Patents

Literature

8007results about How to "Meet environmental protection requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for (S)-4-hydroxyl-2-oxo-1-pyrrolidine ethanamide

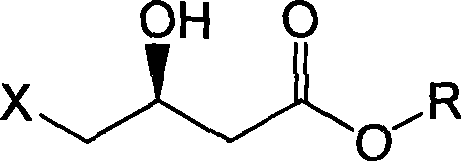

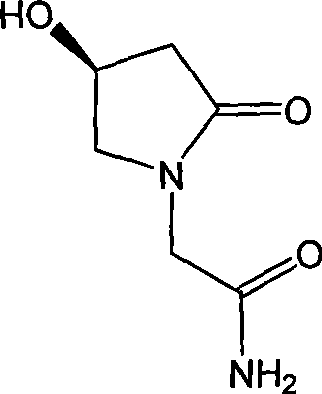

The present invention provides a preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide. The preparation method comprises: (S)-4-halogen-3-hydroxyl butyric ester as a raw material reacts under the conditions with polar solvent and alkalinity to prepare the crude product of (S)-4-hydroxyl-2-oxo-1-pyrrolidine acetamide; and the crude product is purified. The preparation method is characterized in that inorganic alkali is added for a plurality of times in the reaction process under the condition with alkalinity so as to control the pH value in the reaction to be less than or equal to 8.5. A large quantity of repeated tests are completed to determine that the optimum pH value of the reaction under the condition with alkalinity is less than or equal to 8.5, and the alkali is added in batches to strictly control the pH value of the whole reaction process, so that the alkali conditions required in the reaction can be satisfied and the reaction can be performed completely, and the target product (S)-oxiracetam is prevented from being damaged in the alkaline solution, thereby improving the yield rate of the target product (S)-oxiracetam and reducing the cost.

Owner:CHONGQING RUNZE PHARM CO LTD

Flexible ceramic wear-resistant heat-proof dual-anticorrosive coating

InactiveCN1528844AIncreasing the thicknessReduce the probability of water seepageAnti-corrosive paintsEpoxy resin coatingsCoated surfaceSaline water

The invention is a kind of flexible ceram wearing and heat resisting heavy corrosion preventing paint, which is made up of epoxy resin and several kinds of ceram powder, rust-protection paint and firming agent, the weights of each ingredient are: (1) epoxy resin: 100; (2) additive: 50-120; (3) rust protection paint: 8-25; (4) ceram powder: 100-200; (5) compound solvent: 40-70; paint: firming agent=(35-50):1. The paint needn't base coat, it can be painted directly or brushed on the surface of metal under normal temperature, it has excellent wearing and corrosion prevention performance, impact resisting performance and flexibility, it can insulate acid, alkali, salt, saline water. The surface is smooth; it can be applied to oil pipe, oil pot, and chemical device, ship, wheel vane, pump, dust catcher, etc.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

Oil-displacing agent for enhancing crude oil recovery efficiency in tertiary recovery

InactiveCN101665685AOvercome elasticityOvercome structureDrilling compositionSalt resistanceActive agent

The invention relates to an oil-displacing agent for enhancing crude oil recovery efficiency in tertiary recovery and a preparation method thereof, belonging to the technical field of intensified oilproduction in oil fields. The surface active agent used in the invention comprises following components in percentage by weight: 0.01-0.3 percent of water soluble high molecular polymer, 0-20 percentof non-ionic surface active agent, 5-65 percent of anion active agent, 0-5 percent of ampholytic active agent, 0.01-1.5 percent of additive and the balance of water. The oil-displacing agent and the polymer are based on a novel intensified oil displacing system which has complementary structure and good compatibility and is obtained by various associations and the interaction among molecules. Thesystem has the performances of high temperature resistance, salt resistance, higher viscosity, ultralow interfacial tension, and the like, is in accordance with the environmental requirement and can obviously enhance the oil recovery efficiency of oil fields after being used for oil-displacing.

Owner:TIANJIN NORMAL UNIVERSITY

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

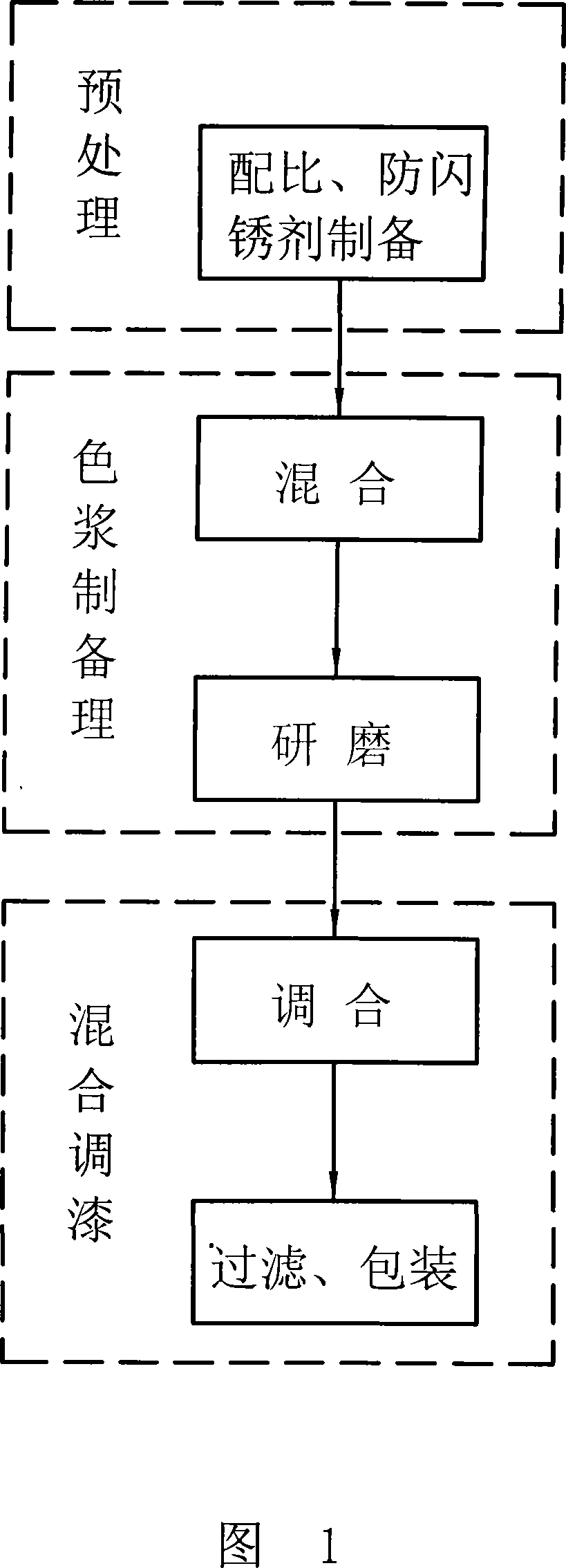

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

Water epoxy paint for ground floor and its mfg. process and construction technology

The invention relates to a water epoxy ground floor coating and its making method and constructing process, where one component is low-molecular weight liquid-state epoxy resin assorted with active diluter in a proper proportion, and the other component is a dispersoid with hydrophilic curing agent as the principal thing, containing water-borne curing agent, water, acid-resistant wearable color filler, various auxiliaries, etc. and its producing method is simple and mainly includes mechanical dispersing and mixing; it does need to clean paint-covered surface as used on humid basal surface; the paint film has excellent properties of oily products and unilateral permeability. It uses water as dispersing medium, has no VOC, safe and environmental-protection.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Pet used cat litter and preparation method thereof

The invention relates to pet cat litter and its preparation method, which comprises preparing organic base-material 20- 60%, clay 30-80%, binder 0-10%, water absorber 0-20%, surface adsorption substance0- 5%, crushing organic base-material to 30 screen mesh bulkload, processing clay to powder finer than 200 screen mesh, picking organic base material and clay proportionally to making cat litter base body, mixing and stirring the remaining material to making mixed covering material, placing cat litter base body in high-velocity rotating vibration machine, rotating making hydrosphere seeping to the surface of base body, then adding mixed covering material, vibrating slightly for mixing, then sifting and drying, sifting out powder. The inventive cat litter has good deodorant effect, good conglobation property after using, and waste cat litter can combust in favor of environment protection.

Owner:HANGZHOU LINAN KUROKAWA BENTONITE

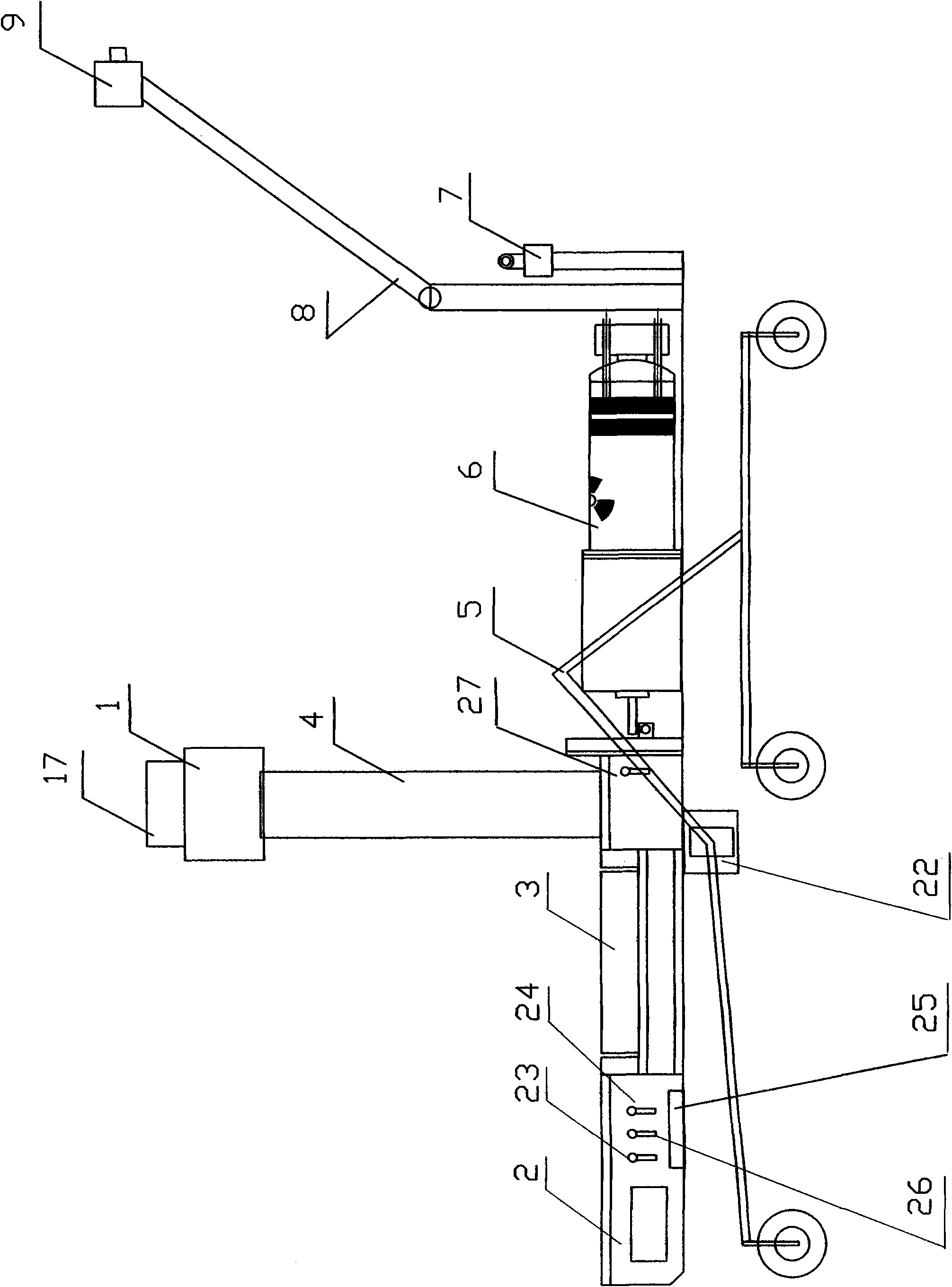

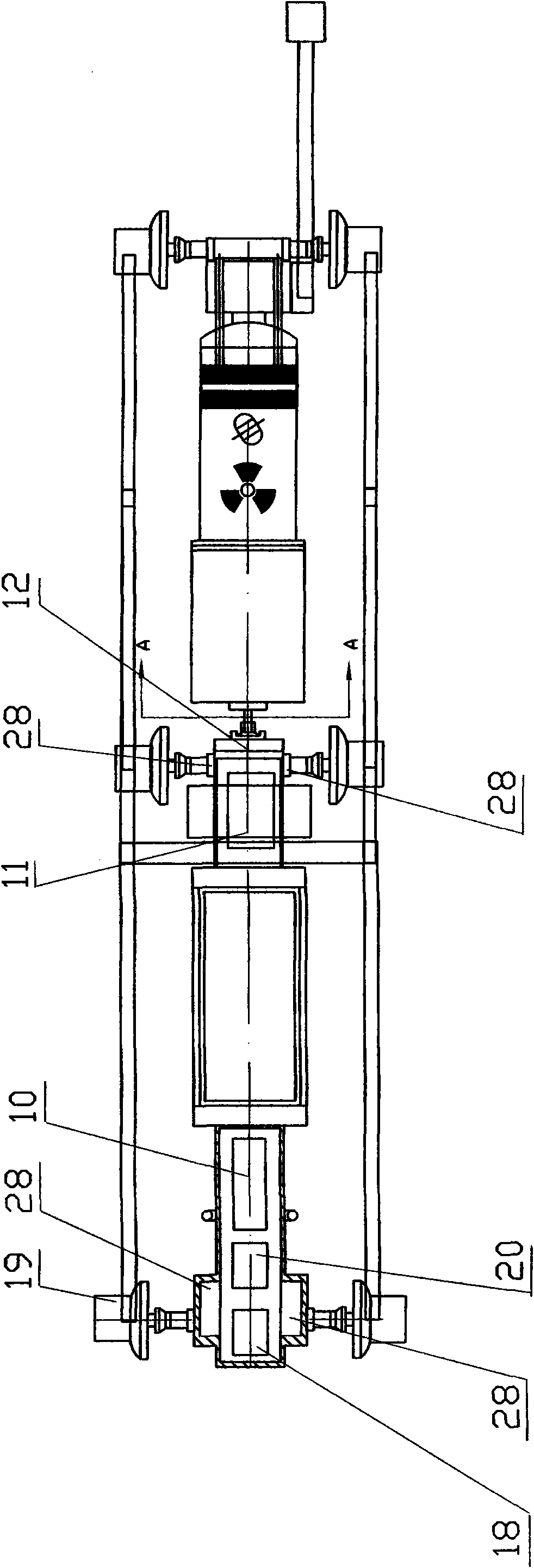

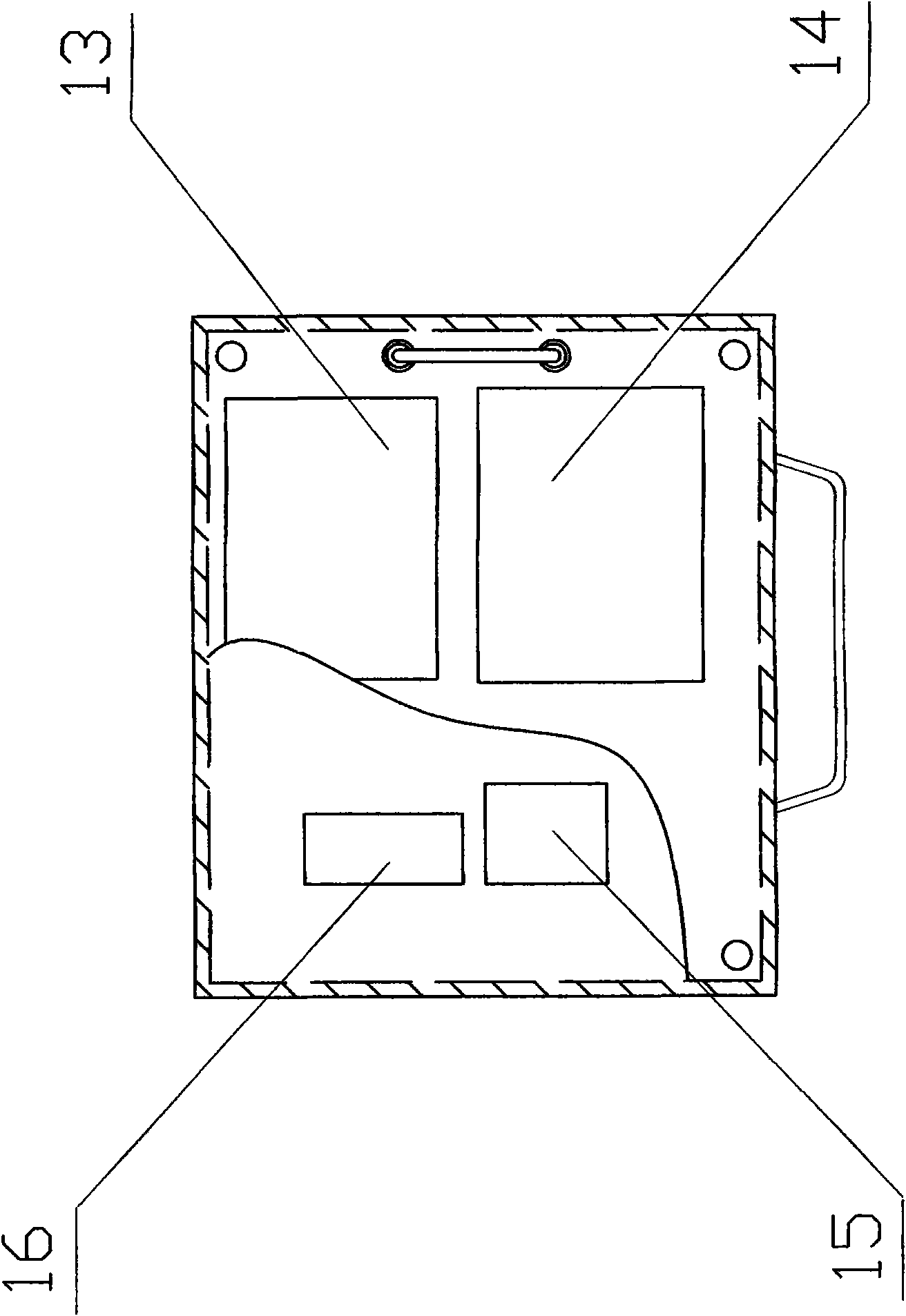

Wheel-type X-ray flaw detection robot device

InactiveCN101887037AEasy to operateHigh precisionManipulatorMaterial analysis by transmitting radiationVIT signalsVideo transmission

The invention relates to a wheel-type X-ray flaw detection robot device which comprises an X-ray flaw detection device, a remote wireless transmission device, a computer control device, a differential GPS (Global Positioning System), a fuel battery (or lead acid battery pack) and a robot body, wherein four infrared cameras are arranged on the robot body, and real-time images are remotely transmitted to an operator through video transmission equipment; a direct current voltage regulator is adopted in the controller of an X-ray generator; and the regulator is connected with an inverter by a tube voltage regulation knob, so that the tube voltage of the X-ray generator can be regulated. The operational control and operational state of the robot body are as follows: a digital data radio is adopted to transmit filed signals to an upper control computer; video signals are displayed on a display with visual display and convenient operation; isotope sources are not used, thereby meeting the requirement for environment protection; and a suspension system enables the robot body not to deflect and turn laterally on pipelines and rocks.

Owner:DONGDAN AOLONG RADIATIVE INSTR GRP

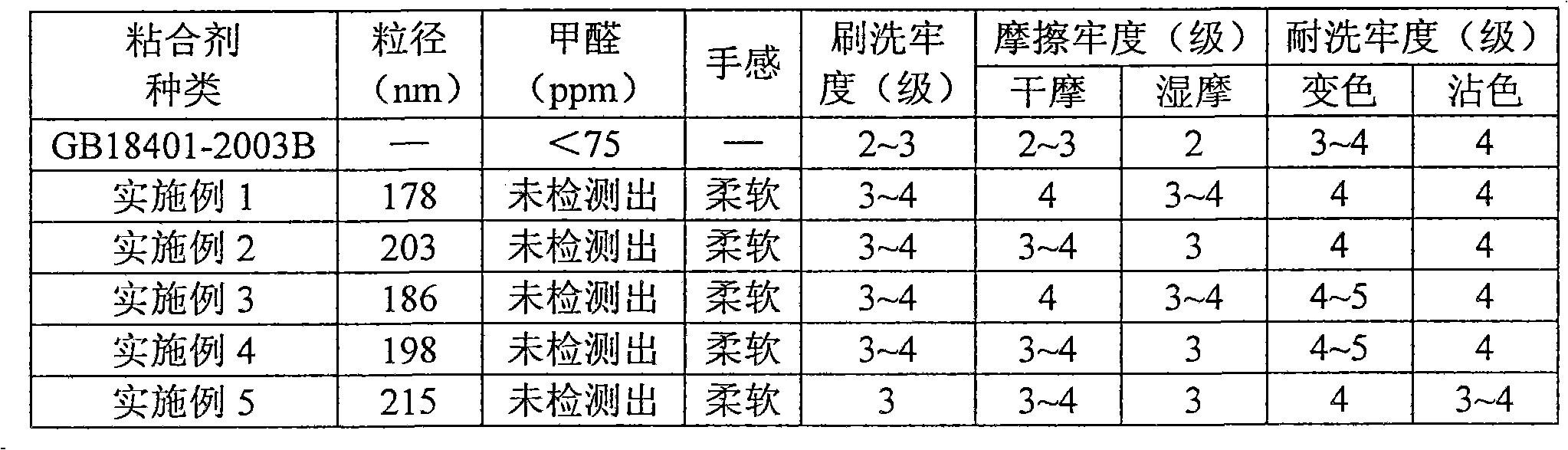

Environmentally-friendly acrylic ester coating printing adhesive emulsion and preparation method

InactiveCN101928367AThe polymerization process is stableEvenly distributedEster polymer adhesivesDyeing processEpoxyFunctional monomer

The invention discloses environmentally-friendly acrylic ester coating printing adhesive emulsion and a preparation method. An emulsion polymerization process is adopted. The emulsion comprises the following raw materials in part by weight: 50 to 90 parts of soft monomer, 10 to 20 parts of hard monomer, 2 to 10 parts of functional monomer, 2 to 5 parts of emulsifying agent, 0.2 to 0.5 part of initiator, 0.2 to 0.5 part of pH buffer, 80 to 120 parts of deionized water and a proper amount of pH adjustor, wherein the total amount of the soft monomer, the hard monomer and the functional monomer is 100 parts by weight. The three monomers are cooperatively used as functional monomers for generating carboxyl crosslinking, hydroxy crosslinking, epoxy crosslinking and the like so that the obtained printing adhesive emulsion has excellent water tolerance and mechanical property. The crosslinking monomers and the emulsifying agent do not contain the components such as N-methylol acrylamide, APEO and the like, so the emulsion does not release formaldehyde during baking and using and is suitable for high-grade environmentally-friendly printing adhesive.

Owner:SOUTH CHINA UNIV OF TECH

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

Non-toxic polyaniline modified anti-corrosive coating and preparation method thereof

ActiveCN101643618AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsAfter treatmentPhytic acid

The invention relates to coating technology, in particular to a non-toxic polyaniline modified anti-corrosive coating and a preparation method thereof to solve the problems that that prior antirust pigment has poor corrosion resistance, and the coating is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The non-toxic polyaniline modified anti-corrosive coating comprises a film forming matter, polyaniline modified antirust pigment, and the like. A polyaniline coating layer is formed on the surface of the antirust pigment by an oxidative polymerization method; the antirust pigment after treatment has passivating effect on metal; and a phytic coating layer on the surface of the antirust pigment also has corrosion inhibiting effect on the metal. The non-toxic polyaniline modified anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment,pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

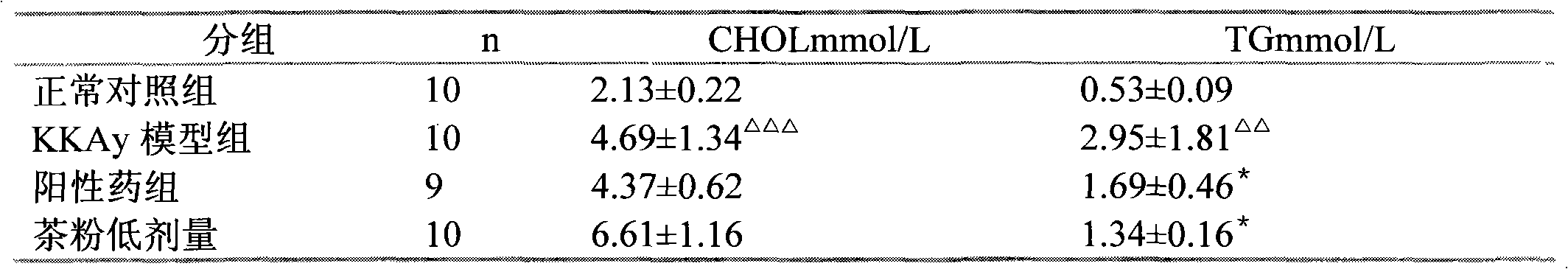

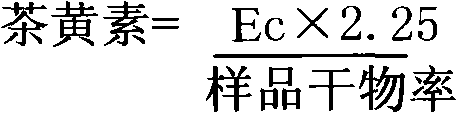

Pu-erh tea extract, preparation method and application

ActiveCN101961061APromote conversionPromote dissolutionMetabolism disorderTea extractionOperabilityBULK ACTIVE INGREDIENT

The invention relates to a Pu-erh tea extract, a preparation method and application. The Pu-erh tea extract has high active ingredient content and low caffeine content, and can reduce blood sugar obviously and lower safety risks. Through the preparation method, active ingredients can be converted and dissolved out effectively. The process has the advantages of meeting the requirements of environmental protection along with simpleness, strong operability, low cost and industrialization; and the quality of the Pu-erh tea extracts is table and controllable.

Owner:TIANJIN TASLY GROUP

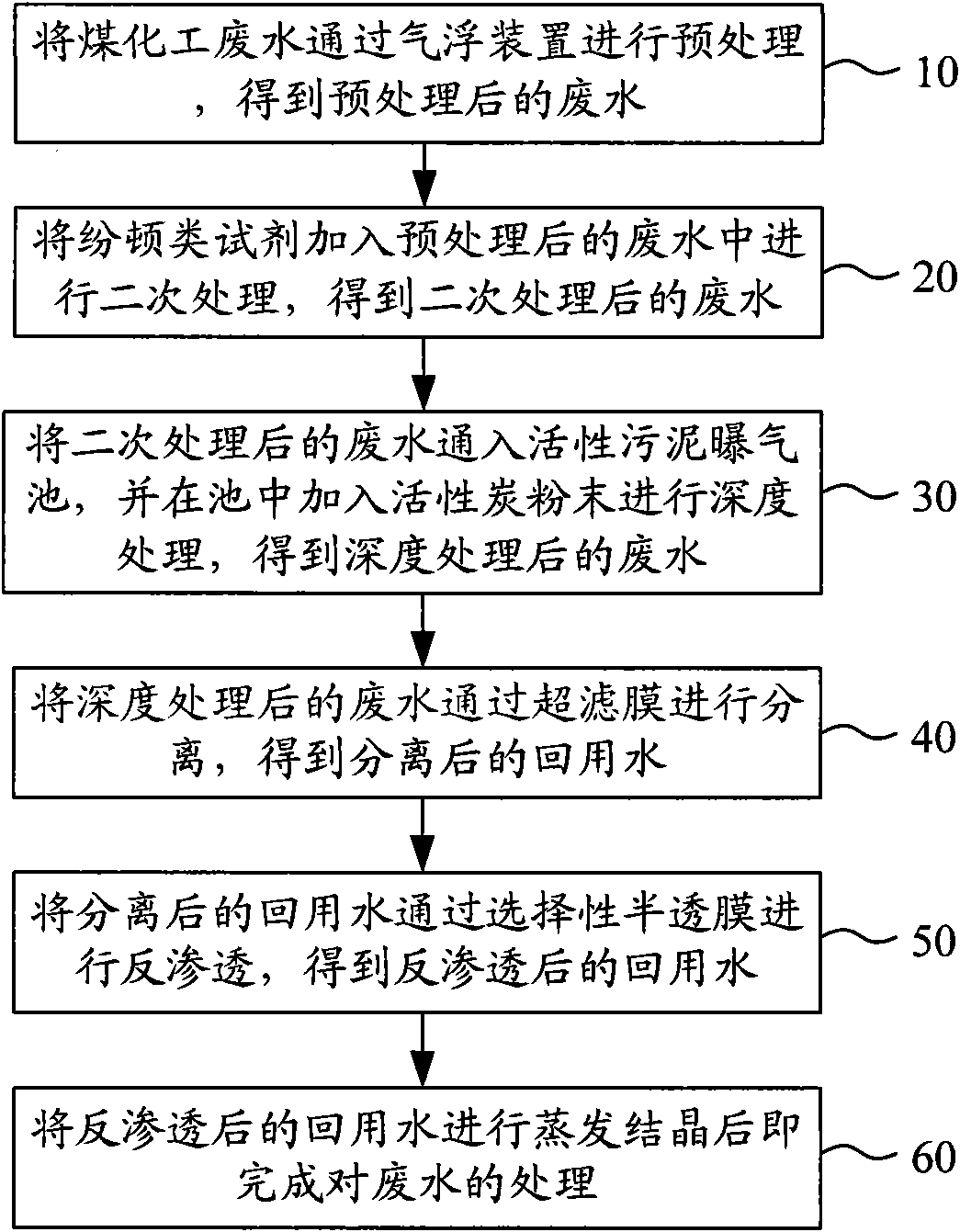

Coal chemical wastewater treating technique

InactiveCN101560045AMeet environmental protection requirementsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentActivated sludgeActivated carbon

The invention relates to a coal chemical wastewater treating technique, which comprises the following steps of: pretreating the coal chemical wastewater by an air-floatation device and obtaining pretreated wastewater; adding a fenton reagent into the pretreated wastewater to carry out secondarily treatment and obtaining secondarily treated wastewater; putting the secondarily treated wastewater into an activated sludge aeration pool and adding active carbon powder into the pool for deep treatment to obtain deeply treated wastewater; separating the deeply treated wastewater with a hyperfiltration membrane and obtaining separated recycled water; reversely penetrating the separated recycled water with a selective semi-permeable membrane and obtaining reversely penetrated recycled water; evaporating and crystallizing the reversely penetrated recycled water and finishing the wastewater treatment. The wastewater, after treated by the coal chemical wastewater treating technique, can realize the 'zero discharge' standard, meet the national environmental requirements, and obtain good economic and social benefits.

Owner:POTEN ENVIRONMENT GRP

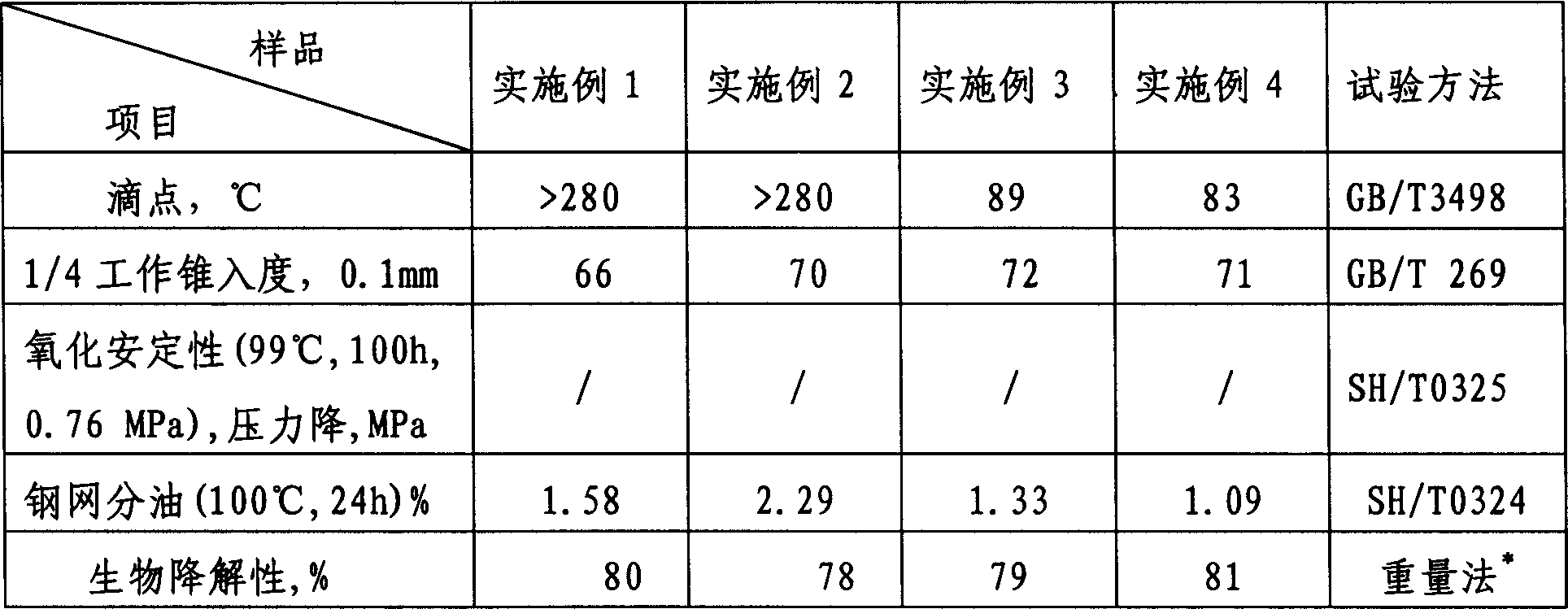

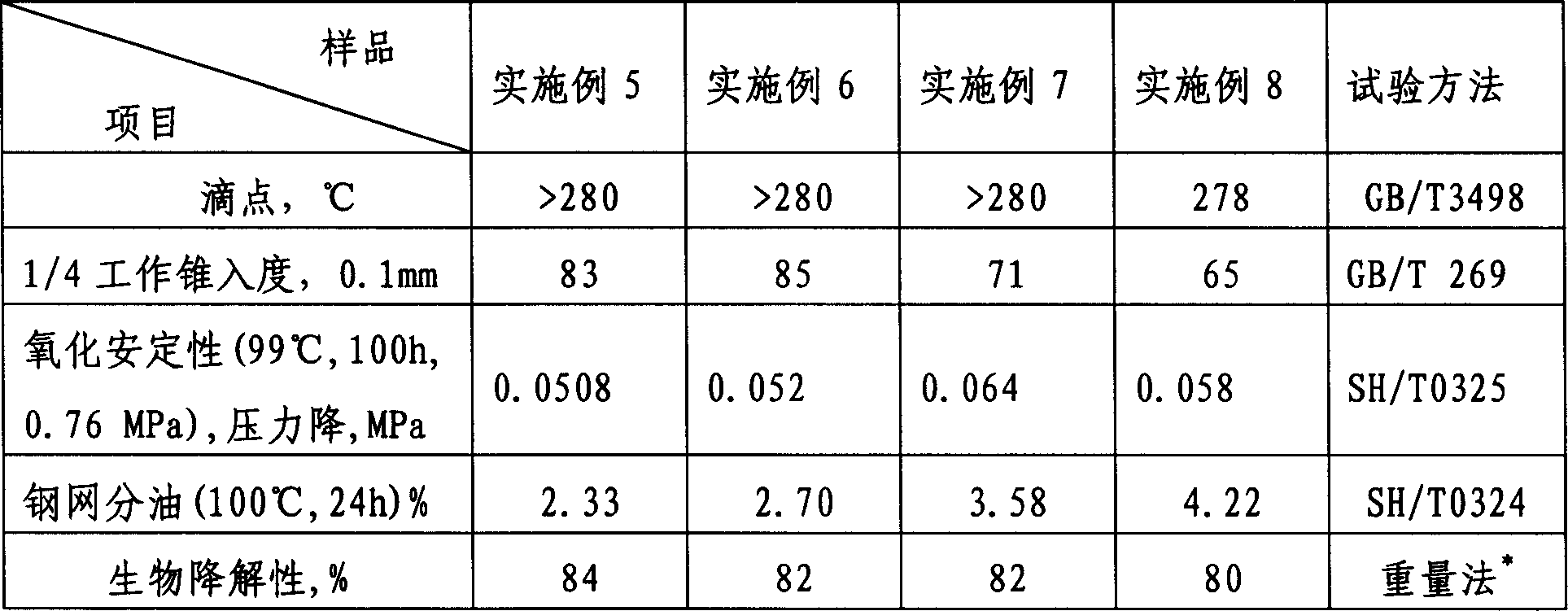

Biodegradable lubricating grease

InactiveCN1504552AExcellent conventional physical and chemical propertiesWill not polluteLubricant compositionLithium oxideVegetable oil

A biodegradable lubricating grease comprises (overall composition weight as benchmark) (1) 70-94% vegetable oil whose kinetic viscosity is 100-250 square mm per second, (2) 6-30% thickening agent, wherein the thickening agent is alta-mud, or single saponin or composite saponin produced through the reaction of C1-C20 organic acid with calcium hydroxide, calcium oxide, lithium hydroxide or lithium oxide, (3) 0-2% amine antioxidant or phenol and amine mixed anti-oxidant. The lubricating grease possesses both fine normal physical chemical properties and good bio-ecological characteristics.

Owner:CHINA PETROLEUM & CHEM CORP +1

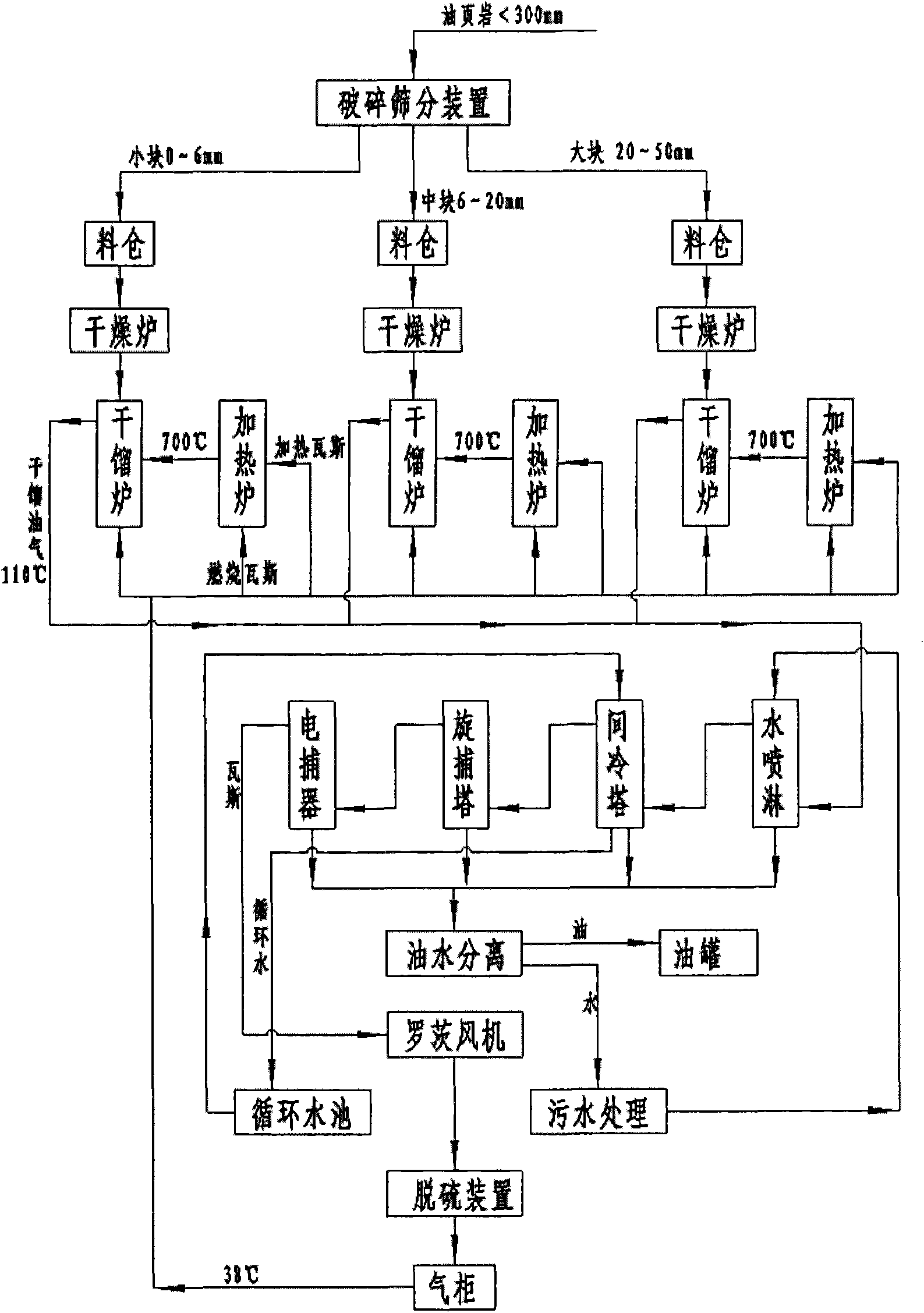

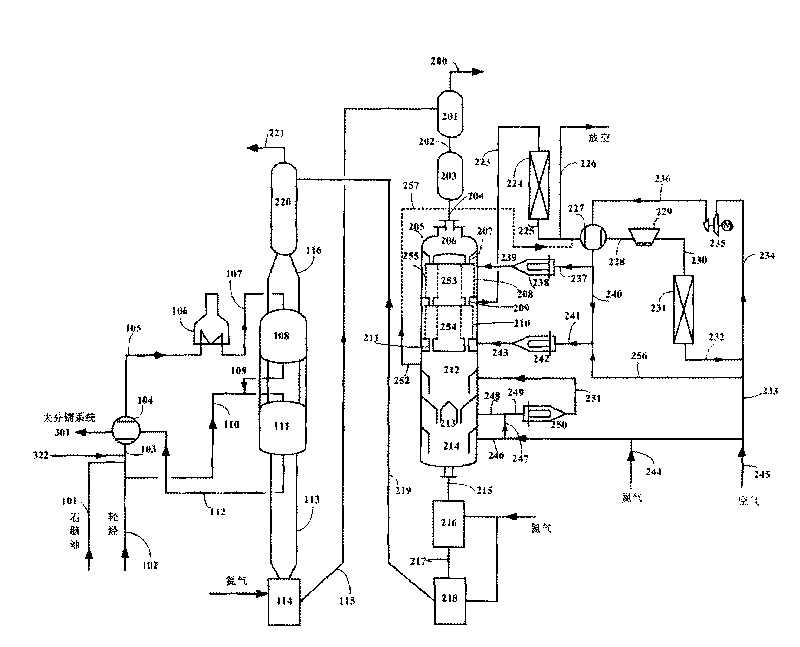

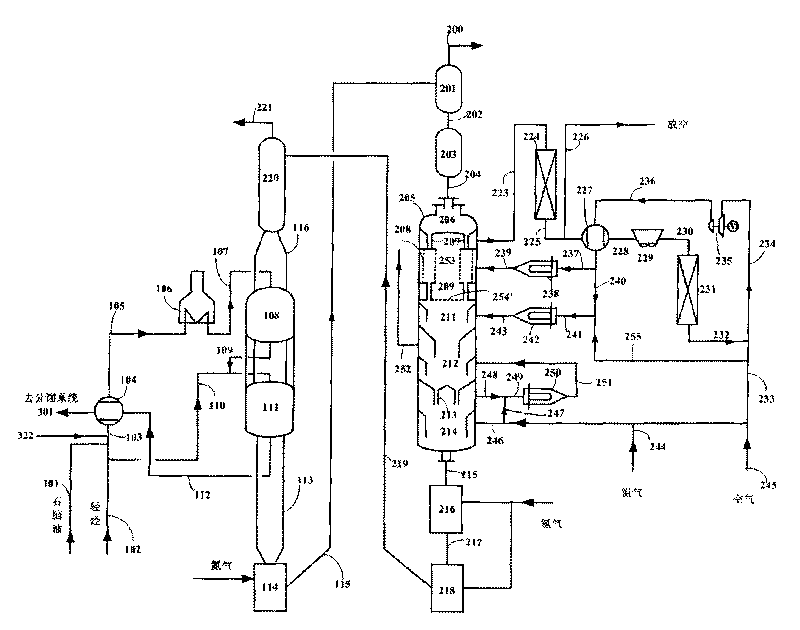

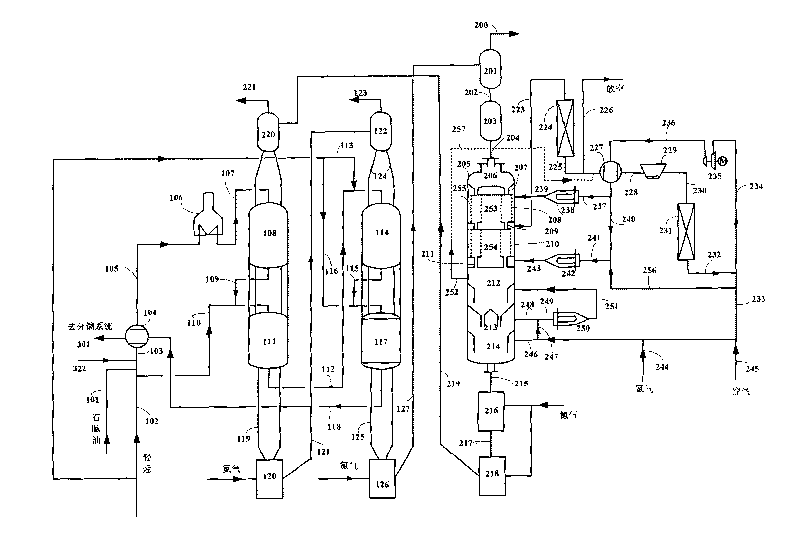

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

Cleaning agent for integrated circuit substrate silicon chip and its cleaning method

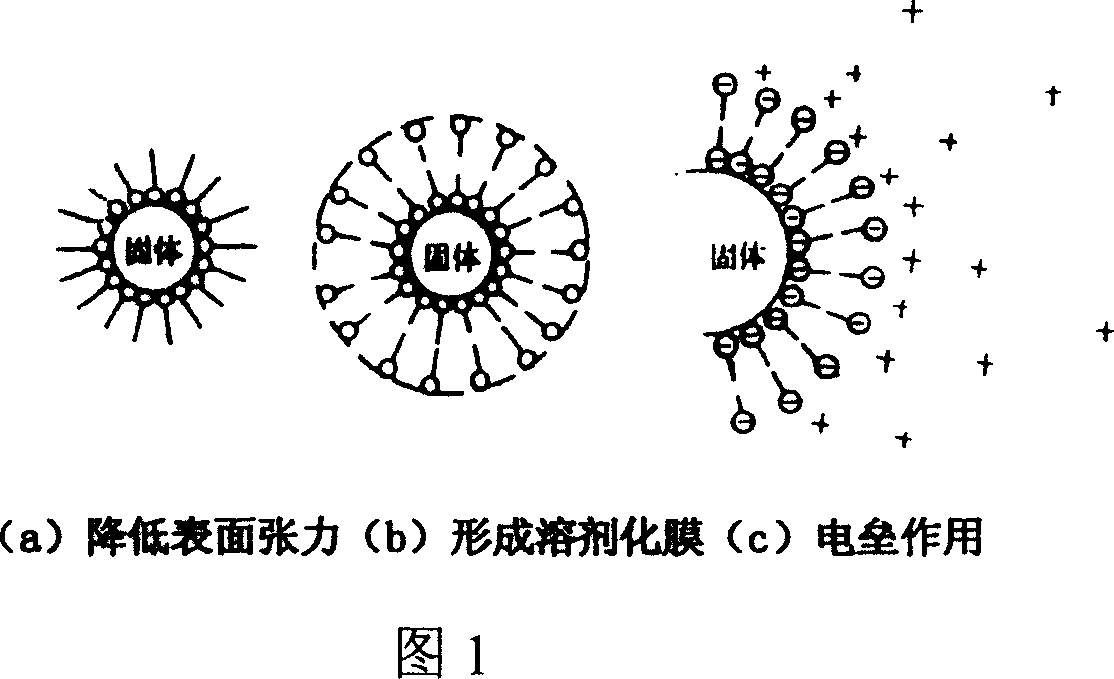

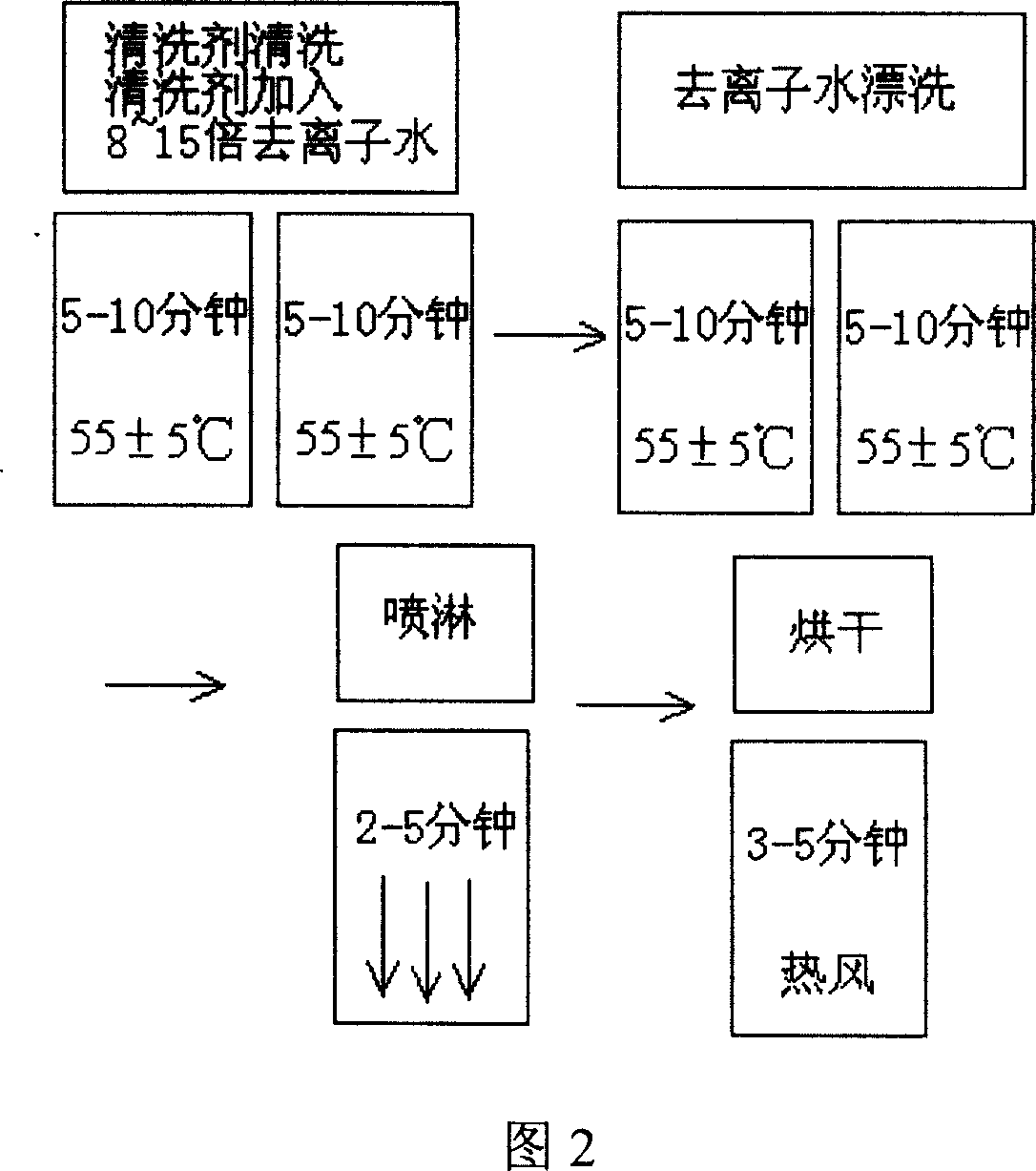

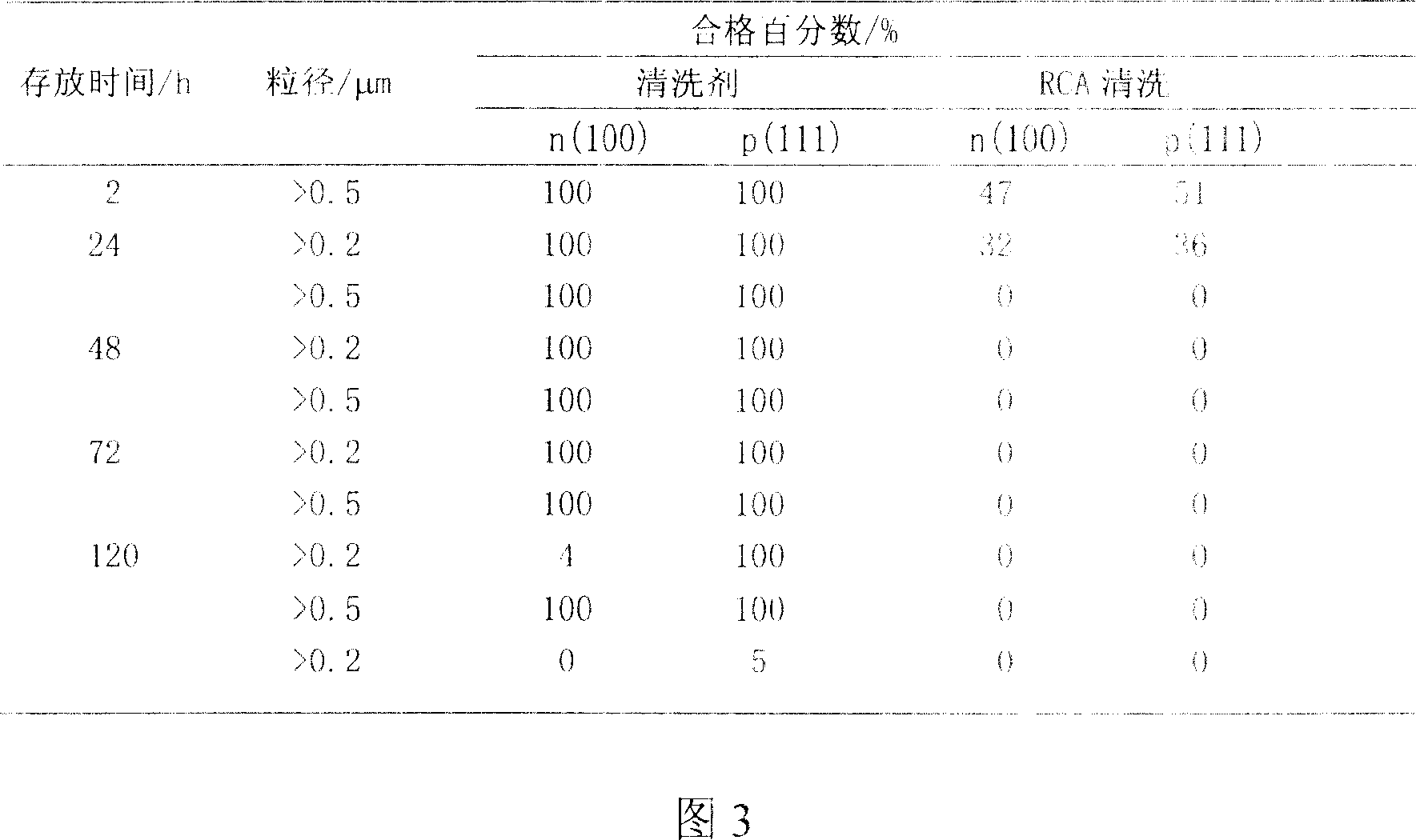

InactiveCN1944613AReduce surface tensionIncrease surface tensionNon-ionic surface-active compoundsOrganic detergent compounding agentsOrganic baseCleansing Agents

The cleaning agent for integrated circuit substrate silicon chip features that it consists of organic base functioning as pH regulator, complexing agent, corrosion inhibitor, dispersant and oxidizing assistant simultaneously in 40-45 %, surfactant functioning to lower surface tension of the solution, enhance mass transfer and eliminate metal ion simultaneously in 7-15 %, and water in 40-53 %. The cleaning method with the cleaning agent includes adding deionized water in 8-15 times, twice ultrasonic cleaning at 50-60deg.c for 5-10 min each, twice ultrasonic rinsing in deionized water at 50-60deg.c for 5-10 min each, sprinkling and stoving. The present invention has the advantages of excellent cleaning effect, simple preparation process, convenient operation and environment friendship.

Owner:天津晶岭电子材料科技有限公司

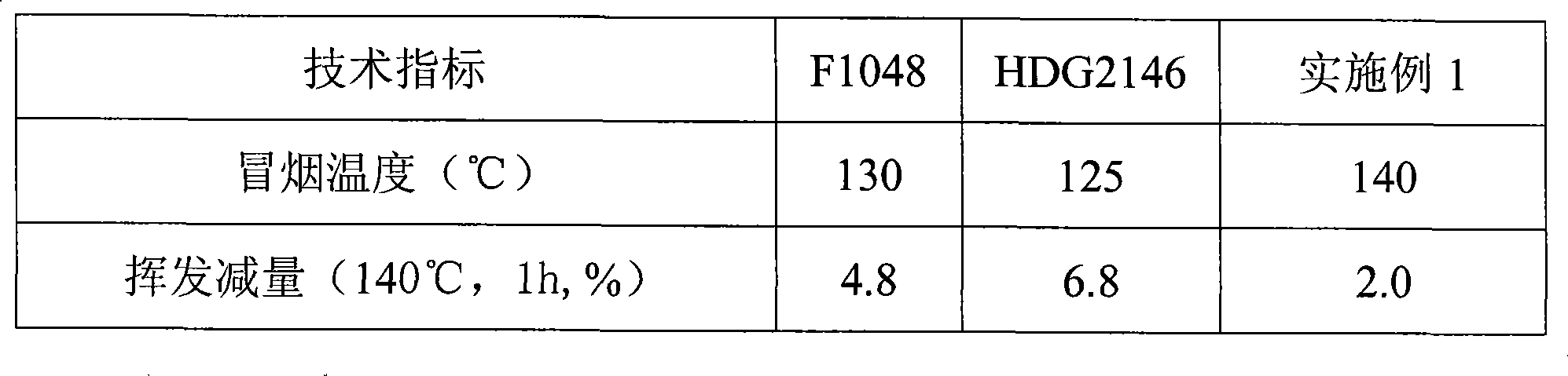

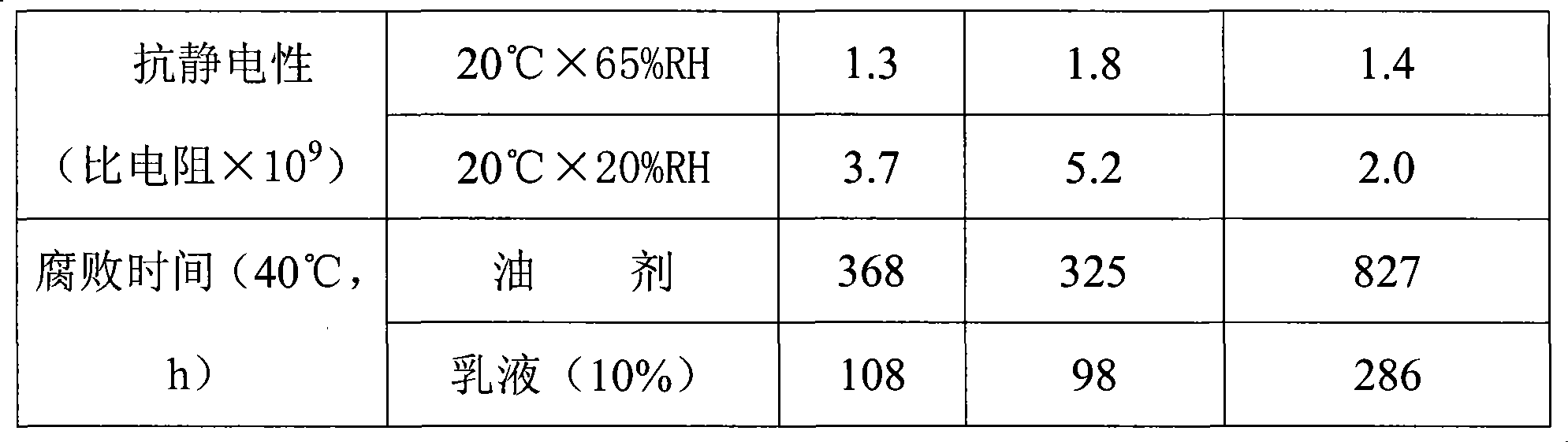

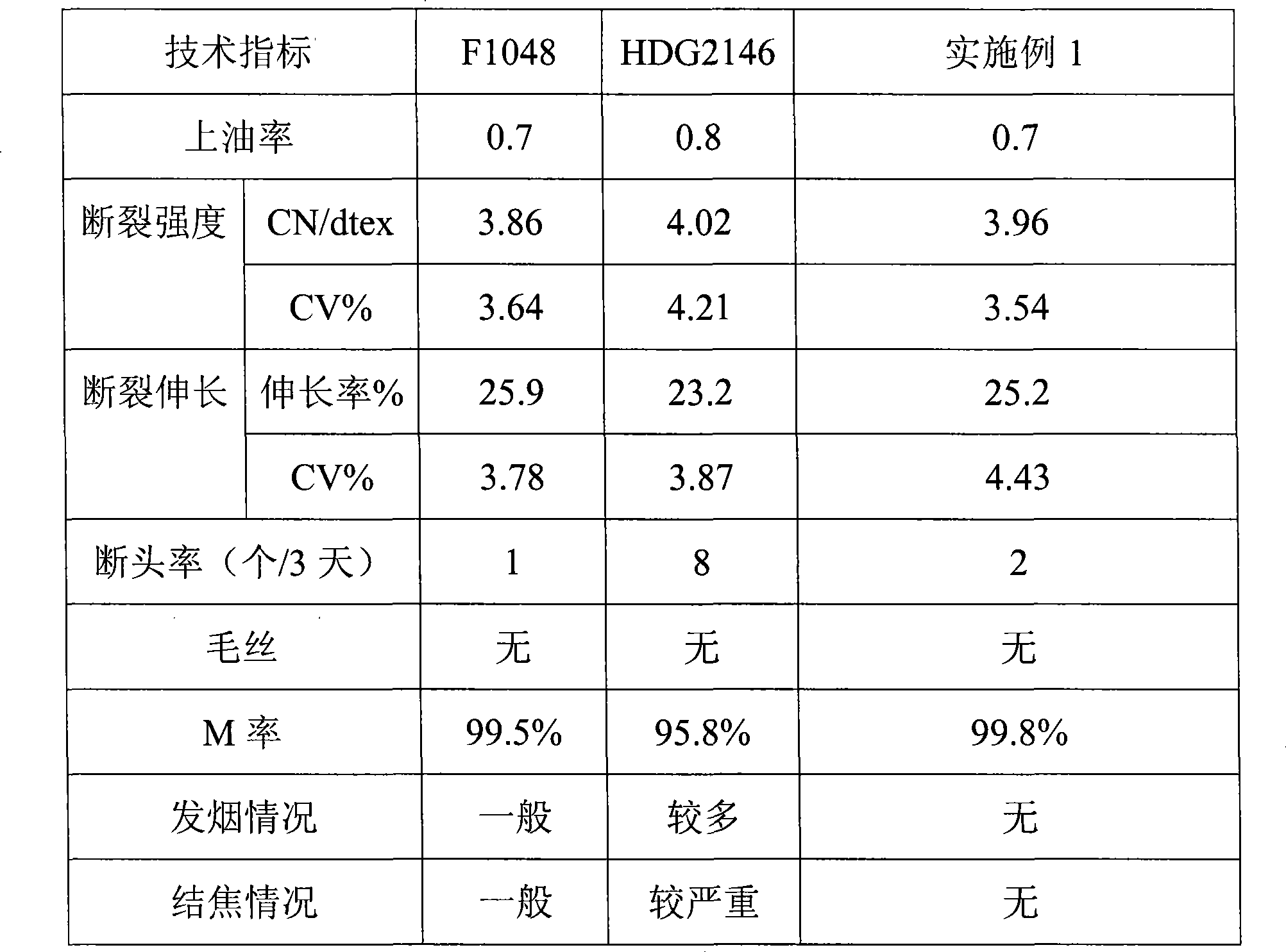

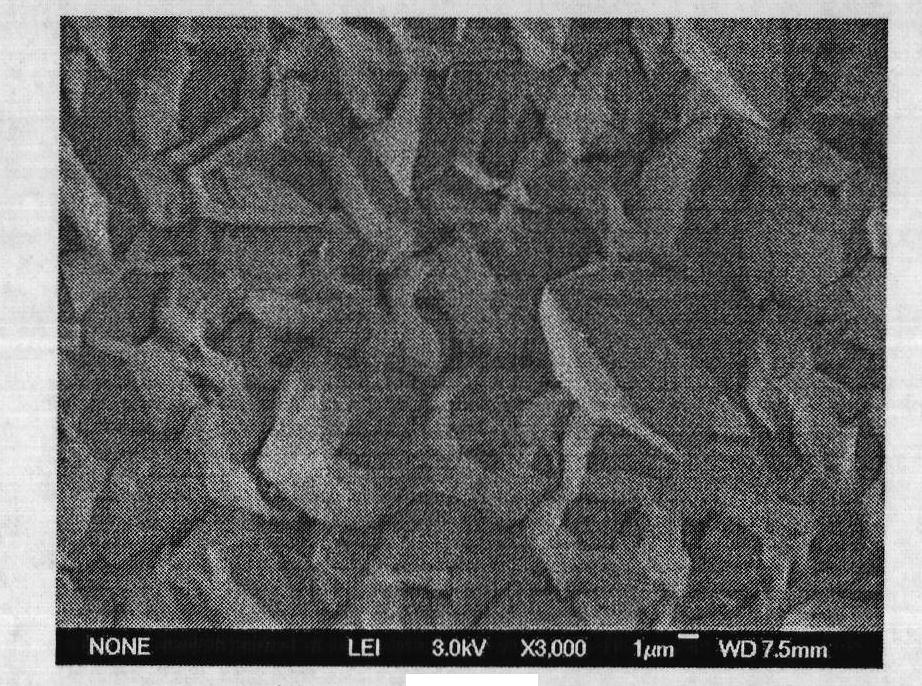

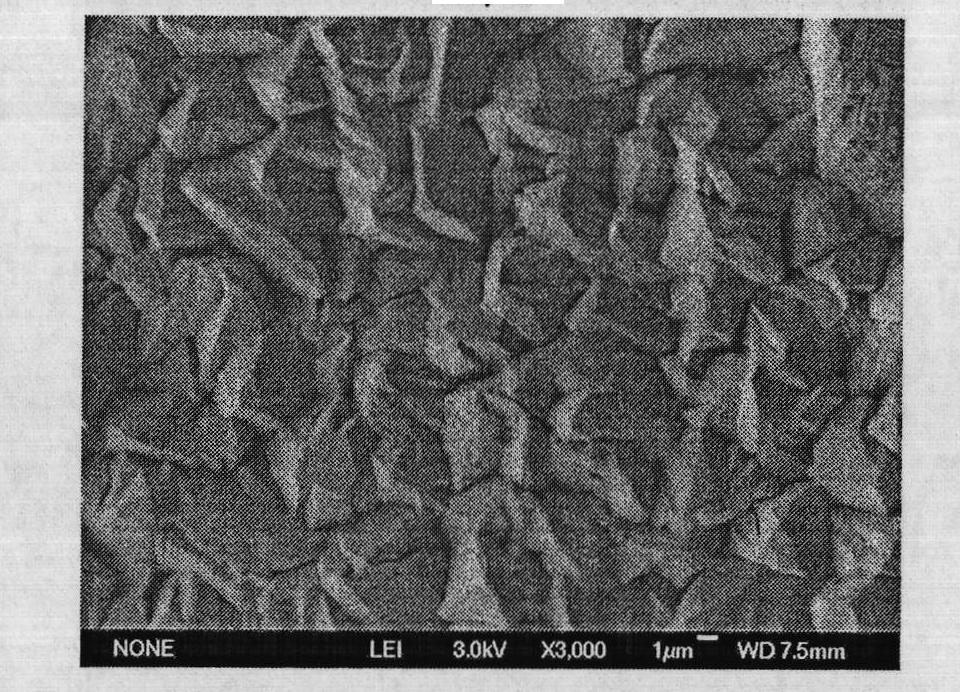

Terylene FDY oil and preparation method thereof

The invention discloses a polyester FDY oil agent and a preparation method thereof. The heat resistance of the existing oil agent is poor with serious volatilization, which results in heavy smog in the workshop and seriously affects the working environment and the body health of the workers; also the oil agent has serious coking phenomena and causes yarn waste and broken ends. The ingredients of the invention and the weight percentages are as follows: 55-65% of high-temperature smoothing agent, 15-25% environment-friendly emulsifying agent, 3-10% binder, 5-8% compound anti-static agent and the rest is additive; and the high-temperature smoothing agent contains special polyether. The invention has good heat resistance and is suitable for the high-speed spinning technique of various polyester fibers (including the high denier); and the oil agent provided by the invention does not generate smoke and does not coke on the hot roll.

Owner:HANGZHOU TRANSFAR CHEM LTD

Environment protecting wood wax oil

InactiveCN101550316ANo pollution in the processMeet environmental protection requirementsCoatingsWood impregnation detailsWaxVegetable oil

The present invention relates to an environment protecting wood wax oil which comprises the following main components by weight: 75-85 parts of vegetable oil, 0.1-1 part of vegetable wax or animal wax, 11-22 parts of rosin resin, 1-2 parts of drier and 0.1-1 part of cosolvent. The preparing method of the wood wax oil comprises the following steps: heating and melting the vegetable oil and wax mixing system, reducing the temperature and adding other materials, and mixing to uniform for obtaining the wood wax oil. The wood wax oil related to the invention can totally penetrate into the wood. The wood wax oil of the invention is remarkably different with the traditional paint with the existence of paint skin. The surface of wood wax oil has an open texture effect. The different woods can represent different real tactile sensation. Furthermore the wood with the environment protecting wood wax oil can be partially restored and retrofitted without mark. The wood wax oil can preserve various excellent performances of wood and effectively prevent the seasoning cracking of wood. The wood is caused to possess the excellent performances of ventilation, drying, corrosion resistance, worm resistance, flame resistance, etc. The using quality of wood can be increased comprehensively.

Owner:TIANJIN XIANDAIREN RE EMPLOYMENT SERVICE

Methanesulfonic acid-based matte pure tin electroplating solution and additive thereof

The invention relates to a methanesulfonic acid-based matte pure tin electroplating solution and an additive thereof. Each liter of an aqueous solution agent of the additive comprises the following components based on concentration: 1.5g / L-3g / L of grain refiner, 100g / L-200g / L of non-ionic surfactant, 10g / L-30g / L of antioxidant and 100g / L-150g / L of organic solvent, wherein the grain refiner is particularly heterocyclic compounds, amine compounds or a mixture of the two. The electroplating solution prepared by the additive in the invention has the advantages of good scatter performance, high flexibility and extensibility of the pure tin-based electroplating layer, and good weldability, and prevents the tin whisker from growing for a long time; and meanwhile, the electroplating solution contains no non-biodegradable substances or surfactant harmful to the environment and the like, thus facilitating the treatment of sewage and meeting the requirements for environmental protection. The invention is worthy of popularizing and applying.

Owner:济南德锡科技有限公司

Method for non-hydroaromatizating and desulfurizing catalytically cracked gasoline

InactiveCN1485414ANo change in octaneMeet environmental protection requirementsTreatment with hydrotreatment processesHydrogenHydrodesulfurization

A process of crackling and aromatizing gasoline, and desulfurizing. It comprises: all fractions of crackling gasoline by catalysizing or light fractions entering an aromatizing desulfurizing reactor,and aromatizing olefin, hydrogenating and desulfurizing with hydrogen produced by aromatizing are hydrogenated, reducing the contents of olefin and sulfur in gasoline, deodorizing the products, then obtaining high-grade gasoline product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Modifying method for naphtha and light hydrocarbon aromatization

ActiveCN101747933ALower end pointReduce carbon deposition rateCatalytic naphtha reformingLiquid productHydrogen

A modifying method for naphtha and light hydrocarbon aromatization comprises: contacting naphtha and C3-C5 light hydrocarbon with aromatization catalyst in the presence of hydrogen-containing gas to carry out aromatization modifying reaction, wherein the reaction temperature is 250-600 DEG C, and the volume ratio of hydrogen to naphtha is 20-400. The method can convert naphtha with low octane value and low-carbon hydrocarbon into gasoline component with high octane value and excellent liquefied gas, the final distilling point of liquid product and the carbon-accumulating speed of catalyst areobviously reduced, and the service life of catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-soluble soldering flux dedicated for lead-free solder

InactiveCN1836825AImprove solderabilityImprove performanceWelding/cutting media/materialsSoldering mediaOrganic acidWater soluble

The water soluble soldering flux specially for lead-free soldering material consists of boric acid and organic acid activator 5.0-10.0 wt%, non-ionic surfactant or cationic surfactant 0.1-1.0 wt%, co-solvent 8.0-20.0 wt%, filming agent 0.1-1.0 wt%, corrosion retardant 0.1-0.5 wt%, except deionized water. The compounding process includes the following steps: mixing co-solvent and partial deionized water, adding filming agent under stirring, adding the rest deionized water, activator and surfactant after dissolving, adding corrosion retardant while stirring to dissolve, stilling, and filtering to obtain the filtrate as the soldering flux. The water soluble soldering flux has excellent soldering assisting performance on lead-free soldering material, environment friendship and other advantages.

Owner:BEIJING UNIV OF TECH

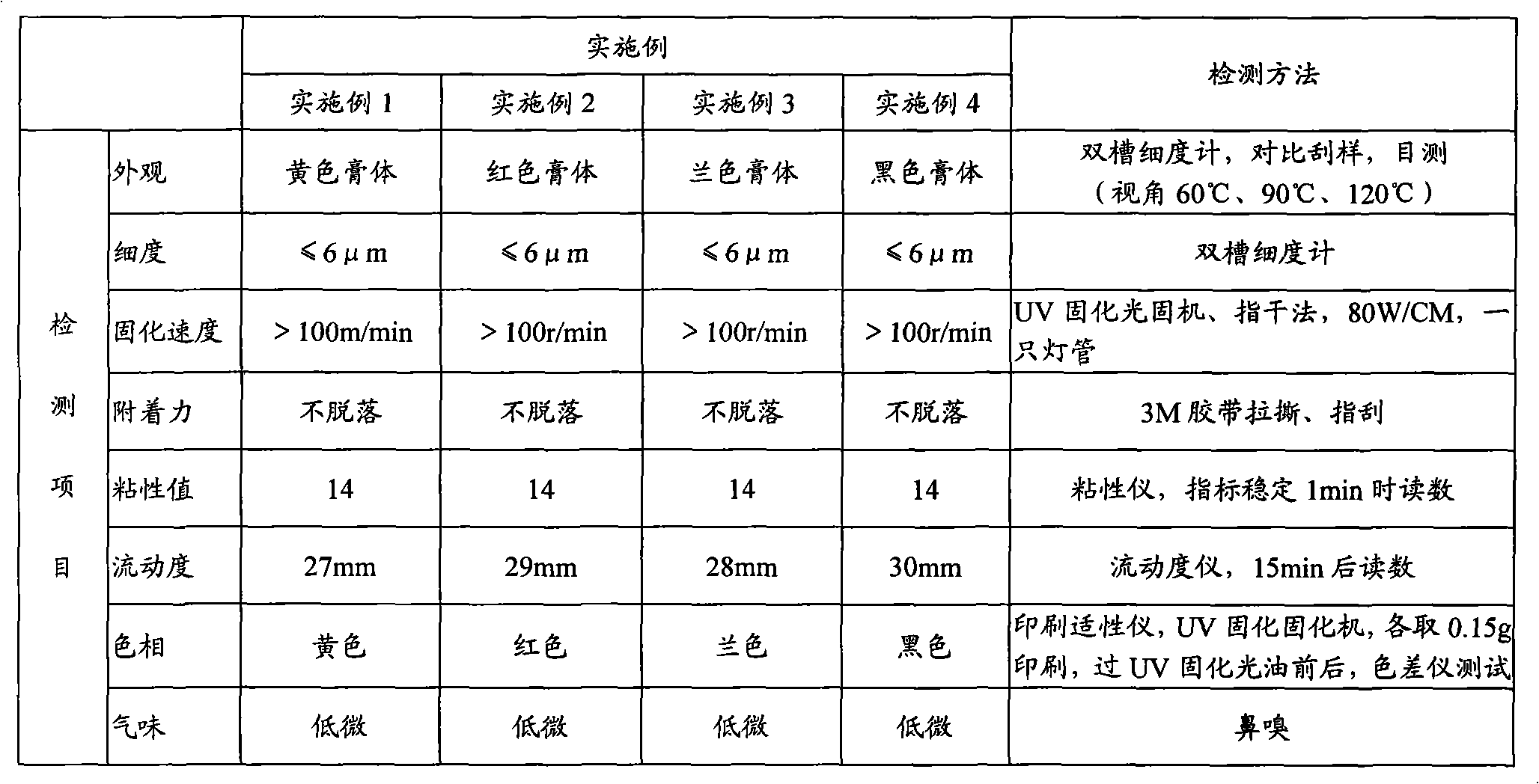

UV curing offset printing ink and use

The invention relates to UV cured lithographic ink and purposes thereof. The ink is a compound which comprises the following components by the weight percent: 30 to 50 of polyester acrylic ester, 0 to 15 of epoxy acrylic ester, 2 to 22 of high-viscosity monofunctional polyurethane acrylic ester, 0 to 10 of acrylic monomer, 10 to 15 of photoinitiator, 2 to 5 of filler and 16 to 22 of pigment. The UV curing glue printing ink of the invention can be cured at high speed, can meet the requirements of high-speed packaging, printing and environment protection, does not contain VOC, has little irritation to the human skin, and can be used as lithographic ink for the high-speed printing, and paper and plastic printing of packaging and printing.

Owner:深圳市美丽华科技股份有限公司

Environmental protection type base fibre film, and its mfg. process

ActiveCN1559176AHigh strengthLose weightOrganic fertilisersPlant protective coveringsAdhesiveEngineering

An environmental protection type bast fibre film which is air permeable and impervious is prepared from bast fibres through opening fibres, removing dust and impurities, carding, stripping for netting, airflow netting, chemical sticking by adhesive to become film, applying the hydrophobic agent onto its surfaces, and cold rolling.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

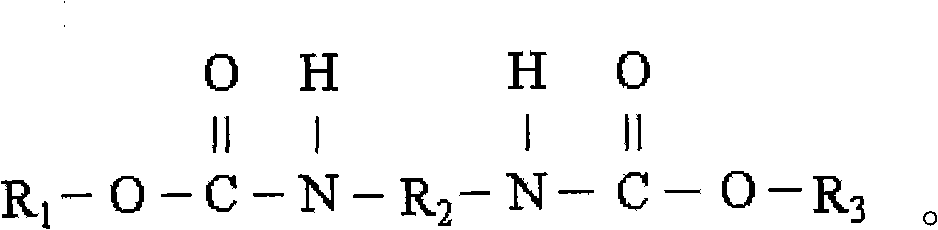

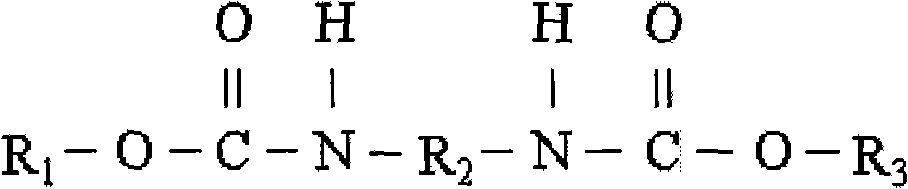

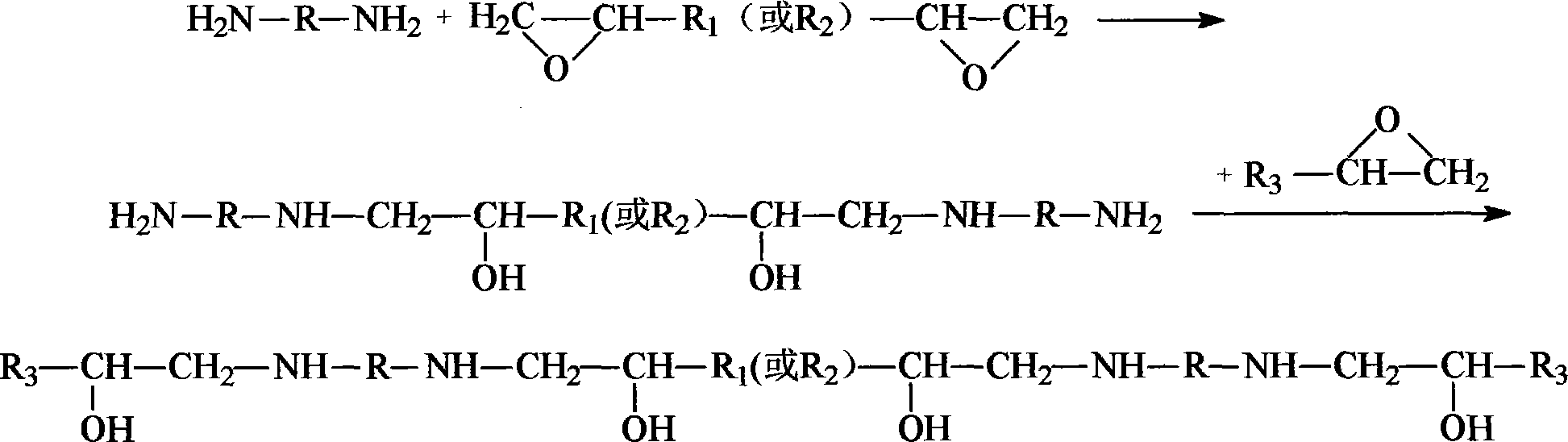

Self-emulsifying type aqueous latex of epoxy hardener, and preparation method

ActiveCN101050300AAvoid situations that require high temperaturesThe synthesis process is simple, safe and energy-savingEpoxyAdhesive

This invention relates to a method for preparing self-emulsifying waterborne epoxy curing agent emulsion, which is composed of: primary amine 7-20 wt.%, epoxy resin 12-27 wt.%, epoxy-terminated polyether 3-8 wt.%, epoxy active diluter 10-30 wt.%, and deionized water 35-60 wt.%. The method comprises: adding primary amine into a reactor, slowly dropping a mixture of epoxy resin and epoxy-terminated polyether, reacting at a certain temperature, slowly dropping monofunctional epoxy active diluter, reacting, adding water, and emulsifying to obtain white waterborne epoxy curing agent emulsion. The method has such advantages as simple process, low reaction temperature (below 100 deg.C), high safety and low energy consumption. The obtained waterborne epoxy curing agent emulsion has such advantages as low VOC content, high stability, high water resistance, high compatibility with epoxy resin, high impact resistance, good luster, high toughness and high adhesiveness, and can be used in paint, adhesive and polymer concrete.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

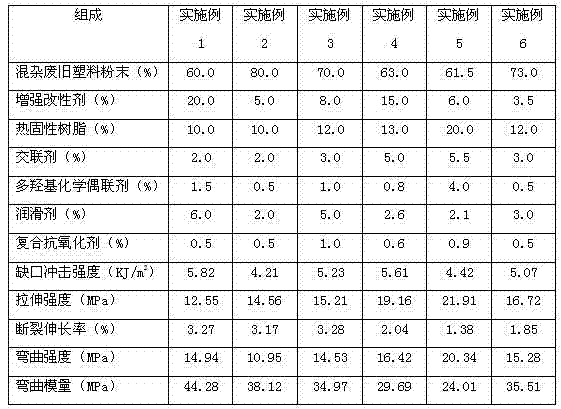

Composite board based on mixed waste polymers and preparation method thereof

The present invention discloses a composite board based on mixed waste polymers and a preparation method thereof. The preparation method of the composite board based on the mixed waste polymers is characterized by comprising the following steps of: (1) weighing the raw materials according to a certain proportion, adding the raw materials to a high-speed mixer, mixing at the temperature of 40-60 DEG C and the rotation speed of 800-2000 rpm for 20-30 minutes, cooling to room temperature and discharging; and (2) adding the mixed material to a mold, vulcanizing at the temperature of 150-180 DEG C and the pressure of 10-15 MPa for 10-20 minutes, cooling and relieving pressure. The composite board based on the mixed waste polymers provided by the invention does not need to consider the complex compatibility and plasticizing problems of multiple polymers, effectively solves the problems that the existing mixed waste polymers can not be classified and are discarded, and can be used as the substitute for wood to be applied in the tray manufacturing field and other fields. The production process provided by the invention is simple, uses existing equipment and is suitable for mass production.

Owner:佛山市南海承骏科技有限公司 +1

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

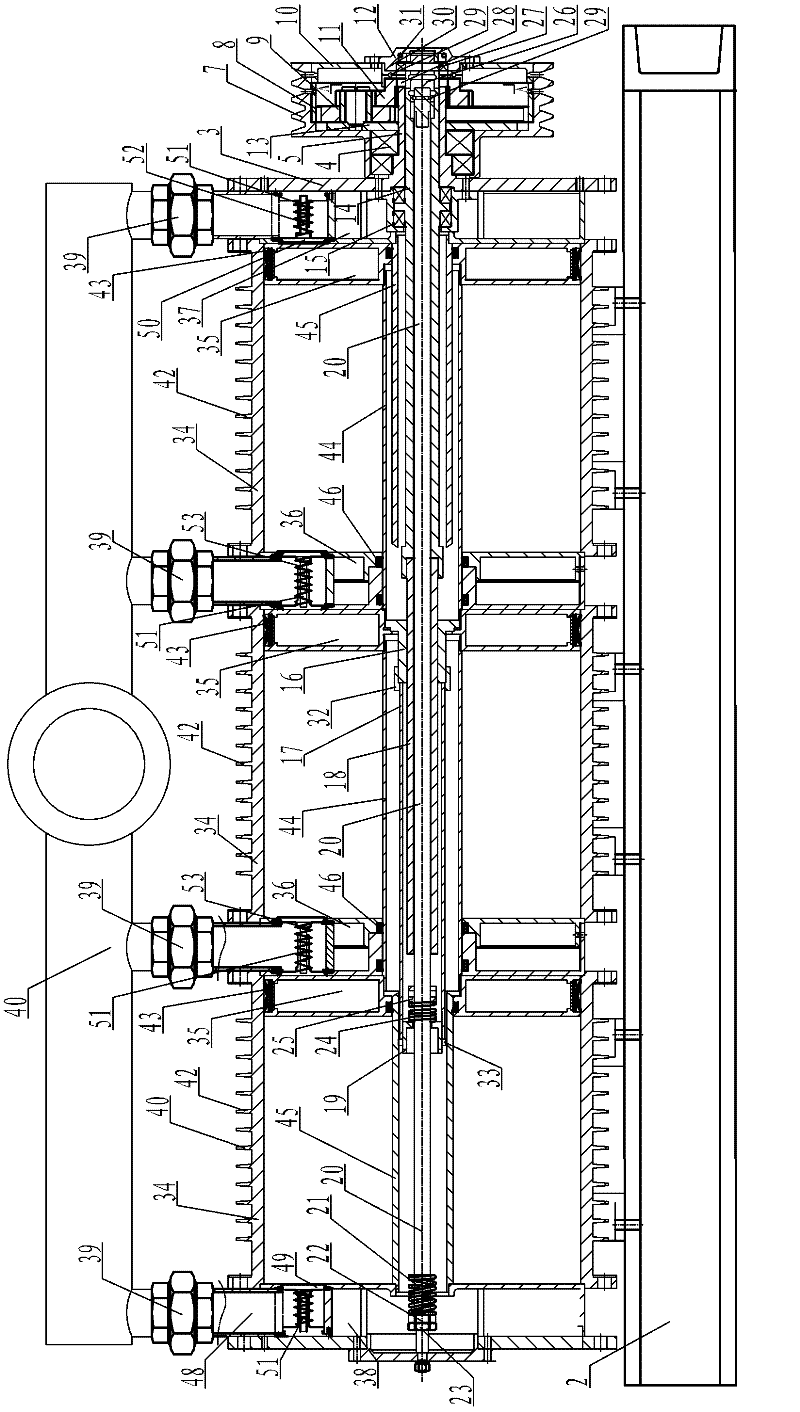

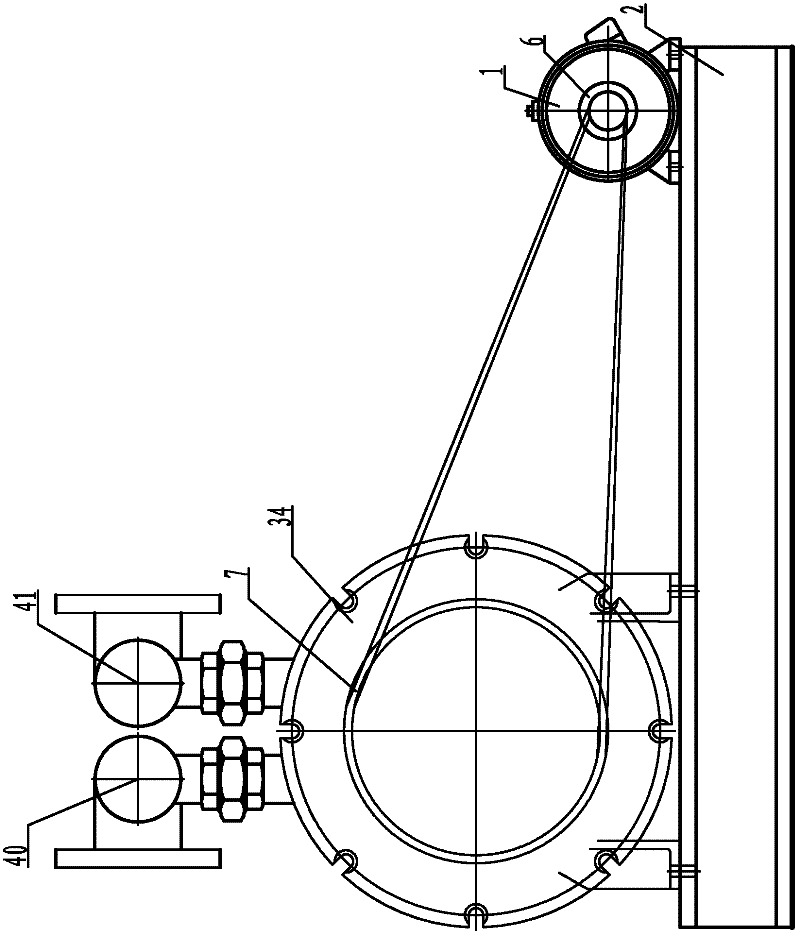

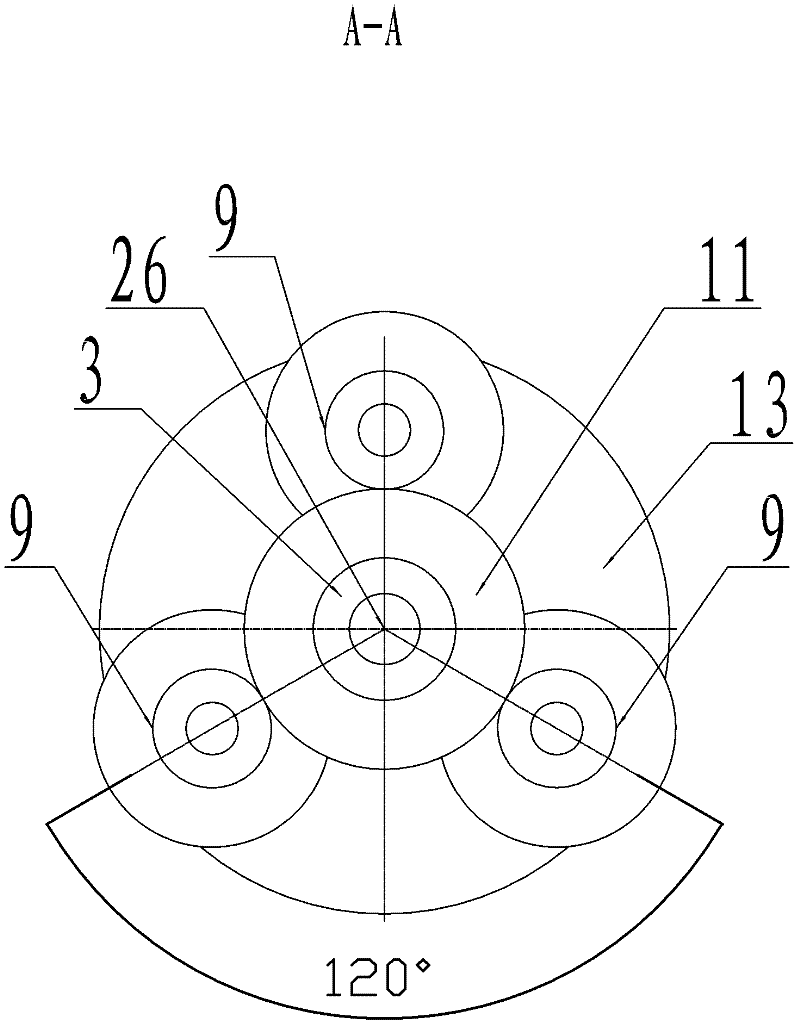

Reciprocating screw vacuum compressor

InactiveCN102226450ARealize forward and reverse commutation rotationReasonable designMechanical actuated clutchesPumpsExhaust valveDrive wheel

The invention relates to a reciprocating screw vacuum compressor. The compressor is characterized in that a driven wheel is provided with a reciprocating screw transmission mechanism formed by a driven wheel supporting shaft, a gear transmitting and reversing system, hollow shafts, bearing blocks, hollow screw rods, nuts, nut sleeves, connecting sleeves, reversing rods, a spring mechanism and a jaw clutch; tandem piston units in a vacuum compression device formed by cylinders, pistons, sealing connecting pipes, sealing elements A, intermediate separate cavities, sealing elements B, a front separate cavity, a rear separate cavity, three-way intake valves, three-way exhaust valves, intermediate three-way exhaust valves, intermediate three-way intake valves, a main exhaust pipe and a main intake pipe are driven by reversion of the reversing rods in the reciprocating screw transmission mechanism to continuously reciprocate in the cylinders, thus realizing the vacuumizing and compressing functions of the vacuum compressor. The vacuum compressor not only has reasonable design and compact structure, but also has the advantages of energy conservation, no vibration, no noises, conformity with the environmental protection requirement, stable operation, convenience in operation and use and the like.

Owner:DALIAN JINGGONG MACHINERY EQUIP

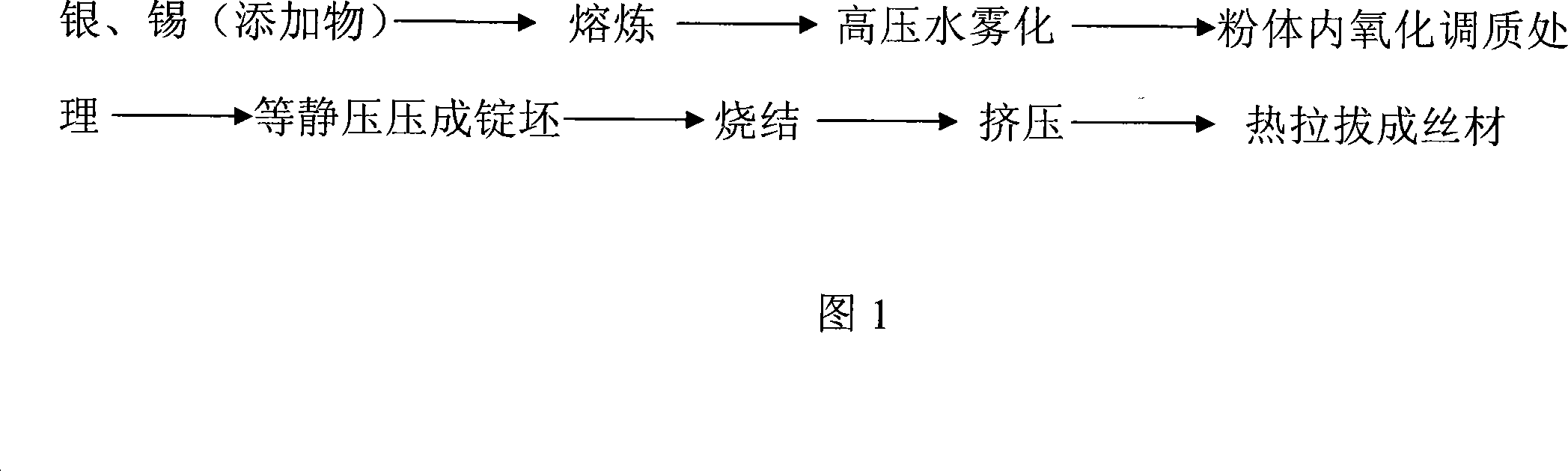

Method of preparing novel silver tin oxide silk electrical contact material

InactiveCN101202169AGranularity is easy to controlImprove surface activityContactsIntermediate frequencyElectric properties

The invention relates to a novel preparing method of a material used for a silver tin oxide wire electric contact. The invention has a process that the material prepared by silver, tin and additives according to a certain proportion is put into an intermediate frequency smelter for melting; a high pressure water atomizing device is adopted for high pressure alloy atomization; atomized alloy powder is dried and oxidated for modification; an isostatic pressing ingot is formed after isostatic pressing treatment; the ingot is agglomerated in a heating furnace; the agglomerated ingot is delivered into an extruding machine to extrude wires; the extruded wire is pulled and annealed to get a finished wire. The material property and electric property of the silver tin oxide wire electric contact material manufactured by the method can satisfy the use condition with high requirement.

Owner:FUDA ALLOY MATERIALS

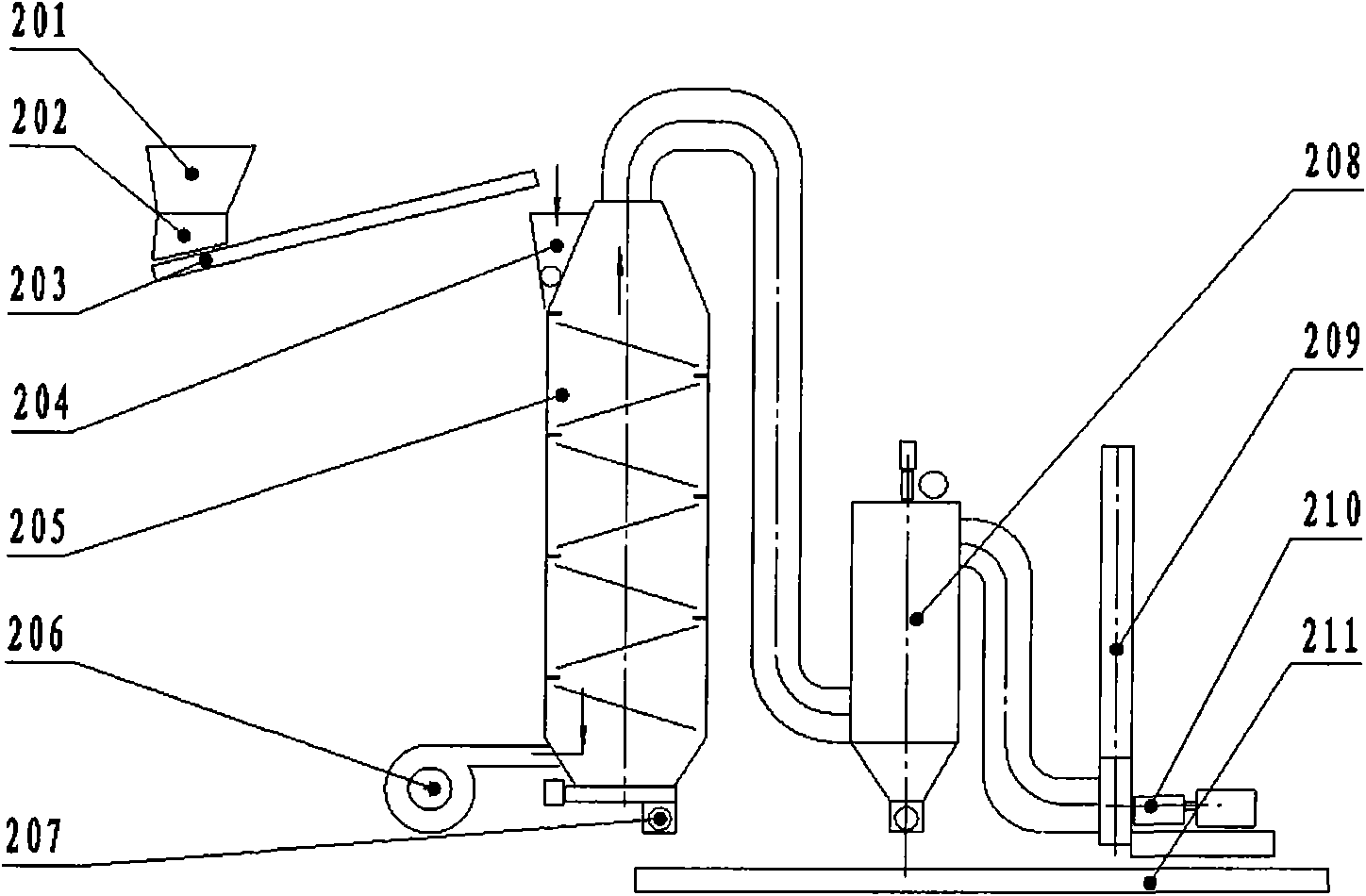

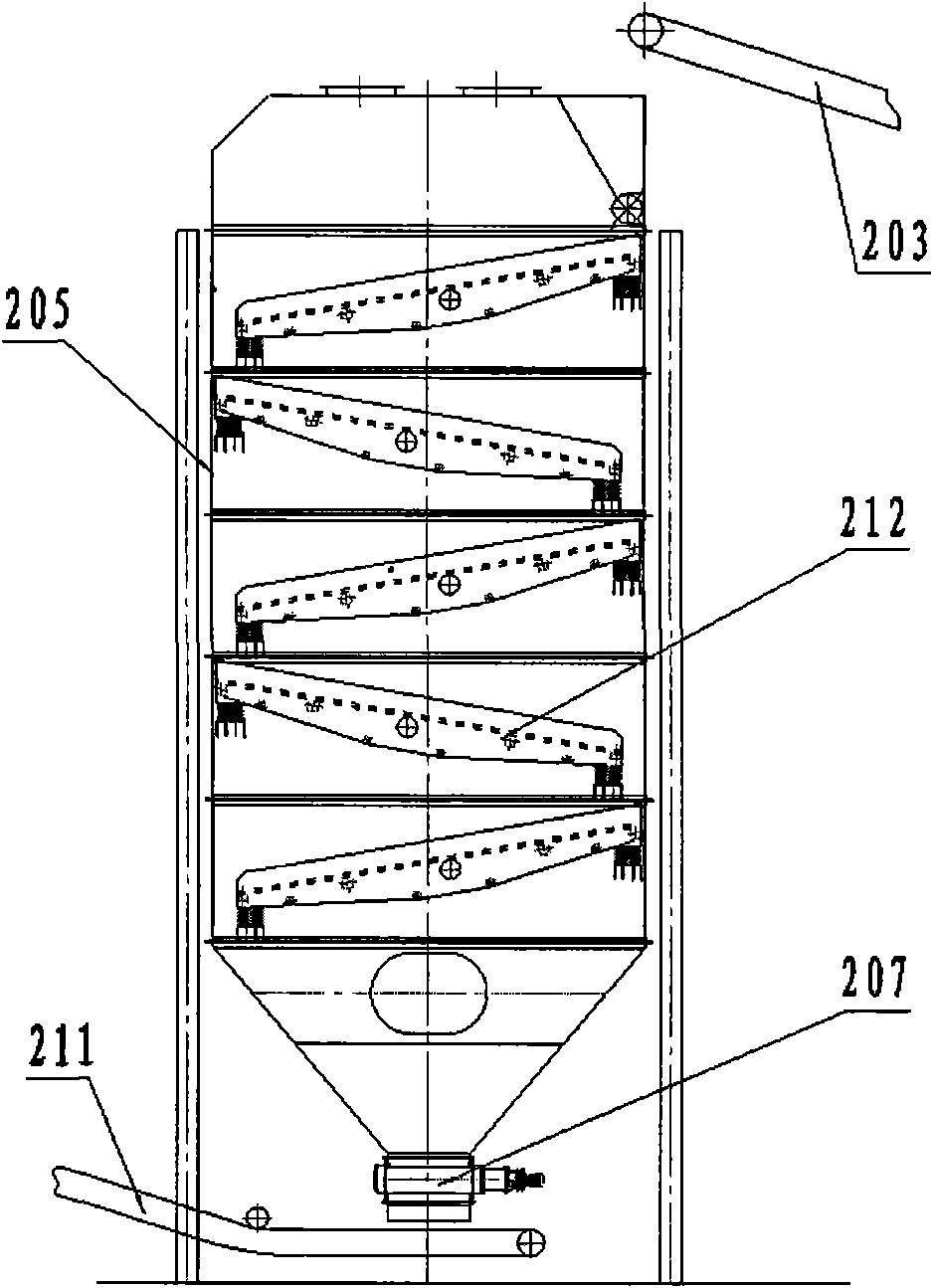

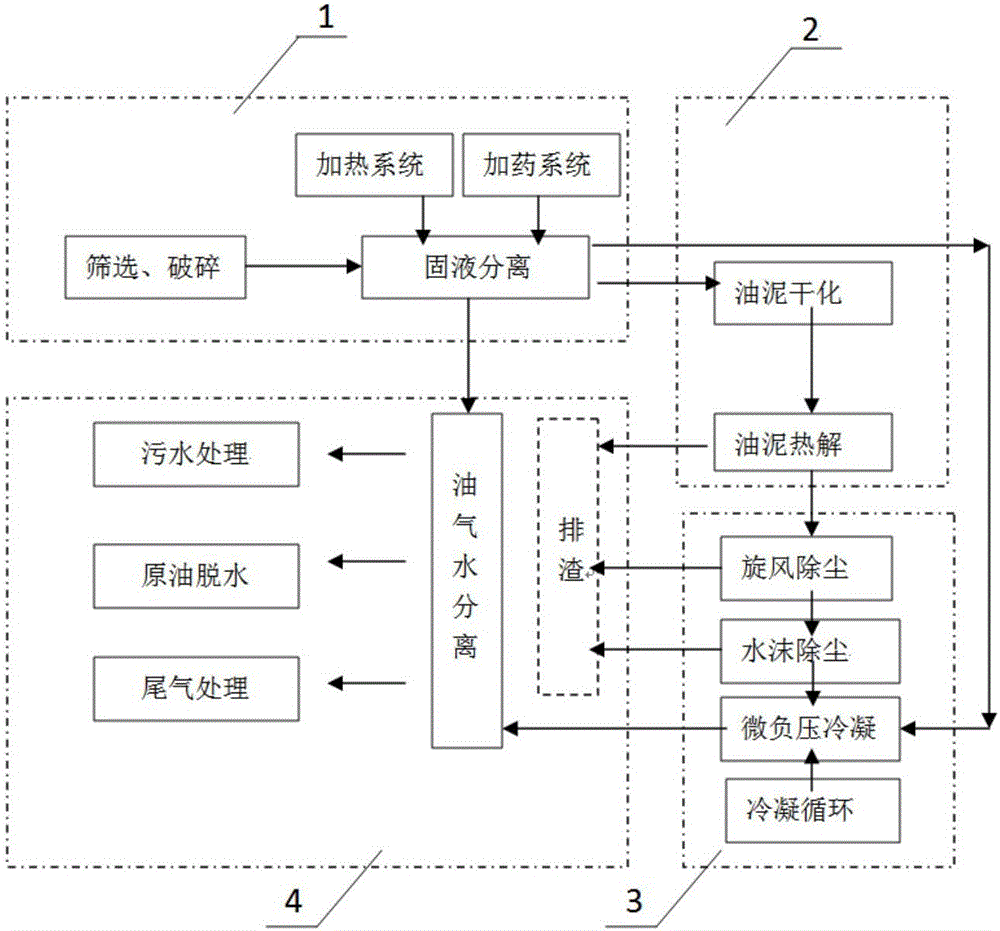

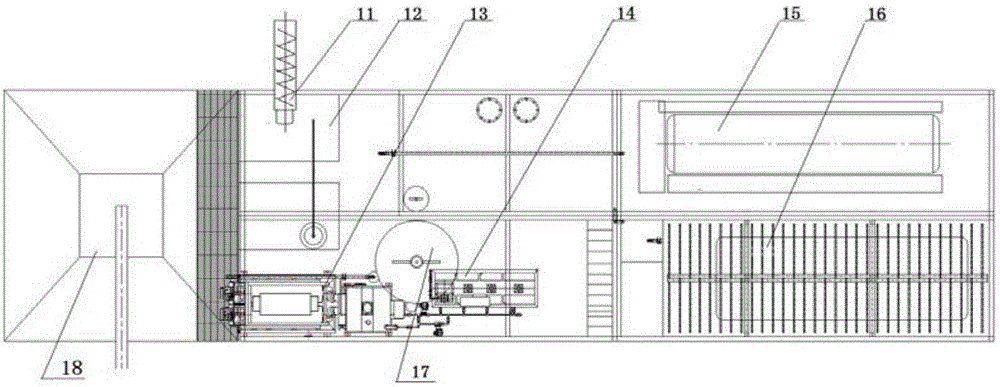

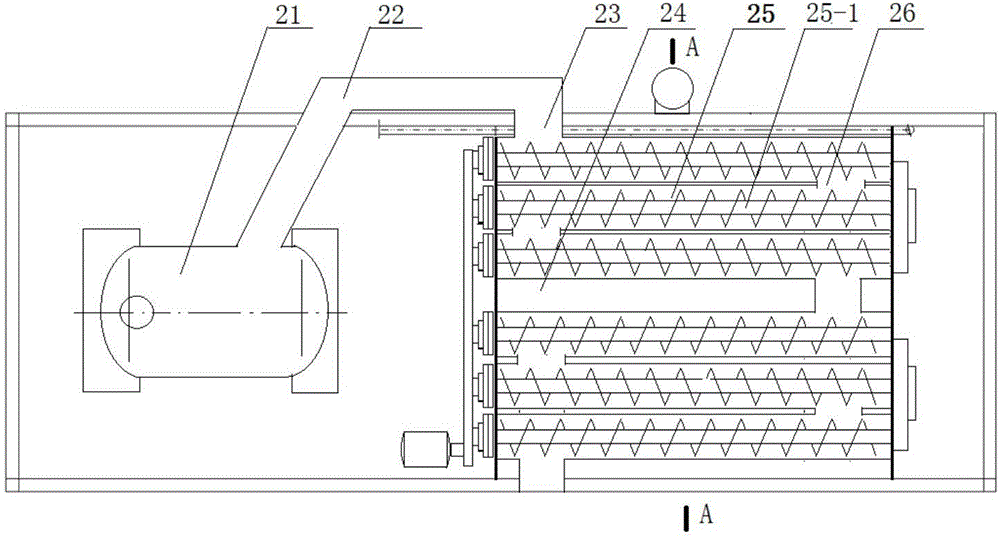

Industrialization scale pyrolysis treatment system and method for oily sludge

InactiveCN106746419ALarge amount of processingEasy to operateCombination devicesSludge treatment by de-watering/drying/thickeningPetroleumPyrolysis

The invention belongs to the field of waste disposal in petroleum industry, and relates to an industrialization scale pyrolysis treatment system for oily sludge. The industrialization scale pyrolysis treatment system comprises a feeding pre-separation unit for performing secondary screening and solid-liquid separation on the oily sludge, a drying pyrolysis unit for performing drying and pyrolysis reaction on the oily sludge, a dust removal and condensation unit for performing dust removal and condensation on a pyrolysis gas mixture generated by the drying pyrolysis unit, and a discharge treatment unit which receives and treats separated substances of the other units respectively. Solid or solid-liquid mixed waste such as the oily sludge can be finally treated to achieve reduction, stabilization, harmlessness and recycling.

Owner:PANJIN NINGTAI ENERGY TECH

Working device setted on one place and engineering machinery using it

InactiveCN1831253AShorten the timeImprove operational skillsMechanical machines/dredgersVehiclesState of artEngineering

The invention is a working device arranged in some place, composed of two or above working devices arranged in some place, back-to-back, side-arranged, opposite, staggered, side-by-side, up and down, rotatable, inclinable, turnable, movable, liftable or in other form. And an engineering machine applying it is composed by arranging it in corresponding position on a corresponding vehicle or chassis or connecting it with the correspond position. And it can compose various engineering machines by various vehicles or chassises, compact, multifunctional, low-cost, high-efficiency and energy-saving, and having strong practicality.

Owner:姚实现

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com