Patents

Literature

6465 results about "Propanediol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propanediol may refer to either of three isomeric organic chemical compounds: 1,2-Propanediol 2,2-Propanediol 1,3-Propanediol

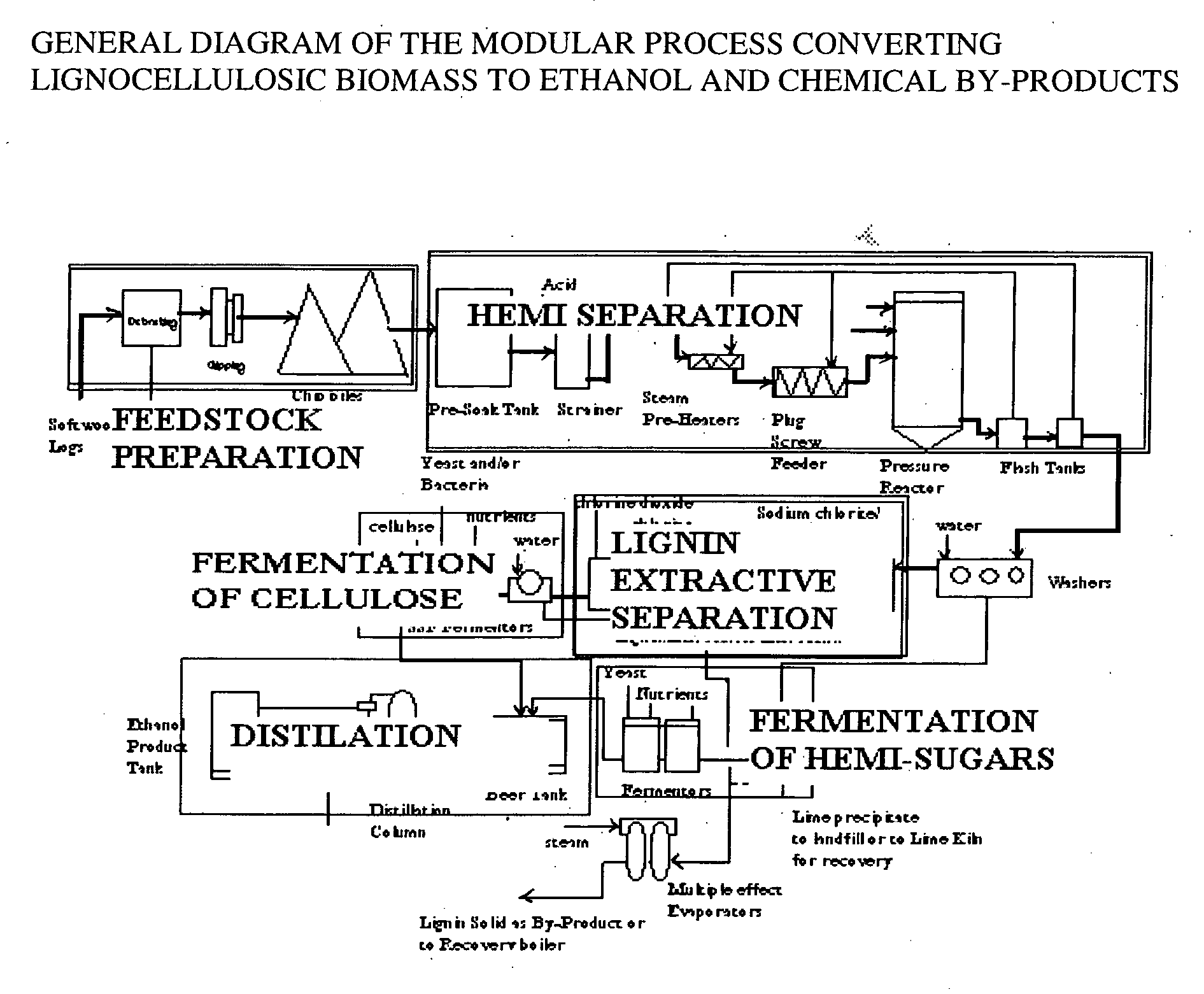

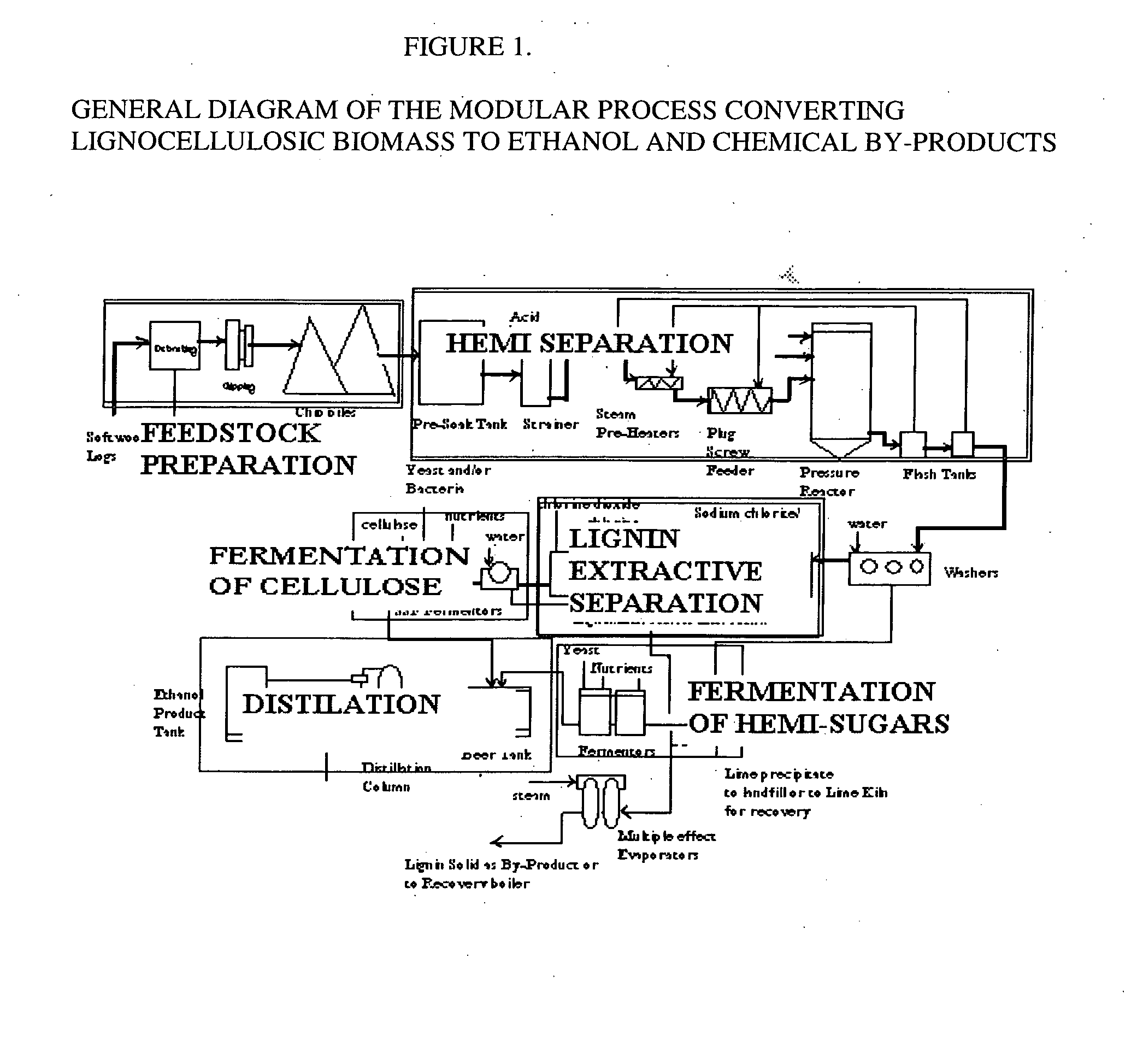

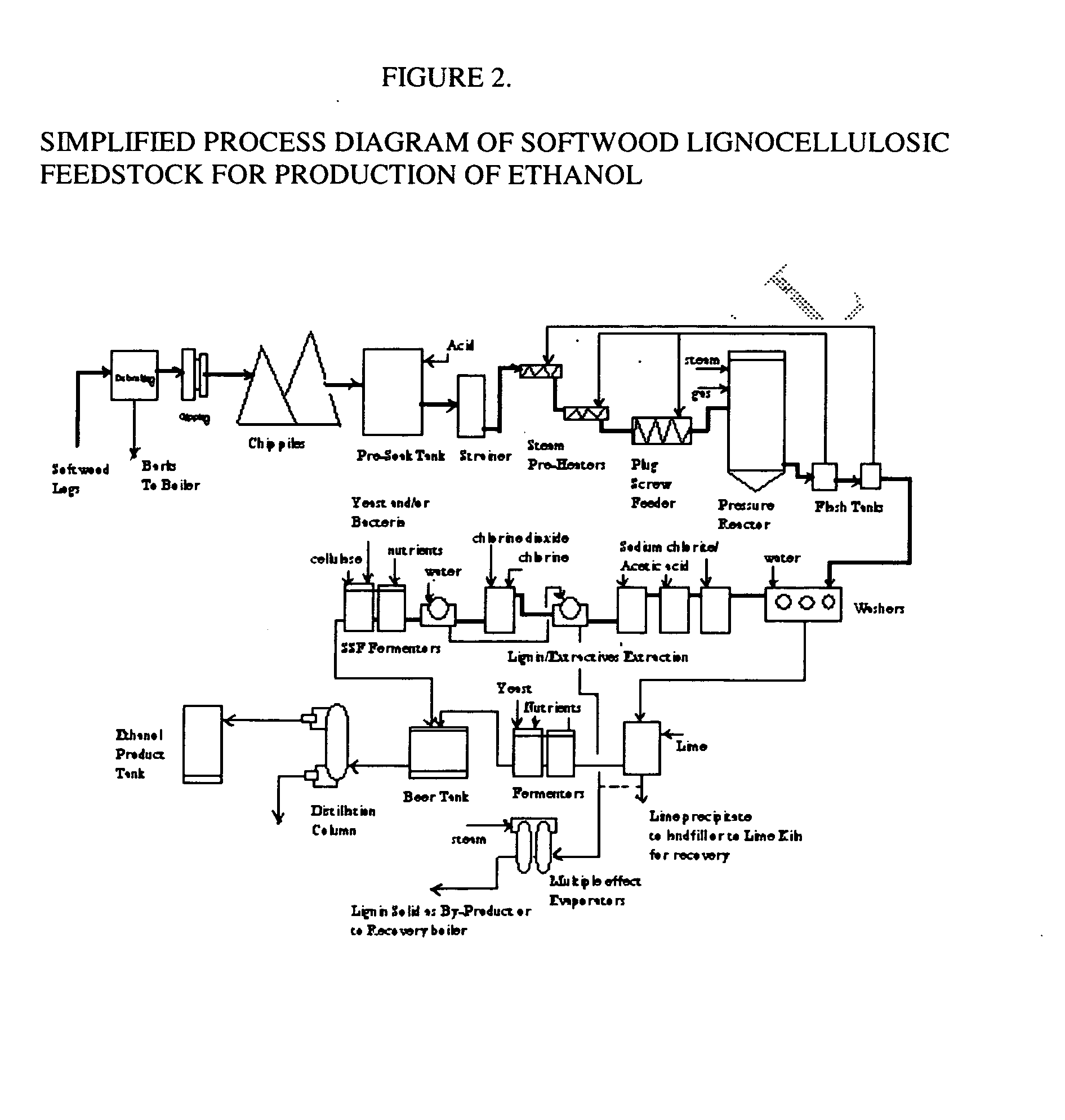

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

Purification of biologically-produced 1,3-propanediol

InactiveUS20050069997A1Reduce the amount of waterFermented solutions distillation/rectificationMembranesEscherichia coliDistillation

A process for purifying 1,3-propanediol from the fermentation broth of a cultured E. coli that has been bioengineered to synthesize 1,3-propanediol from sugar is provided. The basic process entails filtration, ion exchange and distillation of the fermentation broth product stream, preferably including chemical reduction of the product during the distillation procedure. Also provided are highly purified compositions of 1,3-propanediol.

Owner:DUPONT IND BIOSCIENCES USA LLC +1

Bioconversion of a fermentable carbon source to 1,3-propanediol by a single microorganism

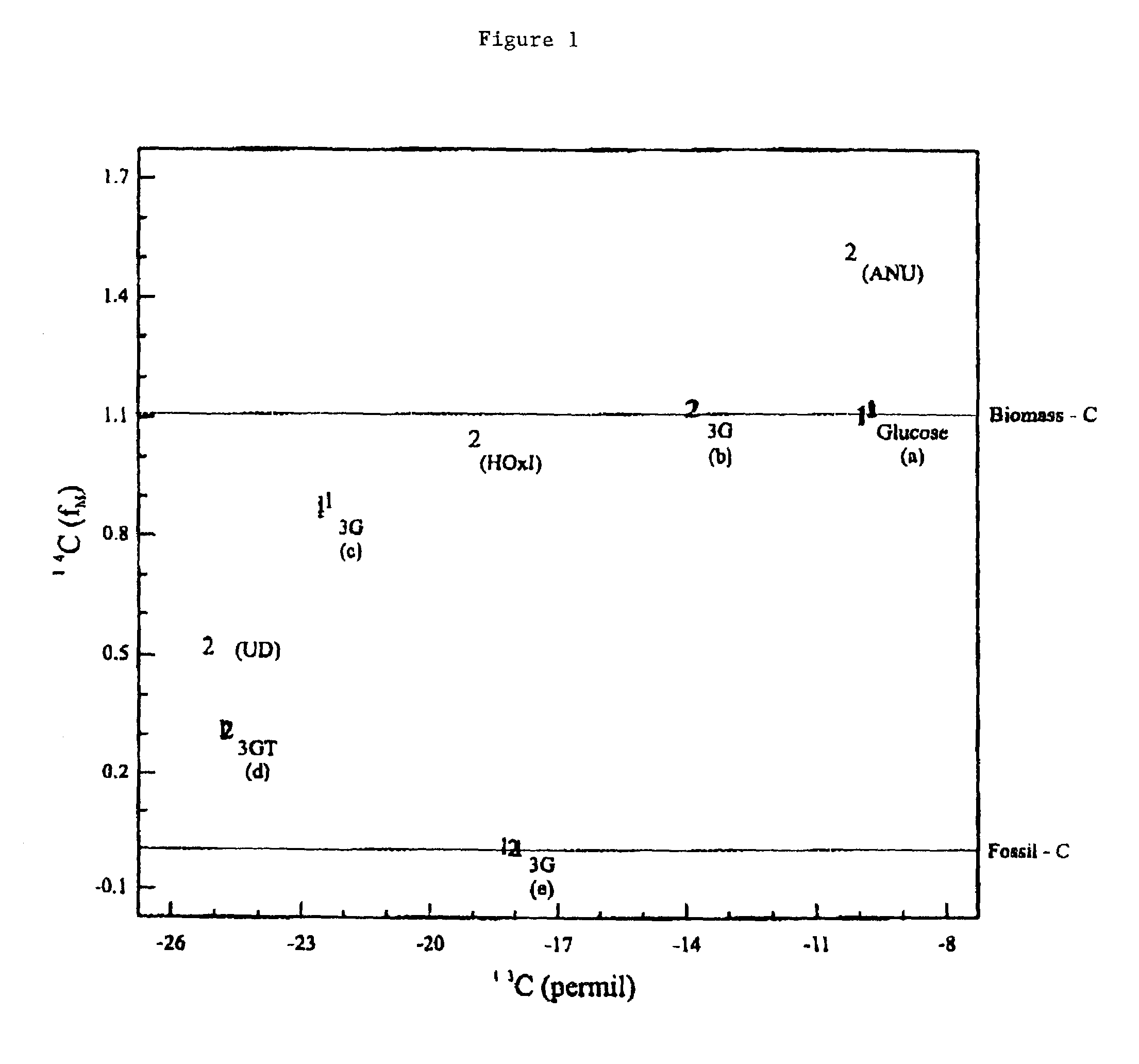

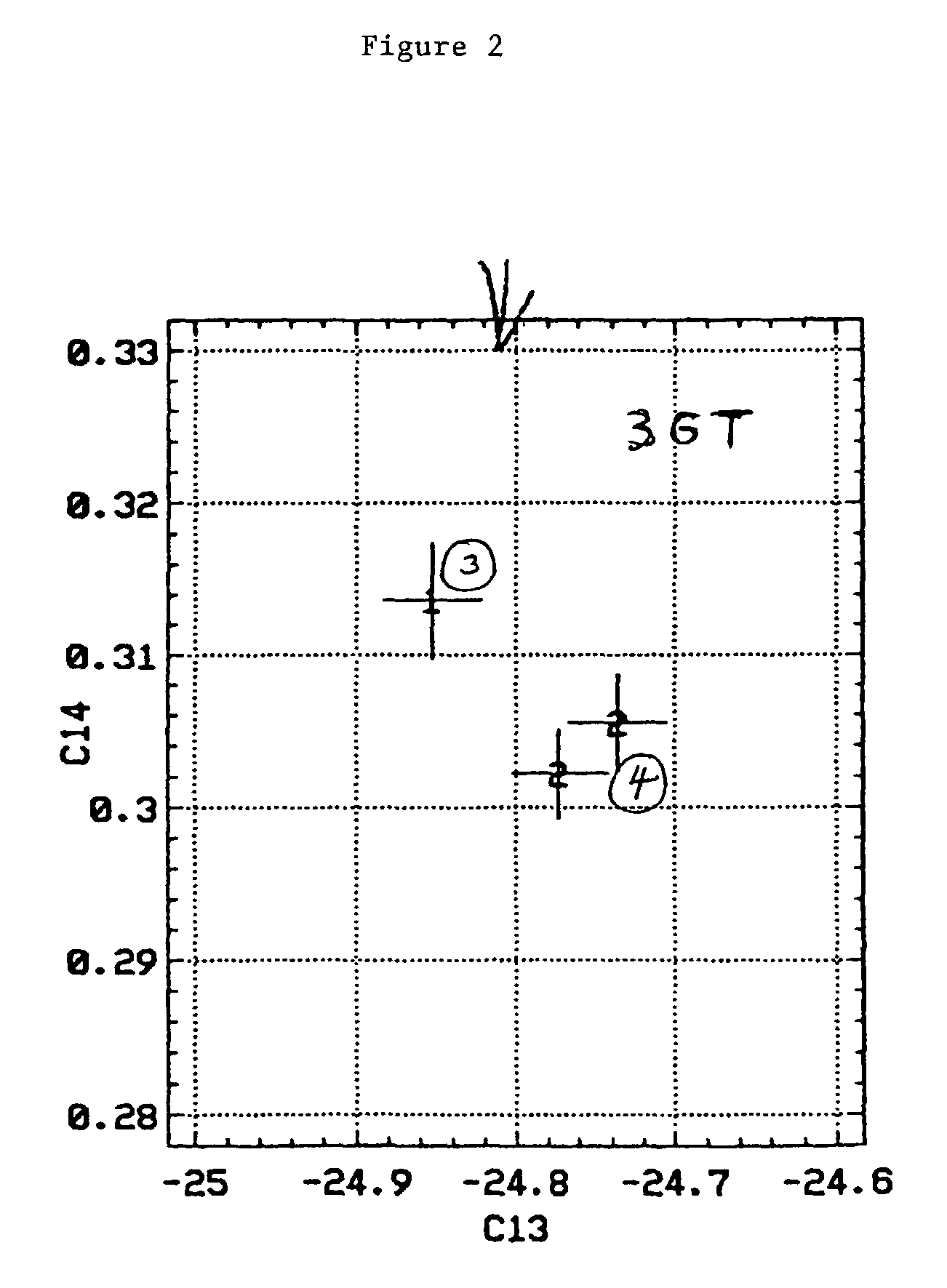

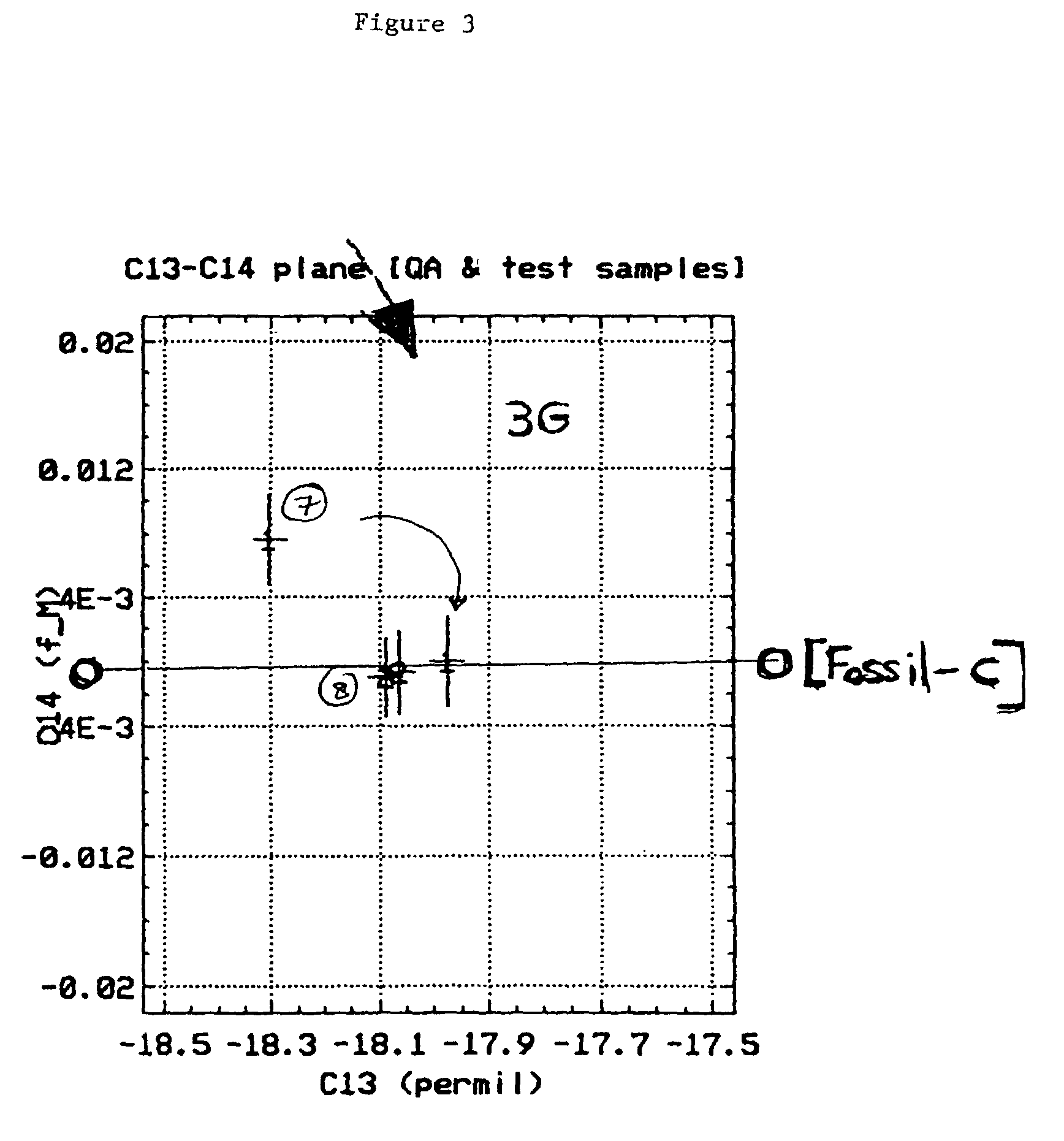

A new polypropylene terephthalate composition is provided. The polypropylene terephthalate is comprised of 1,3-propanediol and terephthalate. The 1,3-propanediol is produced by the bioconversion of a fermentatble carbon source, preferable glucose. The resulting polypropylene terephthalate is distinguished from petrochemically produced polymer on the basis of dual carbon-isotopic fingerprinting which indicates both the source and the age of the carbon.

Owner:EI DU PONT DE NEMOURS & CO +1

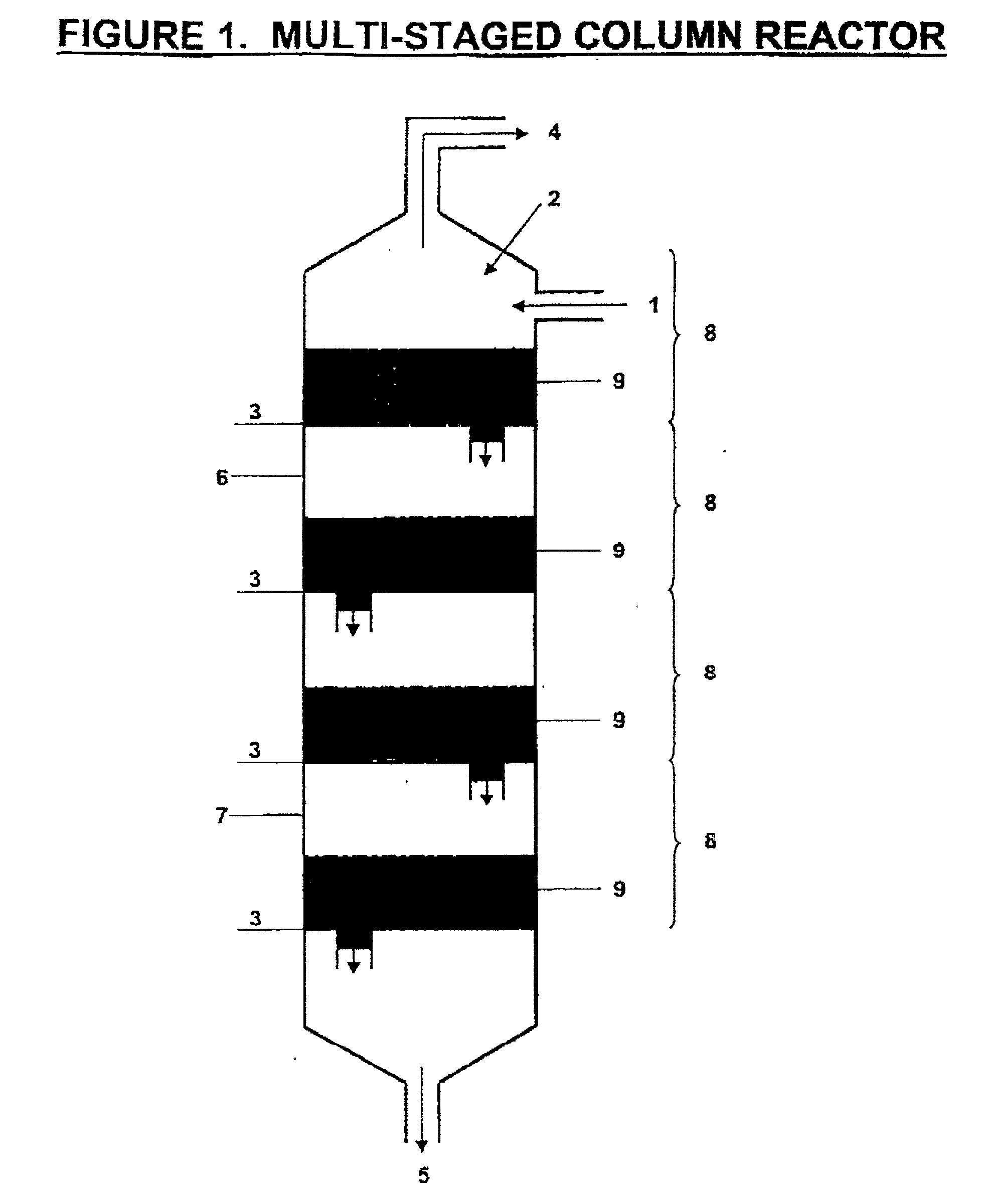

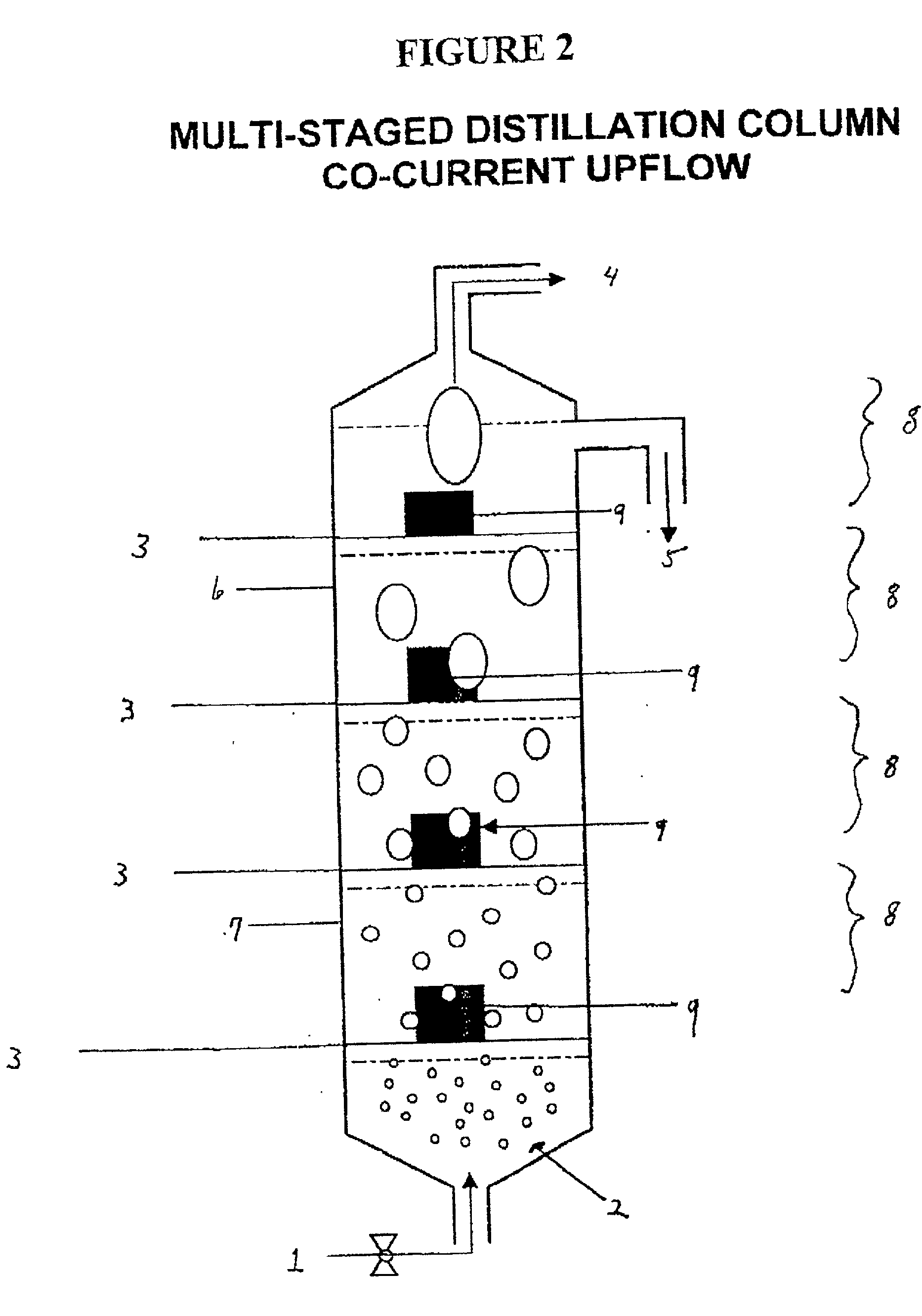

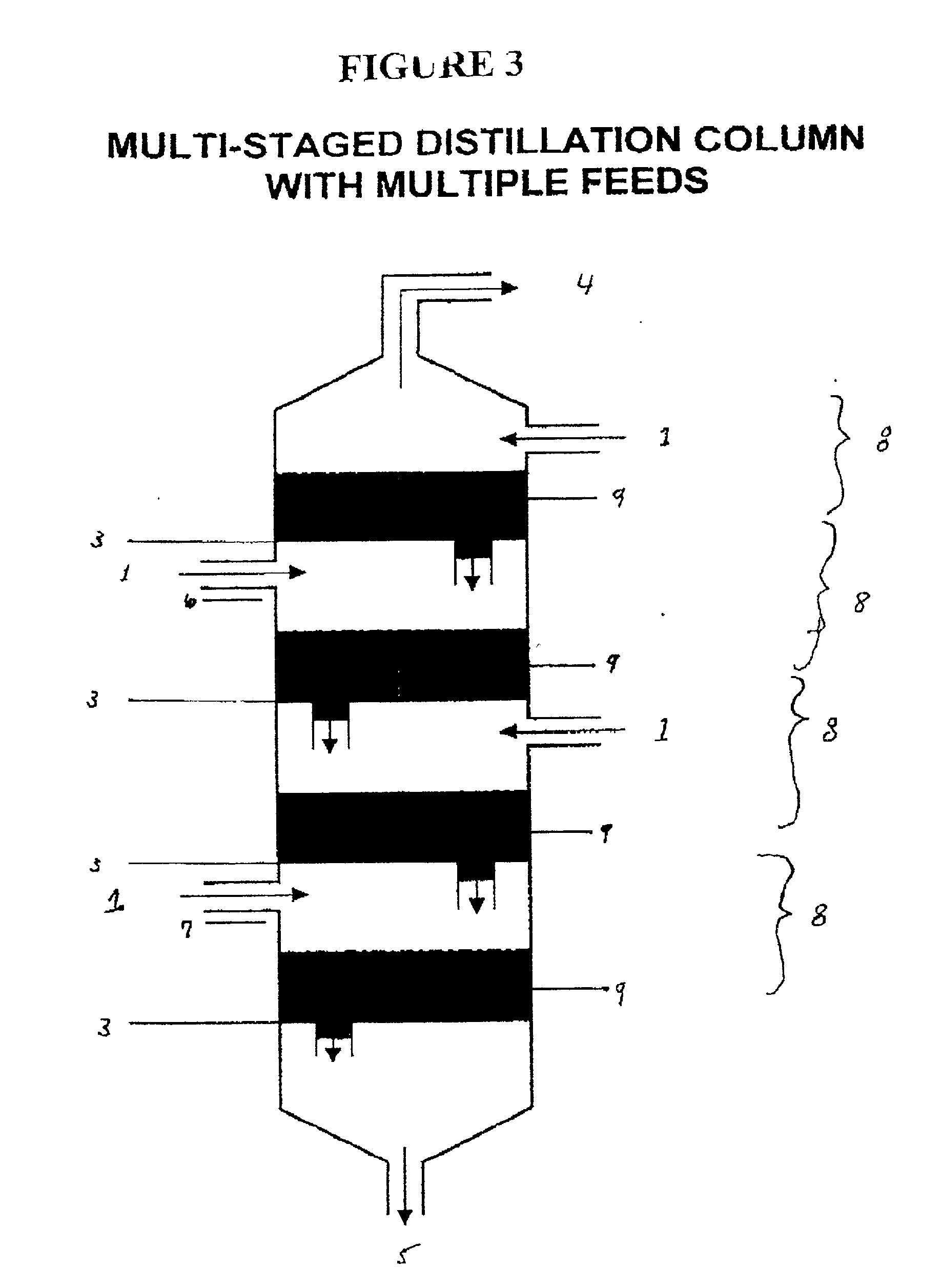

Continuous process for the preparation of polytrimethylene ether glycol

InactiveUS6720459B2Liquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationGas phaseEther

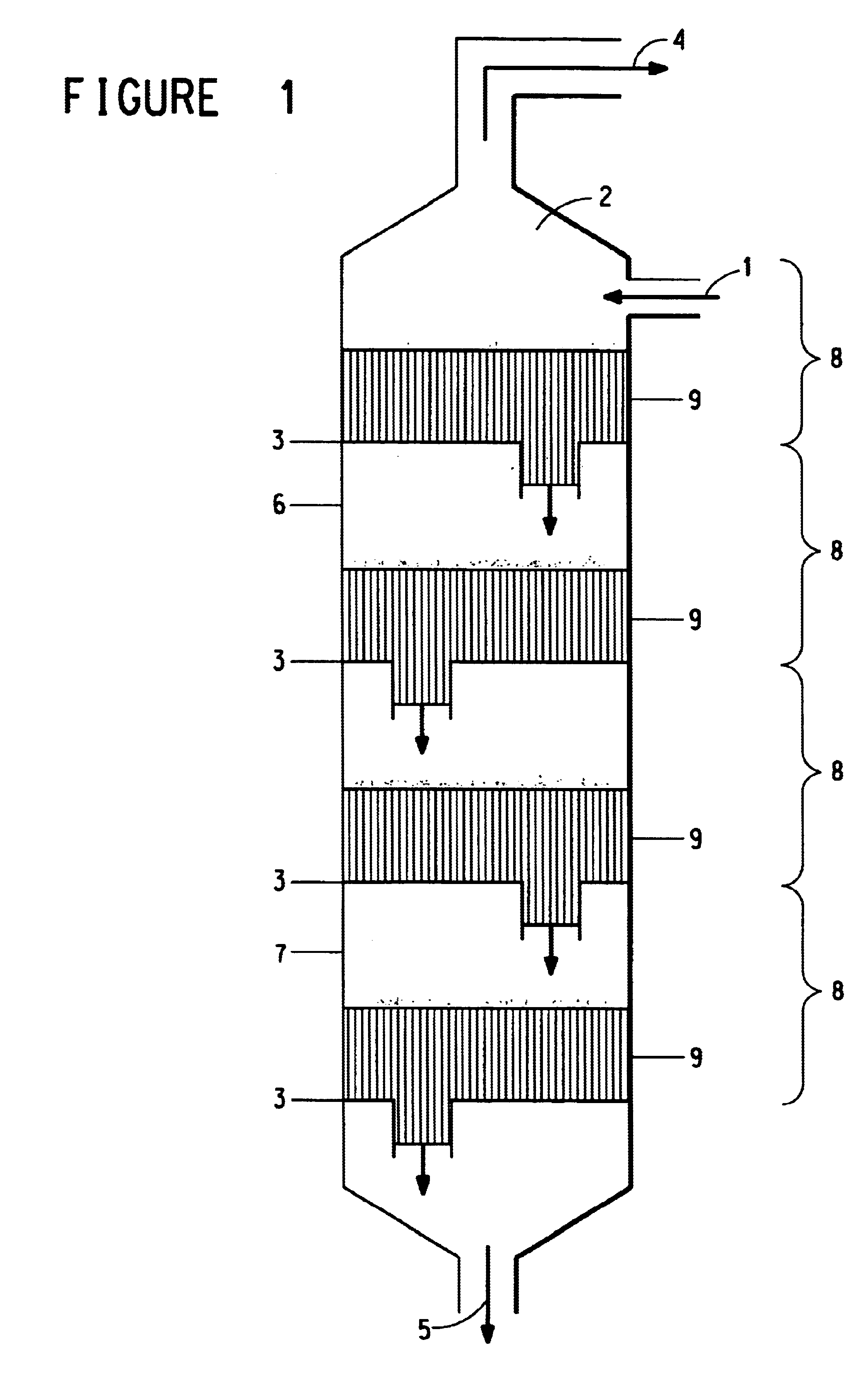

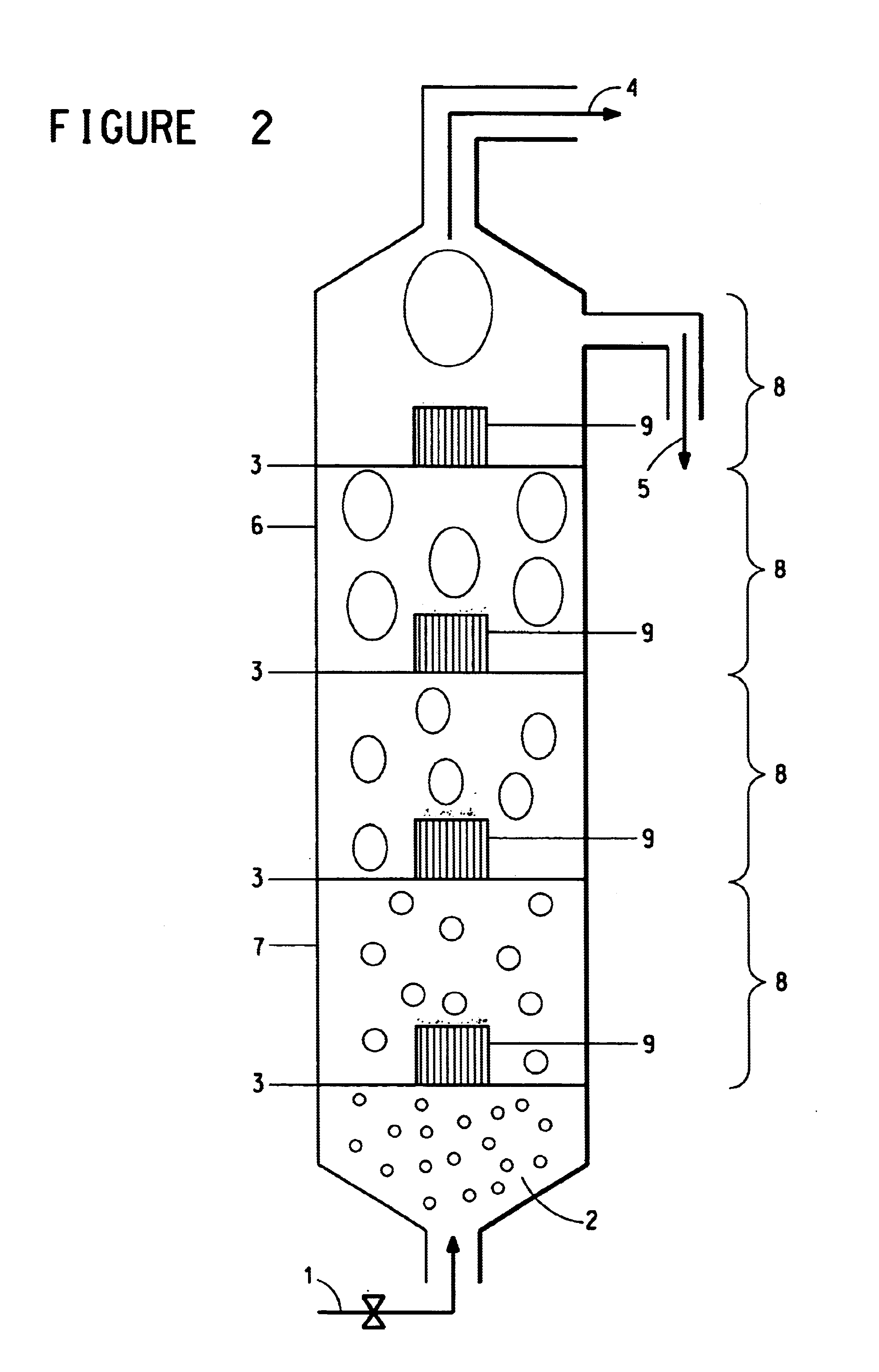

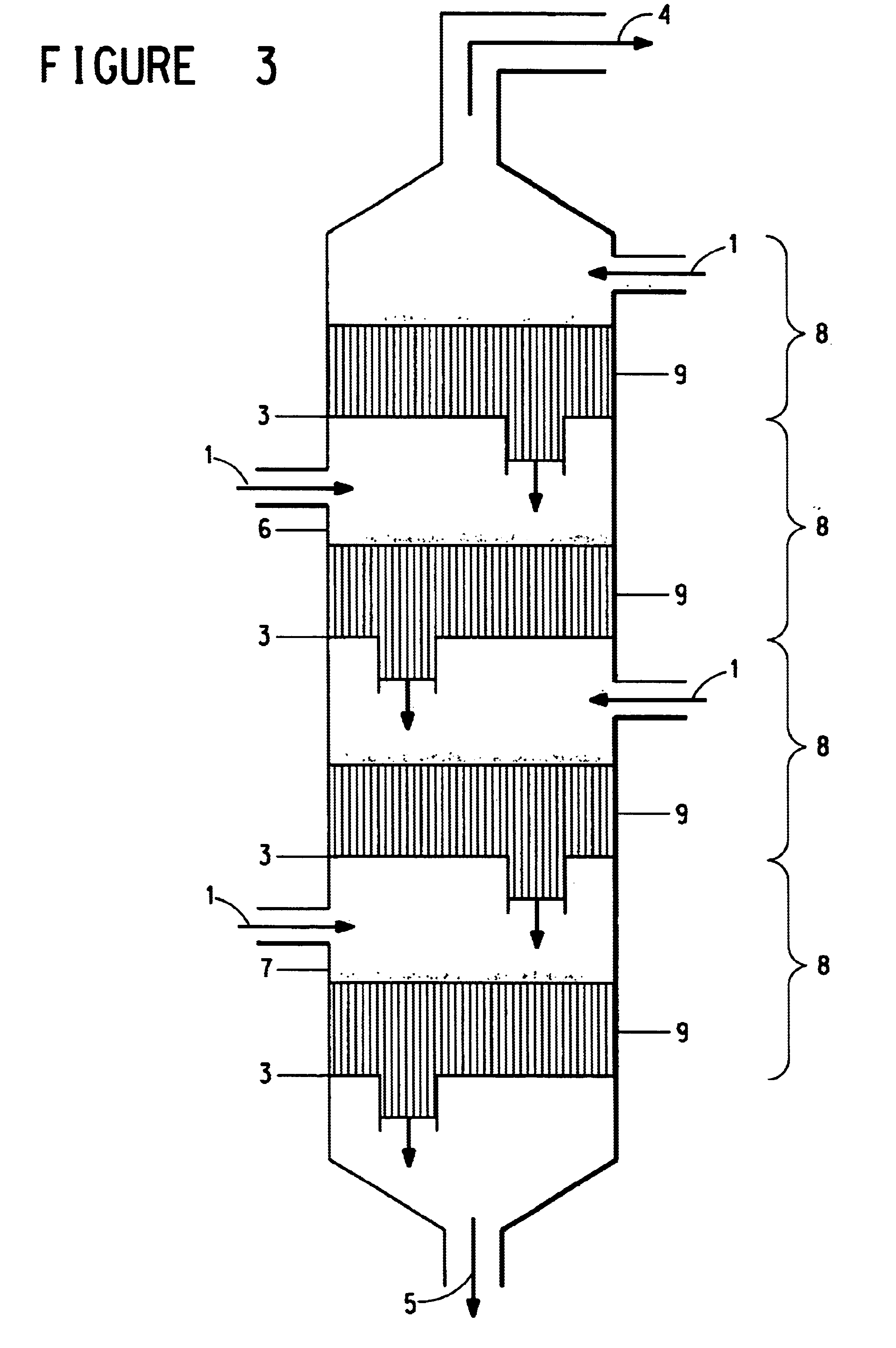

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

Hydrogenolysis of 6-carbon sugars and other organic compounds

InactiveUS6841085B2High selectivityHigh activityBiocideHydroxy compound active ingredientsHydrogenAlcohol sugars

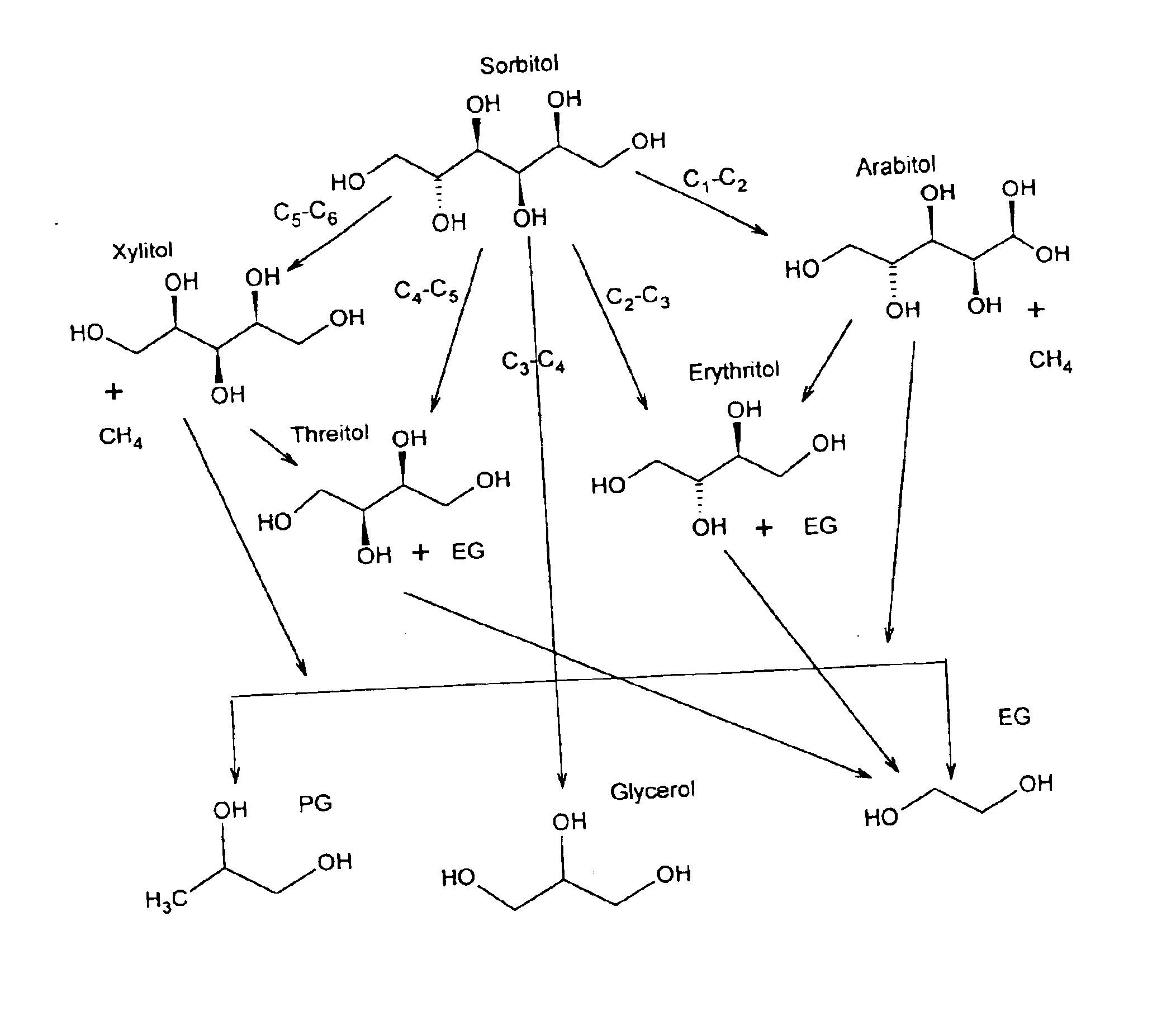

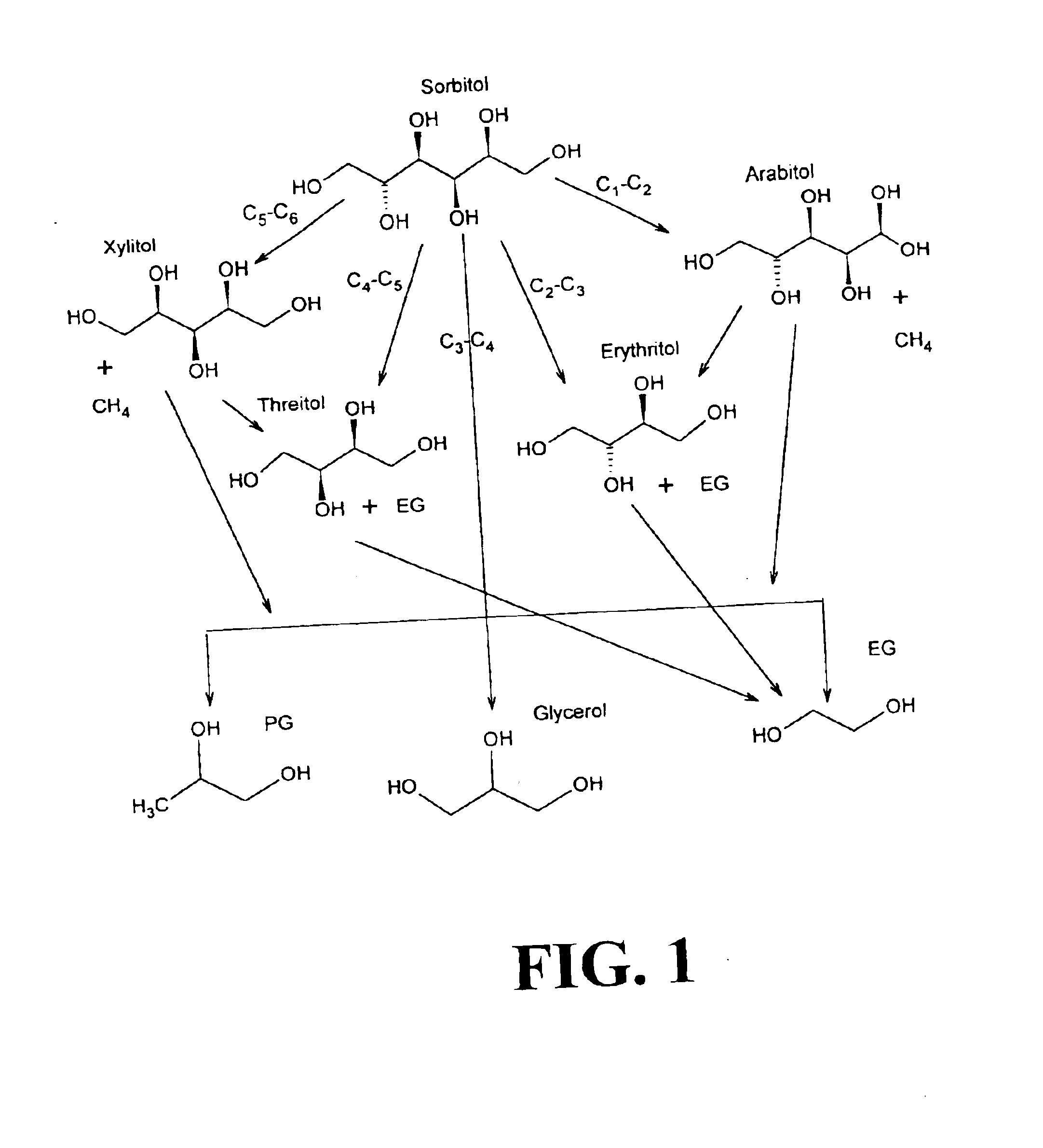

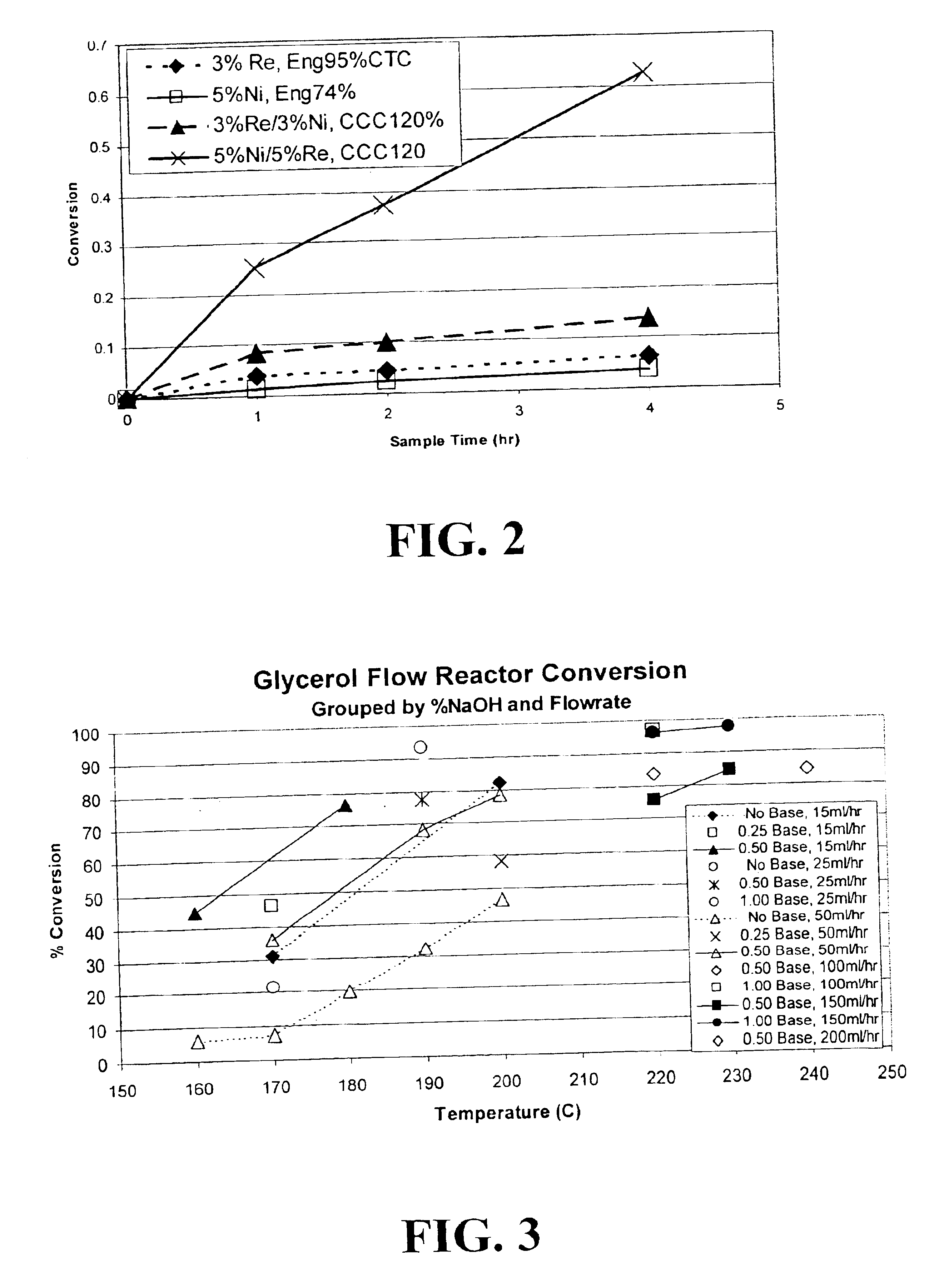

Methods for hydrogenolysis are described which use a Re-containing multimetallic catalyst for hydrogenolysis of both C—O and C—C bonds. Methods and compositions for reactions of hydrogen over a Re-containing catalyst with compositions containing a 6-carbon sugar, sugar alcohol, or glycerol are described. It has been surprisingly discovered that reaction with hydrogen over a Re-containing multimetallic catalyst resulted in superior conversion and selectivity to desired products such as propylene glycol.

Owner:MICHIGAN STATE UNIV +1

Polypropylene glycol foamable vehicle and pharmaceutical compositions thereof

The present invention teaches a foamable pharmaceutical carrier comprising polypropylene glycol (PPG) alkyl ether, a surface-active agent water and a liquefied hydrocarbon gas propellant; and pharmaceutical compositions thereof. The present invention further teaches a foamable pharmaceutical carrier comprising polypropylene glycol (PPG) alkyl ether, a surface-active agent, and a liquefied hydrocarbon gas propellant; and pharmaceutical compositions thereof.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Process for the purification of 1,3-propanediol

InactiveUS6235948B1Organic compound preparationOxygen compounds purification/separation1,3-PropanediolPropanediol

Disclosed is a process for the removal of impurities, especially color forming impurities, from 1,3-propanediol.

Owner:EI DU PONT DE NEMOURS & CO

Pharmaceutical composition

InactiveUS6946120B2Improve solubilityImprove abilitiesCosmetic preparationsOrganic active ingredientsAlcoholPolyol

A pharmaceutical composition for topical administration, including, as the pharmaceutically active component, at least 5% by weight, based on the total weight of the composition of a piperidinopyrimidine derivative or a pharmaceutically acceptable salt thereof; an acid in an amount to completely solubilise the piperidinopyrimidine derivative or a pharmaceutically acceptable salt thereof; a solvent composition including at least two of water, a lower alcohol and a co-solvent selected from one or more of the group consisting of aromatic and polyhydric alcohols; wherein when the co-solvent includes propylene glycol, it is present in an amount of less than approximately 10% by weight.

Owner:STIEFEL RESEARCH AUSTRALIA PTY LTD

Process for the biological production of 1,3-propanediol with high yield

The present invention provides a microorganism useful for biologically producing 1,3-propanediol from a fermentable carbon source at higher yield than was previously known. The complexity of the cofactor requirements necessitates the use of a whole cell catalyst for an industrial process that utilizes this reaction sequence to produce 1,3-propanediol. The invention provides a microorganism with disruptions in specified genes and alterations in the expression levels of specified genes that is useful in a higher yielding process to produce 1,3-propanediol.

Owner:NUTRITION & BIOSCIENCES USA 4 INC +1

Polytrimethylene ether glycol and polytrimethylene ether ester with excellent quality

A process is provided comprising contacting 1,3-propanediol with a suitable polymerization catalyst to produce polytrimethylene ether glycol or random polytrimethylene ether ester, wherein the 1,3-propanediol comprises about 10 microg / g or less peroxide compounds, based on the weight of 1,3-propanediol, and about 100 microg / g or less carbonyl compounds based on the weight of the 1,3-propanediol. Preferably, the 1,3-propanediol comprises about 100 microg / g or less of monofunctional alcohol compounds based on the weight of the PDO. In addition, polytrimethylene ether glycol and random polytrimethylene ether ester prepared by the process.

Owner:DUPONT IND BIOSCIENCES USA LLC

Production of polytrimethylene ether glycol and copolymers thereof

A process for the manufacture of polytrimethylene ether glycol comprising the steps of: (a) providing (1) 1,3-propanediol reactant selected from the group consisting of 1,3-propanediol and / or oligomers or prepolymers of 1,3-propanediol having a degree of polymerization of 2-9 and mixtures thereof, and (2) a polycondensation catalyst; and (b) polycondensing the 1,3-propanediol reactant to form a polytrimethylene ether glycol at less than one atmosphere pressure, and the product of the process. In addition, polytrimethylene ether glycol has a number average molecular weight greater than 1,500, an APHA color of less than 120, an unsaturation of less than 20 meq / kg, and a content of cyclic ether oligomers of less than 2%.

Owner:DUPONT IND BIOSCIENCES USA LLC

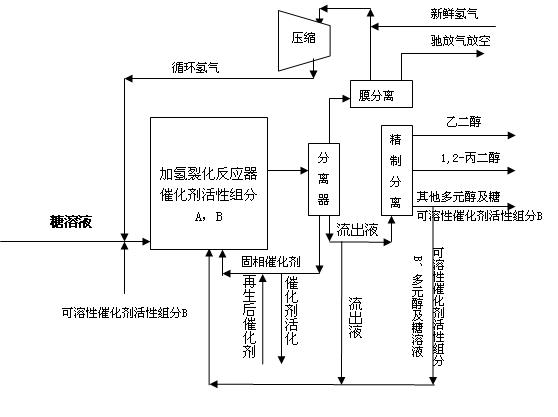

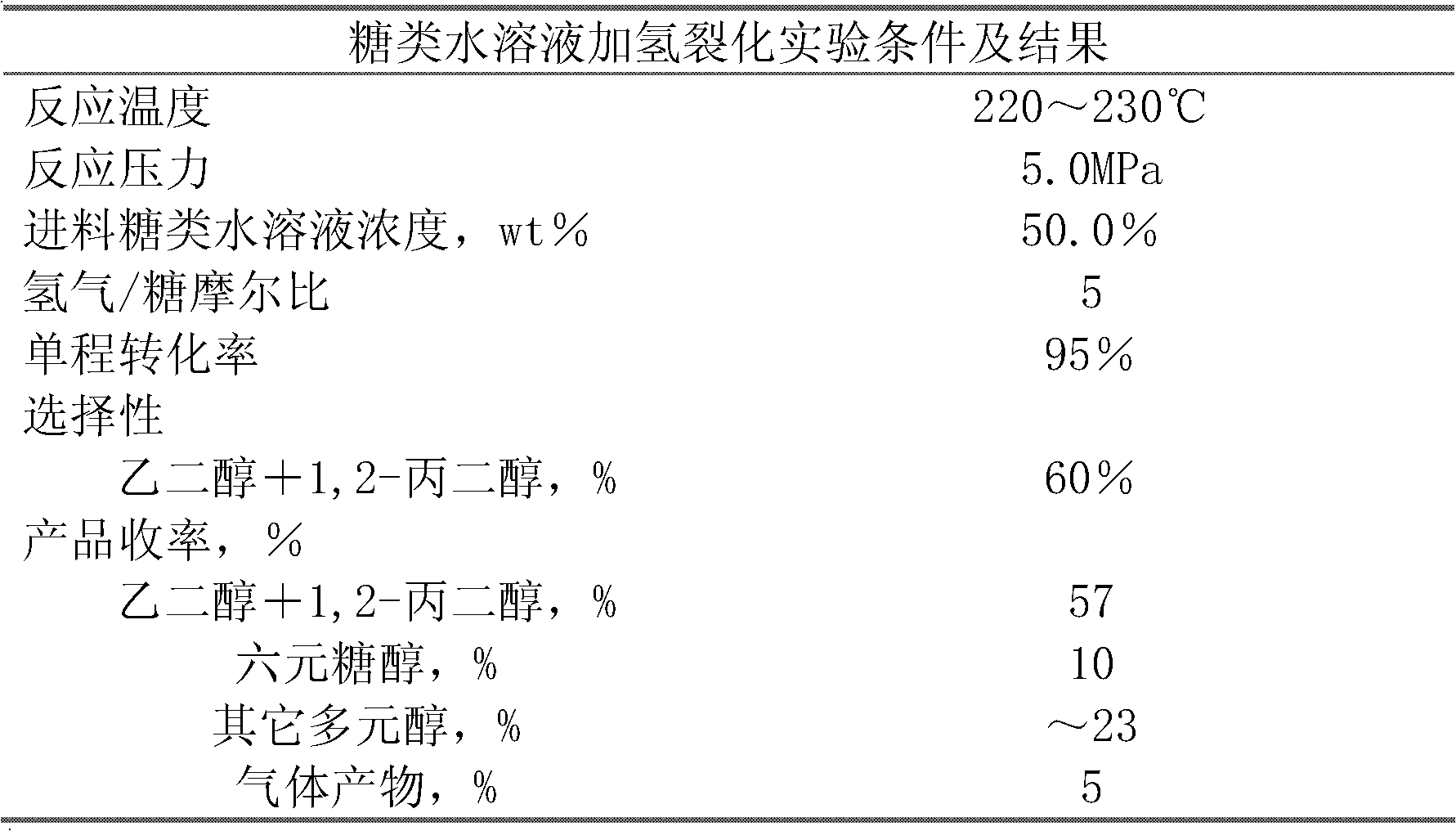

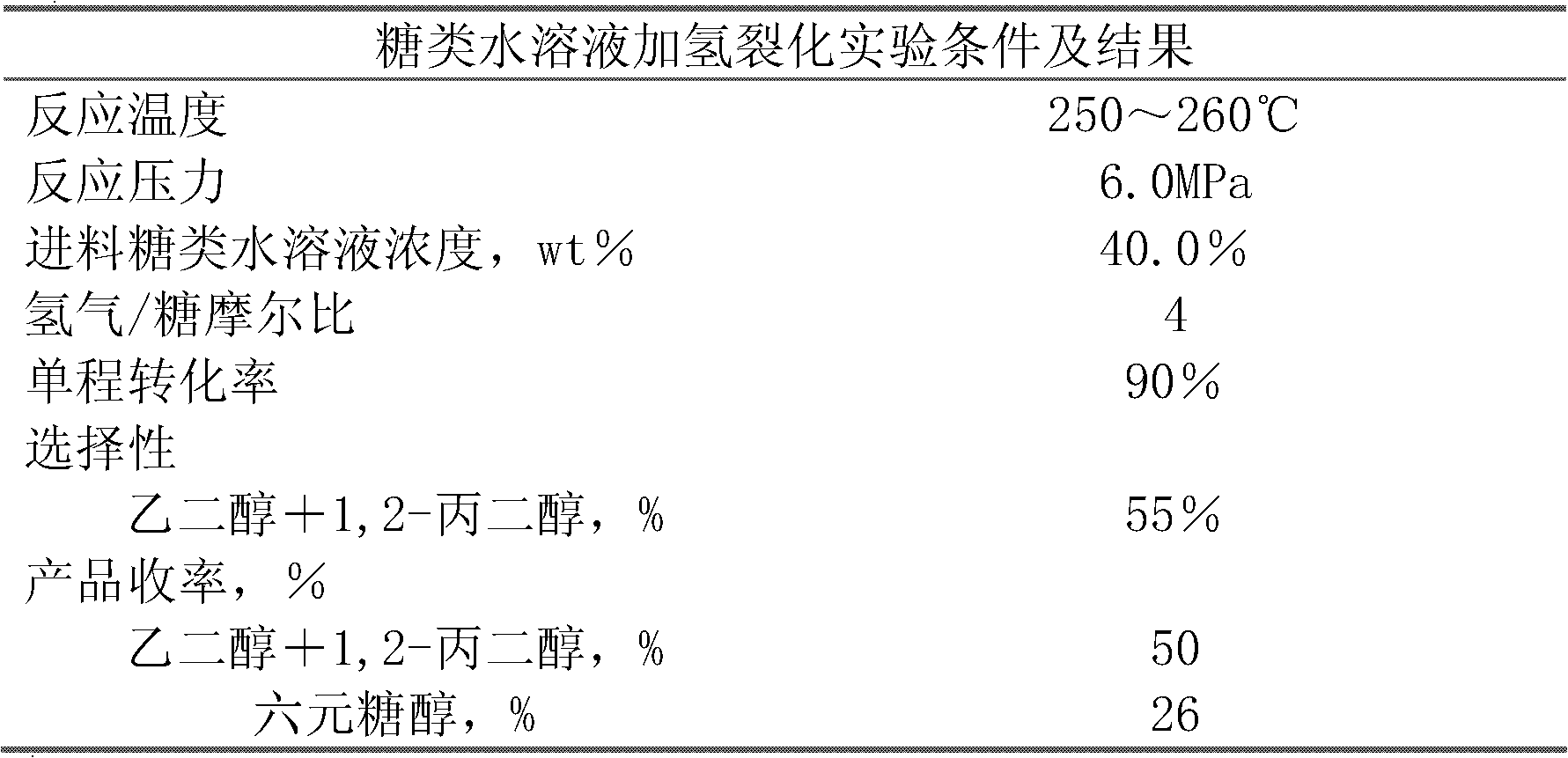

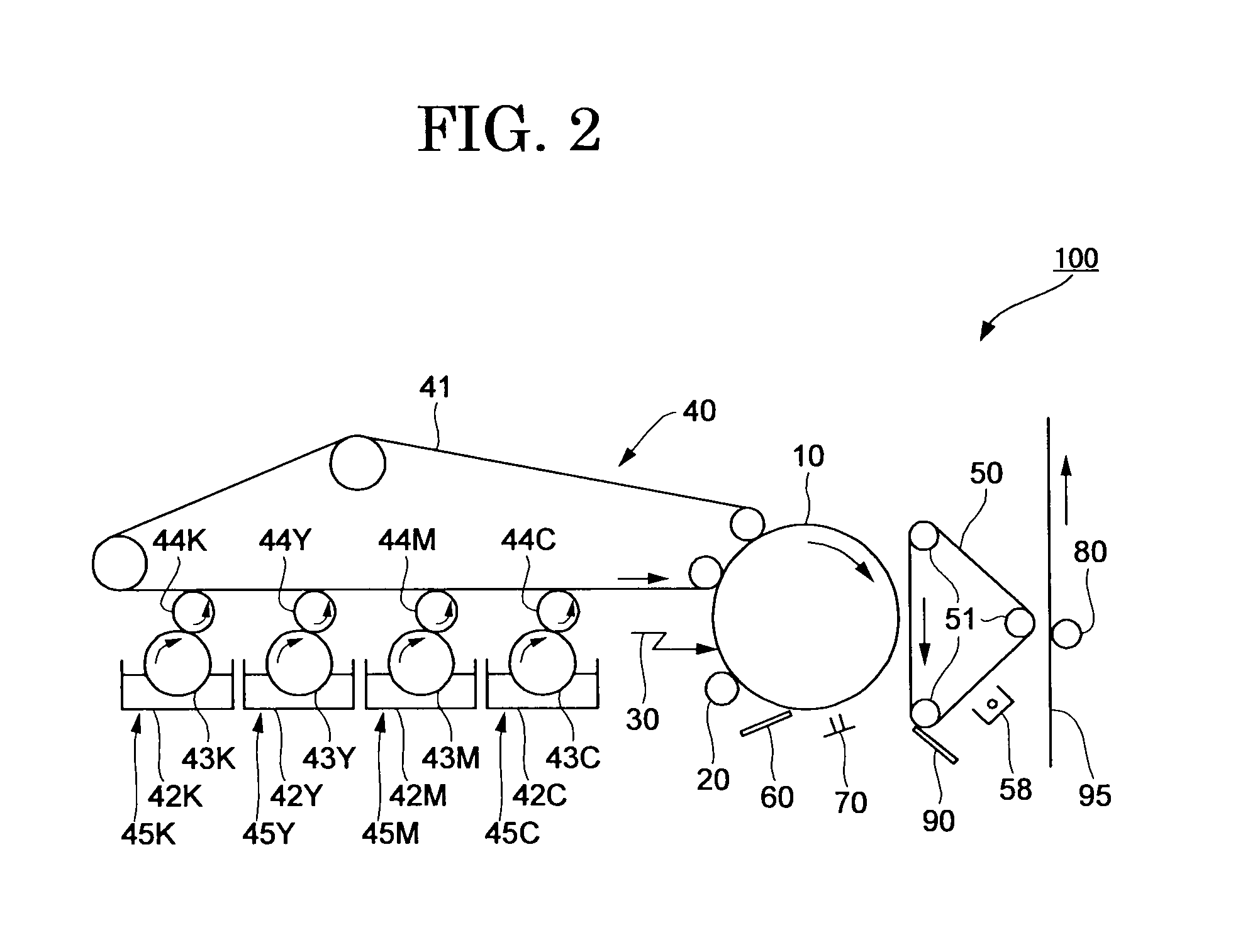

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165ARealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationGas phaseOligosaccharide

The invention relates to a continuous reaction process flow for producing ethylene glycol and 1, 2-propylene glycol through continuous hydrocrackin of sugars and provides a method for producing the ethylene glycol and the 1,2-propylene glycol through continuous hydrocrackin of sugars. In the process flow, sugars (comprising one or more than two of sugar, glucose, fructose, xylose, soluble xylo-oligosaccharide and starch) are hydrocracked in the presence of a catalyst in a reactor and the hydrocracked product enters a separating system. Hydrogen gas in a gas phase is recycled by separating and recovering; a liquid phase product partially reflows to the reactor and other liquid phase products are refined and separated to form the ethylene glycol, the propylene glycol and other polyhydric alcohols; and concentrated soluble catalyst components in the refined and separated residual component liquid phase are partially returned to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Continuous process for the preparation of polytrimethylene ether glycol

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

Preparation of poly(trimethylene terephthalate)

In one embodiment, the invention is a process for the preparation of poly(trimethylene terephthalate) comprising (a) contacting terephthalic acid with 1,3-propanediol in the presence of an organic tin catalyst to form a bis(3-hydroxypropyl)terephthalate monomer; and (b) polymerizing said monomer in the presence of organic titanate polycondensation catalyst to obtain the poly(trimethylene terephthalate). In another embodiment, the invention is a process for the preparation of poly(trimethylene terephthalate) containing less than 1.6 mol % of DPG said process comprising contacting terephthalic acid with a 1.6 to 1 to 2:1 molar amount of 1,3-propanediol in the presence of 20 to 120 ppm (as tin), by weight of the poly(trimethylene terephthalate), of a organic tin catalyst, to form a bis(3-hydroxypropyl)terephthalate monomer and polymerizing said monomer to obtain the poly(trimethylene terephthalate). The invention is also directed to poly(trimethylene terephthalate) produced by the processes.

Owner:DUPONT IND BIOSCIENCES USA LLC

Purification of chemical 1,3-propanediol

InactiveUS7038092B2Organic compound preparationOxygen compounds purification/separationHydrogen1,3-Propanediol

Owner:EI DU PONT DE NEMOURS & CO

Suspension formulations of nepafenac and other ophthalmic drugs for topical treatment of ophthalmic disorders

Topical aqueous suspension compositions of sparingly soluble ophthalmic drugs are disclosed. The compositions comprise a combination of a poloxamer or meroxapol surfactant and a glycol tonicity-adjusting agent such as propylene glycol.

Owner:NOVARTIS AG

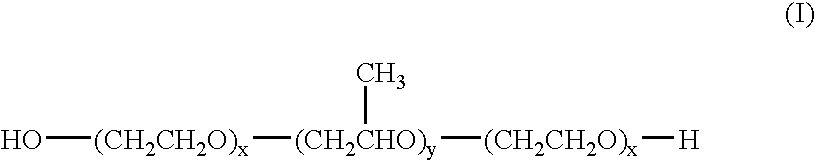

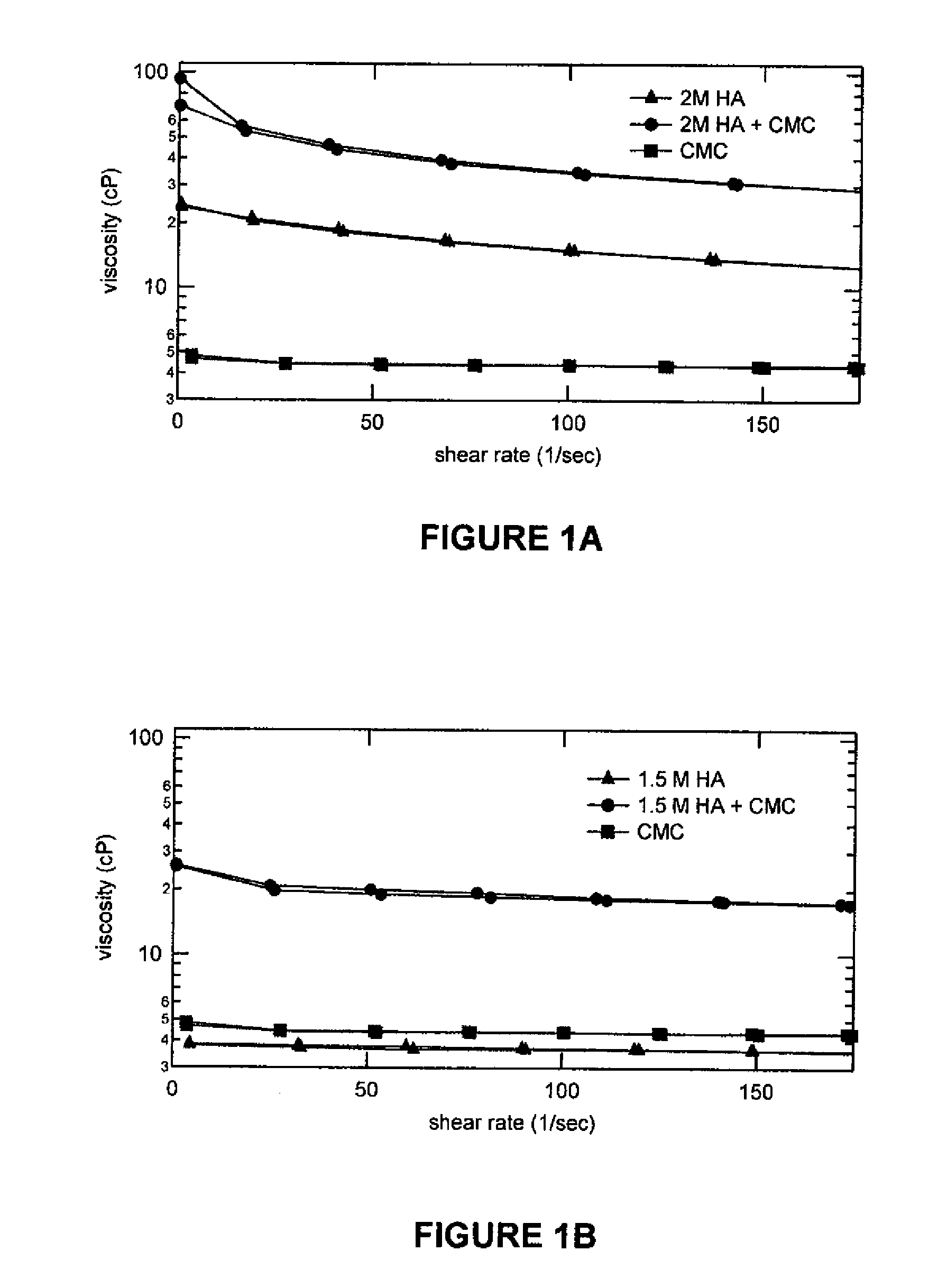

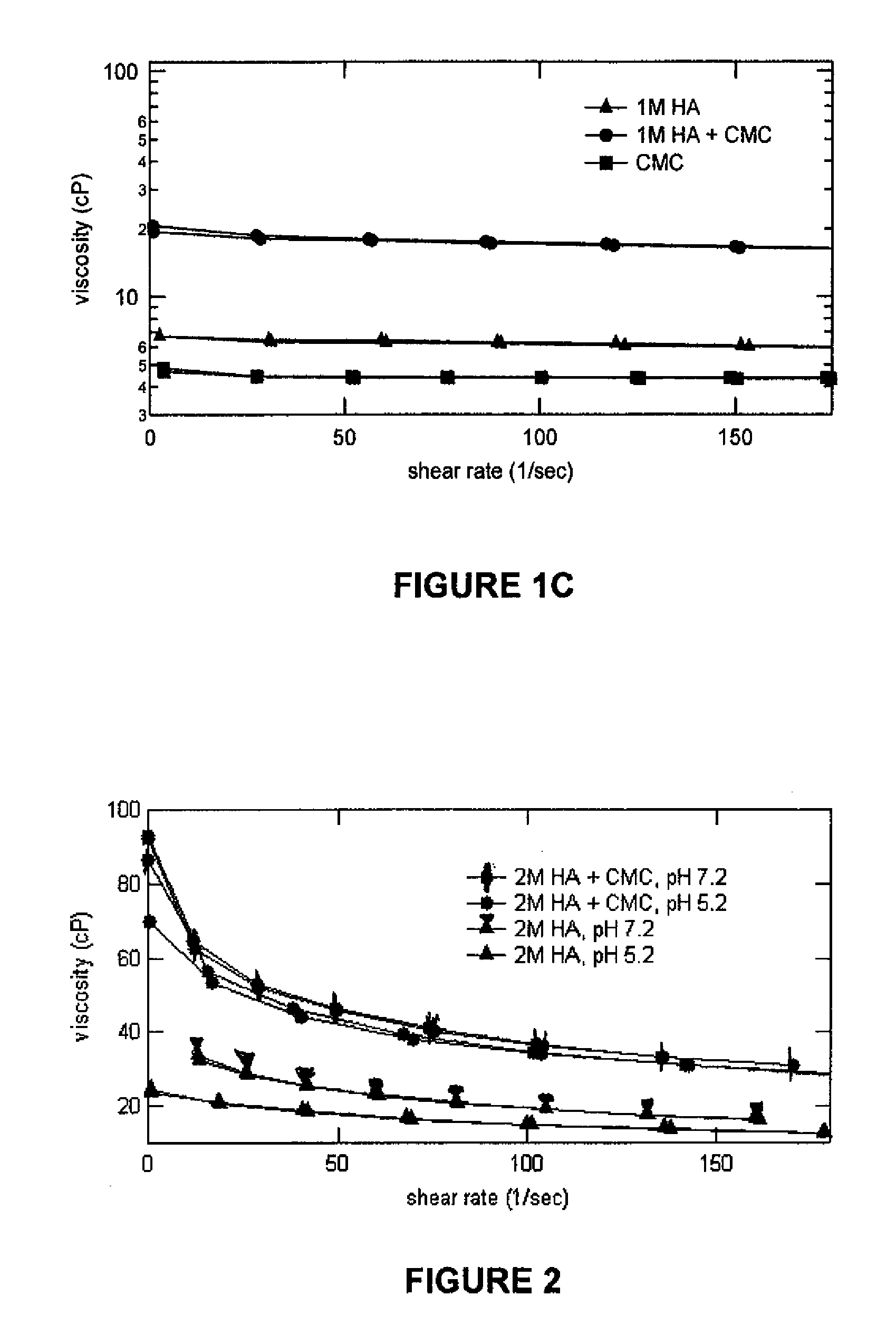

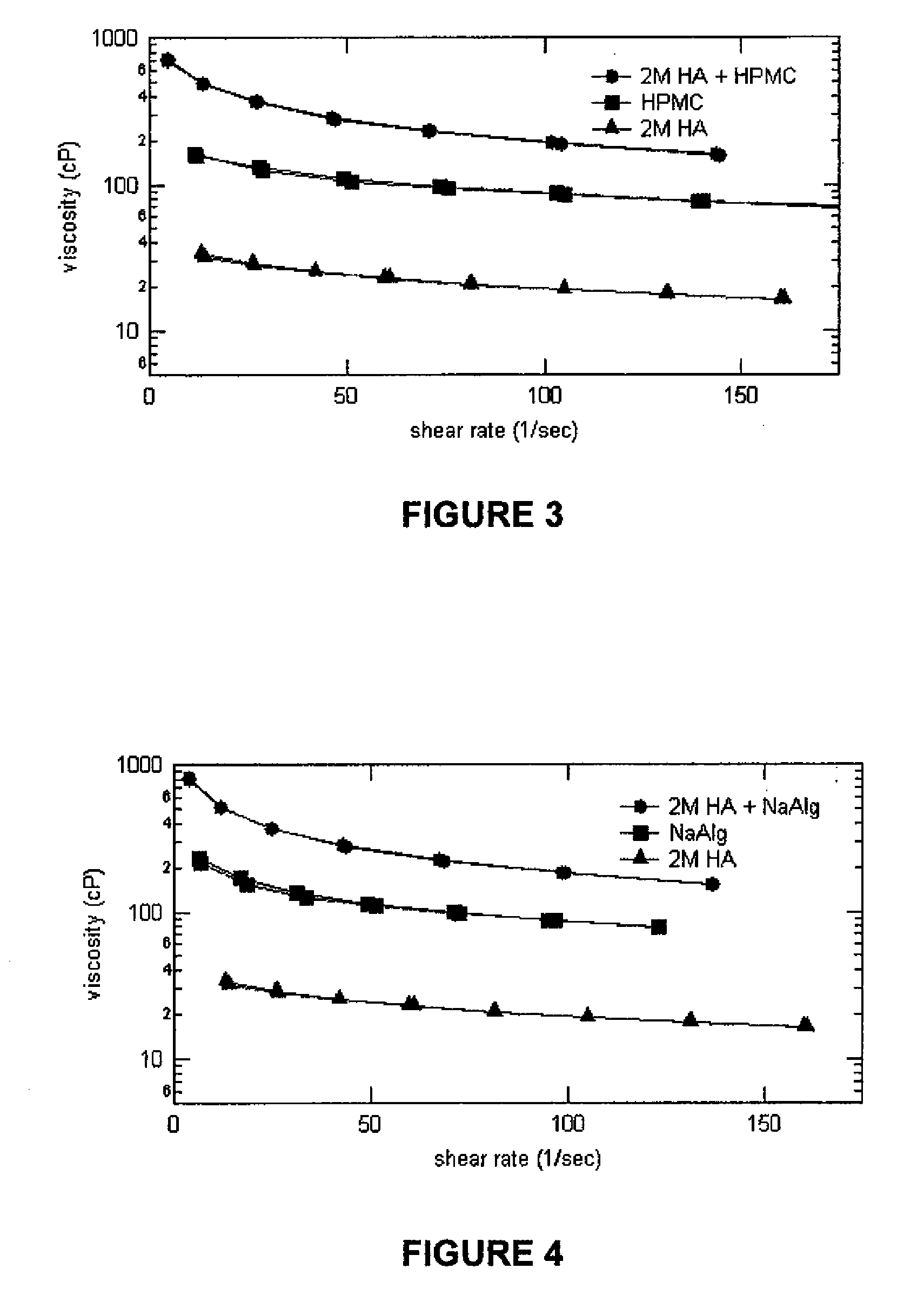

Stabilized Glycosaminoglycan Preparations and Related Methods

Compositions comprising a glycosaminoglycan (e.g., a hyaluronan, hyaluronic acid, hyaluronate, sodium hyaluronate, dermatan sulfate, karatan sulfate, chondroitin 6-sulfate, heparin, etc.) in combination with at least one component selected from; i) polyglycols (e.g., polyethylene glycol), ii) long chain hydroxy polyanionic polysaccharides (e.g., dextran, sodium alginate, alginic acid, propylene glycol alginate, carboxymethyl cellulose and carboxyethyl cellulose, hydroxyl ethyl starch, hydroxyl propyl methyl cellulose, hydroxy propyl ethyl cellulose, hydroxy propyl cellulose, methyl cellulose, polylysine, polyhistidine, polyhydroxy proline, poly ornithine, polyvinyl pyrolidone, polyvinyl alcohol, chitosan, etc.) and iii) long chain Nitrogen containing polymers (e.g., Polylysine, Polyvinylpyrrolidone, and polyvinyl alcohol). The invention also includes methods for using such compositions (e.g., as substance delivery materials, tissue fillers or bulking agents, as moistening or hydrating agents, etc.)

Owner:S K PHARMA INC

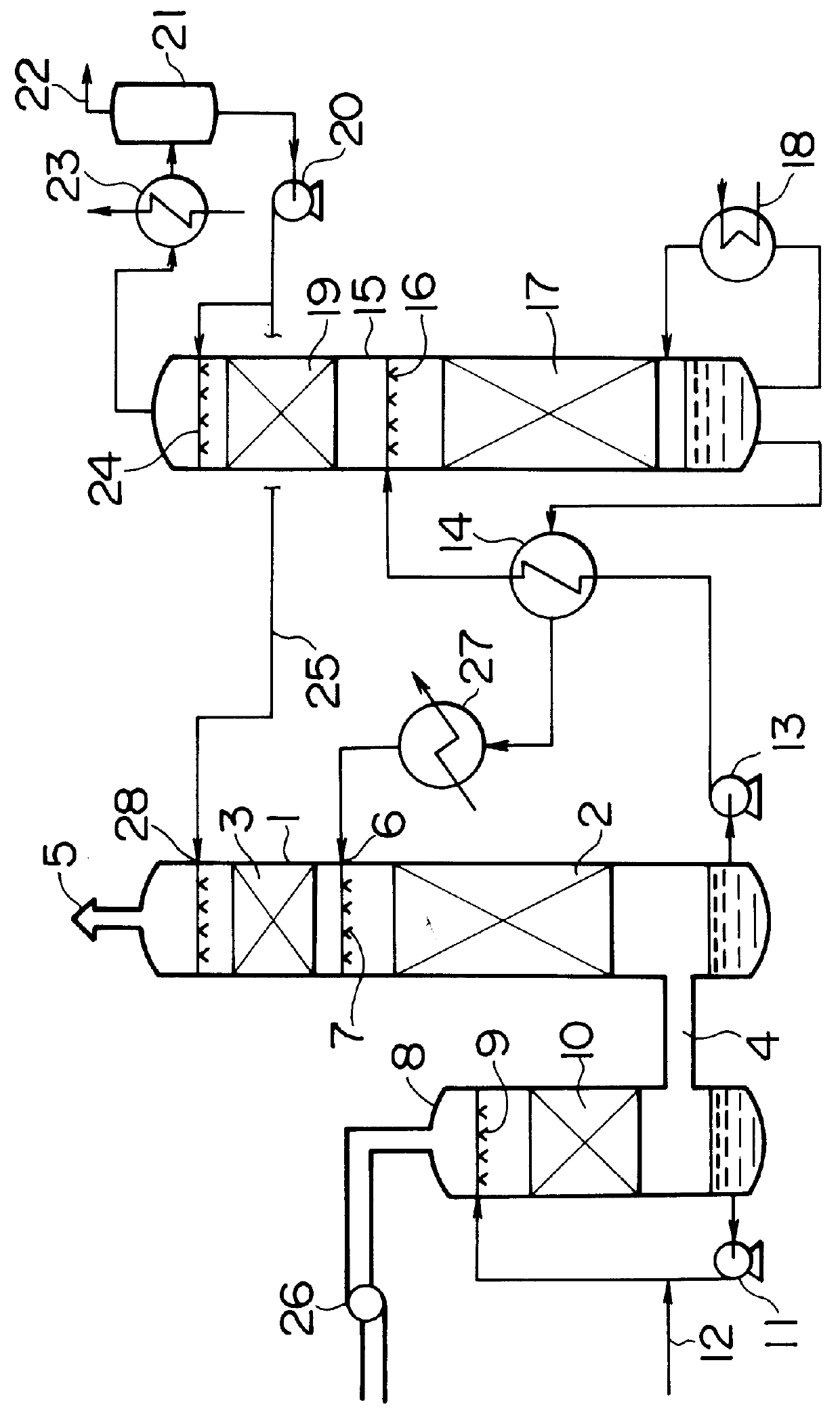

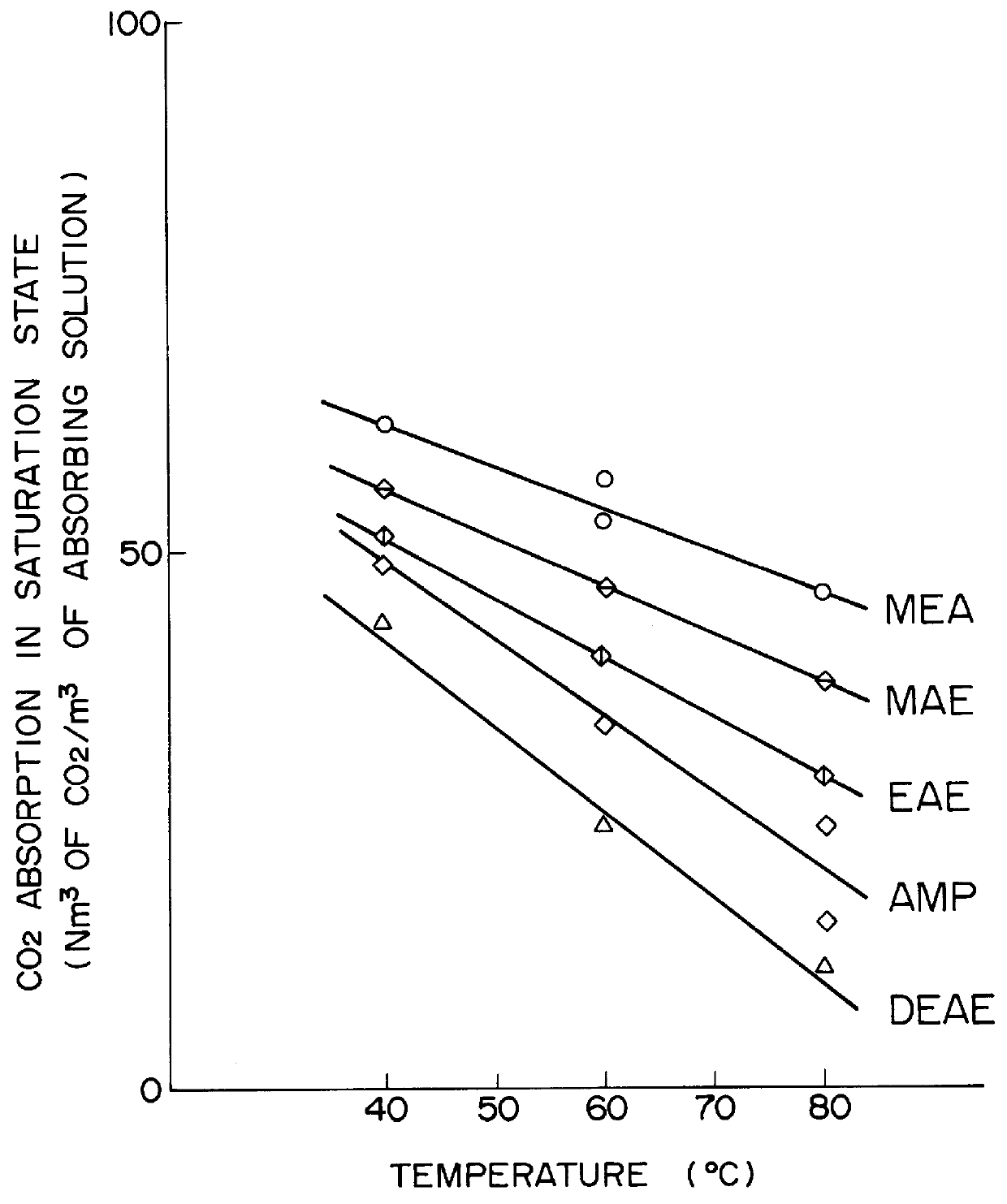

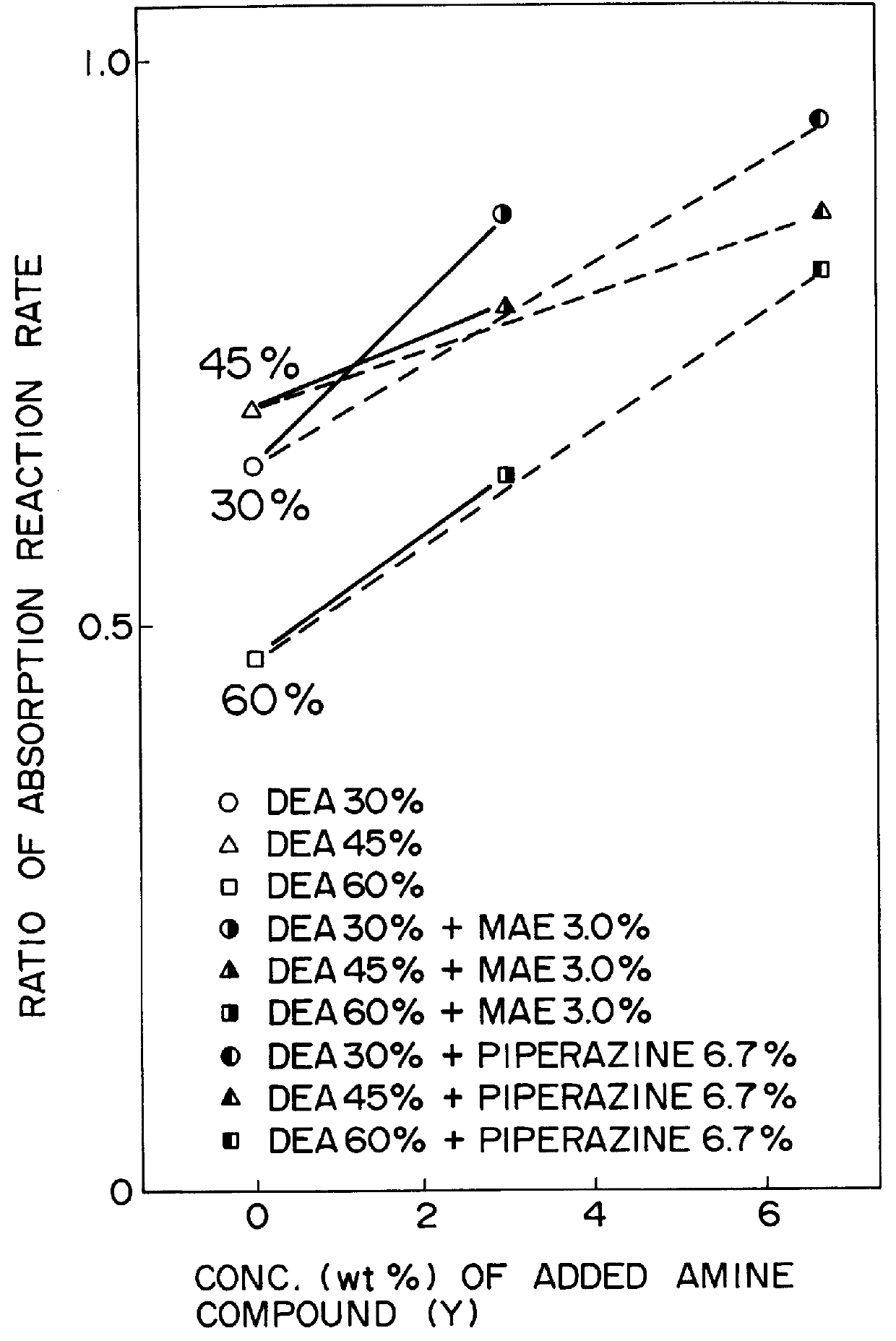

Method for removing carbon dioxide from combustion exhaust gas

InactiveUS6036931AHigh absorption rateImprove absorption rateDispersed particle separationHydrogen sulfides2-methylaminoethanolMorpholine

There are disclosed a method for removing CO2 from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with an aqueous solution of a hindered amine selected from the group consisting of 2-amino-2-methyl-1-propanol, 2-methylaminoethanol, 2-ethylaminoethanol and 2-piperidineethanol; and another method for removing carbon dioxide from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with a mixed aqueous solution of 100 parts by weight of an amine compound (X) selected from the group consisting of 2-amino-2-methyl-1,3-propanediol, 2-amino-2-methyl-1-propanol, 2-amino-2-ethyl-1,3-propanediol, t-butyldiethanolamine and 2-amino-2-hydroxymethyl-1,3-propanediol; and 1-25 parts by weight of an amine compound (Y) selected from the group consisting of piperazine, piperidine, morpholine, glycine, 2-methylaminoethanol, 2-piperidineethanol and 2-ethylaminoethanol.

Owner:THE KANSAI ELECTRIC POWER CO +1

Novel copolyester compositions with improved impact strength at low temperatures

This invention relates to a polyester composition comprising: (i) diacid residues comprising at least 80 mole percent, based on the total moles of diacid residues, of one or more residues of: terephthalic acid, naphthalenedicarboxylic acid, 1,4-cyclohexanedicarboxylic acid, or isophthalic acid; and (ii) diol residues comprising from about 25 to about 70 mole percent, based on the total moles of diol residues, of the residues of 1,4-cyclohexanedimethanol, and from about 75 to about 30 mole percent, based on the total moles of diol residues, of the residues of 1,3-propanediol. This invention has surprising improved impact strength at low temperatures.

Owner:EASTMAN CHEM CO

Catalytic hydrogenation of 3-hydroxypropanal to 1,3-propanediol

InactiveUS6342646B1Improves performance and lifetimeImprove hydrogenation activityOrganic compound preparationOxygen compounds preparation by reductionAsymmetric hydrogenation1,3-Propanediol

The present invention provides an improved process for the hydrogenation of 3-hydroxypropanal to 1,3-propanediol which comprises purifying an aqueous solution of 3-hydroxypropanal by contacting said aqueous solution with a purifying agent prior to hydrogenation.

Owner:EI DU PONT DE NEMOURS & CO

Hydrogenation of biochemical derived 1,3 -propanediol

InactiveUS7098368B2Organic compound preparationOxygen compounds purification/separationDownstream processingHydrogenation process

The invention discloses a hydrogenation process for removing impurities and controlling acid for use in downstream processing of biochemically-derived 1,3-propanediol. Preferably, the biochemically-derived 1,3-propanediol, before the contacting, has an initial color and, after the contracting, has a color that is lower than the initial color.

Owner:EI DU PONT DE NEMOURS & CO

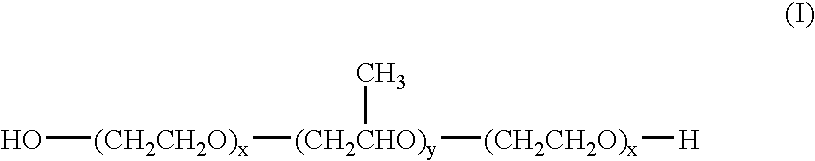

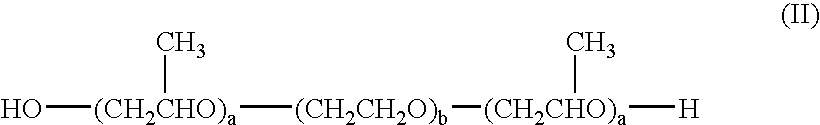

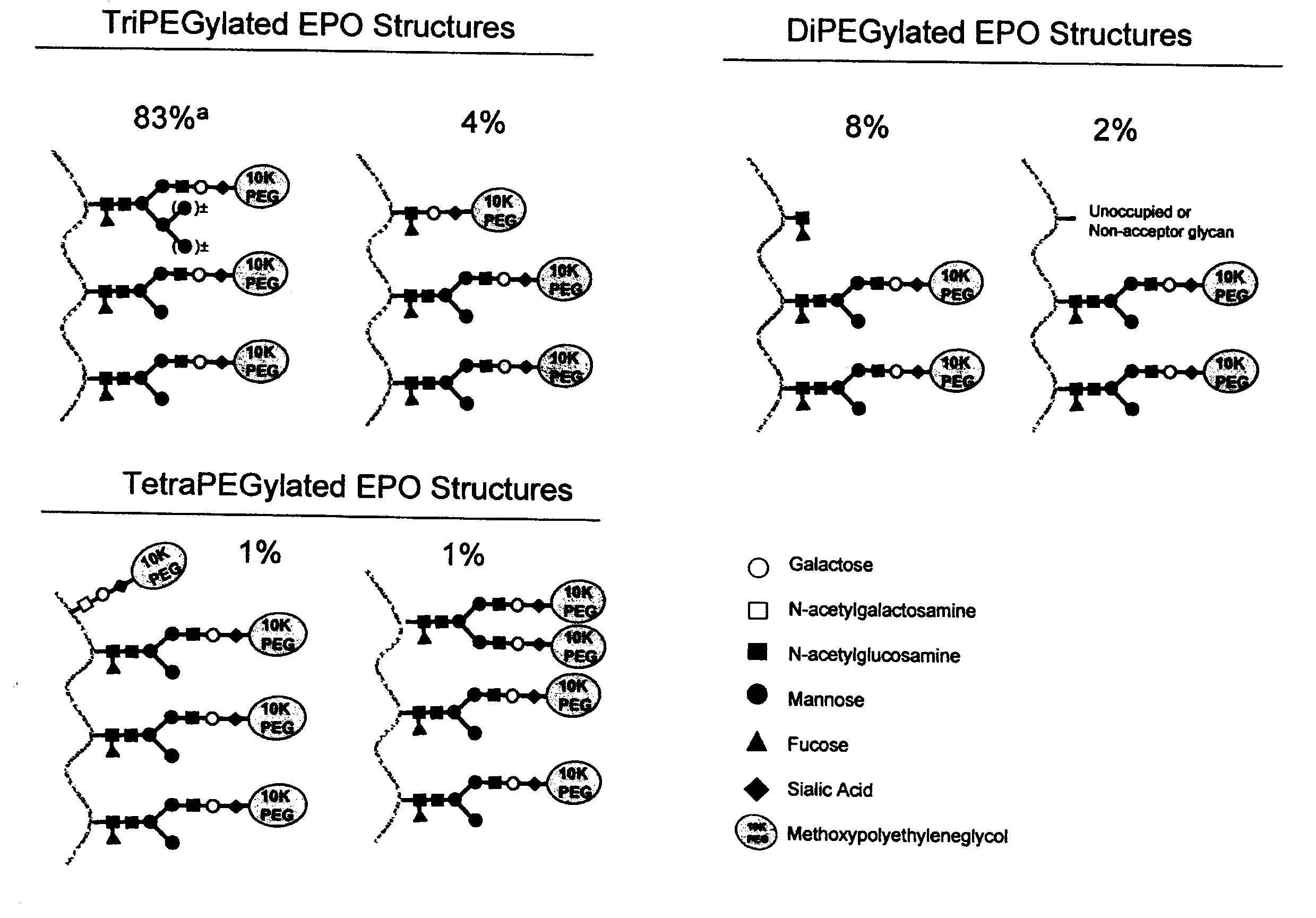

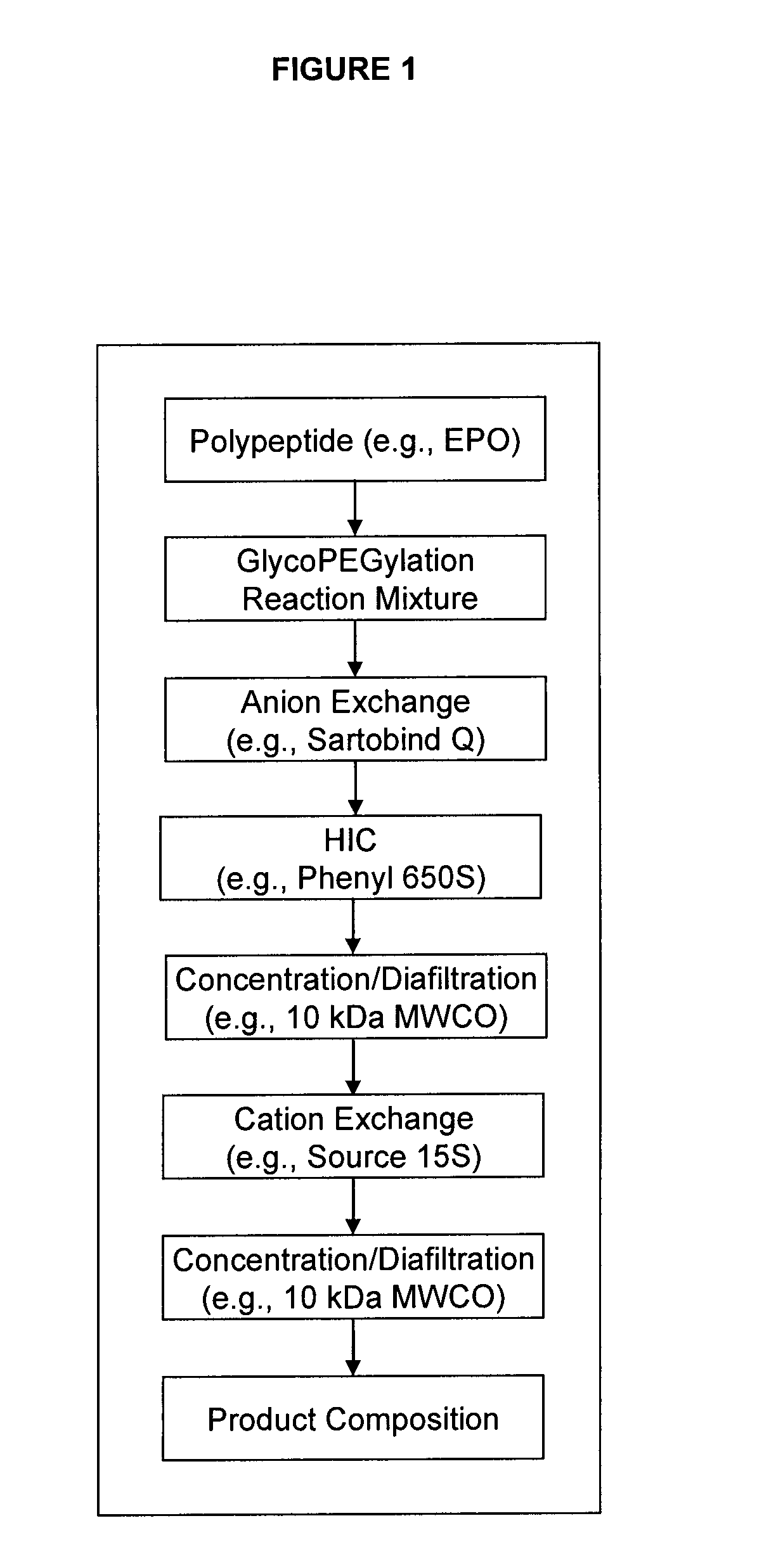

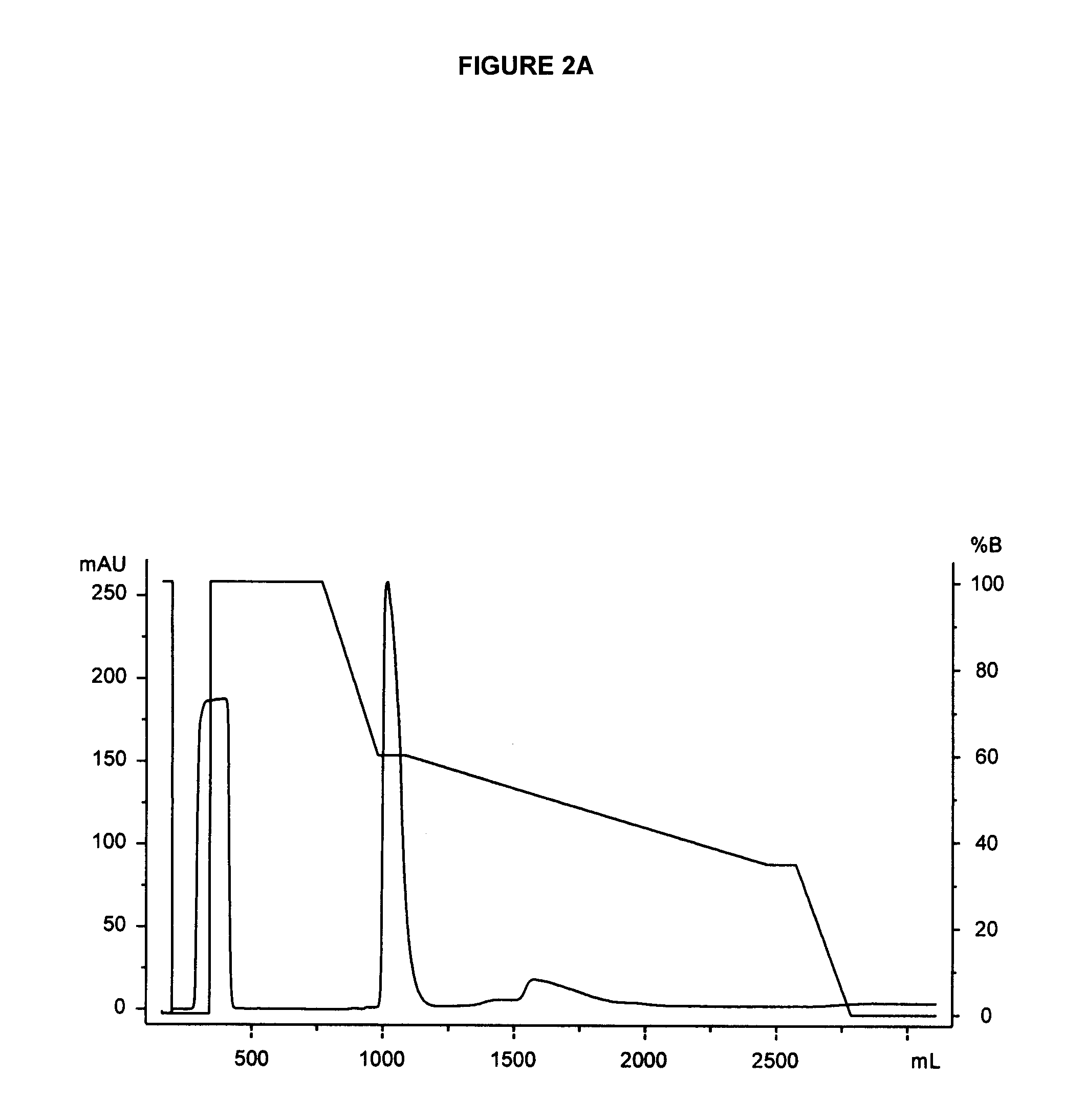

Methods for the purification of polypeptide conjugates

InactiveUS20100035299A1Peptide/protein ingredientsImmunoglobulinsPolymer sciencePolypropylene glycol

The present invention provides processes for the manufacturing of polypeptide conjugates. In particular, the invention provides methods for the purification of polypeptide conjugates, which include at least one polymeric modifying groups, such as a poly(alkylene oxide) moiety. Exemplary poly(alkylene oxide) moieties include poly(ethylene glycol) (PEG) and poly(propylene glycol). In an exemplary process, hydrophobic interaction chromatography (HIC) is used to resolve different glycoforms of glycoPEGylated polypeptides.

Owner:NOVO NORDISK AS

Preparation of poly(trimethylene terephthalate) with low level of di(1,3-propylene glycol)

A process of preparing poly(trimethylene terephthalate) containing less than 2.0 mole % of DPG comprising:(a) providing a molar amount of 1,3-propanediol:C1 to C4 dialkyl ester of terephthalic acid of 1.2:1 to 1.9:1,(b) reacting the 1,3-propanediol with the C1 to C4 dialkyl ester of terephthalic, acid to form bis(3-hydroxypropyl)terephthalate monomer in the presence of 10-100 ppm (as titanium metal) of an organic titanate catalyst, by weight of the poly(trimethylene terephthalate), and(c) polymerizing the bis(3-hydroxypropyl)terephthalate monomer to obtain the poly(trimethylene terephthalate); andpoly(trimethylene terephthalate) produced by the process.

Owner:DUPONT IND BIOSCIENCES USA LLC

Polyhydroxyalkanoate production from polyols

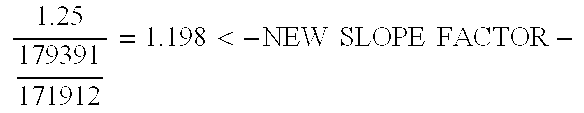

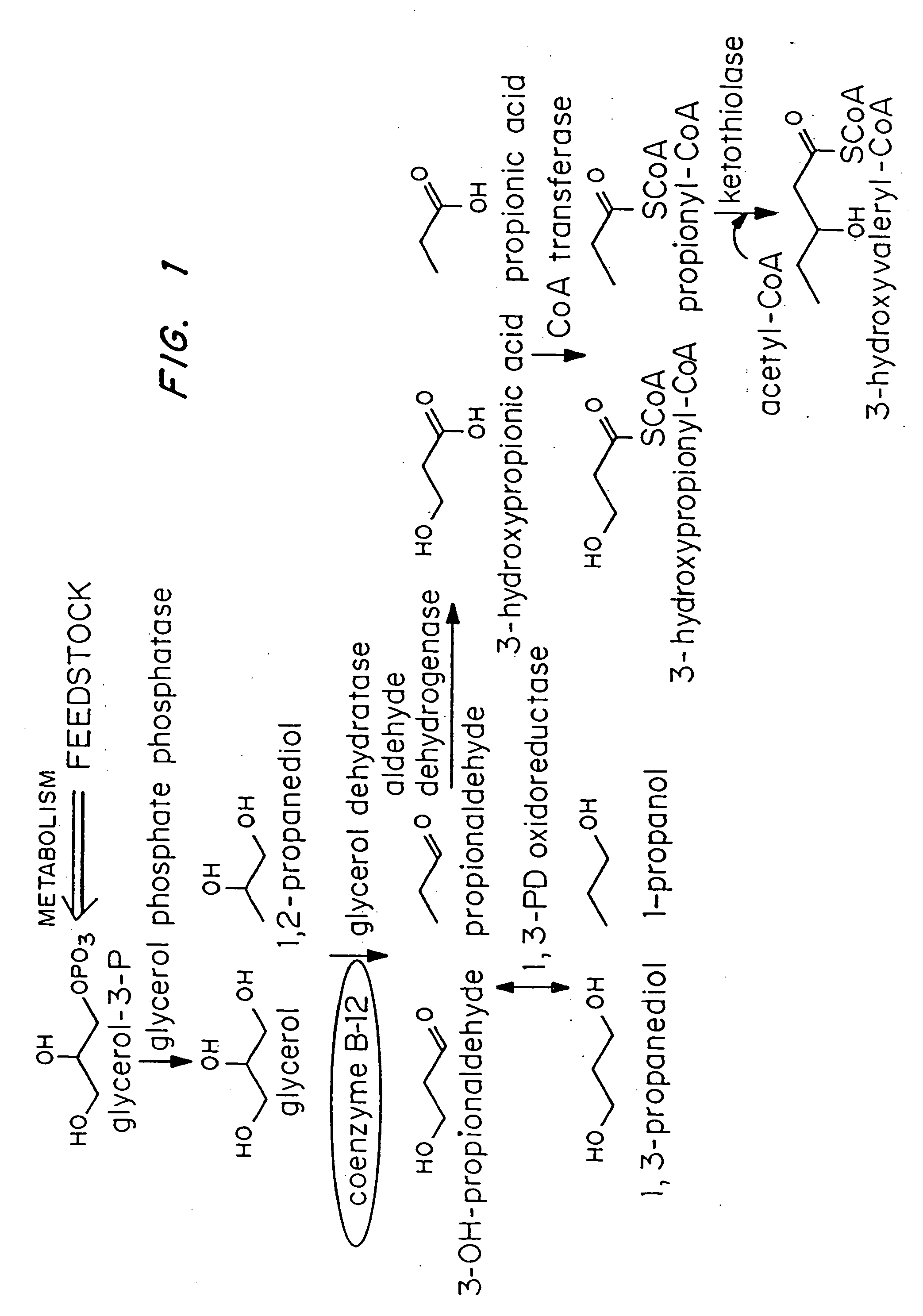

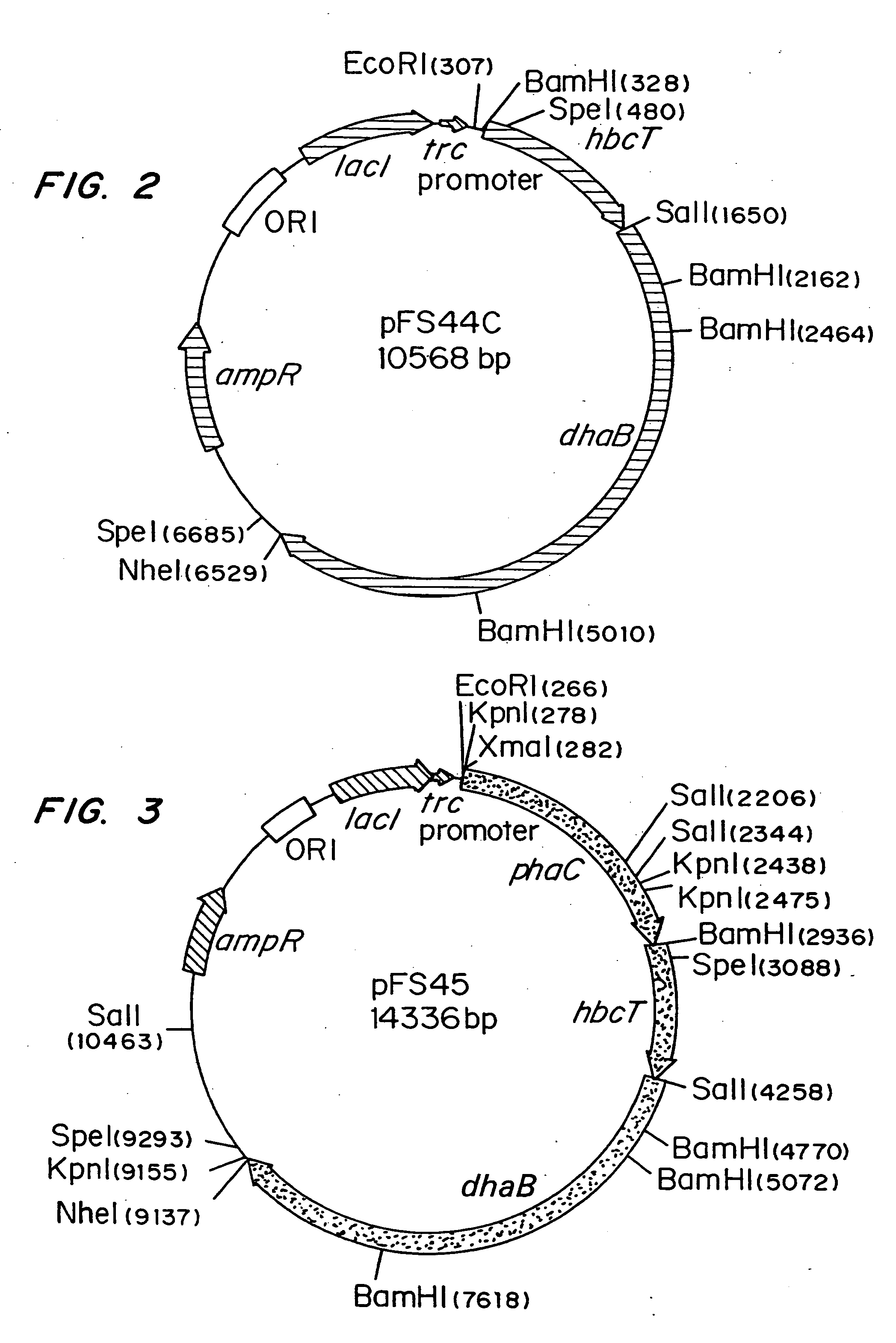

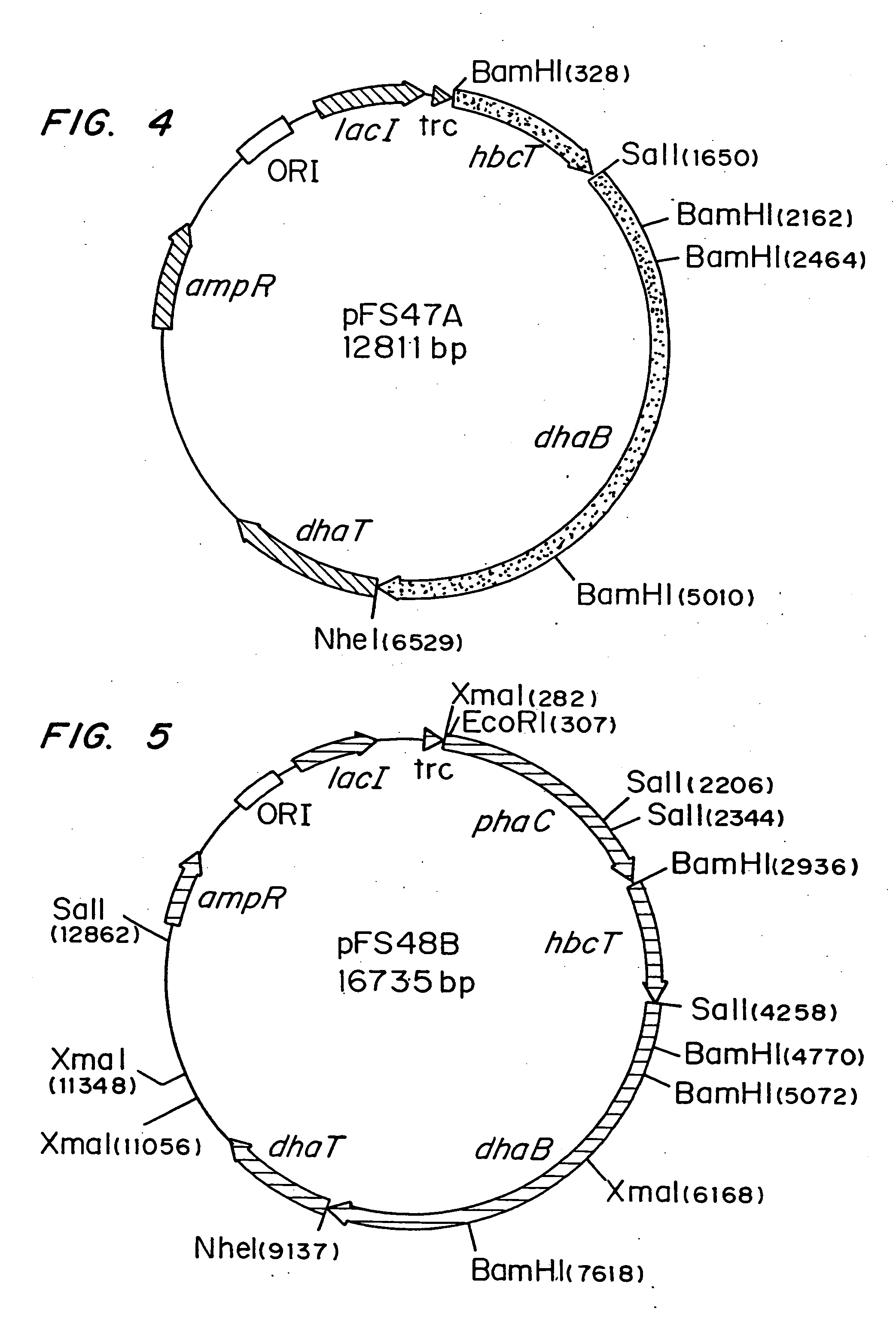

InactiveUS20050239179A1Promote recoveryProduct can be usedBacteriaMicroorganism based processes3-Hydroxypropionic acidPropanoic acid

Organisms are provided which express enzymes such as glycerol dehydratase, diol dehydratase, acyl-CoA transferase, acyl-CoA synthetase β-ketothiolase, acetoacetyl-CoA reductase, PHA synthase, glycerol-3-phosphate dehydrogenase and glycerol-3-phosphatase, which are useful for the production of PHAs. In some cases one or more of these genes are native to the host organism and the remainder are provided from transgenes. These organisms produce poly (3-hydroxyalkanoate) homopolymers or co-polymers incorporating 3-hydroxypropionate or 3-hydroxyvalerate monomers wherein the 3-hydroxypropionate and 3-hydroxyvalreate units are derived from the enzyme catalysed conversion of diols. Suitable diols that can be used include 1,2-propanediol, 1,3 propanediol and glycerol. Biochemical pathways for obtaining the glycerol from normal cellular metabolites are also described. The PHA polymers are readily recovered and industrially useful as polymers or as starting materials for a range of chemical intermediates including 1,3-propanediol, 3-hydroxypropionaldehyde, acrylics, malonic acid, esters and amines.

Owner:CJ CHEILJEDANG CORP

Fuel additive composition and method for treatment of middle distillate fuels and gasoline

InactiveUS6923838B2Increase and improvement of performanceIncrease and improvement of and lubricityLiquid carbonaceous fuelsFuel additivesVegetable oilAntioxidant

A fuel additive for middle distillate fuels is a mixture of at least one methyl, ethyl, propyl or butyl ester of a vegetable oil or a C16-C18 fatty acid, at least one alkyl ether of propylene glycol, a surfactant, and an antioxidant. A fuel additive for gasoline is a mixture of ligroin or toluene / xylene, at least one alkyl ether of propylene glycol, a surfactant, and tertiary amyl methyl ether.

Owner:ADVANCED COMBUSTION TECH

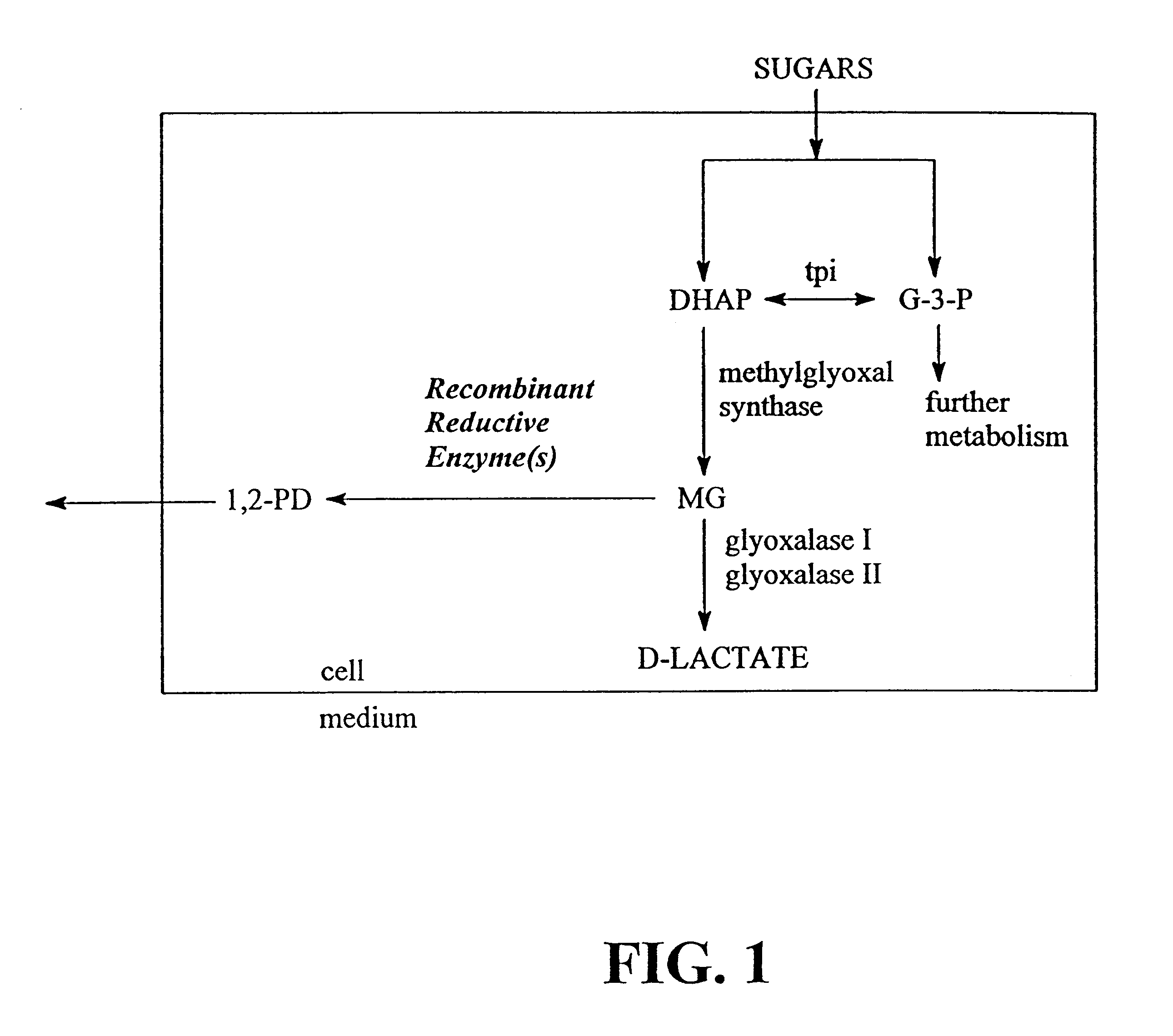

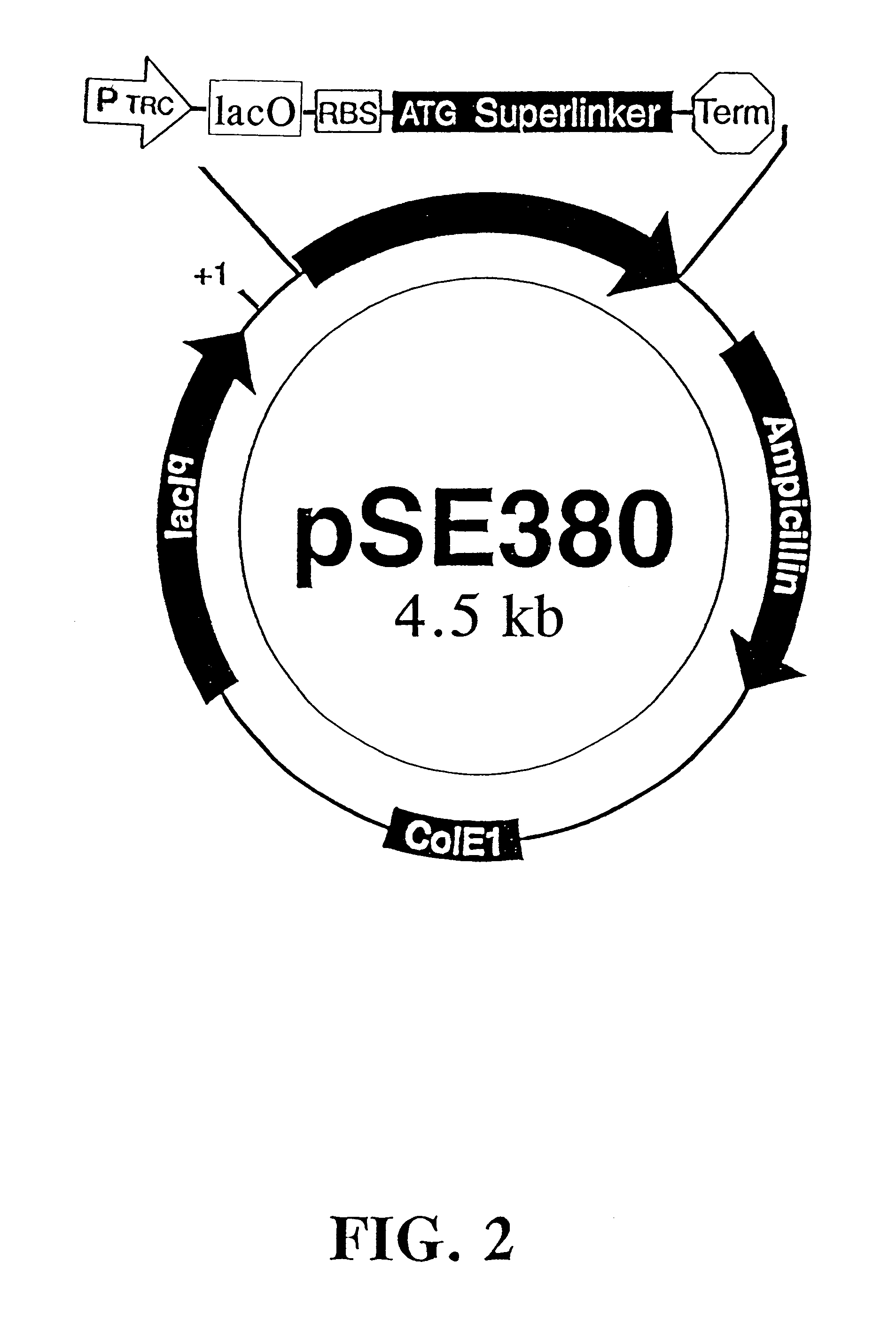

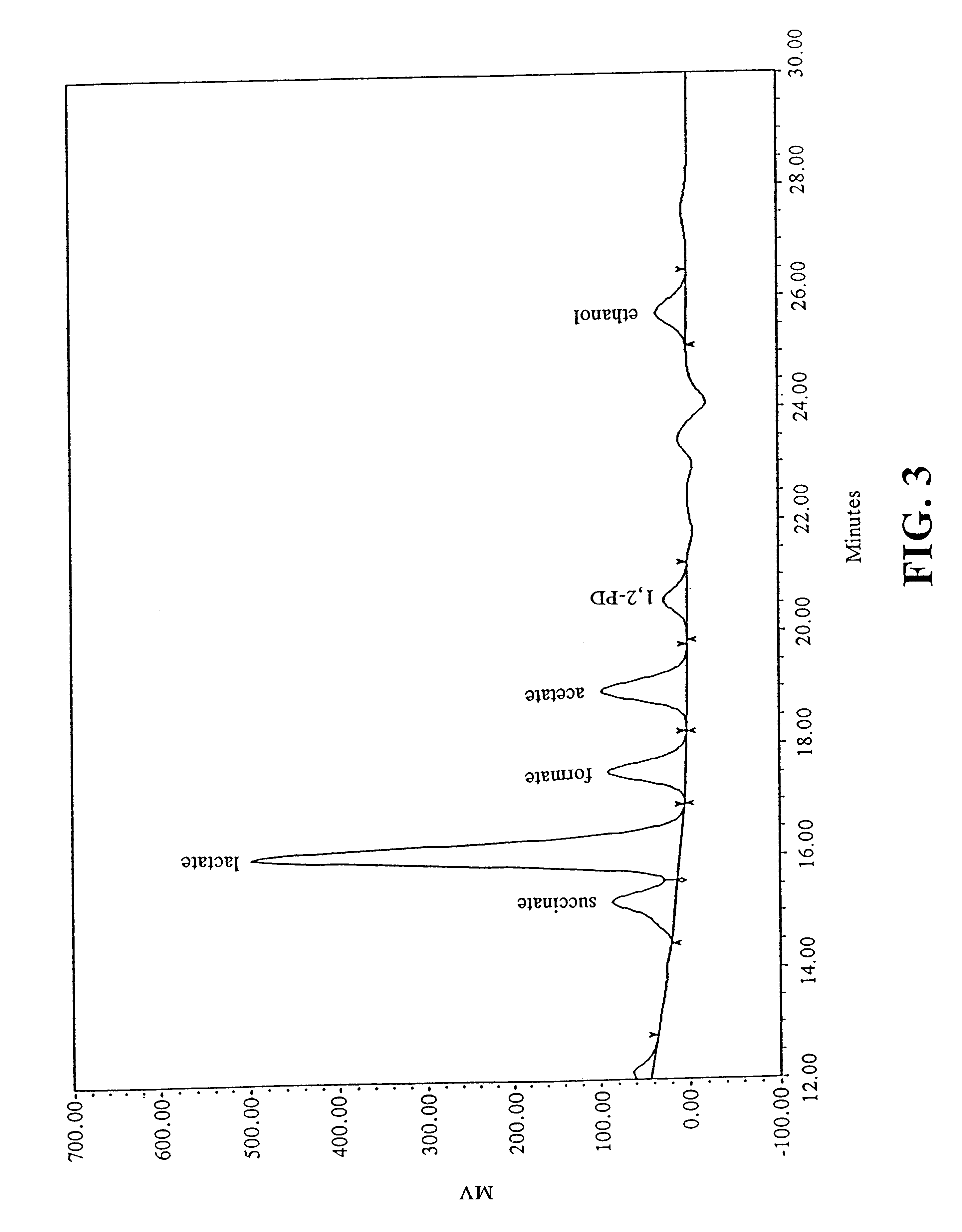

Microbial production of 1,2-propanediol from sugar

Microorganisms which ferment common sugars into 1,2-propanediol, synthetic operons to effect the transformation, and methods to produce 1,2-propanediol by fermentation of common sugars using the transformed microorganisms are disclosed.

Owner:WISCONSIN ALUMNI RES FOUND

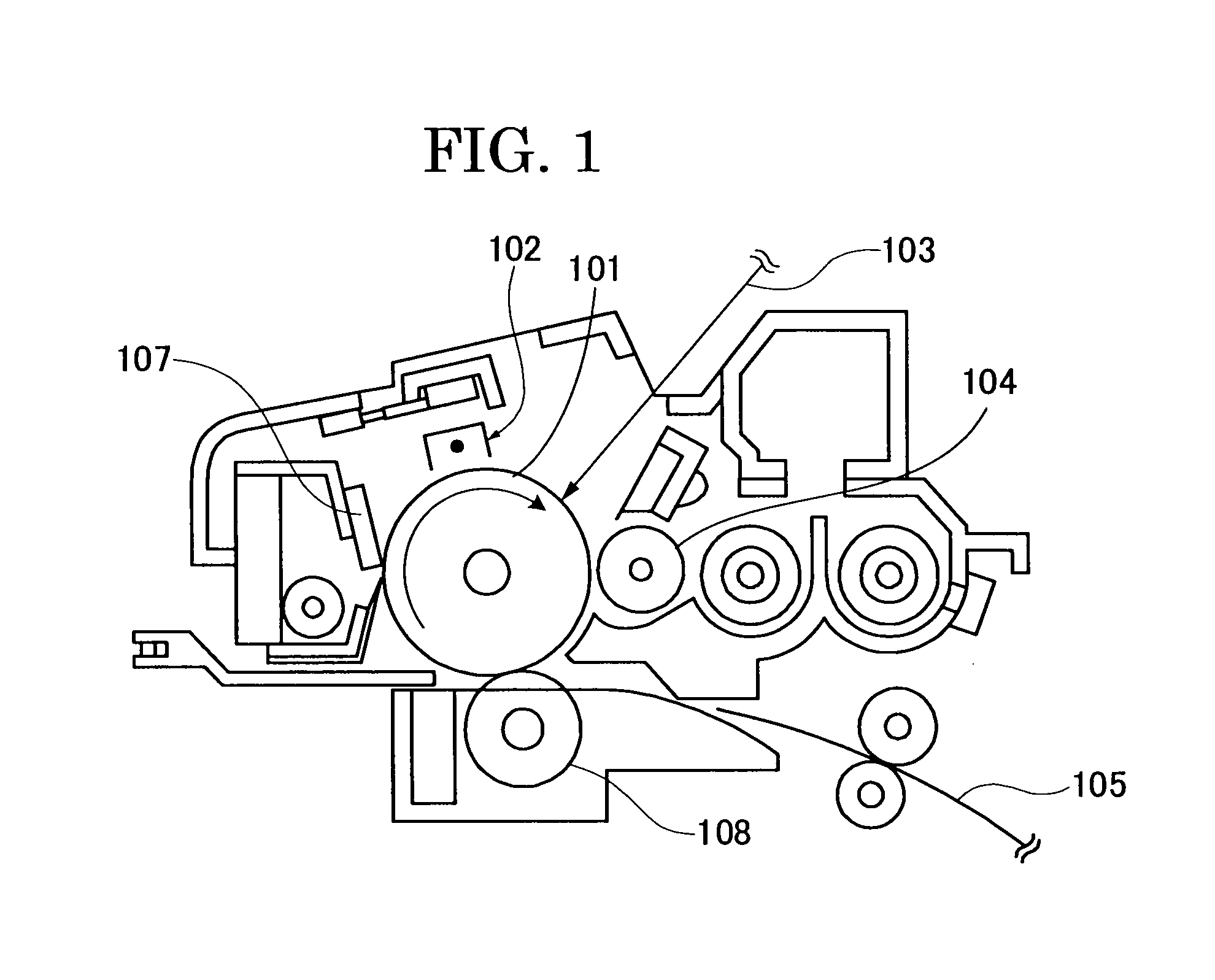

Toner, as well as image forming apparatus and image forming method using the same

ActiveUS20080280218A1Good storage stabilityLow temperature-fixing propertyDevelopersElectrographic process apparatusCarboxylic acidPropanediol

To provide a toner produced by emulsifying or dispersing in an aqueous medium particles containing at least polyester resin particles and by aggregating the polyester resin particles, wherein the polyester resin particles contain a polyester resin, the polyester resin is produced by condensation polymerization of an alcohol component containing 65 mol % or more 1,2-propanediol in a dihydroxy alcohol component and a carboxylic acid component containing purified rosin, and the softening point of the polyester resin is 80° C. or more and less than 120° C., and wherein the toner comprises a colorant and a releasing agent.

Owner:RICOH KK

Polyurethane PSA

ActiveUS7160976B2Polyureas/polyurethane adhesivesSynthetic resin layered productsPolymer sciencePolypropylene glycol

Pressure-sensitive adhesive based on polyurethane, characterized in that the polyurethane is composed of the following starting materials which are reacted with one another in the stated proportions:a) at least one aliphatic or alicyclic diisocyanate having in each case an asymmetrical molecular structure,b) a combination of at least one polypropylene glycol diol and at least one polypropylene glycol triol,the ratio of the number of hydroxyl groups in the diol component to the number of hydroxyl groups in the triol component being between 0.7 and 9.0, preferably between 1.5 and 2.5,additionally the ratio of the number of isocyanate groups to the total number of hydroxyl groups being between 0.9 and 1.1, preferably between 0.95 and 1.05, and the diols and triols alternatively being selected and combined in each case as follows:diols having a molecular weight of less than or equal to 1000 are combined with triols whose molecular weight is greater than 1000, preferably greater than or equal to 3000,diols having a molecular weight of greater than 1000 are combined with triols whose molecular weight is less than 1000.

Owner:TESA SE

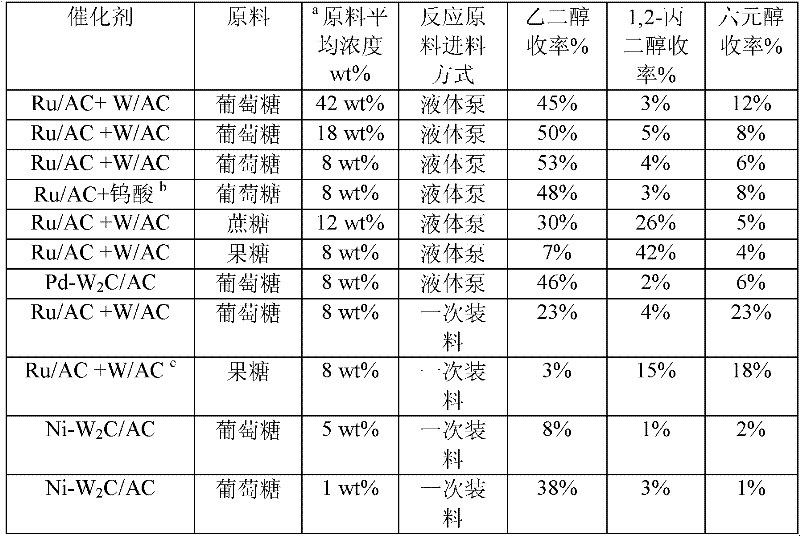

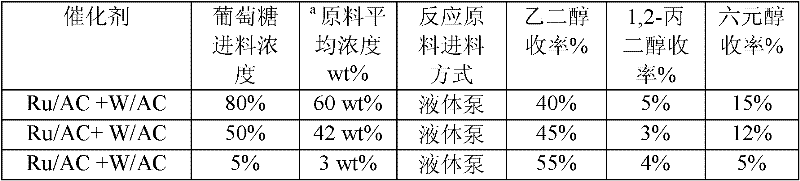

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

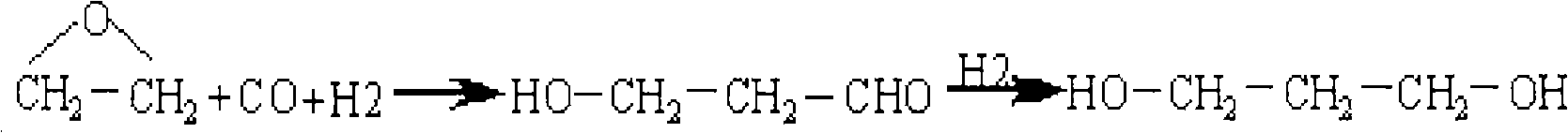

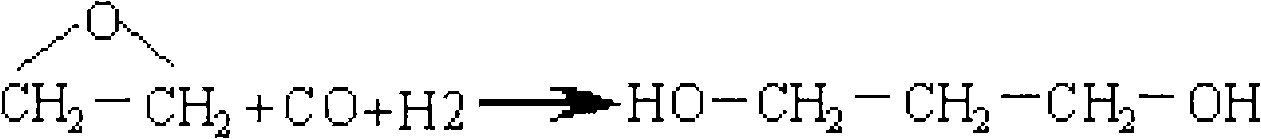

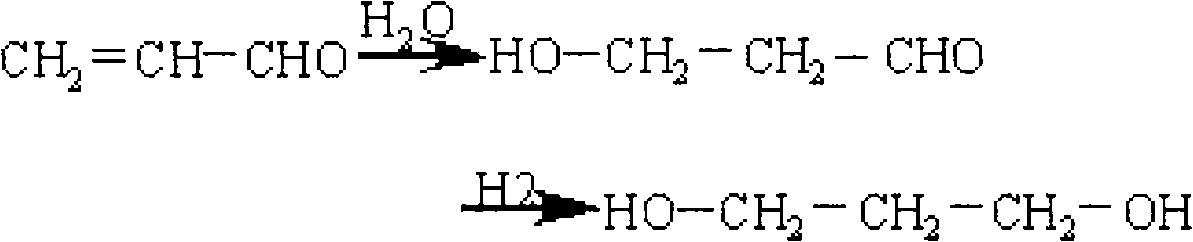

Method for simultaneously producing 1,3-propylene glycol and 1,2-propylene glycol

The invention relates to a chemical material production method, in particular to a method for simultaneously producing 1,3-propylene glycol and 1,2-propylene glycol. Alkyl carboxylic acid vinyl ester carries out hydroformylation with carbon monoxide and hydrogen under the action of olefin hydroformylation catalyst, so that 3-alkylacyloxy propaldehyde and 2- alkylacyloxy propaldehyde are produced, the 3-alkylacyloxy propaldehyde and the 2- alkylacyloxy propaldehyde react with hydrogen under the action of aldehyde hydrogenation catalyst, so that 3-alkylacyloxy propyl alcohol and 2-alkylacyloxy propyl alcohol are produced, and the 3-alkylacyloxy propyl alcohol and the 2-alkylacyloxy propyl alcohol are hydrolyzed under the action of esterolytic catalyst, so that the 1,3-propylene glycol and the 1,2-propylene glycol are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com