Preparation method of zymolytic lignin modified water reducing agent

A technology of enzymatically decomposing lignin and water reducing agent, applied in the field of preparation and new material development, can solve the problems of unsatisfactory water reducing effect, high price, resource depletion, etc., and achieve environmental protection, low manufacturing cost, expansion The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

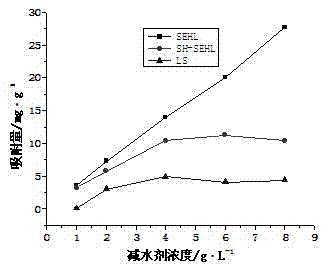

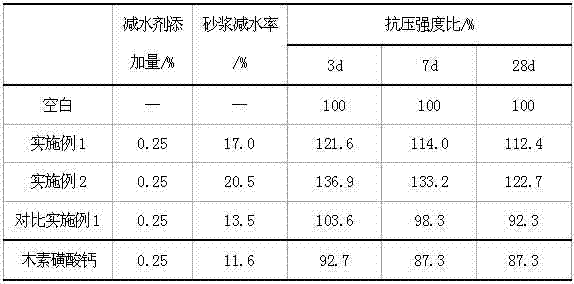

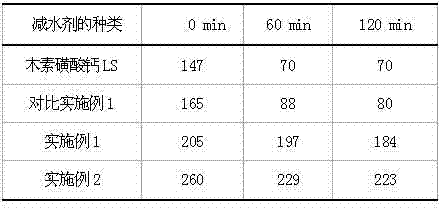

Examples

Embodiment 1

[0043] Example 1. Enzymatic hydrolysis of lignin derivatives catalyzed by solid acid

[0044] 50gZrOCl 2 ·8H 2 O was dissolved in distilled water to make a solution with a mass fraction of 8%, and 55 ml of concentrated ammonia water was slowly added dropwise to the solution under stirring to adjust the pH to 9.0 to form a gel. Suction filtration after sedimentation at room temperature for 24 hours, repeated washing until no Cl - (0.1 mol / L silver nitrate solution test). Dry the solid in an oven at 105°C for 24 hours, grind it into a fine powder, pass through a 100-mesh sieve, and divide the obtained 28.6 g powder into two parts, one part is impregnated with 214ml 0.5 mol / L dilute sulfuric acid, and the other part is impregnated with 214ml Immerse in 1mol / L sodium nitrate solution, filter with suction without washing. The resulting filter cake was dried at 105 °C for 24 hours to obtain ZrO 2 / SO 4 2- and Na 2 O / ZrO 2 The initial sample was finally calcined at 680 °C f...

Embodiment 2

[0046] Example 2. Enzymolysis of lignin derivatives catalyzed by solid acid and solid base

[0047] Add 10 g of enzymatic lignin, 100 ml of water and 3 g of sodium hydroxide into a three-necked flask equipped with a heating and stirring device at 65 ° C, stir for 25 min, dissolve evenly, add 3 g of sodium sulfite, and then add 3 g of the product prepared in Example 1 Solid acid catalyst, when the temperature is raised to 90°C, the reaction is carried out for 4.0h. After the sample is cooled to room temperature, the solid acid catalyst is filtered and separated to obtain a solid acid-catalyzed enzymatic lignin derivative solution with a solid content of 20.1%, and then 10 g of 37% formaldehyde, heat up to 70°C for 2.0h, then add 3 g of sodium sulfite and 4g of the solid base catalyst prepared in Example 1, when the temperature rises to 90°C, the reaction proceeds for 3.0h, and the sample is cooled to room temperature and then filtered to separate the solid base Catalyst, obtain...

Embodiment 3

[0049] Add 10 g of enzymatic lignin, 100 ml of water and 3 g of sodium hydroxide into a three-neck flask with a heating and stirring device at 65 ° C, stir for 25 min, dissolve evenly, add 3 g of sodium sulfite, and then add the solid recovered in Example 1 Acid catalyst 3g, when the temperature is raised to 90°C, the reaction is carried out for 4.0h, the sample is cooled to room temperature and then filtered to separate the solid acid catalyst to obtain a solution of sulfonated lignin modified derivatives with a solid content of 20.0%, which is distilled under reduced pressure and dried. 12.7 g of solid acid-catalyzed enzymatically hydrolyzed lignin derivatives (SEHL) powder were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com