Patents

Literature

46results about How to "Retain chemical activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive utilization method of corn cob

ActiveCN101628920AEasy to separatePromote conversionBiofuelsLignin derivativesSocial benefitsState of art

The invention provides a comprehensive utilization method of corn cob, which effectively separates hemicellulose, lignin and cellulose contained in a reproducible biological resource of corn cob in a reasonable process order at low cost and high efficiency, and makes full use of every type of biomass components, thereby solving the problem of utilization of residue in the biomass refining process of preparing ethanol and butanol by extracting xyio-oligosacchandes and enzymolysis from the corn cob in the prior art, and making reasonable and effective use of main components of biomass contained in the corn cob; particularly, the lignin can substitute partial petrochemical materials to prepare modified high-molecular materials, thereby reducing the cost of high-molecular materials and saving the energy consumption of petrochemical materials to bring great social benefit; in addition, the comprehensive utilization method of corn cob is featured by simple processing technique, easy implementation and favorable effect.

Owner:重庆辉泰化工销售有限公司

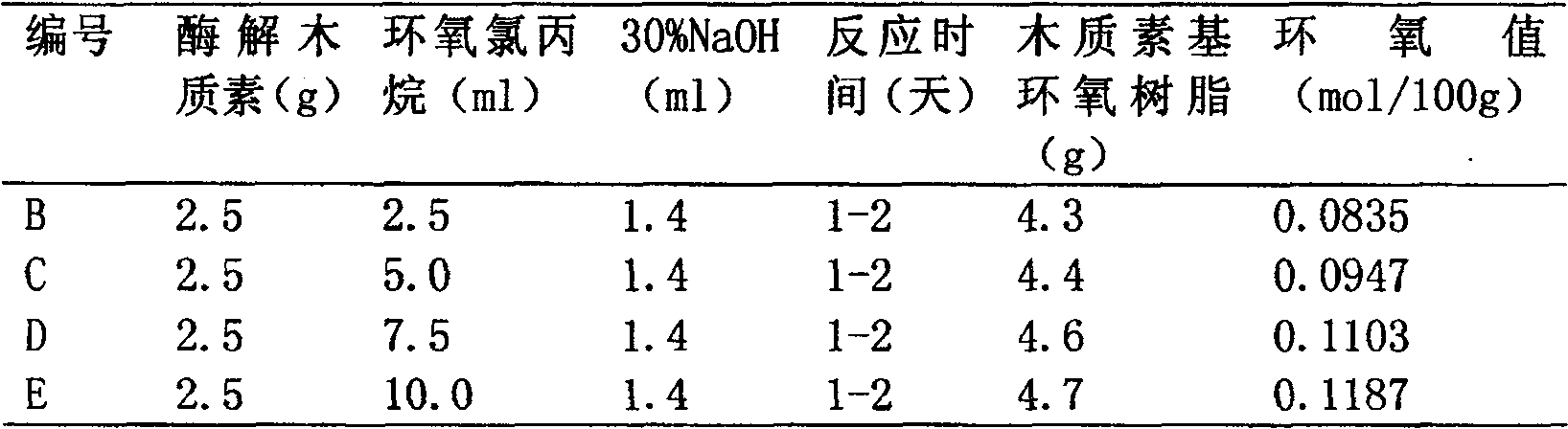

Enzymatic hydrolysis lignin epoxide resin and preparation thereof

The invention provides an enzymolysis lignin epoxy resin and a preparation method thereof. The raw materials include: an enzymolysis lignin-dianhydride prepolymer, a glycidol ether, a catalyst, a curing agent and a filler. The preparation method comprises the following steps that: under the action of the catalyst, an etherification of a hydroxyl group contained in the enzymolysis lignin or a derivative of the enzymolysis lignin and dianhydride is carried to synthesize a prepolymer of enzymolysis lignin-dianhydride; then the prepolymer reacts with the glycidol ether and undergoes etherification and ring closing reaction to obtain an enzymolysis lignin--polyester type epoxy resin. The enzymolysis lignin adopted by the method is natural macromolecular material extracted from the residues which is produced in the preparation of alcohol through the fermentation of wood chips, bamboo and stalk, thereby not only effectively utilizing biological resources, but also replacing petrochemical raw materials. The enzymolysis lignin epoxy resin which can be used as a modifier for engineering materials, adhesives, paints and macromolecular materials has a broad application prospect.

Owner:重庆辉泰化工销售有限公司

Material formula of polyurethane of enzymolysis lignin, and preparation method

This invention provides a method for preparing cellulolytic enzyme lignin polyurethane and its raw materials. The raw materials comprise: cellulolytic enzyme lignin or its derivative, polyisocyanate, polyol oligomer, chain extension and crosslinking agent, organic solvent and additive. The method comprises: (1) dissolving cellulolytic enzyme lignin or its derivative in the organic solvent, mixing with polyol or a mixture of polyol and organic solvent, and heating or stirring to mix uniformly; (2) adding polyisocyanate, heating, adding conventional additives or fillers, heating to react completely, and vacuum-distilling to obtain brown solid; (3) washing the solid with water, and drying to obtain cellulolytic enzyme lignin polyurethane. The cellulolytic enzyme lignin is a natural polymeric material extracted from wood, bamboo and straw, thus can effectively utilize biomass resources and replace petrochemical raw materials. The method largely improves the process for preparing cellulolytic enzyme lignin polyurethane, which has a better modification effect than traditional sulfonated lignin, and lower cost than high-boiling-point alcohol lignin.

Owner:FUZHOU UNIVERSITY

Enzymolysis xylogen or its derivative modified asphalt composite material, and preparation method thereof

The present invention provides an enzymolysis lignin or enzymolysis derivant modified asphalt composite material and a preparation method. The raw materials include the enzymolysis lignin or the enzymolysis lignin derivant, the asphalt and other modification assistant agents. The preparation steps: the enzymolysis lignin or the enzymolysis lignin derivant, other modification assistant agents and filling agent are mixed in advance to the melted asphalt substrate to be uniformly mixed, and then the mixture is displaced for solidification. The present invention makes full use of the renewable living resource, and not only resolves the problem of the present polymer modified asphalt that depends on the synthesis of the petrochemical raw materials, but also can reduced the use cost of the polymer modified asphalt; appropriate enzymolysis additive can be selected according to different requirements of the modified asphalt product to substitute partial petrochemical raw materials, thus improving the anti-aging performance of the polymer asphalt product; moreover, the craftwork is simple and is easy to implement, thereby can reduce the production cost and improve the competition strength of the product.

Owner:FUZHOU UNIVERSITY

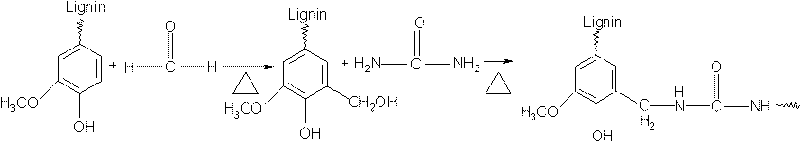

Preparation method for solvent-based lignin-cyanamide derivative flame retardant

The invention relates to a preparation method for a solvent-based lignin-cyanamide derivative flame retardant. The method is characterized in that: after being subjected to a hydroxymethylation reaction, solvent-based lignin is subjected to a condensation polymerization with cyanamide and urea to prepare the solvent-based lignin-cyanamide derivative flame retardant. The solvent-based lignin-cyanamide derivative flame retardant has characteristics of high performance, halogen free, low cost, simple preparation method, and good flame-retardant effect, and can be widely applicable for the modified fields of polymers such as rubber, plastic and the like, and has good economic benefit and social benefit.

Owner:FUZHOU UNIVERSITY

Method for preparing water-coal-slurry additive taking enzymatic hydrolysis lignin as raw material

InactiveCN101921639ARetain chemical activityHigh purityLiquid carbonaceous fuelsCelluloseActive agent

The invention provides a method for preparing a water-coal-slurry additive taking enzymatic hydrolysis lignin as a raw material. In the method, the chemical activity of the enzymatic hydrolysis lignin is utilized to directly perform polycondensation with sodium hydrogen sulfite, sodium metabisulfite, acetone and methanal to a prepare enzymatic hydrolysis lignin-sulphonated acetone-methanal condensation polymer (LSAF); the enzymatic hydrolysis lignin-sulphonated acetone-methanal condensation polymer (LSAF) is compatible with other types of surfactants, and is compounded with the surfactants, such as sodium dodecyl benzene sulfonate, PVA, carboxymethyl cellulose sodium and the like to prepare the water coat slurry which has higher stability and lower viscosity; and the liquidity of the water coat slurry is improved. The enzymatic hydrolysis lignin replaces the partial petrochemical raw materials to prepare modified high molecular materials, which not only lowers the cost of high molecular materials, but also can save the consumption of the petrochemical materials, and can generate significant social benefit; and the processing technique for preparing the water-coal-slurry additive taking the enzymatic hydrolysis lignin as a raw material is simple, is easy to implement and has good effect.

Owner:FUZHOU UNIV

Method for preparing friction-resistant composite material by modifying solvent type lignin

ActiveCN101891933ARetain chemical activityHigh purityOther chemical processesSolvent basedChemical activity

The invention provides a new method for preparing a friction-resistant material by taking lignin as a modifying raw material. The new method is used for preparing the friction-resistant material by taking the solvent type lignin as the modifying raw material. The method can utilize the renewable lignin and has the advantages of strong chemical activity, high purity and the like, the solvent type lignin is taken for replacing phenols for preparing lignin-modified phenolic resin, and the resin has more polar groups in comparison with the traditional phenolic resin and stronger affinity in comparison with other components for preparing the friction-resistant material, thereby not only improving the performances of the friction-resistant material, but also fully utilizing the renewable resource and reducing the consumption of petroleum chemicals; simultaneously, the method can reduce the cost of preparing the friction-resistant material, save energy, reduce emission and produce great social benefits; furthermore, the process for preparing the friction-resistant material is simple and easy to implement and can produce good effects.

Owner:FUZHOU UNIV

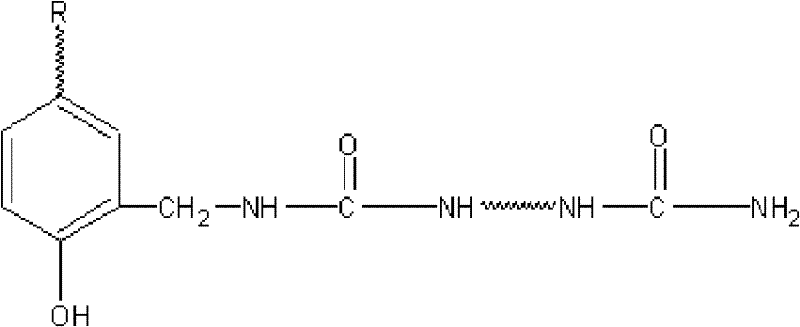

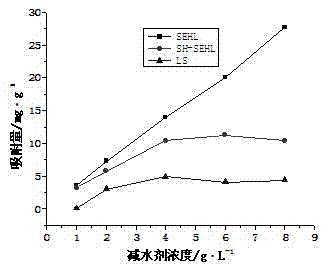

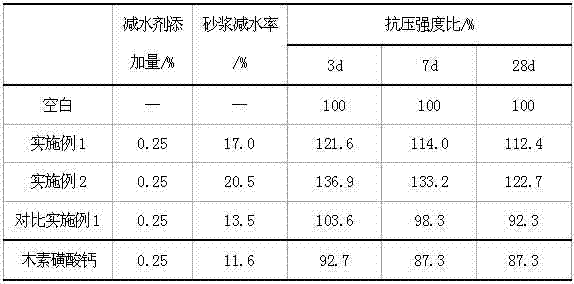

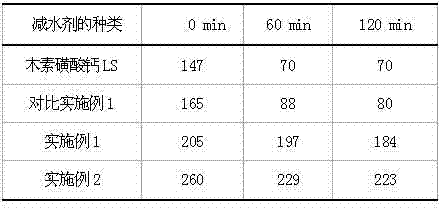

Sulfonated acetone-formaldehyde high-efficiency water reducing agent modified by enzymatic hydrolysis lignin or by derivatives thereof, and preparation method thereof

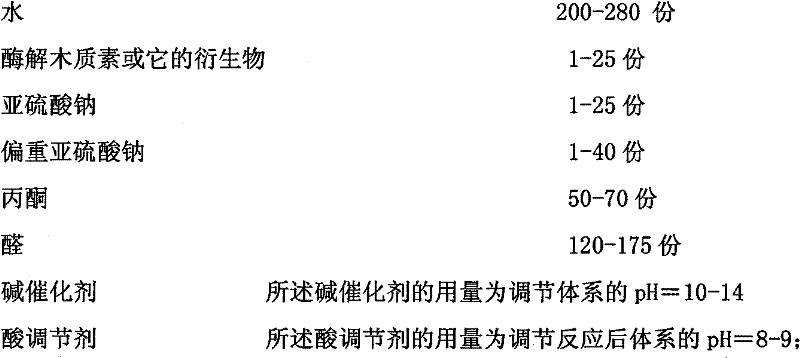

The invention provides a sulfonated acetone-formaldehyde high-efficiency water reducing agent modified by enzymatic hydrolysis lignin or by derivatives thereof, and a preparation method thereof, raw materials comprise the enzymatic hydrolysis lignin or the derivatives thereof, acetone, aldehyde, sodium sulfite and sodium metabisulfite, a base catalyst and an acid regulator; the preparation steps comprise: mixing the sodium sulfite, the sodium metabisulfite with the water, heating at constant temperature and agitating, dropwise adding the acetone, adding the enzymatic hydrolysis lignin or the derivatives thereof, regulating pH value by the base catalyst, dropwise adding the aldehyde, continuous reacting for 3 hours, and adding the acid regulator to regulate the pH so as to result in product. The invention sufficiently utilizes reproducible biological resources, which not only solves the defect of low water reducing efficiency of the lignin-sulphonate water reducing agent extracted from papermaking 'black liquor' in the prior art, but also can replace partial petrochemical raw materials and reduce the production cost of the high-efficiency water reducing agent; the enzymatic hydrolysis lignin- or the derivatives thereof-modified high-efficiency water reducing agent has great use effect.

Owner:FUZHOU UNIV

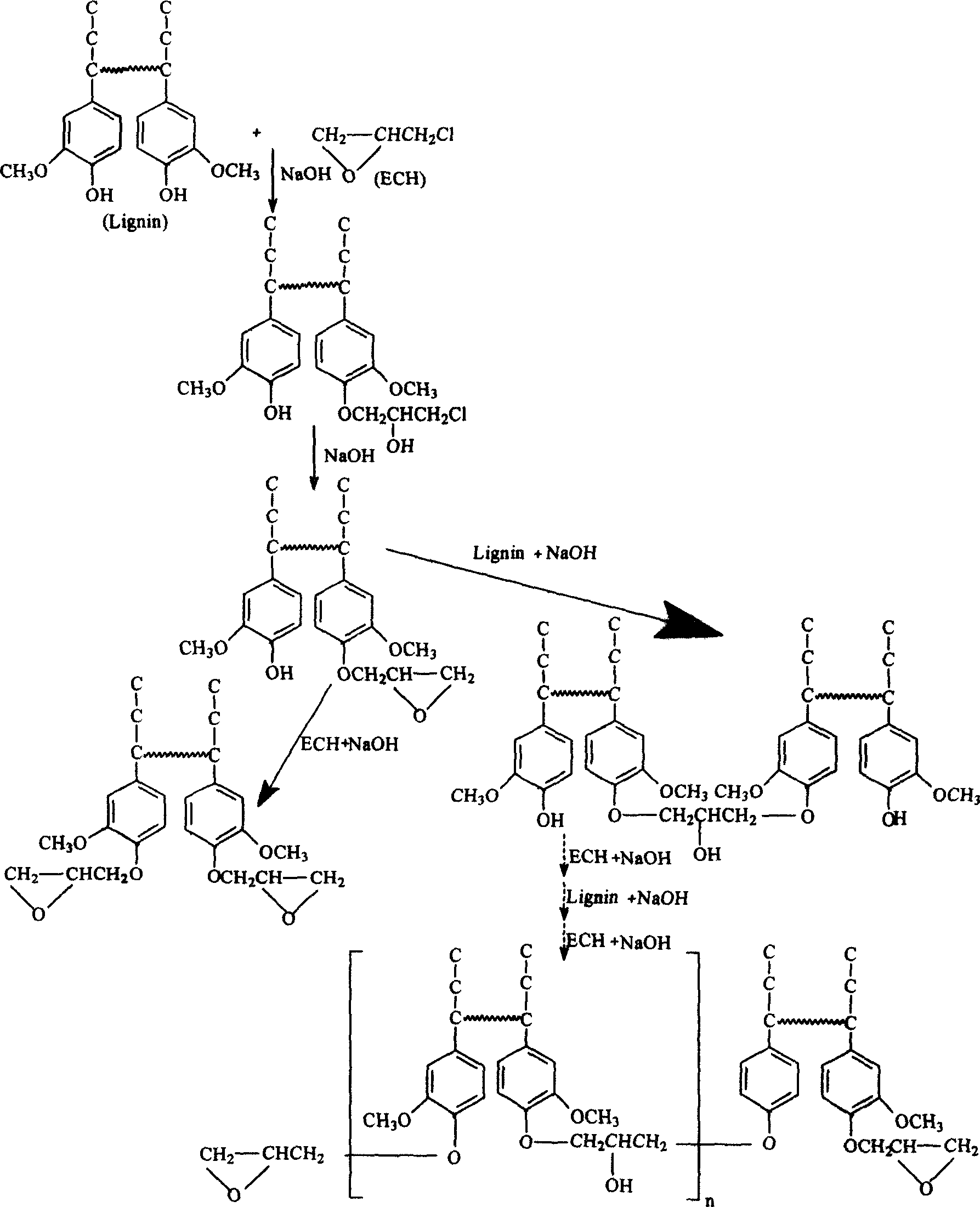

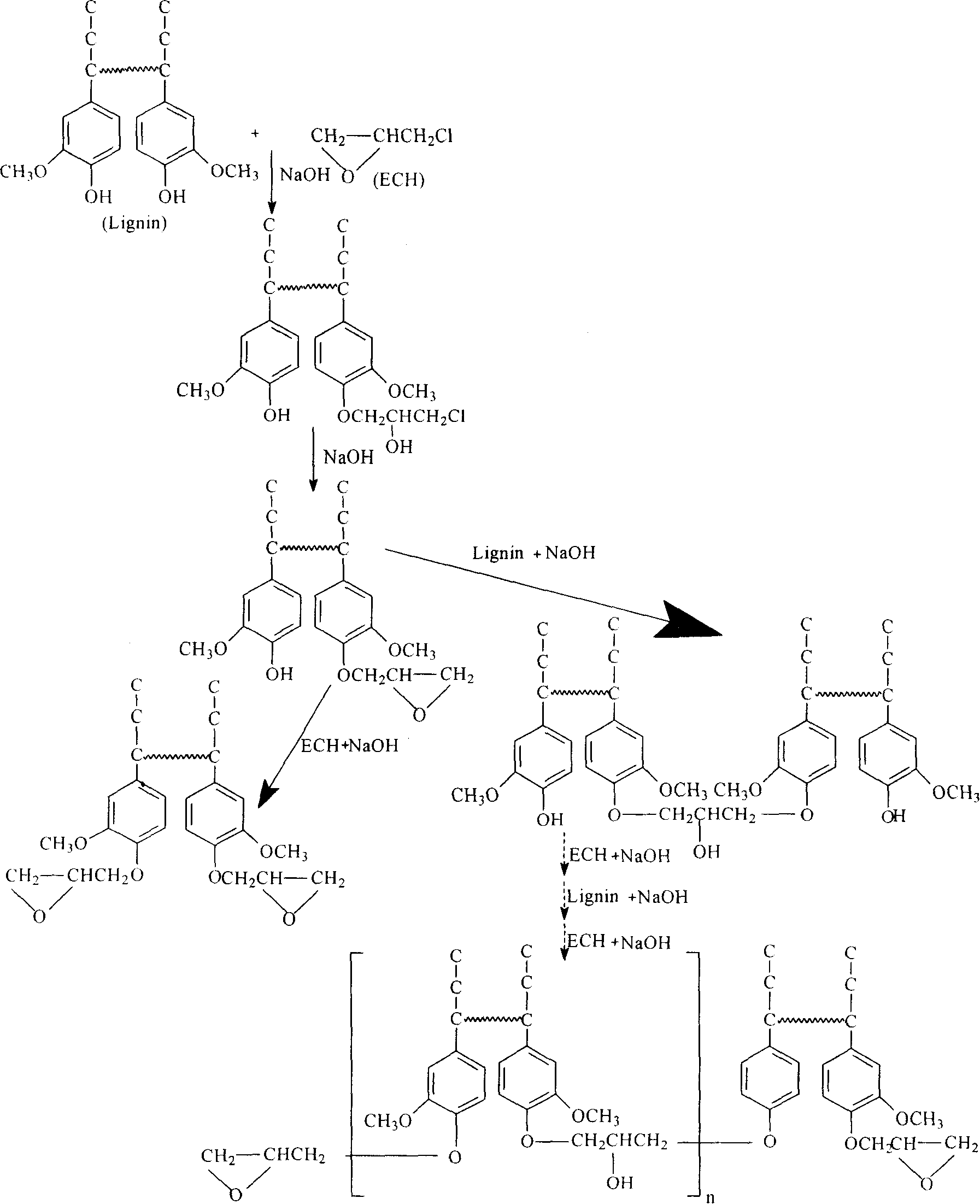

Prepn of high-boiling alcohol lignin epoxy resin

The present invention is preparation process of epoxy resin with high-boiling alcohol lignin and its derivative. High-boiling alcohol lignin or its derivative is dissolved in chloropropylene oxide solution or the mixed solution of chloropropylene oxide and organic solvent through stirring and heating, and the mixture is reacted completely via adding catalyst and heating to prepare epoxy resin. The preparation process is simpler compared with traditional lignin epoxy resin, and the present invention has low cost, simple preparation process and high product performance.

Owner:FUZHOU UNIV

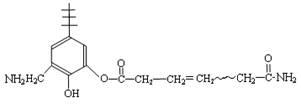

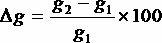

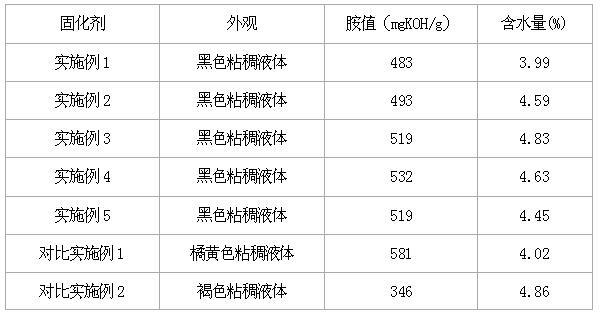

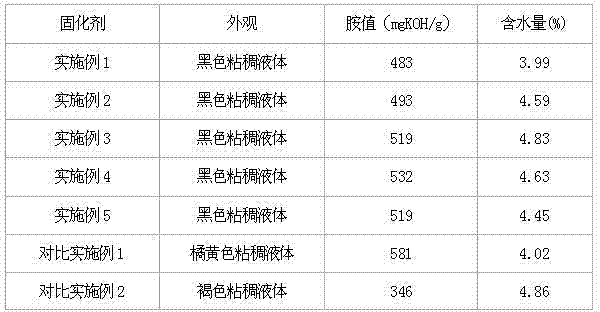

Solvent lignin-modified epoxy resin curing agent and preparation method thereof

InactiveCN102134305ARetain chemical activityHigh purityEpoxy resin coatingsPtru catalystMannich reaction

The invention provides a solvent lignin-modified epoxy resin curing agent and a preparation method thereof. The epoxy resin curing agent is prepared from the following raw materials in part by weight: 10 to 30 parts of solvent lignin or derivative of the solvent lignin, 30 to 60 parts of phenol, 15 to 35 part of aldehyde, 20 to 45 part of ammine and 0.05 to 0.2 part of sulfuric acid catalyst. The phenol-aldehyde-ammine epoxy resin curing agent is prepared by the Mannickreaction of the solvent lignin or derivative of the solvent lignin and the phenol, aldehyde and ammine. When the solvent lignin-modified phenol-aldehyde-ammine epoxy resin curing agent provided by the invention is used, petrochemical and coal chemical products can be replaced, the consumption of the petrochemical and coal chemical products is reduced, the cost of the epoxy resin is reduced, the lignin renewable resource in the waste from biorefinery is fully utilized, and the development of low-carbon economy is promoted.

Owner:FUZHOU UNIV

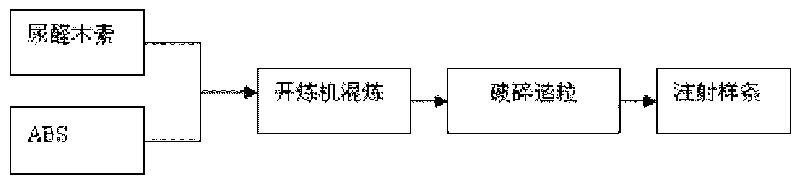

Preparation of macromolecular compatible additive, namely urea-formaldehyde modified lignin and application of macromolecular compatible additive

Owner:FUZHOU UNIV

Modified rosin resin with high-boiling point alcohol lignin and its derivative and production thereof

InactiveCN1817994AHigh purityHigh chemical activityNatural resin chemical modificationPhenolUnsaturated polyester

Rosin modified resin of high-boiling point alcohol lignin and its derivative and its production are disclosed. The procedure is carried out by mixing high-boiling point alcohol lignin or its derivative with rosin, adding into polylol, phenols and aldehyde, heating, smelting, agitating while mixing homogeneously, adding into catalyst, heating, reacting to generate high-boiling point alcohol lignin modified rosin resin, vacuum supplying and dewatering. It has less consumption and improves softening point and viscosity. It can be used for modified additive or paint of rubber, polyurethane or unsaturated polyester.

Owner:FUZHOU UNIV

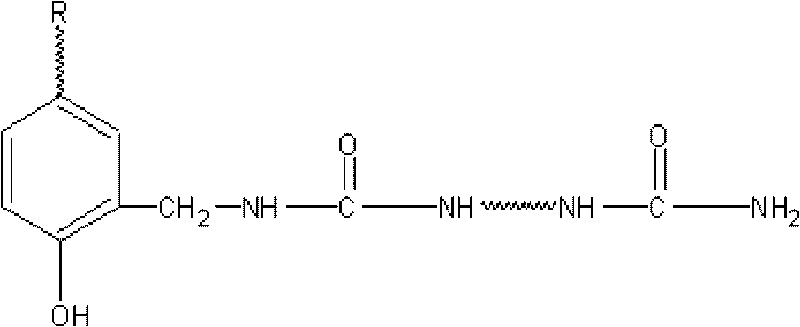

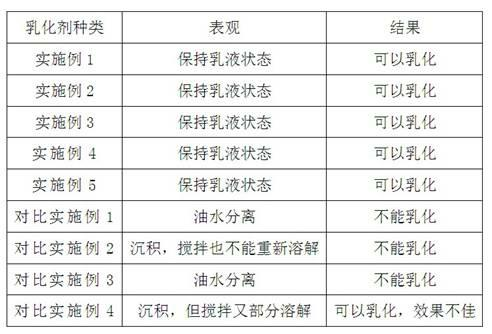

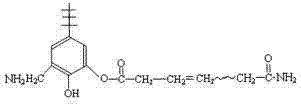

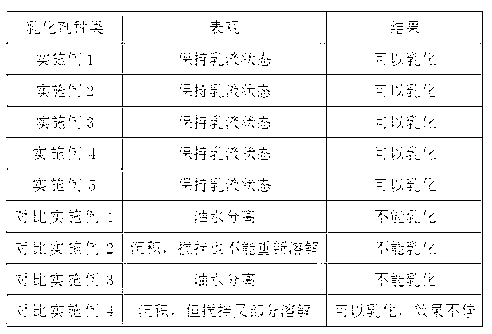

Emulsified bitumen and preparation method thereof

The invention discloses an emulsified bitumen and a preparation method thereof. Solvent-type lignin, aldehyde, cyanamide and amine carry out condensation reaction to prepare cyanamide and amine derivative of solvent-type lignin; and the cyanamide and amine derivative of solvent-type lignin are used as emulsifier and treated with emulsification to prepare emulsified bitumen. The method has low cost; and the prepared emulsified bitumen has excellent performance and can be used in road paving or as building material, so as to fully utilize reproducible resource, reduce consumption of petroleum chemicals and gain substantial economic and social benefits.

Owner:程贤甦

Lignin modified high molecular compatible additive and preparation method thereof

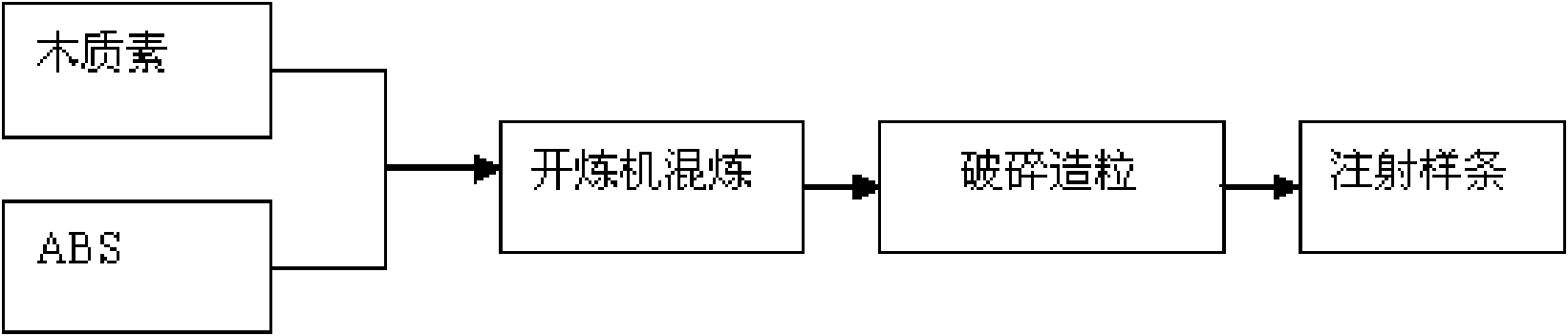

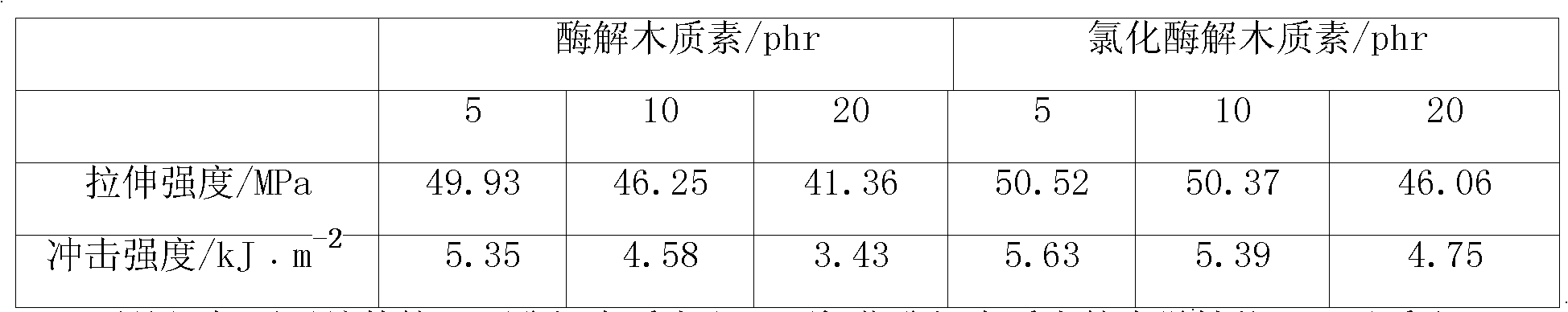

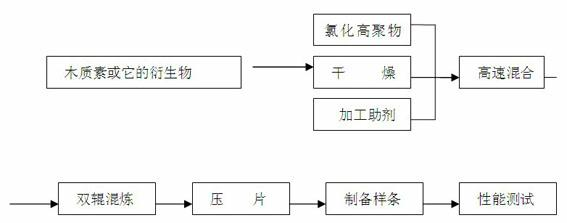

The invention provides a lignin modified high molecular compatible additive and a preparation method thereof, belonging to the technical field of high molecular compatilizer. The lignin modified highmolecular compatible additive is chloridized lignin or derivatives thereof obtained by modifying lignin by chlorine or the derivatives thereof. Compared with the lignin extracted by other methods, thesolvent-type lignin contains abundant phenolic hydroxyls in structure and maintains various active groups better as well as has higher chemical activity. Active hydrogen in the benzene ring of the solvent-type lignin provides a basis for reacting with chlorine. Using the chloridized lignin derivatives as high molecular compatilizers ensures the full use of the regenerative biological resource oflignin, thereby overcoming a deficiency that an original lignin molecular structure has no enough polar groups, is difficult to be compatible with polar polymers so as to influence the performance oflignin-polar high polymer composite material, and further reducing the cost of high polymer composite material; the lignin modified high molecular compatible additive has simple processing technique,and is easy to implement with favorable modifying effect.

Owner:FUZHOU UNIV +1

Method for comprehensively utilizing xanthoceras sorbifolia shells

InactiveCN101899475AEasy to separatePromote conversionBio-organic fraction processingClimate change adaptationBiodieselMethanation

The invention provides a method for comprehensively utilizing xanthoceras sorbifolia shells. The method comprises the following steps of: performing steam explosion pretreatment on the xanthoceras sorbifolia shells to obtain a slurry material; transforming hemicellulose and partial cellulose sugar into biological natural gas through acidification and methanation by adopting a microorganism transformation principle; extracting and separating enzymatic hydrolysis lignin contained in residues of the xanthoceras sorbifolia shells, wherein the enzymatic hydrolysis lignin can be effectively taken as a modifier for a high polymer material; and converting cellulose in the residues from which the lignin is extracted into bioethanol so as to reasonably and effectively utilize three natural major high polymer components in the xanthoceras sorbifolia shells, namely the hemicellulose, the lignin and the cellulose. The utilization problem of the xanthoceras sorbifolia shells after biodiesel is extracted from xanthoceras sorbifolia nuts in the prior art is solved, major biomass components contained in the xanthoceras sorbifolia shells are utilized reasonably and effectively, the produced biological natural gas and the bioethanol are clean renewable energy sources, and another product, namely, the enzymatic hydrolysis lignin can replace partial petrochemical materials and is used for modifying the high polymer material. Recycling and comprehensive utilization of xanthoceras sorbifolia shell waste can contribute to lowering the cost of the biodiesel, saving energy, reducing emission and bringing high social benefit; and processing technology for comprehensively utilizing the xanthoceras sorbifolia shells is simple and easy to implement and has good effect.

Owner:FUZHOU UNIV

Novel sewage treatment agent and preparation method thereof

ActiveCN101560002ARetain chemical activityHigh chemical activityWater/sewage treatment by flocculation/precipitationSolvent basedPetrochemical

The invention provides a sewage treatment agent prepared by using solvent-based lignin or derivatives thereof. The raw materials are as follows: solvent-based lignin or derivatives thereof, aldehyde, urea, a base catalyst and an acid regulating agent; the preparation comprises the following steps of: mixing the lignin and derivatives and water, adding alkali solution to adjust the pH, adding the aldehyde, heating, reacting, adding the urea with the needed using amount, continuously reacting, also being capable of adding the urea by two times according to the needs, adding acid to adjust the pH, carrying out polycondensation, adding alkali to adjust the pH, adding the post urea, reacting, adding the acid regulating agent to adjust the pH, depositing, extracting and filtering, drying and obtaining the sewage treatment agent product. The invention can utilize the renewable biological resources reasonably, thus not only solving the defects that the existing sewage treatment has high cost and lower efficiency, but also being capable of replacing partial of petrochemical materials; and the sewage treatment agent of urea formaldehyde modified derivatives prepared by using solvent-based lignin is used for treating the sewage containing dye or heavy metal ions and has good using effect.

Owner:FUZHOU UNIV

Corn cob lignin and application

The invention relates to the technical field of reutilization of corn cob, and particularly relates to corn cob lignin. The corn cob lignin is obtained filtering a corn cob black liquid obtained by separating hemicelluloses and celluloses from the corn cob; adjusting a pH value of the filtrate to 2.5-4.5 so as to allow the corn cob lignin to be precipitated; cooling to a room temperature; centrifuging; washing and drying. The invention also relates to an application of the corn cob lignin in preparation of polyurethane foams. The obtained lignin has high purity, retains chemical activity of natural lignin well, and is more suitable for being used as a polyhydric alcohol to replace polyether polyol to prepare the polyurethane foams than other lignin. The corn cob lignin can not only reduce production cost of the polyurethane but also change wastes into treasure, realize reutilization and reduce usage amounts of petrochemical materials, thereby benefiting sustainable development of society and economy. The performance of the prepared rigid polyurethane foams can be comparable with or event superior to that of regular rigid polyurethane foams, so that production cost is effectively reduced and competitiveness of a product is increased.

Owner:JINAN SHENGQUAN GRP SHARE HLDG CO LTD

Chlorinated high polymer with good heat stability and preparation method thereof

The invention discloses a chlorinated high polymer with good heat stability and a preparation method thereof. The chlorinated high polymer with good heat stability is prepared by mixing solvent lignin or derivatives of the solvent lignin which serves or serve as additives with high polymers such as polrvinyl chloride and chlorinated polyethylene which contain chlorine atoms in high polymer chain sections. The lignin additives used by the method come from natural high polymers without causing environment pollution and have low cost. The prepared chlorinated high polymer composite material has good heat-resistant stability. The lignin additives are suitable for Polymer processing technologies such as hot pressing or plastic extrusion. Renewable resources can be fully utilized, and consumption of petroleum chemicals can be reduced, thereby having remarkable economic and social benefits.

Owner:程贤甦

Sulfonated acetone-formaldehyde high-efficiency water reducing agent modified by enzymatic hydrolysis lignin or by derivatives thereof, and preparation method thereof

The invention provides a sulfonated acetone-formaldehyde high-efficiency water reducing agent modified by enzymatic hydrolysis lignin or by derivatives thereof, and a preparation method thereof, raw materials comprise the enzymatic hydrolysis lignin or the derivatives thereof, acetone, aldehyde, sodium sulfite and sodium metabisulfite, a base catalyst and an acid regulator; the preparation steps comprise: mixing the sodium sulfite, the sodium metabisulfite with the water, heating at constant temperature and agitating, dropwise adding the acetone, adding the enzymatic hydrolysis lignin or the derivatives thereof, regulating pH value by the base catalyst, dropwise adding the aldehyde, continuous reacting for 3 hours, and adding the acid regulator to regulate the pH so as to result in product. The invention sufficiently utilizes reproducible biological resources, which not only solves the defect of low water reducing efficiency of the lignin-sulphonate water reducing agent extracted frompapermaking 'black liquor' in the prior art, but also can replace partial petrochemical raw materials and reduce the production cost of the high-efficiency water reducing agent; the enzymatic hydrolysis lignin- or the derivatives thereof-modified high-efficiency water reducing agent has great use effect.

Owner:FUZHOU UNIV

Prepn of high-boiling alcohol lignin epoxy resin

The present invention is preparation process of epoxy resin with high-boiling alcohol lignin and its derivative. High-boiling alcohol lignin or its derivative is dissolved in chloropropylene oxide solution or the mixed solution of chloropropylene oxide and organic solvent through stirring and heating, and the mixture is reacted completely via adding catalyst and heating to prepare epoxy resin. The preparation process is simpler compared with traditional lignin epoxy resin, and the present invention has low cost, simple preparation process and high product performance.

Owner:FUZHOU UNIV

Solvent lignin-modified epoxy resin curing agent and preparation method thereof

InactiveCN102134305BRetain chemical activityHigh purityEpoxy resin coatingsPtru catalystMannich reaction

The invention provides a solvent lignin-modified epoxy resin curing agent and a preparation method thereof. The epoxy resin curing agent is prepared from the following raw materials in part by weight: 10 to 30 parts of solvent lignin or derivative of the solvent lignin, 30 to 60 parts of phenol, 15 to 35 part of aldehyde, 20 to 45 part of ammine and 0.05 to 0.2 part of sulfuric acid catalyst. Thephenol-aldehyde-ammine epoxy resin curing agent is prepared by the Mannickreaction of the solvent lignin or derivative of the solvent lignin and the phenol, aldehyde and ammine. When the solvent lignin-modified phenol-aldehyde-ammine epoxy resin curing agent provided by the invention is used, petrochemical and coal chemical products can be replaced, the consumption of the petrochemical and coal chemical products is reduced, the cost of the epoxy resin is reduced, the lignin renewable resource in the waste from biorefinery is fully utilized, and the development of low-carbon economy is promoted.

Owner:FUZHOU UNIV

Enzymatic hydrolysis lignin epoxy resin material formula and its preparation method

The invention provides a raw material formula of enzymatic lignin epoxy resin and its preparation method. The formula is enzymatic lignin or its derivatives, bisphenol A compound, epichlorohydrin or its mixed solution with an organic solvent, and a catalyst , curing agent, filler; the preparation method is to add enzymatic lignin or its derivatives to epichlorohydrin solution or its mixed solution with organic solvent, stir and dissolve, then add catalyst and add curing agent or curing agent and filler at the same time The mixture is heated to complete the reaction, and the final reactant is evaporated under reduced pressure to remove excess epichlorohydrin or organic solvent to obtain a water-insoluble brown solid, which is washed with water and dried to obtain an enzymatic lignin epoxy resin. The enzymatic lignin used in this method is a natural polymer material extracted from wood chips, bamboo, and grass straw, which not only effectively utilizes biological resources but also can replace petrochemical raw materials. The enzymatic lignin epoxy resin prepared can be used for engineering materials, Adhesives, coatings or modifiers of polymer materials have broad application prospects.

Owner:重庆兆演化工产品有限公司

Method for preparing enzymatic hydrolysis (EH) lignin-dimer fatty acid derivative

The invention provides a method for preparing an enzymatic hydrolysis (EH) lignin-dimer fatty acid derivative by adopting enzymatic hydrolysis (EH) lignin and dimer fatty acid. In the method, the enzymatic hydrolysis (EH) lignin and dimer fatty acid are prepared into the enzymatic hydrolysis (EH) lignin-dimer fatty acid derivative by radical induction and polycondensation in an organic solvent in the presence of an initiator, a catalyst and a polymerization inhibitor. The invention improves flexibility and low crystallinity of materials, has low cost and favorable economic value, and can be applied in high polymer material modification fields such as rubber, plastics, coating, adhesive and the like. The invention can utilize regenerative biomass materials as raw materials to prepare the enzymatic hydrolysis (EH) lignin-dimer fatty acid derivative which can serve as a high polymer modified additive, thus not only lowering cost, reducing petroleum chemical consumption, but also saving energy and reducing emission, and generating great social benefit; and the prepared enzymatic hydrolysis (EH) lignin-poly diacid derivative has simple processing technology, easy implementation and good effect.

Owner:FUZHOU UNIV

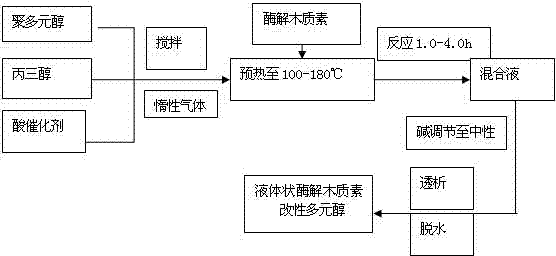

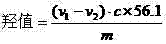

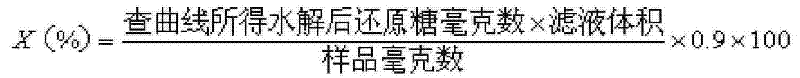

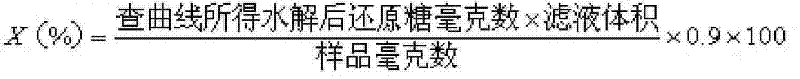

Formula and preparation method of enzymatic hydrolysis (EH) lignin modified polyalcohol

The invention provides a formula and a preparation method of enzymatic hydrolysis (EH) lignin modified polyalcohol. The formula comprises the following components in parts by weight: 8-50 parts of EH lignin, 50-80 parts of polyalcohol, 5-25 parts of glycerol, 1-7 parts of acid catalyst and 1-8 parts of alkali regulator. The preparation method comprises the following the steps: evenly mixing the polyalcohol, the glycerol and the acid catalyst according to the blending ratio, and preheating to the temperature of 40-55 DEG C; adding the EH lignin while stirring, boosting the temperature to 100-180 DEG C, and reacting for 1.0-4.0h under the protection of inert gas; and adding the alkali regulator so as to regulate the pH value of the solution to be 7.0-7.5, dialyzing, and performing reduced pressure distillation to obtain the enzymatic hydrolysis (EH) lignin modified polyalcohol which can be directly used for synthesizing polyurethane. The invention prepares reproducible biological resource EH lignin into liquid polyalcohol, solves the defects that the EH lignin has poor dissolubility and is difficult to be used as a modifier for the polyurethane and alkyd resin, can replace part of petrochemical complex raw materials, and lowers the production cost of the polyalcohol; and the enzymatic hydrolysis (EH) lignin modified polyalcohol has good application effect, simple process and easy implementation.

Owner:FUZHOU UNIV

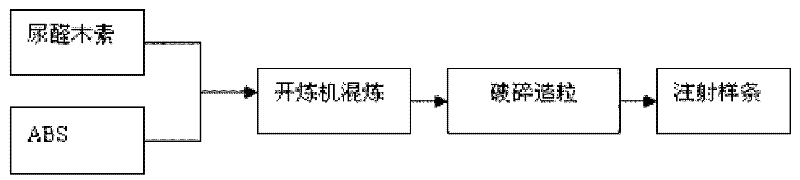

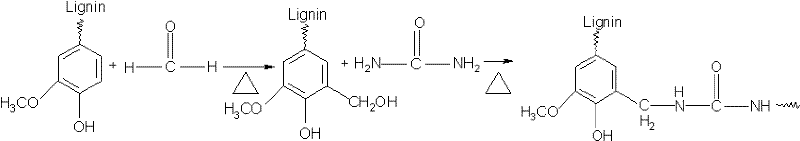

Preparation of macromolecular compatible additive, namely urea-formaldehyde modified lignin and application of macromolecular compatible additive

The invention provides preparation of a macromolecular compatible additive, namely urea-formaldehyde modified lignin and application of the macromolecular compatible additive, belonging to the field of macromolecular materials and modification thereof. The invention overcomes the defects caused because the polar groups in the molecular structure of the original lignin are insufficient, have difficulty in being compatible with the polar polymers and affect the performance of the lignin-polar polymer composite. In the invention, the lignin or the derivatives of the lignin are used as the main raw materials to carry out polycondensation reaction with formaldehyde and urea to obtain the urea-formaldehyde modified lignin. The modified lignin can be used as the macromolecular compatible additive to modify the macromolecular materials. The urea and the formaldehyde used in the invention are chemical raw materials at low cost. Using the urea-formaldehyde modified lignin to modify the macromolecular materials not only expands the application range of the lignin, a regenerative resource, but also further lowers the cost of the macromolecular composite. In addition, the processing technic issimple, implementation is easy and the modification effect is good.

Owner:FUZHOU UNIV

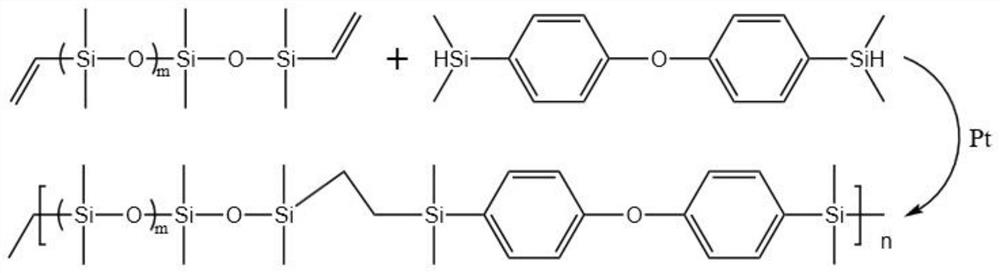

Preparation method and application of straight-chain methyl vinyl polysiloxane with fluorescence function

InactiveCN114805819APrecipitation detection is effectiveDoes not affect the chemical reaction processFluorescence/phosphorescenceLuminescent compositionsPolymer scienceChemical reaction

The invention discloses a preparation method and application of straight-chain methyl vinyl polysiloxane with a fluorescent function. The straight-chain methyl vinyl polysiloxane is synthesized by carrying out hydrosilylation reaction on polysiloxane with a straight-chain molecular structure and a hydrosilyl compound containing a fluorescent group according to a certain molar ratio. Compared with a traditional mode of directly introducing a fluorophore to a polysiloxane main chain, the preparation method disclosed by the invention selects a hydrosilyl compound containing the fluorophore and a silicon-hydrogen bond and polysiloxane containing vinyl, and utilizes an addition reaction of the silicon-hydrogen bond and the vinyl, so that the fluorophore is introduced to the main chain of the polysiloxane; consumption of silicon and hydrogen in polysiloxane can be avoided, and the chemical activity of the raw materials is reserved. The material can display a bright special color under the irradiation of ultraviolet light with a specific wave band, and the chemical reaction process of the material cannot be influenced by adding a certain proportion of the material into conventional linear methyl vinyl polysiloxane, so that the material can be effectively used for polysiloxane precipitation detection of an organic silicon material.

Owner:锐腾新材料制造(苏州)有限公司

Preparation method of zymolytic lignin modified water reducing agent

The invention provides a preparation method of zymolytic lignin modified water reducing agent. In the method, zymolytic lignin is used as raw material; solid acid and solid alkali generate catalytic and sulfonation reactions to prepare a cement water reducing agent. By using the advantages of strong chemical activity, high purity and the like of the zymolytic lignin and using a zymolytic lignin derivative sulfonated by the solid acid and the solid alkali as the cement water reducing agent, the performance of the zymolytic lignin modified water reducing agent is obviously superior to that of lignin sulfonate of a traditional byproduct of paper making industry. Used catalysts of the solid acid and the solid alkali can be repeatedly used; renewable resources can be thoroughly used; the consumption of petrochemicals is reduced; the cost of the preparation method is low so that great social and economic benefits are generated; and the process of preparing the cement water reducing agent has the advantages of simplicity, easy implementation and good effect.

Owner:重庆辉泰化工销售有限公司

Emulsified bitumen and preparation method thereof

The invention discloses an emulsified bitumen and a preparation method thereof. Solvent-type lignin, aldehyde, cyanamide and amine carry out condensation reaction to prepare cyanamide and amine derivative of solvent-type lignin; and the cyanamide and amine derivative of solvent-type lignin are used as emulsifier and treated with emulsification to prepare emulsified bitumen. The method has low cost; and the prepared emulsified bitumen has excellent performance and can be used in road paving or as building material, so as to fully utilize reproducible resource, reduce consumption of petroleum chemicals and gain substantial economic and social benefits.

Owner:程贤甦

Comprehensive Utilization Method of Corn Cob

ActiveCN101628920BEasy to separatePromote conversionSugar derivativesBiofuelsSocial benefitsMolecular materials

The invention provides a comprehensive utilization method of corn cob, which effectively separates hemicellulose, lignin and cellulose contained in a reproducible biological resource of corn cob in a reasonable process order at low cost and high efficiency, and makes full use of every type of biomass components, thereby solving the problem of utilization of residue in the biomass refining process of preparing ethanol and butanol by extracting xyio-oligosacchandes and enzymolysis from the corn cob in the prior art, and making reasonable and effective use of main components of biomass contained in the corn cob; particularly, the lignin can substitute partial petrochemical materials to prepare modified high-molecular materials, thereby reducing the cost of high-molecular materials and saving the energy consumption of petrochemical materials to bring great social benefit; in addition, the comprehensive utilization method of corn cob is featured by simple processing technique, easy implementation and favorable effect.

Owner:重庆辉泰化工销售有限公司

Enzymatic hydrolysis lignin epoxide resin and preparation thereof

The invention provides an enzymolysis lignin epoxy resin and a preparation method thereof. The raw materials include: an enzymolysis lignin-dianhydride prepolymer, a glycidol ether, a catalyst, a curing agent and a filler. The preparation method comprises the following steps that: under the action of the catalyst, an etherification of a hydroxyl group contained in the enzymolysis lignin or a derivative of the enzymolysis lignin and dianhydride is carried to synthesize a prepolymer of enzymolysis lignin-dianhydride; then the prepolymer reacts with the glycidol ether and undergoes etherification and ring closing reaction to obtain an enzymolysis lignin--polyester type epoxy resin. The enzymolysis lignin adopted by the method is natural macromolecular material extracted from the residues which is produced in the preparation of alcohol through the fermentation of wood chips, bamboo and stalk, thereby not only effectively utilizing biological resources, but also replacing petrochemical rawmaterials. The enzymolysis lignin epoxy resin which can be used as a modifier for engineering materials, adhesives, paints and macromolecular materials has a broad application prospect.

Owner:重庆辉泰化工销售有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com