Patents

Literature

260 results about "Worsted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Worsted (/ˈwɜːrstɪd/ or /ˈwʊstɪd/) is a high-quality type of wool yarn, the fabric made from this yarn, and a yarn weight category. The name derives from Worstead, a village in the English county of Norfolk. That village, together with North Walsham and Aylsham, formed a manufacturing centre for yarn and cloth in the 12th century, when pasture enclosure and liming rendered the East Anglian soil too rich for the older agrarian sheep breeds. In the same period, many weavers from Flanders moved to Norfolk. "Worsted" yarns/fabrics are distinct from woollens (though both are made from sheep's wool): the former is considered stronger, finer, smoother, and harder than the latter.

High-count single-warp single-abb worsted plus single thread and processing method thereof

The invention discloses a high denier single spinning single yarn and the processing method. The yarn general branch is 35-60S / 1. The material is pure wool or the mixing yarn by wool and terylene, mucilage glue, nylon, the cashmere and floret. It selects the proper material and the using mass in process; also in strip dye and combing process, the animal fiber such as wool, cashmere and floret is dying in low temperature, but for terylene, it uses the dye water in 130deg.C to add the assistant agent in dye or back treat process. In spinning process, it uses the compact spinning or multi spinning to protect the wool fiber and improve the dye quality. So the single yarn has little feather and big strength, good elasticity and good abrasion resistance.

Owner:JIANGSU DANMAO TEXTILE

Method of processing semi-worsted flax blended yarn

The present invention involves a processing method of semi-worsted flax blended yarn, and it belongs to flax blended yarn technical field. The counts of the semi-worsted flax blended yarn is 30-85 Nm / 2D, the raw materials consists of flax 10-60 and other fiber 40-90; degelatinizing, dyeing and preserving flax, pretreating other fiber, then putting together wool, blowing cotton, carding and drawing, then prespinning and shirting, last the products are prepared after cheese winding, twisting and double twisting processes. The invention combines the 'straight' of flax fiber and the 'softness' of other fibers effectively; the prepared semi-worsted flax blended yarn has many advantages of good textile strands and less granulite, it is suitable for the face fabric of thin summer inner wear and coat.

Owner:山东恒泰纺织有限公司

Process for production of radioresistant worsted face fabric

InactiveCN101012591ASolve the difficulty of uneven final surface in shrinking productionSolve the difficulty of unevennessWoven fabricsYarnPolyesterWorsted

The invention relates to a manufacturing method for anti-radiation spinning fabric. At first, wool and polyester are combed in double and spun into the wool yarn; then the wool yarn and fine stainless steel wire are combined into fine stainless steel yarn; finally anti-radiation spinning fabric is generated by the wool yarn and fine stainless steel yarn through weaving and dyeing. The fabric manufacturing method makes that the fabric is not only provided with anti-radiation performance but also high-grade fabric and good wearability by folding and stranding, weaving and dyeing. It can satisfy demands of office white collar class to the fabric of business wear.

Owner:杨毅方

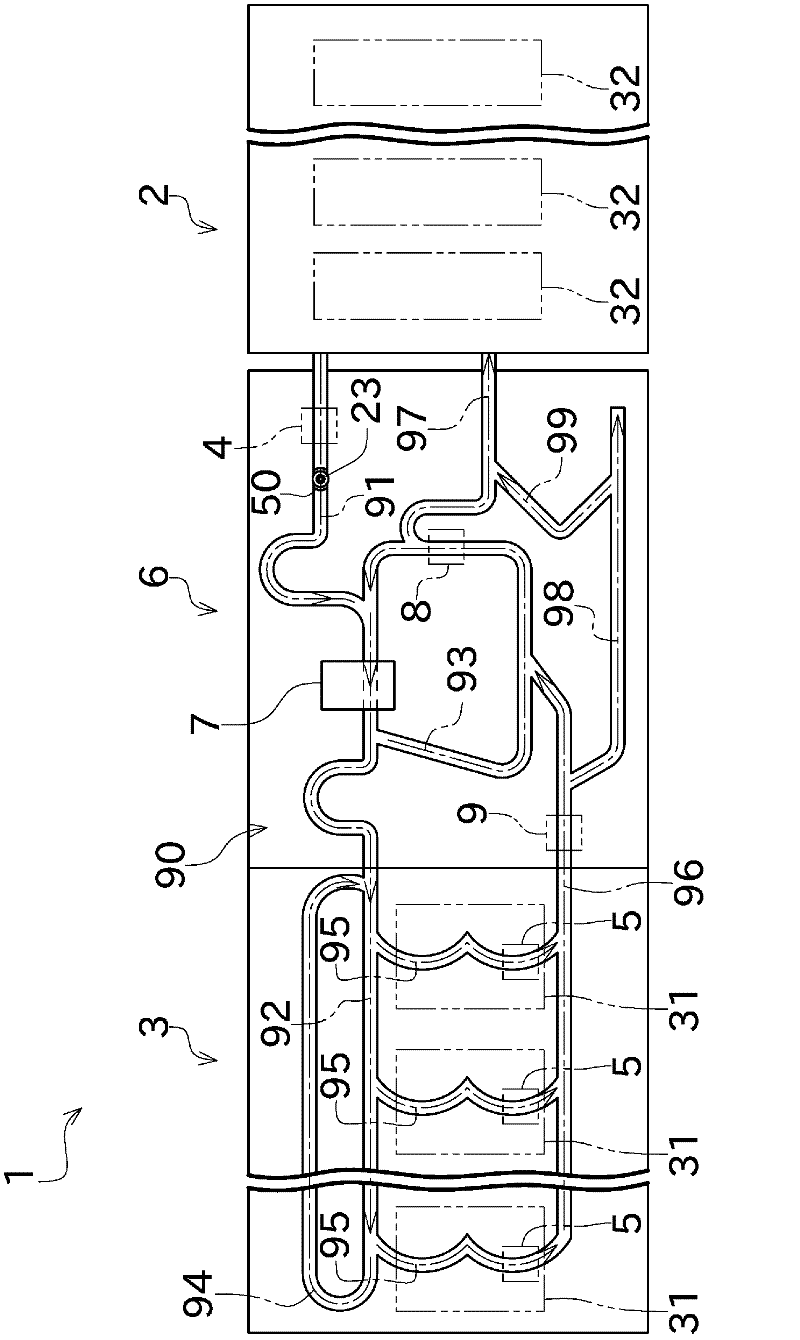

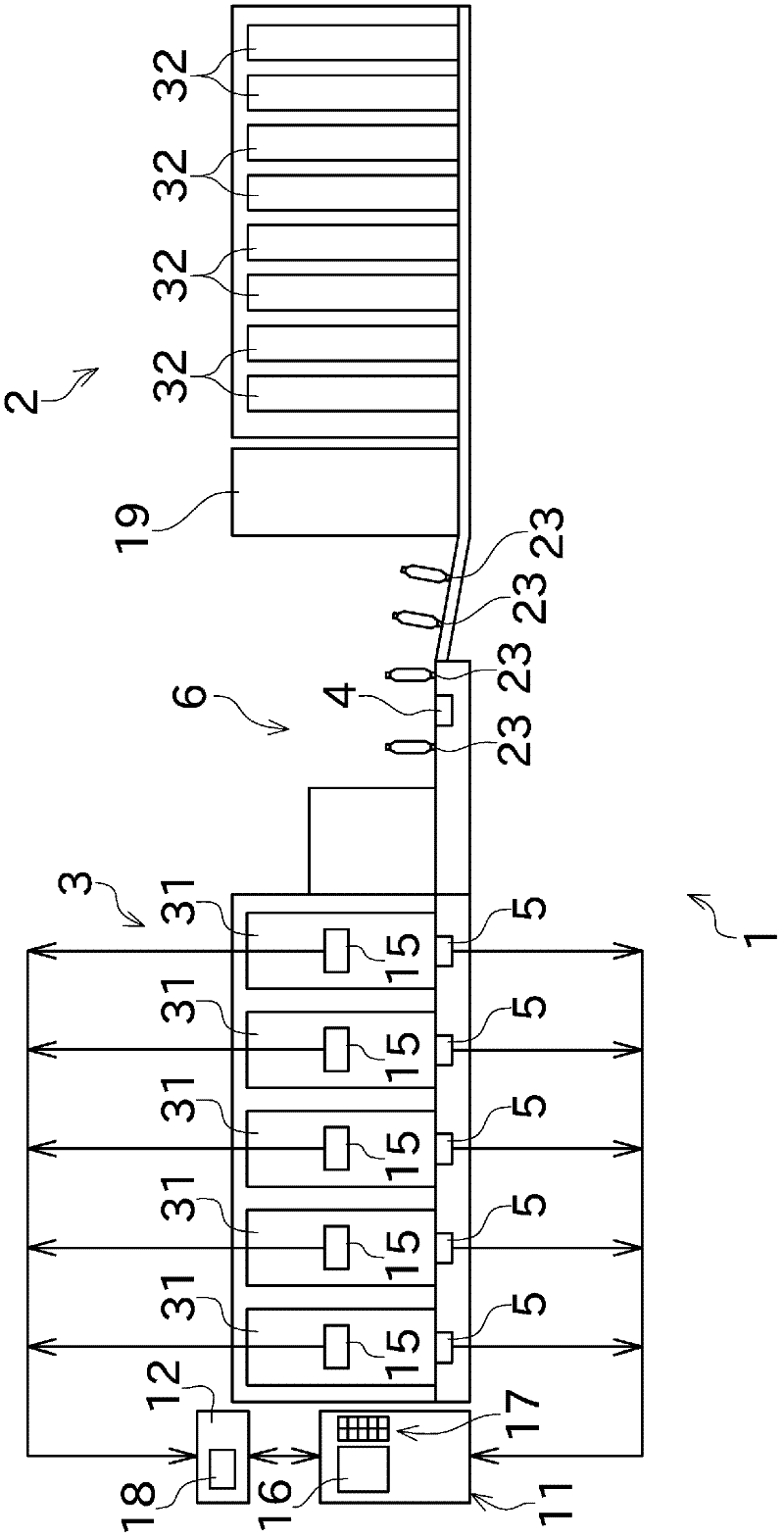

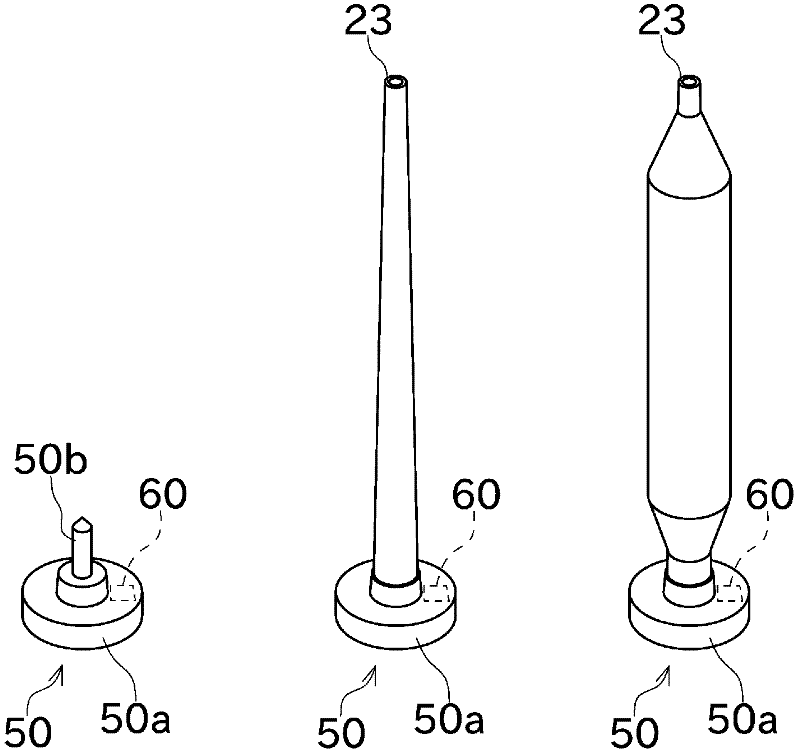

Management system for fine spinning winder and fine spinning winder

Disclosed is a management system for a fine spinning winder, which is capable of automatically analyzing the tendency toward which the fluff of yarn spun by a fine spinning unit is produced in units of bobbins. Trays on which bobbins (23), around which yarn is wound by a spinning frame (2), are set have RF tags capable of recording information for identifying fine spinning units (32) in which theyarn is wound around the bobbins (23) that are set on the trays. Also, winding units (31) have clearers (15), unit control sections, and RF readers (5). A quality inspection section of an automatic winder records the amount of fluff together with the unwound yarn length when the clearers (15) have detected the amount of the fluff, and conducts the quality inspection of the yarn spun by the fine spinning units (32) in units of bobbins (23).

Owner:MURATA MASCH LTD

Method for producing radioresistant worsted fabric

InactiveCN101413172AImprove the finishImprove the accuracy of weft insertionWoven fabricsYarnRadiation resistantWorsted

The invention relates to a production method for a radiation-resistant fine spun fabric, which mainly comprises the following steps: dyeing and recombing wool first, and then combing the wool into colored wool tops, mixing the colored wool tops and metallic short fiber strips in spinning and mixing processes to spin into metallic yarns, and weaving, dyeing and finishing the metallic yarns to produce the radiation-resistant fine spinning fabric. Through spinning and mixing the metallic short fibers, the production method for the fabric makes the metallic fibers distributed in the fabric more evenly and improves radiation-resistant effect; the diameters of the metallic short fibers are softer than that of fine fibers, and so on, so the fabric is softer and more subtle; through the control for the weaving, dyeing and finishing processes, the fabric also has the advantages of high-grade appearance, neat hand feel, fine and pure face and excellent wearing property at the same time of having radiation-resistant function; and the fabric has most popular natural memory fold function at present simultaneously. Therefore, the fabric is suitable for producing male and female fashion coats which can show grace, luxury, romance and grade after being worn.

Owner:JIANGSU SUNSHINE +1

Method for producing electrostatic resistance and ray-proof worsted cloth

ActiveCN101250787AMeeting urgent needsSuitable for worsted processing needsDry-cleaning apparatus for textilesWoven fabricsPolyesterWorsted

The invention relates to method for manufacturing antistatic ray-proof worsted fabric, which successively comprises the following steps: firstly, carrying out the cleaning treatment and the sizing and film mulching treatment to rust-less steel fiber, secondly, blending by selecting treated rust-less steel fiber with wool, polyester fiber, bamboo fiber, tenel, modal fiber or spun silk, manufacturing mixed sliver with homogeneous mix, thirdly, spinning the mixed sliver and obtaining the worsted spinning yarn, fourthly, warping, weaving and obtaining the grey fabric, fifthly, carrying out birth repairing, dyeing and finishing and post-processing to the grey fabric, namely obtaining the antistatic ray-proof worsted fabric, wherein the materials feeding proportion by weight of the wool, the polyester fiber, the bamboo fiber, the tenel, the modal fiber, the spun silk, viscose or cashmere are respectively that the rust-less fiber 15-45 parts, the wool 45-75 parts, the polyester fiber 5-50 parts, the bamboo fiber, the tenel, the modal fiber, the spun silk, the viscose or the cashmere 5-20 parts. The method of the invention selectes length and fineness of the rust-less fiber and carries out the prophase film mulching treatment to the fiber, which enables the performances of the fiber is suitable for the requirements of the worsted process and enables the fiber to achieve the goal of being applied at high proportion.

Owner:山东希努尔男装有限公司

Worsted goods and ready-made garment shape permanent stability finishing process

A finishing process for making the shape of worsted goods and clothes durable and stable is characterized by antifelting agent WFI-1 and a shape fixating agent WS-1, which are prepared from the water-soluble polyurethane, are provided for them.

Owner:SHANGHAI UNIV OF ENG SCI

Semi-worsted ultra-thin double-faced overcoating wool fabric

The invention discloses a semi-worsted ultra-thin double-faced overcoating wool fabric. The fabric is formed by blending high-quality wool with tencel fibers, warp yarns and weft yarns of the fabric are semi-worsted yarns, the fabric keeps a double-faced wool style and each square meter of fabric is 530 to 550g. In a processing method, a coarse spinning and fine weaving mode is adopted, the warp yarns and the weft yarns of the fabric are the semi-worsted yarns, positive and negative fluffing double-evaporation multi-cutting process technology is adopted in the after finishing process, and ironing and preshrinking technology and a low-temperature multi-ironing process are adopted, so that the true color of the high-quality wool is displayed, and the positive and negative surfaces of the fabric have the same shrinkage due to the preshrinking process; and teasel inverse combined overcoating technology is adopted, and two teasels jointly work to finish a positive and negative overcoating process at one time inversely. The invention has the advantages that: the fabric can keep the double-faced wool style and meets the consumption requirement that people pursue health and fashion currently.

Owner:张家港市金陵纺织有限公司

Process for production of ultra-fine wool worsted face fabric

The invention relates to a manufacturing method for superfine wool worsted fabric. It selects superfine wool with the diameter of 14.5um and produces superfine wool worsted fabric by stripe dyeing, spinning, weaving and after-treatment. Merits of the invention are that the high quality of superfine wool worsted fabric is outstanding; the fabric is provided with good quality, exquisite handle feeling and good spring-back; it is also provided with high-grade quality, high added value and it has higher social and economical benefits.

Owner:杨毅方

Multi-functional wool-worsted western-style clothes fabric

ActiveCN103431559AImprove waterproof performanceExcellent oil repellencyWoven fabricsProtective garmentBreaking strengthWorsted

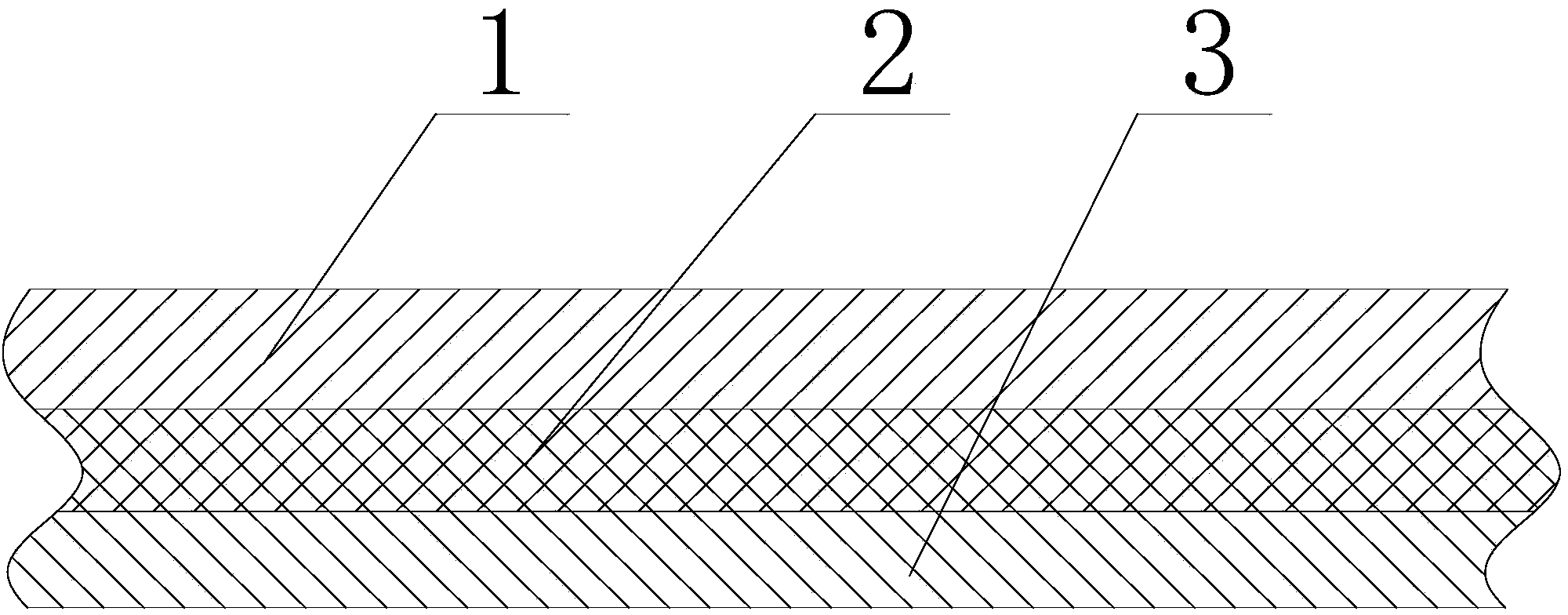

The invention discloses a multi-functional wool-worsted western-style clothes fabric. The multi-functional wool-worsted western-style clothes fabric comprises a surface layer, a middle layer and a lining layer and is characterized in that the surface layer is connected with the lining layer with the middle layer serving as the foundation, surface layer yarn is woven to form the surface layer, aramid-based conductive fibers with the length ranging from 20mm to 45mm are woven to form the surface layer yarn, middle layer yarn is woven to form the middle layer, Thermolite hollow fibers with the length ranging from 25mm to 40mm and aramid fibers are woven in a blended mode to form the middle layer yarn, lining layer yarn is woven to form the lining layer, and Australian wool with the length ranging from 50mm to 80mm is woven to form the lining layer yarn. The multi-functional wool-worsted western-style clothes fabric has the warm-keeping function, the anti-static effect, ultra-strong breaking strength and ultra-strong tearing strength. In addition, the multi-functional wool-worsted western-style clothes fabric has the good anti-microbial and deodorization function, and has the excellent waterproofing function, the excellent oil-resistant function and the excellent dirt-resistant function.

Owner:JIANGSU AOYANG TEXTILE IND

Method for producing pure pashm worsted plus material

The invention relates to a producing method for a pure wool spinning lining by using wool as raw material, comprising steps of top dyeing, spinning, weaving and finishing. The advantages of the invention are that the produced lining has good quality, delicate hand feeling, good flexibility, high added value and is provided with good social benefit and economic effectiveness.

Owner:杨毅方

Semi-worsted double-face different-color nap-down corrugated fleece and production process thereof

InactiveCN106192132AFluff evenlyOrnamental textile articlesLiquid/gas/vapor removalWorstedEngineering

The invention provides semi-worsted double-face different-color nap-down corrugated fleece and a production process thereof and relates to improvement in double-face corrugated fleece and a production process thereof. The semi-worsted double-face different-color nap-down corrugated fleece is characterized by comprising a fabric body; the fabric body is cloth woven from fine warp and coarse weft, the double faces have different colors, semi-combed section dyed yarn is arranged on the front face, semi-combed color yarn is arranged on the reverse side, and the upper portion and the lower portion are tied to form a double-layer organization structure; the front and reverse face texture of the fabric body is 1 / 3 broken twill. A brand-new process is adopted for the product, and the effects of jacquard weave and printing of former drap-de-berry are exceeded. The semi-worsted double-face different-color nap-down corrugated fleece presents a new appearance for people. The semi-worsted double-face different-color nap-down corrugated fleece is a pioneer of the double-face fleece product style, and the blank in domestic drap-de-berry pattern type products is filled in.

Owner:阜新新溢达毛纺织有限公司

Heating blended yarn and spinning process thereof

The invention discloses a heating blended yarn and a spinning process thereof. The heating blended yarn comprises the following components in percentage by weight: 5% to 15% of heating fiber, 25% to 30% of anti-pilling acrylic fiber, 20% to 25% of modal fiber, 20% to 25% of tencel fiber and 20% to 25% of viscose fiber. The fibers are spun to yarn through a semi-comb spinning process. The spinning process sequentially comprises a dyeing process, a cotton carding process, a drawing process, a roving process, a spinning process and a spooling process. The heating blended yarn is formed by blending various types of fibers, highlights the characteristics of each fiber by reasonably arranging the weight ratio of each fiber, integrates the advantages of various types of the fibers into a whole, maintains the basic performance of the yarn, and has the heating and warming functions. The yarn is more fluffy and softer than spun yarn and is more uniform and glossy than the coarse yarn. The adaptability of the semi-comb spinning process route to raw materials is wider, the spinning quantity can be high or low, the technology is popularized, equipment investment is low, and occupied plant area is small.

Owner:JIANGNAN UNIV +1

Sorona/wool semi-worsted spinning yarn as well as manufacturing process thereof and application thereof

The invention relates to the textile field, in particular to a sorona / wool semi-worsted spinning yarn as well as a manufacturing process thereof and an application thereof. The invention provides the yarn; and the key technical point is as follows: the yarn is a three-stranded knitted yarn with count of 36 N / 3, which is obtained through spinning 70% of wools and 30% of sorona fiber by weight. The invention further provides the manufacturing process of the sorona / wool semi-worsted spinning yarn; and the process comprises the following steps of dyeing, blending, cotton carding, drawing of three strands, rough yarn forming, spun yarn forming, spooling and doubling. The invention further provides a sweater using the sorona / wool semi-worsted spinning yarn. According to the invention, an environment-friendly sorona fiber with a certain ratio is adopted for the knitted sweater, so that the finished product sweater has the advantages of soft and rich handle, vivid color, good moisture absorbing property, good air permeability and excellent heat retention property; and compared with the traditional sweater product, the sweater has the advantages of better water washing size stability and machine washability.

Owner:劲霸男装(上海)有限公司

Method for producing worsted cloth by mixed spinning hemp and wool

InactiveCN1431346AWith ecological health functionMeet consumer demandBiochemical fibre treatmentYarnWorstedEngineering

Owner:凯诺科技股份有限公司

Kuralon fiber finely woven fabric and preparation method thereof

A kuralon fiber finely woven fabric is characterized by comprising the following components by weight percent: 70-80% of wool or wool and other fibers and 20-30% of kuralon fiber; and the preparation method comprises the following steps: 1) selecting raw materials; 2) recombing; 3) spinning; 4) weaving; and 5) dyeing and finishing. The kuralon fiber finely woven fabric produced by the method of the invention has bulky and soft hand feeling and the hollowness is up to 20-30%. The selection of kuralon is reasonable, the mixing method ensures that the kuralon fiber finely woven fabric can be smoothly spun, the spinnability is good, the fiber is easy to draw, the evenness is good, the fault is less, the weaving efficiency is high, and the characteristics that the fabric is hollow and the hand feeling is bulky and soft, of the kuralon fiber finely woven fabric can be better embodied after finishing.

Owner:JIANGSU DANMAO TEXTILE

Multicomponent fiber semi-worsted functional blended yarn and preparation method and application thereof

The invention discloses a multicomponent fiber semi-worsted multifunctional blended yarn, and a preparation method and an application thereof, wherein the fiber is made from the following raw materials in percentage by weight: 20-45% of aloe viscose fiber, 20-40% of far infrared polyester fiber, 20-50% of Formotex fiber and 15-35% of wool fiber. The performance index of the blended yarn is as follows: the single yarn breaking strength is 11.9-20.8cN / tex, the variable coefficient value Cv of the single yarn breaking strength is 8.9-19.2%, and the variable coefficient value Cv of yarn evenness is 13.3-22.8%. The yarn disclosed by the invention has the advantages that fabric weaved by the blended yarns not only has the health-care functions of antibiosis, bacteria prevention, bacteria inhibition, inflammation diminishing, skin care and body building, beautifying and skin moistening and the like, and is good in skin care and better in comfort, but also is high in fabric strength, good in moisture absorption and ventilation, good in dyeing performance and flexible in feel. The product is noble and elegant in appearance, bright in color, glossy, good in ultraviolet protecting performance, and unique in appearance, and has health-care functions of far infrared rays, negative ions and the like. The product is wide in use, and can be prepared to various knitting or weaving health-care textiles such as various clothes, beddings, underwear, sportswear and fitness clothes.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for preparing cashmere fabric

The invention discloses a method for preparing a cashmere fabric, comprising the following steps of: with basolan undercoat, cashmere, coffee carbon fiber and soft loose fiber as raw materials, blending, and carrying out semi-worsted spinning to obtain high count semi-worsted yarns which are taken as wraps, wherein wefts are mercerized cotton yarns; spinning the wraps and the wefts under the conditions that 2 / 2 texture is adopted and total tightness is 95-100, so as to obtain a grey fabric; and carrying out the following processes on the grey fabric: sizing, single boiling, double boiling, scouring, milling, double boiling, drying, middle inspection, finishing, brushing, softening and smoothening, napping, shearing, decating and natural lustre finishing, thus obtaining the finished product. According to the technical scheme provided by the invention, after finishing combines the advantages of fine spinning and roving processes, the obtained product has mild nature, soft feel and silkylustre and also has antibacterial, deodorizing and heat insulating effects, and the cashmere fabric reaches the requirement on relaxation size of 1*7A and can be washed by a machine.

Owner:ZHANGJIAGANG HUALU WOOL SPINING

Worsted fabric and manufacturing method thereof

The invention discloses a worsted fabric. The worsted fabric comprises a surface layer, a middle layer and an inner layer, wherein the warp yarn and weft yarn of the surface layer are a twined yarn of a strand of 8 to12tex of wool yarn and a strand of 2.2 to 4.4tex of mulberry silk; one kind of the warp yarn and weft yarn of the middle layer is 6.2 to 8.3tex*2 of spun silk, and the other kind of the warp yarn and weft yarn of the middle layer is 6.5tex*2 of metallic silk; and the warp yarn and weft yarn of the inner layer are two strands of twined yarns of mixed yarns of 10 to 12.5tex of wool and cashmere. The invention also discloses a manufacturing method of the worsted fabric, which comprises the following steps of: preparing yarns, preparing twined yarns, warping, weaving, and performing after finishing. The worsted fabric has layering effect and three-dimensional effect, and patterns of the worsted fabric are three-dimensional, full and various.

Owner:嵊州雅戈尔毛纺织有限公司

Method for producing spinning yak woollen sweater

InactiveCN1730756AImprove spinnabilitySolve processing problemsWeft knittingYarnTextile technologyWorsted

The present invention relates to textile technology, and is especially production process of fine yak wool sweater. The production process includes following steps: selecting fiber material including yak wool fiber in 95-97 wt% and silk fiber in 3-5 wt%; mixing the yak wool fiber and the silk fiber inside one mixer; spinning; knitting yak wool sweater pieces in one flat knitting machine; sewing the pieces in sewing machine into yak wool sweater in the required style; and finishing. The present invention is superior to background technology.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Process for production of superbright glossy wool worsted face fabric

InactiveCN101012614ASoft and delicateUnique textureSingeingHeating/cooling textile fabricsWorstedCombing

The invention relates to a manufacturing method for the worsted fabric with super-bright gloss, which selects wool and terylene to product the worsted fabric with super-bright gloss by double combing, spinning, weaving, dyeing and finishing. In the manufacturing method of invention, by setting dyeing and finishing process, selecting and proportioning assistant, and selecting calendering equipment, the effect of increasing brightness is achieved for production and the hand feeling of fabric is guaranteed at the same time. Merits of invention are that the produced fabric is provided with soft and fine hand feeling, unique texture, and gloss as silk; it breaks through the style of conventional fabric; and the fabric can maintain high gloss after ironing in high temperature and dry-cleaning.

Owner:杨毅方

Production method of anti-creasing shirts

The invention discloses a production method of anti-creasing shirts. The production method comprises the following steps: carrying out liquid ammonia treatment on full-cotton worsted fabrics; pre-shrinking the fabrics with a pre-shrinking machine; padding the fabrics in an impregnation liquid containing an anti-creasing agent, wherein the pressure is 1.5-2kg / cm<2> and the liquid take-up rate is 60-70%; drying and tailoring the treated fabrics and making clothes with the fabrics; and ironing and setting for 10-20 minutes at 140-150 DEG C by adopting a drying and setting machine. According to the invention, the anti-creasing agent is formed by the following components in parts by weight: 45-55 parts of waterborne polyurethane, 15-20 parts of bis[monoethyl(3,5-di-tert-butyl-4-hydroxylbenzyl) phosphonate, 35-40 parts of chitosan, 2-5 parts of silane coupling agent and 0.5-1.2 parts of sodium polyacrylate dispersing agent; and water is added to the anti-creasing agent to prepare the 15-45% impregnation liquid. The anti-creasing agent can be firmly bonded with the shirt fabrics and is strong in durability, so the shirts have excellent anti-creasing effect.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

Digital printing technology for worsted cashmere fabrics

The invention discloses a digital printing technology for worsted cashmere fabrics. The digital printing technology includes the steps of pretreating, digital printing, aging and cleaning drying, wherein the pretreating step includes spraying operation of a rare-earth chloride water solution or roller painting operation of the rare-earth chloride water solution. According to the digital-printing technology for the worsted cashmere fabrics, the rare-earth chloride water solution is subjected to roller painting or sprayed to the semi-dry slurry-film-forming surface, moisture in the water solution and film forming substances in slurry are hydrated, and rare-earth chloride is evenly arranged on a printing surface layer accordingly; as rare-earth positive ions and negative charges on the cashmere-fiber surface are adsorbed, the rare-earth positive ions, cashmere fibers and dye molecules are reacted to form a stable complex, and the dyeing rate and the color fastness can be increased.

Owner:JIANGSU SUNSHINE GRP CO LTD

Method for producing cigarette smell resistant wool worsted fabric

ActiveCN102912649AImprove breathabilityReduce releaseFibre treatmentLiquid/gas/vapor removalFiberWorsted

The invention provides a method for producing a cigarette smell resistant wool worsted fabric; and the cigarette smell resistant wool worsted fabric is woven by adsorbing a fragrance slow-release microcapsule and an odor adsorbing microcapsule in a breathable wool worsted fabric; the process comprises weaving of the breathable wool worsted fabric and after finishing of the cigarette smell resistant breathable wool worsted fabric; and the machining principle is as follows: first, machining a wool worsted fabric with better breathability, wherein good fabric breathability is beneficial for temporarily remaining odors like cigarette smell and so on in the fabric to be rapidly lost to the air; and adhering the two different microcapsules to fabric fibers through an after finishing method, wherein one part of the microcapsule is capable of very slowly producing enduring fragrance and the other part of the microcapsule is capable of absorbing unpleasant cigarette smell and sweat smell; and after being washed by water, the adsorbed odors of the fabric can be released.

Owner:山东如意毛纺服装集团股份有限公司

Elastic worsted fabric with contact coldness sense and preparation method thereof

InactiveCN102534949AIncrease elasticityFeel coolWoven fabricsYarnWorstedPolytrimethylene terephthalate

The invention relates to an elastic worsted fabric with a contact coldness sense and a preparation method thereof. The fabric comprises polytrimethylene terephthalate (PTT) fibers with a contact coldness sense effect, wherein the PTT fibers are prepared by spinning PTT slices which contain mineral powder with the contact coldness sense and are taken as raw materials, or prepared by taking PTT slices as raw materials and adding mineral powder with the contact coldness sense effect in the spinning process; the PTT fibers have high heat conductivity, can quickly absorb heat on the surface of skin, and are not stuffy when external temperature is high, and the coolness and comfort of the worsted fabric can be kept all the time; and the PTT fibers have high spinnability, evenness and weaving efficiency and a few yarn faults and are easy to draw, and the elasticity of the worsted fabric with the contact coldness sense is better reflected through after finishing.

Owner:JIANGSU DANMAO TEXTILE

Production method of worsted shell fabric containing polyolefin elastic fibers

InactiveCN103898645ALittle change in elasticityReduce disadvantagesBiochemical fibre treatmentYarnPolyesterPolymer science

The invention discloses a production method of worsted shell fabric containing polyolefin elastic fibers. The shell fabric is formed by spinning wool fibers, cashmere fibers, bamboo charcoal polyester fibers, superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers, and anti-pilling treatment, enzyme treatment and softening treatment are respectively conducted on the wool fibers and the cashmere fibers; the wool fibers, the cashmere fibers, the bamboo charcoal polyester fibers, the superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers are spun into the shell fabric according to the weight ratio of 55-75 : 12-18 : 18-28 : 12-15 : 5-8, and eventually aftertreatment is conducted on the shell fabric through a water-soluble polyurethane wool anti-shrinking agent. The production method has the advantages that damage to wool fiber products can be greatly reduced, the pilling phenomenon is reduced, the shell fabric made of the wool fibers, the cashmere fibers, the bamboo charcoal polyester fibers, the superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers as major raw materials is softer, the felting shrinking percentage is greatly reduced, and the quality of the shell fabric is better.

Owner:汤丽娟

Worsted fabric with function of temperature adjustment and fabrication method thereof

ActiveCN101671901AComfortable to wearIt has two-way temperature adjustment function of warm in winter and cool in summerLiquid/gas/vapor treatment of indefinite length materialsDyeing processFiberWorsted

The invention discloses worsted fabric with the function of temperature adjustment and a fabrication method thereof. The worsted fabric adopts wool strips and air-conditioning fiber cheese as the rawmaterial; as the air-conditioning fiber is formed by combining micro capsules of 2-30 nanometers, paste olefin is injected into the micro capsules; the olefin has the function of energy conversion, can make corresponding reaction on skins to the change of ambient temperature, and adjust the temperature fitting for human bodies through heat absorption, heat storage and heat release and has buffer function on temperature change, so that the worsted fabric made by blending the wool strips and the air-conditioning fiber cheese has the function of bidirectional temperature adjustment so as to trulyachieve the effect of warm in winter and cool in summer; on the other hand, as the air-conditioning fiber cheese is not added with any chemicals and the function of bidirectional temperature adjustment is achieved totally by the self function of the product, the worsted fabric is ecological, environment-friendly and energy-saving, can reduce consumption, and is elegant in quality, smooth in feeling and comfortable in wearing.

Owner:嵊州雅戈尔毛纺织有限公司

Worsted and rove composite cashmere fiber yarn and manufacturing method of knitwear thereof

The invention discloses a technology for manufacturing worsted and rove composite cashmere fiber yarn. The technology comprises the steps of (A) manufacturing rove, (B) manufacturing worsted, (C) conducting doubling on the rove and the worsted in a composite mode, and (D) obtaining the worsted and rove composite cashmere fiber yarn after heating is conducted through steam. Compared with the prior art, composite doubling at different ratios is conducted on cashmere rove single yarn and cashmere worsted single yarn which are different in thickness, and then the worsted and rove composite cashmere fiber yarn with different hand feels is formed. The manufactured worsted and rove composite cashmere fiber yarn integrates the characteristics that the rove yarn and knitwear made of the rove yarn are soft in hand feel and fluffy and the worsted yarn and knitwear made of the worsted yarn are clear in grain and good in elasticity, and overcomes the defects that according to the rove yarn and the knitwear made of the rove yarn, hairiness is too much, the yarn is loose and fuzzing and pilling are prone to occurrence; in addition, different pieces of manufactured worsted and rove composite cashmere fiber yarn with different mixing ratios have different elasticity degrees and different softness degrees, and therefore different types of cashmere knitwear can be produced.

Owner:CONSINEE GRP CO LTD

Ultrathin semi-worsted nap up blazer fabric and preparation process thereof

ActiveCN106757613AImprove qualitySoft qualityHeating/cooling textile fabricsWoven fabricsPolyesterFiber

The invention discloses an ultrathin semi-worsted nap up blazer fabric and a preparation process thereof. The fabric comprises Australian wool short cutting, cotton cashmere, polyester loose fiber and modal lose fiber; the preparation method comprises the steps that raw materials are dyed, opened, blended and stuffed by wool loosing and dyeing processes; then, roving is prepared by carding and two wool line blending by a carding machine and the roving is spun into a single yarn by a spinning frame; after being automatic winding, the single yarn is doubling and then is twisted into semi-worsted double yarn; by the adoption of same longitude and latitude mode, the semi-worsted double yarn is woven into gray fabric on a weaving machine; the step gray fabric is put into water to wash for the first time, and then put into a scouring and milling combined machine to mill, the gray fabric after the milling is placed into a steel-wire napper to nap, and then, is set and dried after being brushed by a damping brushing machine, the dried gray fabric is lustered and sheared, and finally, the ultrathin semi-worsted nap up blazer fabric is obtained by decating. The ultrathin semi-worsted nap up blazer fabric and the preparation process thereof use semi-worsted spinning, are combined with a roving fabric nap up process and prepare the ultrathin semi-worsted fabric which is good in quality, soft, comfortable and warm-keeping.

Owner:LILANG CHINA

Black woolen worsted fabric and production method thereof

InactiveCN104032444AMeet the damageSo as not to damageFibre treatmentWoven fabricsTextile technologyColor effect

The invention relates to a production method of a black woolen worsted fabric. According to the production method of the black woolen worsted fabric, spinning materials are directly and sequentially processed under recombing, spinning, weaving and finishing without dying; the spinning materials comprises natural black wool fiber and can also comprise spun-dyed chemical fiber such as terylene, nylon, viscose and acrylic fiber, wherein the mass percentage of the natural black wool fiber in the spinning materials is larger than or equal to 30%; during the finishing process, fluoro three-proofing auxiliaries and silicon oil softener can be utilized for deep finishing. The invention also relates to the black woolen worsted fabric produced through the method and belongs to the technical field of wool textile. The production method of the black woolen worsted fabric can obtain good color effects without the dying process and have not damage to wool and is energy-saving, environmentally friendly and high in economic value; the black woolen worsted fabric produced through the method can maintain natural elasticity.

Owner:JIANGSU DANMAO TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com