Solvent-free polyurethane resin for synthetic leather, preparation method thereof and application thereof in aqueous/solvent-free polyurethane synthetic leather

A solvent-free polyurethane and synthetic leather technology, used in textiles and papermaking, etc., can solve the problem of low water-based/solvent-free peel strength, and achieve the effect of enhancing production operation tolerance, soft hand feeling, and improving initial peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

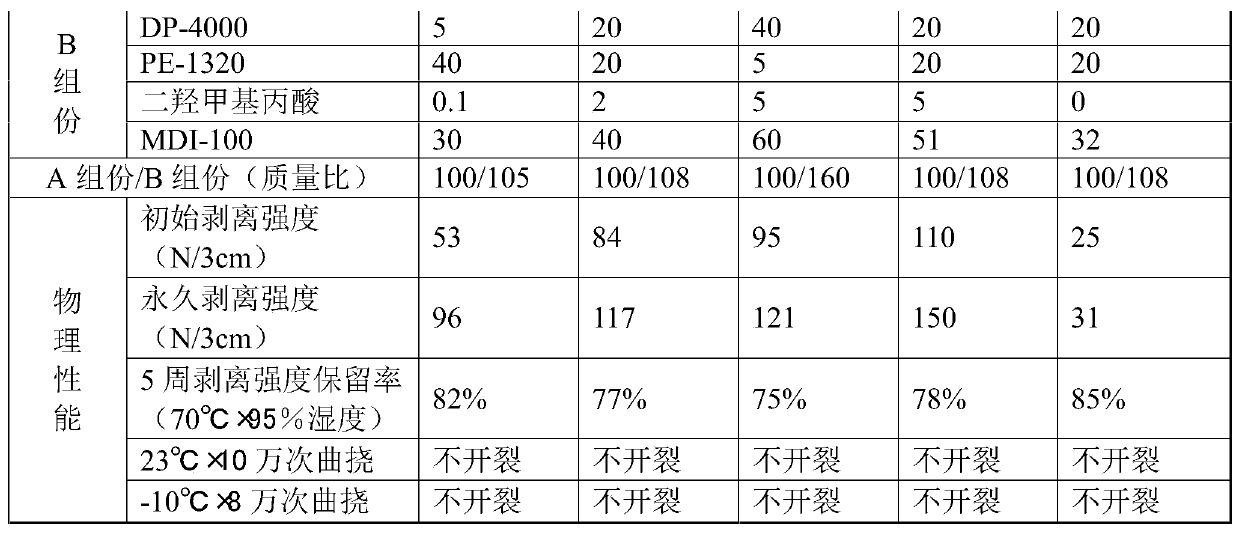

[0033] (3) Preparation of water-based / solvent-free synthetic leather:

[0034] Coat the KTC716 carboxylic acid water-based resin of Hefei Water-based Ketian Material Co., Ltd. on the release paper, and dry it at 130°C for 2 minutes to obtain the surface layer; cast component A and component B at a low pressure according to a certain mass ratio Fully mix in the machine to obtain solvent-free polyurethane resin, pour and coat on the water-based surface layer, then enter the 110°C oven for pre-reaction for 60 seconds, after the pre-reaction is completed, attach the base fabric, and then continue to react at 100-150°C for 7 minutes , to make it cross-linked and solidified; after curing and forming, the release paper is peeled off and rolled up to obtain high-stripping water-based / solvent-free synthetic leather.

[0035] Test the peel strength (that is, the initial peel strength), and the prepared water-based / solvent-free synthetic leather is aged at 70°C for 24 hours to test the p...

Embodiment 1

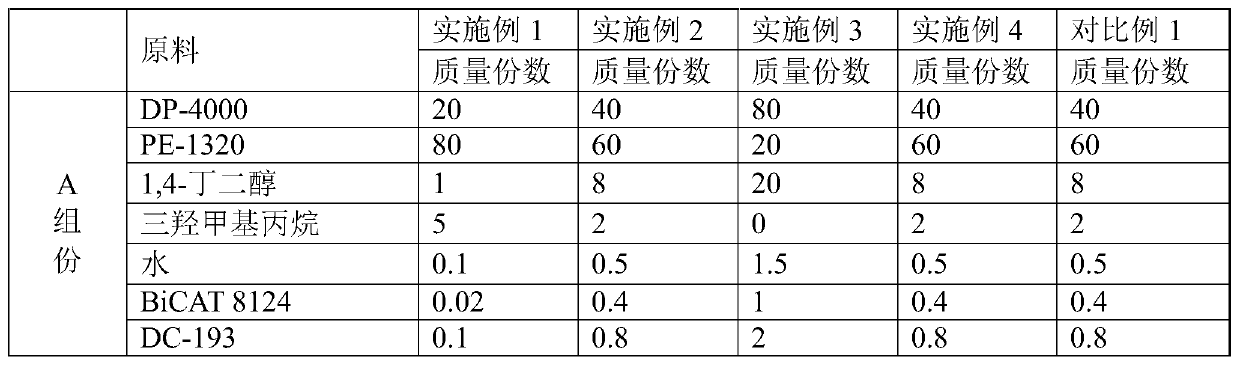

[0046] (1) Preparation of component A:

[0047] Dehydrate DP-4000 and PE-1320 at 90-110°C and -0.08MPa~-0.1MPa for 3-5h for later use; add 20 parts of DP-4000 and 80 parts of PE-1320 after dehydration into the reactor, Adjust and keep the temperature at 40-60°C, then add 1 part of 1,4-butanediol, 5 parts of trimethylolpropane, 0.1 part of water, 0.02 part of BiCAT 8124, 0.1 part of DC-193, and stir for 4-6 hours , to obtain component A.

[0048] (2) Preparation of component B:

[0049] Put 30 parts of MDI-100 into the reaction kettle and stir to mix evenly, then add 5 parts of dehydrated DP-4000, 40 parts of PE-1320, 0.1 part of dimethylol propionic acid, heat up to 70-80°C, and stir to react 4-6h, component B is obtained.

[0050] (3) Preparation of water-based / solvent-free synthetic leather:

[0051] Coat the KTC716 carboxylic acid water-based resin of Hefei Water-based Ketian Material Co., Ltd. on the release paper, and dry it at 130°C for 2 minutes to form a surface la...

Embodiment 2

[0054] (1) Preparation of component A:

[0055] Dehydrate DP-4000 and PE-1320 at 90-110°C and -0.08MPa~-0.1MPa for 3-5 hours for later use; add 40 parts of DP-4000 and 60 parts of PE-1320 after dehydration into the reactor, Adjust and keep the temperature at 40-60°C, then add 8 parts of 1,4-butanediol, 2 parts of trimethylolpropane, 0.5 parts of water, 0.4 parts of BiCAT 8124, 0.8 parts of DC-193, and stir for 4-6 hours , to obtain component A.

[0056] (2) Preparation of component B:

[0057] Put 40 parts of MDI-100 into the reaction kettle and stir to mix evenly, then add 20 parts of dehydrated DP-4000, 20 parts of PE-1320, 2 parts of dimethylol propionic acid, heat up to 70-80°C, and stir to react 4-6h, component B is obtained.

[0058] (3) Preparation of water-based / solvent-free synthetic leather:

[0059] Coat the KTC716 carboxylic acid water-based resin of Hefei Water-based Ketian Material Co., Ltd. on the release paper, and dry it at 130°C for 2 minutes to form a su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com