Patents

Literature

2281results about "Non-woody plant/crop pulp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hesperaloe tissue having improved cross-machine direction properties

ActiveUS10337148B2Satisfactory softness and strength and bulkNegatively effecting tissue product strength and stiffness and bulkPaper/cardboardTissue/absorbent paperFiberMedicine

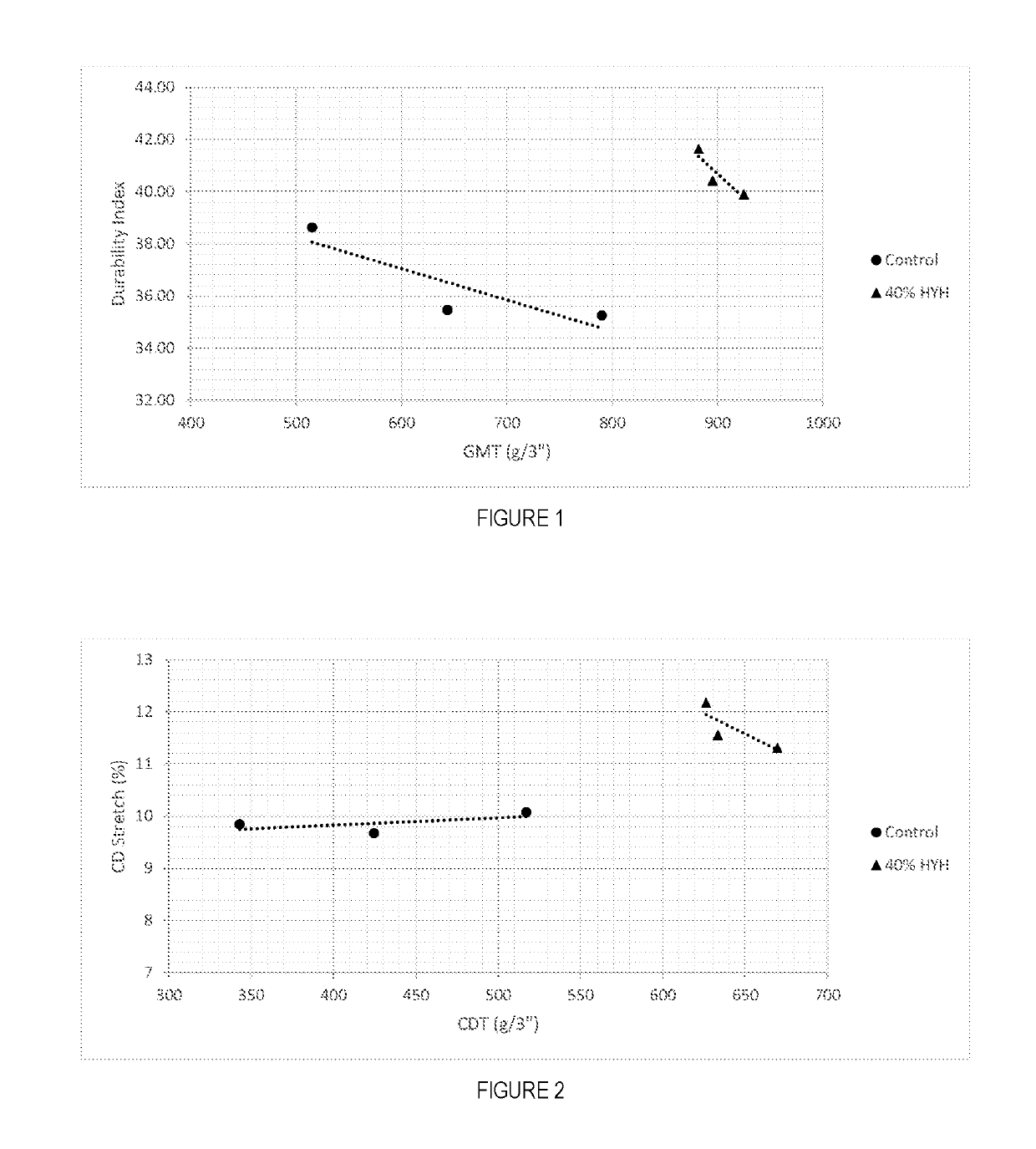

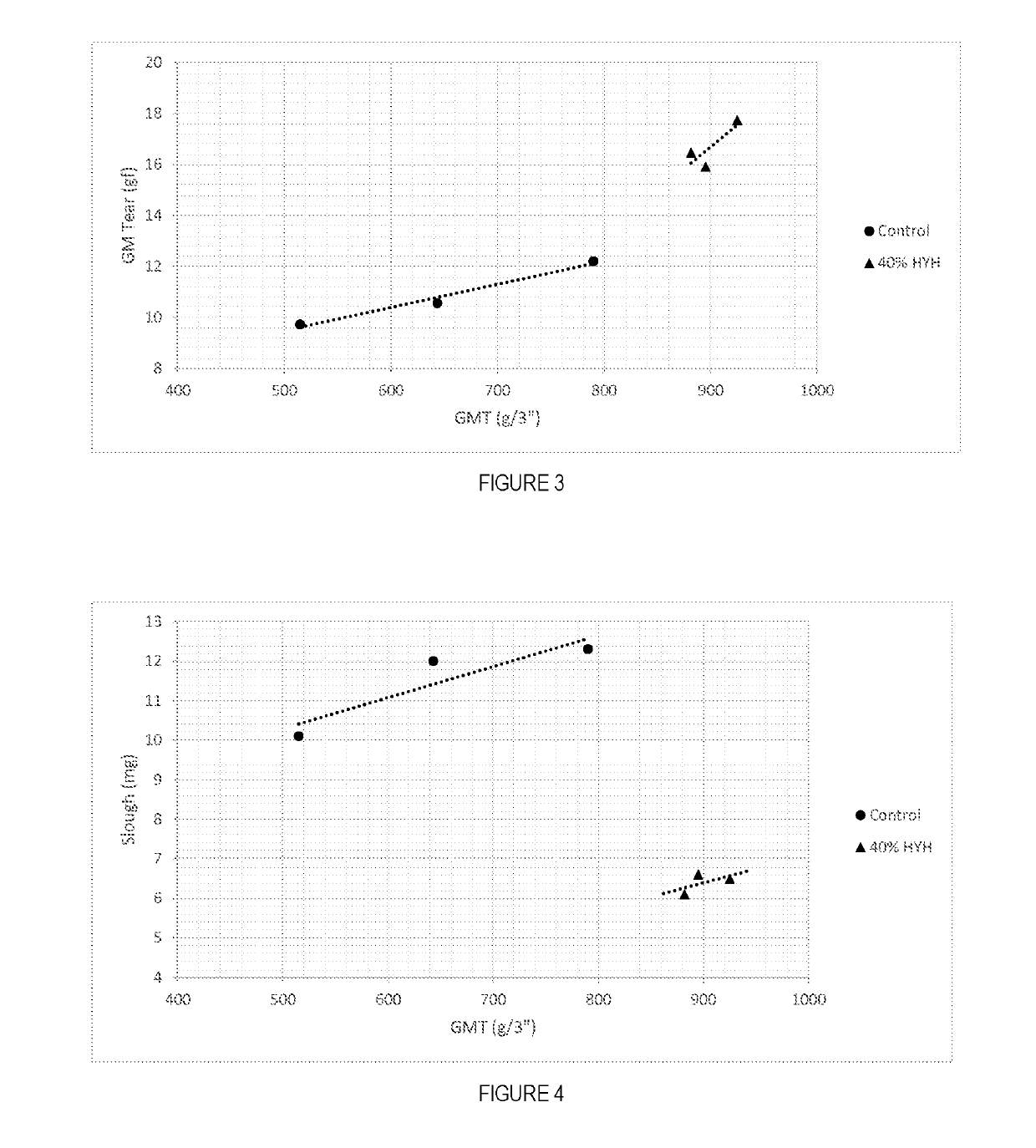

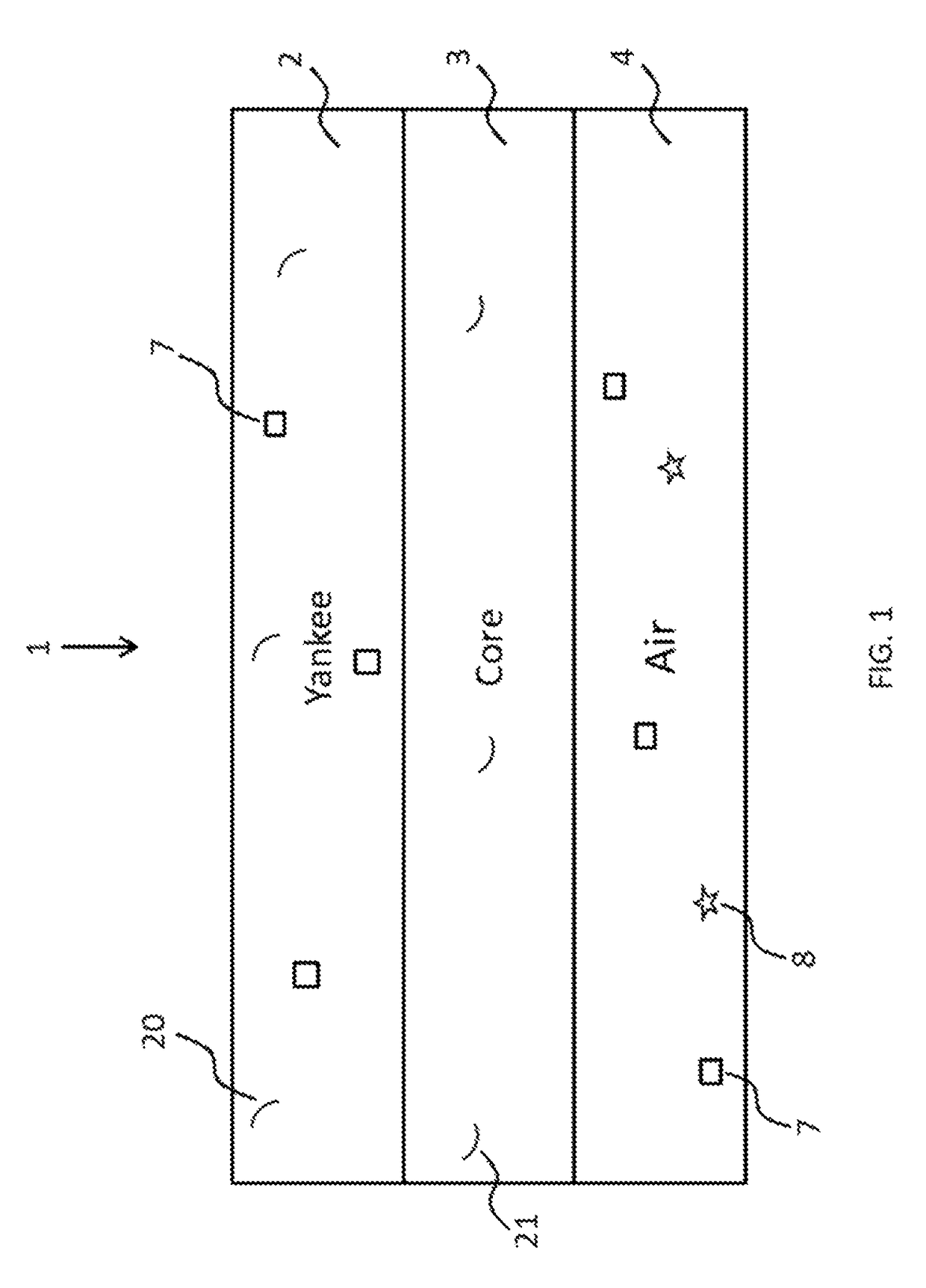

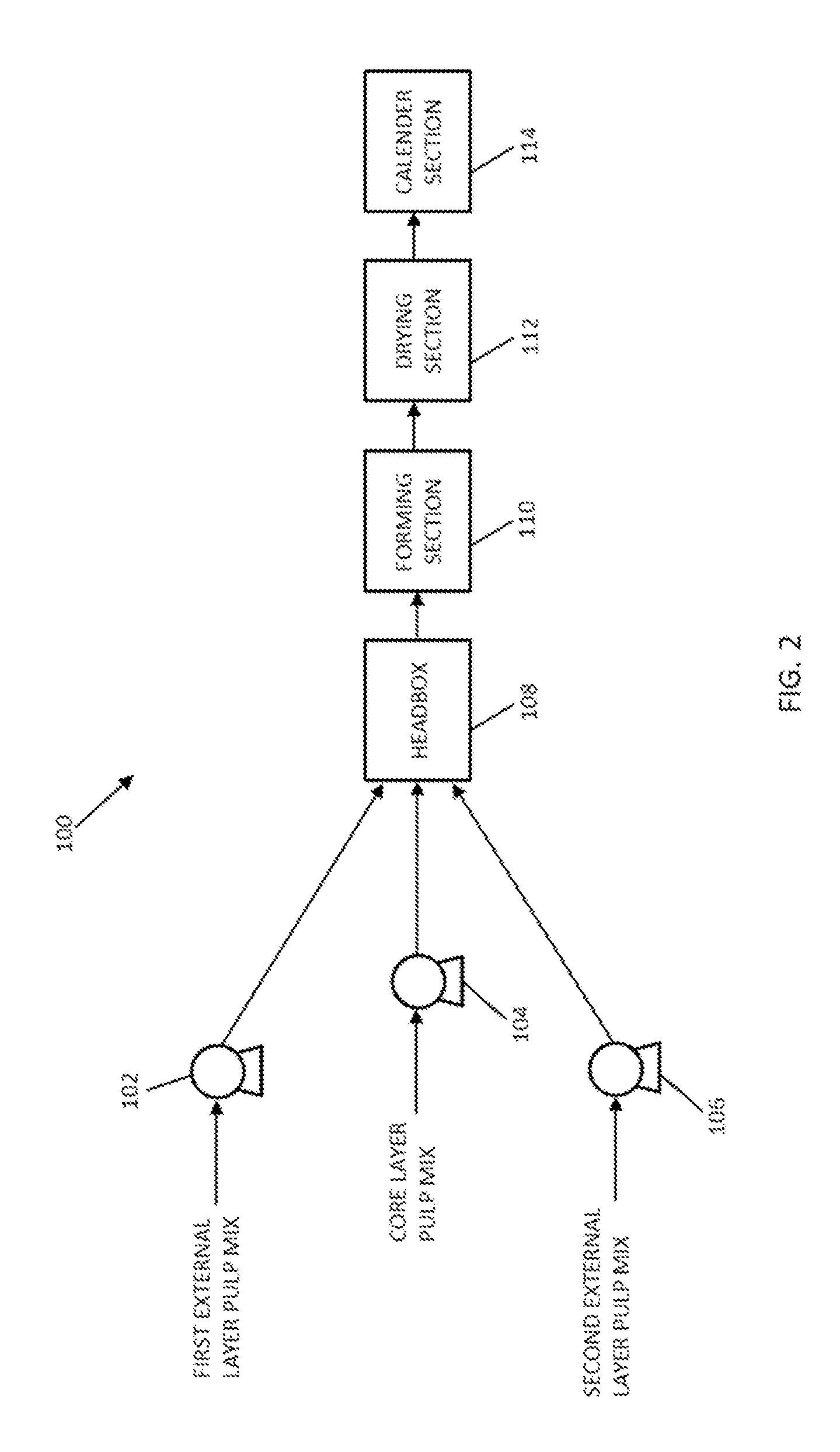

Soft, durable and bulky tissue products comprising non-wood fibers and more particularly high yield hesperaloe pulp fibers are disclosed. The tissue products preferably comprise at least about 5 percent, by weight of the product, high yield hesperaloe pulp fiber and have relatively modest tensile strengths, such as a geometric mean tensile (GMT) less than about 1,000 g / 3″, and improved durability and cross-machine direction (CD) properties, such as a CD Stretch greater than about 10 percent. Additionally, at the foregoing tensile strengths the products are not overly stiff. For example the tissue products may have a Stiffness Index less than about 10.0.

Owner:KIMBERLY-CLARK WORLDWIDE INC

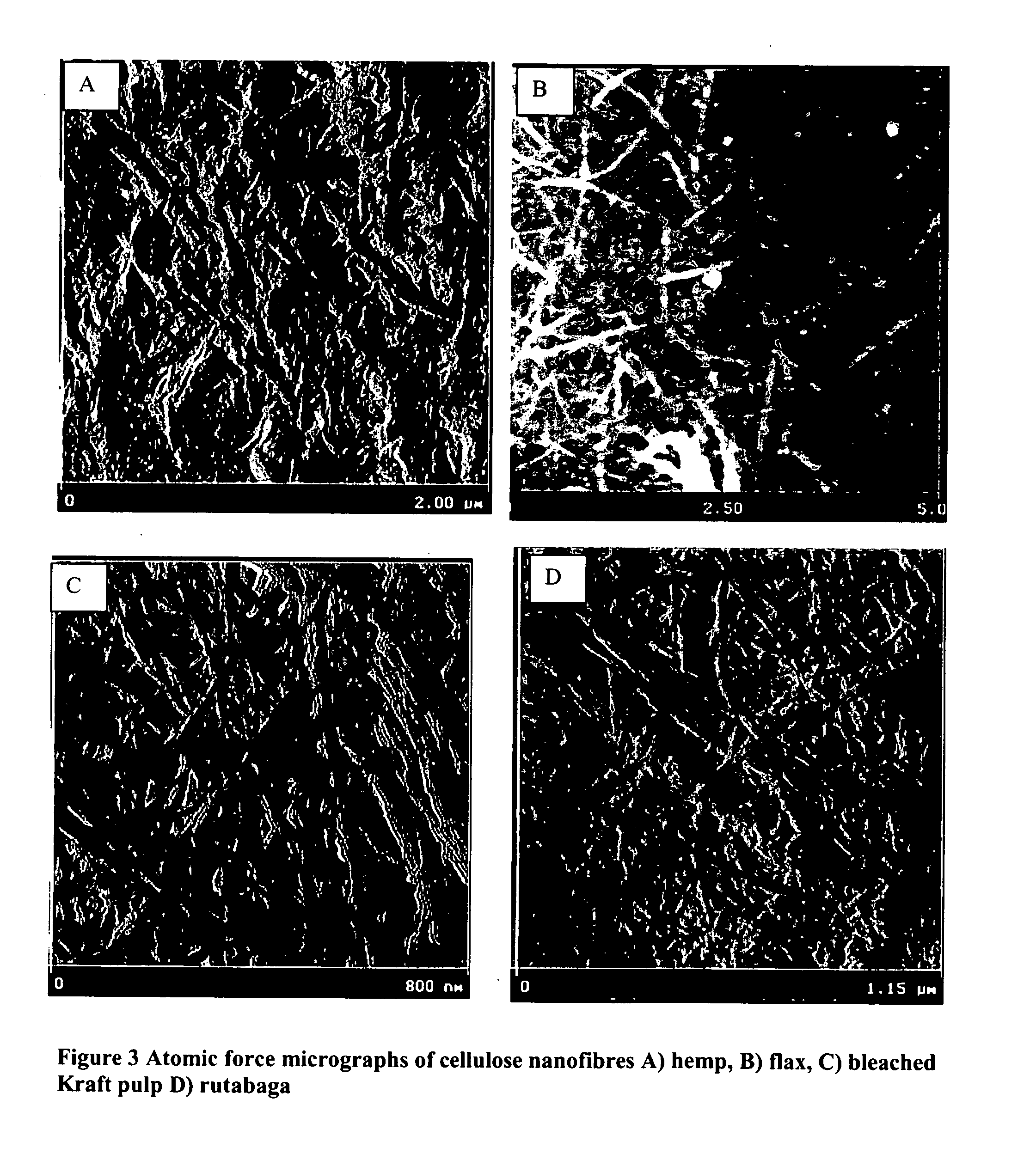

Manufacturing process of cellulose nanofibers from renewable feed stocks

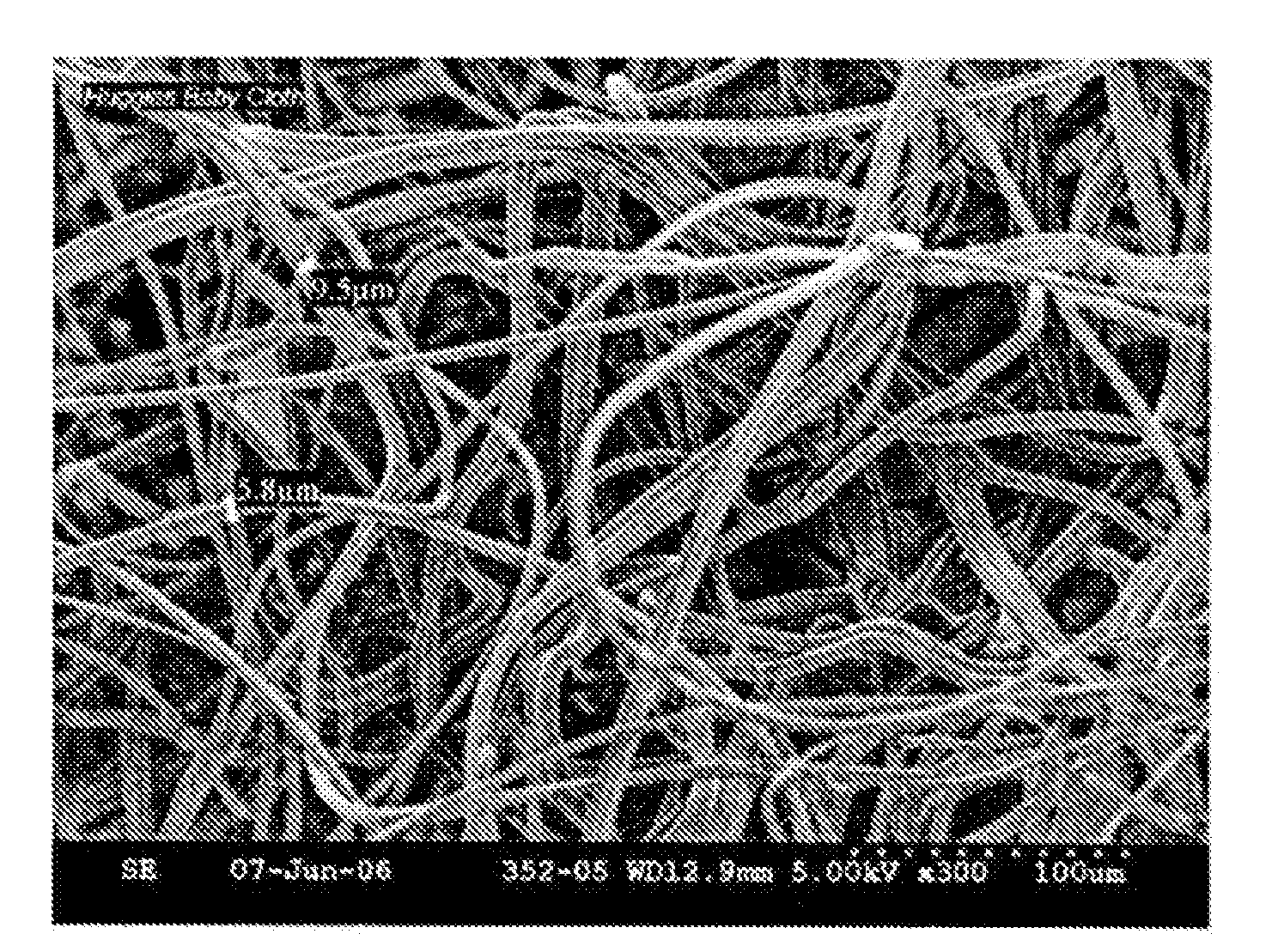

InactiveUS20080146701A1High aspect ratioRaise the potentialMaterial nanotechnologyFats/resins/pitch/waxes removal in pulpCelluloseNatural fiber

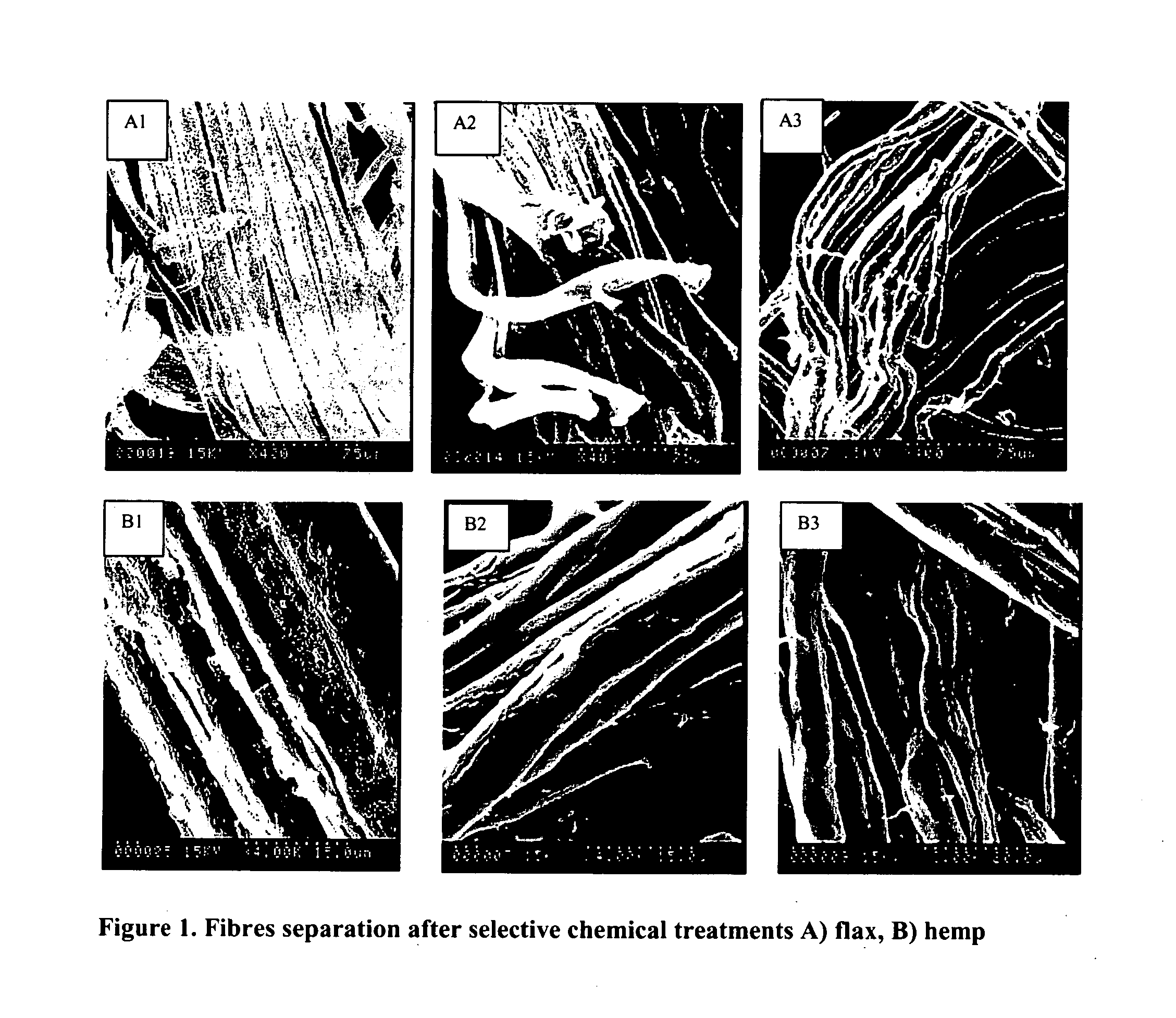

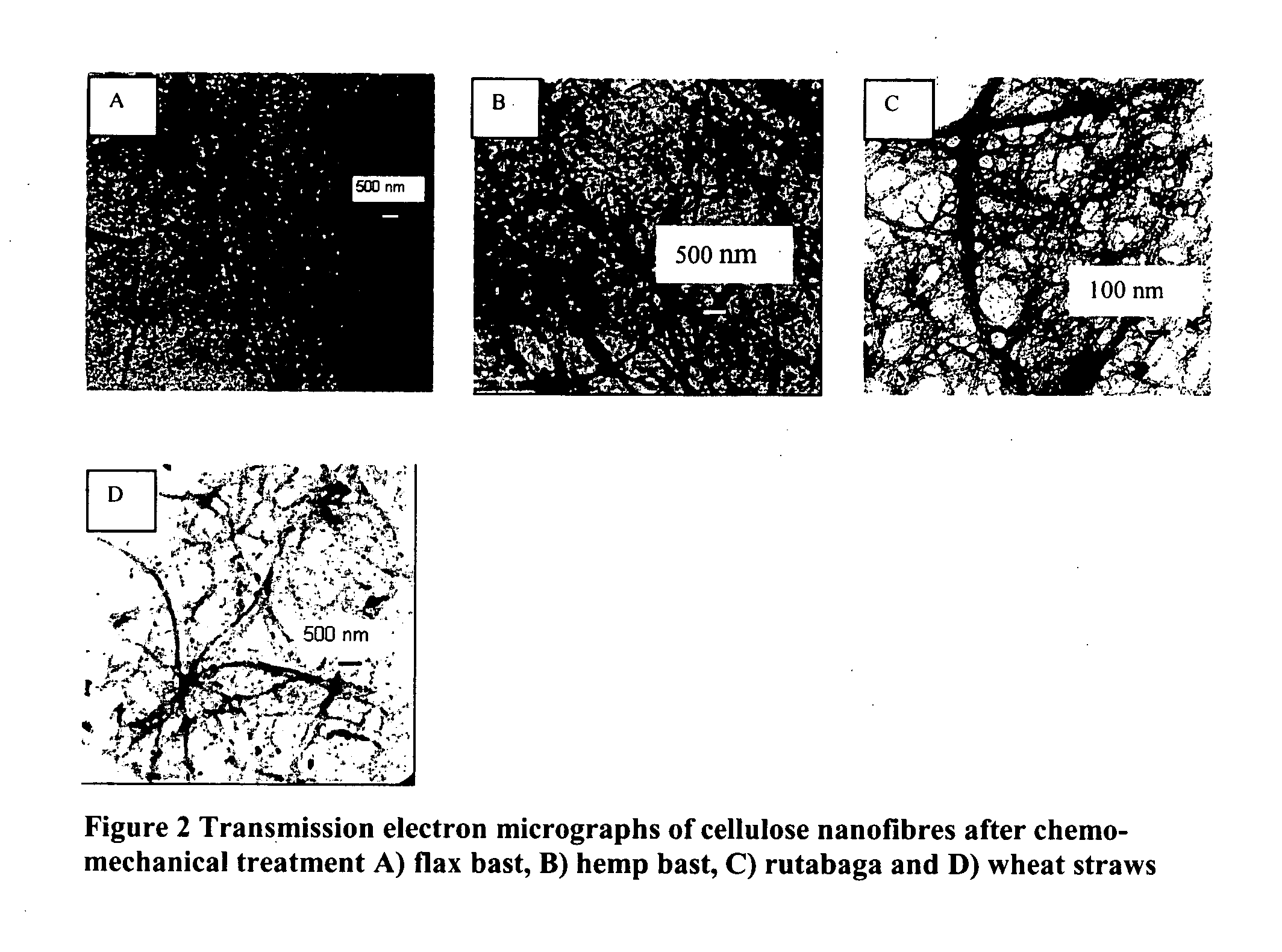

Cellulose nanofibers have been processed from renewable feedstock in particularly from natural fibers, root crops and agro fibers, wherein the pulp was hydrolysed at a moderate temperature of 50 to 90 degree C., one extraction was performed using dilute acid and one extraction using alkali of concentration less than 10%; and residue was cryocrushed using liquid nitrogen, followed by individualization of the cellulose nanofibers using mechanical shear force. The nanofibers manufactured with this technique have diameters in the range of 20-60 nm and much higher aspect ratios than long fibers. Due to its lightweight and high strength its potential applications will be in aerospace industry and due to their biodegradable potential with tremendous stiffness and strength, they find application in the medical field such as blood bags, cardiac devices, valves as a reinforcing biomaterial.

Owner:SAIN MOHINI M +1

Fibrous structure product with high softness

Owner:SHEEHAN JEFFREY GLEN +3

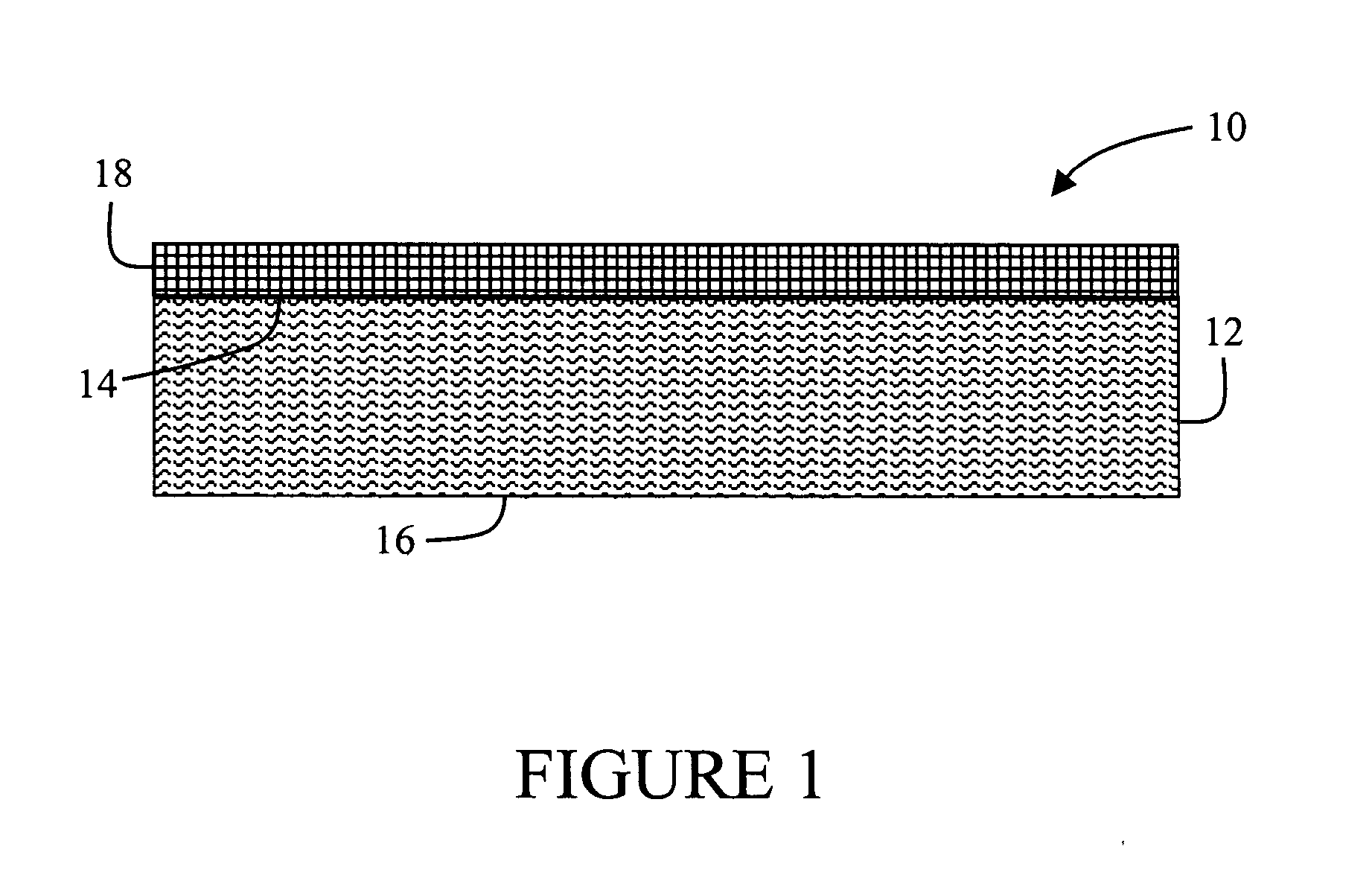

Cellulose Nonwoven Fabric

ActiveUS20070207692A1Raw materials are simpleSimple structureFats/resins/pitch/waxes removal in pulpPaper/cardboardPorosityCellulose fiber

Disclosed is a cellulose nonwoven fabric containing cellulose fibers having a maximum fiber diameter of not more than 1500 nm and a crystallinity determined by solid state NMR techniques of not less than 60%. The porosity of the cellulose nonwoven fabric is not less than 40% and not more than 99%.

Owner:ASAHI KASEI KK

Composite thermoplastic sheets including natural fibers

A composite sheet material includes, in an exemplary embodiment a porous core that includes at least one thermoplastic material and from about 20 weight percent to about 80 weight percent of natural fibers based on a total weight of the porous core. The natural fibers include at least one of kenaf fibers, jute fibers, flax fibers, hemp fibers, cellulosic fibers, sisal fibers, and coir fibers.

Owner:HANWA AZDEL INC

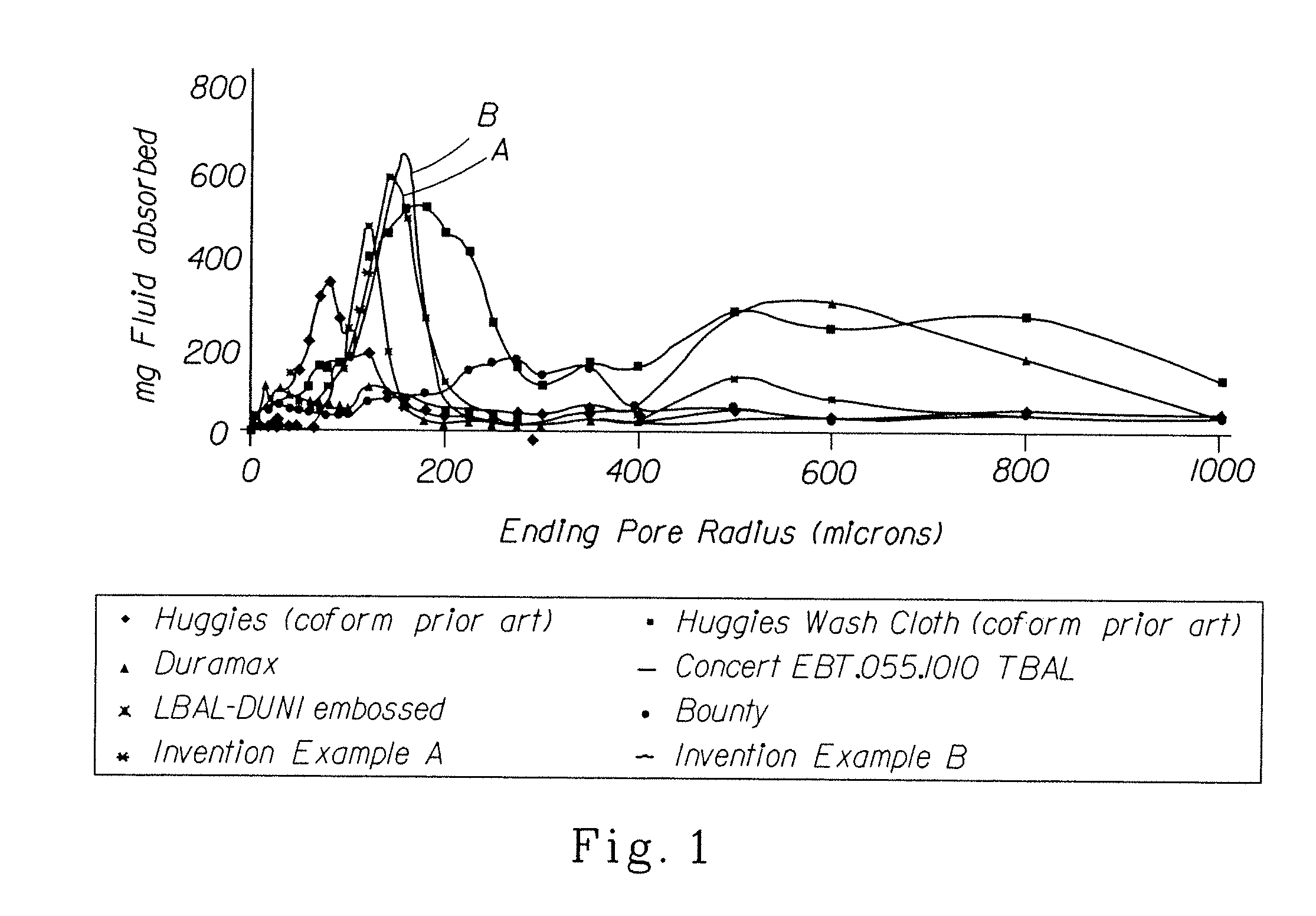

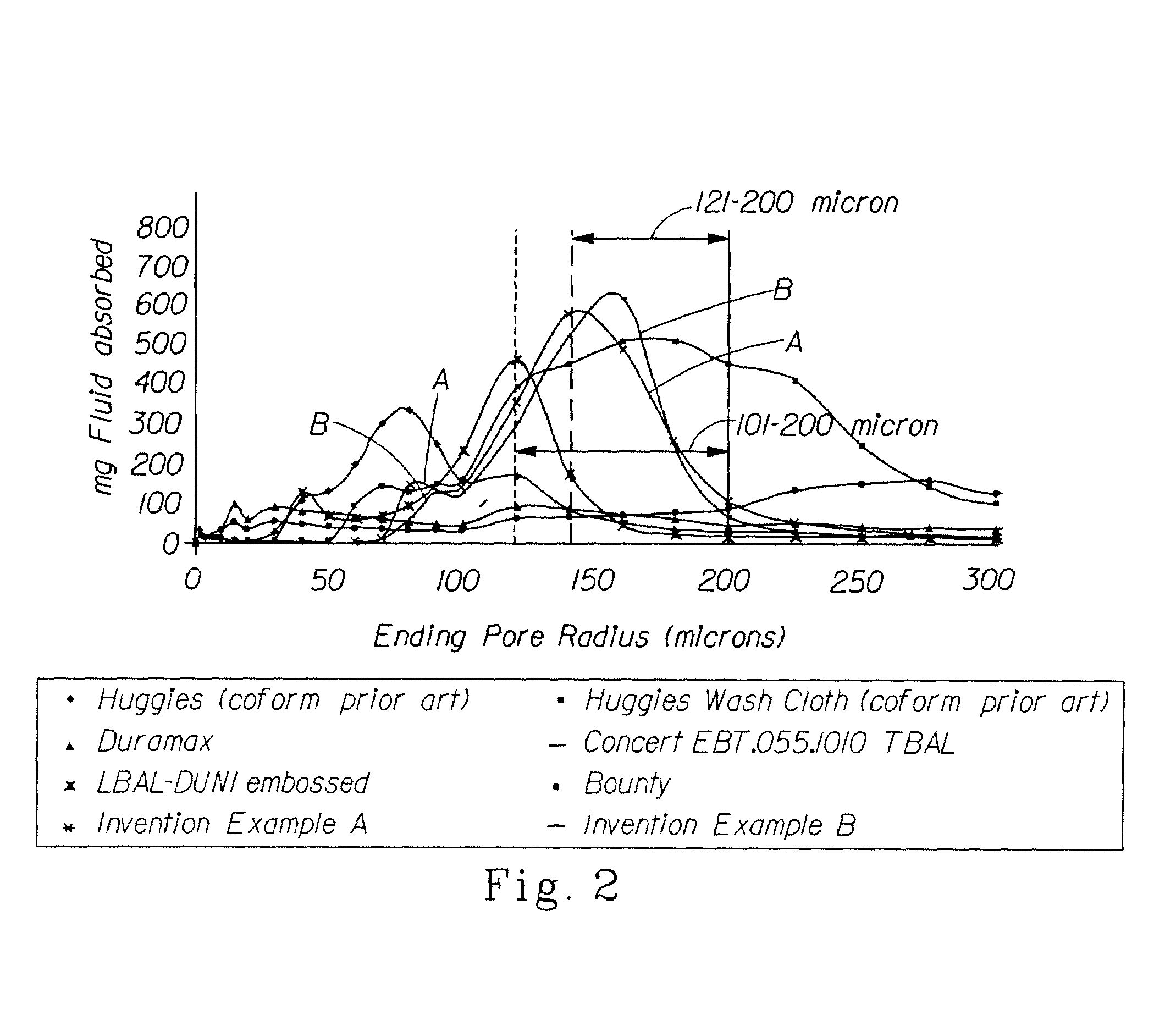

Fibrous structures and methods for making same

ActiveUS20090084513A1Improved absorbency and strength propertyCellulosic pulp after-treatmentNon-fibrous pulp additionFiberMaterials science

Fibrous structures that exhibit improved consumer recognizable properties, especially a VFS of greater than about 11 g / g, and to methods for making such fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation method of reed or straw cellulose pulp

InactiveCN101736646AEfficient separationImprove protectionNon-woody plant/crop pulpFinely-divided material pretreatmentChemistryFiber

The invention belongs to a technical field of chemical fiber, in particular to a preparation method of cellulose pulps of reed or straw and the like. The method comprises the following steps of: firstly, carrying out steam explosion treatment on reed or straw raw materials in steam explosion treatment equipment, secondly, washing raw materials of reed or straw and the like after steam explosion treatment with water, and soaking the washed materials in an organic solvent for treatment to finish cellulose pulping technology. The technology utilized by the invention has obvious advantages of shortening the technological process, saving energy, protecting the environment (the organic solvent can be recycled by distilling to reutilize), and being beneficial to clean production and environmental protection.

Owner:INST OF CHEM CHINESE ACAD OF SCI

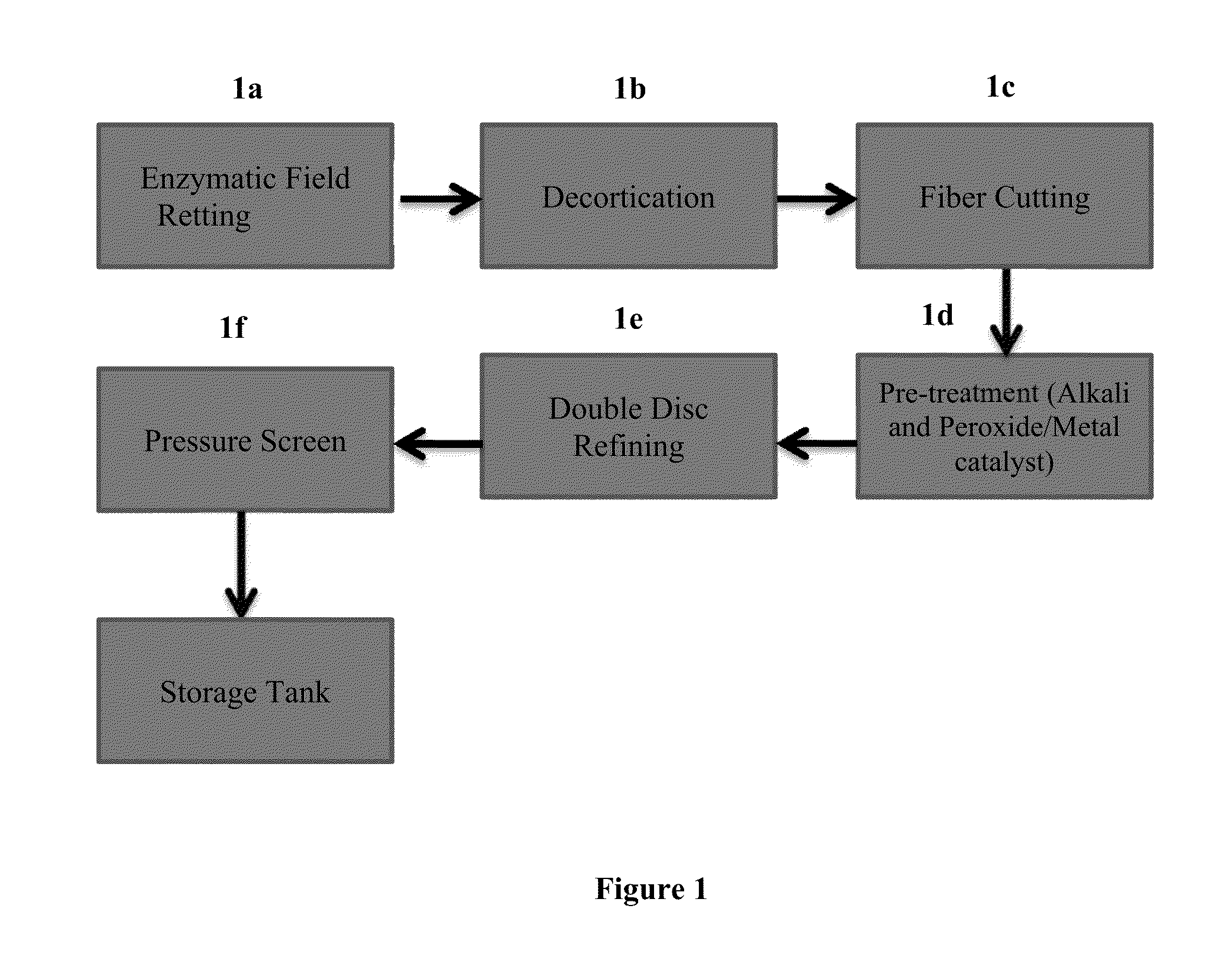

Cannabis fiber, absorbent cellulosic structures containing cannabis fiber and methods of making the same

ActiveUS20160130762A1Reduce manufacturing costLose weightNon-fibrous pulp additionPaper after-treatmentCelluloseBleach

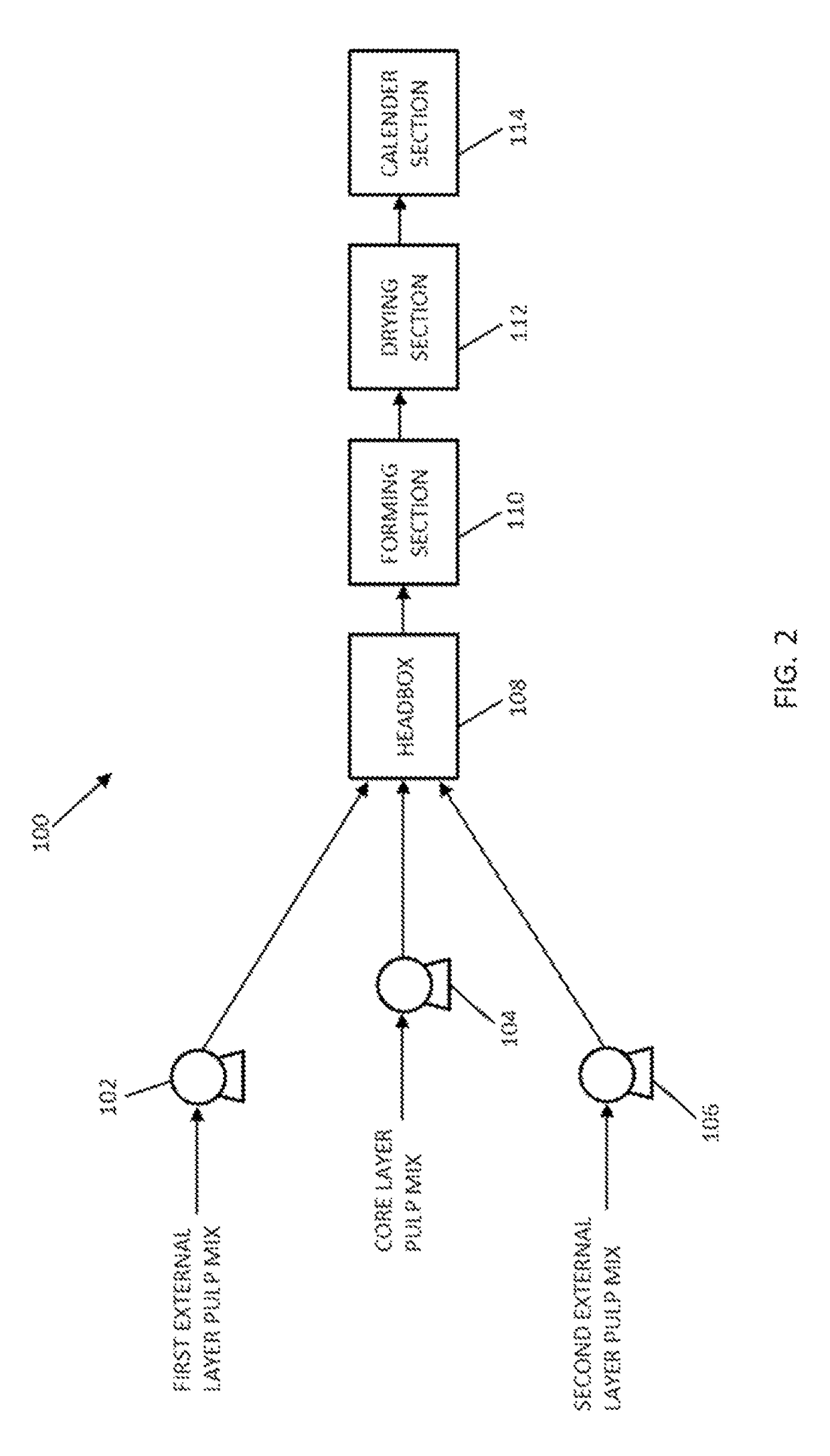

A method to prepare, pulp, and bleach cannabis bast and hurd fibers to allow for the fiber to be incorporated into absorbent cellulosic structures on a wet-laid paper machine while keeping the pectin within the fibers. The wet laid paper machine can use the ATMOS, NTT, ETAD, TAD, or UCTAD method to produce the absorbent cellulosic structure. Absorbent cellulosic structures are produced with the cannabis bast and hurd fibers or with the bast fibers alone with the hurd fibers being combined with paper mill sludge or dust to form a fuel pellet.

Owner:FIRST QUALITY TISSUE

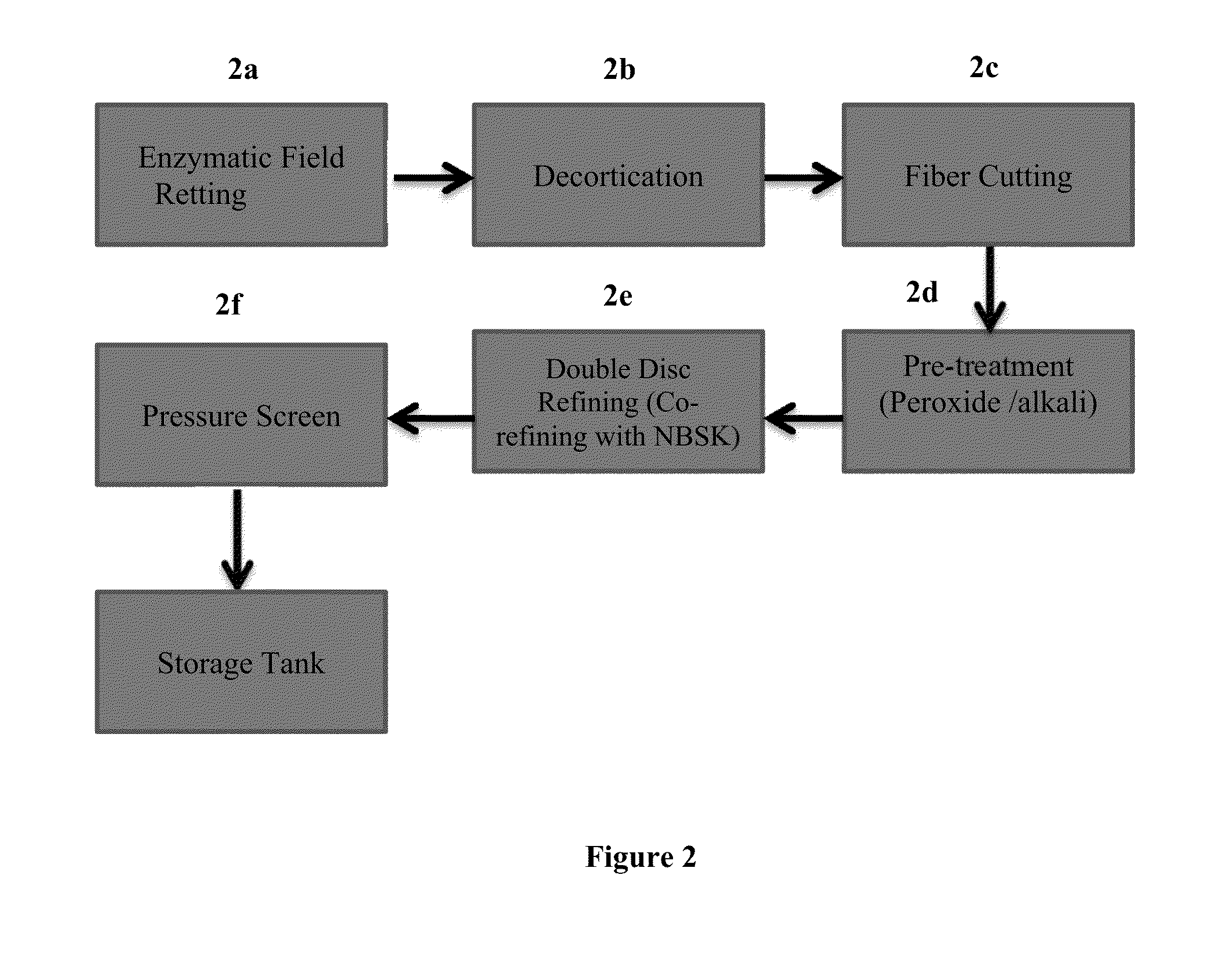

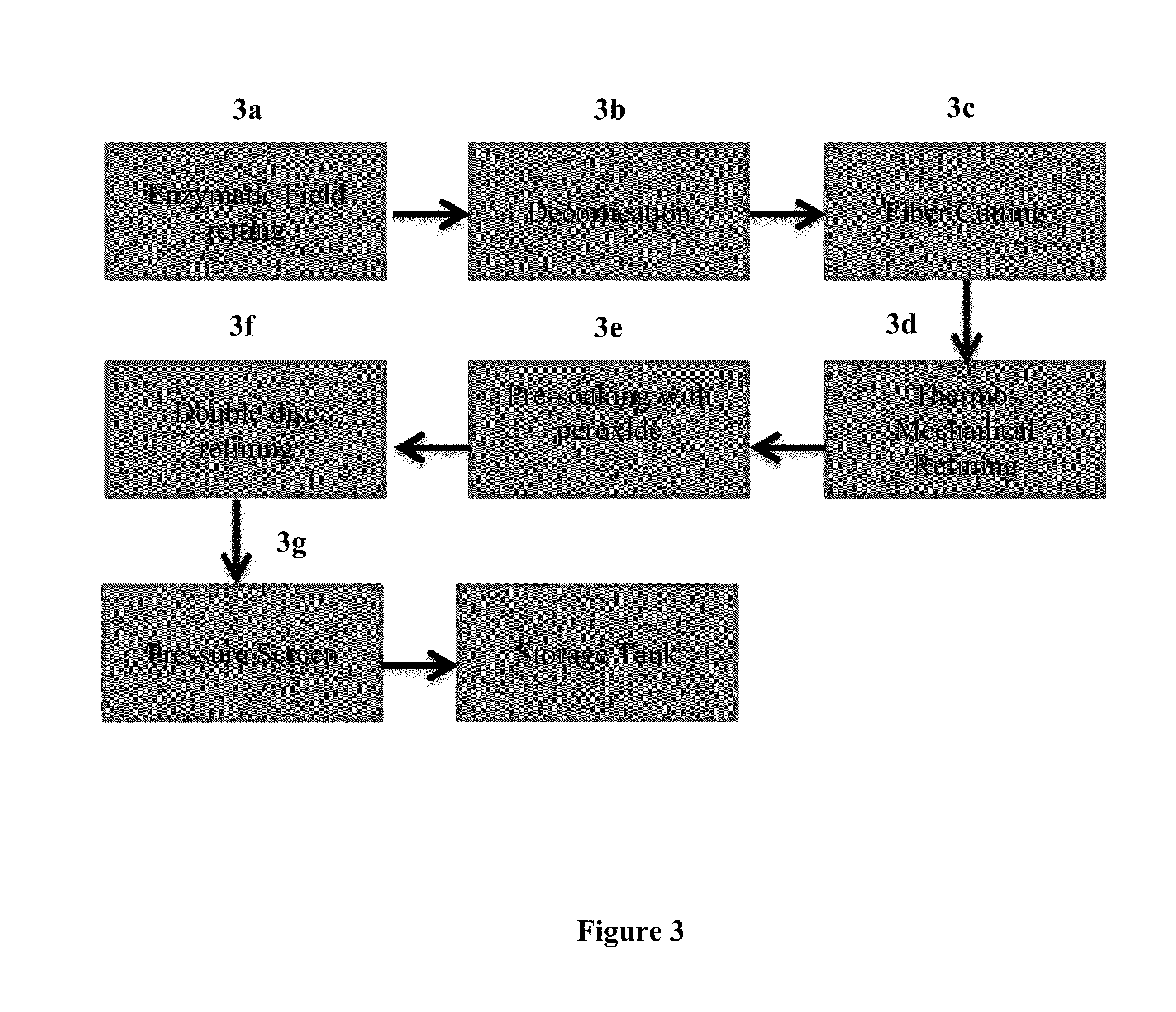

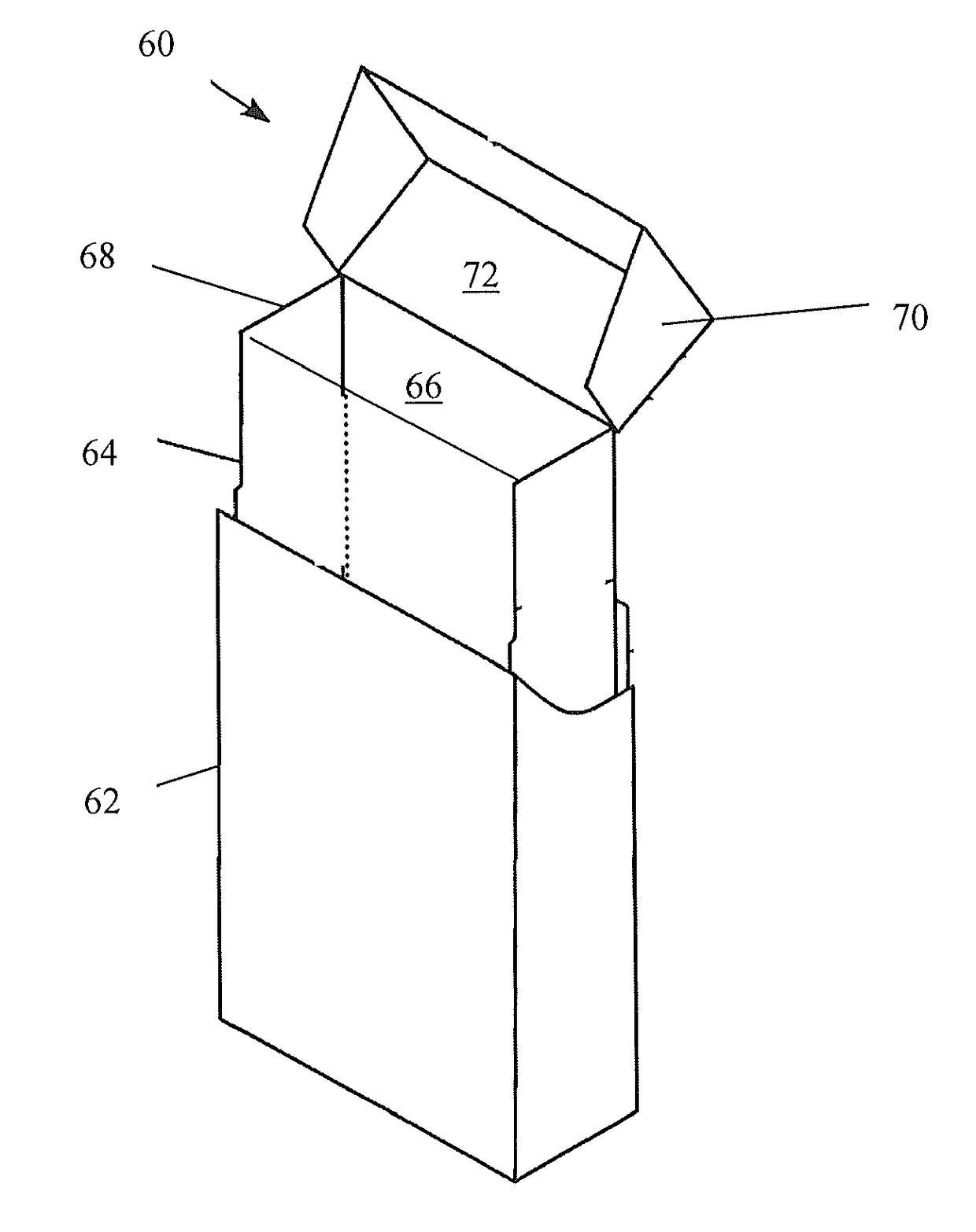

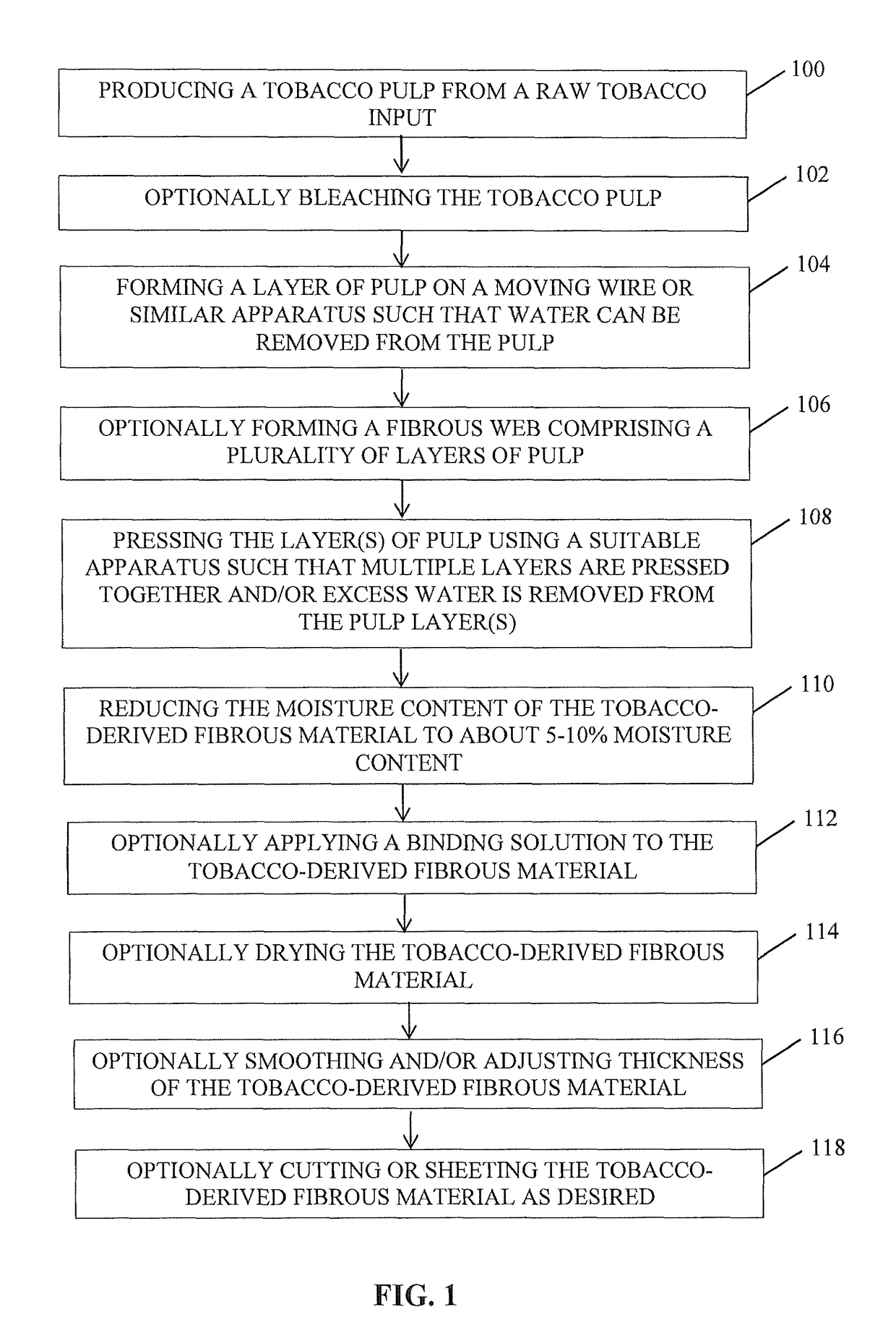

Tobacco-derived cellulose material and products formed thereof

A paper material is provided herein, wherein the paper material includes a fibrous material including at least 5 dry weight percent of fibers derived from a plant of the Nicotiana species; wherein the paper material has a basis weight ranging from about 5 g / m2 to about 450 g / m2; and wherein the paper material has a caliper ranging from about 0.01 mils to about 200 mils. The paper material can be suitable for use in a smoking article in the form of at least one of a tipping material, a plug wrap and a wrapping material. The paper material can be suitable for use in at least one of a soft carton container suitable to house smoking articles, a label, a paper substrate of a barrier layer, a hard carton suitable to house smoking articles and a container suitable to house smokeless tobacco products.

Owner:R J REYNOLDS TOBACCO COMPANY +1

Method for manufacturing high-breathability non-woven wallpaper body paper and product

The invention discloses a method for manufacturing high-breathability non-woven wallpaper body paper and a product. The existing non-woven wallpaper has the disadvantages that the hand feel thereof is not soft enough, the principal plane stereoscopic impression is not strong and the opacity degree is low. The method of the invention comprises the following steps: beating plant fiber containing chemical wood pulp until the beating degree is 20-30OSR, and mixing with non-plant fiber containing chemical fiber; adding chemical addition agent into the mixed fiber; manufacturing the mixed fiber containing the chemical addition agent into body paper semi-finished products by utilizing a fourdrinier wire or inclined wire paper machine; mixing pigment, chemical addition agent and adhesive to form coating liquor, carrying out dip coating on the body paper semi-finished products inside or outside the machine; and drying and finishing the body paper subject to dip coating, and rolling the body paper to form finished paper of body paper, thus obtaining non-woven wallpaper which contains continuous fiber, has high breathability, and can be directly printed. The principal plane has natural lines; and the finished paper has the advantages of soft hand feel, good processability, excellent shape stability, rich color, distinct image and strong stereoscopic impression.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

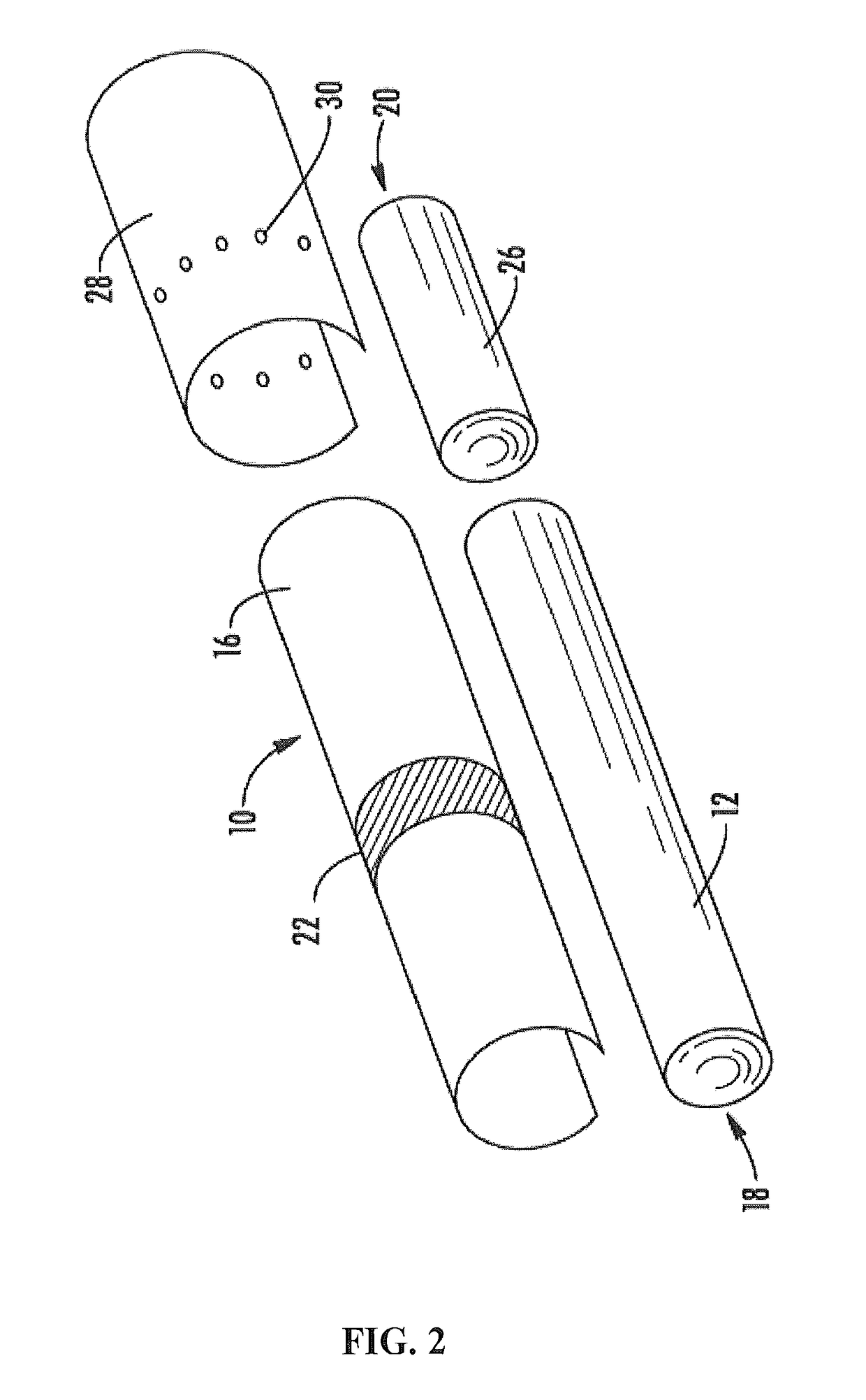

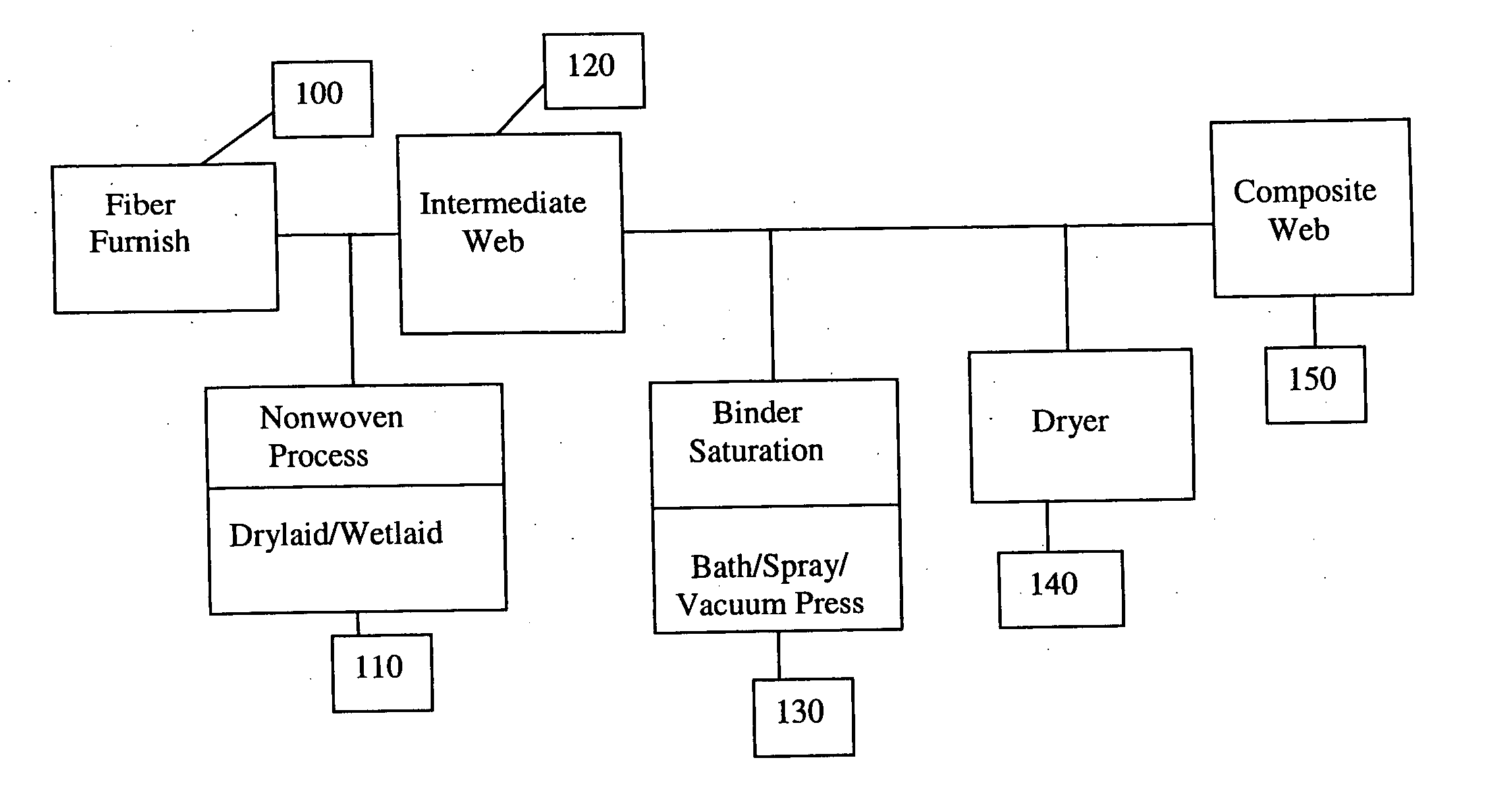

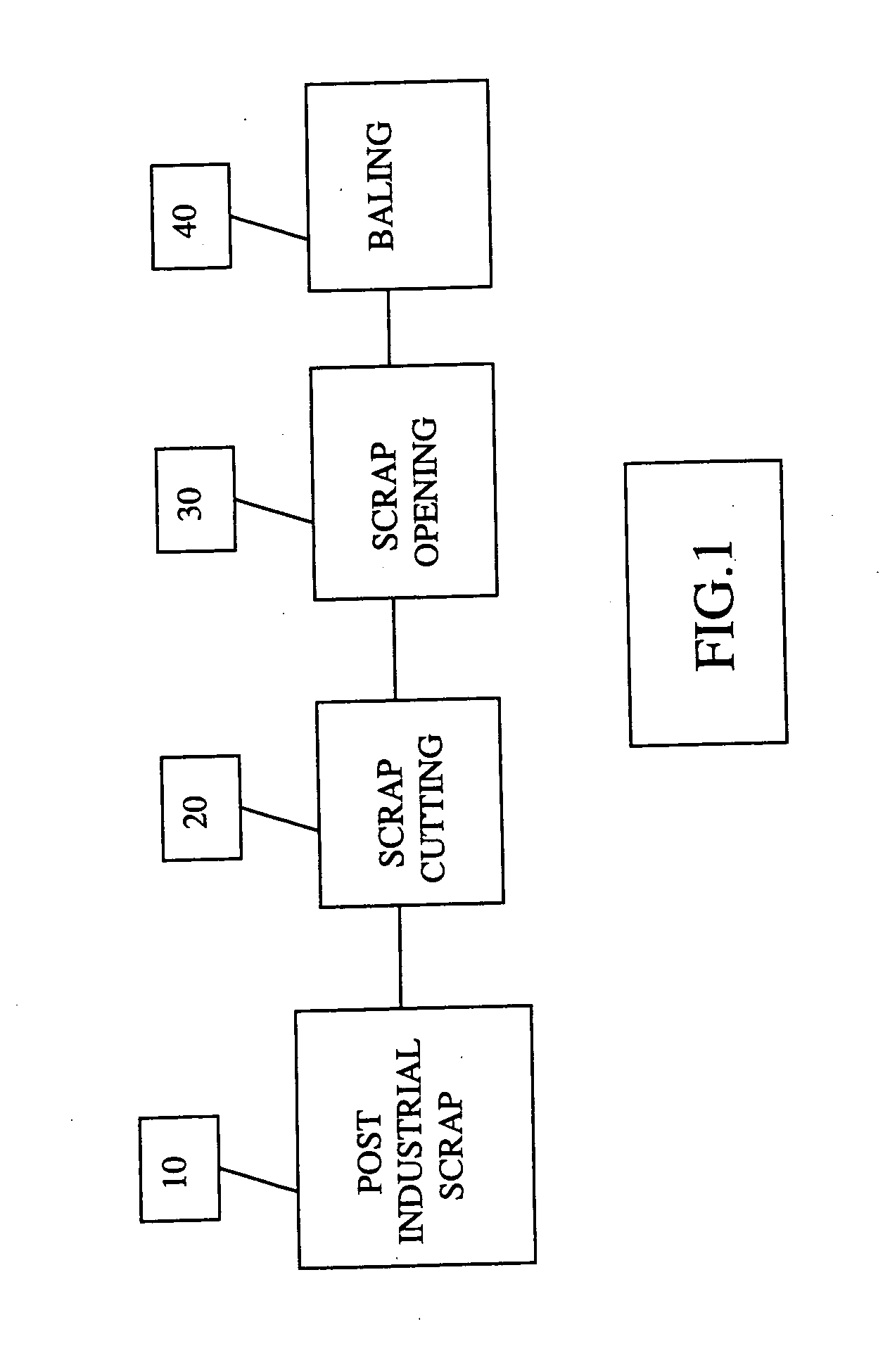

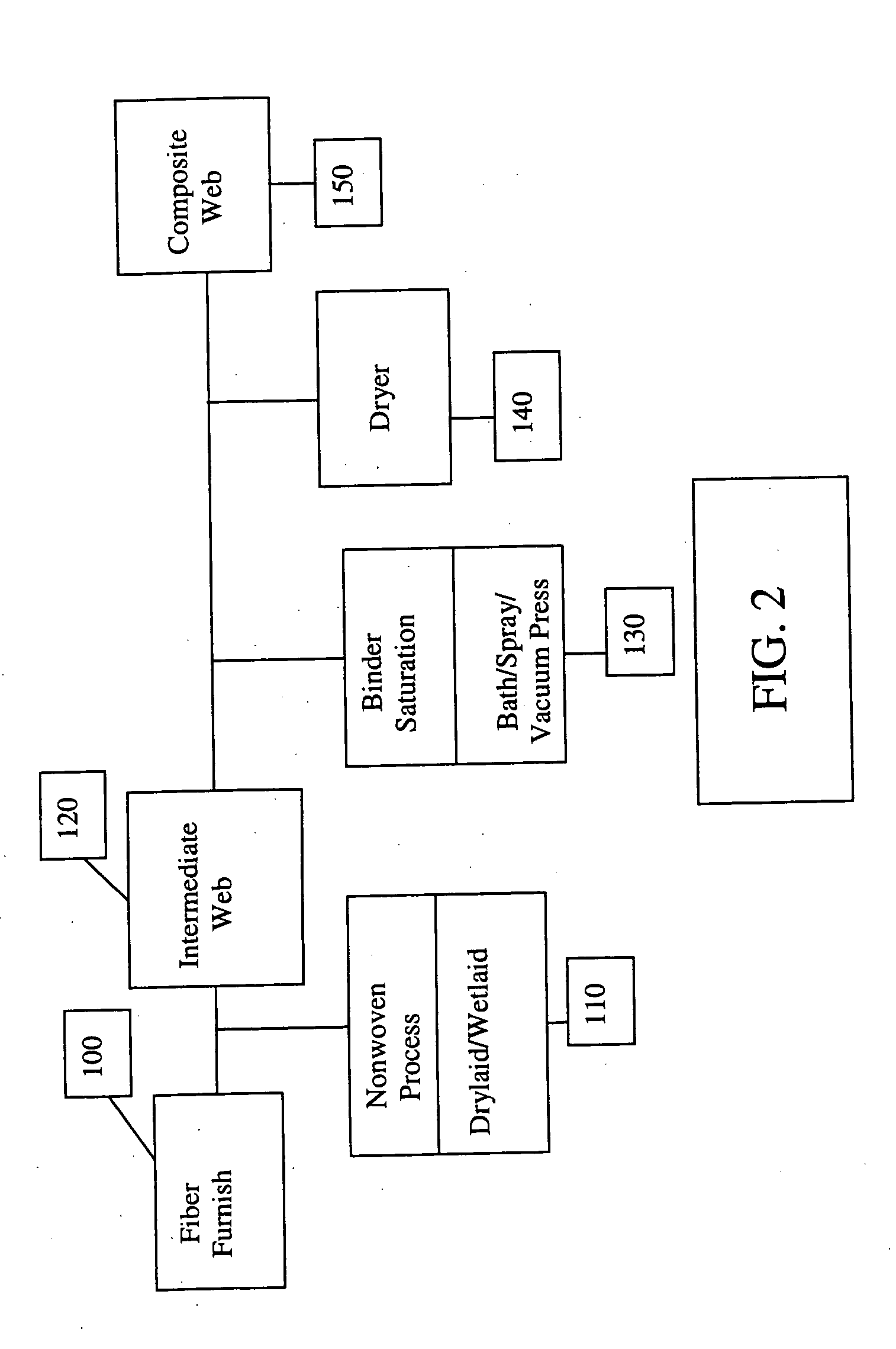

Composite web and process for manufacture from post-industrial scrap

A composite web and process for manufacture from post-industrial scrap wherein the fibers are pre-opened and cut to an average fiber length of about 4 mm. A scrap fiber component and a cellulosic component of such fibers are blended into a fiber furnish. The scrap fiber component includes at least 15% synthetic fibers and may include a blend of natural fibers, high melting point synthetic fibers, and low melting point synthetic fibers. The cellulosic component may include post-industrial cotton fibers which may be refined before blending with the scrap fiber component. The fiber furnish is processed into an intermediate web such as by a drylaid or a wetlaid nonwoven process. The intermediate web is saturated with a latex binding agent and pressed and / or dried to form a composite web capable of further processing into molded or formed consumer or industrial products. The process is capable of producing a high basis weight composite web.

Owner:SSI TECH INC

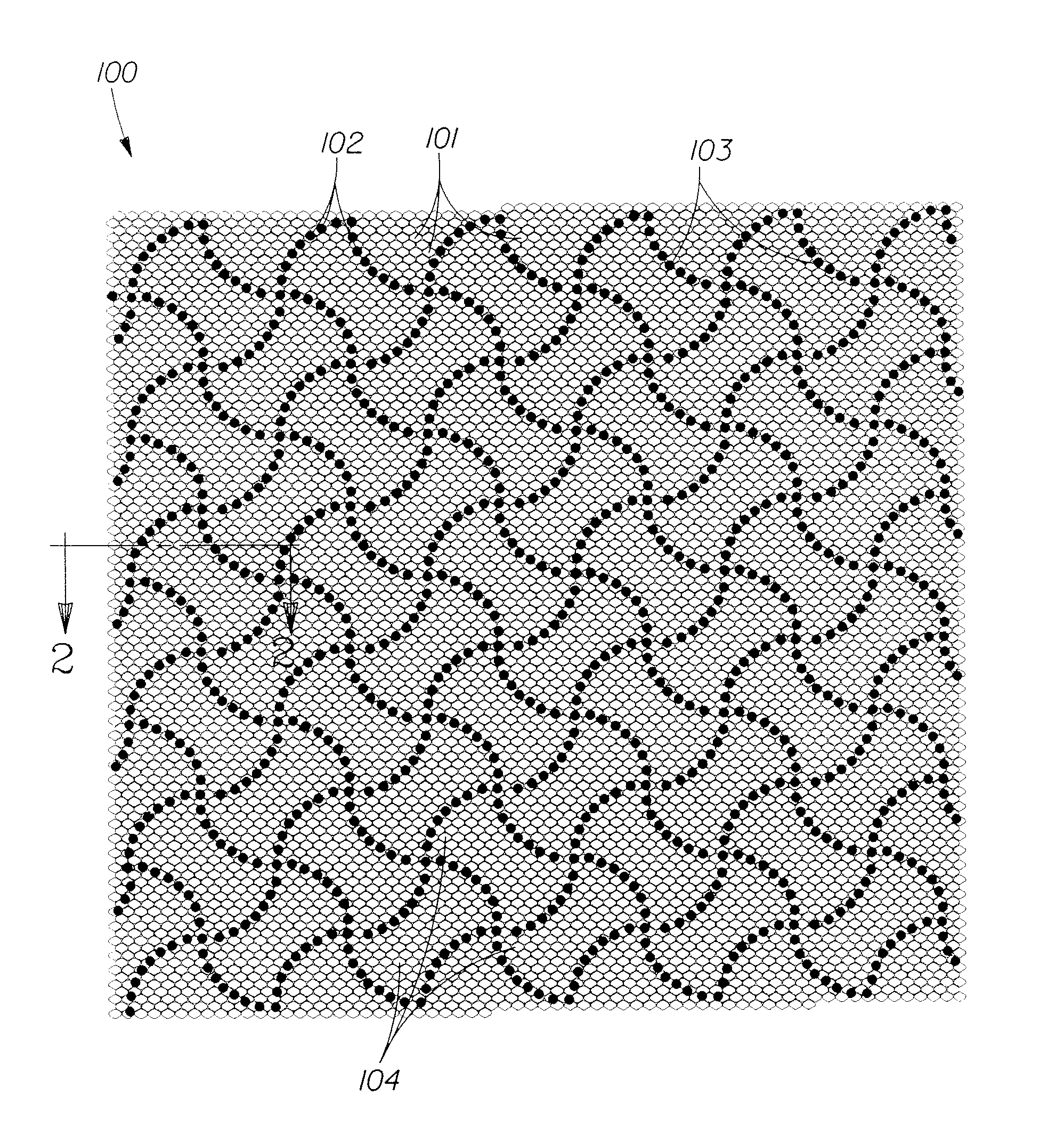

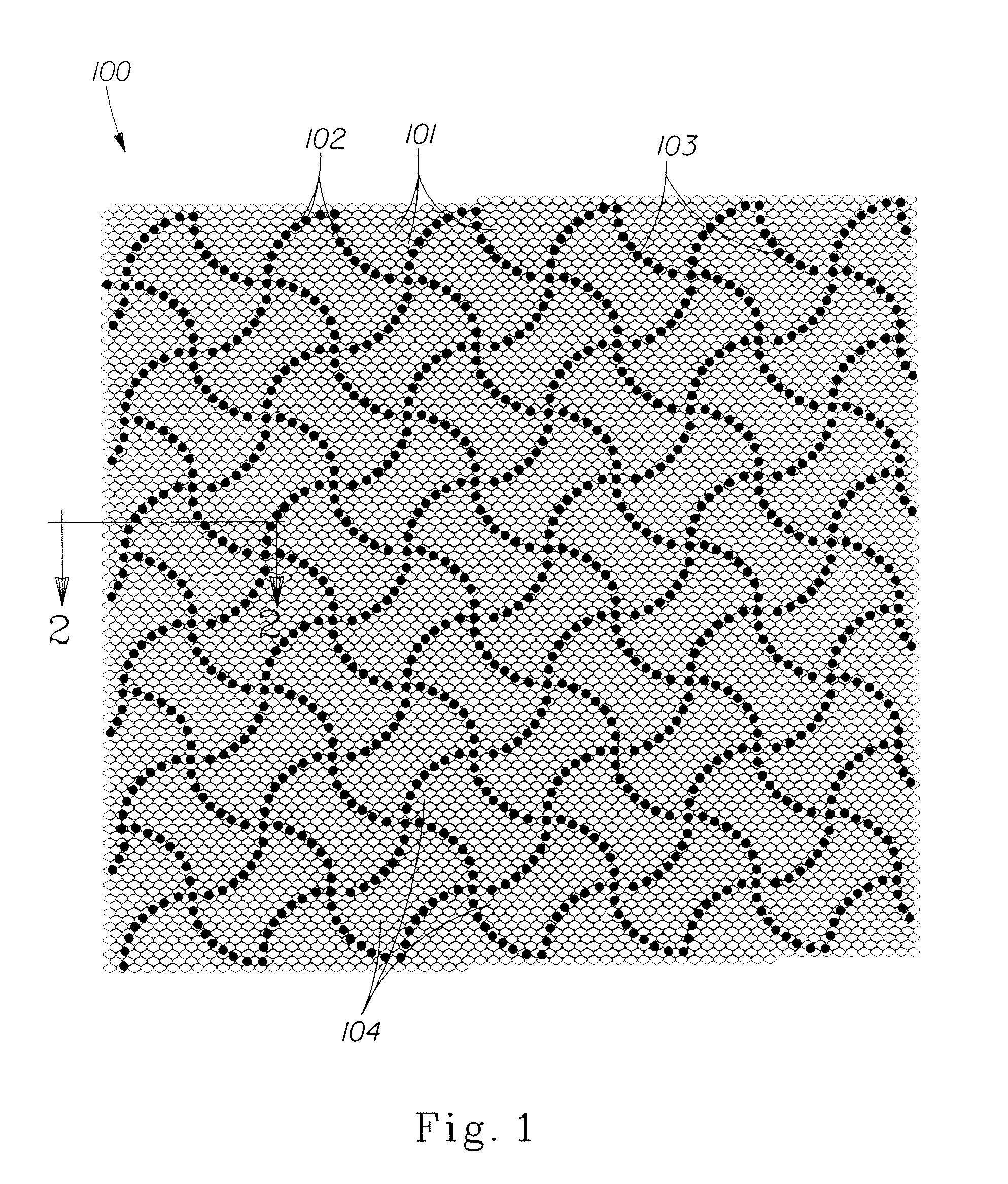

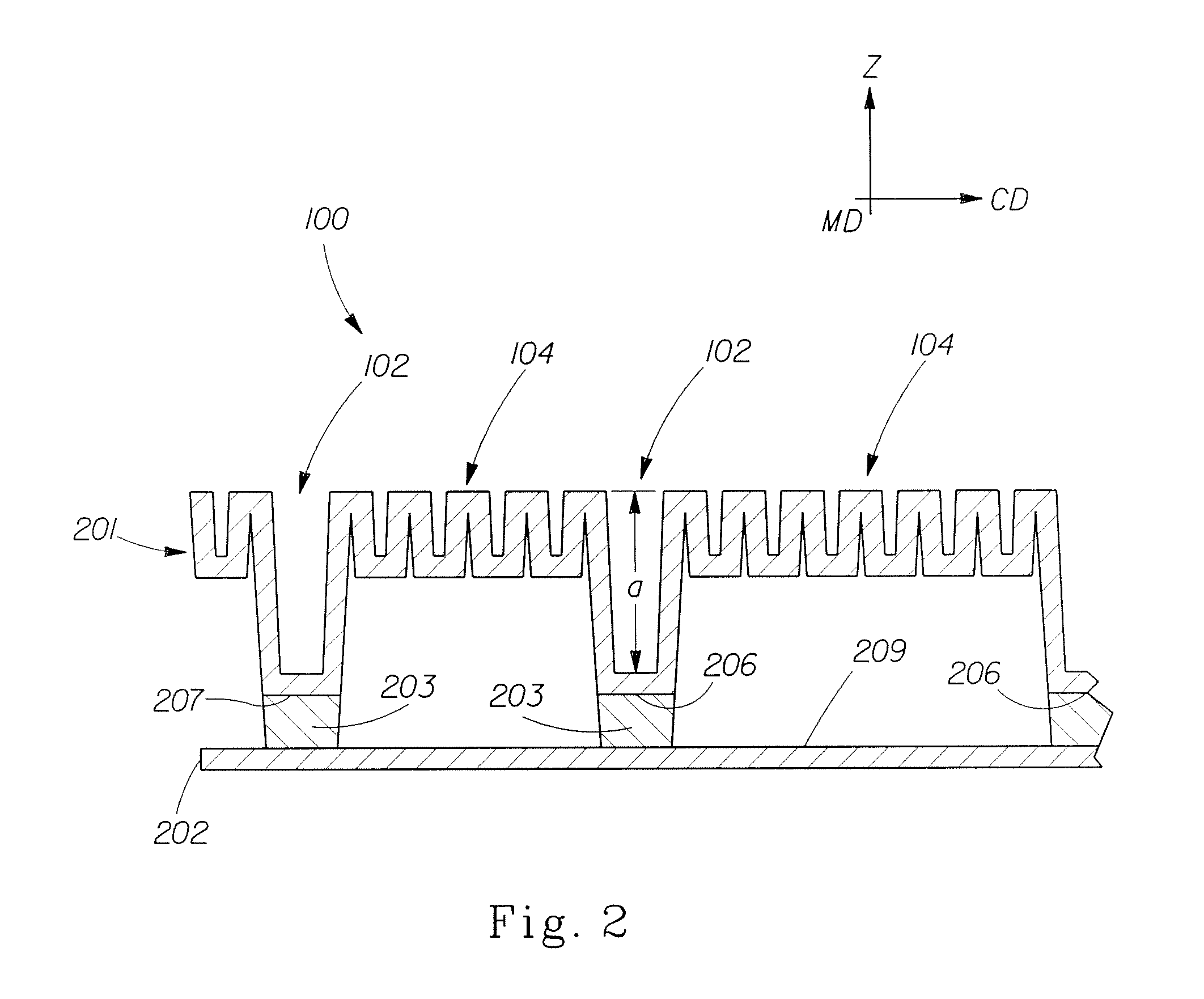

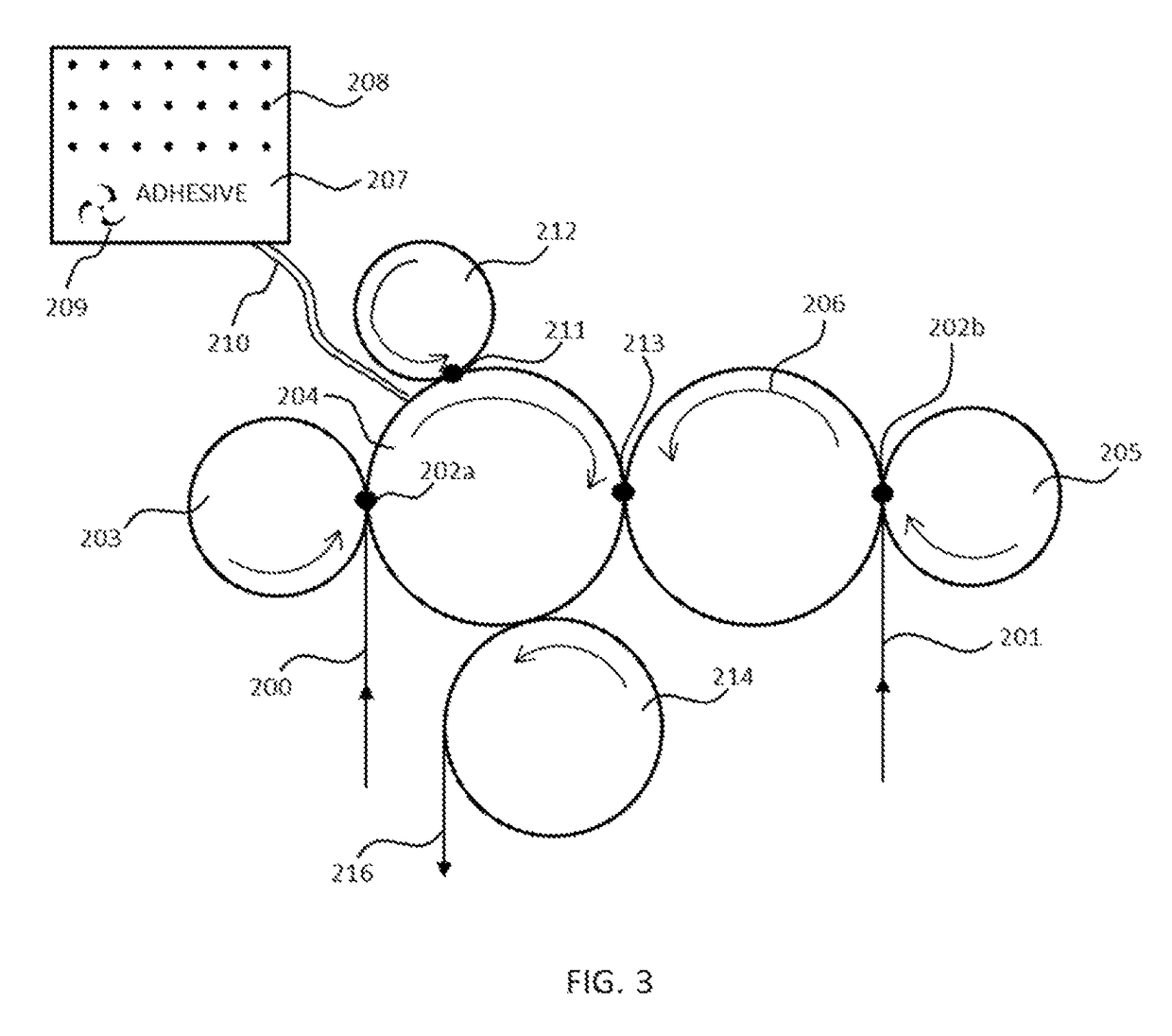

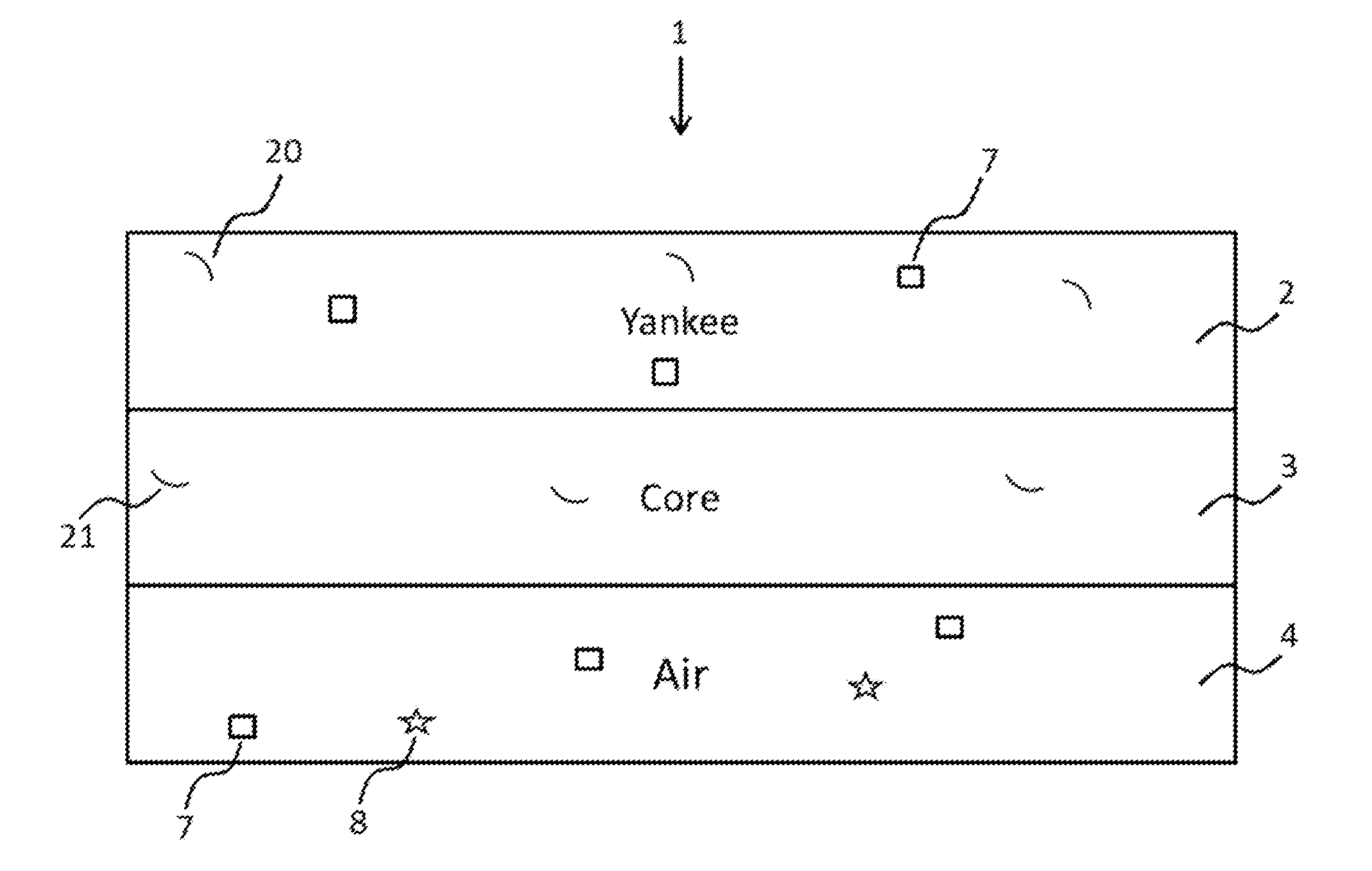

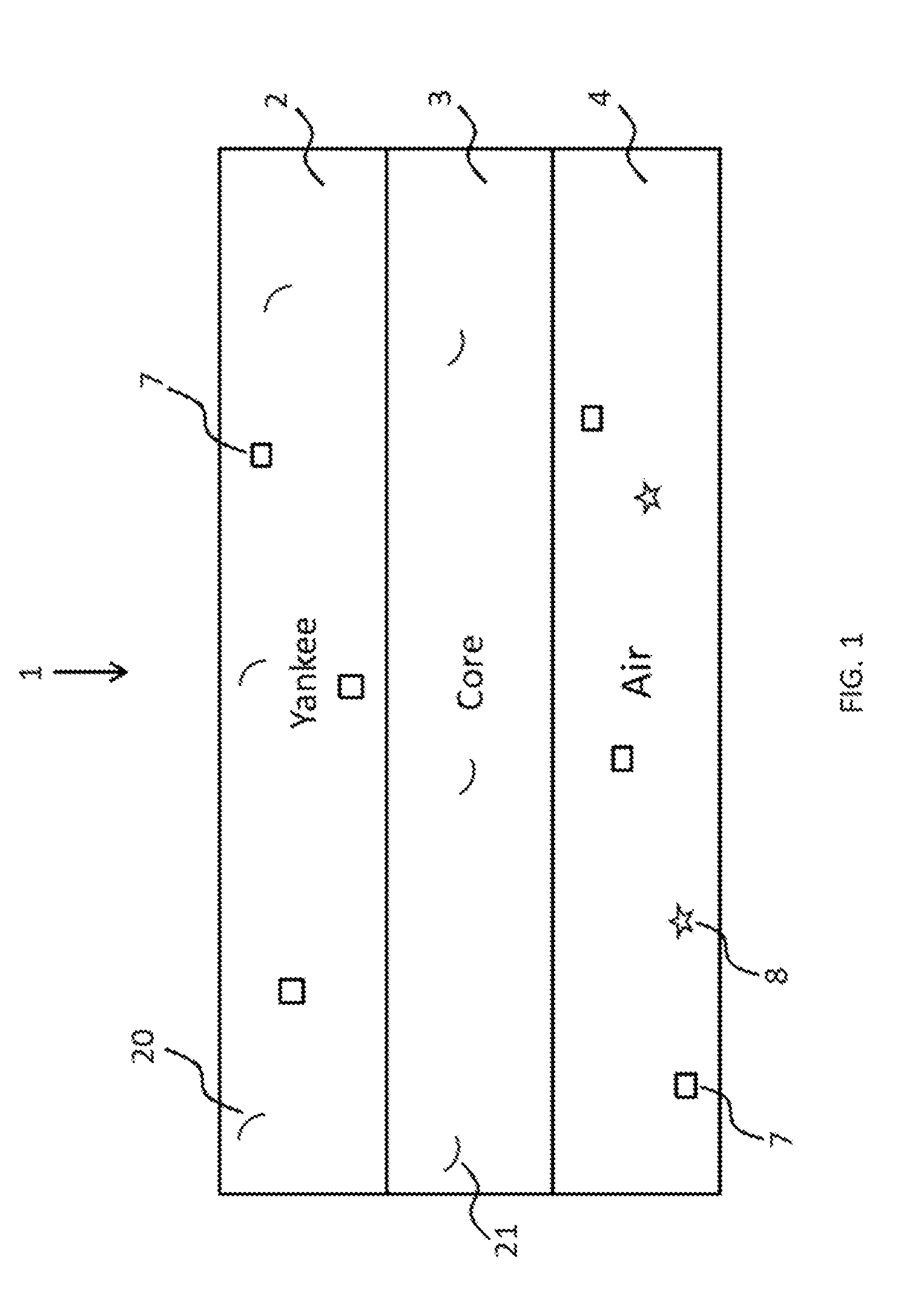

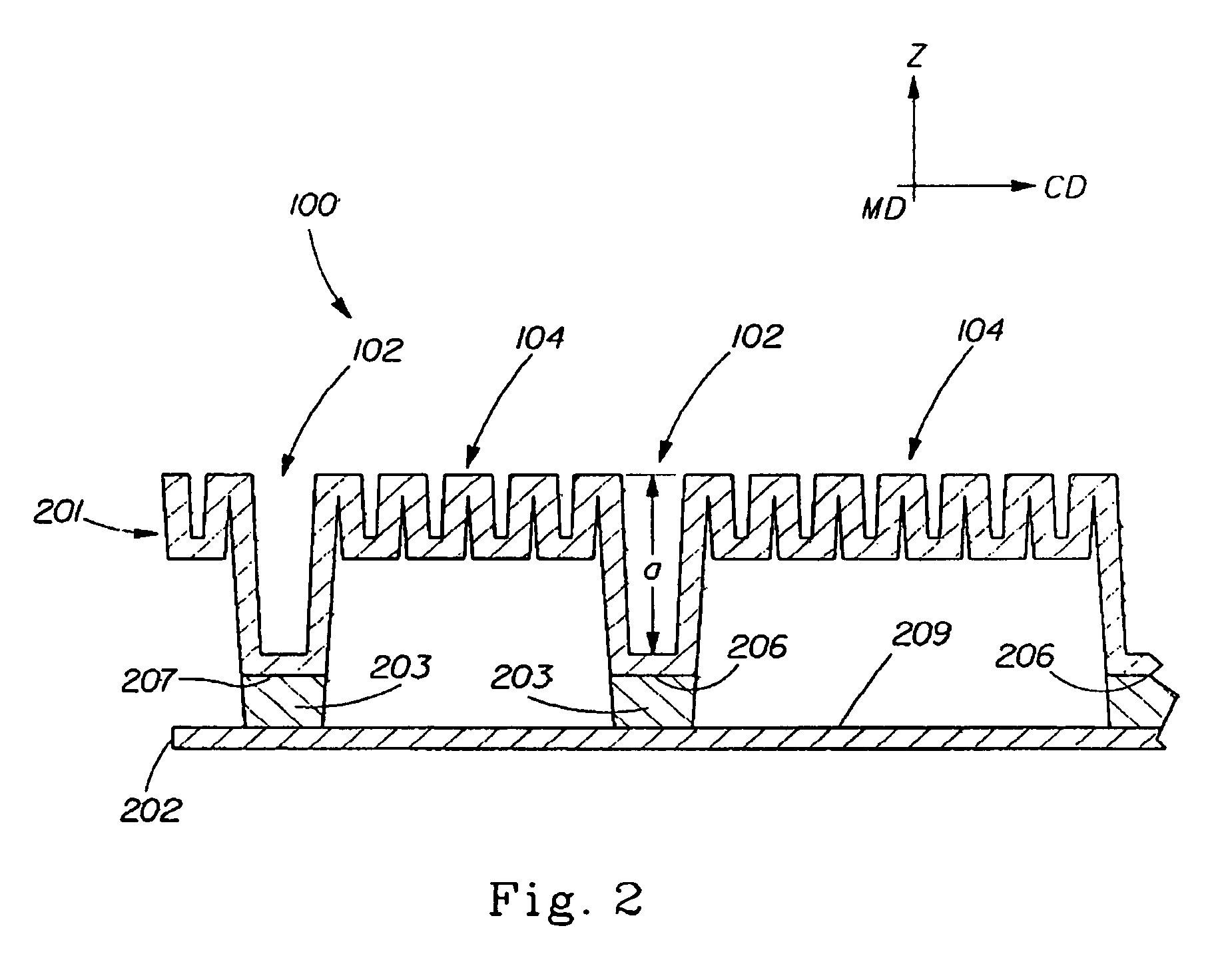

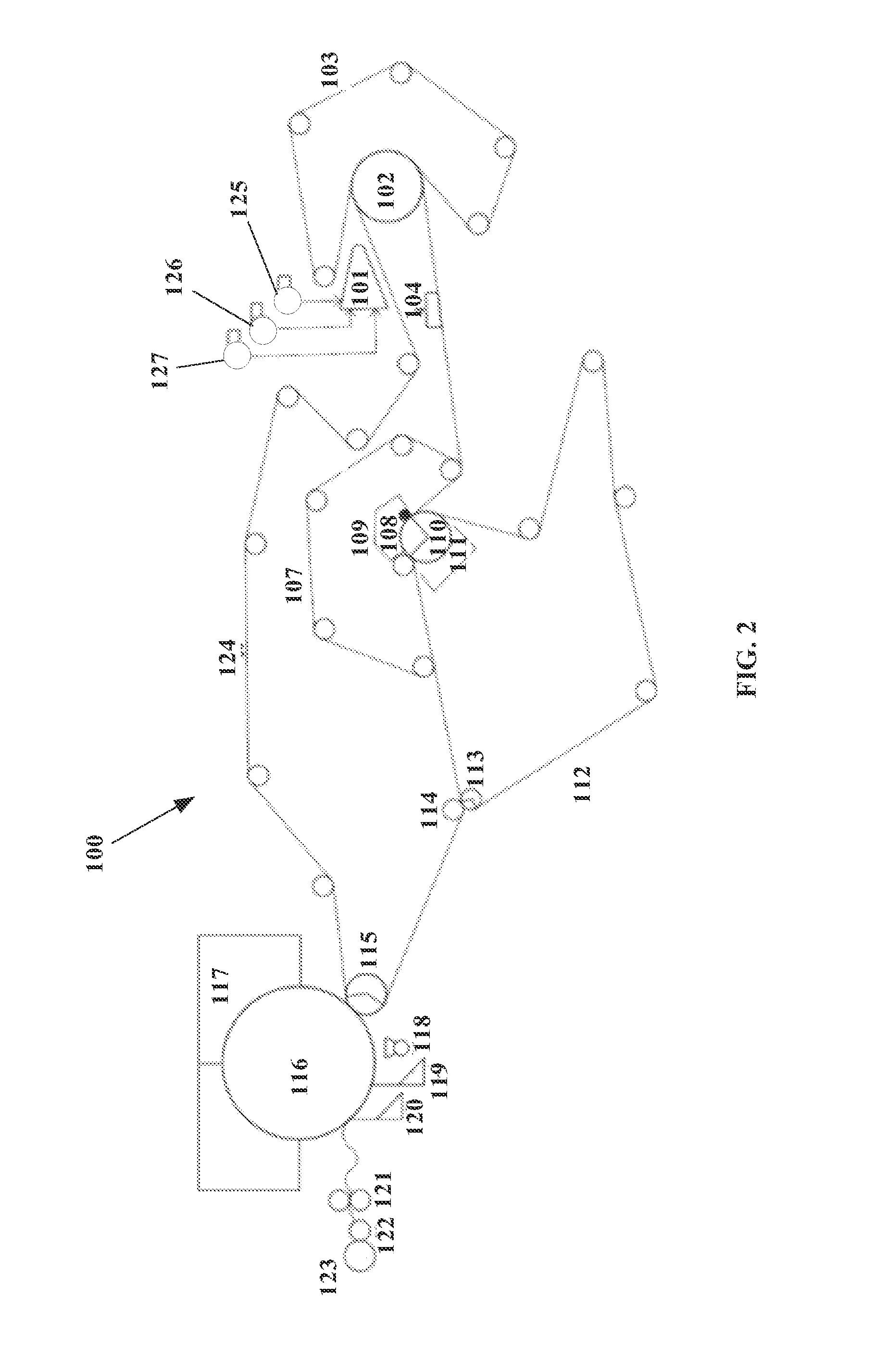

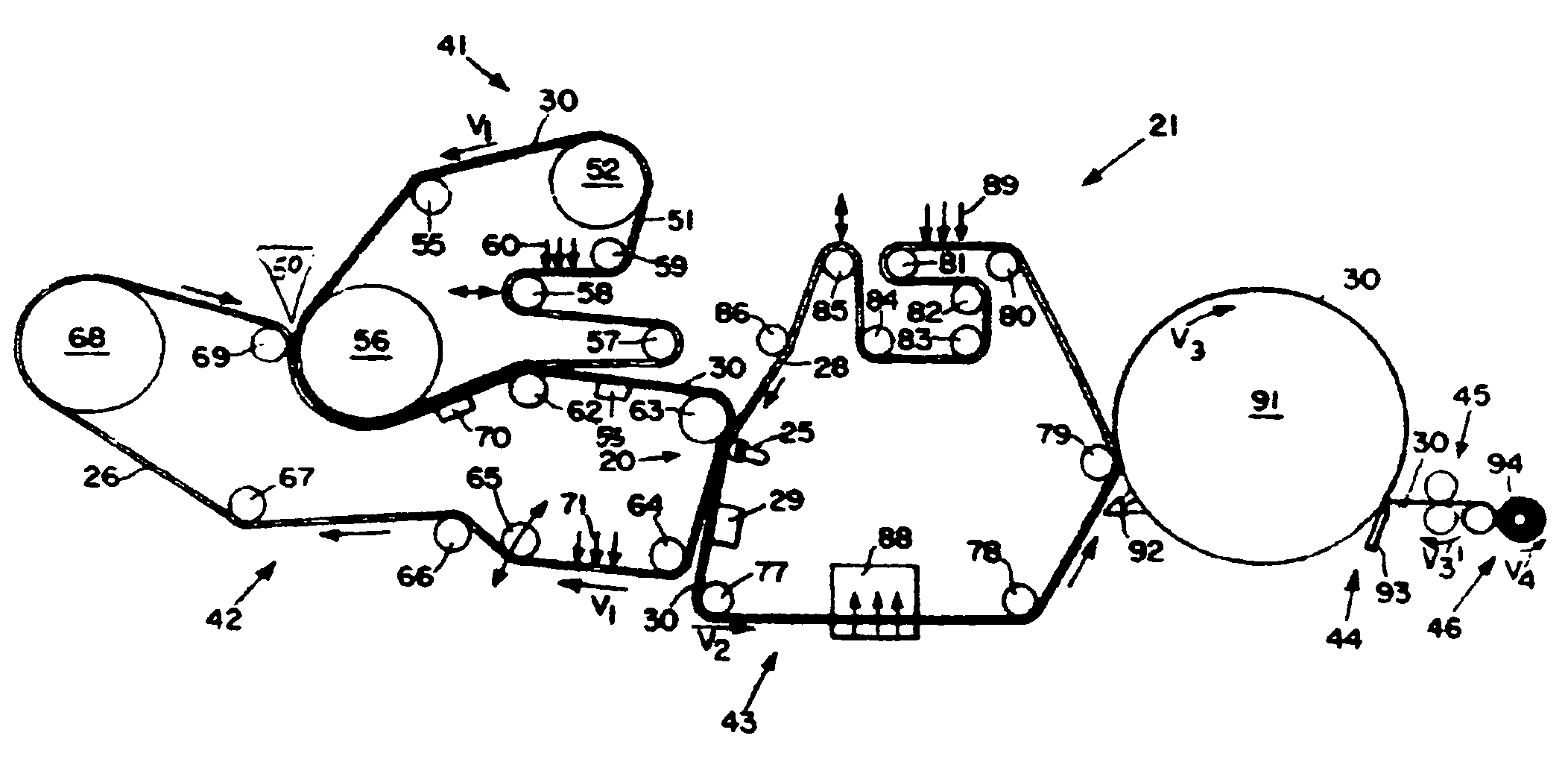

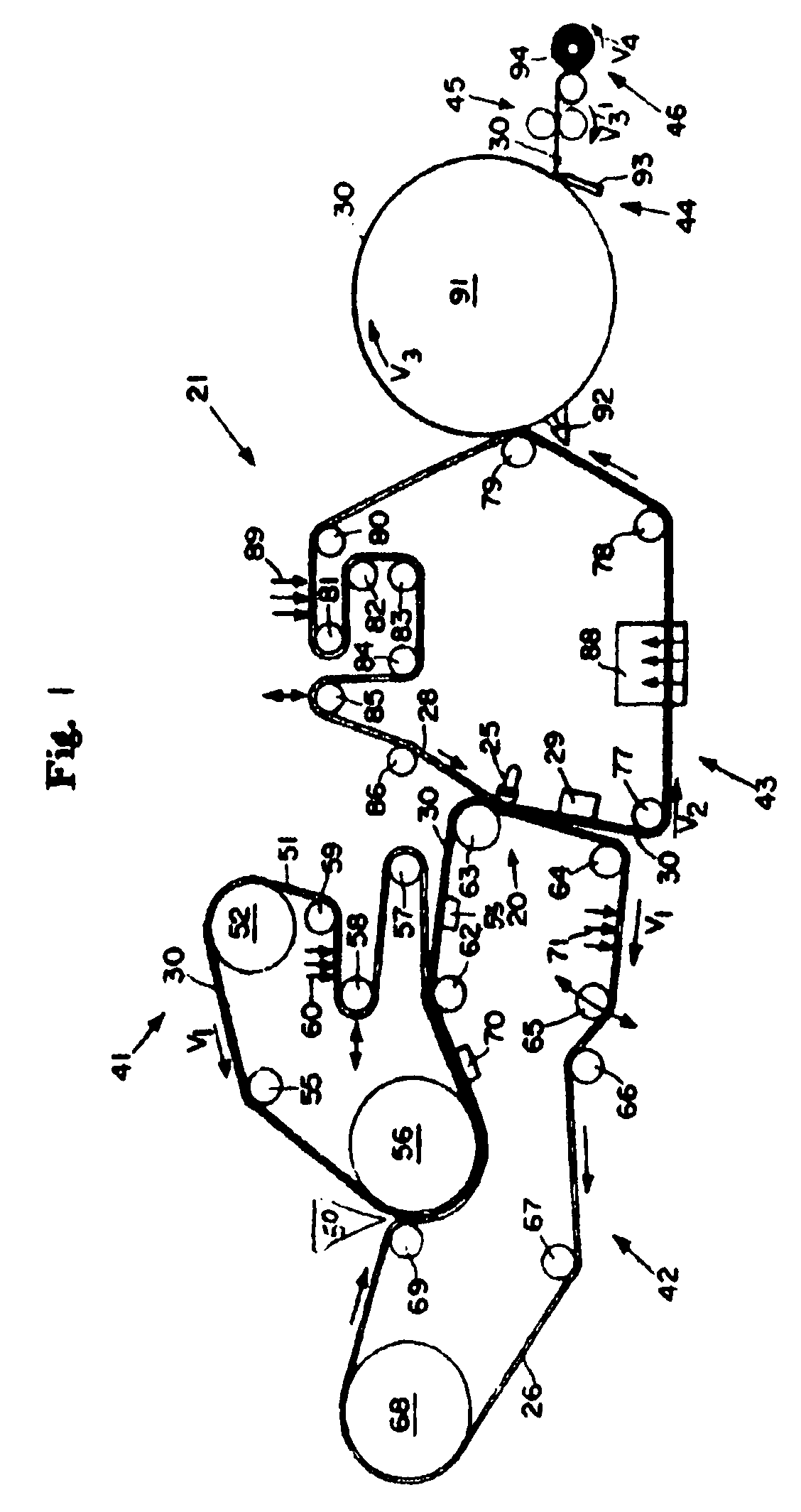

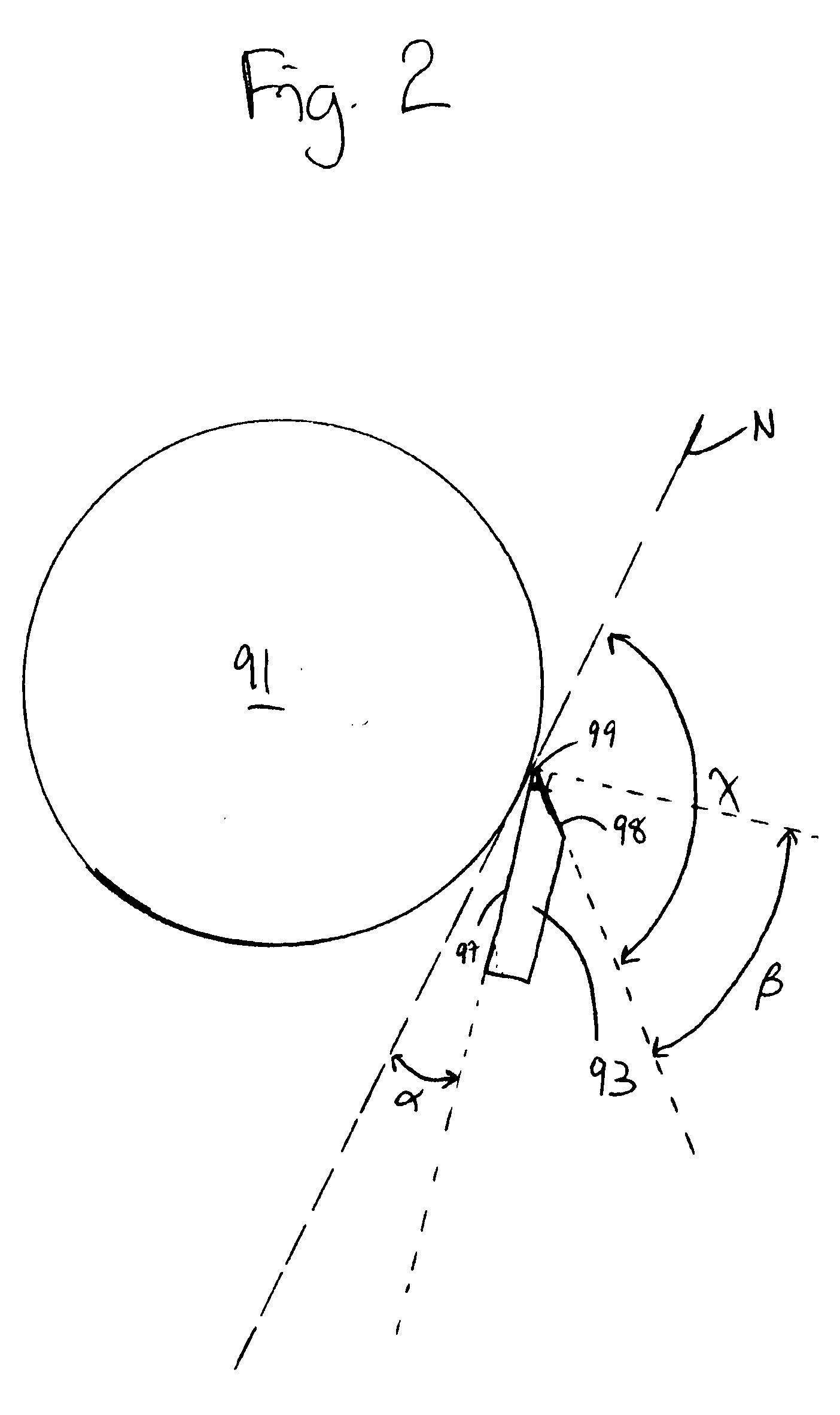

Towel with quality wet scrubbing properties at relatively low basis weight and an apparatus and method for producing same

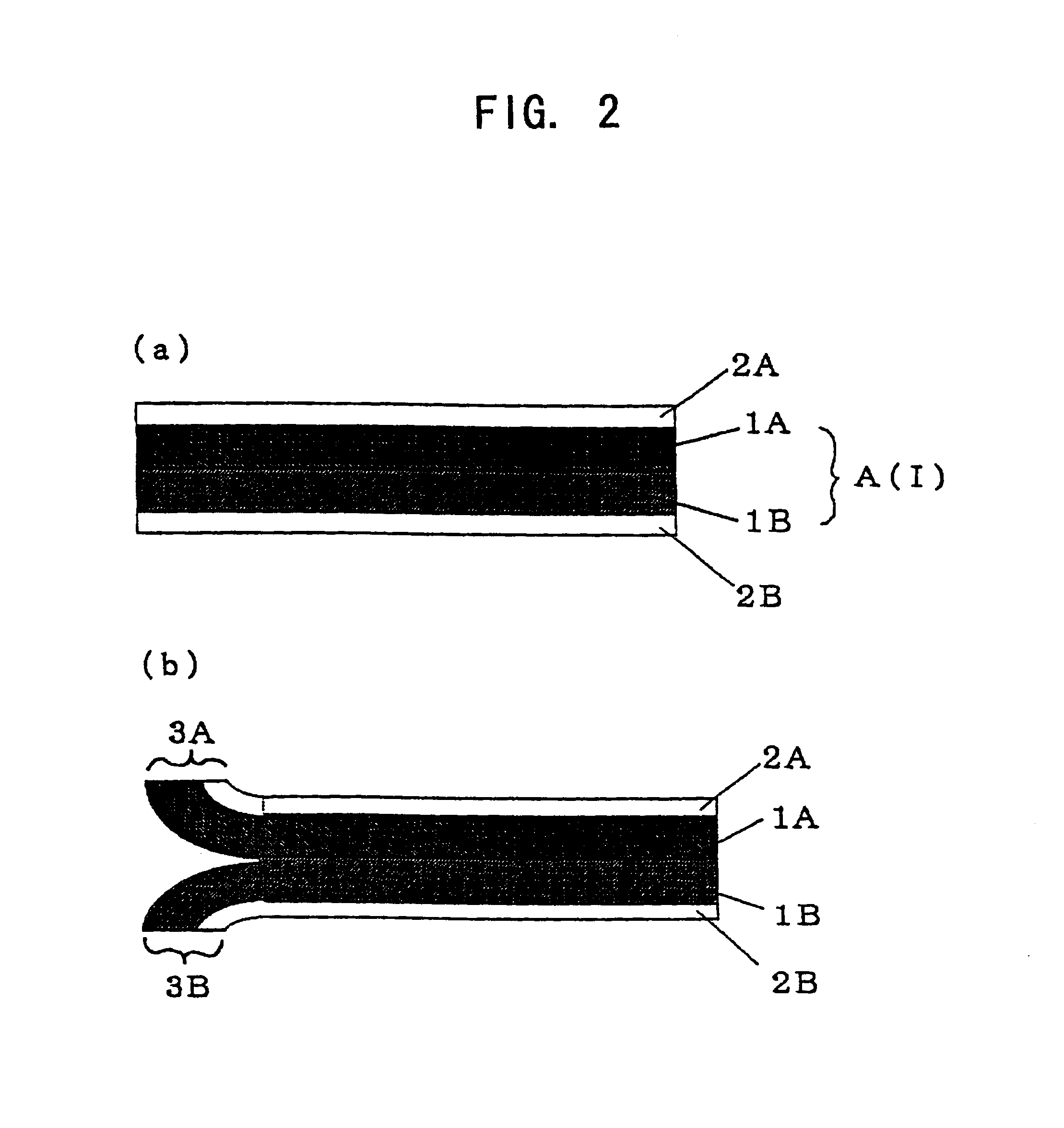

ActiveUS9719213B2Improve the level ofLose weightLamination ancillary operationsLaminationGramAdhesive

A multi-ply absorbent product having a wet scrubbing resistance greater than 120 revolutions and a basis weight of between 30 and 50 grams per square meter. A heated adhesive is applied between two single plies / webs, the multiple plies are embossed according to particular parameters, and the embossed webs are compressed with a marrying roll. The adhesive is heated to a temperature of between approximately 32 degrees C. to 66 degrees C. for application between the multiple plies. For each ply, the embossed area generally occupies between approximately 5 to 15% of the total surface area of a surface of the ply, the depth of embossment of the surface is generally between approximately 0.28 and 0.43 centimeters deep, and the embossment of the surface is generally between approximately 0.04 to 0.08 square centimeters in size.

Owner:FIRST QUALITY TISSUE LLC

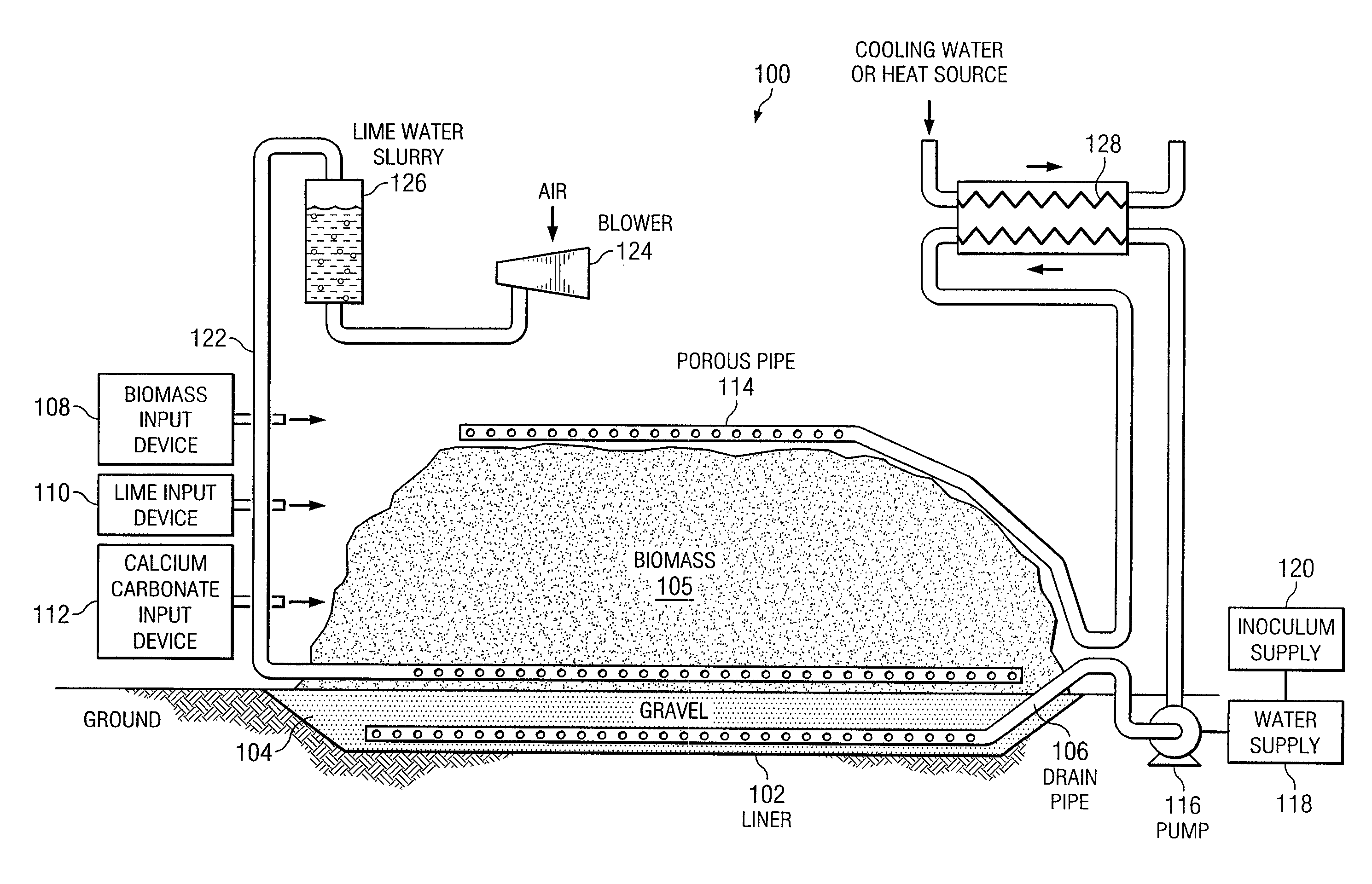

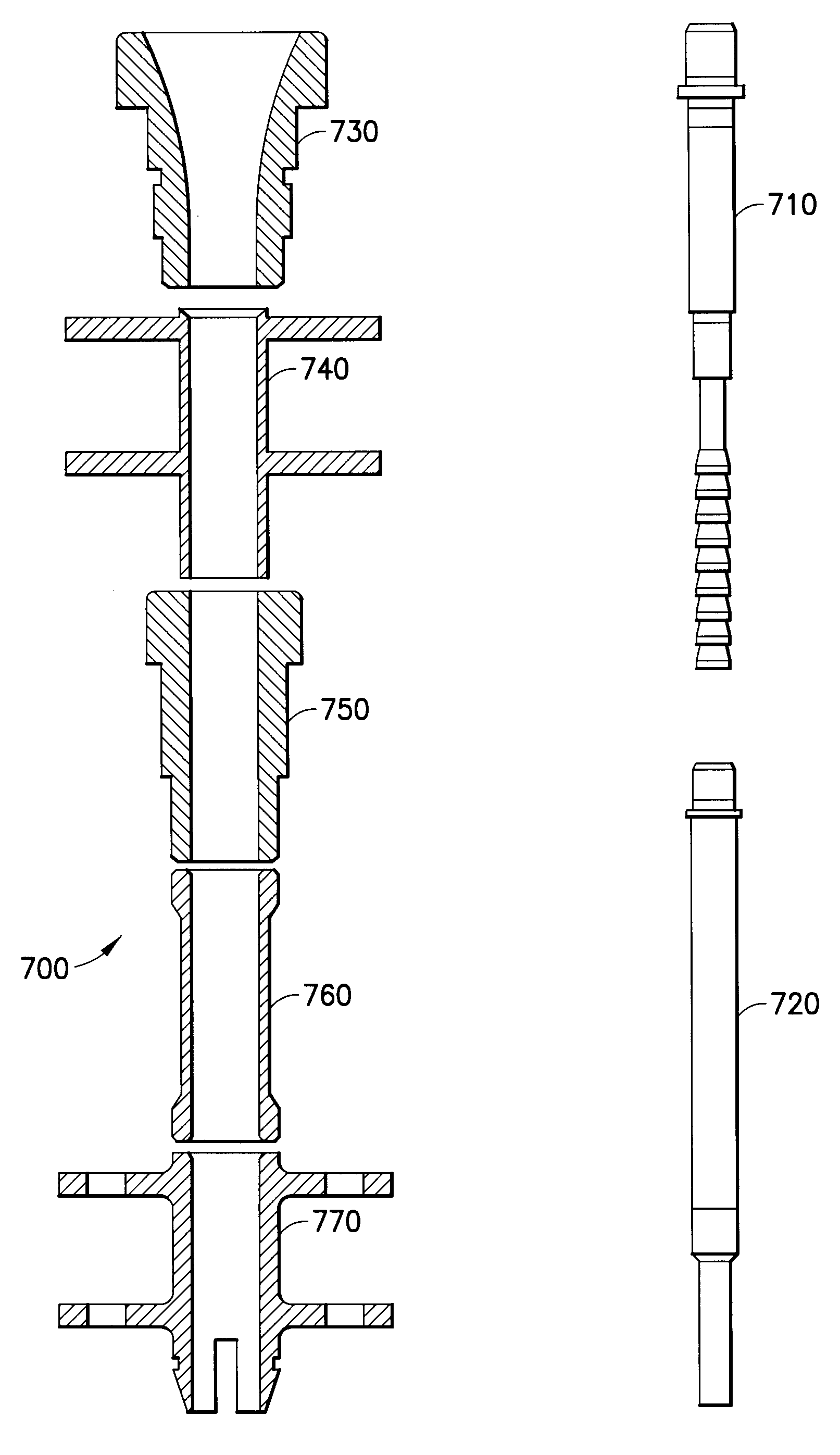

Methods and Systems for Pretreatment and Processing of Biomass

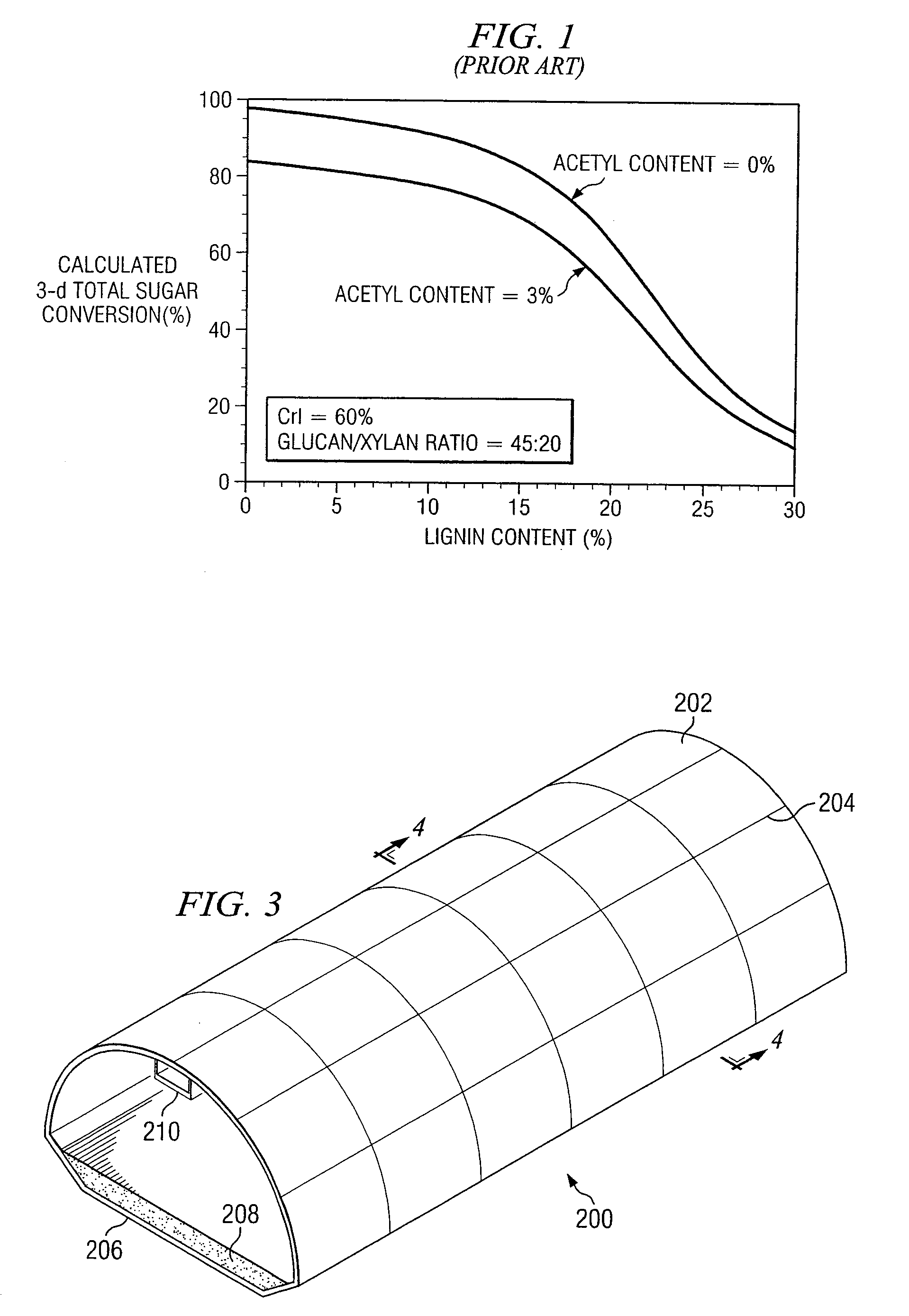

InactiveUS20080121359A1Increasing enzyme digestibilityLow lignin contentBio-organic fraction processingProductsEnzymatic digestionCellulose

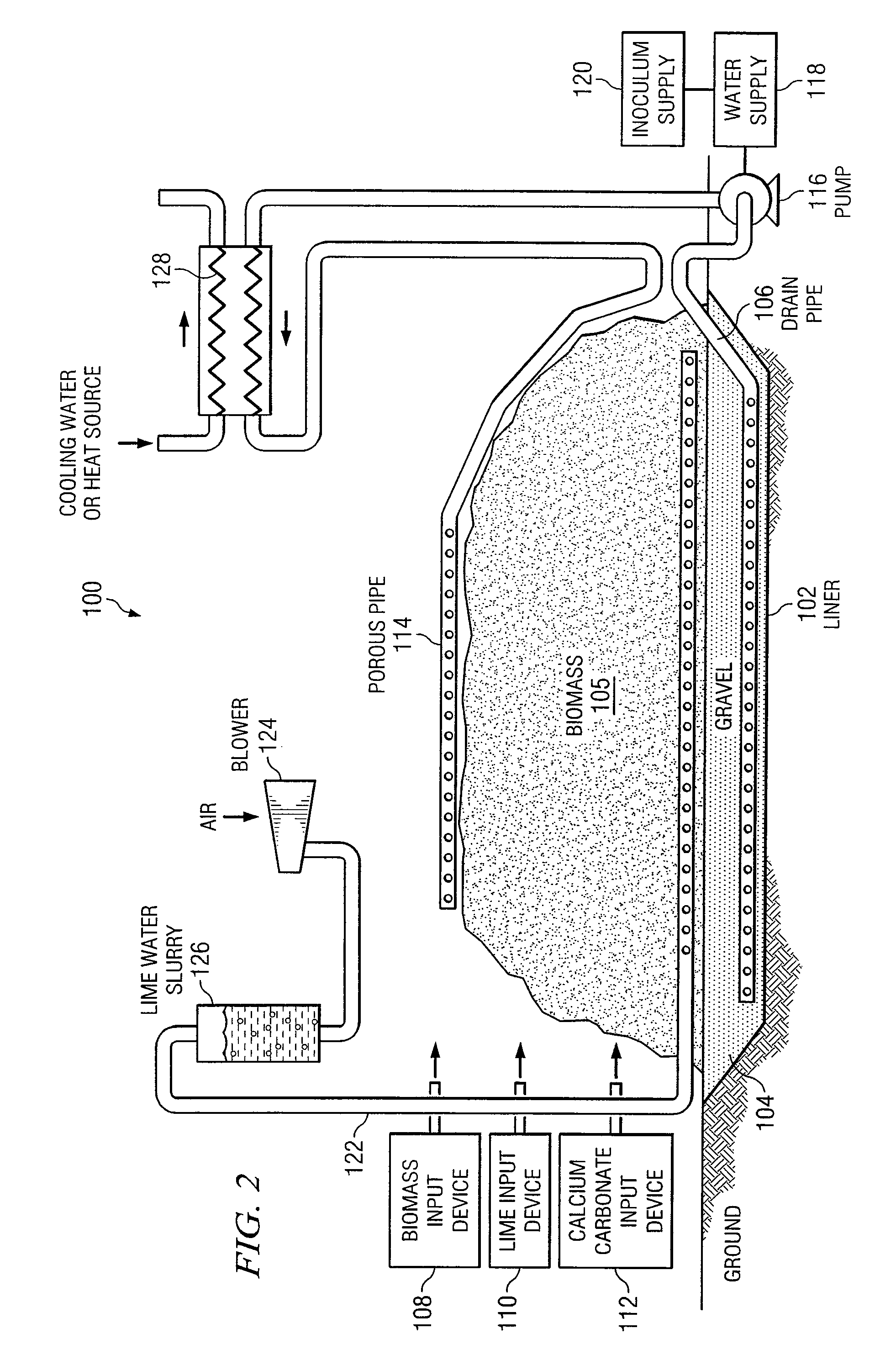

According to one embodiment of the invention, a system for processing biomass includes a water-impermeable bottom liner, a gravel layer supported by the bottom liner, a drain pipe disposed within the gravel layer, a biomass input device operable to deliver biomass over the gravel layer to form a biomass pile, a lime input device operable to deliver lime to the biomass for pretreating the biomass, a distribution pipe elevated above the gravel layer, and a pump operable to circulate water through the biomass pile by delivering water to the distribution pipe and receiving water from the drain pipe after it has traveled through the biomass pile.According to another embodiment, a method for biomass pretreatment with alkali, conducted at ambient pressure for approximately 4-16 weeks at temperatures ranging from approximately 25° C. to 95° C. Biomass may be lignocellulosic biomass and may be rendered suitable for enzymatic digestion or pulp production.

Owner:TEXAS A&M UNIVERSITY

Towel with quality wet scrubbing properties at relatively low basis weight and an apparatus and method for producing same

ActiveUS20160160448A1Improve the level ofLose weightPaper after-treatmentOrnamental structuresFiberAdhesive

A multi-ply absorbent product having a wet scrubbing resistance greater than 120 revolutions and a basis weight of between 30 and 50 grams per square meter. A heated adhesive is applied between two single plies / webs, the multiple plies are embossed according to particular parameters, and the embossed webs are compressed with a marrying roll. The adhesive is heated to a temperature of between approximately 32 degrees C. to 66 degrees C. for application between the multiple plies. For each ply, the embossed area generally occupies between approximately 5 to 15% of the total surface area of a surface of the ply, the depth of embossment of the surface is generally between approximately 0.28 and 0.43 centimeters deep, and the embossment of the surface is generally between approximately 0.04 to 0.08 square centimeters in size.

Owner:FIRST QUALITY TISSUE

Fibrous structure product with high softness

Owner:PROCTER & GAMBLE CO

Soft tissue produced using a structured fabric and energy efficient pressing

ActiveUS20160145810A1Avoid disadvantagesLarge structureMechanical working/deformationPaper after-treatmentGram-forceEngineering

Owner:FIRST QUALITY TISSUE

Enzymatic straw material pulping process

InactiveCN1421570AWell mixedChemical/chemomechanical pulpNon-woody plant/crop pulpLignin peroxidaseXylanase Y

The enzymatic straw material pulping process includes three stages of mechanical pre-treatment, enzyme treatment and chemical pulping or chemical-mechanical pulping. After being pretreated mechanically in a pulp grinder, the straw material is treated with hemicellulase liquid or mixed enzyme liquid comprising hemicellulase and lignin peroxidase at pH 3.5-6.5 and 40-60 deg.c for 1-10 hr. In chemical pulping, the material is presoaked with waste pulp-making liquor before extruding out wastes liquor and digested; and in chemical-mechanical pulping, the material is first treated with EDTA, NaOH and H2O2 at 40-80 deg.c for 30-120 min and then ground to form the pulp. The present invention is used in papermaking enterprises with straw as material and has the advantages of low pollution load, high, paper pulp quality, easy-to-process waste liquor, etc.

Owner:SHANDONG UNIV

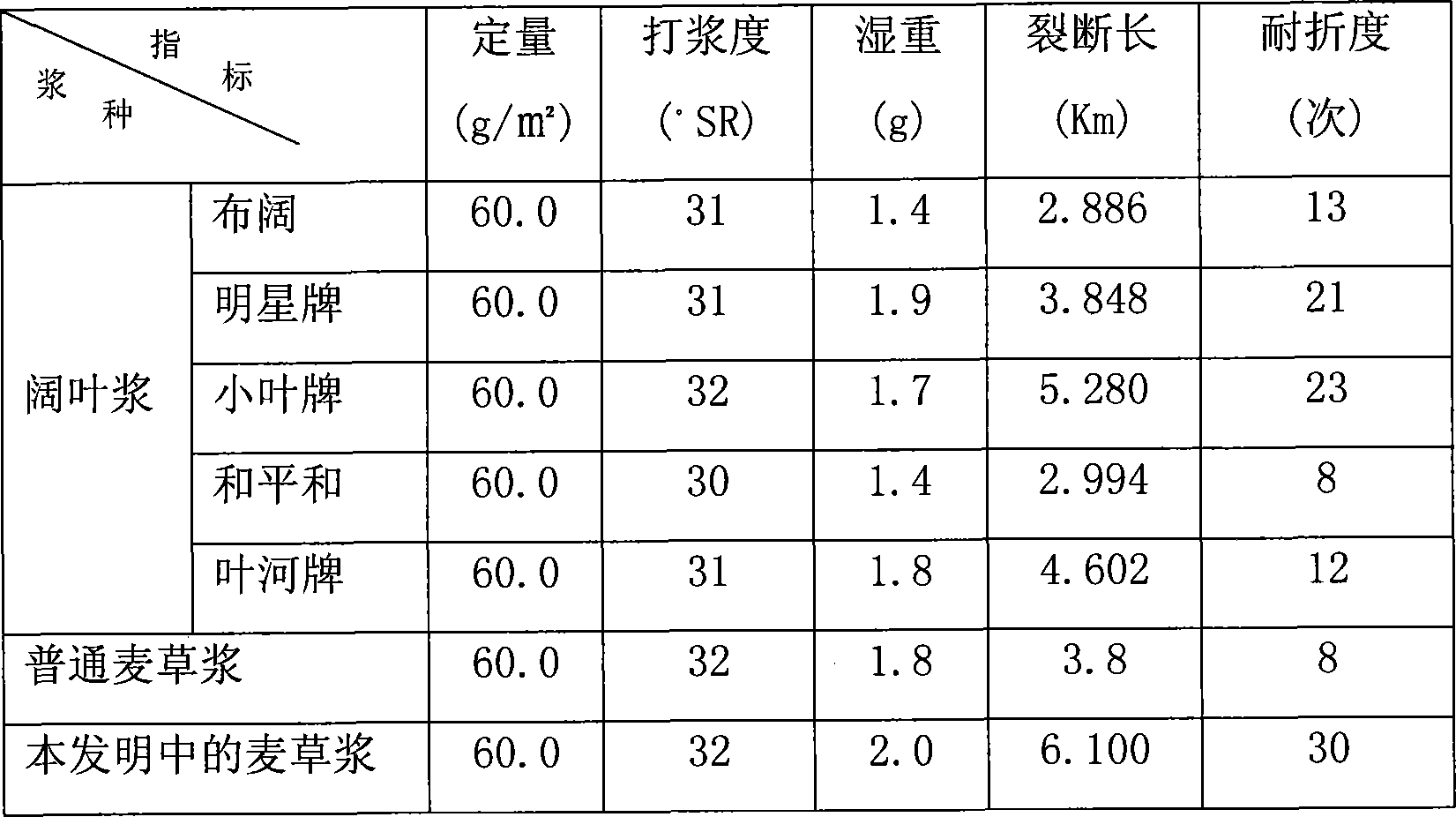

Pulp using rice grass and wheatgrass as raw material and preparation method thereof

ActiveCN101089292AHigh mechanical strengthChemical/chemomechanical pulpNon-woody plant/crop pulpPulp and paper industryHardness

The present invention relates to a paper pulp prepared by using rice straw and wheat straw as raw material. The breaking length of said paper pulp is 4500-8100 km. and its tearing strength is 180-280 mN. Besides, said invention also provides its preparation method and concrete steps.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Prepared high hardness pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089290AReduce dosageReduce manufacturing costDigestersPulping with acid salts/anhydridesKappa numberHardness

The present invention discloses a method for preparing high-hardness pulp by using graminoid plant as raw material and its cooking process. The hardness of said high-hardness pulp is equal to Kappa number 24-50. The described cooking method includes the following steps: preparing graminoid plant raw material, soaking said raw material, feeding said raw material into a cooker, adding cooking liquor into said cooker, introducing steam to make heating operation to attain the requird pressure, then heat-insulating to the required time.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Prepared bleach chemical pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089291AReduce manufacturing costQuality improvementDigestersPulp de-wateringKappa numberFolding endurance

The present invention discloses a bleached chemical pulp prepared by using graminoid plant as raw material and its preparation method. Said invention is characterized by that it utilizes a high-hardness pulp which is obtained by using cooking process and whose permanganate number is 16-28 and equal to Kappa number 26-50 and makes said high-hardness pulp undergo the processes of pulp-washing and bleaching treatment so as to obtain the invented bleached chemical pulp whose breaking length is 4500-8000 m and folding endurance is 20-70 times.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Method for preparing fiber wallboard through wet process

InactiveCN101638874ALarge stockWide variety of sourcesWater-repelling agents additionPaper/cardboardFiberHigh intensity

The invention discloses a method for preparing a fiber wallboard through a wet process. The method comprises the following steps: 1) pulping: mixing non-wood type natural plant fiber pulp with gramineous plant pulp according to a dry weight ratio of 1:0-1.5 and adding water into the raw materials to dilute the pulp; 2) storing the pulp: placing the obtained mixture pulp into a pulp storage pond and adding water for dilution; 3) carrying out suction filter and formation: inputting the pulp obtained from the previous step into a die cavity for cold-pressing, dehydration and formation so as to obtain a wet blank; and 4) carrying out hot-pressing formation and drying; transferring the wet blank into a hot-pressing mould for hot pressing, removing water generated during the hot pressing, and obtaining the fiber wallboard. The fiber wallboard obtained by using the method has the characteristics of environment-friendliness and high strength.

Owner:陈集双

Method for comprehensive utilization of grass type stalk

ActiveCN101451315AHigh in Fulvic AcidSmall molecular weightPulp liquor regenerationDigestersCelluloseBlack liquor

The invention relates to a comprehensive utilization method for grass straws. Firstly, cellulose in the straws is utilized to pulp to serve as a raw material of paper pulp; during the pulping, lignin is dissolved in a stewing liquor to become a main constituent of a solid in a black liquor; the lignin is fully refined through the stewing and has easy degradation, and crops are easy to absorb, so the black liquor becomes a good organic fertilizer; at the same time, a fulvic acid with considerable quantity can be formed under conditions of high temperature and high pressure during the pulping, so the black liquor can be prepared into a high-quality fulvic acid fertilizer; the aim of comprehensive utilization of the grass straws is achieved through the steps, and the good economic benefit can be obtained thanks to the fact that the paper pulp and the fulvic acid fertilizer are expensive.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

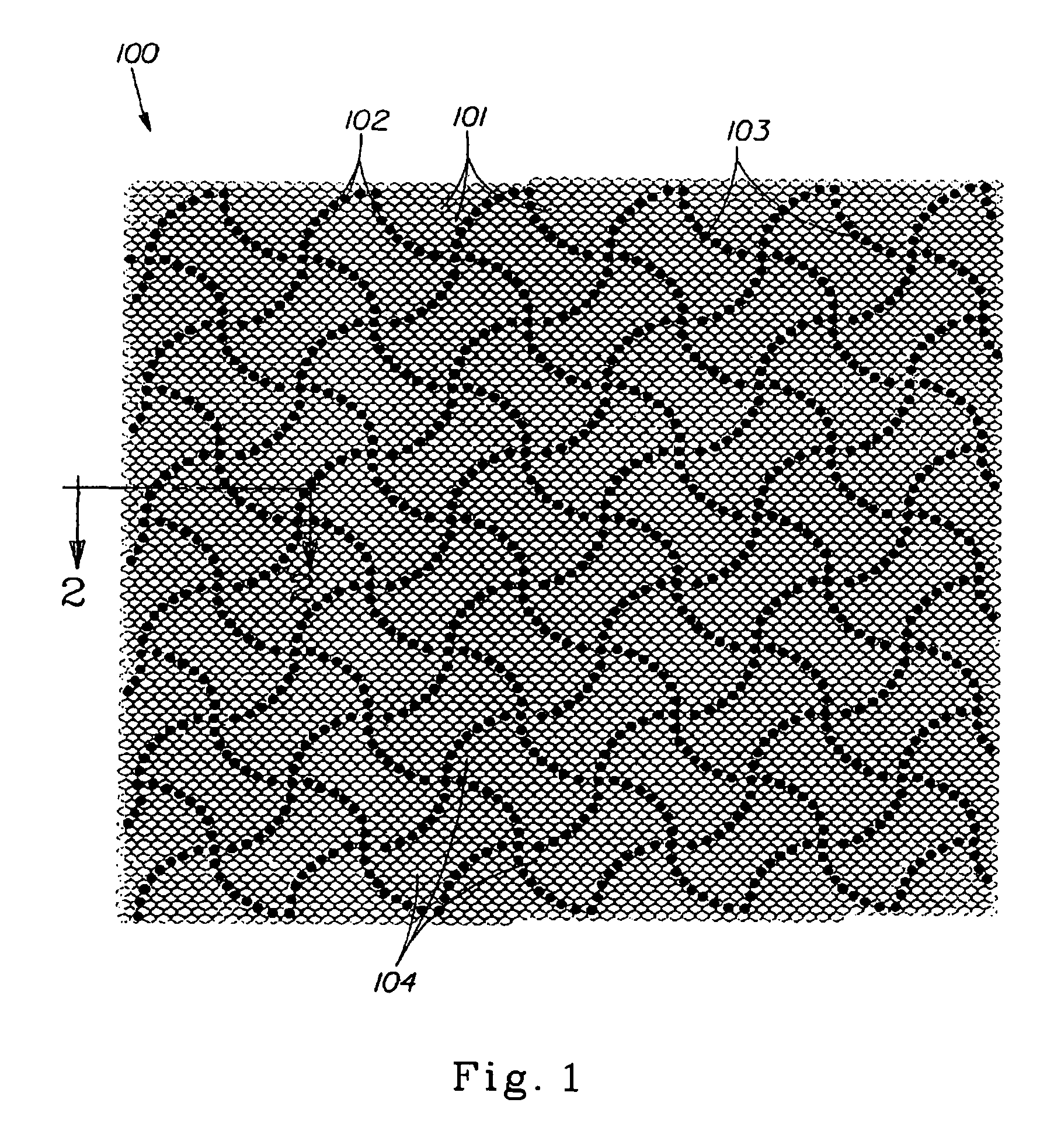

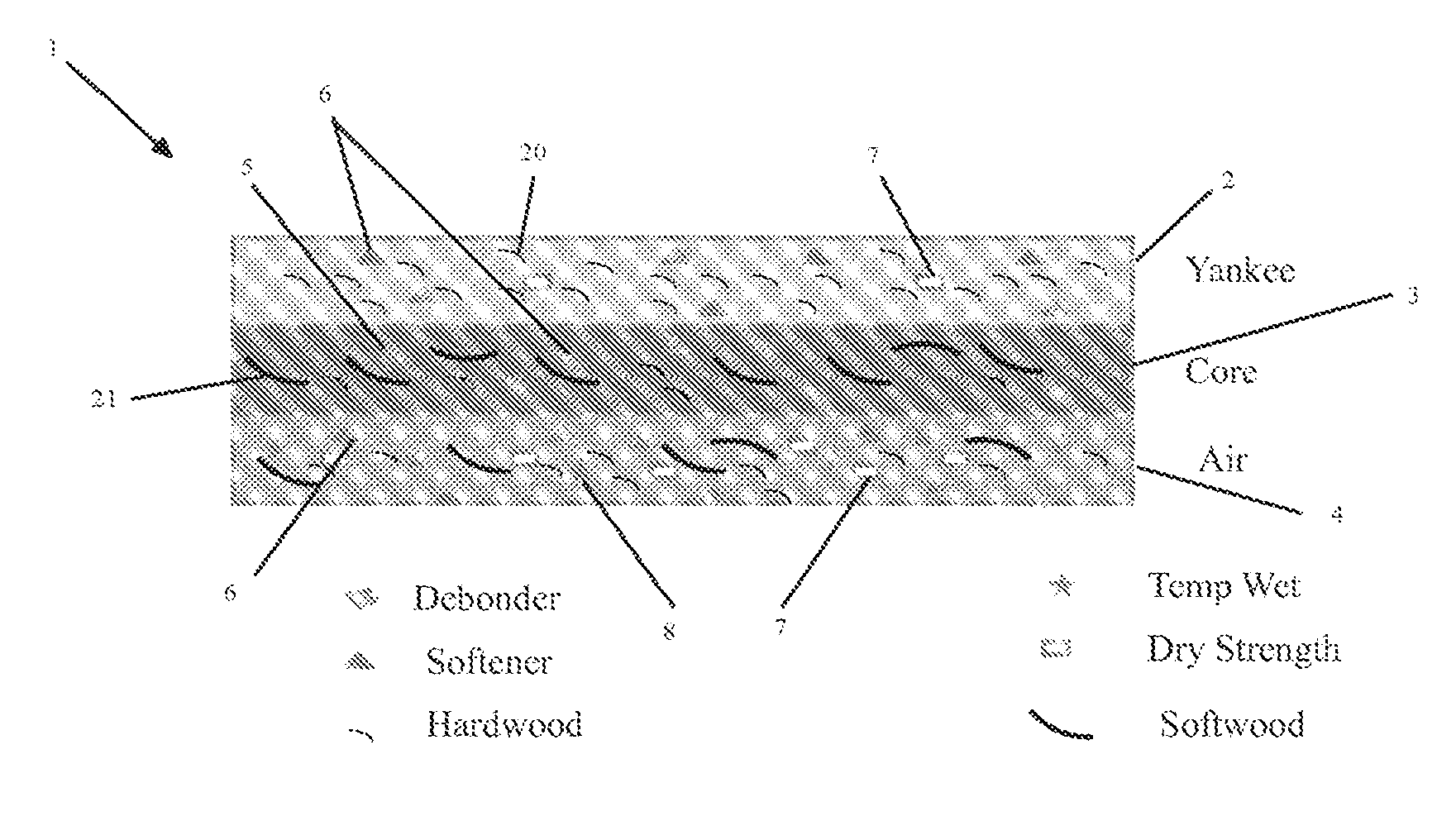

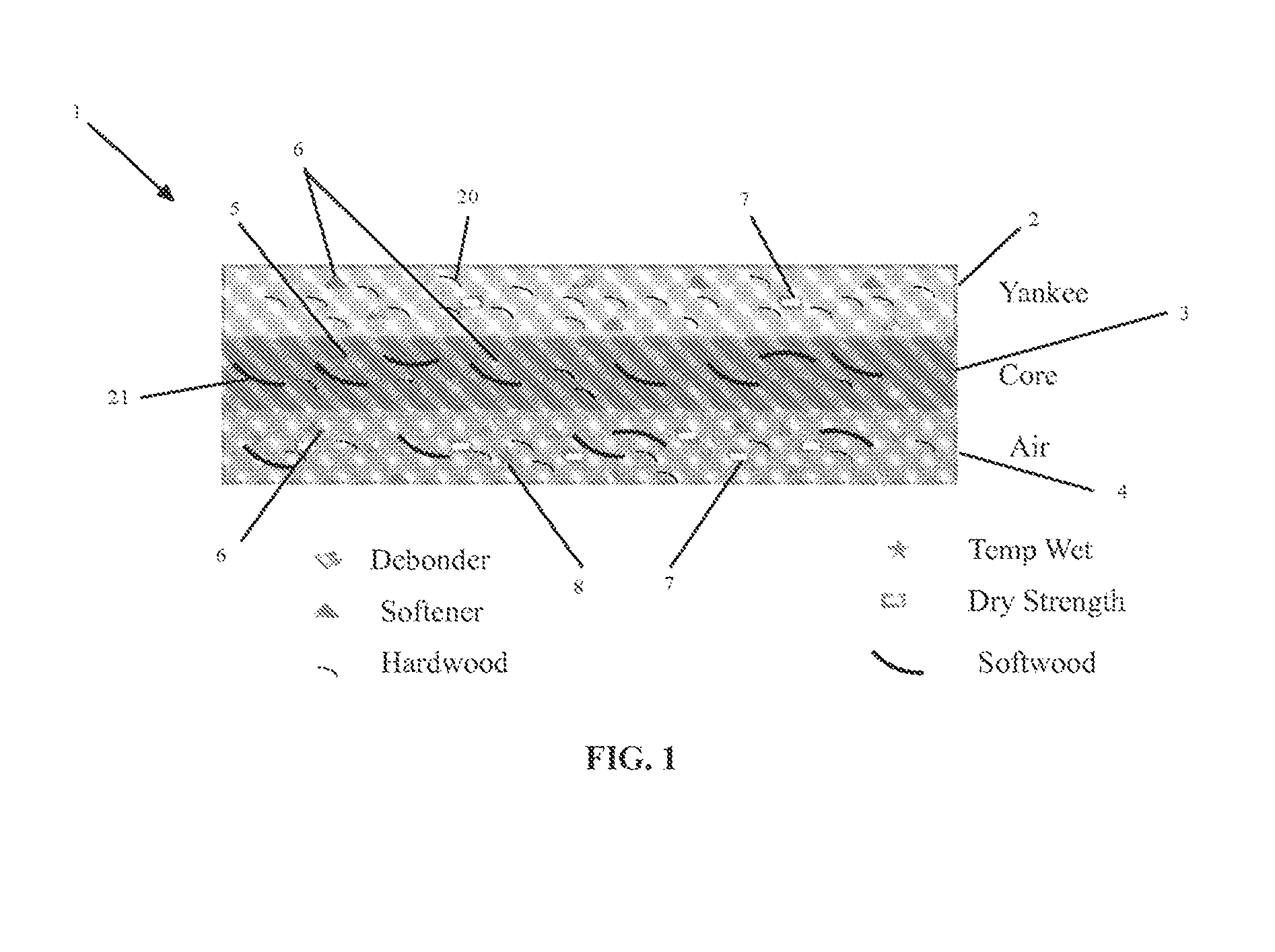

Layered sanitary tissue product having trichomes

A layered fibrous structure having a machine direction, cross machine direction, and Z-direction. The fibrous structure also has a consumer side and first and second layers in the Z-direction where the first layer has a plurality of trichomes. The trichomes make up greater than about 0.1%, by weight, of the fibrous structure.

Owner:THE PROCTER & GAMBLE COMPANY

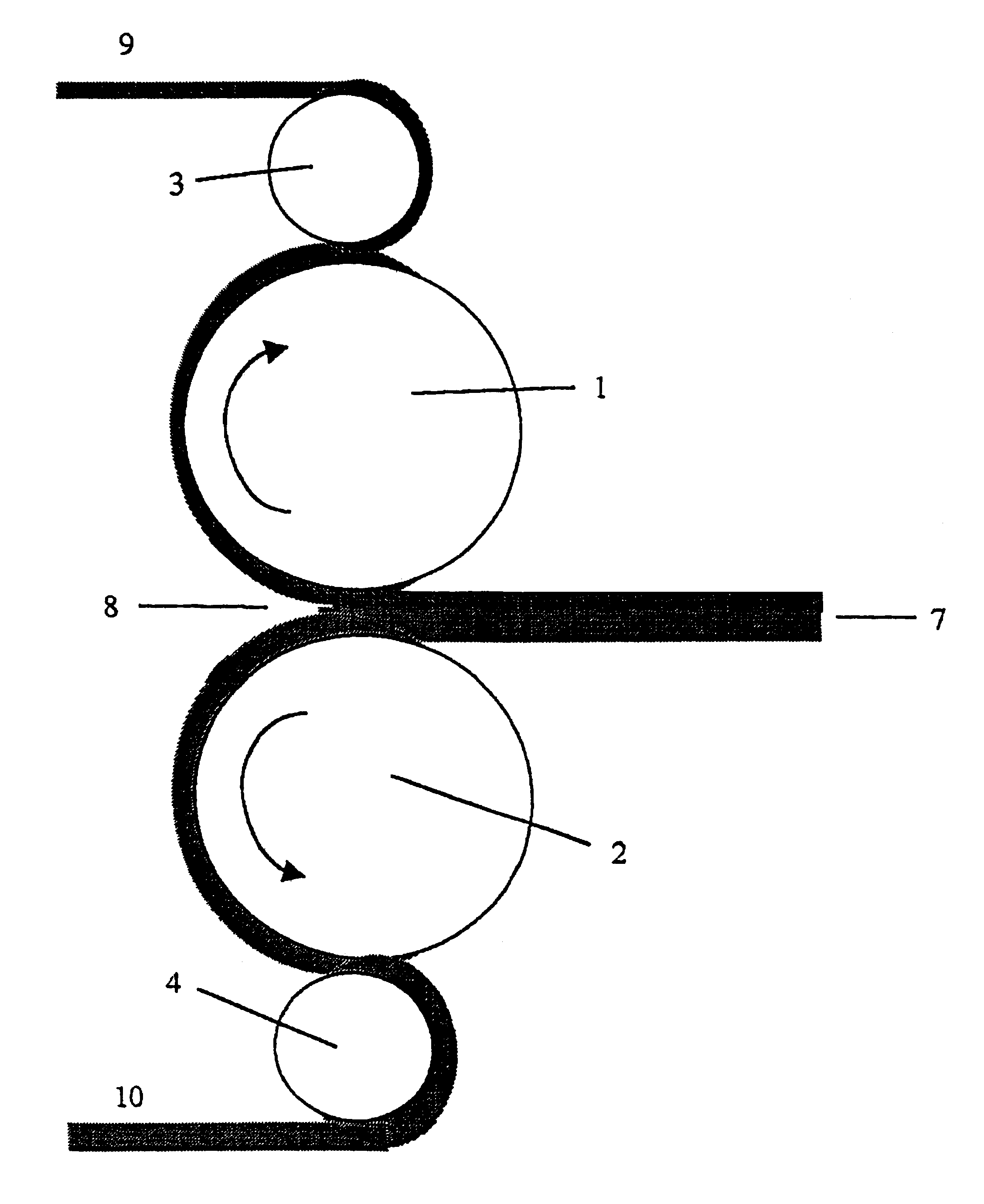

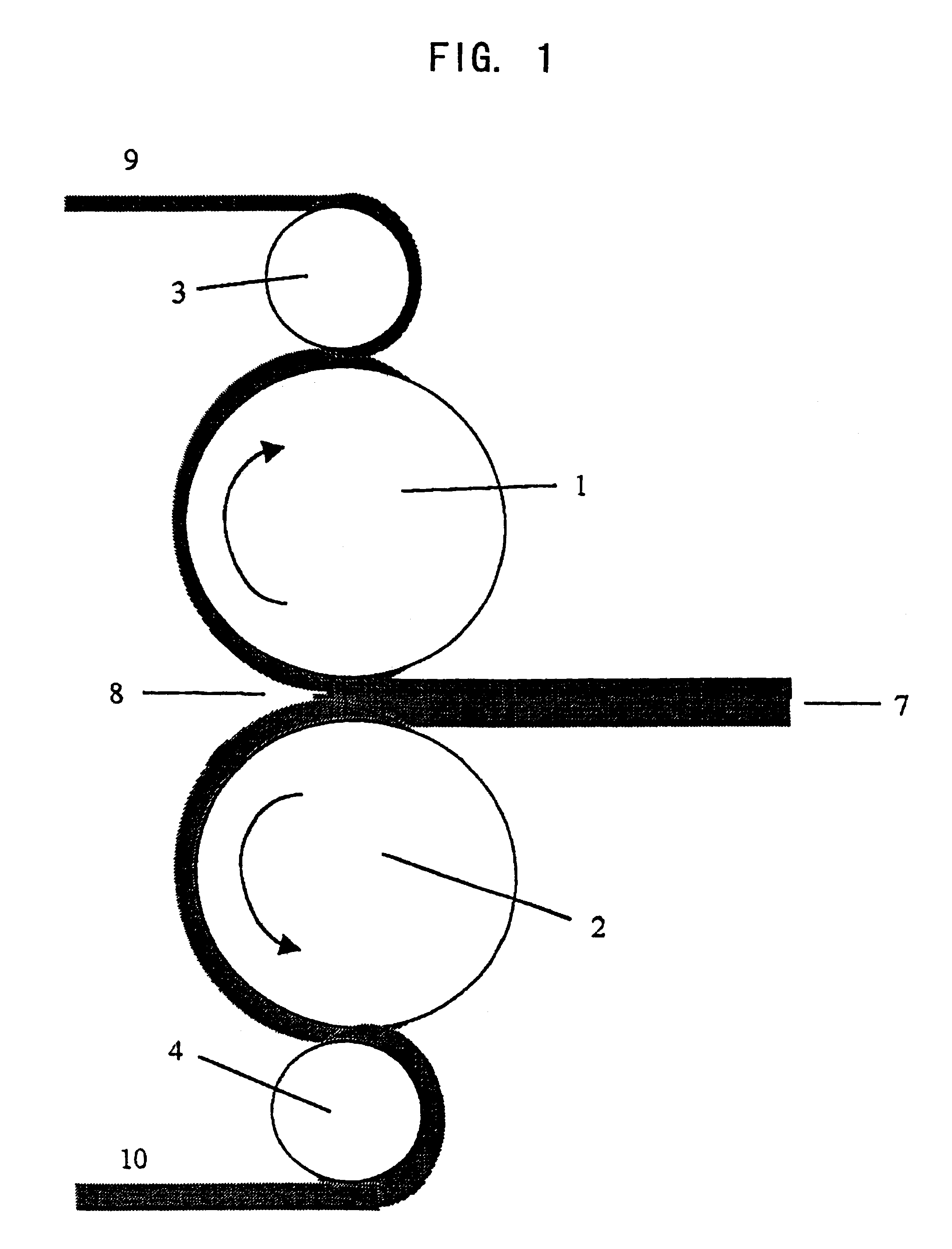

Multi-layer paper peelable into at least two thin sheets

InactiveUS6977111B2Low densityLose weightNon-fibrous pulp additionSpecial paperWood veneerStencil printing

Disclosed is a multi-layer paper suitable as a material for preparing heat-sensitive stencil printing masters. The multi-layer paper is produced by combining a plurality of thin paper layers by paper making. The multi-layer paper has a peel strength of 10 N / m or less and may be delaminated into at least two tissue sheets.

Owner:RICOH KK +1

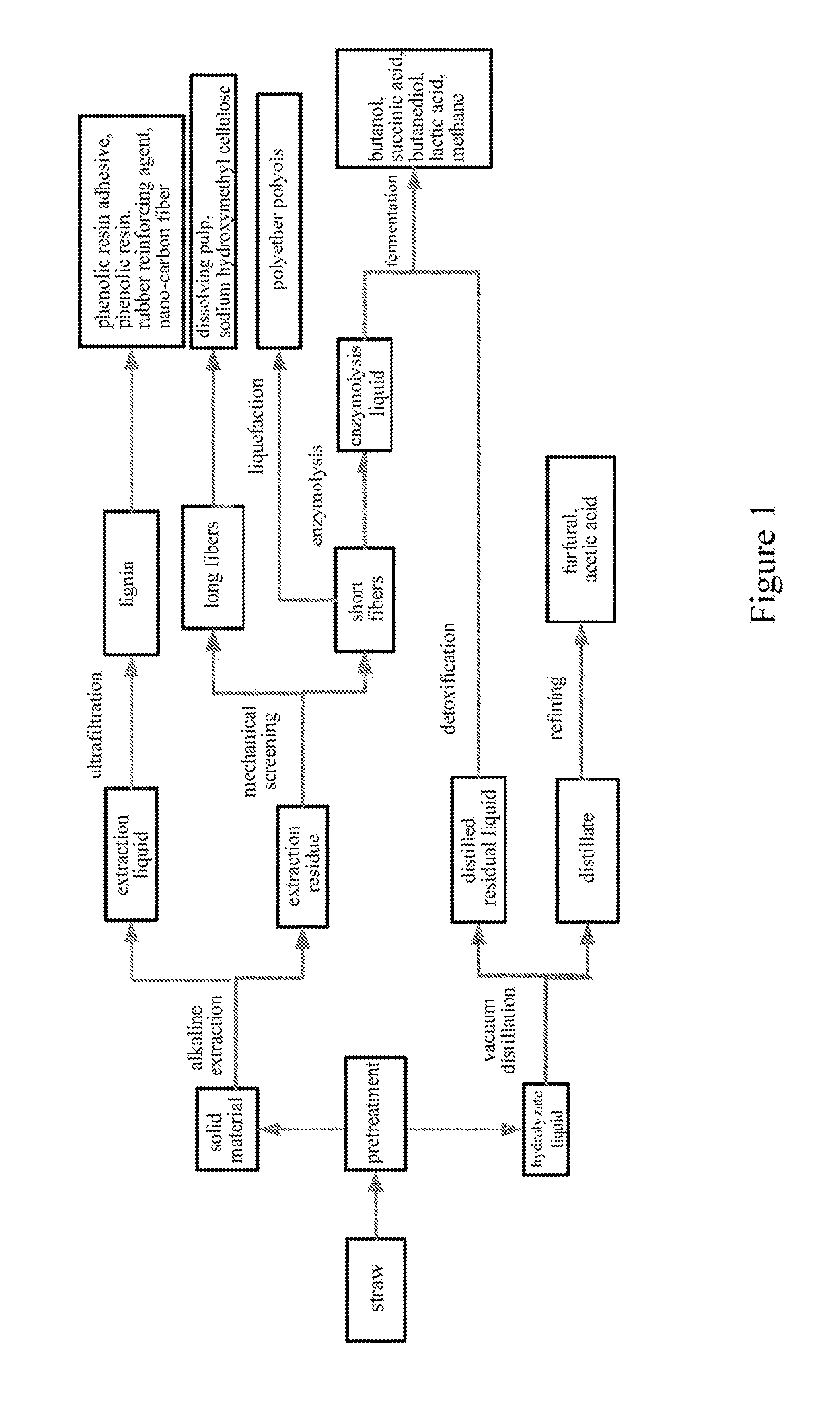

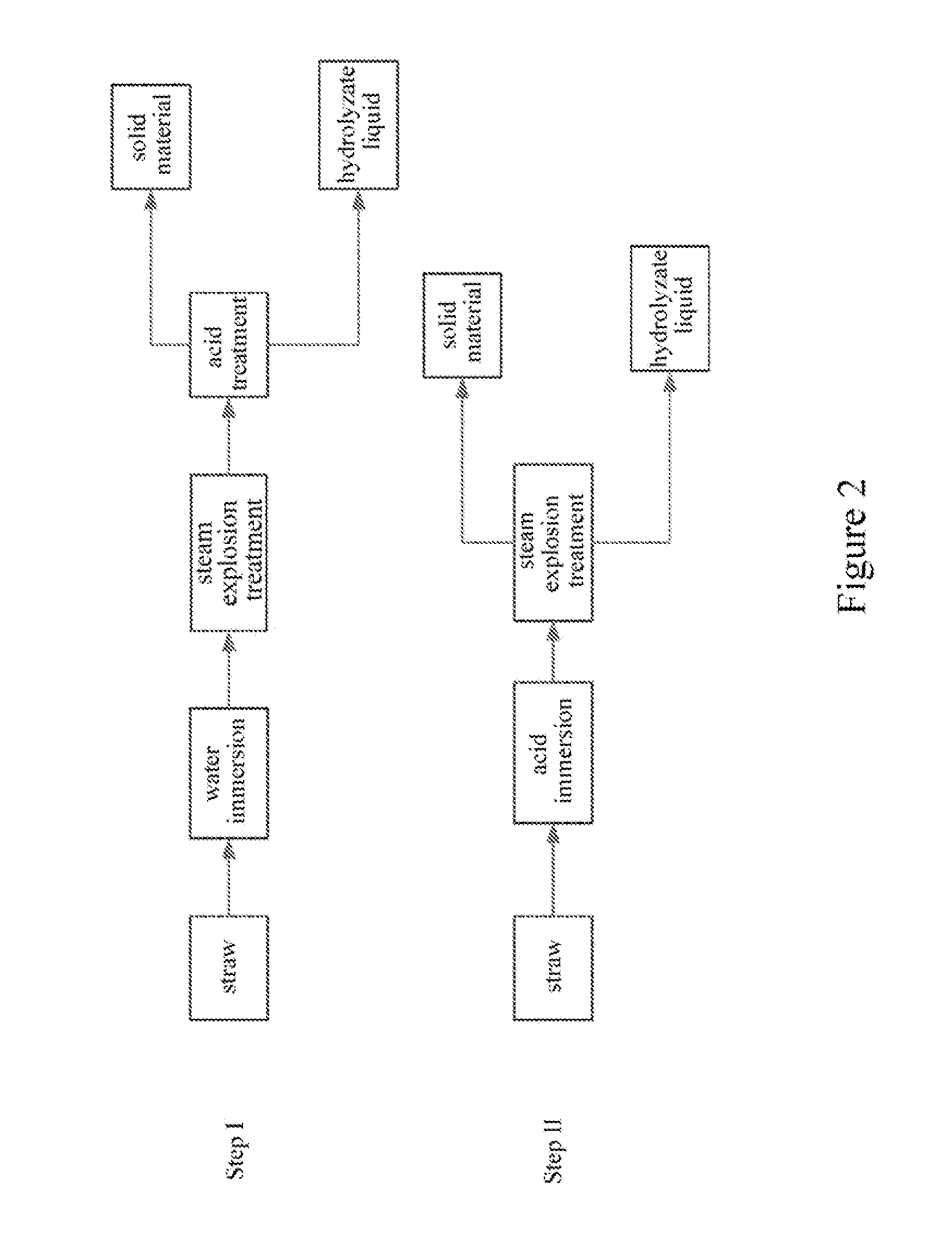

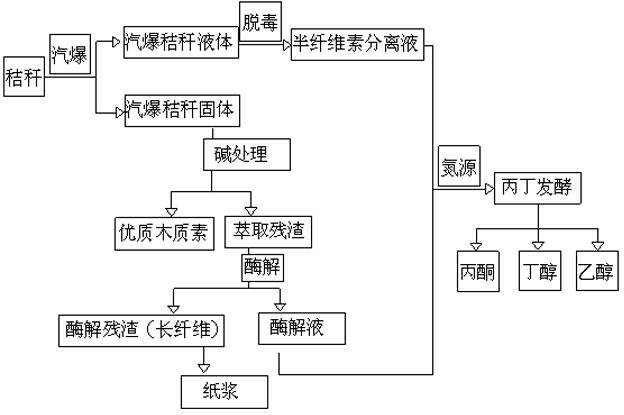

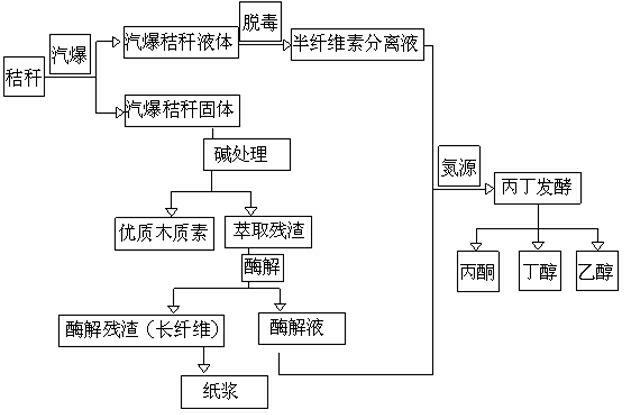

Process for producing bio-based product from straw hemicellulose and fully utilizing the components thereof

ActiveUS20130252293A1Low costHigh value utilizationPretreatment with water/steamBacteriaHigh concentrationSuccinic acid

Provided is a process for producing biomass-based product from straw hemicellulose and utilizing the components thereof thoroughly. Steam-explosion and acid-hydrolysis are combined in the pre-treatment of straw in the process, thus a higher concentration of a sugar liquid can be obtained, and furfural and acetic acid can be recovered. The hemicellulose obtained by the pre-treatment can be used directly as ferment materials for producing butanol, succinic acid, butylene glycol, lactic acid, hydrogen and firedamp, which reduces the cost of these biomass-based products. The cellulose and lignin obtained by extracting the straw with an alkaline solution can produce products, such as sodium hydroxymethyl cellulose etc. In the process, all components in the straw can be utilized thoroughly and waste and pollutant will not be produced.

Owner:HAINAN SUPER HEALTHY GRAIN CO

Method of producing a pulp from cellulosic material using formic acid and hydrogen peroxide

InactiveUS6183597B1Facilitate lignin breakdownIncrease brightnessPulp liquor regenerationPulping with organic compoundsCardboardCellulose

A process for producing a pulp from cellulose-containing material, wherein the material is reacted with formic acid as the solvent, and cooked at approximately the boiling temperature of the solvent, whereby return condensation is used. Annual plants, deciduous or coniferous wood can be used as the cellulose-containing material. In one variant of the process, the cellulose-containing material is only slightly warmed, whereby backflow cooling is used, and then a precisely predetermined quantity of hydrogen peroxide is slowly added to the liquid at a constant rate. This process variant can be repeated at a lower cooking temperature. The pulp thus obtained is preferably utilized in the production of cellulose, and in particular in the production of paper or cardboard. It is proposed that the lignin, which is isolated from the cellulose-containing material, have further applications, whereby such lignin is, after the pulp has been separated from the solvent, itself precipitated out in water. The lignin thus obtained can be used as a new building material, as a filler material or as an output substance to be used in the manufacture of aromatic products.

Owner:NATURAL PULPING

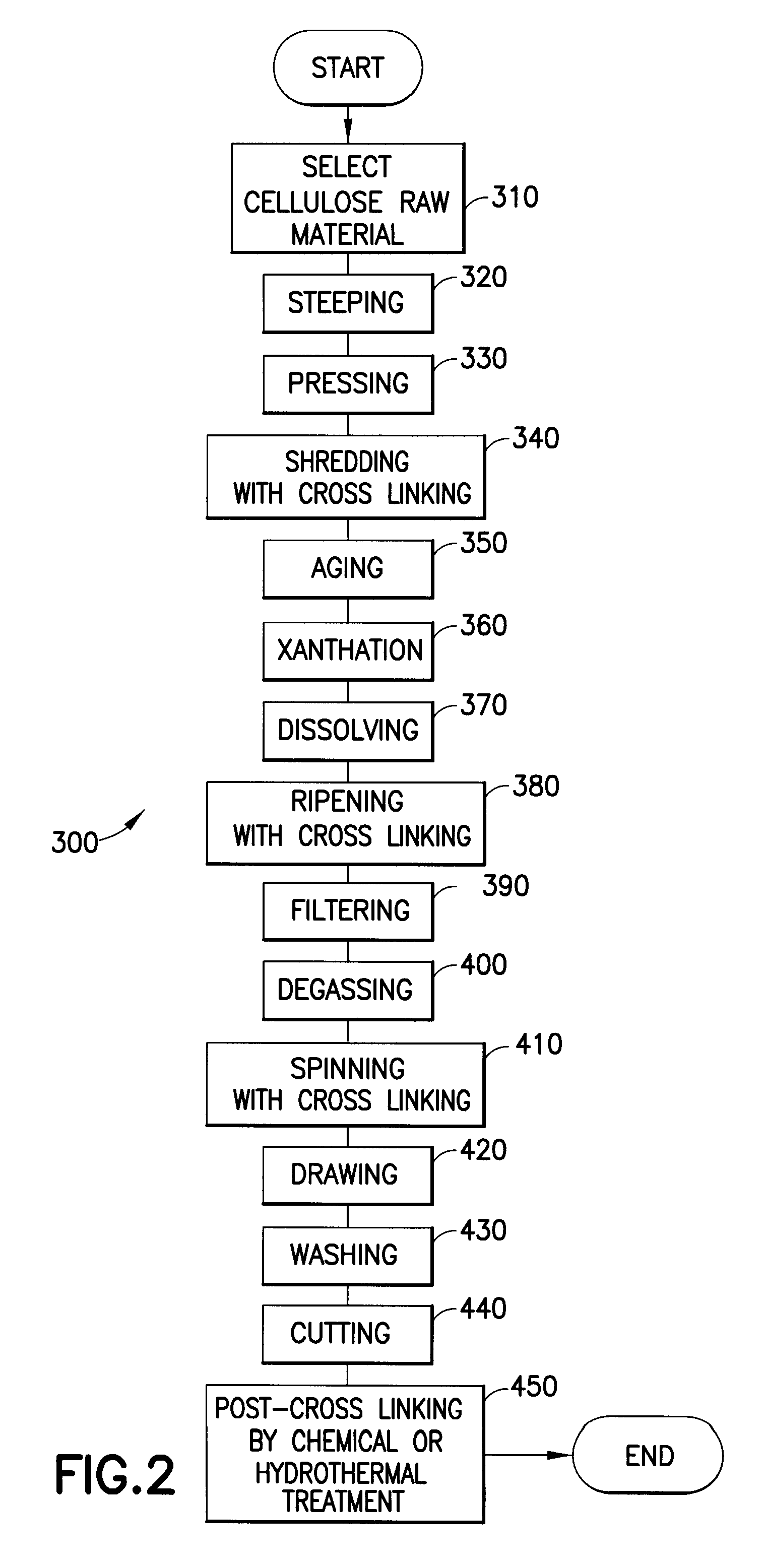

Tampon including crosslinked cellulose fibers and improved synthesis processes for producing same

InactiveUS20090227975A1Promote absorptionImprove wettabilityPulp properties modificationArtificial filaments from viscoseCellulose fiberGlyoxal

A tampon pledget includes crosslinked cellulose fibers having microstructures treated to provide improved absorbency and higher wet strength. The fibers are treated with a crosslinking agent to provide at least one of a molecular weight between crosslinks of from about 10 to 200 and a degree of crystallinity of from about 25% to 75%. The crosslinking agent includes citric acid in 1% by weight. The crosslinking agent may further include sodium hypophosphite in 1% by weight. In another embodiment, the crosslinking agent may be a difunctional agent including a glyoxal or a glyoxal-derived resin. In still another embodiment, the crosslinking agent is a multifunctional agent including a cyclic urea, glyoxal, polyol condensate. The crosslinking agent is added in an amount from about 0.001% to 20% by weight based on a total weight of cellulose fibers to be treated and, preferably, in an amount of about 5% by weight.

Owner:EVEREADY BATTERY CO INC

A method for comprehensive utilization of straw raw materials

ActiveCN102277391AImprove use valueWide variety of sourcesMicroorganism based processesFermentationFiberCellulase

The invention relates to a comprehensive utilization method of straw raw materials. The method is characterized by comprising the following steps: a, carrying out solid-liquid separation on steam-exploded straws, using an alkaline cooking method to process solid bodies of the steam-exploded straws, and extracting good xylogens from an alkaline extract liquor by an acid-out method; b, carrying out enzymolysis on the extracted residues in the step a to obtain zymolytic residues and a zymolytic liquid, wherein the zymolytic residues are used for preparing pulps; and c, after the steam-exploded straws in the step a are detoxificated, mixing a zymolytic liquid with the zymolytic liquid in the step b and adding nitrogen sources to butylicum fermentation. The method has the advantages that sources of raw materials are wide; the separation of celluloses (continuous fibers and staple fibers), hemicelluloses, xylogens and the like in the straws is realized, thus sufficiently realizing the value of each component; and the celluloses are divided into the continuous fibers which are difficult to realize enzymolysis and the staple fibers which are easy to realize enzymolysis, thus reducing the usage amount and cost of the cellulase, improving the comprehensive utilization value of the straws and solving the source problem of raw materials in industrialization production of the butylicum fermentation.

Owner:NANTONG HEBAO BIOTECH

Compact laminate having powder coated surface

InactiveUS20090197089A1Good dimensional stabilityStrong internal bondLiquid surface applicatorsPaper coatingCoated surfaceWood fibre

A compact laminated assembly based upon a saturation grade paper made using a grass fiber or grass / wood fiber blend, instead of the conventional wood fibers from trees. A plurality of the grass paper sheets are substantially impregnated using a thermosetting resin and stacked in a superimposed relationship. The assembled stack of resin impregnated paper sheets are heat and pressure consolidated into a substantially homogenous monolithic mass with the thermosetting resin being substantially completely cured. A film of a substantially completely cured solid powder coating composition is laminated to at least a portion of an outer surface of the compact laminated assembly.

Owner:TRIMBLE NAVIGATION LTD

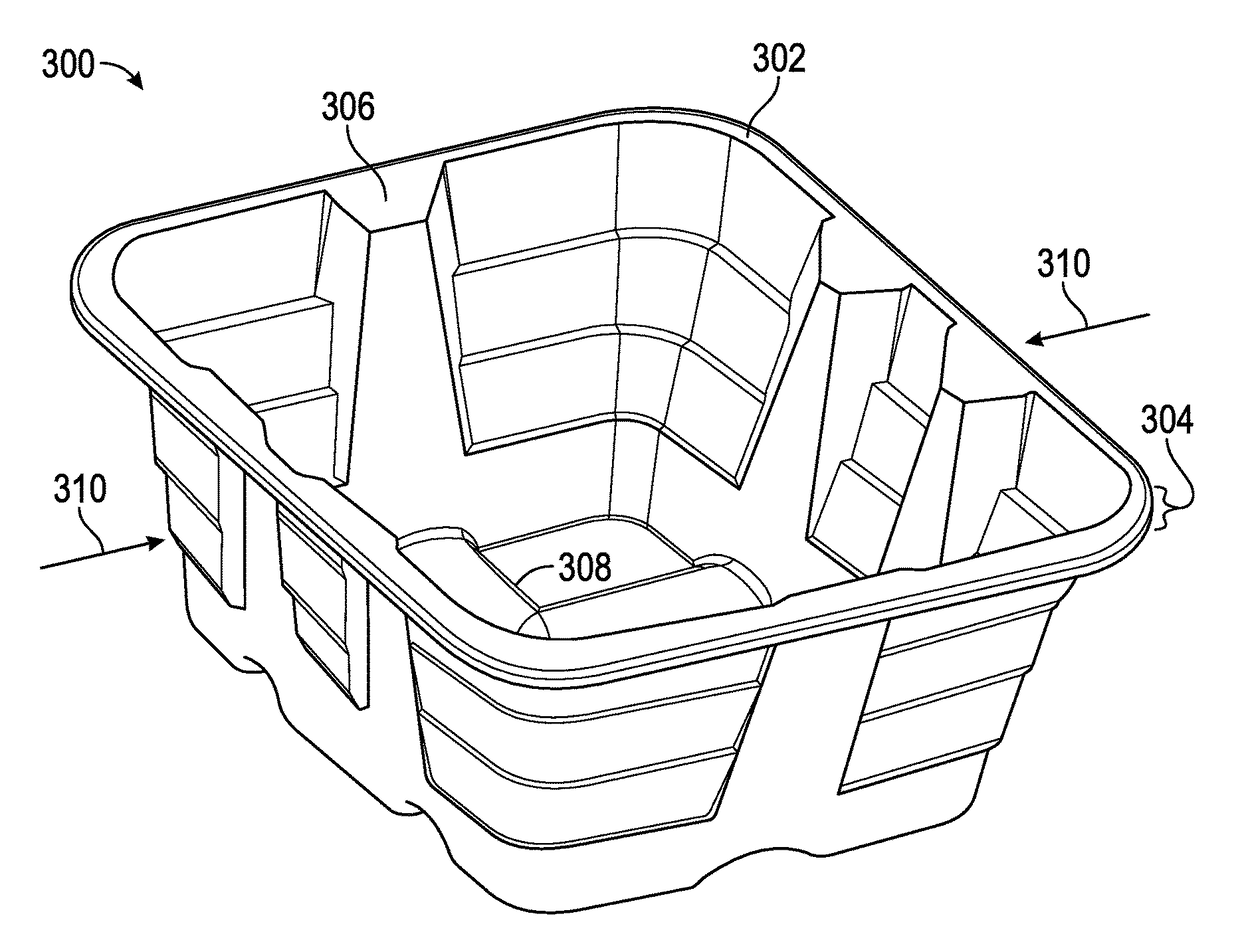

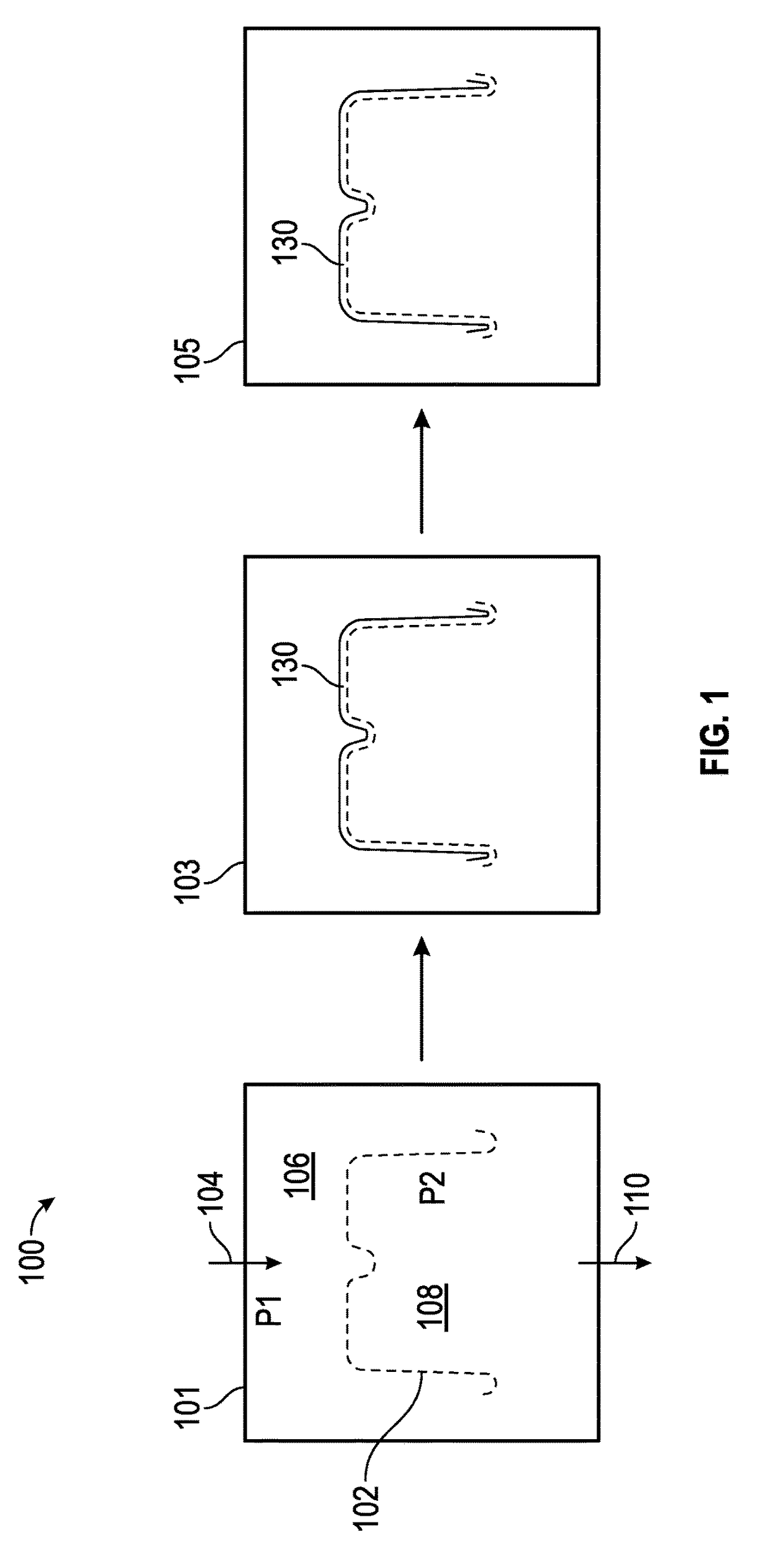

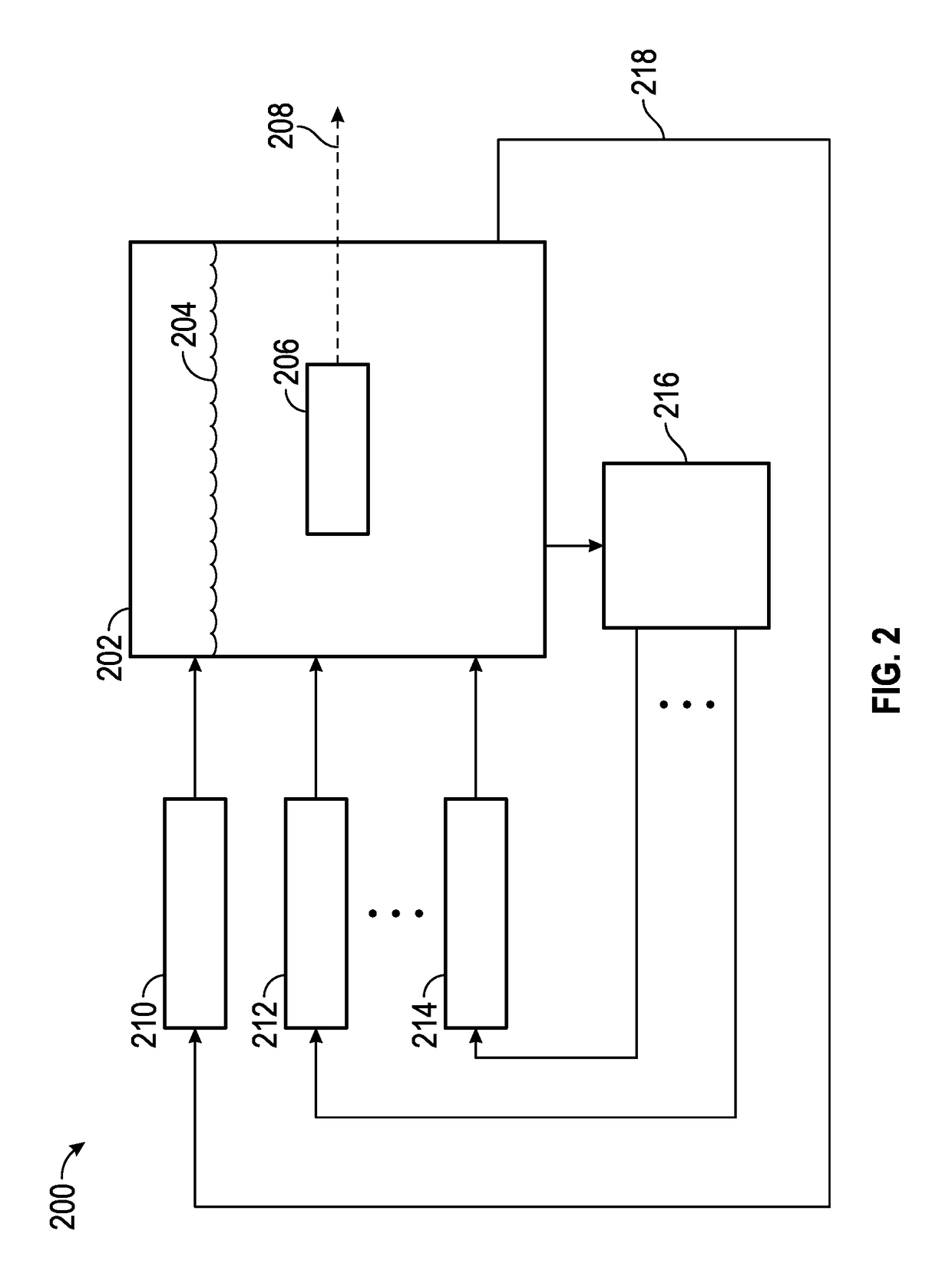

Method for manufacturing fiber-based produced containers

ActiveUS9856608B1Increase in sizeImprove structural rigidityWrappersWater-repelling agents additionFiberSlurry

Owner:FOOTPRINT INT LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com