Novel method for preparing nickel phosphide by low-temperature reduction

A new method, the technology of low-temperature solvothermal method, is applied in the direction of phosphide, which can solve the problems of easy ignition of phosphine, environmental pollution, hidden dangers of production safety, etc., and achieves mild and fast reaction conditions, simple and mild reaction conditions, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

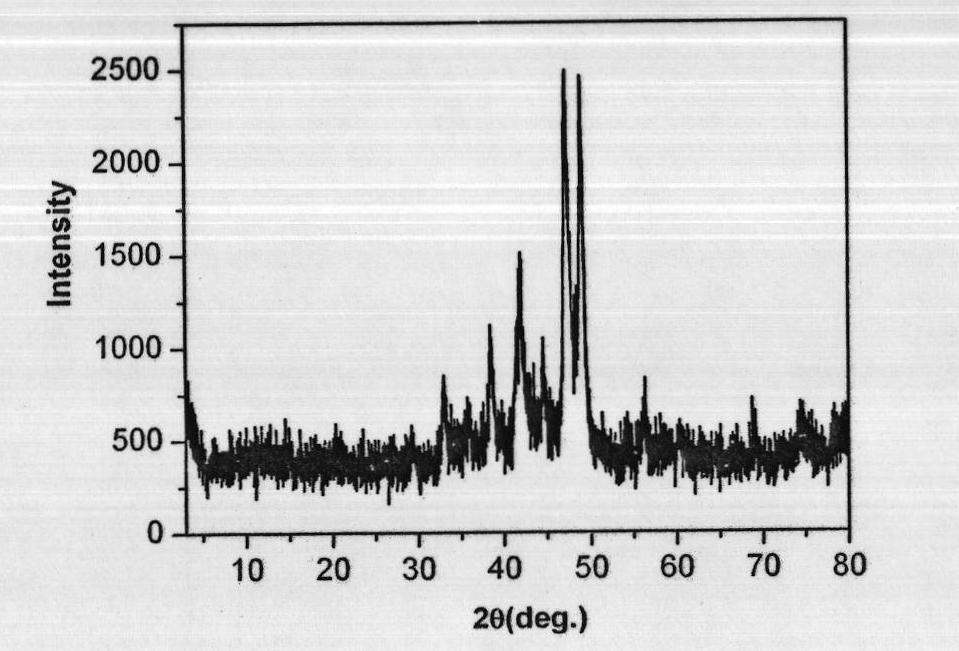

[0015] Weigh 0.3g NiCl respectively 2.6 h 2 O with 1.54g NaH 2 PO 2 .H 2 O was dried at 120°C, then dissolved in 25ml of ethylene glycol, and stirred magnetically at room temperature until the solution was clear and transparent. The solution was poured into a stainless steel autoclave lined with polytetrafluoroethylene, and placed in an electric thermostat blast drying oven heated to 140°C to react for 24 hours. After the reaction, the autoclave was taken out and cooled to room temperature naturally. Open the autoclave, and wash the black product obtained by the reaction with deionized water. Finally, the product was put into a vacuum oven and dried under vacuum at 60°C. That is, the Ni described in the present invention is obtained 12 P 5 catalyst, which has figure 1 Characteristics.

Embodiment 2

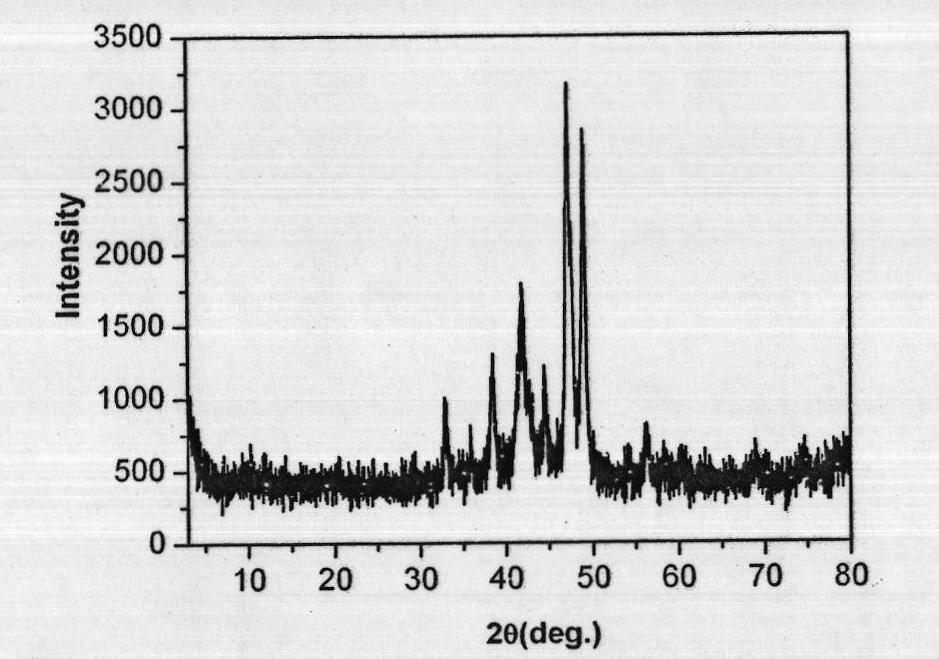

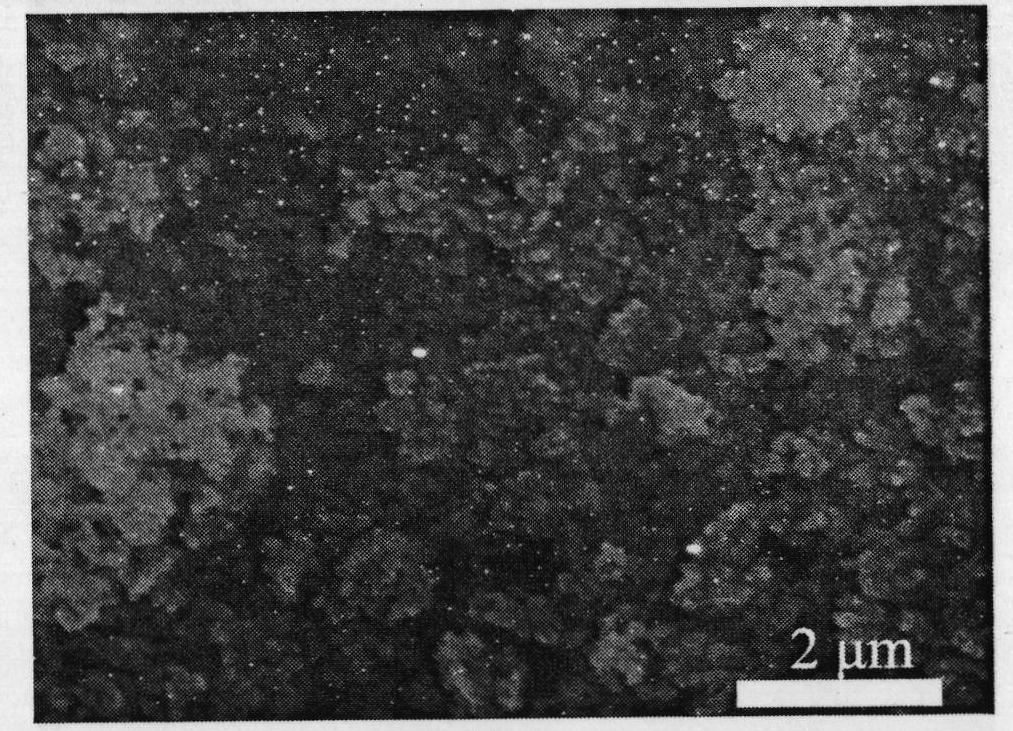

[0017] Weigh 0.2g NiCl respectively 2.6 h 2 O with 0.8g NaH 2 PO 2 .H 2 O was dried at 120°C, then dissolved in 25ml of glycerol, and stirred magnetically at room temperature until the solution was clear and transparent. The solution was poured into a stainless steel autoclave, and placed in an electric thermostat blast drying oven heated to 240° C. to react for 2 h. After the reaction, the autoclave was taken out and cooled to room temperature naturally. Open the autoclave, and wash the black product obtained by the reaction with deionized water. Finally, the product was put into a vacuum oven and dried under vacuum at 60°C. That is, the Ni described in the present invention is obtained 12 P 5 nanoparticles, which have figure 2 And attached image 3 Characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com