Composite polymer sludge dewatering agent and preparation method thereof

A technology of sludge dehydrating agent and composite polymer, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of uncontrollable molecular structure, less industrialized products, and poor solubility, so as to save preparation cost and increase Sedimentation, the effect of simplifying the dosing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

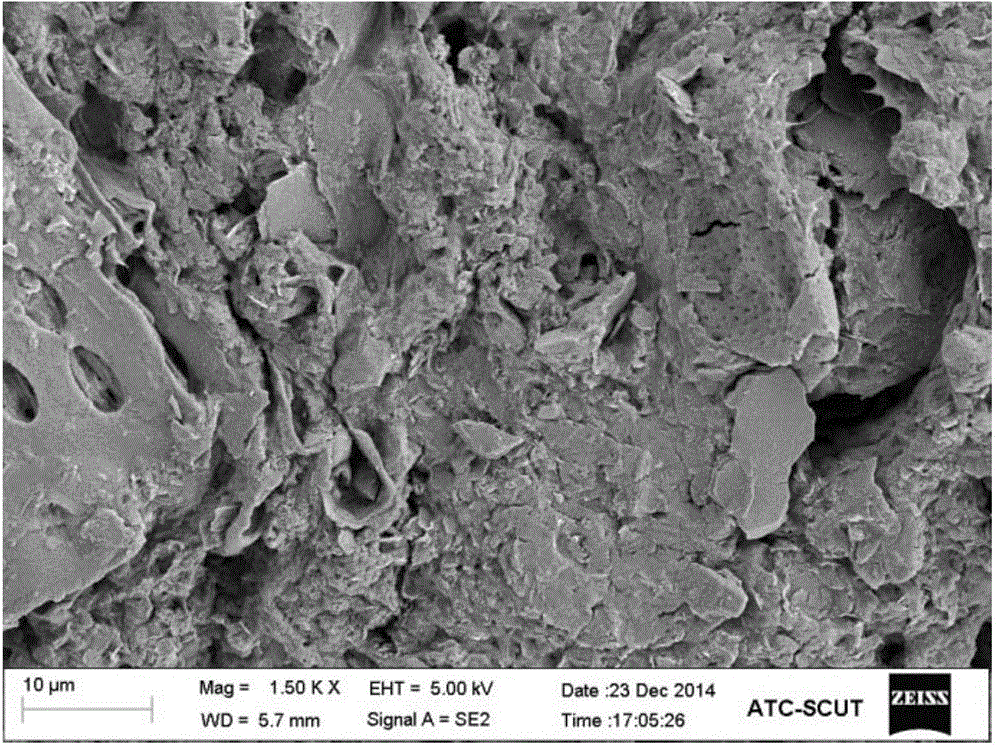

Image

Examples

Embodiment 1

[0033] (1) 0.76kg methyl acrylate (industrial refined liquid, Jiangxi Changjiu Company, the same below) was made into 7.6kg aqueous solution and 0.08kg 2-acrylamido-2-methylpropanesulfonic acid (concentration Be 60% industrial refining solution, U.S. Lubrizol Company, the same below) is made into 0.48kg aqueous solution, 0.26kg acryloyloxyethyltrimethyl ammonium chloride (concentration is the industrial refining solution of 70%, Jiangsu Nantian Company, The same below) was made into 1.8kg aqueous solution. Add the above three aqueous solutions into an enamel reaction kettle with a stirrer and a heating jacket, adjust the pH to 4 with 1% mass fraction hydrochloric acid and sodium hydroxide, start stirring, and pass nitrogen to remove oxygen;

[0034] (2) Add respectively 0.0035kg ammonium persulfate, 0.003kg sodium bisulfite, 0.003kg azobisisobutylamidine hydrochloride (industrial refined crystallization, Guangzhou Chuangyuan Company, the same below), 0.002kg kg of EDTA-2Na, t...

Embodiment 2

[0039] (1) 0.73kg methyl methacrylate (industrial refining liquid) was made into 7.3kg aqueous solution, 0.13kg 2-acrylamido-2-methylpropanesulfonic acid (60% industrial refining liquid) with deionized water solution) was made into 0.8kg aqueous solution, and 0.22kg acryloyloxyethyltrimethylammonium chloride (concentration is 70% industrially refined solution) was made into 1.5kg aqueous solution. Add the above three aqueous solutions into an enamel reaction kettle with a stirrer and a heating jacket, adjust the pH to 3 with 1% hydrochloric acid and sodium hydroxide, start stirring, and pass nitrogen to remove oxygen;

[0040] (2) Add 0.004kg potassium persulfate, 0.002kg sodium sulfite, 0.005kg azobisimidazolinyl propane dihydrochloride, 0.004kg EDTA-2Na respectively to the solution of the reactor, and control the reaction temperature to be 30°C;

[0041] (3) When the reaction is carried out for 3 hours, add 0.1 kg of ferric sulfate, fully stir, continue to pass nitrogen gas fo...

Embodiment 3

[0043] (1) 0.68kg ethyl acrylate (industrial refined liquid) is made into 6.8kg aqueous solution respectively with deionized water, 0.14kg acrylic acid (concentration is the industrial refined solution of 60%) is made into 0.82kg aqueous solution, 0.33kg dimethyl dimethicone Allyltrimethylammonium chloride (concentration is 70% industrial refining solution) is made into 2.3kg aqueous solution. Add the above three aqueous solutions into an enamel reaction kettle with a stirrer and a heating jacket, adjust the pH to 5 with 1% hydrochloric acid and sodium hydroxide, start stirring, and pass nitrogen to remove oxygen;

[0044] (2) In the solution of reactor, add 0.004kg potassium persulfate respectively, 0.005kg sodium bisulfite, 0.004kg azobisisobutylamidine hydrochloride, add the EDTA-2Na of 0.004kg again, control reaction temperature to be 45 ℃, to promote chain initiation and chain growth reactions;

[0045] (3) When the reaction is carried out for 4 hours, add 0.2 kg of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com