Patents

Literature

3696 results about "Cotton fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cotton Fibre is a crafting material that is obtained through farming. Harvesting a cotton plant will drop cotton fibre. It can be refined into cotton wool at a Spinning Wheel. Wild cotton plants can be found growing in garden biomes and can drop seeds when harvested.

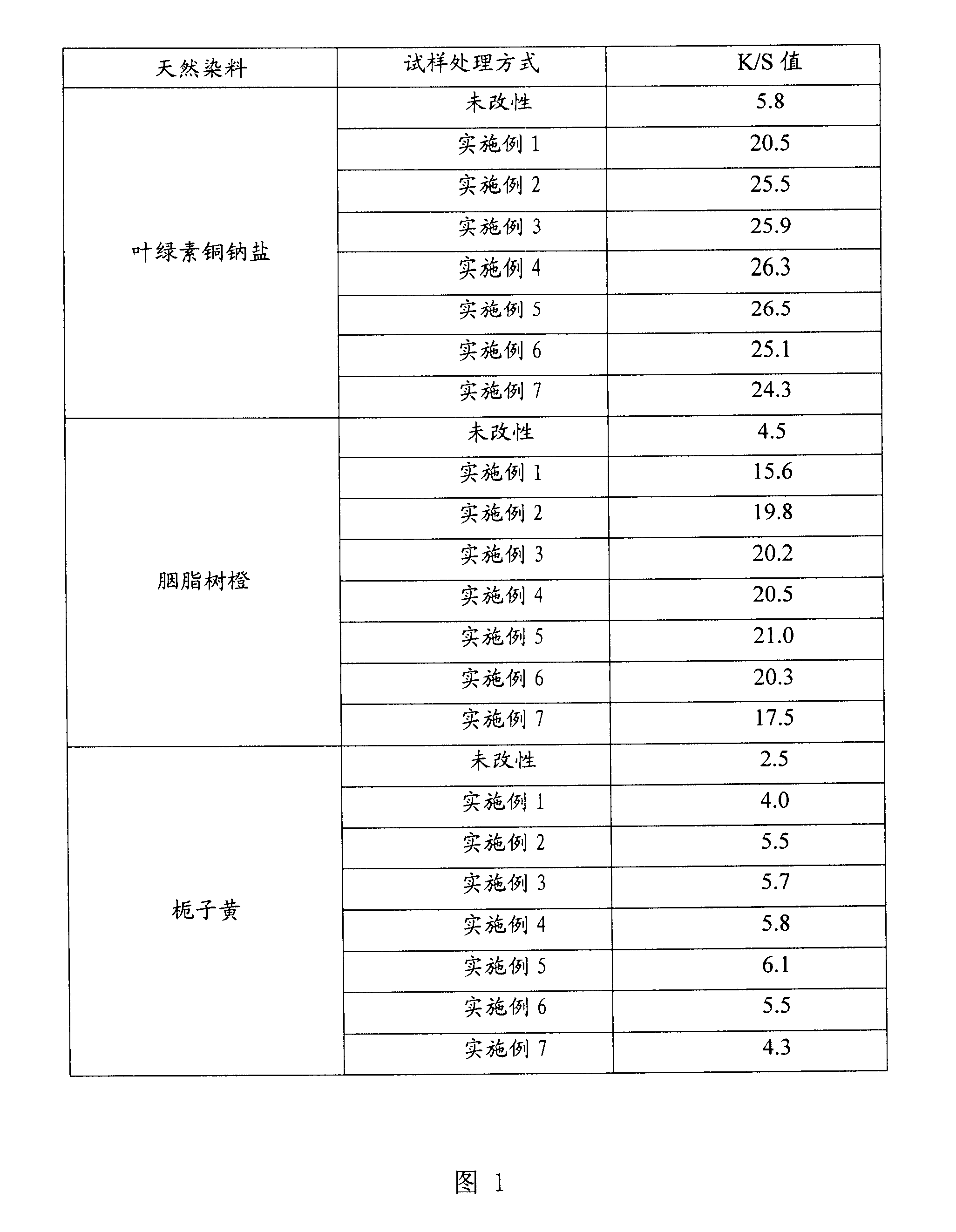

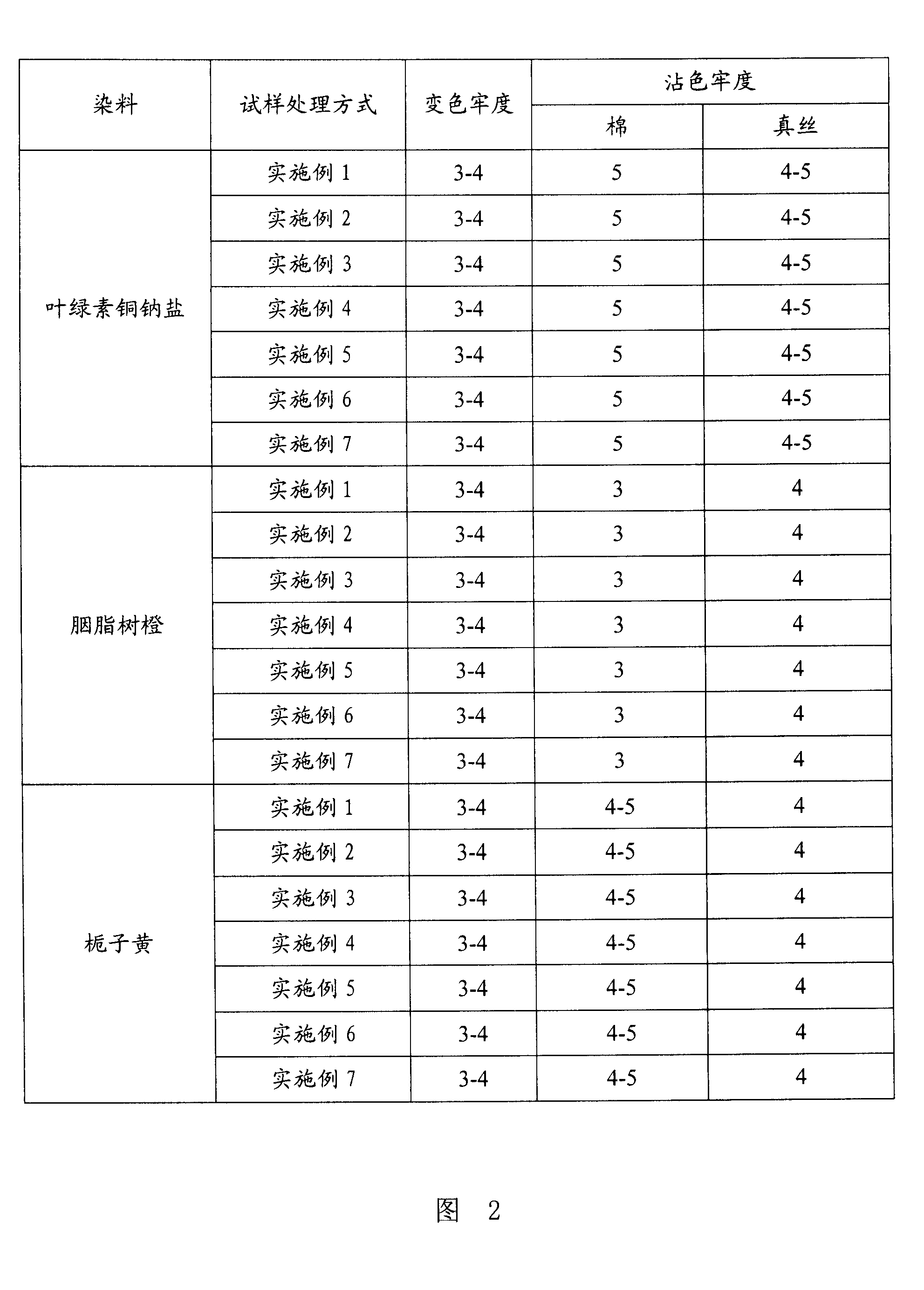

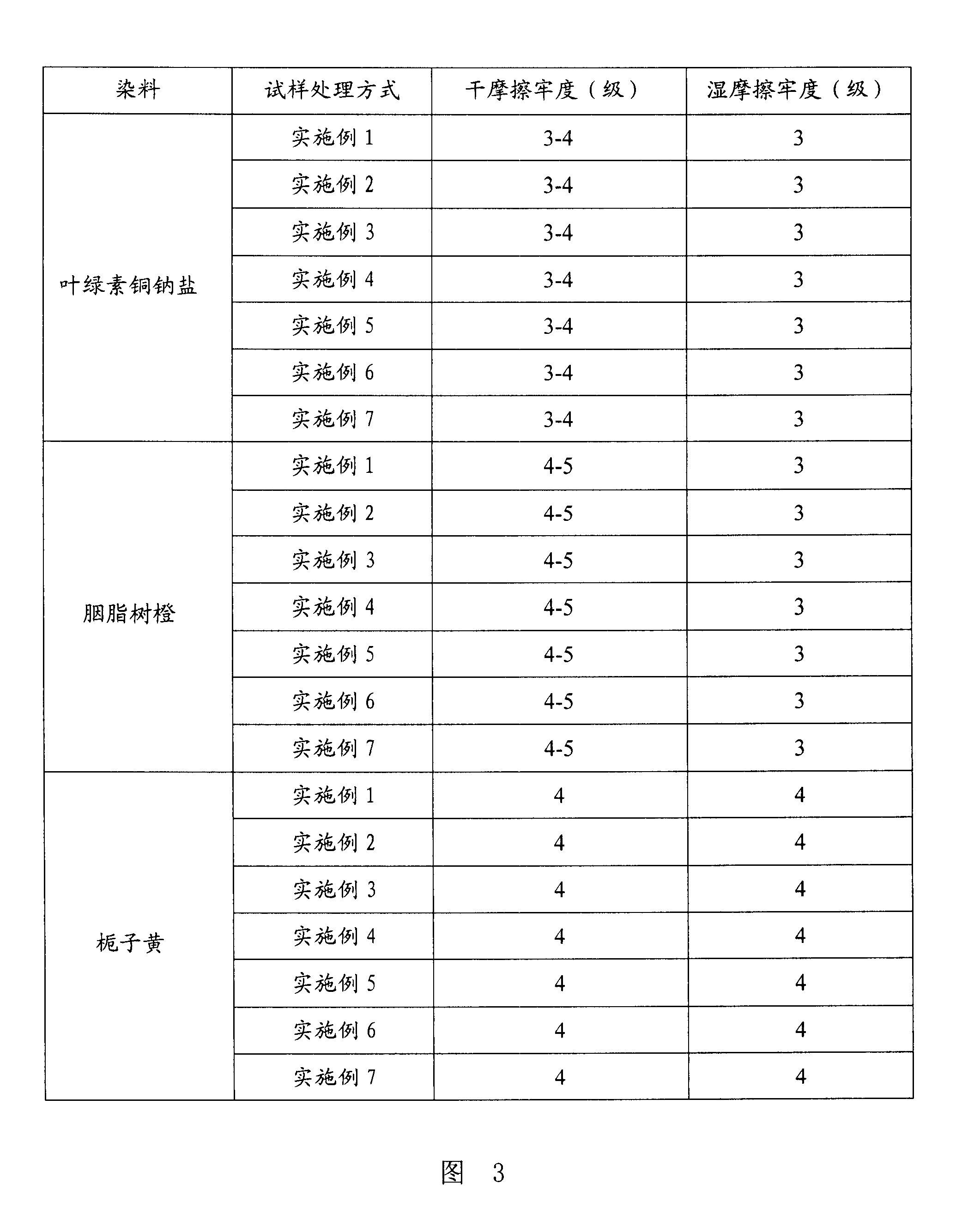

Natural dye dying method based on cotton fiber modification

ActiveCN101187175AImprove adsorption capacityImprove dye uptakeDyeing processCotton fibreNatural dye

The invention relates to a dyeing method of natural dye material of cotton fabric, which belongs to the field of fabric dyeing and finishing technique and comprises: processing the modifying liquid by use of the modifying agent containing anode ions group, firstly modifying the cotton fabric and dyeing the fabric with the natural dyeing material, after cleaning, fulfilling the dyeing with the natural dye material of cotton fabric, wherein due to the modifying process on the cotton fabric in advance, the anode ion base is introduced into the cotton fabric to strengthen the combination ability from the cotton fabric to the natural dye material of cathode ion, which effectively improves the cotton fabric dyeing rate, color depth and dyeing evenness and distinctly improves the anti-washing and anti-abrasion firmness of the dyed cotton fabric. The process has simple operation, even dyeing and wide application prospect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Super hydrophobic cotton fabric and preparation method thereof

The invention belongs to the fabric water-repellent finishing and processing field, in particular relates a super hydrophobic cotton fabric and a preparation method thereof. The preparation method of the super hydrophobic cotton fabric is characterized in that the epoxy-functionalized modification is performed to the cotton fiber of fabric, then aminated nano-SiO2 and epoxy-functionalized nano-SiO2 are used to impregnate the cotton fabric in turn so as to increase the surface roughness of the fabric, finally a low-surface-energy material is adopted to perform hydrophobization treatment to the fabric; the contact angle between the prepared cotton fabric and water drops is more than 150 degrees; the method utilizes the covalent reaction of epoxy groups of cotton fabric, amino groups of nano-SiO2 and epoxy groups of nano-SiO2 to ensure the built rough surface to have good fastness; and the built surface has a large number of Si-OHs and epoxy groups so as to facilitate the chemical combination of the low-surface-energy material and the surface, thus the superhydrophobic property of the prepared fabric has excellent stability.

Owner:SHAANXI UNIV OF SCI & TECH

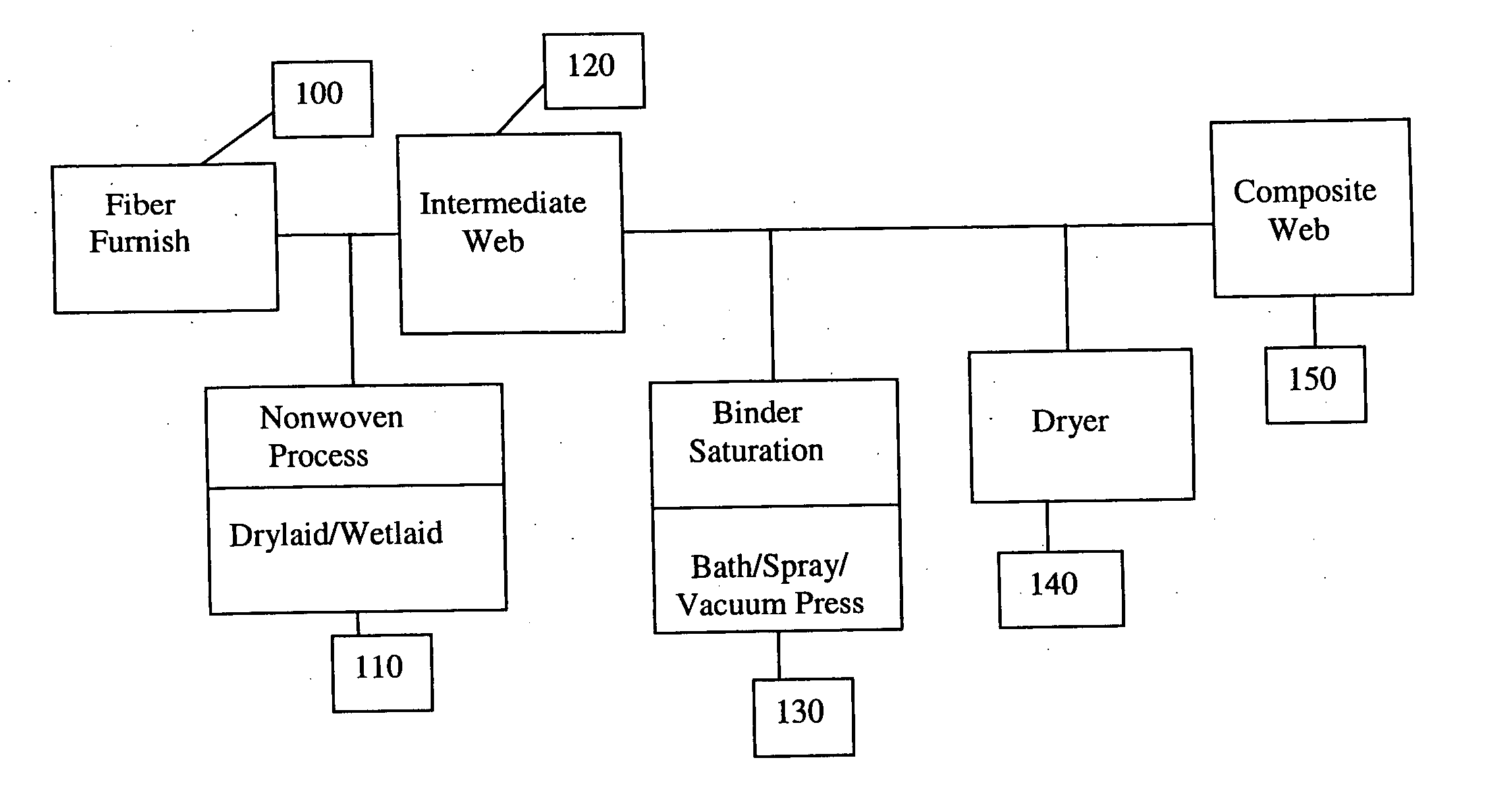

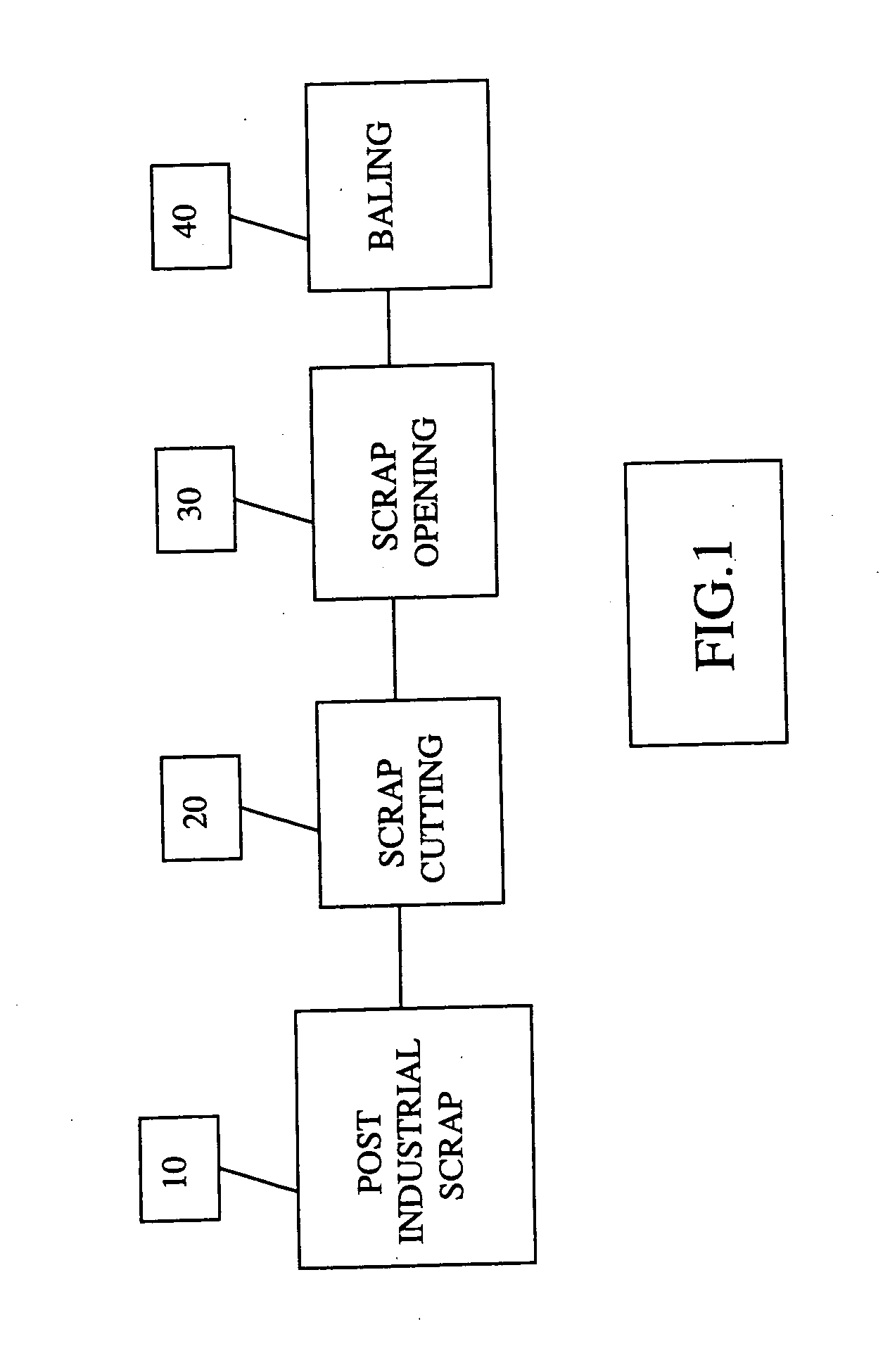

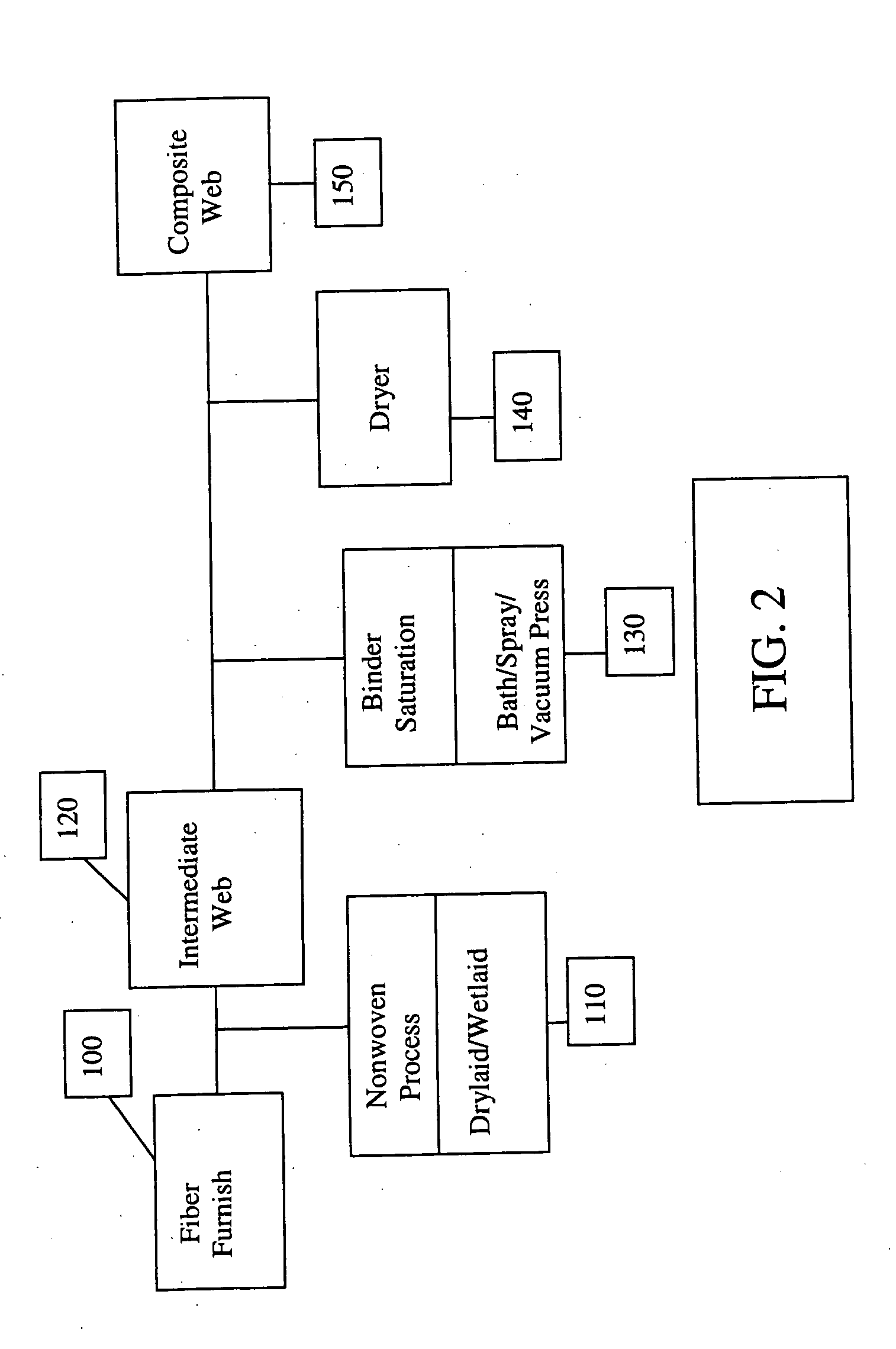

Composite web and process for manufacture from post-industrial scrap

A composite web and process for manufacture from post-industrial scrap wherein the fibers are pre-opened and cut to an average fiber length of about 4 mm. A scrap fiber component and a cellulosic component of such fibers are blended into a fiber furnish. The scrap fiber component includes at least 15% synthetic fibers and may include a blend of natural fibers, high melting point synthetic fibers, and low melting point synthetic fibers. The cellulosic component may include post-industrial cotton fibers which may be refined before blending with the scrap fiber component. The fiber furnish is processed into an intermediate web such as by a drylaid or a wetlaid nonwoven process. The intermediate web is saturated with a latex binding agent and pressed and / or dried to form a composite web capable of further processing into molded or formed consumer or industrial products. The process is capable of producing a high basis weight composite web.

Owner:SSI TECH INC

Cotton fiber particulate and method of manufacture

InactiveUS7594619B2Improve abilitiesExcellent characteristicsPulp properties modificationSynthetic resin layered productsParticulatesCotton fibre

A cotton fiber particulate and method of manufacture including, generally, obtaining cotton fibers; mixing the cotton fibers with a solvent such as water to obtain a fiber furnish; milling the fiber furnish; and drying the fiber furnish to recover the cotton fiber particulate. Other steps include modifying the pH of the fiber furnish with a material such as calcium carbonate in an effort to make the fibers brittle, and filtering the fiber furnish to recover the cotton particulate. The fibers are milled to between 5-25 microns in length with a mean length of less than 50 microns with a mean length of 20 microns preferred.

Owner:SSI TECH INC

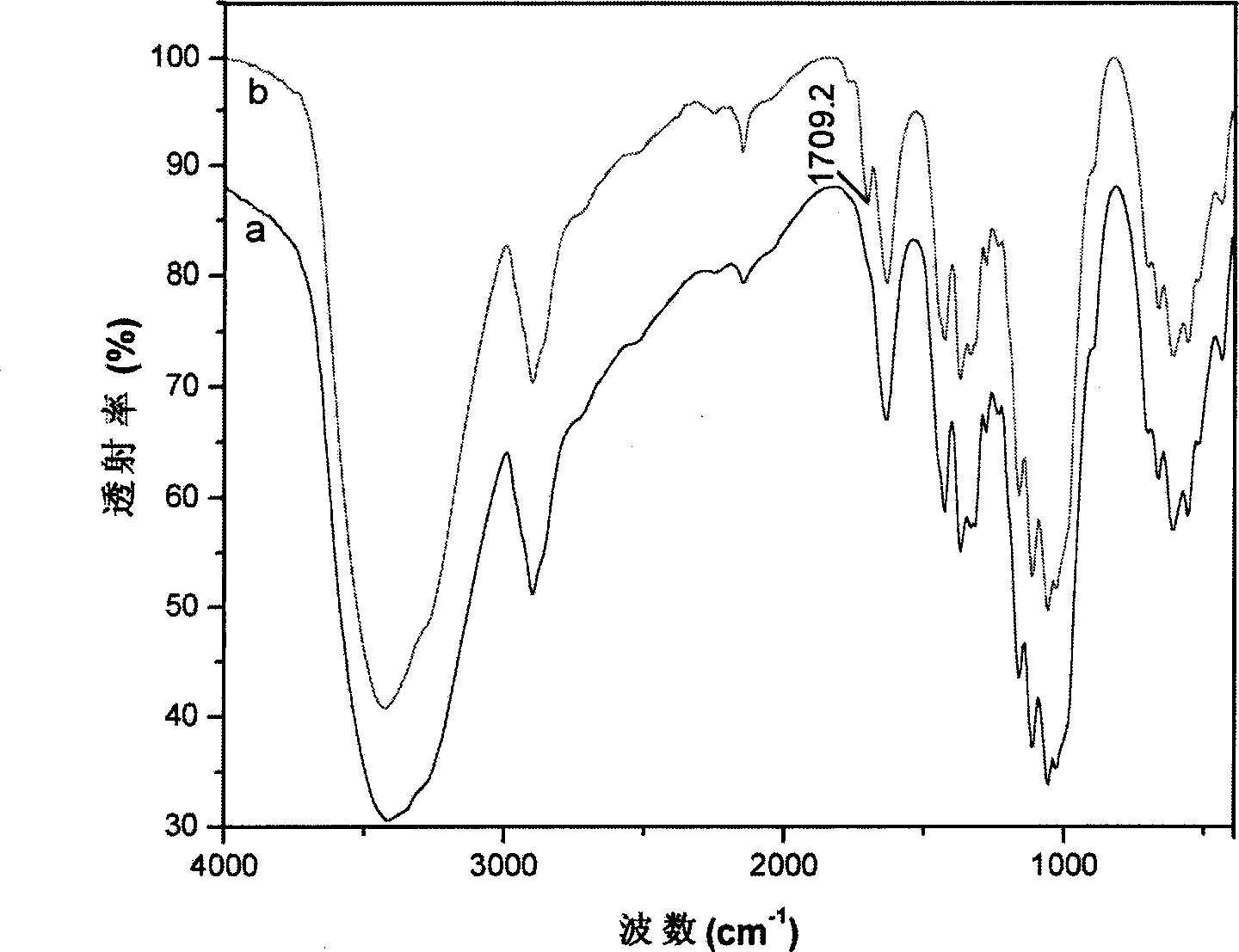

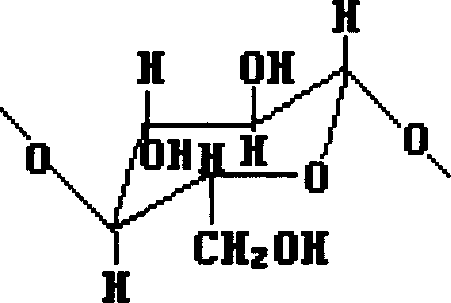

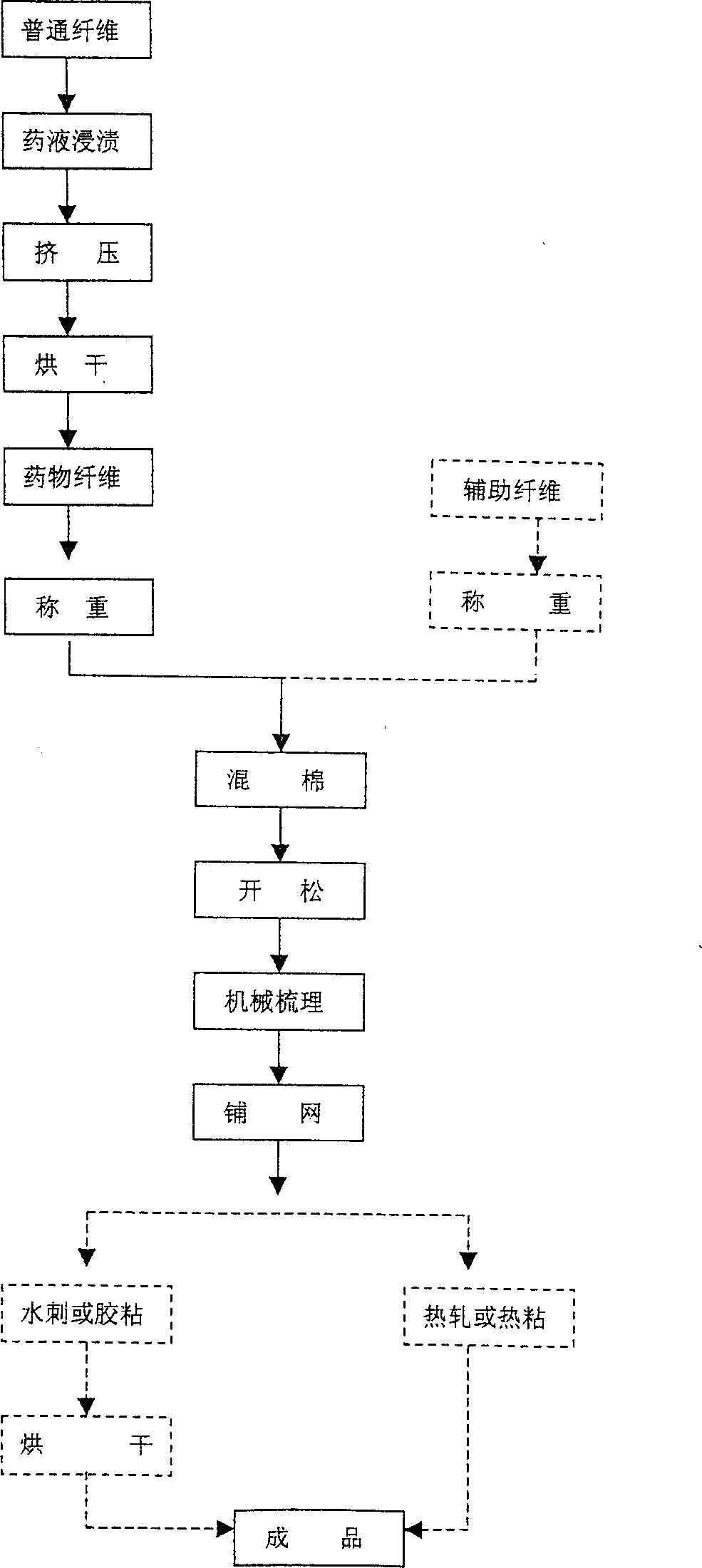

Process for preparing modified cotton fibre

The invention relates to a modified cotton fiber manufacturing method. It belongs to textile fiber material modification technique. It includes the following steps: boiling-off twisted cotton yarn and bleaching; processing selective oxidation reaction by putting the cotton yarn into periodate with 0.1-3g / L concentration at 30-60 centigrade degree for 1-2h; removing the oxidant; washing; dehydrating; drying; gaining oxidation cotton fiber with less than 25% strength stretch ratio; using the matter with -NH2, -OH active group to graft and cross link. Thus the cotton fiber is modified to gain multifunction composite cotton fiber. It can increase its wearability and addition value, expand application area, and solve the cotton fiber function in textile fiber material field.

Owner:SUZHOU UNIV

High water-absorption, high moisture-absorption, super-flexible blended tended tender twisted yarn and its production process

The invention discloses a high-bibulous, high-hydroscopic, super-soft blending weak-twisting yarn and the producing technique. The yarn character; the blended high-bibulous Terylene and cotton fiber are doubly twisted with water-soluble yarn and the three matters' weight ratio: 1.5-6:1-3. The technical character: blend the high-bibulous Terylene and cotton fiber into single yarn and purely spin the water-soluble fiber into smaller yarn and then doubly twist them to make the weak-twisting yarn.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE +1

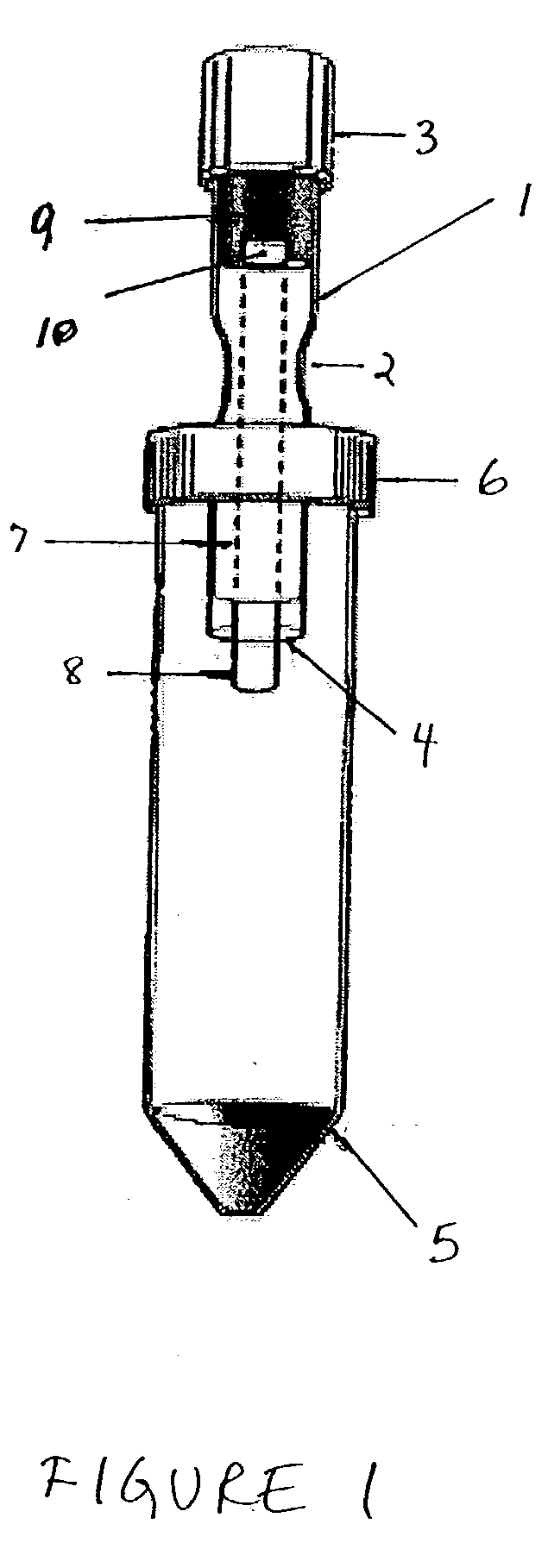

Antimicrobial medical articles containing a synergistic combination of anti-infective compounds and octoxyglycerin

Medical articles impregnated with antimicrobial compositions containing synergistic combinations of octoxyglycerin and other anti-infective compounds are disclosed. Such medical articles may include urinary catheters, central venous catheters, tracheal catheters, arterial grafts, wound dressings, sutures, or any other medical articles derived from polymeric substrates such as biomedical polyurethane, biomedical polyvinylchloride (PVC), biomedical silicon, biodegradable polymers, polytetrafluoroethylene (PTFE), etc. or from natural products including natural rubber, silk or cotton fiber.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

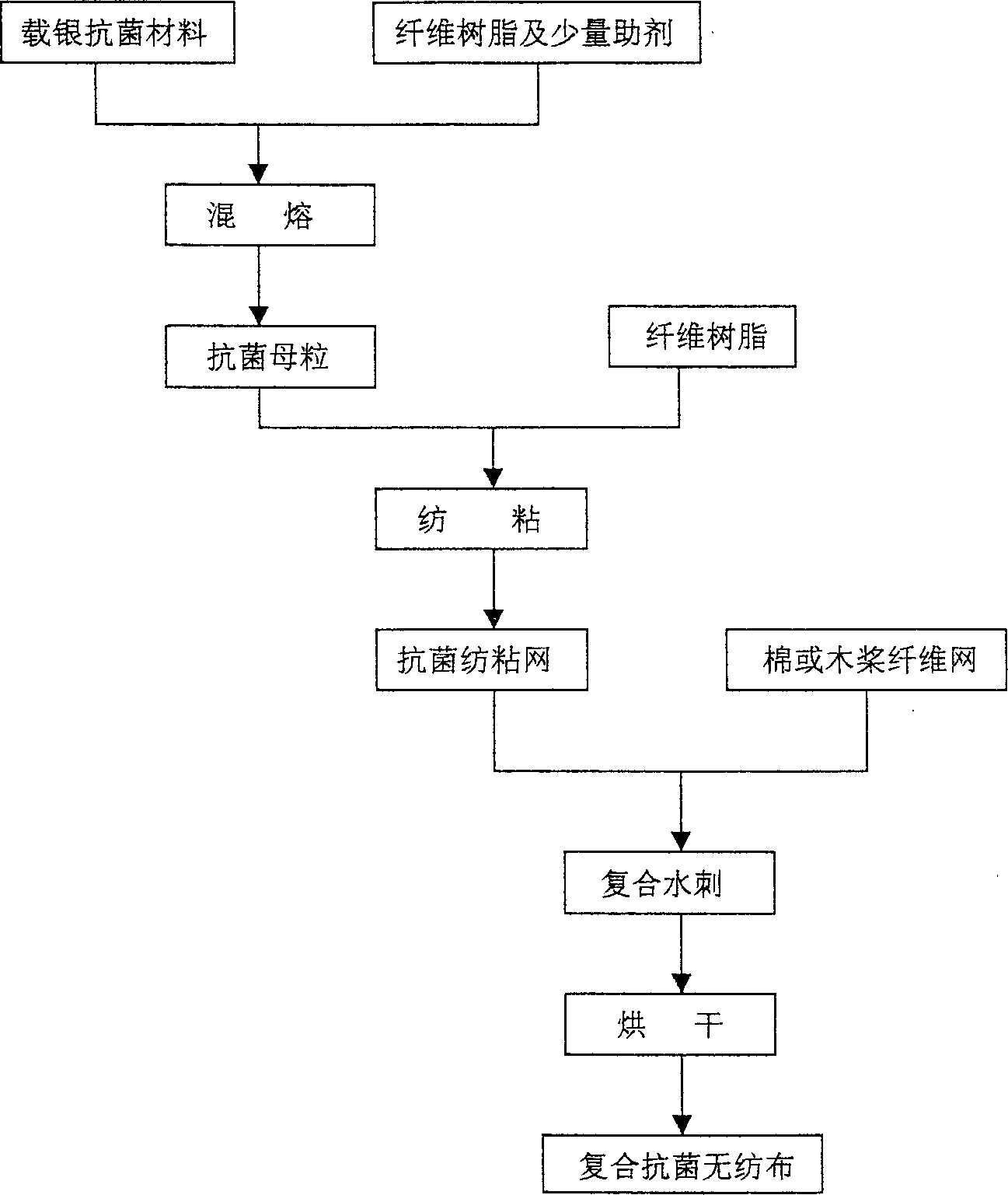

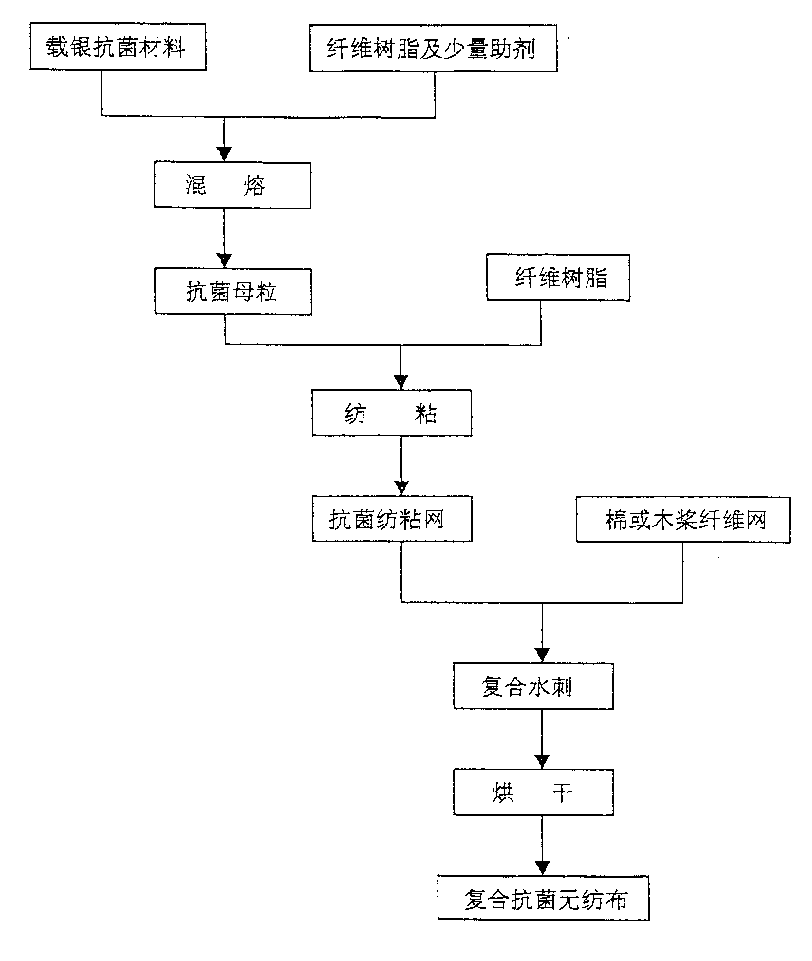

Process for preparing Ag-carried antibacterial composite non-woven fabric

InactiveCN1346905ANot easy to fall offImprove antibacterial propertiesNon-woven fabricsArtifical filament manufacturePolymer scienceCotton fibre

A process for preparing Ag-carried antibacterial composite non-woven fabric includes preparing antibacterial mother particles from Ag-carried antibacterial material, fibre resin and plastic assistant by screw extruding, preparing antibacterial spun-bonded mesh from said antibacterial mother particles and fibre resin, combining said antibacterial spun-bonded mesh with cotton fibre mesh or wood pulp fibre mesh, hydro-entangling, and drying. Its advantages are high antibacterial power and durability, and broad spectrum.

Owner:韦卫军

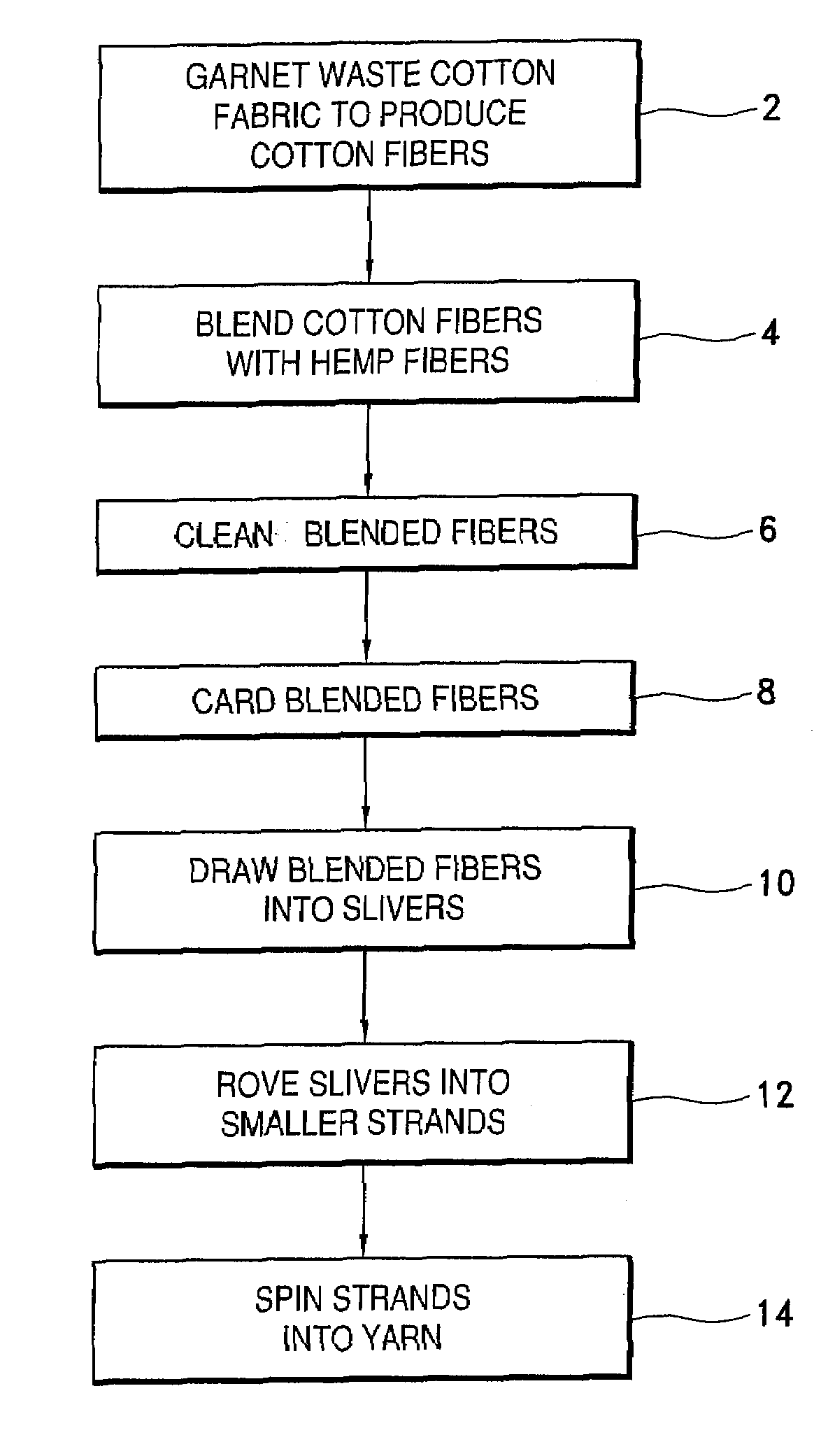

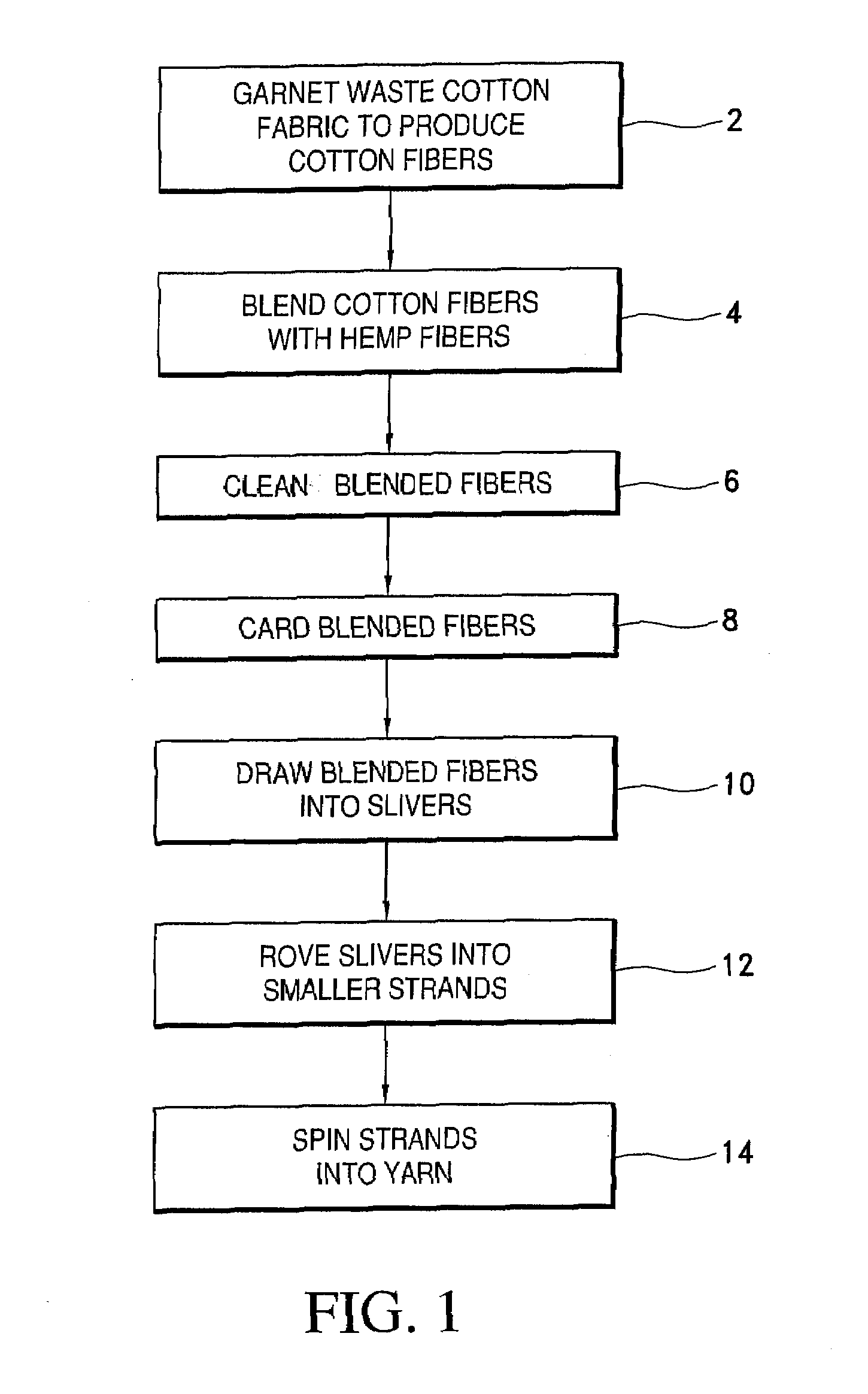

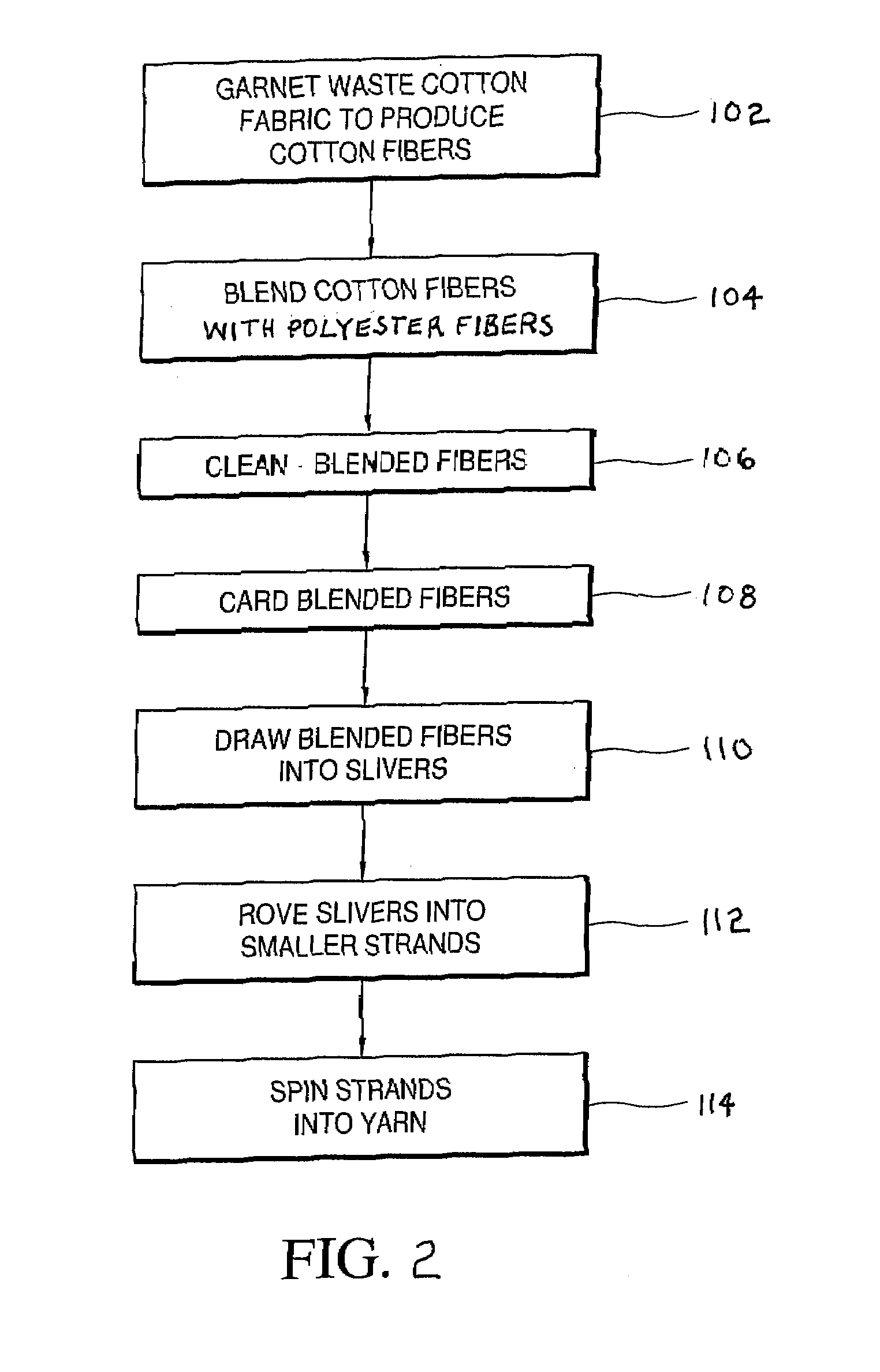

Composite cotton and polyester yarn and method for making same

InactiveUS20090173055A1Reduce impurityFibre mixingTextile disintegration and recoveryCotton fibrePolyester

A composite polyester and cotton yarn is formed by blending polyester fibers with cotton fibers which have been regenerated from waste cotton material such as trimmings and cuttings from the apparel manufacturing industry. The fibers are cleaned and blended, then carded to align the fibers into strands. Depending on the size and texture of the desired yarn, the fibers are stretched and drawn into slivers prior to spinning to join the fibers together. The polyester fibers are preferably recycled polyethylene terephthalate fibers which are up to three time longer than the regenerated cotton fibers, so that the polyethylene terephthalate fibers overlap and braid onto the regenerated cotton fibers during spinning. The resultant yarn is stronger and more absorbent than yarns made solely out of regenerated cotton fibers. The yarn is suitable for producing woven or knit fabric for the production of colorful and functional clothing and home textiles without the need for further bleaching or dyeing.

Owner:SILVER SCOTT

Self-lubricating composite gasket for bearing and preparing method for gasket

InactiveCN102535167AEasy to pasteReduce coefficient of frictionFibre treatmentBearing componentsPolyesterPolymer science

The invention discloses a self-lubricating composite material gasket for a bearing and a preparing method for the gasket. A fiber mixed fabric is formed by weaving PTFE (polytetrafluoroethylene) fiber with at least one type of other fiber; an impregnated material is coated on the surface of the fiber mixed fabric; the final thickness of the fiber mixed fabric is 0.30 to 0.55 mm; the thickness of the gasket is 0.35 to 0.60 mm; the weight ratio of the PTFE fiber to the gasket is 0.3 to 0.7; and the other types of fibers can be any one or a few of aramid fiber, carbon fiber, high-strength polyester fiber and cotton fiber. The self-lubricating gasket has the characteristics of high strength and low friction coefficient, and is suitable to be used in heavy-duty occasions under the temperatures ranging from -50 to 180 DEG C.

Owner:JIANGSU CCVI BEARING

Cotton fibers with antibacterial and insect-resisting effects and production method of cotton fibers

InactiveCN104278359AEasy to cleanNot easy to fluffConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCnidium monnieriFatty alcohol

The invention discloses cotton fibers with antibacterial and insect-resisting effects. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 21-24 parts of cotton fibers, 10-12 parts of apocynum venetum fibers, 6-8 parts of silk fibers, 7-9 parts of cashmere fibers, 9-11 parts of pineapple fibers, 4-7 parts of polypropylene fibers, 6-8 parts of taxus chinensis superfine micro-powder, 3-5 parts of ailanthus altissima leaf extracted powder, 1-3 parts of zeolite powder, 1.1-2.3 parts of chitosan, 0.5-0.7 part of magnesium nitride, 0.8-1.4 parts of N,N-dicyanoethylaniline, 5-7 parts of sulfonated castor oil, 15-18 parts of fatty alcohol alkoxy ether, 1-2 parts of mashed garlic, 1.3-2.5 parts of cnidium monnieri cuss, 2.1-3.6 parts of coptis chinensis, 90-95 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-100 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the cotton fibers, the taxus chinensis superfine micro-powder is added into raw materials by adopting an ultrasonic technology and a prepared cotton textile has a very good health effect and a useful pain-relieving effect on tumor patients and female symptoms; furthermore, the other active ingredients are added so that the good clothes properties of sweat absorption, breathability, softness, allergy prevention, easiness of washing, low probability of fuzzing and balling up and the like of natural cotton fibers are maintained, and the cotton fibers have good antibacterial and insect-resisting functions, a good electromagnetic radiation shielding function and the like.

Owner:ANHUI SWAN TECH IND GRP

High polymerization degree cotton pulp and method for making the same

InactiveCN101130886AHigh fiber contentHigh whiteness valueVegetable materialCotton fibreDegree of polymerization

The present invention discloses a cotton pulp with high degree of polymerization and method for preparing said cotton pulp with high degree of polymerization by using cotton linters as raw material. Said preparation method includes the following steps: preparing raw material, digesting, washing material, pulping, removing sand, bleaching, acid treatment, water-washing, filtering and pulp-making, etc.

Owner:CHTC HELON

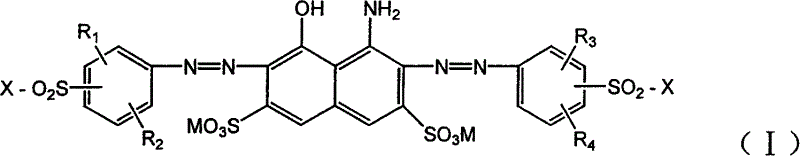

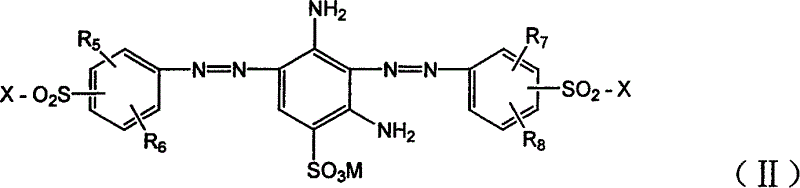

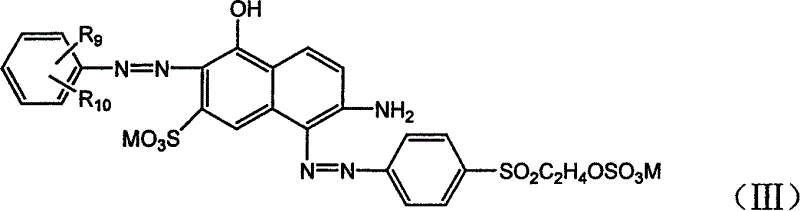

Composite active black dye

The present invention relates to a kind of disazo dyestuffs composition, the described composite active blank dyestuff mainly contains four dyestuffs, said invention also provides their structure formulas. The described composite dyestuff is suitable for dyeing dark colour fabrics, such as cellulose fibre, cotton fibre and synthetic fibre, etc., and has good level-dyeing property, repeatability, high dyeing fastness, fastness to washing and wet rubbing fastness.

Owner:SHANGHAI KEHUA DYESTUFF IND

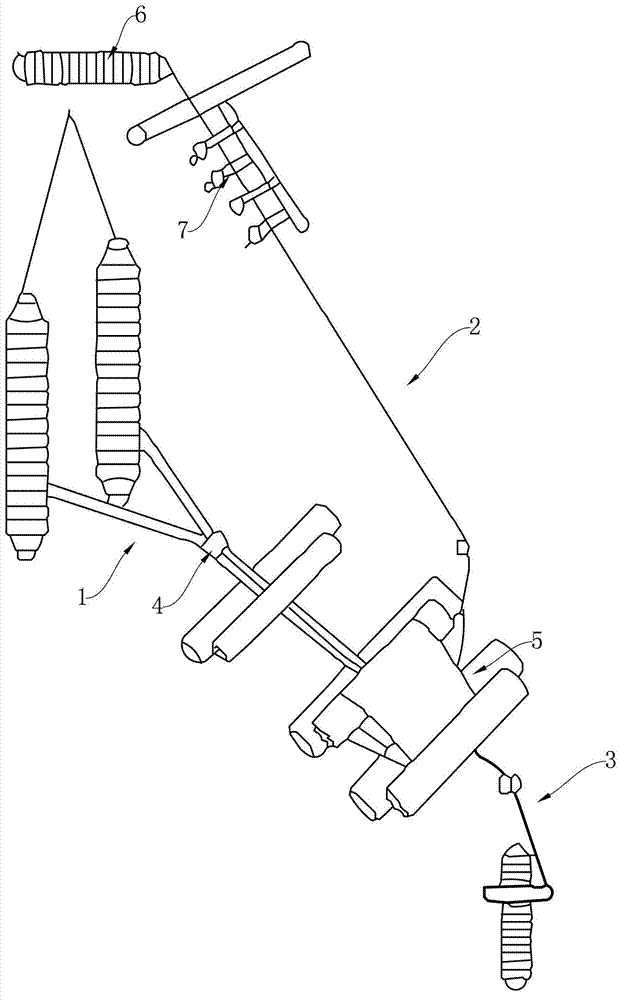

Spinning process of covering yarn with high hollowness degree, prepared covering yarn and process for weaving towel by utilizing covering yarn

ActiveCN102888686AIncrease warmthHigh hollownessBiochemical fibre treatmentBleaching apparatusCotton fibreEngineering

The invention provides a spinning process of covering yarn with high hollowness degree, a prepared covering yarn and a process for weaving towel by utilizing the covering yarn. The spinning process comprises the following steps of: compositing and twisting two crude cotton yarns and water-soluble vinylon filament with number of 4.1-7.3 tex to prepare a spun yarn with cotton fiber covering the water-soluble vinylon filament; and hydrolyzing the water-soluble vinylon filament to obtain the covering yarn with the high hollowness degree. The strength and the hollowness degree of the covering yarn with the high hollowness degree, prepared by the spinning process disclosed by the invention, are higher than the strength and the hollowness degree of a common hollow covering yarn with the same yarn count, the overing yarn with the high hollowness degree is soft and fluffy and has strong water absorbability and improved heat insulation performance; and the woven towel prepared by the process of the invention is light and fluffy, and has good heat insulation performance and resilience, high water absorption speed, large unit-area water absorption amount and high drying speed.

Owner:SUNVIM GROUP

Weaving process of hemp textile product

InactiveCN101838876AHigh degree of automationEasy windingFabric breaking/softeningBiochemical fibre treatmentYarnEngineering

The invention discloses a weaving process of a hemp textile product, which comprises the process steps of winding, warping and weaving. Blended yarns bended by hemp fibers and cotton fibers are weaved by warps and wefts in the process, wherein the rotary speed of a grooved drum is 600 plus or minus 5r / min, and the ratio of hemp fibers to cotton fibers is 35:65. The process also comprises processing steps of refining, singeing, softening, drying and calendering. The hemp textile product produced by the invention has less filoplume, biodegradability, and excellent moisture absorbance and sweat release properties, keeps the natural antimicrobial and health-care functions of hemp, has good soft and comfortable properties, excellent ultraviolet resistance, radiation resistance and antibacterial properties, excellent high-temperature resistance and unique odor absorption and waste discharging properties; and the hemp textile product feels soft and comfortable compared with other hemp products, and is a new-generation environment-protection product.

Owner:SUNVIM GROUP

Multifunctional thermal underwear fabric and processing method thereof

InactiveCN102312342AFunction increaseGood warmth retentionWeft knittingFibre treatmentPolyesterTextile technology

The invention relates to a multifunctional thermal underwear fabric and a processing method thereof, belonging to the field of textile technology. The multifunctional thermal underwear fabric comprises a face weave and a bottom weave, wherein the face weave consists of cotton fibers, polyester fibers, spandex fibers, bamboo charcoal fibers, viscose fibers, wool fibers and plant protein fibers; and the bottom weave consists of polyester fibers. The content of the cotton fibers accounts for 34-60 percent of the total components, the content of the polyester fibers accounts for 26-39 percent of the total components, the content of the spandex fibers accounts for 5-6 percent of the total components, the content of the bamboo charcoal fibers accounts for 0.5-6 percent of the total components, the content of the viscose fibers accounts for 1-17 percent of the total components, the content of the wool fibers accounts for 1-5 percent of the total components, and the content of the plant protein fibers accounts for 0.5-7 percent of the total components. The multifunctional thermal underwear fabric has the advantages that the functions of the fabric are expanded by guaranteeing an excellent warmth keeping performance through the cotton fibers, by guaranteeing ideal elasticity through the spandex fibers, by reflecting a good moisture absorbing performance and air permeability through the polyester fibers and by reflecting a good antibiotic property through the bamboo charcoal fibers; and since function processing, baking and secondary ironing processes are increased, the fabric has an aromatic long-lasting effect.

Owner:CHANGSHU MENGXI FURNISHINGS

Moisture-absorbing and perspiring anti-bacterial fabric and preparation technology thereof

InactiveCN105421055AImprove antibacterial propertiesSoft and wear-resistantBiochemical fibre treatmentLiquid/gas/vapor removalWater basedMoisture

The invention relates to a moisture-absorbing and perspiring anti-bacterial fabric and a preparation technology thereof. The moisture-absorbing and perspiring anti-bacterial fabric is blended and weaved by the following raw materials in parts by weight: 40 to 80 parts of bamboo fibers, 40 to 80 parts of long staple, 10 to 30 parts of ramie, 10 to 30 parts of coolmax fibers, 10 to 20 parts of corn fibers, 10 to 20 parts of Delight fibers, and 5 to 20 parts of Tancel, and then is treated by anti-bacterial finishing liquid; the anti-bacterial finishing liquid comprises 5 to 10 parts of chitosan, 5 to 10 parts of silk fibroin, 0.5 to 3 parts of butyl ricinoleate sodium sulfate, 0.5 to 3 parts of lemon acid, 0.5 to 2 parts of butyl methacrylate, 5 to 8 parts of dodecyl diphenyl ether sodium disulfonate, 5 to 10 parts of hydroxypropyl methyl cellulose, 5 to 10 parts of polyhexamethylene biguanidine, 5 to 15 parts of organosilicon quaternary ammonium salt, 3 to 8 parts of dodecyl trimethyl ammonium chloride, and 5 to 10 parts of water-based polyurethane. The moisture-absorbing and perspiring anti-bacterial fabric has the advantages that the anti-bacterial property is higher, the moisture-absorbing, perspiring, anti-pilling and air-ventilation properties are realized, the softness is realized, and the abrasion is resisted; the moisture-absorbing and perspiring anti-bacterial fabric is particularly suitable for being applied to the fields of underwear, overwear, sportswear and bedding articles.

Owner:杜名胜

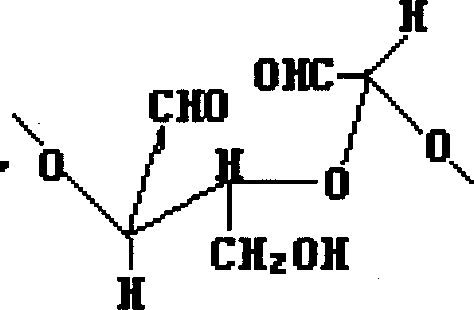

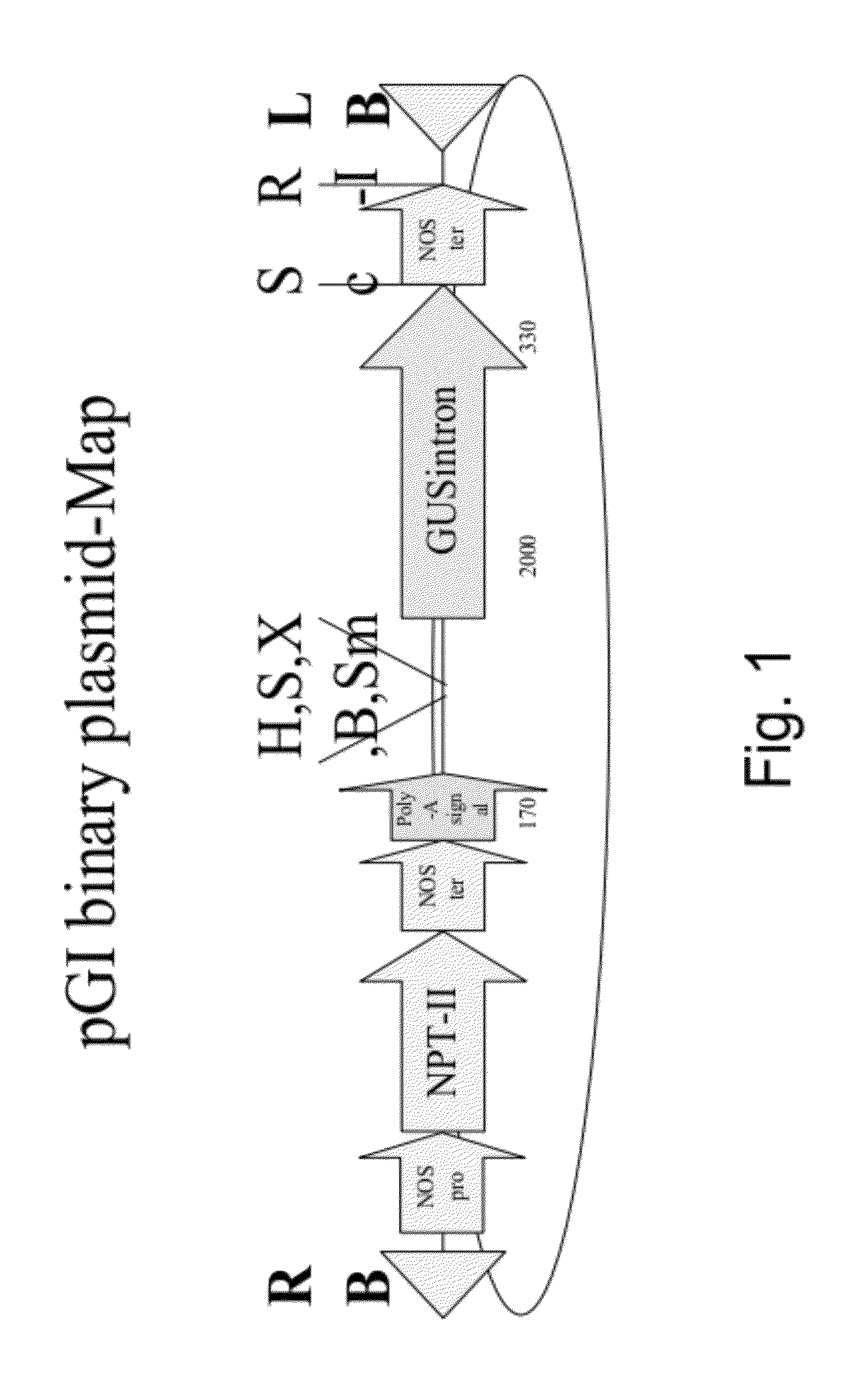

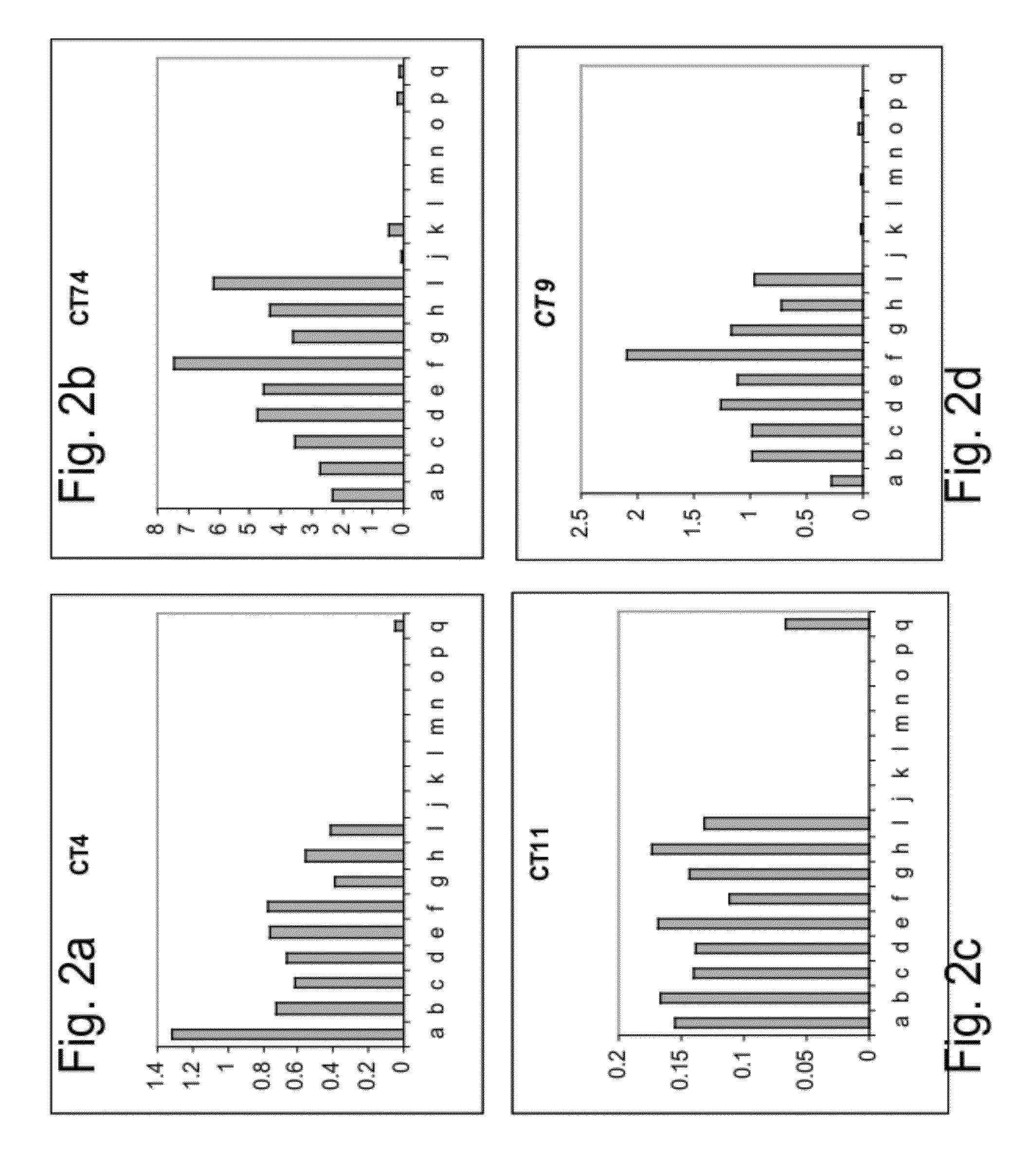

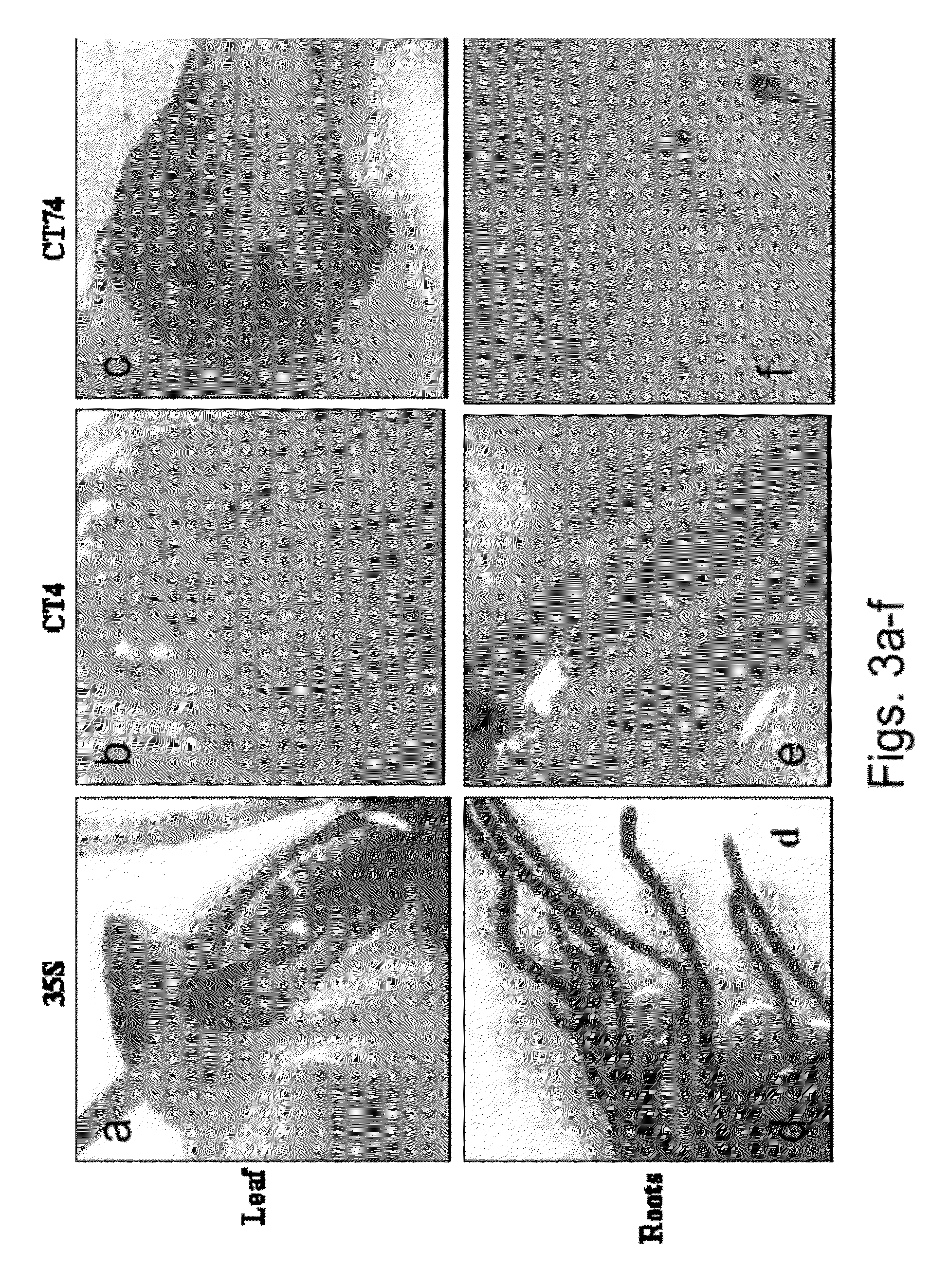

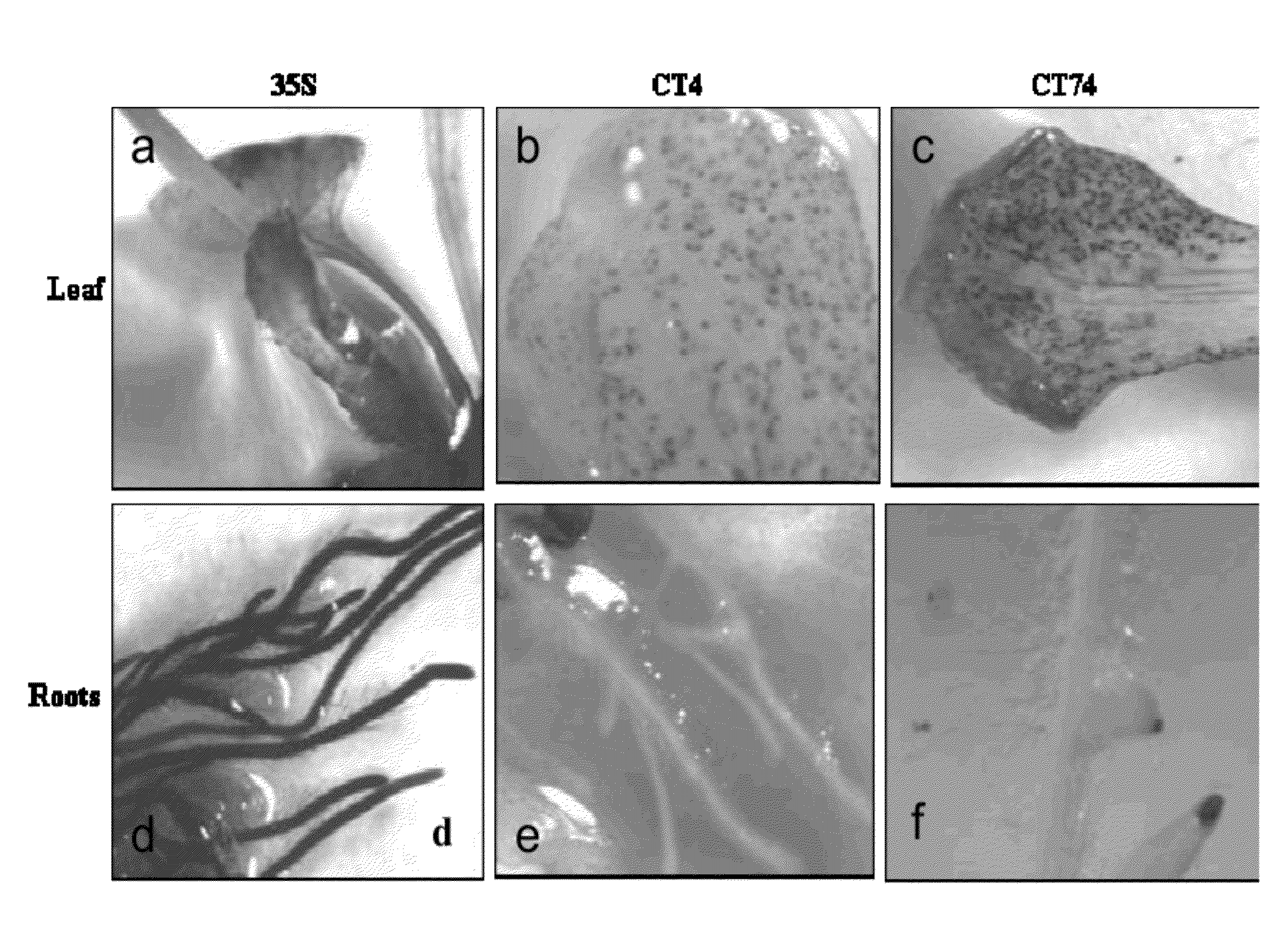

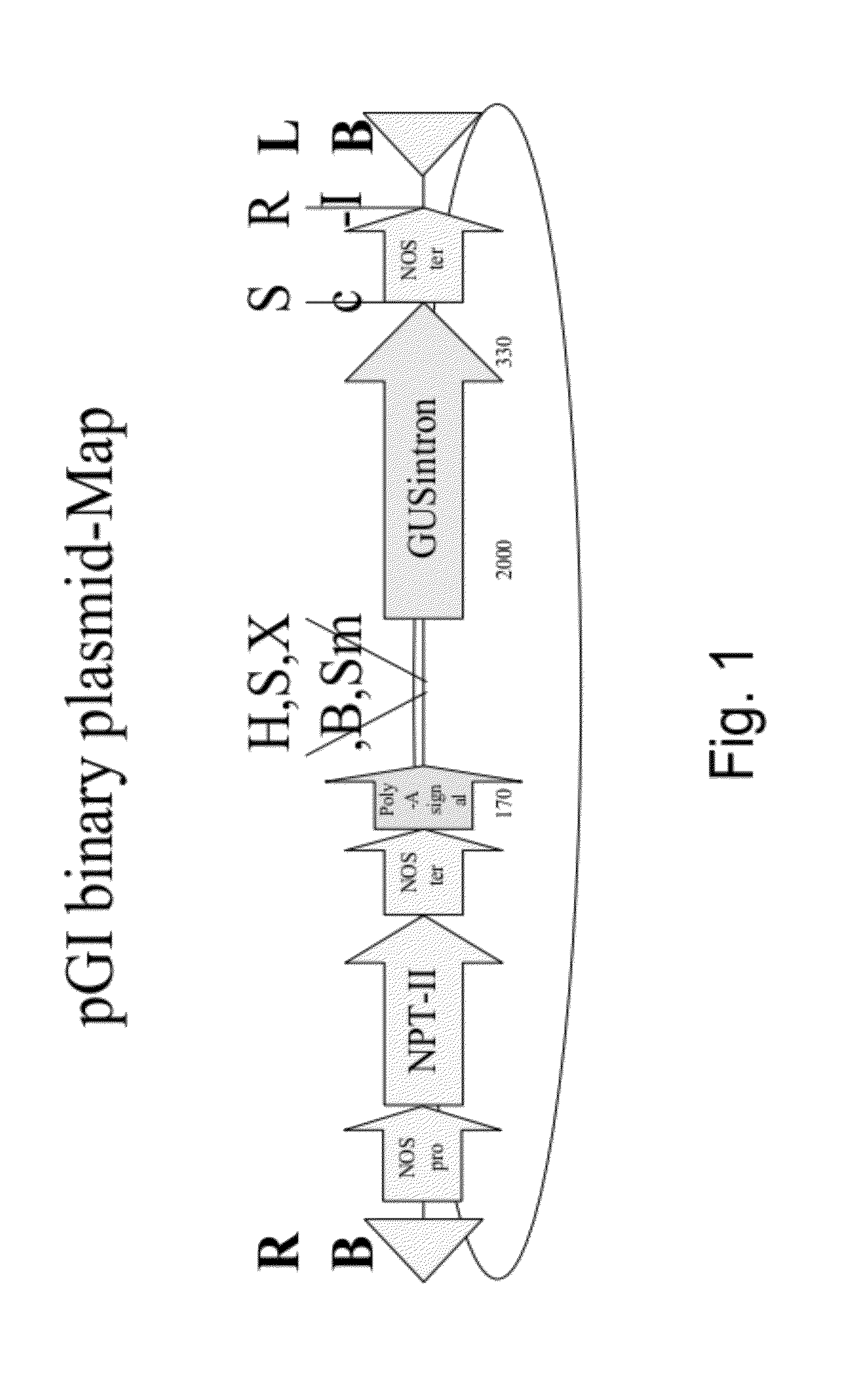

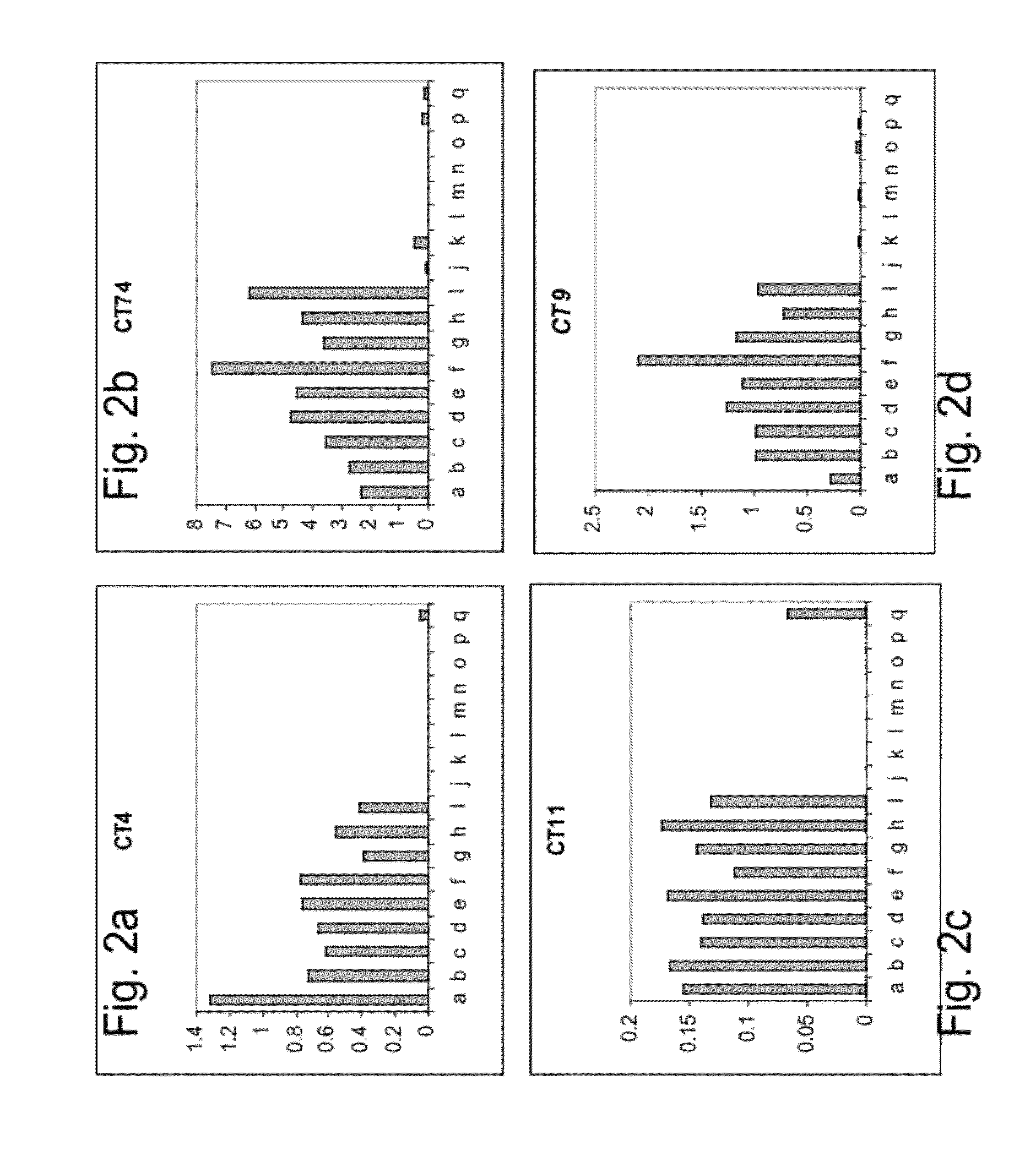

Polynucleotides and polypeptides involved in plant fiber development and methods of using same

ActiveUS8168857B2Increase biomassIncreasing the biomass of the plantSugar derivativesClimate change adaptationBiotechnologyPlant fibre

Isolated polynucleotides are provided. Each of the isolated polynucleotides comprise a nucleic acid sequence encoding a polypeptide having an amino acid sequence at least 80% homologous to SEQ ID NOs:130-258 and 536-791, wherein the polypeptide is capable of regulating cotton fiber development. Also provided are methods of using such polynucleotides for improving fiber quality and / or yield of a fiber producing plant, as well as methods of using such polynucleotides for producing plants having increased biomass / vigor / yield.

Owner:EVOGENE LTD

Antibacterial fabric, preparation technology thereof and textile thereof

InactiveCN103255522ANon-irritatingImprove thermal stabilityWeft knittingCarbon fibresBiotechnologyPolyester

The invention relates to the field of functional fabrics, in particular to an antibacterial fabric, a preparation technology of the antibacterial fabric and textile of the antibacterial fabric. The antibacterial fabric comprises, by weight, 10-20 parts of short fiber silk, 20-25 parts of anion polypropylene staple fibers, 15-25 parts of nano bamboo carbon fiber, 2-5 parts of nano-titanium dioxide, 5-10 parts of nano-silver fiber, 2-4 parts of anti-mite finishing agent, 3-8 parts of sweat-absorbent quick-drying processing agent, 12-18 parts of binder, 2-4 parts of dispersing agent, 3-5 parts of fabric softener and 80-85 parts of polyester cotton fiber. Due to the fact that the anion polypropylene staple fibers are added, effects of nerve stability, sleep improvement, inflammation diminishing and pain relief are provided. Due to the fact that the anti-mite finishing agent is added, trouble caused by mites to a human body can be effectively prevented. Due to the fact that the sweat-absorbent quick-drying processing agent is added, sweat generated by the body can be rapidly absorbed, discomfort can be reduced, and breeding of germs under a humid environment can be prevented. The antibacterial fabric can be applied to clothing, home textiles, sports goods, medical care, bacteria resistance and insect prevention textiles.

Owner:广东雄兴内衣实业有限公司

Polynucleotides and polypeptides involved in plant fiber development and methods of using same

ActiveUS20120180164A1Increase biomassIncreasing the biomass of the plantFermentationVector-based foreign material introductionBiotechnologyPlant fibre

Isolated polynucleotides are provided. Each of the isolated polynucleotides comprise a nucleic acid sequence encoding a polypeptide having an amino acid sequence at least 80% homologous to SEQ ID NOs:130-258 and 536-791, wherein the polypeptide is capable of regulating cotton fiber development. Also provided are methods of using such polynucleotides for improving fiber quality and / or yield of a fiber producing plant, as well as methods of using such polynucleotides for producing plants having increased biomass / vigor / yield.

Owner:EVOGENE LTD

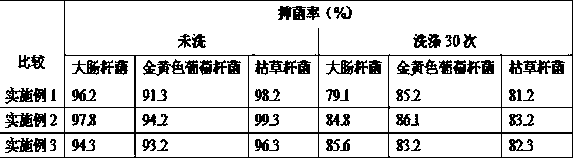

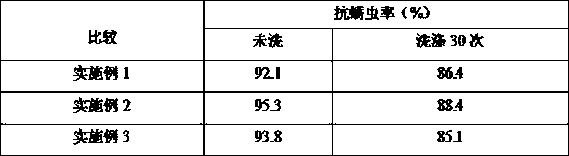

Composite antibiotic finishing agent and preparation method and finishing process thereof for application to mucilage glue and cotton fiber interweaved jacquard fabric

The invention discloses a composite antibiotic finishing agent which comprises an organic antibacterial active component, an inorganic antibacterial active component, a penetrating agent, an adhesive, a softening agent, a suspending agent and the balance of water, wherein a non-dissolution type polymer antibacterial agent is selected as the organic antibacterial active component, and silver-loaded nanometer titanium dioxide is selected as the inorganic antibacterial active component. The invention also discloses a method for preparing the composite antibiotic finishing agent and a process used for finishing a mucilage glue and cotton fiber interweaved jacquard fabric. The main material of the composite antibiotic finishing agent for textiles is formed by the organic antibacterial active component and the inorganic antibacterial active component, thus the composite antibiotic finishing agent has a high-efficiency inhibiting capacity of more than 20 kinds of harmful bacteria such as escherichia coli, staphylococcus aureus, gonococcus and the like; the bacteria inhibiting rate is higher than 99 percent; the repelling and preventing rate of dust mites, gamasid mites and chigger is higher than 99 percent; the repelling and preventing rate of dust mites, gamasid mites and chigger is higher than 95 percent, and the killing rate is higher than 90 percent after the mucilage glue and cotton fiber interweaved jacquard fabric is washed for 50 times; and the gonococcus, escherichia coli, staphylococcus aureus and the like do not grow on the fabric which is not washed for 30 times, 50 times or 100 times, and the bacteria inhibiting rate is higher than 99 percent.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Photosensitive composite fabric

InactiveCN104983103AAct as photosensitizerSynthetic resin layered productsProtective garmentYarnPolymer science

The invention provides a photosensitive composite fabric. The photosensitive composite fabric is composed of a comfortable fabric layer (1) and a photosensitive fabric layer (2) from inside to outside, the comfortable fabric layer (1) is weaved by blended yarns of polyamide fibers, polyester fibers and cotton fibers, the photosensitive fabric layer (2) is weaved by photosensitive composite fibers, the photosensitive composite fibers are skin-core type composite fibers, photosensitive color-changing fibers serve as the core layer, polyester fibers serve as the skin layer, and the ratio of the diameter of the core layer to the overall diameter of the composite fibers is (4-9):10. In the photosensitive composite fabric, by means of the structural design of the fabric, the outer fabric layer has a photosensitive effect, and the comfortable fabric layer is beneficial to contact comfortableness.

Owner:NANTONG ZHONGHE CHEM FIBER

Cotton fiber particulate and method of manufacture

InactiveUS20070062009A1Increased uniformity in fiber lengthShorten the lengthPulp properties modificationSynthetic resin layered productsParticulatesCotton fibre

A cotton fiber particulate and method of manufacture including, generally, obtaining cotton fibers; mixing the cotton fibers with a solvent such as water to obtain a fiber furnish; milling the fiber furnish; and drying the fiber furnish to recover the cotton fiber particulate. Other steps include modifying the pH of the fiber furnish with a material such as calcium carbonate in an effort to make the fibers brittle, and filtering the fiber furnish to recover the cotton particulate. The fibers are milled to between 5-25 microns in length with a mean length of less than 50 microns with a mean length of 20 microns preferred.

Owner:SSI TECH INC

Natural green health care knitwear and its mfg. method

A health-care knitting fabric is made up of hemp fibre, color cotton fibre, bamboo fibre, soybean protein fibre, chitin fibre, and natural wooden pulp fibre through twisting, knitting, boiling, softening, baking and high-pressure ironing.

Owner:王新文

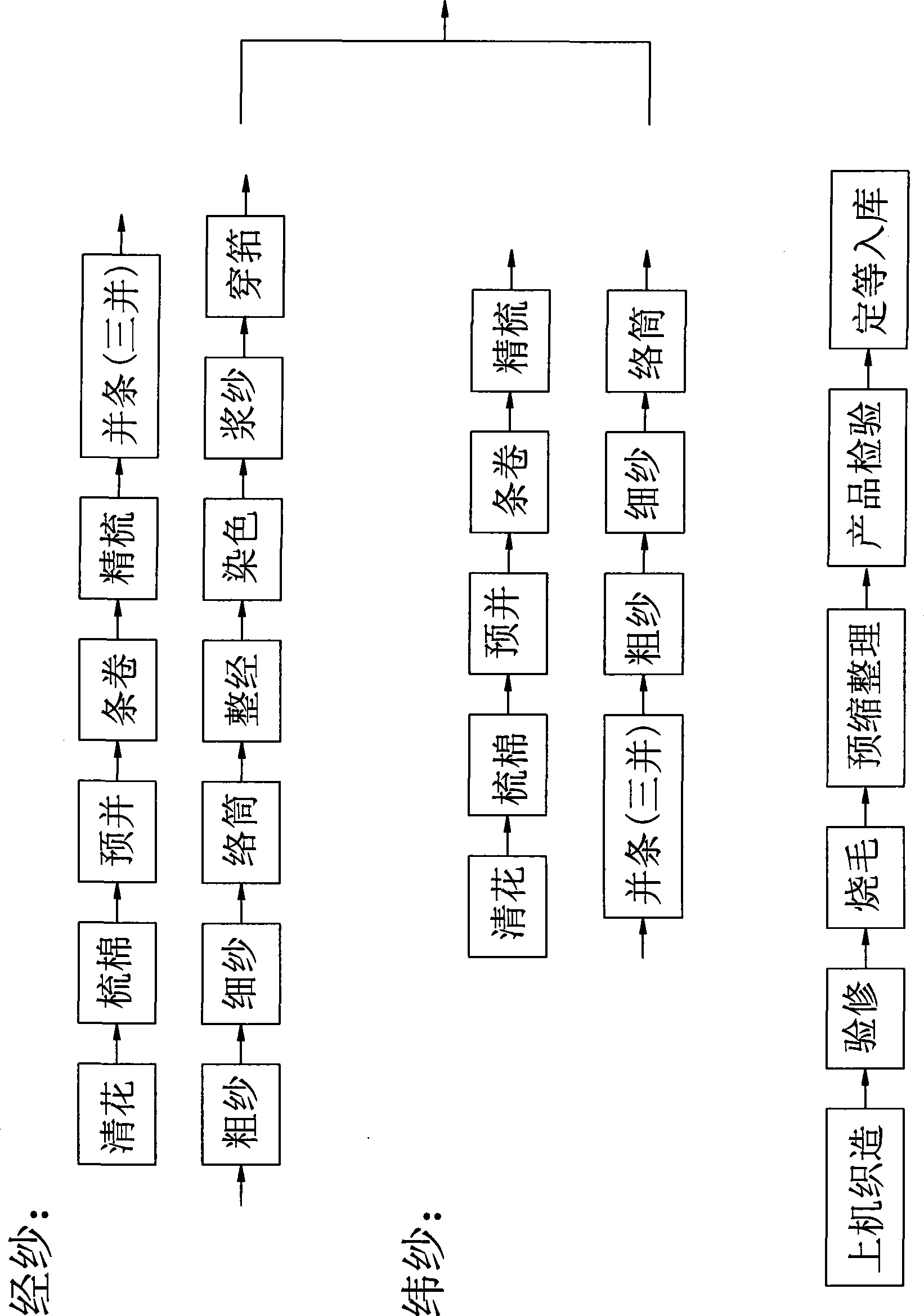

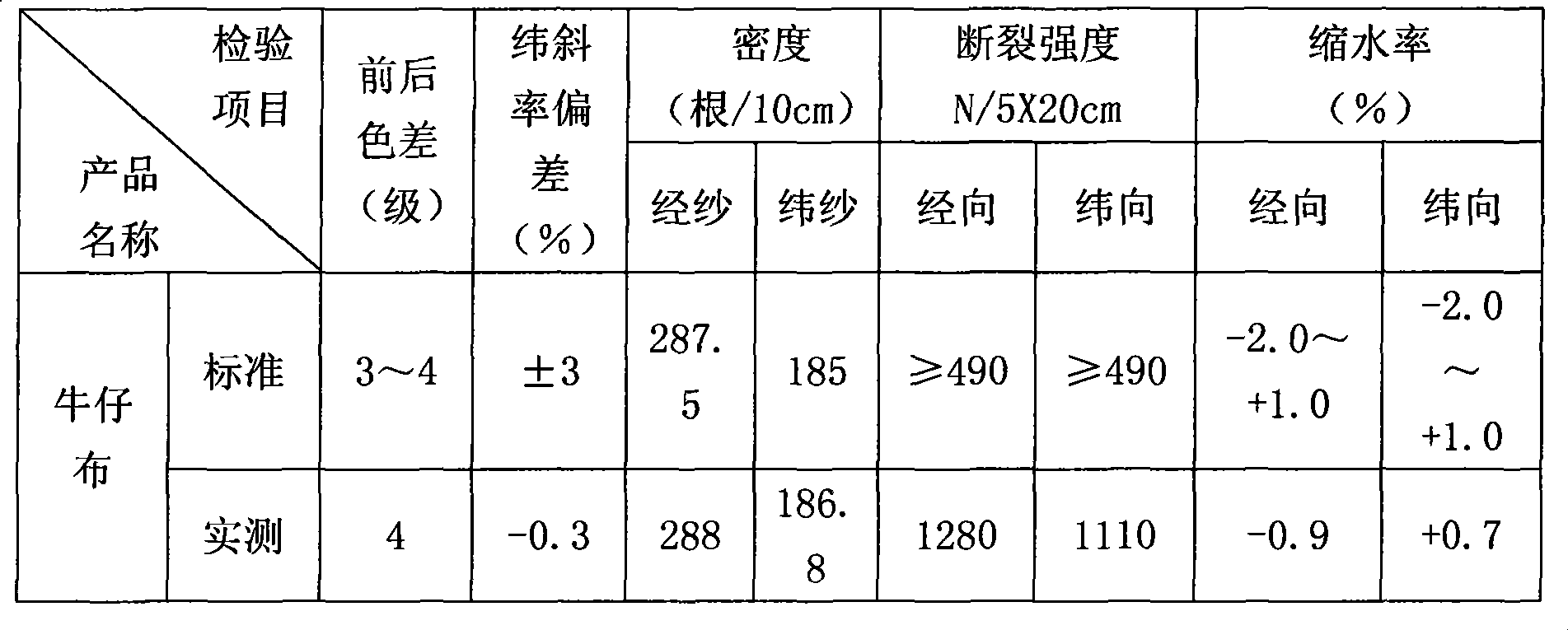

Production method of corn fiber, bamboo fiber and cotton fiber blending pant fabric

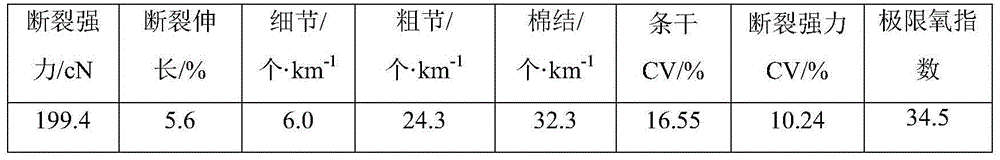

InactiveCN101775686AEasy to weaveHas natural elasticityBiochemical fibre treatmentSingeingYarnBreaking strength

The invention relates to a corn fiber, bamboo fiber and cotton fiber blending pant fabric and a production method thereof. The pant fabric belongs to a woven fabric which is characterized by a yarn material and is produced by blending and weaving the following raw material fibers by weight percent: 20 to 30 percent of corn fiber, 40-51 percent of bamboo fiber and 20-30 percent of cotton fiber. The production method comprises three production process steps of spinning, weaving and dyeing and finishing. The invention provides the ideal corn fiber, bamboo fiber and cotton fiber blending pant fabric which also has natural elasticity and does not deform on the premise of keeping all natural ecological functions and good properties of the corn fiber, the bamboo fiber and the cotton fiber and is easy to weave and the production method thereof. The invention solves the problem that corn fiber weaving process has strict requirements, broken ends are increased because the single-fiber breaking strength of the bamboo fiber is lower and the cotton fiber has lower rebound resilience, and fabrics are easy to crinkle and do not resist mycete. The invention is especially suitable for pant fabric. Resources can be recycled, and thereby the pant fabric is beneficial to ecological environment protection.

Owner:青岛奈琦尔生物科技有限公司

Viloft shengma smooth edge denim and production technology thereof

The invention relates to VILOFT sunn crotataria plain edge jean which comprises the following components by weight percentage: 20-40% of VILOFT fiber, 20-40% of sunn crotataria, 20-40% of one or multiple of cotton fiber, color cotton fiber, prolivon, cashmere, milk fiber, soybean fiber, tencel yarn, flax, silk, etc. In the picking process, the lap pressure is weighted, multi-combing and little beating, combing instead of beating are adopted, the speed of each beater is reduced, and the gauge of the beater and grid bars is enlarged. In the carding process, the lap is fully carded and the card sliver quota is increased; in the drawing process, the clockwise drawing process is adopted, the gauge is enlarged; the pressurizing quantity is improved and the vehicle speed is reduced, the combination process and the three blending combination process are adopted, and the first tension drawing multiple is grasped in a slightly large way; in the spinning process, large postzone roller gauge, small postzone draft multiple and small nip gauge are required, the vehicle speed is reduced, and the pressure is increased. The fabric of the jean has the advantages of environment protection, moderate elastic, soft texture, good luster and drapability, and obviously bamboo joint effect.

Owner:山东万泰创业投资有限公司

Method for producing towels by utilizing bamboo fiber and cotton fiber

InactiveCN101694037AImprove breathabilityInstant water absorptionWoven fabricsYarnCardingCotton fibre

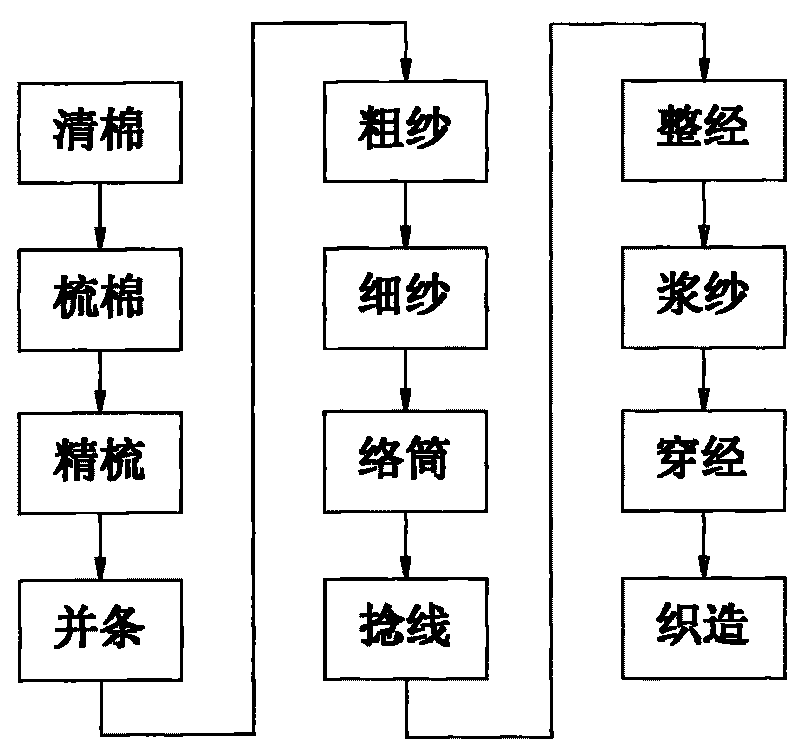

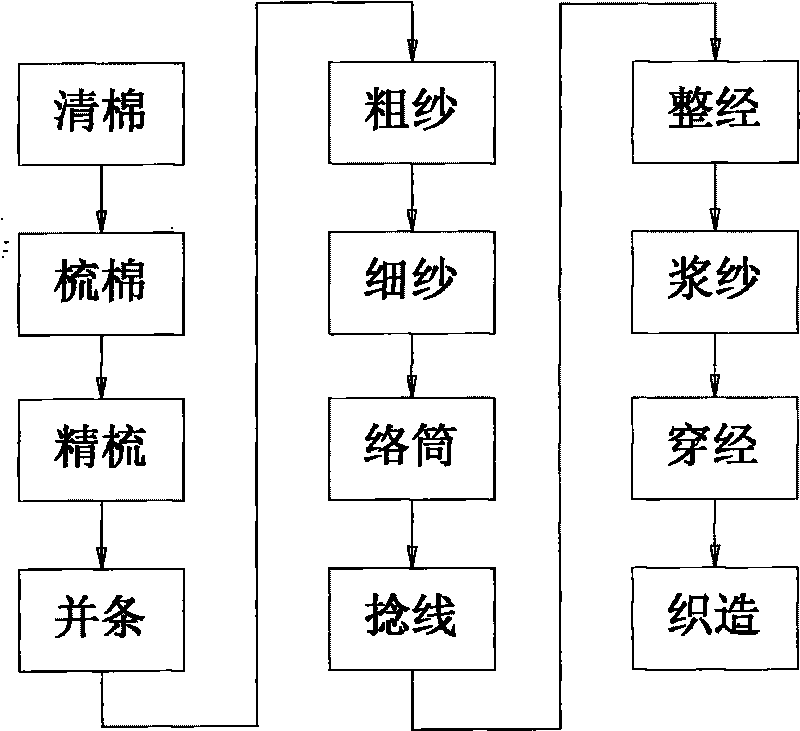

The invention relates to a method for producing towels by utilizing bamboo fiber and cotton fiber, comprising twelve steps such as cotton cleaning, cotton carding, combing, drawing, roving, spinning, winding, twisting, warping, sizing, passing, weaving, and the like, wherein in the fourth step, a finished cotton silver and the cotton silver of the cotton fiber are combined, a blending cotton silver is generated, and then the blending cotton silver is taken as the basis to implement the next steps, thereby leading the bamboo fiber and the cotton fiber to be mixed and taken as raw materials for weaving the towels; and the towels produced by the adopting the method have good air permeability, instant water absorption, strong wear resistance, good dyeing performance and other excellent performances.

Owner:黄学进

Flame retardant blended yarn and production method thereof

InactiveCN104404671AImprove flame retardant performanceIncrease added valuePhysical treatmentYarnCotton fibreSingle fiber

The invention relates to a flame retardant blended yarn and a production method thereof. According to weight percentage, the flame retardant blended yarn is formed by the following components through blending: 25-30% of flame retardant polyester filament yarns, 20-25% of flame retardant acrylic fibers, 20-30% of hemp fibers and 20-30% of cotton fibers. The production method includes: making hemp fibers and cotton fibers into card slivers respectively and tearing the card slivers into loose fibers, and making the card slivers into hemp / cotton blended combed silvers through second blowing carding in a single fiber type mixing way; making the flame retardant acrylic fibers into flame retardant acrylic card silvers; producing blended rough yarns by use of the hemp / cotton blended combed silvers and the flame retardant acrylic card silvers; producing flame retardant blended yarns by use of spun yarns in a core spun mode; producing the needed flame retardant blended yarns after plasma preprocessing and yarn flame retardant finishing. According to the flame retardant blended yarn and the production method thereof, the hemp fibers, the cotton fibers and two flame retardant fibers are selected for blending, and accordingly the produced yarns have excellent flame retardant performance as well as good antibacterial, moisture absorptive and ventilate wearing performances; the spun yarns are in the core spun mode so the tare effect is eliminated and the flame retardance is improved.

Owner:青岛博徕施纺织有限公司

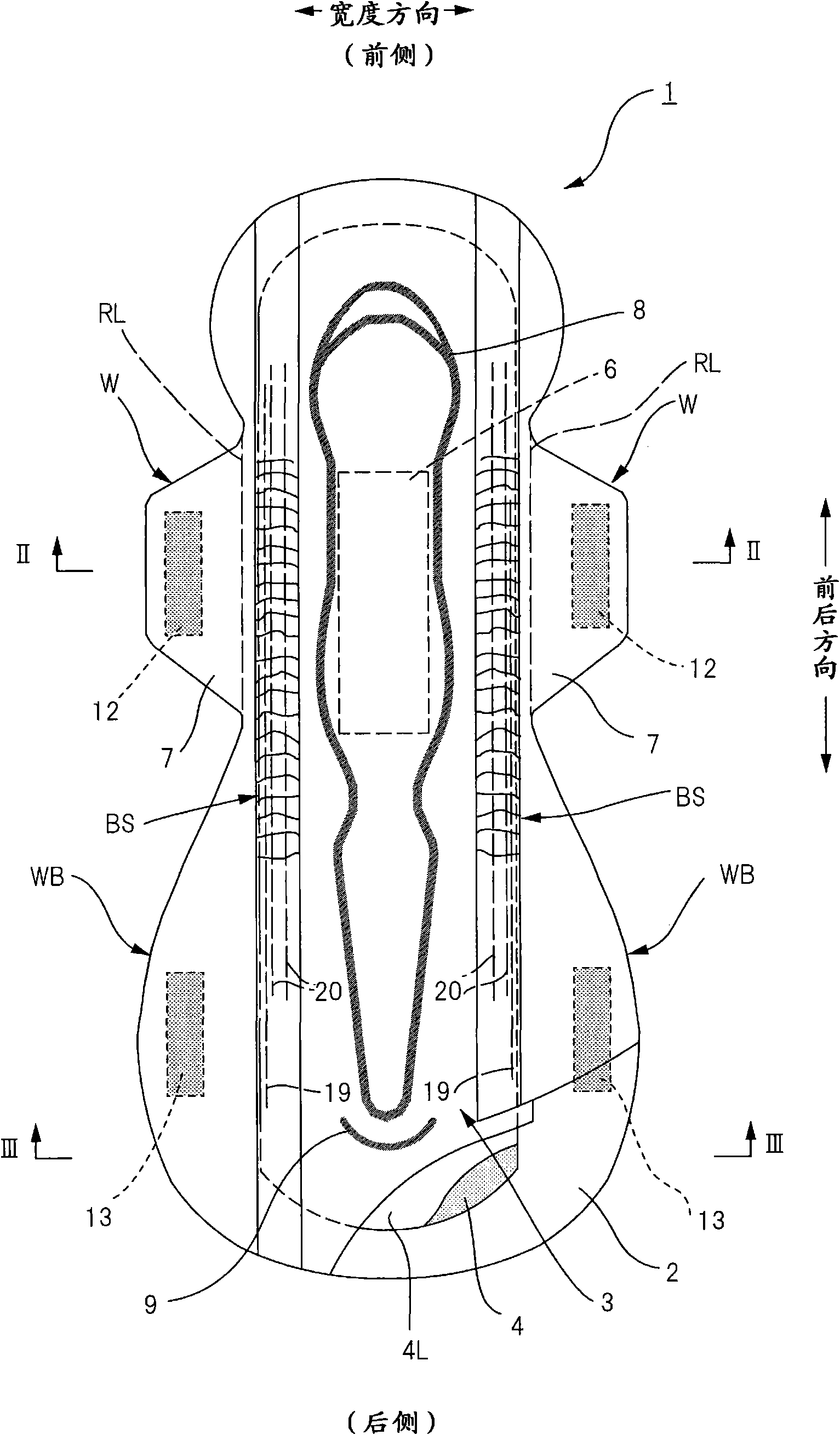

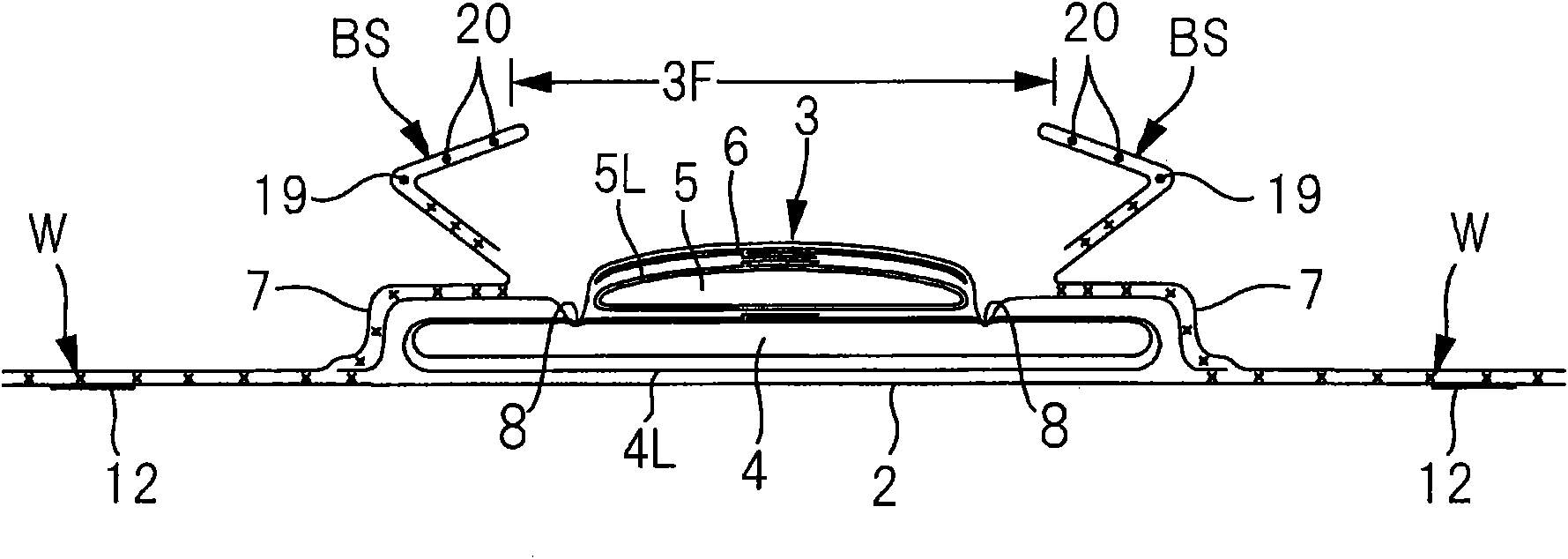

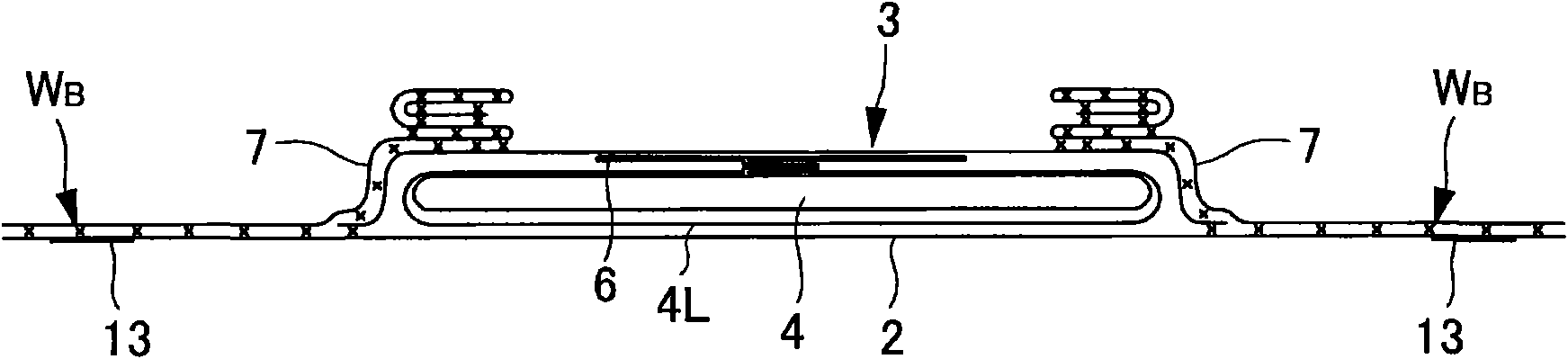

Absorbability article

ActiveCN101892557AFully concealed absorptionAvoid stickingSanitary towelsBaby linensSkin contactCotton fibre

The present invention provides an absorbability article, having an upper sheet material made of cotton fibre with a good skin feel, and capable of ensuring sufficient waterproofness of the upper sheet material and preventing the surface from residual liquid. Said upper sheet material is made of hydro-entangled nonwoven fabric which is composed of 40-100 wt% cotton fibre and 60-0 wt% synthetic fiber. The nonwoven fabric is provided with a plurality of through openings, and waterproof agent is coated on one side or two sides. A water absorption degree (JIS L 1907Byreck method) of a skin contact surface of the sheet material is set 0-5mm.

Owner:DAIO PAPER CORP

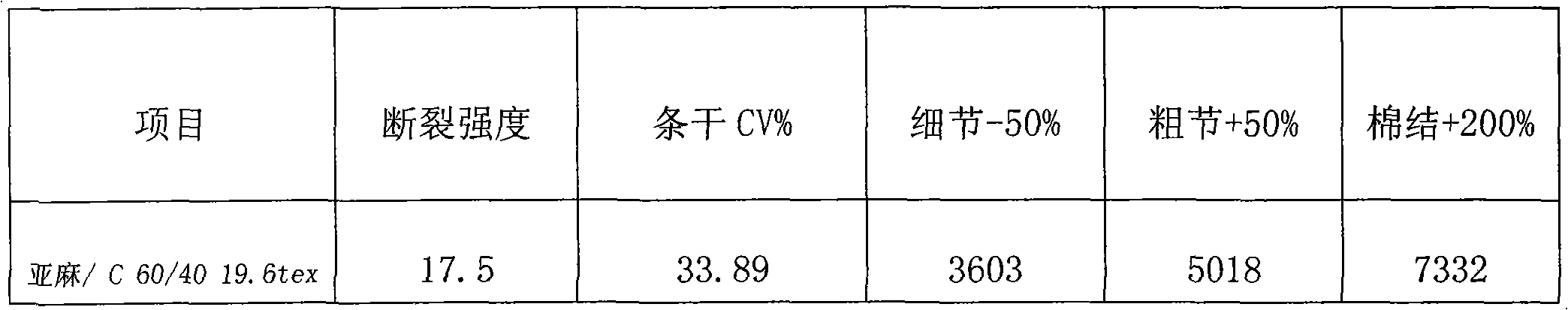

Blended yarn of flax fibers and cotton fibers and preparation process thereof

The invention discloses a blended yarn of selected flax fibers with superior count and cotton fibers and a preparation process thereof. The blended yarn consists of the flax fibers with superior count and the cotton fibers, wherein the flax fiber content accounts for 20 to 60 percent of the total weight of the blended yarn, and the cotton fiber content accounts for 40 to 80 percent of the total weight of the blended yarn. The preparation process comprises the following steps of: dividing the flax fibers with superior count and carded sliver or combed sliver into small heaps by proportioning; preparing uniform aqueous solution; and performing steps of fiber mixing, cleaning, cotton carding, drawing, roving and spinning to prepare the blended yarn of flax fibers and cotton fibers, wherein the relative humidity for the production environment of each step is 58 to 65 percent. The product produced by the invention can be made into various blended fabrics and thus provides a purely natural and comfortable textile product for the field of textile industry.

Owner:JIHUA 3542 TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com