Patents

Literature

496results about How to "Reduce alkali consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

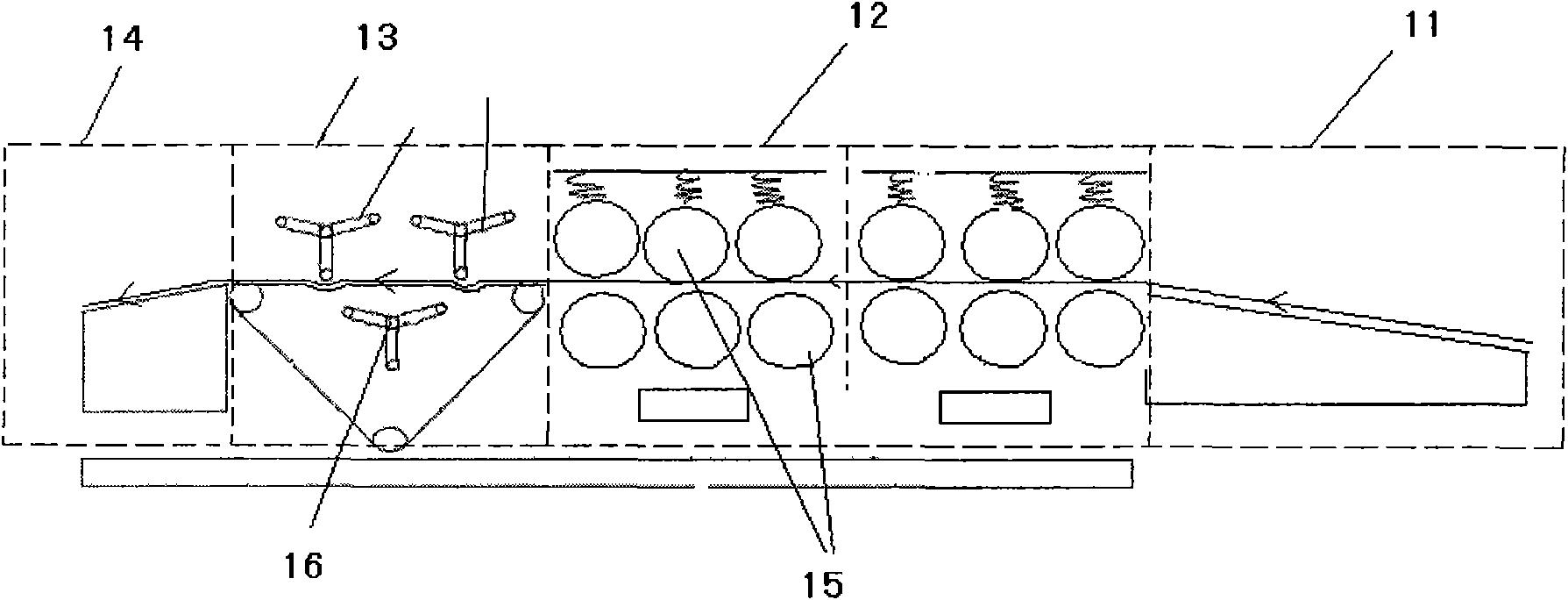

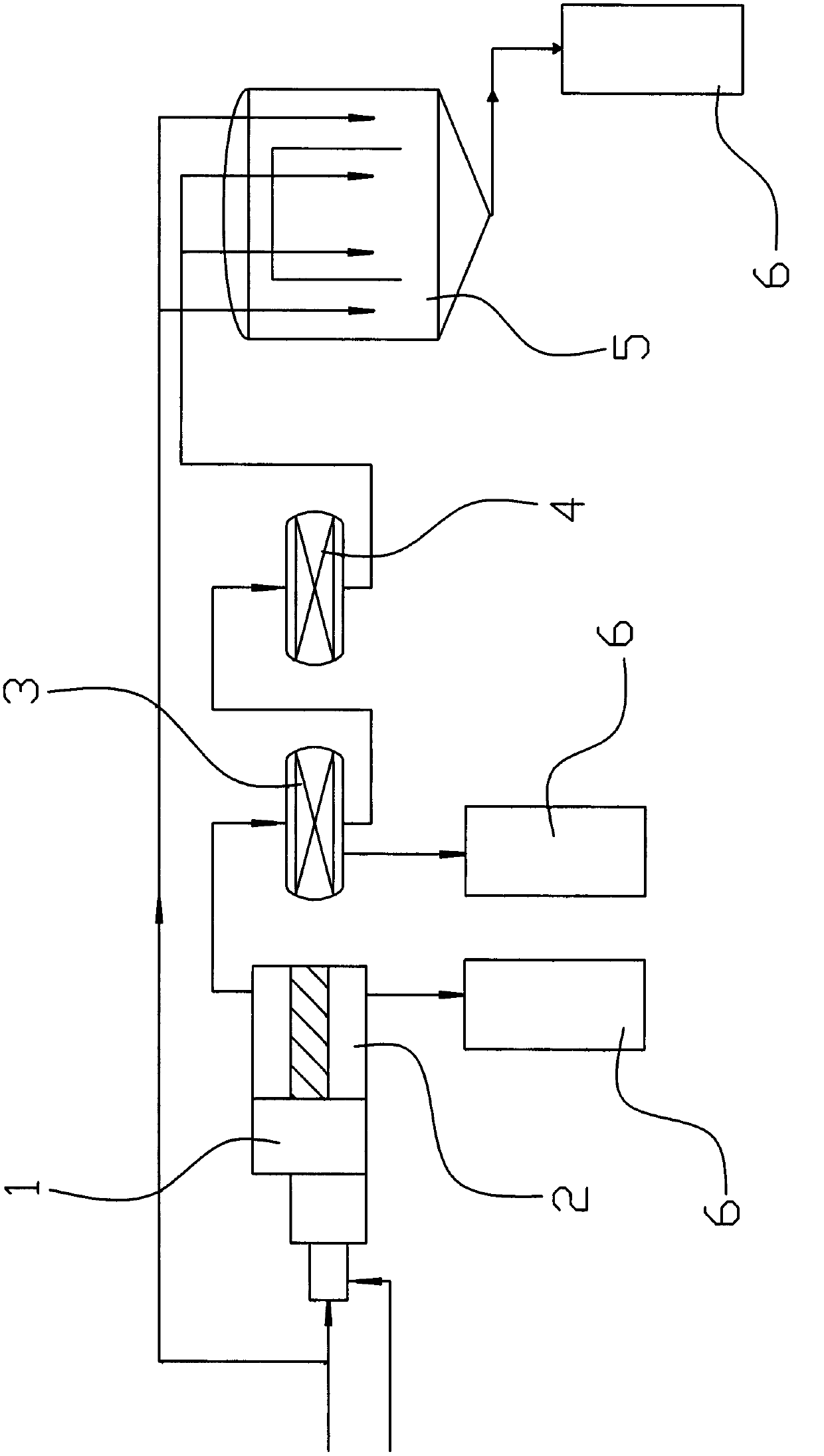

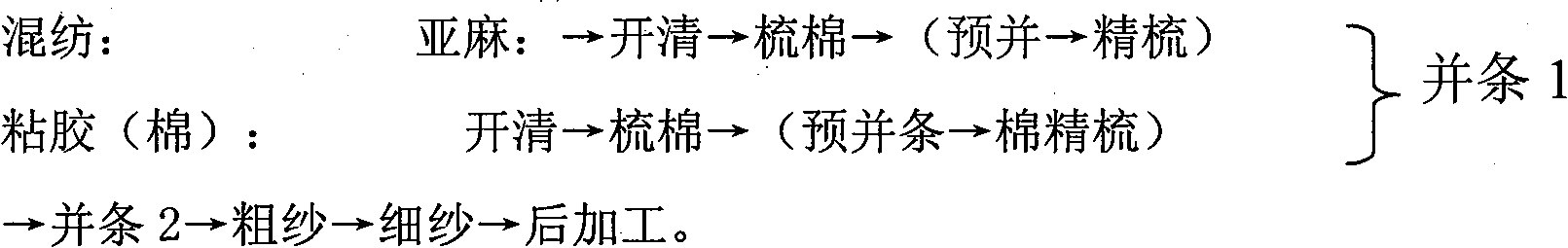

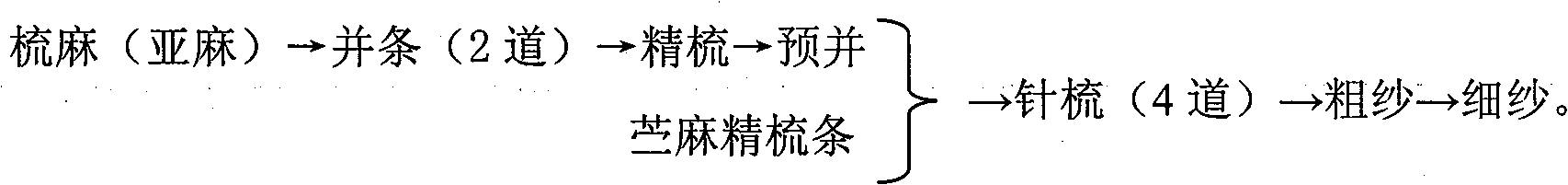

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

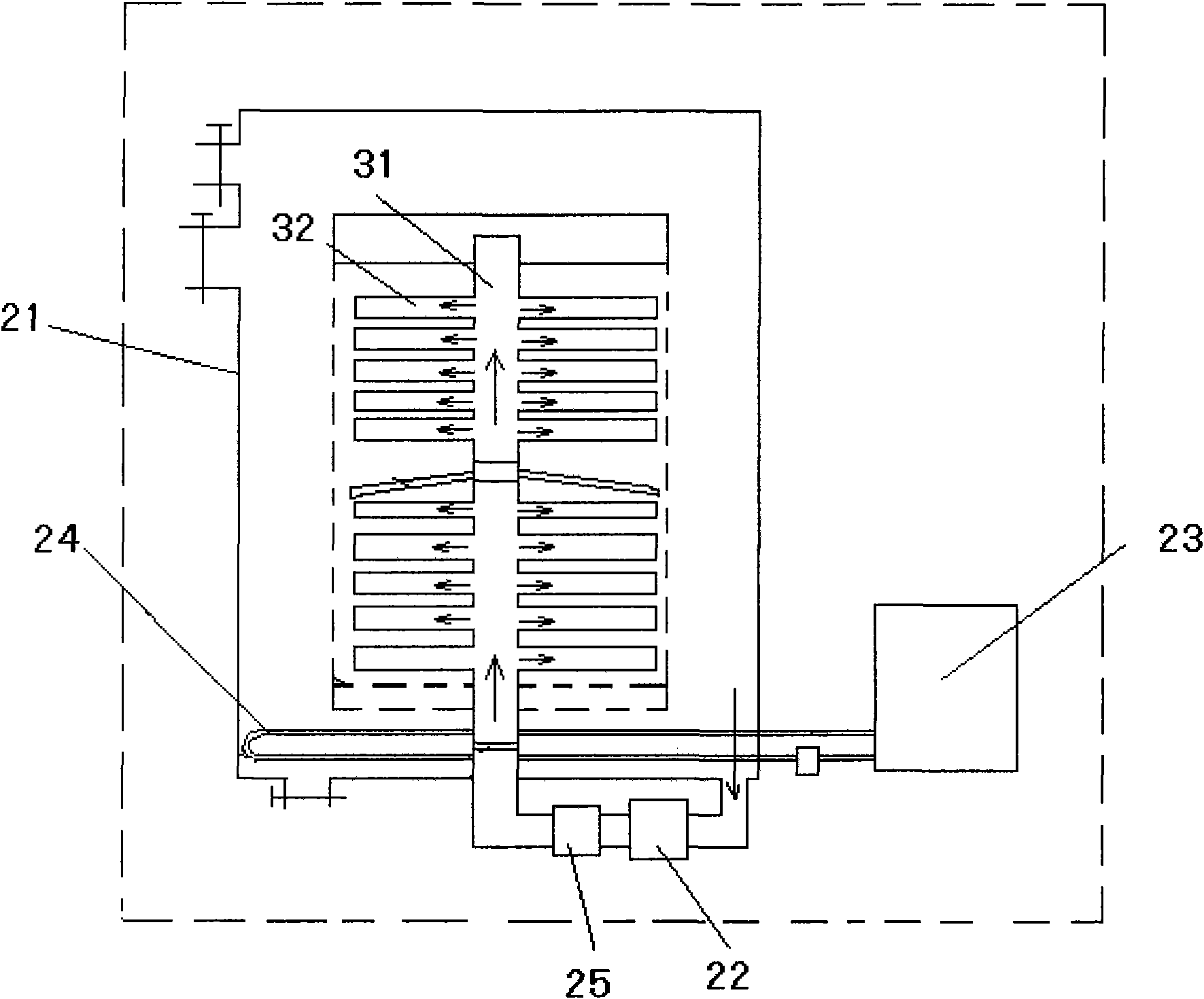

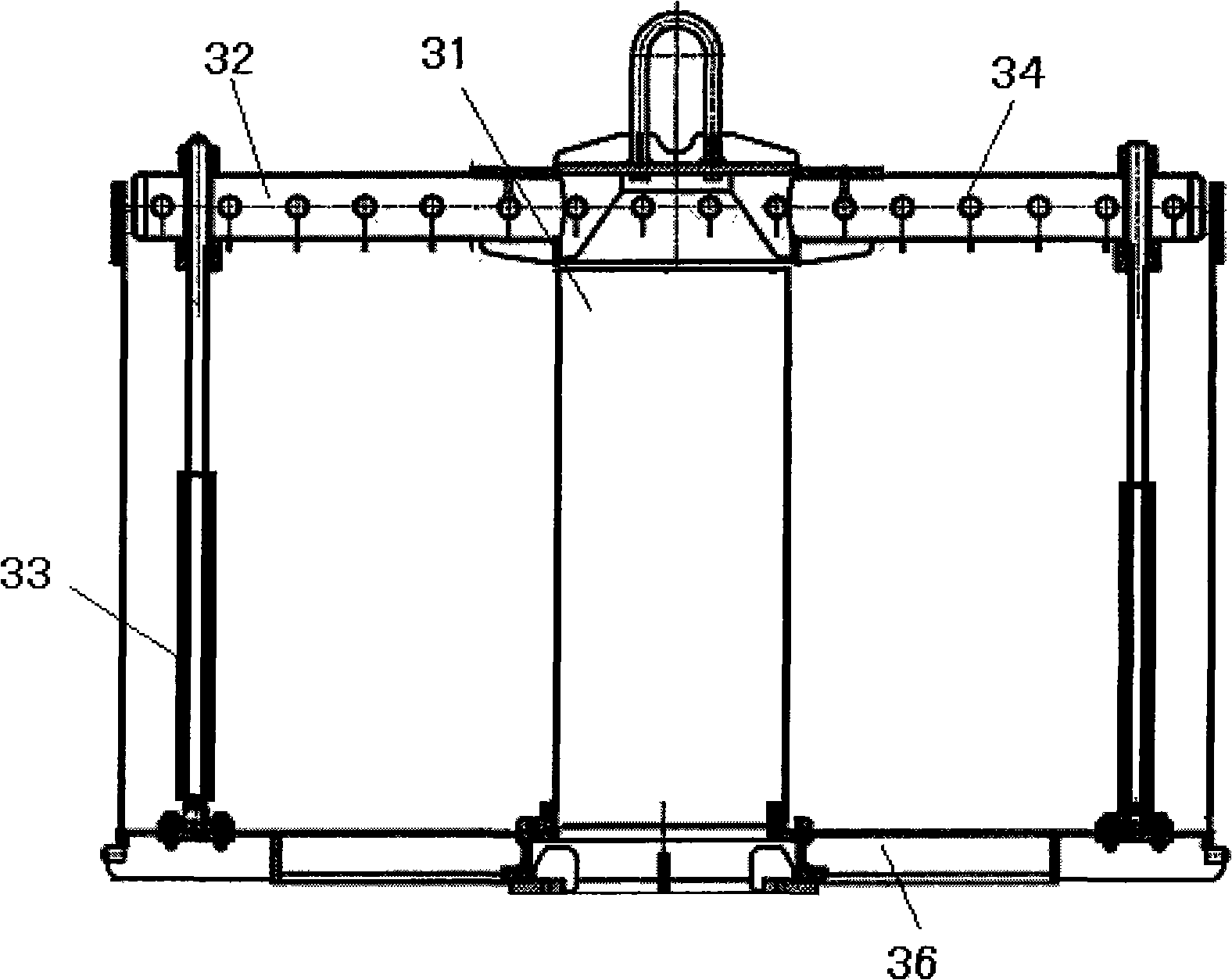

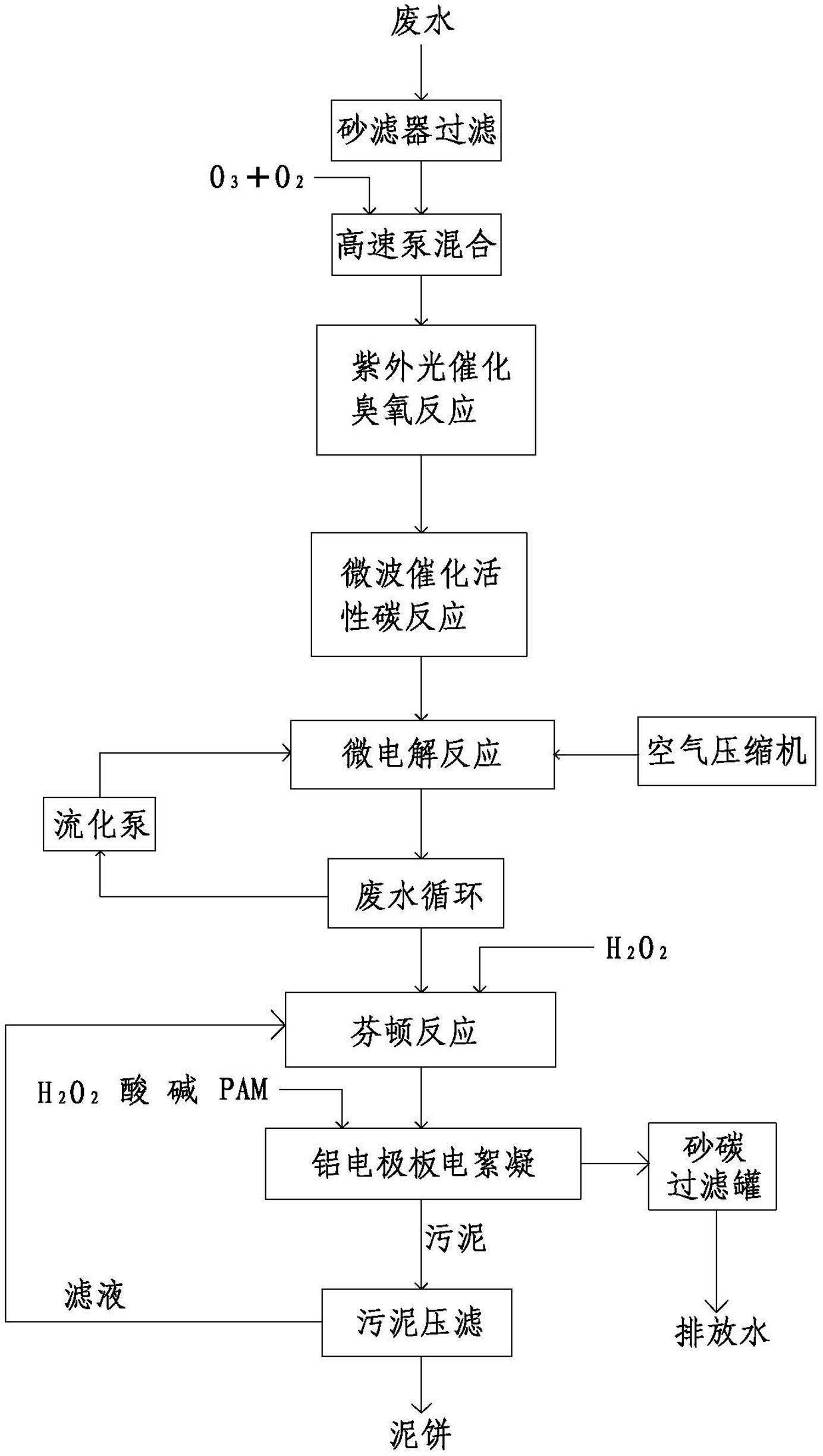

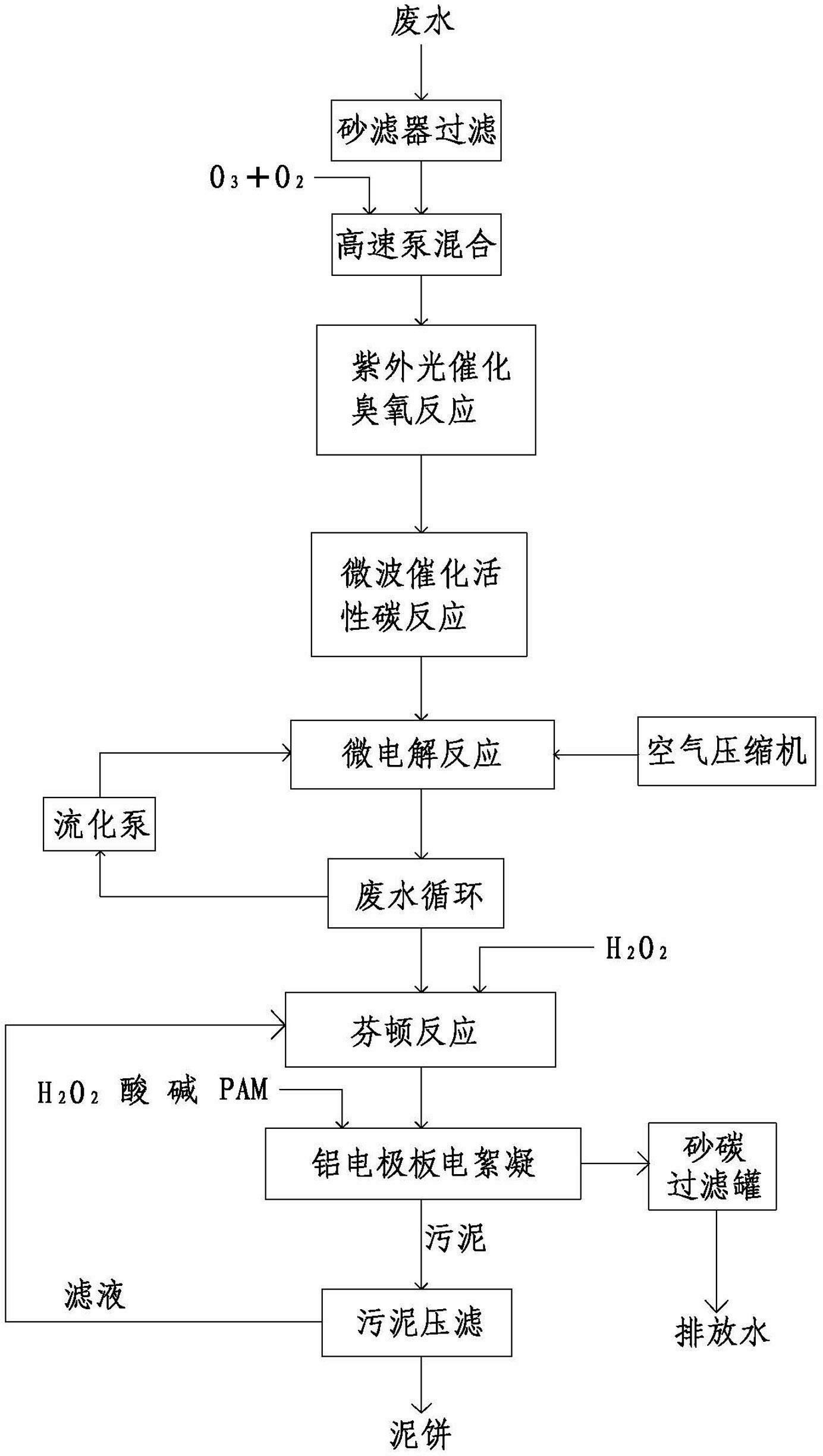

Complex heavy-metal waste water emergency quick treatment method

ActiveCN102603103AIncrease contact areaQuick responseMultistage water/sewage treatmentChemical oxygen demandSludge

The invention relates to a complex heavy-metal waste water emergency quick treatment method, comprising the following steps of: filtering by a sand filter; mixing by a high-speed pump; carrying out an ultraviolet catalyzing ozone reaction; carrying a microwave catalyzing active carbon reaction; carrying micro-electrolytic reaction; circulating waste water; carrying out a Fenton reaction; carryingout electric flocculation on an aluminum electrode plate; and pressing and filtering sludge. Waster water in a circulating slot is pumped into an iron carbon fluidized bed by a fluidizing pump to be circularly treated; an air compressor is connected with the iron carbon fluidized bed and prevents a filler in the iron carbon fluidized bed from blocking; and the microwave active carbon reactor is an active carbon filling tower, and a microwave emitter is arranged outside the body of the active carbon filling tower. The complex heavy-metal waste water emergency quick treatment method disclosed by the invention is used for treating the complex heavy-metal waste water, associated devices are simple, easy, quick, can meet an emergency, and can update and convert, no various chemical raw materials are fed, and various complex heavy-metal waste water with unknown elements can be quickly treated as long as the current magnitude is regulated, and thus the heavy metal in the waste water and chemical oxygen demand can immediately reach the standard and are discharged.

Owner:东莞市珠江海咸水淡化研究所有限公司

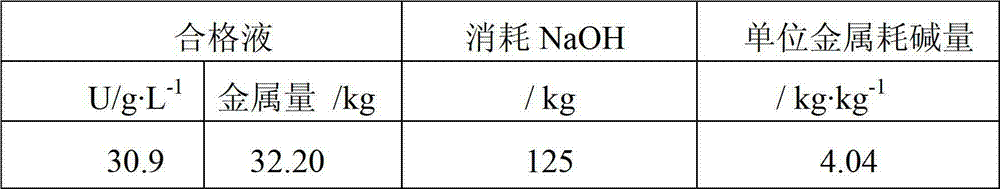

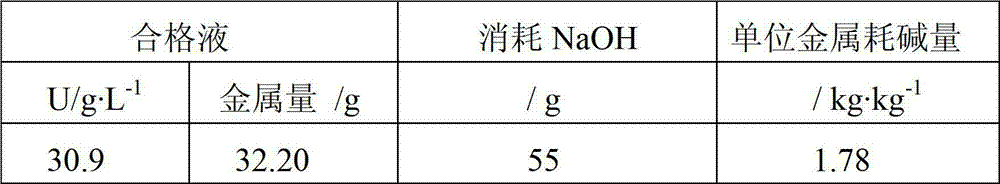

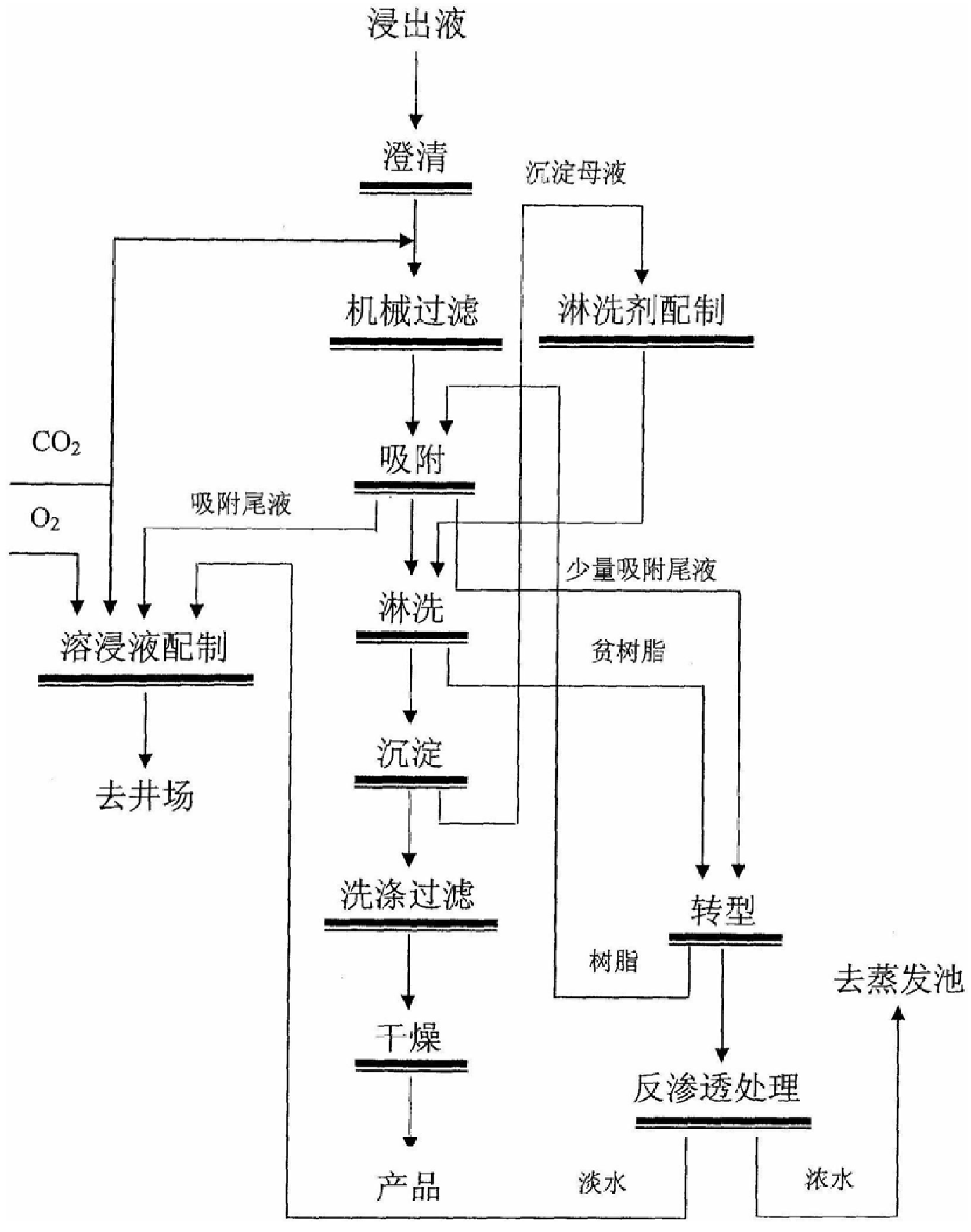

In-situ uranium leaching and mining treatment method by adding O2 into CO2

The invention provides an in-situ uranium leaching and mining treatment method by adding O2 into CO2. The invention comprises the steps of (1) adding O2 into leaching solution, then injecting an underground mine-water contained layer into a liquid injection pipeline, and preparing the leaching solution by adopting different oxygenation concentrations according to different underground leaching periods; (2) adding 100-300mg / L of CO2 into the leaching solution containing uranium; (3) conducting ion exchange adsorption on the leaching solution containing uranium, adopting macroporous styrene strong-base anion exchange resin, adsorbing to obtain saturated resin adsorption tail solution; and (4) washing saturated resin by adopting an eluting agent, and then analyzing uranyl carbonate ion solution to obtain Na2U2O7 sediment slurry and sediment mother liquor. According to the method, a high-temperature heating device is eliminated, so that the energy consumption and equipment investment are lowered greatly, the alkali consumption is lowered, control parameters are refined, the consumption of alkali is saved, and the production cost is lowered.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur

ActiveCN104208992AHigh activityReduce energy consumptionDispersed particle separationSulfur preparation/purificationCombustionLiquid state

The invention discloses a method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur. The method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur sequentially comprises the following steps: introducing the acid gas into a combustion furnace to be mixed with air introduced by the other pipeline so as to carry out a combustion reaction; introducing the gas reacted in the combustion furnace into a cooler to be cooled to 230-250 DEG C, after cooling, separating the cooled liquid sulfur at a liquid outlet, introducing mixed gas in the combustion furnace into a catalyst reactor, enabling hydrogen sulfide to react with sulfur dioxide in the catalyst reactor so as to generate sulfur and water, and separating the generated liquid sulfur at the liquid outlet of the catalyst reactor; introducing the mixed gas in the catalyst reactor into a hydrogenation reactor and enabling the sulfur dioxide to react with hydrogen in the hydrogenation reactor; introducing the gas in the hydrogenation reactor into a hydrogen sulfide absorption device and preparing the hydrogen sulfide into elemental sulfur under the action of an alkaline solution, a complex catalyst and the introduced air. The method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur has the advantages of short process route, high quality of produced sulfur and low energy consumption, is capable of fully removing SO2 gas and is green and environmentally friendly.

Owner:NINGBO RES & DESIGN INST OF CHEM IND

A method for preparing dissolving pulp by steam explosion prehydrolysis sulfate method of crop straw

InactiveCN102268833AReduce alkali consumptionReduce the effect of ashWashing/displacing pulp-treating liquorsPulp bleachingChemistryInorganic salts

The invention discloses a method for preparing dissolving pulp by carrying out steam explosion on crop straw and adopting a prehydrolytic sulfate process. The method has the following advantages: steam explosion and washing are adopted to remove about 80% of hemicellulose, 10% of lignin and 72% of inorganic salt in advance and the excellent long fibers and the short fibers are separated through mechanical carding, thus solving the problems of short fibers of the crop straw, prominent non-uniformity and high ash content; the excellent long fibers obtained through separation are cooked by a sulfate process; the prepared dissolving pulp has excellent performances and can replace wood pulp, thus widening the application range of the dissolving pulp; at the same time, the washing solution obtained after steam explosion and washing and the fine fibers obtained through carding and screening are directly used for fermenting biogases; the cooking black liquor undergoes acid precipitation and washing to prepare high-purity lignin; and the excellent long fibers of the crop straw are used for preparing the dissolving pulp and the fine fibers, the hemicellulose and the lignin are simultaneously effectively separated and utilized, thus realizing comprehensive utilization of the straw resources, being beneficial to reduction of the production cost and realizing industrialized application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

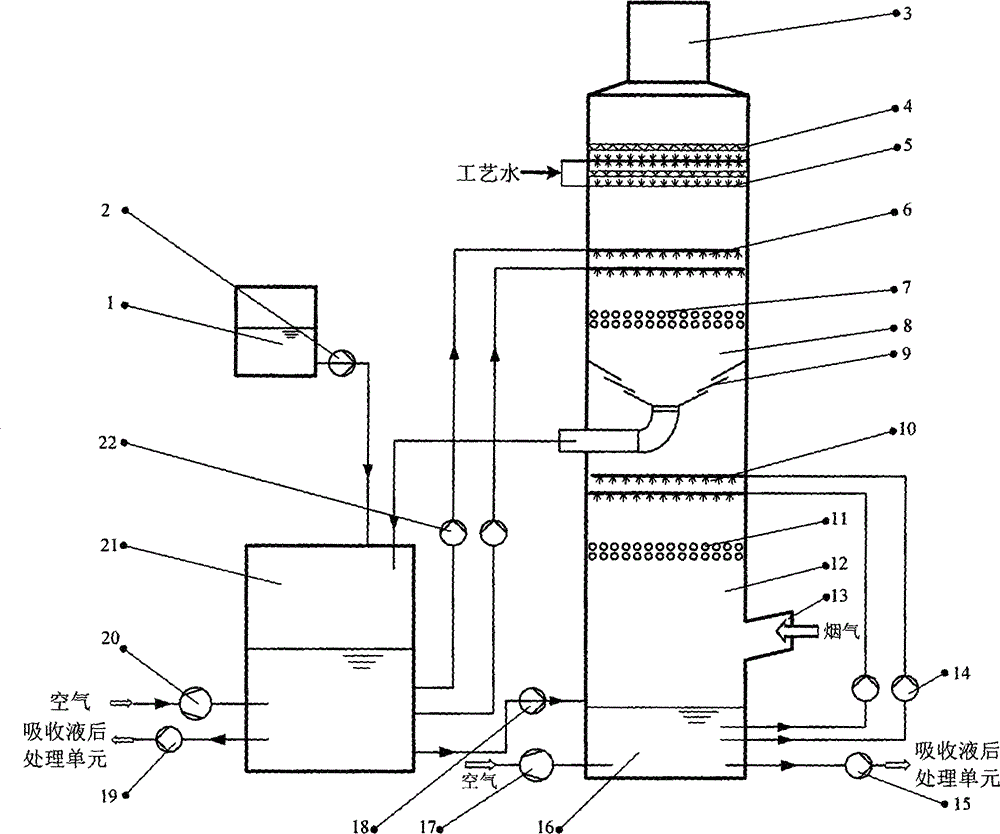

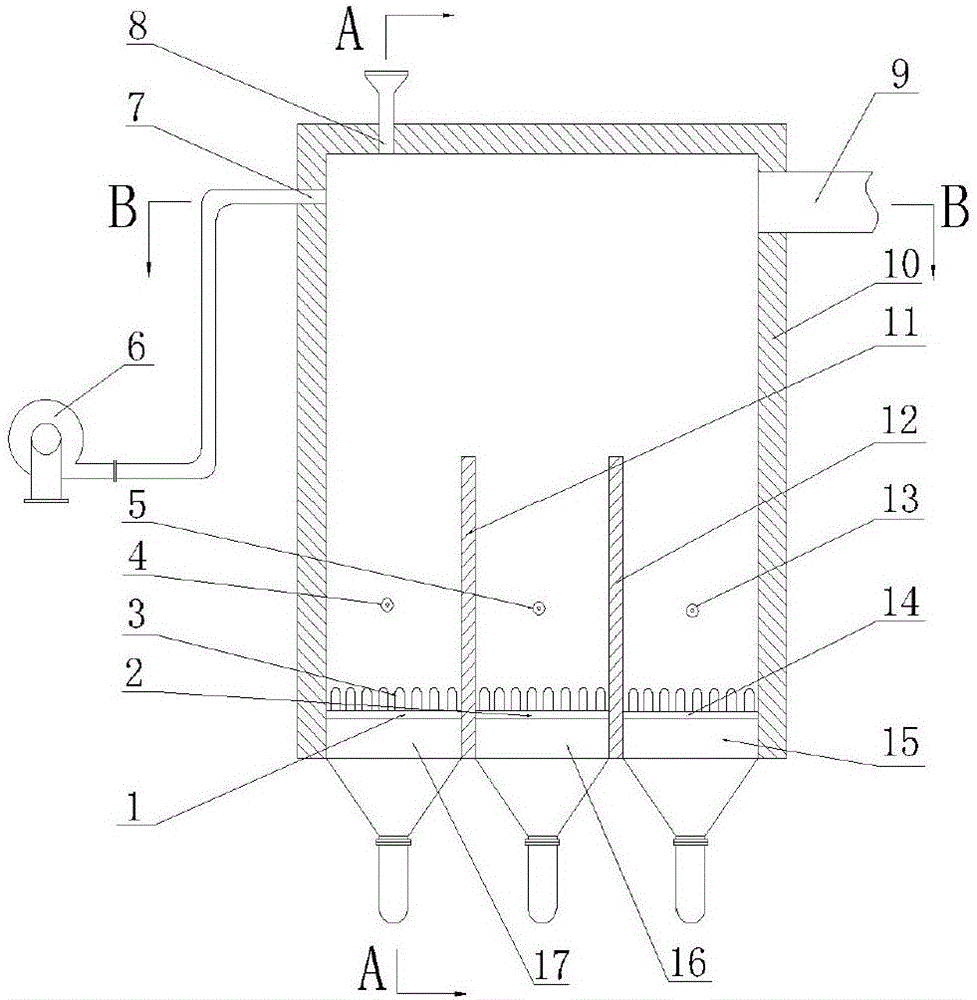

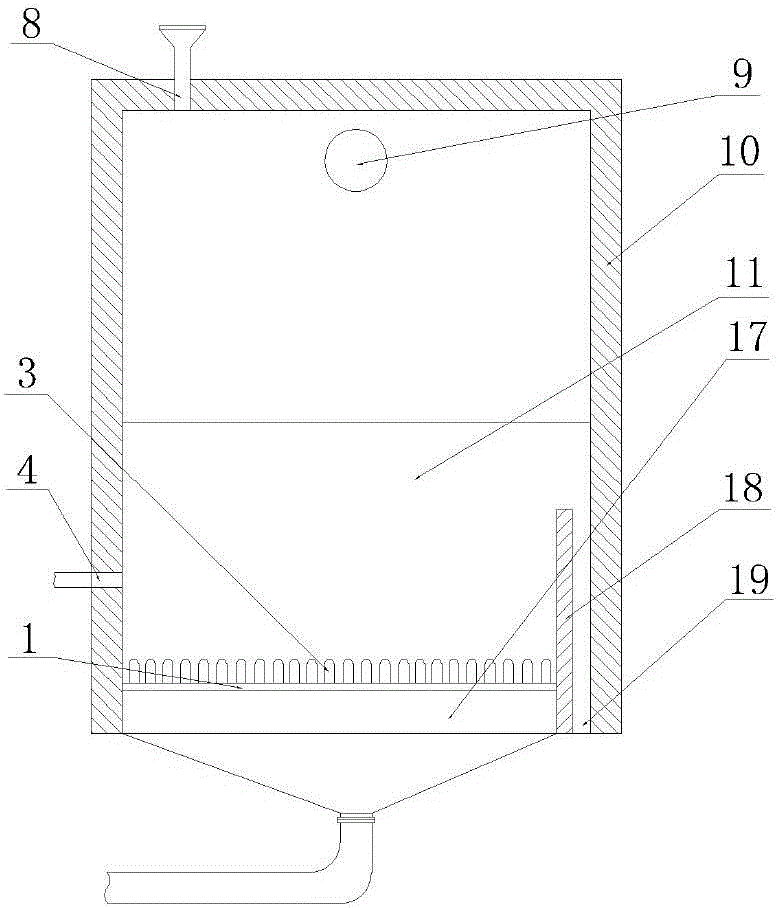

Flue gas dust removal desulphurization system of double-circulation Venturi rod tower

The invention belongs to the field of environment protection, and discloses a wet-method flue gas dust removal desulphurization system of a double-circulation Venturi rod tower. The system comprises an adsorption-liquid supplying unit, a flue-gas purification unit and an adsorption-liquid postprocessing unit. The flue-gas purification unit comprises an upper Venturi rod tower section, a lower Venturi rod tower section, a shutter-type separation cone separating the upper Venturi rod tower section and the lower Venturi rod tower section, an upper circulation liquid pool, a lower circulation liquid pool, upper circulation-liquid sprayers, lower circulation-liquid sprayers, and demisters. Flue gas in the upper tower section and flue gas in the lower tower section are in series connection. A circulation-liquid spraying system is operated independently. Dust removal and desulphurization are separately optimized and performed. The "homogenization" gas flow distribution, "gas in liquid" efficient mass transfer, highly-turbulent "self-cleaning", and other effects of Venturi rod layers are fully utilized by the system so as to perform efficient cooling, dust removal desulphurization of the flue gas. The system is advantages by high dust removal desulphurization efficiency, low operation liquid gas ratio, small resistance, less scale, small occupation area, low investment, low operation energy consumption, less discharge of high-salt water, and the like, and is suitable for dust removal and desulphurization for various kinds of flue gas, particularly suitable for processing of high-temperature high-dust high-sulfur flue gas such as regenerated flue gas of a petroleum catalytic cracking device.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

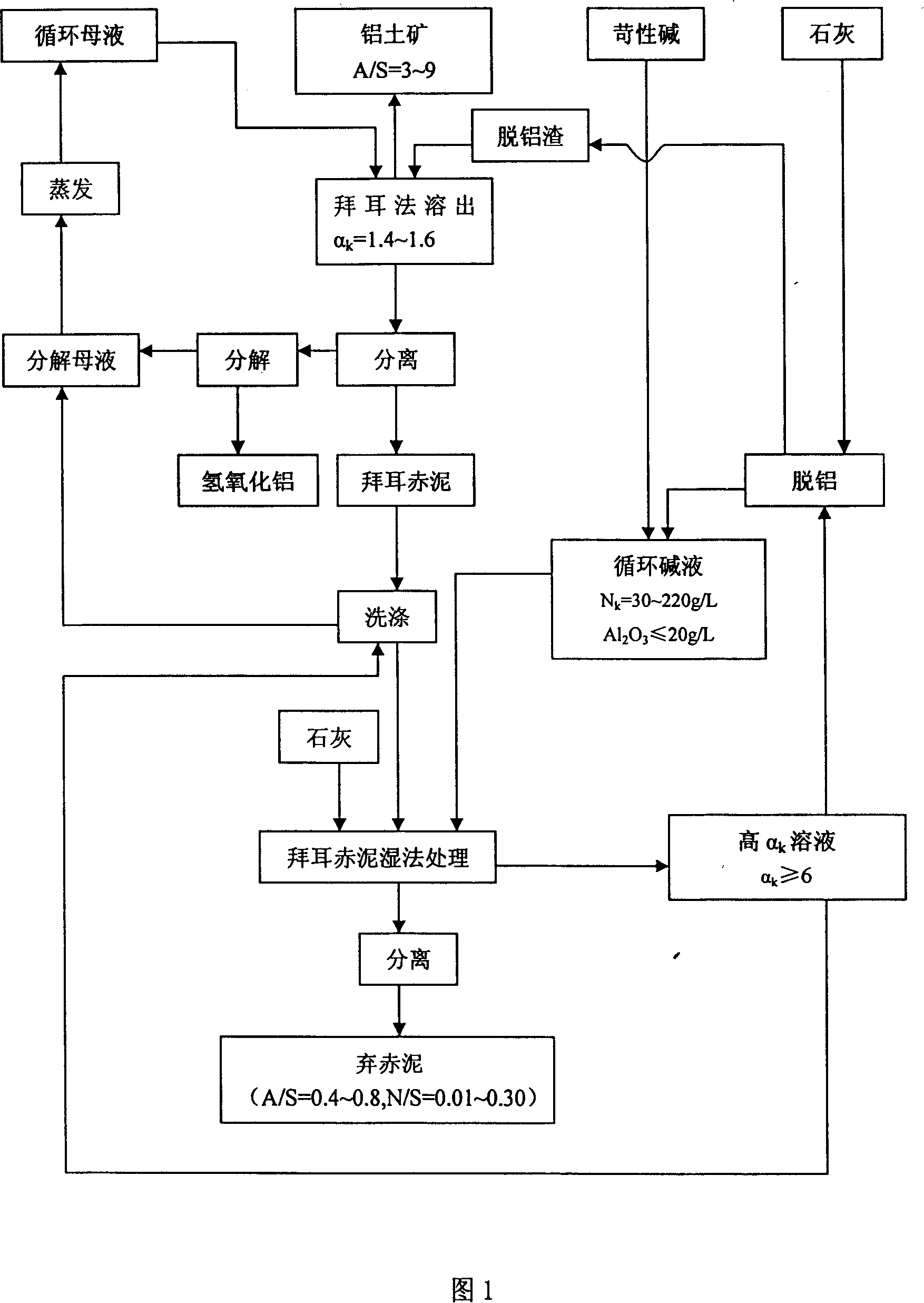

Method for producing aluminium oxide by middle-low grade alumyte

ActiveCN101113001AReduce energy consumptionReasonable processAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateResource utilization

A method to produce aluminum oxide with middle-low bauxite relates to a method to produce aluminum oxide with middle-low bauxite by the means of Bayer-method. The invention is characterized in that: during the Bayer-method process, digestion process is to add dealuminization slag instead of lime as additive in middle-low bauxite to do Bayer process digestion; after digestion and backward washing of red mud, the red mud is mixed with recycle alkaline liquor, the lime is added, the digestion reaction is done, the red mud is separated from the slurry and discharged outside, the solution part obtained oppositely washes with Bayer-method, is sent to Bayer-method system to supplement alkali after digesting the red mud, the lime is added partly and is reacted, then, dealuminization slag and recycle alkaline liquor that goes through Bayer-method red mud wet treatment are gotten and dealuminization slag calcium aluminate hydrate instead of lime is added into the Bayer process digestion. The method of the invention belongs to all wet treatment, has simple process, low energy consumption, low alkali consumption and high recovery rate of aluminum oxide and is suitable for treating Chinese bauxite that is mainly middle-low bauxite; besides, the resource utilization is high, the amount of discharged red mud is low and the red mud is easy to be utilized comprehensively.

Owner:中铝郑州有色金属研究院有限公司

Multifunctional bio-charcoal and preparation method thereof

The invention relates to a multifunctional bio-charcoal and a preparation method thereof. According to the technical scheme, the preparation method comprises the steps of dipping biomass into 1-15wt% caustic alkali solution for 1-50h, washing with water to be neutral, and drying to obtain treated biomass; then charring the treated biomass in a tube furnace in mixed gas at 300-900 DEG for 1-130h to obtain the multifunctional bio-charcoal. The biomass is one of rice straw, wheat straw, sawdust, wood, green grass, fruit peel and animal tissue waste; the biomass contains 30-60wt% of volatile organic carbon of charcoal, 10-40wt% of fixed carbon, 1-30wt% of ash and 10-60wt% of water. The preparation method disclosed by the invention has the characteristics of low production cost, high yield, simple process, controllable production process and environment friendliness, and the prepared multifunctional bio-charcoal has a good adsorption effect on heavy metals and high stability and can be used for repairing water bodies, solid matrixes and soil which are polluted by heavy metals.

Owner:WUHAN UNIV OF SCI & TECH

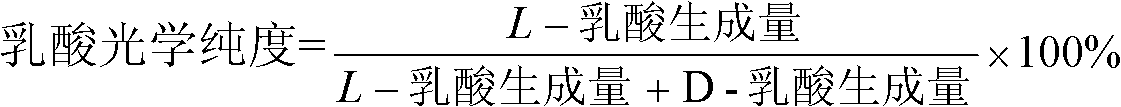

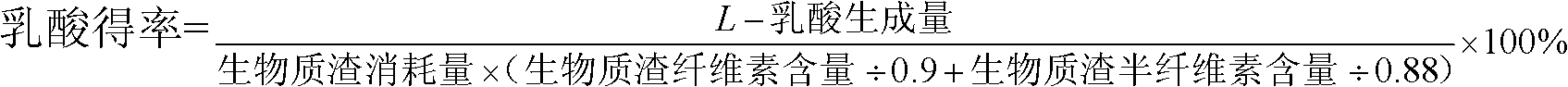

Method for producing L-lactic acid through biomass fermentation

ActiveCN102174602AReduce alkali consumptionImprove efficiencyMicroorganism based processesFermentationWater dischargeWastewater

The invention discloses a method for producing L-lactic acid through biomass fermentation. The method comprises the following steps: after the biomass is subjected to alkaline liquid heat treatment, performing solid-liquid separation to obtain a liquid I and residues II; adding a culture medium containing the residues II into a saccharification fermentation tank, adding a cellulose degradation enzyme and performing a hydrolysis reaction for 0.5-6 hours at 50-55 DEG C; keeping the temperature of the saccharification fermentation tank at 50-55 DEG C; adjusting the pH value of the culture medium to 6.0-6.5 by using the liquid I; inoculating bacillus coagulans into the saccharification fermentation tank; and performing synchronous saccharification fermentation on the residues II for 48-96 hours in an anaerobic condition to produce L-lactic acid, and adding the liquid I in flow to keep the pH value of the fermentation liquid at 5.2-5.8. Compared with the prior art, the method disclosed by the invention not only can improve the comprehensive efficiency of converting cellulose and hemicellulose into lactic acid, and adopts an alkaline waste liquid to neutralize lactic acid in the fermentation process so as to reduce alkali consumption and waste water discharge in the lactic acid production industry.

Owner:NANJING FORESTRY UNIV

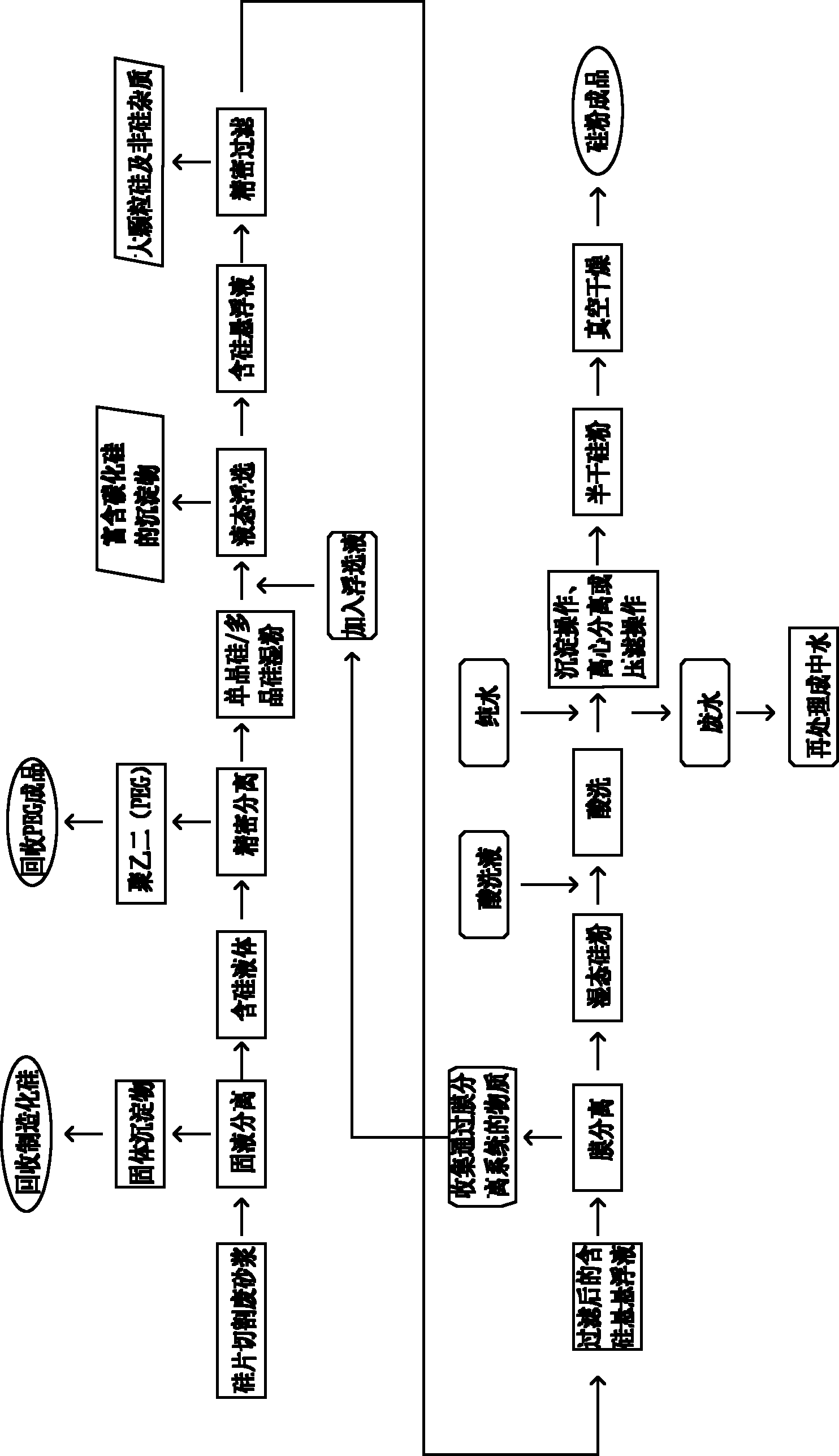

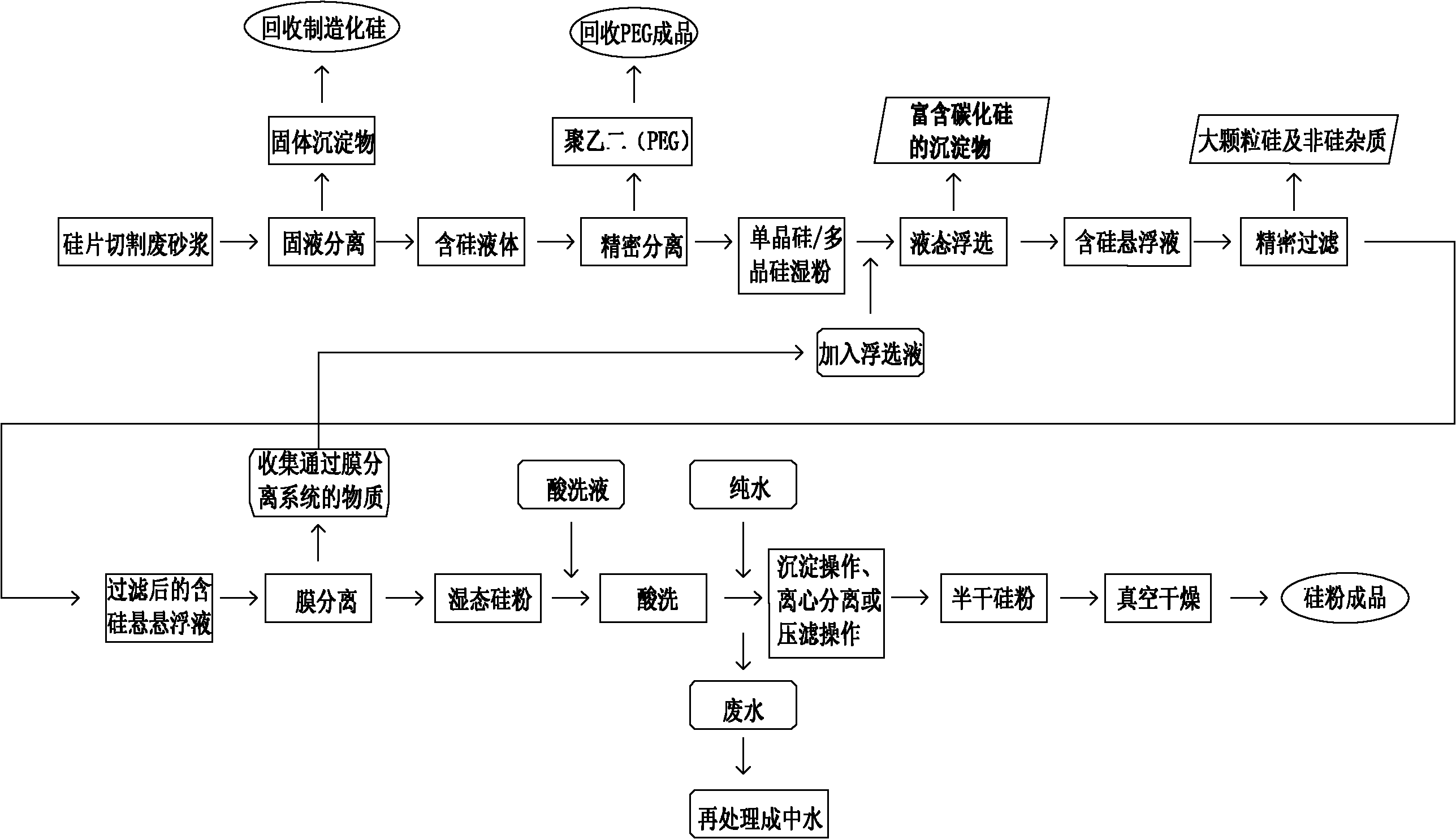

Method for recycling silicon powder from silicon slice cut waste mortar

InactiveCN102173419AAchieve recyclingImprove applicabilitySiliconLubricant compositionPolyethylene glycolSilicon chip

The invention relates to a method for recycling silicon powder from silicon slice cut waste mortar. The invention comprises seven procedural steps of solid-liquid separation of silicon slice cut waste mortar, precision separation of silicon-contained liquid, liquid flotation, precision filtering, film separation, pickling and vacuum drying. The method in the invention is used to produce silicon powder with a purity of 99.5-99.9% and solve the problems existing in the existing silicon slice cut waste mortar recycling industry, such as difficult separation between solid and liquid, low purity of recycled products, poor recycling rate, incomplete recycling process and the like. In the invention, the polyethylene glycol and carborundum can be recycled and the recycling of polycrystalline silicon and monocrystalline silicon can be realized, which improves the material recycling ratio of the solar equipment industry and come up to the cleanness standards.

Owner:常州广正知识产权代理有限公司

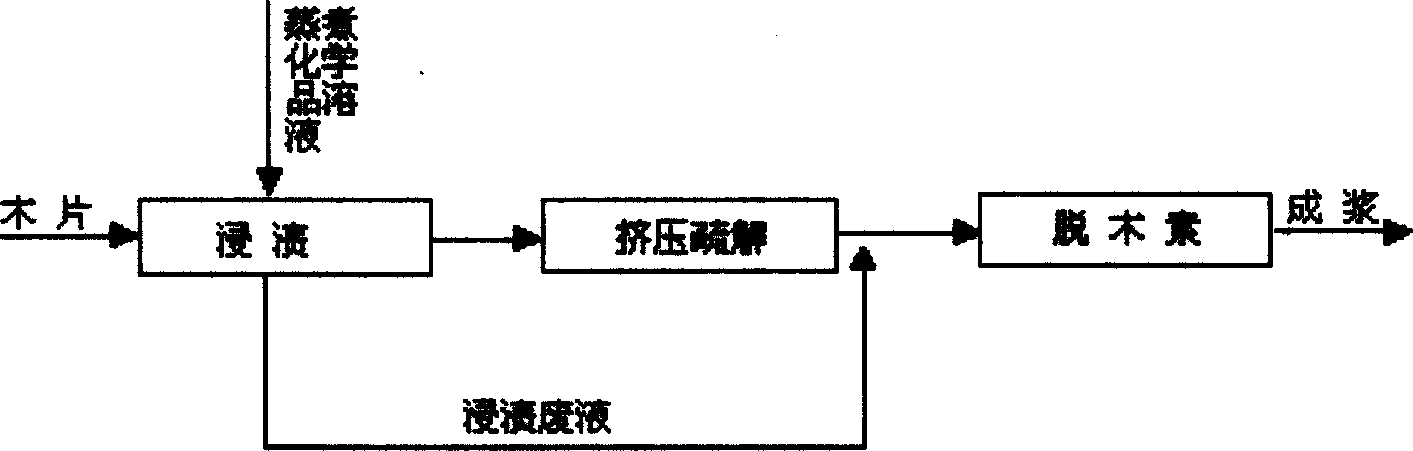

Method for producing chemical wood pulp

InactiveCN1563564AIncrease production capacityTake advantage ofCellulose material pulpingMaterials sciencePressed wood

This invention is a chemical wood pulp productive method. It contains following steps: 1) To soak, Put the thin piece wood plate into the soak liquid container, the soaking temperature is 50-90 deg.C. Soaking time is 15-50 minutes; the soak liquids use part or whole boiling liquid. 2) To relieve squeeze and press; relieve the pressed wood plate, the pressing ratio is 3-6:1. 3) To take-out lignin: put the pressing wood plate and its soak liquid into the boiler, boiling them to do the reaction of take-out lignin.

Owner:QILU UNIV OF TECH

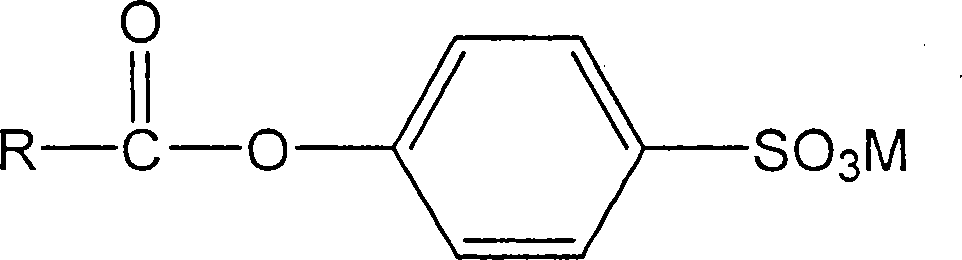

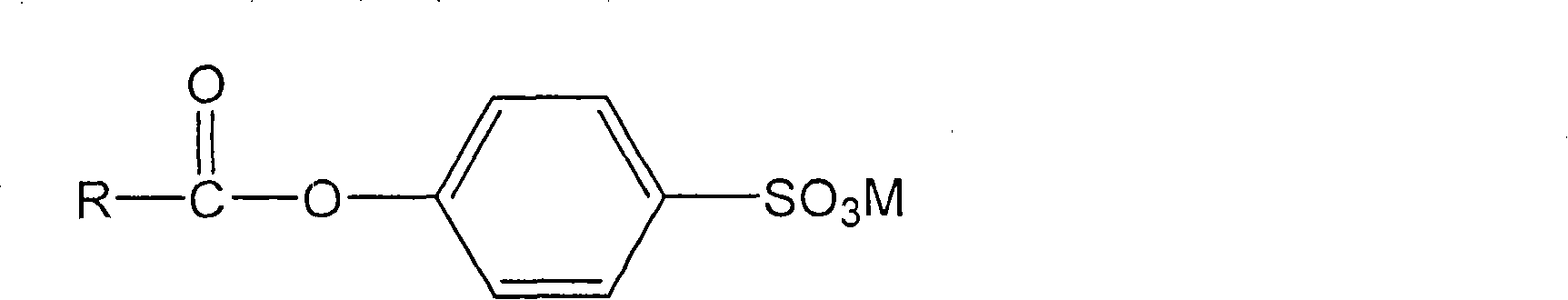

Cold-pad-batch method for textile materials

InactiveCN101135113AAchieve the bleaching effectAvoid damageTextile storage in wounded formFibre treatmentEngineeringBatch method

The present invention discloses process of cold padding, stacking and actively bleaching fabric. The process includes through steps, including one step of compounding bleaching solution and padding, one step of winding and stacking, and one step of hot water washing and cold water washing. The present invention adopts alkanoylxy benzene sulfonate bleaching activator, hydrogen peroxide / activator bleaching system, and cold padding and stacking treatment to reach excellent fabric bleaching effect. Compared with traditional bleaching technology, the present invention has the advantages of excellent fabric bleaching effect, lowered alkali consumption, reduced stacking time, less fabric damage, raised production efficiency and environment friendship.

Owner:ZHEJIANG SCI-TECH UNIV

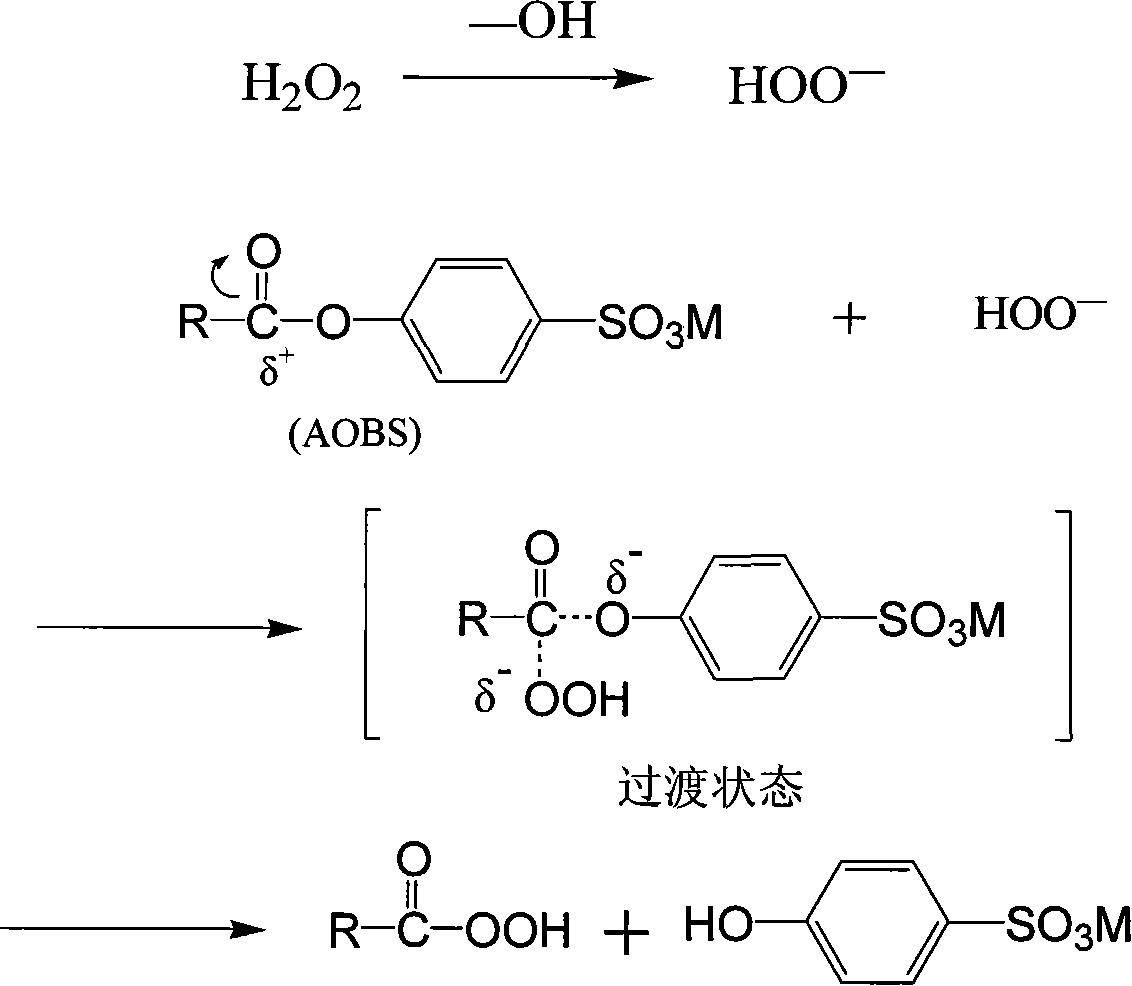

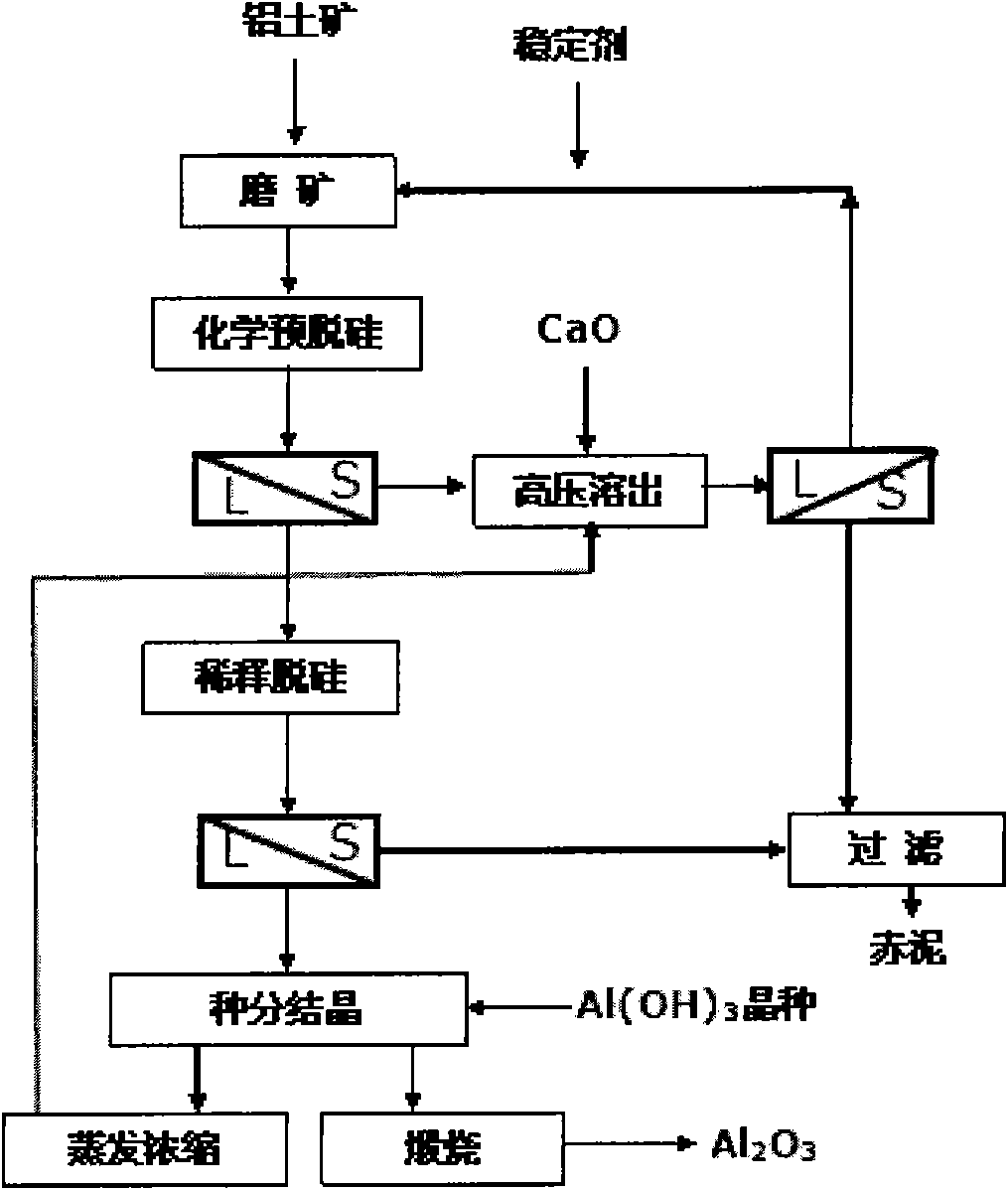

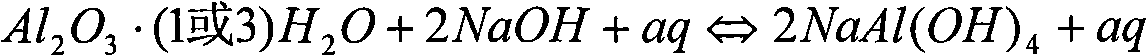

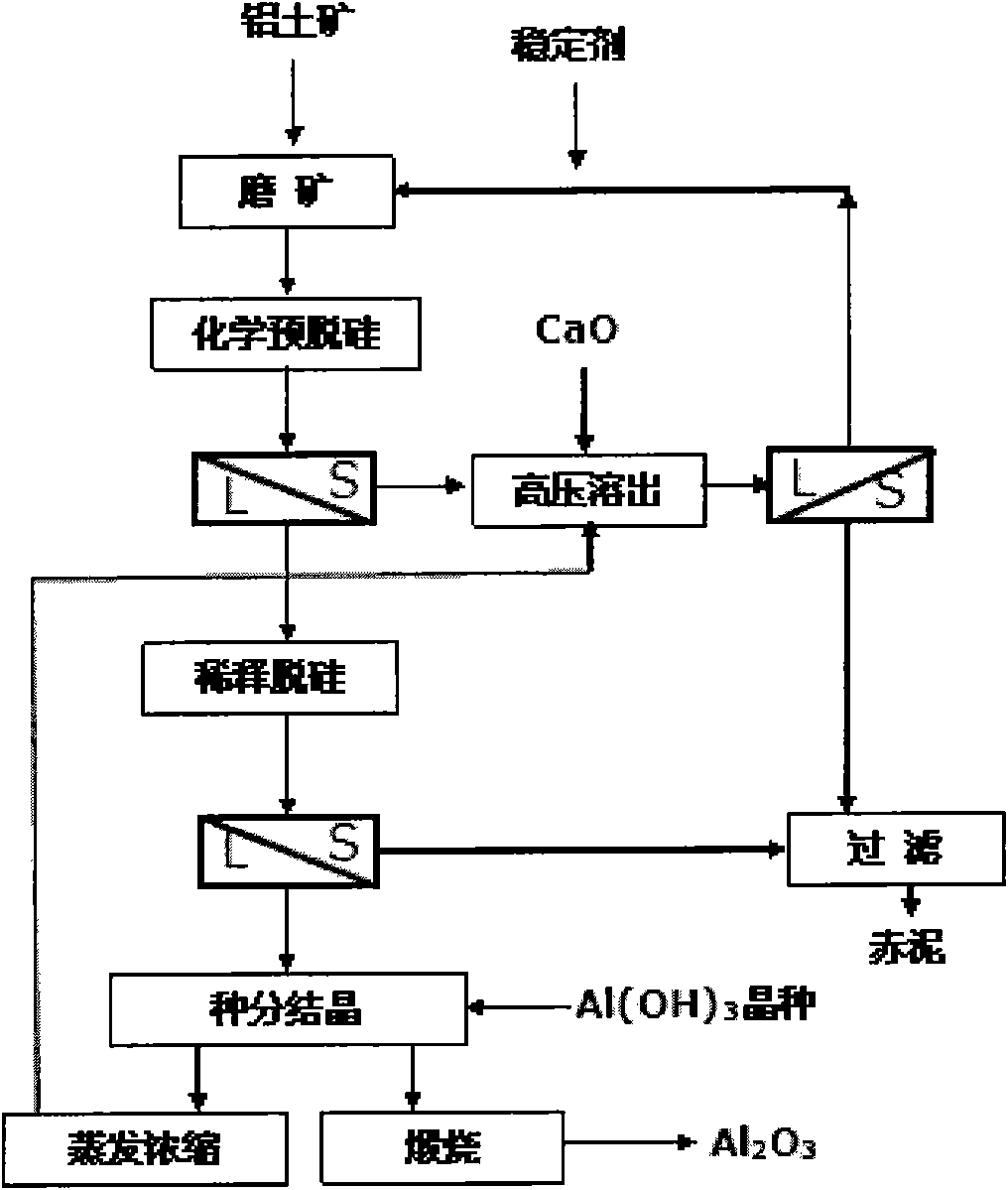

Method for modifying Bayer process, processing low-grade diaspore bauxite and producing alumina

The invention provides a method for modifying a Bayer process, processing low-grade diaspore bauxite and producing alumina. The method comprises steps that: (1) silicon is chemically pre-removed, wherein the low-grade bauxite is immersed into a sodium aluminate solution containing a stabilizing agent, such that a slurry containing dissolved silica is obtained; (2) obtained high-silicon sodium aluminate solution is processed through desilication, wherein desilication crystal seeds are added to the slurry processed through filtration, such that desilication is carried out; (3) the sodium aluminate solution is processed through seed precipitation, wherein aluminum hydroxide crystal seeds are added to the sodium aluminate solution processed through desilication, such that seed precipitation is carried out; (4) the obtained aluminum hydroxide product is baked, such that an alumina product is obtained; (5) a high-pressure dissolution process is carried out, wherein the obtained seed precipitation mother liquor is processed through evaporation and alkali supplementation, and is used in high-pressure dissolution of a concentrate obtained in the step (2); a stabilizing agent is added to the obtained sodium aluminate solution, the sodium aluminate solution is then used for processing the next batch of bauxite, and the steps (1) to (4) are repeated. The method provided by the invention is suitable to be used for processing low-grade diaspore bauxite. With the method, a silicon scaling problem in alumina industries can be effectively solved, energy consumption can be substantially improved, and the quality of the finished product alumina can be improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

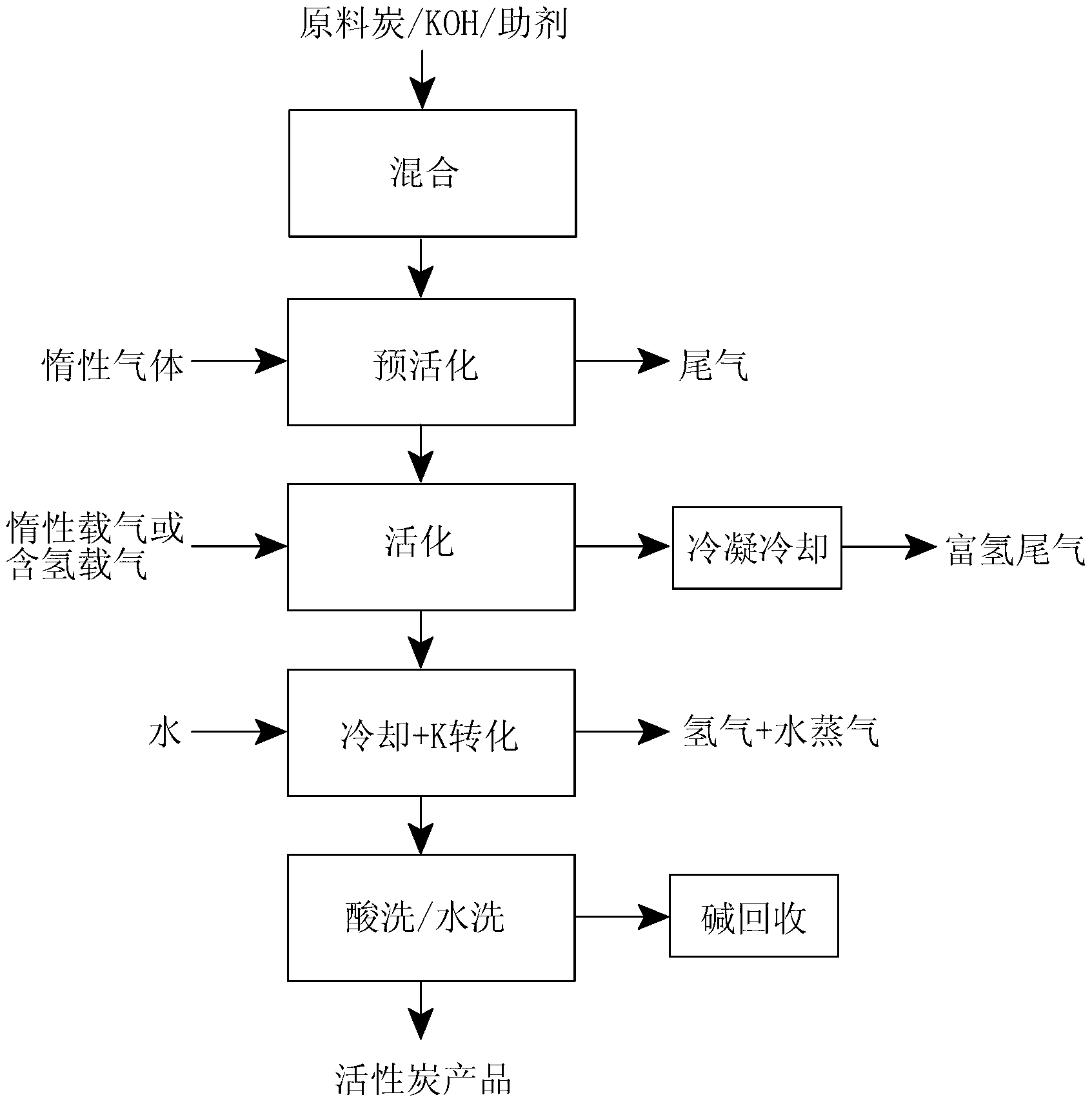

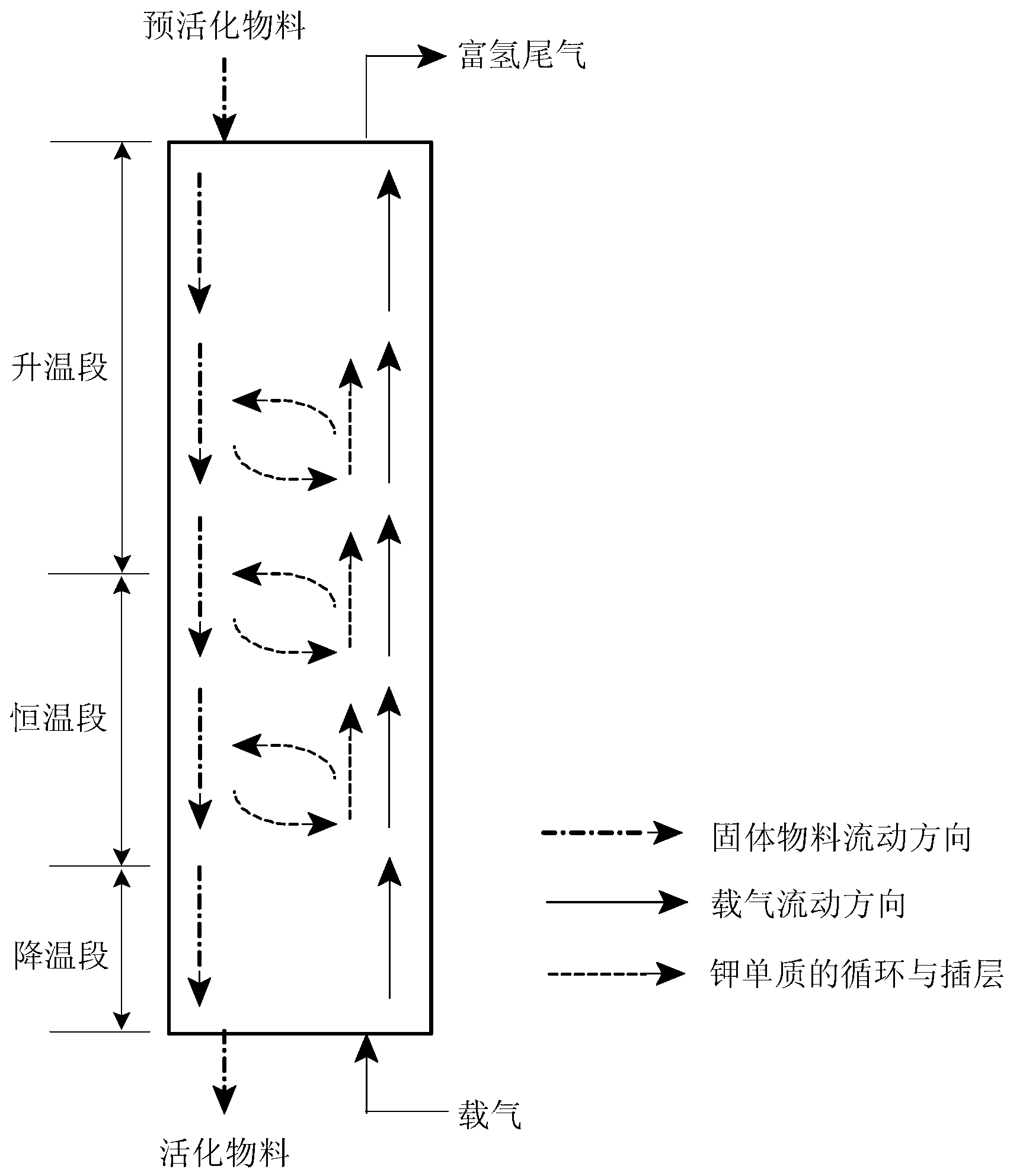

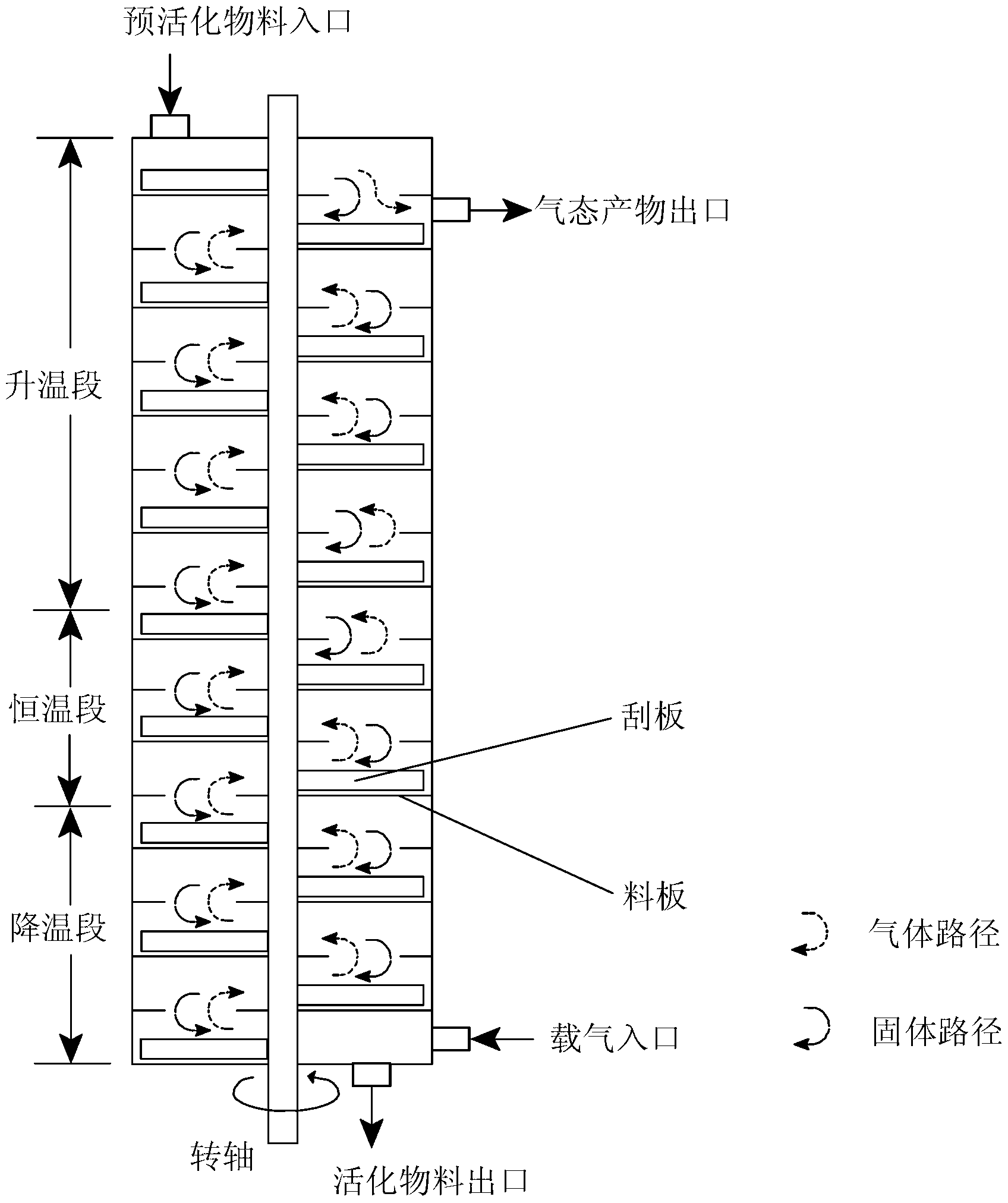

Continuous alkali activation device and method for preparing activated carbon with high specific surface area

ActiveCN103072985APromote activationImprove intercalation effectCarbon compoundsActivated carbonAcid washing

The invention provides a continuous alkali activation device and method for preparing activated carbon with high specific surface area. The method includes the following steps: enabling uniformly-mixed alkali-carbon mixture to be subjected to pre-activating, activating and potassium elementary substance conversion treatment through a pre-activating reactor, a continuous activating oven and an activating product collector respectively, so as to obtain the activating product; and enabling the activating product to be subjected to acid-washing, washing and drying to obtain a final activated carbon product. Inside a continuous vertical activating oven, the alkali-carbon mixture and a carrier gas continuously flow and are contacted in the reverse direction, pass by a warming section, a constant temperature section and a cooling section, so that generated elementary substance potassium during the activated process furthest circulates inside the activating oven, the intercalation function of potassium on graphite microcrystal in carbon is enhanced, carbon activation is facilitated, the activating effect and utilizing efficiency of alkali are improved, the product quality and production efficiency of activated carbon are improved, alkali consumption and production cost are reduced, and environmental pollution is reduced; and meanwhile, the activating product collector is further arranged inside the continuous activating device for safe conversion of K elementary substance, and the prevention of potential safety hazard brought by residual K in the activated product is eliminated.

Owner:DALIAN UNIV OF TECH

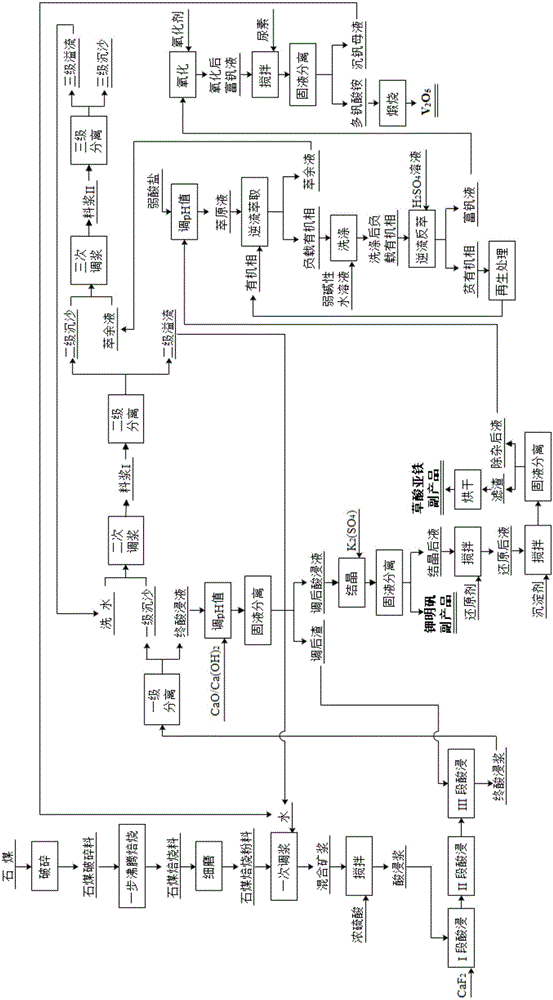

Method for preparing high-purity vanadium pentoxide by use of stone coal one-step method

The invention relates to a method for preparing high-purity vanadium pentoxide by use of a stone coal one-step method. The technical solution is as follows: a fluidized bed furnace for one-step roasting of stone coal is adopted to perform one-step fluidized bed roasting on the stone coal; roasted materials are leached in three segments, final pickling slurry is subjected to primary separation so as to obtain final pickle liquor, secondary overflow is returned to be subjected to primary size mixing, and tertiary overflow is returned to be subjected to secondary size mixing; the pH value of the final pickle liquor is regulated, and slags obtained after regulation are returned to a segment III so as to be leached; the regulated pickle liquor is crystallized to obtain a potassium alum byproduct; after crystallization, the liquid is subjected to reduction and precipitation-based impurity removal, and filter residues are dried to obtained a ferrous oxalate byproduct; after impurity removal, pH value regulation is performed on the liquid by use of weak acid salt, then counter-current extraction is performed on the liquid, and extraction raffinate is returned to be subjected to tertiary size mixing; after being washed, the loaded organic phase is subjected to countercurrent reverse extraction; a lean organic phase is regenerated and then is returned to be extracted; after a vanadium-rich solution is oxidized, urea is added, stirring is performed, the obtained molybdenum precipitation mother solution is returned to be subjected to primary size mixing, and ammonium polyorthovanadate is calcinated to prepare vanadium pentoxide. The method has the characteristics of short process flow, less pollution, low energy consumption, less chemical usage, high vanadium recovery rate and high product purity.

Owner:WUHAN UNIV OF SCI & TECH

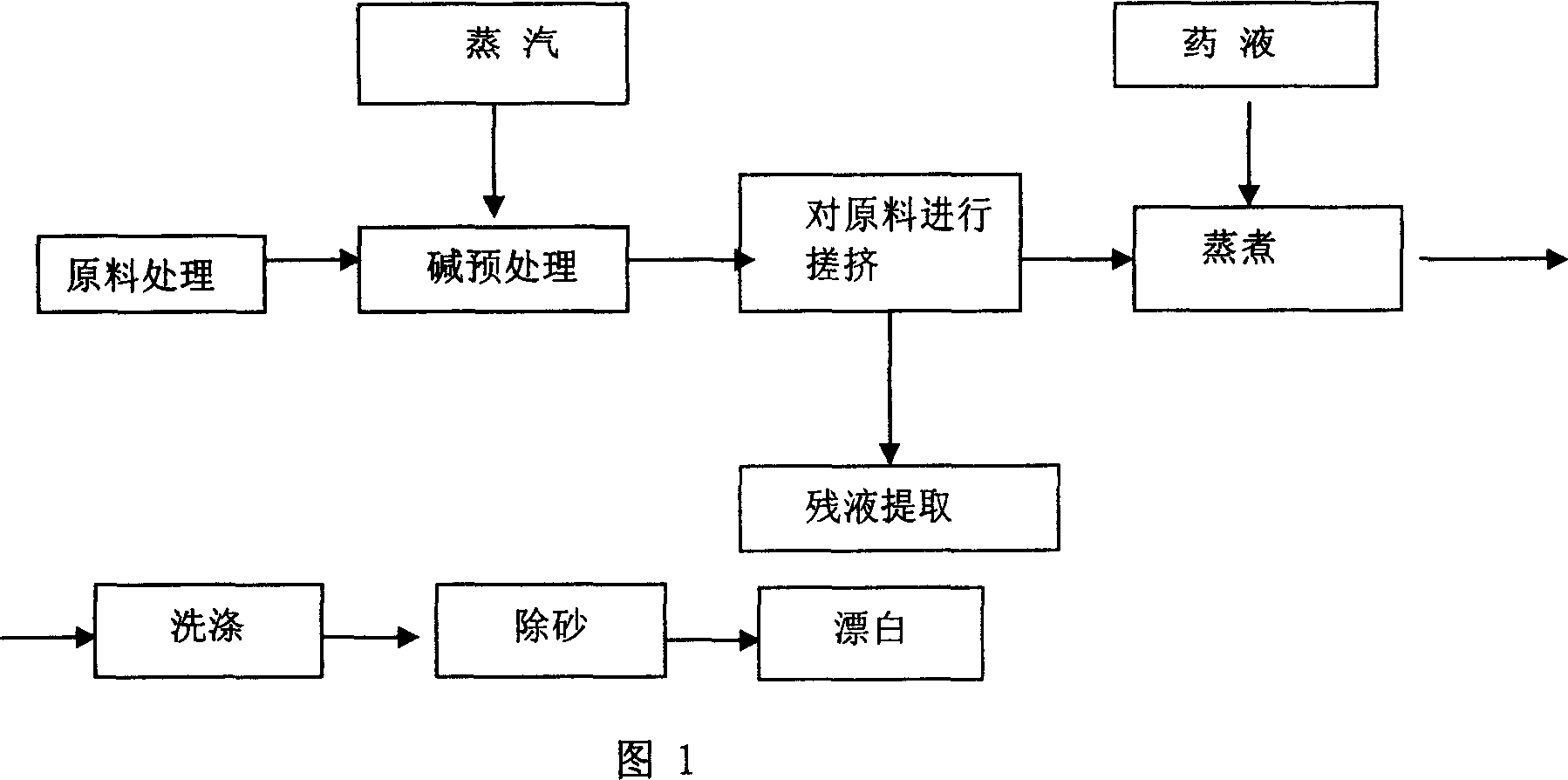

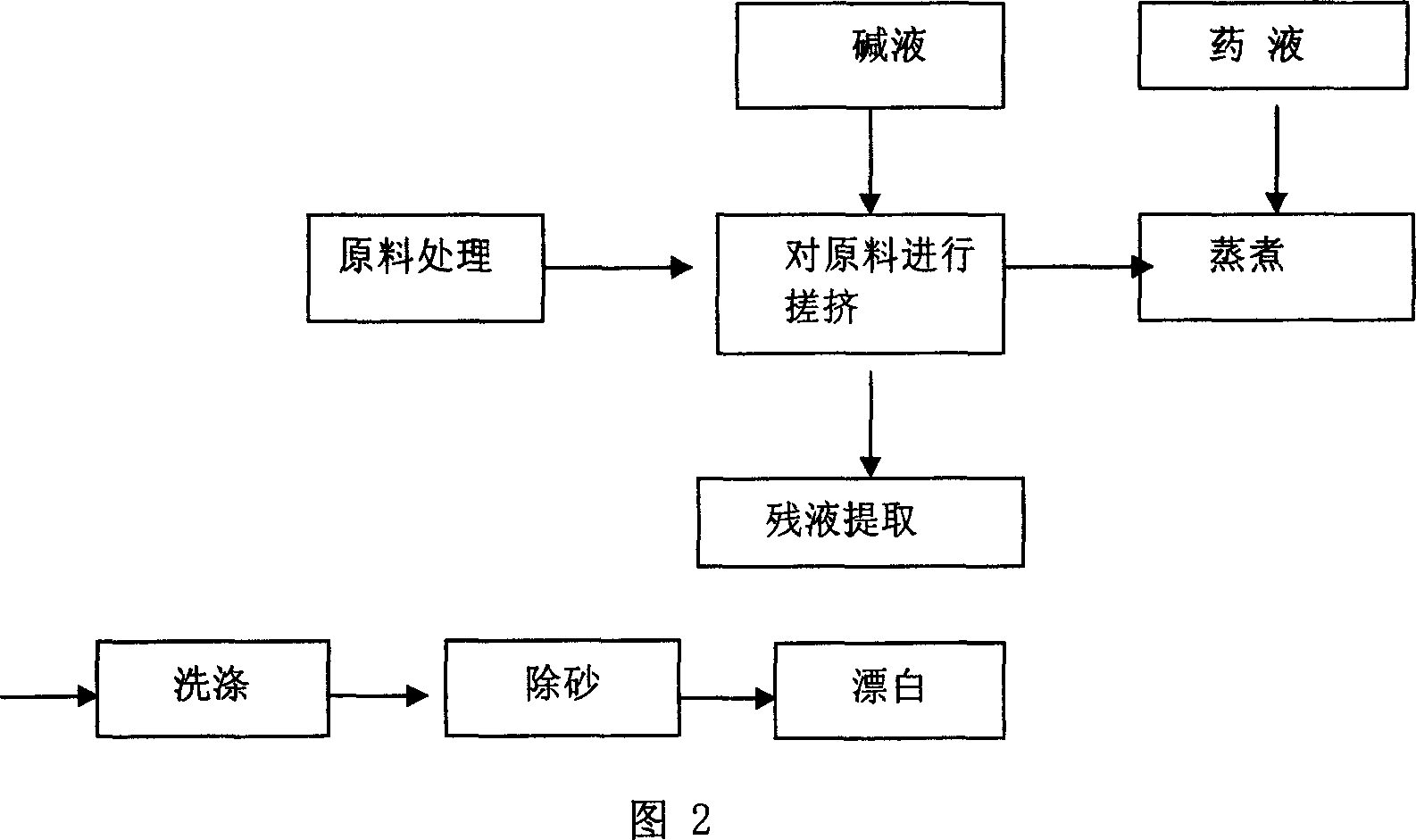

Method for producing chemical fiber pomace with fiber as raw material

InactiveCN1974922APerformance activationImprove impregnation effectCellulosic pulp after-treatmentDigestersBlack liquorPlant fibre

The present invention relates to a method for producing chemical fibre pulp by using plant fibre as raw material. Said method includes the following several steps: raw material treatment, making the treated raw material undergo the processes of rubbing and extruding, cooking, washing, removing sand and bleaching treatment. It is characterized by that in the preparation process of said chemical fibre pulp a screw extruding machine and a rubbing-extruding machine are adopted.

Owner:湖南吉湘生物科技有限公司

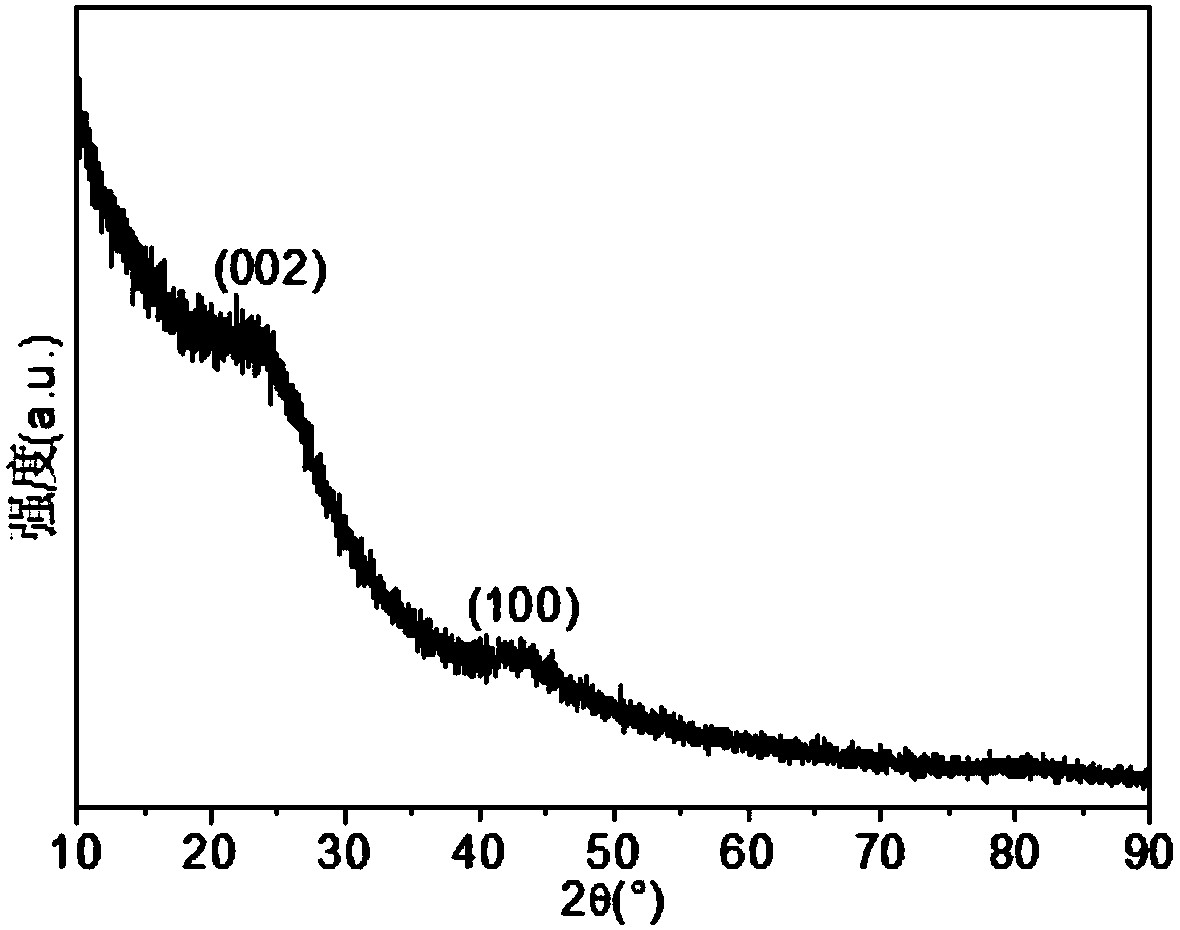

Activated carbon, preparation method thereof, and application of activated carbon in supercapacitor electrode

InactiveCN106698427AImprove performanceIncrease capacityCarbon compoundsHybrid capacitor electrodesActivated carbonCapacitance

The invention relates to activated carbon, a preparation method thereof, and application of the activated carbon in a supercapacitor electrode. The method comprises the following steps of firstly drying, smashing and sieving an activated carbon raw material; then uniformly mixing the treated activated carbon raw material and an activating agent according to a certain mass ratio, under the protection of an inert atmosphere, heating in a sealed furnace body for carrying out activating agentmelt-impregnation, and then continuously warming for activating; purifying, ball-milling and sieving an obtained activated product, and finally carrying out high-heat treatment under the protection of an inert atmosphere to obtain the activated carbon. The specific surface area of the activated carbon provided by the invention is larger than 2000m<2> / g, and the specific surface area and the pore size distribution are controllable. The mass ratio capacitance of a supercapacitor prepared by adopting the activated carbon provided by the invention and a TEABF4 / PC organic system is larger than 130F / g. In addition, the activated carbon provided by the invention is simple in production process, low in preparation cost, short in period, good in comprehensive economic benefit, and easy to realize industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

Grey cloth cold batch mercerizing process method for cotton and cotton blended fabric

ActiveCN101858020AAvoid spendingReduce consumptionTextile storage in wounded formSingeingWastewaterEngineering

The invention provides a grey cloth cold batch mercerizing process method for cotton and cotton blended fabric, which belongs to a dyeing and finishing pretreatment process for cotton and cotton blended fabric. The process method comprises processes of singeing, alkali padding, rolling, reverse rolling and heaping, washing, oxygen bleaching, weft finishing and tentering; in the alkali padding process, alkali liquor is padded by using a padding liquor roller, the NaOH content of the alkali liquor in an alkali liquor tank is 160 to 180 grams per liter, the balance is water, and the alkali liquor in the alkali liquor tank is circulated by using a circulating pump; in the washing process, counter current washing is performed in a de-sizing machine by using 90 to 95 DEG C hot water, the speed is 48 to 52 meters per minute, and the cloth falls with tide; and in the oxygen bleaching process, the speed is 45 minutes per minute, the temperature in a track-type steam box is between 96 and 99 DEG C, and the heaping is performed for 45 minutes. The mercerizing process method combines the mercerizing process and the de-sizing process into a one-step process so as to shorten the process flow, reduce the steam consumption, relatively reduce the consumed caustic soda quantity and save the wastewater treatment expense.

Owner:YUYUE HOME TEXTILE

Method for desulfurizing acid gas containing hydrogen sulfide and recovering sulfur

ActiveCN104208992BHigh activityReduce energy consumptionDispersed particle separationSulfur preparation/purificationCombustionSulfur

Owner:NINGBO RES & DESIGN INST OF CHEM IND

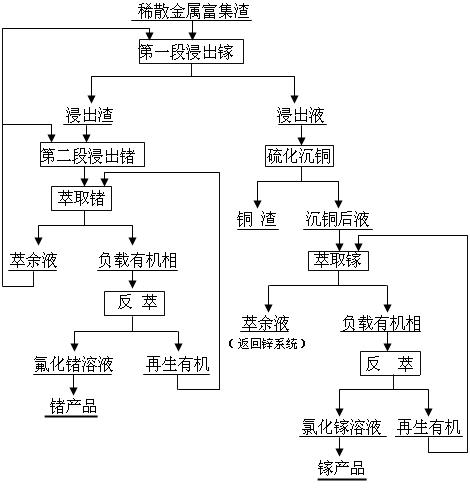

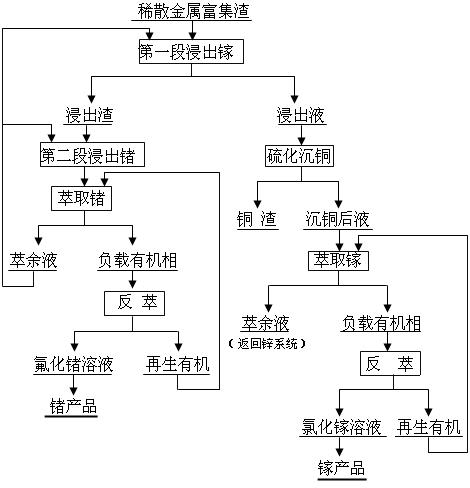

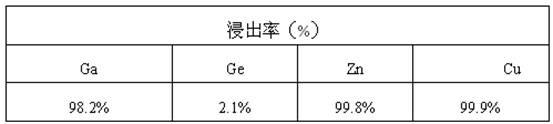

Method for extracting gallium and germanium from zinc smelting slag

InactiveCN102560133AEmission reductionLeave out the baseProcess efficiency improvementWastewaterGallium

The invention relates to a method for extracting gallium and germanium from zinc smelting slag, in particular to a method for wet extraction of gallium and germanium metals from zinc smelting slag. The method is characterized in that: in the extraction process, the zinc smelting slag is subjected to two-stage acid leaching, the gallium is leached out in the first stage, and then the acid leaching slag after the gallium is leached out is subjected to the second-stage acid leaching, so that the germanium is leached out. According to the method, the leaching characteristics of scattered metal enriched slag gallium and germanium and the extraction characteristics of the gallium and the germanium are found in experiments, a process flow that the gallium and the germanium are leached out and extracted by steps to enrich the gallium and the germanium is provided, so that the germanium leaching and extraction form a closed loop, the alkali neutralization work procedure is eliminated, the alkali consumption is eliminated, the acid consumption is reduced, and the wastewater drainage is reduced.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

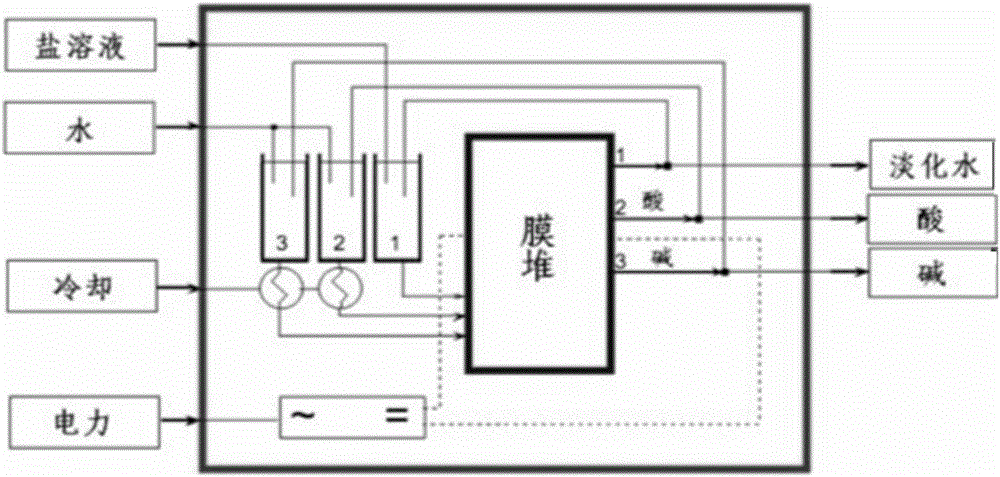

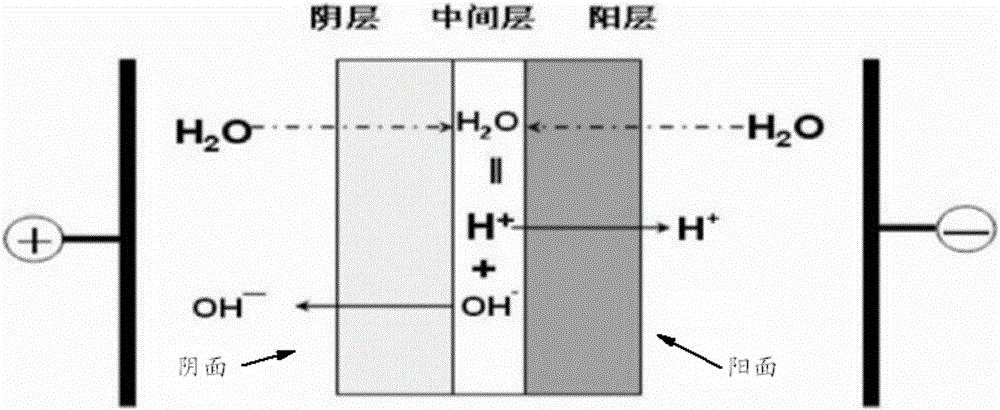

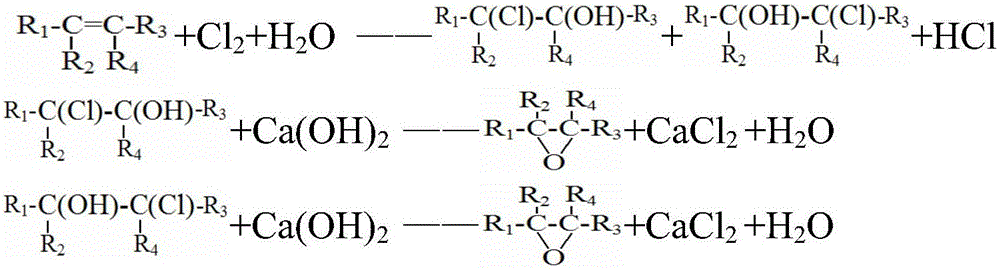

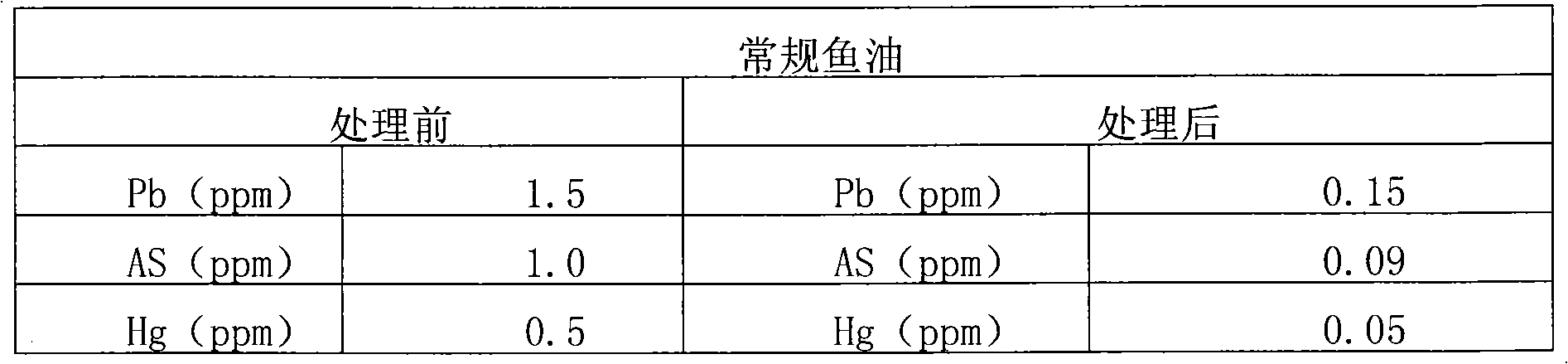

Method for preparing halogenohydrin and epoxide

ActiveCN106518624AEasily damagedSolve intractableWater contaminantsDispersed particle separationHalogenWastewater

Owner:JIANGXI SUKEER NEW MATERIAL

Method for preparing chitin and process for preparing chitosan by using chitin

The invention discloses a method for making crust element which comprises the following steps that: a crab shell which is cleaned and soaked for the first time is put into a sodium hydrate solution for heat preservation; the crab shell which is washed by tap water to the neutral is soaked for the second time, the acid liquor is scoured off by the tap water; the curst element soaked by hydrochloric acid is put into the sodium hydrate solution for heat preservation and then is fished out as well as is washed by the tap water to the neutral, and the crust element is obtained. The method for making chitosan by the crust element comprises the following steps that: the crust element is put into the sodium hydrate solution and is sealed, after temperature preservation and the reaction, the mixture is soaked by the tap water and is washed by the tap water; the processed chitosan is taken out to be dried and put into the sodium hydrate solution as well as be sealed while preserving the temperature, after the reaction, the chitosan is taken out and is soaked in the tap water as well as is taken out and dried, thereby obtaining the chitosan. By processing by the method, the reaction speed is increased by 30 times, the alkali liquor dosage is reduced by 50 percent; the made crust element has white color, the crust element is washed by water and soaked to produce the chitosan, the molecular weight is great, the deacetylation is more than or equal to 95 percent, and the viscosity coefficient is more than or equal to 2000MPa.S.

Owner:石勇

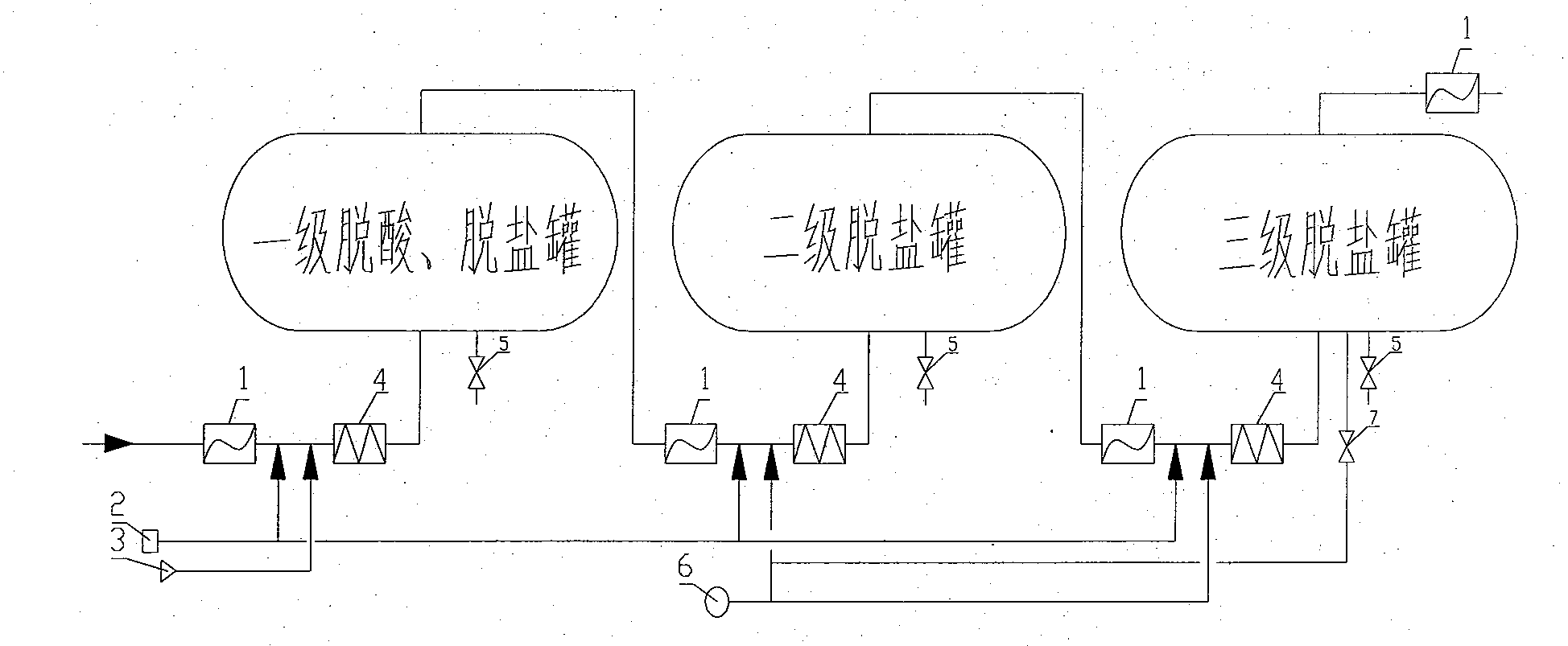

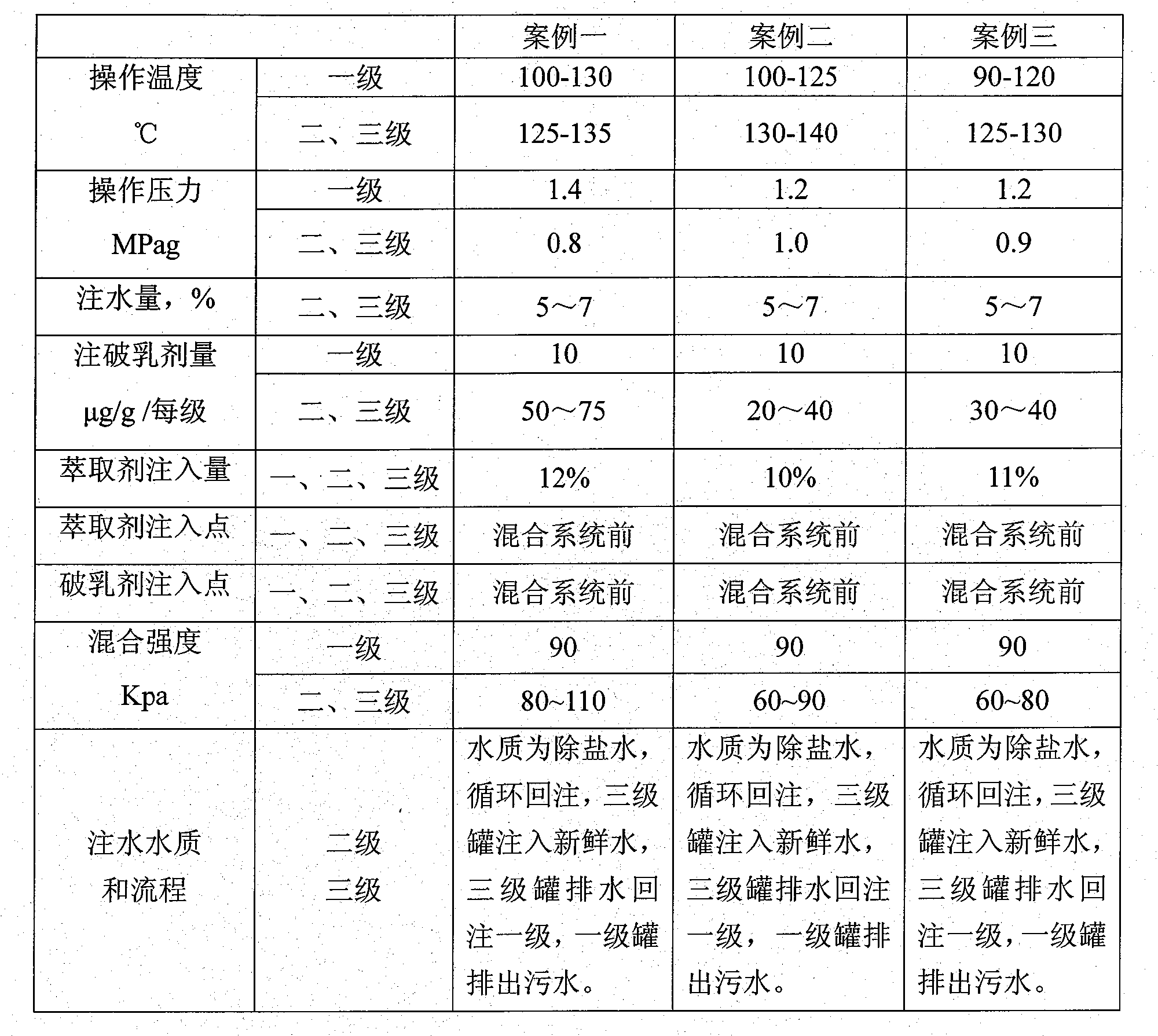

Pre-treatment process method of high acid crude oil

ActiveCN103805227AAvoid corrosionSimple processDewatering/demulsification with electric/magnetic meansRefining with two or more solventsDemulsifierDesalination

The invention relates to a pre-treatment process method of high acid crude oil. The method comprises the following steps that high acid crude oil is treated by coupling deacidification and electro-desalting processes by combining chemical extraction and electro-desalting; a first level tank is taken as a deacidification and electro-desalting tank; a demulsifier and an extractant are injected before a crude oil electro-desalting static mixer; after being fully mixing with crude oil, the mixture enters into the first level desalting tank; generated naphthenate and salt-containing sewage in the crude oil are dissolved in the extractant; treated deacidified oil enters into second and third level desalting tanks after being mixed with the demulsifier and water through the static mixer for desalination and dehydration; treated crude oil enters into a subsequent heat exchange unit; after a period time of operation of an electro-desalting system, impurities such as mud in raw material oil are flushed by a non-stop back purge device to discharge mud-containing sewage out of the tank; an extract phase is acidified to separate out naphthenic acid which is further extracted and purified by light dydrocarbon, and the extractant is purified and recovered and recycled.

Owner:长江三星能源科技股份有限公司

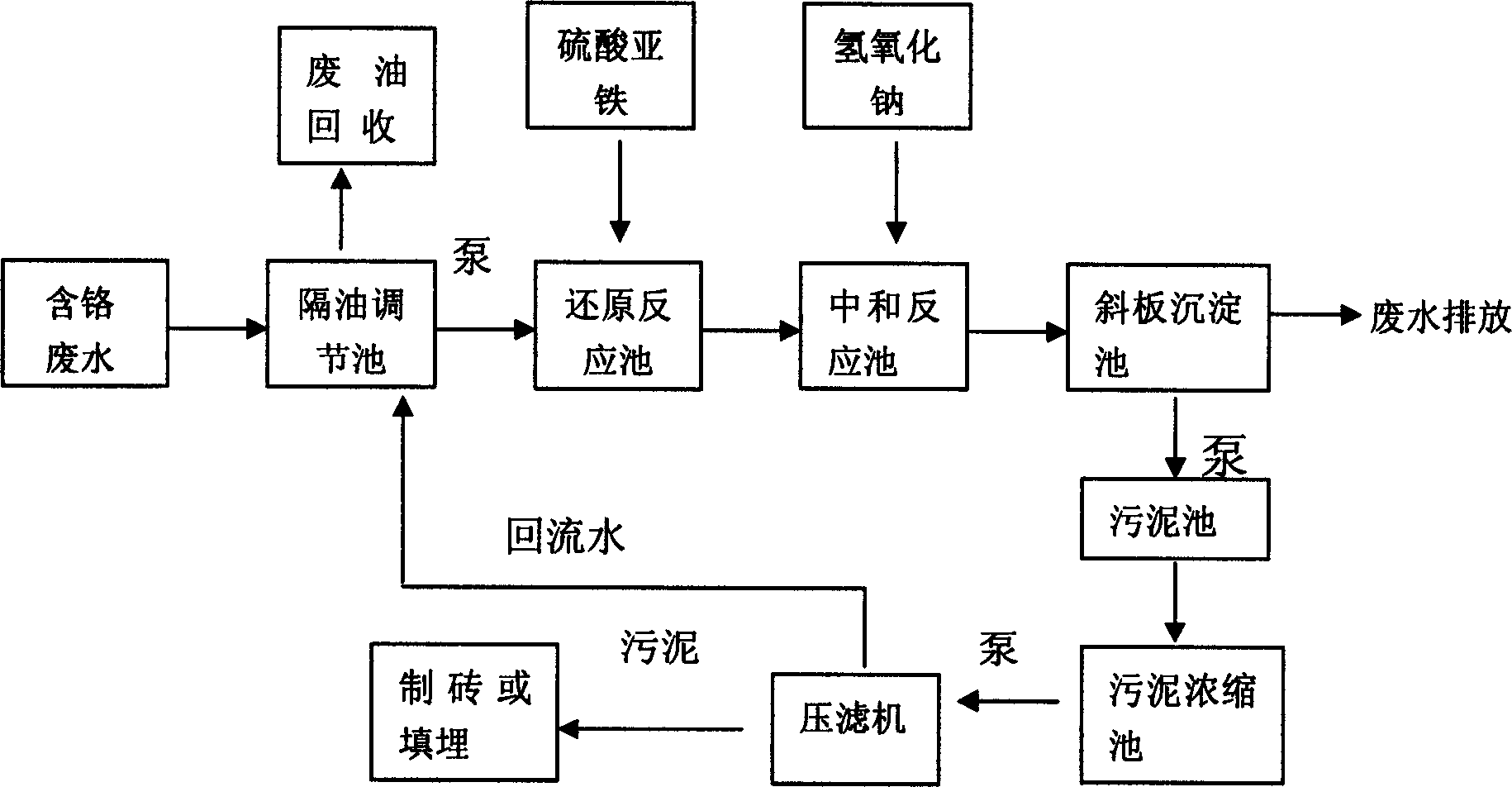

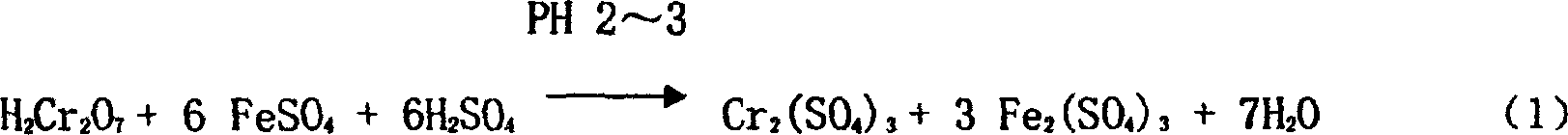

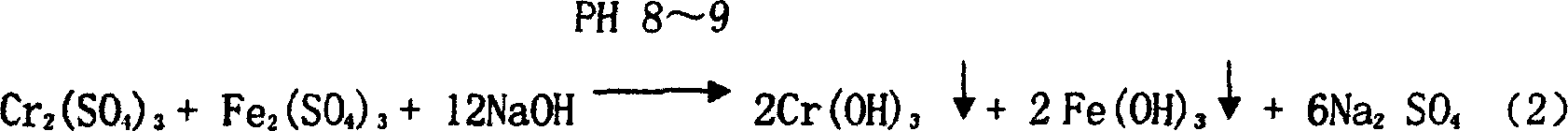

Chromium containing waste water treatment method

InactiveCN1556048AHigh activityGuaranteed successful processingWater/sewage treatmentMultistage water/sewage treatmentSludgeDisplacement reactions

A process for treating the Cr-contained sewage includes preparing liquid-state ferrous sulfate by displacement reaction, removing oil from said sewage, adding said liquid-state ferrous sulfate, reduction reacting to reducing 6-valence Cr to 3-valence Cr, adding alkali to generate deposit of chromium hydroxide, deposit separation, discharging water, and press filter of mud.

Owner:DONGFENG MOTOR FASTENER CO LTD

Flax fibers and preparation method thereof

ActiveCN101818379AImprove finenessOvercome the defect of only spinning coarse-count yarns of about 24-36 public countsFibre cleaning/openingCarding machinesFlax fiberFineness

The invention relates to flax fibers. The strength of the flax fibers is 3.0 to 8.0cN / dtex and the fineness of the flax fibers is 1,500 to 3,500 Nm; preferably, the strength of the flax fibers is 4.0 to 7.0cN / dtex and the fineness of the flax fibers is 1,500 to 3,000Nm; more preferably, the strength of the flax fibers is 4.5 to 6.5cN / dtex and the fineness of the flax fibers is 1,800 to 2,800Nm; and optimally, the strength of the flax fibers is 5.0 to 6.0cN / dtex, and the fineness of the flax fibers is 2,300 to 2,700Nm. The invention also relates to the preparation method of the flax fibers, which comprises the steps of acid impregnation, washing, oxidization, fiber spinning, oil feeding, oil and water removal, fiber softening, oil feeding and wetting, stowing and mechanical loosing. The flax fibers provided by the invention have high strength and fineness. The preparation method is short in process and light in pollution.

Owner:CHINA GARMENT BUYITIANXIA BEIJING TRADING

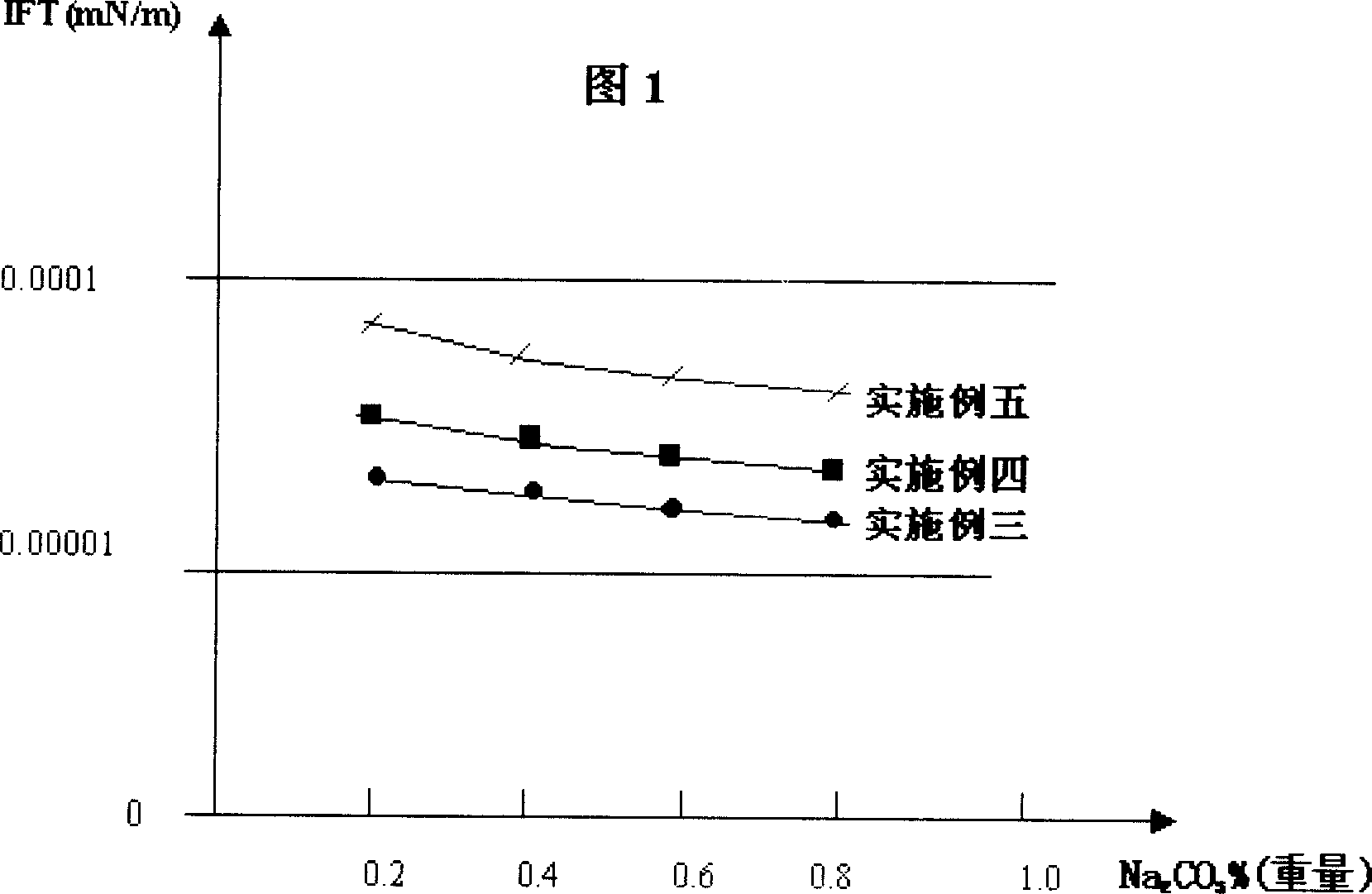

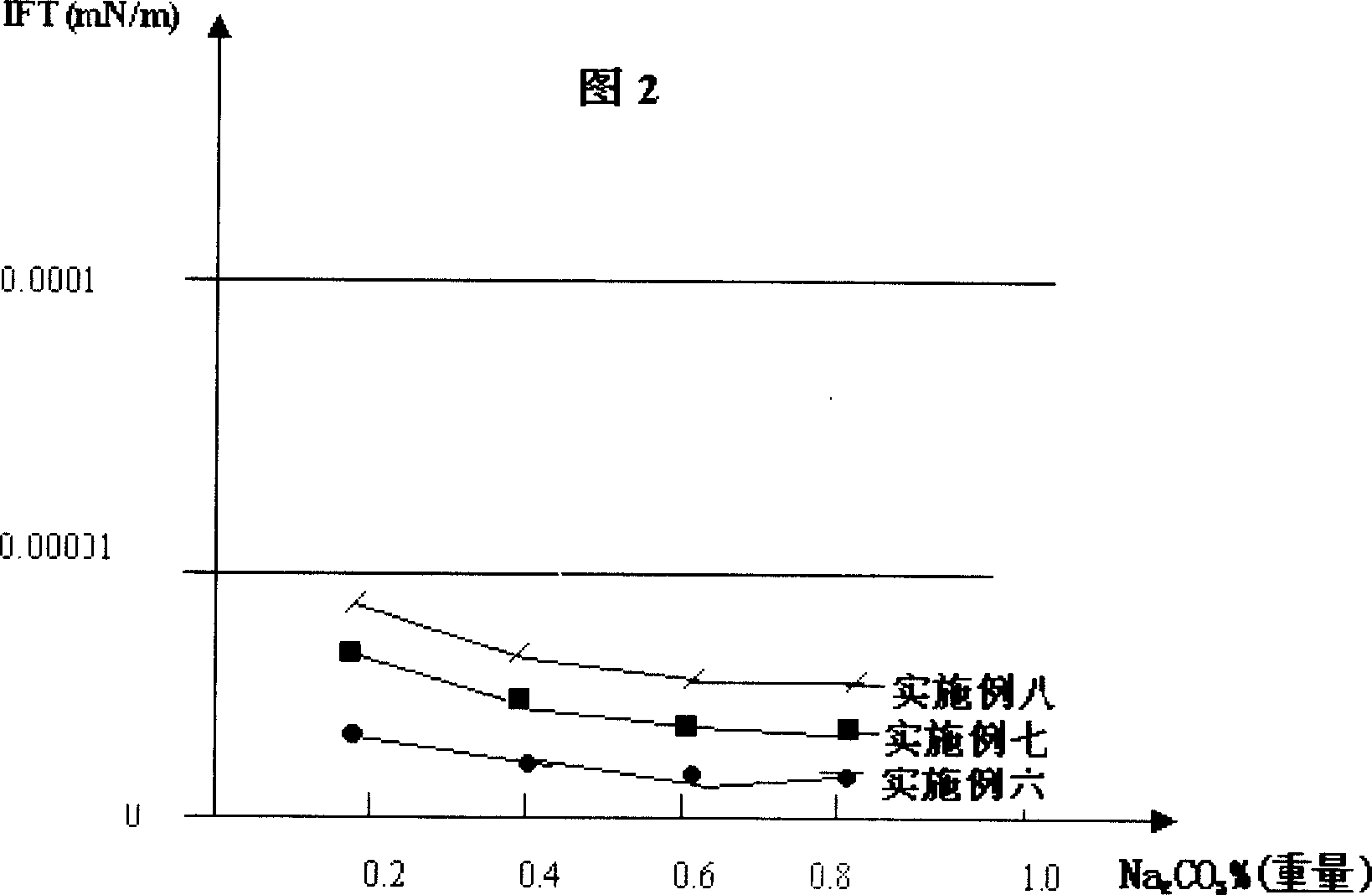

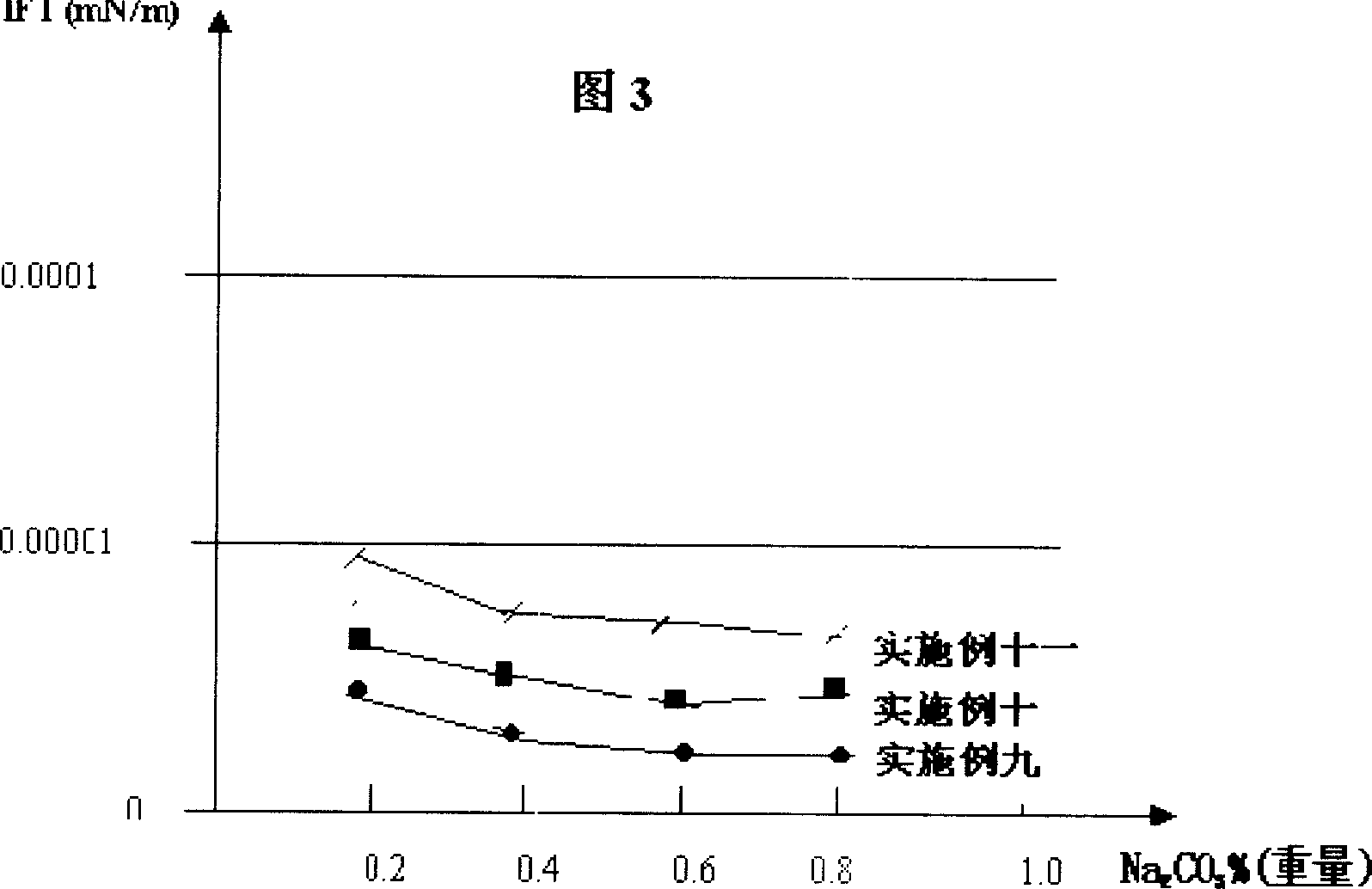

Alkyl aryl alkyl-sulfonate surfactant composition and its application in tertiary oil recovery

InactiveCN1566258AOvercome great damageOil displacement effect is goodFluid removalChemistryRecovery factors

The invention discloses an novel alkyl aryl alkyl-sulfonate surfactant composition and its application in tertiary oil recovery, the surfactant-alkali-polymeric ternary oil driving system prepared from the surfactant and the underground crude oil can reach a ultralow interfacial tension of 0.0001-0.00001 mN / m, thus can effectively substitute the residual oil in the oil reservoir, the crude oil recovery factor can be increased by over 30%.

Owner:大庆高新区鑫诺精细化工有限公司

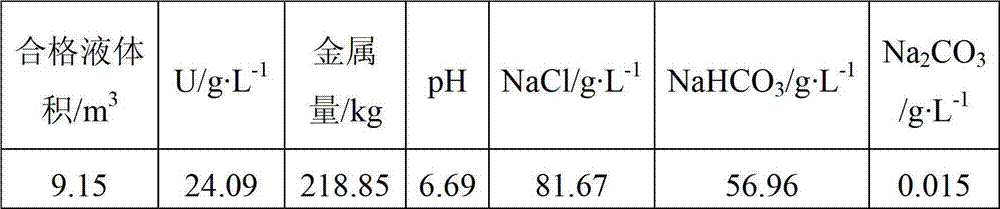

In-situ leaching and leachate treatment method with co2 and o2 added to heavy carbonic acid type groundwater

The invention provides a method for adding CO2 and O2 in-ground leaching in heavy carbonic acid type ground water and leachate, which comprises the following steps: (1) adding CO2 and O2 into the leaching solution to leach uranium underground to obtain uranium leachate; (2) adding uranium to the uranium Add CO2 to the leaching solution to adjust the pH value of the uranium leaching solution, and then filter it mechanically; (3) perform ion exchange adsorption on the uranium leaching solution in the adsorption tower; (4) perform leaching on the saturated resin to obtain Cl-type poor resin and leaching qualified solution (5) transforming the Cl-type poor resin with the adsorption tail liquid; (6) acidifying the eluting qualified liquid, adding alkali and aging precipitation at room temperature, washing, filtering and drying the precipitated slurry to obtain uranium products. The method of the invention only adds O2 and CO2 without adding other reagents, which will not cause blockage of ore beds and pollution of underground water; at the same time, the preparation process is integrated, the operation is simplified, and the cost is saved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

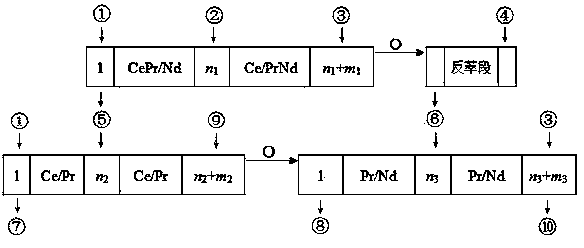

Technique for preparing high-purity praseodymium from industrial praseodymium raw material

InactiveCN103526058AEmission reductionWide variety of sourcesProcess efficiency improvementCeriumTechnical grade

The invention discloses a technique for preparing high-purity praseodymium from an industrial praseodymium raw material. According to the technique, a high-purity praseodymium (99.99%-99.9995%) product is prepared from industrial praseodymium (98%-99.9%). The technique consists of three fractional extraction systems: cerium-praseodymium / praseodymium-neodymium grouping separation, cerium / praseodymium separation and praseodymium / neodymium separation, wherein separation of cerium-praseodymium from neodymium is realized in an extraction section of the cerium-praseodymium / praseodymium-neodymium fractional extraction system; separation of cerium from praseodymium-neodymium is realized in a washing section of the cerium-praseodymium / praseodymium-neodymium fractional extraction system; the cerium / praseodymium separation fractional extraction system is directly serially connected to the praseodymium / neodymium separation fractional extraction system. Compared with an existing technique, the technique has the advantages that alkali consumption (including alkali for saponification and alkali for neutralization) is reduced by 13%, and acid consumption (including acid for washing and acid for reextraction) is reduced by 13%.

Owner:NANCHANG HANGKONG UNIVERSITY

Stewing method for preparing bamboo wood dissolving pulp

InactiveCN102337689AIncrease productionQuality improvementPretreatment with water/steamPulping with inorganic basesLiquid wasteBlack liquor

The invention belongs to the technical field of dissolving pulp preparation and relates to a stewing method for preparing bamboo wood dissolving pulp, which comprises the following steps of: (a) introducing vapor to a boiler: preparing bamboo wood raw materials into slice materials, conveying the slice materials to a digester, and introducing low pressure vapor to the digester while conveying theslice materials; (b) vapor heating and pre-hydrolyzing: heating through the vapor after introducing the vapor to the boiler to pre-hydrolyze the slice materials; (c) neutralizing through white liquor: neutralizing the slice materials and vapor condensed water in the digester through the white liquor in a hot white liquor tank; (d) replacing through hot black liquor: replacing the neutralization liquid waste in the digester through the hot black liquor in a hot black liquor tank; (e) heating and stewing in a temperature control manner to prepare virgin pulp of the bamboo wood dissolving pulp; (f) replacing the washing black liquor, washing and cooling the virgin pulp; and (g) discharging at a low temperature. The invention has the advantages of reducing the production cost, increasing the production efficiency, effectively utilizing the stewing heat and improving the yield and the quality of the bamboo wood dissolving pulp.

Owner:CHONGQING LEE & MAN PAPER MFG

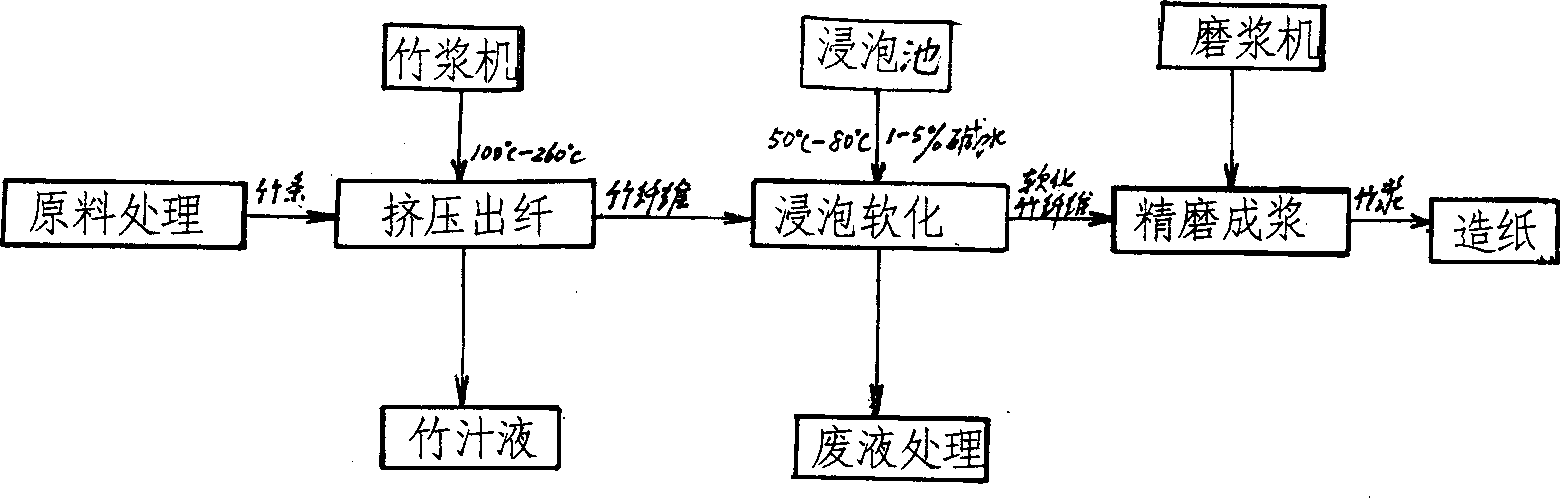

Technological process of mechanically making bamboo pulp

InactiveCN1354303ATime-saving extraction processEnergy saving during extractionMechanical/thermomechanical pulpFiberHigh pressure

The present invention relates to a mechanical pulping method of bamboo pulp, including the procedures of raw material treatment, extrusion to extract fibre, soaking-softening and grinding to make pulp. It is characterized by that the procedure of extrusion to extract fibre uses bamboo pulp-making machine to extrude bamboo material, and separates the bamboo fibre from bamboo juice liquid uner the action of high temp. and high pressure to extract bamboo fibre. The soaking-softening procedure includes the steps: soaking bamboo fibre in hot alkali water whose alkali content is 1%-5% for 1-2 hr. and softening and dissolving lignin and hemicellulose; and the grinding and pulping procedure is to place the soaked bamboo fibre in pulp grinder and grind it to obtain monomer fibre pulp stock.

Owner:李斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com