Patents

Literature

382results about "Regeneration of alkali lye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

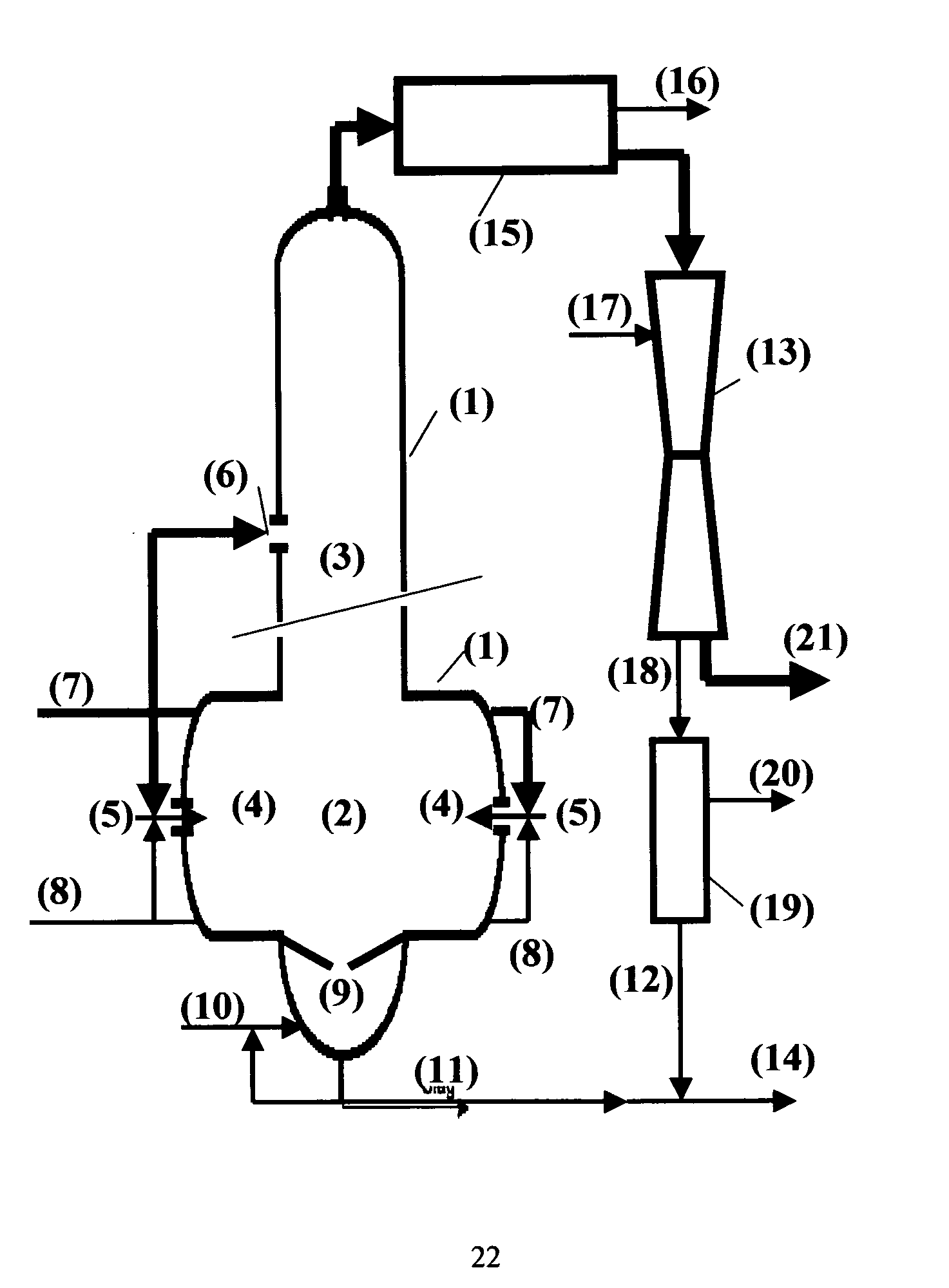

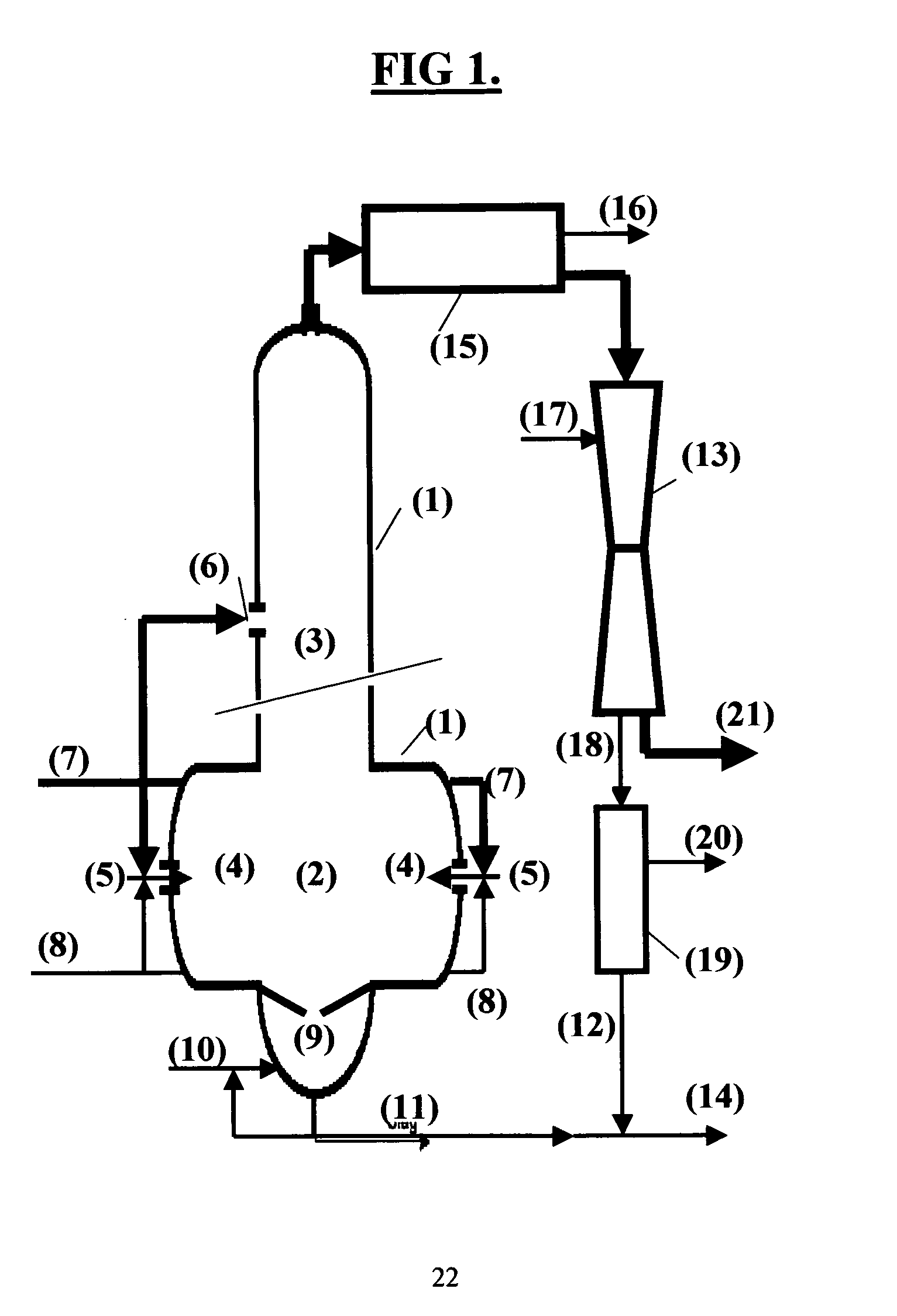

Method for producing pulp and lignin

InactiveUS20040244925A1Pretreatment with acid reacting compoundsPulp bleachingCellulosePtru catalyst

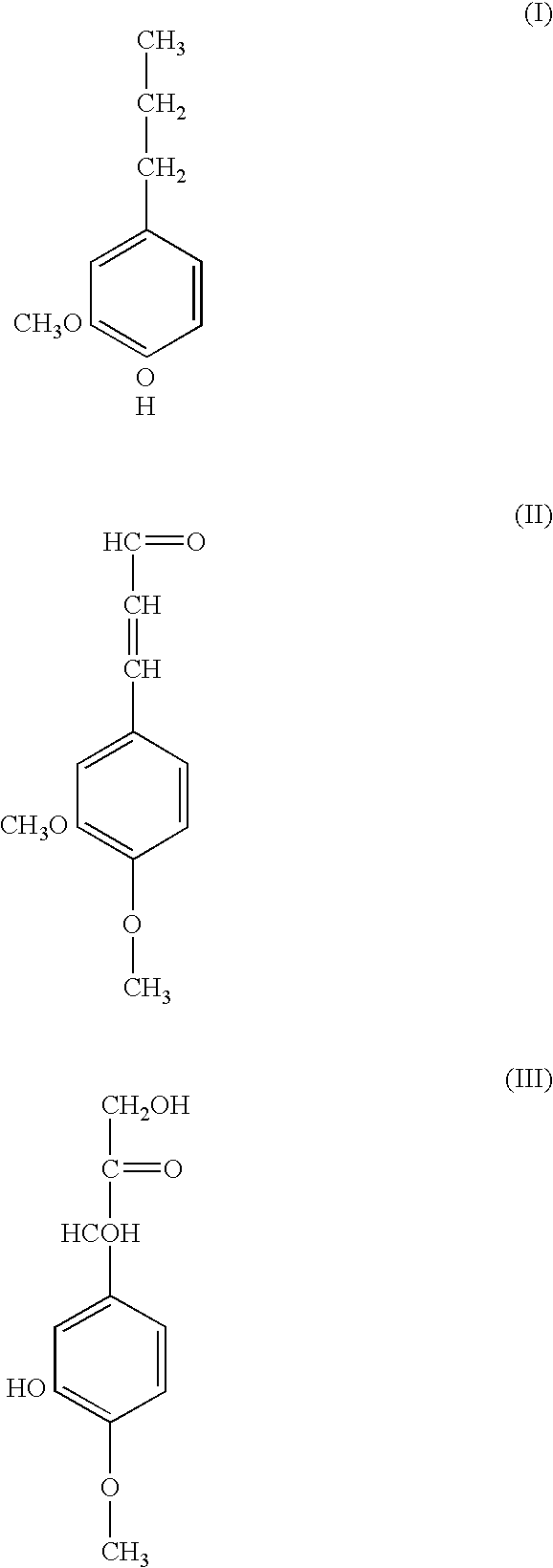

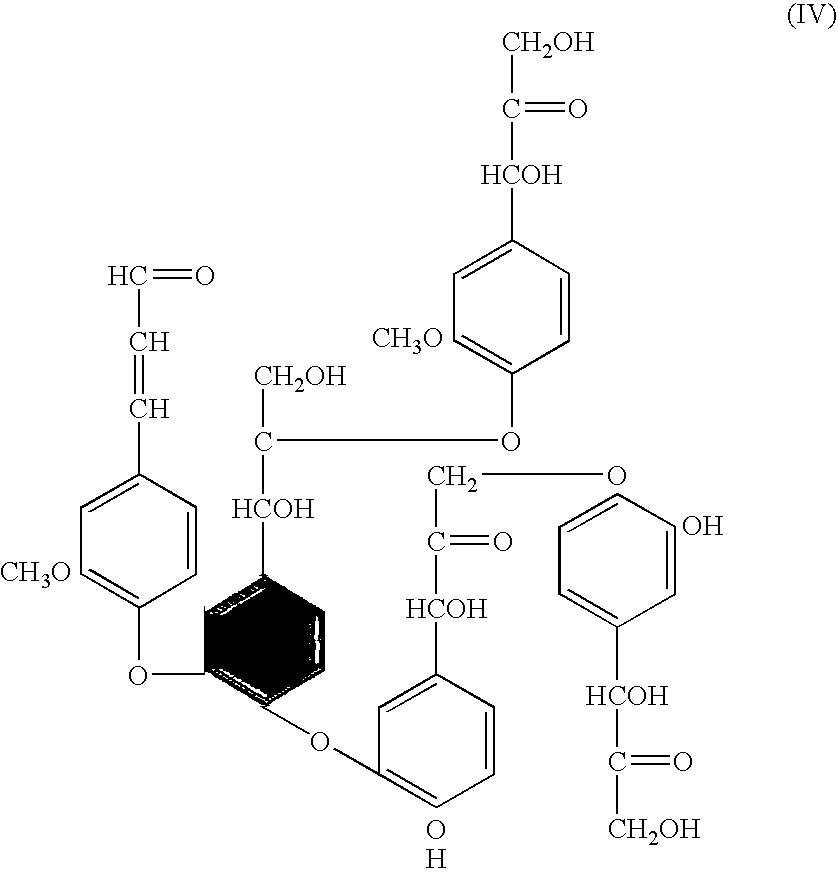

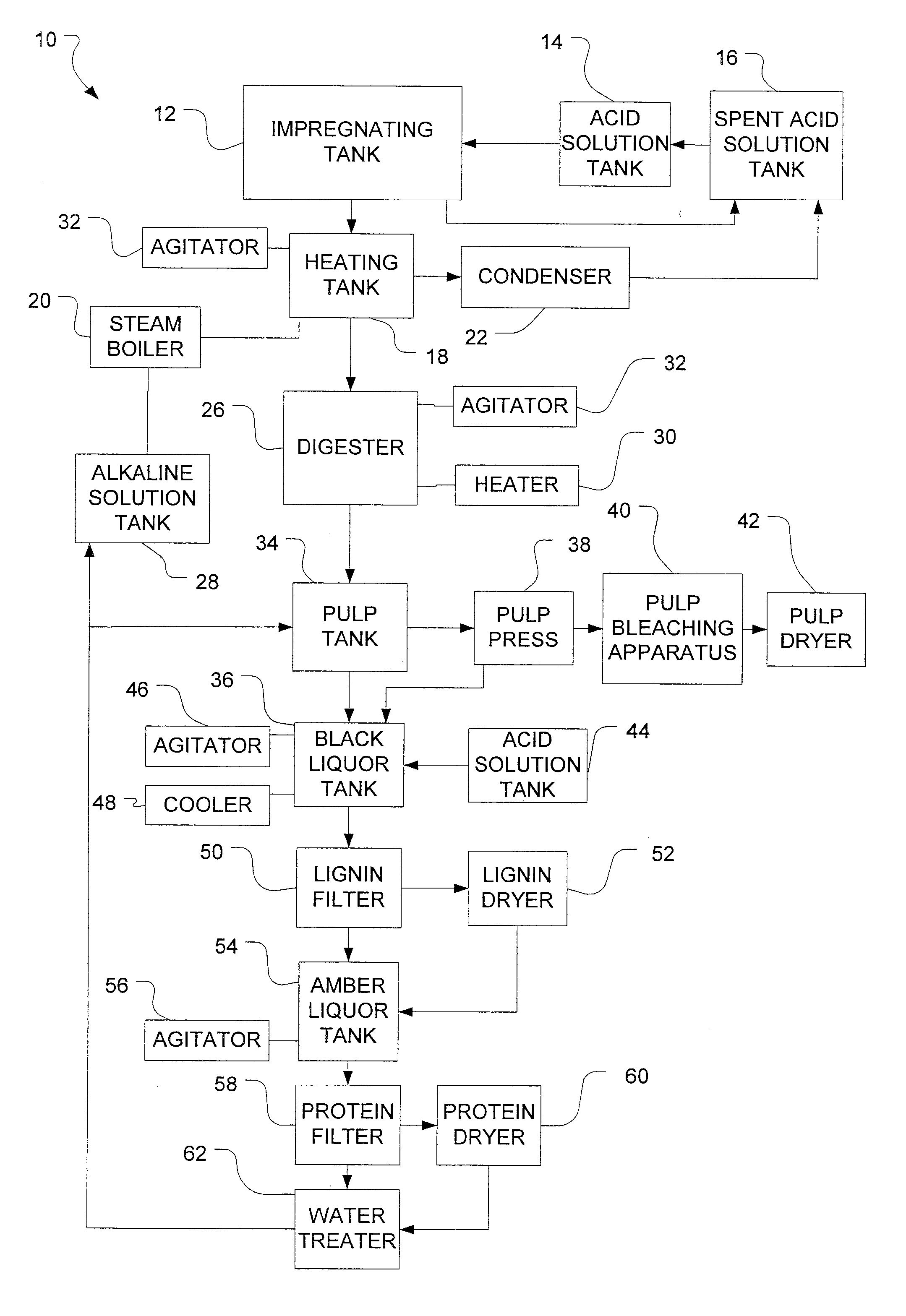

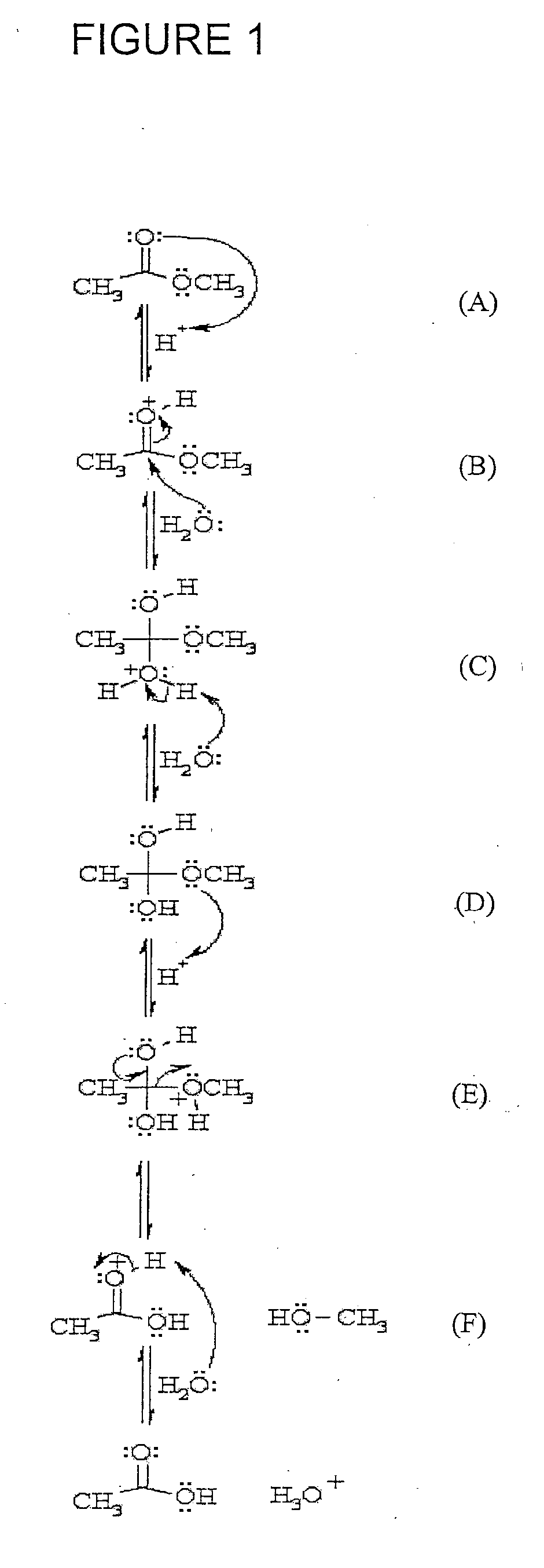

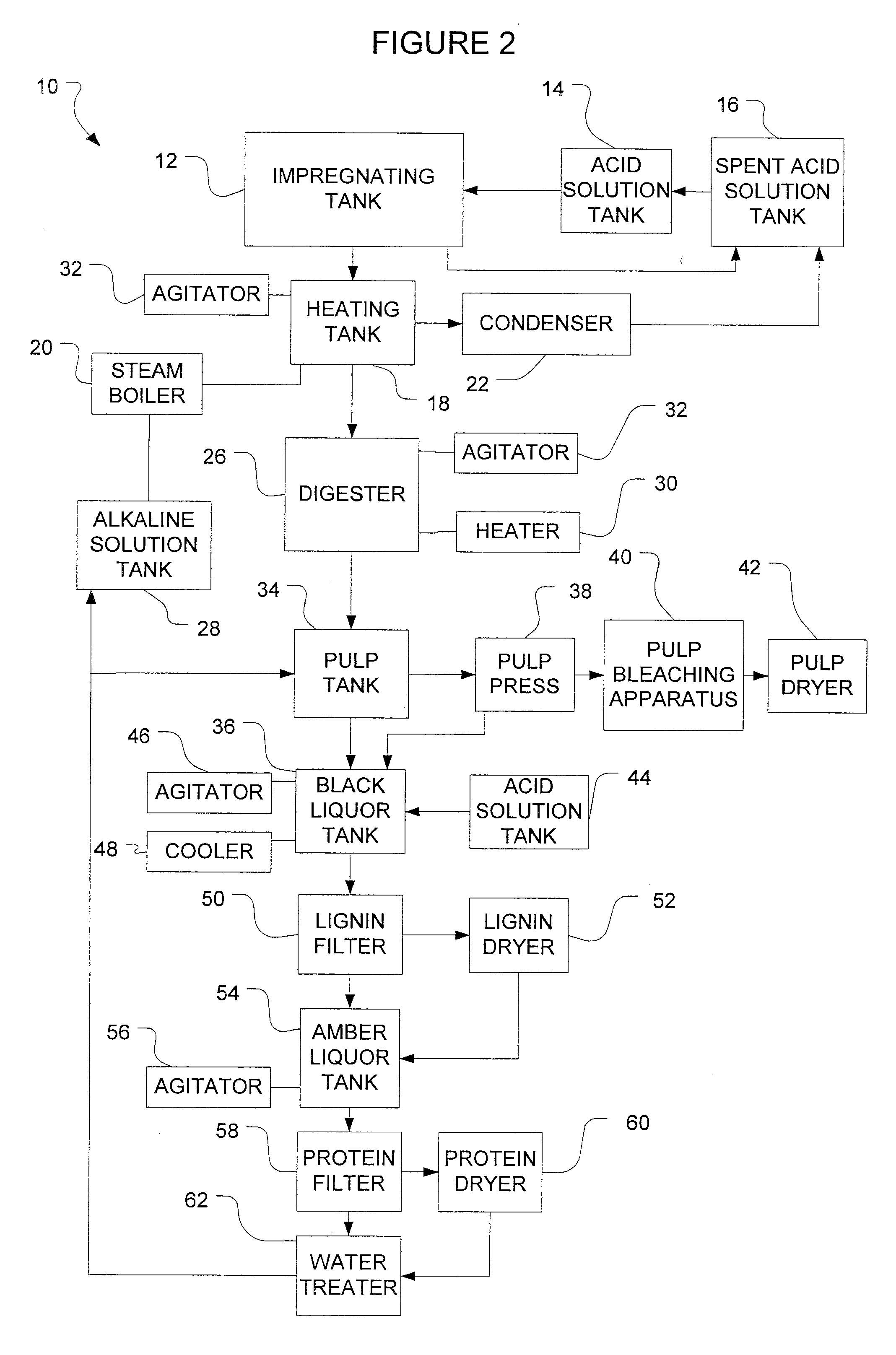

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

Method for Separating Lignin from Black Liquor

ActiveUS20080047674A1Smoother resultAvoid cloggingLignin derivativesPulp by-products recoveryLignin degradationBlack liquor

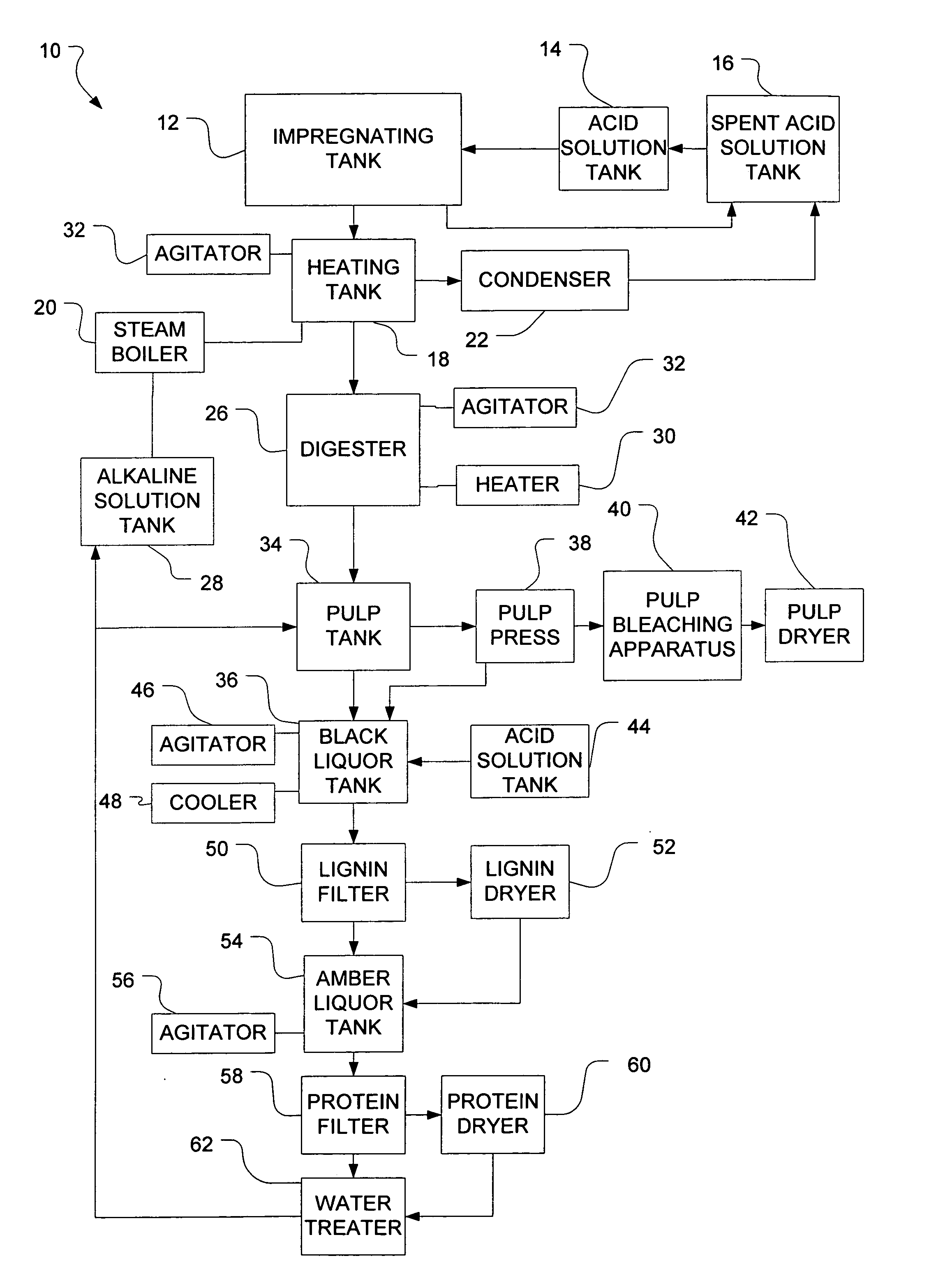

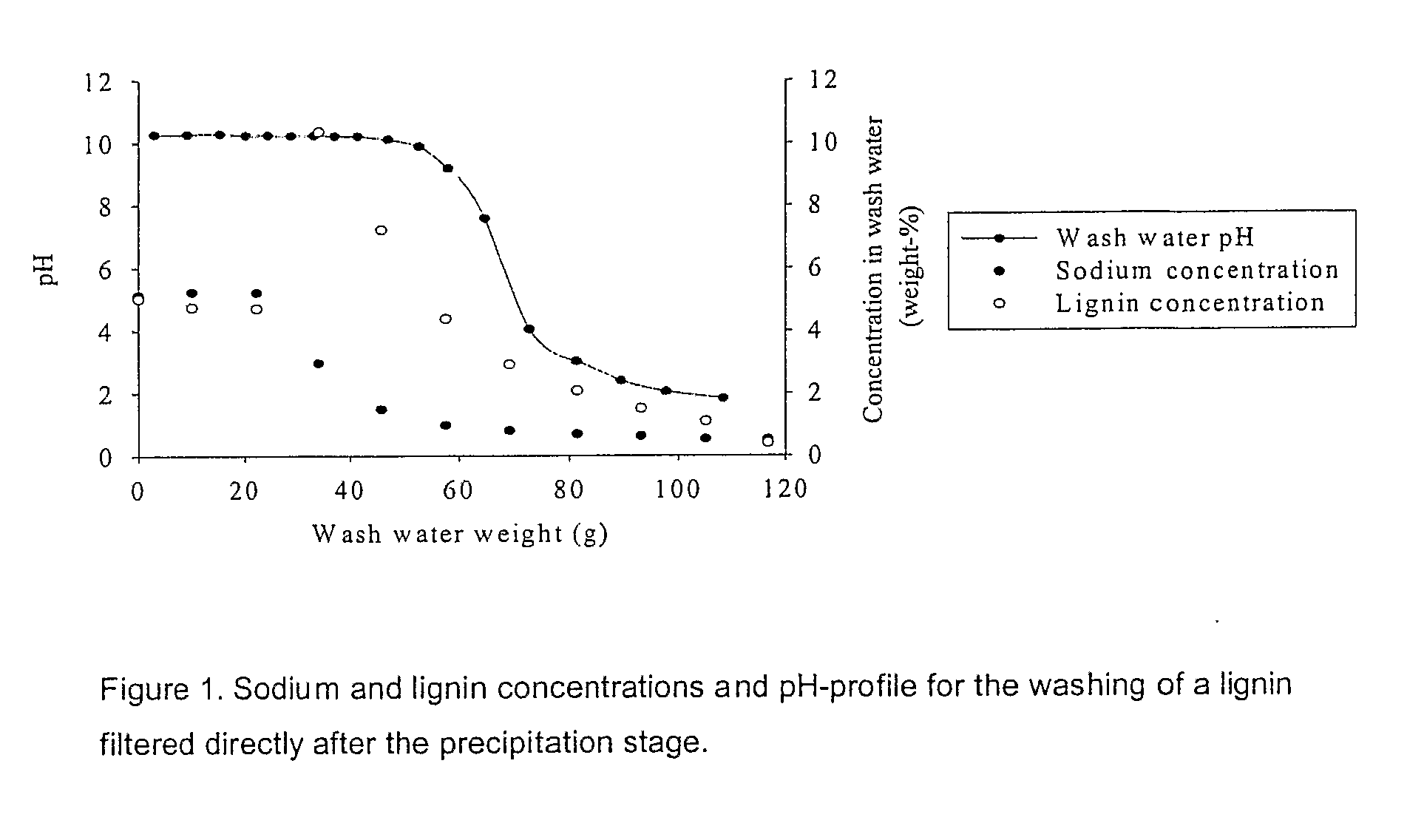

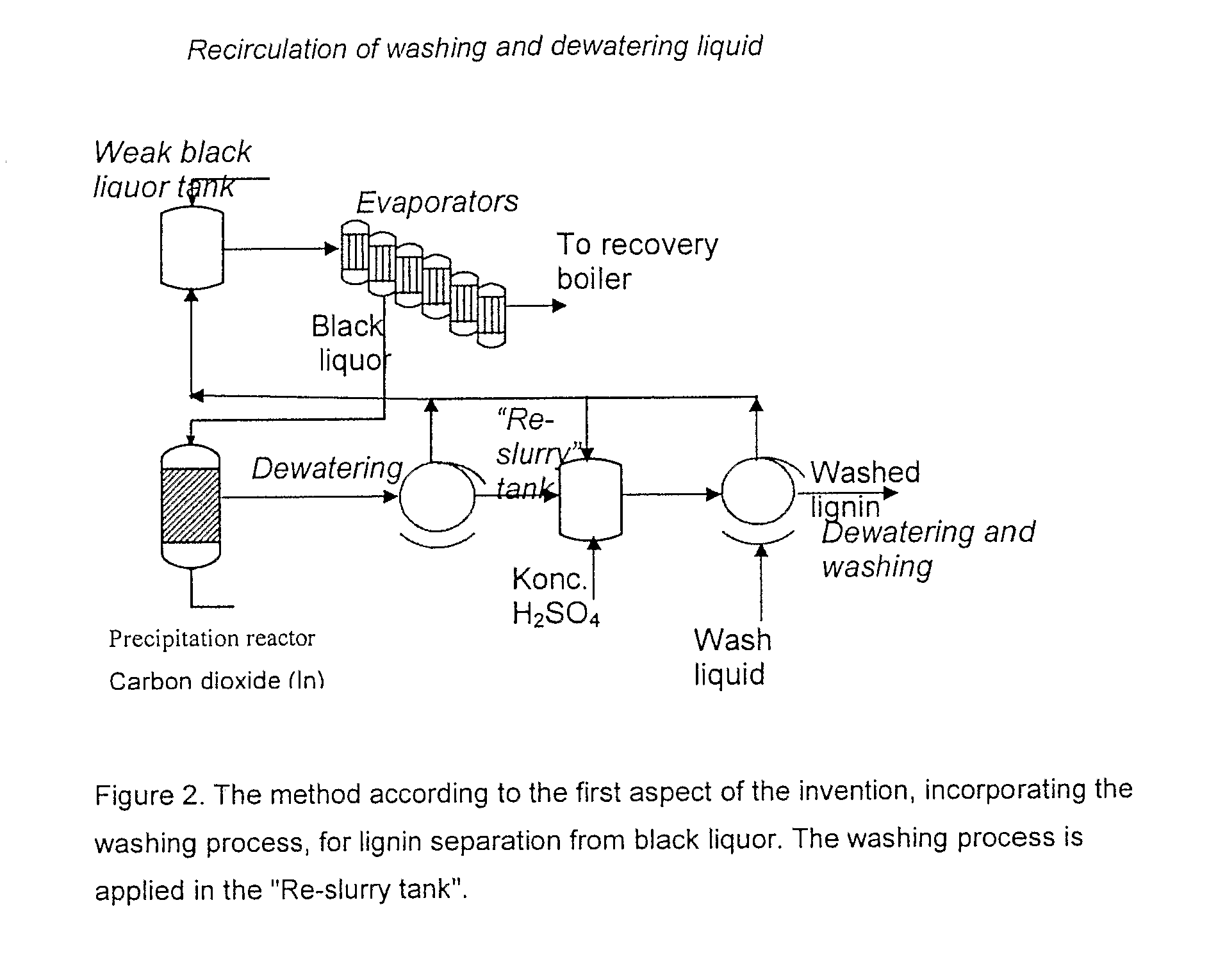

Method for separating lignin from black liquor includes the following steps: a) precipitating lignin by acidifying black liquor and thereupon dewatering, b) suspending the lignin filter cake obtained in step a) to obtain a second lignin suspension and adjusting the pH level to approximately that of the washing water of step d) below, c) dewatering of the second lignin suspension, d) adding washing water and performing a displacement washing at substantially constant conditions without any dramatic gradients in the pH, and e) dewatering the lignin cake produced in step d) into a high dryness and displacing the remaining washing liquid in the filter cake, whereby a lignin product is obtained which has an even higher dryness after the displacement washing of step d). The lignin product or an intermediate lignin product obtained by the method, and its use, preferably for the production of heat or chemicals is also disclosed.

Owner:LIGNOBOOST

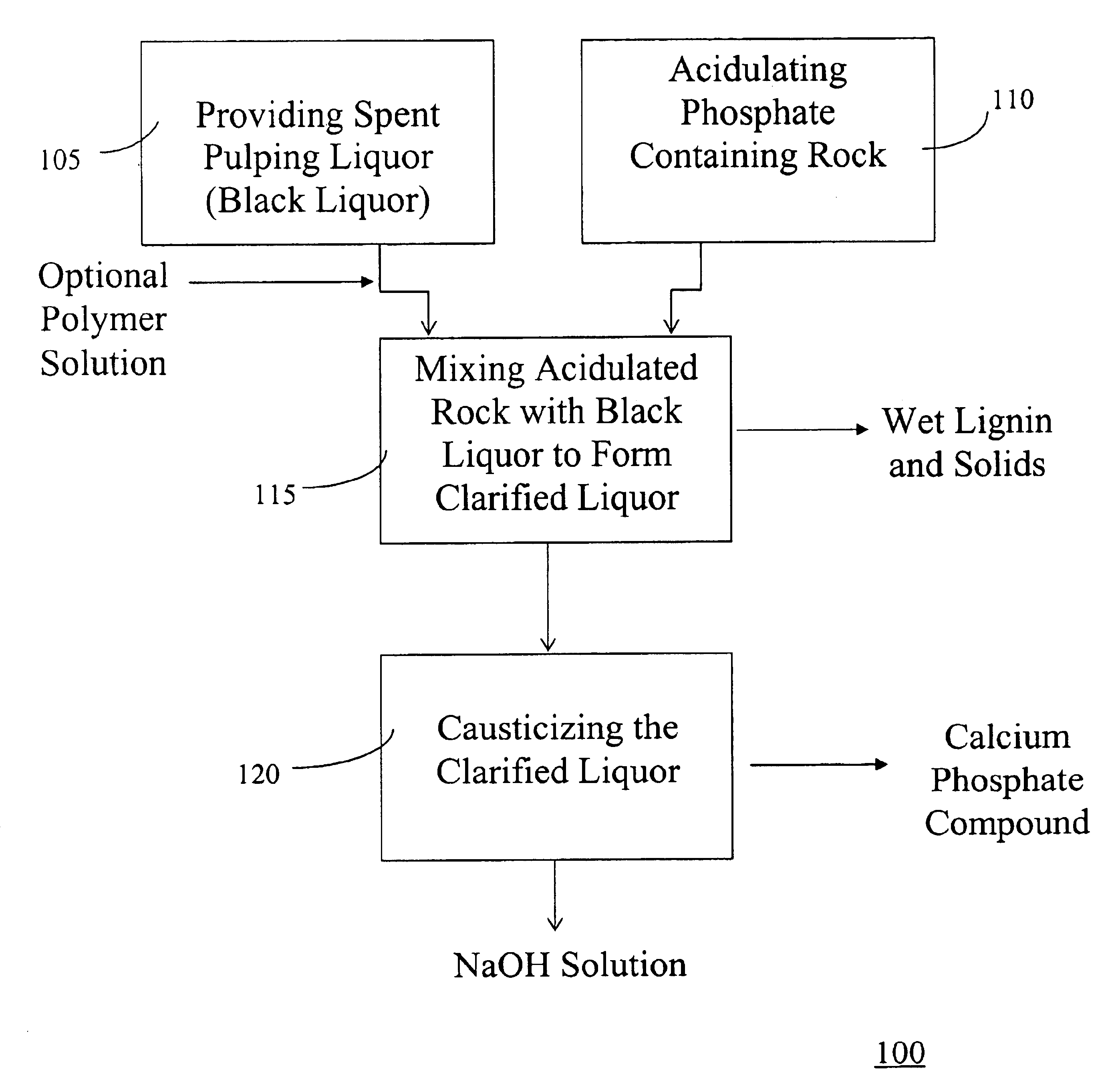

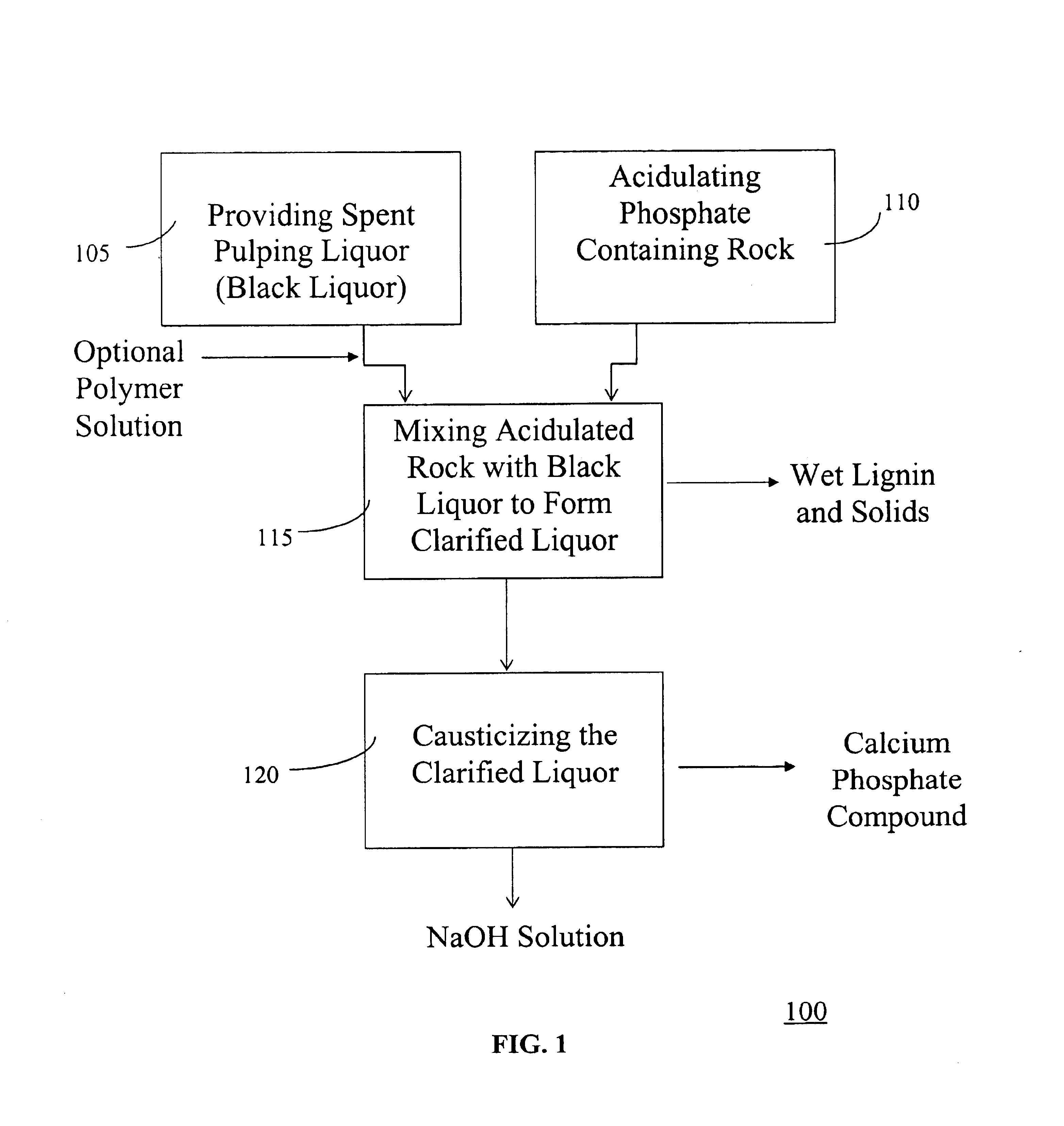

Treatment of spent pulping liquor with lignin separation to recover alkali pulping chemicals in manufacture of paper pulp

InactiveUS6830696B1Minimize dilutionPermit recoverySeparation devicesMachine wet endActive polymerBlack liquor

A method of treating spent alkaline pulping liquor (black liquor) includes the steps of providing black liquor containing lignin, and acidulating a phosphate containing material, wherein phosphoric acid is generated by the acidulating step. The black liquor is mixed with phosphoric acid from the acidulated phosphate containing material, wherein lignin is separated and clarified liquor results. The method can include the step of adding a water soluble, surface active, polymeric, coagulant agent to the black liquor before mixing with the phosphoric acid from the phosphate containing material. The clarified liquor comprises anion species including phosphate.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Novel cellulose extraction process

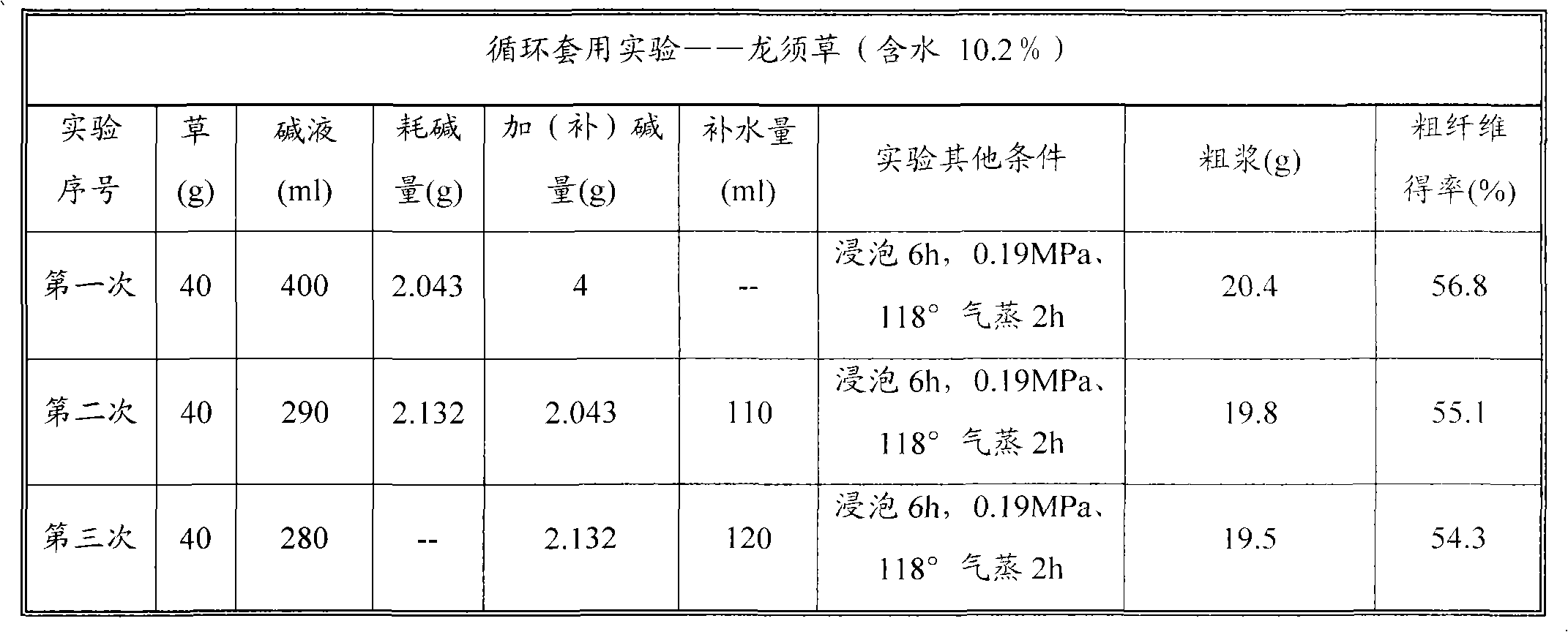

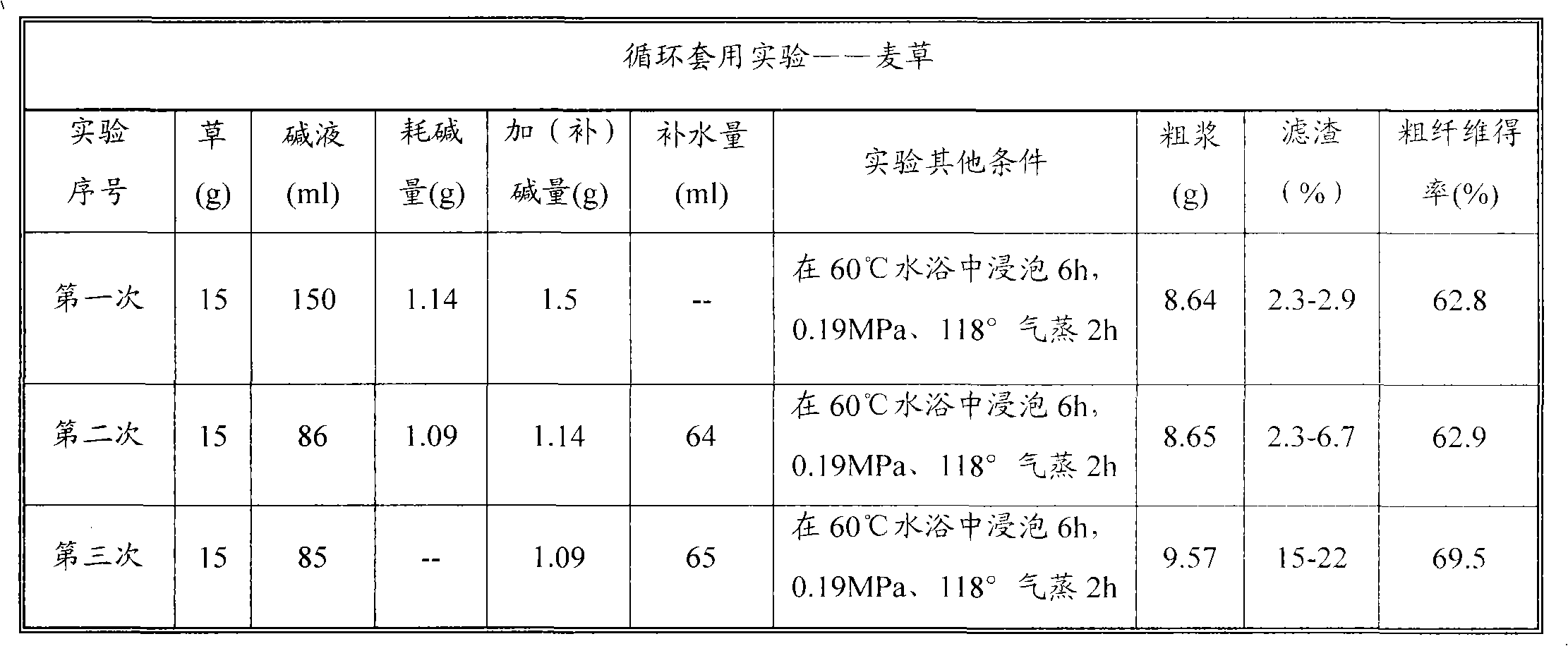

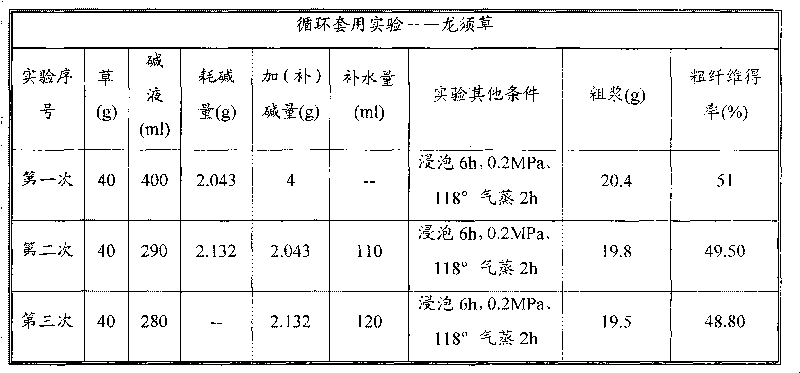

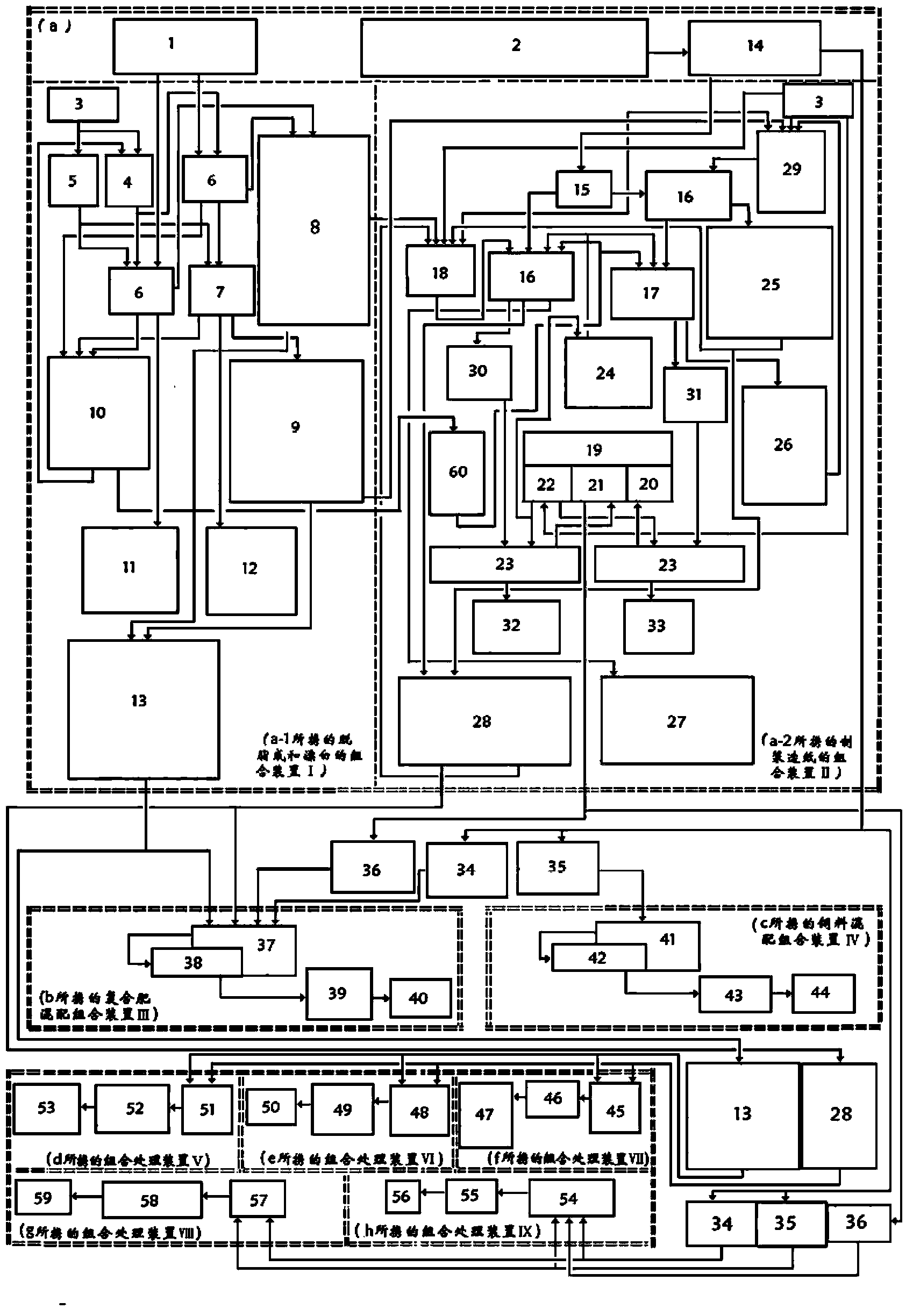

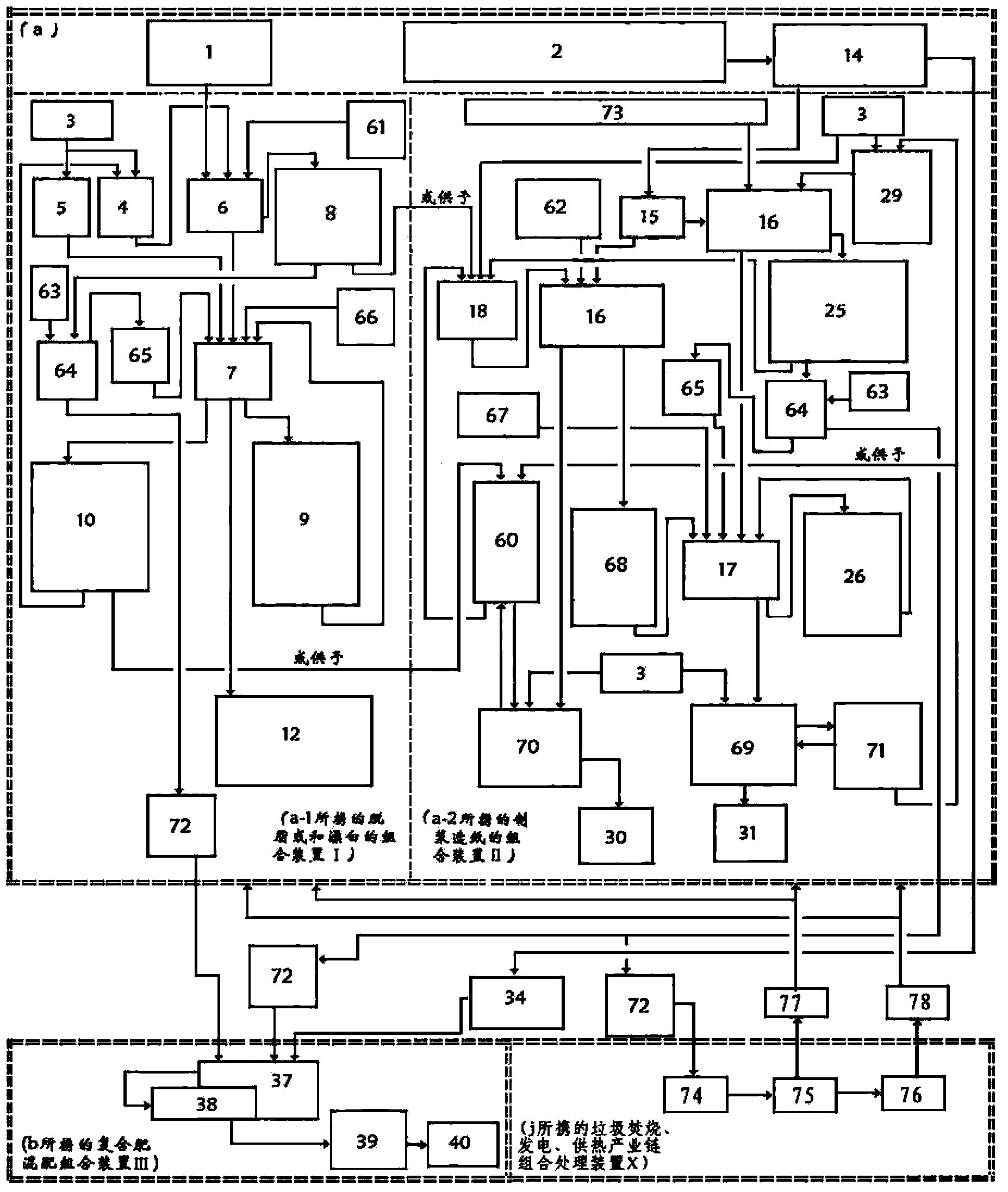

ActiveCN101748633BLight colorPromote growthPretreatment with alkaline reacting compoundsDigestersCelluloseHigh concentration

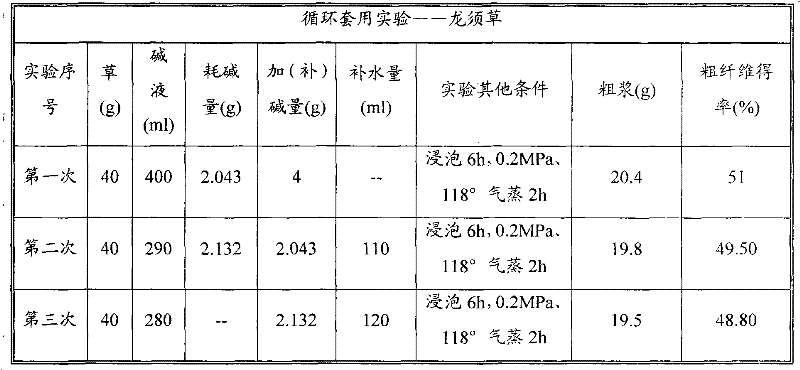

The invention relates to a novel sectional type process which extracts cellulose from plant bodies, and comprises the following steps: the process is that dilute alkali is first used for soaking the plant bodies, and then pressurizing, steaming, polishing and pulp washing are carried out so that the cellulose is obtained. The sectional type process has the advantages that very dilute alkali can be used for soaking or evaporating the plant bodies, not only the amount of alkali is greatly saved, but also the heating temperature is reduced, the heating time is shortened, the cellulose can be obtained at yield coefficient, and the secondary pollution brought by using sulfide, anthraquinone and other high pollution auxiliary agents is avoided. The soak solution and the cleaning solution can be used together in a cycling way, so liquid or solid organic fertilizer with high concentration can be conveniently obtained.

Owner:BEIJING INSIGHT BIOMASS

Method for producing pulp and lignin

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

Green process for extracting fibers from plants

ActiveCN101899794ATime consuming to overcomeOvercome efficiencyDigestersPulping with inorganic basesFiberSlag

The invention relates to a sectional green process for extracting fibers from plant raw materials with high efficiency and high yield, which comprises the steps of: firstly, infiltrating or / and soaking plant raw materials with lime water (or carbide slag water solution) or dilute alkali; then steaming or boiling the raw materials; and finally, beating or steaming discharge and pulp washing to prepare fibers. The green process can also be comprehensively used for exploiting the utilization of lignin and extract, so as to realize the full-rate development of plants. The extract in the process can be recycled as a nutrient source for organisms such as plants, microbes, alga and the like, which breaks through the key technical bottleneck of the green and ecological industry, has significant theoretic and application values on the recycling economy, the sustainable development strategy and acquisition of energy sources, advanced materials and biological nutrient source from biomasses, and has extremely profound social benefits, economic benefits and ecological benefits.

Owner:BEIJING INSIGHT BIOMASS

Process for treating and reclaiming black paper-making liquid generated by alkali pulping

InactiveCN1397684AAchieving zero emissionsTake advantage ofRegeneration of alkali lyeBlack liquorSoil conditioner

Owner:阮键华

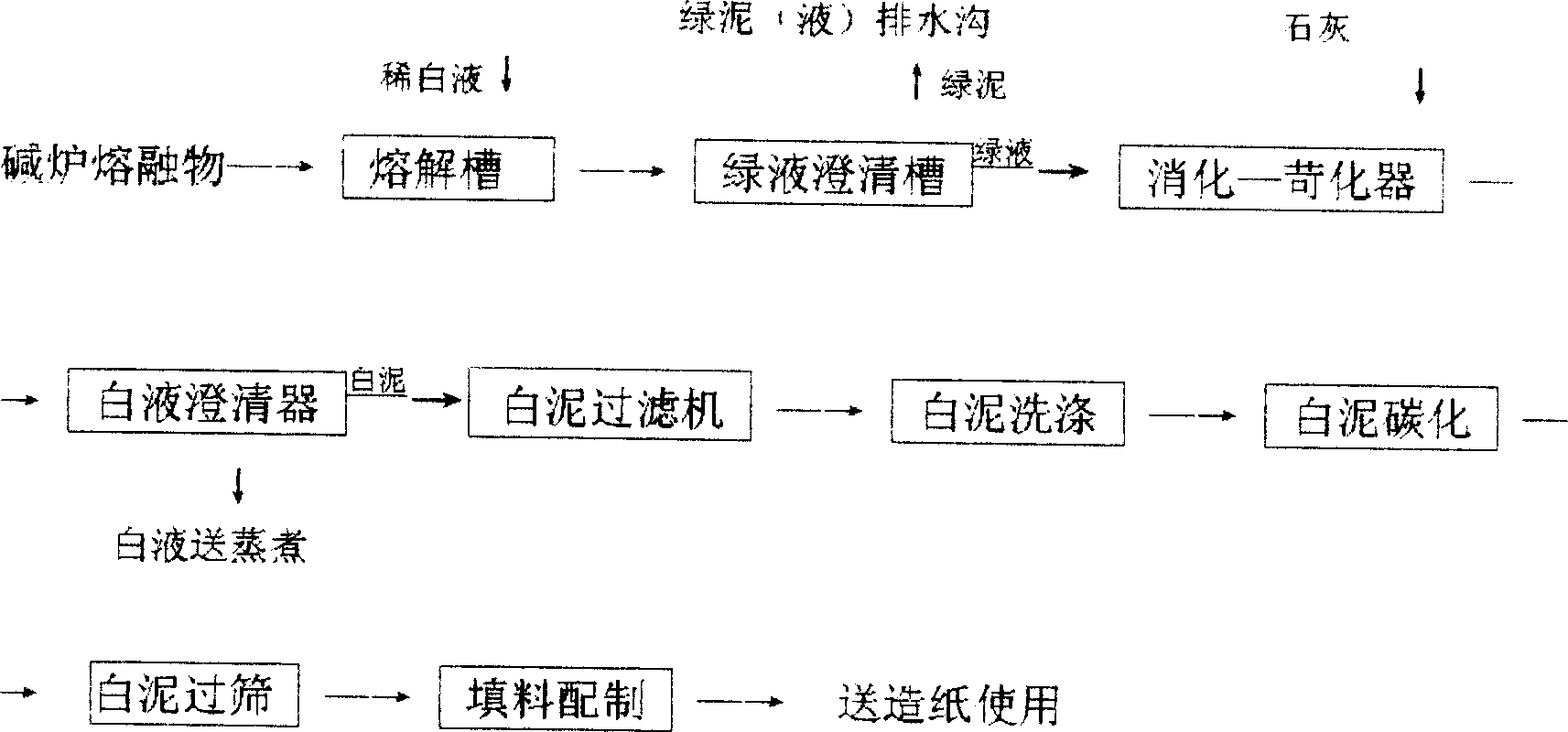

Method for recovering superfine calcium carbonate by clean causticization of green liquor

ActiveCN1641100ALow viscosityIncrease the sedimentation rateRegeneration of alkali lyeAlkalinityCalcium hydroxide

The invention relates to the method to recover super thin calcium carbonate, mainly including the following step: a, join the high macromolecule flocculating agent in green liquid, mix blend even then do away with to descend the sediments, stay the upper level clearness liquid to provide as refined green liquid; b, make the calcium oxide join in the water into the calcium hydroxide syrup, separate the syrup with impurity using the griddle net; c, mix the refined green liquid and the calcium hydroxide syrup, carry on the reaction, add crystal regulator; D: After the syrup responded, carry on the solid- liquid separate, rinse the sieve cake by hot water, take back the sieved liquid; E: prepare sieve cake and waters into suspended liquid syrup, put into the carbon dioxide, get the very thin calcium carbonate syrup.

Owner:SHANGHAI DONGSHENG NEW MATERIALS +1

Eucalyptus dissolving pulp and production method thereof

InactiveCN102493256AReduce productionReduce pollution loadPretreatment with water/steamNatural cellulose pulp/paperSulfateDissolving pulp

The invention discloses a eucalyptus dissolving pulp and a production method thereof, wherein the eucalyptus dissolving pulp is prepared after the steam prehydrolysis, sulfate cooking, oxygen delignification and D0EoPD1 bleaching of eucalyptus pieces, the whiteness is not less than 88%, the alpha cellulose is not less than 94.5%, the pentosan is not higher than 3.0%, the dynamic viscosity is 9-25mPa s, the ash content is not higher than 0.1%, and the iron content is not higher than 15mg kg<-1>. The production method of the eucalyptus dissolving pulp comprises the following steps that: the eucalyptus pieces undergo the steam prehydrolysis, and the P- factor of the steam prehydrolysis is 300-800; the sulfate cooking is carried out after the steam prehydrolysis of the eucalyptus pieces to obtain the pulp; the eucalyptus chemical pulp undergoes the D0EoPD1 bleaching after the oxygen delignification; and after the bleaching, the pulp is washed, dried and processed into the eucalyptus dissolving pulp.

Owner:湖南骏泰新材料科技有限责任公司 +1

Comprehensive utilization method of pulping potash black liquor in paper-making process

InactiveCN1436895AOvercome Physiological AcidityOvercoming problems such as salt damageRegeneration of alkali lyeFertilizer mixturesPh regulationPollution

The comprehensive utilization method of pulping potash black liquor in paper-making process can eliminate pollution, low pollution treating cost and result in high economic benefit. The method includes extracting pulp-making black liquor, neutralizing its alkali with H3OP4 and HNO3 to prepare liquid fertilizer; regulating nutrients, pH regulation and fermentation to produce alcohol or feed protein, mixing the residue with other fertilizer, trace elements, organic matter, etc. to prepare composite fertilizer; adding azotobacteria, phosphate decomposing bacteria, etc. and fermentation to prepare liquid biological fertilizer or inoculating agent; and solid-liquid separation to prepare liquid fertilizer, solid fertilizer or composite fertilizer.

Owner:吴晓丽 +1

Method for preparing bamboo pulp by full-liquid-phase prehydrolysis sulfate displacement cooking process

ActiveCN102182086AReduce pollutionSolve pollutionPretreatment with water/steamPulp bleachingBlack liquorSulfate

The invention discloses a method for preparing bamboo pulp by a full-liquid-phase prehydrolysis sulfate displacement cooking process, which comprises the following steps: preparing materials, washing the materials, prehydrolysizing, cooking, washing, screening, bleaching, regulating polymerization degree, dechlorinating and conducting acid treatment. According to the preparation method, after the cooking is finished, for the obtained pulp, the content of alpha cellulose is more than or equal to 95%, the pepentosan is more than or equal to 4%, and the average polymerization degree is 550-650; after the acid treatment is finished, for the obtained pulp, the content of alpha cellulose is more than or equal to 94%, the pentosan is less than or equal to 3.0%, the average polymerization degree is 400-500, and the white degree is 86-89%. The method has the following advantages: the whole set of technology of full-liquid-phase prehydrolysis, full-liquid-phase cooking, hydrolyzate recovering and recovered black liquid displacement cooking, not only is the waste water pollution degree is alleviated, the temperature rising time and steam amount are saved, the trebling effects of energy saving, emission reduction and yield increasing are achieved, and the problems that the waste water pollution is serious, the energy consumption is high and the output is low in the pulp prepared by the current prehydrolisis sulfate method.

Owner:SICHUAN YONGFENG PAPER MAKING JOINT STOCK

Treatment method for pulping black liquid and application method for product of pulping black liquid

The invention relates to a treatment method for pulping black liquid and an application method for a product of the pulping black liquid, and belongs to the field of alkaline pulping and cellulose and hemicellulose pulp extraction. Lignin and / or pectin and / or silicate which are smelted in the black liquid are converted into lignin calcium (magnesium) salt and / or pectate calcium (magnesium) salt and / or calcium (magnesium) silicate which are not smelted in water by using calcium sulfate or magnesium sulfate salt and can be separated out of the black liquid; due to filtration and separation, the black liquid in a pulping papermaking industry can be treated with low cost; and moreover, various useful chemicals can be obtained.

Owner:秦才东

Novel cellulose extraction process

ActiveCN101748633ALight colorThe solution cannot be appliedPretreatment with alkaline reacting compoundsDigestersCelluloseHigh concentration

The invention relates to a novel sectional type process which extracts cellulose from plant bodies, and comprises the following steps: the process is that dilute alkali is first used for soaking the plant bodies, and then pressurizing, steaming, polishing and pulp washing are carried out so that the cellulose is obtained. The sectional type process has the advantages that very dilute alkali can be used for soaking or evaporating the plant bodies, not only the amount of alkali is greatly saved, but also the heating temperature is reduced, the heating time is shortened, the cellulose can be obtained at yield coefficient, and the secondary pollution brought by using sulfide, anthraquinone and other high pollution auxiliary agents is avoided. The soak solution and the cleaning solution can be used together in a cycling way, so liquid or solid organic fertilizer with high concentration can be conveniently obtained.

Owner:BEIJING INSIGHT BIOMASS

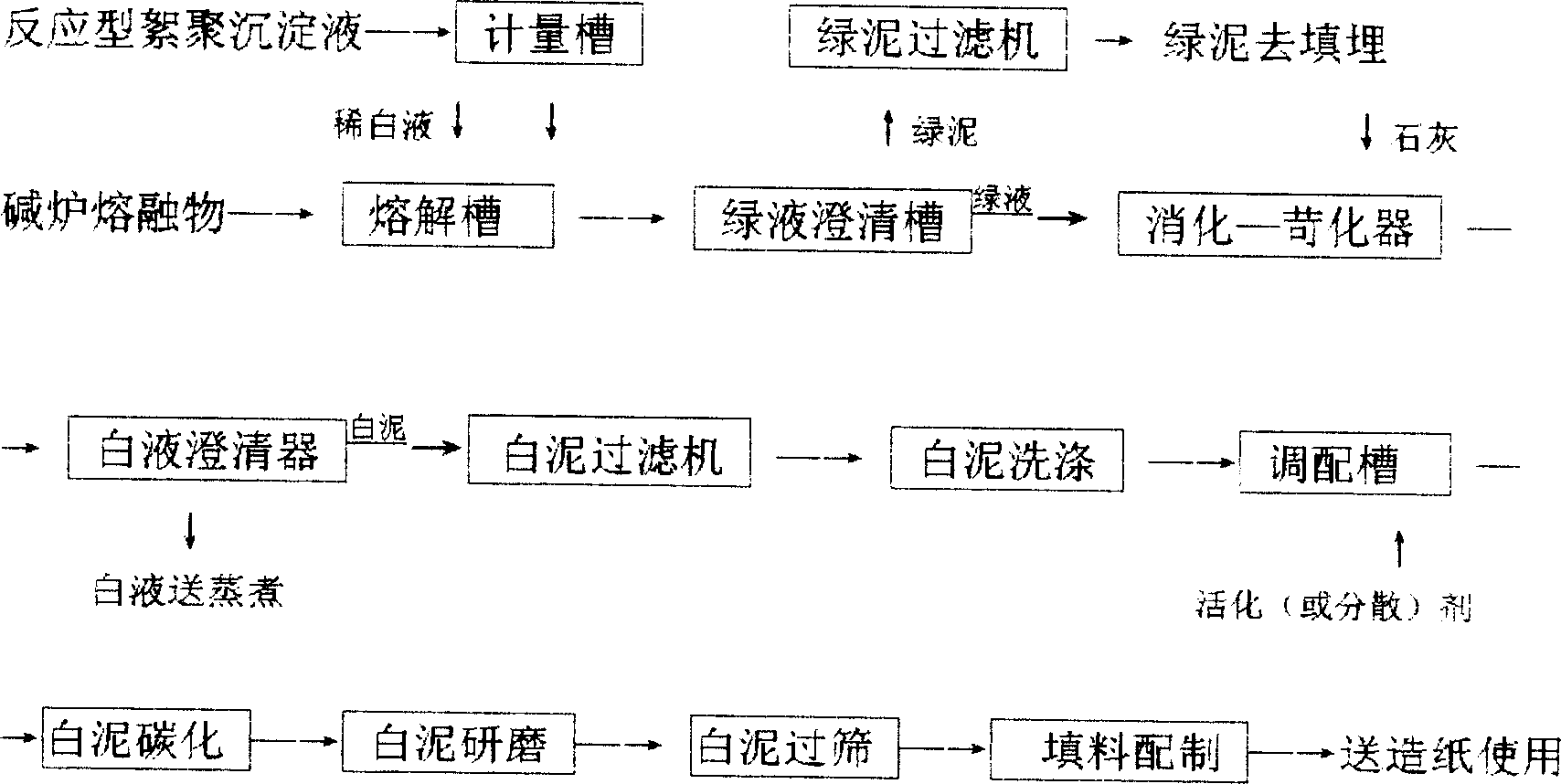

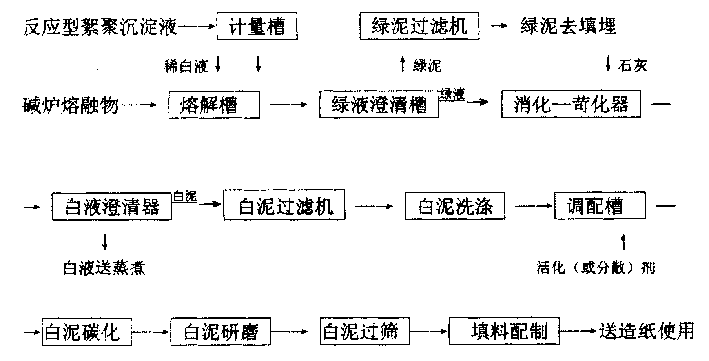

Technological process of recovering white clay to produce stuffing calcium carbonate

InactiveCN1441117AHigh whitenessImprove purity and whitenessCarbonate/bicarbonate preparationRegeneration of alkali lyeWhite liquorCompound (substance)

The technological process of recovering white clay, as one side product of recovering pulping chemical in paper making, to produce stuffing calcium carbonate includes purifying green liquid in dissolving tank by adding reaction type flocculating precipitation assistant; clarifying green liquid, causticizing; clarifying white liquid; and refining white clay through carbonizing and grinding in grinder. The present invention produces white clay with high whiteness white vacuum treating green clay to reduce loss of sodium salt and raise alkali recovering rate. During purifying green liquid, only lime milk as assistant is added.

Owner:王梅林

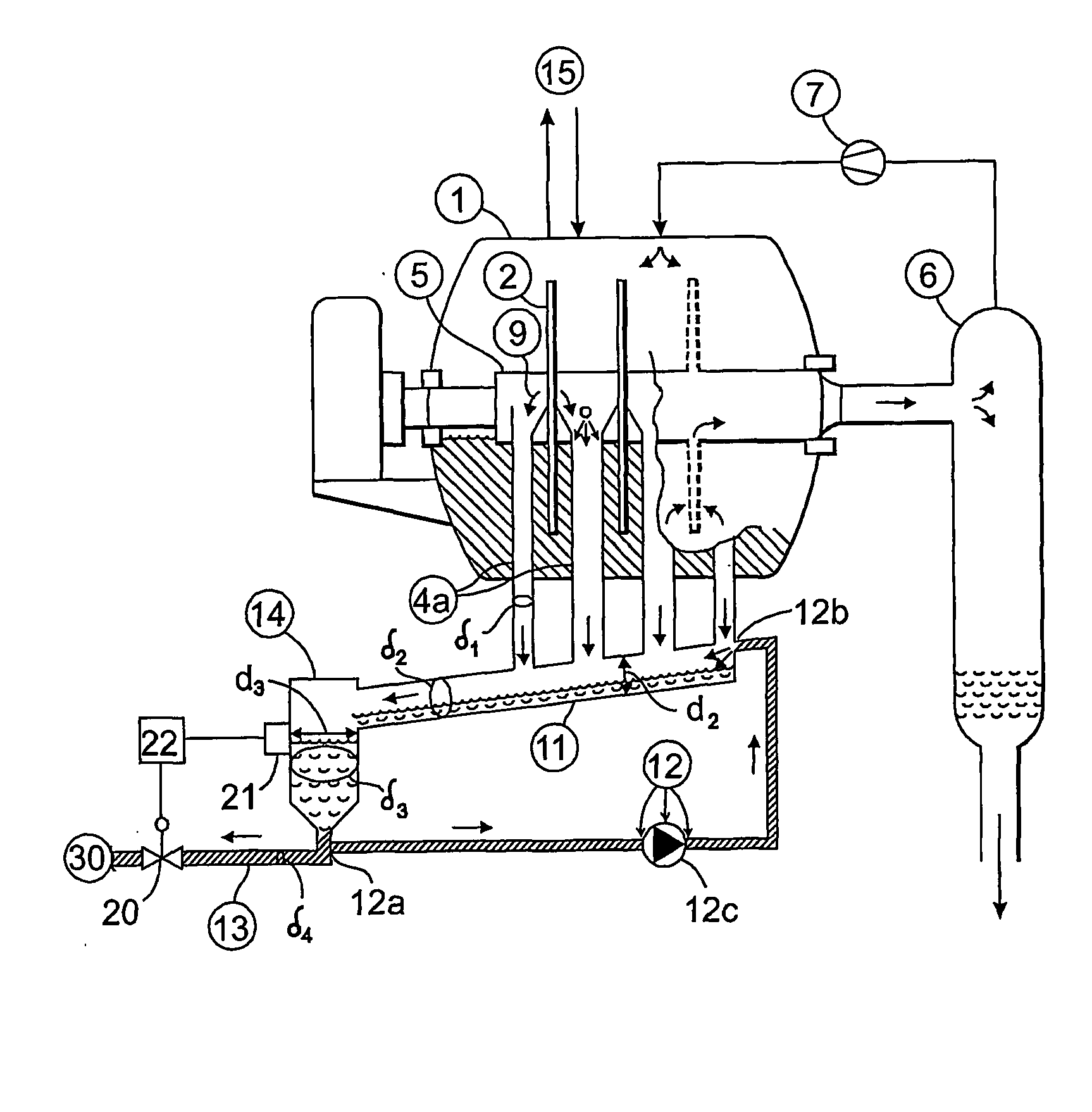

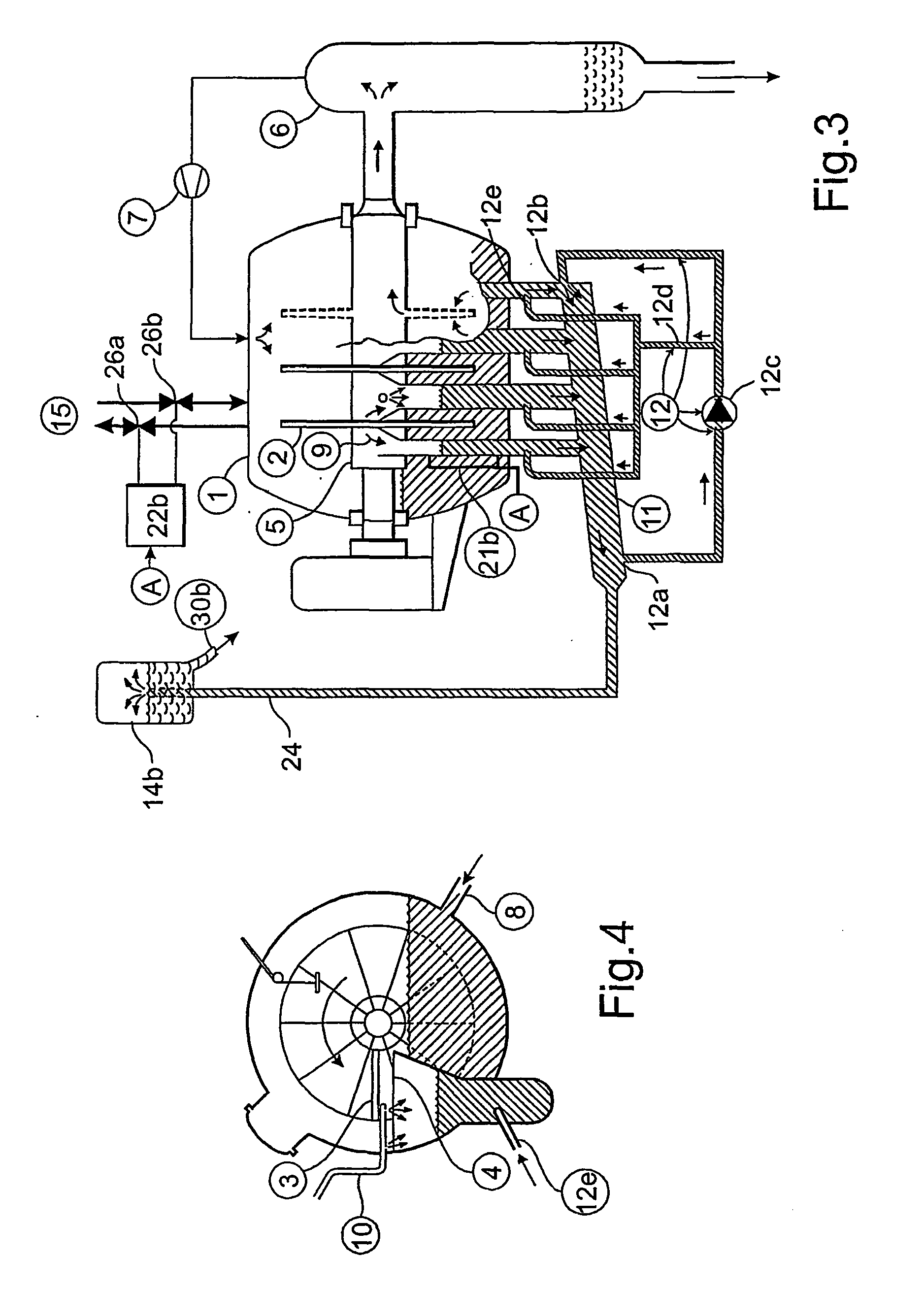

Pipe system for receiving and transporting lime sludge from a white liquor filter

InactiveUS20040069721A1Reduce riskIncrease speedLiquid degasificationSedimentation separationWhite liquorSludge

The pipe system is for receiving and transporting lime sludge from a filter medium in a continuously operating pressurized filter 1 in a causticizing process, where lime sludge is scraped off from the filter medium 2 and falls down into receiving chutes 4a for the lime sludge. Conventional storage tanks for scraped-off lime sludge and their mechanical agitators are thus replaced by a pipe system 11 where the pipe system does not have a mechanical agitator at all but has a flow cross section which maintains a flow rate in the lime sludge so that sedimentation of the lime sludge does not take place from the receiving chute 4a to the feed-out opening 30 of the pipe system.

Owner:METABO PAPER SWEDEN

Processing method of paper-making pulping black liquor

The invention discloses a processing method of paper-making pulping black liquor, and the method comprises polycondensation, acid precipitation, aging, precipitation, solid-liquid separation and drying of the pulping paper-making black liquor, and in the black liquor, the solid phase which mainly comprises lignin and the liquid phase which mainly comprises sodium salt solution are separated; and the Baume degree of the black liquor is larger than or equal to 15 Be degrees. The method has simple process, low cost and wide application range. The obtained lignin can be used as multiple industrial and agricultural raw materials; the chroma, CODcr and BOD5 of the obtained liquid phase are greatly reduced.

Owner:张仲伦

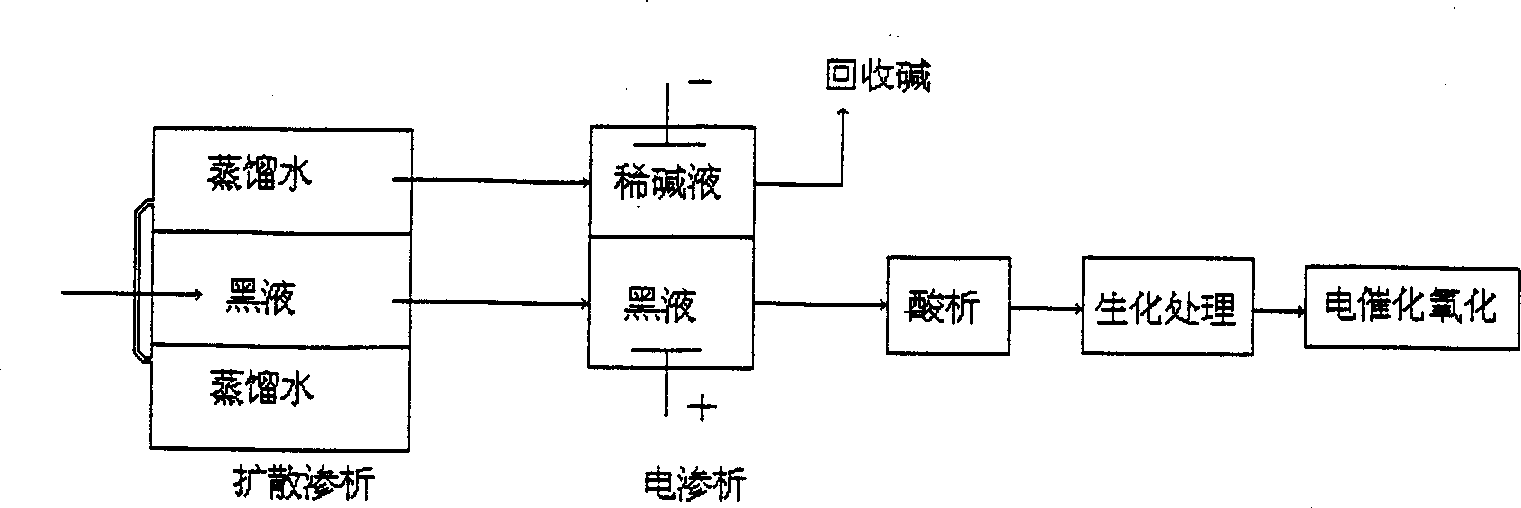

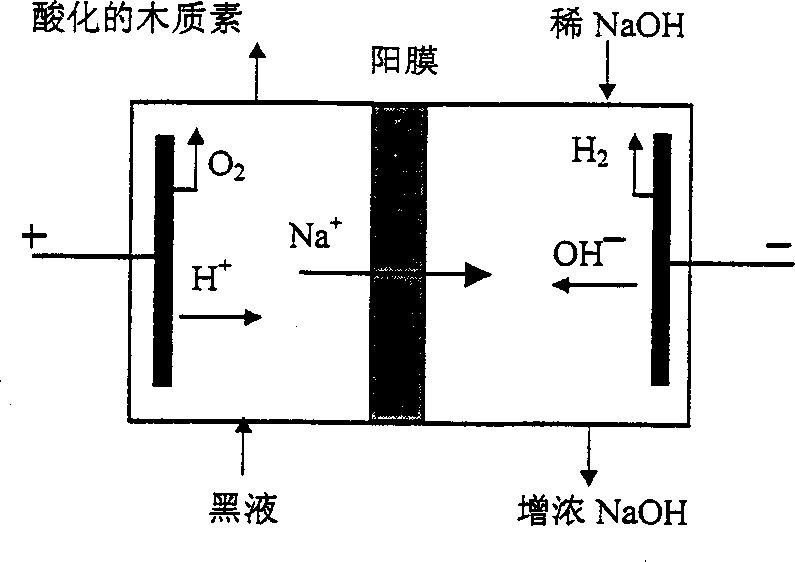

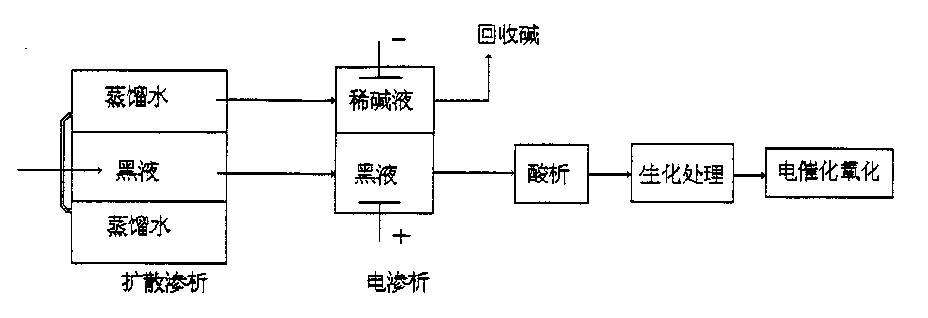

Alkali recovery process for black liquor of straw pulp

InactiveCN1334376AImprove continuitySolve problemsDispersed particle separationWater/sewage treatment bu osmosis/dialysisElectricityBlack liquor

An alkali recovering process for the black liquor of straw pulp includes diffusion dialysis of digested black liquor to obtain diluted alkali solution, dividing electric dialysis chamber into anode and cathode chambers by monocational diaphragm, circulating black liquor in anode chamber, circulating diluted alkali solution in cationde chamber, electric dialysis at ordinary temp and pressure by applying 8-10 v DC voltage and 1 A current, acid separating, biochemical treating, and electrically catalytic oxidization. Its advantages are high recovery yield of alkali, and low energy consumption.

Owner:SHANGHAI JIAO TONG UNIV

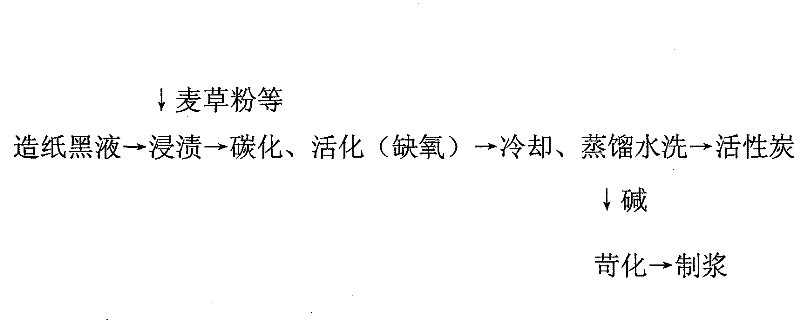

Method for preparing active carbon during alkali recovery of papermaking black liquor

InactiveCN102363930ANo emissionsReduce processing costsRegeneration of alkali lyeActivated carbonBlack liquor

The invention discloses a method for preparing active carbon during the alkali recovery of papermaking black liquor. The method comprises the following steps of: mixing papermaking black liquor with wheat straw powder, cotton straw powder and corn stalk powder, soaking for 10-30 hours, putting into an activating oven, heating to 500-900 DEG C at the heating rate of 5-20 DEG C / min in the anaerobic state for pyrolyzing for 1-4 hours; bleaching an activated product with distilled water, and drying to obtain active carbon; and recovering alkali from the bleaching liquid, and causticizing to obtain alkali for pulping. The methylene blue adsorption value of the prepared active carbon is 4-9 mg / 0.1g, and the active carbon can be used for treating waste water in a papermaking factory and has a good effect; and in the preparing process of the active carbon, no waste water or waste gas is discharged. The problem of treatment of papermaking black liquor can be solved, and the cost for papermaking waste water treatment can be lowered by using the prepared active carbon. The method belongs to the technical fields of pulping and papermaking.

Owner:QILU UNIV OF TECH

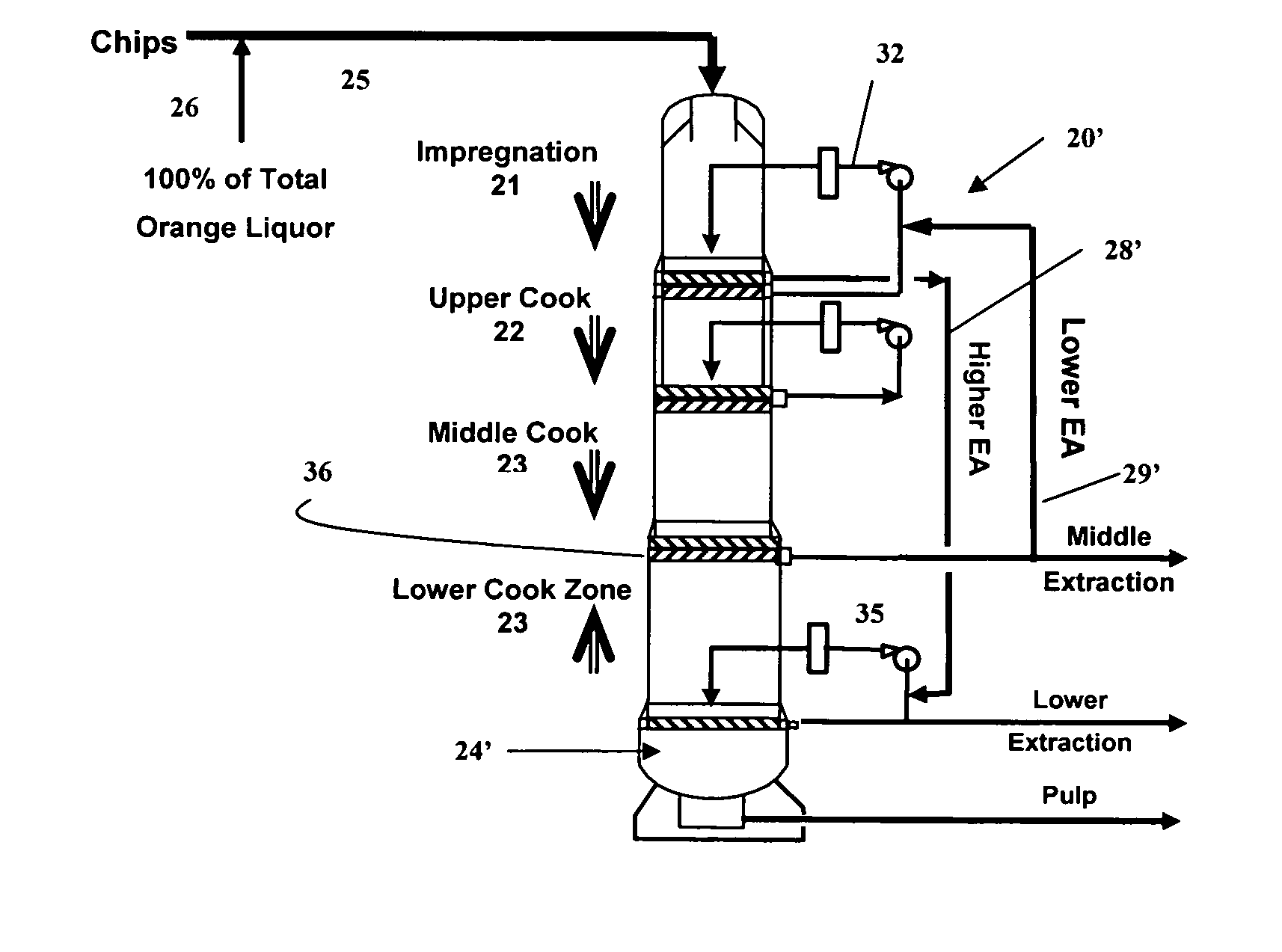

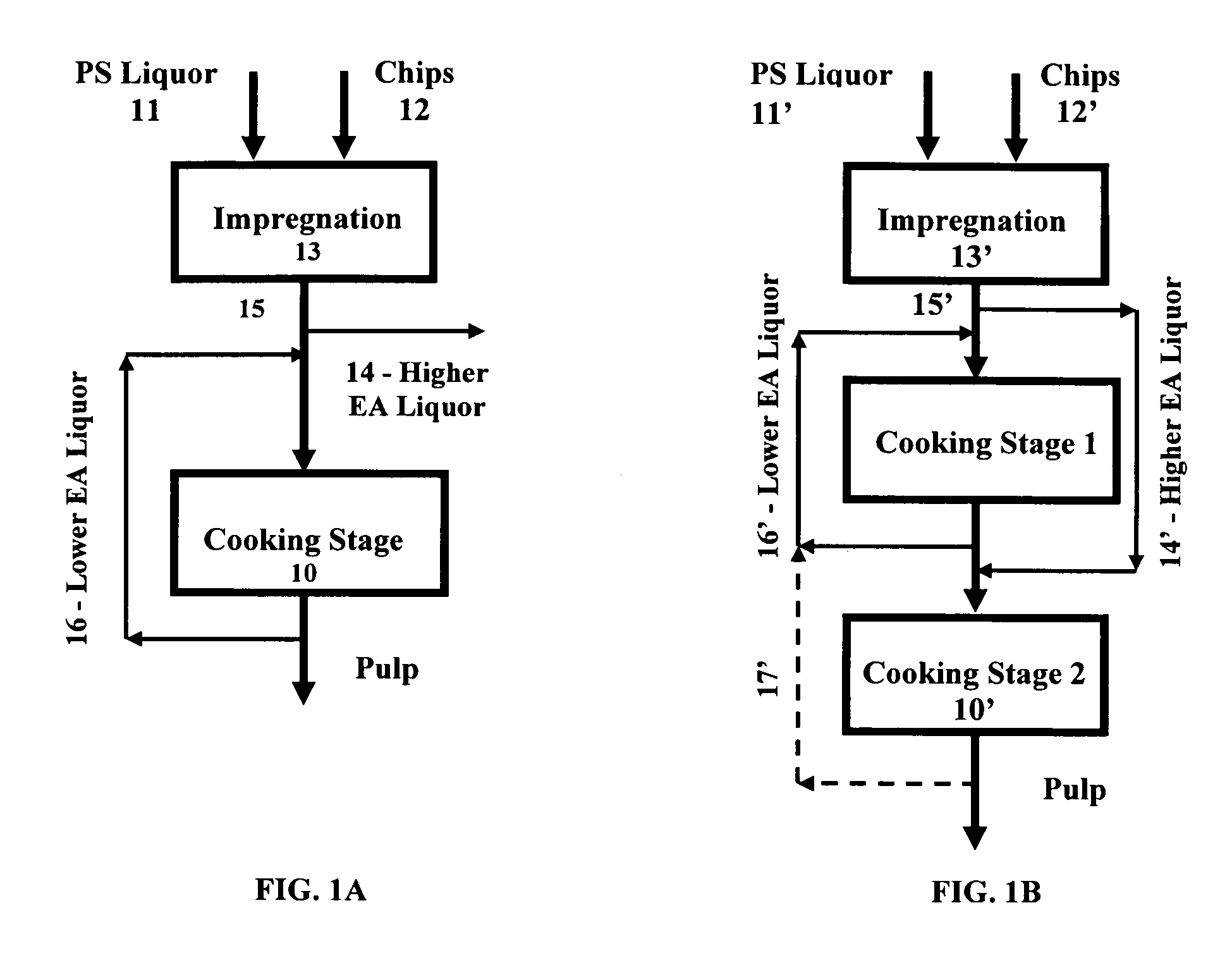

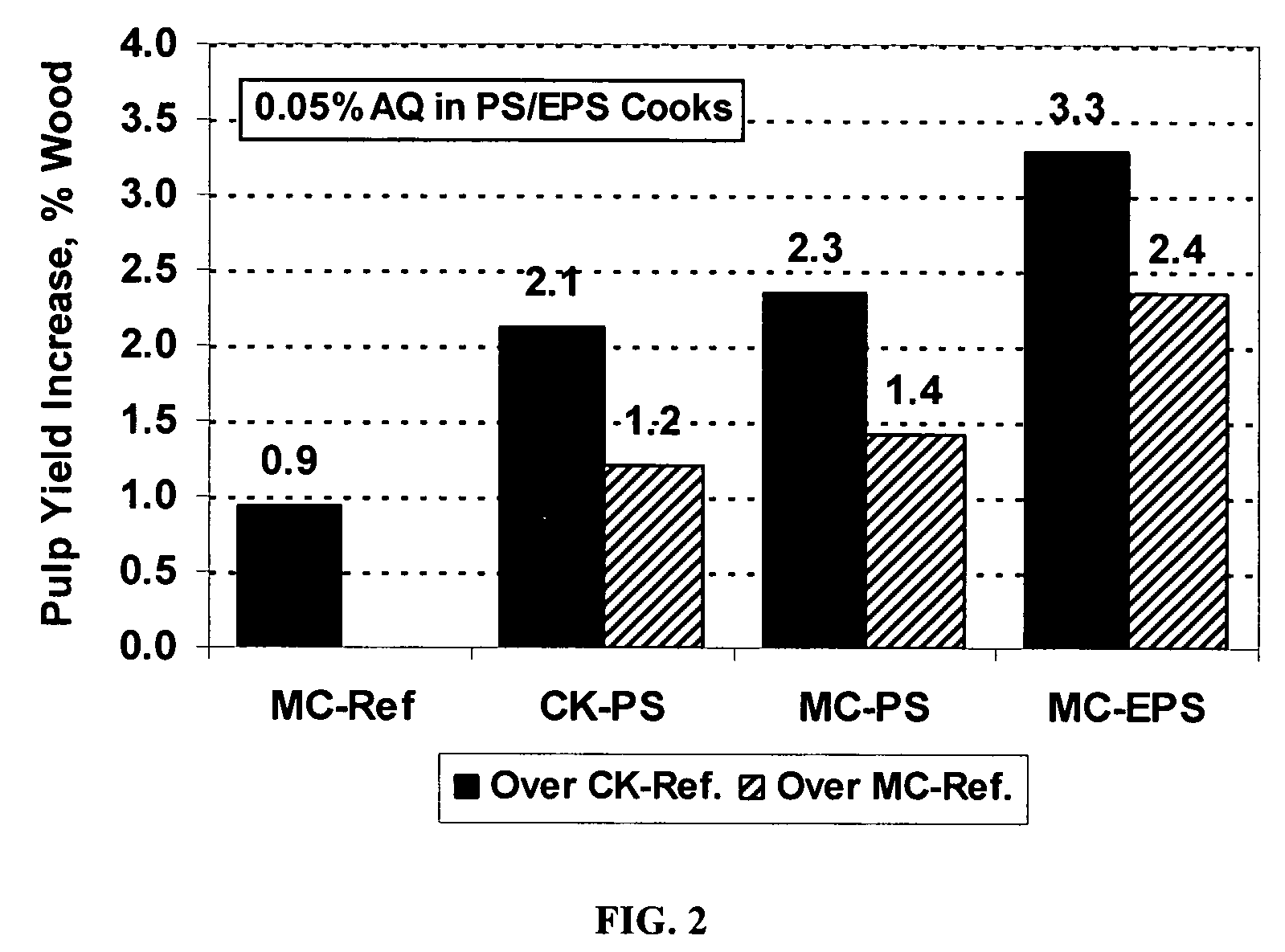

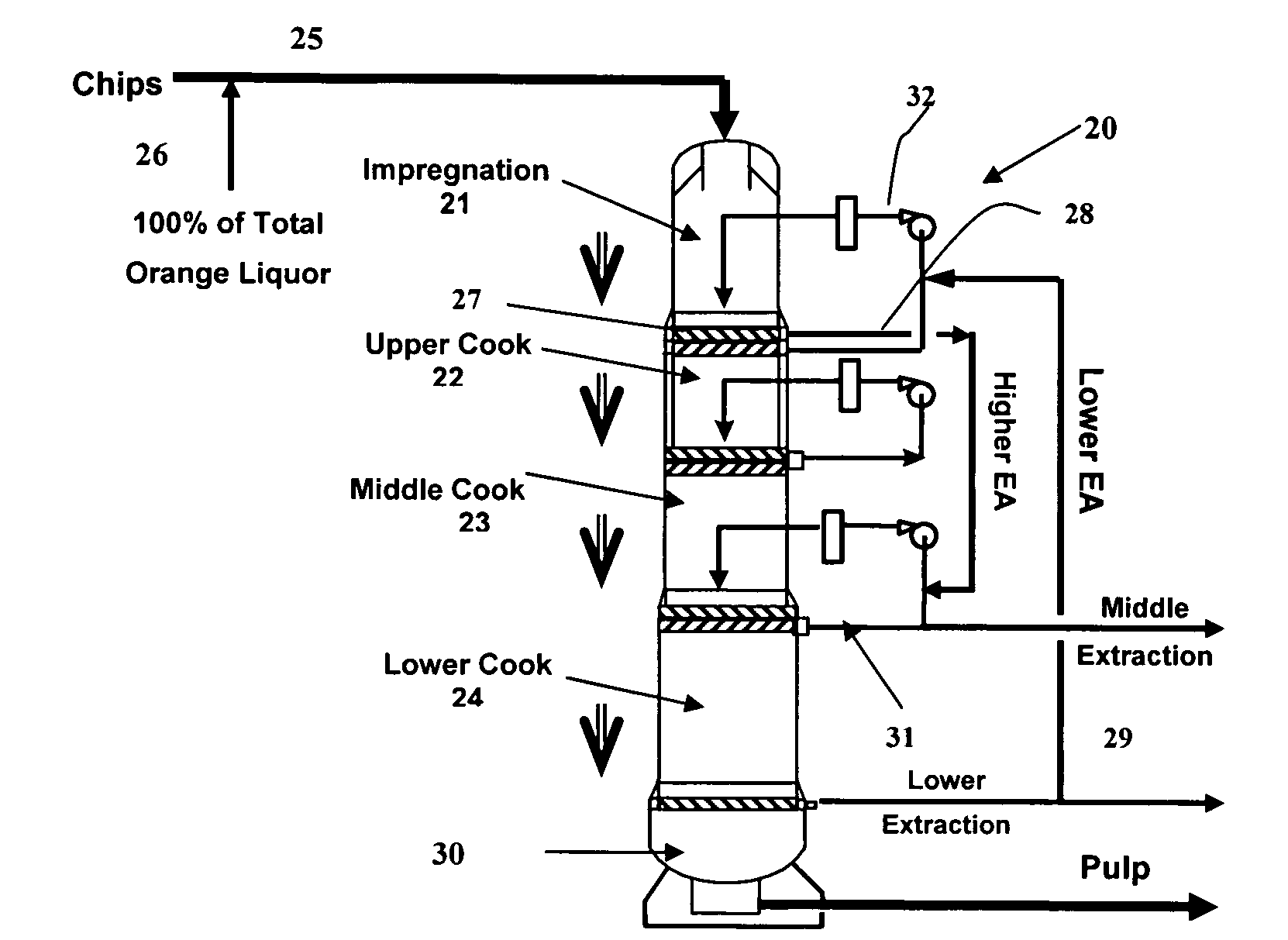

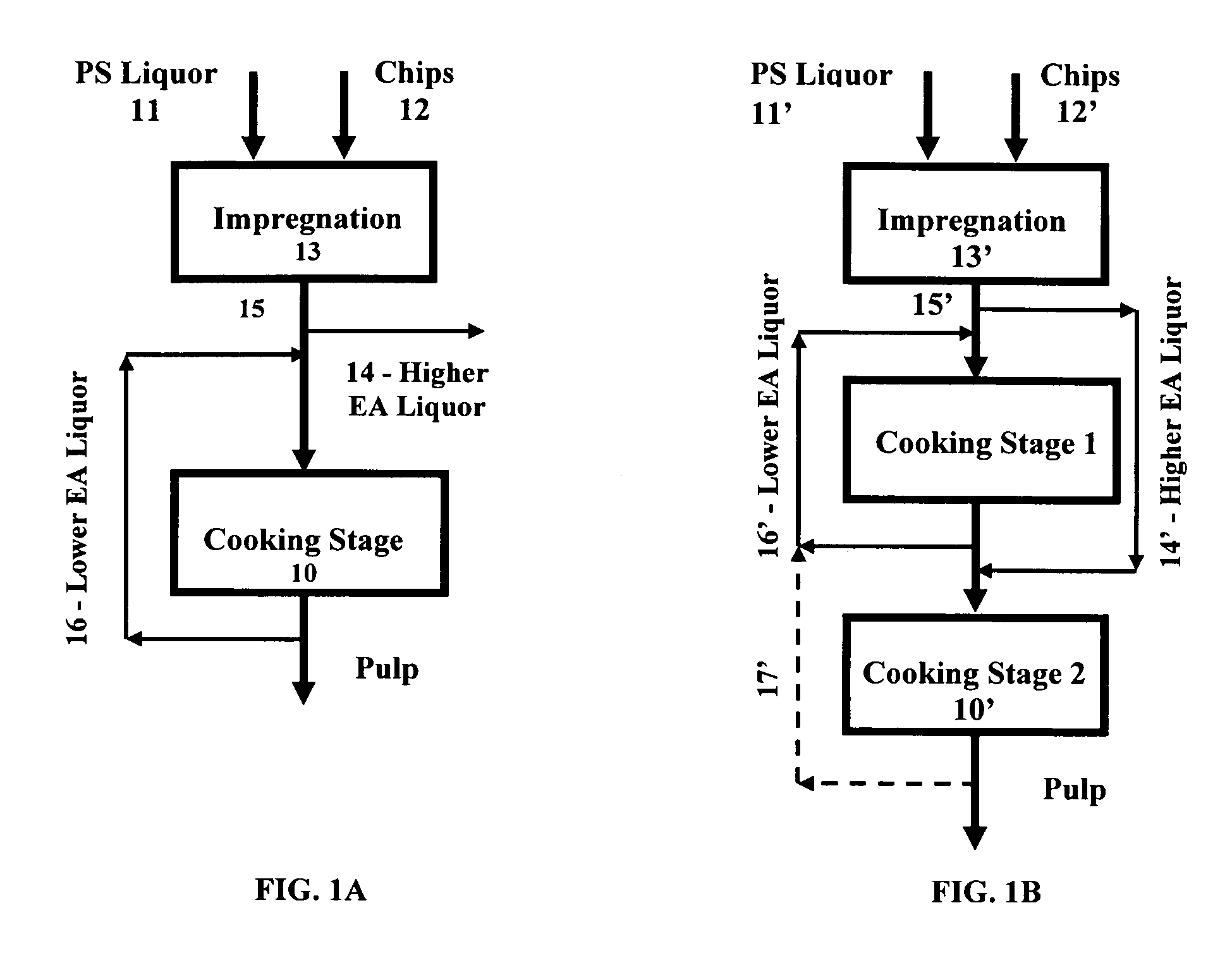

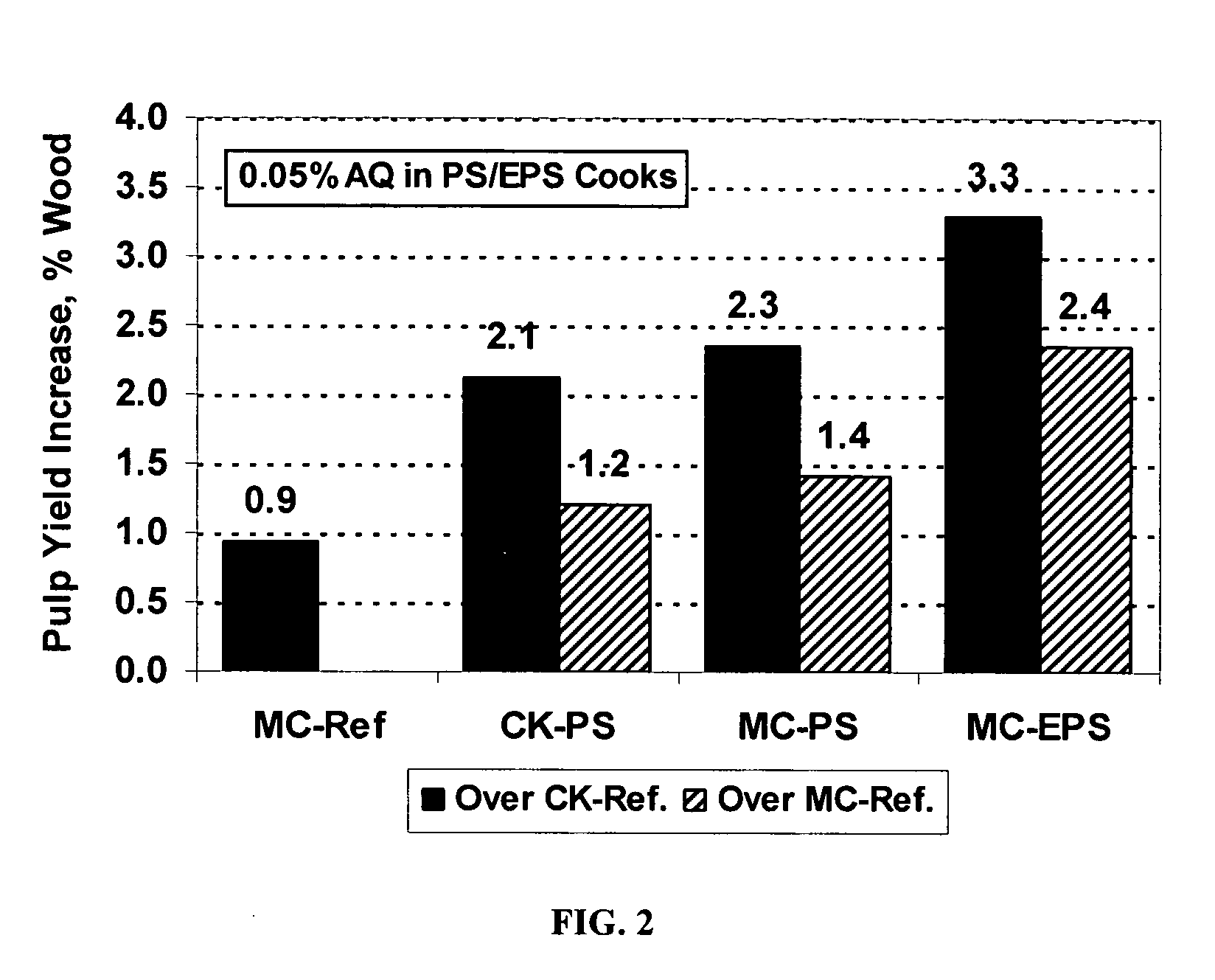

Use of polysulfide in modified cooking

A method for Kraft pulping employing a modified cooking process in conjunction with polysulfide pulping technologies to obtain higher pulping yields than obtained in the prior art. The total required alkali charge (polysulfide liquor) is added to the beginning of a cook, and after all polysulfide has essentially reacted with lignocellulosic material at temperature below that at which no significant carbohydrate degradation occurs, a first quantity of the cooking liquor high in effective alkali (EA) concentration is removed from a first point in the pulping process and replaced with a cooking liquor low in EA concentration removed from another process point. The first quantity is then added elsewhere in the pulping process, where the EA concentration is low. This cooking liquor “exchange” obtains the full yield benefit from polysulfide pulping and a more uniform EA concentration profile to retain the major benefits of modified cooking.

Owner:INT PAPER CO

Partial oxidation of cellulose spent pulping liquor

InactiveUS20050076568A1Sulfur contentEasy to cleanPressurized chemical processPulp liquors combustionCellulosePartial oxidation

The present invention relate to a two-stage gasification process using a gas generator for the recovery of strongly alkaline chemicals and energy value from a cellulose spent liquor. The temperature in the first reaction zone of the gas generator is maintained between 1000 C. and 1400 C. by the controlled addition of an oxygen containing gas. A strongly alkaline smelt comprising alkali oxide, alkali hydroxide, alkali carbonate and alkali borate's corresponding to at least 75% by weight of the smelt is recovered from below the first reaction zone of the gas generator. A gaseous components stream formed by exothermal reactions in the first reaction zone are directed to a second reaction or gas transfer zone of substantially of updraft or up-flow design, wherein the gaseous stream is cooled to a temperature below about 1000 C, said cooling preferably achieved by endothermal decomposition of cellulose spent liquor injected into the gaseous stream.

Owner:STIGSSON LARS LENNART

Clean production method of plant fiber product

InactiveCN103523945ARealize cleaner productionReduce processing costsMultistage water/sewage treatmentWaste water treatment from plant processingSludgeSugar industry

The invention discloses a clean production method of a plant fiber product, relating to the regeneration treatment on the black liquid generated by the deinking or degreasing or / and delignification in a production process of the plant fiber product or / and the implementation of interception-type recycling of the black liquid containing sodium ions, relating to the circulating water treatment and application in a production process in the field of different sub-products of the field of plant fiber products, relating to the treatment and utilization of the sludge obtained in black liquid regeneration and circulating water treatment processes, and relating to the blending treatment and utilization of drain water, wherein the plant fiber at least comprises any one of cotton and fibrilia crops, crop straw including any one of cotton straw, rice straw, wheat straw, reed, corn straw and the like, weed including any one of carex meyeriana, solidago decurrens and the like, broadleaf wood and the like including any one of poplar and eucalyptus, bagasse discarded by the sugar industry and any one of waste paper and old cotton or the combination of more than one waste plant fiber product and the like.

Owner:上海橡本永拓环保科技发展有限公司 +4

Use of polysulfide in modified cooking

A method for Kraft pulping employing a modified cooking process in conjunction with polysulfide pulping technologies to obtain higher pulping yields than obtained in the prior art. The total required alkali charge (polysulfide liquor) is added to the beginning of a cook, and after all polysulfide has essentially reacted with lignocellulosic material at temperature below that at which no significant carbohydrate degradation occurs, a first quantity of the cooking liquor high in effective alkali (EA) concentration is removed from a first point in the pulping process and replaced with a cooking liquor low in EA concentration removed from another process point. The first quantity is then added elsewhere in the pulping process, where the EA concentration is low. This cooking liquor “exchange” obtains the full yield benefit from polysulfide pulping and a more uniform EA concentration profile to retain the major benefits of modified cooking.

Owner:INT PAPER CO

Method for producing calcium carbonate

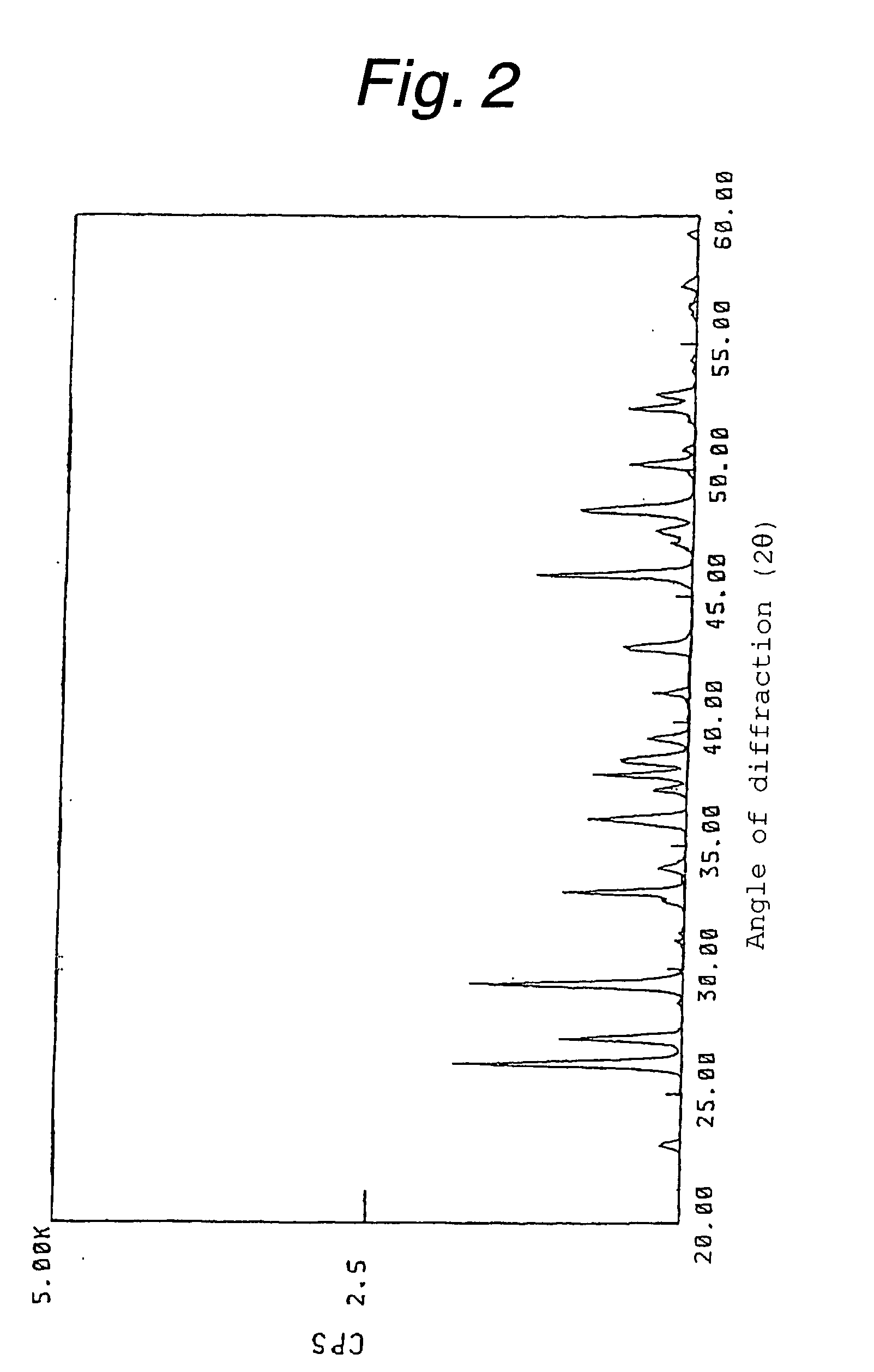

InactiveUS20030049194A1Promote precipitationReduce the ratioCalcium/strontium/barium carbonatesCoatings with pigmentsPersulfateSulfate

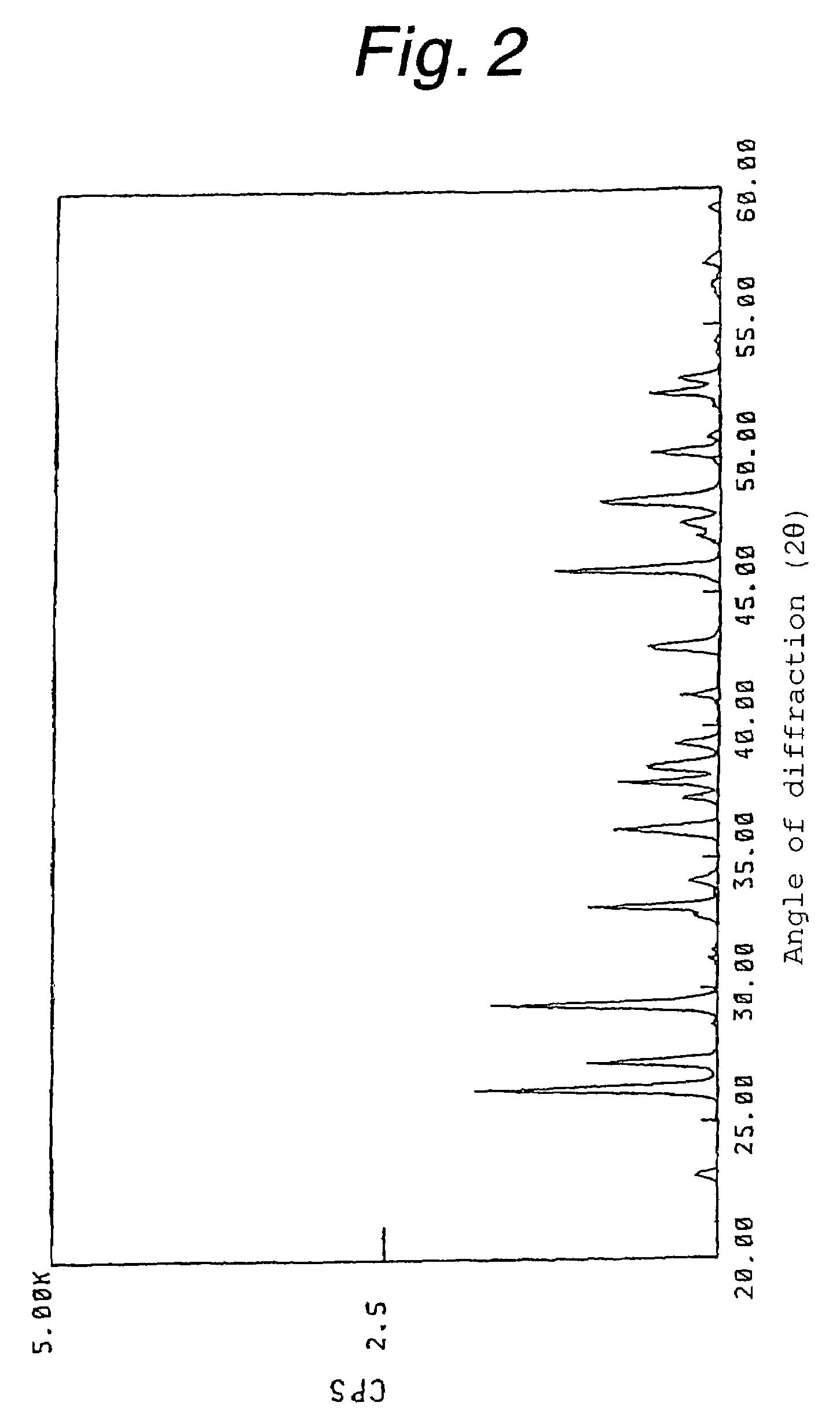

Calcium carbonate in the form of aragonite crystals suitable for use as a filler for papermaking to give useful properties for bulk, whiteness, opacity, wire abrasion and yield is obtained by taking advantage of the causticization step. Herein disclosed is a process for producing calcium carbonate in the form of aragonite crystals which is useful as a filler for papermaking via the causticization step of the sulfate or soda pulping process, comprising adding an aqueous alkaline solution having a hydroxide ion level of 3 mol / l or less and containing 0.25 mol or less of carbonate ion per 1 mol of quick lime to quick lime and / or slaked lime at a quick lime concentration of 1-60% by weight with stirring to prepare milk of lime, and then adding green liquor to said milk of liquor at a loading rate of 0.002-0.12 g (sodium carbonate) / min / g (quick lime) to perform a causticization reaction at a temperature of 30-105° C.

Owner:NIPPON PAPER IND CO LTD

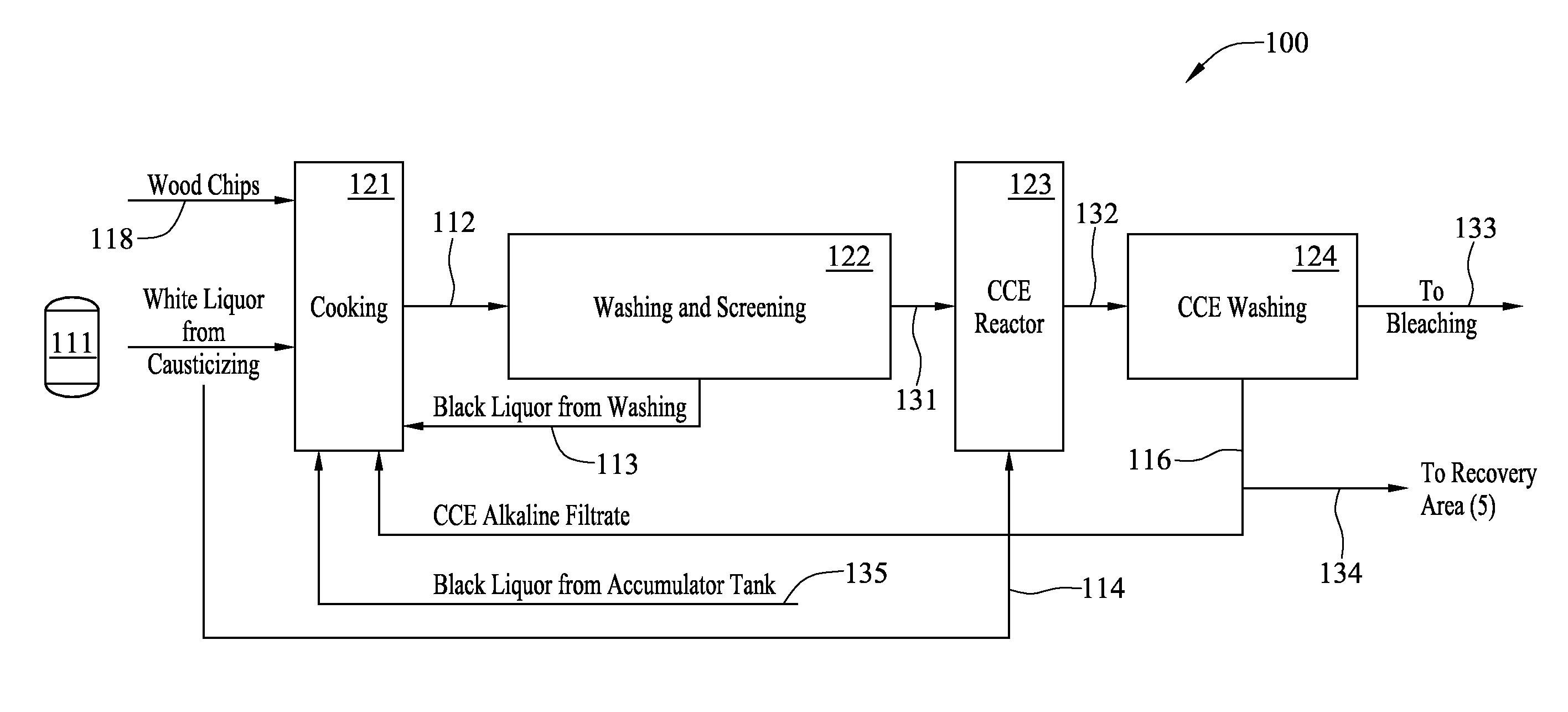

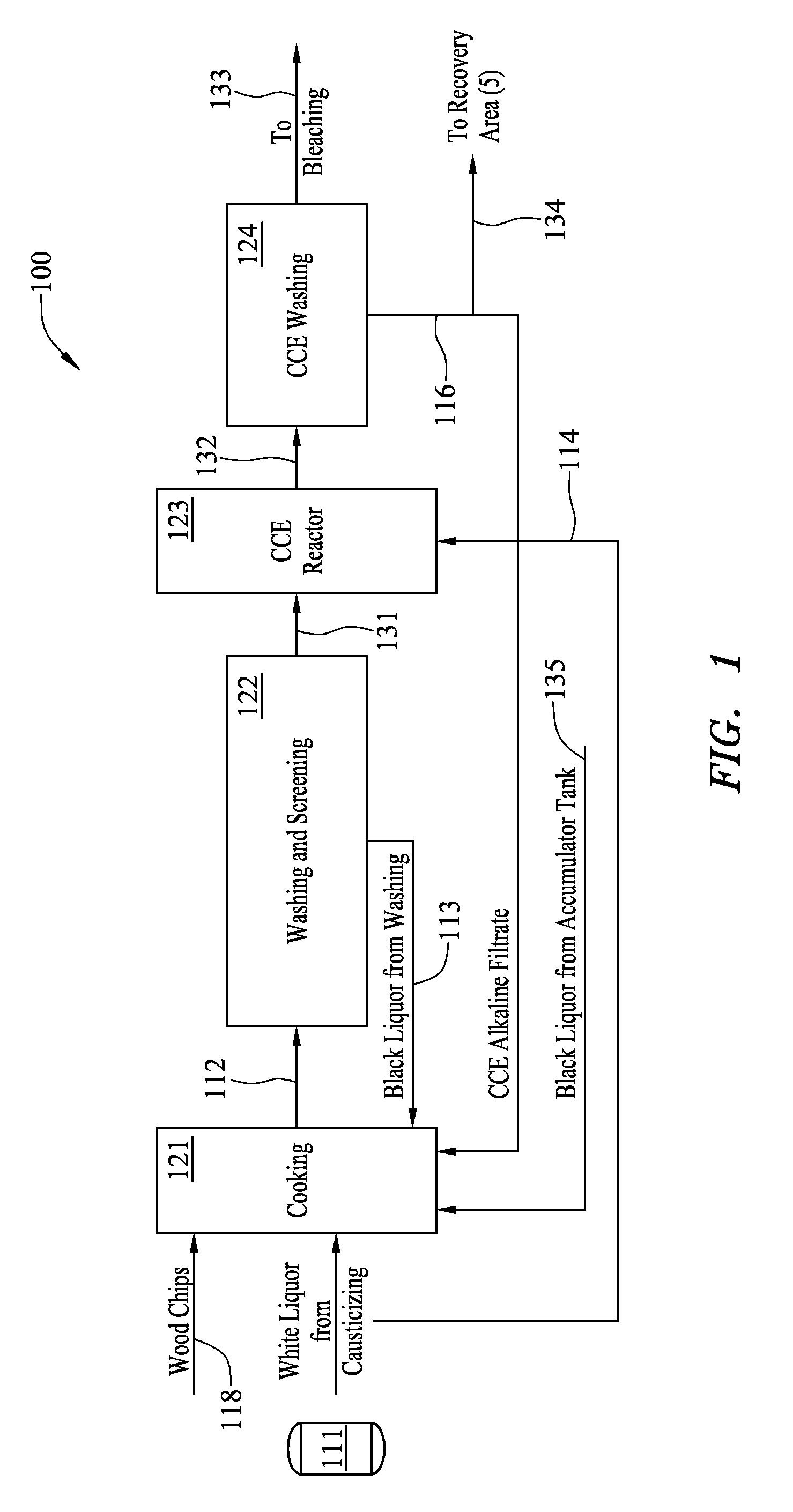

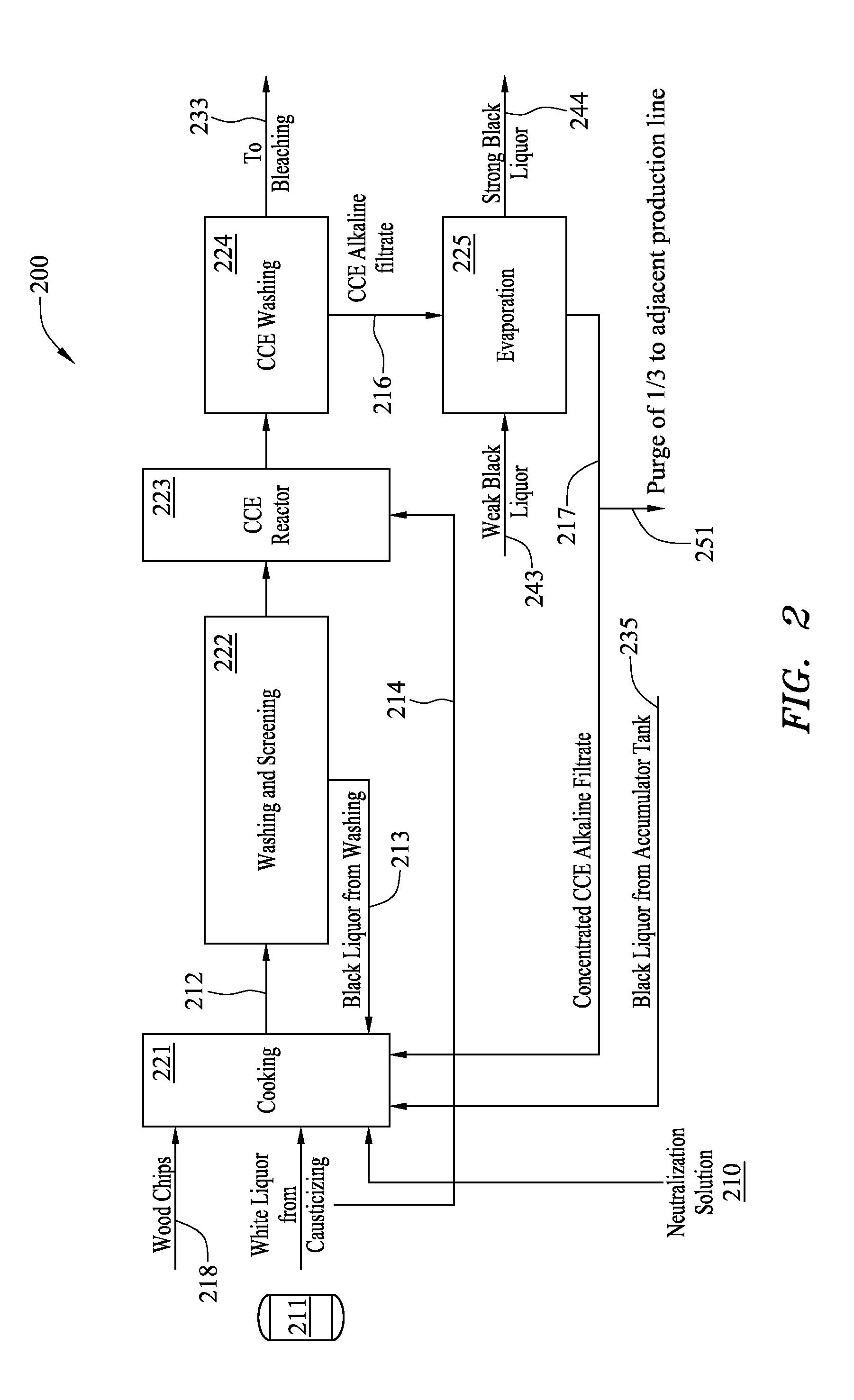

Method and system for pulp processing using cold caustic extraction with alkaline filtrate reuse

ActiveUS20110272109A1Improve efficiencyHigh purityPretreatment with water/steamNatural cellulose pulp/paperWood fibreEvaporation

A method for pulp processing includes a cold caustic extraction stage in which the spent cold caustic solution and the spent liquid used to wash the extracted pulp are concentrated by an evaporation system. The concentrated liquid can be used as part of the neutralization and cooking liquor in the pulp process, leading to increased efficiency without significant reduction in pulp quality. Highly concentrated filtrate from the cold caustic extraction stage may help reduce hemicellulose deposition on wood fiber during the cooking step.

Owner:BAHIA SPECIALTY CELLULOSE

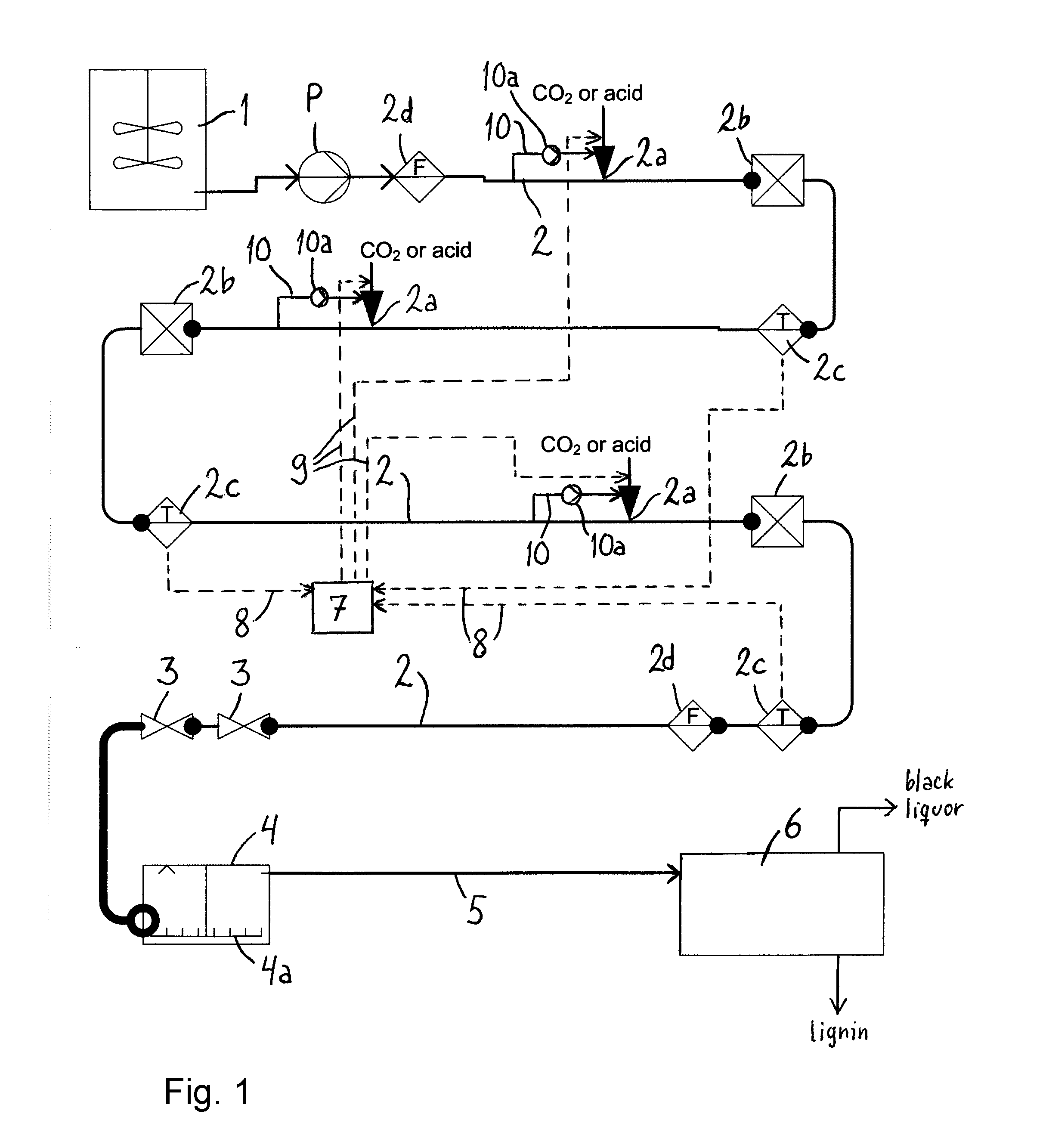

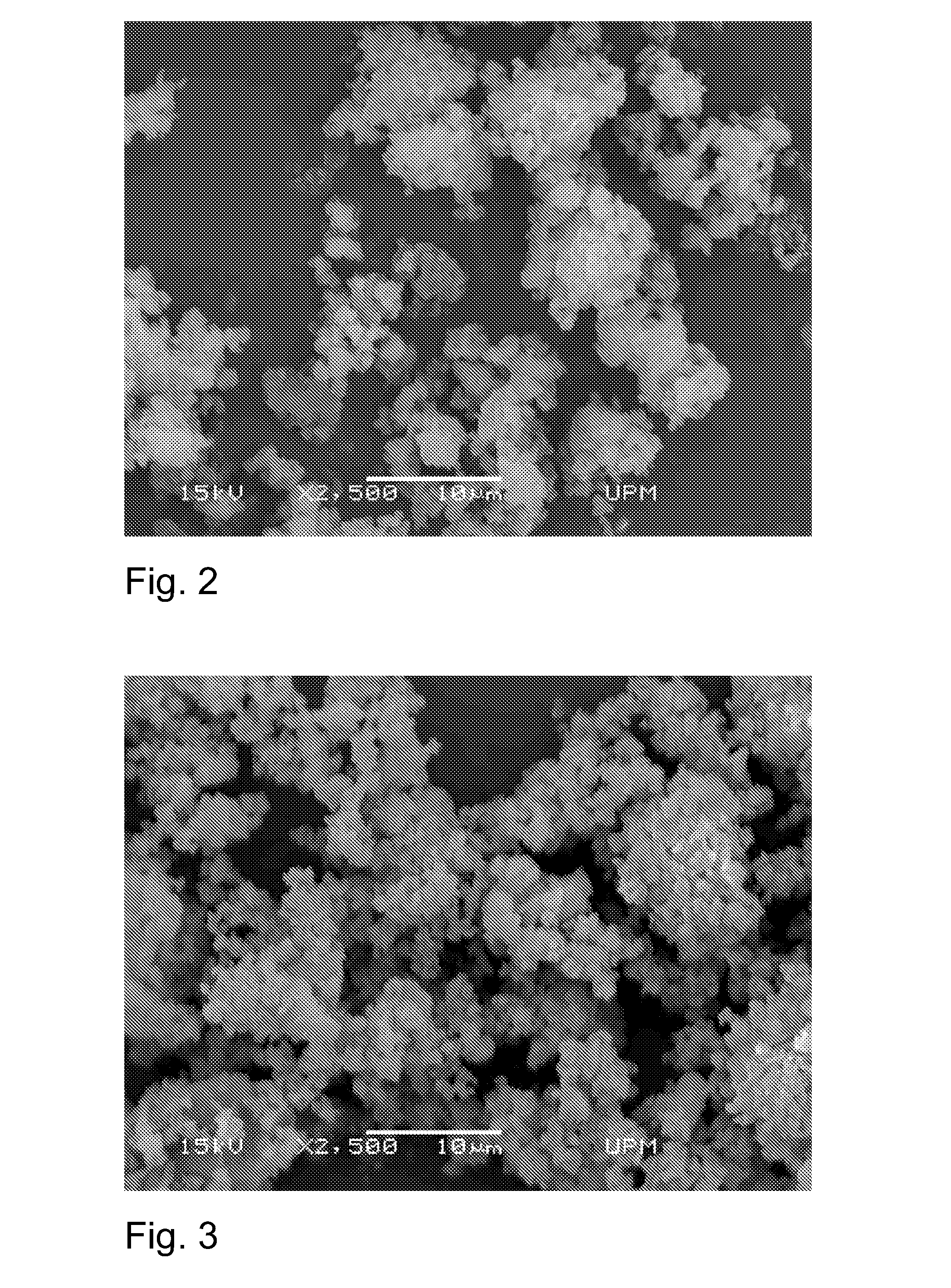

Continuous method for the precipitation of lignin from black liquor

ActiveUS20130203972A1Reduce dwell timeReduce operating costsPressurized chemical processLignin derivativesBlack liquorPrecipitation

In a method for the continuous precipitation of lignin from black liquor black liquor is provided so as to flow as a pressurized flow in a reactor (2) with a dwell time of less than 300s,—an acidifying agent selected from the group of carbon dioxide, acid and their combinations is led to the flow at one or more feeding sites (2a) to lower the pH of black liquor,—the pH is allowed to decrease by the effect of the acidifying agent in the pressurized flow to the precipitation point of lignin, the pressure of the pressurized flow is abruptly released, and lignin particles are separated from black liquor.

Owner:UPM-KYMMENE OYJ

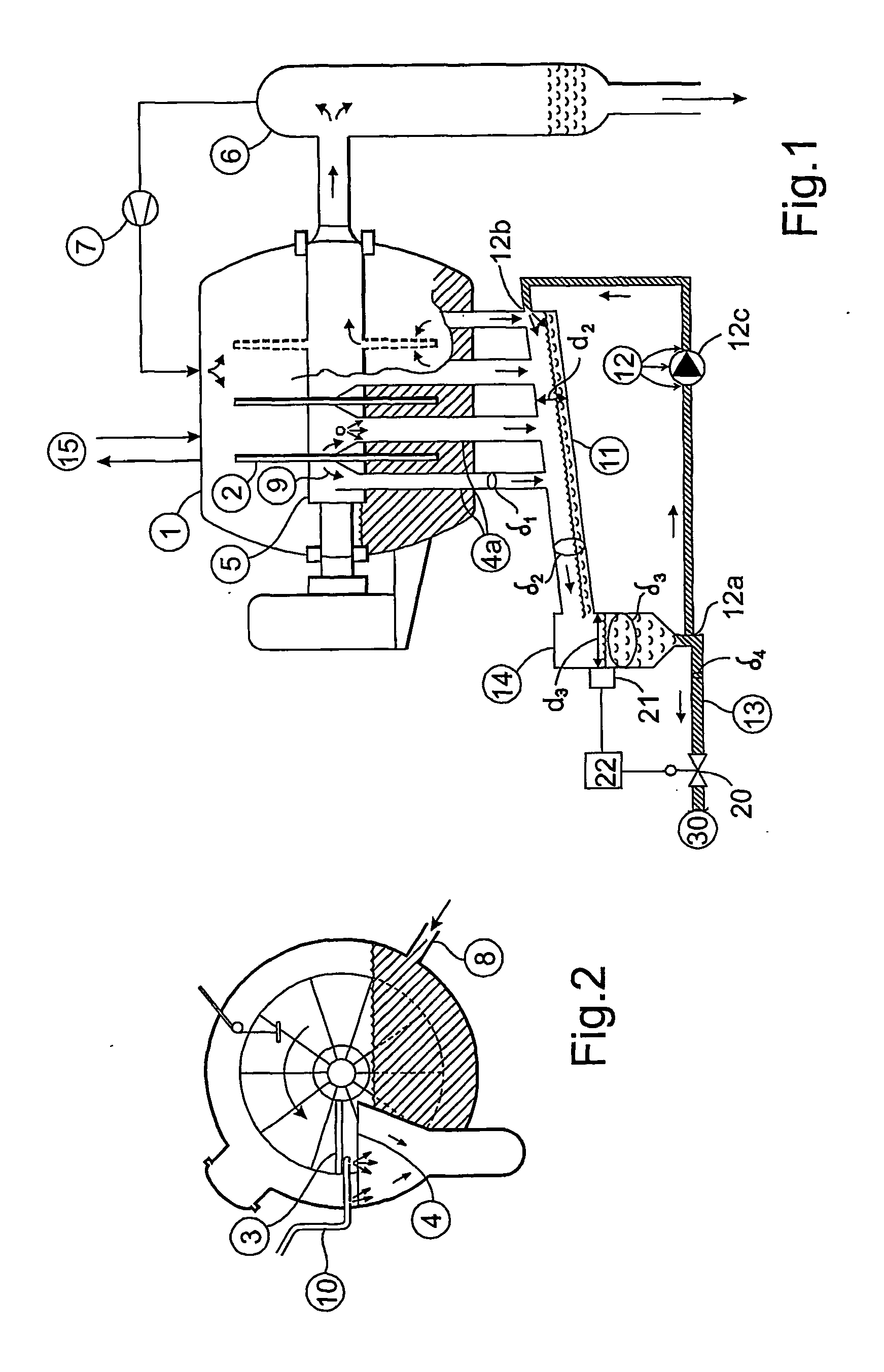

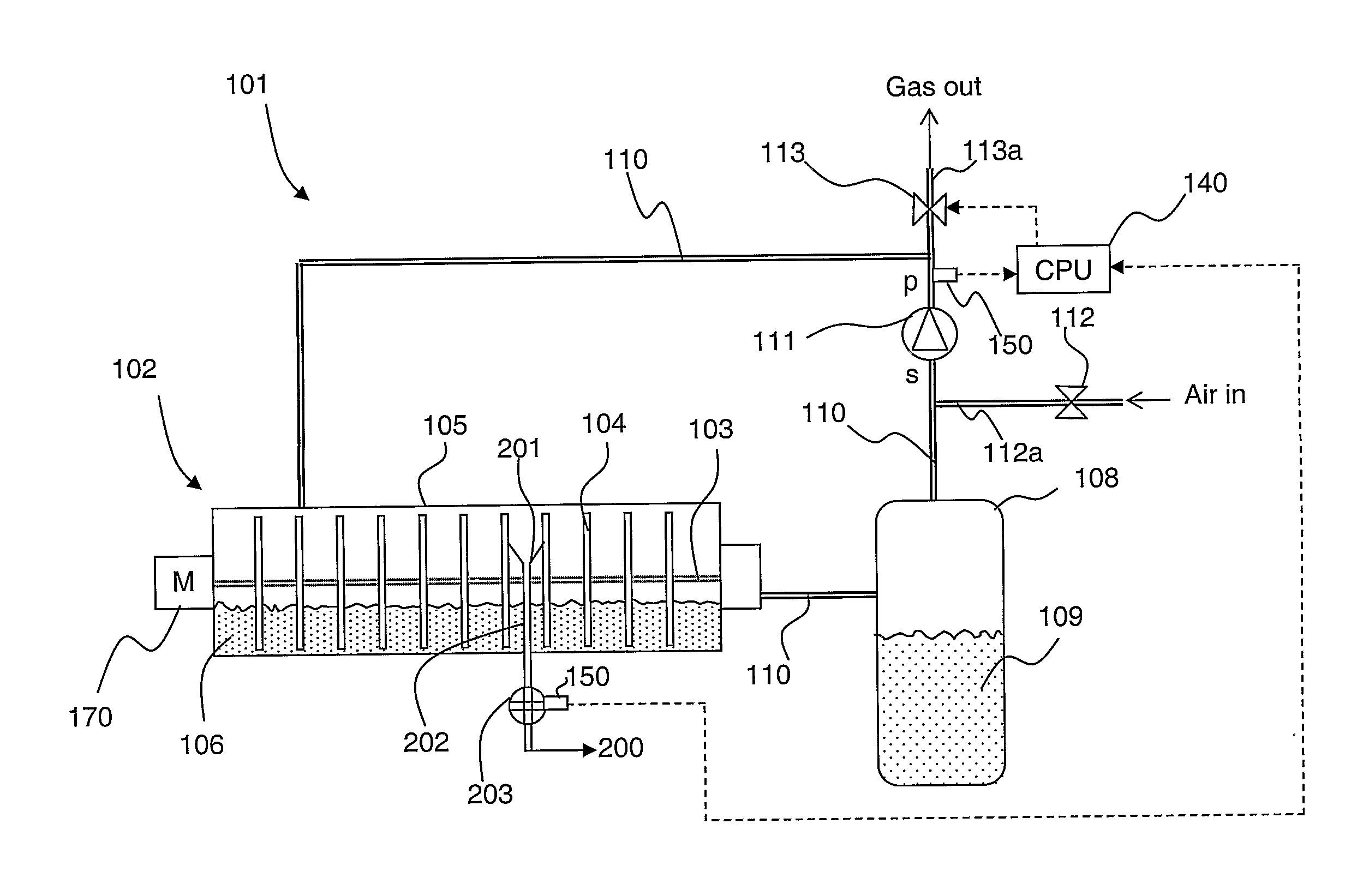

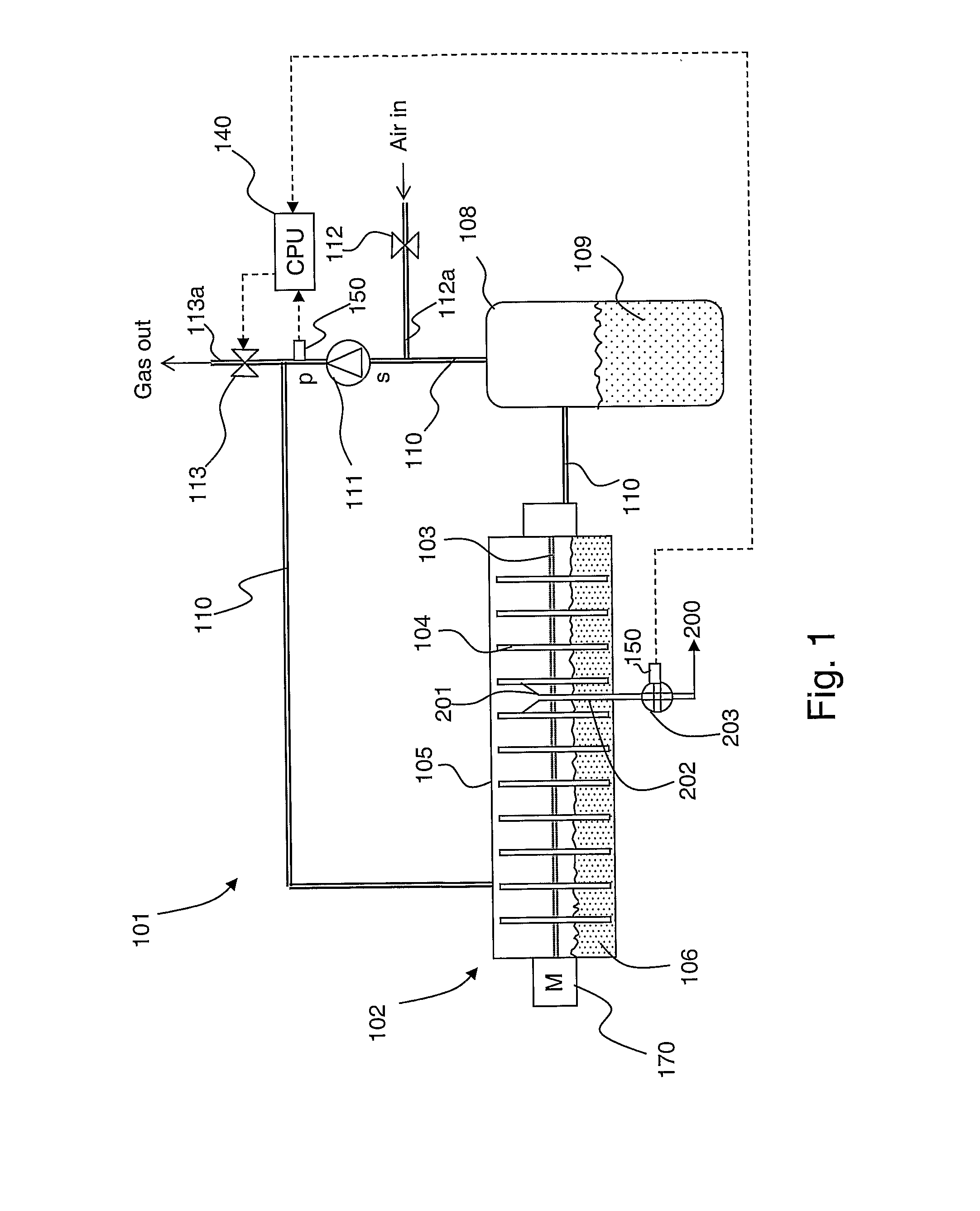

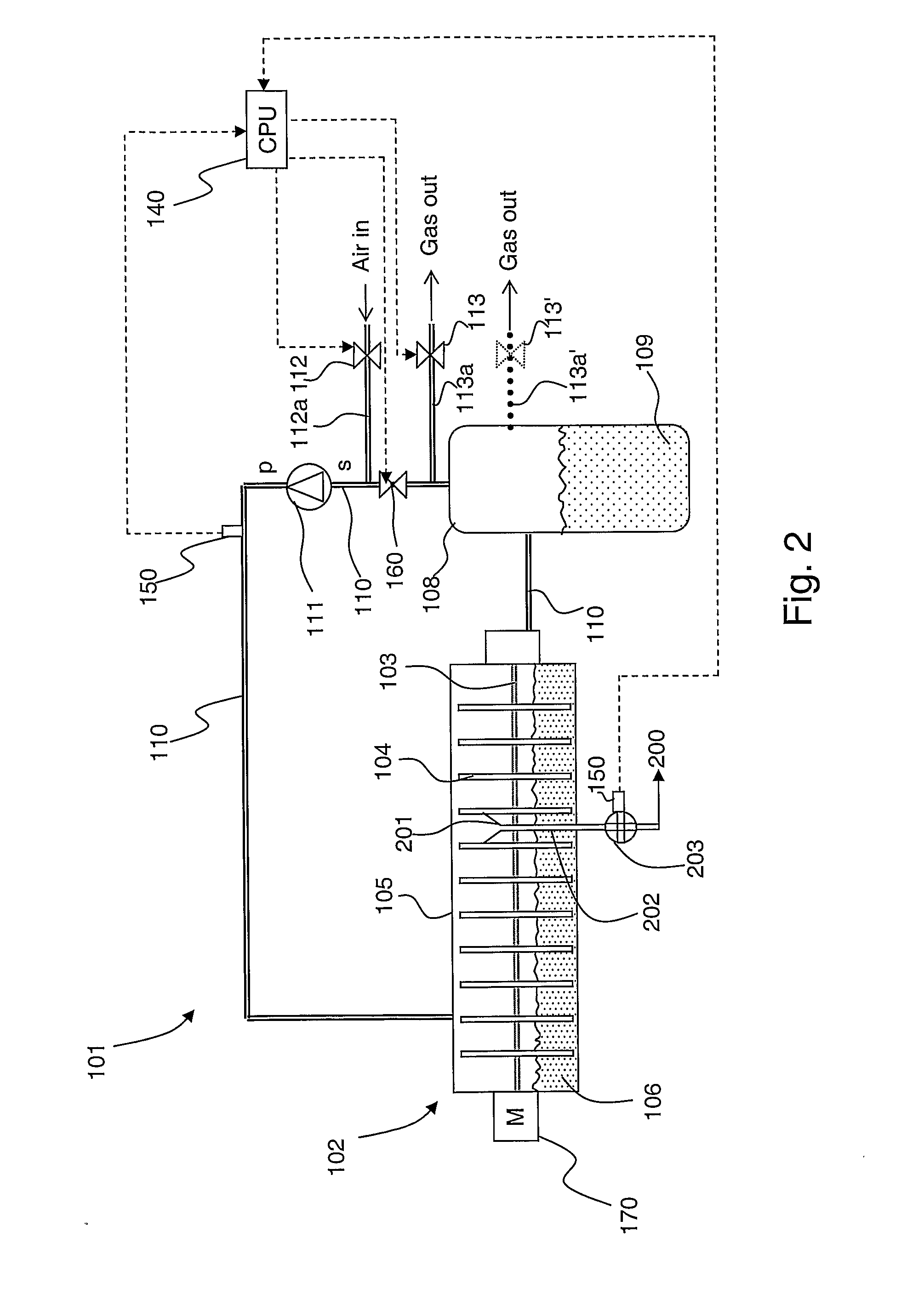

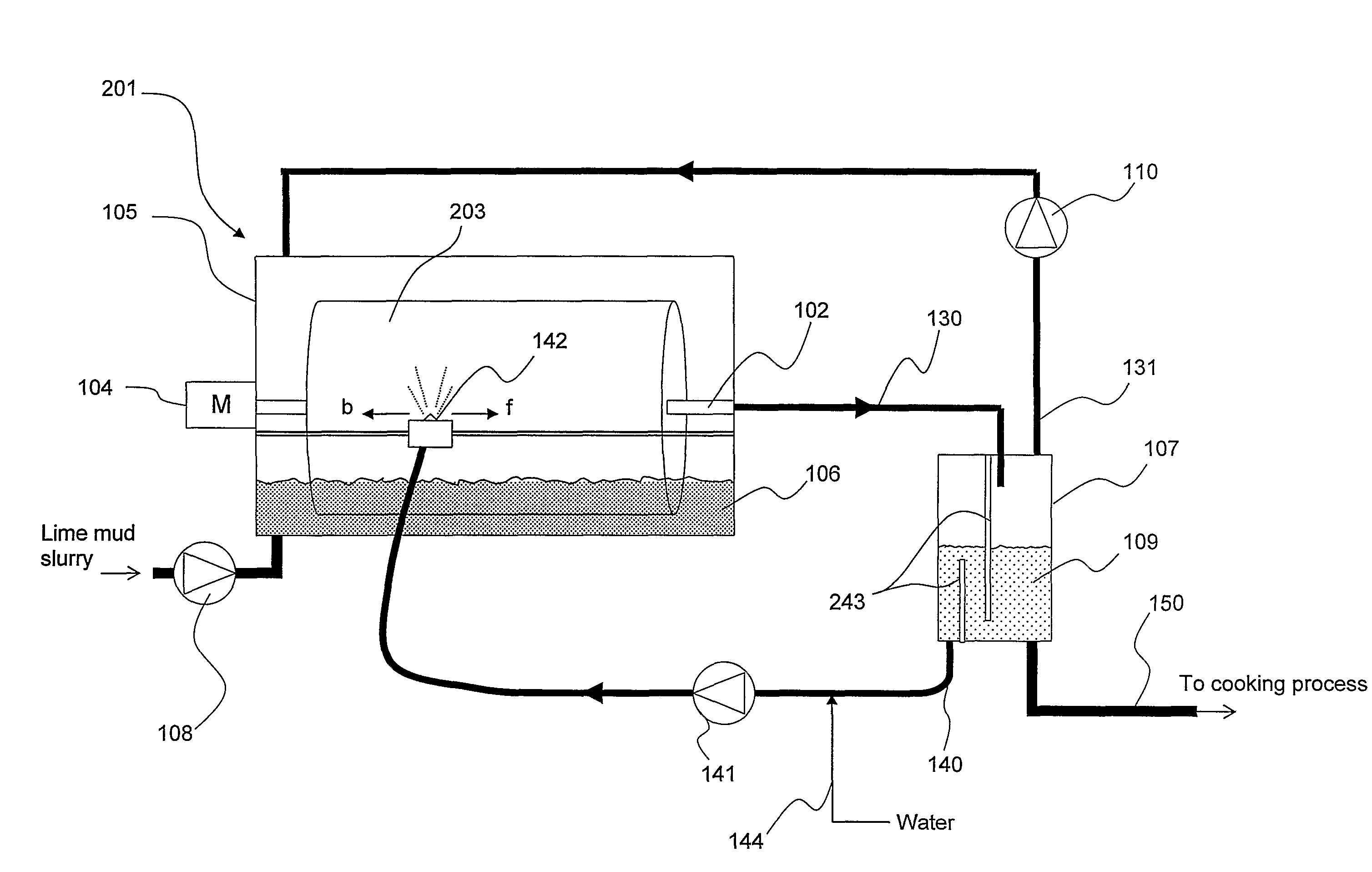

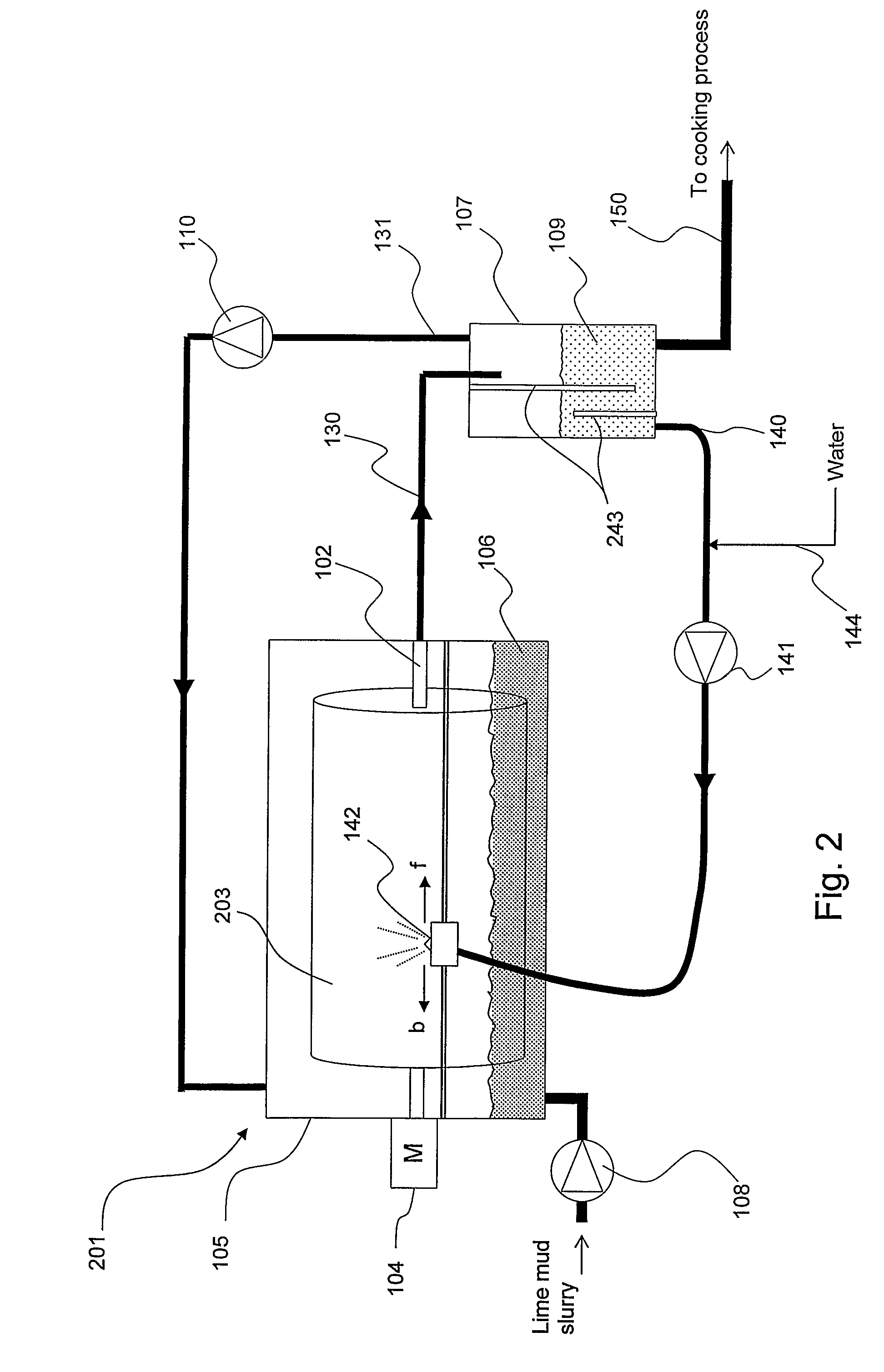

Method and Device for Washing of Lime Mud

InactiveUS20070221345A1Use minimizedPromote oxidationWater/sewage treatmentLoose filtering material filtersGas phaseFresh air

The method and an arrangement are for dewatering and washing lime slurry before the dewatered lime mud is passed to a lime mud kiln. The lime slurry is dewatered in a pressurized lime mud filter of disc or drum type. The pressurized lime mud filter is pressurized through a compressor drawing on its suction side (s) gas phase from the filtrate tank and pressurizing on the pressurized side (p) of the compressor the pressure vessel on the lime mud side of the filter. A certain pre-determined amount of gas phase in the gas circulation system is vented and an equivalent pre-determined amount of fresh air is added to the recycled gas phase with the aim of maintaining the partial pressure of oxygen gas above a certain minimum level.

Owner:METABO PAPER SWEDEN

Method for producing calcium carbonate

InactiveUS7097819B2Proportion of aragonite crystals tends to be loweredPromote precipitationCalcium/strontium/barium carbonatesCoatings with pigmentsPersulfateSulfate

Calcium carbonate in the form of aragonite crystals suitable for use as a filler for papermaking to give useful properties for bulk, whiteness, opacity, wire abrasion and yield is obtained by taking advantage of the causticization step. Herein disclosed is a process for producing calcium carbonate in the form of aragonite crystals which is useful as a filler for papermaking via the causticization step of the sulfate or soda pulping process, comprising adding an aqueous alkaline solution having a hydroxide ion level of 3 mol / l or less and containing 0.25 mol or less of carbonate ion per 1 mol of quick lime to quick lime and / or slaked lime at a quick lime concentration of 1–60% by weight with stirring to prepare milk of lime, and then adding green liquor to said milk of liquor at a loading rate of 0.002–0.12 g (sodium carbonate) / min / g (quick lime) to perform a causticization reaction at a temperature of 30–105° C.

Owner:NIPPON PAPER IND CO LTD

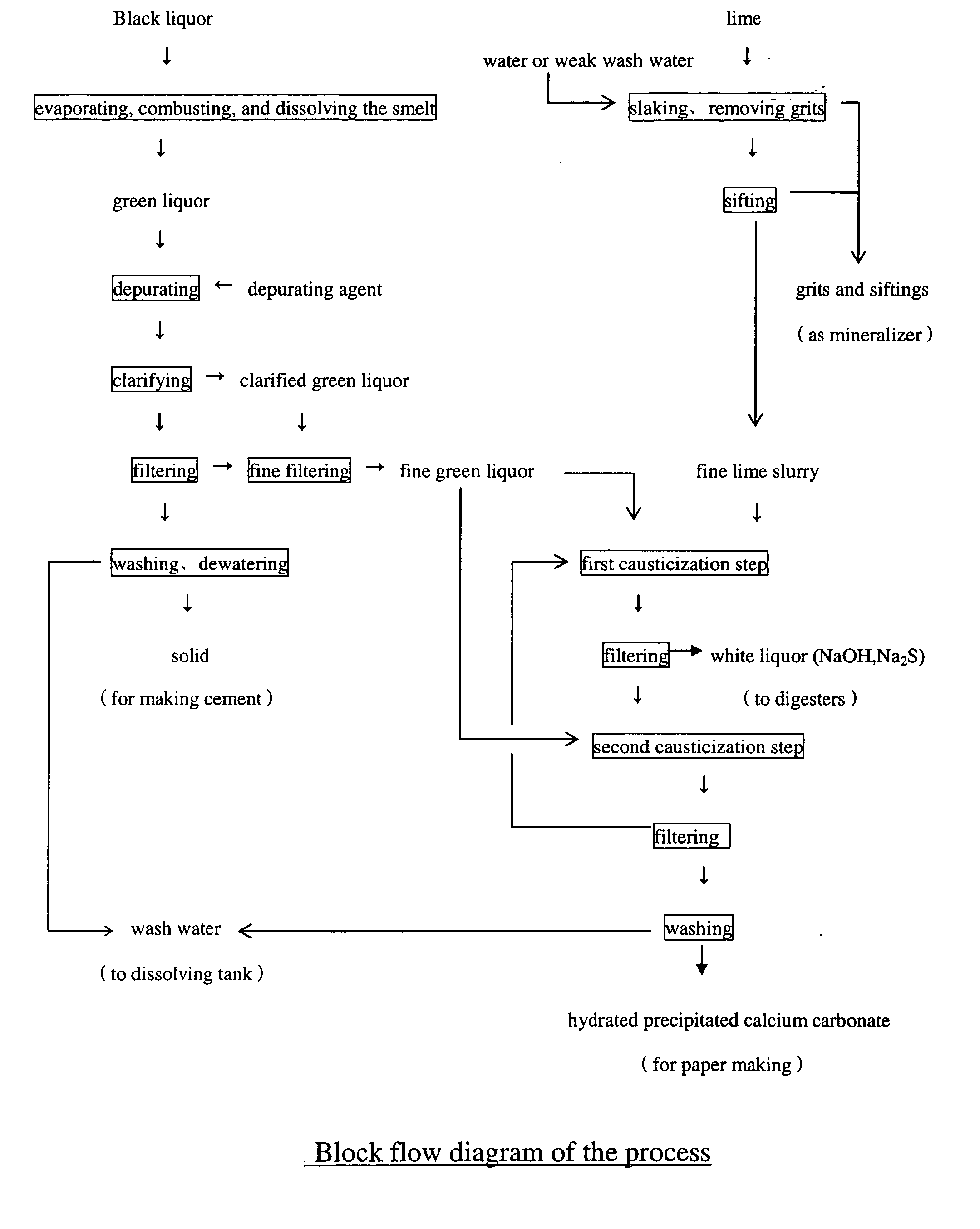

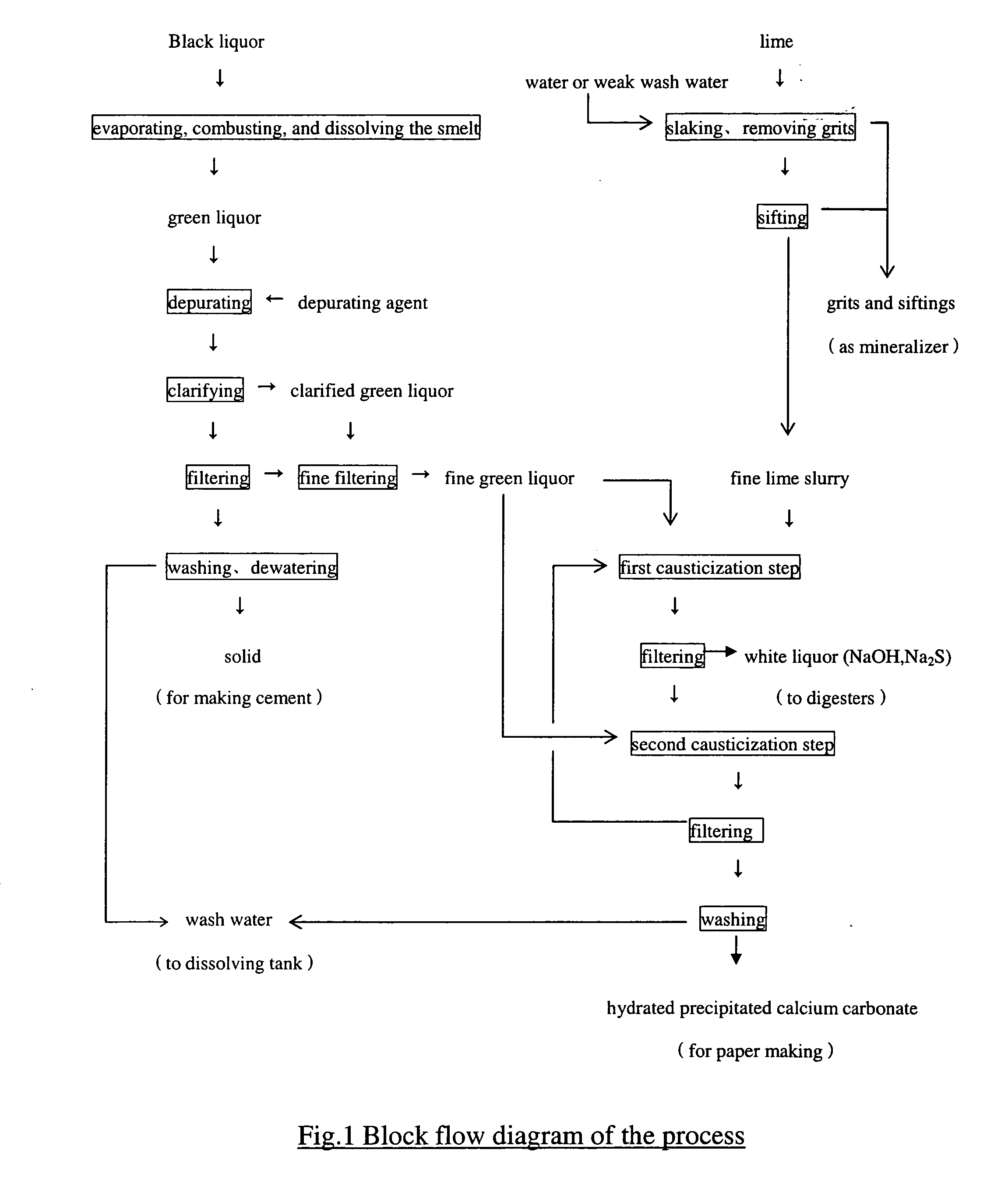

Process of recovering alkali from black liquor of papermaking

InactiveUS20050199358A1Equipment investmentReduce energy consumptionCalcium/strontium/barium carbonatesPulp liquors combustionBlack liquorPrecipitated calcium carbonate

This invention provides an improved process for recovering chemicals from black liquor in alkaline pulping, which is achieved by introducing depuration treatments of green liquor and lime before causticization reaction and a two-step-causticization procedure in the causticization procedure of the conventional chemical recovery process. The process of this invention not only avoids the generation of the waste residue (lime mud) from the beginning and saves the recovery and treatment of lime mud, but also can directly produce a series of precipitated calcium carbonate products with various particle sizes by regulating process conditions while the alkali is recovered, said CaCO3 products including a CaCO3 suitable for making coated paper, wherein >=50% of the CaCO3 has a particle size below 2 mum; a CaCO3 suitable for making neutral sized paper, wherein >=90% of the CaCO3 have a particle size below 2 mum; a superfine CaCO3 having an average particle size <1 mum. The present invention can be used for treatment of pollution of black liquor in the alkaline pulping.

Owner:AI TIANZHAO +3

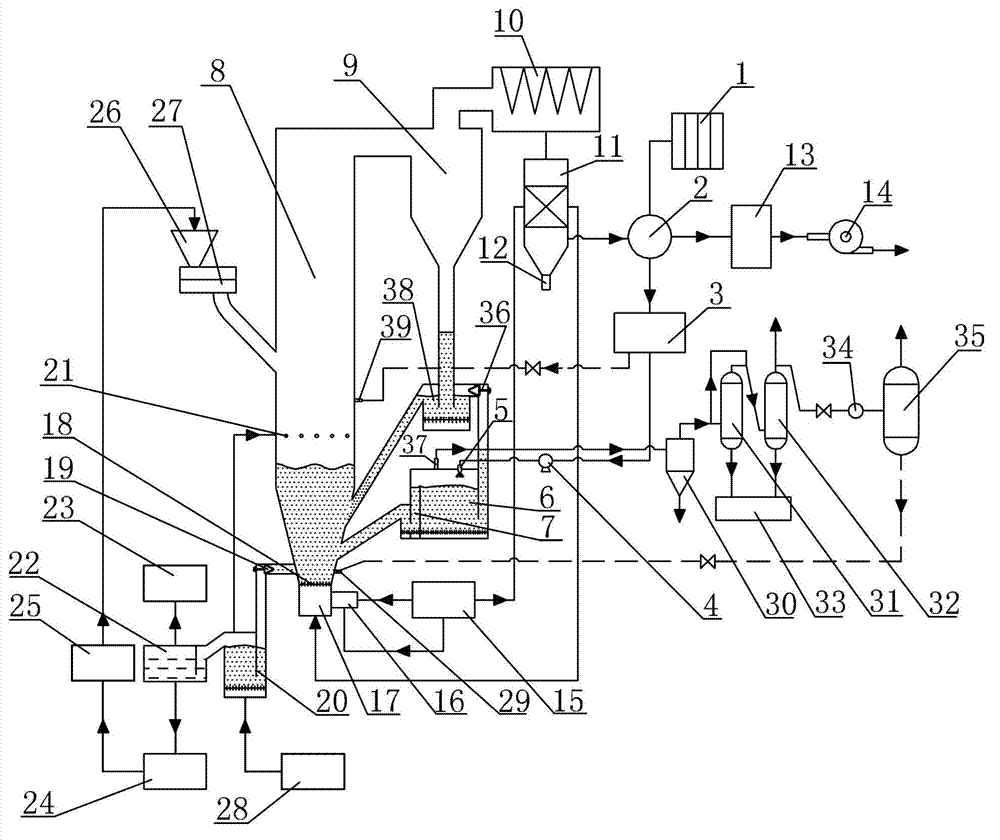

Device and method for recycling gasified and burned alkali for straw pulp papermaking black liquor circulating fluidized bed

ActiveCN102864674AEfficiently provideSolve processing problemsRegeneration of alkali lyeAir preheaterSlag

The invention provides a device and a method for recycling gasified and burned alkali for a straw pulp papermaking black liquor circulating fluidized bed and relates to the device and the method for recycling the alkali of papermaking black liquor. The device and the method are used for solving the problems that the prior art is difficult to be used for recycling the straw pulp papermaking black liquor, the auxiliary fuels are added to a recycling process and the running cost is increased. The device comprises a multi-effect evaporator, a disc evaporator, a thick black liquor tank, a pump, a spraying gun, a gasifying chamber, a feedback valve, a waste heat boiler, an air pre-heater, a bag-type dust collector, a draught fan, a cone valve, a heat exchange chamber, a dissolving tank, a causticizer, a chain plate type slag conveyor, a drier, a secondary air fan, a second gas-solid separator, a tar condensing tower, a spraying dehydrating tower, a sewage treatment plant, a water annular compressor, an air storage tank, a circulating ash distributing chamber and a circulating fluidized bed, wherein the dissolving tank is respectively communicated with the causticizer and the chain plate type slag conveyor and the chain plate type slag conveyor is communicated with the drier. The device provided by the invention is used for recycling the alkali of the straw pulp papermaking black liquor.

Owner:哈尔滨工大华实环保科技有限公司

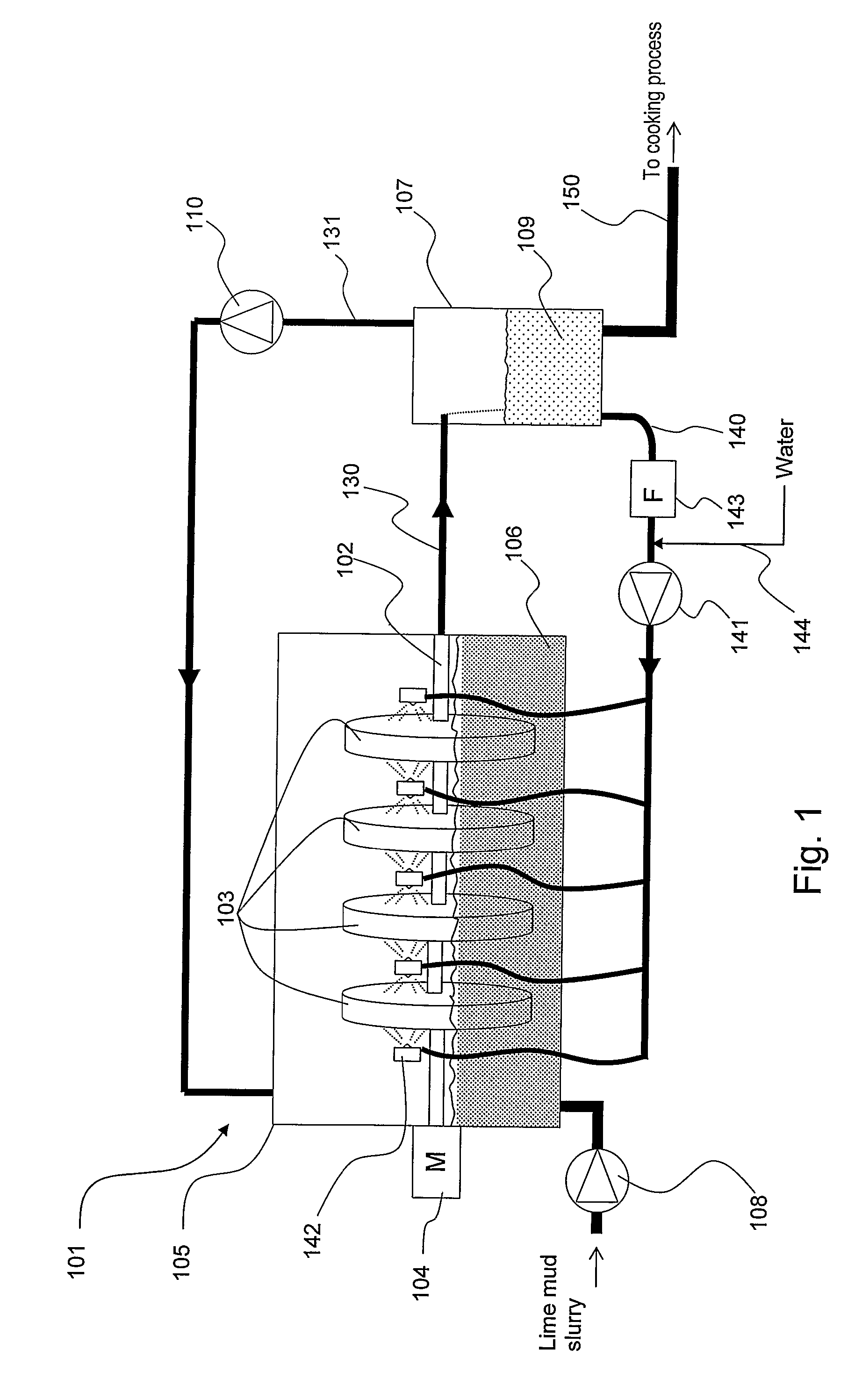

Method and device for cleaning of filter

The method and arrangement is for cleaning at least one of filter sheets and filter cakes in a pressurized white liquor filter with spray nozzles and driving fluid. The white liquor filter is used in a causticizing process in which green liquor is causticized before the white liquor filter by the addition of lime and in which it forms during the process a lime mud slurry. The white liquor filter 101 is used to separate white liquor from the lime mud. The driving fluid for the spray nozzle is constituted principally by the filtrate that is obtained from the filter.

Owner:METABO PAPER SWEDEN

Popular searches

Pulping with acid salts/anhydrides Vegetable material Angiosperms/flowering plants Fibre treatment to obtain bast fibre Lime production Differential sedimentation Water/sewage treatment by neutralisation Water/sewage treatment by flocculation/precipitation Multistage pulping process Non-woody plant/crop pulp

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com