Patents

Literature

88results about How to "Not easy to fluff" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cotton fibers with antibacterial and insect-resisting effects and production method of cotton fibers

InactiveCN104278359AEasy to cleanNot easy to fluffConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCnidium monnieriFatty alcohol

The invention discloses cotton fibers with antibacterial and insect-resisting effects. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 21-24 parts of cotton fibers, 10-12 parts of apocynum venetum fibers, 6-8 parts of silk fibers, 7-9 parts of cashmere fibers, 9-11 parts of pineapple fibers, 4-7 parts of polypropylene fibers, 6-8 parts of taxus chinensis superfine micro-powder, 3-5 parts of ailanthus altissima leaf extracted powder, 1-3 parts of zeolite powder, 1.1-2.3 parts of chitosan, 0.5-0.7 part of magnesium nitride, 0.8-1.4 parts of N,N-dicyanoethylaniline, 5-7 parts of sulfonated castor oil, 15-18 parts of fatty alcohol alkoxy ether, 1-2 parts of mashed garlic, 1.3-2.5 parts of cnidium monnieri cuss, 2.1-3.6 parts of coptis chinensis, 90-95 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-100 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the cotton fibers, the taxus chinensis superfine micro-powder is added into raw materials by adopting an ultrasonic technology and a prepared cotton textile has a very good health effect and a useful pain-relieving effect on tumor patients and female symptoms; furthermore, the other active ingredients are added so that the good clothes properties of sweat absorption, breathability, softness, allergy prevention, easiness of washing, low probability of fuzzing and balling up and the like of natural cotton fibers are maintained, and the cotton fibers have good antibacterial and insect-resisting functions, a good electromagnetic radiation shielding function and the like.

Owner:ANHUI SWAN TECH IND GRP

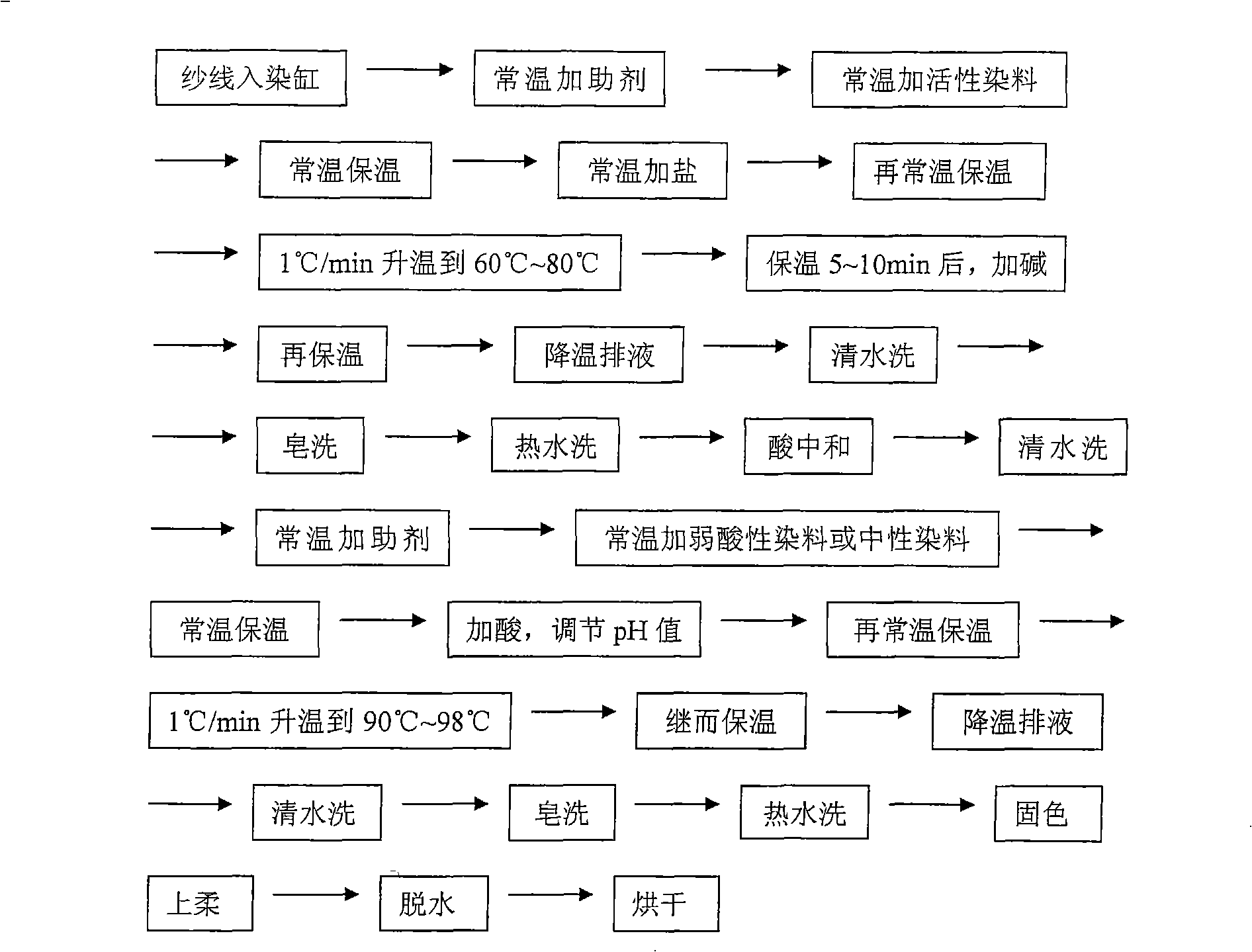

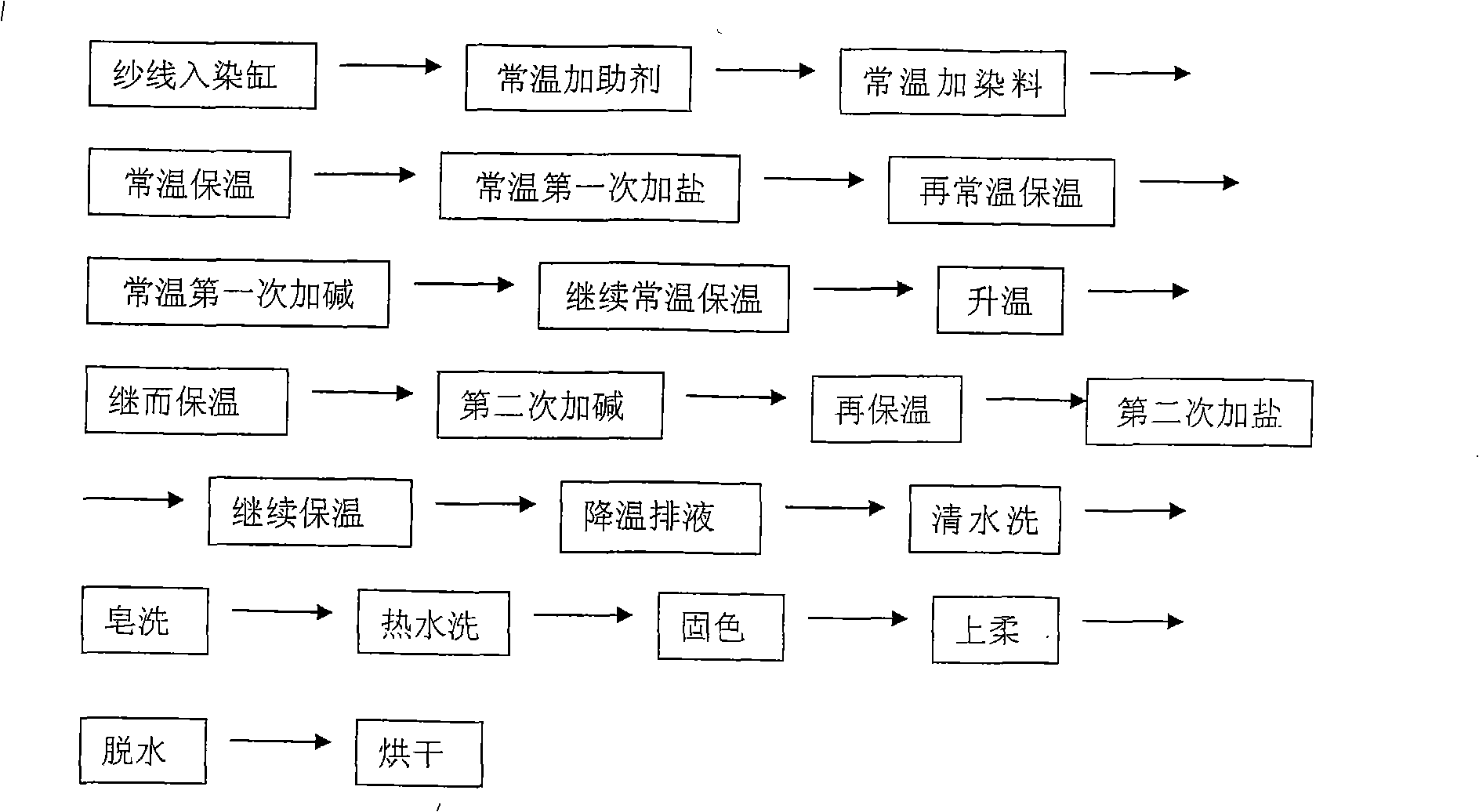

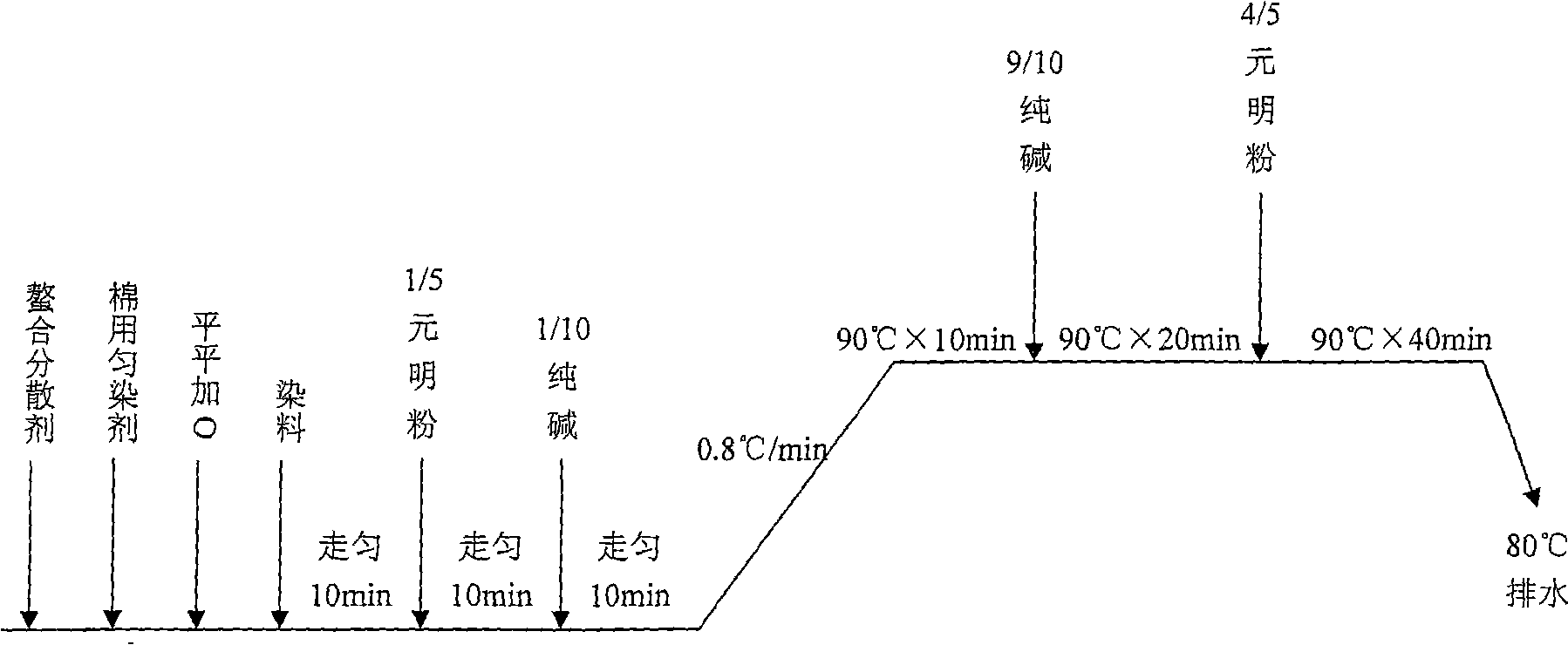

Dyeing process for silk and pashm blended yarn

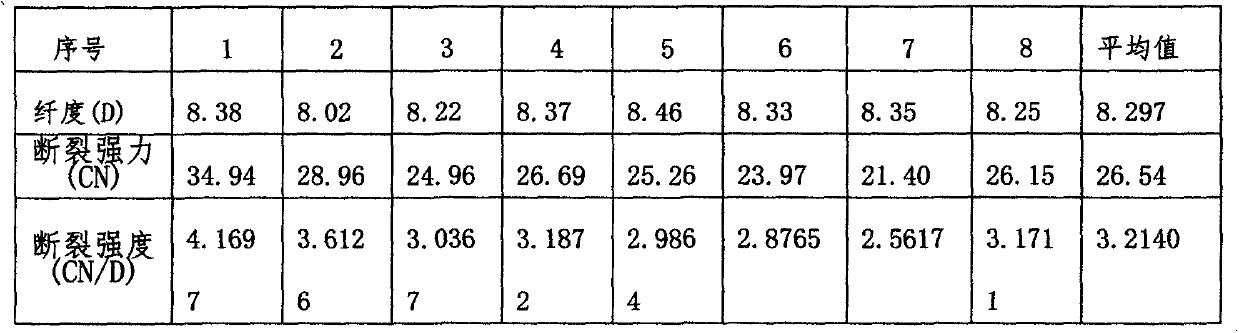

InactiveCN101289812ALow costEmission reductionBeaming machinesDyeing processColour fastnessBreaking strength

The invention provides a process for dyeing silk-cashmere blended yarns, belonging to the weaving yarn dyeing technical field. The process comprises the following steps that: silk-cashmere blended yarns ready to be dyed are put in a dye vat, water is added in the dye vat, and the bath ratio is controlled; at the normal temperature, auxiliary agent and dyes are added in the dye vat; the dye vat is kept warmth at the normal temperature; at the normal temperature, salt is added in the dye vat for the first time; the dye vat is kept warmth at the normal temperature again; alkali is added in the dye vat for the first time; the dye vat is kept warmth at the normal temperature again; the dye vat is heated, and the temperature-rise speed is controlled; the dye vat is kept warmth; alkali is added in the dye vat for the second time; the dye vat is kept warmth again; salt is added in the dye vat for the second time; the dye vat is kept warmth again; finally after sequent steps of temperature drop and liquid discharging, fresh water washing, soap washing, hot water washing, color fixation, upper flexibility, dewatering and drying, dyed silk-cashmere blended yarns are obtained. The process has the advantages of high color fastness, good level-dyeing property, good homochromaatism, high breaking strength, bright color, filled yarns, uneasy teasing, time conservation, low dye cost, simple processing step, energy consumption reduction, low sewage discharge and environment protection.

Owner:常熟市亨时特染织有限公司

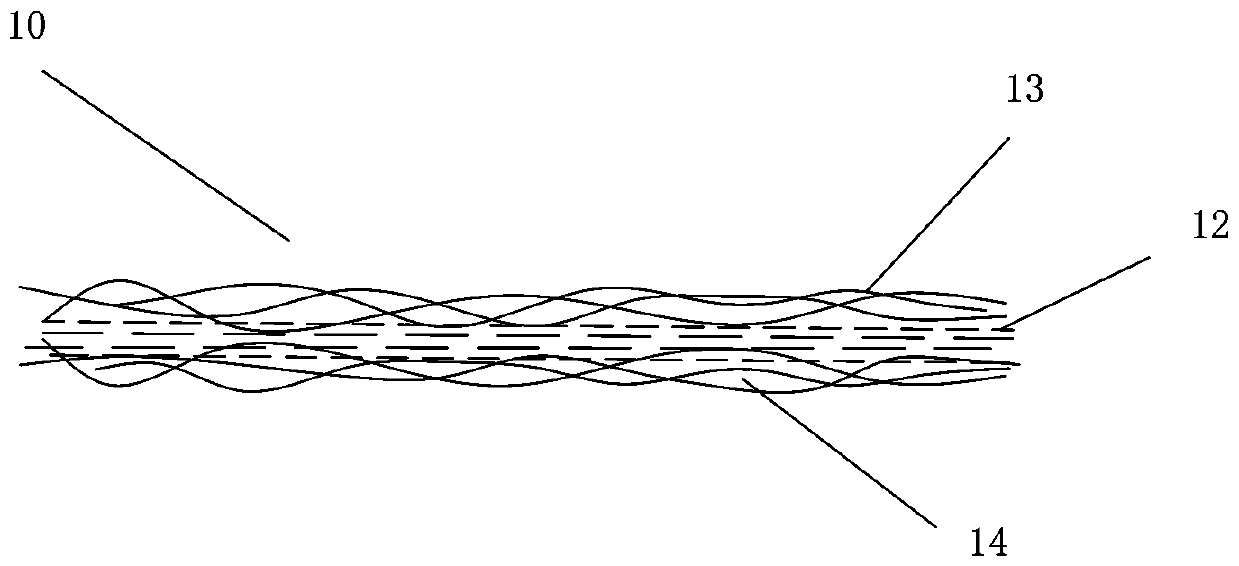

Manufacturing method of fuzz-pilling resistant cellulose fiber weft-knitted fabric

The invention provides a manufacturing method of a fuzz-pilling resistant cellulose fiber weft-knitted fabric, comprising the following steps: (1) processing spun yarn: synchronously drawing and spinning two ribbons consisting of cellulose fiber and cotton to obtain a blended yarn of the cellulose fiber and cotton fiber; (2) taking the blended yarn of the cellulose fiber and the cotton fiber, which is obtained in the step (1), as a wire gauze, and knitting the blended yarn with a naked spandex yarn by a weft plain knitting method, wherein each knitting system knits one wire gauze and one naked spandex yarn plating yarn together to obtain a weft-knitted single-face plain knitting platedwork fabric; and (3) heating and pre-shaping the weft-knitted single-face plain knitting platedwork fabric, and then dyeing and shaping the weft-knitted single-face plain knitting platedwork fabric to obtain the fuzz-pilling resistant cellulose fiber weft-knitted fabric. The invention not only solves the problem of fuzz-pilling resistance of a blended fabric taking the cellulose fiber as the main part, but also has large elastic extension and small elastic-restoring force, and also has soft and comfortable hand feeling after being knitted into clothes and trousers.

Owner:SHANGHAI THREE GUN GROUP +1

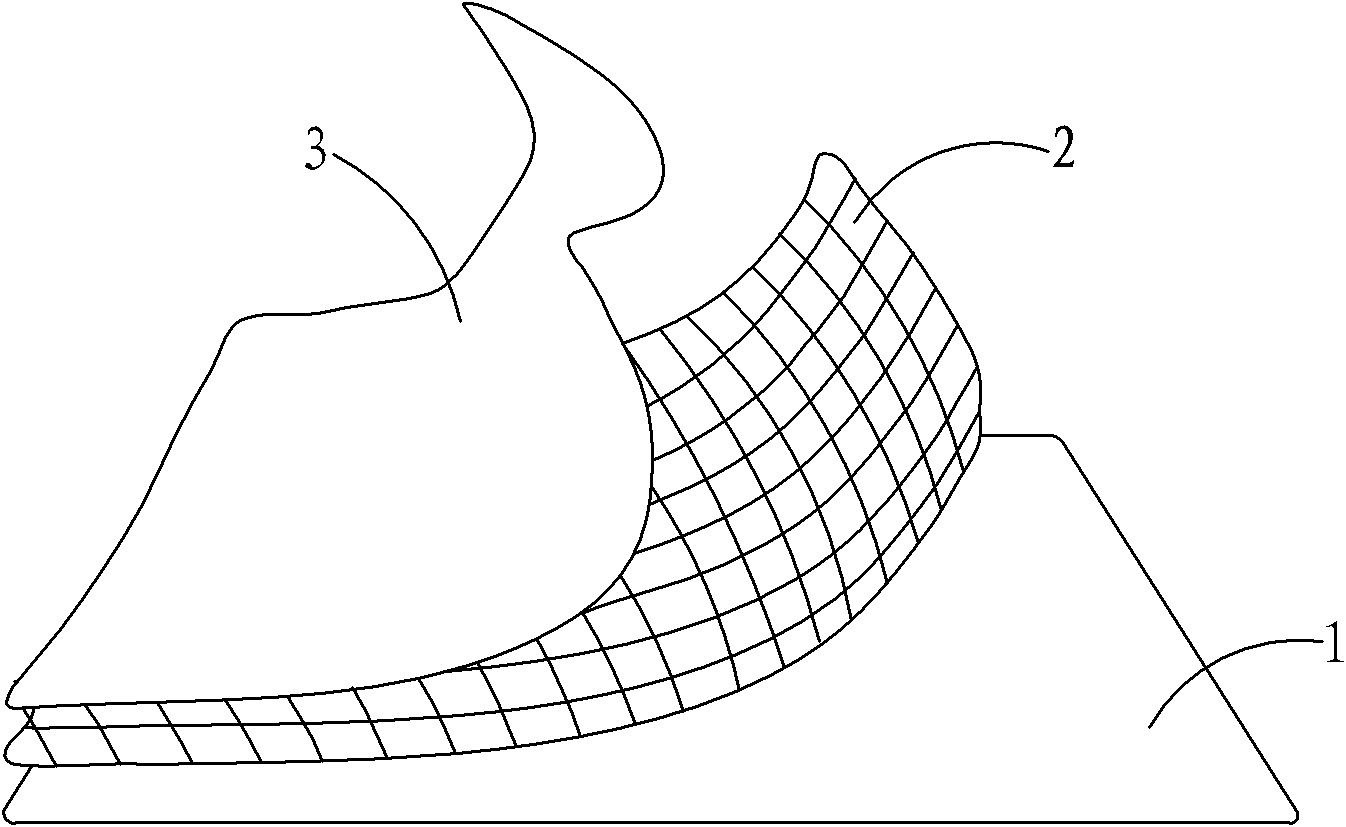

Silk hot-air non-woven fabric

The invention discloses a silk hot-air non-woven fabric which prepared by fine-denier fibers, silk fibers and ES fibers through a hot-air bonding technology.Non-hot melting silk fibers are adopted as the silk fibers, and the melting point of the ES fibers is 130 DEG C.A preparation method of the silk hot-air non-woven fabric comprises the following steps that 1, the ES fibers and the silk fibers are mixed and carded into a web to obtain a fiber web; 2, hot-air bonding reinforcing is performed on the fiber web obtained in the step 1 to obtain the hot-air non-woven fabric; in the carding process of the step 1, the obverse side of the fabric adopts messy carding, and the reverse side of the fabric adopts a dual-carding technology comprising messy carding and vertical carding.The non-woven fabric is comfortable in handfeel, silky and not prone to be fluffed, and the silk fibers can directly make contact with the skin, so that the skin friendliness is achieved; the breakthrough of producing a natural fiber non-woven fabric through a hot-air technology is achieved, the using performance of the silk hot-air non-woven fabric is improved, and the great application prospect is achieved.

Owner:SHANGHAI FENGGE NONWOVEN

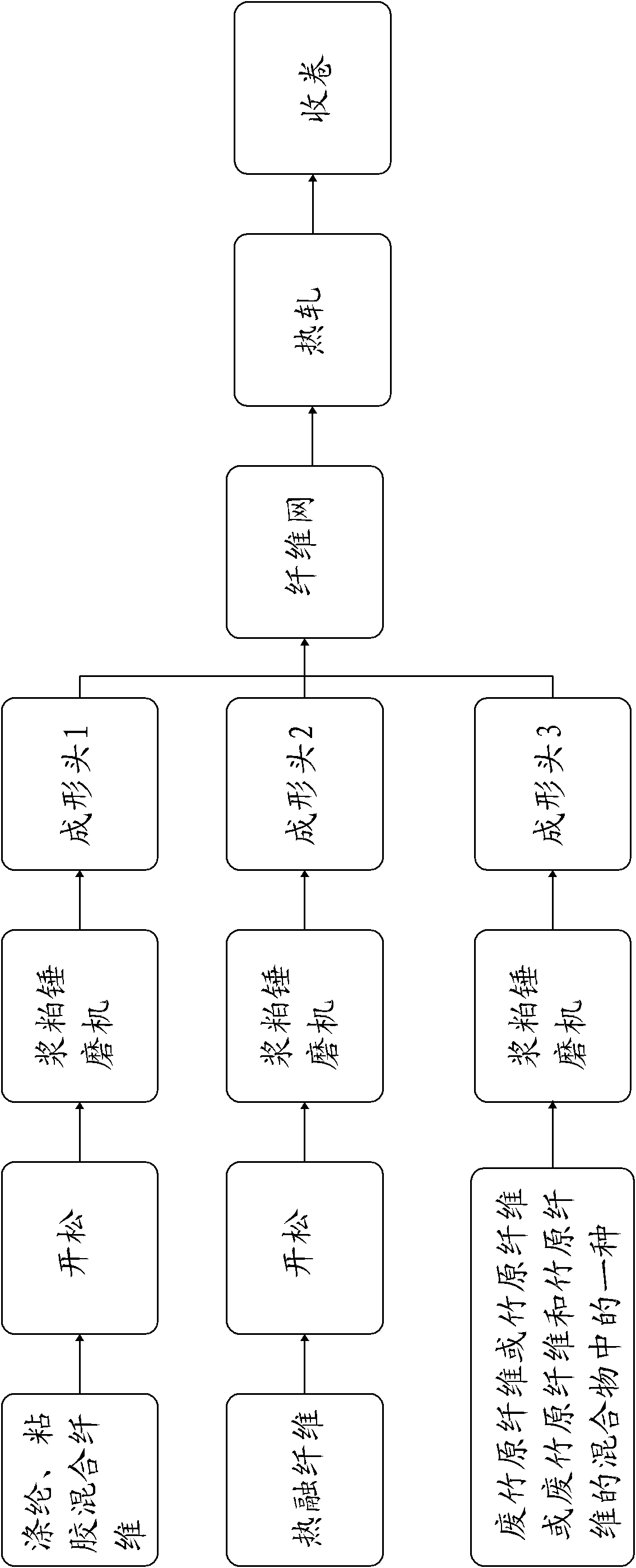

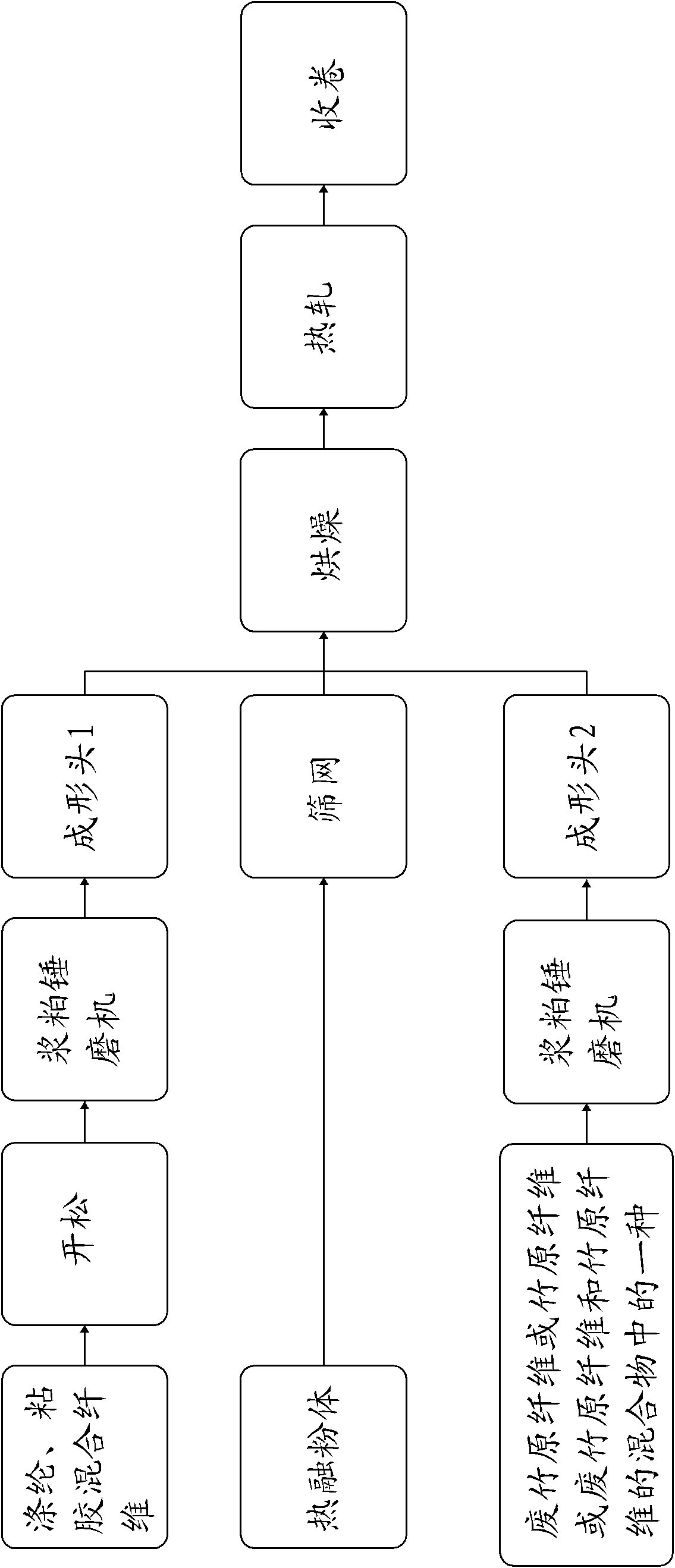

Antibacterial hygienic material made from bamboo proto fibers and manufacturing process and application thereof

InactiveCN102154785ASpeed up exportPrevent re-violationAbsorbent padsNon-woven fabricsPolyesterHot melt

The invention provides an antibacterial hygienic material made from bamboo proto fibers and a manufacturing process and application thereof. The material consists of the following raw materials in percentage by mass: 30 to 60 percent of one of waste bamboo proto fibers or bamboo proto fibers or mixture of waste bamboo proto fibers and bamboo proto fibers, 10 to 60 percent of viscose fibers, 0 to 30 percent of polyester fibers, and 8 to 12 percent of one of hot melt fibers or hot melt powder or latex. The material is prepared according to different raw material formulas and manufacturing processes; the high-permeable moisture-transfer natural antibacterial hygienic material is mainly applied to disposable hygienic products, ensures comfort of the human excretion part, can effectively inhibit bacteria from infringing upon the human body, and is safe, efficient, healthy and environment-friendly; and the process has the advantages of short production flow, simple operation, high efficiency and low cost. The waste bamboo proto fibers are reclaimed wastes generated in the textile processing process, so environmental pollution is lightened, and resources are saved.

Owner:FUJIAN DANHAI MATTRESS

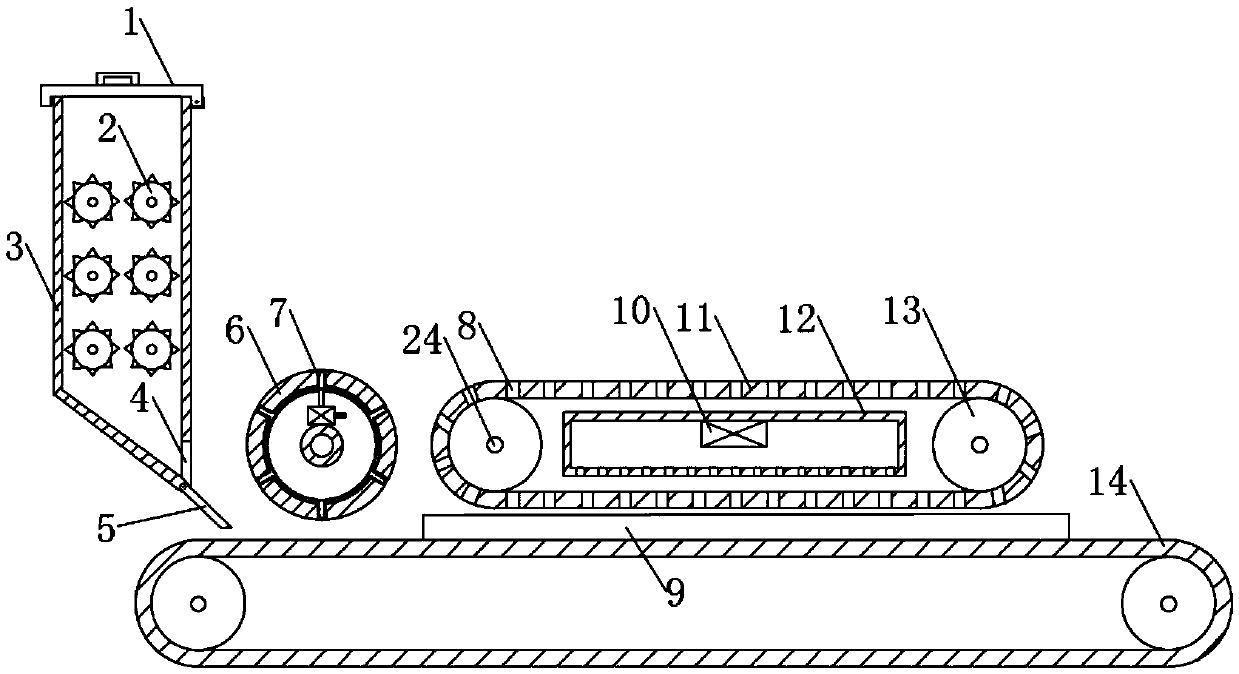

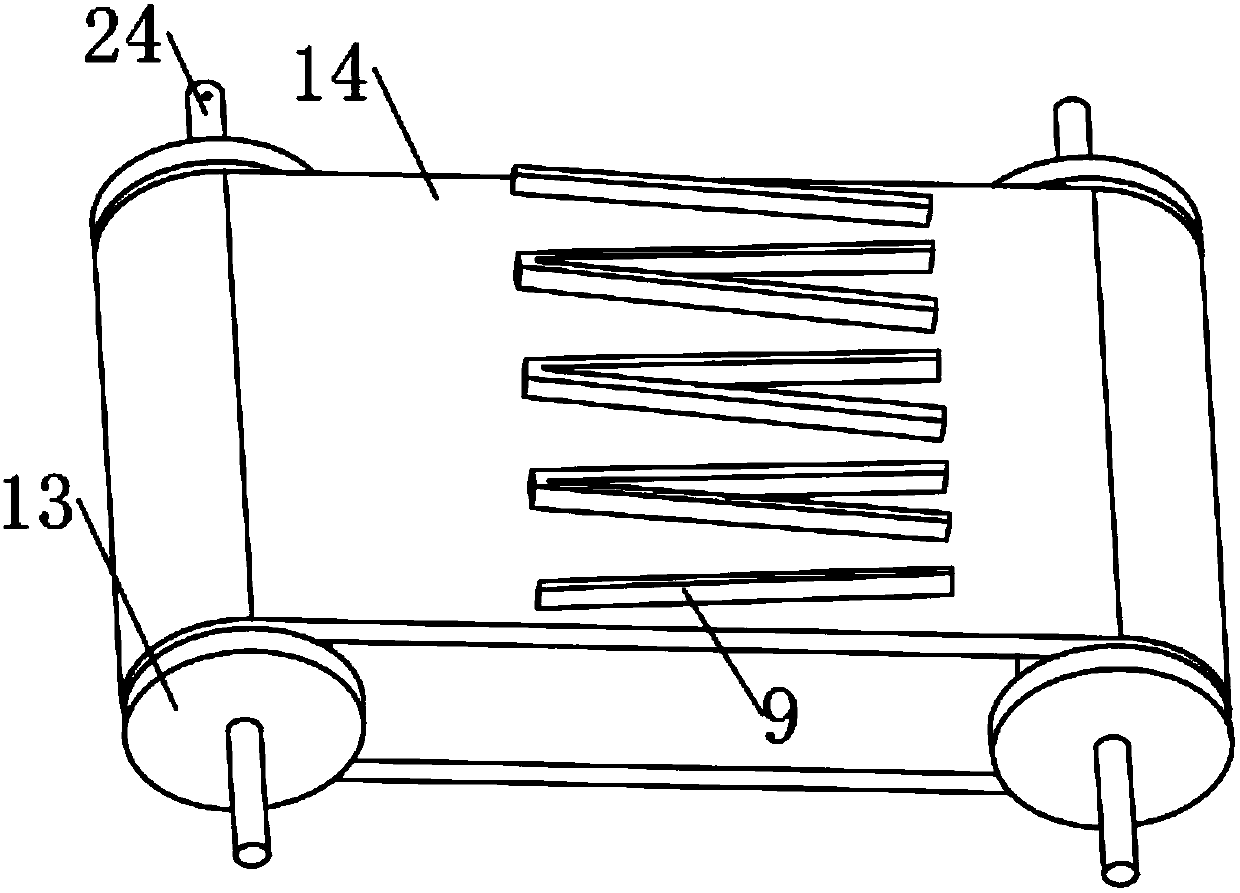

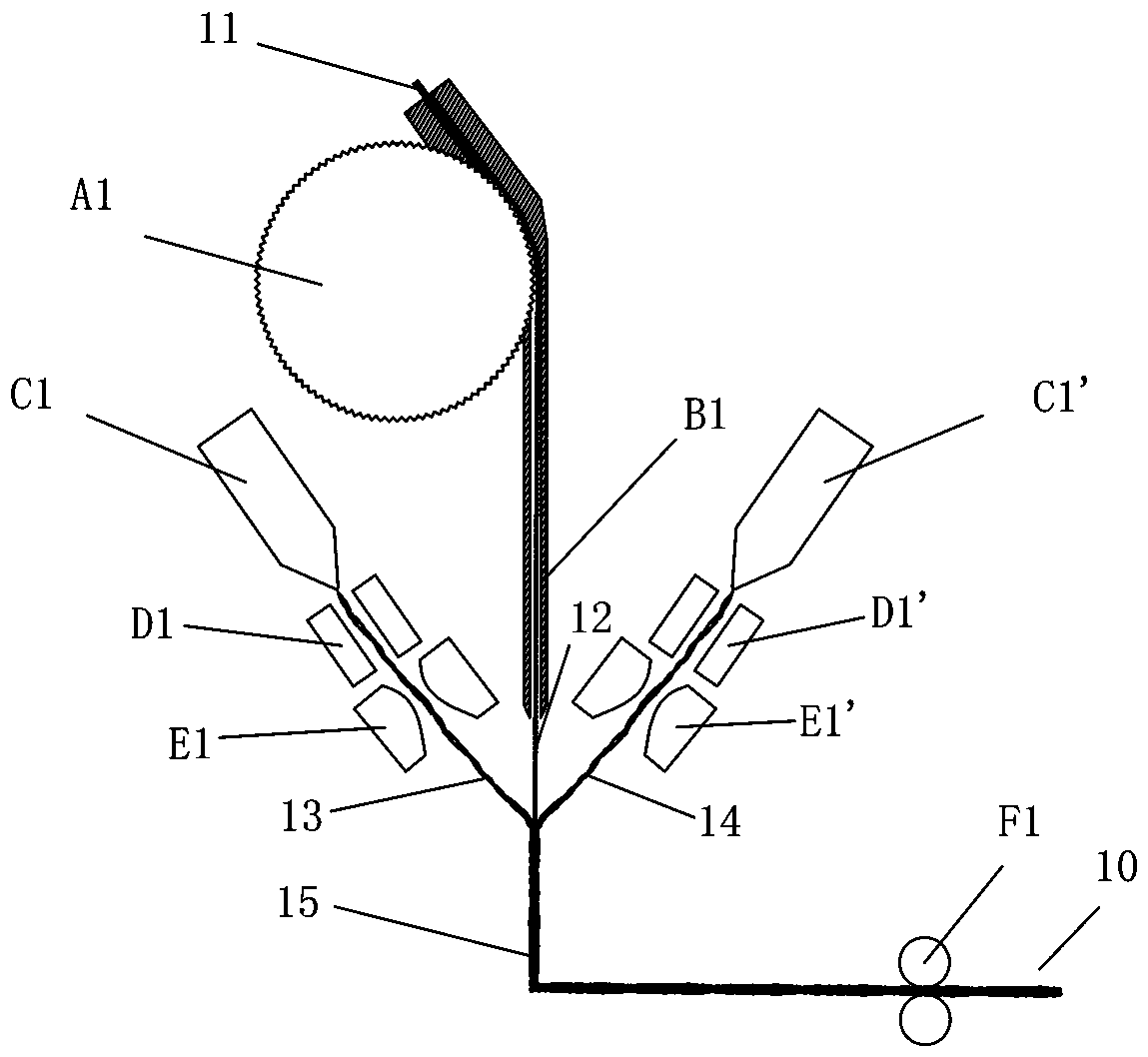

Distributing, positioning and carding device for natural cotton spinning

ActiveCN109594152AEasy to processNot easy to dustCarding machinesLiquid/gas/vapor removalFiberPulp and paper industry

The invention discloses a distributing, positioning and carding device for natural cotton spinning. The device comprises a charging box, carding plates, a lower belt, an upper press belt, a primary hydraulic roller and a hot air box, wherein a box cover is clamped at the upper end of the charging box, and three carding wheel sets are arranged in the charging box from top to bottom. Natural cottonis added to the device from the upper end of the charging box and primarily carded by the carding wheel sets and enters the upper side of the lower belt from a discharging port, the primary hydraulicroller sprays water while rolling, and the cotton is conveyed onto the lower belt below the upper press belt and subjected to distributing, positioning and carding by the carding plates, so that the carded cotton is convenient to process. The natural cotton is wetted by water in a water cavity in the primary hydraulic roller when passing through the primary hydraulic roller and is not prone to dust and fiber rising and easy to card.

Owner:兰溪市京华纺织有限公司

Thin-texture woven fabric formed by superfine mulberry silk fibers

ActiveCN103243446AMeridian defect is smallDo not pull white and strong is goodWoven fabricsEngineeringSilk fiber

The invention discloses thin-texture woven fabric formed by superfine mulberry silk fibers. The thin-texture woven fabric is formed by interweaving of 1 / 7D / 9D mulberry silk monofilaments serving as warp and 1 / 7D / 9D mulberry silk monofilaments serving as weft, the weft adopts brimless barreled silk for interweaving, the warp adopts warp beam silk obtained by warping brimless barreled silk for being interwoven with the weft, the thickness of finished fabric is 2M / M, the warp beam silk is subjected to plain interweaving with the weft under the condition that weaving tension ranges from 11CN to 13 CN, and the weaving tension is controlled to be smaller than loom tension 3CN-5CN of a warp beam. By adopting the scheme, the warp is smooth in backing during weaving, so that end breaking caused by silk embedding is avoided, and defects of warp whitening and high end-breaking rate which are caused by overlarge tension in warp weaving and wrinkling and leno generating which are caused by the fact that tension in warp weaving is too small are overcome. Therefore, the thin-texture woven fabric with the thickness of 2M / M is few in warp-direction defects, high in rate of graded products and ideal in anti-clefting effect.

Owner:DALI SILK ZHEJIANG

Elm timber softening treatment method

InactiveCN106272810AGood softening effectFeatures have little effectWood treatment detailsWood impregnation detailsMedicinePre treatment

The invention discloses an elm timber softening treatment method and belongs to the technical field of timber processing. The elm timber softening treatment method comprises the following steps of 1 timber preprocessing, 2 steam explosion treatment, 3 soaking treatment, 4 drying treatment, 5 ultrasonic treatment and 6 secondary drying treatment. The softening treatment has the remarkable softening effect on elm timbers, has the smaller influence on the original properties of the elm timbers and has a better usage value, the cracking rate is lower during processing, and fluffing is not likely to occur.

Owner:阜南县环宇柳木工艺制品有限公司

Process for producing high soft and high elastic novel spun-laced clothing dressing

InactiveCN101397723AUnrestricted fiber requirementsSoft touchGarmentsCarding machinesInterliningCarding

The invention discloses a production technique of the dressing of high soft and elastic novel spunlaced clothes, which pertains to the technical field of textile materials. The technique essentially comprises the following steps: weighing and supplying, loosening mixed cotton, fine loosening, precise mixing, fine loosening, automatically leveling cotton supplied, porous drum-type fast carding, multistage rotary drum spunlaced tangling, drying, defect examination, winding, dividing and packaging. The production technique has few limitations to raw materials and can meet the production of different raw materials. A produced product has good performance of suspending weight, air permeability, soft touch feeling, small shrinking rate, high strength and wide thickness changing scope, is not easy to have fuzz or pick, does not contain chemical adhesives and is a relatively ideal base fabric for manufacturing the adhesive interlinings of high-grade clothes.

Owner:洪桂焕

Process for producing natural elastic yarn-dyed fabrics with mulberry boiled-off silk wefts

The invention discloses a process for producing natural elastic yarn-dyed fabrics with mulberry boiled-off silk wefts, and belongs to the technical field of production of natural elastic yarn-dyed fabrics with mulberry silk. The process includes warp preparation, weft processing, yarn dyeing and after finishing. Warps are made of 23 dtex mulberry raw color silk f1, weft processing sequentially includes steps of doubling, primary twisting, primary type approval, coiling, degumming, dyeing, sizing, heavy twisting and secondary type approval, and doubling includes carrying out zero-twist doublingon every four 4 pieces of 23 dtex mulberry raw silk f1; primary twisting is carried out under the condition of 500 twist / meter in S twist directions; primary type approval is carried out at the temperature of 80 DEG C for 40 min; sizing slurry comprises sodium alginate with the mass concentration of 5 g / L, the bath ratio is 1:15, and heat is preserved at the temperature of 50 DEG C for 20 min; the twist directions of strong twisting are identical to the twist directions of primary twisting, and strong twisting is carried out under the condition of 2600 twists / meter; secondary type approval iscarried out at the temperature of 90 DEG C for 60 min; after finishing includes hot water loose type low-tension type approval, the bath ratio is 1:10, water is heated until the temperature of the water reaches 60 DEG C, heat is preserved at the temperature of 60 DEG C for 30 min, and after finishing is carried out to obtain the natural elastic yarn-dyed fabrics which are finished products. The process has the advantages that the natural elastic yarn-dyed fabrics are easy to weave, the mulberry boiled-off silk wefts for weaving the natural elastic yarn-dyed fabrics are low in type approval temperature and little in strength damage after being twisted, and the natural elastic yarn-dyed fabrics have good hand feeling.

Owner:DALI SILK ZHEJIANG

Spunbond wipe and manufacturing method thereof

PendingCN109554829ANot easy to fluffClosely arrangedFilament/thread formingSanitary towelsSurface layerMaterials science

The invention discloses a spunbond wipe and a manufacturing method thereof. At least one of upper and lower layers of the spunbond wipe is a spunbond long fiber layer while a middle layer is a wood pulp fiber mesh layer, and spunbond long fibers in the spunbond long fiber layer are inserted into the wood pulp fiber mesh layer. The manufacturing method can be used for manufacturing the spunbond wipe. Since at least one surface of the wipe is provided with the spunbond long fiber layer made of the spunbond long fibers, the middle layer is the wood pulp fiber mesh layer, and the spunbond long fibers in the spunbond long fiber layer are inserted into the wood pulp fiber mesh layer, the wood pulp fibers close to the surface layer are fixed into the wood pulp fiber mesh layer; since the surfacespunbond long fiber layer is densely arrayed due to fine fibers, residues of the wood pulp fibers on wiped articles due to movement of the wood pulp fibers from the middle layer to the surface of thewipe are effectively prevented.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

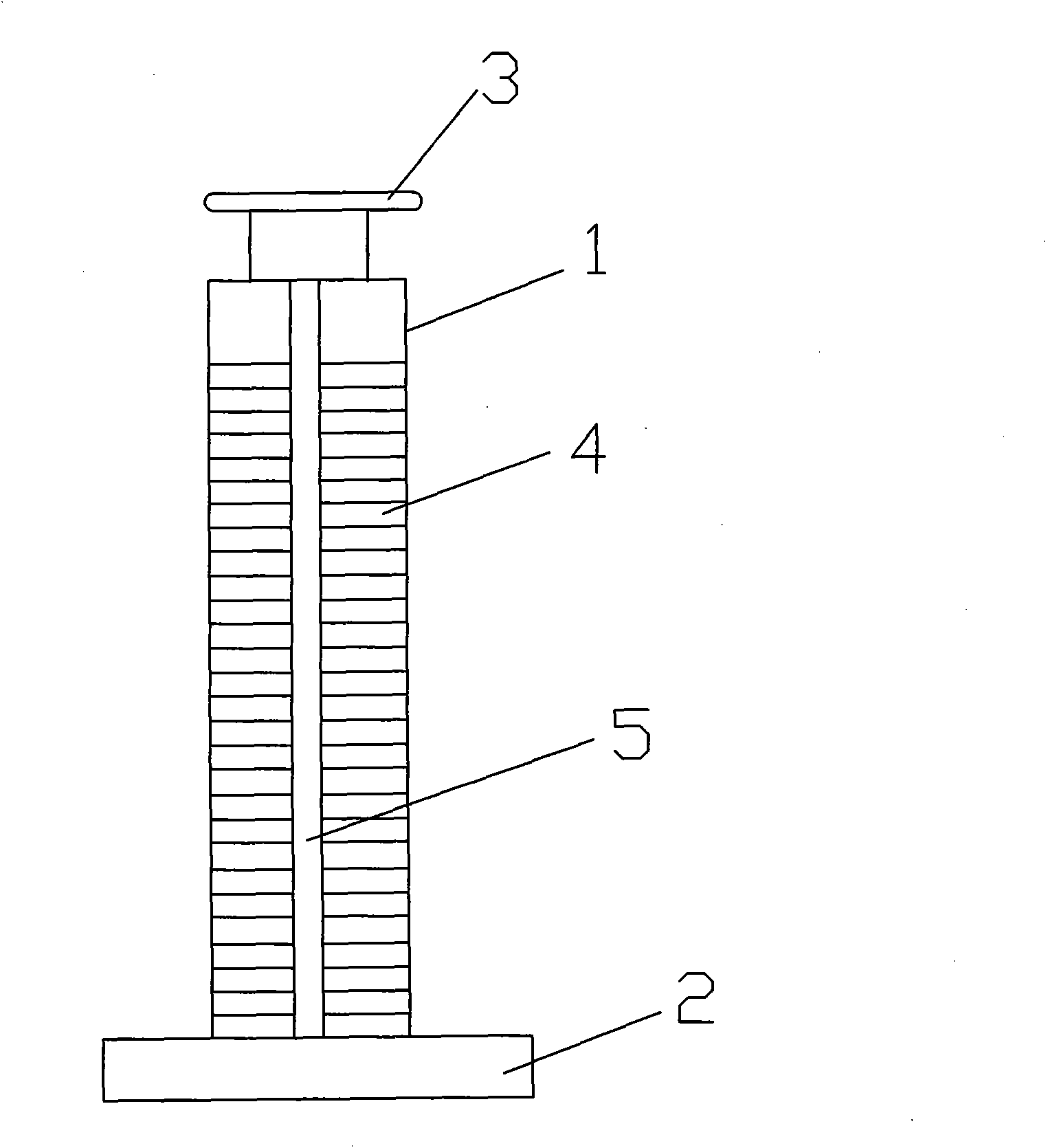

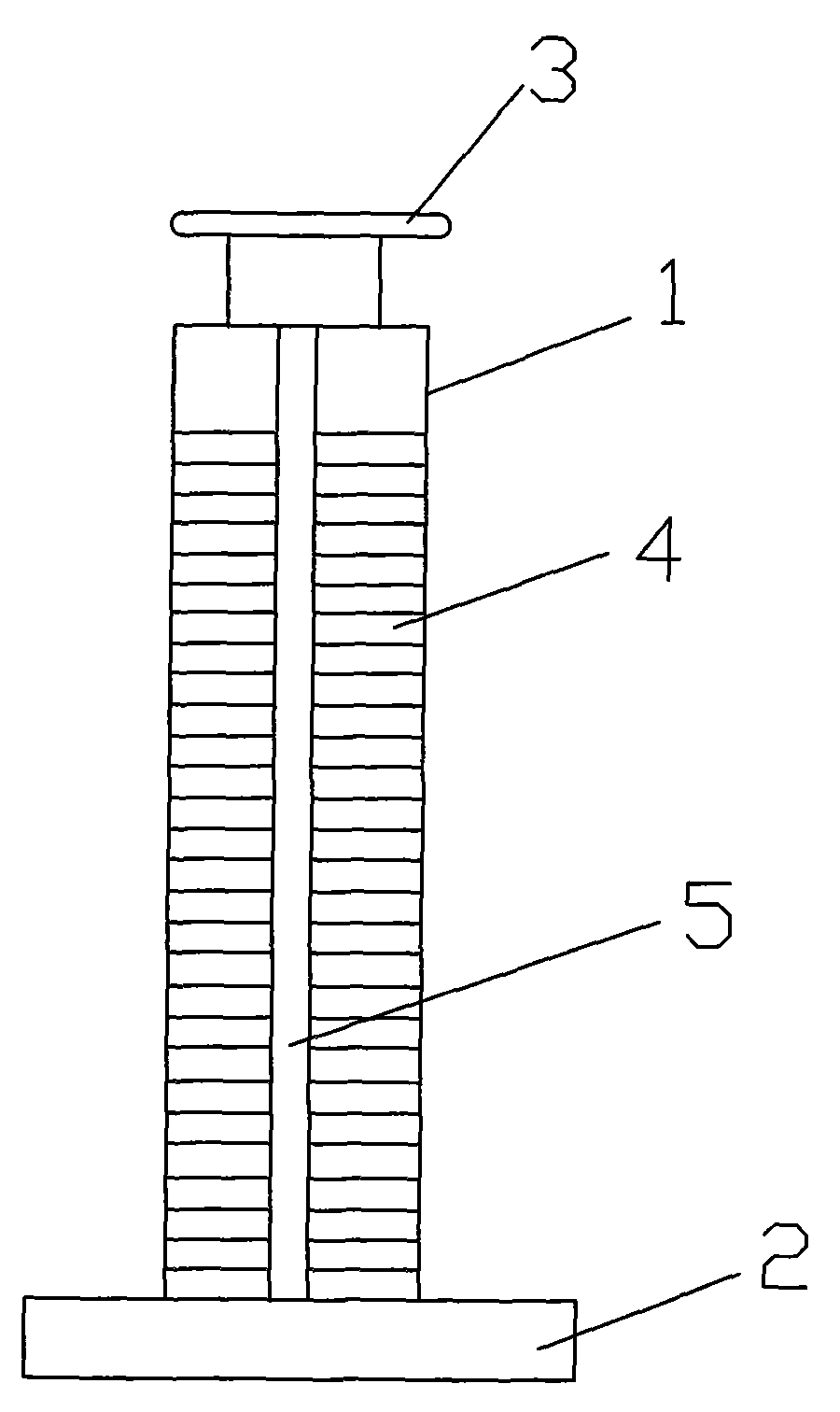

Bobbin

InactiveCN102114998ANot easy to fluffNot prone to loose bubbles and other phenomenaBobbinEngineering

The invention provides a bobbin. The bobbin comprises a base and a bobbin core, wherein, the surface of the bobbin core is equipped with a locking slot and a yarn unwinding slot, and a yarn guide head is arranged on the front end of the bobbin core. The bobbin has the beneficial effects that strength is high, surface is smooth, and the phenomena such as fuzzing, bubbling and the like can be avoided on yarn during the production process in procedures, thus effectively ensuring the quality of the finished yarn; and the bobbin can be reused, thus being convenient for collection, greatly lowering production cost and improving economic benefit.

Owner:CHANGSHU FANGYUAN TEXTILE EQUIP FACTORY

Lightweight antibacterial sportswear fabric

InactiveCN102926096AGood hygroscopicityImprove smoothnessWoven fabricsYarnYarnAntibacterial property

The invention discloses a lightweight antibacterial sportswear fabric. The lightweight antibacterial sportswear fabric is weaved by warps and wefts. The warps are 40-60% of the fabric in weight; the wefts are 40-60% of the fabric in weight; the warps and the wefts are blended yarns of tencel fibers and linen fibers, wherein the tencel fibers are 40-50% of the blended yarns in weight, and the linen fibers are 50-60% of the blended yarns in weight. Therefore, the fabric has the advantages of excellent hygroscopicity, flexicity and elegant property, light weight, comfort, good toughness, antibacterial property and environmental protection and cannot pill easily.

Owner:WUJIANG HONGKAI TEXTILE

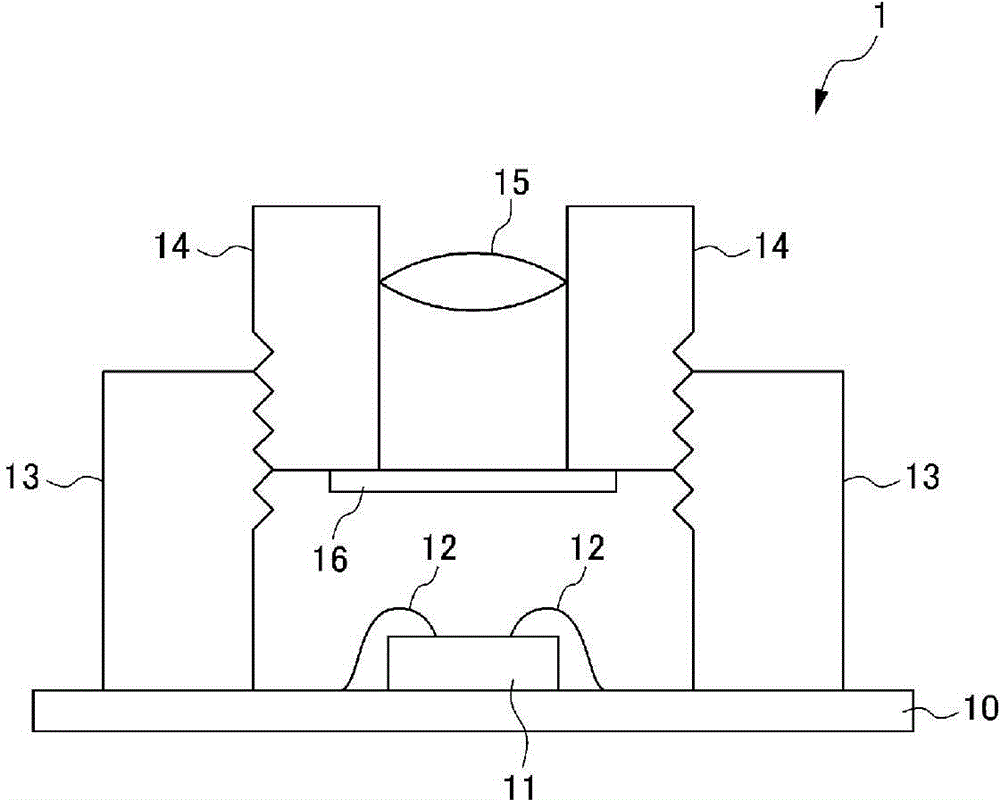

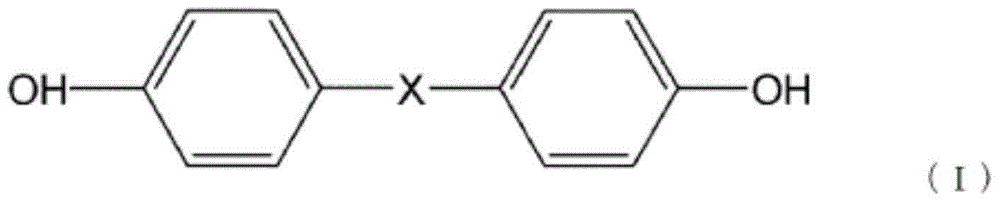

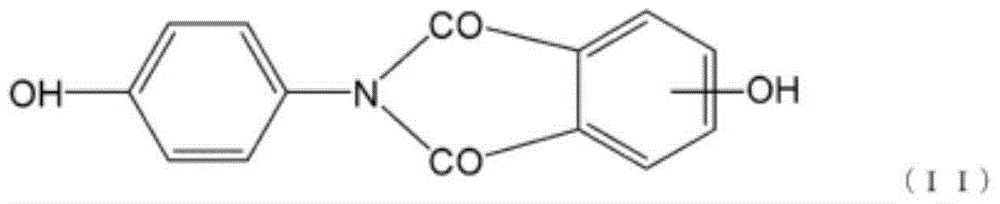

Liquid crystal resin composition for camera modules

Provided is a liquid crystal resin composition for camera modules, which is used for the purpose of producing a camera module component. The surface of a molded body of this liquid crystal resin composition for camera modules is not easily raised. This resin composition is obtained by blending at least one kind of (B) an inorganic filler that is selected from among (B1) fibrous fillers and (B2) non-fibrous fillers and at least one kind of (C) a copolymer that is selected from among (C1) olefin copolymers and (C2) styrene copolymers into (A) a liquid crystal resin, so that the component (A) is 65-93% by mass, the component (B) is 5-20% by mass and the component (C) is 2-10% by mass. The component (B1) has an average fiber diameter of 1.0 mum or less and an average fiber length of 5-50 mum, and the component (B2) is at least one filler that is selected from among plate-like fillers and granular fillers having an average particle diameter of 50 mum or less. The component (C1) and the component (C2) are respectively configured of specific components.

Owner:POLYPLASTICS CO LTD

Glue pudding

The invention provides a glue pudding. The filling of the glue pudding is obtained by frying salad oil. Due to the low melting point of the salad oil, after the glue pudding with the filling is cooked thoroughly, the filling is still viscous and non-stiff in water at about 0 DEG C, thus the glue pudding is suitable for people to eat in an iced condition in summer.

Owner:ZHENGZHOU SYNEAR FOOD

Method of producing flat fibers for plastic woven bags and flexible freight containers by using waste PET (polyethylene terephthalate) bottles

InactiveCN105538640ANo pollution in the processGood self-extinguishingPlastic recyclingArtificial filament heat treatmentPolyesterFiber

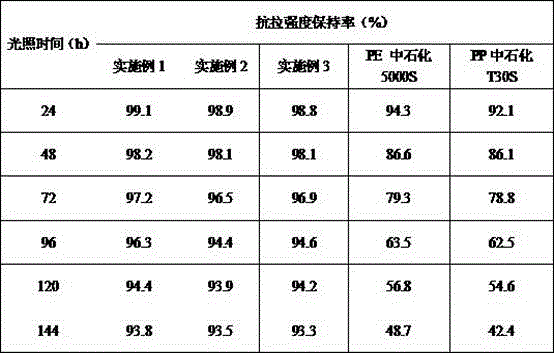

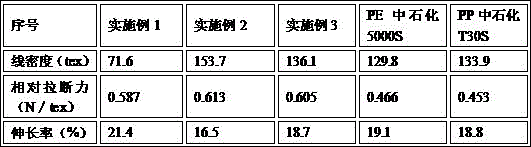

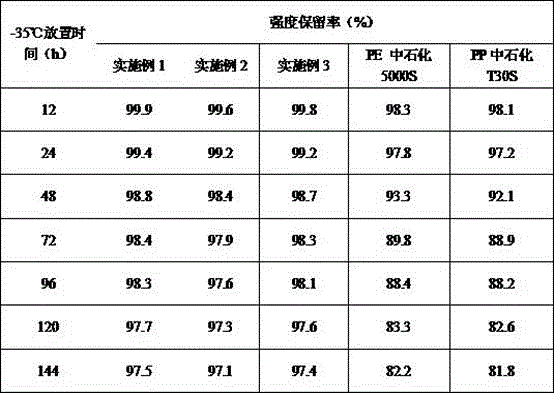

The invention relates to a method of producing flat fibers for plastic woven bags and flexible freight containers by using waste PET (polyethylene terephthalate) bottles. The method is characterized by comprising the following steps of: mixing the waste PET bottles which are dried or crystalized in advance with a compatibilizer, an antioxidant, a tackifier, a filling agent, a color masterbatch, a lanthanide series metallic compound and additives, then adding the mixture to an extruder, carrying out extrusion, filtering and measurement in sequence, carrying out tape casting by using a die head, and cooling on a cooling roller to obtain films. The relative pulling strength (N / tex) of the flat fibers is greater than or equal to 0.58; the elongation rate (%) of the flat fibers is 16.5-21.4; the oxygen index of the flat fibers is above 26; the linear density (tex) of the flat fibers reaches 71.6-153.7; the tensile strength retention rate of the flat fibers is 93.3%-93.8% when the flat fibers are placed for 144 hours; the strength retention rate of the flat fibers is 97.1%-97.5% when the flat fibers are placed for 144 hours at the temperature of minus 35 DEG C; when being placed for 2 hours at the temperature of 140 DEG C, the shrinkage rate of the 10 cm flat fiber is 0; and the ink layer combination firmness of the flat fibers is 92%-99%.

Owner:QINGDAO UNIV +1

Anti-pilling wool-like knitted fabric and preparation method thereof

InactiveCN109281174AImprove comfort and elasticityIncrease elasticityWeft knittingHeating/cooling textile fabricsYarnChemistry

The invention discloses an anti-pilling wool-like knitted fabric and a preparation method thereof. The preparation method comprises the following steps: (1) preparation of first yarns and second yarns; (2) weaving of a gray fabric: selecting the first yarns and the second yarns and performing front-back interweaving by using a thick-and-thin needle alternating structure via a knitter so as to weave the gray fabric; (3) dyeing: dyeing the above gray fabric with a cationic dye and a reactive dye; (4) anti-pilling finishing: subjecting the dyed gray fabric to softening treatment and anti-pillingtreatment successively; and (5) post-treatment: subjecting the dyed gray fabric to tentering, shaping, perching and rolling. The anti-pilling wool-like knitted fabric prepared by using the method of the invention can imitate the rough style of a woolen sweater; since cotton yarns are used for weaving, the elasticity of the fabric is improved, and the fabric has good elasticity and a fine back surface, and can be worn next to the skin; and the pilling effect of the fabric is improved compared with wool fabrics, and the fabric is not easy to fluff and has low cost.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

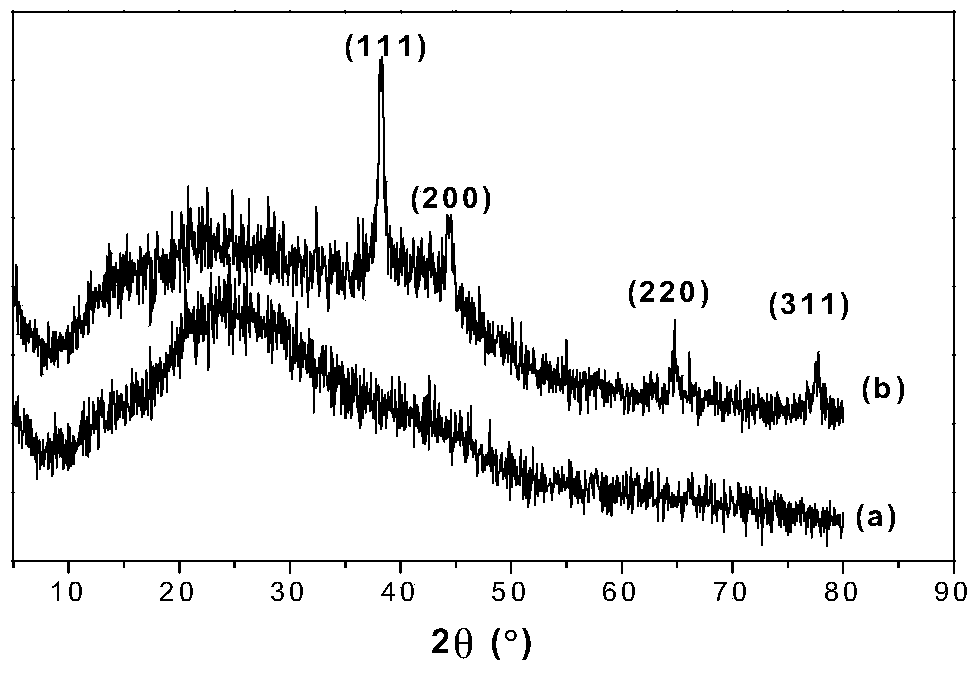

Preparation method for silver golden regenerated cellulose fiber/silver golden regenerated cellulose fiber fabric

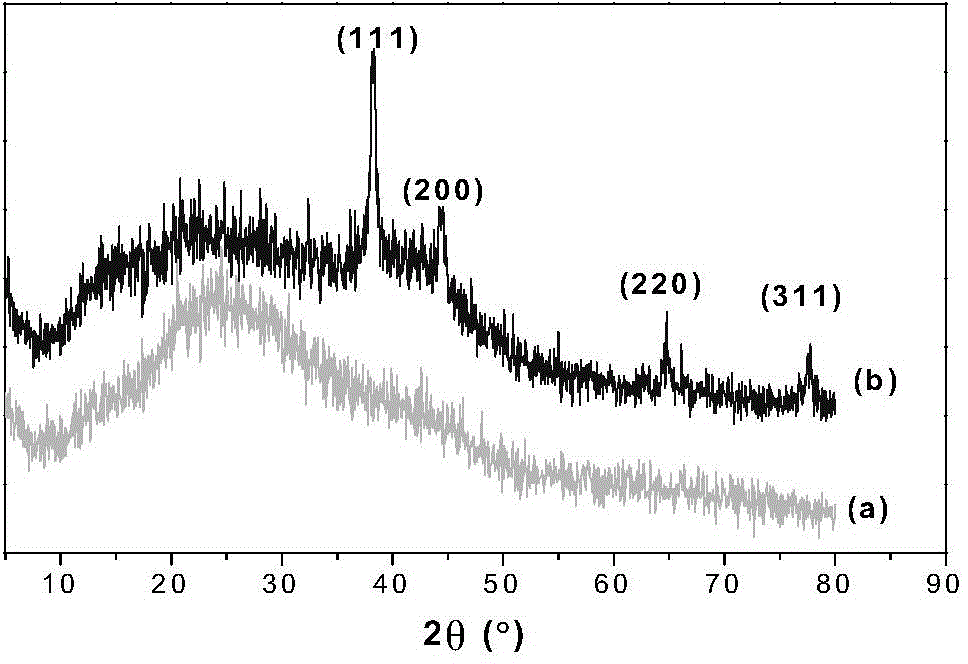

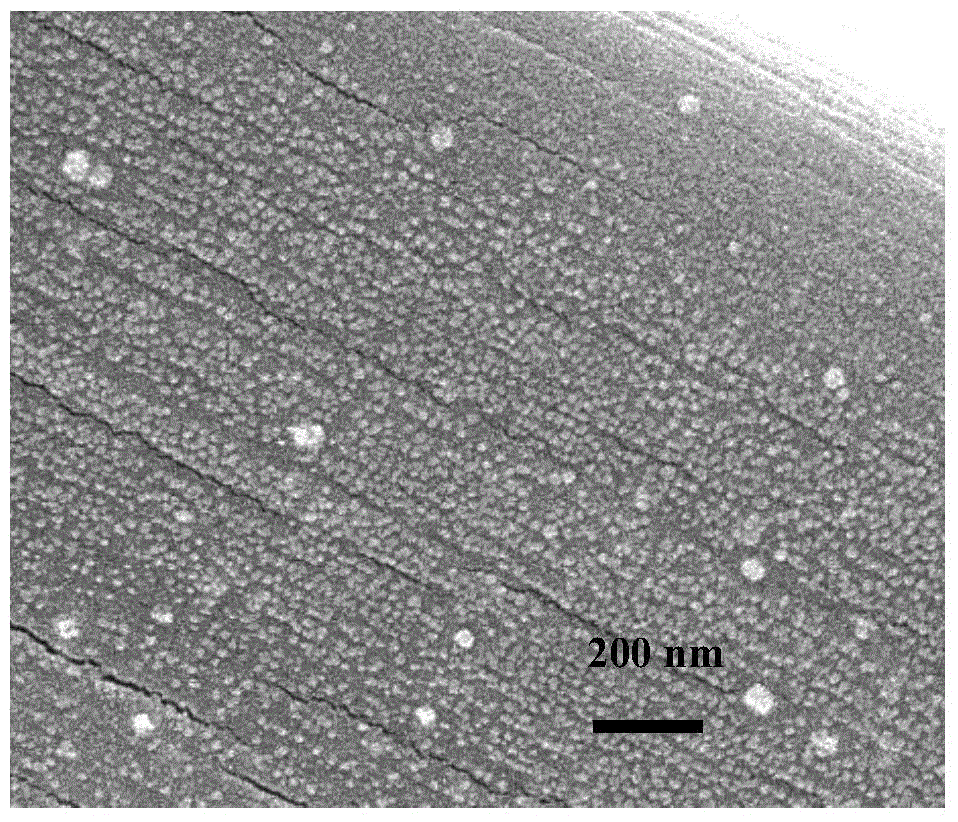

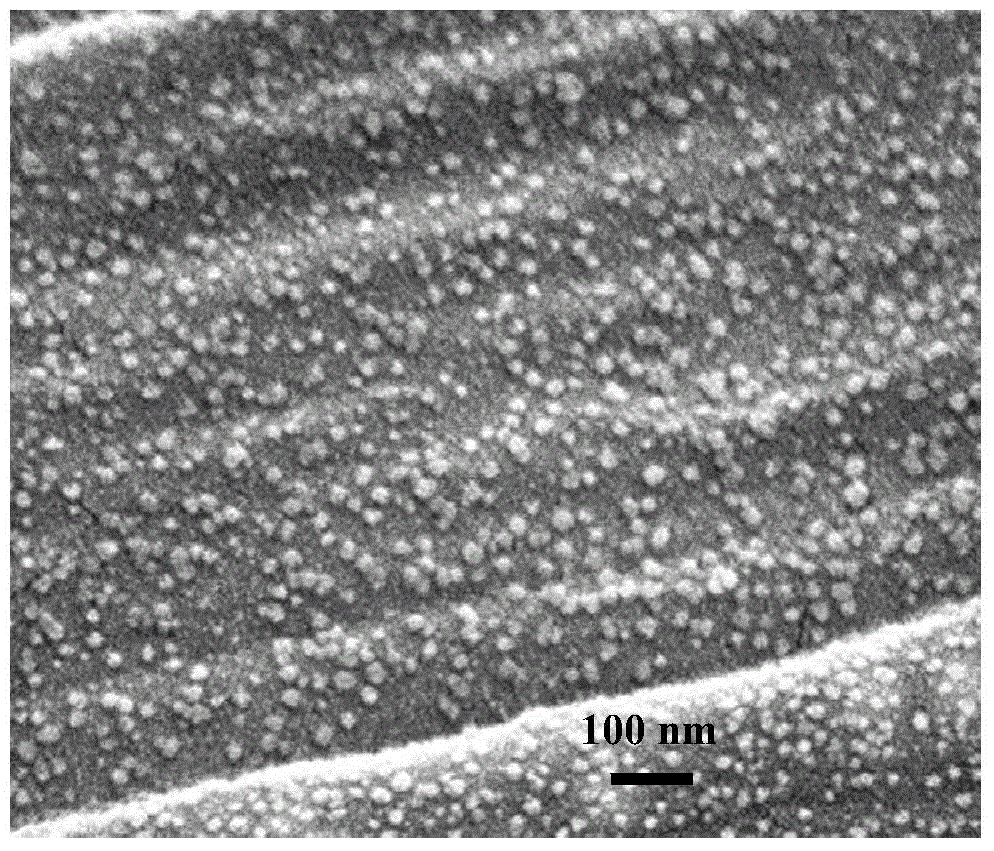

ActiveCN103820992AIncrease added valueImprove the decorative effectVegetal fibresChemical platingPolymer science

The invention discloses a preparation method for a silver golden regenerated cellulose fiber / silver golden regenerated cellulose fiber fabric. According to the preparation method, regenerated cellulose fiber and / or regenerated cellulose fiber fabric is taken as a raw material and soluble silver salts are adopted to obtain the golden regenerated cellulose fiber / golden regenerated cellulose fiber fabric, under the action of lewis acid catalysts and by adopting a catalytic nano chemical plating technology. The silver golden regenerated cellulose fiber / silver golden regenerated cellulose fiber fabric has the functions of antibiosis, deodorization, static electricity resistance and anti-electromagnetic radiation, and can be applied to the fields of military, medical treatment, public health, home furnishing and clothing. The regenerated cellulose fiber, adopted as the raw material by the invention, is cotton pulp regenerated cellulose fiber, wood pulp regenerated cellulose fiber, bamboo pulp regenerated cellulose fiber, or sodium alginate regenerated cellulose fiber; the regenerated cellulose fiber fabric, adopted as the raw material by the invention, is pure fabrics or blended fabrics of the regenerated cellulose fibers, or the blended fabrics of the regenerated cellulose fibers and other chemical fibers.

Owner:QINGDAO UNIV

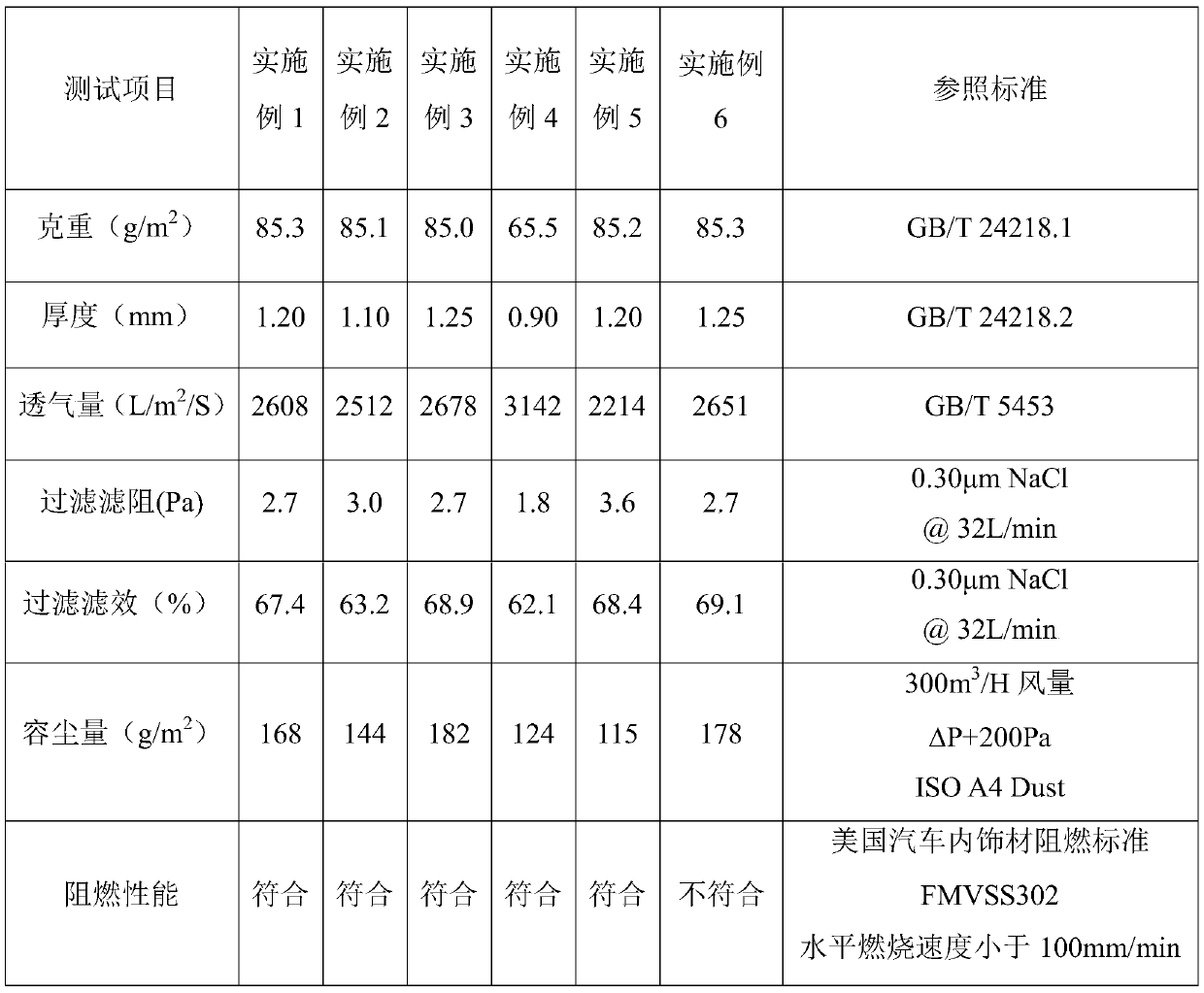

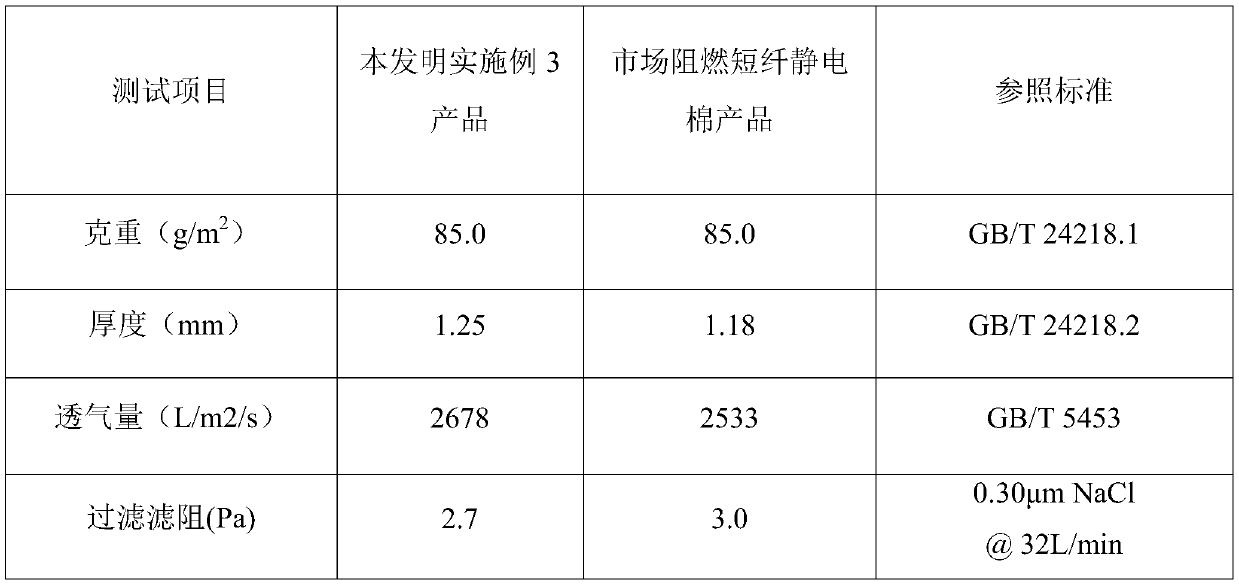

Static cotton material and preparation method and application thereof

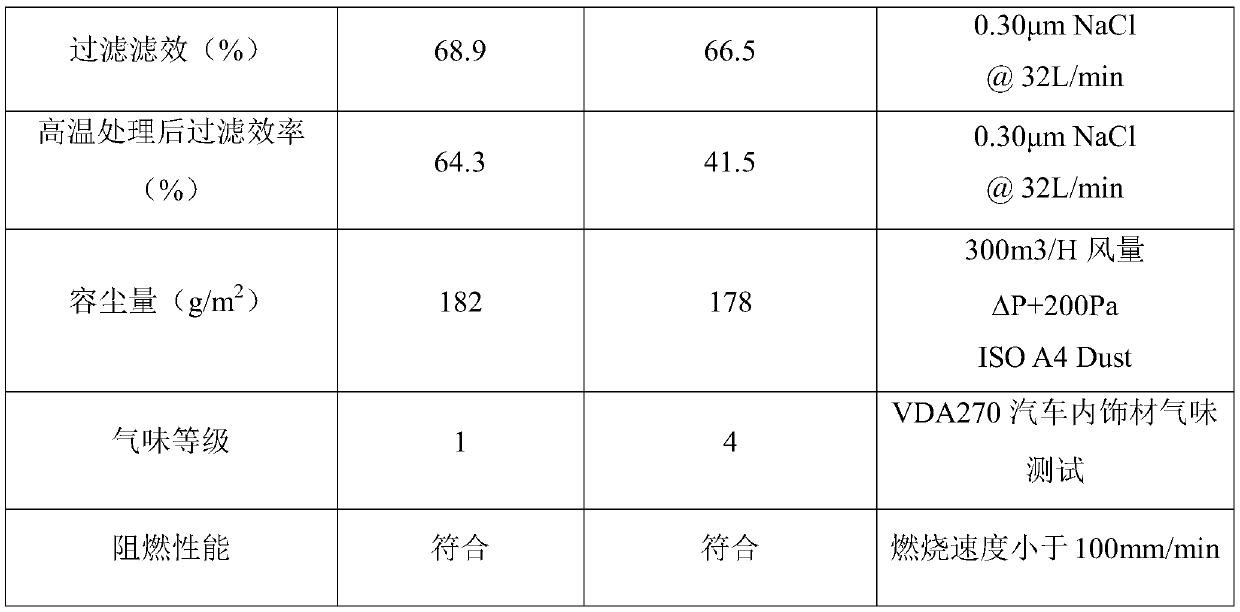

ActiveCN110499586AStrong residencyLess static decayHuman health protectionFlame-proof filament manufactureAir filtrationFresh air

The invention provides a static cotton material and a preparation method and application thereof. The static cotton material is composed of a double-component composite filament yarn, the two components are of a parallel structure in the composite filament yarn, wherein the melt index of the component material A is 34-42 g / 10 minutes, the intrinsic viscosity of the component material B is 0.60-0.69 dl / g, and the oxygen index of the component material B is higher than 28.0%. the production process of the static cotton material is completely environmentally friendly, in use, the high-temperatureenvironment filter efficiency is little attenuated, the static cotton material has a bright filament yarn aesthetic cloth cover style, is low in smell and has a flame-retardant effect, and the staticcotton material is used for a high-dust-holding-capacity material in the field of building fresh air systems or vehicular air filtration application.

Owner:上海精发实业有限公司

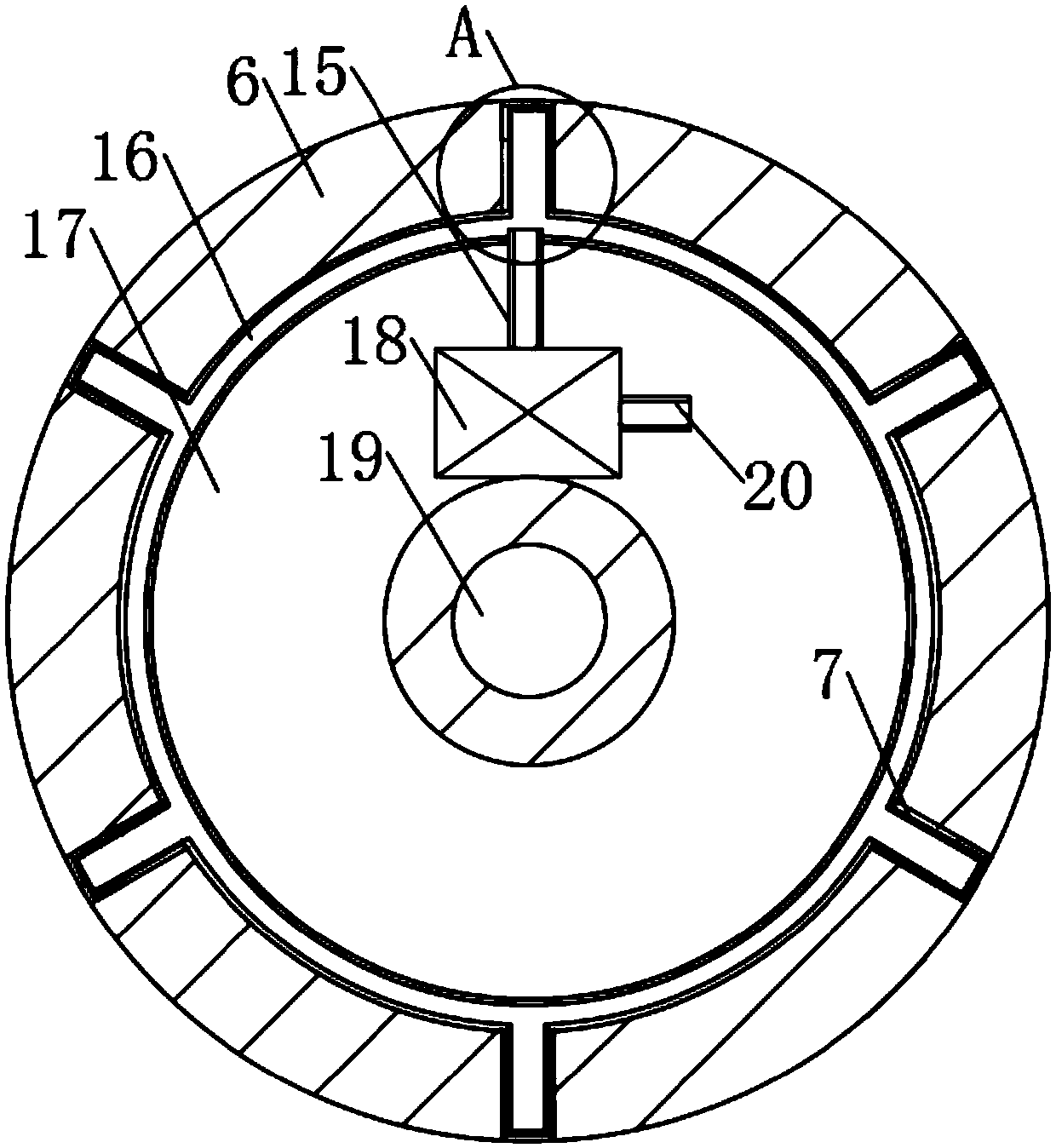

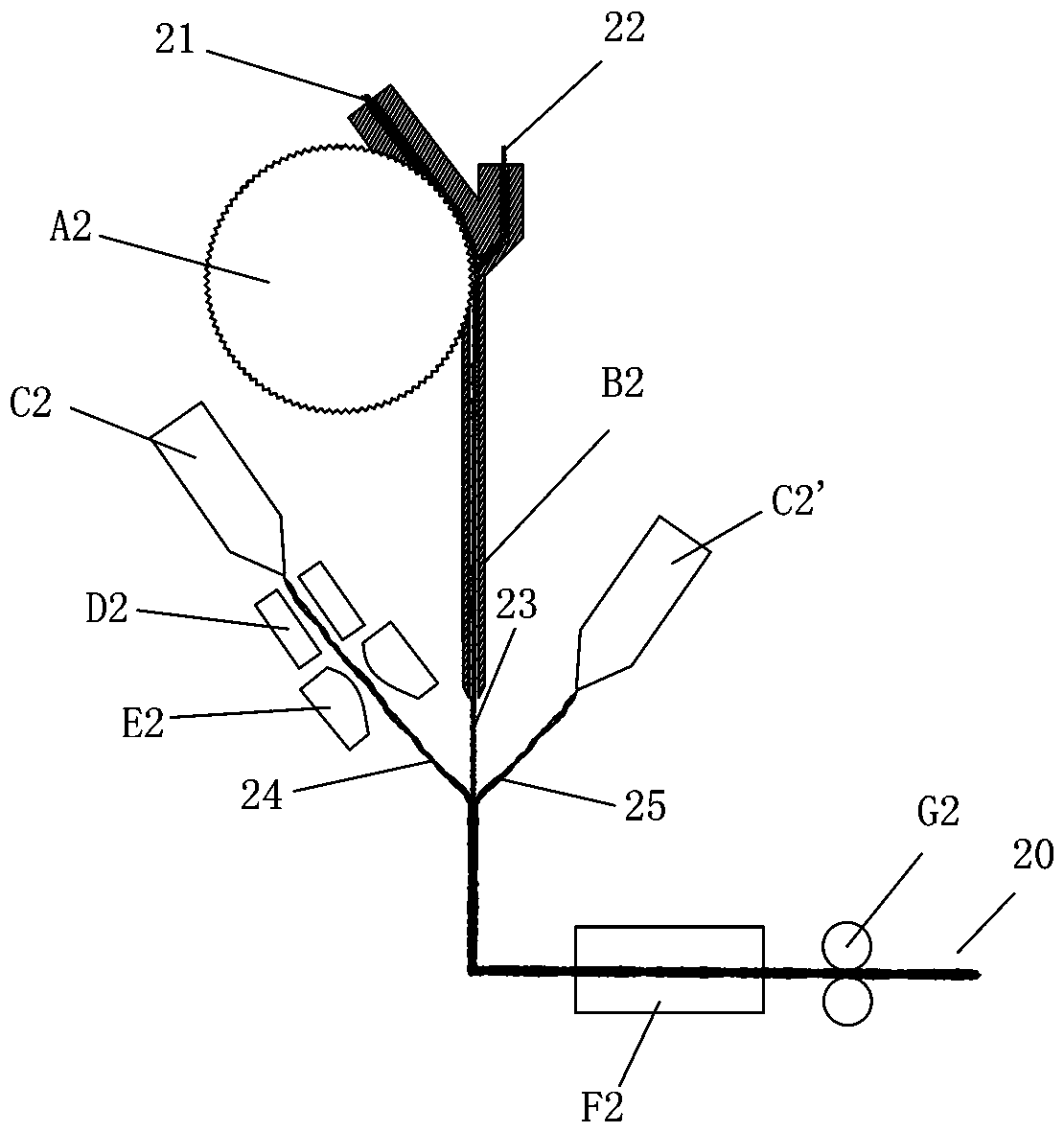

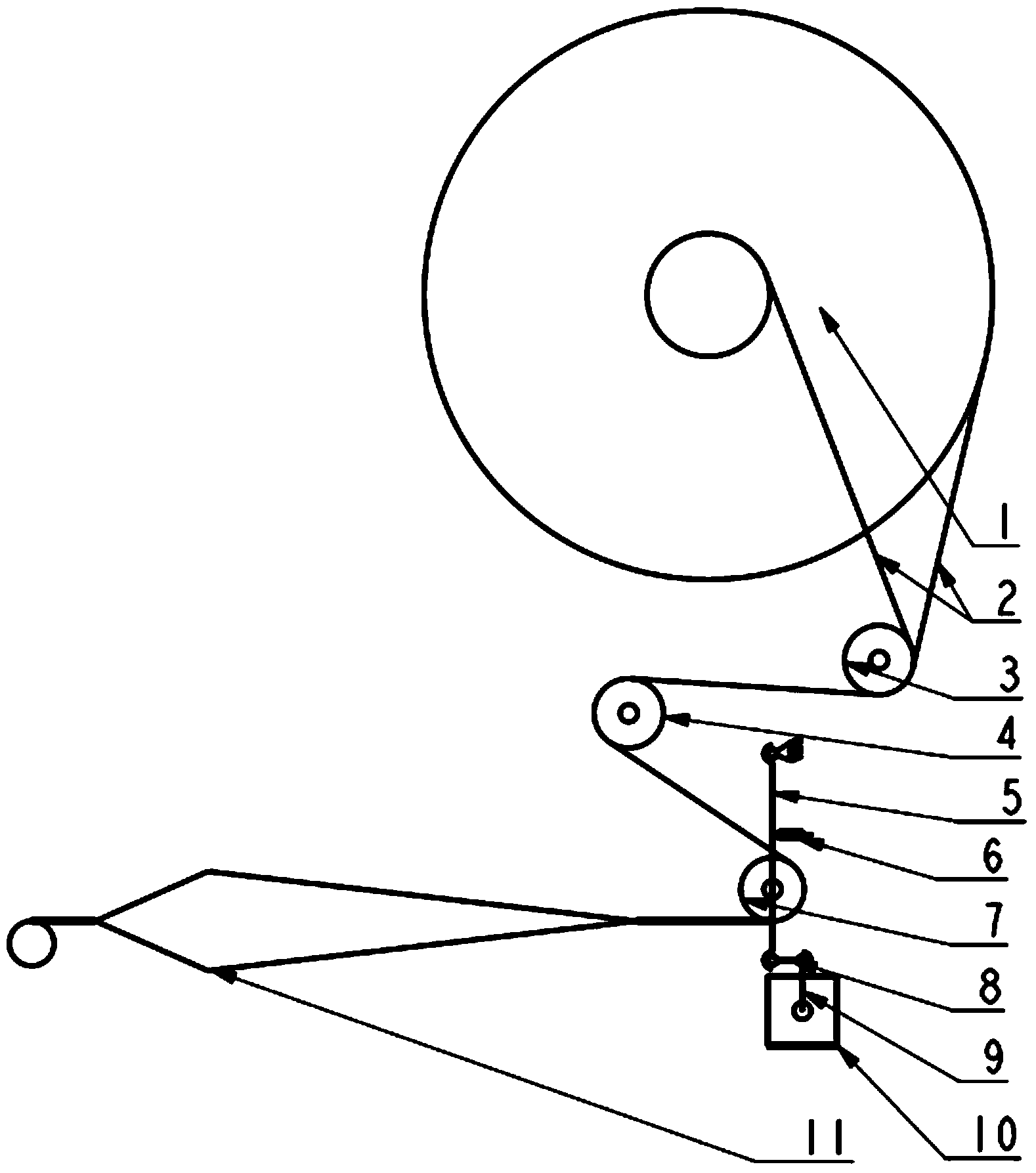

Dynamic balance control device for tension of warps of weaving machine

The invention discloses a dynamic balance control device for tension of warps of a weaving machine. The dynamic balance control device comprises a wool warp beam and yarns coiled on the wool warp beam, wherein a warp moving guide roller is arranged between a wool warp fixing guide roller shaft group and a fabric fell, the warp moving guide roller is arranged on a swing rod, the head of the swing rod is hinged to a fixing head, the tail end of the swing rod is connected to a connecting rod mechanism, the connecting rod mechanism is driven by a servo motor, a displacement sensor capable of detecting a gap between the swing rod and the displacement sensor is arranged on one end of the swing rod, and the servo motor can keep stable output and stable tension of the yarns according to a signal fed back by the displacement sensor. The dynamic balance control device has the advantages that the purpose of tension adjustment can be realized quickly and flexibly, and meanwhile, and the error is small during dynamic adjustment in a high-speed operation process of the weaving machine. The tension is stable in a warp output process, so that the warps have small vibration amplitude in a weaving process and are difficult to fuzz, and the quality of the fabric is greatly improved.

Owner:HANGZHOU CHUANGXING WEAVING EQUIP TECH

Antibacterial infant wet tissue capable of being scattered through washing

InactiveCN106420447AHigh tensile strengthAvoid breakingAntibacterial agentsCosmetic preparationsFiberAdditive ingredient

The invention discloses an antibacterial infant wet tissue capable of being scattered through washing. The antibacterial infant wet tissue comprises two parts, namely, a wet tissue body and wet tissue liquid, wherein the wet tissue body is prepared by taking wood pulp cellulose and cellulose acetate fibers as raw materials through airflow wet formation and spunlace sizing; the wet tissue liquid is prepared from the following components: alkyl polyglucoside, a preservative, radix scutellariae extract, fructus gardeniae extract, folium artemisiae argyi extract, peach leaf extract, propylene glycol, glycerol and deionized water. The wet tissue can be washed to be scattered by water flow, therefore, after use, the wet tissue can be directly abandoned in a closestool, and the blockage of the closestool and a sewer can not be caused. In addition, the infant wet tissue is soft and mild, can not stimulate the skin of the infant, and has the sterilizing and disinfecting effects.

Owner:佛山慧创正元新材料科技有限公司

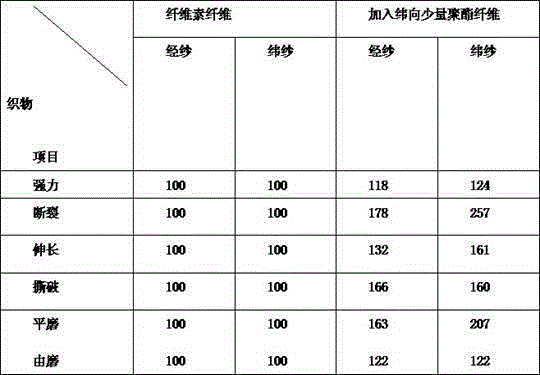

Polyester viscous cotton interweaving method

InactiveCN101368311AColorfulStrong three-dimensional senseWoven fabricsPolyesterPulp and paper industry

The invention relates to a polyester / viscose cotton interweaving method. A single-warp double-weft structure is adopted; the warp yarns are 40,50 or 60 branches of pure cotton yarns and the weft yarns feature in odd-even alternation; wherein the odd number weft yarns are DTY bright threads or FTY bright threads; and the even number weft yarns are artificial viscose cotton 150D or artificial viscose cotton 120D. The warp yarns and the weft threads are perpendicularly arranged alternatively. The three materials are orderly combined by a weaving CAD system. Through different arrangements, the warp yarns at the binding points are pressed down on the weft yarns or that the weft yarns are pressed down on the warp yarns. The weft yarns and the warp yarns are arranged and lined according to certain order, forming different patterns with different visual effects. The fabric with single-warp double-weft structure woven by a weaving machine then undergoes printing, dyeing and neatening processes. The polyester / viscose cotton is bright in color, strong in third dimension, clear in graph lays, high in intensity, small in washing shrinkage and good in hand sense and is not easy to fluff and is more comfortable.

Owner:顾洪

Nano anti-pollen fabric and preparation method thereof

InactiveCN104988714AHigh strengthDistribute quicklyWoven fabricsVegetal fibresPollen AllergyChemistry

The present invention discloses a nano anti-pollen fabric and a preparation method thereof. The method comprises the following steps: (1) taking a 20-40g / l nano anti-pollen finishing agent, and adjusting the pH value of the solution to 5.0 to 5.5; (2) adding a 5-20g / l 3130 softener into the solution prepared in the previous step; (3) soaking the fabric into the solution for 20s and taking out; (4) drying the fabric. The anti-pollen allergy fabric is resistant to water washing, dry-cleaning and mechanical friction, can be used to make clothing and masks, prevents the pollen from adhering to the fabric surface; even if pollen is adsorbed on the surface of the fabric, the pollen can be gently removed by slight flap; therefore, the allergic people can avoid allergens, and the probability of allergy is reduced.

Owner:石狮市展耀纺织科技有限公司

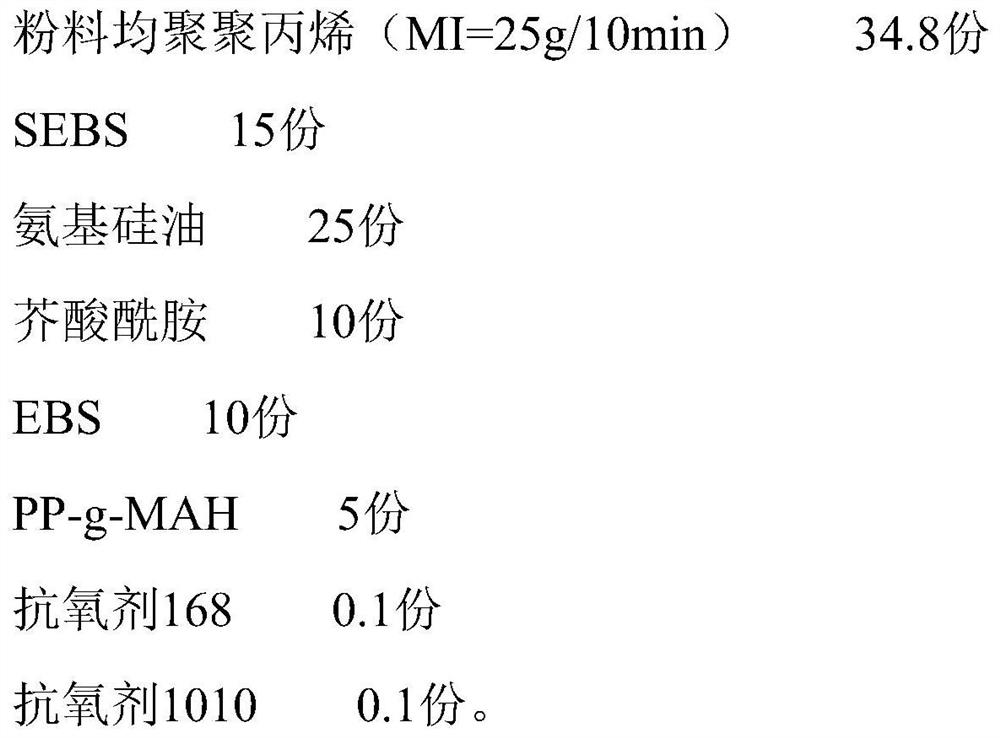

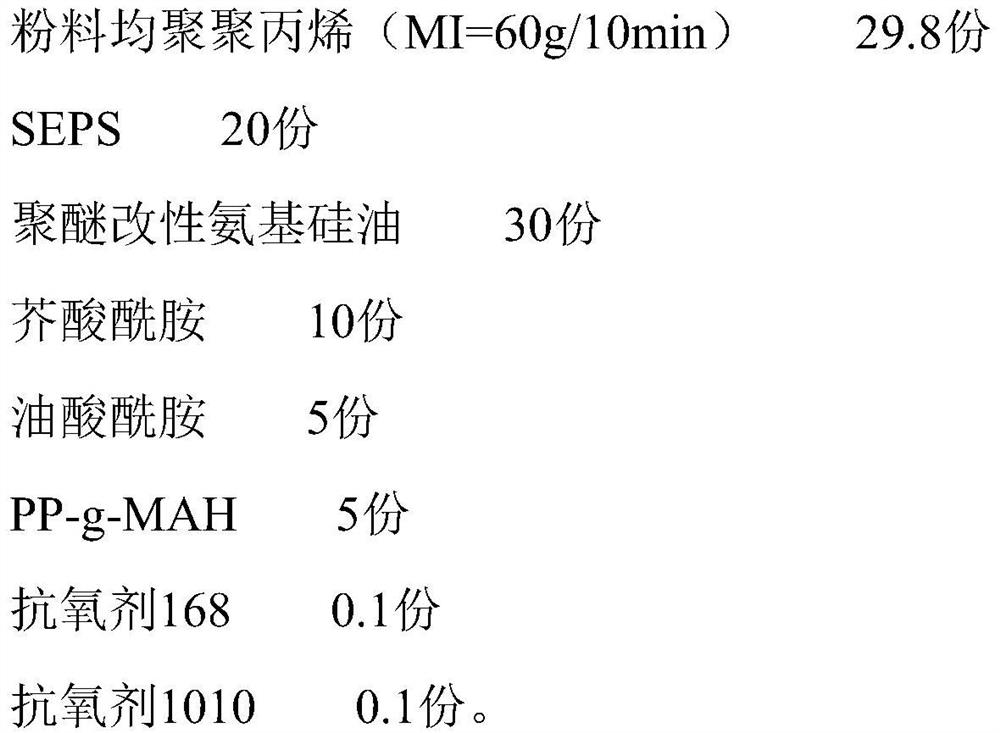

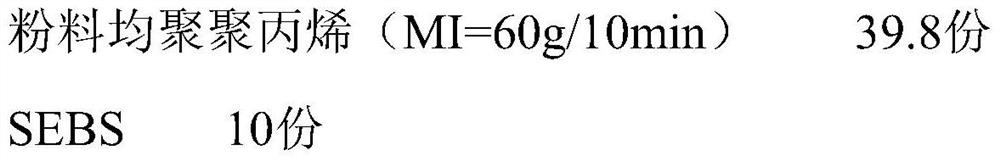

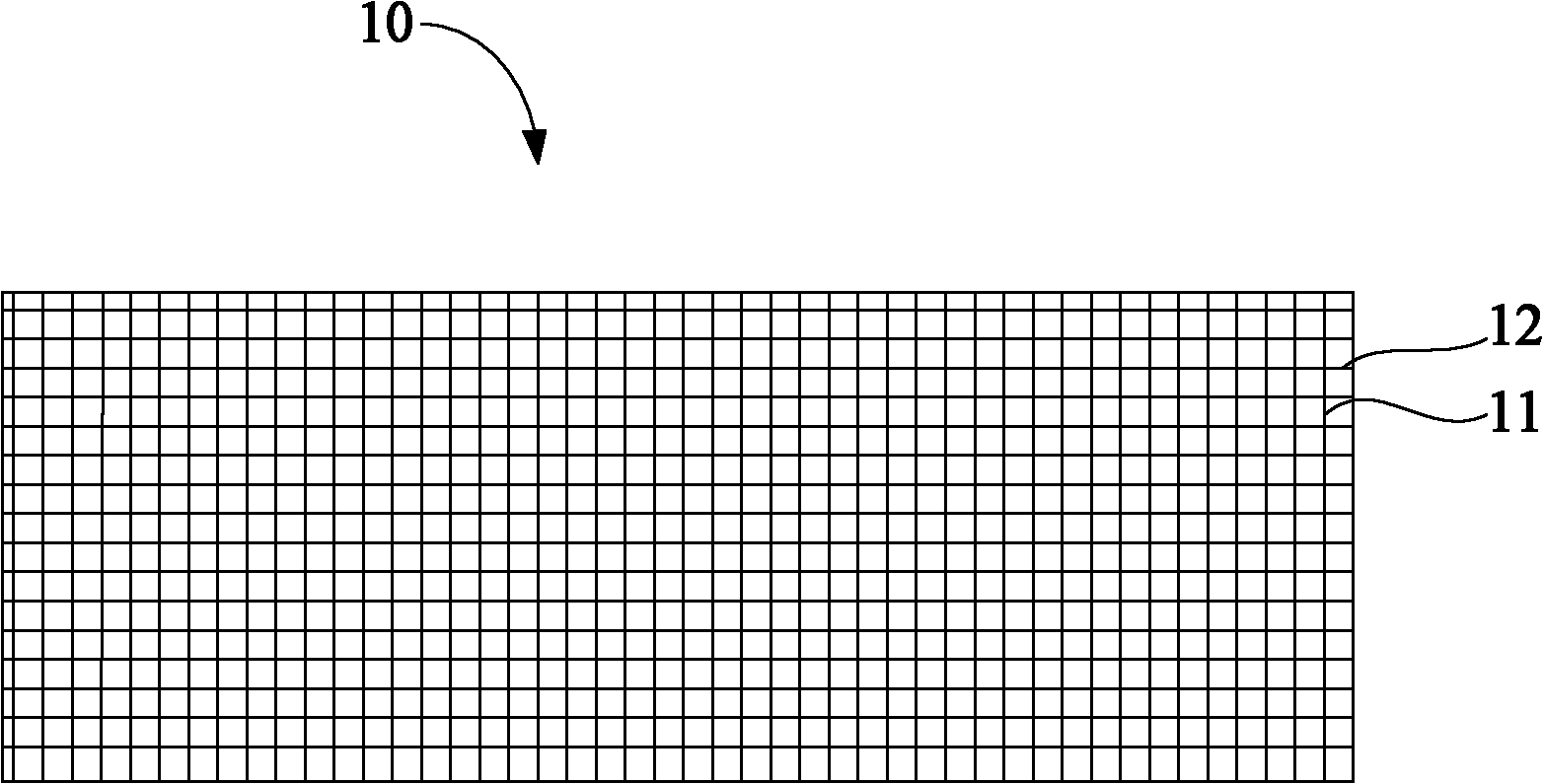

Polypropylene non-woven fabric soft master batch material as well as preparation method and application thereof

PendingCN114752144AImprove flexibilitySoft touchNon-woven fabricsMonocomponent polyolefin artificial filamentNonwoven fabricPolypropylene

The invention discloses a polypropylene non-woven fabric soft master batch material as well as a preparation method and application thereof. The polypropylene non-woven fabric soft master batch material comprises the following components: polypropylene, a styrene block copolymer, an organic silicon softener, a lubricating softener and a compatilizer, and optionally comprises an antioxidant. The prepared polypropylene non-woven fabric soft master batch product is good in flexibility, and the non-woven fabric prepared from the polypropylene non-woven fabric soft master batch product is soft in touch, high in filling power, not prone to fuzzing, comfortable, skin-friendly and good in rebound resilience. The polypropylene non-woven fabric soft master batch product prepared by the invention is high in effective concentration, small in addition amount in the non-woven fabric and capable of being directly added in a fabric forming process, so that the prepared non-woven fabric is good in uniformity. Meanwhile, the preparation process of the polypropylene non-woven fabric soft master batch is simple, the existing non-woven fabric production process does not need to be adjusted when the polypropylene non-woven fabric soft master batch is used for soft non-woven fabric production, a filter screen is not blocked, the fabric softening finishing procedure can be reduced, and therefore the technological process is shortened.

Owner:联泓(江苏)新材料研究院有限公司

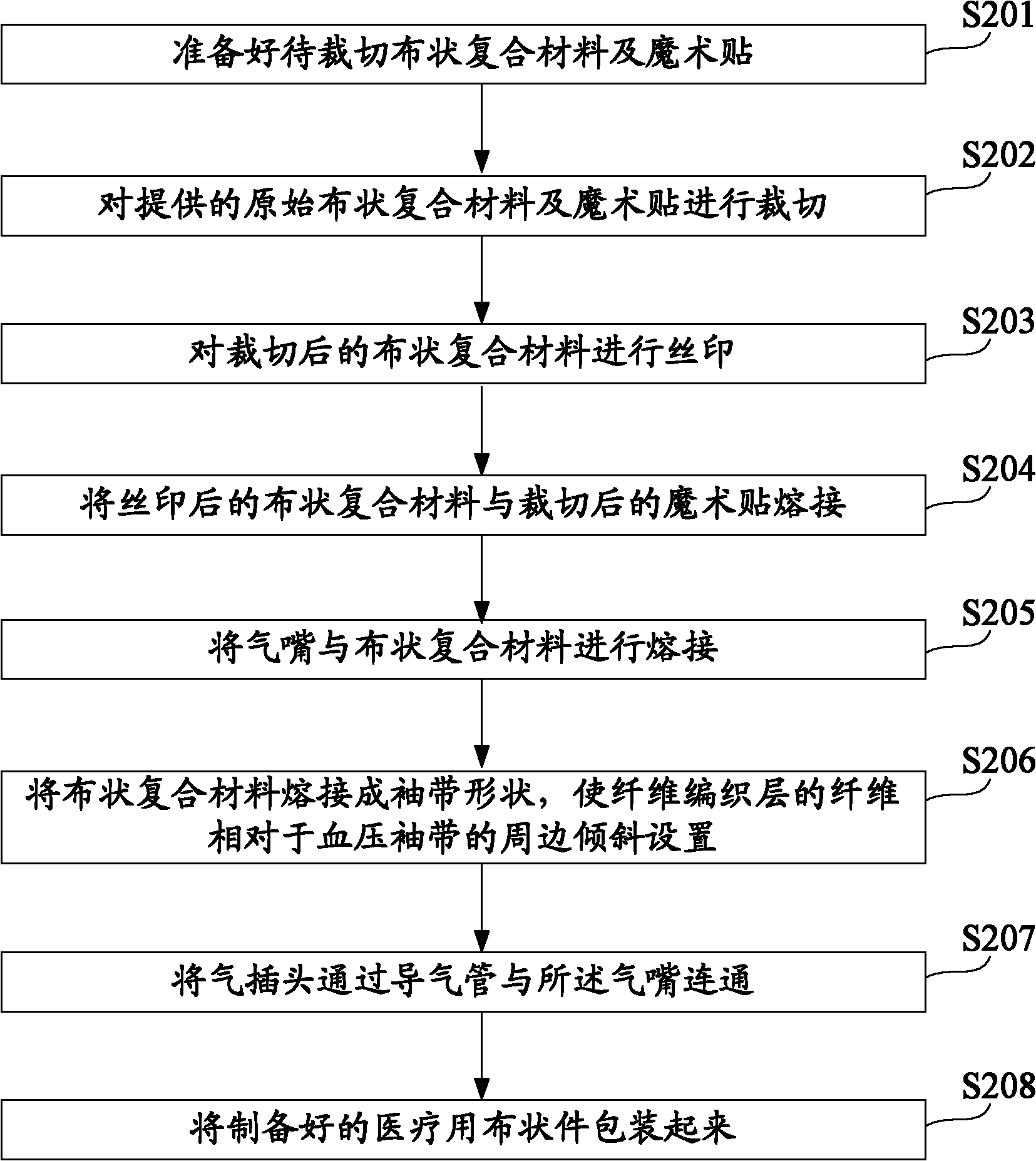

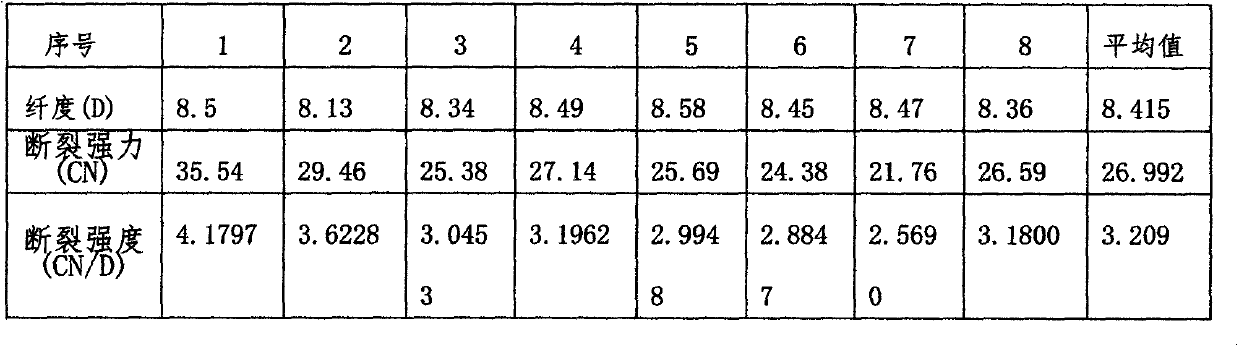

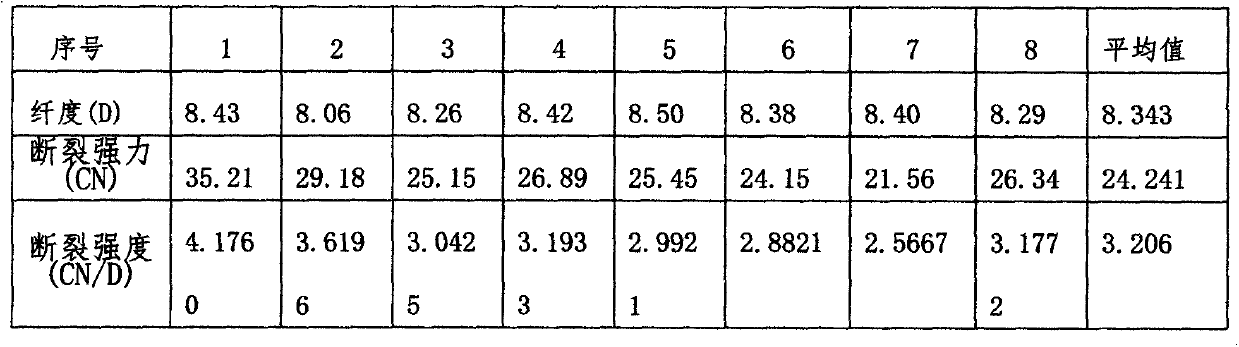

Blood pressure cuff

ActiveCN103142220AImprove abrasion resistanceNot easy to fluffEvaluation of blood vesselsAngiographyFiberBlood pressure cuffs

The invention provides a blood pressure cuff which comprises a main body made from a cuff wrapping cloth material. The fiber distributing direction of the cuff wrapping cloth material is inclined by a certain angle relative to the periphery of the blood pressure cuff. After the crossed direction between the fibers of a fiber layer of the blood pressure cuff and the periphery of the blood pressure cuff is changed, a certain inclined angle is available between the fiber distributing direction and the periphery of the blood pressure cuff rather than a parallel or perpendicular relationship, and the friction resistance of the blood pressure cuff can be improved due to the fiber direction. Therefore, the phenomena, i.e. the fuzzing and the fiber falling, hardly appear at the periphery of the blood pressure cuff.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

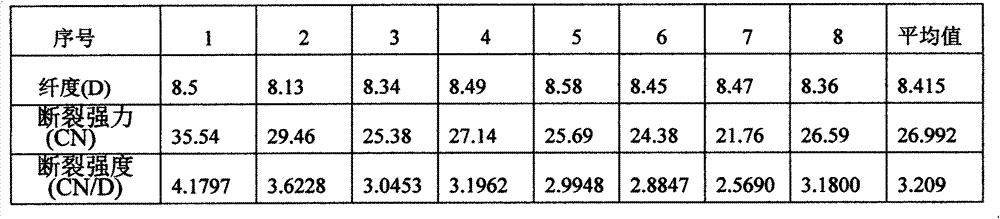

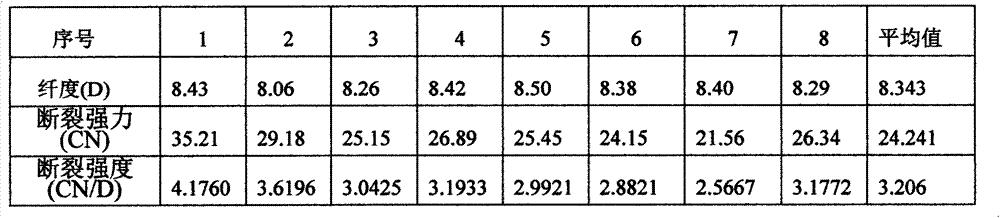

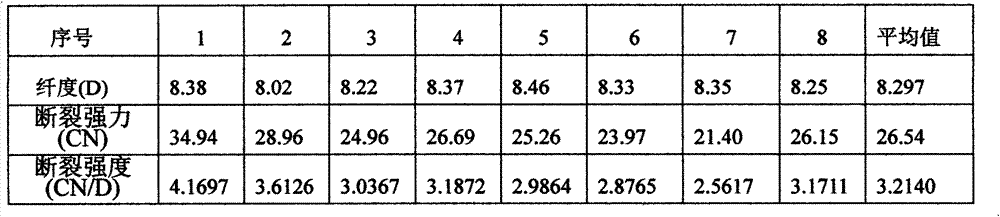

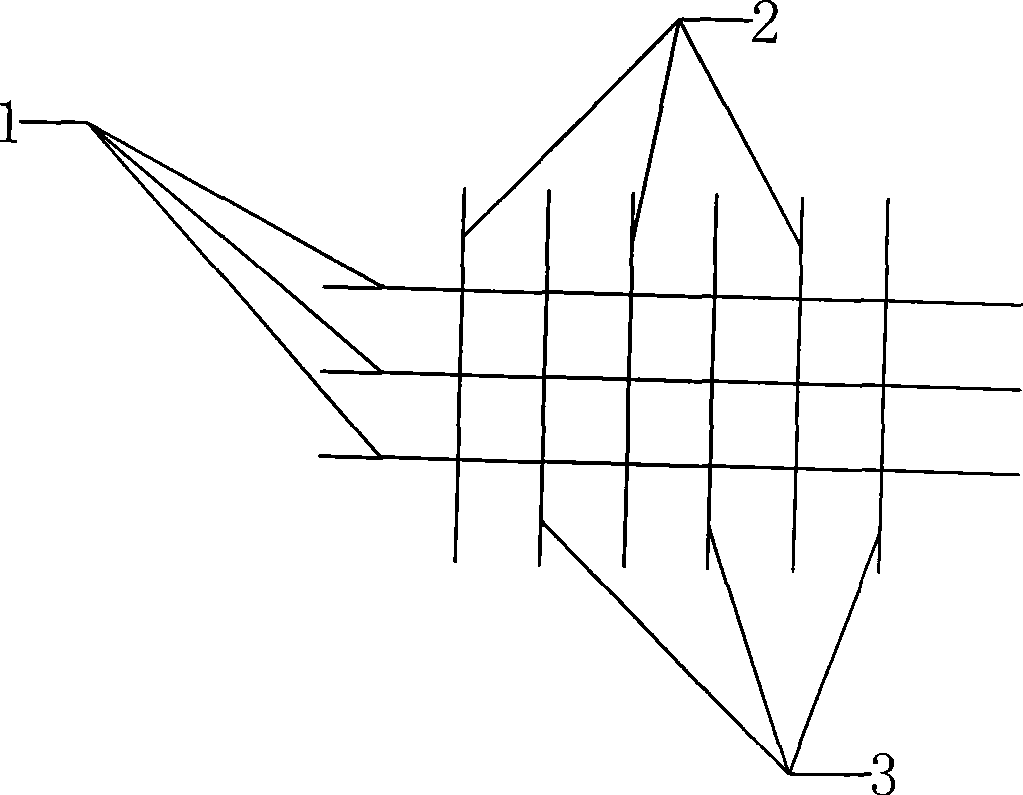

Production process of superfine mulberry silk fiber woven fabric

The invention discloses a production process of superfine mulberry silk fiber woven fabric, which comprises the following steps: the warp and weft yarns in the process specification design are all 1 / 7D / 9D mulberry silk, and the warp and weft density and plain weave of the upper machine are determined; The tension and hardness of the tube are 1.5~3CN, 22-24, 2~4CN, 24-26 respectively; 8 pieces of male and female matching steel sheet healds and one-way threading heald method, determine the reed number and the number of reed penetrations; plain weaving tension is 11CN ~ 13CN, heald frame stroke is 9 ~ 10cm; whitening finishing process conditions are: The concentration of the refining solution is 3-4g / l, the liquor ratio is 1:50, and the temperature is 95-98°C. The process of the present invention has strong productivity, the tension of each process is optimized, and they are reasonably matched with each other, greatly reducing warp flaws, and no dipping process is required. Therefore, the production process has strong productivity, thus obtaining the 2M / M of the present invention Thick thin ground woven fabrics are of good quality.

Owner:DALI SILK ZHEJIANG

Method for preparing silver-texture golden regenerated cellulose fabric

ActiveCN104928916AIncrease added valueImprove the decorative effectVegetal fibresPolymer scienceCellulose fiber

The invention discloses a preparation method for a silver golden regenerated cellulose fiber / silver golden regenerated cellulose fiber fabric. According to the preparation method, regenerated cellulose fiber and / or regenerated cellulose fiber fabric is taken as a raw material and soluble silver salts are adopted to obtain the golden regenerated cellulose fiber / golden regenerated cellulose fiber fabric, under the action of lewis acid catalysts and by adopting a catalytic nano chemical plating technology. The silver golden regenerated cellulose fiber / silver golden regenerated cellulose fiber fabric has the functions of antibiosis, deodorization, static electricity resistance and anti-electromagnetic radiation, and can be applied to the fields of military, medical treatment, public health, home furnishing and clothing. The regenerated cellulose fiber, adopted as the raw material by the invention, is cotton pulp regenerated cellulose fiber, wood pulp regenerated cellulose fiber, bamboo pulp regenerated cellulose fiber, or sodium alginate regenerated cellulose fiber; the regenerated cellulose fiber fabric, adopted as the raw material by the invention, is pure fabrics or blended fabrics of the regenerated cellulose fibers, or the blended fabrics of the regenerated cellulose fibers and other chemical fibers.

Owner:QINGDAO UNIV

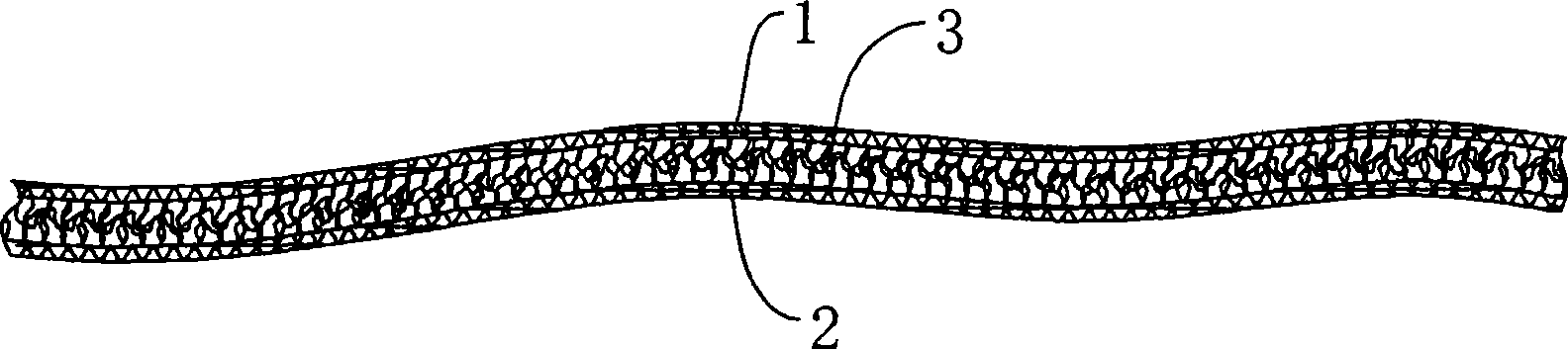

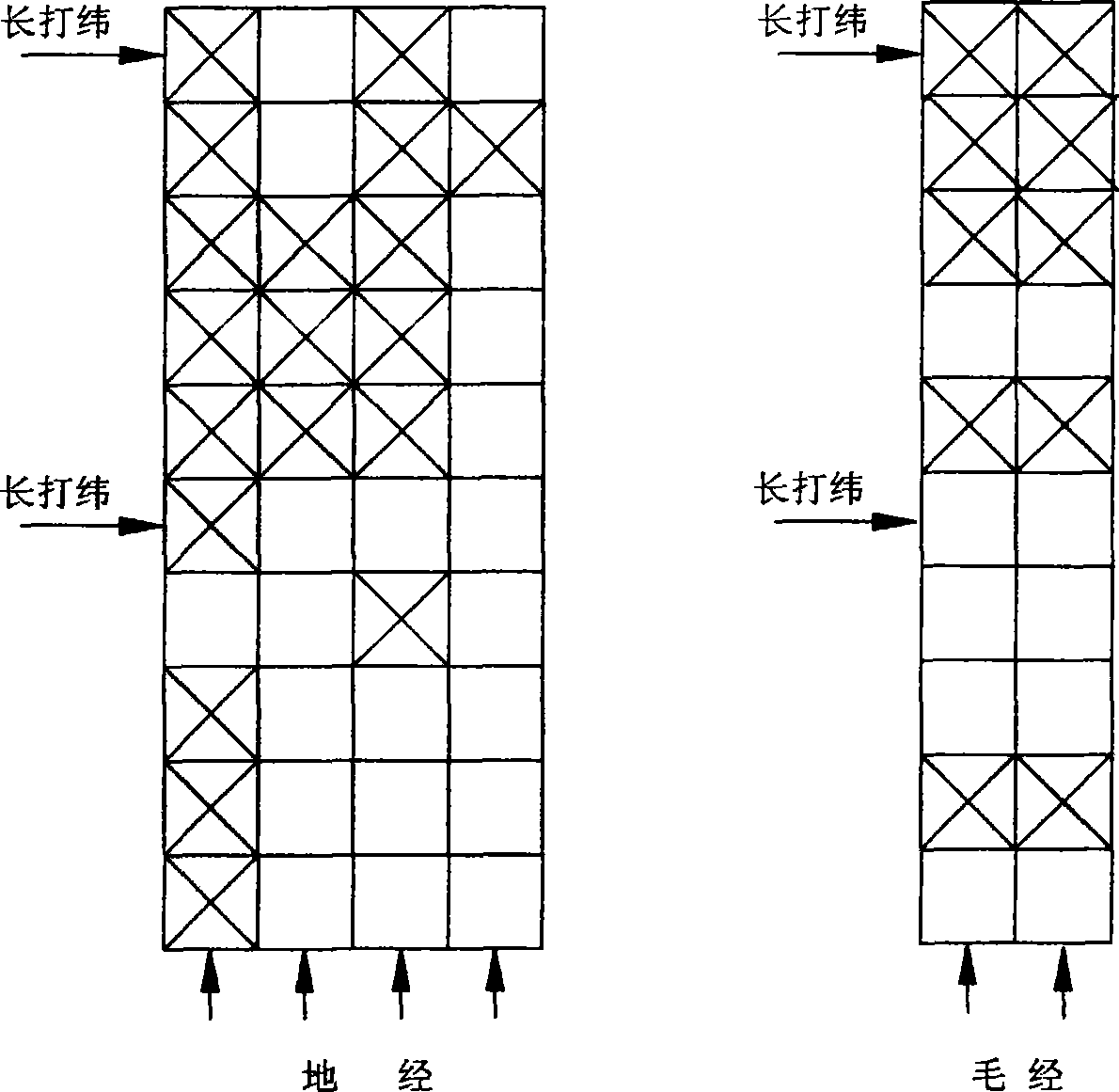

Built-in terry type towel and manufacturing process thereof

ActiveCN101503839AThe surface of the product is smooth and smoothIncrease elasticityWoven fabricsWeft yarnCivil engineering

The invention discloses an embedded terry-type towel and a manufacturing process thereof. The towel is woven by ground warp and napping warp with weft yarn, wherein the ground warp is divided into two layers which are woven with the weft yarn to form two layers of foundation fabric; the napping warp is woven with the weft yarn on the two layers of foundation fabric to form terry to make the upper and lower layers of foundation fabric tied; moreover, the interwoven terry is positioned between the two layers of foundation fabric. The towel product manufactured by the process has smooth and flat surface and is soft and rich in flexibility; moreover, laddering and fluffing occur infrequently during use.

Owner:SUNVIM GROUP

Bio-enzyme and rare earth type jute fiber oil and production method thereof

ActiveCN101768855ANot easy to fluffNot easy to fall offBiochemical fibre treatmentVegetal fibresFiberRare-earth element

The invention provides bio-enzyme and rare earth type jute fiber oil and a production method thereof. In the method, hydrogenated refined 150SN base oil and tea oil are adopted as an oiliness additive and an assistant; proper bio-oil and bio-enzyme technology is introduced; and new compound technology is adopted, and superfine microemulsion decoloration and degradation are coordinated. The bio-enzyme and rare earth jute fiber oil comprises the following raw materials: hydrogenated refined 150SN base oil, refined tea oil, solution of ionic surfactant, a non-ionic surfactant, bio-enzyme, and rare earth elements. The bio-enzyme and rare earth type jute fiber oil can soften the fiber, so that long and hard fiber of the jute fiber is bulked and refined, desquamation and end breakage rate are reduced, and the fiber hardly fuzzes and falls off. The sisal fiber treated by the product has the yarn diameter of less than or equal to 0.2mm and has the brute force of spun yarn of 346.5. Therefore, the friction coefficient between the fiber and machinery can be reduced effectively, and the jute fiber has higher abrasion resistance and hygroscopic property and is hardly ruptured in the spinning process so as to achieve the effects of reducing the end breakage rate and improving the finished product rate.

Owner:南宁飞日润滑科技股份有限公司

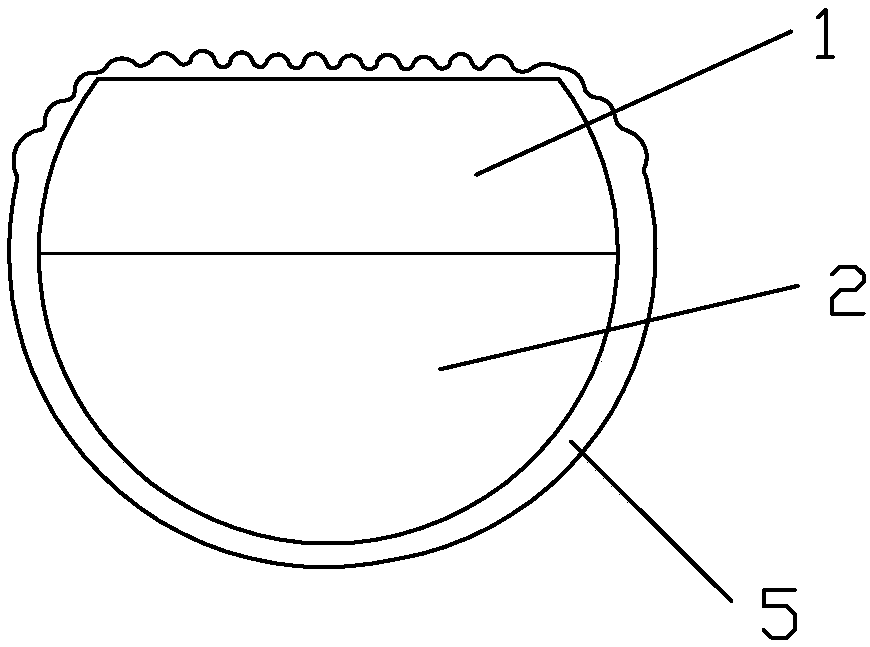

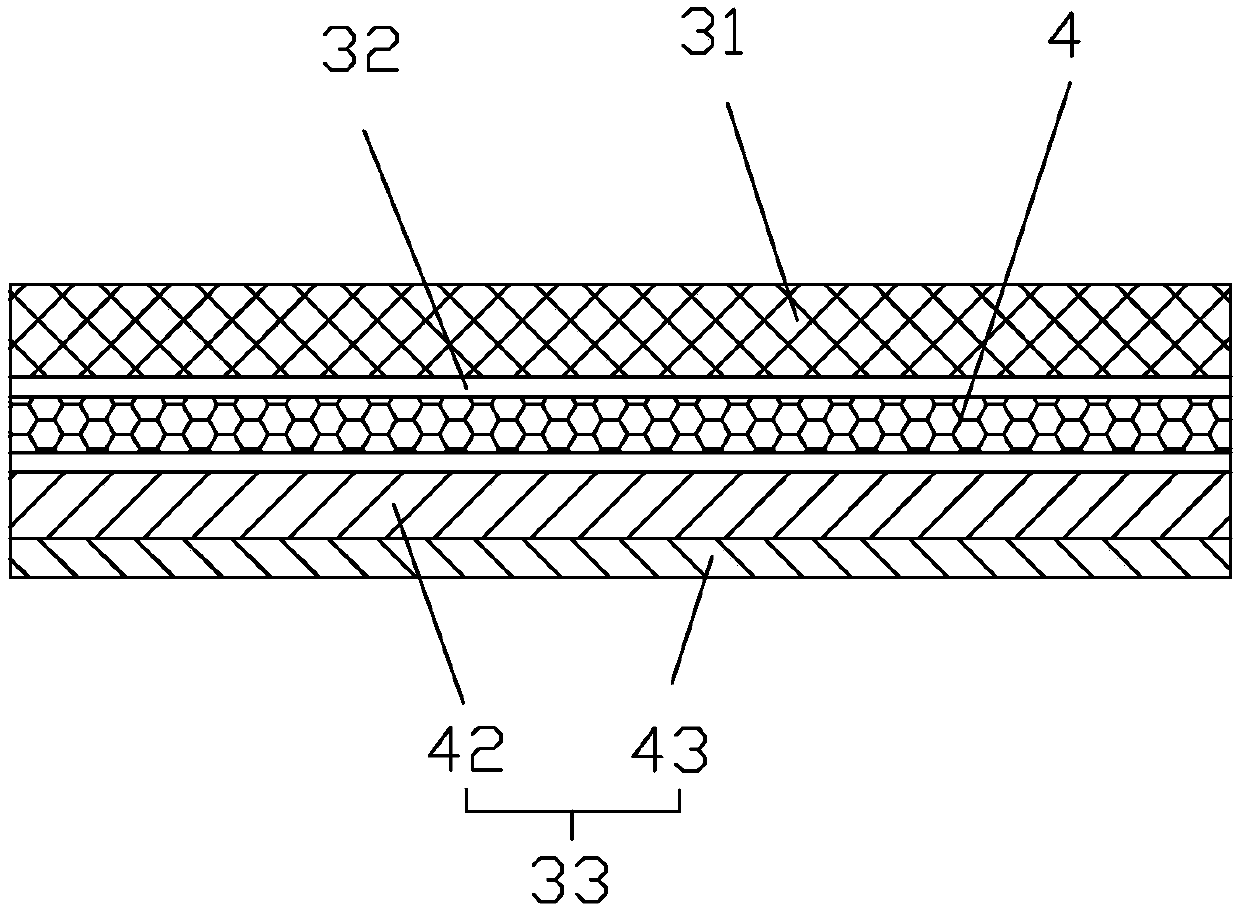

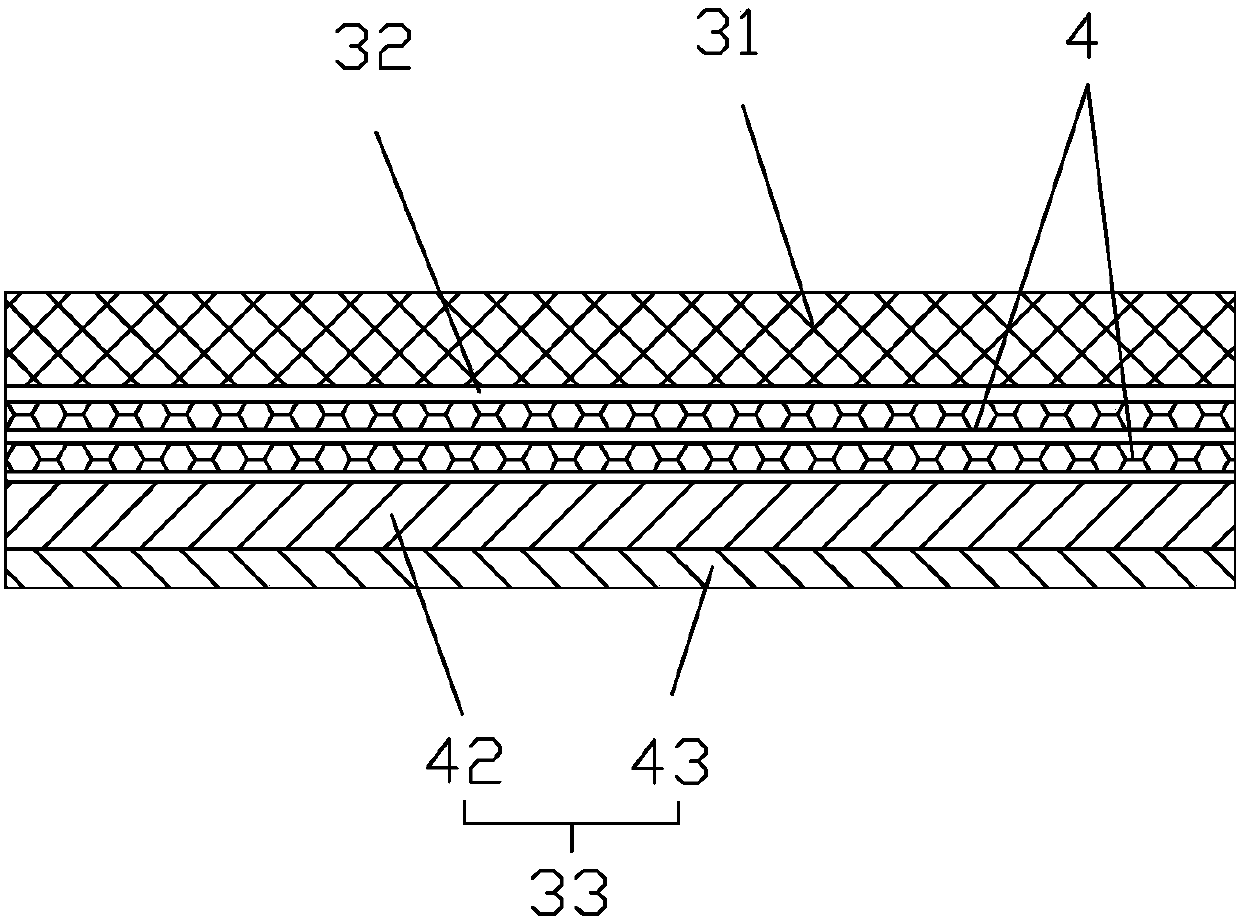

Disposable chest supporting breast pad

InactiveCN107928880AAvoid breakingPrevent seepageBreast bandagesLiquid/gas/vapor removal by squeezing rollersSurface layerComposite film

The invention discloses a disposable chest supporting breast pad and a raw material processing method thereof. According to the technical scheme, the disposable chest supporting breast pad comprises abreast pad main body, wherein the breast pad main body is composed of an upper part and a lower part which are mutually cooperated; the upper part is represented as a 2 / 3-cyclce; the lower side is ofa semicircular structure; both the upper part and the lower part comprise surface layers, middle layers and back side layers; the middle layers are composite cores; the back side layers are waterproof and breathable composite films; the upper side adopts one layer of the composite core, and the lower side adopts two layers of the composite cores; the surface layers adopt hydrophilic, hot-air andwaterproof non-woven fabrics; the middle layers are composite cores; and the back side layers adopt waterproof and breathable composite films, wherein the hydrophilic, hot-air and waterproof non-wovenfabric, mainly with polypropylene resin as a raw material, is prepared by virtue of a spunlacing process step. According to the disposable chest supporting breast pad provided by the invention, the absorbing capacity of the lower half part of the breast pad is increased, uniform absorption is guaranteed and service safety is enhanced; in addition, a chest supporting effect is achieved; and the breast pad is made from an environment-friendly material, so that the surface layers can be kept dry, and subsequently, cracked nipples are prevented and using comfort is enhanced.

Owner:浙江贝莱康孕产护理用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com