Patents

Literature

1291 results about "Lignosulfonates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lignosulfonates, or sulfonated lignin, (CAS number 8062-15-5) are water-soluble anionic polyelectrolyte polymers: they are byproducts from the production of wood pulp using sulfite pulping. Most delignification in sulfite pulping involves acidic cleavage of ether bonds, which connect many of the constituents of lignin. The electrophilic carbocations produced during ether cleavage react with bisulfite ions (HSO₃⁻) to give sulfonates.

Method for treating wood with a metal-containing treating agent and wood treated thereby

InactiveUS6541038B1Reduce leachingEasy to fixBiocideHeavy metal active ingredientsLignosulfonatesMetal

A method for treating wood, characterized by impregnating wood with a metal-containing treating agent containing lignin and / or lignin derivatives and a metal, a metal compound, and / or a metal ion and oxidizing and / or macromolecularizing of the lignin and / or lignin derivatives in the wood to fix the metal component in the wood, and wood and woody materials obtained by the treating method. According to the method of the present invention, while effectively utilizing lignins, lignosulfonic acids, or lignosulfonic acid salts, leaching of the metal component can be suppressed to a low level to thereby retain the effects due to the incorporation of the metal components for a prolonged period.

Owner:SDS BIOTECH CO LTD

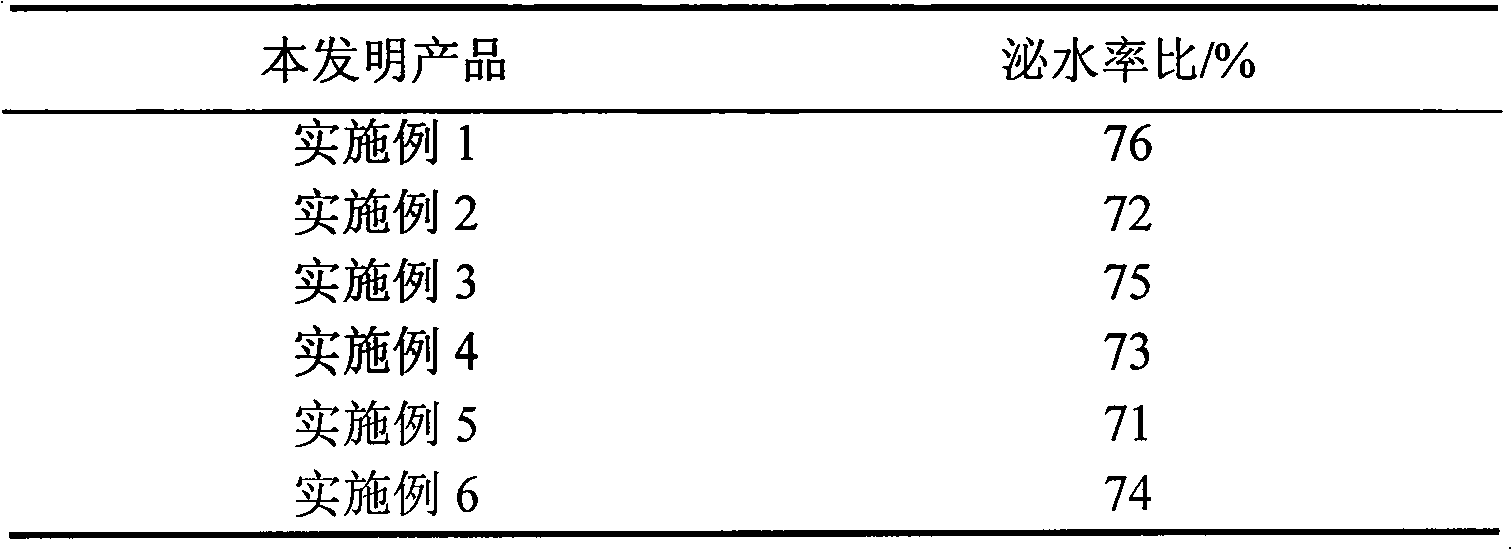

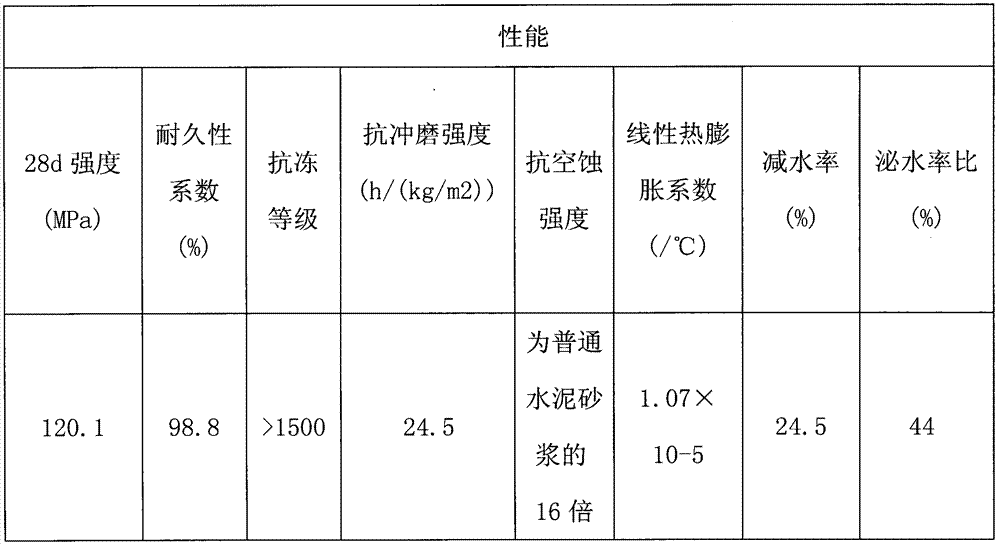

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

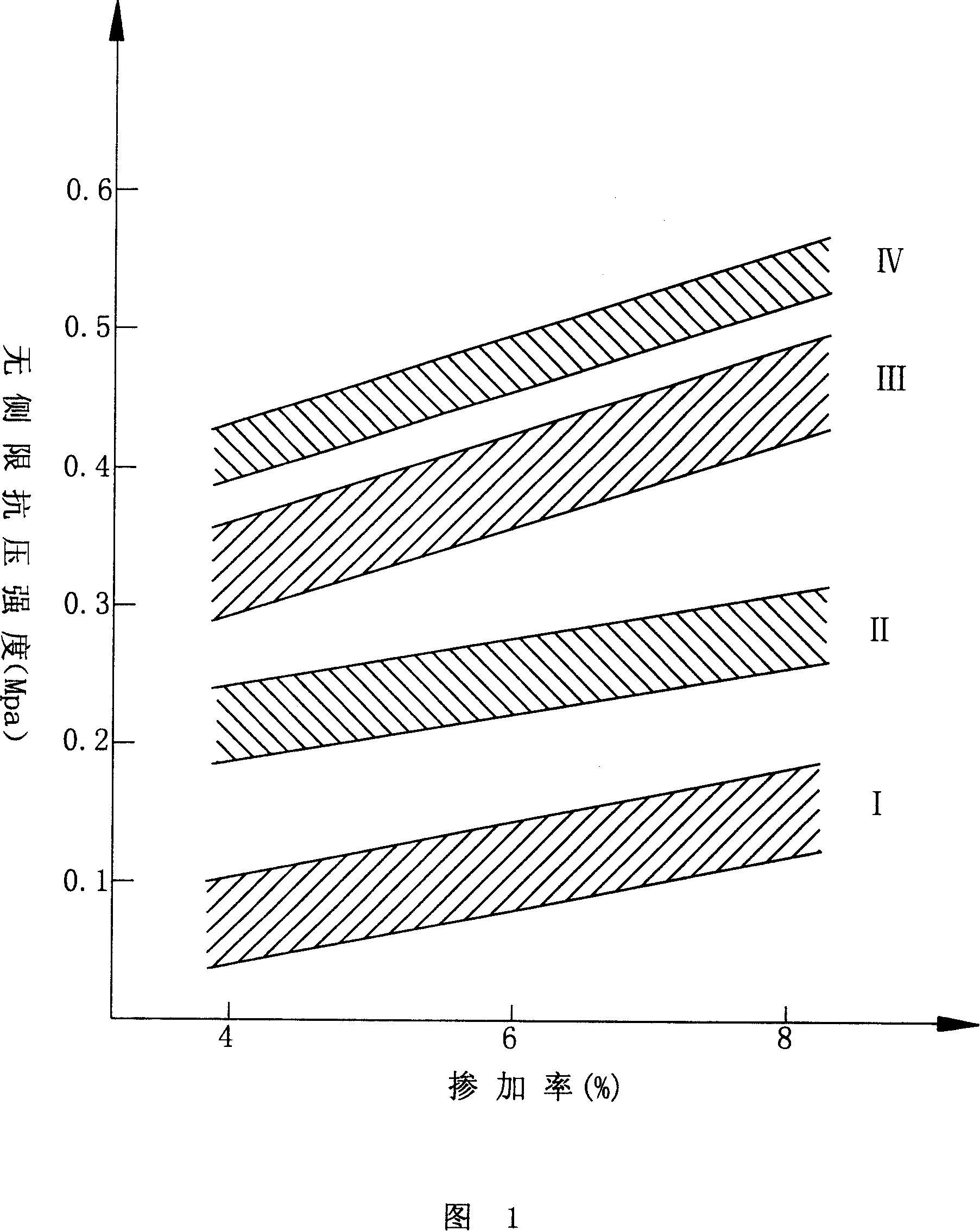

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

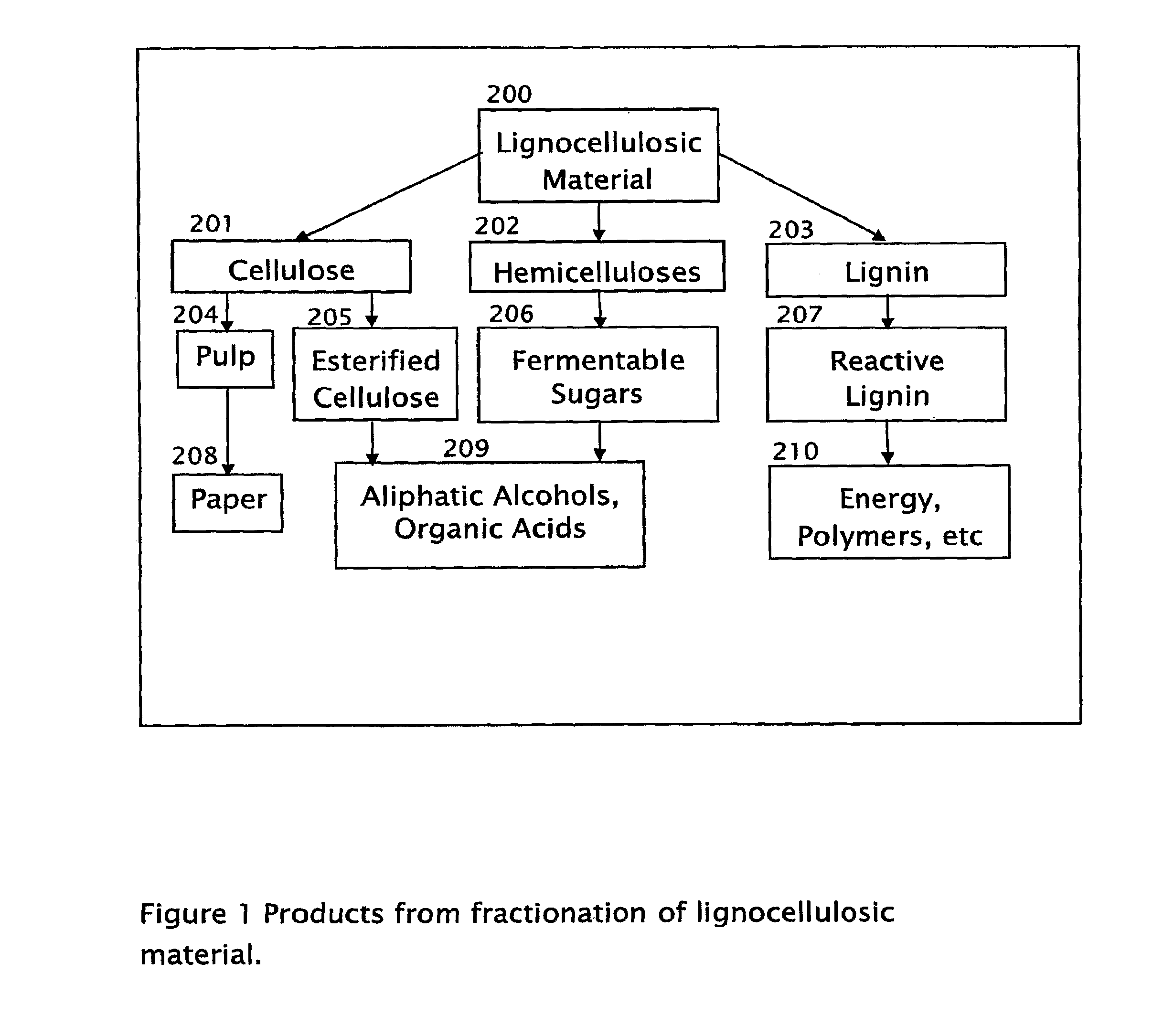

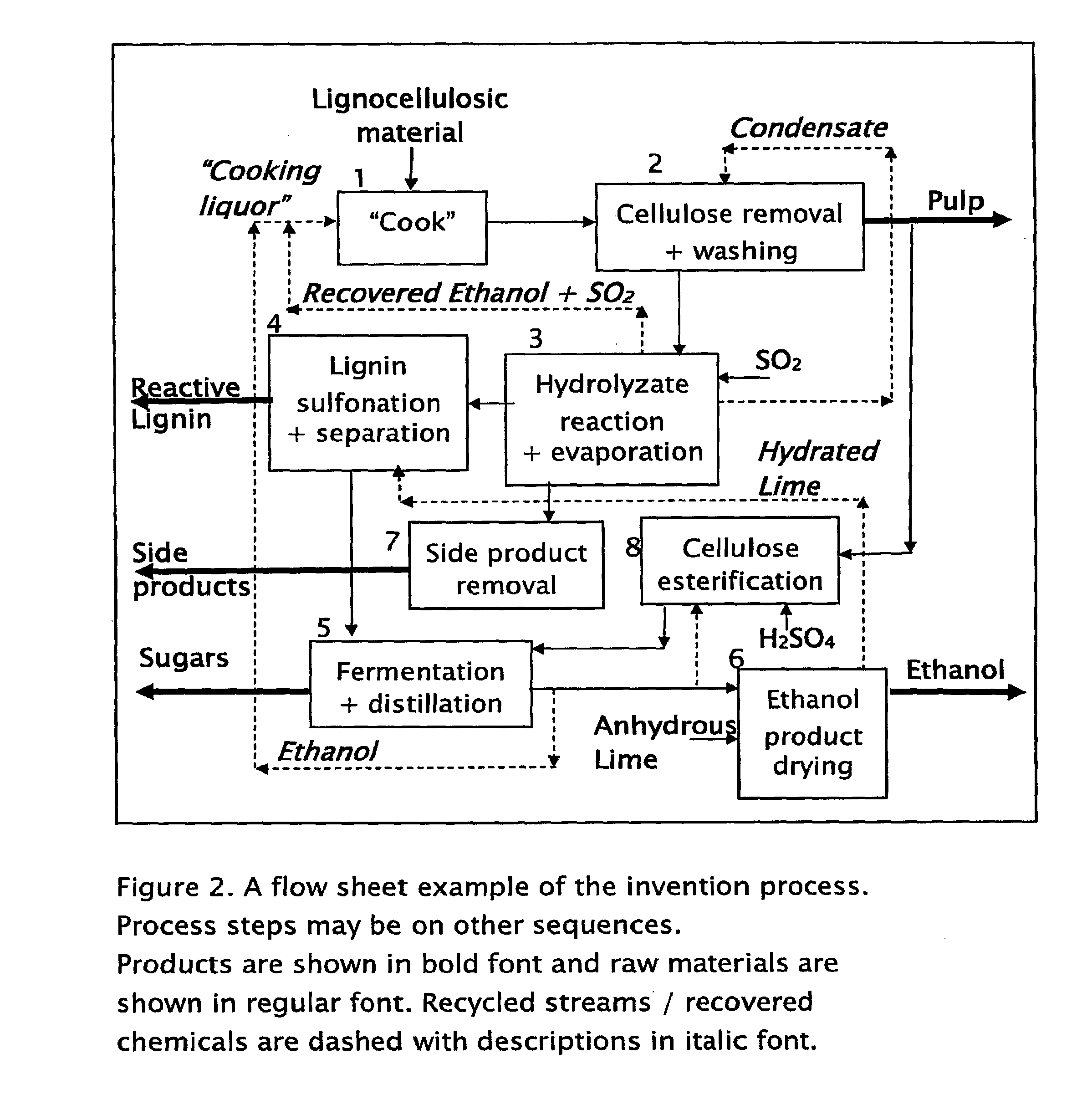

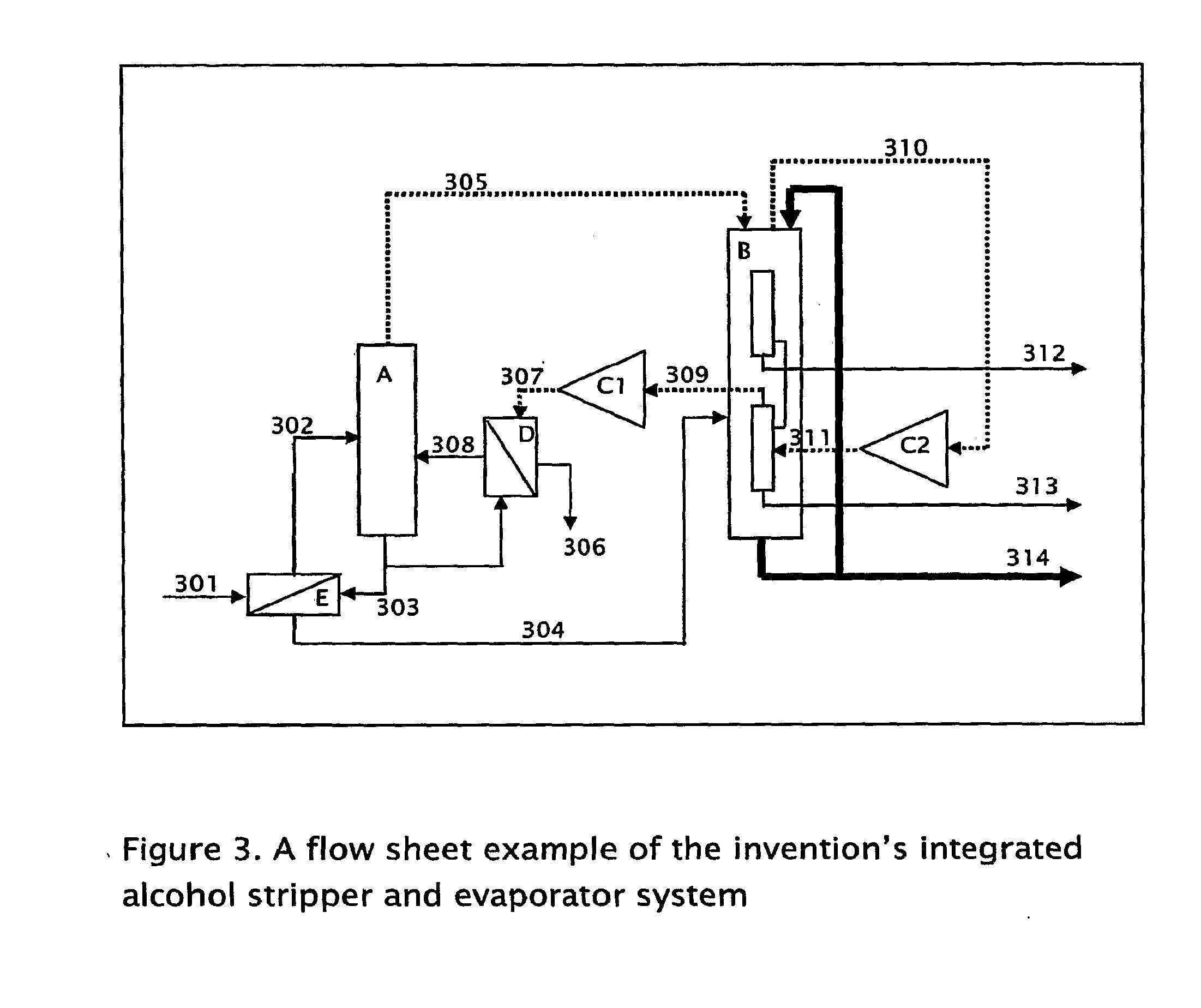

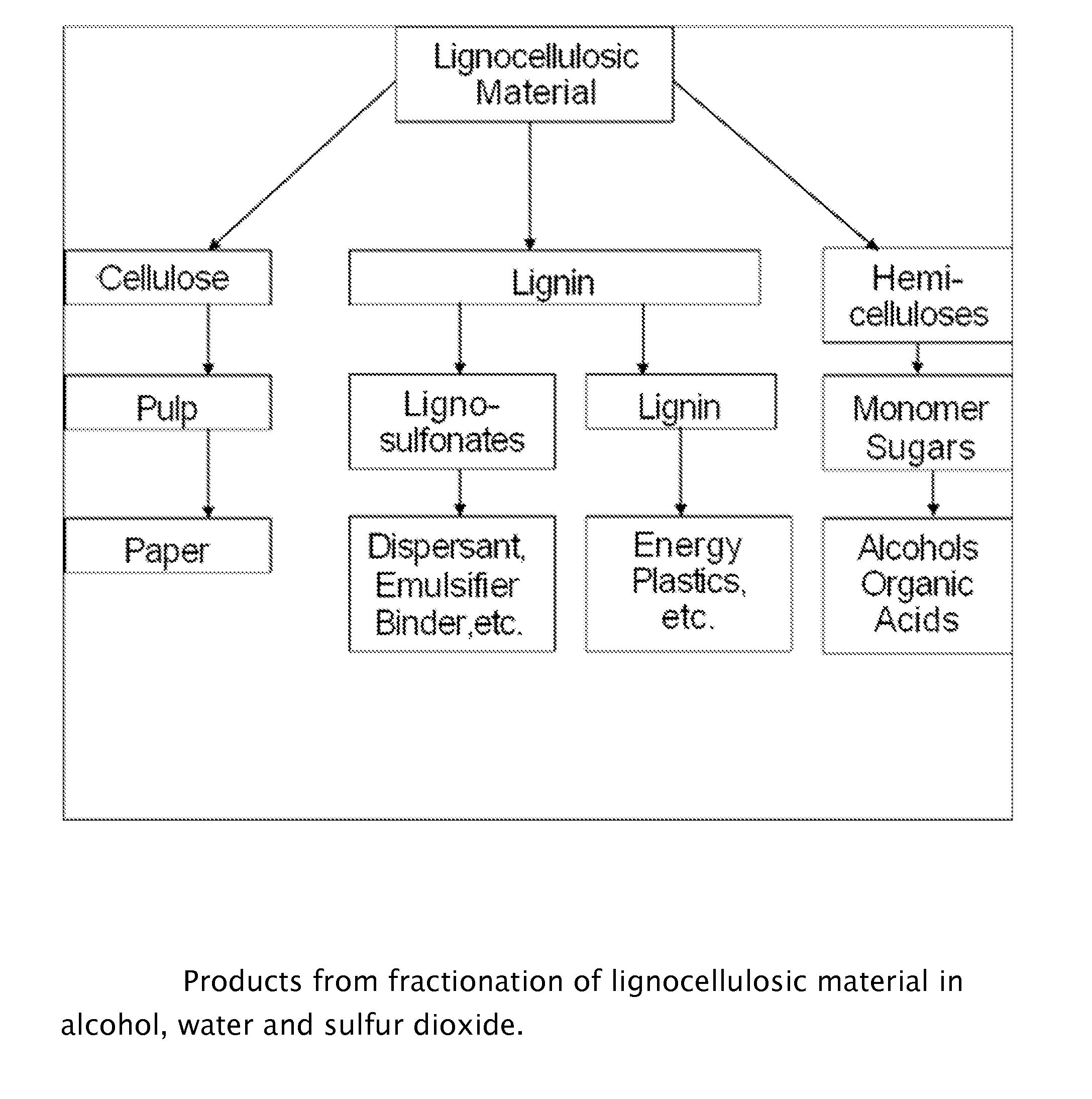

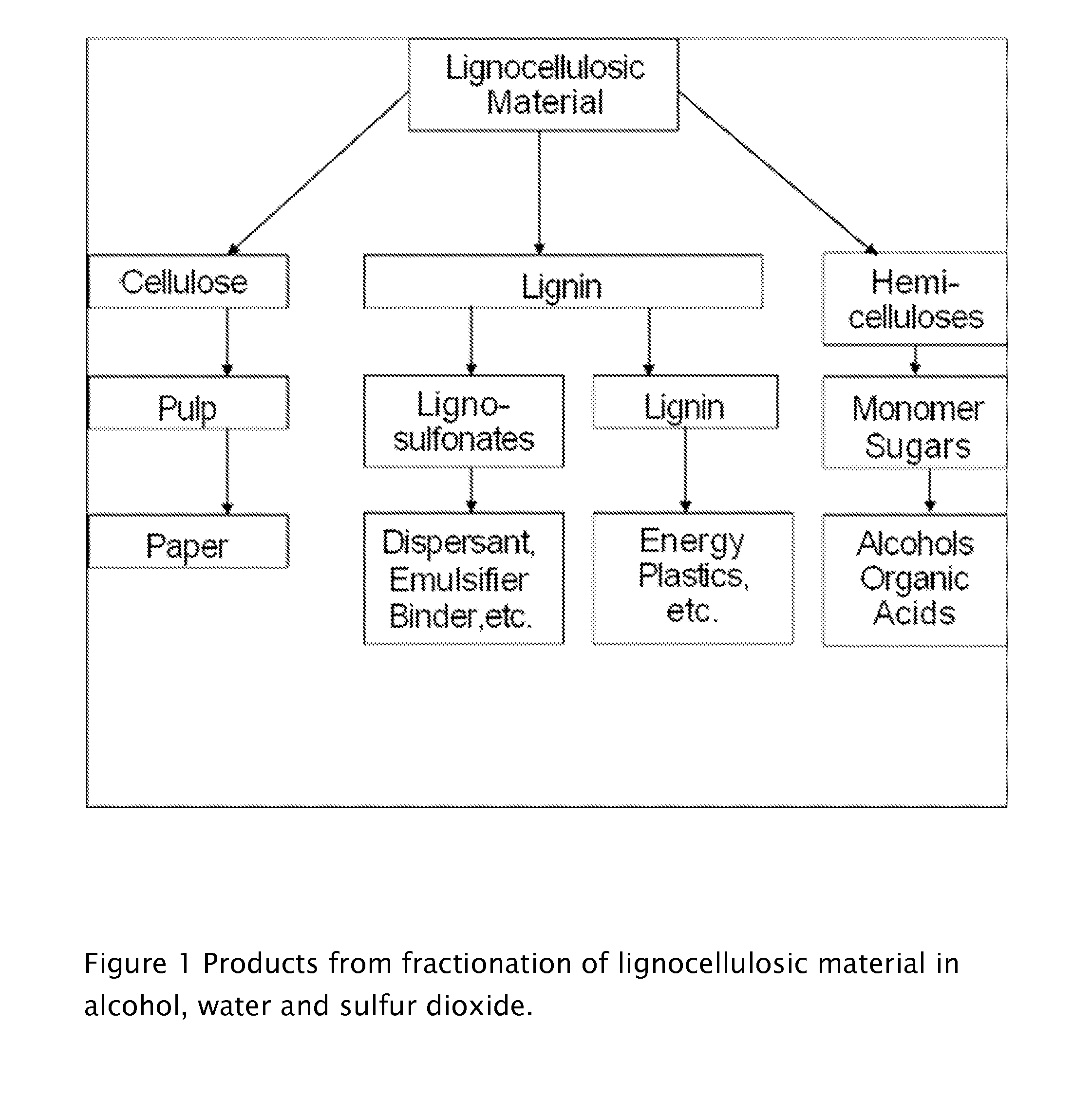

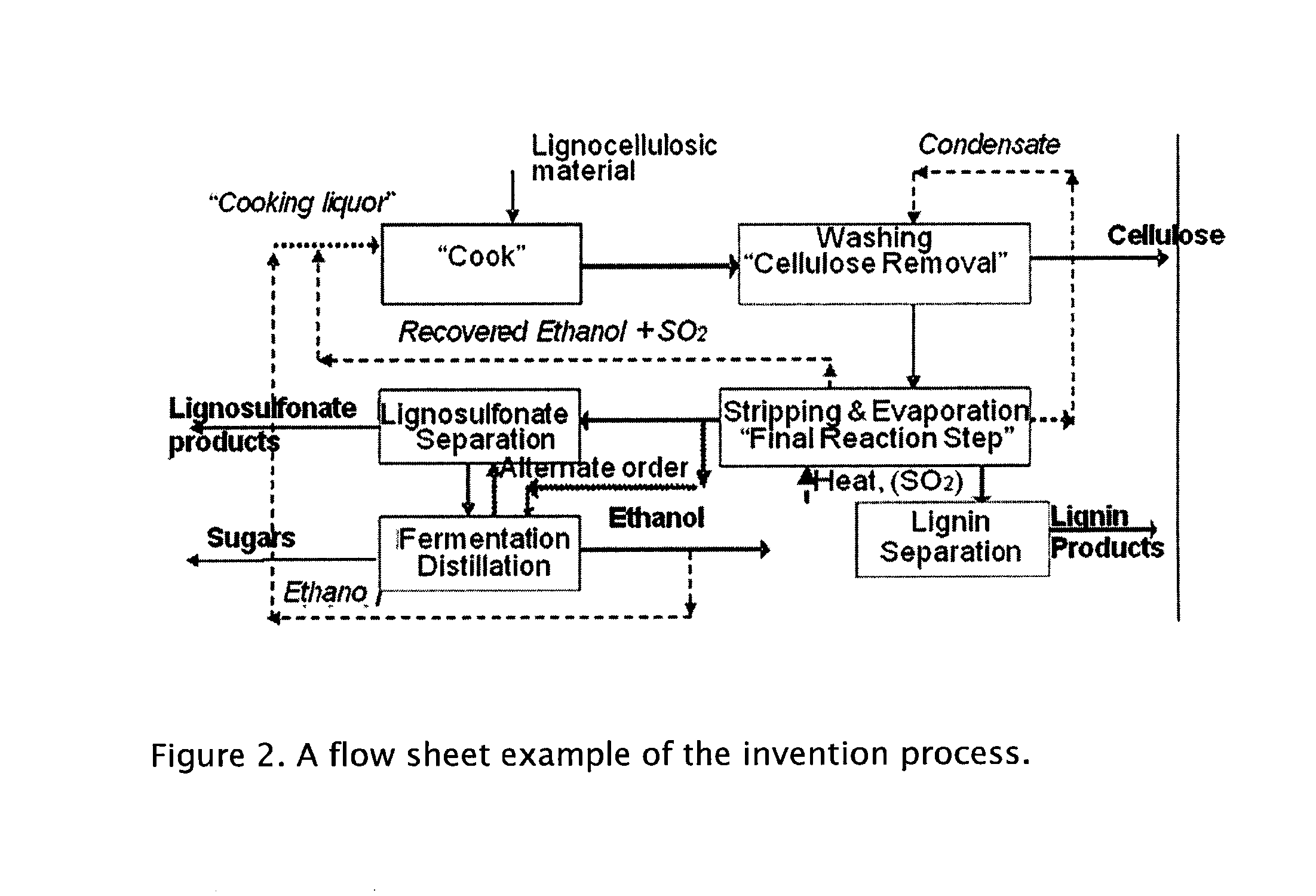

Process for the stepwise treatment of lignocellulosic material to produce reactive chemical feedstocks

InactiveUS20110003352A1Using liquid separation agentCalcium/strontium/barium sulfatesSulfonateLignosulfonates

A method for the fractionation of lignocellulosic materials into reactive chemical feedstock in a batch or semi continuous process by the stepwise treatment with aqueous aliphatic alcohols in the presence of sulfur dioxide or acid. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, or converted to esterified cellulose, cooking chemicals are reused, lignin is separated in the forms of reactive native lignin and reactive lignosulfonates and hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. In an integrated vapor compression stripper and evaporator system, aliphatic alcohol is removed from a liquid stream and the resulting stream is concentrated for further processing.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC +1

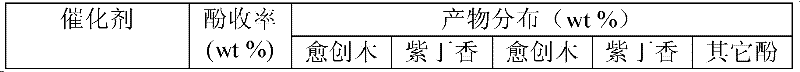

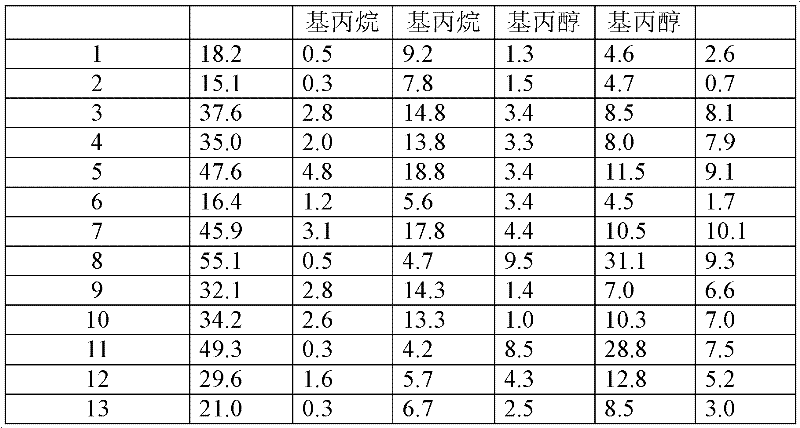

Application of tungsten-based catalyst in lignin catalytic hydrogenation for producing aromatic compound

ActiveCN102476980AWide variety of sourcesLow costCatalyst carriersOrganic compound preparationIridiumHydrogen pressure

The invention relates to hydrocracking of lignin, and specifically relates to a method for applying a tungsten-based catalyst to catalyze lignin hydrocracking for producing an aromatic compound. The catalyst comprises a main active component of non-zero-valent tungsten, and a second metal component of a small amount of one or more transition metals selected from zero-valent nickel, cobalt, ruthenium, iridium, palladium, platinum, iron, and copper. According to the method, raw materials such as lignin, biomass hydrolysis residue, lignosulfonate, and alkaline lignin are subject to catalytic hydrogenation under a hydrothermal condition with a temperature of 120 to 450 DEG C and a hydrogen pressure of 1 to 20MPa; the raw materials are cracked into C6-C9 phenolic compounds with high selectivity. A maximal phenol yield reaches 55.6%. Compared to existing technologies, according to the invention, renewable natural biomasses are adopted as raw materials, such that the raw materials are cheap, and have wide sources; inorganic acid and alkali are not required, such the production of a large amount of alkaline solution in traditional lignin catalysis is avoided; the tungsten-based catalyst is cheap; the reaction process is green, and has atom economical characteristics.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

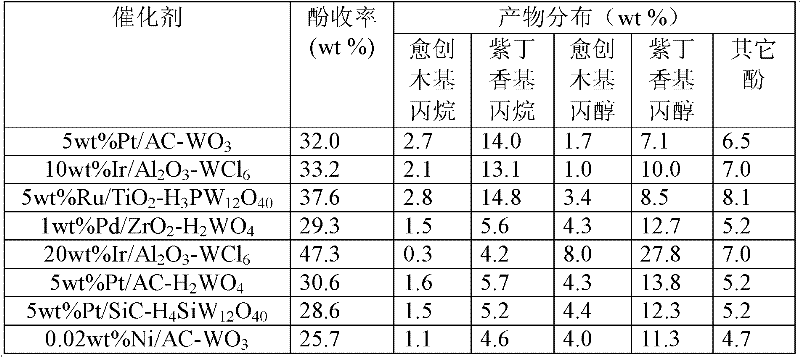

Slump Retaining and Dispersing Agent for Hydraulic Compositions

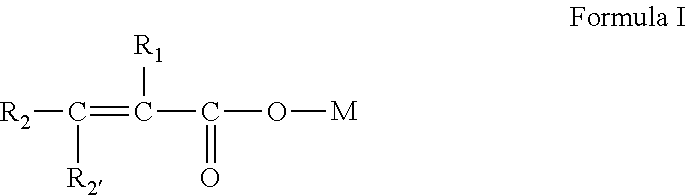

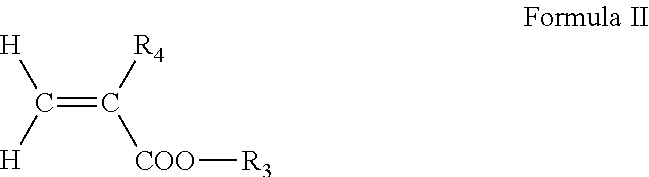

InactiveUS20130231415A1Avoid settingLow and no air entraining effectDrilling compositionLignosulfonatesSuperplasticizer

The invention relates to copolymers effective as slump retention agents for hydraulic compositions such as cement, mortar and concrete. The copolymers are formed by reacting monomers A, B and C, wherein monomer A is a compound of formula I, monomer B is a compound of formula II, and monomer C is a compound of formula III or IV as shown herein. The copolymers may be used alone or in combination with a water reducing agent or slump retaining agent, e.g. a superplasticizer such as PNS or PMS or a low range water reducer such as lignosulfonate. The copolymer includes a group that is hydrolyzable at elevated pH (e.g. around pH 12) typically present in hydraulic compositions, so that the group hydrolyzes when present in such compositions and forms a charged group that provides extended slump retention properties without introducing undesirable air-entraining characteristics.

Owner:RUETGERS POLYMERS LTD

Modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate and preparation method thereof

The invention relates to a method for preparing a modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate, belonging to the field of concrete water-reducing agents. The invention adopts acetone and formaldehyde as condensation monomers and lignosulfonate as a modifying agent and carries out sulfonating and condensation reactions under an alkaline condition to produce anovel high-efficiency concrete water-reducing agent. The preparation method of the novel high-efficiency concrete water-reducing agent comprises the following steps: (1) adding a sulfonating agent, acetone and water to a reactor, increasing the temperature to 25-65 DEG C and reacting for 0.1-1.5 hours; (2) dipping part of formaldehyde solution for 0.25-2.5 hours, increasing the temperature to 70-95 DEG C and reacting for 1-6 hours; and (3) decreasing the temperature to below 60 DEG C, adding the lignosulfonate and the rest of the formaldehyde solution to the reactor, using an alkaline regulator to regulate a pH value of the system to be 8.0-14.0, increasing the temperature to 70-98 DEG C, reacting for 1-5 hours and decreasing the temperature before discharging. The modified aliphatic high-efficiency water-reducing agent is suitable for producing commercial concrete which has similar color as normal concrete and has smaller collapsed slump loss. By adjusting the process, such as proportioning raw materials, and the like and effectively utilizing the lignosulfonate, the invention not only decreases the product cost, but also lessens environmental pollutants and has favorable industrialized prospects.

Owner:NANJING FORESTRY UNIV

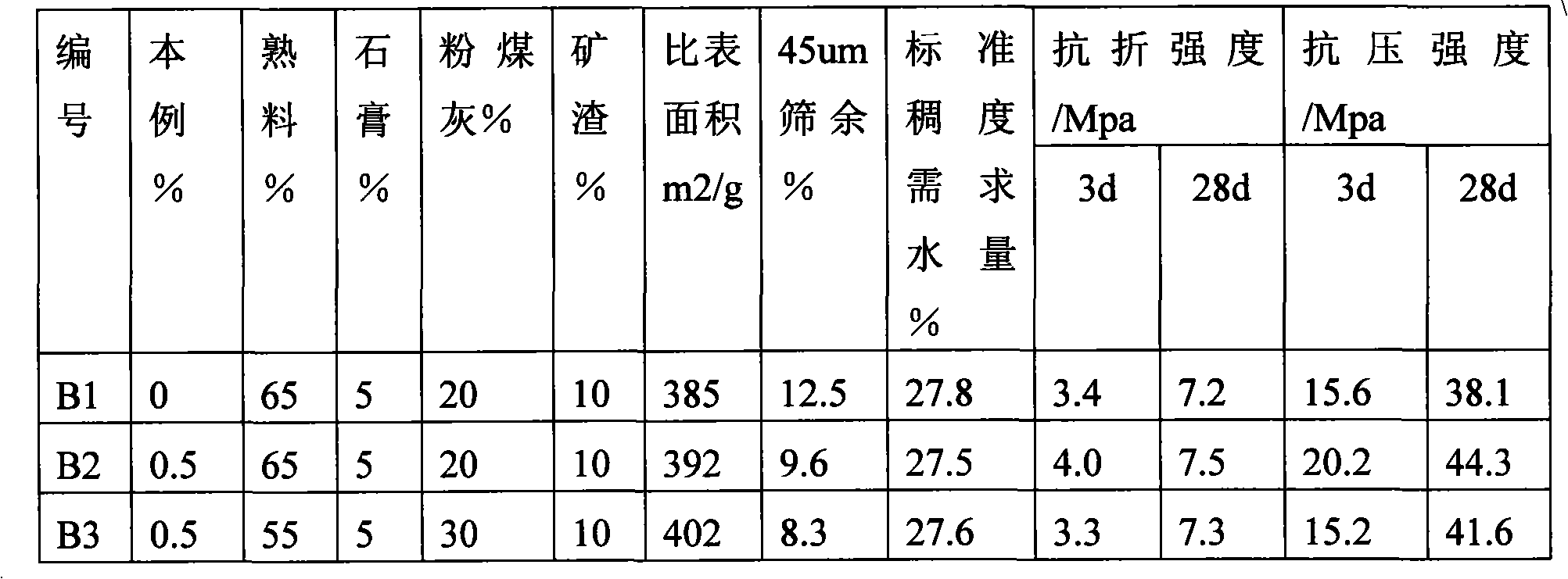

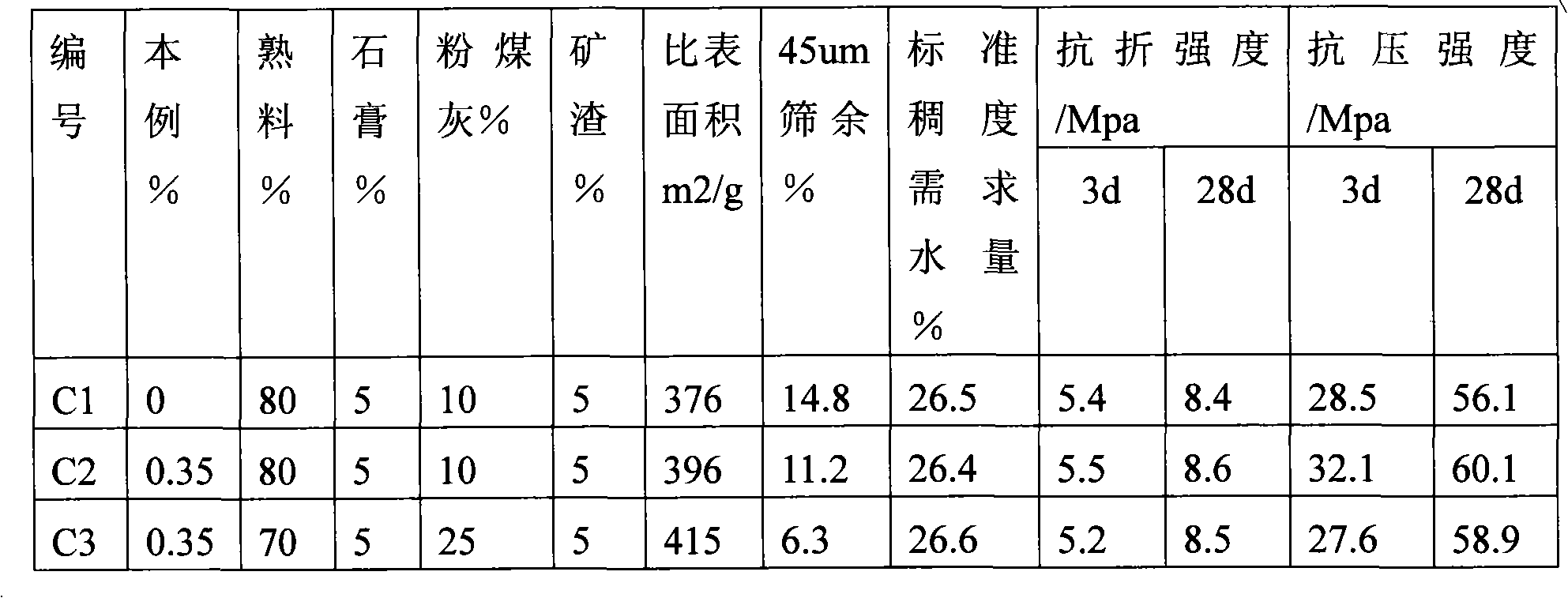

Chlorine-free powdery cement grinding aid and preparation method thereof

InactiveCN101665338AHigh strengthStrong compound synergistic effectCement productionSulfateLignosulfonates

The invention discloses a chlorine-free powdery cement grinding aid suitable for fly ash, which comprises the following components in parts by weight: 0-5 parts of alkanolamine, 2-5 parts of polylol,15-75 parts of sulfate, 5-20 parts of acetate, 0-5 parts of lignosulphonate, 2-6 parts of carbohydrate organic matter, 5-25 parts of miltonite, 0-25 parts of carbamide and 5-50 parts of inorganic carrier material. The invention also discloses a preparation method of the chlorine-free powdery cement grinding aid suitable for the fly ash. A compound grinding aid can lower the cement cost and uses the fly ash for replacing partial clinker to save the clinker dosage by 10-15 percent on the premise of keeping the cement strength unchanged, and uses extra 10-15 parts of fly ash without increasing the required water amount of cement standard consistency; the cost of the cement per ton is lowered by more than 10 Yuan.

Owner:NANJING ZHUJI ENERGY SAVING TECH

Separation of Lignin From Hydrolyzate

ActiveUS20110165643A1Pulp liquor regenerationPulping with acid salts/anhydridesWater insolubleLignosulfonates

A method for the production water insoluble reactive lignin having low sulfur content and lignosulfonates from lignocellulosic material in a batch or continuous process. Lignocellulosic material is fractionated to produce water insoluble native lignin and lignosulfonates in various ratios, while preserving the cellulose and hydrolyzed hemicelluloses using water, ethanol and sulfur dioxide.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

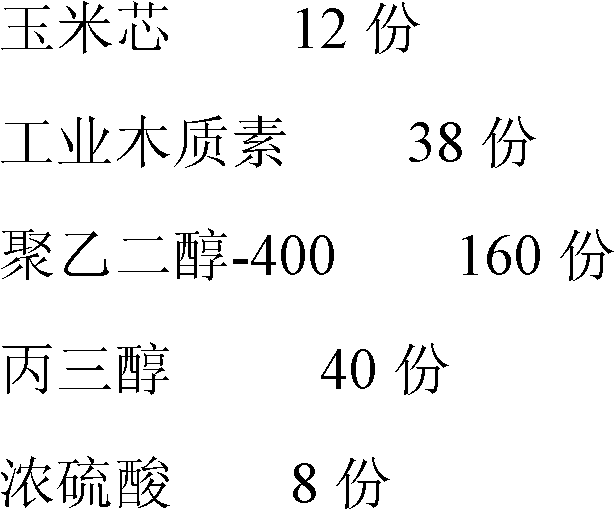

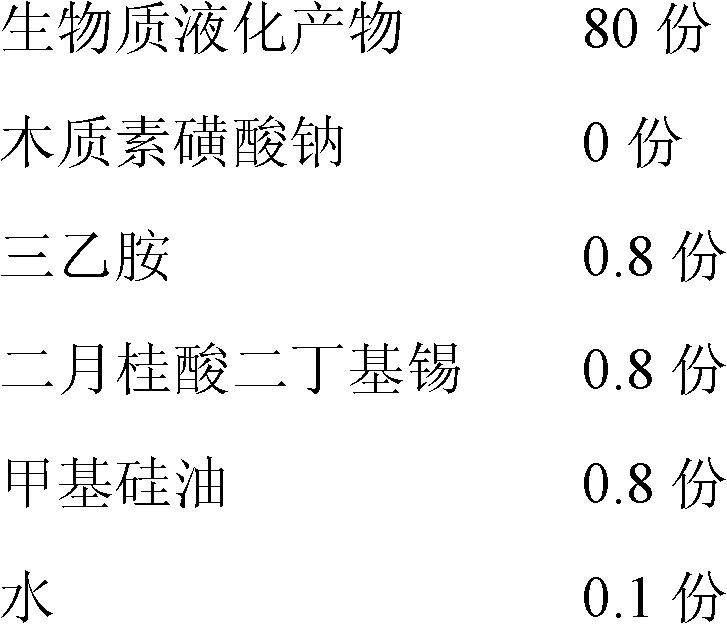

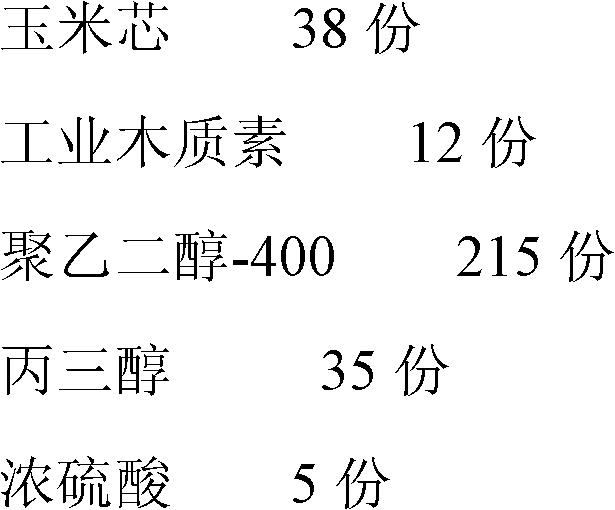

Preparation method of biomass-base polyurethane foam material

The invention discloses a preparation method of a biomass-base polyurethane foam material, belonging to the technical field of chemical industry. The method mainly comprises the following steps: mixing polybasic alcohol liquefier and liquefying catalyst, putting the mixture in a container, heating to 150-200 DEG C, adding biomass waste and industrial lignin, liquefying, and cooling to room temperature to obtain a biomass liquefied product; and mixing the prepared biomass liquefied product, foaming catalyst, foam stabilizer, foaming agent and lignosulphonate into a component A, using isocyanate as a component B, mixing the component A and component B in a mixing vessel, stirring at 20-40 DEG C at 8000-14000 rpm for 5-30 seconds, pouring the mixture into a die, naturally foaming for 5-60 seconds, standing at 80-120 DEG C for 8-24 hours, and storing at room temperature for 8-24 hours until the mixture is sufficiently aged and formed. The invention can obviously improve the properties of the biomass-base polyurethane foam.

Owner:CHINA AGRI UNIV

Composition board binding material

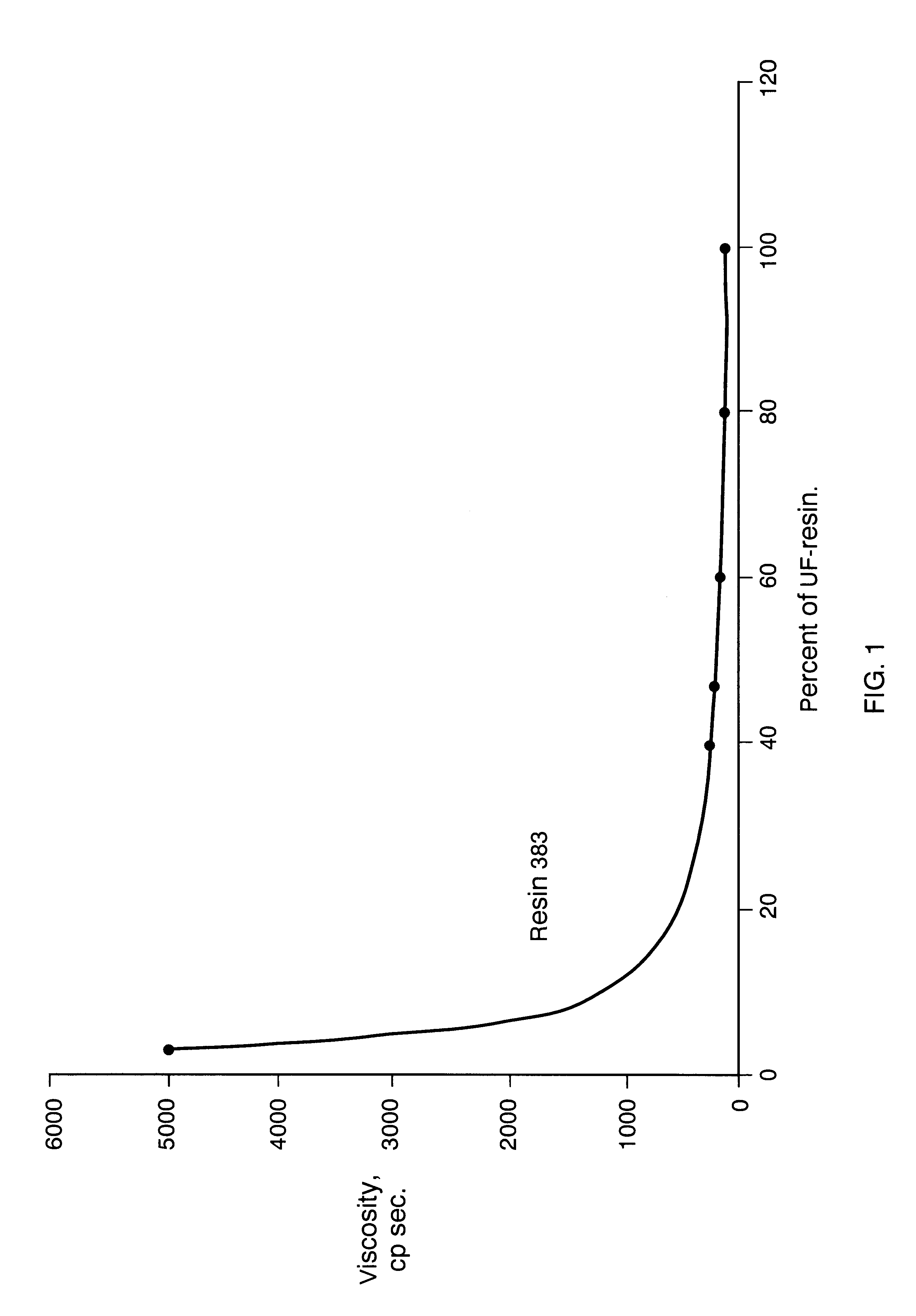

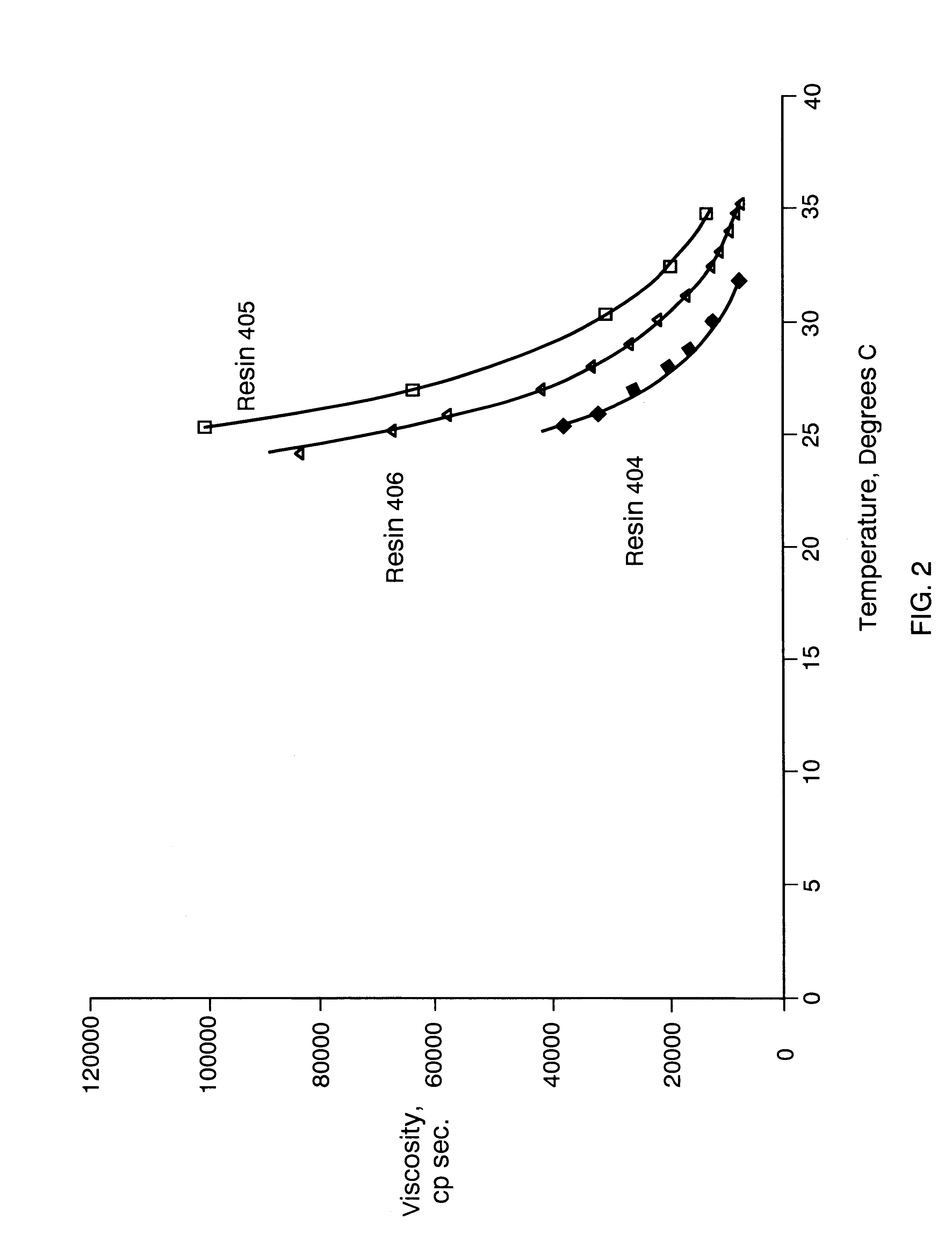

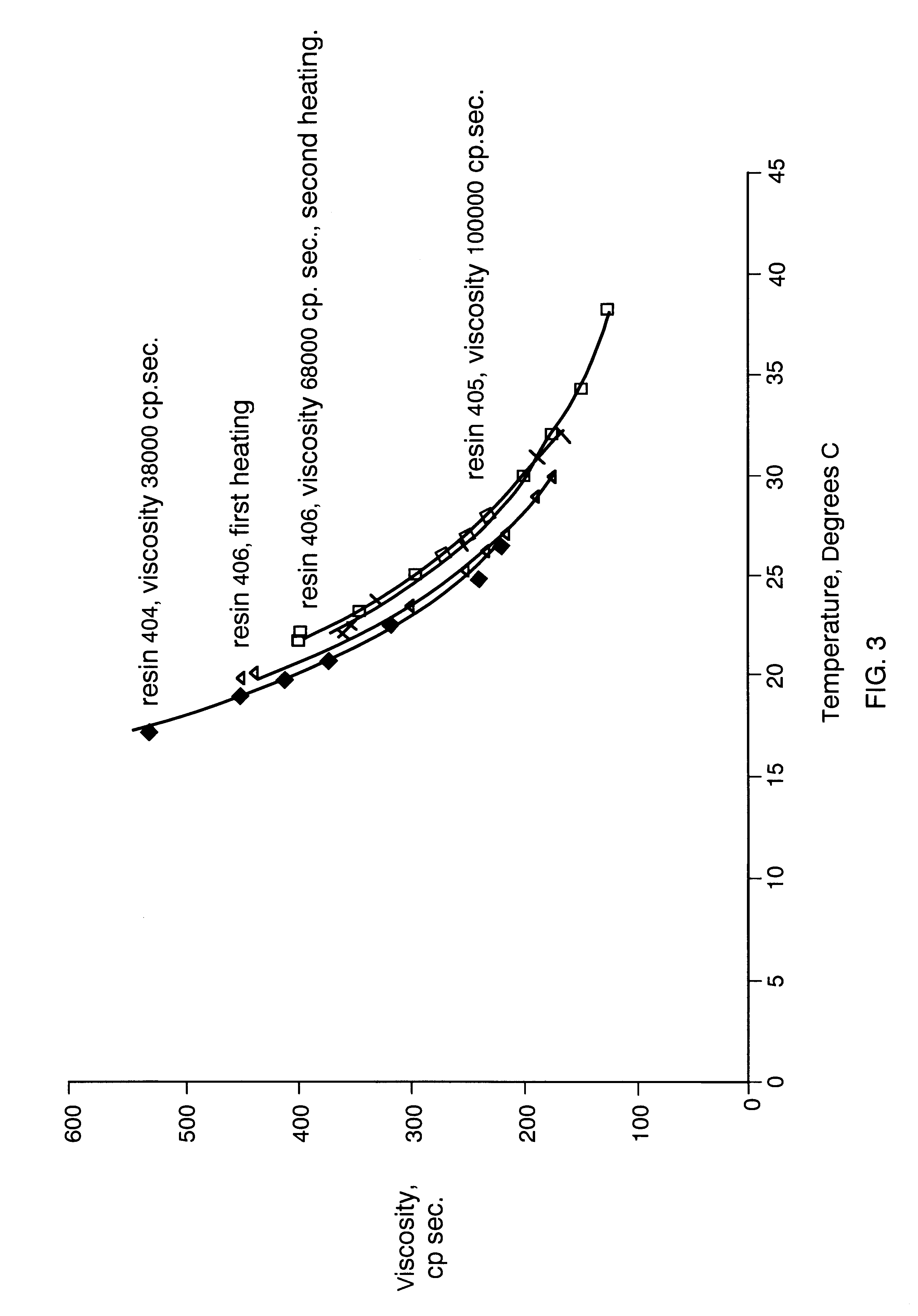

InactiveUS6291558B1Good dispersibilityImprove stabilityInksLignin derivativesLignosulfonatesReaction step

This invention features a graft copolymer of lignosulfonates reacted with an unsaturated carbonyl compound and an aldehyde, in two separate reaction steps. The resin can be used as a substitute for a majority of pure urea formaldehyde resin in the manufacture of composite board products. The resin can also be introduced directly into the urea formaldehyde resin production process.

Owner:CELLUTECH

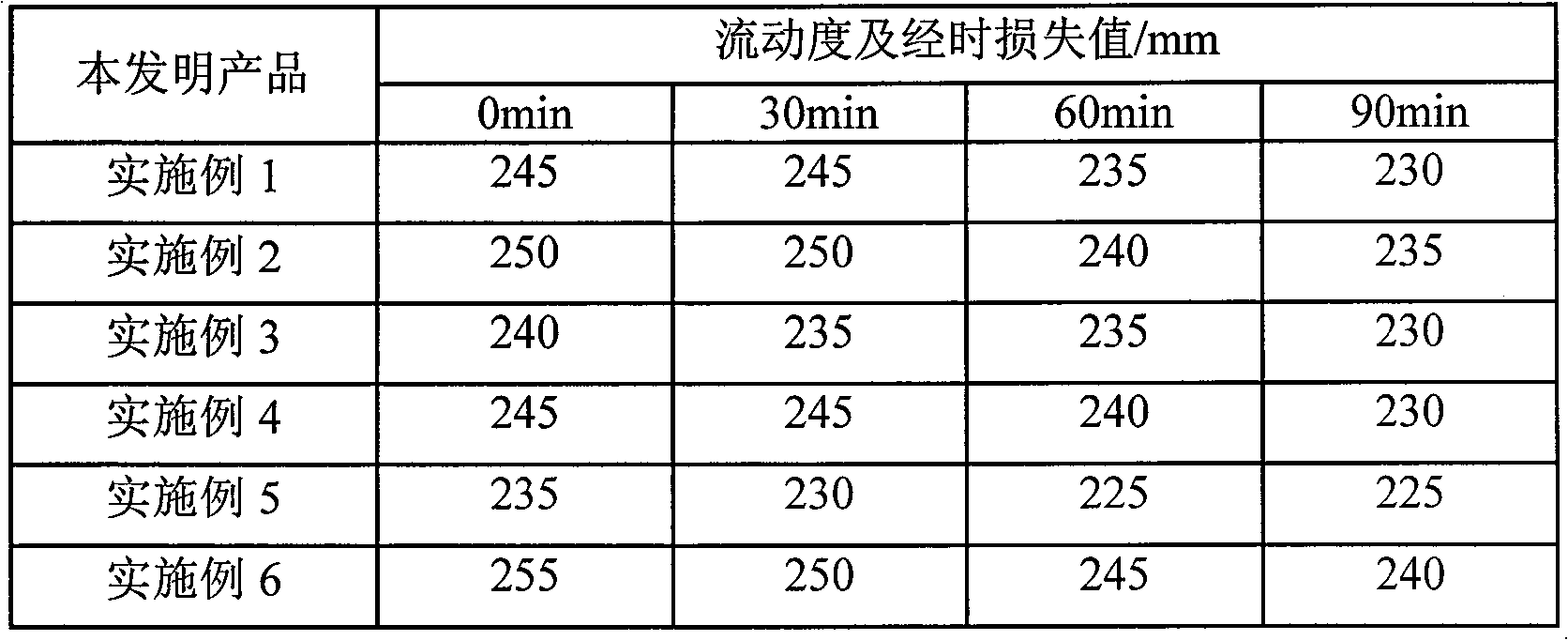

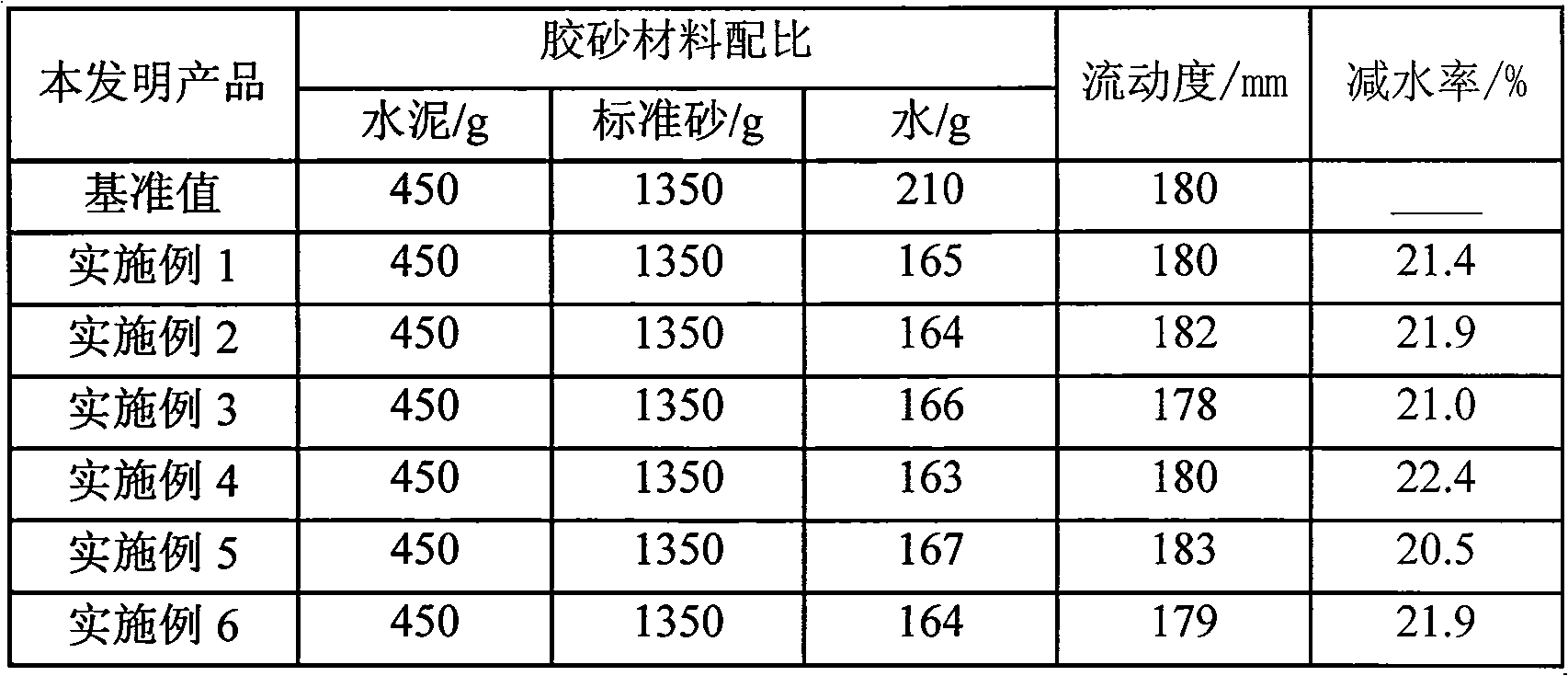

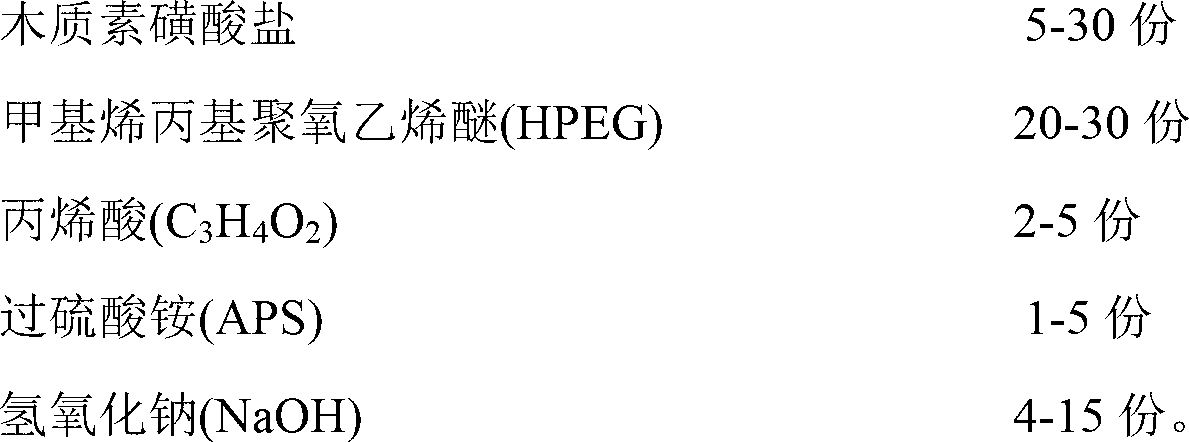

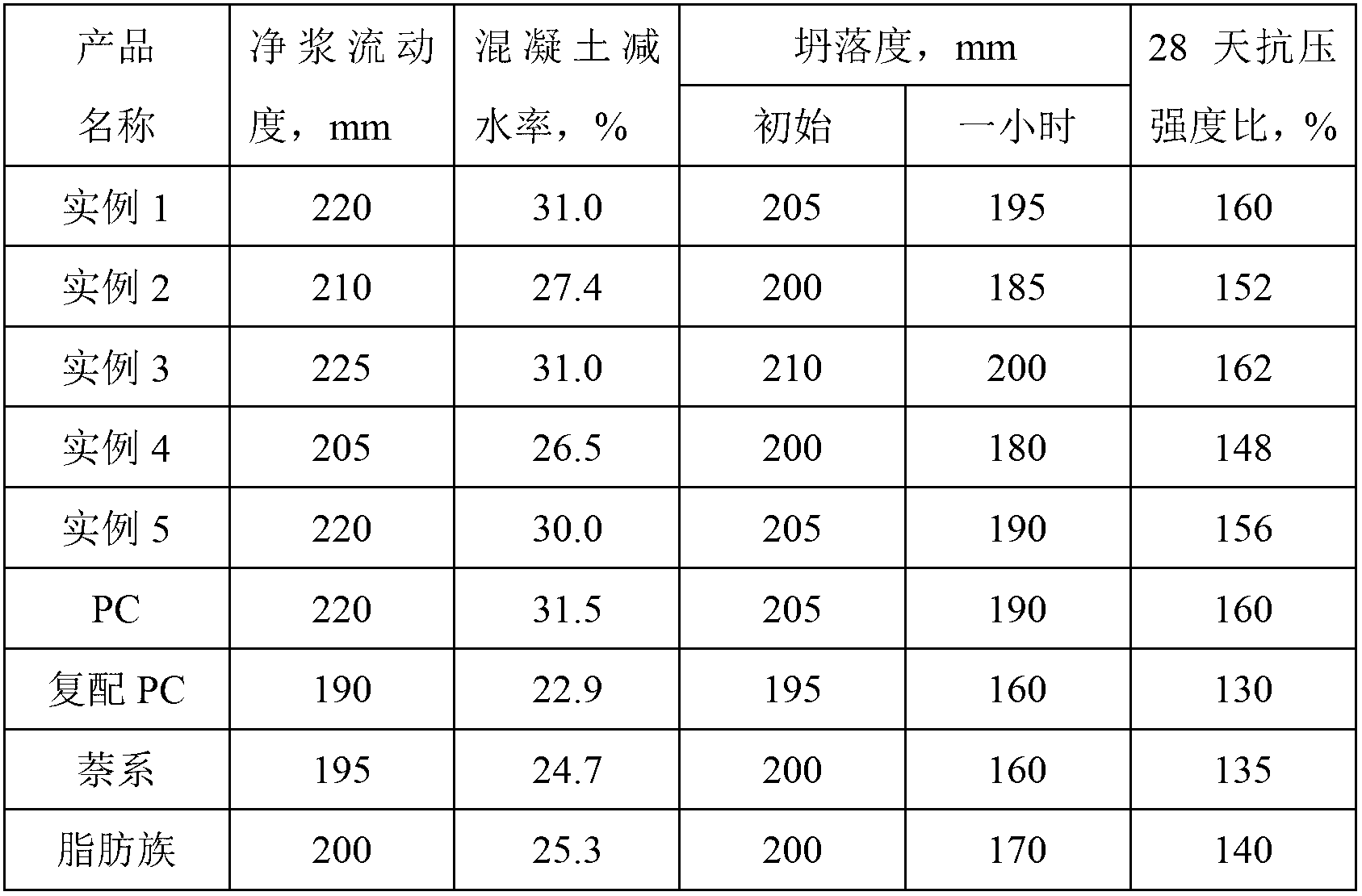

Lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and preparation method thereof

The invention discloses a lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and a preparation method thereof. The high-performance water reducer comprises the components in parts by weight: 5-30 parts of lignosulfonate, 20-30 parts of methyl allyl polyethenoxy ether, 2-5 parts of acrylic acid, 1-5 parts of ammonium persulfate, 4-15 parts of sodium hydroxide and water. The preparation method comprise the steps as follows: lignosulfonate, methyl allyl polyethenoxy ether and acrylic acid are directly synthesized under the action of ammonium persulfate, and the mixture is neutralized by sodium hydroxide to obtain the high-performance water reducer. As the high-performance water reducer is made from natural recycled materials, the high-performance water reducer is low in price, stable in performance, high in water-reducing rate, good in collapse prevention property, remarkable in improved effect, and is unlikely to bleed, separate and deposit after concrete is added, the quality problems of sand leakage, honeycomb-like phenomenon and leakage due to cracking in the middle and low-strength concretes are effectively avoided, and the safety performance is improved.

Owner:MAANSHAN CHINASEA NEW MATERIAL

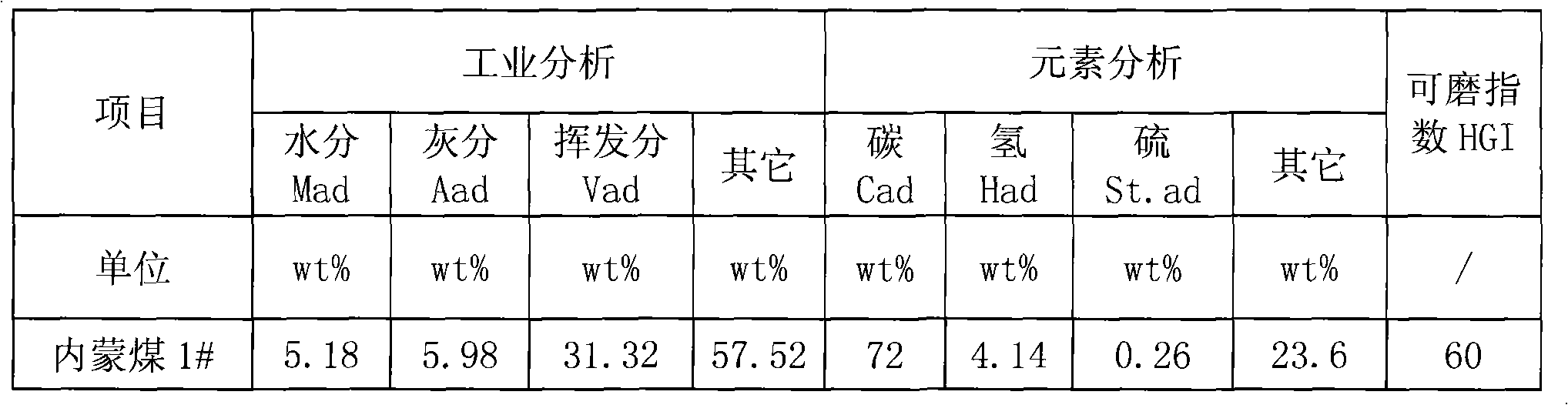

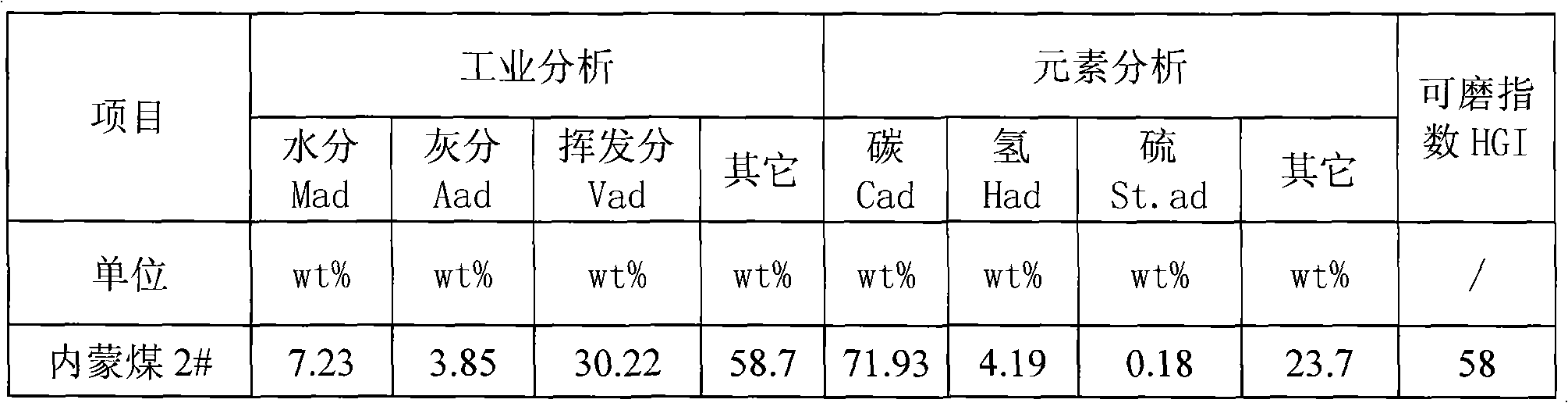

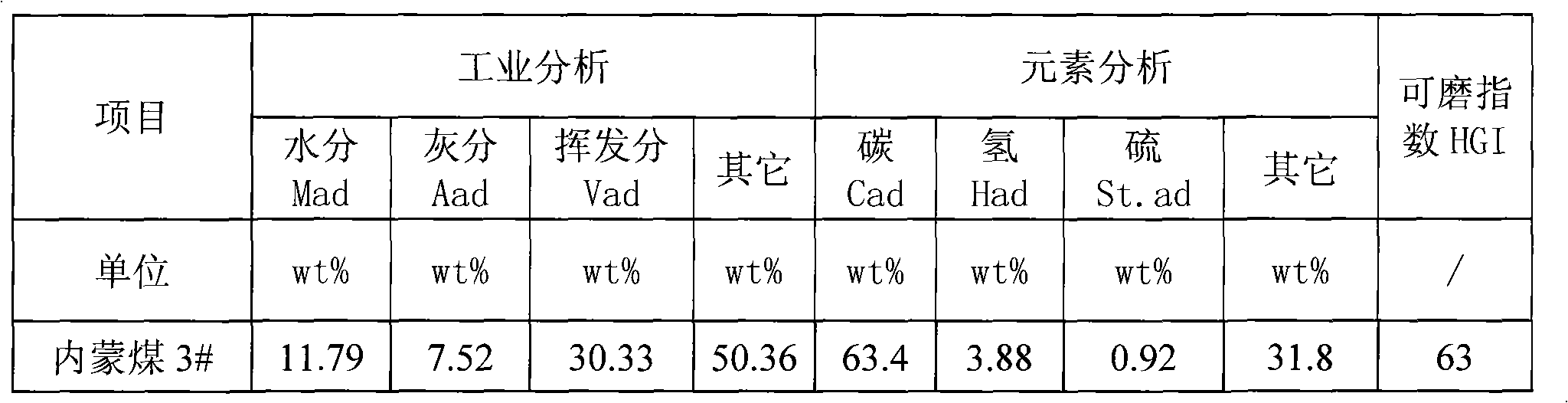

Special composite coal water slurry additive for coal gasification

InactiveCN103509617ALess unit consumptionHigh slurry concentrationLiquid carbonaceous fuelsPowder mixturePhosphate

The invention relates to a special composite coal water slurry additive for coal gasification, which is mixed and prepared from the following components in percentage by weight: 30-75% of lignosulfonate, 10-45% of sulfonate formaldehyde condensate, 5-15% of polyethenoxy ether, 5-25% of phosphate, 0-5% of pH regulator and 0-2% of stabilizer. The components are proportionally prepared into a solid powder mixture or a water solution with arbitrary concentration, and are added into dry-basis coal powder to be uniformly stirred, wherein the additive on dry basis accounts for 0.4-1.0 wt% of the dry-basis coal powder. The finished product coal water slurry prepared from the additive has the advantages of high slurry concentration, low viscosity, favorable rheological property, high stability and wide adaptability to coal types.

Owner:湖南东盈节能环保科技开发有限公司

Water-coal-slurry additive and preparation method thereof

ActiveCN101550369AImprove hydrophilicityReduce viscosityLiquid carbonaceous fuelsAlkylphenolMethyl group

The invention provides a water-coal-slurry additive and a preparation method thereof. The additive is compounded by anionic surfactant naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and non-ionic surfactant alkylphenol polyethenoxy ether (methyl) acrylic ester according to mass ratio of 8:1:1 to 1:8:1. The invention uses the naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and alkylphenol polyethenoxy ether (methyl) acrylic ester in the preparation technology of water-coal-slurry, and the additive has wide adaptability to coal, in particular to coal with low degree of metamorphism. When ternary compound additive reaches 0.1-1wt percent of the weight (dry basis) of the coal, the water-coal-slurry with the content of coal dust being 62-70wt percent can be prepared. The slurry has good fluidity, lower apparent viscosity and favorable steady state stability. The ternary compound additive is simple in production process, excellent in performance and wide in the range of applicable coal.

Owner:ENN XINNENG BEIJING TECH

Coal water slurry additive and preparation method and application thereof

The invention discloses a coal water slurry additive and a preparation method and application thereof. The method is characterized in that the coal tar fraction wash oil is taken as the starting material, carries out sulfonation reaction with a sulfonating agent and then carries out polycondensation reaction with aminobenzene sulfonate, phenols and formaldehyde; and neutralization is carried out after reaction is completed. The method can greatly lower the production cost, and the obtained additive has the advantages of small mixing amount, excellent dispersibility, good slurry forming ability and stability and reduction of the stabilizing agent in the coal water slurry. The additive can not only be independently used for preparing the coal water slurry, but also be used by being compounded with other types of additives, such as naphthalene sulfonate-formaldehyde condensates, polycarboxylic acid additives or lignosulfonate and other anionic surfactants and synthesize the coal water slurry suitable for different types of coal by adjusting the production conditions. The coal water slurry prepared by the additive has the solid content between 63% and 70% and is easy to flow and clean. The viscosity of the coal water slurry is controlled below 1200mPa.s at the shearing rate of 100s<-1>.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD +1

Preparation of high boiling point alcohol lignin polyurethane

A process for preparing the high-boiling-point alcohol lignin polyurethane includes such steps as preparing high-boiling-point alcohol lignin from wood, bamboo, straw and nut shell, dissolving it in organic solvent, mixing with polyol or its solution, stirring, adding polyisocyanate, heating, and thermally reacting while adding modified or filler.

Owner:FUZHOU UNIV +1

Insecticidal Compositions Suitable For Use in Preparation of Insecticidal Liquid Fertilizers

ActiveUS20080206361A1Improve physical stabilityBiocideDead animal preservationSucroseAluminum magnesium silicate

Insecticidal compositions suitable for use in preparation of insecticidal liquid fertilizers comprising a pyrethroid, a hydrated aluminum-magnesium silicate, and at least one dispersant selected from the group consisting of a sucrose ester, a lignosulfonate, an alkylpolyglycoside, a naphthalenesulfonic acid formaldehyde condensate and a phosphate ester are disclosed.

Owner:FMC CORP

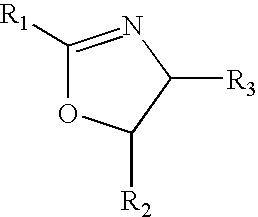

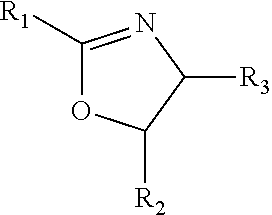

Wood Adhesives Comprising Protein and Oxazoline Polymer or Resin

InactiveUS20100069533A1Improve curing speedEasy curingProtein adhesivesPaper coatingLignosulfonatesMedium density fiberboard

The present invention provides wood adhesive binder compositions comprising a naturally occurring protein component, e.g. soy flour, and an oxazoline-functional group containing polymer or resin component, the two components in a solids weight ratio of from 60:40 to 98:2. As formulated, the compositions may comprise from 40 to 98 wt. % of the naturally occurring protein component, preferably, 50 wt. % or more. Preferably, the wood adhesive binder further comprises lignins or lignosulfonate. Where the wood adhesive binder compositions comprise lignins or lignosulfonates, they remain more fluid and workable at a higher pH such as, for example, 4.5 or more. Any of the compositions may be formulated with one or more in situ acid generator compound to insure more rapid cure on heating or pressing. The binder enables the provision of mechanically sound, low cost and biodegradable composites, such as, medium density fiberboard (MDF).

Owner:BRADY JEAN M +4

Novel active water fracturing fluid for fracturing of coal bed gas well

InactiveCN101948684AWith anti-expansion effectHas the effect of reducing resistanceDrilling compositionPotassiumFracturing fluid

The invention relates to a fracturing fluid for the fracturing construction of coal bed gas well. In general, a coal bed gas well cannot be put into operation before the fracturing construction. Owing to the characteristics of small harm, low cost, convenient preparation and the like, the active water is extensively applied to the fracturing construction of coal bed gas well. The typical active water fracturing fluid is generally prepared from clear water, anti-swelling agent (typically potassium chloride) and cleanup additive (typically complex of surfactants, typical cleanup additive for oil field is D-60 and HP-8, etc.) based on certain proportions. The active water fracturing fluid shows, when being used for the fracturing construction, the defects of high frictional resistance and no dispersion effect on coal dusts generated in the process of the fracturing construction. The active water fracturing fluid according to the invention is prepared in a manner of adding the typical active water fracturing fluid with drag-reducing agent (anionic or nonionic polyacrylamide) and coal dust dispersing agent (lignosulfonate, such as sodium lignin sulfonate) based on the mass percents as below: 1%-2% of potassium chloride, 0.02% to 0.06% of drag-reducing agent and 0.01% to 0.03% of dispersing agent. The fracturing fluid according to the invention has the characteristics of simple formula, the effect of reducing frictional resistance of construction tubular columns and uniformly dispersing coal dusts, small harm to coal bed and easy flowback.

Owner:CHINA UNITED COALBED METHANE +1

Low temperature method for manufacturing high thermal shock superhigh temperature zircite product

The invention discloses a method for manufacturing a high thermal shock ultra-temperature zirconium dioxide product at low temperature. The manufacturing method is to use electric-melting high-purity zirconium dioxide fine powder with granularity less than 47mum (using one of Y2O3, (CaO+Y2O3), (CaO+MgO) and (MgO+Y2O3) as a stabilizing agent) as a substrate, Y2O3 fine powder with granularity less than 5mum as an additive, one of ZrO2 collosol and ZrOCl solution or combination of one of lignosulphonate and phenolic resin with the ZrOCl solution as a bonding agent to fire the product after milling, forming and drying at a temperature ranging from 1,630 to 1,700 DEG C. Heavy and light high purity zirconium dioxide products which are manufactured by the method have high thermal shock stability, high compressive strength, good high temperature stability, strong impermeability and erosion resistance, good thermal insulation effect and the like, and can be used in a high temperature environment over 2,200 DEG C for long time; and the manufacturing method has the advantages of simple manufacturing process, easy industrial popularization and application and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Stable Mixtures of Microencapsulated and Non-Encapsulated Pesticides

The present invention is directed to a composition comprising i) a microencapsulated pesticide, ii) a dispersant selected from the group consisting of a lignin, b) a lignosulfonate salt and c) a lignosulfonate salt combined with the sodium salt of substituted naphthalene sulfonate formaldehyde polymer, iii) a salt selected from the group consisting of magnesium sulfate, sodium chloride, sodium nitrate and calcium chloride, and iv) a non-encapsulated pesticide. The present invention is also directed to methods of making and using the compositions of the present invention.

Owner:FMC CORP

Insecticidal compositions suitable for use in preparation of insecticidal liquid fertilizers

ActiveUS8029827B2Improve physical stabilityBiocideDead animal preservationAluminum magnesium silicateSucrose

Insecticidal compositions suitable for use in preparation of insecticidal liquid fertilizers comprising a pyrethroid, a hydrated aluminum-magnesium silicate, and at least one dispersant selected from the group consisting of a sucrose ester, a lignosulfonate, an alkylpolyglycoside, a naphthalenesulfonic acid formaldehyde condensate and a phosphate ester are disclosed.

Owner:FMC CORP

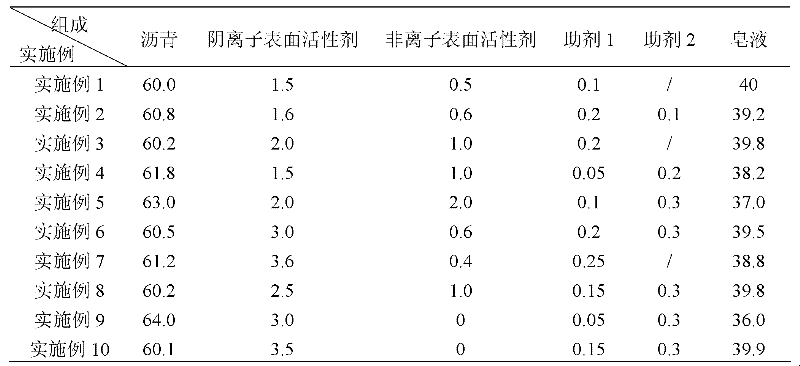

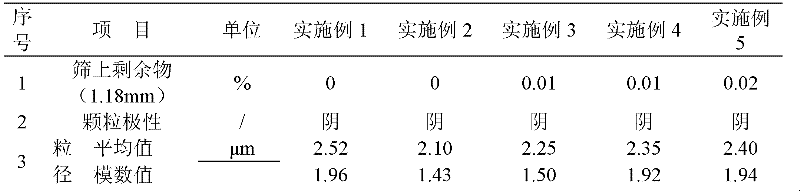

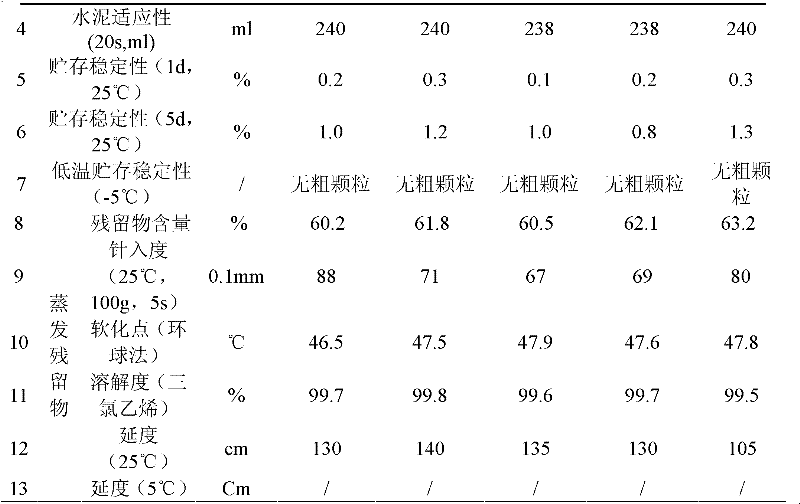

Anionic emulsified asphalt and preparation method thereof

ActiveCN102286205AAdvanced preparation technologyImprove homogeneityBuilding insulationsSulfateLignosulfonates

The invention provides anionic emulsified asphalt and a preparation method thereof. The cement emulsified asphalt comprises the following components in percentage by weight: 55 to 65 percent of asphalt, 0.5 to 5 percent of anionic surfactant, 0.02 to 4 percent of aid, and the balance of water. The anionic surfactant can be one of tall oil sulfonate, alkyl sulfonate, alkylbenzene sulfonate, alkyl sulfate and lignosulfonate. The emulsified asphalt provided by the invention has the advantages of good storage stability, wide temperature adapting range, good adaptability with cement, good compatibility and the like; and the cement emulsified asphalt mortar prepared by using the emulsified asphalt has good flow property, long service life and wide temperature adapting range, does not produce dissociation or lamination, has excellent physical and mechanical properties, and fully meets the requirement of construction, so that the emulsified asphalt can be effectively used for the cement emulsified asphalt mortar in plate type ballastless tracks of high speed railways.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Carboxylated lignin based binders

InactiveUS20110159768A1Improve curing speedEasy curingSpecial tyresWoven fabricsLignosulfonatesWet strength

The present invention provides binder compositions comprising an ethylenically unsaturated carboxy acid grafted lignin or lignosulfonate component, and an oxazoline-functional group containing polymer or resin component, the two components in a solids weight ratio of from 50:50 to 98:2. As formulated, the compositions may comprise from 40 to 98 wt. % of the acid grafted lignosulfonate, preferably, 50 wt. % or more. Preferably, the binder composition further comprises one or more in situ acid generator compound to insure more rapid cure on heating or pressing. The binder enables the provision of low cost composite materials comprising a majority component derived from natural materials, and having a reasonable wet strength.

Owner:CRESCIMANNO STEPHEN A +1

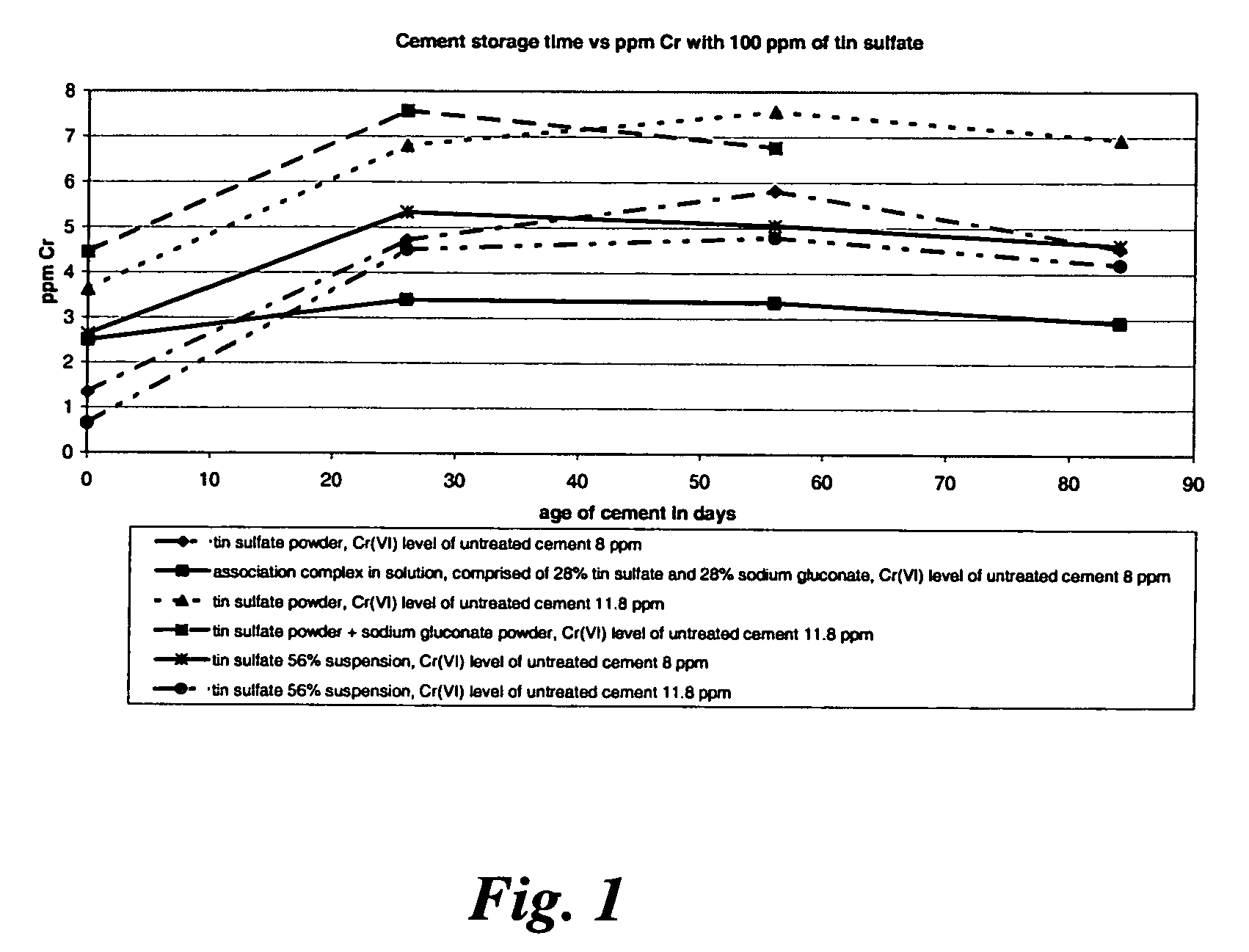

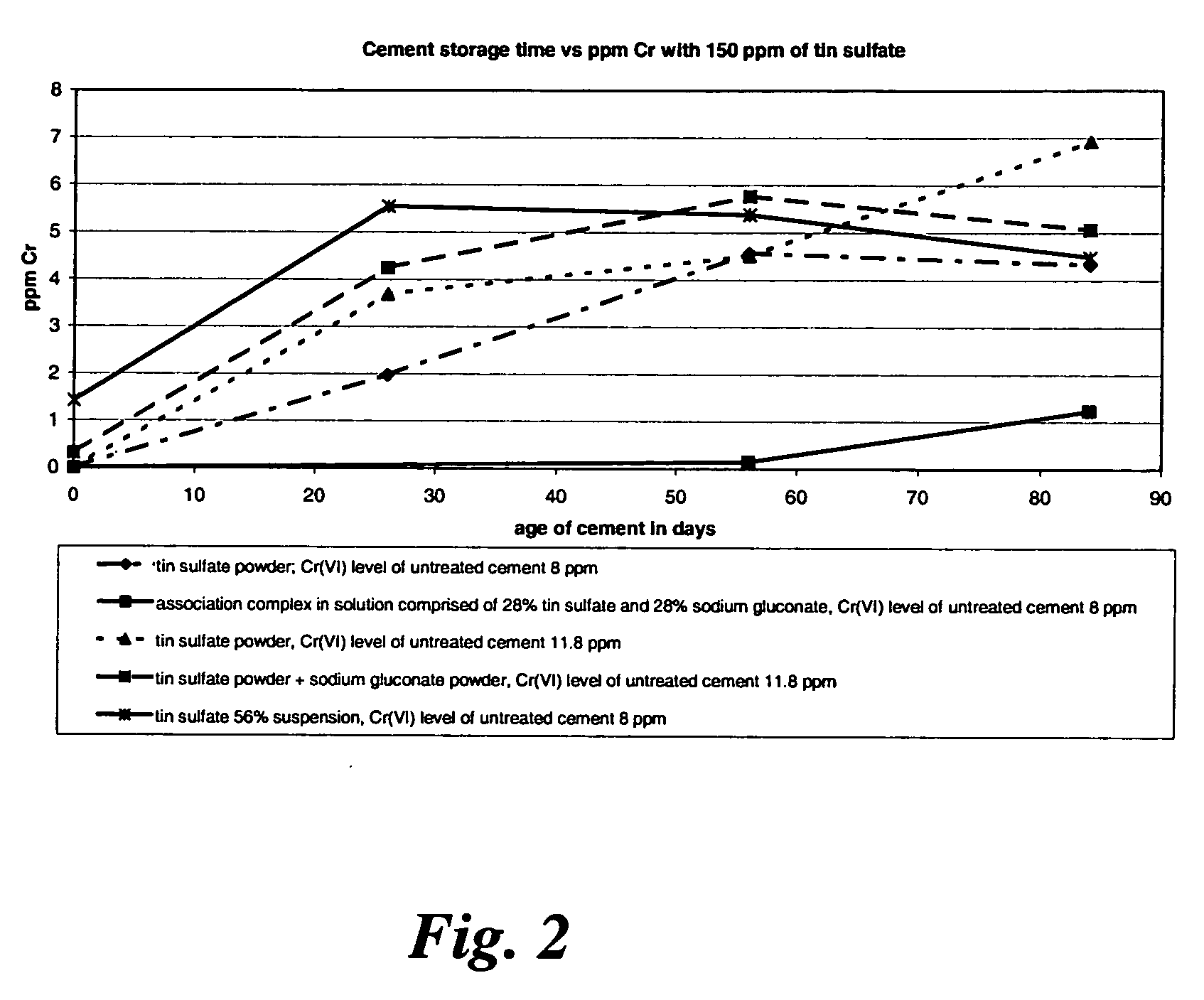

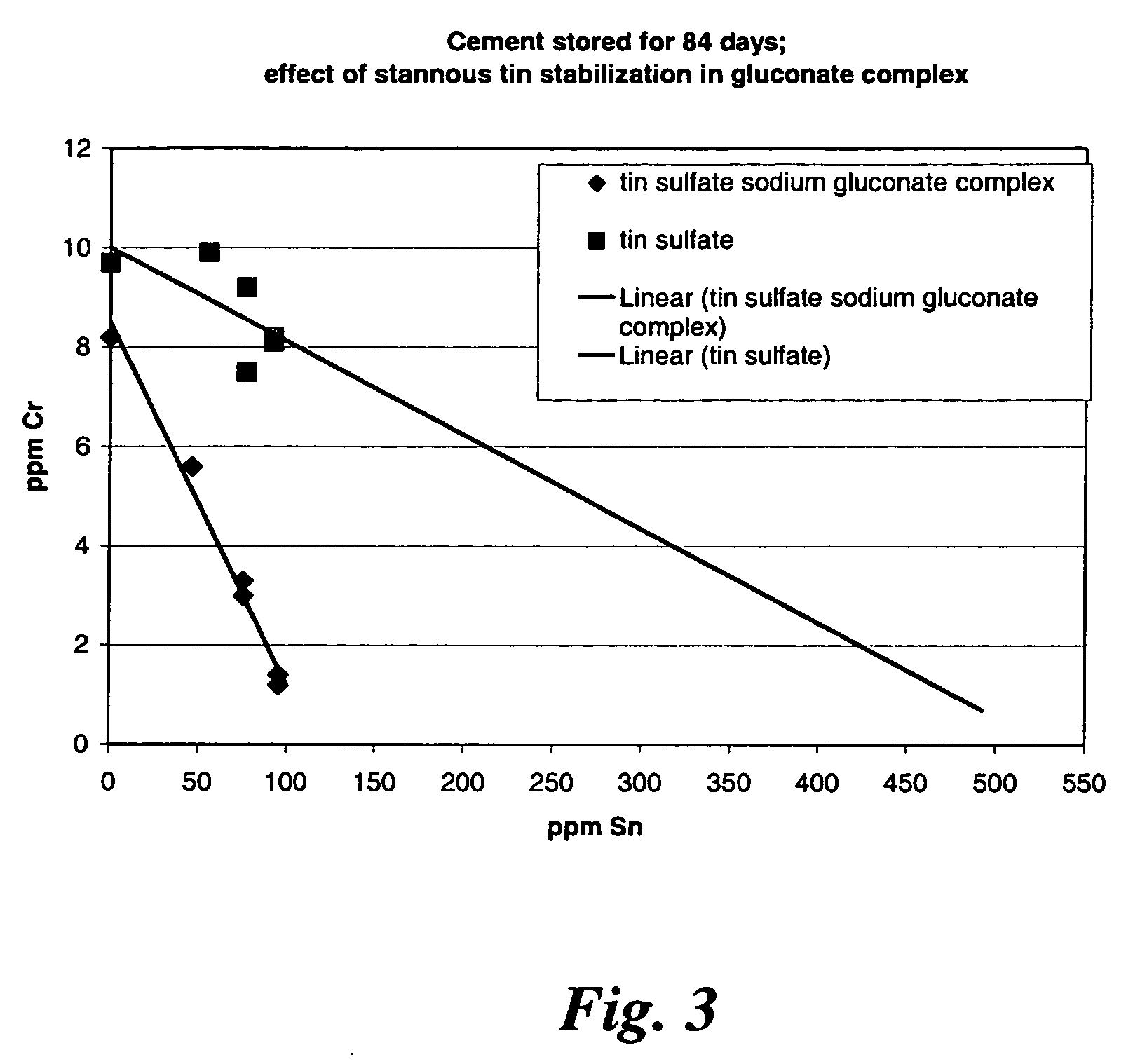

Dosage efficient, storage stable compositions for reducing chromium (VI) in cement

InactiveUS20070034118A1Maintain curative effectMaintaining the efficacy of chromium reducers in cement over timeHydration reactionSulfonate

An association complex formed in a liquid environment from a metal-based chromium (VI) reducer and a non-lignosulfonate-based complexing agent is introduced into cement clinker or hydratable cement particles. In preferred embodiments, the formation of the association complex provides storage stability to the chromium reducer within the cement, such that the level of chromium (VI) after water is added to the cement remains less than 2 ppm for certain duration after mixing with water and without the necessity for further additions of chromium reducer during said duration (e.g., 26-84 or more days after addition). Compositions having the association complex are also described.

Owner:WR GRACE & CO CONN

Lignosulfonate series air entraining and water reducing admixture for concrete and its prepn process and application

The present invention relates to preparation process of serial lignosulfonate air entraining and water reducing admixtures for concrete. The preparation process includes the following steps: dissolving solid lignosulfonate in water of the same weight, adding catalyst and oxidant, heating after reaction, adding amine and partial aldehyde to aminate, and dropping the rest aldehyde for condensation reaction to obtain the product; adding surfactant and polymer through stirring, and cooling to obtain liquid phase lignosulfonate as air entraining and water reducing admixture. The present invention is used as the admixture for concrete, and has relatively high water reducing rate, capacity of raising the strength of concrete, and certain setting retarding effect to delay the appearance of cement setting heat peak and reduce crack caused by temperature change.

Owner:SOUTH CHINA UNIV OF TECH

Concrete material and preparation method thereof

The invention provides a concrete material, comprising the following components with corresponding proportions: cement, fine aggregate, coarse aggregate, fly ash, silica fume, carbon nanotube, nano silica, ceramsite, polyphenyl particles, steel fibers, nano kaolin particles, ultrafine natural zeolite powder, gypsum, polymer emulsion, a diol compound, modified lignosulfonate, a layered silicate mineral material, polysiloxane, oxalic acid, styrene acrylic emulsion, crystalline hydrated magnesium aluminum silicate minerals, water, a super plasticizer, a barium-containing naphthalene superplasticizer, an organic polymer plastic retaining agent, a composite retarder and an air entraining agent. The invention further relates to a preparation method of the concrete material. Compared with the existing concrete, various properties of the concrete material provided by the invention are greatly improved. The concrete material has a wide application range, a significant practical engineering value and remarkable technical and economic significance.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Set retarders for foamed cements

InactiveUS6372037B1Simple methodImprove propertiesDrilling compositionCeramicwareLignosulfonatesSulfur content

An improved non-dispersing set retarder additive for foamed cements, cement compositions containing the additive, and methods of cementing in a subterranean zone penetrated by a well bore are provided. The set retarder additive includes a blend of a sulfonated lignin, preferably a lignosulfonate, with an alkali lignin, preferably a kraft lignin, having an organic sulfur content of 0-3.5% by weight in a ratio of about 6:4 to 8:2. The methods are basically comprised of the steps of preparing a foamed cement composition comprised of hydraulic cement, a non-dispersing set retarder, sufficient water to form a slurry, sufficient gas to foam the slurry and a foaming and foam stabilizing surfactant present in an amount sufficient to facilitate the formation of the foam and stabilize the foamed cement composition.

Owner:LIGNOTECH USA INC

Method for removing metals from acid mine drainage

InactiveUS20040094484A1Increase settling velocityHigh densityWaste water treatment from quariesSolid waste disposalFerrous saltsSludge

A method for removing metal contaminants from acidic mine wastewater using lignin derivatives, such as lignosulfonates and kraft lignin, an alkali coagulant, such as a lime compound, and an alkaline composition for increasing the pH. The lignin derivatives are dispersed in the wastewater and the coagulant is added, increasing the pH to about 4.5-8.5 and causing the formation of a floc. The alkaline composition is then added to bring the pH to about 9 to 10, causing the further formation of a floc. Optionally, air oxidation is carried out, reducing the pH to about 8.1-8.6. Optionally, a ferric or ferrous salt may also be added. The flocs comprise metal-lignin colloids, metal hydroxides and metal salts. The flocs coagulate to form a sludge. Optionally, fly ash or diatomaceous earth may be added to increase the density and stability of the sludge. The sludge that is formed contains the metals and is separated from the treated water by filtration.

Owner:NORAM ENG & CONSTRS

Oil-soluble pesticide nano capsules and preparation method thereof

InactiveCN101461358AMild conditionsEase of industrial productionBiocideAnimal repellantsCypermethrinAbamectin

Disclosed is an oil soluble pesticide nm capsule and preparation method, having weight ration of: pesticide: 0.5-4%; high molecular compound: 8-25%; mixed-surfactant: 8-20%; cosurfactant 3-10%; crosslinking agent 0.5-1.0%; organic solvent 3-10%; water: added to 100%, wherein the high molecular compound is selected from sodium lignosulfonates, chitosan, gum arabic or glutin, one or two is / are selected for agglutination reaction, forming capsule skin of the nm capsule; the capsule core is pesticide bulk drug, selected from diflubenzuron, emamectin benzoate, abamectin, imidacloprid, ivermectin or highly active cypermethrin. The mixed-surfactant adopts nonionic surfactant and anionic surfactant for compound. The pesticide nm controlled release preparation prepared by the invention is easy in storage, high in stability, large in drug-loading rate and high in dispersion.

Owner:NANJING NORMAL UNIVERSITY

Composite water-retaining thickening material for commodity mortar and using method thereof

ActiveCN101186463AImprove cohesionImprove water retentionSolid waste managementSodium BentoniteThermal insulation

The invention belongs to the technical field of building materials, in particular to a compound water-preservation and viscosity promoting material used in commercial mortar and a preparation method thereof. Ca-bentonite, na-bentonite, kaolin, sepiolite, zeolite, cellulose ether (viscosity 10000mPa.s-200000mPa.s), fly ash and lignosulfonate are mixed and then ground till sieve residue is less than 40 percent with 0.08mm square opening sieve. The invention can greatly improve the cohesiveness and consistency of mortar, reduce the stratification of mortar and improve the water retaining rate of the mortar and perfect the uniformity, stability and constructability of mortar mixture, thus promoting construction efficiency and reducing environmental pollution. Being added with the material of the invention, the strength and durability of the mortar can be improved and the hazard of shrinkage and crack can be obviously reduced. The invention is specially used in the preparation of (dry-mixed, ready-mixed) mortar for masonry, plastering and ground commodities and also applied to the preparation of thermal insulation mortar and decorative plaster, etc.

Owner:上海曹杨建筑粘合剂厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com