Patents

Literature

2188results about "Carding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

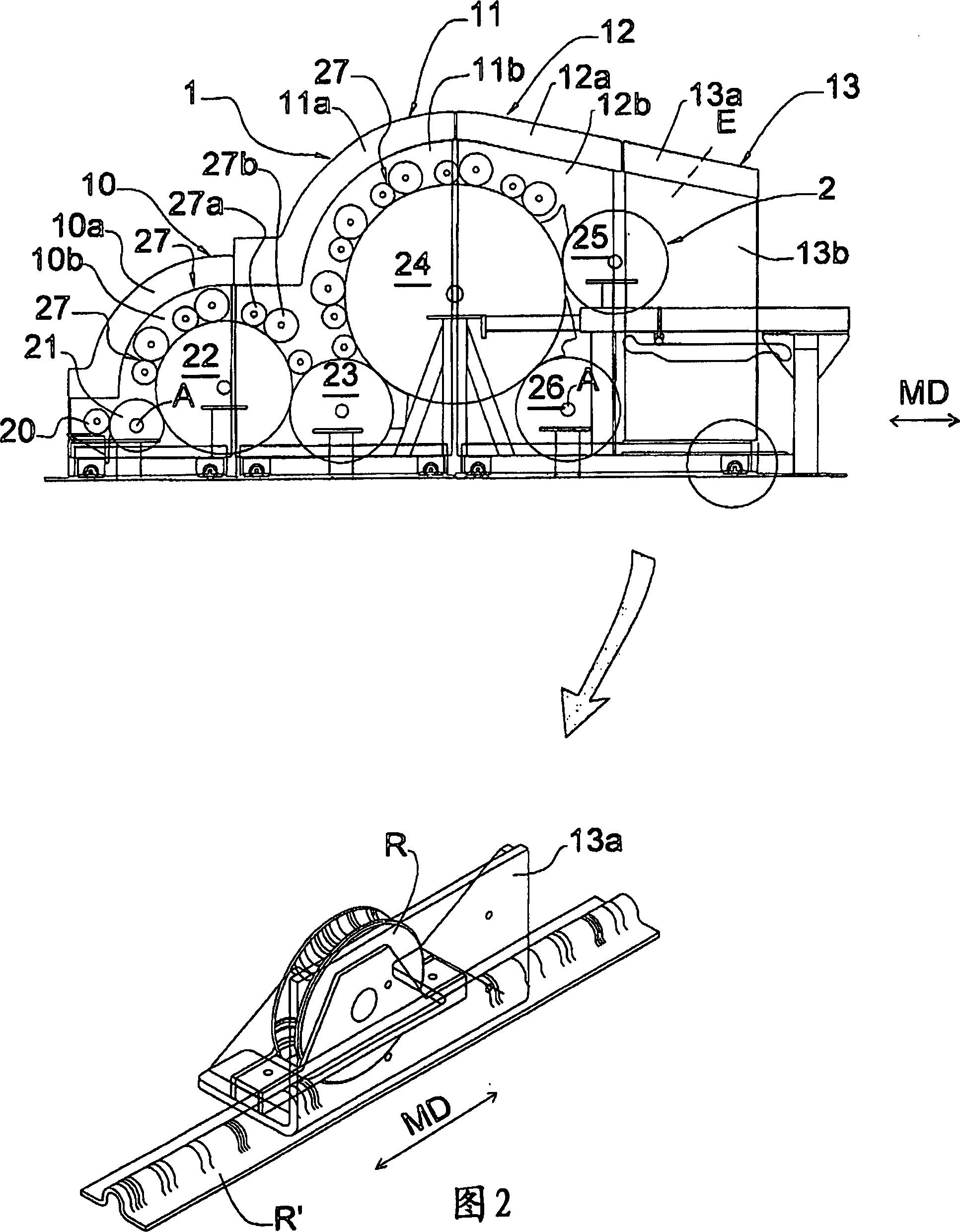

Non-woven sheet, manufacturing method thereof and absorbent article

InactiveUS20130158497A1Increase volumeReduce the amount requiredLayered productsFibre mixingNonwoven fabricBiomedical engineering

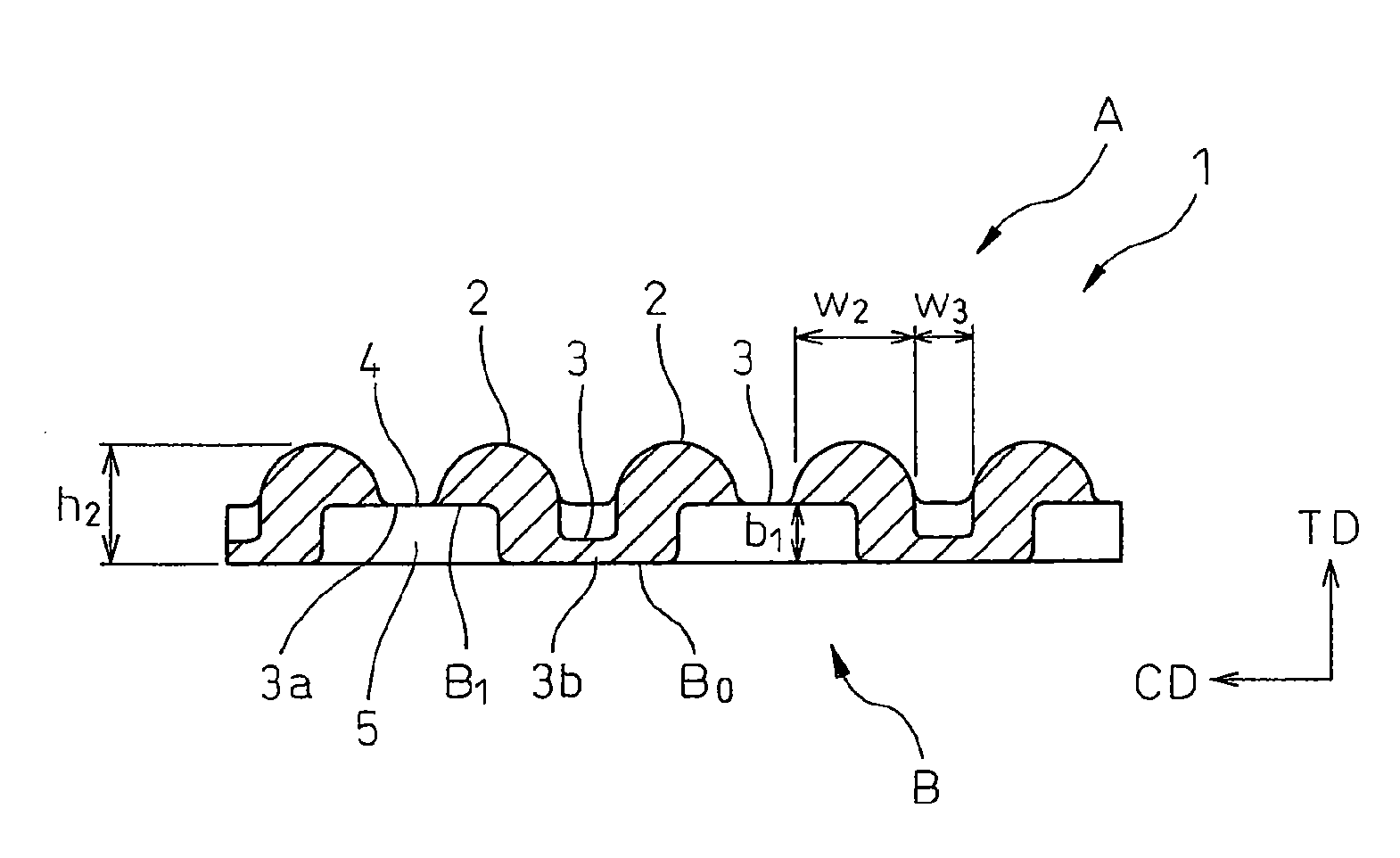

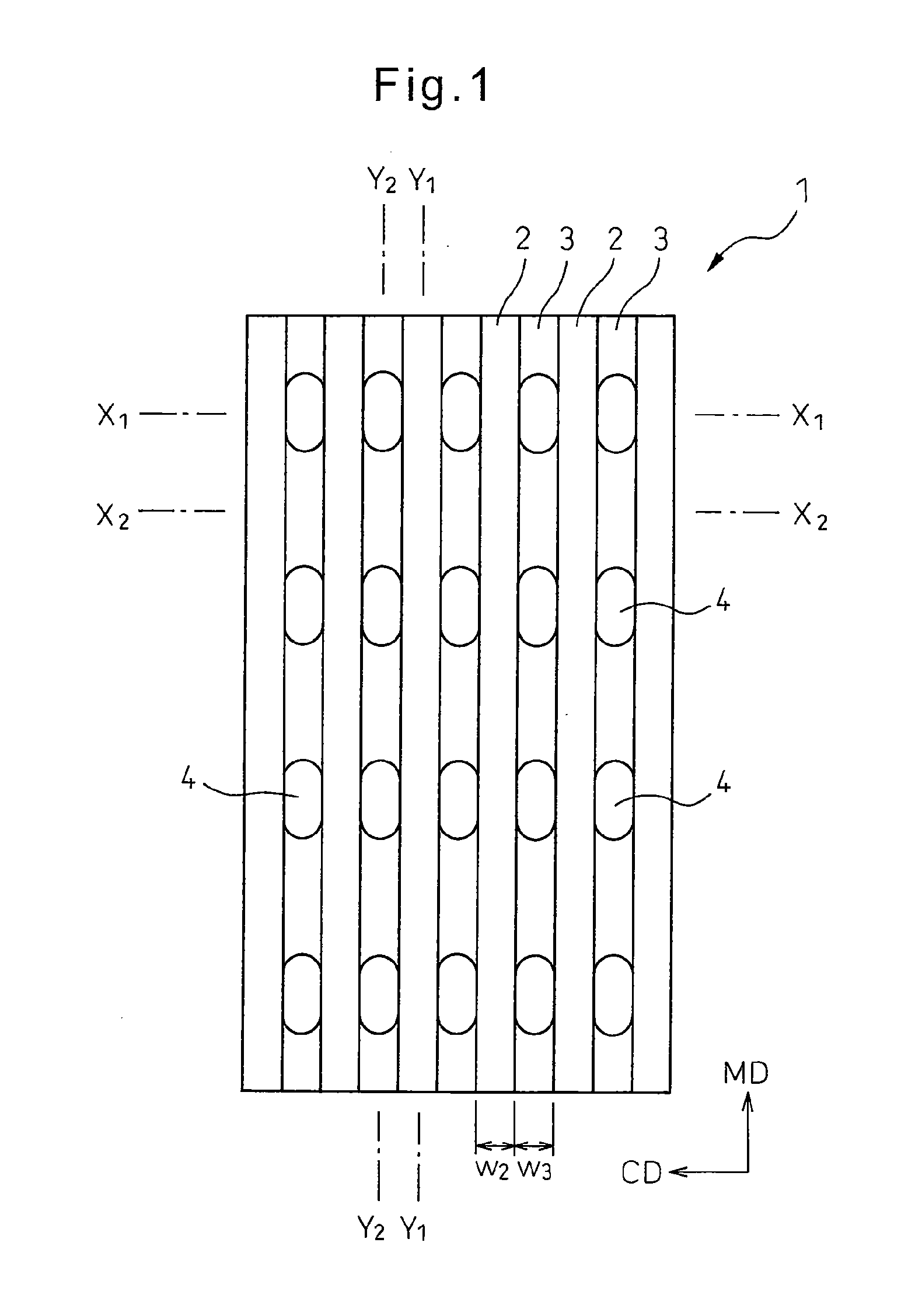

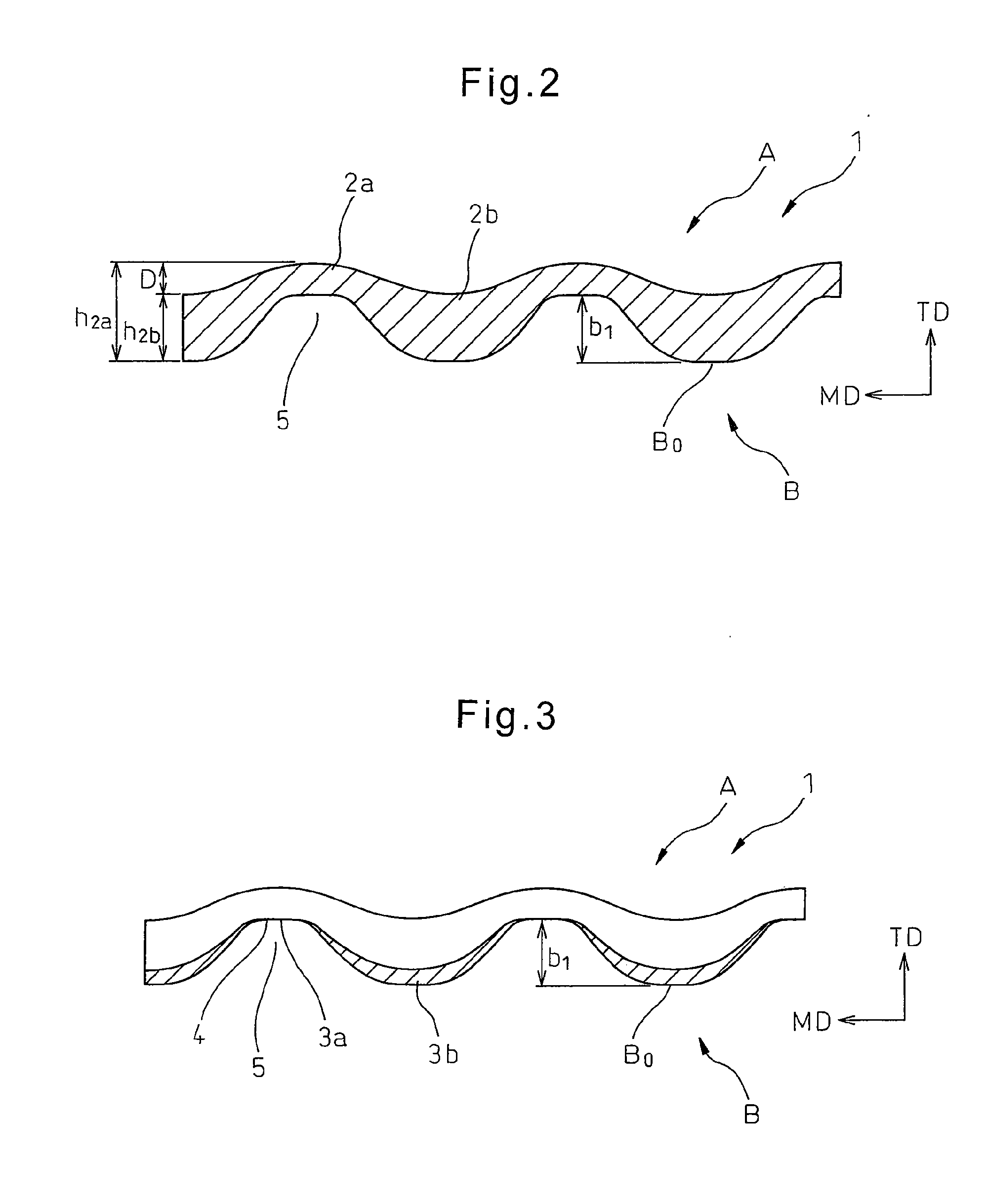

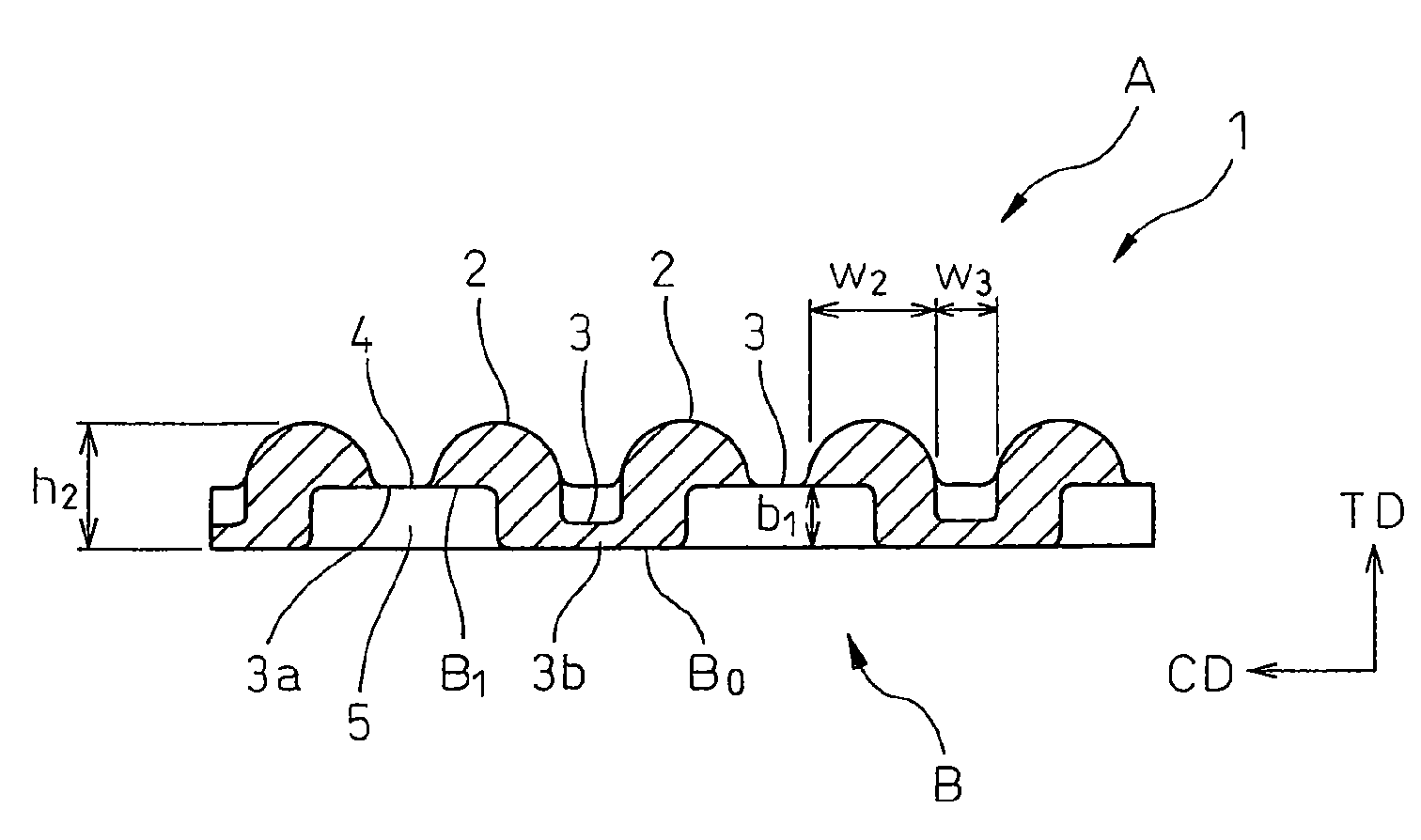

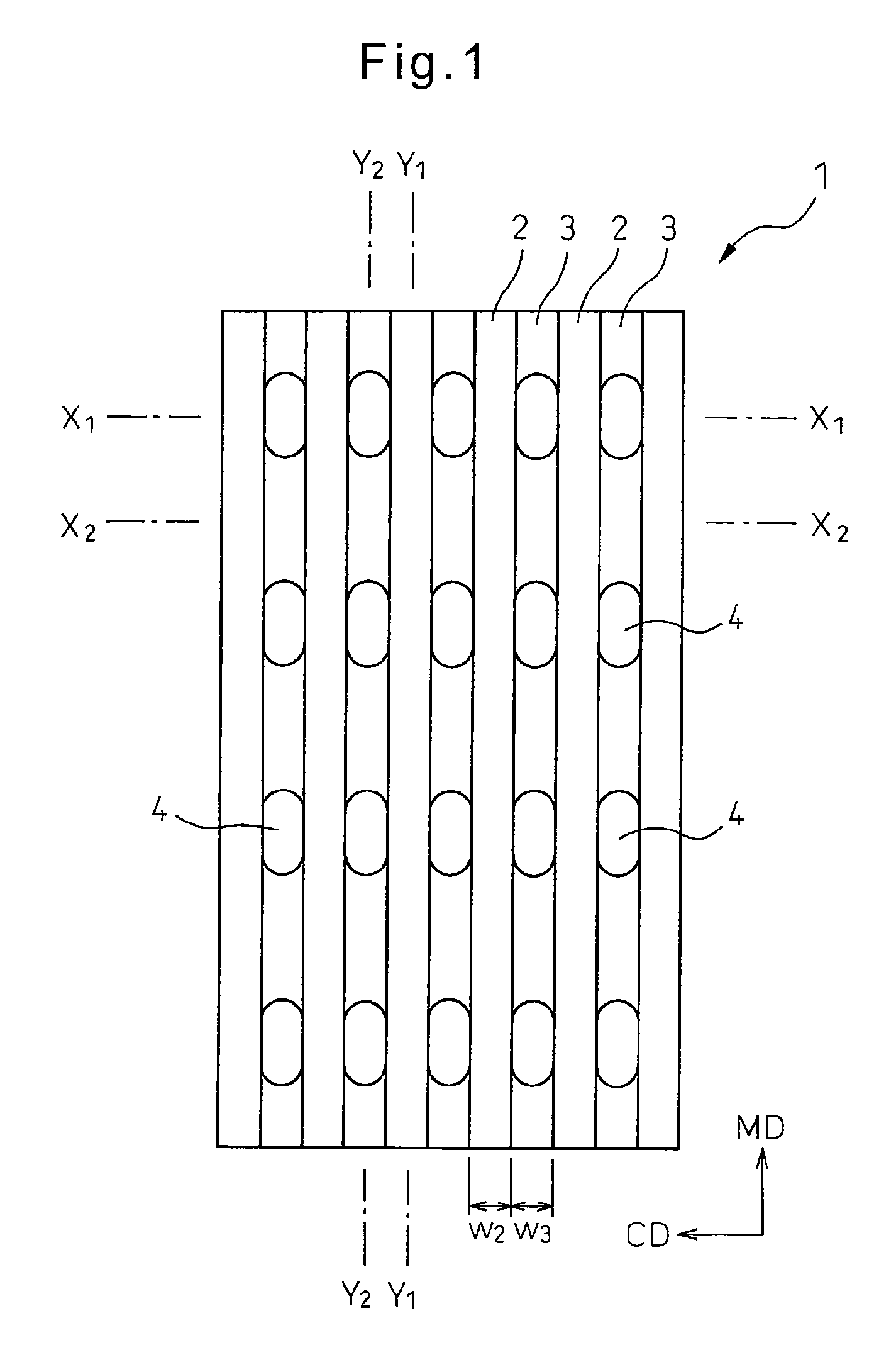

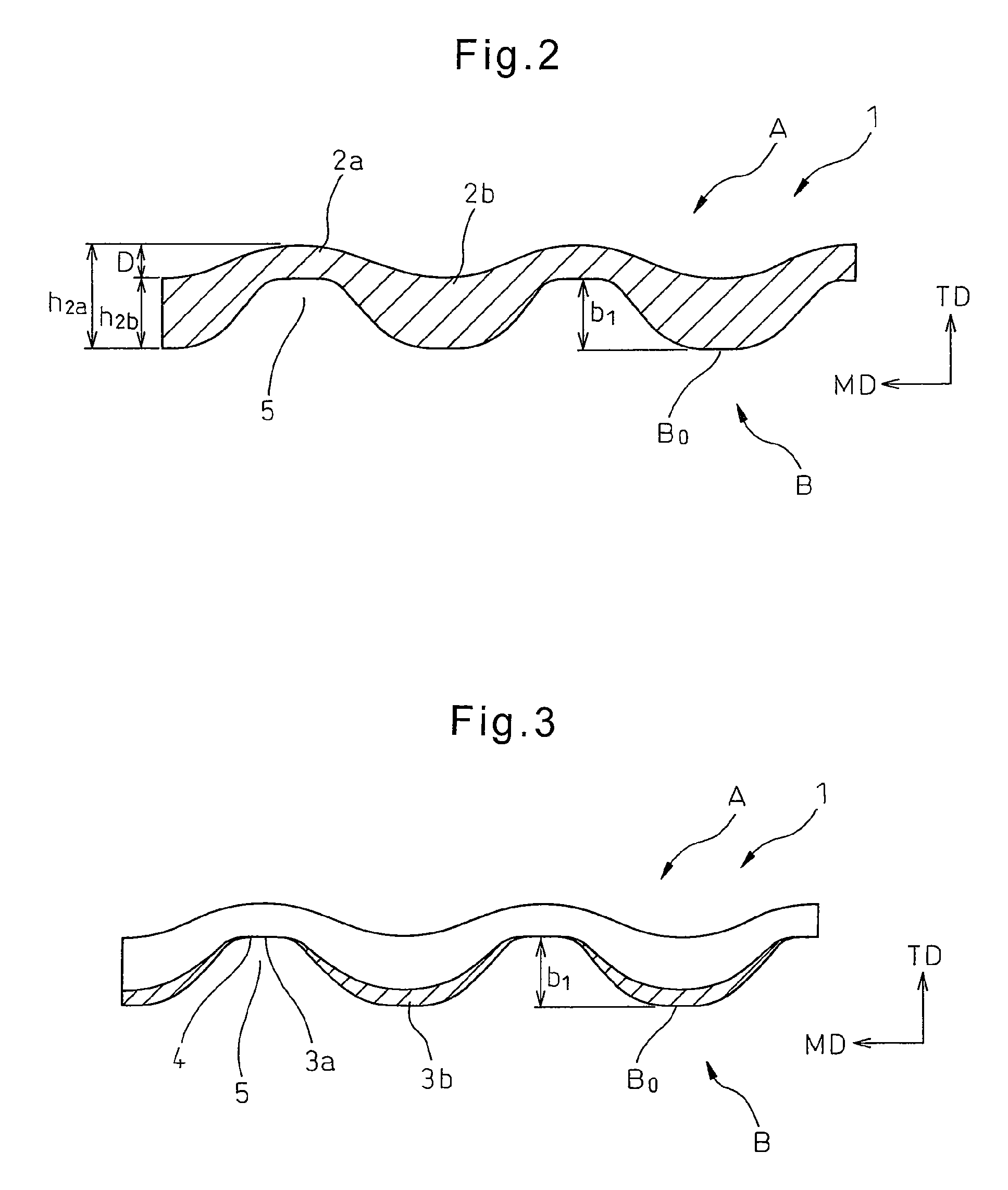

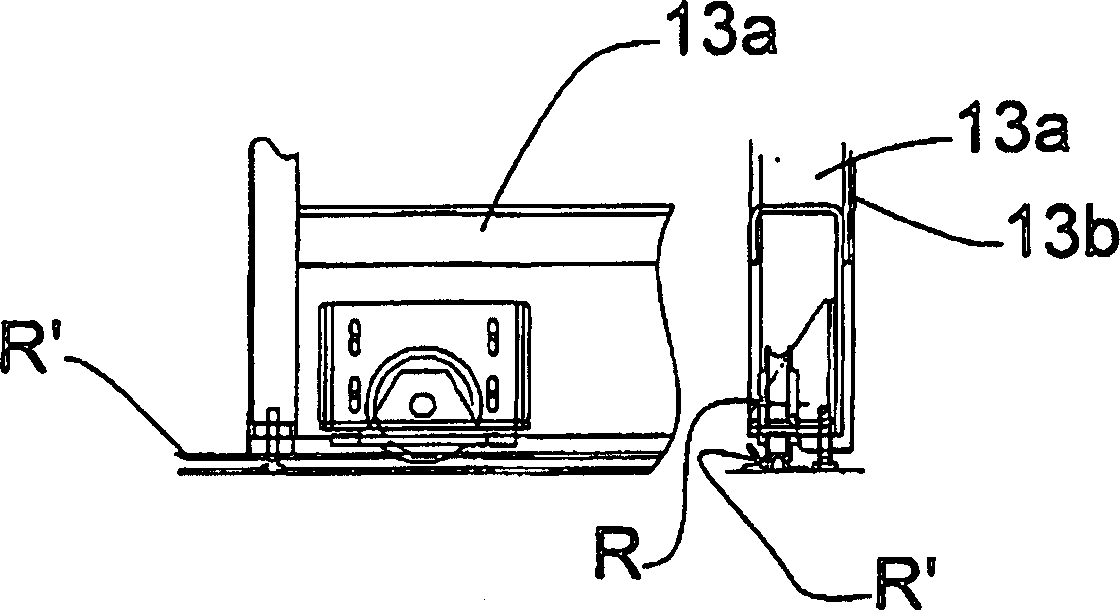

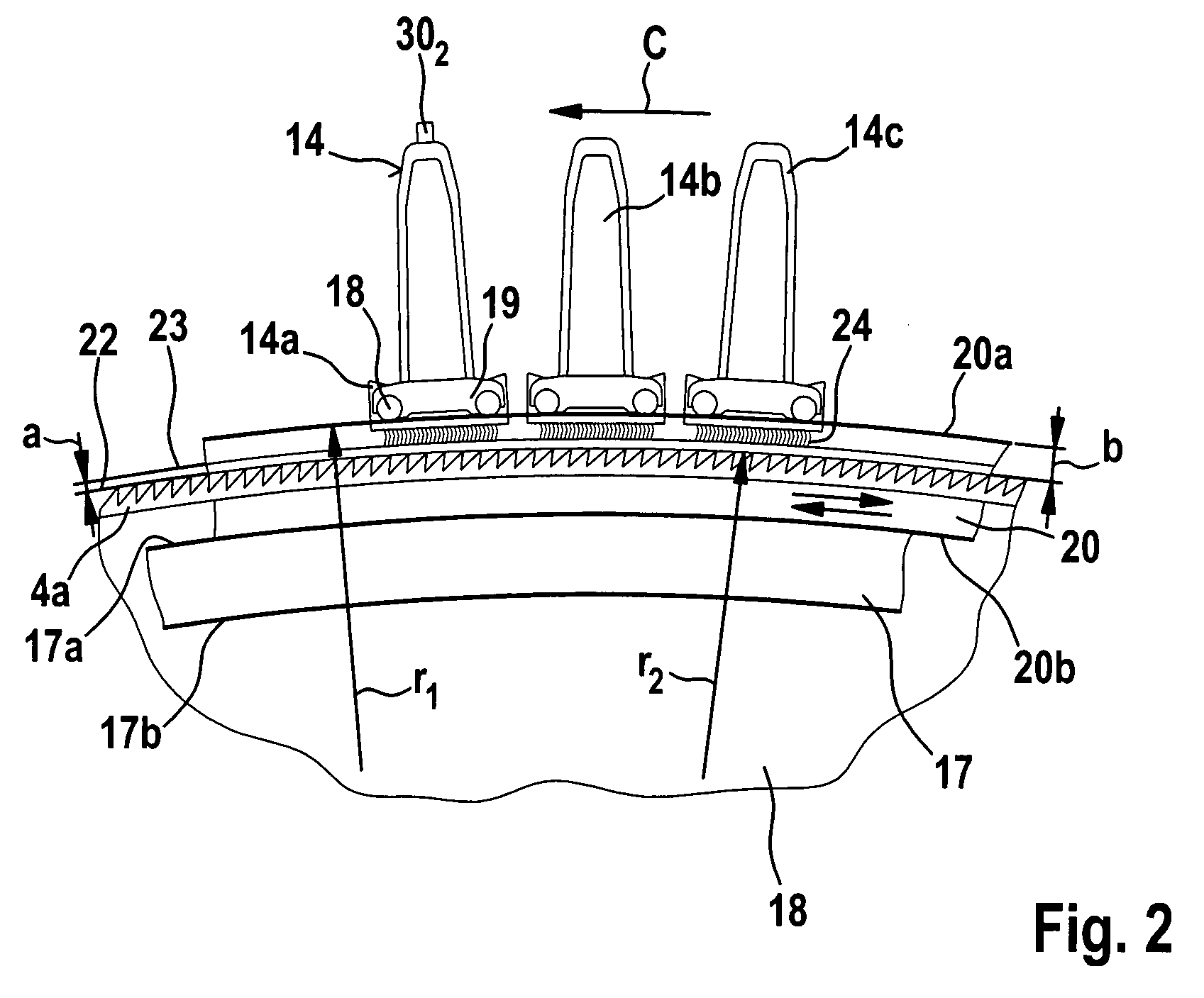

A nonwoven sheet for use in absorbent articles such as disposable diapers which is capable of reducing the range of surface diffusion of, and reducing re-adhesion to the skin of, highly viscous fluid excretion. The nonwoven sheet has mutually perpendicular longitudinal, transverse and thickness directions, and has in the aforementioned thickness direction a front surface and a back surface opposite thereof. Ridges and grooves are formed alternately so as to extend in parallel in the aforementioned longitudinal direction and so as to form repeated undulations in the aforementioned transverse direction. The nonwoven sheet has a bottom surface which, when the aforementioned nonwoven sheet is placed on a horizontal surface with the back surface (opposite of the front surface in contact with the skin of the wearer) down, is the surface that contacts the aforementioned horizontal surface. On the back surface of the aforementioned grooves are formed in the aforementioned longitudinal direction alternately areas where the height from the bottom surface is relatively high and parts corresponding to the bottom surface. Openings are formed at least in the areas where the height from the bottom surface is relatively high, and a space is provided below said openings.

Owner:UNI CHARM CORP

Non-woven sheet, manufacturing method thereof and absorbent article

InactiveUS9095477B2Increase volumeReduce the amount requiredLayered productsFibre mixingEngineeringBiomedical engineering

A nonwoven sheet for use in absorbent articles such as disposable diapers which is capable of reducing the range of surface diffusion of, and reducing re-adhesion to the skin of, highly viscous fluid excretion. The nonwoven sheet has mutually perpendicular longitudinal, transverse and thickness directions, and has in the aforementioned thickness direction a front surface and a back surface opposite thereof. Ridges and grooves are formed alternately so as to extend in parallel in the aforementioned longitudinal direction and so as to form repeated undulations in the aforementioned transverse direction. The nonwoven sheet has a bottom surface which, when the aforementioned nonwoven sheet is placed on a horizontal surface with the back surface (opposite of the front surface in contact with the skin of the wearer) down, is the surface that contacts the aforementioned horizontal surface. On the back surface of the aforementioned grooves are formed in the aforementioned longitudinal direction alternately areas where the height from the bottom surface is relatively high and parts corresponding to the bottom surface. Openings are formed at least in the areas where the height from the bottom surface is relatively high, and a space is provided below said openings.

Owner:UNI CHARM CORP

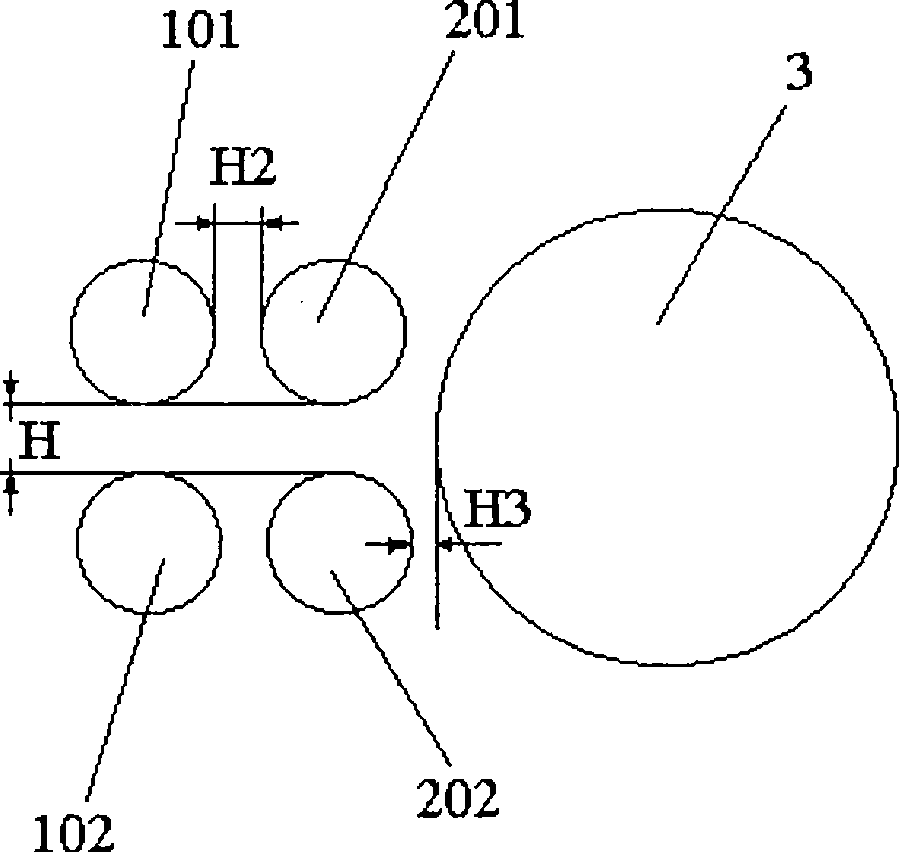

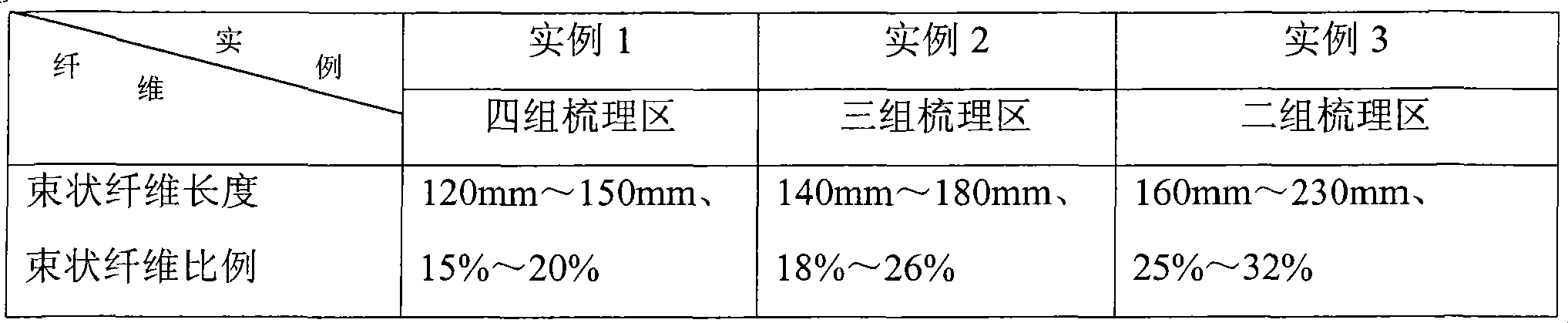

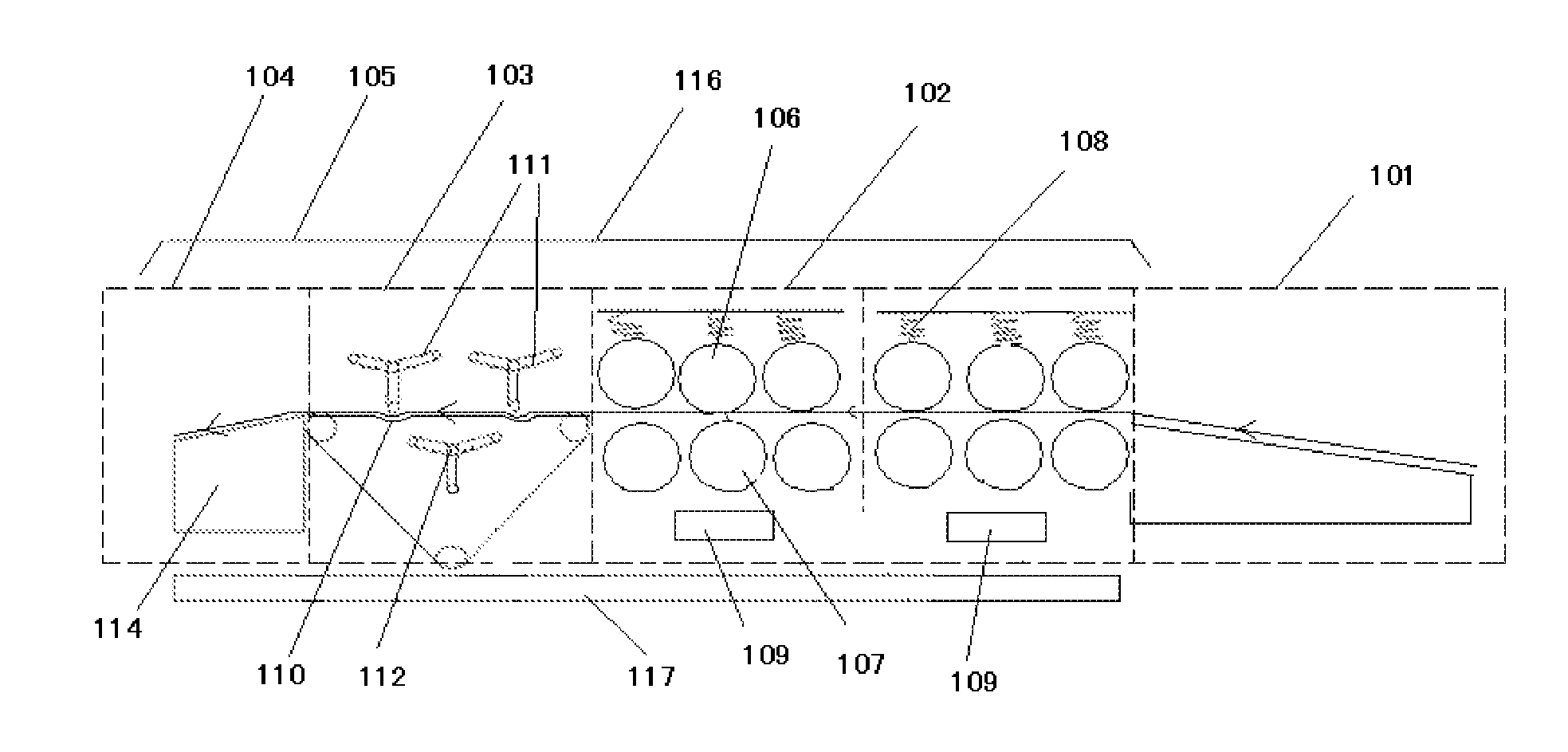

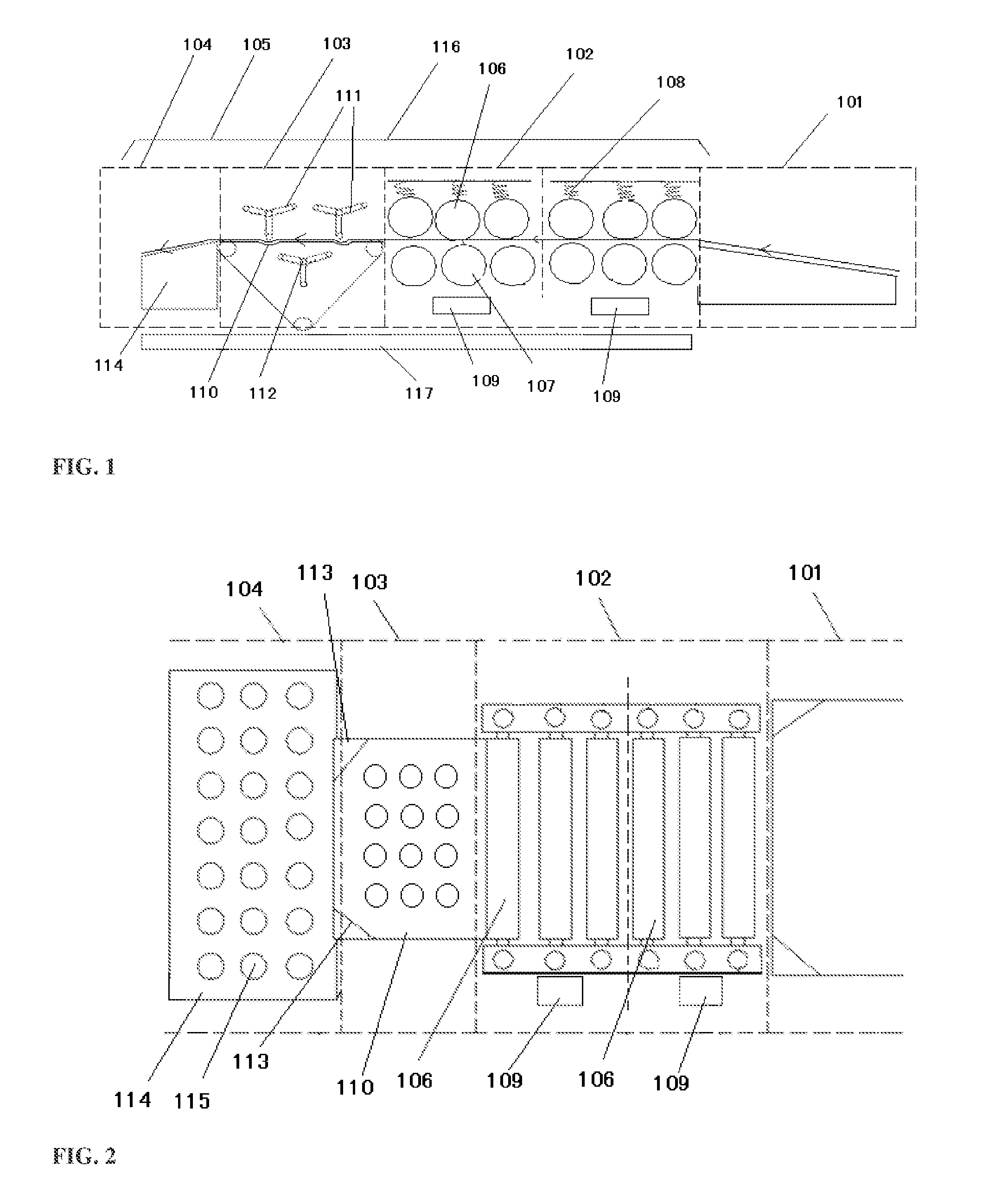

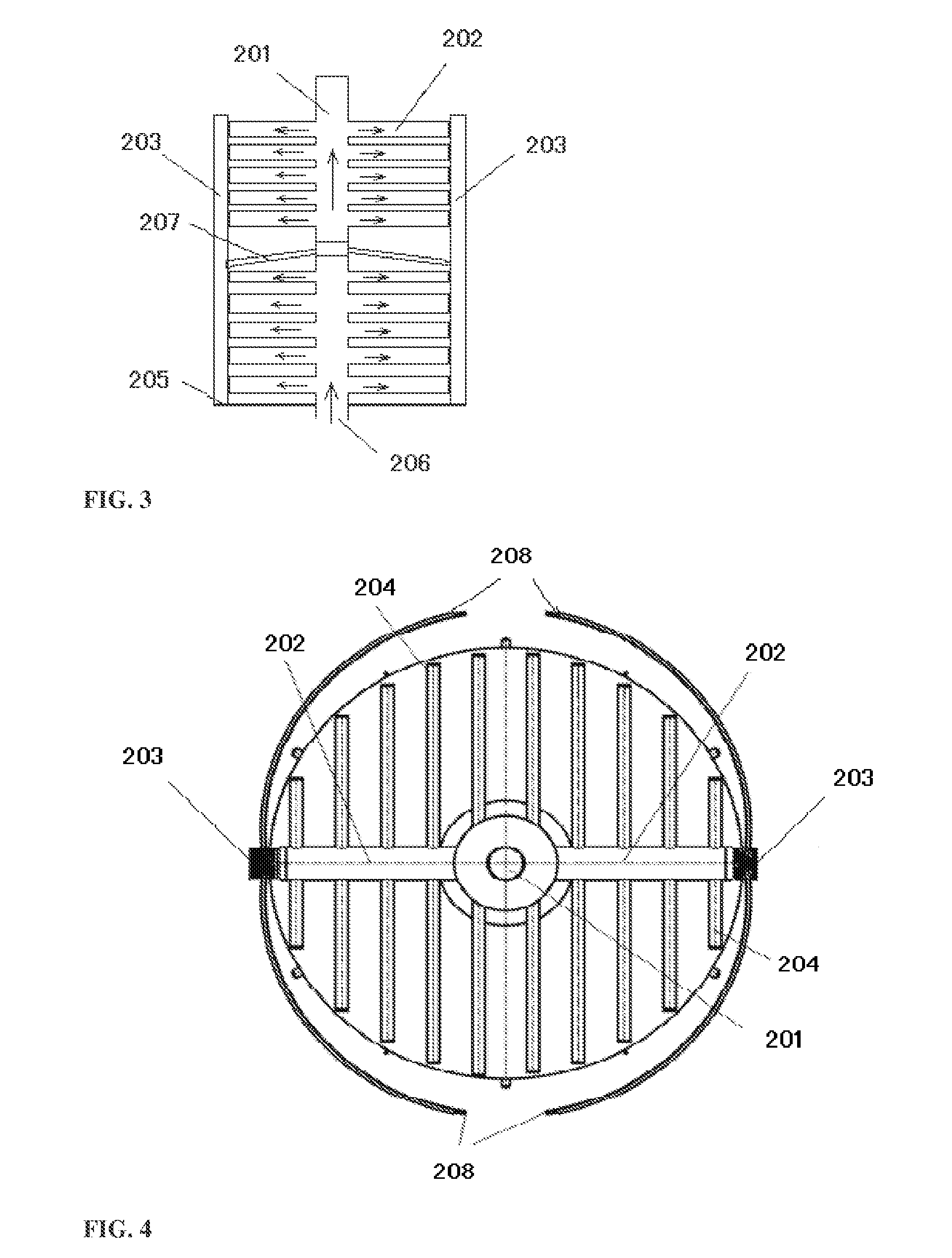

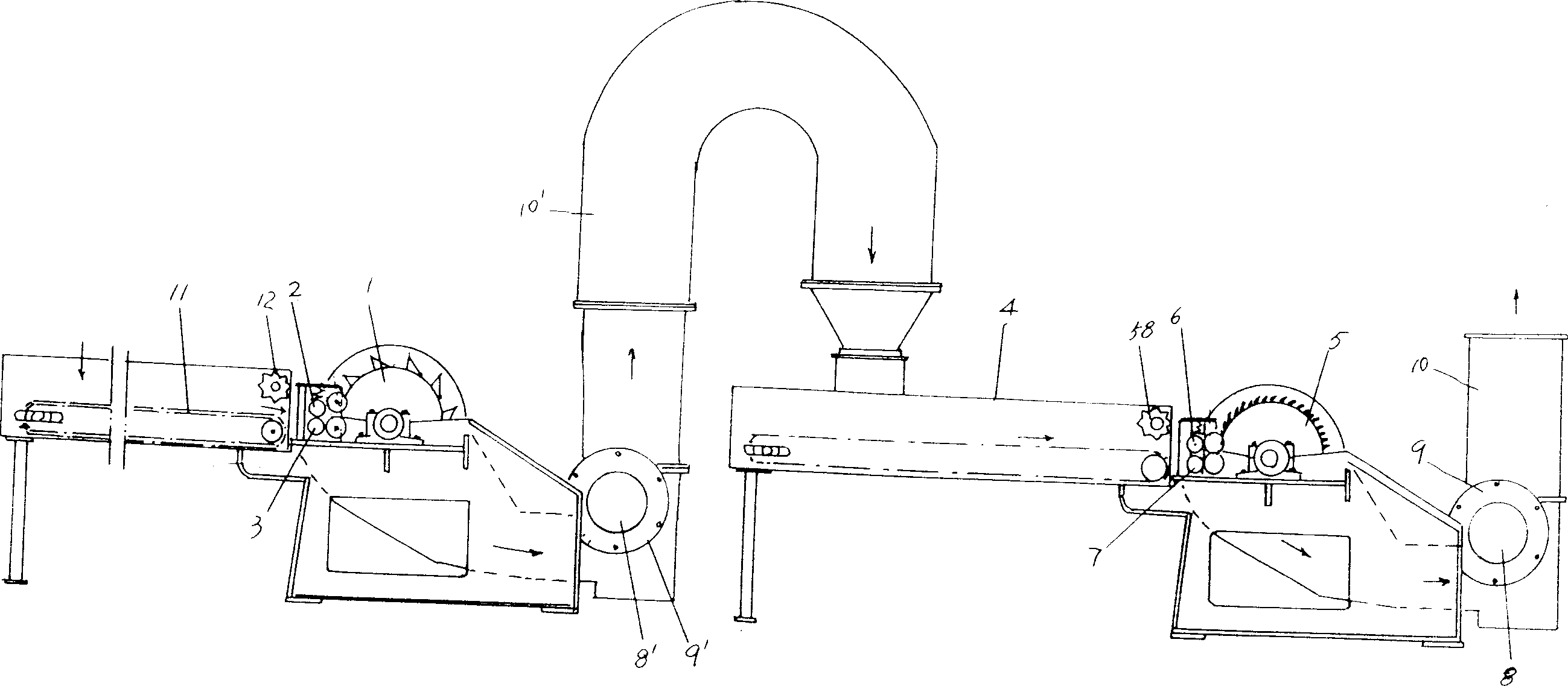

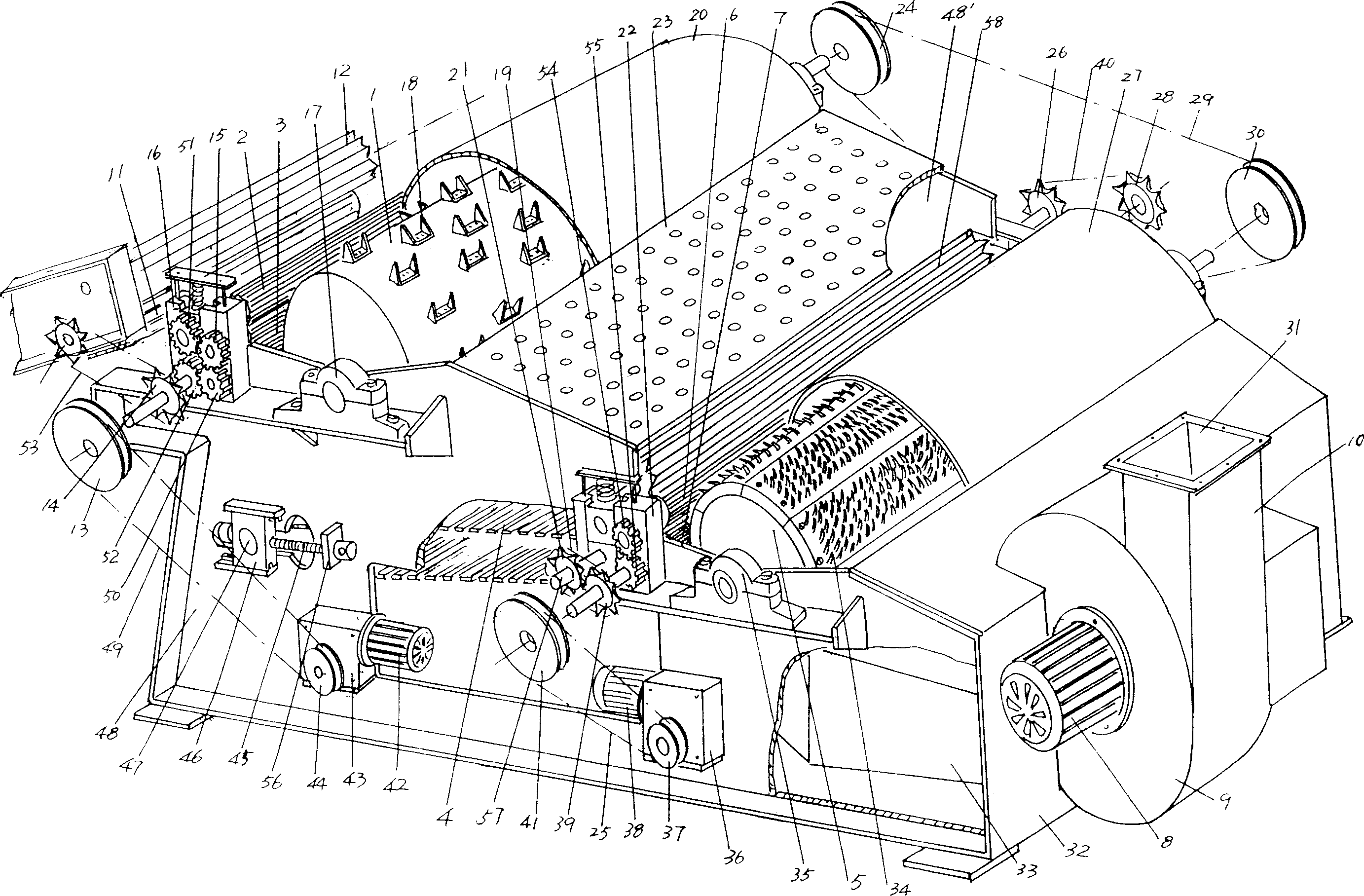

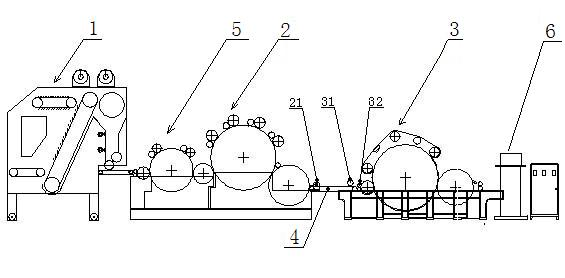

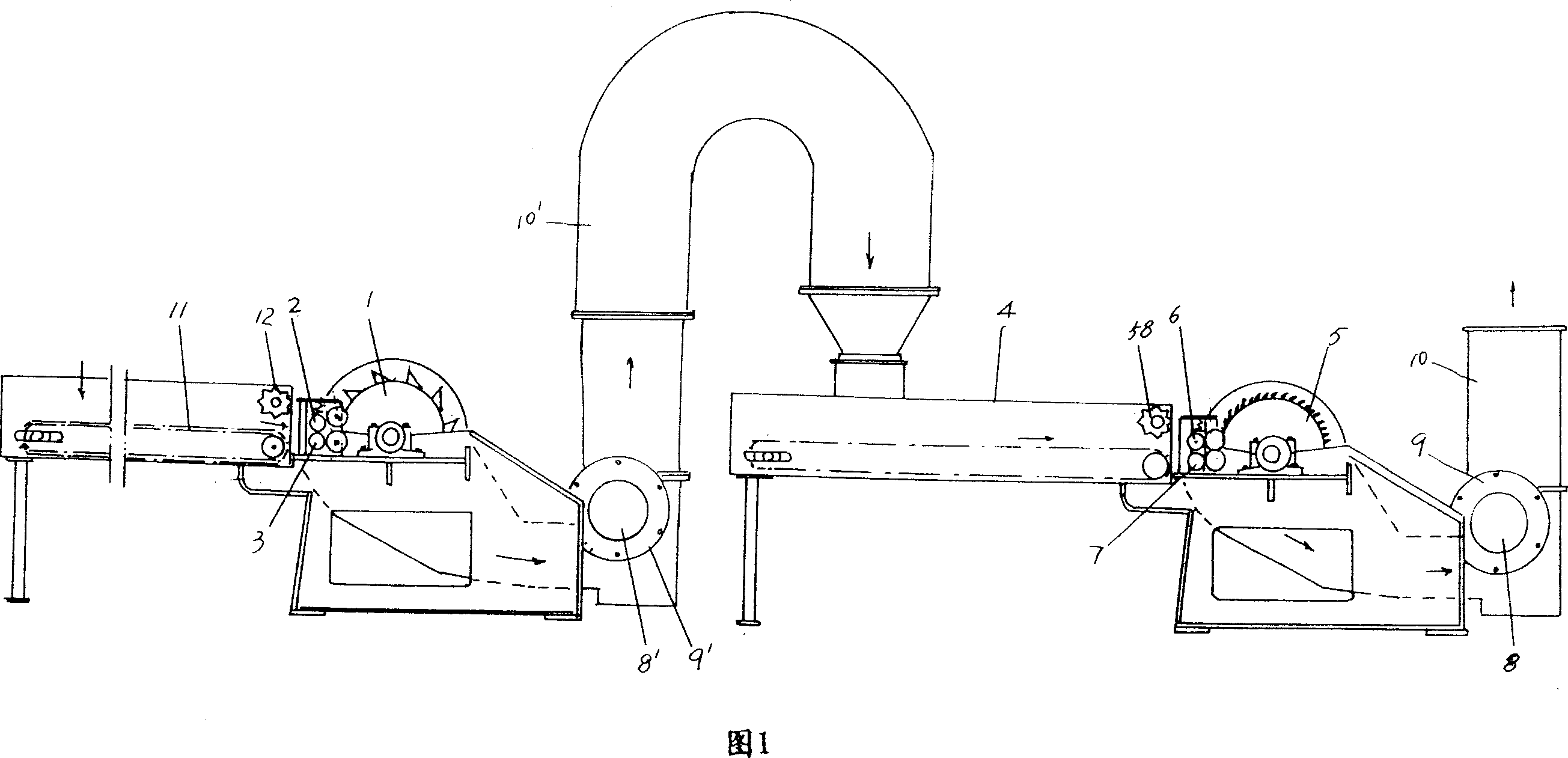

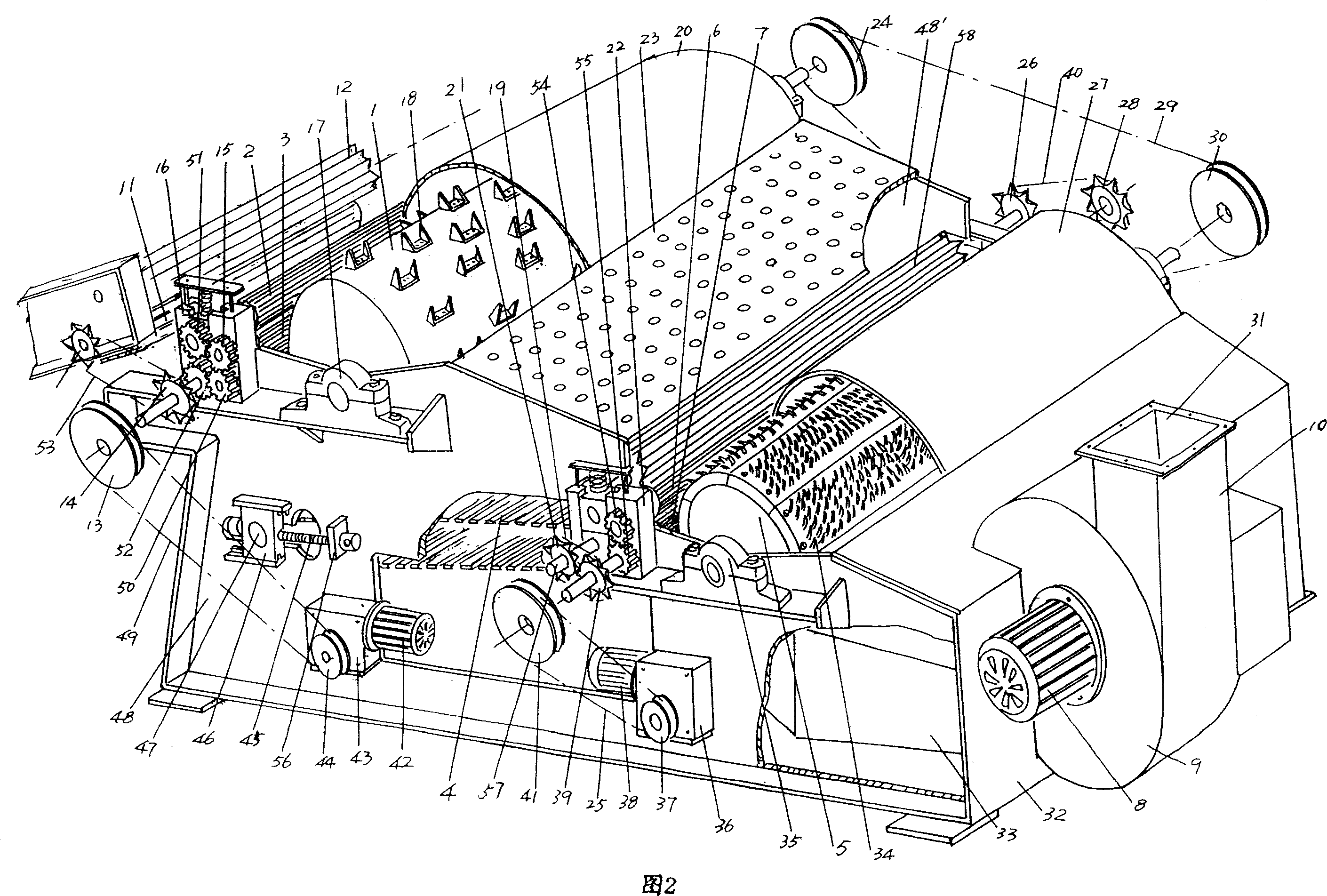

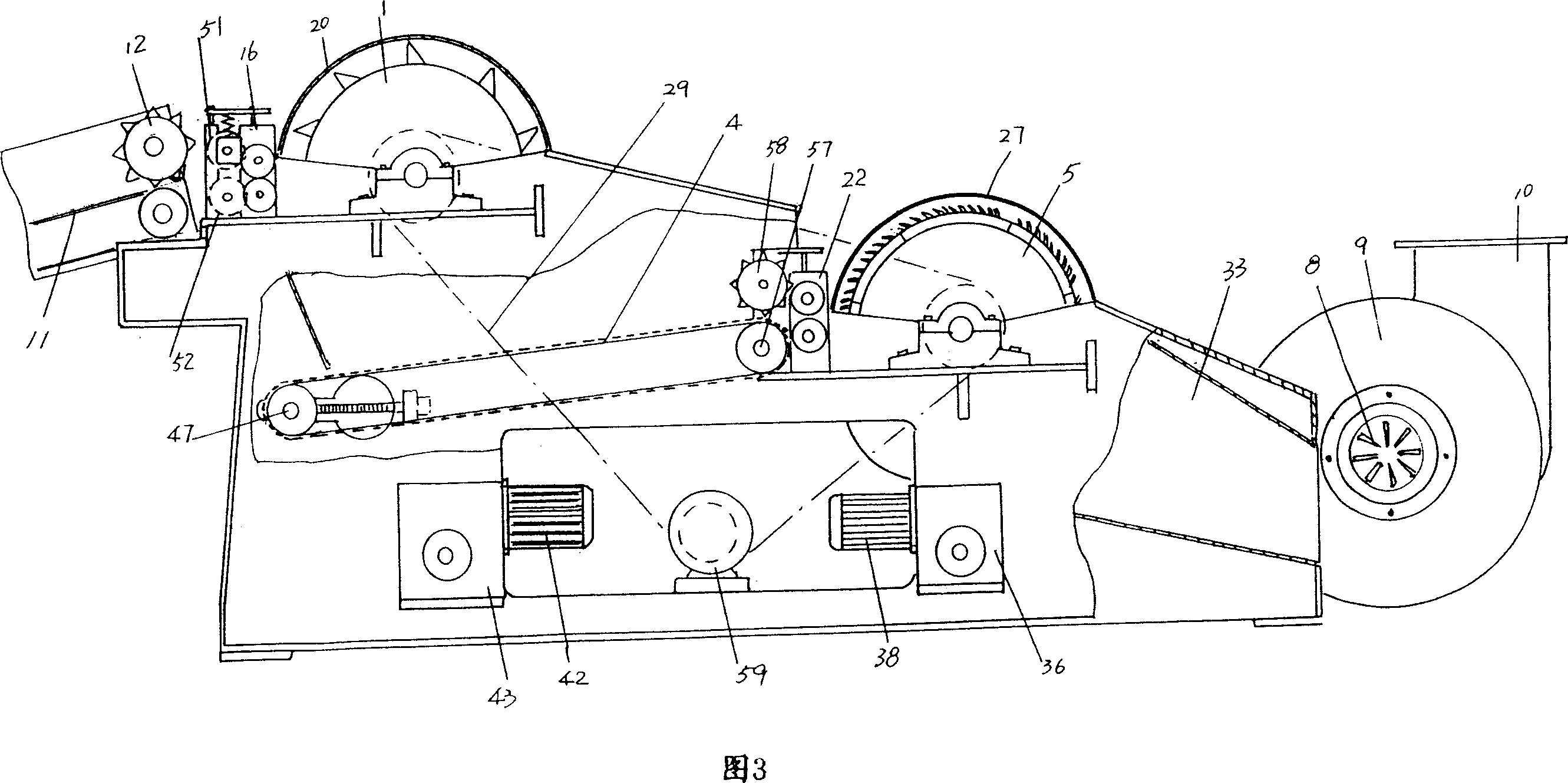

Feeding and carding system for hackling machine

InactiveCN100510211CAvoid damageMeet the characteristic requirementsCarding machinesGlass fiberCarding

The invention discloses a feeding and carding system of card clothing, characterized in that two to four pairs of carding region and two stripping regions are set on cylinder; the distance between principal up-down rollers is 10-70mm; the distance between secondary up-down rollers is 10-70mm, the distance between principal feeding roller and secondary feeding roller is 20-100mm, and the distance between principal feeding roller and thorny roller is 10-80mm. the invention is provided with smaller damage for fiber. Especially aiming to the carding for flax fiber, glass fiber, there is smaller tearing and rupturing to fiber. It can card cutting fiber with the length of 120mm-250mm. There is no influence to indexes such as drawing, bending of the fiber forming felt produced after prepared technology and so on and the product can satisfy the special demand of decoration material in special automobile. It is especially applied in carding for compound fiber, nature flax fiber, bamboo fiber, and glass fiber so on.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

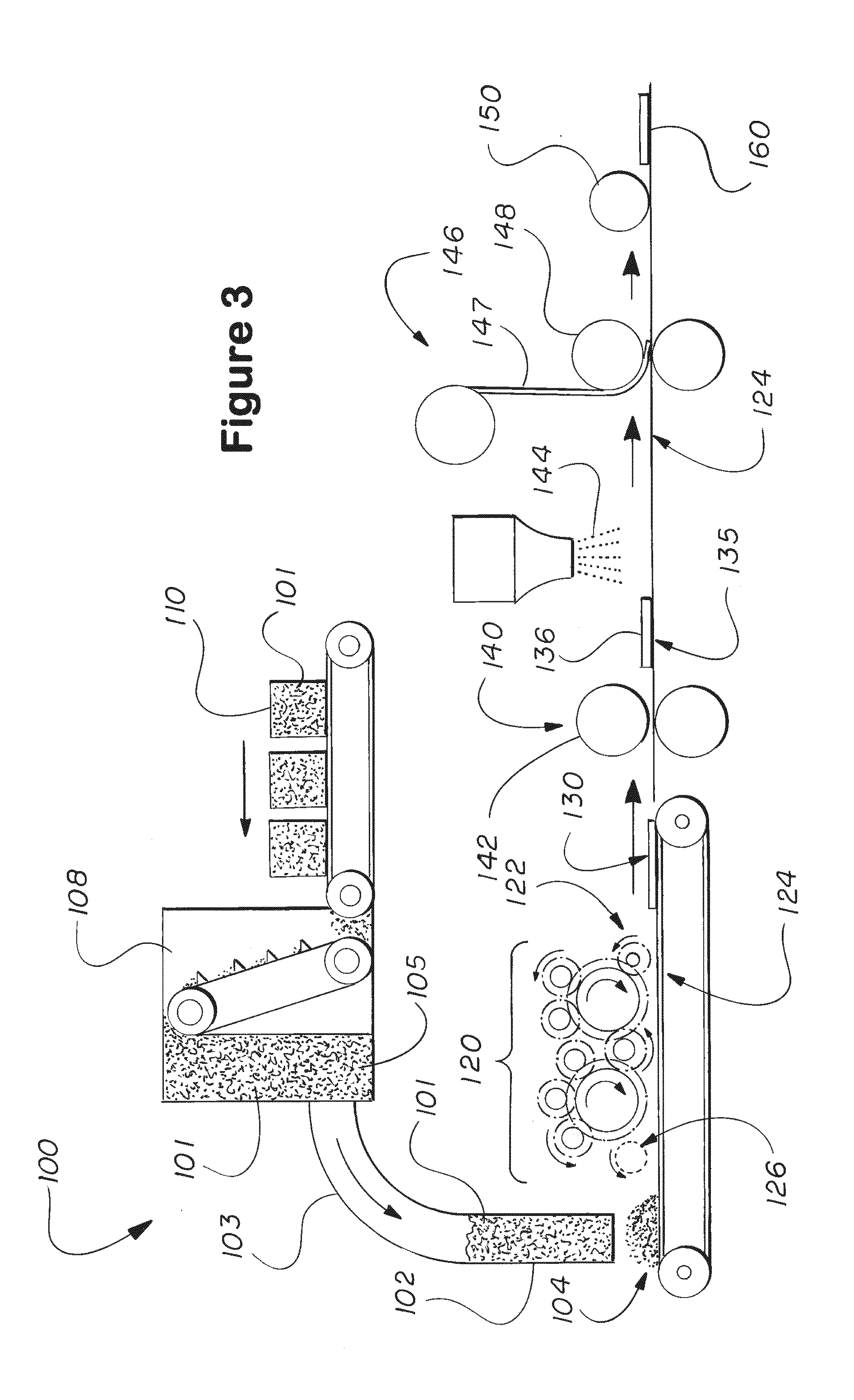

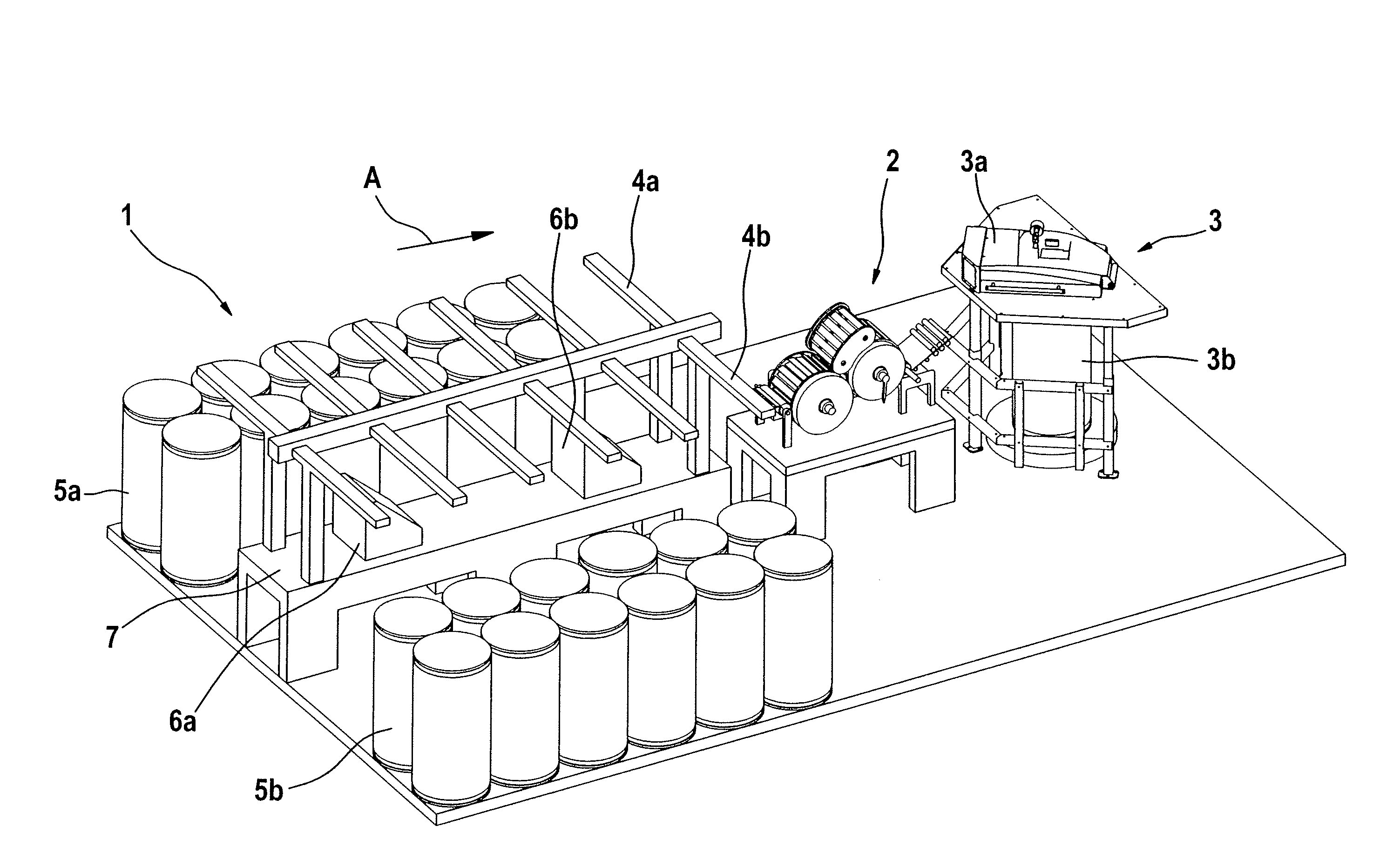

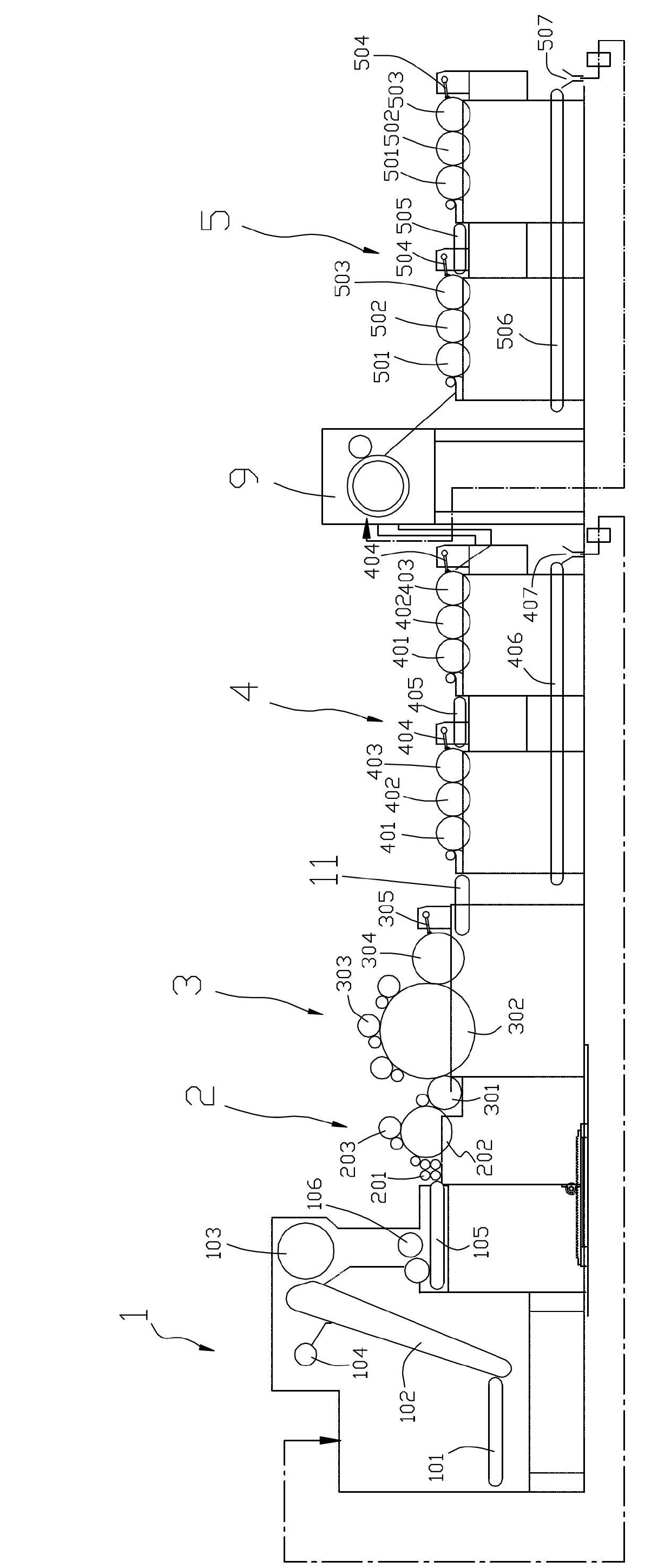

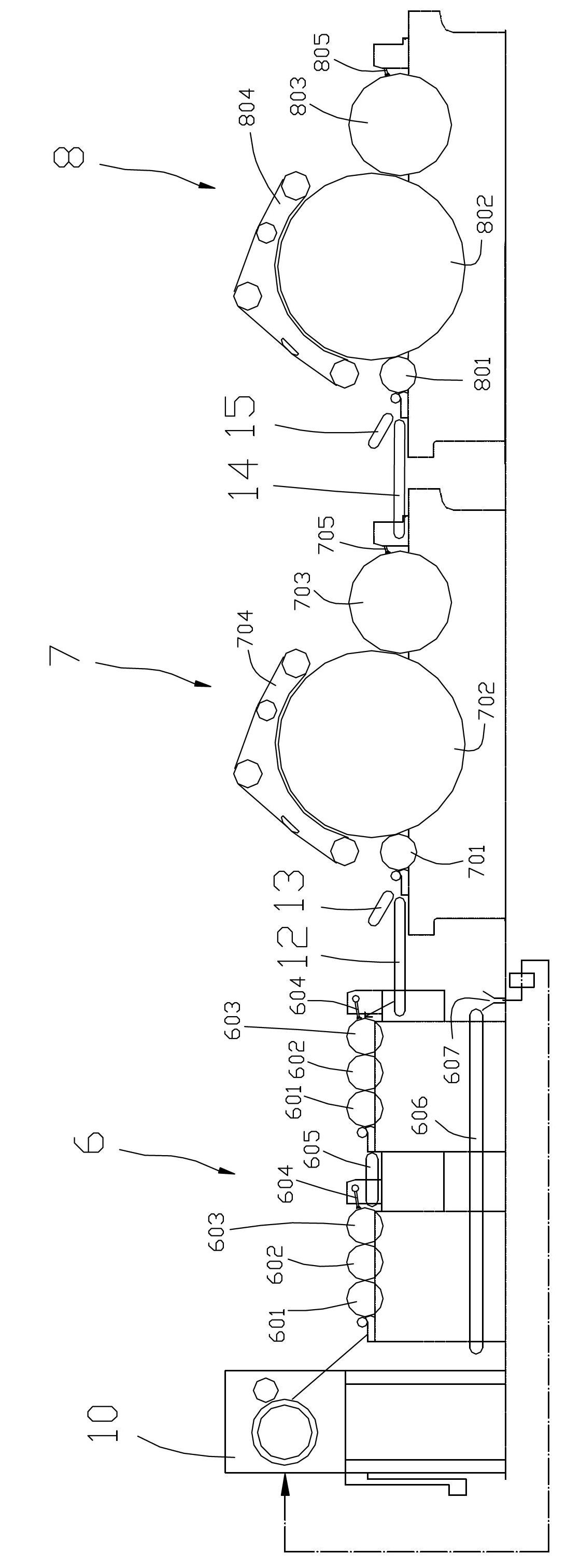

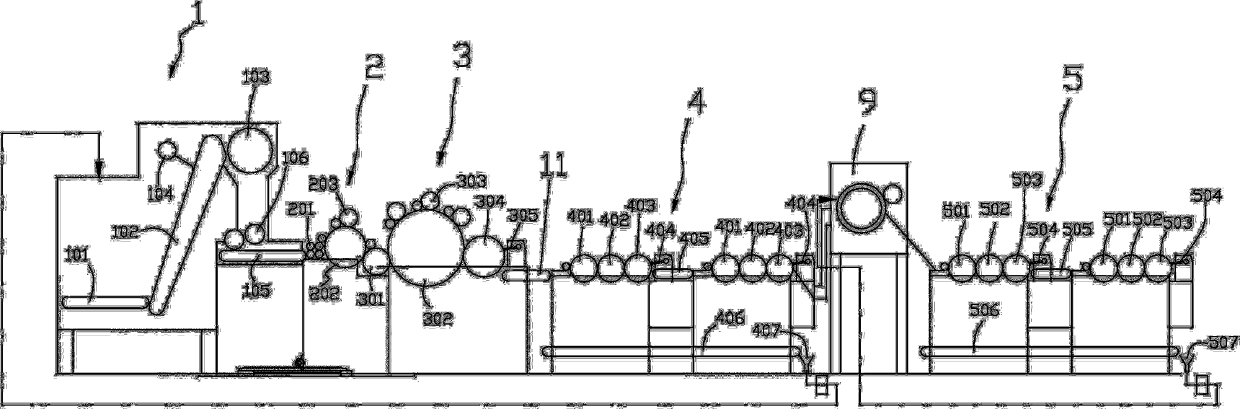

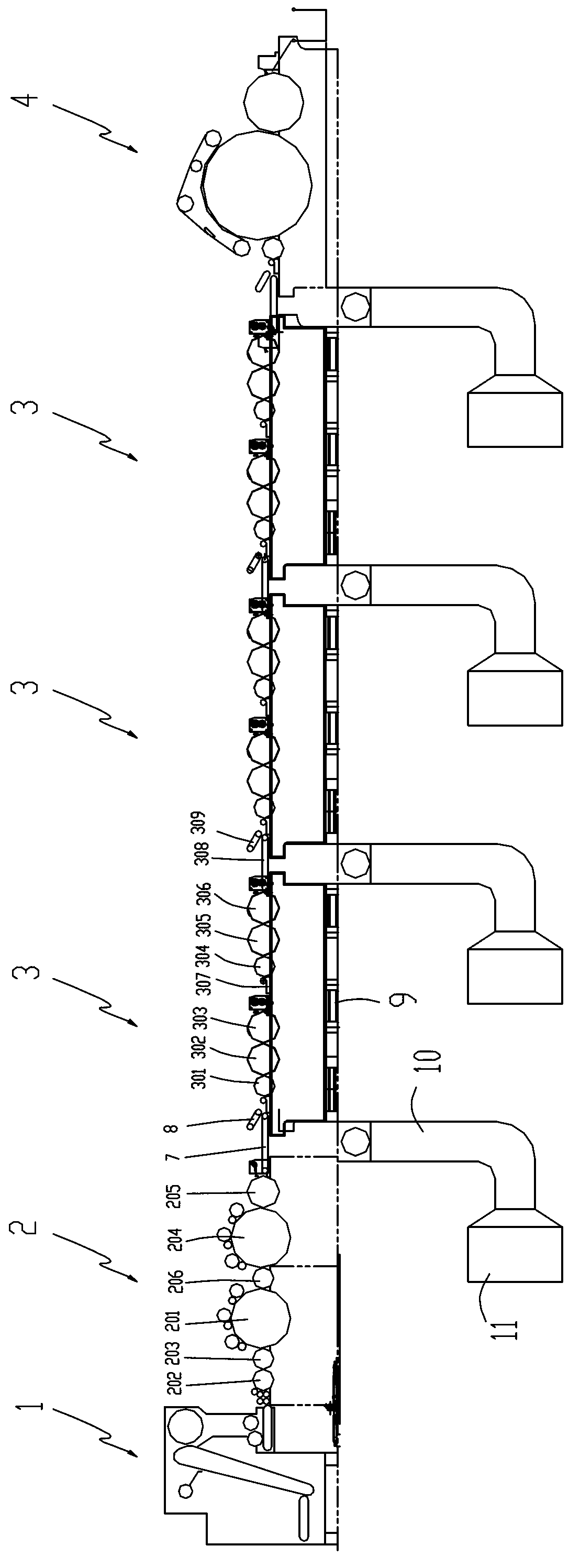

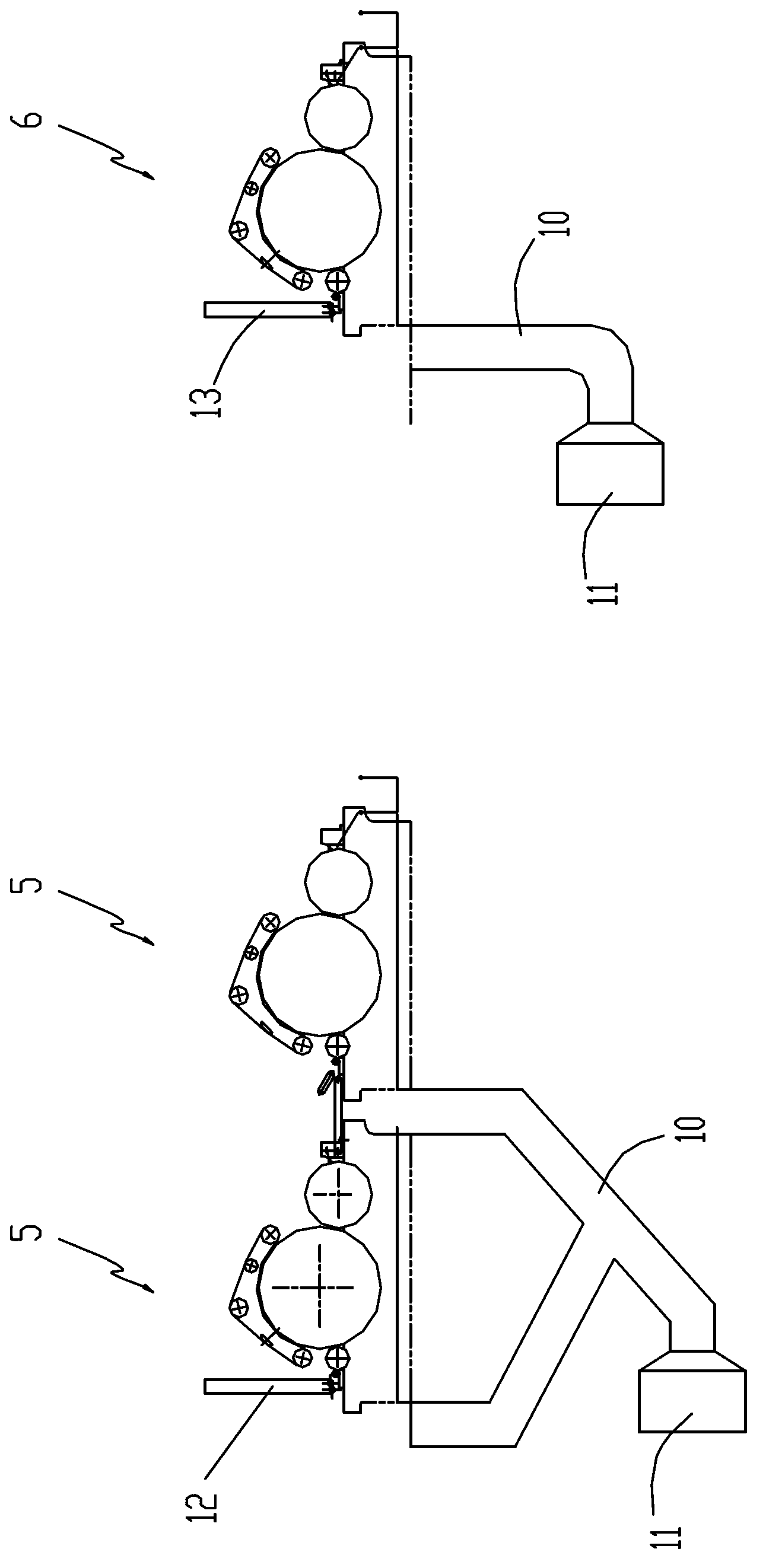

Processing Line of Bast Fiber

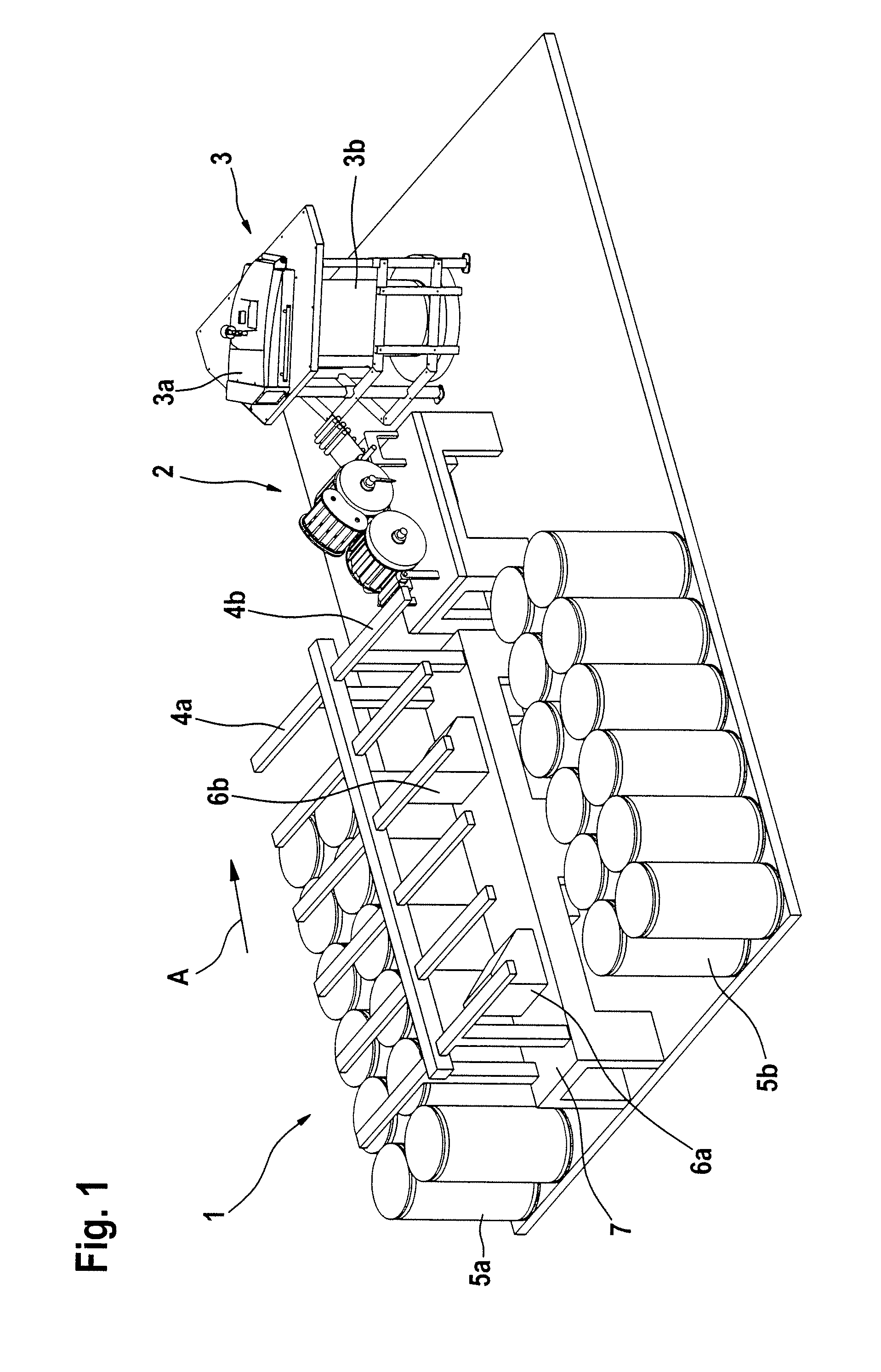

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

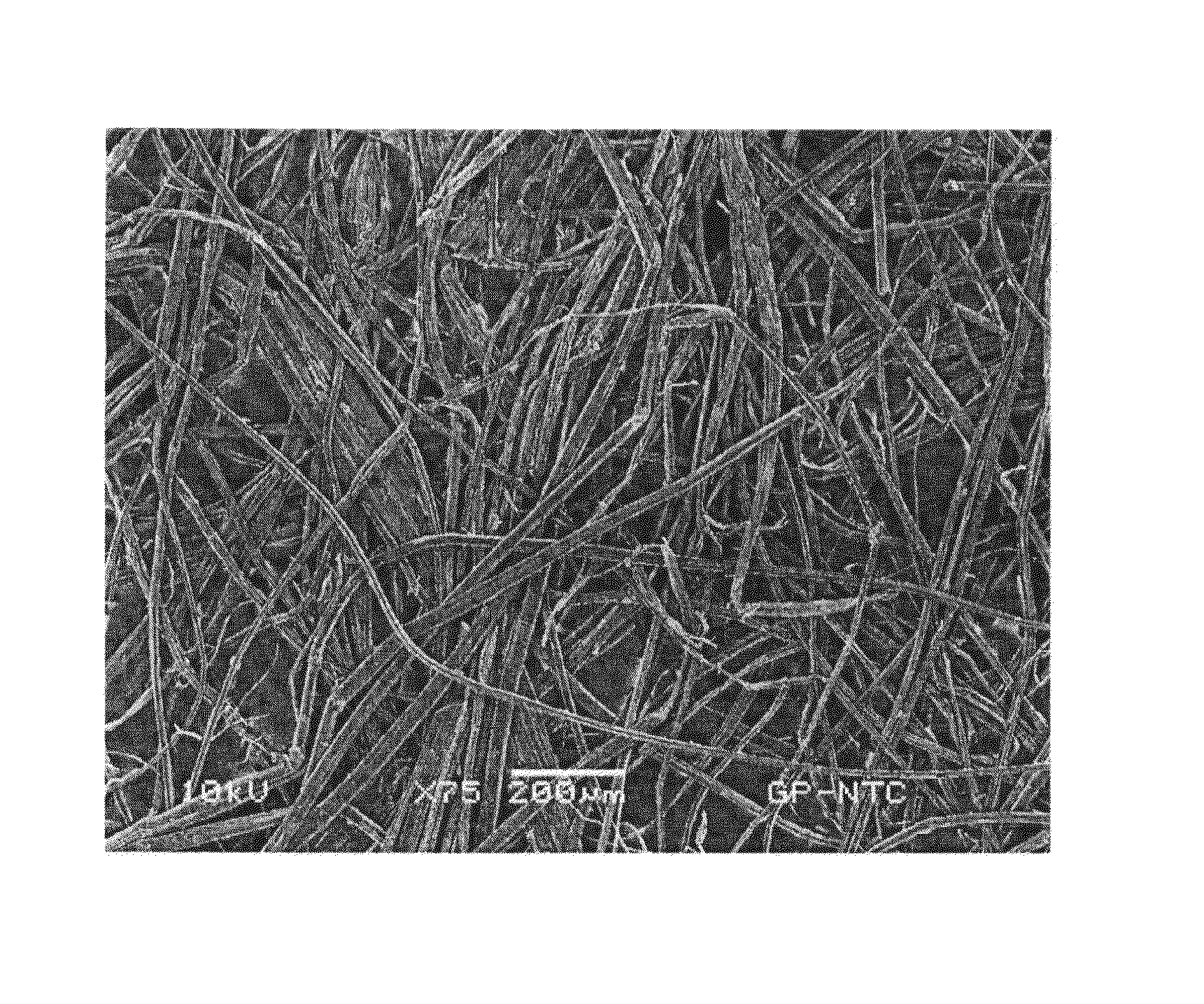

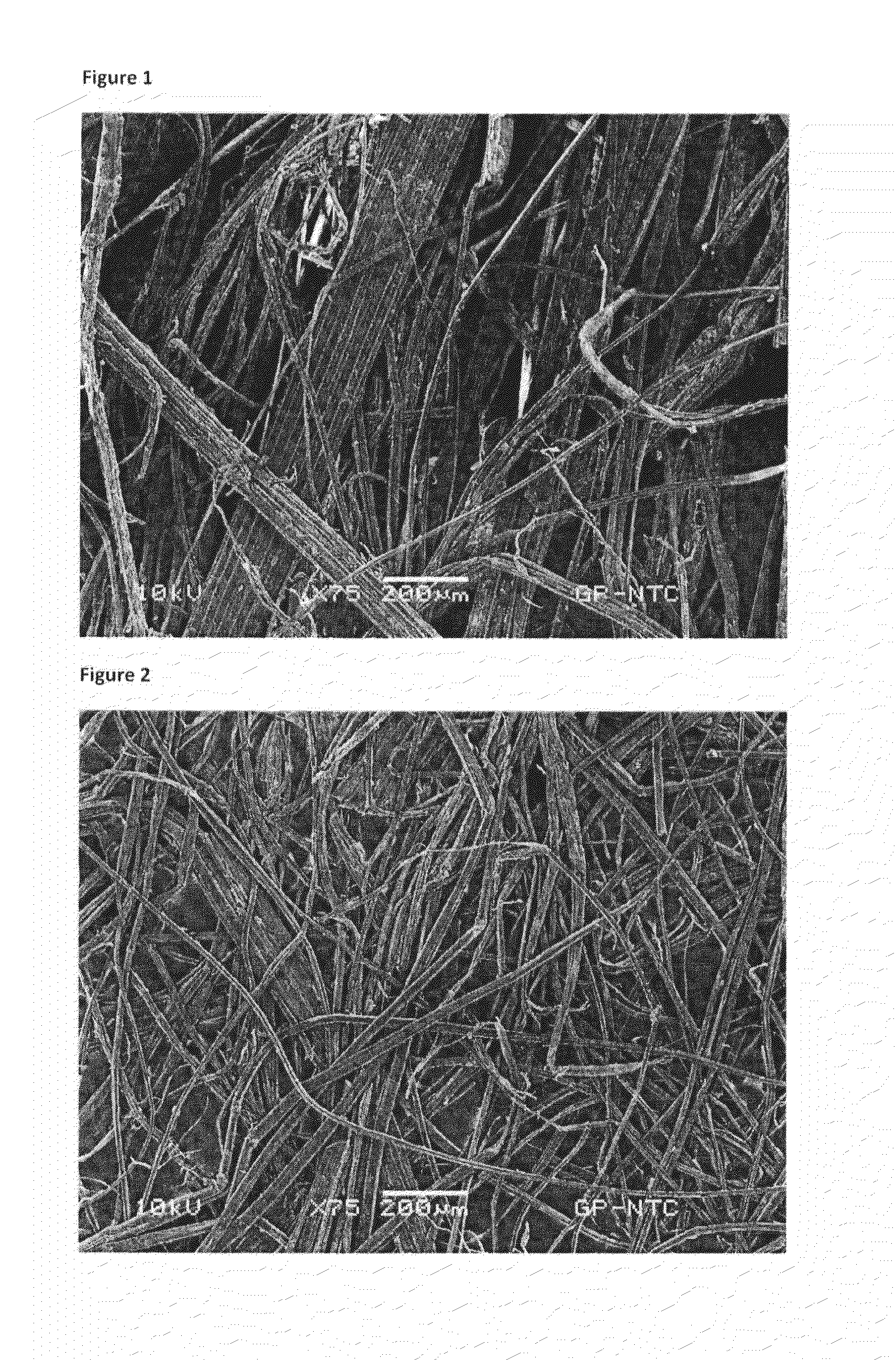

Nonwoven Fabrics Comprised of Individualized Bast Fibers

Nonwoven textile fabrics in accordance with the present invention are formed primarily of individualized bast fibers substantially free of pectin. The nonwoven fabric can include staple fibers to a lesser extent than the individualized bast fibers. Individualized bast fibers include fibers derived from the flax and hemp plants. The nonwoven textile fabric is formed into a web while in a dry state and subsequently bonded to produce a nonwoven fabric.

Owner:GPCP IP HLDG LLC

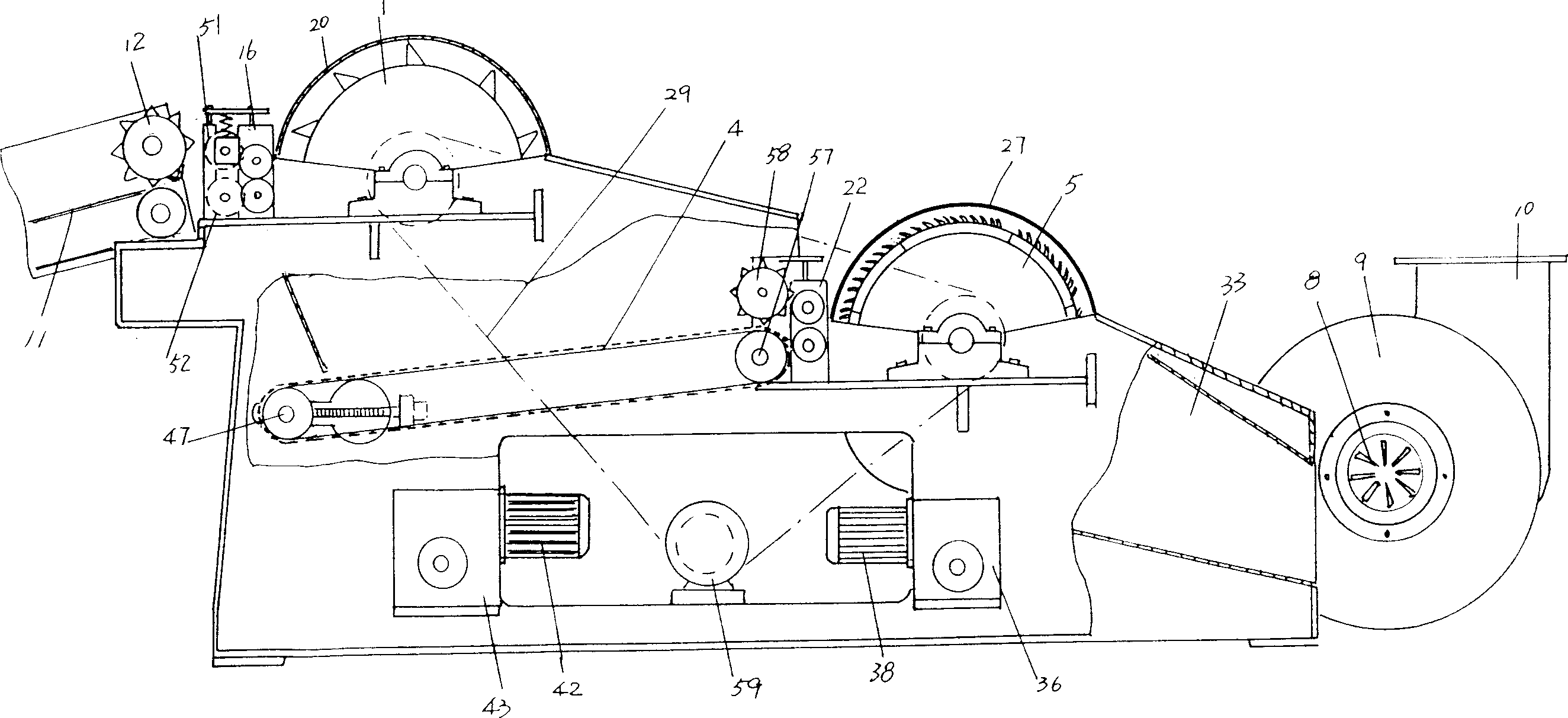

Garnett machine

The opening machine comprises a pair of frame wall opposite to each other. One end of the pair of frame wall is higher than the other end. A pre-opening mechanism composed of the first roller, the second roller and coarse opening roller is set at the high end of the frame wall, and the fine opening mechanism composed of the third roller, the fourth roller and fine opening roller is set at the low end of the frame wall. A rolling curtain is set on the frame wall and between the said two opening mechanisms. A cotton collection bucket is set between the pair of frame wall and is communicated with the opening roller. A cotton-discharging mechanism is set the enclosure plate jointed to the end part of the frame wall. It also comprises a first motor driving the first roller and the second roller to rotate, a second motor driving the third roller, the fourth roller and the rolling curtain to move and the third motor driving the coarse opening roller and the fine opening roller to move. Advantages: saved cotton-feeding mechanism and reduced processing and using cost.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

High ratio blended spinning technique for ultrashort low-density fibre based on cotton spinning device

InactiveCN101148797ARaise the ratioReasonable workmanshipFibre cleaning and opening machine combinationsCarding machinesYarnPolymer science

The present invention discloses the process of producing blended cheese yarn with high content of ultra short low density fiber in cotton spinning apparatus. A punching with high homogeneity and great cohesion is first produced through mixing ultra short low density fiber and other fiber in an opening and picking step much loosening and less beating; and then produced into cheese through the steps of combing, drawing, roving, spinning and coning. The blended cheese yarn consists of ultra short low density fiber 51-95 wt%, natural fiber 5-49 wt% and chemical fiber 5-49 wt%. The blended cheese yarn with high content of ultra short low density fiber is light, soft, lofty and high in strength, and its produced fabric has high color fastness.

Owner:DONGHUA UNIV +1

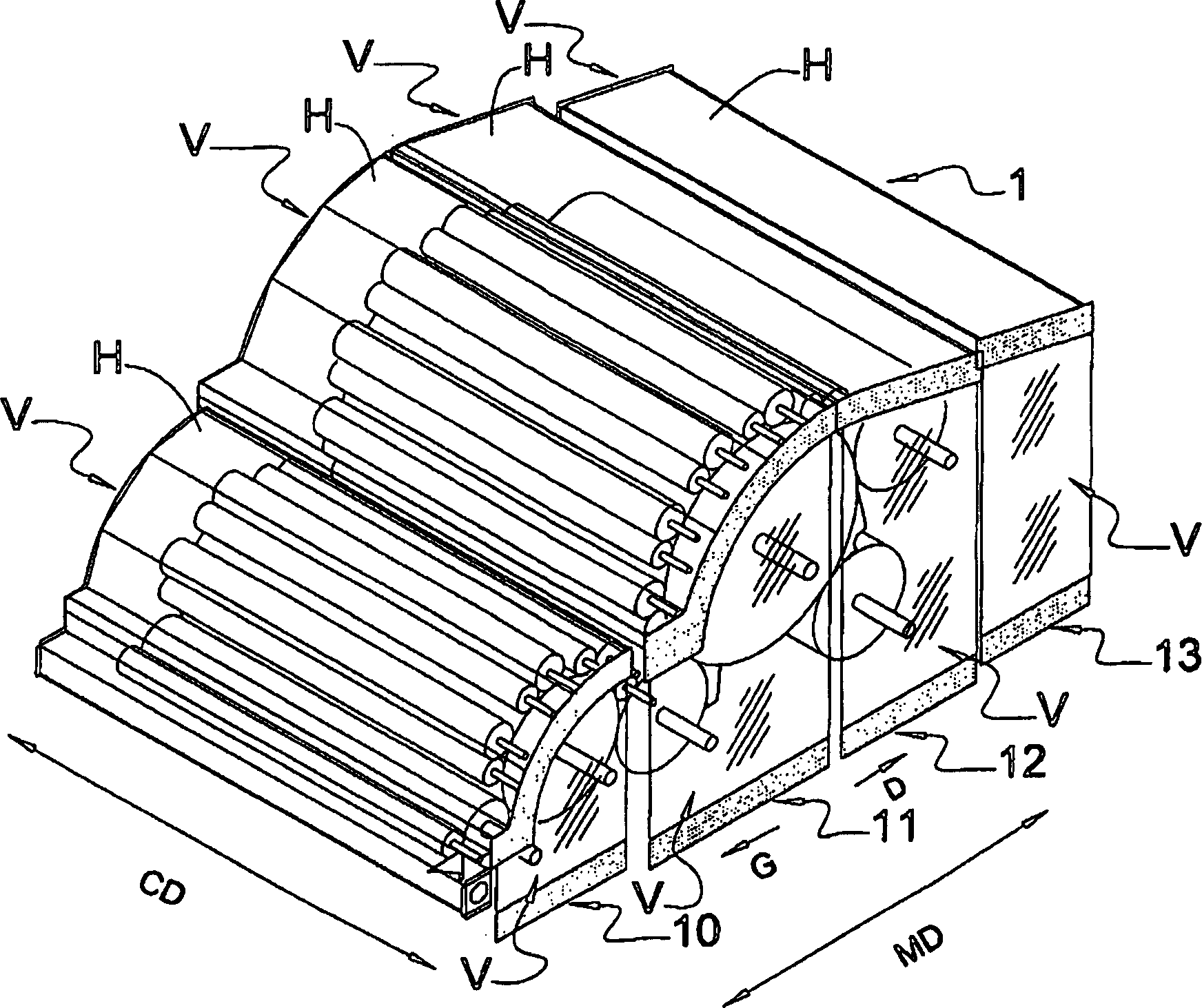

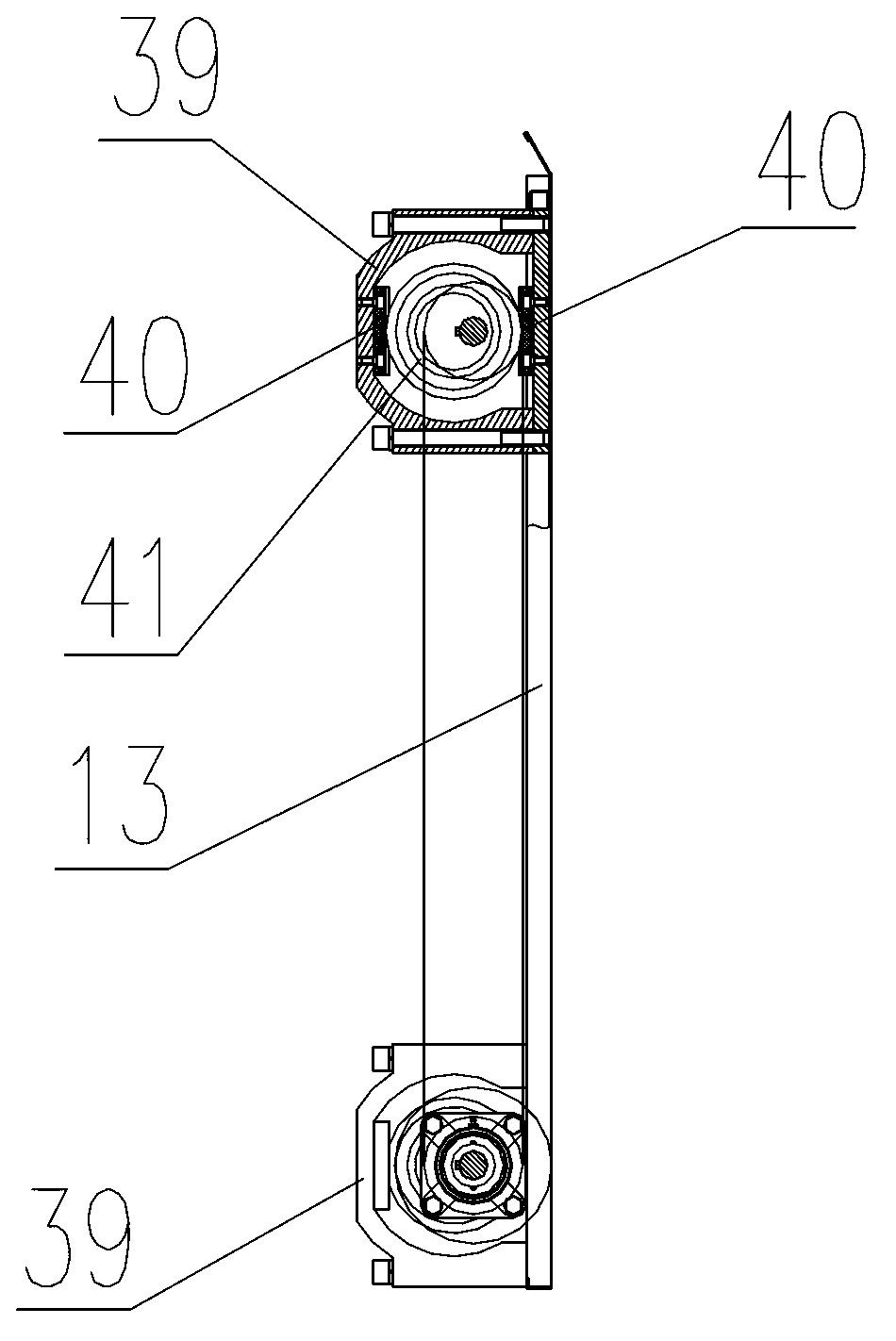

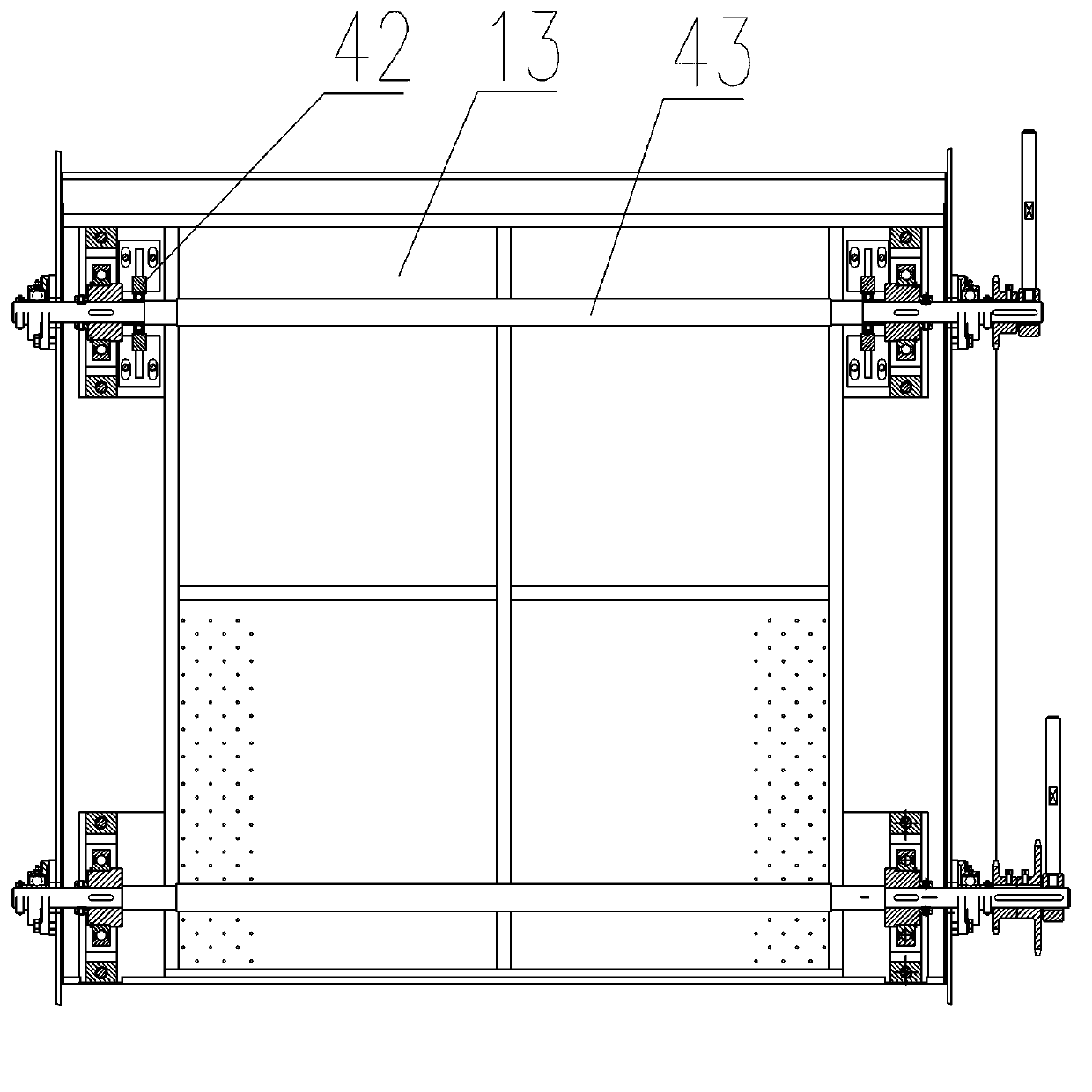

Carding machine with linearly movable casing

InactiveCN1811027AAddress accessibility issuesIncrease contactCarding machinesEngineeringMechanical engineering

The invention relates to a carding machine which is provided with a plurality of drums (20,21,22 and so on) and a covering device, wherein the covering device (1) can form an encloser (E), and the drums of the carding machine is contained in the encloser. The covering device (1) is provided with at least a covering element (10, 11, 12, and 13), and the covering element is vertical to the vertical direction of the drums of the carding machine along a shaft line (MD) and can do translational motion between a covering position and an end portion opening position, the covering position exclusively belongs to the covering unit on the position, at least one portion of the drums of the carding machine is covered by the covering element, and the drums are not covered by the cover element on the end portion opening position.

Owner:ASSELIN THIBEAU

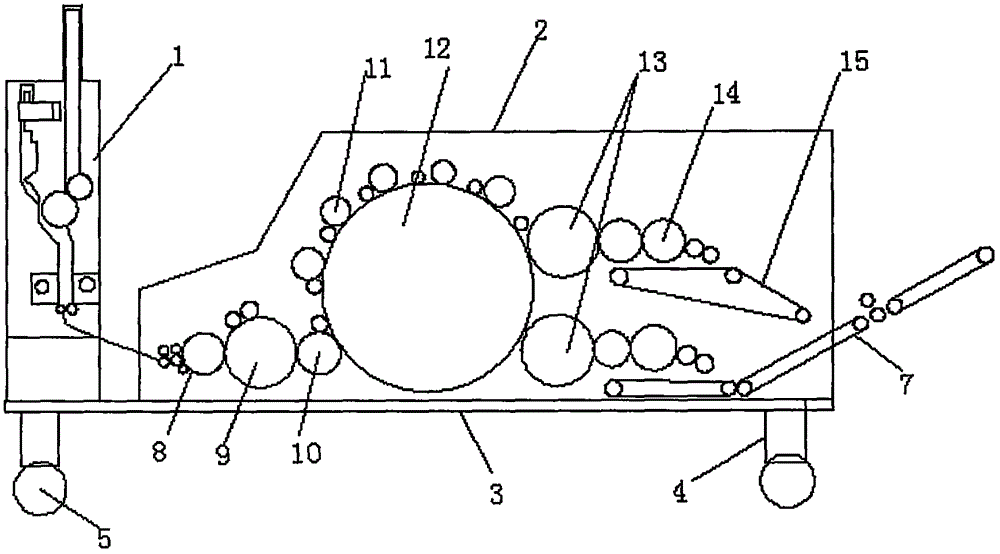

Carding machine equipment for textile fibers

The invention discloses carding machine equipment for textile fibers. The equipment comprises a feeding case, a casing, a machine base, supporting legs, a pre-carding mechanism, a main carding mechanism, double-doffer stripping-carding rollers, a conveying curtain mechanism and a discharging conveying belt, wherein the feeding case and the casing are arranged on the machine base, the supporting legs are arranged below the machine base, and a feeding conveying belt mechanism is arranged above the feeding case. The equipment is simple in structure and convenient to operate; the feeding case and the casing are arranged above the machine base, the pre-carding mechanism, the main carding mechanism, the double-doffer stripping-carding rollers, the conveying curtain mechanism and the discharging conveying belt are arranged in the casing sequentially, small impurities left in the equipment after pre-carding, main carding and processing by the double-doffer stripping-carding rollers and backing-off rollers are cleared, matched cotton composition fibers are sufficiently mild in a single-fiber state, uniform cotton slivers are prepared, requirements of the later process are met, and the practicability is high.

Owner:EASTERN LIAONING UNIV

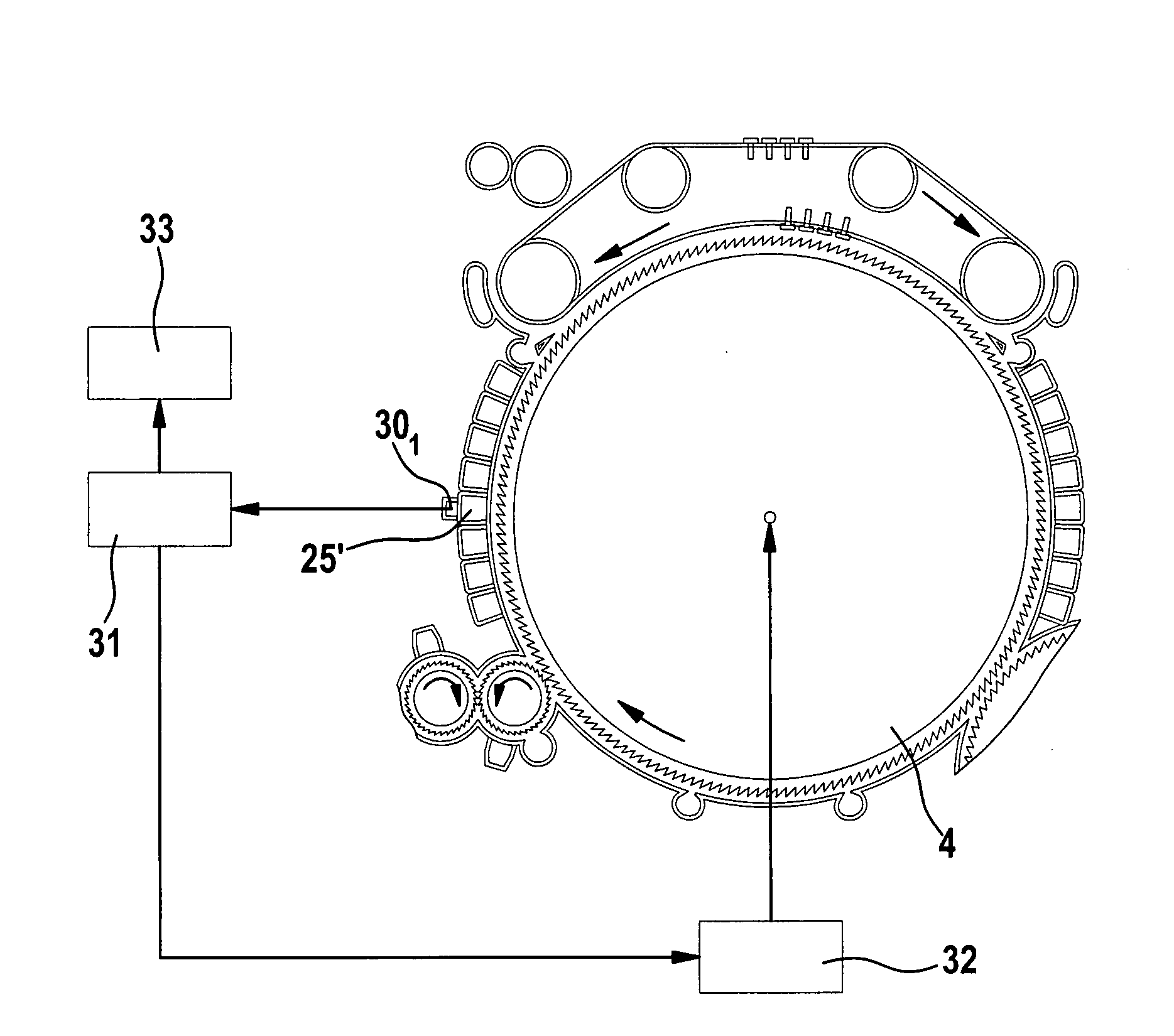

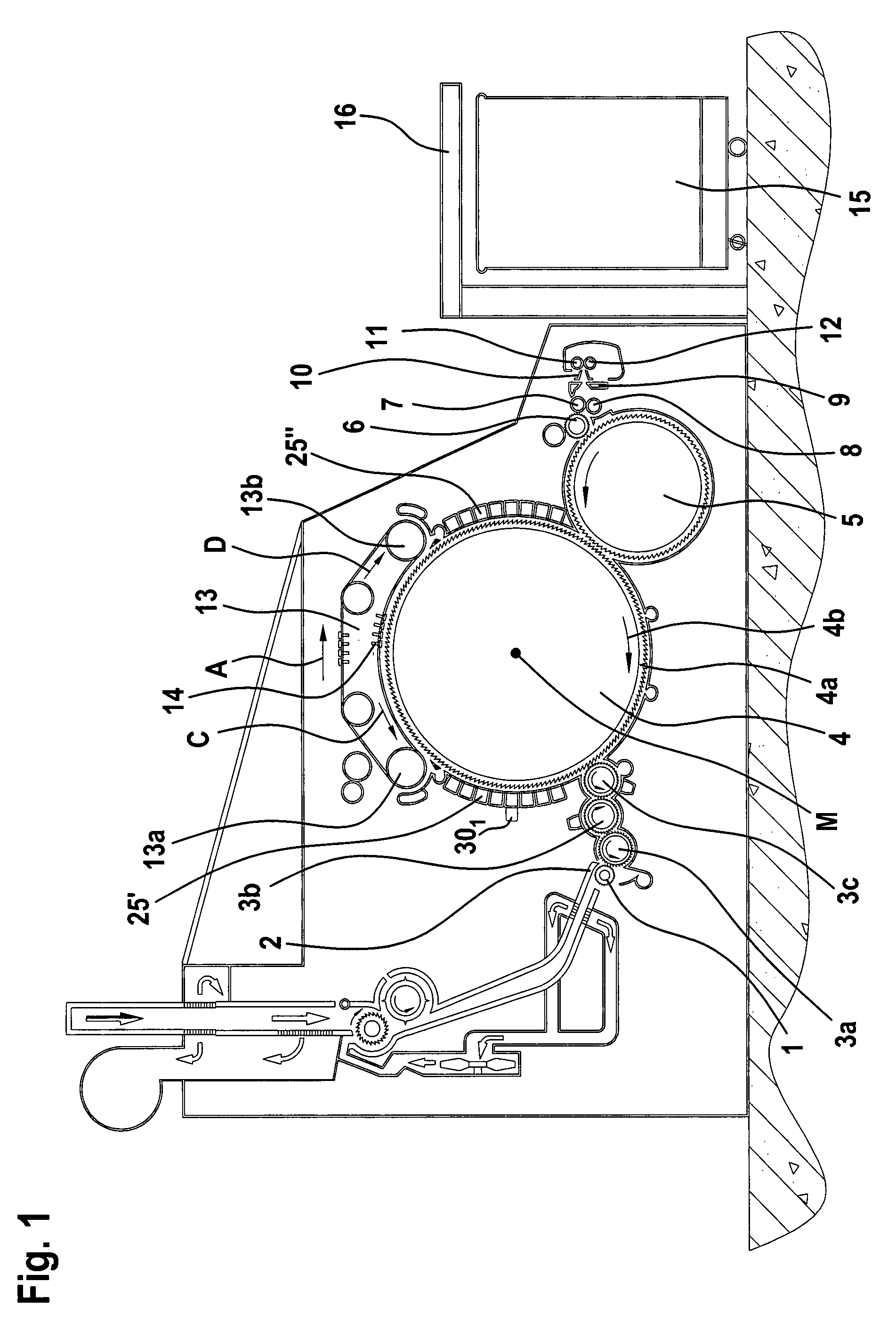

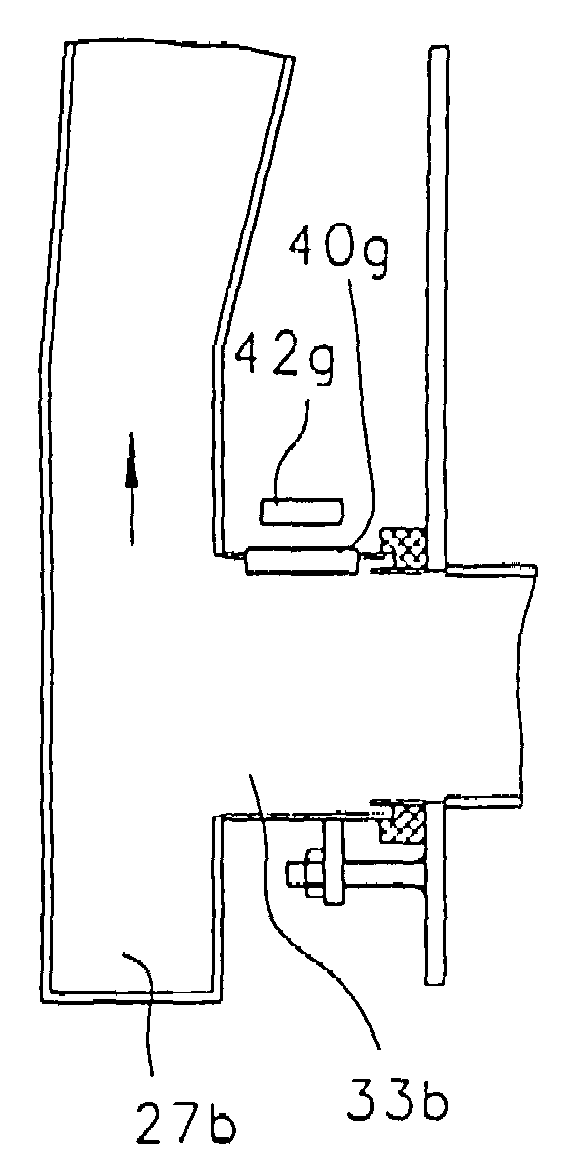

Apparatus at a spinning preparation machine, especially a flat card, roller card or the like, for ascertaining carding process variables

InactiveUS20070266528A1High sensitivityCarding intensity can be measuredCarding machinesElectricityDisplay device

In an apparatus at a spinning preparation machine, wherein a clothed roller is located opposite at least one clothed component, there is associated with the component, in contact therewith, a piezoelectric sensor which is connected to an electrical evaluation device in communication with a display device and / or switching device. In order, by simple means to make it possible to ascertain the carding intensity, the piezoelectric sensor is a structure-borne sound sensor and the electrical evaluation device is capable of determining the carding intensity from the structure-borne sound.

Owner:TRUETZSCHLER GMBH & CO KG

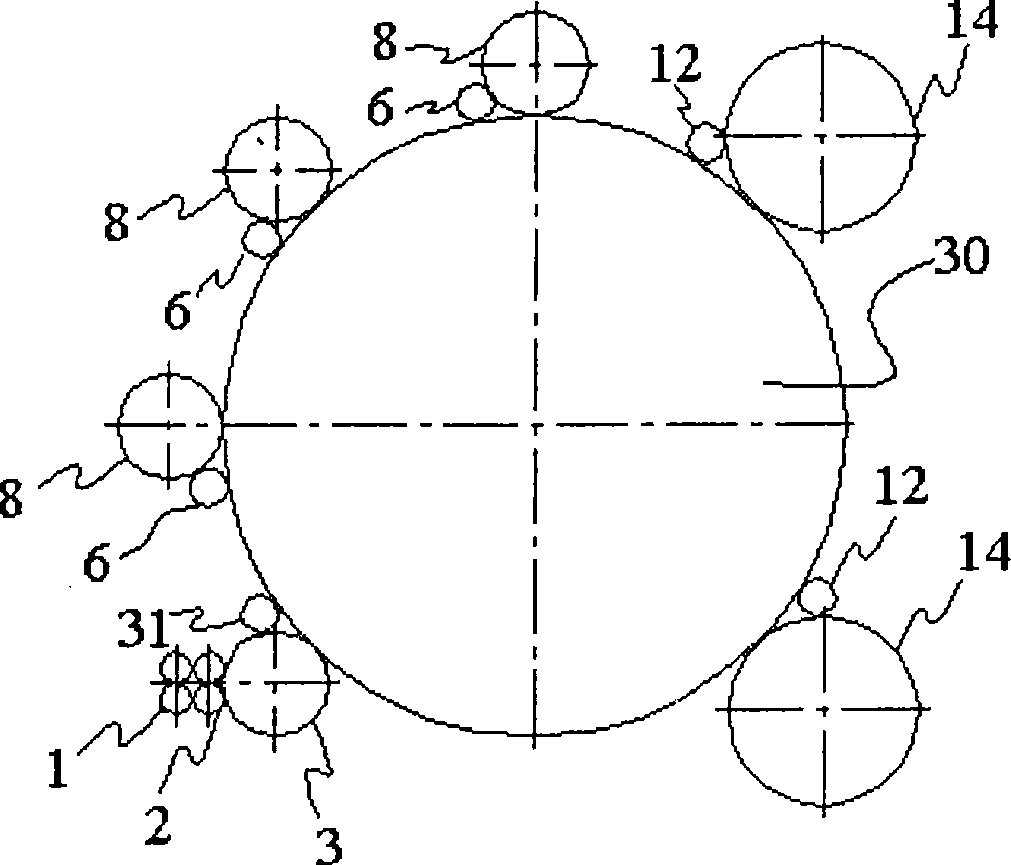

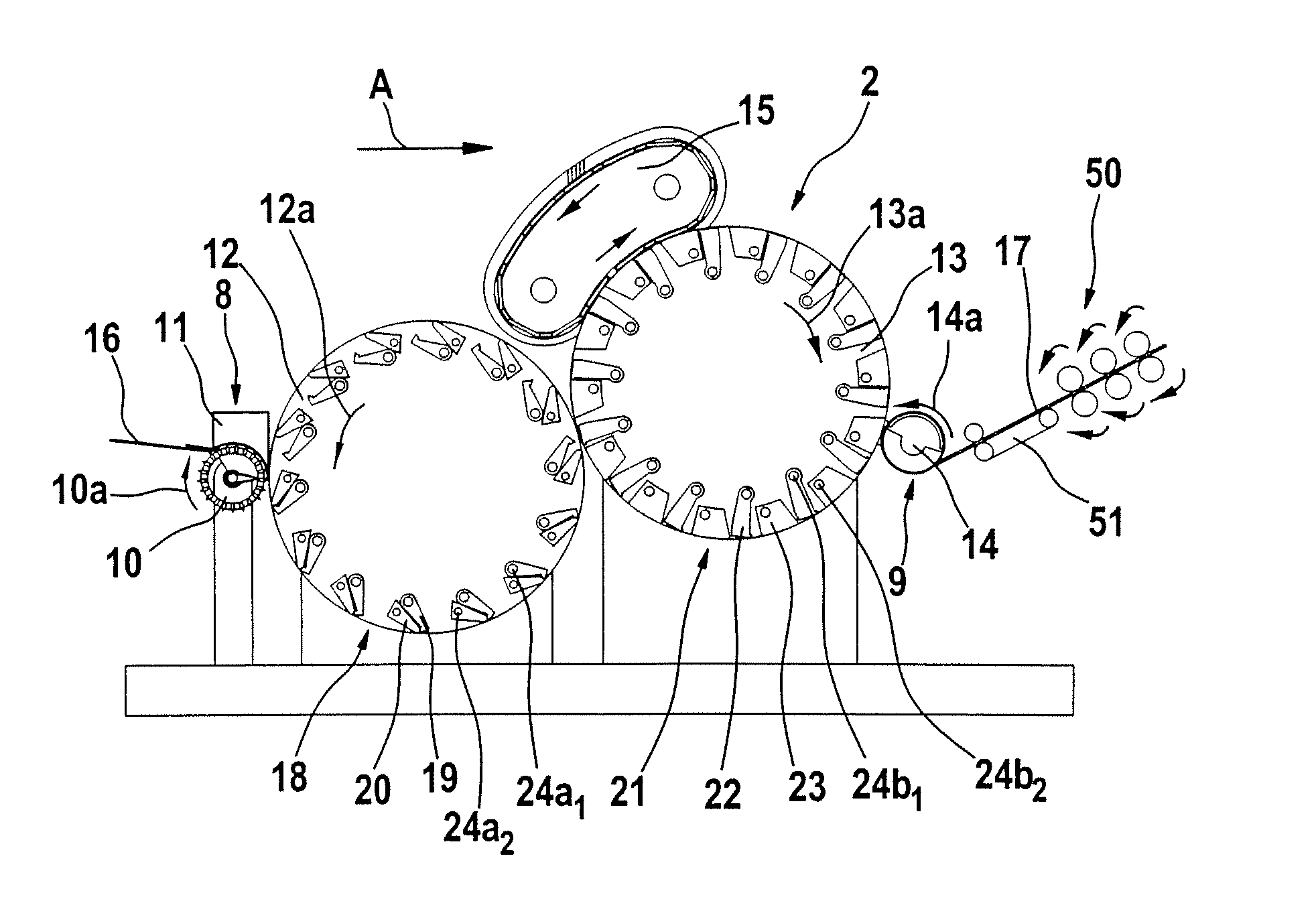

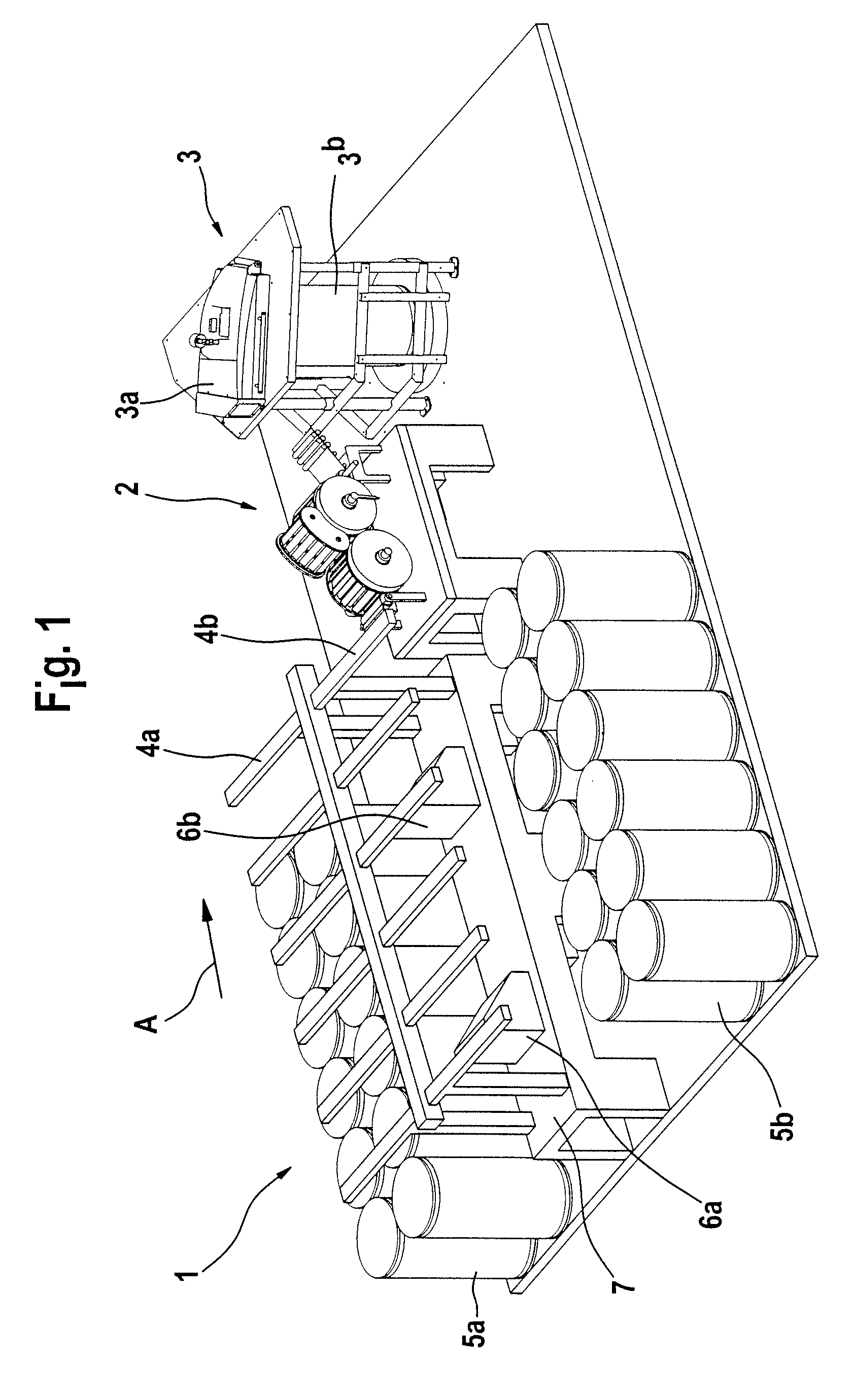

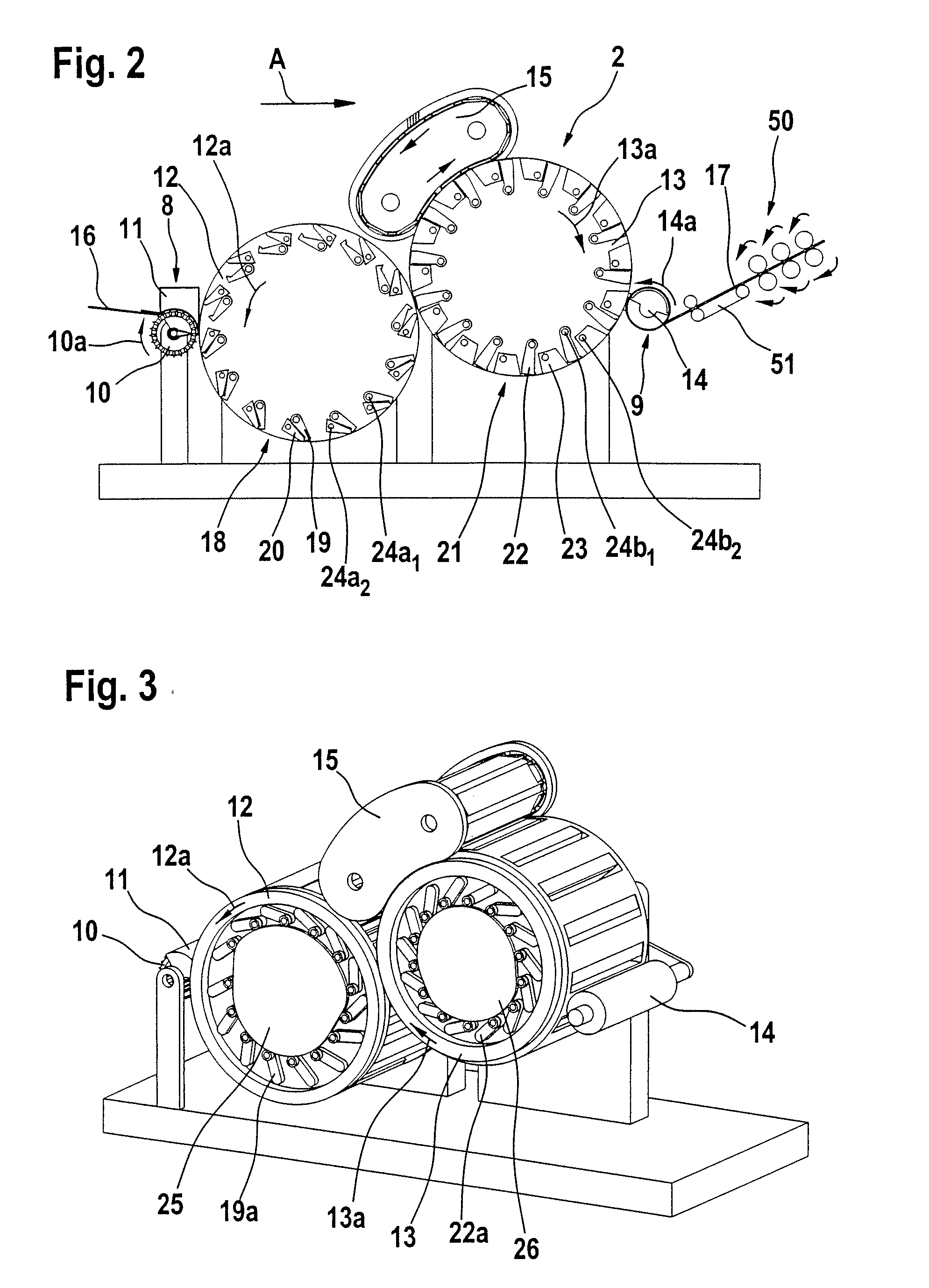

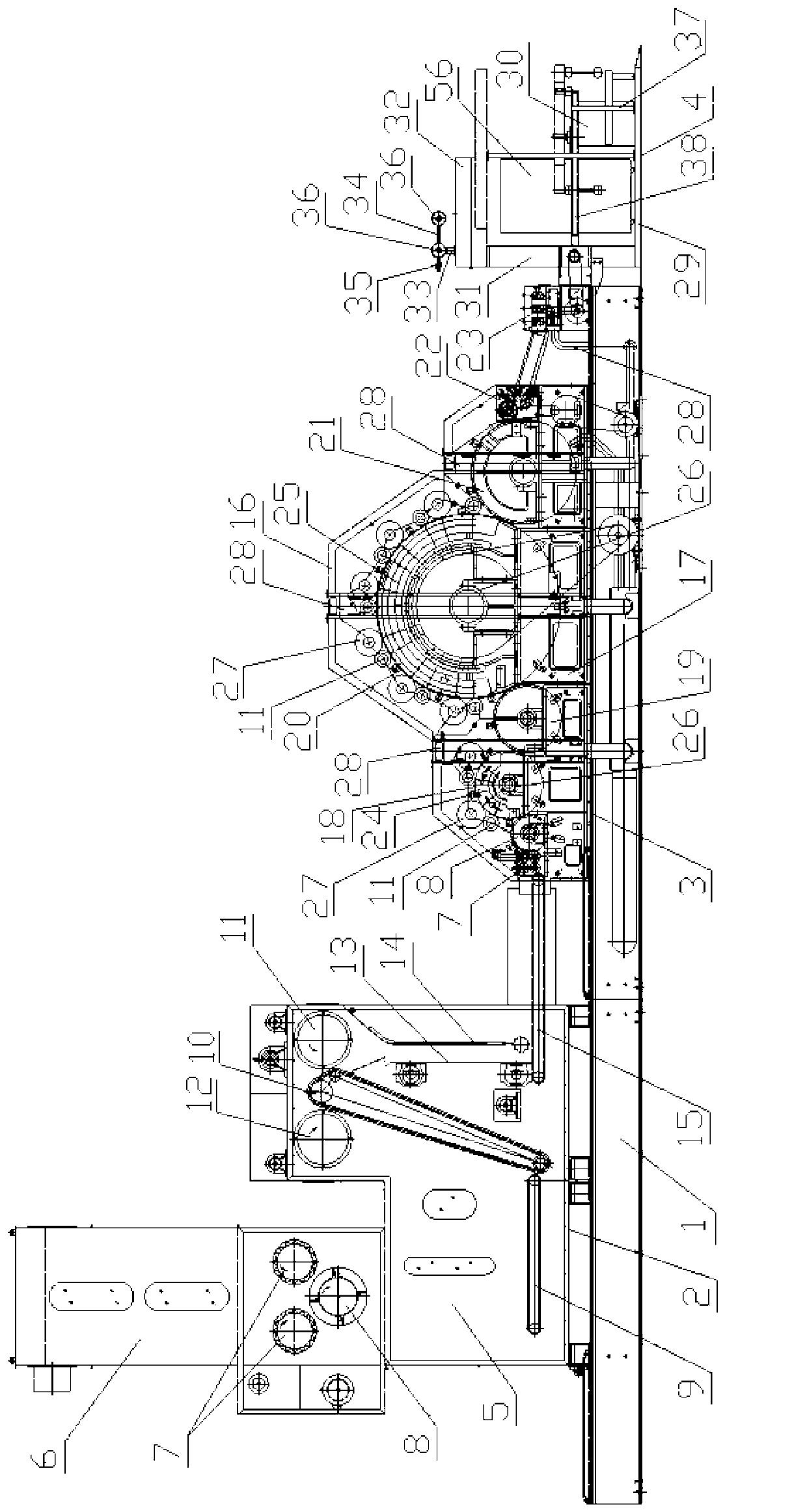

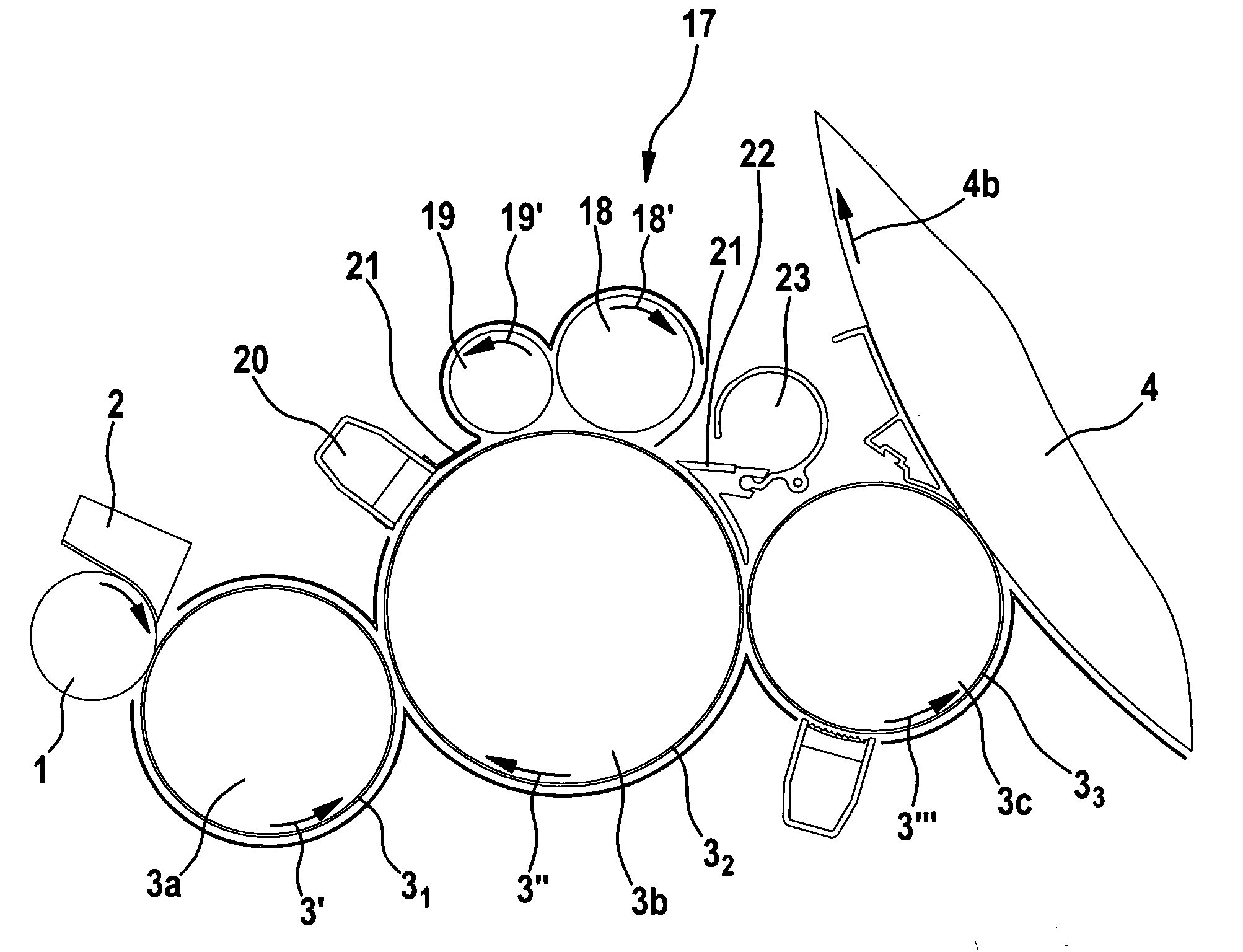

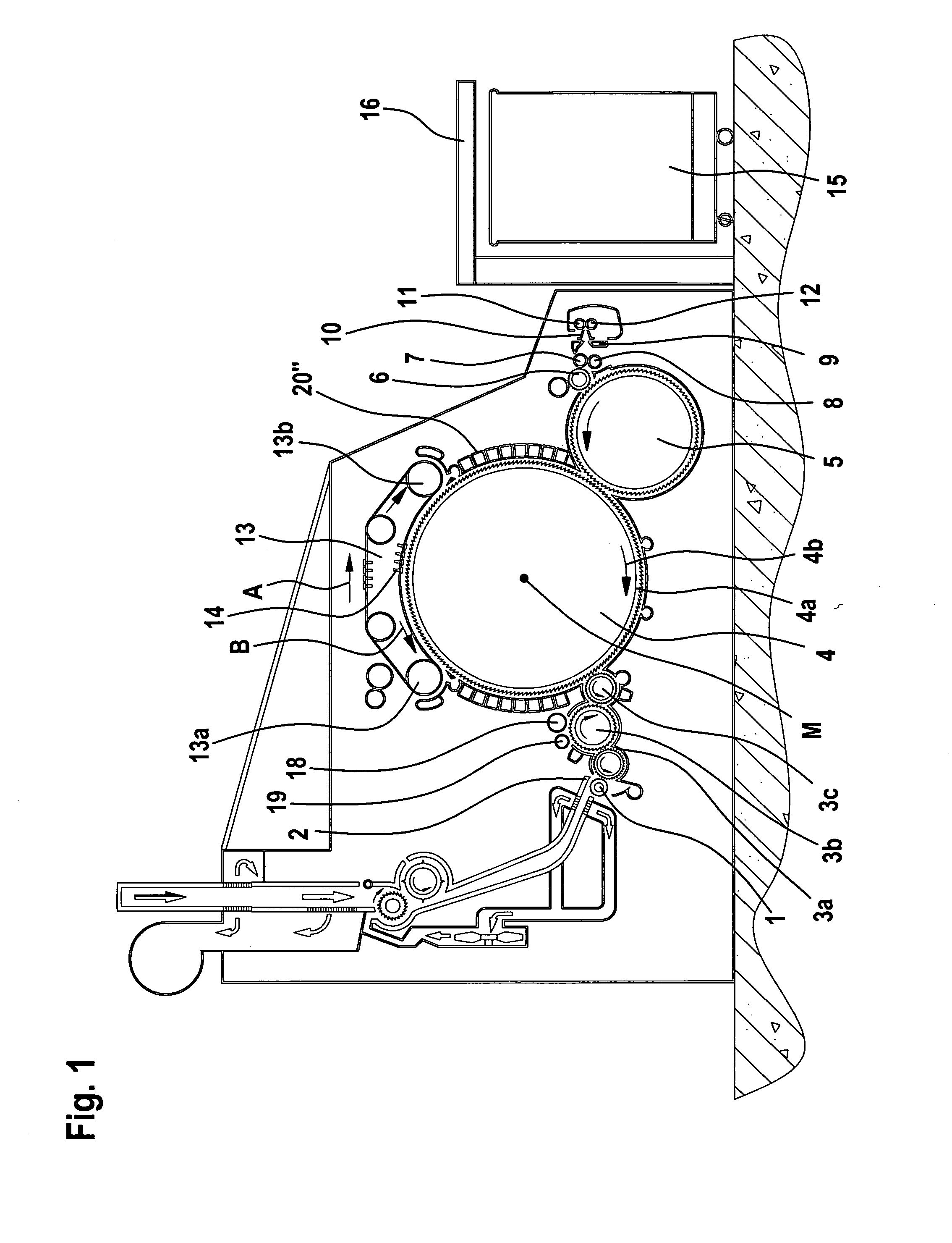

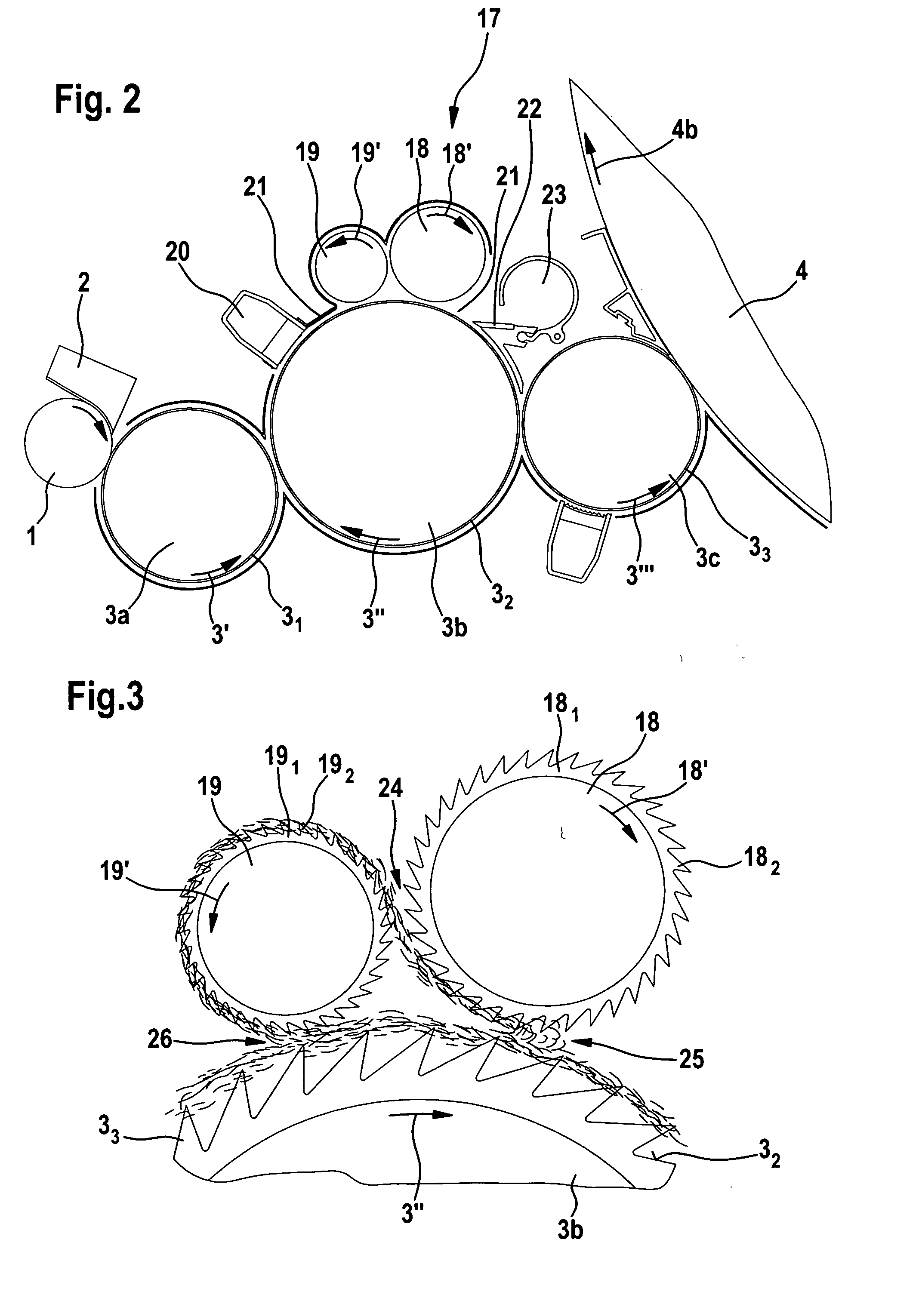

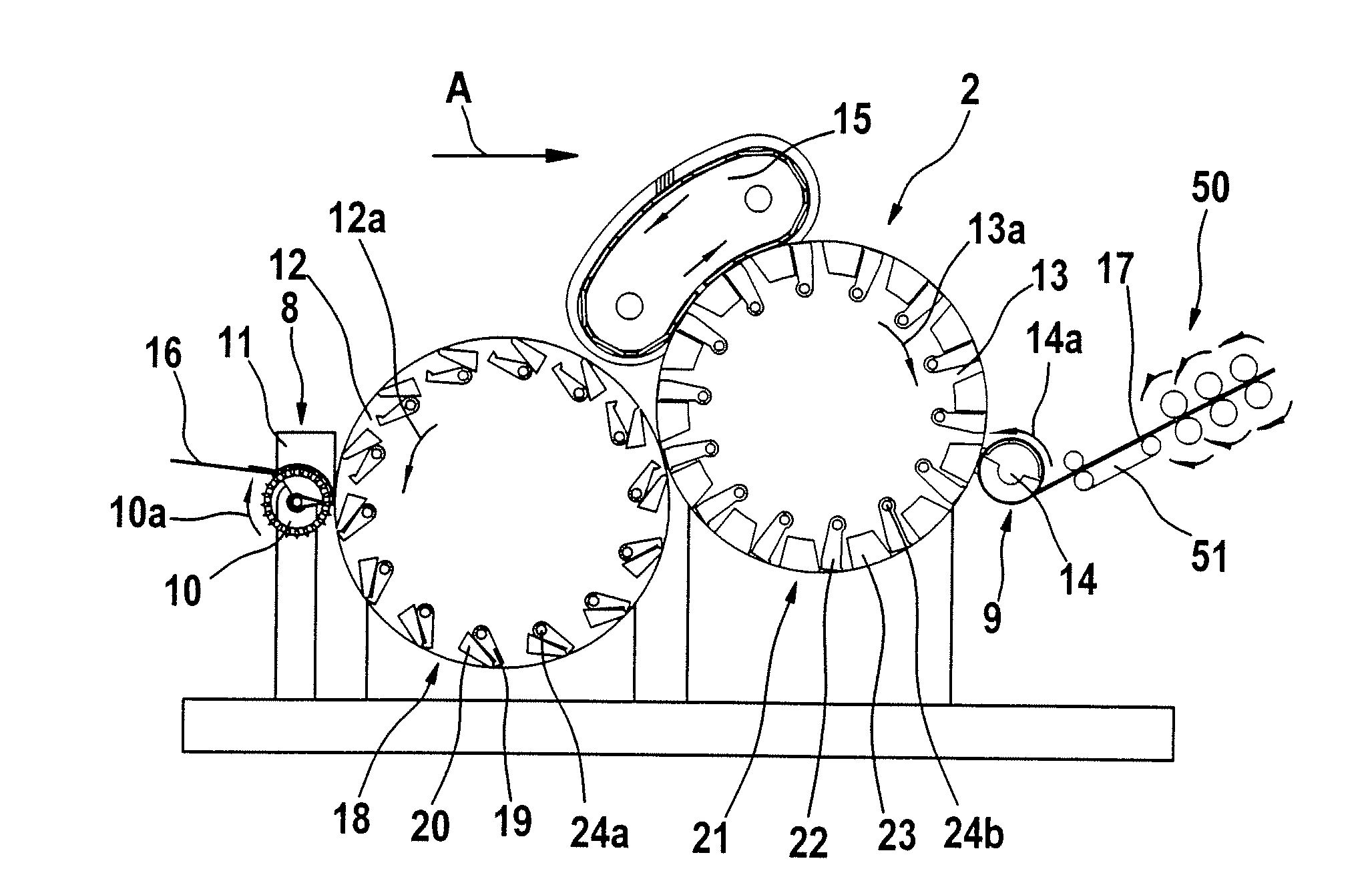

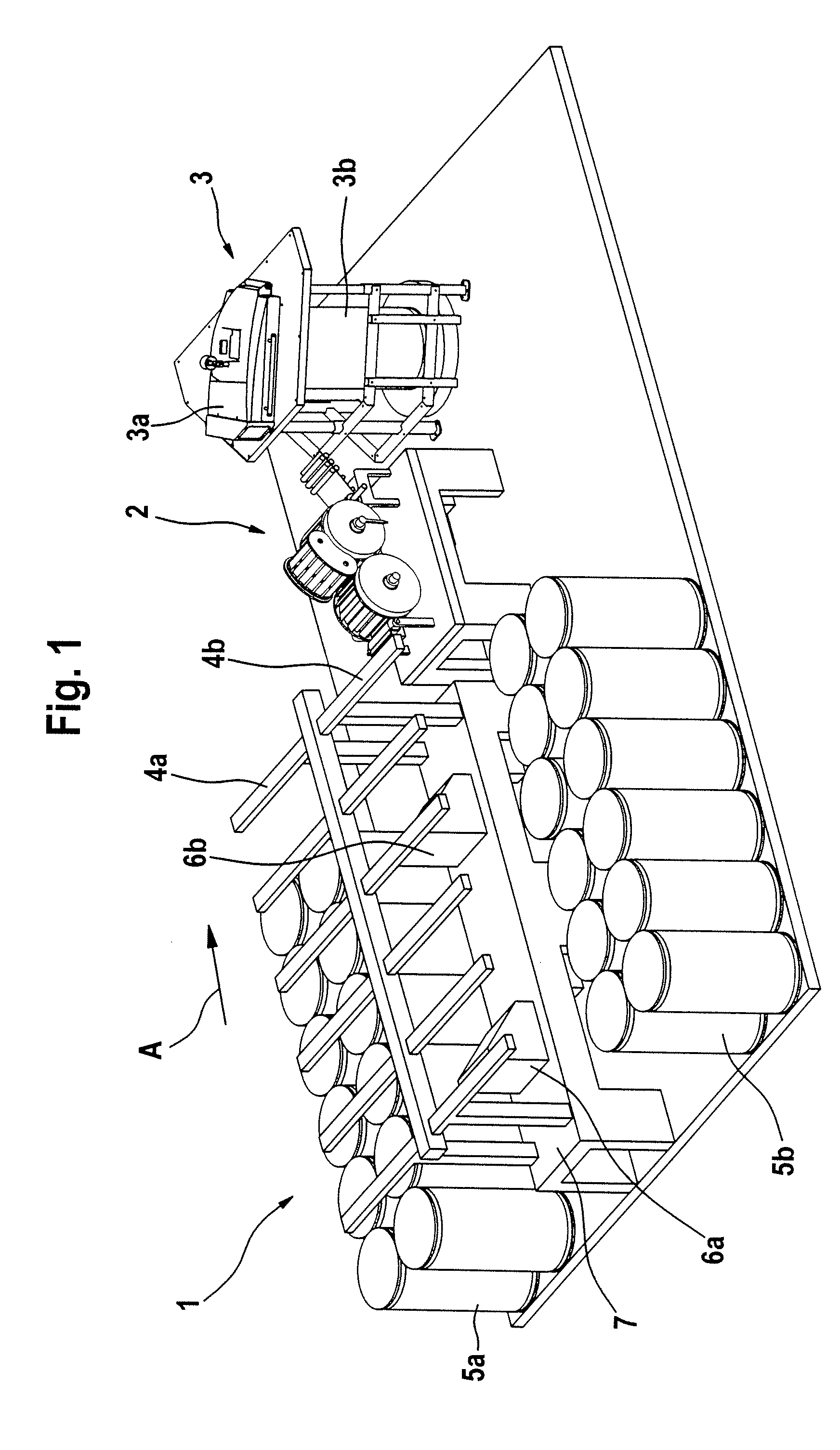

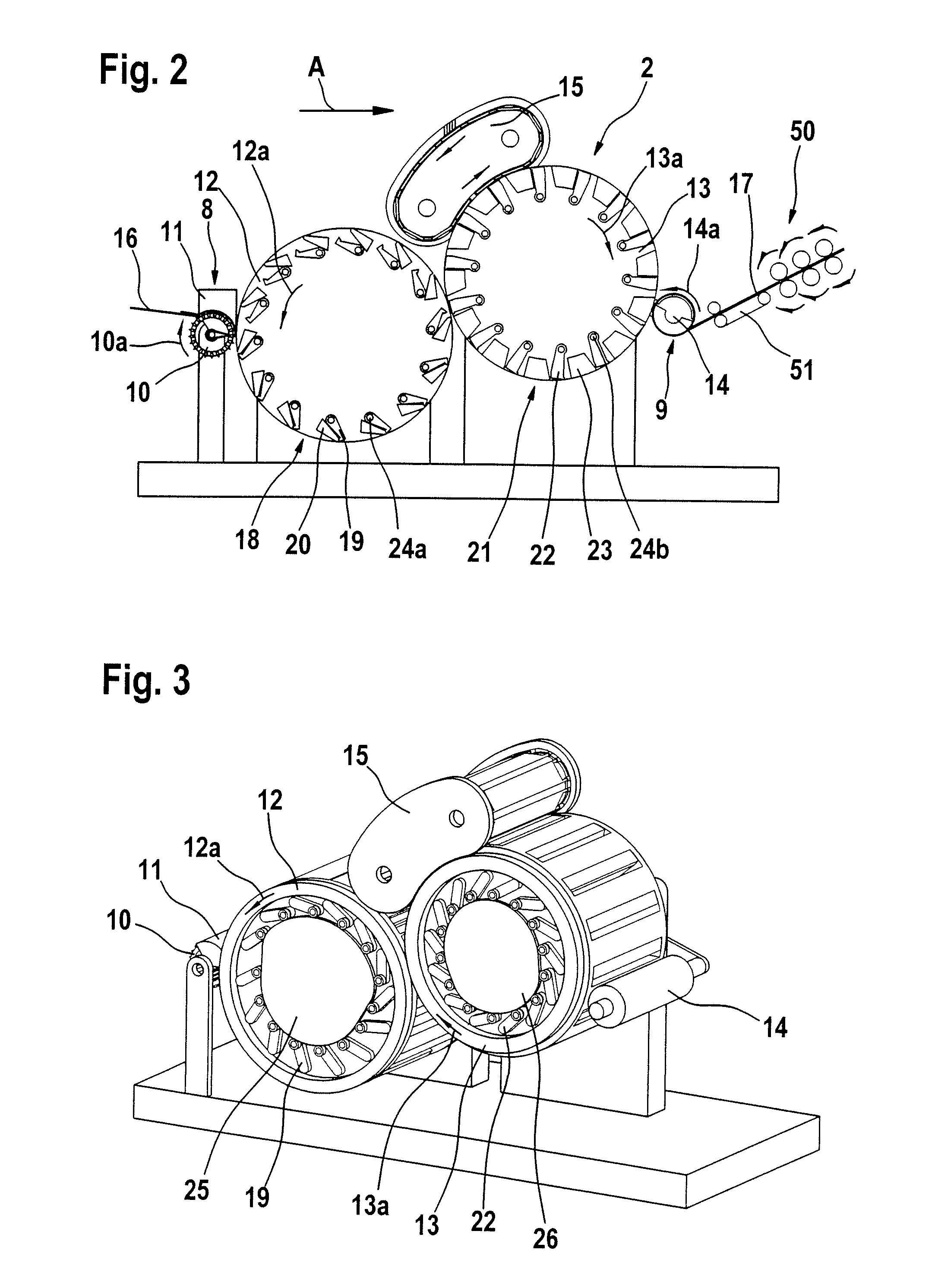

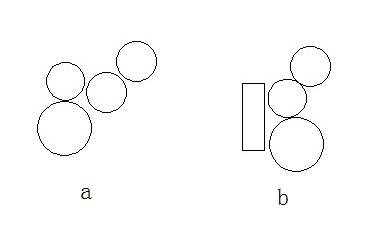

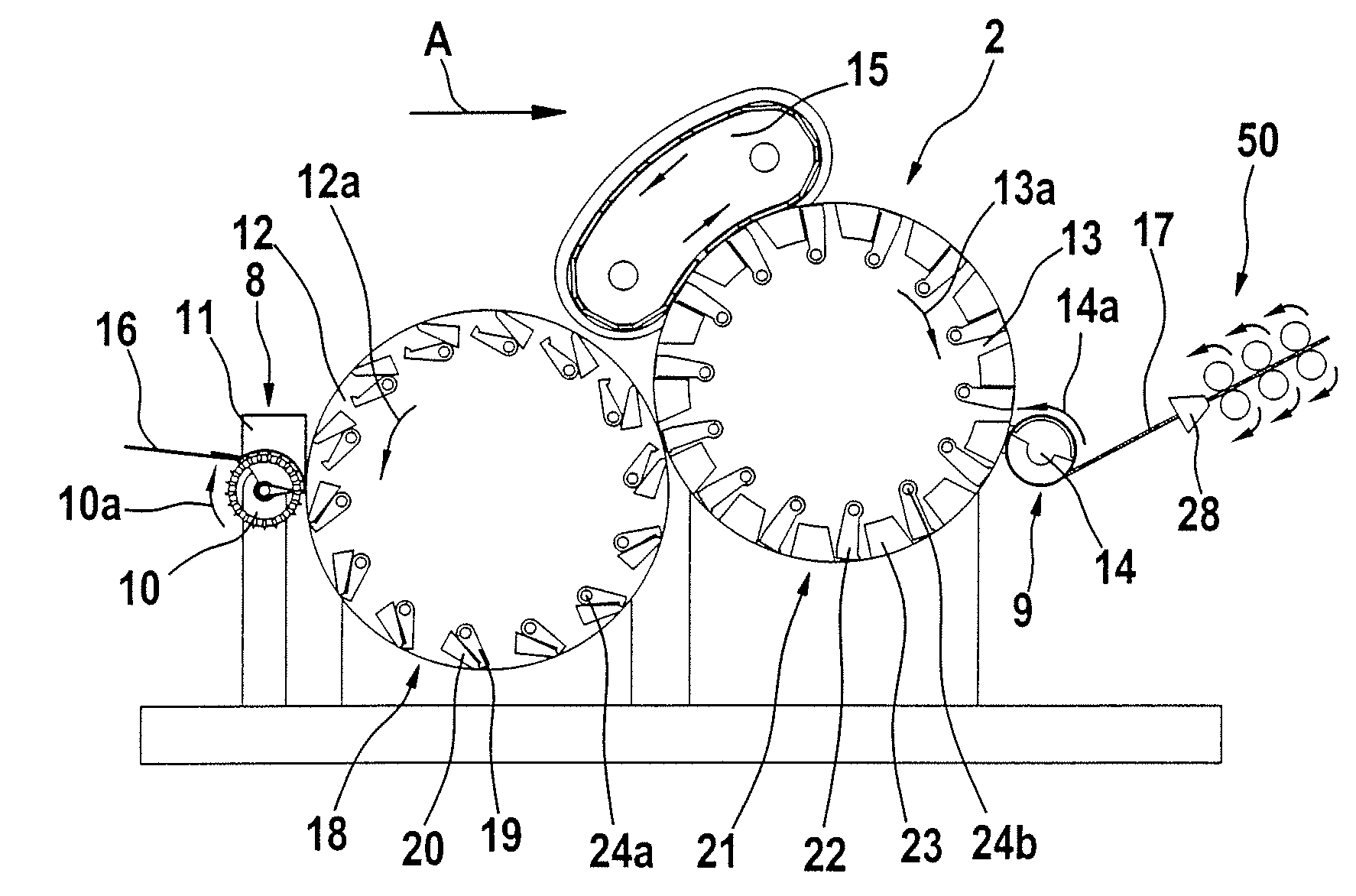

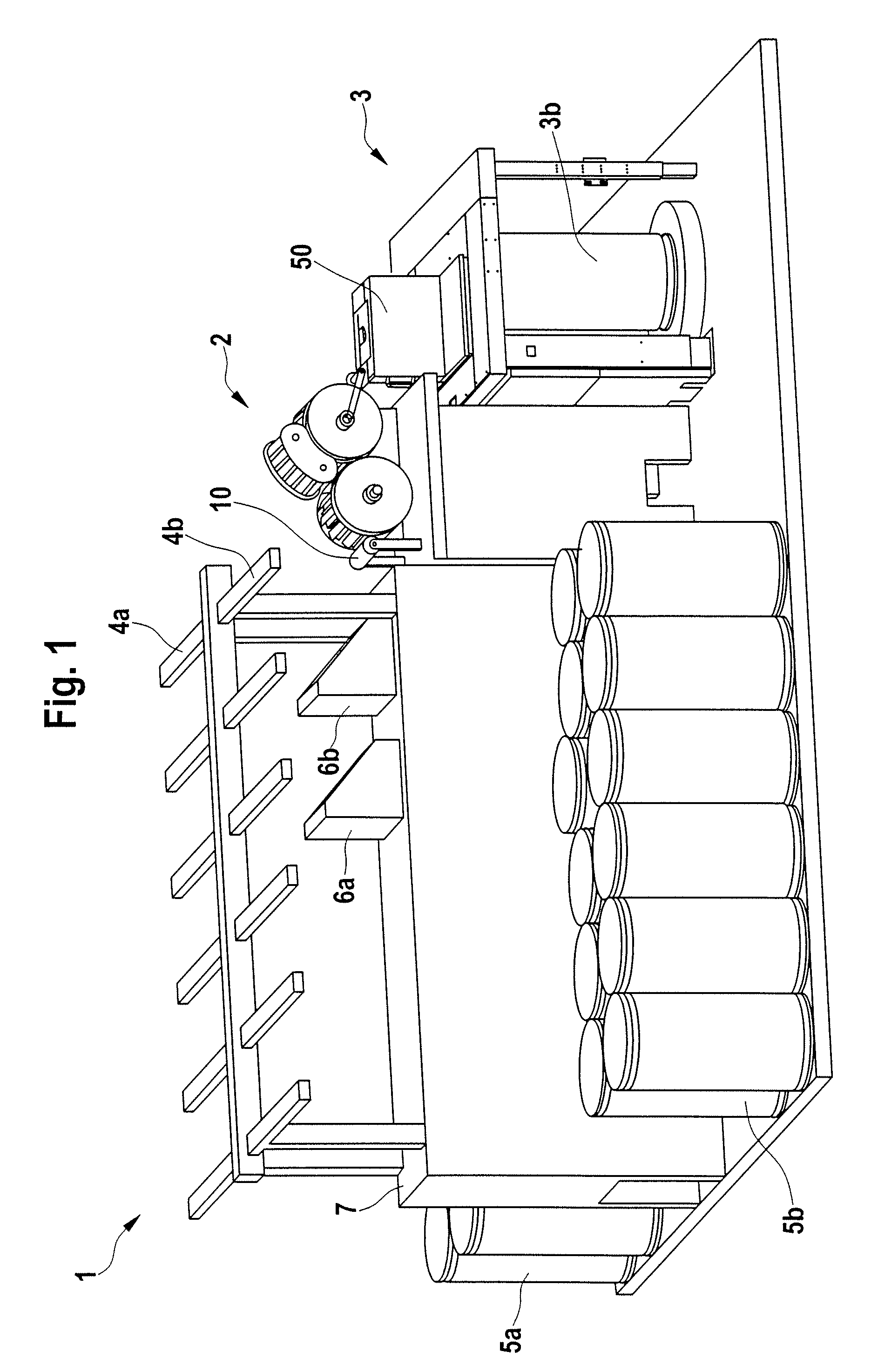

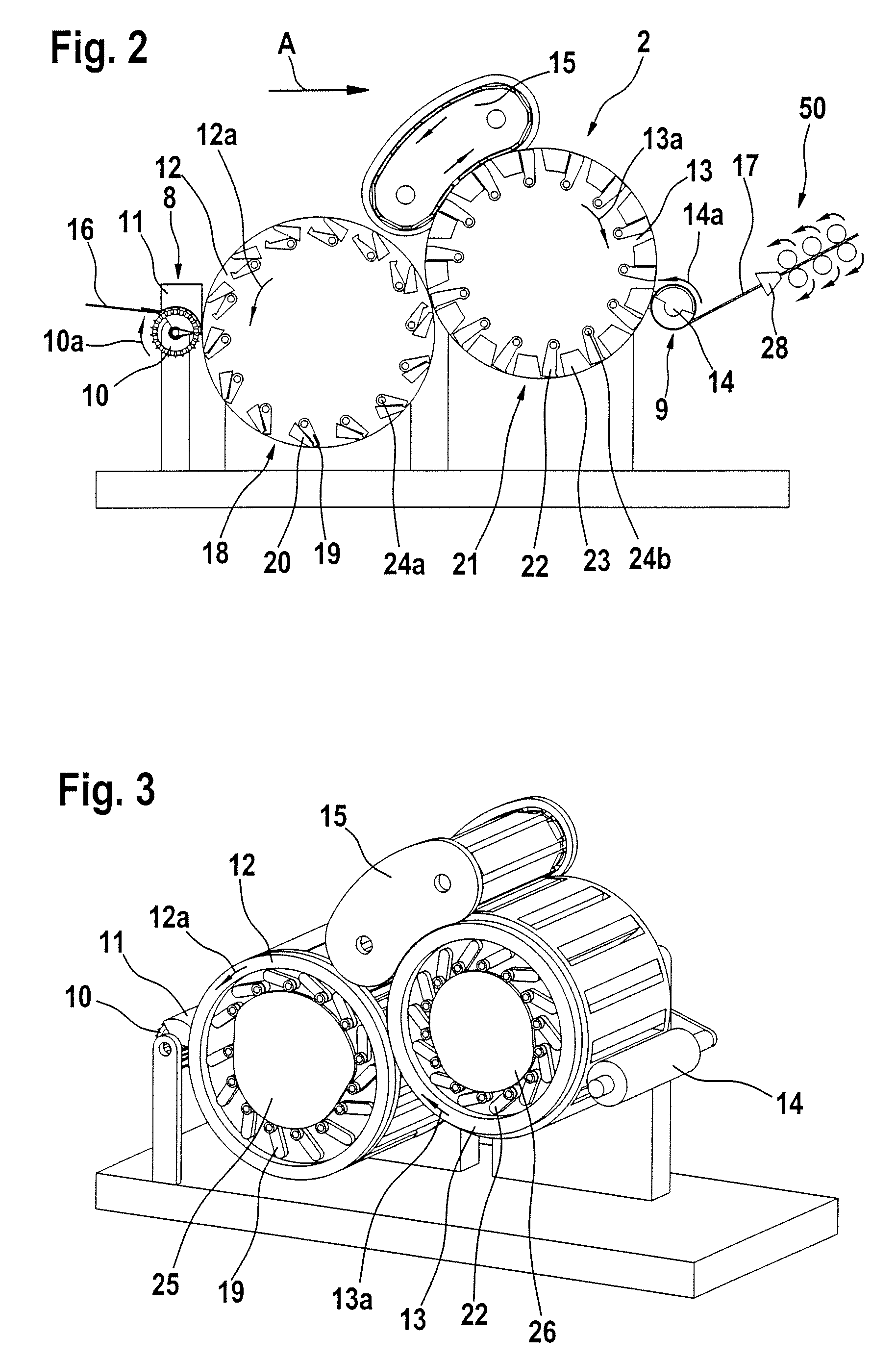

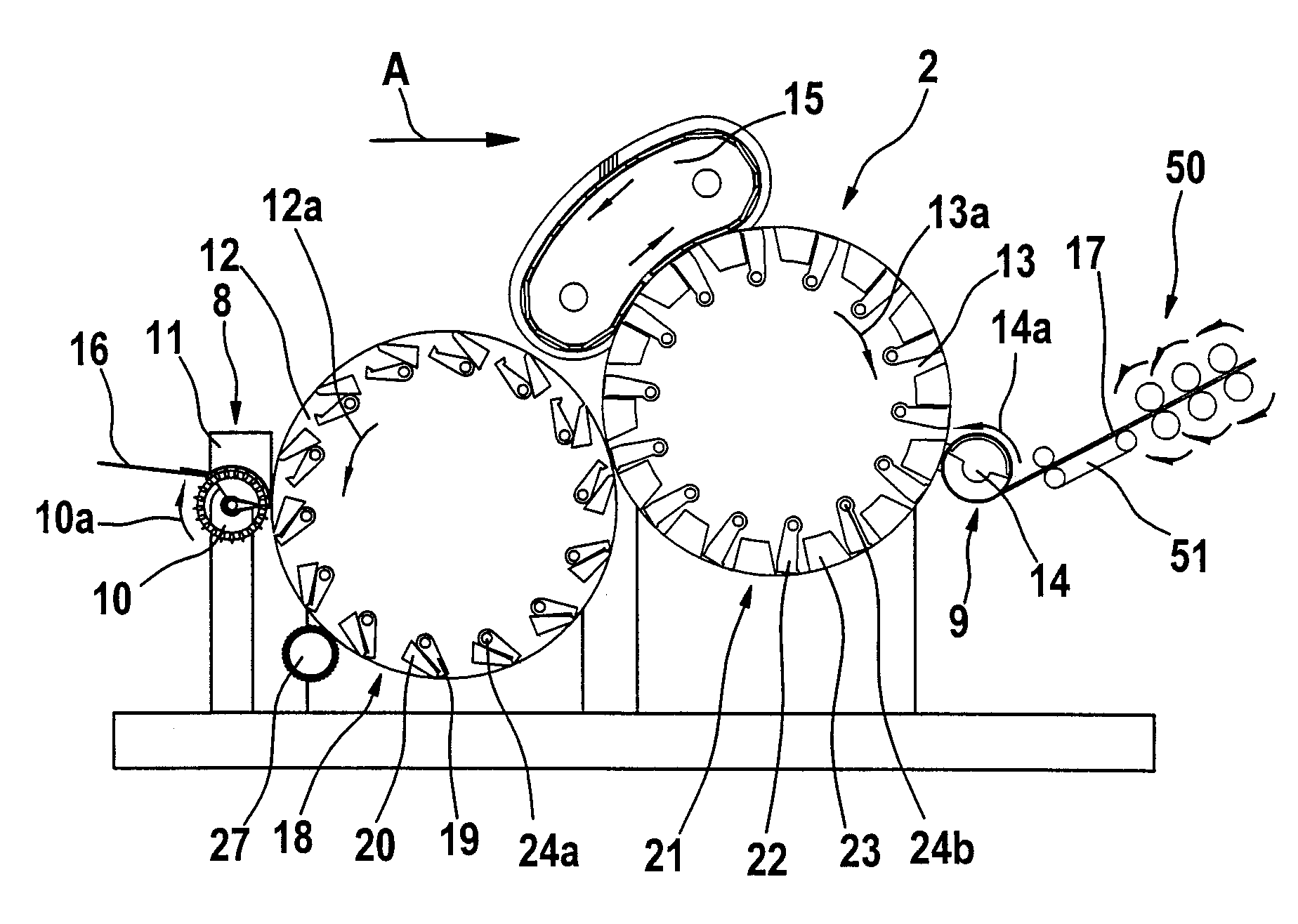

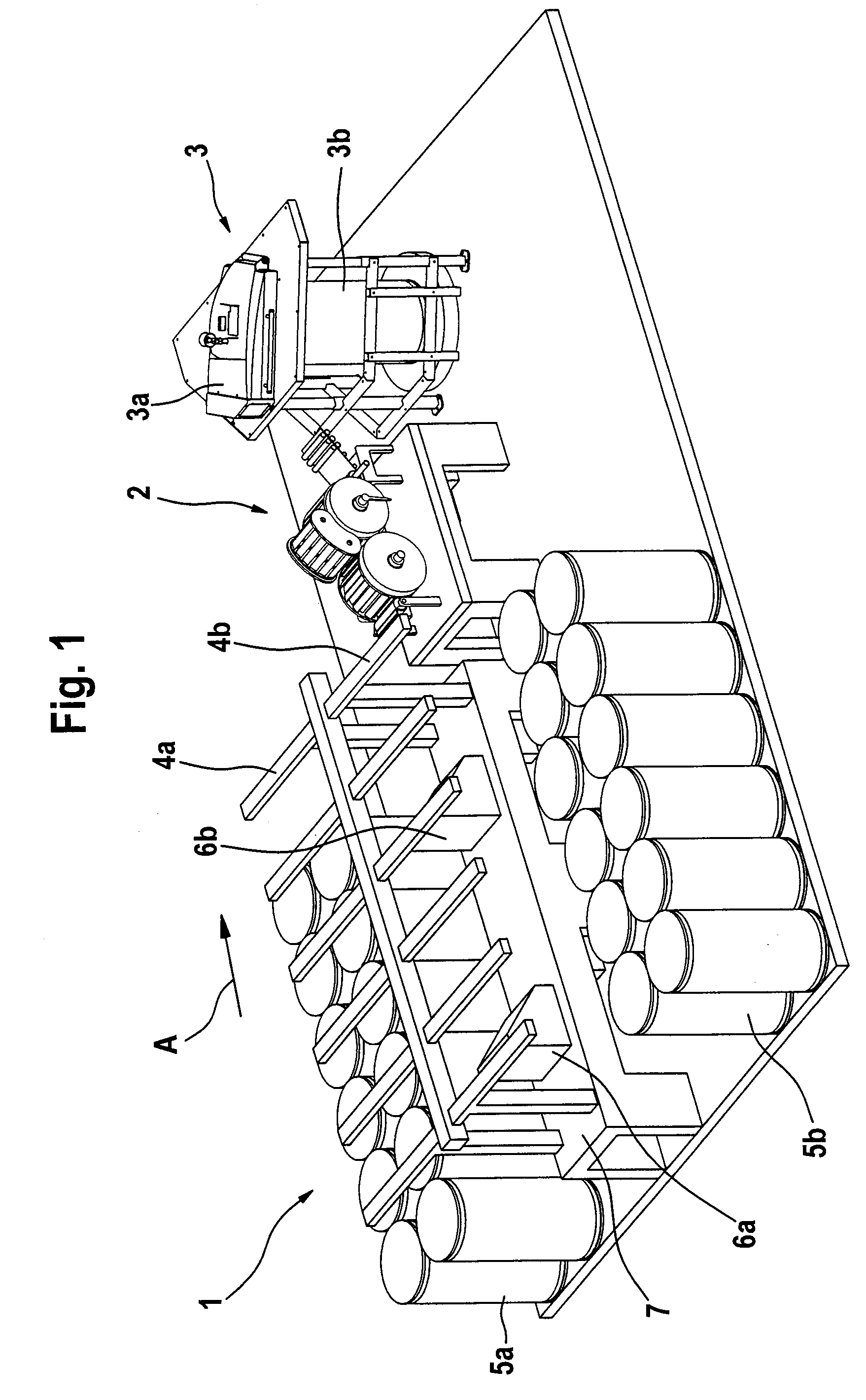

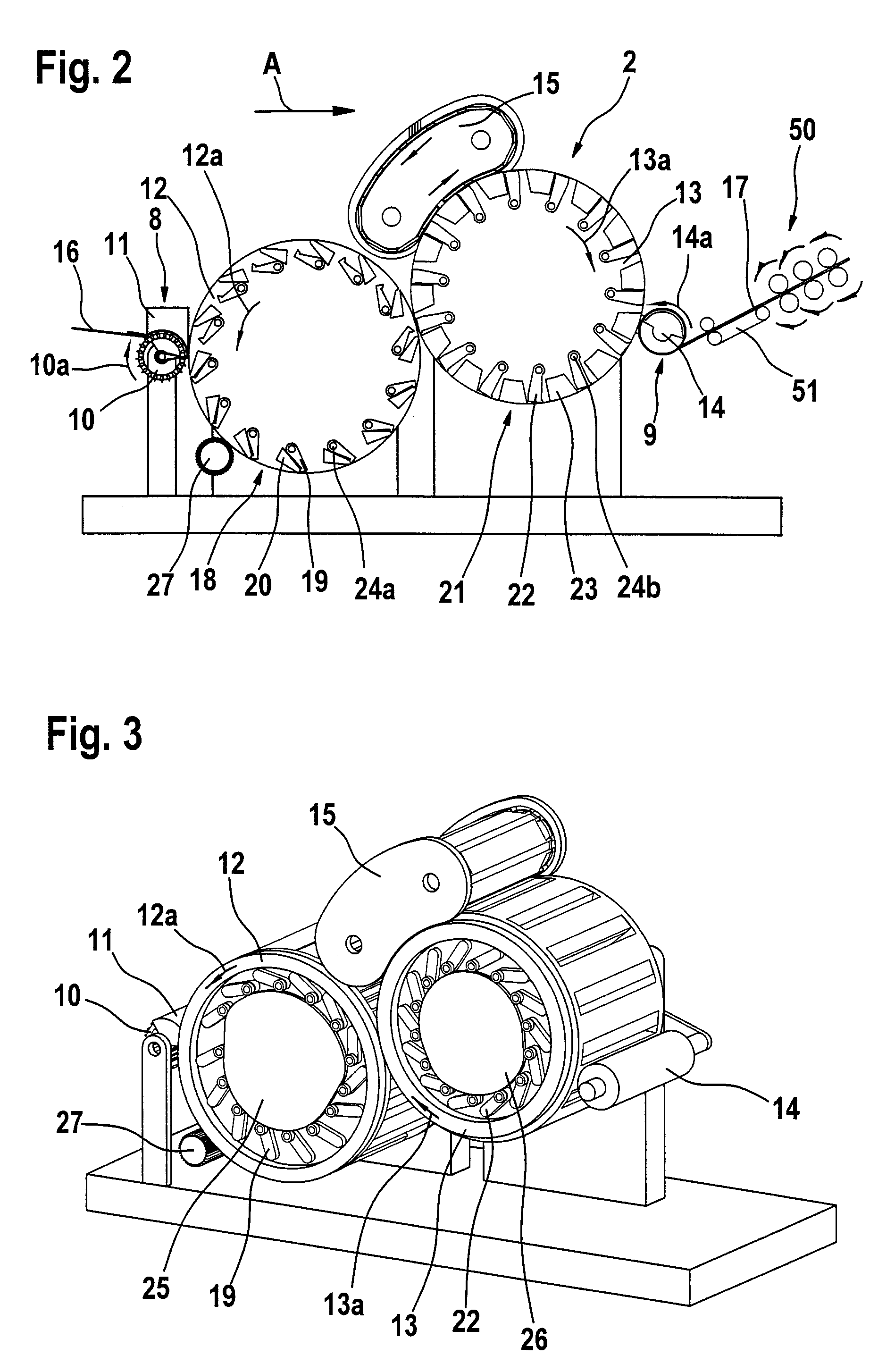

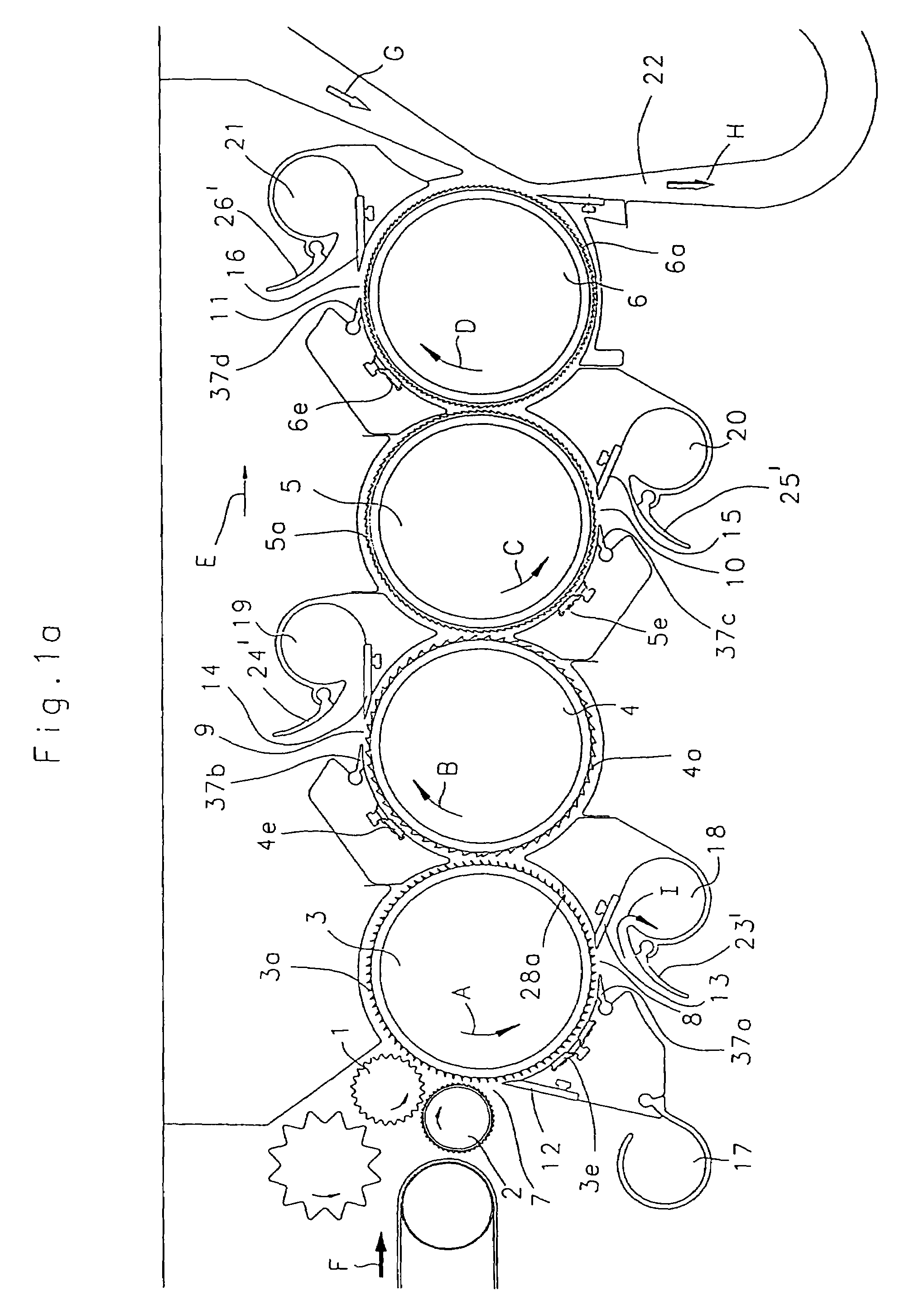

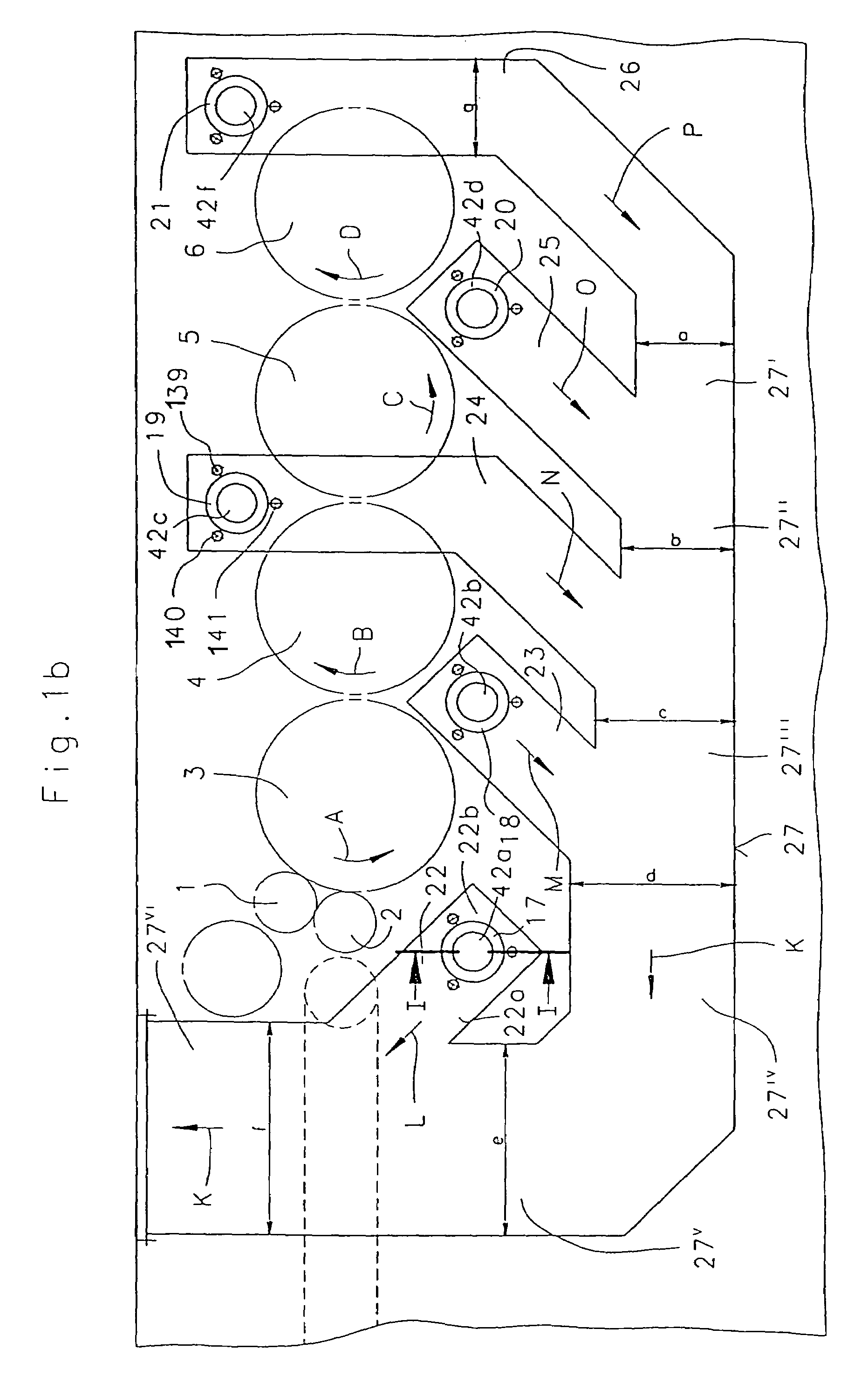

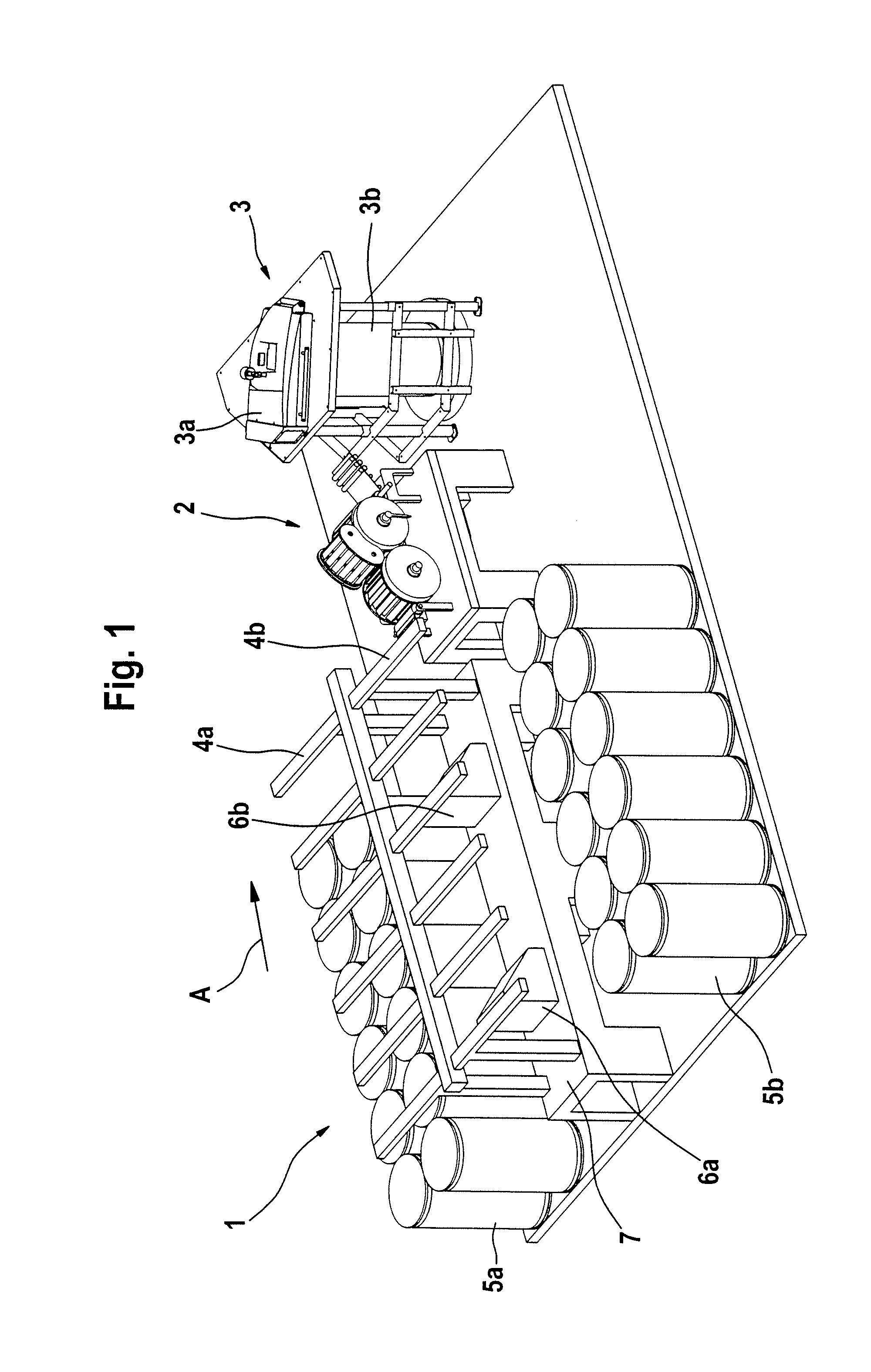

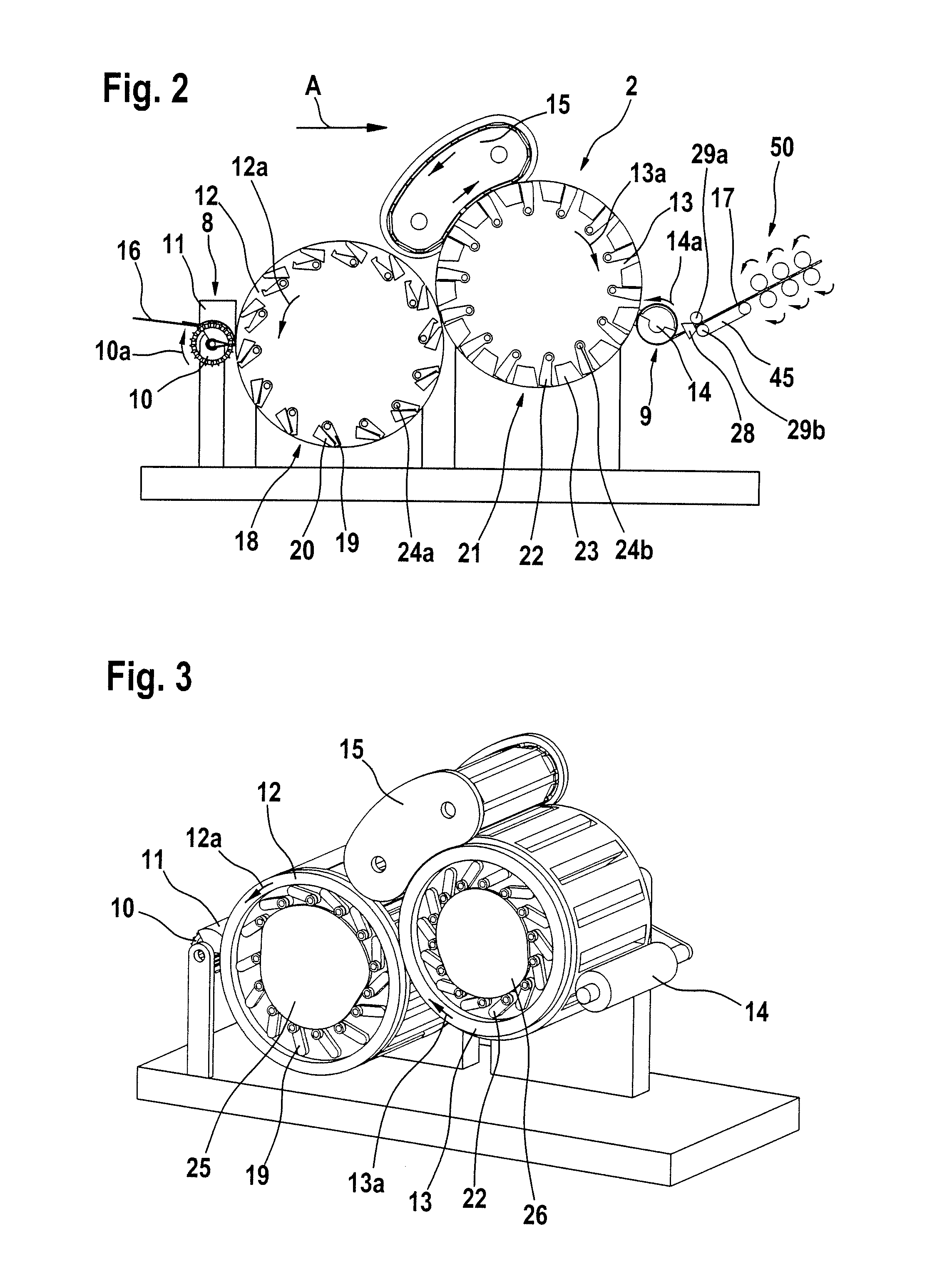

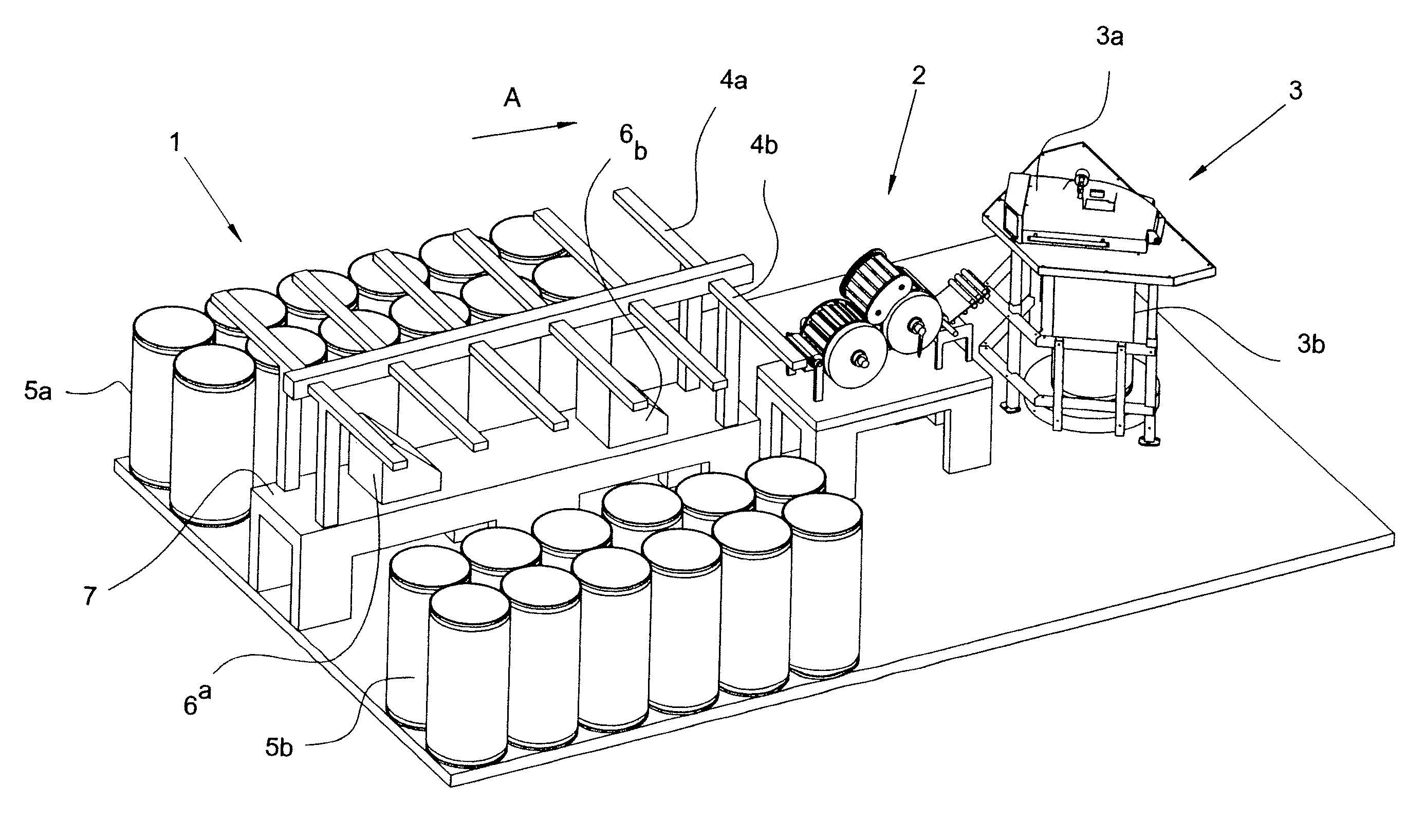

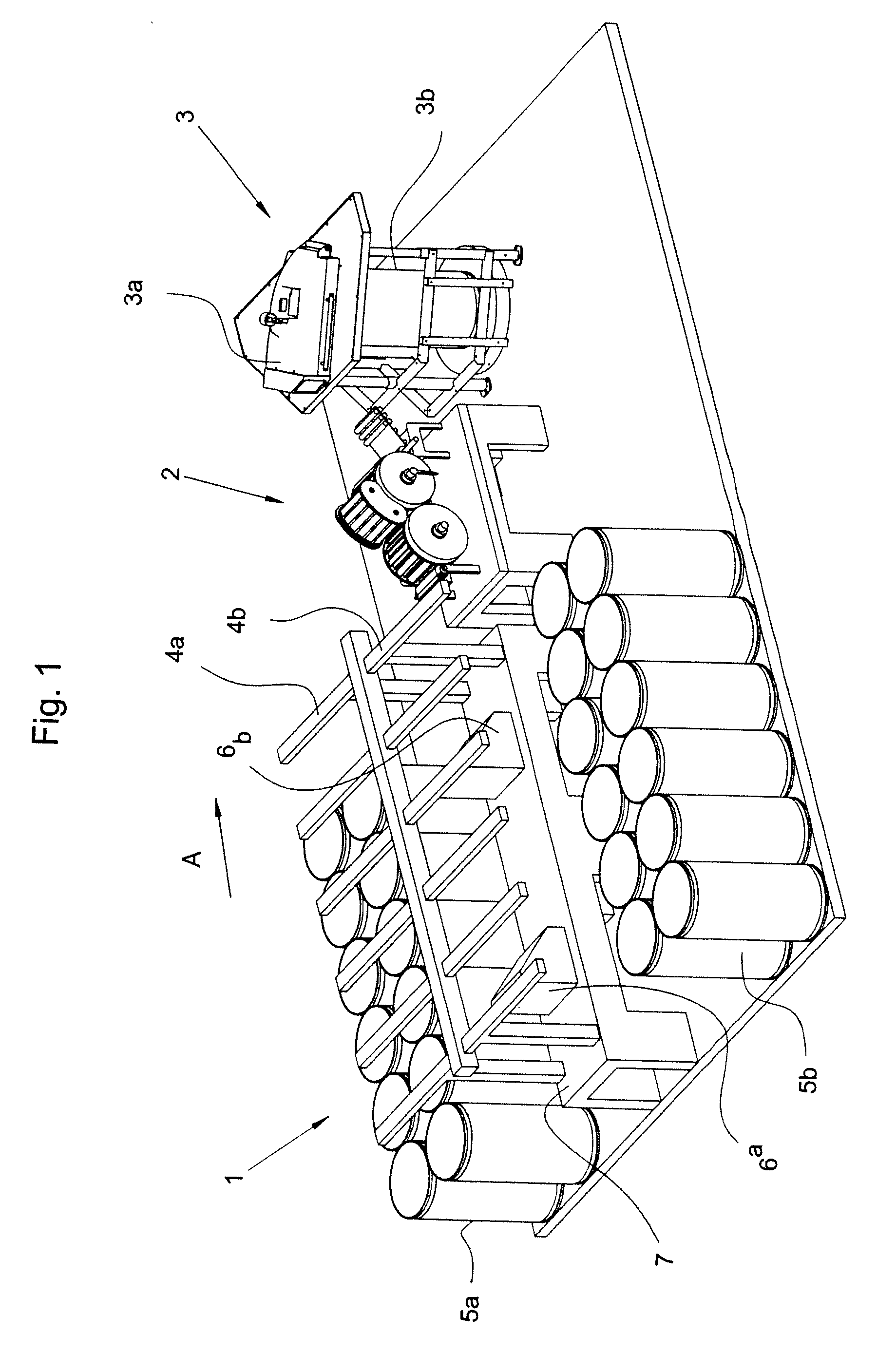

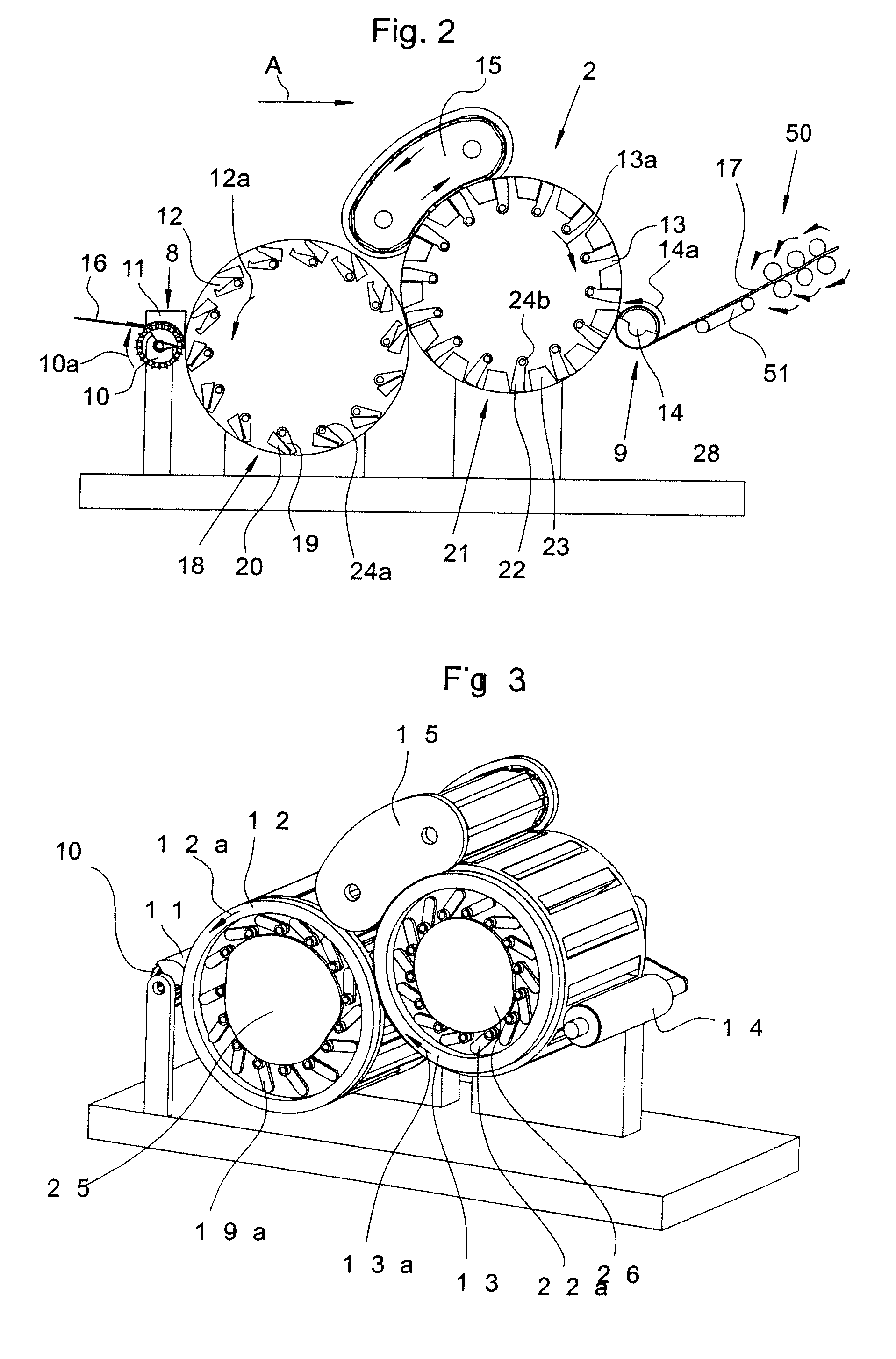

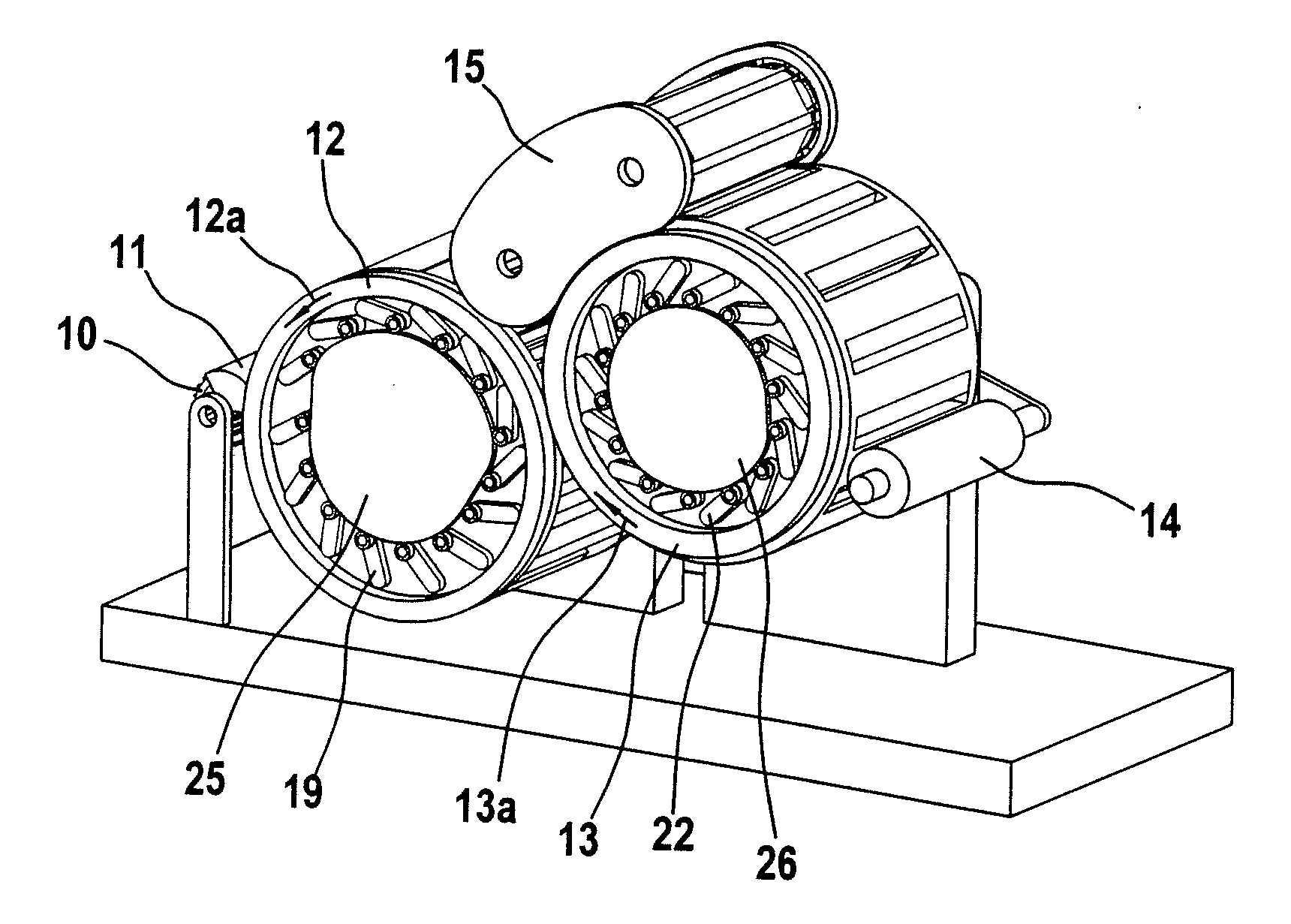

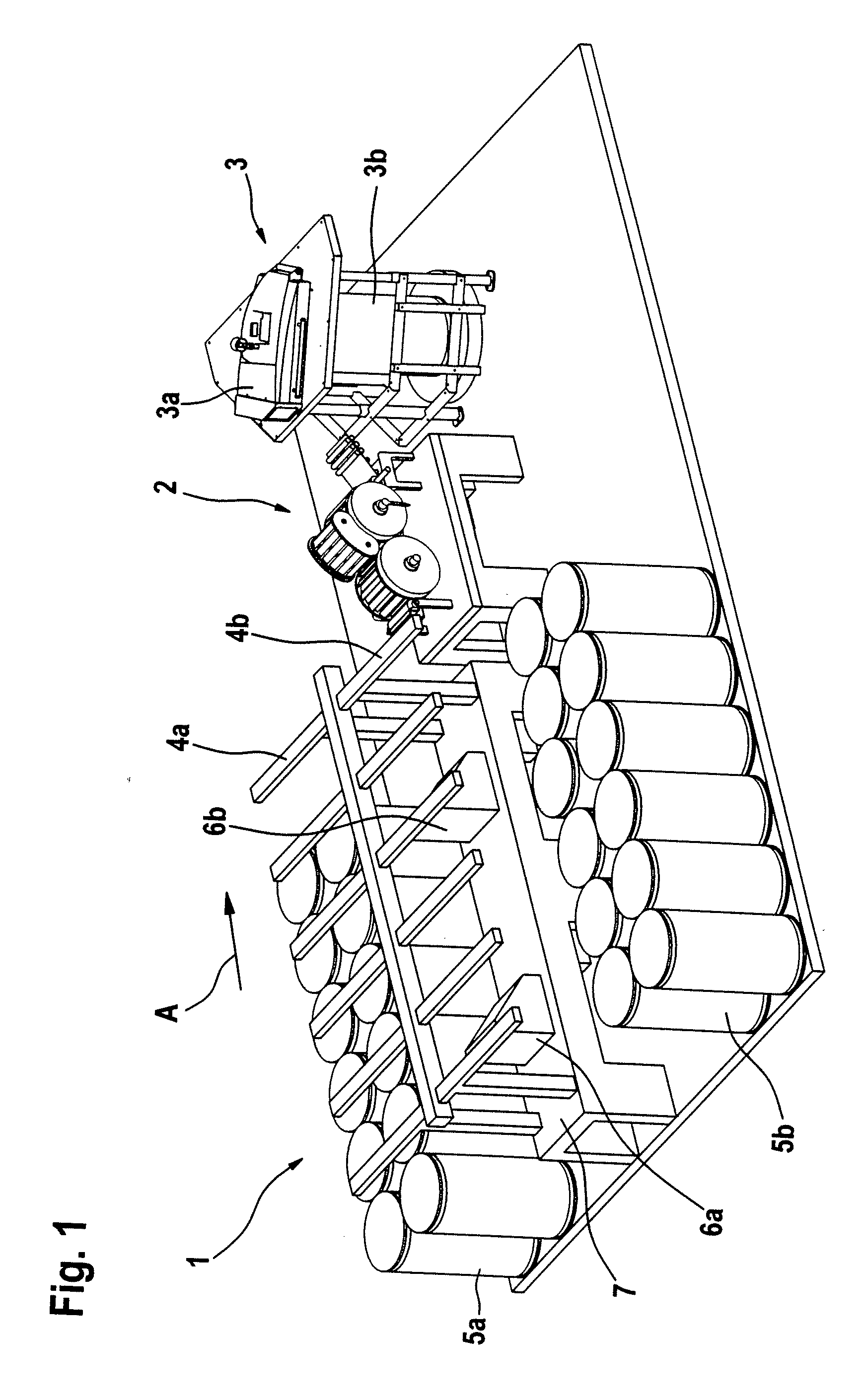

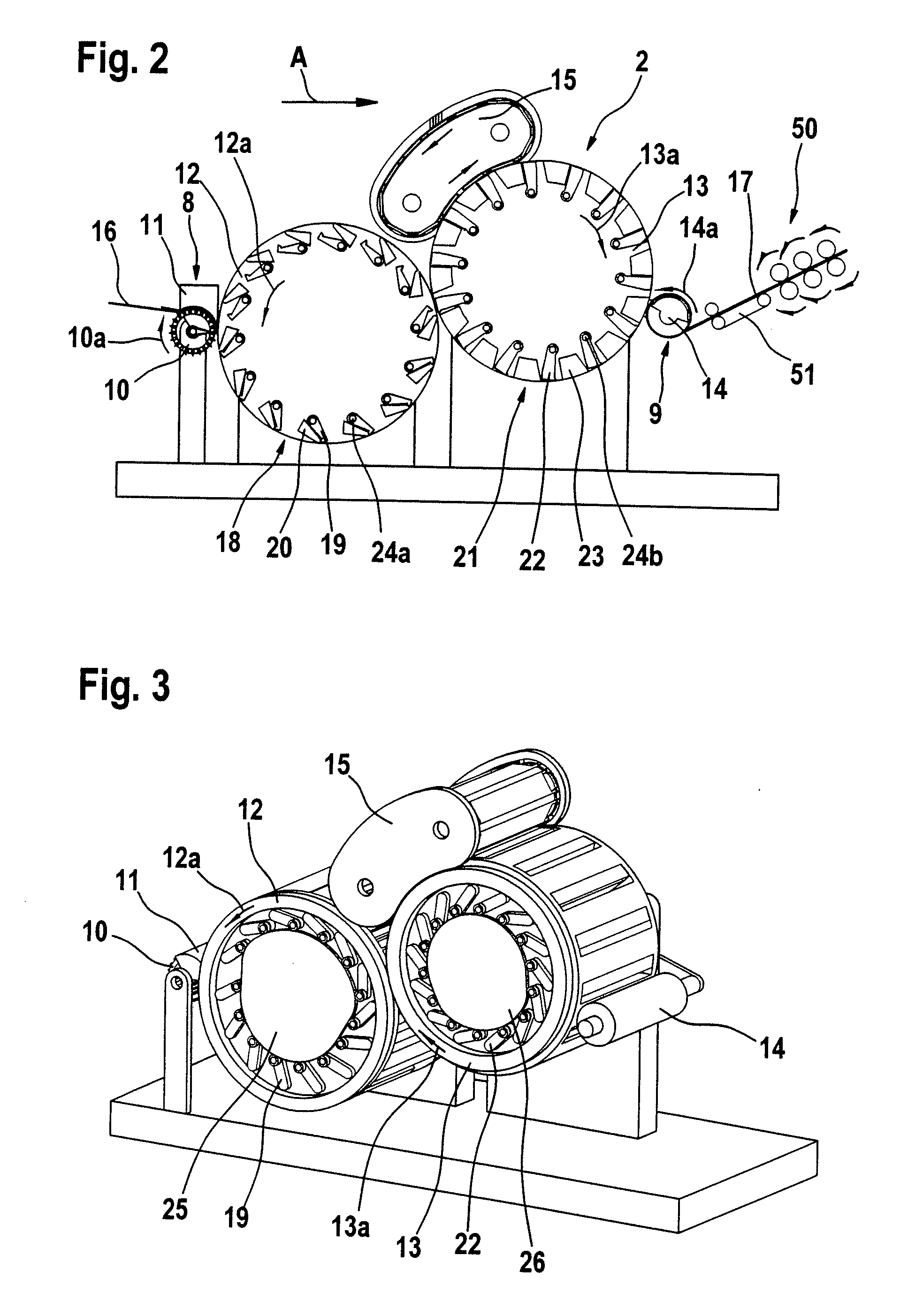

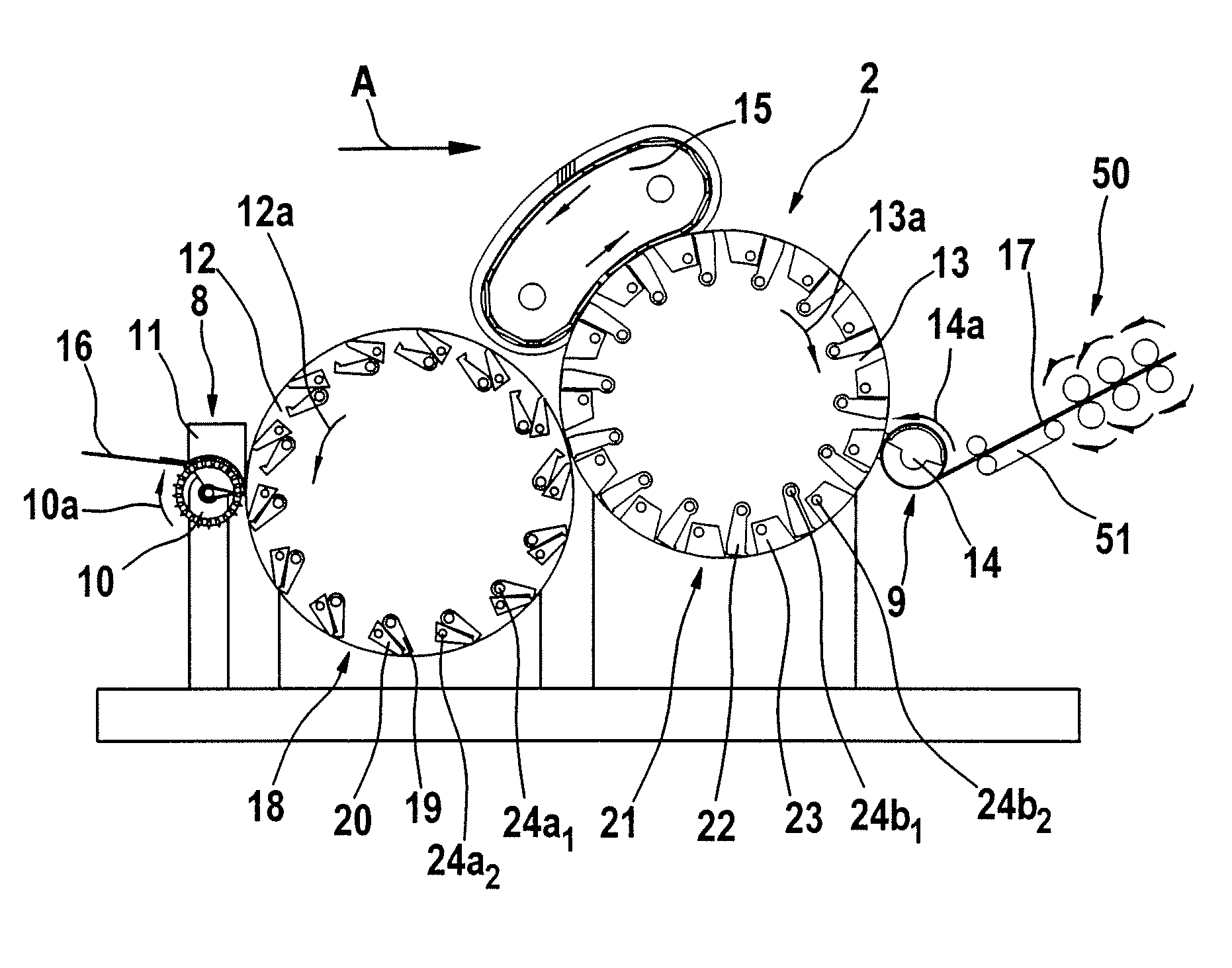

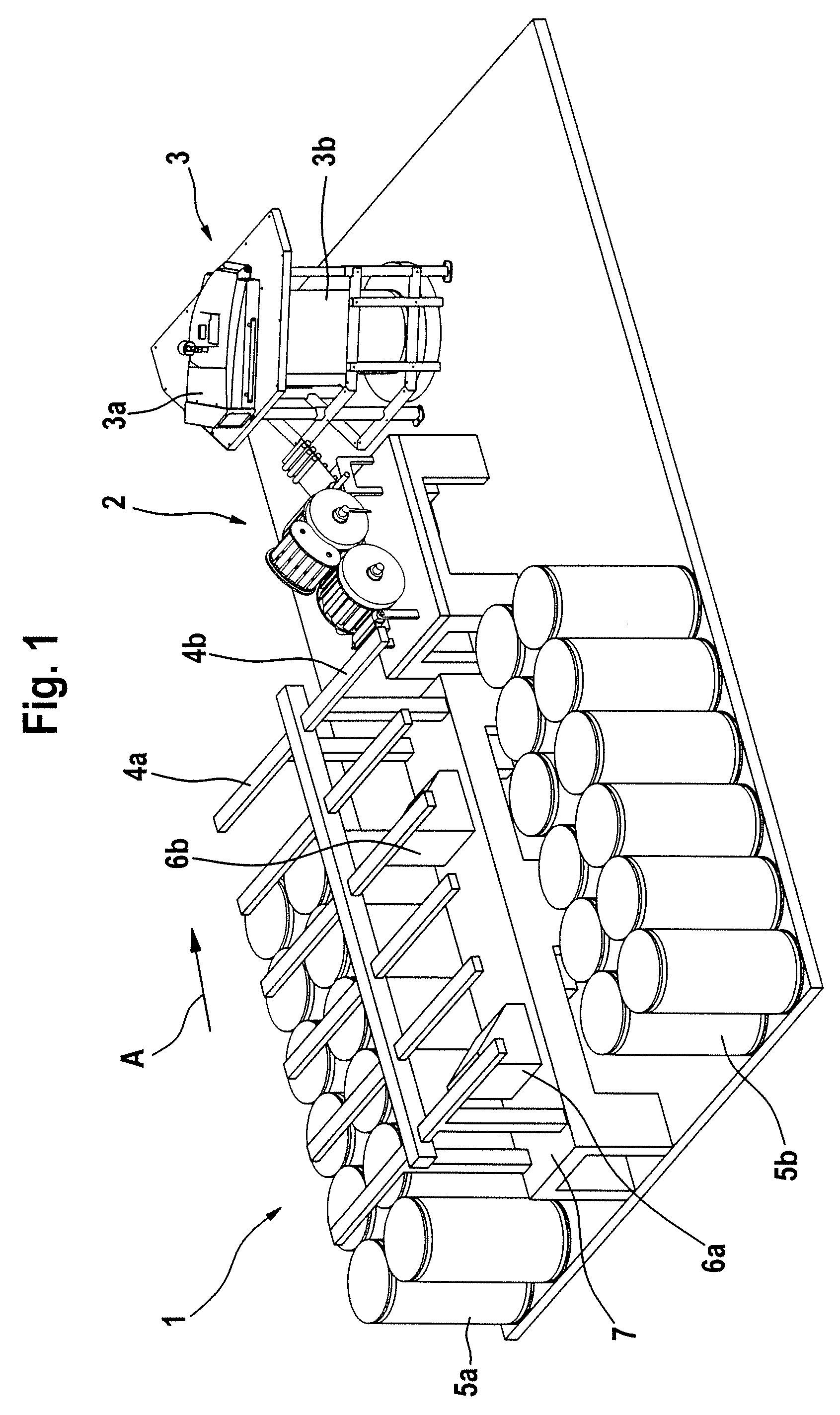

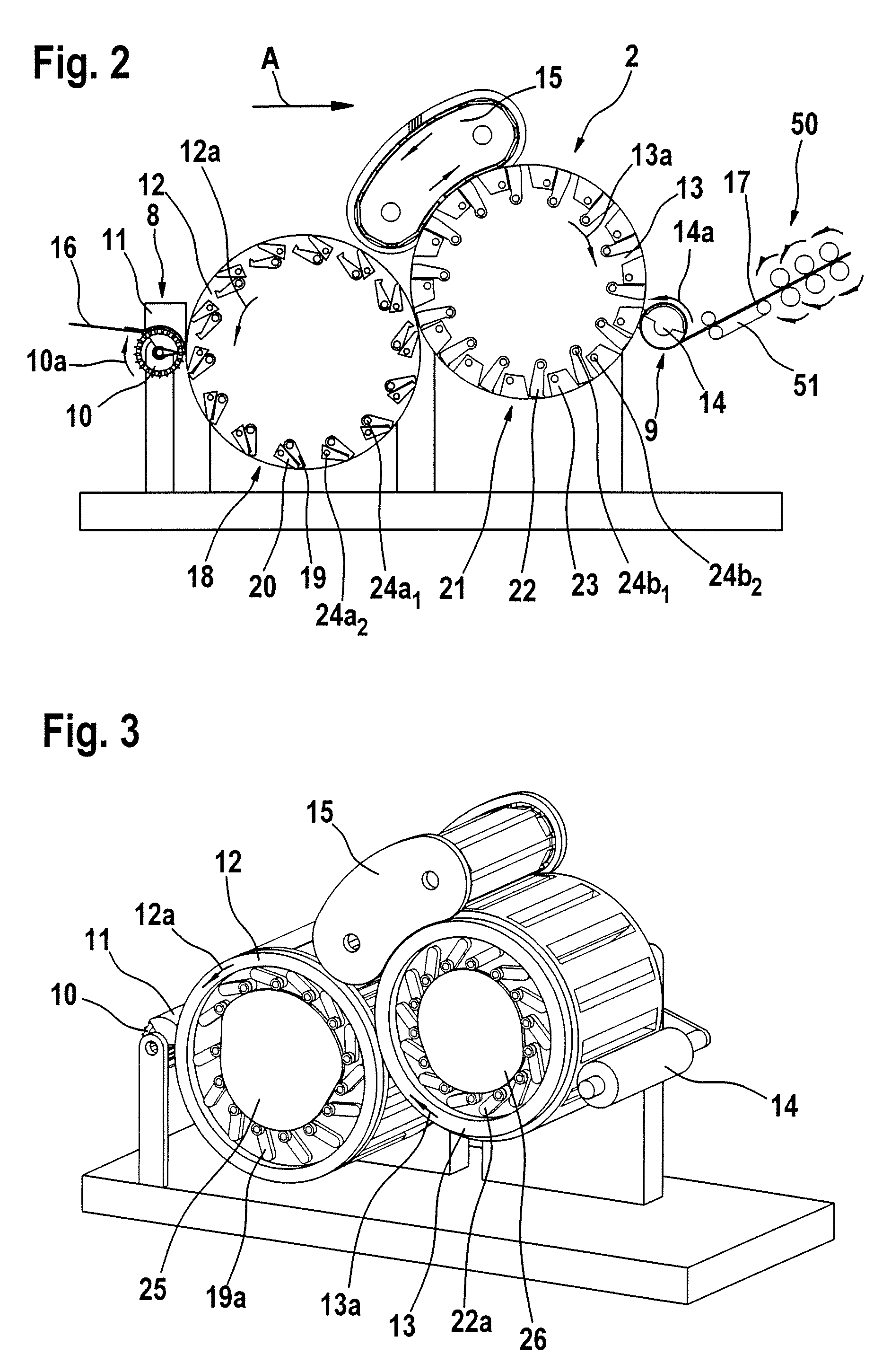

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

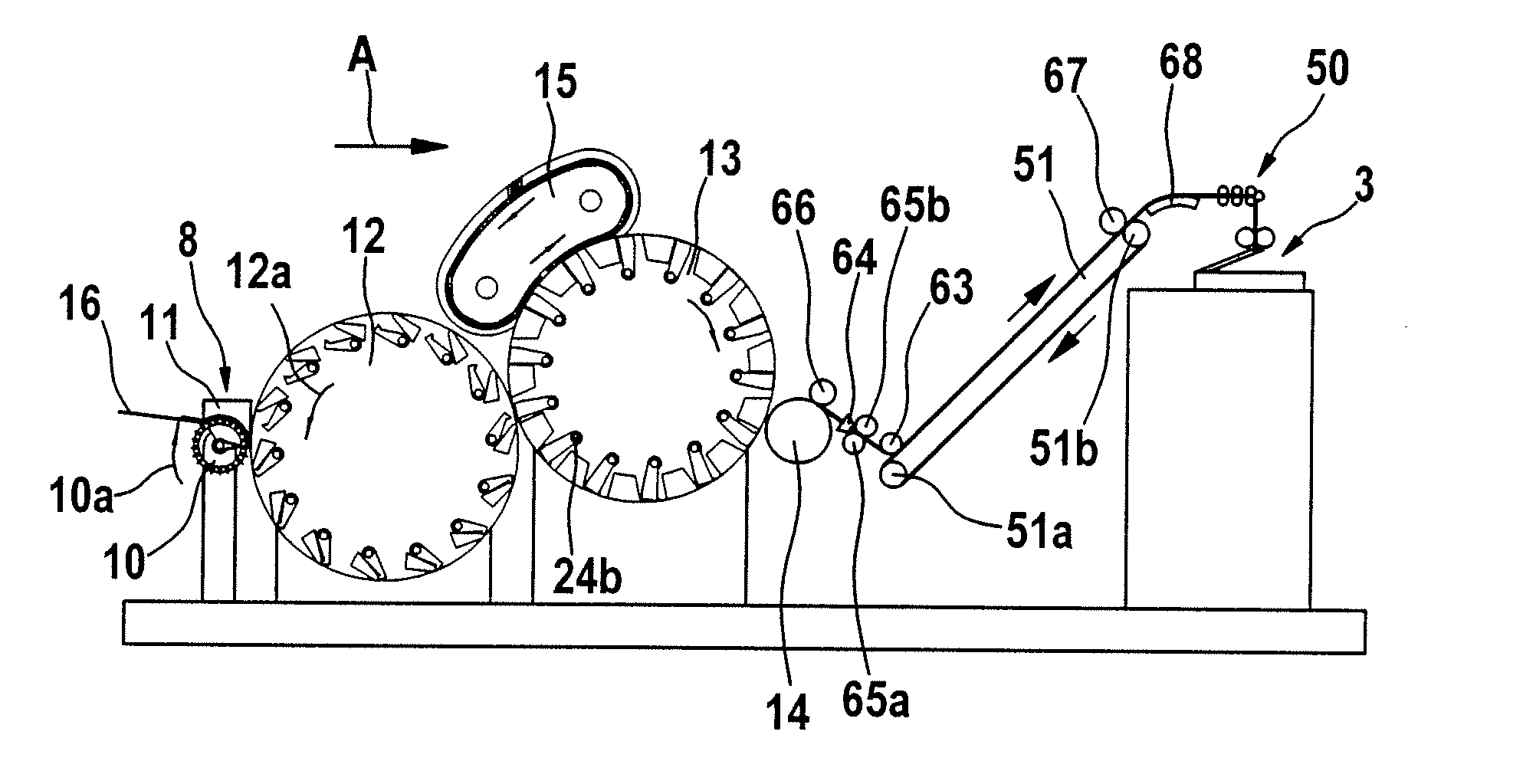

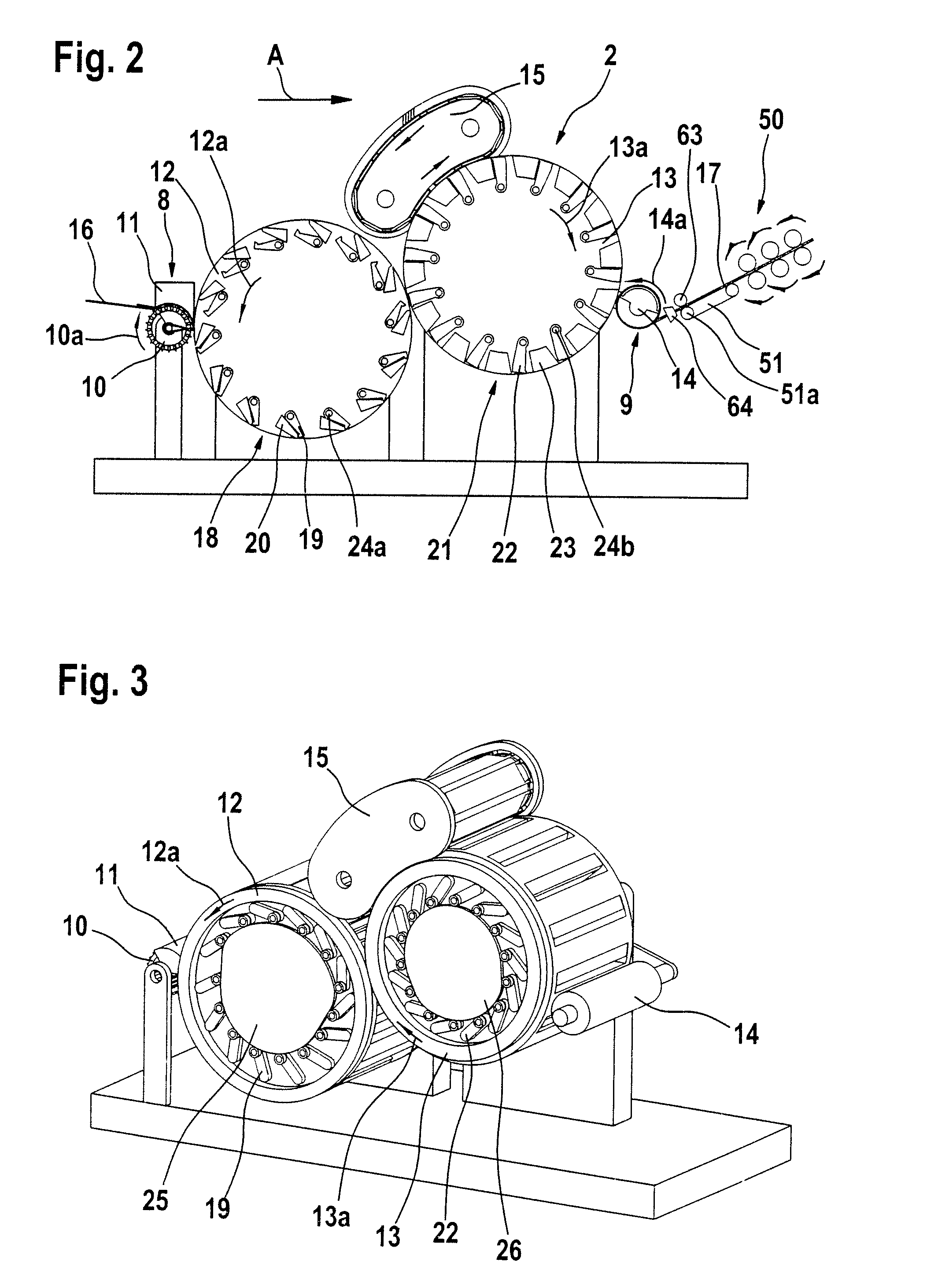

InactiveUS20090000067A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by means of a supply device to a fibre-sorting device, especially a combing device, for removal of the combed fibre material at least one take-off device with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and obtain an improved combed sliver, downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, which are provided with the clamping devices for the fibre bundle, and between the sliver-forming element and the drafting system at least one conveyor element for a formed combed sliver is present.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000077A1Improved sliverIncrease volumeCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part at least partially of a lightweight material. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUETZSCHLER GMBH & CO KG

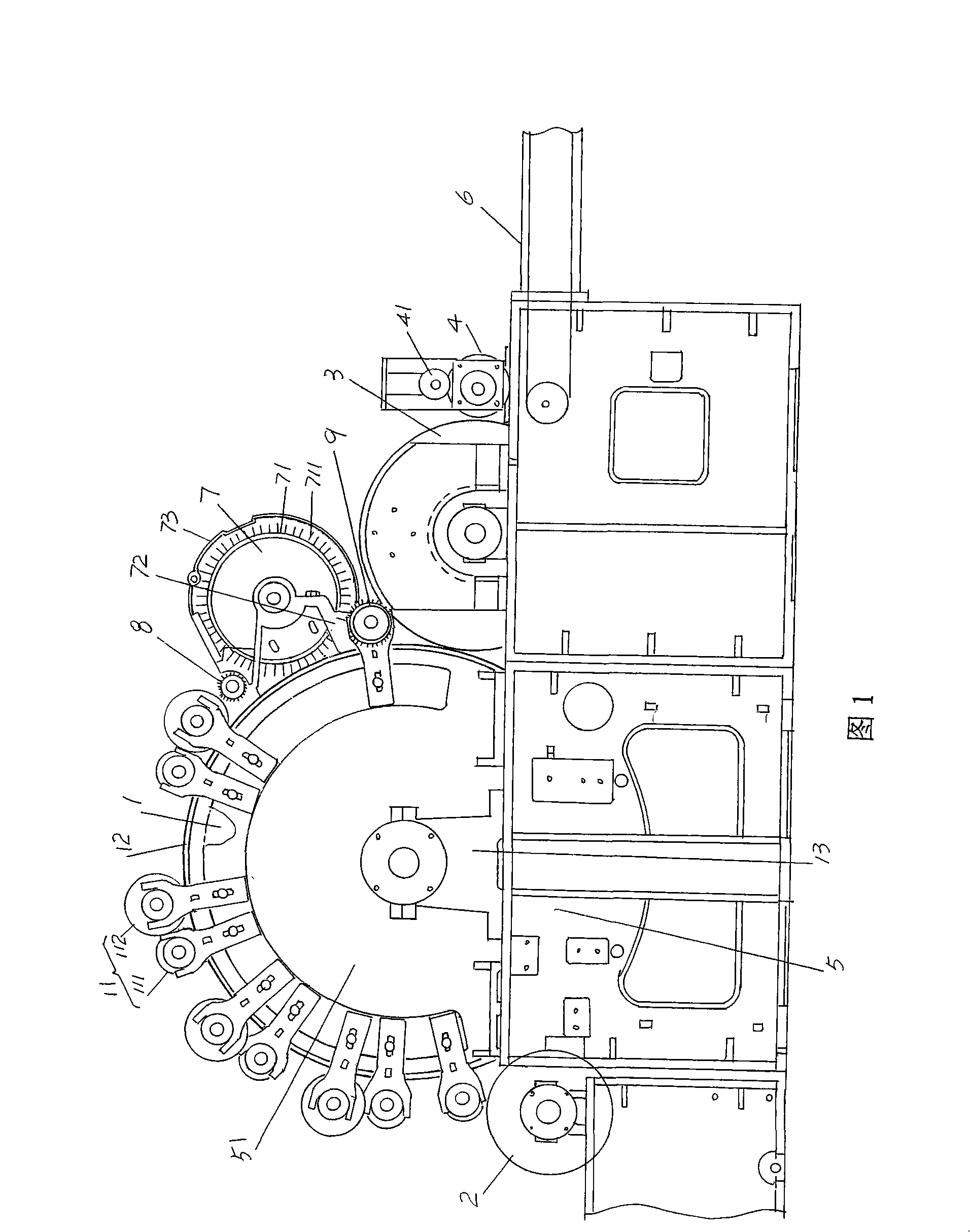

High-speed carding machine

InactiveCN102995167AGuaranteed stabilityGuaranteed speedCarding machinesEngineeringUltimate tensile strength

A high-speed carding machine comprises a base and a vibration wool feeding machine, a high-speed carding device and an automatic three-position barrel changing device which are connected with one another sequentially. The vibration wool feeding machine in the high-speed carding machine utilizes a translational vibration plate and a baffle to push textile raw materials uniformly, and moreover, the falling and outputting speeds of the textile raw materials are increased. A shaft seat of the high-speed carding machine is arranged on a breast cylinder wallboard and a large cylinder wallboard, so that the phenomenon that the positions of a breast cylinder and a large cylinder are changed relatively to the positions of a working roller and a wool stripping roller due to the high-speed rotation is avoided, the production quality is ensured, a suction pipe is arranged to suck the textile raw materials and reduce air flow which is generated by high-speed rotation, and the operation stability and high speed of the carding machine are ensured. The automatic three-position barrel changing device can control rotating wheels to change collection barrels, so that the high-speed carding machine is simple in structure and the labor intensity of the working personnel is reduced; and a U-shaped guardrail can ensure that the operation tracks of the collection barrels are stable when the collection barrels are changed, so that the whole barrel changing operation is carried out stably, and the collection barrels are prevented from tipping over during the barrel changing process.

Owner:青岛诚利佳机械有限公司

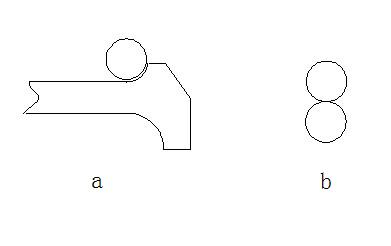

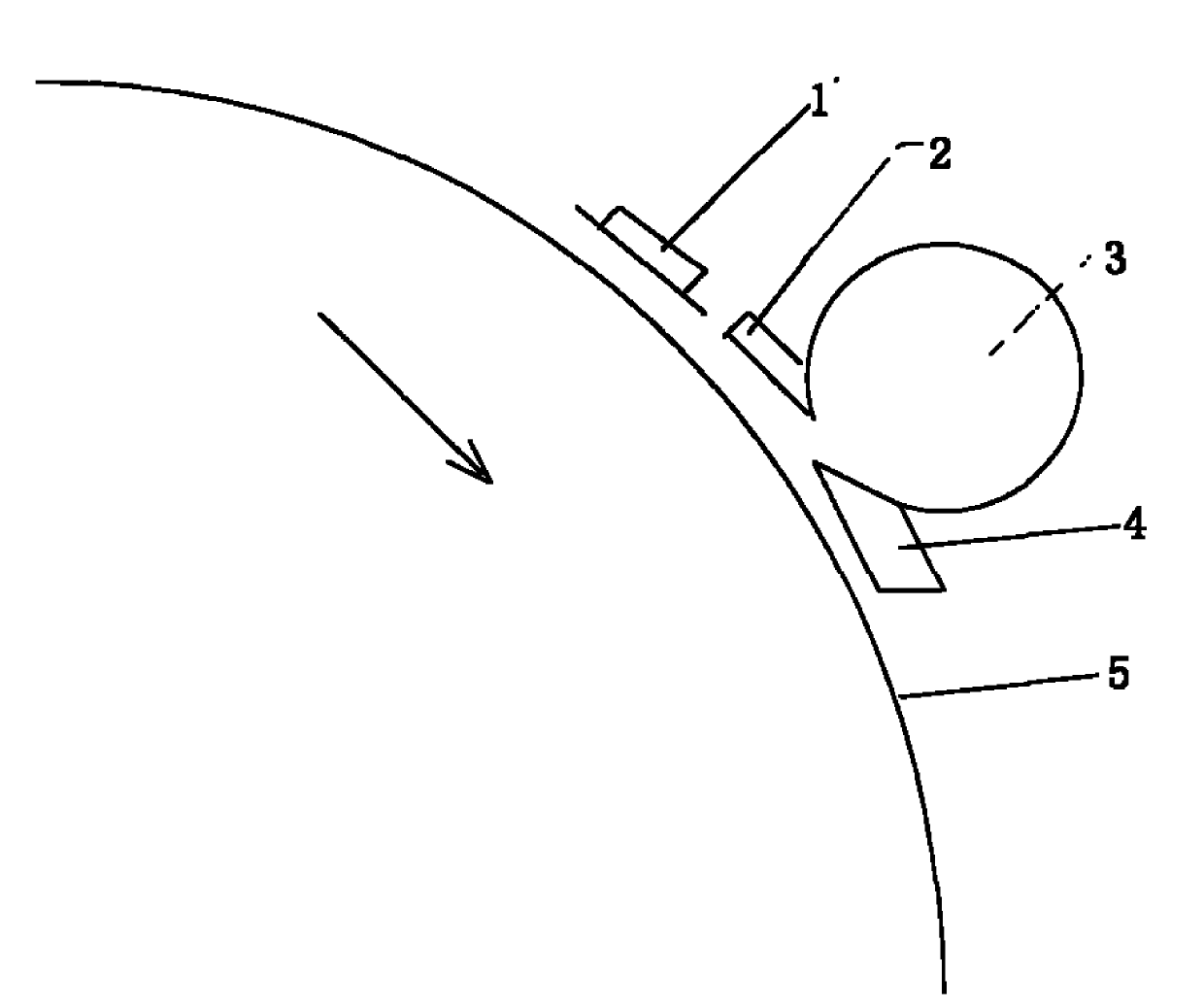

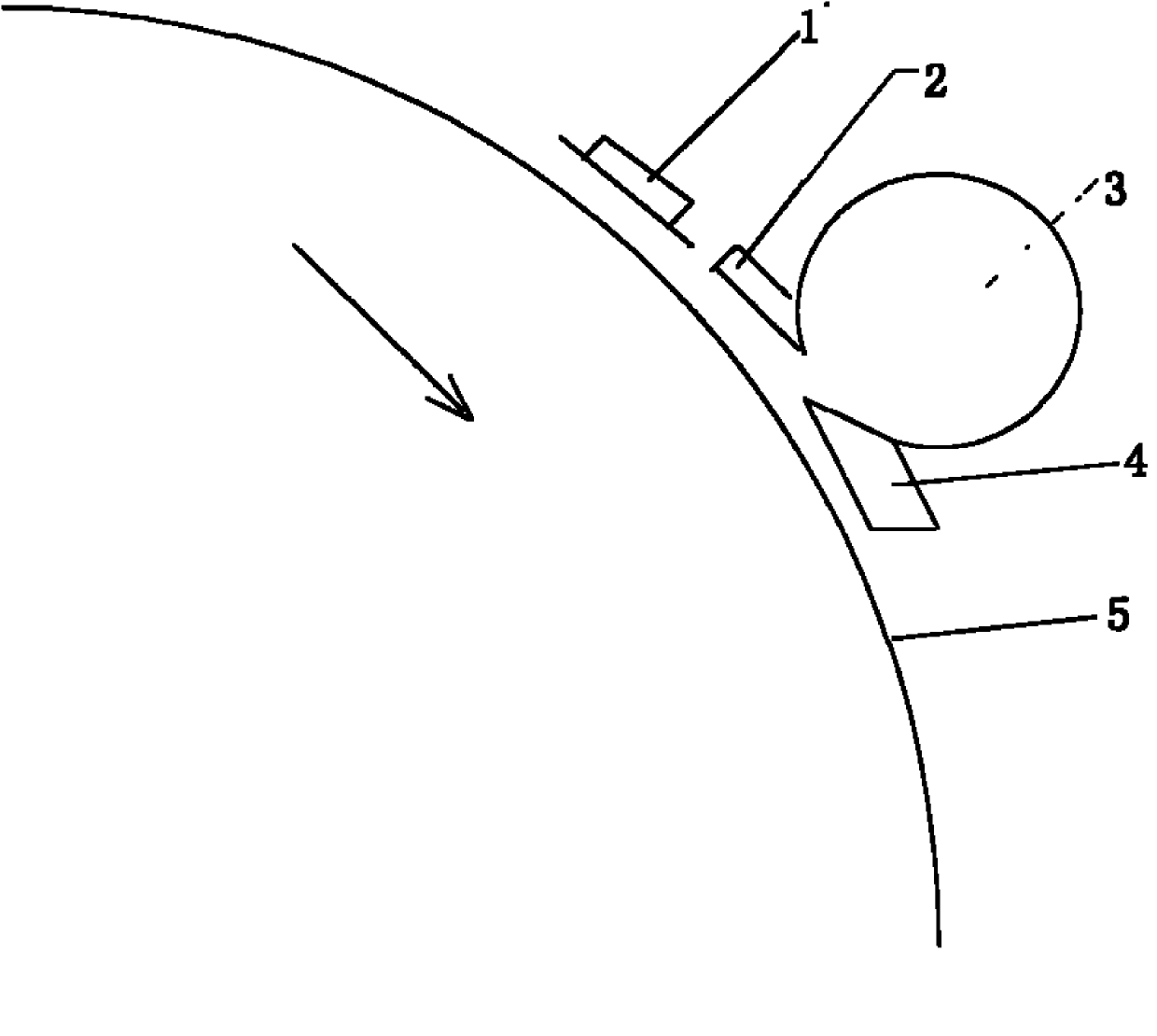

Apparatus on a textile machine for cleaning fibre material, for example of cotton, comprising a high-speed first or main roller

InactiveUS20070180660A1Improve cleanlinessEasy to separateCarding machinesFiberMechanical engineering

An apparatus on a textile machine for cleaning fibre material has a first roller for conveying a travelling fibre web, and second and third rollers which have respective nips with one another and with the first roller on rotation of the three rollers. The second roller is arranged downstream of the third roller and co-operates with the first roller so that fibre is detached, the fibre is transferred to the nip with the third roller and conveyed by the third roller to the nip with the first roller. The rollers have clothing with tips which are inclined in the direction of rotation. To improve the cleaning the front angle a of the tips of the second roller is about from 10° to 50° and the clothing gaps may be large to obtain a higher filling volume for fibres.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000066A1Improved sliverIncrease volumeCombing machinesCarding machinesFiber bundleEngineering

In an apparatus for the fibre-sorting or fibre-selection of fibre material which is supplied by means of a supply device to a fibre-sorting device, mechanical means are present which generate a combing action to remove non-clamped constituents such as short fibres. Downstream of the supply device there are arranged at least two rotatably mounted rollers with clamping devices for the fibre bundles, and the supply device comprises a feed unit, which feed unit comprises a feed roller and at least one feed tray defining a nip between said feed roller and said feed tray, and the retaining force in the nip optimally retains the short fibres completely or substantially completely in the nip during separation of a fibre bundle by said clamping devices.

Owner:TRUETZSCHLER GMBH & CO KG

Combined roller top card

InactiveCN102505201AAvoid damageCarding evenlyContinuous processingCarding machinesCardingEngineering

The invention discloses a combined roller top card, which comprises a wool feeding hopper, an opening device, a wool carding device and a cotton carding device. The wool feeding hopper, the opening device, the wool carding device and the cotton carding device are connected in sequence to form a combine. An output portion of the wool carding device is a cutting and stripping device. The cotton carding device is provided with double feed rollers for feeding. The output portion of the wool carding device is connected with a feed portion of the cotton carding device through a feed curtain. A pressure roller is disposed on the feed curtain and close to the front of the double feed rollers of the cotton carding device. An output portion of the cotton carding device is a spinning coiler. The combined roller top card is modified from original cotton spinning and wool spinning equipment, and has the advantages that wool top carding is uniform, neps and impurities are few, fiber damage is reduced, and silver quality is improved, while a gap of semi-worsted product equipment is bridged.

Owner:WENSHANG RUYI TIANRONG TEXTILE

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000065A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by means of supply device to a fibre-sorting device, especially a combing device for removal of the combed fibre material at least one take-off means with a sliver-forming element is present, downstream of which is a drafting system to enable productivity to be substantially increased and an improved combed sliver to be obtained, downstream of the supply device there is arranged at least one rotatably mounted roller rotating rapidly without interruption, which is provided with clamping devices for the fibre bundle, which clamping devices are distributed spaced apart in the region of the periphery of the roller and the combed sliver formed is arranged to be supplied directly to the drafting system.

Owner:TRUETZSCHLER GMBH & CO KG

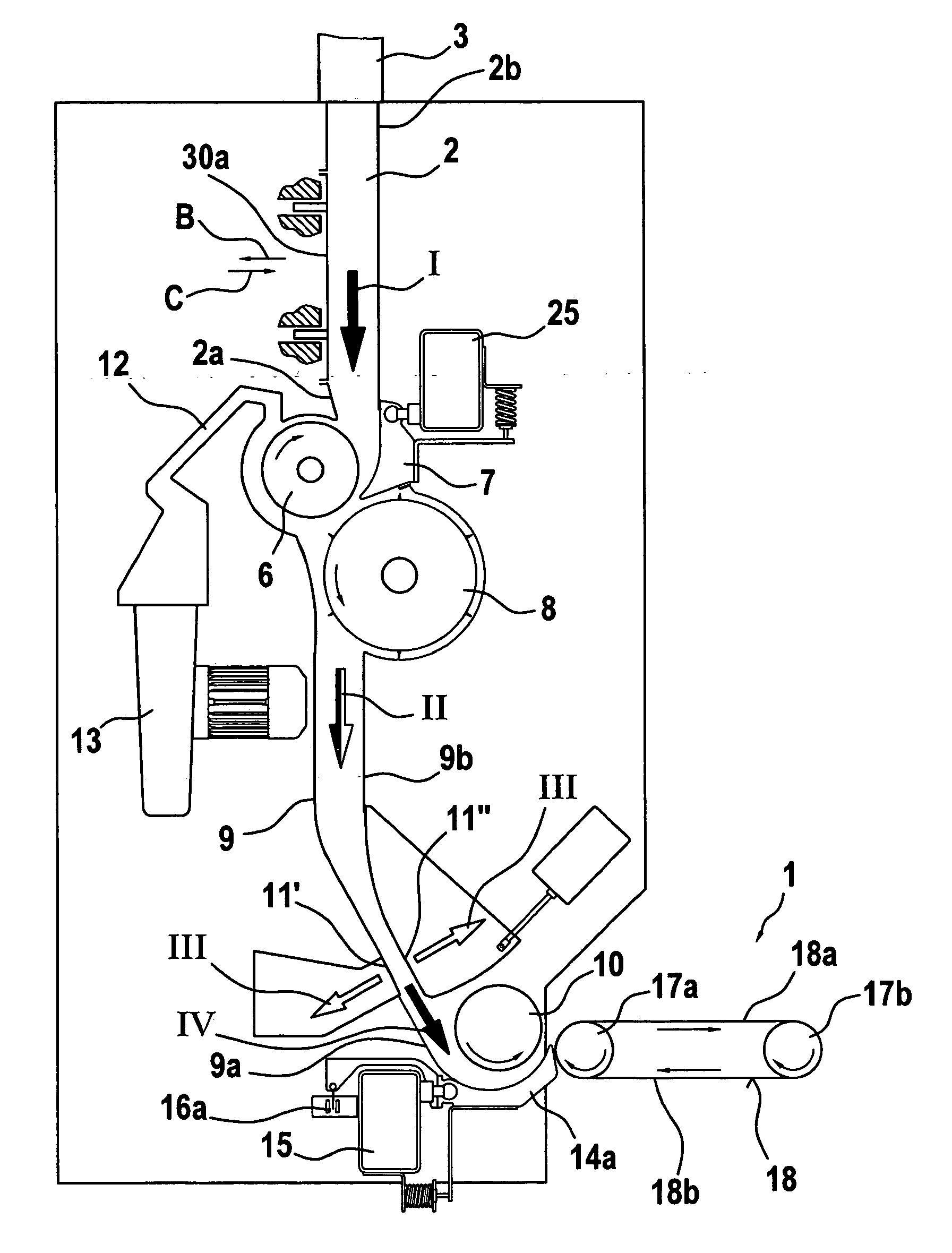

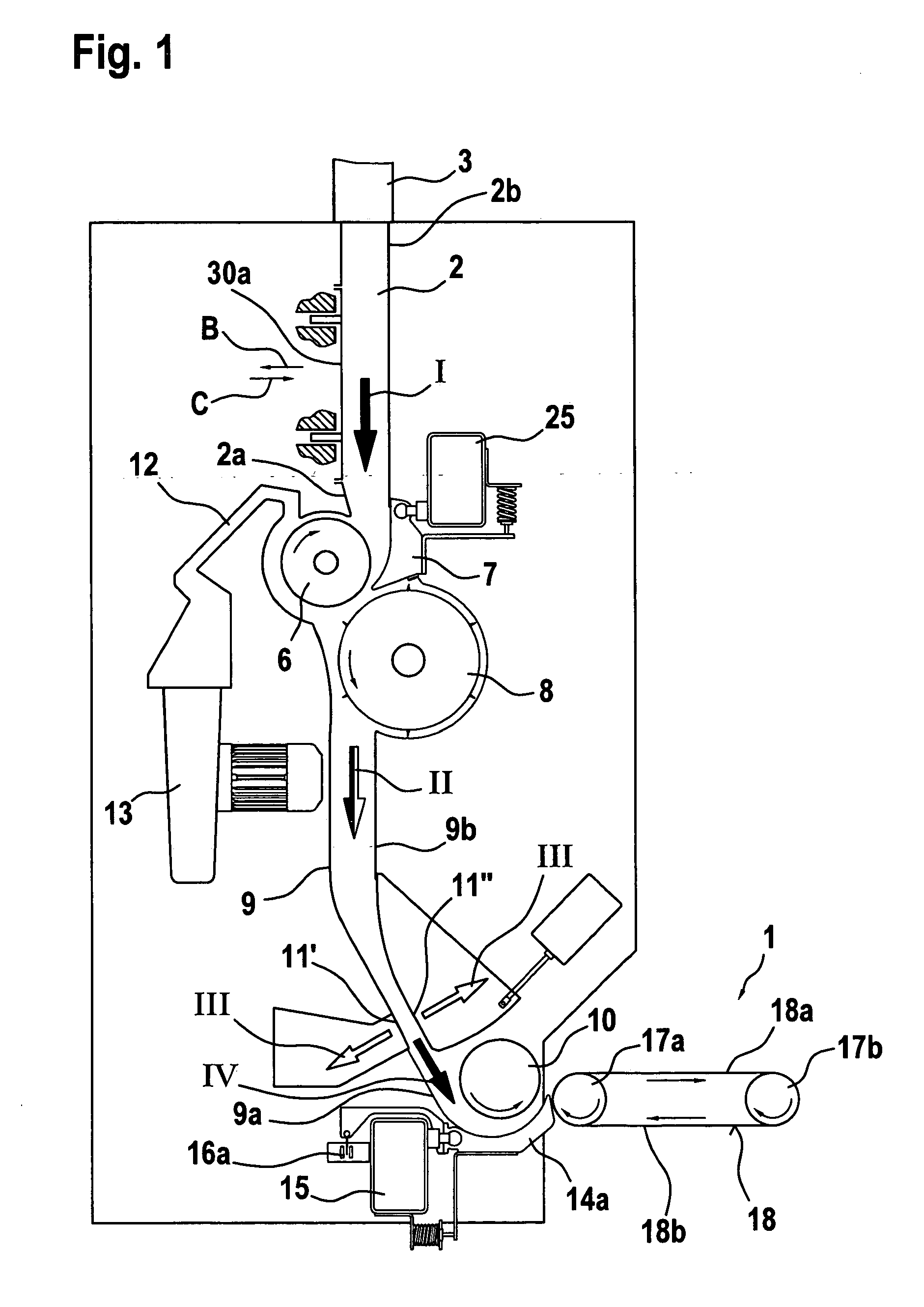

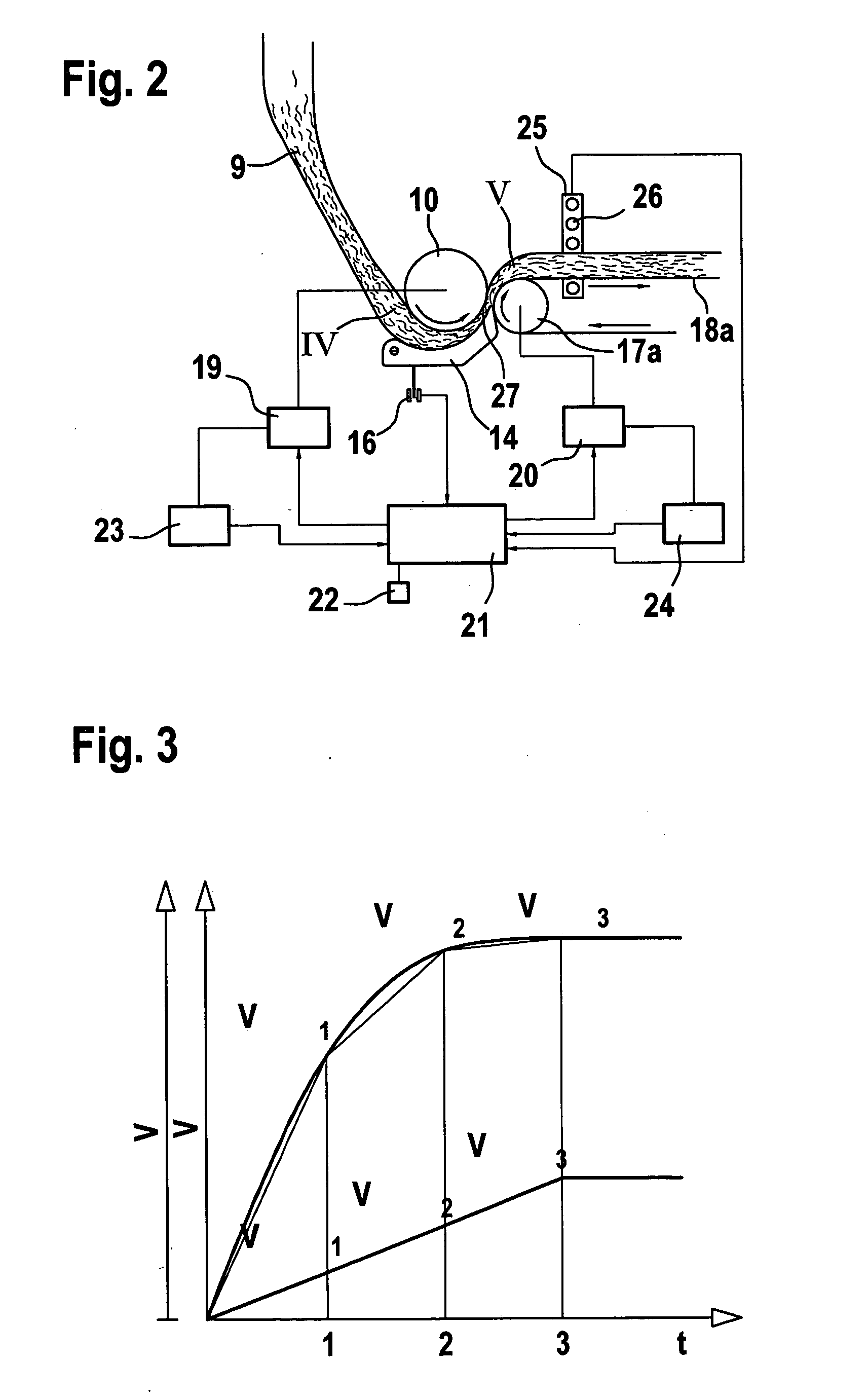

Device on a spinning preparation machine, for example a tuft feeder, having a feed device

A device on a spinning preparation machine, for example a tuft feeder, having a feed device comprising at least one slow-speed feed roller and a counter-element, for example a feed tray, with which fibre material can be supplied to a downstream transport device, has a driven transport element, for example a conveyor belt. In order to provide improved delivery from the feed device, or improved takeover by the downstream transport device, and to allow troublefree operation, for the purpose of determining setting values for the optimum speed of the transport element, a function between the measured values of the feed roller speed and the measured values of the transport speed is so determined that the fibre material lies on the moving surface of the transport element.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the Fibre-Sorting or Fibre-Selection of a Fibre Bundle Comprising Textile Fibres, Especially For Combing

InactiveUS20090000070A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateMechanical engineering

In an apparatus for the fibre-sorting or fibre-selection of fibre material which is supplied by means of supply means to a fibre-sorting device, at least one mechanical device is present which generate a combing action to remove non-clamped constituents such as short fibres. To enable productivity to be substantially increased in a simple manner and an improved combed sliver to be obtained, downstream of the supply device there are arranged at least first and second rotatably mounted rollers with clamping devices for the fibre bundles, and the apparatus further comprises at least two supply devices and / or at least one further high-speed roller and / or at least two take-off devices.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus at a spinning preparation machine for detecting waste separated out from fibre material

InactiveUS7173207B2Automatic detectionEasy to adjustSafety devices for fibre treatmentCarding machinesForeign matterEngineering

In an apparatus at a spinning preparation machine, for example a cleaner, opener, carding machine or the like, for detecting waste which is separated out from fibre material, for example cotton, and consists of foreign matter and good fibres and which is collected in a collecting device, there is provided an optical measuring device having a brightness sensor, which measuring device examines the waste.In order to make it possible, by simple means, for the content of good fibres in the waste to be detected and to allow optimum adjustment of the composition of the waste, especially with a high content of trash and low content of good fibres, the waste material is moved past at least one sensor arrangement responding to good fibres, and the sensor arrangement comprises a light source, the light reflected by the moving good fibres being detected by the brightness sensor and being converted into electrical signals, from which the good fibre content can be determined.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000075A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateCombing

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied by a supply device to a fibre-sorting device, especially a combing device, having clamping devices, which clamp the fibre bundle at a distance from its free end, for combing to remove non-clamped constituents, at least one take-off device 14 with a sliver-forming element is present, downstream of which is a drafting system. To increase productivity and improve the combed sliver, the fibre-sorting device has at least two rotatably mounted rollers rotating rapidly without interruption, having the clamping devices and between the sliver-forming element and the drafting system the at least one fibre sliver is present in the form of a fibre structure having a width greater than its height, for example, following spreading by a web-spreader.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000064A1Improved sliverIncrease volumeCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is supplied to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and each clamping device comprising at least one nipper part which is at least partially resilient. The clamping jaws may have a high coefficient of friction in the region of their clamping surfaces.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000068A1Improved sliverIncrease volumeCombing machinesCarding machinesTextile fiberProduction rate

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, fibre is supplied by a supply device to a fibre-sorting device, especially a combing device. Clamping devices clamp the fibre bundle at a distance from its free end, and a mechanical device combs the free end to loosen and remove non-clamped constituents, for example, short fibres, neps, dust and the like. To increase productivity and obtain an improved combed sliver, downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, which are provided with the clamping devices, and measured value sensors for detecting values relating to the fibres or machine settings are connected to a control and regulation device, which is arranged to effect actions in dependence on the measured values.

Owner:TRUETZSCHLER GMBH & CO KG

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000069A1Increase volumeImproved combed sliverCombing machinesCarding machinesProduction rateFiber bundle

In an apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, which is suppled by a supply device to a fibre-sorting device, especially a combing device, having clamping devices which clamp the fibre bundle at a distance from its free end, which is combed to remove non-clamped constituents, the clamping devices each comprise two clamping jaws. To increase productivity and to enable an improved combed sliver to be obtained, downstream of the supply device there are arranged at least two rotatably mounted rollers rotating rapidly without interruption, the clamping devices being spaced apart in the region of the periphery of the rollers, and the clamping jaws of the each clamping device are arranged to be movable in relation to one another and separately drivable.

Owner:TRUETZSCHLER GMBH & CO KG

Garnett machine

InactiveCN100368612CLow costIntensiveFibre cleaning/opening by toothed membersCarding machinesMotor driveEngineering

The opening machine comprises a pair of frame wall opposite to each other. One end of the pair of frame wall is higher than the other end. A pre-opening mechanism composed of the first roller, the second roller and coarse opening roller is set at the high end of the frame wall, and the fine opening mechanism composed of the third roller, the fourth roller and fine opening roller is set at the low end of the frame wall. A rolling curtain is set on the frame wall and between the said two opening mechanisms. A cotton collection bucket is set between the pair of frame wall and is communicated with the opening roller. A cotton-discharging mechanism is set the enclosure plate jointed to the end part of the frame wall. It also comprises a first motor driving the first roller and the second roller to rotate, a second motor driving the third roller, the fourth roller and the rolling curtain to move and the third motor driving the coarse opening roller and the fine opening roller to move. Advantages: saved cotton-feeding mechanism and reduced processing and using cost.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

Cashmere carding machine

The invention discloses a cashmere carding machine, which comprises a feeding mechanism, an opening mechanism, a coarse wool and impurity removing mechanism and a carding mechanism, wherein the coarse wool and impurity removing mechanism comprises a plurality of coarse wool and impurity removing units, and each coarse wool and impurity removing unit comprises two coarse wool and impurity removing subunits, each coarse wool and impurity removing subunit comprises a licker-in, a cylinder and a doffer, the licker-in, the cylinder and the doffer are arranged in a straight line, the coarse wool and impurity removing unit also comprises a bottom delivery flat curtain used for collecting dropped material, the front side of the bottom delivery flat curtain is provided with a material collecting groove, a condenser is arranged between two adjacent coarse wool and impurity removing units, and the material collecting grooves in the coarse wool and impurity removing units are connected with the feeding mechanism or the condensers through a conveying fan and a feedback pipeline. By the cashmere carding machine, the removing effect of impurities in raw material fiber can be further improved, and machine is conductive to improving the quality of a finished animal fiber product and at the same time helps to improve the extraction ratio of dehaired wool.

Owner:青岛东佳纺机(集团)有限公司

Cashmere carding combination machine

The invention discloses a cashmere carding combination machine which comprises a feeder, an opener, a plurality of coarse purifying units and a plurality of cover plate carding machines. The cashmere carding combination machine is characterized in that each of the coarse purifying units comprises first and second purifying subunits; each of the purifying subunits comprises a purifying subunit puncturing roller, a purifying subunit cylinder and a purifying subunit doffer which are arrayed in a form of a straight line; the cover plate carding machines are divided into first, second and third-level cover plate carding machines in total; the coarse purifying units are arranged in turn; the first-level cover plate carding machine is arranged in front of the coarse purifying unit which is located on the forefront; the first-level cover plate carding machine is connected with a second-level cover plate carding machine through an airflow feeding device; and the second-level cover plate carding machine is connected with the third-level cover plate carding machine through the airflow feeding device. The cashmere carding combination machine can be used for further promoting the effect of removing the impurities, such as coarse wools in raw fibers, is beneficial to the further promotion of the quality of the lint fiber end product and is also beneficial to the increasing of the lint-free extraction efficiency.

Owner:青岛东佳纺机(集团)有限公司

Electrostatic type crosrol web cleaner for carding machine

InactiveCN101906680AImprove sliver qualityThe index of impurity content has not been improvedCarding machinesBiochemical engineeringDissemination

The invention provides an electrostatic type crosol web cleaner for a carding machine, relating to the technical filed of textile, taking gauge adjustment of electrostatic plates and voltage adjustment as the key technology, and providing the installation form and the use effect of the electrostatic type crosol web cleaner for the carding machine. In the invention, a guide plate type crosrol web cleaner with the electrostatic plate is loaded at the position of a front knife plate of the carding machine; under the normal production condition, the different gauges between the electrostatic plate and cylinder as well as the different voltages are adjusted to influence the quality of a carded sliver; a Uster AFIS filament tester is used for carrying out quality testing on the carded sliver produced under the condition of the different gauges of the static electric plates and the voltages, a statistical analysis technique is used for analyzing the testing result which shows that under the condition of the appropriate dereferencing of the voltages and the gauges of the static electric plates, when the electrostatic type crosol web cleaner for the carding machine is loaded to the position of the front knife plate of the carding machine, the quality of the carded sliver can be improved. In the process of utilization, the loaded electrostatic plates have simple structure and small change on the traditional crosol web cleaner form, are convenient to manufacture and install and are favor of wide application and dissemination.

Owner:EASTERN LIAONING UNIV

Natural cotton fiber spunlaced nonwoven fabric for medical health and production method thereof

ActiveCN104313795AImprove removal efficiencyImprove pass rateCarding machinesHeating/cooling textile fabricsEngineeringMoisture absorption

The invention relates to a natural cotton fiber spunlaced nonwoven fabric for medical health and a production method thereof. The method is performed according to the following steps: preprocessing fibers; preliminarily combing cotton fibers; performing fine mixing; performing fine combing; forming a fiber net and performing drafting; performing hydraulic entanglement on the fiber net to form a cotton fiber spunlaced nonwoven fabric, and squeezing a bleaching solution into the fabric; performing cold pad-batch; removing cotton wax and pectin substances through a one-step method; performing cloth cover modification or jacquard treatment on a jacquard spunlaced device; drying the cotton fiber spunlaced nonwoven fabric on a tentering and setting machine; cutting the natural cotton fiber spunlaced nonwoven fabric, packaging the cut cotton fiber spunlaced nonwoven fabric, and warehousing the packaged cotton fiber spunlaced nonwoven fabric. According to the natural cotton fiber spunlaced nonwoven fabric for medical health, the gram weight deviation of the unit area does not exceed the range of minus 7% to plus 7%, the whiteness is greater than and equal to 85, the water absorption time is smaller than or equal to 5 s, the pH value is 6-8, the water-soluble matters are less than or equal to 0.5%, the soluble matters in ether are less than or equal to 0.5%, and the surface active substances are smaller than or equal to 2 mm. The natural cotton fiber spunlaced nonwoven fabric for medical health, provided by the invention, has the advantages of good hand feeling, good moisture absorption, good air permeability and no irritation to skins, the nonwoven fabric can be naturally degraded after being used, and the nonwoven fabric completely meets the requirement of environmental protection. The nonwoven fabric can be widely applied to the fields of medical care, hygiene, cosmetology, daily life, industrial cleaning, clean rooms and the like.

Owner:XINLONG HLDG GROUP +1

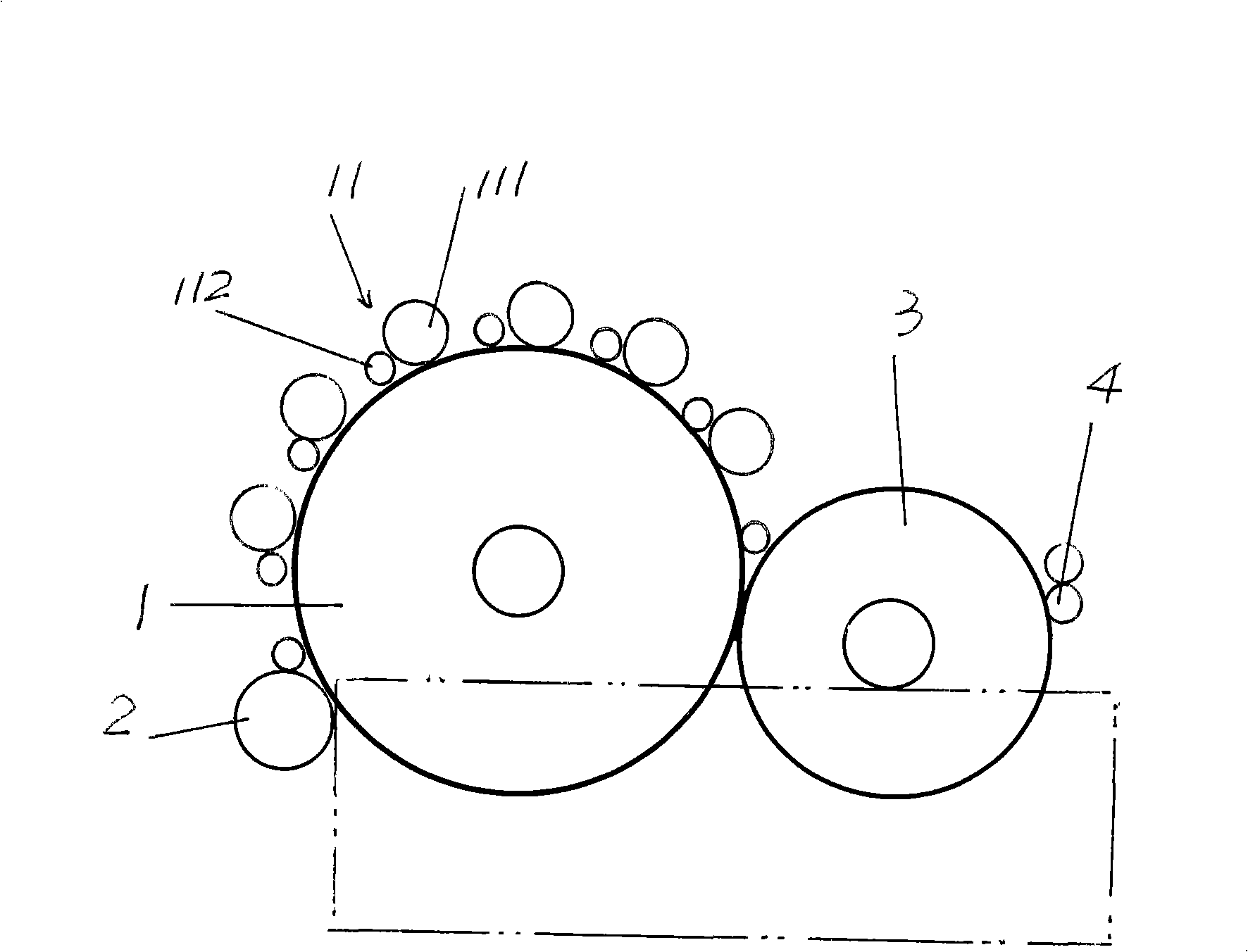

Main carding mechanism of interlaced fabric carding machine

InactiveCN101294317AMeet the requirements of cardingNo build-up in the clothing of the main carding cylinderCarding machinesLap forming devicesWall plateFiber

A main carding mechanism of non-woven cloth carding machine, which belongs to the field of non-woven machinery technology, comprises main cotton carding drums arranged on wall plates on two corresponding sides of a frame, a plurality of carding unit groups consisting of a working roller and a cotton stripping roller and similarly arranged on the wall plates of the two corresponding sides of the frame, and a web making roller and a stripping roller arranged on two corresponding sides of the frame rotatablely at both ends, wherein a transfer roller and the stripping roller are independently rotatablely arranged on the frame. The main carding mechanism is characterized in that a high-speed cotton stripping roller matched with the main cotton carding drums is arranged on the frame at a position substantially above the space between the main cotton carding drums and the web making roller and corresponds to the length directions of the main cotton carding drums and the web making roller. The main carding mechanism has the advantages that the fiber on the main cotton carding drums are completely transferred to the web making roller to make the weights of thin cotton webs reaching a transfer curtain consistent with each other, so that the production can be carried out continuously without periodically stopping machine to clean the main cotton carding drums.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com