Patents

Literature

103 results about "Kraft lignin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

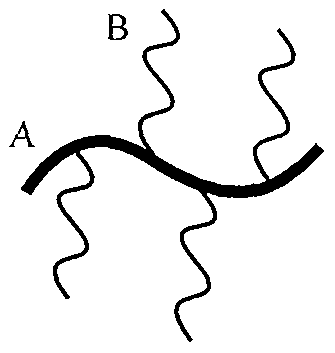

The kraft process entails treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulfide (NaS2), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose.

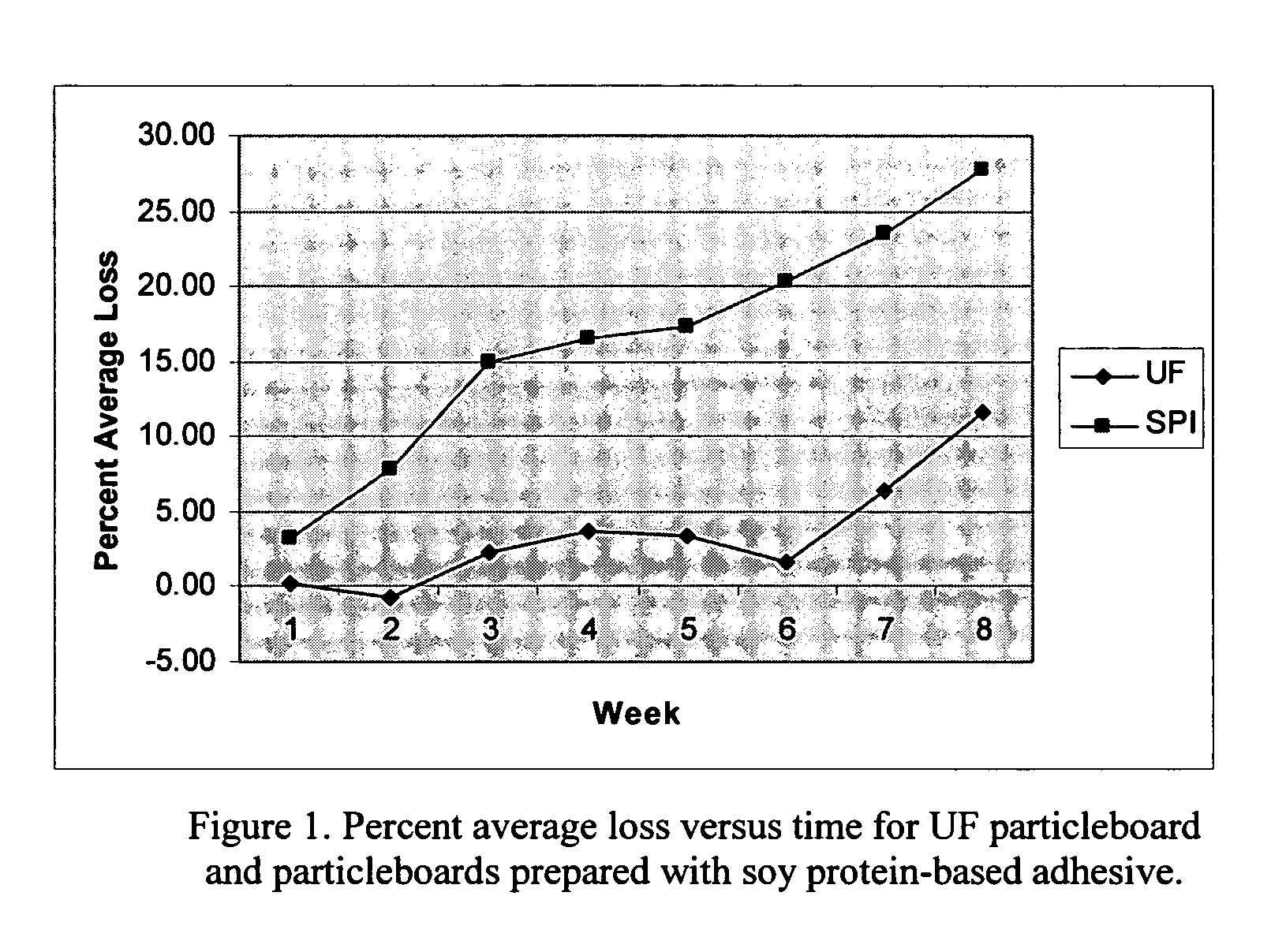

Soy protein based adhesive and particleboard

An adhesive composition that can be used in particleboards and other composites is formed from an aqueous mixture of soy protein, zinc sulfate heptahydrate, calcium oxide, sodium benzoate, pine oil, wax emulsion and non-sulfonated kraft lignin. In a second embodiment the composition further includes an acid.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Soy protein based adhesive and particleboard

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

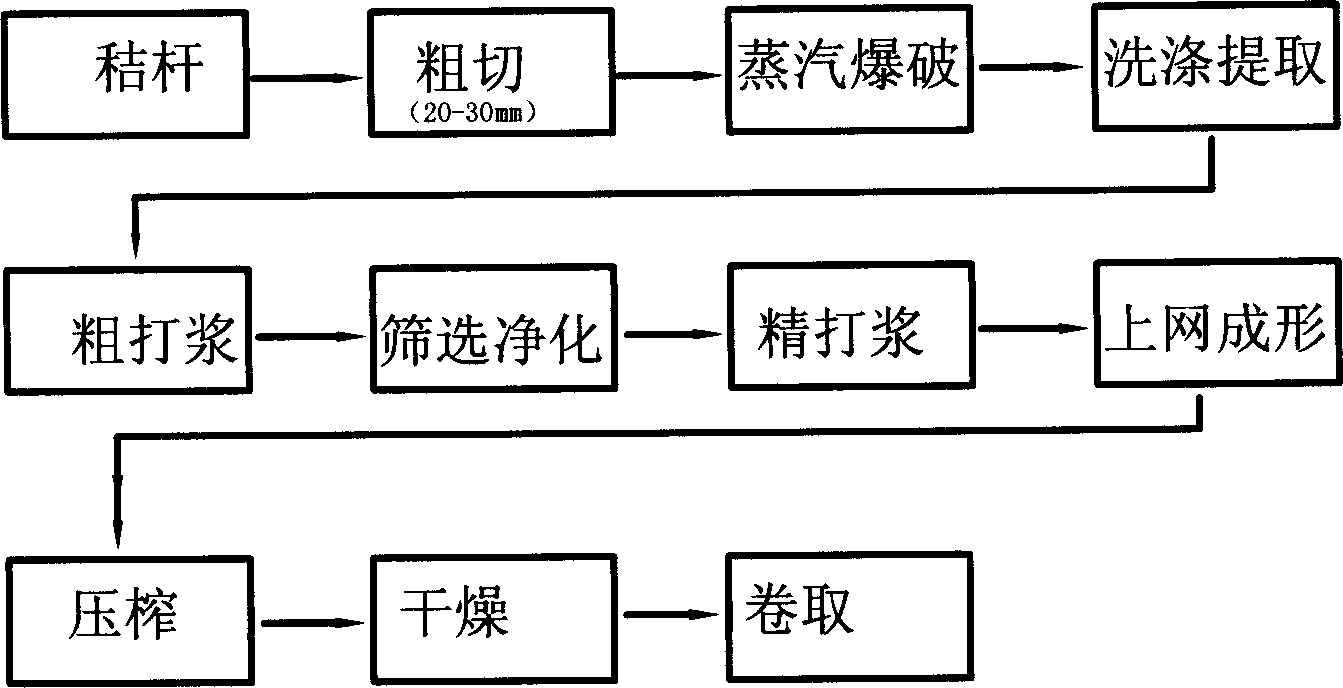

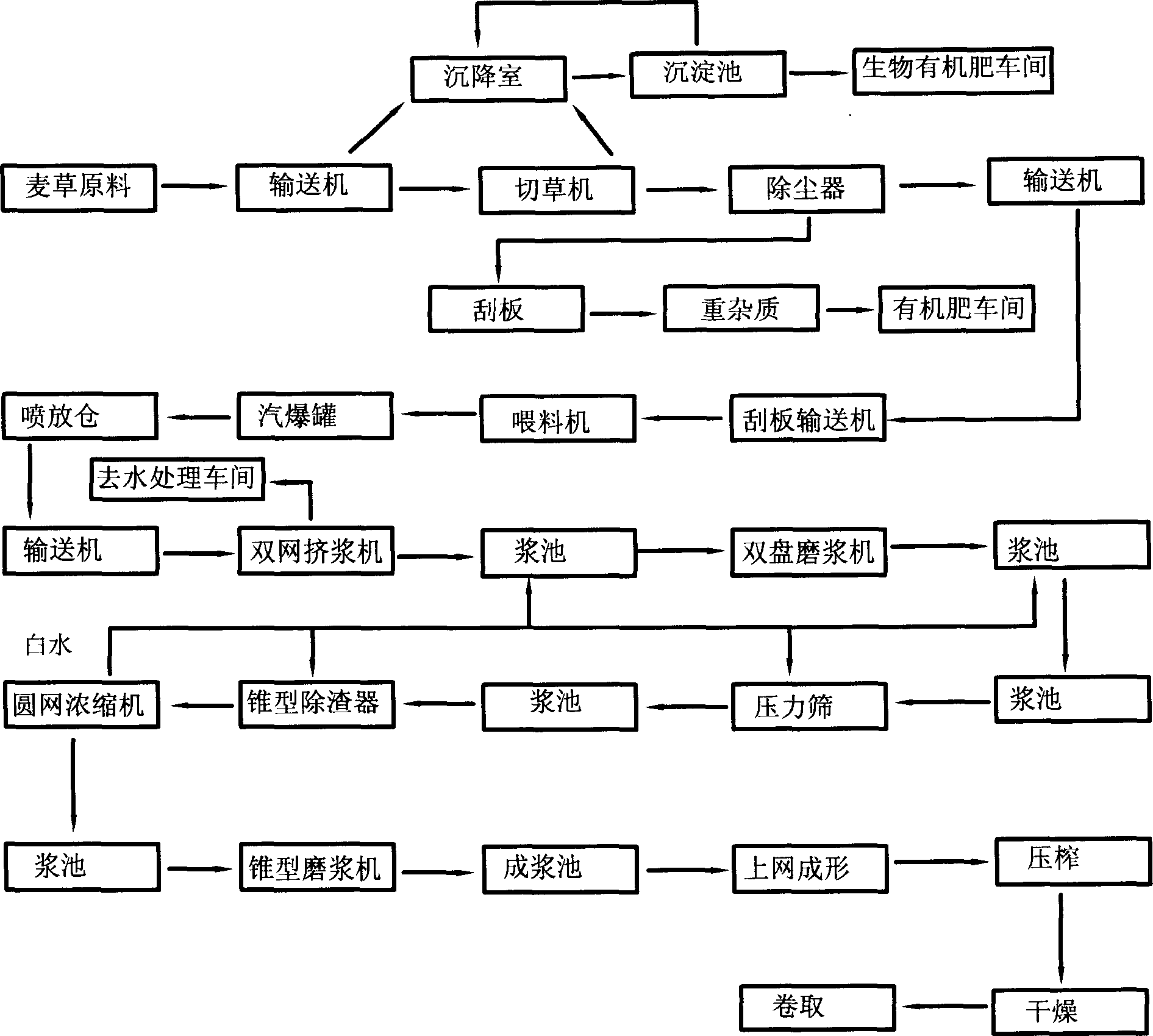

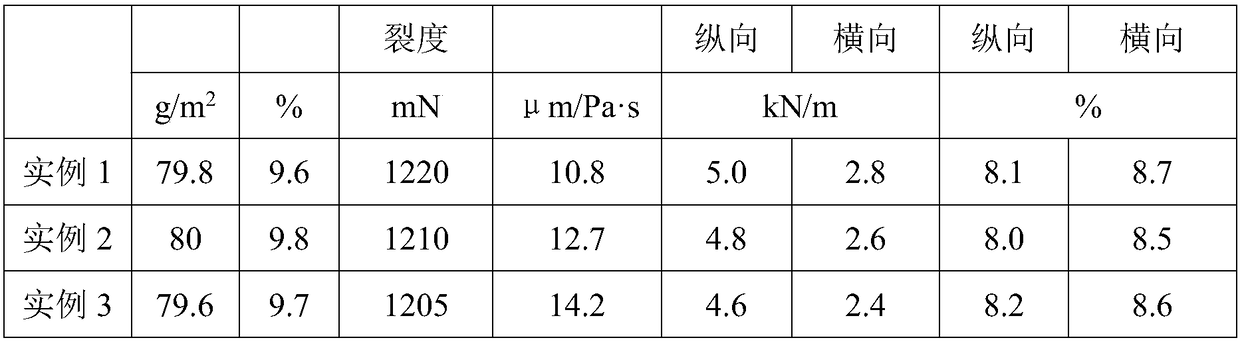

Corrugated paper produced by steam blasting straw to pulp and its production method

The invention relates to light weight high fatigue resistance semi-chemical corrugated paper produced by steam blasting stalk Kraft process and its manufacturing method. The method includes the following steps: using stalk as the raw material; do steam blasting after coarse cutting; adding its 0.5-2% bone dry weight into caustic soda; filling in steam blasting pot; vapor phase boiling temperature is 145-180 deg.C; pressure is 0.9-2.0MPa; treatment is time 12-18 min; gaining steam blasting stalk; washing and extracting; coarse beating; sieving; purifying; fine beating; gaining steam blasting ryegrass pulp; mixing the pulp and the existing natural color long fiber with 50-70% and 30-50% of their absolute dry percentages; facing wire and forming; pressing; drying; balling up to gain finished products. The invention has the advantages of low energy consumption, low pollution, and high yield. And it is good for environmental protection. The produced semi-chemical corrugated paper has the features of light weight, high fatigue resistance, and flat appearance.

Owner:山东丰源中科生态科技有限公司

Process For Producing A Pulp

ActiveUS20090312536A1Easy to solvePretreatment with water/steamNon-fibrous pulp additionKraft processPulp and paper industry

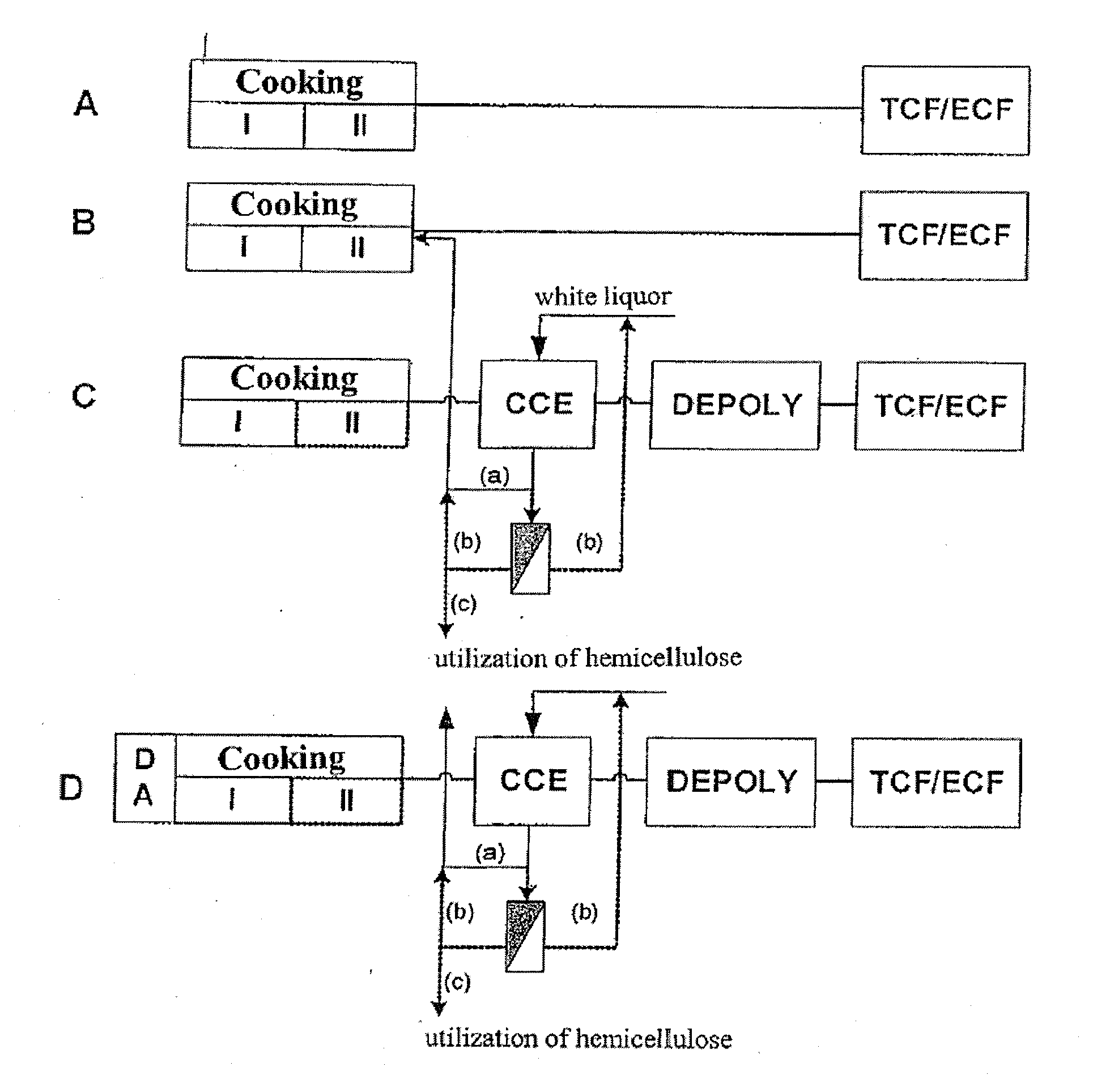

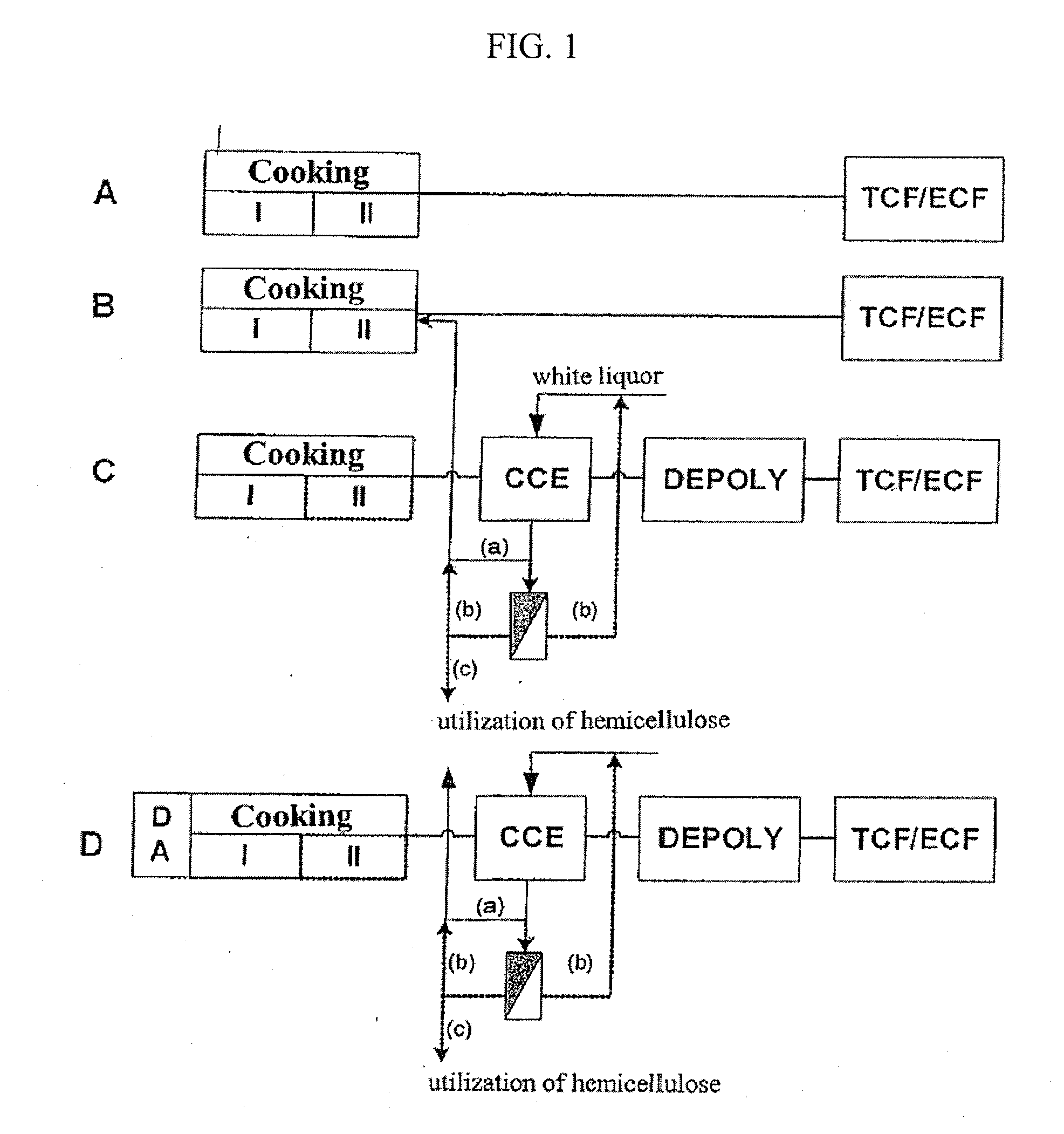

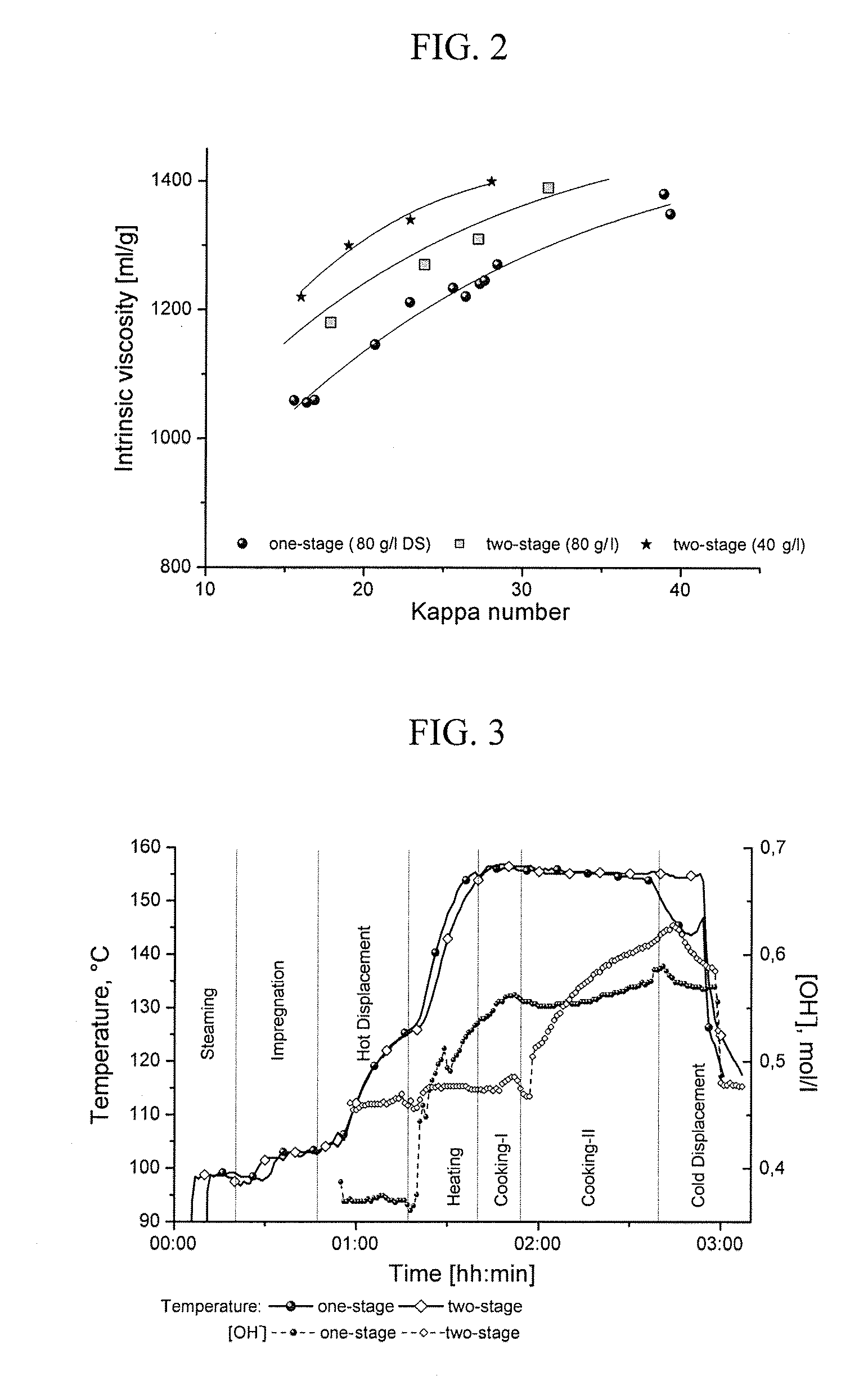

The invention relates to a process for producing a dissolving pulp from a cellulosic starting material using the kraft process, comprising the step of cooking the starting material with a cooking liquor. The process according to the invention characterized in that the starting material is exposed to a steam treatment prior to cooking and that the pulp obtained by cooking is subjected to cold caustic extraction (CCE) in the course of further processing.

Owner:LENZING AG

Asphalt emulsion composition

InactiveUS6840991B2Sufficiently secure the time required for mixing aggregatesIn situ pavingsAdhesivesSufficient timeEmulsion

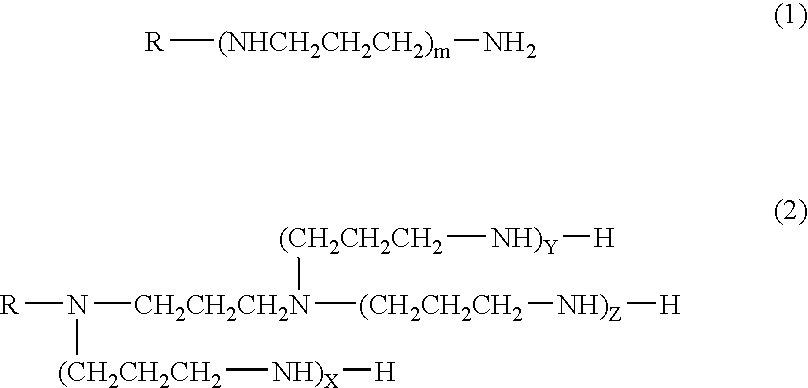

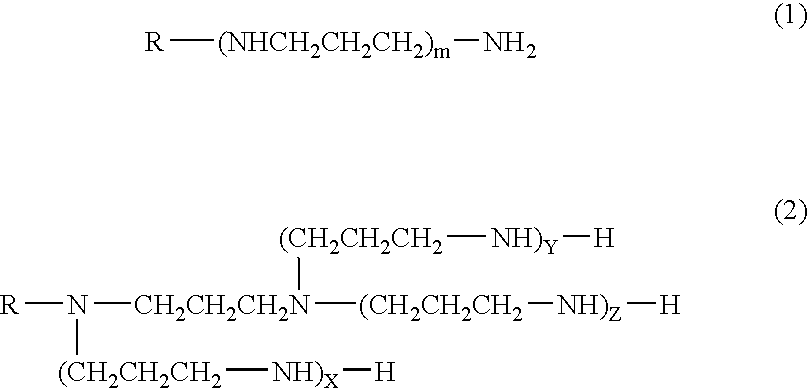

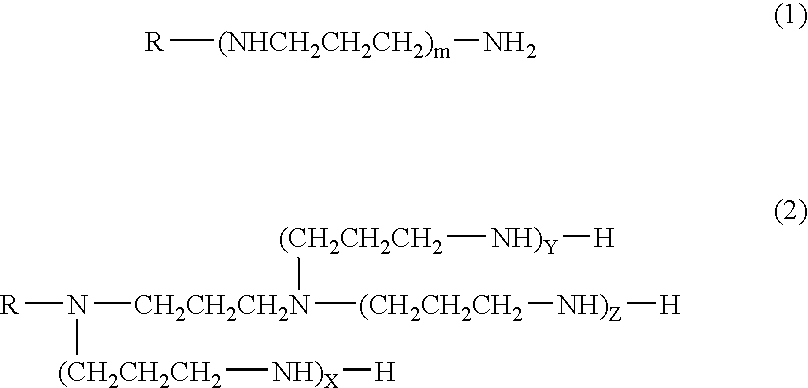

Provided is, particularly, a cationic asphalt emulsion composition which is scarcely affected by temperature during paving and by the characteristics of the aggregates to be used, can secure a sufficient time required to mix aggregates and enables slurry fluidity suitable for paving. The asphalt emulsion composition contains asphalt and water, the composition comprising kraft lignin (A) having a molecular weight of 4000 to 60000 and a specific polyamine (B) in each specific ratio to the asphalt emulsion composition.

Owner:KAO CORP

Method for removing metals from acid mine drainage

InactiveUS20040094484A1Increase settling velocityHigh densityWaste water treatment from quariesSolid waste disposalFerrous saltsSludge

A method for removing metal contaminants from acidic mine wastewater using lignin derivatives, such as lignosulfonates and kraft lignin, an alkali coagulant, such as a lime compound, and an alkaline composition for increasing the pH. The lignin derivatives are dispersed in the wastewater and the coagulant is added, increasing the pH to about 4.5-8.5 and causing the formation of a floc. The alkaline composition is then added to bring the pH to about 9 to 10, causing the further formation of a floc. Optionally, air oxidation is carried out, reducing the pH to about 8.1-8.6. Optionally, a ferric or ferrous salt may also be added. The flocs comprise metal-lignin colloids, metal hydroxides and metal salts. The flocs coagulate to form a sludge. Optionally, fly ash or diatomaceous earth may be added to increase the density and stability of the sludge. The sludge that is formed contains the metals and is separated from the treated water by filtration.

Owner:NORAM ENG & CONSTRS

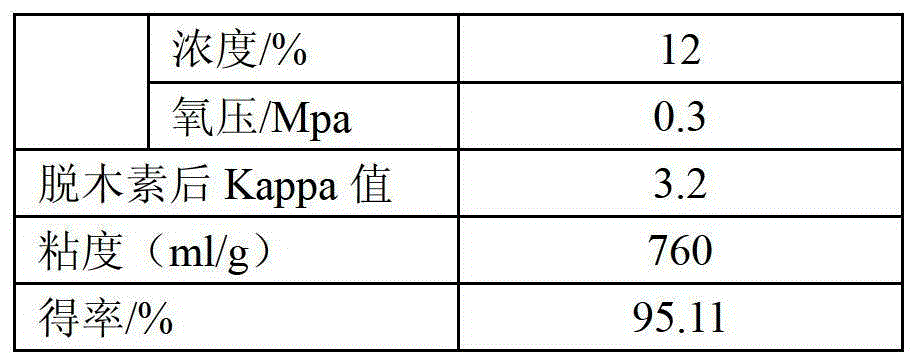

Eucalyptus dissolving pulp and production method thereof

InactiveCN102493256AReduce productionReduce pollution loadPretreatment with water/steamNatural cellulose pulp/paperSulfateDissolving pulp

The invention discloses a eucalyptus dissolving pulp and a production method thereof, wherein the eucalyptus dissolving pulp is prepared after the steam prehydrolysis, sulfate cooking, oxygen delignification and D0EoPD1 bleaching of eucalyptus pieces, the whiteness is not less than 88%, the alpha cellulose is not less than 94.5%, the pentosan is not higher than 3.0%, the dynamic viscosity is 9-25mPa s, the ash content is not higher than 0.1%, and the iron content is not higher than 15mg kg<-1>. The production method of the eucalyptus dissolving pulp comprises the following steps that: the eucalyptus pieces undergo the steam prehydrolysis, and the P- factor of the steam prehydrolysis is 300-800; the sulfate cooking is carried out after the steam prehydrolysis of the eucalyptus pieces to obtain the pulp; the eucalyptus chemical pulp undergoes the D0EoPD1 bleaching after the oxygen delignification; and after the bleaching, the pulp is washed, dried and processed into the eucalyptus dissolving pulp.

Owner:湖南骏泰新材料科技有限责任公司 +1

Wood fibrous material coupled enzymatic saccharification method

The invention relates to a wood fibrous material coupled enzymatic saccharification method which mainly comprises the following steps that: (1) crushed wood fibrous material is primarily pre-treated, and hemicellulose is hydrolyzed into monosaccharides or oligosaccharides solution through dilute acid or water treatment; (2) the solution in step (1) is separated from solid, residue is filtered, and hydrolyzed sugar solution and filtered residue are respectively prepared; (3) the filtered residue is cooked and delignified through a caustic soda method, a sulfate method or a sulphite method; and (4) the cellulose product which is prepared from the cooking in step (3) and is insoluble in reaction solution is filtered and mixed with the hydrolyzed sugar collected in step (2), the pH value is adjusted to be 3 to 7, cellulase, xylanase and cellobiase are added in to be hydrolyzed, and fermentable sugar is prepared. The wood fibrous material coupled enzymatic saccharification method not only reduces a neutralization step required by a one-step treatment (acid or alkali) process, but also improves the utilization rate (reducing sugar yield) of the wood fibrous material.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Production process of bleached chemical pulp with hemp stalk core

InactiveCN1811055ATake advantage ofEfficient use ofFats/resins/pitch/waxes removal in pulpPulp bleachingHypochloriteSulfate

The production process of bleached chemical pulp with hemp stalk core includes the following steps: 1. cutting hemp stalk core as material into 2-3 cm long sections, sieving and digesting in sulfate process to produce pulp; 2. washing and sieving the obtained pulp and oxygen delignifying; and 3. bleaching pulp with small amount of hypochlorite in a short program. Of the process, the medium concentration oxygen delignifying technology is one clean environment friendly bleaching technology with the bleached effluent being recovered and reused completely without environmental pollution, and the medium concentration hypochlorite bleaching can lower the exhausted waste water and reduce chemical and power consumption effectively. The pulp of the present invention can meet the requirement of making common paper.

Owner:SOUTH CHINA UNIV OF TECH

Method for treating metal-contaminated water and soil

InactiveUS20040010955A1Efficient and economical processStabilizing the metal contaminantsWaste water treatment from quariesPicture framesWater useSludge

A method for removing metal contaminants from water uses lignin derivatives, such as lignosulfonates and kraft lignin, a coagulant, such as a metal salt, and a pH-increasing composition. The lignin derivative is dispersed in the contaminated water, the coagulant is added and the pH is adjusted as required to cause flocculation. A sludge is formed that contains the metals and that is separated from the treated water by filtration. Related methods are used to reduce the leachable metal content of contaminated soils. The invention also provides a composition for stabilizing the metal contaminants in soil, comprising lignin derivatives, a coagulant and a composition for increasing the pH. The mixture is blended with the contaminated soil, reducing its leachable metal content.

Owner:NORAM ENG & CONSTRS

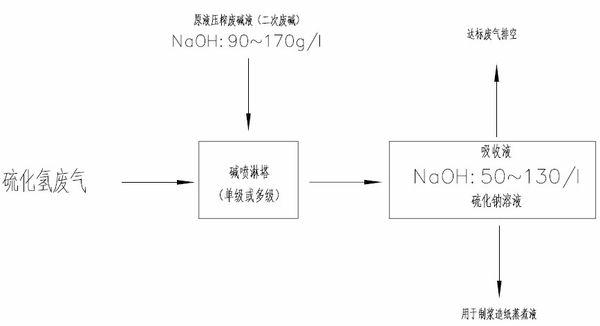

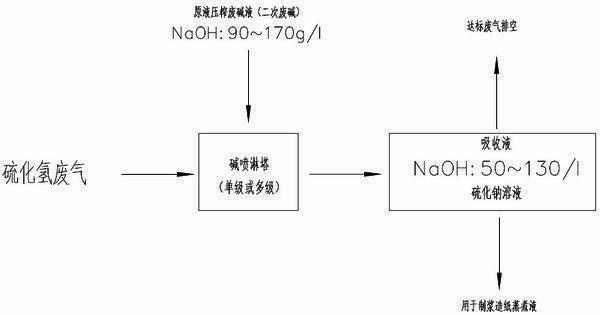

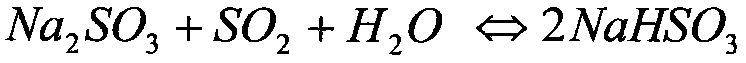

Method for recycling hydrogen sulfide waste gas

InactiveCN102512937ASolve pollutionFix security issuesDispersed particle separationPulp gases treatmentFiberFiltration

The invention relates to the field of waste gas recovery in viscose fiber industry, in particular to a method for recycling hydrogen sulfide waste gas. The method mainly includes the steps: A, squeezing alkali fibers to generate waste alkali liquor, and subjecting the waste alkali liquor to membrane filtration to obtain secondary waste alkali liquor; B, utilizing the secondary waste alkali liquor as alkali absorption liquor, and jointly delivering the secondary waste alkali liquor and the hydrogen sulfide waste gas generated during viscose fiber production to an alkali spray tower; and C, utilizing drained alkali spray absorption liquor as digestion liquor for sulfate pulping, and delivering Na2S (sodium sulfide) obtained by reaction and the rest of NaOH (sodium hydroxide) liquor to a pulping process. The method has the advantages that the method is high in hydrogen sulfide waste gas absorption efficiency and large in treatment quantity in unit time, the problems of environmental pollution and potential production safety hazards due to hydrogen sulfide waste gas emission are solved, and the purposes of treating waste with waste and turning the waste into wealth are realized by the aid of the waste alkali liquor generated by squeezing the alkali fibers.

Owner:YIBIN HIEST FIBER +2

Method for treating metal-contaminated water and soil

InactiveUS7029202B2Efficient and economical processStabilizing the metal contaminants in soilsWaste water treatment from quariesSolid waste disposalFiltrationTreated water

A method for removing metal contaminants from water uses lignin derivatives, such as lignosulfonates and kraft lignin, a coagulant, such as a metal salt, and a pH-increasing composition. The lignin derivative is dispersed in the contaminated water, the coagulant is added and the pH is adjusted as required to cause flocculation. A sludge is formed that contains the metals and that is separated from the treated water by filtration. Related methods are used to reduce the leachable metal content of contaminated soils. The invention also provides a composition for stabilizing the metal contaminants in soil, comprising lignin derivatives, a coagulant and a composition for increasing the pH. The mixture is blended with the contaminated soil, reducing its leachable metal content.

Owner:NORAM ENG & CONSTRS

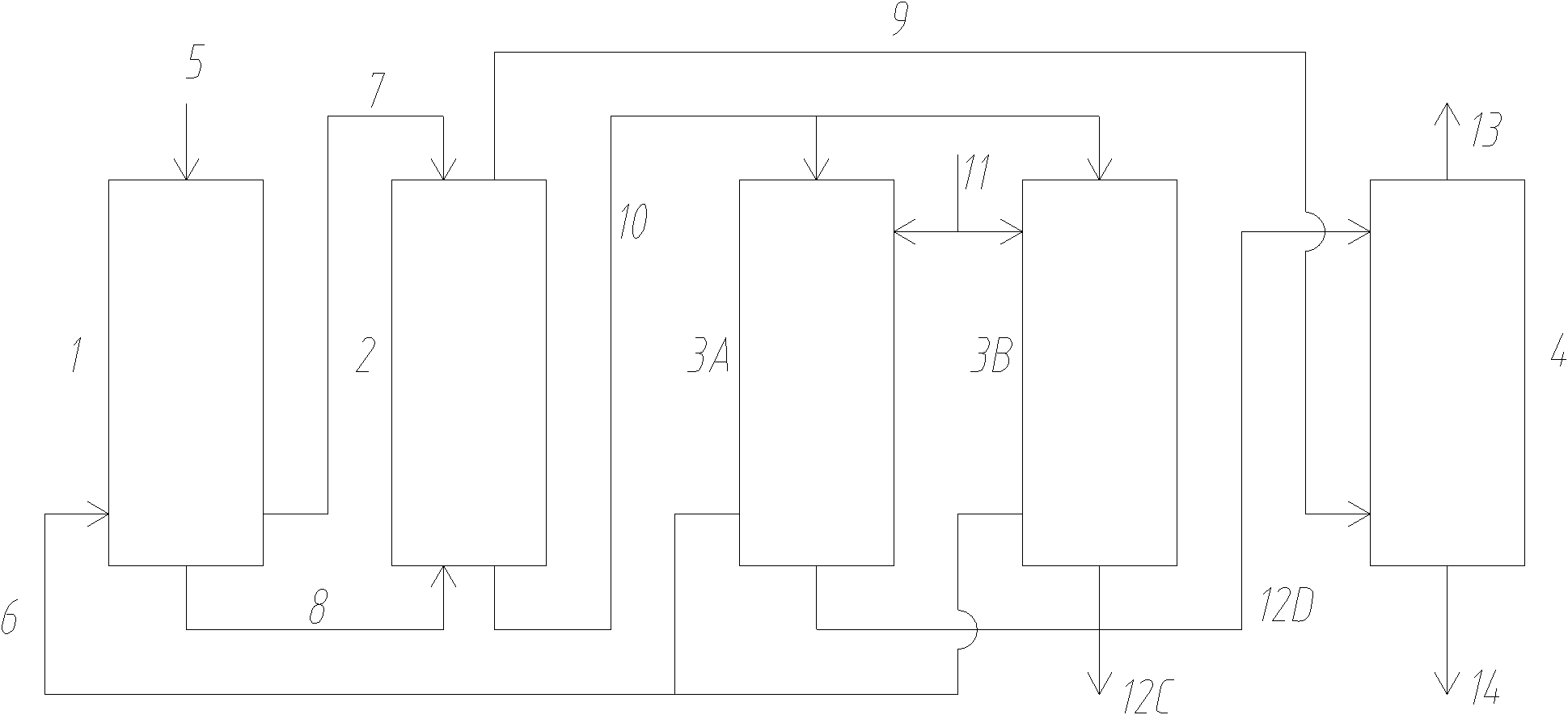

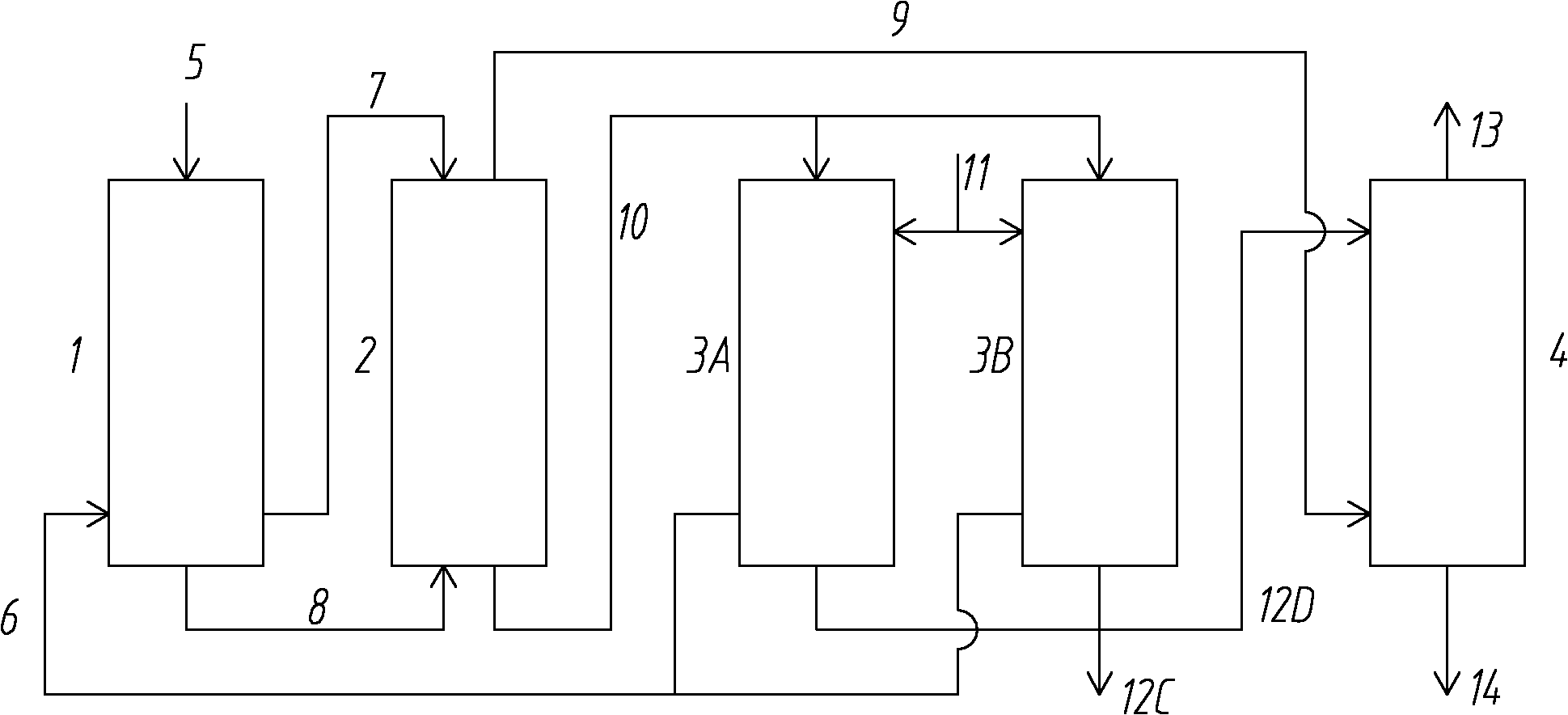

Sulfate pulping process by mixing soft wood with hard wood

ActiveCN102086609AIncrease recycling yieldImprove cooking uniformityDigestersChemical/chemomechanical pulpFiberSteam cooking

The invention discloses a sulfate pulping process by mixing soft wood with hard wood. The process comprises the following steps: preparing materials; steam-cooking by a sulfate process; washing and screening; and bleaching. The process is characterized in that soft wood and hard wood chips are evenly mixed based on the weight ratio of (7-8): (2-3), and then are transferred to a digester for steam-cooking and pulping by the sulfate process. In the process, mixed steam cooking is carried out on the soft wood and the hard wood by a vertical digester without equipment remodeling, and other process flows are basically same as those for producing masson pine sulfate soft wood pulp, thus widening adaptability of a steam-cooking system to raw materials, and relieving pressure of the wood fiber raw materials; and compared with the masson pine pulp, the quality of the wood pulp obtained through mixed steam-cooking is not obviously lowered under the condition that the proportion of poplar wood does not exceed 30%.

Owner:YUEYANG FOREST & PAPER CO LTD

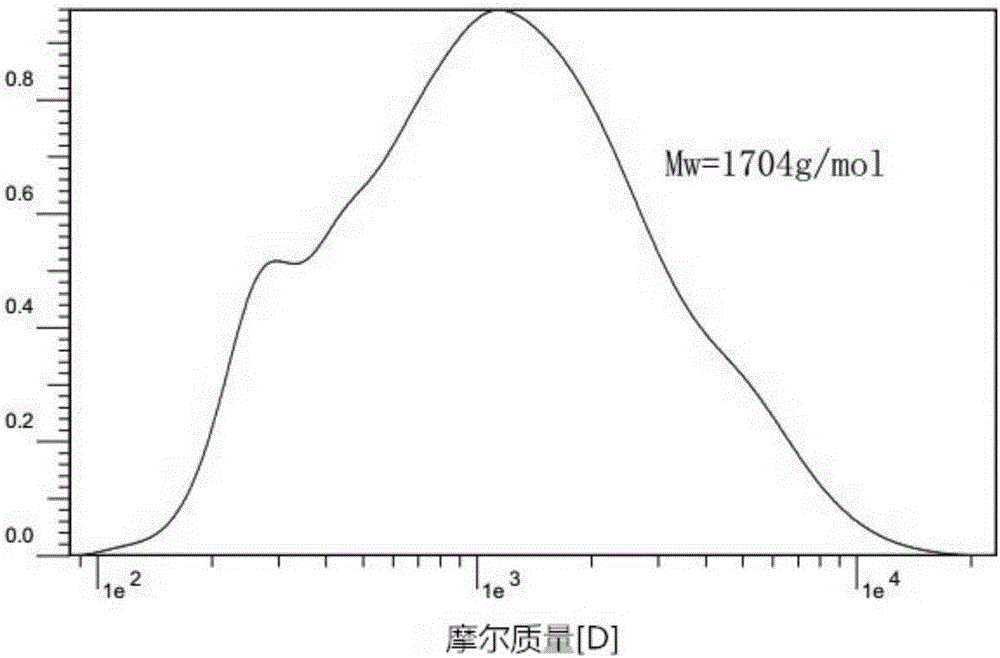

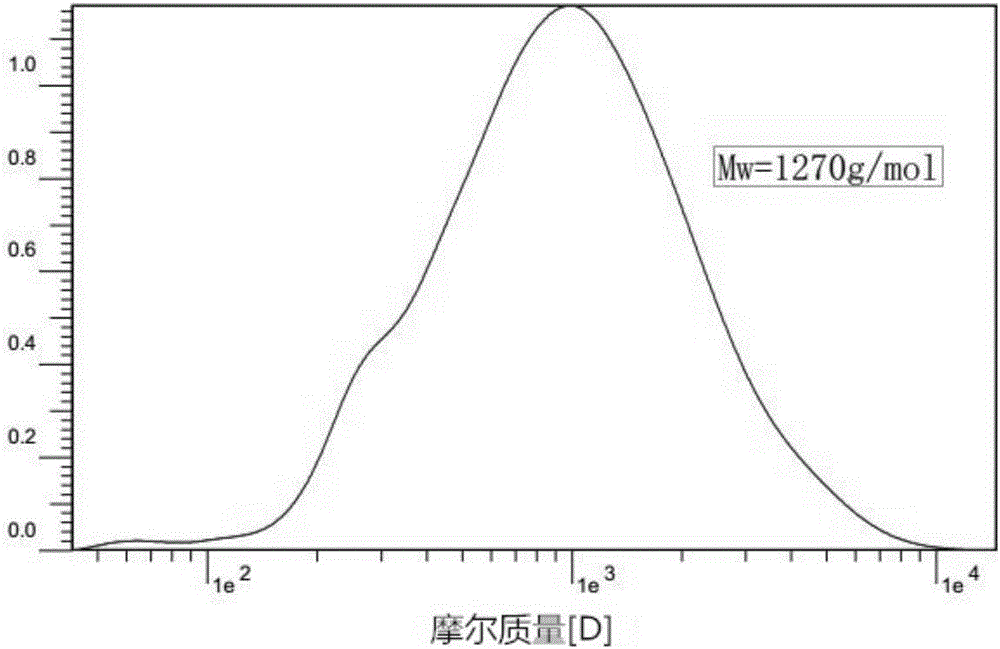

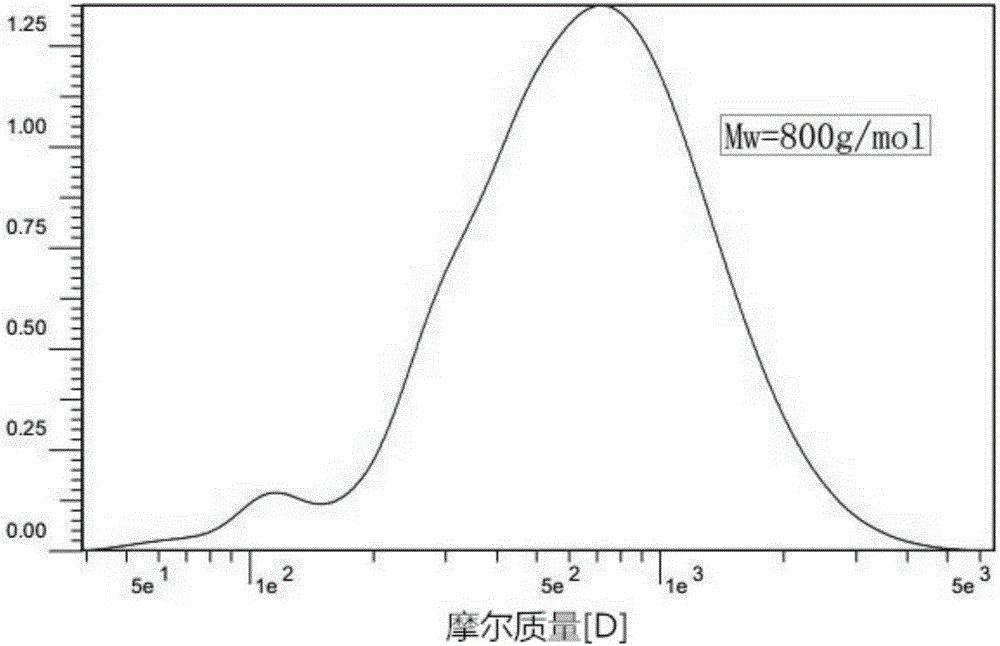

Fractional separation method of kraft lignin

InactiveCN106087513AHigh purityUniform molecular weight size distributionPulp liquor regenerationLignin derivativesBlack liquorSulfate

The invention discloses a fractional separation method of kraft lignin. According to the method, fractional separation is conducted on the lignin by means of a step-by-step acid precipitation method, the lignin with different molecular weight distribution ranges is obtained, the structural performance of the lignin is more uniform, and oriented conversion utilization is conducted on the content of active groups in the lignin with different fractions. According to the extraction method, the pH value of black liquor is adjusted through sulfuric acid step by step to enable the lignin to be precipitated, the obtained lignin is high in purity and uniform in distribution of molecular weight sizes, operation is easy, less equipment and investment are needed, and the comprehensive production cost is low.

Owner:BEIJING FORESTRY UNIVERSITY

Magnetic lignin nano drug carrier

InactiveCN107693506ASmall sizeAdjust particle sizeCosmetic preparationsToilet preparationsWater dispersibleHalf-life

The invention discloses a preparation method and pharmaceutical composition of a plurality of magnetic lignin nanoparticles. Nano micelles are prepared by selecting lignins (such as alkaline lignin, milled wood lignin, Kraft lignin and mixtures thereof). One lignin and liposoluble drugs are dissolved in an organic solvent respectively, and then an aqueous solution of magnetic nanoparticles is slowly dropwise added for self-assembly to form nanoparticles. The pharmaceutical composition contains the lignin nanoparticles, the magnetic nanoparticles and drugs insoluble in water. The magnetic lignin nanoparticles can be used as a drug carrier, can improve the water dispersibility of poorly soluble drugs, reduces toxicity and prolongs the cyclic half-life in organisms.

Owner:TIANJIN UNIV OF SCI & TECH

Sulfate pulping method of broadleaf wood compressed wood chip

InactiveCN102535237AReduce storage spaceImprove transportation efficiencyPulping with inorganic basesChemical/chemomechanical pulpSulfateHardness

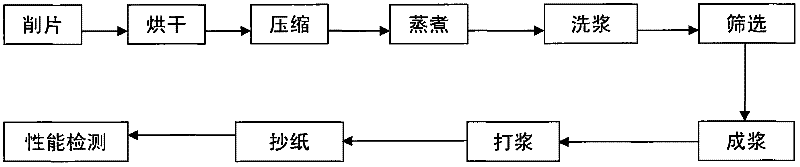

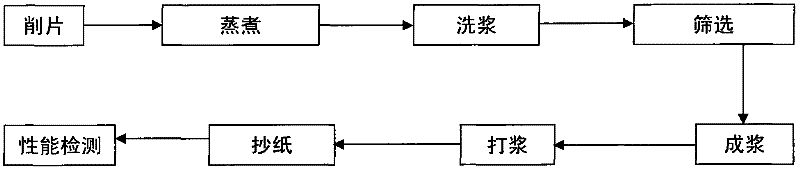

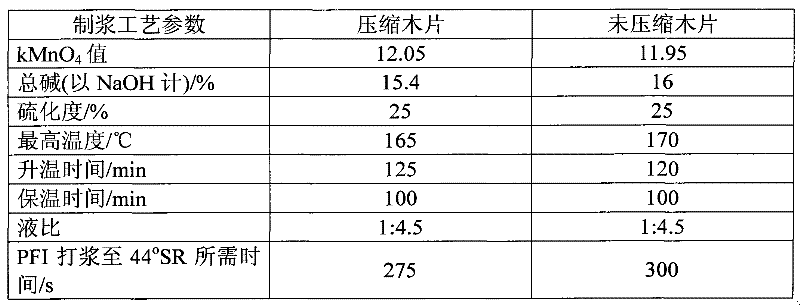

The invention discloses a sulfate pulping method of a broadleaf wood compressed wood chip, which relates to a drying and compressing method of broadleaf wood chips, and a sulfate pulping process of the compressed wood chips. The method solves the difficult problems that bulked broadleaf wood chips are small in volume weight, low in transmitting efficiency, large in storage space and the like, and provides a targeted sulfate pulping process scheme aiming at the broadleaf wood compressed wood chips. Compared with uncompressed wood chips, after being dried and compressed, the broadleaf wood chips reduces volume by 1 / 3-1 / 4 of natural accumulation, so as to greatly improve the transporting efficiency and reduce the transporting cost; under the same sulfate cooking process conditions, the method reduces the full pulp sieving rate by 20-50%; under the premise of achieving same full pulp hardness indexes, the method reduces chemicals cooking consumption by 2-5%, reduces the pulping cost, and reduces the pollution load of pulping waste liquid; and when under the same pulping degree, the method shortens 8-25% of pulping time and obviously reduces the pulping energy consumption.

Owner:北京晨峰投资控股有限公司

Adhesives containing a resin, a kraft lignin, and a surfactant and methods for making and using same

InactiveUS20160096985A1Improve methodGood viscosity stabilityAldehyde/ketone condensation polymer adhesivesLignin adhesivesAdhesiveKraft paper

Adhesives containing an aldehyde-based resin, a kraft lignin, and a surfactant and methods for making and using same are provided. In one or more embodiments, the adhesive can include an aldehyde-based resin; a kraft lignin; a surfactant; an alkaline compound; and water. The adhesive can have a viscosity of about 500 cP to about 5,000 cP, at a temperature of about 25° C. In one example, the adhesive can include about 20 wt % to about 40 wt % of the aldehyde-based resin, about 1 wt % to about 15 wt % of the kraft lignin, about 0.05 wt % to about 2 wt % of the surfactant, about 0.5 wt % to about 10 wt % of the alkaline compound, and about 45 wt % to about 70 wt % of water, where all weight percent values are based on a combined weight of the aldehyde-based resin, the kraft lignin, the surfactant, the alkaline compound, and the water.

Owner:GEORGIA PACIFIC CHEM LLC

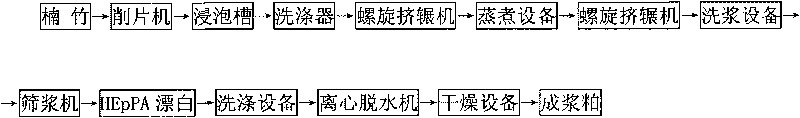

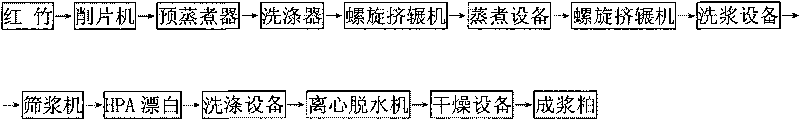

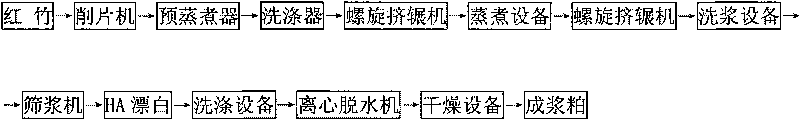

Method for producing bleached pulp for viscose fibers from bamboo

InactiveCN101701431AReduce contentReduce productionPretreatment with water/steamPulp de-wateringHypochloriteSulfate

The invention discloses a method for producing bleached pulp from bamboo, which relates to the fields of pulping and textile and comprises the following steps: (1) cutting bamboo into bamboo pieces which are 1-5cm long and 1-3cm wide; (2) carry out prehydrolysis by soaking the bamboo pieces with water under 10-100 DEG C for 1-10 hours or stewing the bamboo pieces under at least 100 DEG C for 2-300 minutes, wherein the ratio of the bamboo pieces to the liquid for water soaking is 1:1-1:10, and the liquor-to-wood ratio is 1:2-1:10; (3) stewing by a sulfate method at 100-200 DEG C for 60-180 minutes, wherein the solution used for stewing comprises 1-30% of sodium hydroxide, 0-1% of anthraquinone, 0-2% of green oxygen and 1-30% of sodium sulfide, and the liquor-to-wood ratio is 1:1-1:10; (4) processing the product through HEpPA or HPA or HA procedure, wherein the HEpPA procedure comprises the steps of bleaching the cleaned pulp with hypochlorite (H), performing alkali extraction reinforced by hydrogen peroxide (Ep), bleaching with hydrogen peroxide (P) and performing acid-treating (A); and (5) washing the bleached pulp, and drying to obtain the bleached bamboo pulp. The method is suitable for various bamboo materials, and the obtained pulp has superior performance and conforms to the requirements of bamboo pulp products specified in national textile industry standard.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD +1

Process for biological treating collosol material by pulping paper making technology

InactiveCN1786342AReduce the amount addedImprove retentionNon-fibrous pulp additionPaper/cardboardFiberKraft process

The invention relates to collosol material biological treatment method in Kraft process paper technology. It belongs to Kraft process paper technique field. It includes the following steps: adding pectase into bleached mechanics pulp, crushed news paper deink pulp, or off-machine water; the use level of pectase is 20-160g / ton pulp or 1.0-40g / ton off-machine water; treatment temperature is 40-80 centigrade degree; treatment time is 1h-8h; pH value is 7.0-11.0. The invention can greatly reduce mechanics pulp and waste paper pulp DCS charge demand to reduce cation polymer adding quality or cancel, increase fiber fines keeping rate and DCS adsorption, reduce production cost and gooey, and increase paper unit working capability.

Owner:QILU UNIV OF TECH

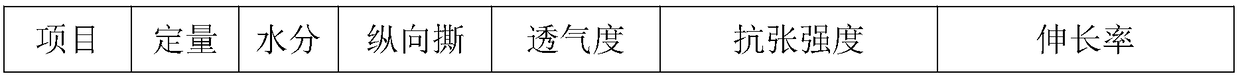

Method for producing high-permeability sack kraft paper by utilizing bamboo pulp

The invention discloses a method for producing high-permeability sack kraft paper by utilizing bamboo pulp. The sack kraft paper is prepared by steps of thickening by a pulp vacuum thickener, high consistency refining, low-consistency disk refining, flow grit removal, pulp screening by a pressurized screen, net molding on a floating flow box, four-roller three-pressure-zone pressing, drying, coiling, recoiling and packing. The method specifically comprises the following steps: mixing bamboo chips and needle wood chips, pulping by adopting a sulfate process, washing and screening the obtained pulp, performing high-consistency pulping to maintain the fiber length, performing low-consistency pulping, adding auxiliary materials, screening the pulp by the pressurized screen, loading on a net, molding on the net, performing four-roller three-pressure-zone pressing, drying by a drying part, and treating by a tensile device, thereby obtaining the sack kraft paper. By utilizing the method disclosed by the invention, the tensile sack kraft paper with low cost, high physical strength and high permeability can be produced.

Owner:FUJIAN QINGSHAN PAPER INDUSTRY CO LTD

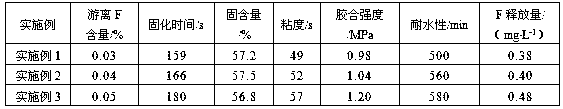

Sulfate lignin modified urea resin adhesive and preparation method thereof

ActiveCN108531116AHigh bonding strengthLow free formaldehyde contentAldehyde/ketone condensation polymer adhesivesSulfateDimethylol urea

The invention belongs to the technical field of urea resin adhesive, and particularly relates to sulfate lignin modified urea resin adhesive and a preparation method thereof. The adhesive is preparedfrom the following raw materials in parts by weight: 100 parts of urea, 149 to 154 parts of formaldehyde solution, 8 to 15 parts of sulfate lignin, 2 to 3 parts of melamine, 1 to 2 parts of polyvinylalcohol, 0.36 to 0.41 part of alkaline catalyst, and 0.28 to 0.32 part of acidic catalyst. By selecting the sulfate lignin modified urea resin and adopting a weak acid-weak alkali-weak acid-weak alkali synthetic process, the content of a first portion of urea, a second portion of urea, a third portion of urea and a third portion of urea are reasonably configured, so that more dimethylol urea can be generated, the adhesion strength can be improved, little urea is added at the last time, the un-reacted free formaldehyde can be captured, the formaldehyde emission of the prepared plywood is ensured to reach grade E0, and the adhesion strength can reach the type-II plywood standard.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Masson pine dissolving pulp and production method thereof

ActiveCN102493257AReduce productionReduce pollution loadPretreatment with water/steamNatural cellulose pulp/paperSulfateOxygen

The invention discloses a masson pine dissolving pulp and a production method thereof, wherein the masson pine dissolving pulp is prepared after the steam prehydrolysis, sulfate cooking, two stages of oxygen delignification and D0EoPD1 bleaching of masson pine pieces, the whiteness is not less than 89%, the alpha cellulose is not less than 91%, the pentosan is not higher than 3%, the dynamic viscosity is 9-25mPa s, the ash content is not higher than 0.1%, and the iron content is not higher than 15mg kg<-1>. The production method of the masson pine dissolving pulp comprises the following stepsthat: the masson pine pieces undergo the steam prehydrolysis, and the P- factor of the steam prehydrolysis is 300-800; the sulfate cooking is carried out after the steam prehydrolysis to obtain the pulp; the pulp undergoes the D0EoPD1 bleaching after two stages of oxygen delignification; and after the bleaching, the pulp is washed, dried and processed into the masson pine dissolving pulp.

Owner:湖南骏泰新材料科技有限责任公司 +1

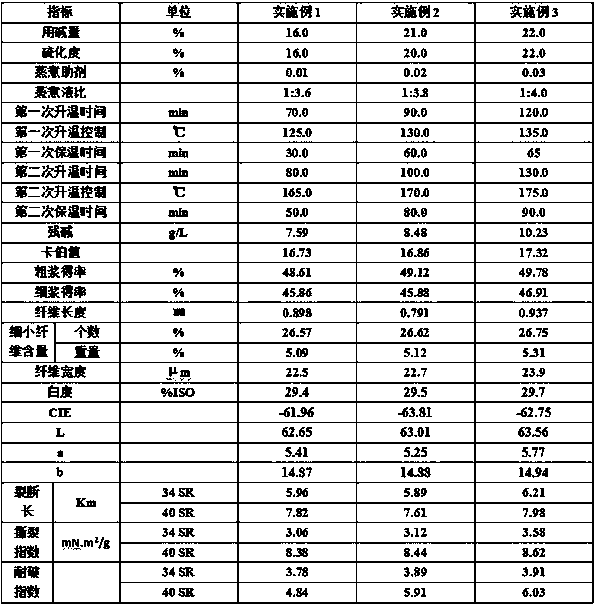

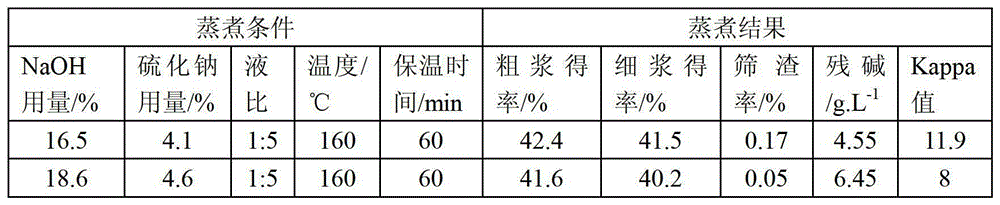

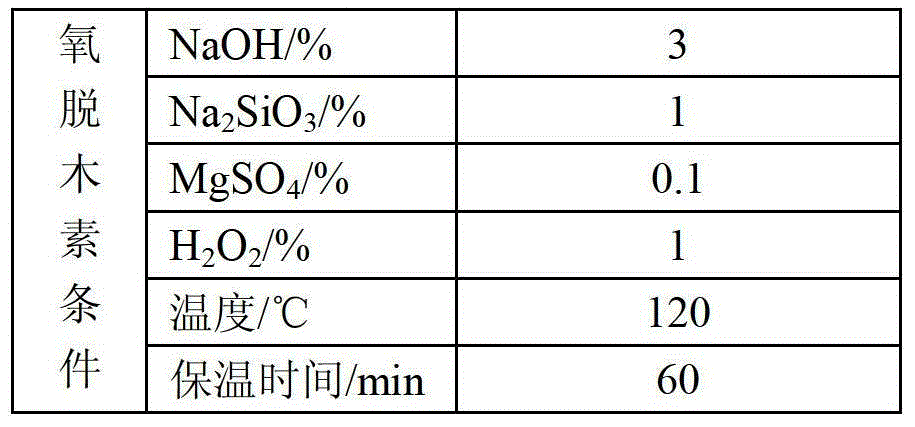

Kraft pulping process of camphorwood

ActiveCN110438834AQuality improvementMeet production needsPulping with inorganic basesChemical/chemomechanical pulpPaper productionSlurry

The invention discloses a kraft pulping process of camphorwood. The kraft pulping process comprises the following preparation steps that 100% camphorwood pieces are taken out for peeling, chipping andscreening operations, sent into a cooking pot for cooking operation, put into a scrubber for washing operation, sent into a pressure screen for screening operation, carried out bleaching operation byusing hydrogen peroxide, and sent into a slurry tower for storage operation. According to the kraft pulping process of the camphorwood, the purpose is that the camphorwood pieces after stewed camphorand camphor oil can be reused, process flow and process parameters can be made according to the material characteristics of camphorwood, the pulping cost is low, the pulp quality is good, and needs of high-grade paper production can be fully met.

Owner:YUEYANG FOREST & PAPER CO LTD

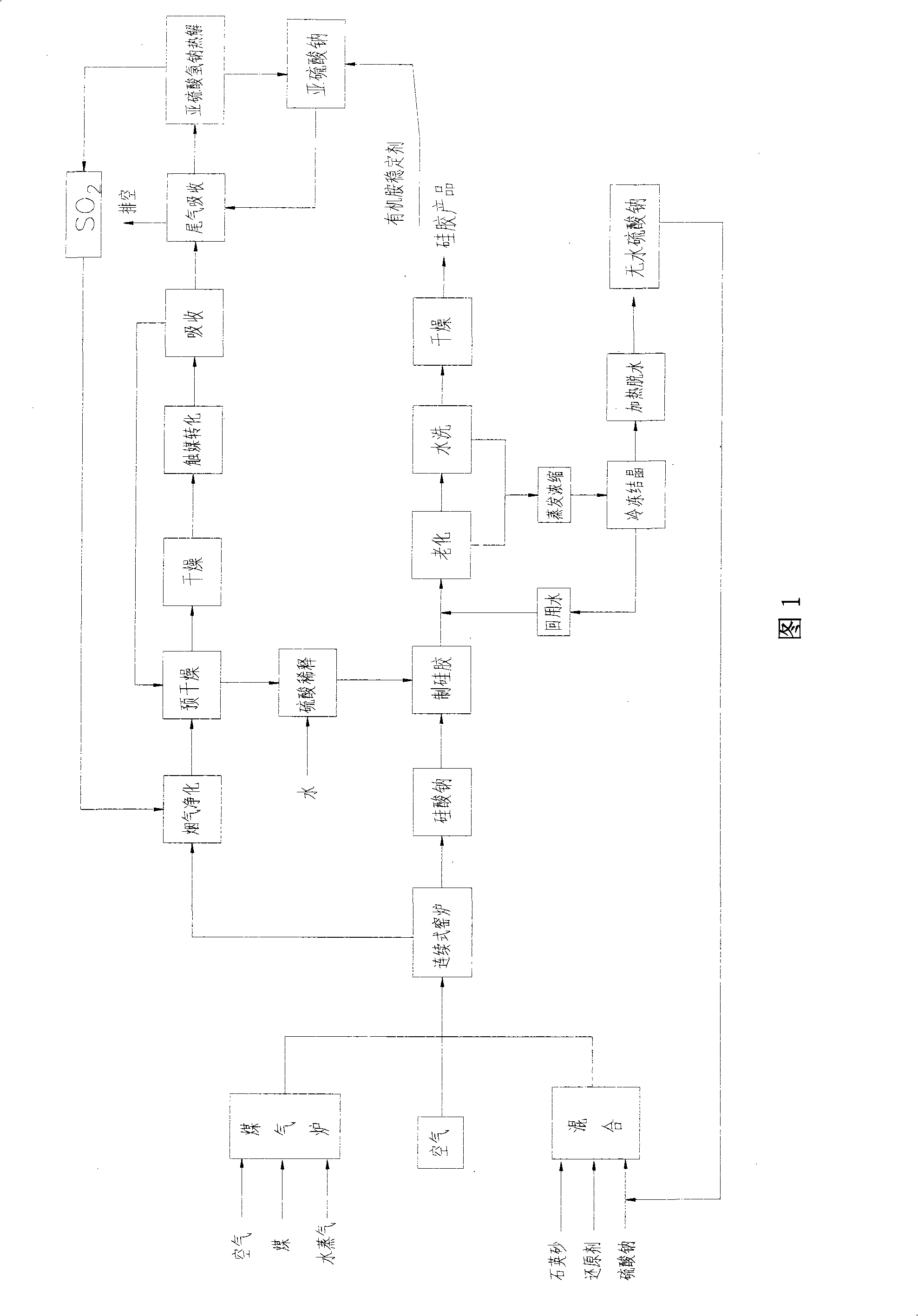

Silica gel cleaning production method and sulfuric acid production method

InactiveCN101327931ASave energyRealize repeated recyclingSilicaSulfur-trioxide/sulfuric-acidHigh concentrationPersulfate

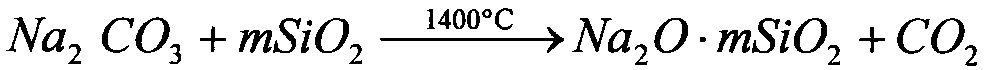

The invention relates to a cleaning production method of a silica gel and a production method of a sulfuric acid belonging to the preparation technology field of the silica gel and sulfuric acid, wherein the silica gel production method employs sulfuric acid to react with alkali metal silicate, the alkali metal silicate is prepared by kraft process and the material sulfuric acid is completely or partially from sulfur compounds in the recovered flue gas during the production of another material alkali metal silicate. The production method of the invention achieves the repeated recycle of the sulfur element and the alkali metal element, improves the resource utilization rate and solves the environmental protection problem. The sulfuric acid production method of the invention is to recover the sulfur compounds in the flue gas during the production of the alkali metal silicate and to produce sulfuric acid by the unsteady conversion technology, which overcomes the problems of higher concentration of sulfur dioxide and little fluctuation required in the acid-making technology and achieves the autothermal equilibrium of the conversion with little investion and low energy consumption.

Owner:QINGDAO MAKALL GROUP CO LTD

Manufacturing method of soluble bamboo pulp

InactiveCN1693581AStable sourceGood removal effectCellulosic pulp after-treatmentCellulose material pulpingFiberSulfonate

This invention relates to a manufacturing method of soluble bamboo pulp. The materials is bamboo dregs, and technique is that bamboo dregs to boiling to materials washing to refinery to material washing to sand eliminating to chlorination to alkali sluicing to bleaching to neutralization to copy manufacturing to soluble bamboo pulp. Sulfate method is used to make pulp in boiling process, and boiling is processed in rotary spherical digester device or continuous boiling device. Sulfate method plus additive method is used in refinery process, the additive is polyxylose enzyme or woody prime sodium sulfonate, and they are also processed in rotary spherical digester device or continuous boiling device. The advantages are good quality of alpha pulp material for regenerated fiber generation, and fully using resource, protecting environment.

Owner:黄楚和 +1

High-purity sulfate pulp, as well as production method and application thereof

ActiveCN102619126AHigh pulping yieldEmission reductionPulp bleachingPulping with inorganic basesSolubilityOxygen

The invention relates to high-purity sulfate pulp, as well as a production method and an application thereof. The high-purity sulfate pulp is prepared by stewing wood fiber raw material through a sulfate process for pulping, performing oxygen delignification and bleaching with DOEOPD1P, wherein the content of alpha cellulose in the pulp is not lower than 88% by weight; the content of pentosan is 4.5-6.5% by weight; the alkali solubility S18 of the pulp is 6.0-8.5% by weight; a DCM (dichloromethane) extract of the pulp is 0.1-0.30% by weight; the ash content is not higher than 0.15% by weight; the iron content is not higher than 20mg / kg; the SiO2 content is not higher than 50mg / kg; the inherent viscosity is 450-550dl / g; and the whiteness is not lower than 87% ISO, and the pulp is used for being mixed into dissolving pulp for producing viscose fiber.

Owner:湖南骏泰新材料科技有限责任公司

Preparation method of pollution-free high-whiteness palm silk paper pulp and application of paper pulp in paper product

InactiveCN103334335ARich reservesAddress resource shortagesWashing/displacing pulp-treating liquorsDigestersCardboardHypochlorite

The invention relates to a preparation method of pollution-free high-whiteness palm silk paper pulp and an application of the paper pulp in a paper product. The preparation method mainly comprises the steps that a palm silk raw material is cooked and bleached, and the obtained paper pulp is used for making the paper product. Cooking adopts a sulfate method, and paper pulp bleaching adopts a pollution-free (Total Chlorine Free-TCF) section procedure bleaching technology. Each section in an OPAP1P2 bleaching procedure adopts a medium-concentrated bleaching technique (a concentration of each section of paper pulp is 10-15%), so that the bleaching reaction efficiency can be improved, energy sources can be saved (heating the paper pulp), and the water consumption can be reduced. The bleaching does not require any chlorine (chlorine, pypocholoride or chlorine dioxide), so that bleaching waste water can be used for preparation of a cooking liquid and washing of unbleached pulp, and then enters an alkali recovery system, and the preparation method can save water and energy, reduce environmental pollution and allow resources to be fully used. With the adoption of the bleaching technology, the pollution-free high-whiteness (82-85% of ISO (Isobutanol)) paper pulp can be prepared, can substitute bleaching hardwood pulp, and is matched with bleaching sulfate softwood pulp for making advanced cultural paper as well as paper and cardboards with high hygienic index requirements.

Owner:马志强 +1

Method for recovering pulping black liquor alkali by virtue of sulfate process

InactiveCN102121203ANo or less causticization requiredNo or less need for calcination cyclesRegeneration of alkali lyeLime productionGas phaseWater vapor

The invention relates to a process for recovering pulping black liquor alkali by virtue of a sulfate process by taking gasification and direct causticication as a base. The process comprises: the pulping sulfate black liquor is sprayed by atomizing air into a pyrolysis furnace for partial combustion, thus generating semicoke, vapor, tar, sulfurated hydrogen and other sulfur-containing compounds; the semicoke is mixed with a directly causticizing agent; the mixture is fed to a gasification furnace; gaseous products are also sent to the gasification furnace; organic substances in the semicoke are gasified completely at 800-900 DEG C; the sodium sulfide generated by reduction from sodium sulfate is completely transferred as the sulfurated hydrogen to enter into the gas phase; all sodium carbonate is subjected to carbon dioxide removal to form a solid sodium salt; the solid sodium salt is hydrolyzed to generate sodium hydroxide; the part which is not dissolved in the water is recycled as the directly causticizing agent; the sulfurated hydrogen in the generated gas is absorbed by part of the sodium hydroxide generated by the hydrolysis to prepare a sulfur-rich white liquid; and the gas can be taken as a fuel for downstream combustion equipment. By utilizing the method provided by the invention, a lime calcining kiln can be omitted or the load of the lime calcining kiln can be greatly reduced; and the recovered alkaline can be used for improving a sulfate steaming process.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Set retarders for foamed cements

InactiveUS20020056405A1Simple methodImprove propertiesDrilling compositionCeramicwareLignosulfonatesSlurry

An improved non-dispersing set retarder additive for foamed cements, cement compositions containing the additive, and methods of cementing in a subterranean zone penetrated by a well bore are provided. The set retarder additive includes a blend of a sulfonated lignin, preferably a lignosulfonate, with an alkali lignin, preferably a kraft lignin, having an organic sulfur content of 0-3.5% by weight in a ratio of about 6:4 to 8:2. The methods are basically comprised of the steps of preparing a foamed cement composition comprised of hydraulic cement, a non-dispersing set retarder, sufficient water to form a slurry, sufficient gas to foam the slurry and a foaming and foam stabilizing surfactant present in an amount sufficient to facilitate the formation of the foam and stabilize the foamed cement composition.

Owner:LIGNOTECH USA INC

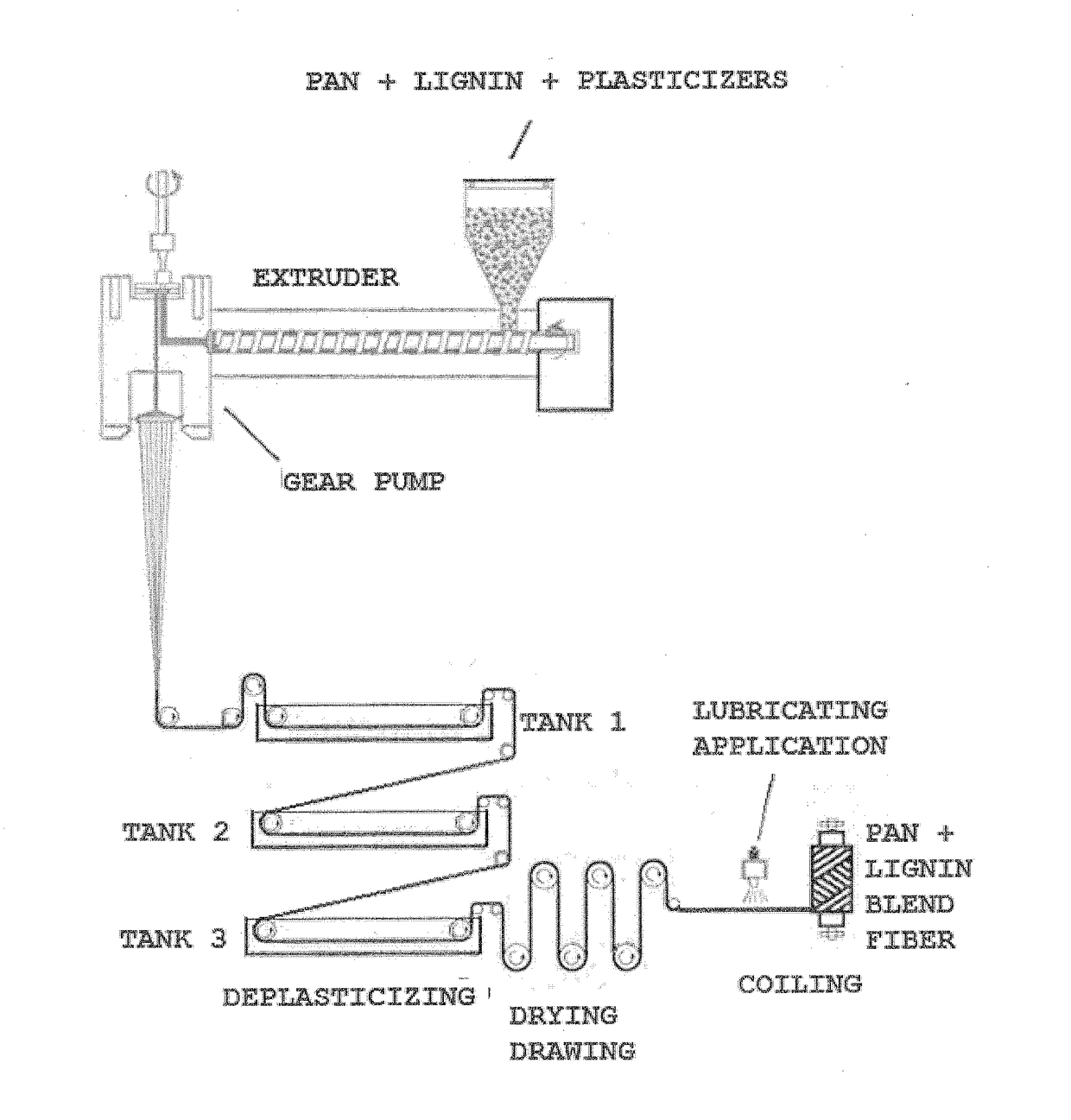

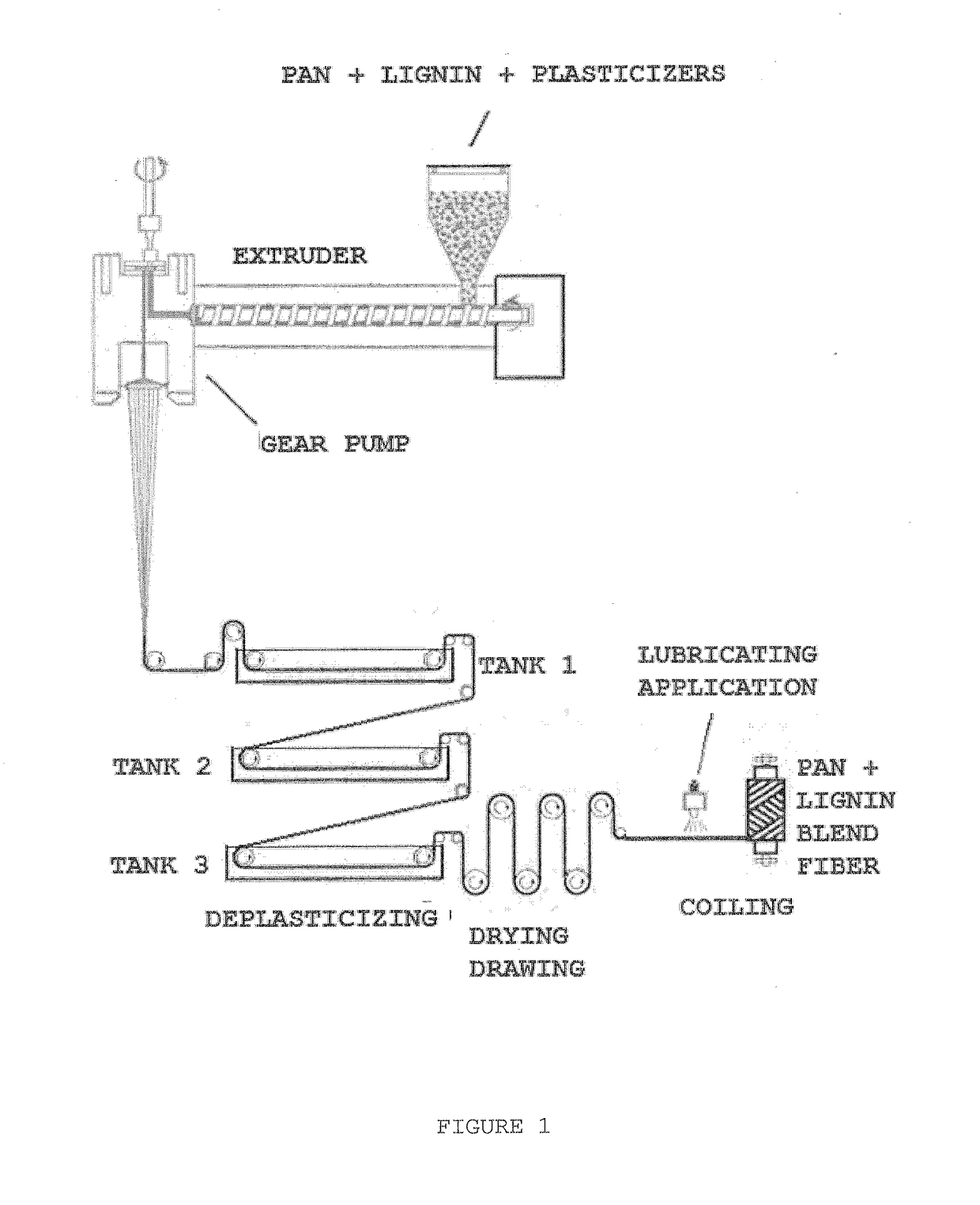

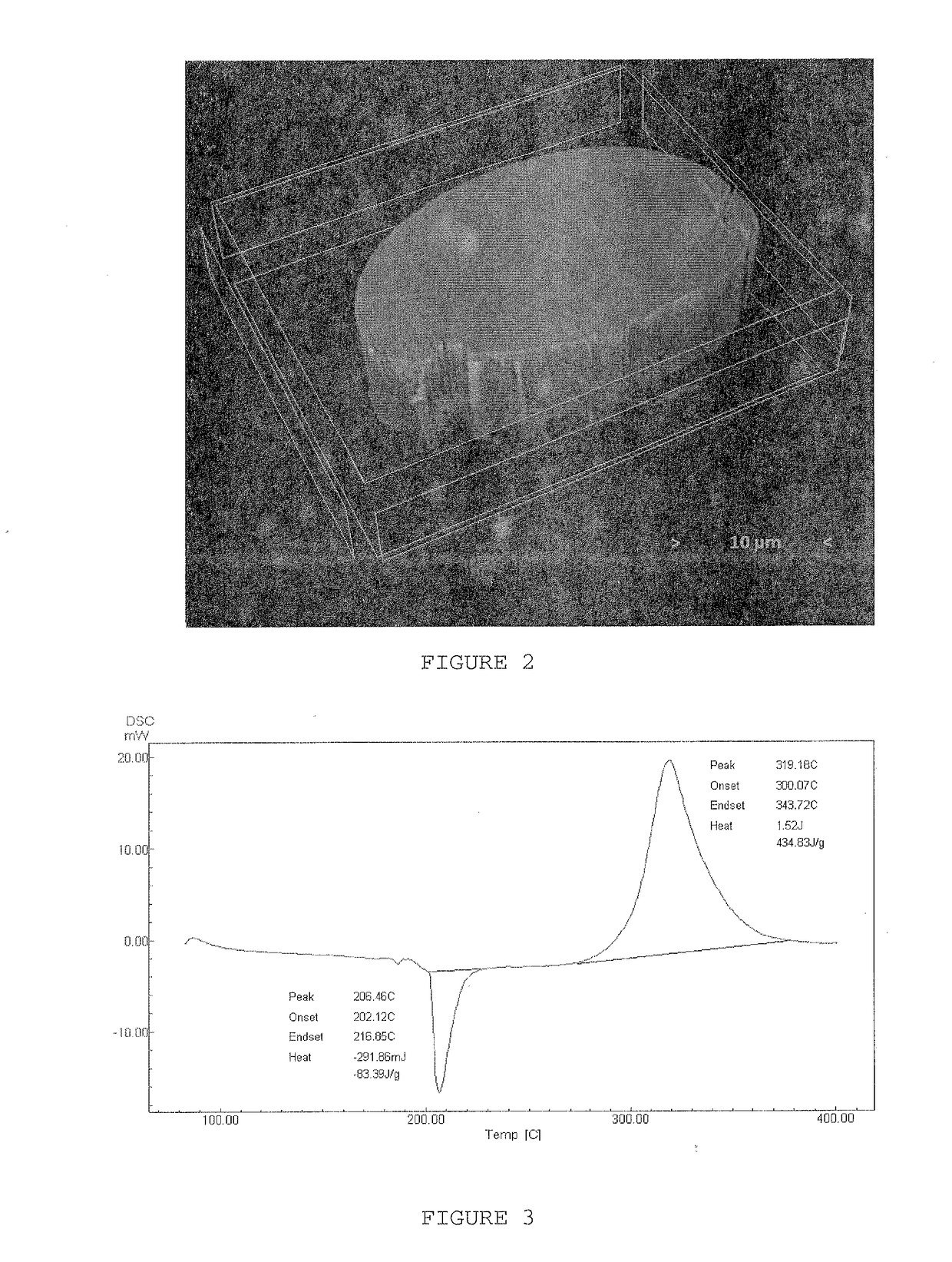

Composition of polyacrylonitrile/lignin blend and use thereof in melt spinning carbon fibre precursors

InactiveUS20180282535A1High productNo toxicityCarbon preparation/purificationMonocomponent synthetic polymer artificial filamentBiodieselCarbon fibers

Described is a method of producing fibers by melting process in spinning extruders by using a composition containing polyacrylonitrile (PAN), lignin and plasticizers with high boiling point and dipolar moment, such as glycerine and glycerol carbonate. The use of thermal stabilizers also derived from halogenated glycerol, known as halodridines, and additives derived from the esterification of glycerin with fatty and phosphoric acids are also described. By removing the plasticizers and the soluble additives in polar solvents, such as water and alcohols, shortly after the spinning step, it is possible to produce fibers from PAN / lignin blend with characteristics similar to those produced by traditional wet spinning process, widely used in the production of carbon fiber. The lignin used may be that obtained by the Kraft Process. The glycerin used as a plasticizer can be derived from the production of biodiesel, which does not need to be purified by distillation process.

Owner:LAB QUIMICOS E METROLOGICOS QUIMLAB LTDA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com