Patents

Literature

2583 results about "Tungsten oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

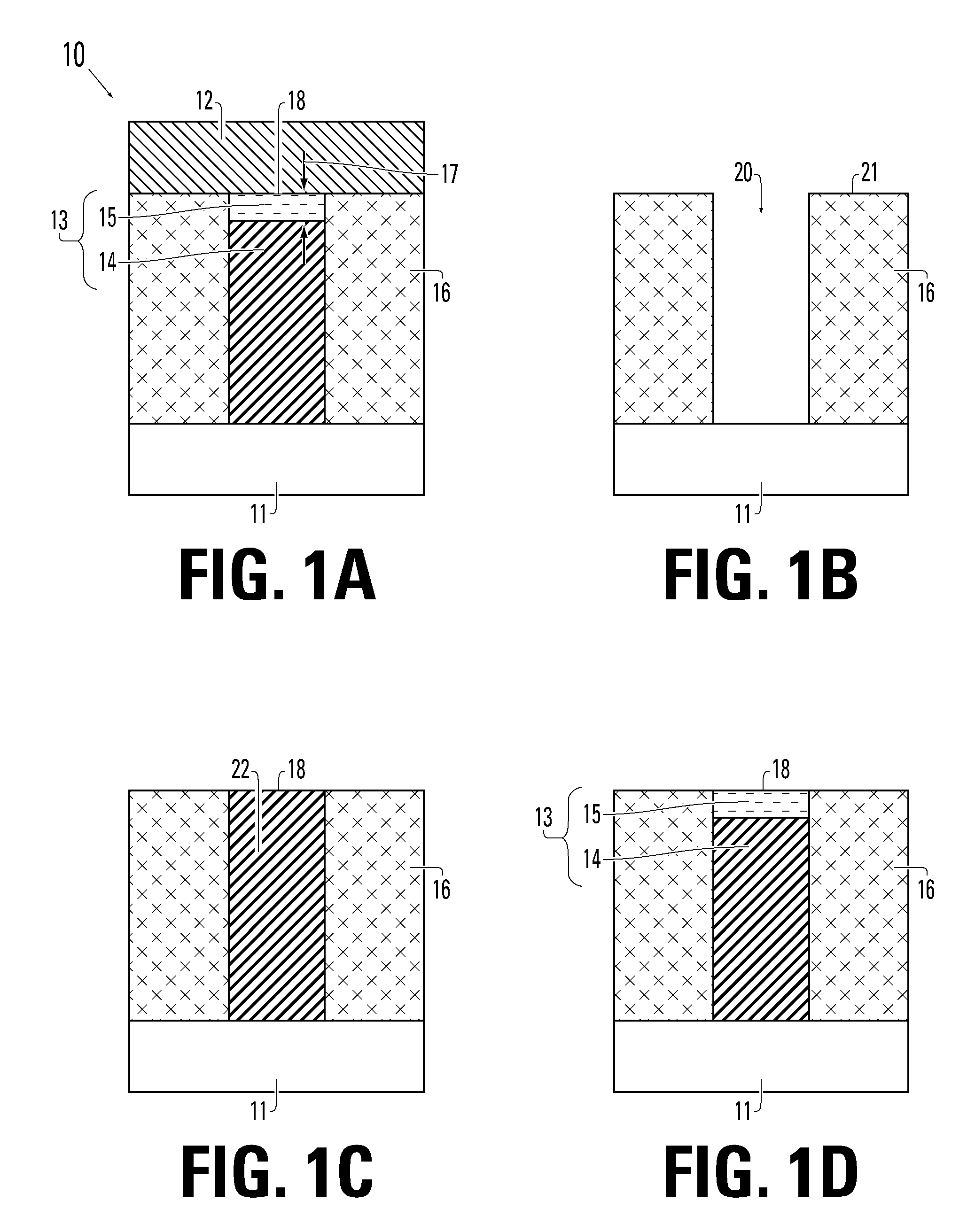

Electroless deposition processes and compositions for forming interconnects

InactiveUS20060252252A1Material nanotechnologySemiconductor/solid-state device detailsHydrogen fluorideTungstate

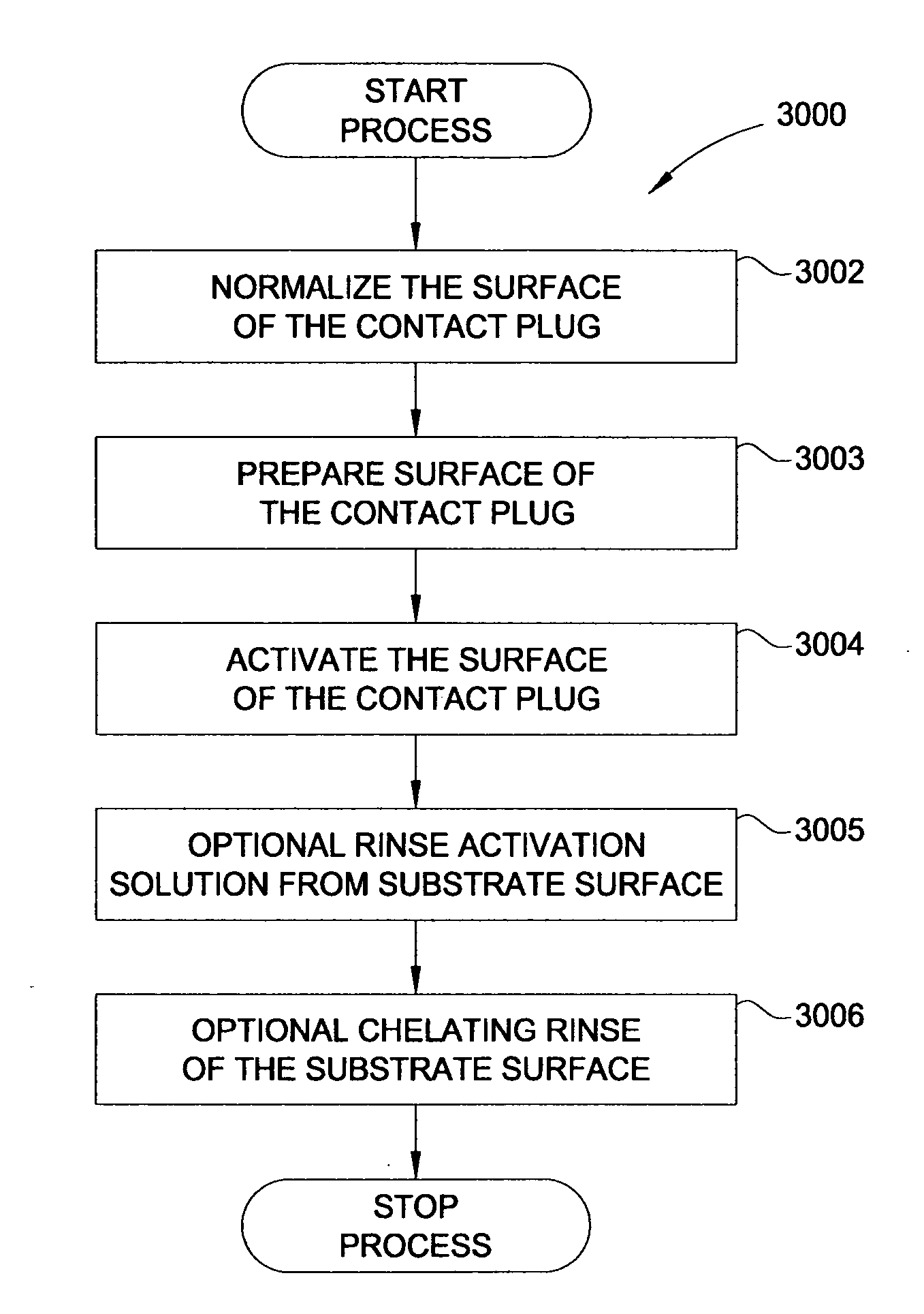

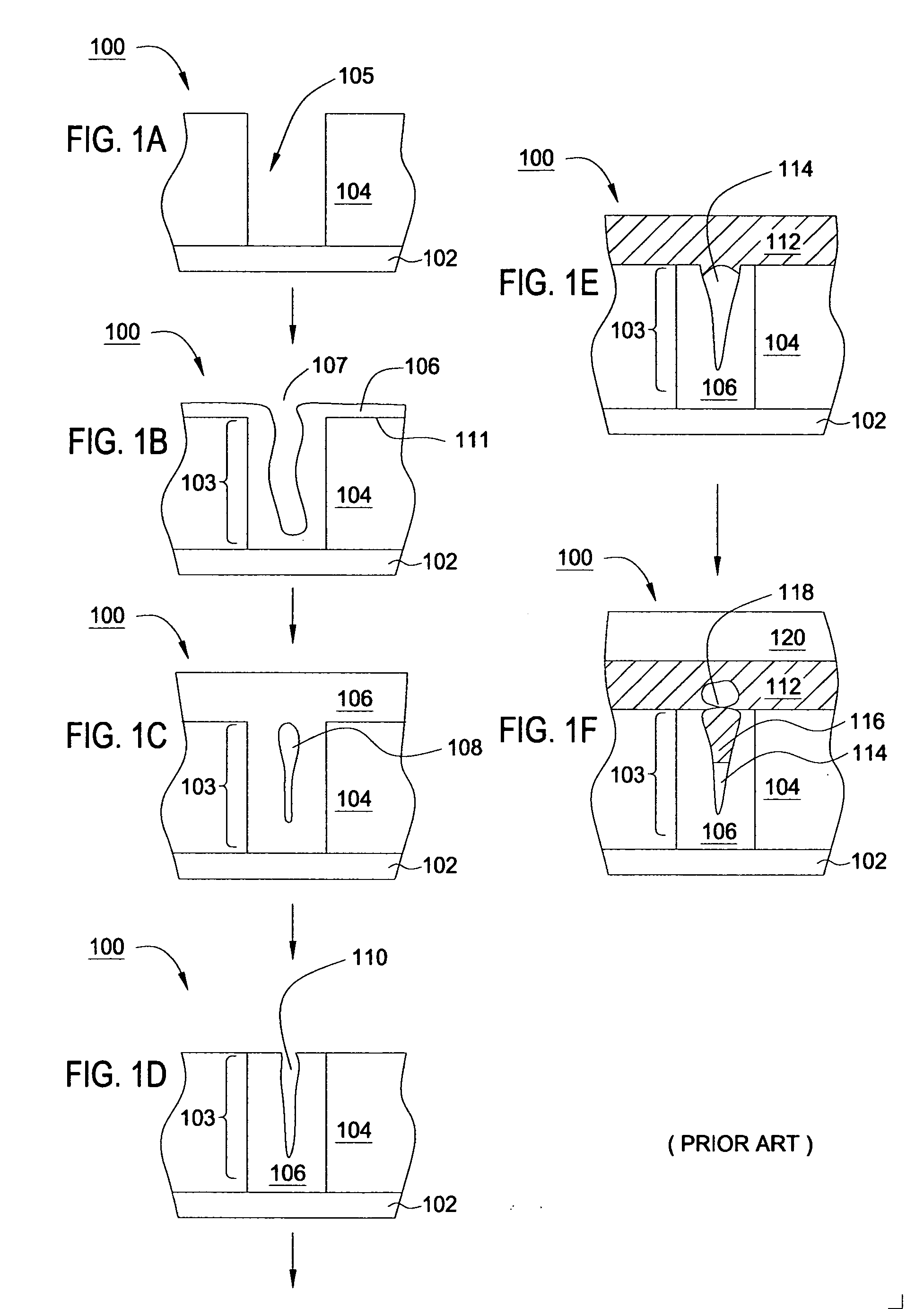

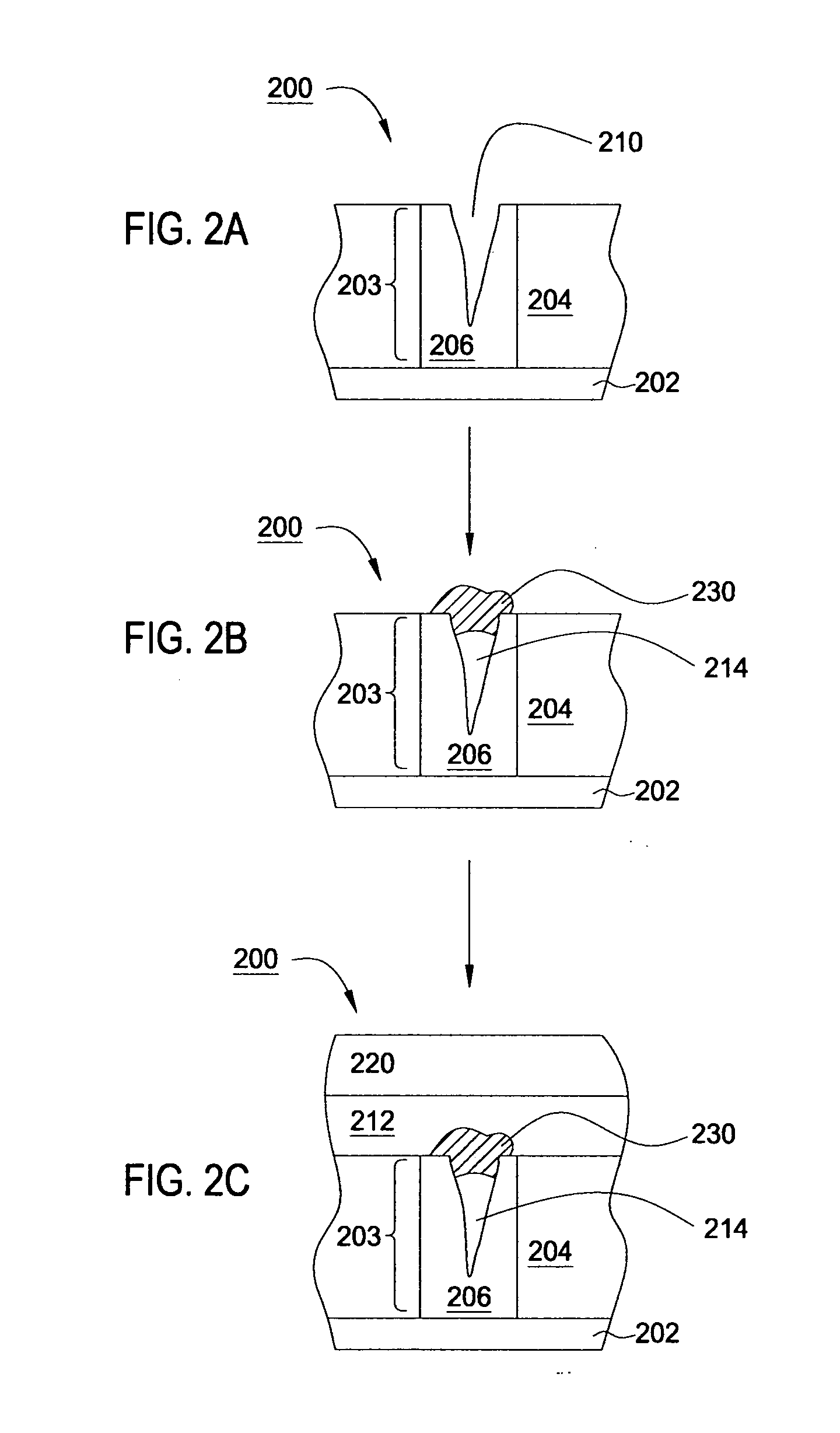

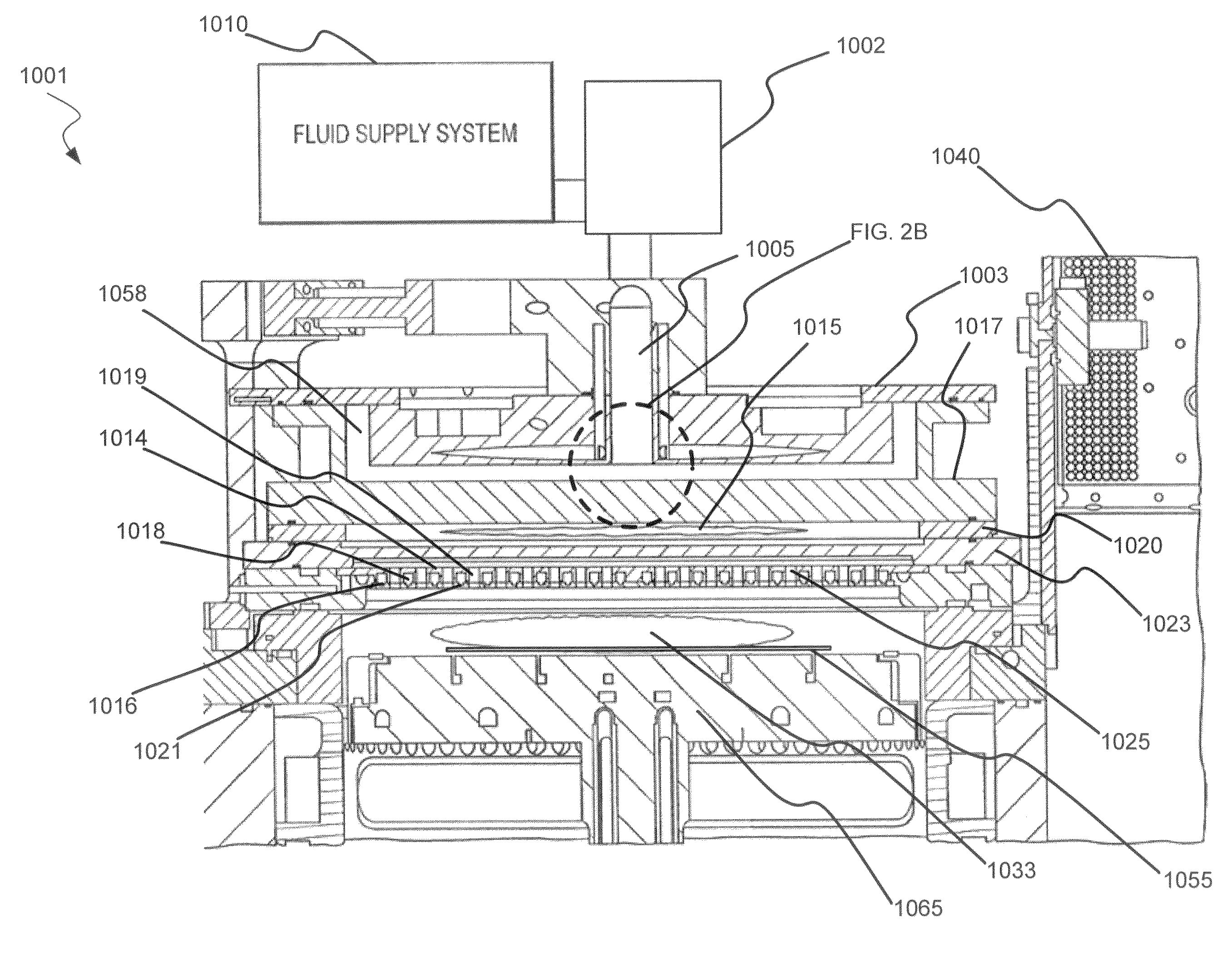

In one embodiment, a method for depositing a material on a substrate is provided which includes positioning a substrate containing a contact within a process chamber, exposing the substrate to at least one pretreatment step and depositing a fill the contact vias by an electroless deposition process. The pretreatment step contains multiple processes for exposing the substrate to a wet-clean solution, a hydrogen fluoride solution, a tungstate solution, a palladium activation solution, an acidic rinse solution, a complexing agent solution or combinations thereof. Generally, the HARC via contains a tungsten oxide surface and the shallow contact via may contain a tungsten silicide surface. In some example, the substrate is pretreated such that both vias are filled at substantially the same time by a nickel-containing material through an electroless deposition process.

Owner:APPLIED MATERIALS INC

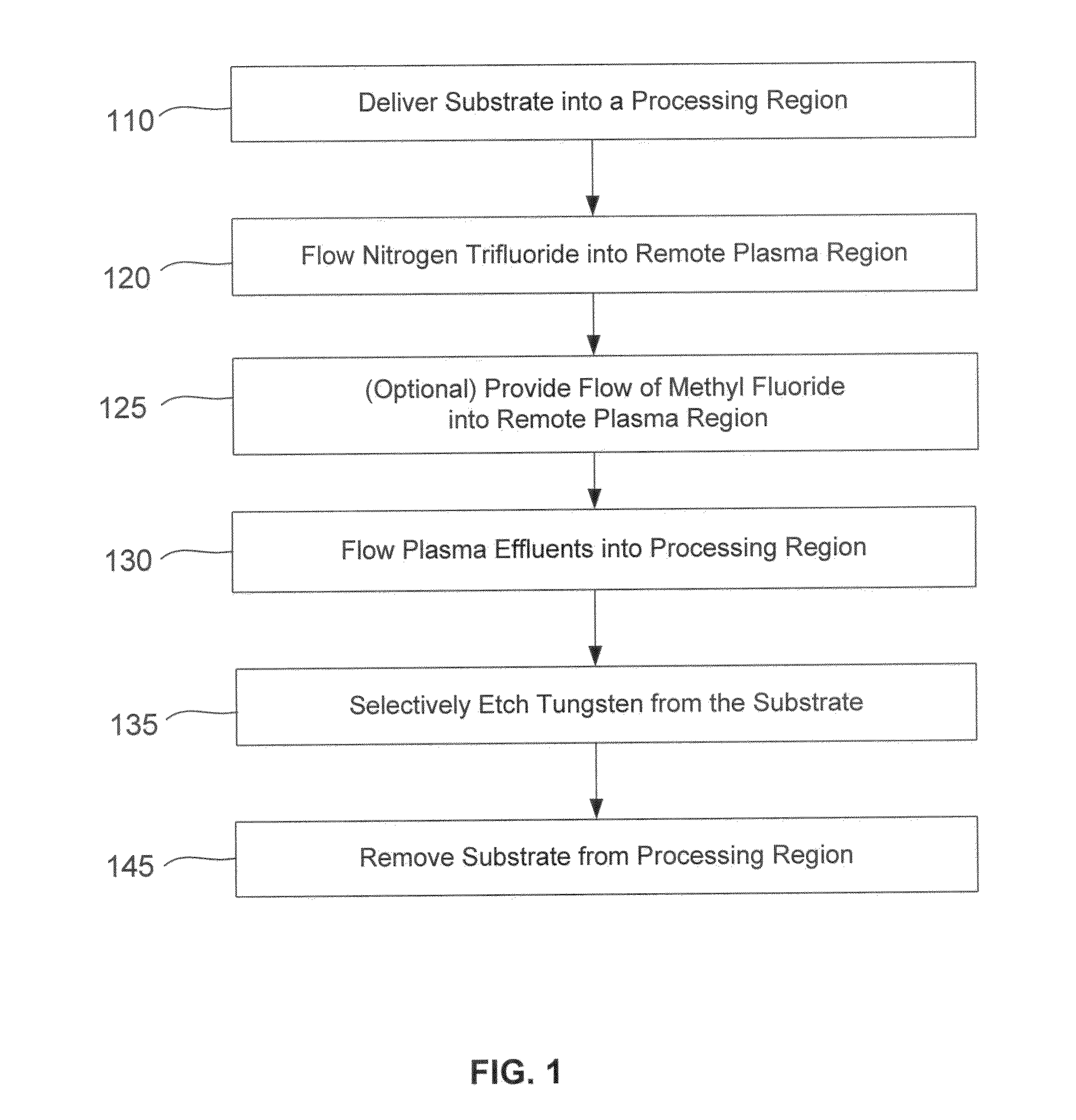

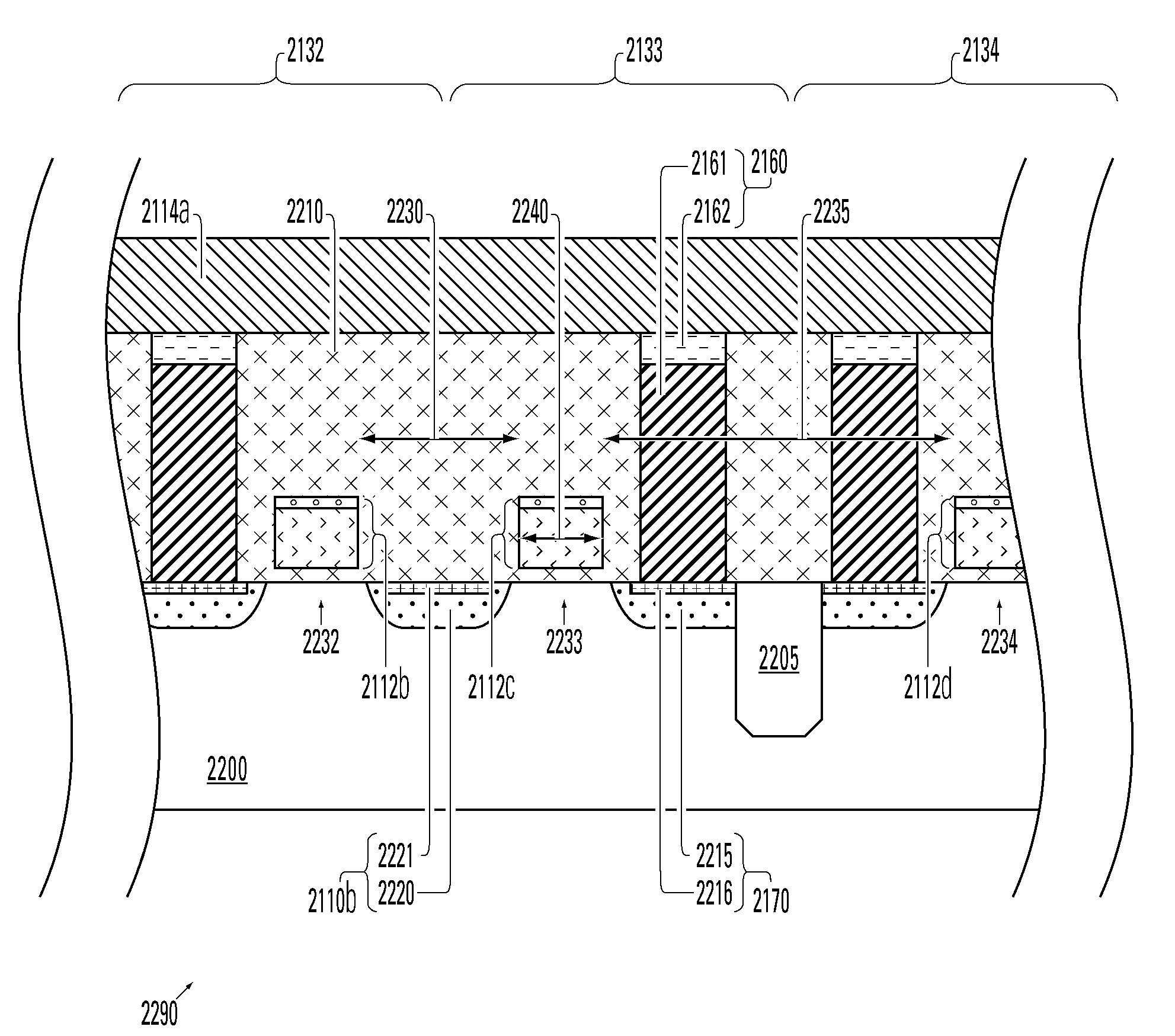

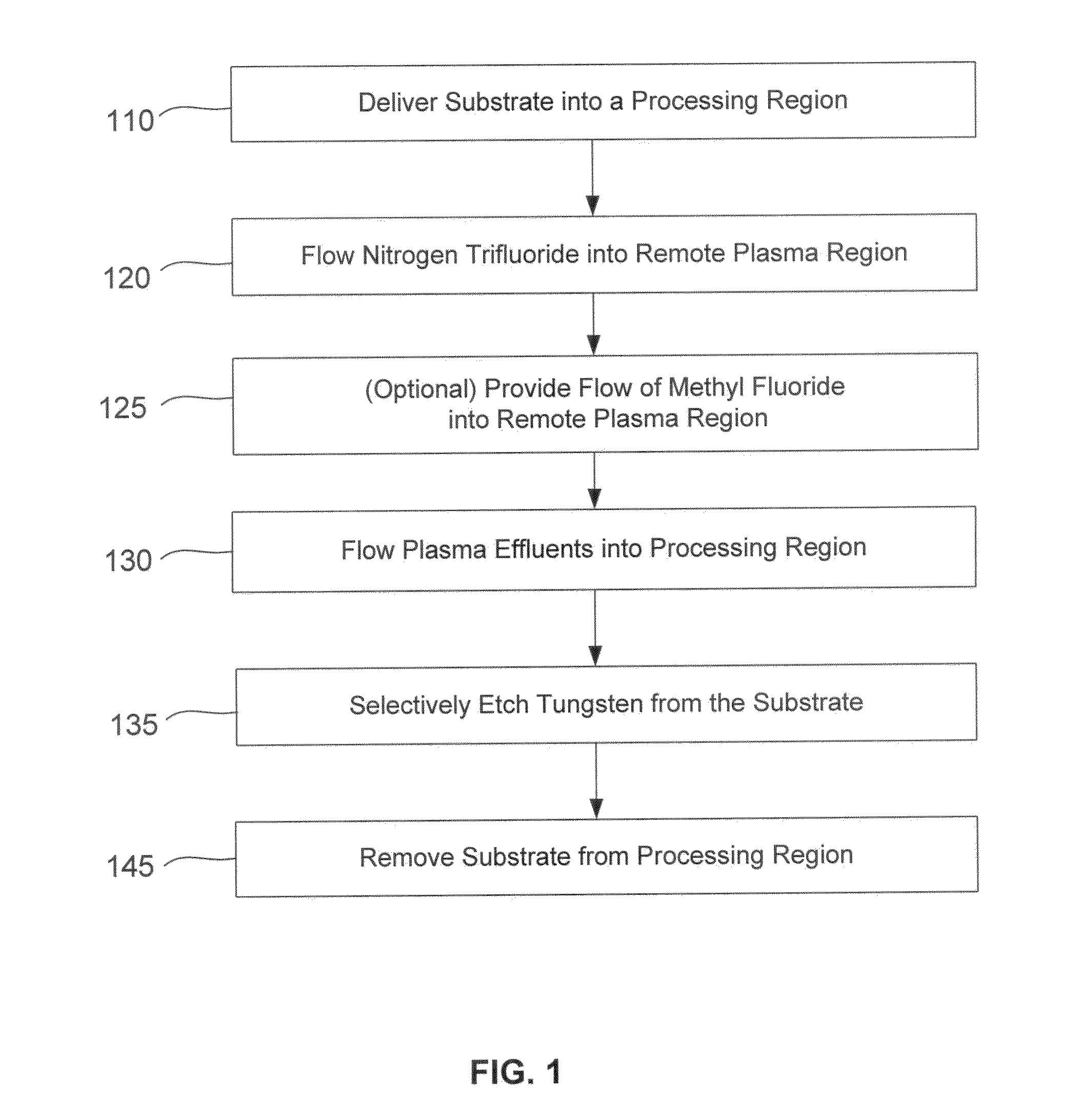

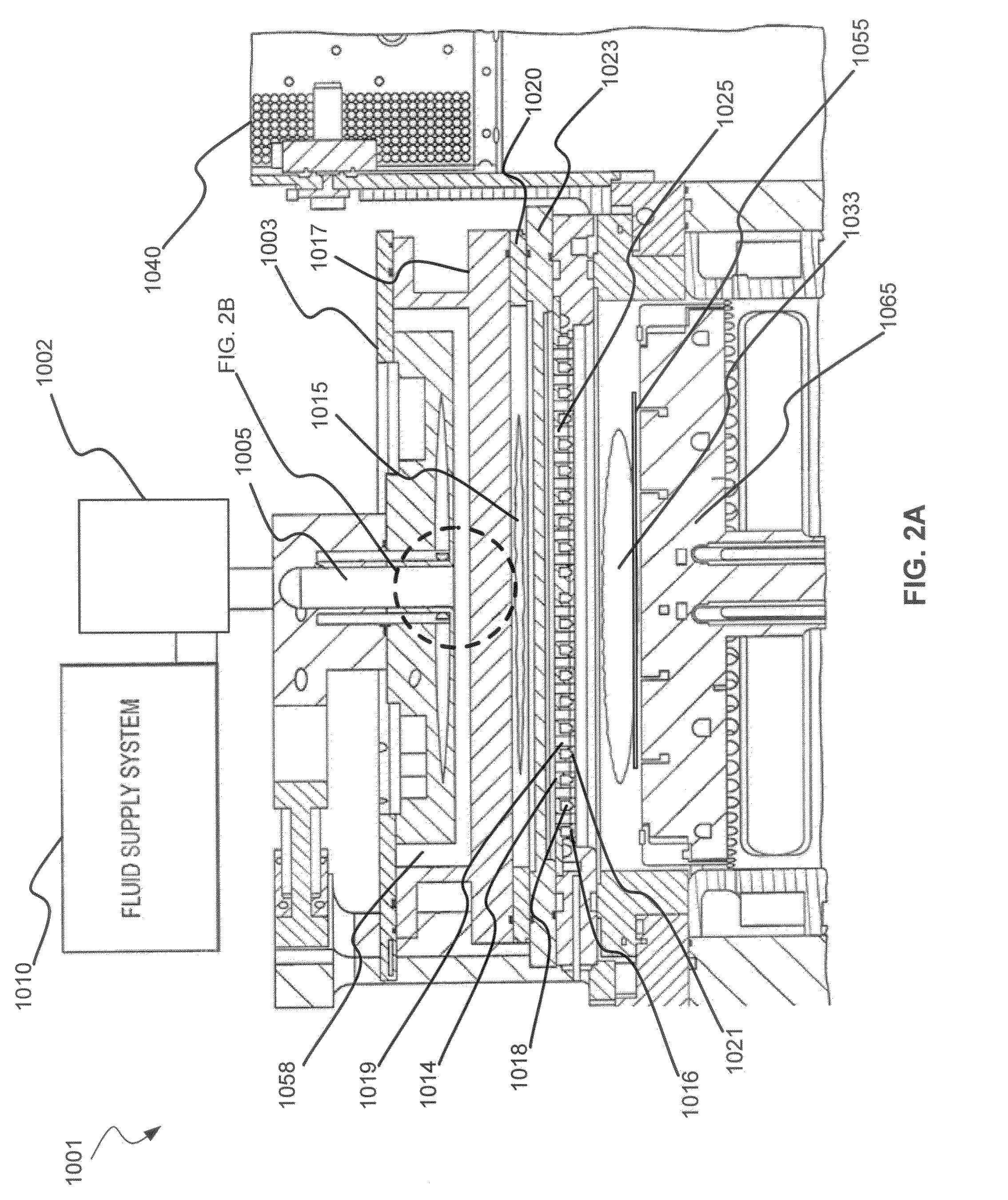

Dry-etch for selective tungsten removal

Methods of selectively etching tungsten relative to silicon-containing films (e.g. silicon oxide, silicon carbon nitride and (poly)silicon) as well as tungsten oxide are described. The methods include a remote plasma etch formed from a fluorine-containing precursor and / or hydrogen (H2). Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the tungsten. The plasma effluents react with exposed surfaces and selectively remove tungsten while very slowly removing other exposed materials. Sequential and simultaneous methods are included to remove thin tungsten oxide which may, for example, result from exposure to the atmosphere.

Owner:APPLIED MATERIALS INC

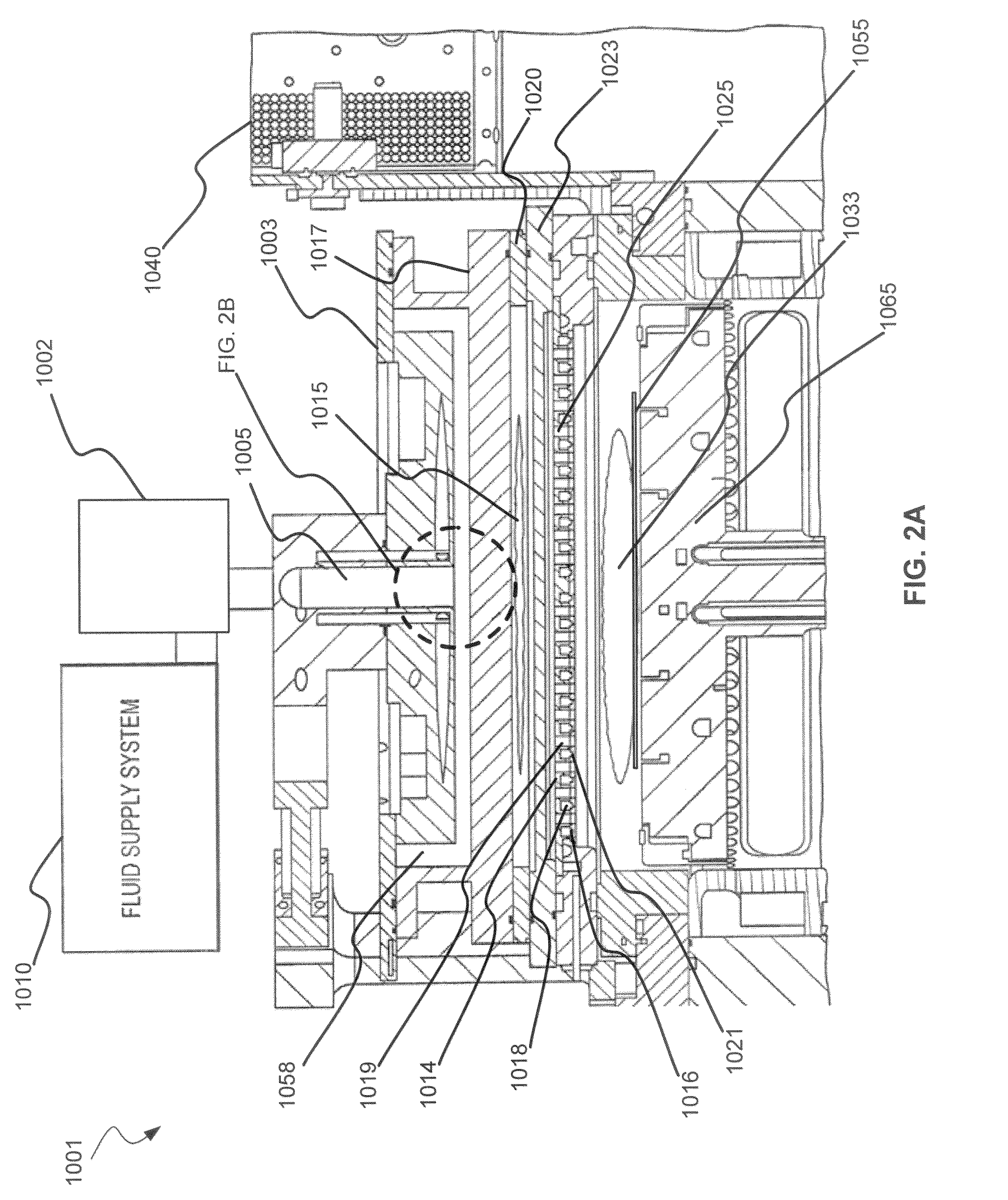

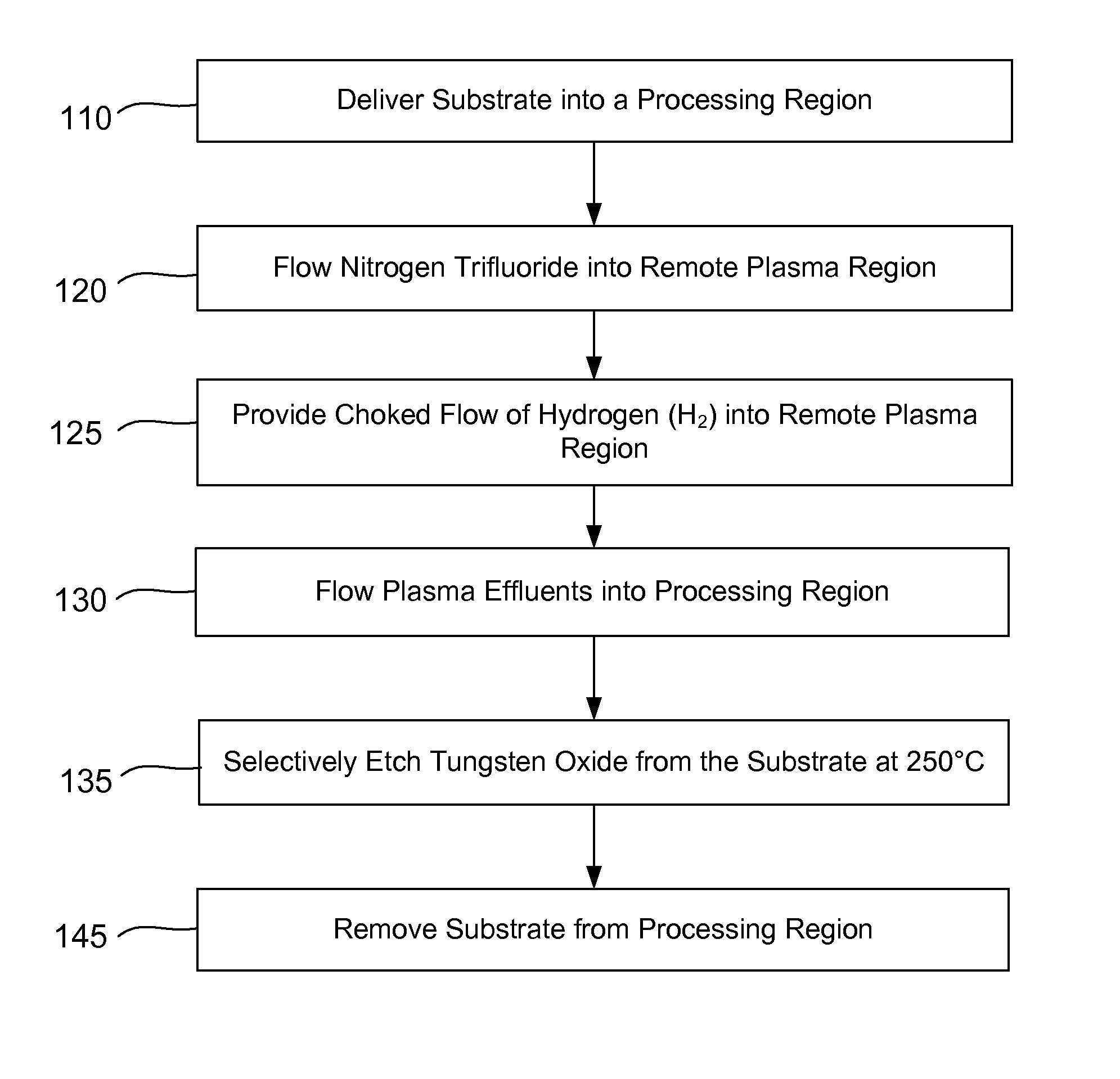

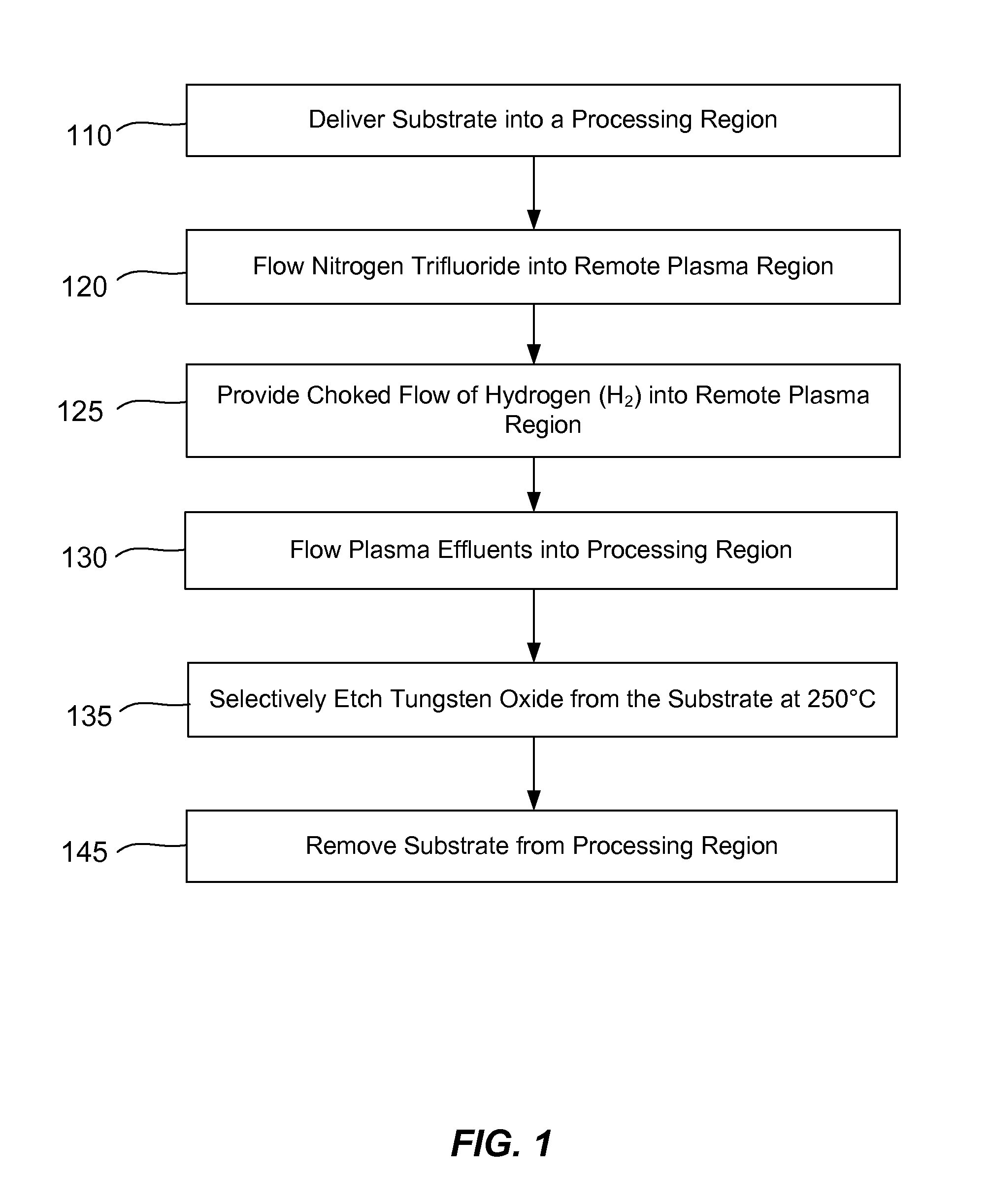

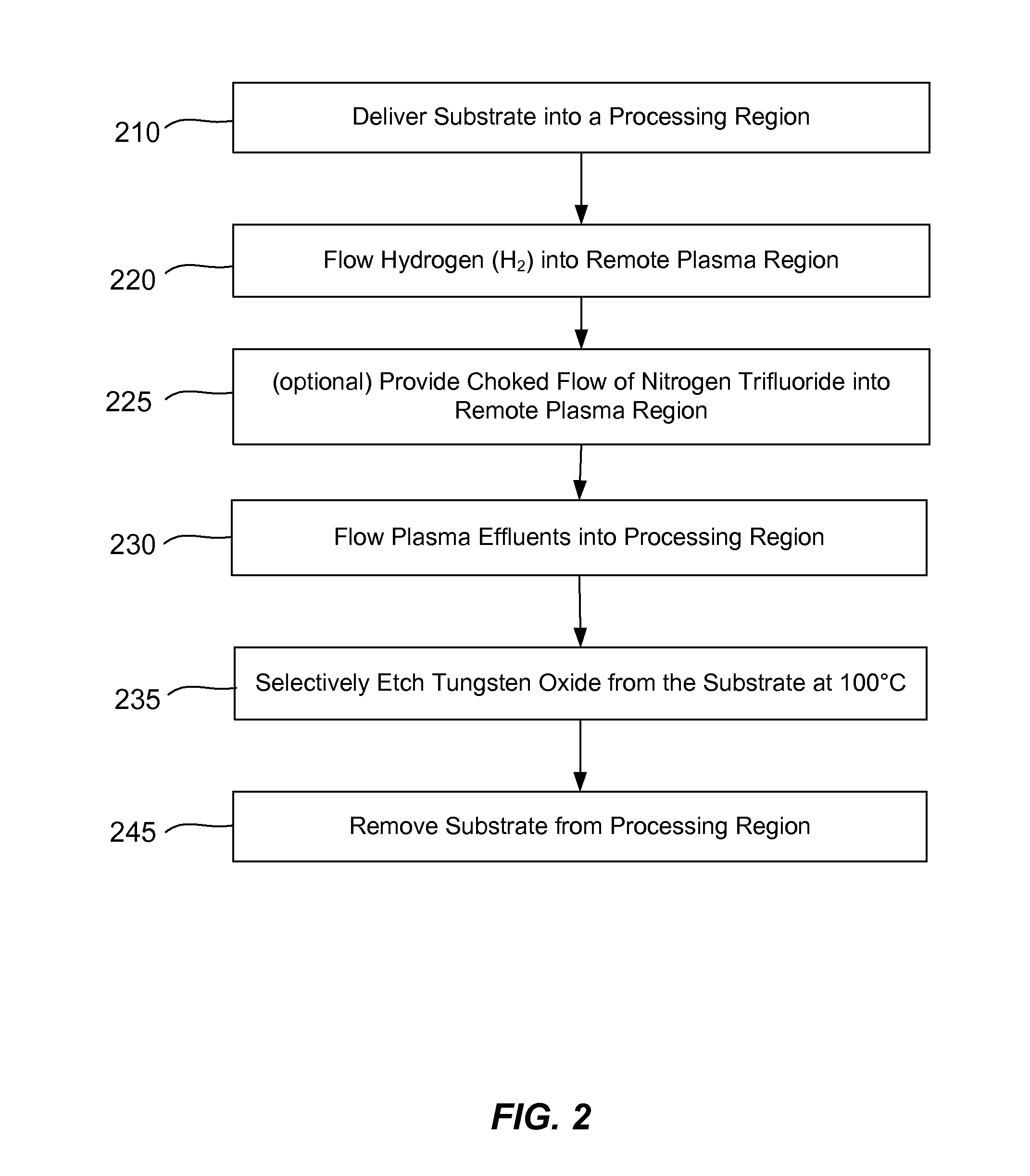

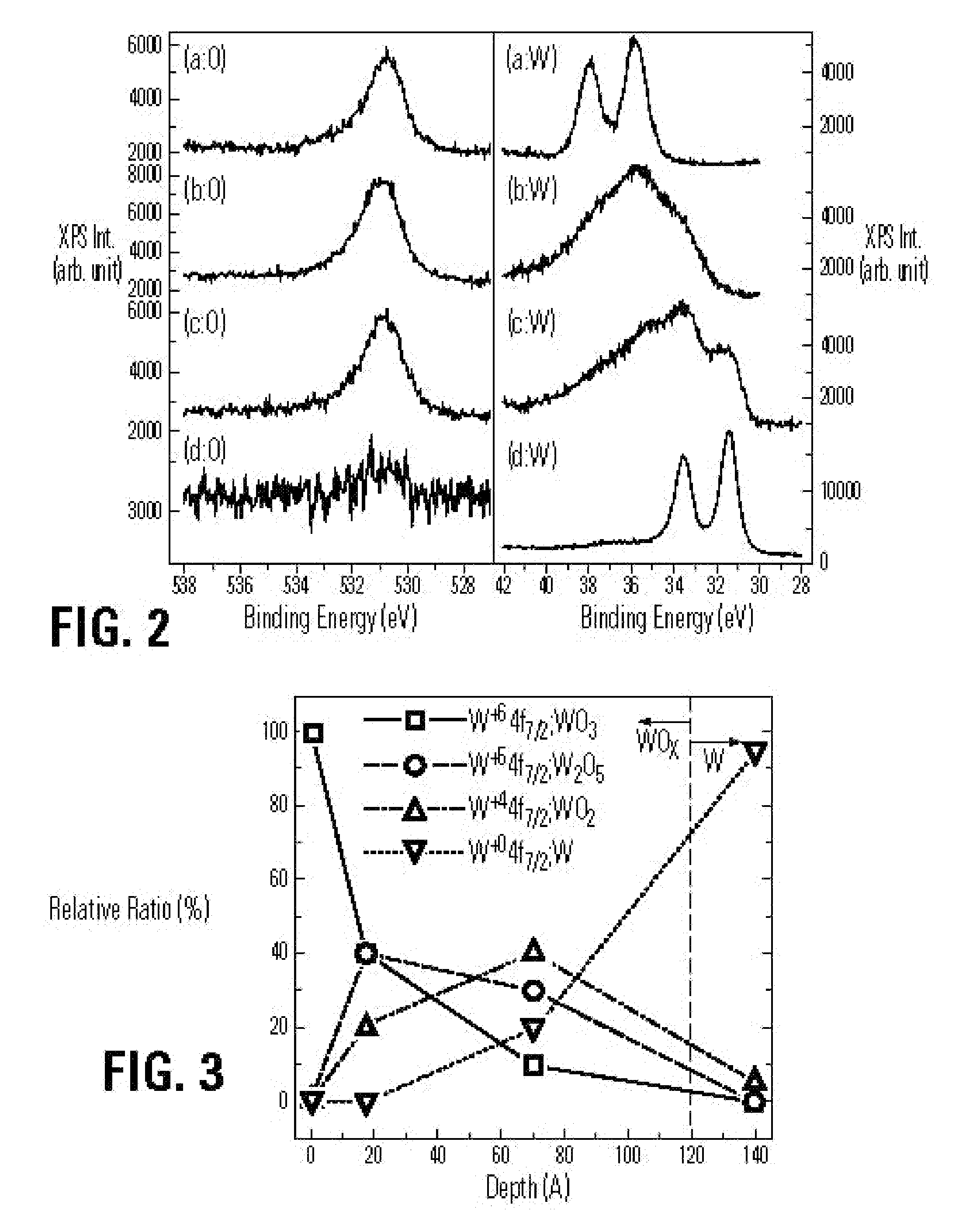

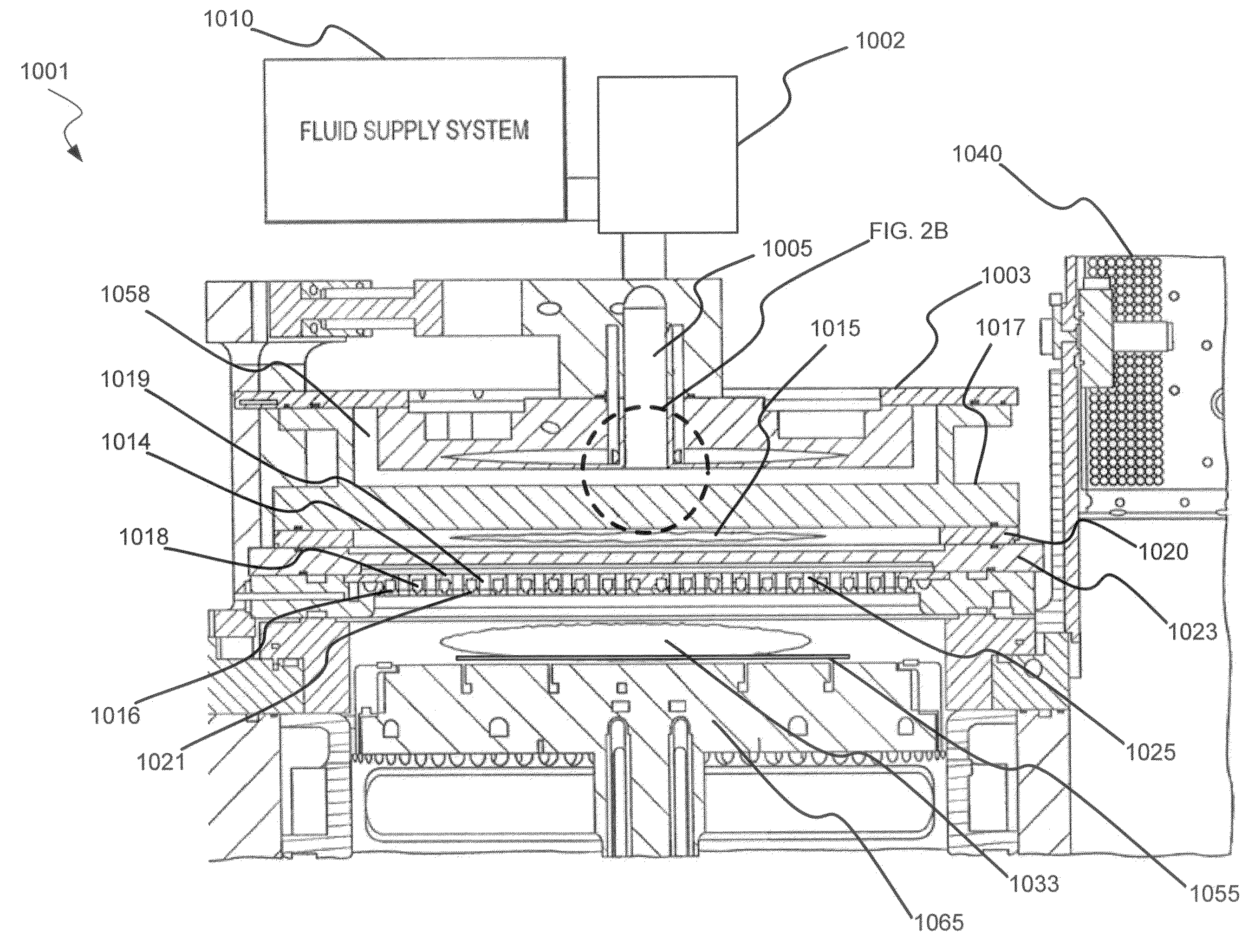

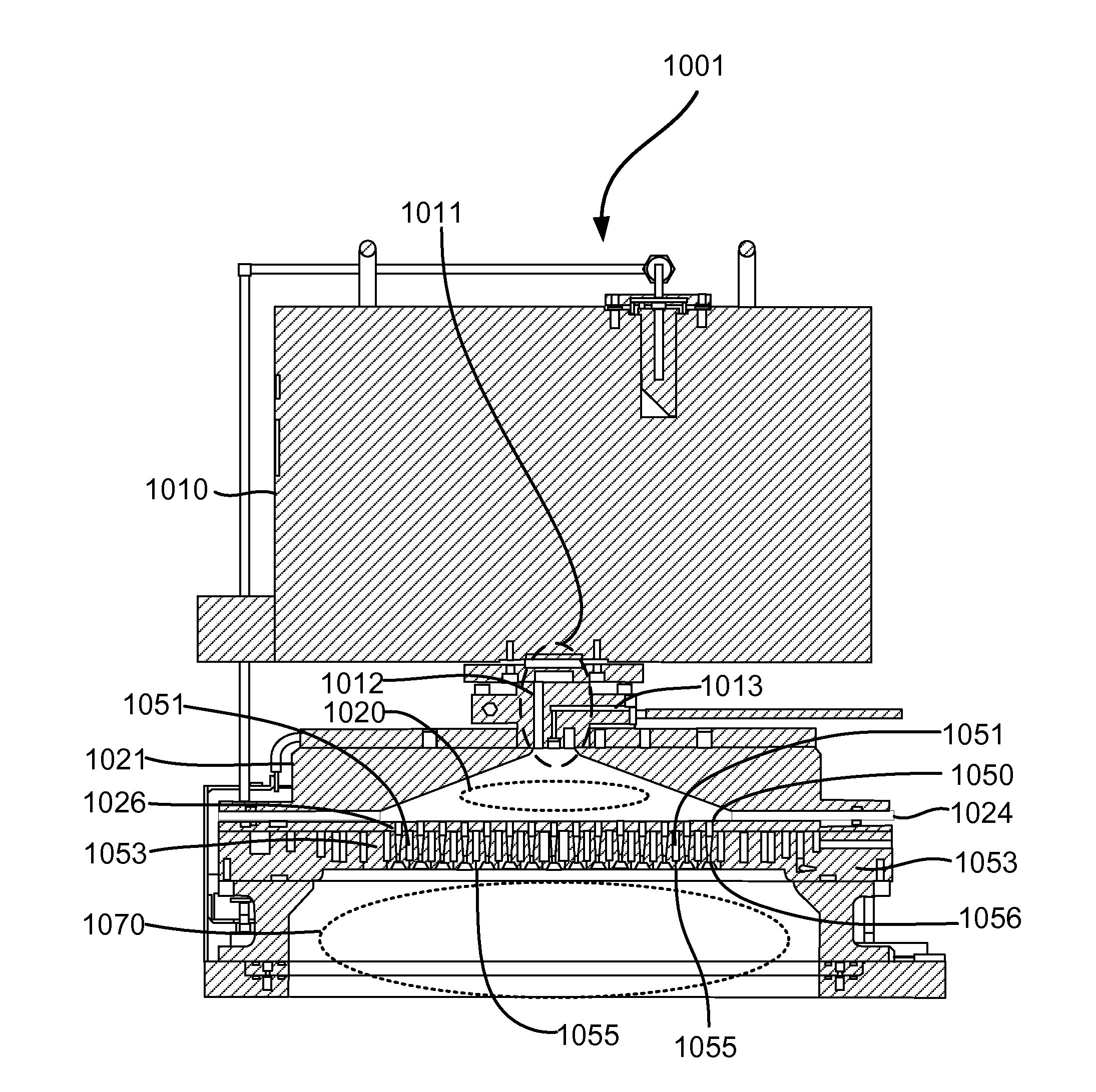

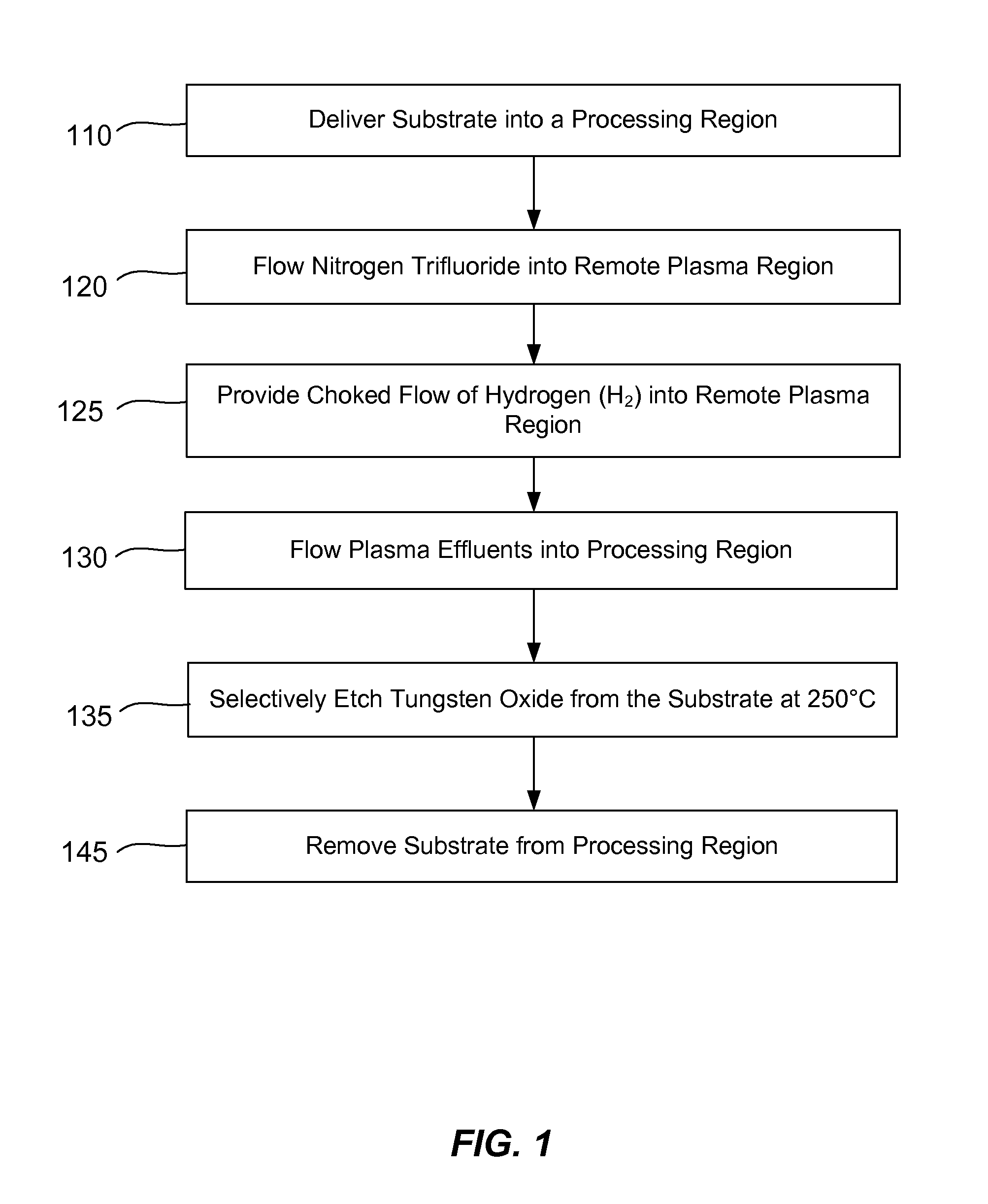

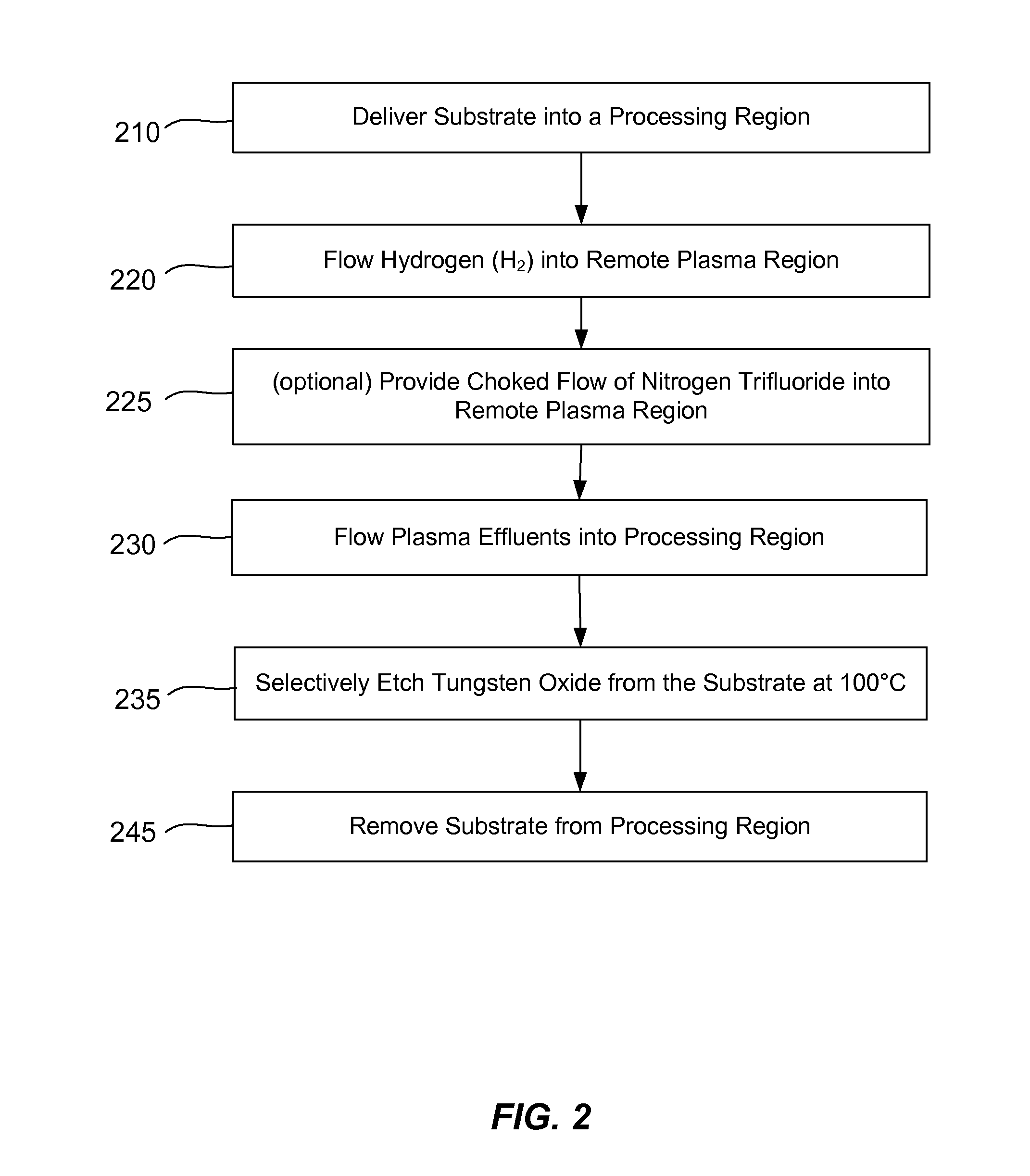

Dry-etch for selective oxidation removal

ActiveUS9064816B2Reduces and substantially eliminates numberMaterial removalElectric discharge tubesDecorative surface effectsSurface reactionRemote plasma

Methods of selectively etching tungsten oxide relative to tungsten, silicon oxide, silicon nitride and / or titanium nitride are described. The methods include a remote plasma etch formed from a fluorine-containing precursor and / or hydrogen (H2). Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the tungsten oxide. The plasmas effluents react with exposed surfaces and selectively remove tungsten oxide while very slowly removing other exposed materials. In some embodiments, the tungsten oxide selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region. The ion suppression element reduces or substantially eliminates the number of ionically-charged species that reach the substrate.

Owner:APPLIED MATERIALS INC

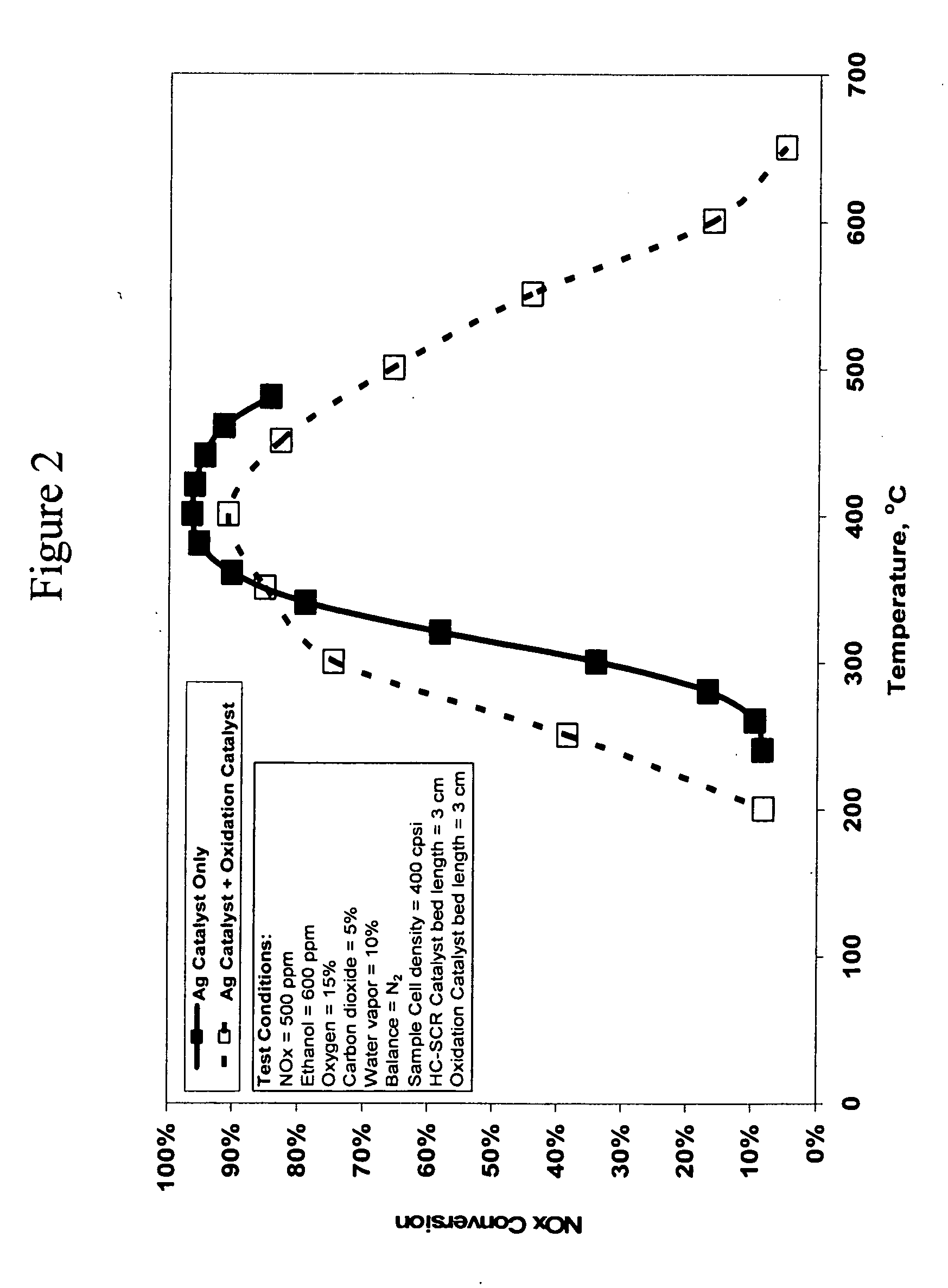

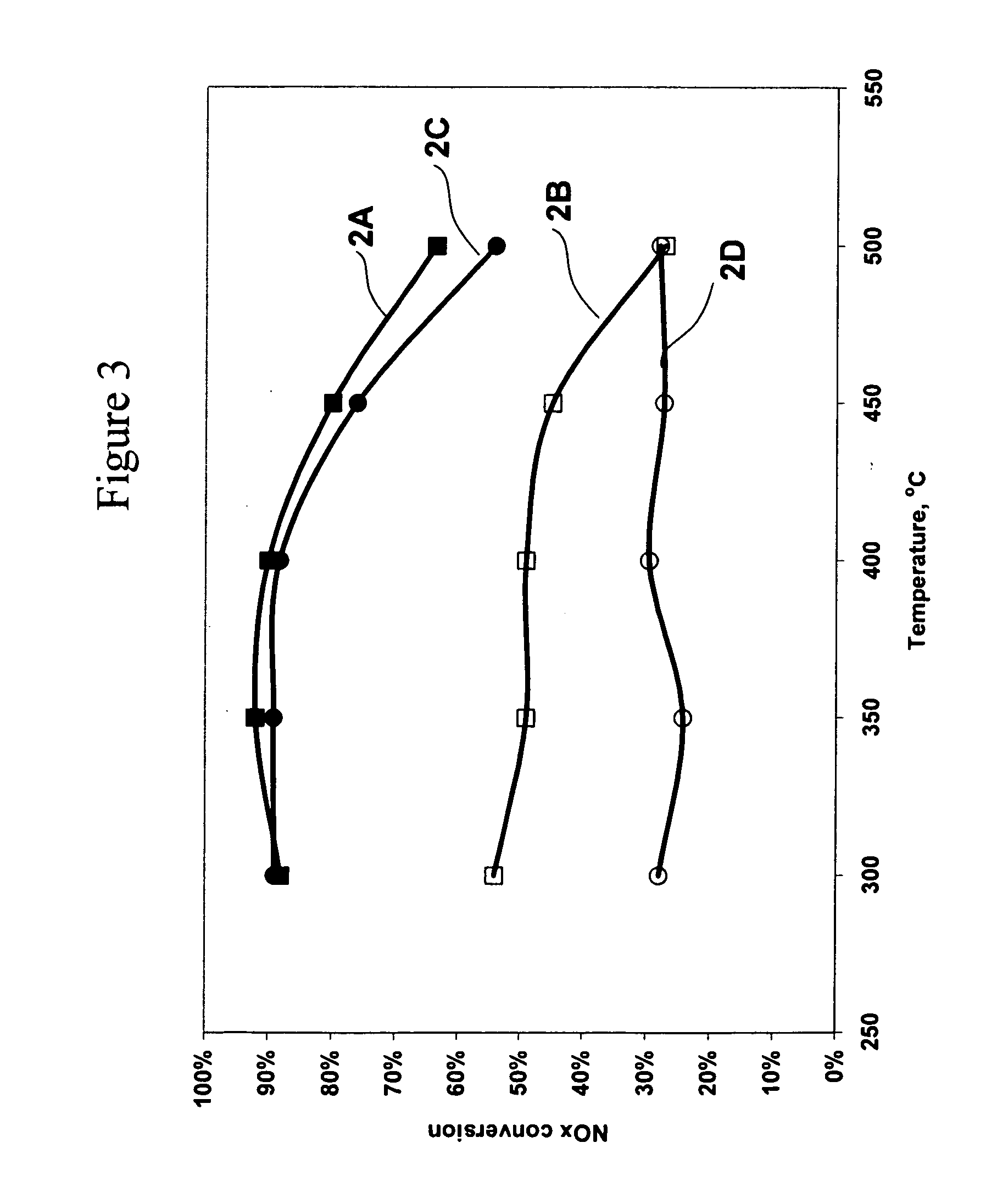

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

Resistance memory with tungsten compound and manufacturing

Memory devices based on tungsten-oxide memory regions are described, along with methods for manufacturing and methods for programming such devices. The tungsten-oxide memory region can be formed by oxidation of tungsten material using a non-critical mask, or even no mask at all in some embodiments. A memory device described herein includes a bottom electrode and a memory element on the bottom electrode. The memory element comprises at least one tungsten-oxygen compound and is programmable to at least two resistance states. A top electrode comprising a barrier material is on the memory element, the barrier material preventing movement of metal-ions from the top electrode into the memory element.

Owner:MACRONIX INT CO LTD

Dry-etch for selective tungsten removal

ActiveUS20140154889A1Electric discharge tubesSemiconductor/solid-state device manufacturingSilicon oxideMaterials science

Methods of selectively etching tungsten relative to silicon-containing films (e.g. silicon oxide, silicon carbon nitride and (poly)silicon) as well as tungsten oxide are described. The methods include a remote plasma etch formed from a fluorine-containing precursor and / or hydrogen (H2). Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the tungsten. The plasma effluents react with exposed surfaces and selectively remove tungsten while very slowly removing other exposed materials. Sequential and simultaneous methods are included to remove thin tungsten oxide which may, for example, result from exposure to the atmosphere.

Owner:APPLIED MATERIALS INC

Dry-etch for selective oxidation removal

ActiveUS20140199850A1Reduces and substantially eliminates numberMaterial removalElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaTitanium nitride

Methods of selectively etching tungsten oxide relative to tungsten, silicon oxide, silicon nitride and / or titanium nitride are described. The methods include a remote plasma etch formed from a fluorine-containing precursor and / or hydrogen (H2). Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the tungsten oxide. The plasmas effluents react with exposed surfaces and selectively remove tungsten oxide while very slowly removing other exposed materials. In some embodiments, the tungsten oxide selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region. The ion suppression element reduces or substantially eliminates the number of ionically-charged species that reach the substrate.

Owner:APPLIED MATERIALS INC

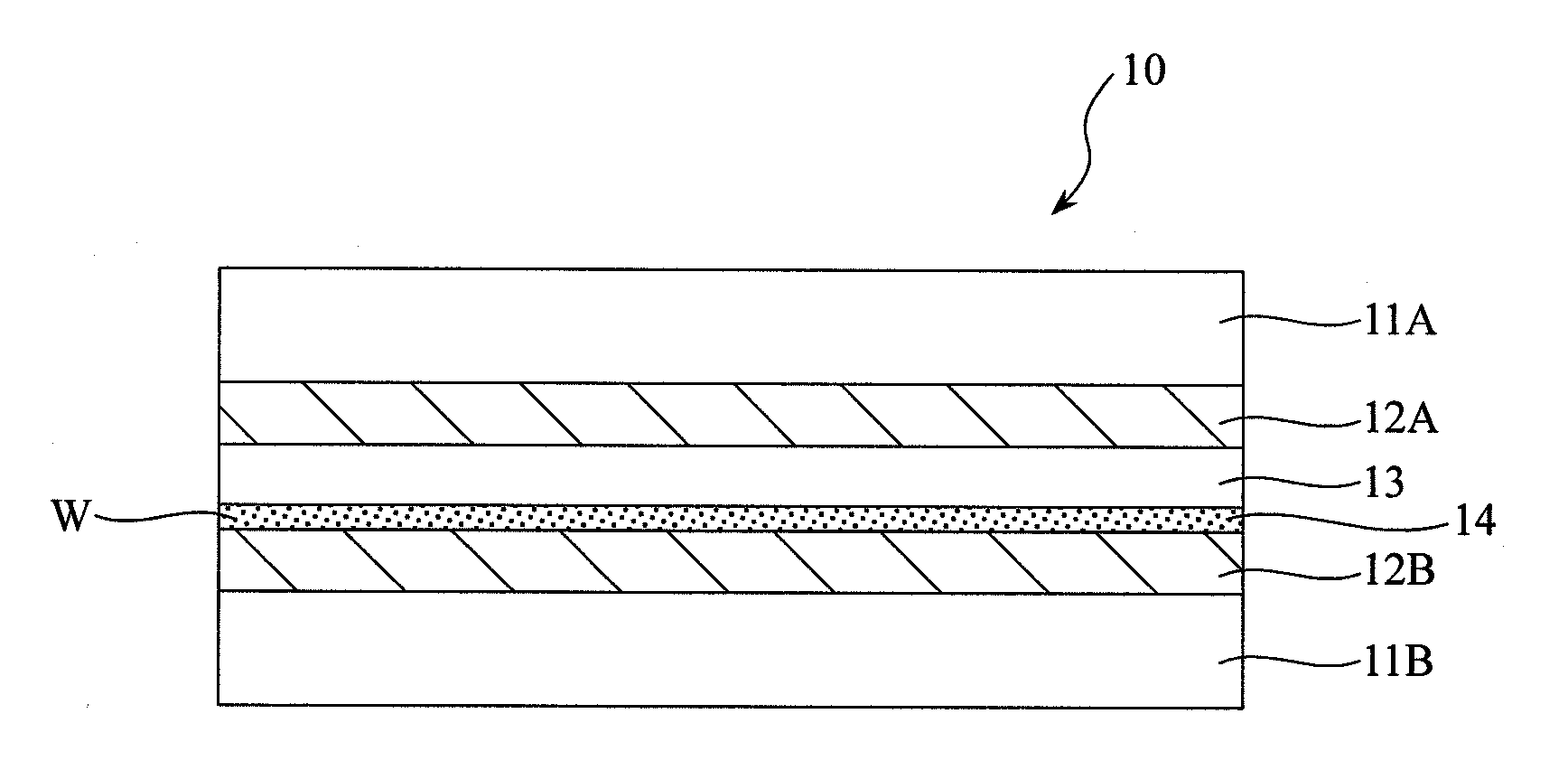

Near-infrared shielding material, laminate including the same, and optical filter for display including the same

InactiveUS20100220388A1Effective shieldingMaintain transparencyMirrorsOther chemical processesDisplay devicePlastic film

To provide a laminate which is excellent in heat-ray shielding properties, transparency, and weatherability and is suitable for use in laminated glass; and an optical filter for display which has excellent near-infrared shielding properties and is excellent in transparency, weatherability, and display performance.The laminate comprises two substrates and an intermediate layer sandwiched therebetween and bonded and united thereto, wherein a heat-ray shielding layer, a plastic film, and an intermediate layer have been interposed between the intermediate layer and the substrate. The heat-ray shielding layer comprises tungsten oxide and / or composite tungsten oxide, and the intermediate layer comprises a compound showing maximum absorption in the wavelength region of 200-500 nm. The optical filter for displays comprises a near-infrared shielding layer containing tungsten oxide and / or composite tungsten oxide and at least one other functional layer containing a compound showing maximum absorption in the wavelength region of 200-500 nm.

Owner:BRIDGESTONE CORP

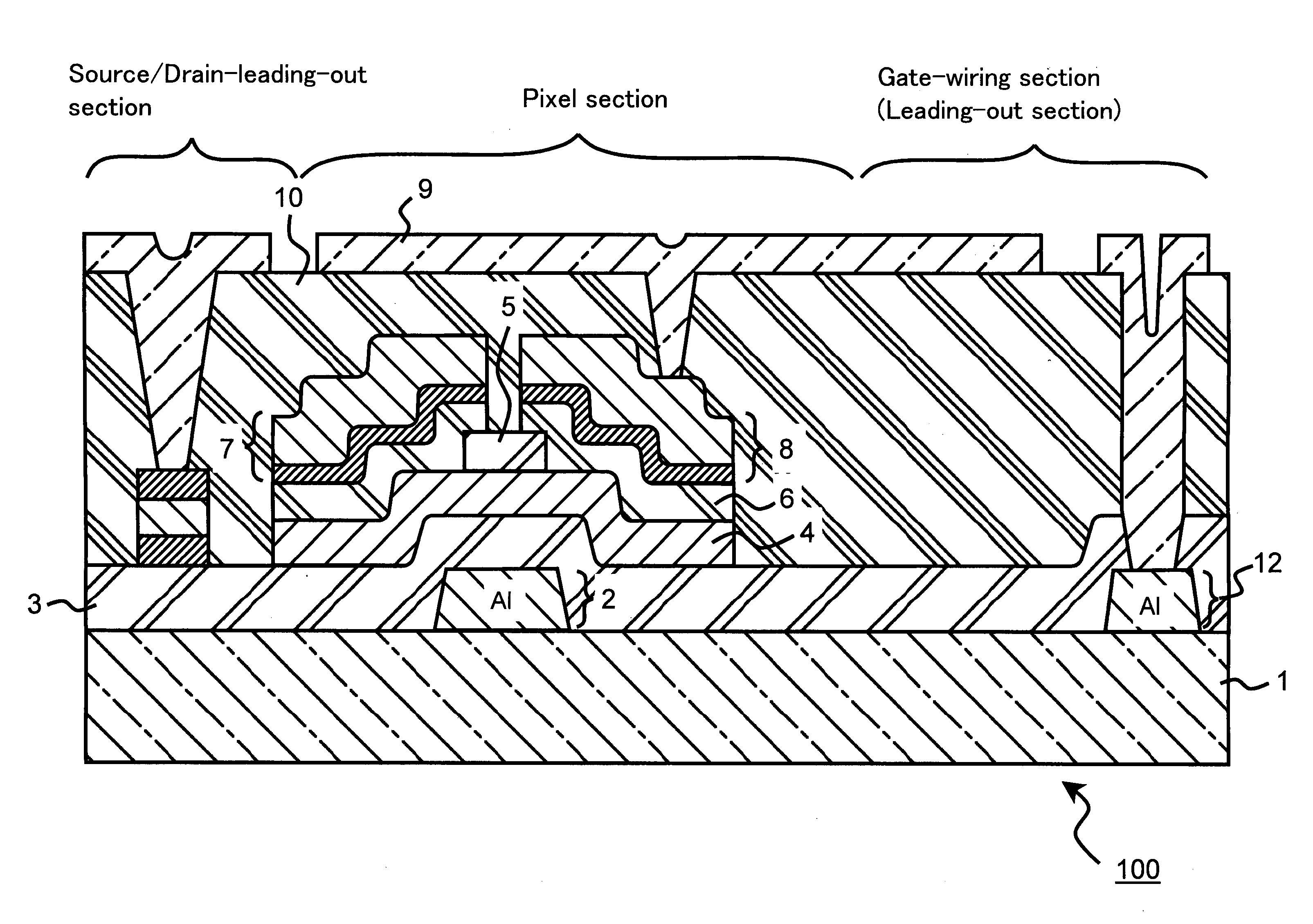

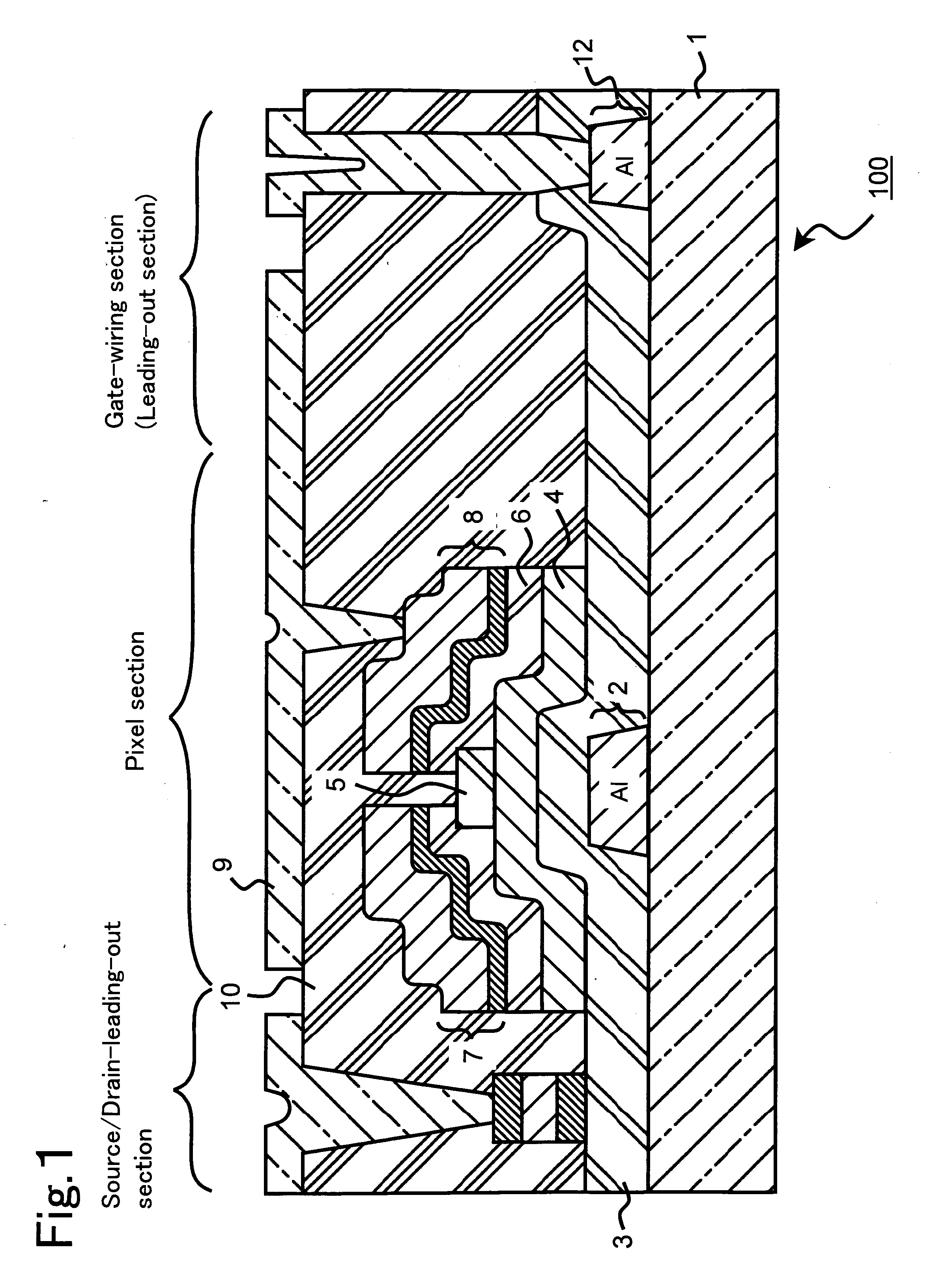

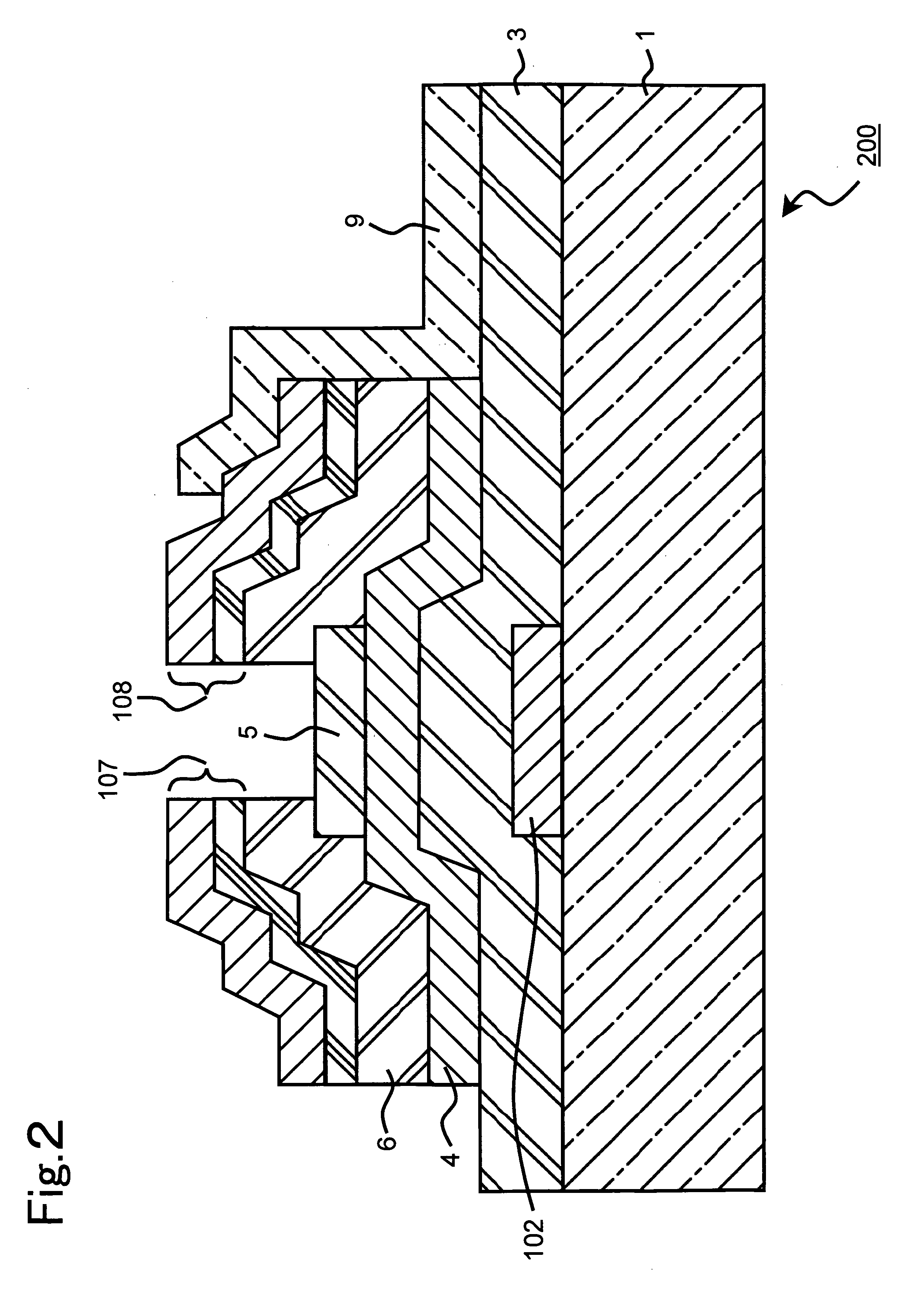

Thin film transistor, thin film transistor substrate, processes for producing the same, liquid crystal display using the same, and related devices and processes; and sputtering target, transparent electroconductive film formed by use of this,transparent electrode, and related devices and processes

InactiveUS20070170434A1Reduce light transmittanceConductive layers on insulating-supportsSemiconductor/solid-state device detailsIndiumLiquid-crystal display

Provided are a thin film transistor substrate having a transparent electroconductive film in which residues and so on resulting etching are hardly generated; a process for producing the same; and a liquid crystal display using this thin film transistor substrate. A thin film transistor substrate, comprising a transparent substrate, a source electrode formed over the transparent substrate, a drain electrode formed over the transparent substrate, and a transparent pixel electrode formed over the transparent substrate, wherein the transparent pixel electrode is a transparent electroconductive film which is made mainly of indium oxide, and further comprises one or two or more oxides selected from tungsten oxide, molybdenum oxide, nickel oxide and niobium oxide, and the transparent pixel electrode is electrically connected to the source electrode or the drain electrode; a process for producing the same; and a liquid crystal display using this thin film transistor substrate.

Owner:IDEMITSU KOSAN CO LTD

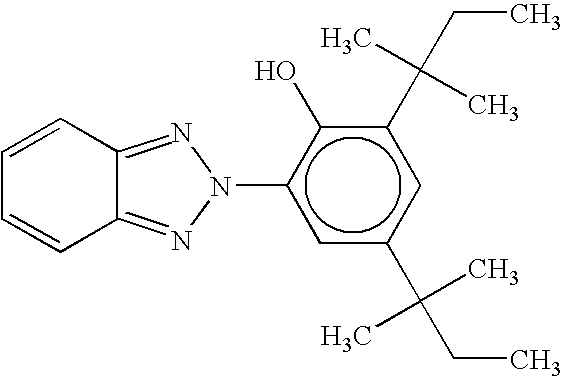

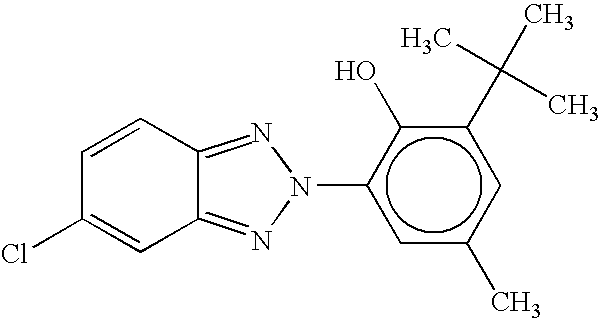

Interlayers Comprising Stabilized Tungsten Oxide Agents

ActiveUS20090035583A1Convenient lightingTimely maintenanceOrganic chemistrySynthetic resin layered productsPlasticizerUltraviolet lights

The present invention includes polymer interlayers that are used in multiple layer glazing panels. Interlayers of the present invention comprise a thermoplastic polymer, a plasticizer, a tungsten oxide agent, and a stabilizing agent that prevents the degradation of the tungsten oxide agent. Interlayers incorporating such components have improved ultraviolet light blocking character, and also maintain optical quality over time.

Owner:SOLUTIA INC

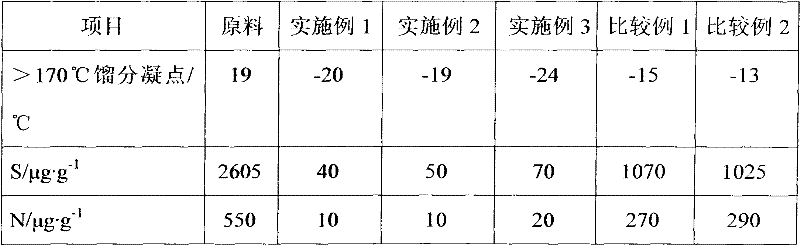

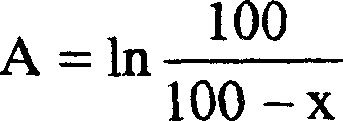

Hydrodewaxing catalyst and its preparation method

ActiveCN102451748AImprove the effect of impurity removalInhibit carbon depositionMolecular sieve catalystsRefining to eliminate hetero atomsImpurityChemistry

The invention discloses a hydrodewaxing catalyst and its preparation method. With the weight of the catalyst as the reference, the catalyst contains the following components of: by weight, 5-10% of tungsten oxide, 1-5% of nickel oxide, 40-50% of nanometer ZSM-5 molecular sieve, 10-40% of macroporous alumina and the balance being a binder. The catalyst is prepared by the following steps of: firstly kneading the nanometer ZSM-5 molecular sieve, macroporous alumina and the binder to prepare a carrier, dipping loaded active metal, and finally carrying out hydrothermal treatment. The hydrodewaxing catalyst provided by the invention has a good shape-selective catalysis function and simultaneously has a good hydrofinishing function, and is especially suitable for the hydrofinishing and pour point reduction processes of a waxy hydrocarbon oil material containing high content of impurities such as sulfur, nitrogen and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

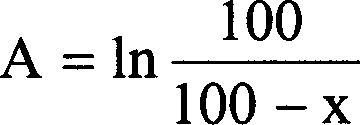

Hydrogenation catalyst of containing phosphor with alumina being as carrier, and preparation

ActiveCN1872960AHigh activityHigh desulfurization activityRefining to eliminate hetero atomsPhosphorMolybdenum

This invention provides a method for preparing hydrogenation catalyst containing phosphorus supported by aluminum oxide. The catalyst is composed of nickel oxide 1-10 wt.%, molybdena oxide and tungsten oxide 10-50 wt.%, phosphorus oxide 1-10 wt.%, and aluminum oxide. The molar ratio of tungsten oxide to molybdena oxide is 2.6-30. The method comprises introducing nickel oxide, molybdena oxide, tungsten oxide and phosphorus oxide into aluminum oxide carrier. The catalyst has such advantage as high hydrogenation activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phosphor-contained hydrogenation catalyst with silicon oxide-alumin as carrier and its production

ActiveCN1853781AHigh activityPhysical/chemical process catalystsRefining to eliminate hetero atomsPhosphorSilicon oxide

A P-contained hydrocatalyst with silicon oxide-aluminum oxide as its carrier contains nickel oxide (1-10 Wt%), molybdenum oxide and tungsten oxide (10-50), phosphorus oxide (1-9) and carrier (rest). It has high hydrorefining performance. It is prepared by introducing P, Mo, Ni and W to carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

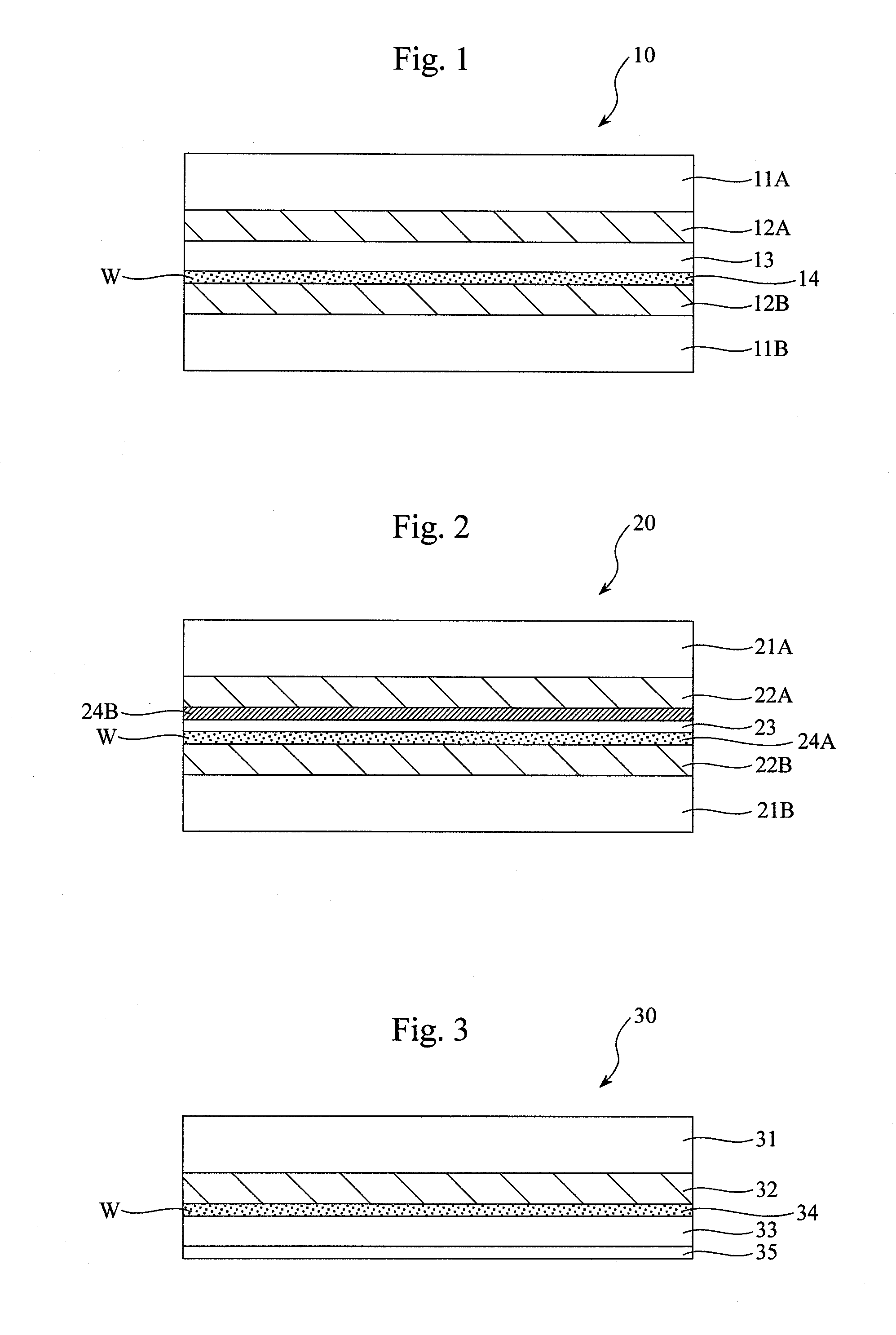

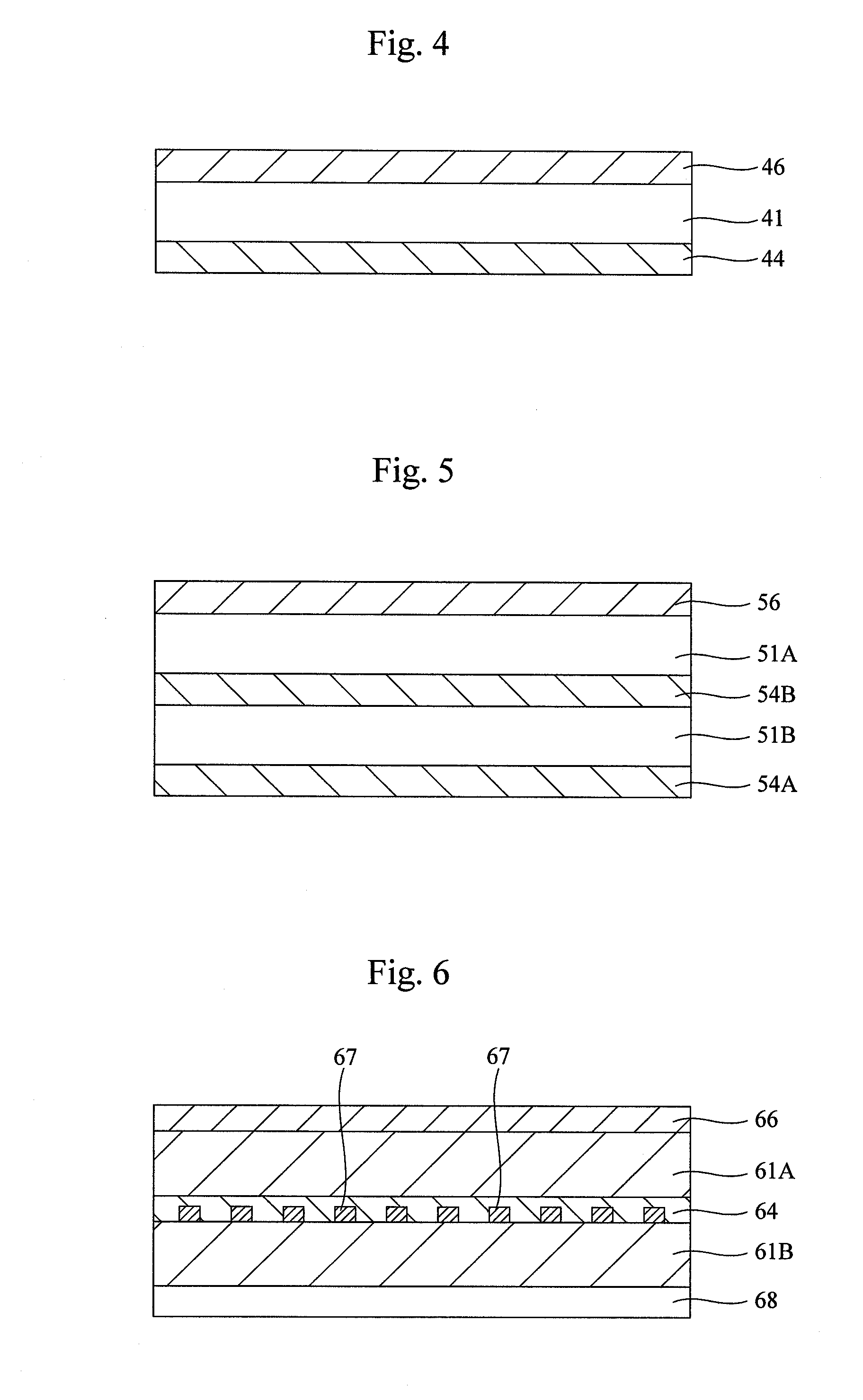

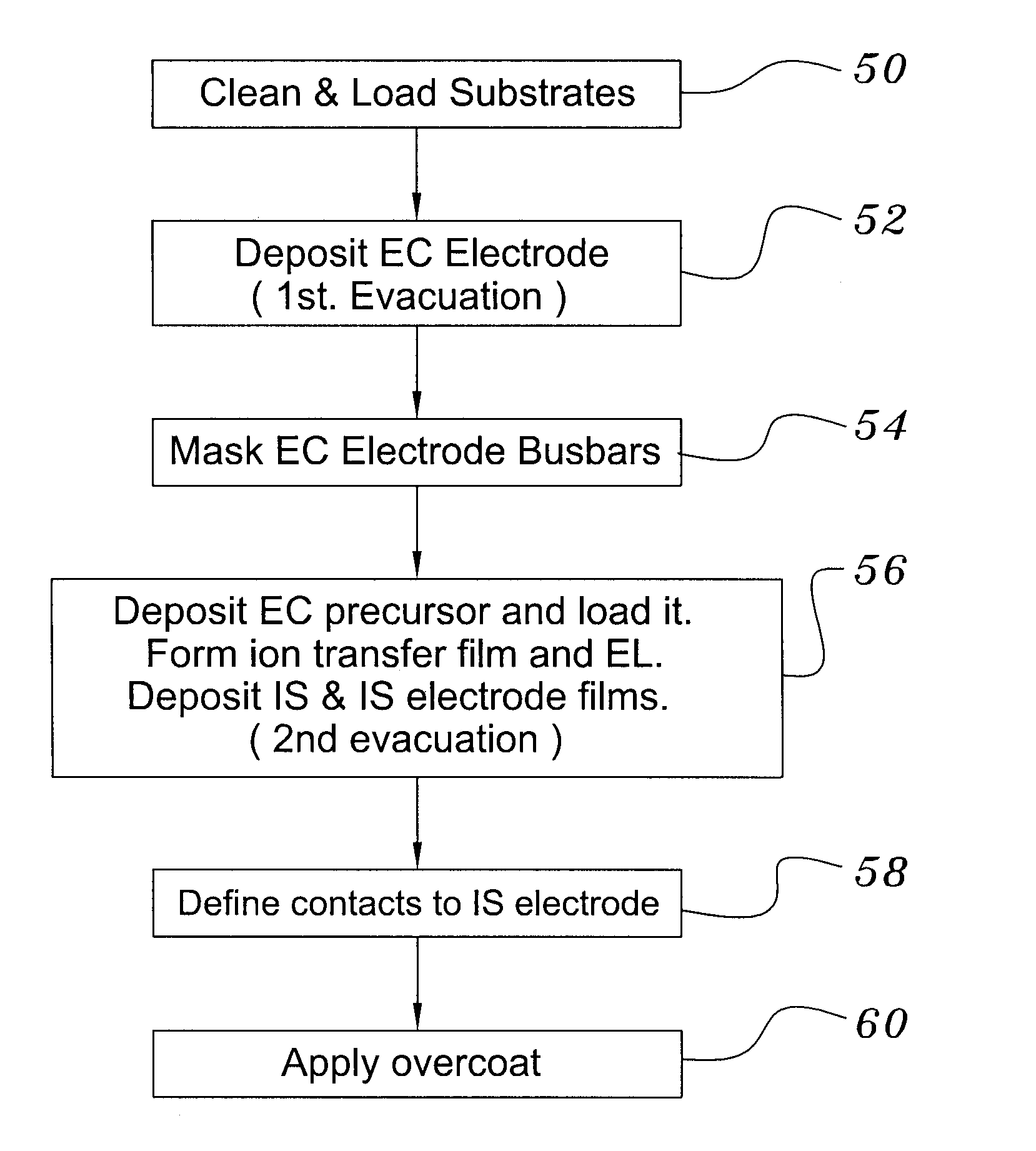

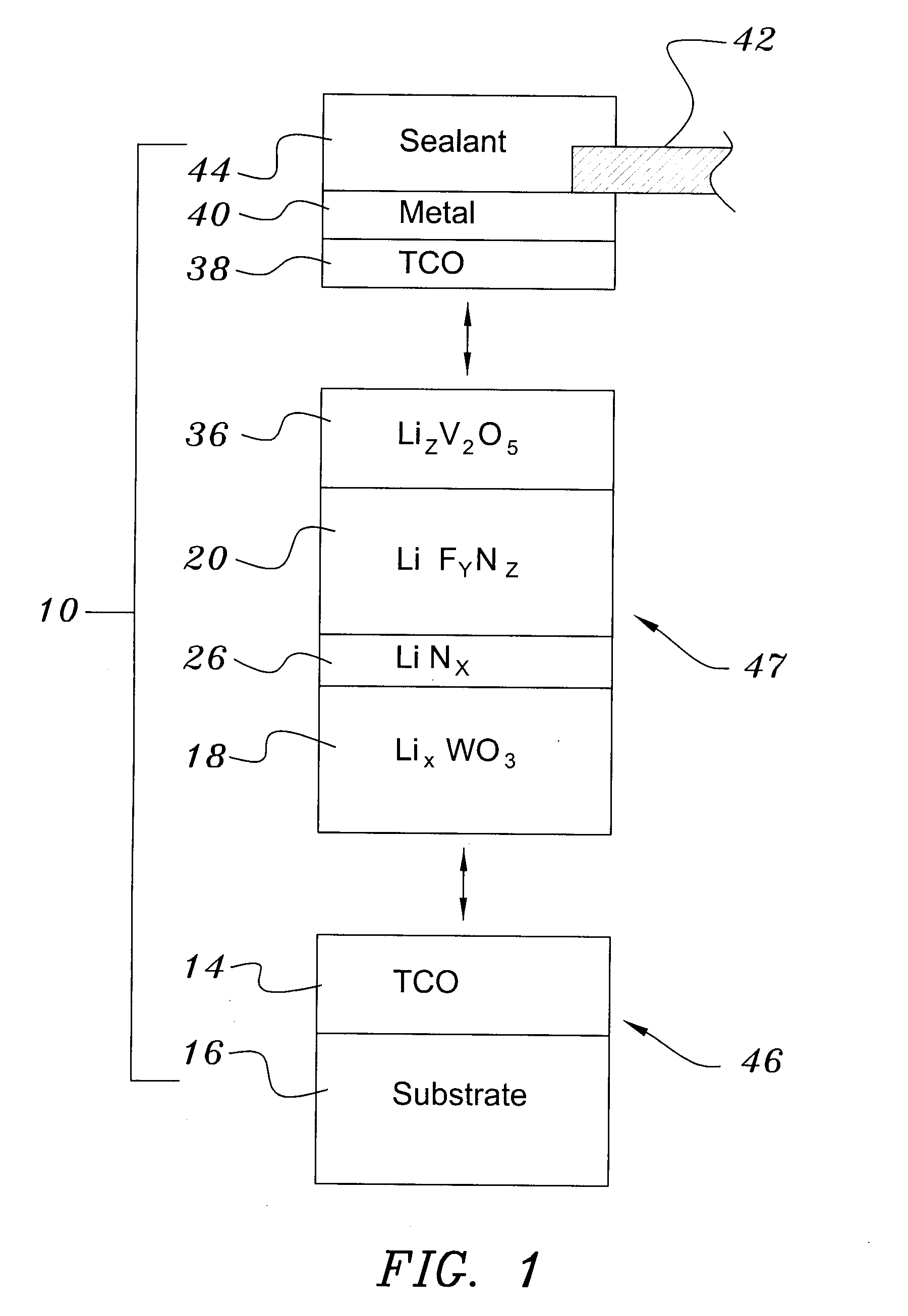

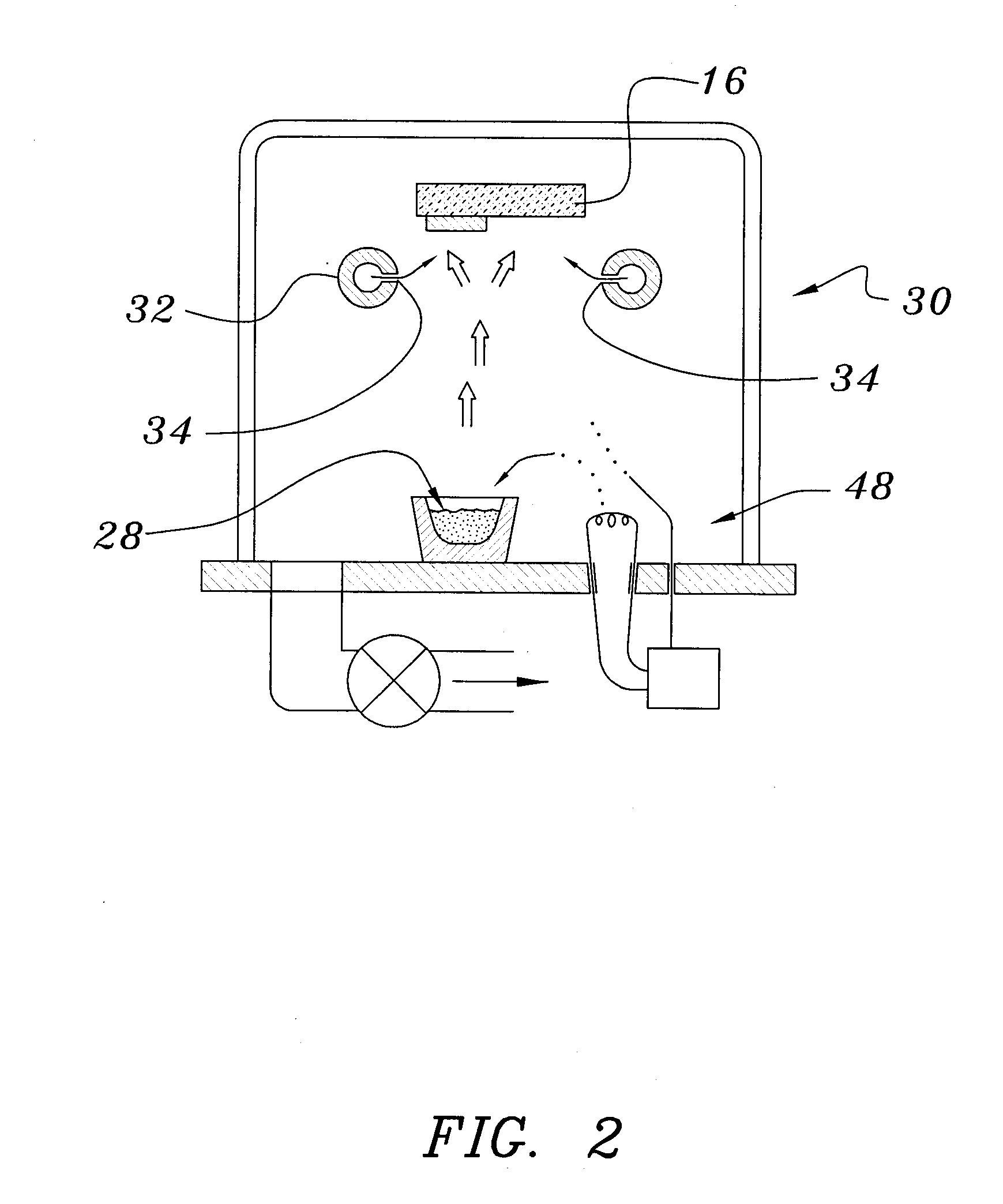

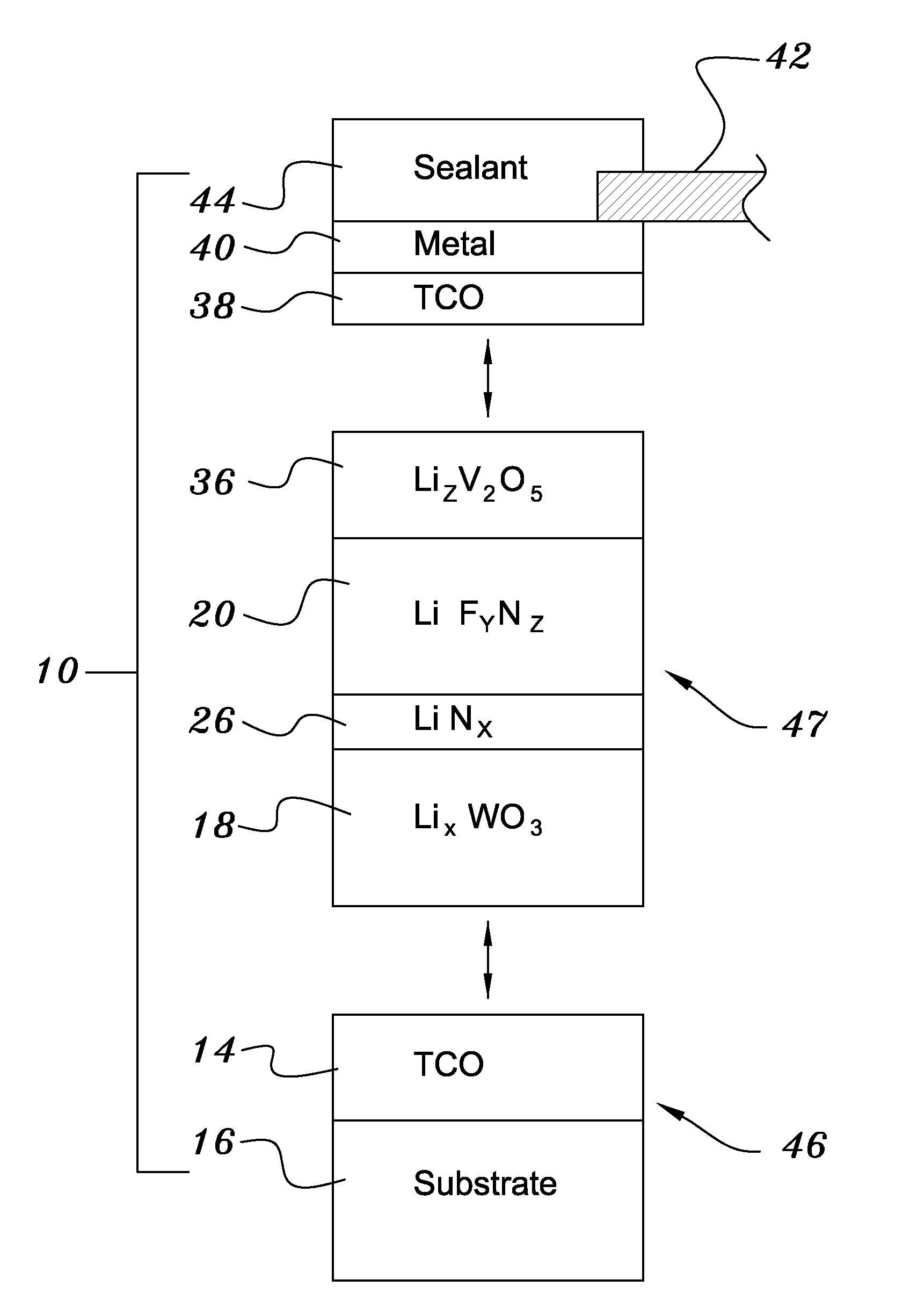

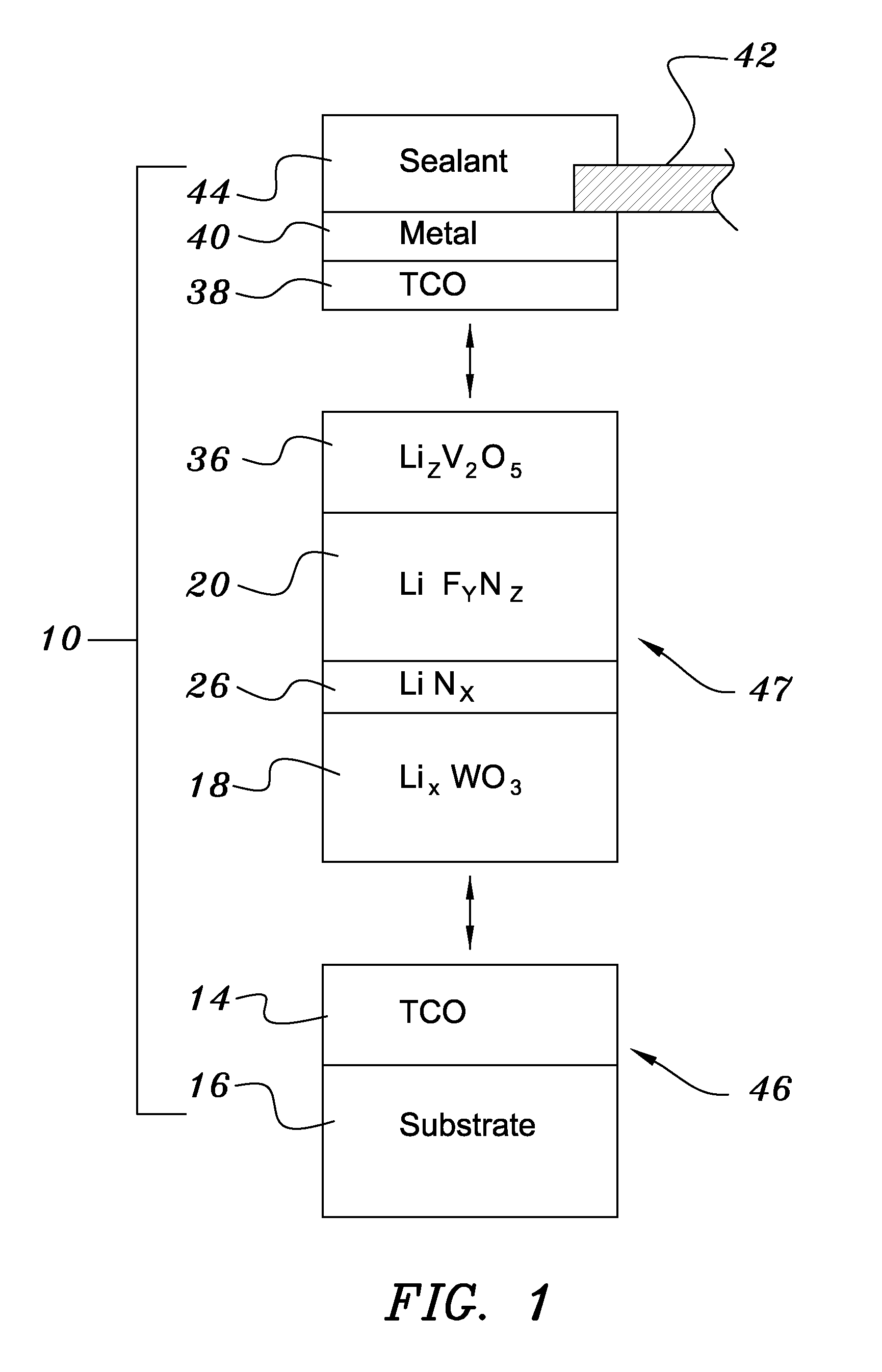

Electrochromic Device with Self-forming Ion transfer Layer and Lithium Fluoro-Nitride Electrolyte

ActiveUS20070292606A1Solve many processesReduce usageCoatingsSpecial surfacesEvaporationElectrochromism

A method of preparing an electrochromic device involves forming multiple layers of selected materials on a substrate in a vacuum processing chamber. A first of these layers is an electrode layer deposited directly on the substrate and used for making contact to a subsequently deposited precursor film, preferably tungsten oxide, from which an electrochromic layer is formed by lithium loading in the presence of ionized nitrogen. This not only forms the electrochromic layer by diffusion of the lithium into the tungsten oxide, but also forms a thin lithium nitride ion transfer layer on the then exposed surface. Subsequently, a lithium fluoro-nitride electrolyte layer is formed on the ion transfer layer by evaporation from a lithium fluoride source in the presence of ionized nitrogen. An ion storage layer, which may be a vanadium oxide and a transparent second electrode layer are subsequently vacuum deposited.

Owner:ECLIPSE ENERGY SYST

Electrochromic device with self-forming ion transfer layer and lithium-fluoro-nitride electrolyte

ActiveUS7265891B1Solve many processesReduce usageElectrolytic capacitorsNon-linear opticsEvaporationElectrochromism

An electrochromic device is prepared by forming multiple layers of selected materials on a substrate in a vacuum processing chamber. A first of these layers is an electrode layer deposited directly on the substrate and used for making contact to a subsequently deposited precursor film, preferably tungsten oxide, from which an electrochromic layer is formed by lithium loading in the presence of ionized nitrogen. This not only forms the electrochromic layer by diffusion of the lithium into the tungsten oxide, but also forms a thin lithium nitride ion transfer layer on the then exposed surface. Subsequently, a lithium fluoro-nitride electrolyte layer is formed on the ion transfer layer by evaporation from a lithium fluoride source in the presence of ionized nitrogen. An ion storage layer, which may be a vanadium oxide and a transparent second electrode layer are subsequently vacuum deposited.

Owner:ECLIPSE ENERGY SYST

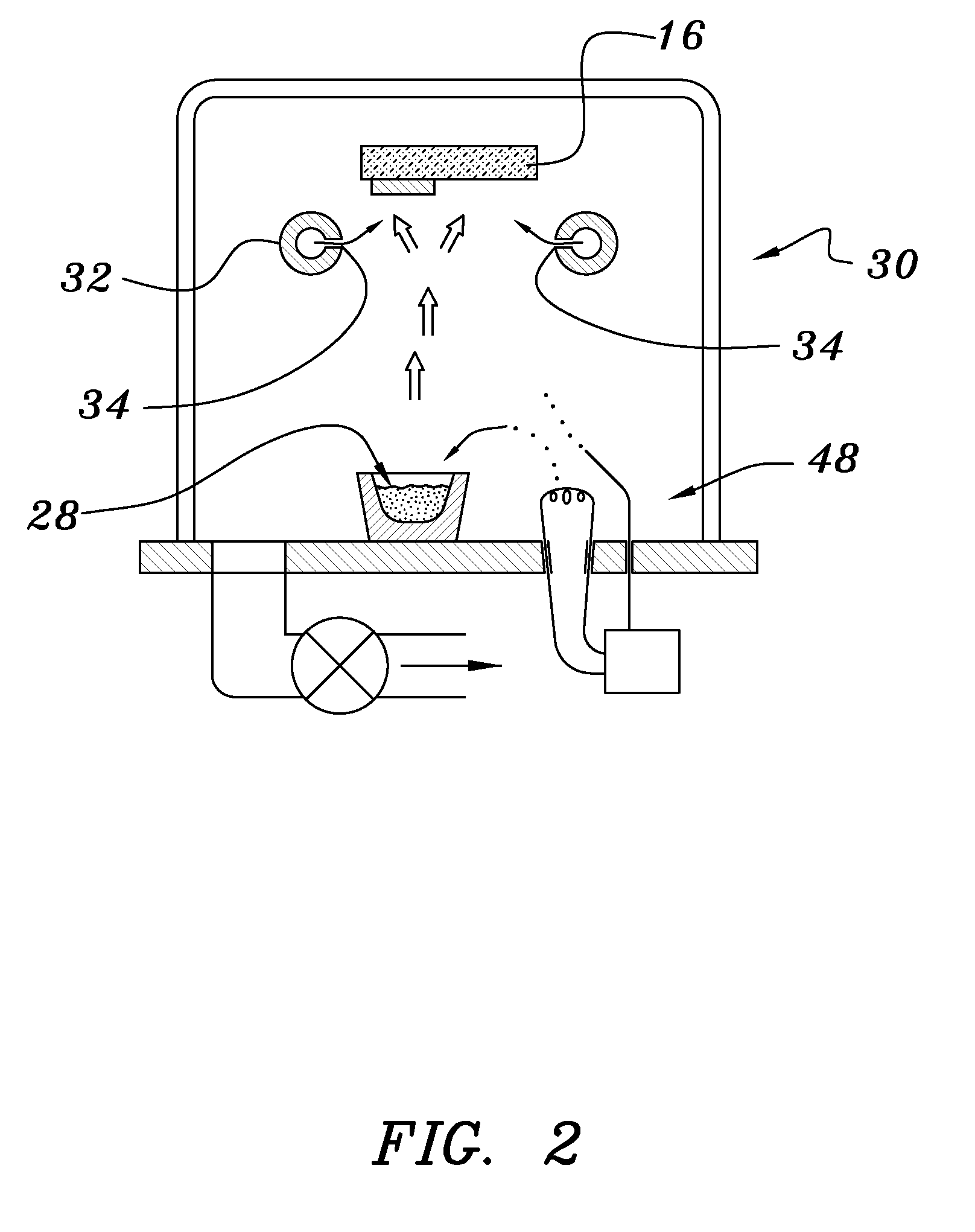

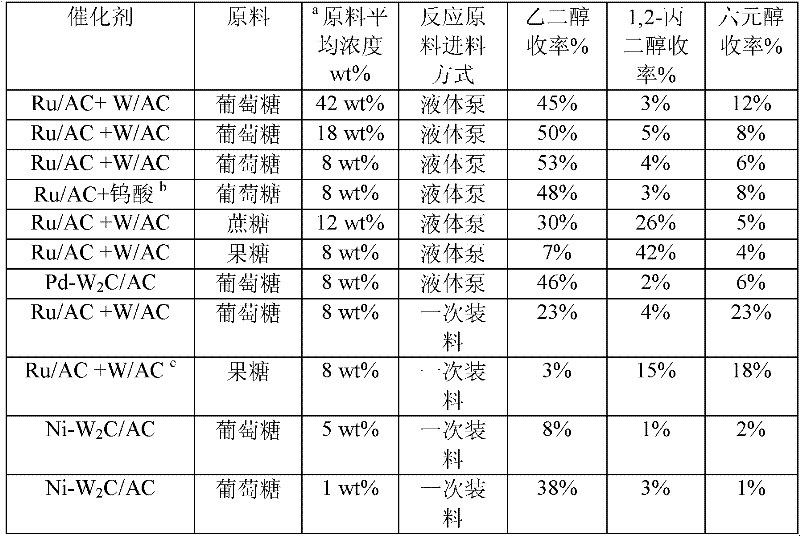

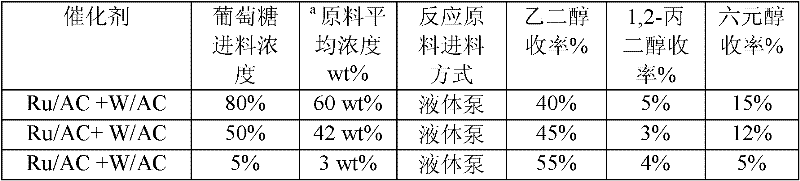

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

Hydrogenation catalyst of containing fluorin with alumina being as carrier, and preparation

ActiveCN1872959AHigh activityImprove denitrification activityRefining to eliminate hetero atomsDenitrificationAluminium oxide

This invention provides a method for preparing hydrogenation catalyst containing fluorine supported by aluminum oxide. The catalyst is composed of nickel oxide 1-10 wt.%, molybdena oxide and tungsten oxide 10-50 wt.%, fluorine 1-10 wt.%, and aluminum oxide. The method comprises introducing nickel oxide, molybdena oxide, tungsten oxide and fluorine into aluminum oxide carrier. The catalyst has such advantage as high hydrogenation and denitrification activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

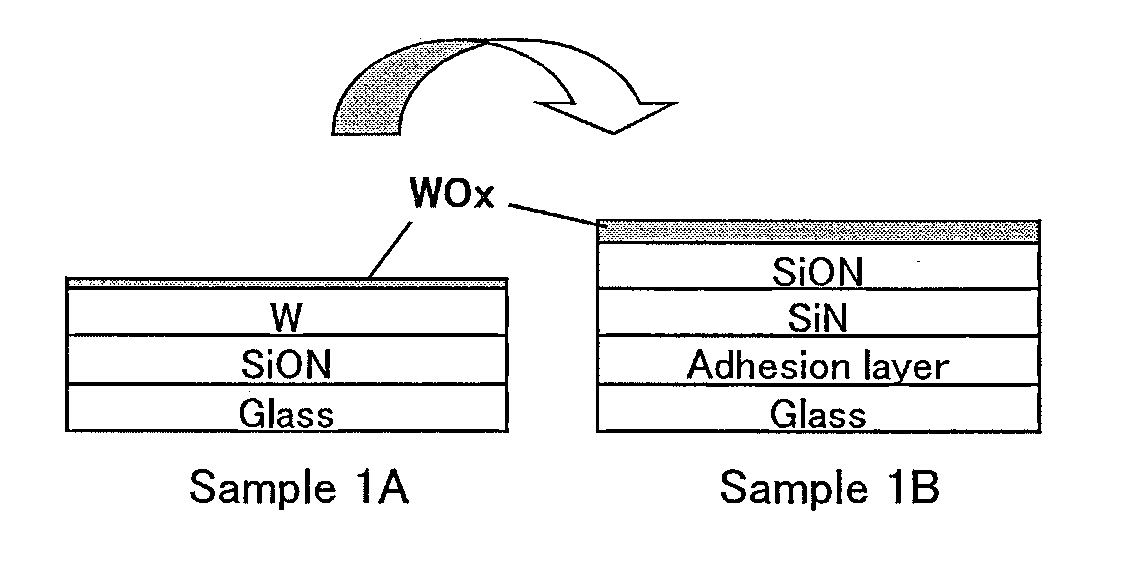

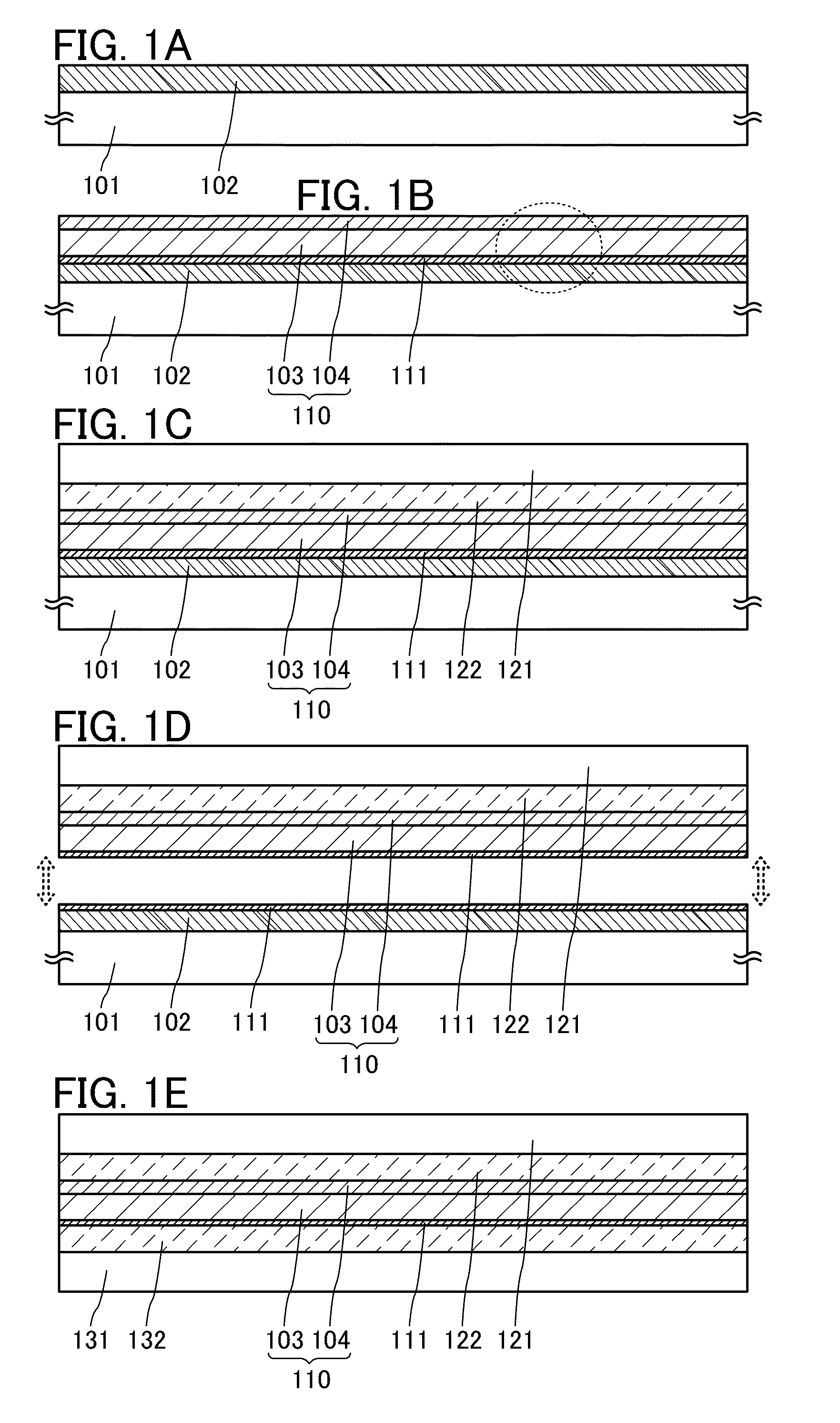

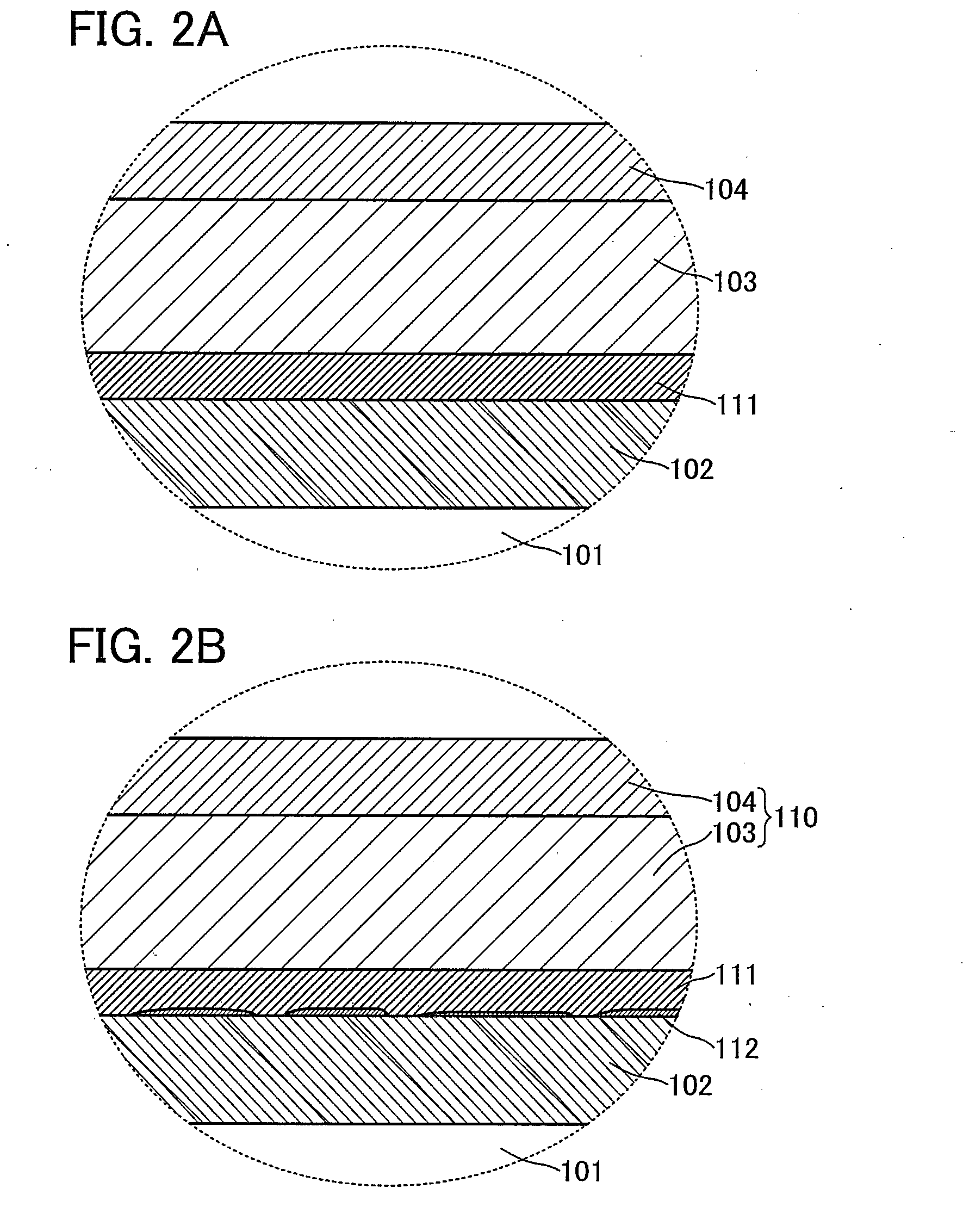

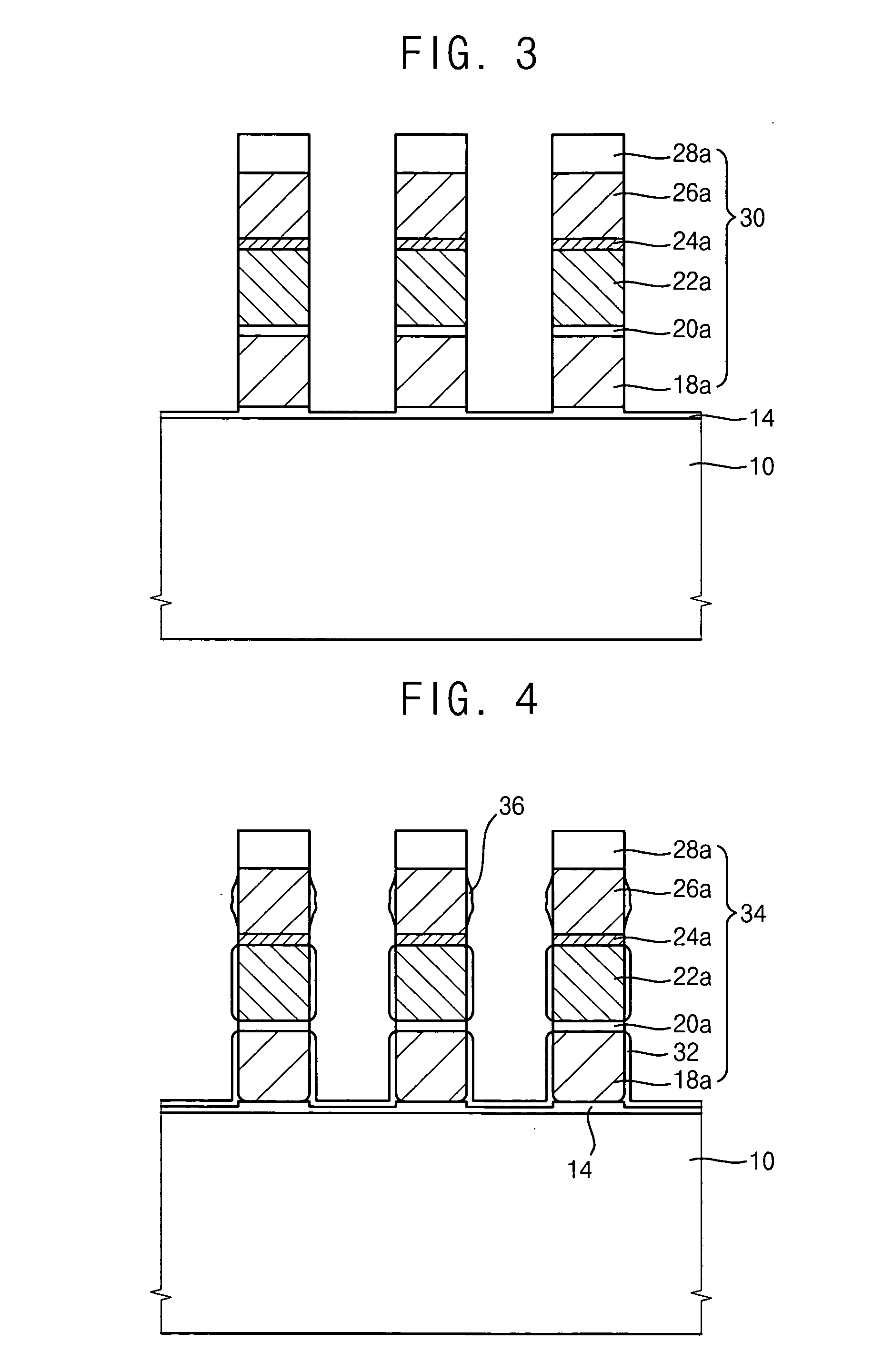

Peeling method, semiconductor device, and peeling apparatus

ActiveUS20140234664A1Good peeling effectImprove reliabilityTransistorLamination ancillary operationsDevice materialNitrogen

To improve peelability, yield in a peeling step, and yield in manufacturing a flexible device. A peeling method is employed which includes a first step of forming a peeling layer containing tungsten over a support substrate; a second step of forming, over the peeling layer, a layer to be peeled formed of a stack including a first layer containing silicon oxynitride and a second layer containing silicon nitride in this order and forming an oxide layer containing tungsten oxide between the peeling layer and the layer to be peeled; a third step of forming a compound containing tungsten and nitrogen in the oxide layer by heat treatment; and a fourth step of peeling the peeling layer from the layer to be peeled at the oxide layer.

Owner:SEMICON ENERGY LAB CO LTD

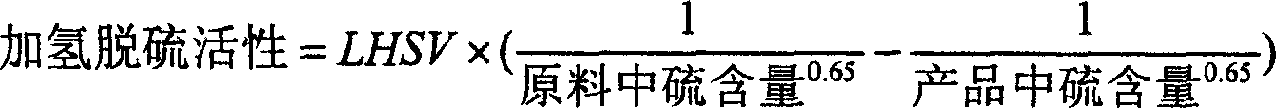

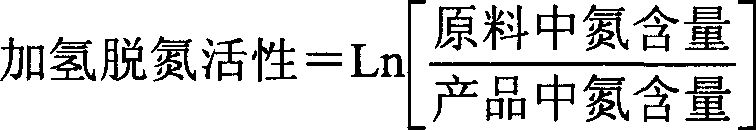

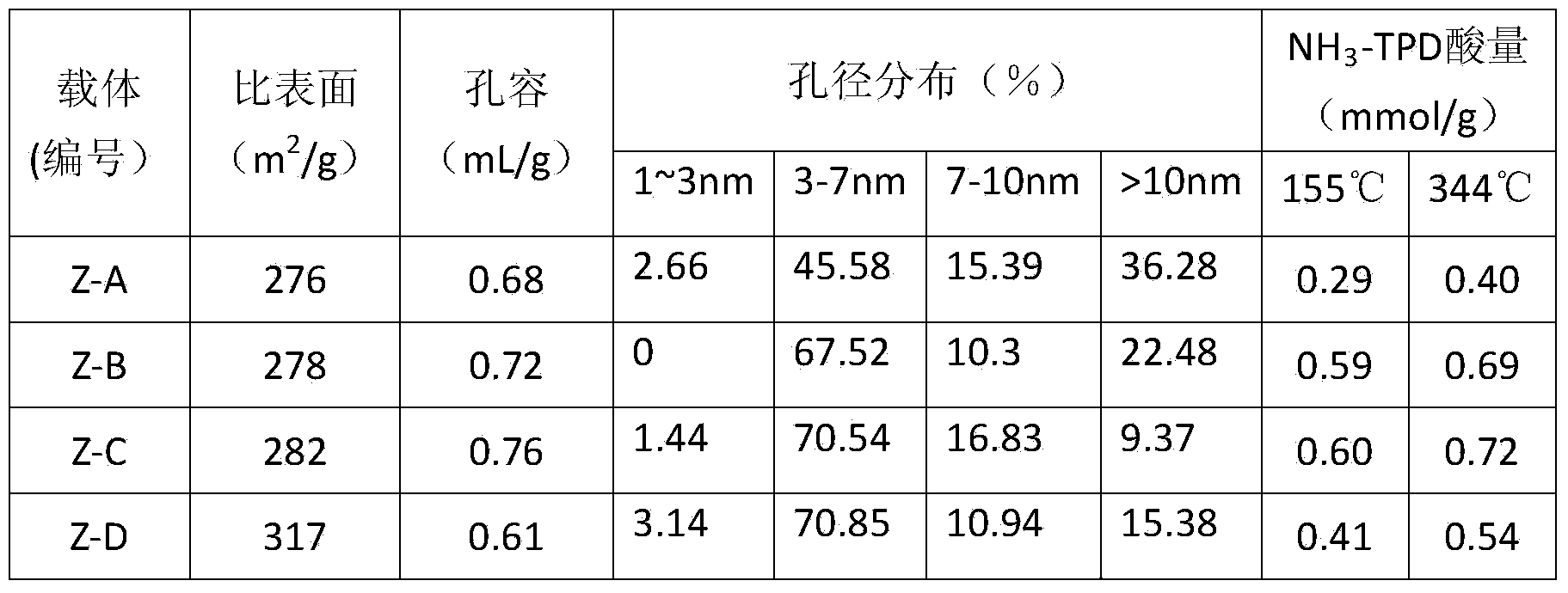

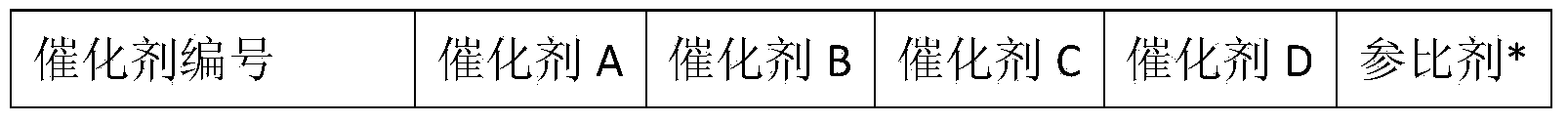

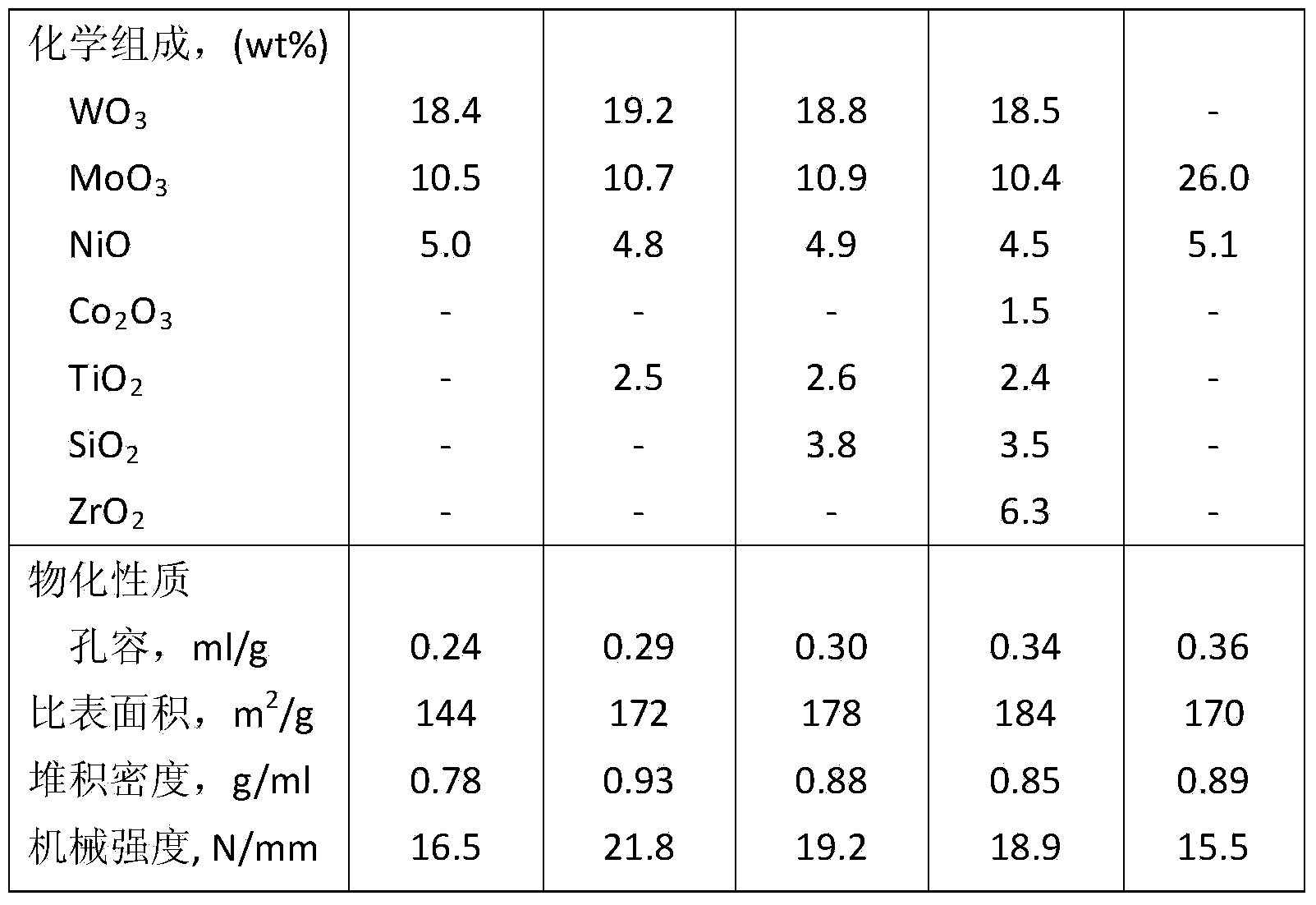

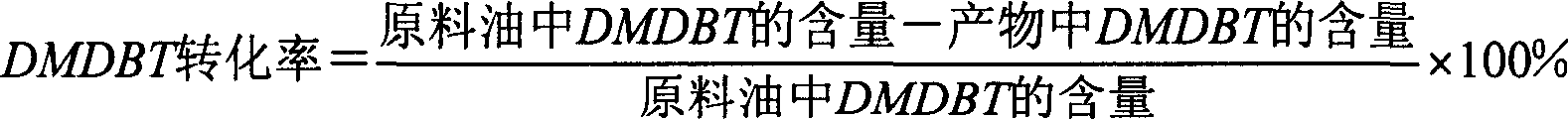

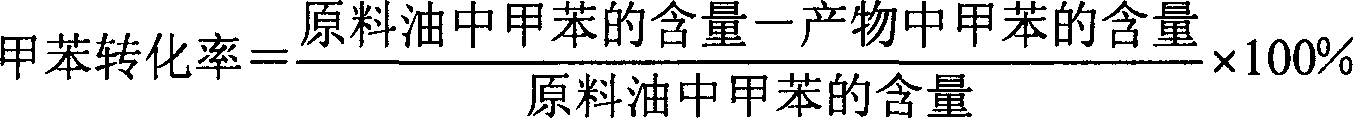

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

High capacity electrode and methods for its fabrication and use

InactiveUS20070099084A1Improve cycle lifeMinimised mechanical strainElectrode manufacturing processesSecondary cellsAlloyBuffering agent

A battery electrode comprises an electrically conductive substrate having an electrochemically active electrode composition supported thereupon. The composition includes an active material capable of reversibly alloying with lithium, which material shows a volume change upon such reversible alloying. The composition includes a buffering agent which accommodates the volume change in the active material and minimizes mechanical strain in the composition. The active composition may further include materials such as carbon. The active material may comprise silicon, aluminum, antimony, antimony oxides, bismuth, bismuth oxides, tin, tin oxides, chromium, chromium oxides, tungsten, and tungsten oxides or lithium alloys of the foregoing. The buffering agent may comprise a metal or a metal oxide or lithium alloys of the foregoing. Also disclosed are batteries which incorporate these electrodes, methods for the fabrication of the electrodes and methods for the fabrication and operation of the batteries.

Owner:A123 SYSTEMS LLC

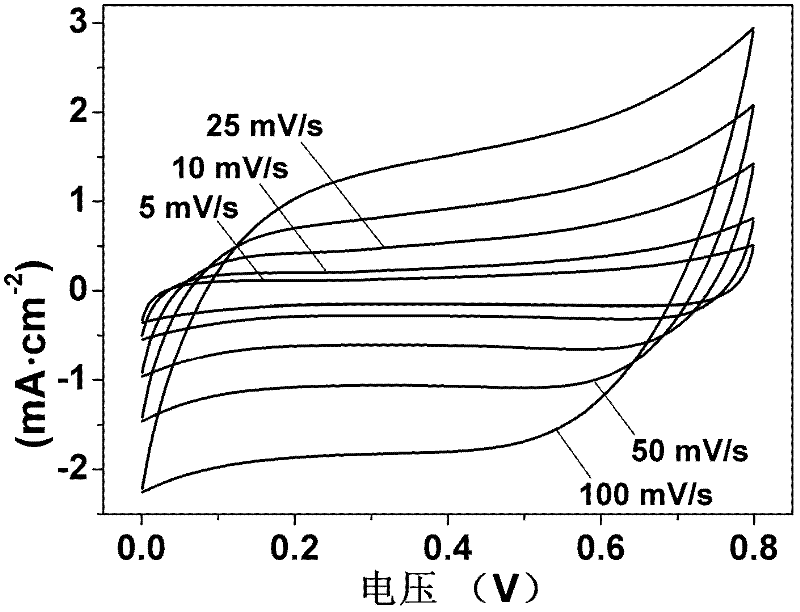

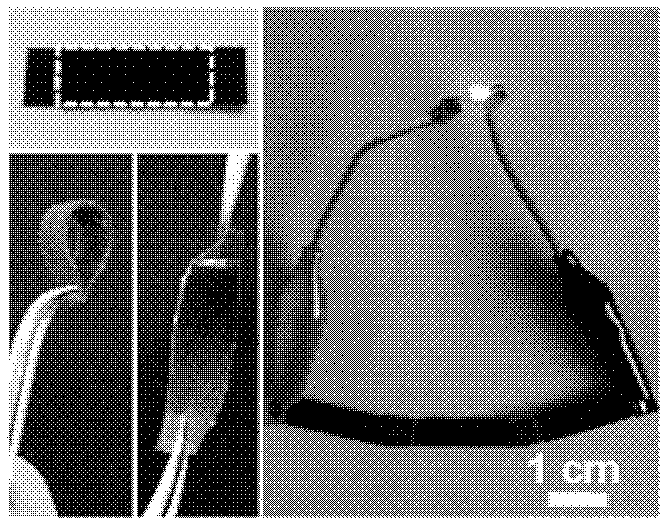

Preparation method of flexible super capacitor based on carbon cloth

InactiveCN102509635ASimple methodEasy to controlSolid electrolytic capacitorsSolid state electrolyteConductive polymer

The invention discloses a preparation method of a flexible super capacitor based on carbon cloth. The preparation method comprises the following steps of: firstly, growing carbon nanometer particles, carbon nanometer tubes, zinc oxides or tungsten oxide on the carbon cloth, or generating molybdenum dioxide on the carbon cloth; then, preparing manganese oxide or conductive polymers on the substances grown or generated on the carbon cloth for forming electrode materials; and finally, overlapping two electrode materials through solid electrolytes, separating the two electrode materials through a diaphragm and preparing the solid super capacitor. The flexible super capacitor prepared by the method provided by the invention has good electrochemical characteristics and the bending performance and has good application prospects in energy storage aspects.

Owner:HUAZHONG UNIV OF SCI & TECH

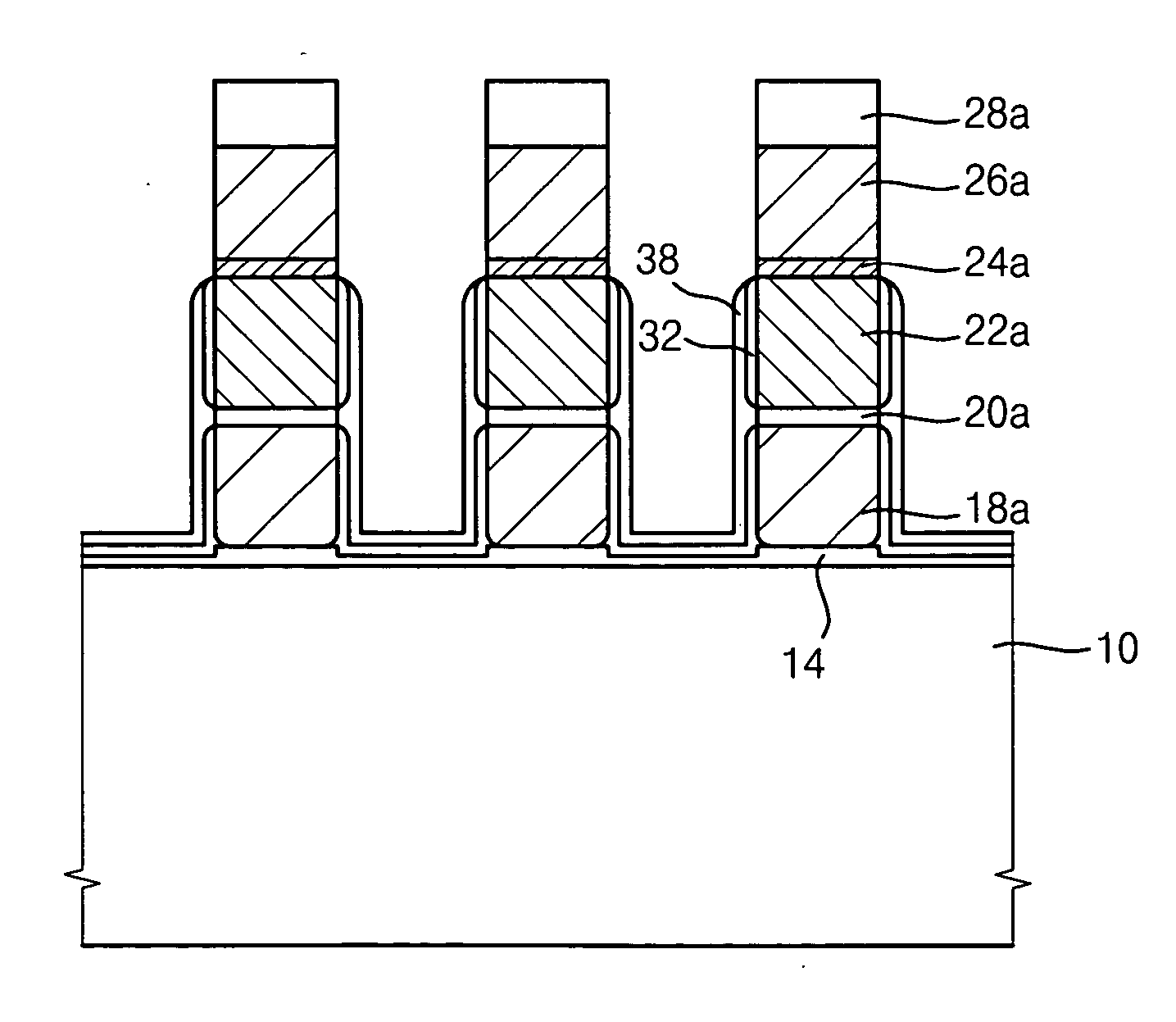

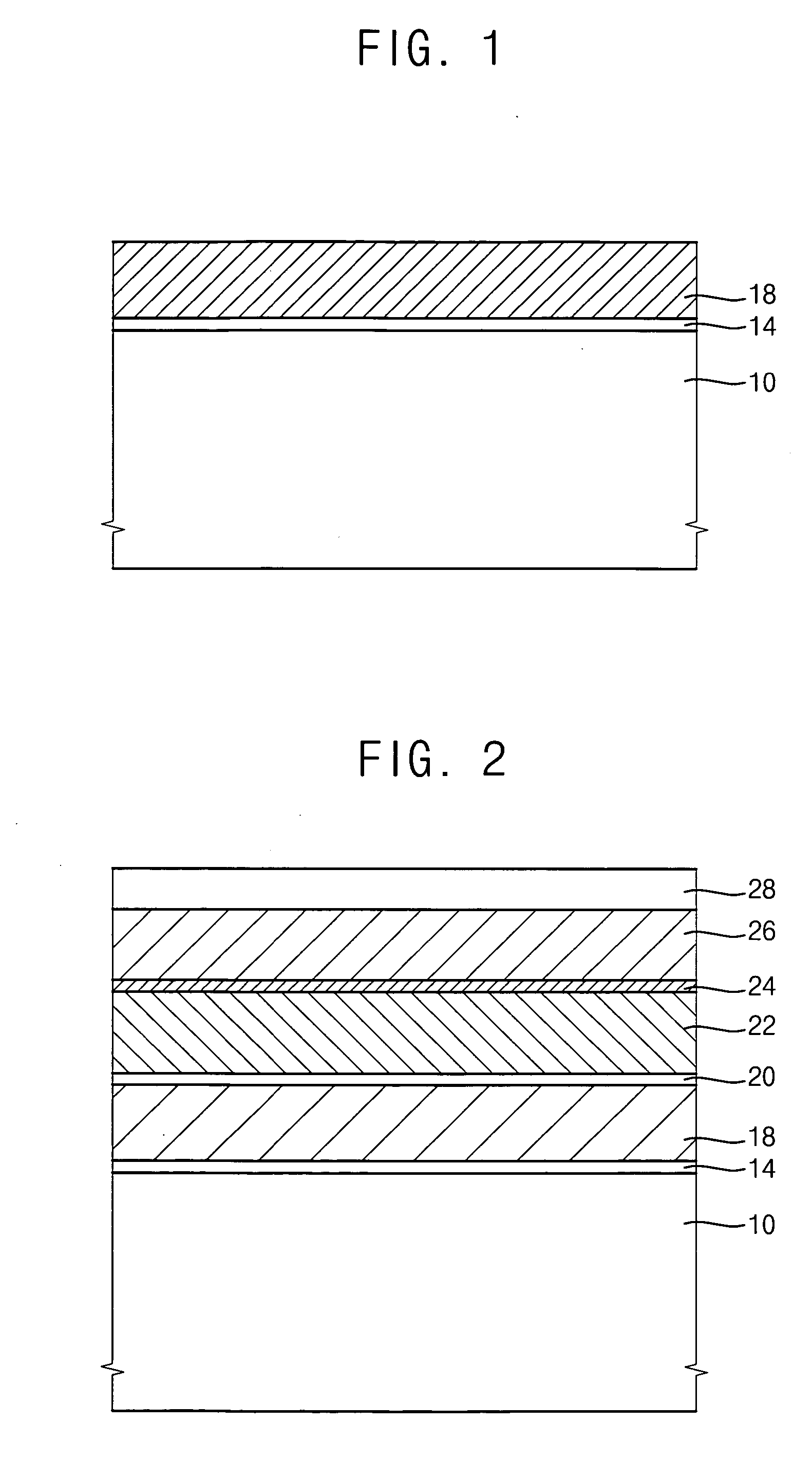

Method of forming a gate of a semiconductor device

ActiveUS20060110900A1Suppresses the generation of whiskersIncrease productionSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

In a method for forming a gate in a semiconductor device, a first preliminary gate structure is formed on a substrate. The first preliminary gate structure includes a gate oxide layer, a polysilicon layer pattern and a tungsten layer pattern sequentially stacked on the substrate. A primary oxidation process is performed using oxygen radicals at a first temperature for adjusting a thickness of the gate oxide layer to form a second preliminary gate structure having tungsten oxide. The tungsten oxide is reduced to a tungsten material using a gas containing hydrogen to form a gate structure. The tungsten oxide may not be formed on the gate structure so that generation of the whiskers may be suppressed. Thus, a short between adjacent wirings may not be generated.

Owner:SAMSUNG ELECTRONICS CO LTD

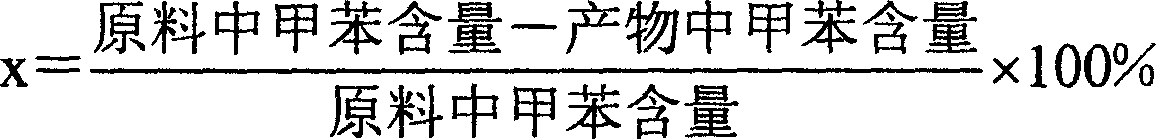

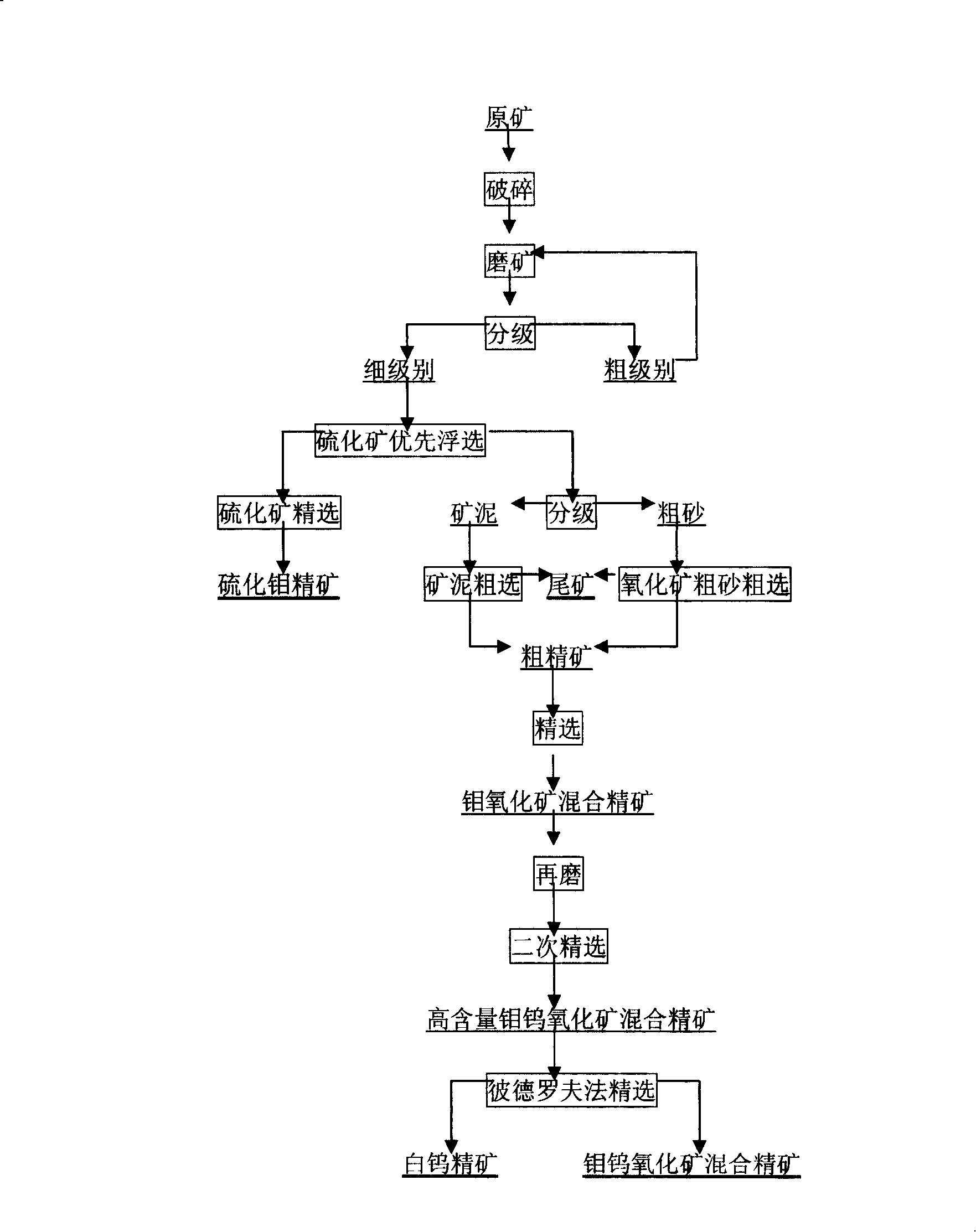

Processing technology for molybdenum and tungsten oxidized ore

InactiveCN101224441AHigh recovery rateResolve recovery rateSievingScreeningLaboratory testFatty acid

The invention discloses a beneficiation process of a molybdenum-tungsten oxide ore. The process of which is that: the liberation degree of ore crushing is higher than or equal to 70%; the flotation of molybdenum sulfide is preferred; the floatation tailing is classified and then a separation of slime and sand is carried out, wherein a slime and sand system takes alkali as the conditioning agent, sodium silicate as the depressant, and emulsified fatty acid as the collecting agent. The rough concentrate obtained from the separation of slime and sand is concentrated after being blended to obtain molybdenum-tungsten oxide ore collective concentrate. The collective concentrate is grounded again and added with the depressant, then a secondary concentrate can be gained through the concentration; the secondary concentrate is concentrated by means of Peter Roph method to obtain scheelite ore and oxidized molybdenum-tungsten beneficiation concentrate. The invention has the advantages that: 1. the invention discloses a beneficiation process flow for treating molybdenum-tungsten oxide ore; 2. the invention solves the difficulty of lowe technical specification of molybdenum - tungsten oxide ore beneficiation; 3. the invention completes laboratory tests and researches and fulfills industrialized implementation for the first time in China.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

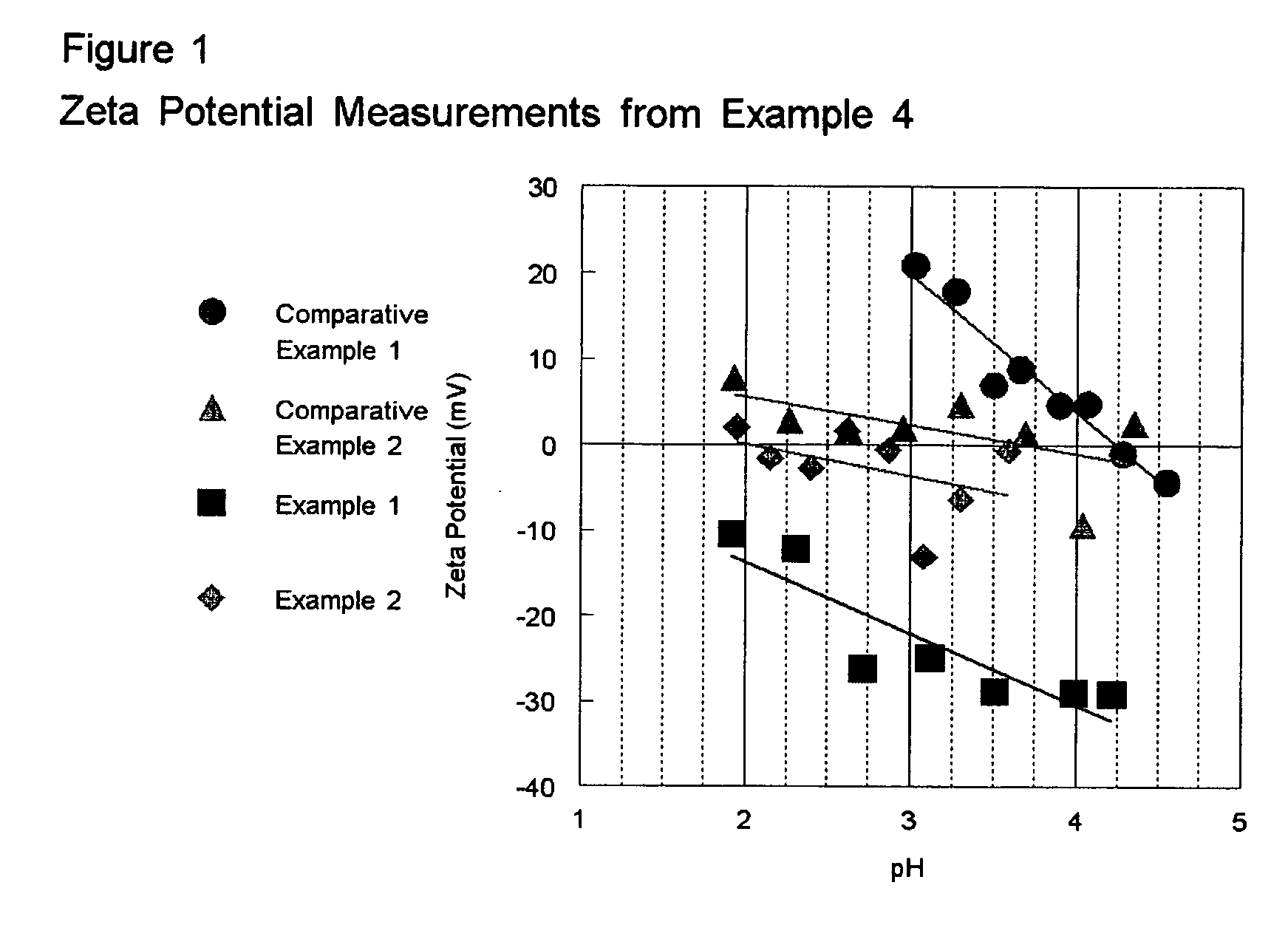

Photocatalyst dispersion liquid and process for producing the same

InactiveUS20090093361A1Improve photocatalytic activityGas treatmentDispersed particle separationTitanium oxideMaterials science

To provide a photocatalyst dispersion liquid obtained by dispersing titanium oxide photocatalyst particles and tungsten oxide photocatalyst particles in a dispersion medium, where the surfaces of both titanium oxide photocatalyst particles and tungsten oxide photocatalyst particles are charged positively or negatively. In the photocatalyst dispersion liquid, the titanium oxide photocatalyst particles and the tungsten oxide photocatalyst particles, which are dispersed in the dispersion medium, are not aggregated easily, and a solid-liquid separation is not generated.

Owner:SUMITOMO CHEM CO LTD

Methods for preparing ethylene glycol from polyhydroxy compounds

ActiveUS20120172633A1High yieldHigh selectivityOxygen-containing compound preparationOrganic compound preparationHydrogen pressureHeteropoly acid

This invention provides methods for producing ethylene glycol from polyhydroxy compounds such as cellulose, starch, hemicellulose, glucose, sucrose, fructose, fructan, xylose and soluble xylooligosaccharides. The methods uses polyhydroxy compounds as the reactant, a composite catalyst having active components comprising one or more transition metals of Groups 8, 9, or 10, including iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium, and platinum, as well as tungsten oxide, tungsten sulfide, tungsten hydroxide, tungsten chloride, tungsten bronze oxide, tungsten acid, tungstate, metatungstate acid, metatungstate, paratungstate acid, paratungstate, peroxotungstic acid, pertungstate, heteropoly acid containing tungsten. Reacting at a temperature of 120-300° C. and a hydrogen pressure of 1-13 MPa under hydrothermal conditions to accomplish one-step catalytic conversion. It realizes efficient, highly selective, high yield preparation of ethylene glycol and propylene glycol from polyhydroxy compounds. The advantage of processes disclosed in this invention include renewable raw material and high atom economy. At the same time, compared with other technologies that converts biomass raw materials into polyols, methods disclosed herein enjoy advantages including simple reaction process, high yield of targeted products, as well as easy preparation and low cost for the catalysts.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrogenation catalyst with silicon oxide-alumina as carrier and its preparation

ActiveCN1840618AHigh activityImprove hydrogenation activityRefining to eliminate hetero atomsSilicon oxideHydrocarbon

Owner:CHINA PETROLEUM & CHEM CORP +1

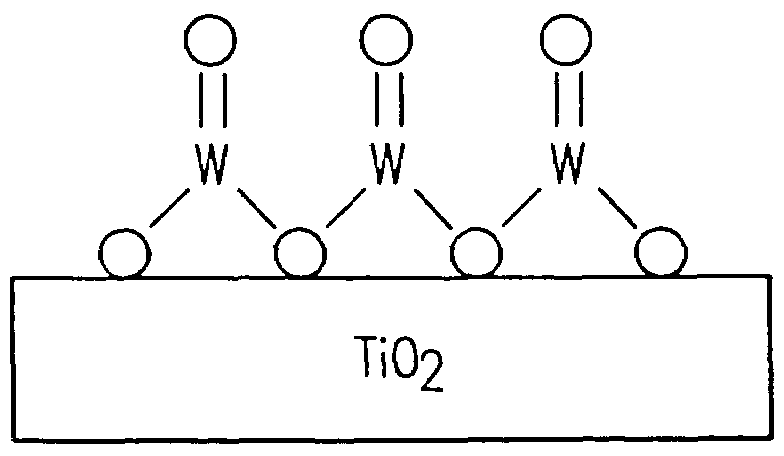

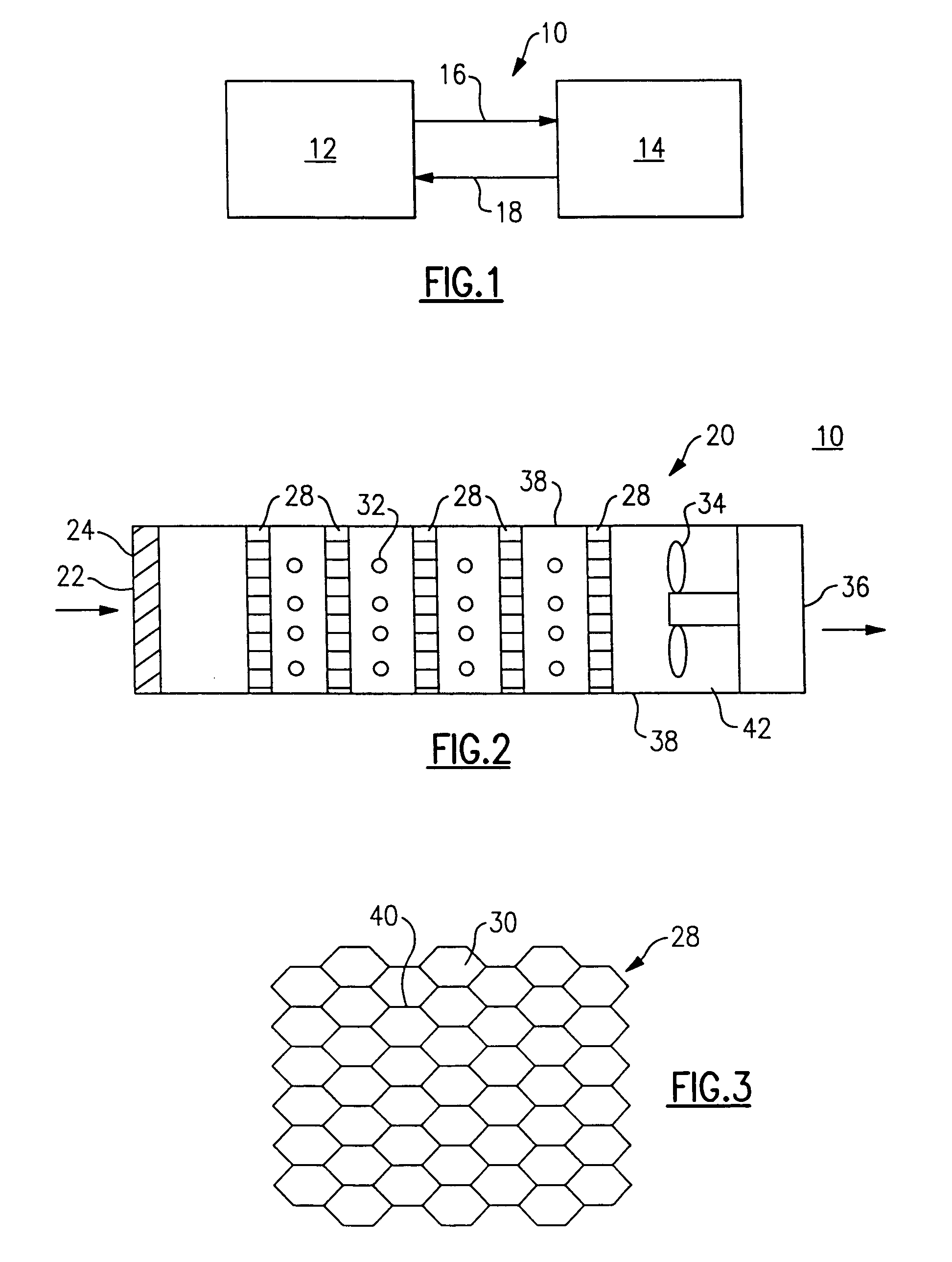

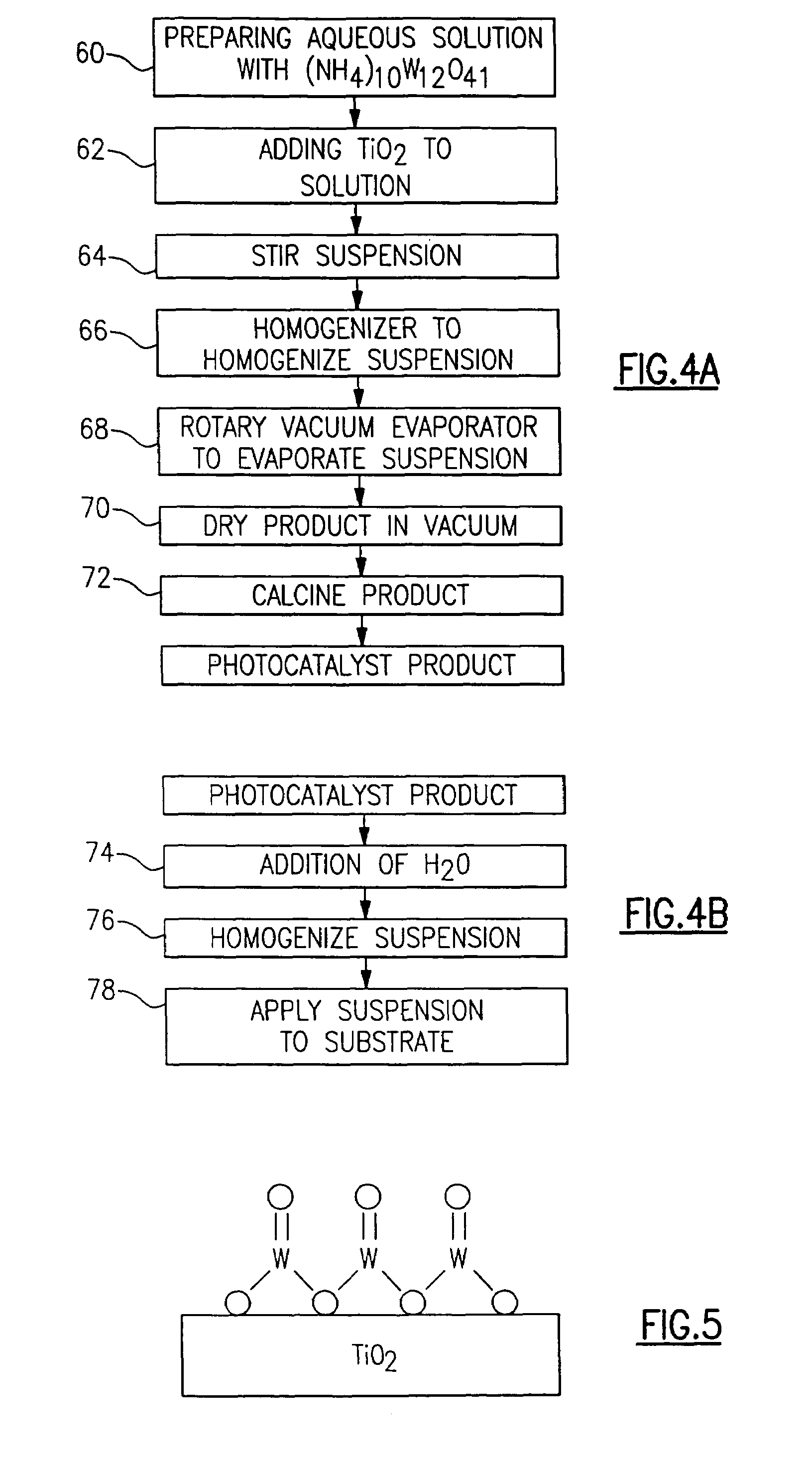

Tungsten oxide/titanium dioxide photocatalyst for improving indoor air quality

InactiveUS7255831B2PurifiesPurifying airIncadescent screens/filtersDispersed particle separationIndoor air qualityUltraviolet lights

A tungsten oxide / titanium dioxide photocatalyst coating oxidizes contaminants in the air that adsorb onto the coating into water, carbon dioxide, and other substances. The tungsten oxide forms a monolayer on the titanium dioxide. When photons of the ultraviolet light are absorbed by the tungsten oxide / titanium dioxide photocatalyst coating, an electron is promoted from the valence band to the conduction band, producing a hole in the valence band. The holes in the valence band react with water applied on the tungsten oxide / titanium dioxide photocatalyst coating, forming reactive hydroxyl radicals. When a contaminant in the air is adsorbed onto the tungsten oxide / titanium dioxide photocatalyst, the hydroxyl radical attacks the contaminant, abstracting a hydrogen atom from the contaminant. The hydroxyl radical oxidizes the contaminant, producing water, carbon dioxide, and other substances. The tungsten oxide / titanium dioxide photocatalytic coating has low sensitivity to humidity variations.

Owner:CARRIER CORP

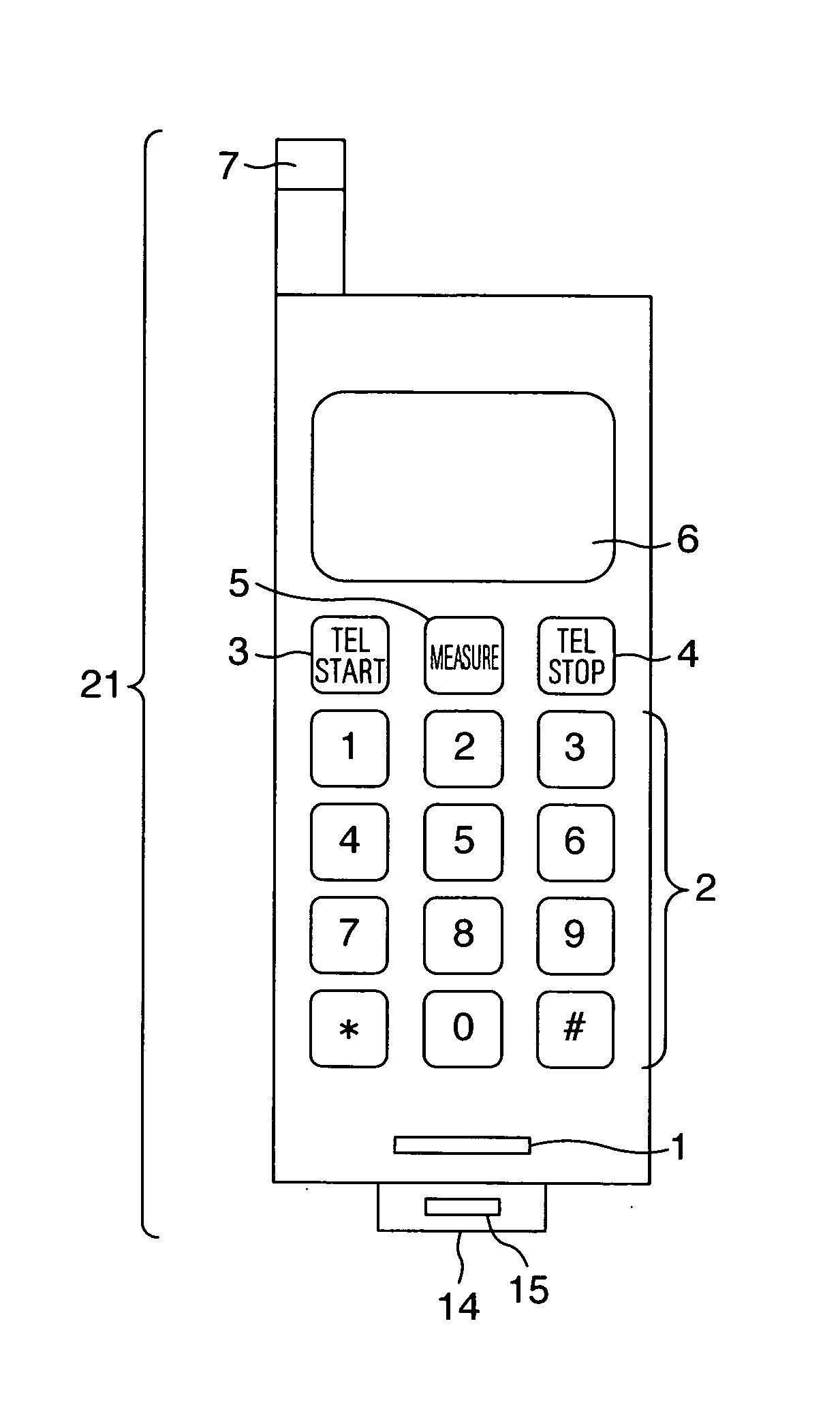

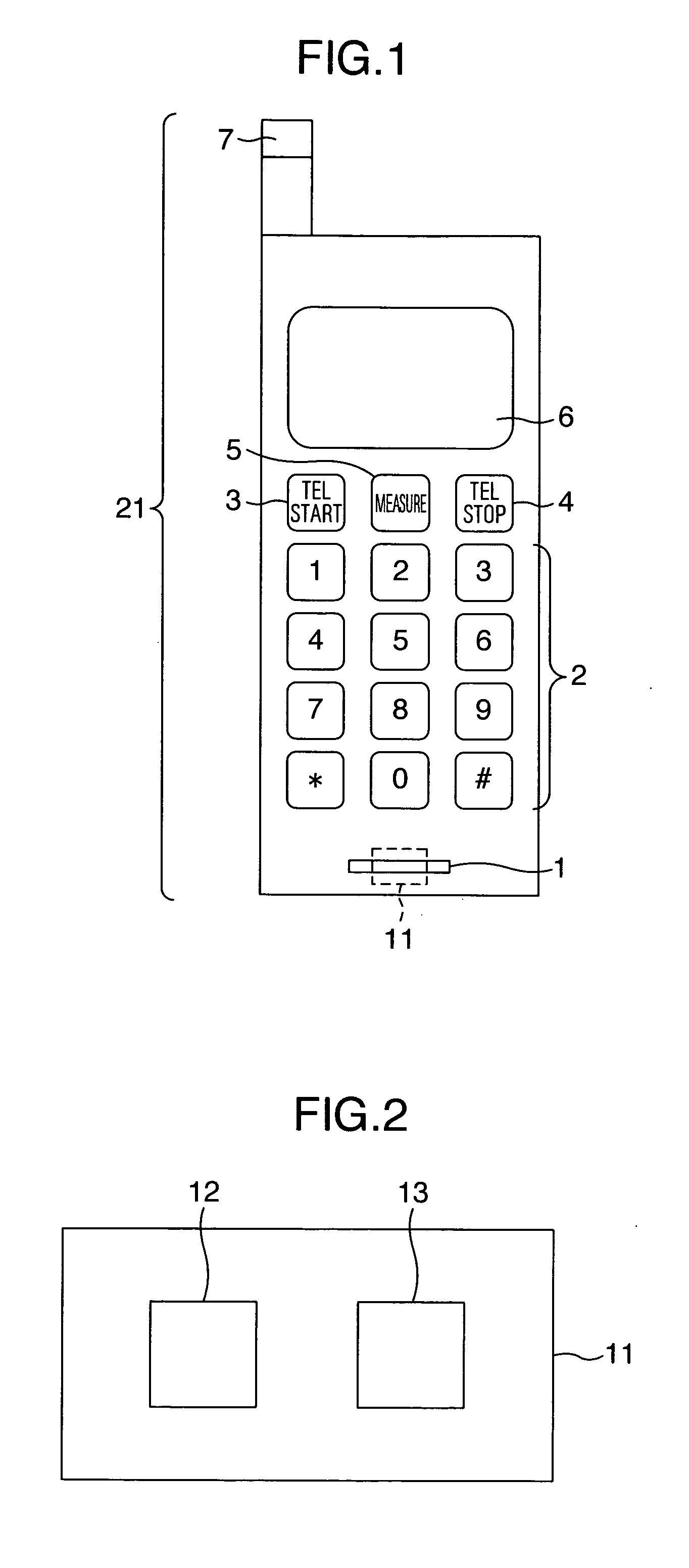

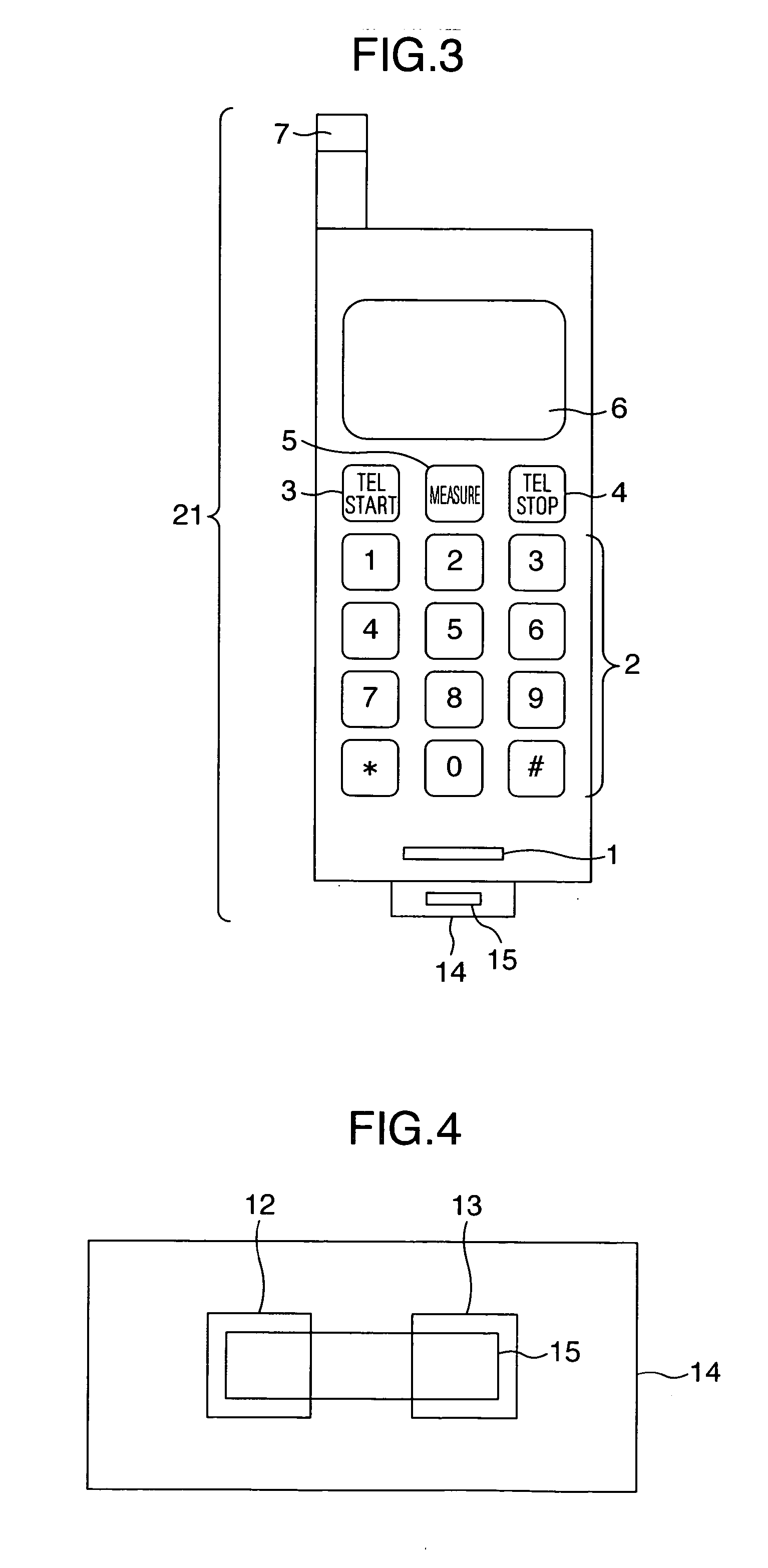

Portable health check apparatus and expiration analysis service method using the same

InactiveUS20060058697A1Easy authenticationNot burdenData processing applicationsPerson identificationHydrogenInformation analysis

A portable health check apparatus incorporating a highly sensitive and compact expiration analysis sensor and an expiration analysis service offered to a specified user at a specified time. Hydrogen is detected using tungsten oxide produced through metalorganic chemical vapor deposition process. The apparatus has a unit for performing personal authentication by using, for example, a voiceprint of a user. The apparatus is also arranged to call up a user at a predetermined time through a cellular phone. Further, a center server receives detection information of an expiration component via a communication circuit, analyzes or statistically processes the detection information, collates a result of the analysis or statistic process with advice information stored in a database and transmits advice information based on a result of the collation from the server to the cellular phone of the user.

Owner:HITACHI LTD

High activity titania supported metal oxide DeNOx catalysts

ActiveUS20060084569A1Reducing the pH of the slurryHigh activityHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystPhysical chemistry

The present invention is directed to high activity titanium oxide DeNOx catalysts. In preferred embodiments, by depositing vanadium oxide on a titania supported metal oxide such as tungsten oxide, an improved catalyst may be generated. This catalyst may be used in the treatment of exhaust from sources such as automobiles and industrial plants.

Owner:TRONOX LLC

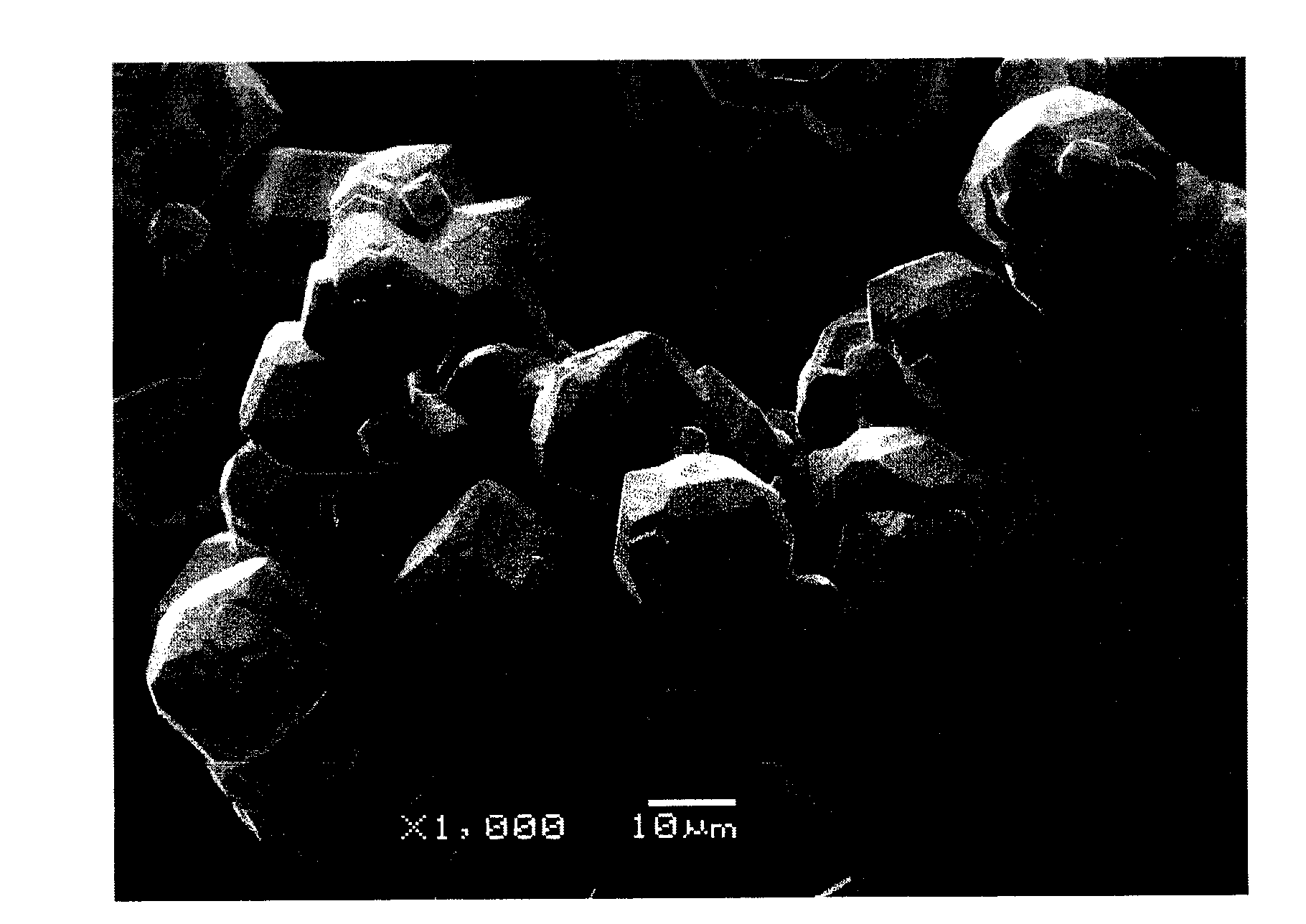

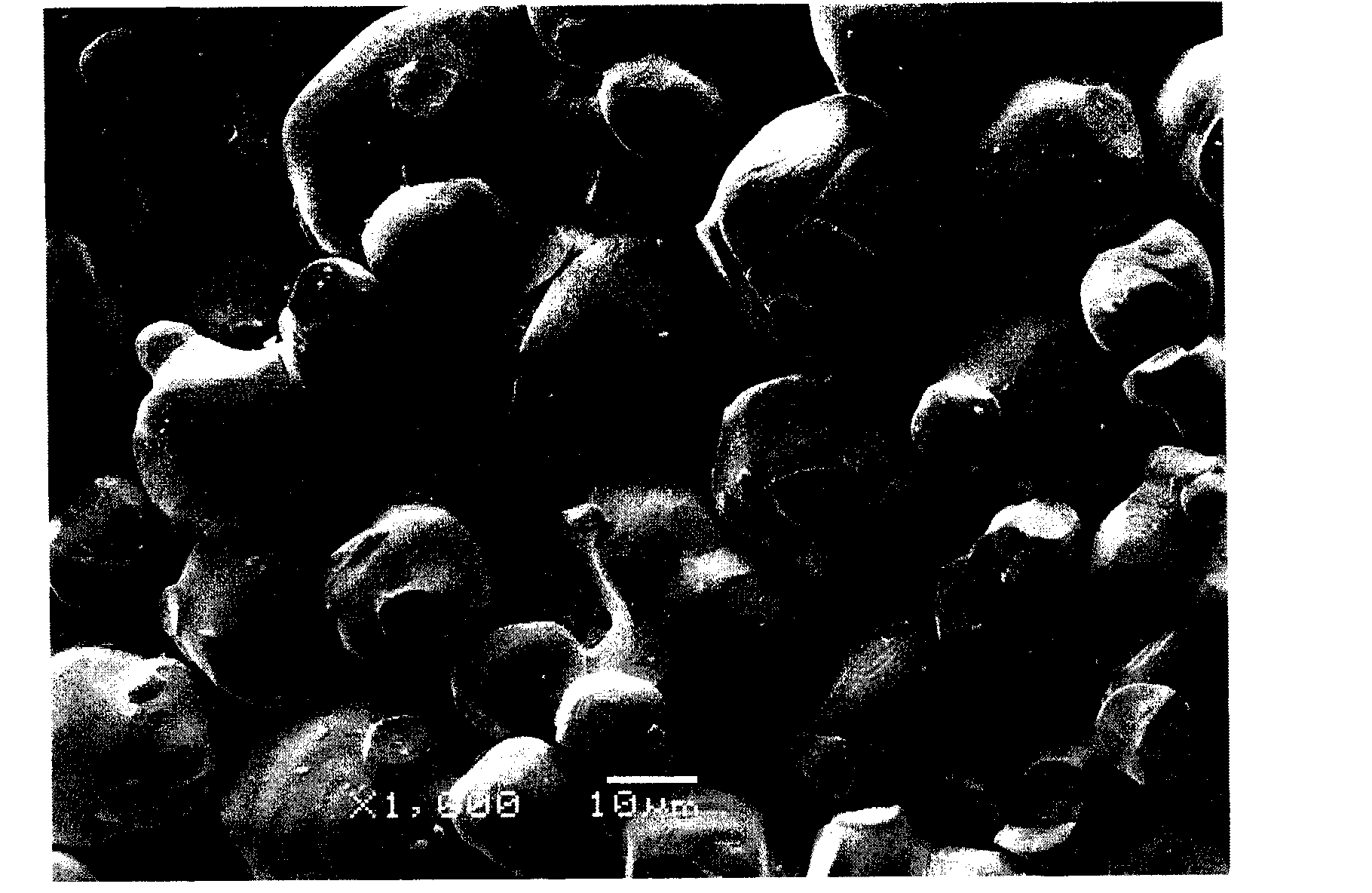

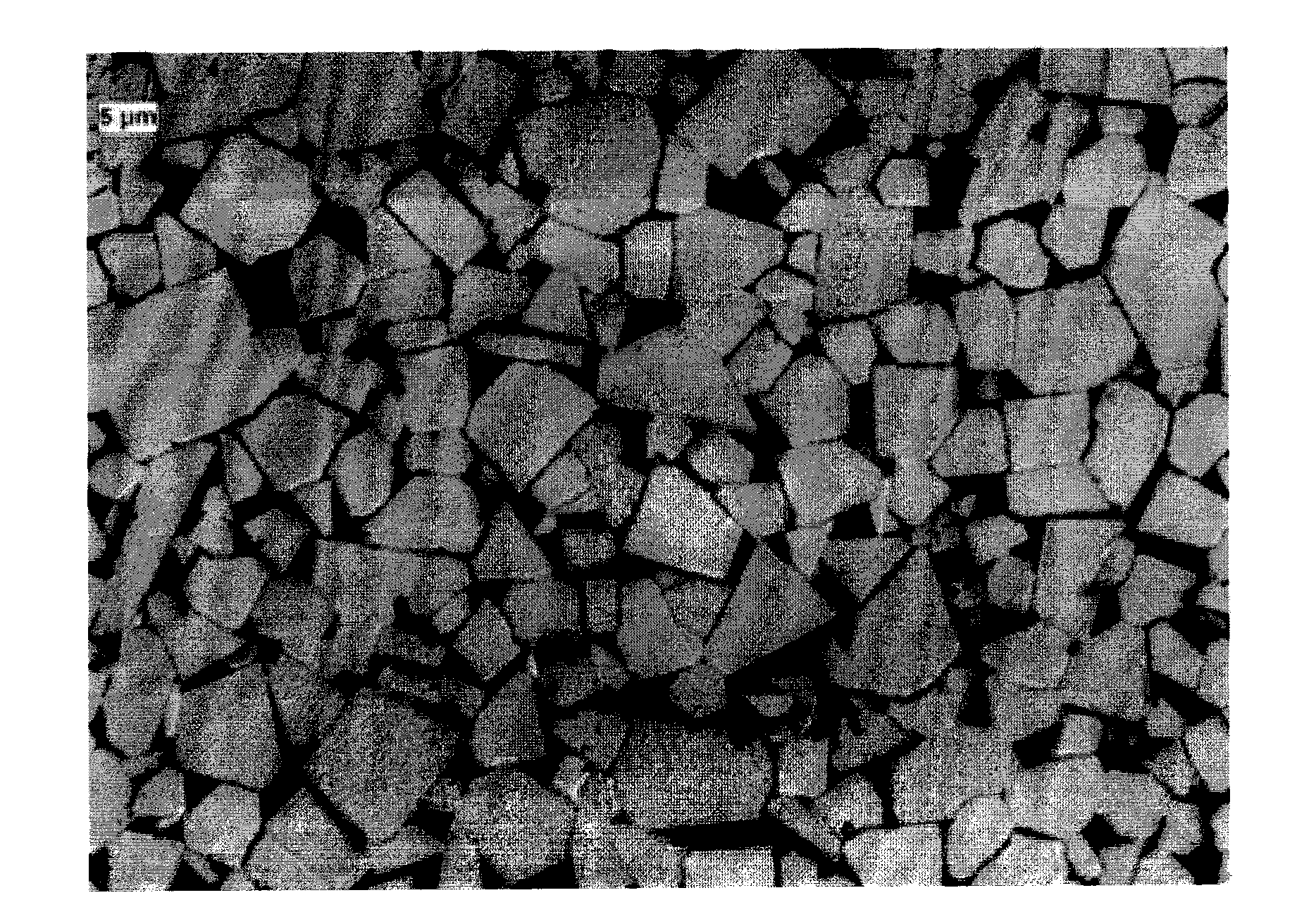

Uniform macromeritic tungsten powder and method for preparing tungsten carbide powder

The invention discloses a uniform macromeritic tungsten powder and a method for preparing macromeritic tungsten carbide powder. During reduction, water vapor and hydrogen or a mixture thereof is sentinto a reducing furnace, and tungsten oxide powder materials or mixture materials of tungsten oxide powder and tungsten powder, which are pushed into the reducing furnace, are reduced to metallic tungsten powder by controlling the partial pressure ratio (PH2O / PH2) of the water vapor and the hydrogen sent into the reducing furnace and the temperature of the furnace. By the adjustment of technological parameters, macromeritic tungsten powder of multiple grades in the range of 10-100 micrometers can be prepared. The prepared macromeritic tungsten powder has the advantages of comparatively uniformgranularity, integrated crystallization, attractive appearance and high purity. After the carbonization of the macromeritic tungsten powder, uniform macromeritic tungsten carbide powder of 12-115 micrometers can be prepared. The invention can be used for producing macromeritic and super macromeritic hard alloy products of more than 4 micrometers and can be also used for the surface spray coating,the spray welding and the like of hard-surface materials.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com