Patents

Literature

375results about "Fermented solutions distillation/rectification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and organisms for the growth-coupled production of 1,4-butanediol

ActiveUS20090047719A1FungiFermented solutions distillation/rectificationMicrobiological growthBiology

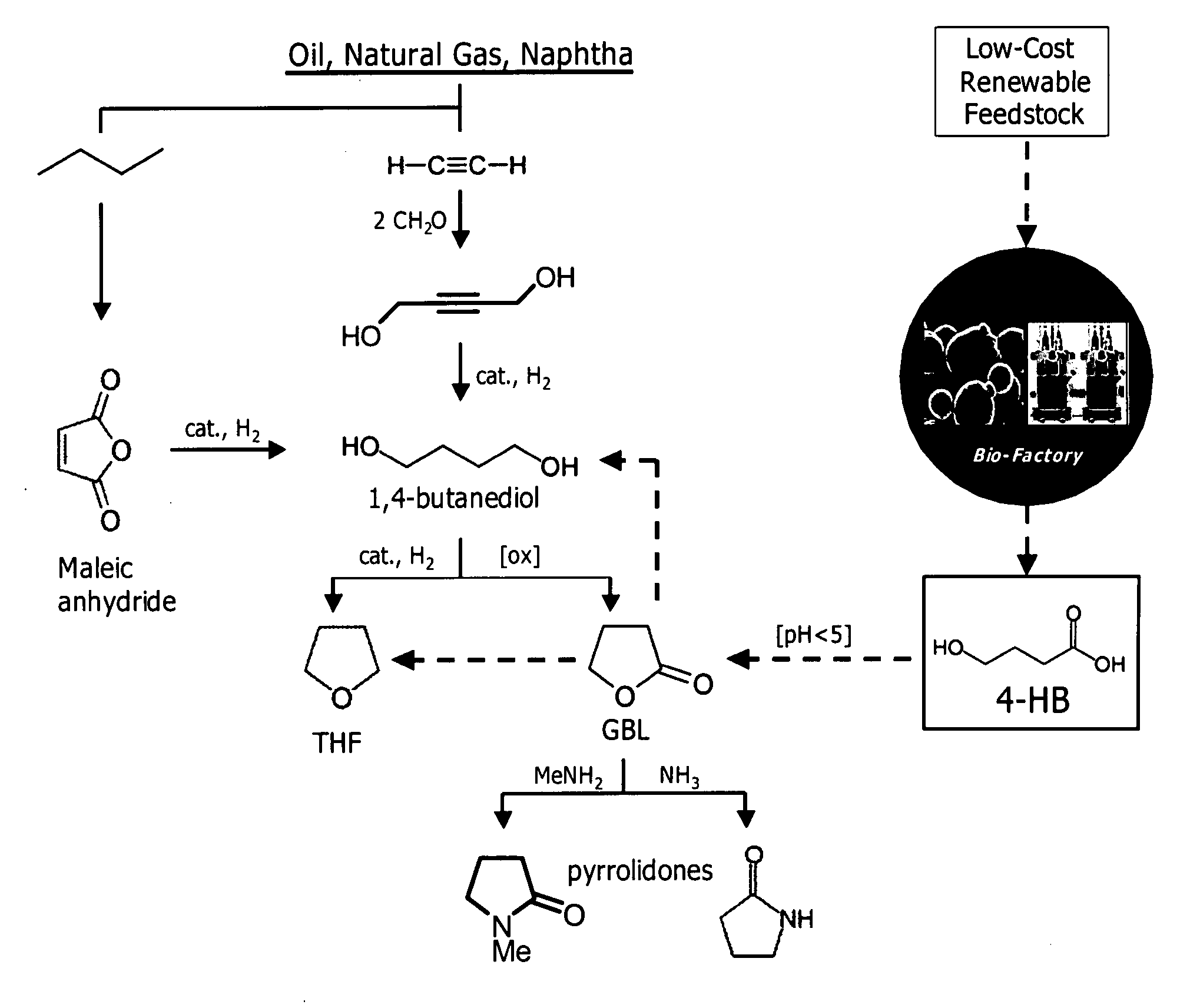

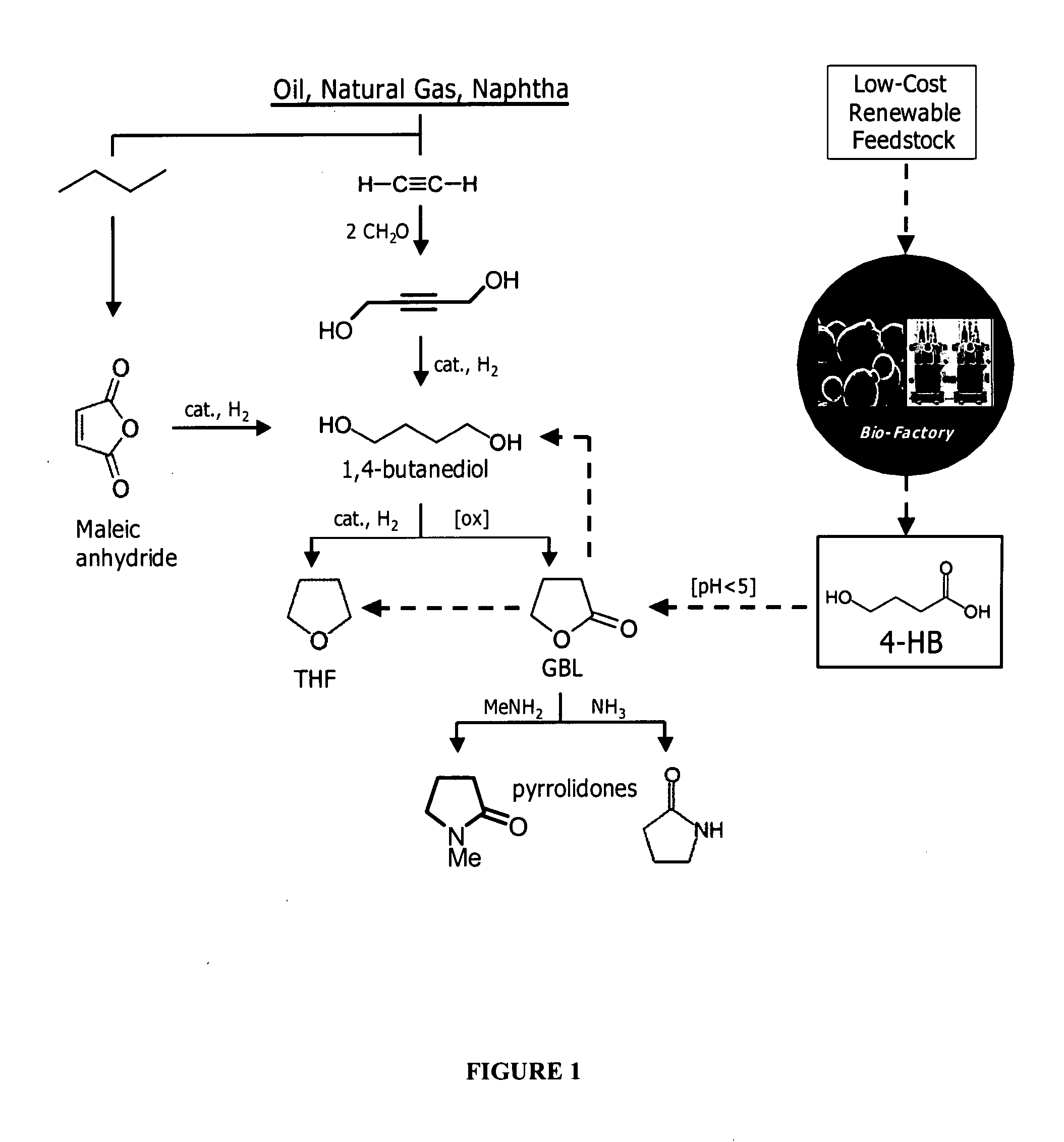

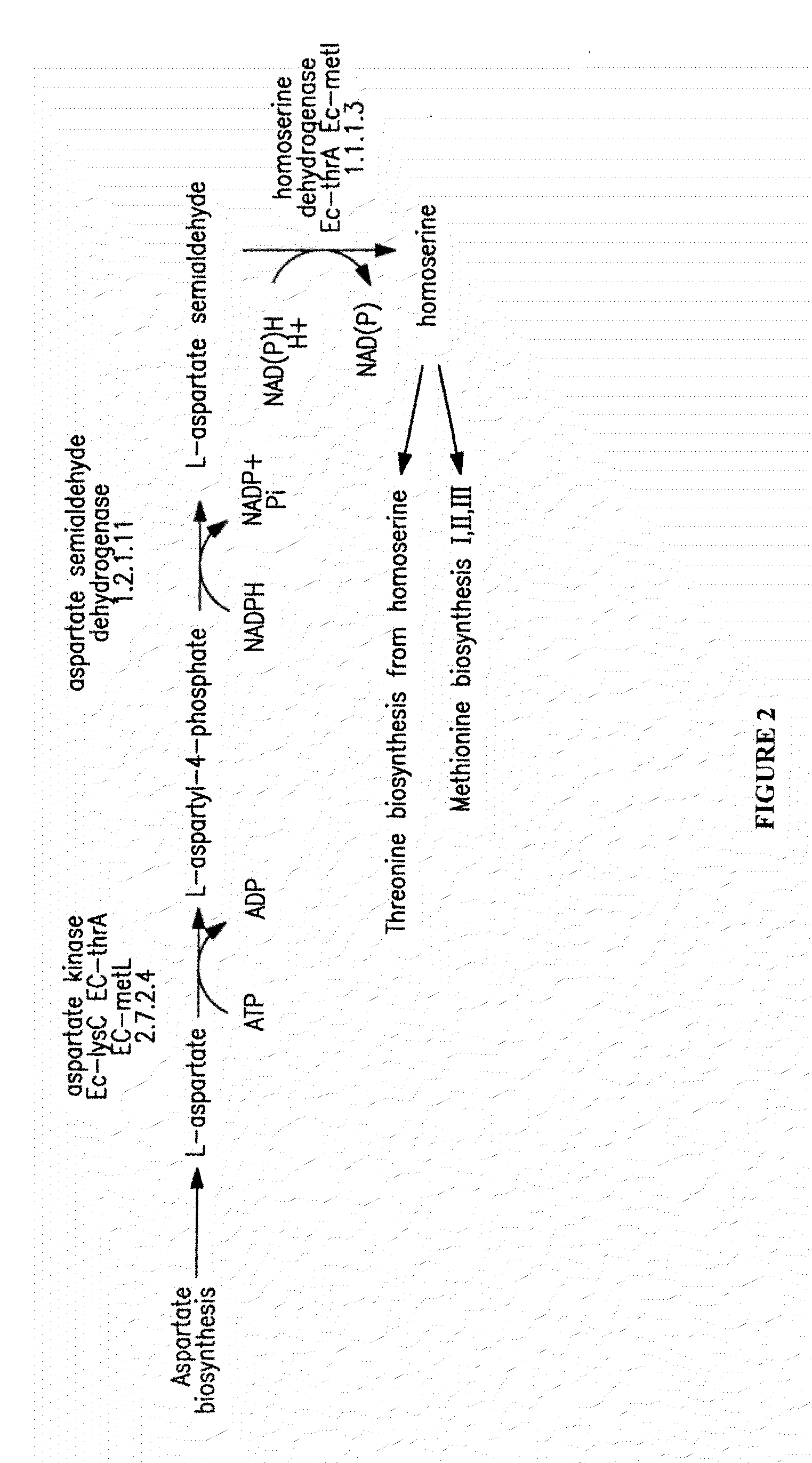

The invention provides a non-naturally occurring microorganism comprising one or more gene disruptions, the one or more gene disruptions occurring in genes encoding an enzyme obligatory to coupling 1,4-butanediol production to growth of the microorganism when the gene disruption reduces an activity of the enzyme, whereby theone or more gene disruptions confers stable growth-coupled production of 1,4-butanediol onto the non-naturally occurring microorganism. The microorganism can further comprise a gene encoding an enzyme in a 1,4-butanediol (BDO) biosynthetic pathway. The invention additionally relates to methods of using microorganisms to produce BDO.

Owner:GENOMATICA INC

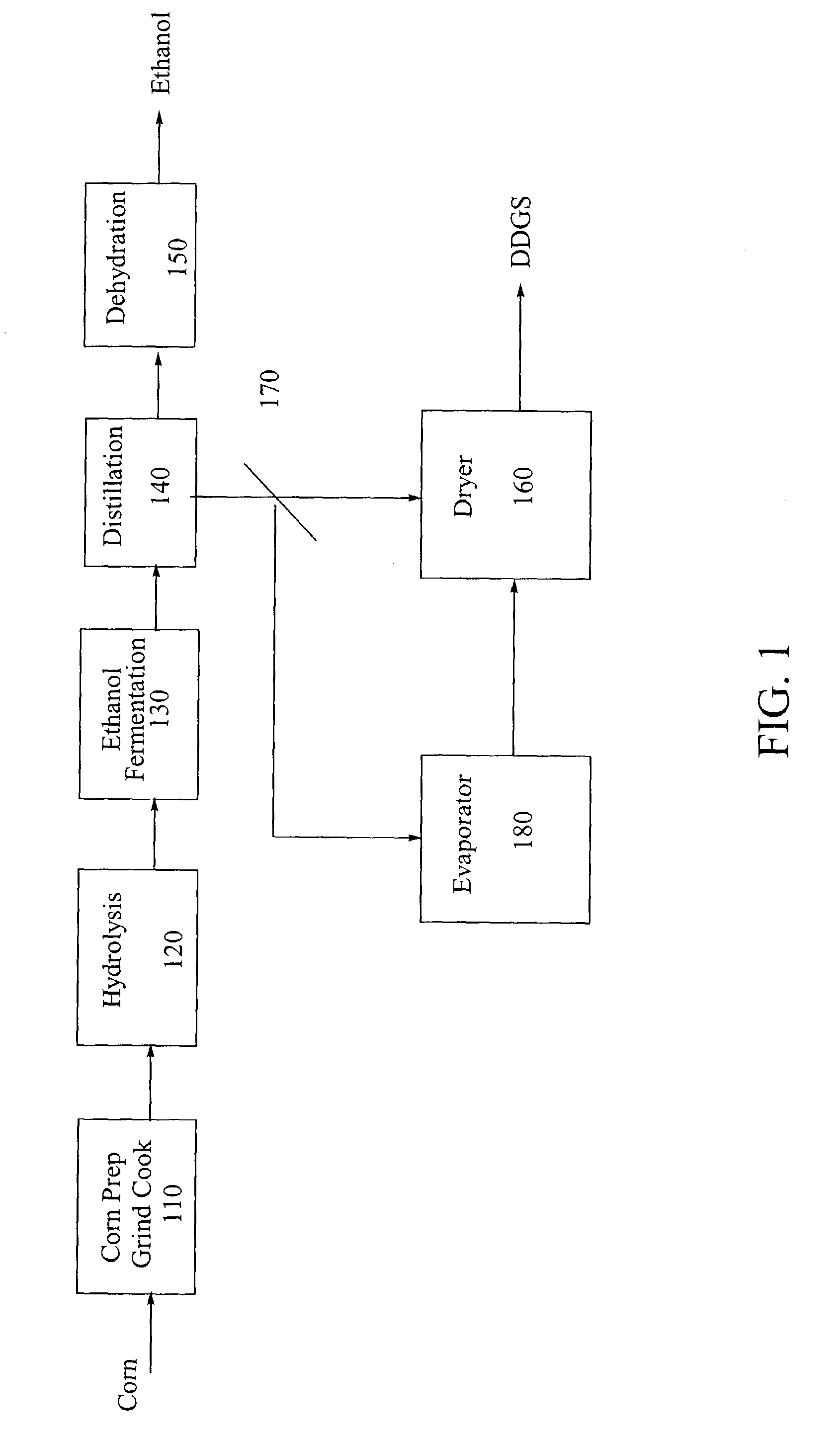

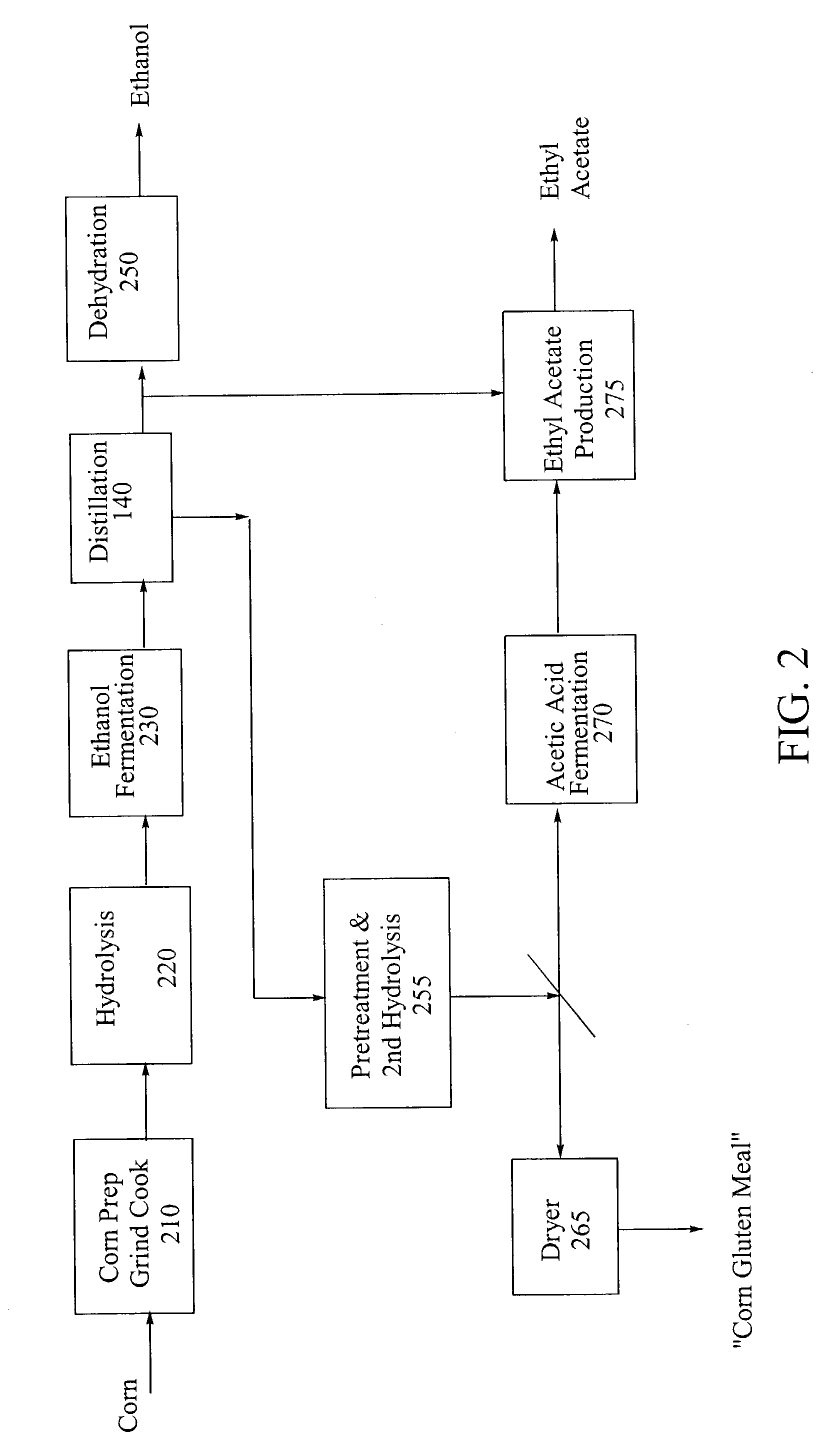

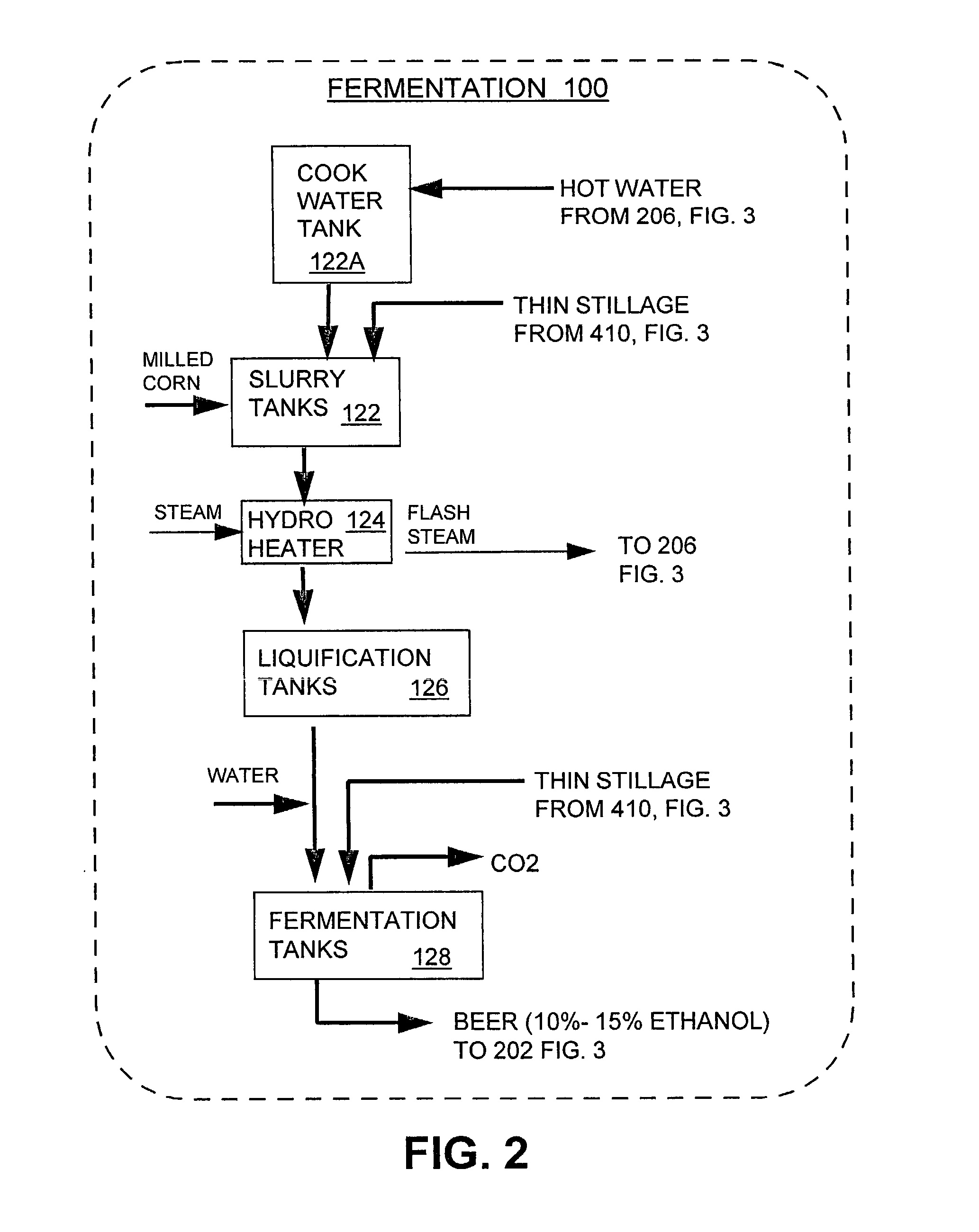

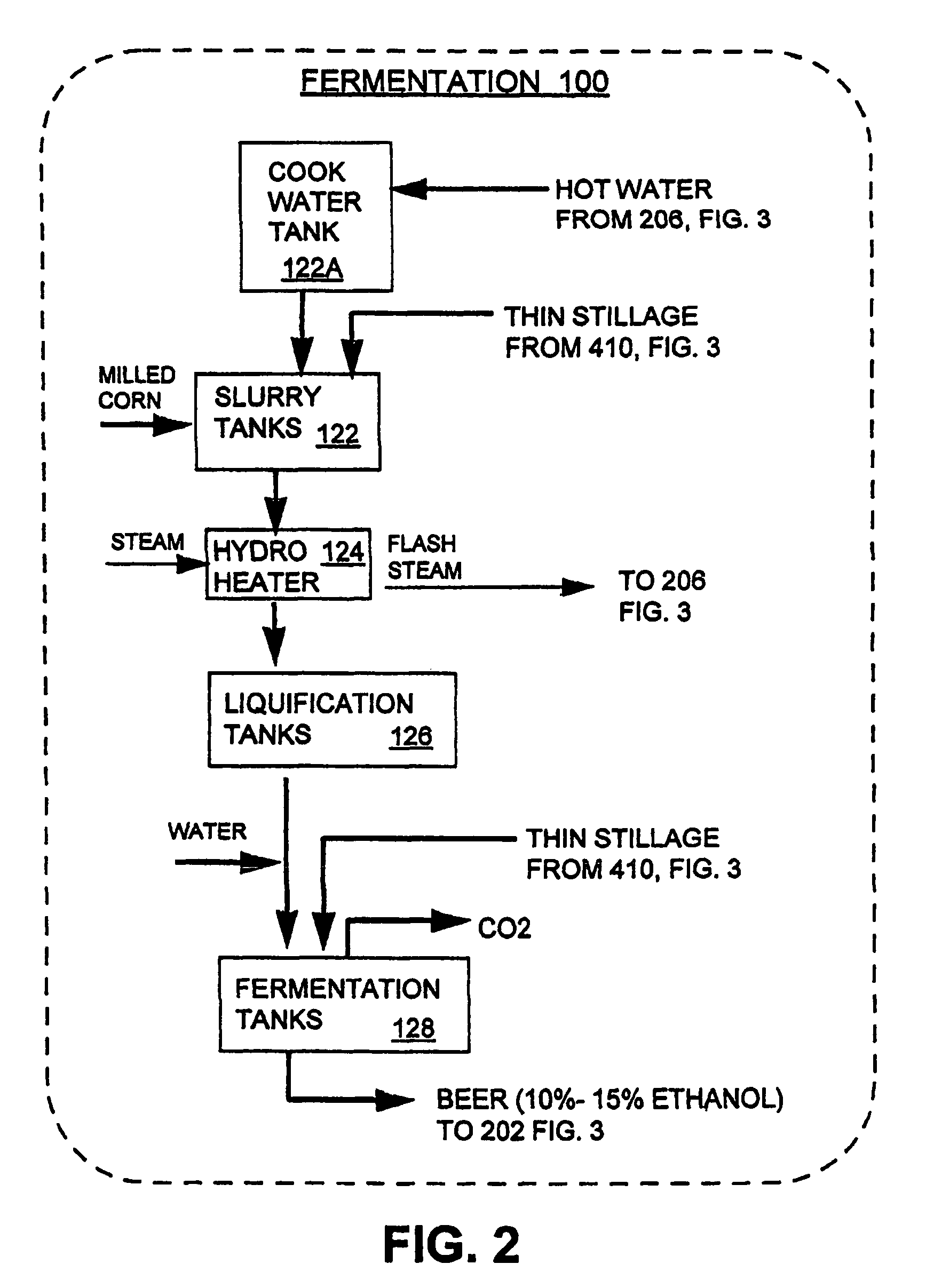

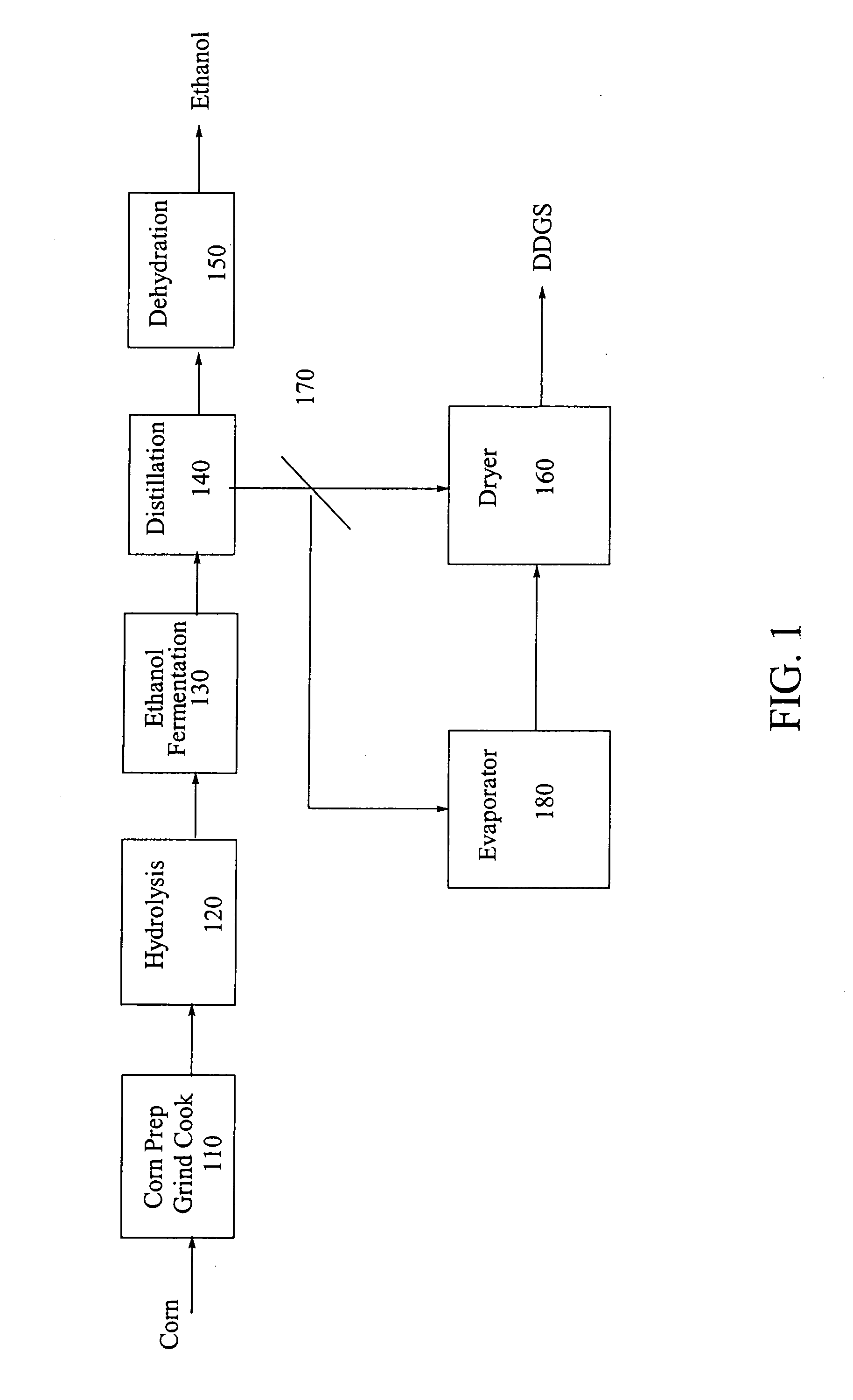

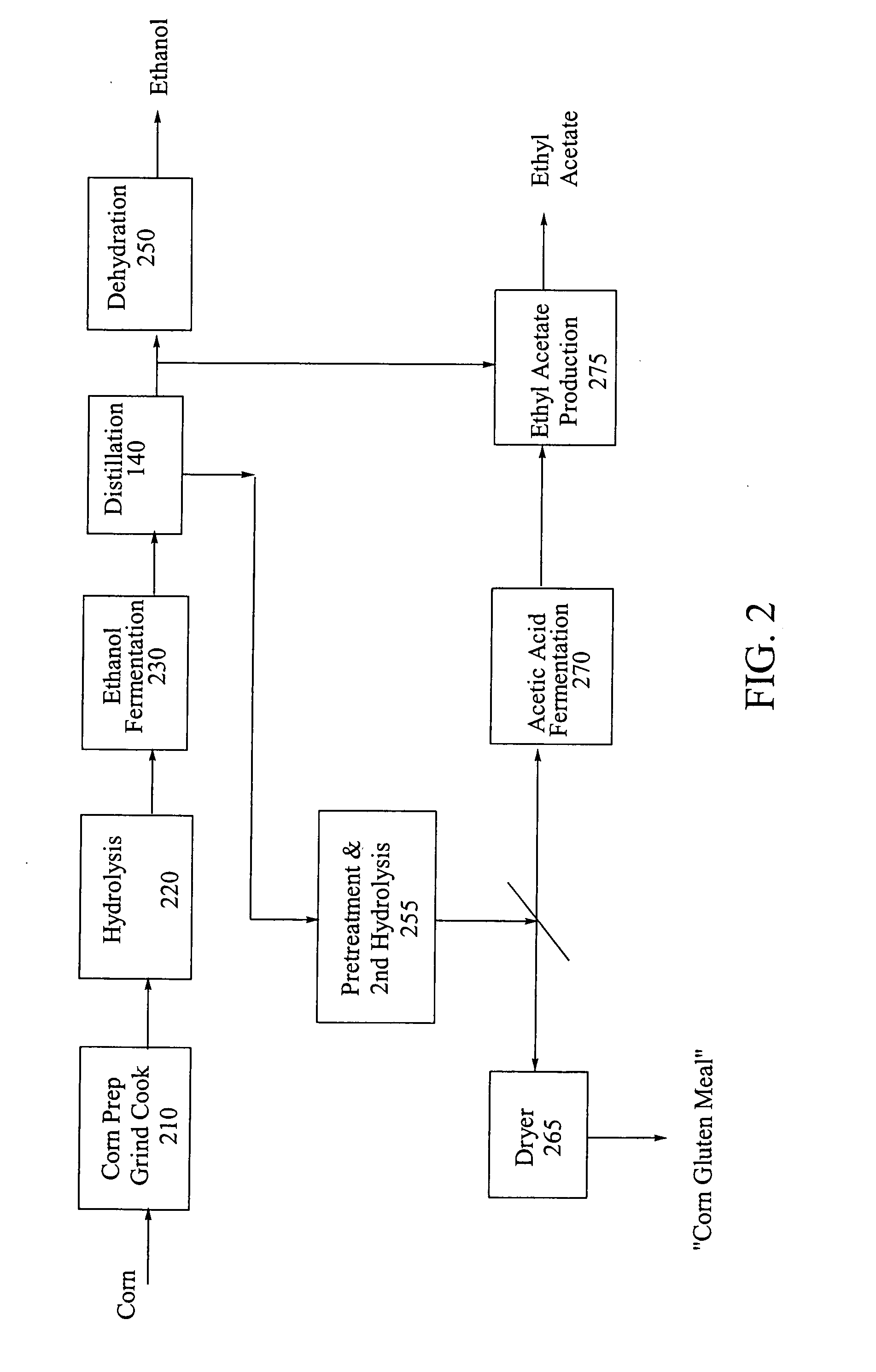

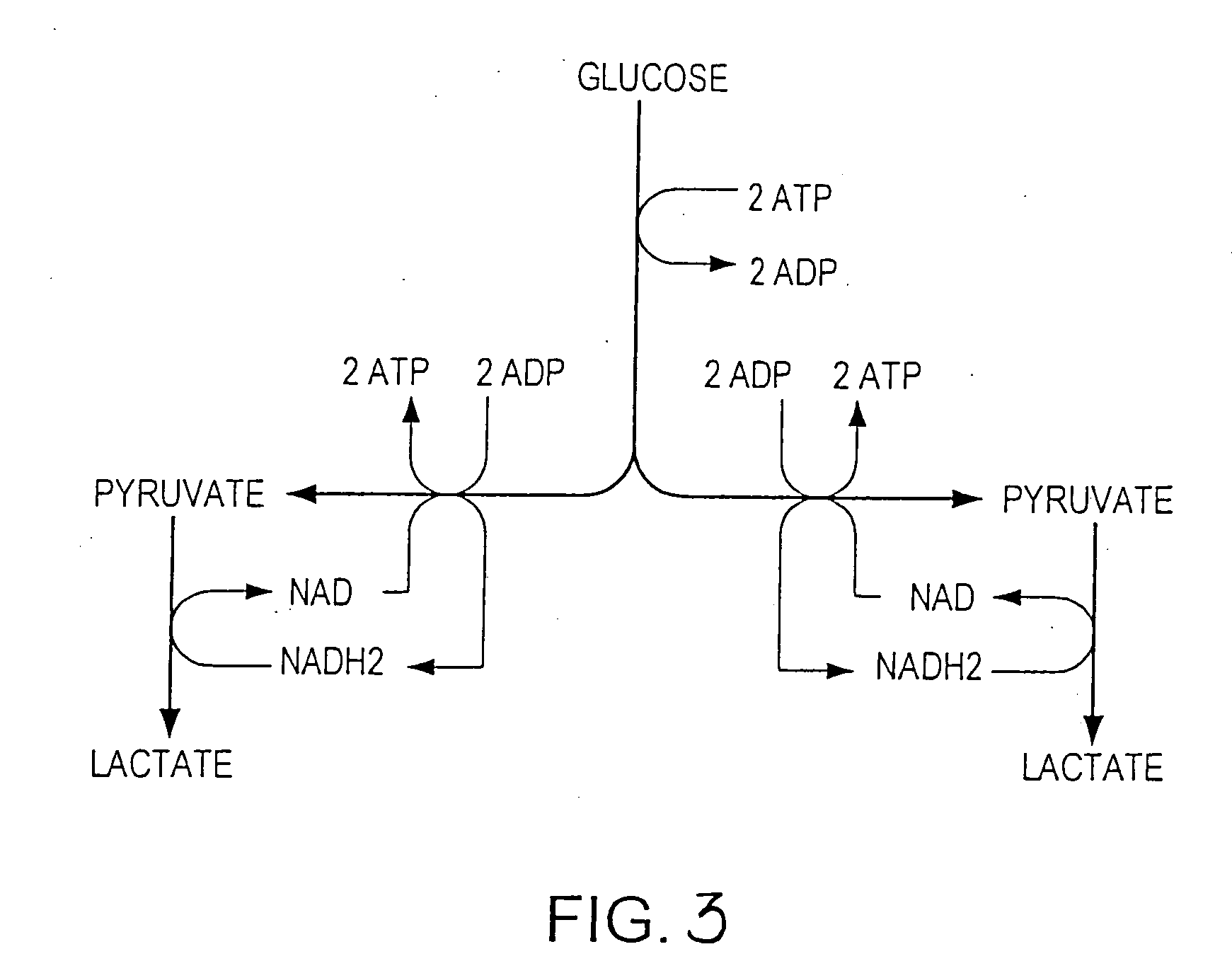

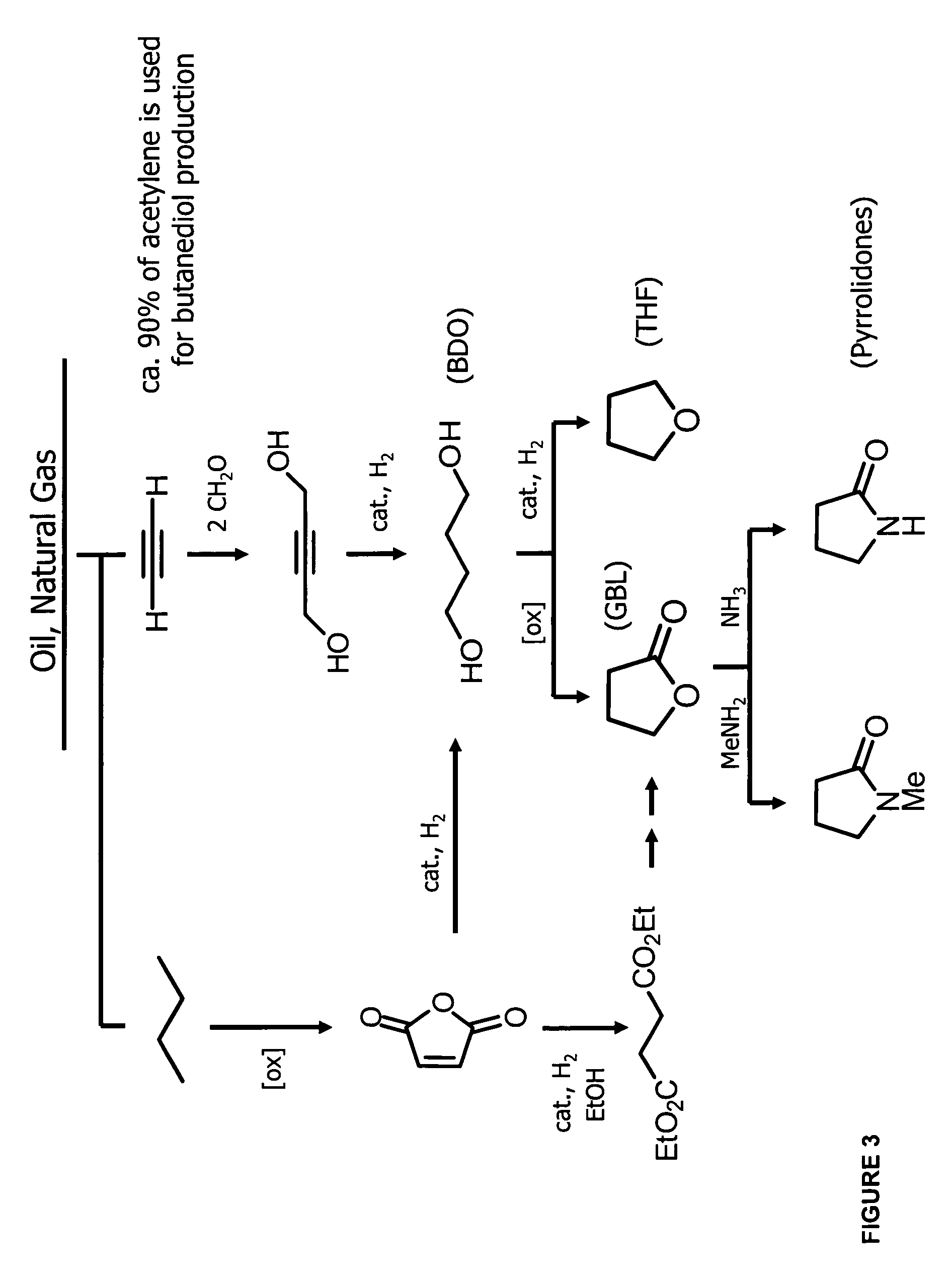

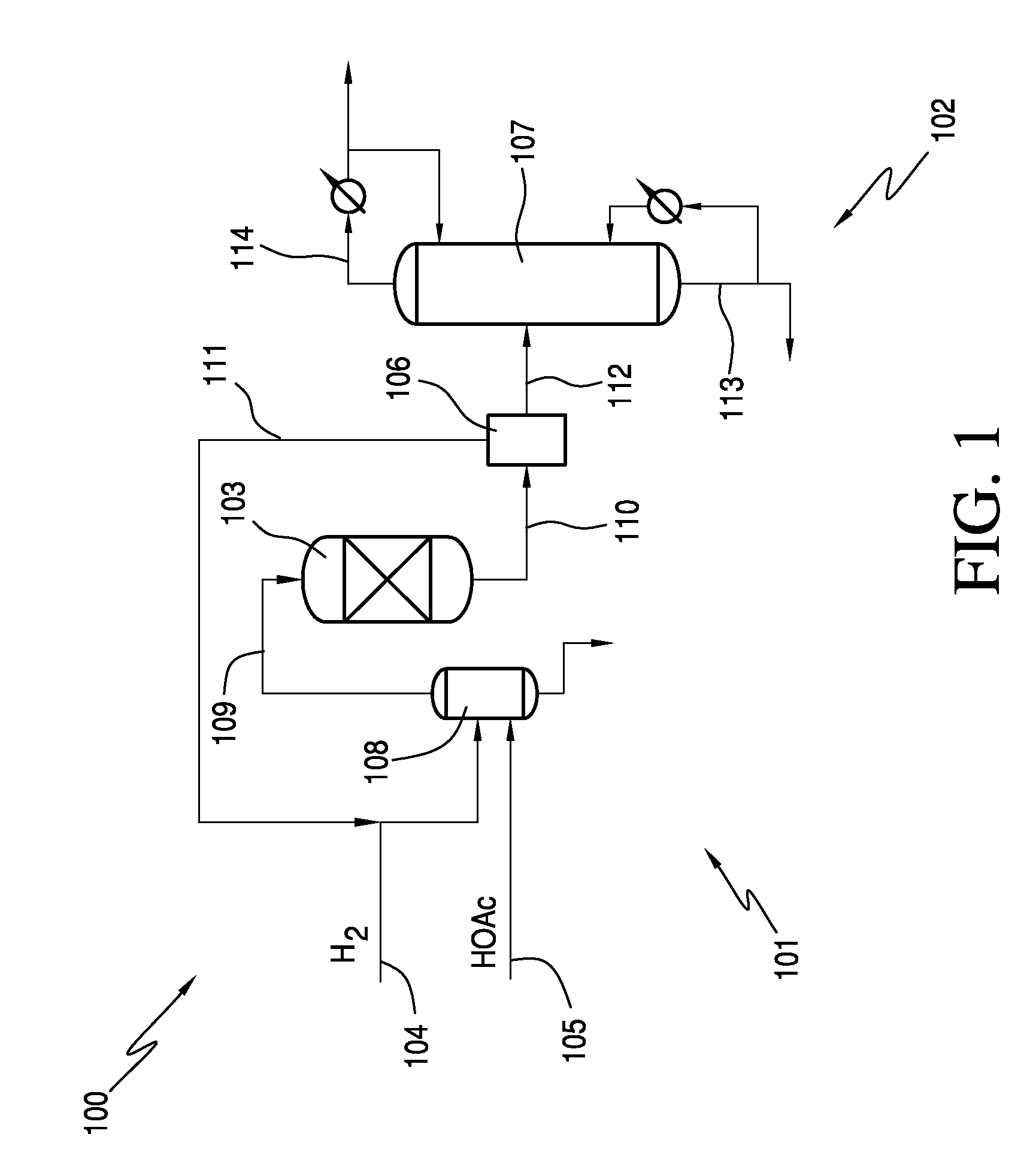

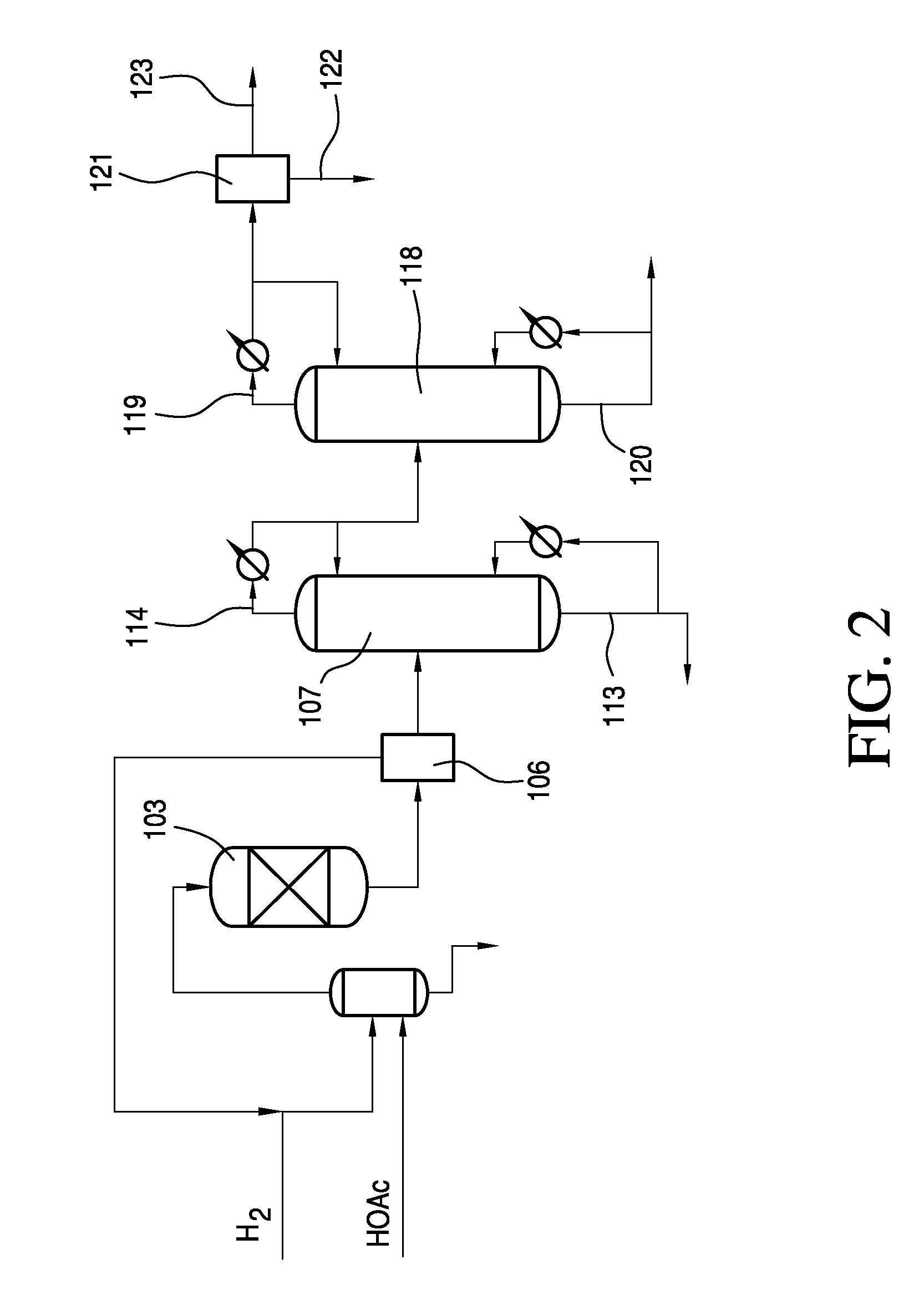

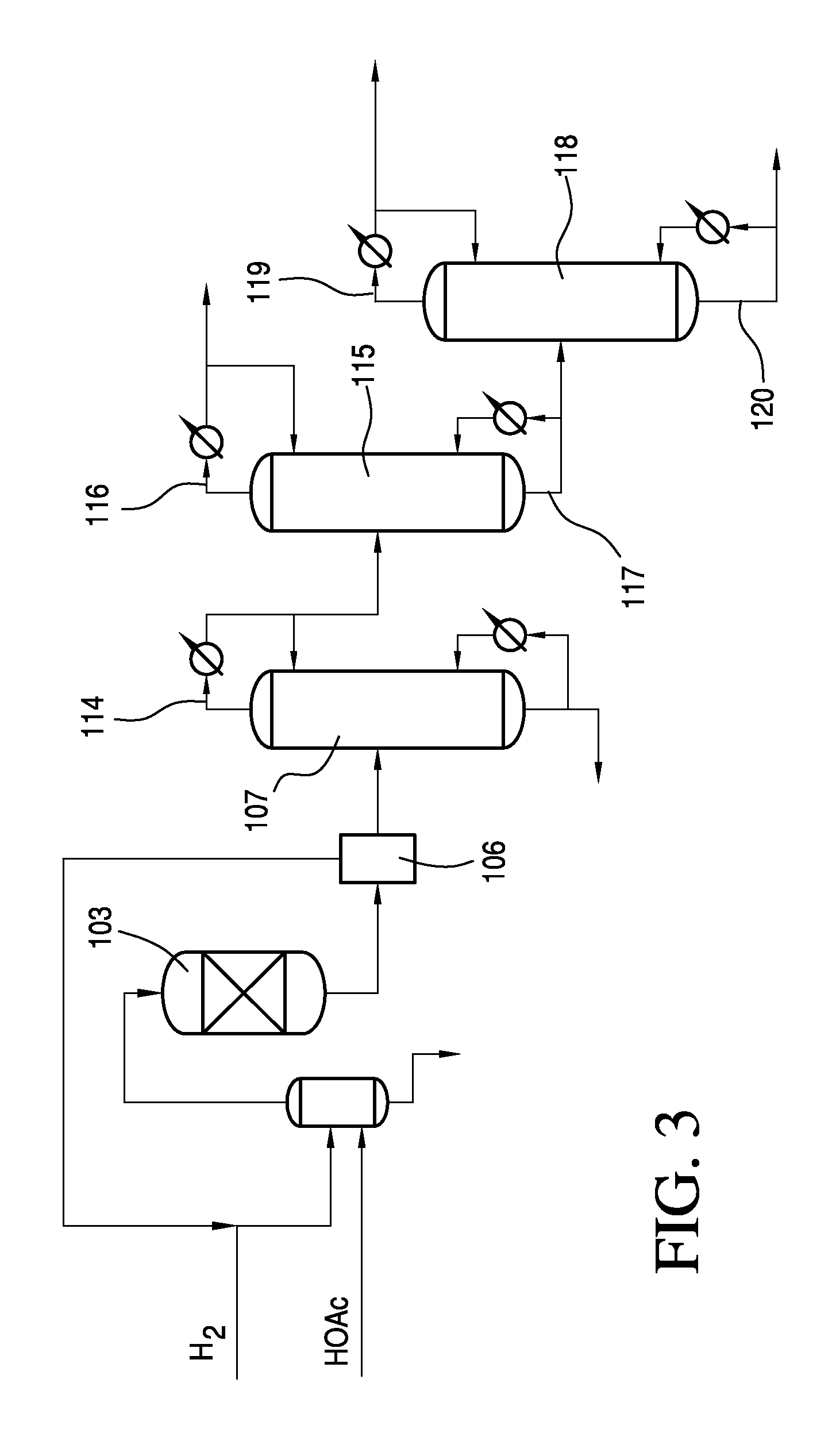

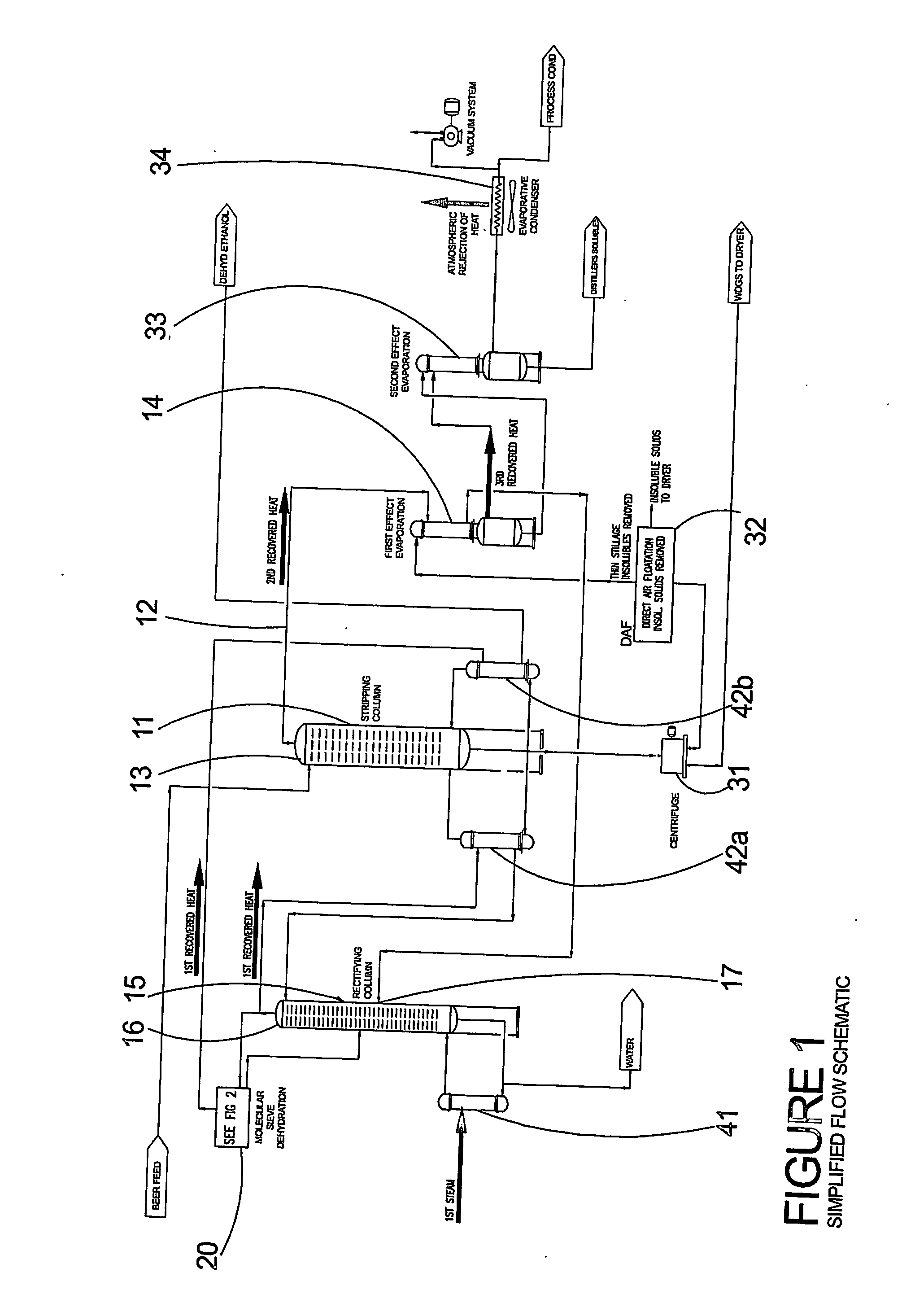

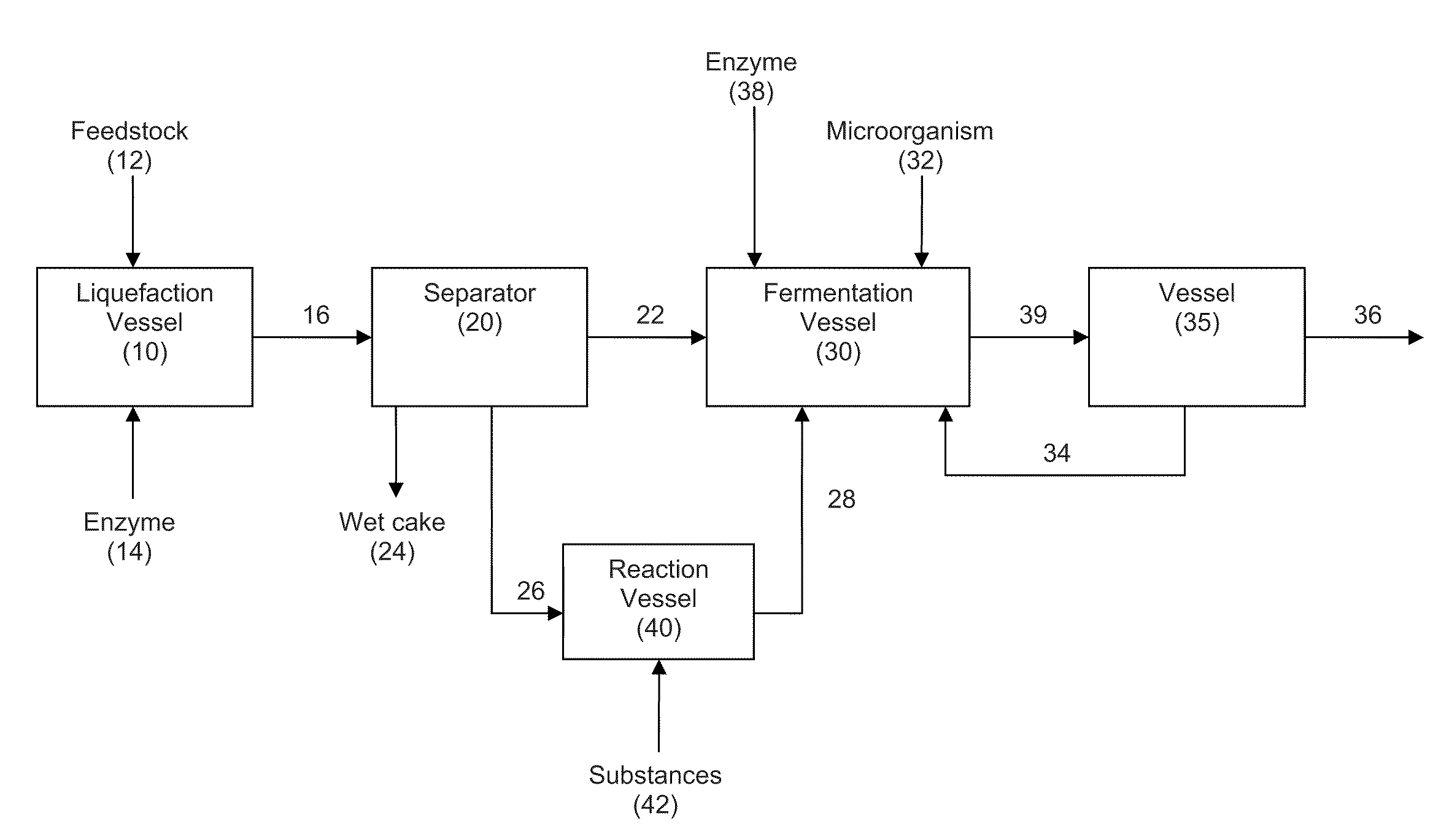

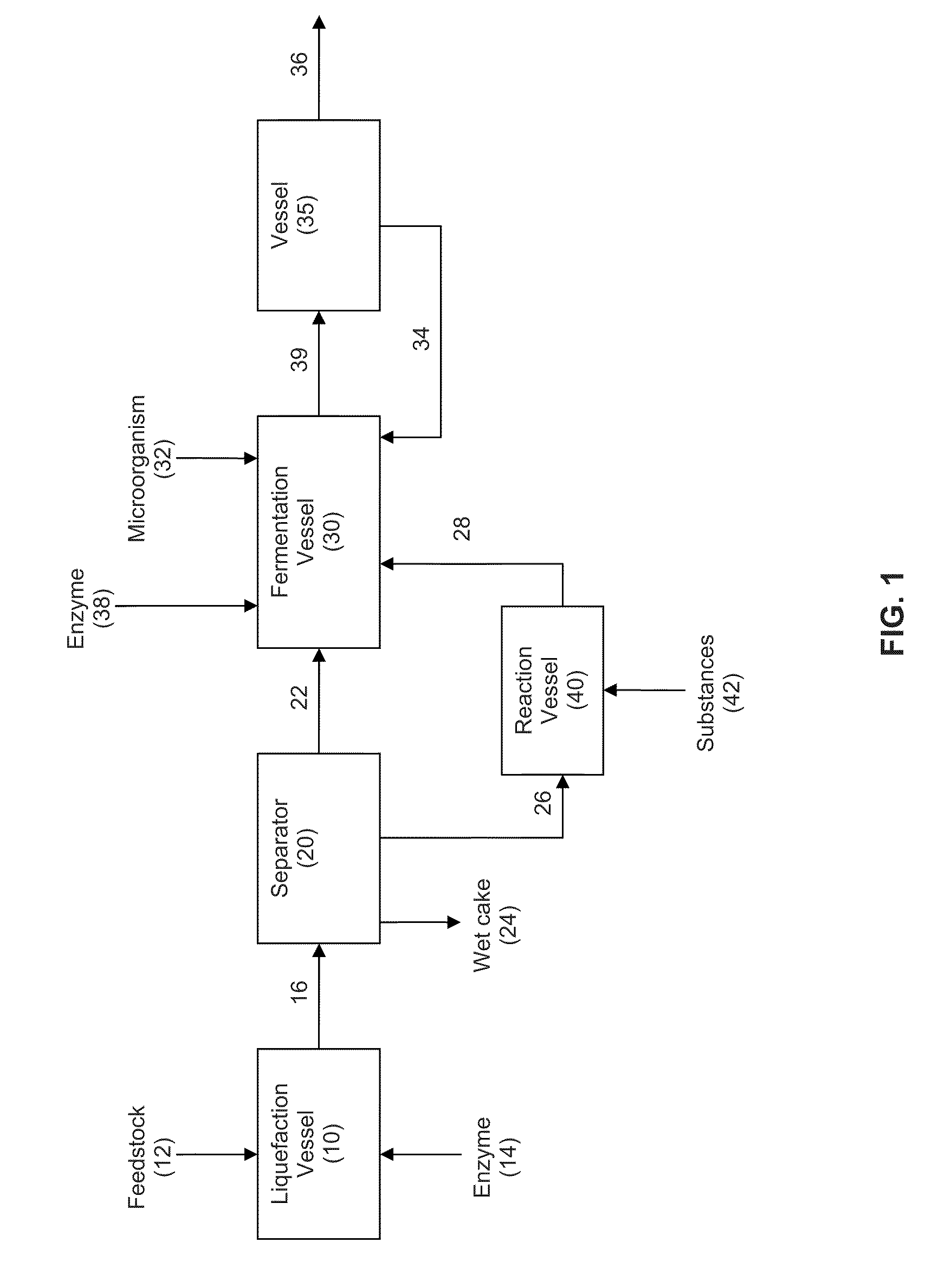

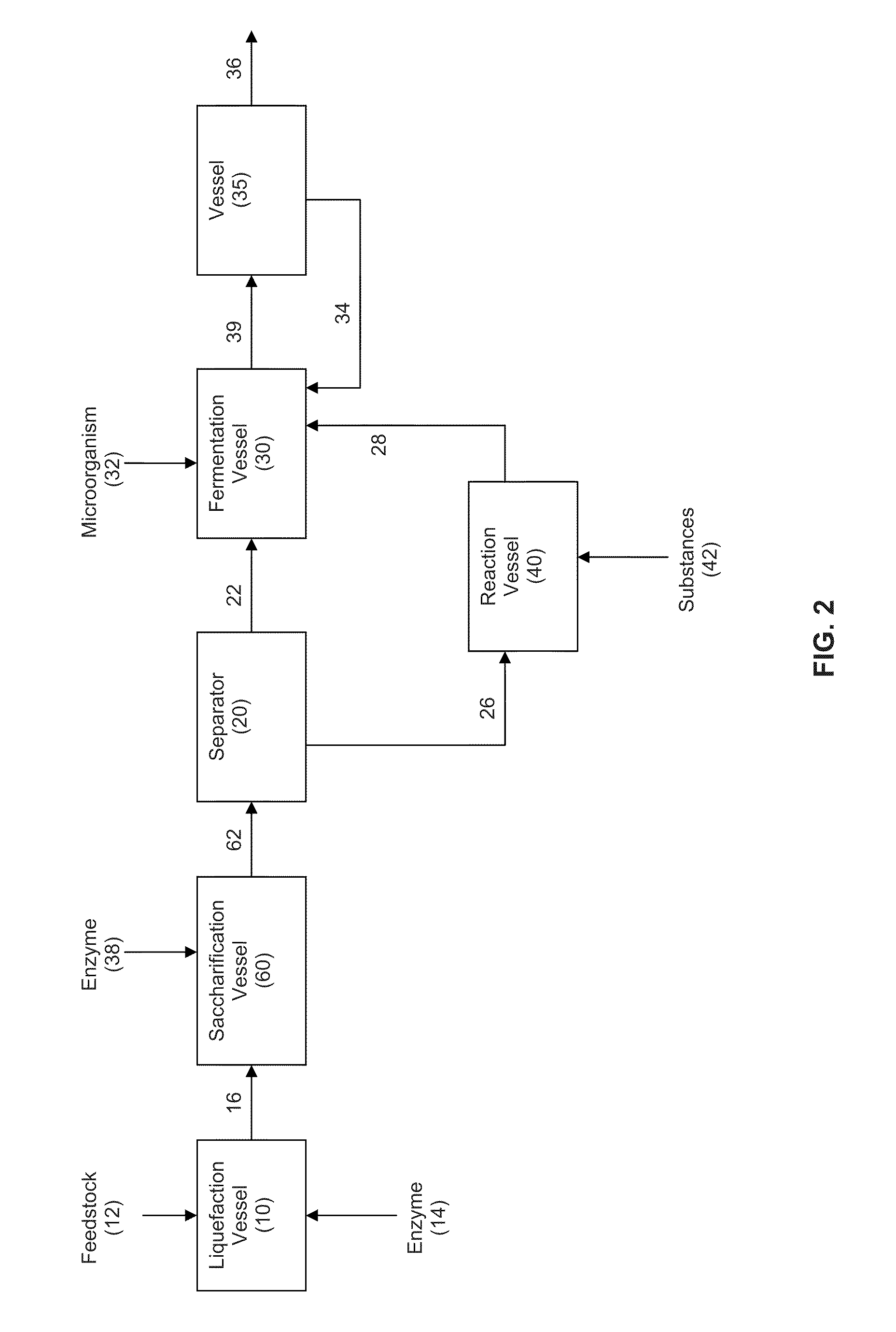

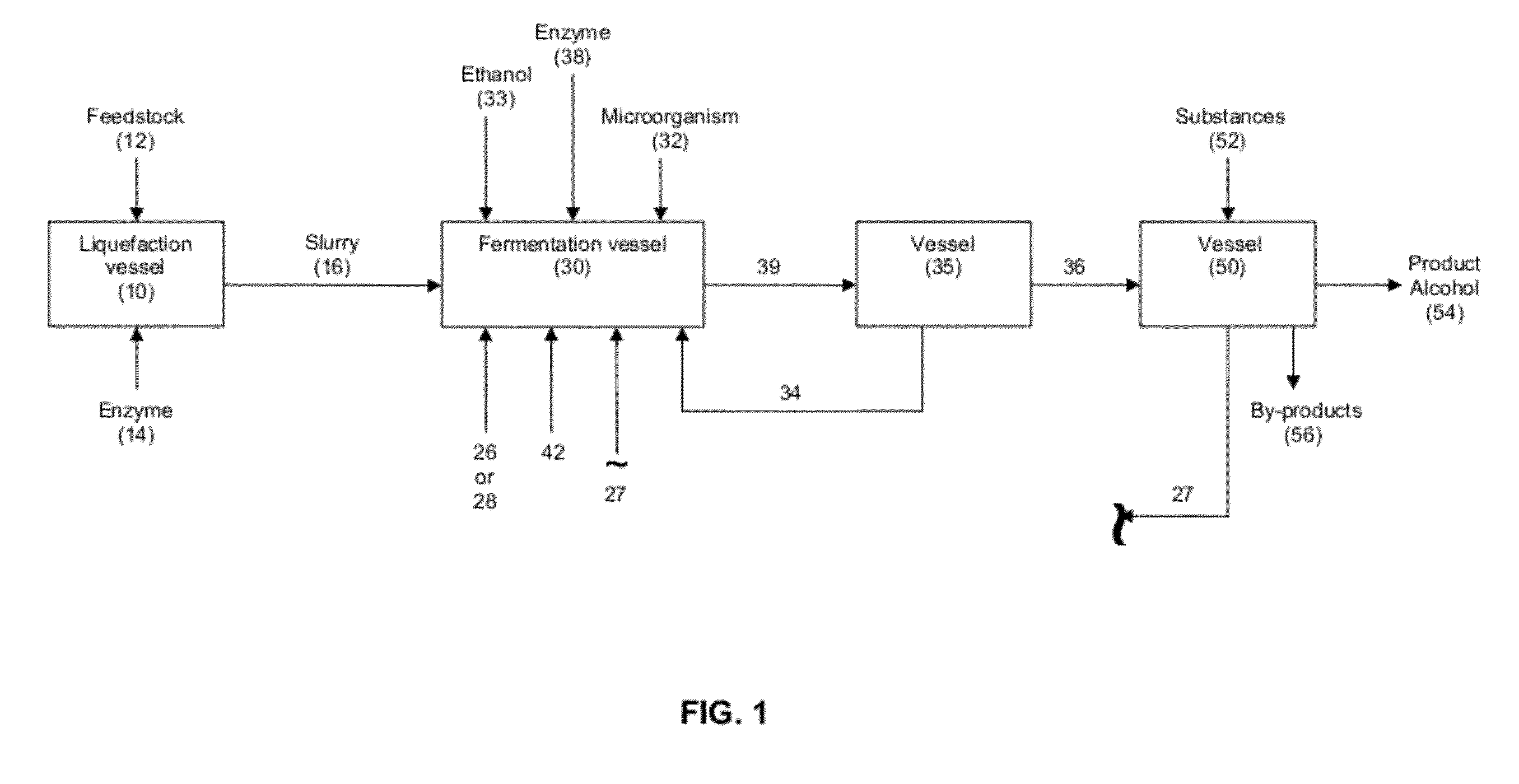

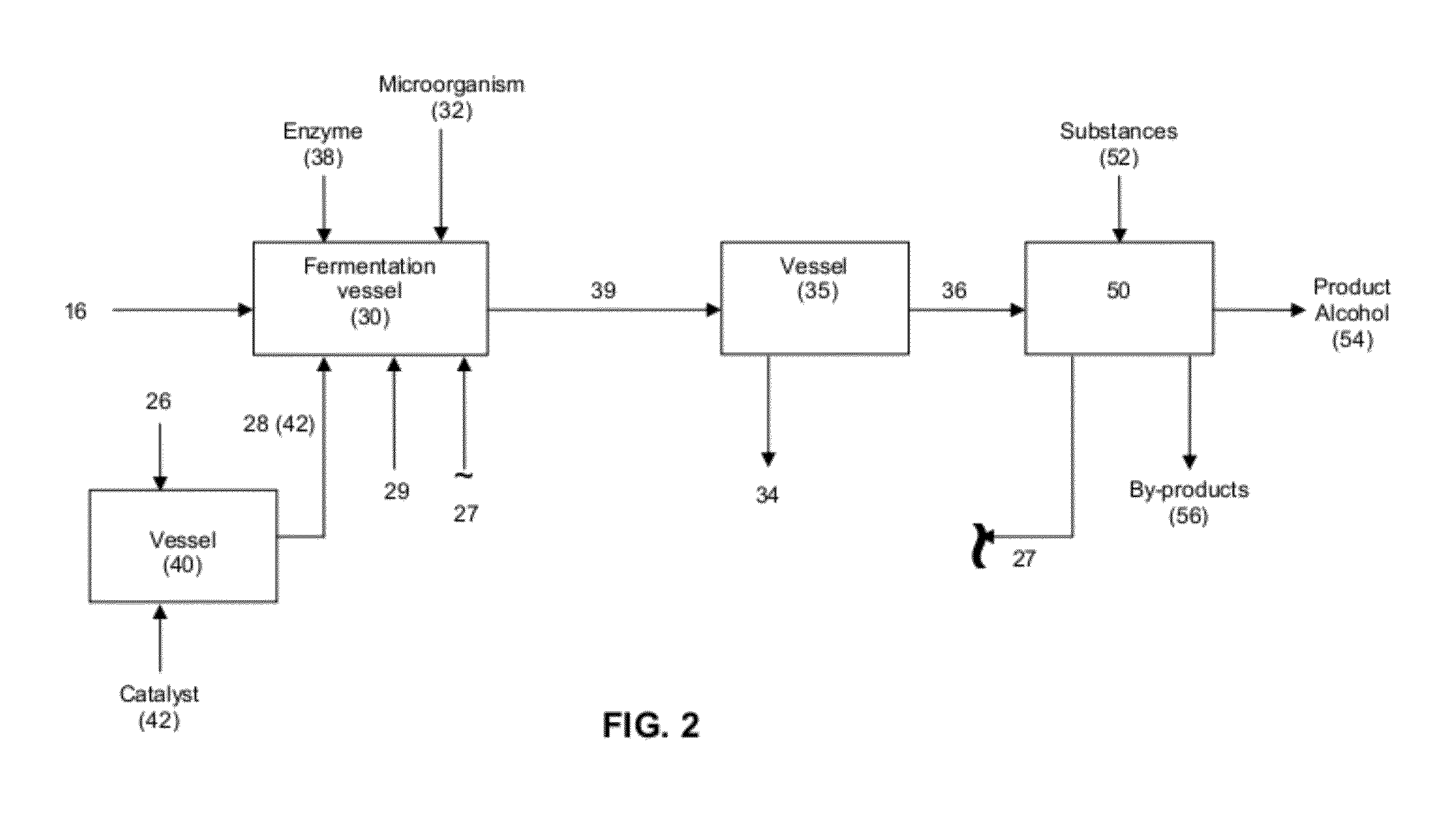

Process for producing ethanol from corn dry milling

InactiveUS7074603B2Fermented solutions distillation/rectificationOrganic compound preparationAcetic acidHydrogenation reaction

A process for producing ethanol by the conversion of carbohydrates from a corn dry milling process in which the bottoms fraction from distillation of ethanol in a conventional yeast fermentation is used in a process including a combination of biochemical and synthetic conversions. The process results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from bottoms fraction, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts of the process include a high protein content solids fraction produced in the fermentation.

Owner:ZEACHEM

Purification of biologically-produced 1,3-propanediol

InactiveUS20050069997A1Reduce the amount of waterFermented solutions distillation/rectificationMembranesEscherichia coliDistillation

A process for purifying 1,3-propanediol from the fermentation broth of a cultured E. coli that has been bioengineered to synthesize 1,3-propanediol from sugar is provided. The basic process entails filtration, ion exchange and distillation of the fermentation broth product stream, preferably including chemical reduction of the product during the distillation procedure. Also provided are highly purified compositions of 1,3-propanediol.

Owner:DUPONT IND BIOSCIENCES USA LLC +1

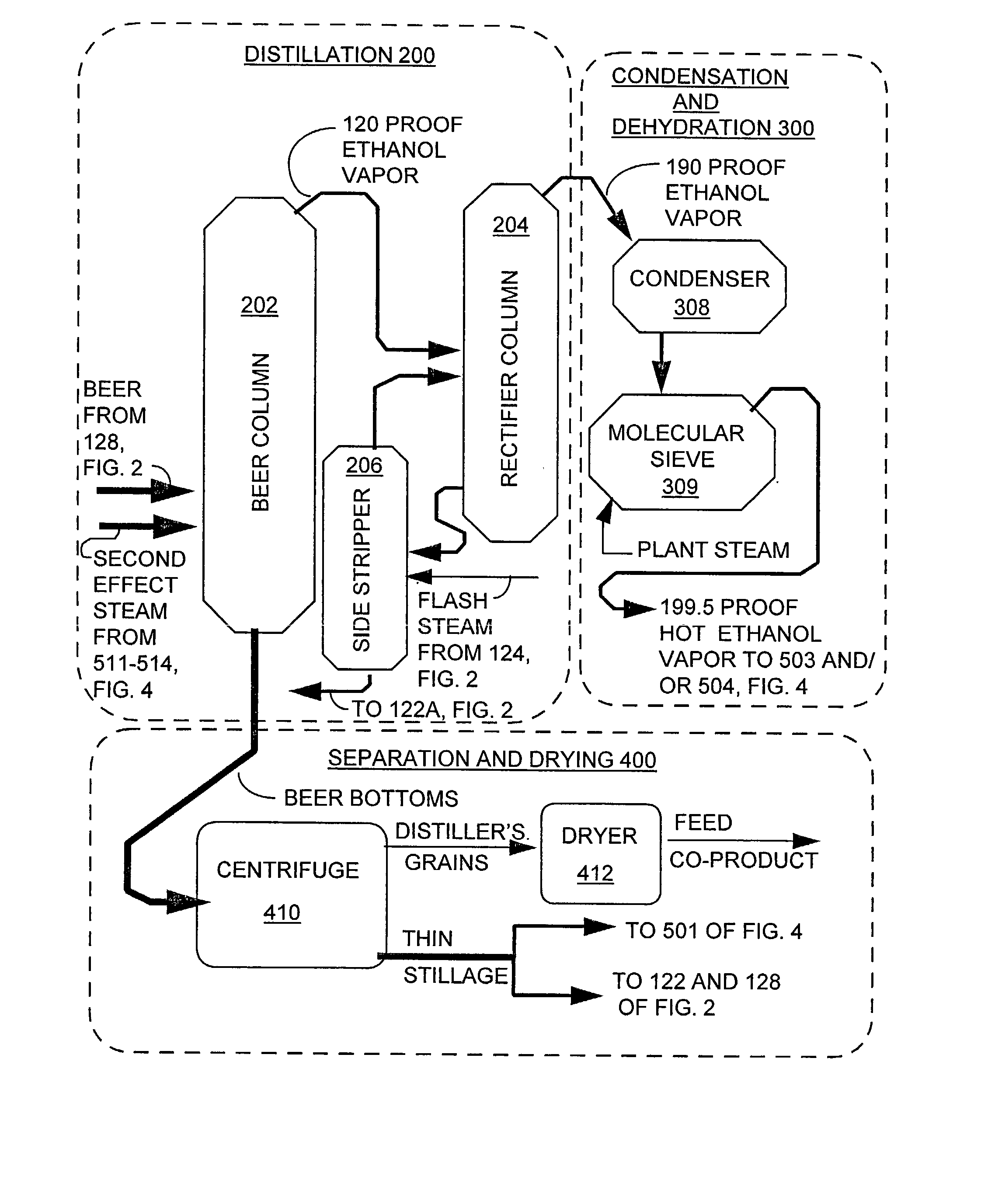

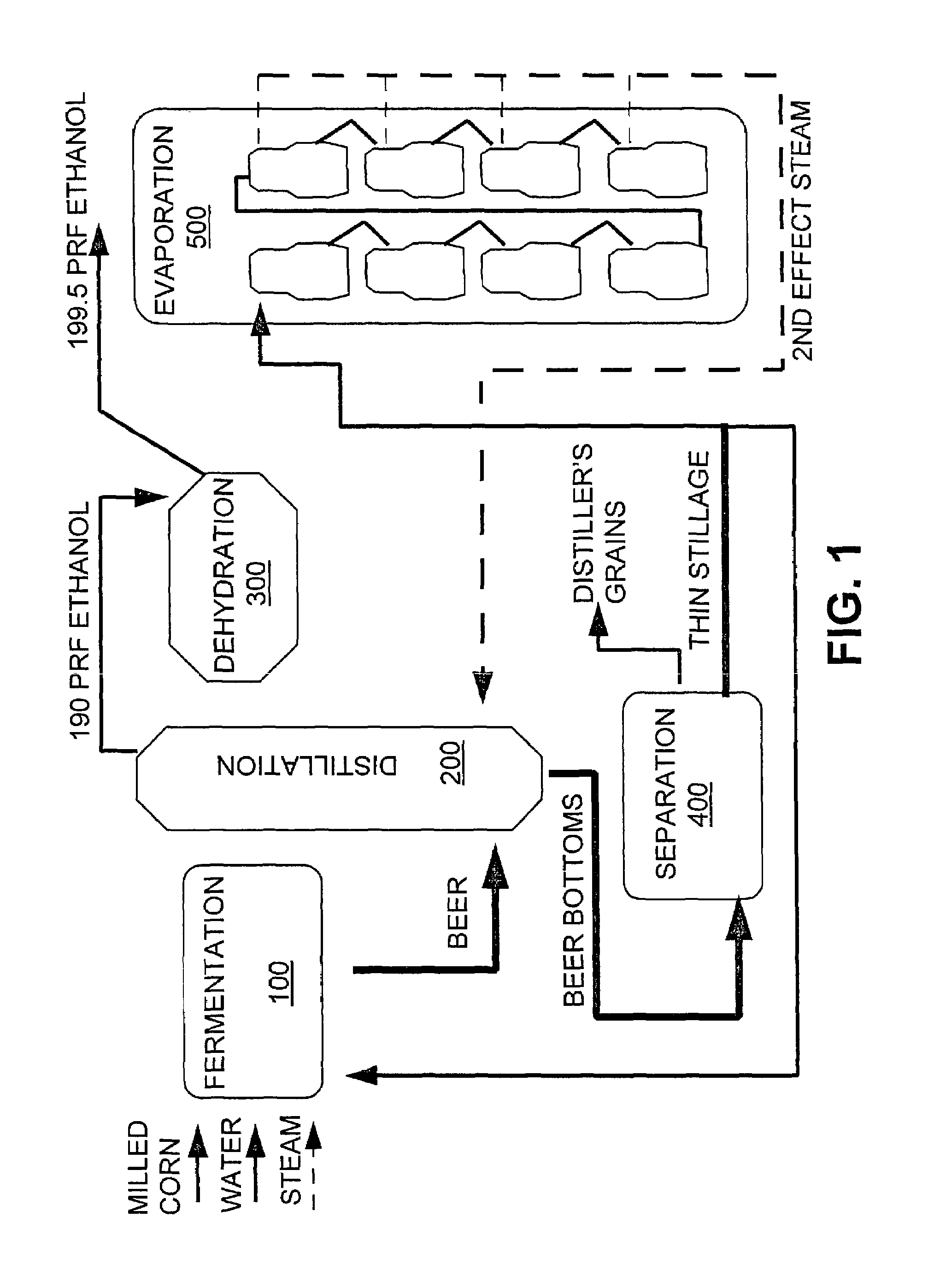

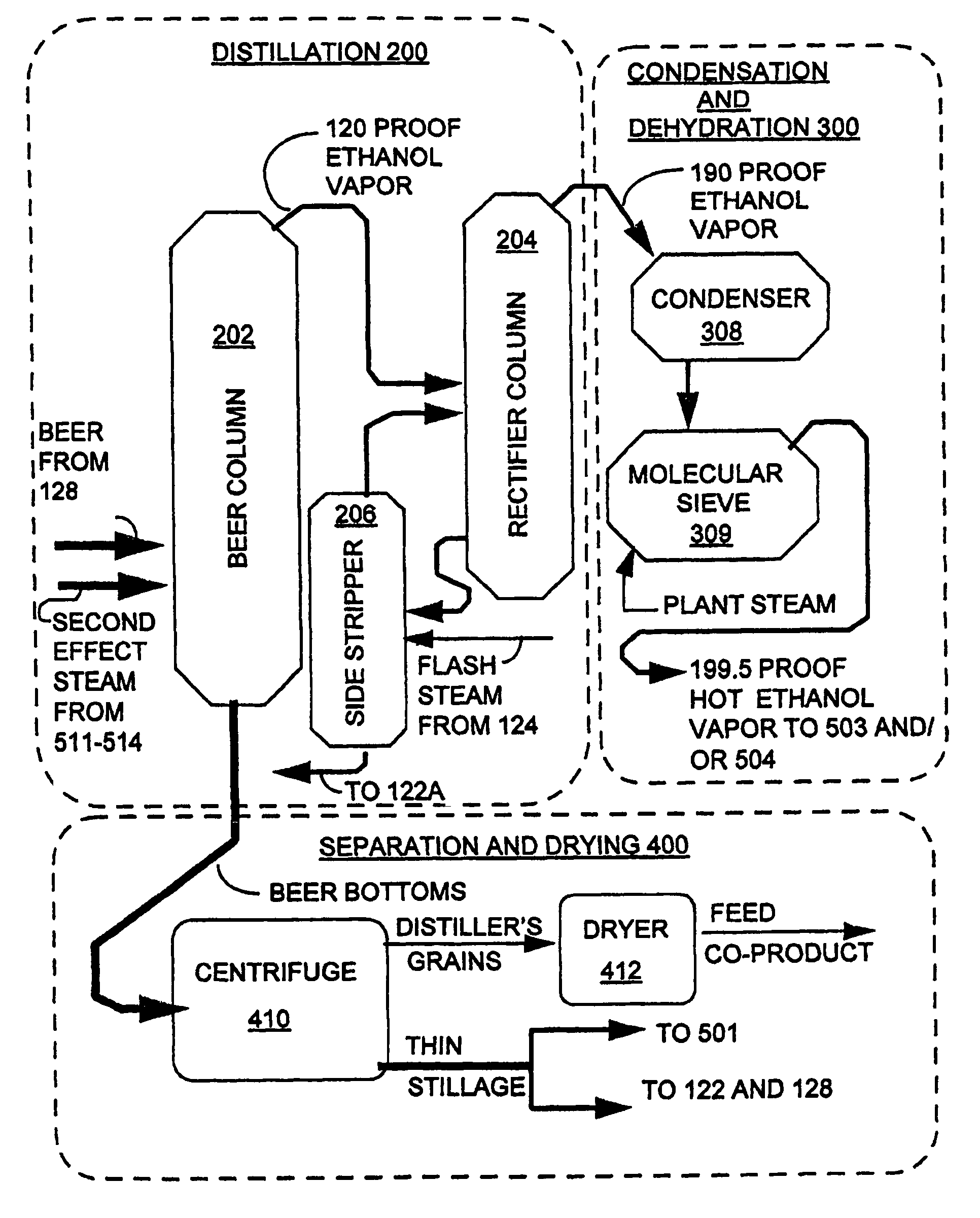

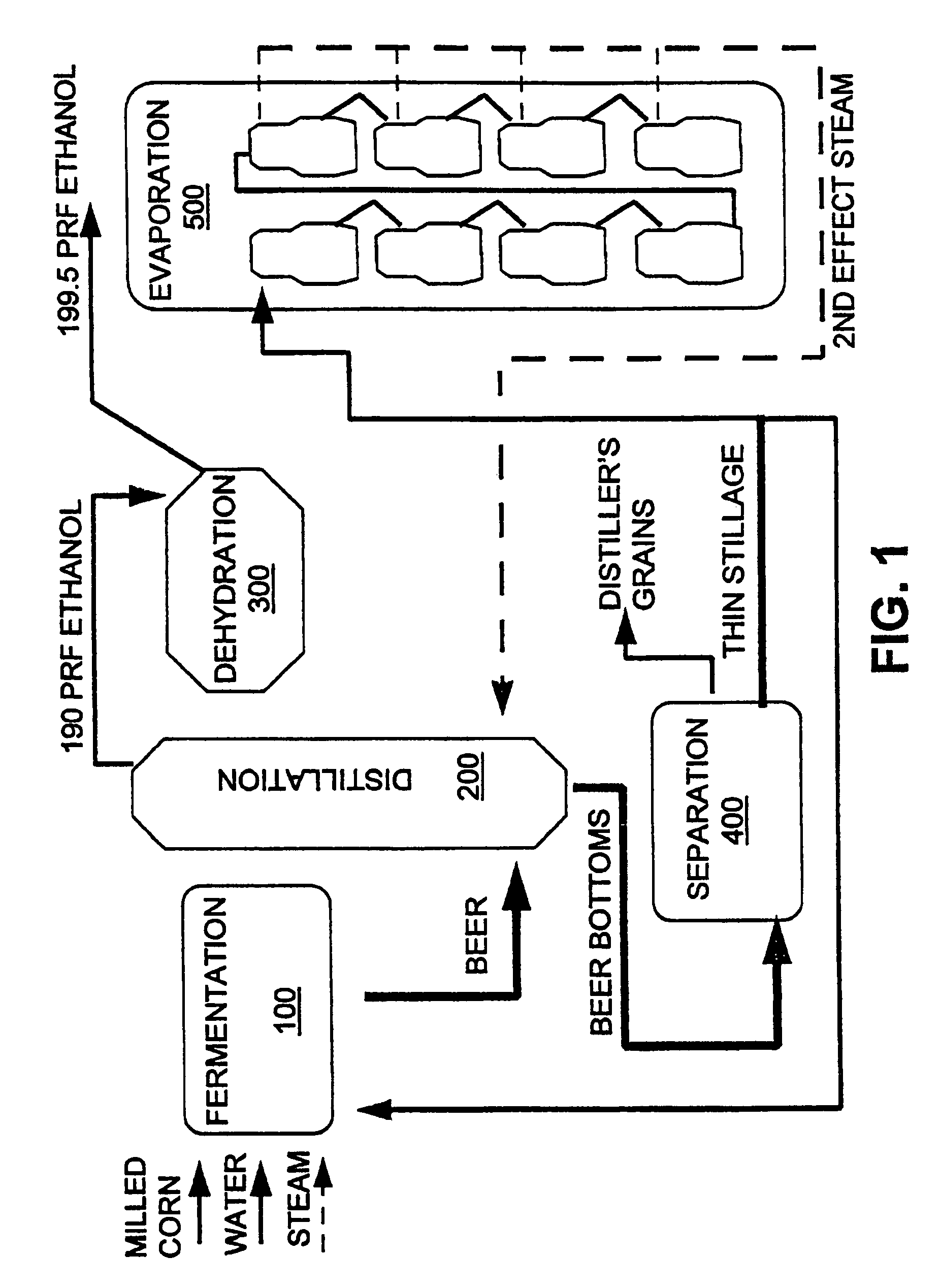

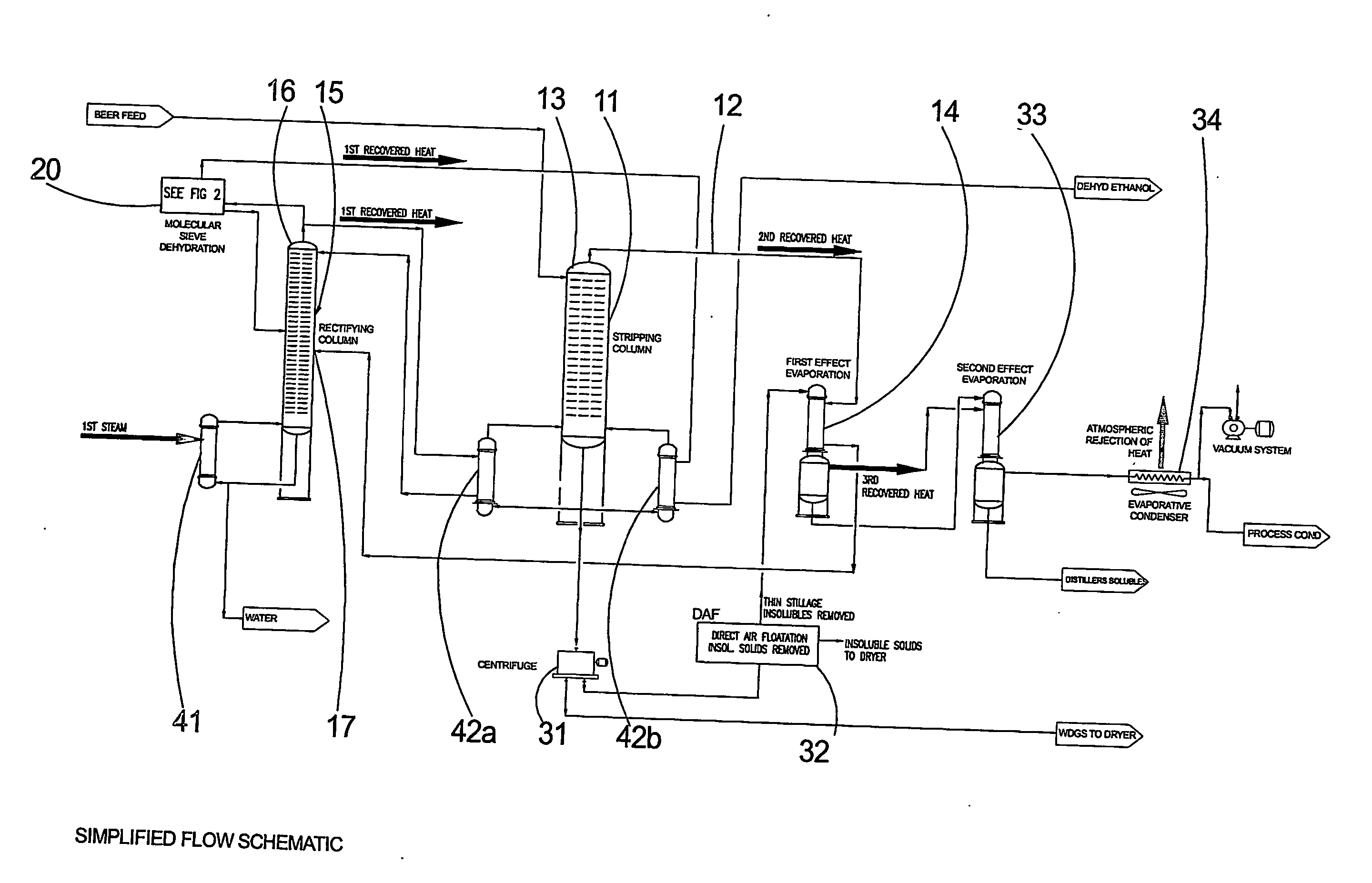

Ethanol distillation process

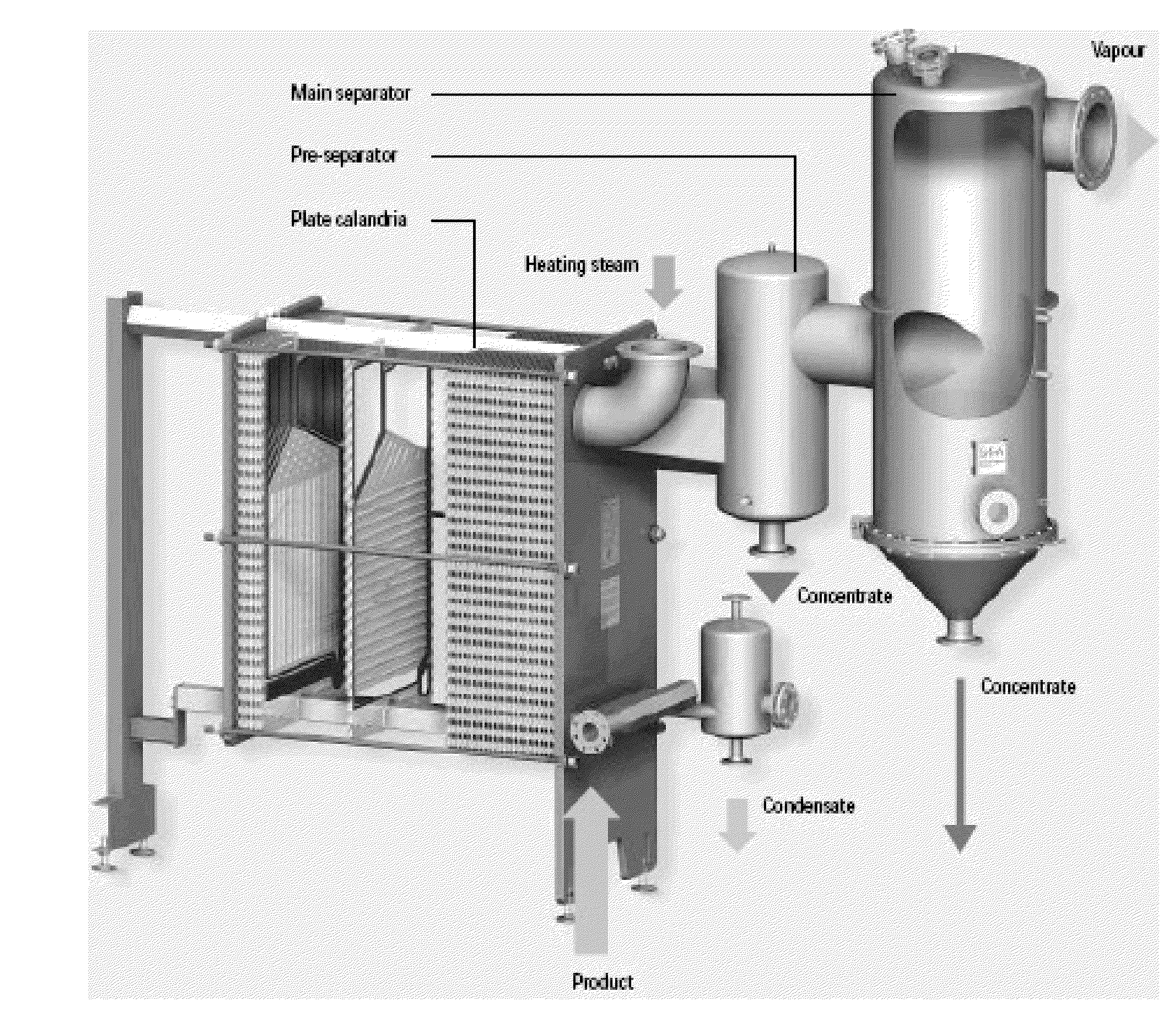

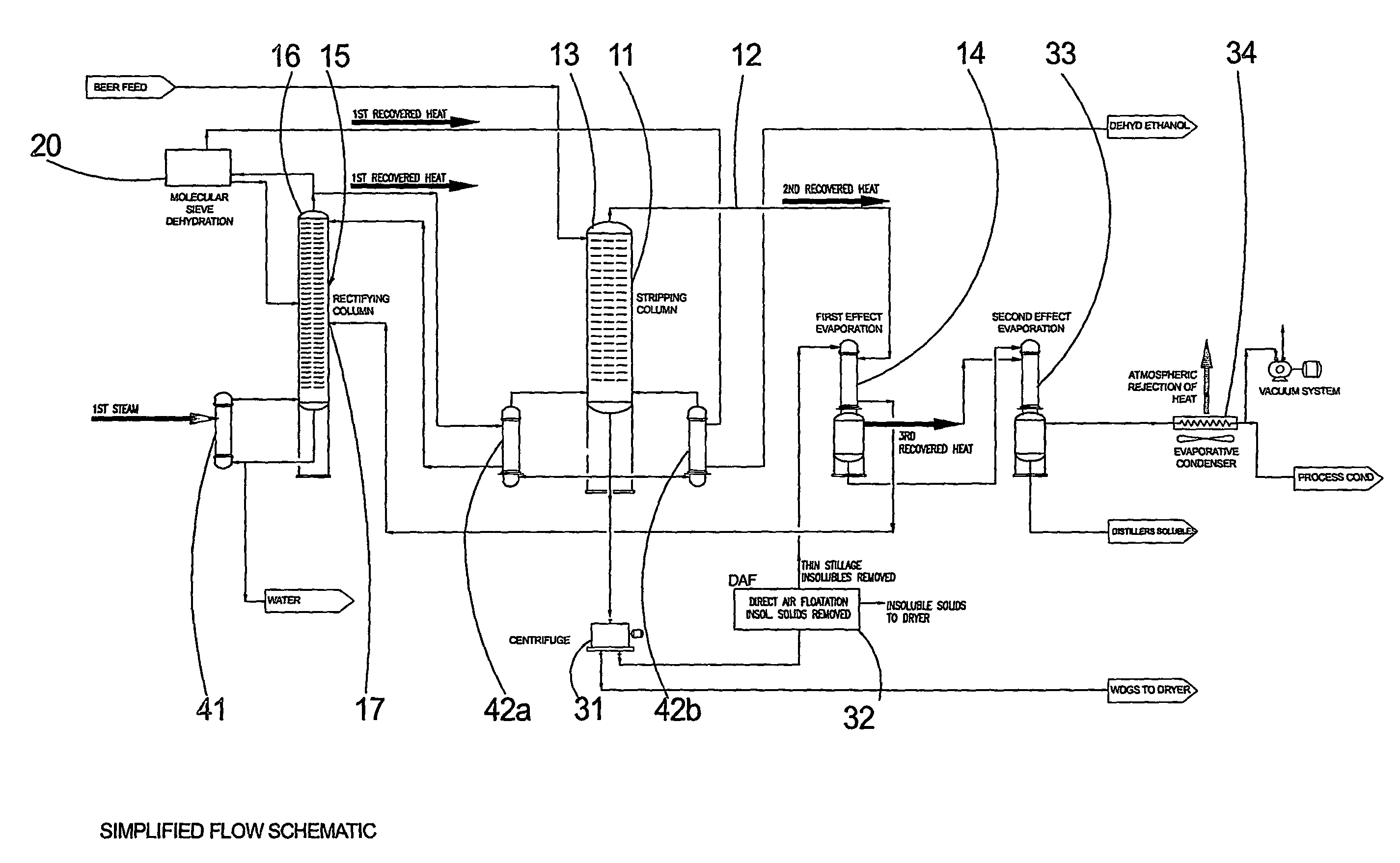

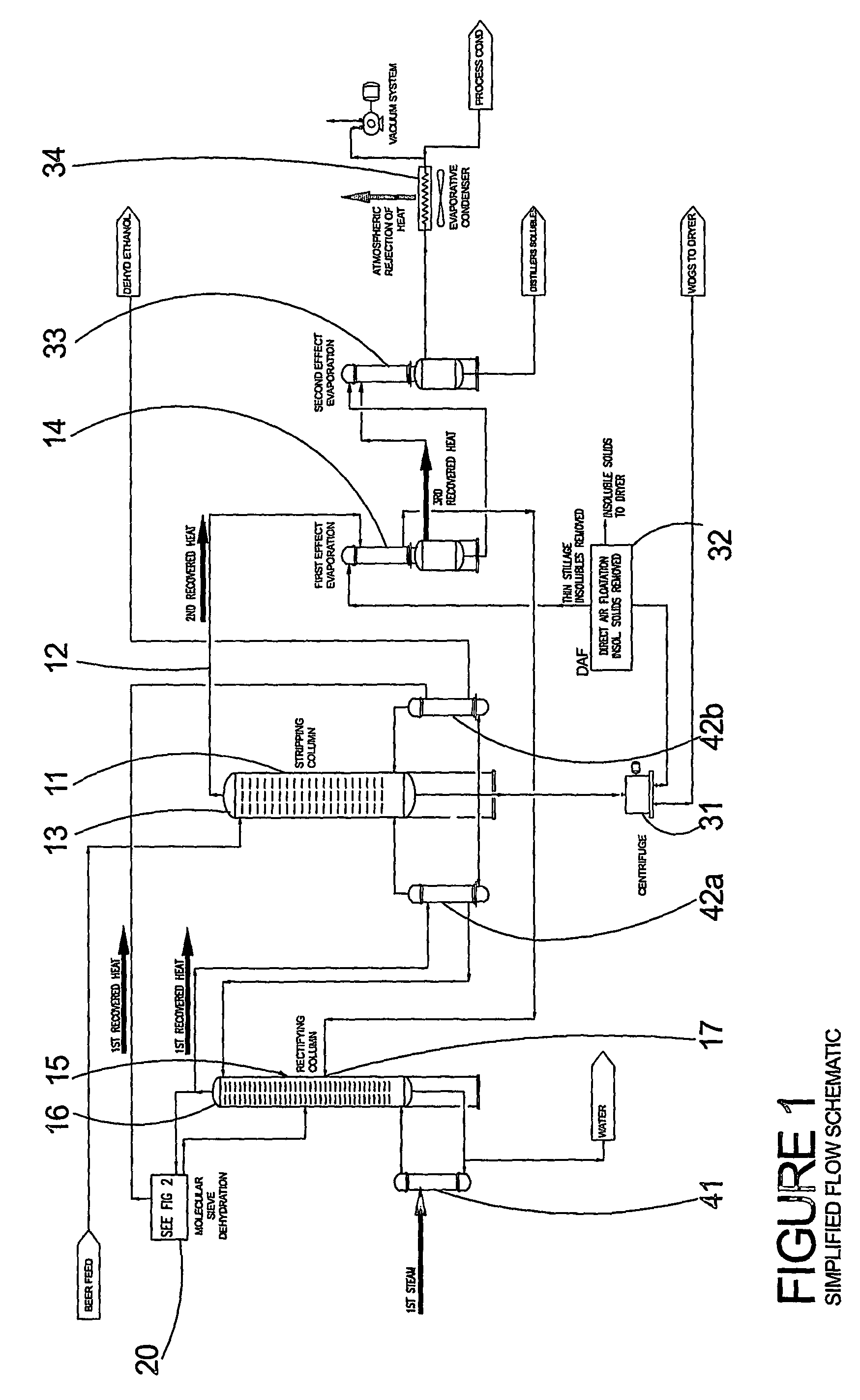

InactiveUS7297236B1Avoid insufficient heatingShorten the timeFermented solutions distillation/rectificationDistillation in boilers/stillsDistillationEvaporation

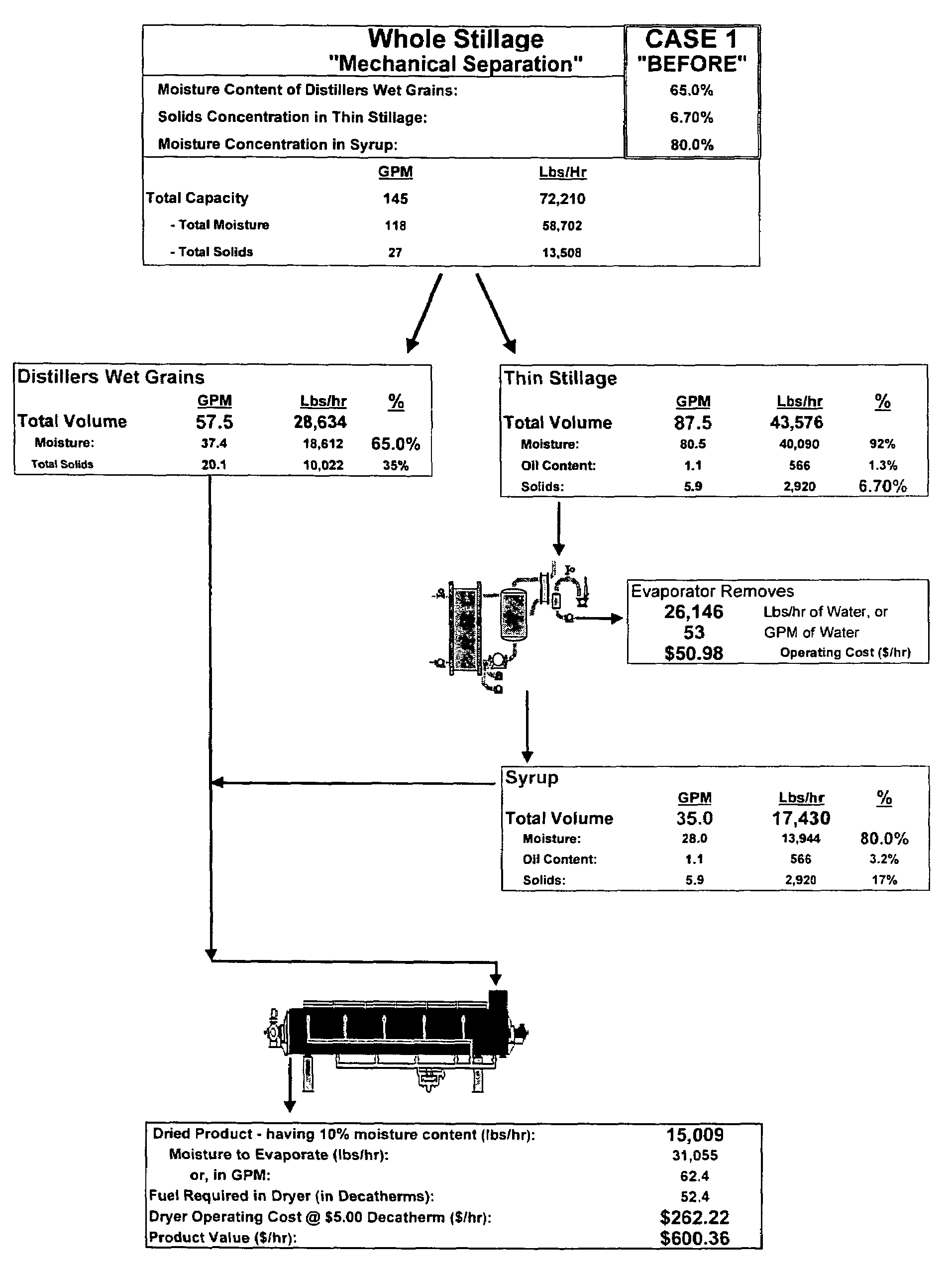

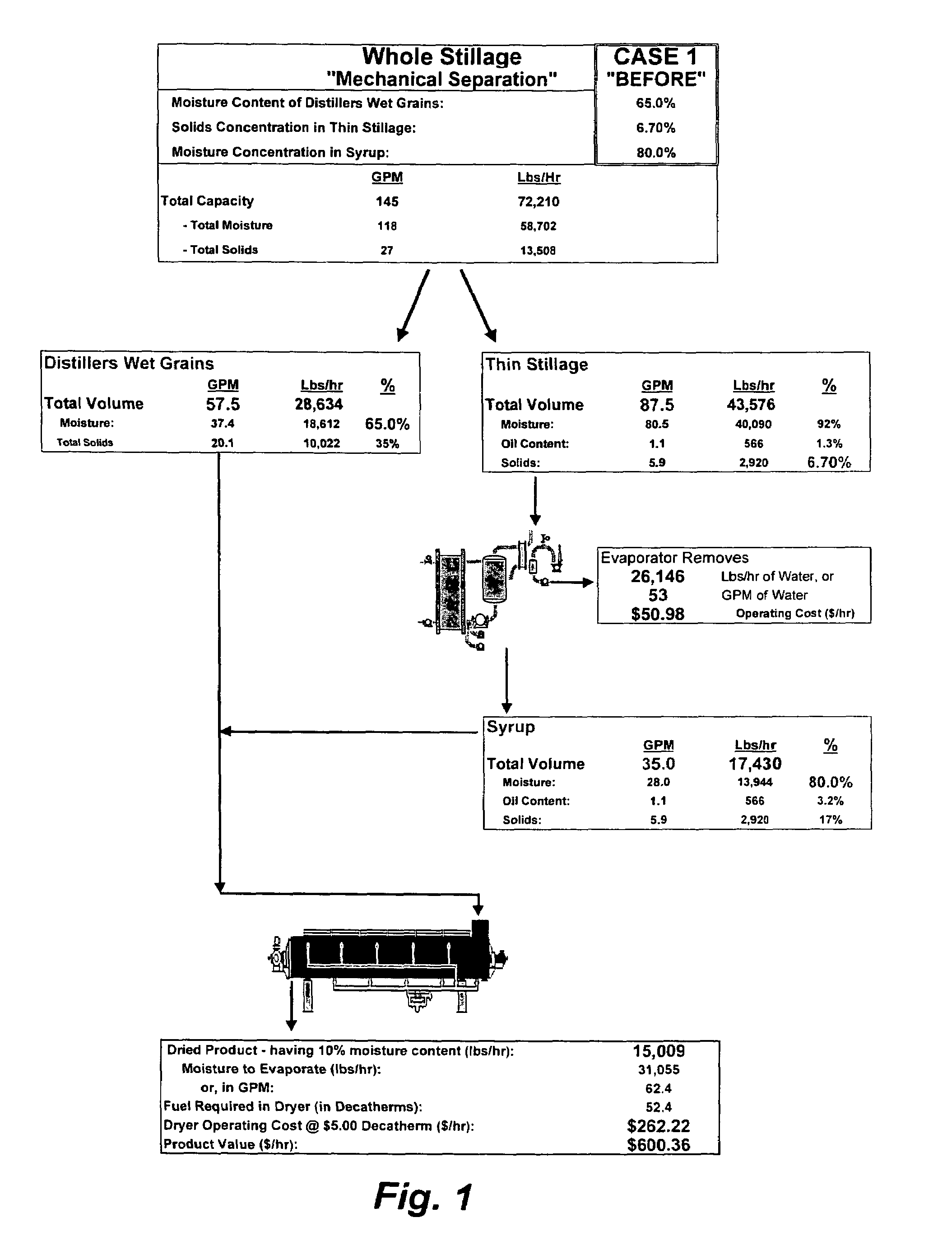

A process arrangement for distilling fuel grade ethanol includes a fermentation portion, a distillation portion, a condensation and dehydration portion, a separation and drying portion and an evaporation portion. The fermentation portion produces beer. The distillation portion, the condensation and dehydration portion and the separation and drying portion receives beer from the fermentation portion and produces hot ethanol vapor and thin stillage. In the evaporation portion, a set of first effect evaporators which are heated either by plant steam or hot ethanol vapor, concentrate thin stillage into mid stillage while producing first effect steam. The first effect steam from the first effect evaporators provides heat to a set of second effect evaporators which concentrate the mid stillage into a syrup for further drying. The second effect evaporators produce second effect steam which is used to heat the distillation portion of the process arrangement. The multiple evaporators of the first and second effects of the evaporation portion can be selectively taken off-line for maintenance while the evaporation portion and the remainder of the process arrangement continue to operate at full capacity.

Owner:ICM

Ethanol distillation process

InactiveUS7572353B1Shorten the timeLess rapidlyFermented solutions distillation/rectificationOrganic compound preparationDistillationEvaporation

Owner:ICM

Process for producing ethanol from corn dry milling

InactiveUS20060127999A1Speed up the conversion processFermented solutions distillation/rectificationOrganic compound preparationAcetic acidDistillation

A process for producing ethanol by the conversion of carbohydrates from a corn dry milling process in which the bottoms fraction from distillation of ethanol in a conventional yeast fermentation is used in a process including a combination of biochemical and synthetic conversions. The process results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from bottoms fraction, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts of the process include a high protein content solids fraction produced in the fermentation.

Owner:ZEACHEM

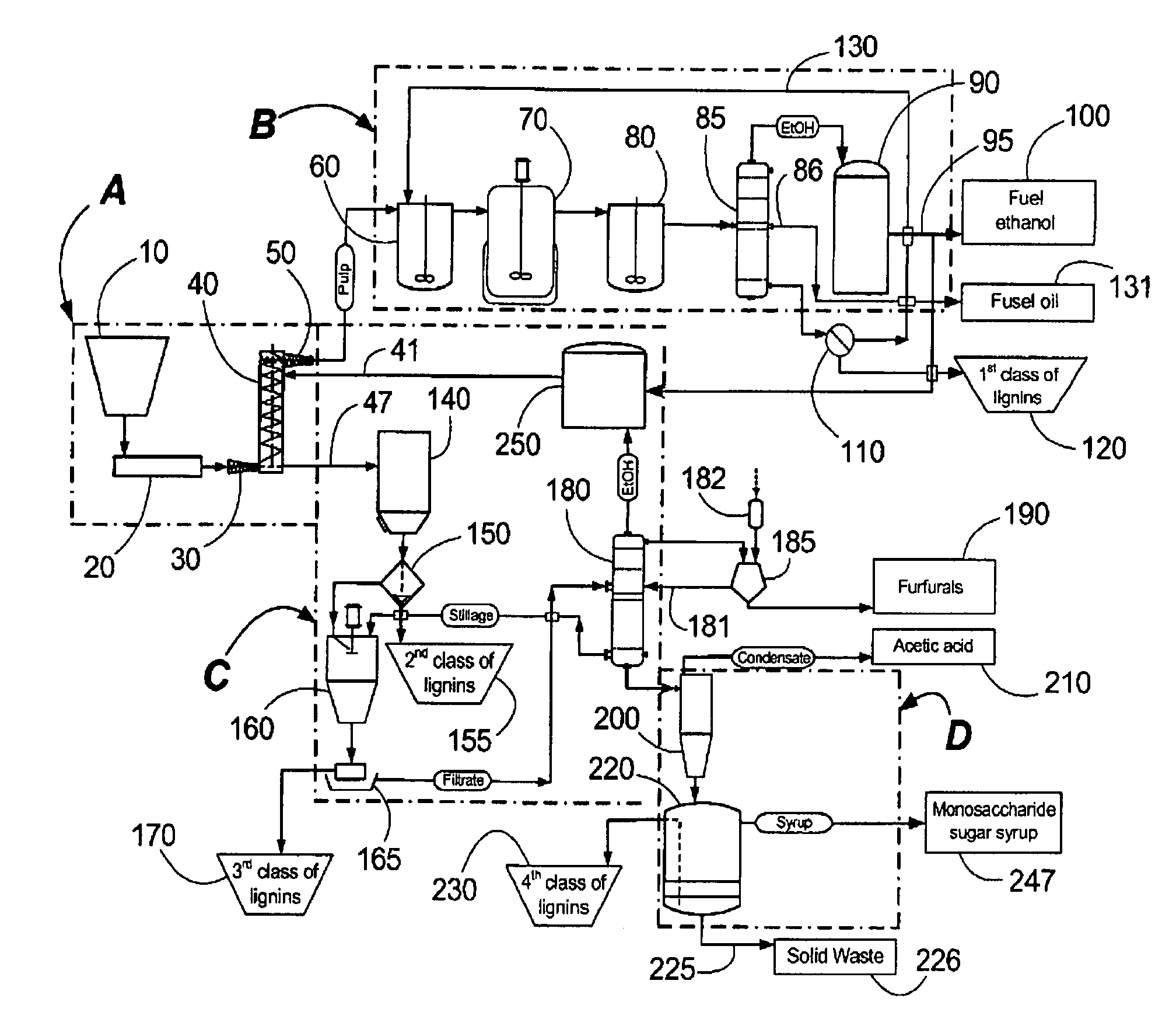

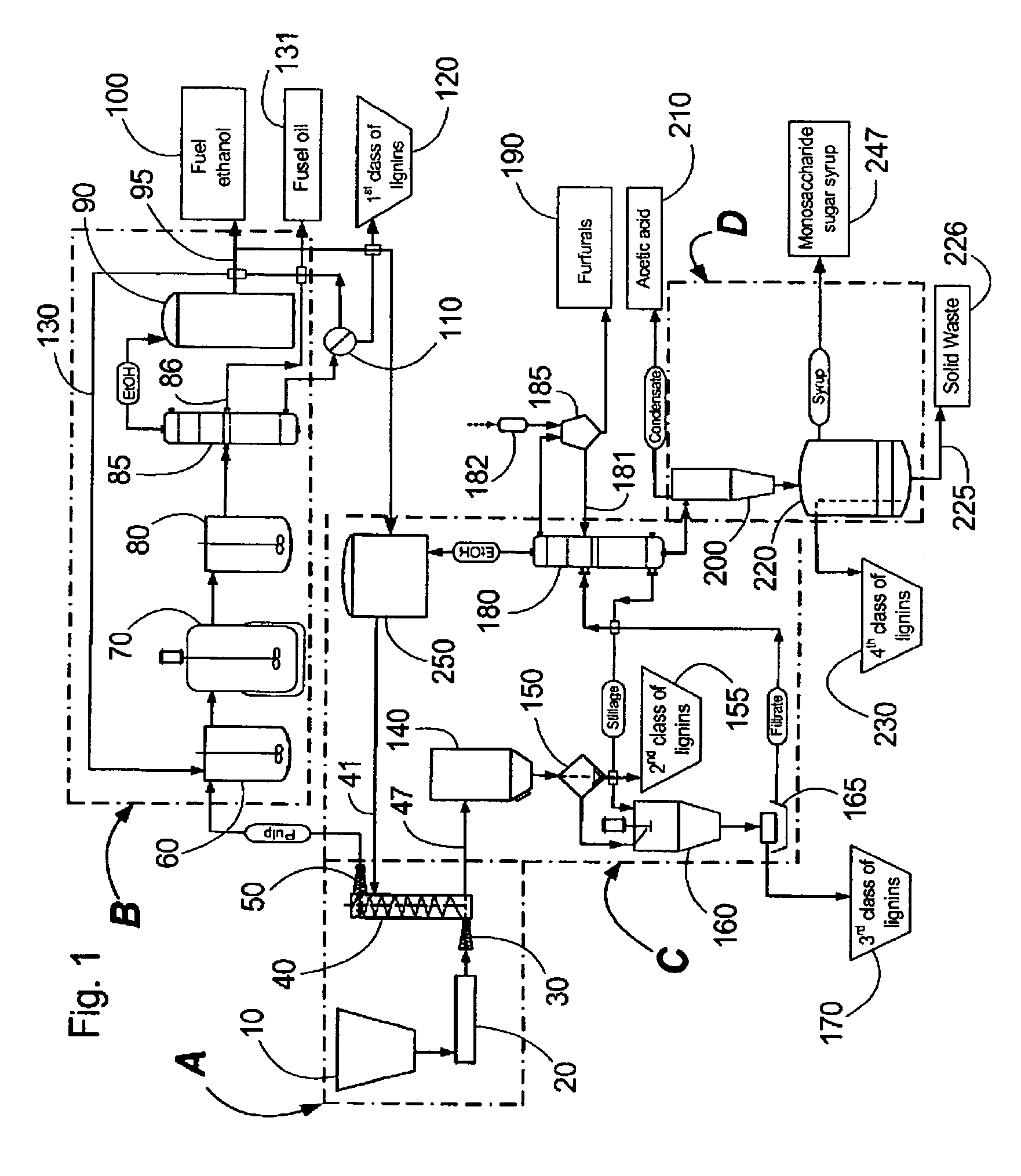

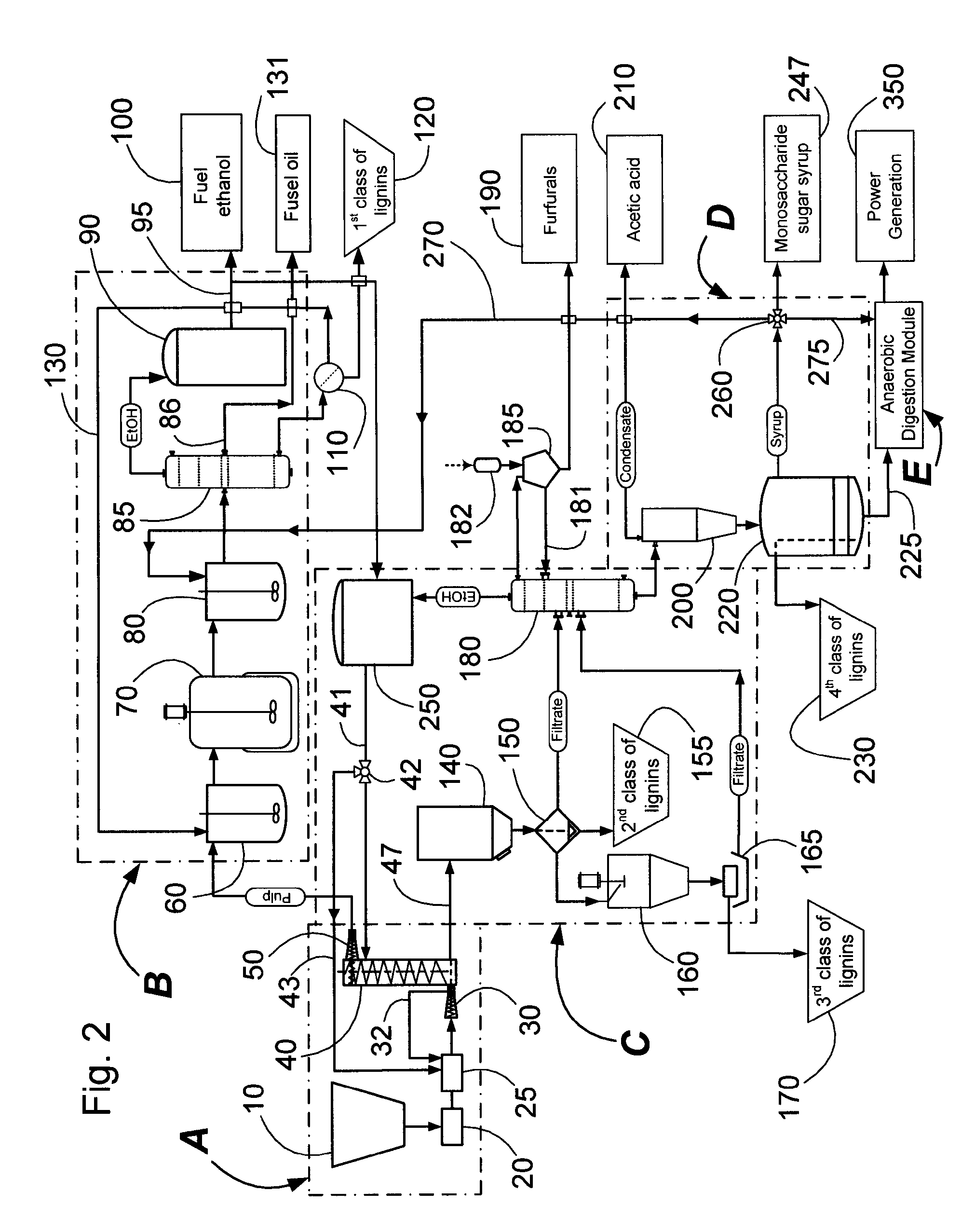

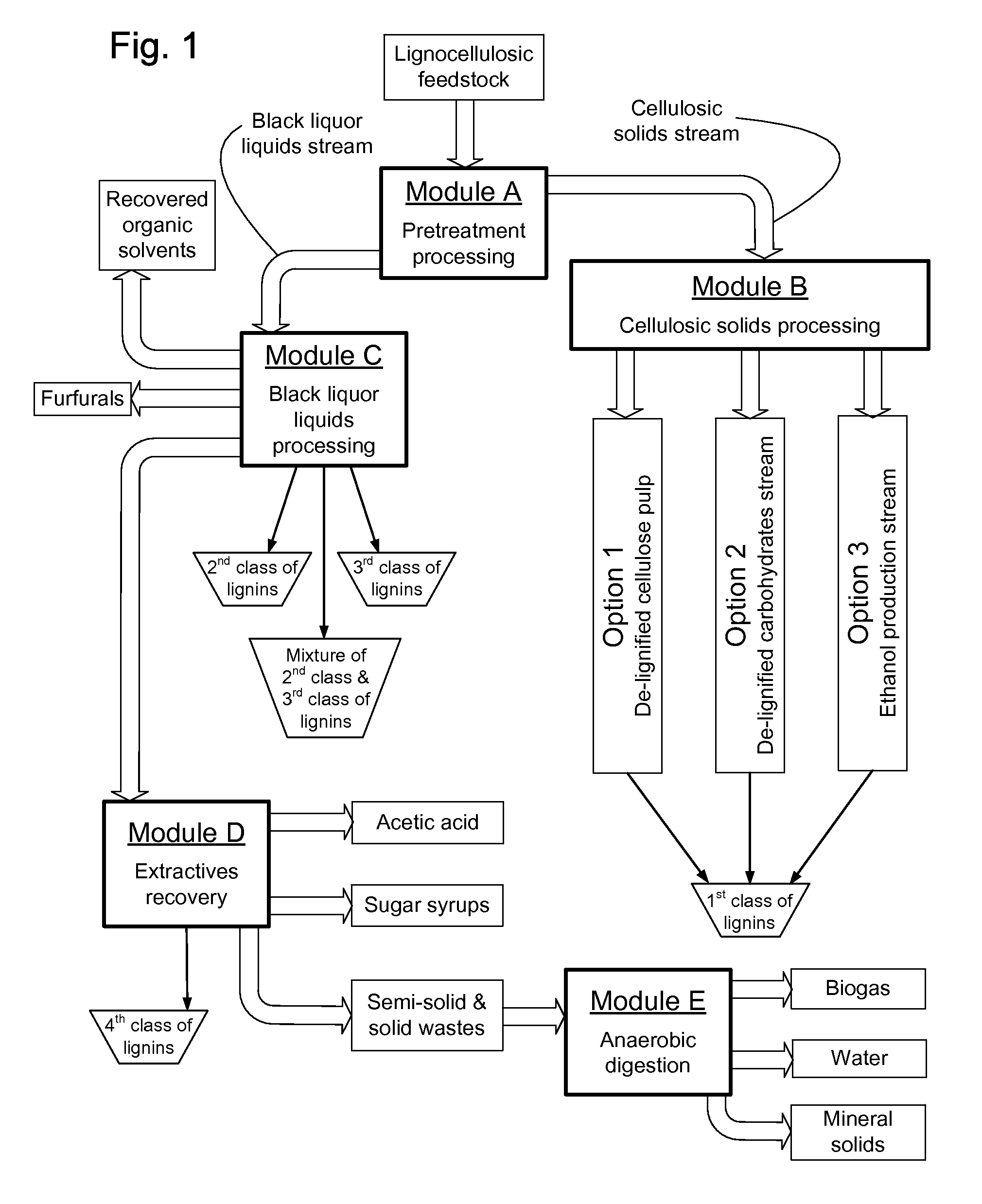

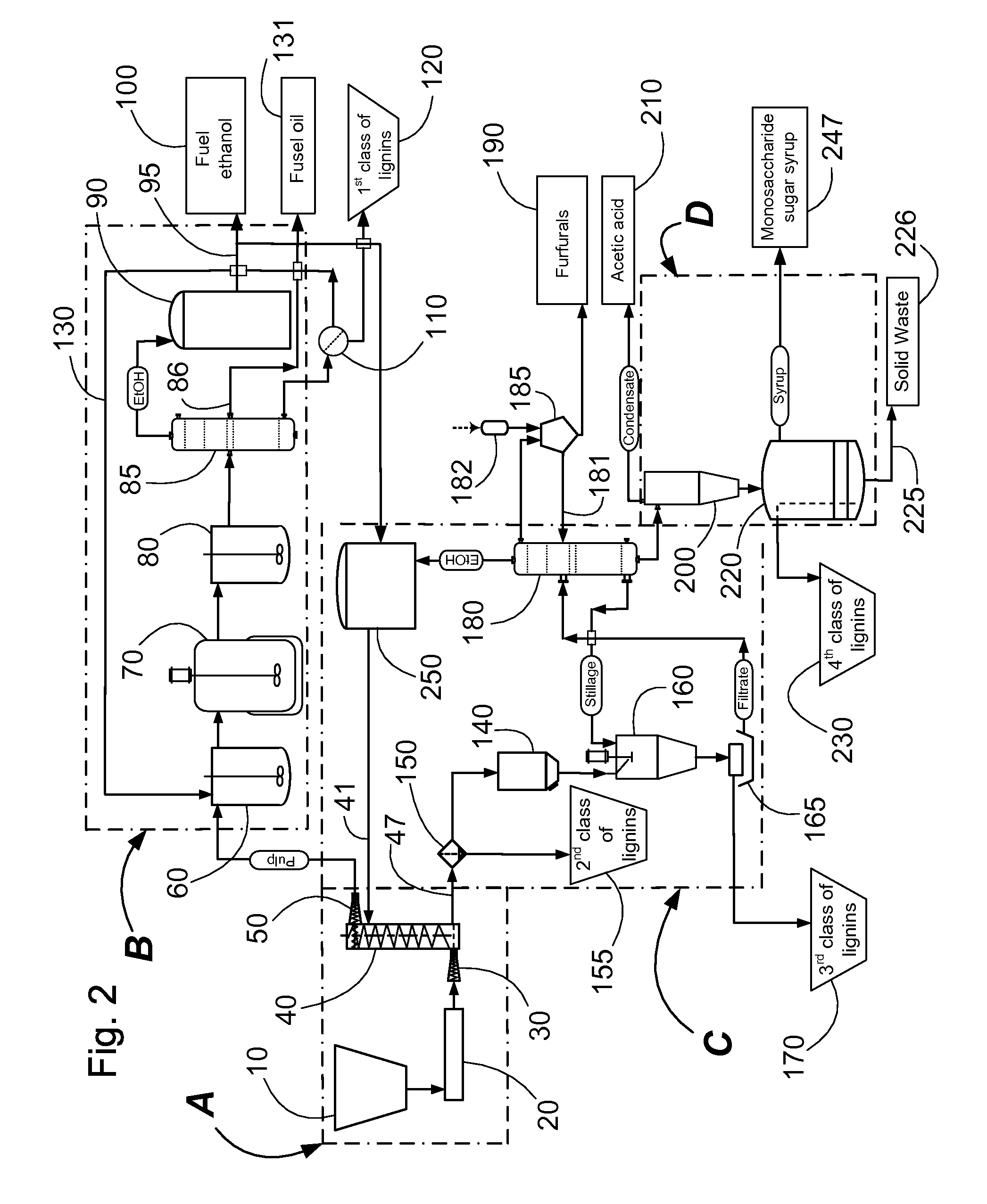

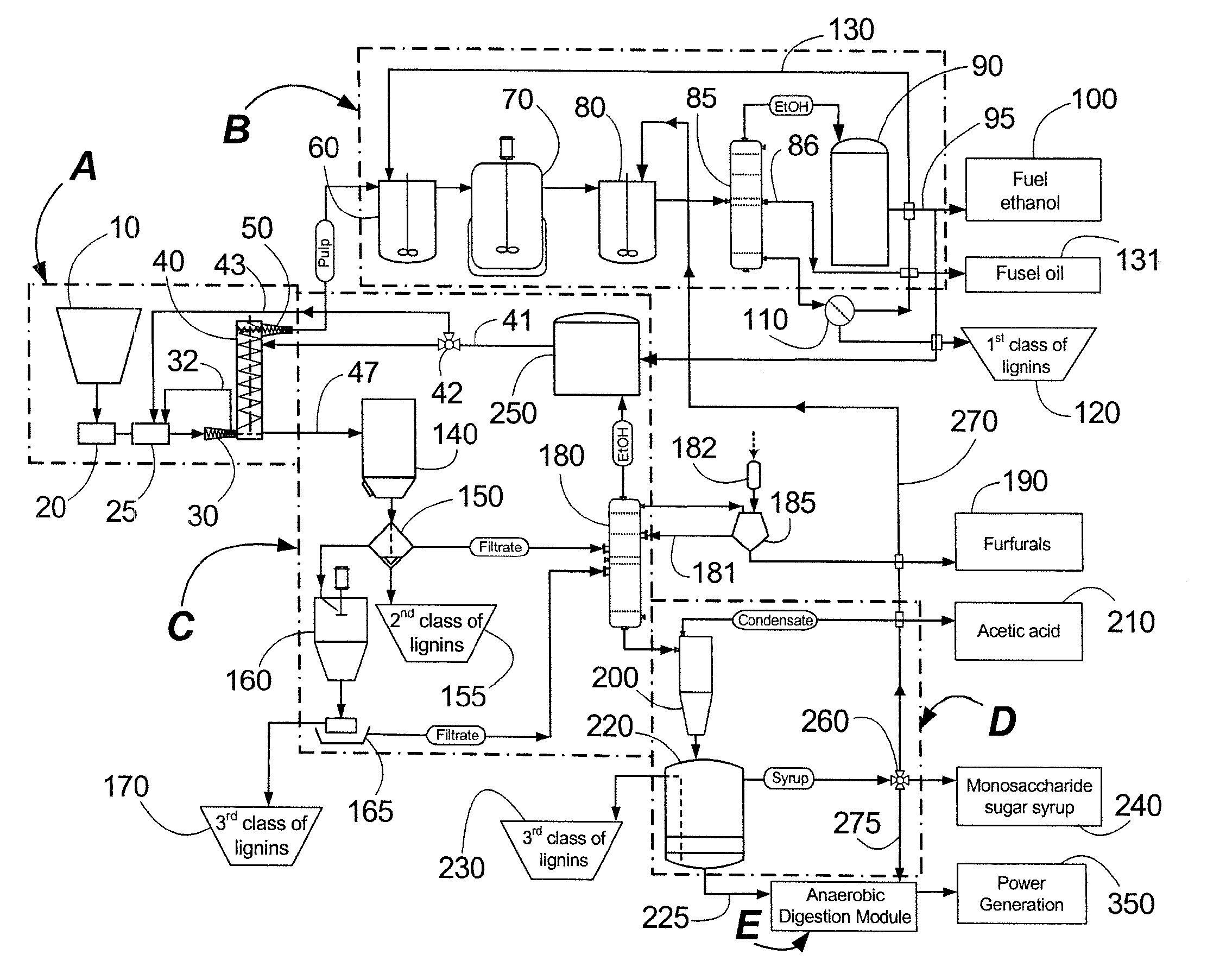

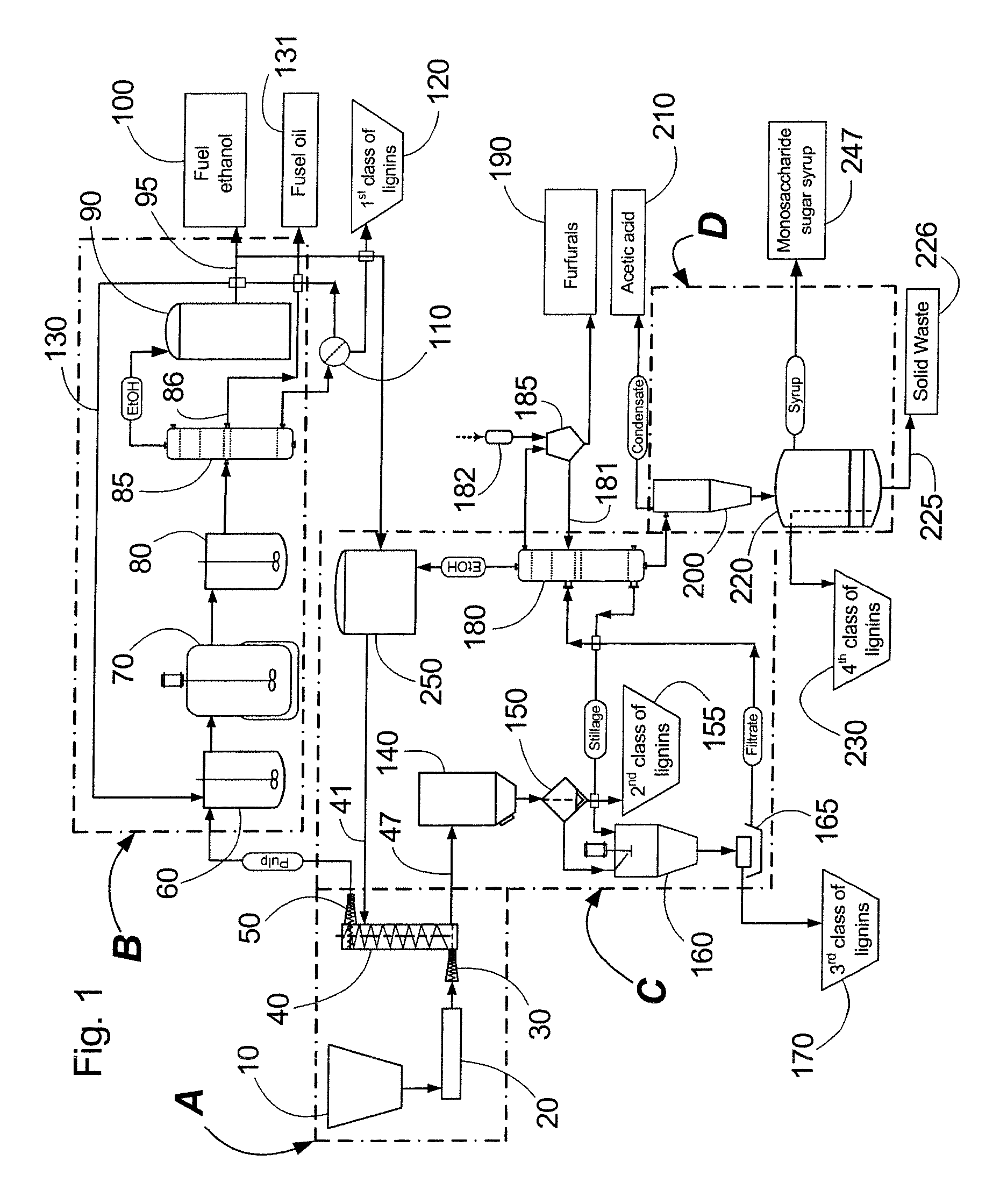

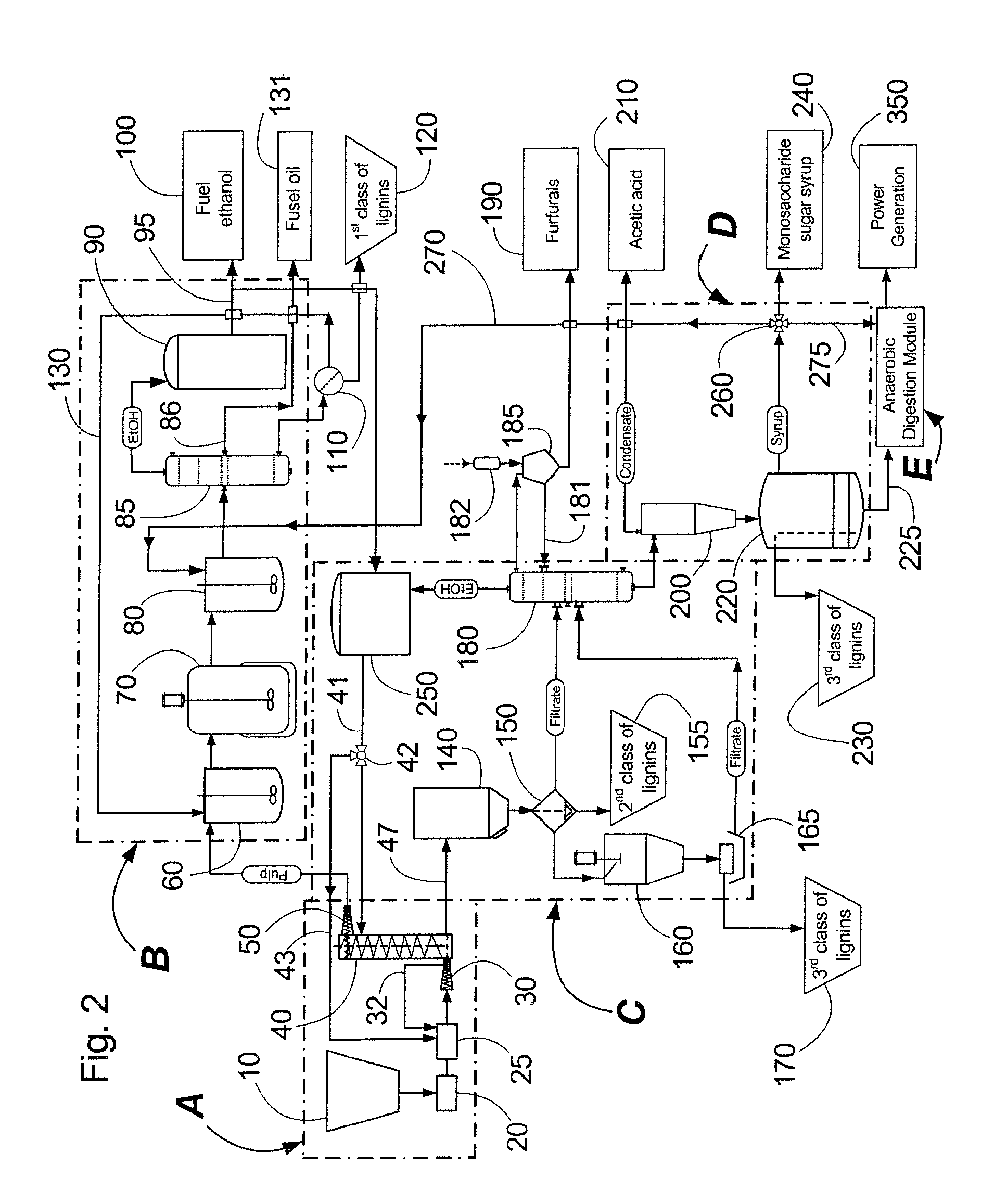

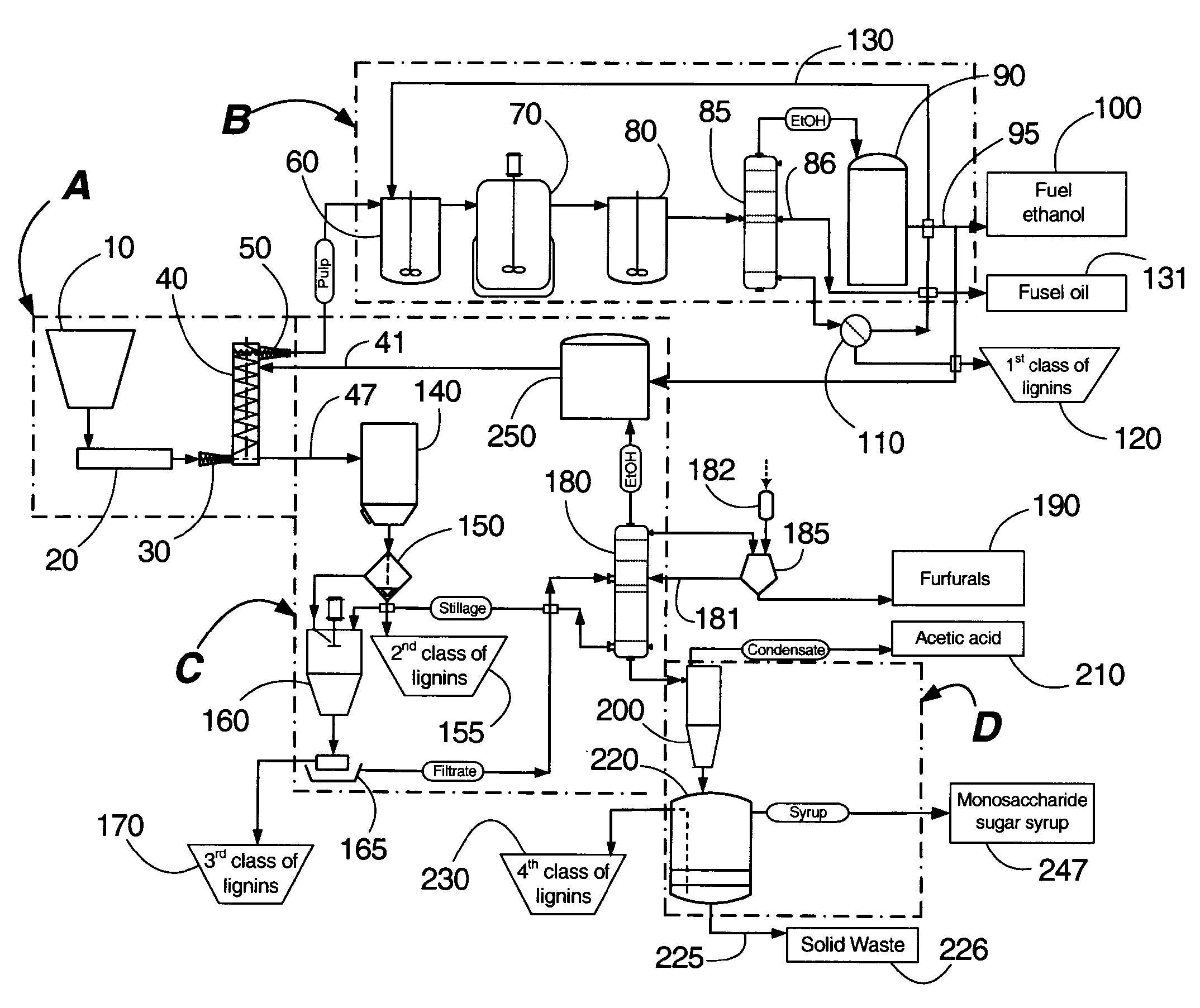

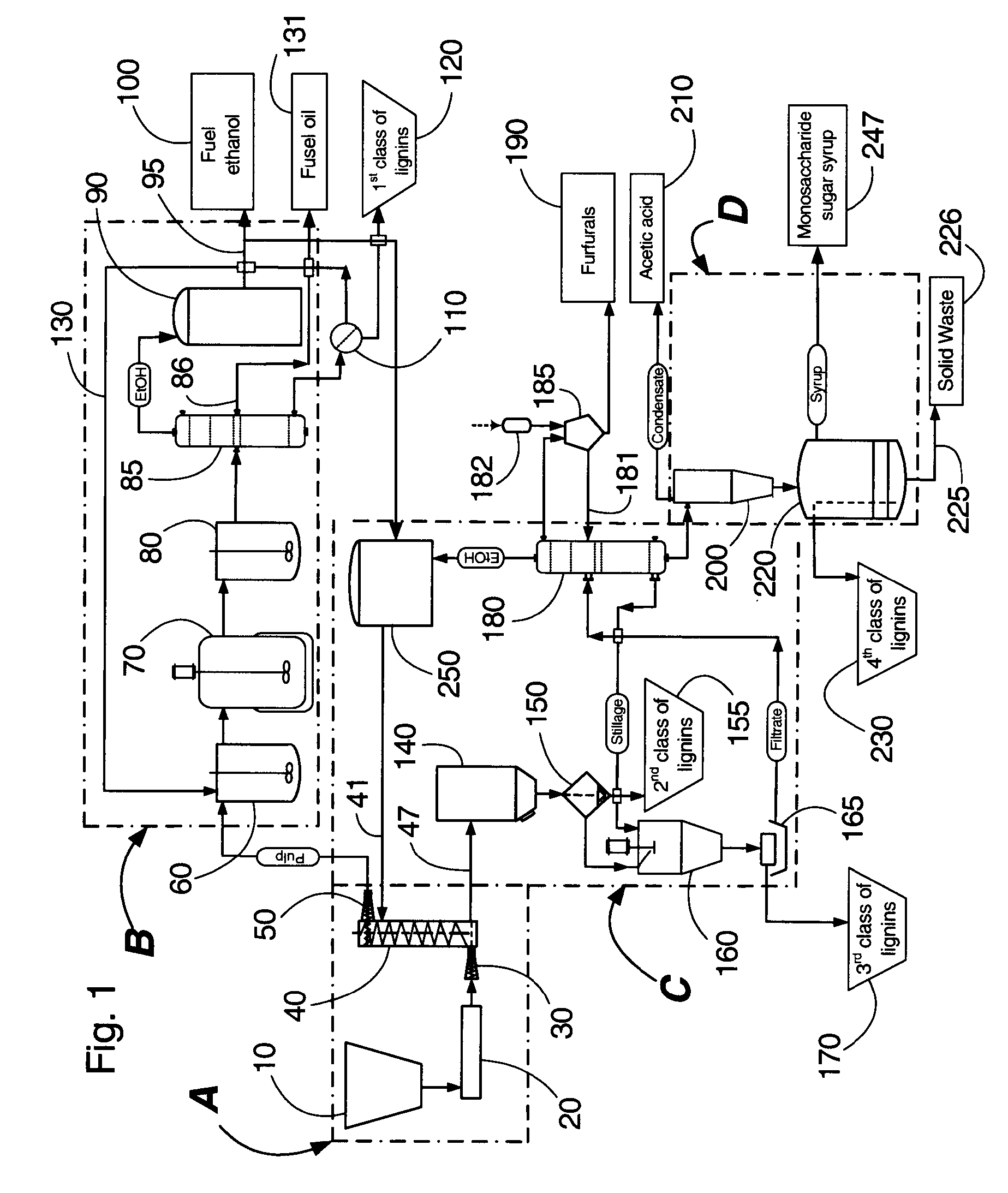

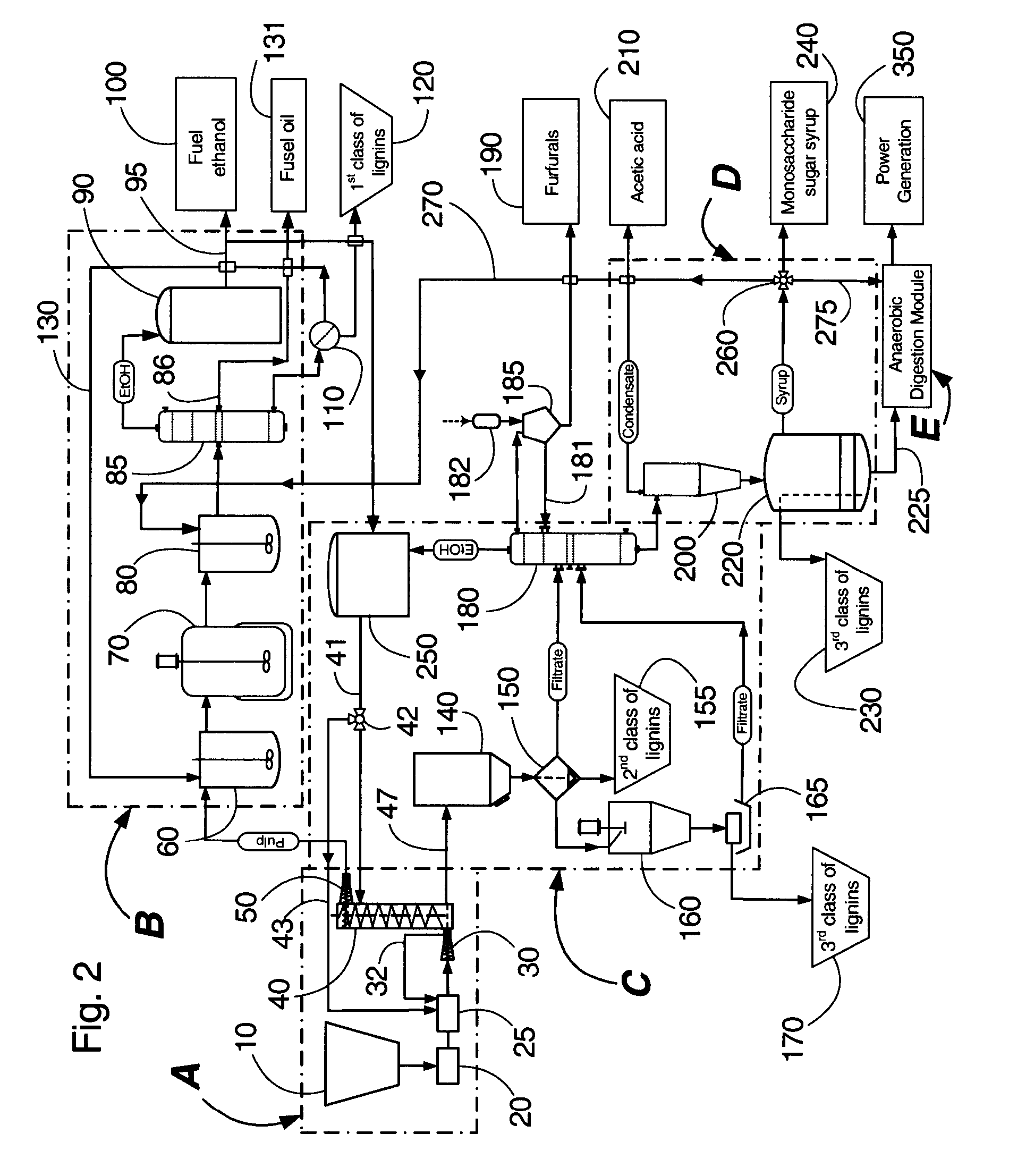

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

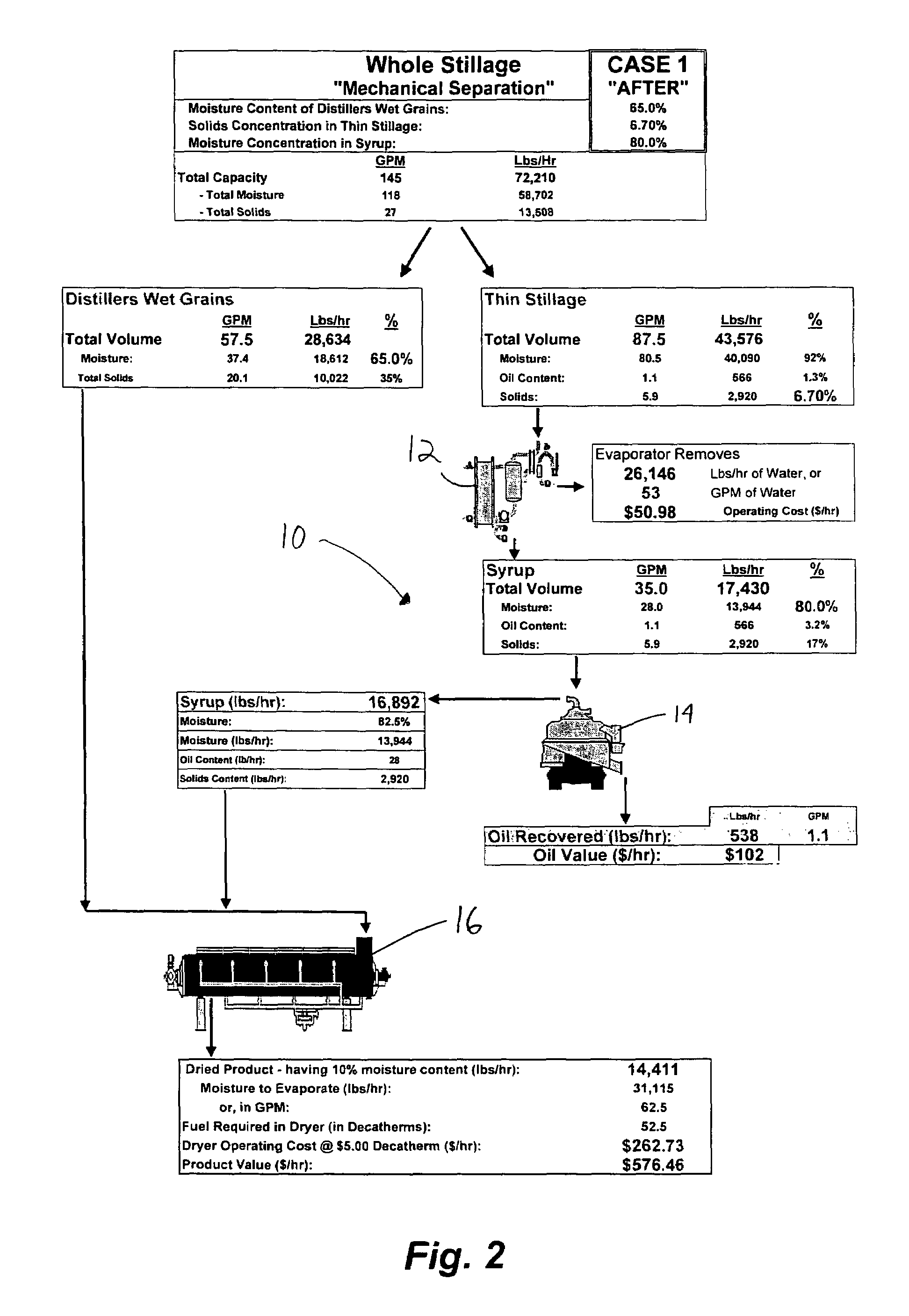

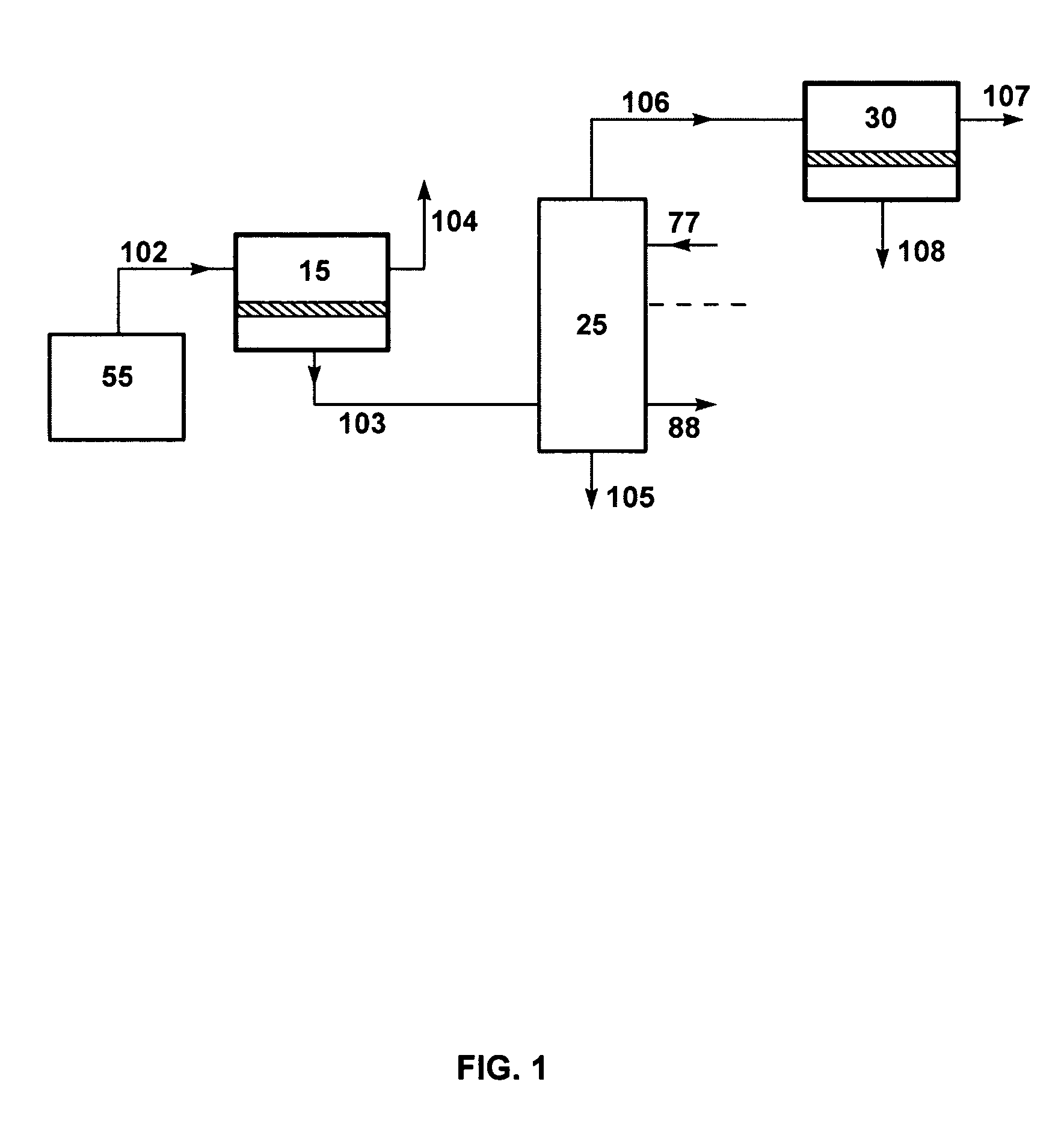

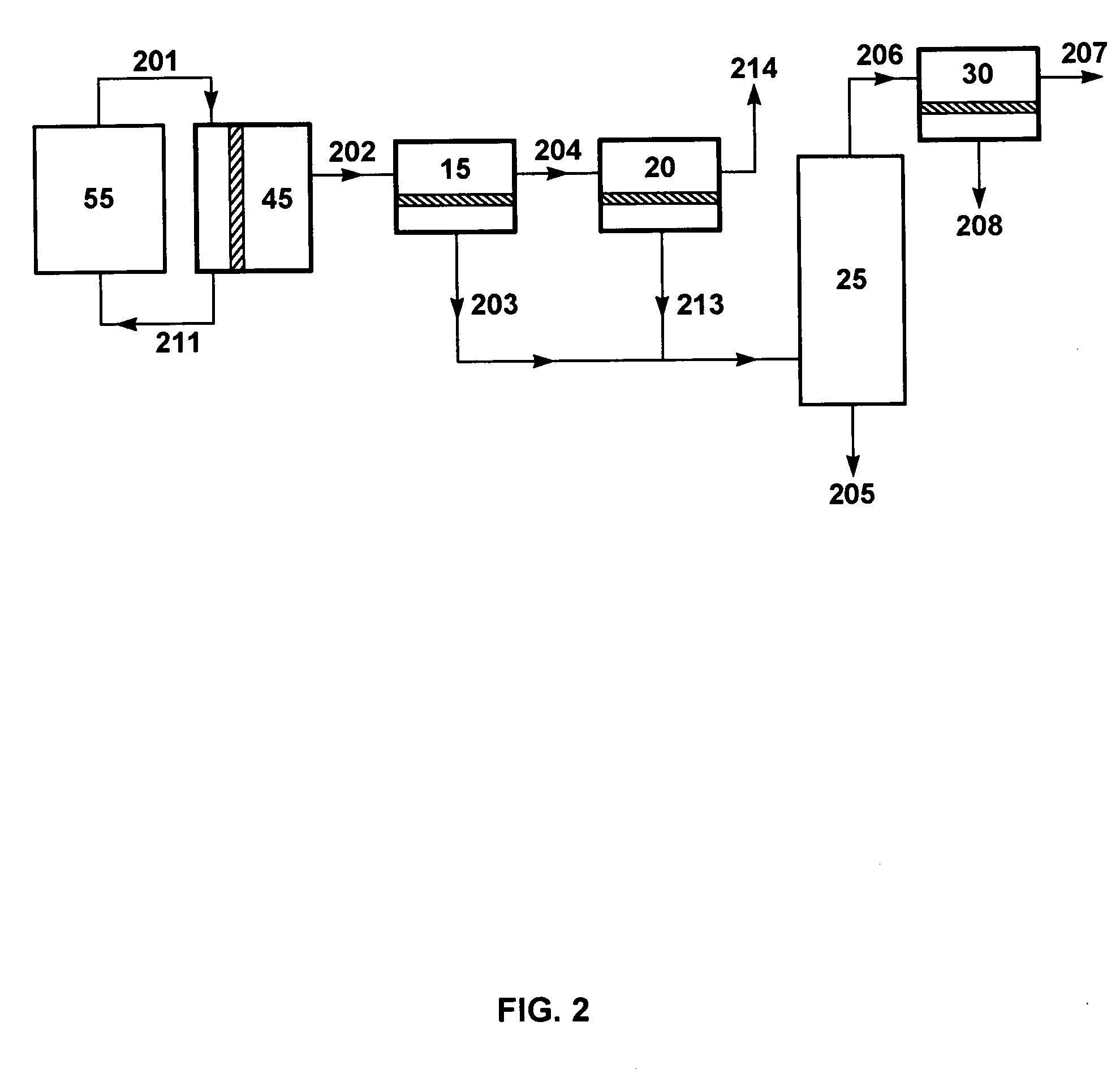

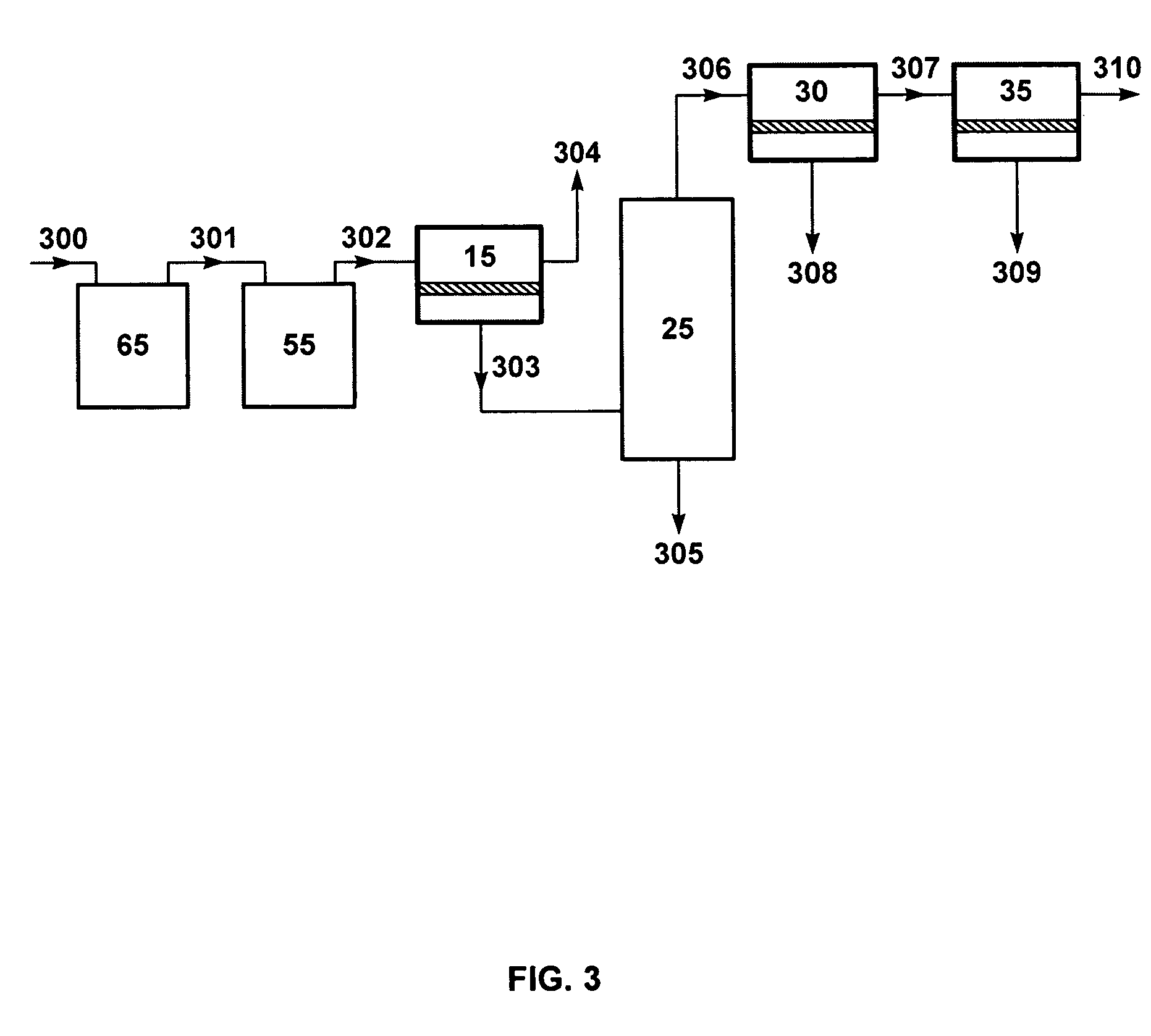

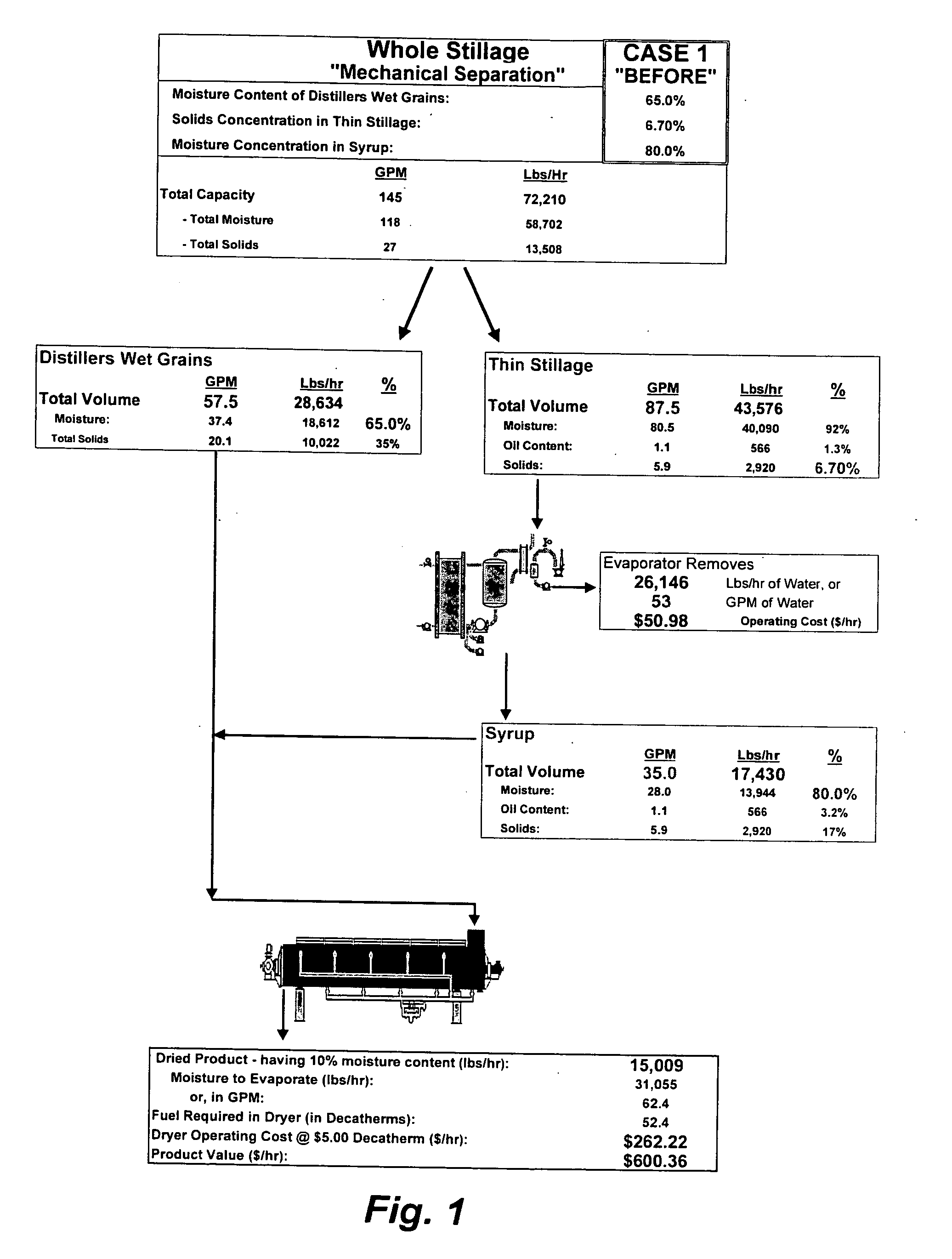

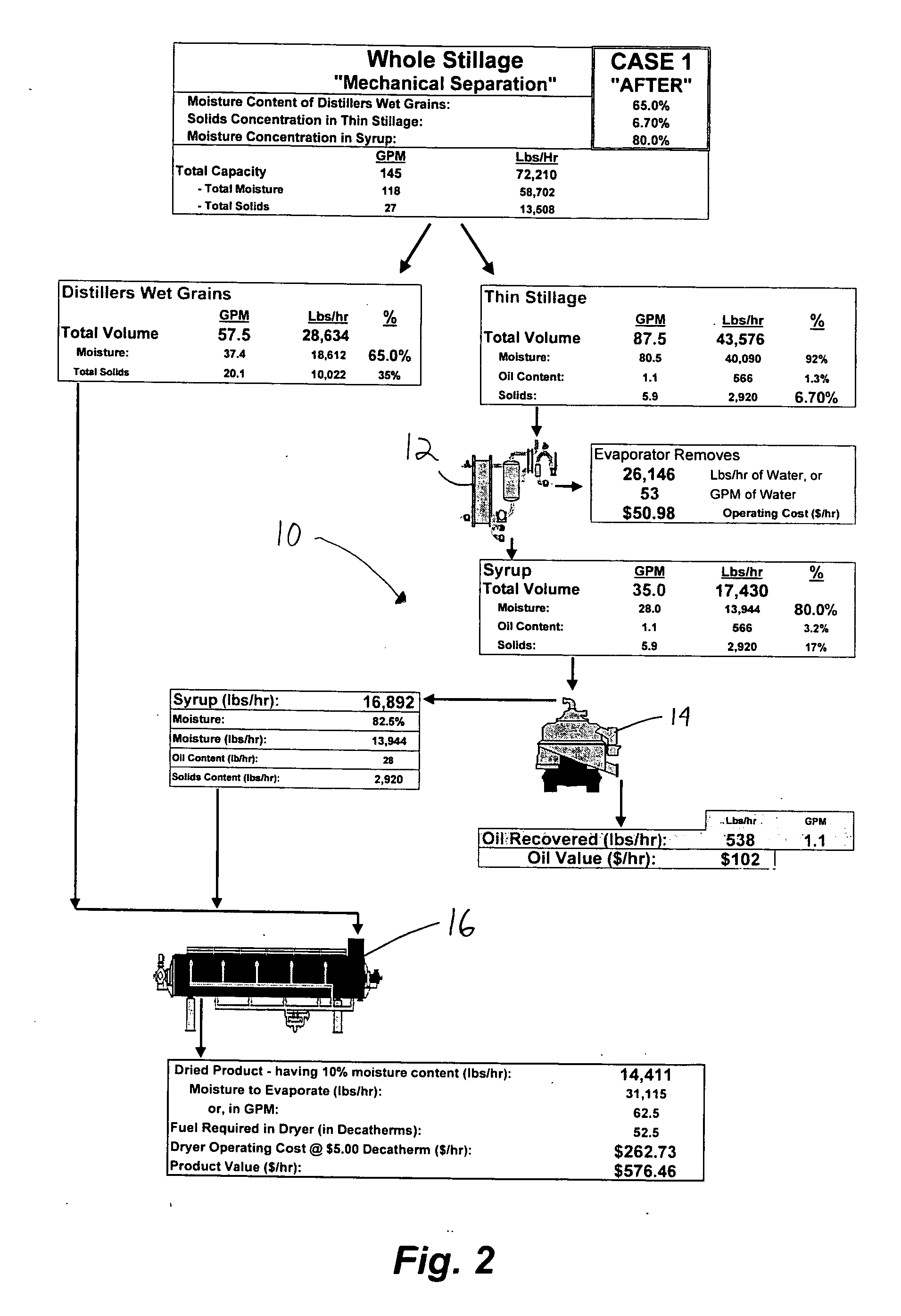

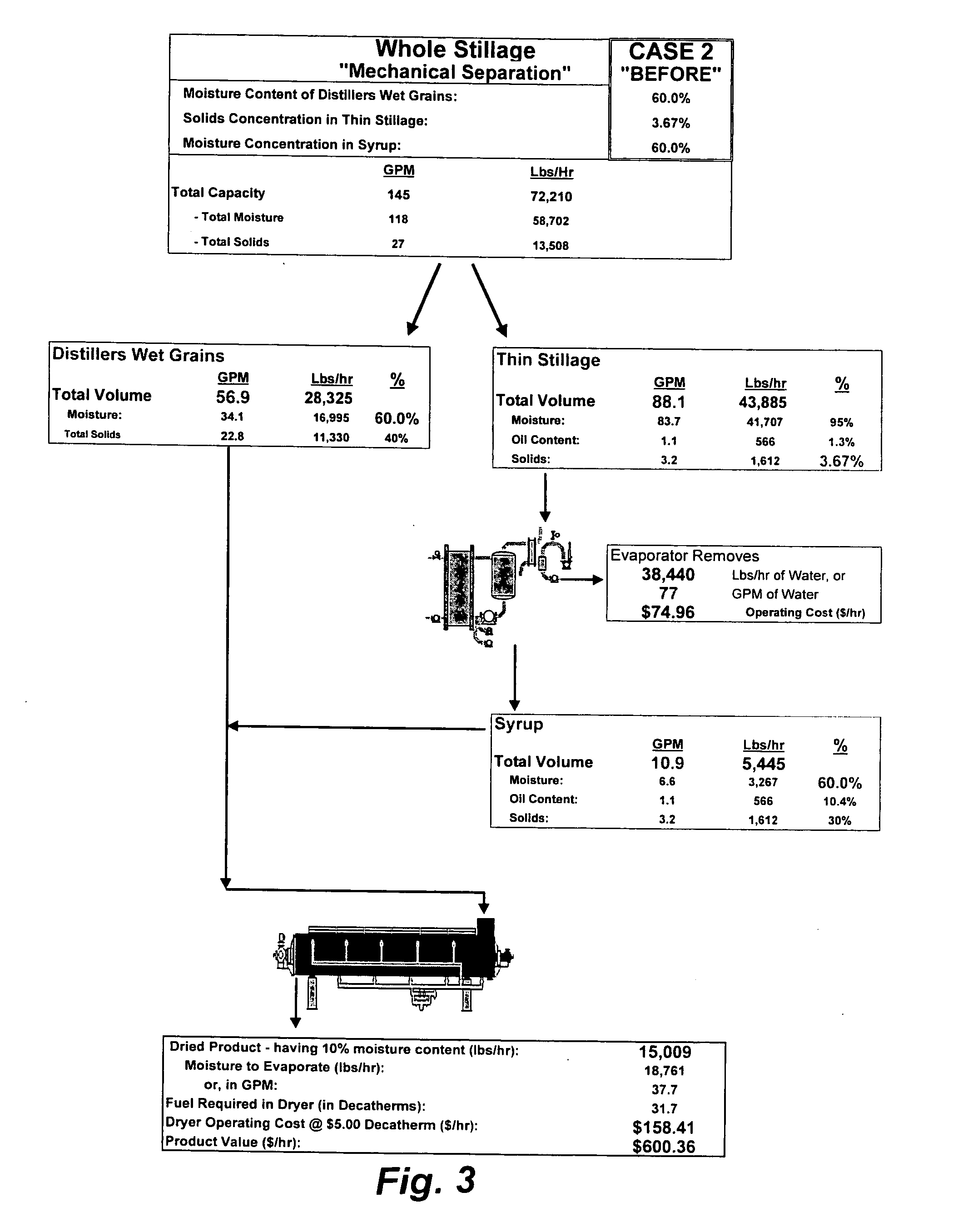

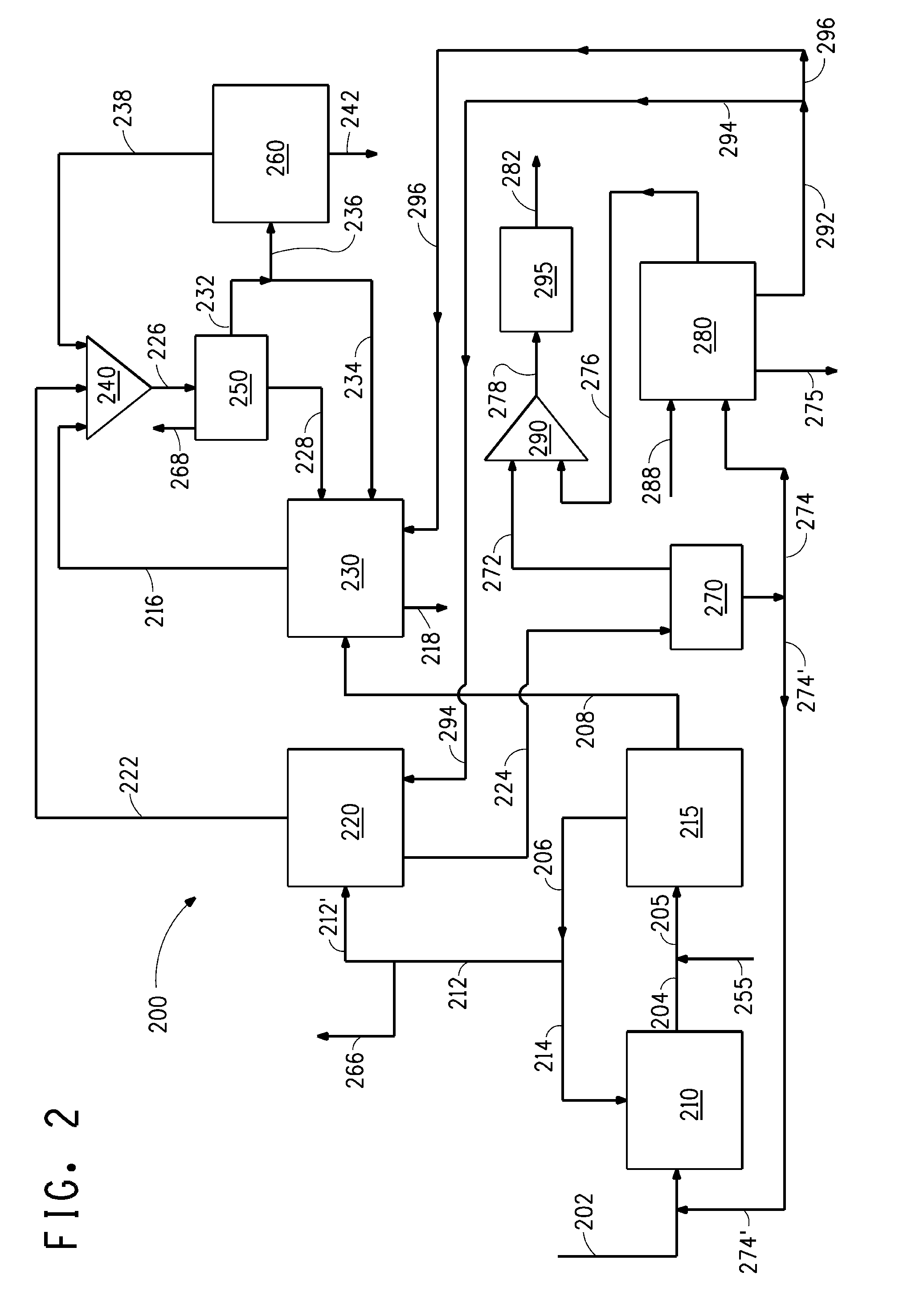

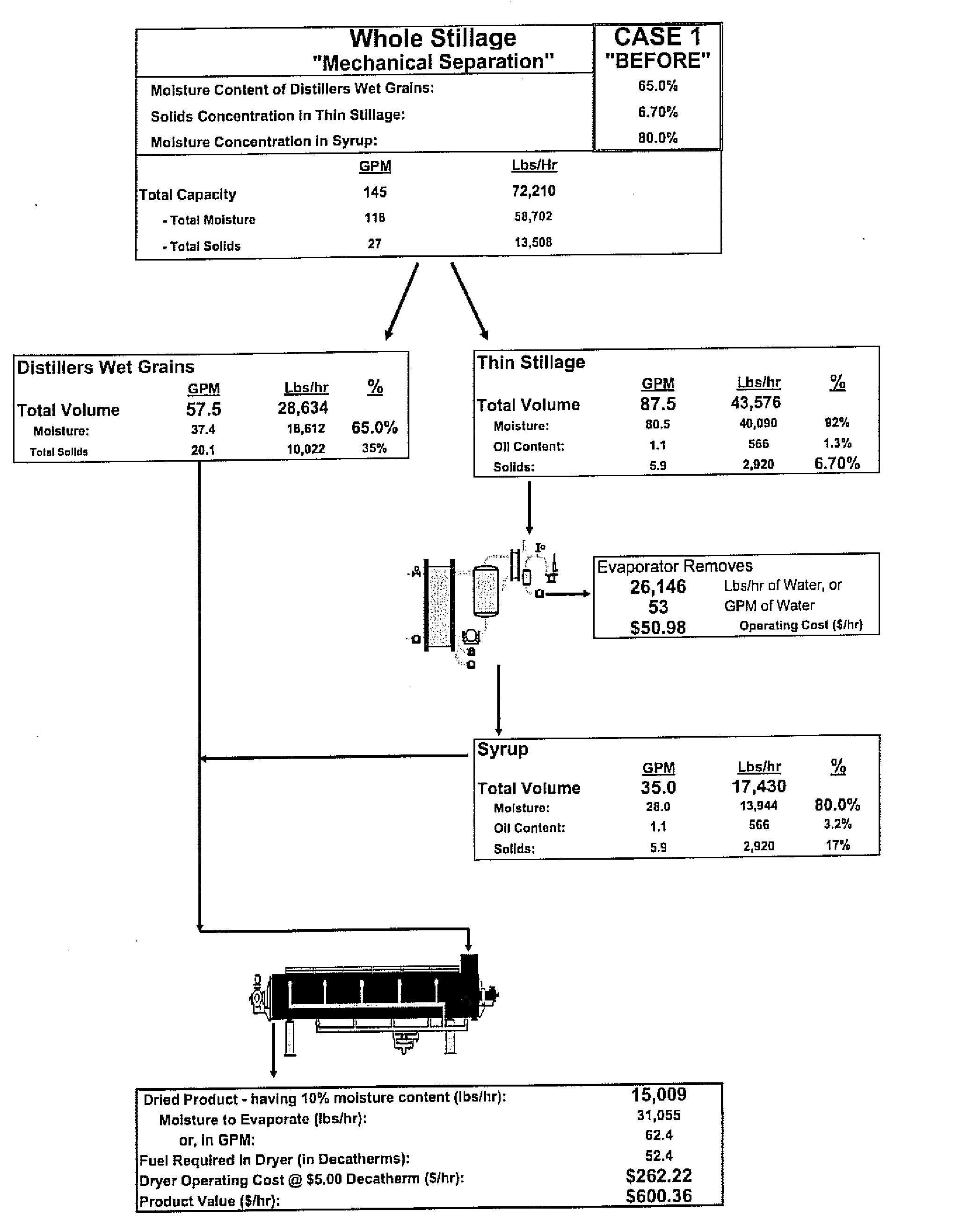

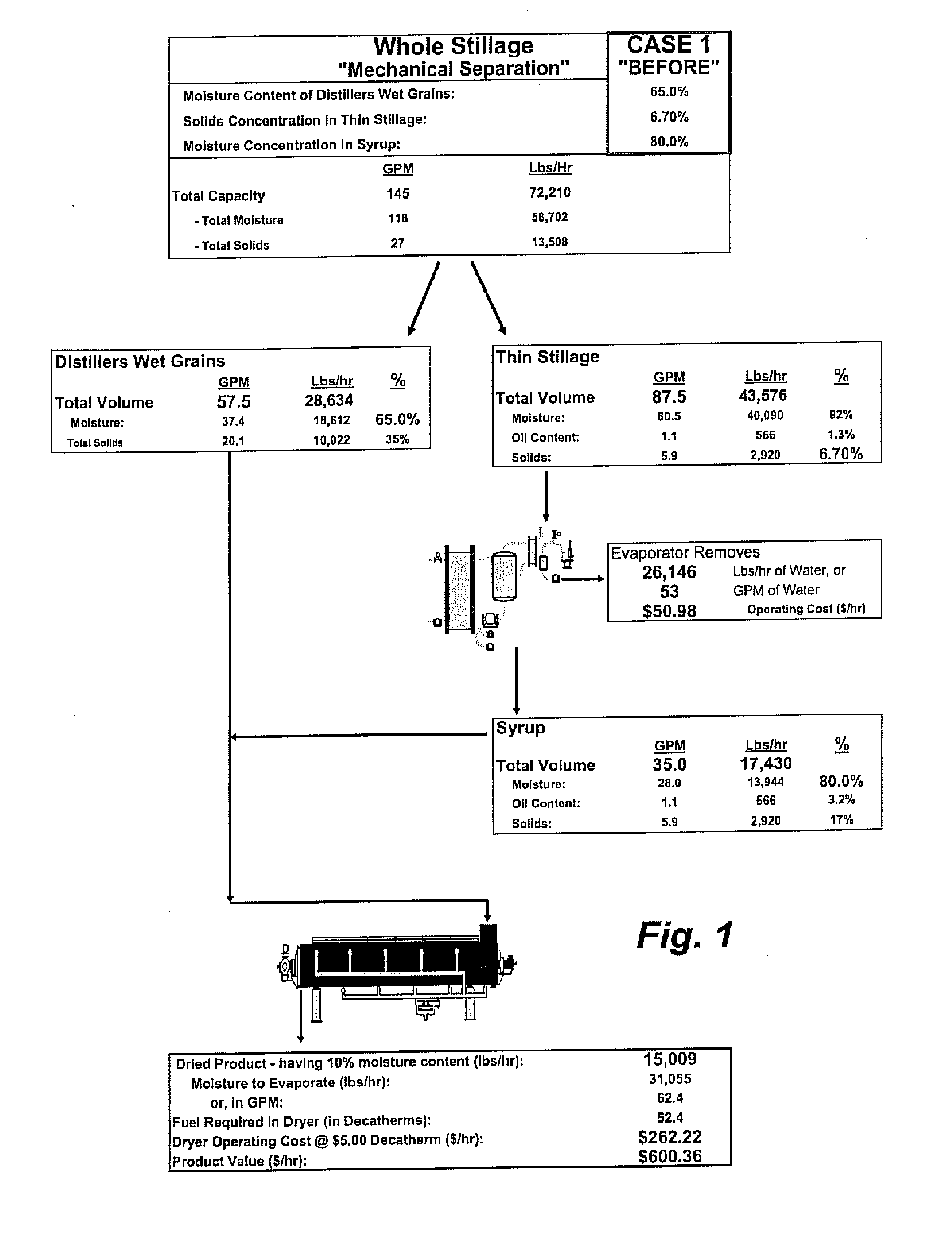

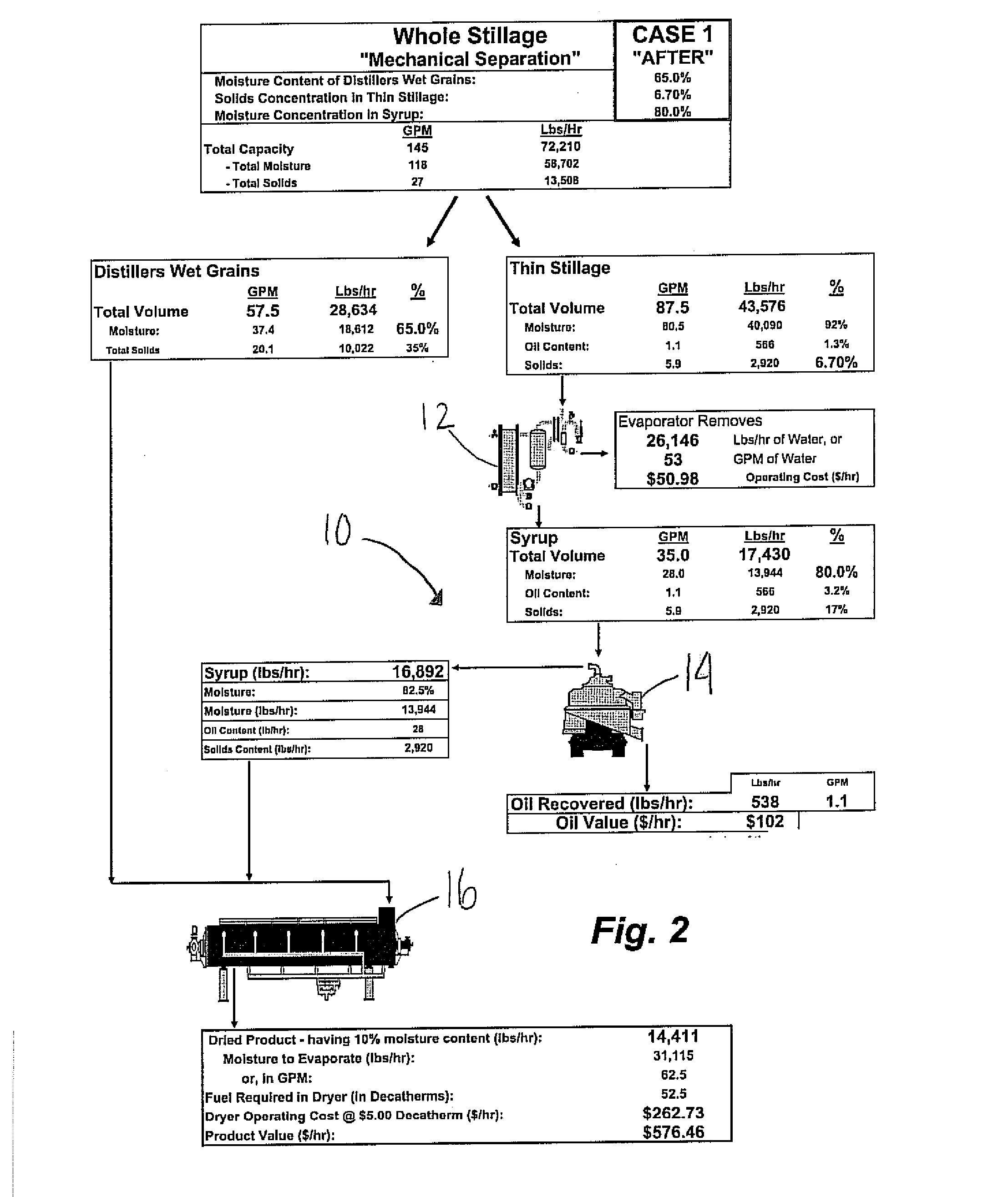

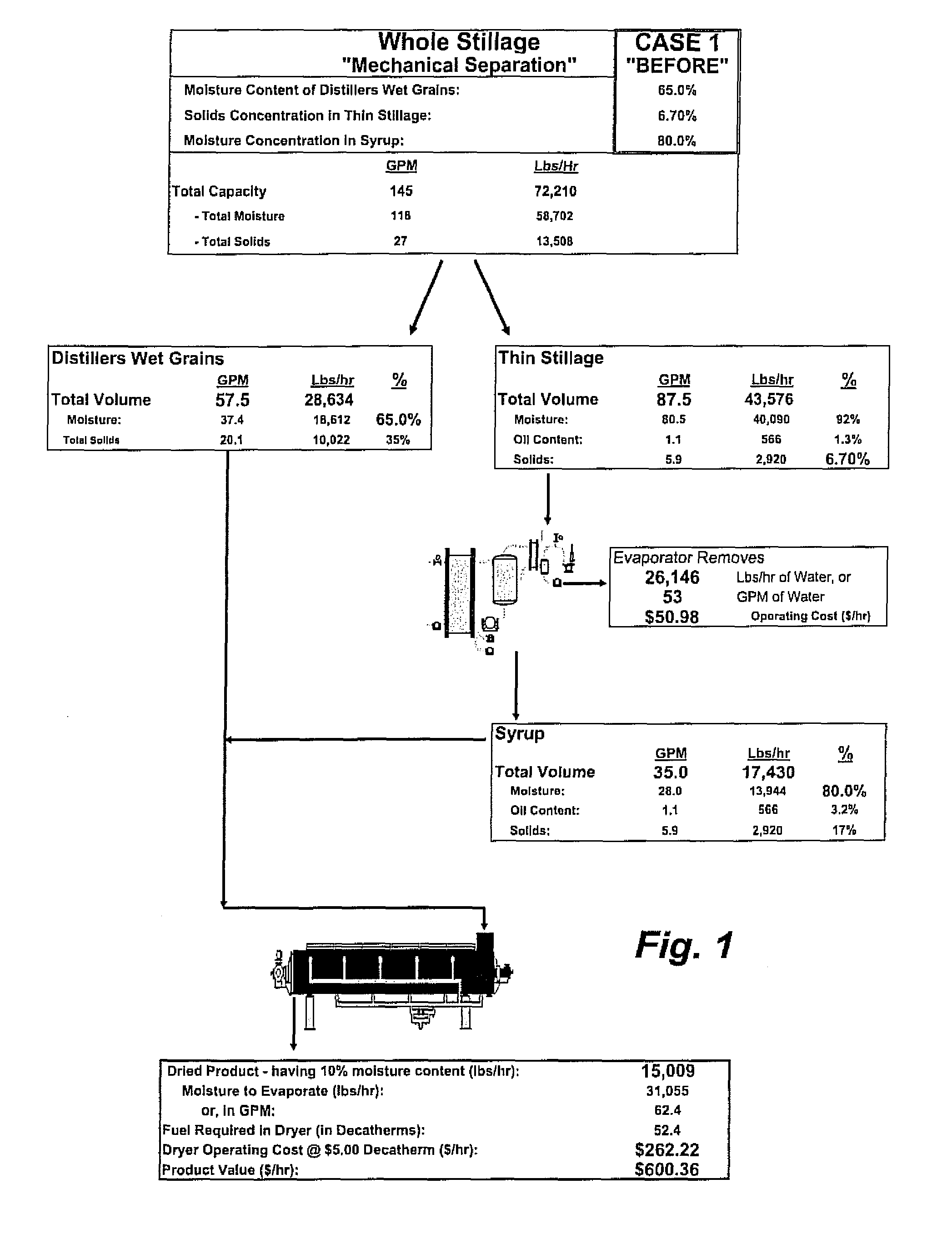

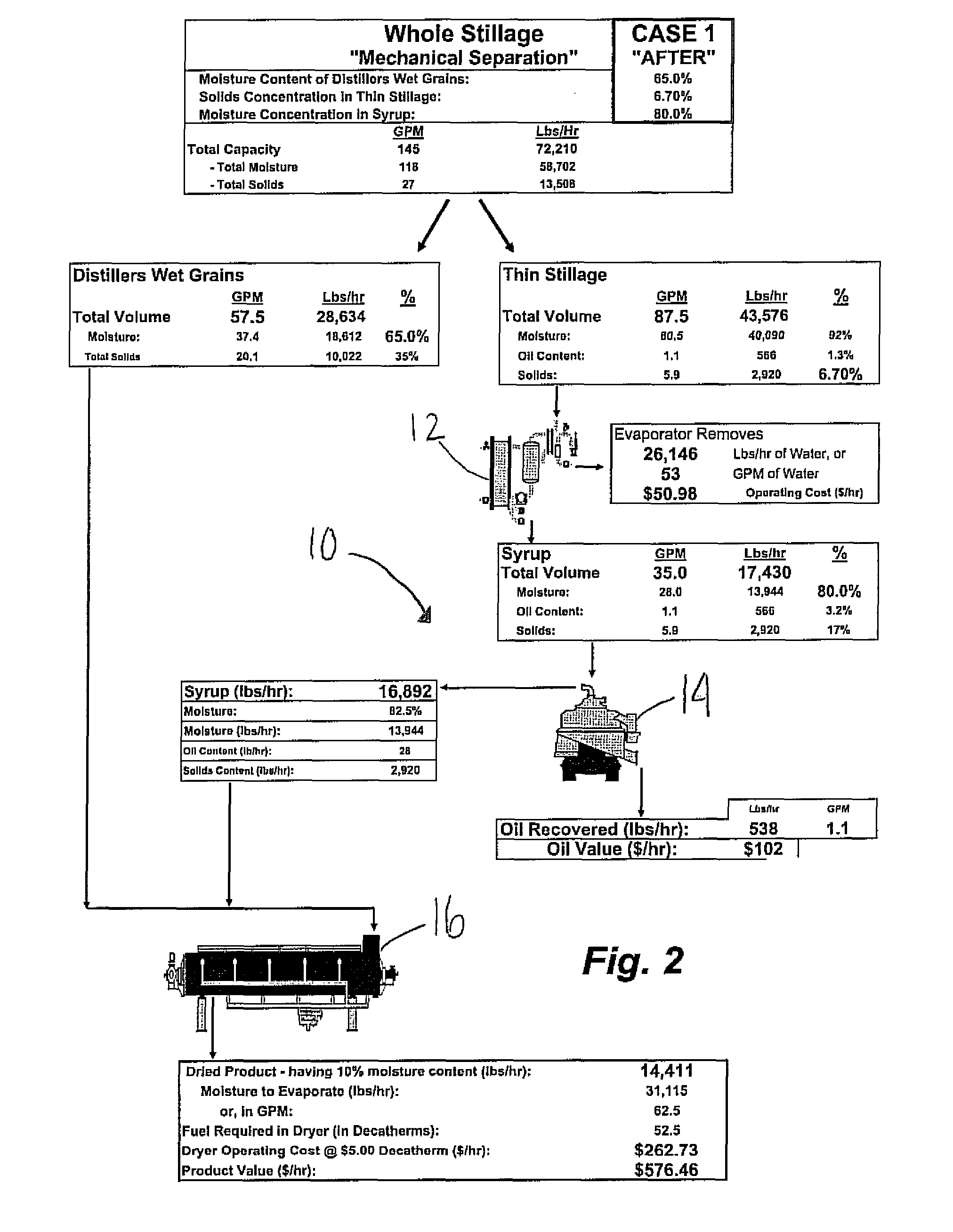

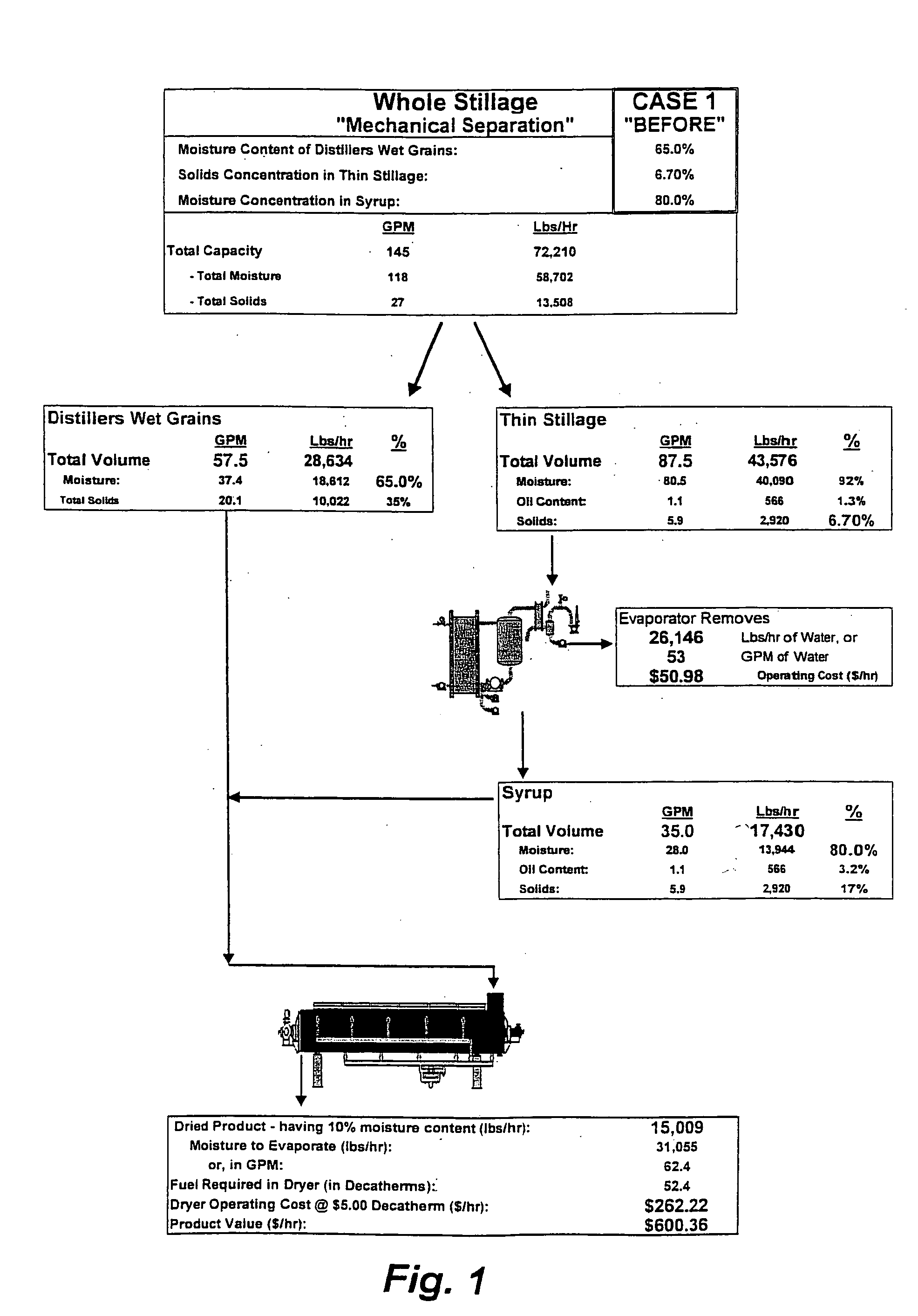

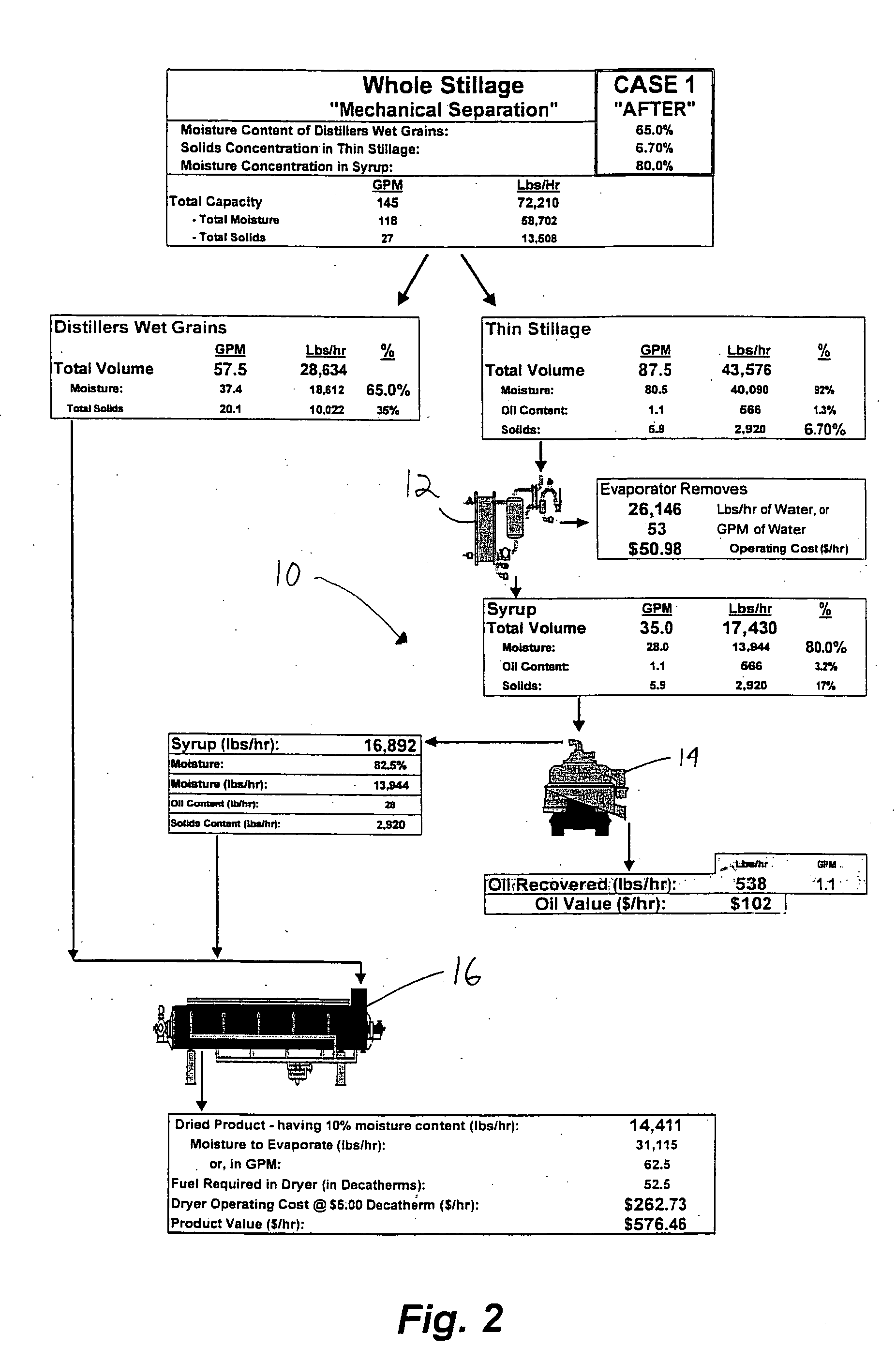

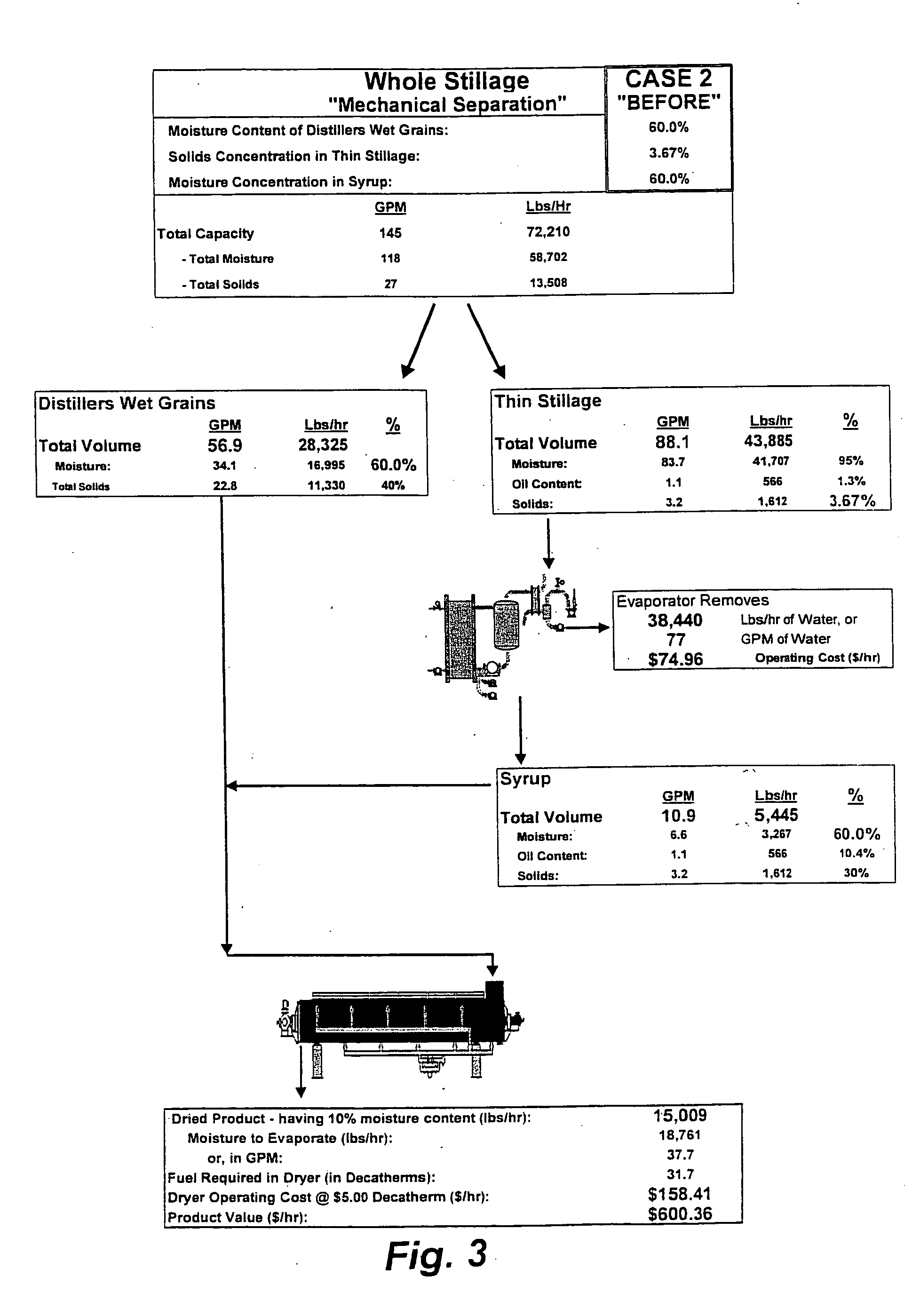

Method of processing ethanol byproducts and related subsystems

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

Ethanol recovery process

ActiveUS20070031954A1Permeate pressureSimple equipmentMembranesFermented solutions distillation/rectificationAlcoholFractionation

A process for producing and recovering light alcohols, particularly ethanol, alcohol mixtures containing ethanol, and ABE mixtures (alcohol mixtures containing acetone, butanol and ethanol), using a combination of steps including fermentation, first membrane separation, dephlegmation and dehydration by second membrane separation.

Owner:MEMBRANE TECH & RES

Methods and organisms for the growth-coupled production of 1,4-butanediol

The invention provides a non-naturally occurring microorganism comprising one or more gene disruptions, the one or more gene disruptions occurring in genes encoding an enzyme obligatory to coupling 1,4-butanediol production to growth of the microorganism when the gene disruption reduces an activity of the enzyme, whereby the one or more gene disruptions confers stable growth-coupled production of 1,4-butanediol onto the non-naturally occurring microorganism. The microorganism can further comprise a gene encoding an enzyme in a 1,4-butanediol (BDO) biosynthetic pathway. The invention additionally relates to methods of using microorganisms to produce BDO.

Owner:GENOMATICA INC

Ethanol recovery process

ActiveUS7732173B2Reduce stressSimple equipmentMembranesFermented solutions distillation/rectificationAlcoholMedicinal chemistry

A process for producing and recovering light alcohols, particularly ethanol, alcohol mixtures containing ethanol, and ABE mixtures (alcohol mixtures containing acetone, butanol and ethanol), using a combination of steps including fermentation, first membrane separation, dephlegmation and dehydration by second membrane separation.

Owner:MEMBRANE TECH & RES

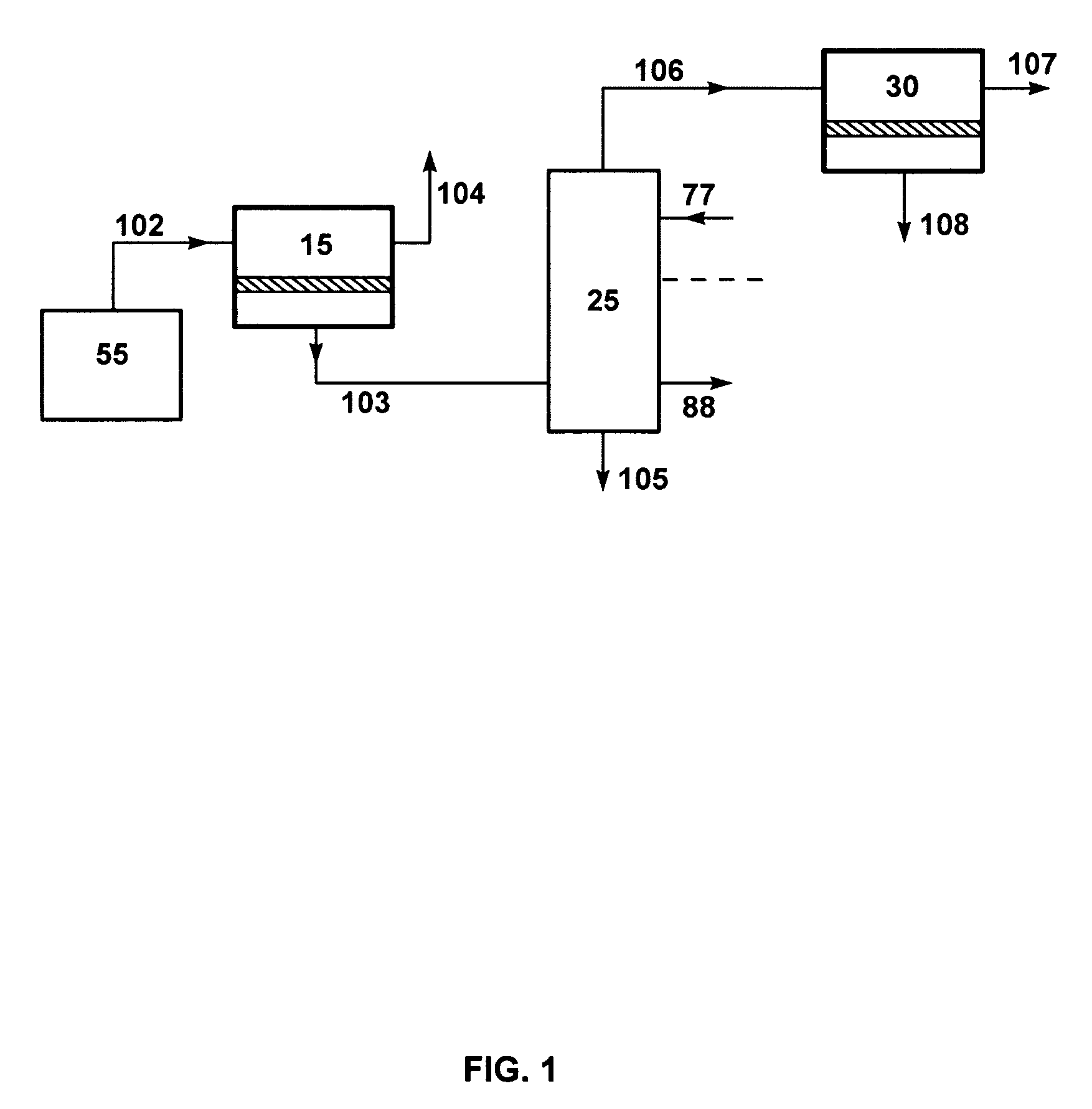

Process of separating components of a fermentation broth

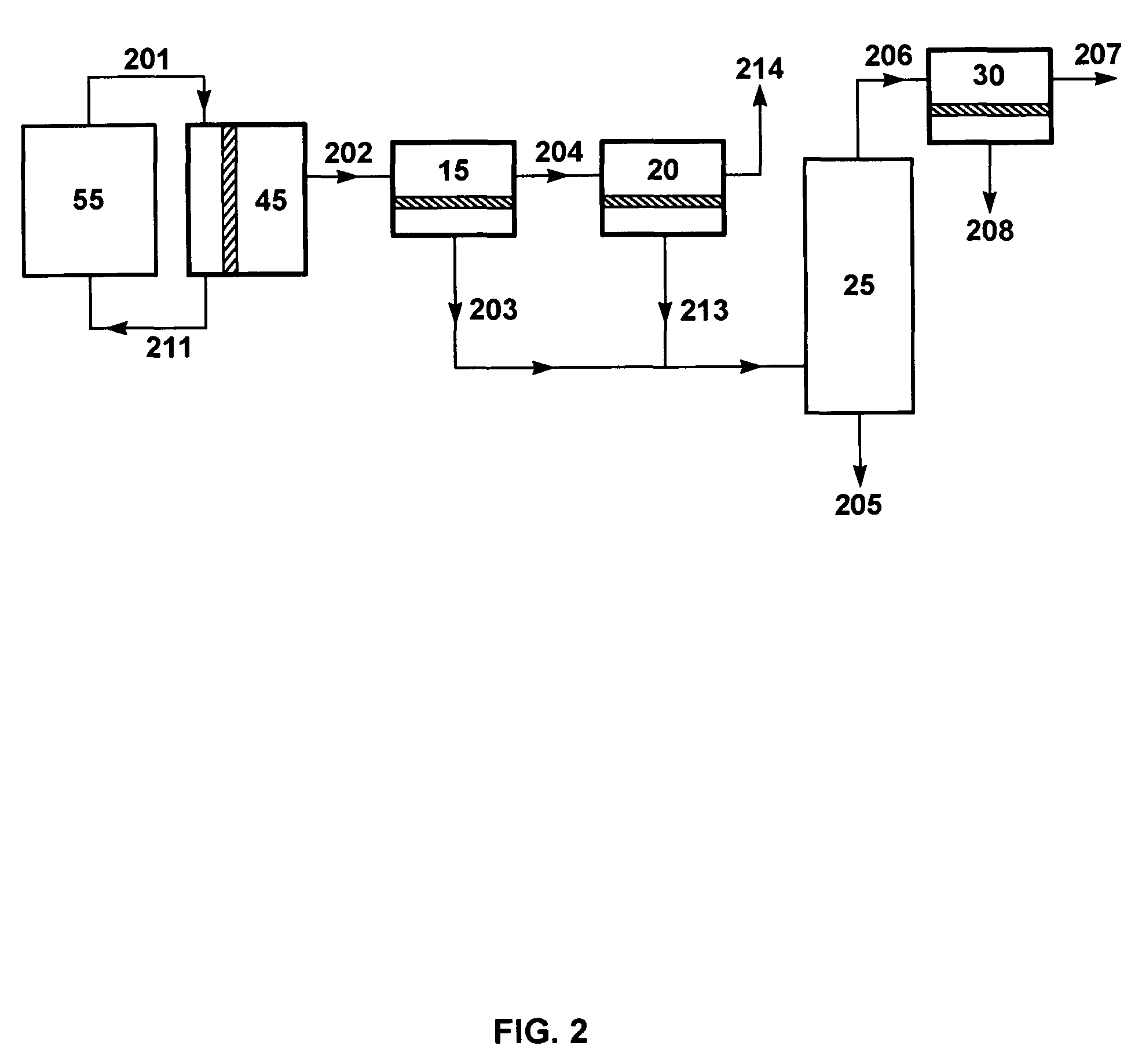

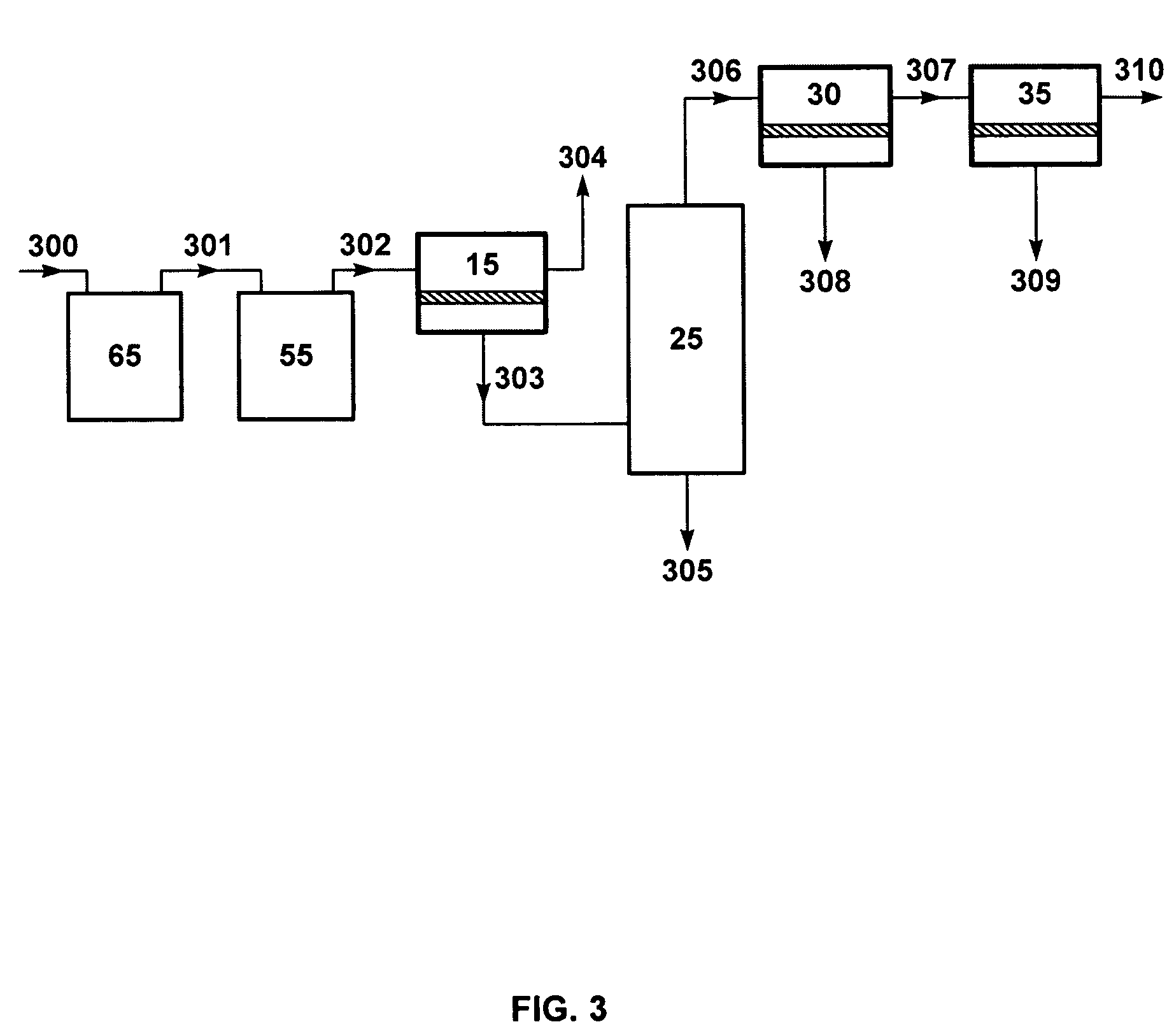

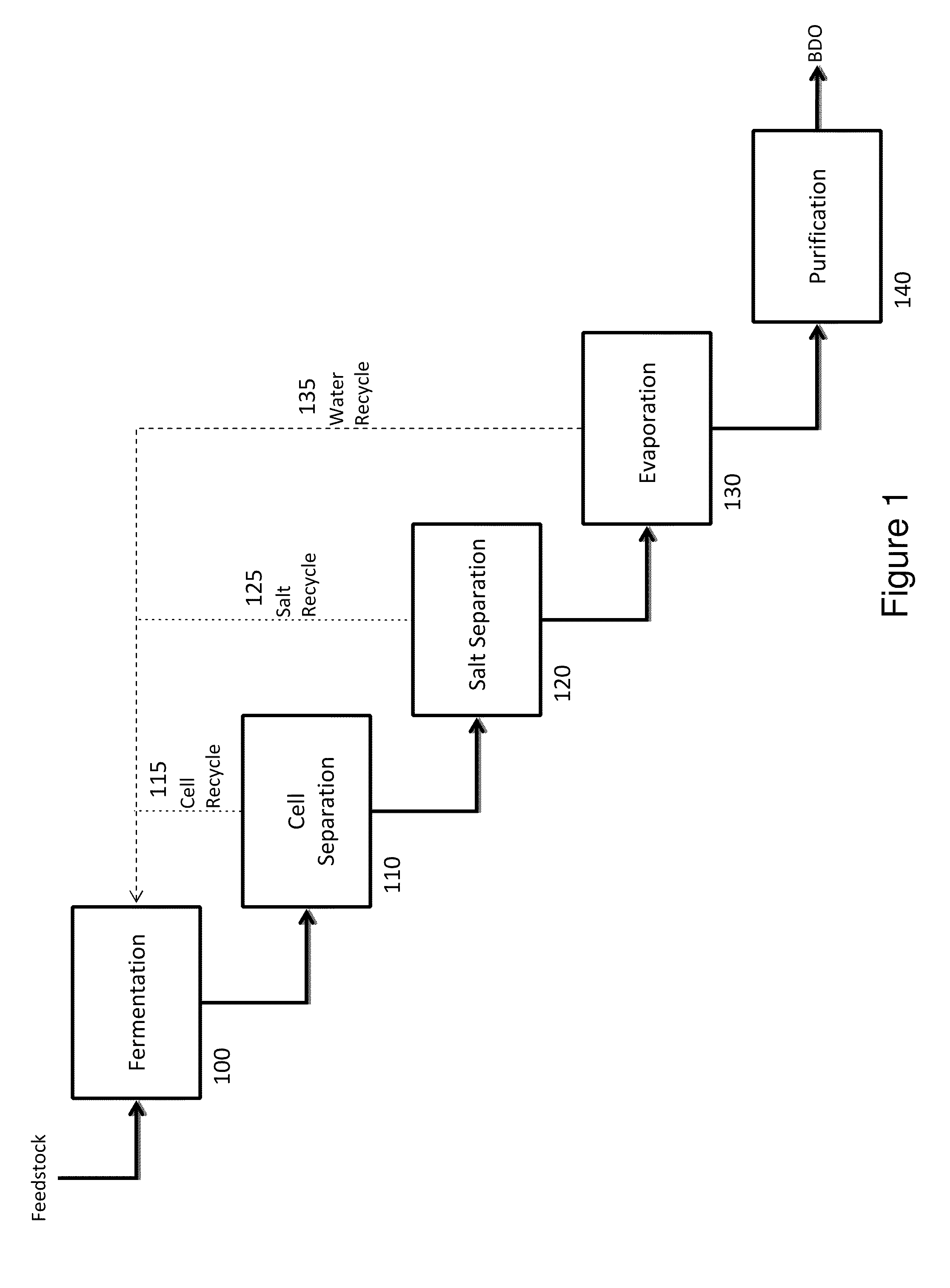

ActiveUS20110003355A1Produce lotFermented solutions distillation/rectificationOrganic compound preparation1,4-ButanediolMicroorganism

A process of isolating 1,4-butanediol (1,4-BDO) from a fermentation broth includes separating a liquid fraction enriched in 1,4-BDO from a solid fraction comprising cells, removing water from said liquid fraction, removing salts from said liquid fraction, and purifying 1,4-BDO. A process for producing 1,4-BDO includes culturing a 1,4-BDO-producing microorganism in a fermentor for a sufficient period of time to produce 1,4-BDO. The 1,4-BDO-producing microorganism includes a microorganism having a 1,4-BDO pathway having one or more exogenous genes encoding a 1,4-BDO pathway enzyme and / or one or more gene disruptions. The process for producing 1,4-BDO further includes isolating 1,4-BDO.

Owner:GENOMATICA INC

Method of processing ethanol byproducts and related subsystems

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

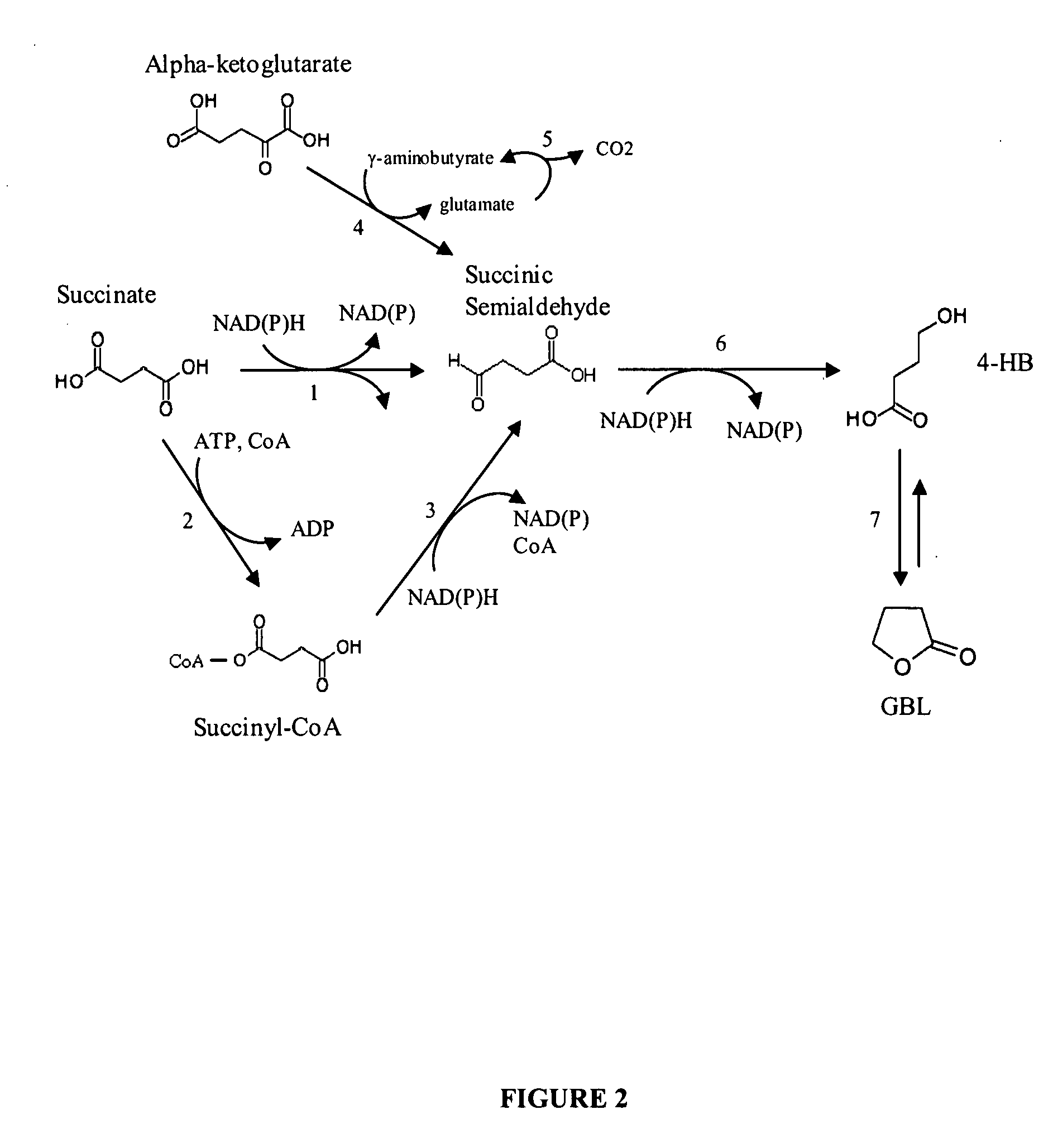

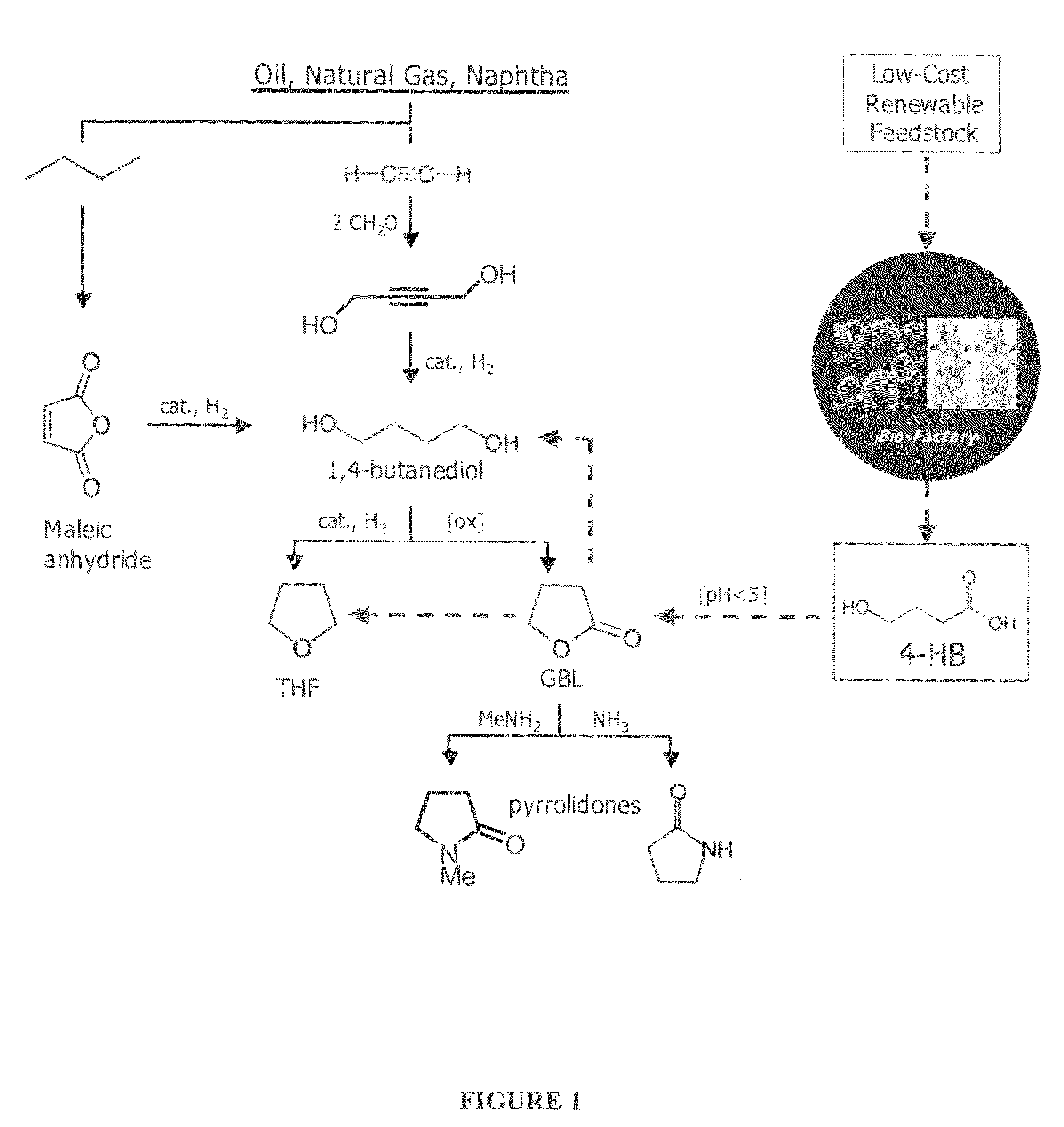

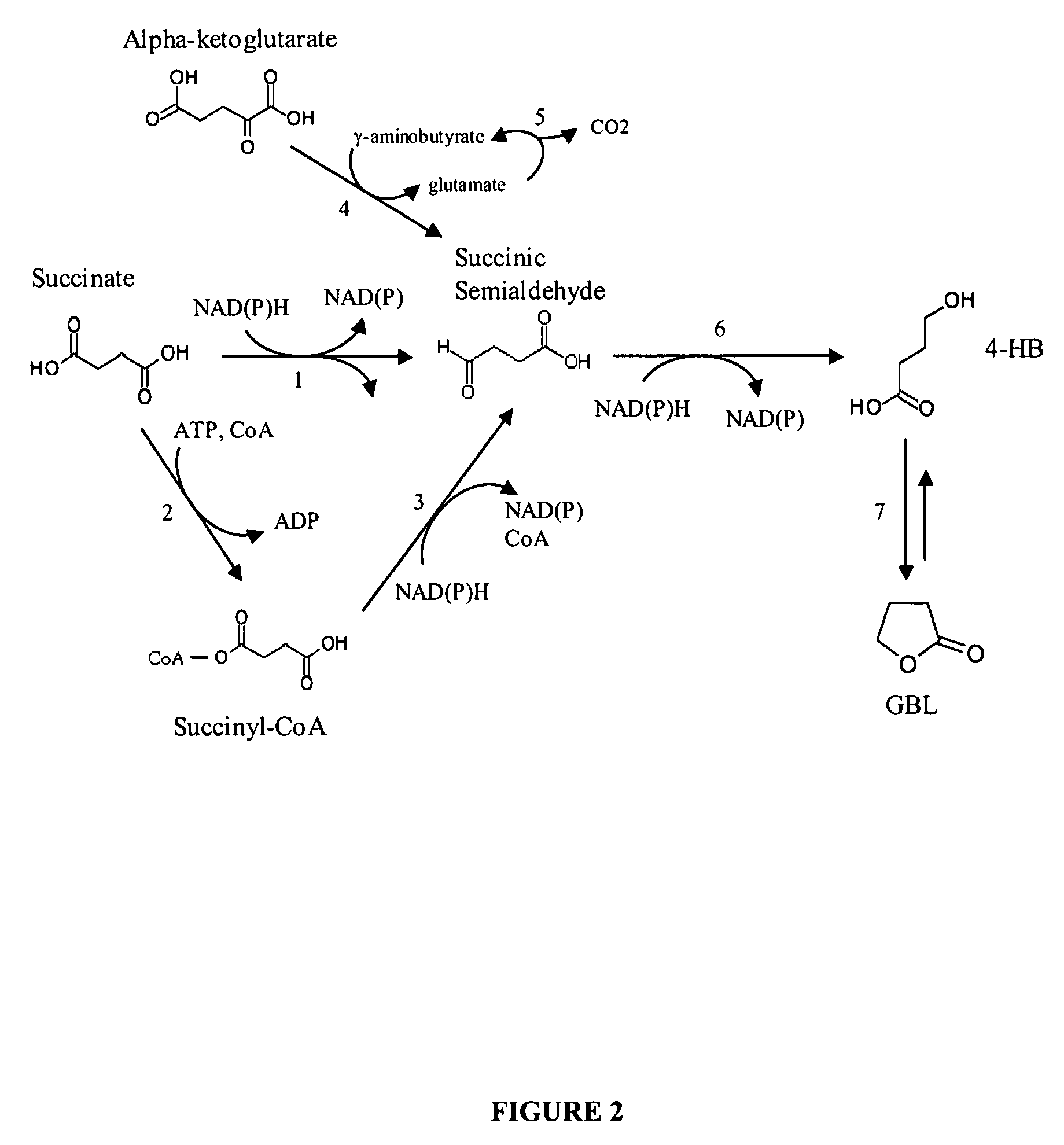

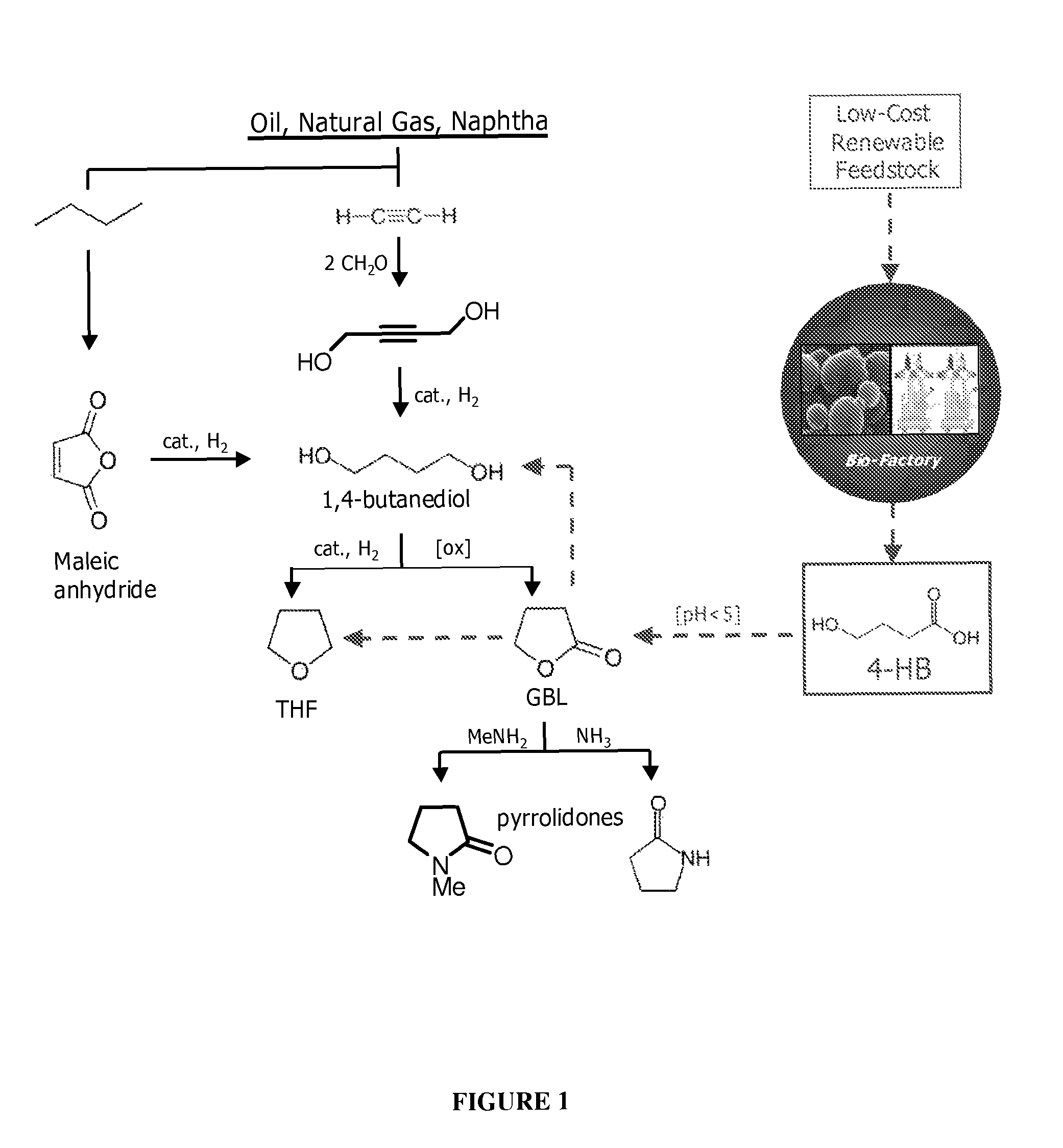

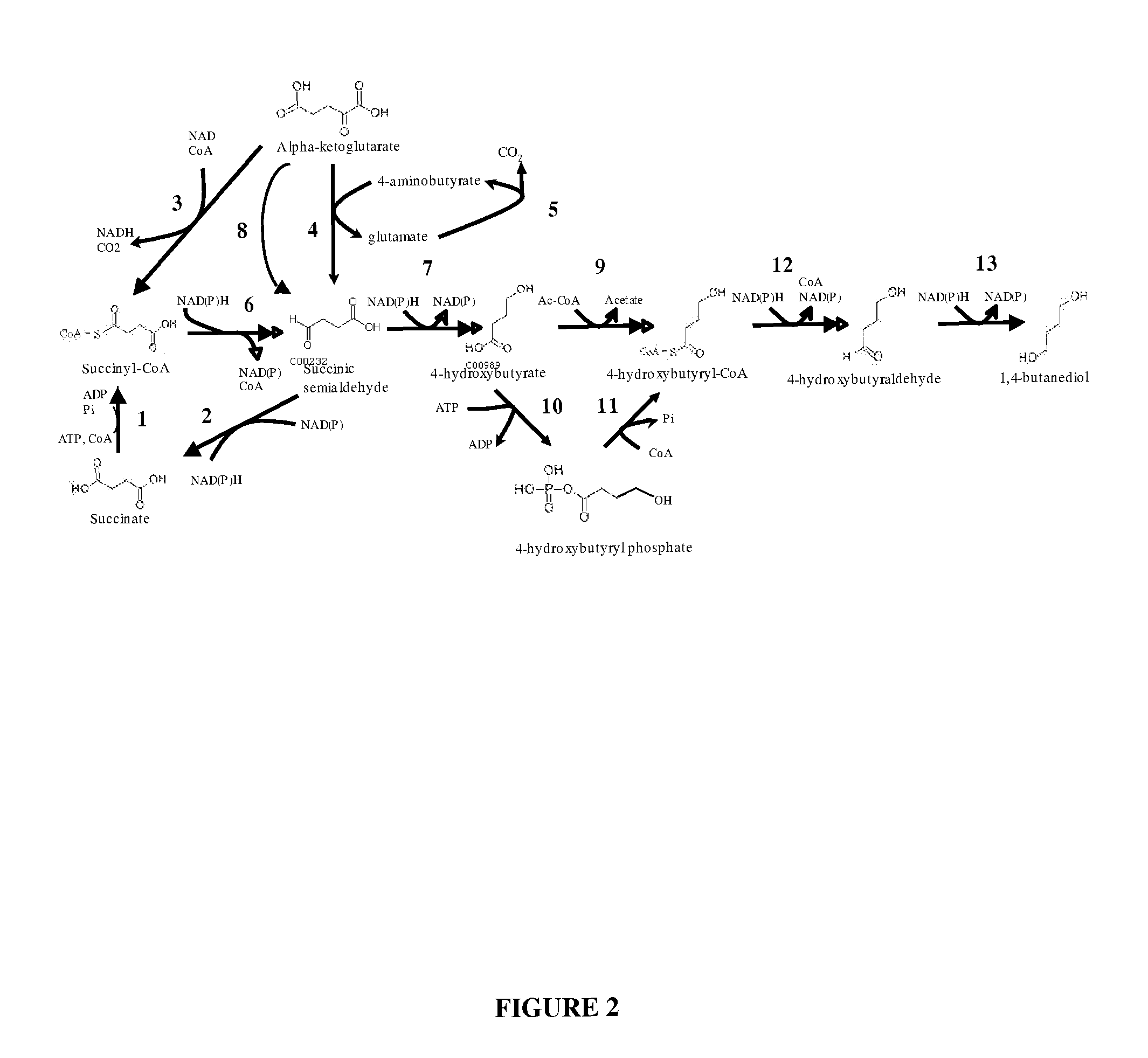

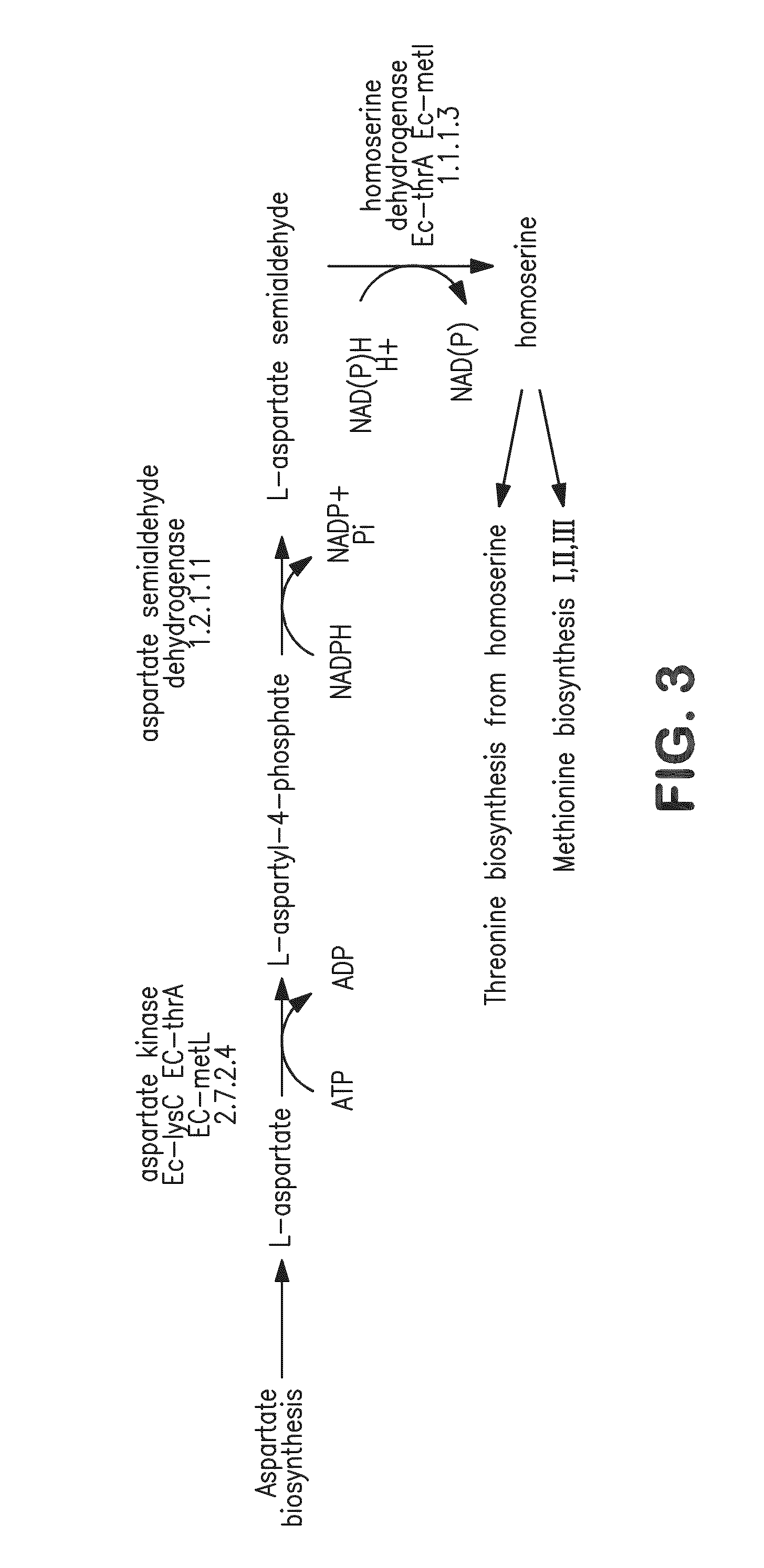

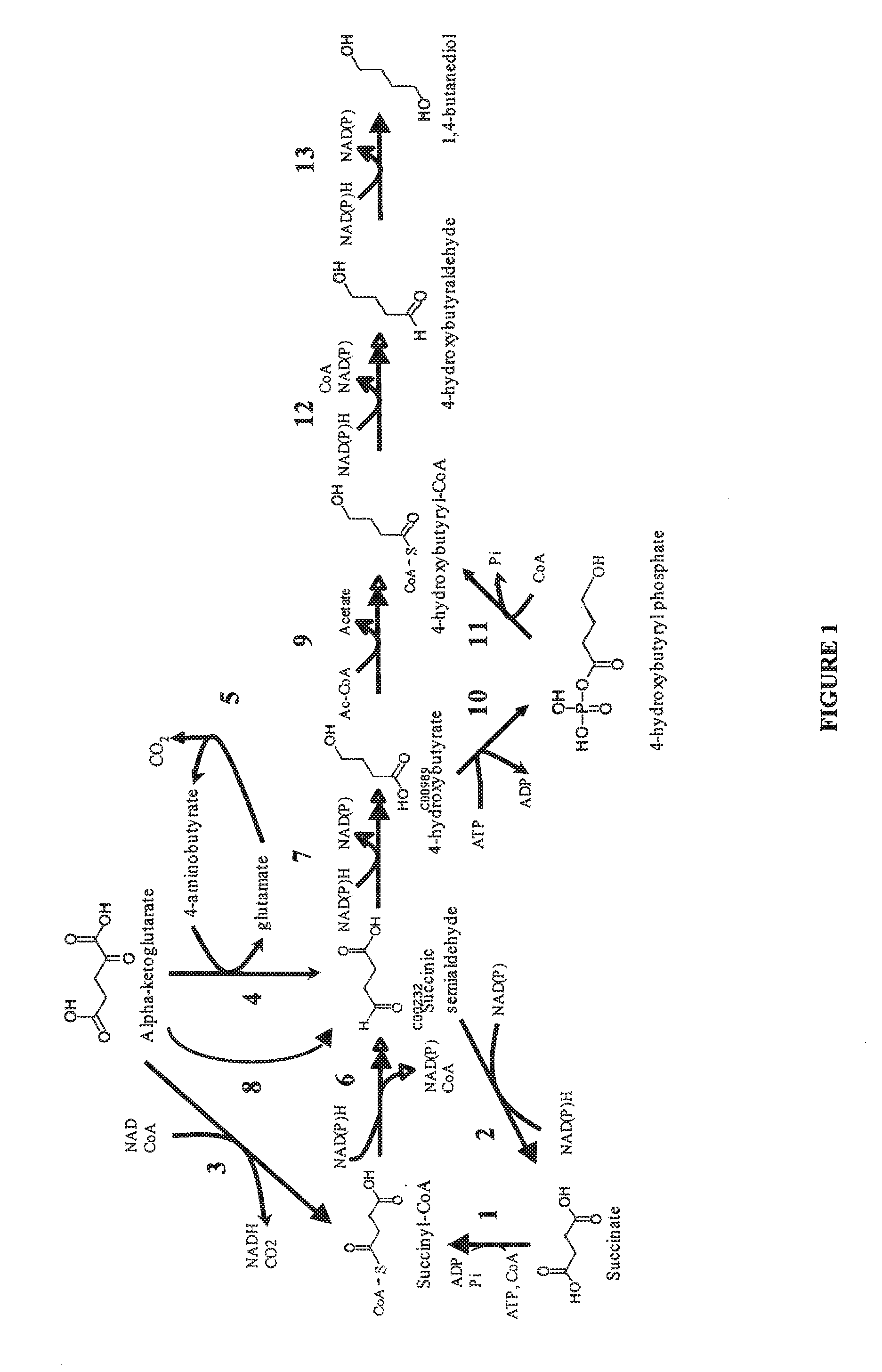

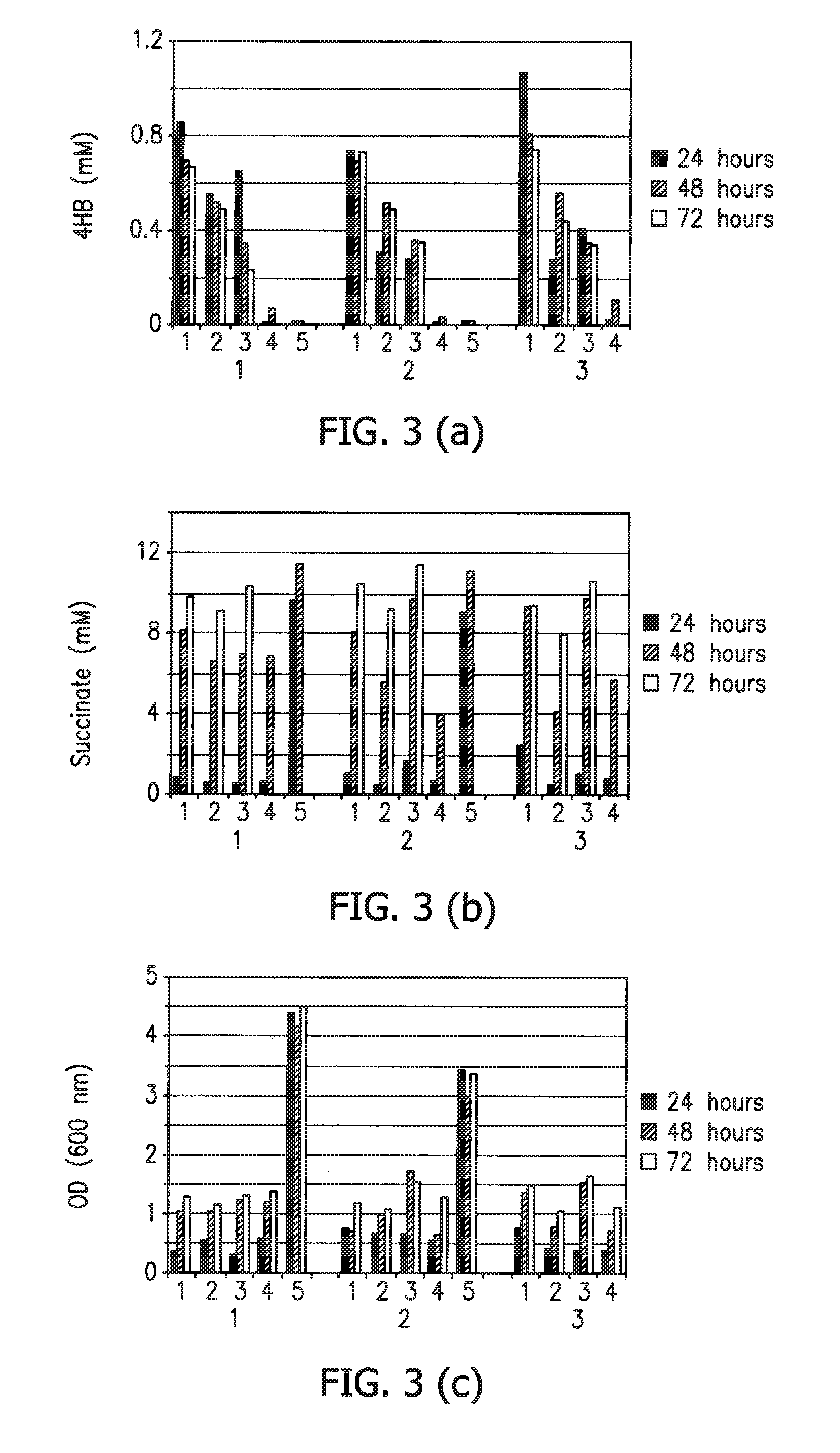

Compositions and methods for the biosynthesis of 1,4-butanediol and its precursors

The invention provides a non-naturally occurring microbial organism having 4-hydroxybutanoic acid (4-HB) and 1,4-butanediol (1,4-BDO) biosynthetic pathways. The pathways include exogenous nucleic acids encoding a) an α-ketoglutarate decarboxylase; b) a 4-hydroxybutanoate dehydrogenase; c) a 4-hydroxybutyryl-CoA:acetyl-CoA transferase or a butyrate kinase and a phosphotransbutyrylase; d) an aldehyde dehydrogenase, and e) an alcohol dehydrogenase, wherein the exogenous nucleic acids are expressed in sufficient amounts to produce 1,4-butanediol (1,4-BDO). Also provide is a method for the production of 1,4-BDO. The method includes culturing the non-naturally occurring microbial organism having 4-HB and 1,4-BDO biosynthetic pathways substantially anaerobic conditions for a sufficient period of time to produce 1,4-BDO.

Owner:GENOMATICA INC

Microorganisms for the production of 1,4-butanediol

The invention provides non-naturally occurring microbial organisms comprising a 1,4-butanediol (BDO) pathway comprising at least one exogenous nucleic acid encoding a BDO pathway enzyme expressed in a sufficient amount to produce BDO. The invention additionally provides methods of using such microbial organisms to produce BDO.

Owner:GENOMATICA INC

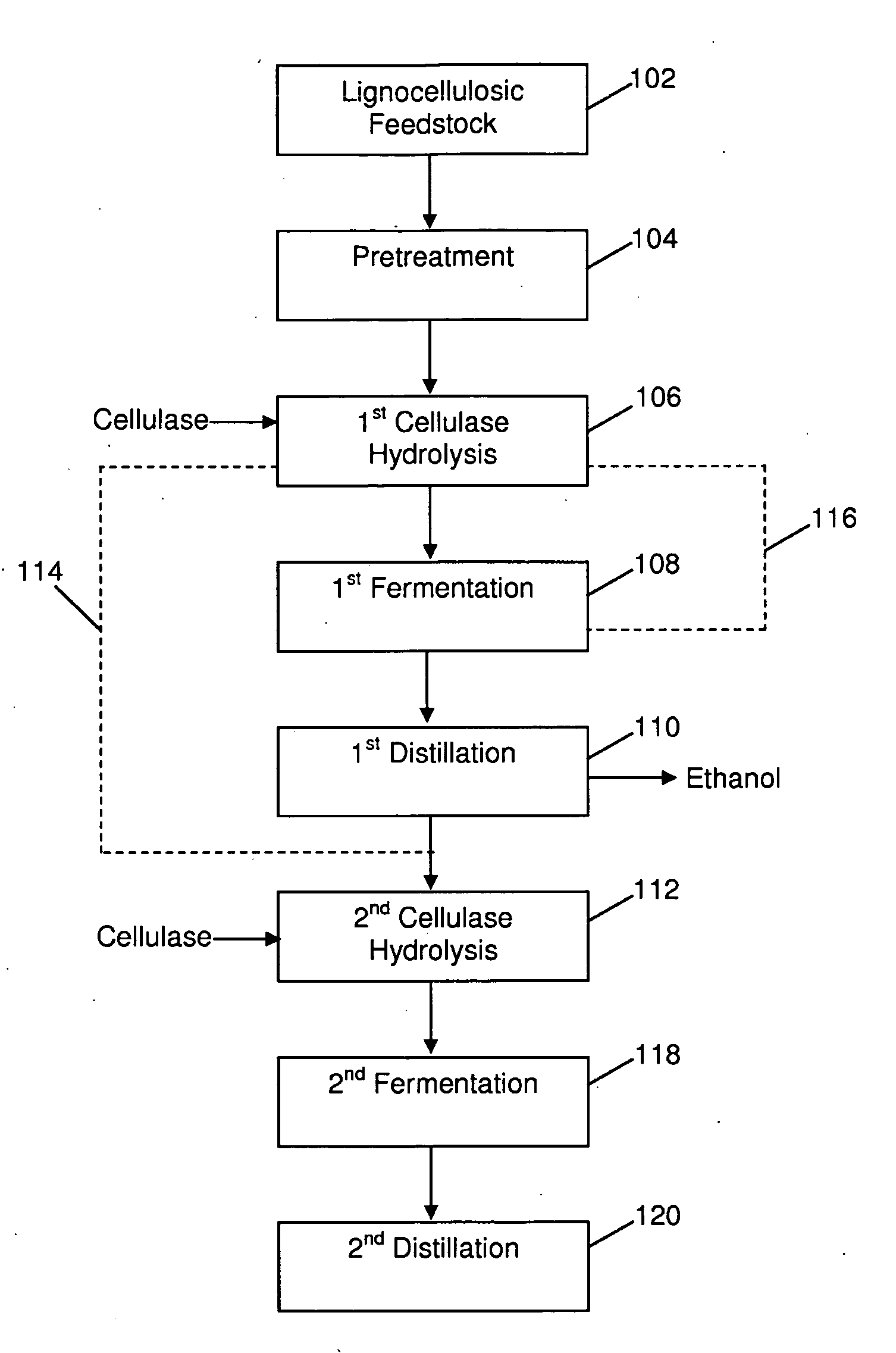

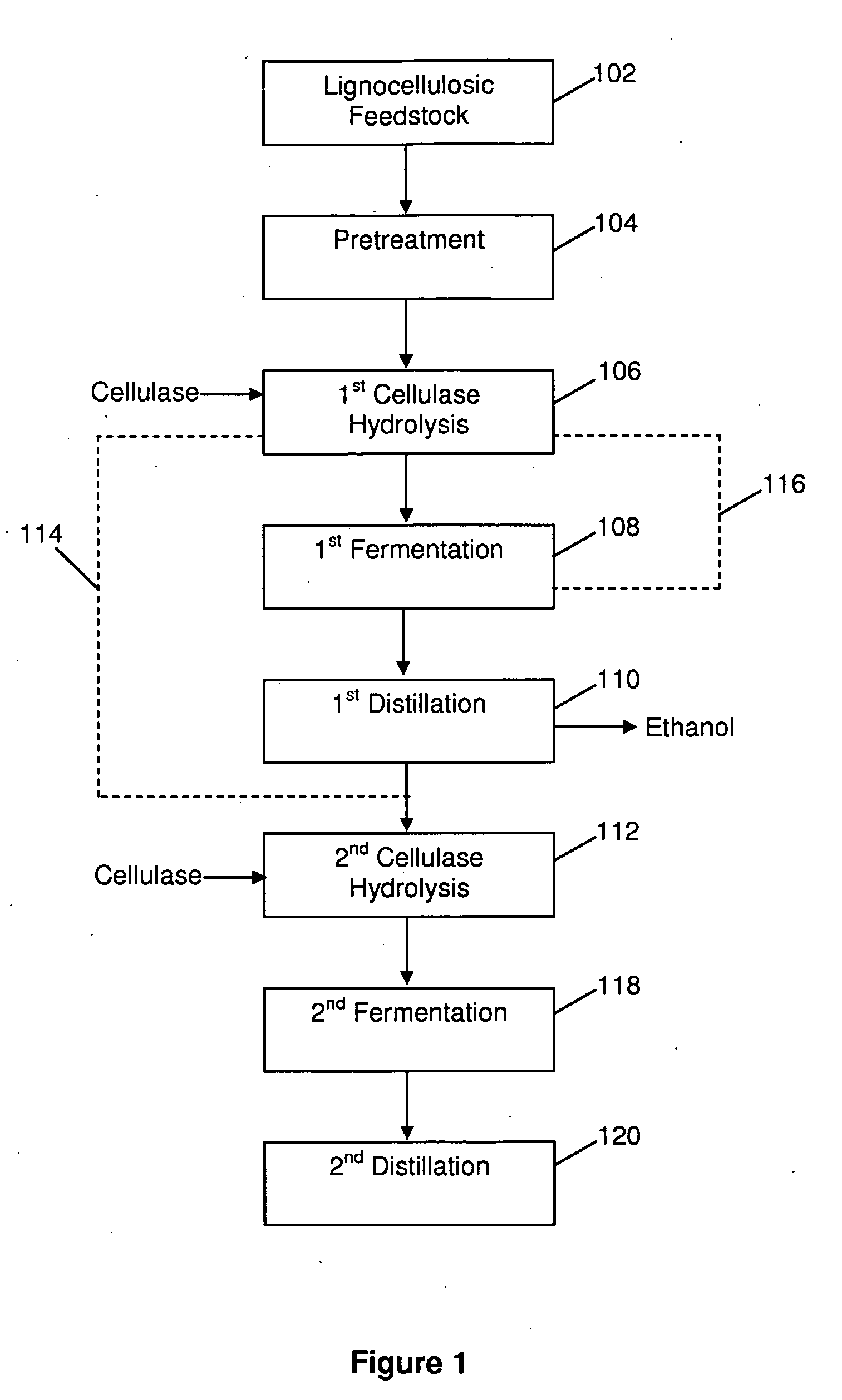

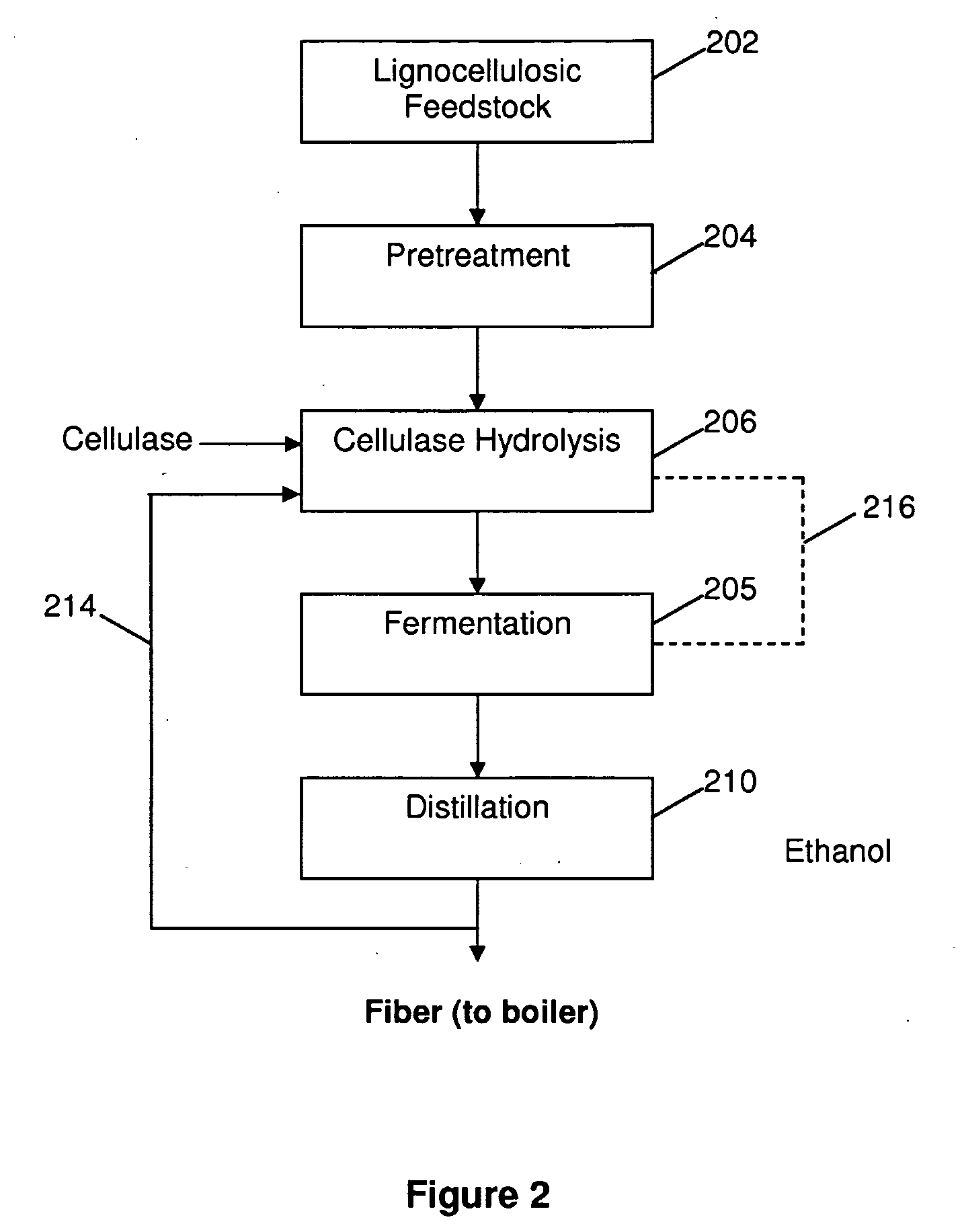

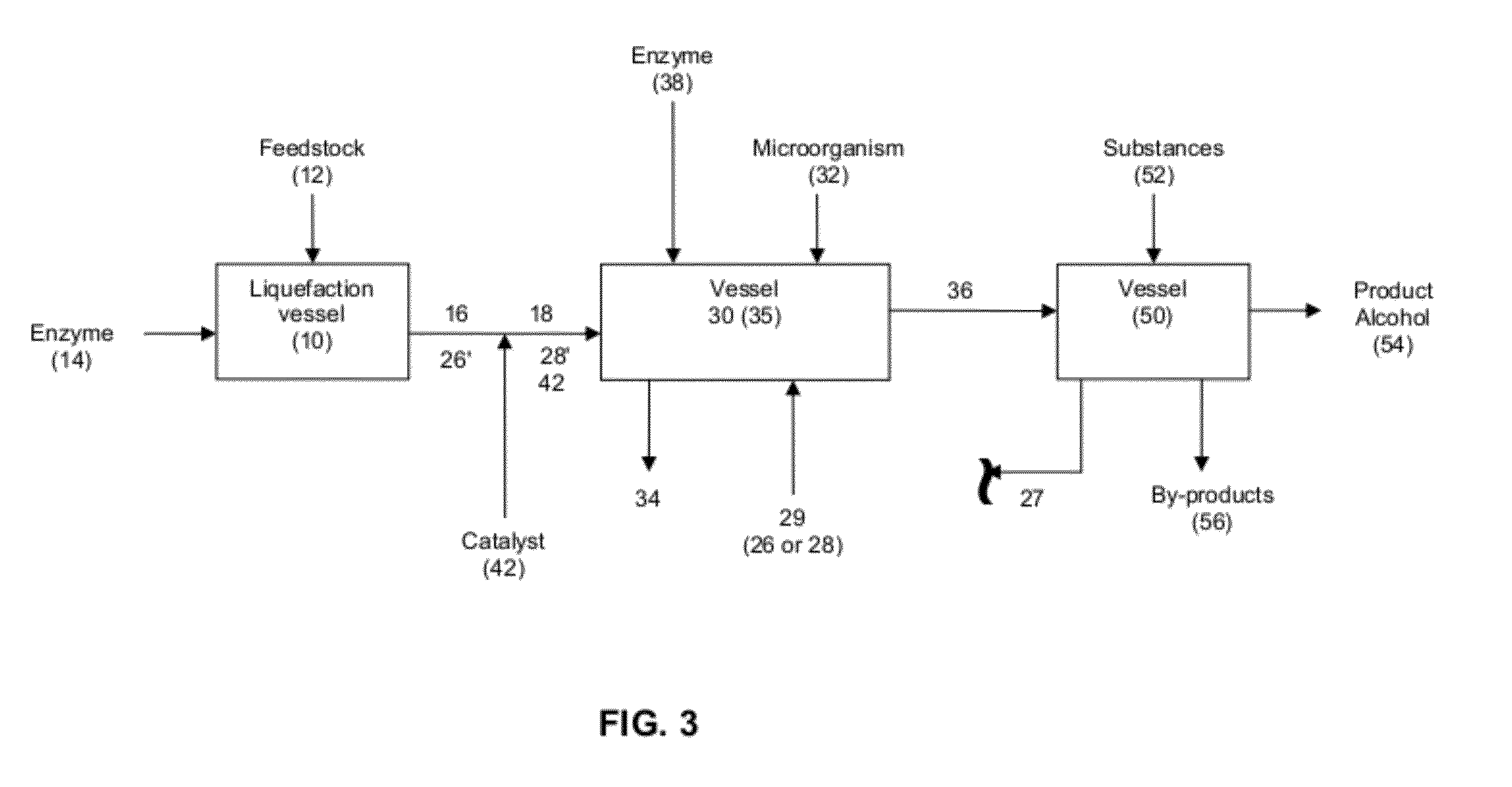

Method for the production of alcohol from a pretreated lignocellulosic feedstock

ActiveUS20090035826A1Increase volumeIncrease productionFermented solutions distillation/rectificationBiofuelsAlcoholSlurry

A process for the production of glucose from a pretreated lignocellulosic feedstock is provided. The method comprises enzymatically hydrolyzing the pretreated lignocellulosic feedstock with cellulase enzymes to produce a hydrolyzate slurry comprising glucose and unhydrolyzed cellulose and fermenting the hydrolyzate slurry in a fermentation reaction to produce a fermentation broth comprising alcohol. A process stream is obtained comprising unhydrolyzed cellulose, which is then subjected to a denaturing step, preferably comprising exposing the unhydrolyzed cellulose to elevated temperatures, thereby producing a heat-treated stream comprising the unhydrolyzed cellulose. The heat-treated stream comprising unhydrolyzed cellulose is then further hydrolyzed with cellulase enzymes to hydrolyze the cellulose to glucose.

Owner:IOGEN ENERGY CORP

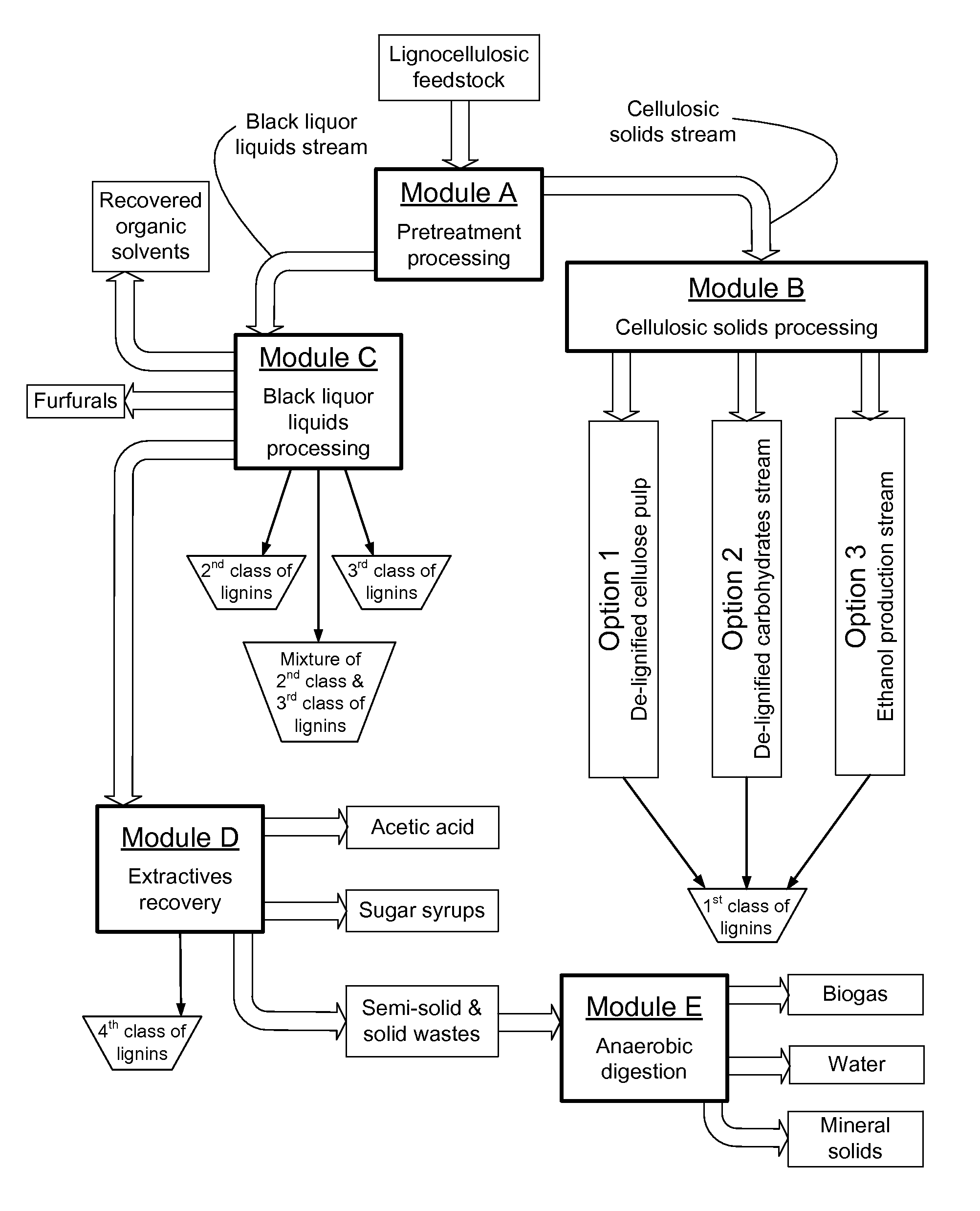

Continuous counter-current organosolv processing of lignocellulosic feedstocks

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into one or more of a de-lignified cellulose stream, a sugar stream, small-chain alcohol streams and four structurally distinct classes of lignin derivatives. The modular process comprises a first processing module configured for digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for recovering small-chain alcohols and optionally a first class of lignin derivatives from the cellulosic solids fraction, a third processing module configured for recovering from the liquid fraction at least one of a second class and a third class of lignin derivatives or mixtures thereof, and waste stream comprising a fourth class of lignin derivatives. The fourth processing module may optionally recover the fourth class of lignin derivatives.

Owner:SUZANO CANADA INC

Reduced Energy Alcohol Separation Process

InactiveUS20120010438A1Fermented solutions distillation/rectificationOrganic compound preparationAcetic acidAqueous alcohol

Recovery of alcohols, in particular ethanol, from a crude ethanol product obtained from the hydrogenation of acetic acid using a reduced energy process. The crude ethanol product may be fed to a distillation column in which a substantial portion of the water is removed with the acetic acid in the residue. The ethanol product is obtained from the distillate.

Owner:CELANESE INT CORP

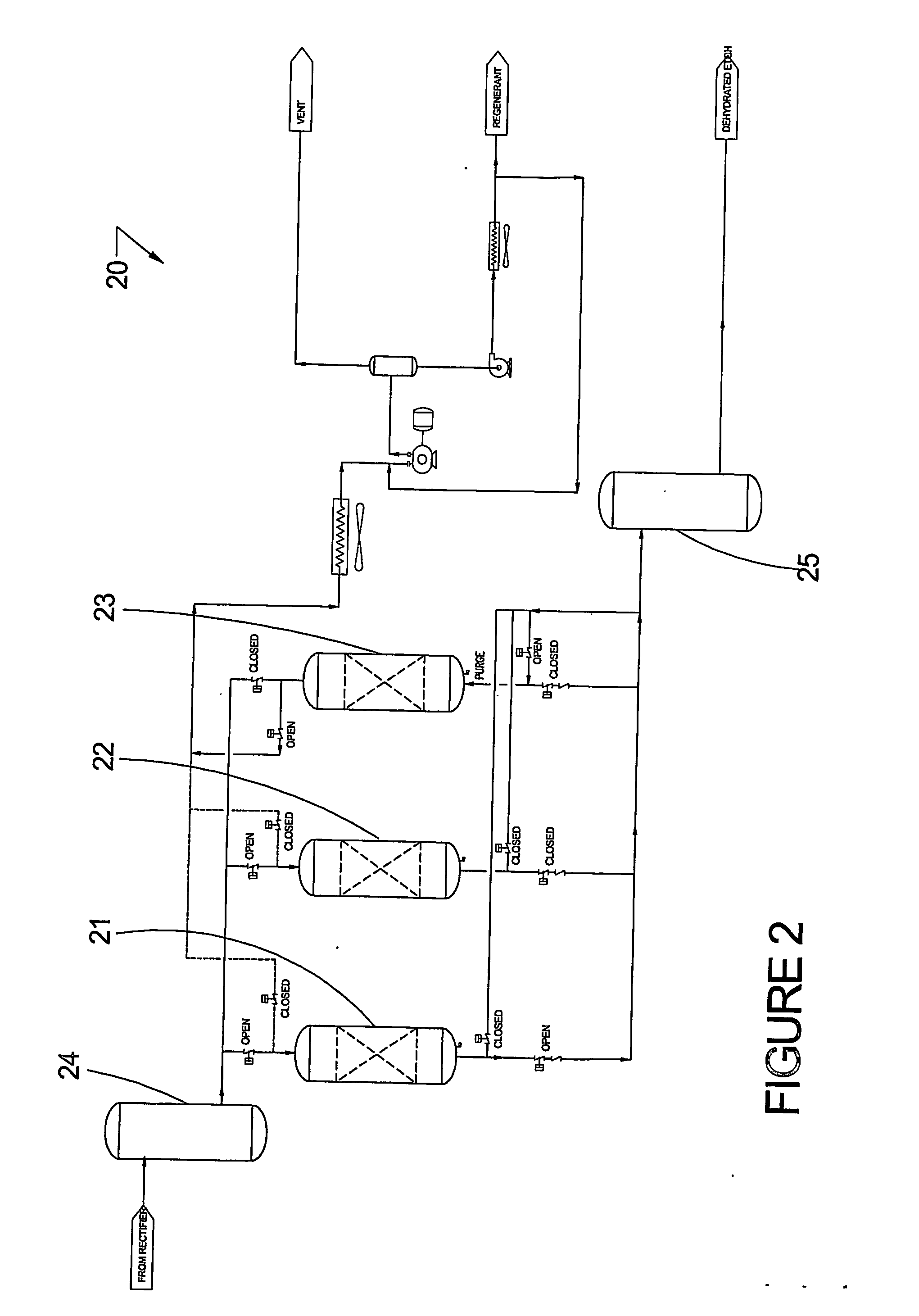

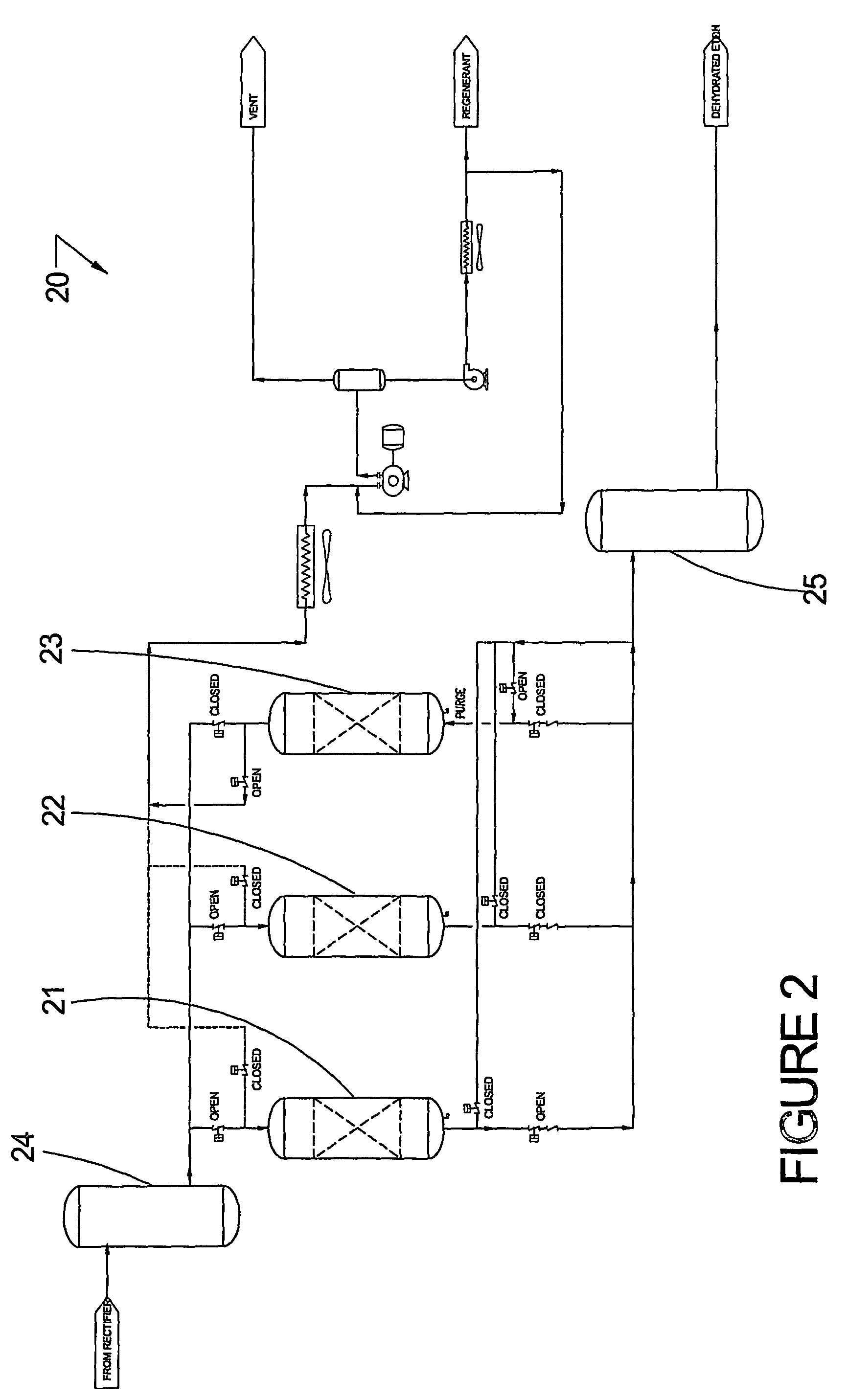

Ethanol distillation with distillers soluble solids recovery apparatus

ActiveUS20070000769A1High operating temperatureReduce drying loadDistillation regulation/controlBiofuelsMolecular sieveAnhydrous ethanol

The present invention relates to a system for producing ethanol from an organic source and that operates to purify and dry ethanol from a beer source. The system for producing substantially anhydrous ethanol comprises: (a) a first distillation stripping column that operates between 160 to 220 degrees F.; (b) a second distillation rectifying column having a higher operating temperature than said stripping column; (c) a molecular sieve dehydration means in fluid communication with said rectifying column; and (d) an energy control means.

Owner:RCM TECH USA INC

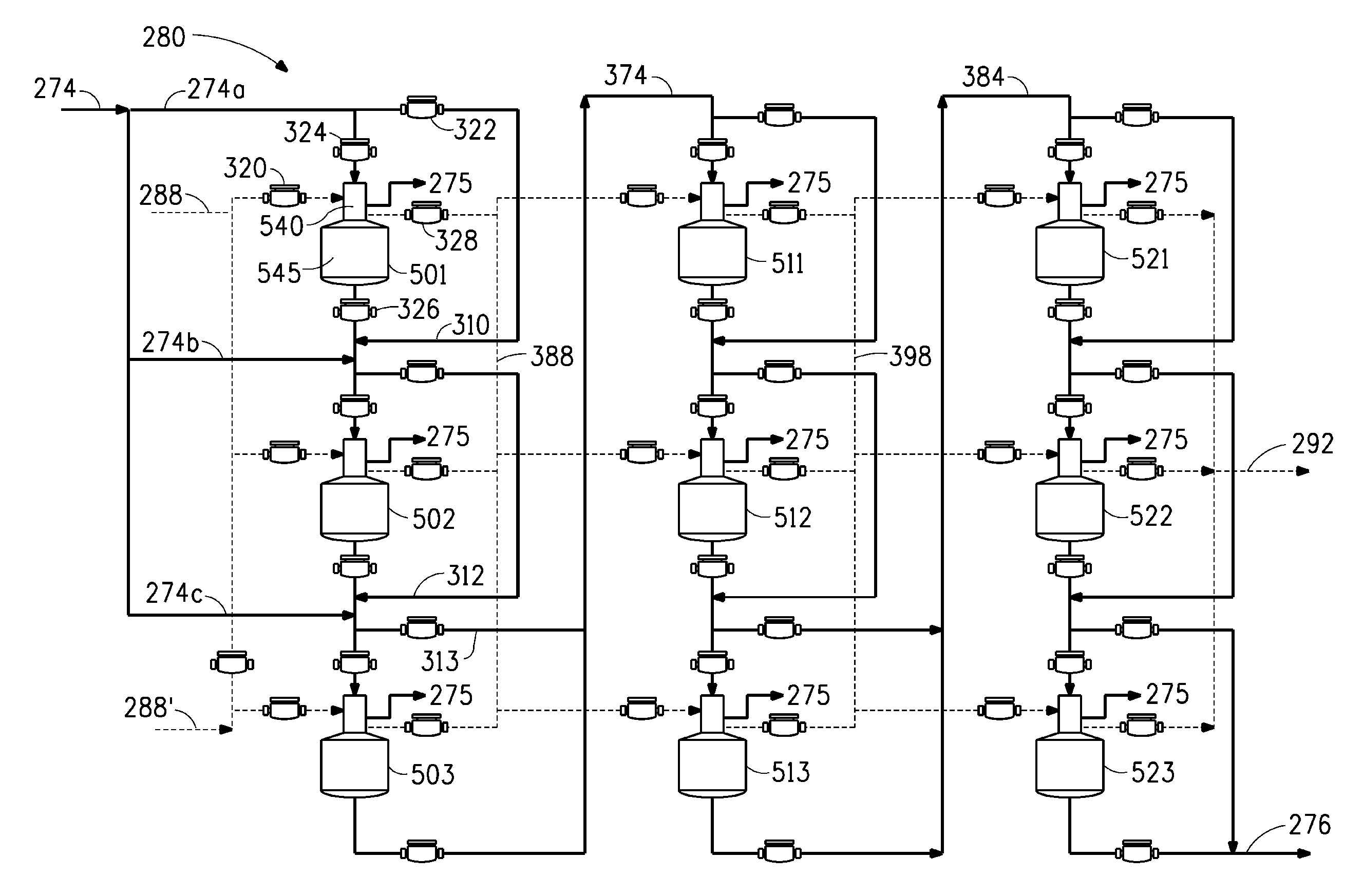

Systems and methods for alcohol recovery and concentration of stillage by-products

ActiveUS20110315541A1Efficient use ofHydrocarbon purification/separationHydroxy compound preparationAlcoholDistillation

Systems and methods for separating an alcohol, and in particular butanol, from a fermented feed and concentrating thin stillage into syrup includes operation of one or more alcohol recovery distillation columns using the heat supplied by steam generated from concentration of the thin stillage in a multi-train, multi-effect evaporation system.

Owner:GEVO INC

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS20080299628A1Facilitate and enhance of fermentation and efficiencyFacilitate and enhance rateBioreactor/fermenter combinationsPressurized chemical processFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:LIGNOL INNOVATIONS

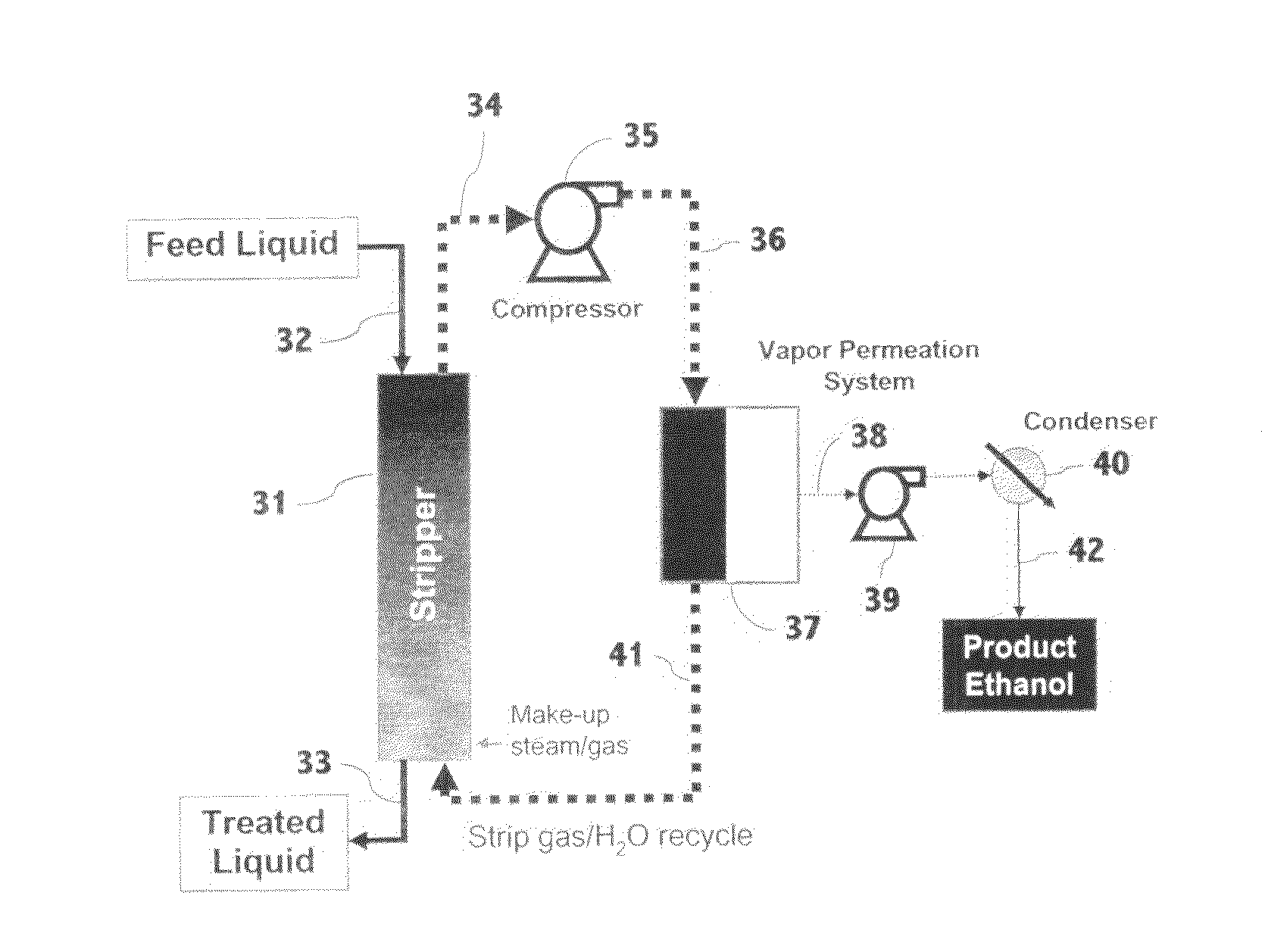

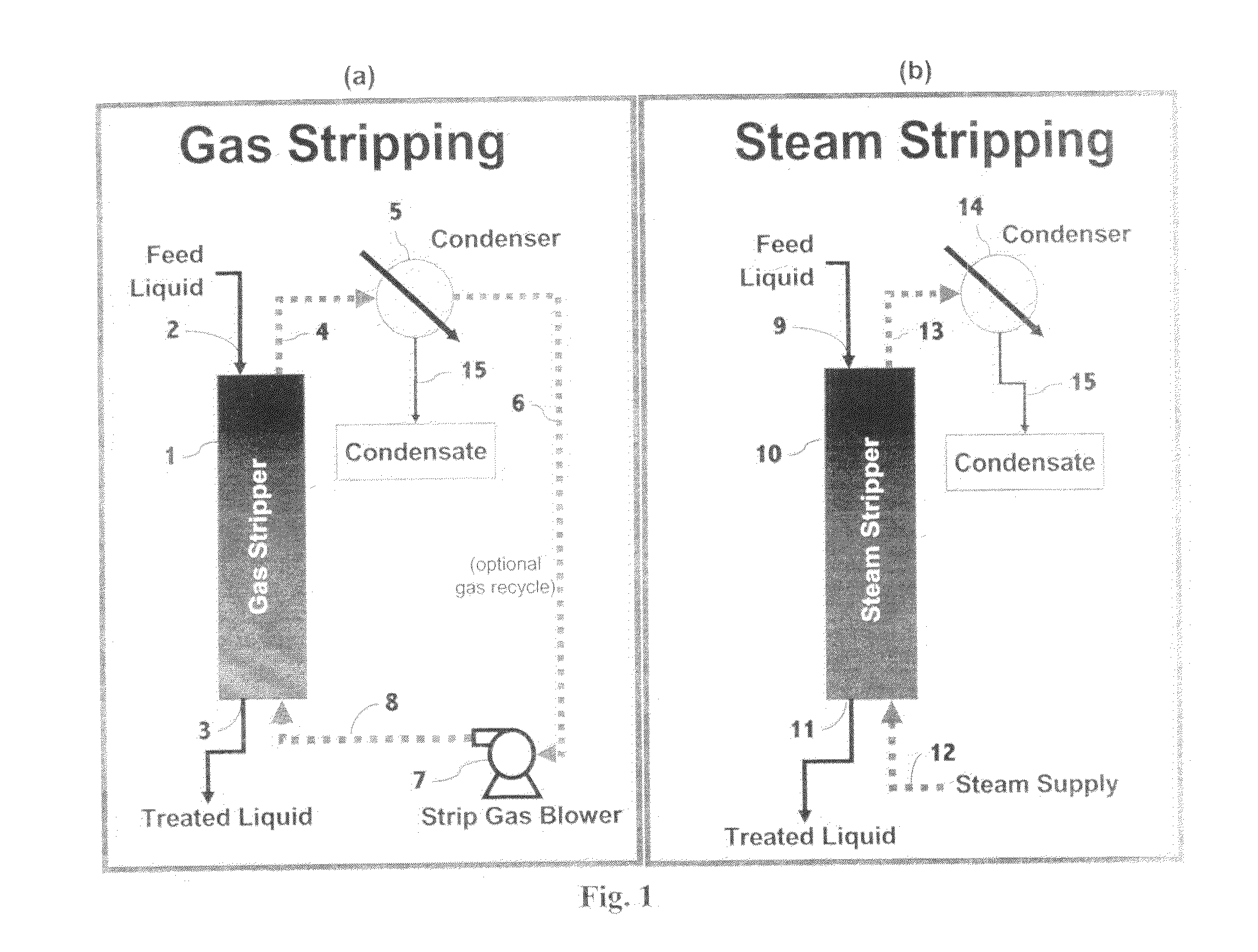

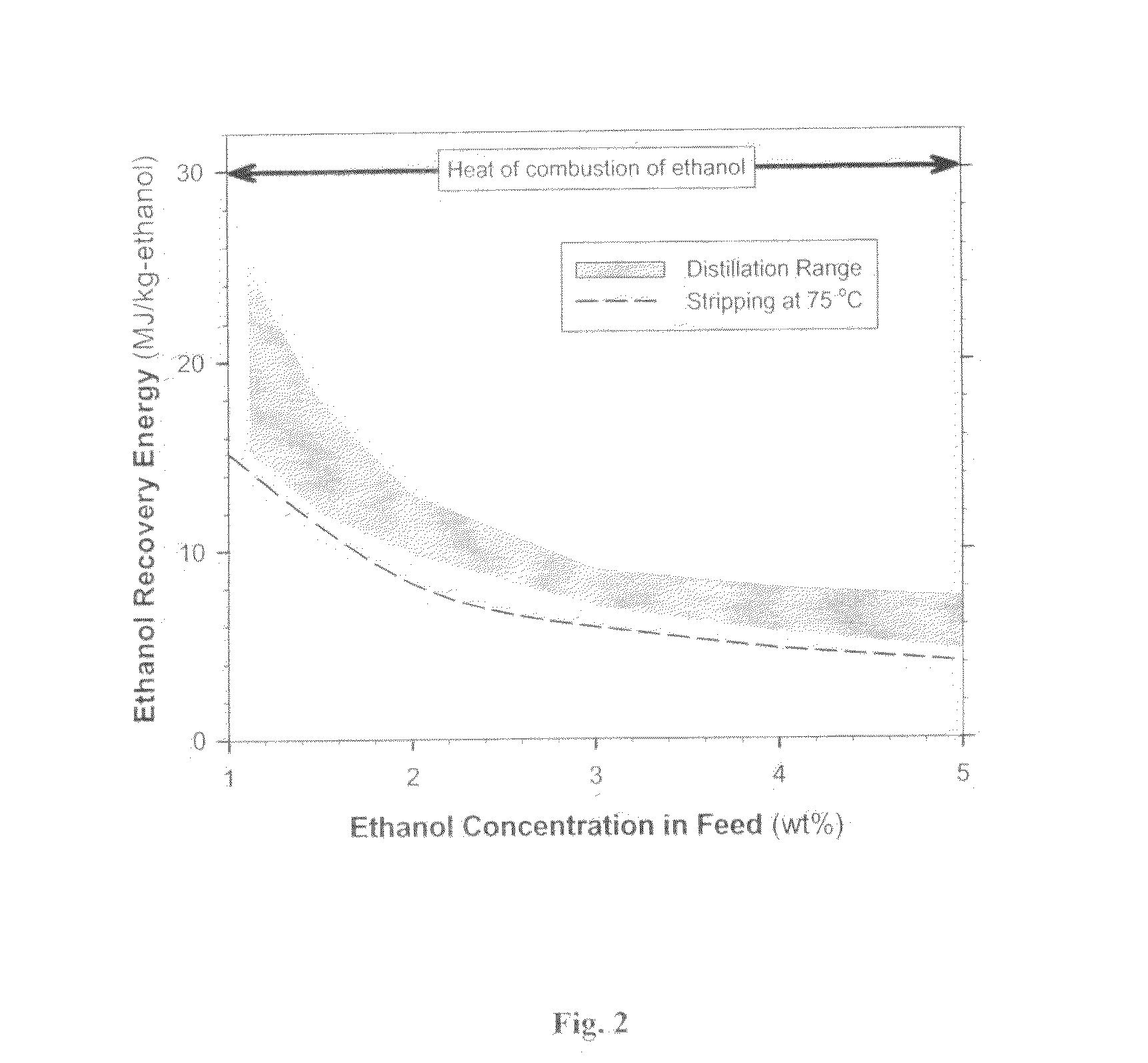

Liquid separation by membrane assisted vapor stripping process

InactiveUS20090057128A1Distillation regulation/controlUsing liquid separation agentImproved methodPermeation

An improved process for separation of liquid mixtures involves vapor stripping followed by mechanical compression of the vapor which is then exposed to a permeation membrane for separation of the compressed vapor.

Owner:VANE LELAND +1

Extraction solvents derived from oil for alcohol removal in extractive fermentation

ActiveUS20110312044A1Reduce the amount requiredReduce decreaseFatty oils/acids recovery from wasteOxygen-containing compound preparationSolventFatty alcohol

In an alcohol fermentation process, oil derived from biomass is chemically converted into an extractant available for in situ removal of a product alcohol such as butanol from a fermentation broth. The glycerides in the oil can be chemically converted into a reaction product, such as fatty acids, fatty alcohols, fatty amides, fatty acid methyl esters, fatty acid glycol esters, and hydroxylated triglycerides, and mixtures thereof, which forms a fermentation product extractant having a partition coefficient for a product alcohol greater than a partition coefficient of the oil of the biomass for the product alcohol. Oil derived from a feedstock of an alcohol fermentation process can be chemically converting into the fermentation product extractant. The oil can be separated from the feedstock prior to the feedstock being fed to a fermentation vessel, and the separated oil can be chemically converted to a fermentation product extractant, which can then contacted with a fermentation product comprising a product alcohol, whereby the product alcohol is separated from the fermentation product.

Owner:GEVO INC

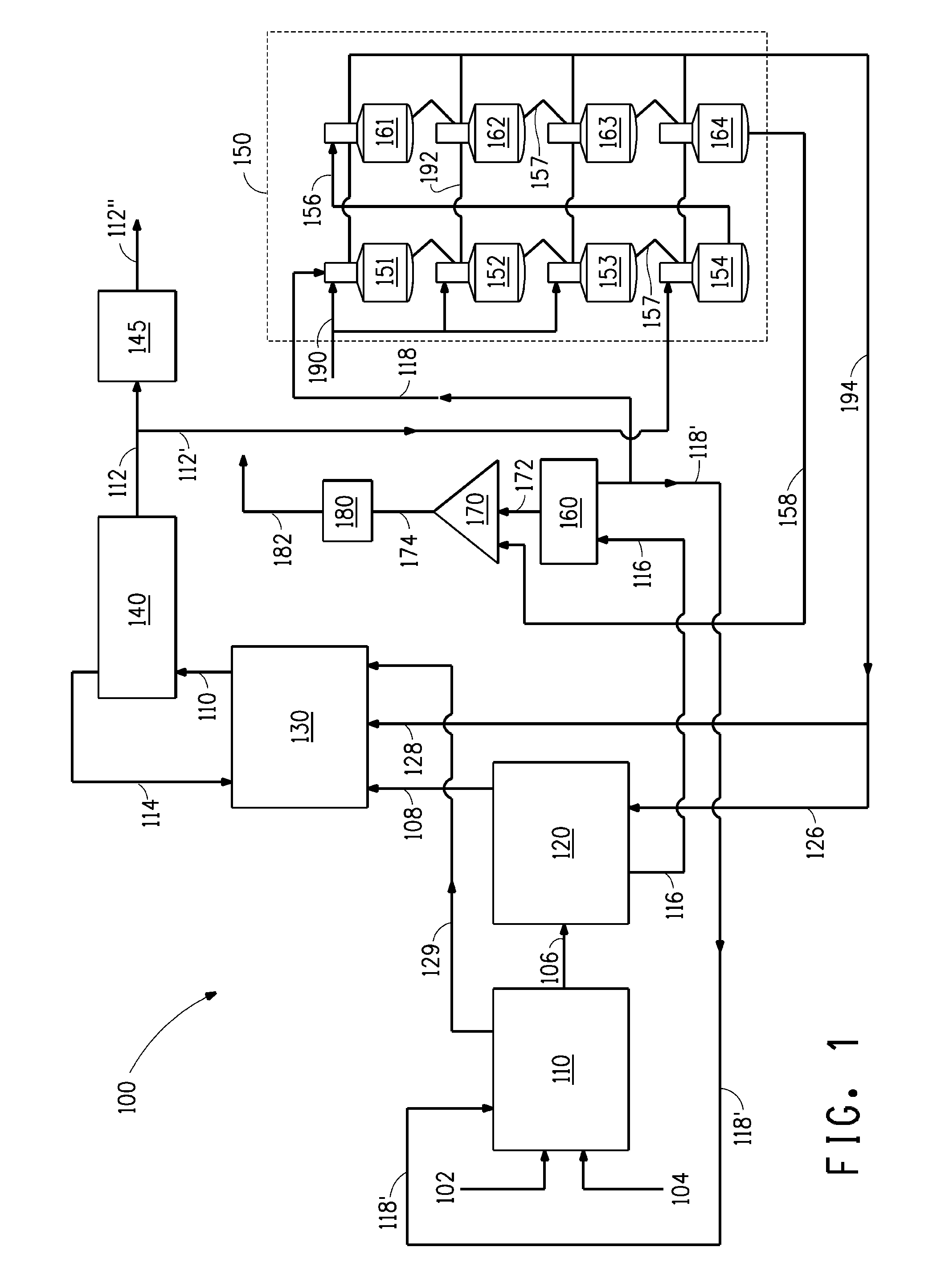

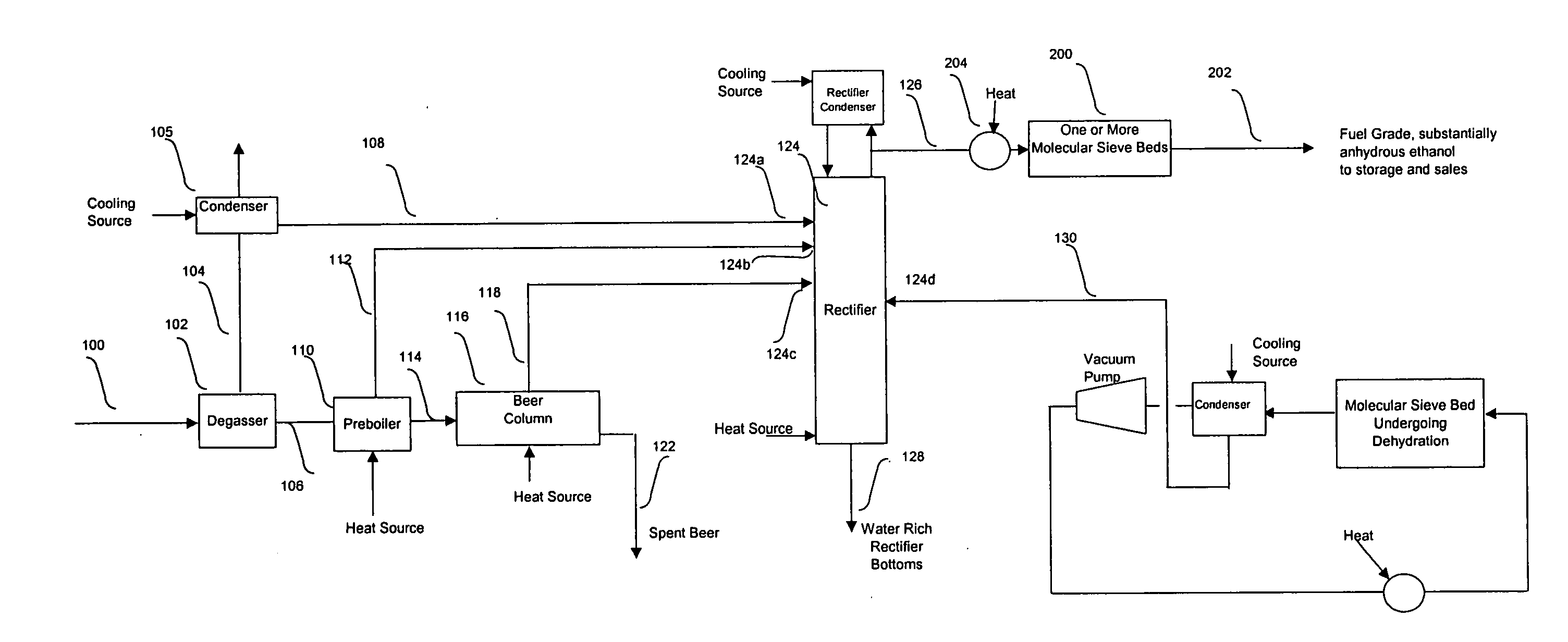

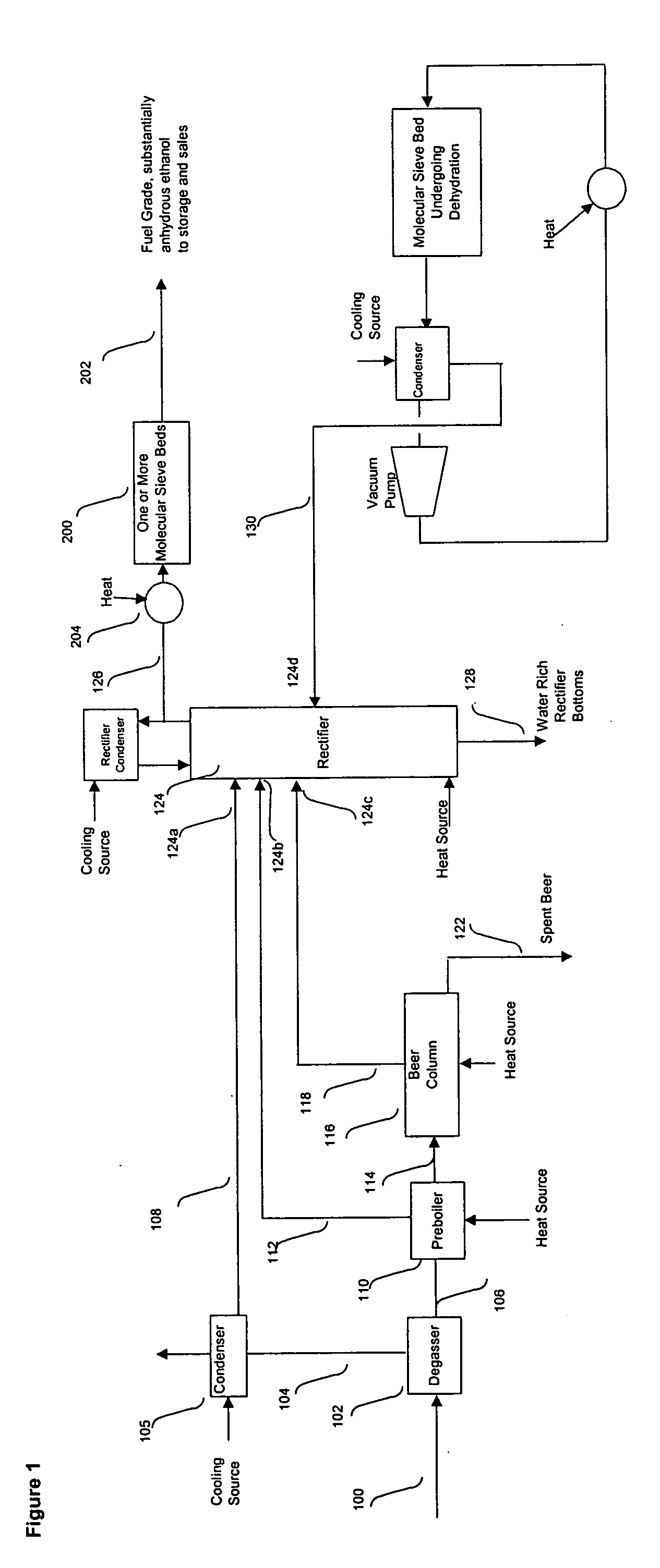

Process for providing ethanol

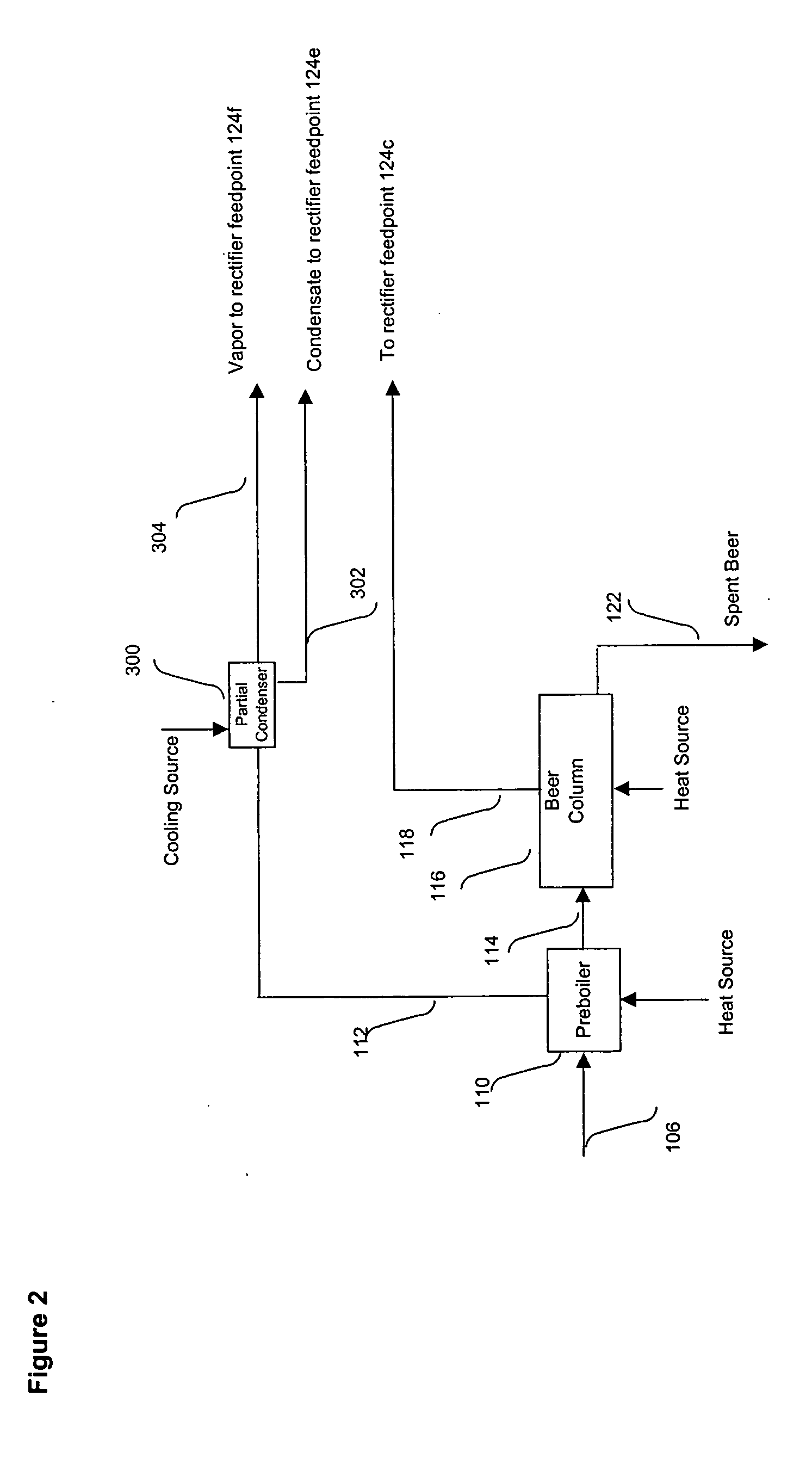

ActiveUS20070144886A1Using liquid separation agentSolid sorbent liquid separationWater vaporRectifier

The invention is a process for the purification of ethanol. In one embodiment the process comprises boiling a degassed beer feed (106) in a pre-boiler (110) to provide a vapor by-pass fraction (112) that by-passes the conventional beer column and is fed into the rectifier column (124). The process allows free capacity in the rectifier column of new or established plants to be filled by ethanol-water vapor and / or condensate streams that do not originate from the beer column.

Owner:SUSTAINABLE TECH CORP

Method and systems for enhancing oil recovery from ethanol production byproducts

ActiveUS20080110577A1Fatty oils/acids recovery from wasteDrying using combination processesEngineeringCentrifuge

Owner:GS CLEANTECH CORP

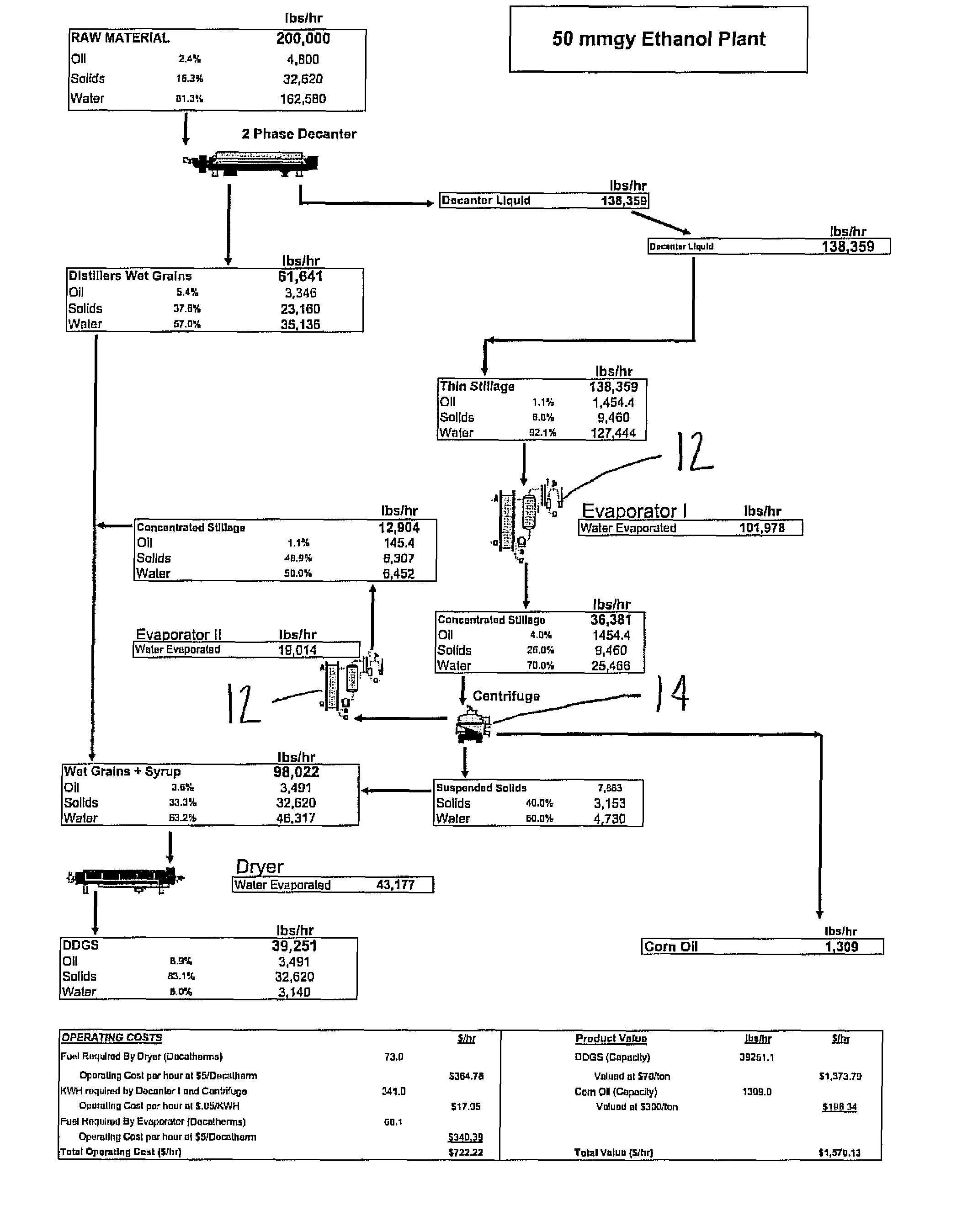

Method and systems for enhancing oil recovery from ethanol production byproducts

InactiveUS8168037B2Fatty oils/acids recovery from wasteDrying using combination processesEngineeringCentrifuge

Methods and related systems efficiently and effectively recover a significant amount of valuable, useable oil from byproducts formed during a dry milling process used for producing ethanol. The method may include forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may include evaporating the byproduct using a multi-stage evaporator, as well as recovering the oil before the final stage of the evaporator. Further, the step of recovering oil from the concentrate may include using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil.

Owner:GS CLEANTECH CORP

Method of processing ethanol byproducts and related subsystems

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

Production of alcohol esters and in situ product removal during alcohol fermentation

ActiveUS20120156738A1Increase productionDecreasing rate of build-upFatty oils/acids recovery from wasteFungiAlcoholCarboxylic acid

An alcohol fermentation process and composition that includes production of alcohol esters by esterification of product alcohol in a fermentation medium with a carboxylic acid (e.g., fatty acid) and a catalyst (e.g., lipase) capable of esterifying the product alcohol, such as butanol, with the carboxylic acid to form the alcohol esters. The alcohol esters can be extracted from the fermentation medium, and the product alcohol recovered from the alcohol esters. The carboxylic acid can also serve as an extractant for removal of the alcohol esters from the fermentation medium.

Owner:GEVO INC

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS20080295980A1Facilitate and enhance of fermentation and efficiencyFacilitate and enhance rateNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:LIGNOL INNOVATIONS

Ethanol distillation with distillers soluble solids recovery apparatus

ActiveUS7867365B2Reduce energy useIncrease concentrationDrying using combination processesDistillation regulation/controlMolecular sieveAnhydrous ethanol

The present invention relates to a system for producing ethanol from an organic source and that operates to purify and dry ethanol from a beer source. The system for producing substantially anhydrous ethanol comprises: (a) a first distillation stripping column; (b) a second distillation rectifying column having a higher operating temperature than said stripping column; (c) a molecular sieve dehydration means in fluid communication with said rectifying column. Heat from the overhead of the second distillation rectifying column and the molecular sieve dehydration are used to heat the first distillation stripping column.

Owner:RCM TECH USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com