Patents

Literature

462results about How to "Low ash content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

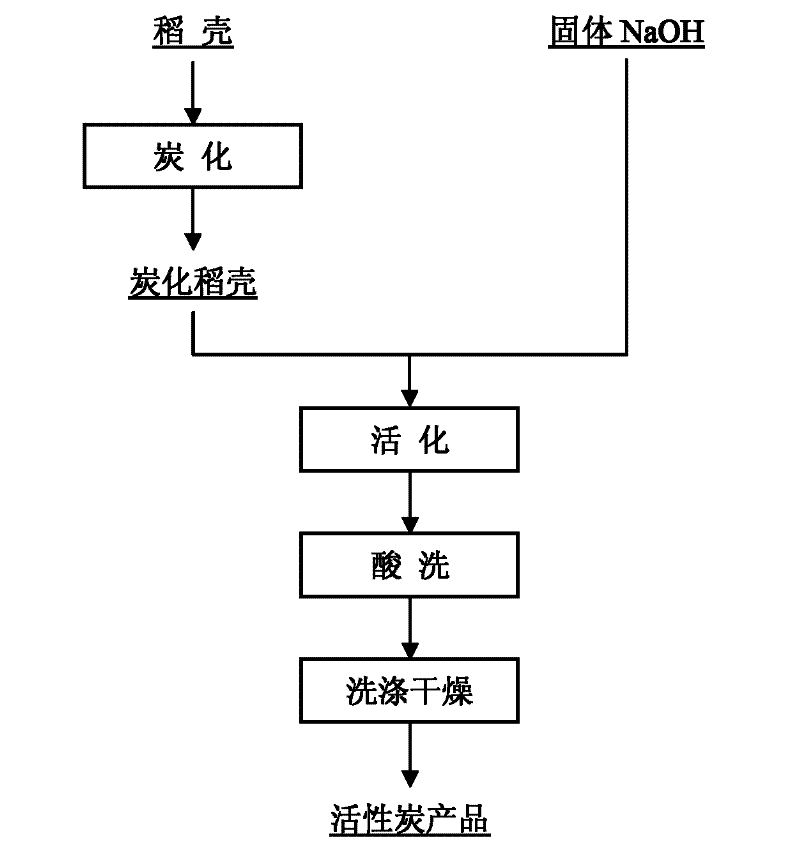

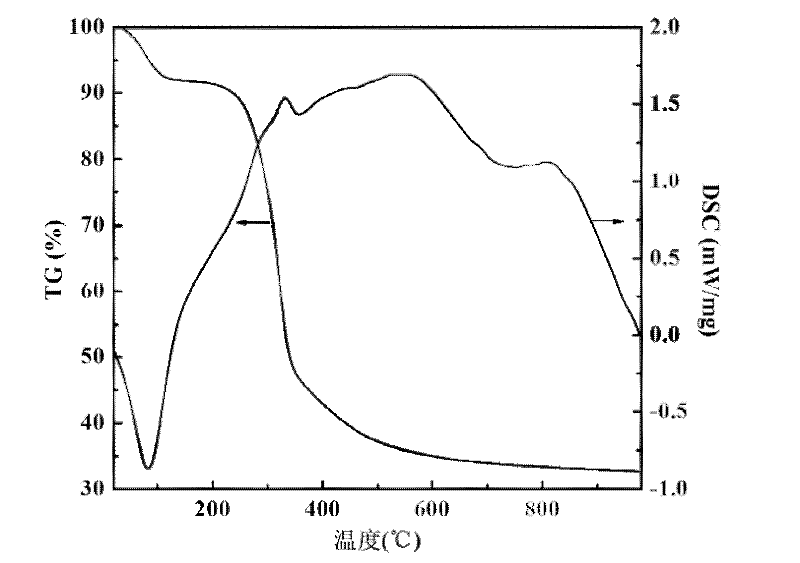

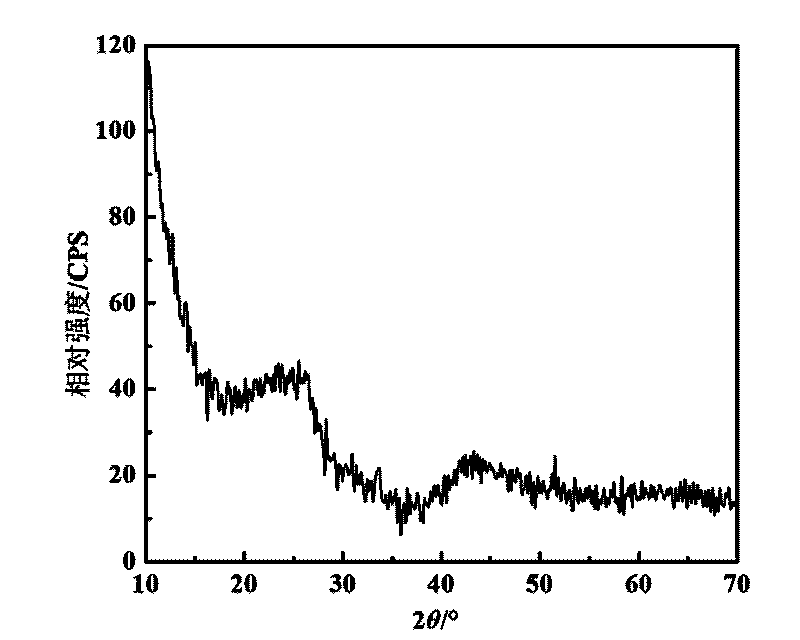

Method for preparing activated carbon

The invention relates to a method for preparing activated carbon. In the method, rice husks are taken as a raw material, NaOH is taken as an activator, and an activated carbon product is prepared through high temperature carbonization and activation, has high specific surface area, low ash content, a large number of distributed micropores, and high adsorption property, and is an ideal adsorption material, an ideal electrode material, an ideal hydrogen storage material and an ideal catalyst carrier. Alkaline solution is not required to be used for impregnation and activation, and the obtained product has a small particle size, has the characteristics of wide raw material source, low cost and simple process, is suitable for popularization, and has certain economic significance and environment-friendly significance.

Owner:CENT SOUTH UNIV

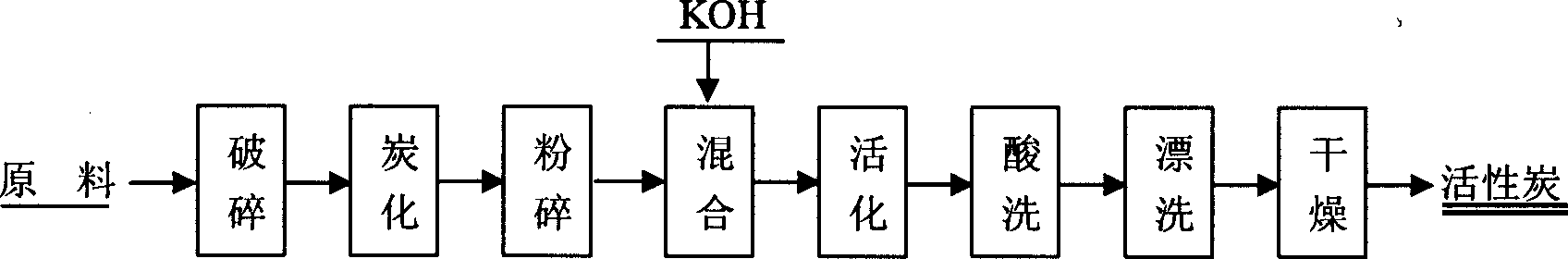

Super active carbon preparation method

The invention relates to a preparation method for super active carbon. Wherein, carbonizing and breaking up the raw material of coco shell or walnut shell to predetermined particle size and mix evenly with solid potassium hydroxide; activating the mixture in microwave oven with nitrogen protection during the process to obtain activation material; clearing the material with muriatic acid and then distilled water for many times to neutrality and obtain the said product. The product with this method has strong adsorption property, high specific surface area and high adsorption value to iodine and methylene blue. The method is simple and convenient to control.

Owner:KUNMING UNIV OF SCI & TECH

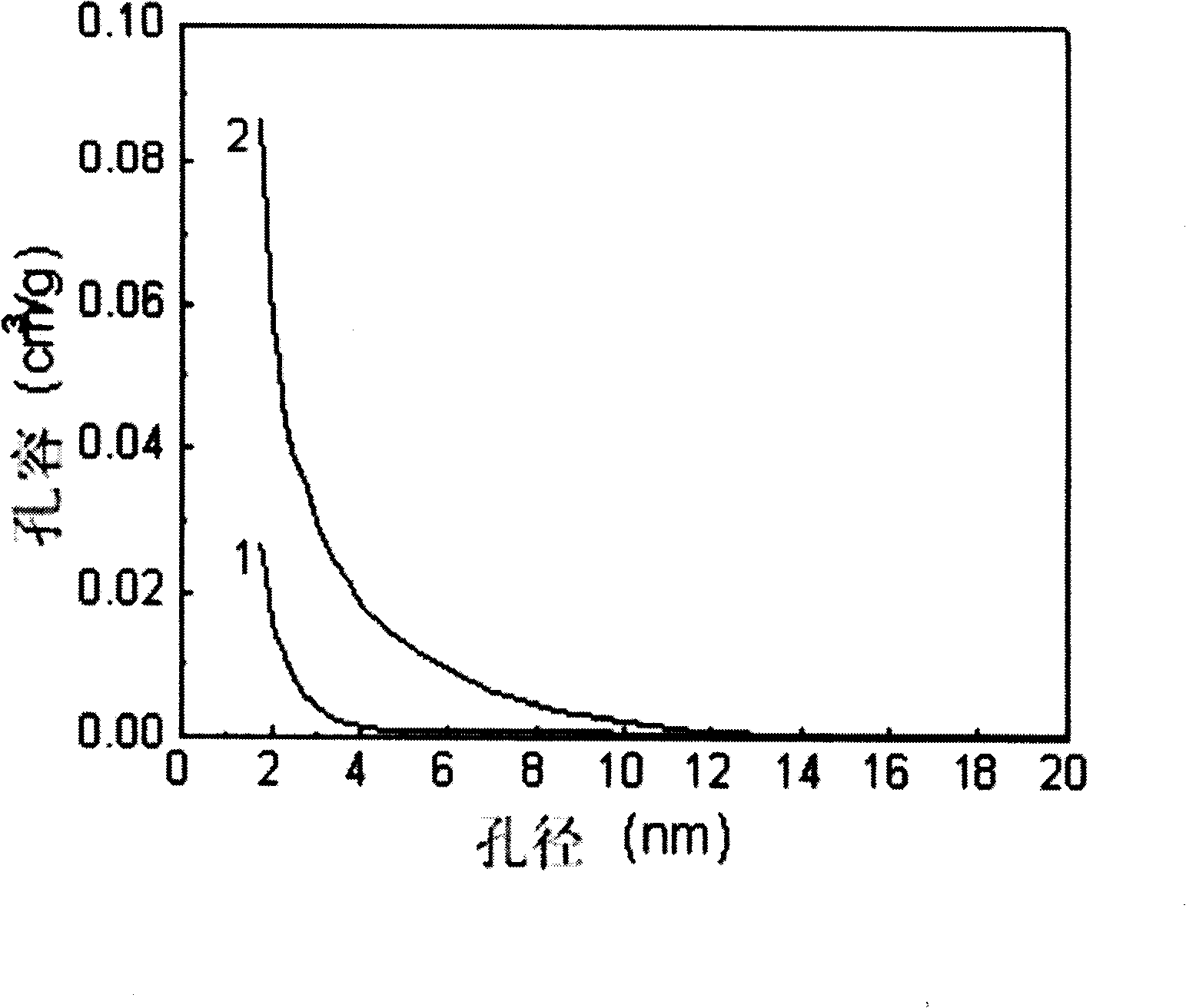

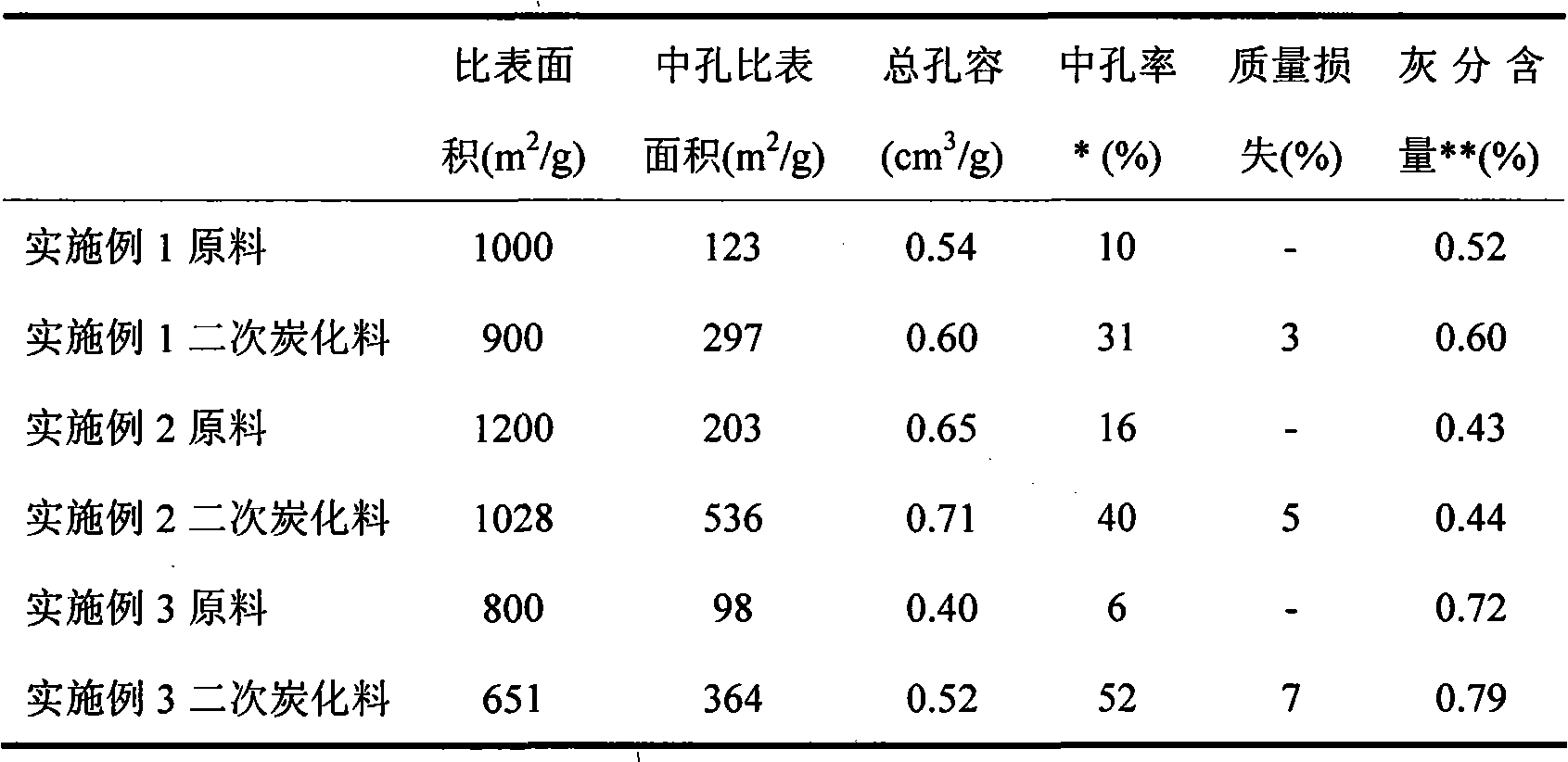

Process for preparing mesopore pitch-based spherical activated carbon by post-carbonizing impregnated metal salts

The invention provides a method for preparing mesoporous asphaltic base globular active carbon by dipping metal salt and secondary carbonization. The method comprises the steps of dipping and mixing the mipor asphaltic base globular active carbon prepared by the traditional method with an inorganic metal salt solution by a certain ration; heating under an inert atmosphere to 600-1200 DEG C at a temperature increasing rate of 1 to 20 DEG C / min for the secondary carbonization; using acid to wash off the remaining metal inside the carbonized material, so as to obtain asphaltic base globular active carbon with high mesoporous rate and narrow distribution of mesoporous spertures.

Owner:EAST CHINA UNIV OF SCI & TECH

Comprehensive utilization method of corn cob

ActiveCN101628920AEasy to separatePromote conversionBiofuelsLignin derivativesSocial benefitsState of art

The invention provides a comprehensive utilization method of corn cob, which effectively separates hemicellulose, lignin and cellulose contained in a reproducible biological resource of corn cob in a reasonable process order at low cost and high efficiency, and makes full use of every type of biomass components, thereby solving the problem of utilization of residue in the biomass refining process of preparing ethanol and butanol by extracting xyio-oligosacchandes and enzymolysis from the corn cob in the prior art, and making reasonable and effective use of main components of biomass contained in the corn cob; particularly, the lignin can substitute partial petrochemical materials to prepare modified high-molecular materials, thereby reducing the cost of high-molecular materials and saving the energy consumption of petrochemical materials to bring great social benefit; in addition, the comprehensive utilization method of corn cob is featured by simple processing technique, easy implementation and favorable effect.

Owner:重庆辉泰化工销售有限公司

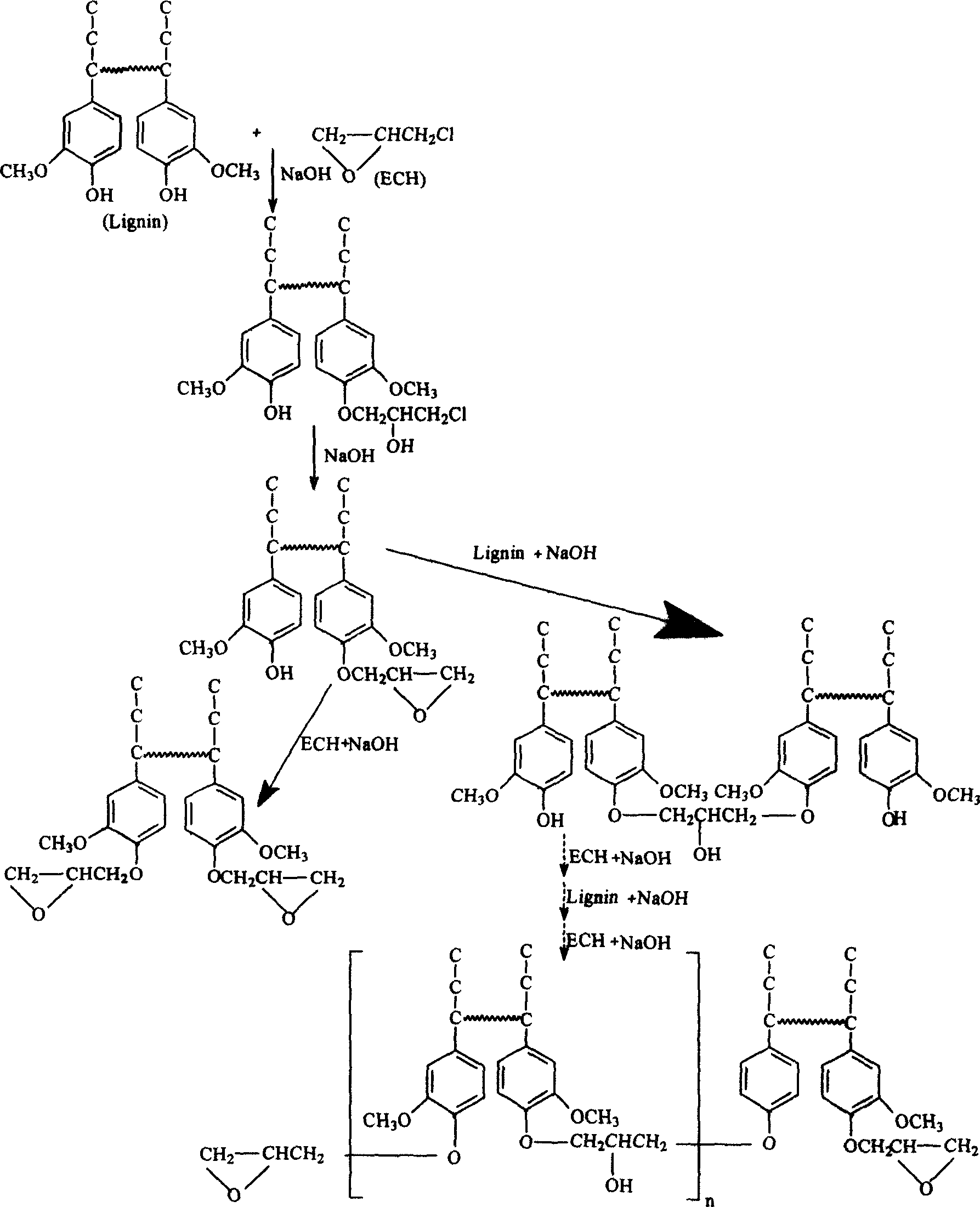

Enzymatic hydrolysis lignin epoxide resin and preparation thereof

The invention provides an enzymolysis lignin epoxy resin and a preparation method thereof. The raw materials include: an enzymolysis lignin-dianhydride prepolymer, a glycidol ether, a catalyst, a curing agent and a filler. The preparation method comprises the following steps that: under the action of the catalyst, an etherification of a hydroxyl group contained in the enzymolysis lignin or a derivative of the enzymolysis lignin and dianhydride is carried to synthesize a prepolymer of enzymolysis lignin-dianhydride; then the prepolymer reacts with the glycidol ether and undergoes etherification and ring closing reaction to obtain an enzymolysis lignin--polyester type epoxy resin. The enzymolysis lignin adopted by the method is natural macromolecular material extracted from the residues which is produced in the preparation of alcohol through the fermentation of wood chips, bamboo and stalk, thereby not only effectively utilizing biological resources, but also replacing petrochemical raw materials. The enzymolysis lignin epoxy resin which can be used as a modifier for engineering materials, adhesives, paints and macromolecular materials has a broad application prospect.

Owner:重庆辉泰化工销售有限公司

Raw material prescription for xylogen-inorganic nano composite material producing process thereof

The invention provides a raw material prescription of lignin-inorganic nanometer composite material and the preparation method thereof. The composite material comprises lignin or derivate, inorganic nm material, water soluble lignin surface finishing agent and other types of surface finishing agent. The preparation method comprises the steps as follows: the inorganic nanometer material is pretreated with the water soluble lignin surface finishing agent, the other types of the surface finishing agent are added to finish pretreatment; the inorganic nanometer material is added into the lignin or the derivate, acid is added for sediment, and is filtered and dried to acquire the lignin-inorganic nm composite material. The invention has simple raw materials prescription, easily-available sources, low cost and simple technique, is favorable for the recirculation and the reuse of biographic resources, and has good product performance, brilliant economical benefit and wide application prospect without pollution.

Owner:FUZHOU UNIV

Material formula of polyurethane of enzymolysis lignin, and preparation method

This invention provides a method for preparing cellulolytic enzyme lignin polyurethane and its raw materials. The raw materials comprise: cellulolytic enzyme lignin or its derivative, polyisocyanate, polyol oligomer, chain extension and crosslinking agent, organic solvent and additive. The method comprises: (1) dissolving cellulolytic enzyme lignin or its derivative in the organic solvent, mixing with polyol or a mixture of polyol and organic solvent, and heating or stirring to mix uniformly; (2) adding polyisocyanate, heating, adding conventional additives or fillers, heating to react completely, and vacuum-distilling to obtain brown solid; (3) washing the solid with water, and drying to obtain cellulolytic enzyme lignin polyurethane. The cellulolytic enzyme lignin is a natural polymeric material extracted from wood, bamboo and straw, thus can effectively utilize biomass resources and replace petrochemical raw materials. The method largely improves the process for preparing cellulolytic enzyme lignin polyurethane, which has a better modification effect than traditional sulfonated lignin, and lower cost than high-boiling-point alcohol lignin.

Owner:FUZHOU UNIVERSITY

Enzymolysis xylogen or its derivative modified asphalt composite material, and preparation method thereof

The present invention provides an enzymolysis lignin or enzymolysis derivant modified asphalt composite material and a preparation method. The raw materials include the enzymolysis lignin or the enzymolysis lignin derivant, the asphalt and other modification assistant agents. The preparation steps: the enzymolysis lignin or the enzymolysis lignin derivant, other modification assistant agents and filling agent are mixed in advance to the melted asphalt substrate to be uniformly mixed, and then the mixture is displaced for solidification. The present invention makes full use of the renewable living resource, and not only resolves the problem of the present polymer modified asphalt that depends on the synthesis of the petrochemical raw materials, but also can reduced the use cost of the polymer modified asphalt; appropriate enzymolysis additive can be selected according to different requirements of the modified asphalt product to substitute partial petrochemical raw materials, thus improving the anti-aging performance of the polymer asphalt product; moreover, the craftwork is simple and is easy to implement, thereby can reduce the production cost and improve the competition strength of the product.

Owner:FUZHOU UNIVERSITY

Method for producing fish scale collagen protein

InactiveCN101418328AReduce churnHigh yieldConnective tissue peptidesPeptide preparation methodsProtein solutionFreeze-drying

The invention relates to a method for preparing fish scale collagen. The method comprises the following steps: fresh fish scales are taken as a material, undergo cleaning, drying and crushing, are soaked in NaOH solution for degreasing, and soaked in hydrochloric acid solution for deashing; the fresh fish scale is added with water of which the weight is 5 to 10 times of that of the fish scales, the pH value is adjusted to between 2 and 4 by acid solution, pepsin of which the weight accounting for the weight of the mixing solution is between 1 and 5 percent is added, the mixing solution undergoes enzymolysis at a low temperature for 4 to 10 hours, and enzyme is killed; enzymatic liquid is filtered twice to obtain extracting solutions, the extracting solutions are mixed, the mixing solution is decolored, sodium chloride of which the weight accounting for the weight of the mixing solution is between 5 and 15 percent is added into the mixing solution for overnight salting out, deposit is separated and collected, and acetic acid of which the weight accounting for the weight of the mixing solution is between 5 and 20 percent is added into the deposit for dissolution to obtain protein solution; the protein solution is dialyzed and desalted to obtain purified collagen liquid; and the collagen liquid is subjected to freeze-drying or spray-drying and micro-crushing to obtain solid particle. The method has the advantages of reasonable process, simple operation, safety, low cost, little loss of nutrient matters of the product, low ash content and high yield and purity of the collagen.

Owner:SHANDONG HOMEY AQUATIC DEV +1

Purification and graphitization method of graphite material

ActiveCN102126721AImprove product qualityLow costChemical industryBromineElectrical energy consumption

The invention discloses a purification and graphitization method of a graphite material, aiming at solving the technical problems of improving the quality of the graphite material, saving energy and reducing cost. The method comprises the following steps: putting a graphite product or a carbon product in a graphite crucible in a furnace body; heating to 900-1700 DEG C, and then introducing nitrogen or argon; continuing to heat to 1000-1950 DEG C, introducing chlorine and then continuing to rising the temperature to 1400-2300 DEG C; simultaneously, introducing bromine or a fluorine-containing gas, heating to 1800-3300 DEG C and then stopping heating; introducing the chlorine until the temperature is reduced to below 1000-2000 DEG C; and feeding nitrogen or argon lasting for more than 0-15 hours. Compared with the prior art, the ash content of the obtained graphite product is less than 0.00011%; electrical energy consumption is reduced; and the method has the advantages that the processis simple, the cost is low, the quality of the graphite product is stable, and energy is saved.

Owner:BTR NEW MATERIAL GRP CO LTD

Enzymatic hydrolysis lignin epoxy resin material formula and its preparation method

The invention provides a raw materials formula of enzymolysis lignin epoxy resin and its fabrication method. The formula includes enzymolysis lignin or its derivatives, bisphenol A-type compound, epichlorohydrin or its mixture with organic solvent, catalyst, curing agent, and filler. The preparation method includes adding enzymolysis lignin or its derivatives into epichlorohydrin solution or its mixture with organic solvent, stirring and adding catalyst, curing agent or the mixture of curing agent and filler, heating and reacting completely, vacuum-distilling to remove the excessive epichlorohydrin or organic solvent to obtain brown solid insoluble in water, washing, and drying to obtain enzymolysis lignin epoxy resin. The adopted enzymolysis lignin is the natural polymer material extracted from wood, bamboo and straw, which not only effectively use the biological resources, but also can replace petrochemical raw materials. The prepared enzymolysis lignin epoxy resin can be used for engineering materials, adhesives, coating or polymer materials modifier, which has a broad application prospect.

Owner:重庆辉泰化工销售有限公司

Biomass particle fuel and preparation method thereof

InactiveCN104927961AQuality improvementImprove qualitySolid fuelsWaste based fuelOrganic matterCow dung

The invention relates to the technical field of biomass fuel, in particular to biomass particle fuel and a preparation method thereof. The biomass particle fuel and the preparation method are characterized in that cow dung, biogas residues, sawdust, yellow mud and corn straw are pre-fermented to change the structure layer of the biomass raw materials and form a compact structure, high-content organic matter is formed, and organic matter components are increased; drainage oil is poured into the organic matter, high-speed stirring is used to allow microscopic biochemical reaction between the drainage oil and the fermented materials, and organic matter mass and quality are increased; the stirred mixture is fermented to further convert the organic matter so as to increase the combustible substances in the organic matter and improve the quality of the organic matter; combustion improver is added and extrusion forming is performed to allow the prepared biomass particle fuel to be good in quality.

Owner:广西稳德福能源科技有限公司

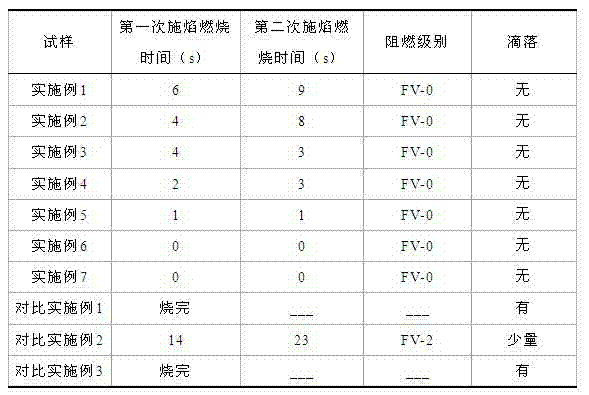

Preparation method for solvent-based lignin-cyanamide derivative flame retardant

The invention relates to a preparation method for a solvent-based lignin-cyanamide derivative flame retardant. The method is characterized in that: after being subjected to a hydroxymethylation reaction, solvent-based lignin is subjected to a condensation polymerization with cyanamide and urea to prepare the solvent-based lignin-cyanamide derivative flame retardant. The solvent-based lignin-cyanamide derivative flame retardant has characteristics of high performance, halogen free, low cost, simple preparation method, and good flame-retardant effect, and can be widely applicable for the modified fields of polymers such as rubber, plastic and the like, and has good economic benefit and social benefit.

Owner:FUZHOU UNIVERSITY

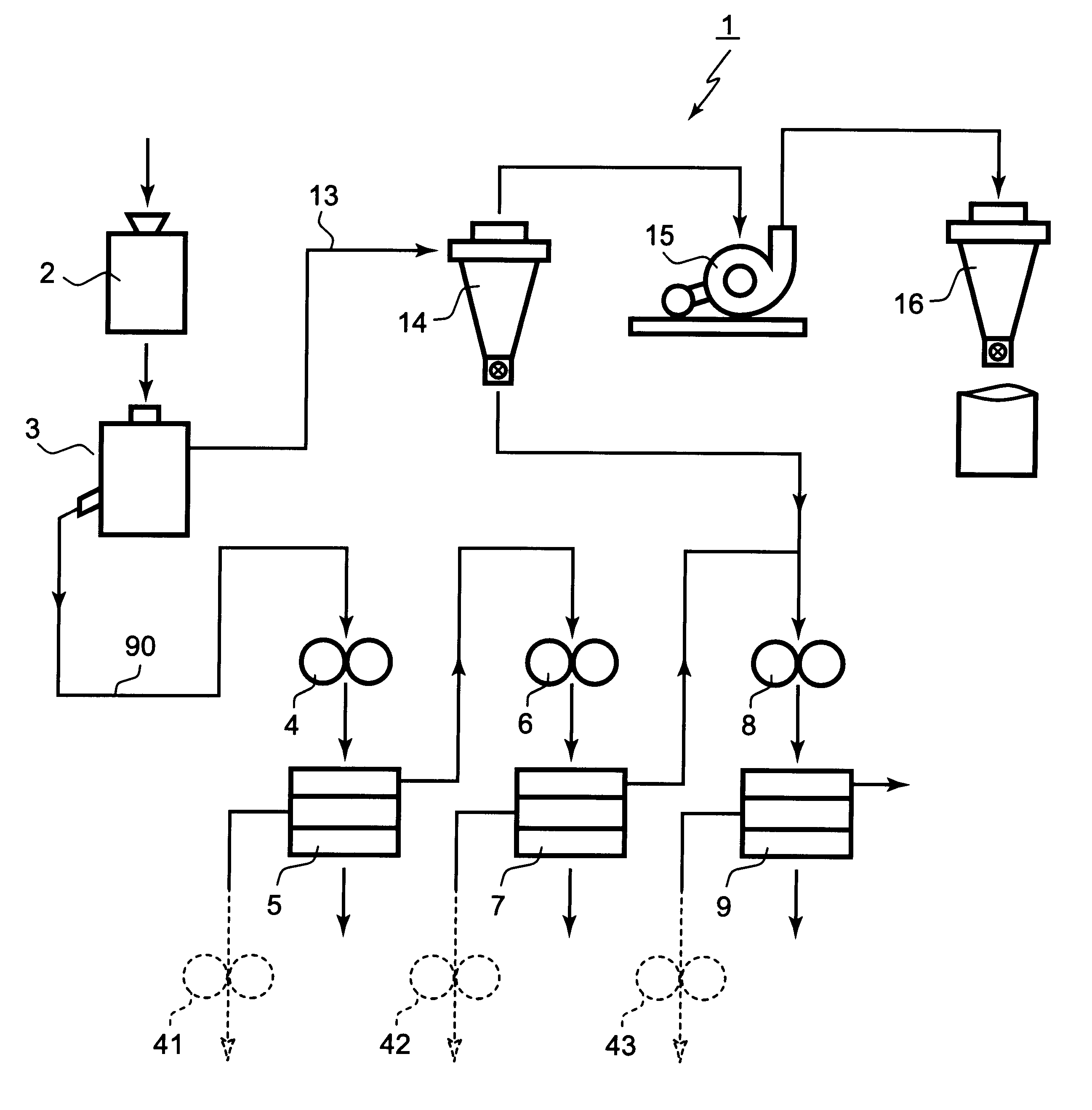

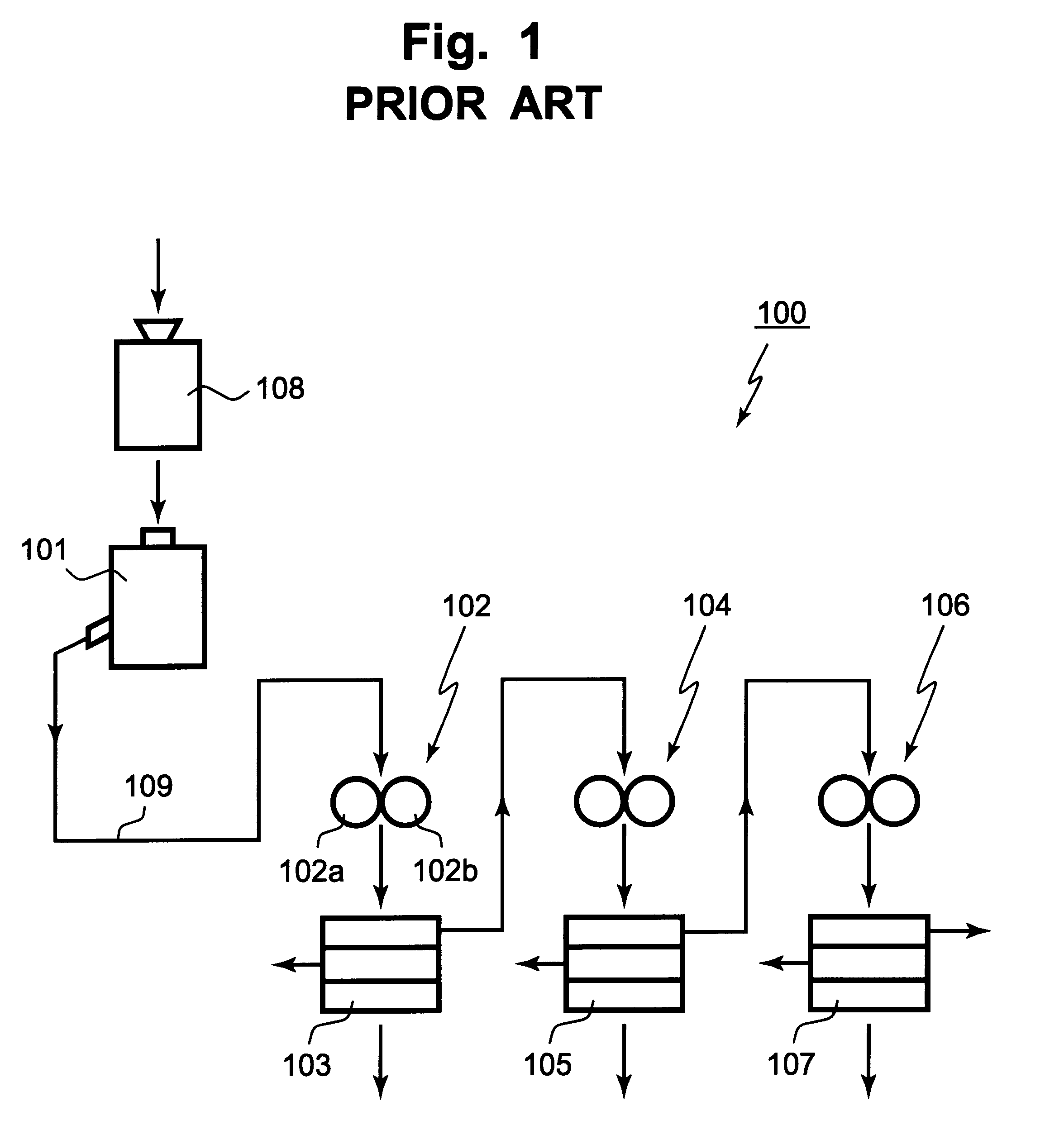

Flour milling method having a sorting step for raw wheat grains and flour milling system adopting the method

InactiveUS6199777B1Enhance advantageous effectHigh yield productionSievingScreeningBiotechnologyRegular Production

A flour milling method and a flour milling system are provided, in which a plurality of milling steps whose milling degrees are different from one another are performed sequentially from an upperstream to a downstream, each of the milling steps including a breaking step and a grading step. The steps are carried out by sorting the raw wheat grains into regular wheat grains and material other than the regular wheat grains, forwarding the sorted regular wheat grains to the uppermost-stream milling step, and forwarding the sorted material other than the regular wheat grains to at least one of downstream milling steps at a downstream of the uppermost-stream milling step. The method and the system enable the production of wheat flour of better quality with better yield than that conventionally produced.

Owner:SATAKE CORP

Method for preparing water-coal-slurry additive taking enzymatic hydrolysis lignin as raw material

InactiveCN101921639ARetain chemical activityHigh purityLiquid carbonaceous fuelsCelluloseActive agent

The invention provides a method for preparing a water-coal-slurry additive taking enzymatic hydrolysis lignin as a raw material. In the method, the chemical activity of the enzymatic hydrolysis lignin is utilized to directly perform polycondensation with sodium hydrogen sulfite, sodium metabisulfite, acetone and methanal to a prepare enzymatic hydrolysis lignin-sulphonated acetone-methanal condensation polymer (LSAF); the enzymatic hydrolysis lignin-sulphonated acetone-methanal condensation polymer (LSAF) is compatible with other types of surfactants, and is compounded with the surfactants, such as sodium dodecyl benzene sulfonate, PVA, carboxymethyl cellulose sodium and the like to prepare the water coat slurry which has higher stability and lower viscosity; and the liquidity of the water coat slurry is improved. The enzymatic hydrolysis lignin replaces the partial petrochemical raw materials to prepare modified high molecular materials, which not only lowers the cost of high molecular materials, but also can save the consumption of the petrochemical materials, and can generate significant social benefit; and the processing technique for preparing the water-coal-slurry additive taking the enzymatic hydrolysis lignin as a raw material is simple, is easy to implement and has good effect.

Owner:FUZHOU UNIV

Method for preparing friction-resistant composite material by modifying solvent type lignin

ActiveCN101891933ARetain chemical activityHigh purityOther chemical processesSolvent basedChemical activity

The invention provides a new method for preparing a friction-resistant material by taking lignin as a modifying raw material. The new method is used for preparing the friction-resistant material by taking the solvent type lignin as the modifying raw material. The method can utilize the renewable lignin and has the advantages of strong chemical activity, high purity and the like, the solvent type lignin is taken for replacing phenols for preparing lignin-modified phenolic resin, and the resin has more polar groups in comparison with the traditional phenolic resin and stronger affinity in comparison with other components for preparing the friction-resistant material, thereby not only improving the performances of the friction-resistant material, but also fully utilizing the renewable resource and reducing the consumption of petroleum chemicals; simultaneously, the method can reduce the cost of preparing the friction-resistant material, save energy, reduce emission and produce great social benefits; furthermore, the process for preparing the friction-resistant material is simple and easy to implement and can produce good effects.

Owner:FUZHOU UNIV

Sulfonated acetone-formaldehyde high-efficiency water reducing agent modified by enzymatic hydrolysis lignin or by derivatives thereof, and preparation method thereof

The invention provides a sulfonated acetone-formaldehyde high-efficiency water reducing agent modified by enzymatic hydrolysis lignin or by derivatives thereof, and a preparation method thereof, raw materials comprise the enzymatic hydrolysis lignin or the derivatives thereof, acetone, aldehyde, sodium sulfite and sodium metabisulfite, a base catalyst and an acid regulator; the preparation steps comprise: mixing the sodium sulfite, the sodium metabisulfite with the water, heating at constant temperature and agitating, dropwise adding the acetone, adding the enzymatic hydrolysis lignin or the derivatives thereof, regulating pH value by the base catalyst, dropwise adding the aldehyde, continuous reacting for 3 hours, and adding the acid regulator to regulate the pH so as to result in product. The invention sufficiently utilizes reproducible biological resources, which not only solves the defect of low water reducing efficiency of the lignin-sulphonate water reducing agent extracted from papermaking 'black liquor' in the prior art, but also can replace partial petrochemical raw materials and reduce the production cost of the high-efficiency water reducing agent; the enzymatic hydrolysis lignin- or the derivatives thereof-modified high-efficiency water reducing agent has great use effect.

Owner:FUZHOU UNIV

Process for preparing sugar from cane

InactiveCN103981290AWell mixedLow ash contentPurification using alkaline earth metal compoundsPurification by physical meansActive carbonActivated carbon

The invention discloses a process for preparing sugar from cane. The process comprises the following steps: pressing, namely horizontally pressing at first and then longitudinally pressing to obtain cane juice; filtering, namely putting the cane juice into a filter to obtain pure cane juice, and separating out cane residues; clarifying and decolorizing, namely heating the pure cane juice, adding citric acid and calcium hydroxide for mixing, adding lime milk for neutralizing, carrying out secondary heating, and adding polyacrylamide for settling separation to obtain clear juice and mud juice; filtering the mud juice to obtain filtered clear juice, combining the clear juice, and adding active carbon into the clear juice for deodorizing; performing evaporation concentration, sugar boiling and crystallization, honey separation and drying to obtain the finished sugar. The process has good filtering, clarifying and deodorizing effects, and is time-saving, labor-saving and simple to operate.

Owner:彭华成

Prepn of high-boiling alcohol lignin epoxy resin

The present invention is preparation process of epoxy resin with high-boiling alcohol lignin and its derivative. High-boiling alcohol lignin or its derivative is dissolved in chloropropylene oxide solution or the mixed solution of chloropropylene oxide and organic solvent through stirring and heating, and the mixture is reacted completely via adding catalyst and heating to prepare epoxy resin. The preparation process is simpler compared with traditional lignin epoxy resin, and the present invention has low cost, simple preparation process and high product performance.

Owner:FUZHOU UNIV

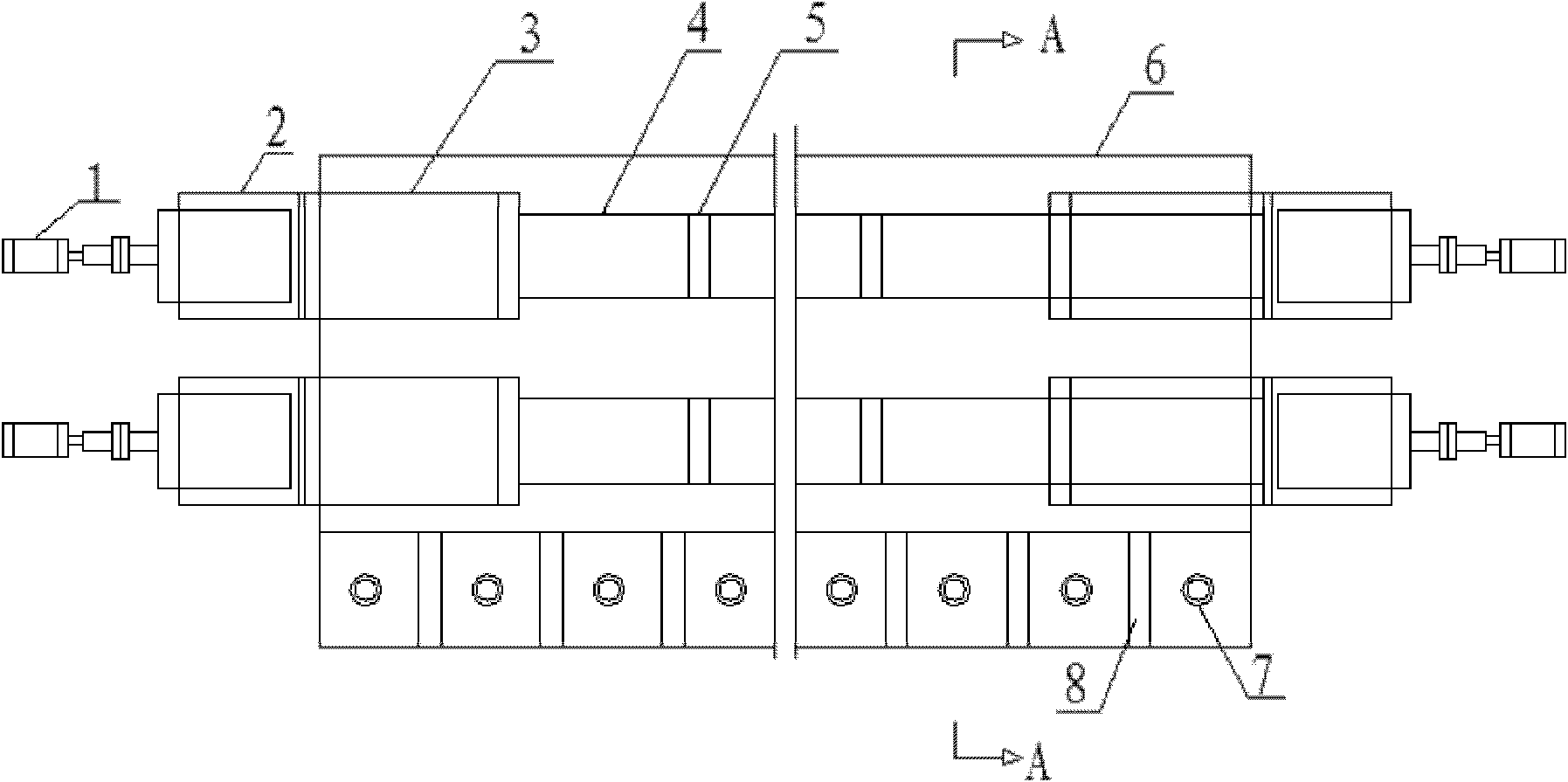

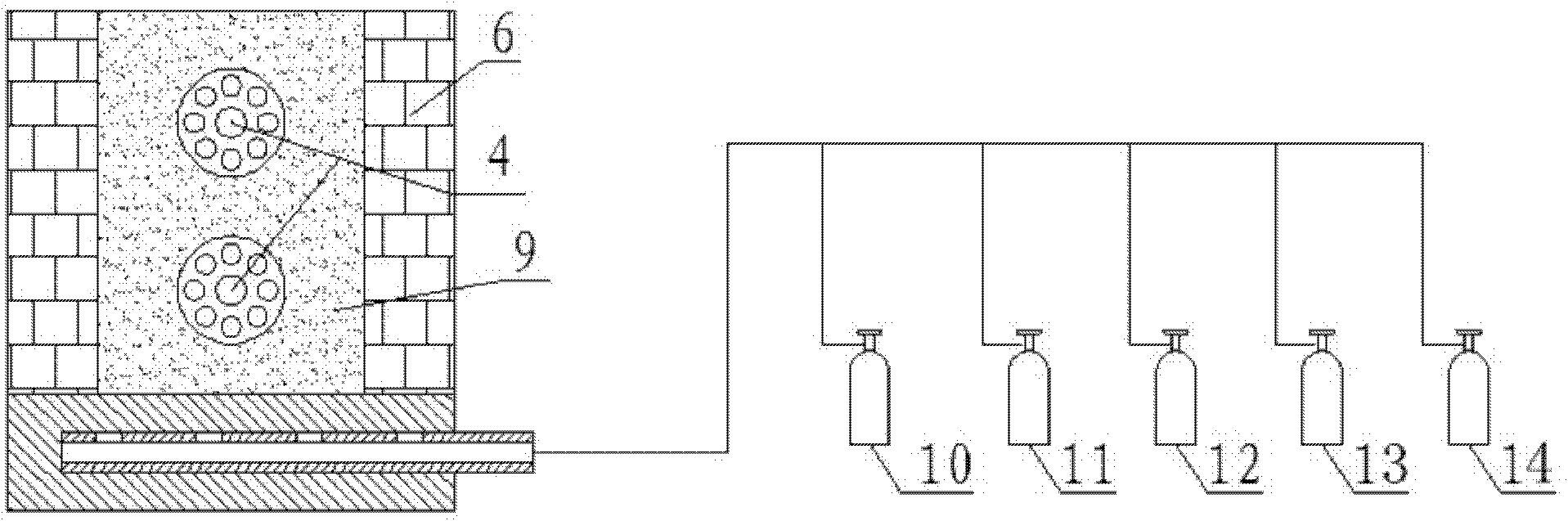

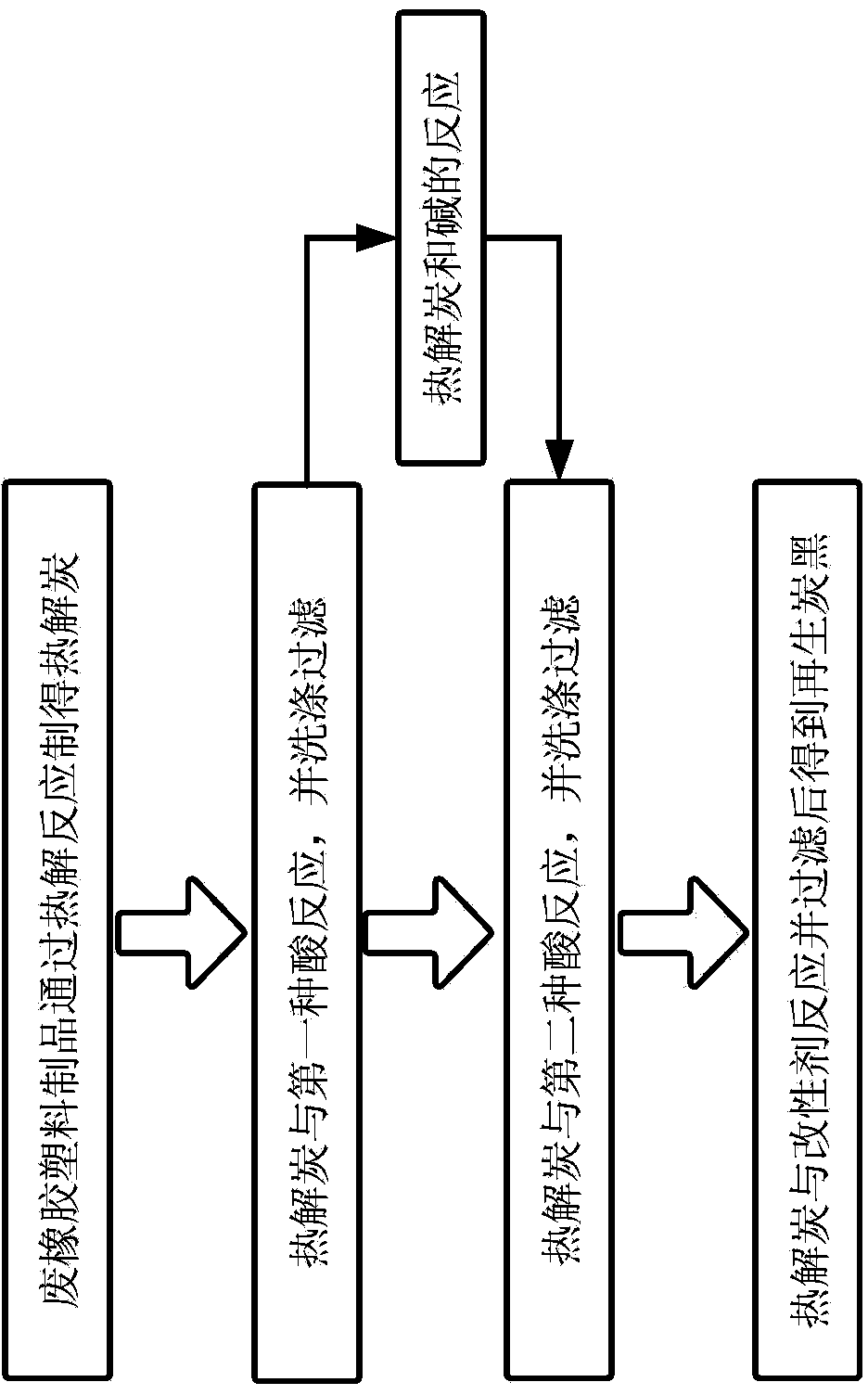

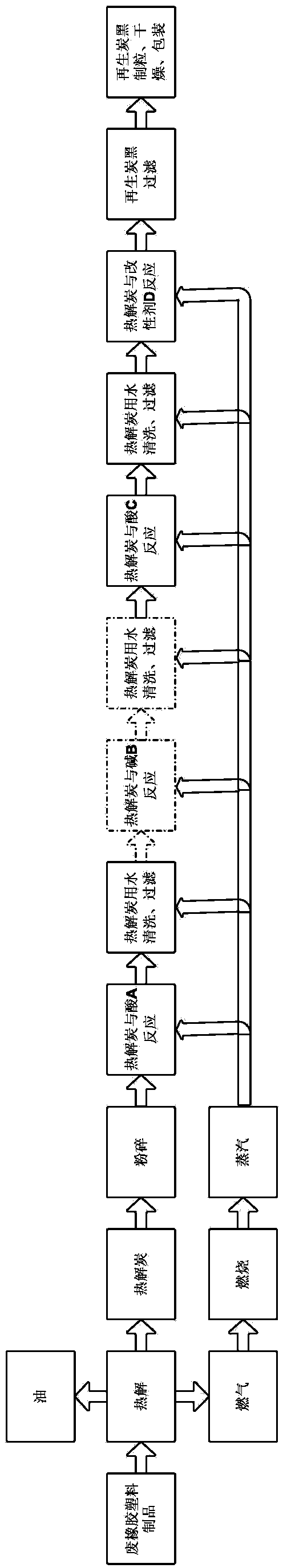

Method and system for preparing regenerative carbon black by deashing and modifying pyrolytic carbon of waste rubber and plastic products

ActiveCN103540172AWell mixedLow ash contentPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPolymer scienceWaste rubber

The invention discloses a method and a system for preparing regenerative carbon black by deashing and modifying pyrolytic carbon of waste rubber and plastic products. The method comprises the following steps: preparing the pyrolytic carbon from the waste rubber and plastic products through a pyrolytic process, and crushing the pyrolytic carbon; respectively carrying out two different acid reactions and one alkali reaction on the pyrolytic carbon to convert the vast majority of ash in the pyrolytic carbon into soluble salts; washing the pyrolytic carbon through water, and filtering to remove the soluble salts; reacting the deashed pyrolytic carbon with a modifier to change the micro chemical environment on the surface of the pyrolytic carbon to form a new combined layer and strength the binding force between the pyrolytic carbon particles and the rubber and the plastic so as to prepare the regenerative carbon black, and by means of the treatment, the ash content in the pyrolytic carbon is greatly decreased, and the waste rubber and plastic products are recycled. Meanwhile, the invention also discloses a system for preparing regenerative carbon black by deashing and modifying pyrolytic carbon of waste rubber and plastic products, and heat needed in the reaction process of the system is obtained from combustible gases generated by pyrolysis of the waste rubber and plastic products, so that cyclic utilization of energy source is realized.

Owner:联智同达(苏州)环境科技有限公司

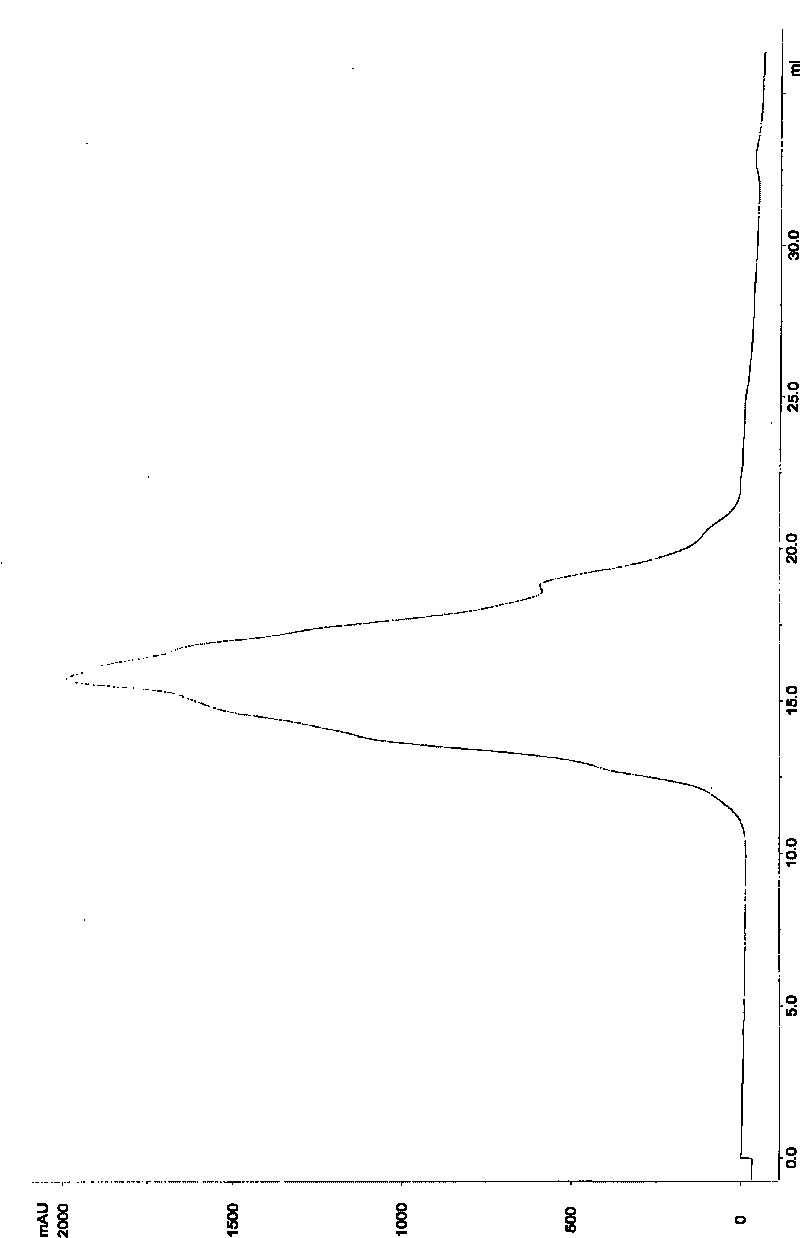

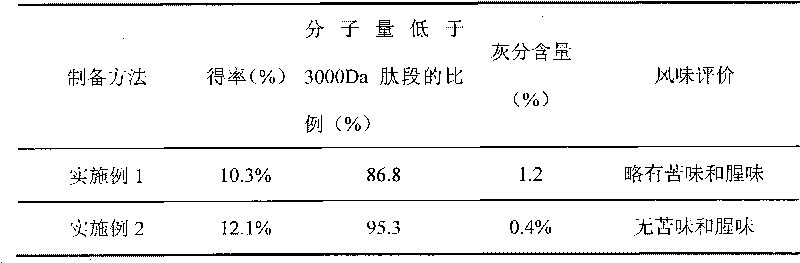

Method for preparing fish skin and scale collagen peptide

ActiveCN101709319AIncrease protease activityPromote growthMicroorganism based processesFermentationPeptideTissue skin

The invention discloses a method for preparing a fish skin and scale collagen peptide, which comprises: (1) starter propagation; (2) high temperature skin and scale collagen peptide extraction; (3) heat preservation and enzymolysis; (4) separation; (5) high molecular weight protein removal; and (6) spray drying to obtain finished powder product of the fish skin and scale collagen peptide. The method can obviously reduce collagen peptide production cost; and the obtained collagen peptide is white and odorless powder containing less than 0.6 percent of ash content and more than 95 percent of peptide segments with a molecular weight of less than 3,000Da. The collagen peptide is free from fishy smell and odors.

Owner:广东华肽生物科技有限公司

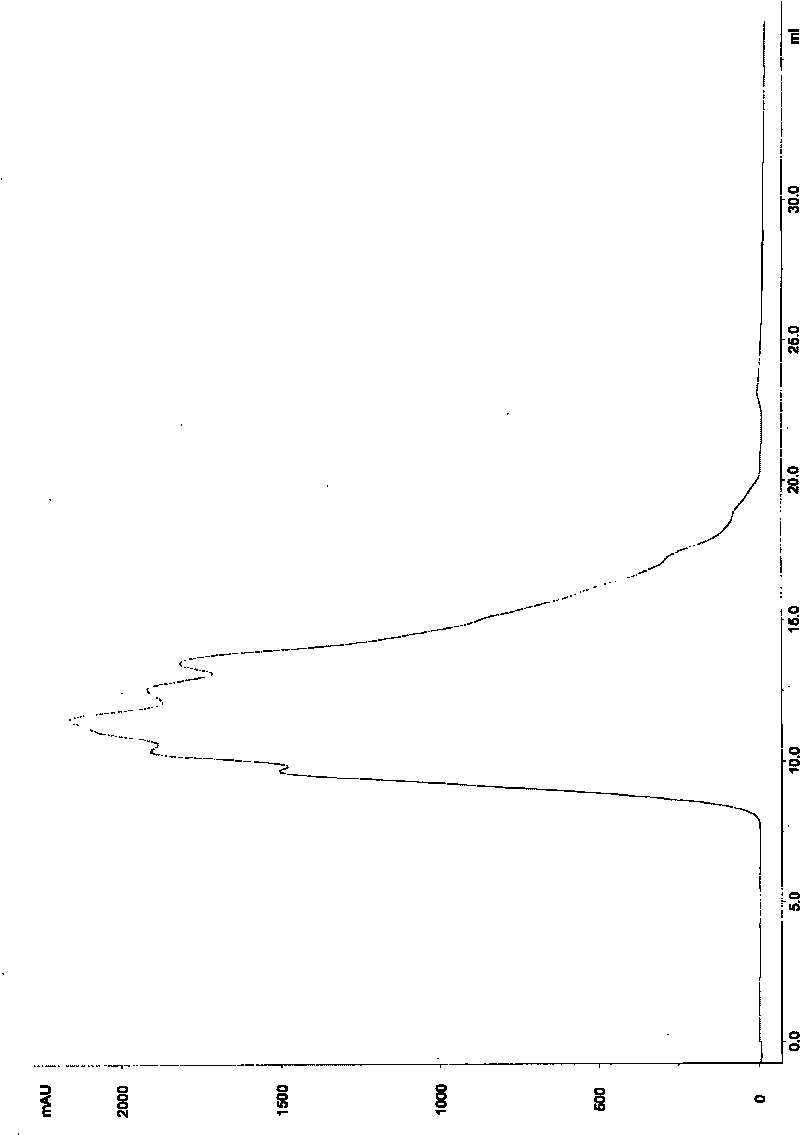

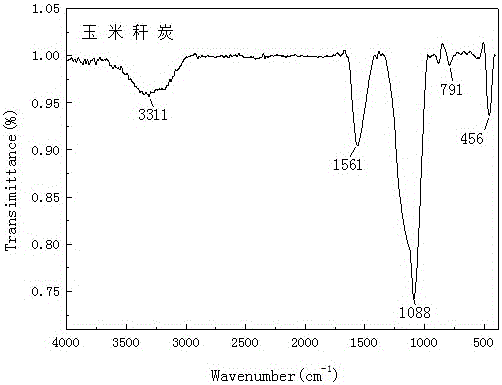

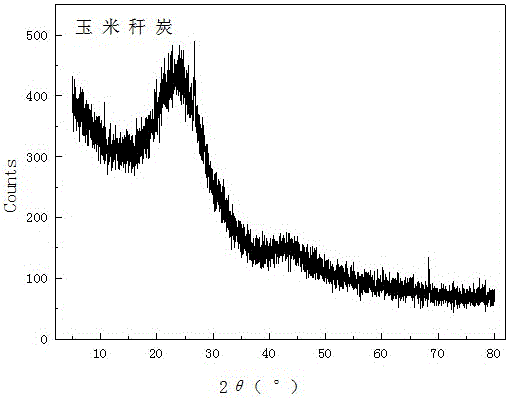

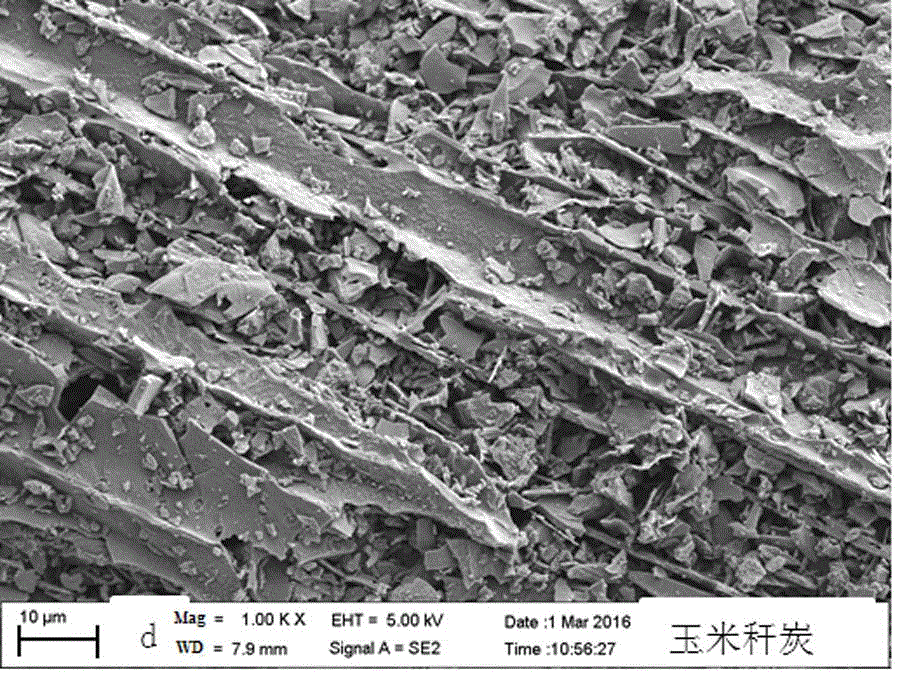

Corn stalk biochar, method for removing sulfonamide antibiotics in water by using corn stalk biochar and application of corn stalk biochar

InactiveCN106040173AImprove adsorption capacityRich pore structureOther chemical processesWater contaminantsCarbonizationAntibiotic Y

The invention relates to corn stalk biochar, a method for removing sulfonamide antibiotics in water by using the corn stalk biochar and application of the corn stalk biochar. The corn stalk biochar is prepared by the following steps: firstly, drying and crushing; secondly, putting into a tubular atmosphere furnace, heating by adopting programs, and performing oxygen-free carbonization under the condition of 500 to 700DEG C for 120 to 180 minutes; thirdly, cooling in the furnace to room temperature, and grinding charcoal ash; fourthly, soaking with hydrochloric acid, filtering, washing, drying to constant weight, and sieving. The corn stalk biochar serving as an adsorbent is put into a water body containing the sulfonamide antibiotics for adsorbing to remove the sulfonamide antibiotics, so that the difficult problem that antibiotics in water are difficult to remove is solved. Meanwhile, the environment problem brought by straw burning is solved, wastes are changed into the valuables, the recycling of corn stalks is realized, and better economic benefits and social benefits are obtained.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Metallic powder injection molding adhesive

The invention relates to a binder which comprises the following components according to weight percentage: 15 percent to 25 percent of chlorinated polyethylene, 15 percent to 25 percent of polyformaldehyde, 3 percent to 10 percent of rubber, 20 percent to 30 percent of petroleum wax, 15 percent to 25 percent of Brazil wax (palm wax), 1 percent to 5 percent of stearic acid and 1 percent to 5 percent of epoxidized soybean oil. In the forming technique of metal powder, the binder can improve the strength of blank, reduce the damage of the blank and improve the finished yield and the production efficiency.

Owner:PINGHU HAITE ALLOY

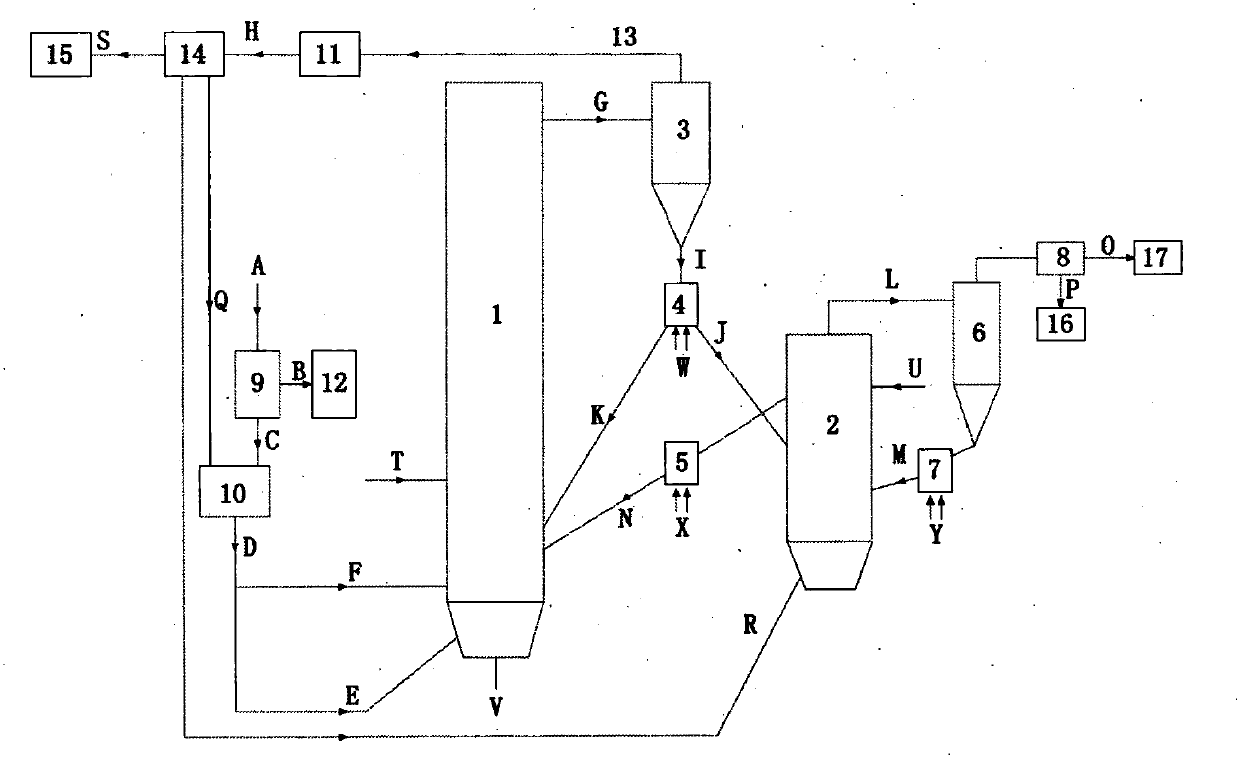

Oxygen-enriched combustion circulating fluidized bed poly-generation system and process

ActiveCN103742899AImprove utilization efficiencyIncrease operating temperatureNitrogen purification/separationFluidized bed combustionGeneration processFlue gas

The invention provides an oxygen-enriched combustion circulating fluidized bed poly-generation system. The oxygen-enriched combustion circulating fluidized bed poly-generation system comprises a circulating fluidized bed combustion furnace and a circulating fluidized bed gasification furnace, wherein the circulating fluidized bed combustion furnace is connected with a separator I, the separator I is connected with a flue at the tail and a two-way material control device, the two-way material control device is connected with the circulating fluidized bed combustion furnace and the circulating fluidized bed gasification furnace respectively, the circulating fluidized bed gasification furnace is connected with the circulating fluidized bed combustion furnace by a return feeder I, the circulating fluidized bed gasification furnace is connected with a ceramic dust collector and a coal gas purification system by a separator II, the flue at the tail is connected with a flue gas distribution valve by a glue gas dust-removal, desulfurization and denitration device, and an outlet of the flue gas distribution valve is divided into three paths. The invention also provides an oxygen-enriched combustion circulating fluidized bed poly-generation process. The oxygen-enriched combustion circulating fluidized bed poly-generation system has high fuel utilization rate, high coal gas yield, good tar quality, small pollutant discharge and low recycling cost, and fuel and flue gas at the tail can be utilized to the maximum extent.

Owner:SHANGHAI BOILER WORKS

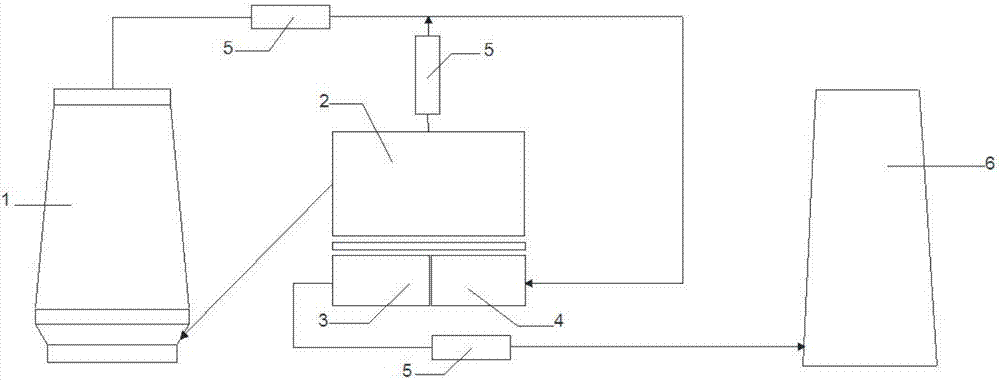

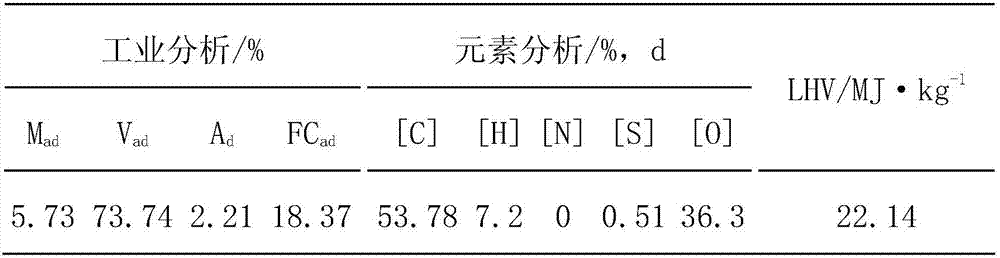

Method for biomass carbonization instead of pulverized coal injection in blast furnace

InactiveCN108003959AExpand the range of optionsIncrease production capacityBiofuelsSolid fuelsCombustion chamberCarbonization

The invention provides a method for biomass carbonization instead of pulverized coal injection in a blast furnace. Dried straw and other biomass raw materials are extruded to obtain a machine-made rod, and the machine-made rod is carbonized by a carbonization furnace to obtain carbon powder at a temperature of 300 to 1000 DEG C. The carbon powder obtained by the furnace is mixed with pulverized coal and injected into the blast furnace to greatly reduce a coal ratio and flux usage amount and improve production efficiency; latent heat of flue gas is fully utilized to reduce emission of exhaust gas; the exhaust gas discharged from a combustion chamber is filtered and discharged into air through a microporous ceramic tube. Biomass resources and sensible heat of the flue gas, and oxygen and carbon monoxide in the flue gas are used in ironmaking production. In addition, the biomass resources can also be used as a substitute for the pulverized coal or coke powder used in iron ore sintering machines. The method comprehensively utilizes existing equipment to treat waste materials such as biomass raw materials and the flue gas, saves coking coal resources, fully exerts potential advantages of biomass energy, protects environment, and reduces costs.

Owner:UNIV OF SCI & TECH BEIJING

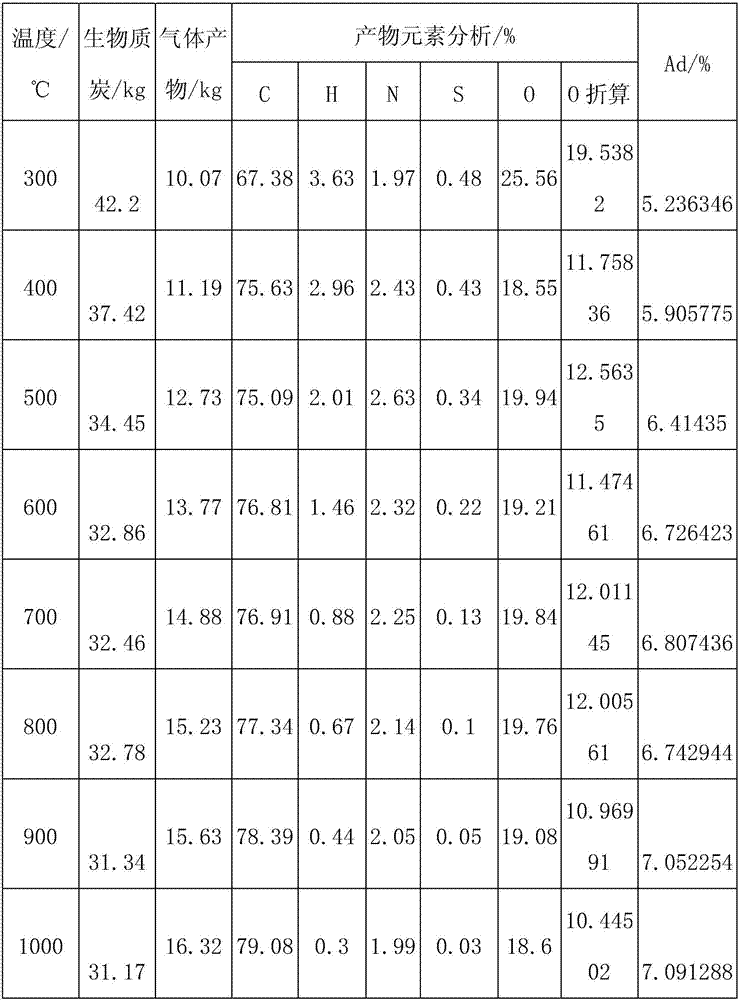

Method for utilizing hydrothermal carbonization for preparing biomass barbecuing charcoal

InactiveCN105602646AHigh strengthReduce manufacturing costBiofuelsSolid fuelsMass ratioReaction temperature

The invention provides a method for utilizing hydrothermal carbonization for preparing biomass barbecuing charcoal. The method is characterized by comprising the following step one of hydrothermal carbonization reaction, wherein a biomass raw material is any one of wood flour, cotton stalks, rice hulls and coconut shells, the biomass raw material and water are placed into a reaction vessel according to the mass ratio of 1: (4-12), inert gas is introduced, the hydrothermal carbonization reaction is carried out on the anoxic condition, reaction temperature ranges from 250 DEG C to 450 DEG C, reaction pressure ranges from 4 Mpa to 5 Mpa, and reaction time ranges from 20 min to 40 min, so that carbonized biomass mixed liquid is obtained; the step two of solid and liquid separation, wherein the carbonized mixed liquid is separated by utilizing a filtering device for obtaining a carbonized substance; the step three of crushing and screening, wherein the carbonized substance is crushed and screened to obtain charcoal particles with the particle size smaller than 0.5 mm; the step four of compressing and forming, wherein the carbonized substance is formed in a hot-pressed mode, so that the biomass barbecuing charcoal is obtained.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

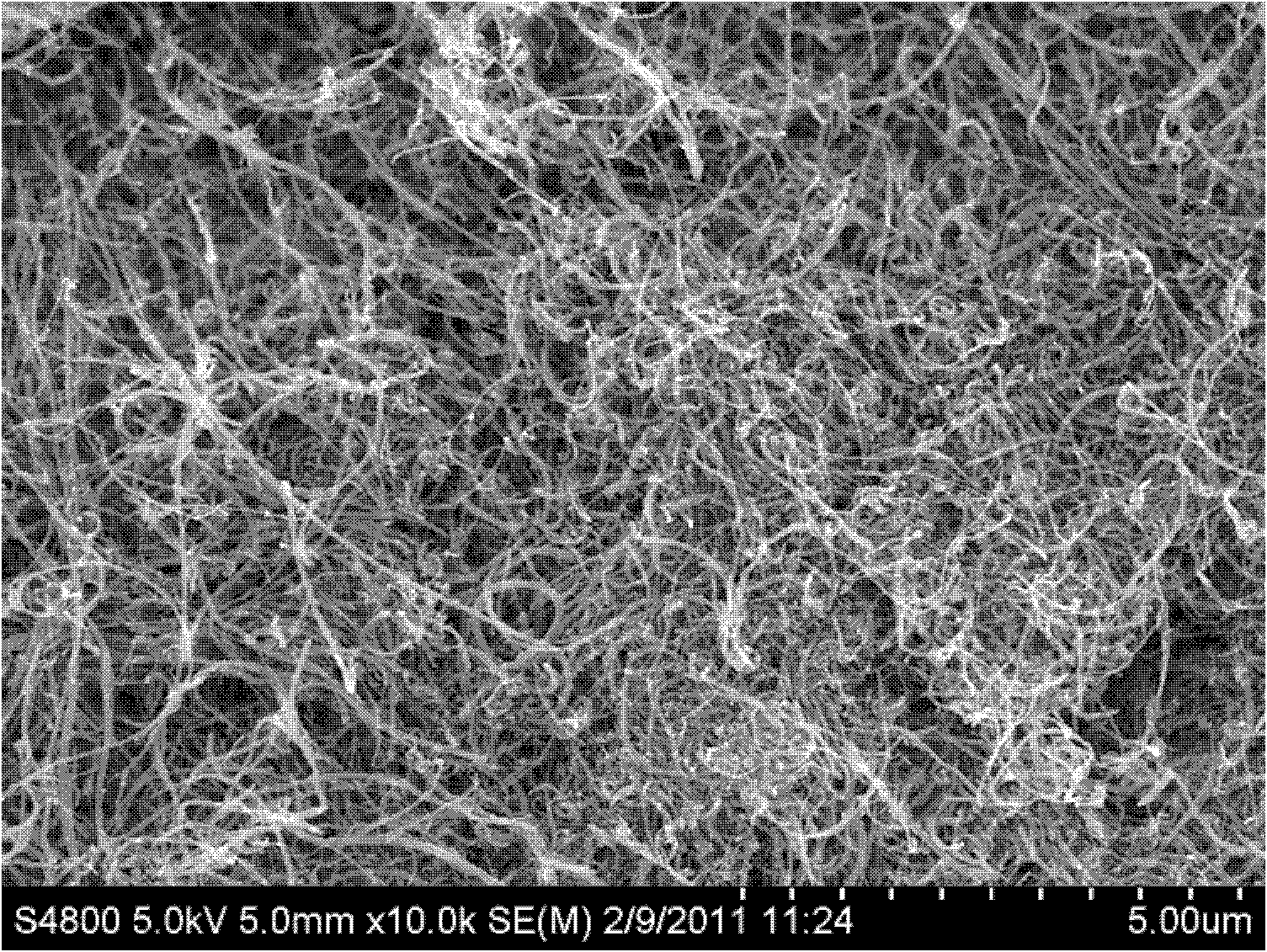

Carbon material with high surface activity and preparation method thereof

The invention relates to an activated carbon materialand a preparation method thereof, in particular to a carbon material with high surface activity and a preparation method thereof. The carbon material with high surface activity is characterized by comprising the raw materials of petroleum coke, tar coke, lignite and husk. The preparation method of the carbon material with high surface activity is characterized by comprising the following steps: a) crushing the petroleum coke, tar coke, lignite and husk, sieving into 80-200-mesh powder, and carbonizing for 0.5-2.5h in a high temperature activating oven under the temperature of 500-620 DEG C; and b) and evenly mixing the carbonized materials with H2PO4 or ZnCl2 or a mixture of the above two in terms of the mass ratio of 1:1 in a mixer according to the mass ratio of 1:0.5-1:3, and reacting for 0.5-2h in a pre-activating oven under the temperature of 300-600 DEG C. Activation time of a product is lowered and the production efficiency is improved by using the carbon material with high surface activity and the preparation method thereof.

Owner:核工业西南勘察设计研究院有限公司

Preparation method of polybutene alloy

The invention discloses a preparation method of a polybutene alloy by a solution process. 1-butene and propylene are dissolved in an aromatic organic solvent to perform sectional solution polymerization, and one polymerization reaction device or a plurality of polymerization reaction devices connected in series is / are utilized for polymerization to obtain the multicomponent-structure polybutene alloy dissolved in the organic solvent. By using the solution polymerization process, the multicomponent structure in the polybutene alloy is uniformly mixed on the molecular level under the action of the organic solvent, thereby obtaining the polybutene alloy material with higher impact strength and toughness than that prepared by a physical blending process; and the catalyst residues can be removed in the after-treatment technique, thereby lowering the ash content in the polybutene alloy and enhancing the aging resistance.

Owner:QINGDAO UNIV OF SCI & TECH +1

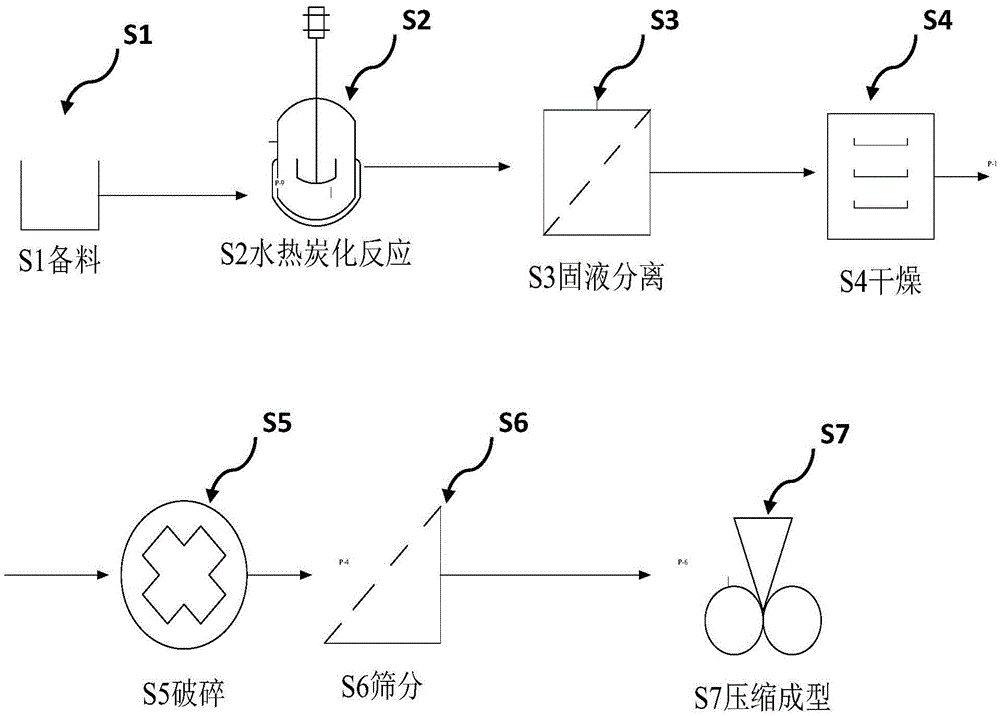

Preparation method of alga-based active carbon precursor for super capacitor

ActiveCN108101051AHelps to create poresDeveloped spatial network structureCarbon compoundsHybrid capacitor electrodesCross-linkDigestion

The invention discloses a preparation method of an alga-based active carbon precursor for a super capacitor. The method mainly comprises the following steps: ultrasound and swelling and other methodsare firstly utilized for carrying out cell wall breaking of alga raw materials, so that alginate in pectin of cell walls and between cells is dissolved; a digestion process is further carried out, under the heating condition with alkali, alginates which are not dissolved in water are converted into water soluble alkali metals and extracted; a cross-linking agent is introduced, and precipitation ofpolymers is formed; washing and filtering steps are carried out, in order to discharge a large amount of inorganic salts, pigments and other impurities which are dissolved in water along with water,and the precursor is obtained. The precursor is carbonized and activated in order to obtain the active carbon material with reasonable pore structure, abundant channels, and massive specific surface area, in order to substantially improve capacity and electrochemical performance of the super capacitor with extremely good industrial application prospects.

Owner:SHANDONG UNIV

Oxidation treatment method for carrier carbon surface

InactiveCN101269345AGood dispersionHigh adsorption rateCatalyst carriersCatalyst activation/preparationEnergy controlUltrasonic radiation

The invention relates to a method of oxidation process on the surface of a carrier carbon, including the following steps that: powdered activated carbon is mixed with nitric acid solution with a concentration ranging from 2 to 12 percent by the weight ratio of 1:3 to 30 to make a powdered activated carbon suspension which is processed by ultrasonic radiation for 20-120min at the temperature between 30 DEG C and 60 DEG C, wherein, the ultrasonic energy is controlled between 1 and 10W / cm<2>. The suspension is filtered and the residue is cleaned by water until the pH value of the washing water ranges from 6.5 to 7. After drying, under the protection of nitrogen, the residue is processed at the high temperature between 800 DEG C and 1100 DEG C for 5 to 15min by microwave with the frequency of 2450 MHz and the power ranging from 200W to 850W. The method provided by the invention can remove most oxygen-functional groups on the surface of the activated carbon, improve the alkalinity and the specific surface area on the surface of the activated carbon and reduce the ash content of the activated carbon. Besides, the method provided by the invention has the advantages of short processing time, high processing efficiency, environmental protection and energy conservation.

Owner:CHENZHOU GAOXIN PLATINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com