Patents

Literature

385results about How to "Feel plump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

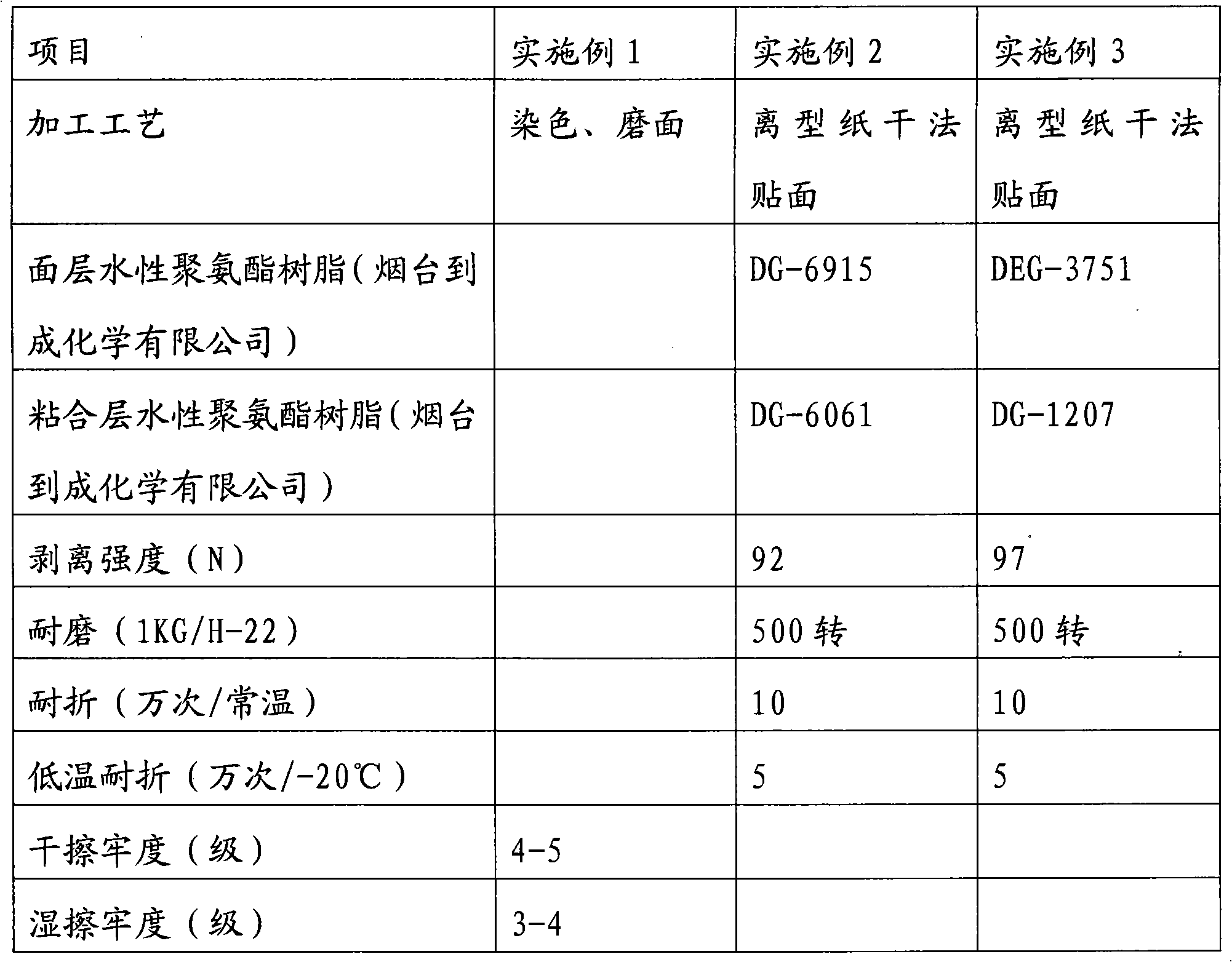

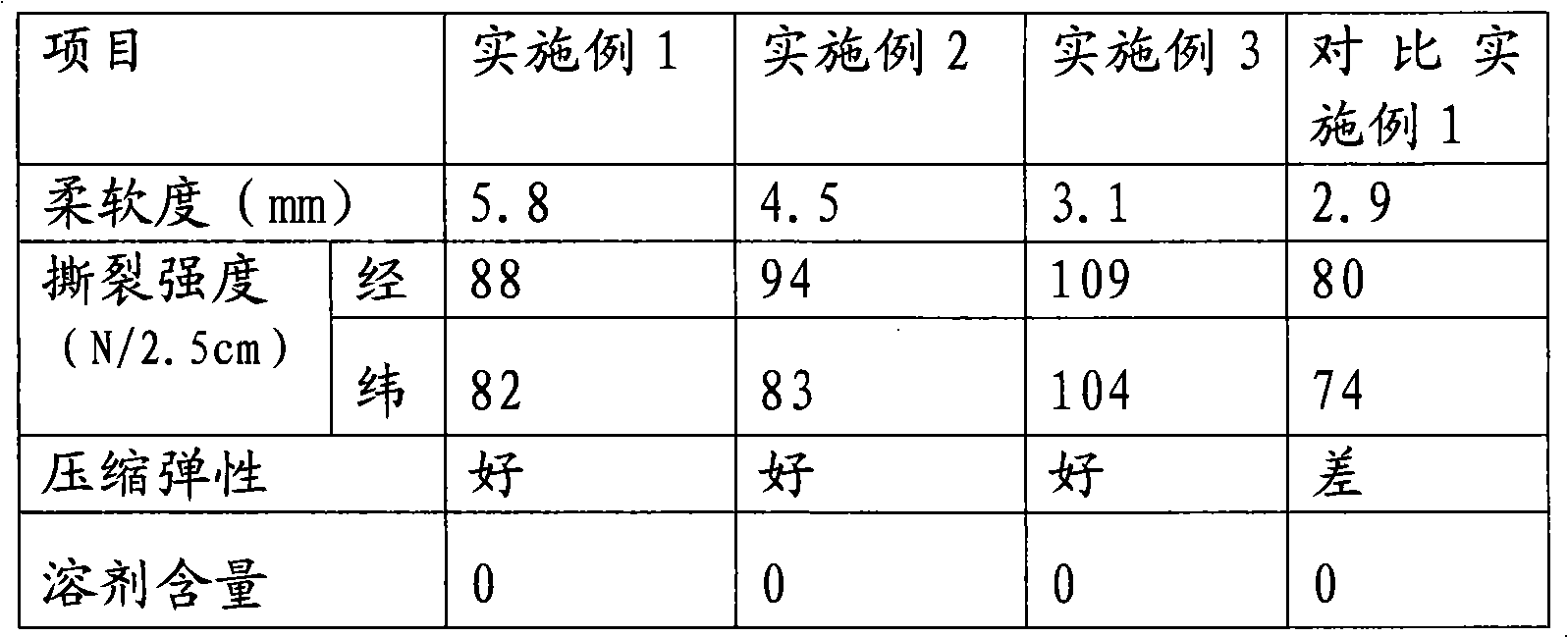

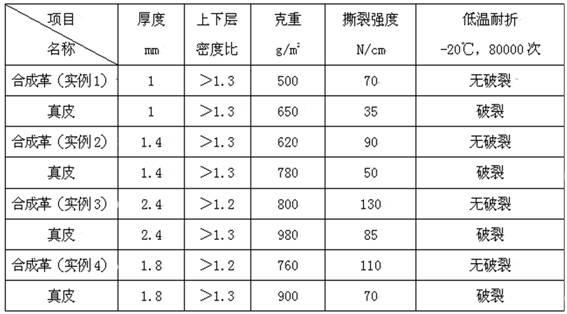

Aqueous polyurethane superfine fiber synthetic leather and preparation method thereof

The invention relates to aqueous polyurethane superfine fiber synthetic leather and a preparation method thereof. The preparation method comprises the following steps of: firstly, adding the following components according to parts by weight, i.e. 2-5 parts of foaming agents, 50-200 parts of water, 2-3 parts of foam stabilizers and 0-3 parts of waterborne colorants, into 100 parts of aqueous anionic polyurethane dipping sizing agents, and stirring the components and the sizing agents uniformly at high speed by using a blender so as to prepare a sizing agent; secondly, dipping non-woven fabricsin the sizing agent, scrapping the surface of the fabrics and keeping partial cells; thirdly, solidifying aqueous polyurethane on the dipped non-woven fabrics through aqueous coagulating liquid so asto form cells; fourthly, carrying out water scrubbing after aqueous polyurethane resin is completely solidified, and drying the aqueous polyurethane resin by an infrared drying oven so as to obtain base cloth; fifthly, treating the dried base cloth through an alkali reducing process; sixthly, treating the base cloth treated through the alkali reducing process through an postprocessing process; and seventhly, preparing the obtained base cloth into the synthetic leather. The aqueous polyurethane superfine fiber synthetic leather is prepared by the method.

Owner:HUADA CHEM GRP CO LTD

Foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU)

ActiveCN102409554AFeel plumpSoft touchSynthetic resin layered productsTextiles and paperManufacturing technologyMicrosphere

The invention provides a foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU). In the manufacturing technology, the WPU is taken as a main raw material, and a hollow microsphere foaming agent is taken as a foaming material; and the technology can be widely used for manufacturing synthetic leathers such as clothing leathers, luggage leathers, shoe upper leathers, sofa leathers, home interior trim leathers and the like. The content of volatile organic compounds (VOC) in the finished leather is lower than 2mg / kg (leather), and the air permeability and moisture penetrability are good, thus meeting the EU (European Union) requirements for the ecological synthetic leather; and in addition, the foaming synthetic leather has the advantages of moderate foaming multiplying power, uniform and compact foaming holes, bulky and firm hand feel as well as good comprehensive performance which is equivalent to or superior to that of a solvent-borne product. The foaming synthetic leather manufacturing technology based on the WPU provided by the invention has the beneficial effects that by adopting the WPU instead of the traditional solvent-borne PU, organic pollution is eliminated from a source, organic solvent resources are saved, the comprehensive energy consumption is lowered, the employment environment of laborers is improved, and the ecological grade of the synthetic leather and the international market competitiveness of the product are enhanced, thus achieving obvious innovativeness and remarkable social and economic benefits.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AUniform cell size and distributionImprove qualityLamination ancillary operationsSynthetic resin layered productsWoven fabricDimethylformamide

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

Chrome-free tannage producing technique for goat glove leather

The invention relates to a processing technique of leather, in particular to a chrome-free tannage manufacturing technique of goat glove leather, aims at solving the problem of heavy environment pollution caused by the chrome sewage in the prior art of chrome tannage. The processing technique of leather adopts a technical proposal that the chrome-free tannage manufacturing technique of goat glove leather comprises a plurality of successively steps as followings: softening, dipping in acid, organophosphor tanning, oxidation, stacking, sammying and extension, shaving, washing, degreasing, rinse, washing, retanning and stuffing, washing, and routine following chrome tanning technique. The processing technique of leather has the advantages of eliminating the environment pollution caused by the heavy metal chrome, reducing the cost of sewage treatment, producing environment-friendly goat glove leather with soft, plumpy, highly resilient, and flowing hand feeling, smooth grain, brilliant color, qualified formaldehyde content as ecological leather, over 88 DEG C shrinkage temperature, and completely same mechanical property as routine chrome tannage leather.

Owner:HAINING SHANGYUAN LEATHER

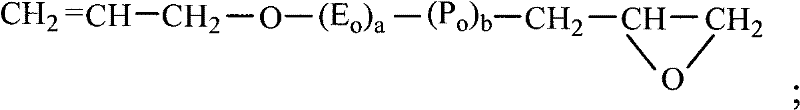

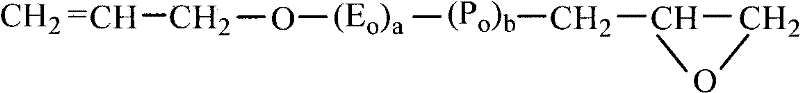

Preparation method for polysiloxanes-amidopolyether block copolymer

InactiveCN102199295ABroad encapsulationWide penetration abilityFibre treatmentPolyelectrolyteEmulsion

The invention discloses a preparation method for a polysiloxanes-amidopolyether block copolymer, comprising the steps of preparation of an intermediate of alpha, omega-hydrosiloxane, preparation of an intermediate of alpha, omega-polysiloxanes diepoxide, and preparation of the polysiloxanes-amidopolyether block copolymer. The polysiloxanes-amidopolyether block copolymer provided in the invention enables a textile finishing agent to be stable under condition of high temperature, a polyelectrolyte, a high pH value or a high shear force without breaking emulsion, sticking to a roller or a cylinder and producing oil marks, allows textiles finished to be returned for repairing, and is widely used in fields like chemical fiber, natural fiber and blended products thereof, etc.

Owner:HANGZHOU MEIGAO HUAYI CHEM

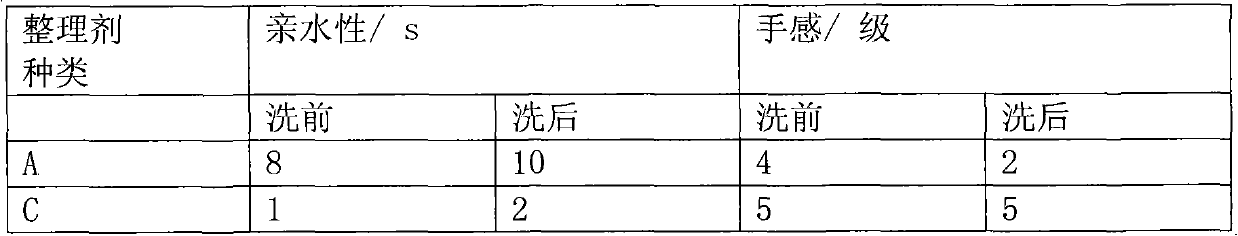

Preparation method of hydrophilic amino silicone oil

The invention discloses a preparation method of hydrophilic amino silicone oil. The invention is characterized in that the preparation method comprises the following steps: A. the preparation of low-hydrogen silicone oil: siloxane ring body, high-hydrogen silicone oil, blocking agent and acid are mixed for reaction and are cooled, and the pH is adjusted; B. the preparation of epoxy silicone oil: the prepared low-hydrogen silicone oil, alkenyl epoxy compound and catalyst are mixed for reaction and are cooled; and C. the preparation of hydrophilic amino silicone oil: the prepared epoxy silicone oil, organic amine and solvent are mixed for reaction, and the solvent is distilled. The bonding is firmer in the form of a chemical bond when the hydrophilic amino silicone oil prepared by the method reacts with the fabric, and the hydrophilic amino silicone oil is washable, has soft effect of the common amino silicone oil, no yellowing and good smoothness and antistatic property, and can be widely used in fabric finishing.

Owner:HUBEI COLOR ROOT TECH CO LTD

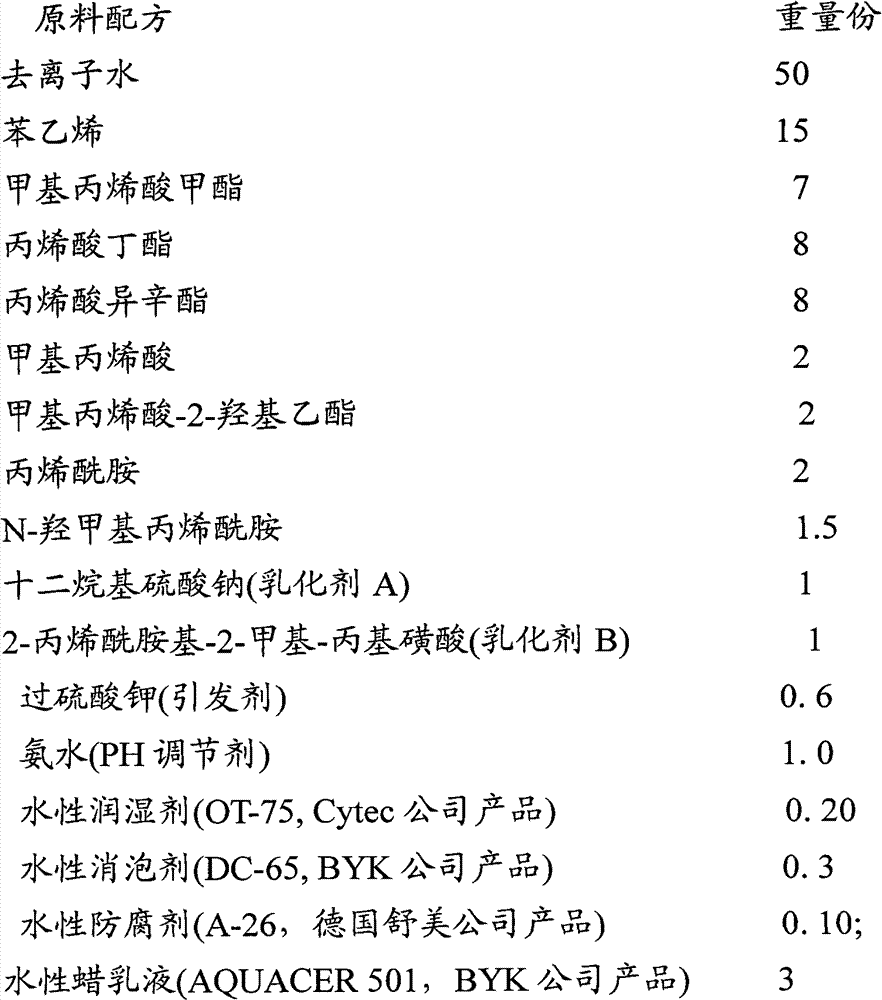

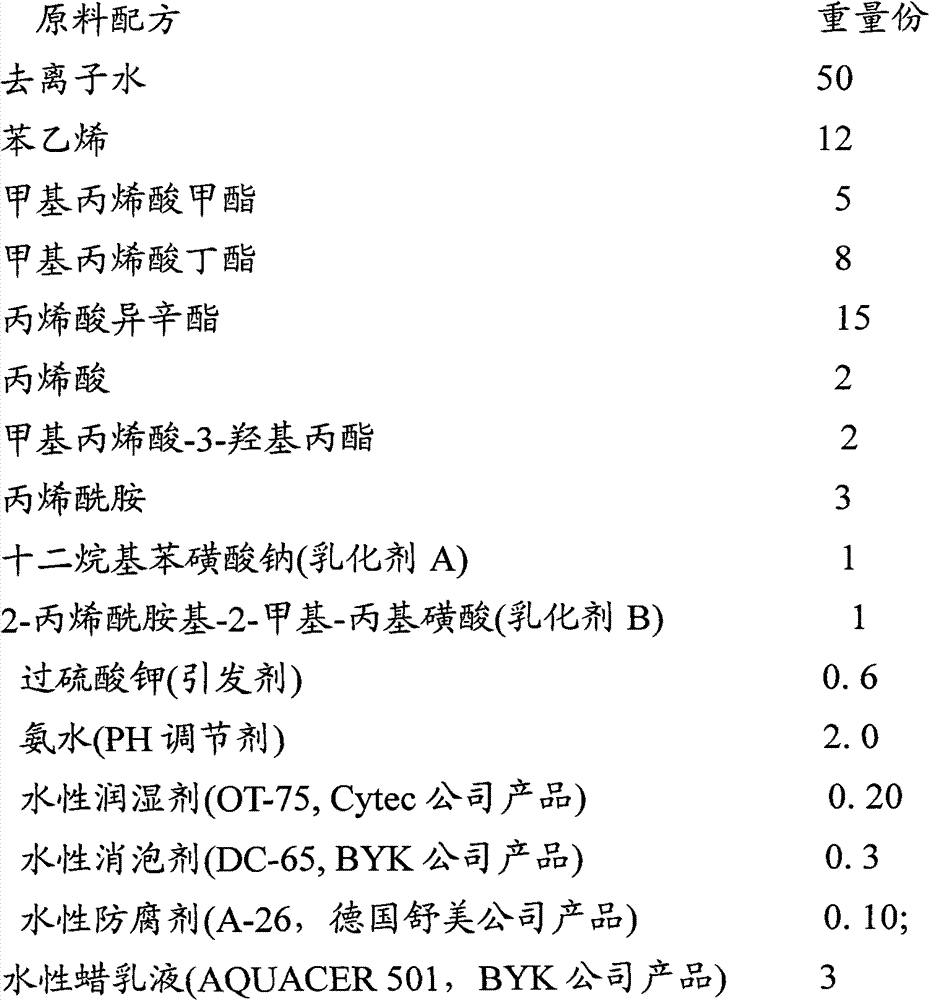

White-gasoline-resistant styrene-acrylic emulsion, white-gasoline-resistant emulsion gloss oil and preparation methods thereof

White-gasoline-resistant styrene-acrylic emulsion is characterized by comprising, by mass, 12-18% of styrene, 5-15% of methacrylic acid alkyl ester, 5-15% of acrylic acid alkyl ester, 1-5% of hydroxyalkyl ester, 1-5% of alkyl carboxylic acid, 1-5% of functional polymerizable monomer, 0.25-0.5% of initiators, 0.5-2.5% of emulsifiers, 40-60% of water, 1-2% of neutralizers and 1-5% of auxiliaries. Gloss oil prepared by the white-gasoline-resistant styrene-acrylic emulsion can be used for glossing common leatherette paper and applicable to glossy leather imitation treatment of various specialty paper such as the leatherette paper and iridescent paper. Resin liquid which is non-toxic, environment-friendly and economic is added with cosolvent, defoaming agents, wetting agents and wax emulsion to be coated on the paper for white-gasoline-resistant testing, and the paper can be wipe-resistant more than 20 times under the pressure of 1KG, resistant to bend, scratches, water and white gasoline, plump in hand feeling and smooth.

Owner:佛山市三水灏诚合成树脂有限公司

Silk afterfinishing compound softening agent and preparation method

The invention relates to a silk afterfinishing compound softening agent and a preparation method. The softening agent is nontoxic, nonirritating, very low in yellowing possibility, good in re-wettability, biodegradable, and completely harmless to an environment. The method comprises the steps that required water temperature is selected between 0 DEG C and 100 DEG C according to used different quaternization raw materials; 1-30% of ester quaternary ammonium salt is added to water, and stirred; and then 1-30% of hydrophilic amino silicone oil is added and stirred uniformly after ester quaternary ammonium salt is completely dissolved or dispersed in the water and forms a uniform white viscous emulsion. The softening agent has the advantages that 1, the softening agent adopts raw animal or plant synthetic chemicals as main components of the softening agent, and is completely nontoxic, nonirritating, very low in yellowing possibility, and good in re-wettability, and 2, the softening agent is biodegradable and completely harmless to the environment, and is an ideal silk fabric afterfinishing softening agent.

Owner:ZHEJIANG HSDP SILK TECH

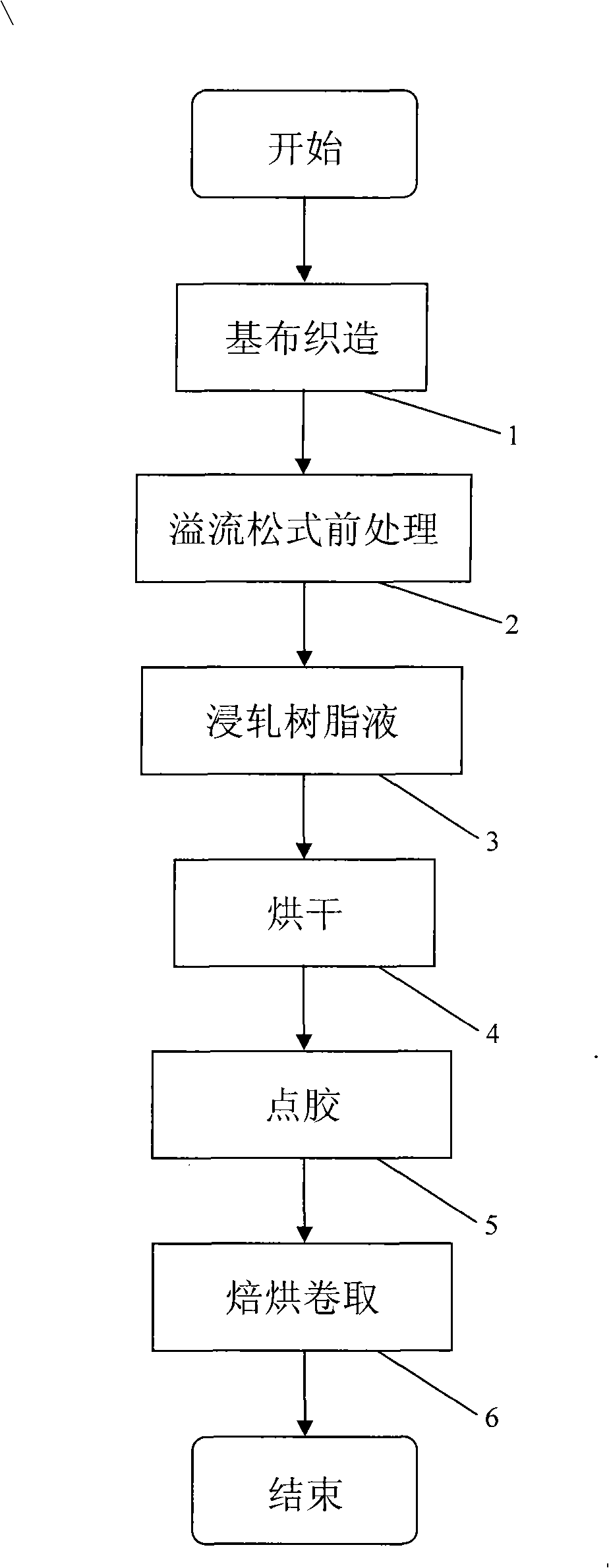

Manufacturing technique of crease-shedding uniforms lining

InactiveCN101288507AImprove deformation recovery performanceImproves wrinkle recoveryGarmentsVegetal fibresFiberPolyamide

The invention discloses a technique for manufacturing anti-wrinkle liner of suits. The technique comprises the processes of weaving base fabric, overflow and loose pre-treatment, immersing in resin liquid and rolling, drying, gluing, baking, coiling and so on. The technique adopts environment-friendly resin liquid with high quality for twice-immersing and twice-rolling treatment which causes the resin liquid to sufficiently permeate into fibers and to become uniformly cross-linking, leads the treated fabric to obtain good anti-wrinkle recoverability and solid hand feeling. Nylon polyamine hotmelt adhesive is used for double-dot coating, which is characterized by strong adhesion fastness, having good drapability after being bonded with the fabric and excellent anti-wrinkle property when in use. The lining cloth has soft hand feeling and good anti-wrinkle property. Suits made from the lining cloth have the advantages of fullness and being docile. The anti-wrinkle property and sizing property after washing are better than any other ordinary adhesive lining cloth. The lining cloth is mainly used for wash-and-wear suits and career wears.

Owner:严华荣

One-way wet-guide quick-drying real silk facing material

InactiveCN101270524ADistinct silk styleSpeed up moisture transferFilament/thread formingWoven fabricsMoisture absorptionEngineering

The invention relates to a unidirectional wicking fast-drying true silk fabric which is characterized in that the front surface of the fabric is two first or three first twill-weave; the back surface corresponding to the front surface is one second or one third twill-weave; the material of the front surface adopts silk with the specification of 15 to111dtex; the material of the back surface adopts ultrathin denier wicking fast-drying terylene DTY long thread with the single thread density of 0.2 to 0.8dtex; the section of the long thread is crisscross; the invention adopts a embedded weaving method for weaving and manufacture. The surface of the fabric obviously assumes the styles of true silk which has fleshy and soft hand feelings as well as excellent moisture absorption and ventilation properties. As the wicking fast-drying terylener is adopted as the back surface of the fabric, the excellent fast-drying property thereof can quicken the wicking speed of the true silk fiber on the front surface after absorbing moisture and simultaneously can not go so far to reveal the defects of hard hand feeling, easy pilling and generating static of the terylener.

Owner:SUZHOU HUACHOU TECH

Synthetic leather prepared from non-woven fabric and slurry and its production method

A synthetic leather is prepared from non-woven fabric and slurry. Said non-woven fabric is prepared from the fibres of small-area leather and chemical fibres. Said slurry is prepared from polyurethane resin, solvent, assistant, pigment and wooden powder. Its preparing process includes such steps as immersing non-woven fabric in slurry, rolling, scrapping, coagulating, washing, squeezing, baking, grinding, wet coating, solidifying, water washing, baking, and coating film or polishing. Its advantages are high quality and low cost.

Owner:徐银松

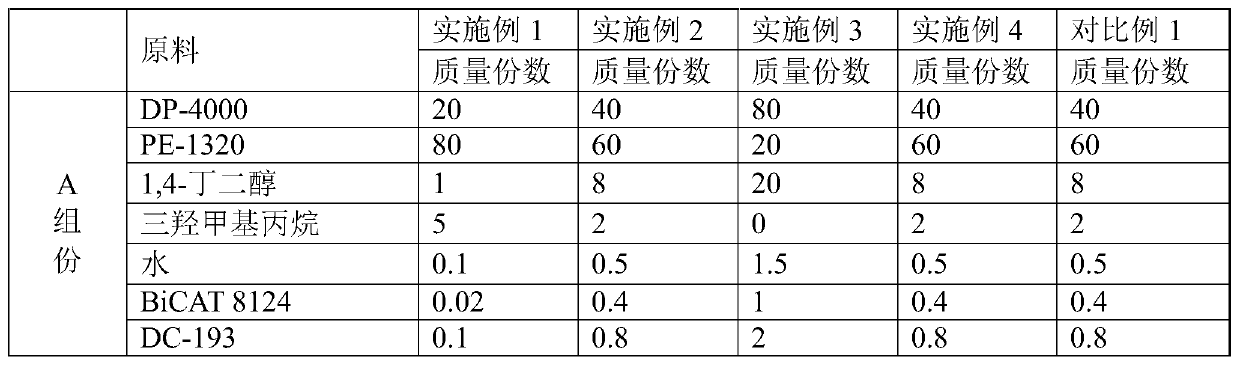

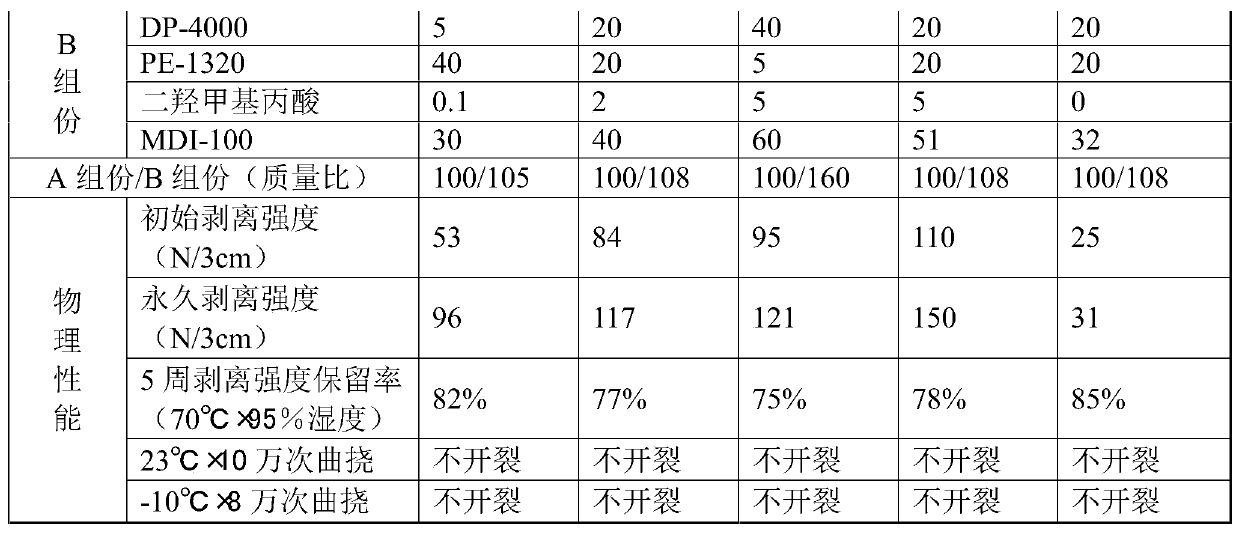

Solvent-free polyurethane resin for synthetic leather, preparation method thereof and application thereof in aqueous/solvent-free polyurethane synthetic leather

The invention provides a solvent-free polyurethane resin for synthetic leather, a preparation method thereof and an application thereof in aqueous / solvent-free polyurethane synthetic leather. The invention provides the solvent-free polyurethane resin for the synthetic leather, which is prepared by mixing and reacting a component A and a component B according to a mass ratio of 1:2-2:1; wherein thecomponent A comprises polyhydric alcohol, a small molecular chain extender, a cross-linking agent, water, a catalyst and a foam stabilizer; the component B comprises polyhydric alcohol, isocyanate and dimethylolpropionic acid. The solvent-free polyurethane resin for the synthetic leather does not contain any organic solvent, has low energy consumption and high production efficiency, and when thesolvent-free polyurethane resin is used for aqueous / solvent-free polyurethane synthetic leather, the obtained aqueous / solvent-free polyurethane synthetic leather product is environment-friendly, softand plump in hand feeling and high in peeling strength.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Softening agent

The invention discloses a softening agent which comprises the following components in parts by weight: 40-60 parts of organosilicone, 10-20 parts of Turkey red oil, 16-20 parts of magnesium chloride, 8-12 parts of polyvinyl alcohol, 20-40 parts of chinlon oil, 10-20 parts of glycerol, 4-8 parts of calcium hydrophosphate, 2-4 parts of tartaric acid, 6-8 parts of glacial acetic acid and 2-4 parts of triethavolamine. The softening agent provided by the invention is convenient to use and produce, and low in price, and can enable real silk, cotton wool, knits, poplin and the like to be full in feeling, soft, smooth, elastic and wear-resistant after clothes are washed or tidied.

Owner:秦燕飞

Method for dyeing and finishing polyester and nylon composite filament corduroy

InactiveCN102605584ADamage intensityHigh strengthSolvent-treatmentFibre typesDisperse dyeNylon material

The invention discloses a method for dyeing and finishing polyester and nylon composite filament corduroy, which comprises the following processes: checking a gray fabric; sewing the gray fabric; pre-shrinking in full width; splitting; pre-shaping; dyeing; soft finishing shaping; and packaging an end product, wherein a full width water washing machine is used for performing the process of pre-shrinking in full width; the process of splitting is performed according to a thermal treatment method and an alkali treatment method; during the process of pre-shaping, the temperature is 195 DEG C-200 DEG C and an assembly line turning speed is 30m / min-35m / min; dye liquor in the process of dyeing is aqueous solution of disperse dye or mixed aqueous solution of disperse dye and acidic dye; and the process of the soft finishing shaping is as follows: the corduroy passes through a material chute containing 10-15g / l softening agent aqueous solution, and then the corduroy is dried and shaped at high temperature, wherein the drying temperature is 165 DEG C-175 DEG C, the assembly line turning speed is 30m / min-35m / min and the softening agent is an organic silicon softening agent. The end product prepared according to the method provided by the invention has the advantages of high strength, full and mild velvet feeling, excellent shape-keeping property, convenience in washing and finishing, uniform dyeing effect, and capability of obtaining specific gigging effects such as frostwork or polyester peach skin, and the like.

Owner:杭州天宇印染有限公司

High-fire-retardancy aminoresin nano-complex-function tanning agent

The invention discloses a tanning agent with high flame-resistance amino-resin nano-composite function, which is prepared by the method as follows: firstly, melamine, dicyandiamide, formaldehyde and acidic components are used as raw material to prepare flame-resistance amino-resin prepolymer; secondly, montmorillonite or organic montmorillonite are modified by tetrakis hydroxymethyl phosphonium and silane coupling agents to obtain modified montmorillonite or modified organic montmorillonite; finally, the prepared flame-resistance amino-resin prepolymer and the obtained modified montmorillonite or the modified organic montmorillonite are processed through in-situ intercalation compounding reaction. The tanning agent not only has better tanning performance and retanning filling performance, but also brings good flame-resistance and washable migration resistance to leather goods, and the addition quantity is less, and the flame retardant efficiency is high.

Owner:SICHUAN UNIV

Water-saving superfine fiber synthetic leather base cloth impregnation method based on cationic water-based polyurethane

ActiveCN105178055AFreeze fastKey technology to solve rapid solidificationFibre typesAqueous sodium hydroxideSolvent based

The invention discloses a water-saving superfine fiber synthetic leather base cloth impregnation method based on cationic water-based polyurethane. The impregnation method includes the steps that 100 parts of the water-based alkali-hydrolysis-resisting cationic polyurethane with the solid content ranging from 20% to 50%, 0 part to 50 parts of water, 5 parts to 10 parts of color paste and 1 part to 3 parts of thickening agents are evenly mixed, and water-based impregnation slurry is prepared; superfine fiber non-woven fabric is immersed into the water-based polyurethane slurry to be impregnated, and finally placed into a 10%-15% sodium hydroxide aqueous solution to be subjected to synchronous solidification and alkali-weight-reduction treatment, wherein the solidification and weight-reduction bath temperature ranges from 95 DEG C to 100 DEG C, the solidification and weight-reduction time ranges from 30 min to 60 min, under the alkali condition, the cationic polyurethane is solidified in superfine fiber synthetic leather and forms a foam structure, and a sea component PET is dissolved under the effect of hot alkali to achieve weight reduction; the base cloth obtained after alkali weight reduction is washed, dried and buffed, and finally superfine fiber synthetic leather is obtained through dry-method surface making and after-treatment. According to the impregnation method, the water-based polyurethane replaces solvent type resin to be used for impregnating the superfine fiber synthetic leather base cloth, and ecological environmental protection is achieved; the foam structure is formed through the characteristic that the cationic polyurethane is rapidly solidified when encountering alkali, and the foam feeling and the fullness of the finished leather are improved; the solidification and alkali-weight-reduction process is completed in one bath, and therefore water consumption, energy consumption and technologies are reduced.

Owner:SICHUAN UNIV

Kuralon fiber finely woven fabric and preparation method thereof

A kuralon fiber finely woven fabric is characterized by comprising the following components by weight percent: 70-80% of wool or wool and other fibers and 20-30% of kuralon fiber; and the preparation method comprises the following steps: 1) selecting raw materials; 2) recombing; 3) spinning; 4) weaving; and 5) dyeing and finishing. The kuralon fiber finely woven fabric produced by the method of the invention has bulky and soft hand feeling and the hollowness is up to 20-30%. The selection of kuralon is reasonable, the mixing method ensures that the kuralon fiber finely woven fabric can be smoothly spun, the spinnability is good, the fiber is easy to draw, the evenness is good, the fault is less, the weaving efficiency is high, and the characteristics that the fabric is hollow and the hand feeling is bulky and soft, of the kuralon fiber finely woven fabric can be better embodied after finishing.

Owner:JIANGSU DANMAO TEXTILE

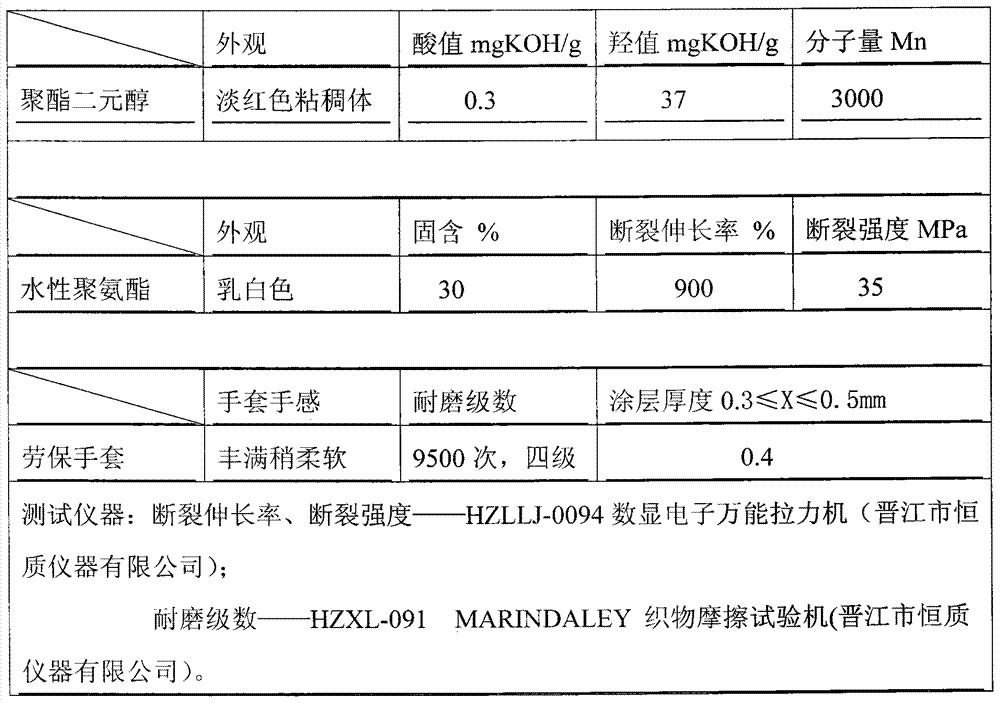

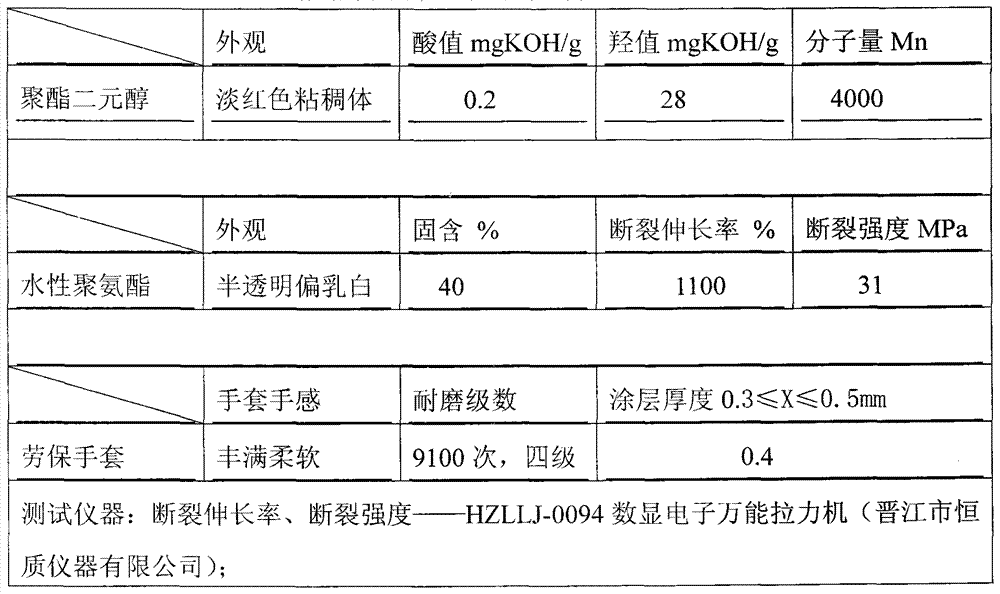

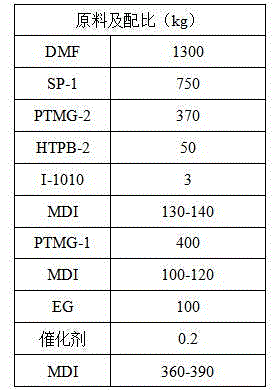

Super-elastic wear-resisting waterborne polyurethane resin and composition and application of super-elastic wear-resisting waterborne polyurethane resin and composition

InactiveCN104497258ASolve the hard feelingSolving Elasticity ProblemsAbrasion resistant fibresPolyesterSlurry

The invention discloses super-elastic wear-resisting waterborne polyurethane resin which is prepared by polymerizing polyester glycol and polyisocyanates. The invention further discloses a preparation method of the resin. By adopting the super-elastic wear-resisting waterborne polyurethane resin disclosed by the invention, slurry can be prepared to coat the surfaces of knitted gloves, so that the problems that in the prior art, knitted gloves made by using a conventional method are hard in hand feeling, poor in resilience, low in wearing resistance, and the like.

Owner:ANHUI LINGDA CHEM TECH

Waterborne PU high smooth wax resin for synthetic leather

The invention discloses a waterborne PU high smooth wax resin for synthetic leather and the resin comprises the following raw materials by weight percent: 30-40% of waterborne silicon-fluorine resin,20-30% of waterborne polyurethane, 10-30% of water, 0.2-0.8% of waterborne wax emulsion, 1-3% of organic silicone oil smoothing agent, 0.5-1% of organic silicone flatting agent, 2-5% of organic silicone defoamer and 0.5-2% of waterborne polyurethane thickener. The waterborne PU high smooth wax resin for synthetic leather provided by the invention uses water as solvent instead of toxic solvents such as dimethyl formamide, butanone and the like and has the advantage of noninflammability, safety, environmental protection, cost-saving and the like. The finished product prepared from the waterbornePU high smooth wax resin for synthetic leather provided by the invention has full hand feeling, high luster and high luminance, extremely smooth waxy feeling, delicate texture and good air permeability; and the prepared synthetic leather has good comprehensive effect in hand feeling, smoothness, water resistance, waxy feeling and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

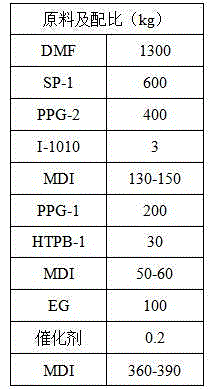

Super-soft high-elasticity hydrolysis resistance high-stripping wet polyurethane resin and preparation method thereof

The invention discloses super-soft high-elasticity hydrolysis resistance high-stripping wet polyurethane resin and a preparation method of the super-soft high-elasticity hydrolysis resistance high-stripping wet polyurethane resin. The super-soft high-elasticity hydrolysis resistance high-stripping wet polyurethane resin is composed of isocyanate, a polyhydric alcohol compound, a chain extender, antioxygen, reaction terminating agent methyl alcohol and catalyst by weight. The additive amount is 0.001%-0.05% of the mass of the polyhydric alcohol compound. The number-average molecular weight of the polyhydric alcohol compound is 1000-3000. The polyhydric alcohol compound is composed of polyester polyol, polyether polyol and polyene polyhydric alcohol, wherein the mass ratio of the polyester polyol, the polyether polyol and the polyene polyhydric alcohol is 1:0.8-1.2:0.1-0.3. The total molar ratio of NCO in the isocyanate to the hydroxyl in the polyhydric alcohol compound and the chain extender is 0.9-1:1. The molar ratio of the polyhydric alcohol compound and the chain extender is 1:1.3-1.7. The super-soft high-elasticity hydrolysis resistance high-stripping wet polyurethane resin greatly solves the problem that soft resin can not achieve high elasticity and high stripping strength at the same time, is durable in use and has market competitiveness.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

Environment-friendly breathable TPU (Thermoplastic polyurethanes) synthetic leather and preparation method thereof

InactiveCN105966027AReduce pollutionMethod route shortLamination ancillary operationsSynthetic resin layered productsPolyurethane adhesiveAdditive ingredient

The invention discloses an environment-friendly breathable TPU synthetic leather and a preparation method thereof. The environment-friendly breathable TPU synthetic leather comprises a decorative surface layer, a TPU surface layer, an adhesive layer and a base cloth layer. The decorative surface layer is coated on The treatment agent on the upper surface of the TPU surface layer is generated, and the TPU surface layer is combined with the base cloth layer through the adhesive layer. The components and parts by weight of the TPU surface layer are: 30 to 95 parts by weight of TPU particles; 3 to 95 parts by weight of the flame retardant 25 parts by weight; 2-15 parts by weight of pigment; 0-5 parts by weight of light stabilizer; 0-5 parts by weight of anti-scratch agent; 0-20 parts by weight of filler. The adhesive is a water-based polyurethane adhesive; the surface treatment agent is a water-based polyurethane surface treatment agent. Adopting the preparation method of extrusion casting, shaping first, then compounding, and negative pressure embossing, the products are environmentally friendly, non-toxic, low-odor, low-VOC, clear in structure, soft in hand, scratch-resistant, wear-resistant, hydrolysis-resistant, genuine leather Strong features.

Owner:常州三聚塑胶科技有限公司

Solvent-free polyurethane resin used for sofa leather middle foaming layer and preparation method thereof

The invention discloses solvent-free polyurethane resin used for a sofa leather middle foaming layer and a preparation method thereof. The solvent-free polyurethane resin is formed by mixing componentA and component B according to the mass ratio of (1: 2) to (2: 1). The solvent-free polyurethane resin prepared in the invention does not contain any solvent, synthetic leather prepared as a middle layer is green, environmentally-friendly, soft and plump in hand feel, the physical performance can reach one hundred thousand times of bending at normal temperature without cracking, eighty thousand times of bending at the cold-resistant temperature of -10 DEG C without cracking, the peeling strength is more than 50 N / 3cm, and the retention rate of the peeling strength for 5 to 7 weeks under the constant temperature and humidity conditions of 70 DEG C and 95% humidity can reach 75%.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

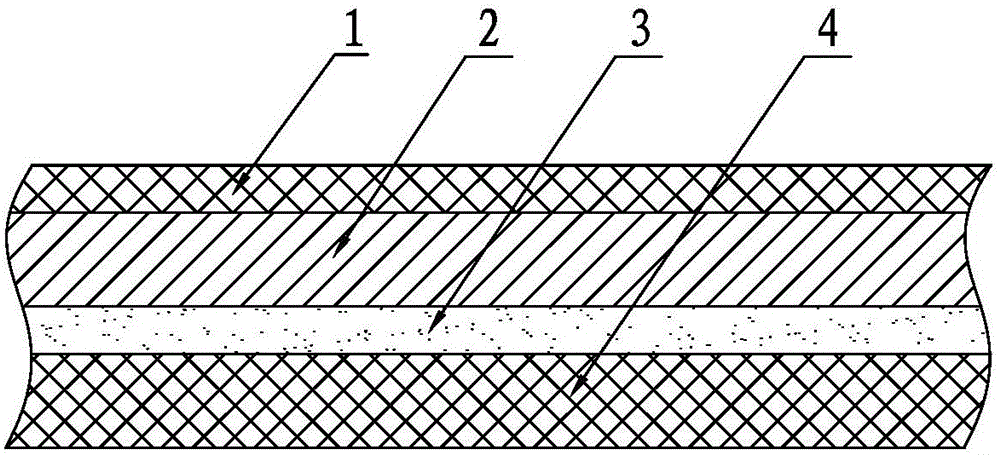

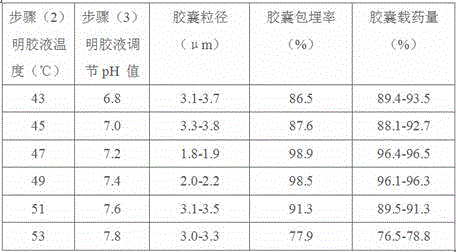

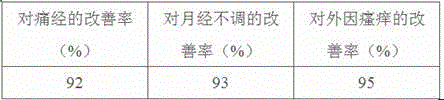

Antibacterial plant cellulose fiber and preparation method thereof and medical waterproof non-woven fabric prepared from fiber

InactiveCN106835343AImprove antibacterial propertiesUniform particle sizeConjugated cellulose/protein artificial filamentsWet spinning methodsCellulose fiberNonwoven fabric

The invention provides an antibacterial plant cellulose fiber which contains a natural antibacterial plant extract microcapsule. The invention further provides a preparation method of the antibacterial plant cellulose fiber. The method comprises a step of preparing natural antibacterial plant extract emulsifying dispersion liquid, wherein the step of preparing the natural antibacterial plant extract emulsifying dispersion liquid comprises the processes of mixing 5-8 parts of a natural antibacterial plant extract and 10-15 parts of a peach gum solution, heating the mixture to 52-60 DEG C and stirring and emulsifying, wherein the stirring speed is 200-300r / min; and emulsifying and dissolving disperse particles to 1-2 microns. Any organic antibacterial agent or inorganic antibacterial agent is not added, so that the prepared antibacterial plant cellulose fiber is safe and environmentally friendly, can be naturally degraded and has good social significance; and the prepared antibacterial fiber is more lasting in antibacterial effect by adopting a special microcapsule slow-release technology.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

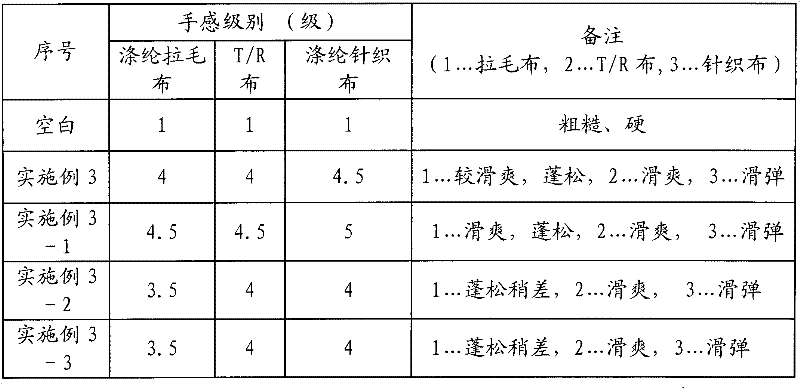

Silicone acrylic emulsion and application of silicone acrylic emulsion as textile finishing agent

The invention discloses silicone acrylic emulsion and the application of the silicone acrylic emulsion as a textile finishing agent. The silicone acrylic emulsion is manufactured by the following raw materials in parts by weight: 24-30 parts of butyl acrylate, 6-14 parts of methyl methacrylate, 0.15-1.0 part of initiator, 42.9-67.7 parts of deionized water, 1.2-6 parts of compound emulsifier, 0.3-0.6 part of pH buffer agent, 1-5 parts of vinyltriethoxysilane and 0.1-0.3 part of ammonium hydroxide. The silicone acrylic emulsion of the invention has the advantages that the composition is simple, the consumption of organosilicone monomer is low, the hydrolyzation of siloxane can be efficiently reduced through the matching of the silicone acrylic emulsion and seed emulsion, the polymerization process and the finally obtained emulsion are stable, and the emulsion is high in solid content, low in viscosity and convenient to use; the emulsion is used as the textile finishing agent so as to enable the textile to gain better weight increment and anti-wrinkle performance under the condition of keeping whiteness and intensity, no methyl aldehyde is realized during finishing, preservation and use, and the emulsion has the characteristics of remarkable effect, environmental protection and low cost.

Owner:SUZHOU UNIV

Production method of worsted shell fabric containing polyolefin elastic fibers

InactiveCN103898645ALittle change in elasticityReduce disadvantagesBiochemical fibre treatmentYarnPolyesterPolymer science

The invention discloses a production method of worsted shell fabric containing polyolefin elastic fibers. The shell fabric is formed by spinning wool fibers, cashmere fibers, bamboo charcoal polyester fibers, superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers, and anti-pilling treatment, enzyme treatment and softening treatment are respectively conducted on the wool fibers and the cashmere fibers; the wool fibers, the cashmere fibers, the bamboo charcoal polyester fibers, the superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers are spun into the shell fabric according to the weight ratio of 55-75 : 12-18 : 18-28 : 12-15 : 5-8, and eventually aftertreatment is conducted on the shell fabric through a water-soluble polyurethane wool anti-shrinking agent. The production method has the advantages that damage to wool fiber products can be greatly reduced, the pilling phenomenon is reduced, the shell fabric made of the wool fibers, the cashmere fibers, the bamboo charcoal polyester fibers, the superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers as major raw materials is softer, the felting shrinking percentage is greatly reduced, and the quality of the shell fabric is better.

Owner:汤丽娟

Method for producing water-based polyurethane synthetic leather

The invention relates to a method for manufacturing water-based polyurethane synthetic leather. The designed technological process comprises the steps of preparing base fabric, humidifying and arranging the base fabric, coating water-based sizing agent, acid-releasing, solidifying, forming, washing, drying and sizing. The method has the advantages that no solvent is added, the organic contamination is thoroughly eliminated from the source, the potential safety hazards are eliminated, the working environment of workers is improved, and green and environment protective cleaning production is achieved indeed; the performances of a product is close to or superior to those of a solvent type product in appearance, structure, hand feeling and physical property, and the product is the best substitute for the solvent type product as well as a mainstream product of synthetic leather field development in the future.

Owner:HUADA CHEM GRP CO LTD

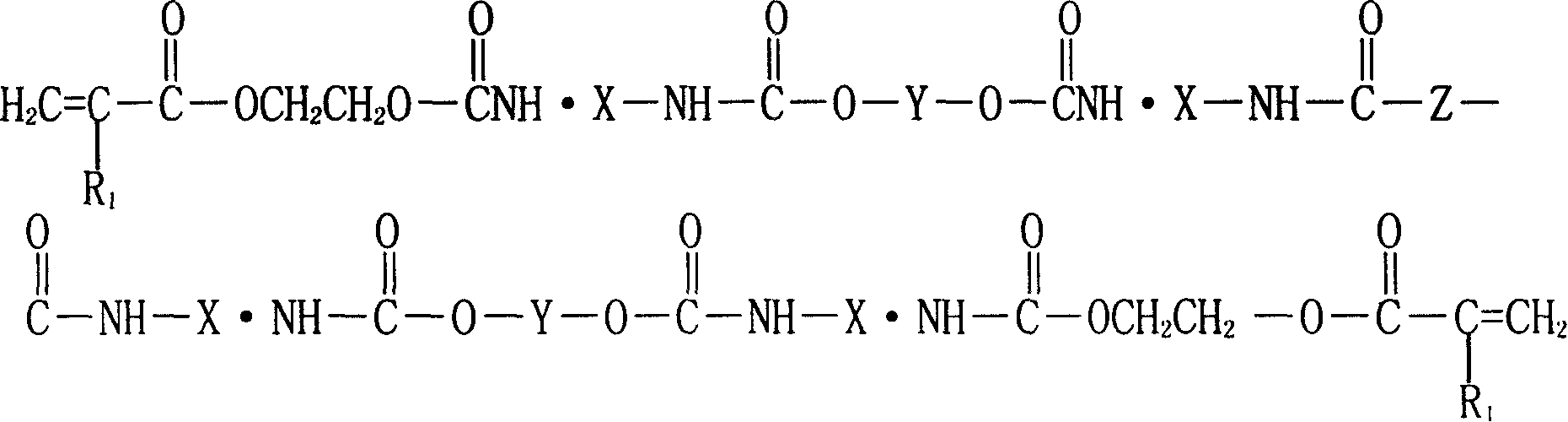

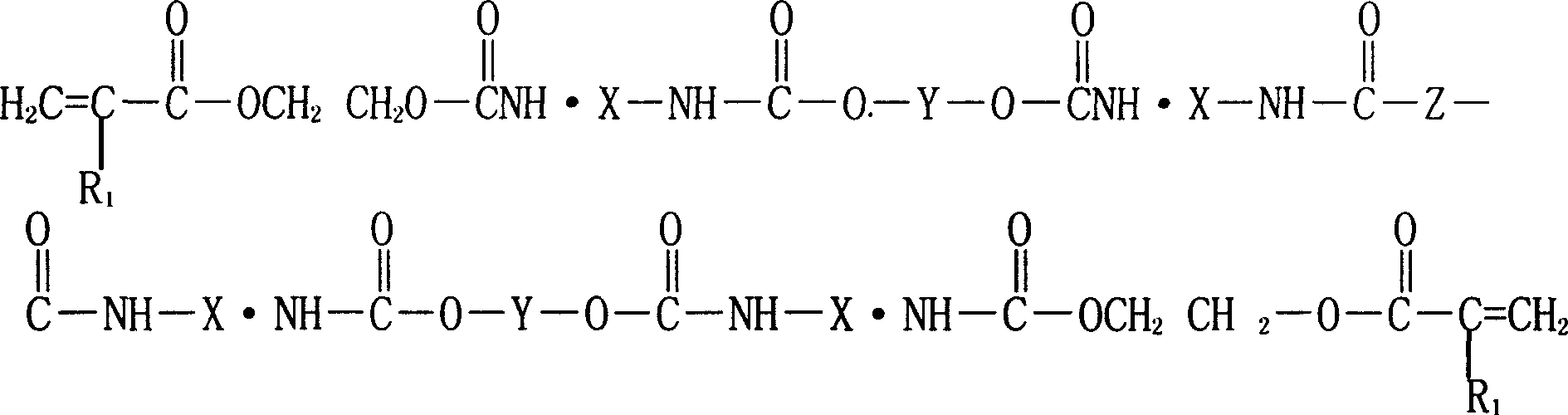

Ultraviolet light solidified water born paint in use for leather or leatheroid

InactiveCN1696226AImprove performanceGood low temperature toughnessLiquid surface applicatorsPolyurea/polyurethane coatingsUltraviolet lightsUrethane acrylate

An ultraviolet solidified water paint for leather and artificial leather contains proportionally aqueous aliphatic or aromatic polyurethane acrylate, aquous acrylate, deionized water and optical trigger.

Owner:湖南亚大新材料科技股份有限公司

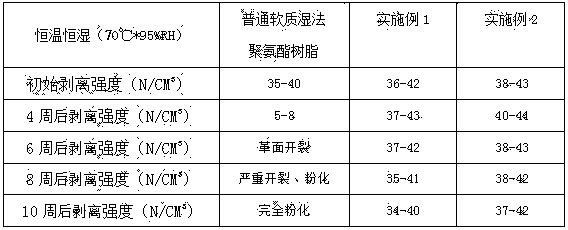

Polyurethane resin for hydrolysis-resistant sofa leather and preparation method thereof

ActiveCN104163909AGood flexibilityImprove constant temperature and humidity performancePolymer sciencePolyol

The invention discloses a polyurethane resin for hydrolysis-resistant sofa leather and a preparation method thereof. The polyurethane resin is prepared from diisocyanate, a polyether-polycarbon polyalcohol mixture, a chain extender, a catalyst, assistants, a solvent and a terminator. The preparation method comprises the following steps: carrying out prepolymerization reaction on the polyether-polycarbon polyalcohol mixture and part of diisocyanate, and adding a small molecule dibasic alcohol-diamine mixture chain extender to carry out chain extension reaction; and finally, adding the terminator and assistants to finish the reaction, so that the viscosity of the resin is controlled within the standard range. The polyurethane resin has the advantages of soft feeling, plumpness and favorable elasticity, and the peel strength is still higher than 90% after the polyurethane resin is under the conditions of constant temperature and humidity (70 DEG C*95% RH) for ten weeks.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

Water-based mechanical microcellular foaming paint and application process thereof in synthetic leather

InactiveCN102757718AFeel plumpGood hygroscopicity and air permeabilityFibre treatmentPolyurea/polyurethane coatingsChemistryFiber

The invention discloses a water-based mechanical microcellular foaming paint which comprises the following components in percentage by mass: 10-95% of water-based polyurethane resin, 0.01-5% of foaming agent, 1-40% of pigment, 0-10% of packing, 0-5% of assistant and the balance of deionized water. The invention also discloses an application process of the water-based mechanical microcellular foaming paint in synthetic leather, which comprises the following steps: well stirring and dispersing the water-based polyurethane resin, the packing, the assistant and the foaming agent, and spreading the slurry on release paper on the premise of mechanically and uniformly stirring to prepare superfine fiber synthetic leather or spreading the slurry on synthetic leather to serve as a coating. The water-based mechanical microcellular foaming paint provided by the invention has the advantages that production raw materials are environment-friendly materials which are harmless to the environment, no three wastes are generated in the slurry preparation and production processes, the requirement of the current production process is met, and the economic and environment benefits are remarkable.

Owner:NANTONG HONGTU MATERIAL TECH

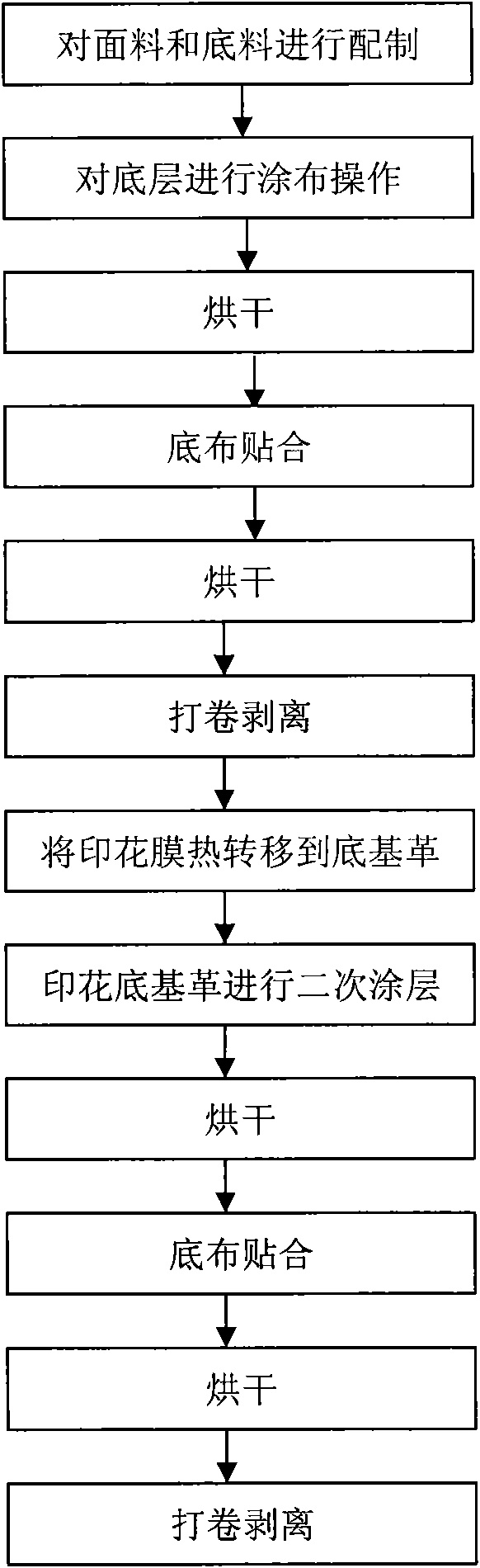

Novel PU printing waterproof and anti-crease fabric and preparation method thereof

InactiveCN101660277AImprove the three-dimensional effectRemove tensionSynthetic resin layered productsDyeing processDisperse dyeAlcohol

The invention discloses a novel PU printing waterproof and anti-crease new fabric, which comprises three layers: the first layer is PU surface layer mainly comprising PU polyurethane; the second layeris printing dyes; the third layer is a PU surface layer mainly comprising PU polyurethane. The printing dyes in the second layer are ink disperse dyes made of disperse dyes and water-soluble carrier,or ink disperse dyes made of the disperse dyes and alcohol-soluble carrier, or ink disperse dyes made of the disperse dyes and oil-soluble resin. The invention also discloses a method for preparing the novel PU printing waterproof and anti-crease fabric, comprising the following steps: firstly, preparing a shell fabric and a backing material; secondly, carrying out coating operation; thirdly, performing the backing lamination; fourthly, drying, rolling and stripping; fifthly, thermally transferring a printing film to base leather; and sixthly, performing the secondary coating on the printingbase leather. The novel PU printing waterproof, anti-crease fabric has advantages of terrific tensile strength and hydrostatic pressure, and is durable in use, fastness to washing, colorfast; and thepreparation method is easy to operate.

Owner:仪征新天地织物面料实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com