Patents

Literature

2320 results about "Molybdenum oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

About Molybdenum(IV) Oxide. Molybdenum(IV) Oxide or Molybdenum Dioxide is a highly insoluble thermally stable Molybdenum source suitable for glass, optic and ceramic applications. Molybdenum oxide is a yellow or light blue solid, it is the most produced molybdenum compound, created by roasting molybdenum disulfide, the chief molybdenum ore.

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

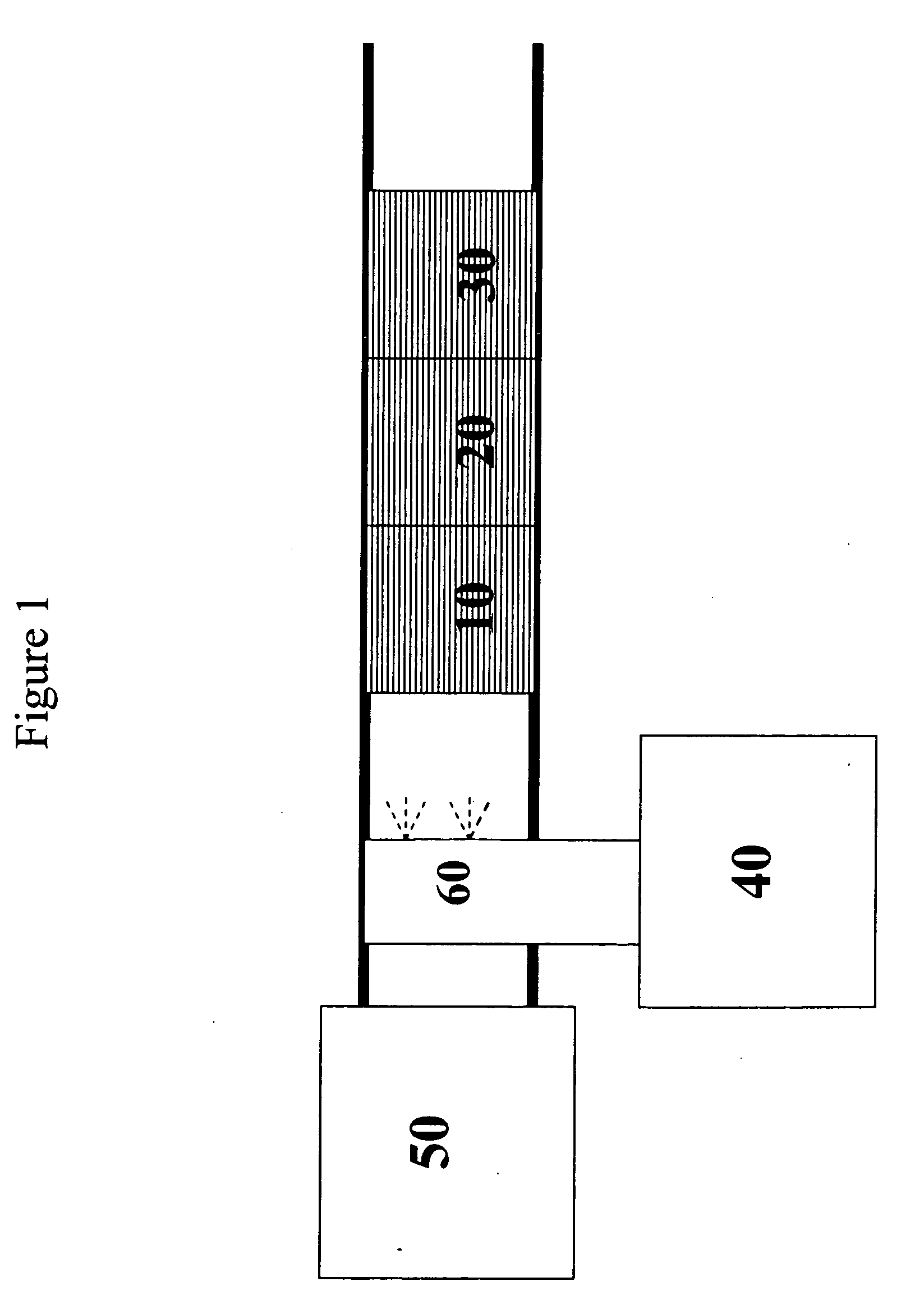

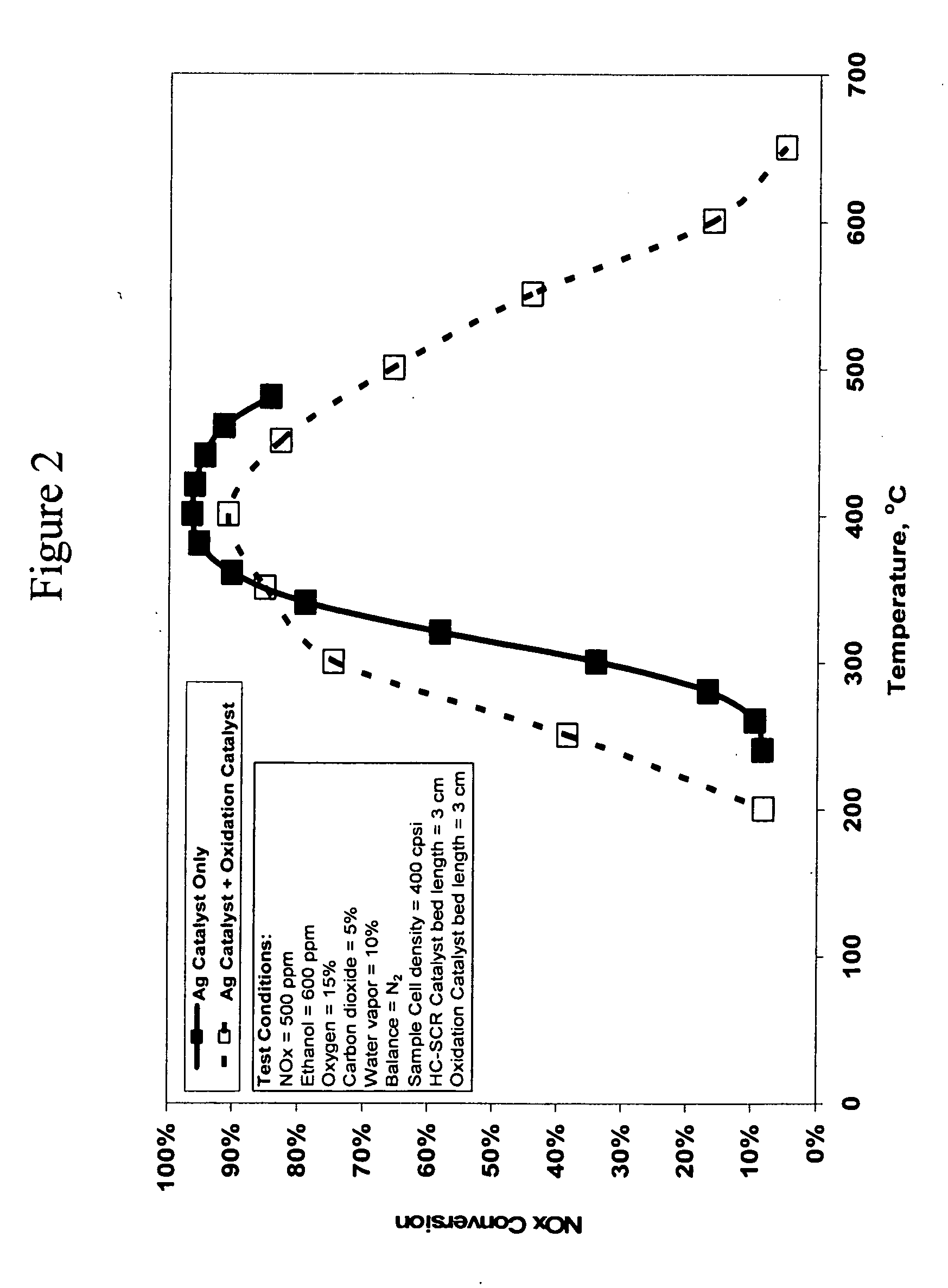

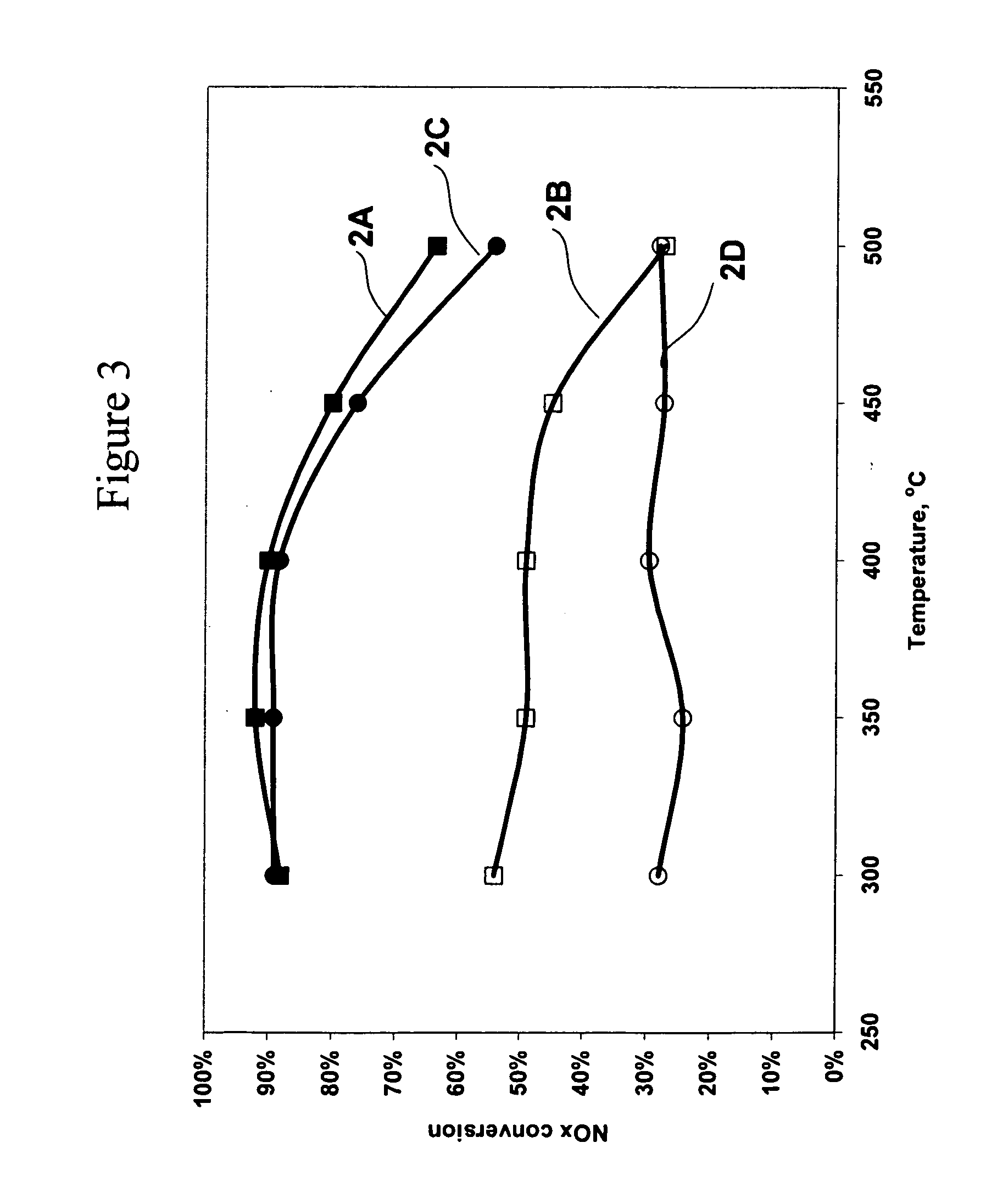

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

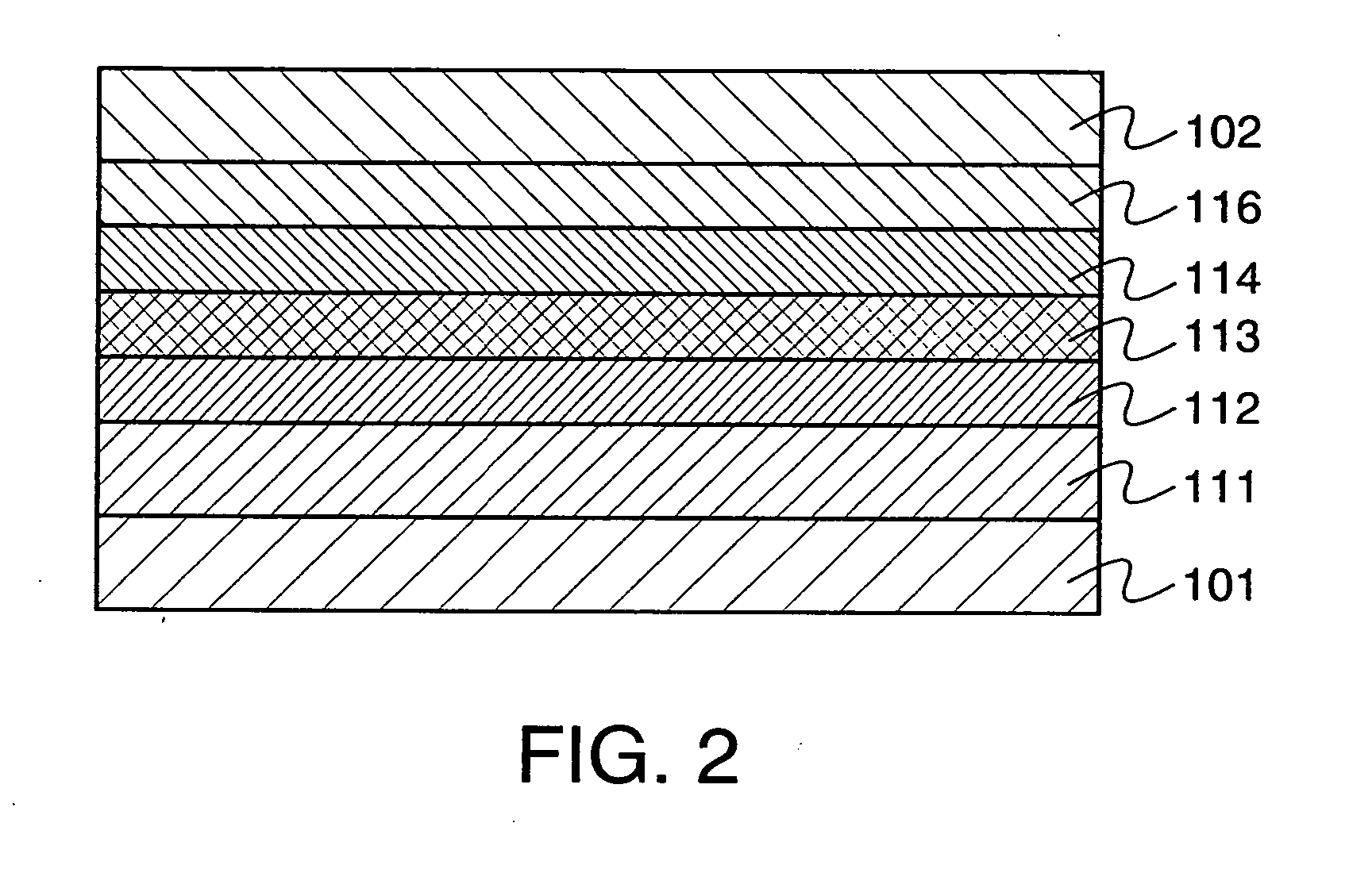

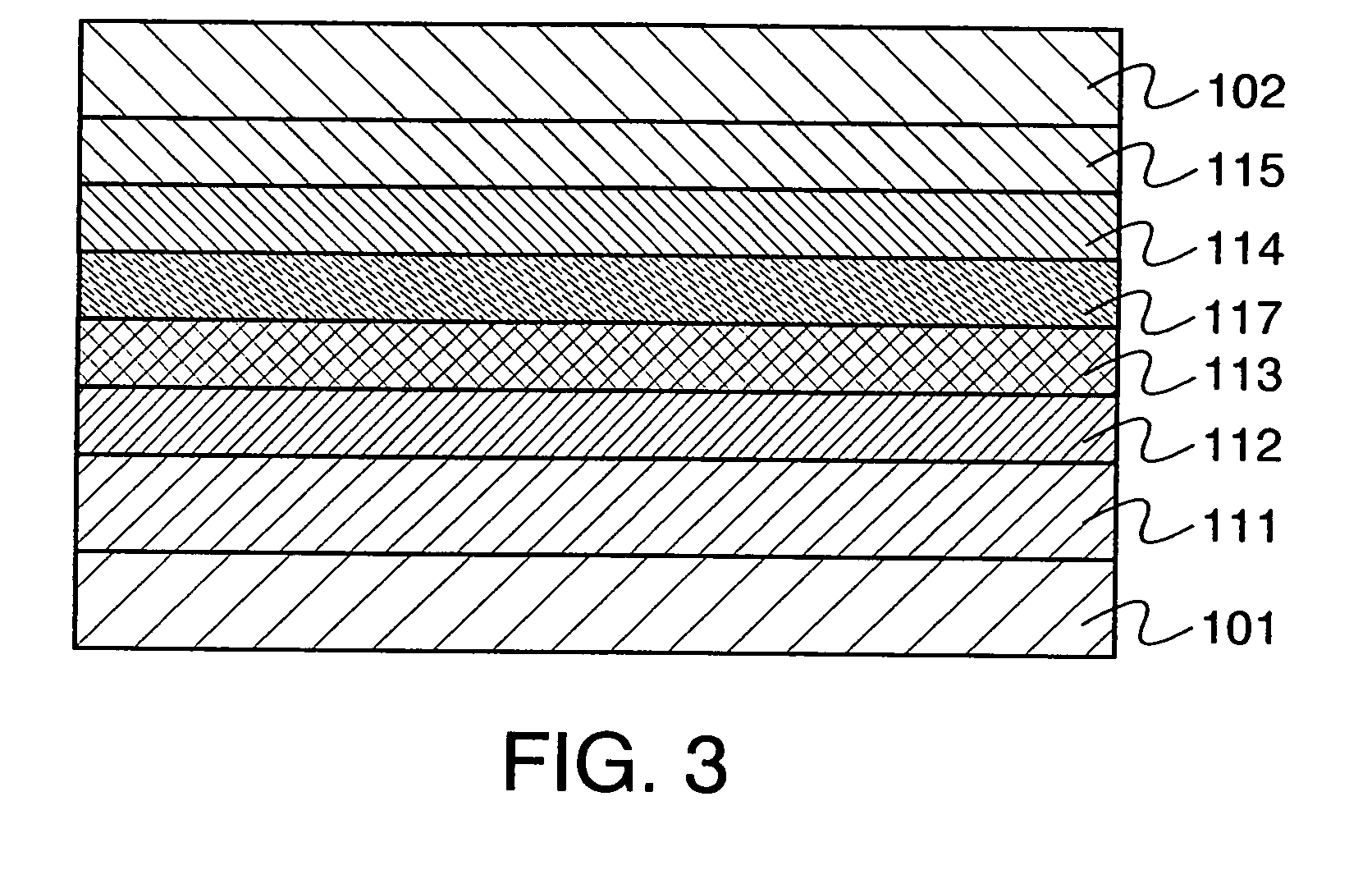

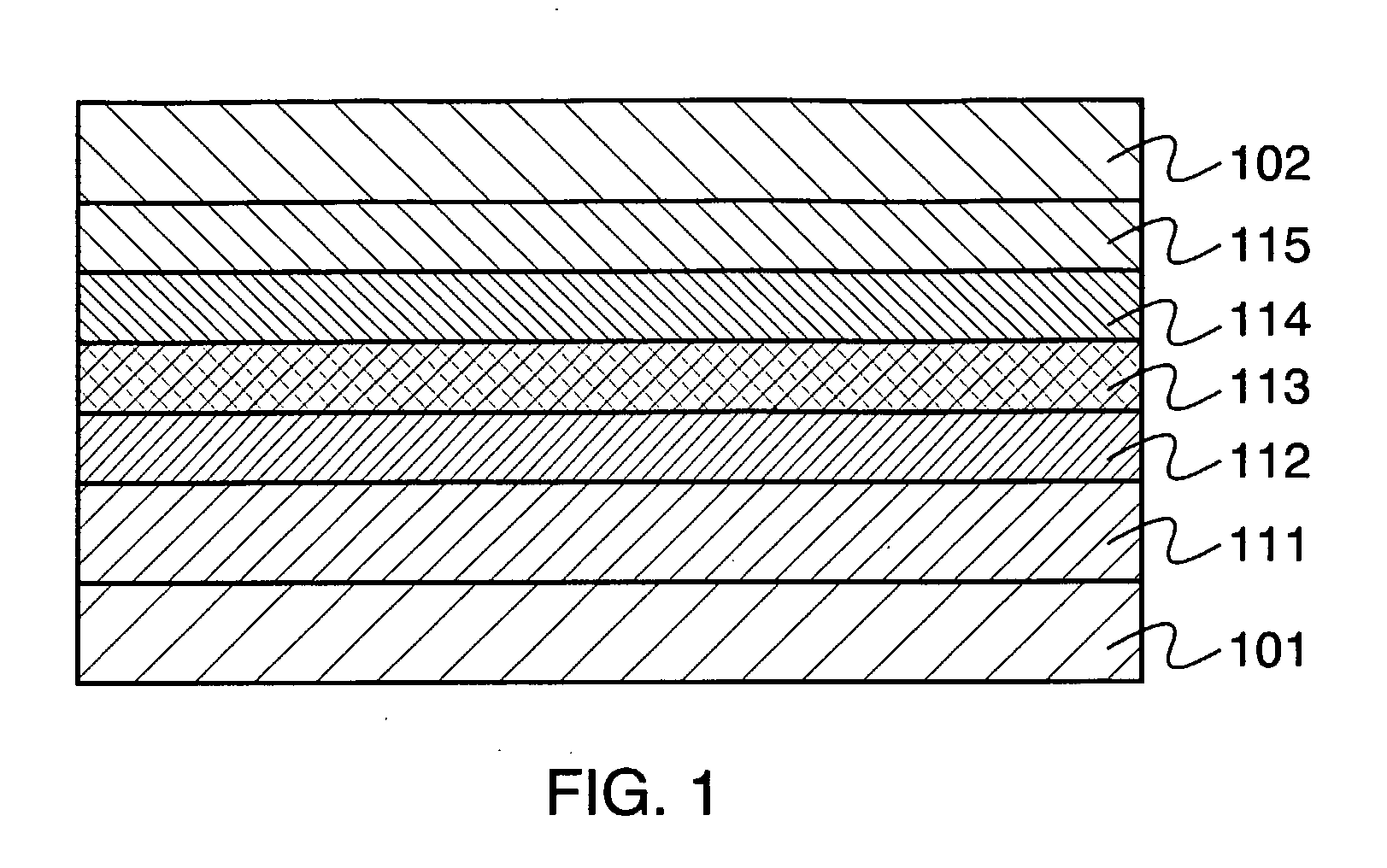

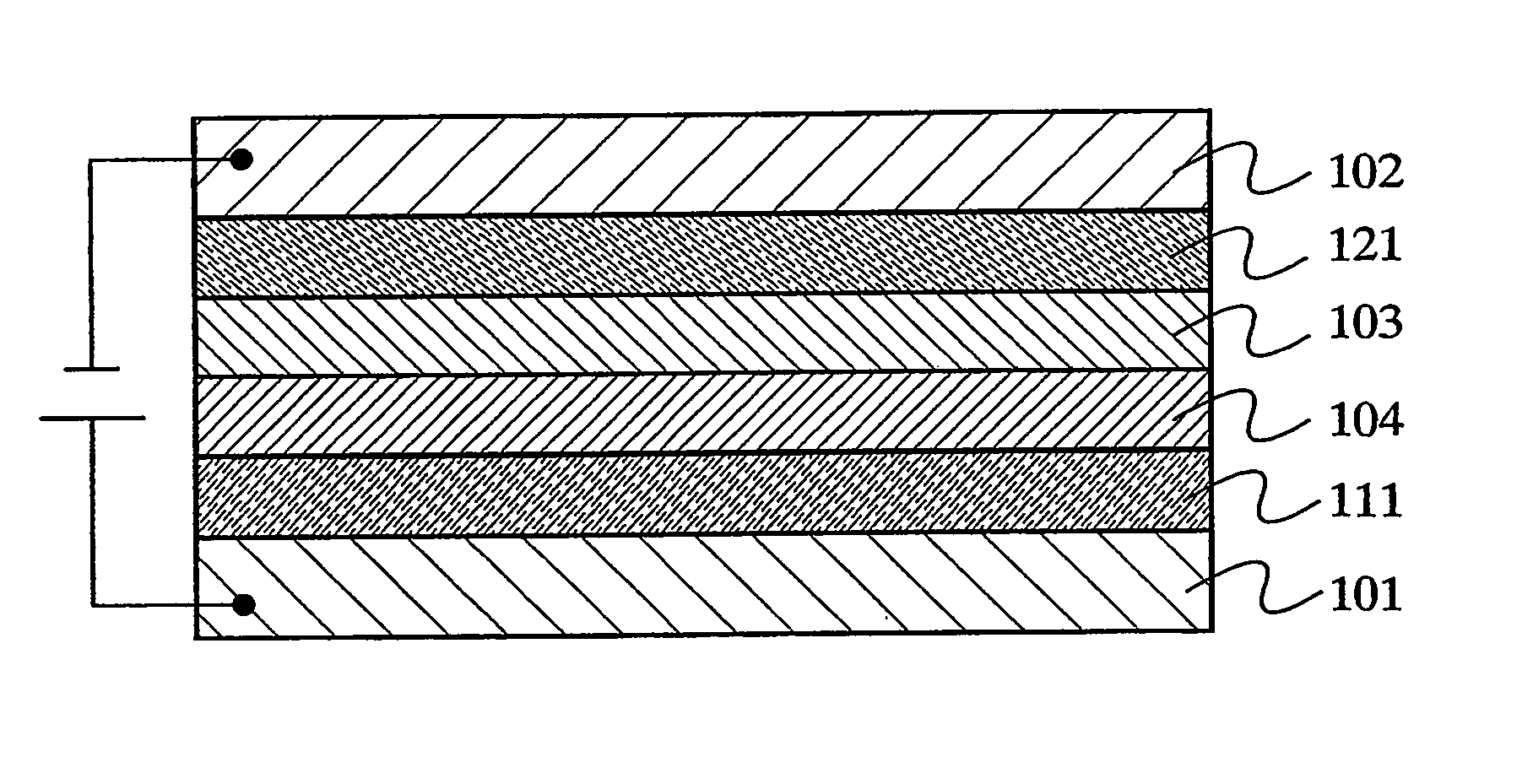

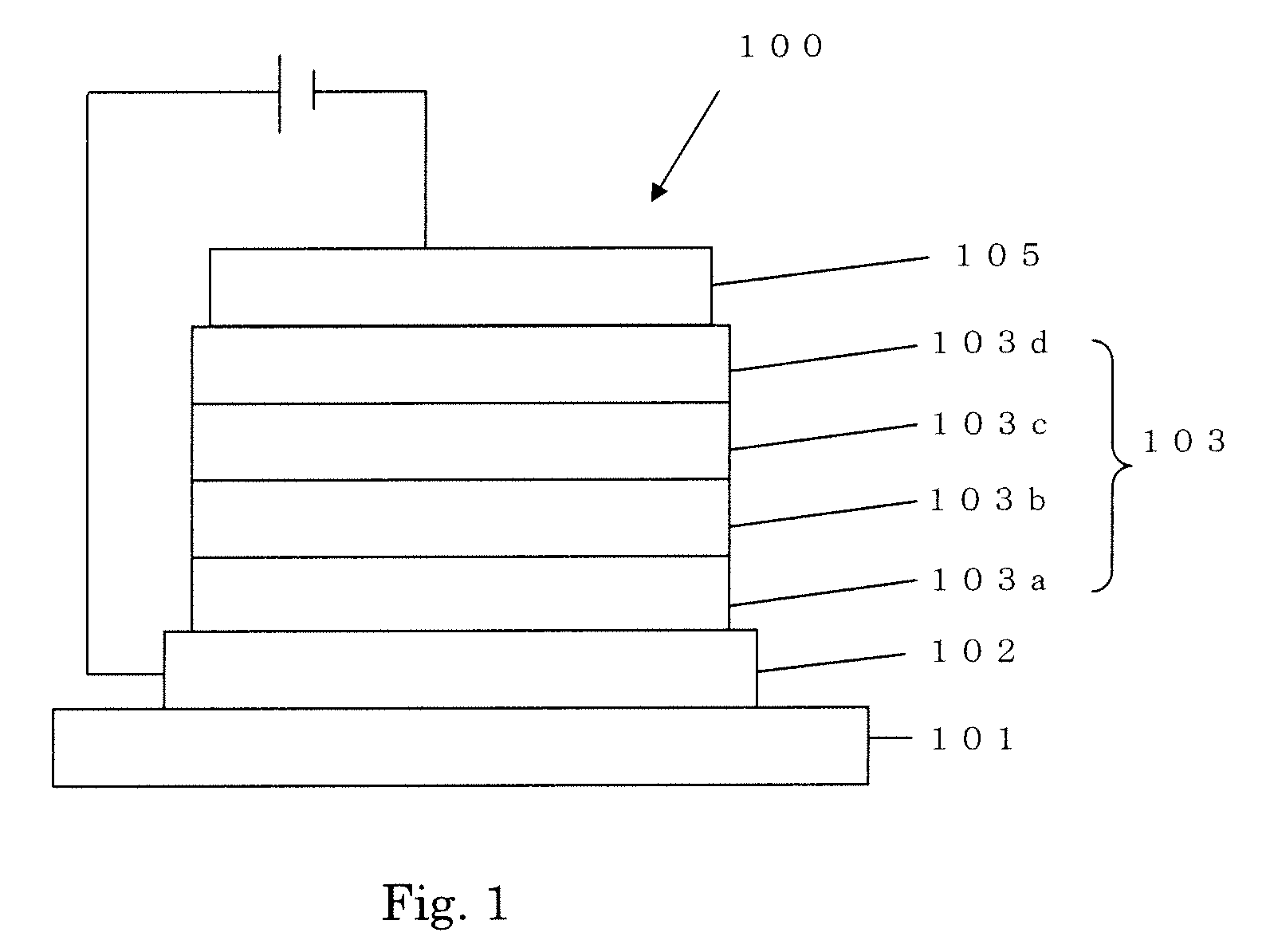

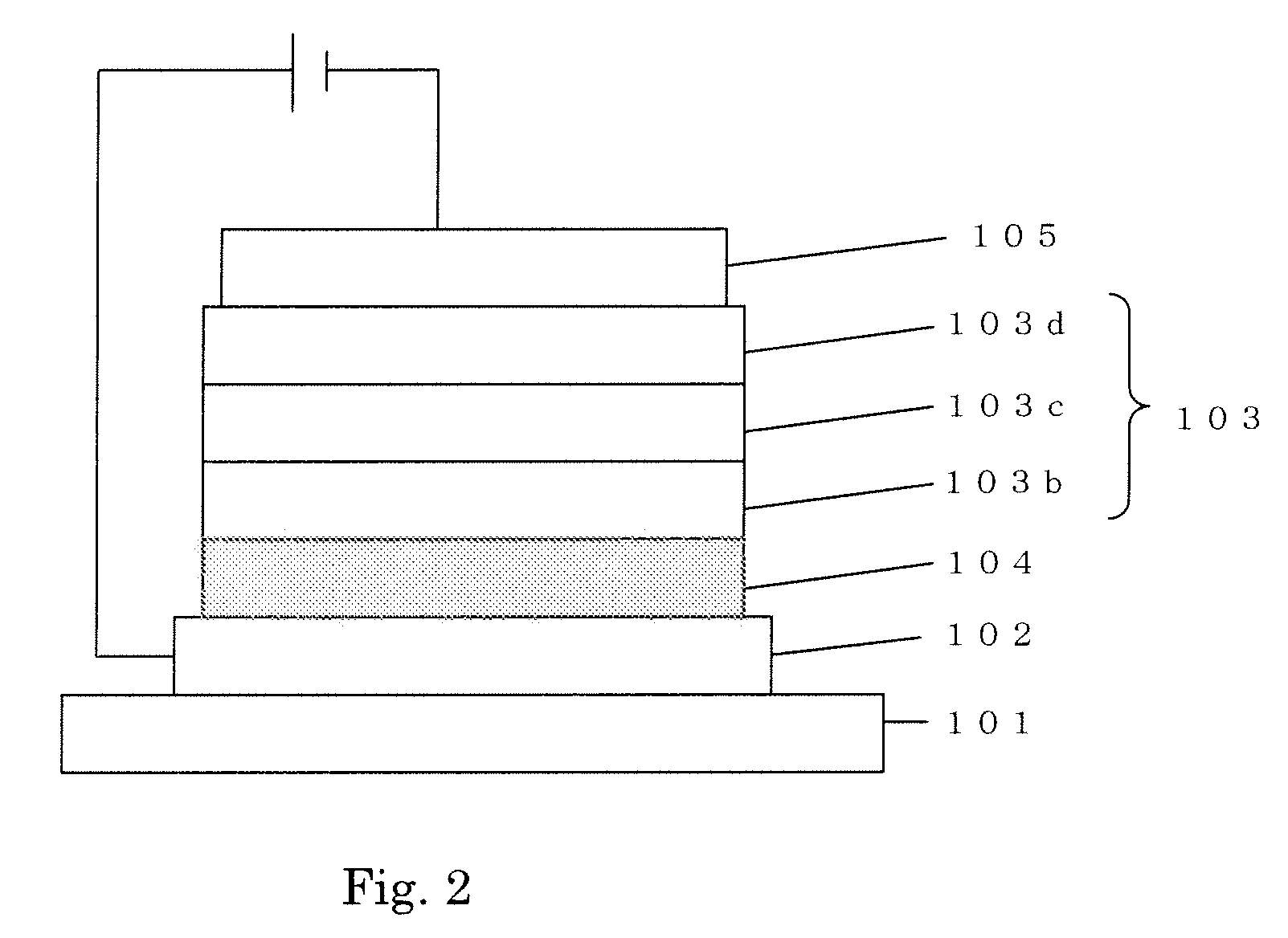

Light emitting device and electronic appliance using the same

InactiveUS20060292394A1Easy to changeDistanceDischarge tube luminescnet screensElectroluminescent light sourcesVanadium oxideOrganic compound

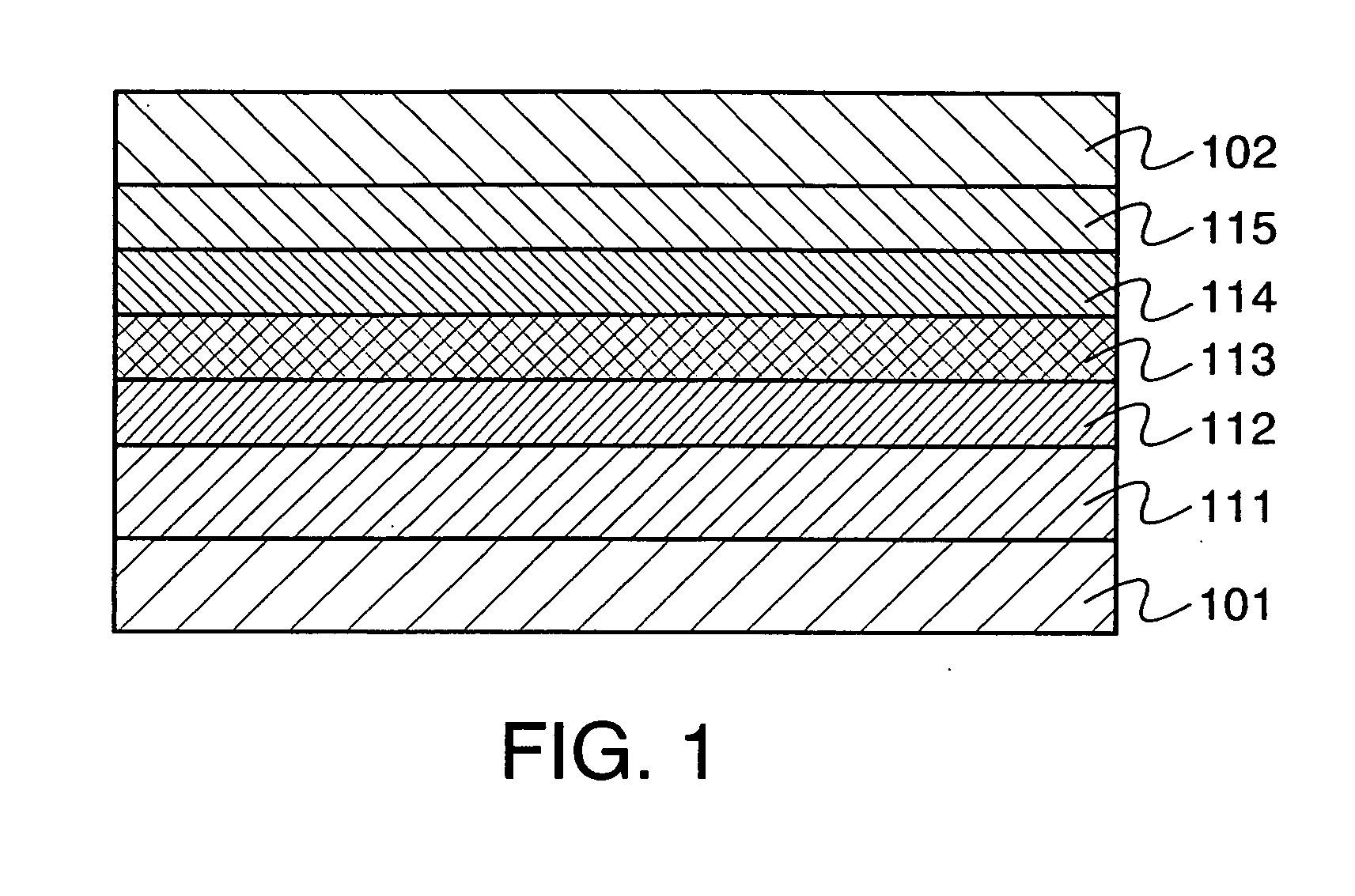

A light emitting device comprises a pair of electrodes and a mixed layer provided between the pair of electrodes. The mixed layer contains an organic compound which contains no nitrogen atoms, i.e., an organic compound which dose not have an arylamine skeleton, and a metal oxide. As the organic compound, an aromatic hydrocarbon having an anthracene skeleton is preferably used. As such an aromatic hydrocarbon, t-BuDNA, DPAnth, DPPA, DNA, DMNA, t-BuDBA, and the like are listed. As the metal oxide, molybdenum oxide, vanadium oxide, ruthenium oxide, rhenium oxide, and the like are preferably used. Further, the mixed layer preferably shows absorbance per 1 μm of 1 or less or does not show a distinct absorption peak in a spectrum of 450 to 650 nm when an absorption spectrum is measured.

Owner:SEMICON ENERGY LAB CO LTD

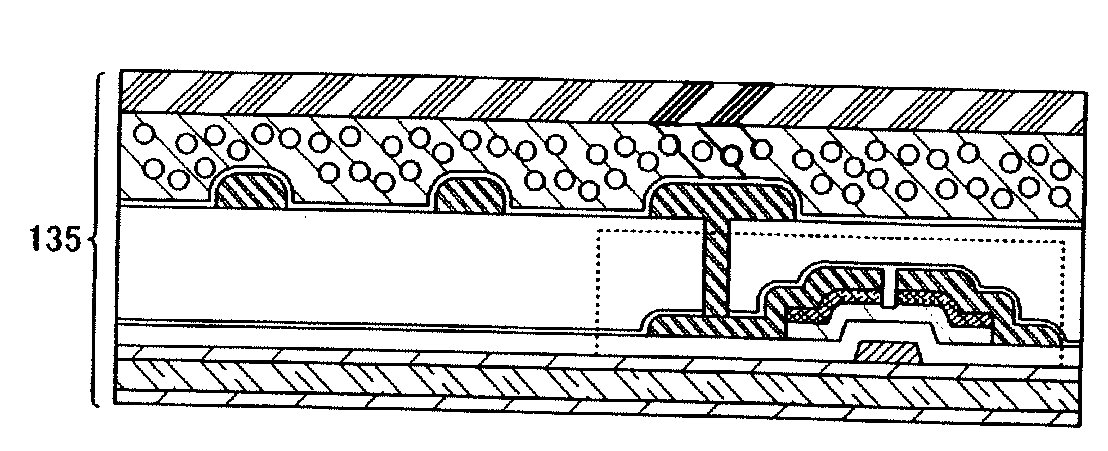

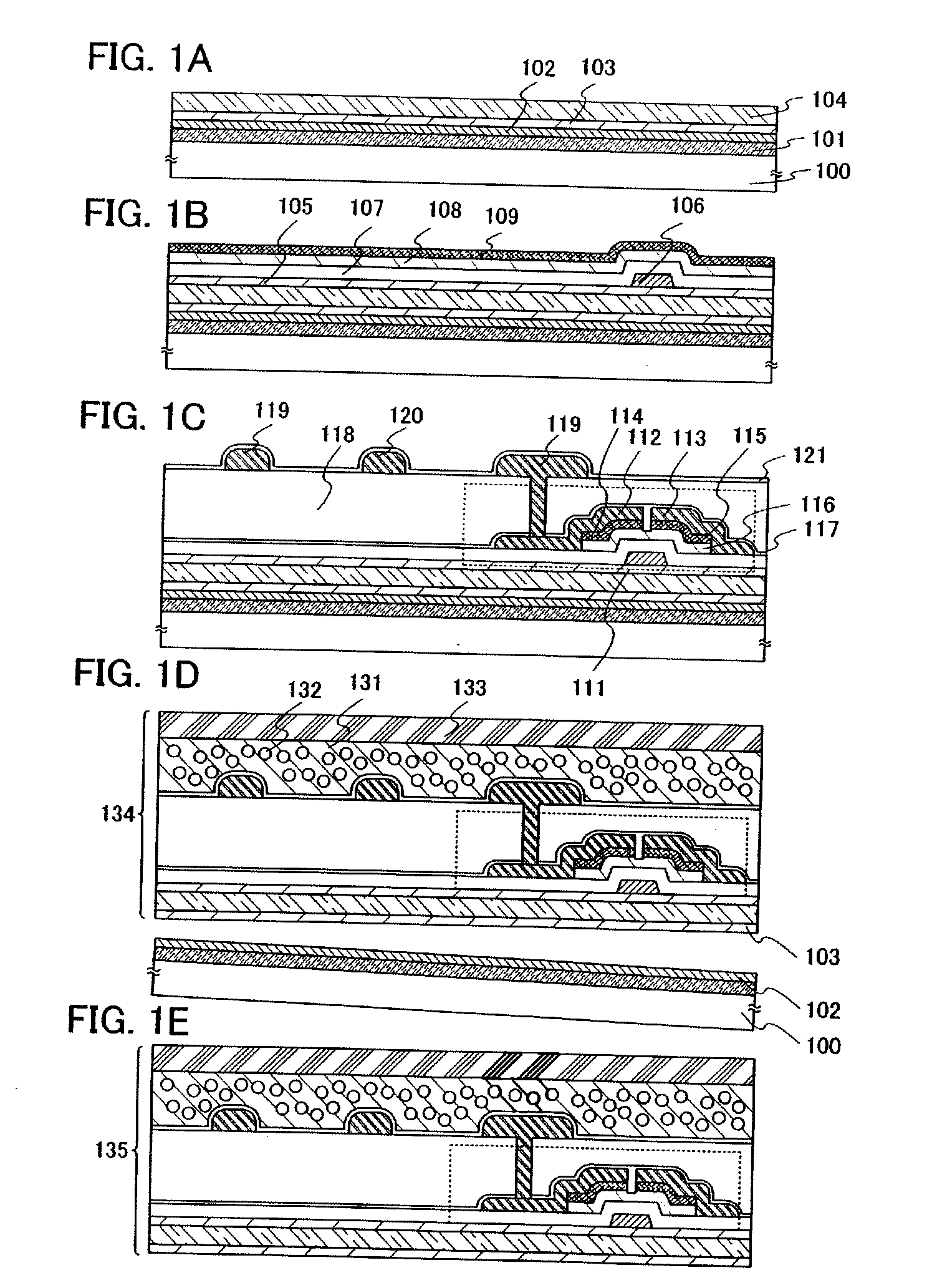

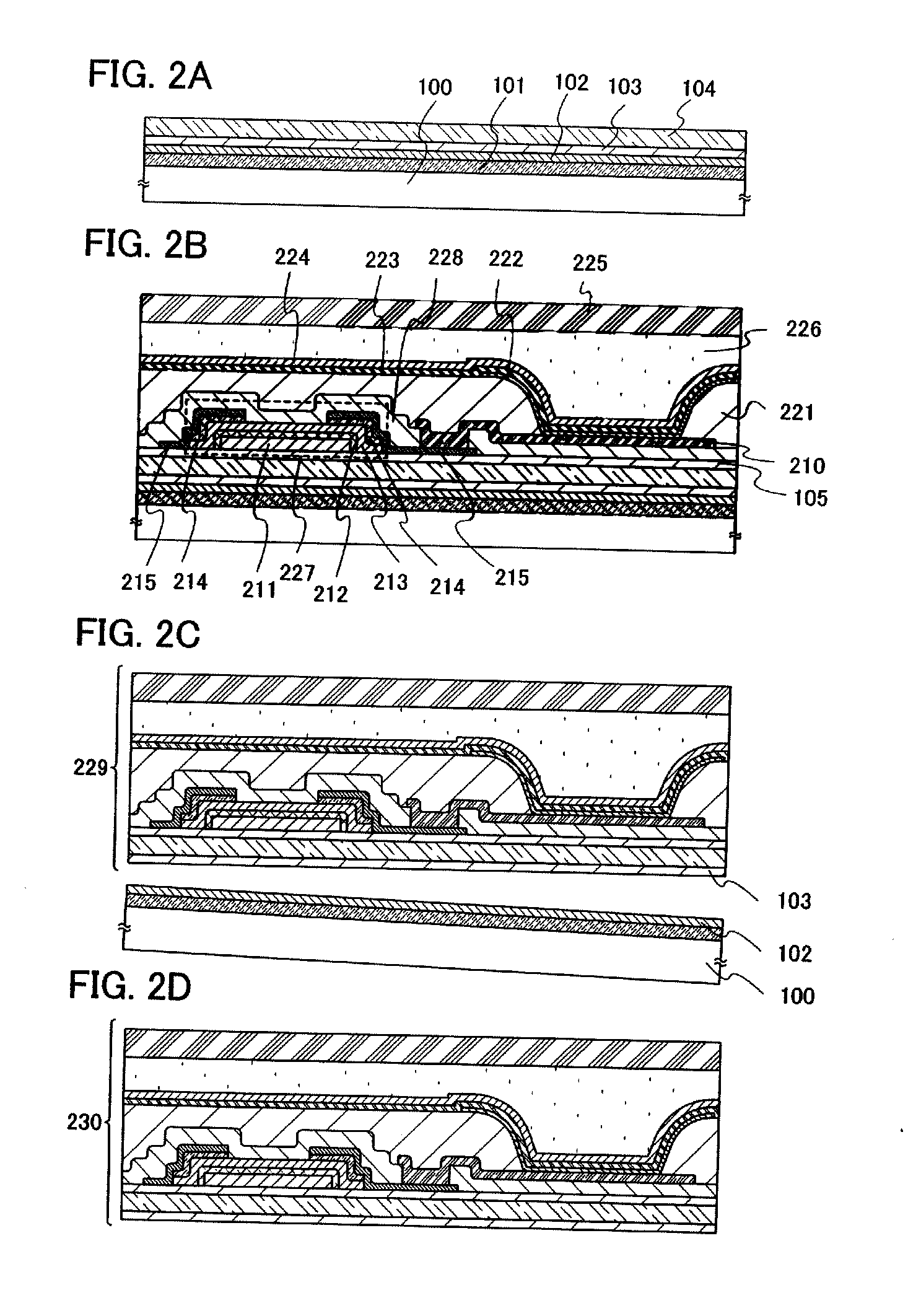

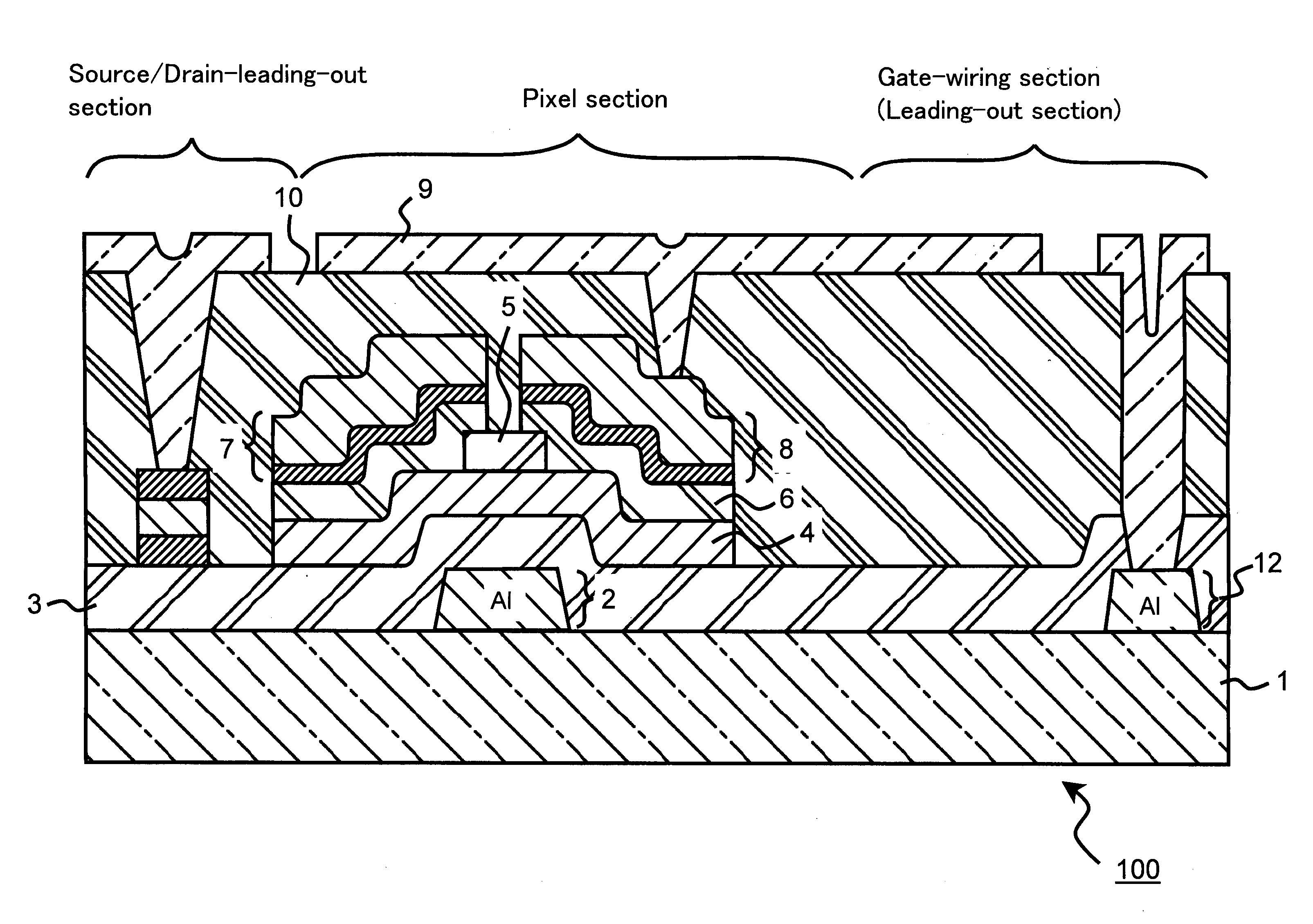

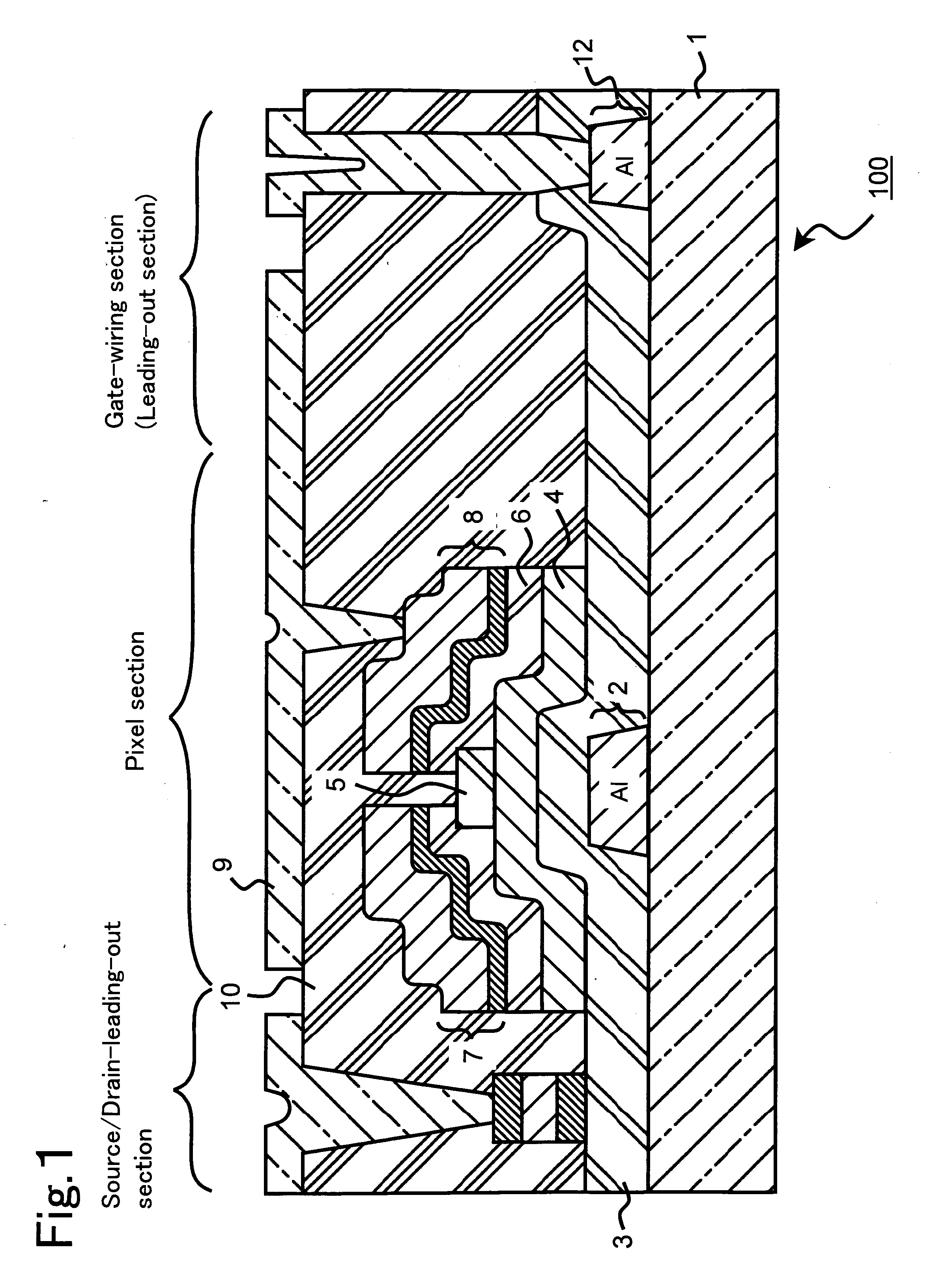

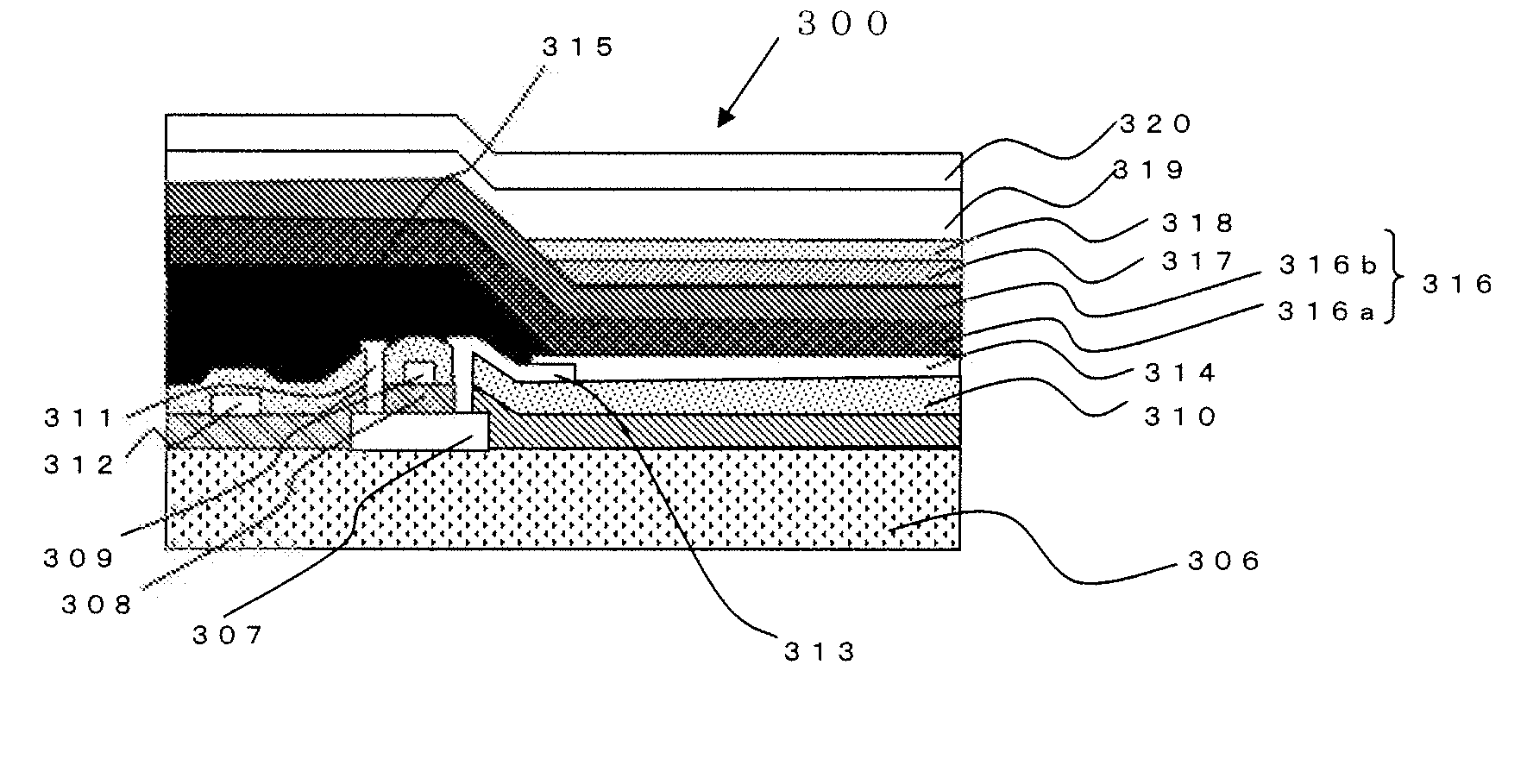

Method of manufacturing semiconductor device

InactiveUS20090004772A1Process stabilityLow costTransistorSolid-state devicesOrganic compoundSemiconductor

An object of the invention is to provide a method for manufacturing semiconductor devices that are flexible in which elements fabricated using a comparatively low-temperature (less than 500° C.) process are separated from a substrate. After a molybdenum film is formed over a glass substrate, a molybdenum oxide film is formed over the molybdenum film, a nonmetal inorganic film and an organic compound film are stacked over the molybdenum oxide film, and elements fabricated by a comparatively low-temperature (less than 500° C.) process are formed using existing manufacturing equipment for large glass substrates, the elements are separated from the glass substrate.

Owner:SEMICON ENERGY LAB CO LTD

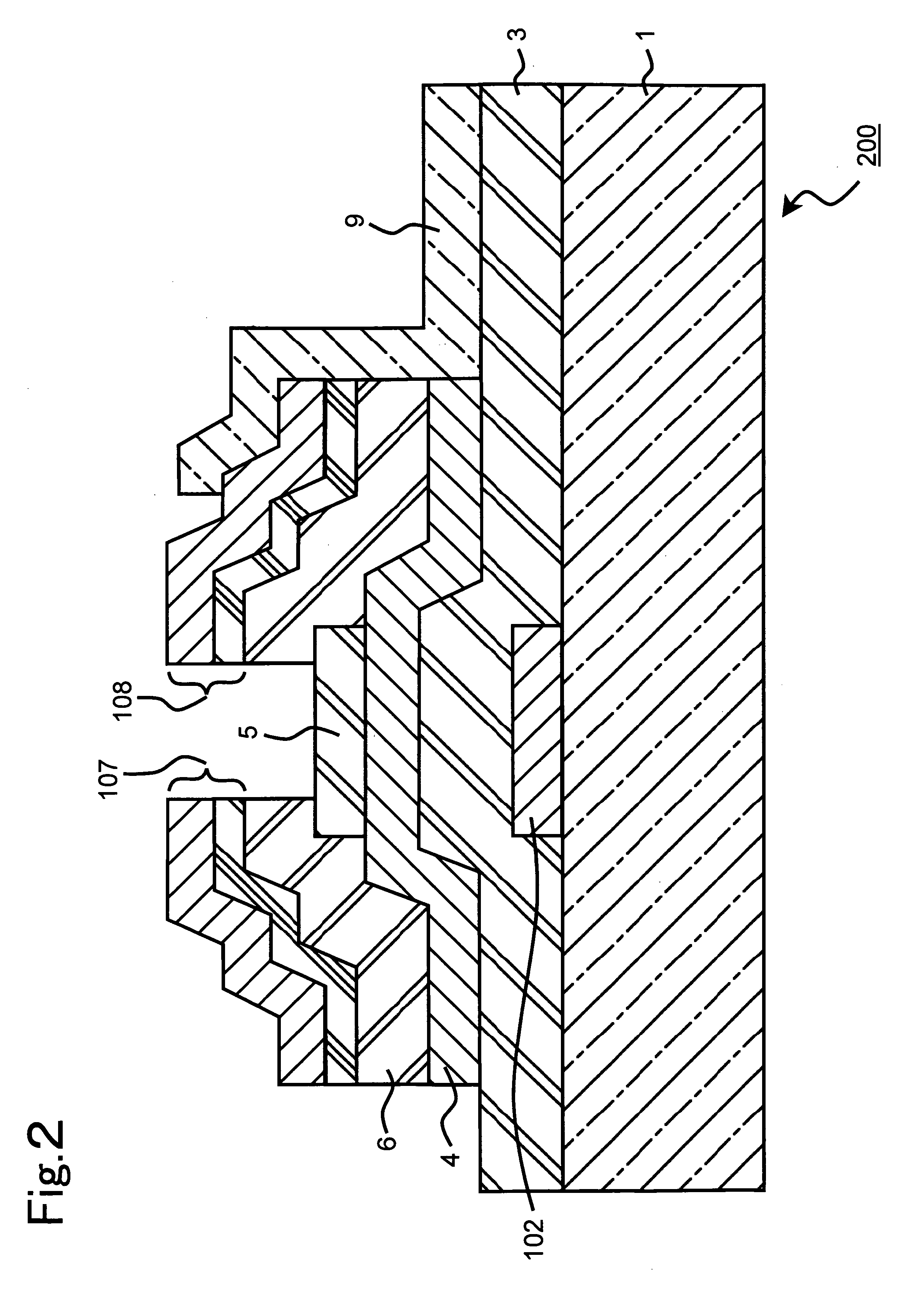

Thin film transistor, thin film transistor substrate, processes for producing the same, liquid crystal display using the same, and related devices and processes; and sputtering target, transparent electroconductive film formed by use of this,transparent electrode, and related devices and processes

InactiveUS20070170434A1Reduce light transmittanceConductive layers on insulating-supportsSemiconductor/solid-state device detailsIndiumLiquid-crystal display

Provided are a thin film transistor substrate having a transparent electroconductive film in which residues and so on resulting etching are hardly generated; a process for producing the same; and a liquid crystal display using this thin film transistor substrate. A thin film transistor substrate, comprising a transparent substrate, a source electrode formed over the transparent substrate, a drain electrode formed over the transparent substrate, and a transparent pixel electrode formed over the transparent substrate, wherein the transparent pixel electrode is a transparent electroconductive film which is made mainly of indium oxide, and further comprises one or two or more oxides selected from tungsten oxide, molybdenum oxide, nickel oxide and niobium oxide, and the transparent pixel electrode is electrically connected to the source electrode or the drain electrode; a process for producing the same; and a liquid crystal display using this thin film transistor substrate.

Owner:IDEMITSU KOSAN CO LTD

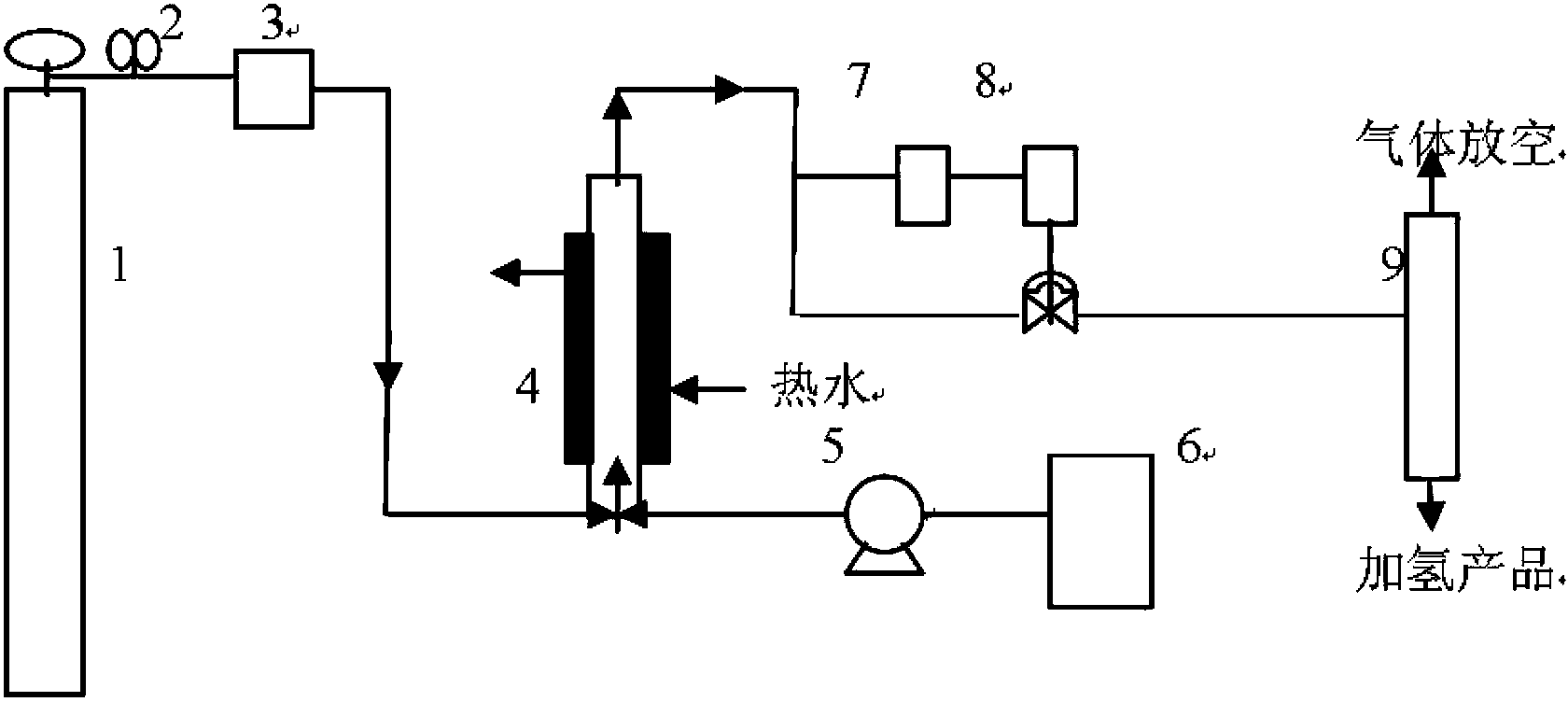

Unsaturated hydrocarbon hydrogenation catalyst, preparation method and applications thereof

ActiveCN102218323ASolve the problem of hydrogenationExpansion of comprehensive utilization channelsHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsCoalCerium oxide

The invention discloses an unsaturated hydrocarbon hydrogenation catalyst which comprises a carrier, an active component and an additive; the active component is a mixture of nickel oxides and other metal oxides; the additive is at least two out of magnesia oxide, lanthanum oxide and ceria; counted by weight percentage, the unsaturated hydrocarbon hydrogenation catalyst comprises 5-15% of nickel oxides, 1-10% of other metal oxides, 1-10% of additive and remaining quantity of carrier; and the metal oxide is one or more oxides out of molybdenum oxide, cobalt oxide and ferric oxide. The invention also discloses a preparation method and applications of the unsaturated hydrocarbon hydrogenation catalyst. The unsaturated hydrocarbon hydrogenation catalyst has the advantages of high hydrogenation precision, strong side effect resistance, good thermal stability, long service life and the like, can be used for processing tail gas in indirect coal oil production industrial and can be also used for processing unsaturated hydrocarbon in synthesis gas.

Owner:THE NORTHWEST RES INST OF CHEM IND

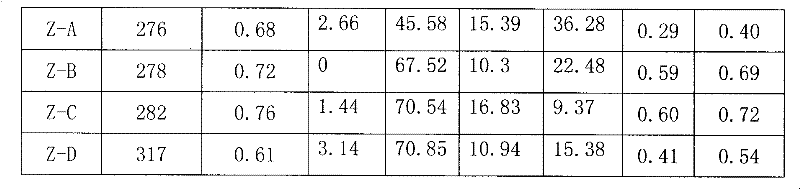

Phosphor-contained hydrogenation catalyst with silicon oxide-alumin as carrier and its production

ActiveCN1853781AHigh activityPhysical/chemical process catalystsRefining to eliminate hetero atomsPhosphorSilicon oxide

A P-contained hydrocatalyst with silicon oxide-aluminum oxide as its carrier contains nickel oxide (1-10 Wt%), molybdenum oxide and tungsten oxide (10-50), phosphorus oxide (1-9) and carrier (rest). It has high hydrorefining performance. It is prepared by introducing P, Mo, Ni and W to carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

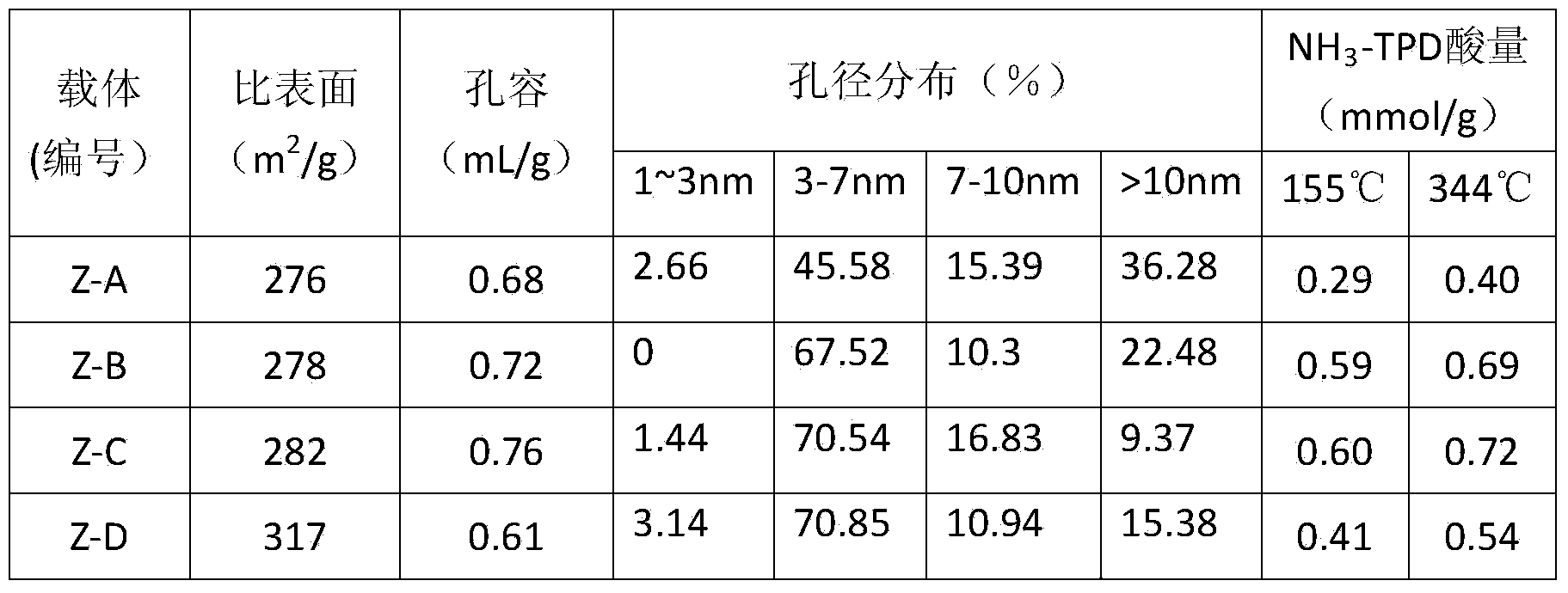

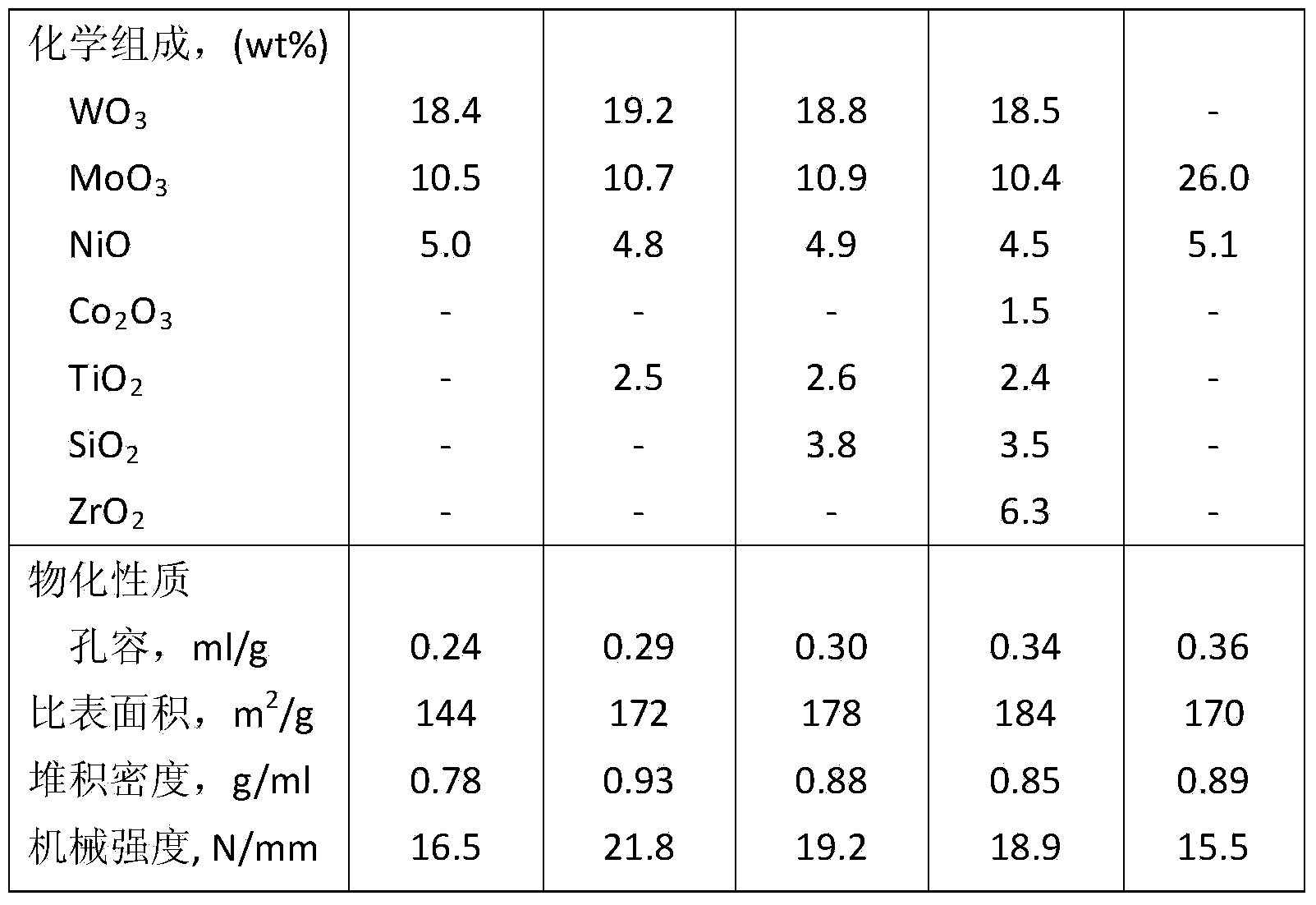

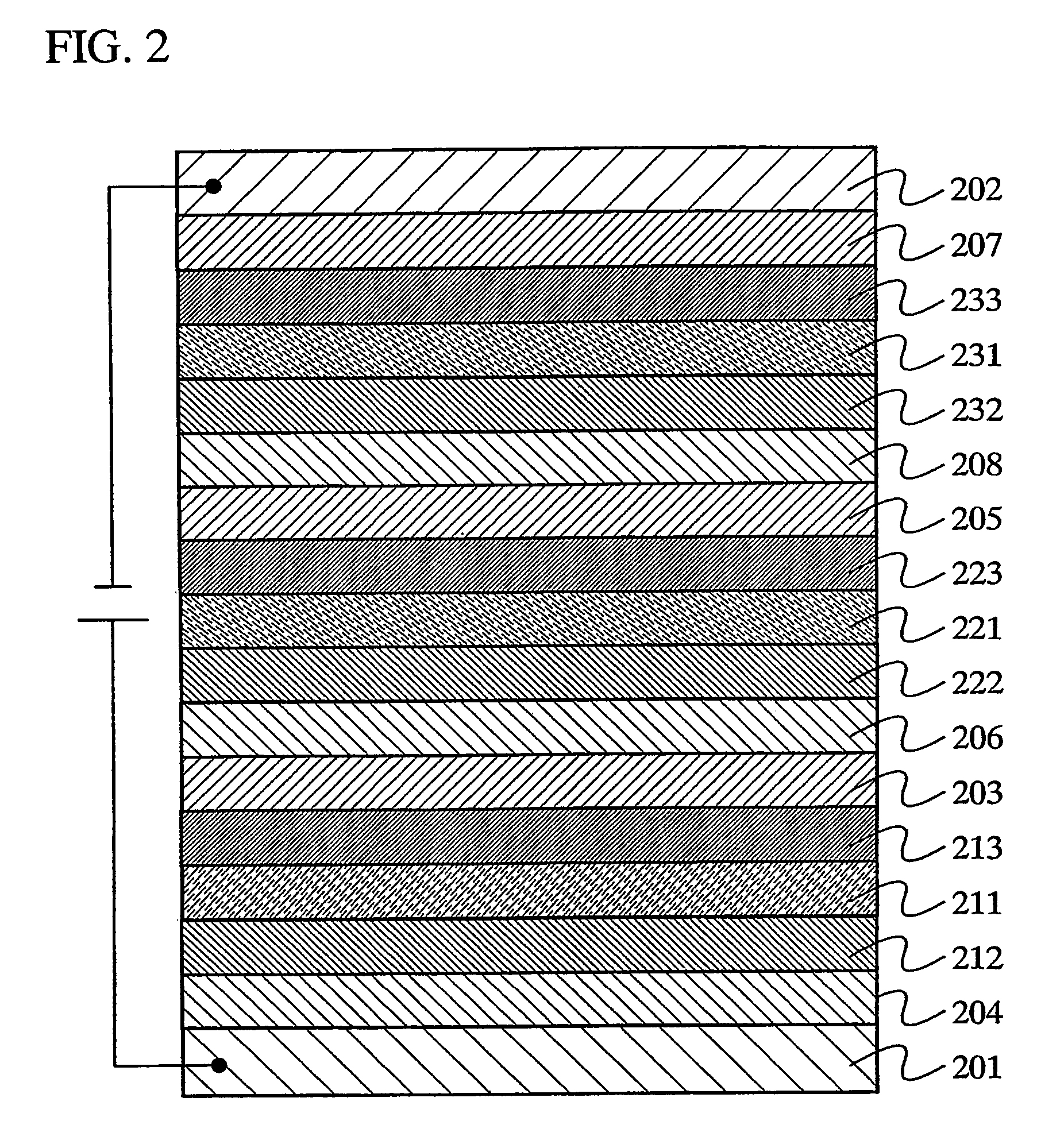

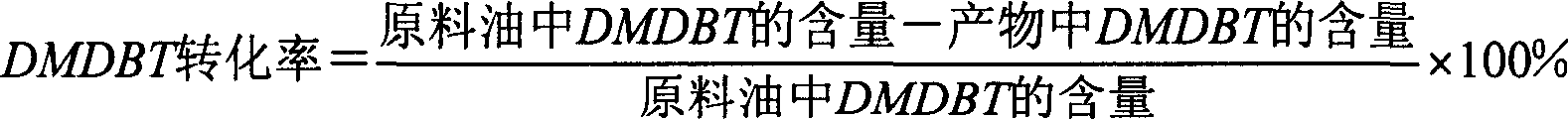

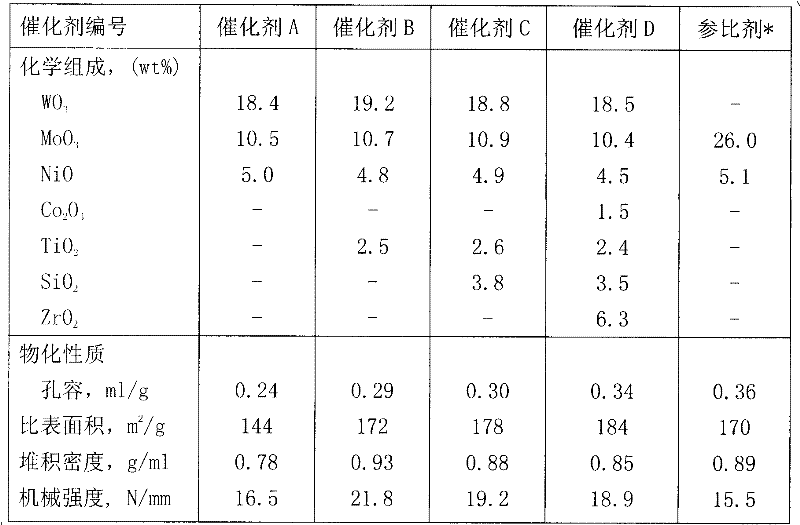

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

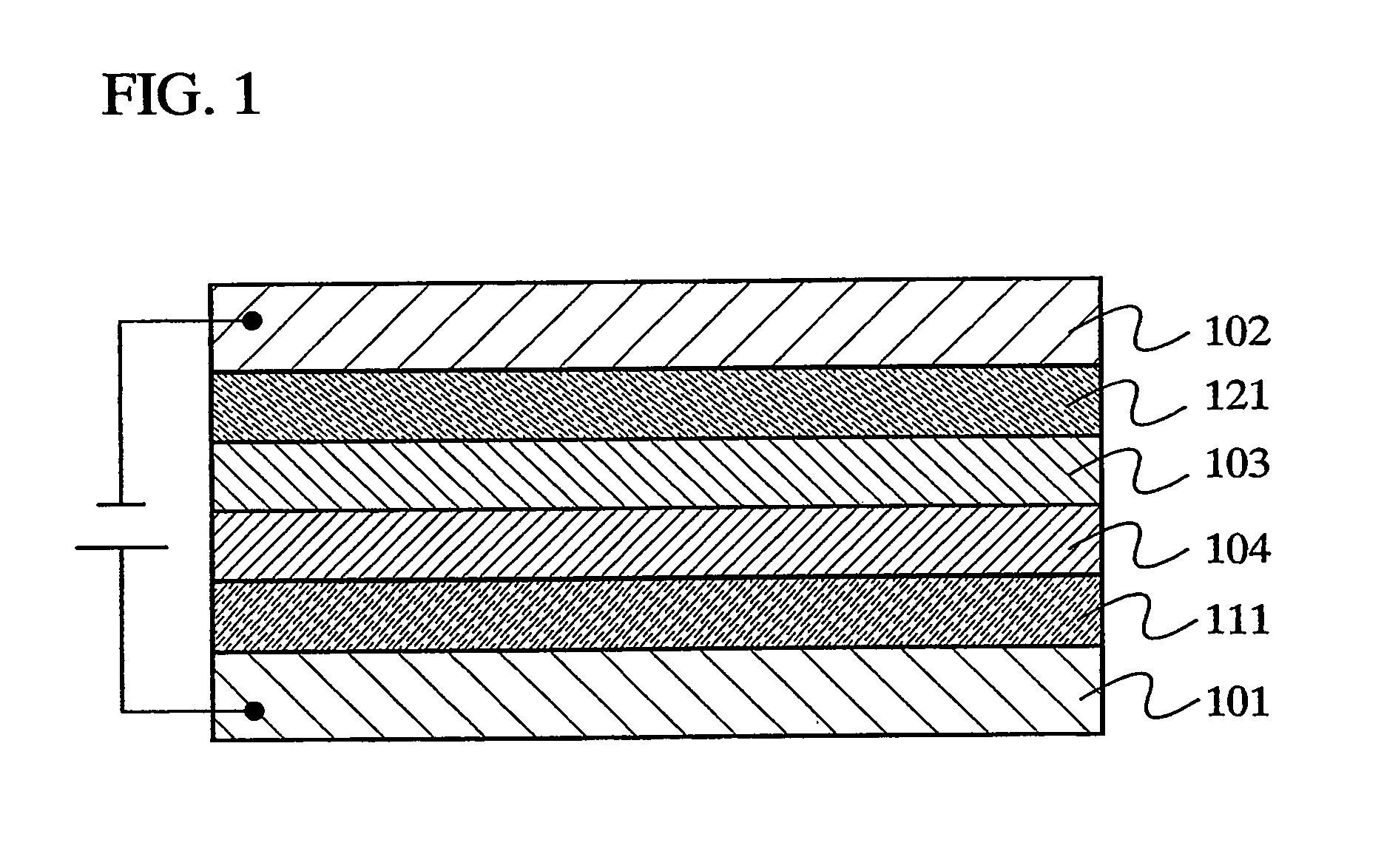

Light emitting element, light emitting device, and electronic device

InactiveUS20090026922A1Operation failureEasy to changeDischarge tube luminescnet screensLamp detailsVanadium oxideTert butyl

One aspect of the present invention is a light emitting element having a layer including an aromatic hydrocarbon and a metal oxide between a pair of electrodes. The kind of aromatic hydrocarbon is not particularly limited; however, an aromatic hydrocarbon having hole mobility of 1×10−6 cm2 / Vs or more is preferable. As such aromatic hydrocarbon, for example, 2-tert-butyl-9,10-di(2-naphthyl)anthracene, anthracene, 9,10-diphenylanthracene, tetracene, rubrene, perylene, 2,5,8,11-tetra(tert-butyl)perylene, and the like are given. As the metal oxide, a metal which shows an electron-accepting property to the aromatic hydrocarbon is preferable. As such metal oxide, for example, molybdenum oxide, vanadium oxide, ruthenium oxide, rhenium oxide, and the like are given.

Owner:SEMICON ENERGY LAB CO LTD

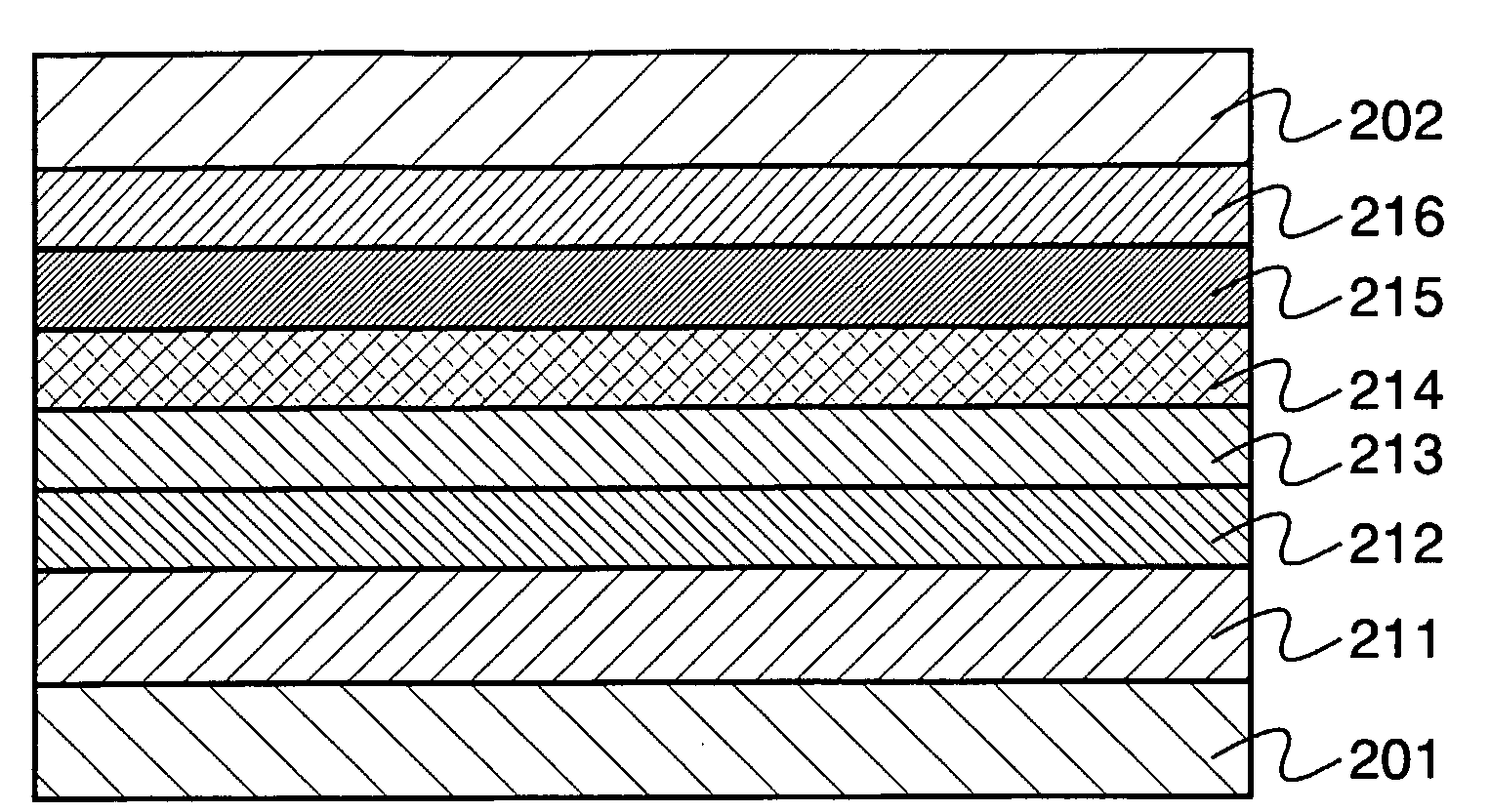

Light emitting element and light emitting device

ActiveUS7598670B2Improve moisture resistanceConvenient lightingDischarge tube luminescnet screensElectroluminescent light sourcesLight-emitting diodeLight emitting device

A light emitting element of the invention includes n pieces of light emitting layers (n is a natural number) between first and second electrodes. A first layer and a second layer are provided between the mth light emitting layer (m is a natural number of 1≦m≦n) and the m+1th light emitting layer. The first and second layers are contacted to each other. The first layer contains a substance that transports holes easily and a substance with an electron accepting property. The second layer contains a substance that transports electrons easily and a substance with an electron donating property. Molybdenum oxide is used as the substance with the electron accepting property.

Owner:SEMICON ENERGY LAB CO LTD

Hydrogenation catalyst with silicon oxide-alumina as carrier and its preparation

ActiveCN1840618AHigh activityImprove hydrogenation activityRefining to eliminate hetero atomsSilicon oxideHydrocarbon

Owner:CHINA PETROLEUM & CHEM CORP +1

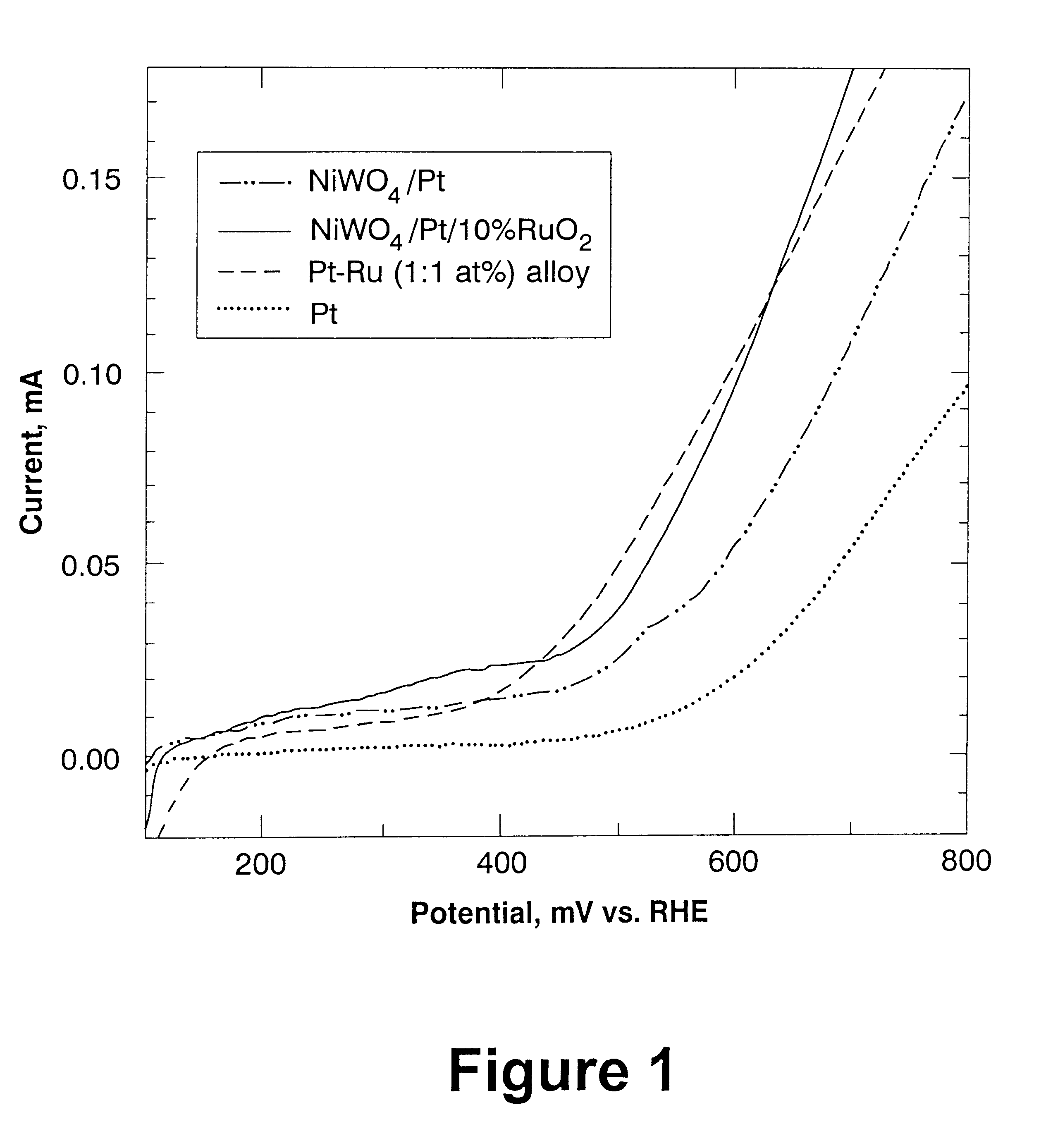

Electrocatalyst for alcohol oxidation in fuel cells

InactiveUS6183894B1Low costImprove stabilityElectrolysis componentsBreech mechanismsPtru catalystFuel cells

Binary and ternary electrocatalysts are provided for oxidizing alcohol in a fuel cell. The binary electrocatalyst includes 1) a substrate selected from the group consisting of NiWO4 or CoWO4 or a combination thereof, and 2) Group VIII noble metal catalyst supported on the substrate. The ternary electrocatalyst includes 1) a substrate as described above, and 2) a catalyst comprising Group VIII noble metal, and ruthenium oxide or molybdenum oxide or a combination thereof, said catalyst being supported on said substrate.

Owner:BROOKHAVEN SCI ASSOCS

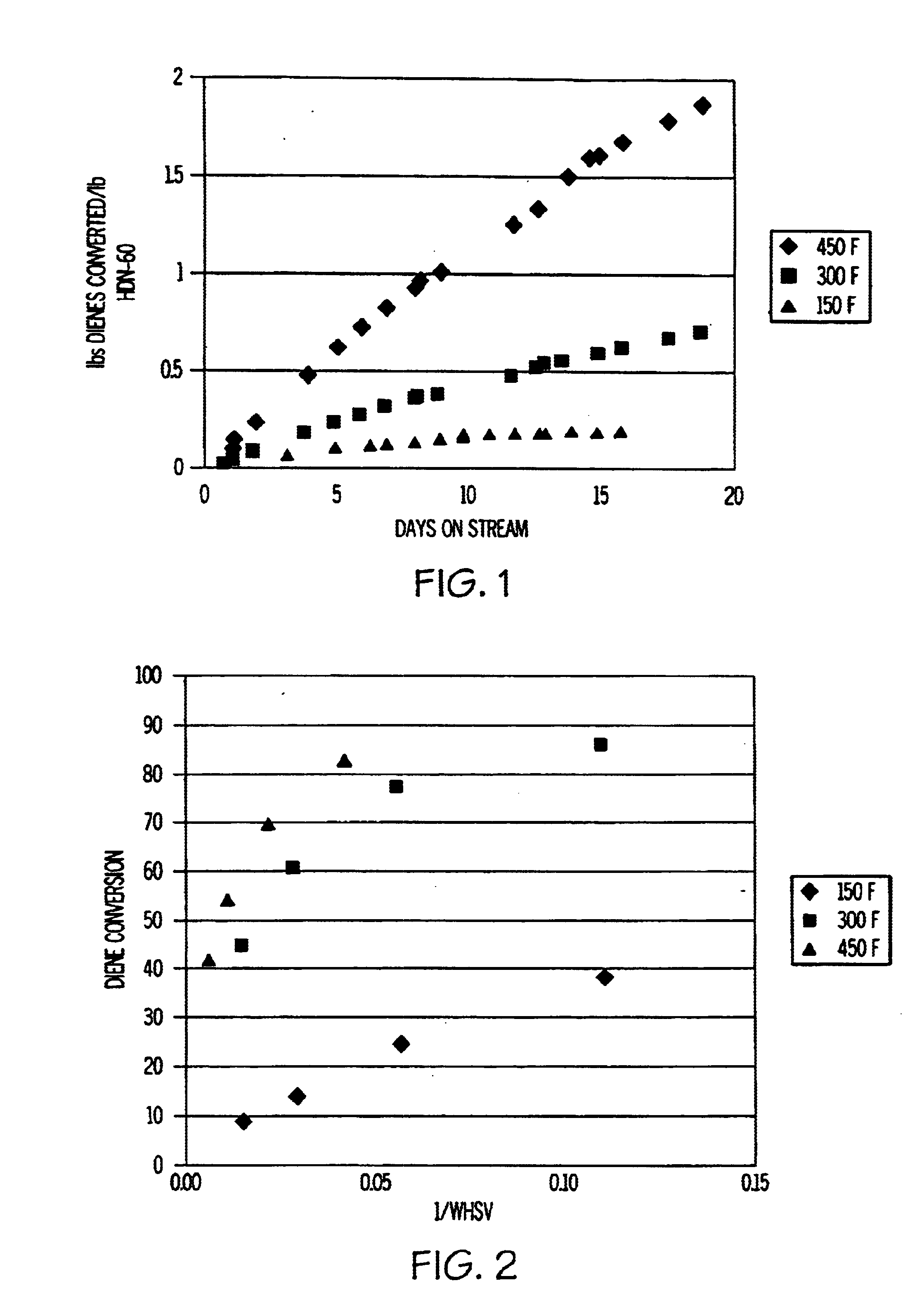

Pyrolysis gasoline nickel system selective hydrogenation catalyst and preparation method thereof

ActiveCN103657670AGood choiceImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationHydrogenation reactionActive component

The invention provides a pyrolysis gasoline nickel system selective hydrogenation catalyst and a preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst and belongs to a catalyst containing metal or metal oxide or hydroxide. The pyrolysis gasoline nickel system selective hydrogenation catalyst is characterized by being provided with a mesopore-macropore or double-mesopore compound pore channel, taking aluminum oxide as a carrier, taking nickel as a main active component, taking molybdenum as an auxiliary active component and taking the metal oxide as an auxiliary agent; the pyrolysis gasoline nickel system selective hydrogenation catalyst is composed of following components in parts by weight: 15-19 parts of nickel oxide, 6.5-20 parts of molybdenum oxide, 2.2-4.5 parts of the auxiliary agent and the balance of the aluminum oxide; the auxiliary agent is one or the combination of more than two of potassium oxide, magnesium oxide and lanthanum oxide. The invention provides the pyrolysis gasoline nickel system selective hydrogenation catalyst which is large in pore capacity and high in specific surface, has good reaction activity, high hydrogenation reaction selectivity, good stability, good arsenic dissolving and glue resisting capabilities and is provided with the compound pore channel, and the preparation method of the pyrolysis gasoline nickel system selective hydrogenation catalyst. When the catalyst is used for selectively hydrogenating full-fraction pyrolysis gasoline, the average diene hydrogenation rate is 99%.

Owner:CHINA PETROLEUM & CHEM CORP

Vanadia-Based DeNOx Catalysts and Catalyst Supports

InactiveUS20110250114A1Improve catalytic performanceImprove retentionNitrogen compoundsDispersed particle separationPhosphateManganese oxide

A vanadia-based catalytic composition for reduction of nitrogen oxides includes a titania-based support material; vanadia deposited on the titania-based support material; a primary promoter comprising tungsten oxide, molybdenum oxide or combinations thereof; and an amount of phosphate to achieve a mole ratio of phosphorus to vanadium plus molybdenum of about 0.2:1 or greater. A zirconia, tin or manganese oxide can be added to further inhibit the volatility of molybdenum. Results show low SO2 oxidation rates and excellent NOx conversion and / or molybdenum stability.

Owner:CRISTAL US INC

Fluorinated hydrogenation catalyst with silicon oxide-alumina as carrier and its production

ActiveCN1853779AHigh activityPhysical/chemical process catalystsRefining by aromatic hydrocarbon hydrogenationSilicon oxideChemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing strong annealed steel hot-rolled sheet coil

ActiveCN101121992ANo investment requiredHigh strengthTemperature control deviceManufacturing convertersSlagManganese oxide

The invention discloses a method of manufacturing a tough steel hot rolled strip coil. The molten steel, waste steel, chromic oxide and molybdenum oxide are mixed into a rotating furnace, and a fluxing medium is added in; the manganese oxide or manganese ore is added in at the earlier stage of blowing; the manganese oxide or manganese ore and the reducing agent are added in by the end of blowing, and nitrogen or argon is blew from bottom during the whole process; tapping is conducted when the components and the temperature of the molten steel are appropriate; during tapping, the composite deoxygener and the reducing desulfurating refining slag are added in the molten steel during tapping, and nitrogen or argon is blew from bottom of a steel ladle during the whole process. The steel ladle adds the metal aluminum in the molten steel from the CAS position to conduct deep deoxidation and microalloying; and then the increasing nitrogen agent, vanadium iron and ferrocolumbium are added in, and nitrogen or argon blowing is kept. The steel ladle is sent to the position of an LF refining furnace, the lime and reducing desulfurating refining slag are added in the LF refining furnace, argon is blew, electricity is supplied, the temperature is raised and argon is blew again, and the calcium line and the boron filament are fed at the later stage of refining; CSP is supplied for continuous casting, and the charging temperature of a cast slab is is more than 950DEG C; the heating temperature, the initial billet temperature, the rolling finishing temperature and the coiling temperature are well controlled. The tough steel hot rolled strip coil manufactured with the method has high strength and good tenacity.

Owner:湖南华菱涟钢特种新材料有限公司 +1

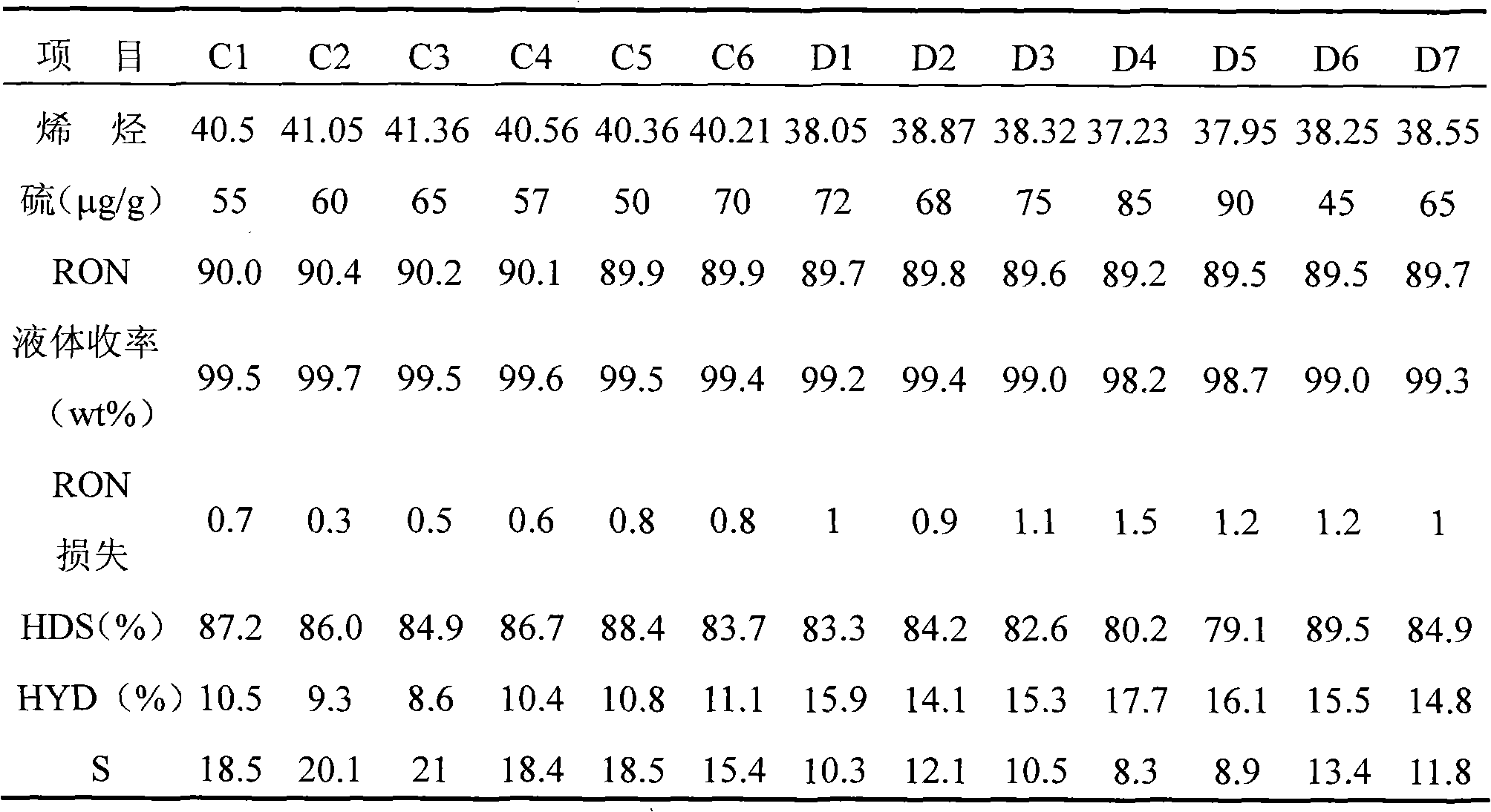

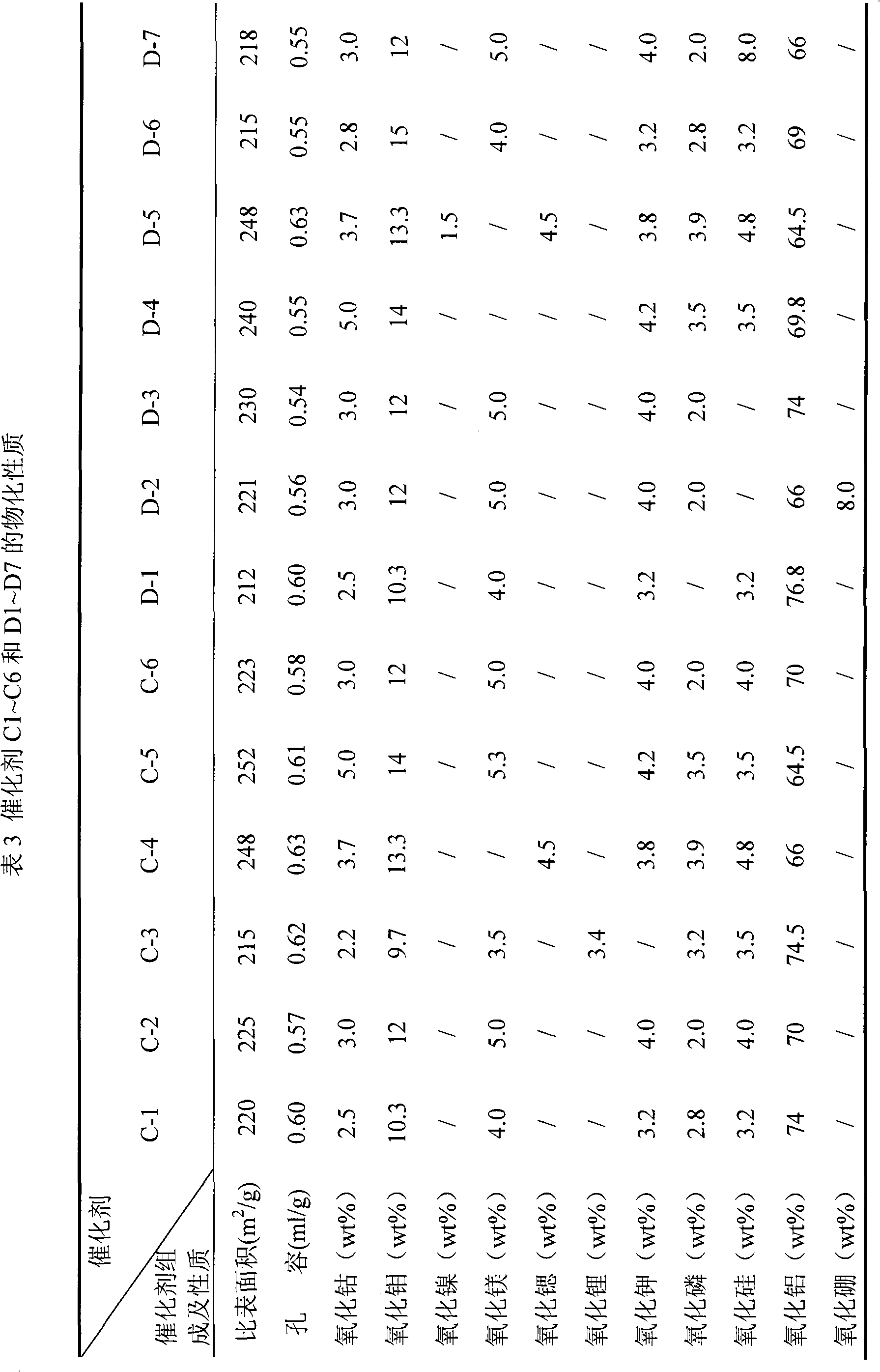

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

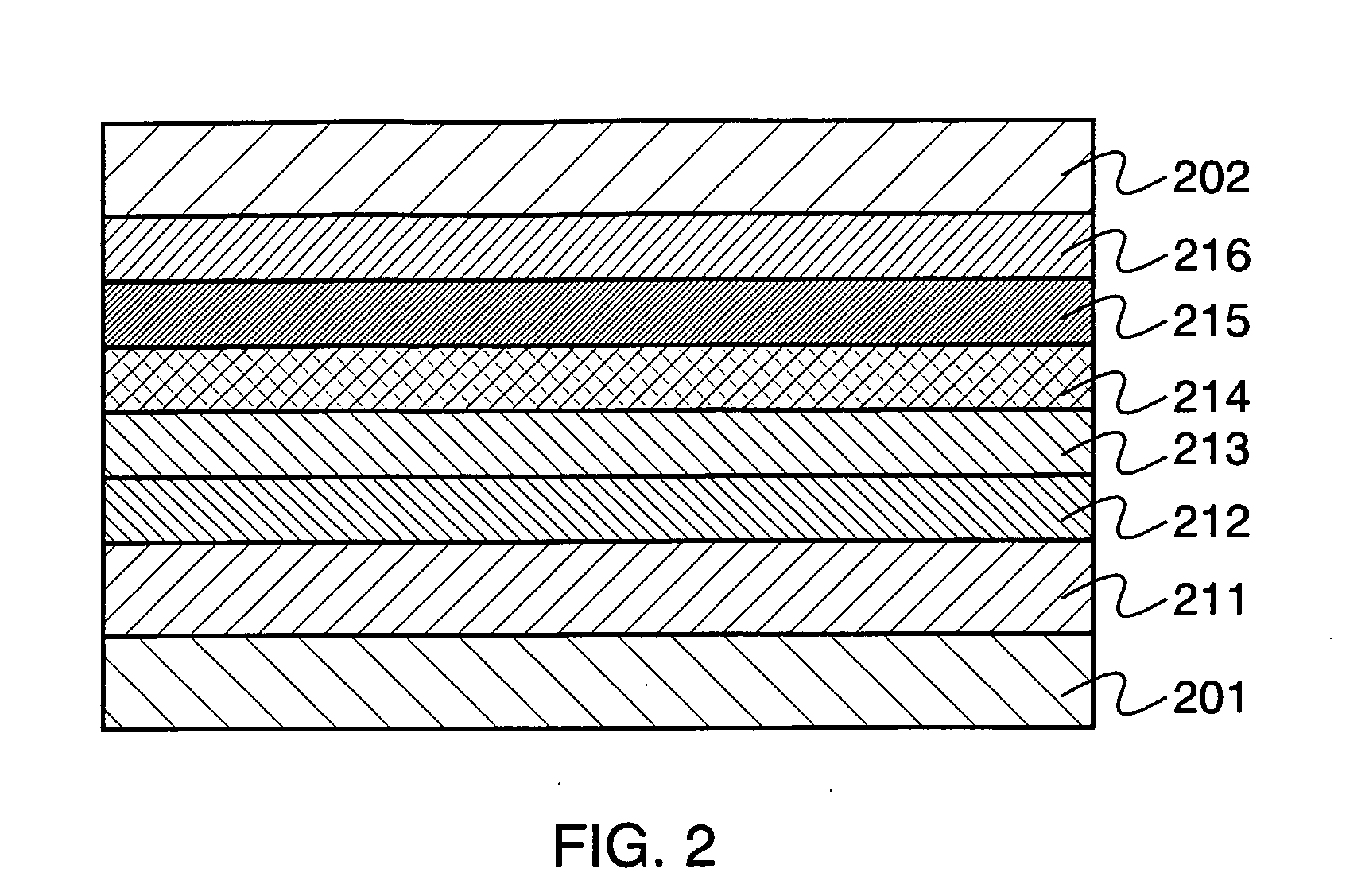

Organic Electroluminescence Element, Method for Manufacturing the Same and Organic Electroluminescence Display Device

InactiveUS20090243478A1Discharge tube luminescnet screensElectroluminescent light sourcesElectron injectionDisplay device

One embodiment of the present invention is an organic electroluminescence element including an anode which is a hole injection electrode; a cathode which is an electron injection electrode, the cathode facing the anode; an organic light emitting layer between the anode and the cathode, the organic light emitting layer including a molybdenum oxide layer, the molybdenum oxide layer including a crystal molybdenum oxide and an amorphous molybdenum oxide, and the crystal molybdenum oxide and the amorphous molybdenum oxide being mixed or stacked.

Owner:TOPPAN PRINTING CO LTD

Catalyst regeneration

A method is disclosed for regenerating regenerating a used catalyst mixture comprising (i) an isomerization catalyst comprising magnesium oxide and (ii) a metathesis catalyst comprising an inorganic carrier and at least one of molybdenum oxide and tungsten oxide. The method comprises (a) decoking the used catalyst mixture in the presence of an oxygen-containing gas to produce a decoked catalyst mixture; and (b) contacting the decoked catalyst mixture with steam at a temperature in the range of 100 to 300° C. to produce a regenerated catalyst mixture.

Owner:LYONDELL CHEM TECH LP

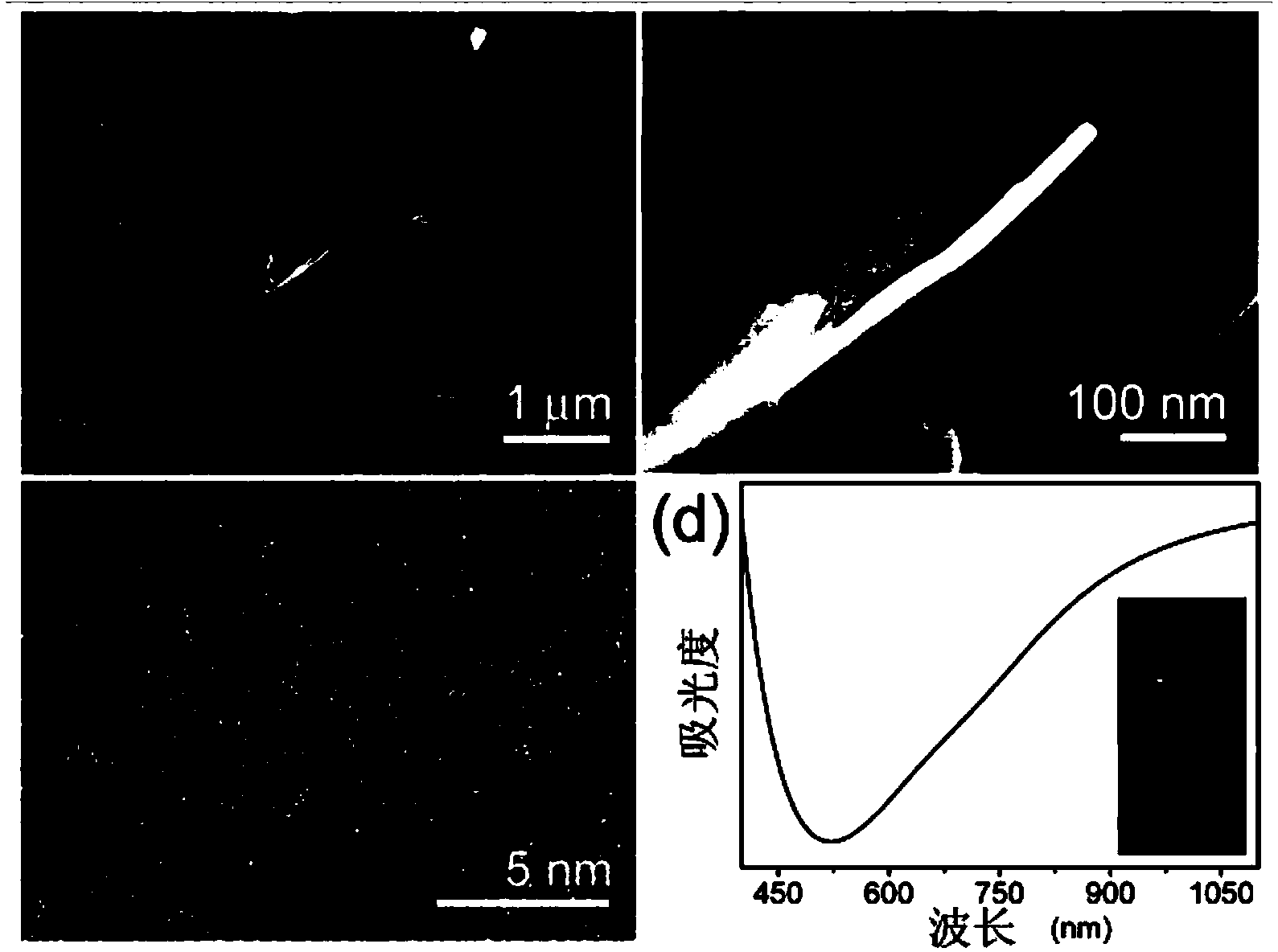

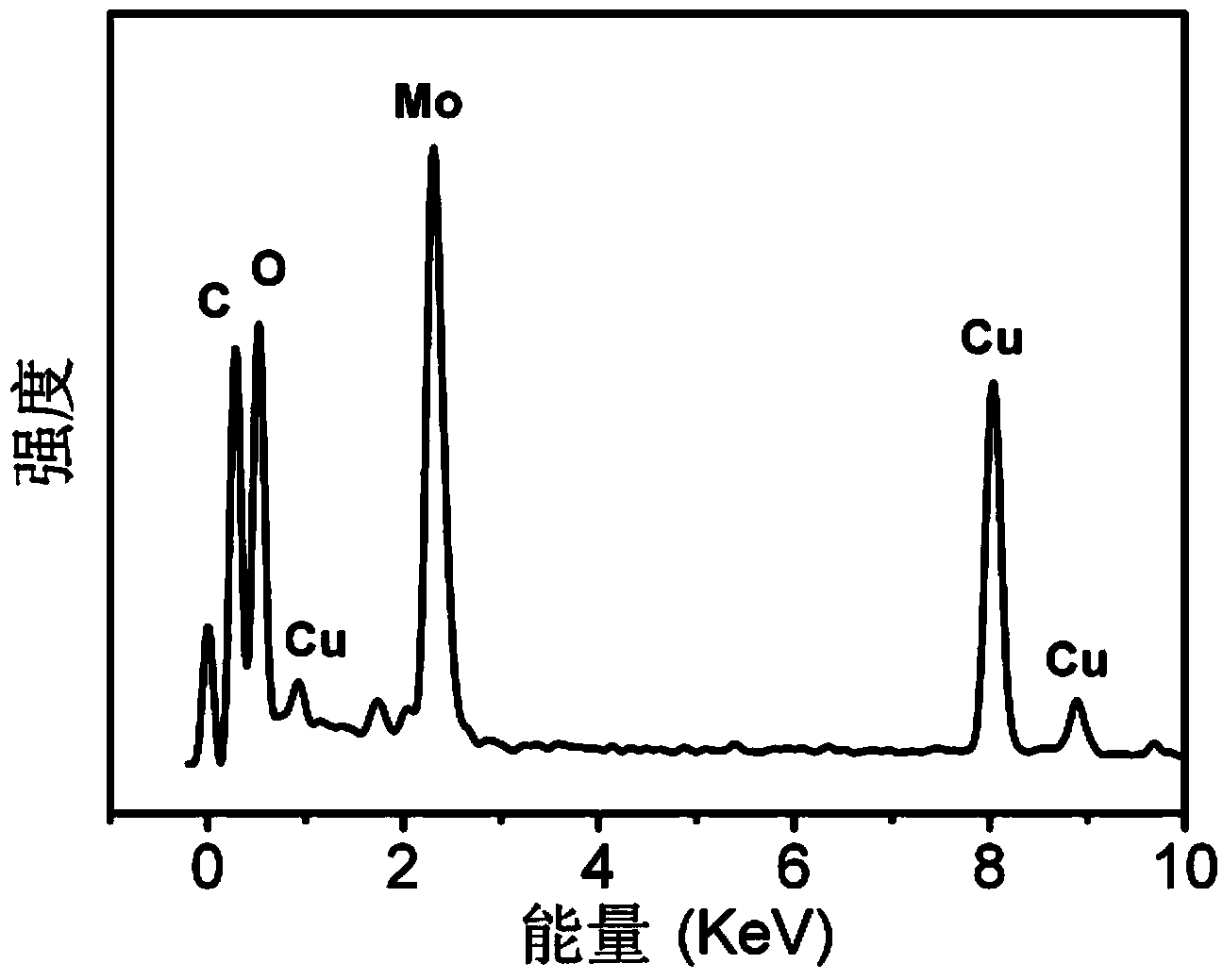

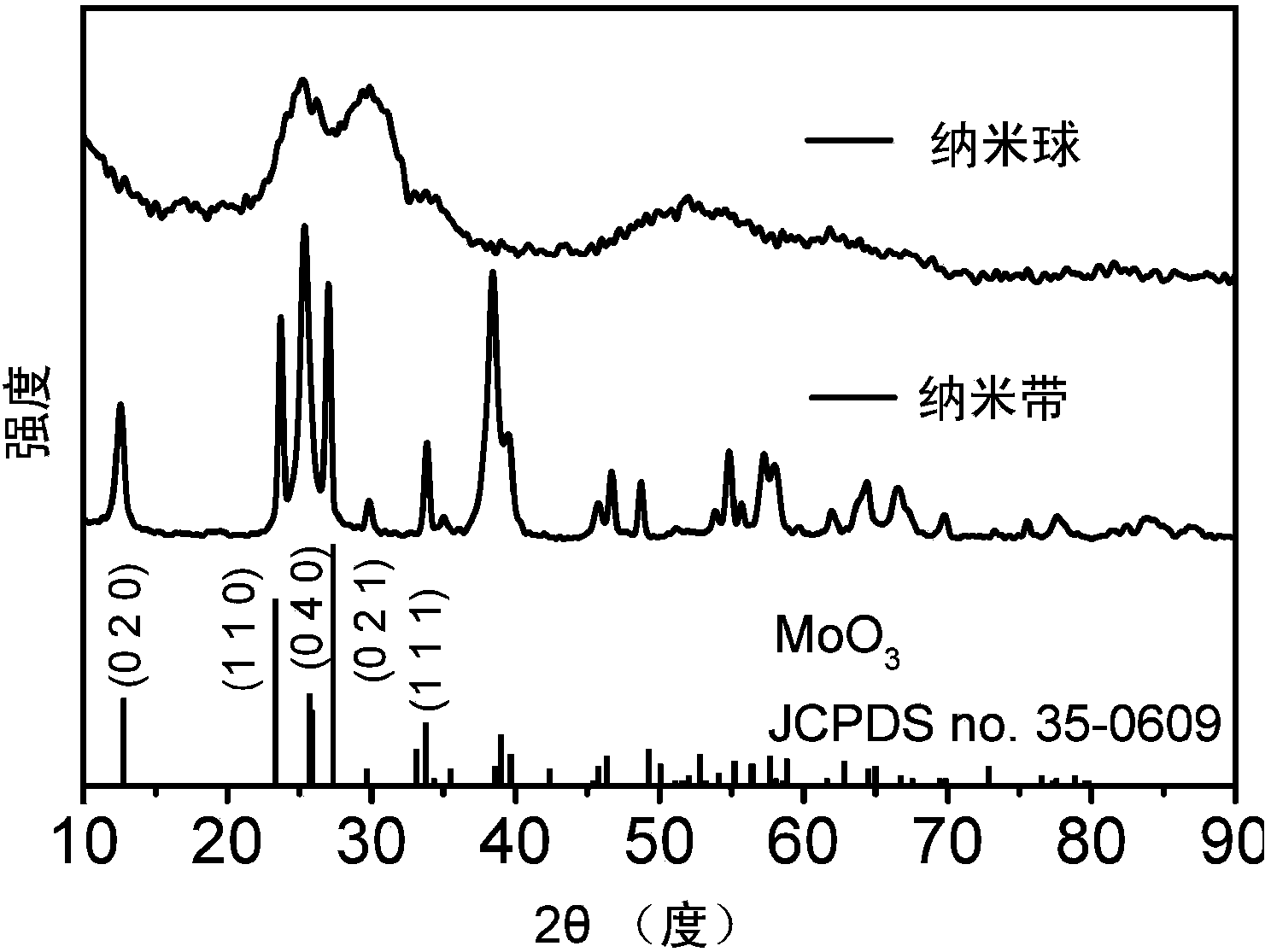

Molybdenum oxide based nano photothermal conversion material and preparation method thereof

InactiveCN103449524AEfficient killingStrong near-infrared light absorptionMaterial nanotechnologyHeavy metal active ingredientsCentrifugationPhotothermal conversion

The invention relates to a molybdenum oxide based nano photothermal conversion material and a preparation method thereof. The photothermal material is a MoO<3-x> nano material, wherein x is not less than 0 and not more than 1. The preparation method of the photothermal material comprises the following steps: adding H2O2 to elementary molybdenum, stirring the materials and then diluting the materials, thus obtaining a molybdenum precursor solution; adding a surfactant to the molybdenum precursor solution, stirring the mixture uniformly and then carrying out hydrothermal reaction and centrifugation, thus obtaining the molybdenum oxide based nano photothermal conversion material. The efficient molybdenum oxide based nano photothermal material is prepared by the simple, environment-friendly and cheap method provided by the invention and shows a huge application value in cancer treatment.

Owner:DONGHUA UNIV

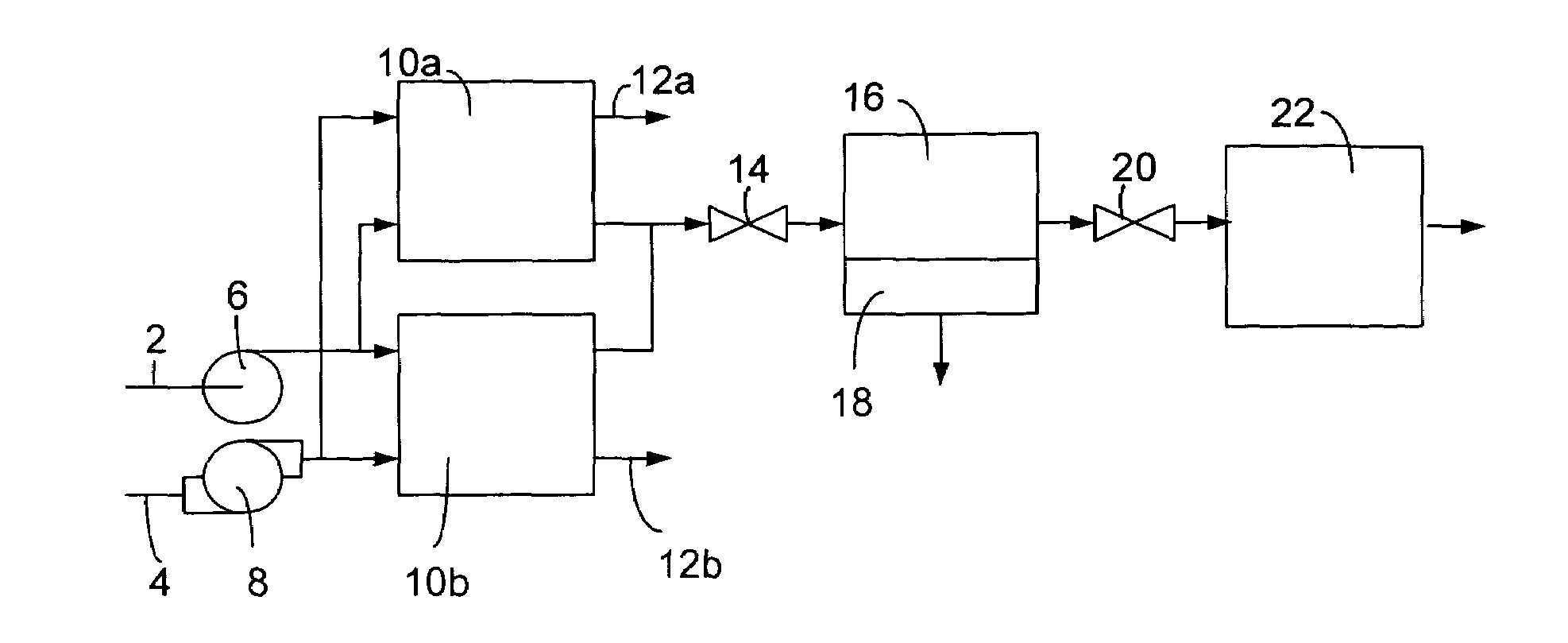

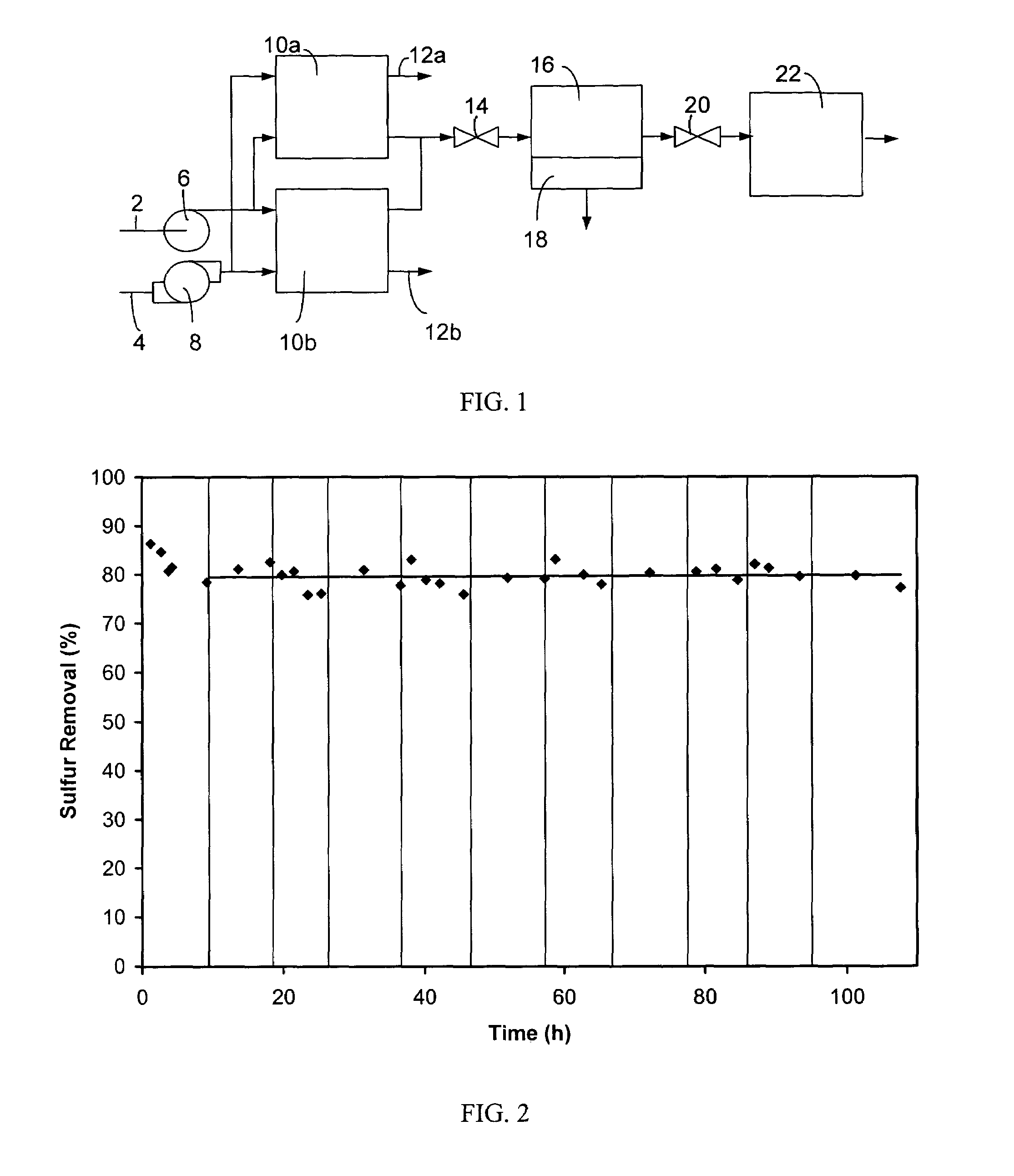

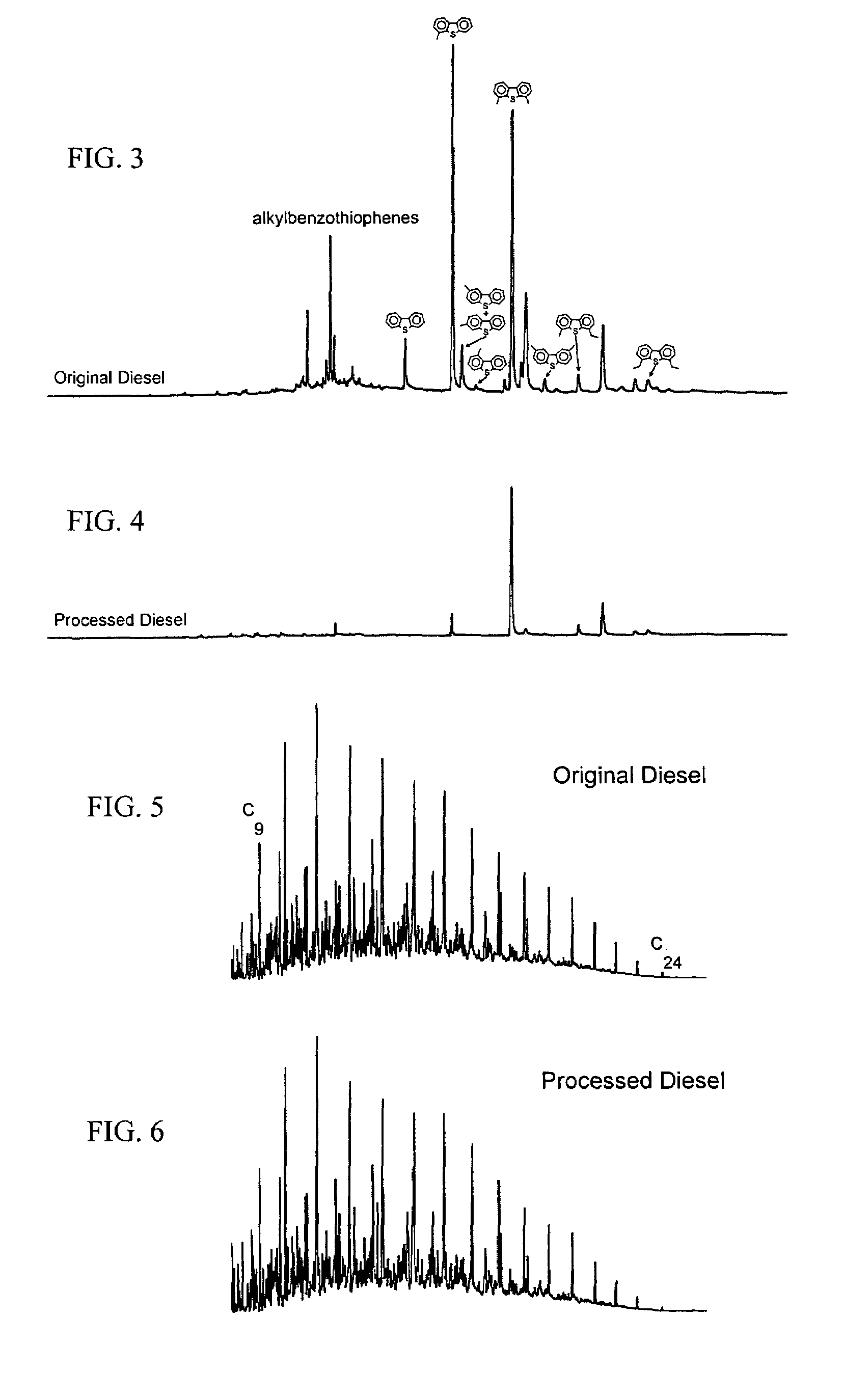

Methods and compositions for desulfurization of hydrocarbon fuels

ActiveUS7309416B2Efficient removalHigh activityTreatment with plural serial cracking stages onlyGas treatmentBoiling pointSulfur

Sulfur is removed from a hydrocarbon fuel via contact with a desulfurization agent; the desulfurization agent is then regenerated (wherein sulfur is released) by exposing it to oxygen. The sulfur removal and regeneration processes each can be carried out at relatively moderate temperatures, e.g., from 300 to 600° C., and pressure, e.g., about 0.79 to about 3.5 MPa; and the desulfurization agent can include a transition metal oxide, such as molybdenum oxide. The process can also include the additional steps of cracking the hydrocarbon, separating high-boiling and low-boiling fractions from the reaction product and contacting the lower-boiling fraction with a secondary desulfurization agent.

Owner:ASPEN PRODS GROUP

Method for recycling vanadium and molybdenum from waste petroleum catalyst

InactiveCN105274344AReduce pollutionAchieve recyclingProcess efficiency improvementPtru catalystPorphyrin

The invention relates to a method for recycling vanadium and molybdenum from a waste petroleum catalyst, and belongs to the technical field of petrochemical industry. The method comprises air-burning and ball-removing, ball-milling, soda roasting-water leaching, aluminum removing, molybdenum precipitating and enriching molybdenum by ion exchange. The method specifically comprises the following steps: firstly, igniting sticky oil in the waste catalyst in air to burn carbon and oils in the waste catalyst; then, oxidizing the vanadium and nickel in the forms of porphyrin compounds in the waste catalyst into vanadium oxide and nickel oxide, converting most of the molybdenum into molybdenum oxide, wherein the waste catalyst subjected to air-burning and oil-removing is more beneficial for crushing, and the crushed waste catalyst and a certain proportion of sodium carbonate are mixed, and are roasted at a high temperature; leaching roasted materials by hot water, dissolving sodium salts of the vanadium and the molybdenum into water to obtain a solution, filtering the solution, introducing the filtered solution into a leaching solution, introducing a little aluminum into the leaching solution, regulating the pH value of the solution to remove aluminum; regulating the pH value of the solution to 8-9, adding ammonium chloride, precipitating and separating out the vanadium in the form of ammonium vanadate; and concentrating vanadium-precipitated solution by adopting an ion exchange process and enriching an ammonium molybdate solution.

Owner:刘楚玲

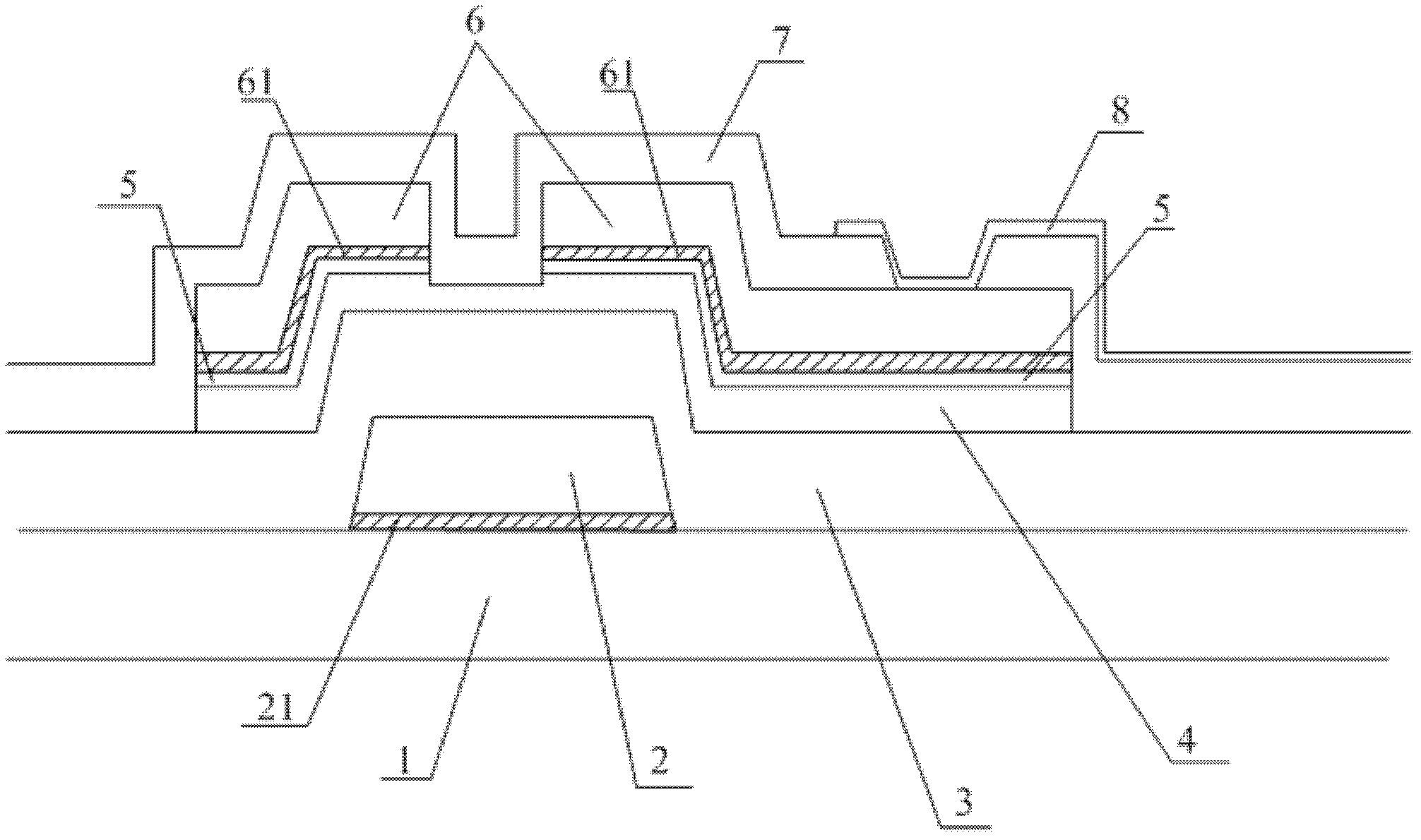

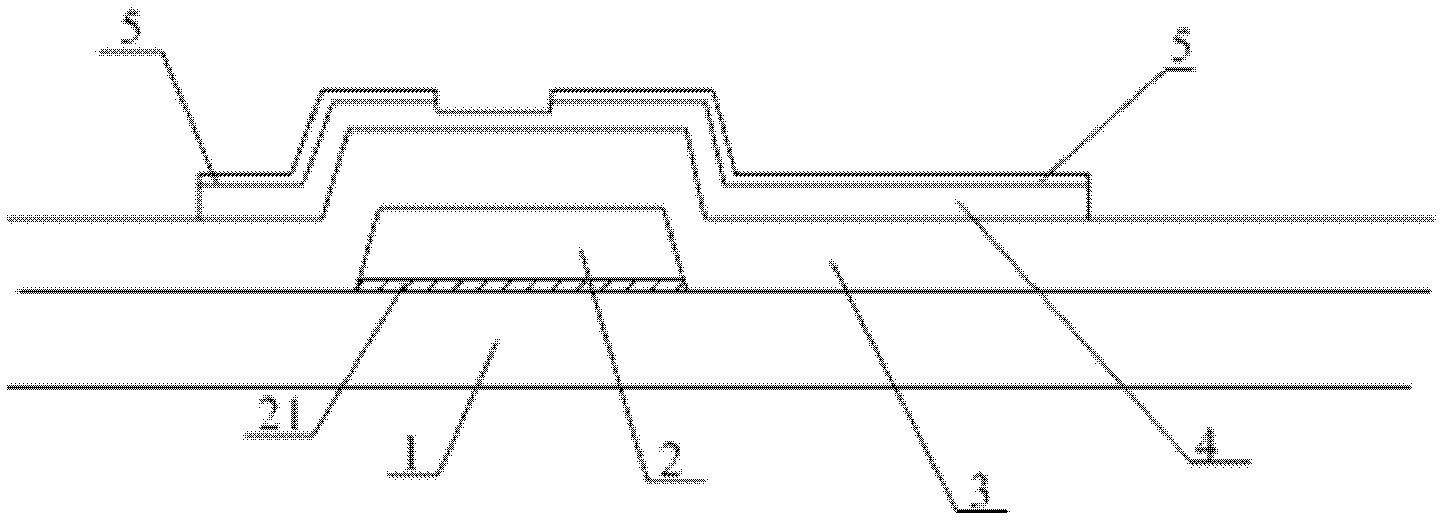

Array substrate and manufacturing method thereof, liquid crystal panel, and display device

InactiveCN102629609APrevent proliferationImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayDisplay device

The embodiments of the invention, which relates to the liquid crystal display technology field, disclose an array substrate and a manufacturing method thereof, a liquid crystal panel, and a display device, thereby effectively preventing metal ions of a metal electrode layer from in a thin film transistor (TFT) structure being diffused to a film layer of silicon series and strengthening an adhesive force between the metal electrode layer and a substrate. The provided array substrate comprises a substrate body, a gate metal layer, an active layer and a source / drain metal layer, wherein the gate metal layer, the active layer and the source / drain metal layer are formed on the substrate. An isolation buffer layer is formed at at least one side of the gate metal layer and / or an isolation buffer layer is formed at at least one side of the source / drain metal layer; and moreover, the isolation buffer layers are formed by molybdenum oxide. According to the embodiments of the invention, the provided schemes are suitable for various display devices employing TFT substrates and an X-ray detector device.

Owner:BOE TECH GRP CO LTD

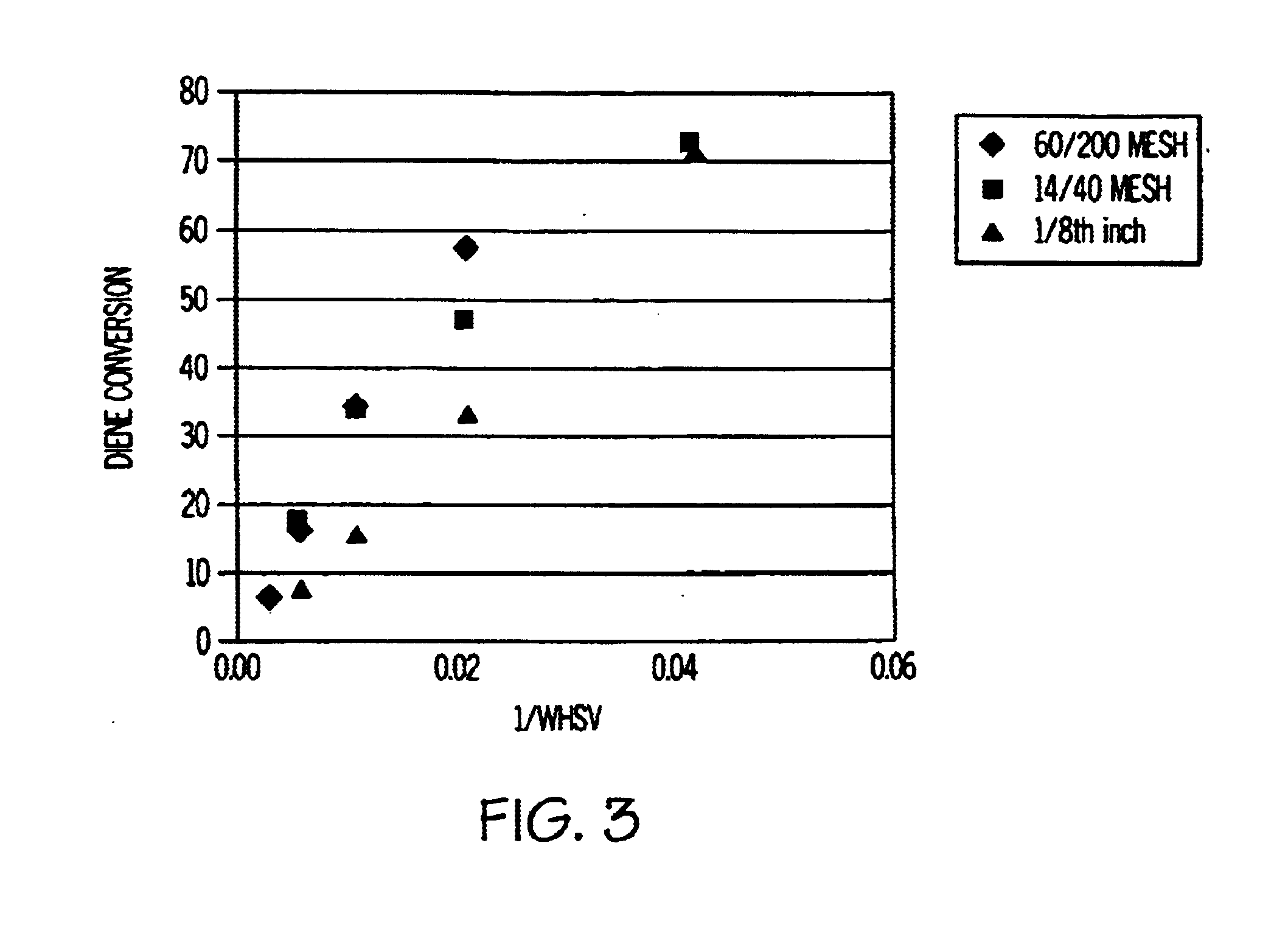

Conversion of unsaturated chemicals to oligomers

InactiveUS6884916B1Reduce operating costsEliminate needLiquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionHydrogenOligomer

An oligomerization process in which hydrocarbon feedstocks are contacted with a hydrotreating catalyst in the absence of hydrogen and in the liquid phase. The catalyst is a heterogeneous catalyst selected from supported reduced metals, metals oxides, metal sulfides and combinations thereof. Preferred catalysts include mixed nickel and molybdenum oxides or mixed cobalt and molybdenum oxides. The process also oligomerizes sulfur compounds so that sulfur containing feedstocks can be treated without deactivating the catalysts.

Owner:MOBIL OIL CORP

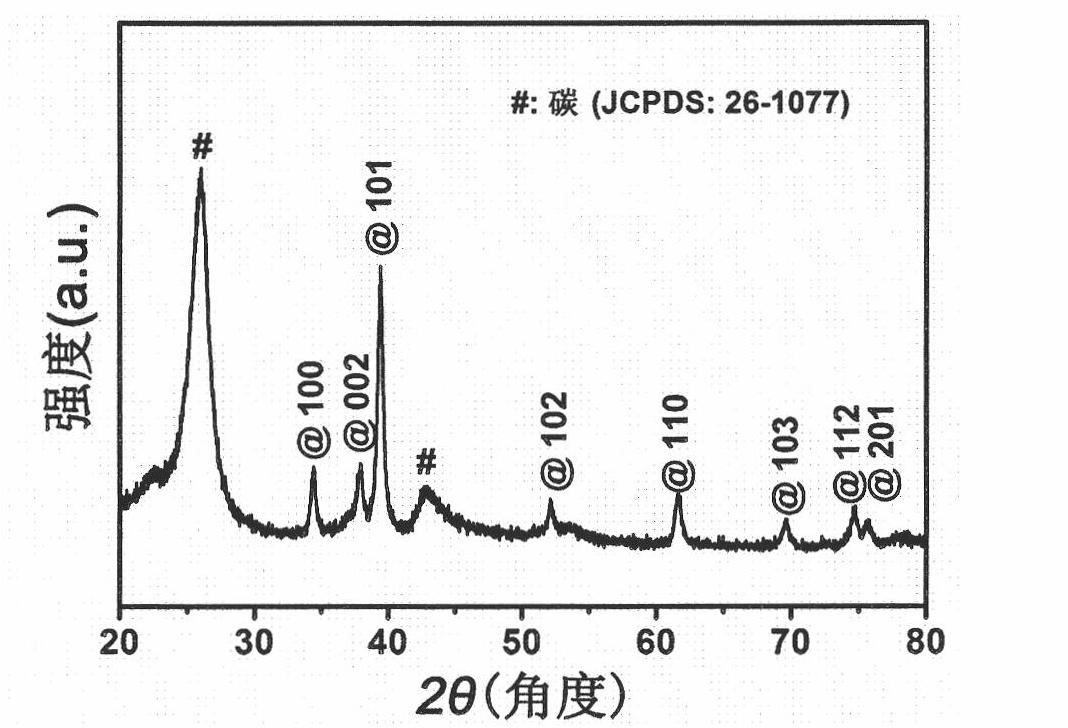

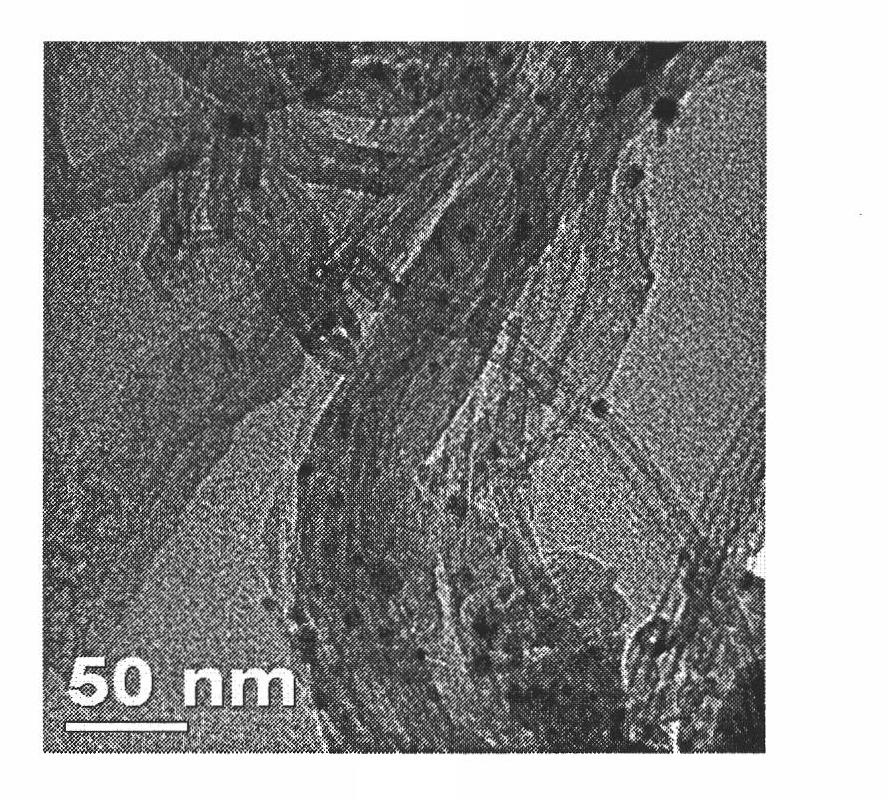

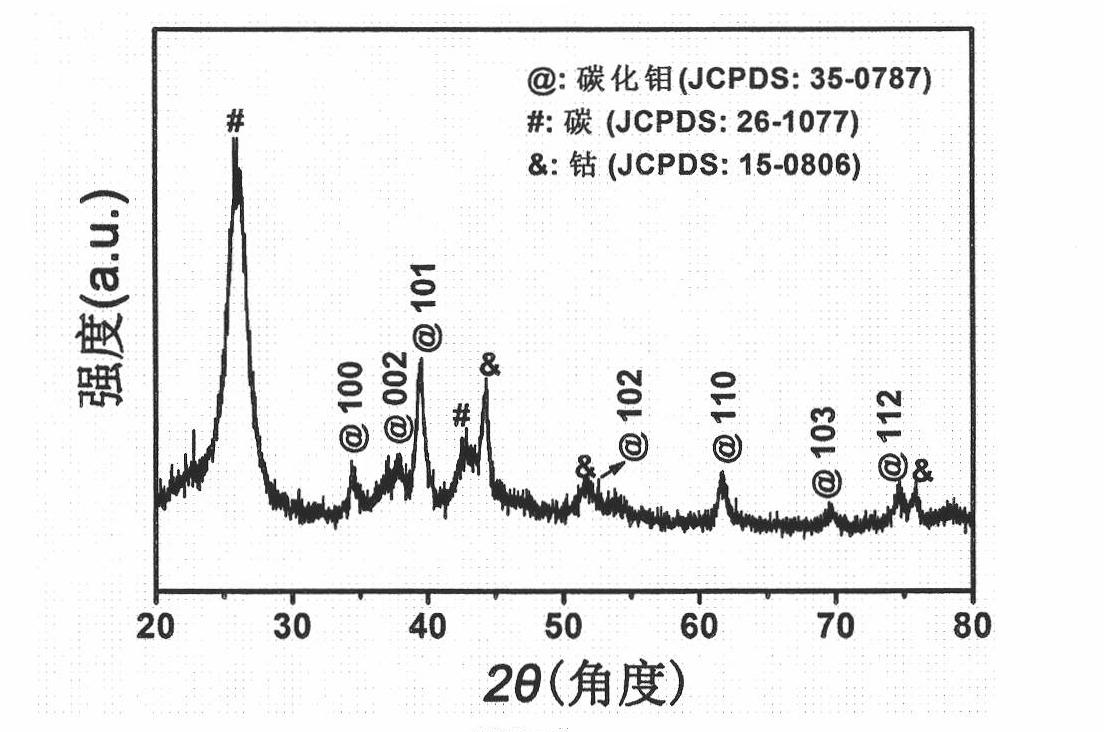

Synthetic method of load type molybdenum carbide catalyst

InactiveCN101829588AFacilitated DiffusionLarger than surfaceHydrogenPhysical/chemical process catalystsCarbon nanotubeMolybdenum carbide

The invention relates to a synthetic method of a load type molybdenum carbide catalyst, which belongs to the field of catalytic materials and comprises the steps of: dispersing organic-inorganic mixed molybdenum oxide-polyaniline used as precursors in H2O / EtO; drying after mixing with carriers, such as carbon nanotubes and the like; and then roasting at an inert atmosphere to obtain the load typemolybdenum carbide catalyst. In the load process, other metal salts can also be added to modify the molybdenum carbide catalyst to obtain a metal modified load type molybdenum carbide catalyst. The molybdenum carbide catalyst prepared by the invention has the advantages of large external surface area, less surface carbon deposition, abundant catalytic performance of precious metal and the like, and can be used for conveniently modifying the catalyst. The loading molybdenum carbide catalyst has important application in various catalytic reactions.

Owner:FUDAN UNIV

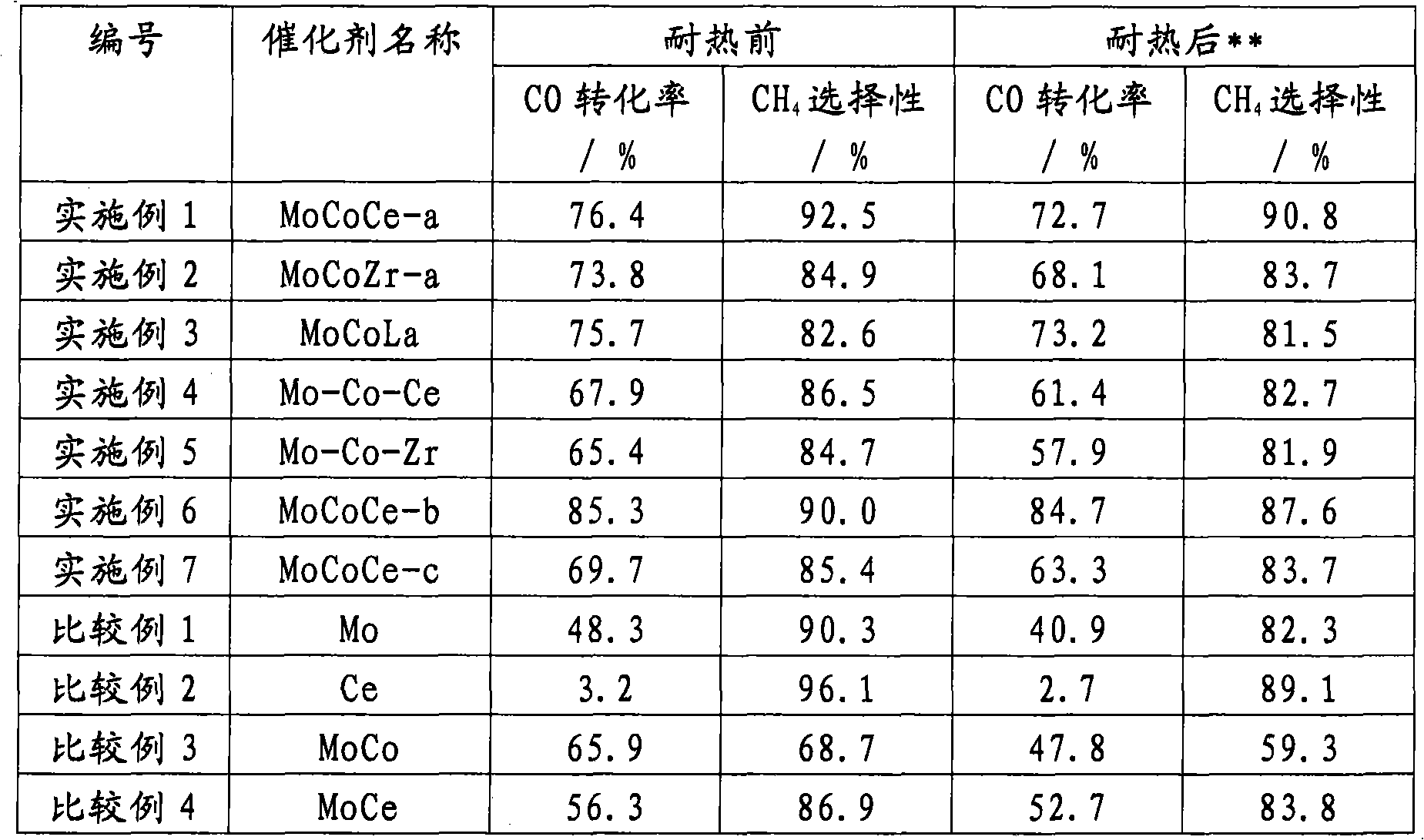

Sulfur-tolerant methanation catalyst and its preparation method

InactiveCN102463118AHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationLanthanum

The invention relates to a sulfur-tolerant methanation catalyst and its preparation method, and relates to a sulfur-tolerant methanation catalyst which can be used under a wide operation condition particularly at high temperature and its preparation method, and the sulfur-tolerant methanation catalyst contains a carrier and an active component loaded on the carrier. The carrier is selected from alumina, silica, zirconium dioxide, active carbon or molecular sieve, the active component comprises a molybdenum oxide taken as a main active component, a cobalt oxide taken as a first auxiliary agent; and a zirconium oxide, a cerium oxide or a lanthanum oxide, or a mixture composed of at least two above oxides which is taken as a second auxiliary agent. The invention also discloses the preparation method of the sulfur-tolerant methanation catalyst which is composed of a dipping step, a drying step and a calcining step.

Owner:ENN SCI & TECH DEV

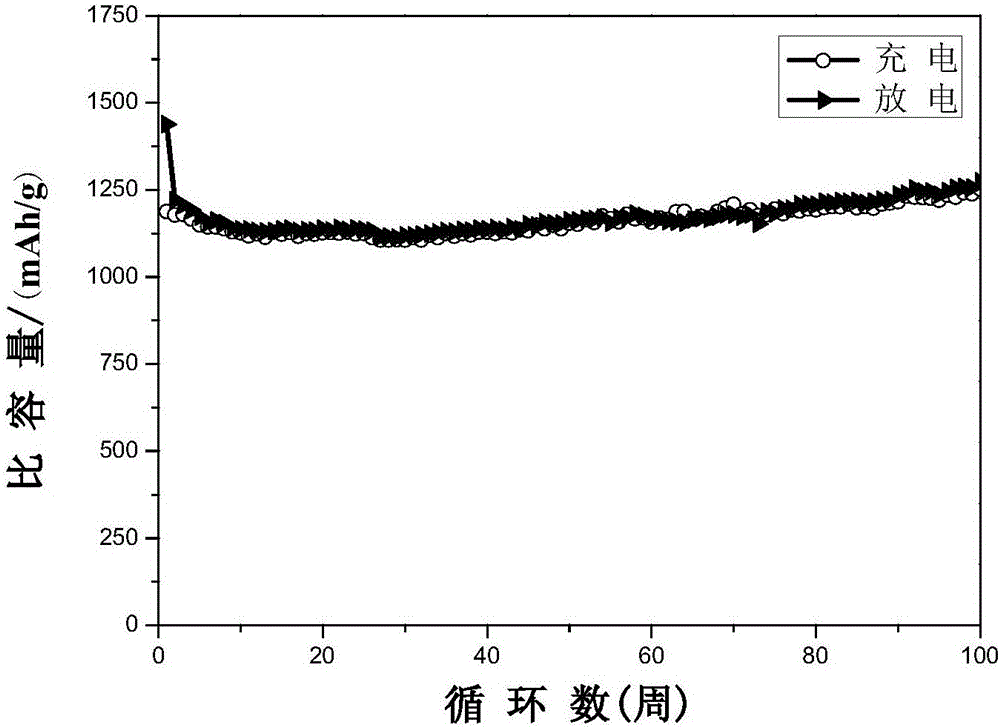

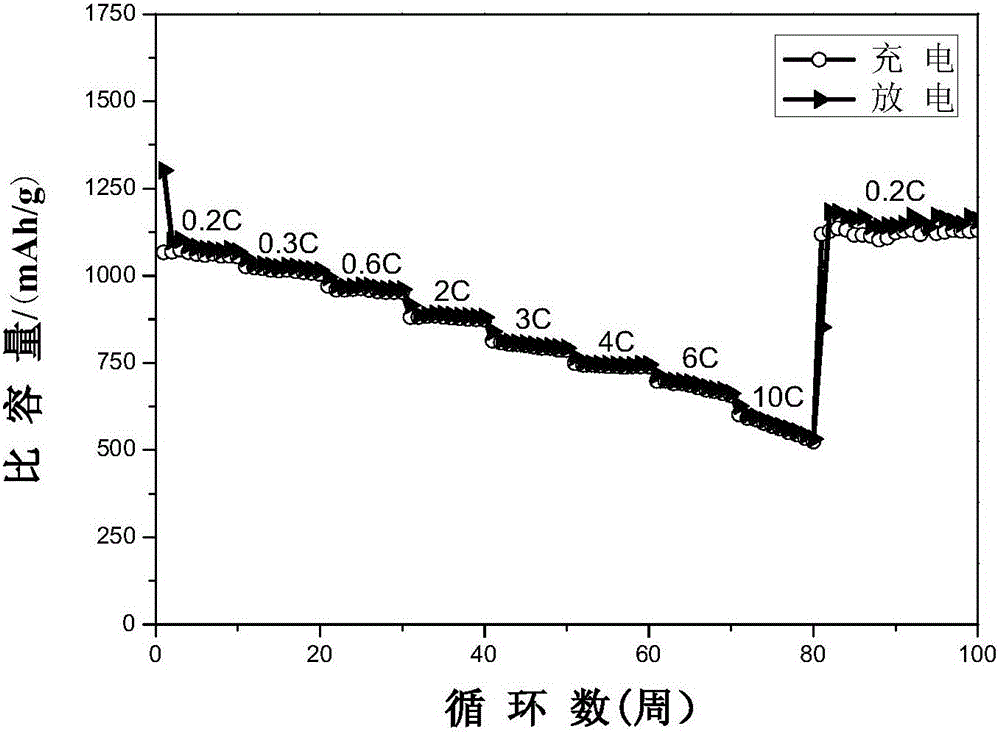

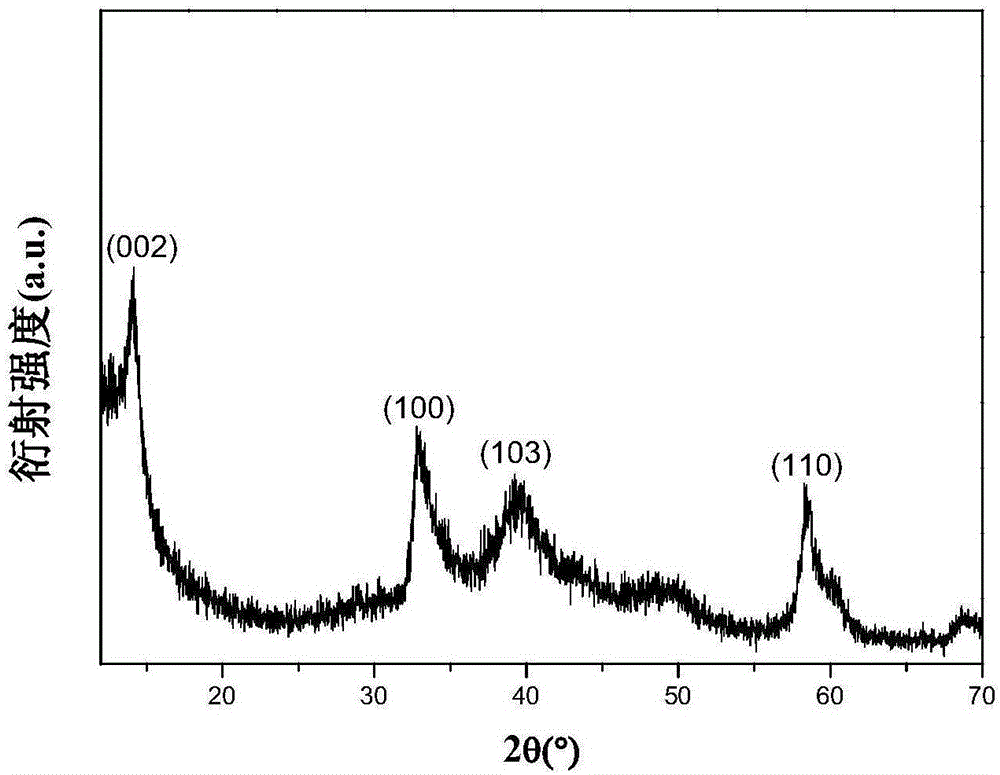

Layered structure molybdenum disulfide/carbon composite material and preparation method and application thereof

ActiveCN106410136AIncrease layer spacingWell formedCell electrodesSecondary cellsCarbon compositesElectronic transmission

The invention discloses a preparation method of a layered structure molybdenum disulfide / carbon composite material and an application. The composite material is prepared by adopting a molybdenum oxide organic / inorganic hybrid compound of an organic amine intercalation layer as a precursor, putting the precursor into a high-temperature area, putting a sulfur source into a low-temperature area and simultaneously carrying out high-temperature vulcanization and carbonization treatment under inert gas protection. The composite material has a layered structure; carbon is located between laminated plates of a few of molybdenum disulfide layers; the composite material can serve as an electronic transmission channel to improve the conductivity of the electrode material; and furthermore, the interlayer distance is expanded and the diffusion ability of Li<+>between the layers is improved. The composite electrode material has relatively high specific capacity and good cycle performance and rate capability, and is simple in process and low in raw material cost; and large-scale industrial production is easy to implement.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

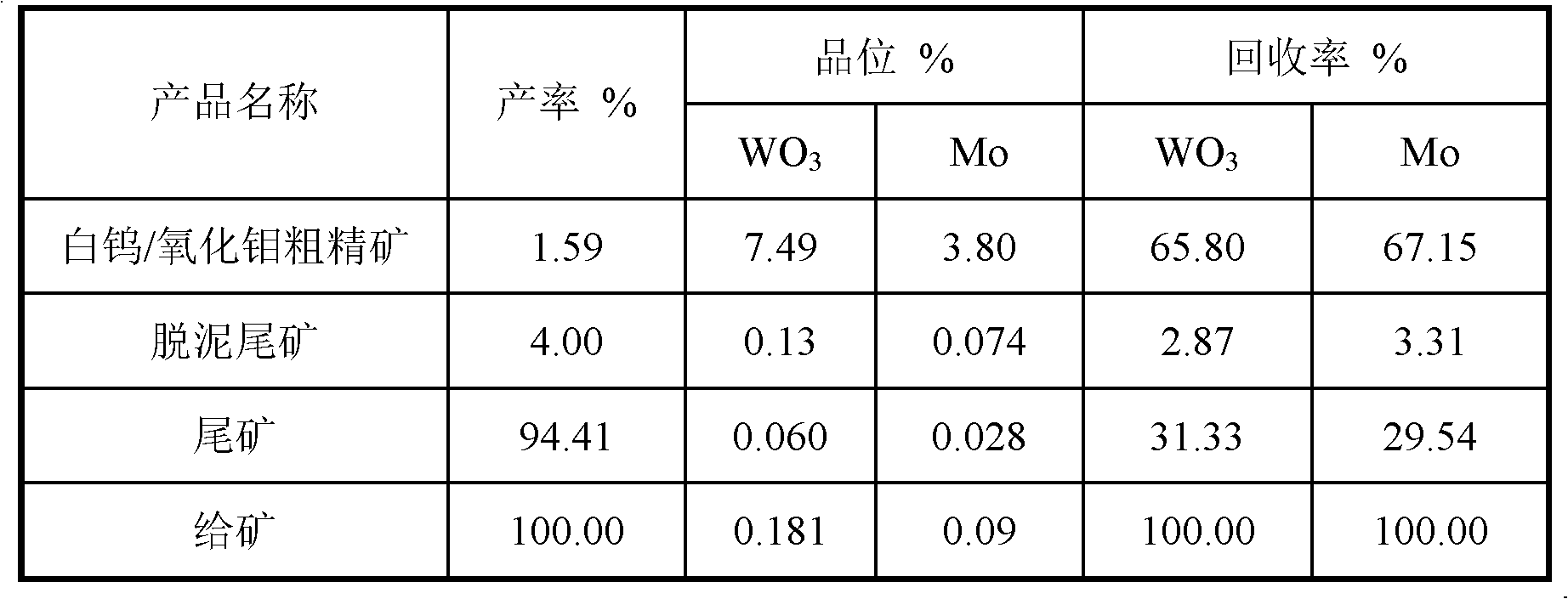

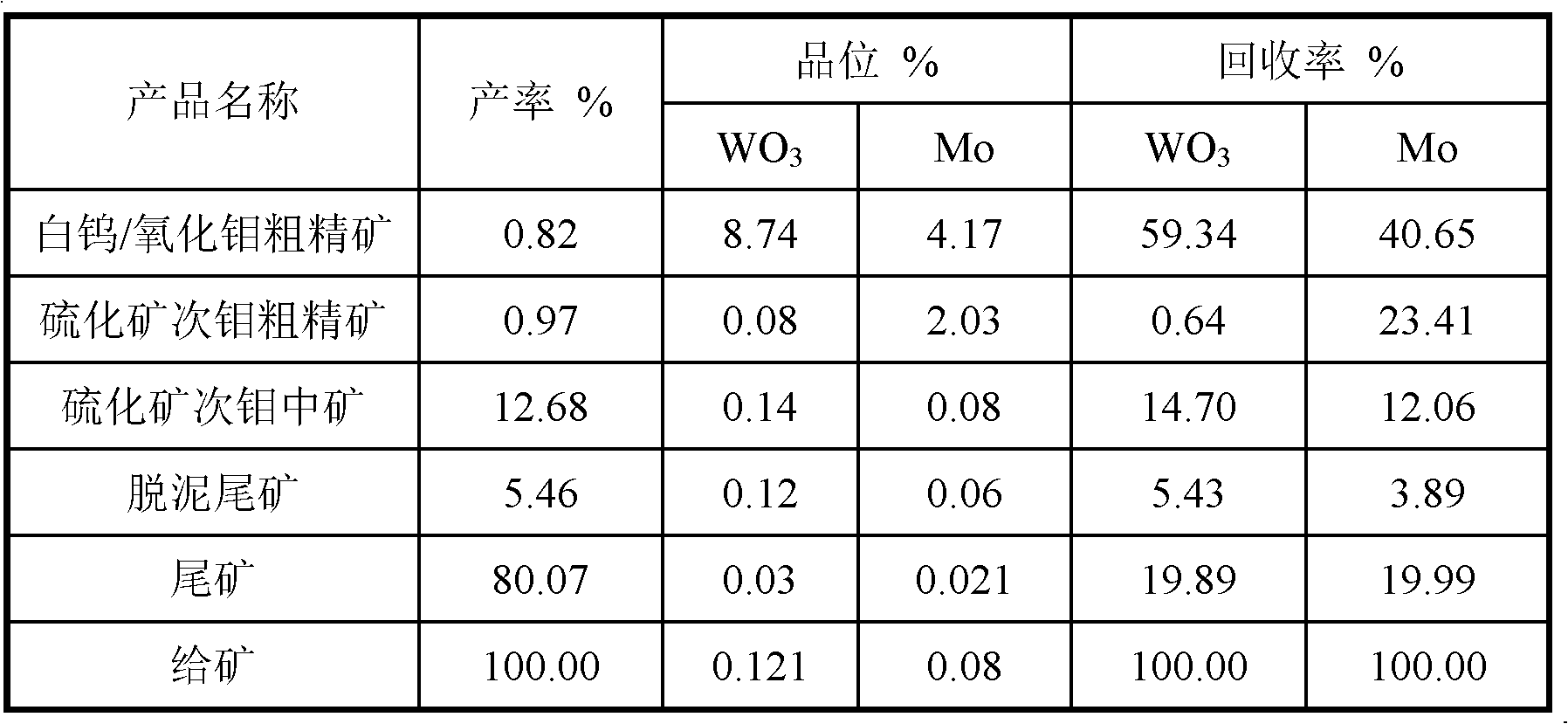

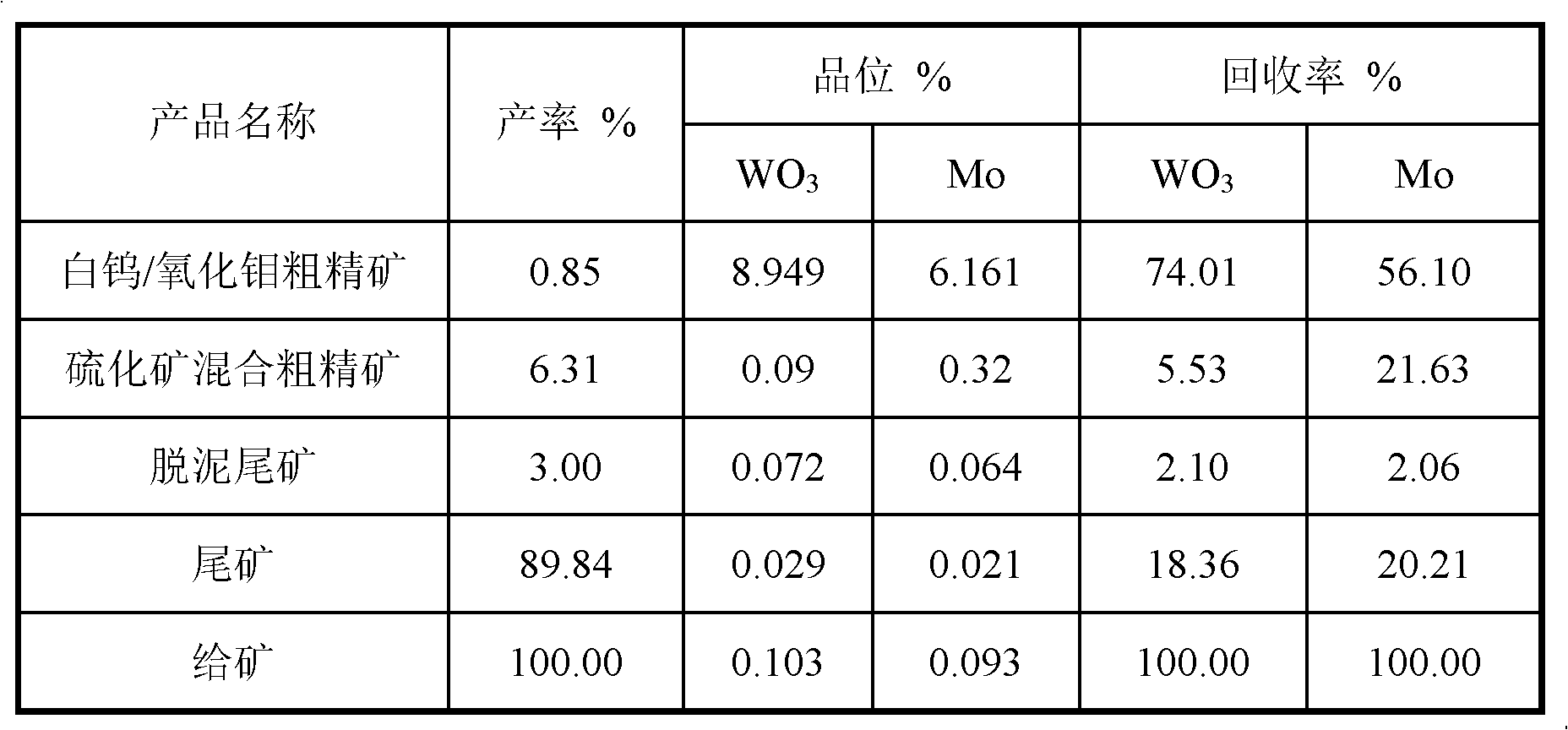

Mineral processing method for recycling scheelite/molybdenum oxide ores from molybdenum sulfide flotation tailings

The invention discloses a mineral processing method for recycling scheelite / molybdenum oxide ores from molybdenum sulfide flotation tailings. The mineral processing method comprises the following steps of: taking the molybdenum sulfide flotation tailings as raw materials and further levigating the raw materials; carrying out reselection and / or flotation and desliming on ore pulp which is levigated according to demands; adding a regulator, an auxiliary inhibitor, an inhibitor and a modified aliphatic acid collecting agent into the flotation tailing pulp; and recycling the scheelite / molybdenum oxide ores at room temperature so as to obtain scheelite / molybdenum oxide ore concentrates after roughing, scavenging and concentrating. The mineral processing method disclosed by the invention has the advantages of simple process flow, low production cost, resource saving, high product level and high recovery.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

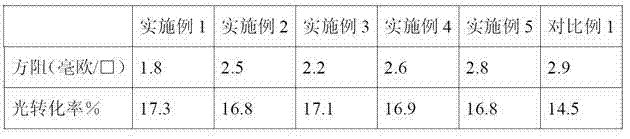

Glass powder and its preparation method and conductive paste for solar cell

ActiveCN102476919AConvenient sourceImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialSemiconductor devicesEngineeringSelenium Oxide

The invention provides glass powder, which comprises bismuth oxide 30wt%-70wt%, titanium oxide 1wt%-20wt%, zinc oxide 5wt%-40wt%, antimony oxide 5wt%-30wt% optional tellurium oxide 0wt%-30wt%, optional molybdenum oxide 0wt%-10wt% and selenium oxide 0wt%-15wt%. The invention also relates to a preparation method of the glass powder and conductive paste for solar cell prepared from the glass powder. The inventive glass powder contains no lead and boron, does no harm to the environment and can be used for preparing conductive paste for solar cell with high photoelectric conversion efficiency.

Owner:BYD CO LTD

Preparation method of catalyst for hydrogenation desulfurization and denitrification of light-weight oil

InactiveCN102247864AGood dispersionIncrease profitCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideTitanium oxide

The invention discloses a preparation method of a catalyst for hydrogenation desulfurization and denitrification of light-weight oil and is characterized in that the composition of the catalyst comprises a carrier, an auxiliary agent and active metals, wherein the carrier contains aluminum oxide, titanium oxide and silicon oxide; the auxiliary agent is phosphorus; the active metals are oxides of nickel, molybdenum and tungsten; and on the basis of the catalyst, the contents of all components in percentage by weight are as follows: 1 to 4 percent of cobalt oxide, 3 to 10 percent of nickel oxide, 2 to 12 percent of molybdenum oxide, 18 to 30 percent of tungsten oxide, 2 to 5 percent of phosphorus pentoxide, 2 to 15 percent of titanium oxide, 2 to 20 percent of silicon oxide, and the balance of aluminum oxide. The catalyst is obtained by the steps of carrier preparation, co-immersion, calcination and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Hydrogenation catalyst and production thereof

ActiveCN1853777AHigh activityMetal/metal-oxides/metal-hydroxide catalystsRefining by aromatic hydrocarbon hydrogenationMolybdenum oxideAluminium oxide

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com