Patents

Literature

174 results about "Tantalite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The mineral group tantalite [(Fe, Mn)Ta₂O₆] is the primary source of the chemical element tantalum. It is chemically similar to columbite, and the two are often grouped together as a semi-singular mineral called coltan or "columbite-tantalite" in many mineral guides. However, tantalite has a much greater specific gravity than columbite (8.0+ compared to columbite's 5.2). Iron-rich tantalite is the mineral tantalite-(Fe) or ferrotantalite and manganese-rich is tantalite-(Mn) or manganotantalite.

Niobate or tantalite fluorescent material used for white light LED and preparation method thereof

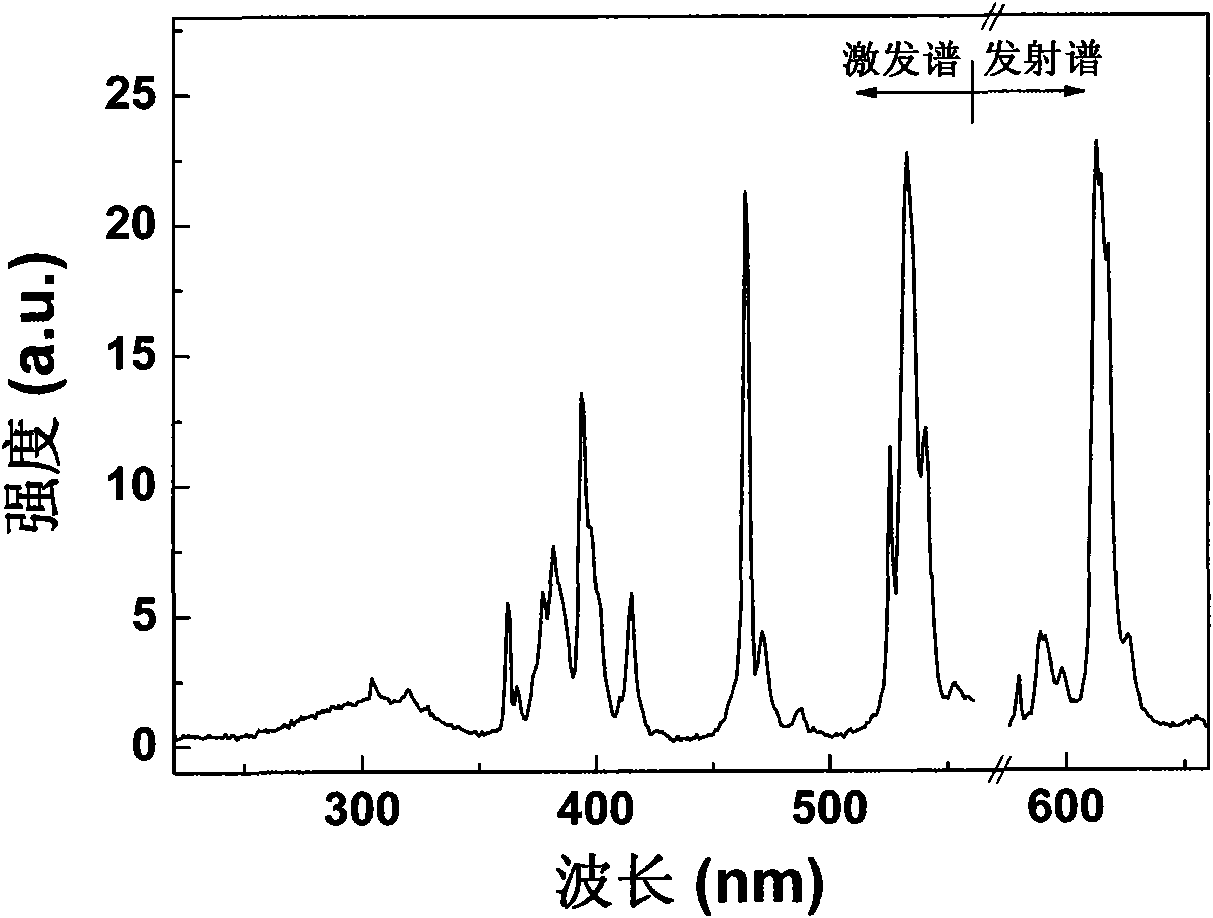

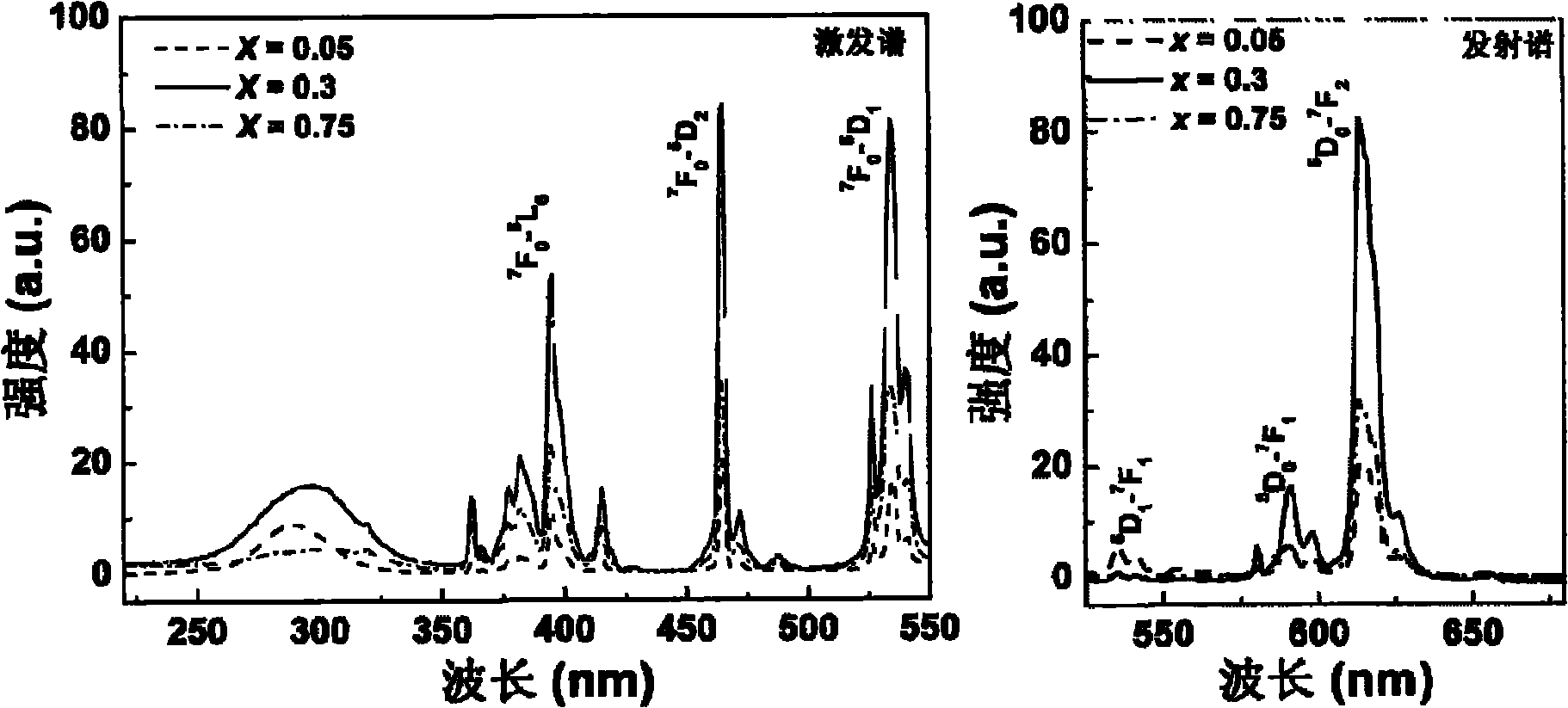

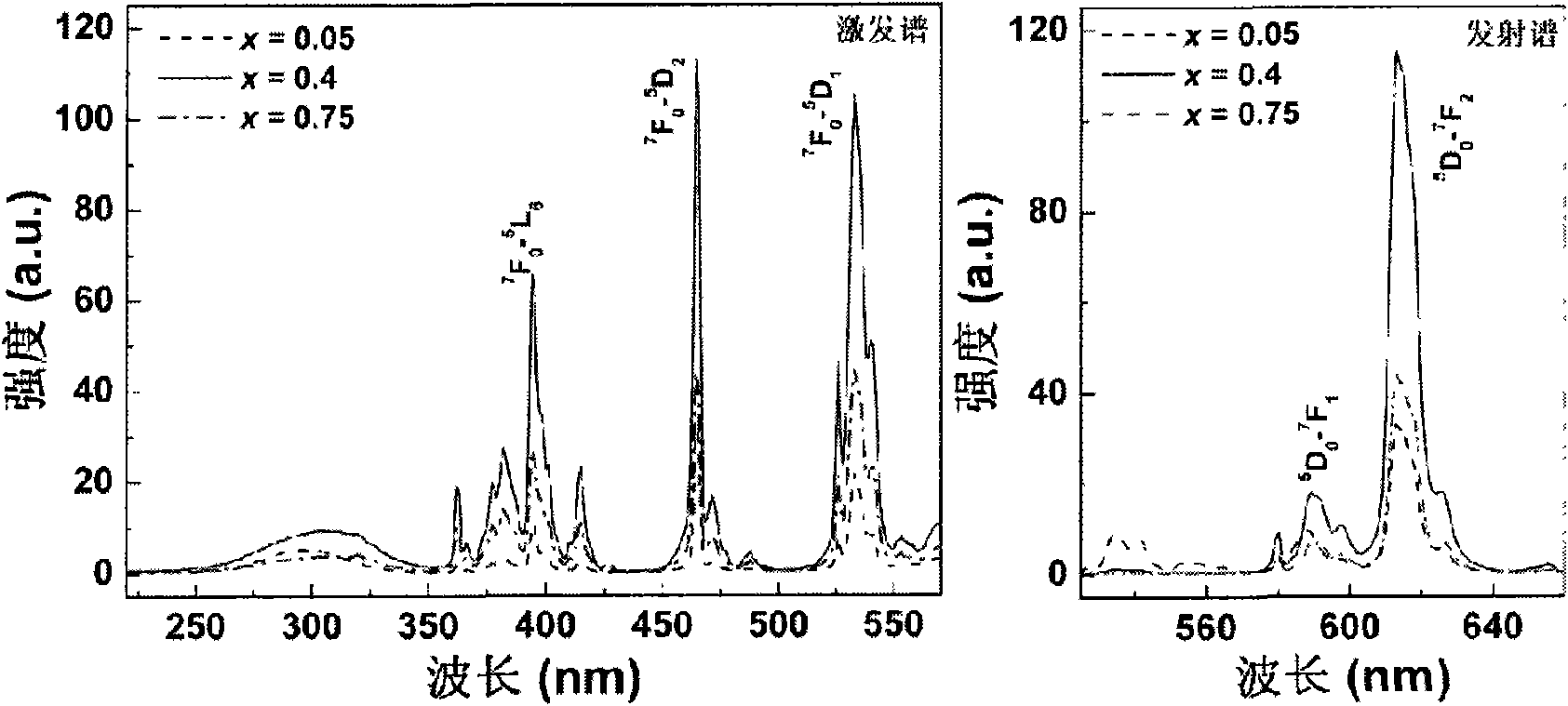

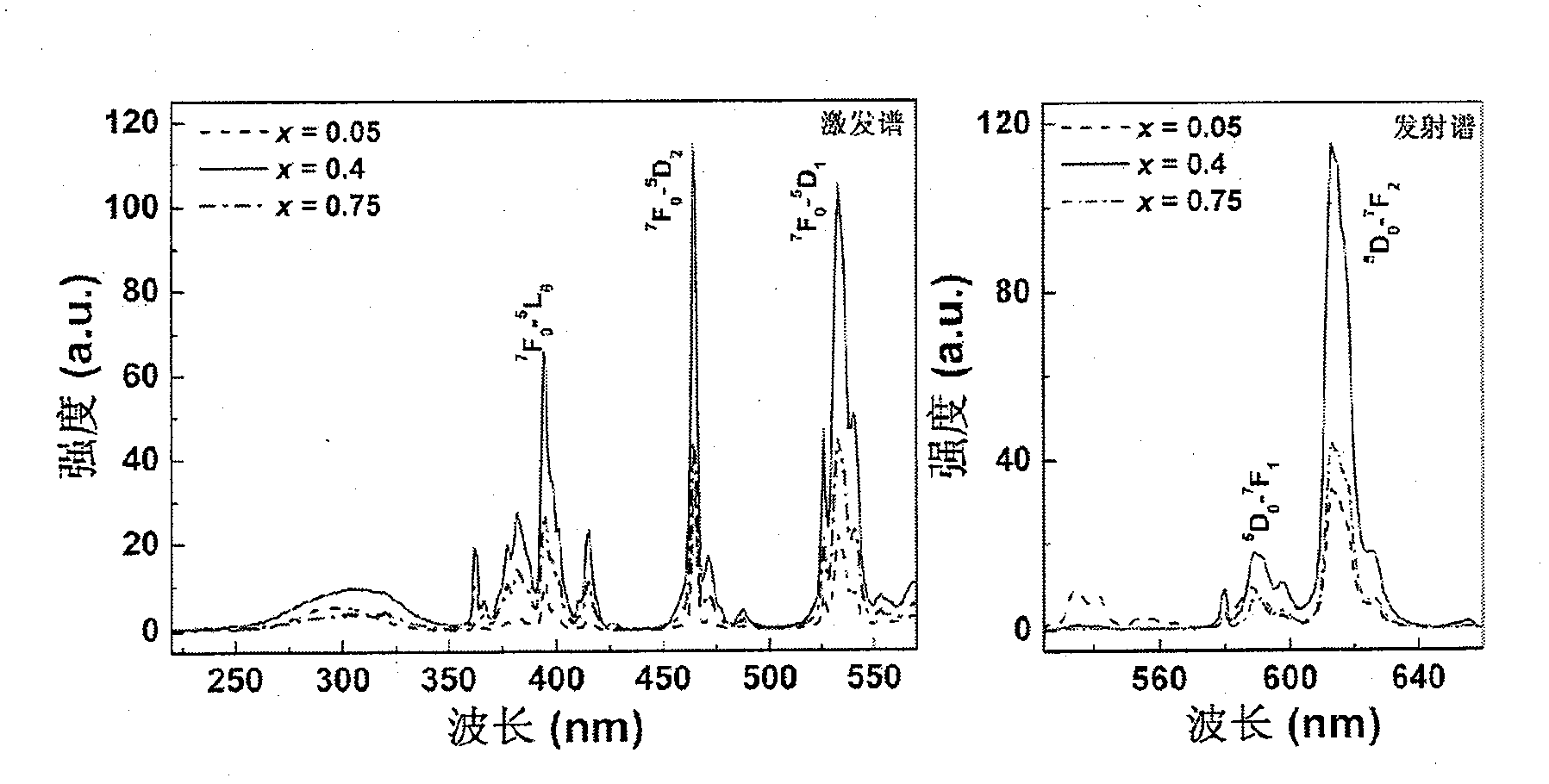

InactiveCN101921589AVariable crystal structureAdjustable Crystal Field StrengthGas discharge lamp usageLuminescent compositionsRare-earth elementEffect light

The invention relates to a niobate or tantalite fluorescent material used for a white light LED and a preparation method thereof. The material comprises the following components: non-doped niobate or tantalite, transition metal doped niobate or tantalite, T1 like ion doped niobate or tantalite with an s2 configuration, rare-earth element doped niobate or tantalite and T1 like ion and rear earth codoped niobate or tantalite. The materials in the invention can be used for the white light LED and related display and lighting devices. The invention has cheap and easy available materials, simple preparation process, stable material chemical property and excellent luminescence performance, and the prepared niobate or tantalite flourescent material is an ideal fluorescent powder candidate material for the white light LED.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

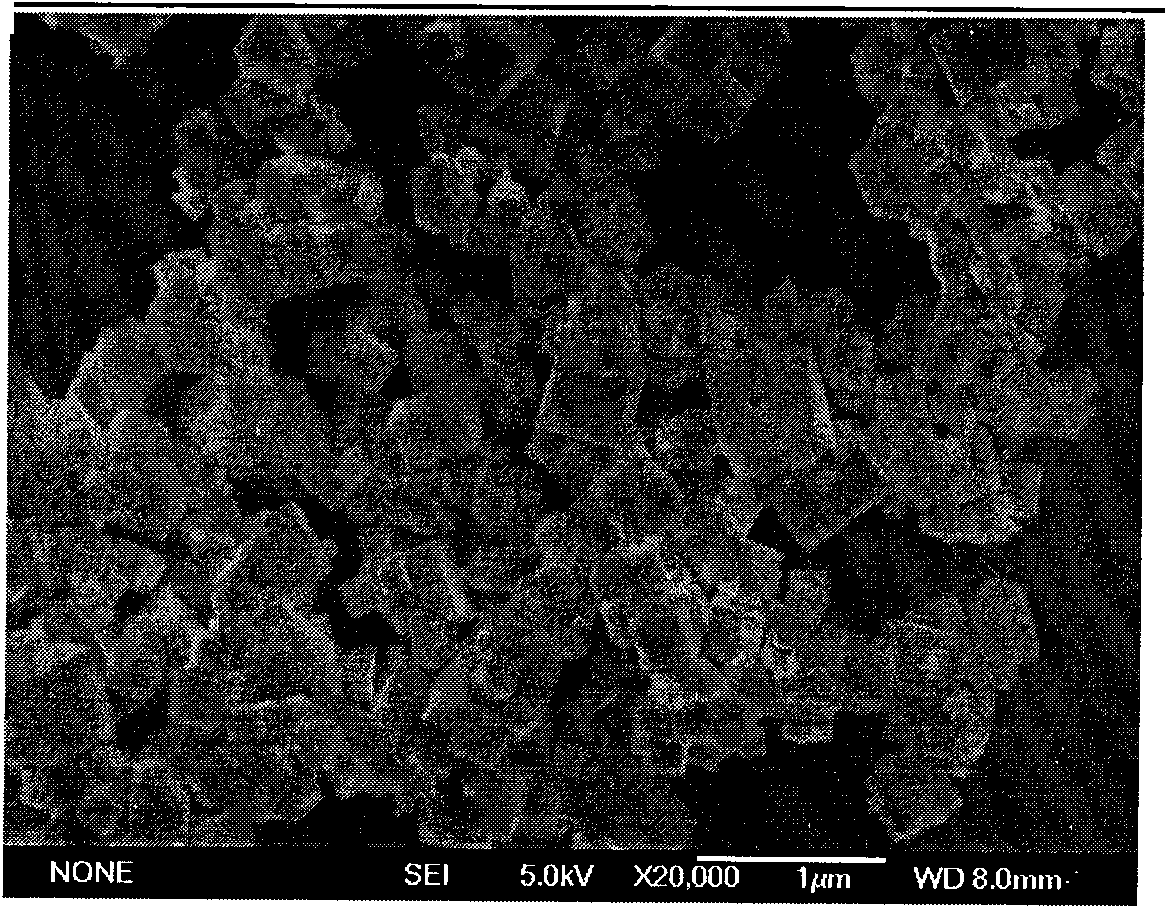

Preparation method of high specific surface area tantalum powder and/or niobium powder

A tantalum powder and / or a niobium powder with high specific surface area are prepared through reaction between the oxides one of tantalum and / or niobium, alkali metal and halide of at least of Mg, Ca, Sr, Ba and Ce. Its advantages are simple preparing process, and high specific surface area, purity and flowability, and thus it is especially suitable for making the anode of capacitor.

Owner:NINGXIA ORIENT TANTALUM IND

Electrochromic lithium nickel group 5 mixed metal oxides

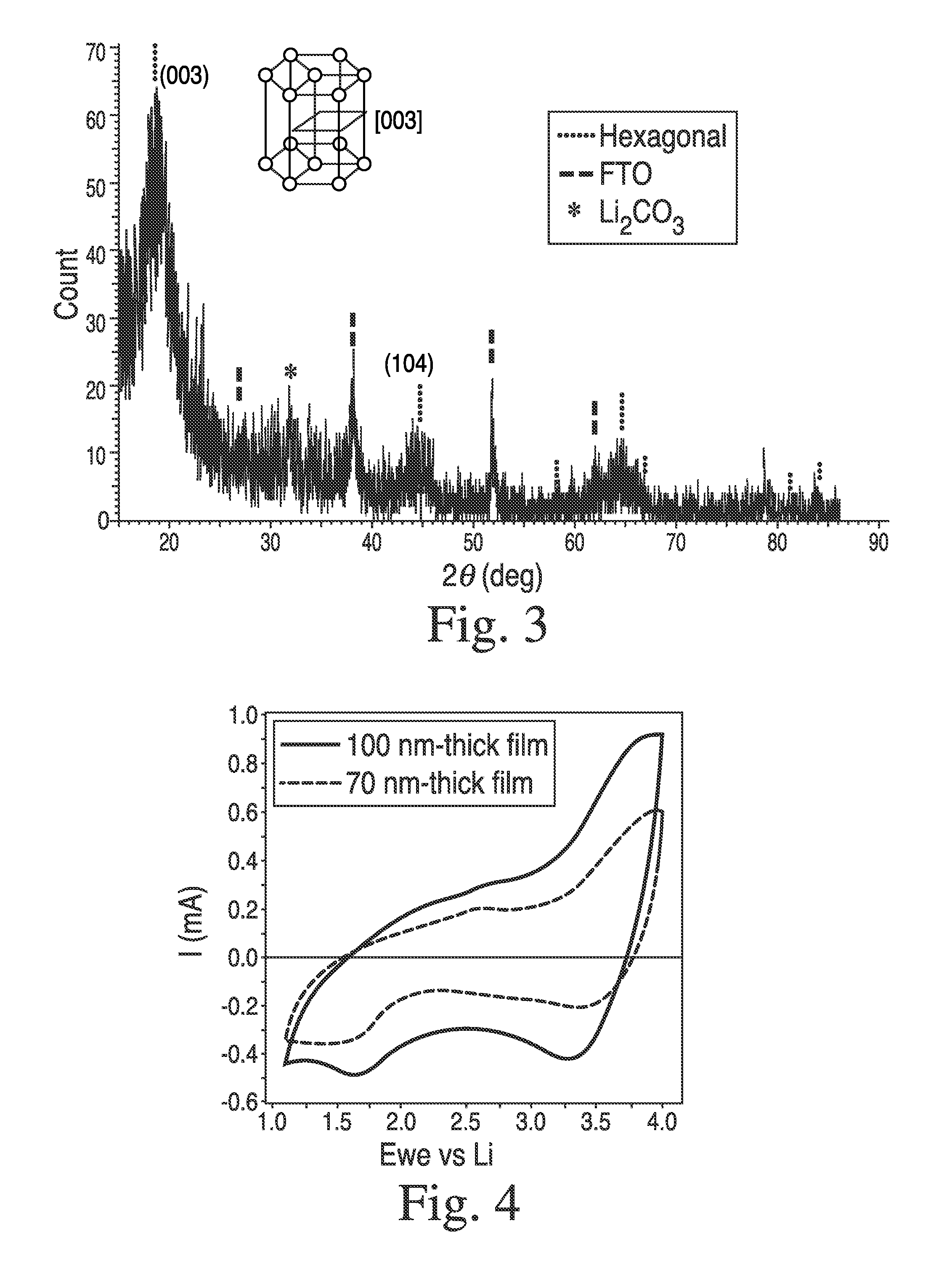

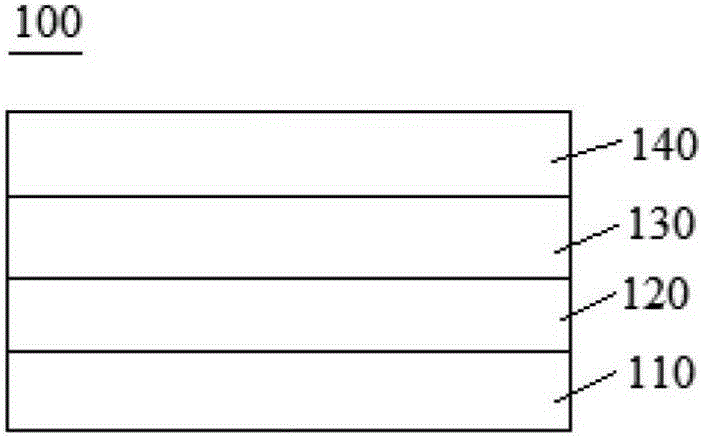

Multi-layer electrochromic structures comprising an anodic electrochromic layer comprising a lithium nickel oxide composition on a first substrate, the anodic electrochromic layer comprising lithium, nickel and a Group 5 metal selected from niobium, tantalum and a combination thereof, wherein (i) the atomic ratio of lithium to the combined amount of nickel, niobium and tantalum in the anodic electrochromic layer is at least 0.4:1, respectively, (ii) the atomic ratio of the combined amount of niobium and tantalum to the combined amount of nickel, niobium and tantalum in the anodic electrochromic layer is at least about 0.025:1, respectively, and (iii) the anodic electrochromic layer exhibits an interplanar distance (d-spacing) of at least 2.5 Å as measured by X-ray diffraction (XRD), comprises at least 0.05 wt. % carbon, and / or has a coloration efficiency absolute value of at least 19 cm2 / C.

Owner:KINESTRAL TECH

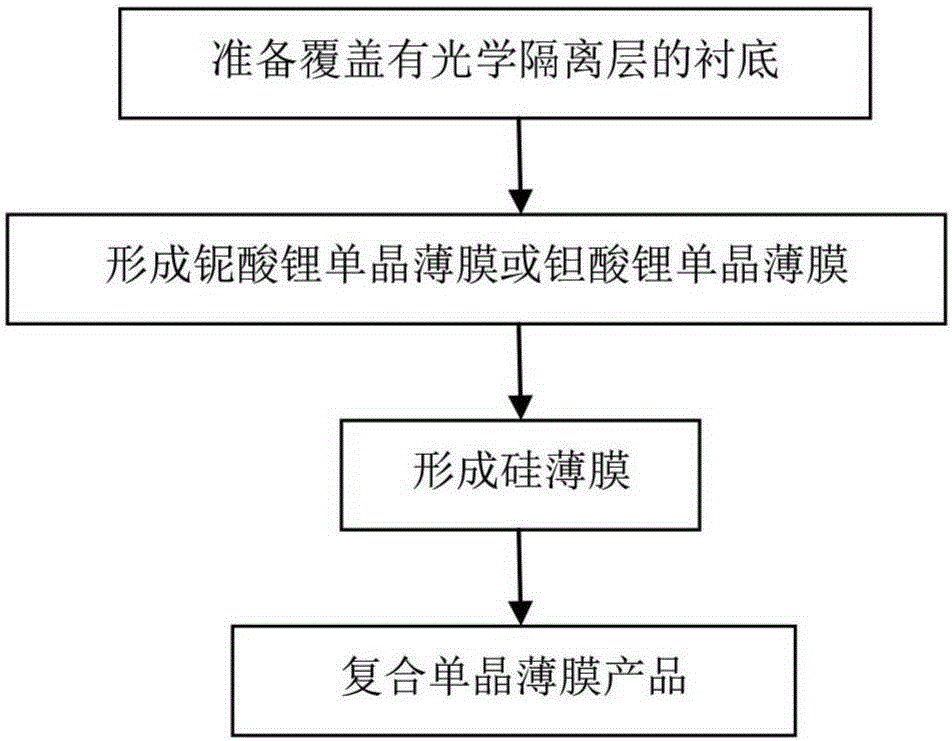

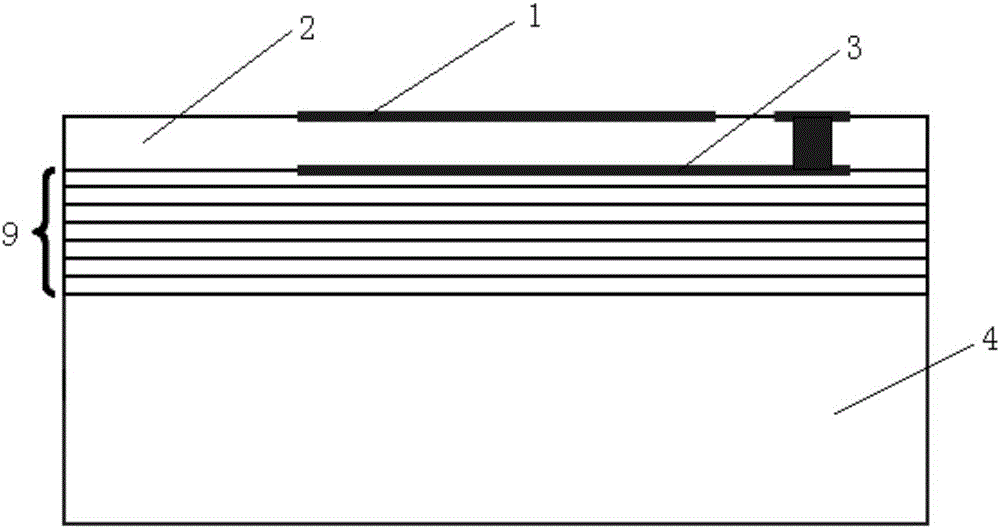

Composite single crystal thin film and method for manufacturing composite single crystal thin film

InactiveCN105321806APerfectly compatibleGood nonlinear opticsFinal product manufactureSemiconductor/solid-state device manufacturingIsolation layerSingle crystal

The invention discloses a composite single crystal thin film and a method for manufacturing the composite single crystal thin film. The composite single crystal thin film comprises a substrate, an optical isolation layer, a lithium niobate single crystal thin film or a lithium tantalate single crystal thin film and a silicon thin film, wherein the optical isolation layer is located on a substrate; the lithium niobate single crystal thin film or the lithium tantalate single crystal thin film is located on the optical isolation layer; and the silicon thin film is located on the lithium niobate single crystal thin film or the lithium tantalate single crystal thin film. The composite single crystal thin film disclosed by the invention has good nonlinear optical effect, acousto-optical effect, electro-optic effect and the like of a lithium niobate or lithium tantalite material, and simultaneously has the characteristic of a mature processing technology of a silicon material, so that the composite single crystal thin film disclosed by the invention can achieve relatively good compatibility with an existing IC production technology and has a broad industrial prospect. In addition, stable and effective industrial production can be achieved according to the method for manufacturing the composite single crystal thin film disclosed by the invention.

Owner:JINAN JINGZHENG ELECTRONICS

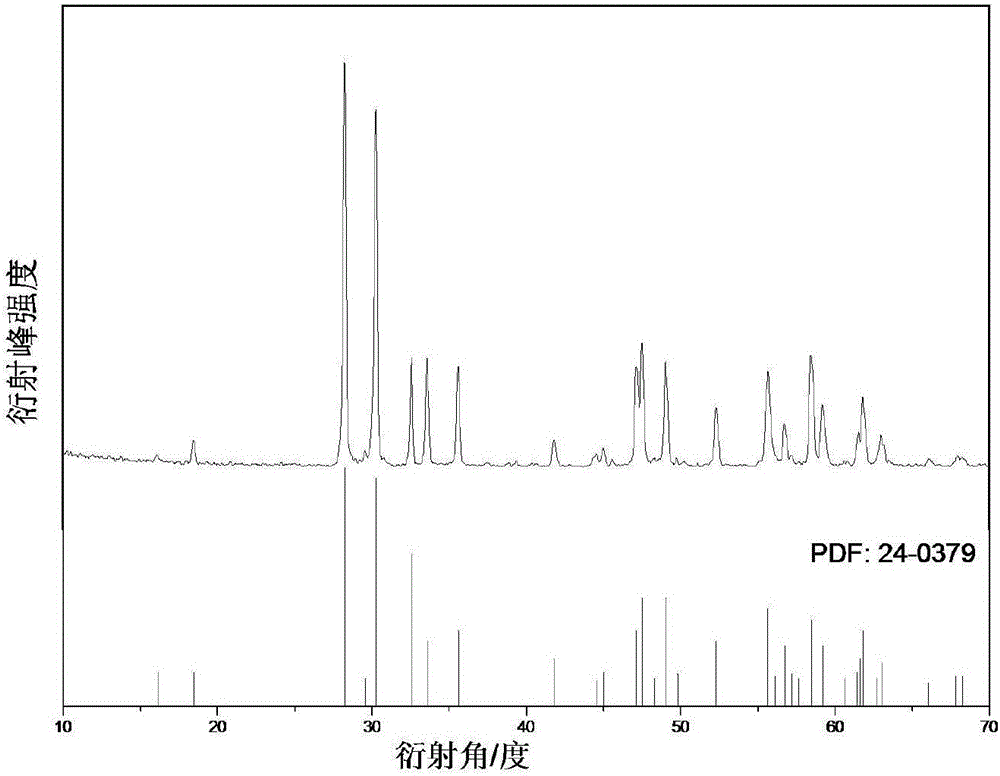

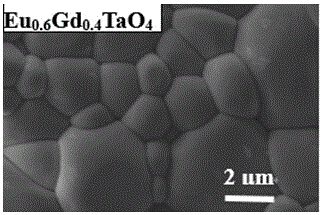

Lanthanide rare-earth tantalite high-temperature ceramic and preparation method thereof

The invention discloses a method for preparing lanthanide rare-earth tantalite ceramic through a solid phase method.The molecular formula of the compound is RETaO4 (RE=Dy, Eu, Lu, Yb, Nd, Gd and Er).The adopted raw materials are Ta2O5, Dy2O3, Eu2O3, Lu2O3, Yb2O3, Nd2O3, Gd2O3 and Er2O3.The raw materials are weighed proportionally, the weighed raw materials are mixed in absolute ethyl alcohol and then placed into a planetary ball mill for ball milling so as to be mixed to be uniform, the mixed powder is dried, screened and placed into a mold to be compacted, and then presintering is performed; cooling is performed, a presintered sample is taken out to be subjected to grinding, ball milling, drying and screening, the screened powder is placed into the mold to be compacted, and then secondary sintering is performed.The technology is high in purity, low in impurity content, low in product preparation cost and suitable for batch production, and the target product is expected to be adopted as a novel high-temperature resistant, antioxidant and anti-wearing ceramic material.

Owner:KUNMING UNIV OF SCI & TECH

Production process of 6-inch lithium niobate or lithium tantalite chips

InactiveCN103921205AIncrease profitEasy dischargePolishing machinesSemiconductor/solid-state device manufacturingHigh volume manufacturingMegasonic cleaning

The invention belongs to the technical field of tools for lithium chips and particularly relates to a production process of 6-inch lithium niobate or lithium tantalite chips. The production process includes the steps of A, cutting to obtain chips 0.6-1mm in thickness; B, charging the chips into a reduction furnace for reduction; C, after grinding, cleaning by ultrasonic; D, pasting the chips; E, grinding; F, polishing; G, cleaning, and boxing. Internal stress of the chips is removed by double corroding, electrostatic charge is removed from the chips by blackening, ultra-smooth planes are obtained by mechanical chemical polishing, TTV is smaller than 5 um, BOW is smaller than 40 um, warp is smaller than 40 um, PLTV is larger than 95%, and the production process is suitable for mass production.

Owner:DEQING JINGHUI OPTOELECTRONICS TECH

Blackening method for lithium tantalite crystal substrate

ActiveCN105463581AEasy to control resistivityUniform colorPolycrystalline material growthAfter-treatment detailsNon oxidativeReducing atmosphere

The invention discloses a blackening method for a lithium tantalite crystal substrate. According to the method, a fluoride material and the to-be-treated lithium tantalite crystal substrate are contacted sufficiently, and the lithium tantalite crystal substrate is subjected to reductive heat treatment at the temperature of 450-600 DEG C in non-oxidative reducing atmosphere for 5-24 h. The volume resistivity of the lithium tantalite crystal substrate after blackening is 10<9>-10<12> omega cm. The method has the advantages that the method is simple, reliable and easy to operate, and the obtained lithium tantalite crystal substrate has good resistivity repeatability and low cost and is applicable to batch production.

Owner:上海召业申凯电子材料有限公司

Method for processing lithium niobate or lithium tantalate wafer

ActiveCN101608342ANo depolarizationLow resistivityPolycrystalline material growthAfter-treatment detailsIron powderLithium carbonate

The invention discloses a method for processing a lithium niobate or lithium tantalate wafer, which comprises the following steps: respectively placing the lithium niobate or lithium tantalate wafer to be processed into a crucible; adding iron powder and lithium carbonate powder evenly mixed in advance according to mass proportion to completely cover the wafer; placing a corundum crucible into a thermal treatment furnace; performing thermal treatment for 3-20 hours at 450-550 DEG C under the nitrogen atmosphere with the flow rate of 0.5-1L / min to prepare a finished product of the lithium niobate or lithium tantalate wafer. The wafer resistivity is at the magnitude order of between 10 and 10, compared with the conventional non-processed wafer, the resistivity is greatly reduced, the method can effectively prepare a wafer needed for a SAW device through the thermal treatment in a short time, and increase a finished product ratio in the manufacture process of an element, therefore, the method for processing lithium niobate or lithium tantalite wafer becomes an industrialized optimizing method.

Owner:CETC DEQING HUAYING ELECTRONICS +1

Refining process for lepidolite in tantalum-niobium ore waste rocks

ActiveCN105251606ASolve the way outHigh Lithium Oxide ContentHigh gradient magnetic separatorsFlotationNiobiumIron removal

The invention relates to a refining process for lepidolite in tantalum-niobium ore waste rocks. A combined method with magnetic separation, high gradient magnetic separation, dense medium separation and flotation is adopted. The flotation adopts the process of rough flotation, dual fine flotations and sweeping. The process for refining the lepidolite from the granite-type tantalum-niobium ore waste rocks is provided. The tantalum-niobium ore waste rocks are crushed, screened, ground and subjected to high-frequency screening, spiral grading, permanent magnet magnetic separation for iron removal, high gradient magnetic separation, dense medium separation and flotation, so that lepidolite concentrates are obtained. By means of the method, the lepidolite concentrates are separated from the tantalum-niobium ore waste rocks. The lepidolite concentrates contain at least 4.5% of Li2O, at least 8.0% of K2O and Na2O and at most 0.10% of TiO2 and Fe2O3, the recovery rate of the lepidolite concentrates is larger than 80%, the qualities of the lepidolite concentrates meet the requirement of national standards, and the recovery rate of the lepidolite concentrates exceeds the industry level.

Owner:江西金辉再生资源股份有限公司

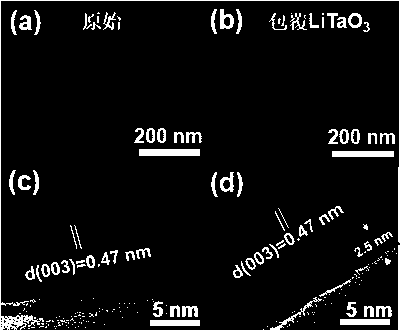

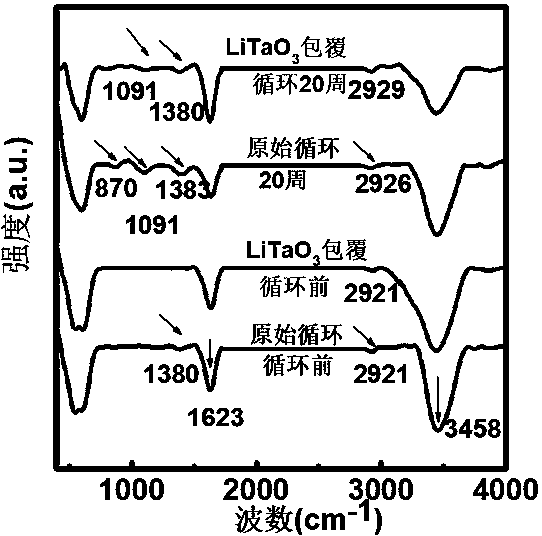

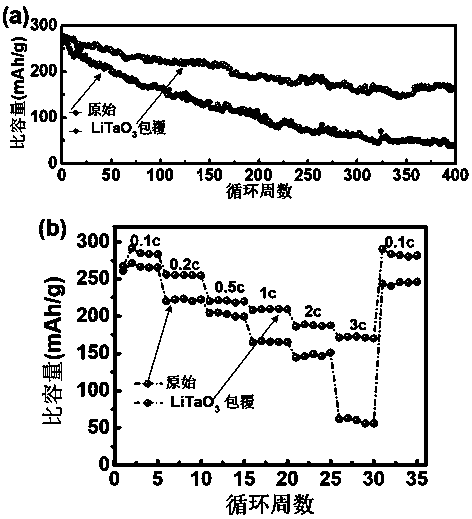

Lithium ion battery anode material coated with piezoelectric material on surface and preparation method thereof

PendingCN109921000AEasy to operateGood repeatabilityCell electrodesSecondary cellsBarium titanatePotassium

The invention provides a lithium ion battery anode material coated with piezoelectric material on the surface and a preparation method thereof. The surface of the battery anode material is coated witha layer of piezoelectric material with piezoelectric effect; the piezoelectric material comprises any one or more of barium titanate, lithium niobate, sodium niobate, lithium tantalite, sodium-potassium metaniobate and barium-strontium metaniobate with piezoelectric effect. The piezoelectric characteristic of the piezoelectric material is utilized to realize a coating modification function for the anode active materials so as to ensure that the volume phase structures of the anode active materials are not influenced and damaged, the growth of solid-electrolyte interface membranes is suppressed, and the diffusion speeds of active material-coating layer interface lithium ions are improved, thereby effectively improving the structure stability and electrochemical cycle performance of the lithium ion battery anode material, improving the pyrolysis temperature of the anode material and then enhancing the safety performance of the lithium ion batteries in the using process.

Owner:HENAN UNIVERSITY

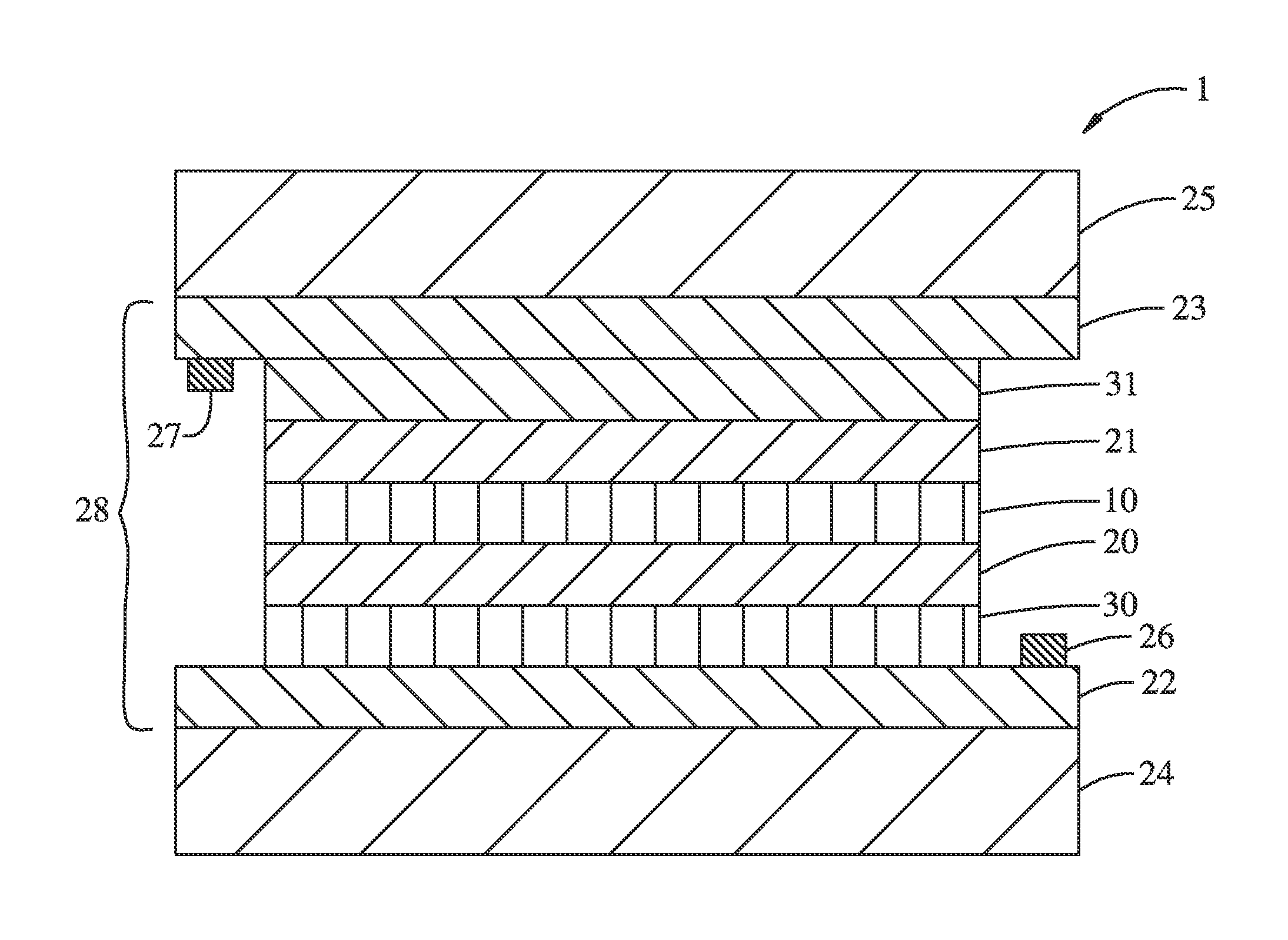

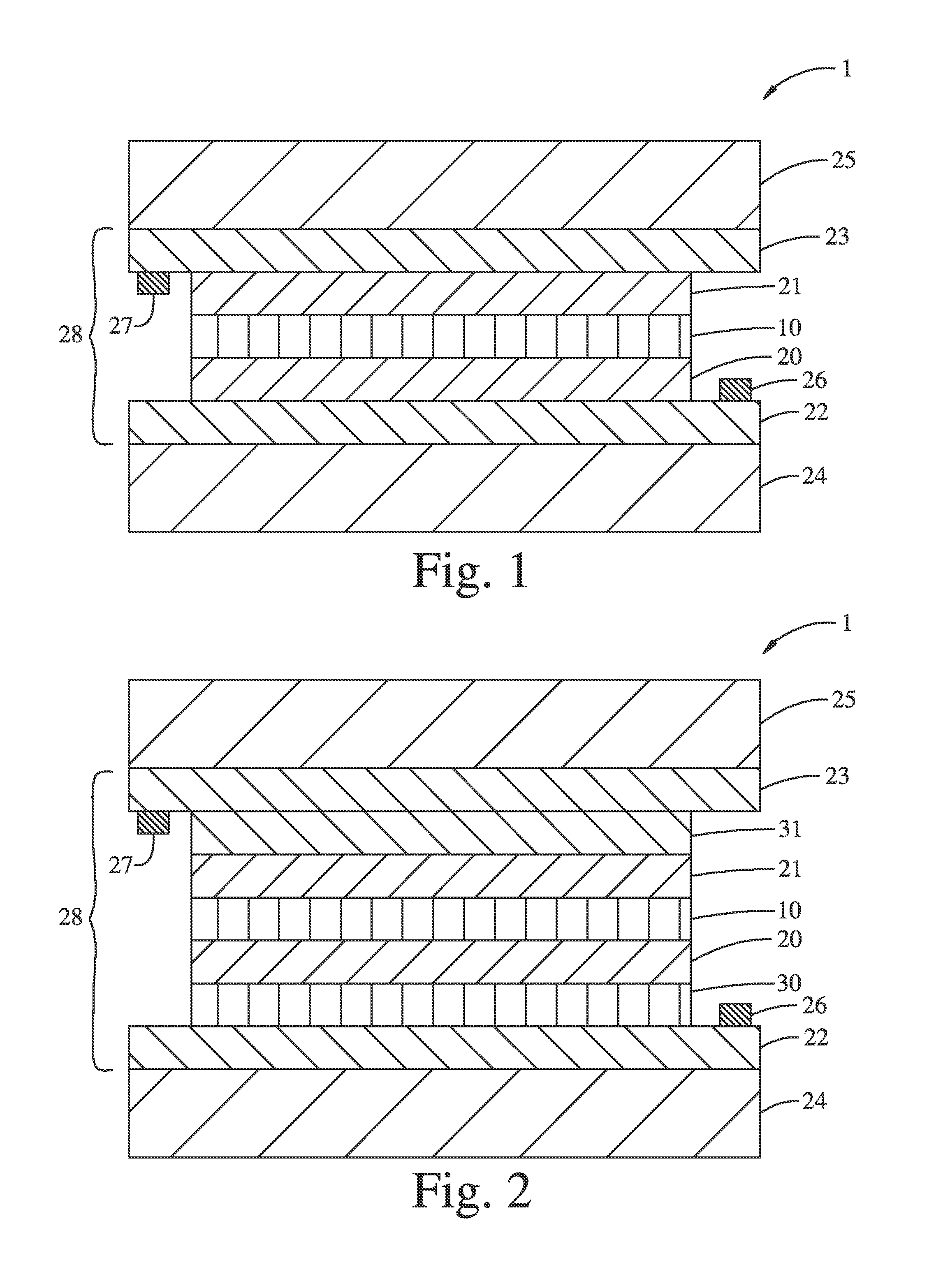

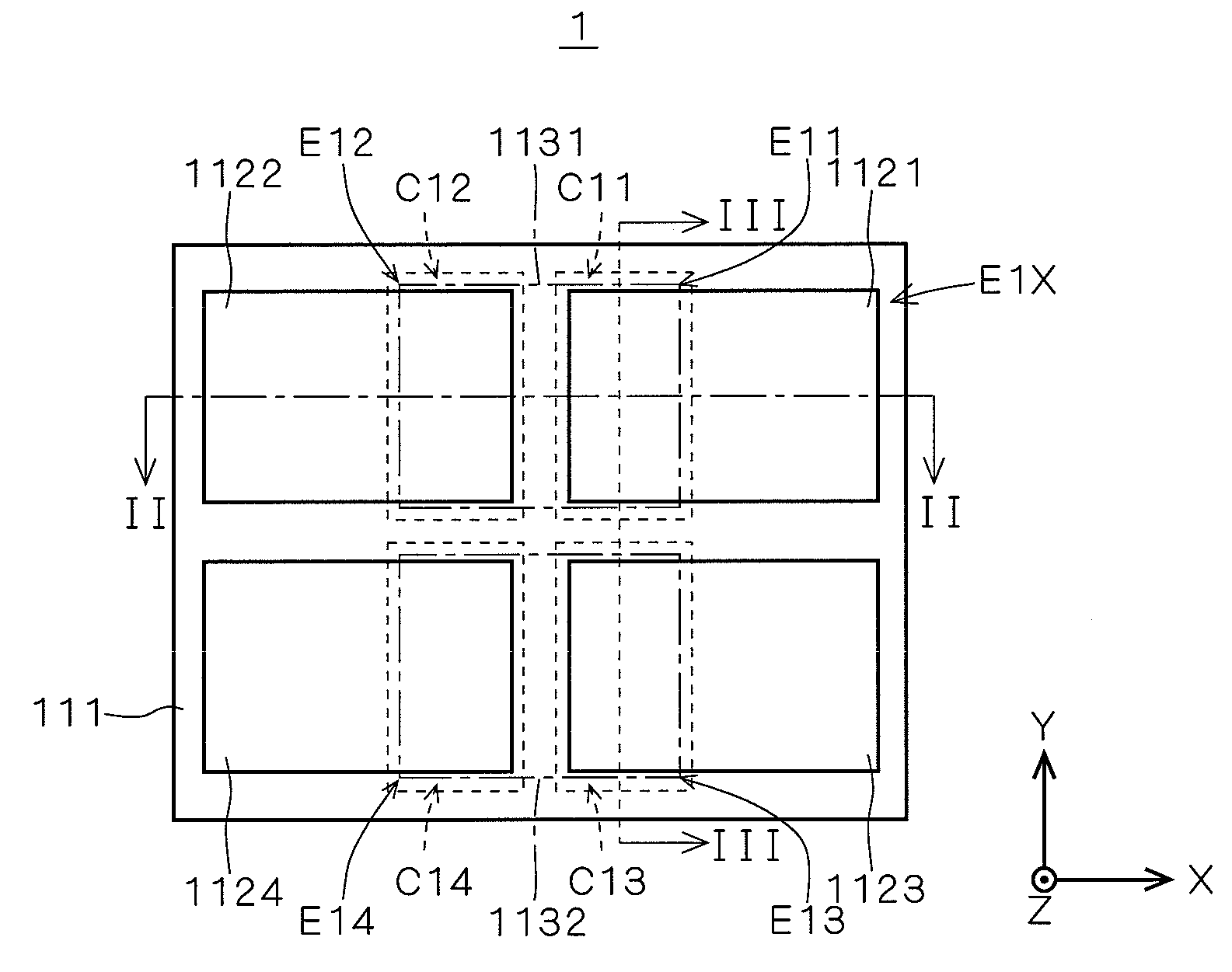

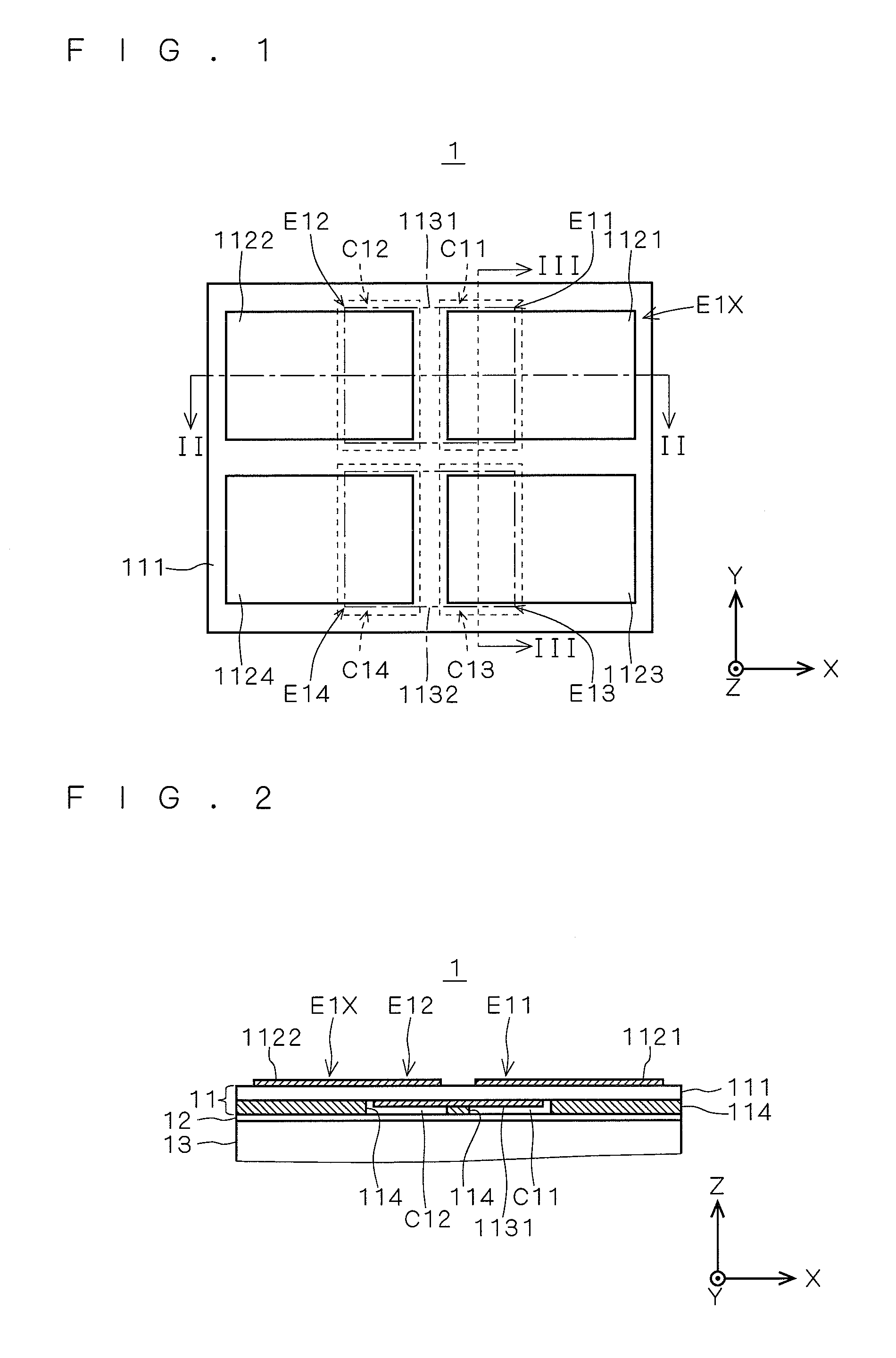

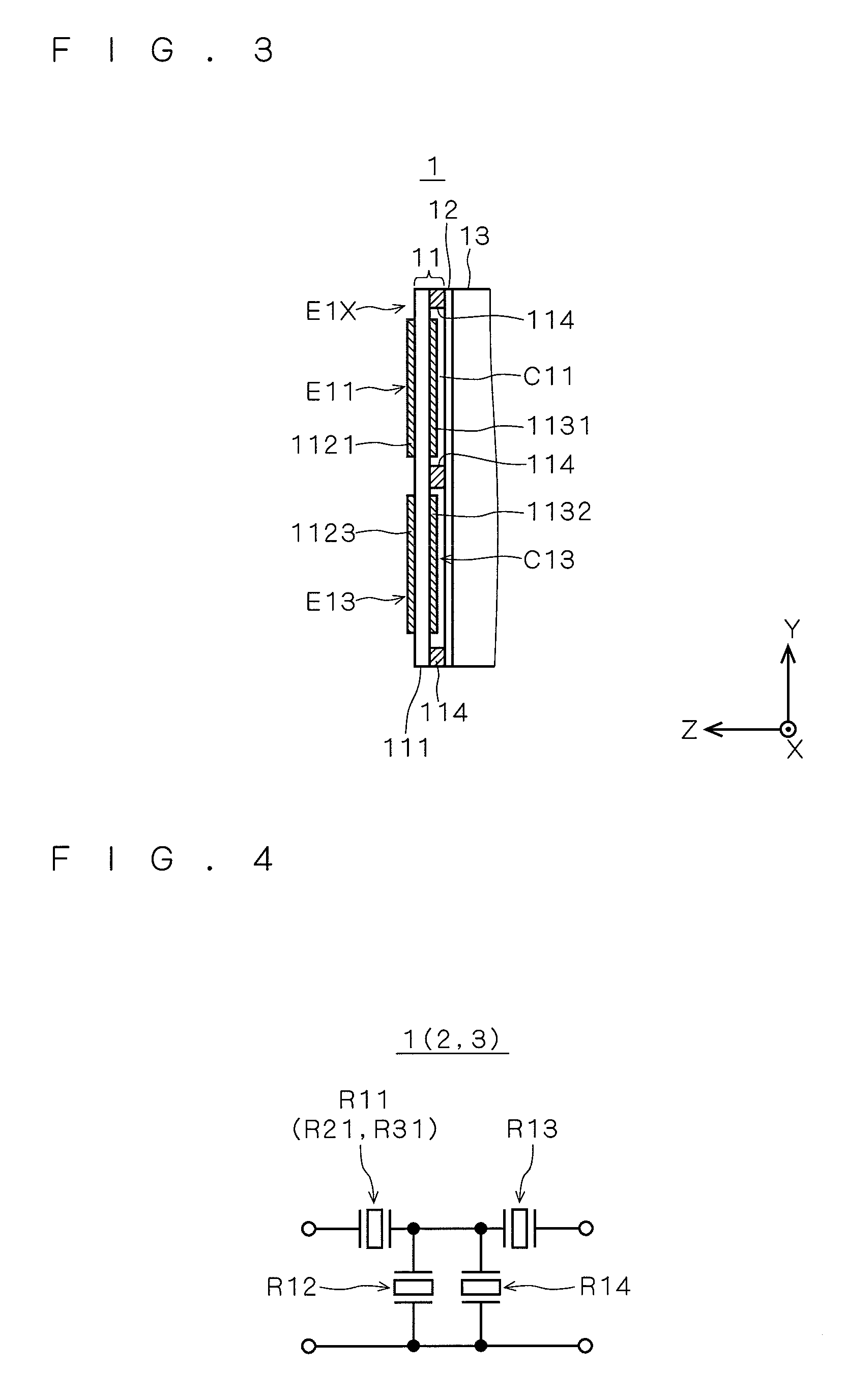

Piezoelectric thin film device

InactiveUS20070200458A1Improve featuresQuality improvementPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesSingle crystalTantalite

The present invention is directed to improving characteristics of a piezoelectric thin film device. A piezoelectric thin film filter including four film bulk acoustic resonators has a configuration where a filter section and a base substrate are bonded to each other via an adhesive layer, the filter section including a piezoelectric thin film which cannot stand up individually under its own weight, the flat base substrate mechanically supporting the filter section. As a piezoelectric material constructing the piezoelectric thin film, it is desirable to use a single-crystal material including no grain boundary, selected from crystal, lithium niobate, lithium tantalite, lithium tetraborate, zinc oxide, potassium niobate, and langasite.

Owner:NGK INSULATORS LTD +1

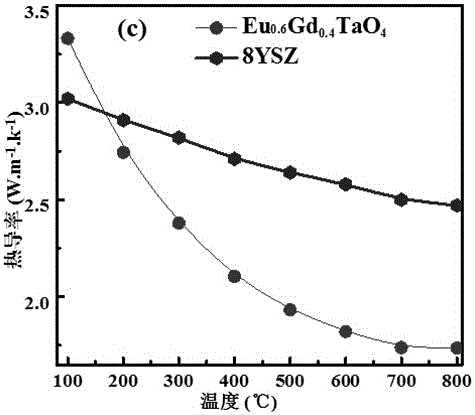

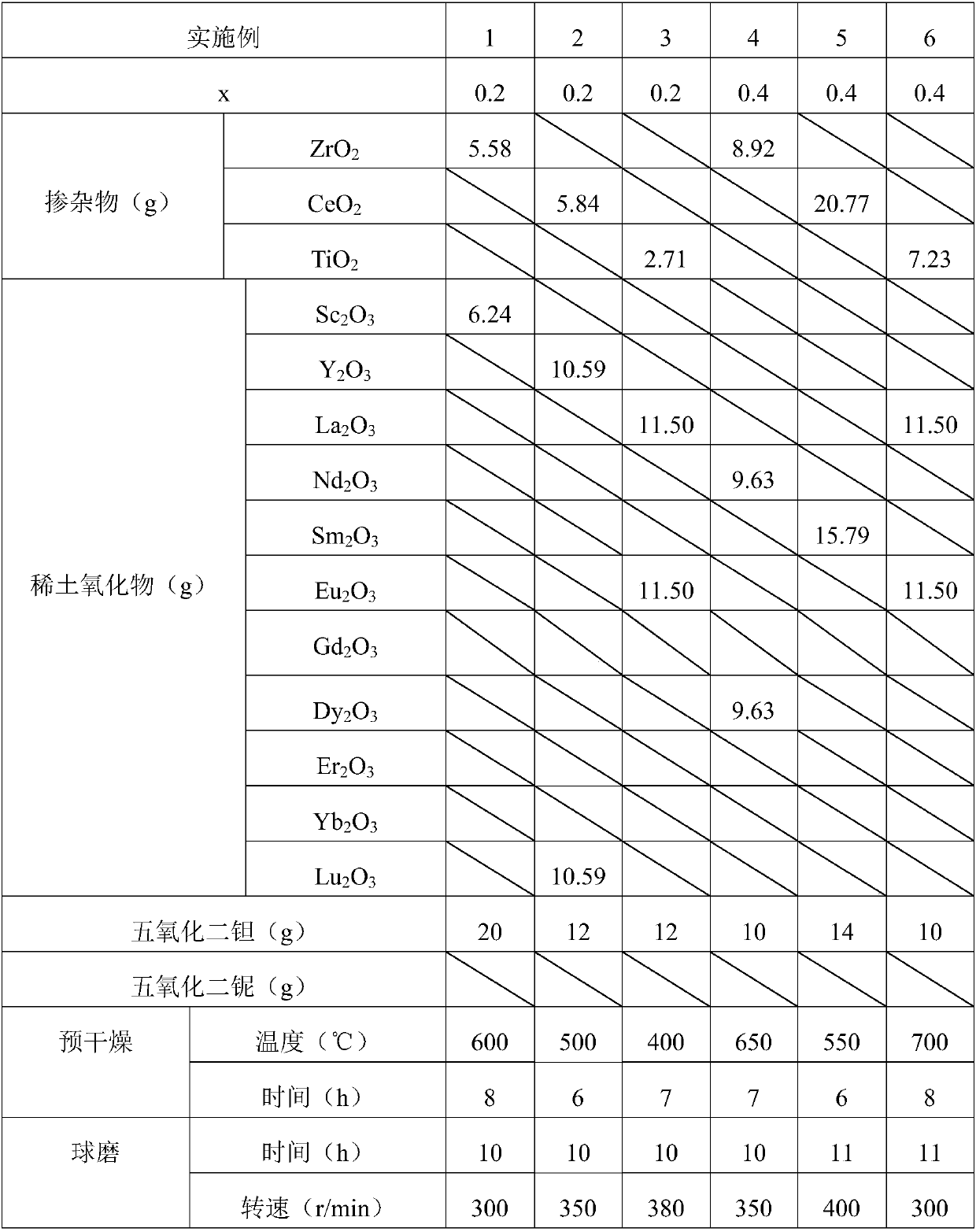

Preparation method of double-rare-earth-ion tantalite high-temperature ceramic

The invention relates to a preparation method of double-rare-earth-ion tantalite high-temperature ceramic and belongs to the technical field of high-temperature ceramic preparation. The molecular formula of the double-rare-earth-ion tantalite high-temperature ceramic is shown in the description (REa / REb = Y, La, Nd, Sm, Eu, Gd, Dy, Er and Yb, and REa and REb are not the same type of rare earth elements). The used raw materials are rare earth oxide and tantalum oxide andare weighed in proportion, the weighed raw materials and absolute ethyl alcohol are put in a ball milling tank for mixing and sealing, then the mixture is put on a planetary ball mill for ball milling, the mixture can be evenly mixed, and primary sintering is performed after the mixed powder is dried and screened; the cooled and taken-out sample is grinded, ball-milled, dried and screened and then is put in a mold for compaction, and then secondary sintering is performed. The preparation method is high in purity, low in impurity content, low in product device cost and suitable for batch production, and the product is expected to be a novel ceramic material resistant tohigh temperature, oxidation and abrasion.

Owner:KUNMING UNIV OF SCI & TECH

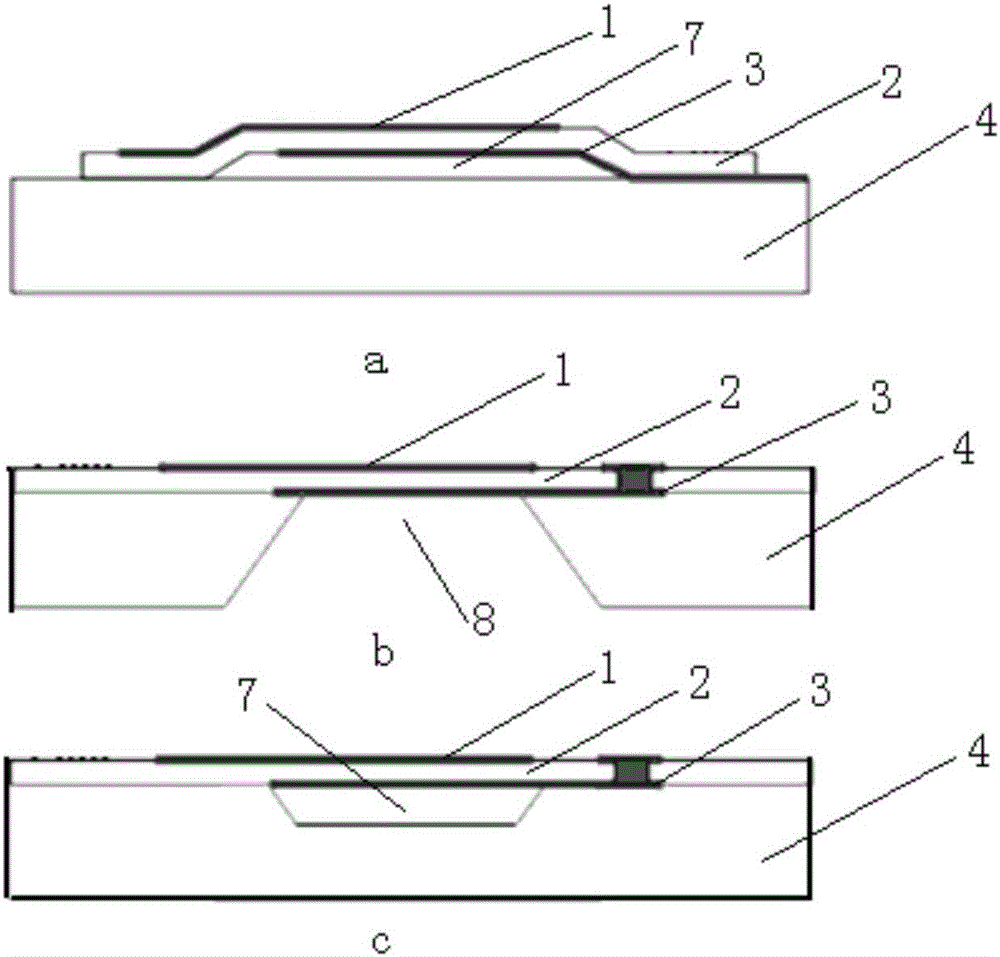

Film bulk acoustic wave resonator prepared by employing ultrathin piezoelectric single crystal

InactiveCN106100601AImprove performanceClear production technologyImpedence networksTantalitePhysics

The invention provides a film bulk acoustic wave resonator prepared by employing ultrathin piezoelectric single crystals. The resonator comprises a high-resistance substrate with a ground chamber, and a sandwich active structure formed by clamping piezoelectrics through an upper metal electrode and a lower metal electrode. The sandwich active structure is arranged at the upper end of the high-resistance substrate. The piezoelectrics are ultrathin piezoelectric single crystals. A plurality of support posts are arranged in the ground chamber. The piezoelectric single crystals applied to the ultrathin piezoelectric single crystals are all practical piezoelectric single crystals, such as quartz, lithium tantalite, lithium tetraborate, bismuth germanate, bismuth silicate, lanthanum gallium silicate series, aluminium orthophosphate and potassium niobate. The high-resistance substrate is made of general substrate materials such as silicon, quartz, silicon carbide, aluminium oxide, sapphire and diamond in the microelectronic technology. The resonator has the advantages that the crystal completeness of the ultrathin piezoelectric single crystals is not damaged, and the ultrathin piezoelectric single crystals are perfect single crystals; the crystals and crystal orientation can be freely selected, and therefore the performance of the device is optimized; and the prospect of the production technology of the ultrathin piezoelectric single crystals is bright.

Owner:CETC DEQING HUAYING ELECTRONICS

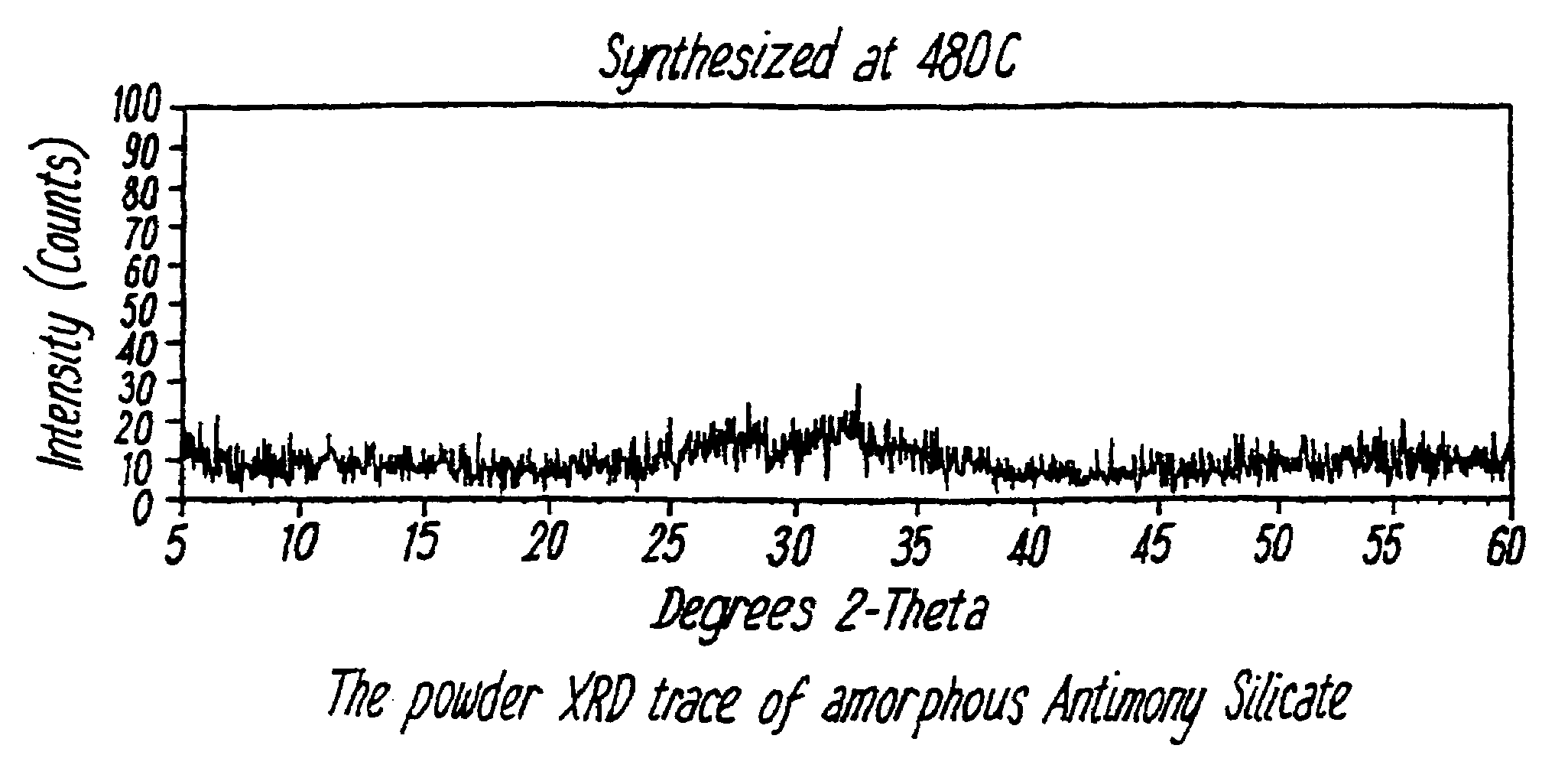

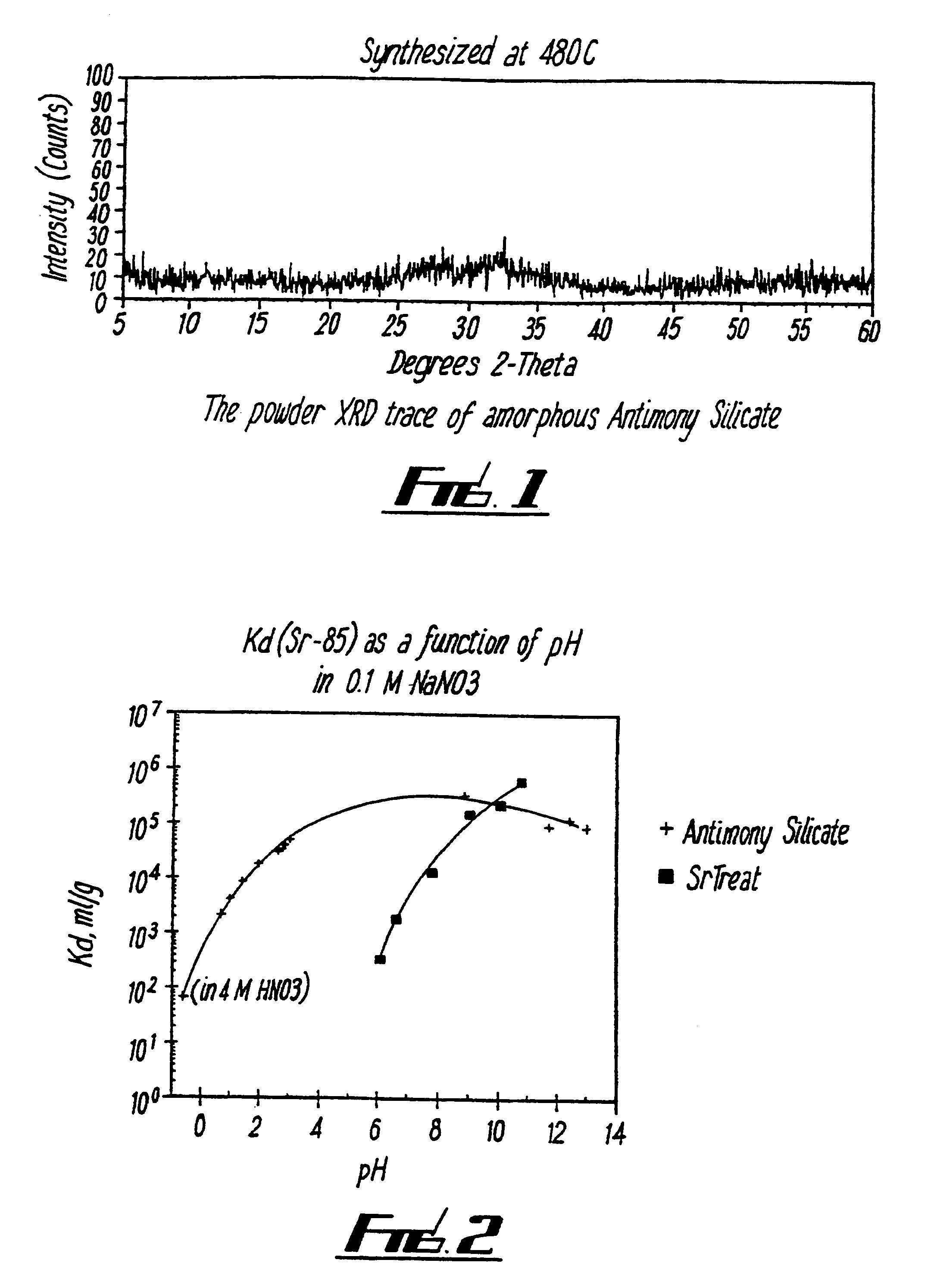

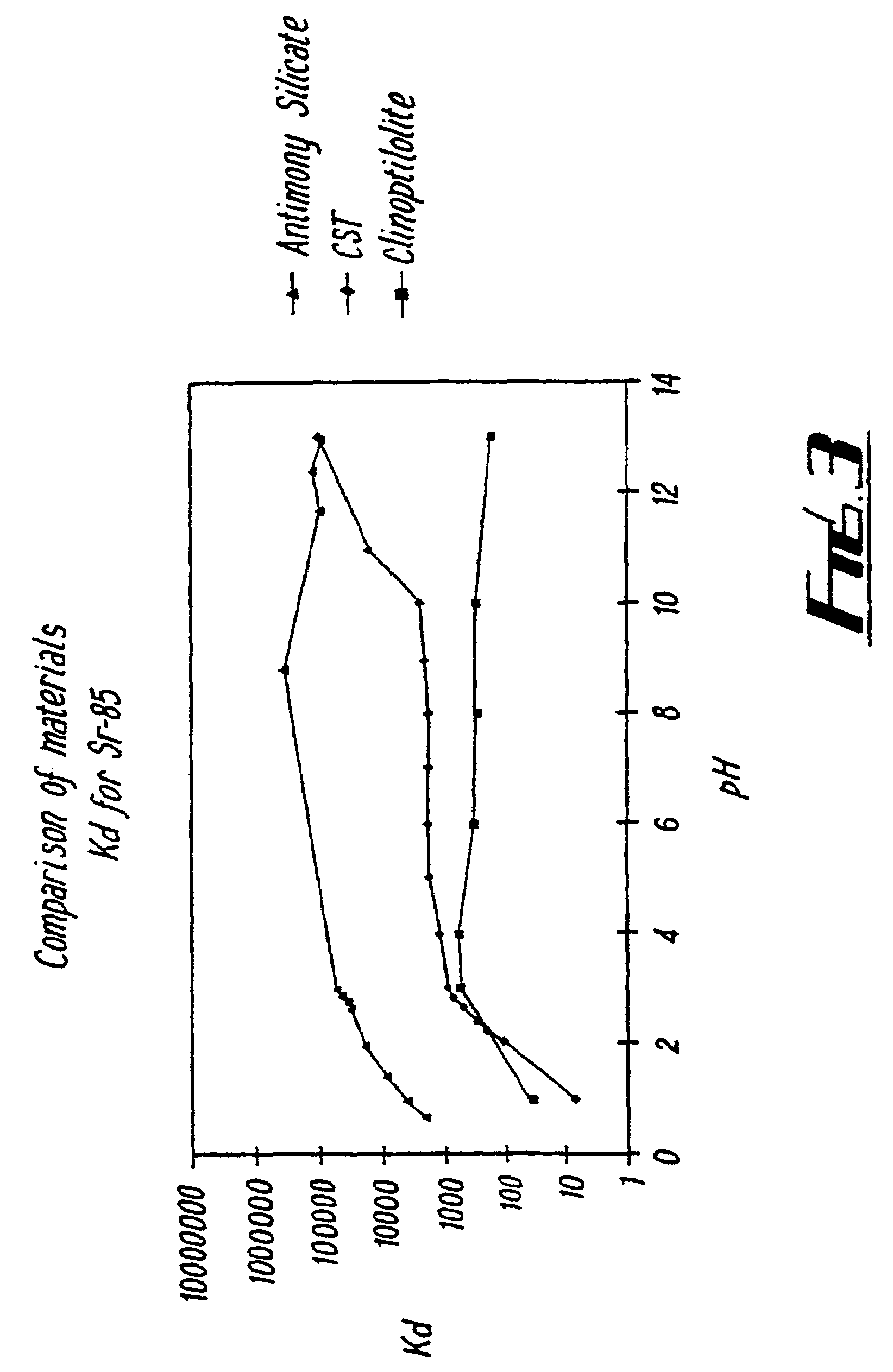

Method of extracting metal ions from an aqueous solution utilizing an antimony silicate sorbent

InactiveUS7332089B2Material efficiencyEfficient removalOther chemical processesSolid sorbent liquid separationLiquid mediumNiobium

The invention provides a use of a material comprising antimony silicate as a sorbent in the removal of metal ions, e.g. radioactive metal ions, from an acidic liquid medium. The metal ions may be selectively removed from amongst other ions such as Na, K, Mg, and Ca ions. Strontium is particularly effectively removable in this way. There is also provided a method of preparing an antimony silicate material for use in removing metal ions. The invention further provides a material comprising antimony silicate doped with one or more elements selected from the group consisting of tungsten, niobium and tantalum. The doped material has been found to be particularly effective as a sorbent in the removal of metal ions from a liquid medium.

Owner:PQ SILICAS UK

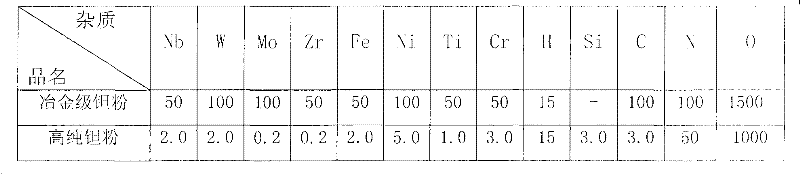

Tantalum or niobium or tantalum and niobium alloy additive manufacturing method

ActiveCN105855566AImprove liquidityShort processAdditive manufacturing apparatusArtificial materialsTantalite

The invention provides a tantalum or niobium or tantalum and niobium alloy additive manufacturing method. The method comprises the following steps that firstly, tantalum powder or niobium powder or tantalum and niobium alloy powder is prepared for 3D printing; and secondly, the prepared tantalum powder or the prepared niobium powder or the prepared tantalum and niobium alloy powder for 3D printing is put into a 3D printer for printing, and then a tantalum or niobium or tantalum and niobium alloy metal product is prepared. By means of the manufacturing method, the cost of raw materials is low, the technological process is simple, the manufactured powder with good fluidity can be directly printed into metal products and artificial material implants according to design drawings or figures converted by scanning bones amputated by doctors, the production process is quick, and post-treatment workload is little.

Owner:湖南华翔医疗科技有限公司

Making method of lithium tantalate black wafer

InactiveCN106544735APossesses monodomain piezoelectric propertiesUniform colorPolycrystalline material growthAfter-treatment detailsElectricityLithographic artist

The invention discloses a making method of a lithium tantalate black wafer. The method comprises the following steps: 1, weighing IV group nonmetal element powder and carbonate powder according to a certain ratio, and uniformly mixing the weighed powders to obtain an embedding material; 2, placing a lithium tantalate wafer to be processed in a crucible container, adding the embedding material to completely embed the wafer, and placing the crucible in a heat treatment furnace; 3, heating the lithium tantalate wafer to a heat insulation temperature in vacuum or inert or reducing flow atmosphere; 4, keeping the heat insulation temperature unchanged for 10-40 h; and 5, cooling the obtained wafer to room temperature after the heat insulation ends, and taking out the lithium tantalate wafer to obtain the black wafer. The method greatly reduces the electric resistivity of the wafer without influencing the piezoelectric performances or the single domain property of lithium tantalite, weakens and even eliminates the self pyroelectric effect of the wafer, enhances the absorption ability in the visible light region, and improves the lithography precision in the device making process.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

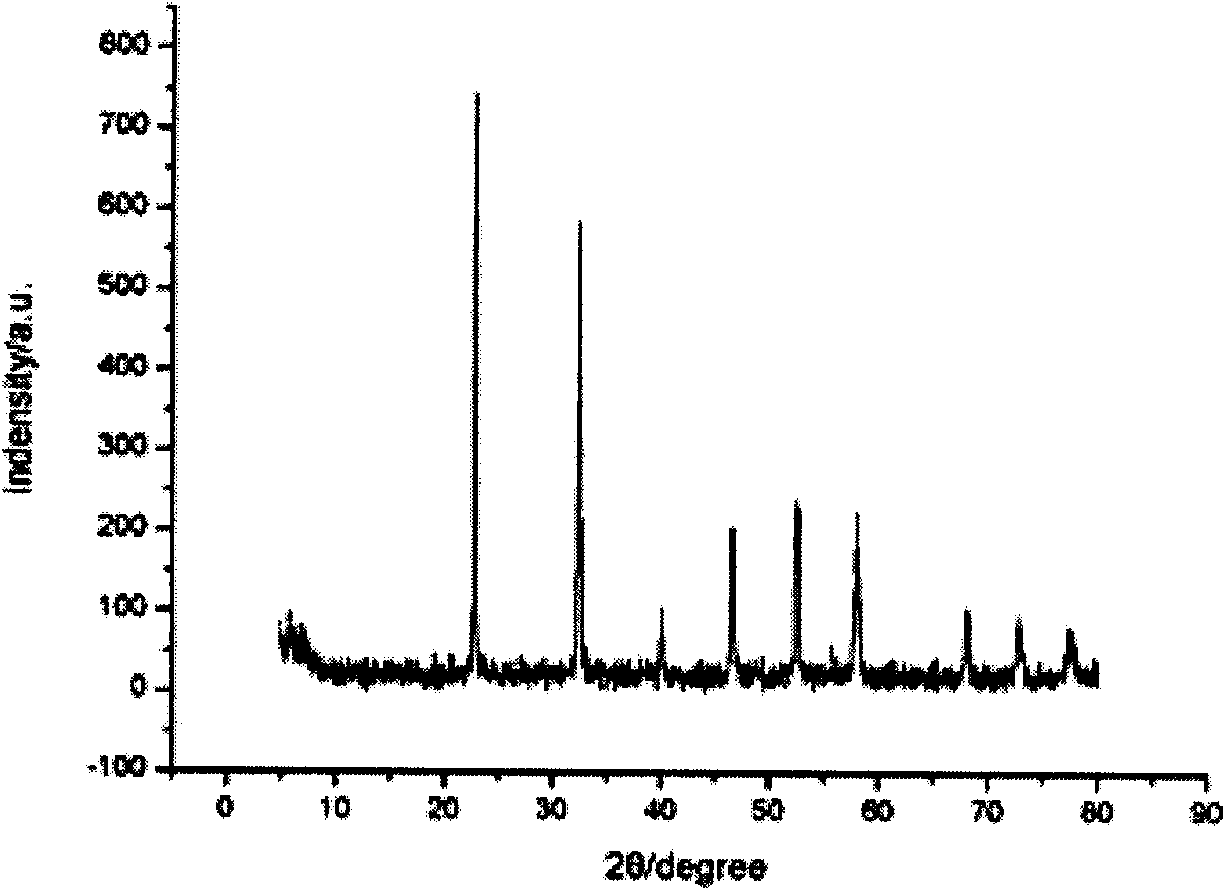

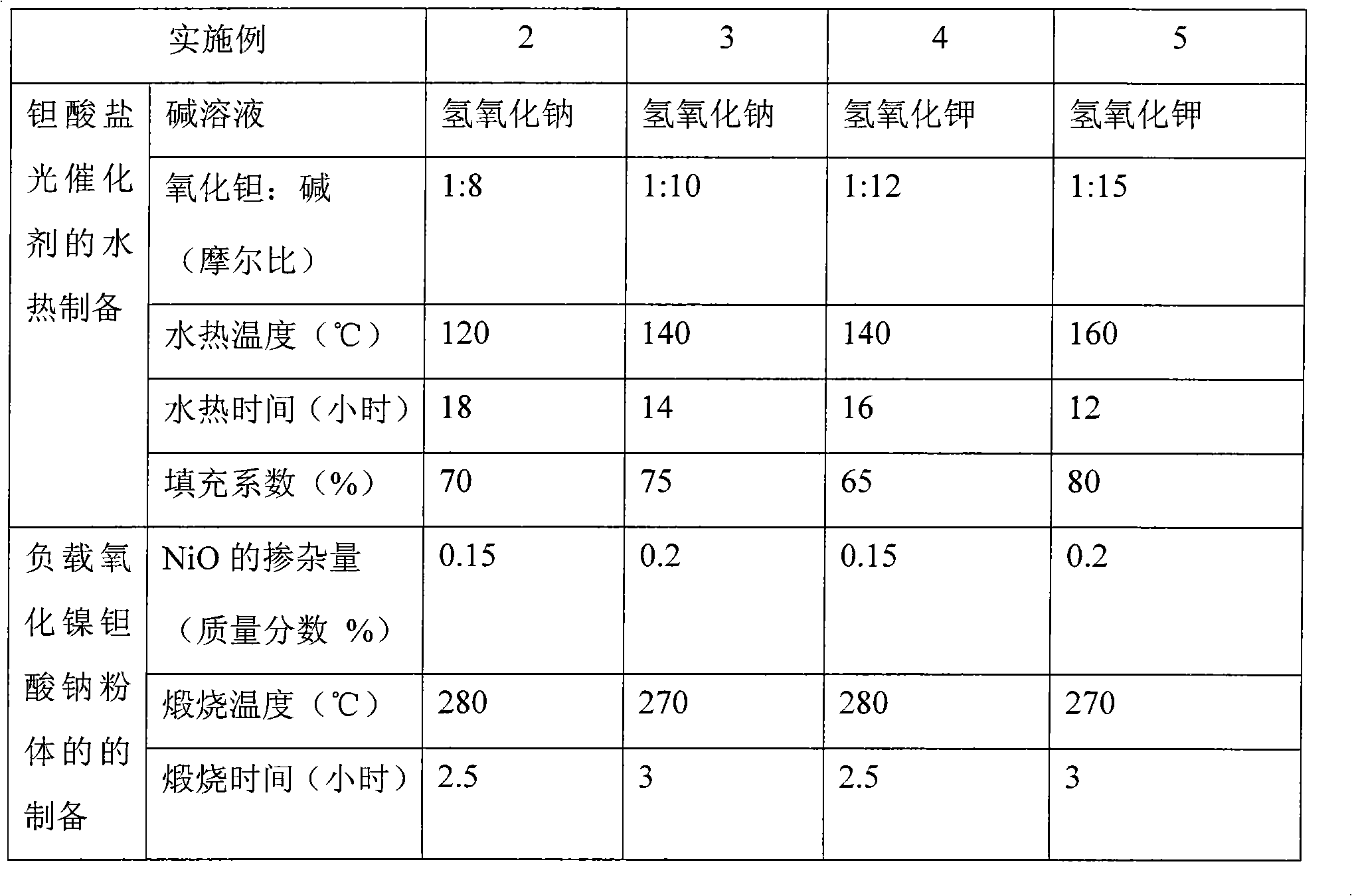

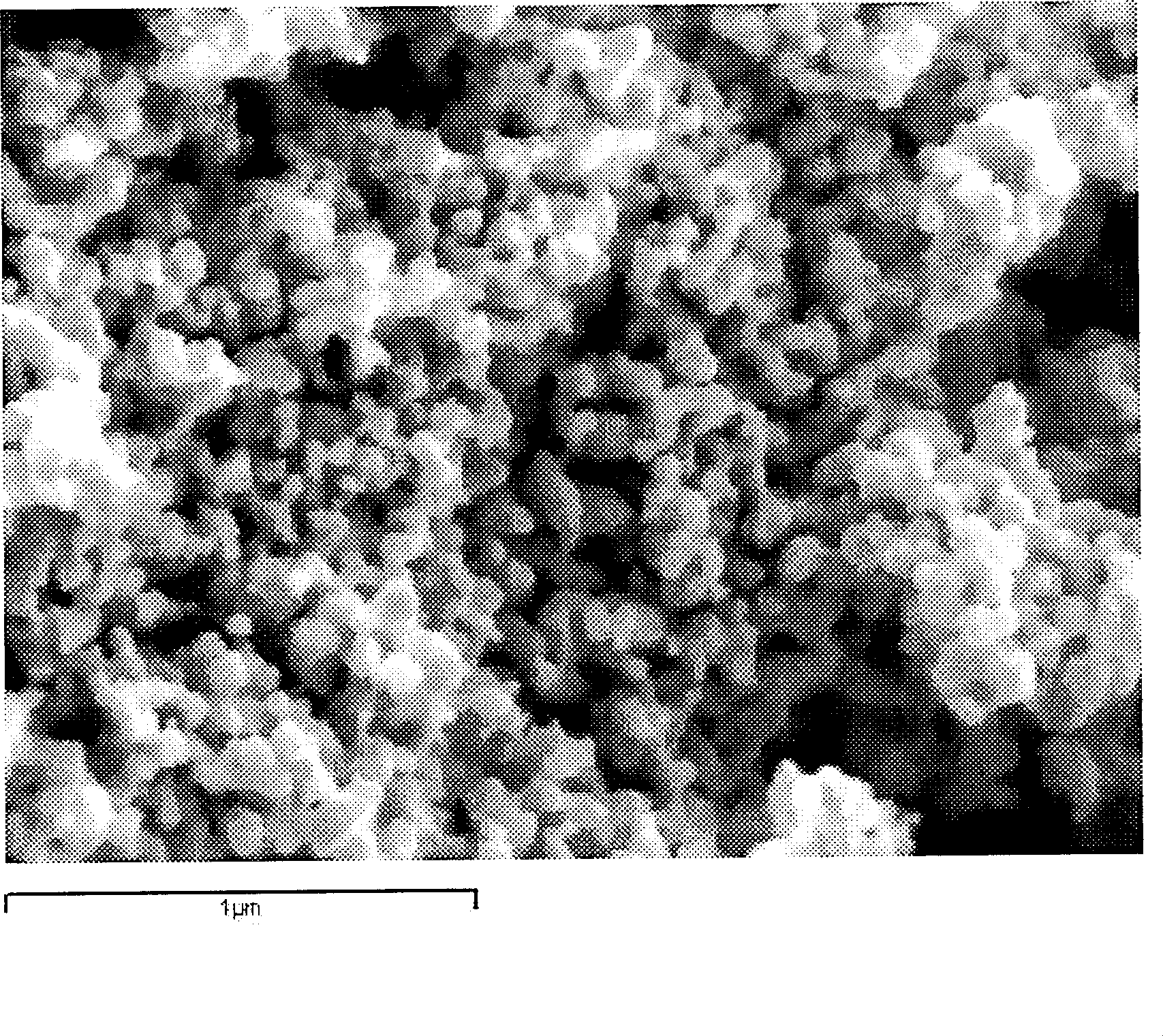

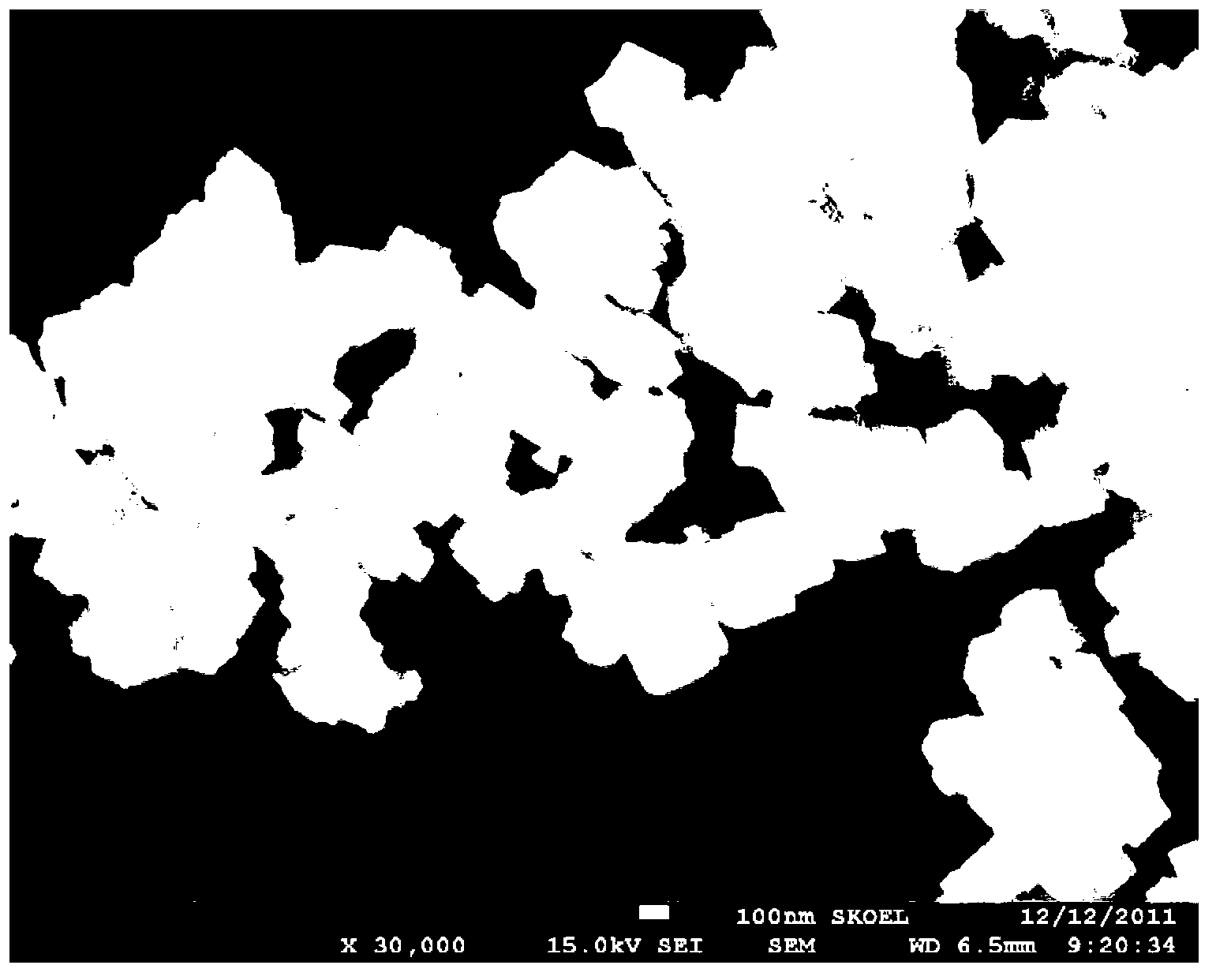

Method for preparing high efficiency photocatalyst of nickel oxide supported tantalate

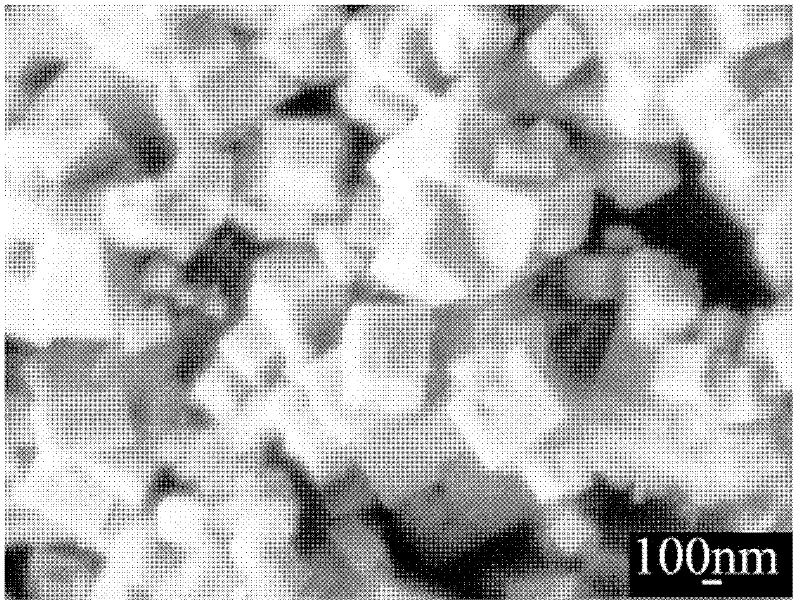

InactiveCN101602002ALess structural defectsLow reaction temperatureWater/sewage treatment by irradiationCatalyst activation/preparationTantaliteMuffle furnace

The invention provides a method for preparing a high efficiency photocatalyst of nickel oxide supported tantalate, comprising the following steps: (1) uniformly dispersing tantalum oxide into excessive aqueous alkali and placing the mixture into a reaction kettle; (2) keeping the reaction kettle for a period of time at the set temperature to ensure full hydrothermal reaction; (3) after the hydrothermal reaction, fully washing and filtering the product in the reaction kettle until eluate is neutral, and preparing tantalate nano powder after drying; (4) uniformly dispersing certain amount of the tantalate nano powder into proper amount of nickel nitrate solution and evaporating the mixed solution at the constant temperature to obtain pressed powder; (5) putting ground pressed powder into a Muffle furnace for calcining to obtain the final product. The method adopts cheap raw materials and has simple equipment and process. The prepared photocatalyst of the tantalate has few structural defects, small grain size and good dispersibility, and the tantalate is endowed with good photocatalytic activity.

Owner:QINGDAO UNIV OF SCI & TECH

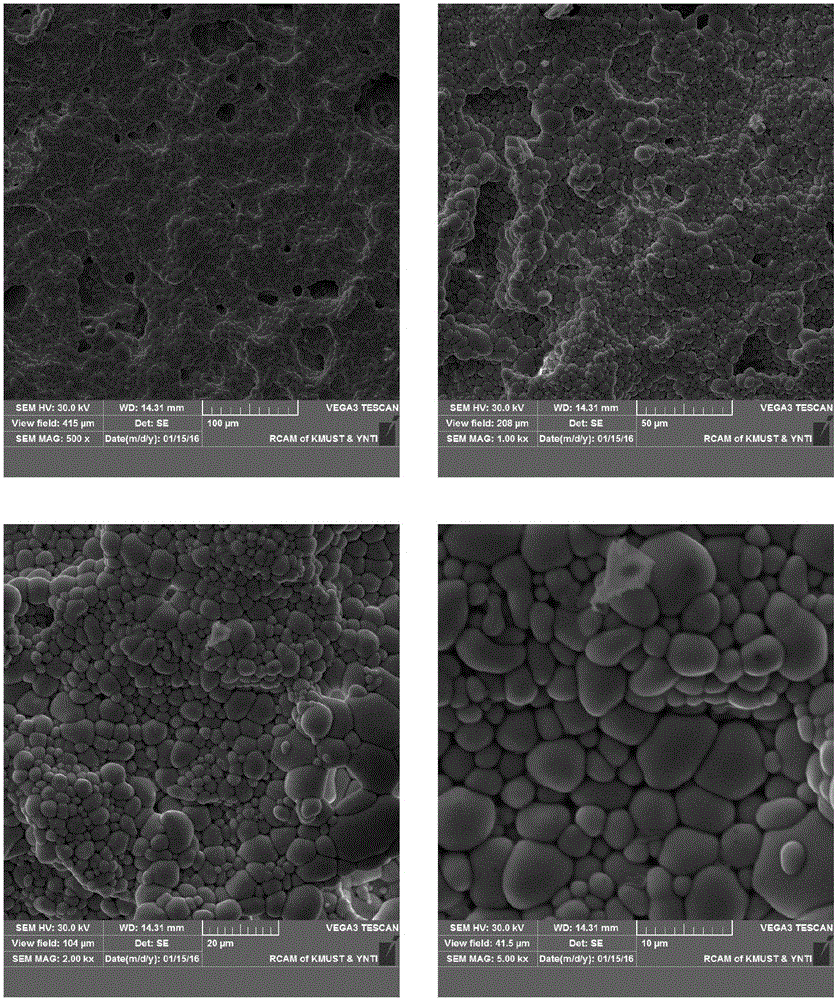

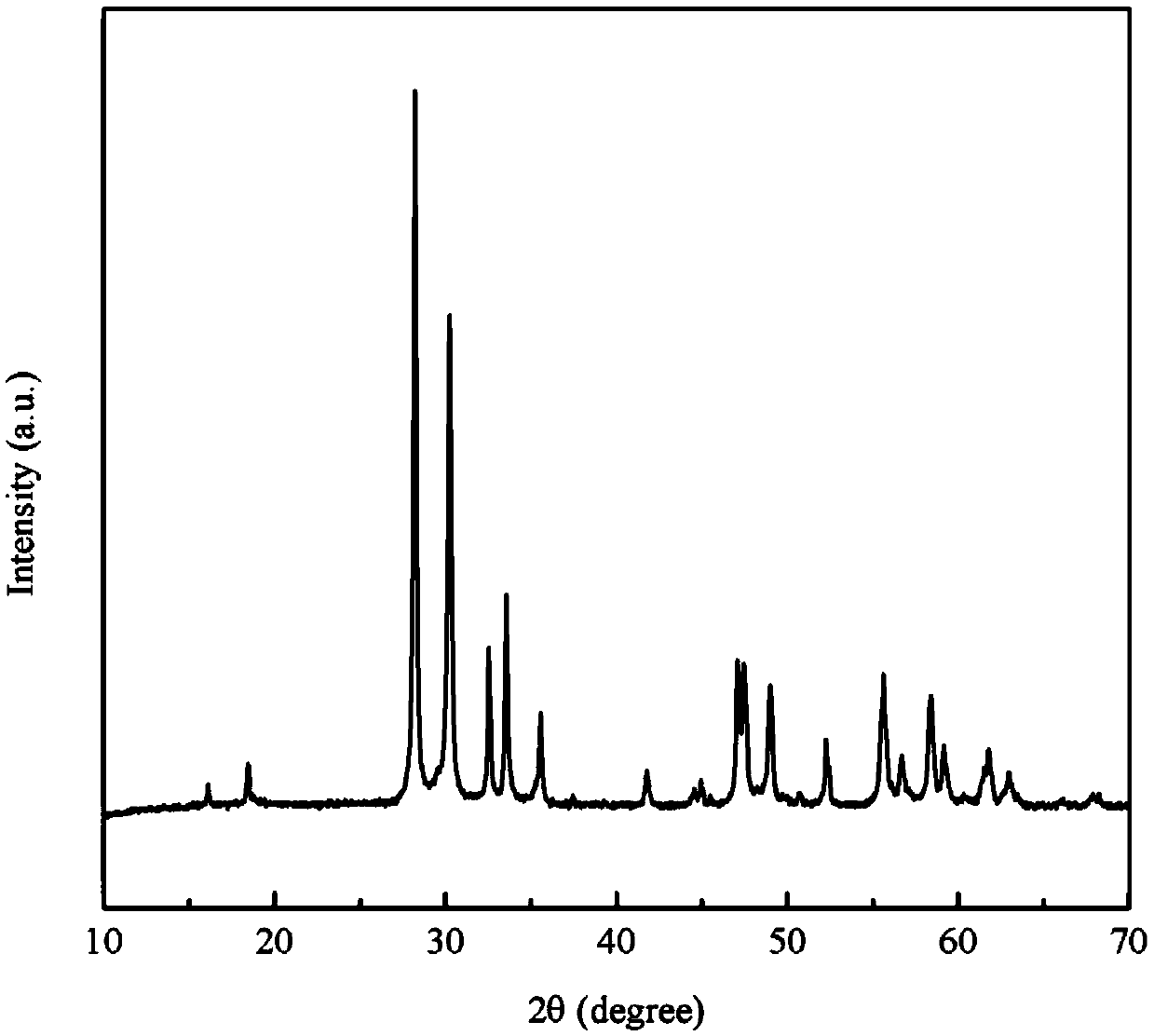

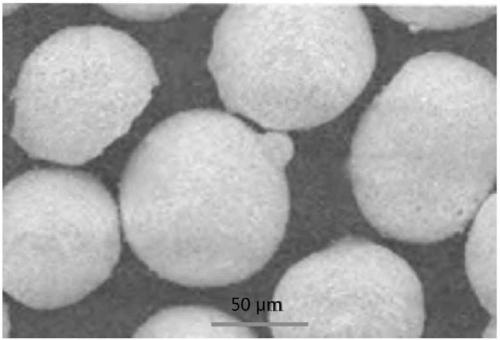

Zirconium oxide/titanium oxide/cerium oxide doped rare earth tantalum/niobate RETa/NbO4 ceramic powder and preparation method thereof

ActiveCN109534814AImprove liquidityMeet the requirements of spraying technologyTantalum compoundsEfficient propulsion technologiesSpace groupMetallurgy

The invention belongs to the technical field of ceramic powder preparation, and discloses zirconium oxide / titanium oxide / cerium oxide doped rare earth tantalum / niobate RETa / NbO4 ceramic powder and a preparation method thereof. The zirconium oxide / titanium oxide / cerium oxide doped rare earth tantalum / niobate RETa / NbO4 ceramic powder has a chemical general formula being RE1-x(Ta / Nb)1-x(Zr / Ce / Ti)2xO4, wherein x is greater than 0 but smaller than 1. The crystal structure of the ceramic powder is an orthorhombic phase; the crystal lattice space group is C2221; the particle diameter is 10 to 70 mum;the ceramic powder is in a spherical shape. During the preparation, the raw materials are subjected to ball milling; then, after the reaction by a high-temperature solid phase method, a mixture is mixed with solvents and organic bonding agents to obtain slurry C; centrifugal atomization is performed to obtain dried particle materials; next, sintering is performed; the zirconium oxide / titanium oxide / cerium oxide doped rare earth tantalum / niobate RETa / NbO4 ceramic powder meeting the requirement of the APS (atmospheric plasma spraying) technology on the ceramic powder is obtained.

Owner:陕西天璇涂层科技有限公司

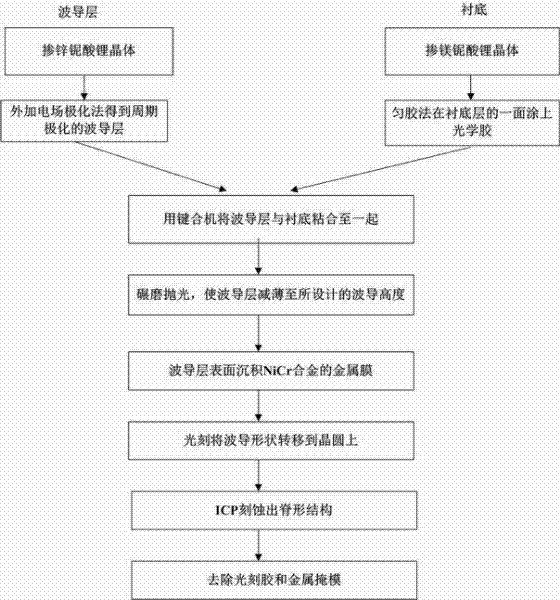

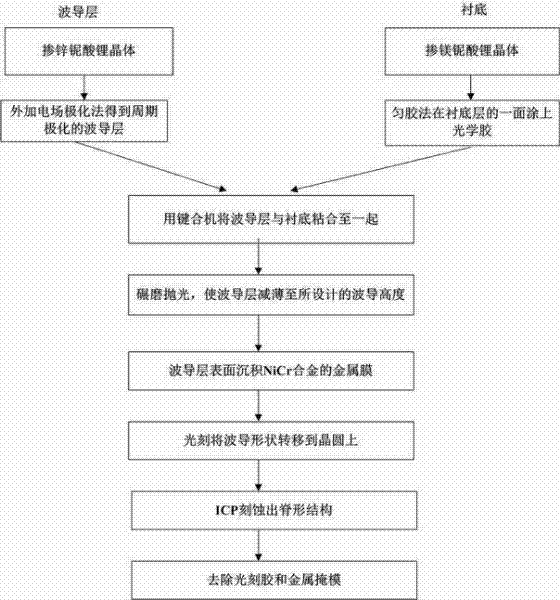

Preparation method of lithium niobate optical waveguide

InactiveCN102253451AStrong light field confinementImprove coupling efficiencyOptical waveguide light guideManufacturing technologyRefractive index

The invention provides a preparation method of a lithium niobate optical waveguide. The preparation method of the lithium niobate optical waveguide comprises the steps of: fabricating a periodical domain inversion structure on a doped lithium niobate crystal by adopting an applied electric field polarization method by selecting a zinc-doped or magnesium-doped lithium niobate crystal; bonding the periodical domain inversion structure as a waveguide layer with a lithium niobate substrate or a lithium tantalite substrate through optical cement the refractive index of which is lower than that of the waveguide layer; and etching to obtain a ridge waveguide structure by using an ICP (inductively coupled plasma) dry method to obtain the lithium niobate optical waveguide. The adhesive layer adopted by the invention has a reflective index more approaching that of air, therefore, in the waveguide, the optical field limiting function is stronger, the optical field is distributed symmetrically, and the coupling efficiency of single mode fibers is higher. By adopting adhesive bonding, the requirement on cleanness and roughness of the surface of a wafer is far lower than that of the surface of a directly bonded wafer, thus the preparation method is realized more easily in technology. The lithium niobate optical waveguide prepared by the method has more excellent performance in the aspects of improving the optical field limiting function, reducing the transmission loss of the waveguide, inhibiting the photorefractive effect, reducing the difficulty in manufacturing technology and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing near-stoichiometric lithium tantalate crystals

InactiveCN101225545AImprove uniformityFacilitate mass productionPolycrystalline material growthBy pulling from meltMolten stateHigh volume manufacturing

The invention discloses a preparation method for near-stoichiometric lithium tantalite crystal, which comprises the following steps: prepare the base material according to the molar ratio proportion of Li2CO3:Ta2O5=48-50:52-50; then add an alkali metal except Li2O as the flux; after grinding and mixing, heat to fully decompose and release CO2; calcine the mixture and get lithium tantalite polycrystalline charge; then press the polycrystalline charge, put in a crucible, heat to the fusion state, keep the temperature and then use the czochralski preparation method for the near-stoichiometric lithium tantalite crystal. The preparation method for near-stoichiometric lithium tantalite crystal has the advantages that: the process of preparing the near-stoichiometric lithium tantalite crystal is made simpler; the near-stoichiometric lithium tantalite crystal with bigger size and good uniformity is made easier to prepare; industrial mass production can be realized and the cost can be reduced.

Owner:NINGXIA ORIENT TANTALUM IND

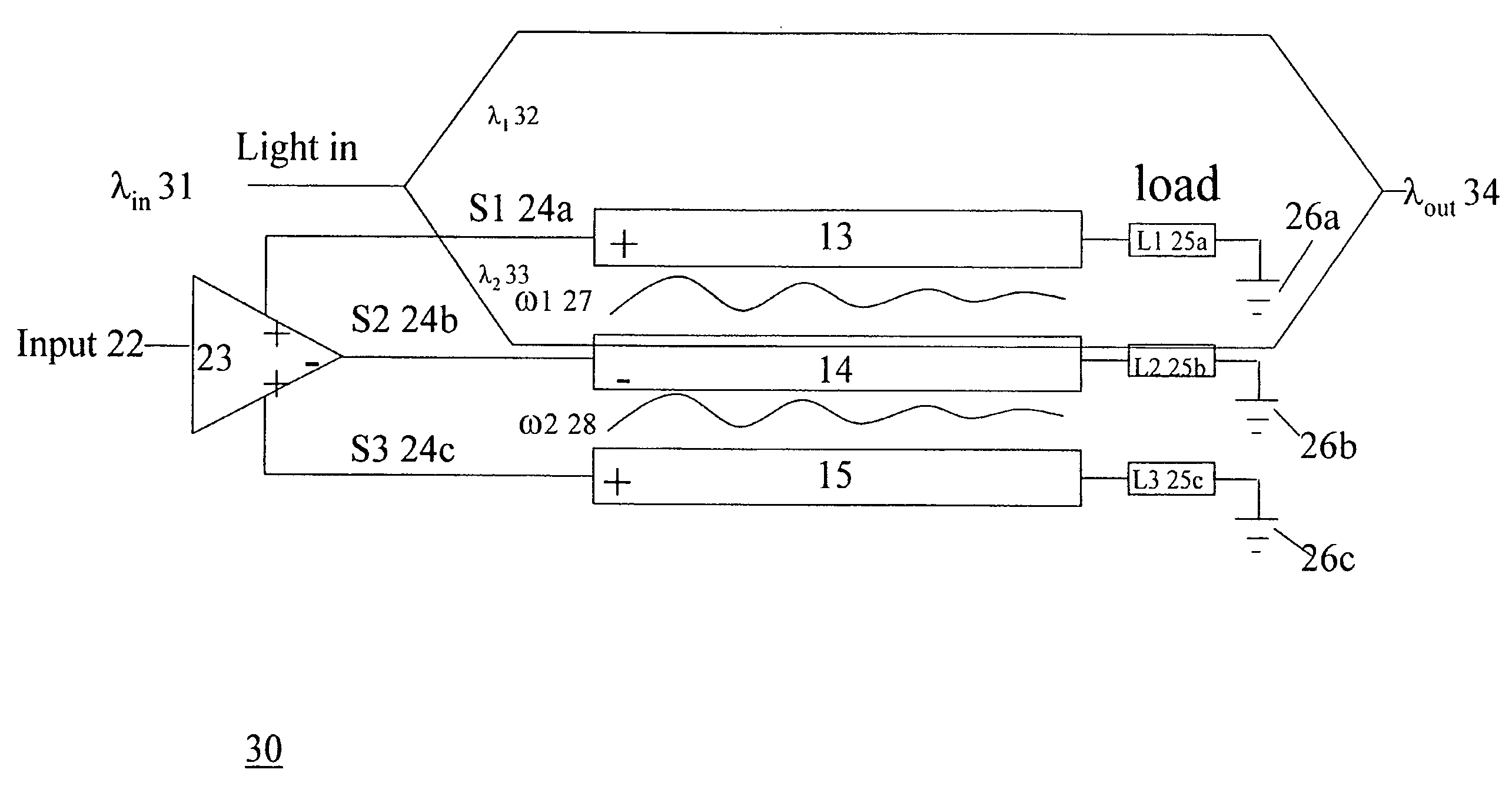

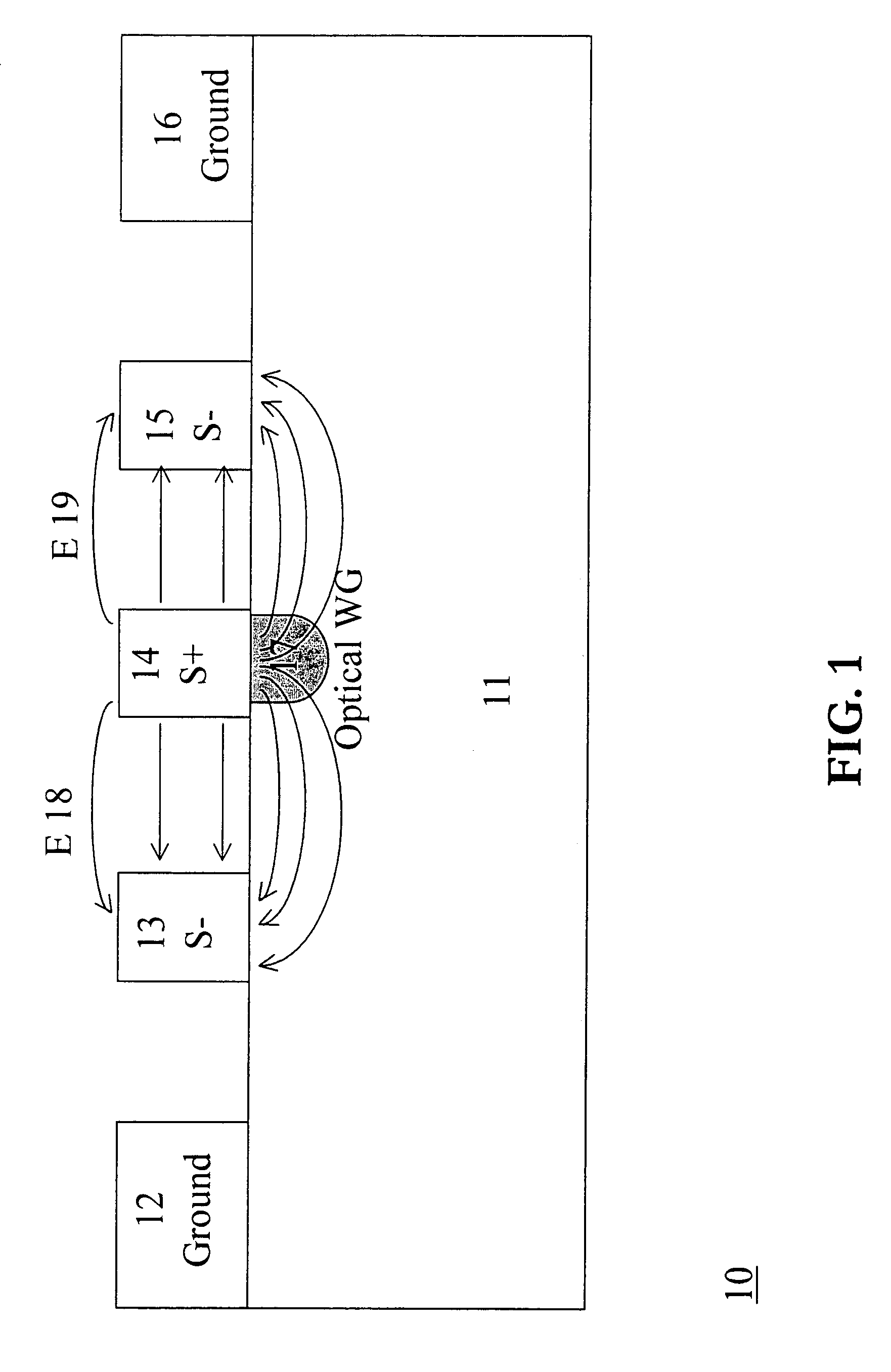

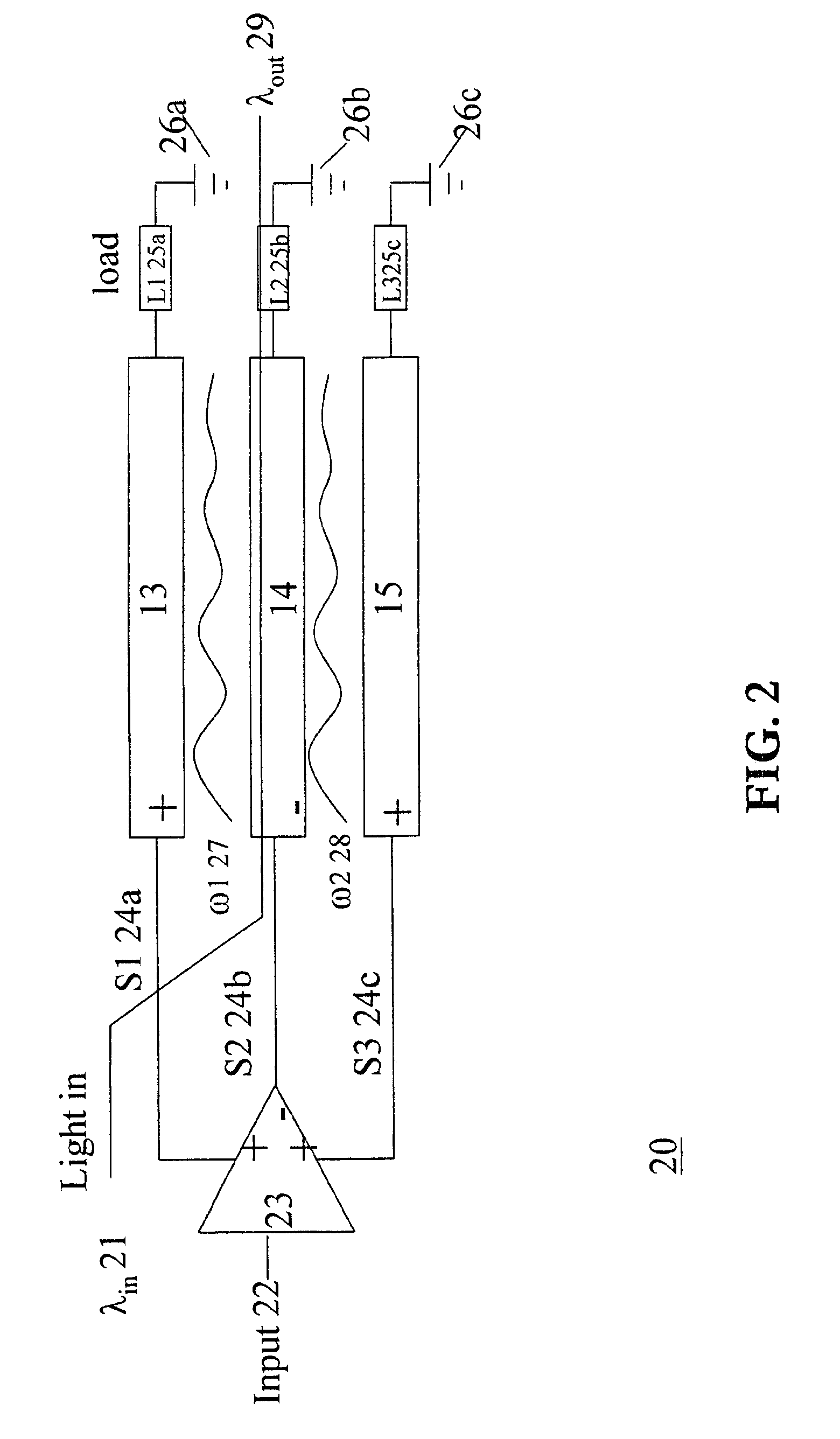

Dual-electrode traveling wave optical phase shifters and methods

The invention discloses phase-shifters, modulators, and method that produces a smaller π by means of a field excitation using multiple electrodes. A negative signal is introduced that travels with the positive signal, which enhances the electric field significantly. The field enhancement is provided by the superposition of the fields accumulated from each electrode. A base or substrate material can be made from any compound having linear electro-optic properties, such as lithium niobate, lithium tantalite, potassium lithium niobate, potassium titanyl phosphate or gallium-arsenide. For lithium niobate, there are two possible orientations of electric field, z-cut orientation or x-cut orientation.

Owner:II VI DELAWARE INC

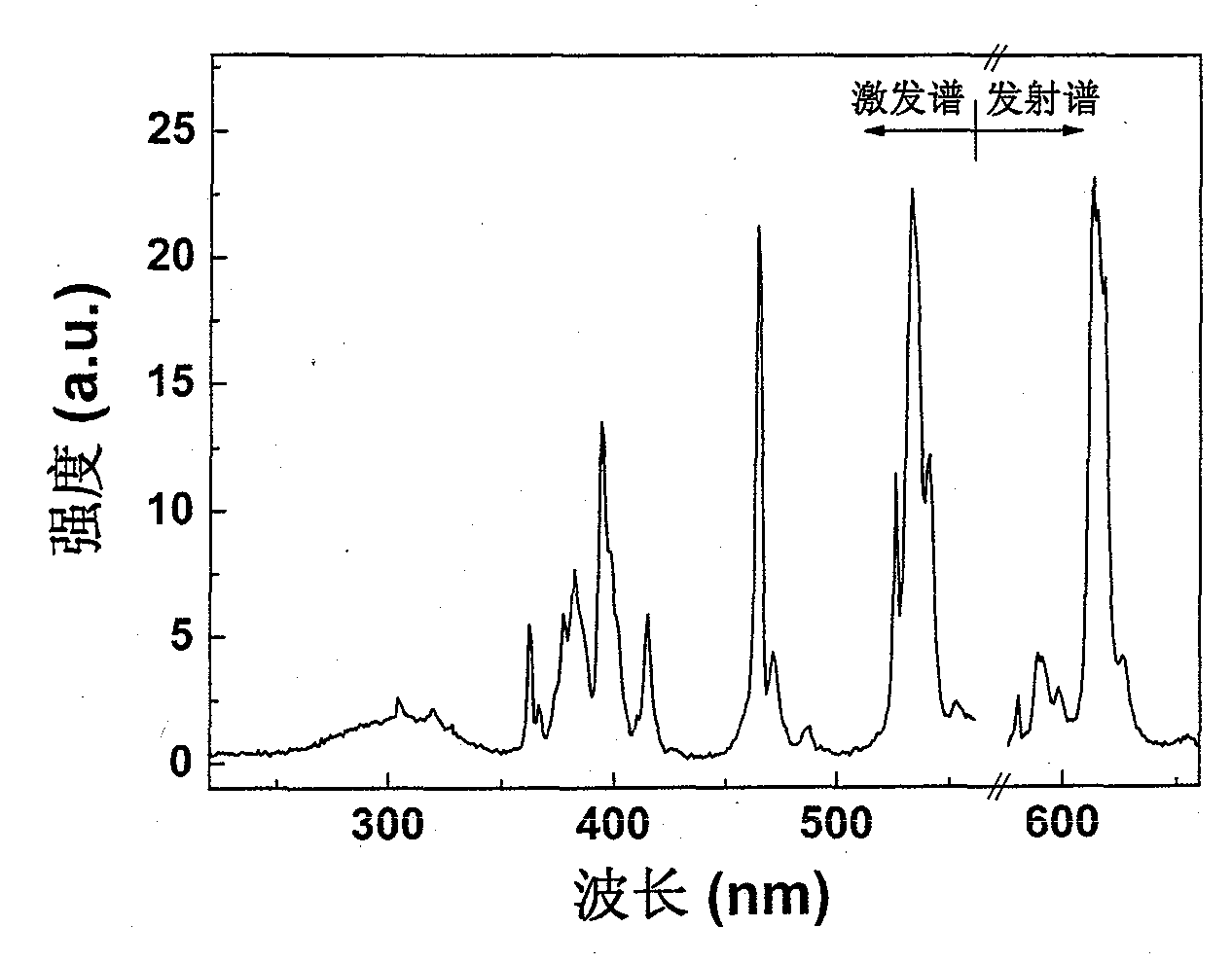

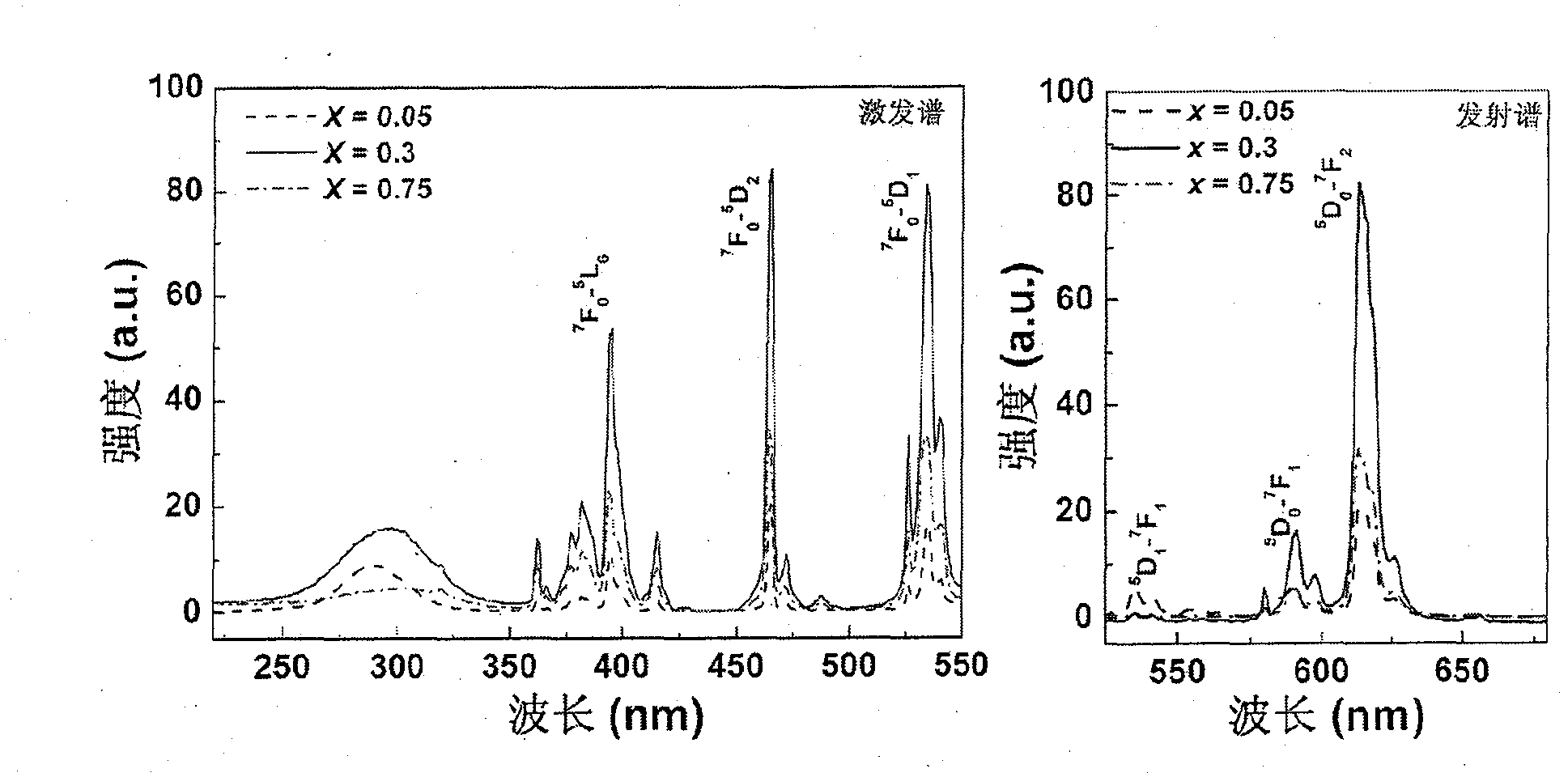

Columbate or tantalate fluorescence material used in white-light LED, and its preparation method

InactiveCN103205253AVariable crystal structureAdjustable Crystal Field StrengthGas discharge lamp usageLuminescent compositionsRare-earth elementFluorescence

The invention relates to a columbate or tantalate fluorescence material used in white-light LED, and its preparation method. The columbate or tantalate fluorescence material comprises undoped columbate or tantalite, transition metal doped columbate or tantalite, Tl-like ion doped columbate or tantalite having an s<2> configuration, rare earth element doped columbate or tantalite, and Tl-like ion and rare earth ion co-doped columbate or tantalite. The material can be used in the white-light LED, and relevant display and illumination devices. The columbate or tantalate fluorescence material has the advantages of cheap and easily available raw materials, simple preparation technology, stable chemical properties, and excellent luminescence performance, and is an ideal phosphor candidate material for the white-light LED.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of high specific surface area tantalum powder and/or niobium powder

A tantalum powder and / or a niobium powder with high specific surface area are prepared through reaction between the oxides one of tantalum and / or niobium, alkali metal and halide of at least of Mg, Ca, Sr, Ba and Ce. Its advantages are simple preparing process, and high specific surface area, purity and flowability, and thus it is especially suitable for making the anode of capacitor.

Owner:NINGXIA ORIENT TANTALUM IND

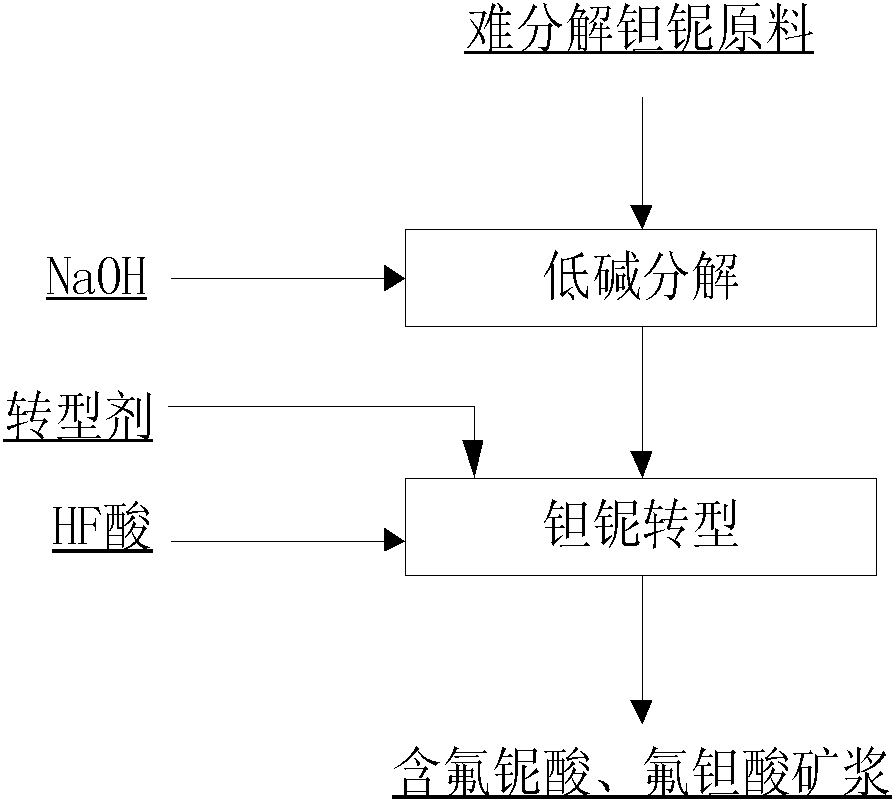

Method for extracting tantalum and niobium through low alkali decomposition of tantalum-niobium ore

InactiveCN103160684ASimple processReduce alkali consumptionProcess efficiency improvementHydrofluoric acidDecomposition

The invention relates to a method for extracting tantalum and niobium through low alkali decomposition of a tantalum-niobium ore. According to the method, a small amount of sodium hydroxide is used as a melting agent for roasting decomposition of the tantalum-niobium ore to allow tantalum and niobium to be converted into sodium metatantalate and sodium metaniobate; and then, under the condition of addition of a conversion agent, tantalum and niobium in a roasting product are extracted with diluted hydrofluoric acid at a low temperature so as to obtain ore pulp containing fluotantalic acid and fluoniobic acid. The method provided by the invention has the advantages of simple process flow, small consumption of alkali, low cost and capacity of realizing nearly 100% of a tantalum-niobium ore decomposition rate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Crystal growth way of crystal pulling method for tantalate

This invention relates to a Czochralski method for growing tantalite crystal. The molecular formula of the grown compound is RE1-xDxTa1-yNbyO4, wherein, RE = Lu, Gd or Y; D = Bi, Ce, Eu or Tb; x and y = 0-1. The raw materials, Ta2O5, Nb2O5, Lu2O3, Gd2O3, Y2O3, Bi2O3, Eu2O3 and Tb4O7 are prepared from other compounds of Ta, Nb, Lu, Gd, Y, Bi, Eu and Tb. The Czochralski method comprises: mixing the raw materials, pressing in a mold into disc shape, and / or sintering at 750-1300 deg.C for 10-24 h to obtain the starting material for RE1-xDxTa1-yNbyO4 crystal. The method can obtain large-size single crystal of Nb5+, Bi3+, Tb3+ or Eu3+-doped RETaO4, which can be used in high-energy physics and nuclear medicine.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

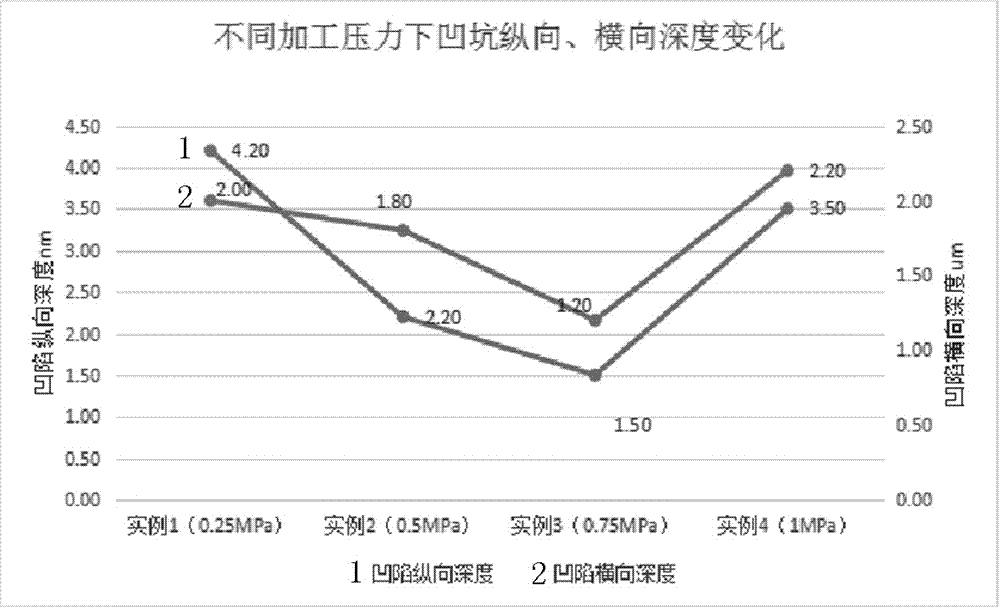

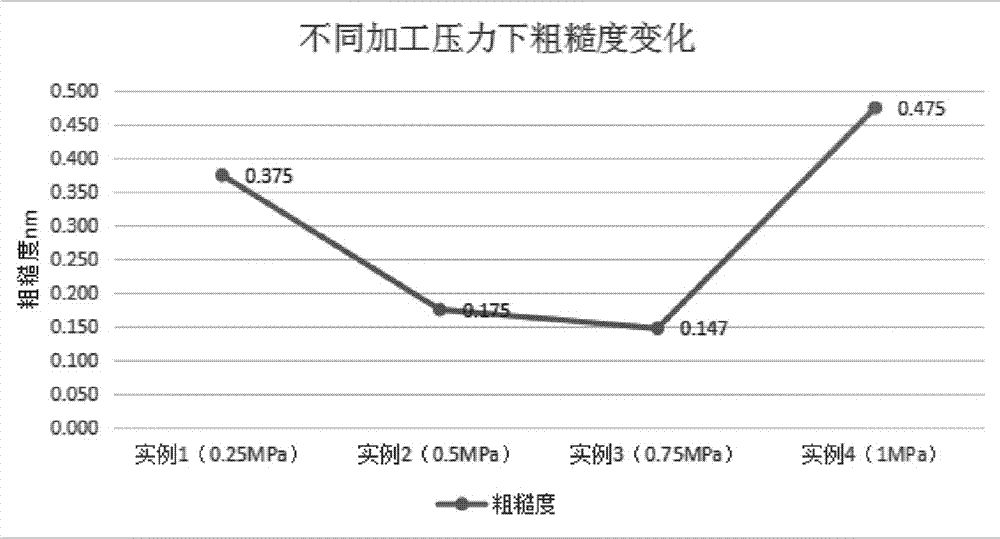

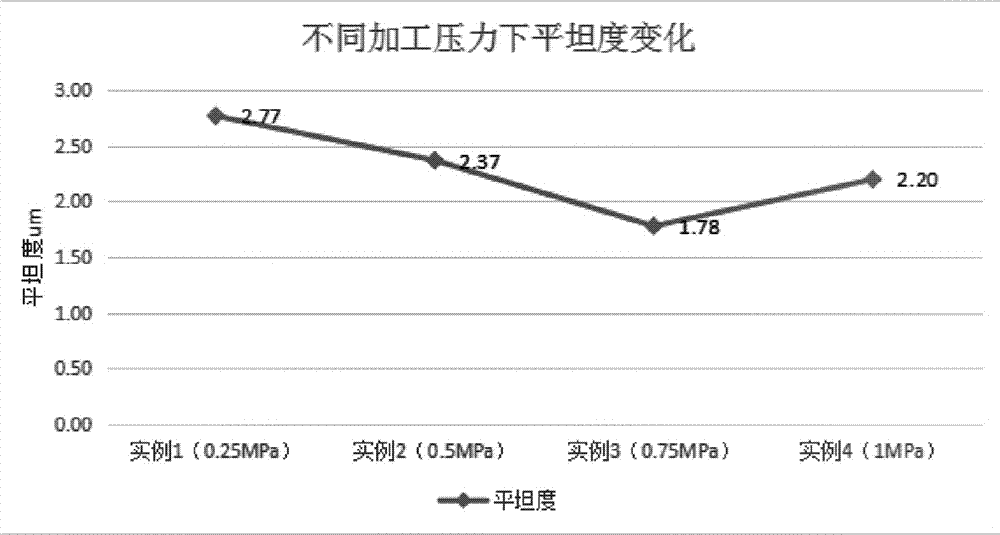

Polishing method for lithium tantalate substrate

The invention discloses a polishing method for a lithium tantalate substrate. The method includes the steps of 1, grinding a cut tantalate lithium wafer with an abrasive material with the particle size of 5-20 microns, and obtaining a lithium tantalate grinding sheet with the surface of a rough structure; 2, directly conducting chemical corrosion on the lithium tantalate grinding sheet in a sealed container filled with the mixed acid of nitric acid and hydrofluoric acid, wherein the roughness of the tantalate lithium wafer is smaller than 200 nm, and the flatness is smaller than 5 microns; obtaining a lithium tantalate corrosion sheet with the surface of a random disordered pit structure; 3, conducting single-side polishing on the lithium tantalate corrosion sheet with a single-polishing machine and a polishing liquid, wherein the polishing pressure is 0.005-1 MPa, the roughness of the tantalate lithium wafer is smaller than 0.5 nm, and the flatness is smaller than 3 microns; obtaining a lithium tantalite polishing sheet. The polishing method has the advantages of one-time polishing, batch production and high polishing efficiency, and the produced lithium tantalate substrate has high surface flatness which determines that the lithium tantalate substrate is not easily broken in the application of devices; the material utilization is high, and the processing yield is high.

Owner:TDG HLDG CO LTD

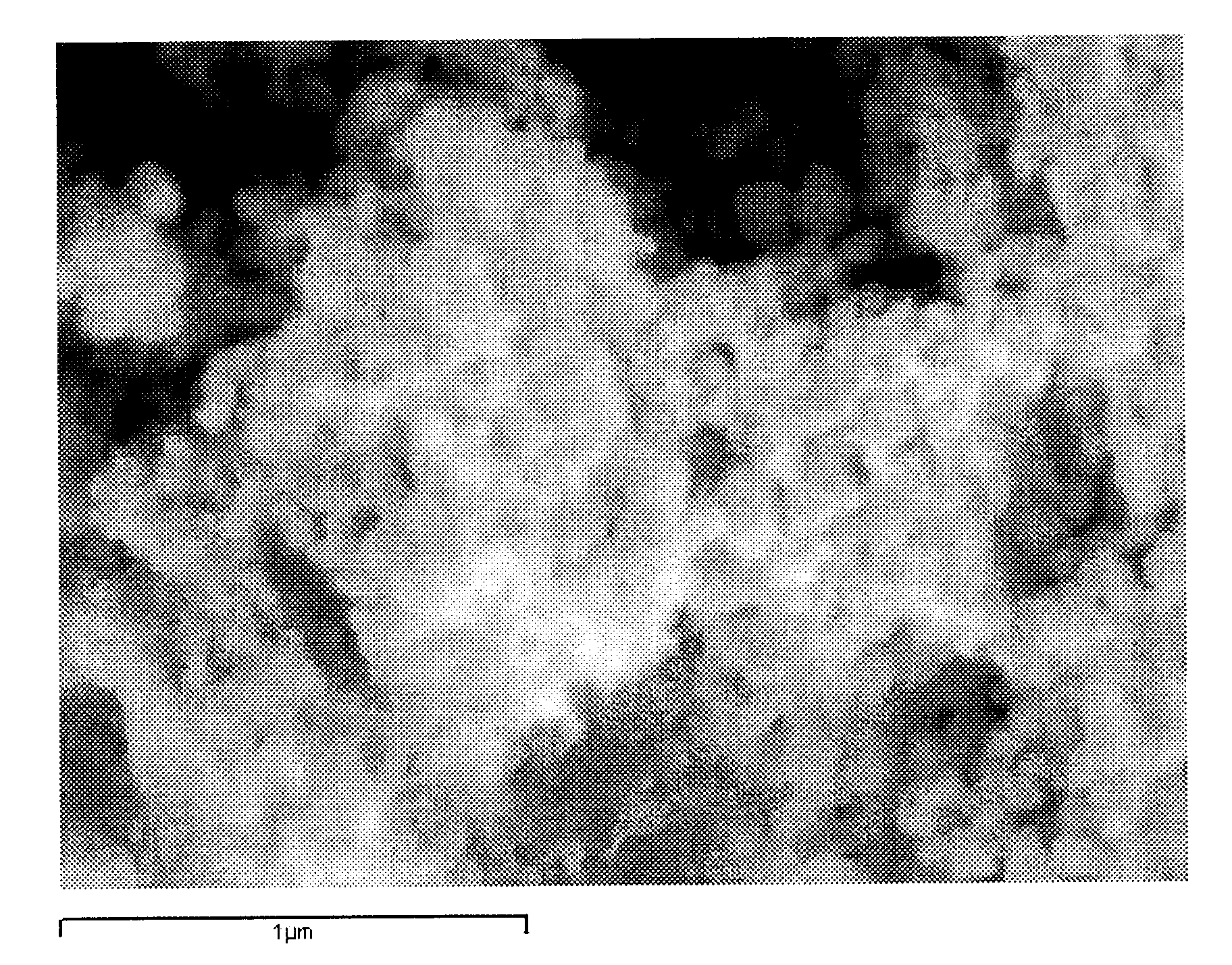

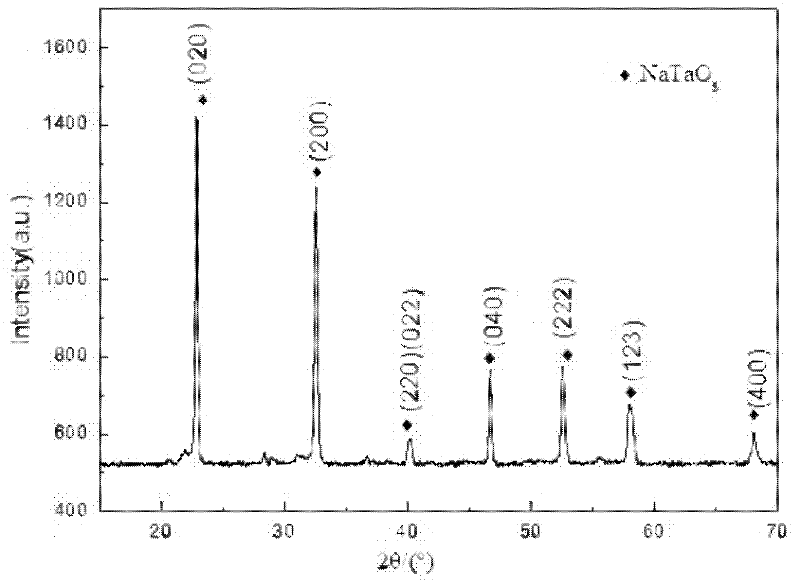

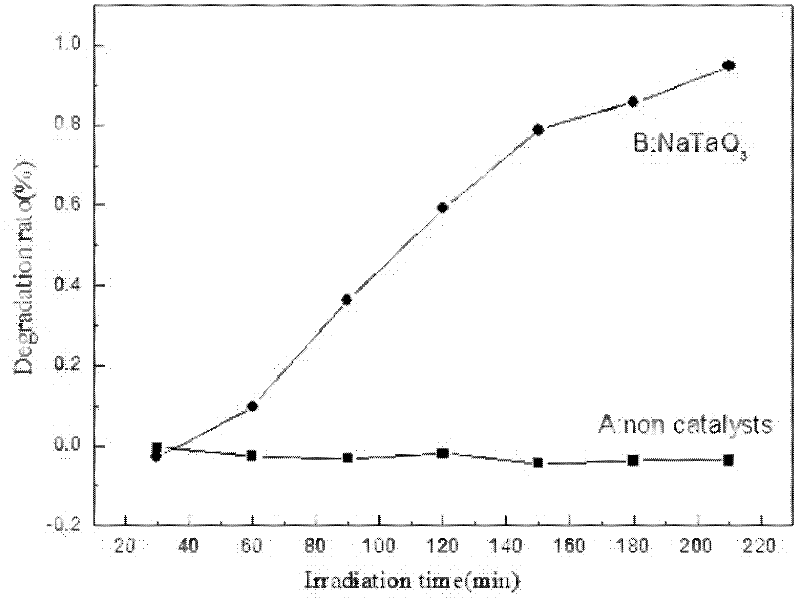

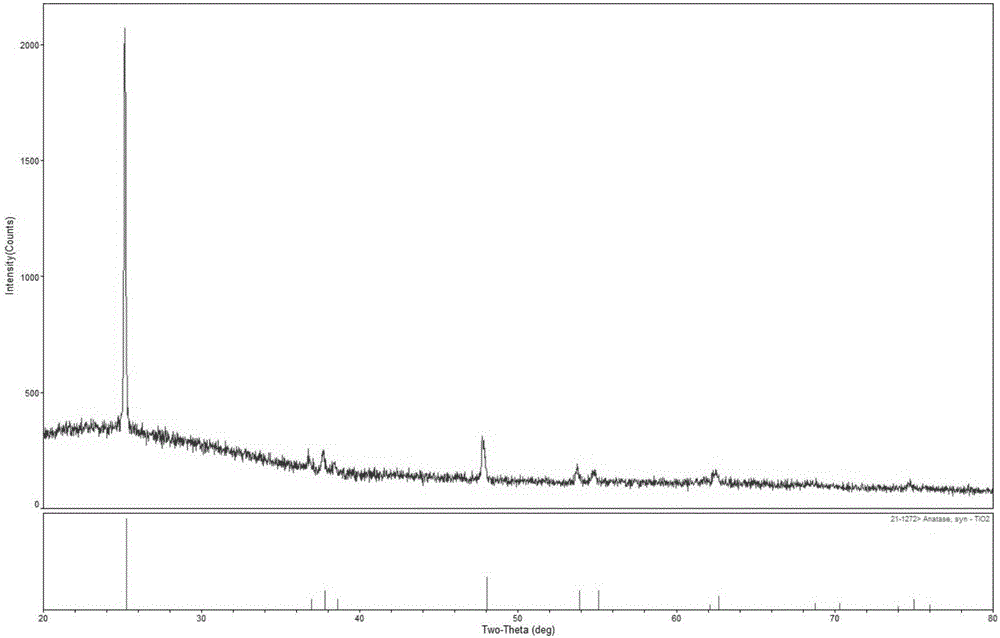

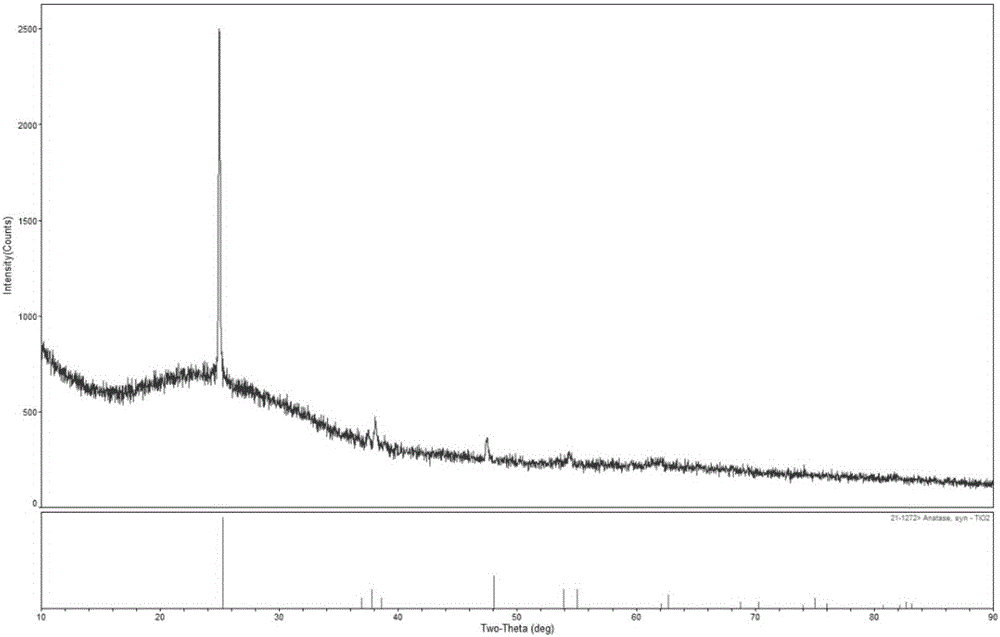

Method for preparing high catalytic activity sodium tantalate photo-catalyst by hydro-thermal method

InactiveCN102553563AImprove photocatalytic activitySmall grain sizeTantalum compoundsMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic reactionReaction temperature

The invention provides a method for preparing sodium tantalate photo-catalyst powder by hydro-thermal method. The method comprises the following steps: using tantalum oxide and sodium hydroxide as raw material, adding water, preparing into solution, stirring fully in order to completely dissolve NaOH, dispersing Ta2O5 into the solution to form precursor solution, arranging the precursor solution into a reaction kettle, reacting at 120-180 DEG C for 12h by hydro-thermal method, cooling after the reaction is finished, taking the precipitate out of the reaction kettle, rinsing into neutrality with de-ionized water and anhydrous ethanol, and drying at constant temperature of 60 DEG C to obtain powder; carrying out photo-catalyzing reaction to the powder with rhodamine B as degradation material, wherein the degradation rate of rhodamine B is higher than 94 percent after 210min under the irradiation of ultraviolet light. The reaction temperature of the invention is low, that is about 140 degrees; and the prepared powder has good photo catalytic activity under the irradiation of ultraviolet light at 140 DEG C.

Owner:SHAANXI UNIV OF SCI & TECH

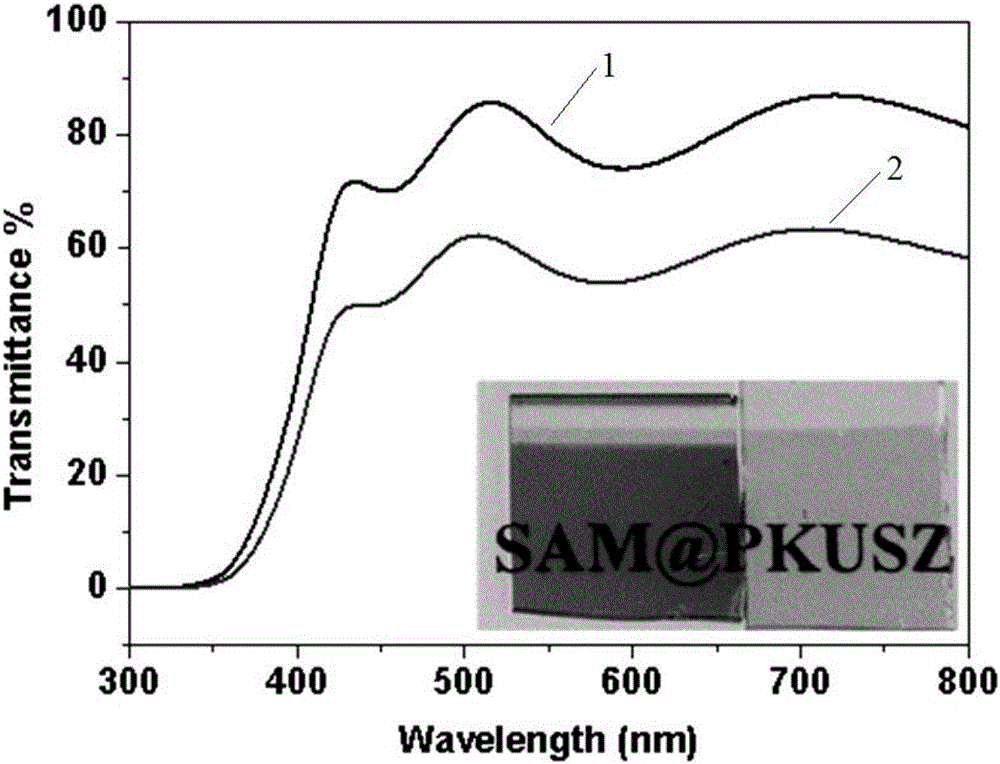

Transparent conductive film as well as preparation method and application thereof

InactiveCN106191775AImprove conductivityImprove temperature resistanceVacuum evaporation coatingSputtering coatingNiobiumTransmittance

The invention discloses a transparent conductive film doped with titanium dioxide as well as a preparation method thereof and an application thereof. The transparent conductive film is a film doped with titanium dioxide, wherein doping is ruthenium doping as well as niobium and / or tantalum doping. According to the transparent conductive film disclosed by the invention, the titanium dioxide is doped with ruthenium, and is also doped with one or two of niobium and tantalum, so that the prepared film doped with titanium dioxide has excellent electrical conductivity, good temperature resistance and high light transmittance; and moreover, the transparent conductive film disclosed by the invention is low in raw material cost and is rich in resource; and the preparation method for the transparent conductive film is simple and easy to operate, can meet needs of large-scale batch production, and lays a foundation for popularization, application and research of the transparent conductive film.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

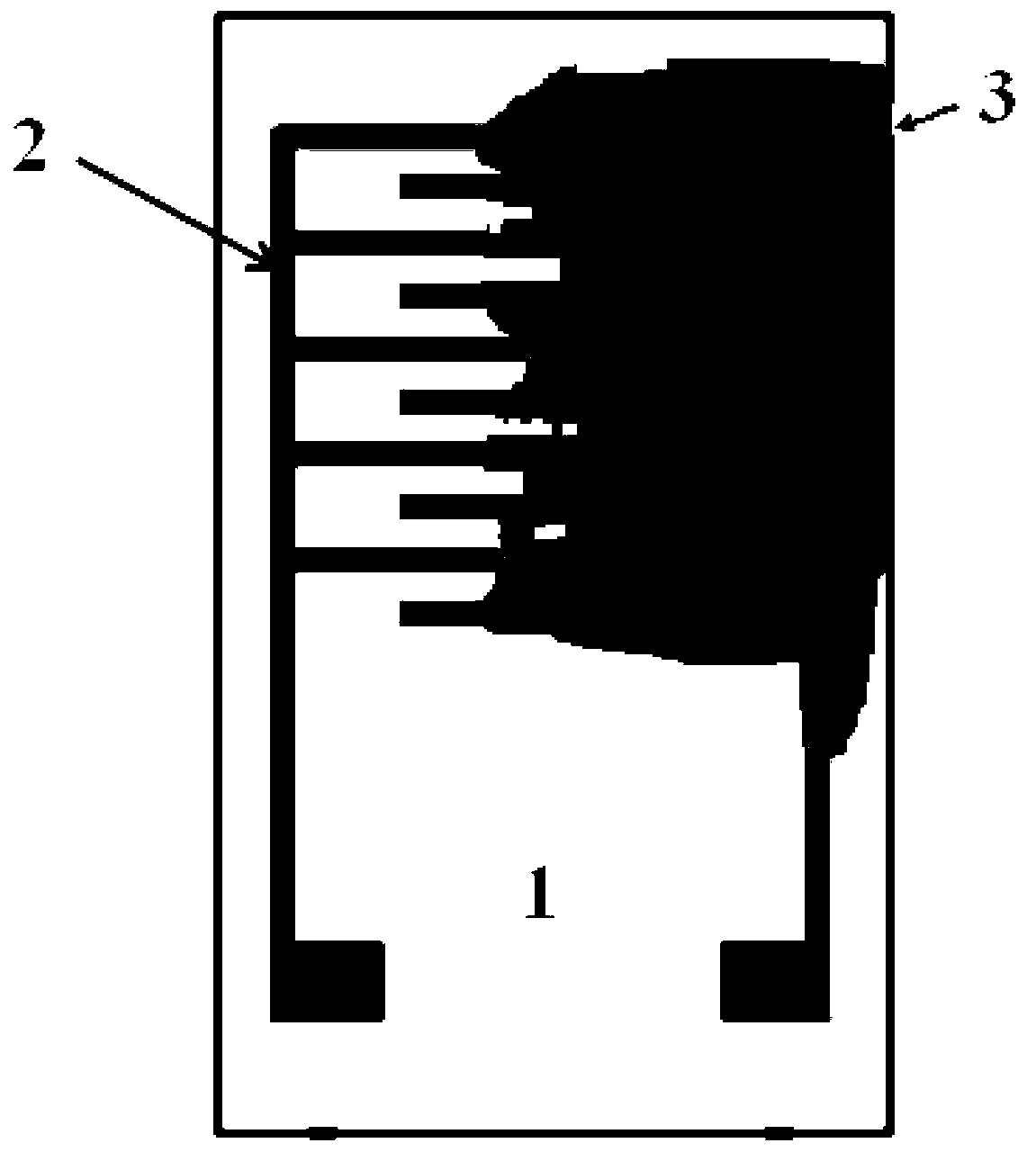

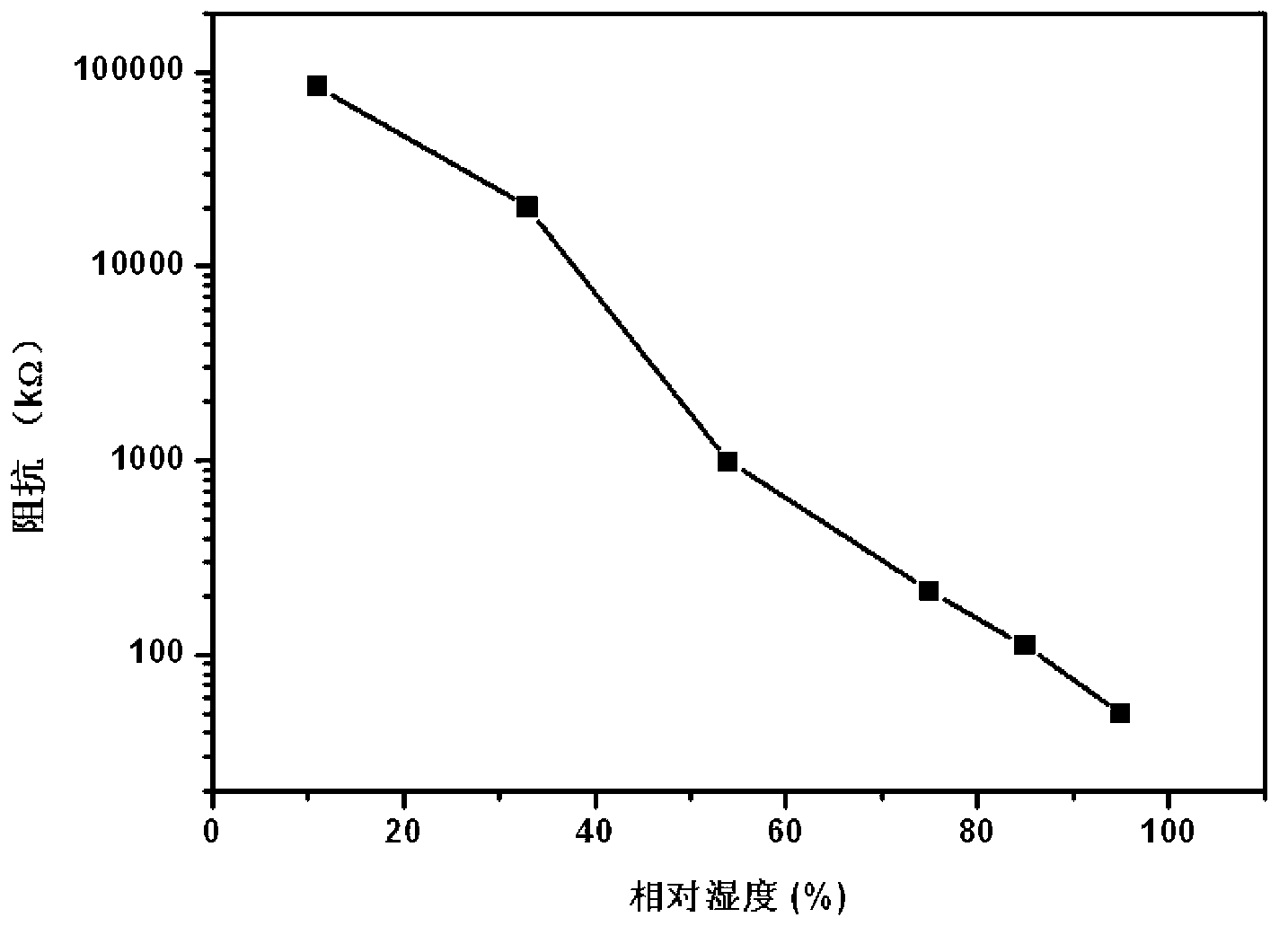

Moisture-sensitive sensor based on potassium tantalite sensitive membrane and preparation method thereof

The invention belongs to the technical field of a moisture sensitive device, and in particular relates to a moisture-sensitive sensor based on a potassium tantalite sensitive membrane and a preparation method thereof. The sensor consists of a ceramic substrate, a gold (Au) metal interdigital electrode and a potassium tantalite sensitive membrane, wherein the Au metal interdigital electrode is prepared on the ceramic substrate by adopting a silk screen printing method, the potassium tantalite sensitive membrane is prepared on the Au metal interdigital electrode by adopting a coating method, the thickness of the potassium tantalite sensitive membrane is 2 to 4 micrometers, and both the width and the interval space of the metal interdigital electrode is 0.15 to 0.20mm. The preparation method comprises following steps of firstly adopting the silk screen printing method to prepare the Au metal interdigital electrode on the ceramic substrate, adopting a hydrothermal method to prepare a potassium tantalite sensitive material, adopting a coating method to coat the potassium tantalite sensitive material onto the metal interdigital electrode to prepare a moisture-sensitive element. The potassium tantalite moisture-sensitive sensor is simple in preparation process, small in size, applicable to mass production, high in sensitivity to the moisture, small in hysteresis, fast in responding time and vast in application value on the aspect of the moisture sensitive detection aspect.

Owner:JILIN UNIV

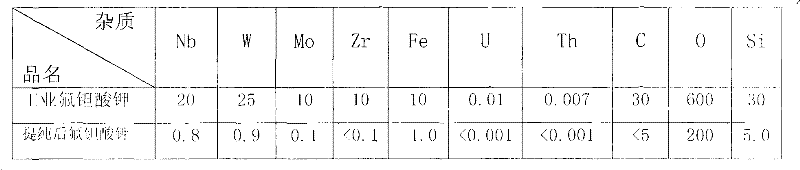

Preparation method of target-grade ultrahigh-purity tantalum metal

The invention provides a preparation method of target-grade ultrahigh-purity tantalum metal. In the method, a recrystallization process is added in tantalum wet-process metallurgy, thereby effectively reducing the contents of high-melting-point metal impurities and radioactive elements. The preparation method comprises: industrial K2TaF7 is put in a pure diluted HF solution, the concentration of crystalline HF is controlled, the temperature of crystalline HF is controlled to 80-90 DEG C, and potassium salt is excessive by 5-10%; after naturally cooling to 35-45 DEG C, cooling water is introduced to cool to room temperature; filtration is carried out while washing with a solution having PH 9 and absolute ethyl alcohol, thus high-melting-point metals, transition metals and impurities such as uranium, thorium, carbon, oxygen and the like are effectively removed; and then in tantalum pyrometallurgy, Si is effectively removed, and the pollution of Fe, Ni and Cr is prevented; and low-melting-point metals of less than 3000 DEG C are further removed in tantalum refining, thereby effectively reducing the contents of C, N and O. By using the preparation method provided by the invention, therefining frequency of an electron beam furnace is saved, and production cost is reduced.

Owner:稀美资源(广东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com