Patents

Literature

795 results about "Sodium hypophosphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium hypophosphite (NaPO₂H₂, also known as sodium phosphinate) is the sodium salt of hypophosphorous acid and is often encountered as the monohydrate, NaPO₂H₂·H₂O. It is a solid at room temperature, appearing as odorless white crystals. It is soluble in water, and easily absorbs moisture from the air.

Poly alcohol-based binder composition

InactiveUS6884849B2Improve curing effectEmission reductionNon-fibrous pulp additionSynthetic resin layered productsAlcoholCarboxylic acid

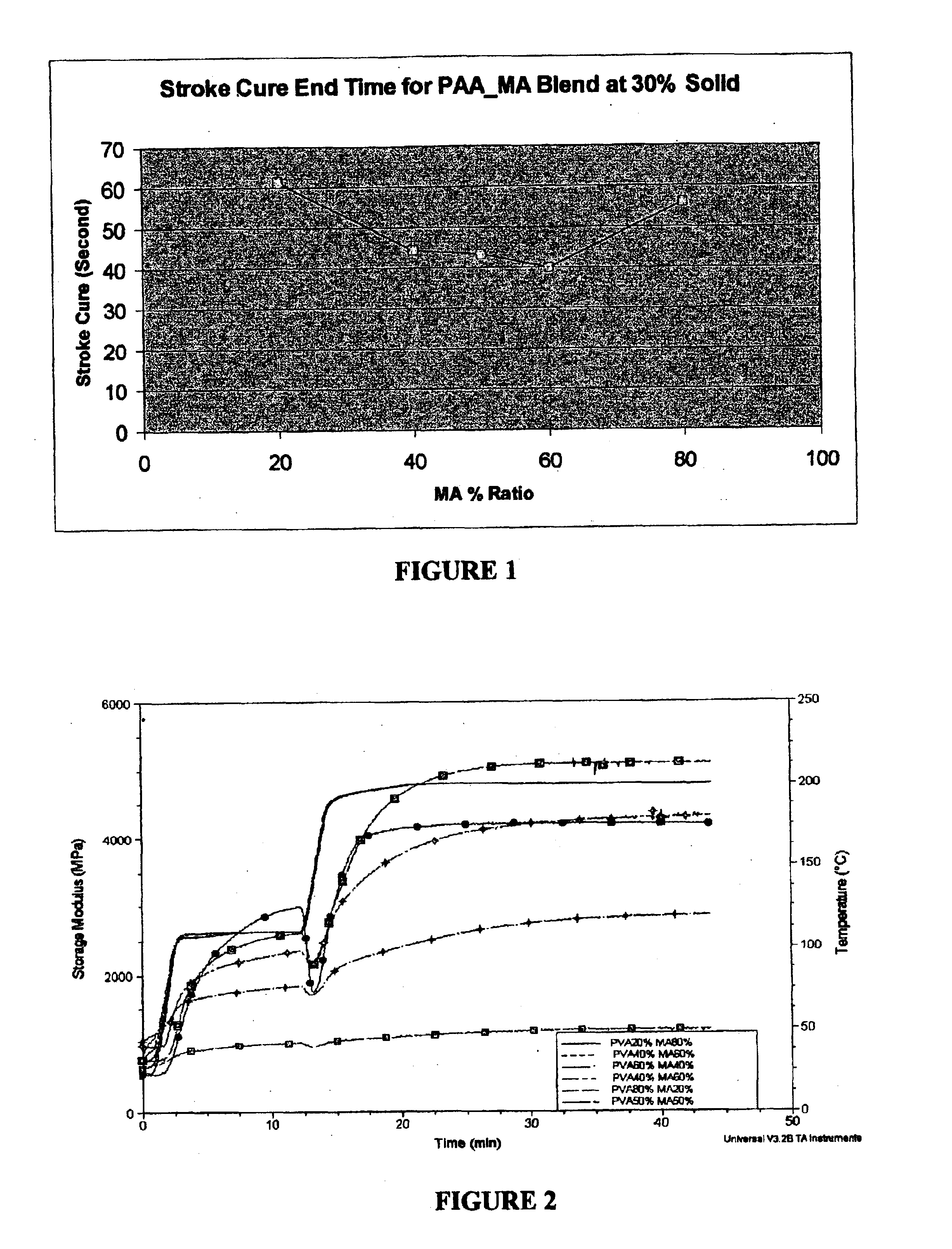

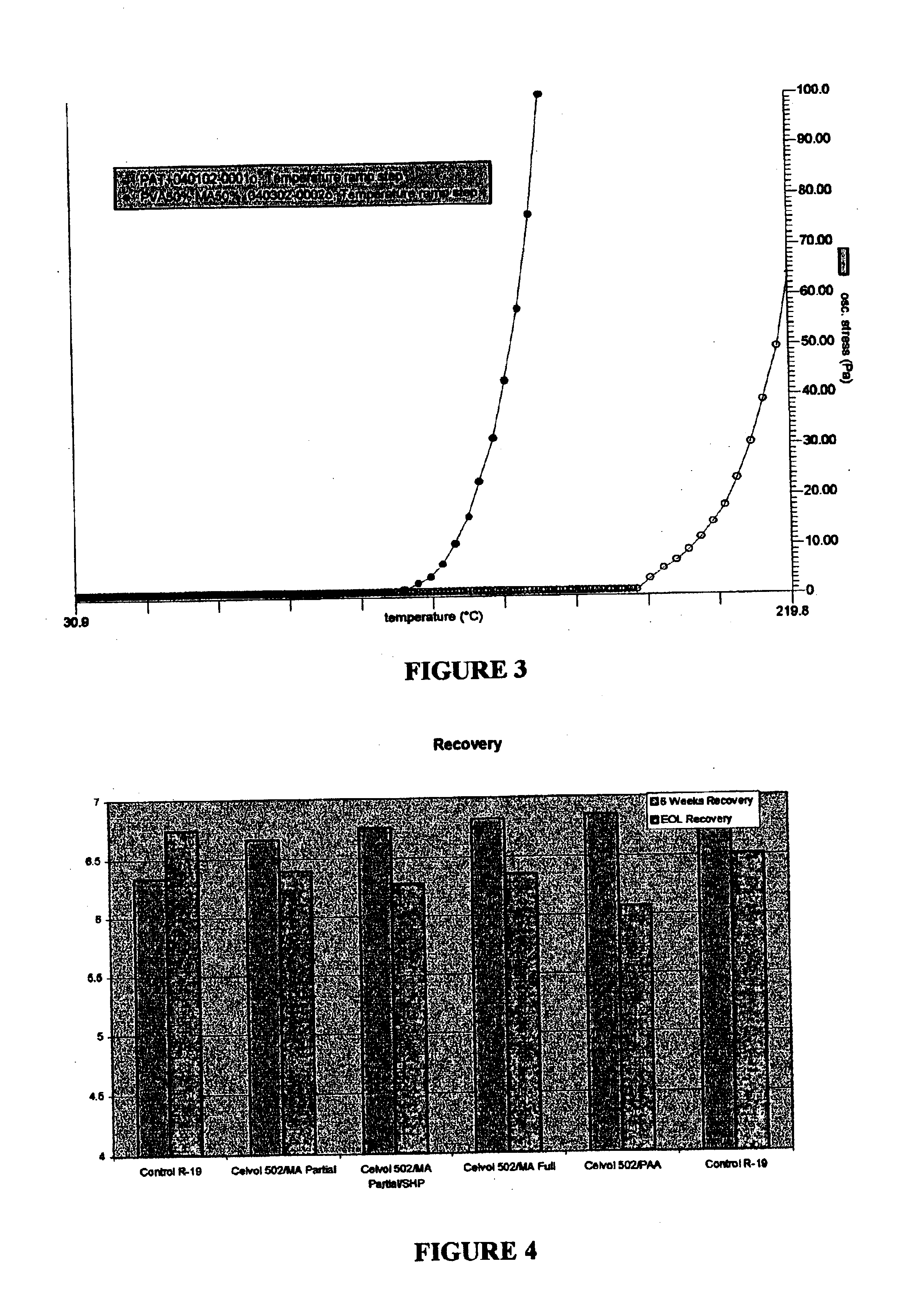

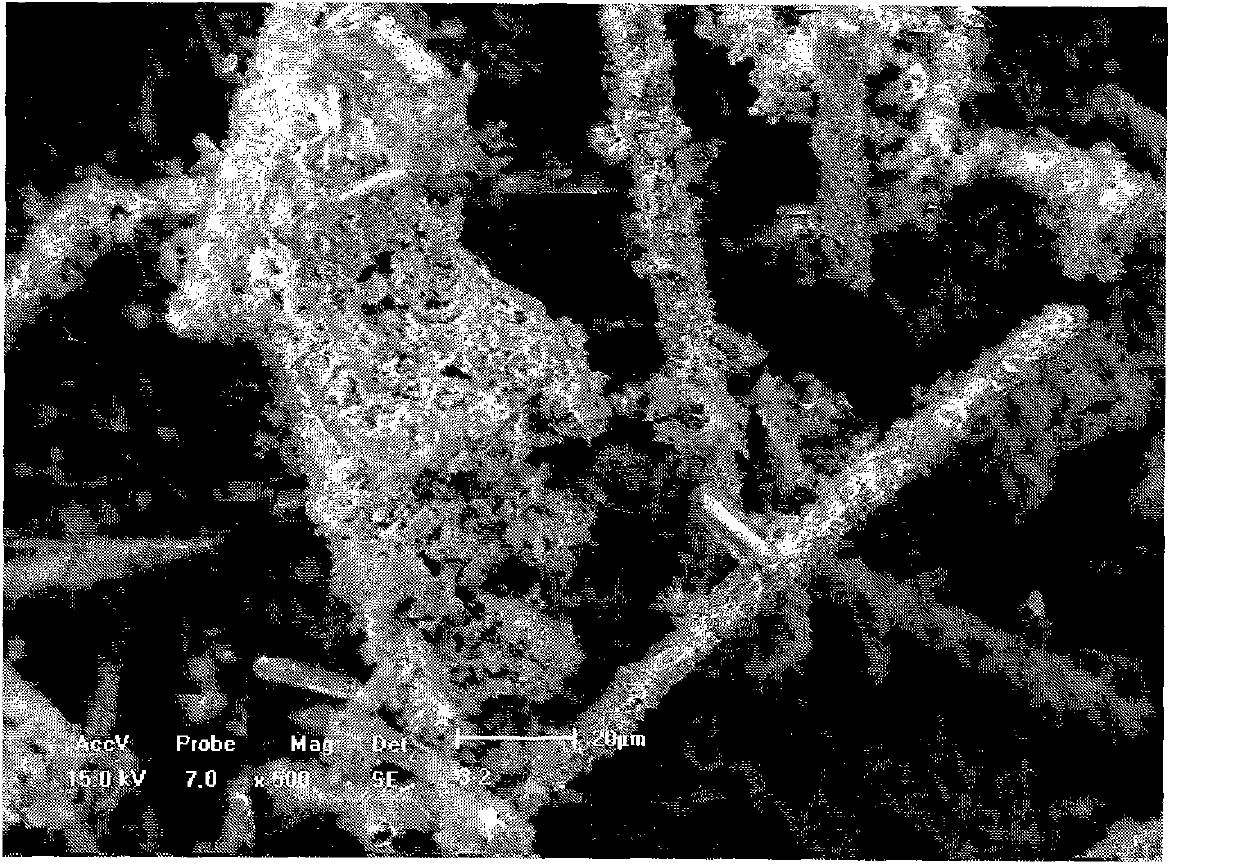

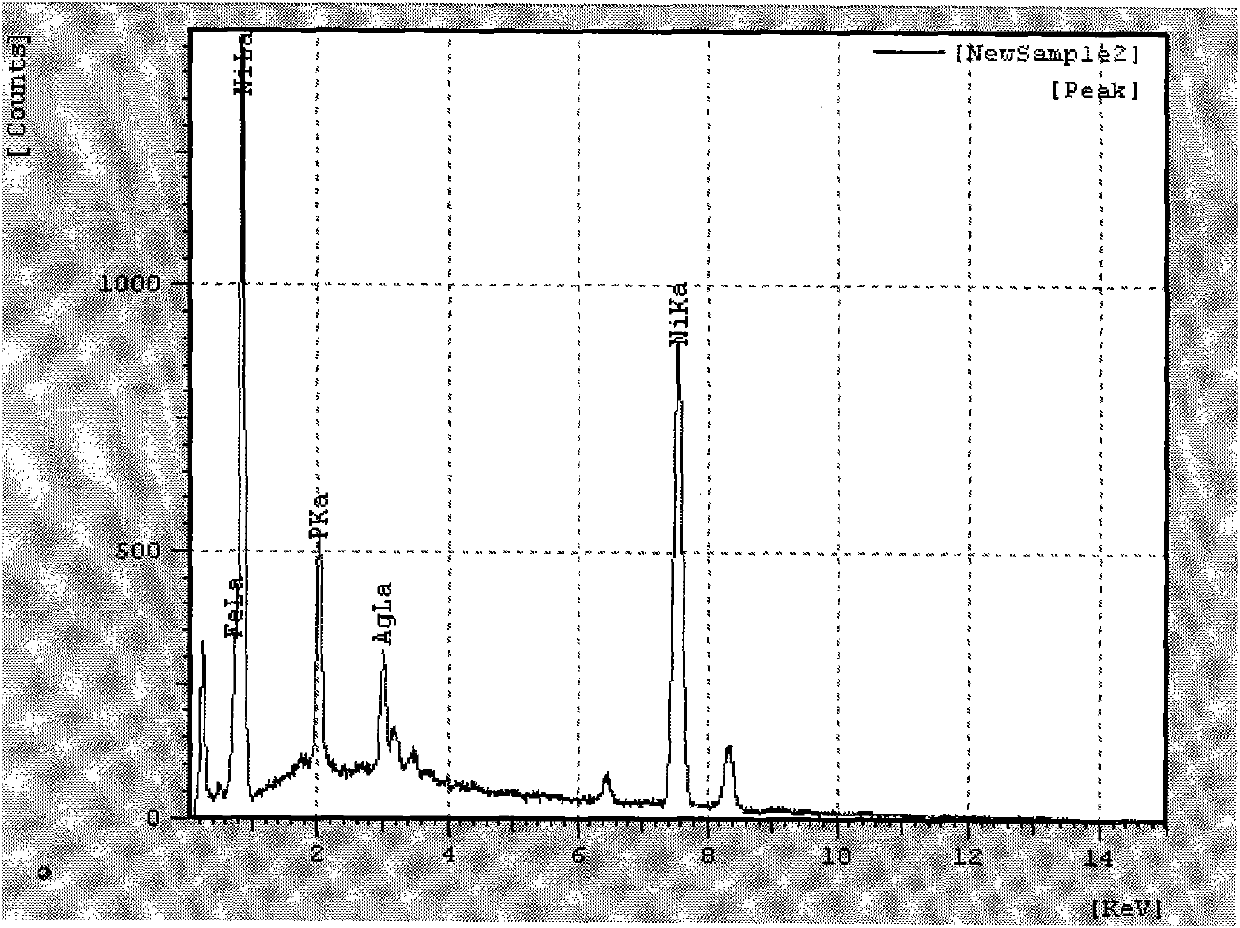

The present invention provides a binder composition comprising a low molecular weight polycarboxylic acid, such as maleic anhydride, and a low molecular weight poly alcohol, such as polyvinyl alcohol, that exhibits improved cure performance with reduced emissions without sacrificing the performance of the final product or complication the manufacturing process. The binder composition may also incorporate a cure catalyst or accelerant such as sodium hypophosphite.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Method for performing electroless nickel plating on surface of aluminum nitride ceramic

ActiveCN101962760AHigh bonding strengthImprove high temperature resistanceLiquid/solution decomposition chemical coatingElectroless nickelSodium acetate

The invention provides a method for performing electroless nickel plating on the surface of aluminum nitride ceramic, belonging to the ceramic thin-film metallization field. The method comprises the following specific steps: 1) polishing the surface of aluminum nitride with a machinery; coarsening the aluminum nitride substrate with mixed acid or alkali, completely cleaning away the residual acid or alkali; 3) sensitizing the coarsened substrate in stannous chloride solution, activating in palladium chloride solution or performing activation without palladium; 4) weighting a certain amount of nickel sulphate, sodium hypophosphite, sodium citrate, sodium acetate, lactic acid, thiourea and sodium dodecyl sulfate in sequence to prepare a chemical plating solution; and 5) adjusting the pH value of the solution to 4.0-6.0 with acid or alkali, heating the solution to 70-95 DEG C, and placing the prepared substrate in the solution to perform electroless nickel plating. The invention is characterized in that the electroless nickel plating can be performed on the surface of the aluminum nitride ceramic substrate which is difficult to plate; and a certain amount of surfactant is added so that the plating becomes denser and smoother, the binding force between the plating and the substrate is increased, and the solderability of the plating is better.

Owner:UNIV OF SCI & TECH BEIJING

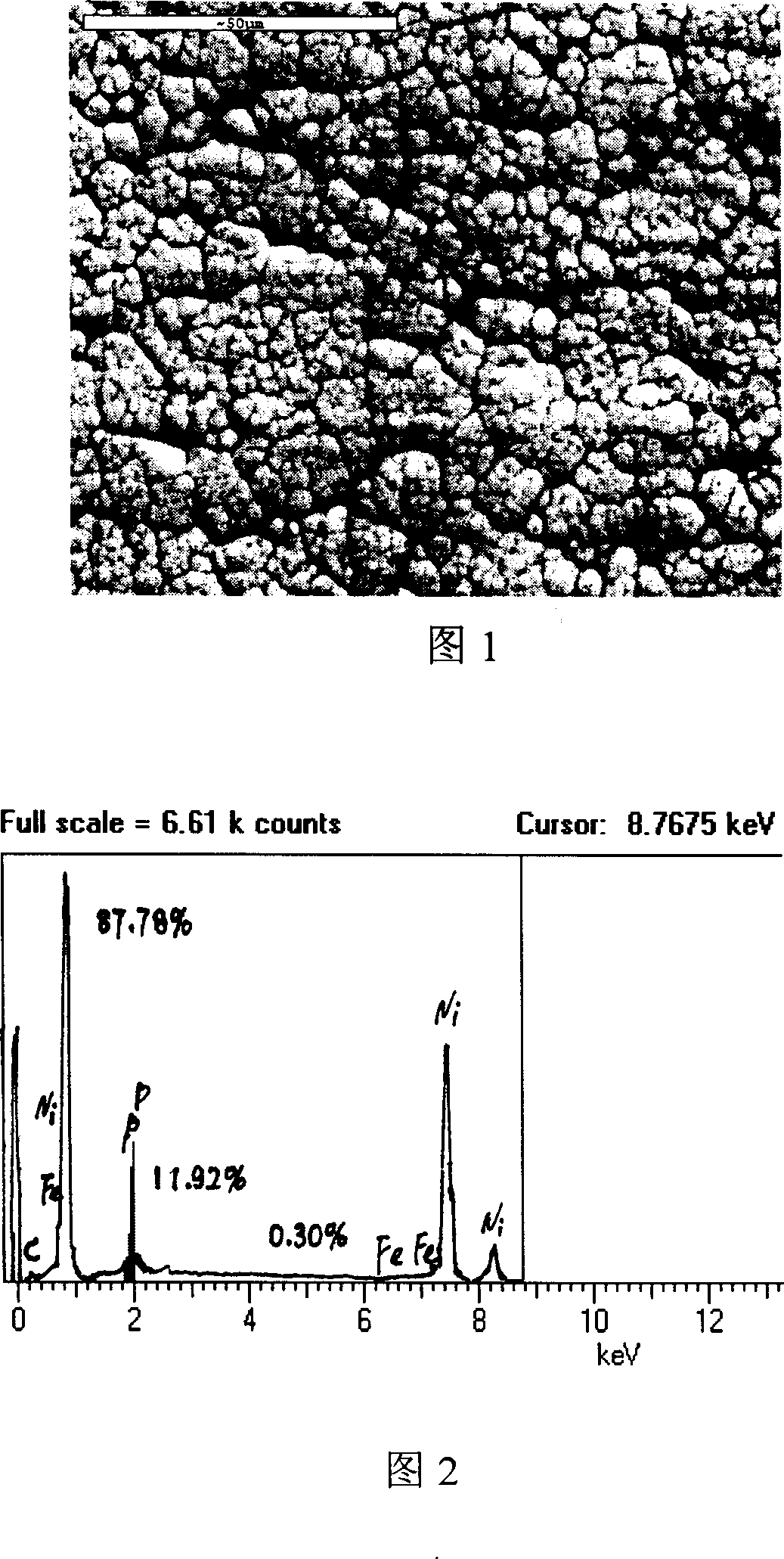

Chemical nickel-plating method for carbon fiber

InactiveCN102086517ALow costEasy to operateLiquid/solution decomposition chemical coatingFiberCarbon fibers

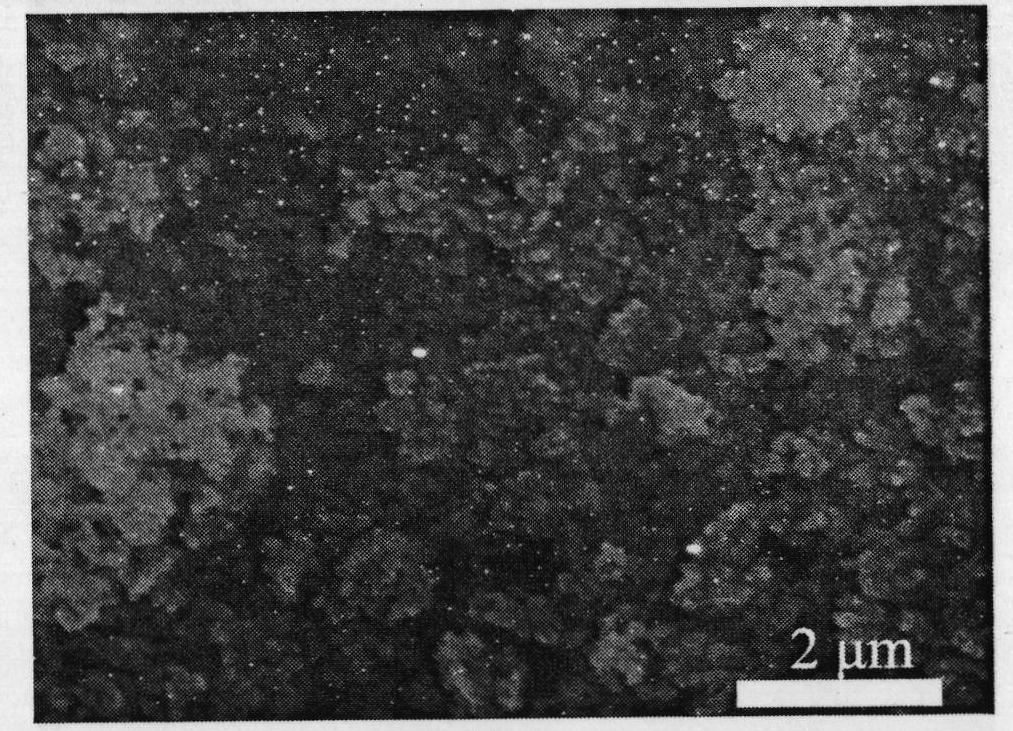

The invention discloses a chemical nickel-plating method for carbon fiber, which is designed for overcoming the disadvantages of high cost, a large number of process steps and poor operability existing in the prior art. In the method, a chemical plating process is adopted; and a pre-treatment is performed on a raw material and chemical plating solution is prepared before the chemical plating. The pre-treatment process comprises the steps of: calcining by using a muffle furnace to remove glue; soaking in solution of absolute ethanol to remove oil; performing surface roughening and activating treatment by using solution of sodium hydroxide and solution of silver ammonia; sensitizing by using a sensitizer, namely stannous chloride; and performing surface reduction by using solution of sodium hypophosphite. The chemical plating solution consists of nickel sulfate hexahydrate, sodium hypophosphite, sodium pyrophosphate and sodium citrate. The chemical nickel-plating on the carbon fiber is finished by placing a pre-treatment product of the chemical plating into the chemical plating solution, and reacting, standing, filtering and drying under a chemical plating condition. The method has the characteristics that: the product has a uniform surface, a compact plating layer and uniform particles.

Owner:沈阳临德陶瓷研发有限公司

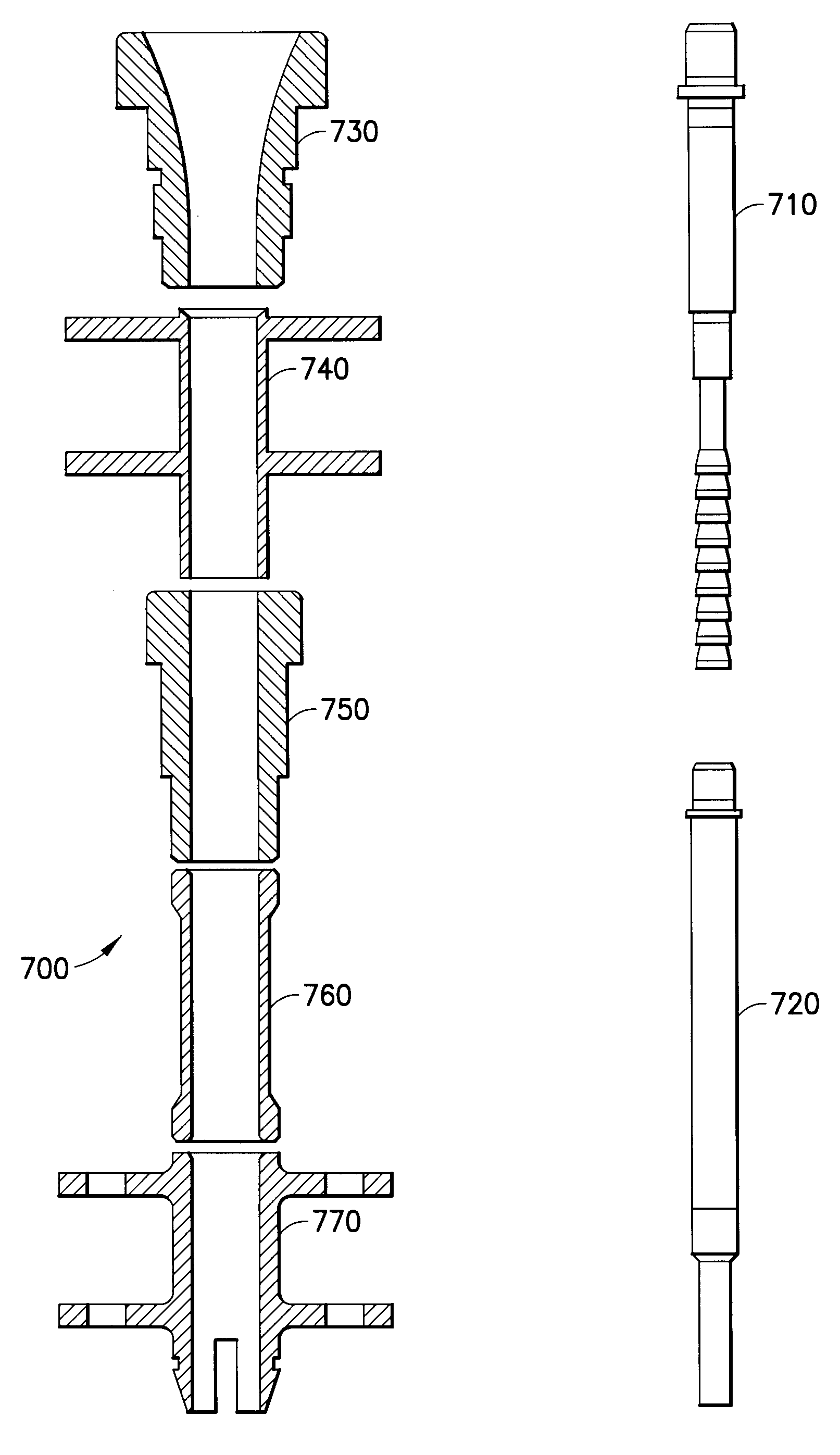

Tampon including crosslinked cellulose fibers and improved synthesis processes for producing same

InactiveUS20090227975A1Promote absorptionImprove wettabilityPulp properties modificationArtificial filaments from viscoseCellulose fiberGlyoxal

A tampon pledget includes crosslinked cellulose fibers having microstructures treated to provide improved absorbency and higher wet strength. The fibers are treated with a crosslinking agent to provide at least one of a molecular weight between crosslinks of from about 10 to 200 and a degree of crystallinity of from about 25% to 75%. The crosslinking agent includes citric acid in 1% by weight. The crosslinking agent may further include sodium hypophosphite in 1% by weight. In another embodiment, the crosslinking agent may be a difunctional agent including a glyoxal or a glyoxal-derived resin. In still another embodiment, the crosslinking agent is a multifunctional agent including a cyclic urea, glyoxal, polyol condensate. The crosslinking agent is added in an amount from about 0.001% to 20% by weight based on a total weight of cellulose fibers to be treated and, preferably, in an amount of about 5% by weight.

Owner:EVEREADY BATTERY CO INC

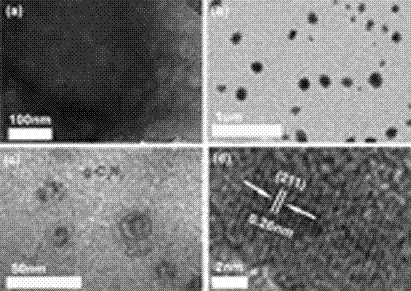

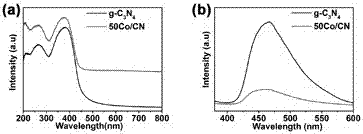

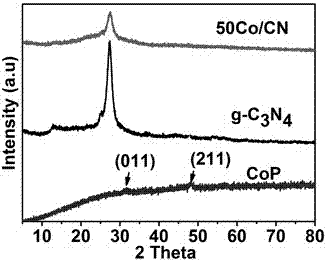

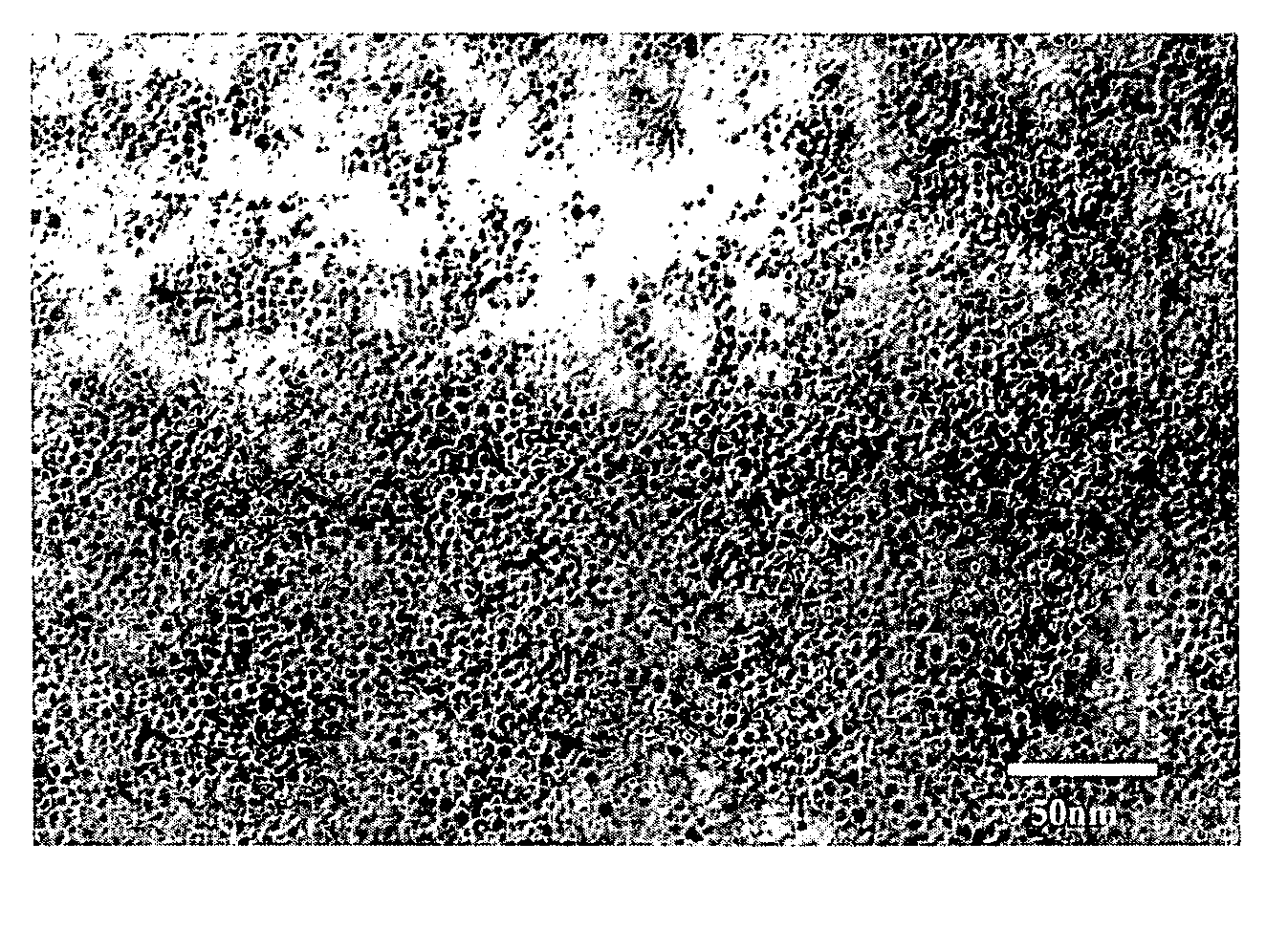

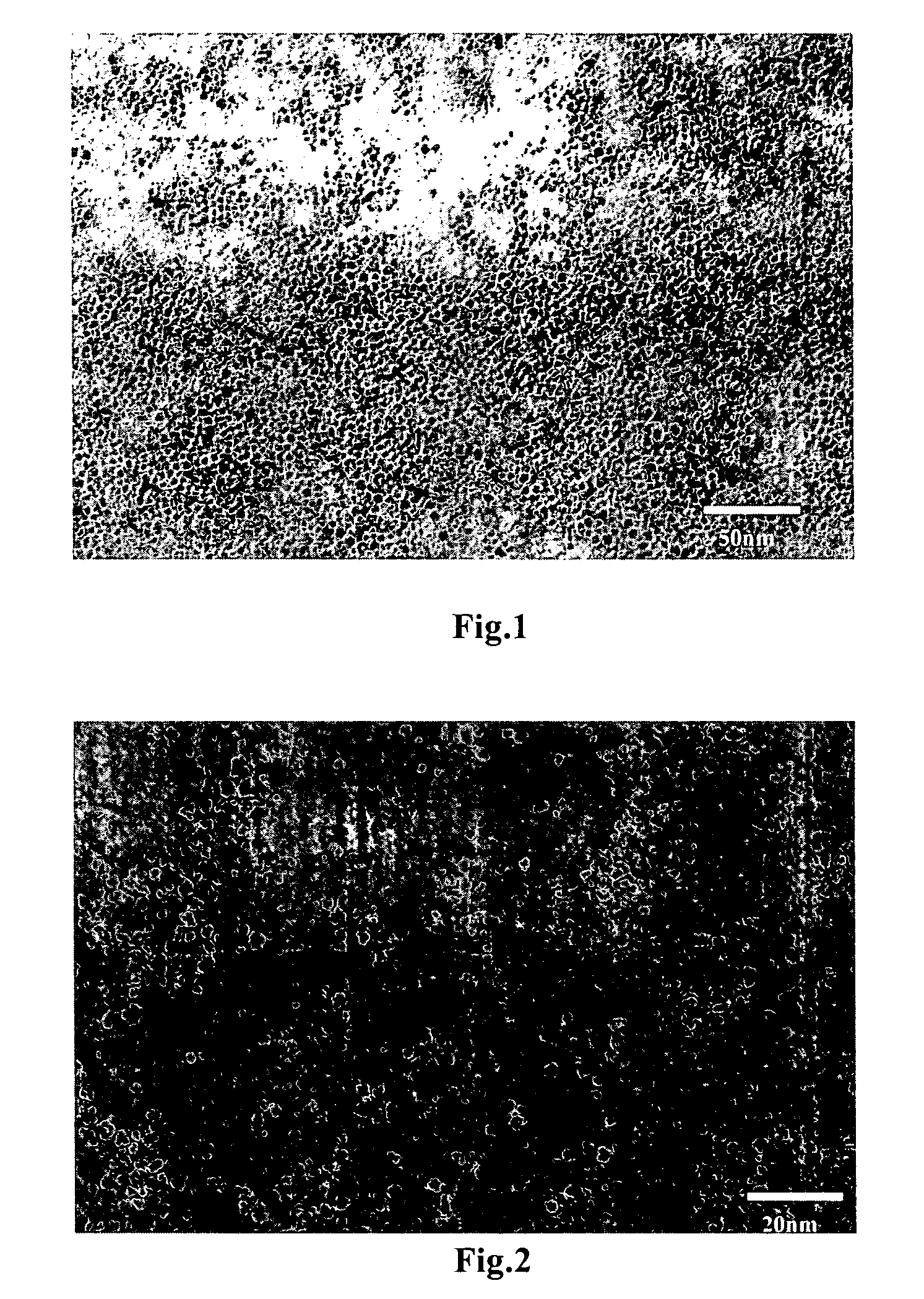

Preparation and application of composite CoP/g-C3N4 photocatalyst

InactiveCN107126971ASmall particlesInhibition releasePhysical/chemical process catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesNanoparticleCarbon nitride

The invention provides a method for in-situ growth of CoP nanoparticles on a g-C3N4 surface and application. The method is mainly characterized in that in-situ growth of Co(OH)2 on carbon nitride is performed according to an in-situ loading method, and then sodium hypophosphite is decomposed under the protection of an inert atmosphere to release PH3 gas to generate CoP. By adoption of the method, the CoP nanoparticles can be uniformly loaded on carbon nitride, and a composite CoP / g-C3N4 photocatalyst is obtained finally. Easiness in raw material acquisition and simplicity in operation are realized, and the composite photocatalyst is innovatively applied to photocatalysis production of hydrogen peroxide; as an auxiliary catalyst, CoP is capable of enhancing visible light absorbability, and owing to the metalloid property of CoP, quick separation of electrons and holes can be realized, and absorbed light can be used more efficiently, and finally catalysis activity of carbon nitride being a main catalyst in photocatalysis production of hydrogen peroxide is effectively improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Process for producing copper nanoparticles

ActiveUS20060053972A1Improve stabilityGood dispersionMaterial nanotechnologyTransportation and packagingHydrazine compoundReducing agent

The present invention provides a process for producing copper nanoparticles, comprising steps of: a) reacting an aqueous solution containing a reductant with an aqueous solution of a copper salt while stirring for 1-8 min, wherein the reductant being one or more selected from a group consisting of hydrazine hydrate, sodium borohydride and sodium hypophosphite; b) adding an apolar organic solution containing the extracting agent and continuing the stirring for 0.5-1.5 hrs, said extracting agent being one or more selected from the group consisting of alkyl dithiocarbonic acid and salts thereof, O,O′-dialkyl dithiophosphoric acid and salts thereof, and dialkylamino dithioformic acid and salts and said apolar organic solution being one selected from the group consisting of benzene, toluene and straight or branched alkanes having 6-12 carbon atoms, wherein the alkyl having 6-20 carbon atoms; and c) post-treating the reaction product to obtain copper nanoparticles.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

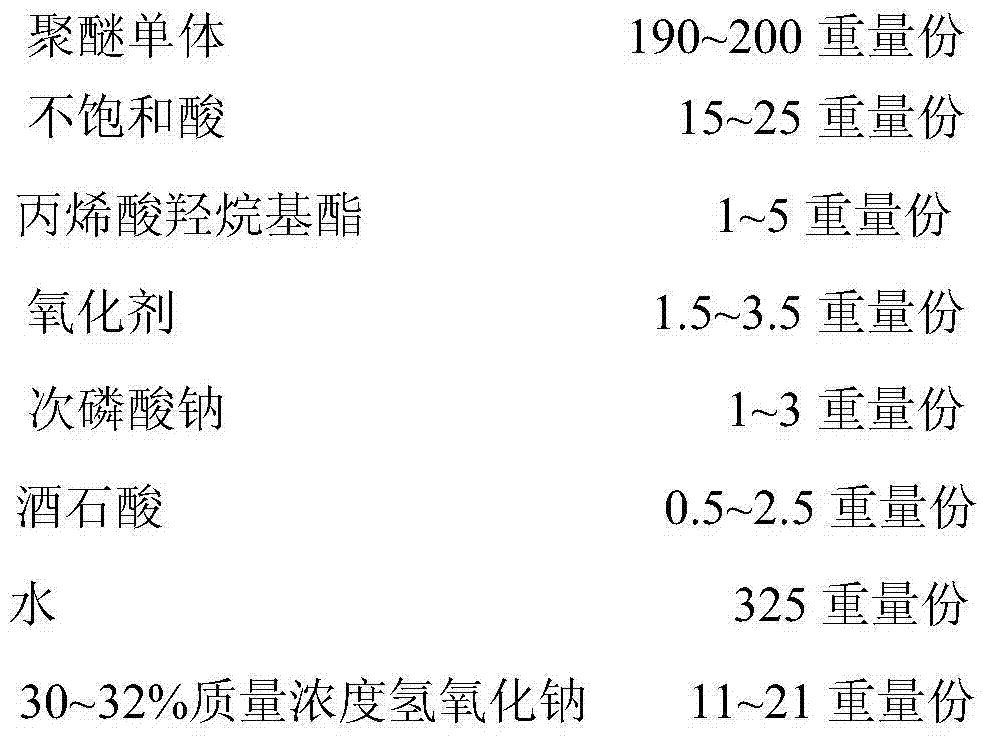

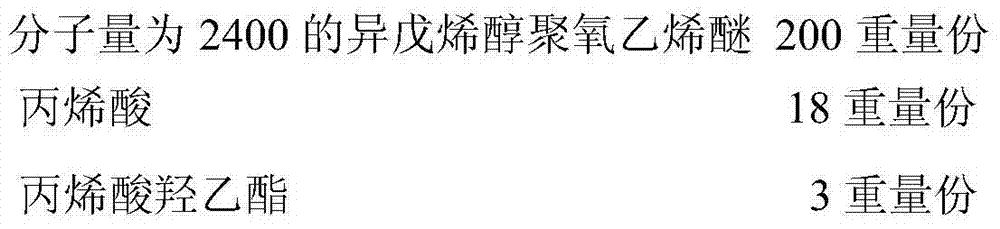

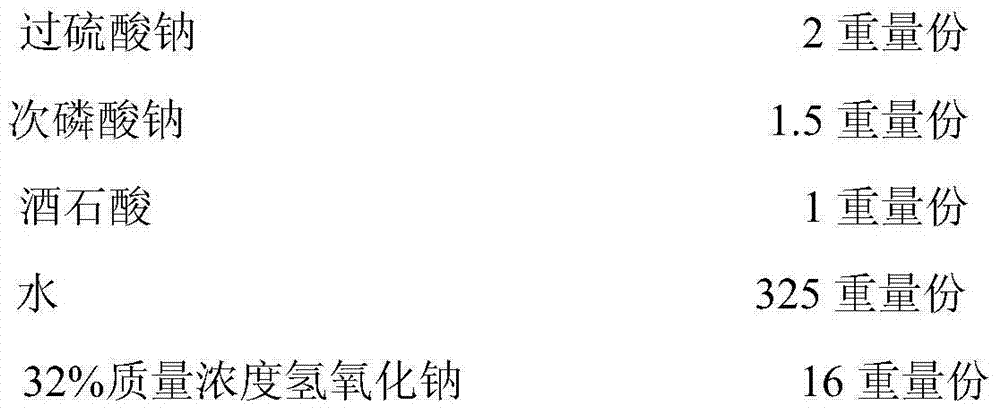

Polycarboxylate superplasticizer and preparation method thereof

The invention discloses a polycarboxylate superplasticizer and a preparation method thereof. The raw materials of the polycarboxylate superplasticizer comprise the following components in parts by weight: 190-200 parts of a polyether monomer, 15-25 parts of unsaturated acid, 1-5 parts of hydroxyl alkyl acrylate, 1.5-3.5 parts of an oxidizing agent, 1-3 parts of sodium hypophosphite, 0.5-2.5 parts of tartaric acid, 325 parts of water and 11-21 parts of 30-32% sodium hydroxide by mass concentration, wherein the polyether monomer is 600-3000 methylallyl polyoxyethylene-polyoxypropylene or isopentenol polyoxyethylene ether. The preparation method of the polycarboxylate superplasticizer, disclosed by the invention, is carried out in a temperature range of 5-40 DEG C and can be used for solving the problem that the initiating efficiency is relatively low at a relatively low temperature when a single reducing agent is used, meanwhile, the dropwise adding time can be shortened, the production cycle is shorter, the energy consumption is relatively low and the production cost is lowered.

Owner:KZJ NEW MATERIALS GROUP CO LTD +2

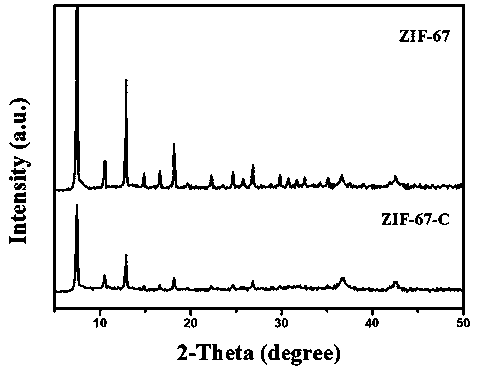

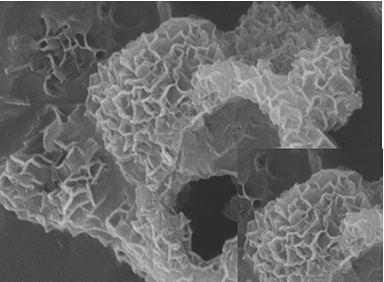

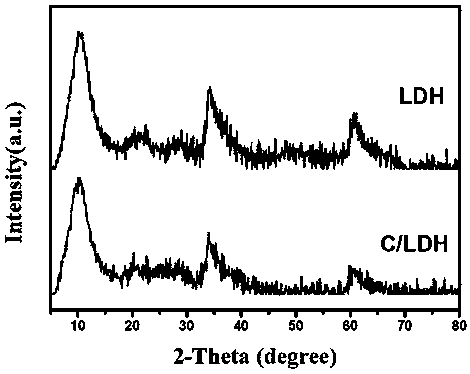

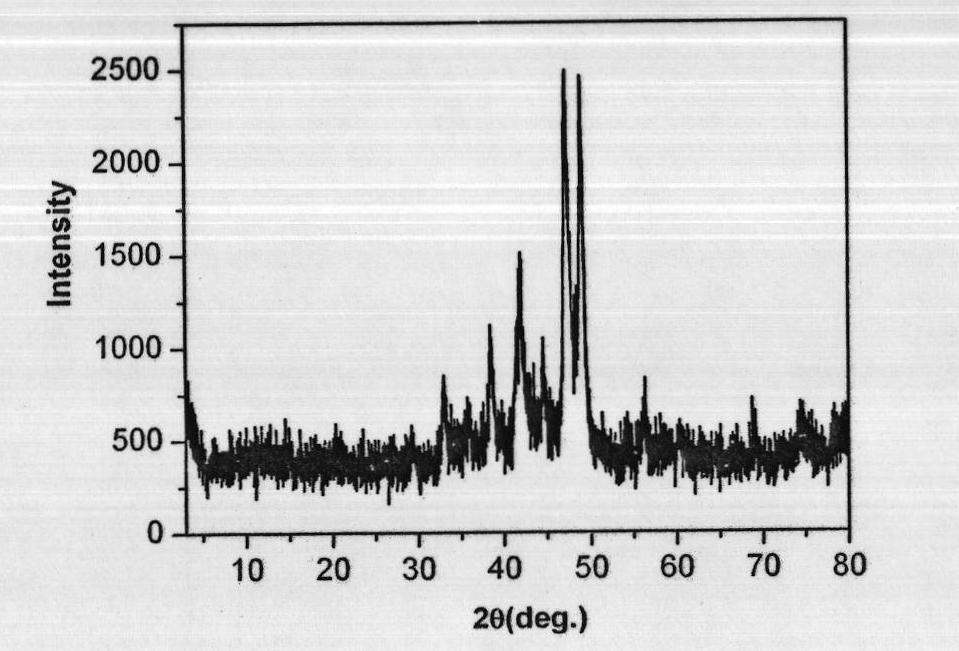

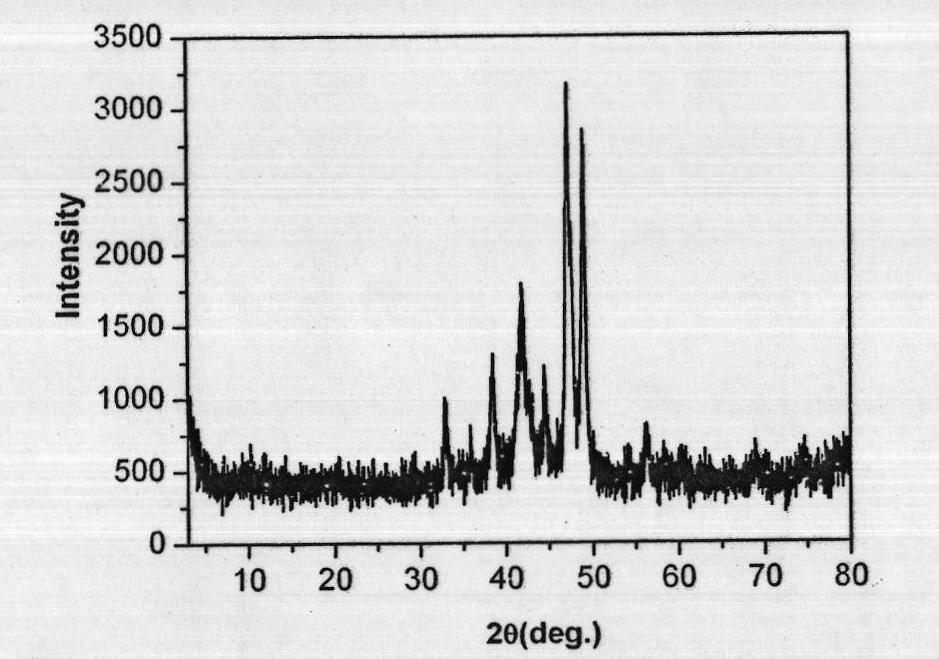

Preparation method of MOF-derived layered double hydroxide electrocatalyst with hollow structure

InactiveCN109652815AOrganic-compounds/hydrides/coordination-complexes catalystsElectrodesElectricityNew energy

The invention discloses a preparation method of a MOF-derived layered double hydroxide electrocatalyst with a hollow structure, and belongs to the technical field of synthesis of new energy electrocatalysts. According to the technical scheme, the electrocatalyst is characterized in that the MOF-derived electrocatalyst prepared under the condition that the mass of a phosphorus source sodium hypophosphite is 150 mg, and the pyrolysis temperature is 200 DEG C has the optimal performance, through further characterization research, self-template in-situ pseudocrystals of MOF are transformed into ahollow skeleton structure with the surface rich in layered double hydroxide, and compared with most phosphides, the MOF-derived electroactive material obtained by using the preparation method shows adesired porous structure and is rich in oxidation-reduction chemical activity and excellent in electrical conductivity.

Owner:HENAN NORMAL UNIV

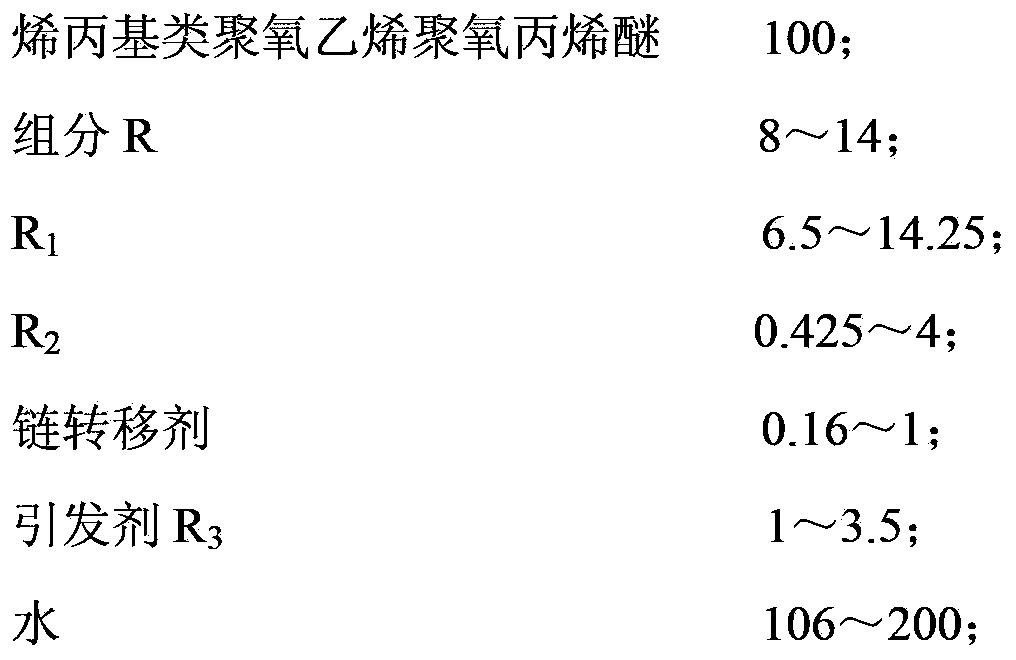

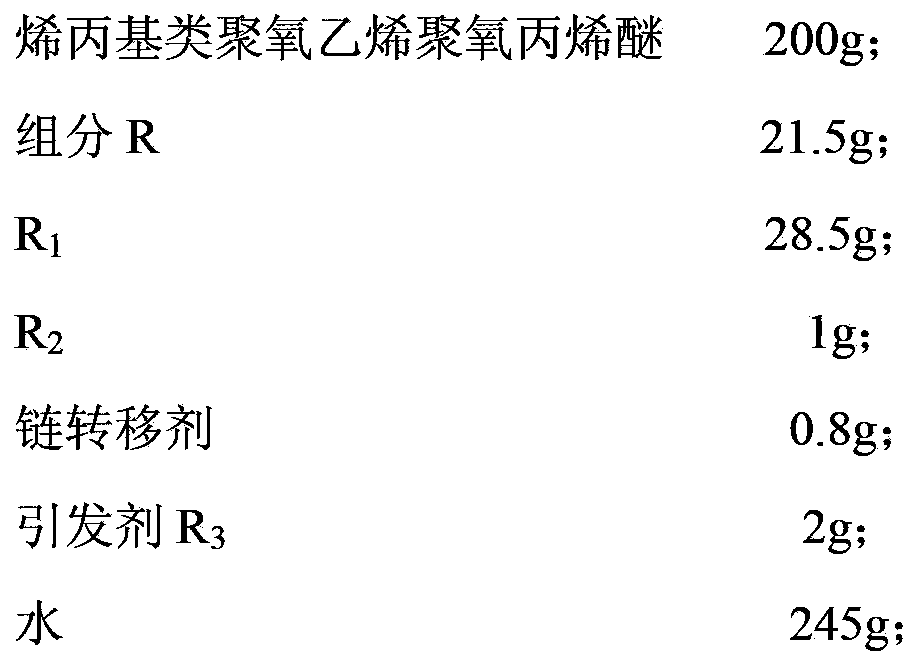

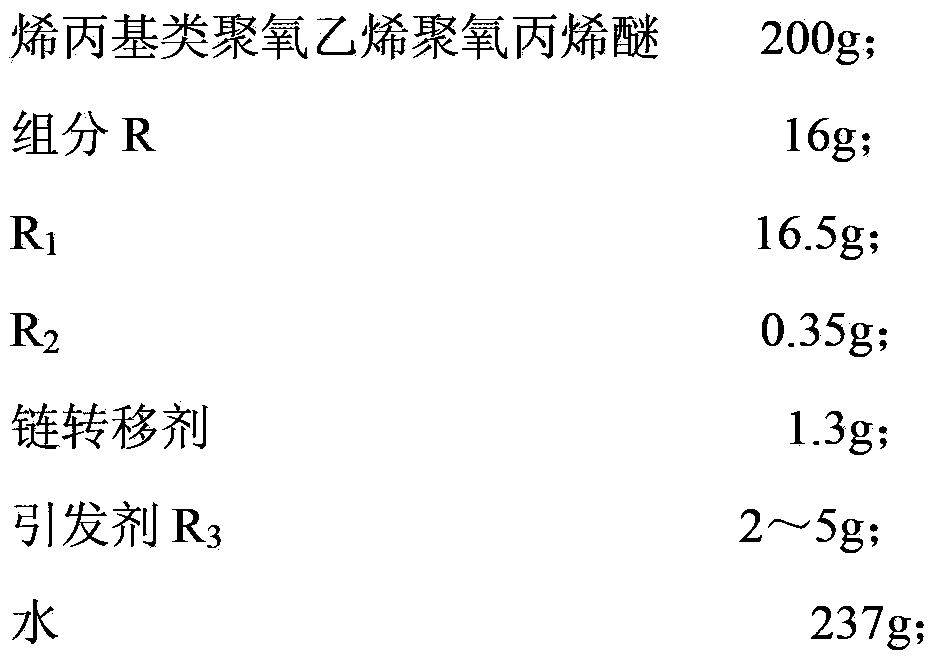

Mud-resistant polycarboxylic acid water reducer and preparation method thereof

The invention discloses a mud-resistant polycarboxylic acid water reducer which is prepared from the following components: allyl polyoxyethylene polyoxypropylene ether, components R, R1 and R2, a chain transfer agent, an initiating agent R3 and water, wherein the component R is one or more of maleic anhydride, sodium methallyl sulfonate, vinyl acetate, itaconic acid, itaconic anhydride and fumaric acid; R1 is one or a mixture of two of acrylic acid and methylacrylic acid; R2 is one or more of ascorbic acid, sodium formaldehyde sulfoxylate, ferrous sulfate, tin sulfate, sodium hypophosphite, sodium hydrogen sulfite and oxalic acid. The invention further discloses a preparation method for the mud-resistant polycarboxylic acid water reducer. The mud-resistant polycarboxylic acid water reducer has the following benefits: the water solubility and the steric hindrance of polycarboxylic acid are effectively kept; a large amount of non-hydrophilic structures on branch chains can be used for effectively preventing soil interlayer adsorption, so that the adsorption speed and effect are greatly reduced and the mud-resistant purpose is achieved.

Owner:SICHUAN TONGZHOU CHEM TECH

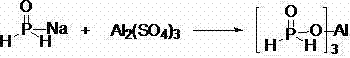

Method for preparing aluminum hypophosphite

The invention relates to a method for preparing aluminum hypophosphite. The method includes the following steps of firstly, preparing sodium hypophosphite solution with concentration of 2-6mol / L, adjusting pH (potential of hydrogen) to be 3-5 preferentially within 3-6.5; secondly, preparing aluminum sulfate solution; and thirdly, subjecting the sodium hypophosphite solution and the aluminum sulfate solution to reaction by heating on the acid condition to generate aluminum hypophosphite. The aluminum sulfate is added into the sodium hypophosphite solution for reaction within a certain temperature range, so that harms caused by volatilization of hypophosphorous acid during preparing of the aluminum hypophosphite are avoided, operation is simplified, yield of products is high, cost is low and industrialization is easy to realize.

Owner:NANJING NORMAL UNIVERSITY

Animal hair solvent and preparation method and use of keratin solution

InactiveCN101979428AHigh molecular contentGuaranteed stabilityFibre treatmentAdditive ingredientSulfite salt

The invention discloses an animal hair solvent and the preparation method and use of keratin solution. The solvent is characterized in that tris(2-carboxyethyl)phosphine hydrochloride, tris(2-cyanoethyl)phosphine or trisphosphine is used as a main ingredient and is mixed with 1 to 8 percent of assistant which may be at least one of mercaptoacetic acid, mercaptoethanol, sodium hydrogensulfite, potassium bisulfate, sodium sulfite, potassium sulfite, sodium hypophosphite, ethanol, methanol and urea. The preparation method adopts the following processes: 1, preparing animal hair solution by using the animal hair solvent of the invention; 2, dissolving animal hair in the solution to prepare keratin solution; and 3, adding a proper amount of acid to perform the post-treatment of the keratin solution. The use is to use the keratin solution as textile finishing liquor or the main functional ingredient of the textile finishing liquor.

Owner:TIANJIN POLYTECHNIC UNIV +1

Nickel-phosphorus chemical precipitation plating layer of aluminium alloy

InactiveCN101638778AExtend your lifeImprove performanceLiquid/solution decomposition chemical coatingSodium acetateGram

The invention relates to a nickel-phosphorus chemical precipitation plating layer of an aluminium alloy, mainly containing the following components in content by weight: 20-30 grams / litre of hexahydrated nickel sulphate, 20-30 grams / litre of sodium hypophosphite, 15-20 grams / litre of sodium acetate, 6-10 grams / litre of butane diacid, 30-50 grams / litre of complexing agents, 20-60 PPM of stabilizingagent and 30-100 PPM of plating midbodies. The nickel-phosphorus chemical precipitation plating layer has the advantages of fast precipitation, well combining force of a plating layer, brightness andcompactness of the plating layer, excellent stable property of tank liquor, long service life, easy maintenance, and the like.

Owner:郑建国 +1

Silvered aramid conductive fiber and preparation method thereof

The invention provides a silvered aramid conductive fiber and a preparation method thereof. The preparation method is conducted according to the steps as follows: a. coarsening: coarsening the aramid fiber through putting the fiber into a mixed solution of sodium hydroxide, absolute ethanol and the balance of water, and neutralizing the fiber by rinsing; b. hydrolyzing: hydrolyzing the coarsened aramid fiber by putting the fiber into an acid solution; c. activation of palladium salt: activating the hydrolyzed aramid fiber subjected to activation of palladium salt in step b by putting the fiber into a mixed solution of hydrochloric acid, palladium chloride, stannous chloride and the balance of water; d. reducing: reducing the palladium salt activated aramid fiber in step c by putting the fiber into a mixed solution of hydrochloric acid, sodium hypophosphite and the balance of water; e. chemical silvering: chemical silvering the reduced aramid fiber in step d by putting the fiber into a chemical silvering solution of silver nitrate, sodium hydroxide, aqua ammonia, a complex agent, a reducing agent and the balance of water; f. drying: drying the chemical silvered aramid fiber in step e in the conventional manner to obtain the silvered aramid conductive fiber.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

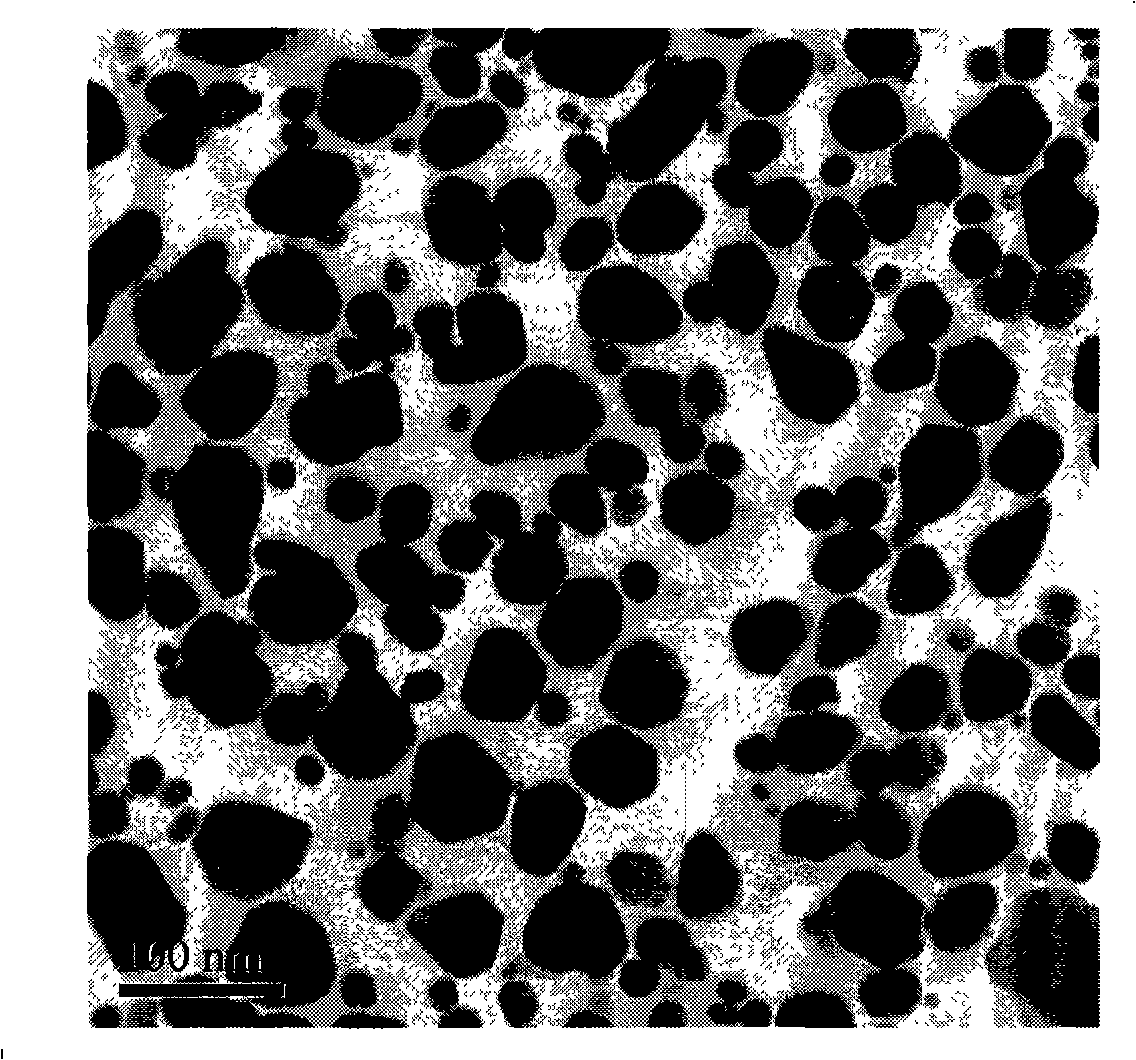

Novel method for preparing nickel phosphide by low-temperature reduction

The invention provides a novel method for preparing nickel phosphide (Ni12P5) by the low-temperature solvothermal method. The method of the invention is characterized by dissolving anhydrous nickel chloride as a nickel source and sodium hypophosphite as a phosphorus source in a high-boiling-point organic solvent at the room temperature, stirring the materials until the organic solvent is transparent, sealing the organic solvent in a high-pressure kettle and heating up to 140-240 DEG C and reacting for certain time to obtain Ni12P5. The method of the invention is characterized by using a high-boiling point organic substance as the solvent, the reaction conditions are simple and mild and the generated Ni12P5 is the nano-particle with the size being 50nm to 200nm and the specific surface area being larger. The method is favorable for hydrodesulfurization, selective hydrogenation and other catalytic hydrogenation reactions, thus having wider application range.

Owner:NANKAI UNIV

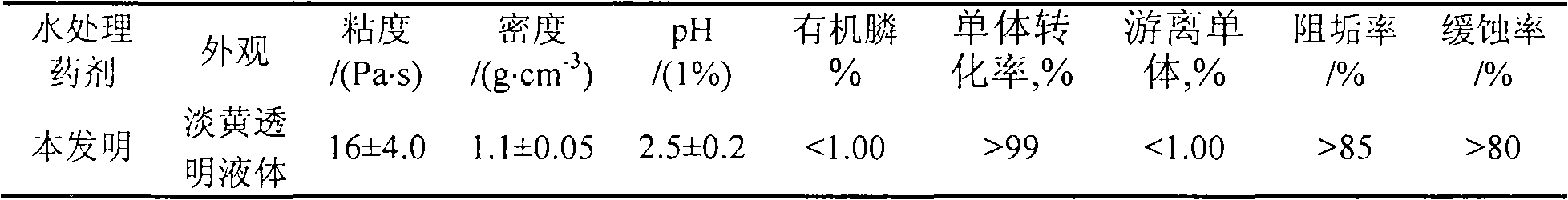

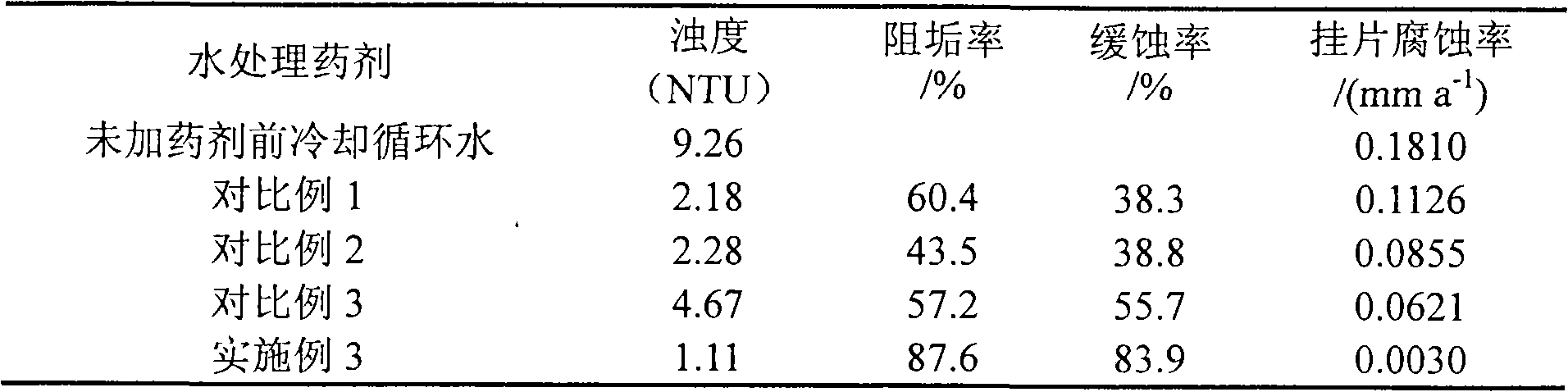

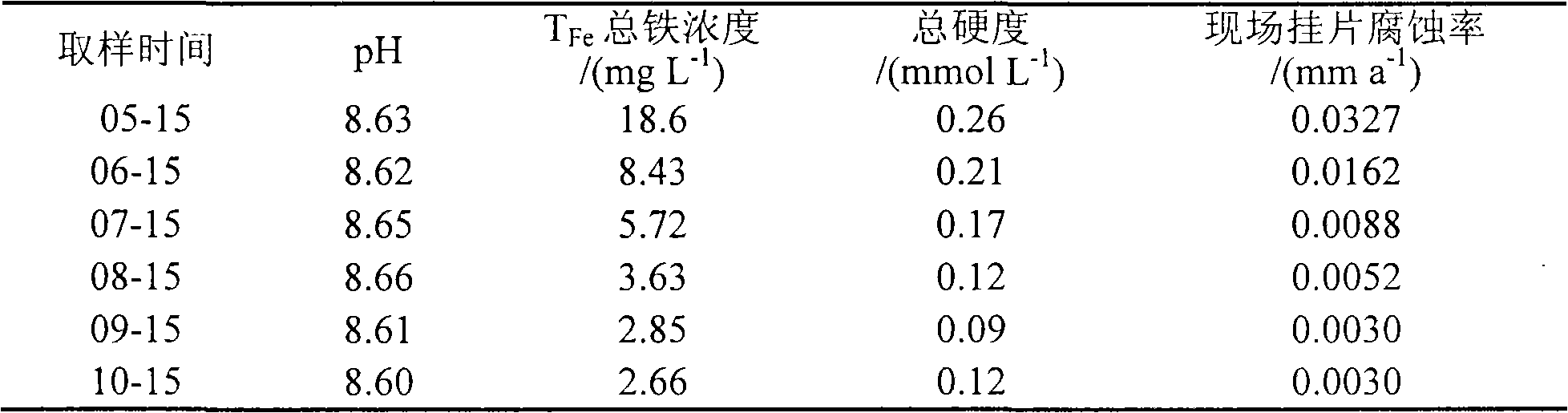

Four-element polymerization type corrosion inhibition antisludging agent and method for preparing same

InactiveCN101289256AAvoid corrosionSimple processTreatment using complexing/solubilising chemicalsPeroxydisulfateNuclear chemistry

The invention discloses a quaternary polymeric form corrosion and scale inhibitor which consists of maleic anhydride, hydroxy-propyl acrylate, acrylic acid, sodium alkyl sulfonate, sodium peroxydisulfate, sodium hypophosphite, isopropyl alcohol and water. The invention also discloses a preparation method of the quaternary polymeric form corrosion and scale inhibitor. The corrosion and scale inhibitor has good performance in inhibiting calcium carbonate scale, calcium sulphate scale, calcium phosphate scale and zinc scale and good dispersing performance for dispersing ferric oxide and is also characterized by corrosion resistance, high temperature resistance, stable molecule structure and low phosphorus content; the whole production process has no emission of 'the three wastes'. The technique of the product of the invention for treating circular cooling water is simple and the product of the invention has the advantages of little dosage, low cost, good effect and good economic benefit and wide social benefit.

Owner:NANJING FORESTRY UNIV

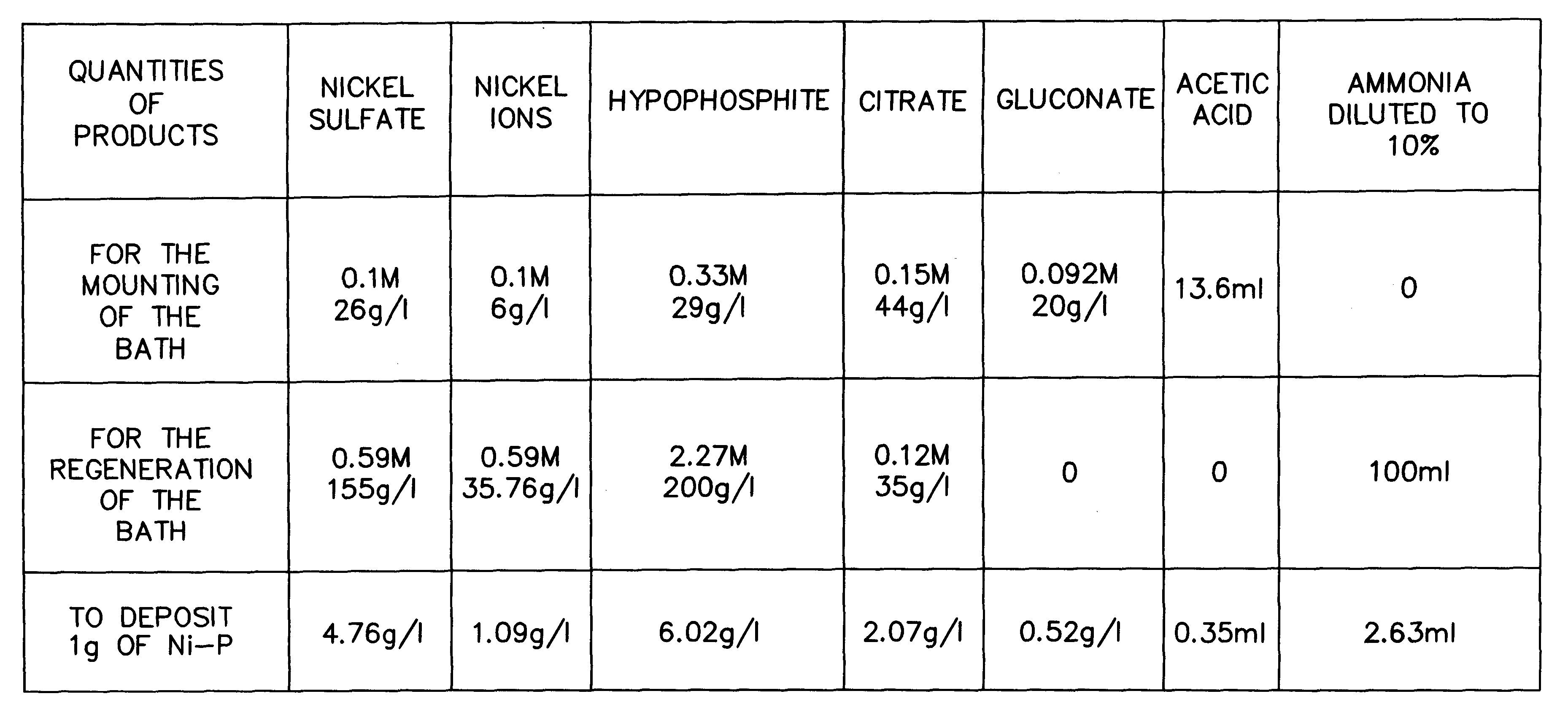

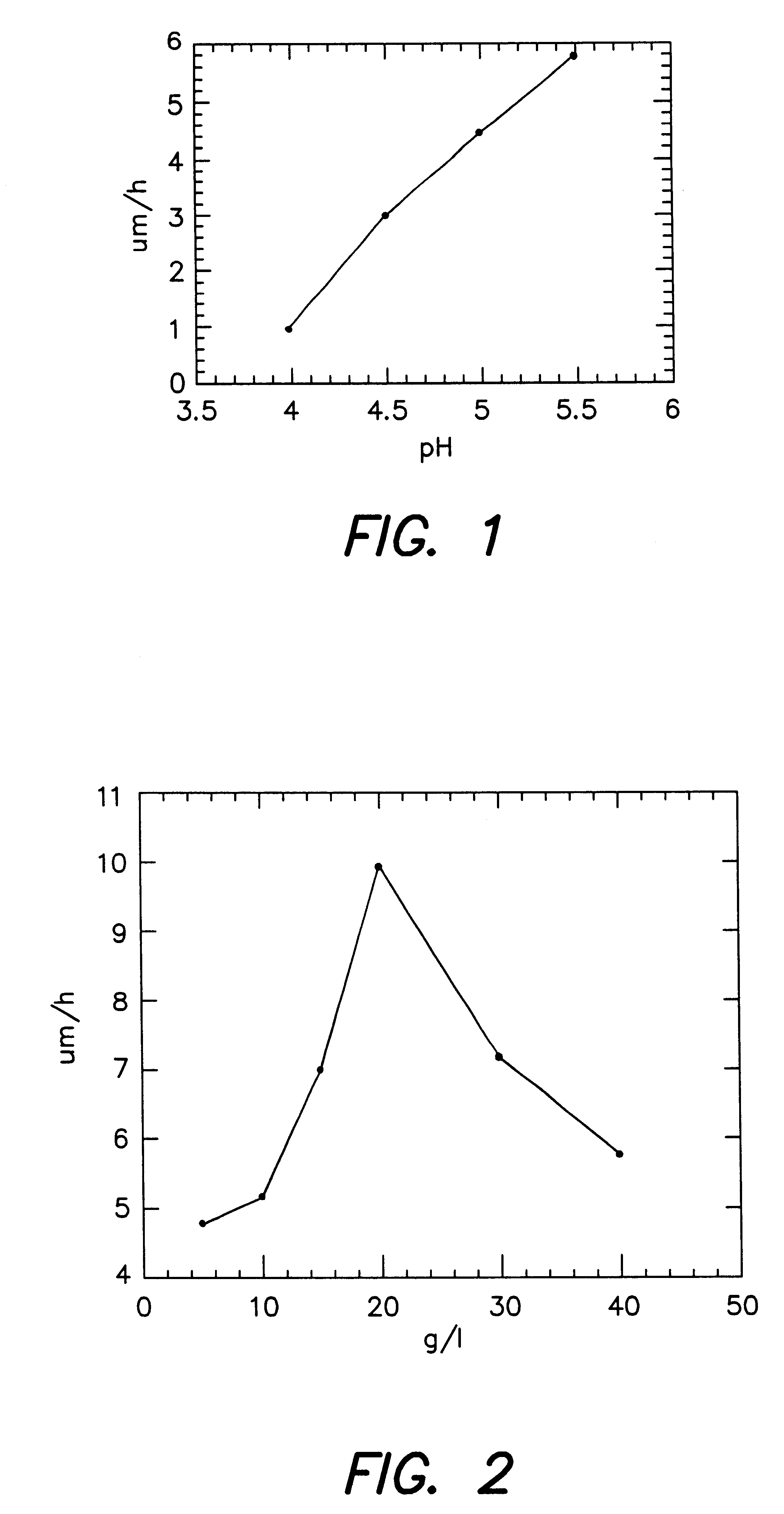

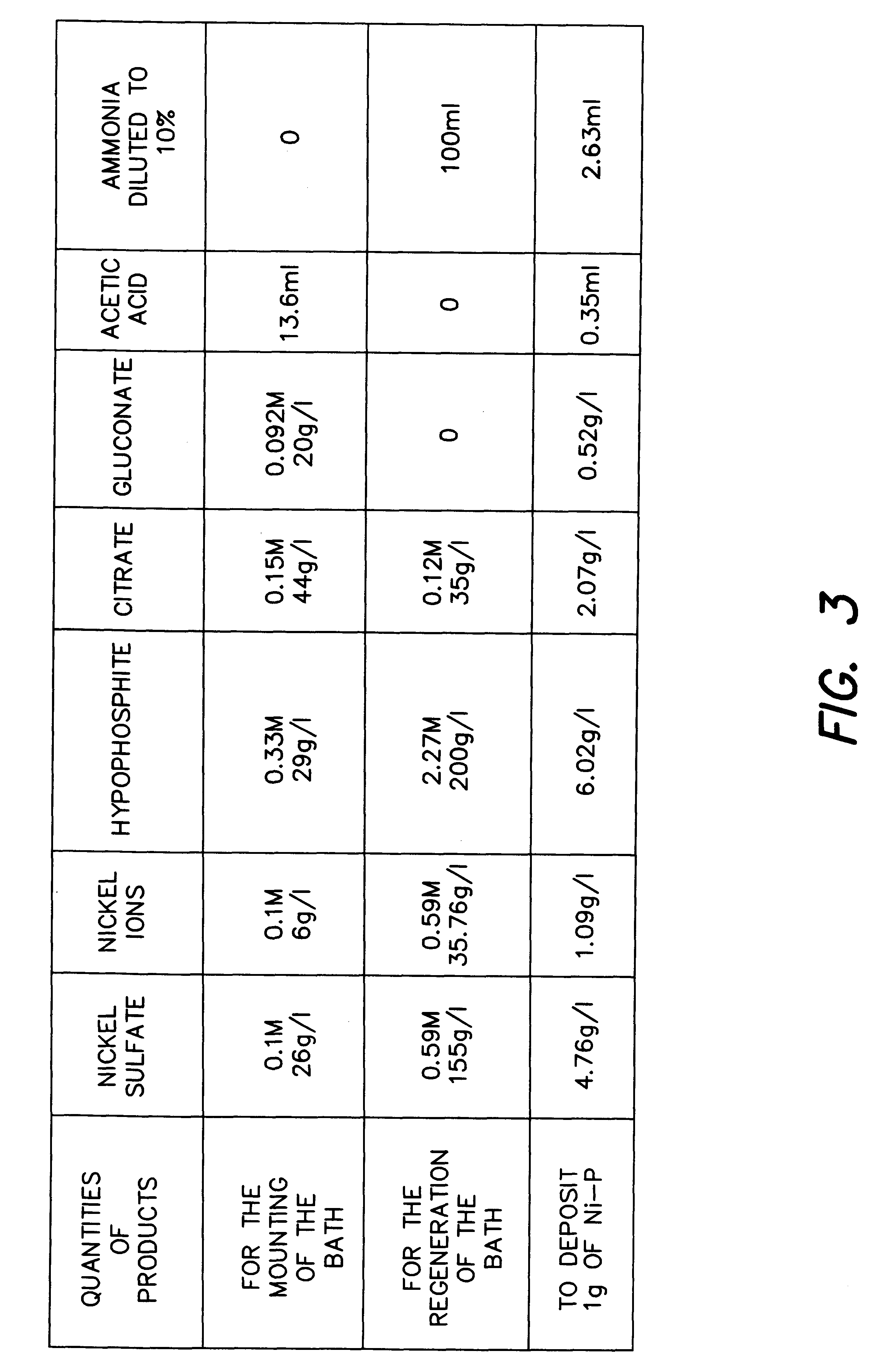

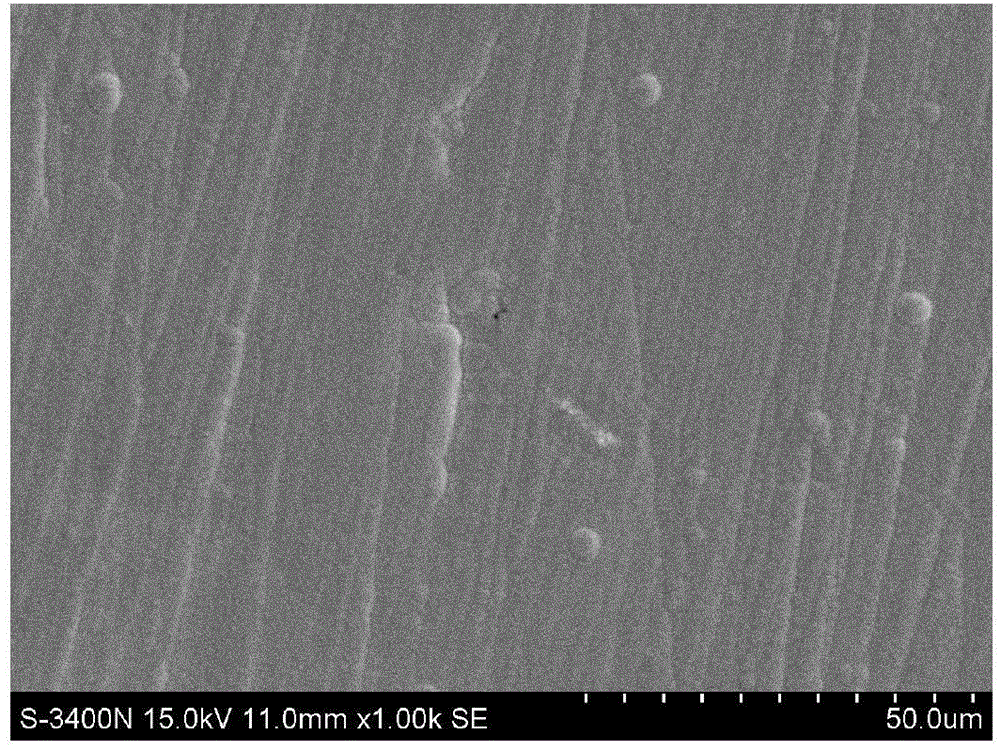

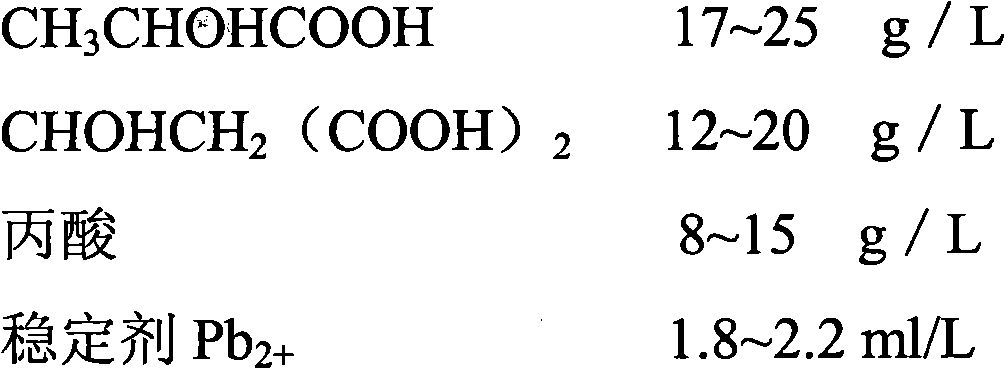

Self-catalytic bath and method for the deposition of a nickel-phosphorus alloy on a substrate

InactiveUS6281157B1Quality improvementIncrease deposition rateLiquid surface applicatorsOther chemical processesAcetic acidCITRATE ESTER

Disclosed are a self-catalytic bath and a method for the deposition of Ni-P alloy on a substrate. The bath comprises nickel sulfate, sodium hypophosphite as a reducing agent, acetic acid as a buffer and traces of lead as a stabilizer. It also includes a citrate used as a complexing agent associated with a gluconate used both as a catalyst and a stabilizer. The disclosed bath makes it possible to tolerate large quantities of hypophosphite and is relatively long-lived. Furthermore, it can be used to prepare large quantities of Ni-P alloy per liter of solution.

Owner:STMICROELECTRONICS SRL

Graphene oxide nickel-phosphorus composite plating solution, preparation method and applications thereof

ActiveCN104862676AImprove responseReduce energy consumptionLiquid/solution decomposition chemical coatingSodium acetateReduction treatment

The present invention discloses a graphene oxide nickel-phosphorus composite plating solution, a preparation method and applications thereof, wherein per liter of the graphene oxide nickel-phosphorus composite plating solution comprises 0.5-1 g of graphene oxide being subjected to reduction treatment, 25-40 g of nickel sulfate, 15-20 g of sodium hypophosphite, 15 g of sodium acetate, 8-10 g of citric acid, 4 ml of lactic acid, 41 mg of a composite stabilizer, and the balance of distilled water. The preparation method comprises preparation of the graphene oxide being subjected to reduction treatment and preparation of the graphene oxide nickel-phosphorus composite plating solution. According to the present invention, the obtained graphene oxide nickel-phosphorus composite plating solution can perform plating on iron and steel at a low temperature of 50-70 DEG C, and the obtained graphene oxide nickel-phosphorus composite plating layer thickness is uniform and the surface is smooth and does not have gap; and the preparation method is simple, and the continuous production can be achieved.

Owner:SHANGHAI INST OF TECH

Preparation of nano aluminum powder for conducting resin and storage method

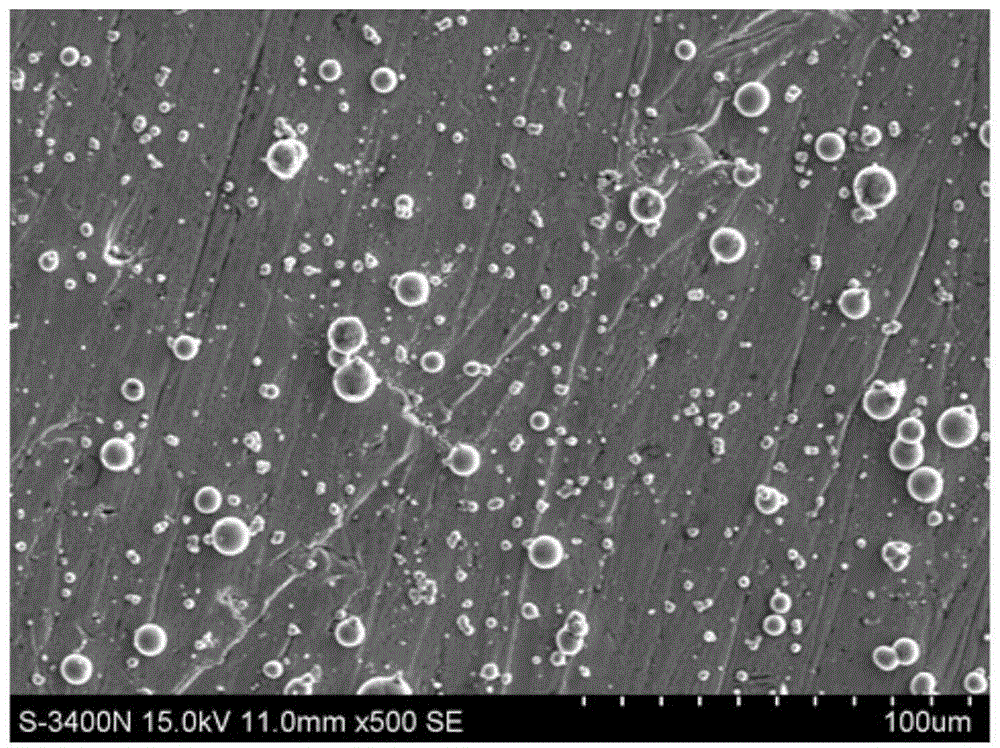

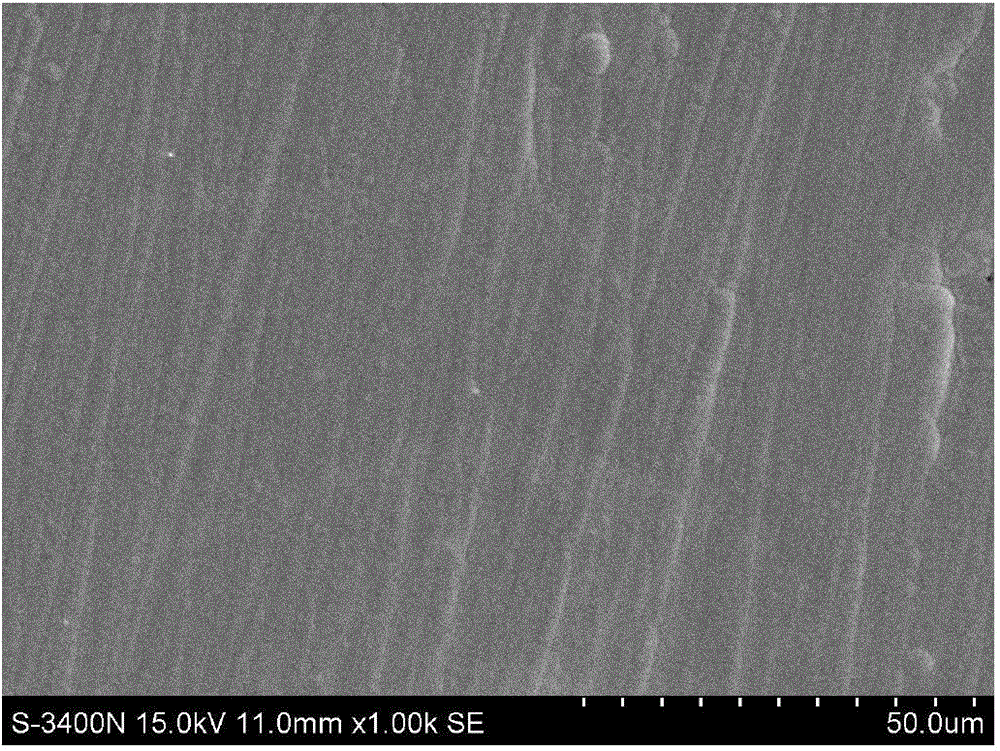

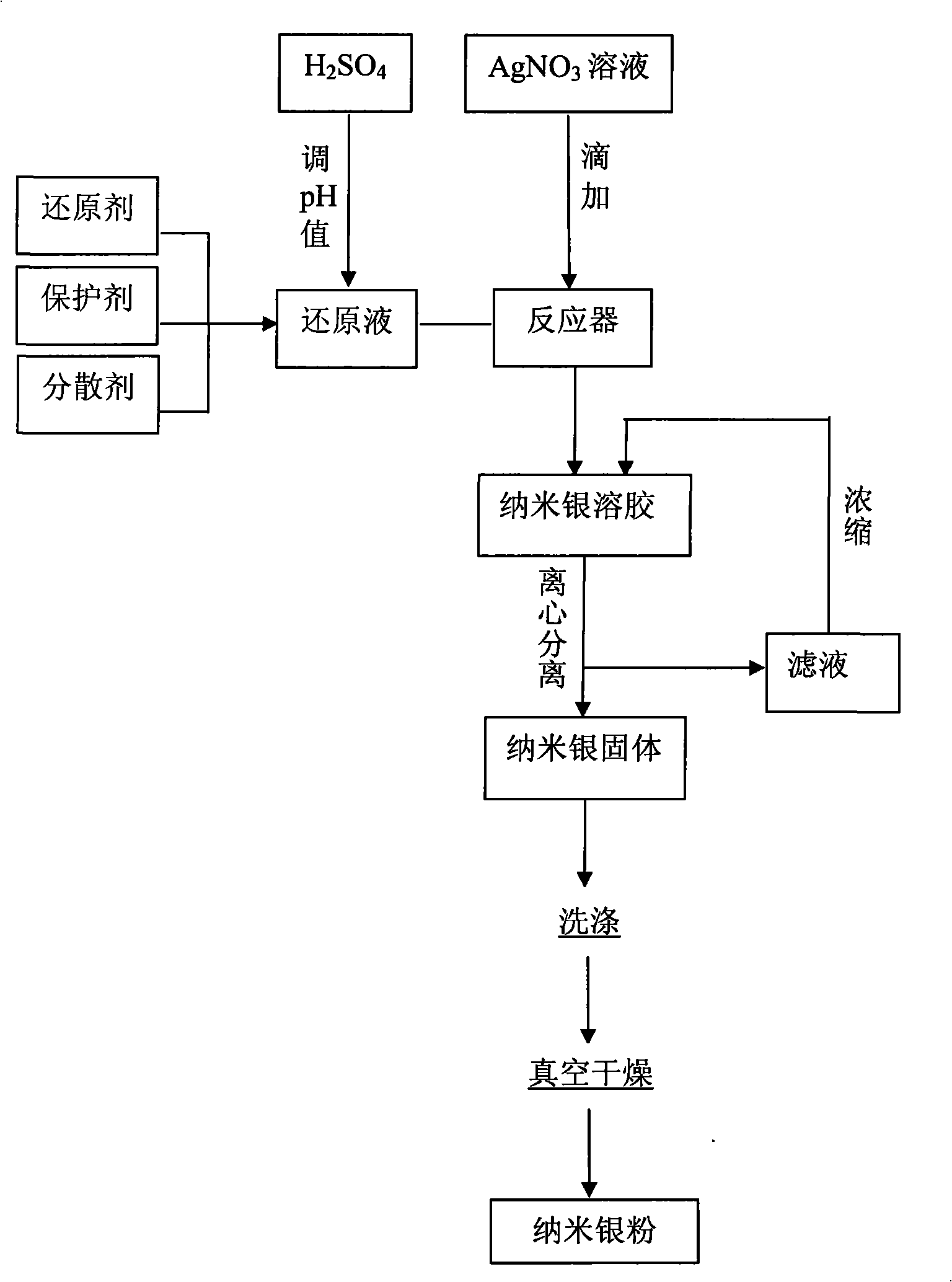

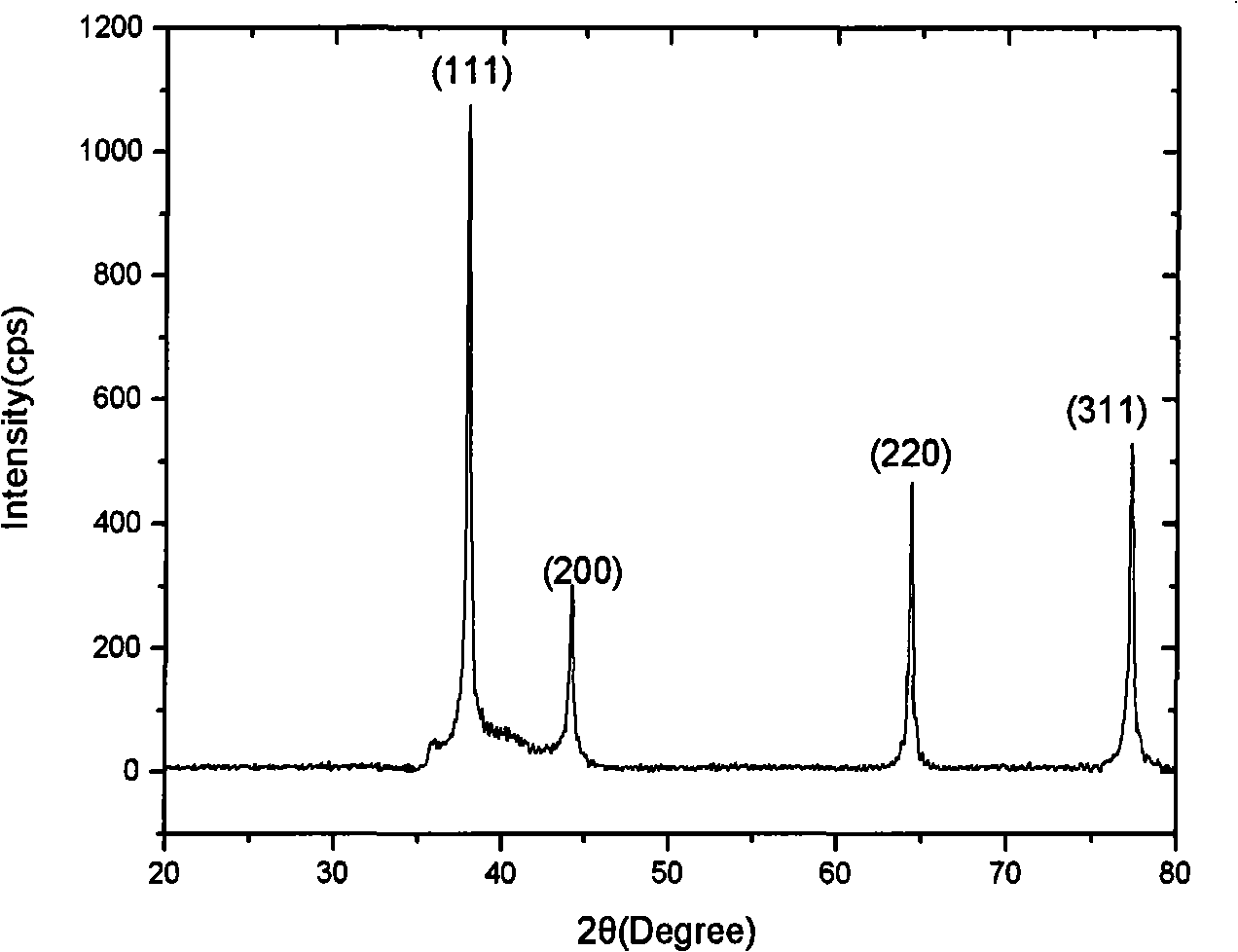

The invention relates to the preparation and storage method of silver nano-particles for conductive adhesive, in particular to a method for preparing silver nano-particles by reducing high-concentration silver nitrate by adopting a chemical liquid-phase method. The method comprises the following steps: mixing sodium hypophosphite, polyvinyl pyrrolidone and sodium hexametaphosphate to obtain reduction solution, adding sulfuric acid dropwise to adjust pH value, adding silver nitrate solution into the reduction solution under magnetically stirring to obtain silver colloid, standing, centrifugally separating, recovering filtrate, concentrating, centrifugally separating, washing the solid, vacuum-drying to obtain silver nano-particles, sealing and packaging, and storing at low temperature. The method adopts high-concentration silver nitrate solution, and has the advantages of simple process flow, high yield of silver powder, short production cycle and good safety. In the separation process, the filtrate can be recovered to improve the coefficient of recovery of silver powder. The silver nano-particle has spherical shape, uniform particle diameter, narrow distribution, high purity, good dispersibility, good storage stability and long storage time without oxidization, and can be used for conductive filler such as conductive adhesive.

Owner:CENT SOUTH UNIV

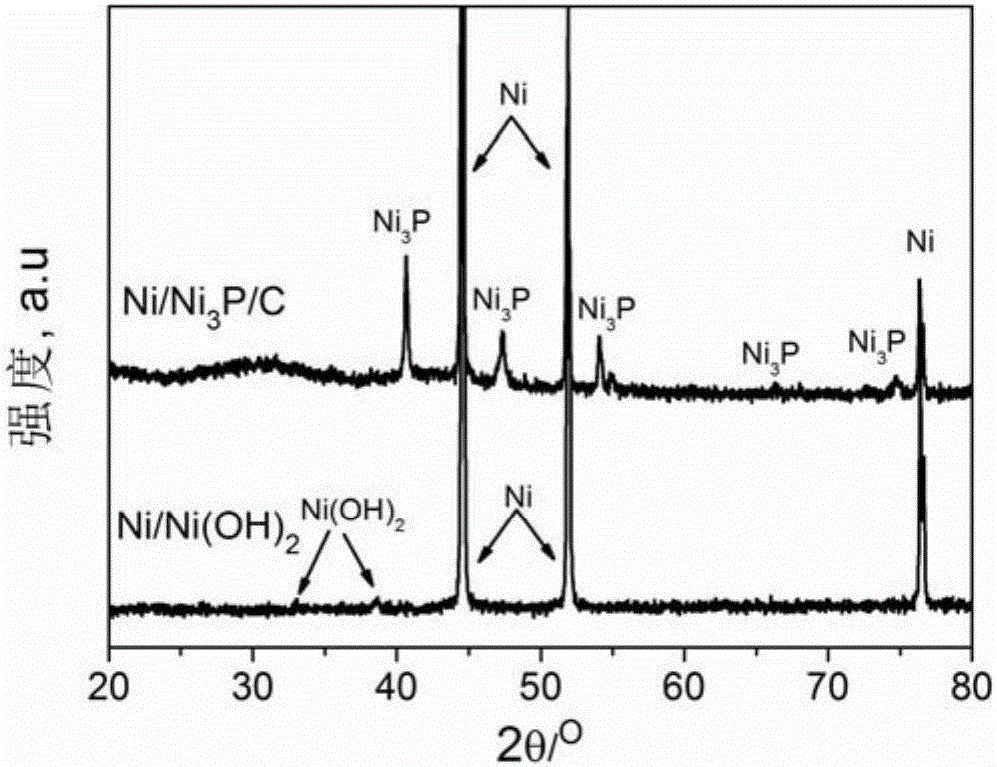

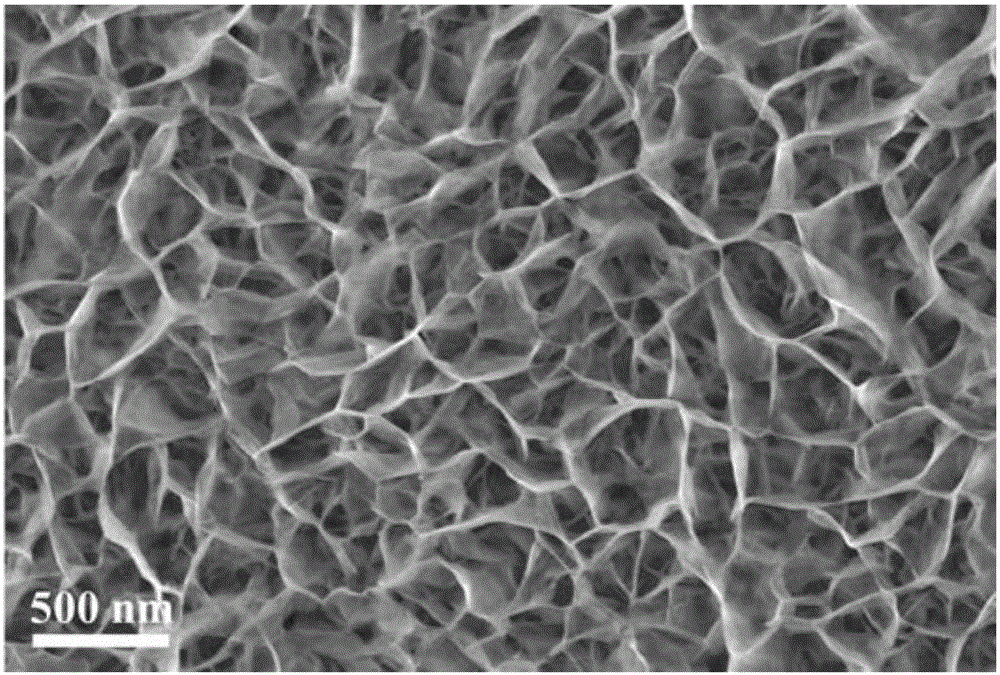

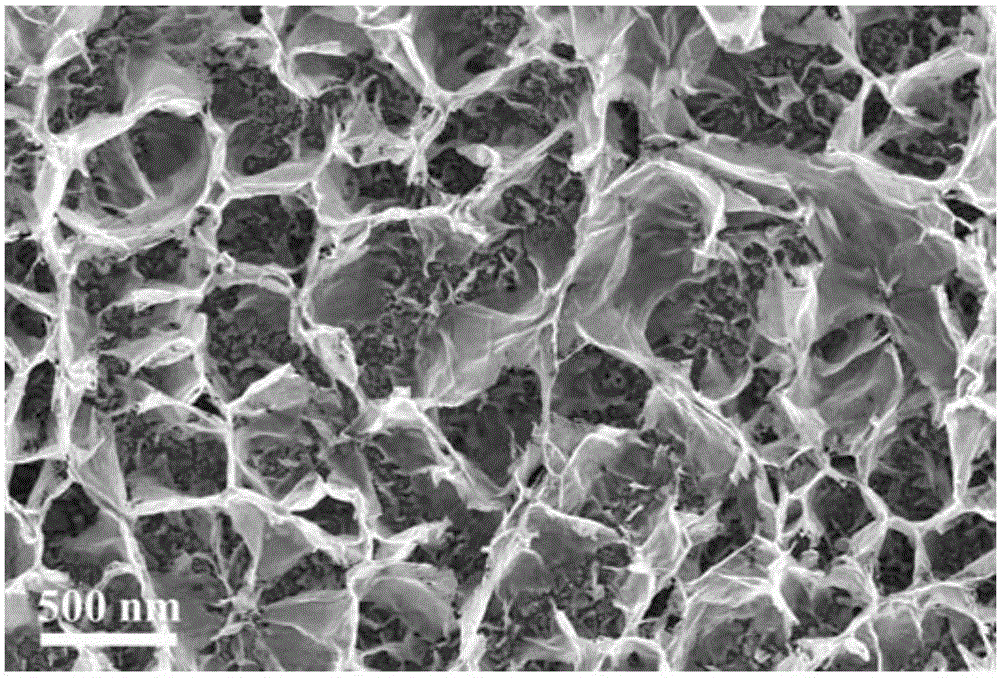

Foamed nickel self-supported flake-shaped Ni3P/C composite material for sodium ion battery negative electrode and preparation method for composite material

ActiveCN105720236AImprove performanceExcellent rate performanceNegative electrodesCarbon coatingThermal insulation

The invention discloses a foamed nickel self-supported flake-shaped Ni3P / C composite material for a sodium ion battery negative electrode and a preparation method for the composite material. According to the composite material, the flake-shaped Ni3P is uniformly growing on the foamed nickel; and the Ni3P is uniformly coated with a C film. The preparation method for the composite material comprises the steps of taking a nickel compound as the raw material, and uniformly growing a flake-shaped nickel hydroxide layer on the surface of the nickel compound through a hydrothermal method; then taking sodium hypophosphite as a phosphorus source, and performing thermal insulation at a temperature of 300 DEG C for 2h to prepare the foamed nickel self-supported flake-shaped Ni3P material; and finally, performing carbon coating on the foamed nickel self-supported flake-shaped Ni3P material to obtain the foamed nickel self-supported flake-shaped Ni3P / C composite material. The sodium ion battery prepared from the Ni3P / C composite material prepared by the invention has excellent specific capacity, rate capability and stable cycling performance; and in addition, the preparation method is simple and feasible, wide in raw material resources and suitable for industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Middle-temperature acidic electroless nickel plating-phosphor alloy formula

InactiveCN101348905AImprove stabilityImprove performanceLiquid/solution decomposition chemical coatingSodium acetateElectroless nickel

The invention provides a formulation of medium-temperature acidic electroless nickel-phosphorus alloy, which is characterized in that the formulation is as follows: 25 to 30 grams of nickel sulfate per liter, 25 to 35 grams of sodium hypophosphite per liter, 12 to 18 grams of sodium acetate per liter, 0.5-1.3 milligrams of thiourea per liter, 7 to 13 milliliters of lactic acid per liter, 7 to 13 milliliters of acetic acid per liter, 4-10 grams of organic acid per liter, 5-16 milligrams of potassium iodide or potassium iodate per liter, and the loadage is between 0.5 and 1.5 dm<2> / L. The invention has the advantages that: the formulation improves the stability of a plating solution, obviously improves plating rate, has good corrosion resistance and the comprehensive properties of plating; the stability of the plating solution can reach over 1800 s; the stability of periodic experiments is more than ten periods; the corrosion resistance of the plating reaches over 130 s; and the hardness of the plating reaches 480 HV.

Owner:NANCHANG HANGKONG UNIVERSITY

Antibacterial wash-and-wear fire-retardant finishing liquid and finishing method thereof

InactiveCN105586768AImprove adsorption capacityGood compatibilityBiochemical fibre treatmentHeat resistant fibresPhosphateGlyoxal

The invention discloses an antibacterial wash-and-wear fire-retardant finishing liquid which is prepared from the following raw materials in parts by weight: 10-15 parts of glyoxal, 10-15 parts of citric acid, 5-8 parts of cyclic phosphate, 5-8 parts of a licorice extract, 3-5 parts of chitosan, 2-3 parts of magnesium chloride, 2-3 parts of sodium hypophosphite, 1-2 parts of a penetrant, 1-2 parts of a coupling agent, 1-2 parts of a softener, 1-2 parts of ethylene glycol, 1-2 parts of a fiber protecting agent, 1-2 parts of a pH adjusting agent and 1-2 parts of a dispersant. The prepared multifunctional antibacterial finishing liquid is environment-friendly and free of pollution, has good efficacies of being wash-and-wear, shrink-proof, antibacterial and flame-retardant, and can meet the requirements of people on various functional aspects of textiles.

Owner:SUNTEX

Ni-W-P alloy plating solution for chemical plating and chemical plating method employing the same

InactiveCN101225516AFast platingLittle change in pHLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention relates to a plating solution for chemical plating nickel-tungsten-phosphor alloy, comprising nickel vitriol of 24 to 28 g / l, sodium citrate of 40 to 70 g / l, gluconic acid sodium salt of 20 to 30 g / l, ammonium sulfate of 30 to 40 g / l, sodium pyroborate of 5 to 15 g / l, sodium tungstate of 30 to 50 g / l, sodium hypophosphite of 20 to 28 g / l, potash iodate of 10 to 20 mg / l, thiourea of 0.5 to 1.5 mg / l and sodium dodecyl sulfate of 5 to 15 mg / l. The plating solution is characterized in that: the chemical plating method using the plating solution comprises the following steps that: the pH value of the plating solution is adjusted to 8 to 9, and then the plating solution is heated to 80 to 90 degree centigrade, and then the processed plating articles are dipped into the plating solution; the time of dip plating is determined by the required plating layer thickness. The plating solution for chemical plating nickel-tungsten-phosphor alloy has the advantages of higher stability and higher plating speed.

Owner:罗森鹤

Chemical plating liquid of high-phosphor chemical plating Ni-P alloy for use on 304 stainless steel surface

InactiveCN101024879AAccelerated corrosionImprove wear resistanceLiquid/solution decomposition chemical coatingSodium acetateChemical plating

The invention relates to a chemical plating solution for high-phosphor chemo-plating Ni-P alloy on the surface of stainless steel 304, belonging to the technical field of process formula of plating solution for chemo-nickeling stainless steel surface, comprising the following materials of: nickel sulfate 25-30g / l, sodium hypophosphite 25-30g / l, lactic acid 15-30g / l, citric acid 4-10g / l, disodium EDTA 4-15g / l, glycin 5-15g / l, hydro-acetic acid 5-18g / l, stabilizing agent KIO3 0.01-0.04g / l, sodium acetate 10-20g / l, and succinic acid 12-20g / l. And the high phosphor coating plated by the chemo-plating solution has excellent acid, alkali and salt corrosion resistance, and especially Cl- corrosion resistance better than the main body of stainless steel 304; in the mechanical performance aspect, improves Cl- corrosion resistance and wearability of stainless steel and has a hardness of 450-550Hv.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

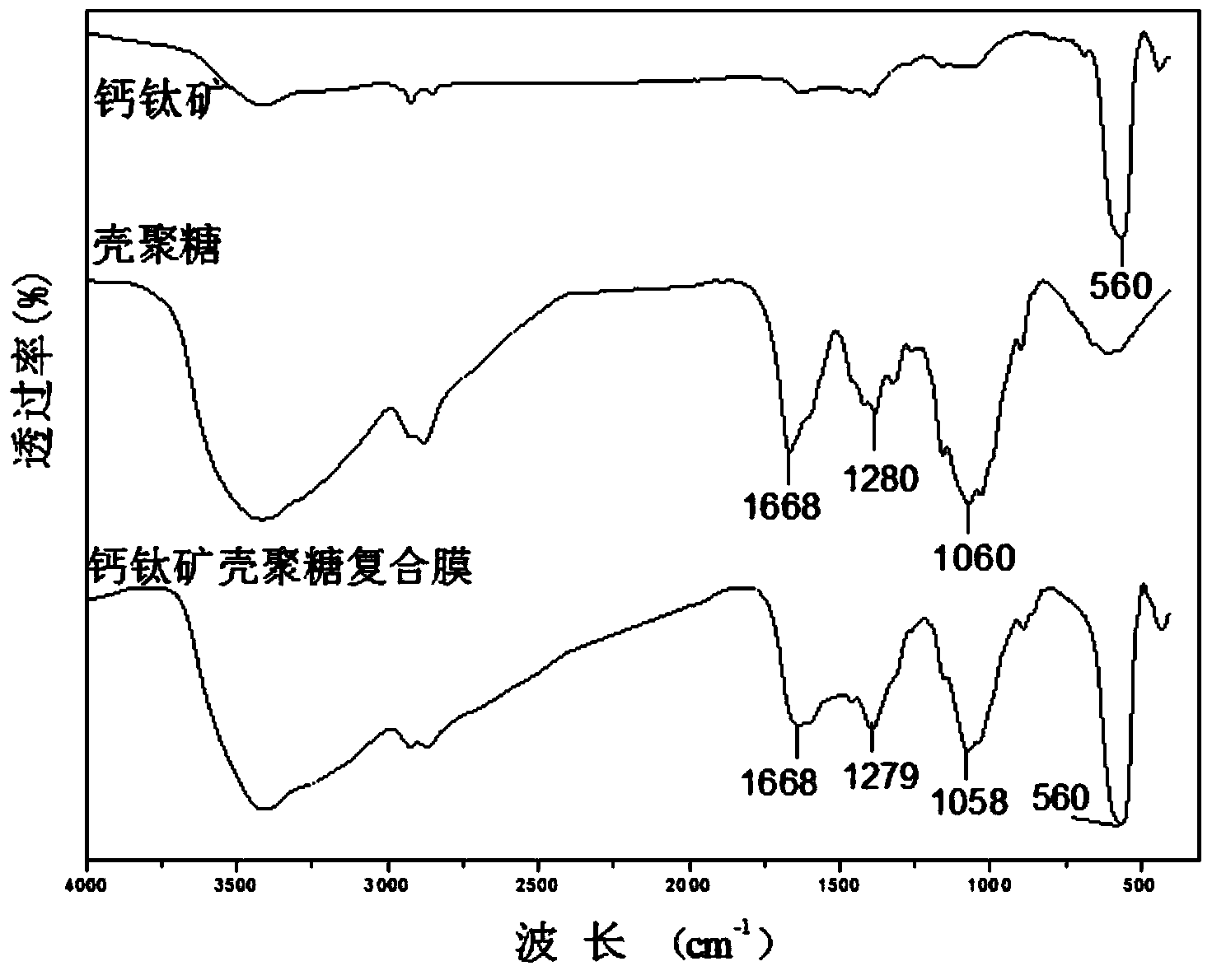

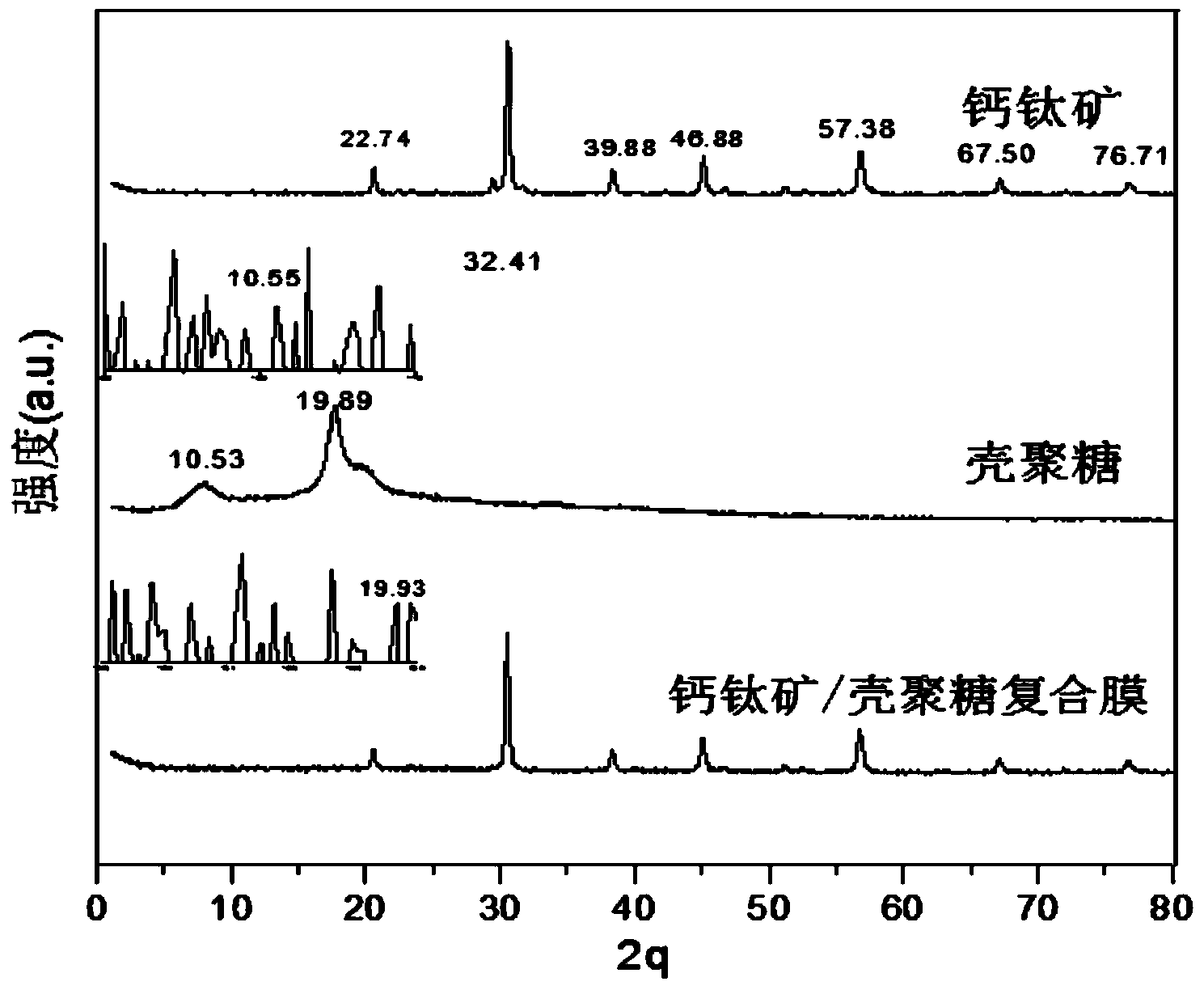

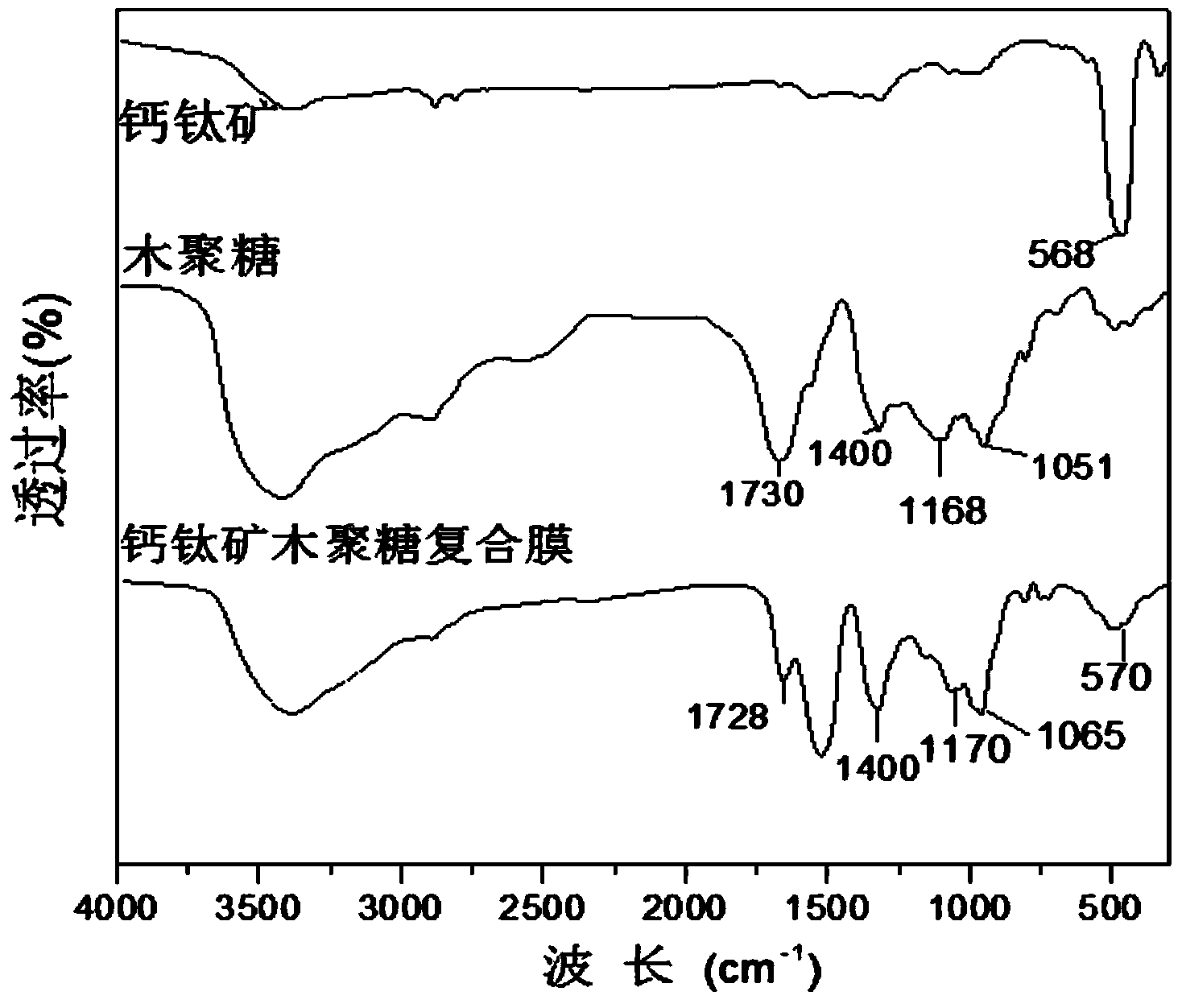

Method for degrading methyl orange by use of perovskite/polysaccharide composite photocatalyst

ActiveCN103936097AGood catalytic degradation effectShorten the timeWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsPhotocatalytic degradationMethyl orange

The invention discloses a method for degrading methyl orange by use of perovskite / polysaccharide composite photocatalyst. The method comprises the following steps: preparing perovskite by utilizing nitrate of La, Cu and Fe, adding the perovskite and chitosan into an acetic acid solution, and performing ultrasonic treatment; drying to form a film to obtain a perovskite / chitosan composite photocatalyst; or adding xylan into distilled water, adding sodium hypophosphite and citric acid solution, adding perovskite, performing ultrasonic treatment, dehydrating, crosslinking to form a film, and washing with ethanol to obtain a perovskite / xylan composite photocatalyst; adding the composite photocatalytic material into the methyl orange solution, respectively reacting for 470-490 minutes at normal temperature in ultraviolet radiation. The polysaccharide used in the method is formed by compounding the catalyst and polysaccharide respectively with chitosan and xylan, the methyl orange photocatlytic degrading capability of the polysaccharide can be improved. The polysaccharide has the advantages of high catalytic efficiency, strong photo-response performance, regeneration, recycling and the like.

Owner:SOUTH CHINA UNIV OF TECH

Treatment method of chemical nickel-plating wastewater

ActiveCN104891632ARemove completelyLow costWaste water treatment from metallurgical processWater/sewage treatmentChelating resinPrecipitation

The invention discloses a treatment method of chemical nickel-plating wastewater. By the aid of hydrogen peroxide, hypophosphite remover can directly react with sodium hypophosphite to generate dissoluble hypophosphite precipitation under the acid condition, and total phosphorus can be more thoroughly removed; the hypophosphite remover contains trace ferrous ions, capable of catalyzing the hydrogen peroxide to generate hydroxyl free radicals of high oxidability, thus organic acid and organic amine complexing agents in the wastewater are completely destroyed. Therefore, after adjusting to alkalinity, the nickel in the wastewater can be directly removed by precipitating, and high-cost chemicals such as chelate resin and recapture agent are needed. The treatment method has no special requirements on equipment, thus investment cost is low, the cost of the chemicals used is low, and running cost is greatly lowered.

Owner:SUZHOU ZHANQING ENVIRONMENT PROTECTION TECHCO LTD

Preparation method and application of hydroxypropyl guar gum/nanocellulose cross-linked adsorption film

ActiveCN106345424AGood adsorption/desorption performanceImprove mechanical propertiesSemi-permeable membranesOther chemical processesCross-linkMethyl violet

The invention discloses s preparation method of a hydroxypropyl guar gum / nanocellulose cross-linked adsorption film. The method takes hydroxypropyl guar gum and microcrystalline cellulose as main raw materials, and comprises the steps: thinning the microcrystalline cellulose in a nano grinder and a high-strength ultrasonic wave generator successively to prepare nanocellulose, then respectively dispersing and dissolving the nanocellulose and hydroxypropyl guar gum in maleic acid, then adding maleic anhydride and sodium hypophosphite, stepwise heating to carry out esterification and cross-linking reaction, centrifuging and defoaming the reactant, shaping the reactant in a mold, forming a film by drying, and cleaning and freeze-drying the film to obtain the adsorption film. The film prepared by the method is light yellow and transparent, has good adsorptive capacity on copper ions, zinc ions, led ions, methylene blue and methyl violet, and simultaneously has higher mechanical properties.

Owner:KUNMING UNIV OF SCI & TECH

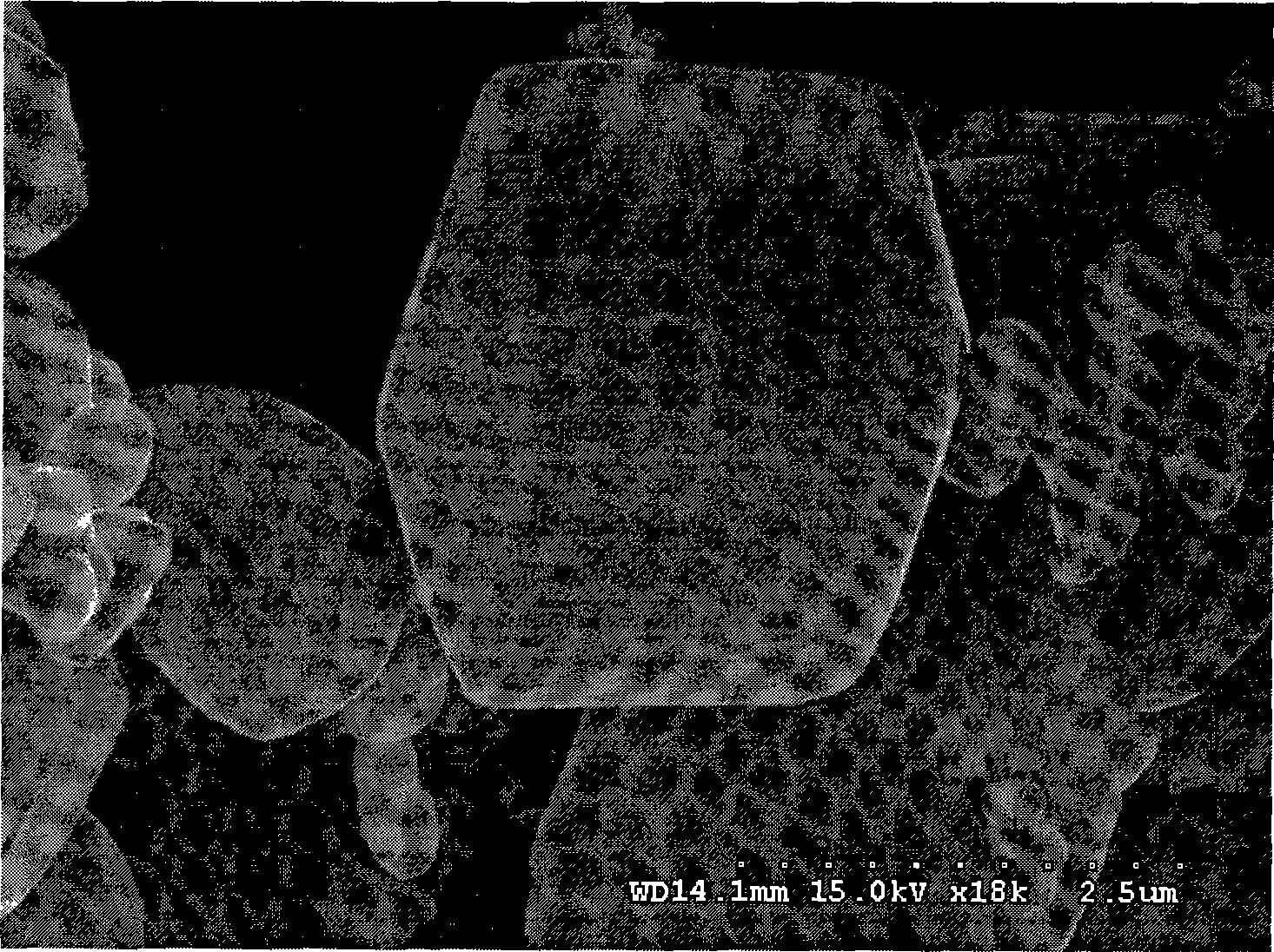

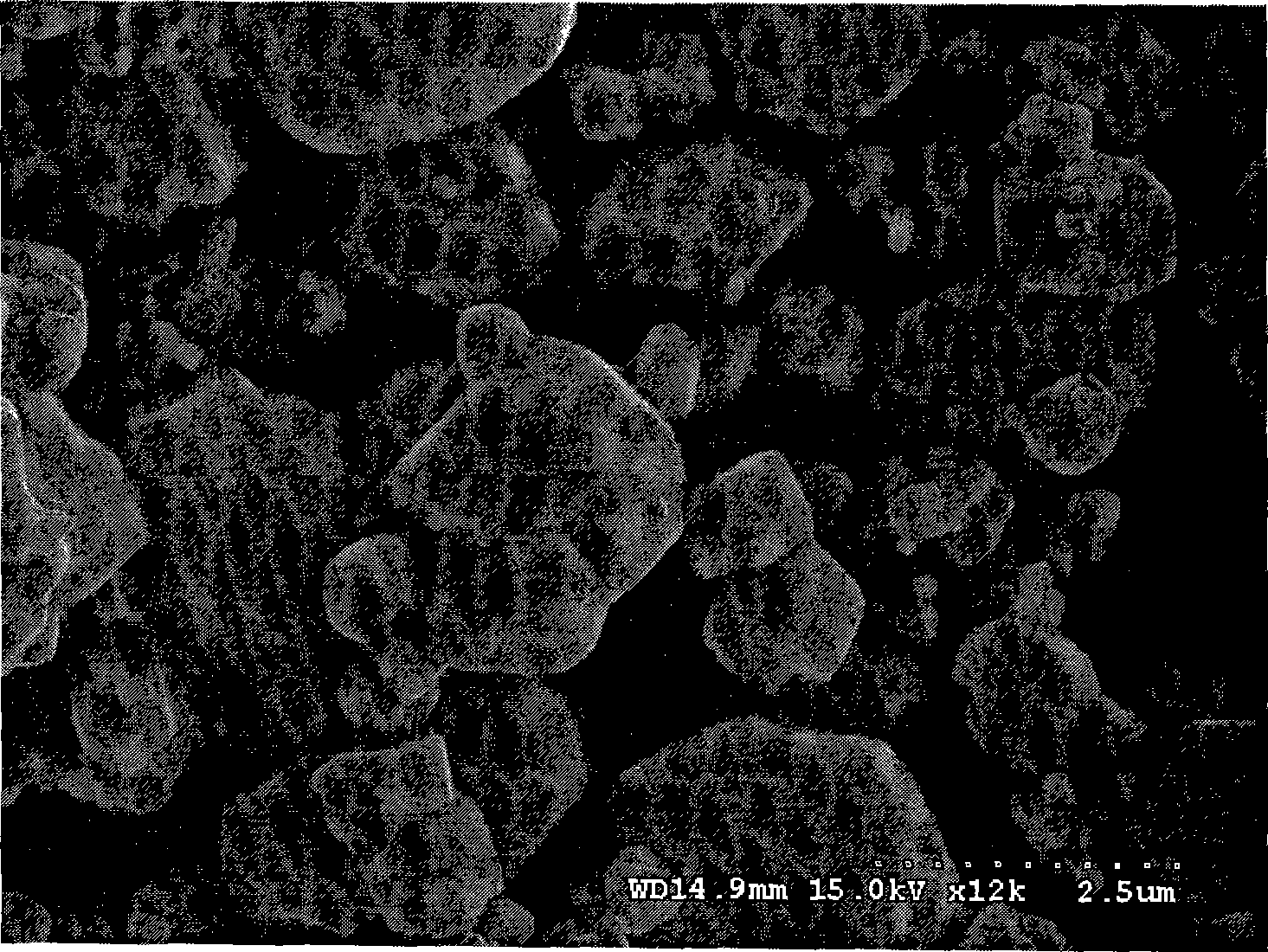

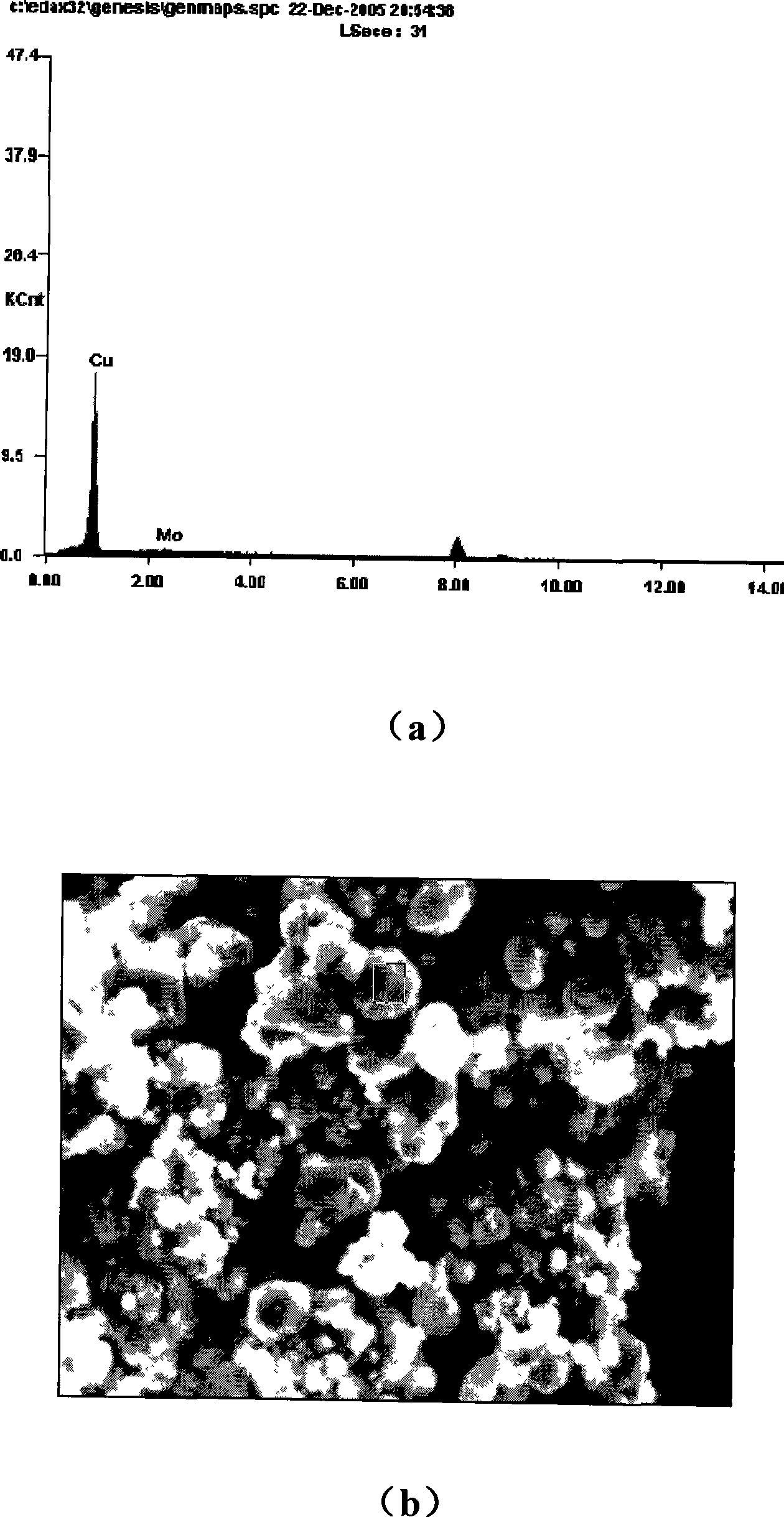

Method of manufacturing ultrafine molybdenum powder or ultrafine tungsten powder surface clad metal copper

The invention relates to a preparation method for a metal copper covered on the surface of ultrafine molybdenum powder or ultrafine tungsten powder, which belongs to the field of new materials. The preparation method is characterized in that the method mainly adopts the ultrafine molybdenum powder or the ultrafine tungsten powder with the average particle diameter D50 not more than 1.3 Mum, which is mixed with Cu<2+> soluble salt solution under the continual stirring, polymeric surfactant of coordination group with N atom and O atom is added, one of hydrazine hydrate, sodium hydrosulfite or sodium hypophosphite is added as reducing agent, and an appropriate amount of alkali is dropwise added to adjust pH value in the period so that pH value of the reaction system is from 5.5 to 12.0; in addition, in the range of 20 to 95 DEG C, the reaction continues for 0.5 to 3 hours; the ultrafine molybdenum powder or the ultrafine tungsten powder is filtered through flushing by diluted NH4Cl or NH4NO3 solution, the powder is pulped by alcoholic solution with 0.2-3.0 percent of fatty acid, and the ultrafine molybdenum powder or the ultrafine tungsten powder is filtered again, the powder is heated and dried by H2, to prepare the ultrafine molybdenum powder or the ultrafine tungsten powder of the metal copper covered with the even surface. Through adjusting the proportion of soluble salt of the ultrafine molybdenum powder or the ultrafine tungsten powder and the copper, the ultrafine molybdenum powder or the ultrafine tungsten powder covered by metal copper with different composition proportions can be prepared to meet different demands.

Owner:GRIMAT ENG INST CO LTD

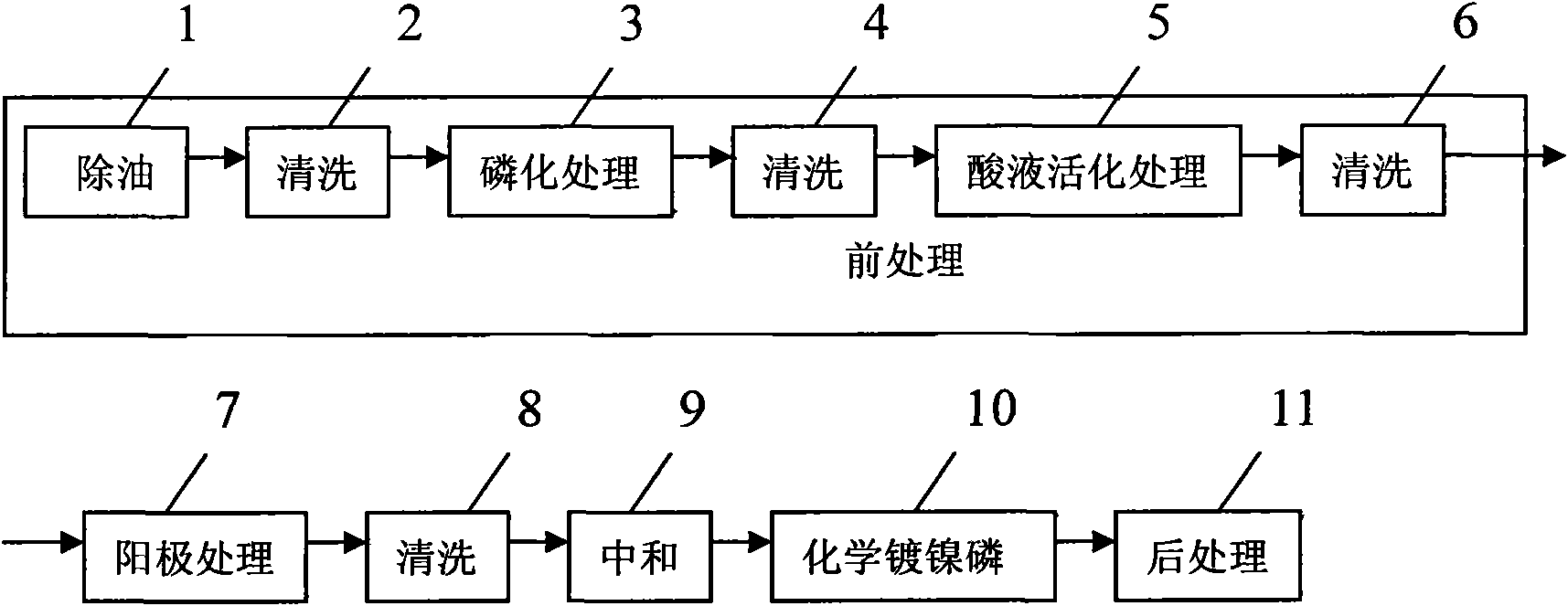

Austenitic stainless steel surface chemical nickel-phosphorus plating method

InactiveCN102051604AImprove acid resistanceGood alkali and salt propertiesLiquid/solution decomposition chemical coatingSalt resistanceNickel salt

The invention relates to an austenitic stainless steel surface chemical nickel-phosphorus plating method, which comprises the following steps of: degreasing: removing greasy dirt from the surface of an austenitic stainless steel; acid liquor activation: putting the austenitic stainless steel into activating solution for erosion; and chemical nickel-phosphorus plating: chemically plating nickel and phosphorus on the austenitic stainless steel in chemical nickel-phosphorus plating solution, wherein the chemical nickel-phosphorus plating solution contains 20 to 30g / L of nickel salt, 20 to 35g / L of sodium hypophosphite and 35 to 60g / L of auxiliary agent. The austenitic stainless steel surface chemical nickel-phosphorus plating method has simple process, can select the phosphorus content of a coating as required, can form a uniform nickel-phosphorus coating with good acid, alkali and salt resistance on the outer surface of the austenitic stainless steel, and enlarges the application field of the austenitic stainless steel.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

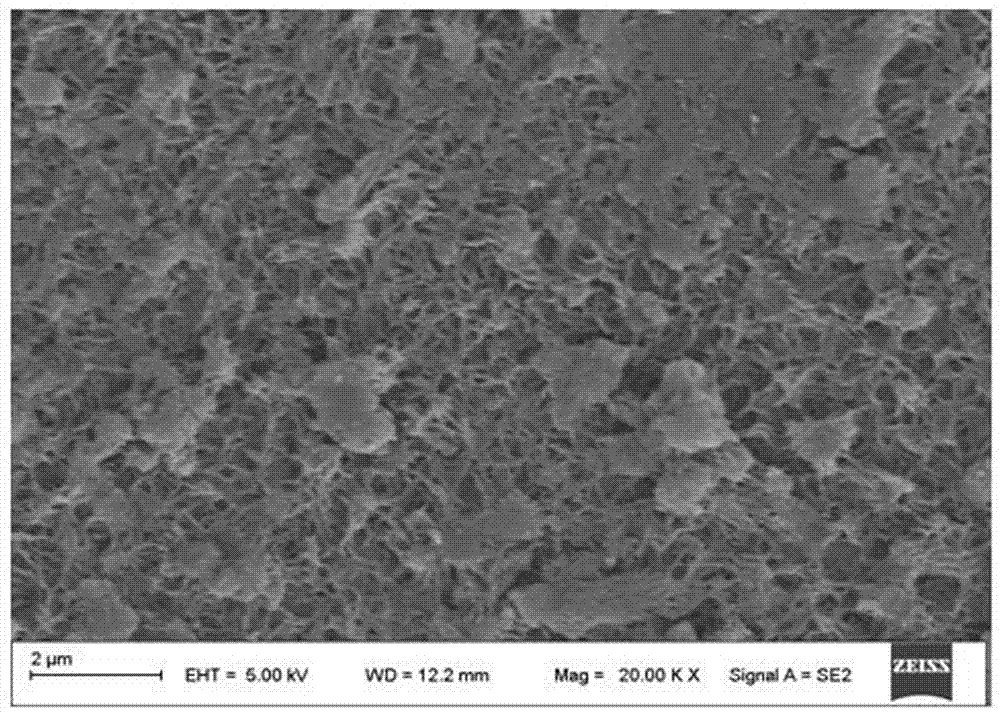

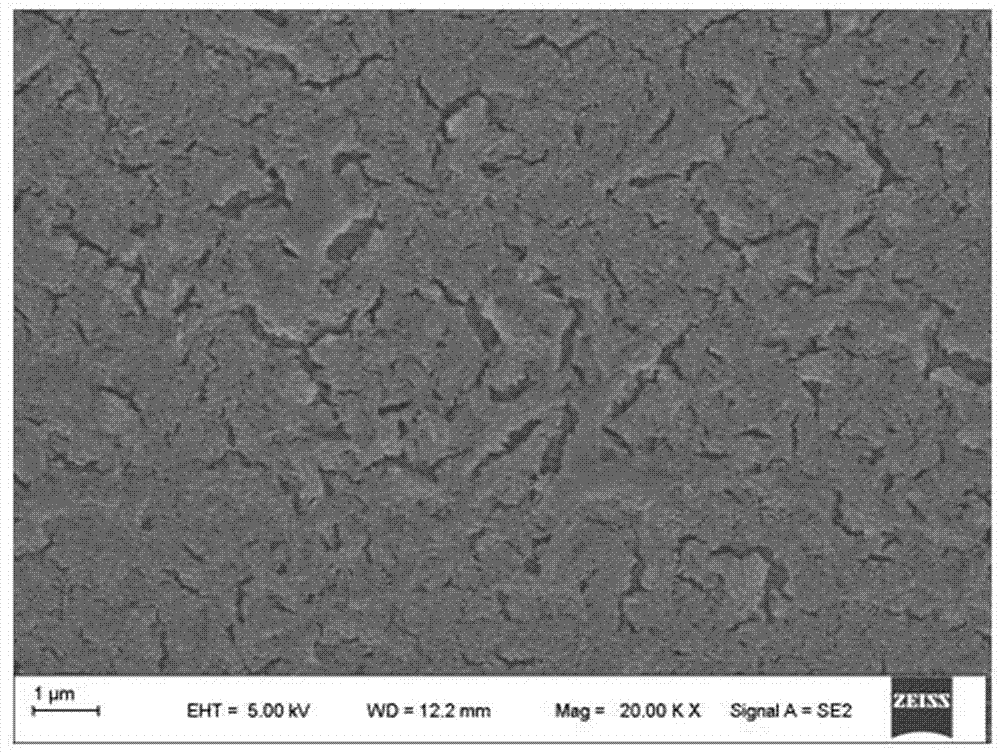

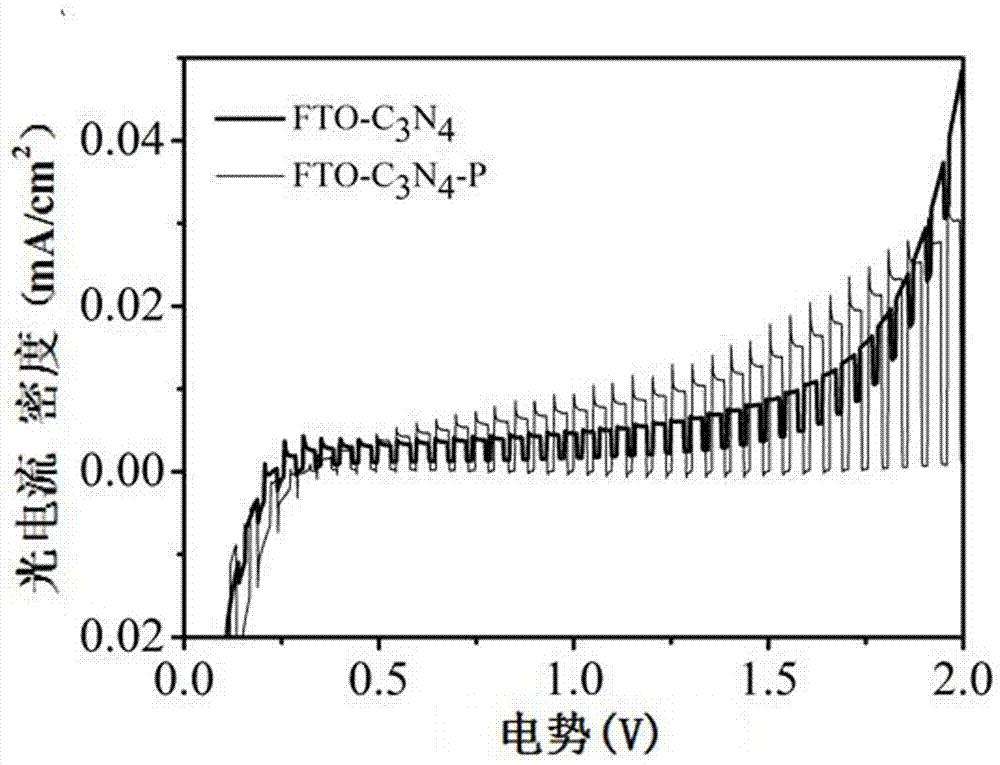

Preparation method of phosphorus-doped graphite phase carbon nitride nano film

InactiveCN107043222AControl the amount of incorporationSimple and fast operationCoatingsNitrogen gasHuman health

The invention discloses a preparation method of a phosphorus-doped graphite phase carbon nitride nano film and belongs to the technical field of semiconductor nano materials. The preparation method comprises the following steps of: firstly, mixing a high molecular polymer 2,4-diamino-1,3,5-triazine with cyanuric acid to react to prepare a precursor of graphite phase carbon nitride; then putting the precursor on the surface of FTO glass and preparing a carbon nitride film by means of a high-temperature calcining method; and finally, putting the carbon nitride film in a magnetic boat and calcining the film in a nitrogen atmosphere by taking sodium hypophosphite as a phosphorus source to obtain the phosphorus-doped graphite phase carbon nitride nano film. By taking FTO conductive glass as a substrate material, the method disclosed by the invention is simple in preparation process and low in cost; the prepared phosphorus-doped graphite phase carbon nitride nano film is good in shape and high in purity, overcomes the defect that a phosphorus-doped graphite phase carbon nitride nano powder material is poor in dispersibility, and is high in photocatalytic activity; and no toxic and harmful substances are generated in the whole preparation process, the environment is not polluted, the human health is not damaged, and the preparation method is safe and environmental-friendly.

Owner:NORTHWEST NORMAL UNIVERSITY

Electroless copper plating solution and electroless copper plating method

InactiveUS20070071904A1Improve responseEfficient productionLiquid surface applicatorsSemiconductor/solid-state device manufacturingCopper platingThiourea

Owner:JX NIPPON MINING & METALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com