Hydrogenation catalyst with silicon oxide-alumina as carrier and its preparation

A technology of hydrogenation catalyst and silicon oxide, which is applied in the direction of refining to remove heteroatoms, etc., can solve the problem of low catalyst activity and achieve high catalyst activity and high desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

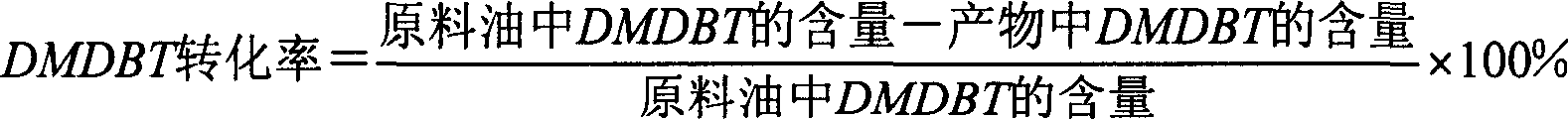

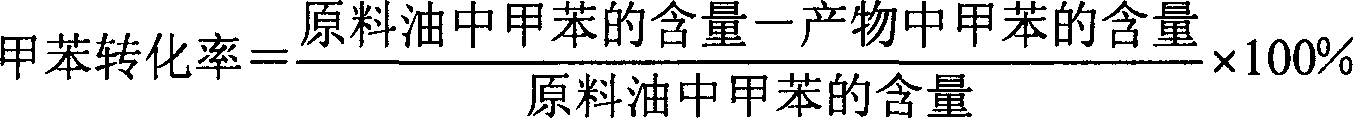

Image

Examples

example 1

[0025] Take by weighing 2920 grams of aluminum hydroxide powder (dried rubber powder produced by Sinopec Changling Branch Catalyst Factory, dry basis 70% by weight) and 908 grams of sol (Qingdao Ocean Chemical Factory product, silicon dioxide content is 25% by weight), with The extruder was extruded into a clover-shaped strip with a circumscribed circle diameter of 1.4 mm, and the wet strip was dried at 120°C for 4 hours and calcined at 620°C for 3 hours to obtain the carrier S 1 , carrier S 1 The silica content in the medium was 10.0% by weight.

[0026] Weigh the carrier S 1 100 grams, impregnated with 96 ml of aqueous solution containing 10.7 grams of ammonium molybdate for 2 hours, dried at 240°C for 5 hours, then impregnated with 87 ml of aqueous solution containing 19.6 grams of nickel nitrate and 28.2 grams of ammonium metatungstate for 1.5 hours, and dried at 160°C 6 hours, catalyst C was obtained 1. Catalyst C 1 The compositions after firing are listed in Table 1...

example 2

[0028] Weigh the carrier S 1 100 grams, impregnated with 96 ml of an aqueous solution containing 8.3 grams of ammonium molybdate for 3 hours, dried at 120°C for 5 hours, then impregnated with 88 ml of an aqueous solution containing 20.0 grams of nickel nitrate and 33.8 grams of ammonium metatungstate for 1.5 hours, and dried at 160°C 6 hours, catalyst C was obtained 2 . Catalyst C 2 The compositions after firing are listed in Table 1.

example 3

[0030] Weigh the carrier S 1 100 grams, impregnated with 96 ml of an aqueous solution containing 5.8 grams of ammonium molybdate and 27.9 grams of glycerol for 3 hours, dried at 120°C for 5 hours, and then impregnated with 85 ml of an aqueous solution containing 19.3 grams of nickel nitrate and 56.9 grams of ammonium metatungstate 1.5 hours, drying at 140°C for 6 hours to obtain catalyst C 3 . The molar ratio of glycerol to nickel, molybdenum and tungsten as oxides was calculated to be 1.0. Catalyst C 3 The compositions after firing are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com