Patents

Literature

6919 results about "Hydrogenation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation, chemical reaction between molecular hydrogen and an element or compound, ordinarily in the presence of a catalyst. The reaction may be one in which hydrogen simply adds to a double or triple bond connecting two atoms in the structure of the molecule or one in which the addition of hydrogen results in...

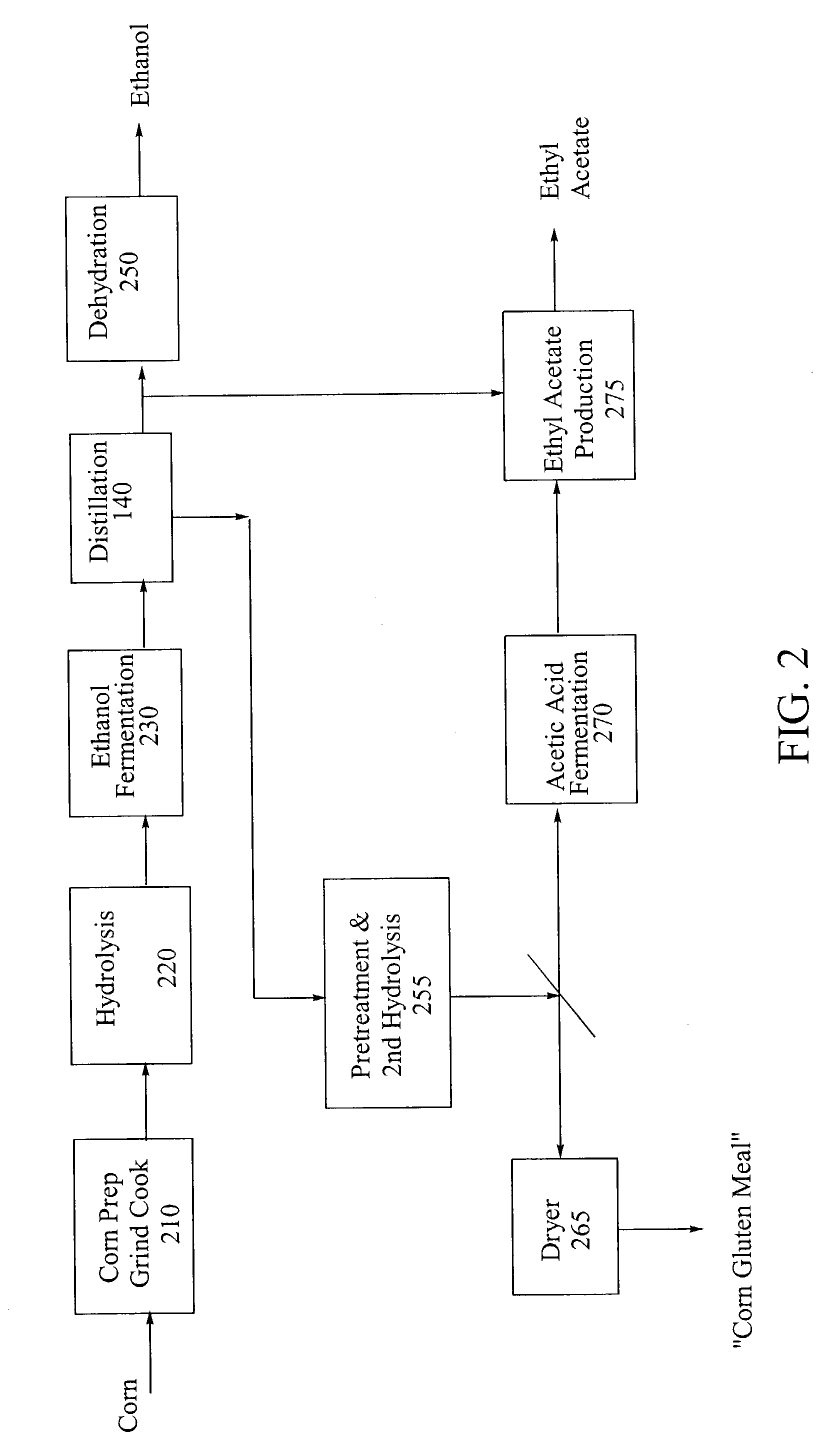

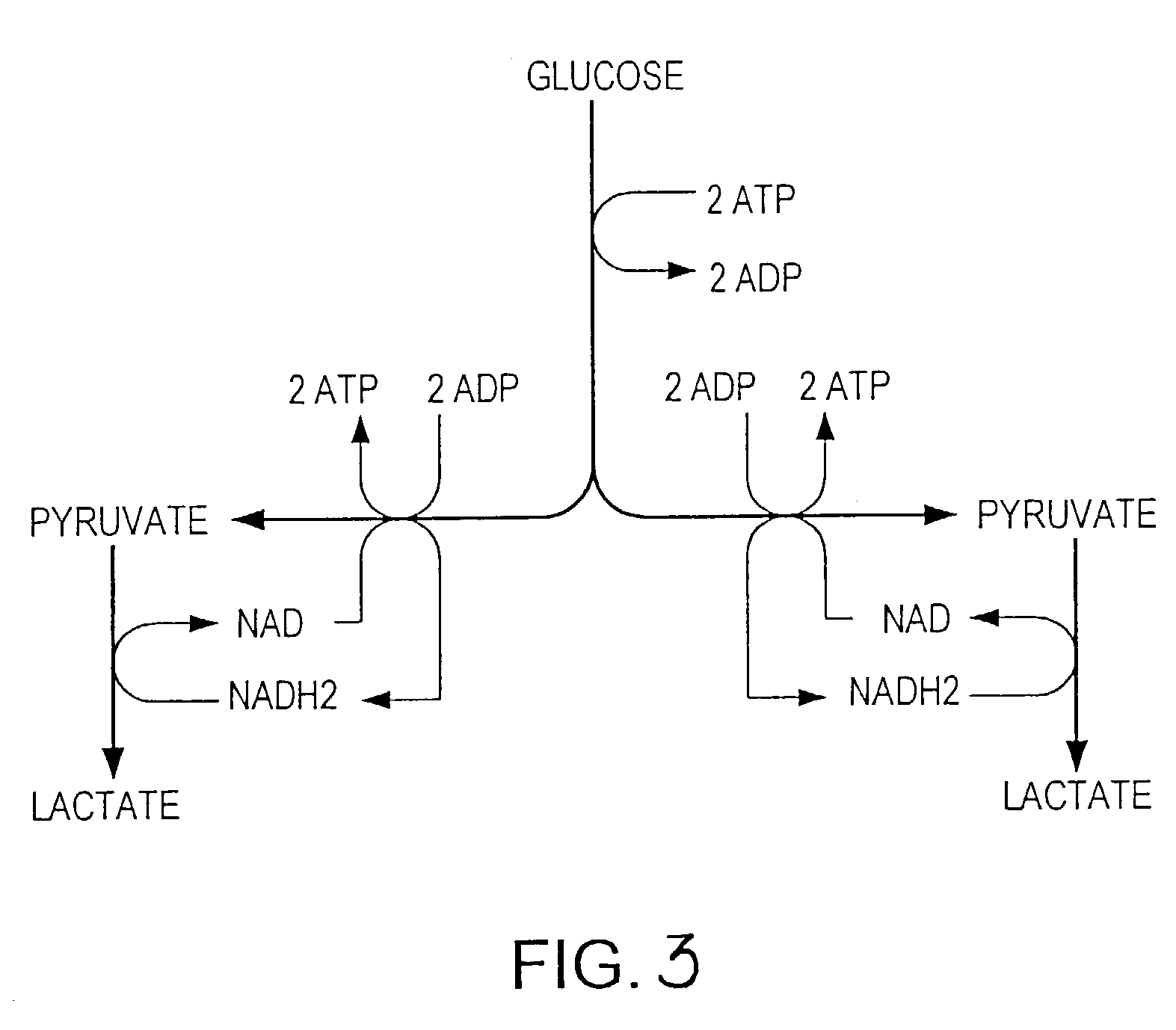

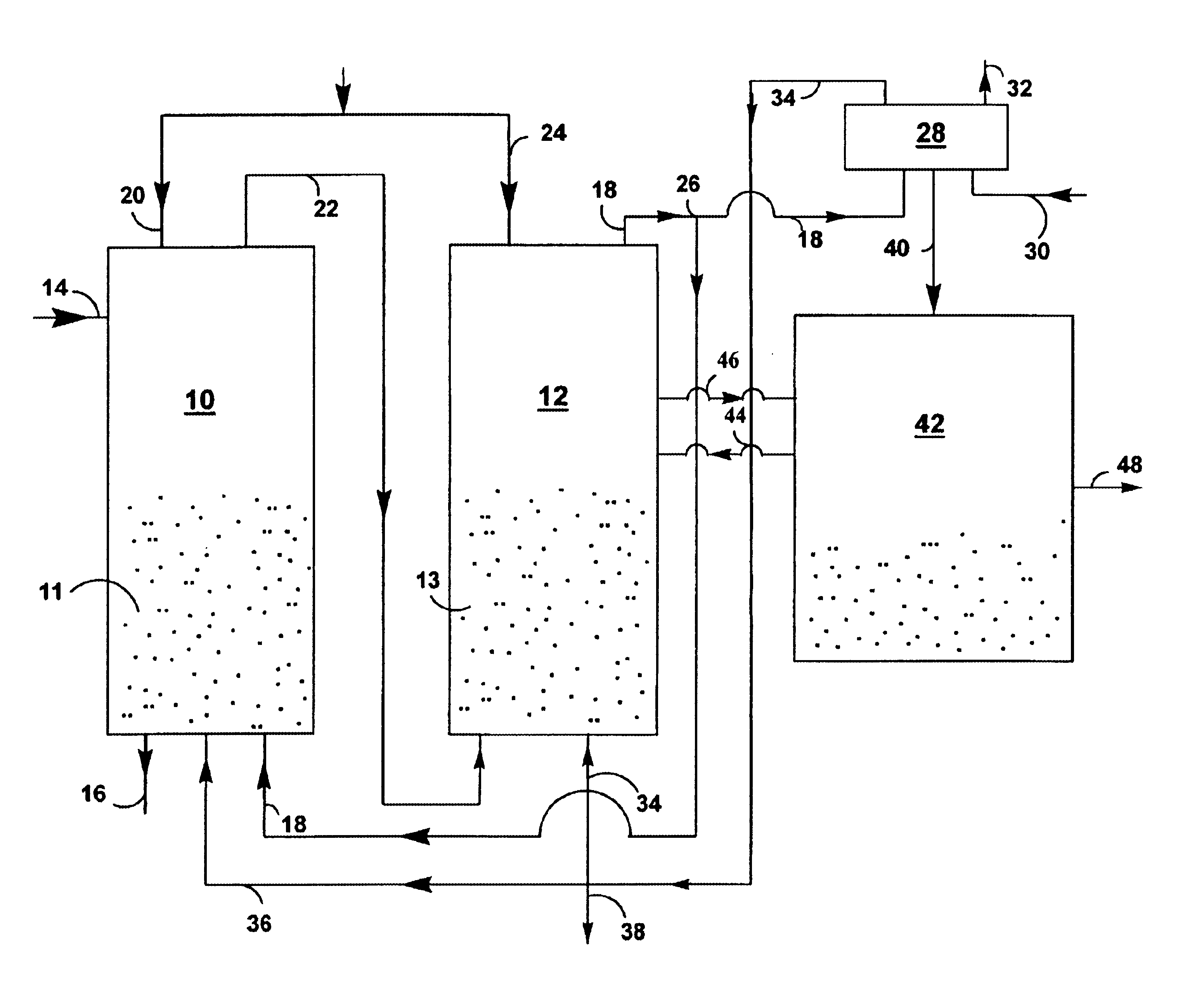

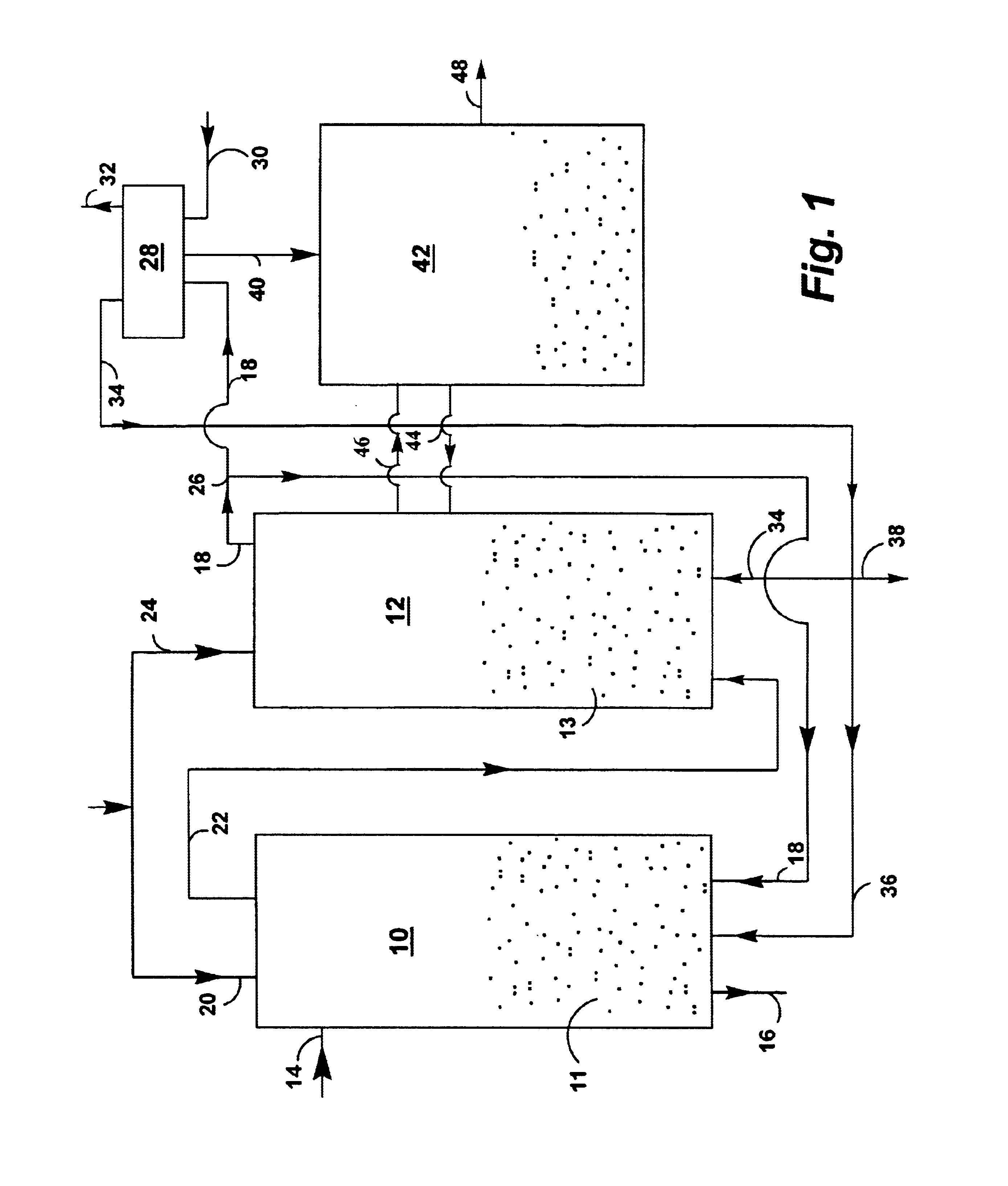

Process for producing ethanol

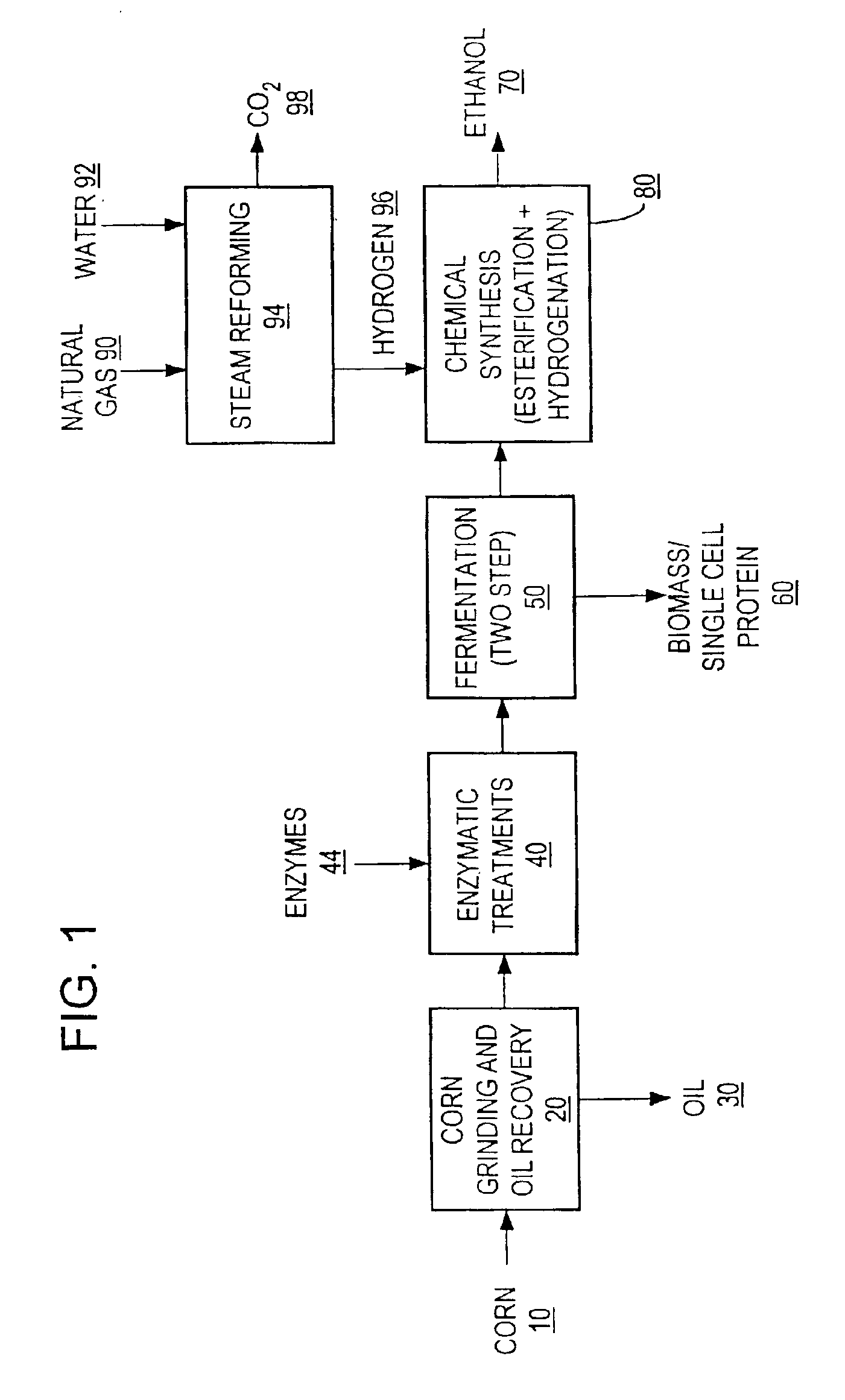

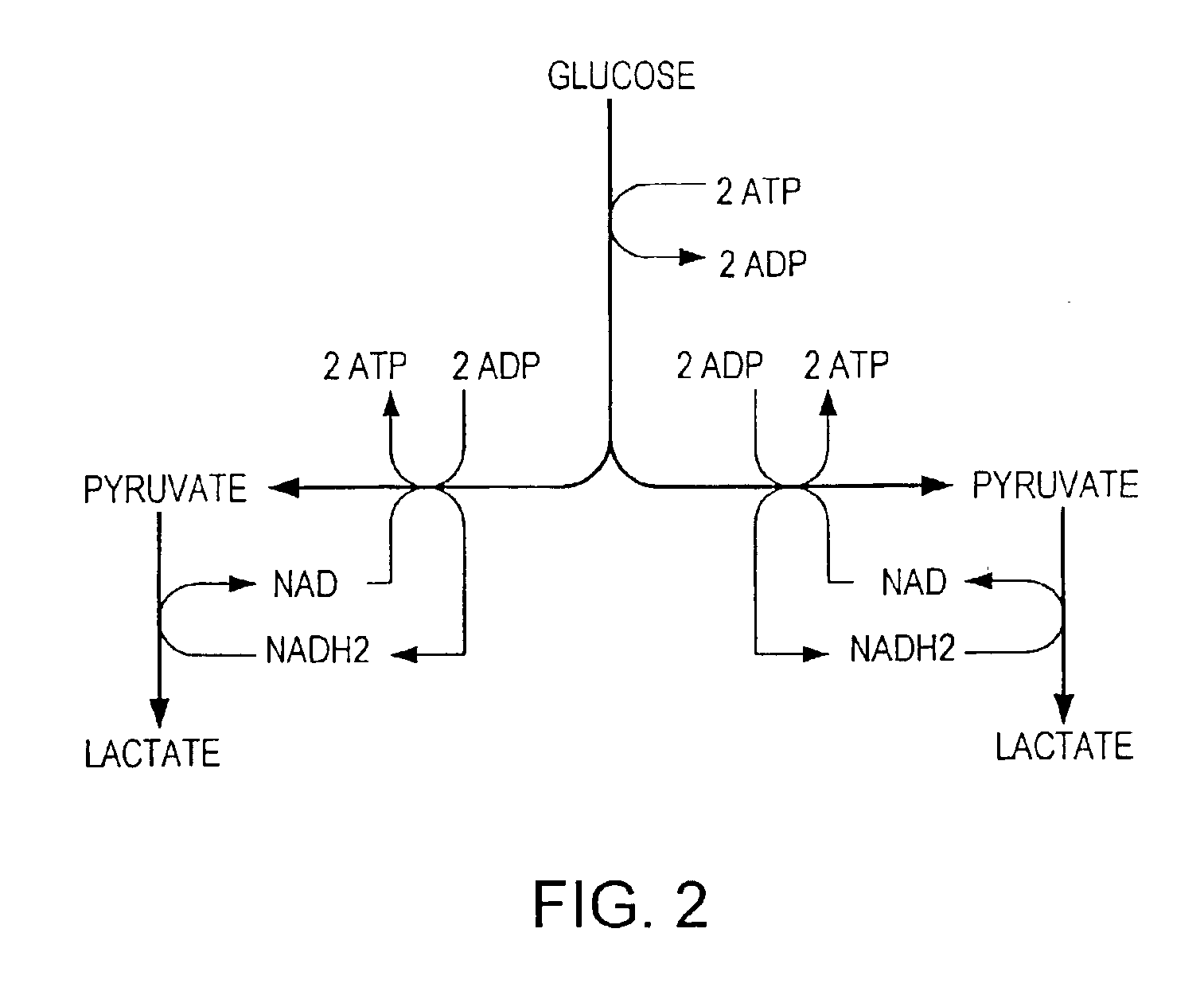

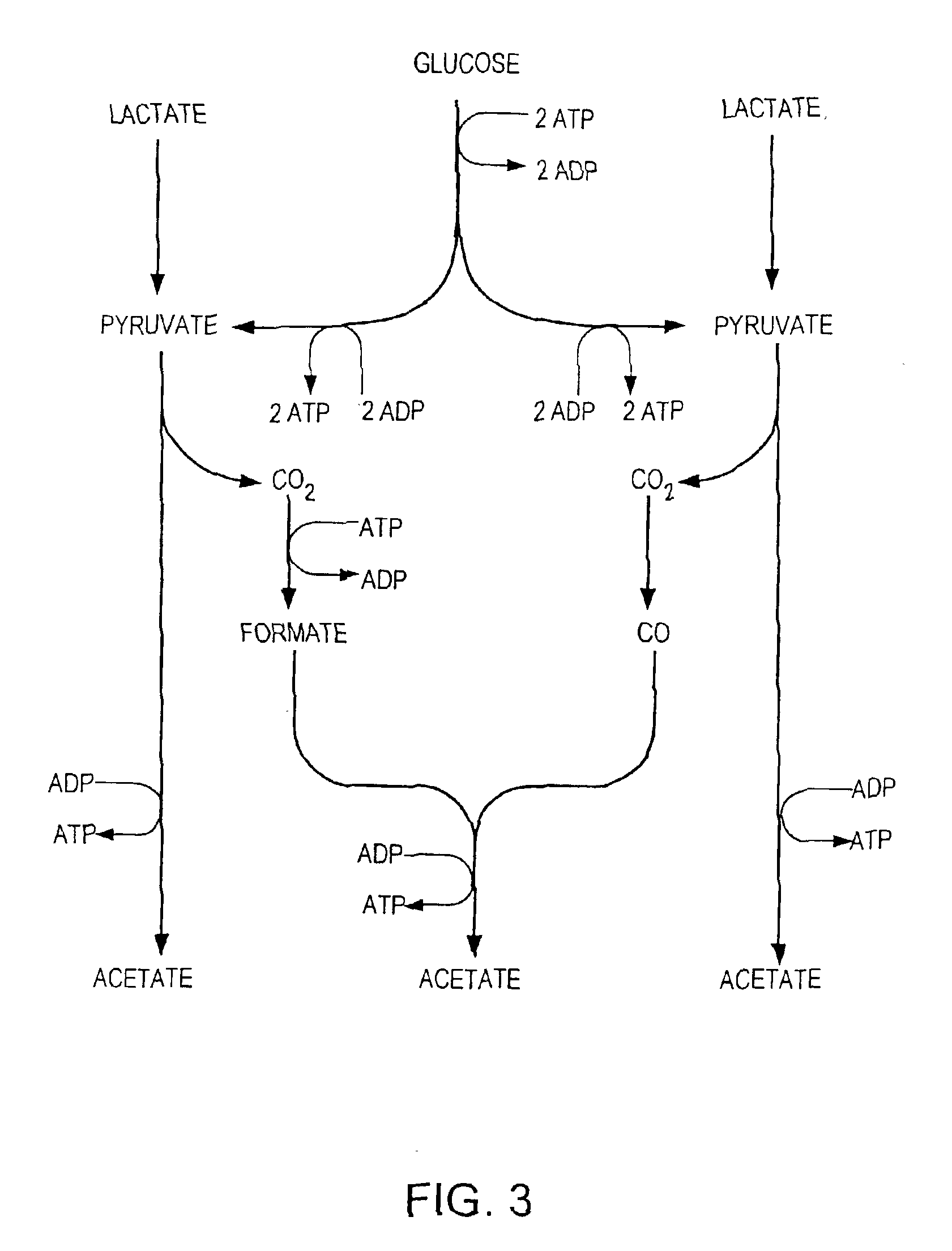

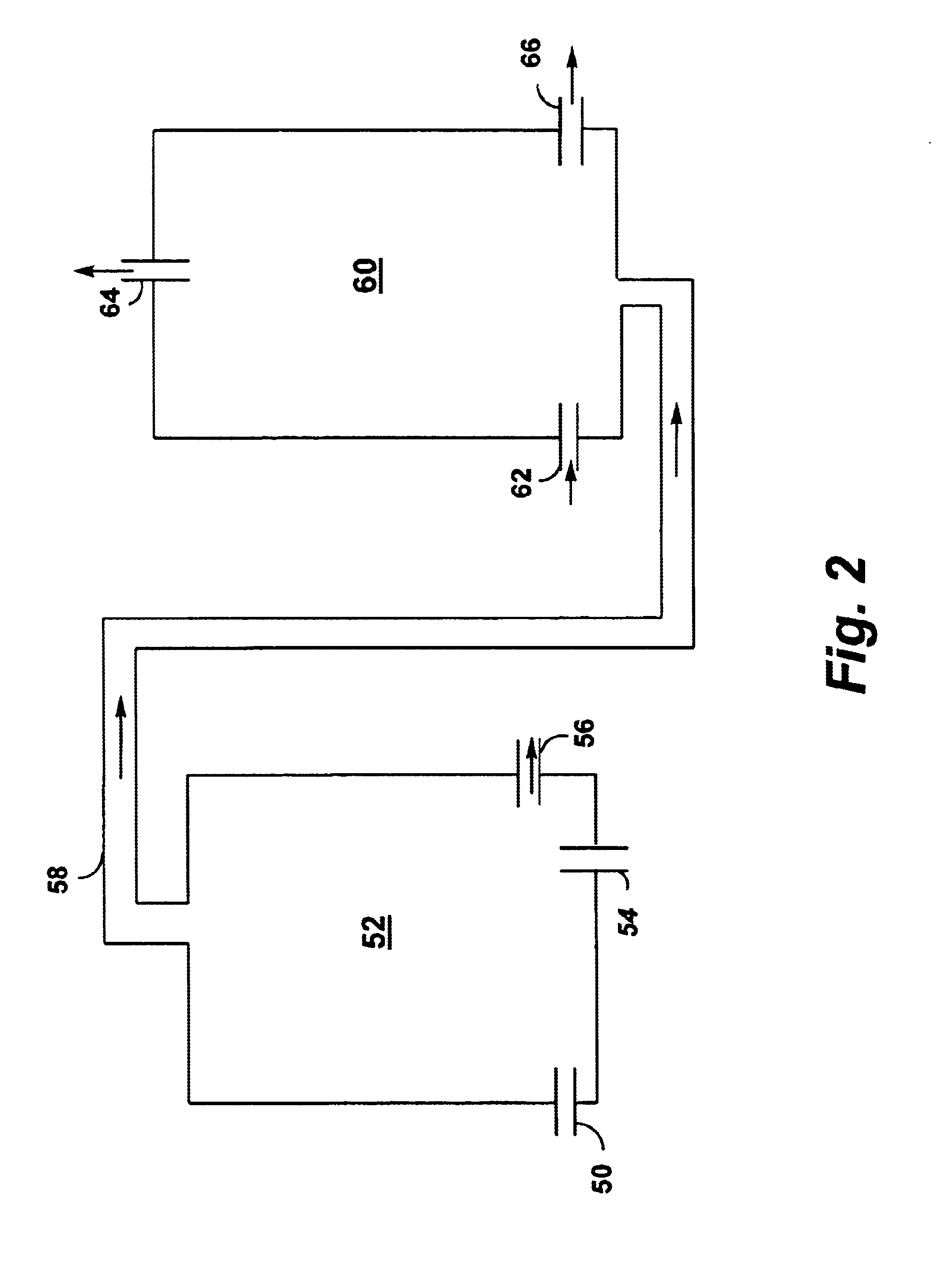

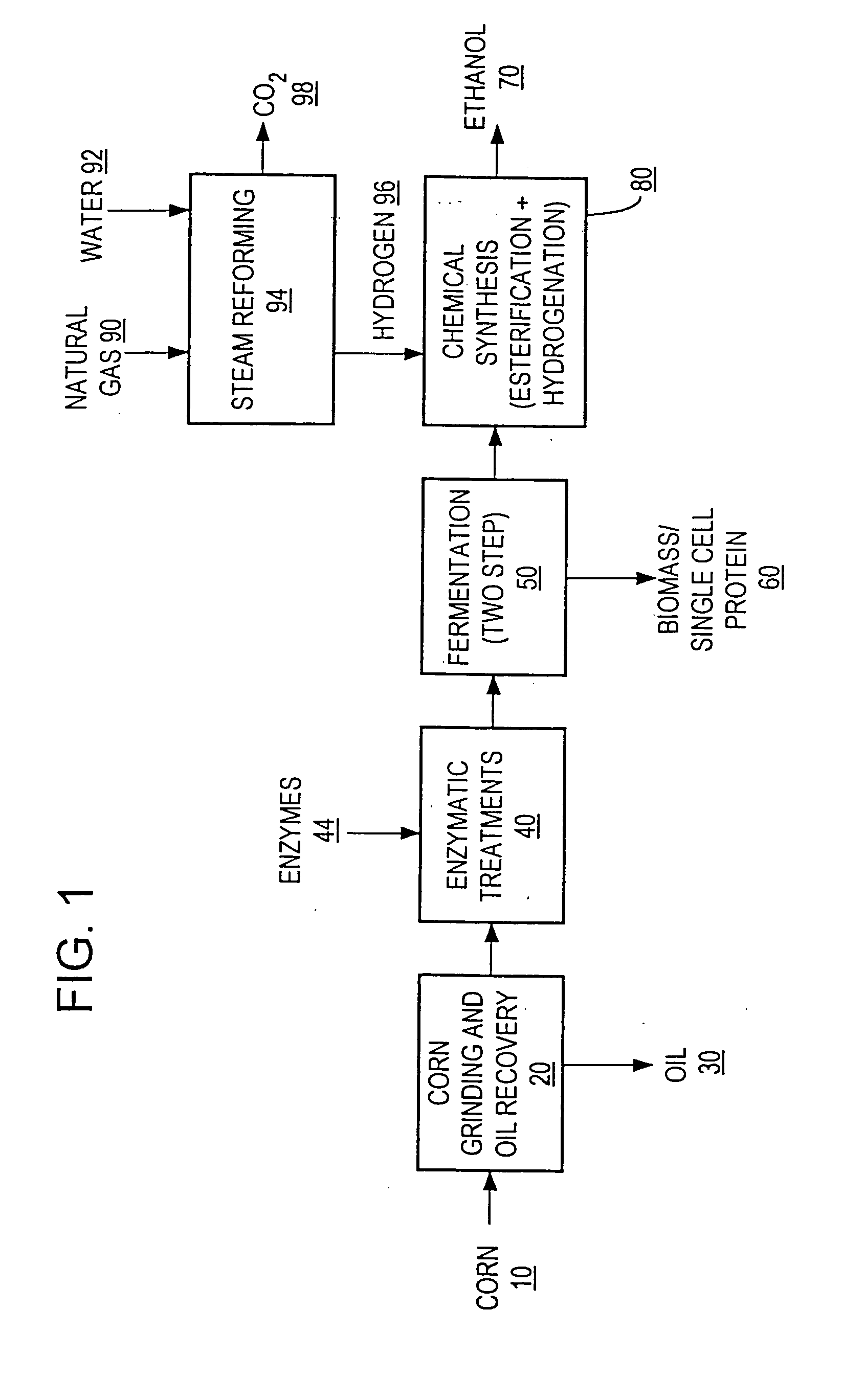

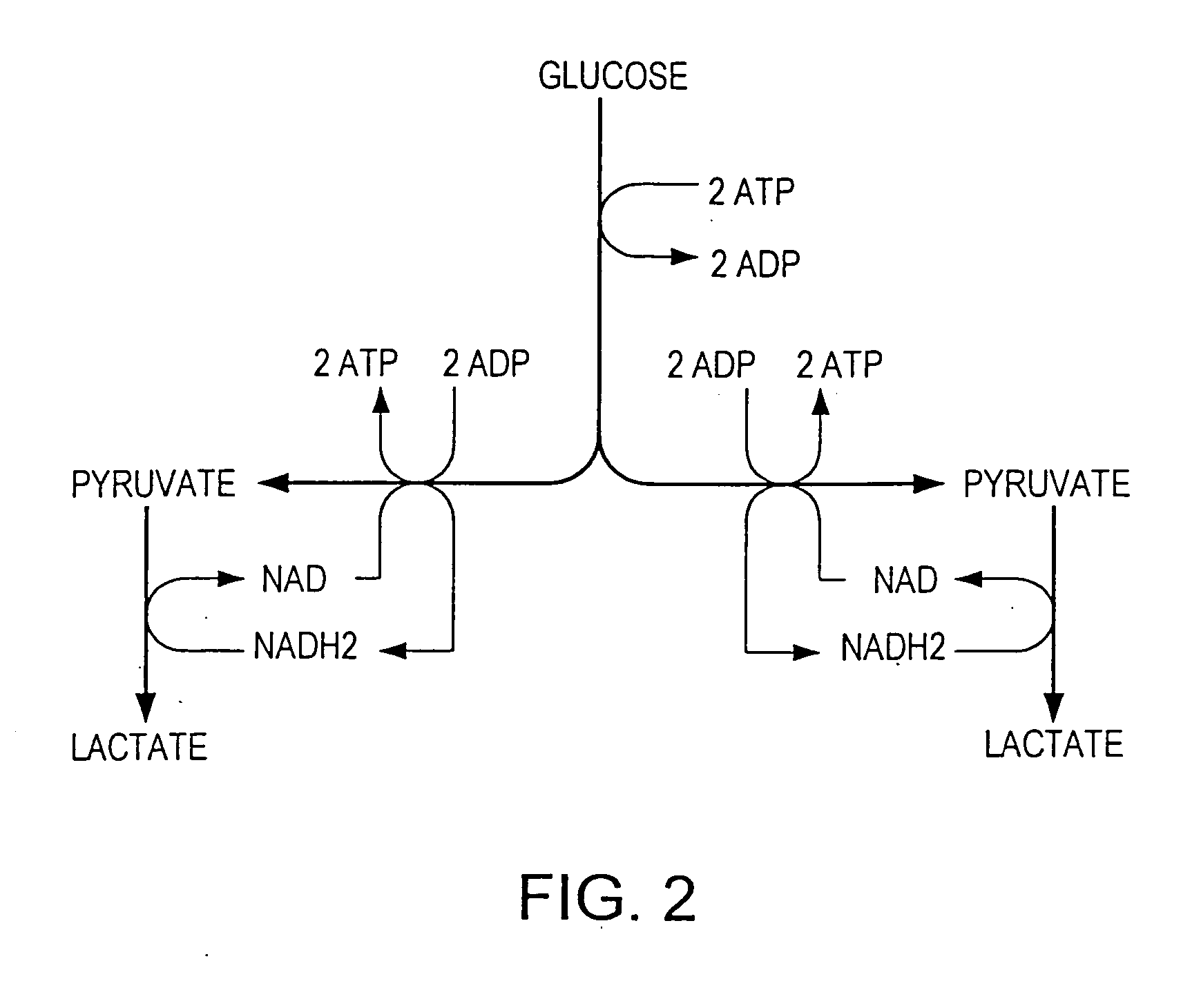

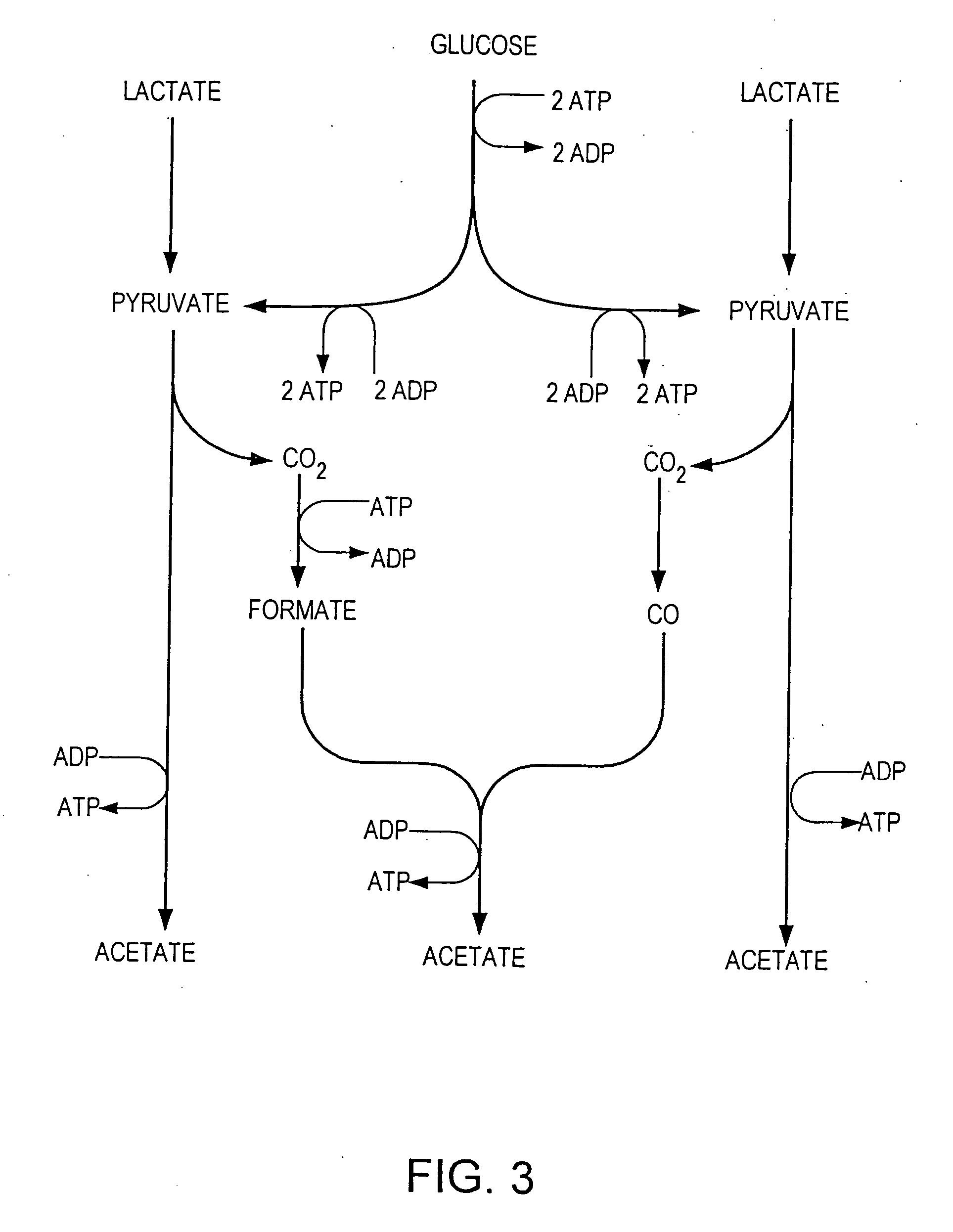

InactiveUS6927048B2High carbon yieldHigh protein concentrationOrganic compound preparationCarboxylic acid esters preparationAcetic acidHydrogenation reaction

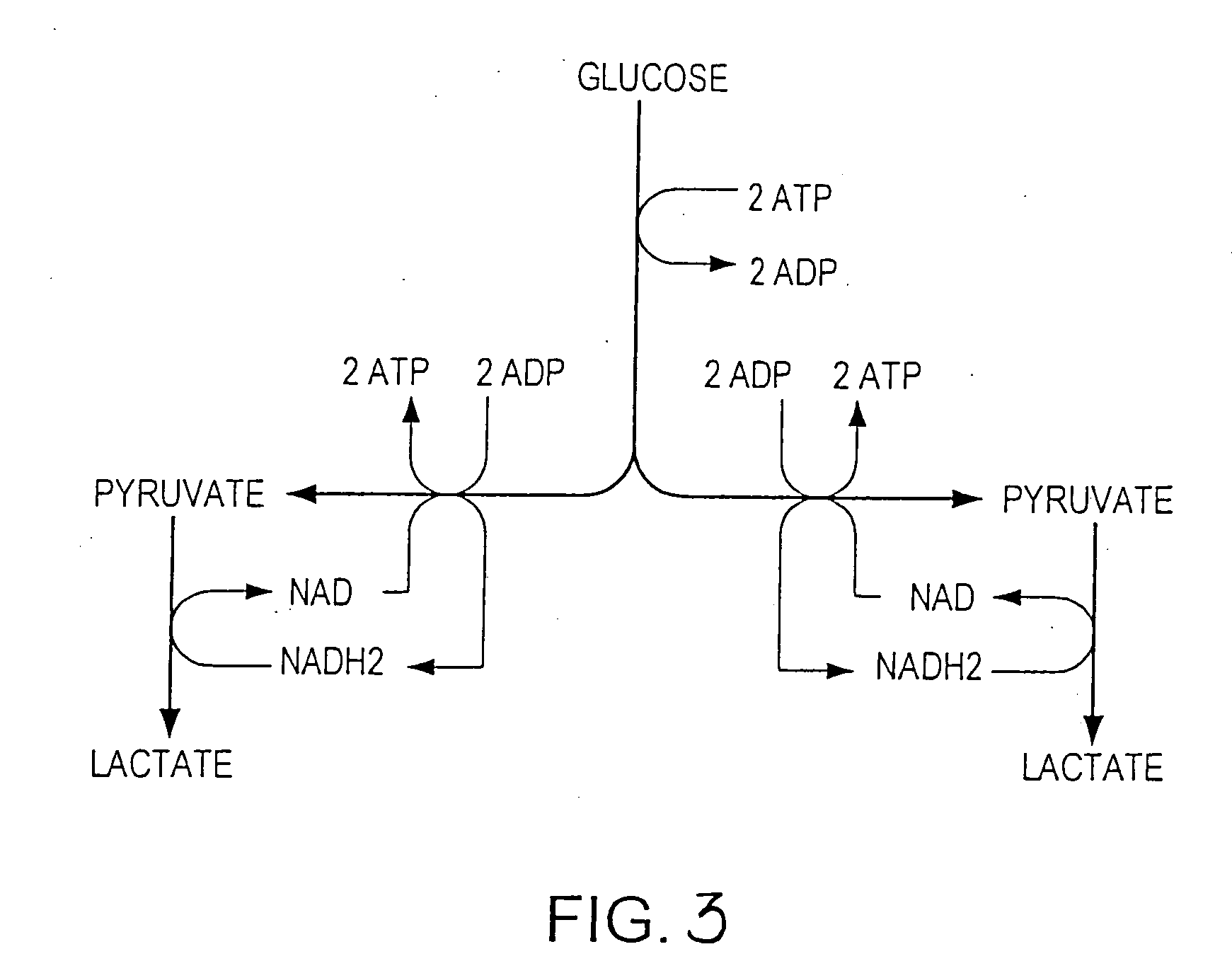

A process for producing ethanol including a combination of biochemical and synthetic conversions results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from carbohydrates, such as corn, using enzymatic milling and fermentation steps, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts can include corn oil, and high protein animal feed containing the biomass produced in the fermentation.

Owner:ZEACHEM

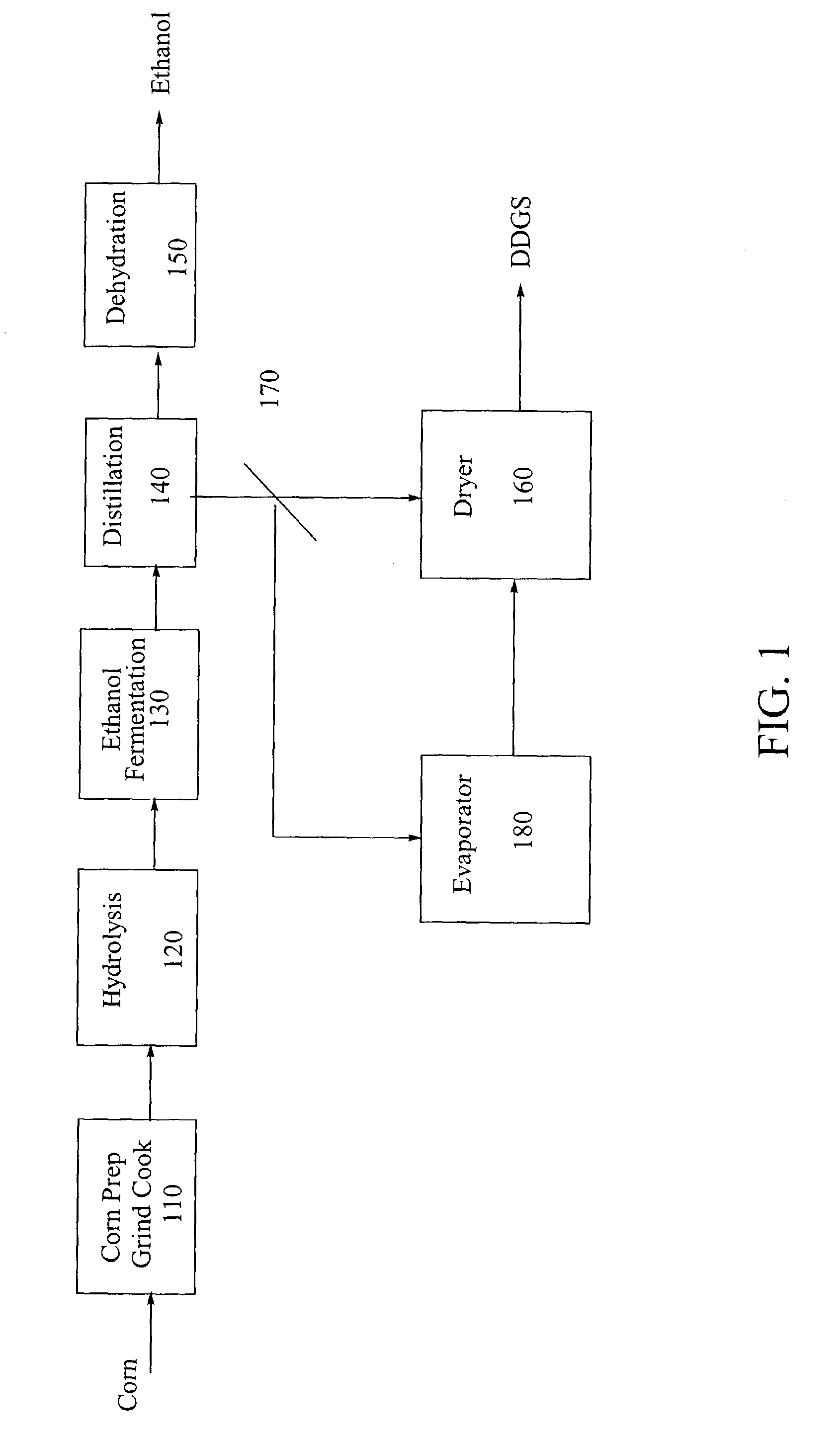

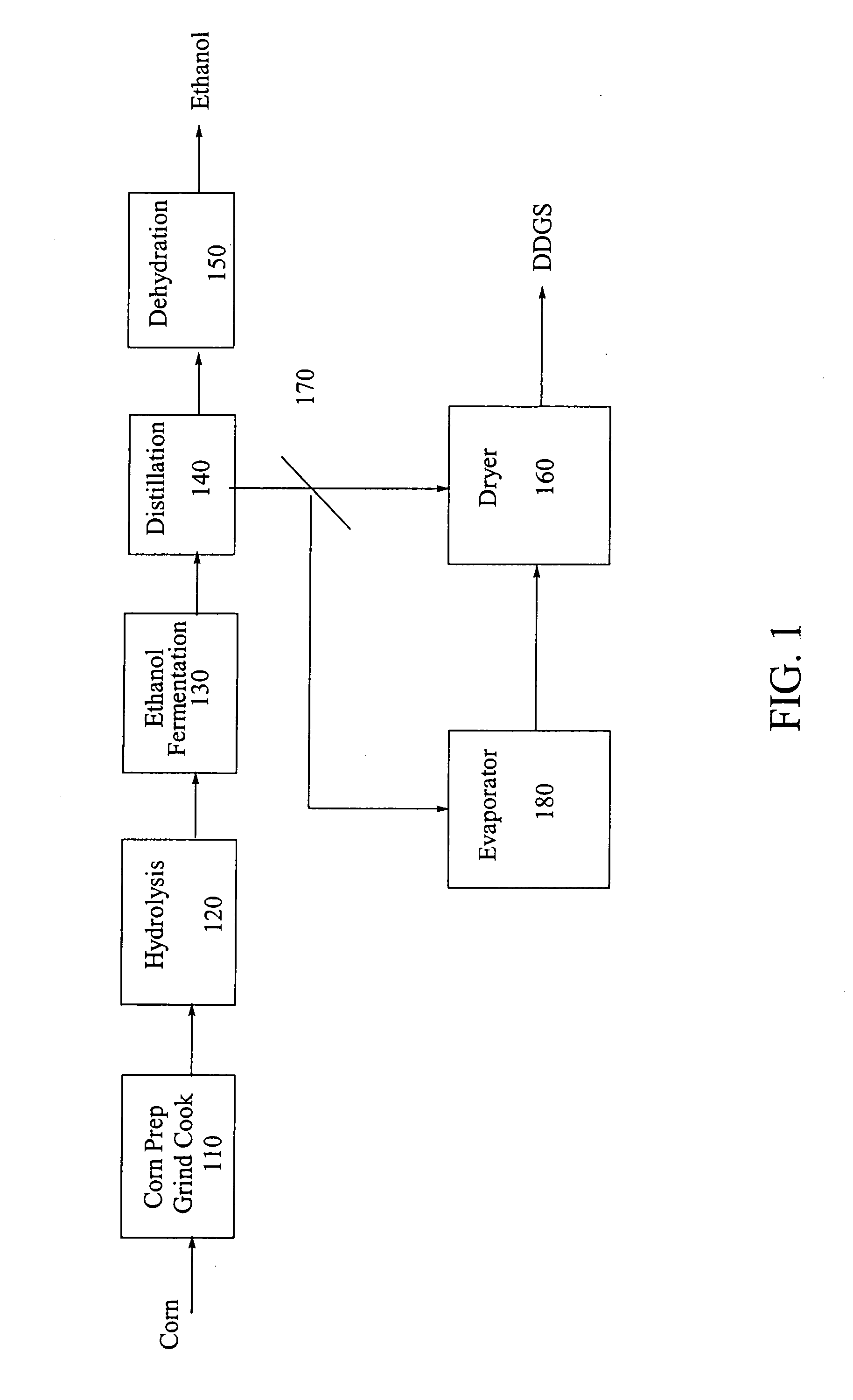

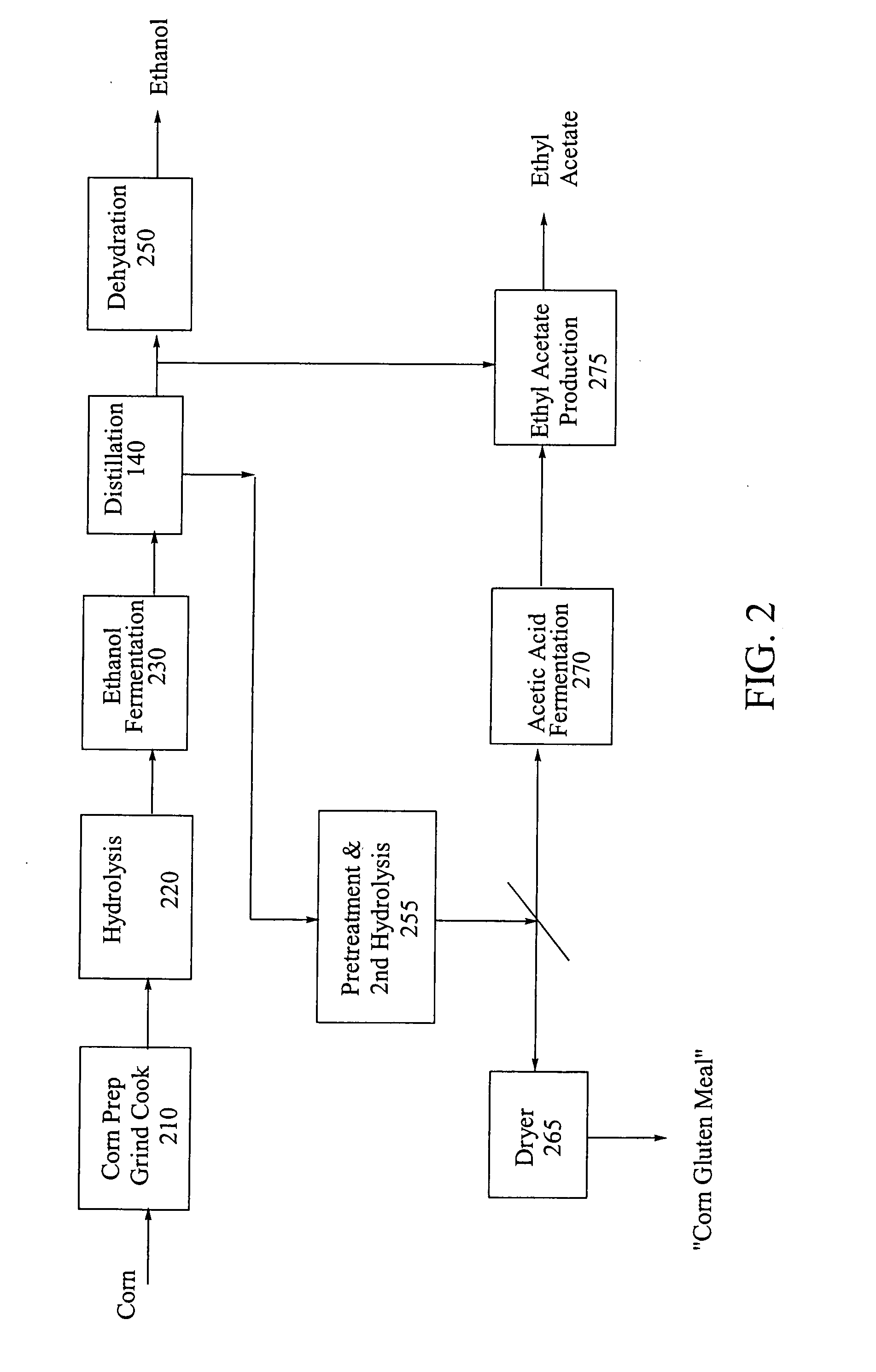

Process for producing ethanol from corn dry milling

InactiveUS7074603B2Fermented solutions distillation/rectificationOrganic compound preparationAcetic acidHydrogenation reaction

A process for producing ethanol by the conversion of carbohydrates from a corn dry milling process in which the bottoms fraction from distillation of ethanol in a conventional yeast fermentation is used in a process including a combination of biochemical and synthetic conversions. The process results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from bottoms fraction, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts of the process include a high protein content solids fraction produced in the fermentation.

Owner:ZEACHEM

Hydrogen production from carbonaceous material

InactiveUS6790430B1Avoid the needCalcium/strontium/barium carbonatesGas turbine plantsCalcinationExothermic reaction

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE +1

Process for producing ethanol

InactiveUS20060019360A1High carbon yieldHigh protein concentrationOrganic compound preparationChemical industryAcetic acidHydrogenation reaction

A process for producing ethanol including a combination of biochemical and synthetic conversions results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from carbohydrates, such as corn, using enzymatic milling and fermentation steps, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts can include corn oil, and high protein animal feed containing the biomass produced in the fermentation.

Owner:ZEACHEM

Process for producing ethanol from corn dry milling

InactiveUS20060127999A1Speed up the conversion processFermented solutions distillation/rectificationOrganic compound preparationAcetic acidDistillation

A process for producing ethanol by the conversion of carbohydrates from a corn dry milling process in which the bottoms fraction from distillation of ethanol in a conventional yeast fermentation is used in a process including a combination of biochemical and synthetic conversions. The process results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from bottoms fraction, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts of the process include a high protein content solids fraction produced in the fermentation.

Owner:ZEACHEM

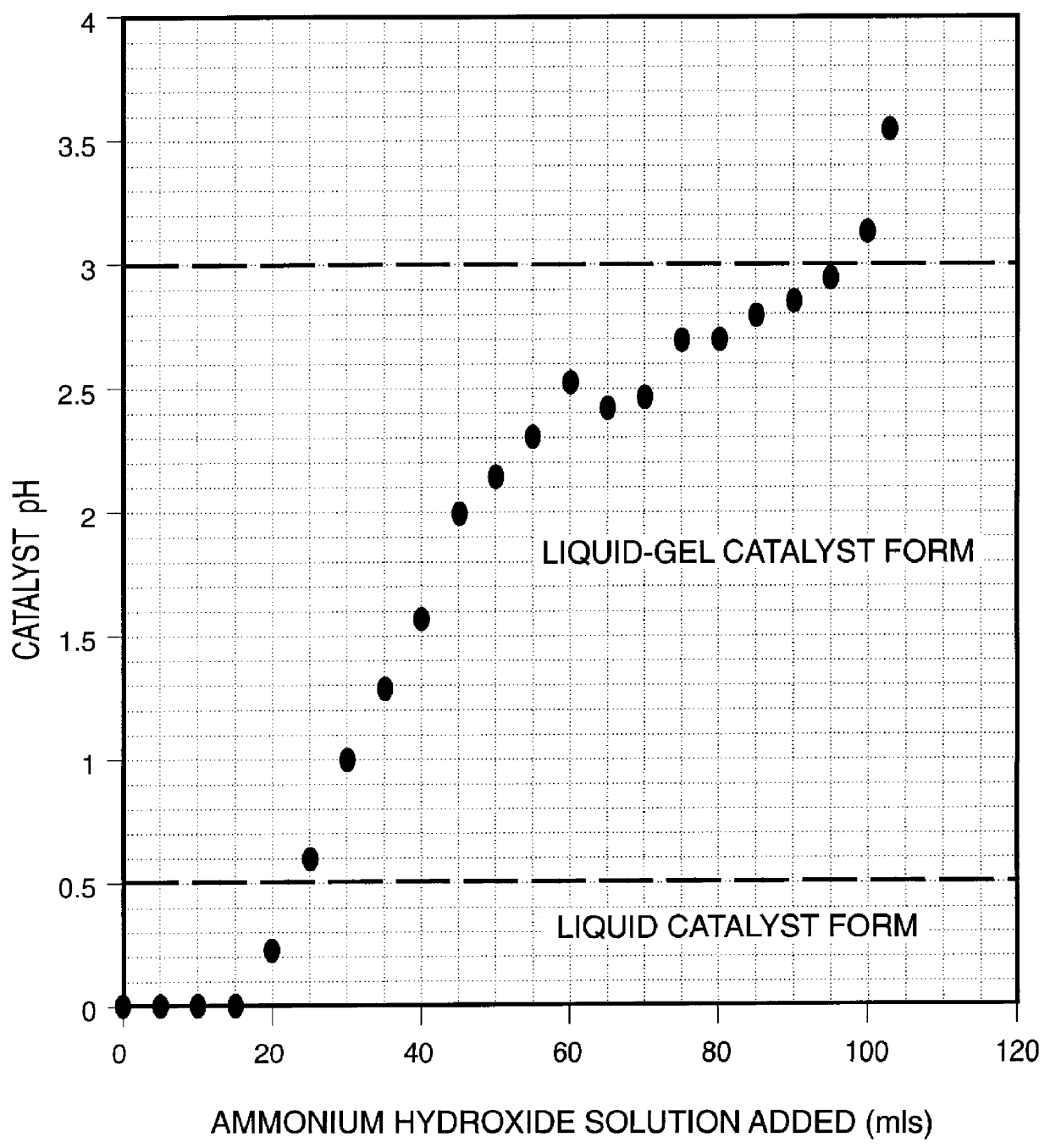

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

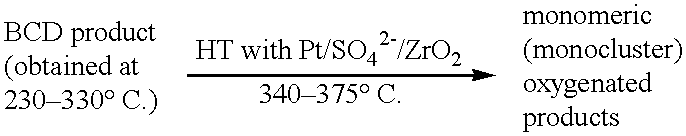

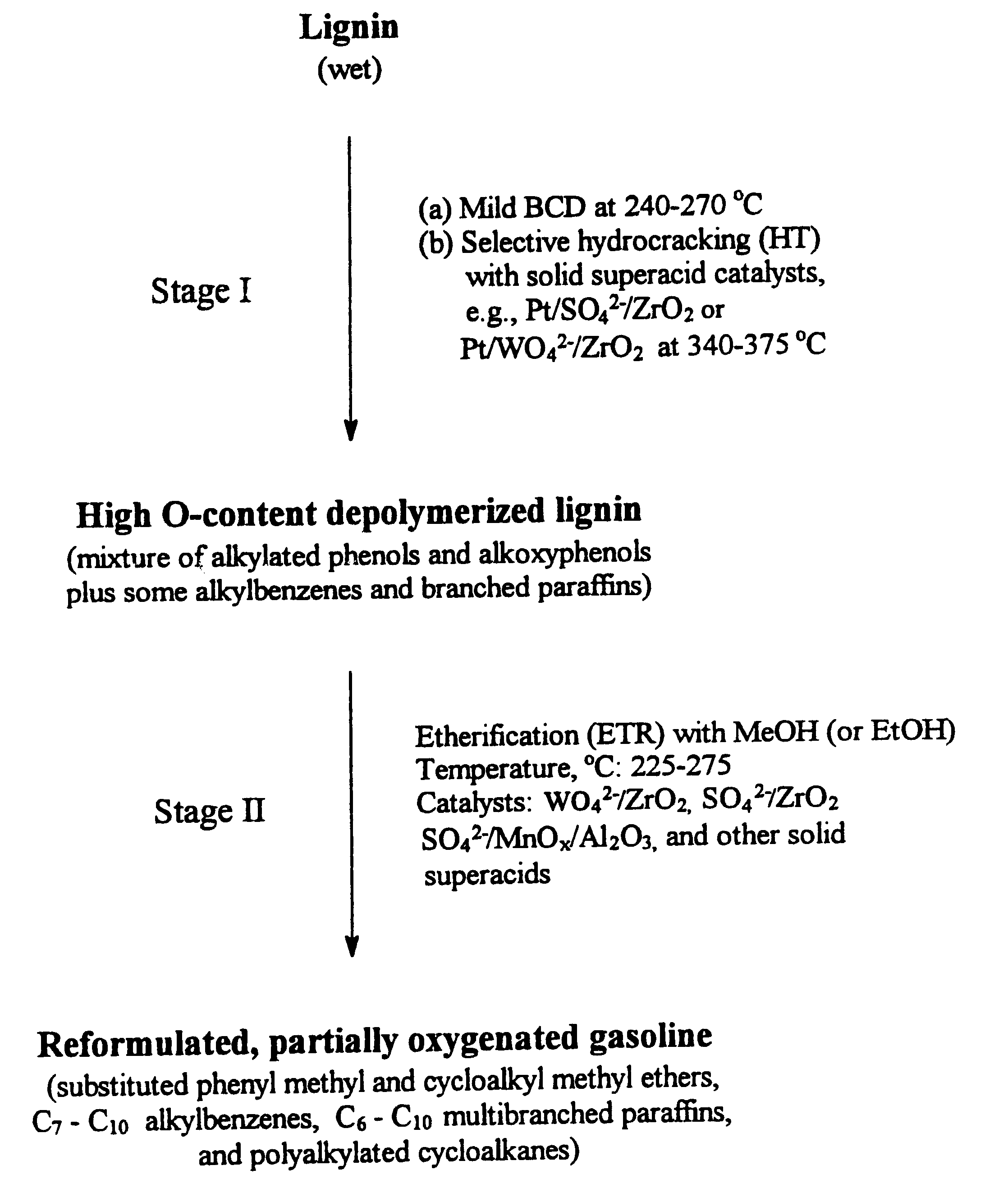

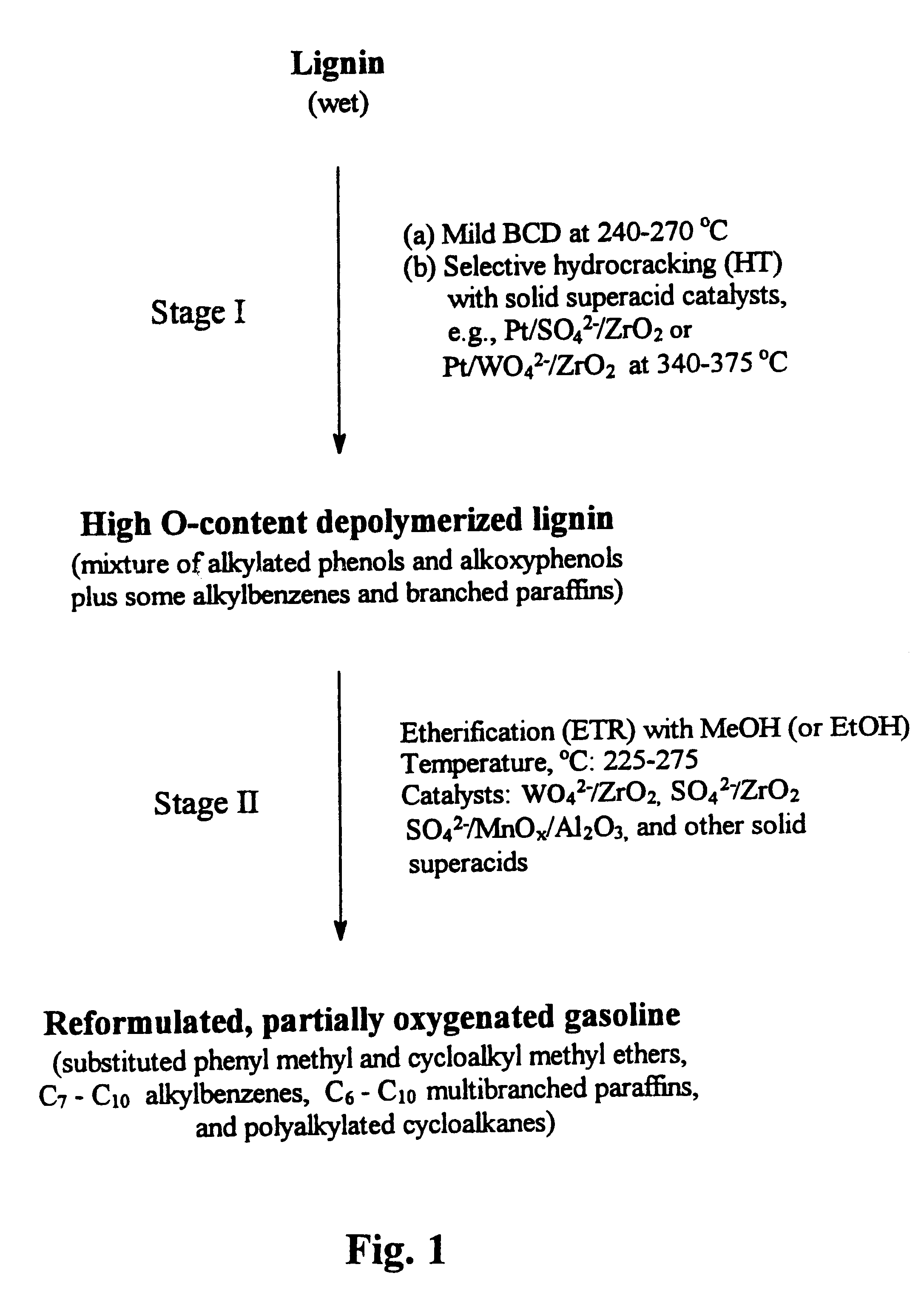

Process for conversion of lignin to reformulated, partially oxygenated gasoline

InactiveUS6172272B1Short reaction timeMaintain good propertiesOrganic compound preparationHydrocarbon from oxygen organic compoundsDepolymerizationMethyl group

A high-yield process for converting lignin into reformulated, partially oxygenated gasoline compositions of high quality is provided. The process is a two-stage catalytic reaction process that produces a reformulated, partially oxygenated gasoline product with a controlled amount of aromatics. In the first stage of the process, a lignin feed material is subjected to a base-catalyzed depolymerization reaction, followed by a selective hydrocracking reaction which utilizes a superacid catalyst to produce a high oxygen-content depolymerized lignin product mainly composed of alkylated phenols, alkylated alkoxyphenols, and alkylbenzenes. In the second stage of the process, the depolymerized lignin product is subjected to an exhaustive etherification reaction, optionally followed by a partial ring hydrogenation reaction, to produce a reformulated, partially oxygenated / etherified gasoline product, which includes a mixture of substituted phenyl / methyl ethers, cycloalkyl methyl ethers, C7-C10 alkylbenzenes, C6-C10 branched and multibranched paraffins, and alkylated and polyalkylated cycloalkanes.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

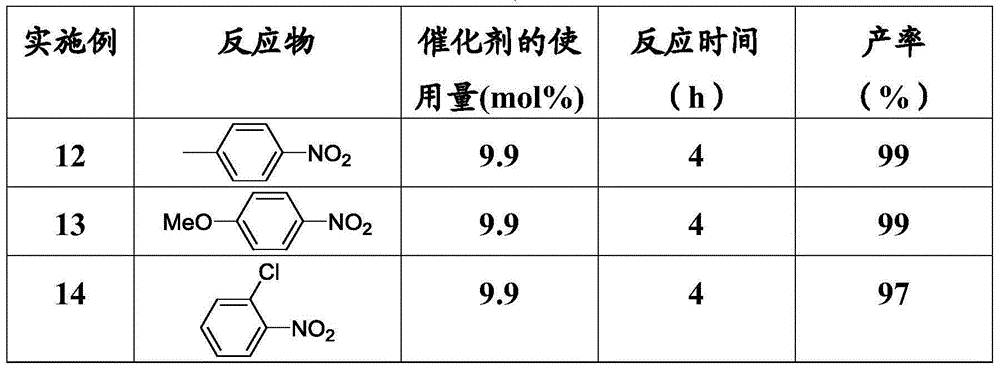

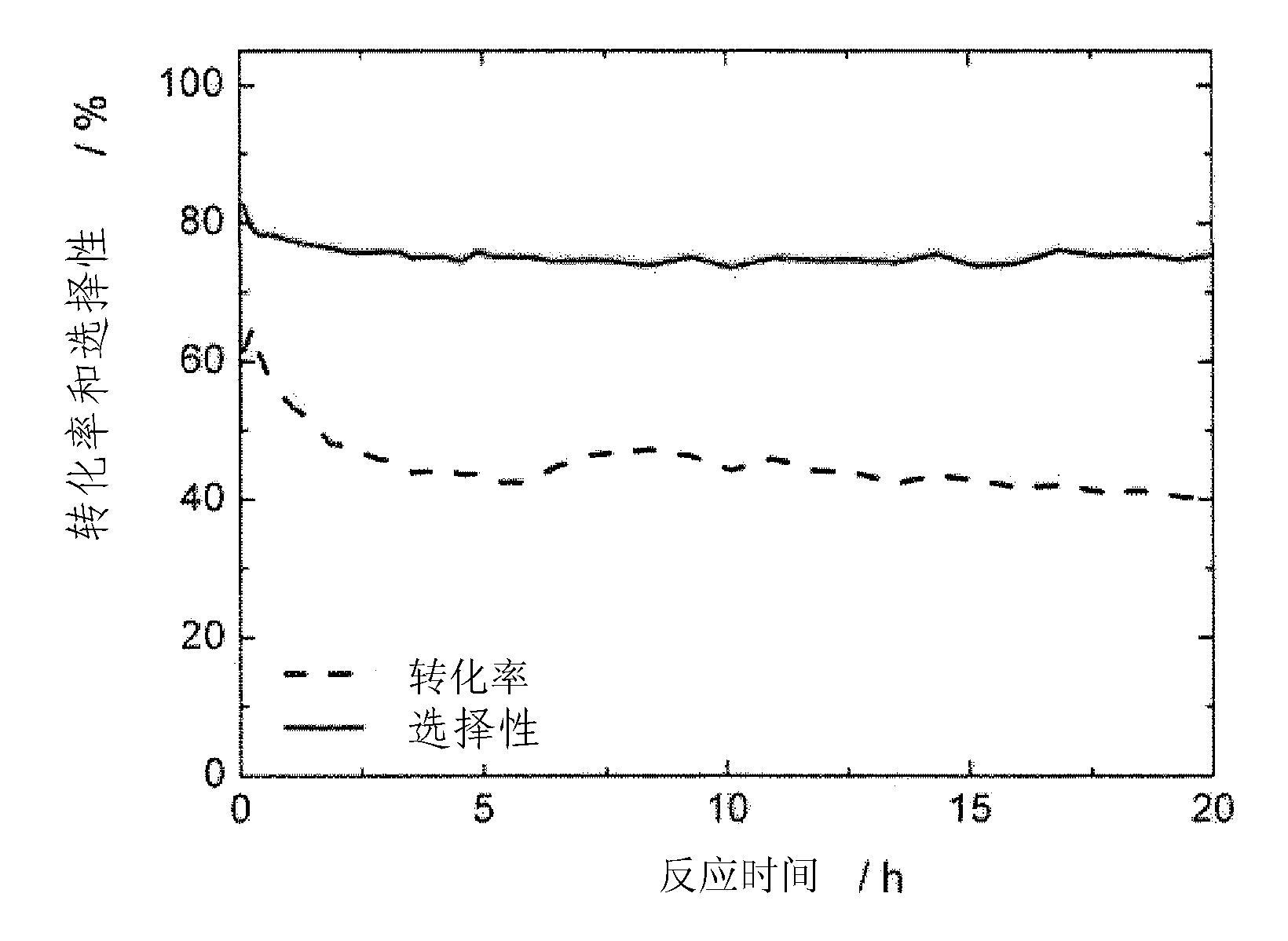

Catalyst for selective hydrogenation reaction of aromatic nitrocompound and preparation method of catalyst

InactiveCN105032424AEasy to storeLow costCarboxylic acid nitrile preparationOrganic compound preparationNitro compoundAlcohol

The invention relates to a catalyst for selective hydrogenation reaction of an aromatic nitrocompound and a preparation method of the catalyst. The catalyst consists of a catalyst carrier and active metal coated with carbon, wherein the catalyst carrier includes a carbon-base carrier, SiO2, TiO2 or Al2O3; the active metal is selected from Co, Fe, Ni or Cu and other poor and noble metals. The catalyst is prepared by adopting a Pechini type sol-gel process which comprises the steps of dispersing an active metal precursor to water containing a coordination compound, adding a polyhydric alcohol solution and a macromolecule auxiliary, then adding the carrier, stirring for dispersion, carrying out hydrothermal reaction, separating out solid on the lower layer, and calcining in the inert atmosphere to obtain the catalyst in which carbon coats the active metal. Compared with the prior art, the catalyst can realize the hydrogenation reaction of a substituted aromatic nitrocompound in the mild condition; substrate conversion rate and production selectivity are high; the catalyst has recyclable economy and good application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

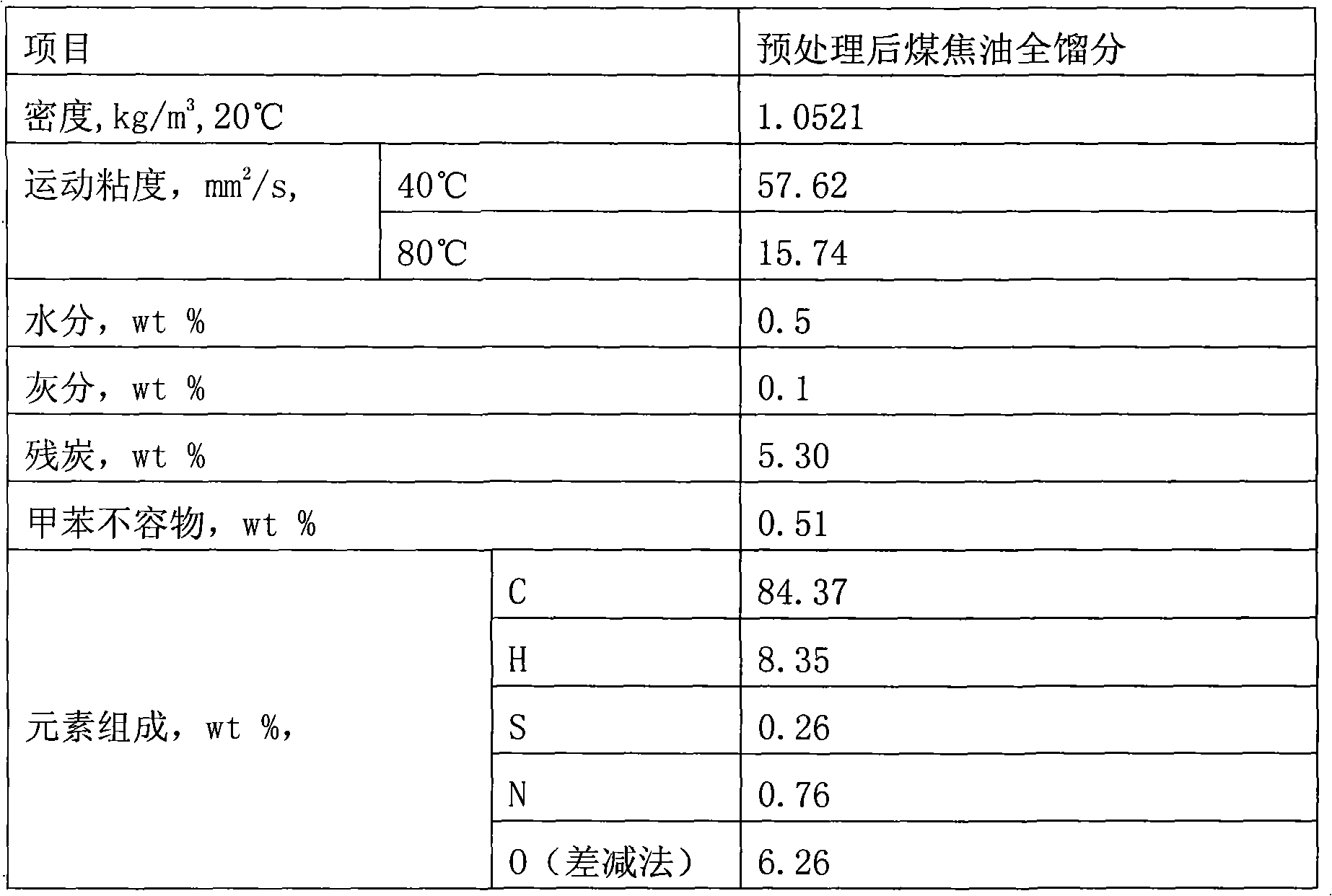

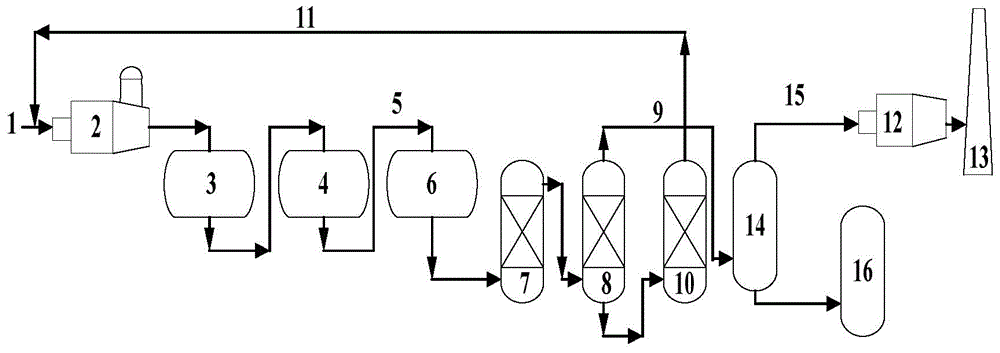

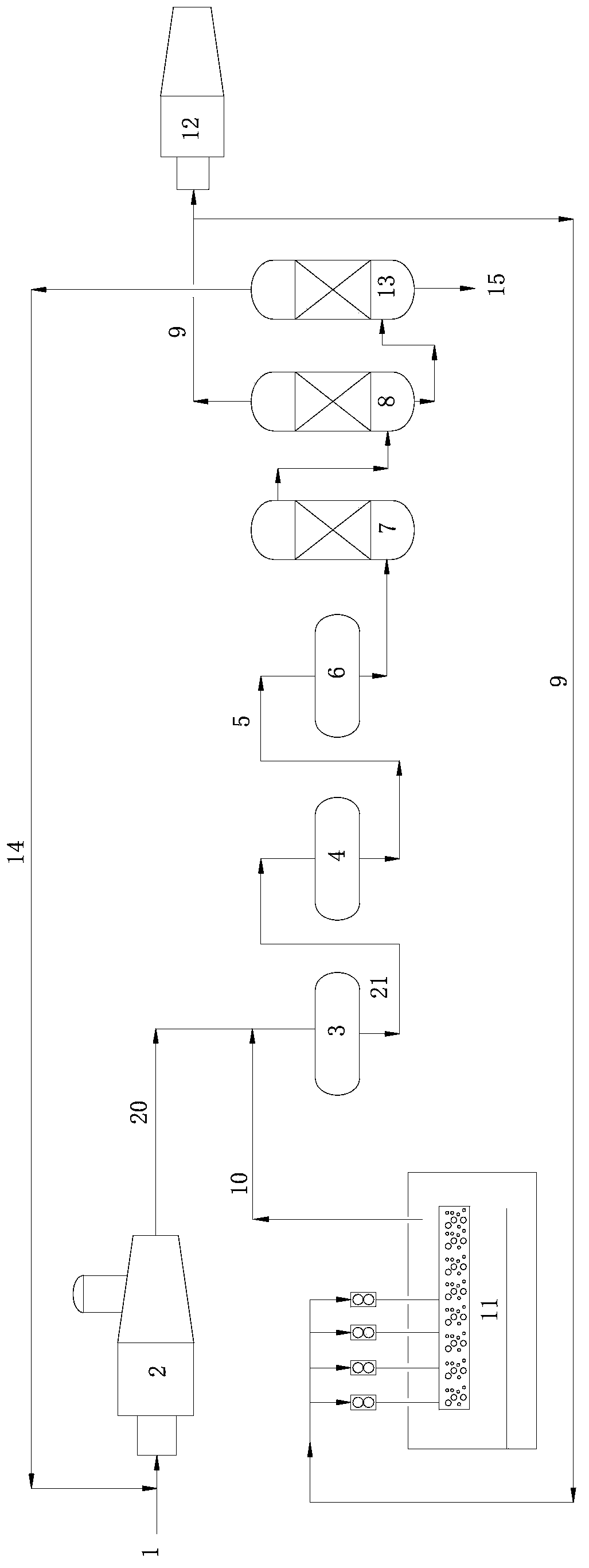

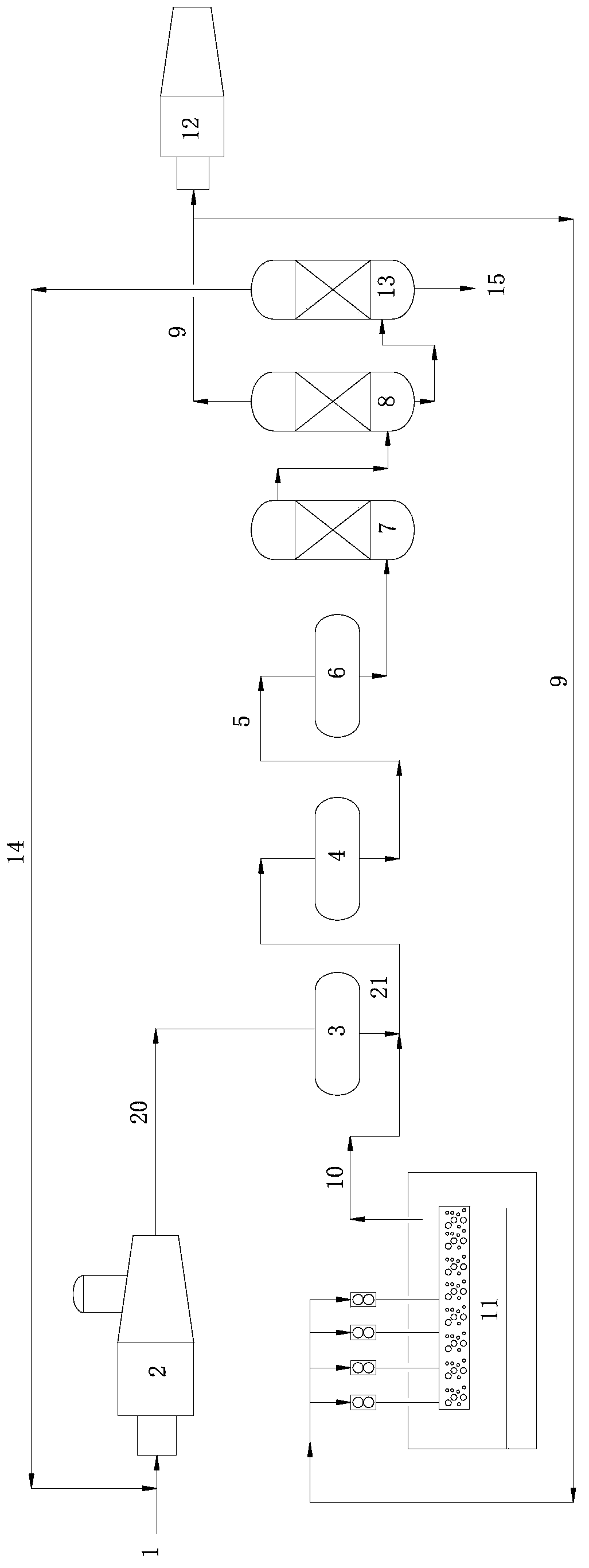

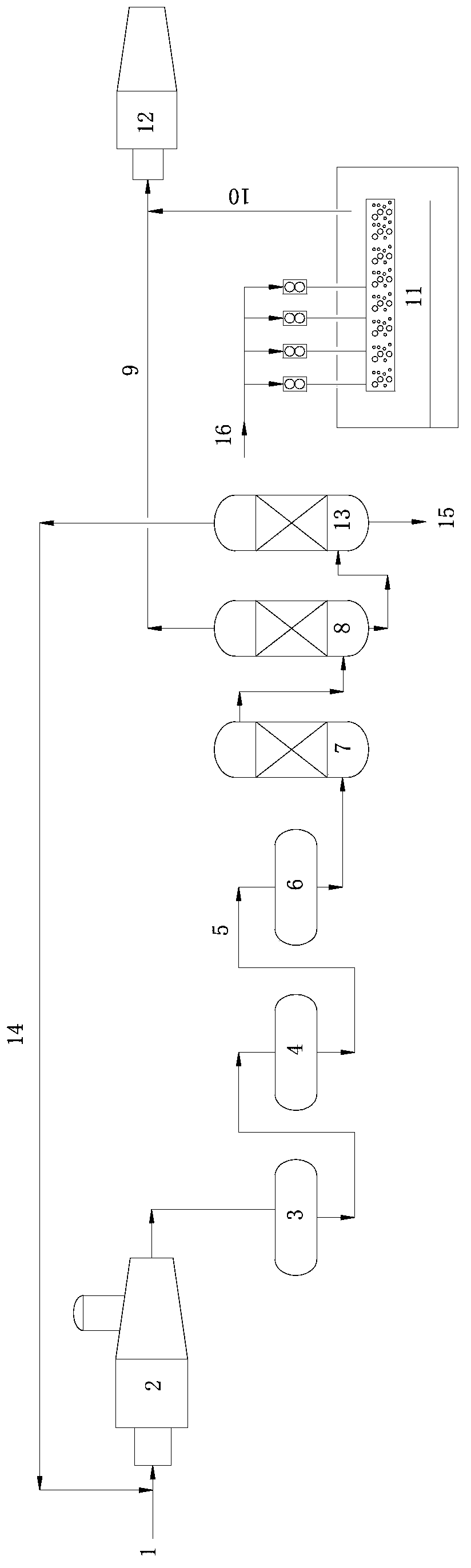

Hydrogenation method for coal tar suspension bed of heterogeneous catalyst

ActiveCN101885982ATo achieve the purpose of recyclingImprove utilization efficiencyTreatment with hydrotreatment processesFuel oilBULK ACTIVE INGREDIENT

The invention relates to a hydrogenation method for a coal tar suspension bed of a heterogeneous catalyst. The method comprises processes of coal tar raw material pretreatment and distillatory separation, coal tar heavy fraction suspension bed hydrogenation cracking and conventional light fraction oil extraction, wherein the suspension bed hydrogenation reaction temperature is between 320 and 480DEG C, the reaction pressure is 8 to 19MPa, the volume air speed is 0.3 to 3.0h<-1>, the hydrogen oil volume ratio is 500 to 2,000, the catalyst is a powdery granular coal tar suspension bed hydrogenation catalyst of a single metal active ingredient containing molybdenum, nickel, cobalt, tungsten or iron or a composite multi-metal active ingredient, the adding amount of the catalyst is based on the ratio of the metal quantity of the active ingredient to the weight of the coal tar raw materials of 0.1: 100-4: 100, most of tail oil containing the catalyst after lightweight oil is separated froma hydrogenation reaction product is directly circulated to a hydrogenation bed reactor, a small part of tail oil is subjected to catalyst removal treatment and then circulated to the hydrogenation bed reactor to be subjected to further lightweight treatment, and the heavy oil is totally or furthest circulated. The method fulfills the purposes of maximum production of the lightweight oil in the coal tar and cyclic utilization of the catalyst, and greatly improves the utilization efficiency of the raw materials and the catalyst.

Owner:CCTEG CHINA COAL RES INST

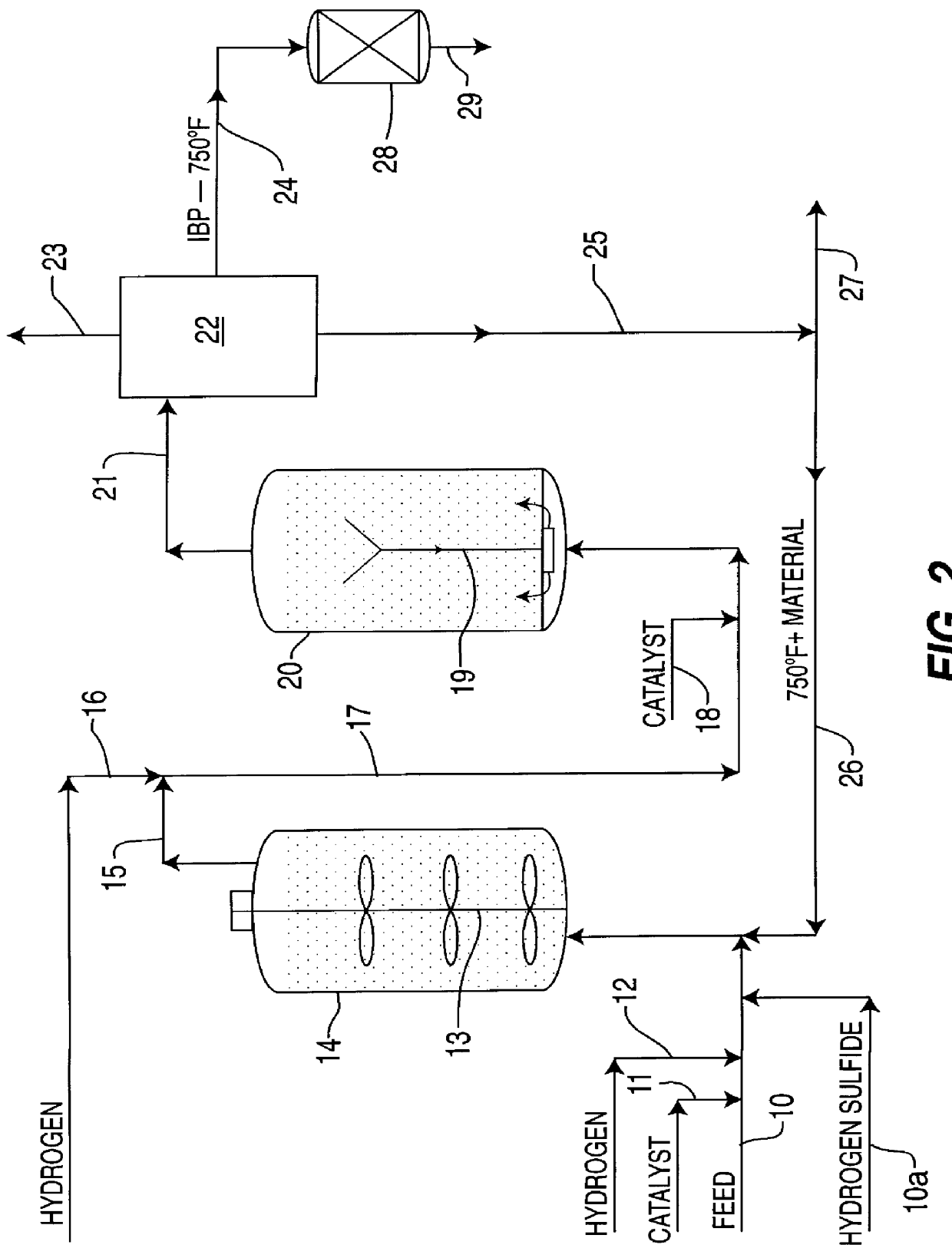

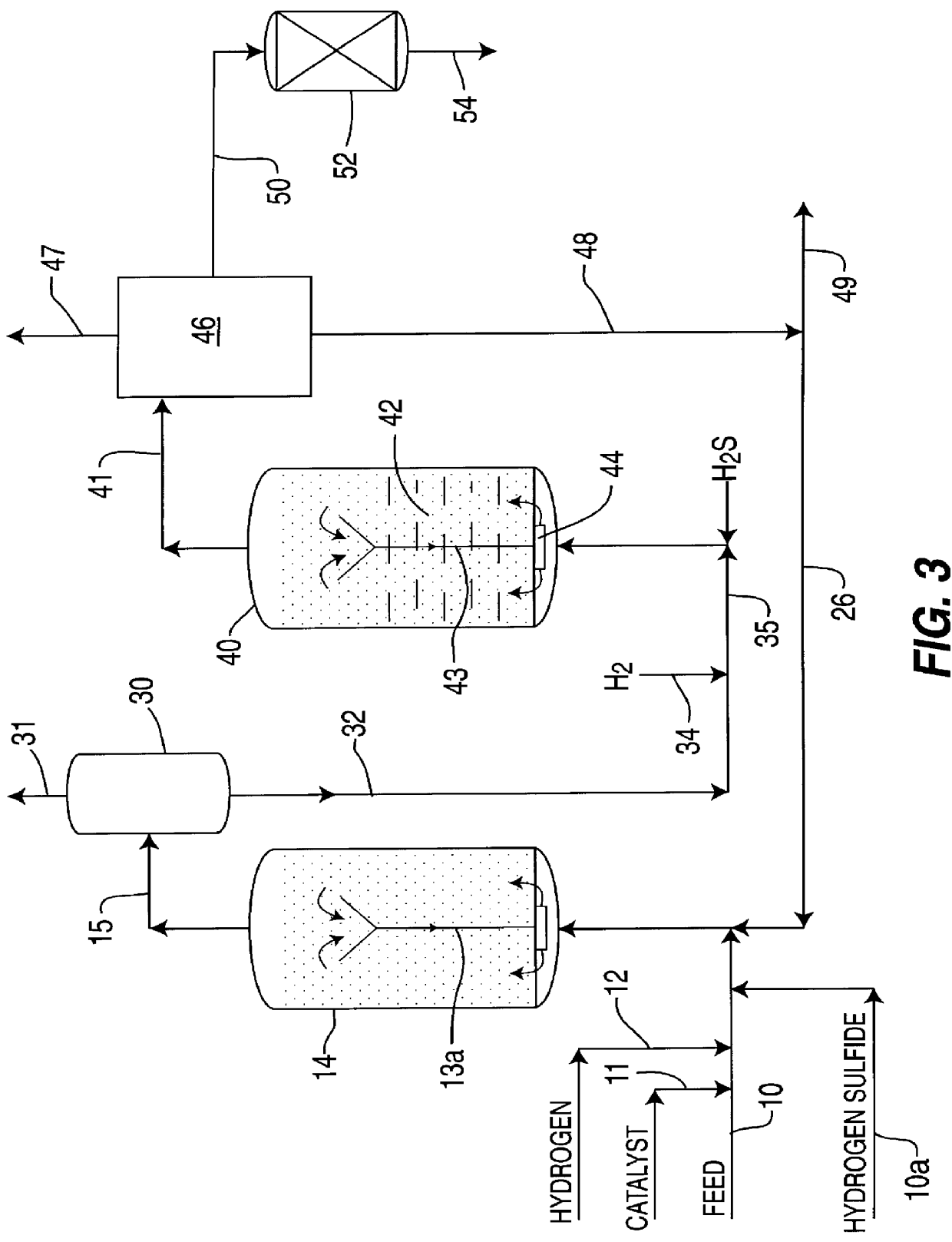

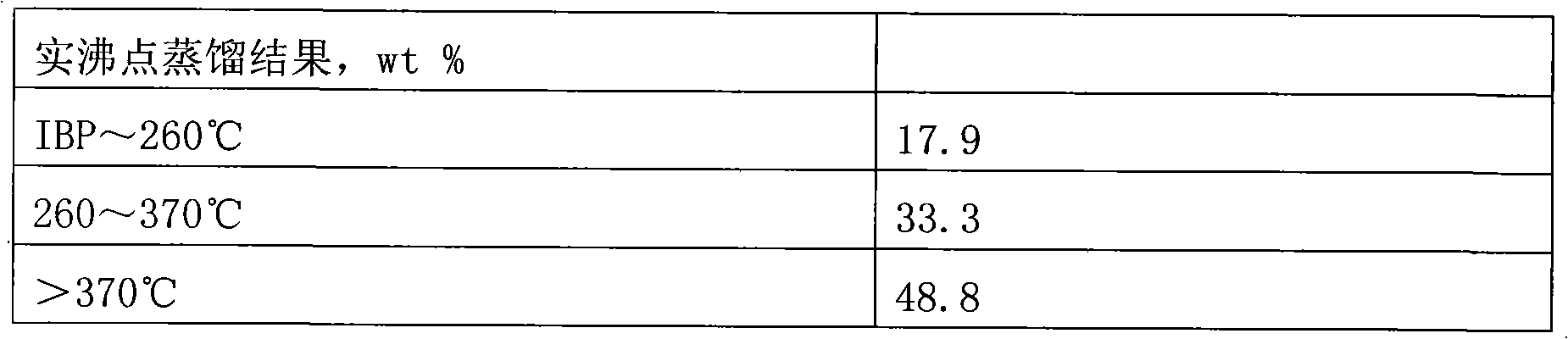

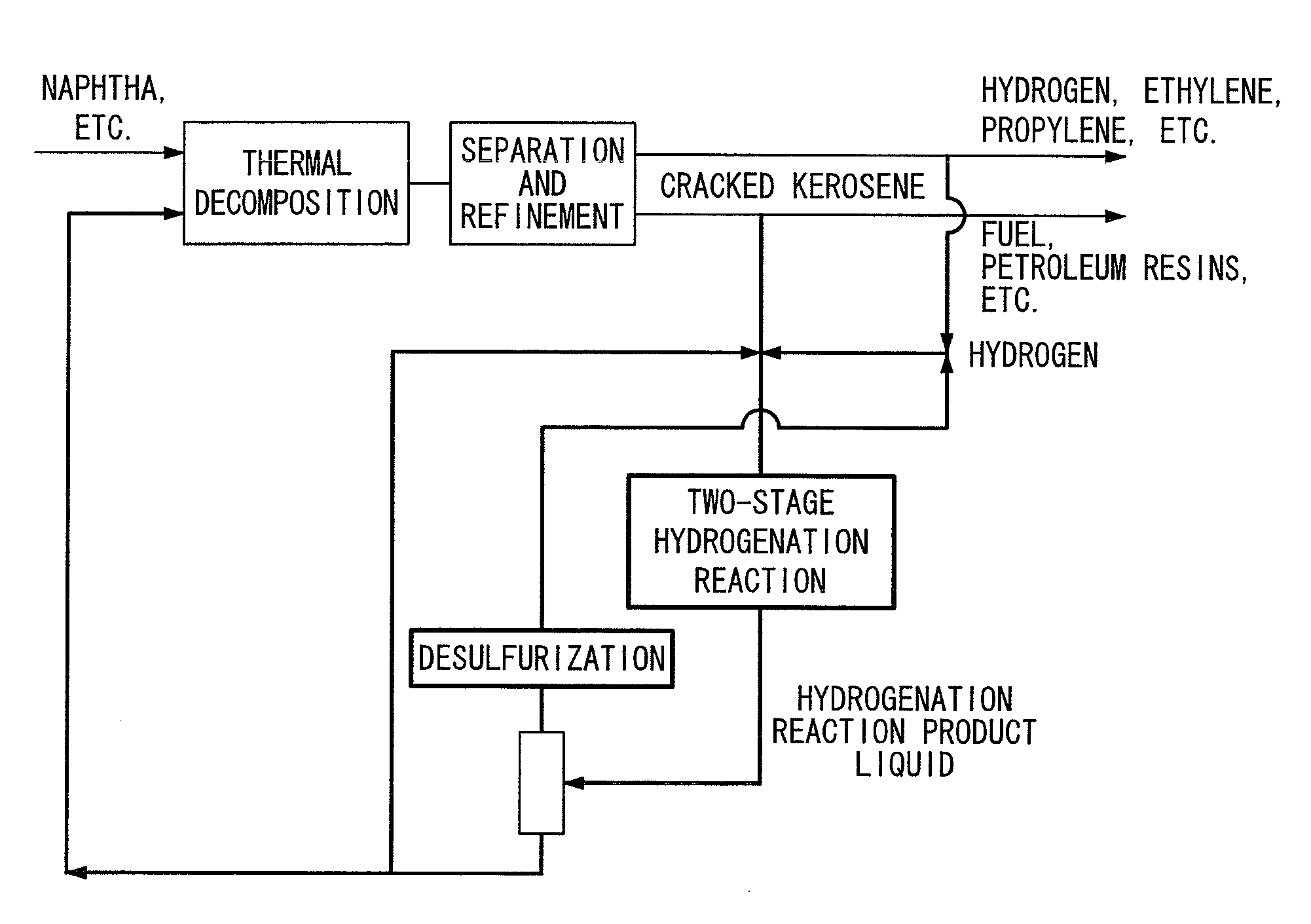

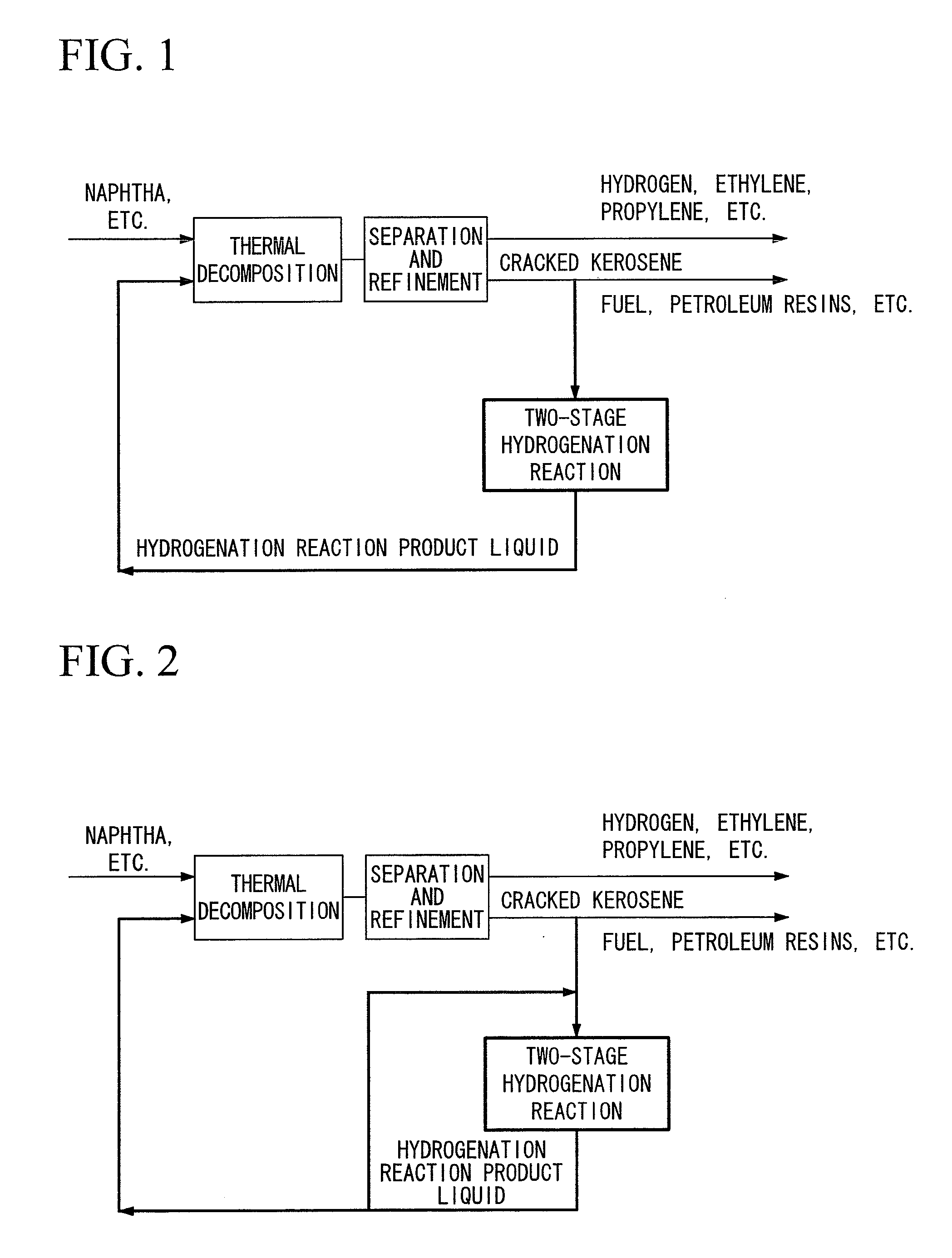

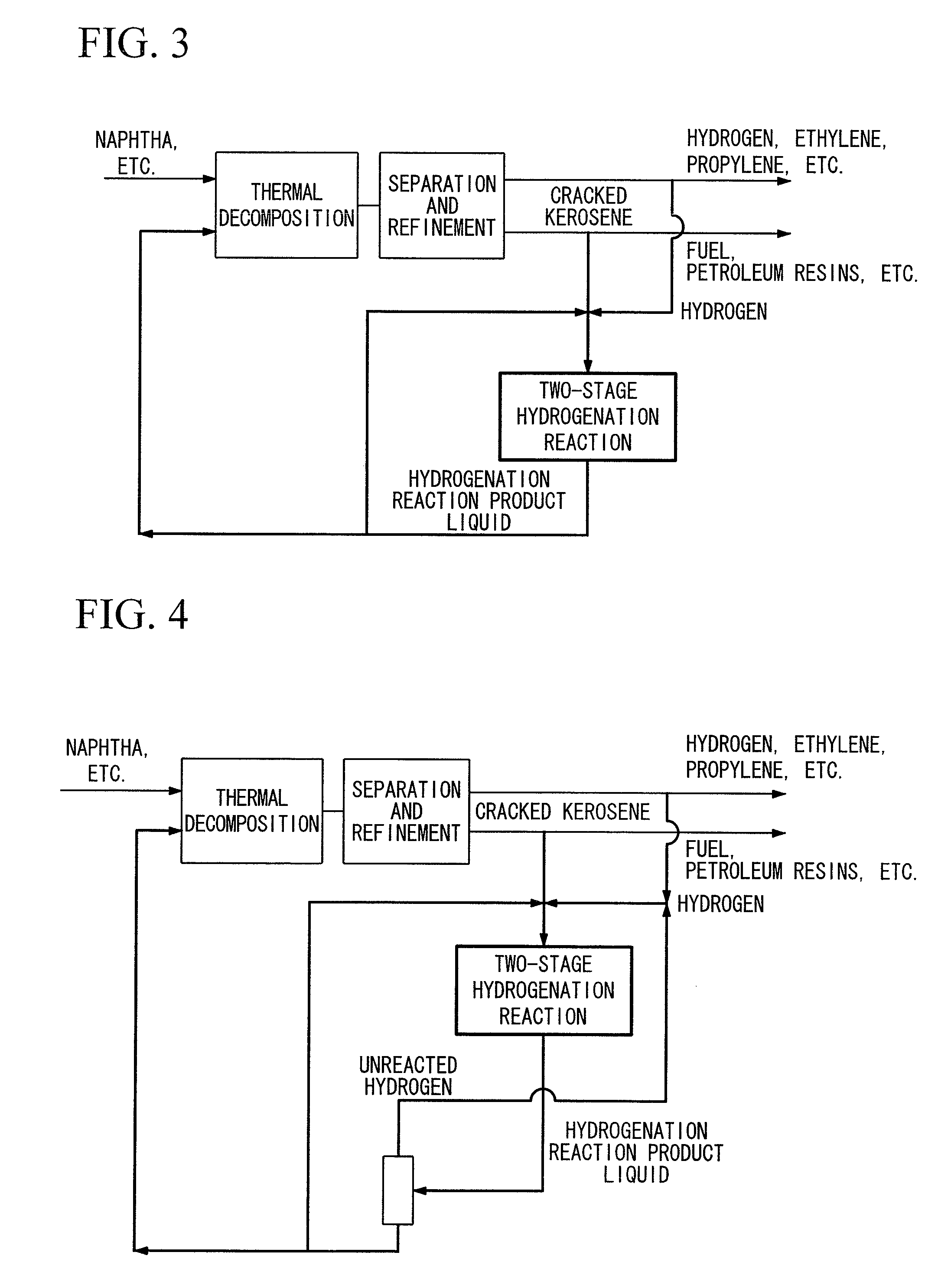

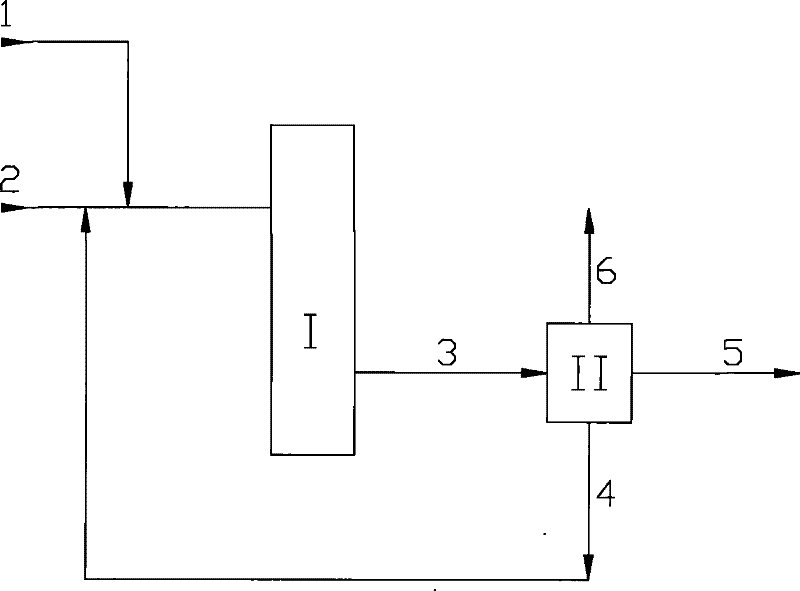

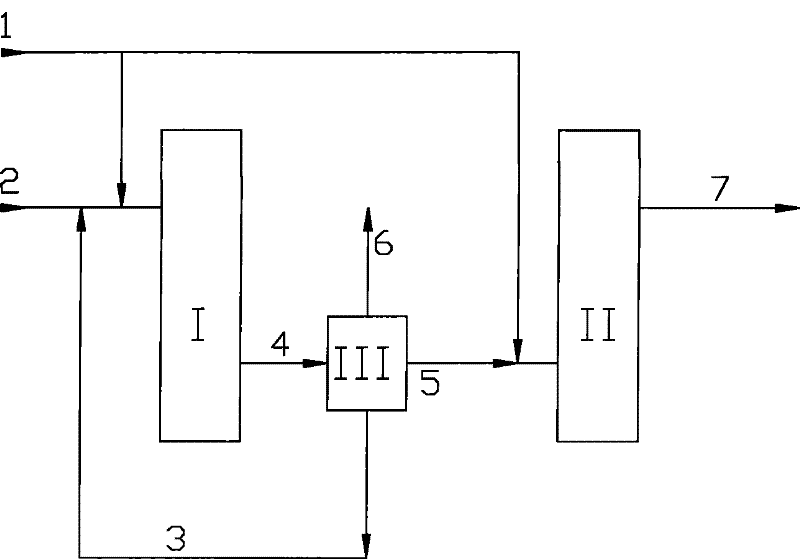

Hydrogenation method and petrochemical process

InactiveUS20100087692A1Long catalyst lifeHigh yieldThermal non-catalytic crackingHydrocarbon by dehydrogenationBenzeneNaphtha

The present invention provides a hydrogenation method capable of converting cracked kerosene into the raw materials for petrochemical cracking having a high thermal decomposition yield by a hydrogenation reaction. The present invention is a petrochemical process for producing at least any of ethylene, propylene, butane, benzene or toluene by carrying out a thermal decomposition reaction at least using naphtha for the main raw material, wherein cracked kerosene produced from a thermal cracking furnace is hydrogenated using a Pd or Pt catalyst in a two-stage method consisting of a first stage (I), in which a hydrogenation reaction is carried out within the range of 50 to 180° C., and a second stage (II), in which a hydrogenation reaction is carried out within the range of 230 to 350° C., followed by re-supplying all or a portion of these hydrogenated hydrocarbons to a thermal cracking furnace.

Owner:SHOWA DENKO KK

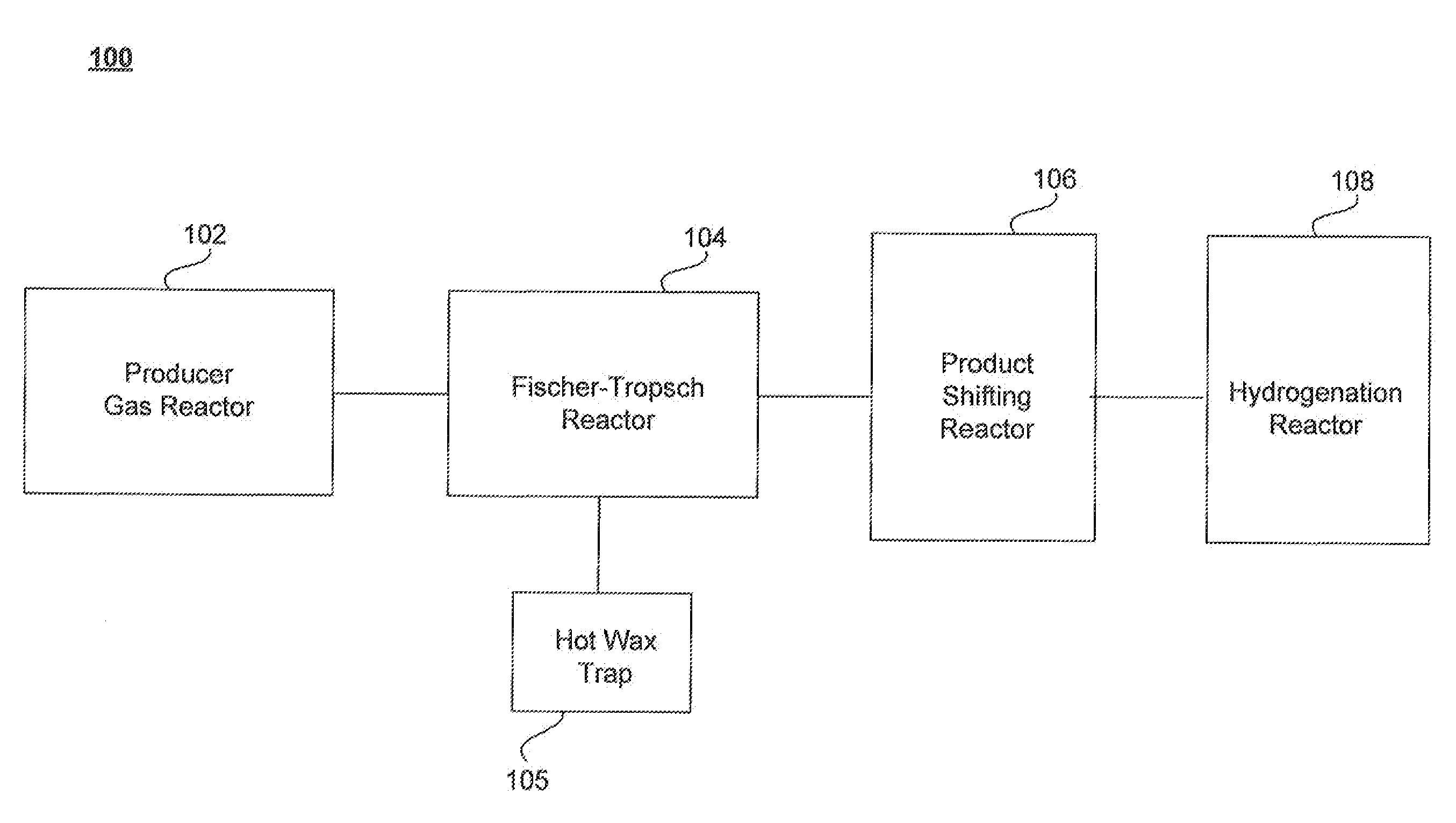

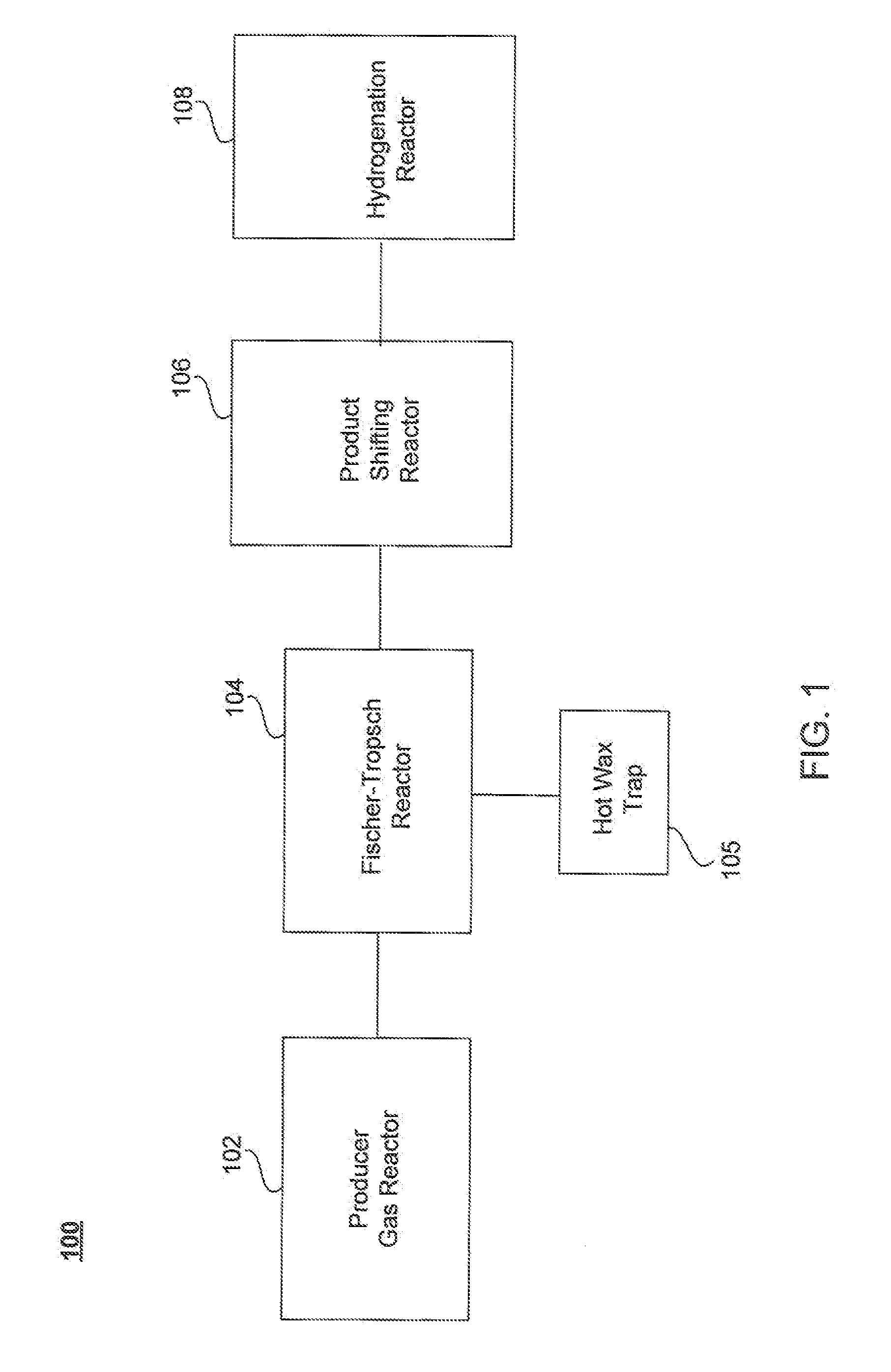

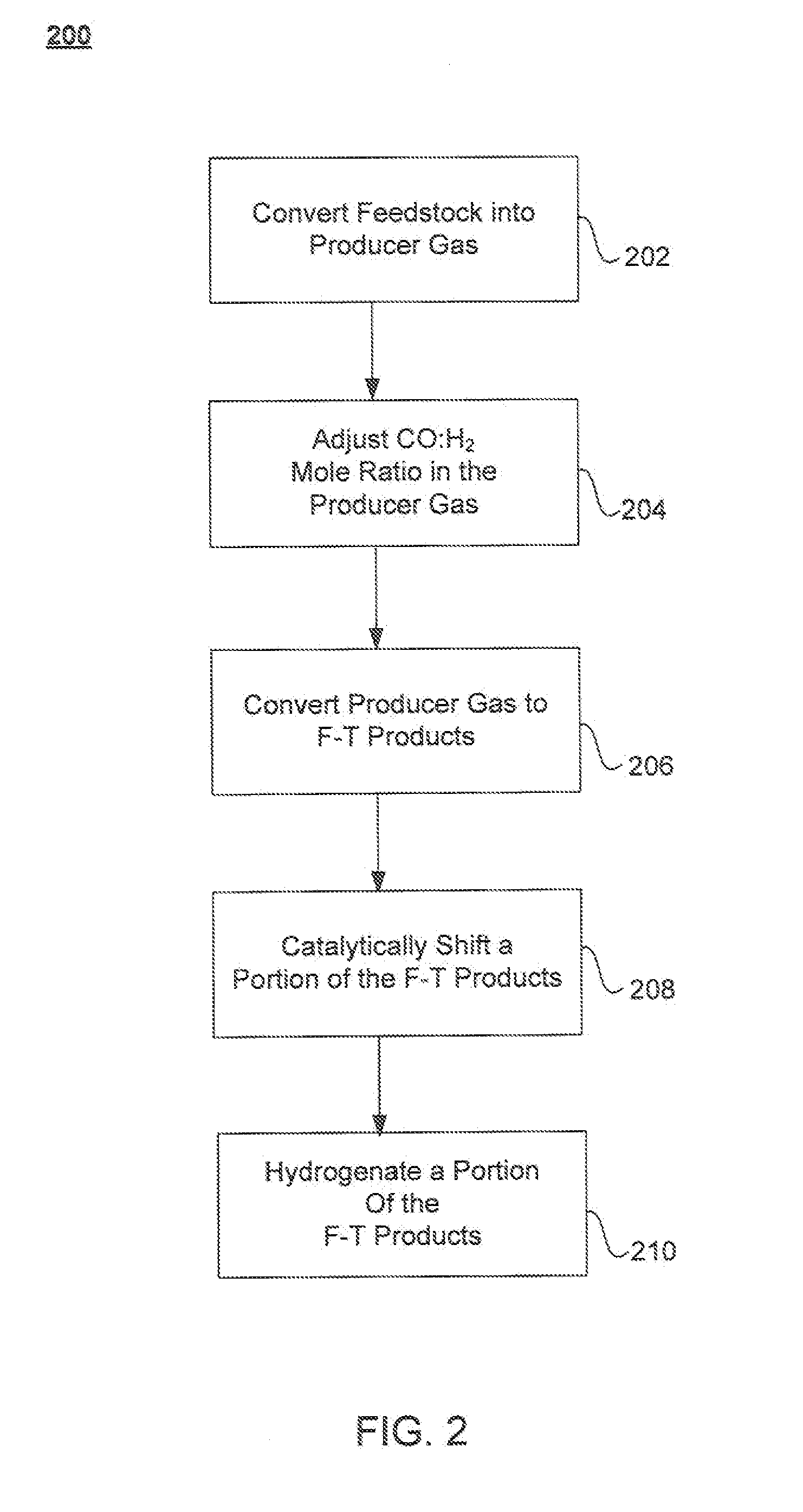

Conversion of biomass feedstocks into hydrocarbon liquid transportation fuels

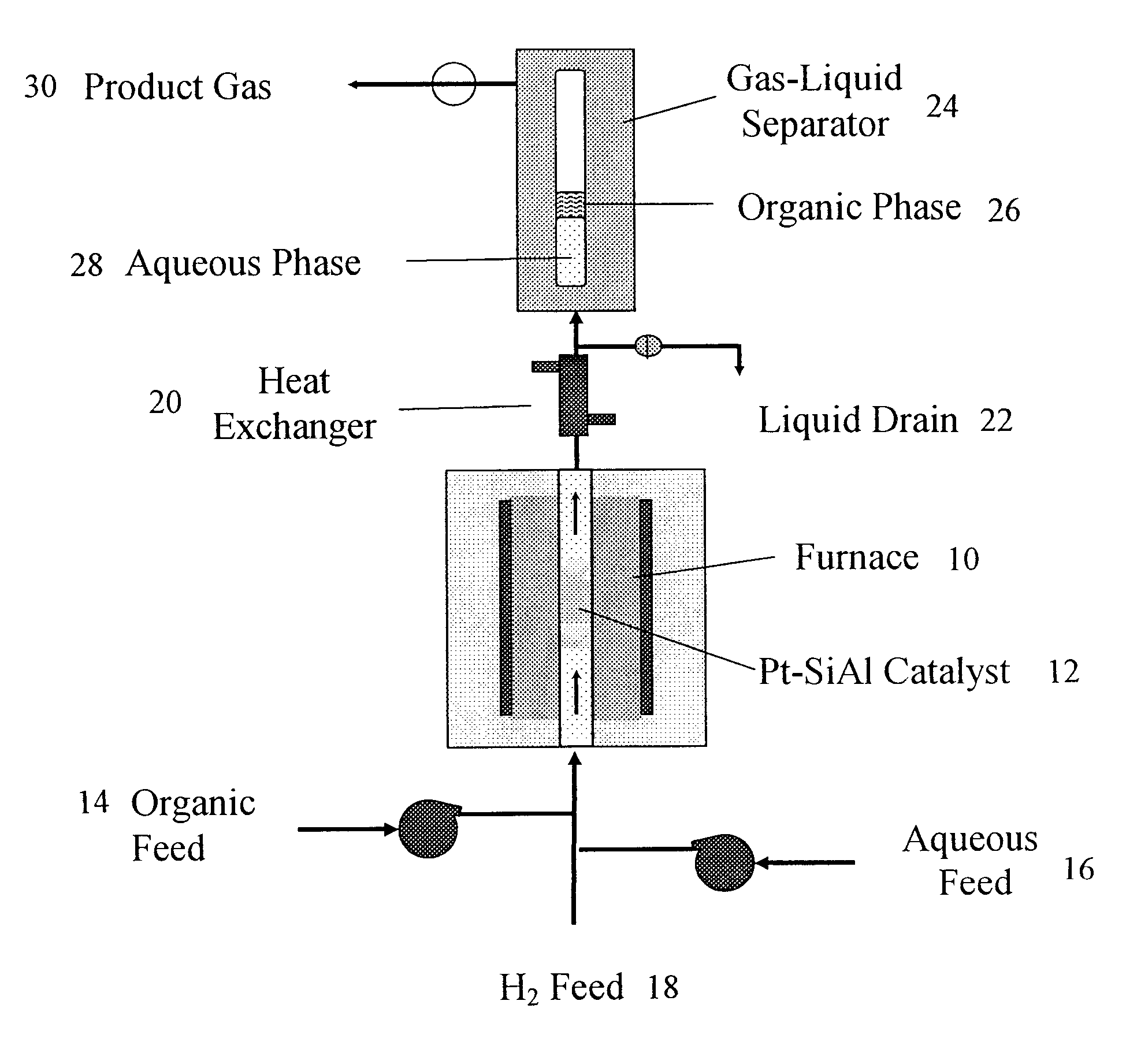

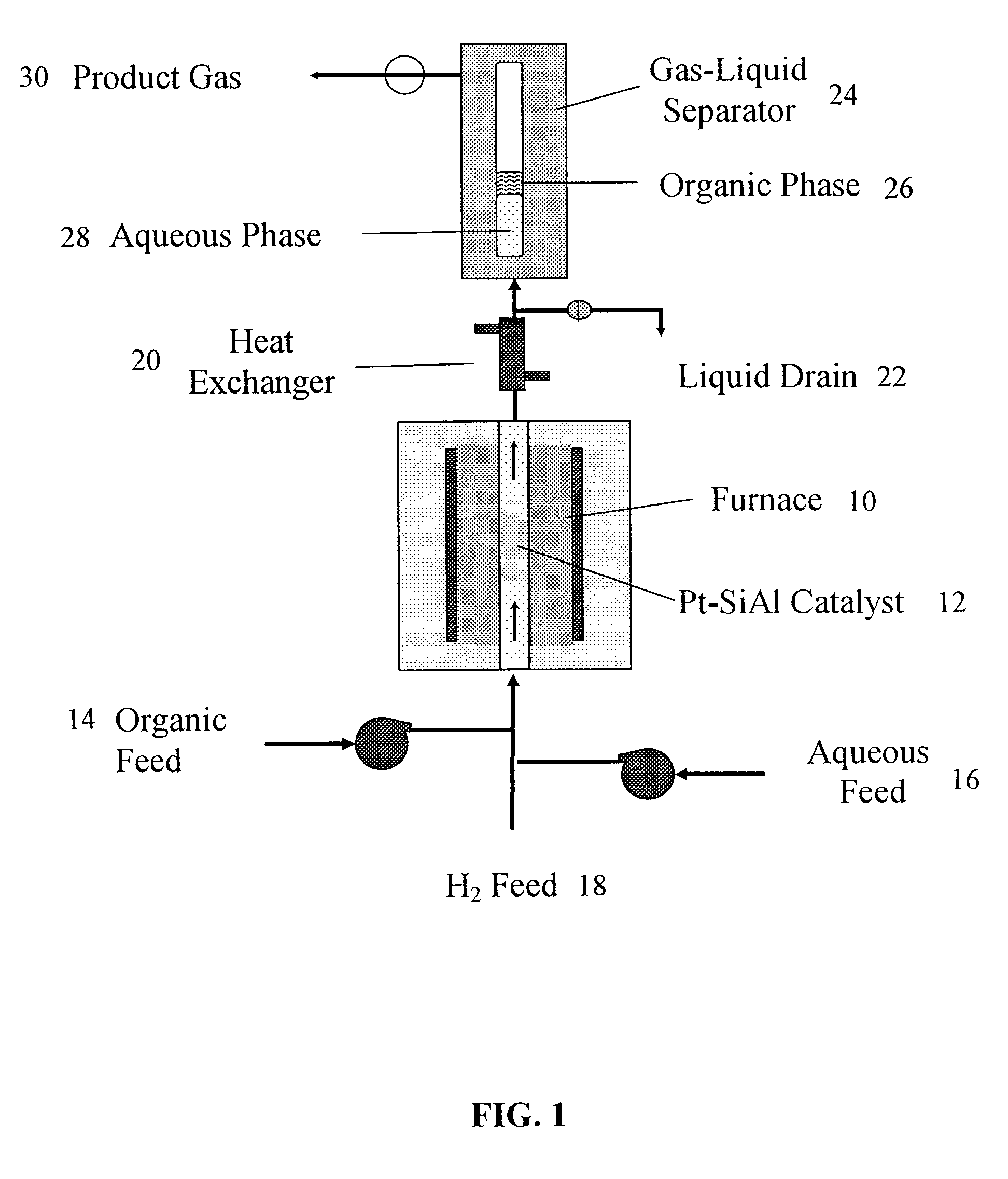

InactiveUS20100036181A1Reducing and even eliminating transportationReducing and even eliminating and distribution costLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesProduct gasHydrocarbon

Methods for converting a carbon-containing feedstock into a fluid transportation fuel are described. The methods may include converting the carbon-containing feedstock into a producer gas comprising H2, CO, CO2, and N2, and reacting the producer gas with a substrate catalyst to produce a combination of Fischer-Tropsch (F-T) products, the F-T products including the fluid transportation fuel. A portion of the F-T products may be catalytically cracked to produce additional amounts of the fluid transportation fuel. A portion of the F-T products may also be hydrogenated to produce additional amounts of the fluid transportation fuel. Apparatuses are also described or converting a carbon-containing feedstock into a fluid transportation fuel. The apparatuses may include a producer gas reactor, a Fischer-Tropsch reactor, a cracking reactor, and a hydrogenation reactor.

Owner:COMMUNITY POWER CORP

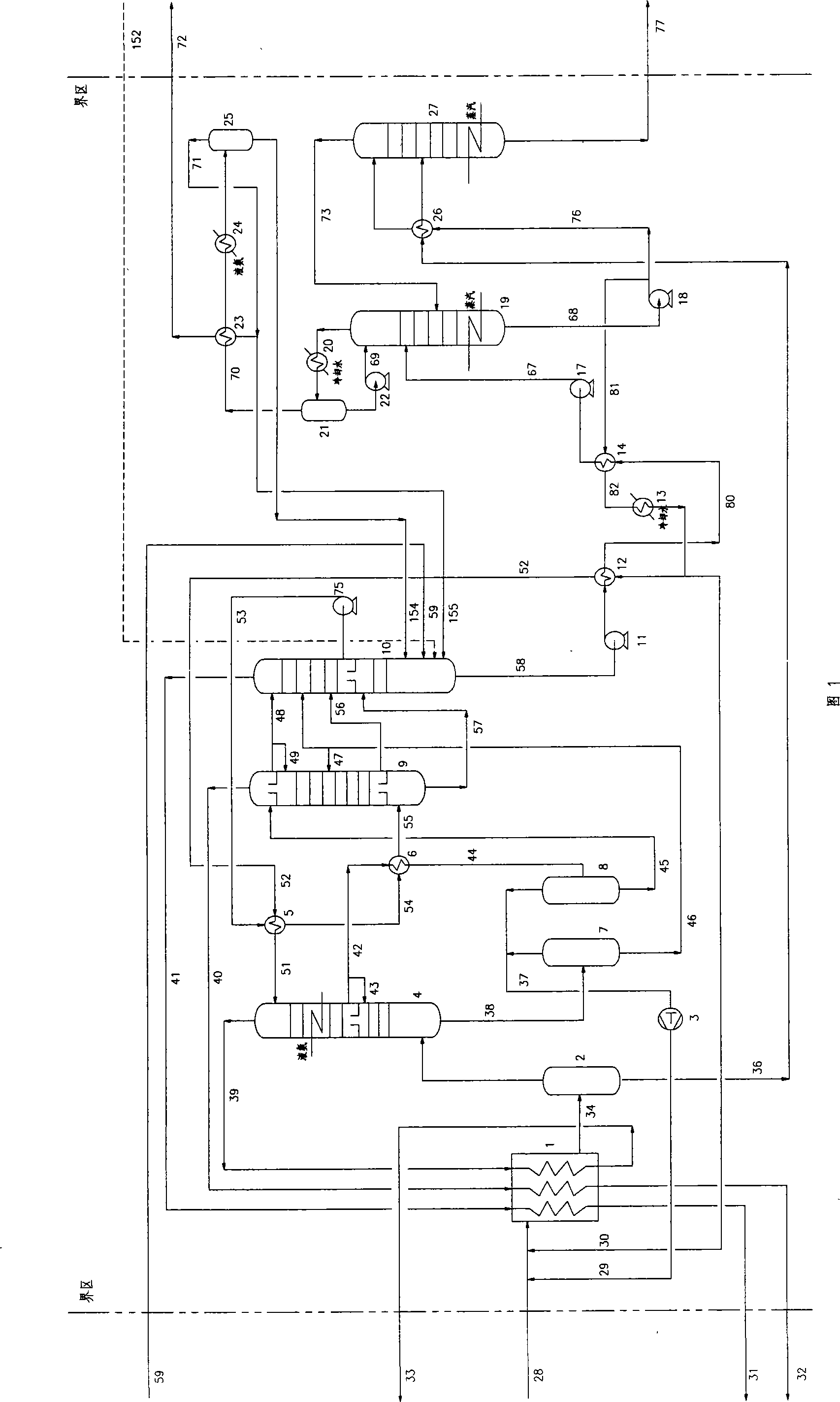

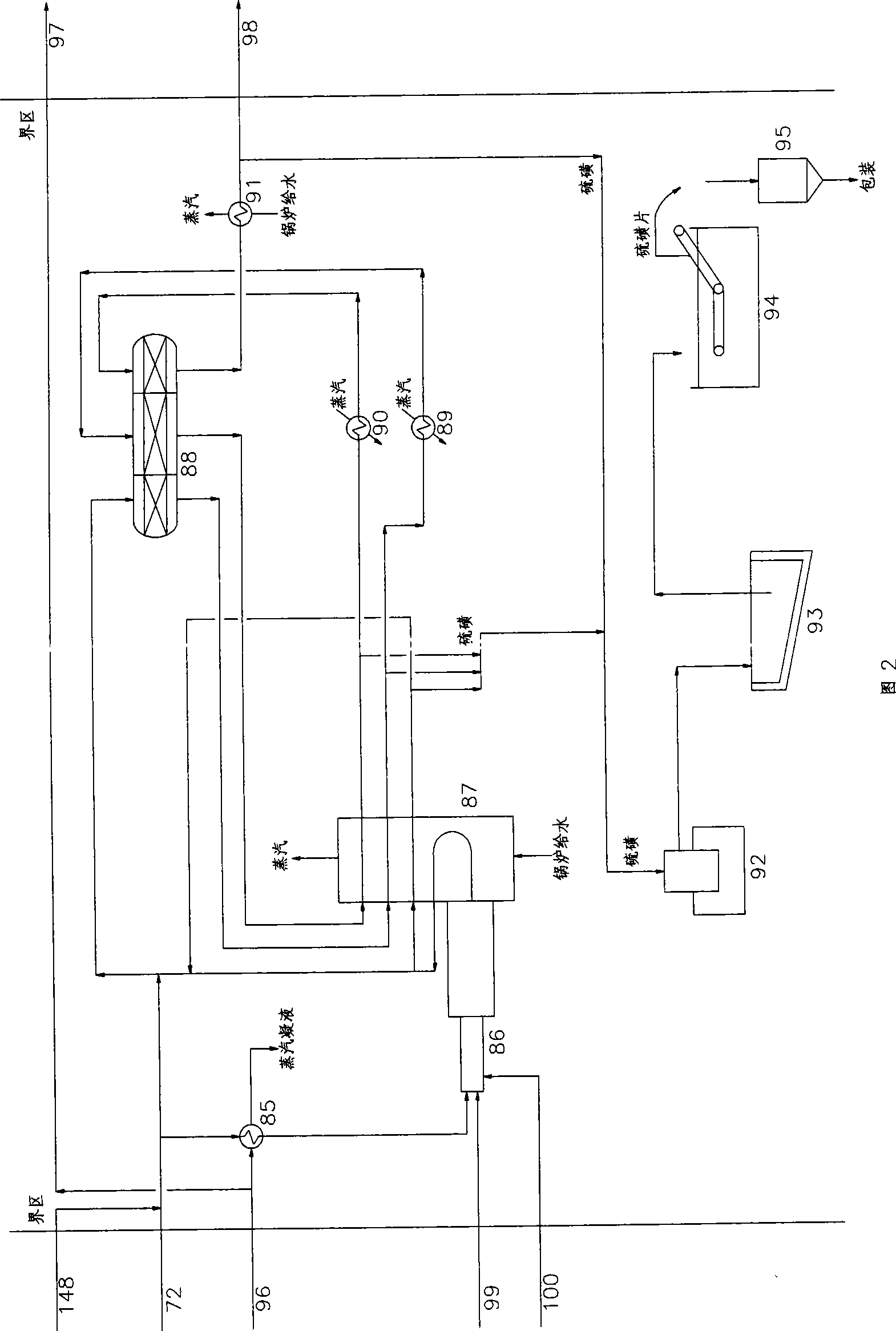

Low temperature methanol washing integrated Claus sulfur recovery system and process

ActiveCN101418246AFlexible processing capacityLow investment costProductsReagentsSulfurHydrogenation reaction

The invention relates to a reclaiming system and a process for low-temperature methanol washing integrated Claus sulfur of coal gas and natural gas. The system is additionally provided with a Claus tail gas washing tower and uses sulfur-free methanol saturated by CO2 from a CO2 product tower as a washing agent, and the washed liquid returns to an H2S concentrating tower; through combination of heating, gas stripping and pressure adjustment, concentration of H2S in acid gas washed by methanol is adjusted flexibly; at the same time, the system is additionally provided with a tail gas pre-heater before hydrogenation reaction to compensate heat loss of a hydrogenation reaction system. The process mainly comprises the following steps: removing H2S-CO2 gas, condensing H2S, reclaiming Claus sulfur, hydrogenising and reducing the gas, selectively absorbing and desulfurizing saturated cold methanol. The process has the advantages that the process can efficiently, flexibly, safely and energy-conservatively treat carbonyl gas with different pressures, temperatures, water content and sulfur concentration; and total sulfur reclamation ratio can reach more than 99.9 percent. The concentration of the H2S in emptied tail gas is below 25 mg / Nm3, so the H2S gas can meet the requirement of environmental protection, and can be exhausted directly without being burnt.

Owner:HUALU ENG & TECH

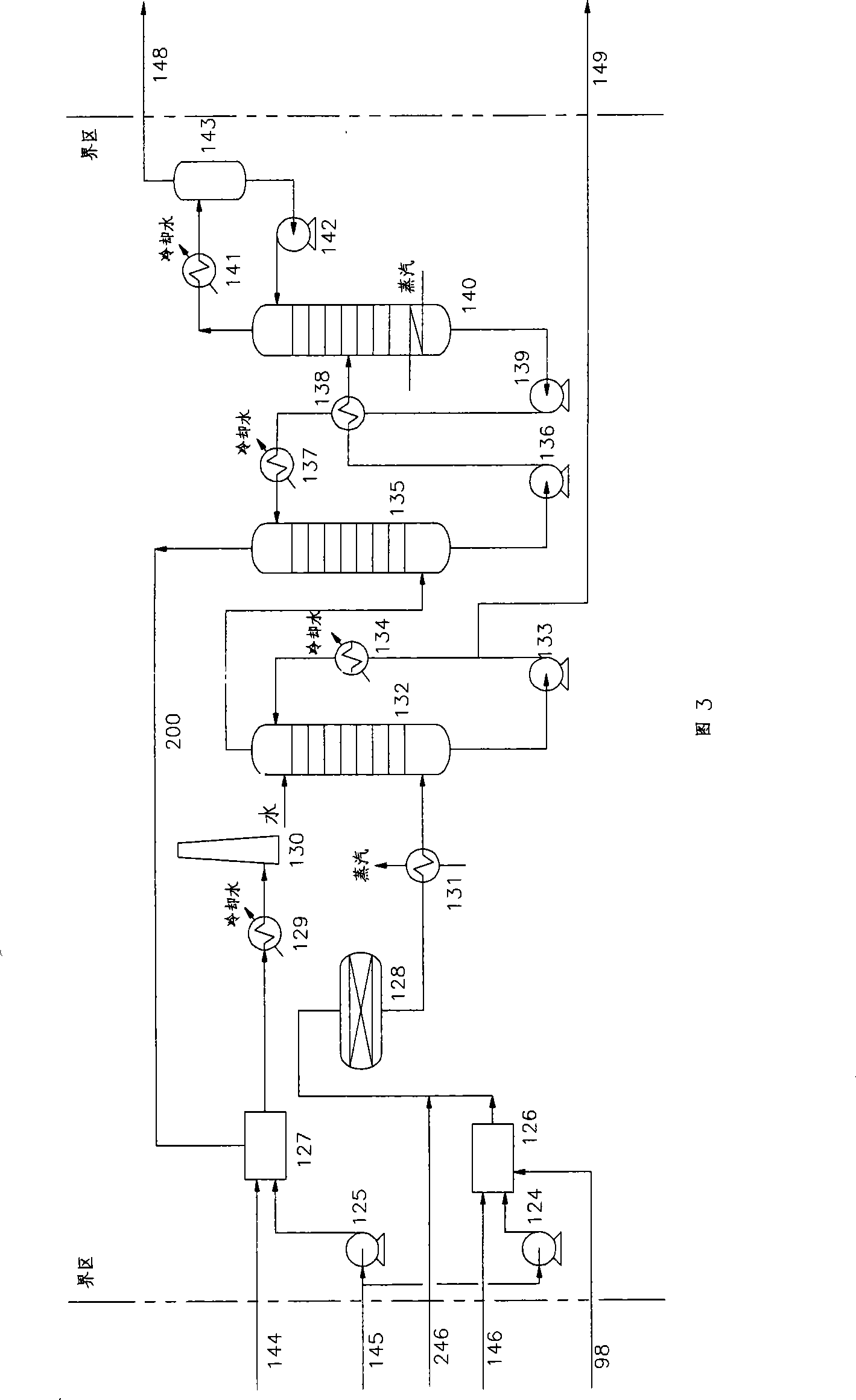

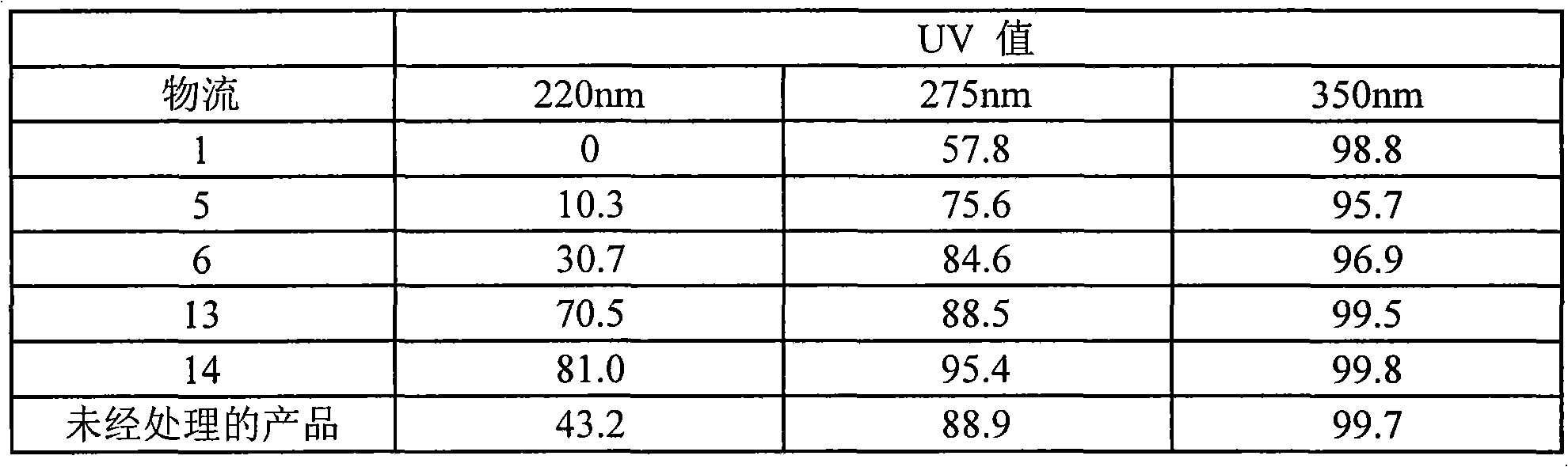

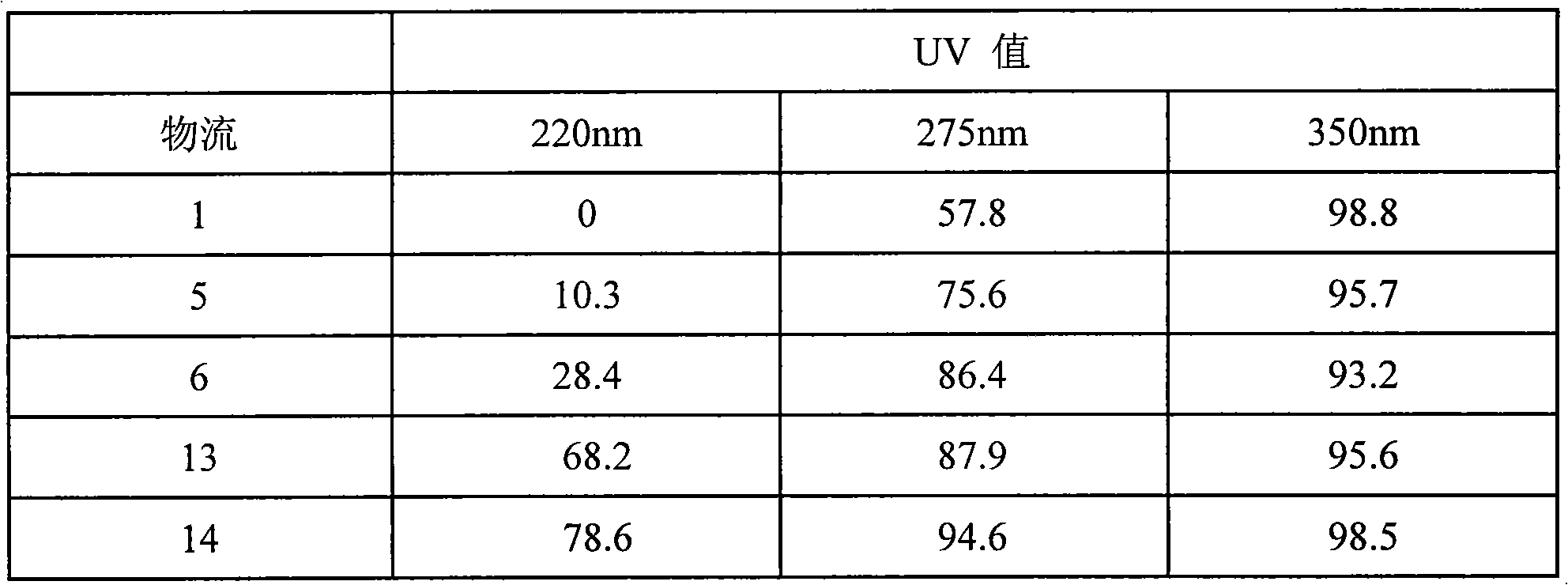

Purification technique for coal glycol rude products

ActiveCN101928201AHigh purityReduce energy consumptionOrganic compound preparationHydroxy compound separation/purificationChemical industryPolyester

The invention belongs to the technical field of chemical industry, in particular to a purification technique for coal glycol rude products. According to the technique, saponification, carbinol-removal, hydrogenation reaction, three-column distillation and absorption treatment are utilized to prepare the glycol with a mass percent more than 99.9% from the coal glycol rude products and the polyester glycol products having high transmissivity to the ultraviolet with wavelength between 220 and 350 mm. The purification technique for coal glycol rude products of the invention is characterized by low energy consumption, easy operation and high efficiency.

Owner:SHANGHAI HUAYI ENERGY CHEM

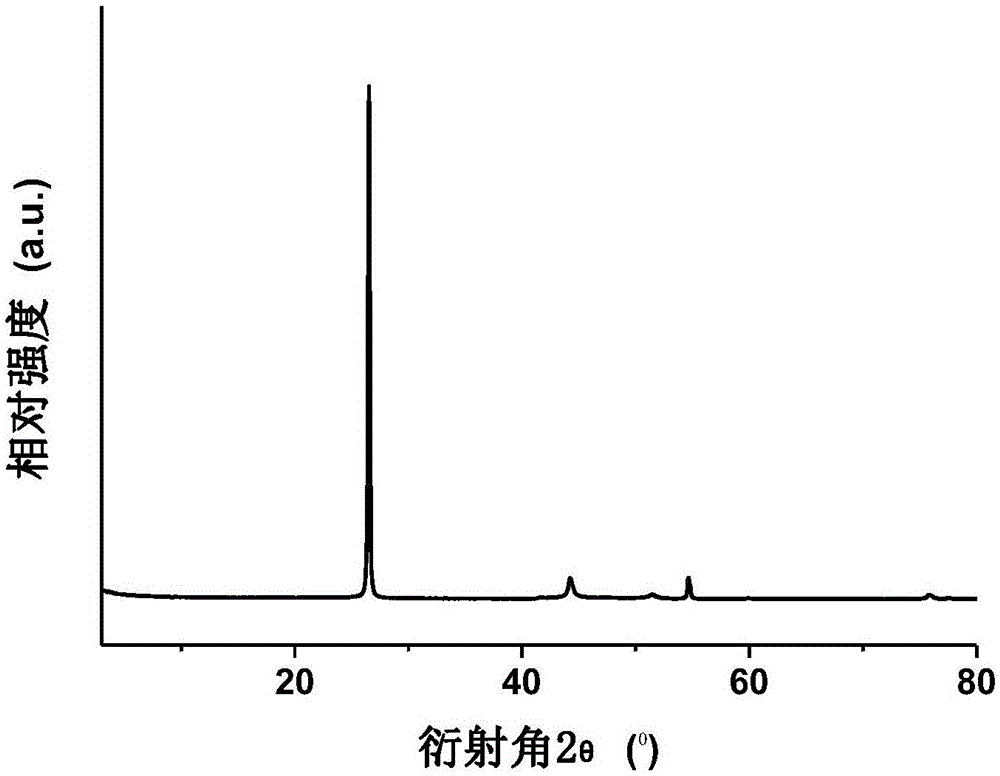

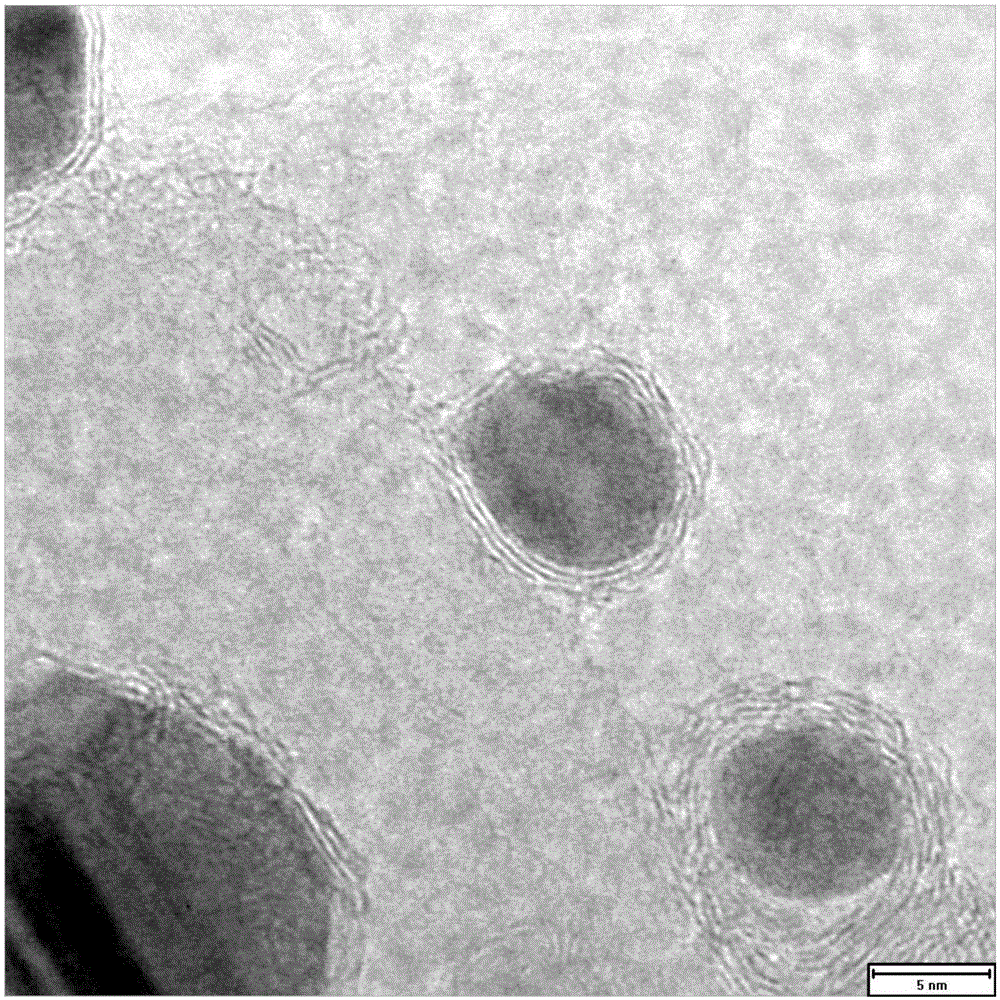

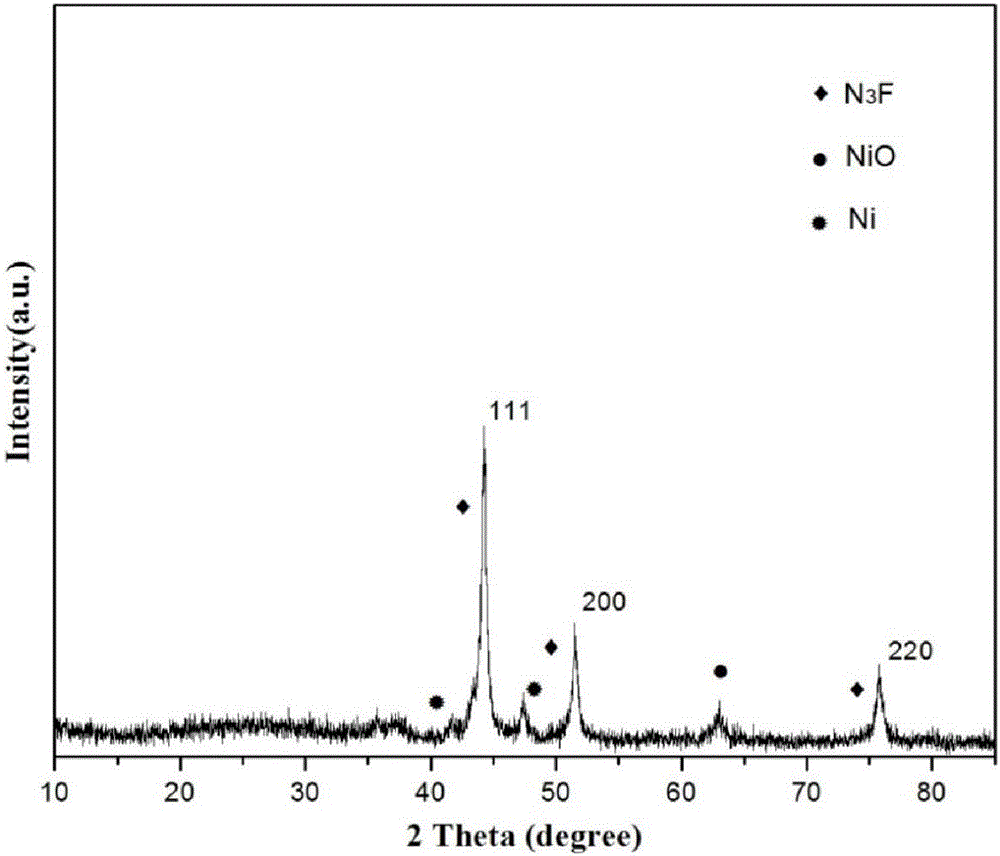

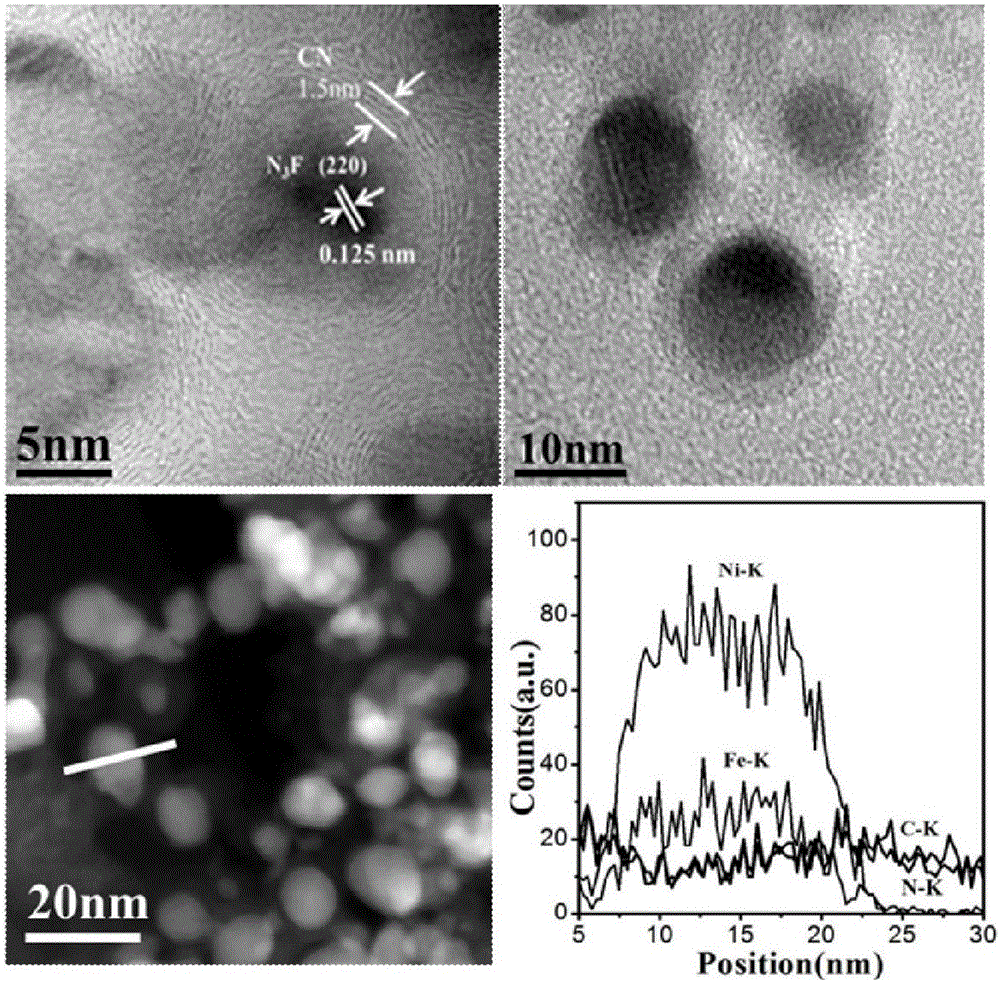

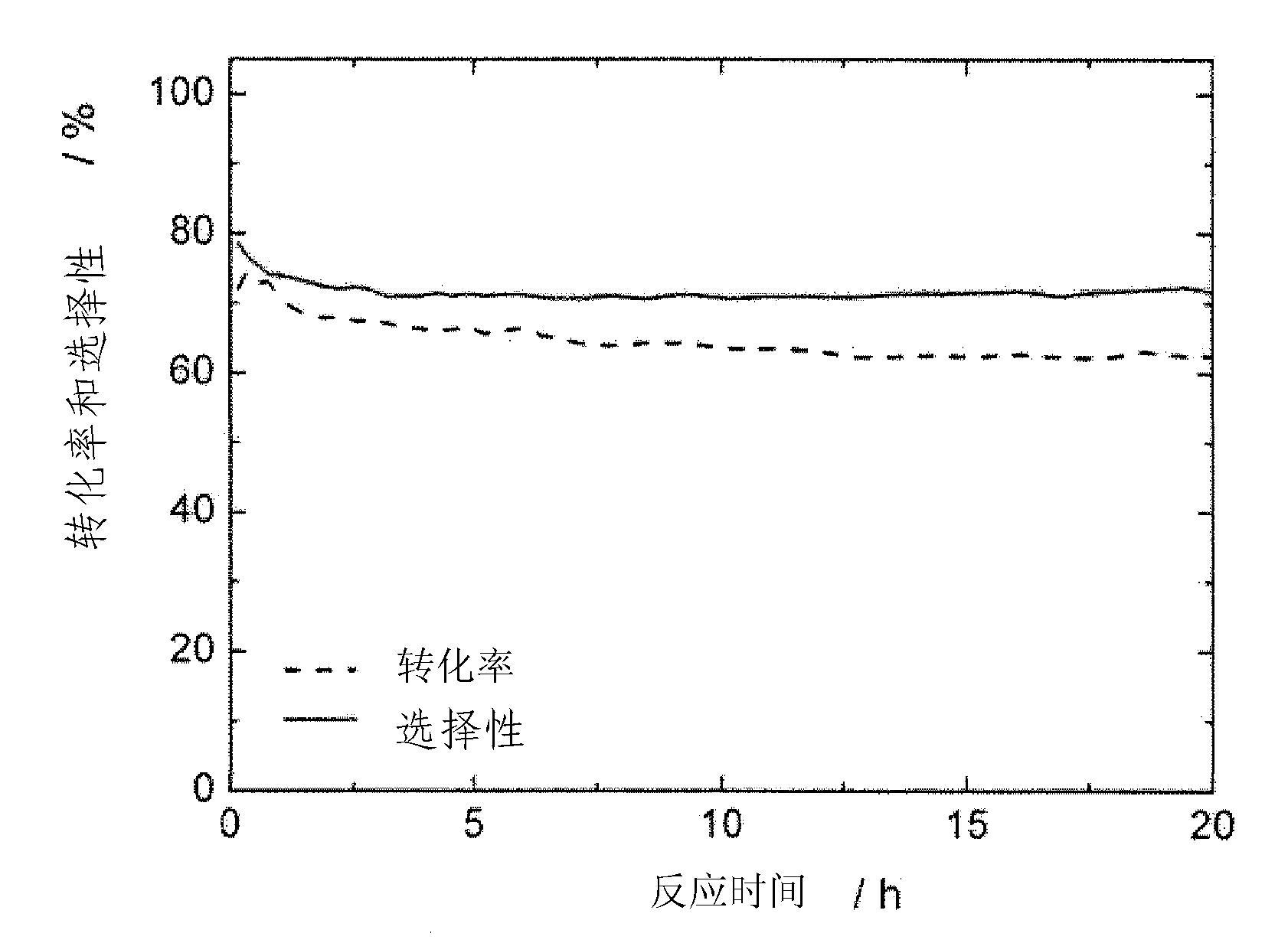

Preparation of nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst and application thereof in catalyzing o-chloronitrobenzene hydrogenation reaction

ActiveCN106732733AMaterial nanotechnologyPhysical/chemical process catalystsNano catalystNitro compound

The invention provides a preparation method of a nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst and the application of the nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst in catalyzing an o-chloronitrobenzene hydrogenation reaction. According to the method, the novel nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst is prepared by synthesizing a ferronickel layered doubled hydroxide precursor with small grain size and high surface energy through a nucleation crystallization isolation method, evenly mixing the ferronickel layered doubled hydroxide precursor with a melamine and dicyandiamide mixed carbon material precursor, and finally self-reducing at high temperature. The nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst is efficiently applied to the reaction where halogenated aniline is generated through catalytic hydrogenation of a nitro-halogen compound, and the conversion rate of o-chloronitrobenzene and the selectivity of o-chloroaniline are respectively up to 95-100% and 98-100%. The structure of the novel nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst is unique and novel, the process is green and energy-saving, the structure of the catalyst is stable, and the catalyst has a broad application prospect.

Owner:BEIJING UNIV OF CHEM TECH

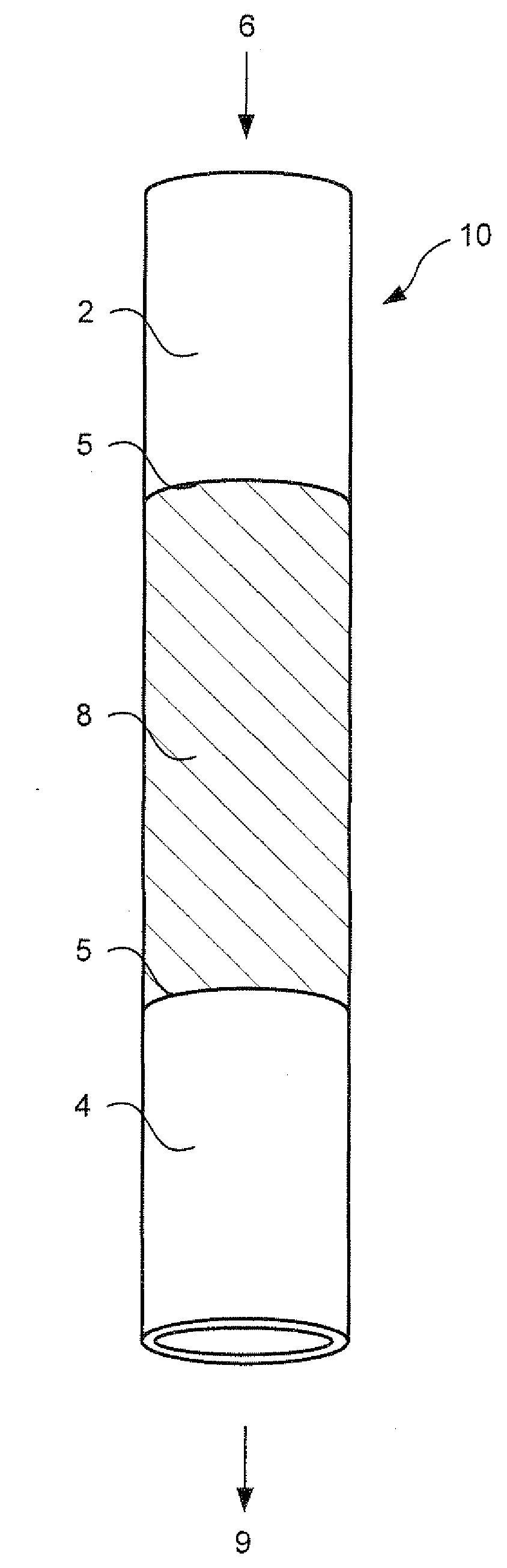

Ordered cobalt-aluminum and iron-aluminum intermetallic compounds as hydrogenation catalysts

InactiveCN102369074ALow costHigh selectivityPolycrystalline material growthHydrocarbon by hydrogenationPtru catalystUnsaturated hydrocarbon

The present invention relates to a process for the hydrogenation, in particular the selective hydrogenation of unsaturated hydrocarbon compounds, such as the selective hydrogenation of acetylene to ethylene, using a hydrogenation catalyst comprising an ordered intermetallic compound, namely an ordered cobalt- aluminum or iron- aluminum intermetallic compound. According to another aspect, the present invention relates to a catalyst comprising a support and at least one specific ordered cobalt -aluminum and / or iron-aluminum intermetallic compound supported thereon, as well as to the use of specific ordered intermetallic cobalt-aluminum and iron -aluminum intermetallic compounds as catalysts. The ordered cobalt-aluminum and iron-aluminum intermetallic compounds proved to be highly selective and long-term stable catalysts, e.g. in the selective hydrogenation of acetylene to ethylene in a large excess of ethylene.

Owner:MAX PLANCK SOCIETY FOR THE ADVANCEMENT OF SCI +1

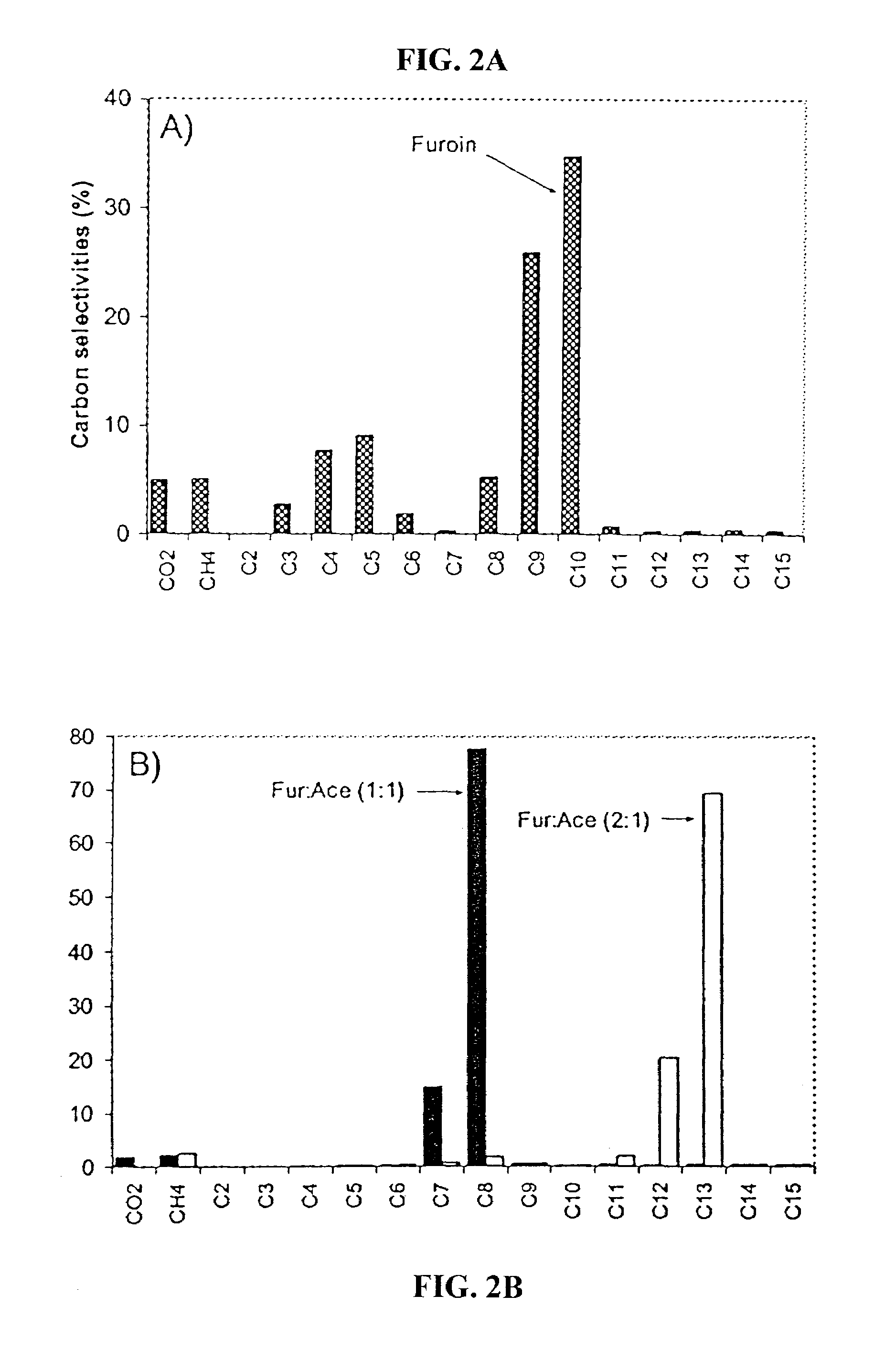

Method to make alkanes and saturated polyhydroxy compounds from carbonyl compounds

ActiveUS7671246B2Hydrocarbon by hydrogenationHydrocarbon purification/separationAldol condensationPolyhydroxy compound

Owner:WISCONSIN ALUMNI RES FOUND

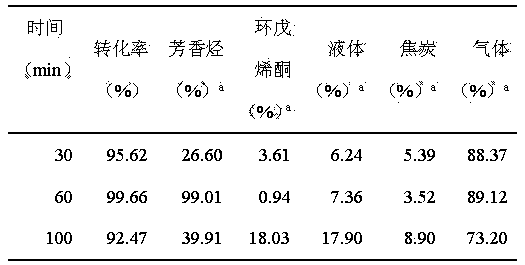

Method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion

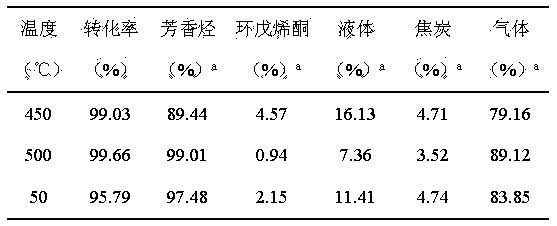

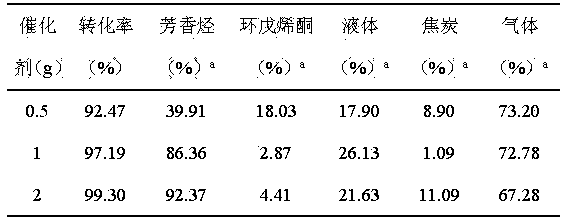

InactiveCN104230615AGood dehydrogenation performanceInhibition of partial polymerizationHydrocarbonsPreparation from heterocyclic compoundsLiquid productReaction temperature

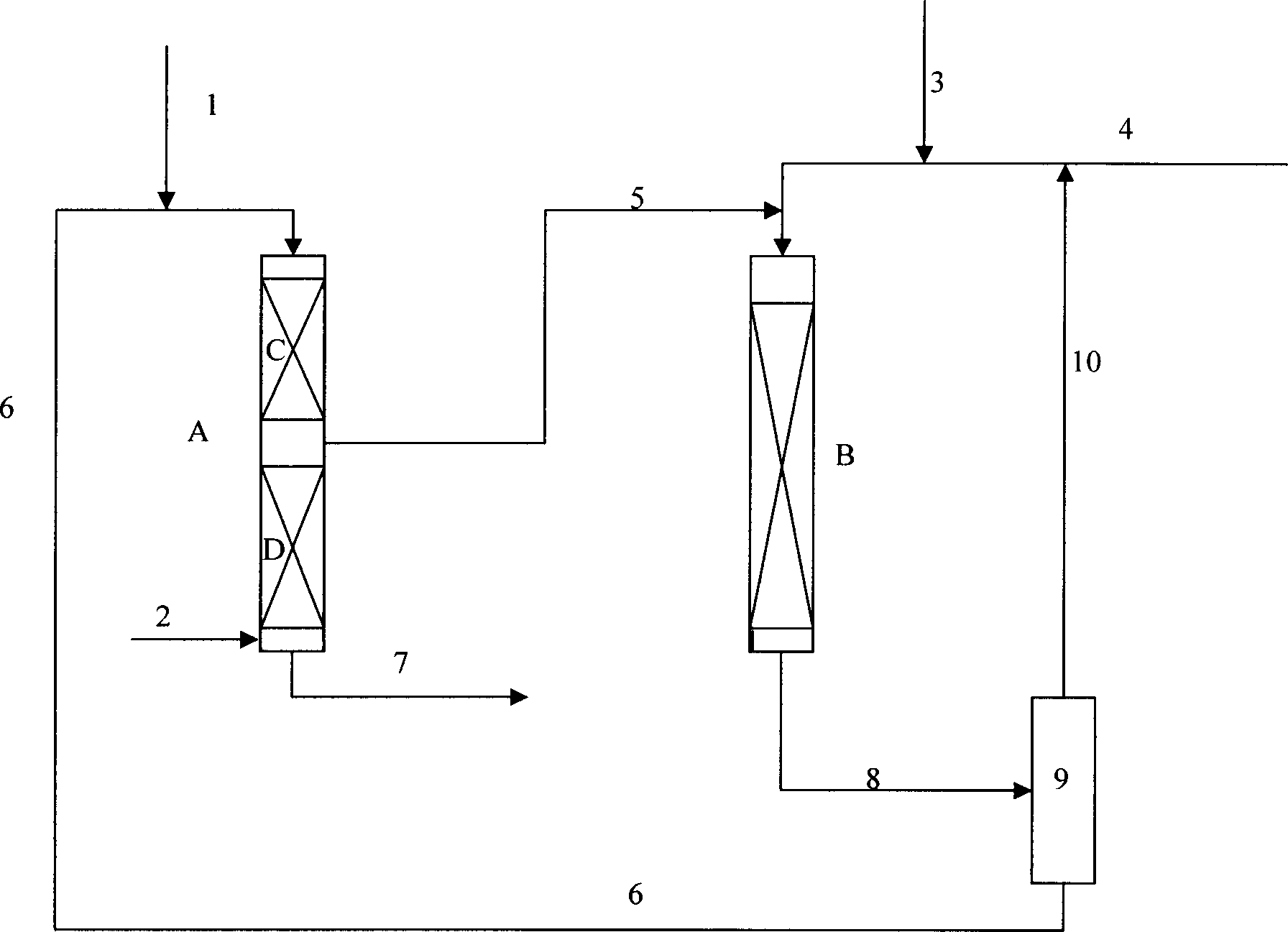

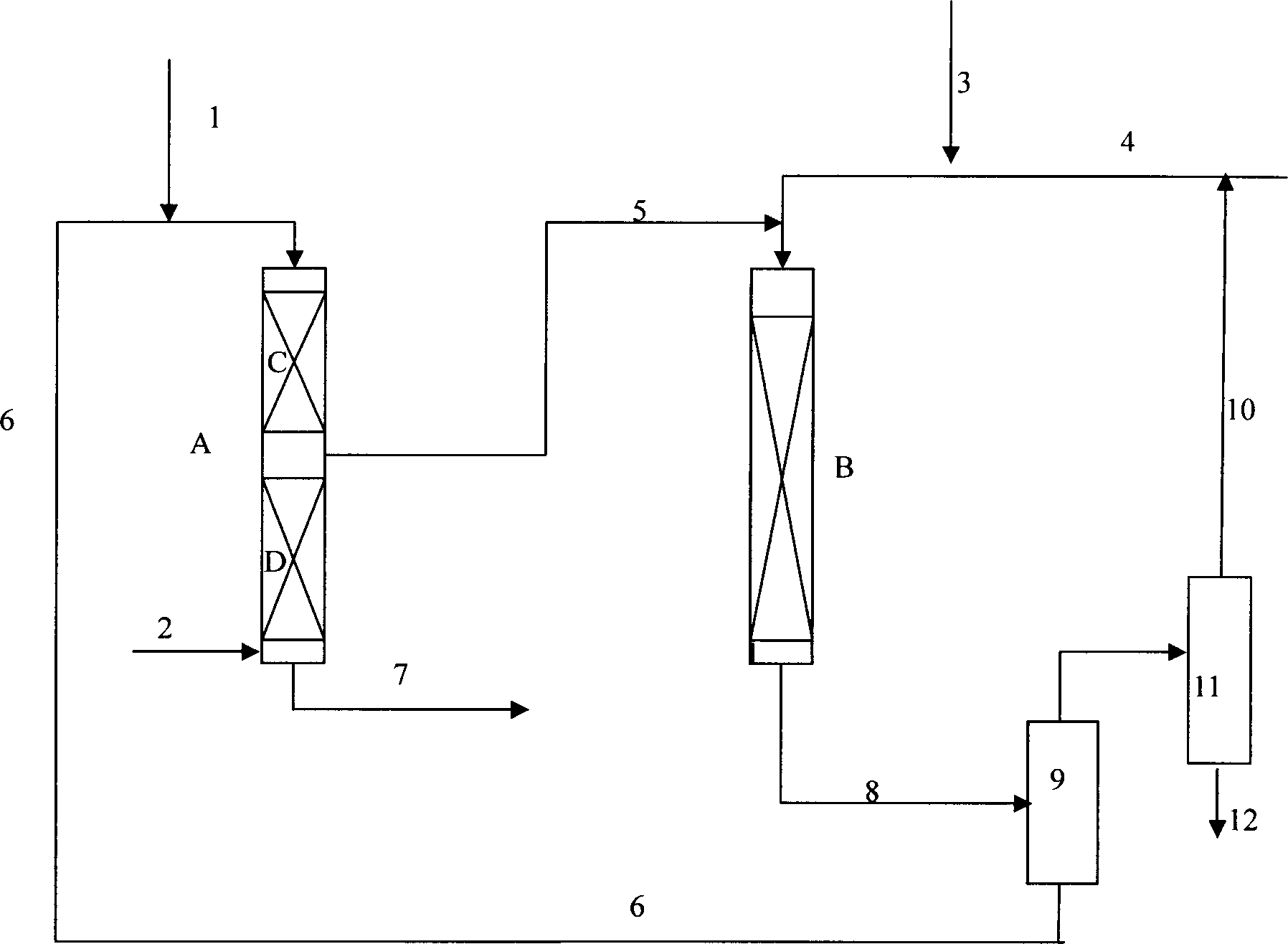

The invention relates to a method for preparing aromatic hydrocarbon and cyclopentenone from biomass derivative gamma-valerolactone by catalytic conversion, which comprises the following steps: (1) using biomass derivative gamma-valerolactone as a raw material, which is prepared by carrying out hydrogenation reaction on levulinic acid; (2) introducing one or more transition metals into a zeolite molecular sieve, and preparing a reaction catalyst at the reaction temperature of 350-550 DEG C by using a fixed bed or fluid bed as a reactor; (3) in an inert or reducing atmosphere, carrying out contact reaction on the raw material gamma-valerolactone and catalyst under the reaction pressure of 0-10 MPa; and (4) after the pyrolysis gas is condensed, collecting the liquid product in the condensation receiver, thereby obtaining the aromatic hydrocarbon product (of benzene, toluene and xylene) and the cyclopentenone product. By using the renewable biomass derivative gamma-valerolactone as the raw material, the method has the advantage of milder reaction conditions, and the catalyst is simple to prepare and easy to recover and reuse.

Owner:湖南清欣绿色环保有限公司

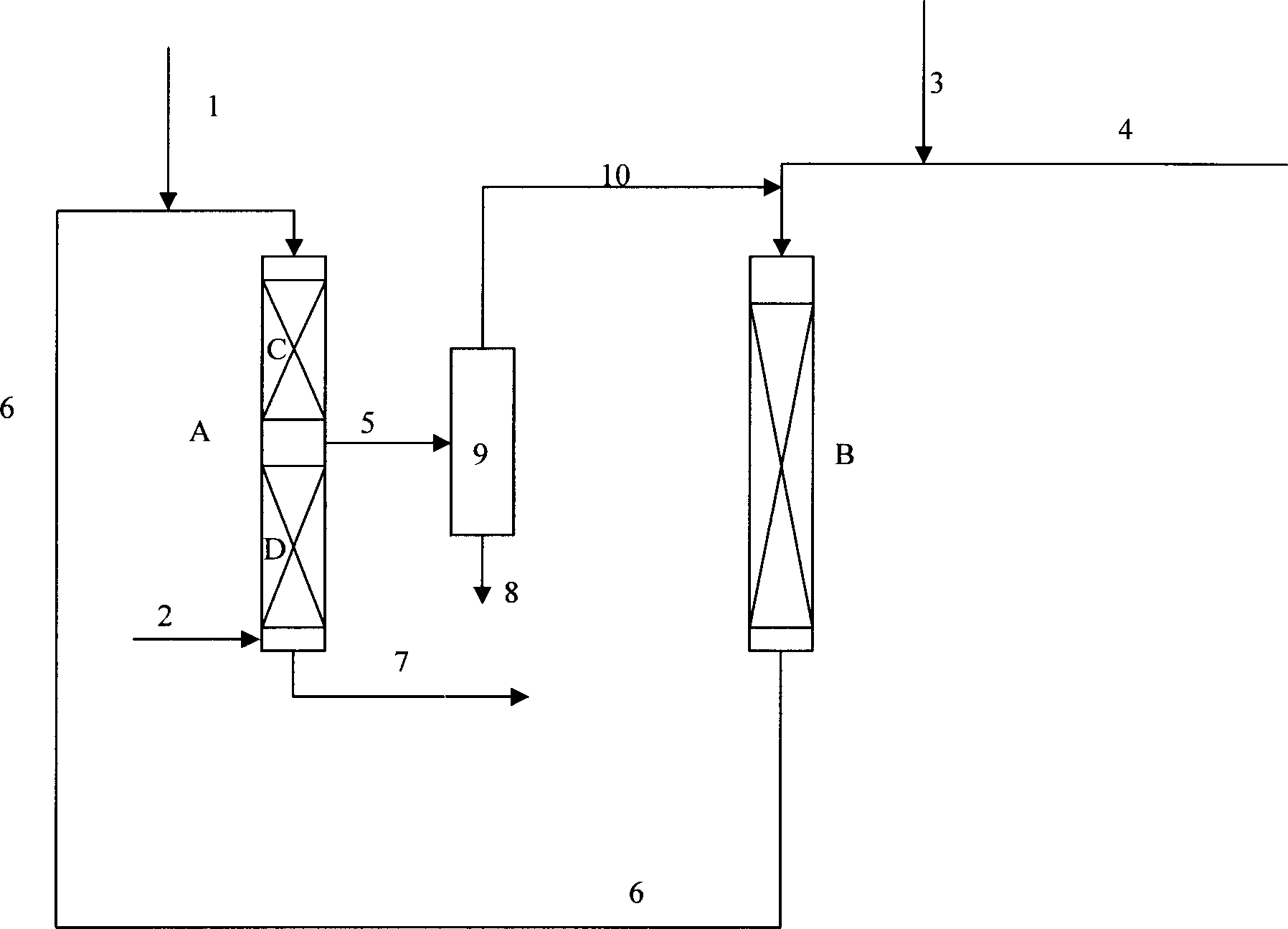

Deep desulphurizing and dearomating process for diesel oil

InactiveCN1552812AReduce loadIncrease flexibilityRefining to eliminate hetero atomsHydrodesulfurizationHydrogenation reaction

The invention relates to deep desulfurization and dearomatization of diesel fuel. A conventional co-current hydrofining reactor is connected with deep hydrodesulfurization and dearomatization reactors. Raw oil gets through the conventional hydrofining reactor firstly, reacted liquid phase material is mixed with fresh hydrogen to feed into the tops of deep hydrodesulfurization and dearomatization reactors, taking gas-liquid co-current hydrogenation, and then, reacted material is separated in gas-liquid separating zone. Gas phase is discharged and fed into the conventional hydrofining reactor, and liquid phase flows down to contact with fresh hydrogen inlet from the bottom of the reactor, finally, refined product is discharged from the bottom of the reactor. The invention process eliminates hepatic gas etc. impurity influence to arena saturation reaction in deep hydrodesulfurization and dearomatization reacting system of process now available, utilizes fully fresh hydrogen resource in the system, improves system reacting activity, usability of different raw oil, controllability and stability of counter- current hydrogenation reaction, and has better flexibility.

Owner:CHINA PETROLEUM & CHEM CORP +1

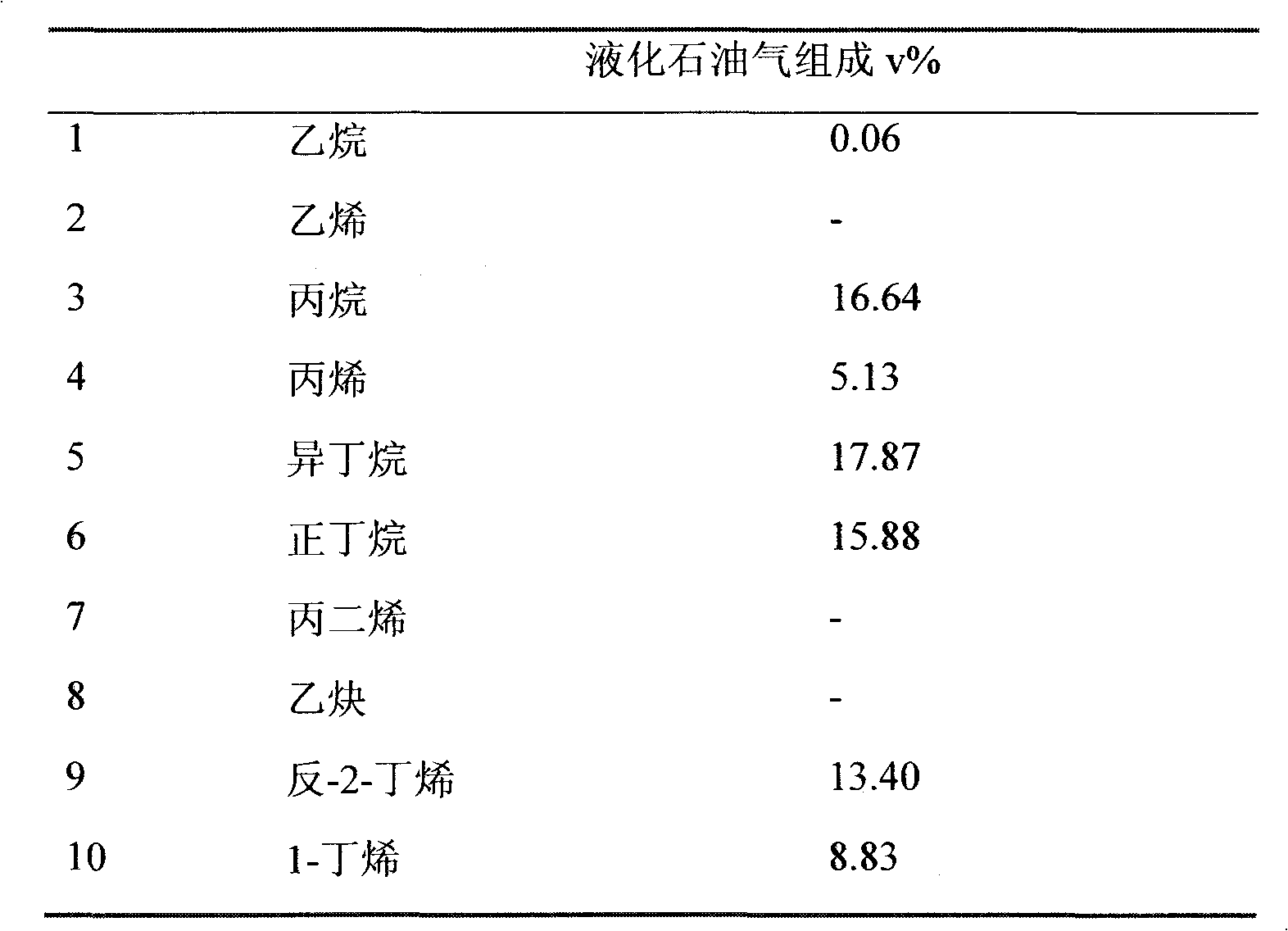

Liquefied petroleum gas-coke gasoline hydrogenation combined process method

ActiveCN102311783AFacilitated DiffusionEasy to take outTreatment with hydrotreatment processesRefining to eliminate hetero atomsHydrogenation reactionGasoline

The invention discloses a liquefied petroleum gas-coke gasoline hydrogenation combined process method, which comprises the following contents: coke gasoline undergoes a hydrogenation reaction in a coke gasoline hydrogenation reaction stage; the efflux of the coke gasoline hydrogenation reaction stage is mixed with the liquefied petroleum gas to enter a liquefied petroleum gas hydrogenation reaction stage; and the reaction efflux of the liquefied petroleum gas hydrogenation reaction stage is subjected to separation to obtain hydrogenated liquefied petroleum gas and hydrogenated coke gasoline. Compared with the prior art, the method disclosed by the invention is favorable for dissipation of reaction heat, lowers reaction temperature, reduces the influences of temperature on reaction balance and improves conversion rate; and the method reduces carbon accumulation of the catalyst, prolongs the single-pass service life of the catalyst and can obtain high-quality hydrogenated coke gasoline and hydrogenated liquefied petroleum gas at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

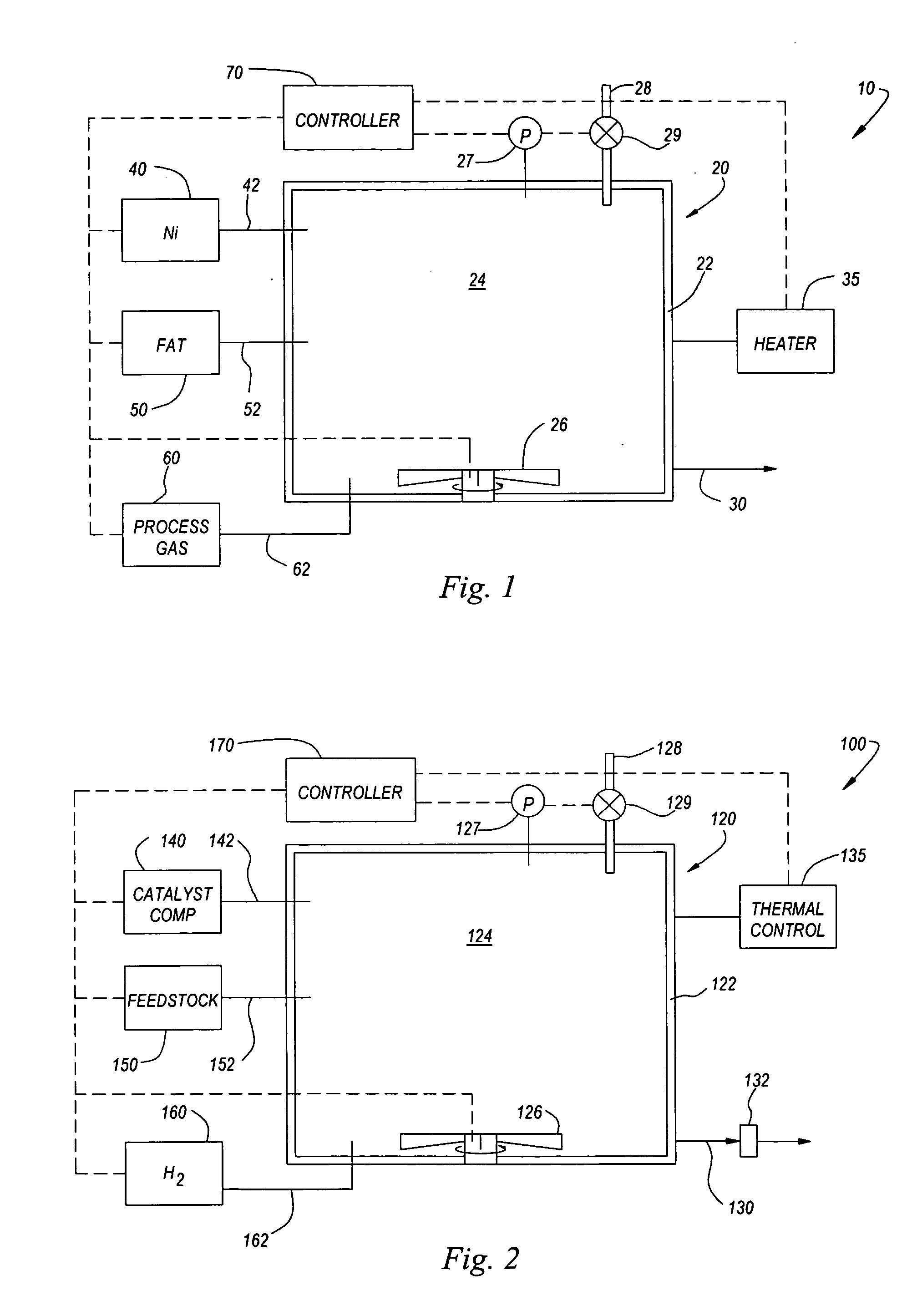

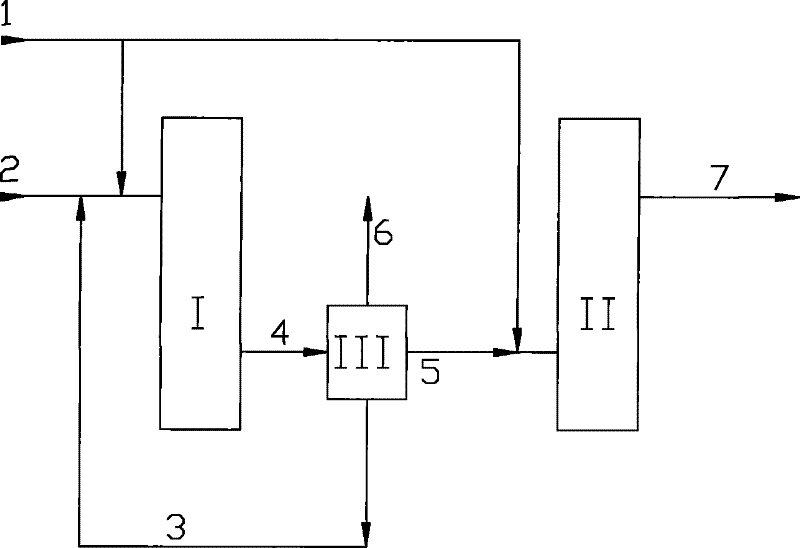

Low trans-fatty acid fat compositions; low-temperature hydrogenation, e.g., of edible oils

InactiveUS20050027136A1Fatty acid hydrogenationOrganic compound preparationPartial hydrogenationHydrogenation reaction

The present disclosure provides low trans-fatty acid fat compositions, methods of hydrogenating unsaturated feedstocks (e.g., oils), and hydrogenation catalyst compositions. One exemplary method involves producing an activated catalyst composition by heating a nickel-based catalyst to a first temperature of at least about 100° C. in the presence of hydrogen and a fat component. An unsaturated feedstock may be contacted with the activated catalyst composition and hydrogenated by sustaining a hydrogenation reaction at a second temperature of no greater than about 70° C. Some specific implementations of the invention permit the production of partially hydrogenated seed oils with low trans-fatty acid contents.

Owner:CARGILL INC

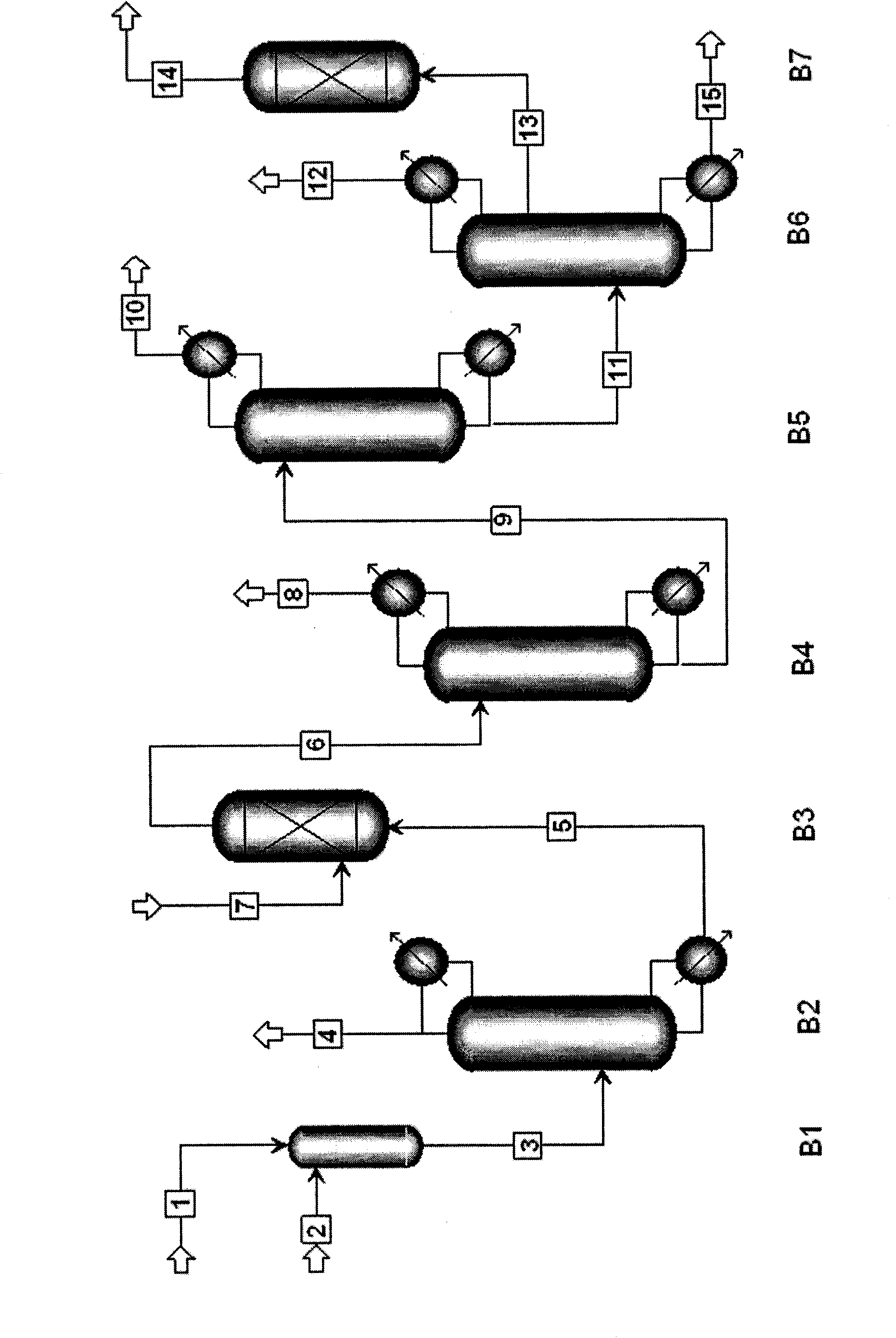

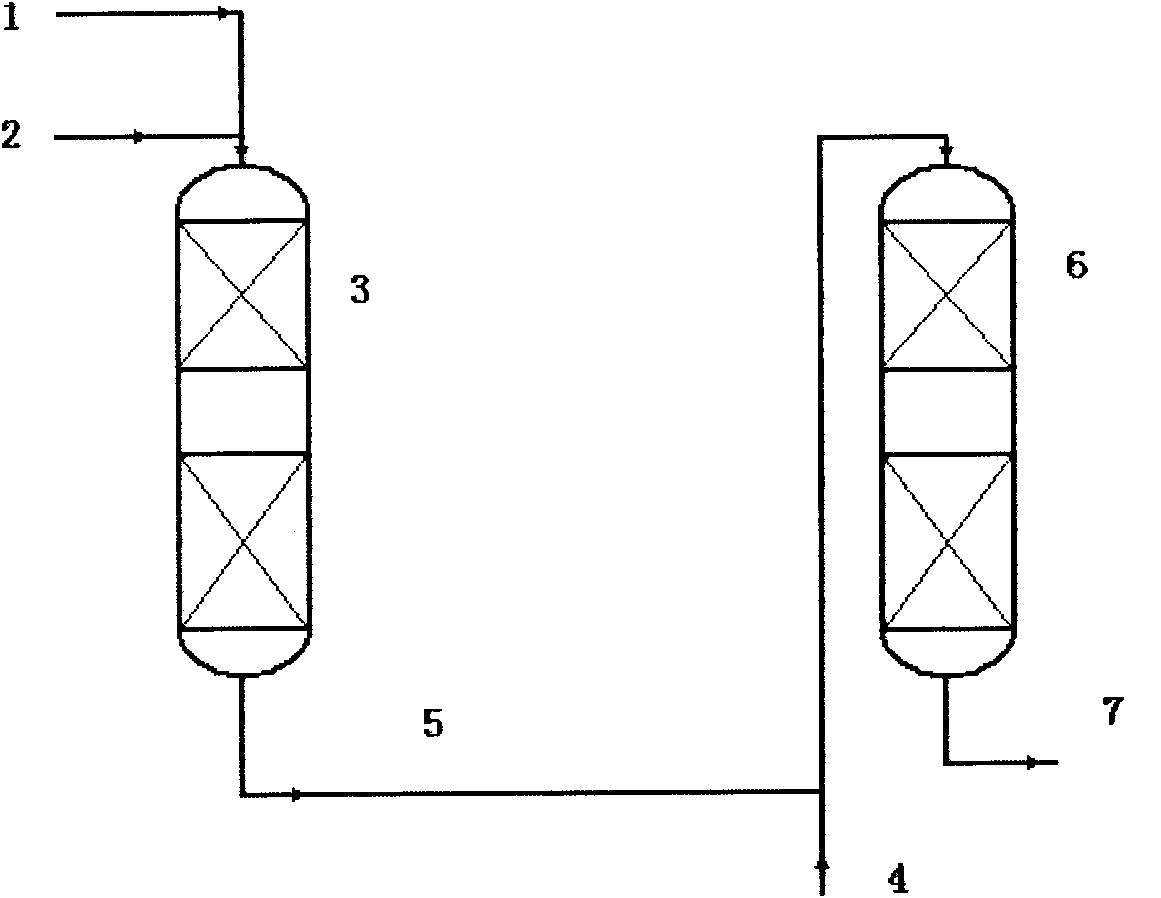

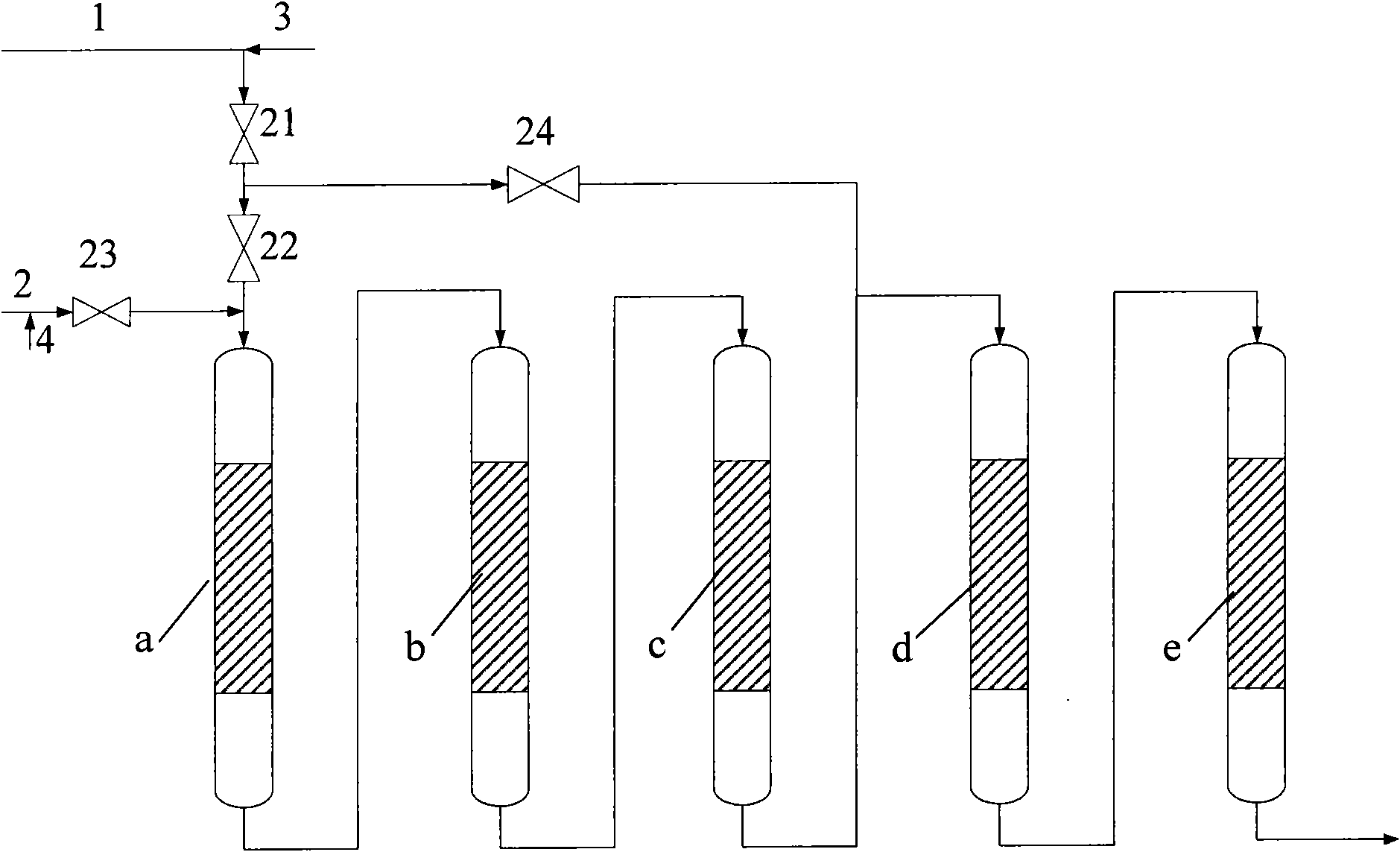

A selective hydrogenation process for C4 stream with high butadiene content

ActiveCN102285859AReasonable useHydrocarbon by hydrogenationHydrocarbon purification/separationHigh concentrationButene

The invention relates to a selective hydrogenation process for a C4 material flow with high concentration of butadiene. The selective hydrogenation process comprises the following steps of: enabling the C4 material flow with the high concentration of butadiene to pass through one or more fixed bed hydrogenation reactors (I) with circulation pipelines, carrying out a selective hydrogenation reaction on the C4 mixture with high concentration of butadiene under the action of a catalyst to remove the butadiene and alkyne and generate butylene, enabling the reactor to pass through a terminal reactor (II) without the circulation pipeline, and further removing the residual butadiene and alkyne from the C4 material flow with the low concentration of butadiene. By utilizing the selective hydrogenation process and the catalyst provided by the invention, the controlled concentration range of the butadiene and the C4 alkyne of the C4 material flow is 5-80wt%, the concentrations of the butadiene and the alkyne of the hydrogenated C4 material flow can be respectively reduced to below 10ppm, the selectivity of the 1-butene generation by the butadiene can be more than 50%, and the butadiene can be taken as the raw material of preparing the 1-butene. According to the selective hydrogenation process disclosed by the invention, the C4 material flow is reasonably utilized.

Owner:CHINA PETROLEUM & CHEM CORP +1

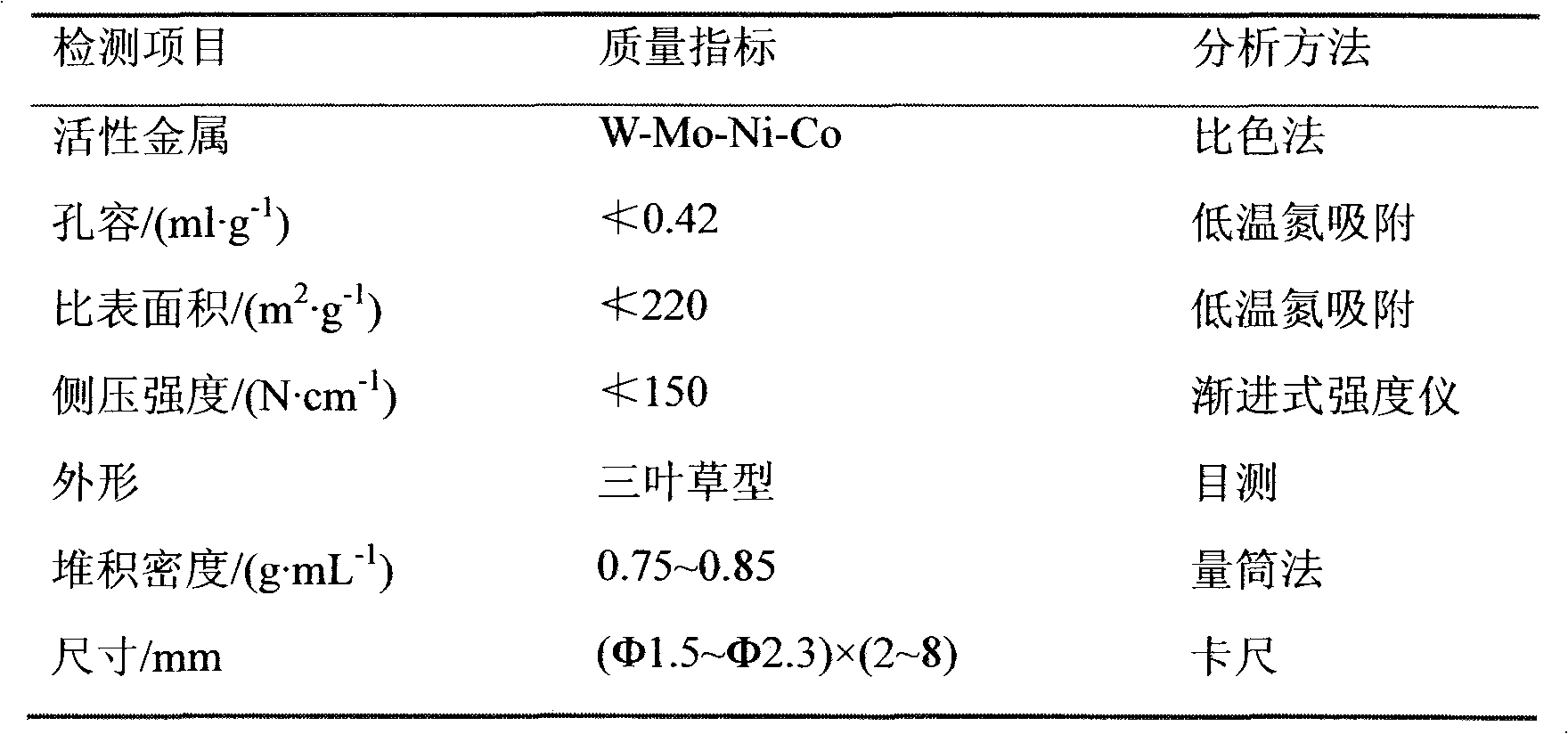

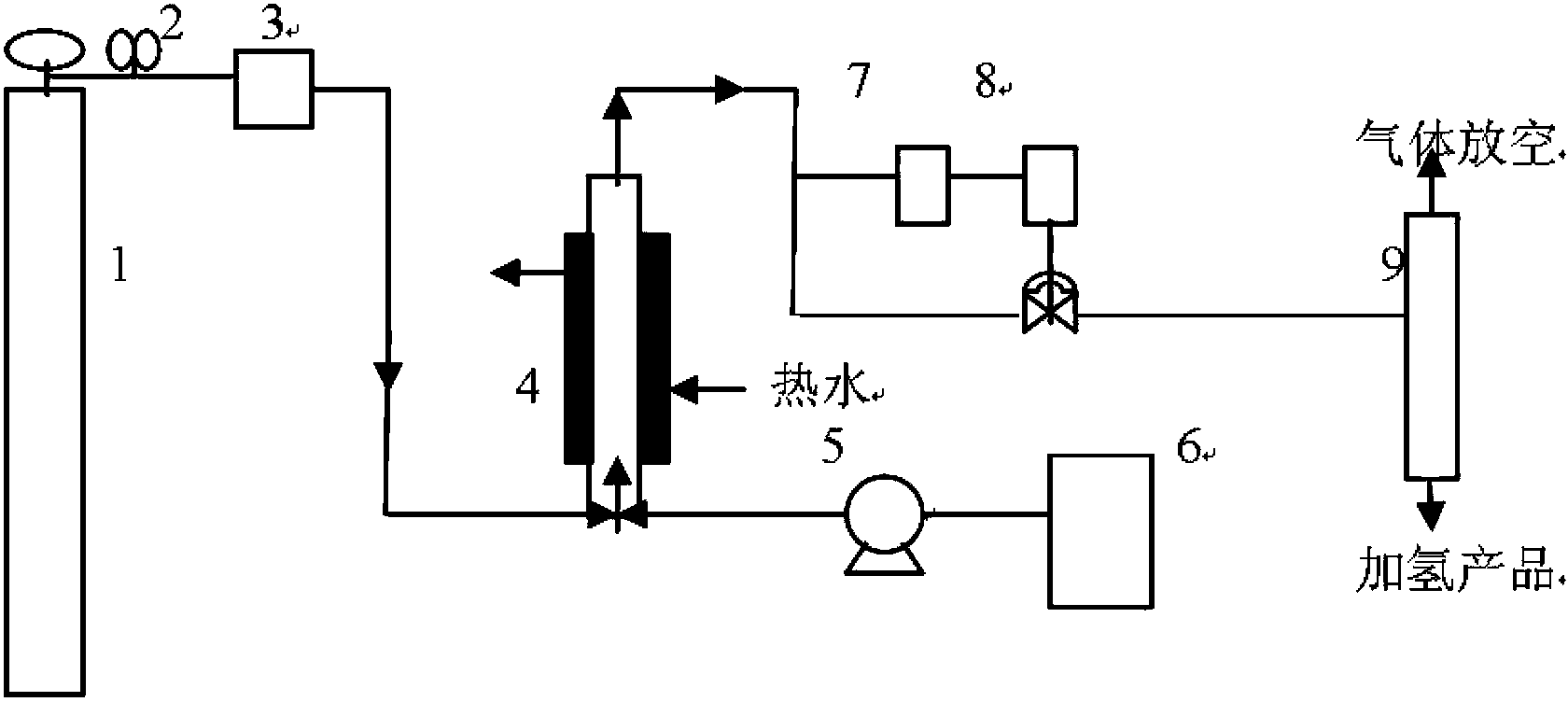

A kind of sulfuration method of hydrogenation catalyst and its application

ActiveCN102284299AGood vulcanization rateNo abnormal smellCatalyst regeneration/reactivationCatalyst activation/preparationPtru catalystHydrogenation reaction

The invention relates to a method for pre-vulcanizing a hydrogenation catalyst outside a hydrogenation reactor and activating the hydrogenation catalyst in the hydrogenation reactor. The method comprises the following steps of: (1) pre-vulcanizing the catalyst outside the hydrogenation reactor; (2) passivating the catalyst; and (3) reactivating the catalyst. A vulcanization method for the hydrogenation catalyst provided by the invention can guarantee high vulcanization rate of the catalyst; the passivated catalyst does not have abnormal odor and does not release hydrogen sulfide gas when being in contact with air or vapor; and the catalyst does not spontaneously combust and is not required to be protected by inert gas. Storage, transportation and filling methods and the like of the catalyst are simple and convenient. The catalyst can reach an activated state in a few hours during reactivation of an atmosphere containing a vulcanizing agent and hydrogen, is short in processing time, convenient to operate and has high catalytic performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for residual oil

ActiveCN101768468ATake advantage ofExtended operating cycleTreatment with hydrotreatment processesHydrodesulfurizationHydrogenation reaction

The invention provides a hydrogenation method for residual oil. The method includes the following steps: under the condition of hydrogenation reaction, residual oil raw materials and hydrogen gas are sequentially guided into two hydrogenation reaction zones connected in series to carry out contact reaction with a plurality of catalyst beds in the hydrogenation reaction zones; according to the flowing directions of a reactant and the hydrogen gas, the first and second hydrogenation reaction zones respectively comprise a hydrogenation protecting catalyst, a hydrogenation de-metallization catalyst and a hydrogenation desulfurization catalyst which are sequentially filled in the catalyst beds; when the pressure drop of at least one catalyst bed in the first hydrogenation reaction zone reaches the upper limit or hot spots appear in the reaction zone, at least one part of the residual oil raw materials and the hydrogen gas is directly guided into the second hydrogenation reaction zone. Compared with the prior art, the method in the invention can prolong the running period of a residual oil hydrogenation device, thereby increasing the running efficiency of the device and improving the economical property of the device as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

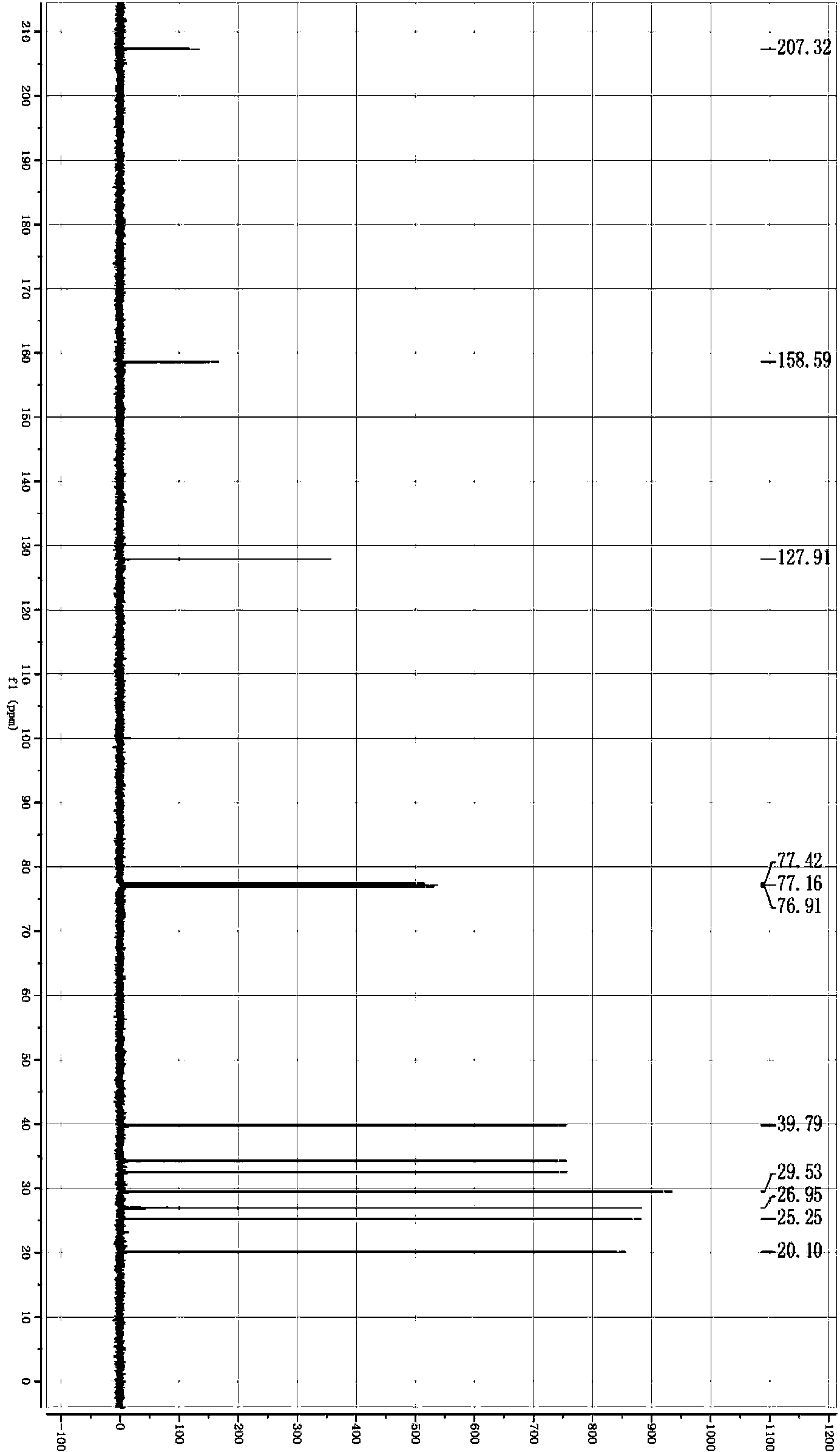

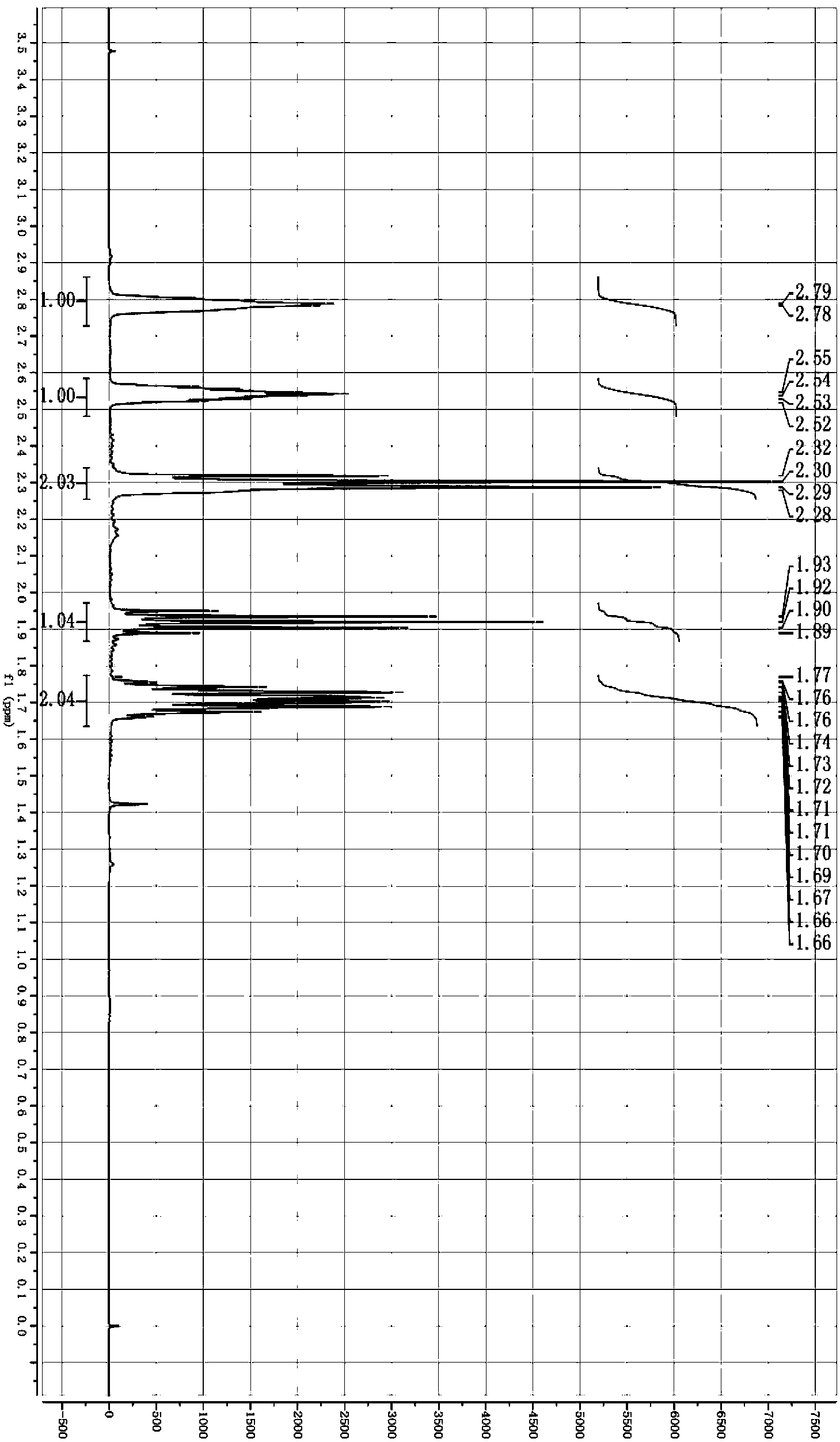

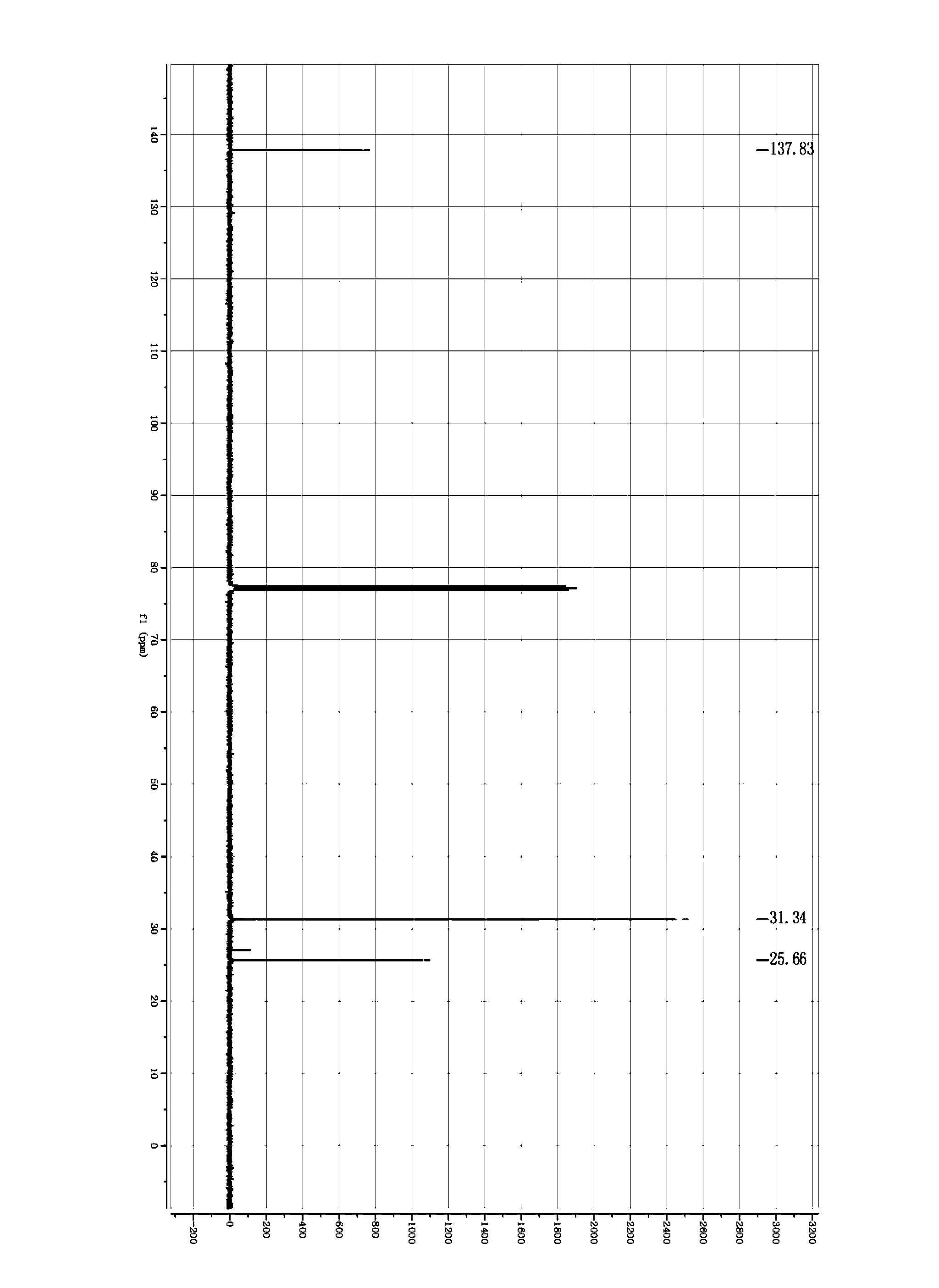

Method for synthesizing high-density aviation fuel by using cyclopentanone as raw material

ActiveCN104232140AImprove combustion effectIncreased carrying energyLiquid hydrocarbon mixture productionBio-feedstockCarbon numberSolvent free

The invention relates to a synthetic route of a hydrocarbon fuel with high density and high volumetric calorific value by using a lignocelluloses-based platform chemical compound as a raw material and completely independent of fossil energy. A liquid fuel obtained by the method can be used in various aircrafts or used as an additive to raise combustion performance of aviation fuel. The method is divided into two parts: 1) under the promotion action of an acid / base catalyst, cyclopentanone (furfural selective hydrogenation product) is subjected to an aldol self-condensation reaction to synthesize unsaturated organic compounds with C10 and C15 polycyclic structures; and 2) a metal loaded A / X catalyst is used to carry out a one-step hydrodeoxygenation and hydrogenation reaction on products generated from the step 1 under low-temperature solvent-free conditions, so as to obtain polycyclic hydrocarbon fuel with carbon number being 10 and 15. The liquid fuel has high density (C10: 0.92g / cm<3>; C15: 1.12g / cm<3>), can be used to effectively raise carrying energy of an aircraft and reduce fuel consumption rate, and meets requirements of high navigational speed, large load and long range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Production process of catalytically hydrogenating nitrobenzene halide to synthesize haloarylamine

InactiveCN1506348AInhibition of hydrodehalogenationHigh catalytic activityOrganic compound preparationAmino compound preparationHydrogenation reactionNitrobenzene

The production process is liquid phase catalytic hydrogenation reaction of nitrobenzene halide, such as o-chloronitrobenzene, p-chloronitrobenzene, 3, 4-dichloronitrobenzene and 3-chloro-4-fluoronitrobenzene, etc. with carbon nanotube carried Pd and Pt as hydrogenation catalyst to produce corresponding haloarylamine. The said production process can inhibit hydrodehalogenation, and has the advantages of high selectivity, high yield and high catalyst stability, etc. and thus high practical value.

Owner:ZHEJIANG UNIV OF TECH

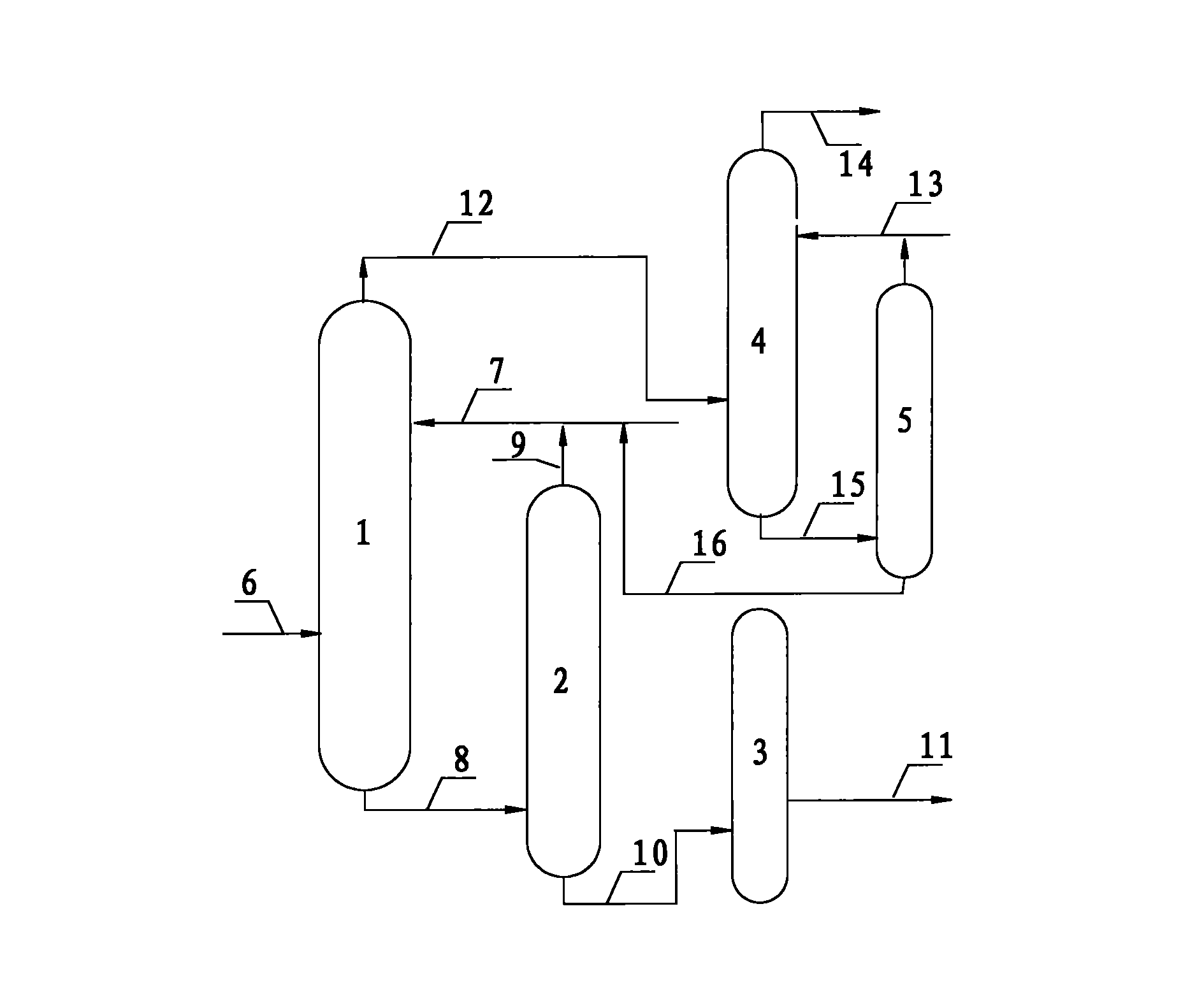

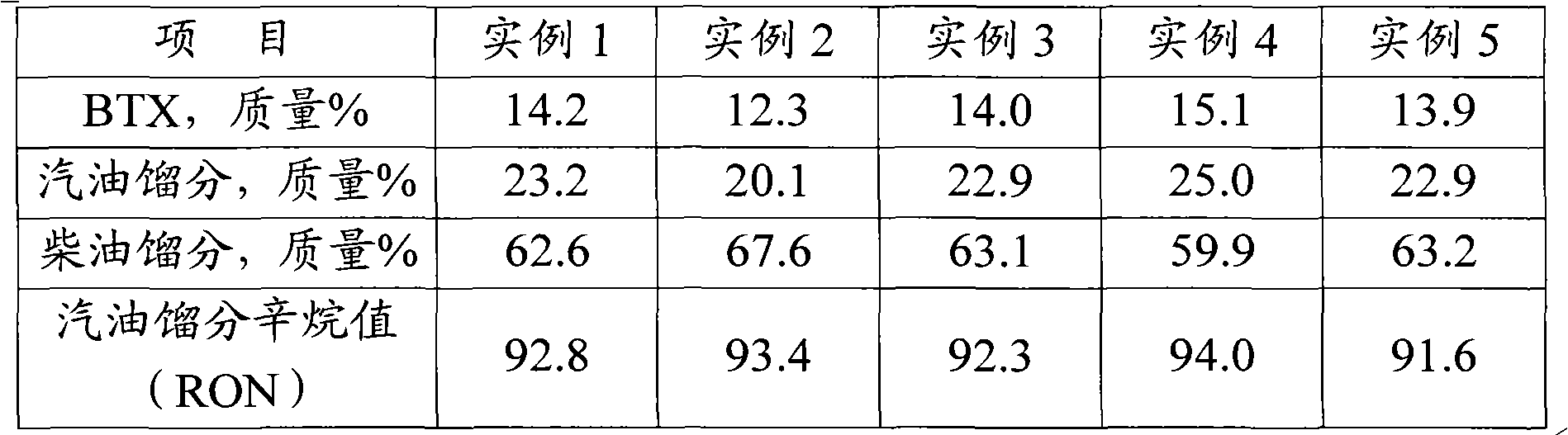

Method for producing light aromatic hydrocarbons and high-quality oil products from catalytically cracked diesel

ActiveCN103214332AEasy to handleReduce the difficulty of operationHydrocarbon purification/separationHydrocarbonsAlkanePolycyclic aromatic hydrocarbon

The invention discloses a method for producing light aromatic hydrocarbons and high-quality oil products from catalytically cracked diesel. The method comprises the following steps of 1, carrying out extraction of catalytically cracked diesel by an extraction solvent to obtain polycyclic aromatic hydrocarbon-rich extract oil and alkane-rich raffinate oil, 2, carrying out hydrofining and hydrocracking of the polycyclic aromatic hydrocarbon-rich extract oil under the hydrogenation reaction conditions to obtain light aromatic hydrocarbons and a high-octane number gasoline fraction. The method can realize production of light aromatic hydrocarbons, high-cetane number diesel and high-octane number gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Purified gas treatment process of sulfur recovery device

InactiveCN104555939AReduce contentDispersed particle separationSulfur preparation/purificationHydrogenation reactionSulfur

The invention relates to a purified gas treatment process of a sulfur recovery device. The purified gas treatment process comprises a thermal reaction phase, a catalytic reaction phase and a tail gas purifying treatment phase, wherein in the tail gas purifying treatment phase, the Claus tail gas generated in the catalytic reaction phase is sequentially subjected to a hydrogenation reaction, cooling in a rapid quenching tower and amine liquid absorption, then the purified tail gas is fed to alkali liquor to be subjected to H2S removal treatment, and the tail gas removed from H2S is combusted and then discharged; the amine liquid amine-rich liquid absorbing H2S is fed to a regeneration tower to be regenerated, the regenerated acid gas is mixed with the acid gas, and then returned to the thermal reaction phase to further recover elemental sulfur; the exhausted lye removed from H2S is subjected to caustic dross biological treatment or acidic water stripping treatment. With adoption of the purified gas treatment process disclosed by the invention, H2S in the purified gas can be removed to 5 mg / m<3> below, the SO2 content in the smoke is obviously reduced within the reduction range of 100-1000 mg / m<3>; the exhausted lye treatment method is further provided, and the exhausted lye is subjected to the caustic dross biological treatment or the acidic water stripping treatment, so that pollution can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Method for reducing SO2 emission concentration of sulfur recovery device

ActiveCN104249995ASmall volumeReduce dosageChemical industryDispersed particle separationHydrogenation reactionExhaust fumes

The invention relates to a method for reducing the SO2 emission concentration of a sulfur recovery device. The method includes: at a tail gas purification processing stage, subjecting Claus tail gas to hydrogenation reaction, quench tower cooling and amine liquid absorption in turn, then taking part of purification tail gas as the stripping gas for liquid sulfur degassing, leading the residual purification tail gas into an incinerator to incinerate, letting the exhaust gas of liquid sulfur degassing enter a catalytic reaction stage, making the amine liquid absorbing hydrogen sulfide enter a regeneration tower to undergo regeneration, mixing a regenerated acidic gas with a raw material acidic gas, and returning the mixture to the thermal reaction section again for further recovery of elemental sulfur. The method for reducing the SO2 emission concentration of the sulfur recovery device provided by the invention is efficient, energy saving and economical, and greatly reduces the SO2 emission concentration.

Owner:CHINA PETROLEUM & CHEM CORP

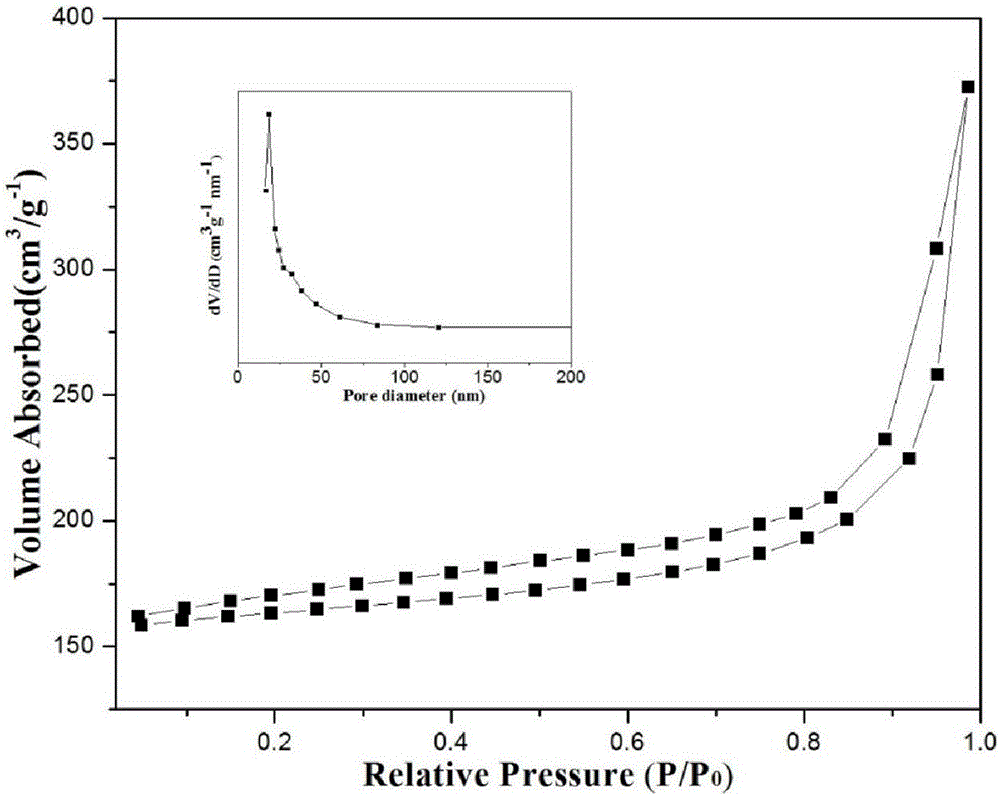

Pyrolysis gasoline nickel system selective hydrogenation catalyst and preparation method thereof

ActiveCN103657670AGood choiceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationHydrogenation reactionActive component

The invention provides a pyrolysis gasoline nickel system selective hydrogenation catalyst and a preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst and belongs to a catalyst containing metal or metal oxide or hydroxide. The pyrolysis gasoline nickel system selective hydrogenation catalyst is characterized by being provided with a mesopore-macropore or double-mesopore compound pore channel, taking aluminum oxide as a carrier, taking nickel as a main active component, taking molybdenum as an auxiliary active component and taking the metal oxide as an auxiliary agent; the pyrolysis gasoline nickel system selective hydrogenation catalyst is composed of following components in parts by weight: 15-19 parts of nickel oxide, 6.5-20 parts of molybdenum oxide, 2.2-4.5 parts of the auxiliary agent and the balance of the aluminum oxide; the auxiliary agent is one or the combination of more than two of potassium oxide, magnesium oxide and lanthanum oxide. The invention provides the pyrolysis gasoline nickel system selective hydrogenation catalyst which is large in pore capacity and high in specific surface, has good reaction activity, high hydrogenation reaction selectivity, good stability, good arsenic dissolving and glue resisting capabilities and is provided with the compound pore channel, and the preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst. When the catalyst is used for selectively hydrogenating full-fraction pyrolysis gasoline, the average diene hydrogenation rate is 99%.

Owner:CHINA PETROLEUM & CHEM CORP

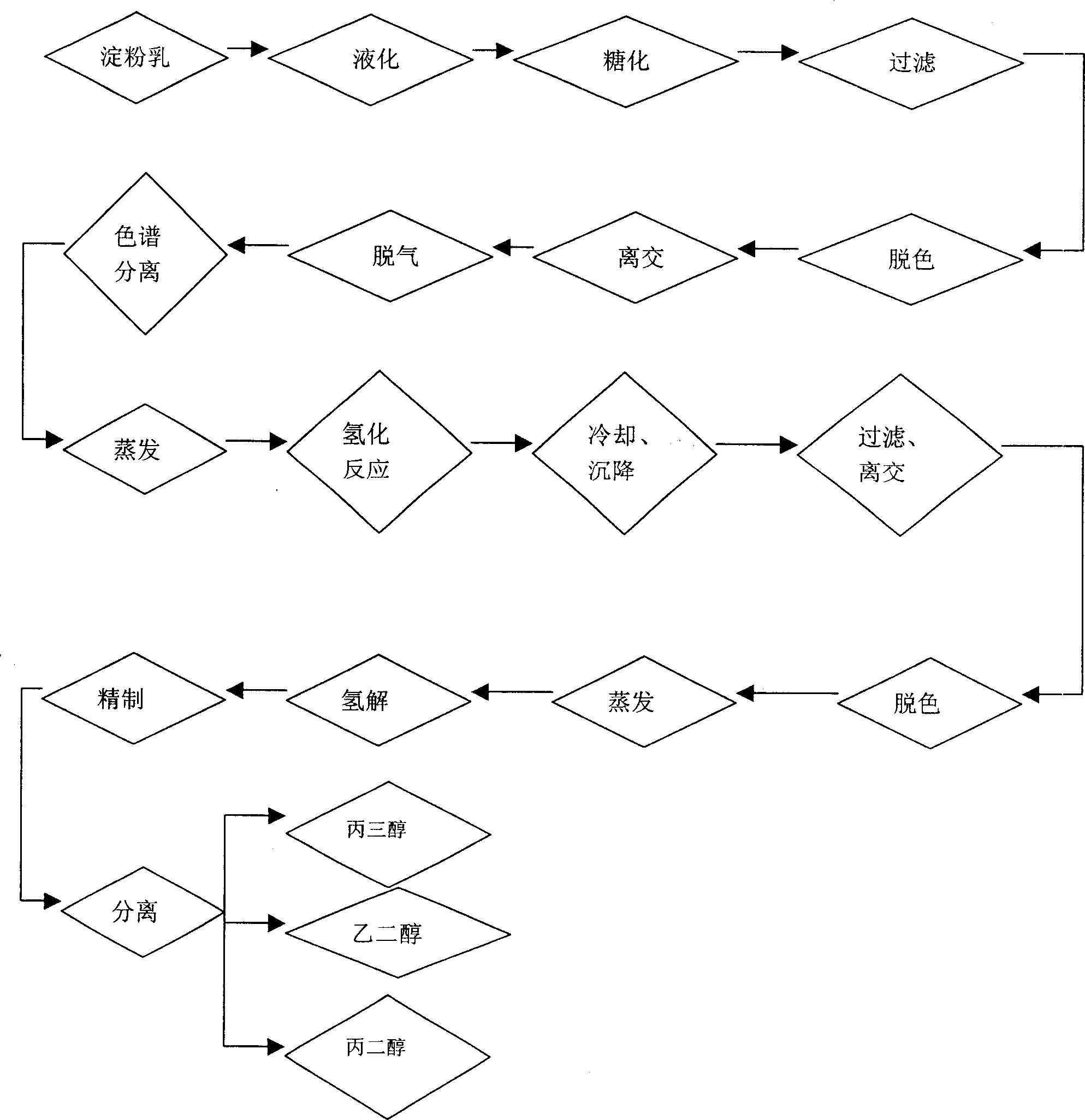

Novel technique for preparing ethylene glycol

InactiveCN1919814AReduce utilizationIncrease productivityOrganic compound preparationHydroxy compound preparationSimulated moving bedSlurry

The invention discloses a new technology to manufacture ethandiol, which is characterized by the following: liquefying starch emulsion; saccharifying; filtering; decolouring; separating through simulated mobile chromatogramic separating system; obtaining DX 99-99.7% glucose slurry; evaporating DX value glucose slurry to 50% as dried material; adopting ruthenium or nickel as catalyst; proceeding hydrogenation reaction to obtain the sorbitol solution; hydrogenolyzing for certain time under one catalyst of Ru, Ni / Ru and Co / Re to produce compound with ethandiol, glycerin and propanediol; cooling multi-alcohol; sedimenting; filtering; separating; decolouring; separating ethandiol, glycerin and propanediol.

Owner:SHANDONG XIWANG SUGAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com