Patents

Literature

33results about How to "Expansion of comprehensive utilization channels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

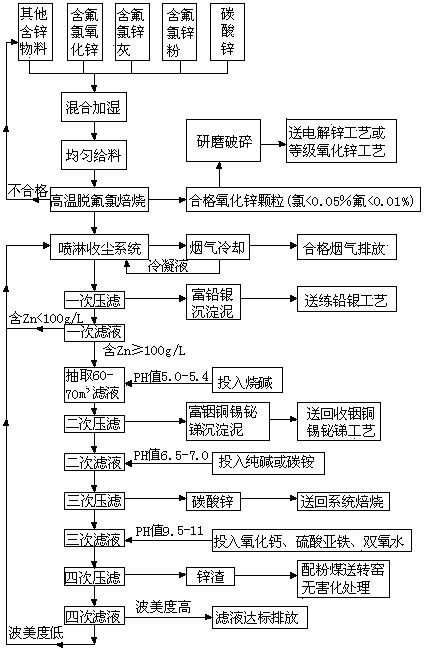

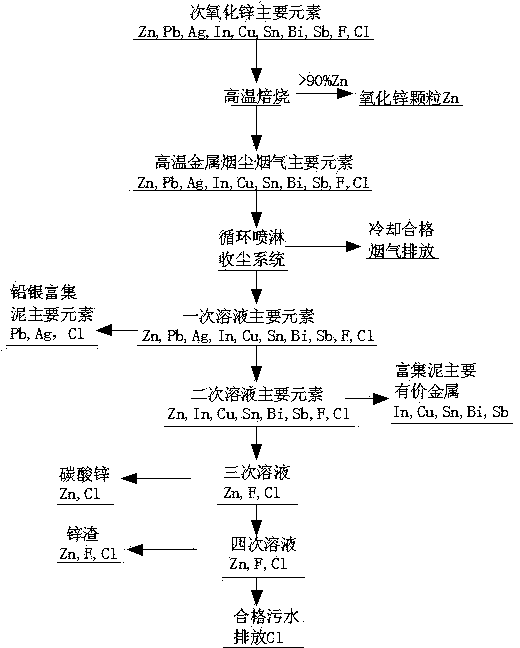

Smelting method for removing fluorine and chlorine out of fluorine-and-chlorine-containing inferior zinc oxide and enriching valuable metals

InactiveCN103924091AReduce water consumptionEasy to handleProcess efficiency improvementHydrometallurgySoot

The invention discloses a smelting method of removing fluorine and chlorine out of fluorine-and-chlorine-containing inferior zinc oxide and enriching valuable metals and relates to the technical field of hydrometallurgy and thermometallurgy of nonferrous metals such as zinc. The method disclosed by the invention comprises the following steps: oxidizing and roasting inferior zinc oxide in a rotary kiln at a high temperature so as to remove fluorine and chlorine and generate high-purity zinc oxide particles; meanwhile, volatilizing valuable metals in form of high-temperature soot and smoke, circularly spraying and washing so that valuable metals enter a spraying solution or precipitate to be enriched; further separating valuable metals in the solution; and finally, treating the sewage containing fluorine and chlorine and discharging the sewage reaching the standard or reusing the sewage by the system. Therefore, the inferior zinc oxide is purified in a primary continuous multi-sectional process to reach the technical index of conventional zinc-making raw materials, and the valuable metals are enriched by 5-20 times. The zinc making enterprises can widely use various types of inferior zinc oxide as the raw material, so that the production process is unified, the production cost is lowered, various valuable metals are comprehensively recovered, and discharge of sewage is reduced.

Owner:何宇波

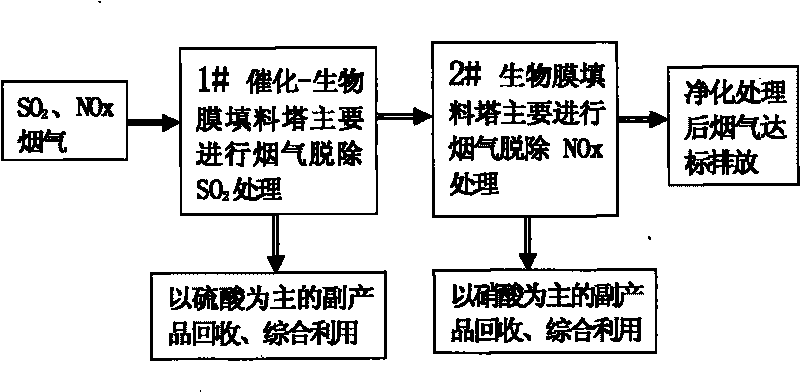

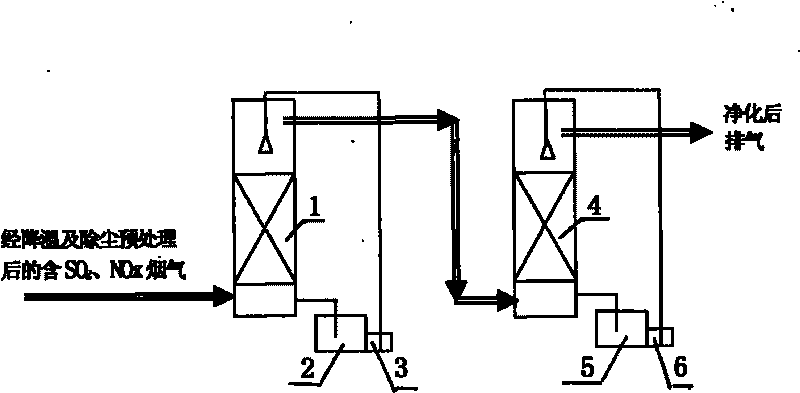

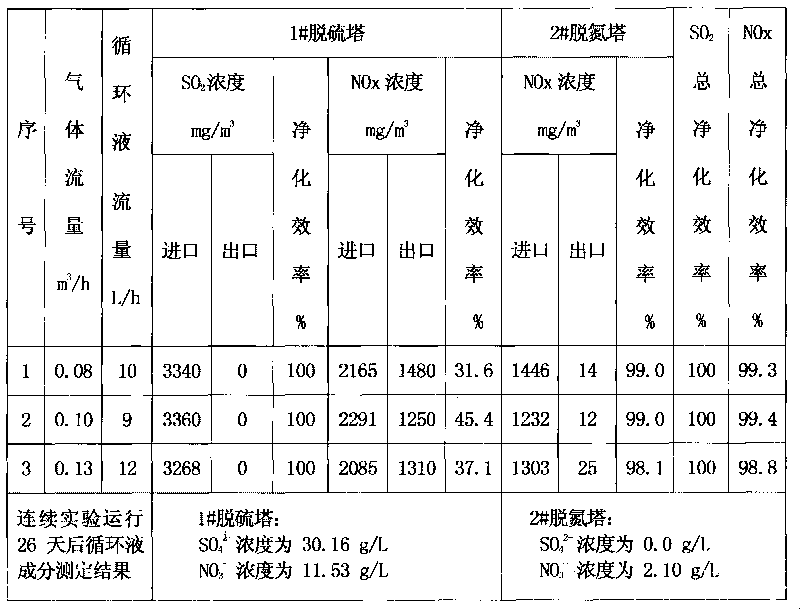

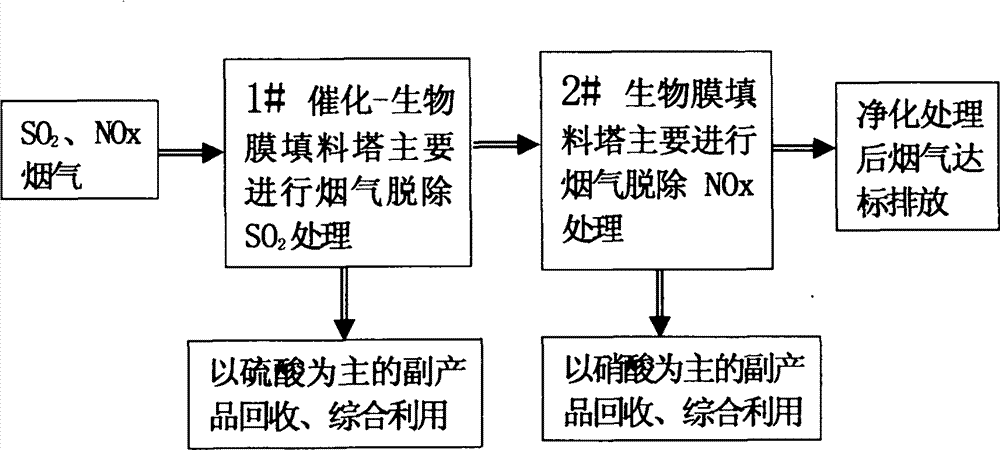

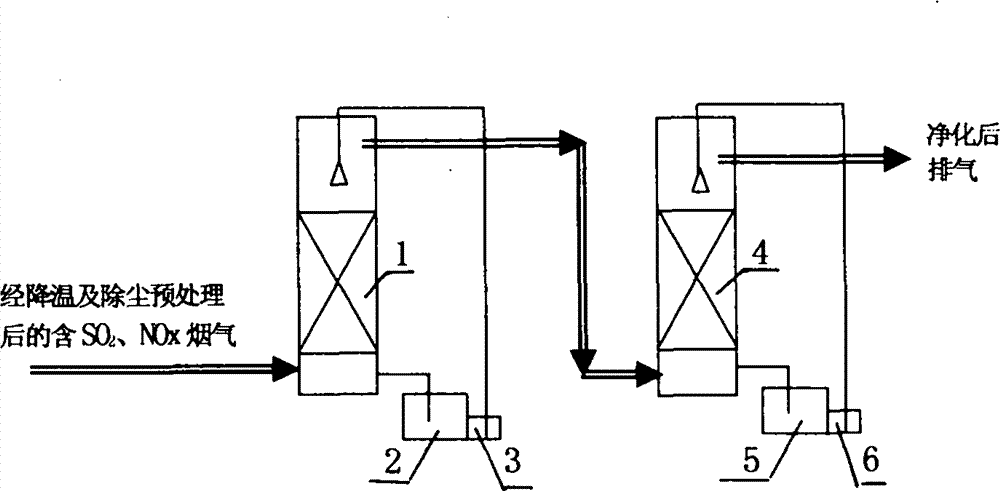

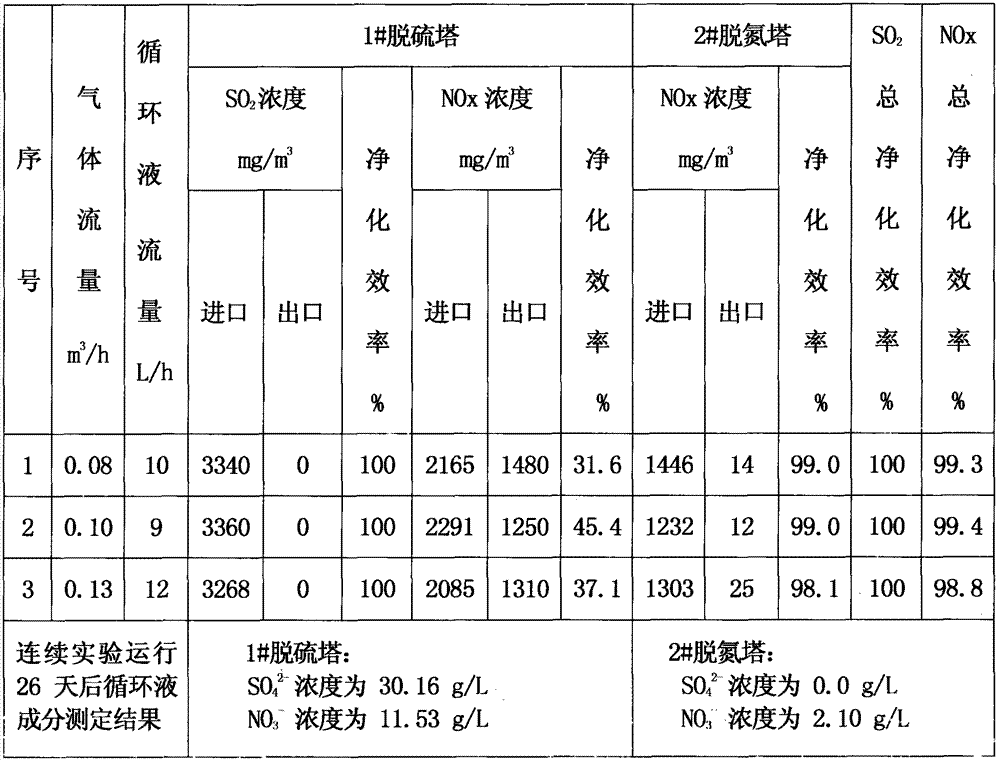

Method for simultaneously removing sulfur dioxide and nitrogen oxide in exhaust gas by twin tower tandem catalysis-biomembrane packing tower system

InactiveCN101708415AGood purification effectEasy to recycle separatelyDispersed particle separationAir quality improvementPh bufferingCatalytic oxidation

The invention provides a twin tower tandem exhaust gas purifying processing combination device which adopts a biomembrane packing tower system utilizing catalytic oxidant cyclically spraying liquid in the front and a biomembrane packing tower system utilizing pH buffering agent cyclically spraying liquid in the rear, which can carry out purifying processing to simultaneously remove the SQ2 and the NOx in the exhaust gas and to obtain by-products, namely, the utilizable sulphuric acid and nitrating acid products. The invention is characterized in that desulphuricants and denitrifier complex bacteria with the performance of simultaneously removing SQ2 and NOx in the exhaust gas under the conditions of liquid-phase catalyzed oxidation and pH acid environment can be obtained by screening and culturing and domesticating, and the composite bacteria biofilm to manufacture the biomembrane packing tower which is arranged in the tandem front end and is mainly used for removing SQ2; and the biomembrane packing tower which is mainly used for removing NOx in the rear is manufactured by adopting the denitrifier complex bacteria biofilm with the performance of removing NOx in the exhaust gas under the condition of pH neutral environment through screening and culturing and domesticating.

Owner:NANJING JIANGDAO INST OF ENVIRONMENT RES CO LTD

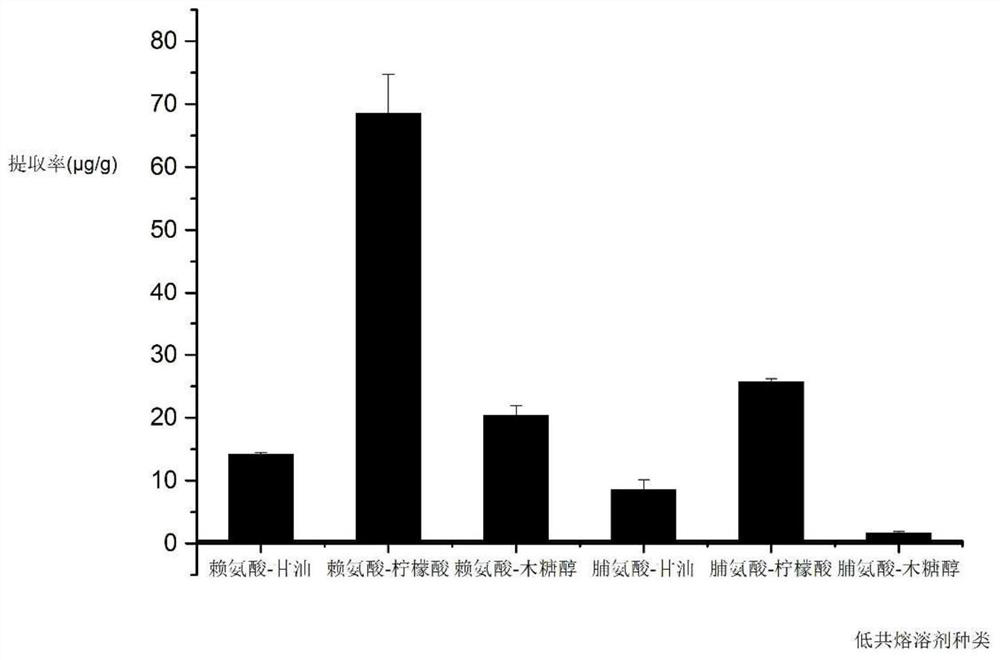

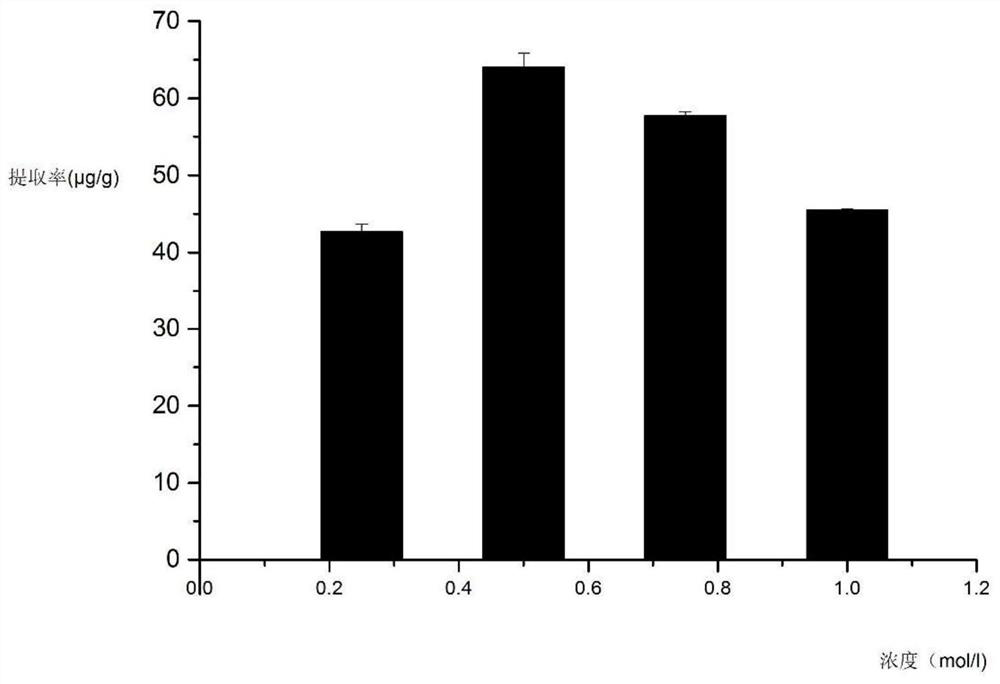

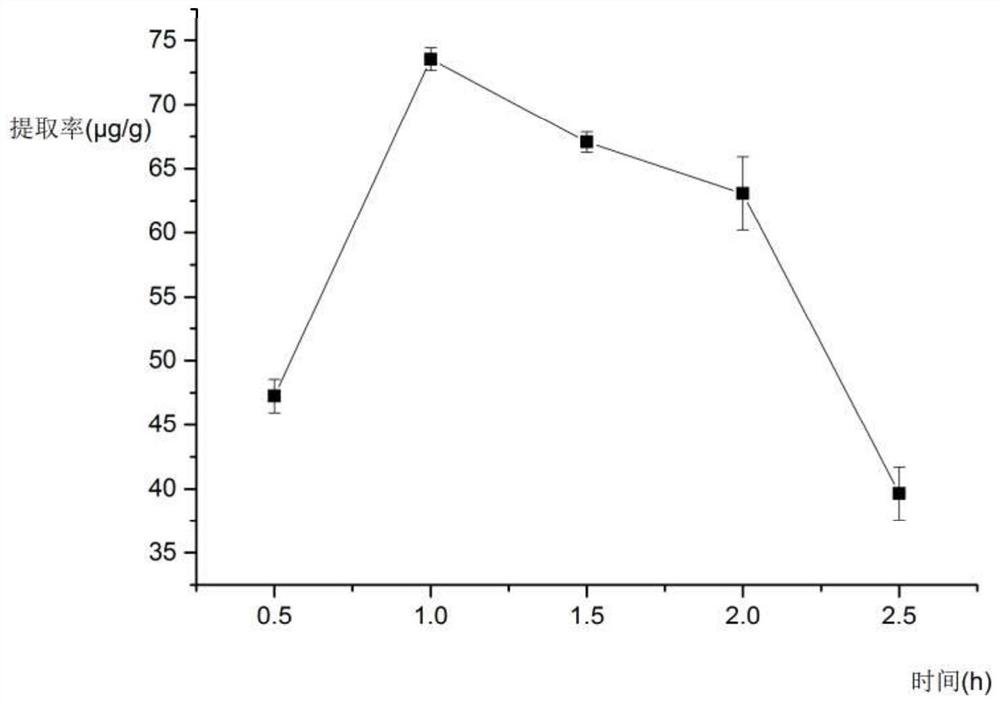

Method for extracting astaxanthin from shrimp shells by using amino acid natural eutectic solvent

PendingCN112159342AImplement extractionExpansion of comprehensive utilization channelsOrganic chemistryAstaxanthinGlycerol

The invention belongs to the technical field of natural product extraction, and particularly relates to a method for extracting astaxanthin in shrimp shells by using an amino acid natural eutectic solvent. The amino acid natural eutectic solvent is obtained by mixing and heating a hydrogen bond donor and a hydrogen bond acceptor, the molar ratio of the hydrogen bond acceptor to the hydrogen bond donor is 1: 1-1: 10, and the hydrogen bond donor comprises citric acid, glycerol and xylitol; and the hydrogen bond receptor comprises Lproline and Llysine. The extraction method comprises the following steps: drying, crushing and sieving shrimp shells, and treating the screened shrimp shell powder with hydrochloric acid to obtain decalcified shrimp shells; and mixing the decalcified shrimp shellswith an amino acid eutectic solvent, adding water, carrying out ultrasonic treatment, centrifuging, and taking the supernatant, thereby obtaining the astaxanthin extract from the shrimp shells. According to the method, the astaxanthin in the shrimp shells is extracted, and the purposes of high extraction efficiency, no organic solvent pollution, low toxicity, environmental friendliness and high product purity are achieved.

Owner:SHENYANG PHARMA UNIVERSITY

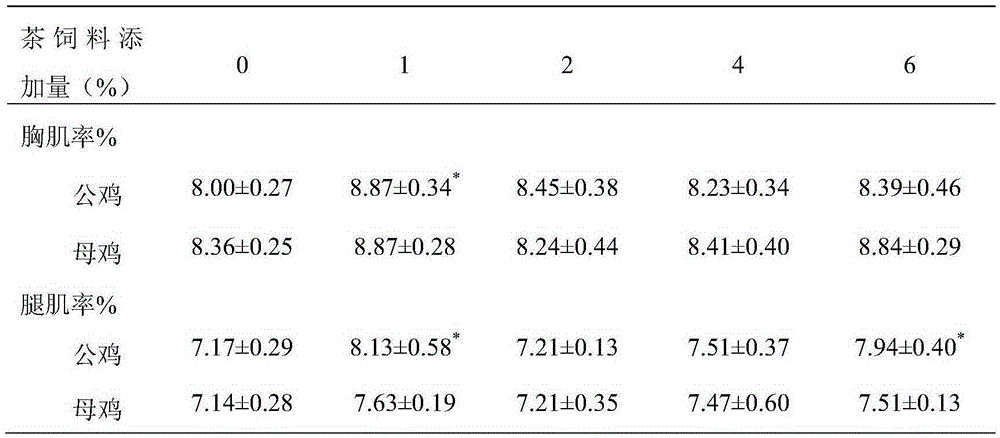

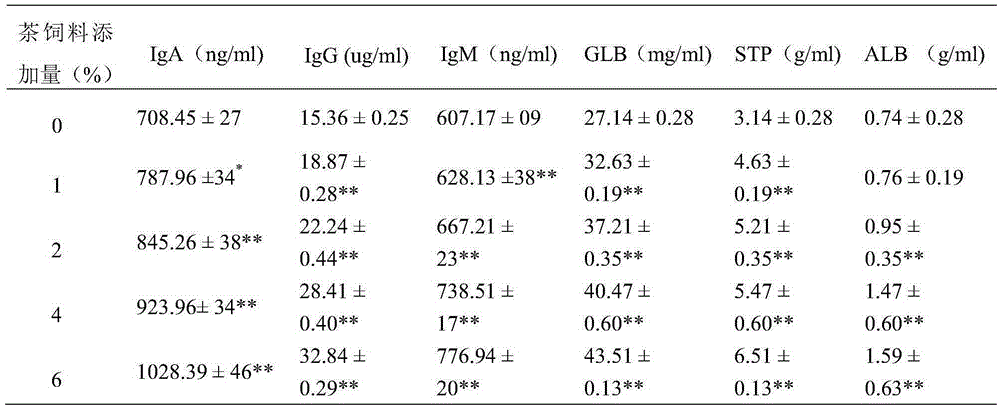

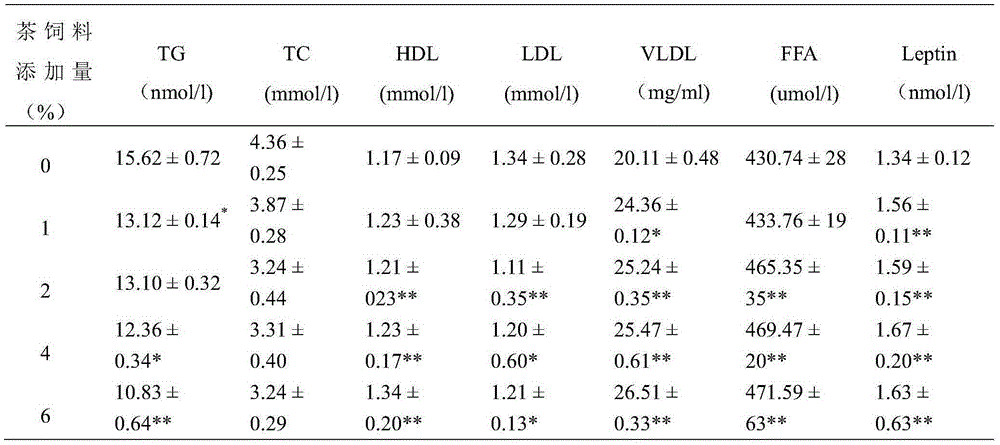

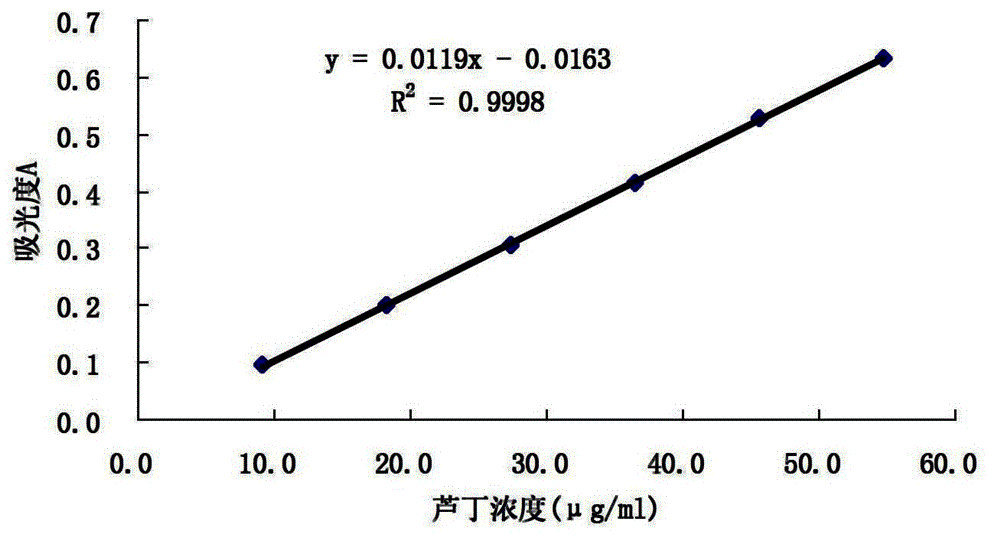

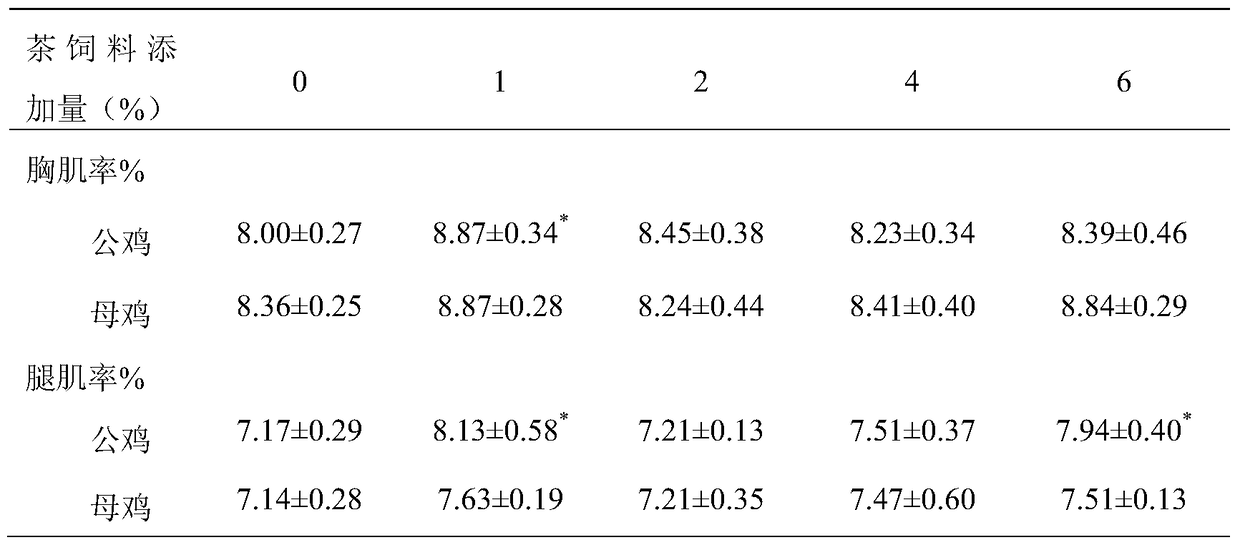

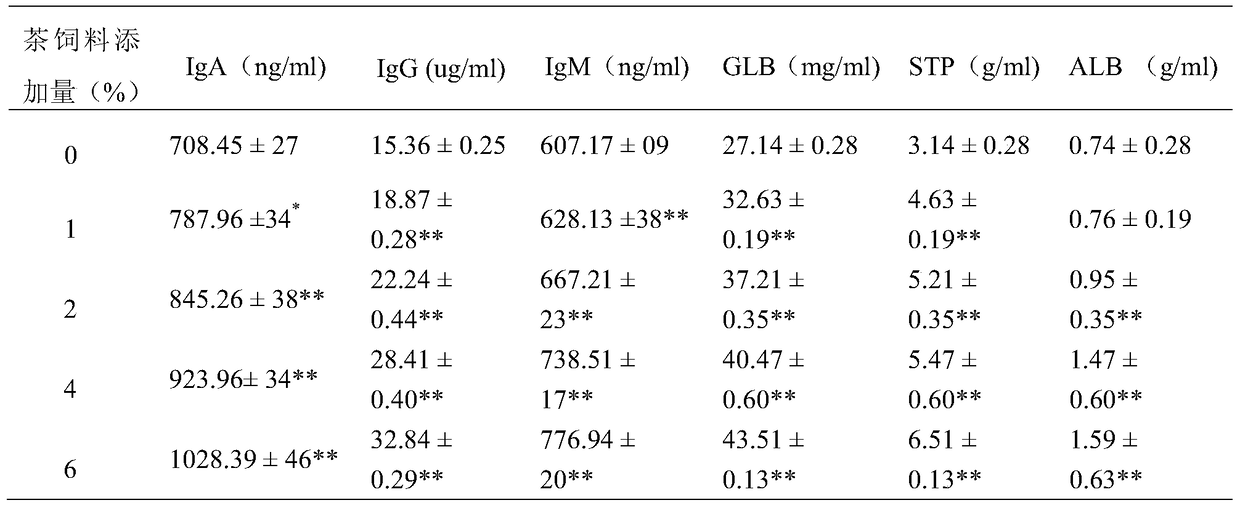

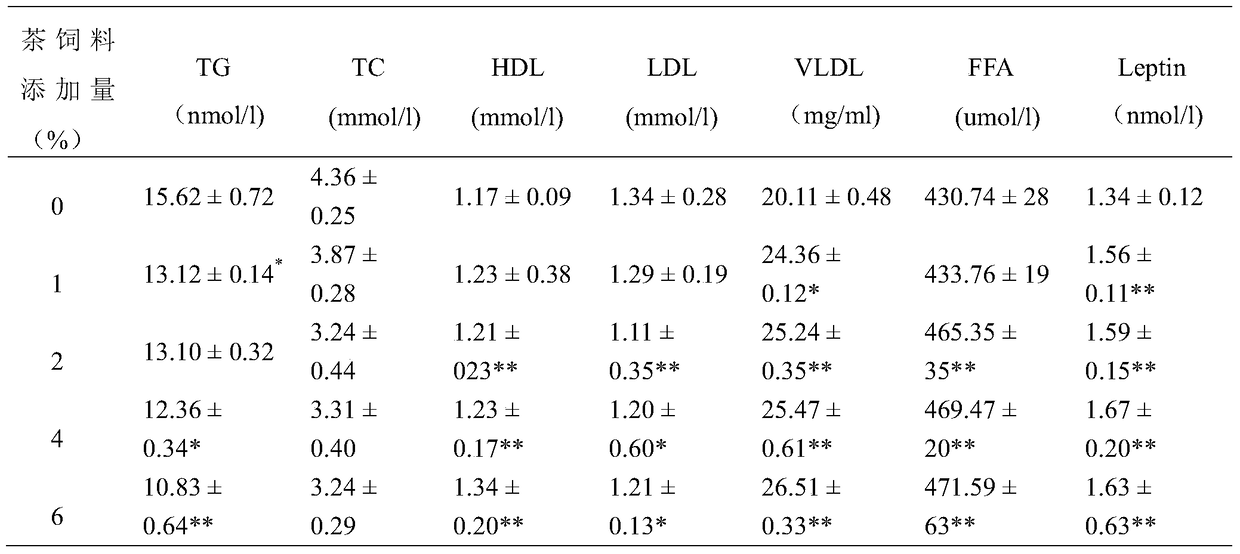

Preparation method of tea feed

InactiveCN105248860AWith hydrogen supply functionAvoid damageAnimal feeding stuffAccessory food factorsZINC LACTATESucrose

The invention discloses a preparation method of tea feed. The method includes the following steps that firstly, tea leaves are soaked in water, the tea leaves are expanded after being taken out, and the expanded tea leaves are prepared; secondly, animal oil and vegetable oil are taken and mixed to prepare compounded grease, emulsifiers, water, zinc lactate, lactic acid or citric acid, sucrose or glucose and sodium cyclamate are added into the compounded grease and are evenly mixed, finally, homogeneous processing is performed, and emulsified fat pulp is prepared; thirdly, the emulsified fat pulp is sprayed to the expanded tea leaves, the tea feed is obtained after even mixing, or the tea feed is obtained through drying after even mixing. The technology is simple and implementation is easy. The prepared tea feed is rich in emulsified fat pulp, tea polyphenol, lactic acid, zinc lactate and other active substances, and the tea feed has the functions of improving immunity and ingestion, promoting digestion, stimulating growth, reducing product cholesterol, improving meat quality of bred animals and the like. The prepared tea feed has the oil oxidization resistance function and can decrease the oil oxidization speed in summer.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Ardealite-based heat insulation mortar and preparation method thereof

ActiveCN108675743AImprove internal structural performanceRadioactive element reductionChemical industryO-Phosphoric Acid

The invention belongs to the technical field of environment protection and energy saving, in particular to ardealite-based heat insulation mortar. The ardealite-based heat insulation mortar is prepared from 12 to 20 parts of cement, 10 to 20 parts of ardealite, 80 to 120 parts of glass beads, 2 to 8 parts of quartz sand, 20 to 30 parts of water, 3 to 6 parts of quicklime and 1 to 2 parts of organic bonding agents in parts by weight. The raw materials use chemical gypsum produced through wet process phosphoric acid production as raw materials; the cost is effectively reduced; the comprehensiveutilization path of the ardealite waste can be widened; the consumption of solid waste in phosphorus chemical industry is increased; the sustainable development of the phosphorus chemical industry canbe promoted.

Owner:江苏腾跃建材有限公司

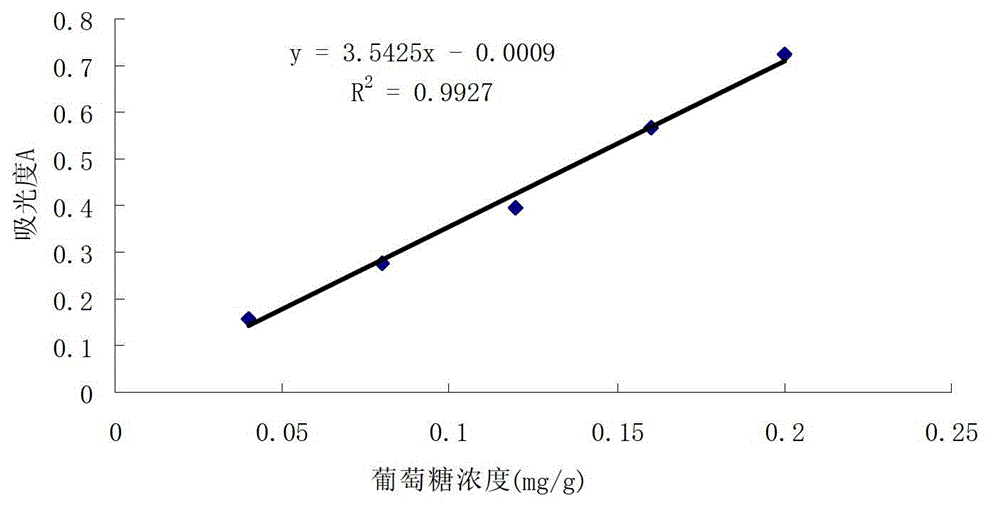

Red date extract extraction method and red date extracts

The invention provides a red date extract extraction method and red date extracts. The method comprises: adding a 60-95% ethanol solution to raw material crushed particles prepared from inferior dried red date, and carrying out microwave extraction; filtering the microwave extracted product to obtain a solution A1 and a precipitate B1; concentrating the solution A1, adding a flocculant, filtering to obtain a solution A2 and a precipitate B2, and concentrating the solution A2 to obtain a date flavonoid extract; dissolving the precipitate B2 with dehydrated alcohol, filtering to remove insoluble substances to obtain a solution A3, and concentrating the solution A3 to obtain a date triterpene extract; adding a solvent to the precipitate B1, carrying out hot extraction, and filtering the hot extracted product to obtain a solution A4 and a precipitate B4; drying the precipitate B4 to obtain a date dietary fiber extract; and carrying out organic solvent impurity removing on the solution A4 to obtain a date polysaccharide extract. According to the present invention, a plurality of red date extracts are respectively subjected to diversion extraction utilization through a process so as to simplify the process and broaden a comprehensive utilization approach of inferior red date.

Owner:申琳 +1

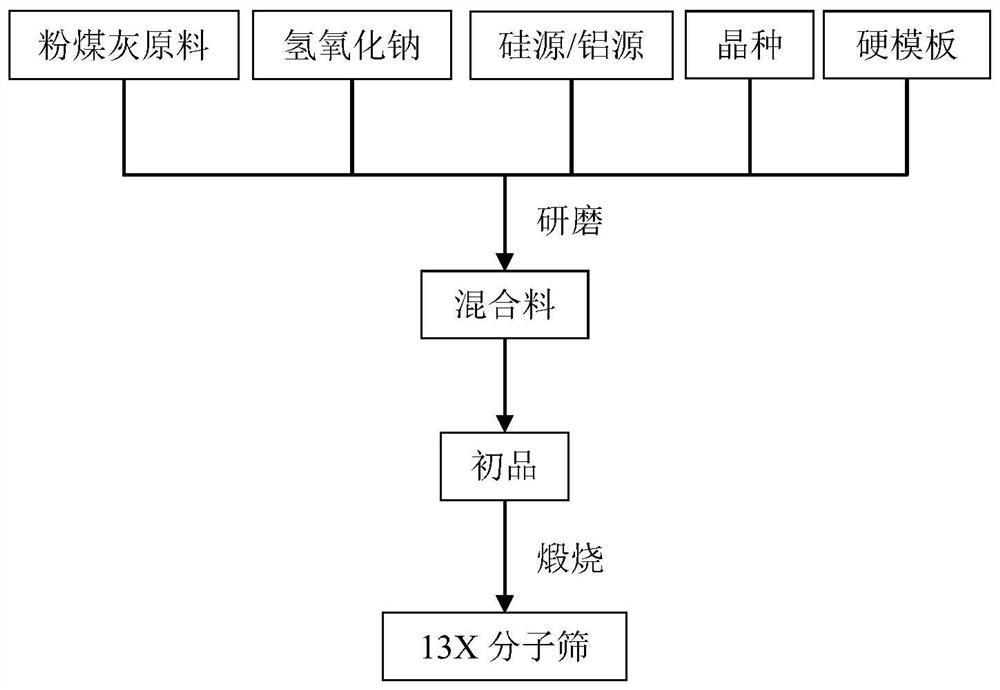

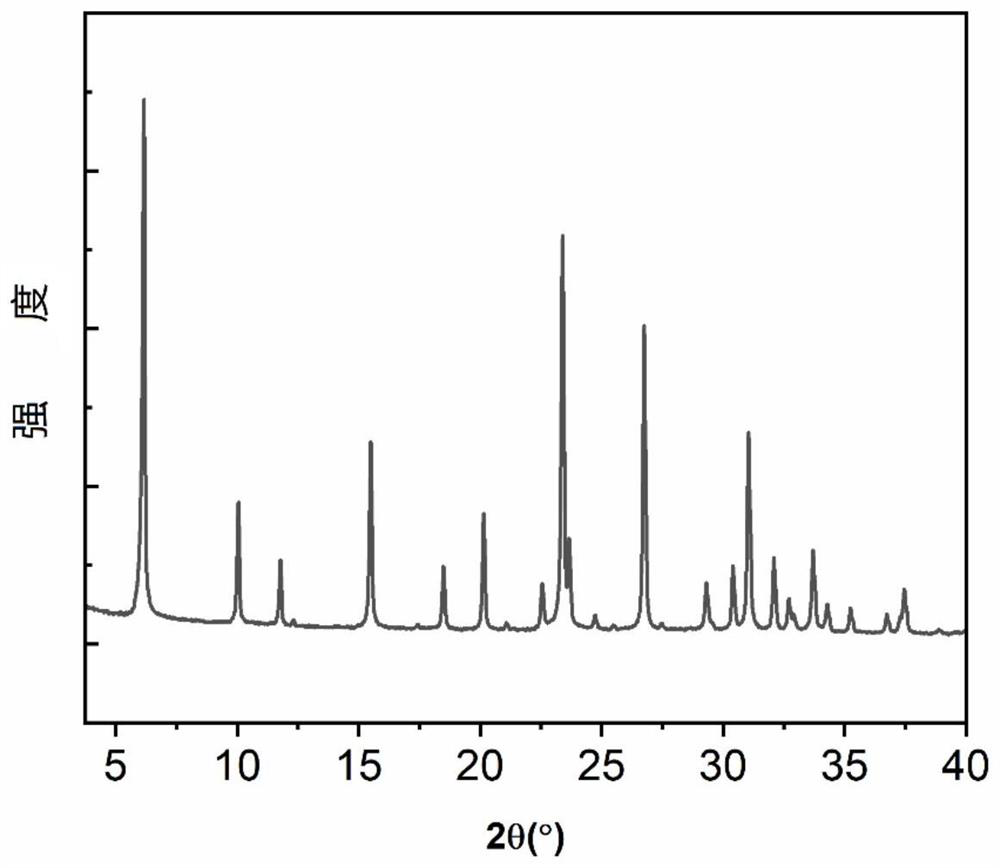

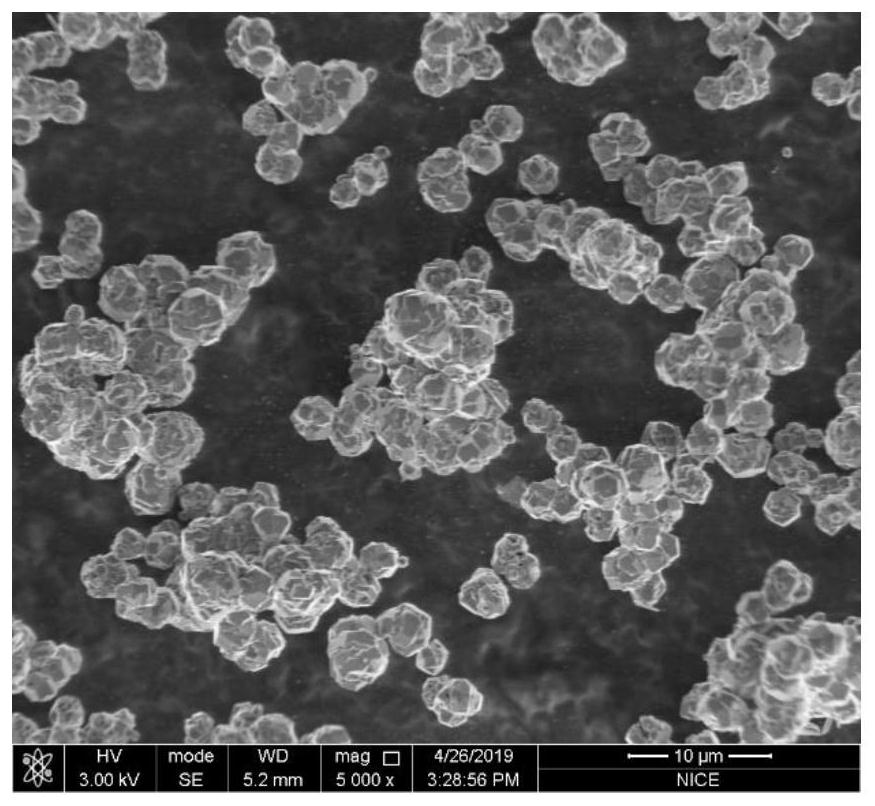

Preparation method of 13X molecular sieve and 13X molecular sieve

InactiveCN111847475ADoes not require roasting activationHigh yieldFaujasite aluminosilicate zeoliteMolecular sievePhysical chemistry

The invention discloses a preparation method of a 13X molecular sieve and the 13X molecular sieve, and belongs to the technical field of solid waste treatment in the field of environmental protection.The preparation method comprises the following steps: providing a fly ash raw material, wherein the mass percentage of the fly ash is 66-85%, mixing the fly ash raw material with sodium hydroxide, asilicon source, an aluminum source, a 13X molecular sieve seed crystal and a hard template, grinding to obtain a mixture, wherein the range of the silica-alumina ratio in the mixture is 3-11, the masspercent of the 13X molecular sieve seed crystal is 8-15% and the mass percent of the hard template is 2-5%, crystallizing the mixture for 15-24 hours at the temperature of 80-98 DEG C to obtain a crystallized product, and cooling the crystallized product to obtain a primary product; and calcining the primary product for 4-8 hours at the temperature of 500-600 DEG C to obtain a calcined product, sequentially cooling, washing and filtering the calcined product, and drying for 10-15 hours at the temperature of 50-70 DEG C to obtain the 13X molecular sieve. According to the preparation method ofthe 13X molecular sieve and the 13X molecular sieve, a roasting activation link is not needed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Process for producing PVC (polyvinyl chloride) section bar by taking phosphogypsum as filler

The invention provides a process for producing a PVC (polyvinyl chloride) section bar by taking phosphogypsum as a filler. The PVC section bar is prepared from the following raw materials in parts by weight: 70-100 parts of polyvinyl chloride resin, 30-45 parts of the phosphogypsum, 3-6 parts of a stabilizer, 0.5-2 parts of an antioxidant, 1-2 parts of a lubricant and 5-10 parts of a composite plasticizer. The process is mainly characterized in that the phosphogypsum is treated, crushed, soaked in a calcium hydroxide solution with the mass concentration of 10-40%, and roasted at the temperature of 600-900 DEG C after dehydration, then soaked in water, roasted at the temperature of 163-400 DEG C after dehydration to obtain anhydrite; and the anhydrite is ground into powder of 400-800 meshes. According to the process, a phosphogypsum crystal is modified, so that the phosphogypsum replaces calcium powder in the preparation process of a conventional PVC section bar, the source of the calcium powder for PVC is expanded, the cost of the calcium powder for PVC production is reduced, the comprehensive utilization way of the phosphogypsum is expanded, and the comprehensive utilization rate of the phosphogypsum is improved.

Owner:GUIZHOU KAILIN GRP CO LTD

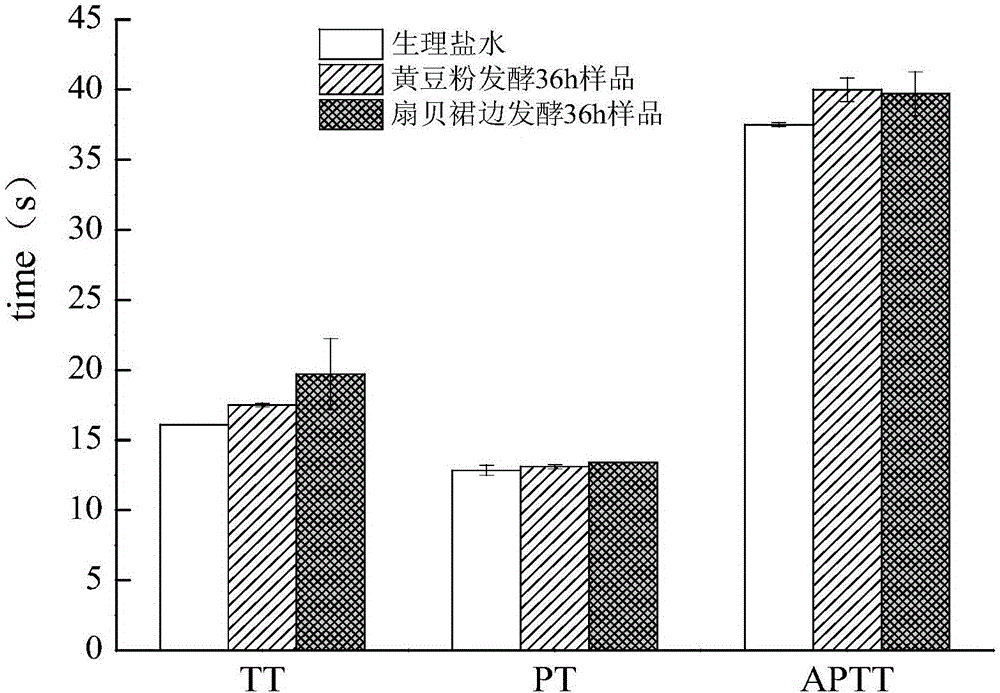

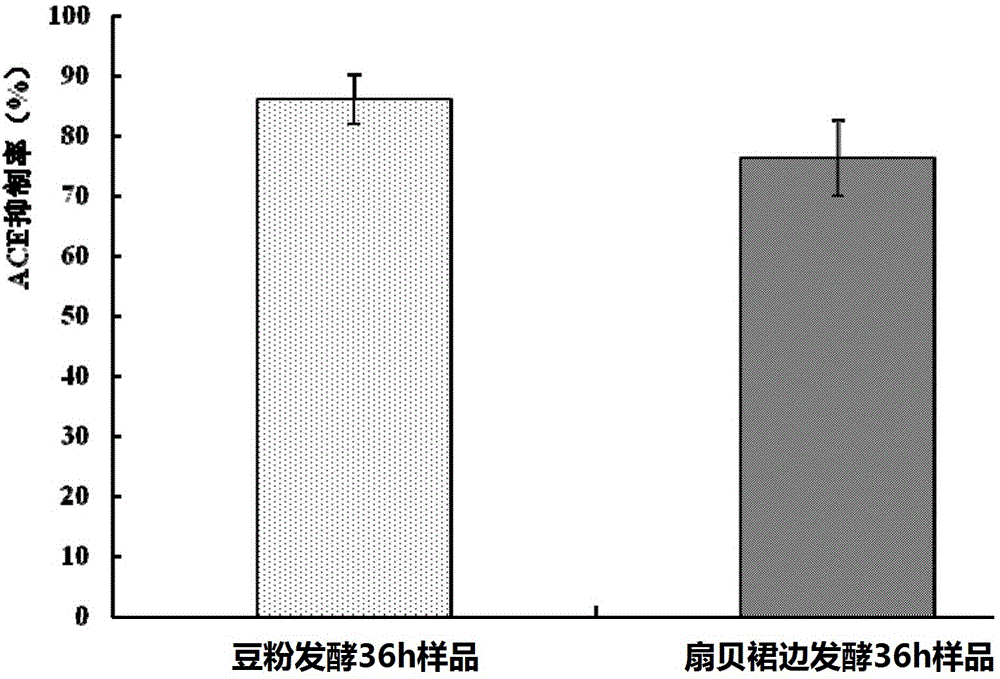

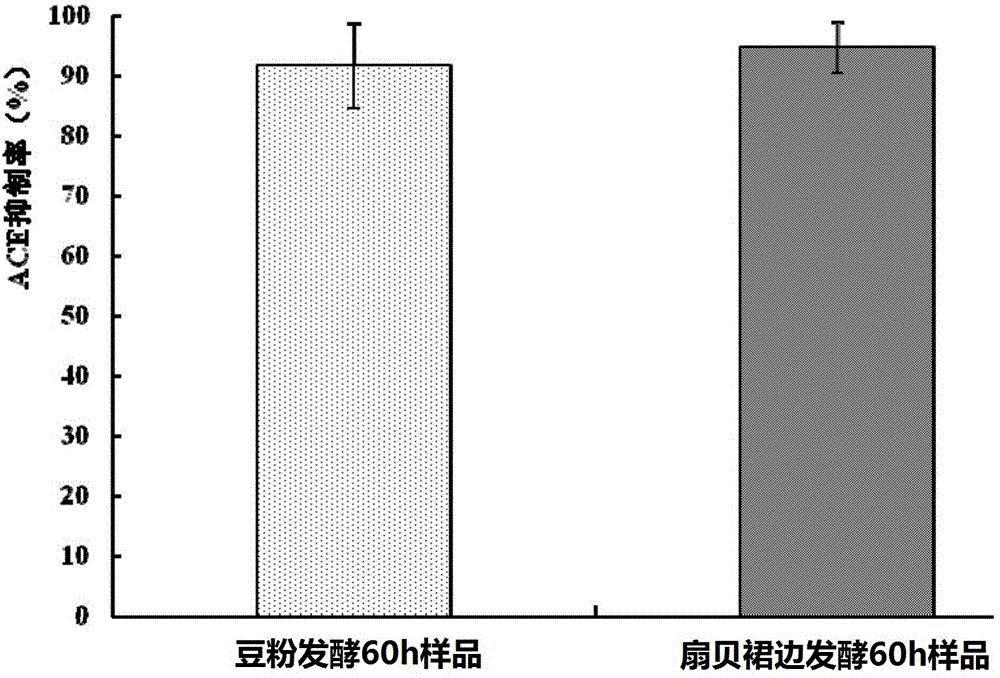

Production method of scallop skirt fermentation product with blood pressure reduction function

InactiveCN106490520AIncreased sensitivityImprove biological activityFood ingredient functionsSucroseFreeze-drying

The invention discloses a preparation method of a scallop skirt fermentation product with a blood pressure reduction function. The preparation method includes the following steps: cleaning scallop skirts, removing impurities and draining prior to freeze-drying and grinding to obtain scallop skirt freeze-dried powder; mixing scallop skirt freeze-dried powder with water and sucrose prior to regulating the initial pH value; performing sterilization, adding bacillus natto bacterial suspension, and performing ventilated culture to obtain scallop skirt fermentation liquor; performing centrifugation, collecting supernate, and performing concentration and freeze-drying to obtain the scallop skirt fermentation product with the blood pressure reduction function. The scallop skirts are fermented via bacillus natto, enzymes with a thrombolytic function can be produced, proteins in the scallop skirts are further degraded into proteins and polypeptides smaller in molecular weight, and digestive absorption is facilitated; functionality of the fermentation product is further improved, the fermentation product fully plays various compound bioactivities such as blood pressure reduction and thrombolysis, scallop processing modes are enriched, processing byproducts are fully utilized to produce products with bioactivity, and development value is improved.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Ultrasonic assisted deep-eutectic solvent extraction method for polyphenols in globe artichoke

InactiveCN110623991ANo pollution in the processLow costPlant ingredientsUltrasonic assistedFreeze-drying

The present invention discloses an ultrasonic assisted deep-eutectic solvent extraction method for polyphenols in globe artichoke. A combination of processing technologies of ultrasonic technology, deep-eutectic solvent, macroporous adsorption resin separation and purification technology, freeze-drying, etc. realizes extraction and purification of high-purity globe artichoke polyphenols, achievespurposes of being high-efficiency in extraction, free of solvent pollution, low in toxicity, environment-friendly and high in product purity, is simple in operation processes, short in extraction time, green and pollution-free and low in cost, and improves extraction rate and purity.

Owner:HUAQIAO UNIVERSITY

Unsaturated hydrocarbon hydrogenation catalyst, preparation method and applications thereof

ActiveCN102218323BSolve the problem of hydrogenationExpansion of comprehensive utilization channelsHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsCoalCerium oxide

Owner:THE NORTHWEST RES INST OF CHEM IND

Method for preparing PVC profile with anti-aging effect

InactiveCN105419151AExpansion of comprehensive utilization channelsIncrease profitAntioxidantPolyvinyl alcohol

The invention provides a method for preparing a PVC profile with the anti-aging effect and belongs to the technical field of PVC profile production. The method is prepared from, by weight, 90-110 parts of polyvinyl chloride resin, 50-60 parts of ardealite, 3-8 parts of titanium dioxide, 1-3 parts of polyvinyl alcohol, 1-2 parts of polylactic acid, 1-4 parts of stabilizer, 0.5-2 parts of antioxidant, 1-2 parts of lubricant and 1-2 parts of composite plasticizer. The method includes the steps of ardealite treating, mixing, extrusion forming and finished product forming. Polyvinyl alcohol is used for modifying ardealite, so that ardealite is used for replacing calcium powder used in the preparation process of a traditional PVC profile, the source of calcium powder for PVC is expanded, the cost of the calcium powder for PVC production is reduced, comprehensive utilization ways of ardealite are expanded, the comprehensive utilization rate of ardealite is increased, in cooperation with titanium dioxide, polylactic acid, stabilizer, antioxidant, lubricant and composite plasticizer, the notch impact strength, tensile strength, bending strength, bending modulus and elongation at break are increased to be better, the service life is longer, and the better anti-aging characteristic is achieved.

Owner:GUIZHOU KAILIN GRP CO LTD

Method for producing PVC profile by taking phosphogypsum-produced hemihydrate gypsum and anhydrite as filler

The invention provides a method for producing a PVC profile by taking phosphogypsum-produced hemihydrate gypsum and anhydrite as filler. According to the invention, phosphogypsum is taken as a raw material to produce the PVC profile, so that the phosphogypsum replaces calcium powder in the traditional PVC profile production process, the source of the calcium powder for the PVC is expanded, the costs of the calcium powder for producing the PVC profile are reduced, the comprehensive utilization way of the phosphogypsum is expanded, and the comprehensive utilization rate of the phosphogypsum is improved. Furthermore, the hemihydrate gypsum and the anhydrite are respectively produced by utilizing the phosphogypsum and are taken as the filler to produce the PVC profile, so that the cooling time of the PVC profile to be produced is shortened, and furthermore, the PVC profile has a more compact structure; therefore, the hardness of the PVC profile can be improved, the produced PVC profile has compression resistance, stretching resistance and wear resistance.

Owner:GUIZHOU KAILIN GRP CO LTD

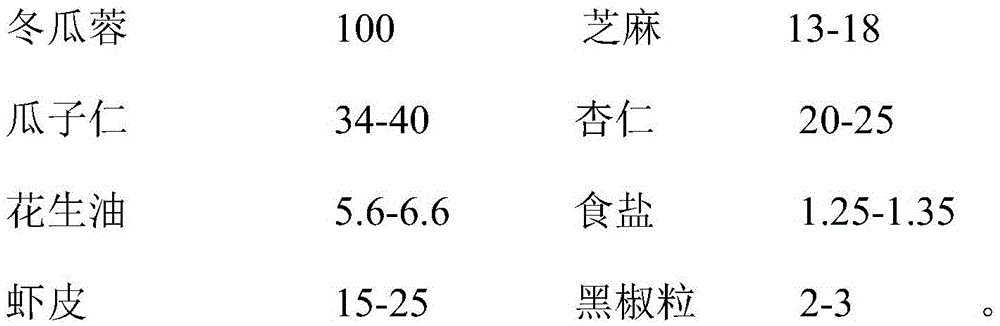

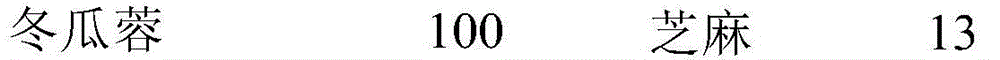

Fresh shrimp moon cake and production method of the fresh shrimp moon cake

The invention discloses a fresh shrimp moon cake and a production method of the fresh shrimp moon cake. The fresh shrimp moon cake comprises wrapper and stuffing packed in the wrapper. The fresh shrimp moon cake is characterized in that the stuffing comprises the following components in parts by weight: 100 parts of Chinese waxgourd paste, 13-18 parts of sesames, 34-40 parts of melon seed kernels, 20-25 parts of almonds, 5.6-6.6 parts of peanut oil, 1.25-1.35 parts of table salt, 15-25 parts of dried small shrimps and 2-3 parts of black pepper grains. The purpose of the invention is to overcome disadvantages of prior art and to provide a fresh shrimp moon cake which is rational in formula, delicious, tasty, rich in nutrition, suitable for both the young and the old, unique in flavor and good in taste.

Owner:JUXIANGYUAN HEALTH FOOD ZHONGSHAN

Straw screening culture medium, preparation method and method using same to cultivate black fungus

InactiveCN110651662APromote growthExpansion of comprehensive utilization channelsCultivating equipmentsMushroom cultivationBiotechnologyStraw

The invention discloses a straw screening culture medium, a preparation method and a method using the same to cultivate black fungus and relates to the technical field of edible mushroom cultivation.The method specifically includes: inoculating, transferring fungus, culturing, treating, accelerating fruiting, cultivating, and harvesting. The straw screening culture medium comprises, by weight, 70-80 parts of corn straw, 20-40 parts of edible fungus, 0.5-2 parts of glucose, 1-3 parts of agar, 10-30 parts of potato powder, 0.5-2 parts of magnesium sulfate, 0.5-2 parts of potassium dihydrogen phosphate, 0.01 part of vitamin B and 55-70 parts of water. The preparation method of the straw screening culture medium includes: smashing corn straw to be 1-3mm in fineness, weighing the edible fungus, glucose, agar, the potato powder, magnesium sulfate, potassium dihydrogen phosphate, vitamin B2 and water, and well mixing and stirring to obtain the screening culture medium. Yield and quality of the black fungus cultivated by taking straw as a base material can be improved remarkably, cost is low, and popularization is easy.

Owner:葫芦岛农函大玄宇食用菌野驯繁育有限公司

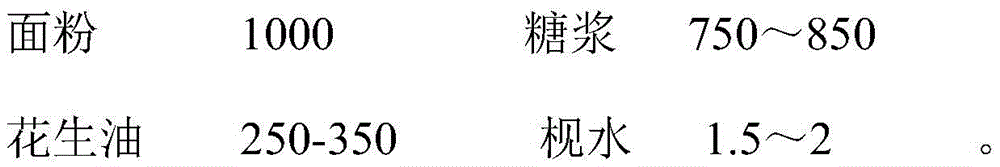

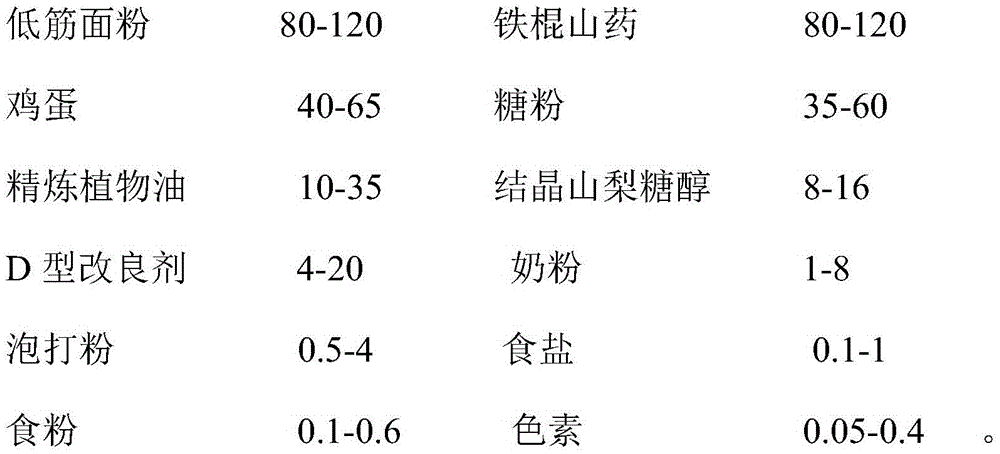

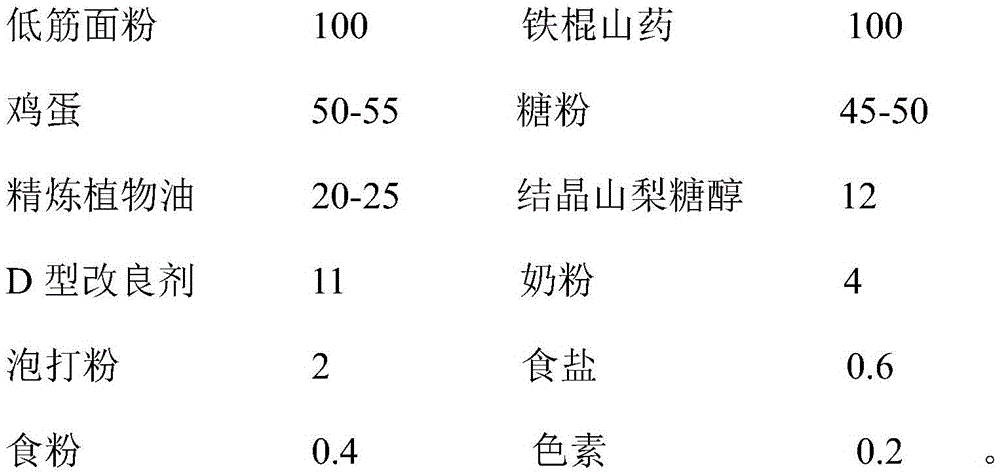

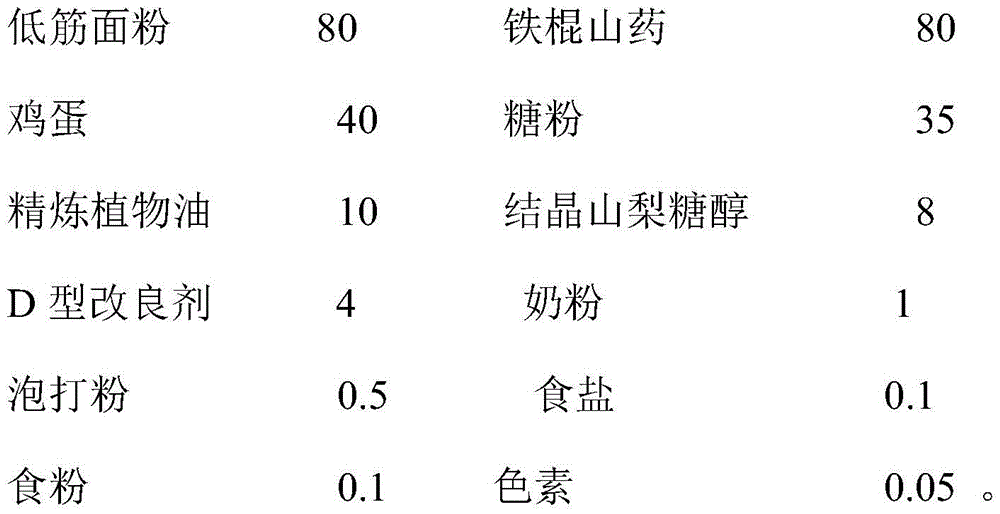

Cantonese dim sum made of dioscorea opposita and production method thereof

InactiveCN105410119ARich in proteinNutritious and deliciousDough treatmentBakery productsFlavorVegetable oil

The invention discloses a Cantonese dim sum made of dioscorea opposita and a production method thereof. The invention is characterized in that the Cantonese dim sum made of dioscorea opposita comprises the following ingredients in parts by weight: low-gluten flour, dioscorea opposita, eggs, sugar powder, refined vegetable oil, crystalline sorbitol, D-type modifier, milk powder, baking powder, table salt, baking soda and pigment. The production method comprises the following steps: step A, pre-treating and mixing ingredients; step B, wrapping and shaping, wherein the speed of the wrapping machine is 55 pieces / minute; taking the Cantonese dim sum out from the wrapping machine then coating the surface by fresh egg liquid; baking by a cabinet oven, wherein the surface fire is 170-200 DEG C, the bottom fire is 130-150 DEG C and the first baking lasts 2-4 minutes; then cooling, coating by fresh egg liquid and performing the second baking, wherein the surface fire is 180-200 DEG C, the bottom fire is 130-150 DEG C and the second baking lasts 12-16 minutes; taking the Cantonese dim sum out from the cabinet oven when the surface is golden; then cooling and packaging, wherein the Cantonese dim sum taken out from the cabinet oven is naturally cooled or cooled by a fan; sending the Cantonese dim sum quickly into a cooling room, then quantitatively packaging after the Cantonese dim sum is naturally cooled to normal temperature. The Cantonese dim sum made of dioscorea opposita is rational in formula, unique in flavor, nutrient and healthy.

Owner:JUXIANGYUAN HEALTH FOOD ZHONGSHAN

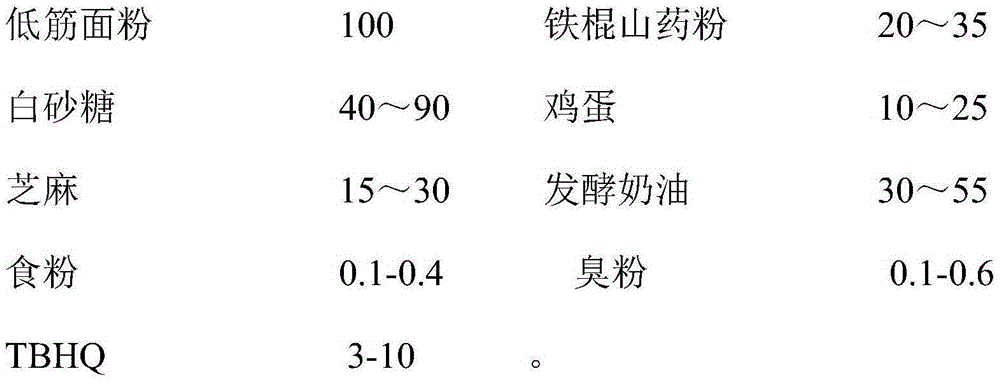

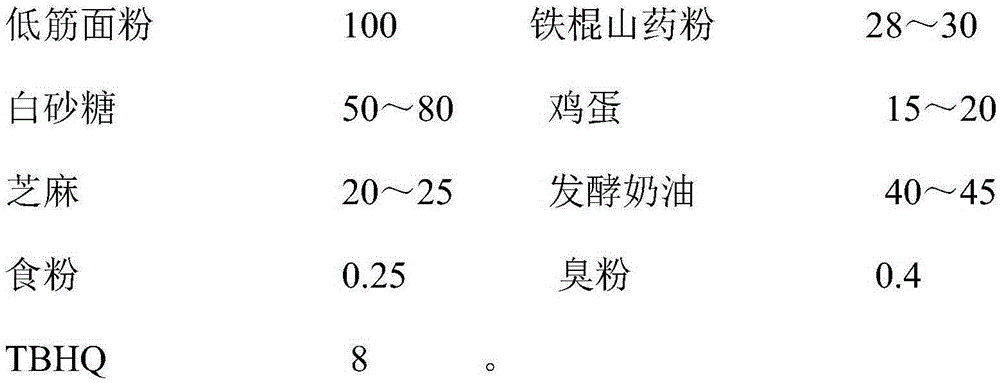

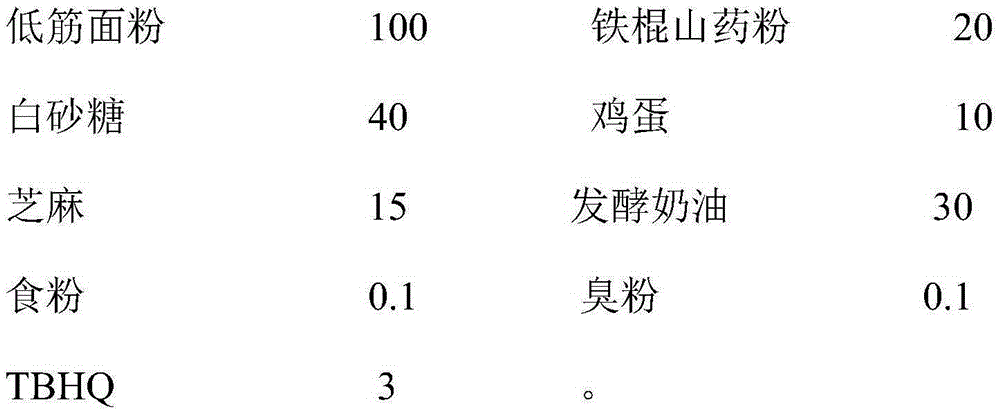

Iron stick yam flaky pastry and making method thereof

InactiveCN105248551ARich in proteinMass consumer marketDough treatmentBakery productsFlaky pastryGluten

The invention discloses an iron stick yam flaky pastry and a making method thereof. The iron stick yam flaky pastry is characterized by being prepared from following components in parts by weight; 100 parts of low-gluten flour, 20-35 parts of iron stick yam powder, 40-90 parts of white granulated sugar, 10-25 parts of egg, 15-30 parts of sesame, 30-35 parts of fermented cream, 0.1-0.4 part of baking soda, 0.1-0.6 part of ammonium bicarbonate and 3-10 parts of TBHQ. The invention aims to overcome defects in the prior art, and provides athe iron stick yam flaky pastry which is reasonable in proportion, unique in taste, healthy and nutritional.

Owner:JUXIANGYUAN HEALTH FOOD ZHONGSHAN

Method for simultaneous removal of sulfur dioxide and nitrogen oxides in flue gas by double-tower series catalytic-biofilm packed tower system

InactiveCN101708415BEasy to cleanEasy to recycle separatelyDispersed particle separationAir quality improvementBiofilmPh buffering

The invention provides a twin tower tandem exhaust gas purifying processing combination device which adopts a biomembrane packing tower system utilizing catalytic oxidant cyclically spraying liquid in the front and a biomembrane packing tower system utilizing pH buffering agent cyclically spraying liquid in the rear, which can carry out purifying processing to simultaneously remove the SQ2 and the NOx in the exhaust gas and to obtain by-products, namely, the utilizable sulphuric acid and nitrating acid products. The invention is characterized in that desulphuricants and denitrifier complex bacteria with the performance of simultaneously removing SQ2 and NOx in the exhaust gas under the conditions of liquid-phase catalyzed oxidation and pH acid environment can be obtained by screening and culturing and domesticating, and the composite bacteria biofilm to manufacture the biomembrane packing tower which is arranged in the tandem front end and is mainly used for removing SQ2; and the biomembrane packing tower which is mainly used for removing NOx in the rear is manufactured by adopting the denitrifier complex bacteria biofilm with the performance of removing NOx in the exhaust gas under the condition of pH neutral environment through screening and culturing and domesticating.

Owner:NANJING JIANGDAO INST OF ENVIRONMENT RES CO LTD

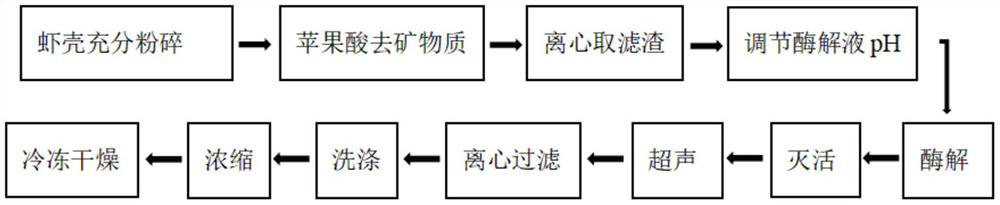

Production method for extracting chitosan oligosaccharide from shrimp shells

InactiveCN113527540ANo pollution in the processImprove the added value of processingFood gradeEngineering

The invention discloses a production method for extracting chitosan oligosaccharide from shrimp shells. The production method sequentially comprises the following steps: mashing, decalcifying, carrying out enzymolysis to remove protein, carrying out enzymolysis to extract sugar, concentrating, freeze-drying and the like to prepare the chitosan oligosaccharide. By means of the method, the chitosan oligosaccharide which is similar to commercially available food-grade chitosan oligosaccharide in the aspects of purity and average polymerization degree and higher in antioxidant activity can be obtained. The method not only effectively utilizes leftover shrimp shells and other wastes in shrimp processing, improves the processing added value of shrimp products, but also reduces environmental pollution, the technological process is green and pollution-free, the production equipment is simple, the cost is low, industrial production is easy to realize, and the method has very important significance for healthy development of the shrimp industry.

Owner:SHANGHAI INST OF TECH

Method for producing PVC (polyvinyl chloride) section bar by preparing beta-semi-hydrated gypsum from phosphogypsum as filler

The invention provides a method for producing a PVC (polyvinyl chloride) section bar by preparing beta-semi-hydrated gypsum from phosphogypsum as a filler. The PVC section bar is prepared from the following raw materials in parts by weight: 70-100 parts of polyvinyl chloride resin, 30-45 parts of the phosphogypsum, 3-6 parts of a stabilizer, 0.5-2 parts of an anti-oxidant, 1-2 parts of a lubricant and 5-10 parts of a composite plasticizer. According to the method, the phosphogypsum is taken as the raw material to produce the PVC section bar, so that the phosphogypsum replaces calcium powder in the preparation process of a conventional PVC section bar, the source of the calcium powder for PVC is expanded, the cost of the calcium powder for PVC production is reduced, the comprehensive utilization way of the phosphogypsum is expanded, and the comprehensive utilization rate of the phosphogypsum is improved; the phosphogypsum is used for producing a part of the beta-semi-hydrated gypsum and the beta-semi-hydrated gypsum is taken the filler to manufacture the PVC section bar, so that the cooling time for manufacturing the PVC section bar is shortened, the PVC section bar has a relatively compact structure, the hardness of the PVC section bar can be improved, and the manufactured PVC section bar has compression resistance, stretching resistance and wear resistance.

Owner:GUIZHOU KAILIN GRP CO LTD

A phosphogypsum-based thermal insulation mortar containing expanded perlite

InactiveCN104163612BExpansion of comprehensive utilization channelsEasy to useThermal isolationMass ratio

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

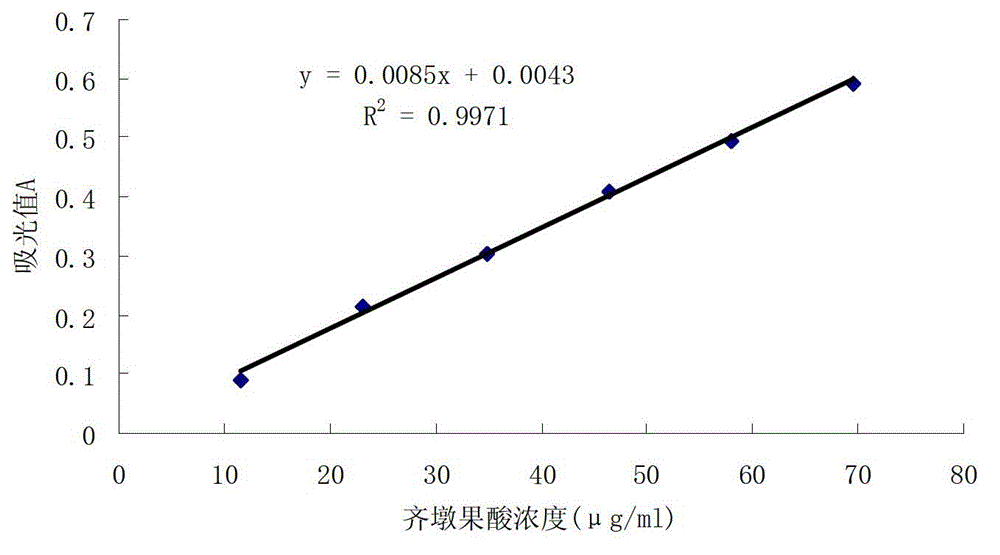

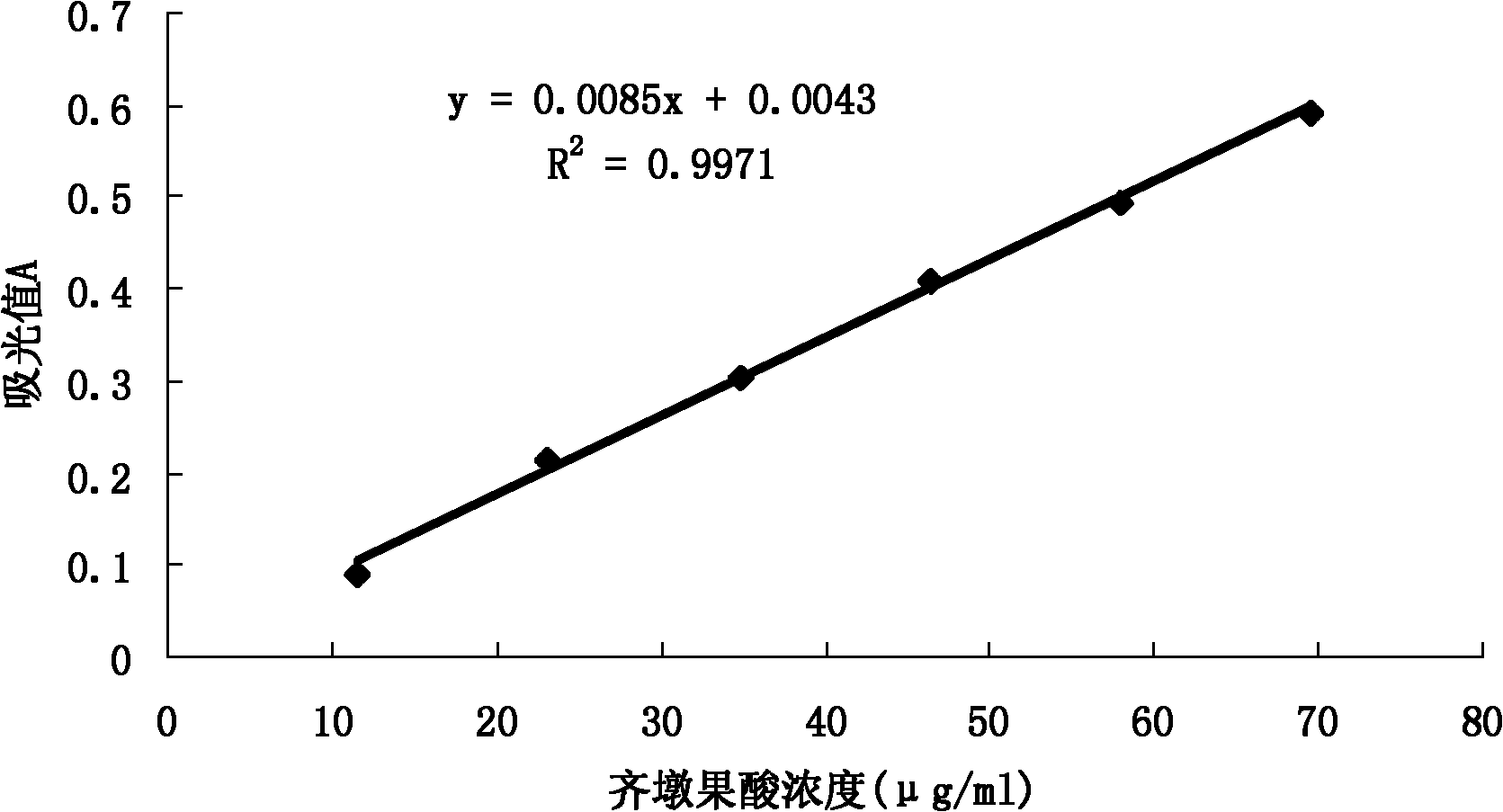

Oleanolic acid and method for preparing oleanolic acid by utilizing red dates

The invention provides oleanolic acid and a method for preparing the oleanolic acid by utilizing Chinese red dates. The method comprises the following steps: denucleating the Chinese red dates, and smashing, thus raw material particles are obtained, wherein the Chinese red dates are imperfect and dry; adding a solvent into the raw material particles to obtain a solution A, wherein the solvent is 80-95% ethyl alcohol, and the mass ratio of the solvent to the raw material particles is (10-18):1; carrying out microwave heating and leaching on the solution A, wherein the microwave power is 70-350W, and the microwave heating time is 90-150 seconds; filtering products after the microwave heating and leaching are carried out, thus a solution B is obtained; concentrating the solution B, removing the solvent, and adding distilled water, thus a solution C is obtained; adding a flocculating agent into the solution C, thus a sediment D is produced; and dissolving the sediment D with absolute ethyl alcohol, filtering, removing undissolved substances, concentrating, and removing the absolute ethyl alcohol, thus the oleanolic acid is obtained. In the invention, a microwave-assisted extraction method is adopted, and the process can be simplified; and, imperfect dry Chinese red dates are taken as raw materials, the raw materials are available, and the cost is low.

Owner:申琳 +1

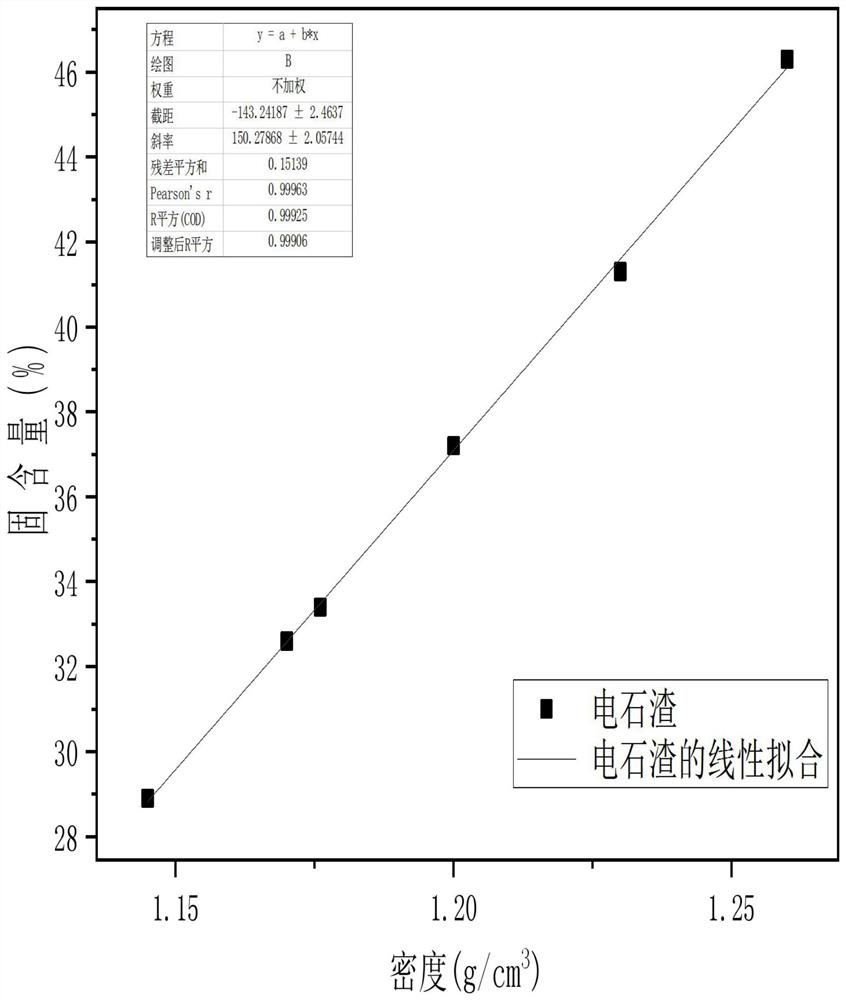

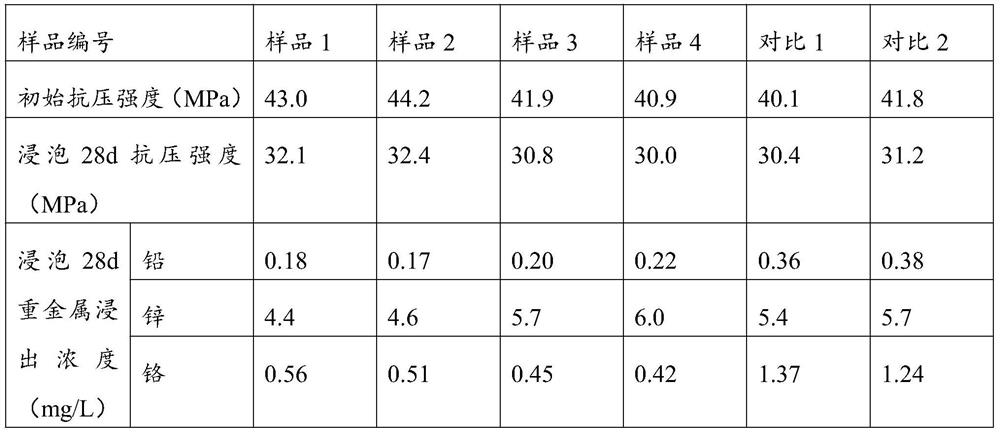

Pavement brick prepared based on domestic waste incineration fly ash and preparation method thereof

The invention relates to the technical field of pavement bricks, in particular to a pavement brick prepared based on domestic waste incineration fly ash and a preparation method thereof. The pavement bricks, measured in parts by mass, include: 540-720 parts of slag and 45 parts of calcium carbide slag 90 parts, 180-450 parts of household waste incineration fly ash and 2600-2750 parts of sand. The pavement brick prepared by the invention not only further reduces the floor space of domestic waste incineration fly ash, calcium carbide slag and slag, but also alleviates the harm to the environment and organisms, and through the rational design of the formula, the interaction between the raw materials Synergistic effect, the prepared pavement brick has good appearance quality and high compressive strength, and at the same time, the present invention does not need sintering, saves energy, has simple method, low cost and good economic benefit, especially in the aspect of heavy metal solidification, in harsh Under the conditions, the leaching concentration of heavy metals still meets the national standard. While preparing pavement bricks with excellent performance, industrial solid waste and hazardous waste are fully utilized to ensure the full utilization of resources.

Owner:YANSHAN UNIV

A kind of preparation method of tea feed

InactiveCN105248860BReduce lossesImprove palatabilityAnimal feeding stuffAccessory food factorsZINC LACTATESucrose

The invention discloses a preparation method of tea feed. The method includes the following steps that firstly, tea leaves are soaked in water, the tea leaves are expanded after being taken out, and the expanded tea leaves are prepared; secondly, animal oil and vegetable oil are taken and mixed to prepare compounded grease, emulsifiers, water, zinc lactate, lactic acid or citric acid, sucrose or glucose and sodium cyclamate are added into the compounded grease and are evenly mixed, finally, homogeneous processing is performed, and emulsified fat pulp is prepared; thirdly, the emulsified fat pulp is sprayed to the expanded tea leaves, the tea feed is obtained after even mixing, or the tea feed is obtained through drying after even mixing. The technology is simple and implementation is easy. The prepared tea feed is rich in emulsified fat pulp, tea polyphenol, lactic acid, zinc lactate and other active substances, and the tea feed has the functions of improving immunity and ingestion, promoting digestion, stimulating growth, reducing product cholesterol, improving meat quality of bred animals and the like. The prepared tea feed has the oil oxidization resistance function and can decrease the oil oxidization speed in summer.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Achymthes bidentata blume leaf tea and production technology thereof

InactiveCN105265639AExpansion of comprehensive utilization channelsTo meet the different needs of the marketPre-extraction tea treatmentLiver and kidneyManufacturing technology

The invention belongs to the technical field of manufacturing of a tea substitute and discloses an achymthes bidentata blume leaf tea and its production technology. Achymthes bidentata blume is mainly produced in Henan and has effects of removing blood stasis and stimulating the menstrual flow, nourishing liver and kidney, strengthening the bones and muscles, inducing diuresis for treating stranguria and guiding herb. Achymthes bidentata blume leaf has similar medicinal value as the traditional Chinese medicine achymthes bidentata blume and has rich sources. During plantation and production process of achymthes bidentata blume, achymthes bidentata blume leaf is mostly abandoned. According to the invention, achymthes bidentata blume leaf is fully utilized, and common medicinal and edible raw materials such as matrimony vine and the like are used in combination with achymthes bidentata blume leaf so as to have a synergistic effect of achymthes bidentata blume leaf in nourishing liver and kidney and strengthening the bones and muscles. Thus, a new variety of tea, namely the achymthes bidentata blume leaf tea, is developed. Meanwhile, the achymthes bidentata blume leaf tea is made into a ready-to-brew form of tea, a tea bag form, a liquid beverage form and the like, and also can be further developed and processed into tablets and capsules or granules. The achymthes bidentata blume leaf tea has a simple processing technology, is convenient to carry and use, is easy to popularize and has good economic value.

Owner:卢鹏伟 +2

Method for preparing fish cream by using low-value red meat fish

ActiveCN104799348AExpansion of comprehensive utilization channelsEffective dissolution and removalFood ingredient functionsFood ultrasonic treatmentBiotechnologyRed meat

The invention discloses a method for preparing fish cream by using low-value red meat fish. The method comprises the following steps of pretreating raw material fish; collecting fish meat and rinsing with ice water; continuously treating the rinsed fish meat by sequentially using peroxidase and a degreasing enzyme; ultrasonically extracting and centrifugally filtering to obtain a primary fish cream product; adding auxiliary materials such as edible salt, newtol, white sugar and composite phosphate into the primary fish cream product to obtain a finished fish cream product. According to the method disclosed by the invention, an enzyme engineering technology is adopted and combined with ultrasonic treatment to effectively decolorize and degrease the low-value red meat fish so as to effectively dissolve out and remove pigments and grease, so that the technical difficulties of preparing the fish cream by using the low-value red meat fish can be solved, fish cream suitable for production of a minced fish product can be researched and developed, and the comprehensive utilization methods of the low-value red meat fish are widened.

Owner:福建盛海达投资发展有限公司

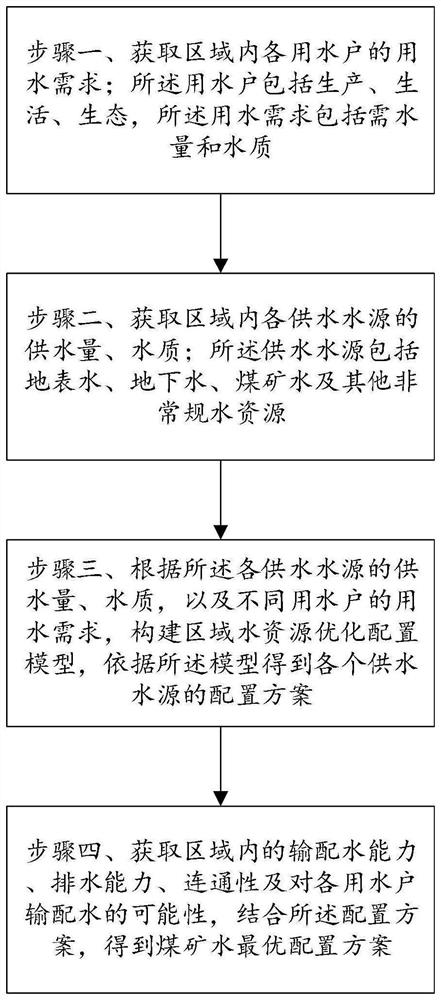

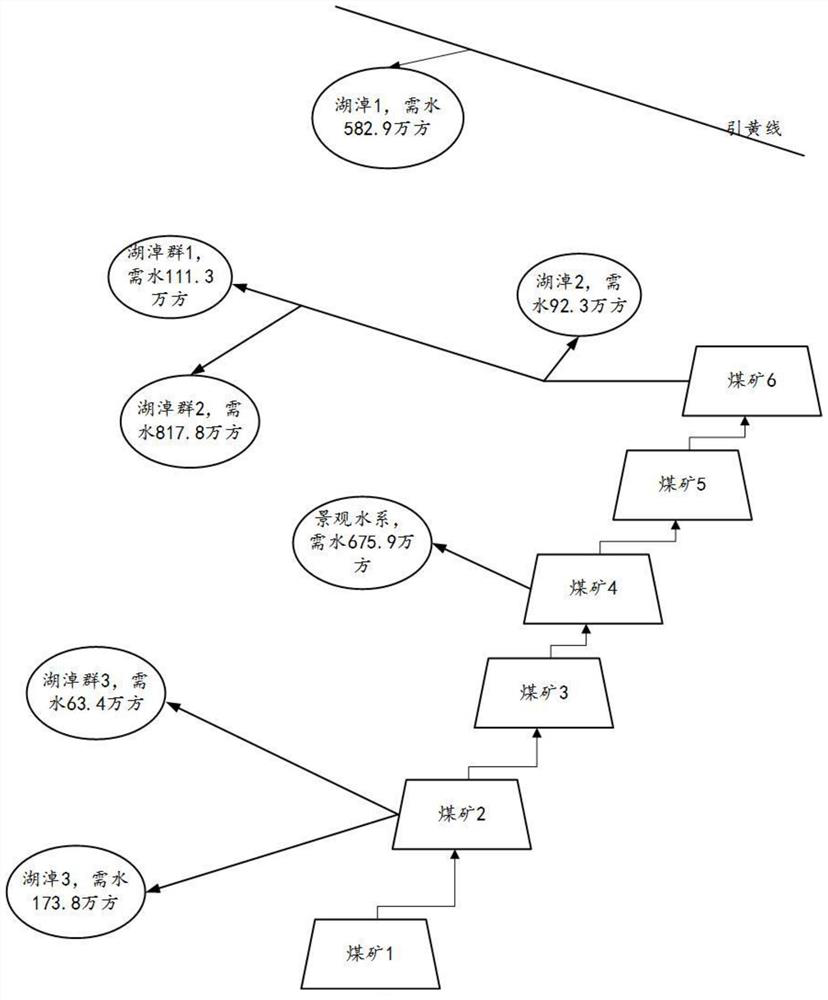

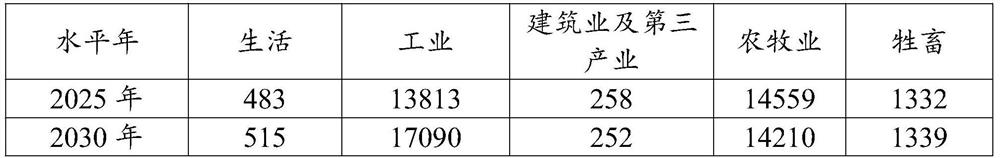

Coal mine water area efficient utilization and optimal allocation method

PendingCN113449890AEfficient use ofExpansion of comprehensive utilization channelsGeneral water supply conservationReservationsWater useEcological environment

The invention discloses a coal mine water area efficient utilization and optimal allocation method, and relates to the technical field of unconventional water resource management, and the method comprises the steps of obtaining the water demands of each water user in an area, the water users including production, life and ecology; obtaining the water supply amount and water quality of each water supply source in the area, wherein the water supply sources comprise surface water, underground water, coal mine water and other unconventional water resources; according to the water supply amount and the water quality of each water supply source and the water demands of different water users, constructing a regional water resource optimal configuration model, and solving the model to obtain a configuration scheme of each water supply source; and obtaining the water transmission and distribution capacity, the drainage capacity, the pipe network connectivity and the water transmission and distribution possibility of each water user in the region, and obtaining an optimal coal mine water configuration scheme in combination with the configuration scheme. The coal mine water is introduced into regional water resource allocation, a regional production and ecology-oriented allocation method is formed, and the dual problems that the regional coal mine water is rich and cannot be fully utilized, and the ecological environment needs to be protected urgently are solved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

Swine hemoglobin enzymolysis and decoloration method

ActiveCN102077901BLow ash contentPromote growth and developmentPeptide/protein ingredientsAnimal feeding stuffWhole blood productProtease preparation

Owner:成都天屹生物科技有限公司

A method for preparing surimi from low-value red meat fish

ActiveCN104799348BExpansion of comprehensive utilization channelsEffective dissolution and removalFood ingredient functionsFood ultrasonic treatmentRed meatIce water

The invention discloses a method for preparing fish cream by using low-value red meat fish. The method comprises the following steps of pretreating raw material fish; collecting fish meat and rinsing with ice water; continuously treating the rinsed fish meat by sequentially using peroxidase and a degreasing enzyme; ultrasonically extracting and centrifugally filtering to obtain a primary fish cream product; adding auxiliary materials such as edible salt, newtol, white sugar and composite phosphate into the primary fish cream product to obtain a finished fish cream product. According to the method disclosed by the invention, an enzyme engineering technology is adopted and combined with ultrasonic treatment to effectively decolorize and degrease the low-value red meat fish so as to effectively dissolve out and remove pigments and grease, so that the technical difficulties of preparing the fish cream by using the low-value red meat fish can be solved, fish cream suitable for production of a minced fish product can be researched and developed, and the comprehensive utilization methods of the low-value red meat fish are widened.

Owner:福建盛海达投资发展有限公司

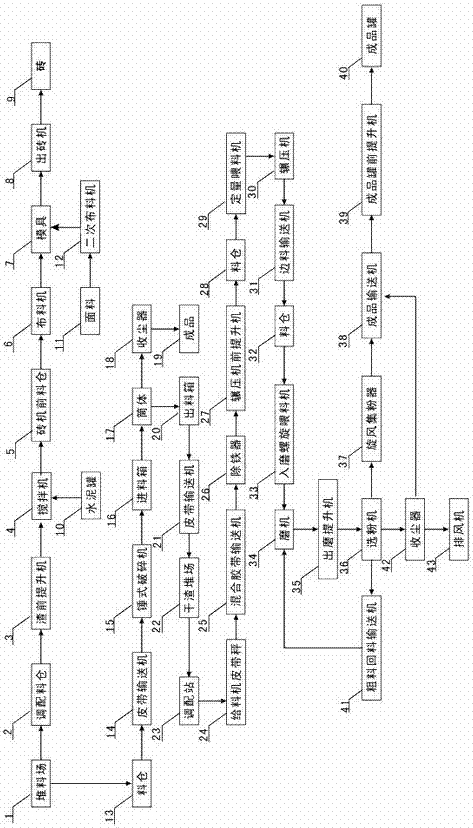

Method for Comprehensive Utilization of Domestic Garbage Incineration Power Generation Residue

ActiveCN105461268BExpansion of comprehensive utilization channelsEasy accessSolid waste managementCement productionBrickIron removal

A comprehensive utilization method of residue from municipal solid waste incineration generating is provided. A brick-making method is as below: stirring residue, stone chips and cement to form a mixture, distributing the mixture to a mold by a distributing machine, to pre-molding the mixture by a hydraulic vibration machine to form preformed bricks, distributing a surface material mixed from white cement, sand and a pigment on the surfaces of the preformed bricks, and pressing the mixed material and surface material by the hydraulic vibration machine to obtain bricks. A method for producing a non-reactive cement mixed material is as below: 1) drying: drying the residue from municipal solid waste incineration generating by a dryer; 2) iron removal: removing iron in the dried residue by a de-ironing separator; 3) rolling: rolling the residue after iron removal by a rolling machine; and 4) grinding: grinding the residue after rolling by a grinding machine. The present invention has the following beneficial effects of: 1, expanding the comprehensive utilization ways of residue from municipal solid waste incineration generating; 2, solving the quality problem caused by high moisture content in non-reactive mixed material in brick-making or cement production, and 3, saving energy and reducing emission.

Owner:襄阳市栋梁环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com