Method for preparing silver-texture golden regenerated cellulose fabric

A technology of regenerated cellulose and fiber fabrics, which is applied in the dyeing and finishing field of regenerated cellulose fibers/regenerated cellulose fiber fabrics, and can solve the problem of sweat absorption, breathability, comfort, no shielding, antibacterial effect, and waste problems that do not have natural cotton fibers. Degradation and other problems, to achieve good wearing comfort, good decorative effect, good moisture absorption and moisturizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) 100Kg of viscose fiber that has been degreased and cleaned is placed in the jet-type after-finishing processing equipment at a bath ratio of 1:4, and 1.6Kg of silver nitrate is added in the batching kettle to prepare a solution and enter the circulation system. React at 35°C for 100 min.

[0035] (2) Following step (1), the five components of ethylenediamine, tetraacetic acid sodium salt, benzotriazole, thiosemicarbazide, and ammonia water are mixed in a ratio of 1:0.2:0.1:0.3:1 in parts by weight Form a compound stabilizer, weigh 1Kg to prepare a solution, enter the circulation system, and react at 40°C for 30 minutes.

[0036] (3) Following step (2), take 0.01Kg of palladium dichloride and prepare it into a solution and then enter the circulation system to circulate for 30 minutes;

[0037] Then weigh 2Kg of glucose to prepare a solution, drop it into the circulation system, and react at a constant temperature of 45°C for 70min.

[0038] (4) Following step (3), th...

Embodiment 2

[0041] (1) 100Kg of degreased and cleaned wood pulp regenerated fiber fabric (modal fiber) is placed in the spray-type finishing processing equipment at a bath ratio of 1:4, and 0.065Kg of silver acetate is added to the batching kettle to prepare After forming a solution, it enters the circulation system and reacts at 75°C for 60 minutes.

[0042] (2) Following step (1), the five components of ethylenediamine, tetraacetic acid sodium salt, benzotriazole, thiosemicarbazide, and ammonia water are mixed in a ratio of 1:0.2:0.1:0.3:3 in parts by weight Form a compound stabilizer, weigh 1.3Kg to prepare a solution, enter the circulation system, and react at 75°C for 40 minutes.

[0043] (3) Following step (2), take 0.05Kg of ammonium hexachloroplatinate and prepare it into a solution and then enter the circulation system to circulate for 40 minutes;

[0044] Then weigh 20Kg of sodium hypophosphite to prepare a solution, drop it into the circulation system, and react at a constant ...

Embodiment 3

[0048] (1) 100Kg of degreased and cleaned bamboo pulp regenerated fiber (Tencel) is placed in the overflow type finishing processing equipment at a bath ratio of 1:100, and 0.11Kg of iminodisulfonic acid is added to the batching kettle Acid-complexed silver concentrated solution (silver content 27%), after being prepared into a solution, enters the circulation system and reacts at 45° C. for 60 minutes.

[0049] (2) Following step (1), the five components of ethylenediamine, tetraacetic acid sodium salt, benzotriazole, thiosemicarbazide, and ammonia water are mixed in a ratio of 1:0.2:0.1:0.3:4 in parts by weight Form a compound stabilizer, weigh 5Kg to prepare a solution, enter the circulation system, and react at 45°C for 50min.

[0050] (3) Following step (2), take 2Kg of nickel dichloride and prepare it into a solution and then enter the circulation system to circulate for 40min;

[0051] Then weigh 20Kg of glucose to prepare a solution, drop it into the circulation syste...

PUM

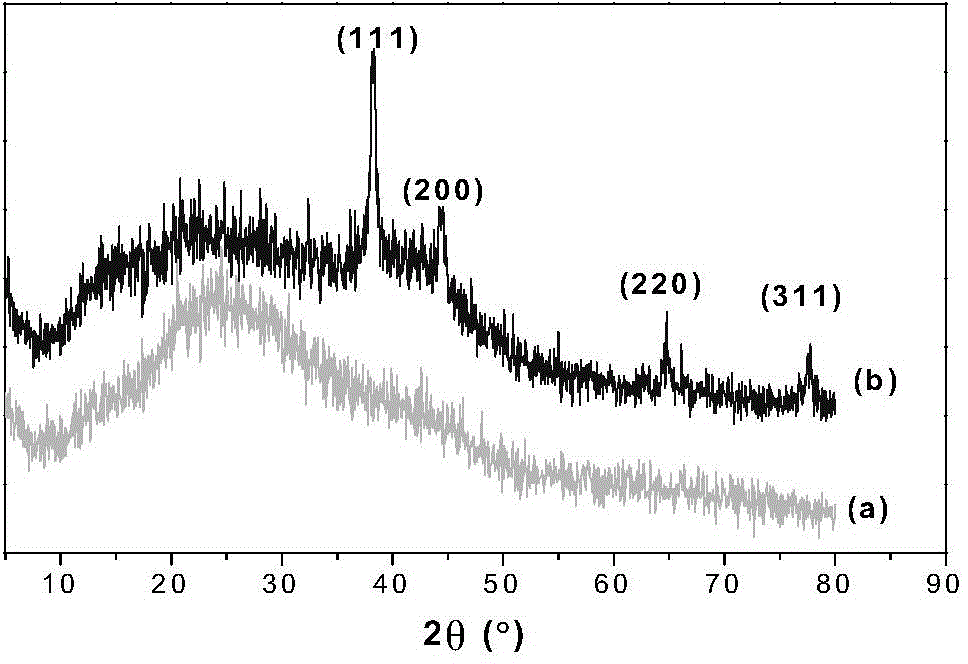

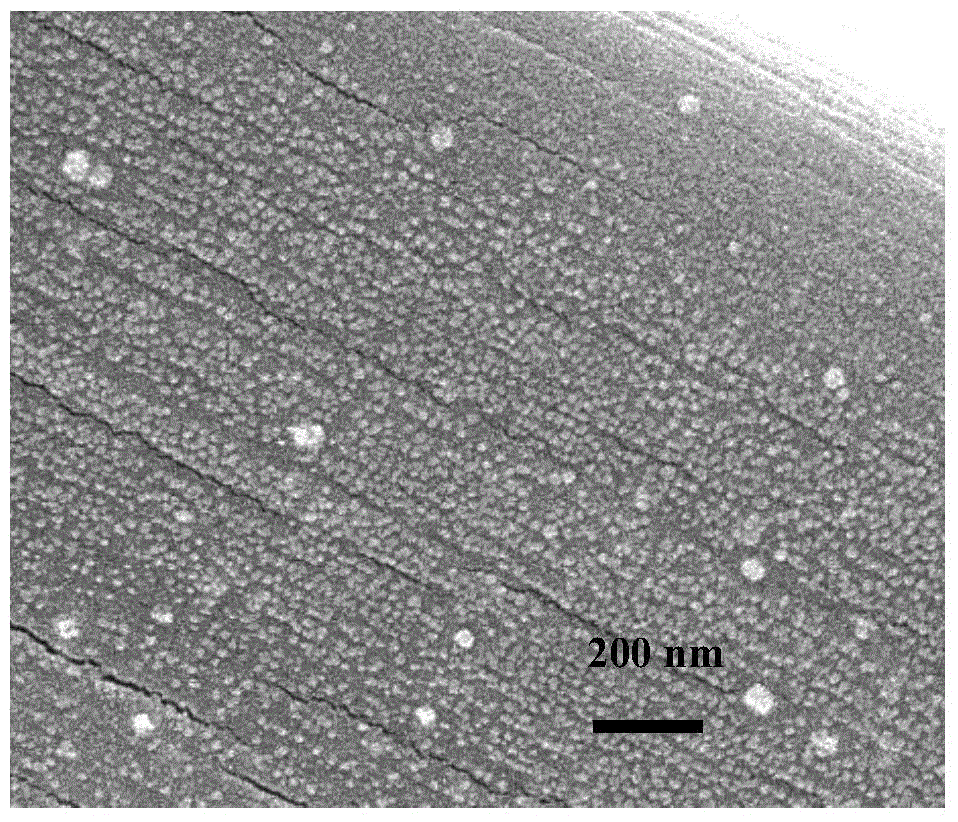

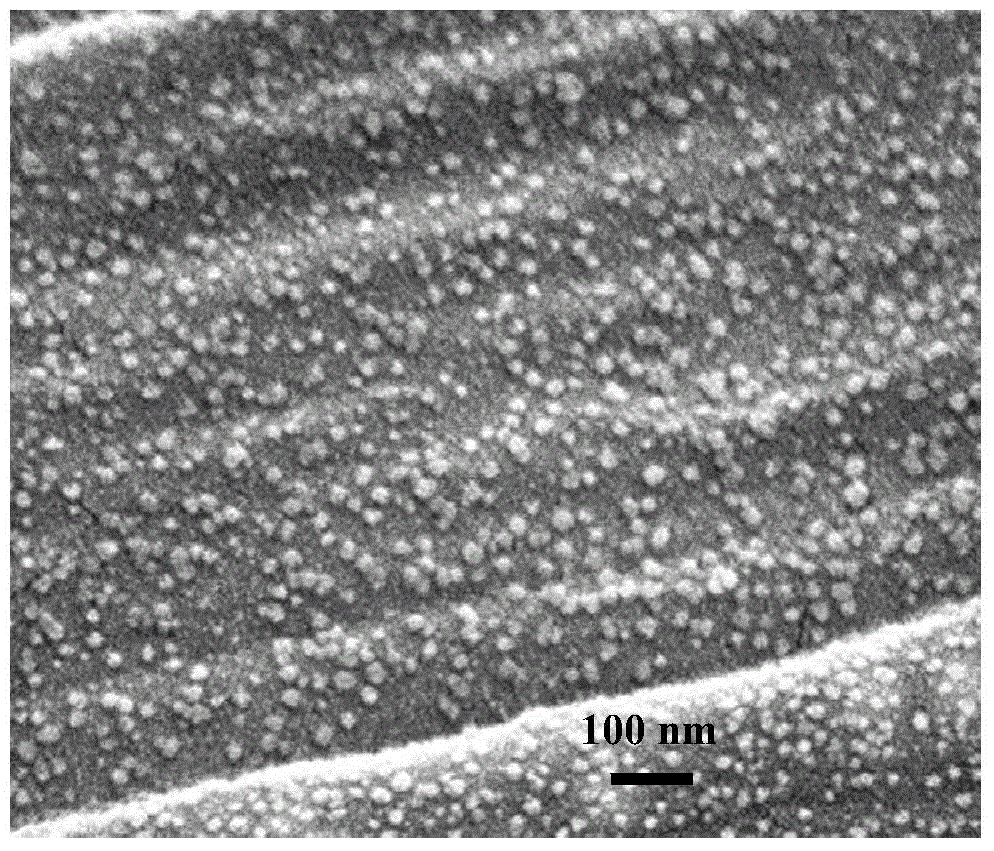

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com