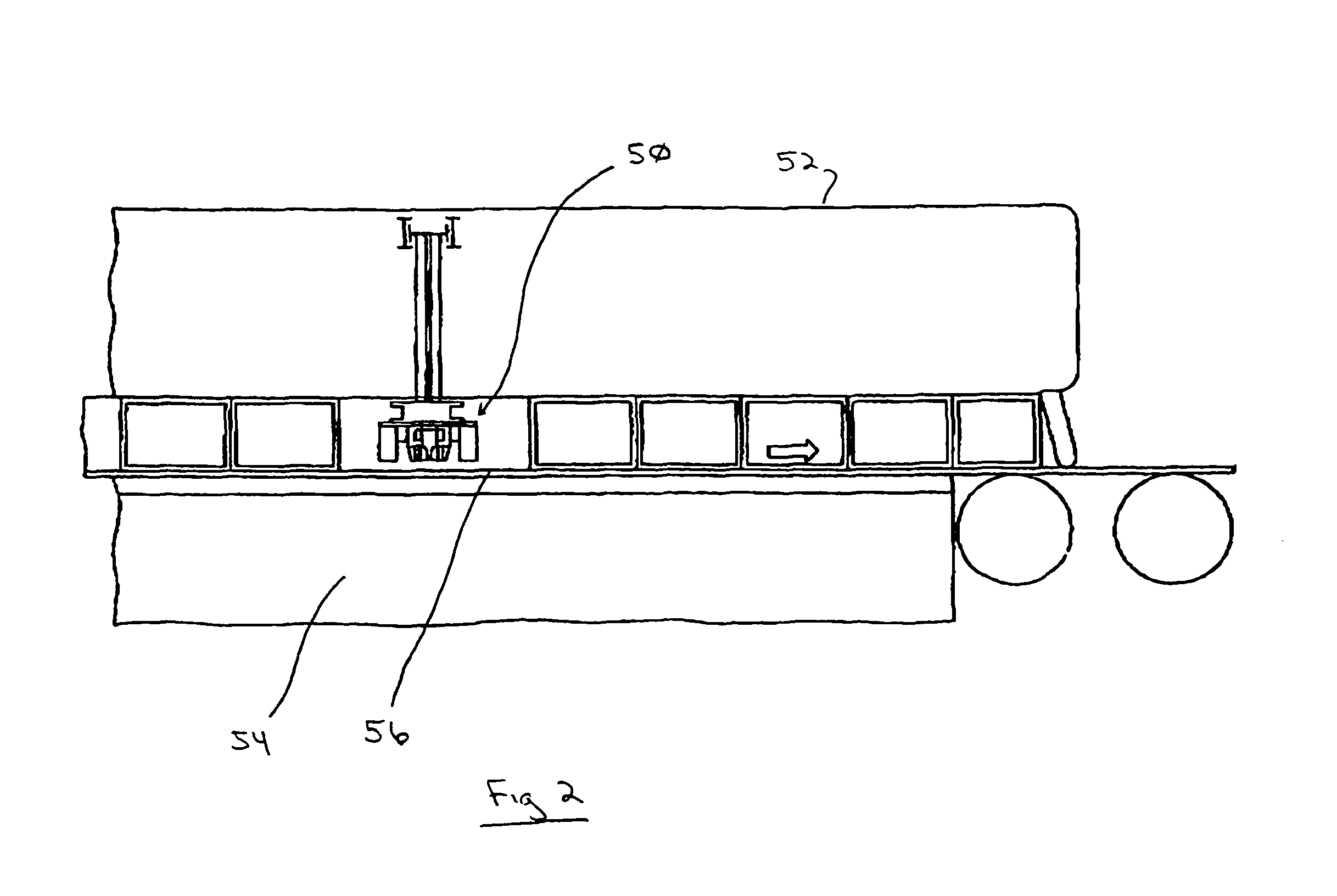

Systems and Methods of the Formation of Solid State Metal Boride and Oxide Coatings

InactiveUS20080003425A1Easy to implementMolten spray coatingLayered productsCelsius DegreeMicrometer

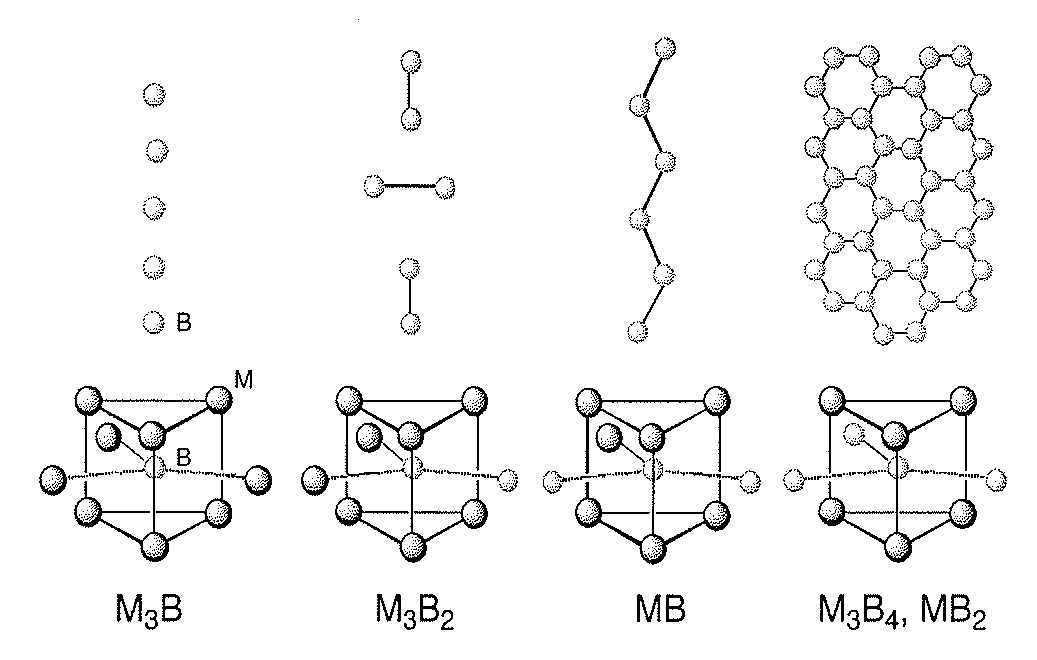

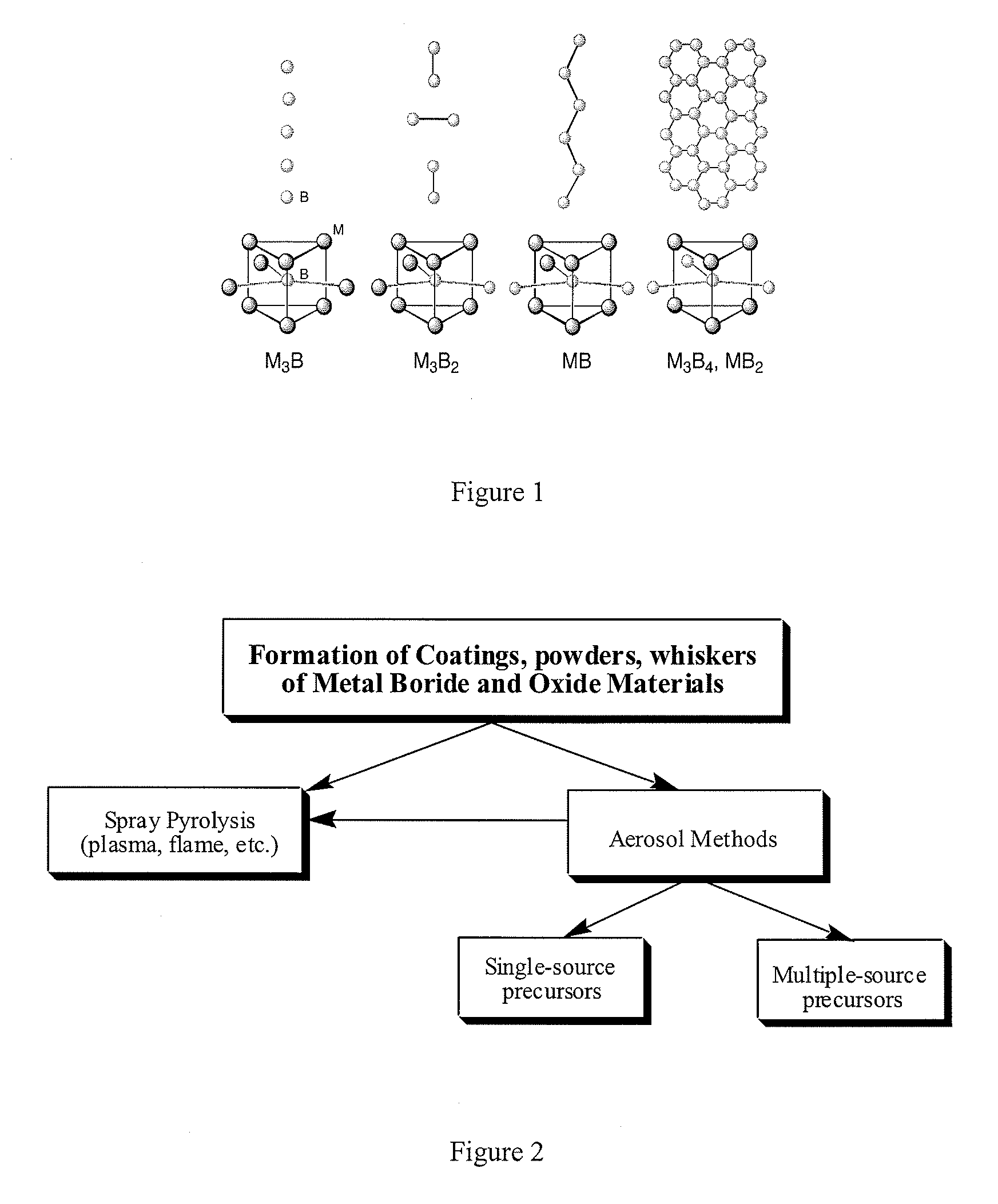

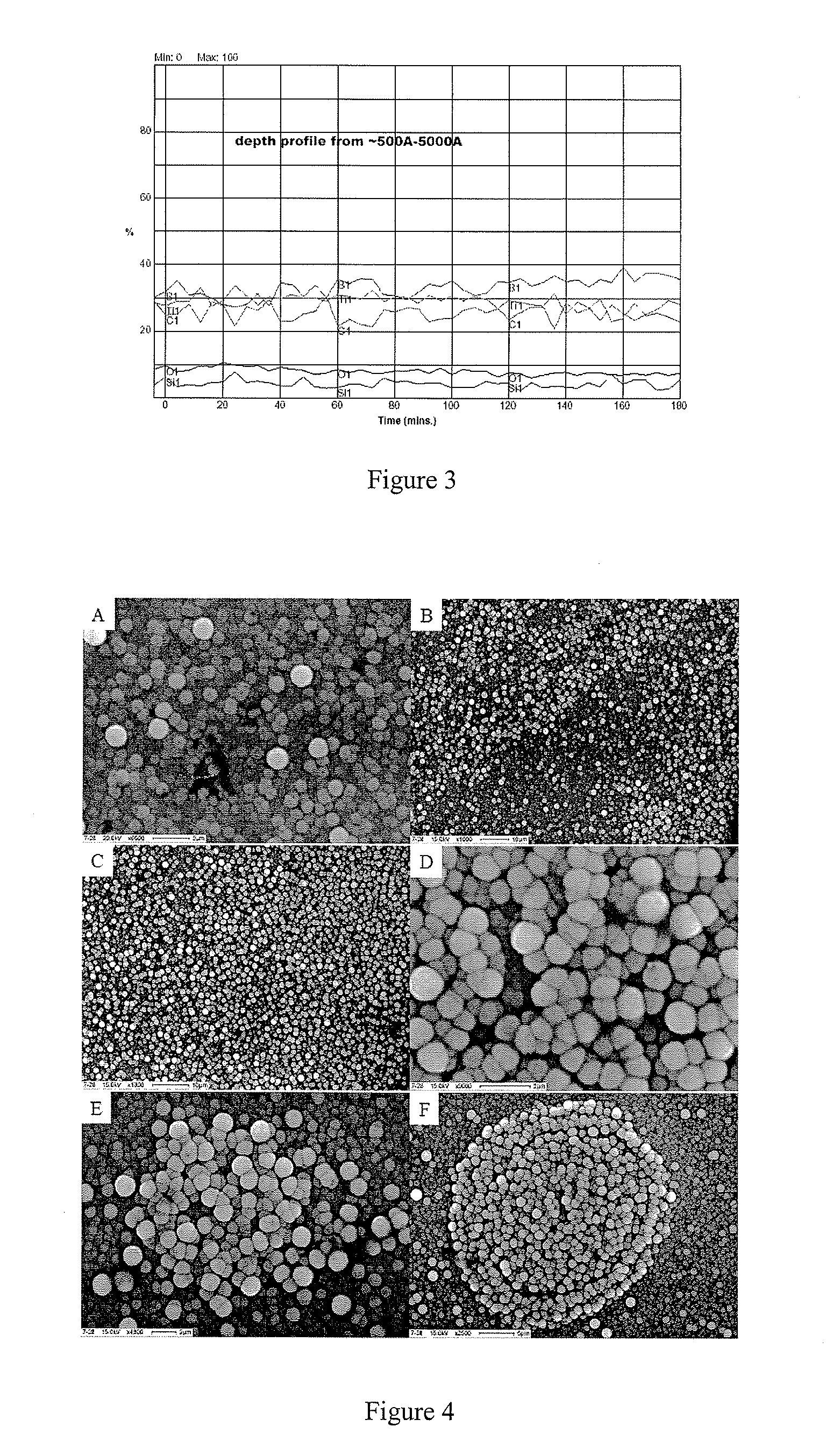

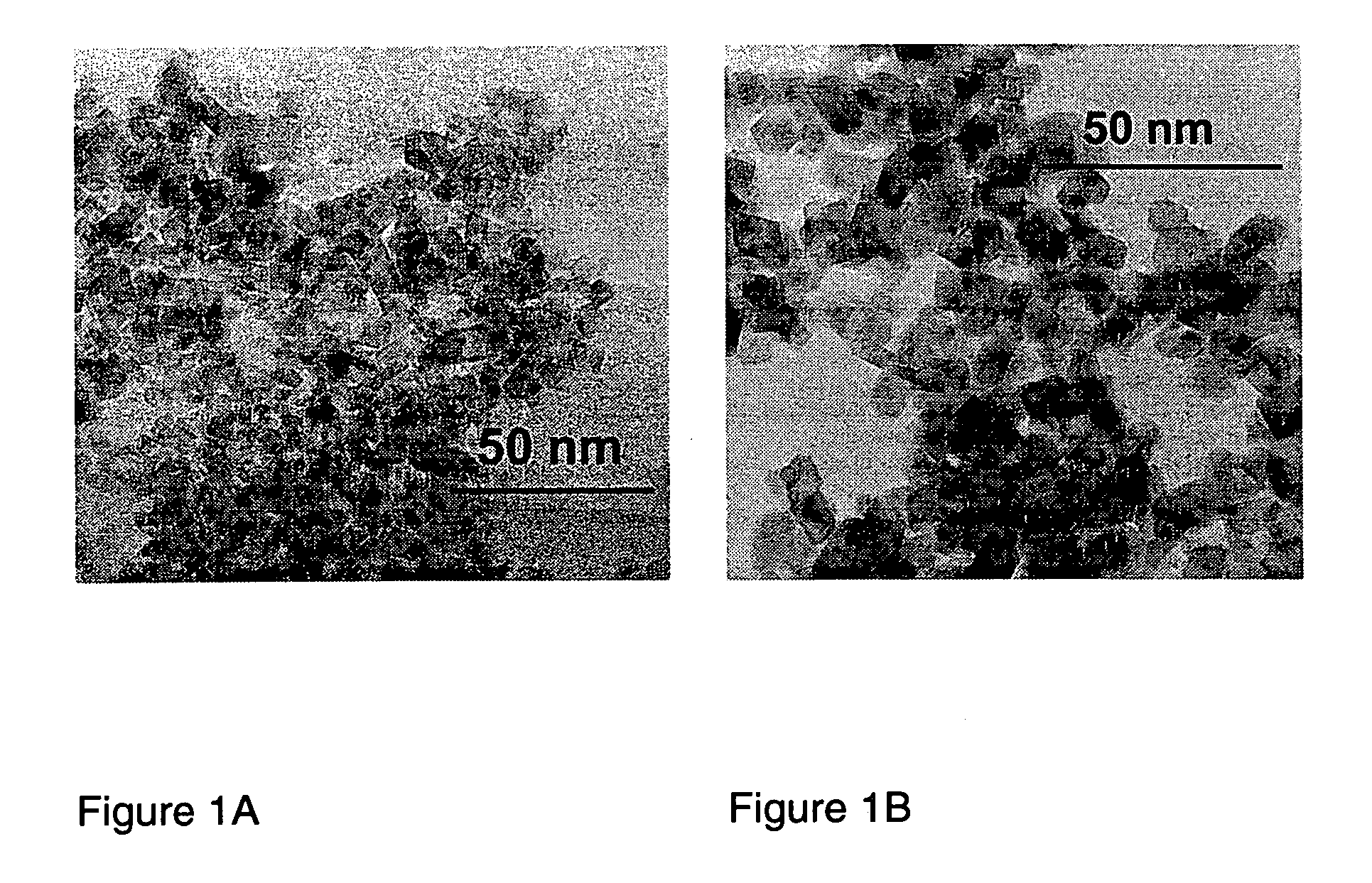

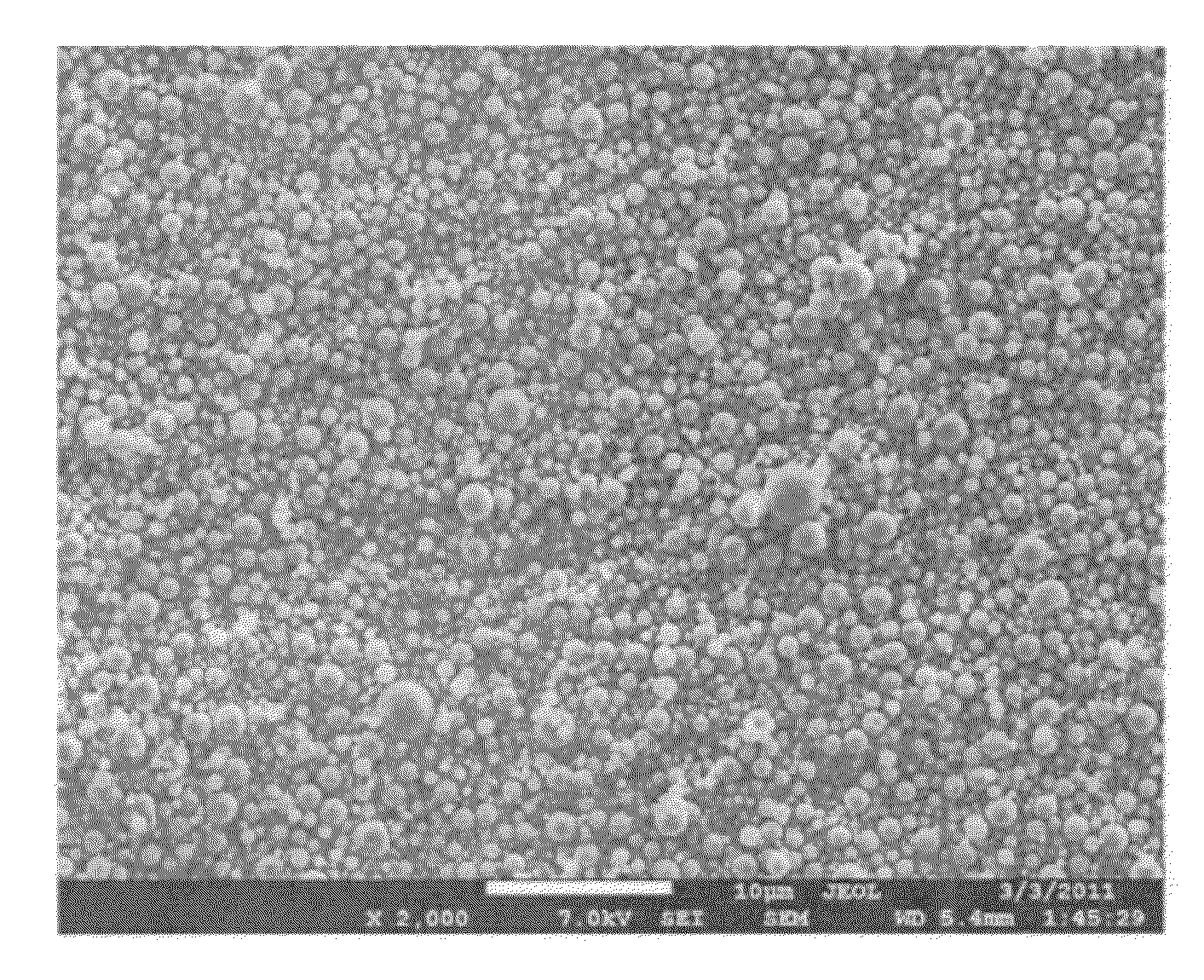

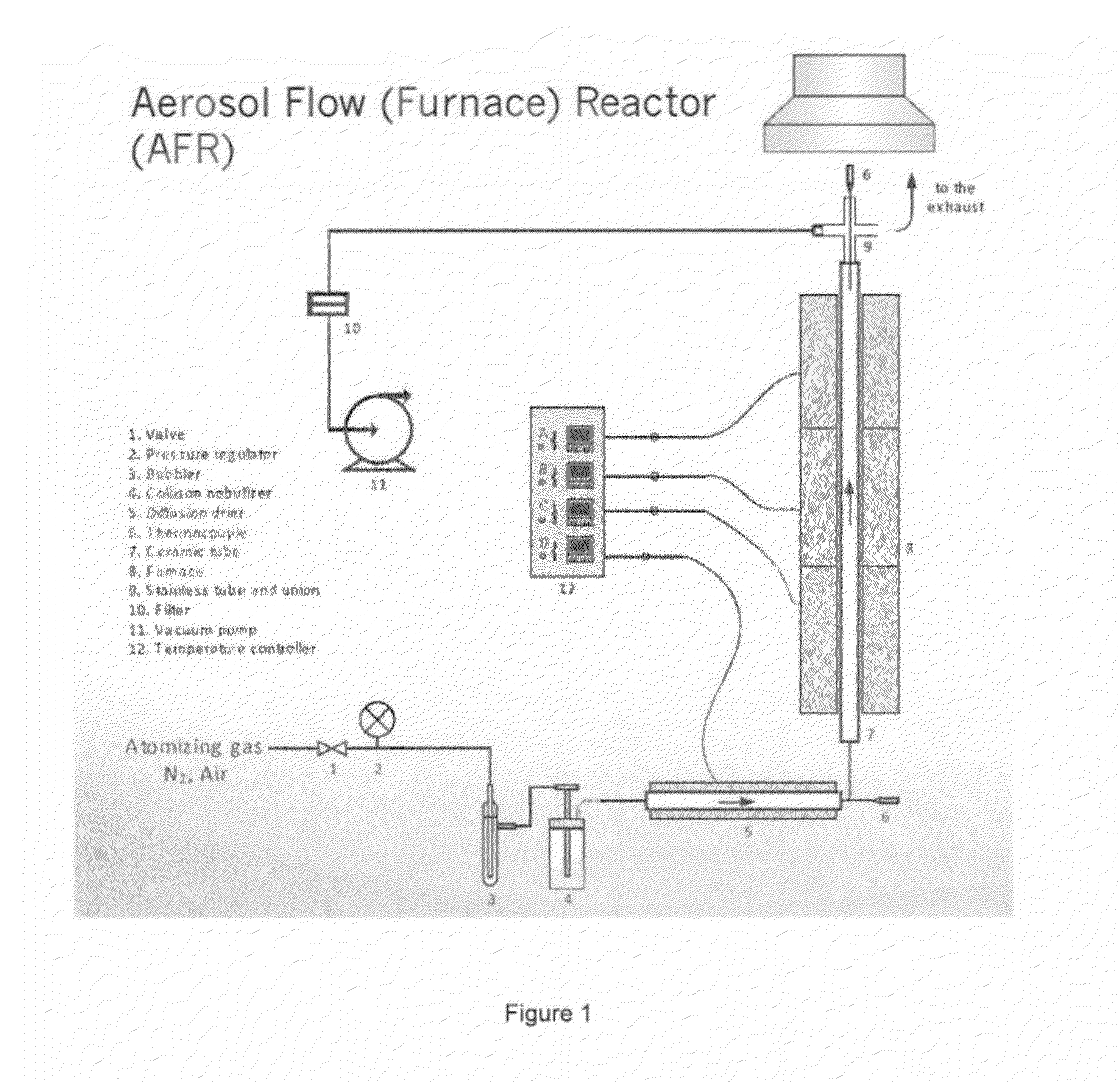

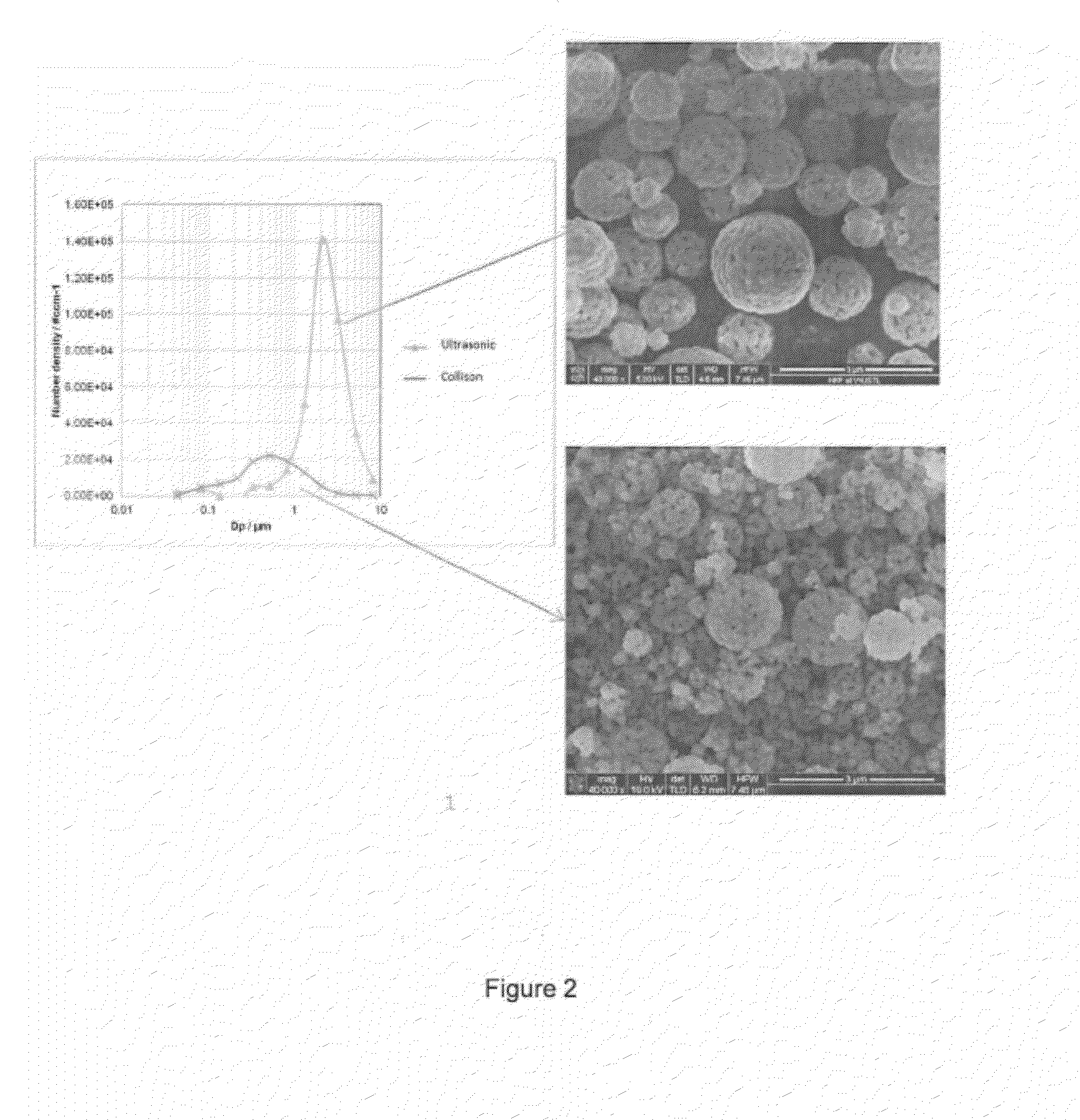

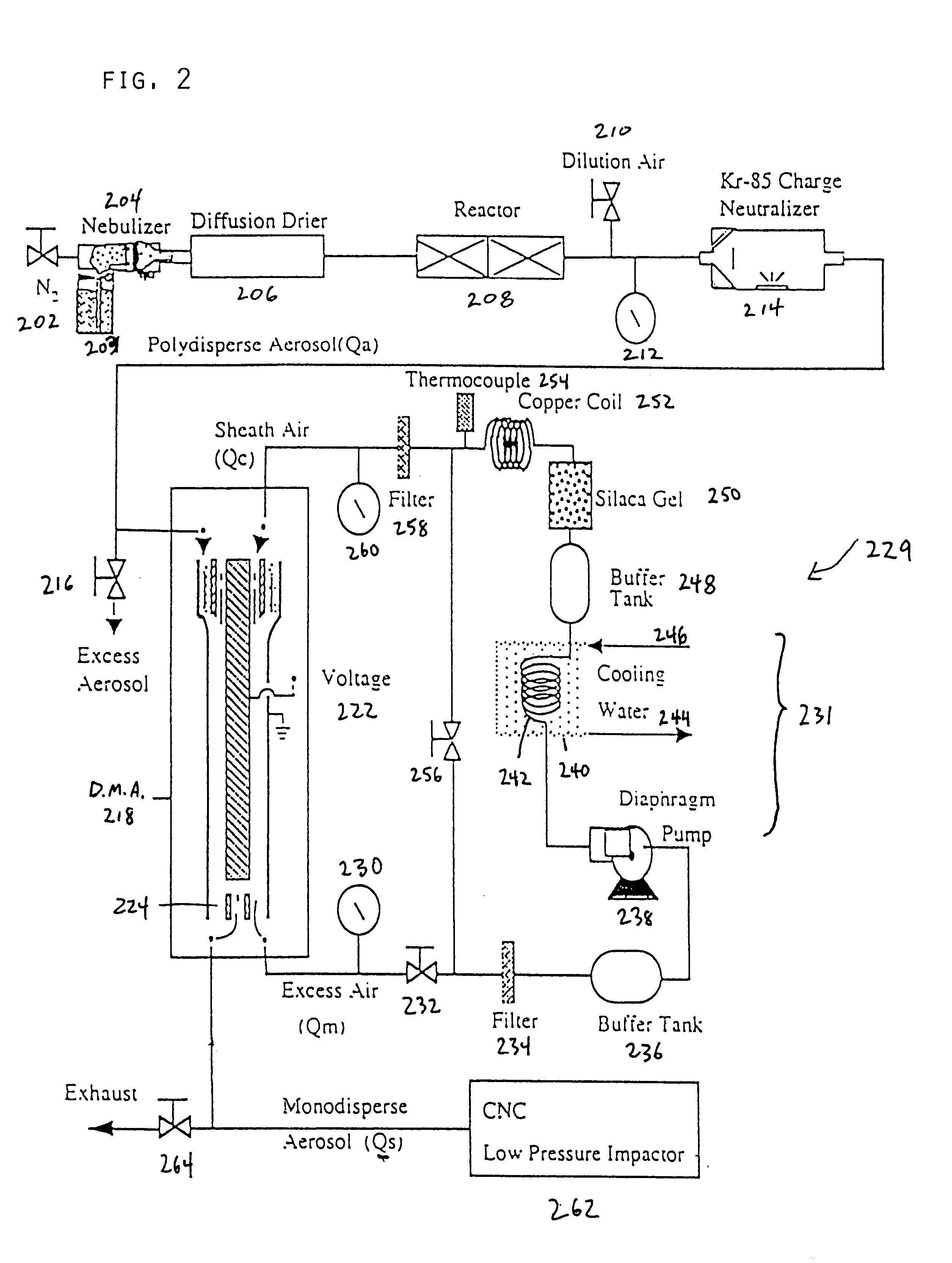

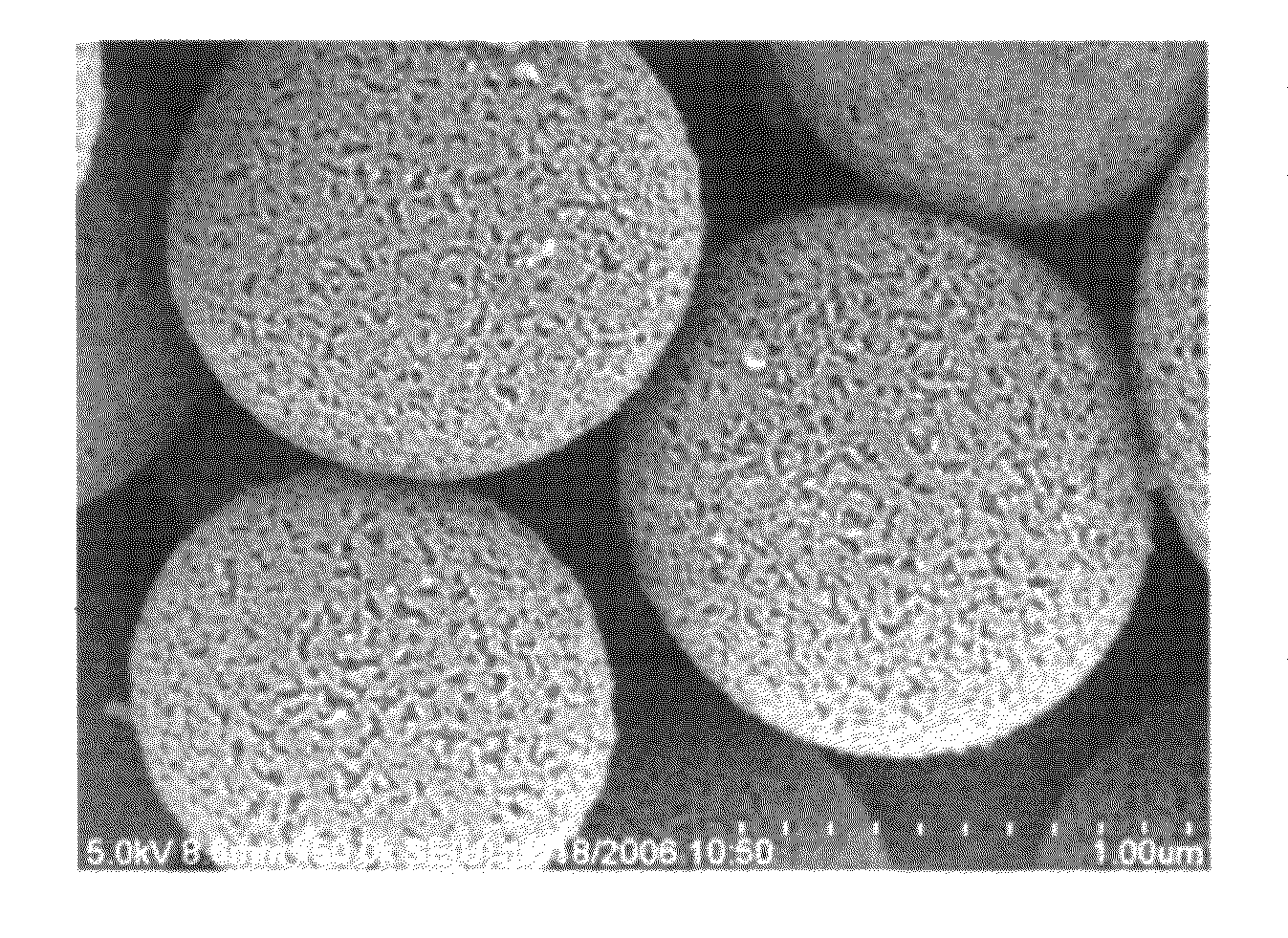

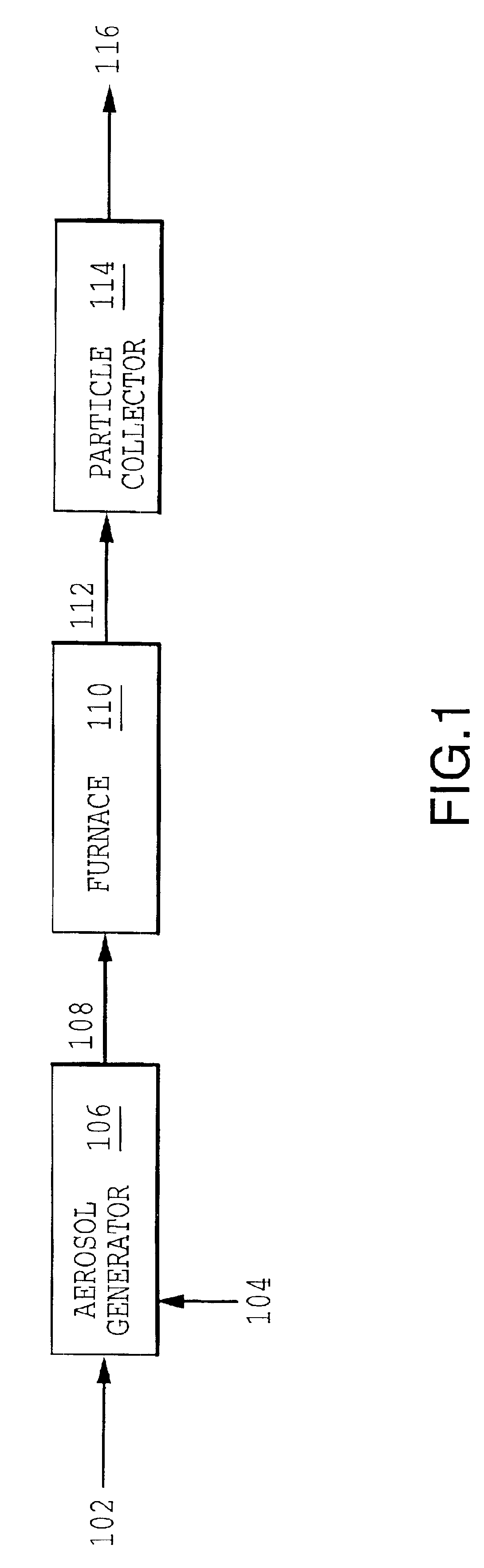

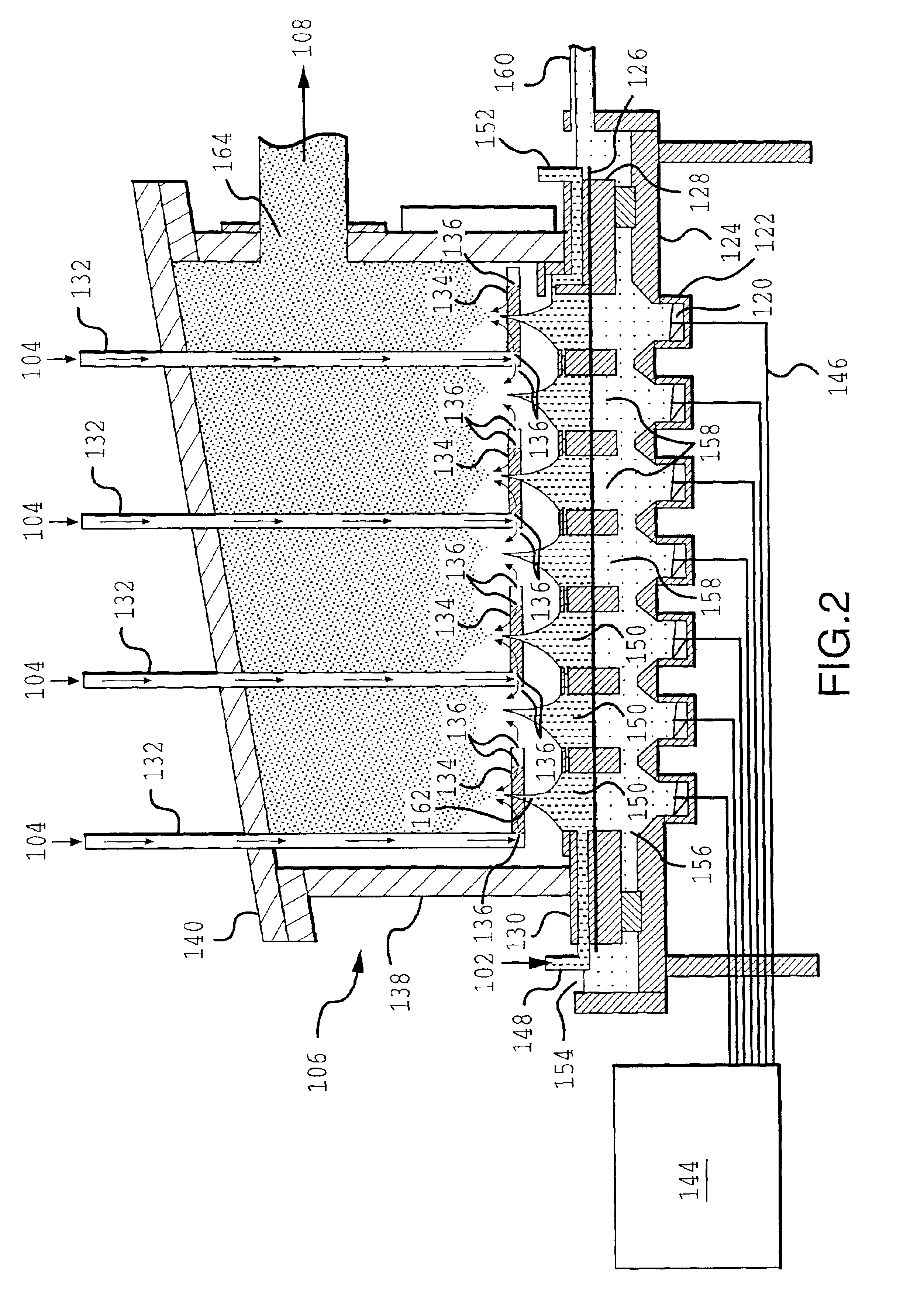

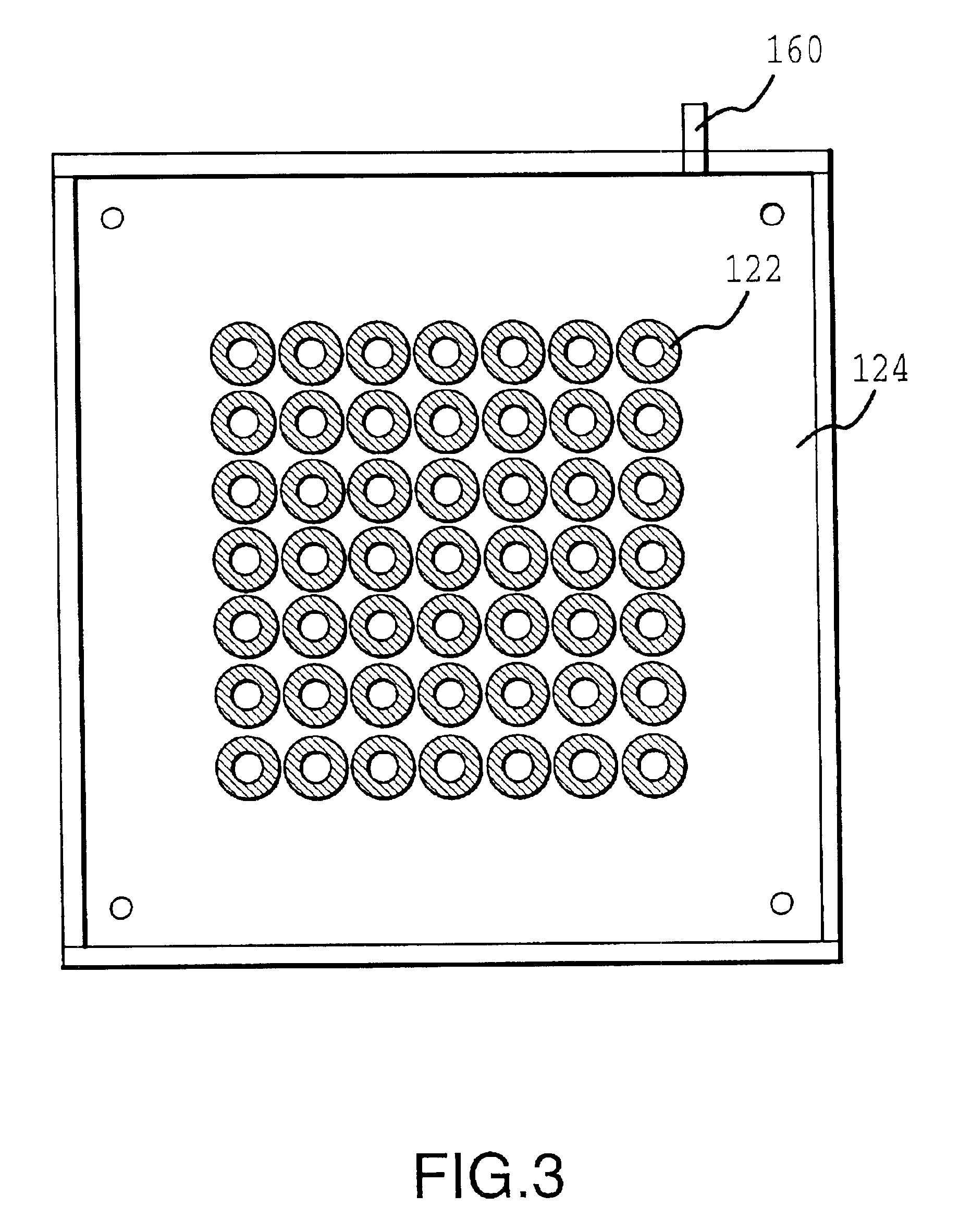

A system and method for the formation of novel small particles, thin films, and coatings of solid state metal boride material. The metal boride materials may be formed using aerosol methods and / or spray pyrolysis to form a generally uniform, thin film coating of boride compound spheres. Boride solutions or compounds are sprayed via a gas nebulizer in a reactor containing a substrate and heated to approximately 900° Celsius. The boride compounds form uniform, spherical particles of approximately one micrometer in diameter. The boride compounds are extremely strong, non-reactive, dense, and, when prepared as films or coating, adhere very well to substrates, such as metals.

Owner:SYRACUSE UNIVERSITY

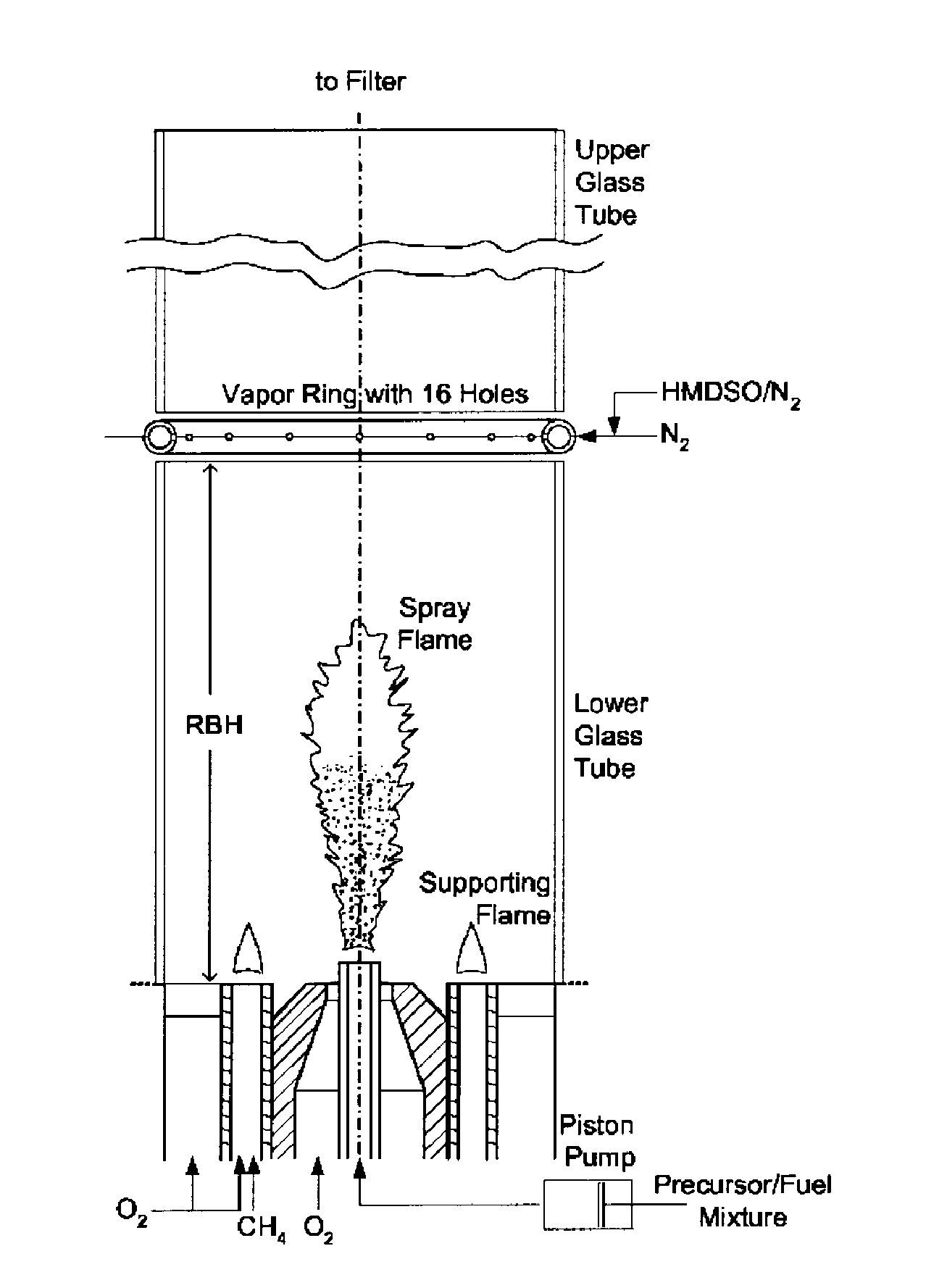

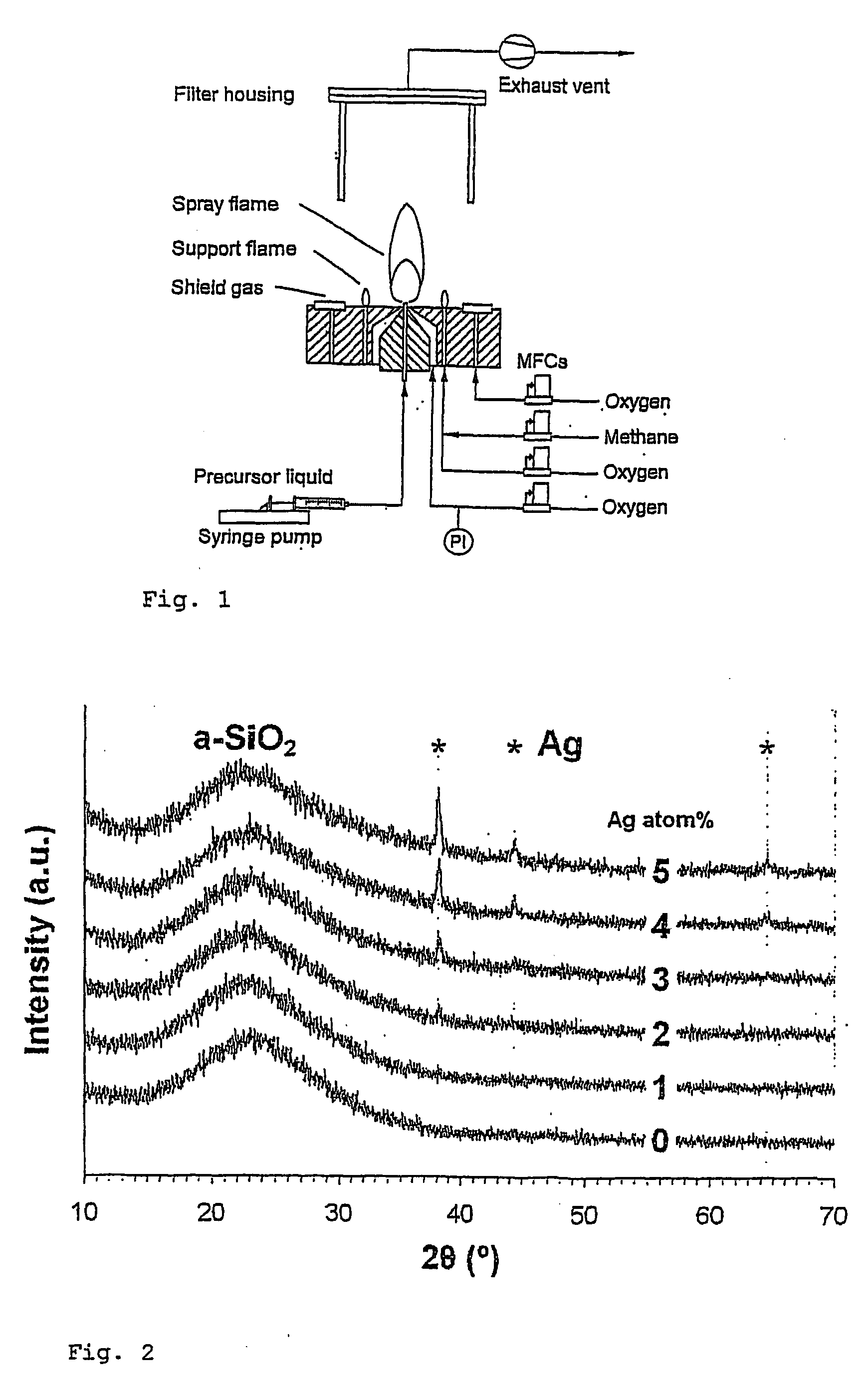

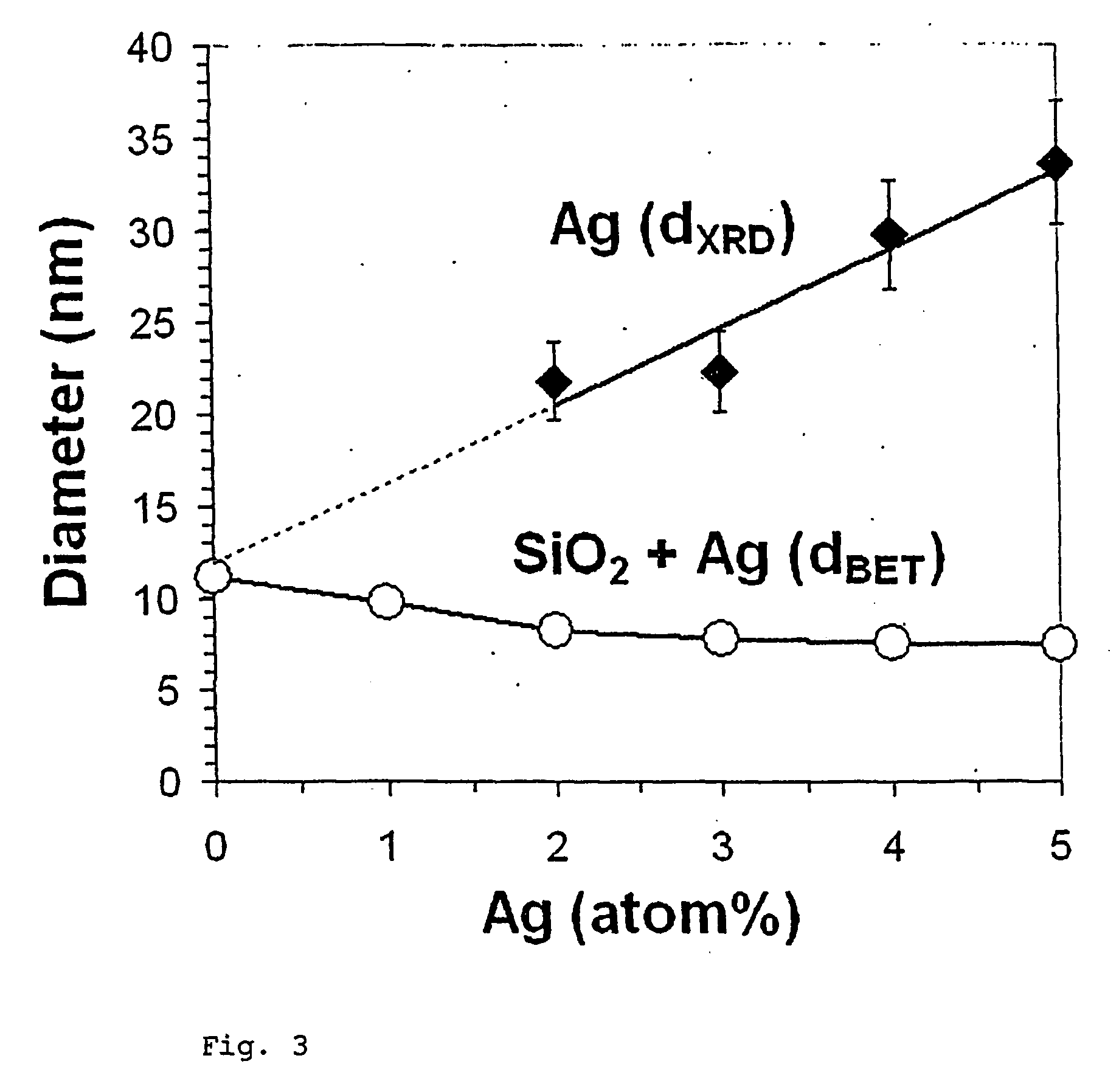

Flame made metal oxides

ActiveUS7211236B2Add featureWell mixedMaterial nanotechnologyZirconium oxidesSpray pyrolysisCarboxylic acid

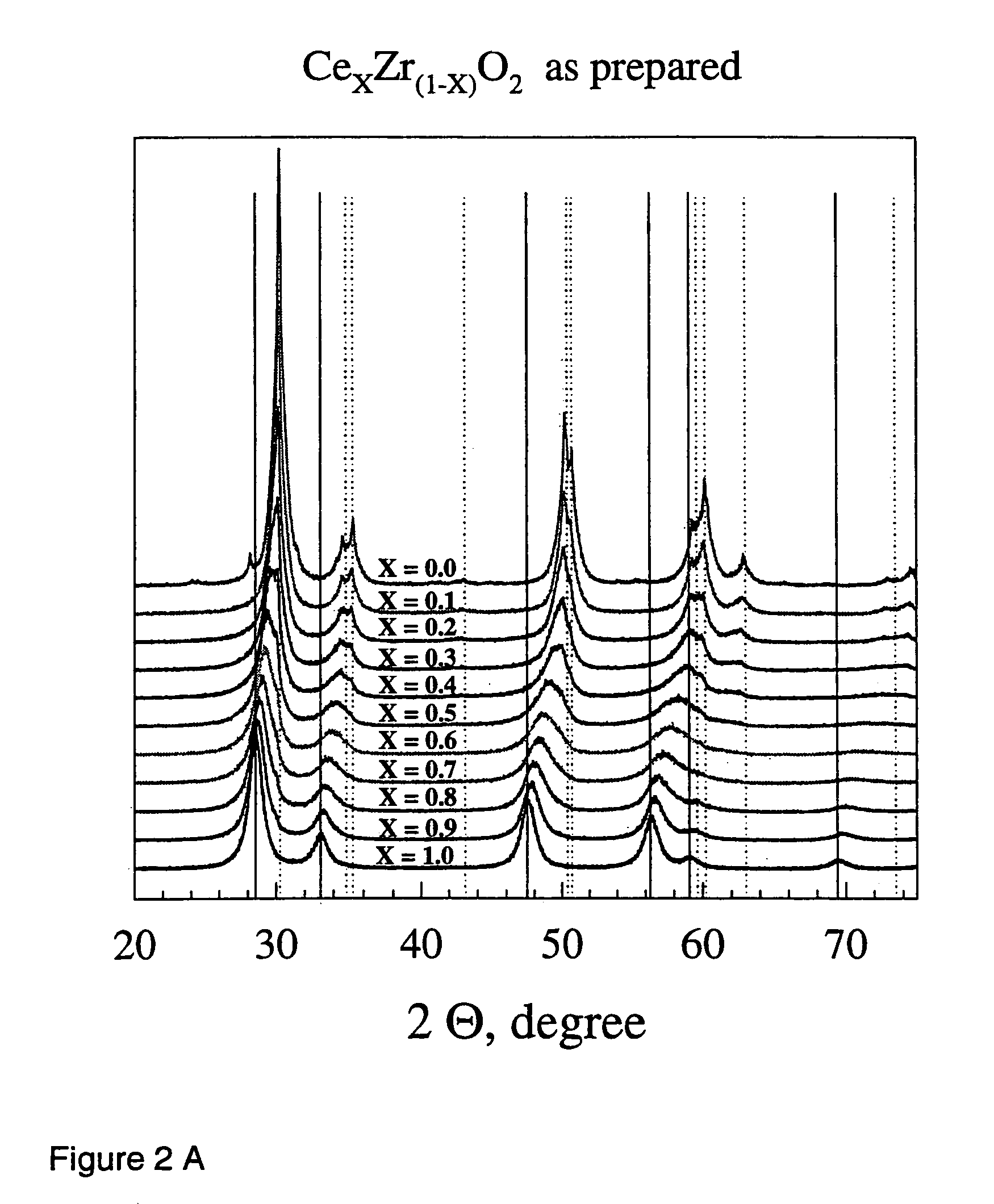

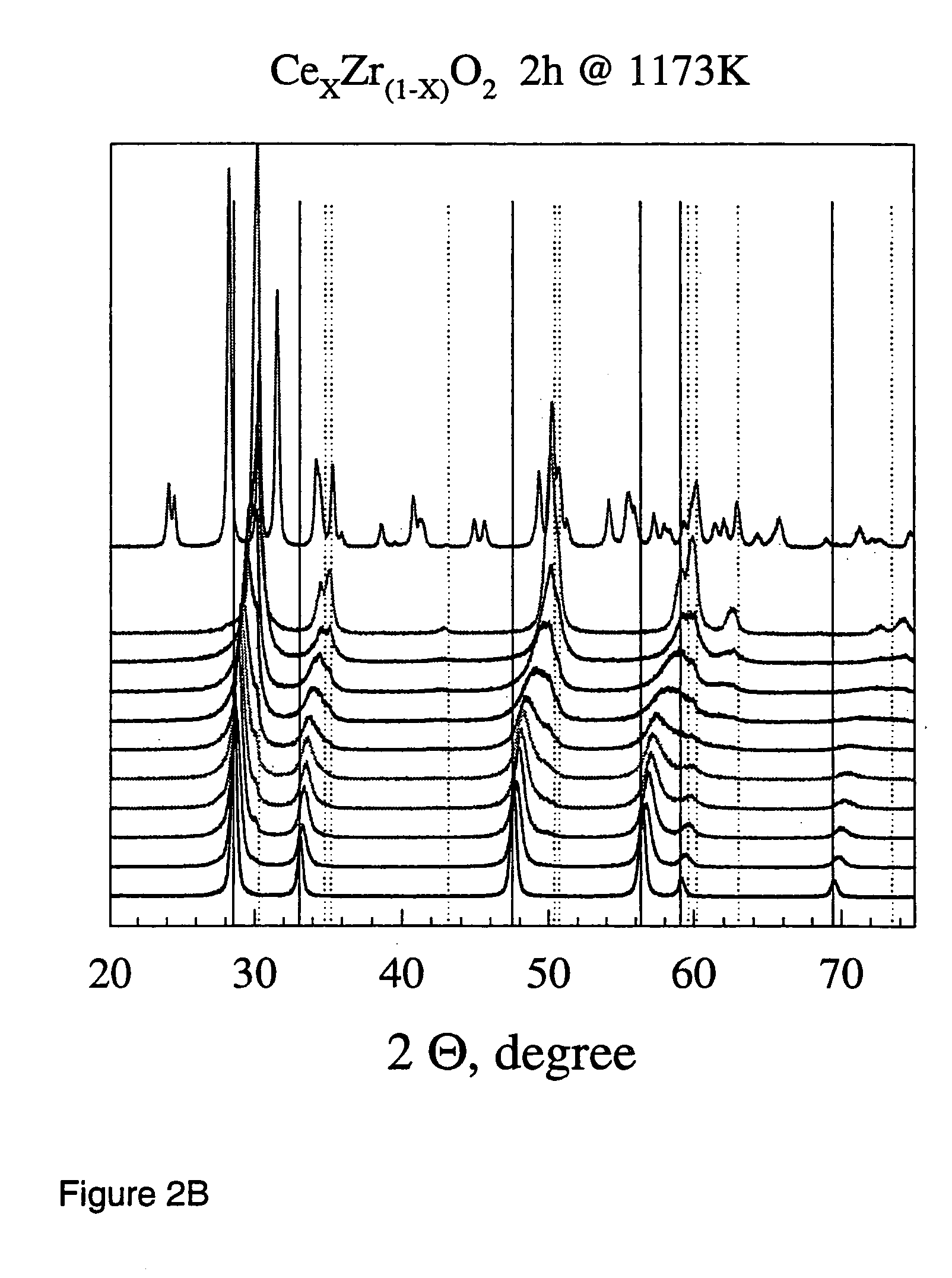

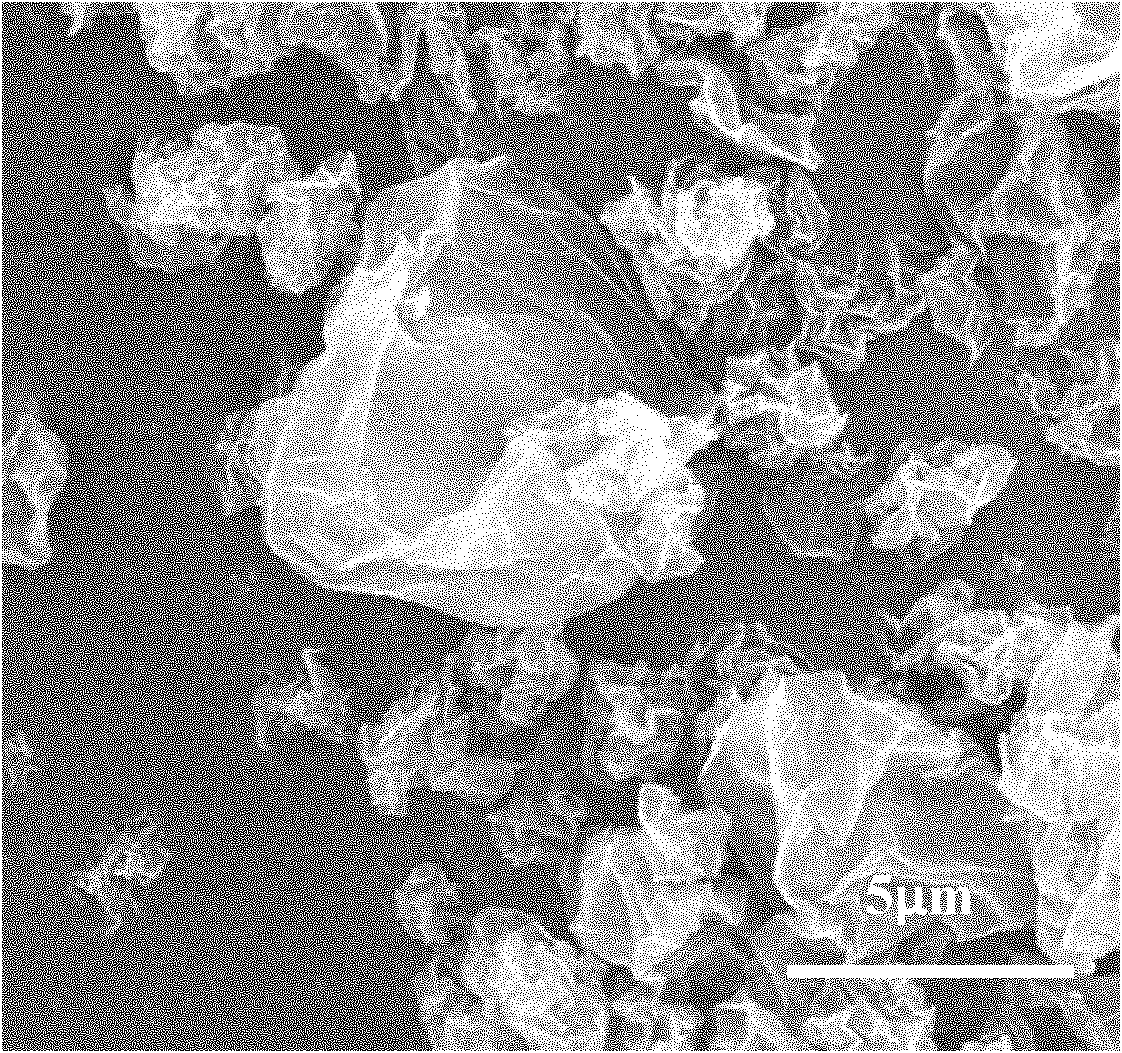

Described is a method for the production of metal oxides by flame spray pyrolysis, in particular mixed metal oxides such as ceria / zirconia, and metal oxides obtainable by said method. Due to high enthalpy solvents with a high carboxylic acid content said metal oxides have improved properties. For example ceria / zirconia has excellent oxygen storage capacity at high zirconium levels up to more than 80% of whole metal content.

Owner:EIDGENOSSISCHE TECHN HOCHSCULE ZURICH

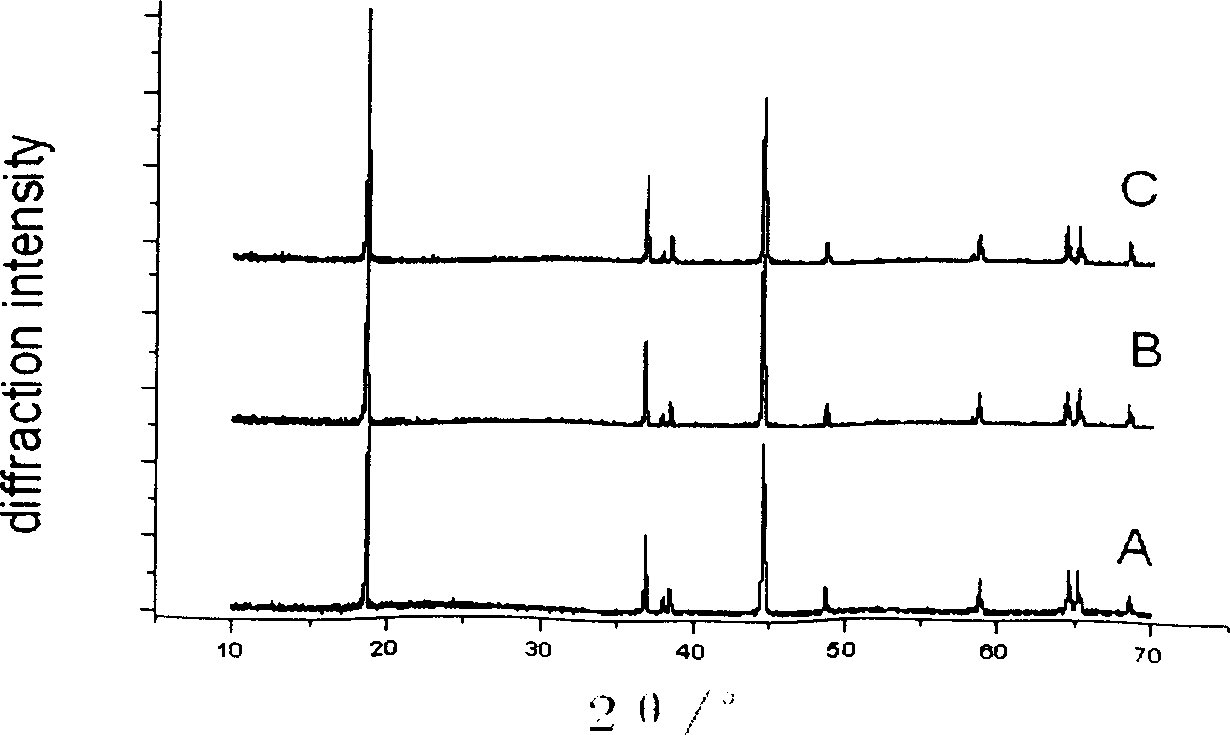

Nanometer doped zinc oxide and its prepn and application in photocatalysis to degrade organic matter and kill bacteria

InactiveCN1772375AImprove photocatalytic activityImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFiberRare earth

The present invention relates to Ag and RE doped nanometer zinc oxide and its preparation process and application in photocatalysis to degrade organic matter and killing bacteria. Ag, RE metals La, Ce, Pr, Nd, Sm, etc. are doped into nanometer zinc oxide to raise its photocatalytic activity in degrading harmful chemical matter and resisting bacteria. Under lighting, the doped nanometer zinc oxide has higher photocatalytic activity and higher antibacterial capacity; and in case of no lighting, it has relatively high antibacterial effect owing to the antibacterial effect one Ag, Zn, RE and other antibacterial ions. The preparation process may be an organic matter complexing process or a sprying pyrolysis process. The doped nanometer zinc oxide may be used through mixing with other material, or used as additive added into plastic, ceramic, fiber, timber, rubber, glass, cement, metal and other material to form various kinds of photocatalytic antibacterial material and product.

Owner:NANJING UNIV

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Spray Pyrolysis Synthesis of Mesoporous Positive Electrode Materials for High Energy Lithium-Ion Batteries

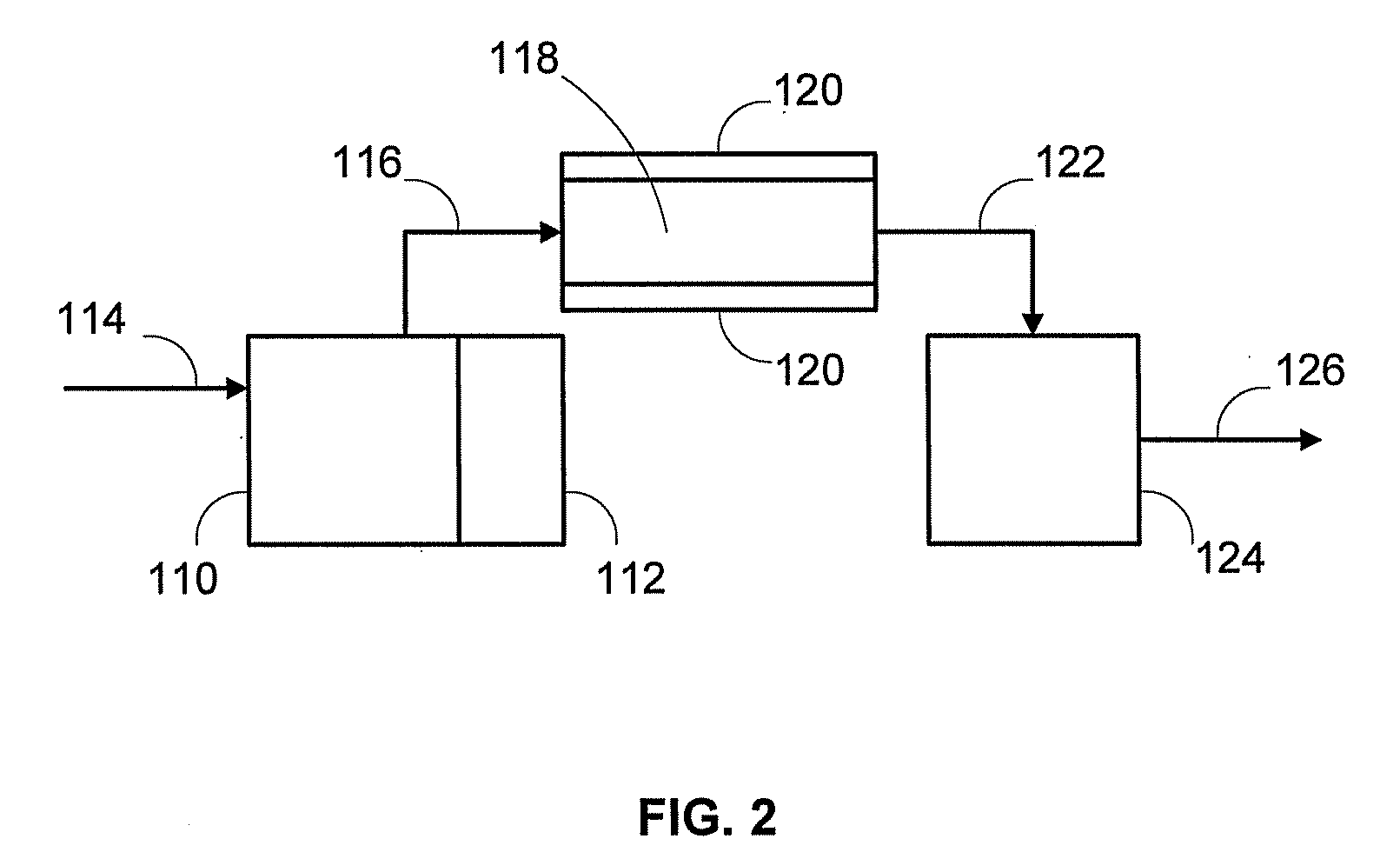

A lithium metal oxide positive electrode material useful in making lithium-ion batteries that is produced using spray pyrolysis. The material comprises a plurality of metal oxide secondary particles that comprise metal oxide primary particles, wherein the primary particles have a size that is in the range of about 1 nm to about 10 μm, and the secondary particles have a size that is in the range of about 10 nm to about 100 μm and are uniformly mesoporous.

Owner:WASHINGTON UNIV IN SAINT LOUIS

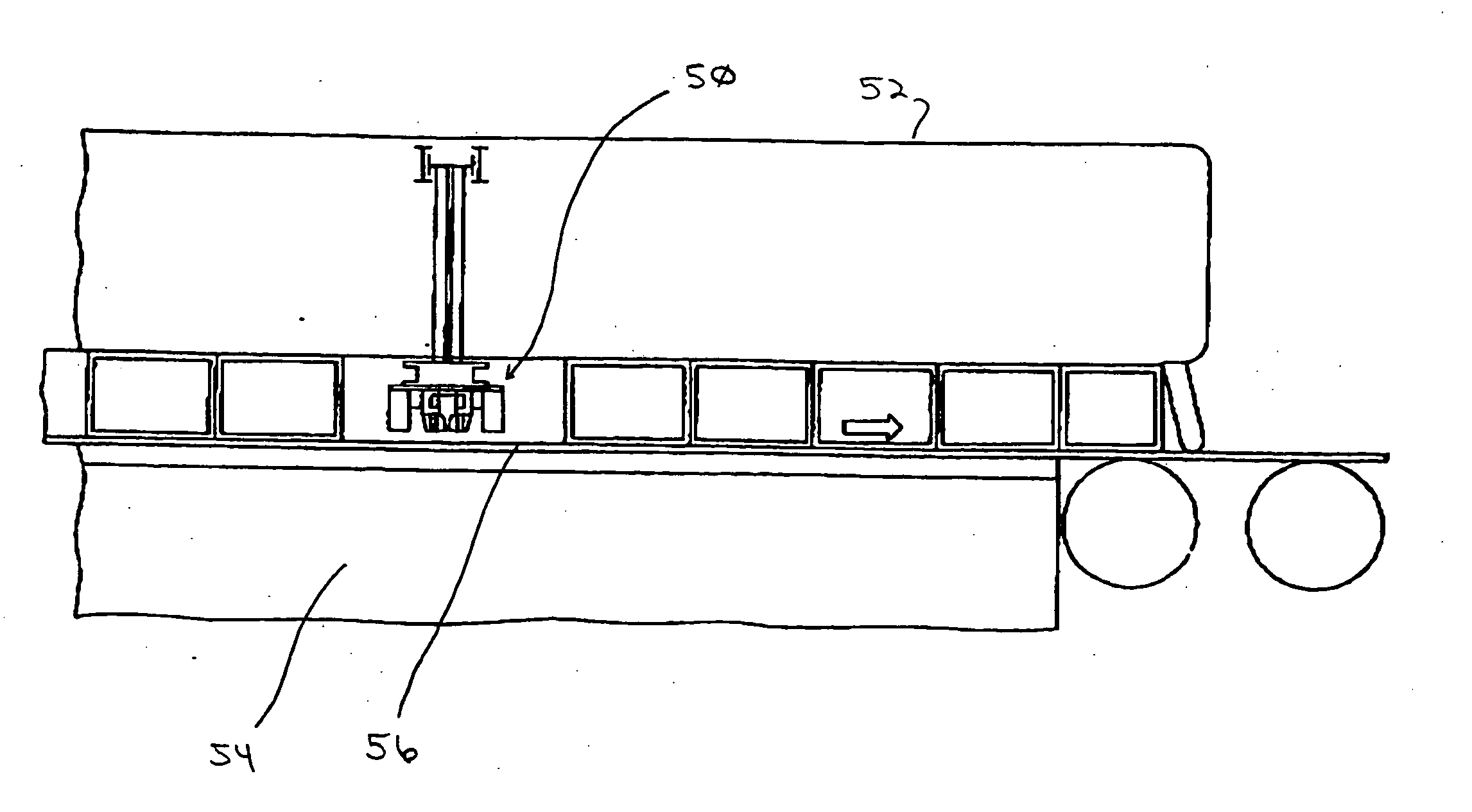

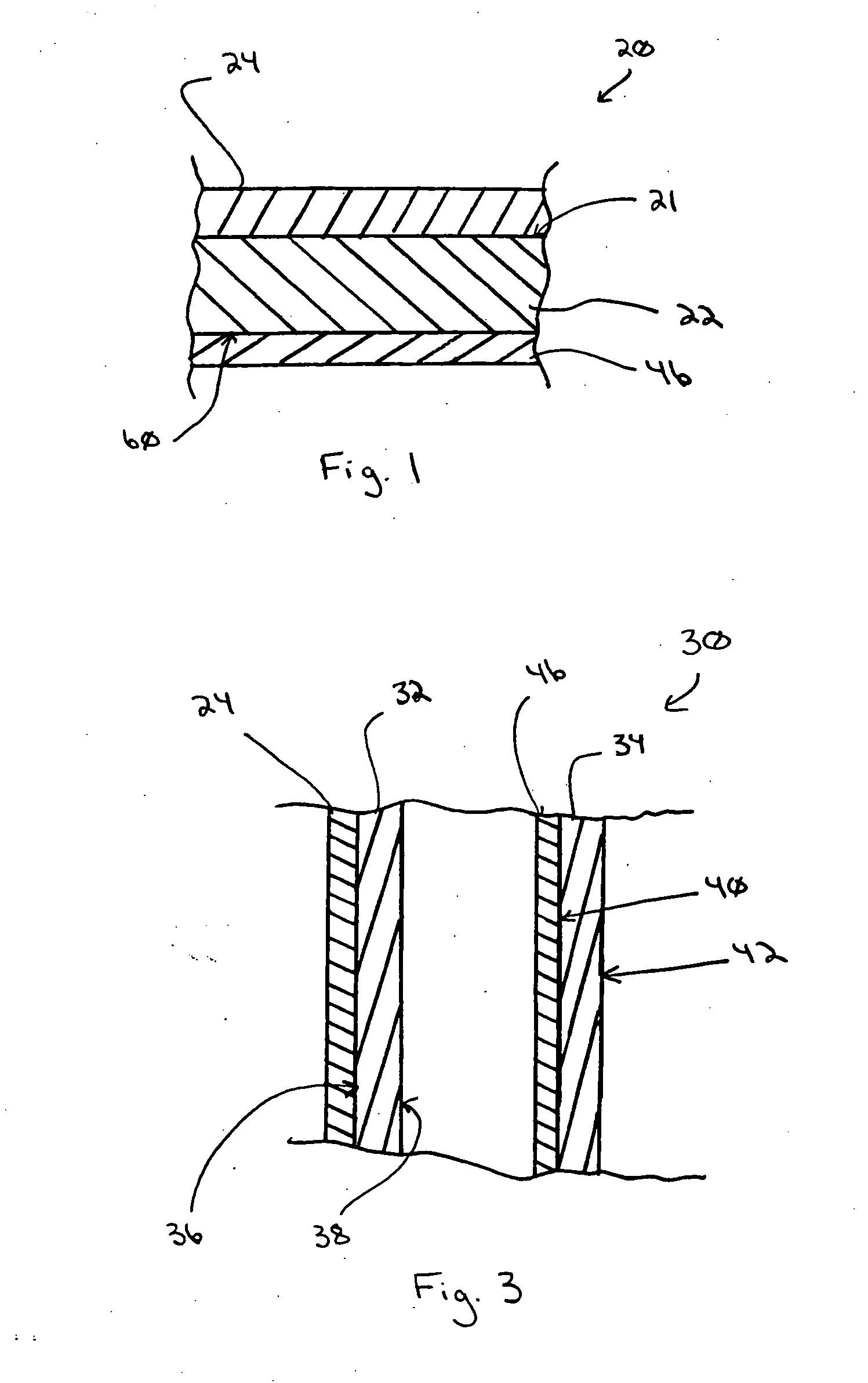

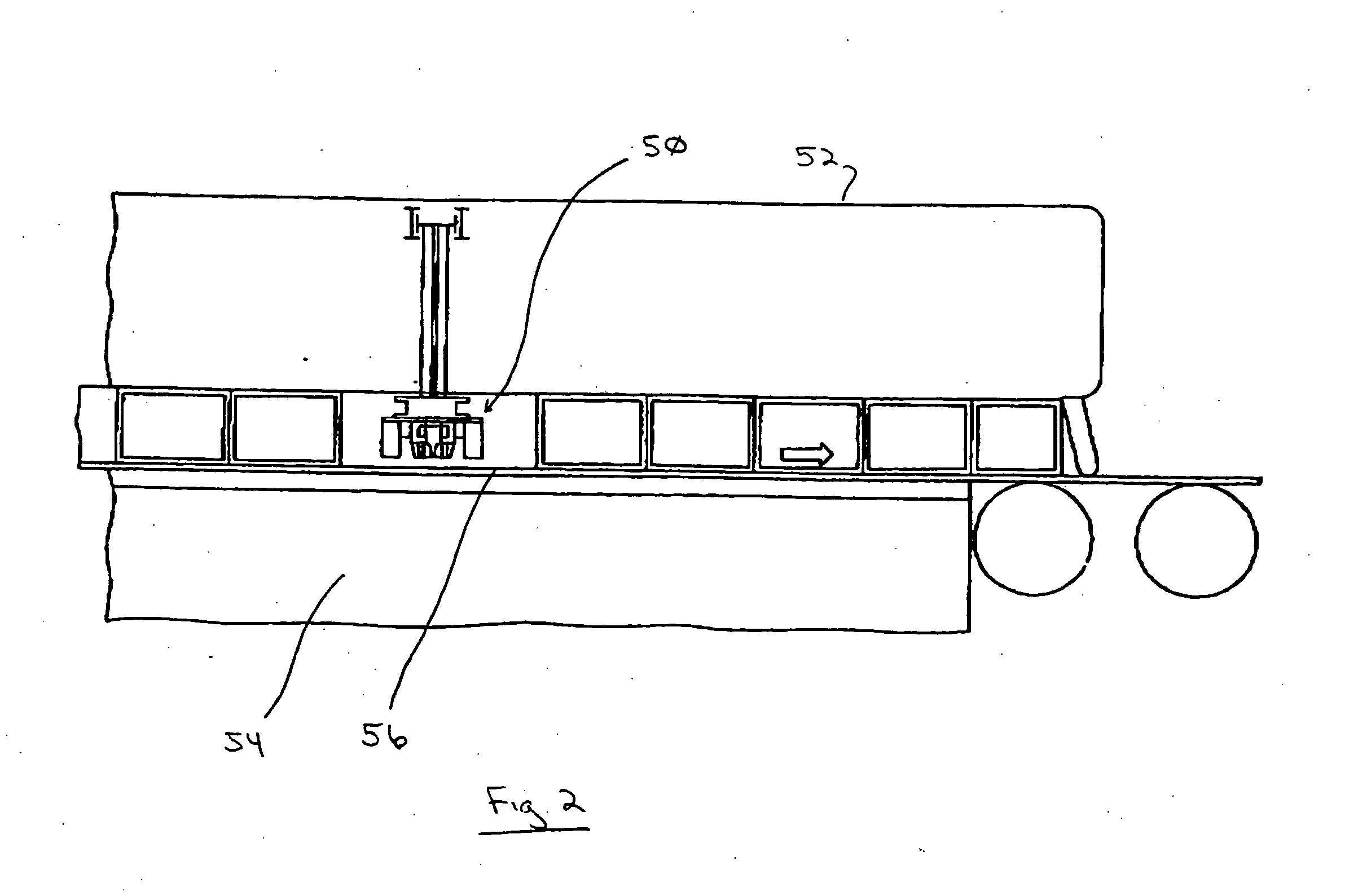

Photo-induced hydrophilic article and method of making same

InactiveUS20070218265A1Easy to cleanEasy to wipeSynthetic resin layered productsVacuum evaporation coatingHydrophilic coatingSpray pyrolysis

Methods and articles are disclosed in which a substrate is provided with a photo-induced hydrophilic surface by forming a photo-induced hydrophilic coating on the substrate by spray pyrolysis, chemical vapor deposition, or magnetron sputter vacuum deposition. The coating can have a thickness of 50 Å to 500 Å, a root mean square roughness of less than 5, preferably less than 2, and photocatalytic activity of less than 3.0×10−3 cm−1 min−1±2.0×10−3 cm−1 min−1. The substrate includes glass substrates, including glass sheets and continuous float glass ribbons.

Owner:VITRO FLAT GLASS LLC

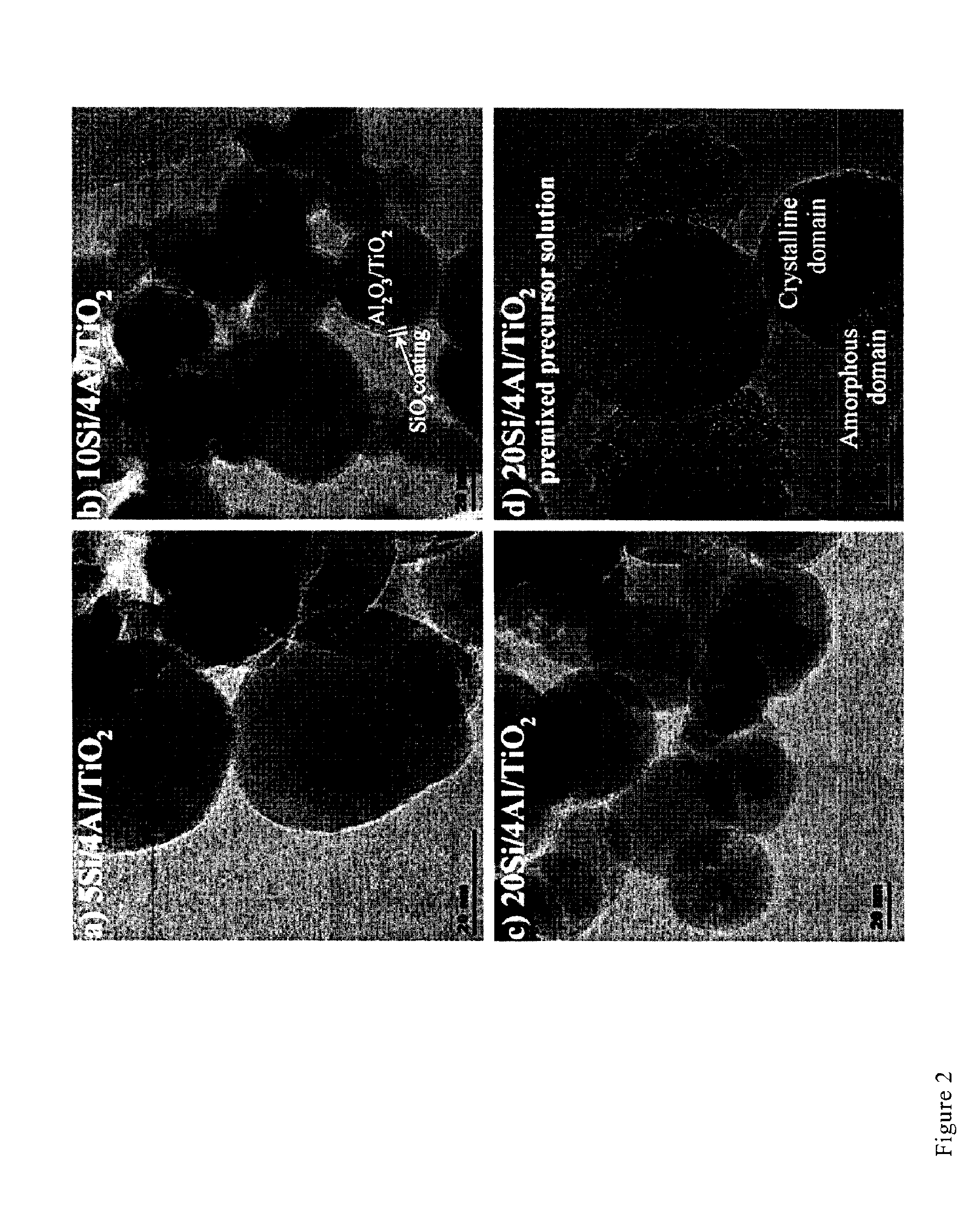

Gas phase production of coated titania

InactiveUS20090126604A1Not to wasteDesired characteristicPigmenting treatmentMaterial nanotechnologyGas phaseSpray pyrolysis

A flame spray pyrolysis process for the preparation of ultrafine titania particles coated with a smooth, homogeneous coating of one or more metal oxides is provided. The metal oxide coating is achieved by contacting the titania particles with a metal oxide precursor downstream of the titania formation zone, after the titania particles have formed. The process provides titania particles with a high rutile content and a smooth and homogeneous coating of a metal oxide.

Owner:TRONOX LLC

Preparation method of silicon/carbon multi-component composite negative electrode material

ActiveCN103545493AGood dispersionDispersion is better than that of materials without surface treatmentMaterial nanotechnologyCell electrodesCarbon nanotubeSilicon oxide

The invention provides a preparation method of a silicon / carbon multi-component composite negative electrode material. The preparation method comprises the following steps: (1) preparing a carboxyl carbon nano-tube by using acid and a carbon nano-tube, or preparing an aminated carbon nano-tube by using the carboxyl carbon nano-tube; (2) oxidizing the surface of nanometer silicon so as to generate a layer of silicon oxide, or aminating slightly oxidized nanometer silicon by using ammonia-containing organosilane under the condition of heating reflux; (3) adding the carboxyl carbon nano-tube and the aminated nanometer silicon, or the carboxyl carbon nano-tube and the slightly oxidized nanometer silicon to an organic carbon source-containing solvent, dispersing and carrying out spray drying-pyrolysis; (4) mixing a material obtained in the step (3) with asphalt, and sequentially carrying out low-temperature, constant temperature and high-temperature heat treatments, thus obtaining a secondary silicon-carbon nano-tube / amorphous carbon composite negative electrode material; and (5) carrying out airflow crushing, grading, adding to the organic carbon source-containing solvent, carrying out spray drying-pyrolysis or spray pyrolysis, and carrying out high-temperature treatment, thus obtaining the silicon / carbon multi-component composite negative electrode material. The silicon / carbon multi-component composite negative electrode material prepared by the method has the advantages of large reversible capacity, designable capacity, good cycle performance, high tap density and the like.

Owner:CENT SOUTH UNIV

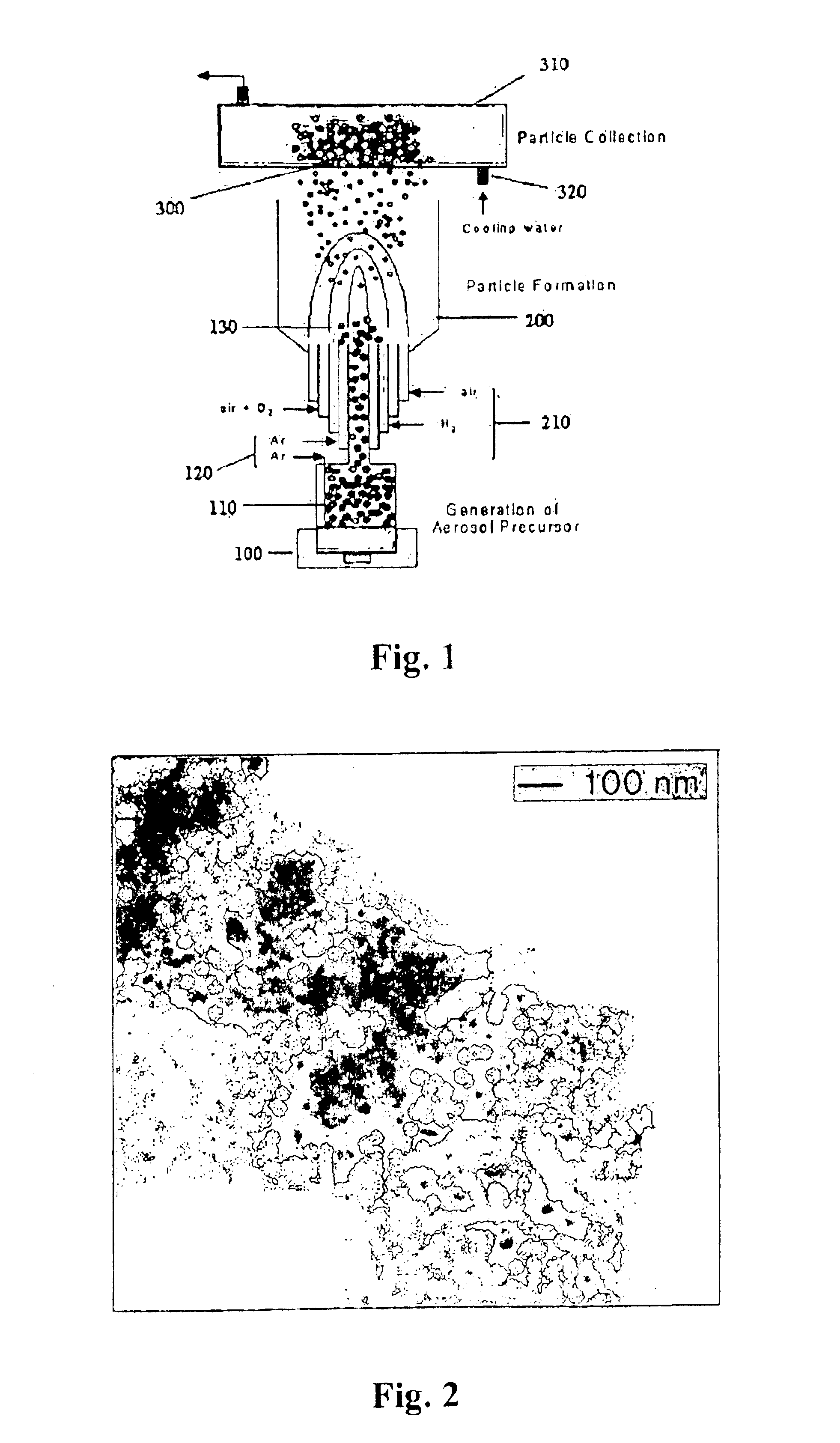

Method of manufacturing nano-sized lithium-cobalt oxides by flame spraying pyrolysis

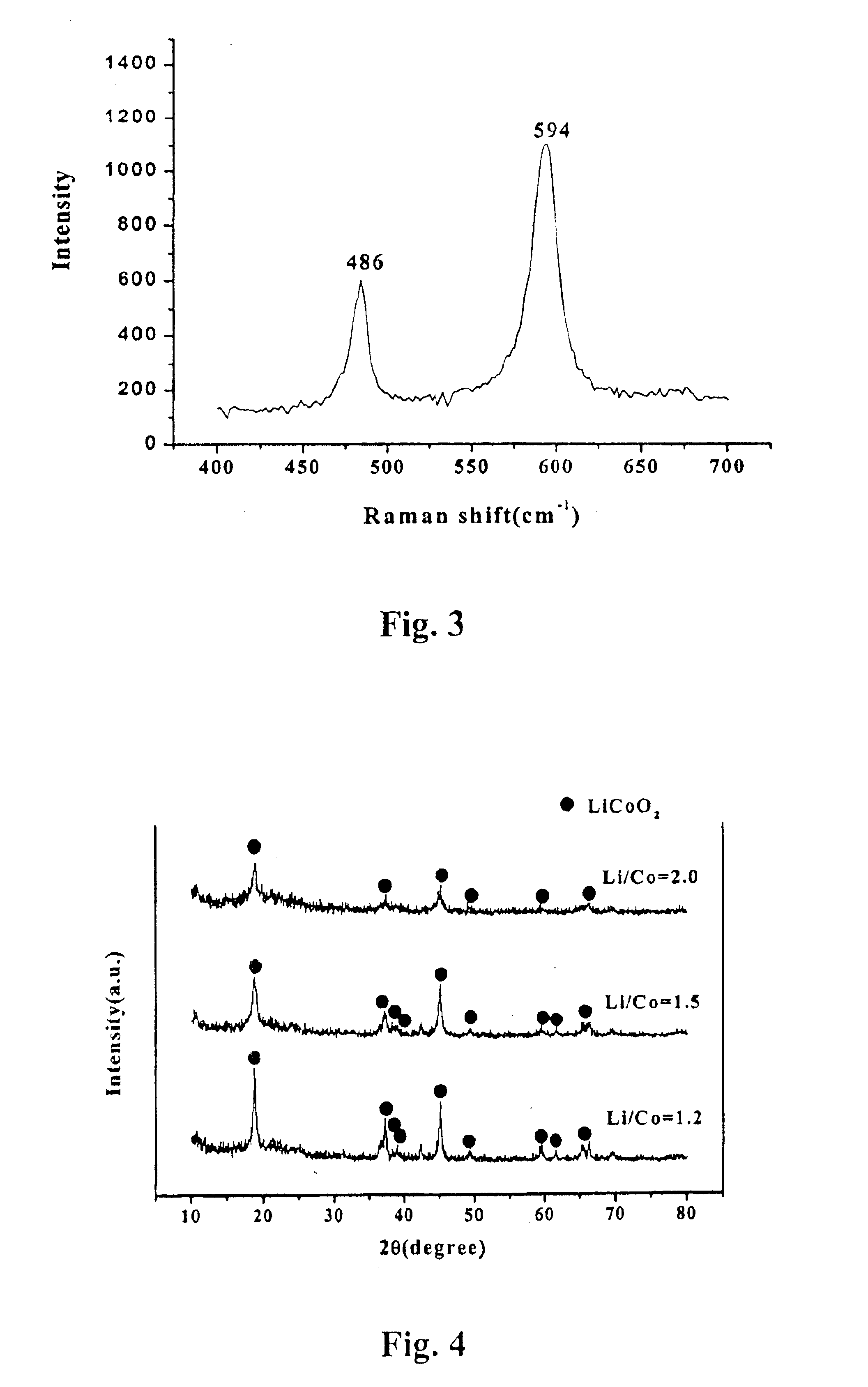

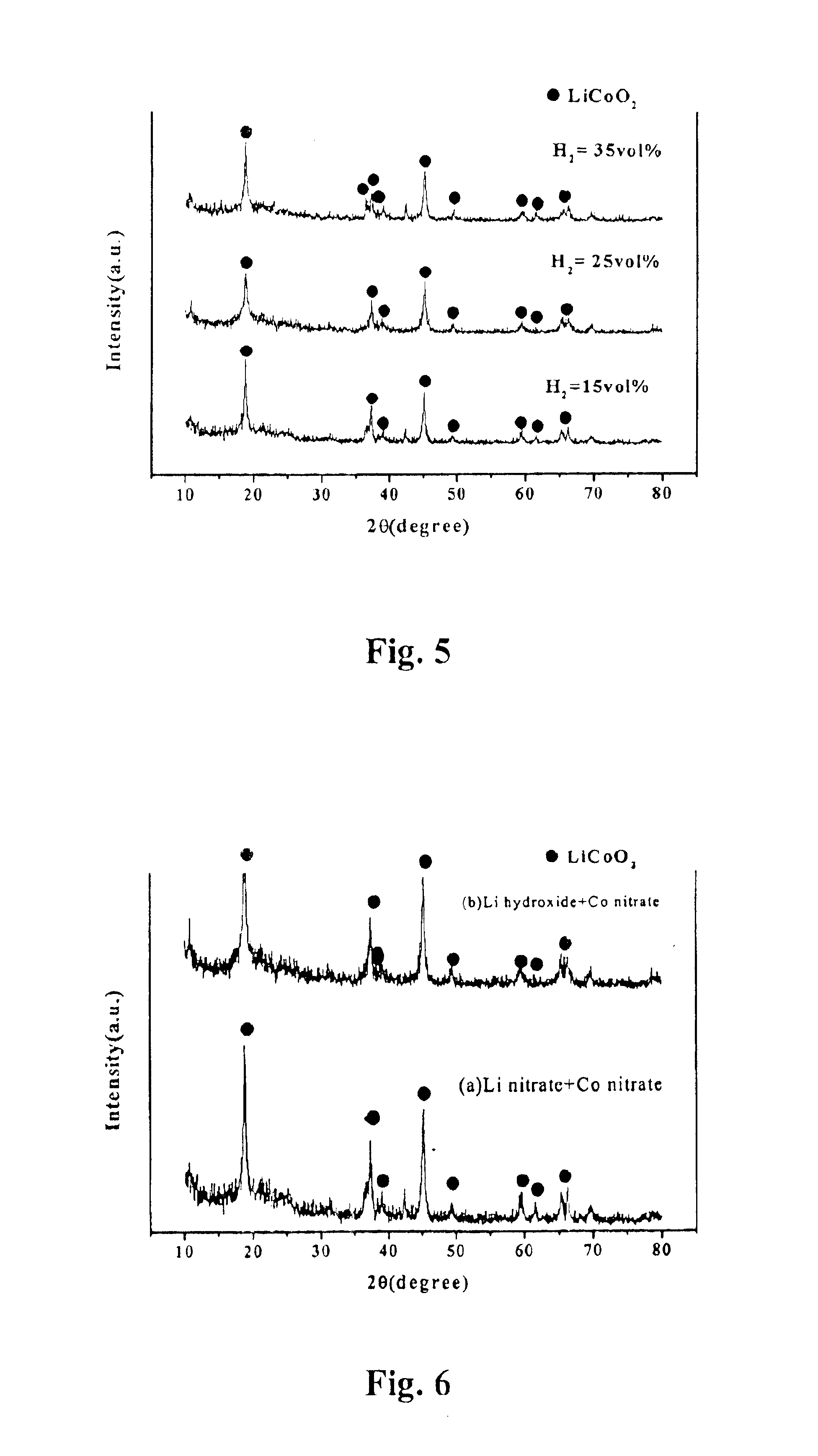

InactiveUS6902745B2Extend your lifeImprove efficiencyHeavy metal active ingredientsMaterial nanotechnologyGas phaseOxygen

A method for producing nano-sized lithium-cobalt oxide is provided by using flame-spray pyrolysis. The method comprises the steps of: spraying minute droplets, which is a solution dissolved lithium salt with cobalt salt at room temperature; atomizing the minute droplets through rapid expansion into a high temperature environment generated by combusting oxygen and hydrogen; decomposing and oxidizing the atomized minute droplets thermally at high temperature to produce nano-sized oxides in gaseous phase: and collecting the produced nano-sized composite oxides particles. The produced nano-sized lithium-cobalt oxide can be applied to a highly efficient lithium battery as the electrode materials and a thin film type of battery as well as to a miniaturized battery.

Owner:KWAK YOUNG HOON

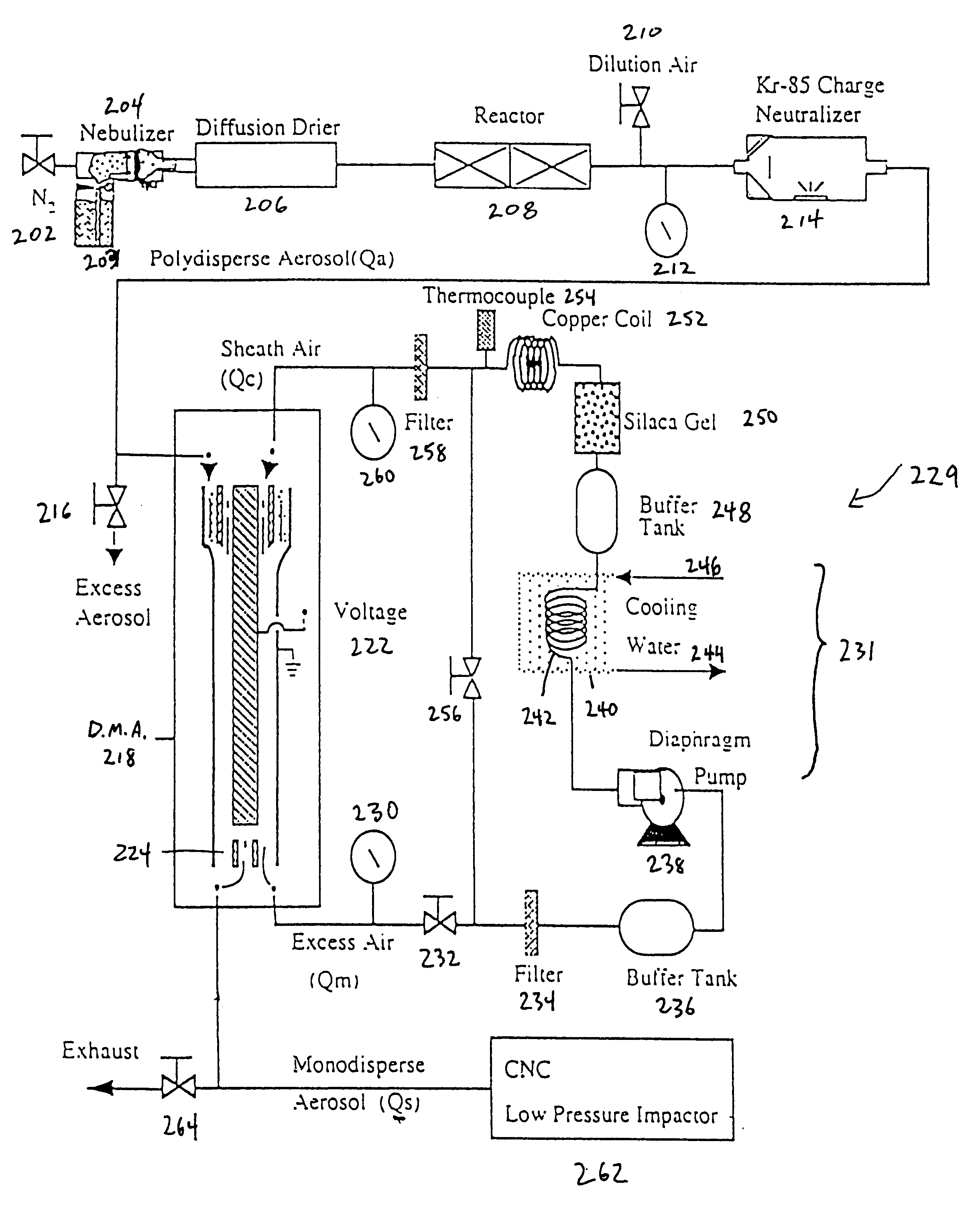

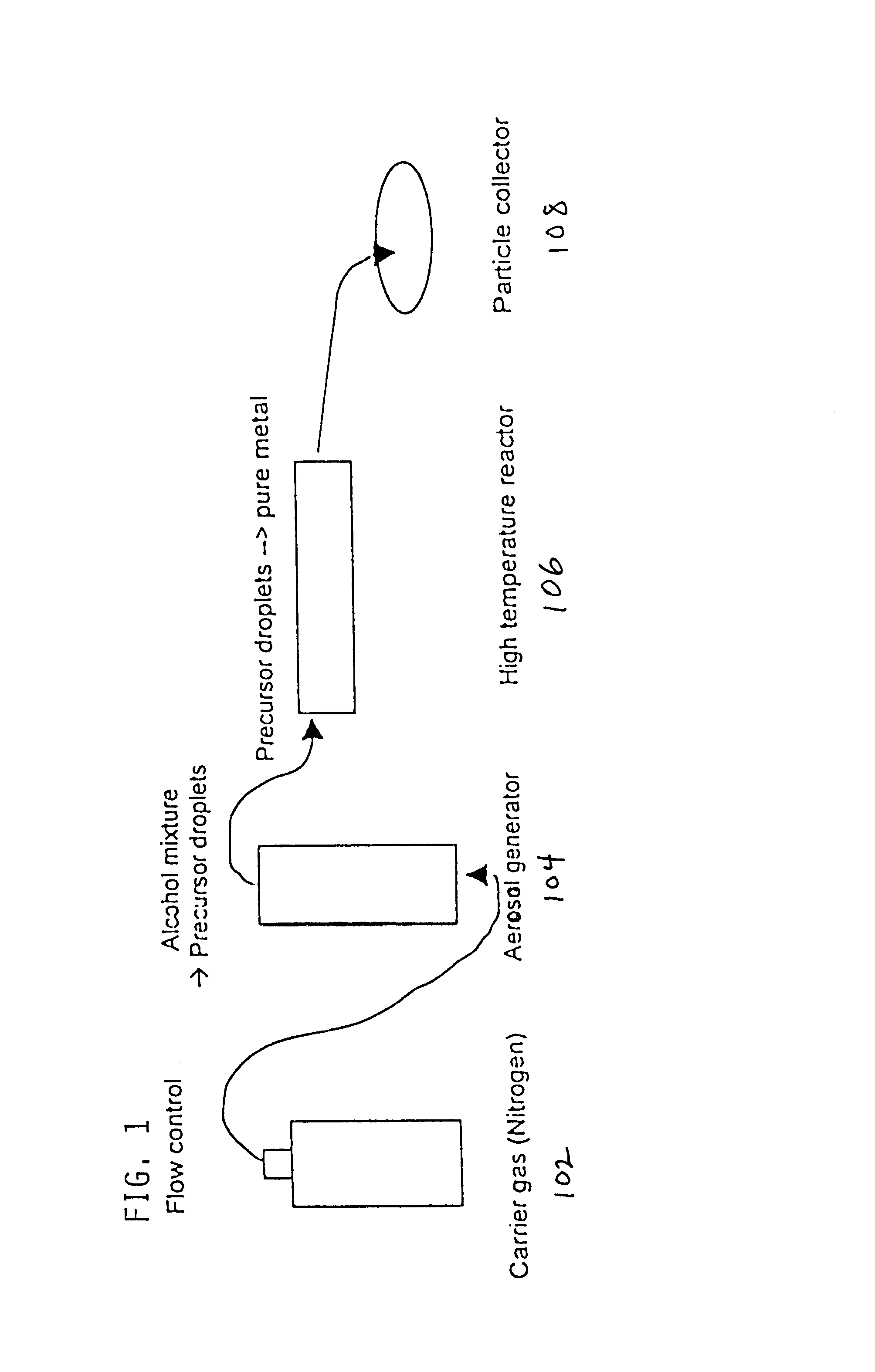

Method of producing metal particles by spray pyrolysis using a co-solvent and apparatus therefor

InactiveUS6679938B1Efficiently provideNanotechTransportation and packagingCarbon numberMetal particle

A spray pyrolysis method for producing pure metal and / or metal oxide particles uses a mixture of a carrier gas and a solution of a metal salt precursor, water and a co-solvent reducing agent. The metal salt precursors preferably comprise metals from the group consisting of Fe, Co, Ni, Cu, Zn, Pd, Ag and Au, whereas the salt anions preferably comprise nitrates, acetates, oxalates and chlorides. The co-solvents are those that act as a reducing agent, are vaporizable, are inert with respect to the carrier gas, and are hydrophilic, such as alcohols, in particular, low-carbon numbered alcohols such as methanol or ethanol.

Owner:GOVERNMENT OF THE US SEC COMMERCE THE +1

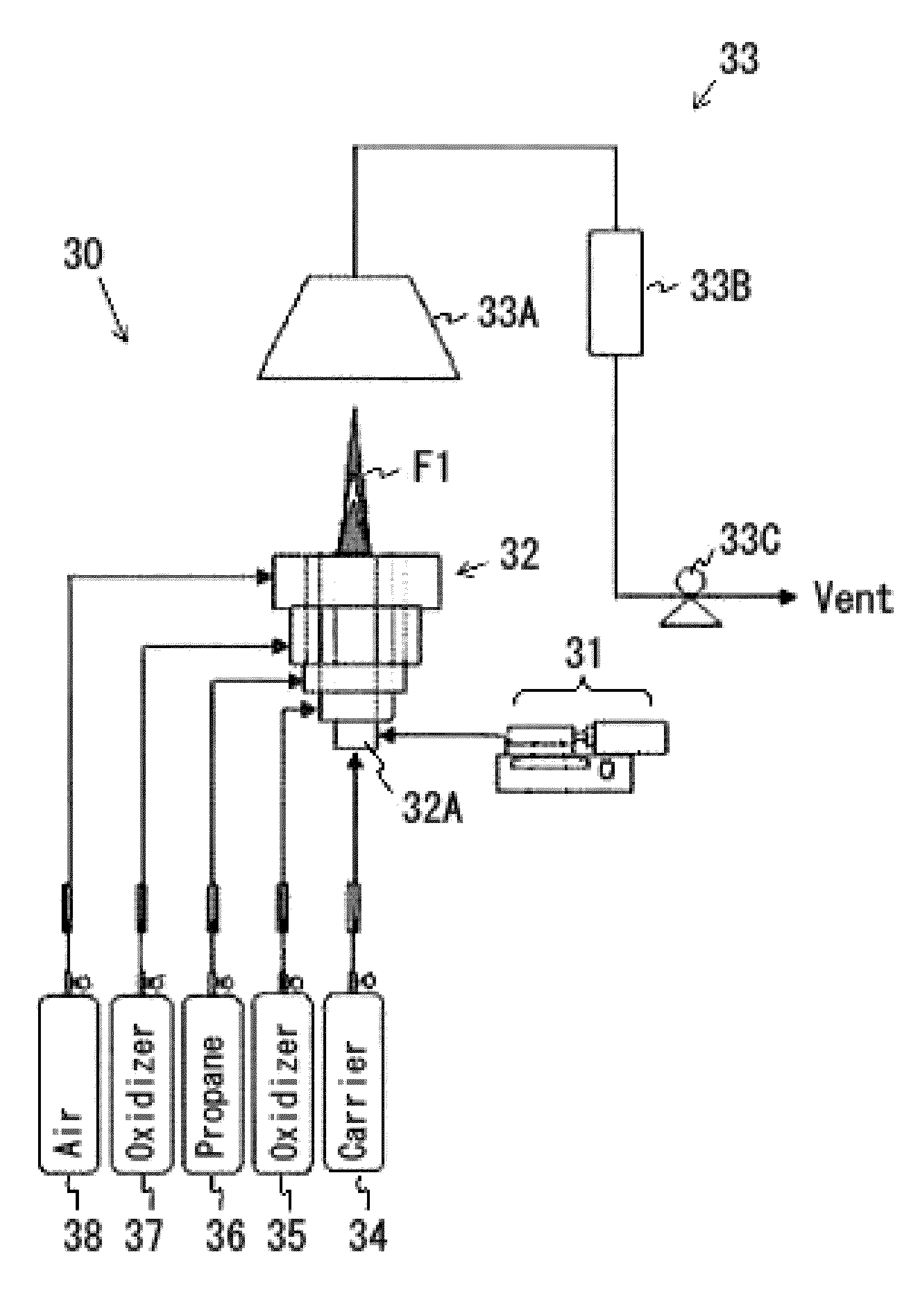

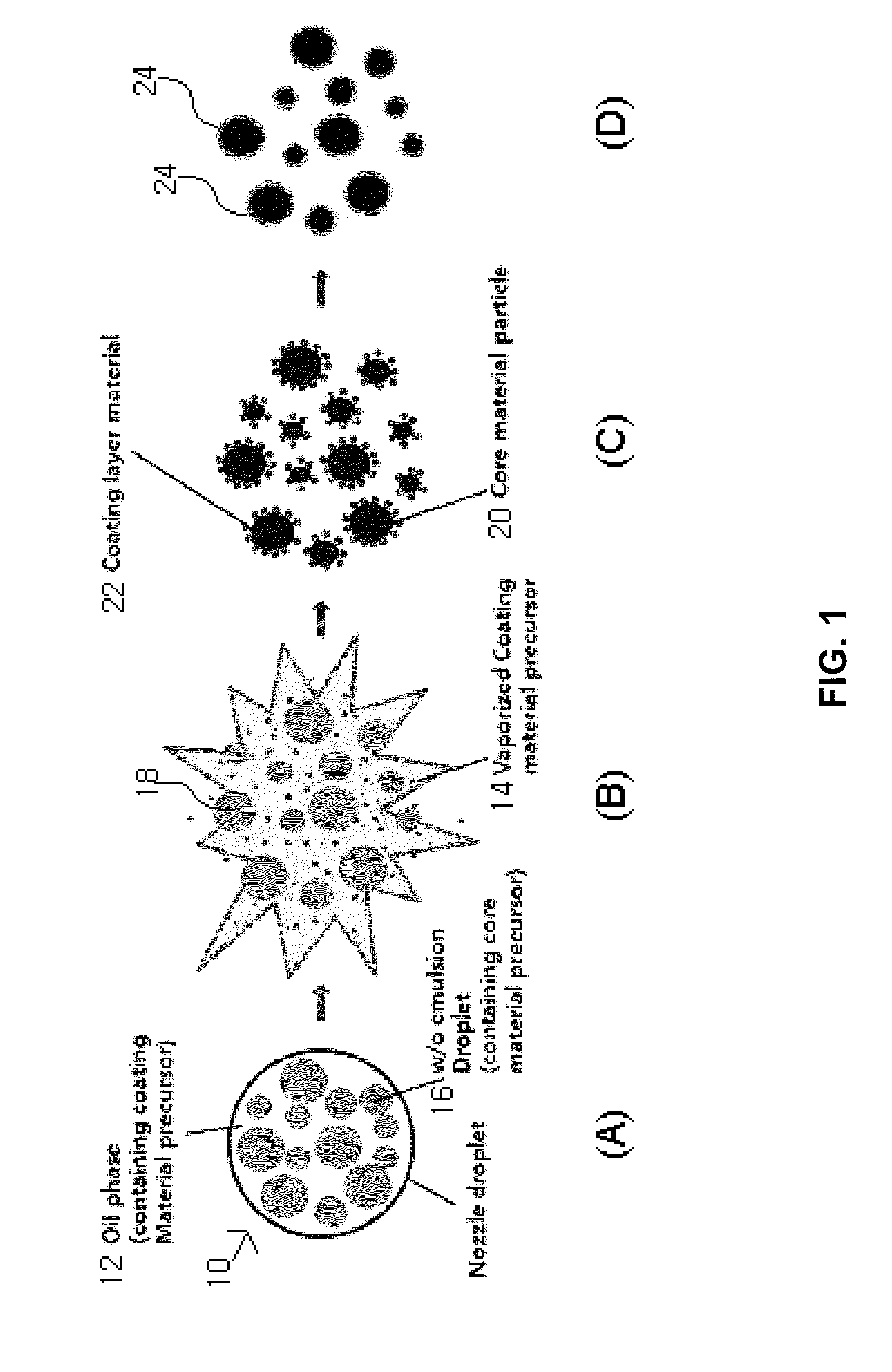

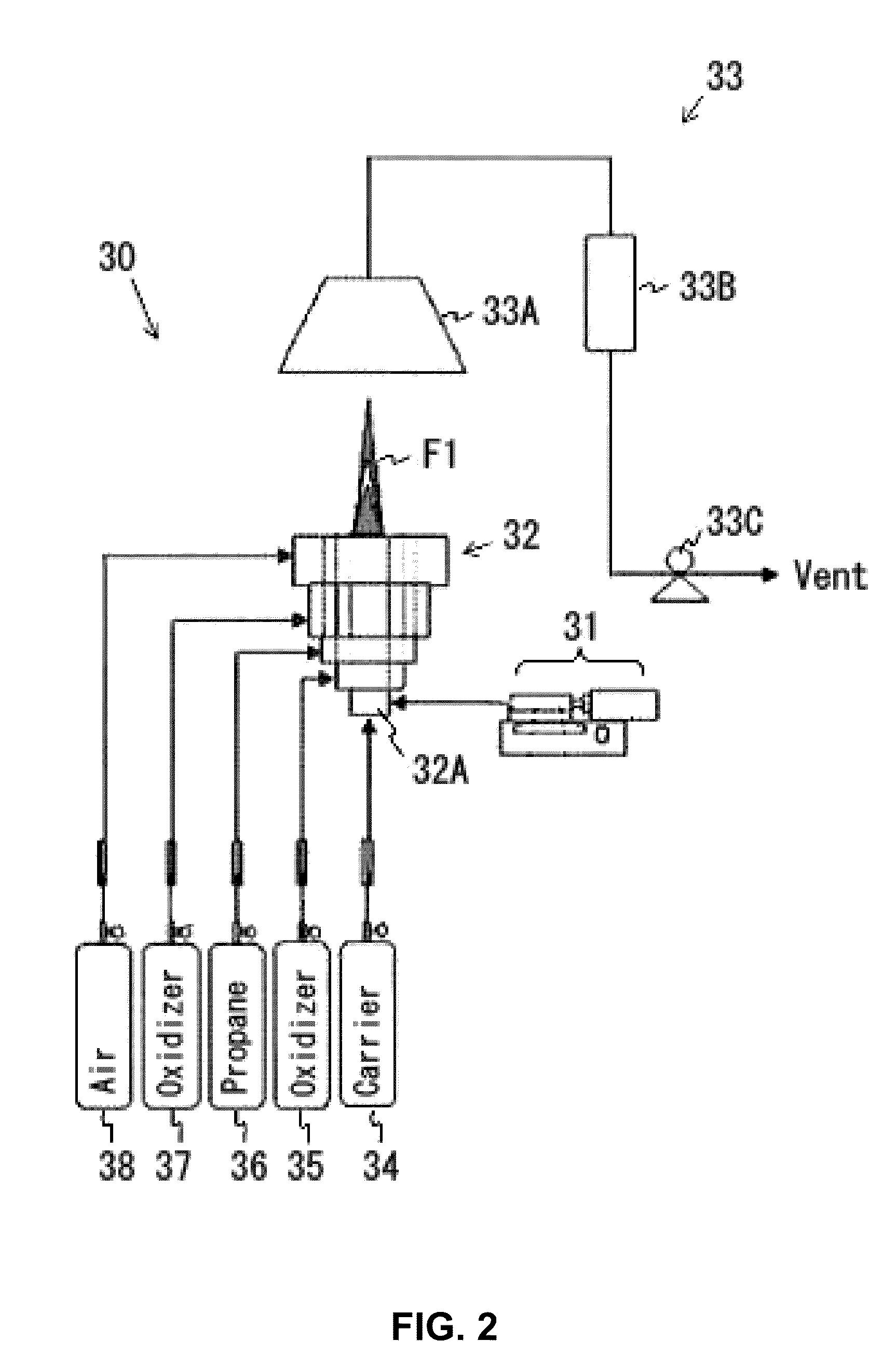

Method for Coating Core Ceramic Particles by Emulsion Flame Spray Pyrolysis

InactiveUS20100055340A1Reduce preparation timeReduce manufacturing costMaterial granulation and coatingLiquid surface applicatorsSingle stageMetallurgy

A method for coating the core ceramic particles by emulsion flame spray is provided. In particular, the method forms a core ceramic particle simultaneously with coating the surface of the formed core ceramic particles by emulsion flame spray pyrolysis. The core ceramic particle may be coated in a single stage by emulsion flame spray pyrolysis conventionally used in the art, through putting coating material precursor into the oil phase of emulsion solution at a stage of preparing emulsion solution in emulsion flame spray pyrolysis process.

Owner:KOREA ADVANCED INST OF SCI & TECH

Surface-modified silicon dioxide-titanium dioxide mixed oxides

Pyrogenically prepared surface-modified silicon dioxide-titanium dioxide mixed oxides are prepared by spraying pyrogenically prepared silicon dioxide-titanium dioxide mixed oxides with a surface-modifying agent. The surface-modified pyrogenically prepared silicon dioxide-titanium dioxide mixed oxides can be used in sun protection formulation.

Owner:EVONIK DEGUSSA GMBH

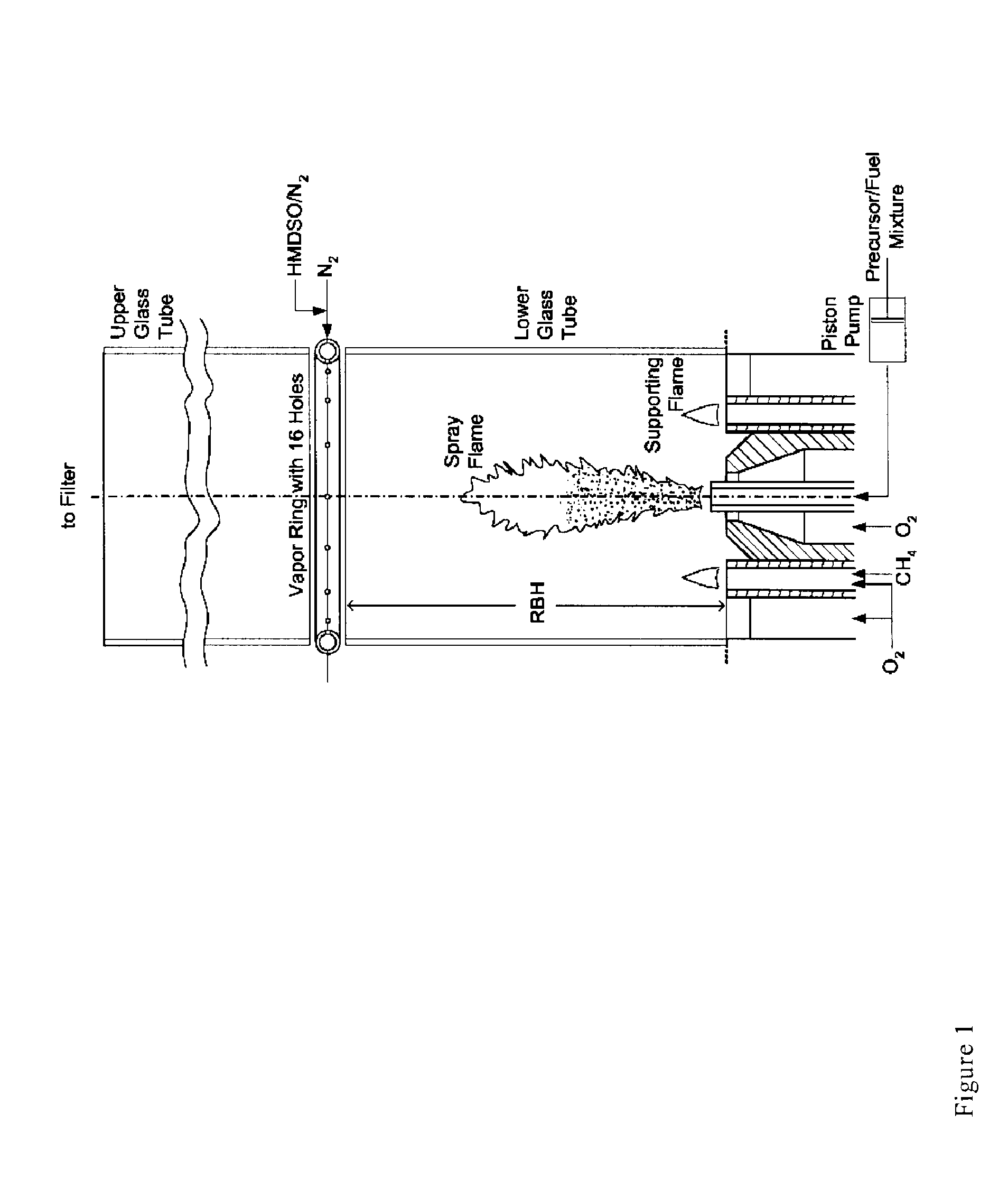

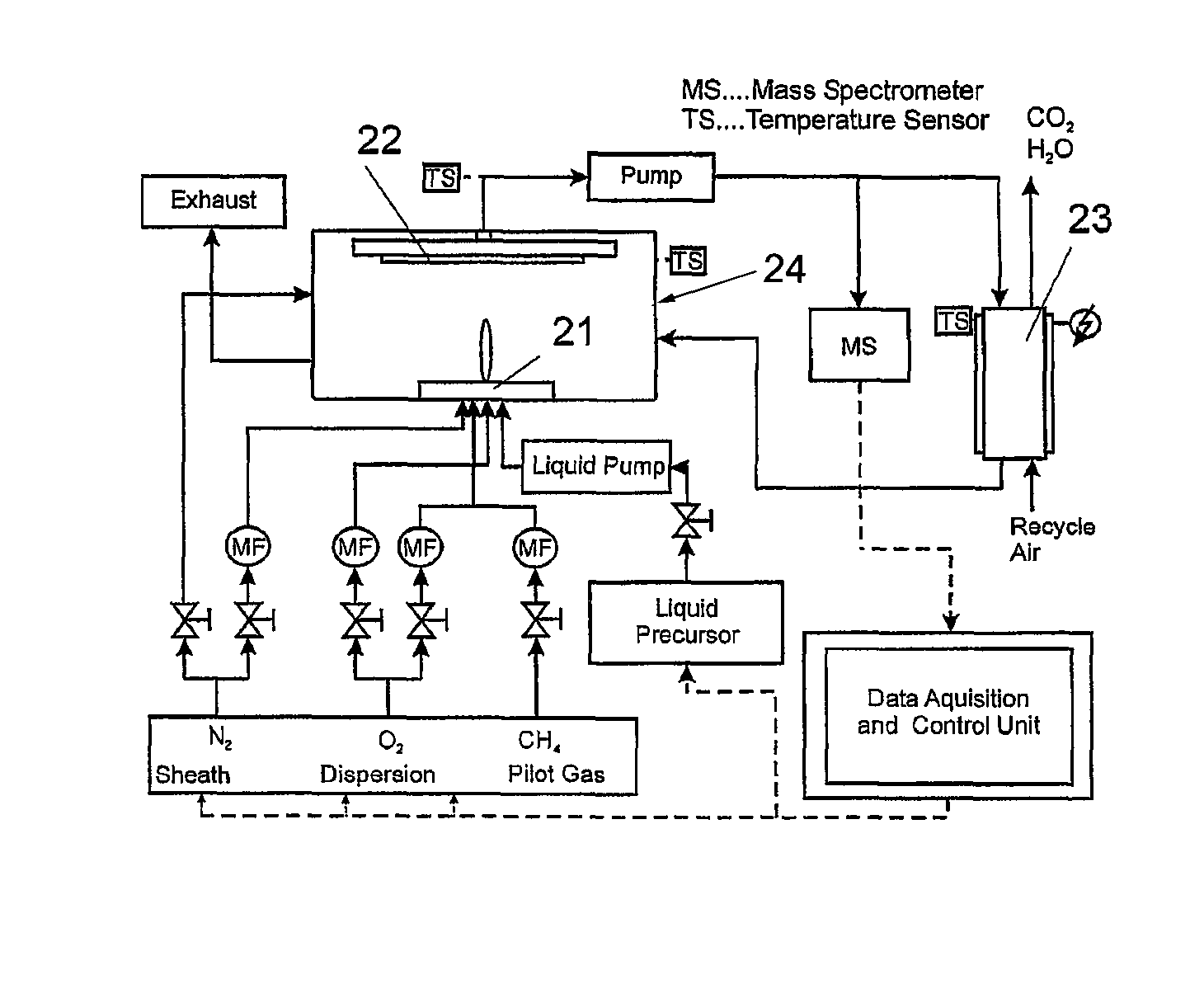

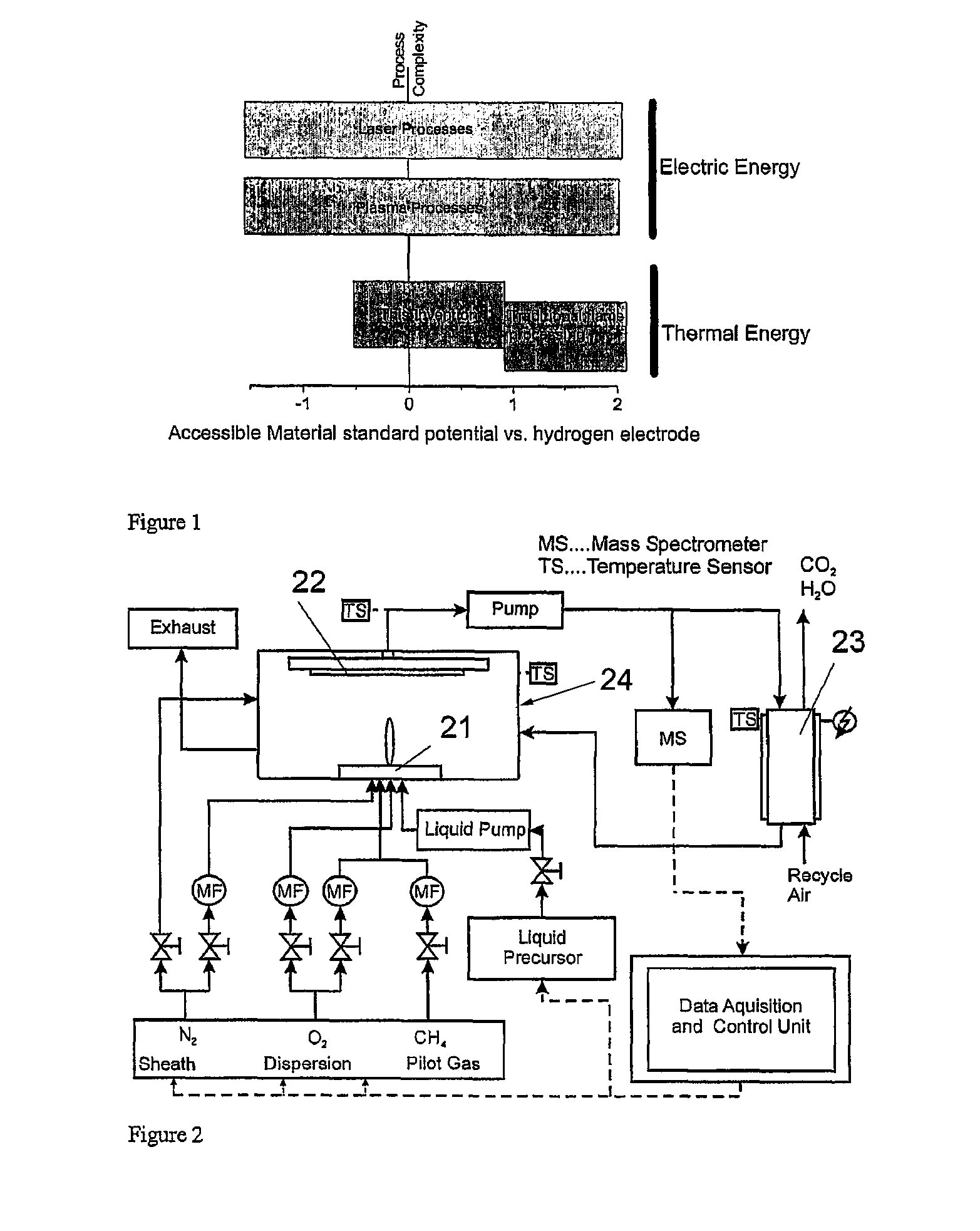

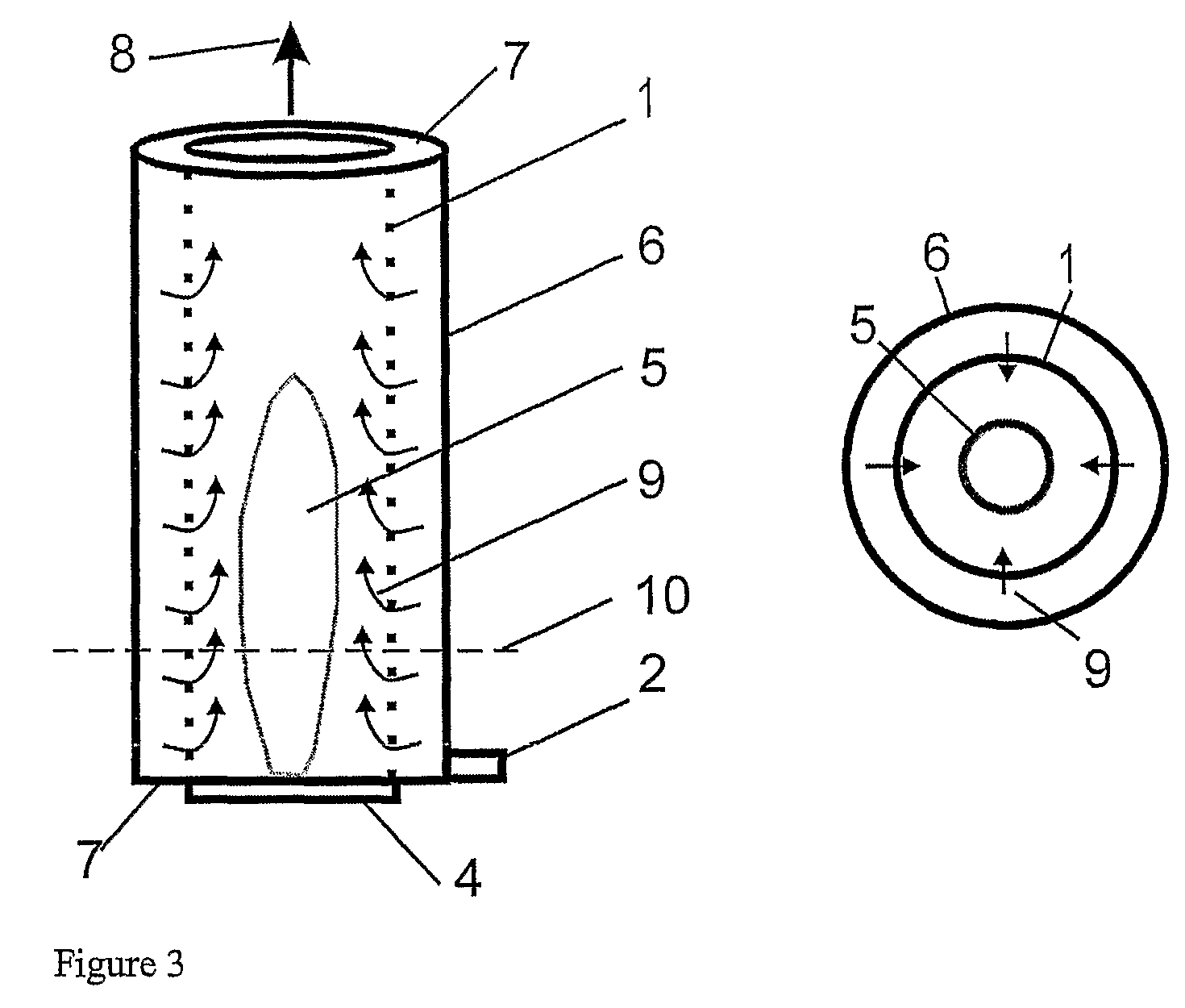

Methods and devices for flame spray pyrolysis

The present invention relates the manufacture of metal powders, non-oxidic ceramic powders and reduced metal oxide powders using an improved flame spray pyrolysis (“FSP”) process. The invention further relates to an apparatus specifically adapted to said process, to powders / naoncomposites obtained by said process and to the use of said powders / nanocompsites.

Owner:ETH ZZURICH

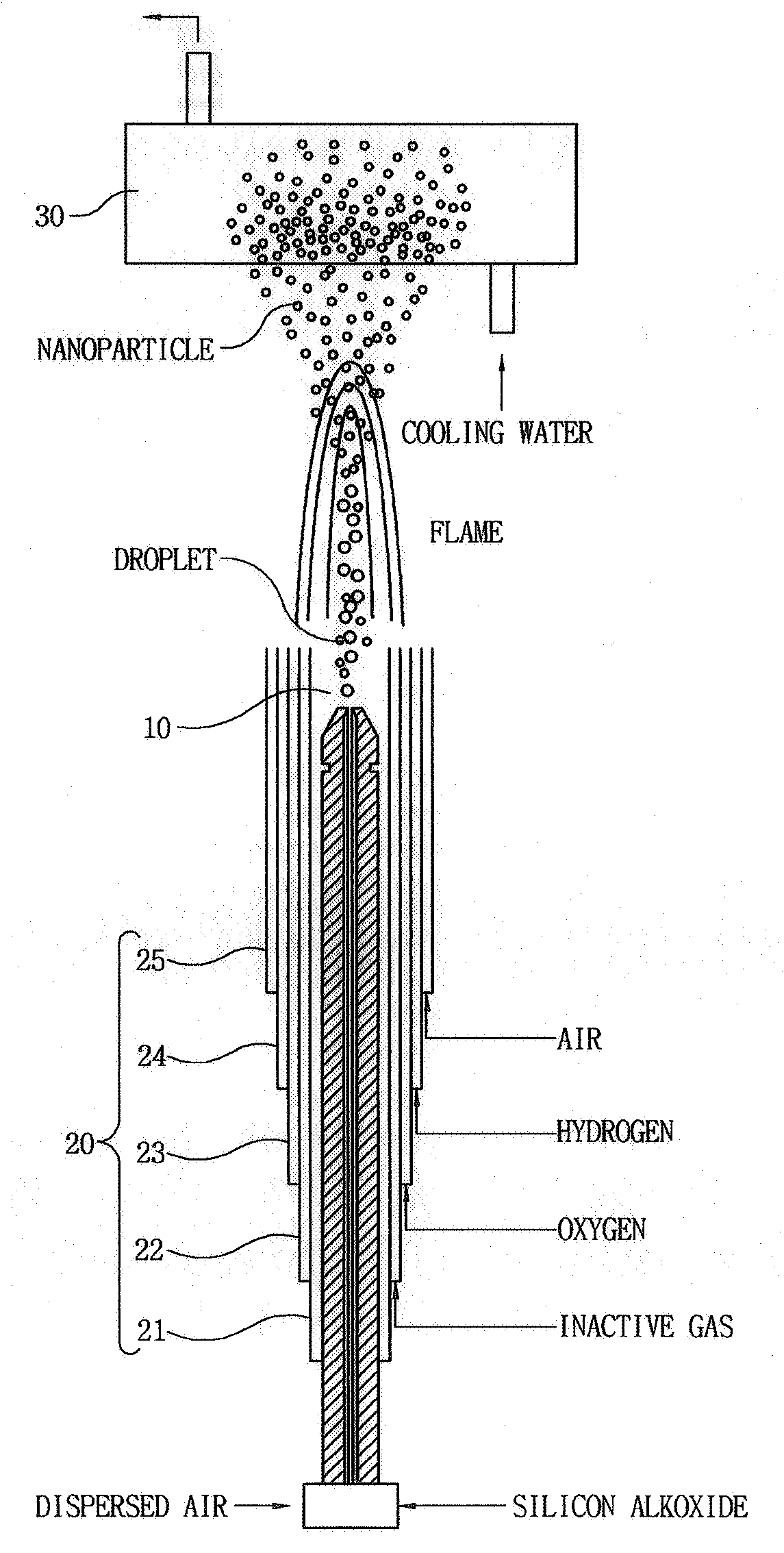

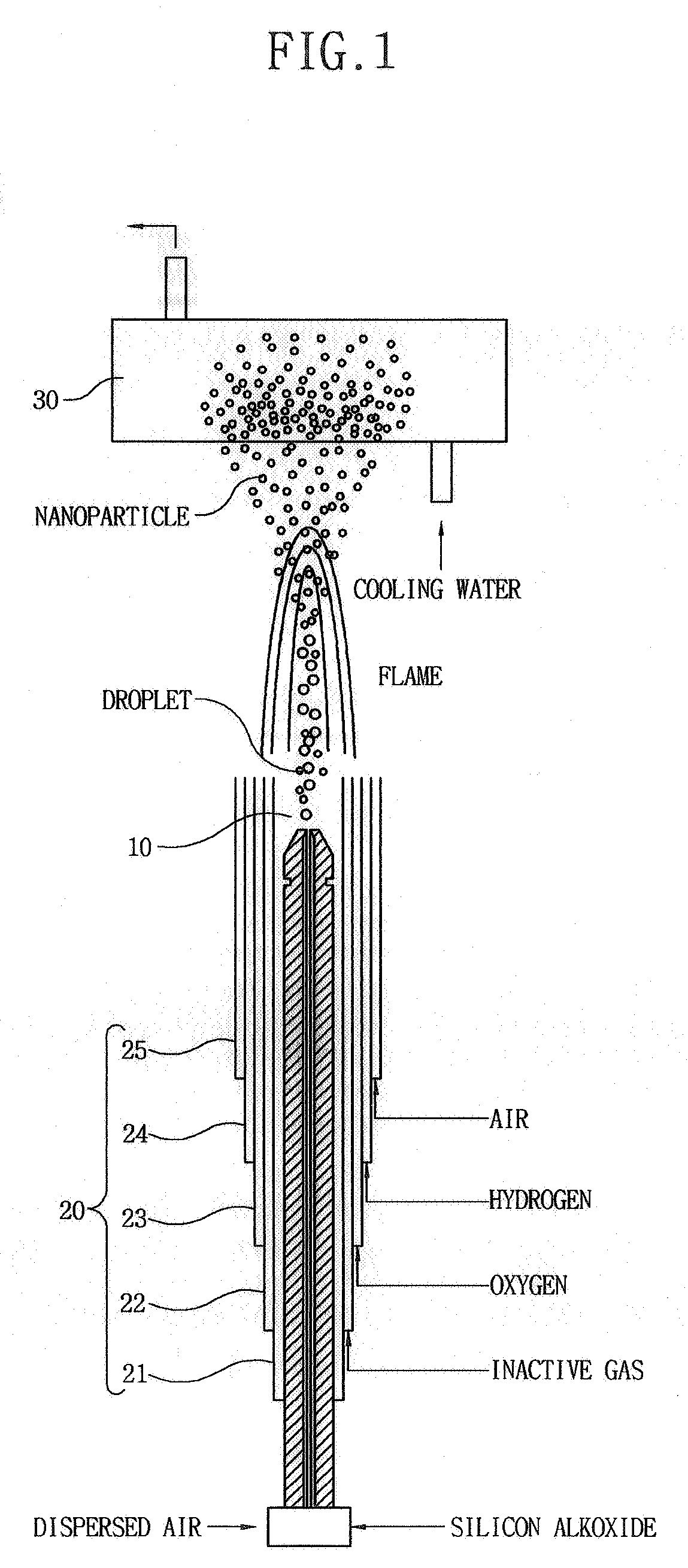

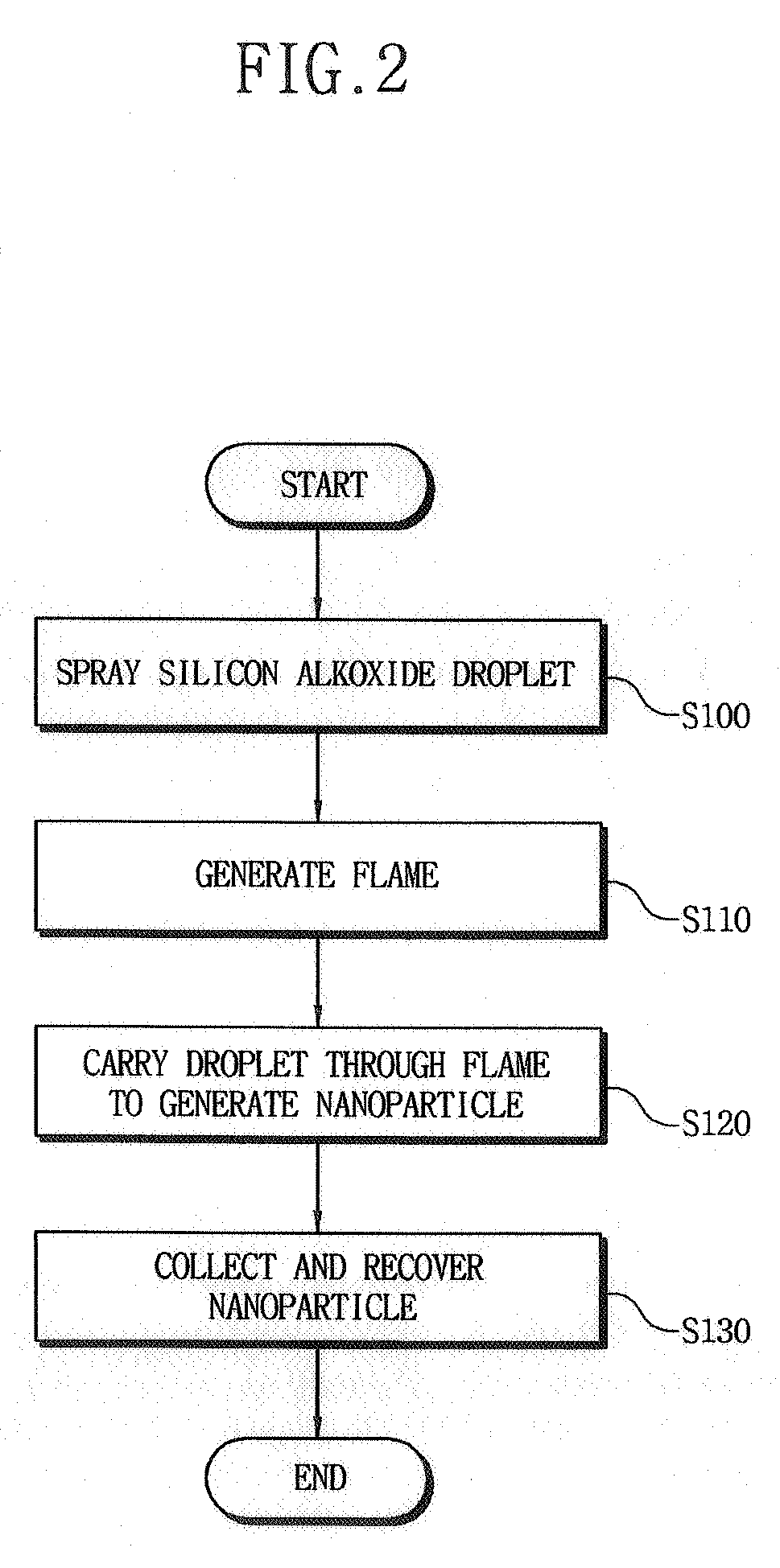

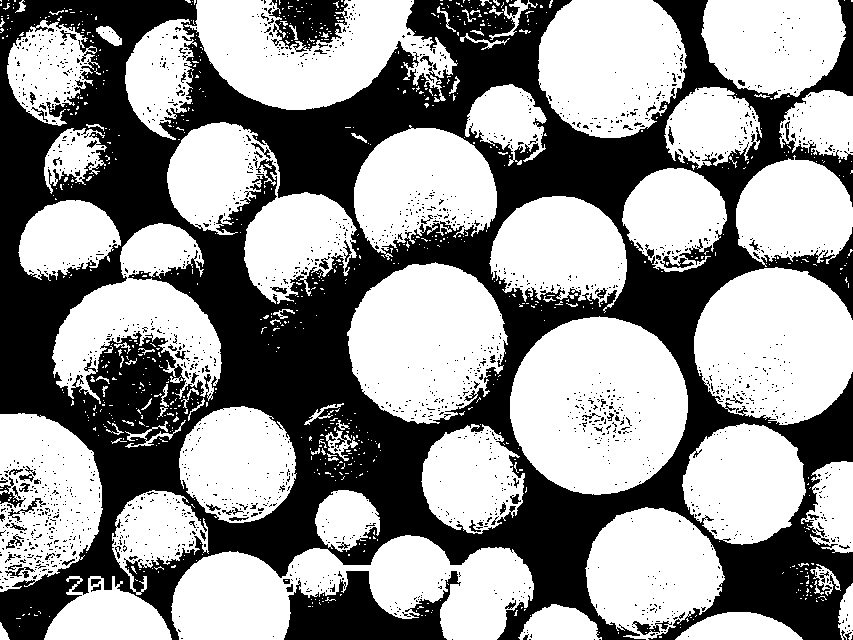

Method for making silica nanoparticles by flame spray pyrolysis adopting two-fluid nozzle

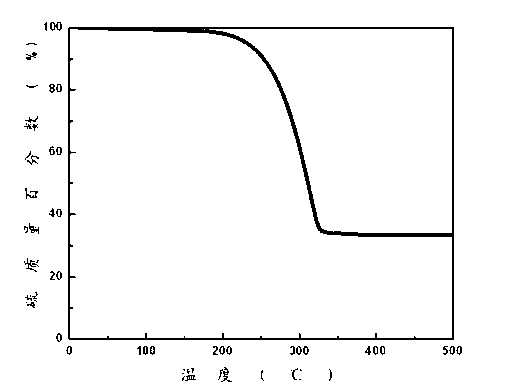

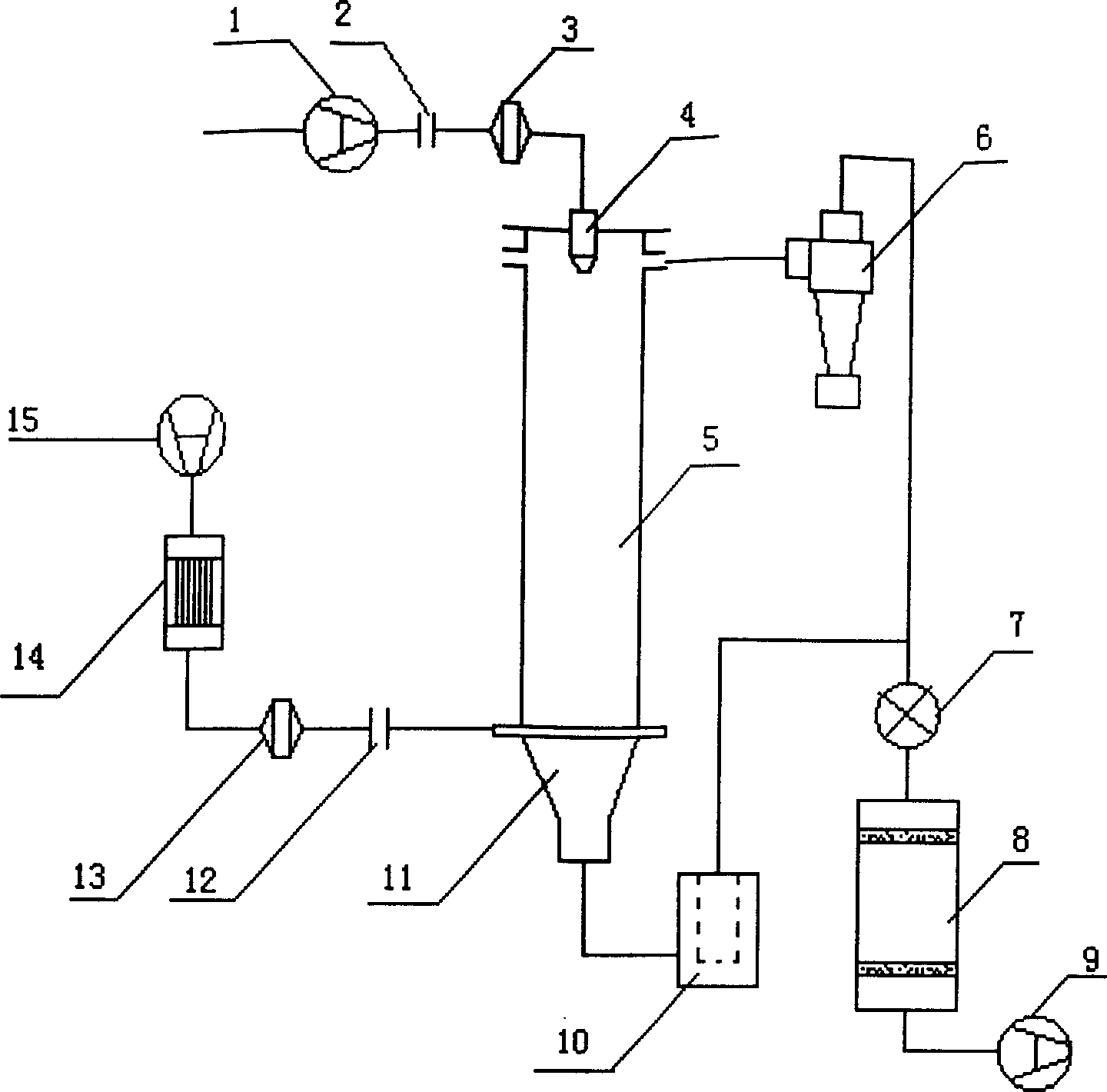

The invention relates to a method for making silica nanoparticles using a flame reactor, which includes a droplet spray having a two-fluid nozzle and a burner of a quintuple tube structure. In this method, droplets of silicon alkoxide as liquid Si compound are sprayed through the droplet spray of the flame reactor. A flame is generated by the flow of inert gas, oxygen, hydrogen and air simultaneously into the burner of the flame reactor. The liquid Si compound is delivered through the flame of the burner to produce silica nanoparticles having a mean particle size ranging from 9 nm to 68 nm. Resultant nanoparticles are collected and recovered in a particle collector. The droplets sprayed under high pressure from a silicon alkoxide solution are directly oxidized in the flame, thereby producing spherical silica nanoparticles.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

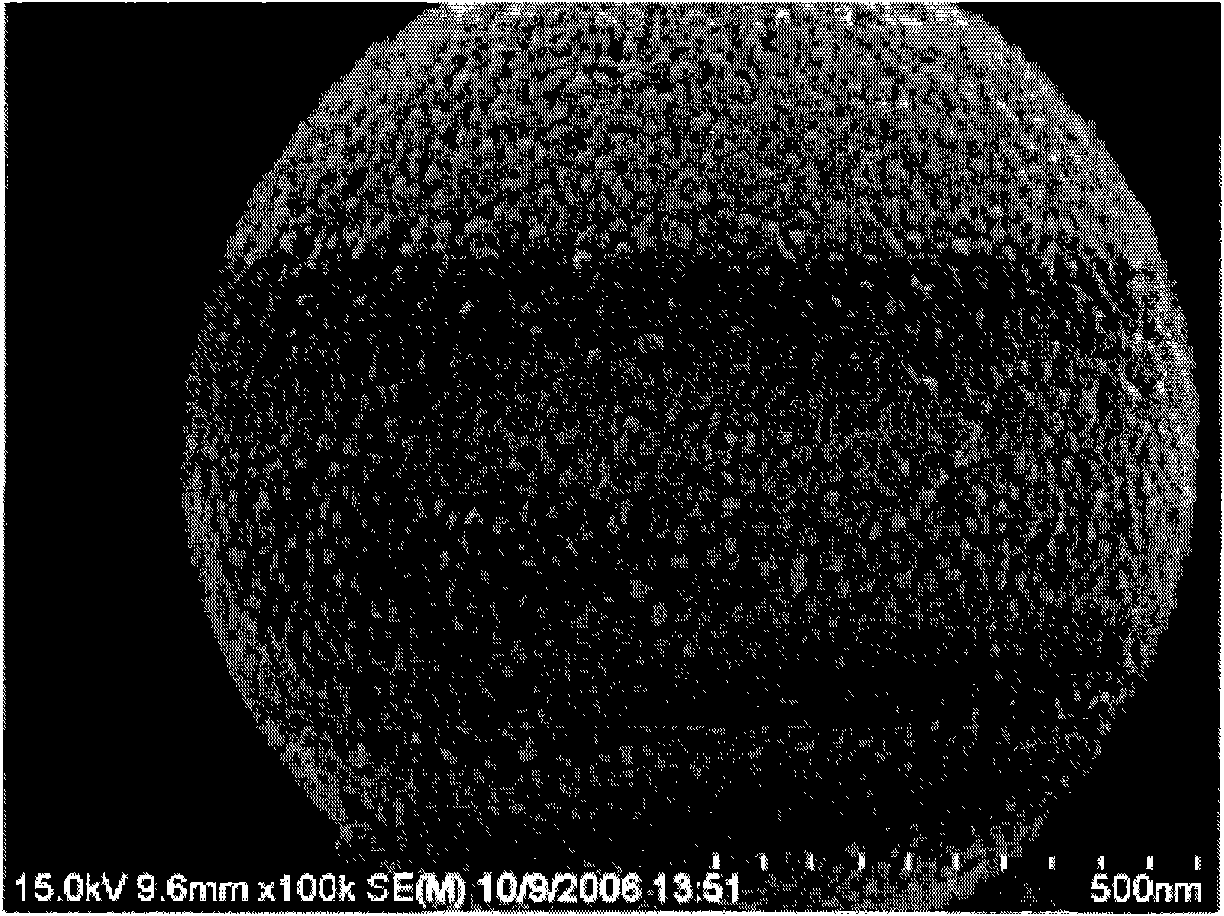

Preparation method for nitrogen-doped porous carbon sphere-sulfur composite positive material

The invention discloses a preparation method for a nitrogen-doped porous carbon sphere-sulfur composite positive material. The preparation method comprises the following steps of: performing spray pyrolysis on a nitrogen-containing carbon source, silica sol and de-ionized water to obtain a spherical nitrogen-doped pyrolytic carbon-silicon dioxide composite, adding the composite into excessive hydrofluoric acid for reaction, and washing and drying the reactants to obtain nitrogen-doped porous carbon spheres; and adding a sulfosalt solution into the nitrogen-doped porous carbon spheres under a vacuum condition, adding glycerin, which is taken as a dispersing agent, into the carbon spheres, adding an acid solution to the carbon spheres under magnetic stirring, and filtering and washing the mixture, and performing vacuum drying on the washed mixture to obtain the nitrogen-doped porous carbon sphere-sulfur composite positive material. The sulfur content of the prepared composite material is 50 to 90 percent, sulfur particles are more uniformly distributed in porous structures of the porous carbon spheres, and carbon and sulfur particles are more closely bound. The material is high in mechanical stability, specific discharge capacity and cycle performance. The method is simple in process, easy to operate, pollution-free and suitable for industrial implementation and batch production.

Owner:SHENZHEN RES INST CENT SOUTH UNIV

Photo-induced hydrophilic article and method of making same

InactiveUS7960043B2Easy to cleanEasy to wipeSynthetic resin layered productsVacuum evaporation coatingHydrophilic coatingSpray pyrolysis

Methods and articles are disclosed in which a substrate is provided with a photo-induced hydrophilic surface by forming a photo-induced hydrophilic coating on the substrate by spray pyrolysis, chemical vapor deposition, or magnetron sputter vacuum deposition. The coating can have a thickness of 50 Å to 500 Å, a root mean square roughness of less than 5, preferably less than 2, and photocatalytic activity of less than 3.0×10−3 cm−1 min−1±2.0×10−3 cm−1 min−1. The substrate includes glass substrates, including glass sheets and continuous float glass ribbons.

Owner:VITRO FLAT GLASS LLC

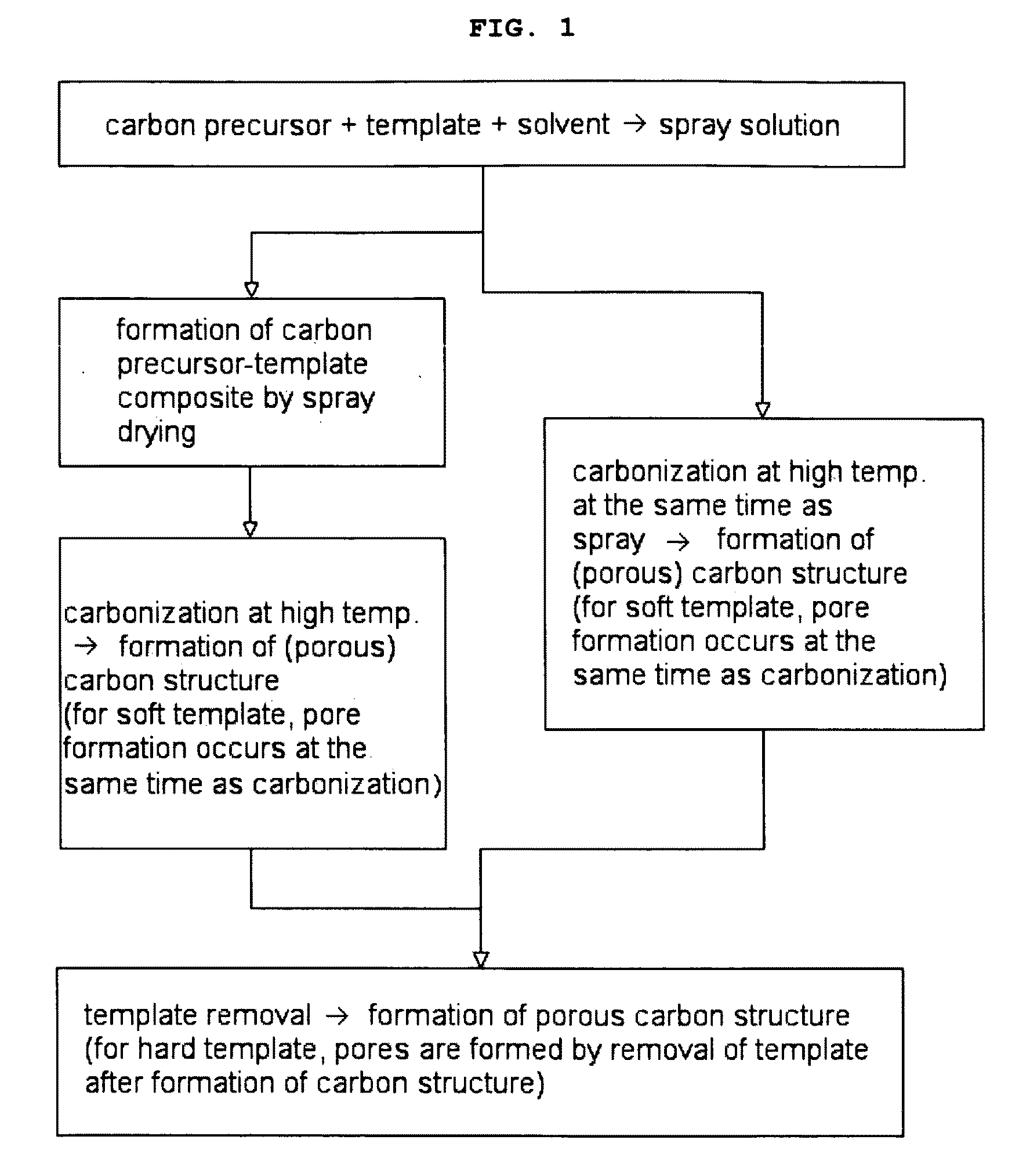

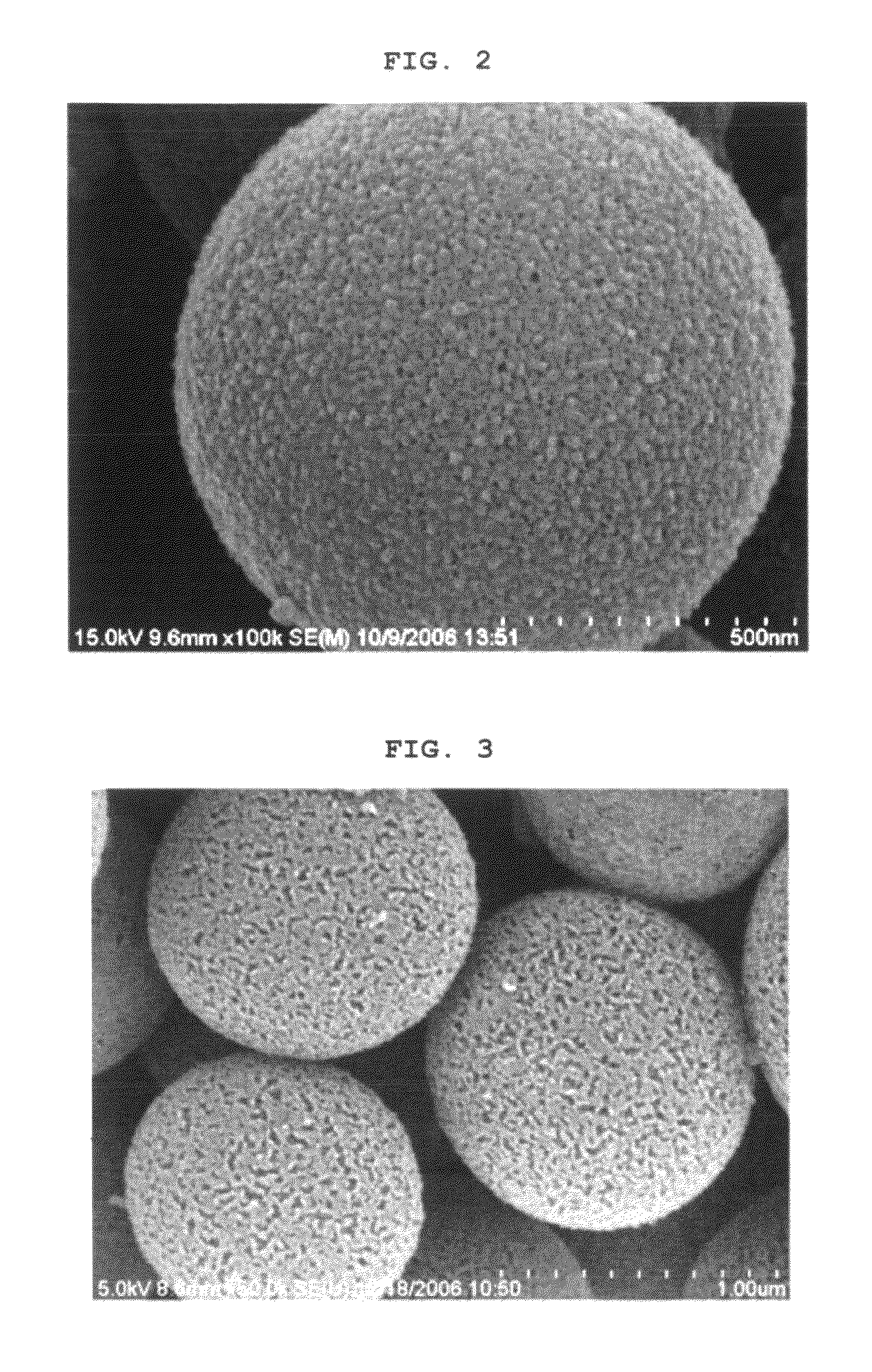

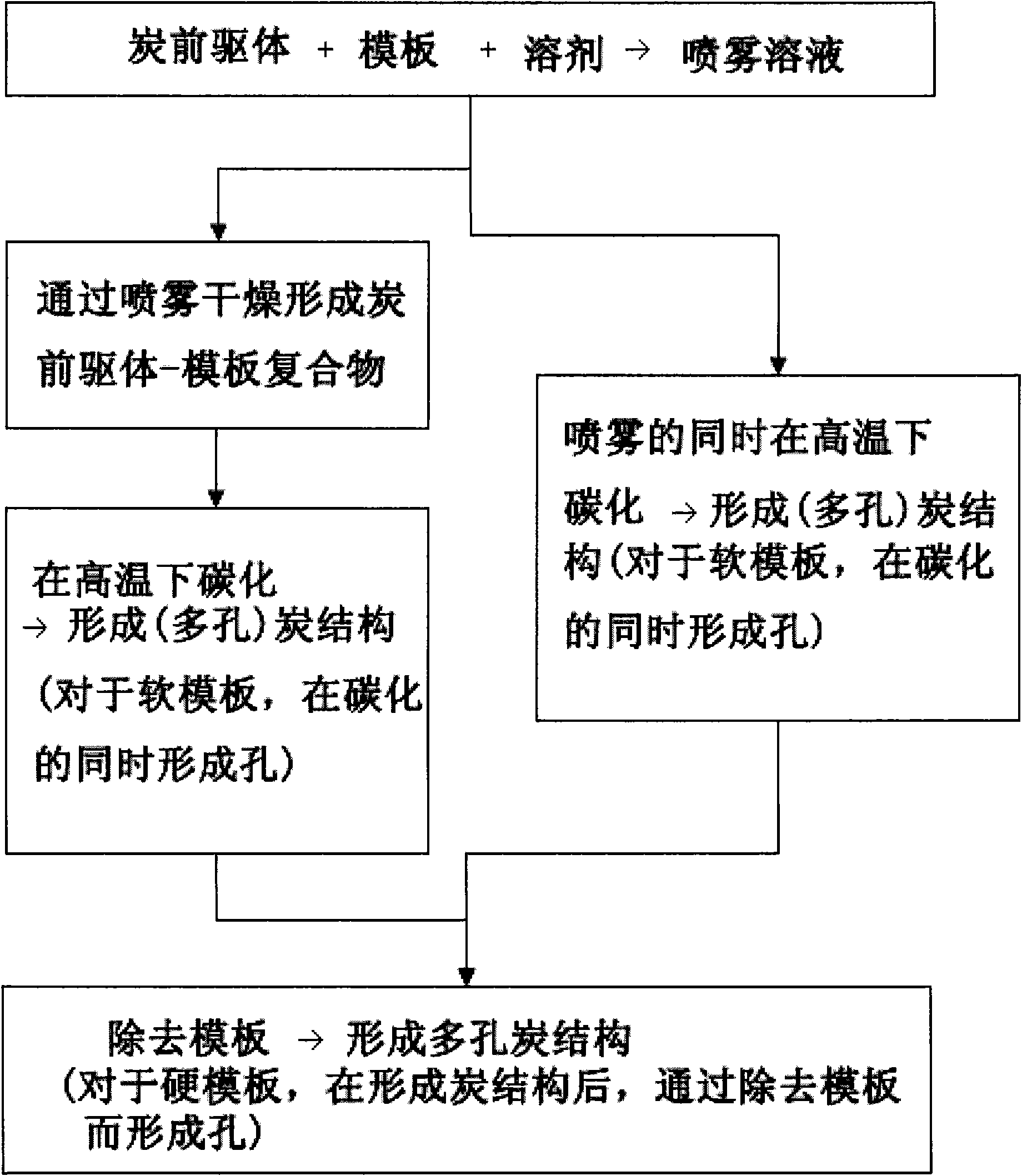

Manufacturing methods of mesoporous carbon structure with spray drying or spray pyrolysis and composition thereof

Disclosed is a method for preparing a porous carbon structure, the method comprising the steps of: (a) mixing a carbon precursor, a pyrolytic template, which is pyrolyzed at the carbonization temperature of the carbon precursor or removed by post-treatment after the carbonization of the carbon precursor so as to form pores, and a solvent, to prepare a spray solution; and (b) subjecting the spray solution either to spray pyrolysis or to spray drying and then spray pyrolysis, so as to form a carbonized carbon structure, and then removing the template from the carbon structure. A mesoporous spherical carbon prepared according to the disclosed method may have a large specific surface area and a large pore volume through the control of the kind and concentration of template, and thus can be used in a wide range of applications, including catalysts, adsorbents, electrode materials, materials for separation and purification, and materials for storing hydrogen and drugs.

Owner:LG CHEM LTD

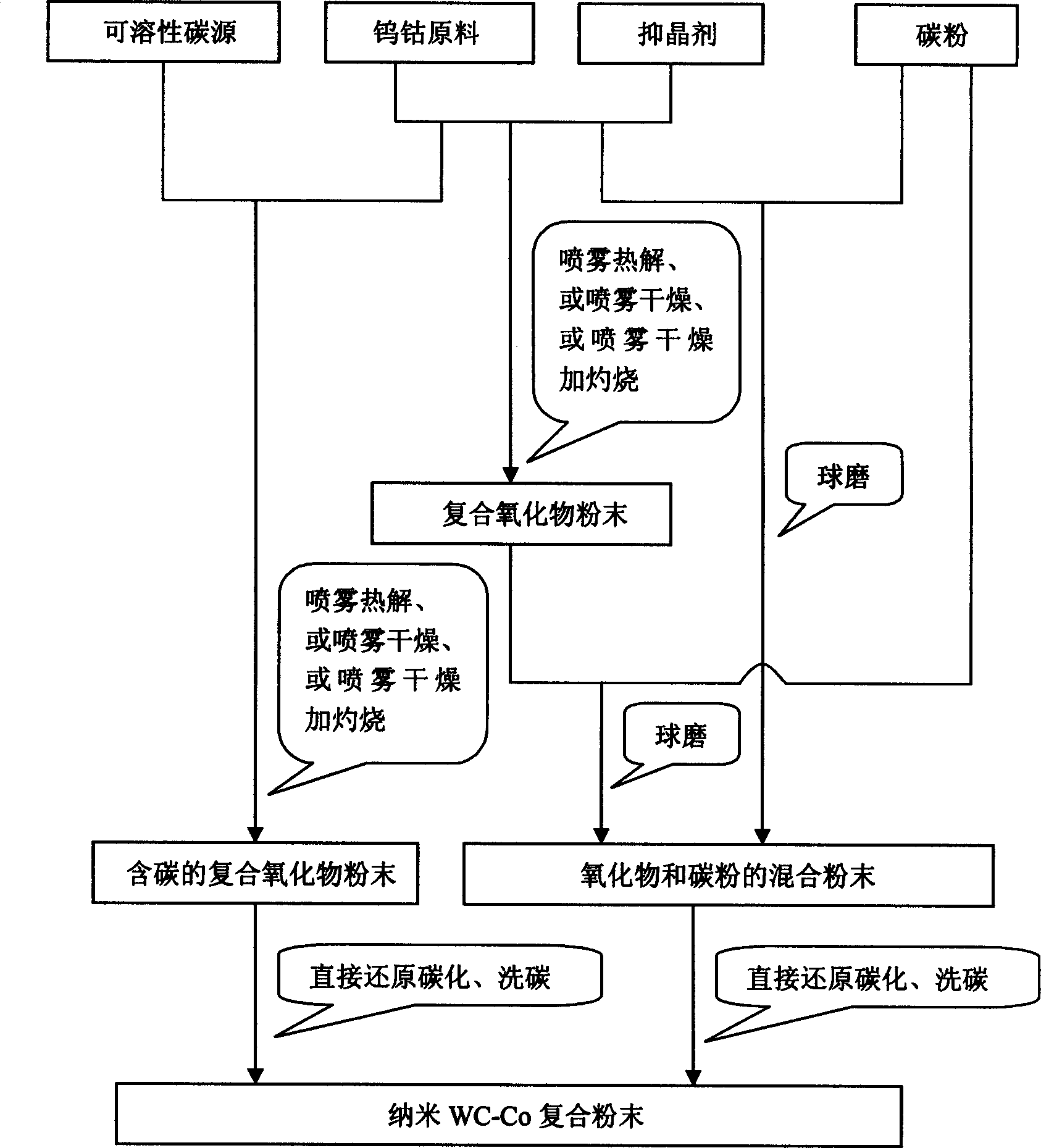

Method for preparing composite powder of nano tungsten carbide-coblt through direct reducition and carbonization

WC-CO nm composite powder is prepared by one of the three ways: 1. W-CO raw material, crystal depressor and carbon powder are mixed in proportion to be milled to mixed powder of the oxide and carbon 2. The W-CO raw material, crystal depressor are processed to oxide powder by a compound technology then to be mixed with carbon powder to be milled to a mixed powder of the oxide and carbon 3. W-CO raw material, crystal depressor and soluble carbon oxide powder with carbon by a compound technology which refers to spray pyrolytic decomposition, spray drying and spray burning. The nm WC-CO composite powder is got by putting the oxide powder in a reacting furnace, controlling temperature of recovery carburization and time and washing carbon temperature and time.

Owner:WUHAN UNIV OF TECH

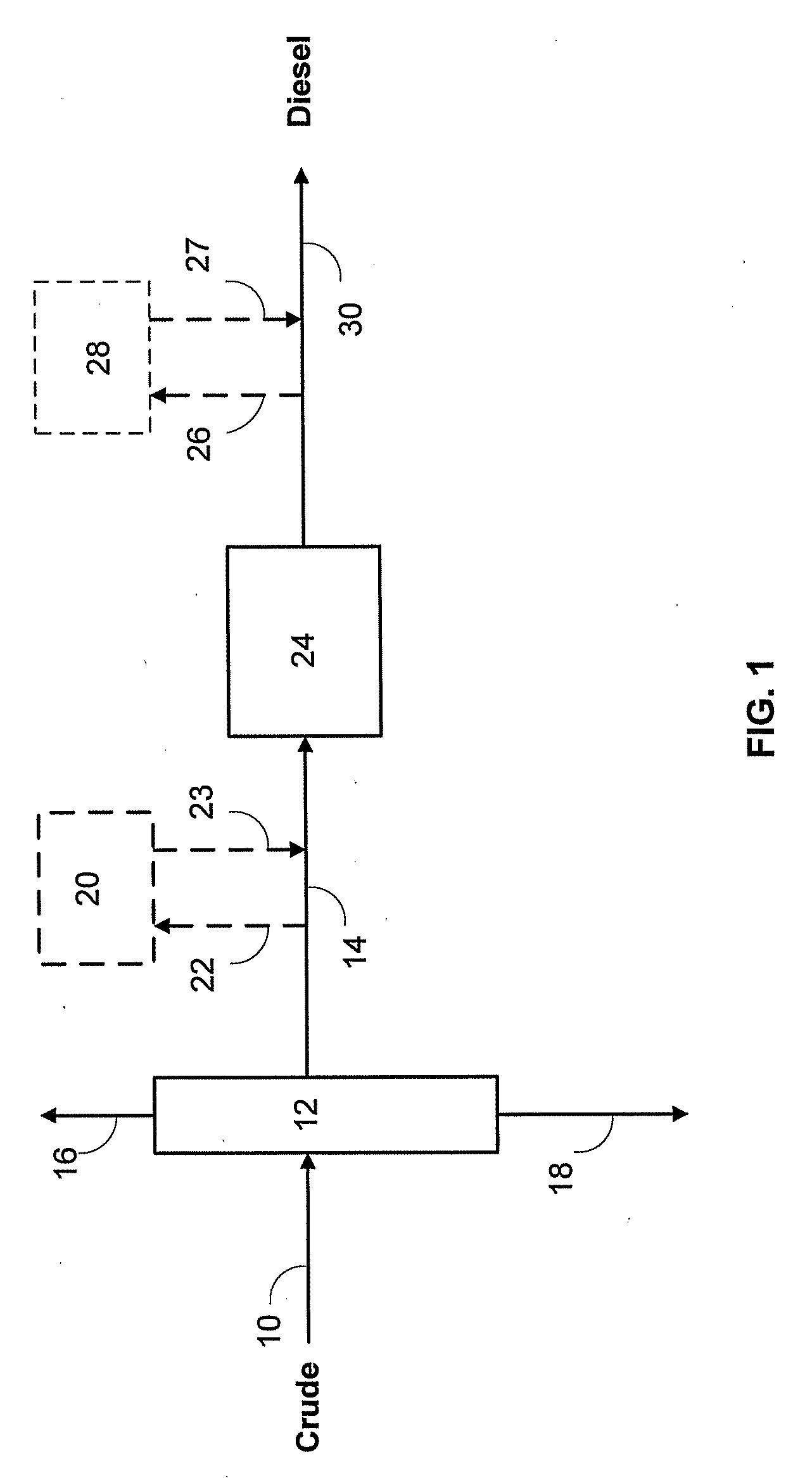

Catalyst to attain low sulfur diesel

InactiveUS20090145808A1High activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationSulfur

This invention relates to a hydrodesulfurization catalyst and a method for preparing the catalyst by spray pyrolysis. The catalyst is useful for the hydrodesulfurization of gas oils, particularly diesel. The catalyst particles can include at least one metal selected from molybdenum, cobalt and nickel, and a silicon dioxide support. The spray pyrolysis technique allows for the preparation of catalyst particles having high loading of catalyst on the substrate.

Owner:SAUDI ARABIAN OIL CO

Manufacturing methods of mesoporous carbon structure with spray drying or spray pyrolysis and composition thereof

Disclosed is a method for preparing a porous carbon structure, the method comprising the steps of: (a) mixing a carbon precursor, a pyrolytic template, which is pyrolyzed at the carbonization temperature of the carbon precursor or removed by post-treatment after the carbonization of the carbon precursor so as to form pores, and a solvent, to prepare a spray solution; and (b) subjecting the spray solution either to spray pyrolysis or to spray drying and then spray pyrolysis, so as to form a carbonized carbon structure, and then removing the template from the carbon structure. A mesoporous spherical carbon prepared according to the disclosed method may have a large specific surface area and a large pore volume through the control of the kind and concentration of template, and thus can be used in a wide range of applications, including catalysts, adsorbents, electrode materials, materials for separation and purification, and materials for storing hydrogen and drugs.

Owner:LG CHEM LTD

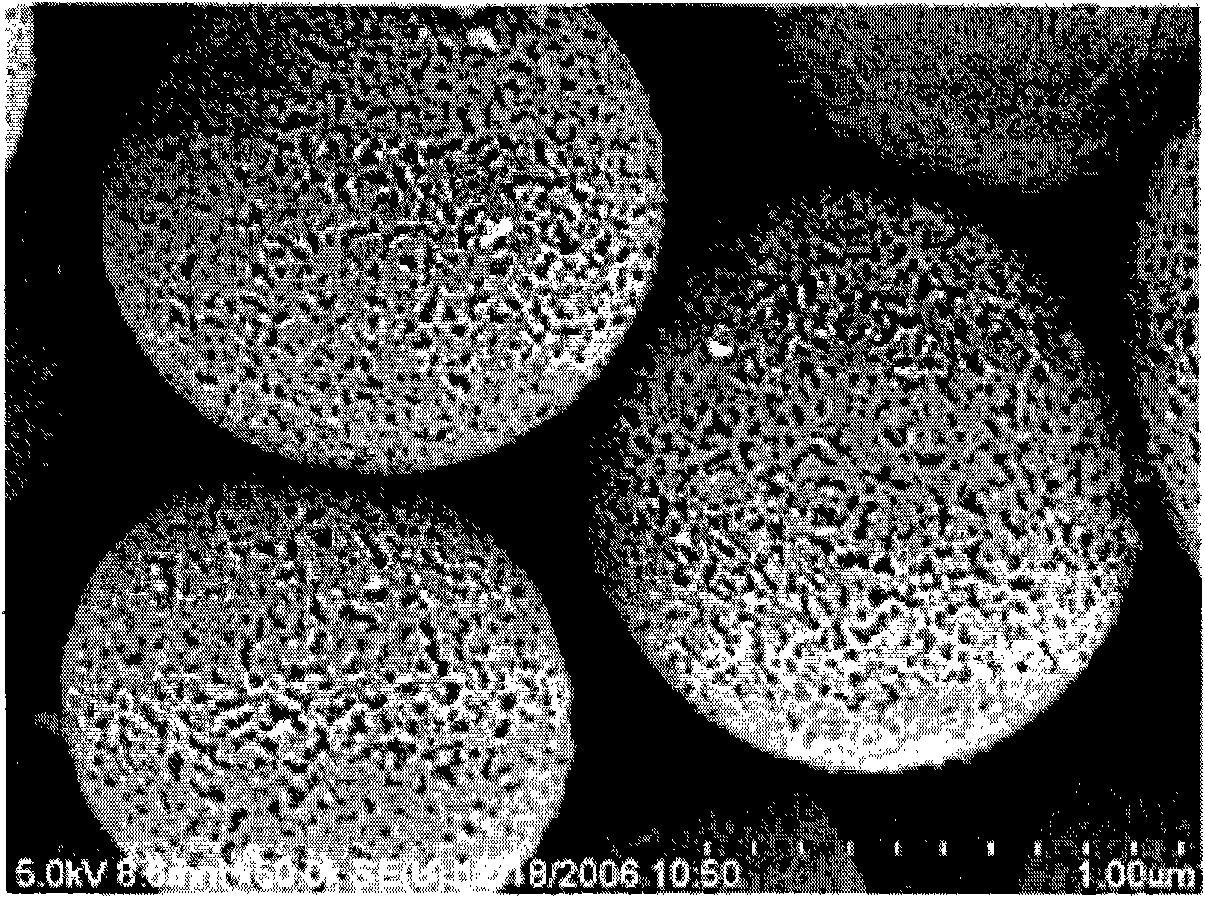

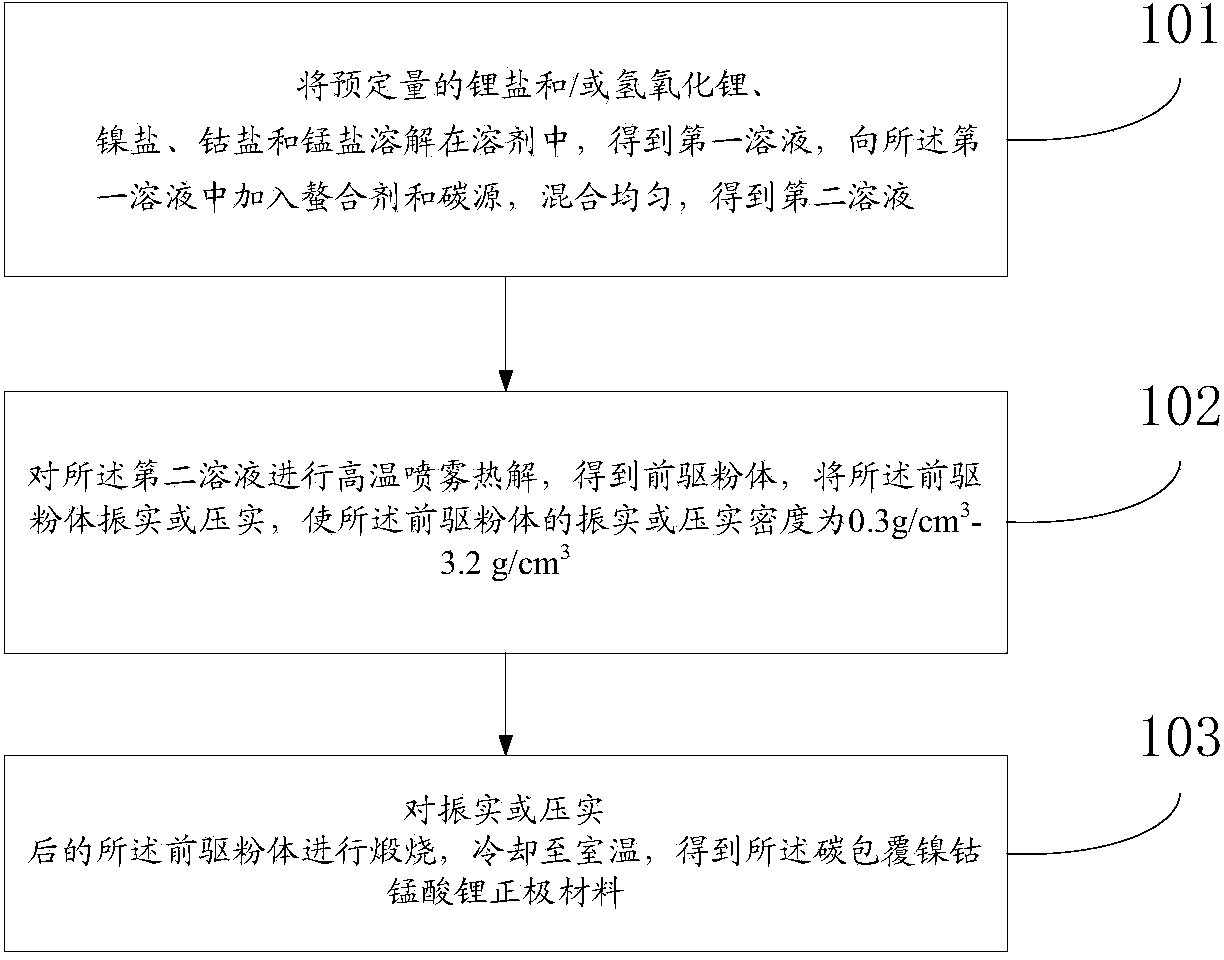

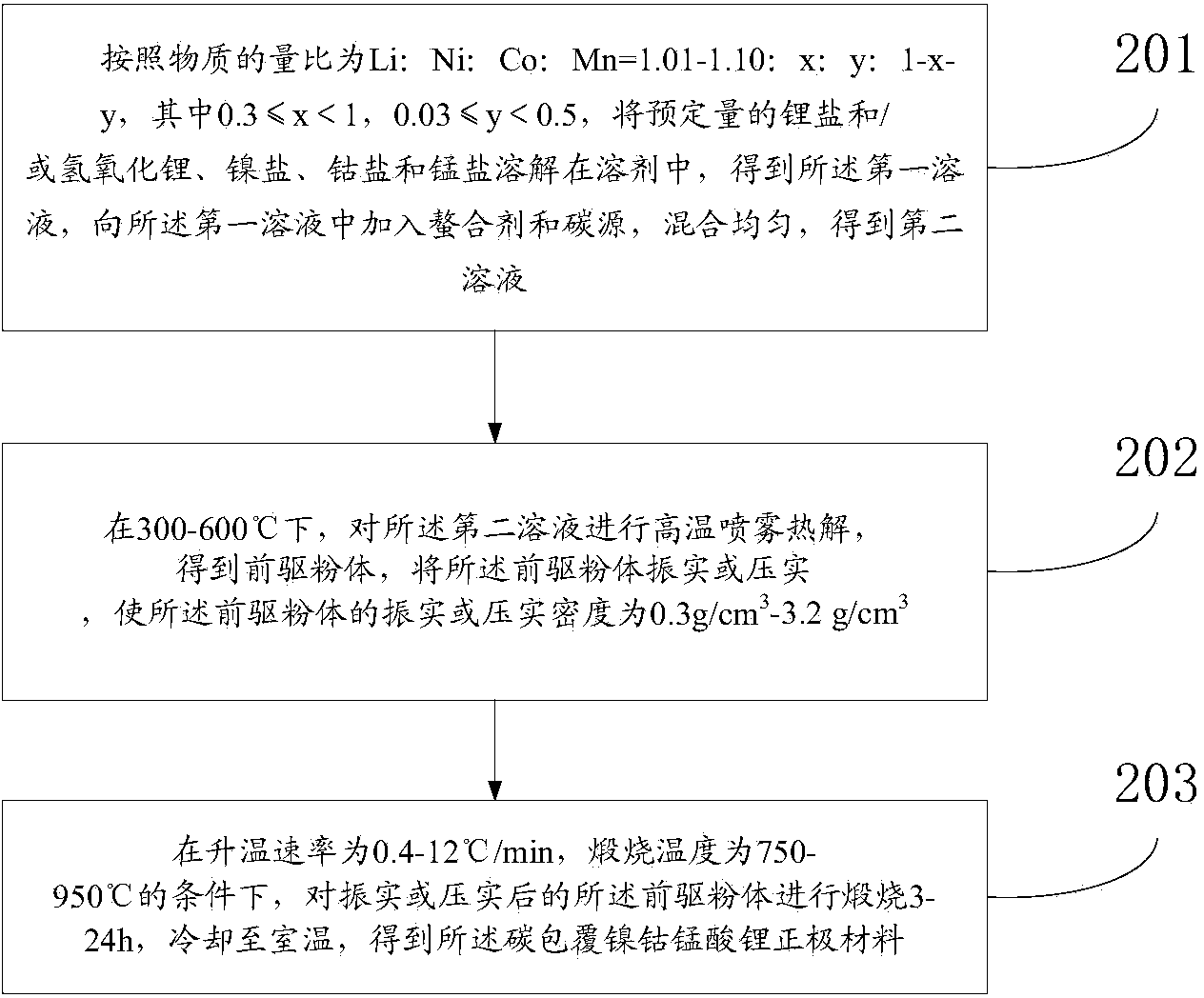

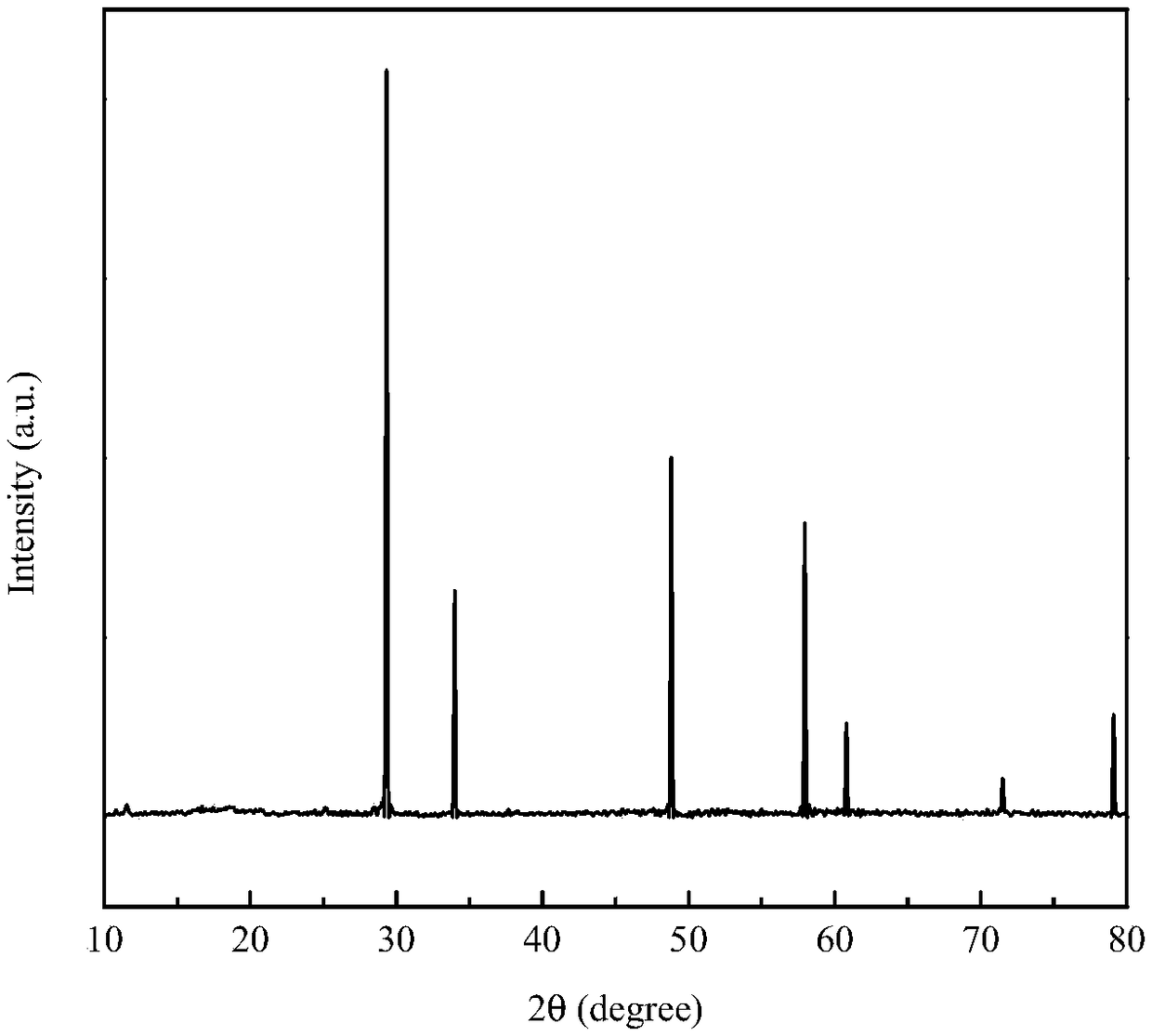

Carbon-coated nickel-cobalt lithium manganate positive electrode material and preparation method thereof

InactiveCN104051724AImprove conductivityImprove cycle stabilityCell electrodesSecondary cellsCarbon coatingNickel salt

The embodiment of the invention discloses a preparation method of a carbon-coated nickel-cobalt lithium manganate positive electrode material, and belongs to the technical field of preparation of a lithium battery positive electrode material. The preparation method comprises the following steps: adding a chelating agent and a carbon source into a solution containing lithium salt, nickel salt, cobalt salt and manganese salt, and performing high-temperature spray pyrolysis to obtain precursor powder; compacting the precursor powder by vibration or pressure, wherein the compaction density by the vibration or the pressure is 0.3-3.2g / cm<3> so that lithium ions, nickel ions, cobalt ions and manganese ions are uniformly dispersed in the powder and are contacted closely; and calcining the precursor powder, and cooling to obtain the carbon-coated nickel-cobalt lithium manganate positive electrode material with the good conductivity and the high cyclic stability. The carbon-coated nickel-cobalt lithium manganate positive electrode material comprises nickel-cobalt lithium manganate and carbon coating the surface of nickel-cobalt lithium manganate. The method disclosed by the embodiment of the invention is easy to operate and easy to control and facilitates the large-scale industrial production.

Owner:CHERY AUTOMOBILE CO LTD

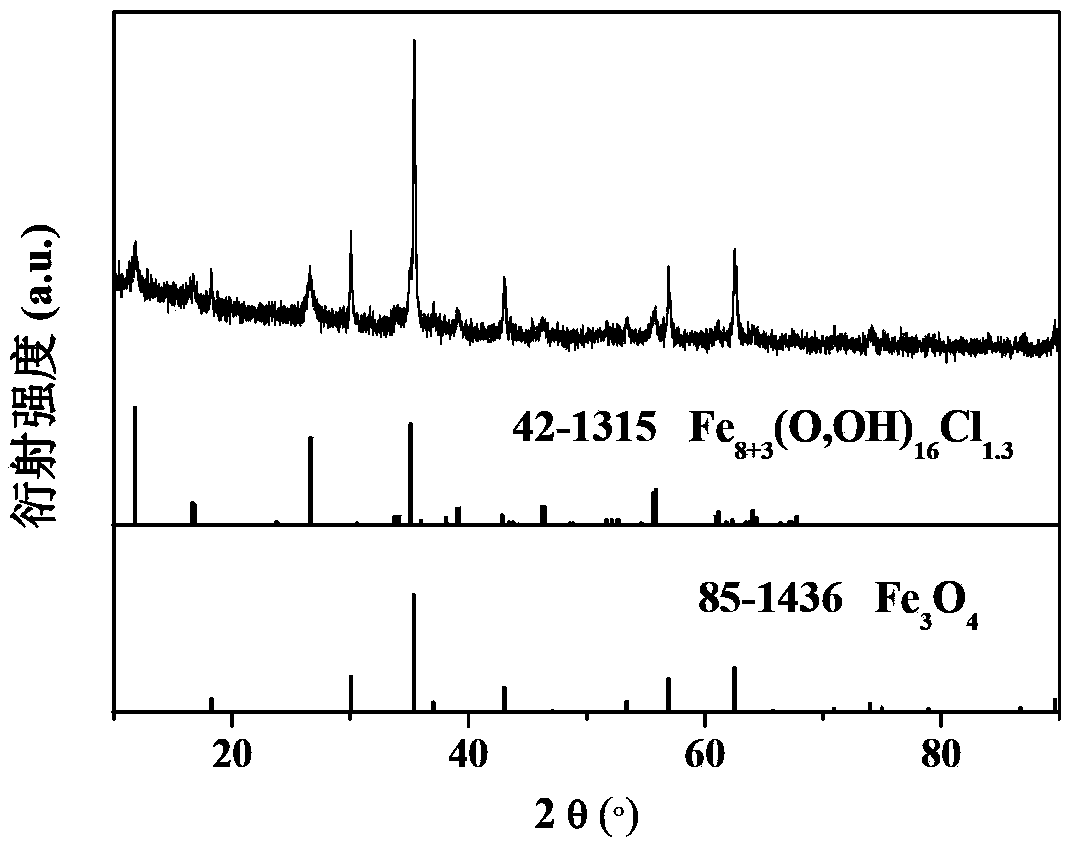

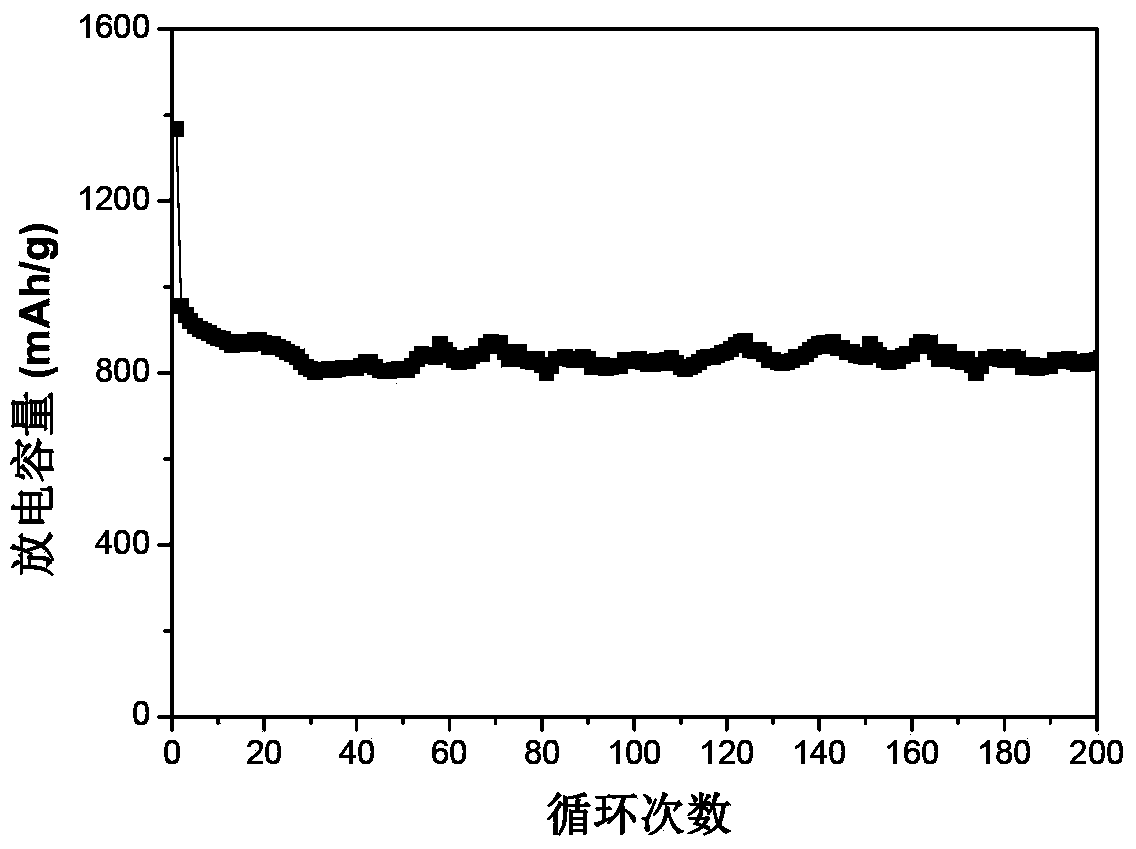

Iron oxide/carbon composite lithium ion battery anode material as well as preparation method and application thereof

ActiveCN103435105ALow priceSimple methodIron oxides/hydroxidesCell electrodesCarbon compositesIron salts

The invention relates to a preparation method for iron oxide / carbon composite material. The preparation method comprises the steps as follows: 1, taking a water-soluble iron salt as an iron source, taking a water-soluble organic carbon source as a carbon source, and uniformly mixing the iron salt water solution, ammonia water with the organic carbon source to form a liquid phase mixture; 2, performing spray drying, freeze drying or spray pyrolysis on the liquid phase mixture to form a powder precursor, and performing calcination on the precursor to prepare into the iron oxide / carbon composite material; or performing spray pyrolysis on the mixed solution directly to prepare into the iron oxide / carbon composite material. The preparation method for the iron oxide / carbon composite material, which is provided by the invention, is high in production efficiency and suitable for large-scale production; the utilization efficiency of the composite material is improved; the iron oxide / carbon composite material provided by the invention is taken as the anode material of a lithium ion battery, so that the lithium storage capacity of the anode material of the lithium ion battery is several times as much as that of commercial carbon anode material.

Owner:宇恒电池股份有限公司 +1

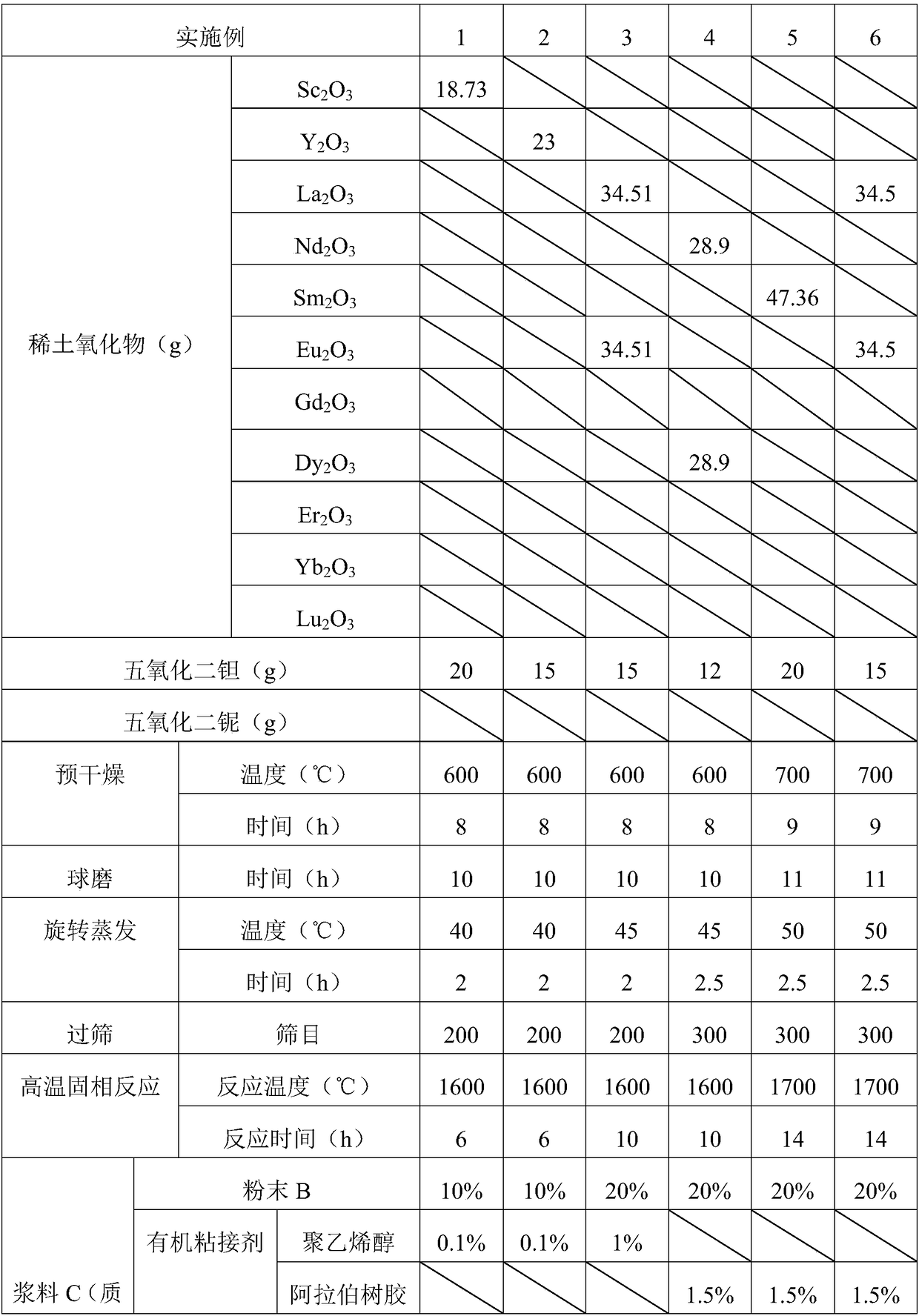

RE3Ta/NbO7 (Rare-Earth Tantalite/Niobate) ceramic powder and preparation method thereof

The invention relates to the technical field of ceramic powder preparation, and specifically discloses RE3Ta / NbO7 (Rare-Earth Tantalite / Niobate) ceramic powder. The preparation method comprises the following steps: carrying out ball milling on RE2O3 powder, Ta2O5 powder or Nb2O5 powder, and carrying out solid-phase reaction, thus obtaining a target phase; mixing the target phase with an organic adhesive, thus forming slurry; drying by adopting a high-temperature spray pyrolysis method, thus obtaining sphere-like powdery particles; sintering, thus obtaining the RE3Ta / NbO7 ceramic powder. A chemical general formula of the RE3Ta / NbO7 ceramic powder is RE3TaO7 / RE3NbO7. A crystal structure of the RE3Ta / NbO7 ceramic powder is an orthorhombic phase, the space group of a crystal lattice is C2221,the particle diameter is 10 to 50 mum, and the RE3Ta / NbO7 ceramic powder is spherical. By adopting the technical scheme disclosed by the invention, the RE3Ta / NbO7 ceramic powder which can meet APS (Atmospheric Plasma Spraying) technical requirements can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

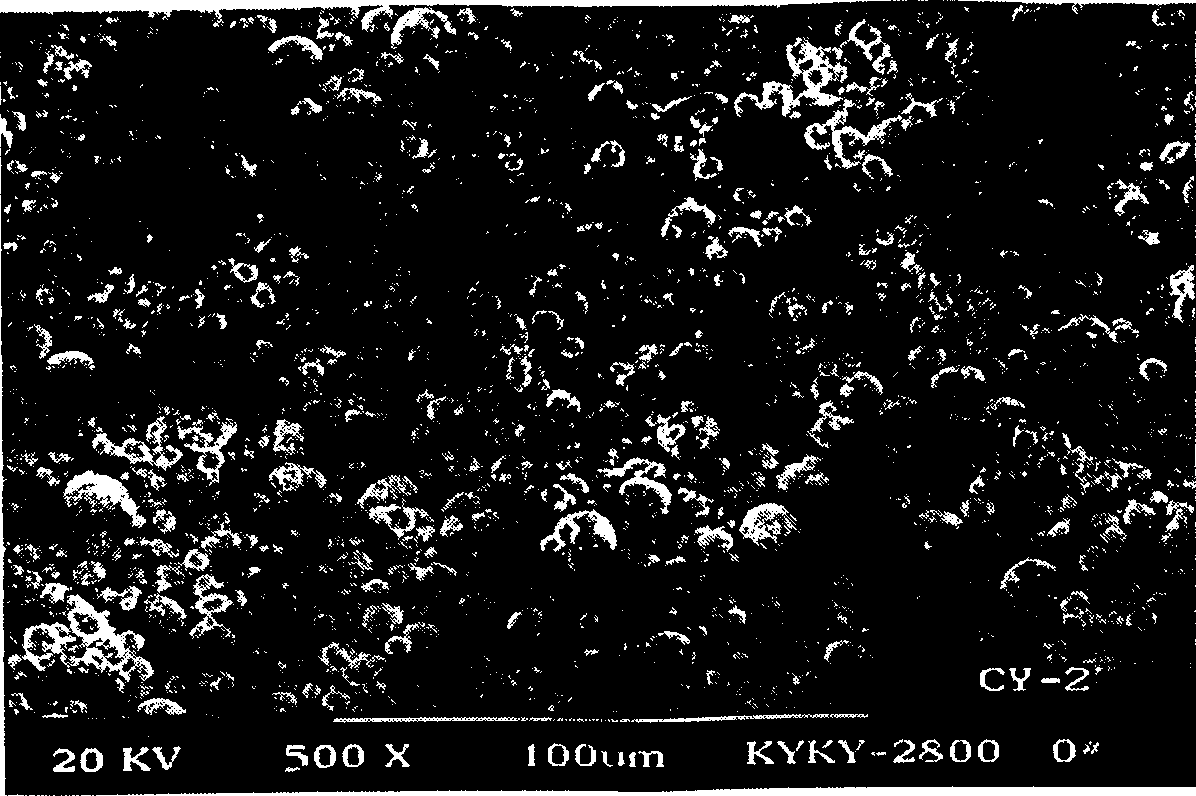

Plasma spraying pyrolyzing process of preparing nanometer hollow oxide microsphere powder

The plasma spraying and pyrolyzing process of preparing nanometer hollow microsphere powder of nanometer crystalline oxide includes preparing precursor solution, atomizing, plasma spraying and pyrolyzing in plasma flame to form solid molten drop, and cooling in liquid to solidify form the hollow spherical nanometer crystal structure. The process is simple and suitable for industrial production.

Owner:WUHAN UNIV OF TECH

Yttrium-aluminium series small crystal transparent ceramic material and preparation method

The invention relates to an yttrium-aluminum series of transparent ceramic material of small crystal and a preparation method, pertaining to the preparation of Y2O3A12O3 series of transparent ceramic. The method of the invention adopts sol gel, coprecipitation, combustion synthesis and spray pyrolysis to prepare the powder while adopts dry compression, iso-static pressing, slip casting, gel casting or electrophoretic deposition to prepare the bisque. The transparent ceramic with small crystal obtained by adopting vacuum sintering, hydrogen sintering, two-step sintering method, spark plasma sintering method and high pressure low temperature sintering method has the content of Y2O3 from 0 to 100 percent, the content of A12O3 from 100 to 0 percent, and the transparent ceramic pellet, the dimension of which is below 300 nm, thus having good transmittance performance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

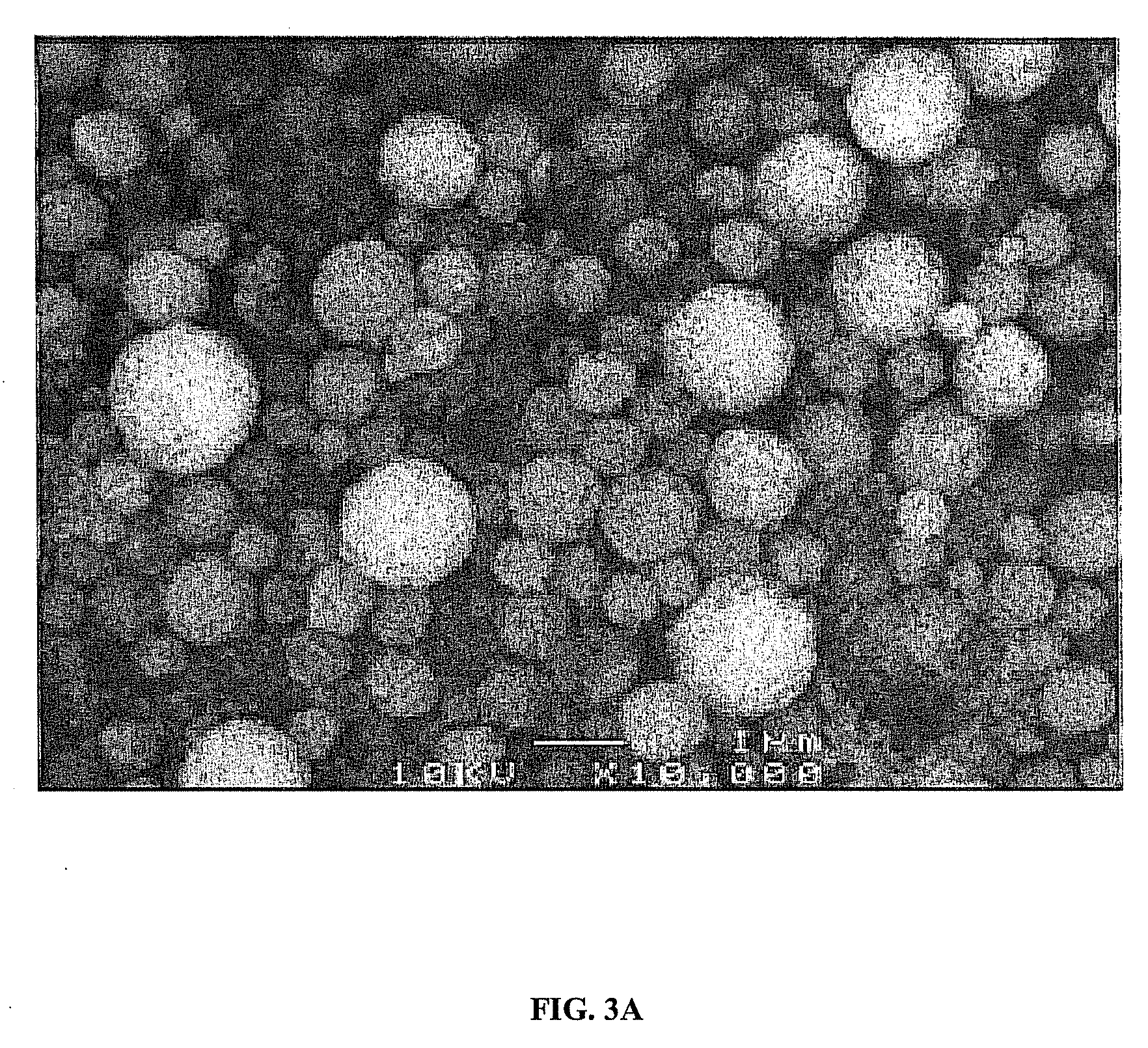

Glass powders, methods for producing glass powders and devices fabricated from same

Glass powders and methods for producing glass powders. The powders preferably have a small particle size, narrow size distribution and a spherical morphology. The method includes forming the particles by a spray pyrolysis technique. The invention also includes novel devices and products formed from the glass powders.

Owner:CABOT CORP

New preparation method of positive and negative electrode materials of lithium ion secondary cell by spraying thermal decomposition

InactiveCN1805182AWell mixedQuality improvementElectrode manufacturing processesLithium compoundsManganeseReaction temperature

The invention relates to a method for preparing the lithium secondary battery anode and cathode material with spraying pyrogenation. It mixes one or several of lithium salt, tin salt, manganese salt, titanium salt or other transition salt as Co, Ni, Mn, V, Ti, Al, and Mg in pure water, alcohol or organic solution, and via the spraying pyrogenation to prepare the anode and cathode material while the pyrogenation furnace reaction temperature is 400-1000Deg. C and the time of particle in the furnace is 4-12s.The invention can prepare the lithium anode and cathode material in different systems in one device by adjusting the processing parameters with better granularity, single shape, uniform distributed components and high vibration density. The invention has simple process, lower cost, continuous process, high yield, high quality and the application for industry production.

Owner:HUNAN RESHINE NEW MATERIAL

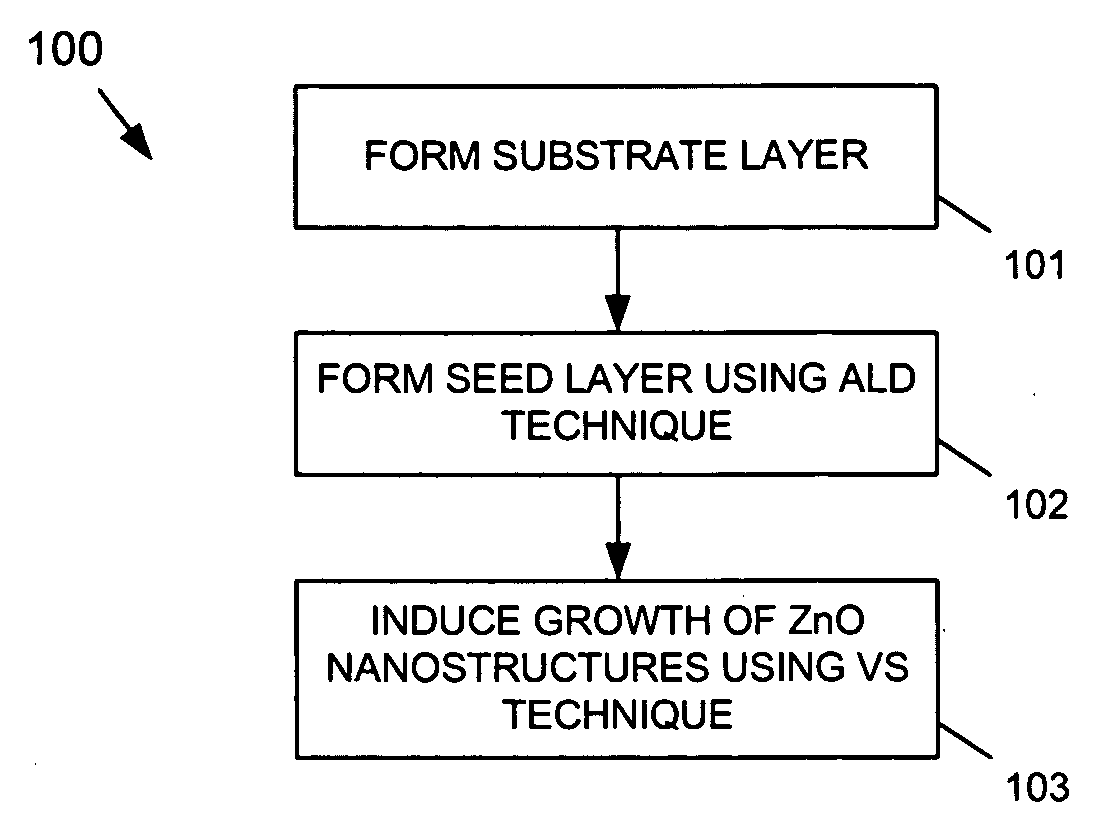

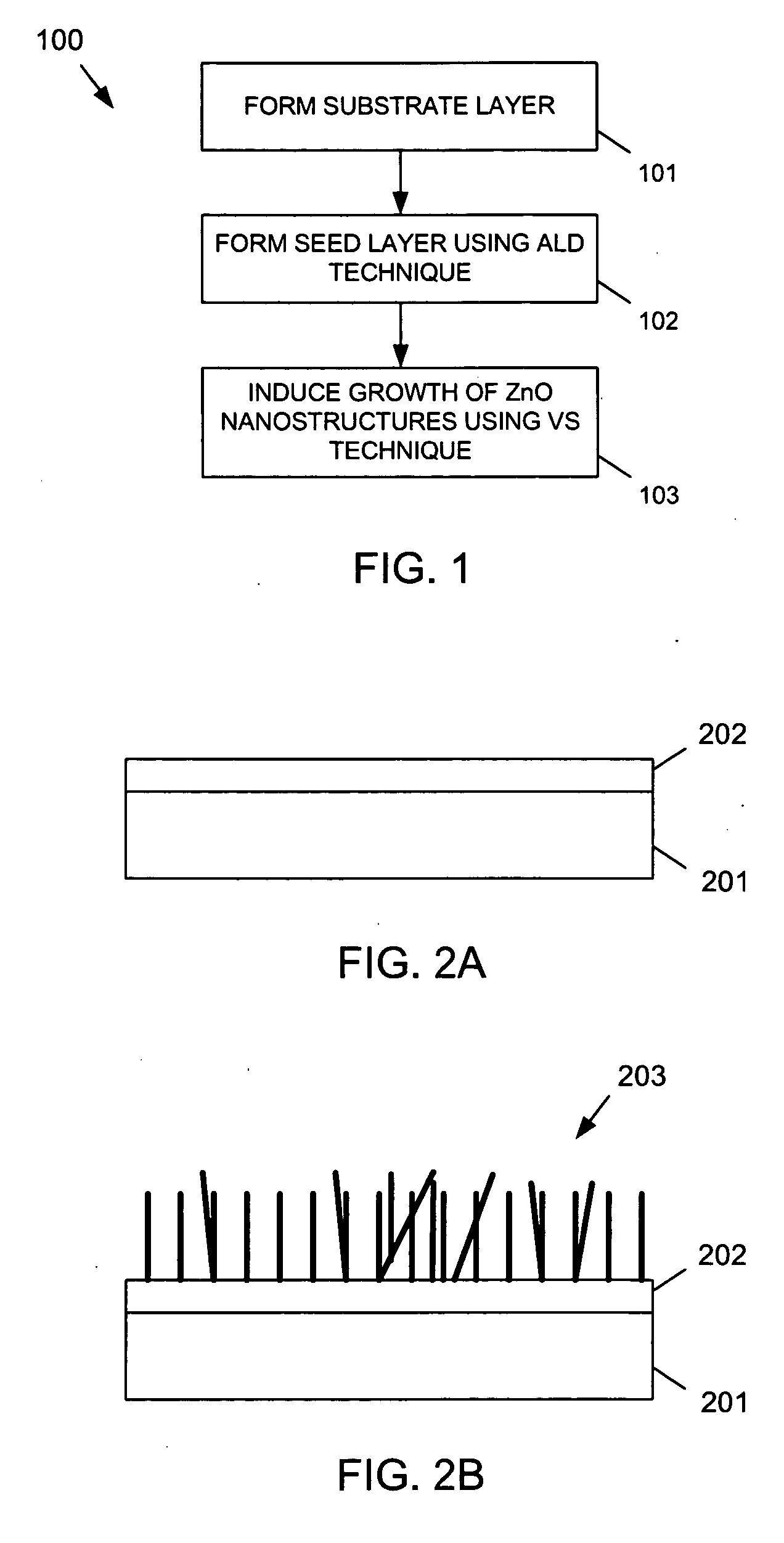

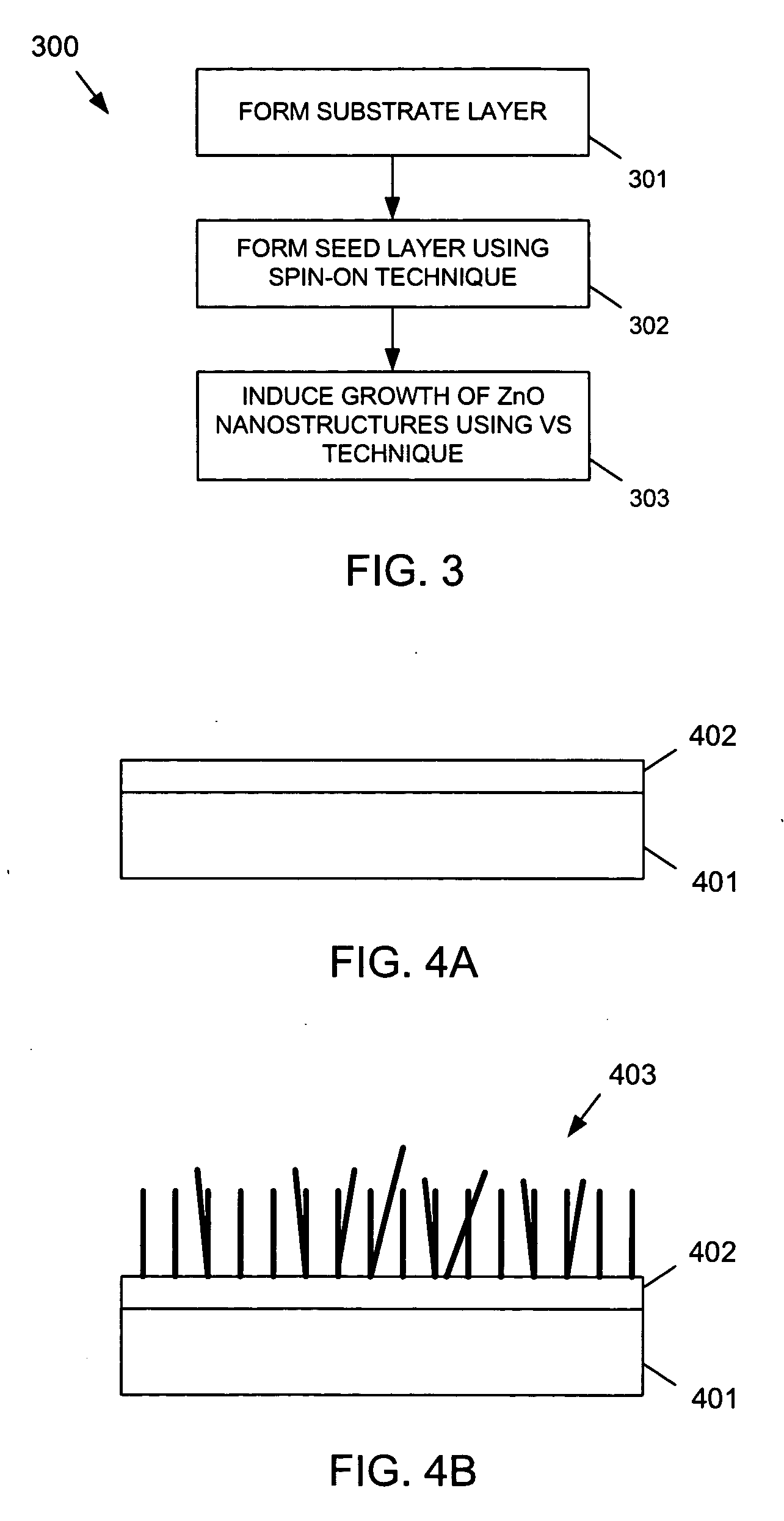

ALD ZnO seed layer for deposition of ZnO nanostructures on a silicon substrate

InactiveUS20060091499A1Polycrystalline material growthSemiconductor/solid-state device manufacturingMetal catalystSpray pyrolysis

Zinc-oxide nanostructures are grown without using a metal catalyst by forming a seed layer of polycrystalline zinc oxide on a surface of a substrate. The seed layer can be formed by an atomic layer deposition technique. Growth of at least one zinc-oxide nanostructure is induced on the seed layer. The seed layer can alternatively be formed by using a spin-on technique, such as a metal organic deposition technique, a spray pyrolisis technique, an RF sputtering technique or by oxidation of the seed layer.

Owner:SHARP KK

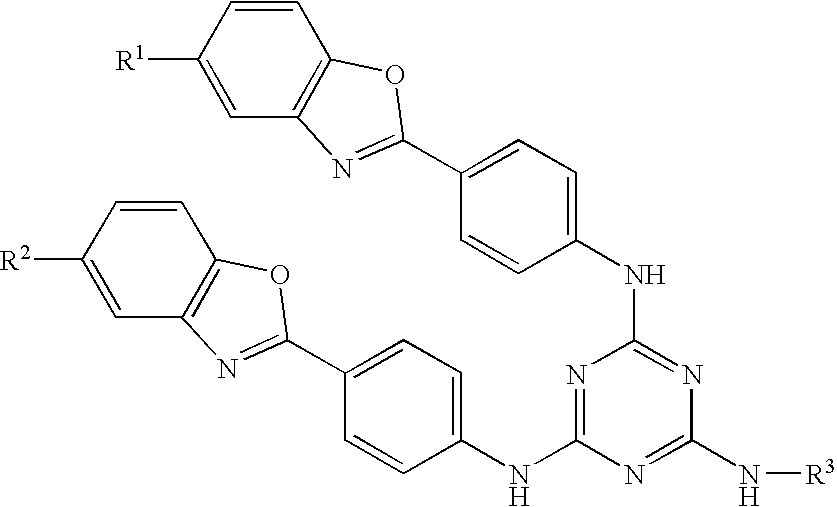

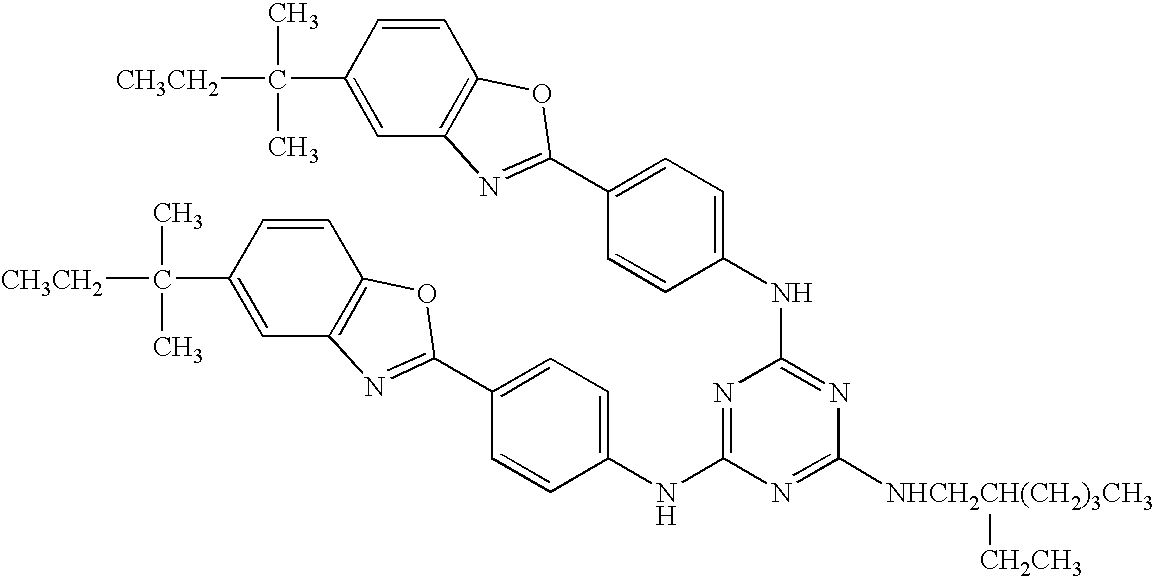

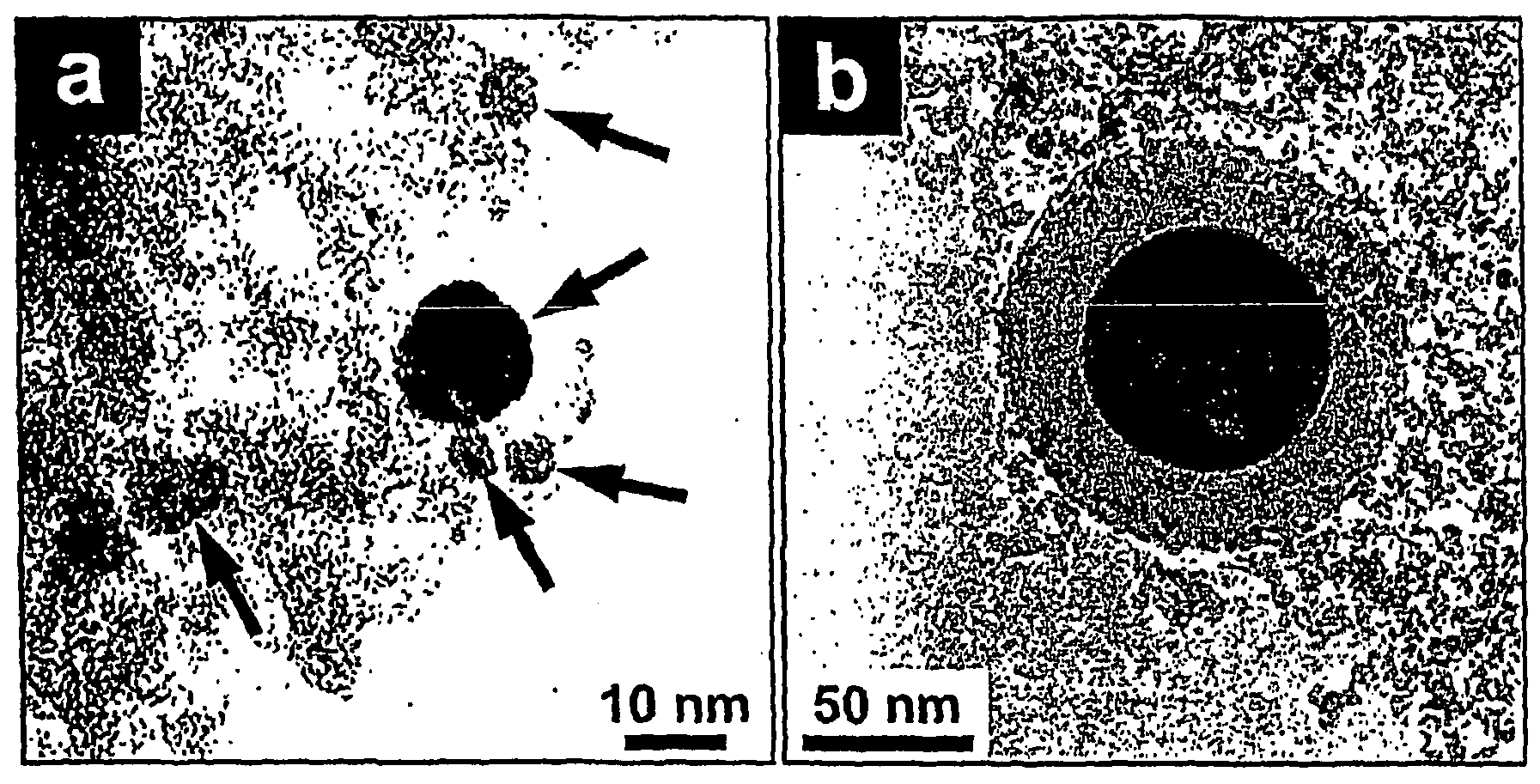

Antimicrobial and Antifungal Powders Made by Flame Spray Pyrolysis

A flame spray pyrolysis method for producing a doped silica(SiO2) having antimicrobial and / or antibacterial and / or antifungal effect and being in the form of particles is disclosed. Said flame made doped silica comprises at least one functional dopant consisting of at least one antimicrobial and / or antibacterial and / or antifungal acting metal and / or metal-oxide, and is produced starting from a precursor solution comprising at least one functional dopant precursor, in particular a silver and / or copper comprising precursor, and at least one silica precursor in an organic solvent. Such doped silica is suitable for being incorporated within e.g. polymeric materials or for being used as impregnating material.

Owner:ETH ZZURICH

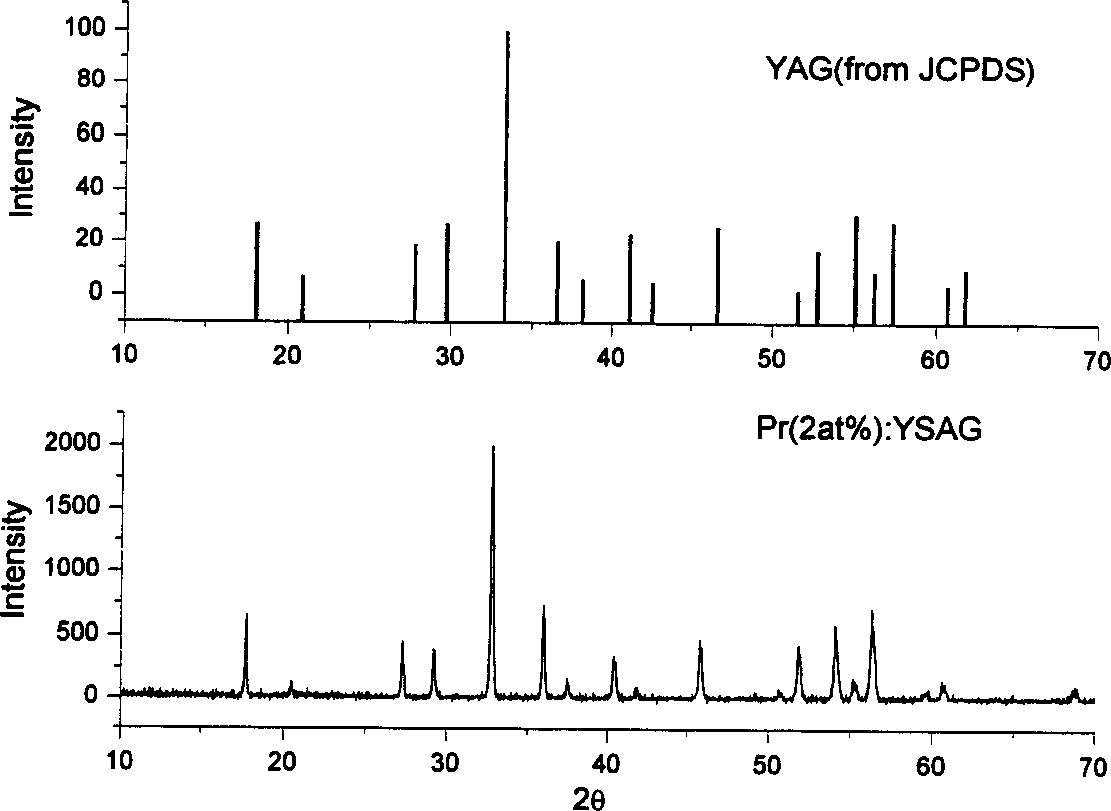

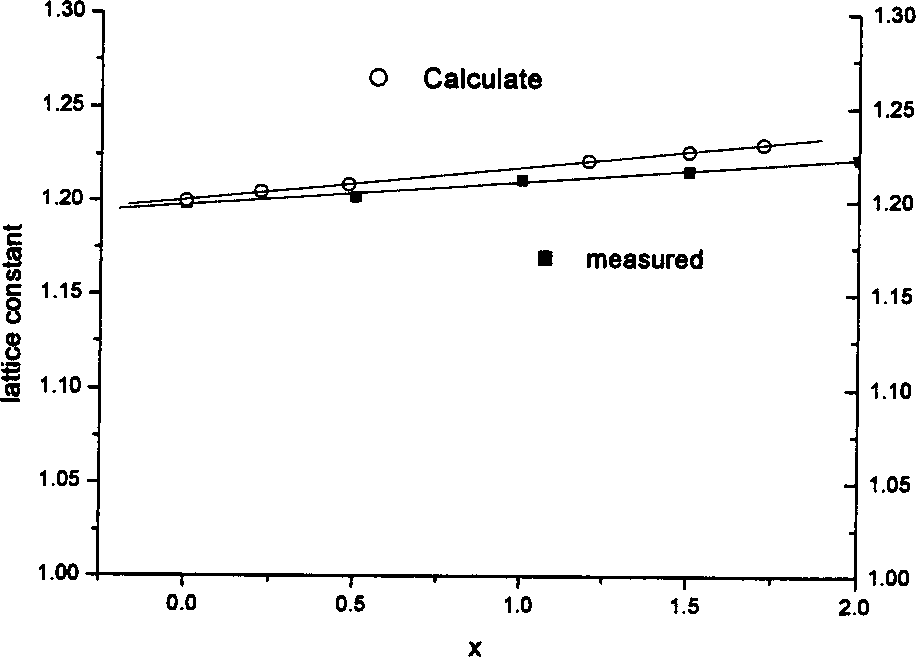

Process for preparing mixed garnet base ceramic material

The preparation process of mixed garnet base ceramic material belongs to the field of light emitting ceramic material technology. The present invention selects relatively large ion to replace Al ion or Y ion so as to expand lattice constant and raising dopping concentration. The preparation process includes compounding powder in the required components, solid reaction or co-precipitation, combustion synthesis or spraying pyrolysis to prepare powder in the required components, and final sintering in reducing atmosphere or vacuum to obtain the polycrystalline mixed transparent garnet base ceramic material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com