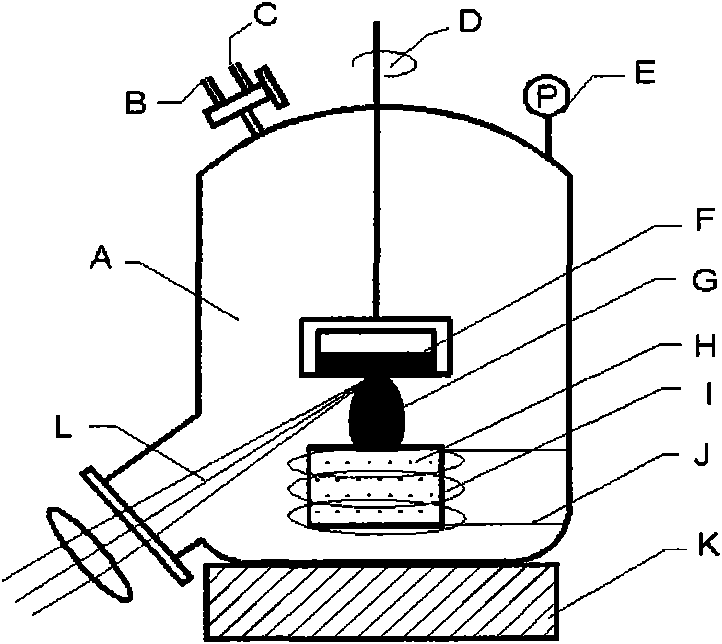

Method for preparing supported nanometer gold catalyst by laser deposition

A laser deposition and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of low carbon monoxide oxidation activity and non-green catalyst preparation process , complex preparation process and other issues, to achieve the effect of great implementation value, important social and economic benefits, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

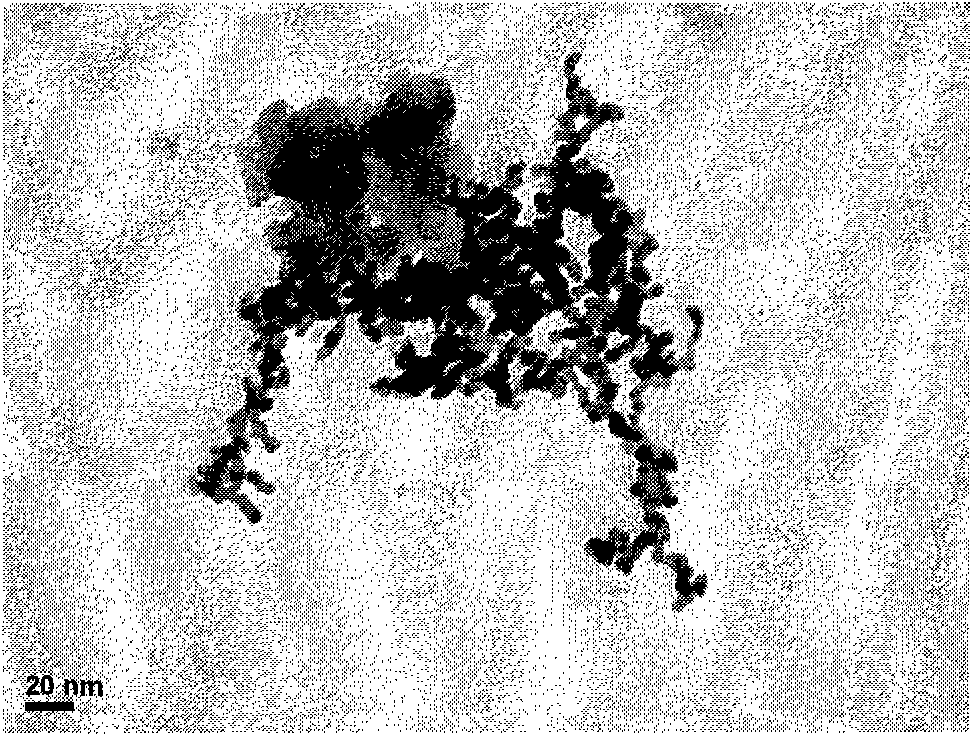

Embodiment 1

[0032] Alumina-supported gold nanoparticles prepared by laser deposition. Alumina was placed directly on the bottom of the laser deposition cell and the support was heated to 25 °C. First replace the air in the deposition tank with Ar, then evacuate to 80Pa, and start magnetic stirring to make the alumina flow. The metal Au is processed into a disc with a thickness of 1 mm and a diameter of 10 mm, which is placed in the center of the deposition pool. Under the condition of vacuum 80Pa, the pulsed laser is focused on the surface of the Au sheet, the laser voltage is 250V, and the focus point is moved to excite the Au atoms to form an atomic beam, which is sputtered to the surroundings and uniformly deposited on the surface of the flowing alumina. The deposition time is controlled as 30min, obtain alumina supported metal Au catalyst, its transmission electron microscope (TEM) is shown in figure 2 , Au nanoparticles with an average diameter of 9 nm. As analyzed by plasma emis...

Embodiment 2

[0034] Alumina supported gold prepared by laser deposition method. Alumina is placed directly on the bottom of the laser deposition cell and the support is heated to 300 °C. First replace the air in the deposition tank with Ar, then evacuate to 80Pa, and start magnetic stirring to make the alumina flow. The metal Au is processed into a disc with a thickness of 1 mm and a diameter of 10 mm, which is placed in the center of the deposition pool. Under the condition of a vacuum of 120Pa, the pulsed laser is focused on the surface of the Au sheet, the laser voltage is 250V, and the focus point is moved to excite the Au atoms into atomic beams, which are sputtered to the surroundings and uniformly deposited on the surface of the flowing alumina. The deposition time is 30min, obtain aluminum oxide supported metal Au, its transmission electron microscope (TEM) is shown in image 3 , showing that the average diameter of Au nanoparticles is 9 nm, and the loading of Au is 0.15% accordi...

Embodiment 3

[0036]Alumina supported gold prepared by laser deposition method. Alumina is placed directly on the bottom of the laser deposition cell and the support is heated to 600°C. First replace the air in the deposition tank with Ar, then evacuate to 80Pa, and start magnetic stirring to make the alumina flow. The metal Au is processed into a disc with a thickness of 1 mm and a diameter of 10 mm, which is placed in the center of the deposition pool. Under the condition of vacuum 80Pa, the pulsed laser is focused on the surface of the Au sheet, the laser voltage is 250V, and the focus point is moved to excite the Au atoms to form an atomic beam, which is sputtered to the surroundings and uniformly deposited on the surface of the flowing alumina. The deposition time is 30min. , to obtain alumina-loaded metal Au, whose transmission electron microscope (TEM) is shown in Figure 4 , showing that the average diameter of Au nanoparticles is 13nm, and the loading of Au is 0.18% according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com