Environmentally-friendly acrylic ester coating printing adhesive emulsion and preparation method

A pigment printing and adhesive technology, applied in the direction of ester copolymer adhesive, adhesive type, dyeing method, etc., can solve the problems of low solid content of adhesive emulsion, high production cost, expensive radiation source, etc. , to achieve the effects of stable polymerization process, small equipment investment and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

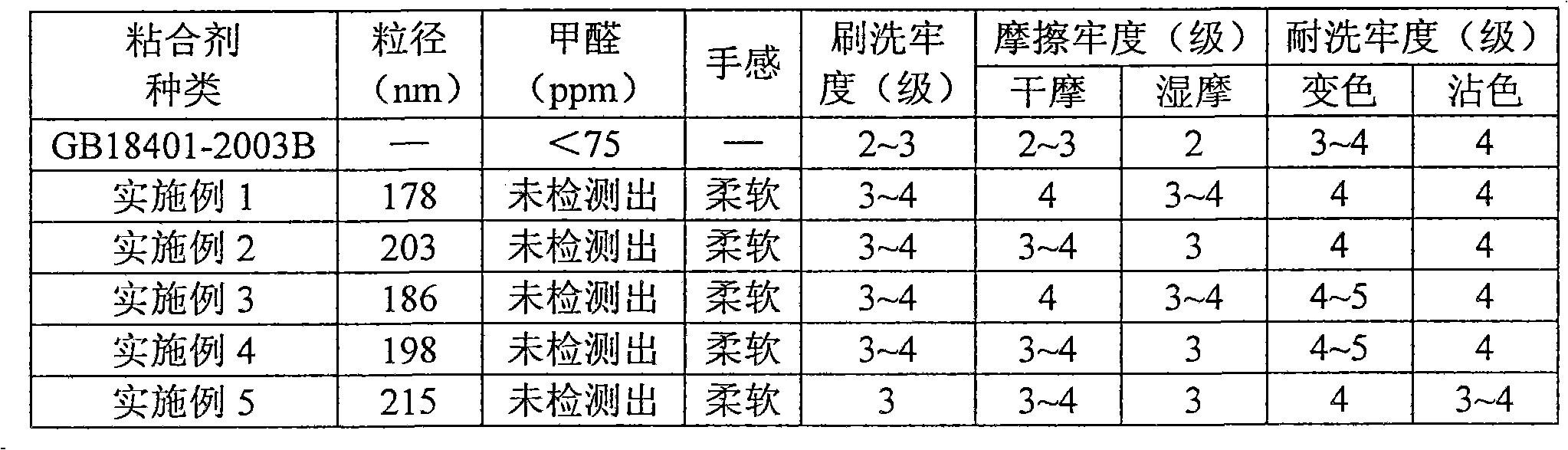

Examples

Embodiment 1

[0043] In terms of parts by weight, the raw material formula of the environment-friendly pigment printing adhesive is as follows, wherein the total amount of soft monomers, hard monomers and functional monomers is 100 parts by weight.

[0044] Butyl acrylate 50.0

[0045] Isooctyl acrylate 20.2

[0046] Methyl methacrylate 10.0

[0047]Acrylonitrile 10.0

[0048] Hydroxyethyl Acrylate 5.0

[0049] Methacrylic acid 3.0

[0050] Glycidyl Methacrylate 1.0

[0051] HA 0.8

[0052] Ammonium persulfate 0.4

[0053] Emulsifier 3.0

[0054] Sodium bicarbonate 0.3

[0055] Deionized water 90

[0056] HA is a hydrophilic cross-linking monomer, provided by Guangzhou Double Bond Trading Co., Ltd., which is a derivative of methacrylate and contains acrylamide groups, which can be used as a cross-linking monomer in the polymerization reaction to improve polymer resistance. Scrubbing performance and mechanical properties, etc.

[0057] The emulsifier is composed of sulfosuccinate ...

Embodiment 2

[0063] In terms of parts by weight, the raw material formula of the environment-friendly pigment printing adhesive is as follows, wherein the total amount of soft monomers, hard monomers and functional monomers is 100 parts by weight.

[0064] Butyl acrylate 46.5

[0065] Isooctyl acrylate 25.0

[0066] Methyl methacrylate 6.0

[0067] Acrylonitrile 8.0

[0068] Styrene 6.0

[0069] Hydroxyethyl Acrylate 5.0

[0070] Methacrylic acid 2.0

[0071] Glycidyl methacrylate 0.5

[0072] HA 1.0

[0073] Ammonium persulfate 0.4

[0074] Emulsifier 2.5

[0075] Sodium bicarbonate 0.25

[0076] Deionized water 90

[0077] HA is a hydrophilic cross-linking monomer provided by Guangzhou Double Bond Trading Co., Ltd. It is a derivative of methacrylate and contains acrylamide groups, which can participate in the cross-linking reaction during the polymerization reaction to improve the scrub resistance of the polymer performance and mechanical properties.

[0078] The emulsifier i...

Embodiment 3

[0084] In terms of parts by weight, the raw material formula of the environment-friendly pigment printing adhesive is as follows, wherein the total amount of soft monomers, hard monomers and functional monomers is 100 parts by weight.

[0085] Butyl acrylate 57.0

[0086] Isooctyl acrylate 15.0

[0087] Methyl methacrylate 8.0

[0088] Acrylonitrile 11.0

[0089] Hydroxyethyl Acrylate 4.5

[0090] Acrylic 3.0

[0091] Glycidyl methacrylate 0.5

[0092] HA 1.0

[0093] Emulsifier 2.0

[0094] Ammonium persulfate 0.4

[0095] Sodium bicarbonate 0.25

[0096] Deionized water 90

[0097] HA is a hydrophilic cross-linking monomer, provided by Guangzhou Double Bond Trading Co., Ltd., which is a derivative of methacrylate and contains acrylamide groups, which can participate in cross-linking reactions during polymerization to improve the scrub resistance of polymers performance and mechanical properties.

[0098] The emulsifier is composed of sulfosuccinate surfactant EF-8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com