Patents

Literature

610results about How to "Low cost of preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

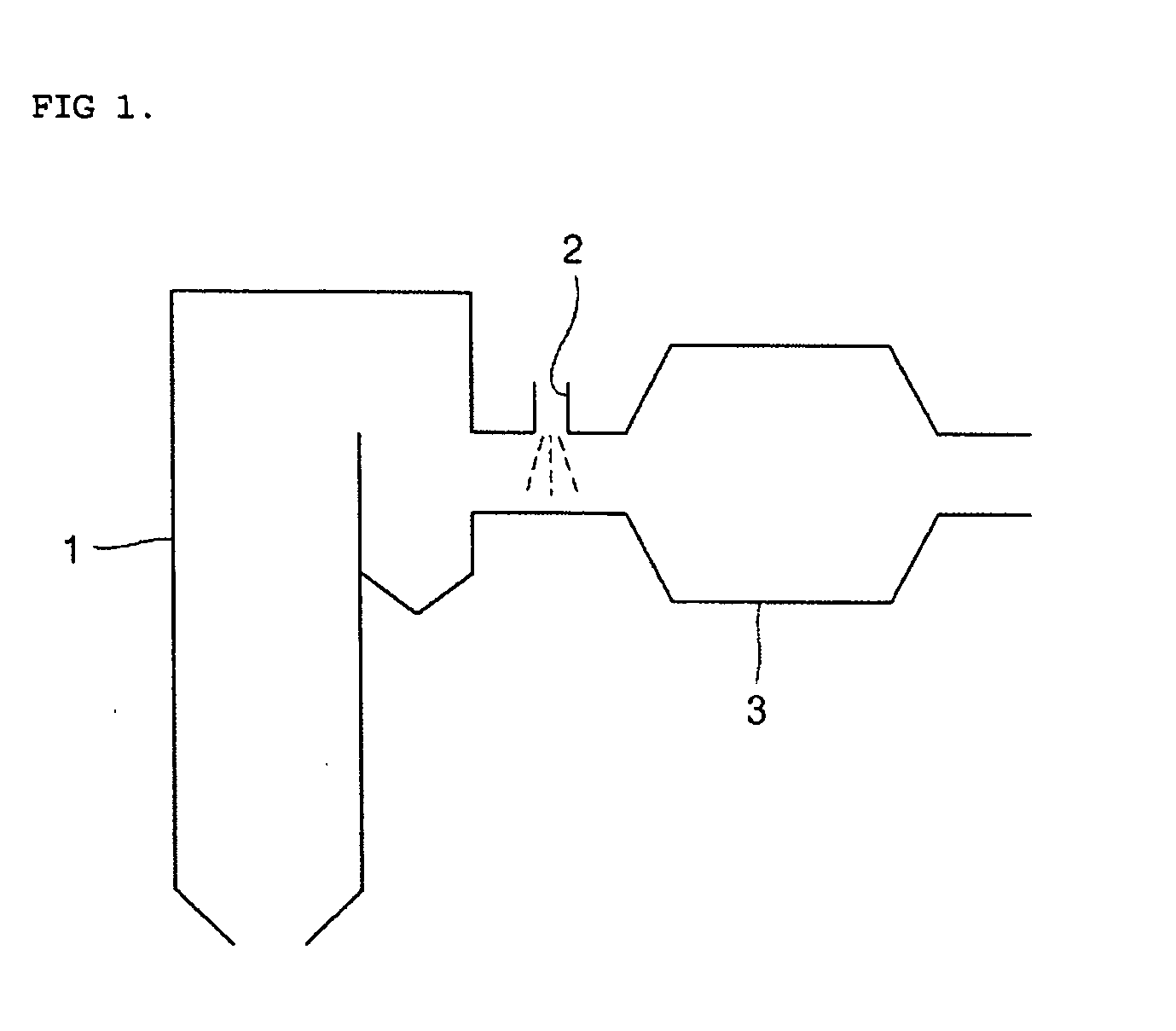

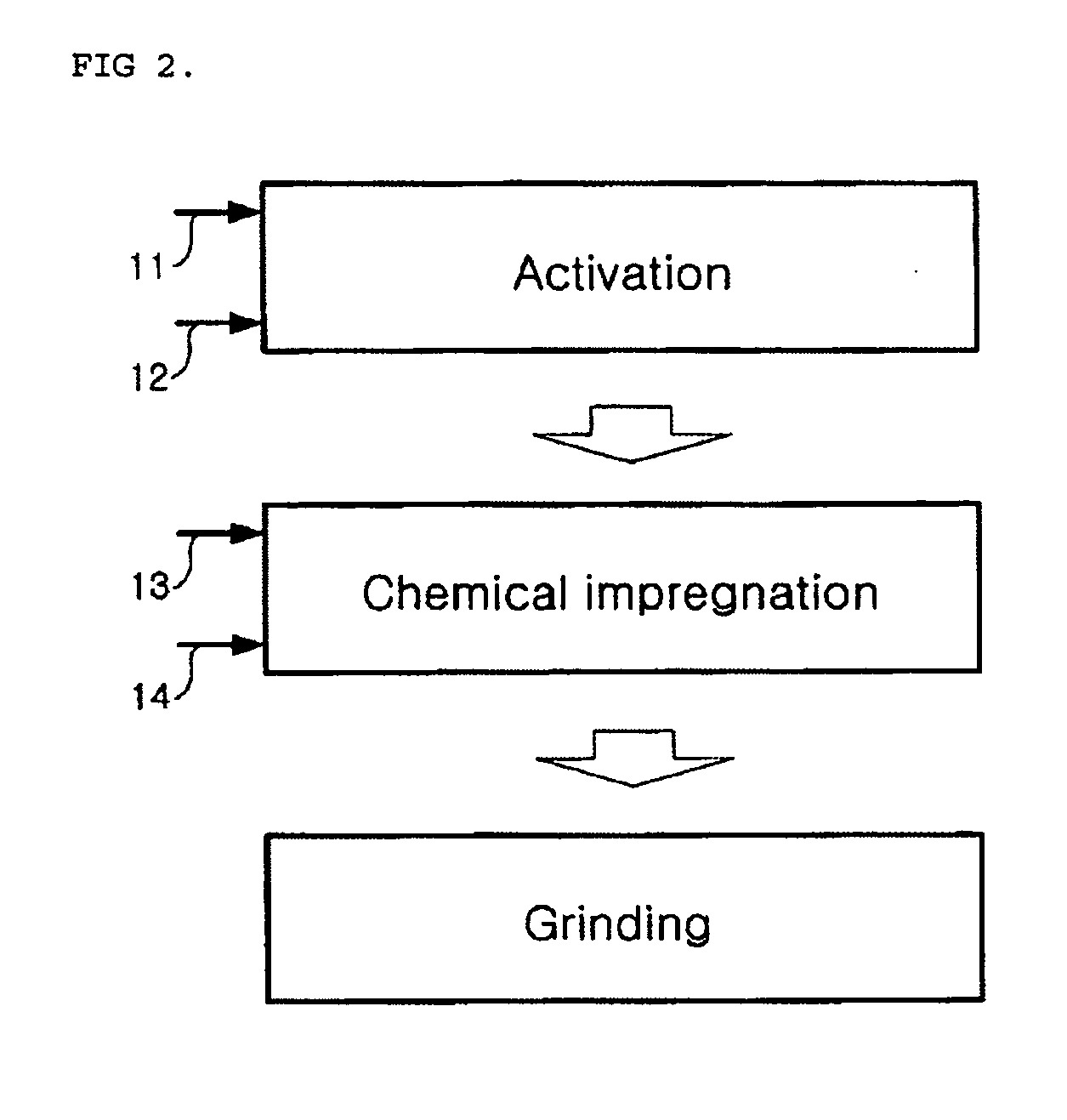

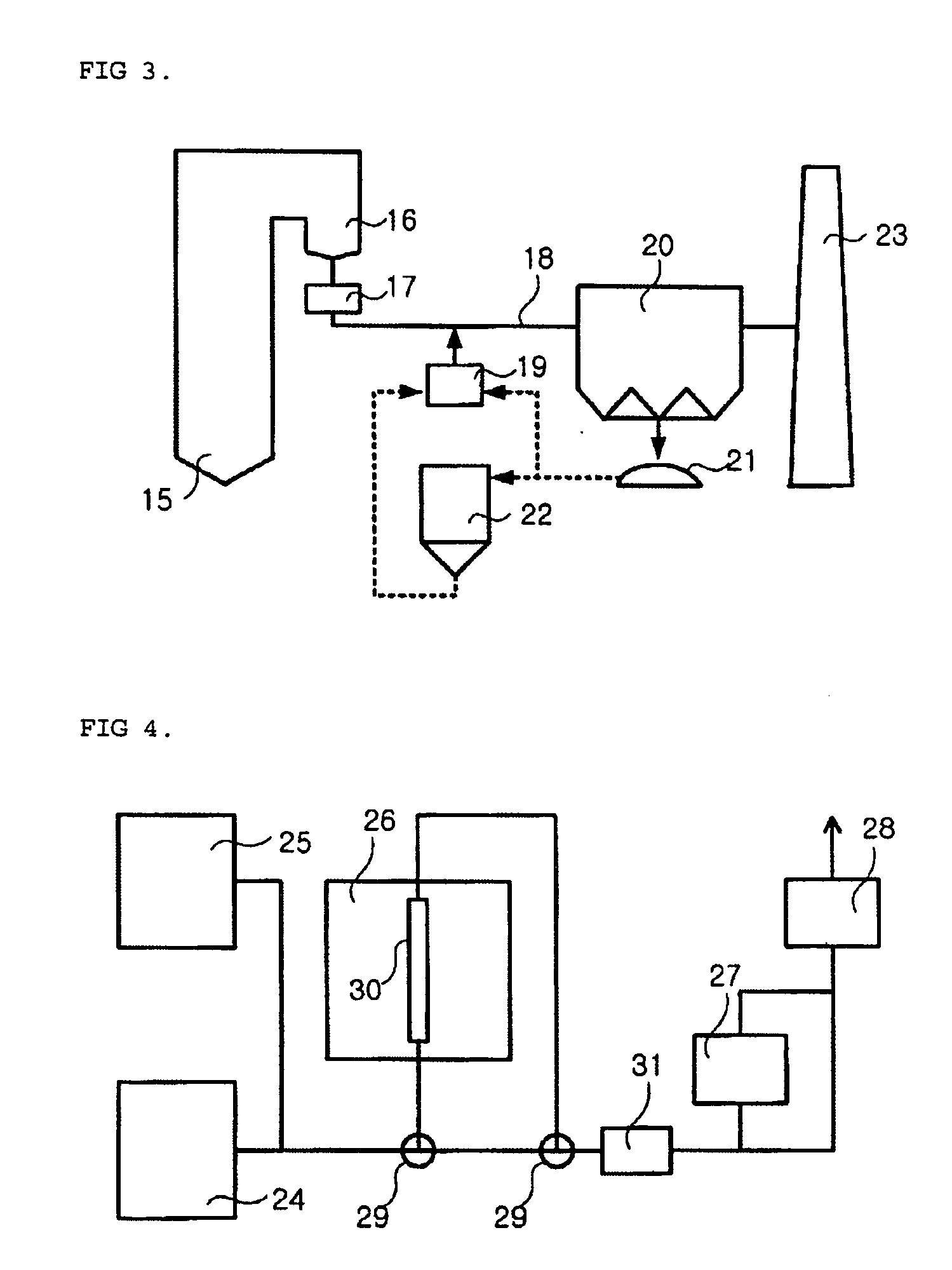

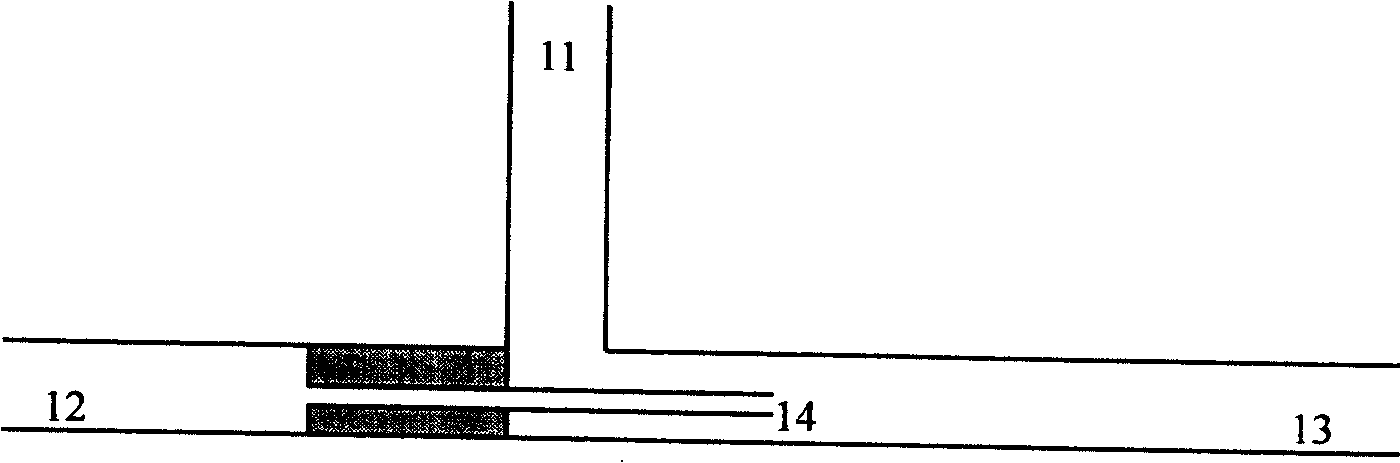

Sorbent for removal of trace hazardous air pollutants from combustion flue gas and preparation method thereof

InactiveUS20070179056A1Low costLow raw material costGas treatmentOther chemical processesSorbentToxic industrial waste

Disclosed is a sorbent for the removal of mercury from combustion flue gas and a preparation method thereof. The sorbent includes an activated heavy oil heavy ash impregnated with 0.1-30% by weight of any chemical substance selected from sulfur, iodine, bromine and chlorine. The sorbent is prepared in an economical manner using heavy oil fly ash, industrial waste generated from heavy oil-fired boilers, and has excellent sorption performance for mercury, so that a low concentration of mercury contained in combustion flue gas discharged from large-scale boilers can be removed by injection of a small amount of the sorbent. Thus, the invention can prevent a reduction in the recycling rate of coal fly ash in coal-fired power plants and minimize operation cost.

Owner:KOREA ELECTRIC POWER CORP

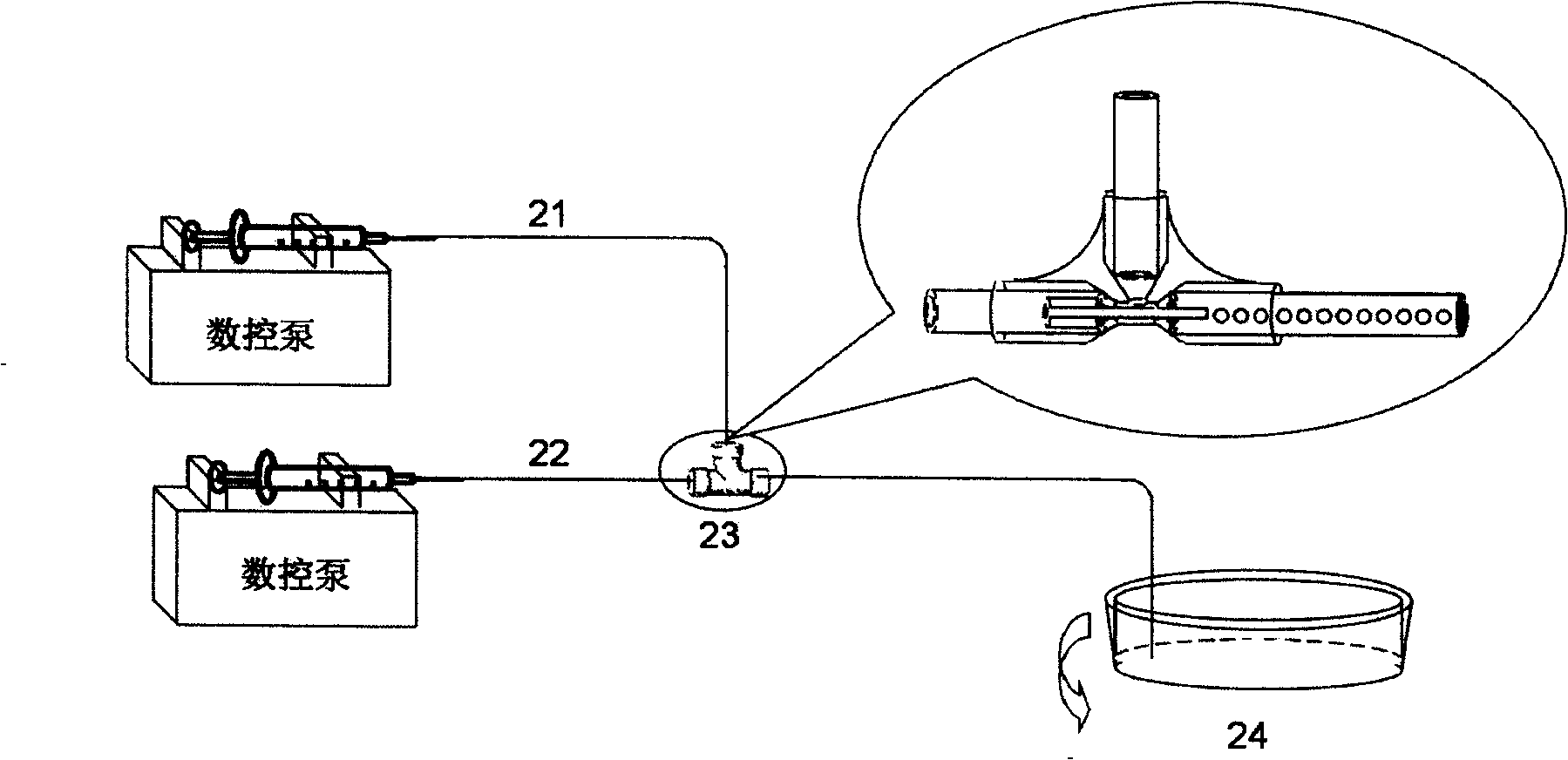

Preparation of microballoons based on microfluid

InactiveCN101279232ALow cost of preparationEasy integration and miniaturizationGranulation by liquid drop formationMicroballoon preparationMicrofluidic channelPolymer chemistry

Owner:NANJING DONGJIAN BIOLOGICAL TECH

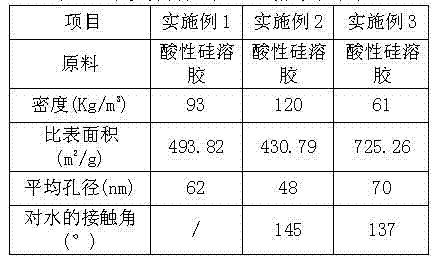

Method for preparing silicon dioxide aerogel by using acidic silica sol

ActiveCN102642842ALow cost of preparationSimple processSilicaBulk chemical productionSolventOrganosilicon

The invention discloses a method for preparing silicon dioxide aerogel by using acidic silica sol and belongs to the field of preparation of inorganic heat-insulating materials. The method comprises the following steps of: directly forming gel under actions of acid and alkali catalysts by using acidic silica sol as a raw material, wherein the process for preparing the gel does not involve organic solvent so as to improve the security of production; and preparing SiO2 aerogel through supercritical or constant pressure drying after the gel is subjected to solvent replacement and surface silylation. According to the method, the process for preparing the sol by using organic silicon as raw material and a complicated process for removing salt in water glass are avoided; and because the acidic silica sol with low cost and stable performance is used as the raw material, the method has the advantages that the process is simple, the production cycle is short, the reaction process is controlled, and the requirement and investment of the equipment are low, so that the industrial production of SiO2 aerogel can be realized.

Owner:纳诺科技有限公司

Preparation method of macroporous-mesoporous alumina

InactiveCN101863499ASimple processLow cost of preparationAluminium oxides/hydroxidesPetrochemicalAluminum Ion

The invention provides a preparation method of macroporous-mesoporous alumina, which comprises the following steps: a, dissolving reaction assistants and aluminum salts into solution of an organic solvent, wherein the molar ratio of the reaction assistants and aluminum ions is (3-5): 1, dissolving a template agent into the solution, wherein the molar ratio of the aluminum ions and the template agent is 1: (0.015-0.025), and finally controlling the PH value of the solution to be 3.5-6.0; b, aging the solution prepared in Step a to gradually remove the organic solvent and water in the system, thereby obtaining a macroporous-mesoporous alumina precursor; c, calcinating at the temperature of 400-800 DEG C, thereby obtaining macroporous-mesoporous alumina powder. The invention has the advantages of simple process, regular pore canals and centralized pore size distribution, and can realize controlled regulation according to specific application conditions. Therefore, the invention has significant value of application in heterogeneous catalysis and adsorptive separation in the petrochemical industry and the use as the catalyst carrier, energy material and the like.

Owner:CENT SOUTH UNIV

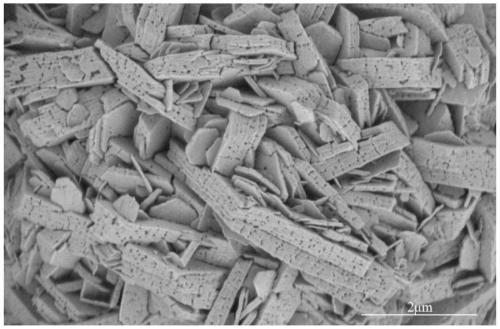

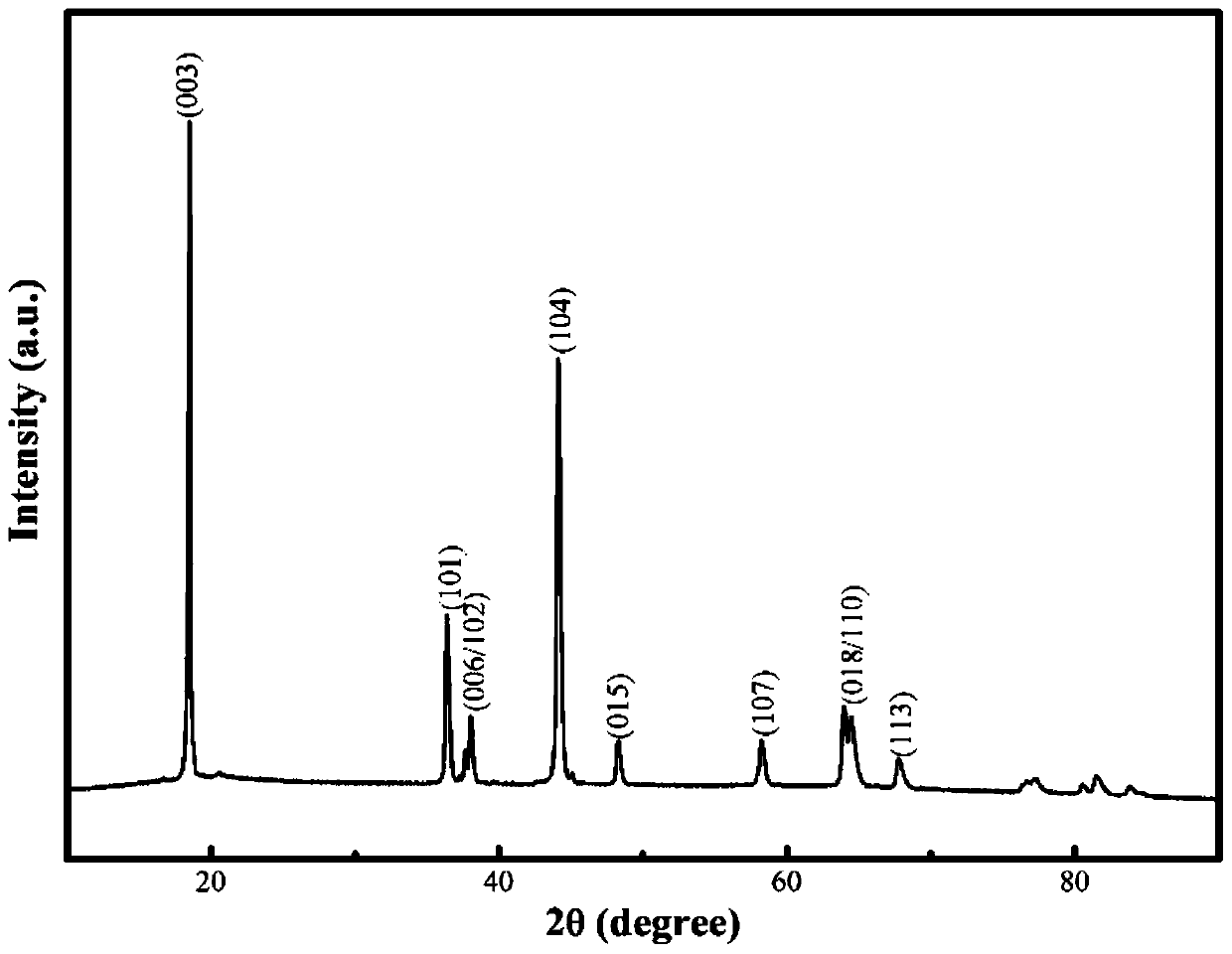

Single-crystal appearance layered nickel lithium manganate positive electrode material and preparation method thereof

ActiveCN109811412ALow cost of preparationReduce mixingPolycrystalline material growthCell electrodesOxideLithium electrode

The invention discloses a single-crystal appearance layered nickel lithium manganate positive electrode material and a preparation method thereof. The single-crystal appearance layered nickel lithiummanganate positive electrode material is prepared by the following preparation method with the steps of (1) performing preparation to obtain nickel manganese precursors by using nickel salts and manganese salts by a wet chemical method, wherein the mol ratio of the Ni to Mn is 1:1; (2) performing pre-sintering on the nickel manganese precursors to obtain the nickel manganese oxide precursors; (3)mixing the nickel manganese oxide precursors with Li source and M source additives; then, performing calcination to obtain the single-crystal appearance layered nickel lithium manganate positive electrode material. The advantage that the single crystal particle has the theory density is sufficiently achieved, so that the compaction density of an electrode plate made of positive electrode materialscan be improved, so that the volume energy density of a lithium ion battery is improved. The defects inside the single crystal particles can be greatly reduced; the structure stability of the positive electrode material in the charging and discharging process can be effectively improved, so that the service life of the lithium ion battery is prolonged.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

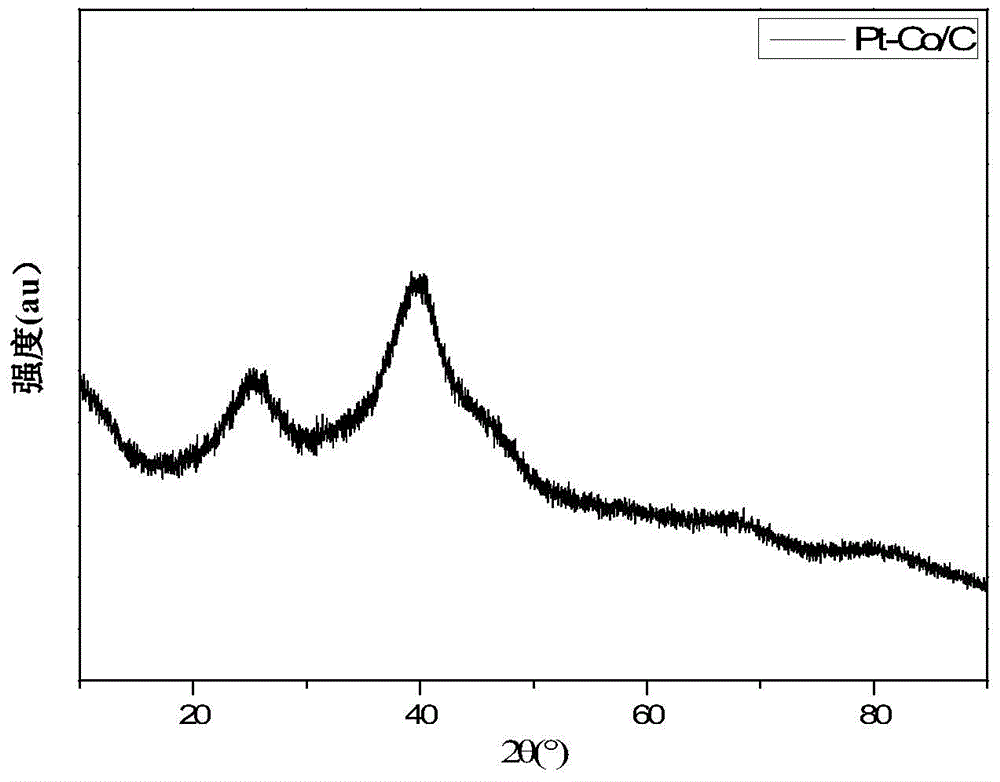

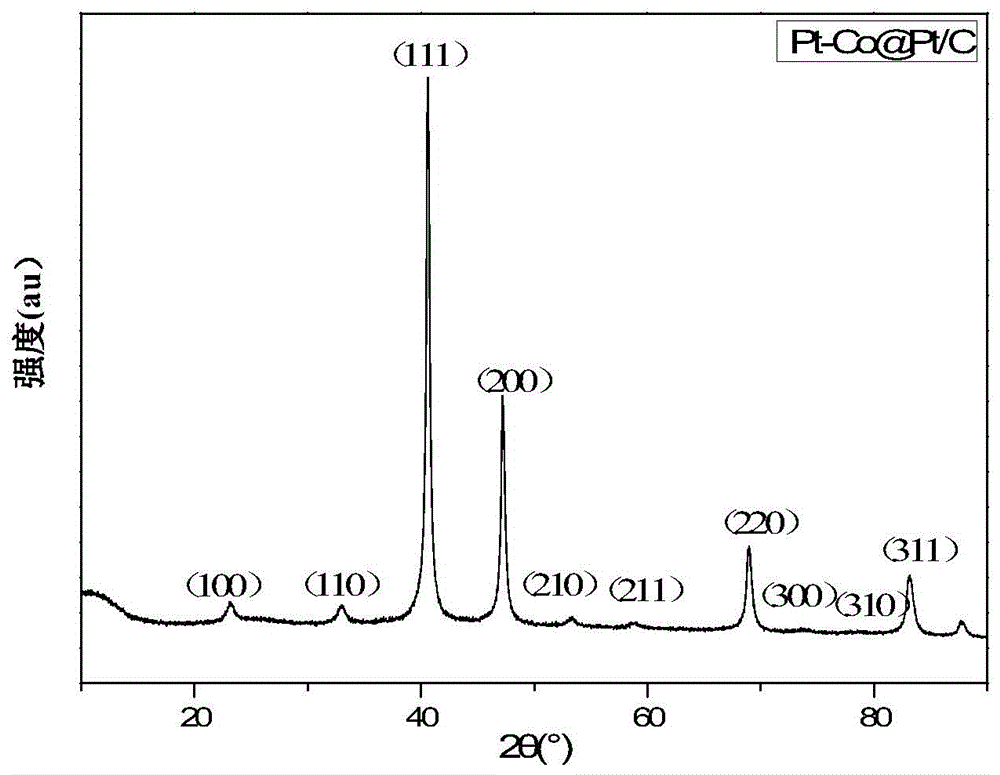

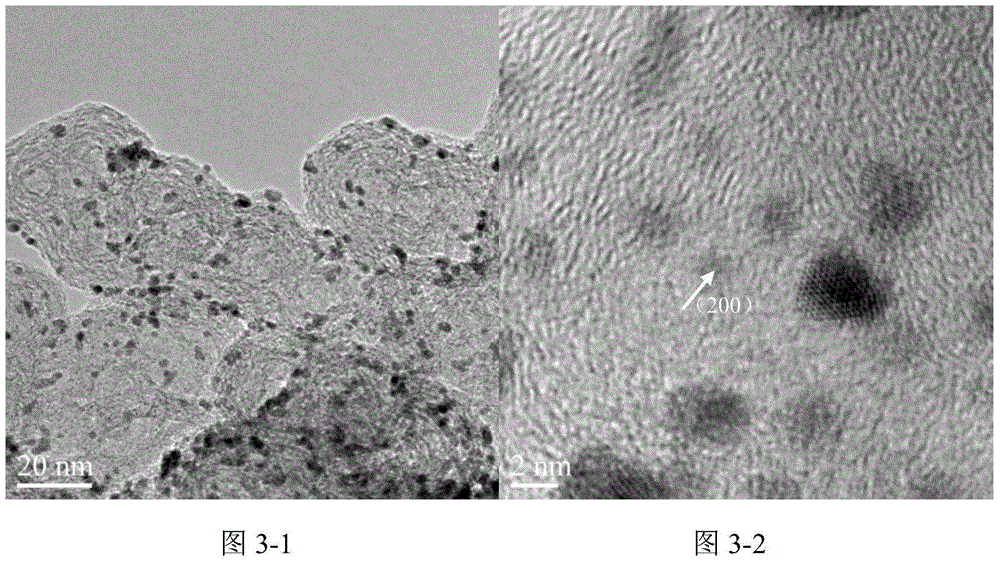

Carbon-supported core-shell type platinum cobalt-platinum catalyst for fuel cells and preparation method for carbon-supported core-shell type platinum cobalt-platinum catalyst

ActiveCN104475126AImprove utilization and stabilityLow cost of preparationCell electrodesMetal/metal-oxides/metal-hydroxide catalystsChemistryCarrying capacity

The invention relates to a carbon-supported core-shell type platinum cobalt-platinum catalyst for fuel cells and a preparation method for the carbon-supported core-shell type platinum cobalt-platinum catalyst, belonging to the field of electrochemistry. The catalyst comprises the following components in percentage by weight: 60%-90% of a carrier, 1%-20% of cobalt, and 9%-20% of platinum. According to the invention, a mixed solution of ethylene glycol and sodium borohydride acts as a reducing agent, the core-shell type platinum cobalt-platinum catalyst Pt-Co@Pt / C with an ordered structure is prepared by high-temperature annealing treatment. The catalyst with the ordered structure, which is prepared by the invention, has the advantages of low Pt carrying capacity, high catalysis activity, high stability and the like, and the development of fuel cells can be promoted further.

Owner:BEIJING UNIV OF CHEM TECH

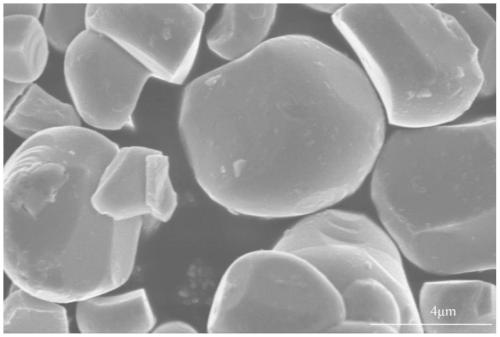

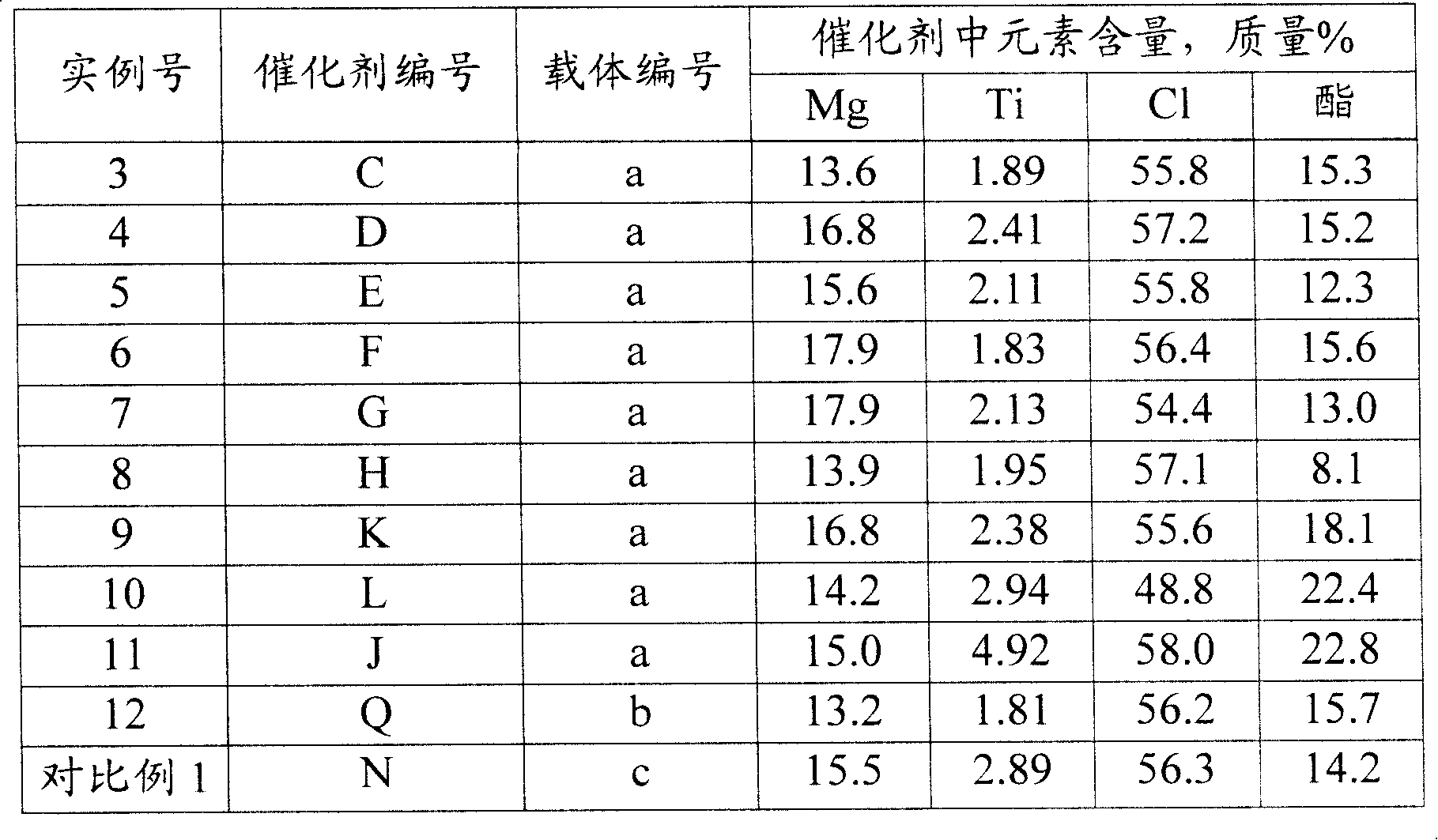

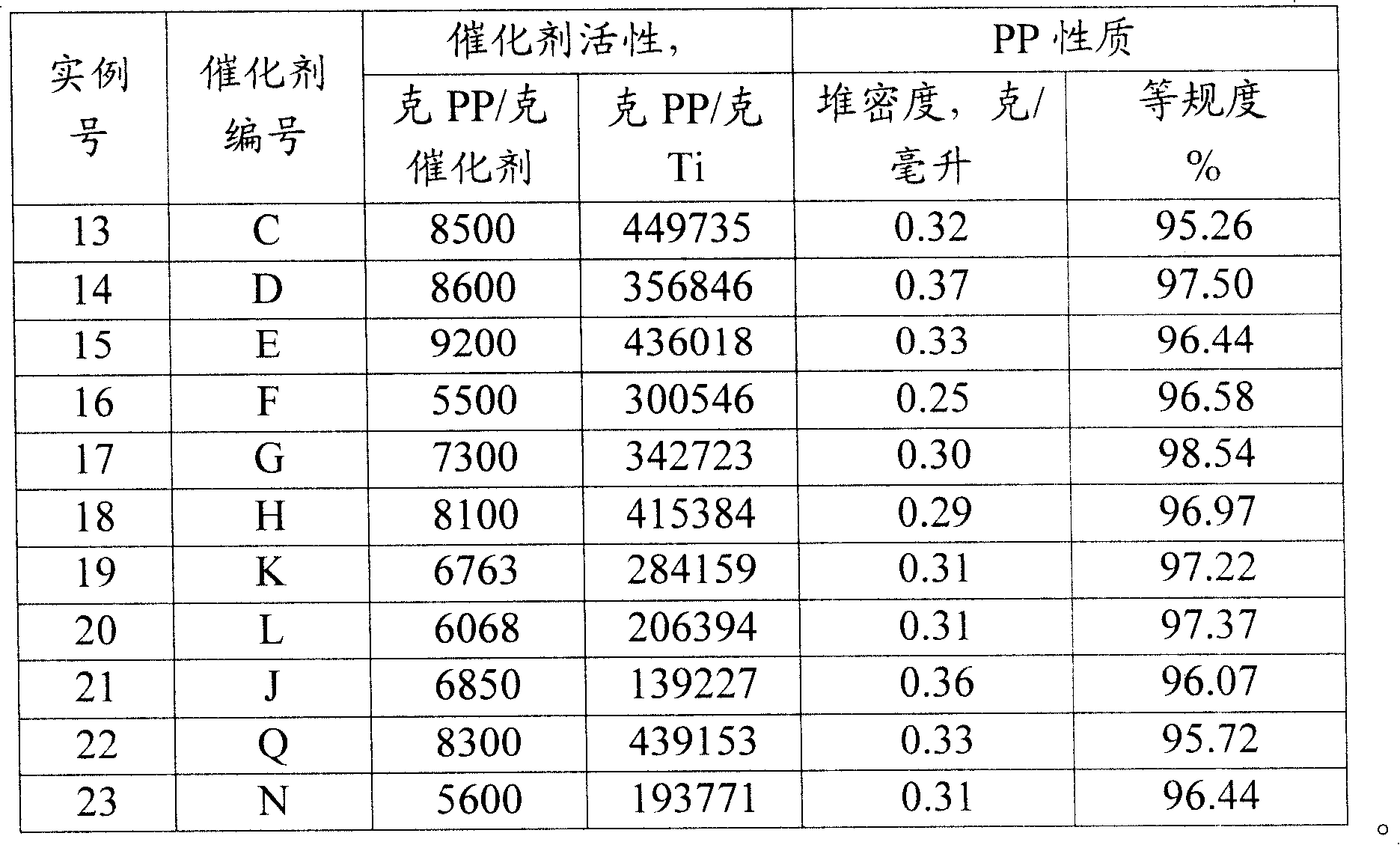

Process for preparing catalyst solid component of olefin polymerization

The invention relates to a preparation of olefin polymerization catalyst solid constituent, and comprises the steps: magniferous composition with general formula C l Mg (OR) . n (ROH) reacts with electron donor compound and tetrahalogen titanium respectively in the presence of unreactive hydrocarbons; solid is collected, washed and dried. R in the general formula is selected from C1-C5 alkyl while n is 0.1-1.0. The method has simple preparation; the produced catalyst solid constituent is used for propylene polymerization and has relatively high activity and tacticity.

Owner:CHINA PETROLEUM & CHEM CORP +1

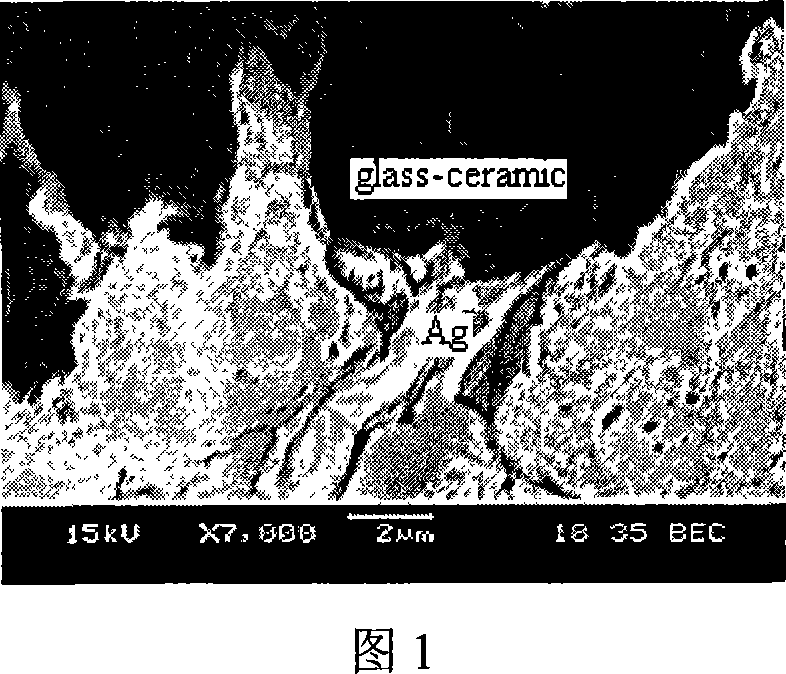

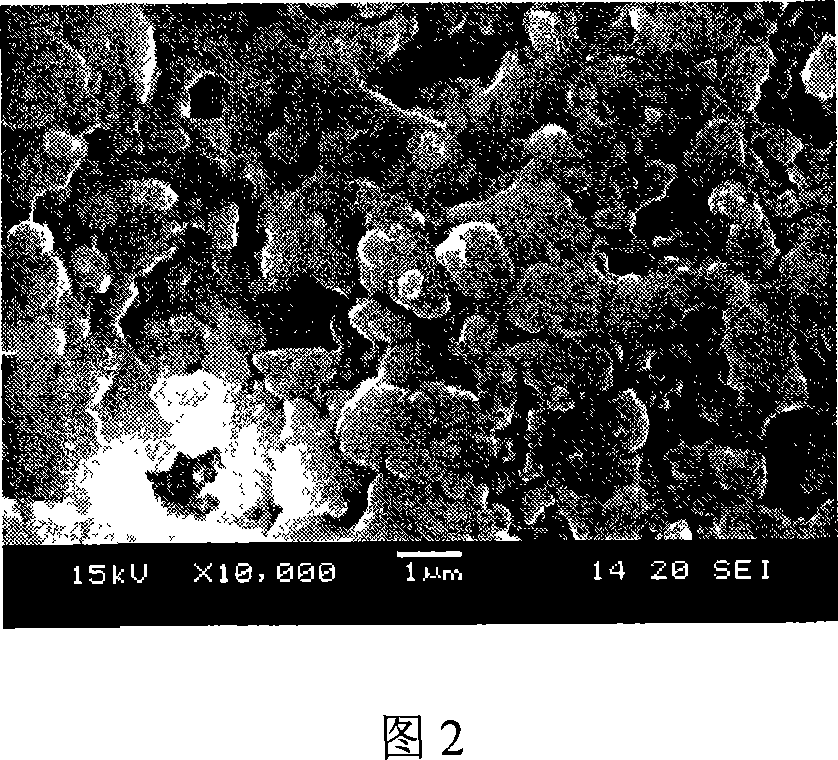

High-frequency low-loss low-temperature co-burning ceramic raw material tape and preparation method thereof

The present invention relates to one kind of high frequency and low loss green ceramic material belt and its preparation process. The green ceramic material belt consists of inorganic glass ceramic material and organic flow casting system. The inorganic glass ceramic material consists of heterogenous Ca-Si-B and borosilicate glass ceramic and nucleating agent; and the organic flow casting system consists of solvent, dispersant, adhesive, plasticizer and defoaming agent. The 127 micron LTCC green ceramic material belt of the present invention is flat and smooth, has smallest winding radius without cracking of 15 mm, and may be sintered at about 850 deg.c to obtain sintered ceramic with excellent dielectric performance, including dielectric constant of 5-7 and dielectric loss lower than 0.002 at 10 GHz.

Owner:南京扬子工大科技有限公司

Polyvinyl wood-plastic composite and method for preparing same

InactiveCN101747641ALow cost of preparationBroad application prospectsPre treatmentPolyvinyl polymer

The invention discloses polyvinyl wood-plastic composite which comprises the following components: 100 portions of wood fiber powder, 1-3 portions of stearic acid, 20-30 portions of waste polyethylene plastic, 3-6 portions of coupling agent, 4-10 portions of lubricant, 0.1-1 portion of ultraviolet resistant agent and 1-3 portions of coloring agent. The surface of the wood fiber powder is preliminarily modified by the stearic acid so that a dense hydrophobic thin film is formed on the surface of wood fiber to ensure that the wood fiber is more compatible with the polyethylene polymer, the dispersion of the wood fiber in the polyethylene polymer is promoted, the polyvinyl wood-plastic composite has excellent comprehensive performance and good processing performance, and the product made from the polyvinyl wood-plastic composite is superior to the domestic similar product in appearance quality and physiochemical performance. In addition, the formula of the polyvinyl wood-plastic composite is more environmental-friendly than the prior art, the cost spent in preparing the polyvinyl wood-plastic composite is lower, and the polyvinyl wood-plastic composite is suitable for industrial production, meets the market demand and has broad application prospect.

Owner:SHANGHAI BESTON PLASTICS

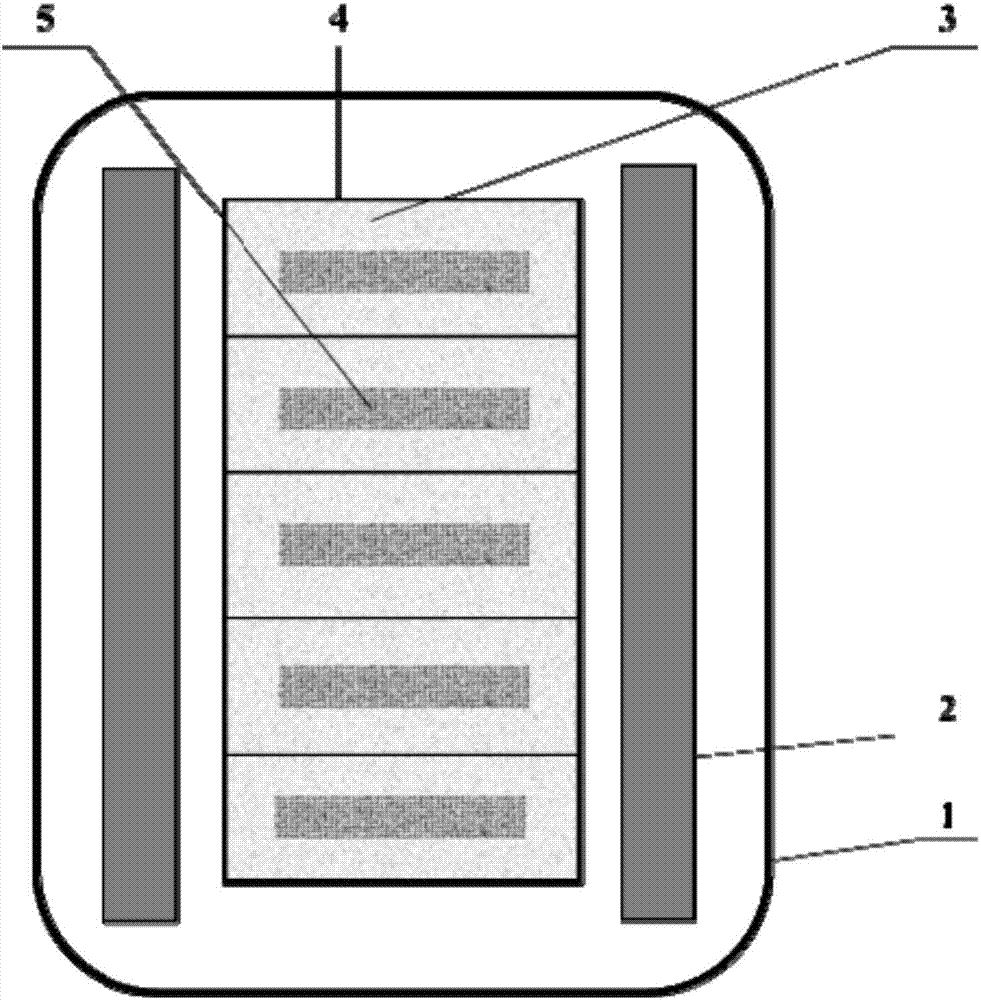

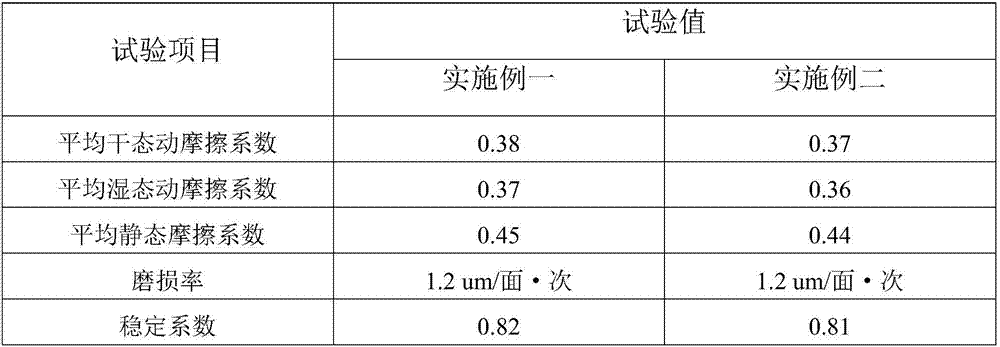

High performance and low cost C/C-SiC composite brake disc, preparation method and application thereof

ActiveCN106966751ALow priceLow cost of preparationBraking discsActuatorsMolten siliconThermal conductivity

The invention relates to a high performance and low cost C / C-SiC composite brake disc, a preparation method and application thereof. The preparation method includes: carbonizing a brake disc prefab, and densifying the carbonized brake disc prefab by chemical vapor infiltration method to obtain a C / C composite material; then performing heat treatment in an inert atmosphere to improve the graphitization degree of the composite material; then conducting machining to obtain a C / C composite blank; treating the C / C composite blank by molten silicon infiltration method to obtain a C / C-SiC composite brake disc; then treating the C / C-SiC composite brake disc by means of chemical vapor infiltration or precursor infiltration pyrolysis; and machining the obtained product into a final design size, thus obtaining a composite brake disc finished product. The C / C-SiC composite brake disc and the preparation method thereof provided by the invention can reduce the preparation cost and improve the mechanical performance, thermal conductivity and friction and wear performance of the brake disc.

Owner:BEIHANG UNIV

Porous biological ceramsite prepared from waste incineration fly ash and biomass pyrolysis gasification residue, and preparation method thereof

InactiveCN105712733ALow cost of preparationGood economic benefitsCeramicwareBiomassTemperature treatment

The invention discloses a method used for producing porous biological ceramsite by taking waste incineration fly ash and biomass pyrolysis-gasification residue as raw materials. The method comprises following steps: household garbage incineration fly ash is subjected to high temperature treatment in the presence of a gasification agent so as to obtain residual ash; biomass is subjected to low temperature pyrolysis-high temperature steam gasification so as to obtain a pyrolytic residue; the residual ash, the pyrolytic residue, flyash, clay, and a pore-forming agent are subjected to mixing, pelleting, drying, and high temperature roasting so as to obtain the porous biological ceramsite product. Technology of the method is simple; operation is convenient; harmlessness treatment of fly ash and biomass pyrolysis gasification residue can be realized; the porous biological ceramsite product is prepared from waste incineration fly ash and biomass pyrolysis residue; quantity demand of ceramsite industrial on natural raw materials is reduced; and environment-protection value and economic value are both high.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

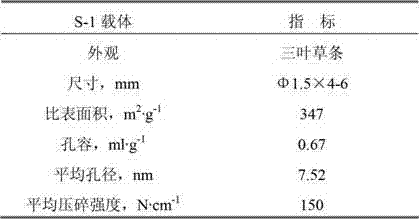

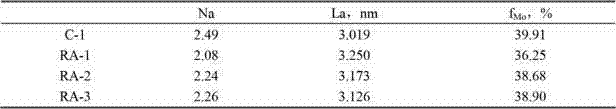

Hydro-fining catalyst roasted at low temperature and preparation method thereof

InactiveCN102784656AImprove activity and stabilityLow cost of preparationPhysical/chemical process catalystsRefining to eliminate hetero atomsOxideFluid catalytic cracking

The invention discloses a hydro-fining catalyst roasted at a low temperature and a preparation method thereof. The preparation method comprises the following steps of: taking aluminum hydroxide dry glue or modified aluminum hydroxide dry glue as a raw material to prepare a catalyst carrier, then impregnating metal active components in VIB and VIII groups and preparing the hydro-fining catalyst through drying and roasting. The content of an alumina carrier is 60-90 weight percent, the content of metallic oxide in the VIB group is 5-35 weight percent, and the content of metallic oxide in the VIII group is 1-10 weight percent. An activity phase of the catalyst has proper stacking layer number and film crystal length, the interaction between the carrier and metal is reduced, the better dispersion state of the active components can be kept, and the HDS (Hydro-desulfurization) ability of sulfide difficult to remove in an oil product is improved. The hydro-fining catalyst is particularly suitable for the hydro-desulfurization of naphtha, the hydro-fining of inferior diesel oil and the hydro-treatment of FCC (Fluid Catalytic Cracking) raw materials or hydro-cracking raw materials and other distillate oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Regular structure adsorbent and application thereof

ActiveCN106669636AThe preparation process is simpleLow cost of preparationOther chemical processesDispersed particle separationSolventChemistry

The invention discloses a regular structure adsorbent and a preparation method to greatly improve the diffusion efficiency of the adsorbent. The regular structure adsorbent is prepared from a support, an adsorbent material, a binder and other additives. The fibrous support, the powdery adsorbent material, the binder and other additives are mixed and dispersed in a solvent, a catalyst precursor is prepared firstly and then dried and activated to form the adsorbent. The regular structure adsorbent is applicable to purification separation processes of multiple gases, such as air separation, hydrogen separation, carbon dioxide separation, methane separation and the like, and the synthesis method is simple, good in repeatability and prone to industrialization.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

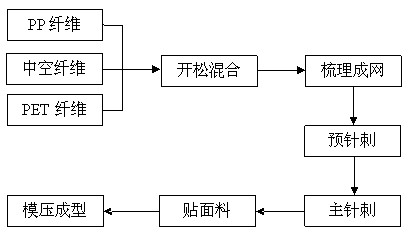

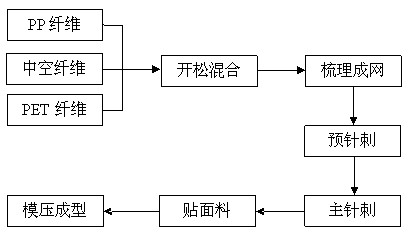

Heat-insulating and noise-reducing nonwoven composite material for automobile interior trim and preparation method thereof

ActiveCN102166864AImprove insulation performanceLow cost of preparationSynthetic resin layered productsLaminationHollow fibrePolypropylene

The invention discloses a heat-insulating and noise-reducing nonwoven composite material for automobile interior trim and a preparation method thereof. The composite material is prepared from certain proportions of PP (polypropylene) fiber, PET (polyester) fiber and hollow PET fiber, the mixed fiber is prepared into a composite felt by a certain acupuncture process, and an appropriate die pressing process is adopted to prepare a composite fiber felt. The composite material disclosed by the invention keeps lower surface density, good bending performance and good dimensional stability, can also meet the functional requirements for heat insulation and sound insulation, and can be used for preparing medium and high-grade automobile interior trim materials.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Preparation method for biomass medicinal charcoal

The invention discloses a preparation method for biomass medicinal charcoal, which belongs to the technical field of processing and preparation of activated charcoal, and aims to reduce ash content in activated charcoal and to improve adsorption performance of the activated charcoal. The method comprises the following steps: crushing biomass and screening the biomass with a 20 to 200 mesh sieve; carrying out pickling and alkali washing on the biomass after screening and removal of impurities; drying the biomass; sending the raw material of the treated biomass to an activation furnace, heating the raw material to a temperature of 300 to 600 DEG C under the protection of nitrogen and carrying out carbonization for 30 to 240 minutes; allowing carbon dioxide to enter into the activation furnace at a temperature of 800 to 1000 DEG C, carrying out carbonization for 30 to 360 minutes, with gas flow being 10 to 300 L / h, and after carbonization, cooling the biomass to room temperature so as to obtain the biomass medicinal charcoal. Ash content, decolouring capacity and adsorption quantity of the prepared biomass medicinal charcoal are all superior to those of wooden activated charcoal; the biomass medicinal charcoal has the advantages of a simple operation process, low cost, suitability for large scale production and strong market competitiveness.

Owner:QINGDAO UNIV OF SCI & TECH

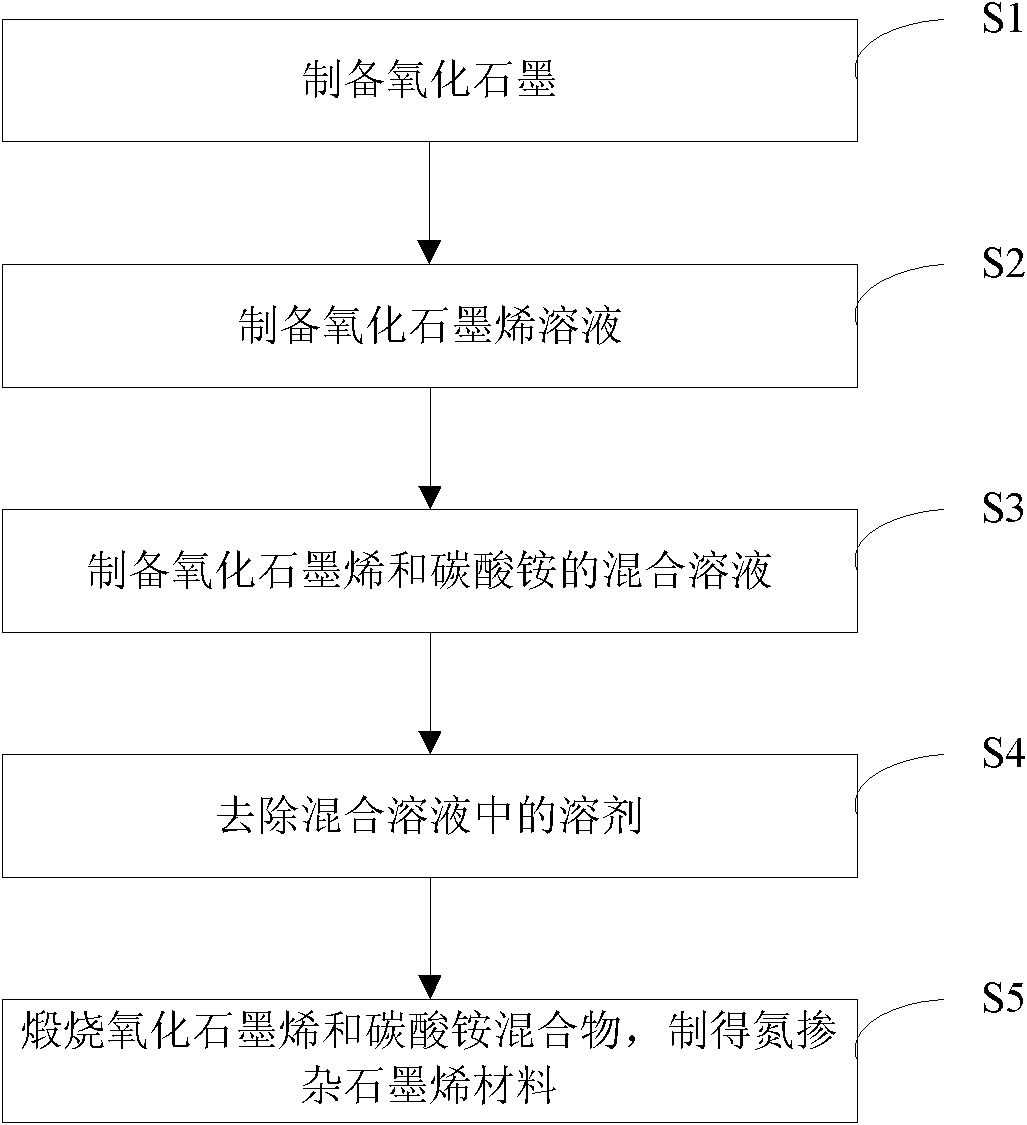

Nitrogen doped graphene material and preparation method thereof

The invention belongs to the field of electrochemical materials and discloses a nitrogen doped graphene material and a preparation method thereof. The preparation method of the nitrogen doped graphene material comprises the following steps of: preparing graphite oxidize; preparing graphene oxide solution; preparing mixed solution of graphene oxide and ammonium carbonate; removing solvent in the mixed solution of the graphene oxide and ammonium carbonate; and calcining mixture of graphite oxide and ammonium carbonate, thus obtaining the nitrogen doped graphene oxide material. The nitrogen doped graphene material and preparation method thereof which are disclosed by the invention have the advantages that preparation cost is lower, mass production is easy to realize, product purity is high, ammonium carbonate is completely decomposed into gas at high temperature and no pollution is produced to a product.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

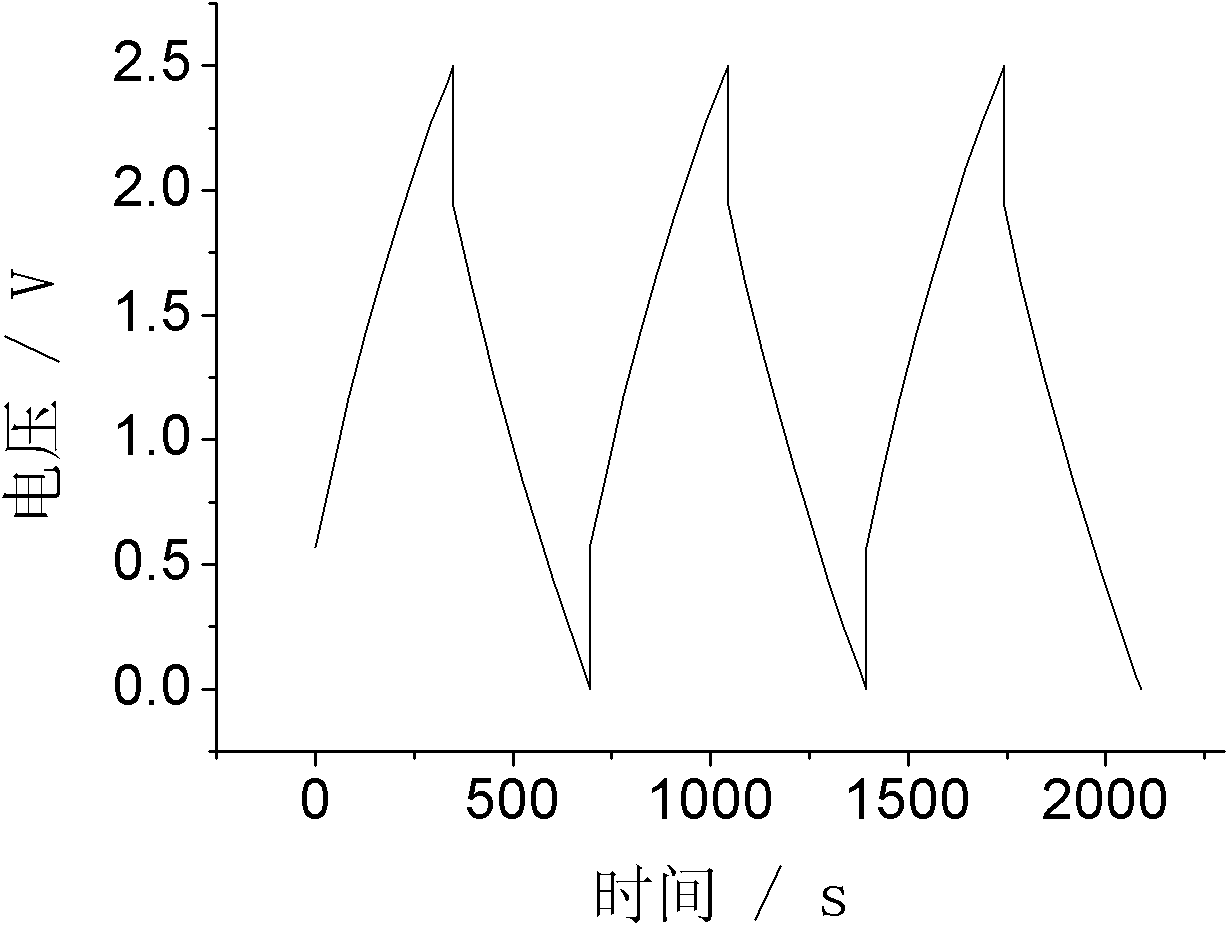

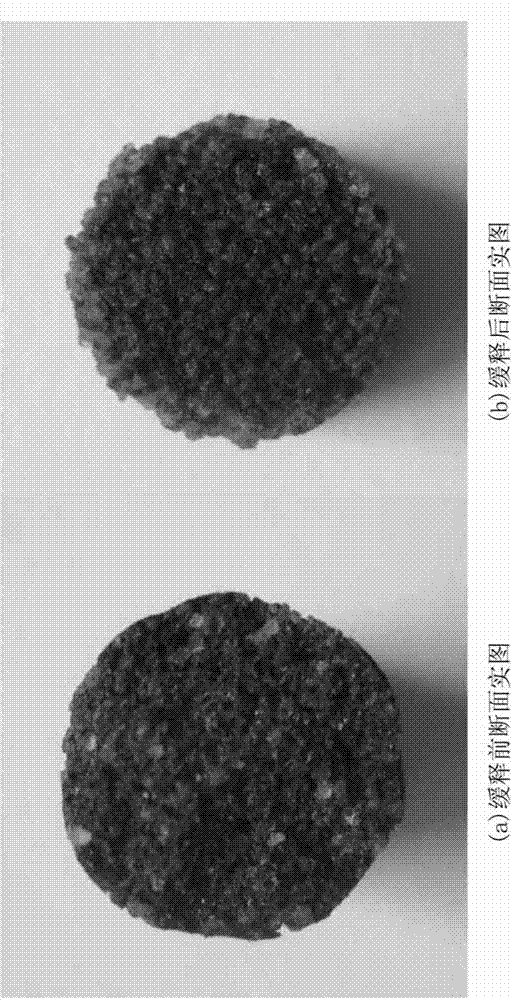

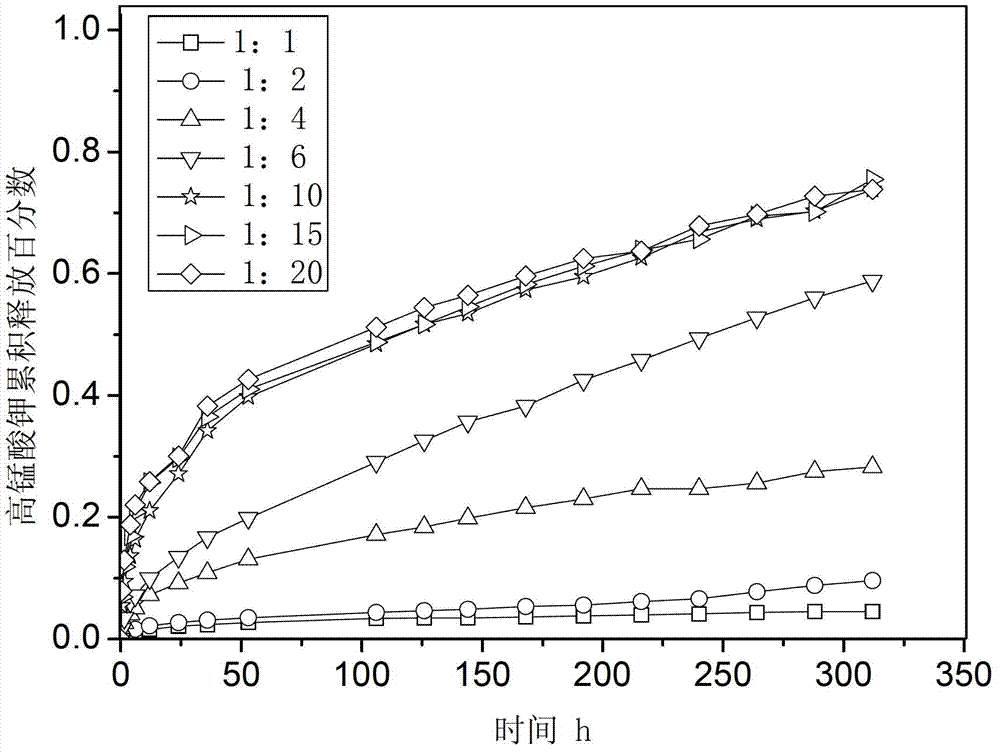

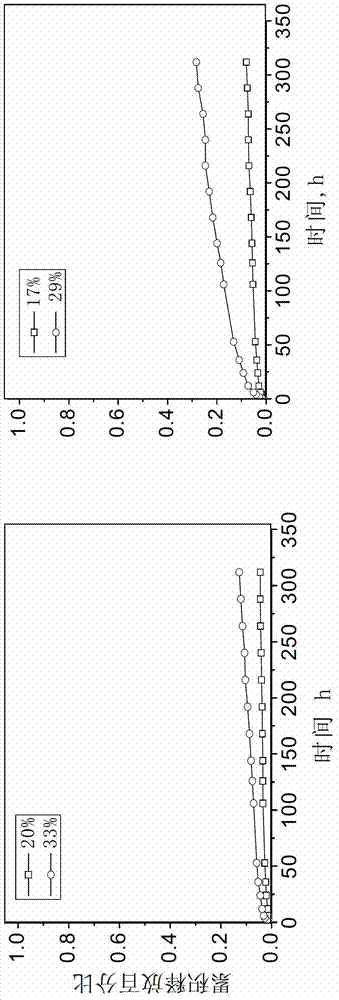

Preparation method of composite potassium permanganate sustained-release agent

InactiveCN102897891ASimple preparation processLow cost of preparationWater/sewage treatment by oxidationParaffin waxChemistry

The invention discloses a preparation method of a composite potassium permanganate sustained-release agent. According to the invention, paraffin is added into a vessel and is heated, until paraffin is completely molten; silica sand is added into paraffin, and the mixture is well mixed by stirring; when silica sand is completely infiltrated by paraffin, potassium permanganate powder is added, and the mixture is well mixed by stirring; when still hot, the mixture is rapidly poured into a mold, and is tamped; and the mixture is cooled and molded, such that composite potassium permanganate sustained-release systems with different sustained-release times can be prepared. The method provided by the invention aims at solving problems of low oxidant utilization rate, large non-selective consumption, oxidizing agent mass transfer and the like in processes of underground water pollutant removing through liquid and powdery potassium permanganate in-situ chemical oxidation. Therefore, oxidant sustained-release, effective transferring, and high-efficiency oxidation are realized.

Owner:HUAQIAO UNIVERSITY

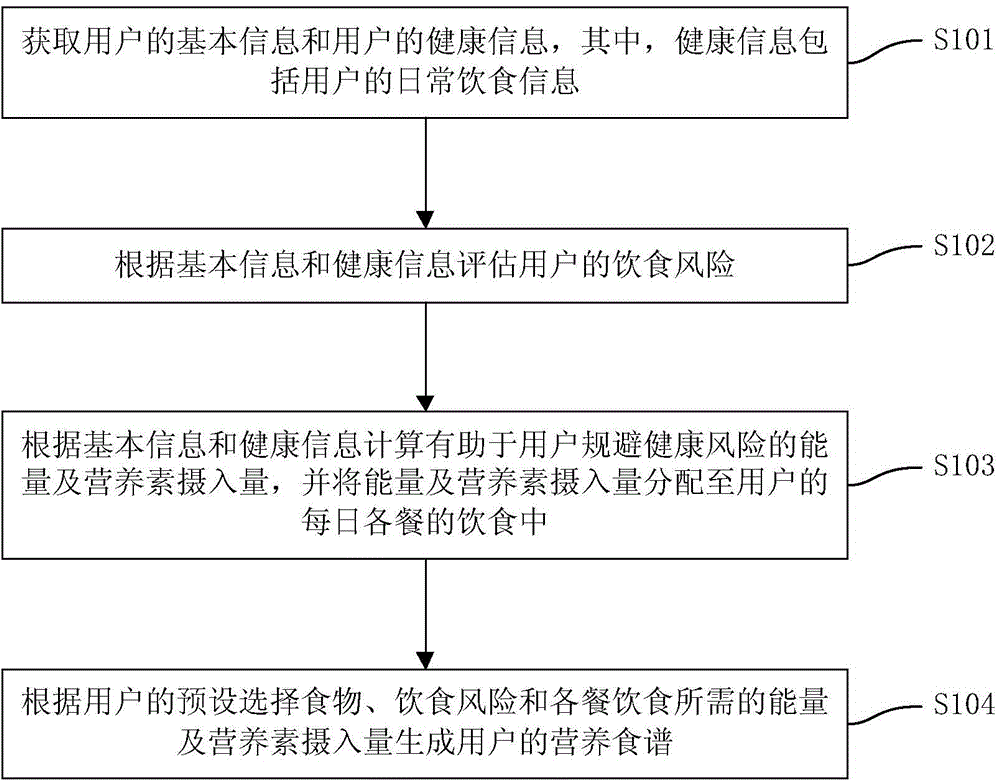

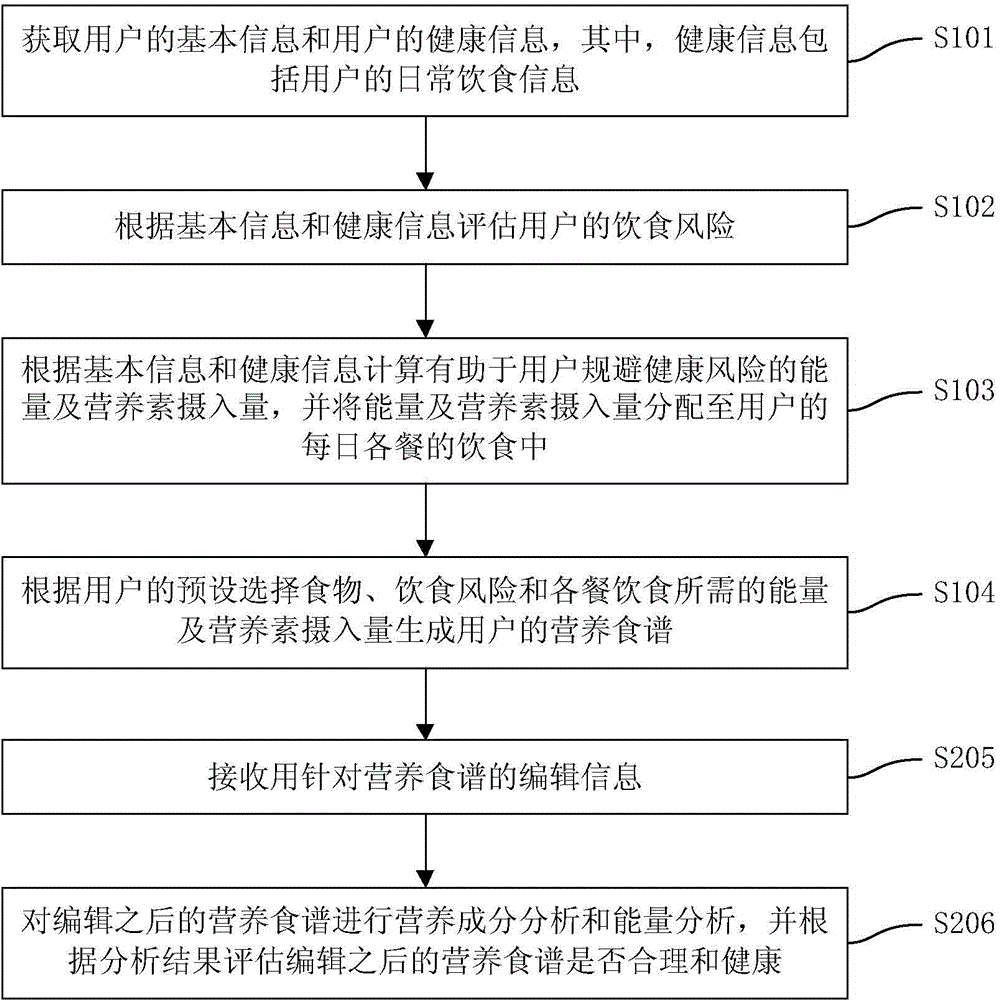

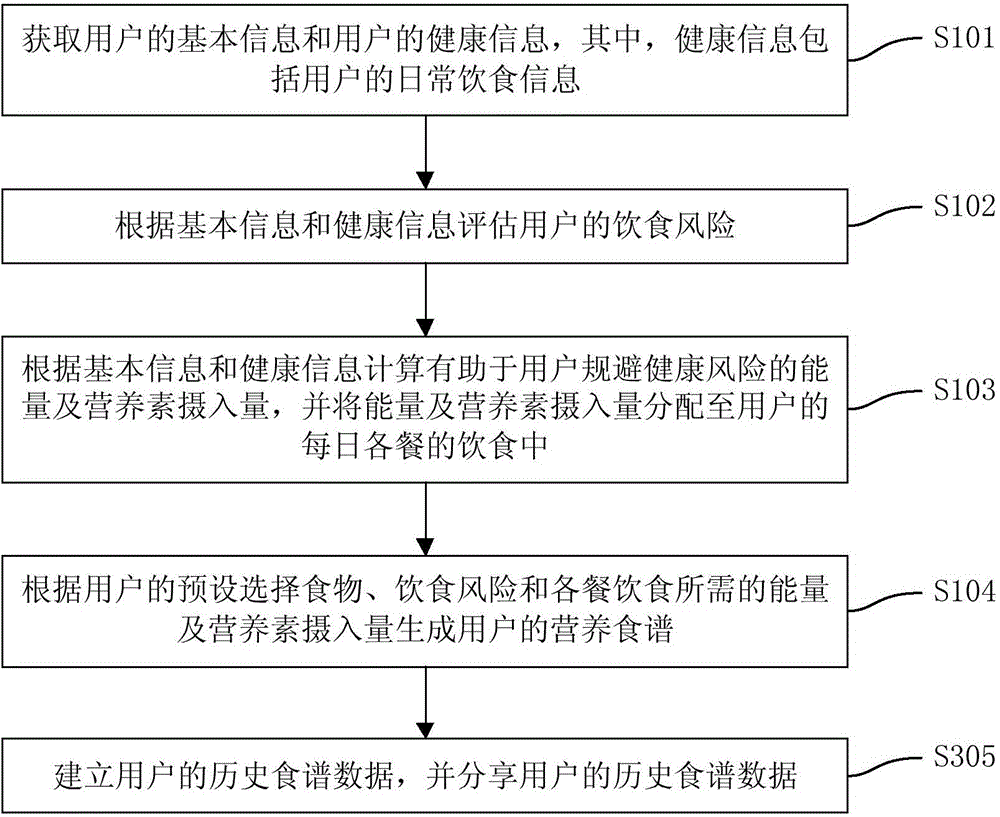

Nutritious recipe generation method and device

InactiveCN105718712AHigh acceptanceLow cost of preparationSpecial data processing applicationsHealth riskThe Internet

The invention discloses a nutritious recipe generation method and device. The method comprises the following steps of acquiring basic information and health information of a user, wherein the health information comprises dietary information of the user; evaluating dietary risk of the user according to the basic information and the health information; calculating energy and nutrient intake quantity which is beneficial for preventing health risk according to the basic information and the health information, and allocating the energy and nutrient intake quantity to diet of each daily meal of the user; and generating a nutritious recipe of the user according to preset selection food, the dietary risk and the energy and nutrient intake quantity required for each meal of the user. By the method, the nutritious recipe conforming to the user can be recommended to the user, and the acceptance degree of the user for the recipe is improved; and moreover, since the generation of the nutritious recipe is dependent on a computer and internet big data technique, the compiling cost of the recipe conforming to the user is greatly reduced.

Owner:MIDEA GRP CO LTD

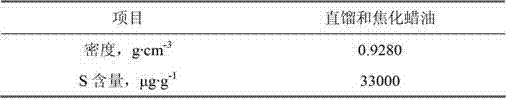

Thermal conductive transformer oil containing nanometer aluminum oxide

The invention relates to transformer oil. The transformer oil comprises base oil and 0.01-0.05wt% of modified nanometer aluminum oxide measured on the basis of the base oil. The base oil comprises 60-70wt% of refined vegetable oil and 30-40wt% of straight-chain alkanes, wherein the straight-chain alkanes are obtained by deep hydrogenation of the vegetable oil. The transformer oil disclosed by the invention solves the problems of worse thermal conductivity and poor oxidation resistance of transformer oil prepared from vegetable oil. By introducing straight-chain alkanes obtained by deep hydrogenation of vegetable oil, the nanometer materials in the transformer oil disclosed by the invention have better dispersion stability and the oxidation resistance of the transformer oil is also further improved.

Owner:JIANGSU HUASHENG ELECTRICAL CO LTD

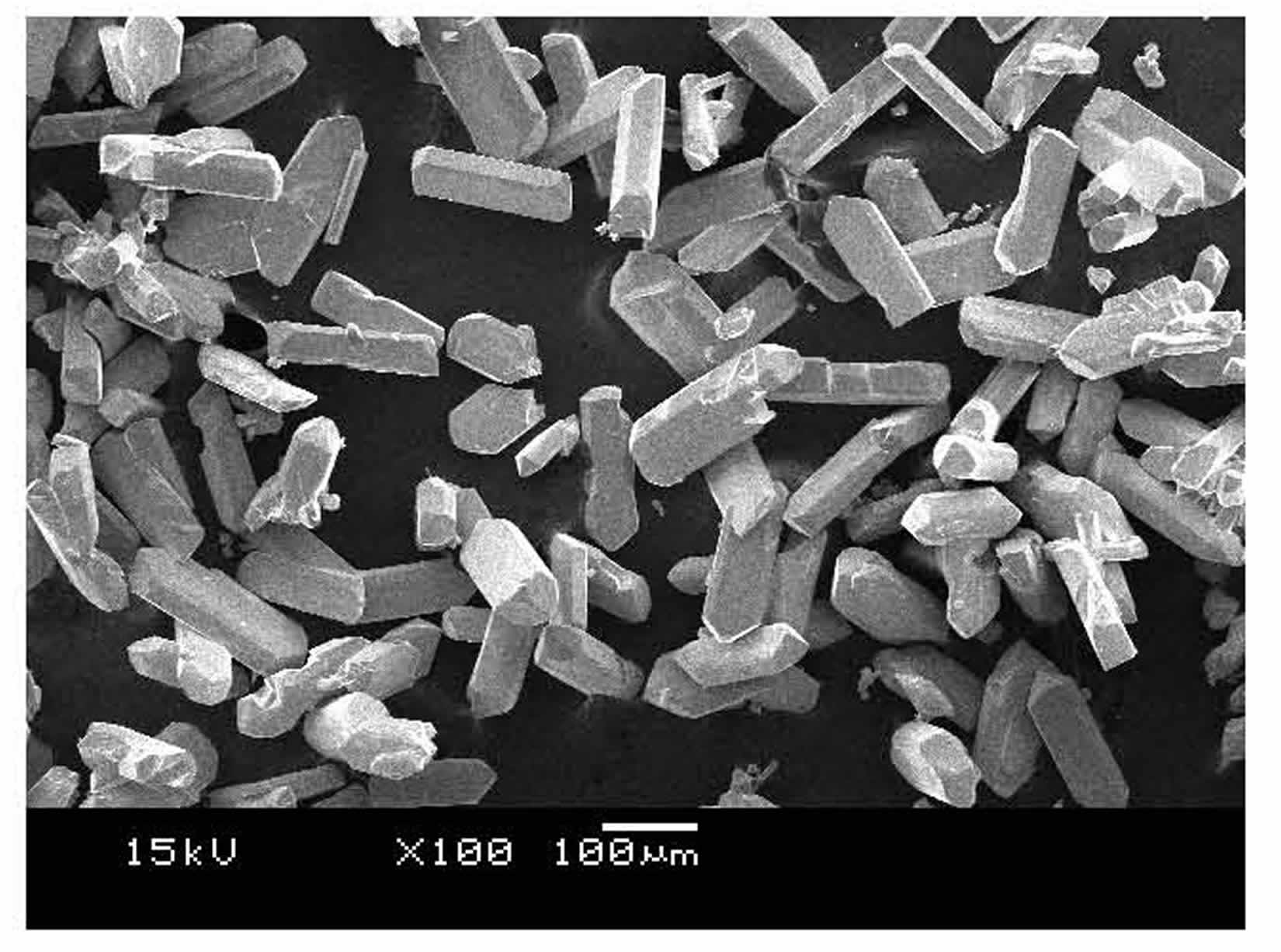

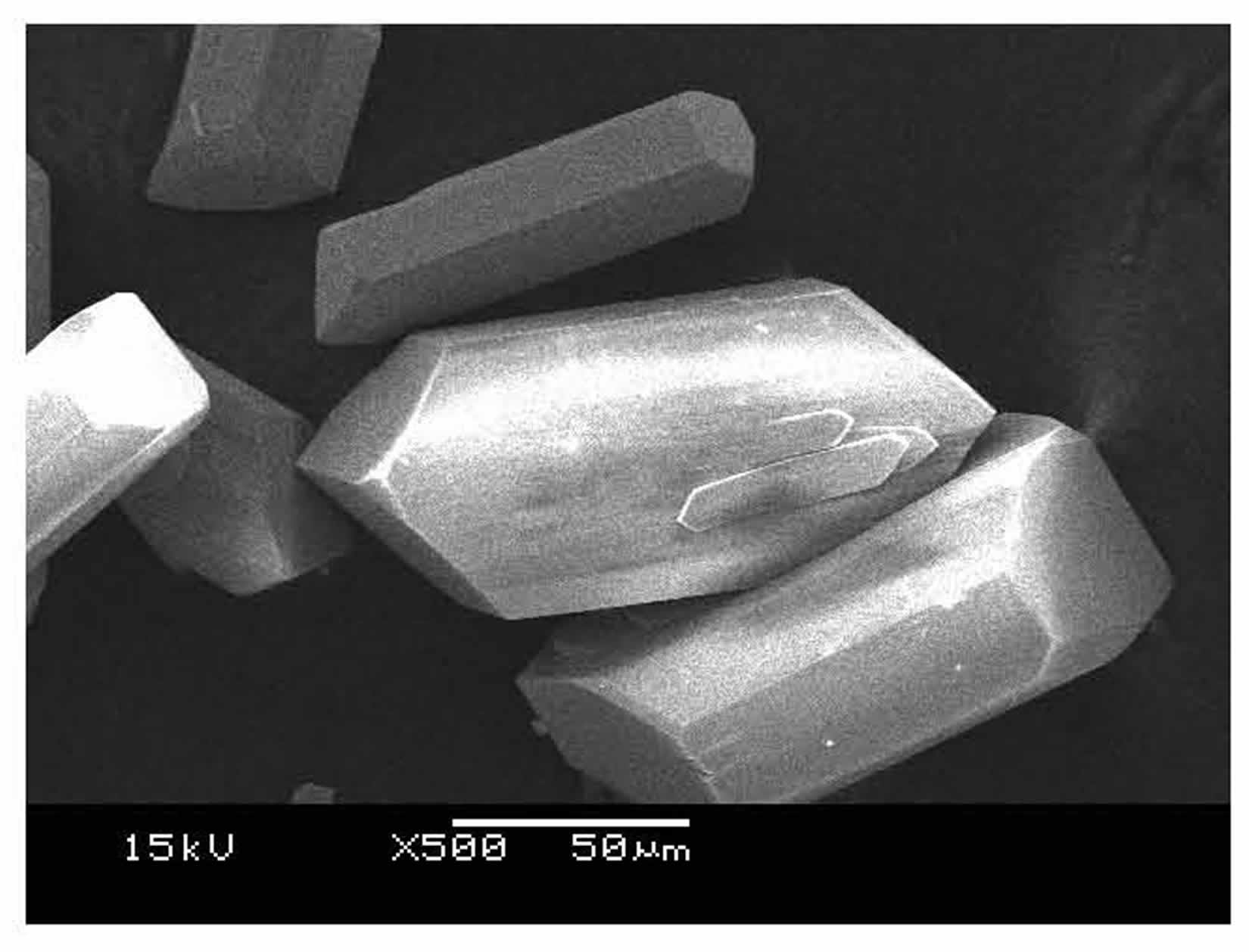

Preparation method of manganese molybdate microcrystal

InactiveCN102616857ASimple process routeLow cost of preparationManganese compoundsManganous chlorideSodium molybdate

The invention which belongs to the inorganic non-metallic material preparation field especially relates to a preparation method of a manganese molybdate (W-MnMnO4) microcrystal. The method comprises the following steps: mixing a soluble manganese salt and sodium molybdate which are treated as raw materials according to a certain molar ratio, carrying out stirring reacting for 5-30min at 20-50DEG C, and carrying out a hydrothermal reaction for 6-48h at 160-230DEG C; and naturally cooling to room temperature after finishing the hydrothermal reaction, filtering, washing, and drying to obtain the manganese molybdate microcrystal. The soluble divalent manganese salt of the invention is a mixture of above one or above two of manganese chloride, manganese nitrate and manganese acetate. The preparation method has the advantages of simple and easily implemented process, high purity, low impurity content, good dispersibility, and low cost; and the diameter and the length of the obtained product are 10-50mum and 100-300mum respectively. The manganese molybdate microcrystal prepared in the invention can be widely applied to the electronic and electrical field, the mechanical field, the chemical engineering field, the building field and the like, and is an excellent predecessor for preparing other manganese salt functional materials.

Owner:BOHAI UNIV

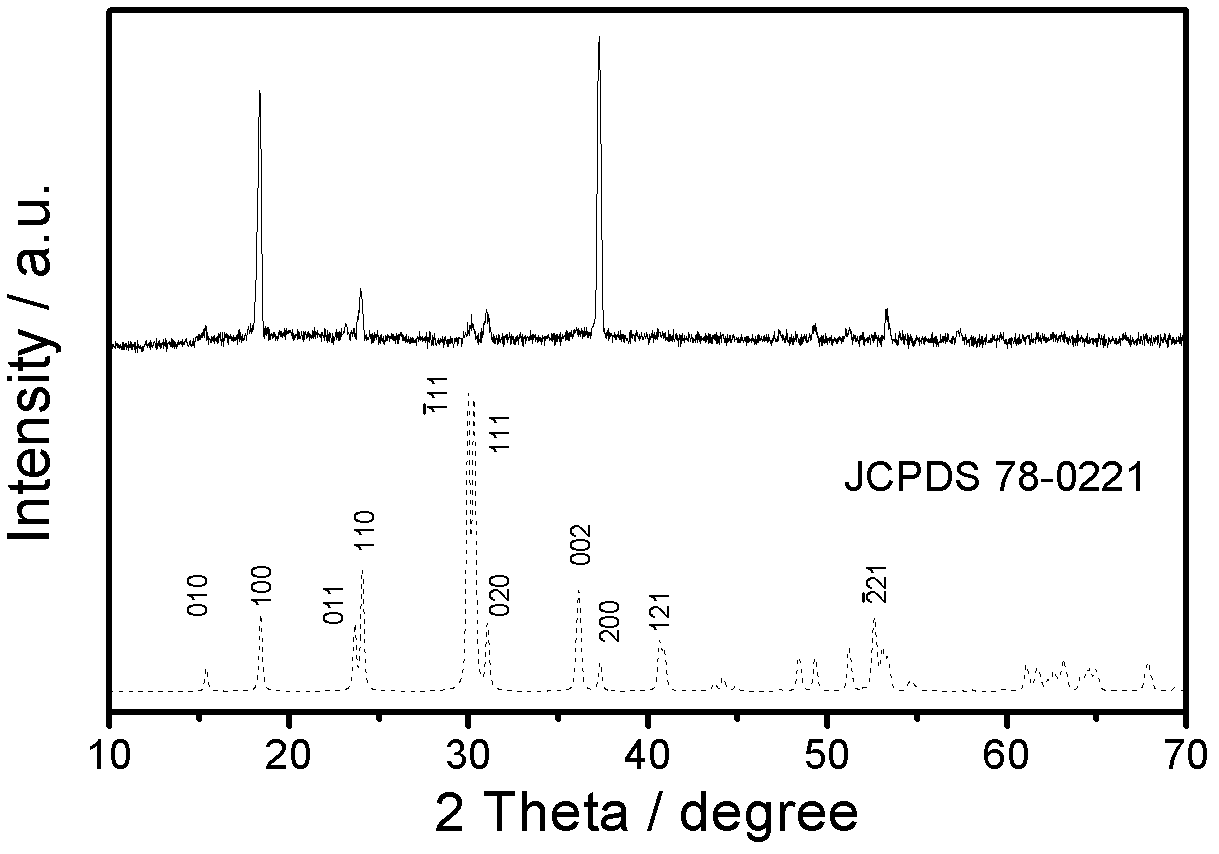

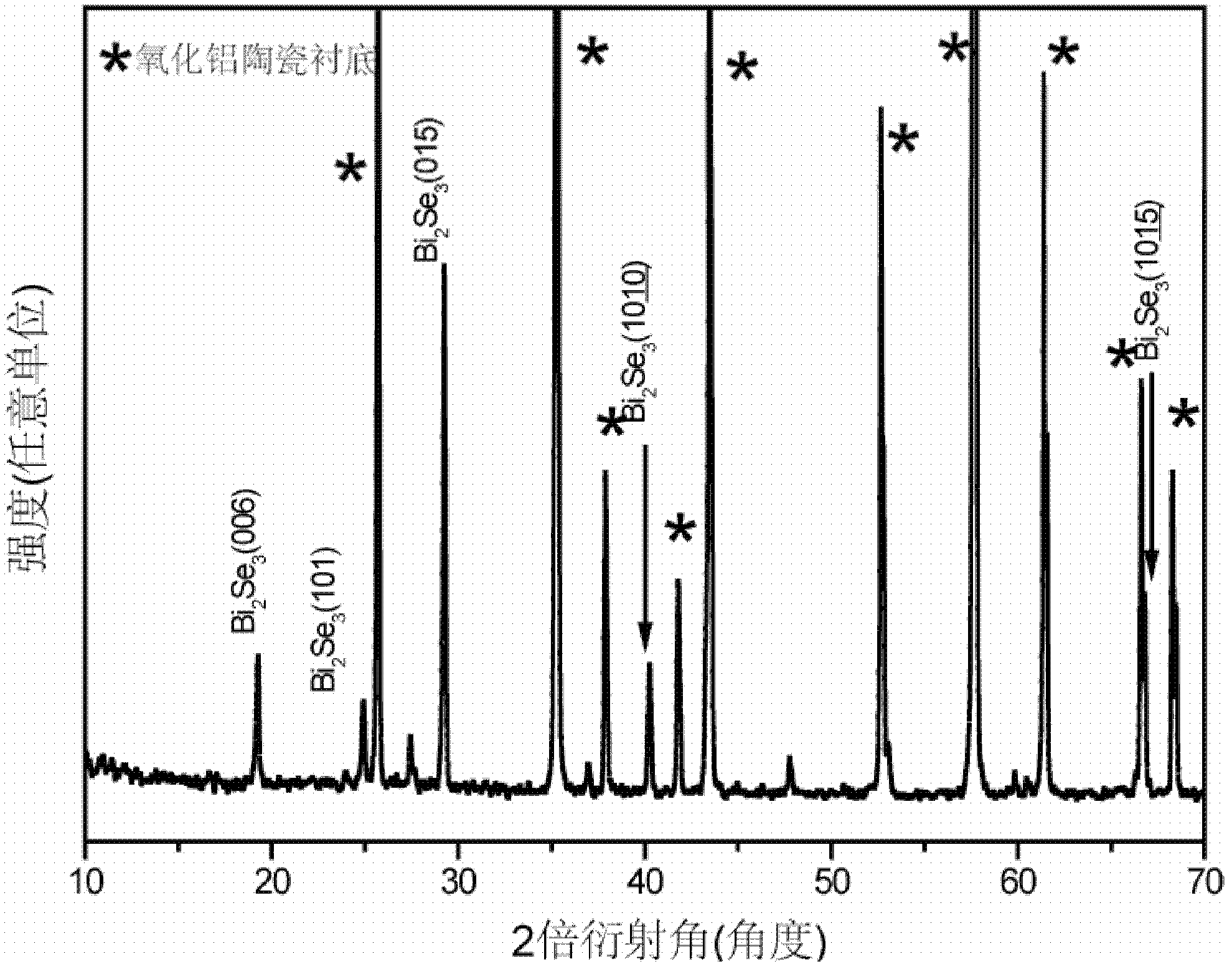

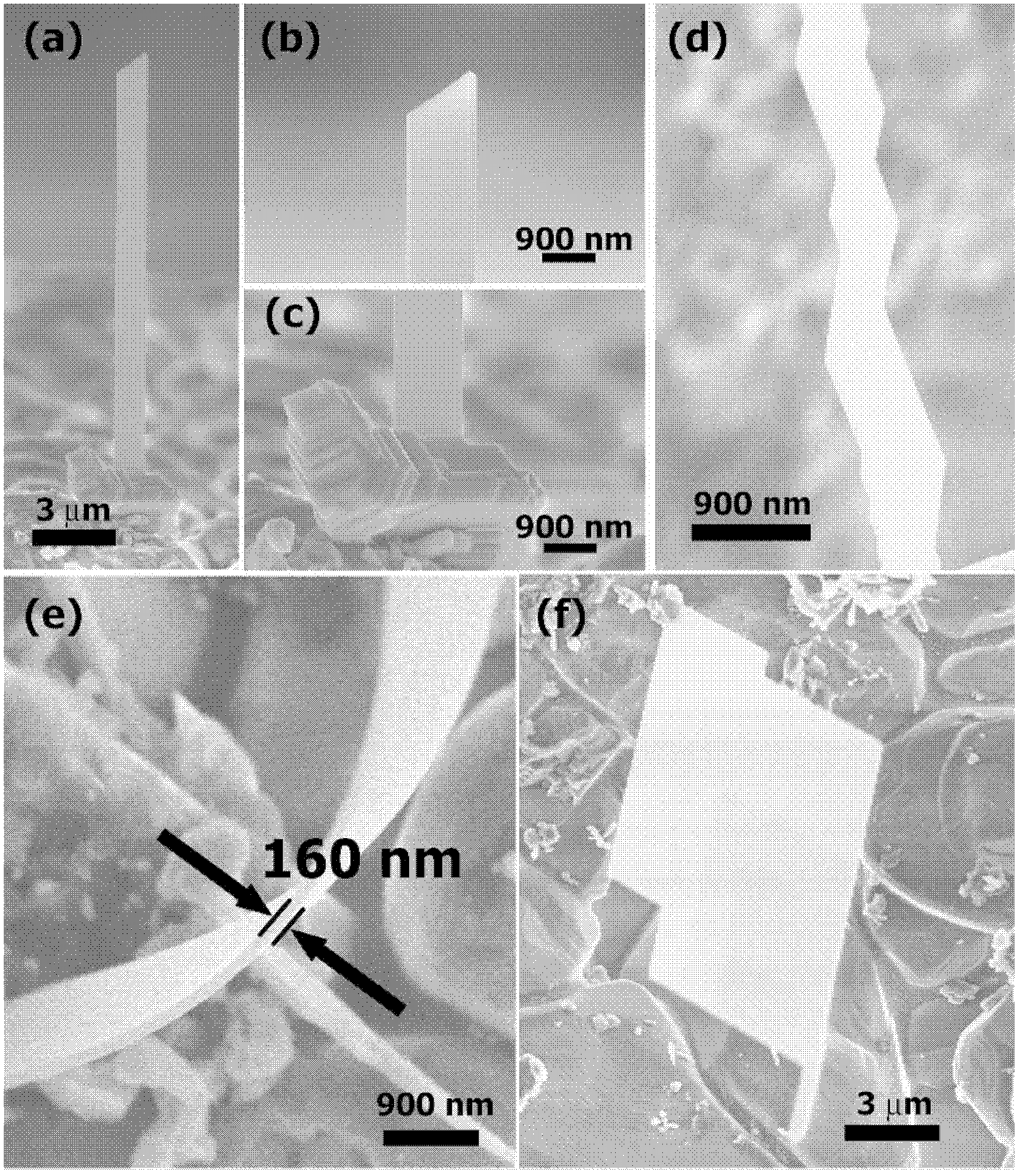

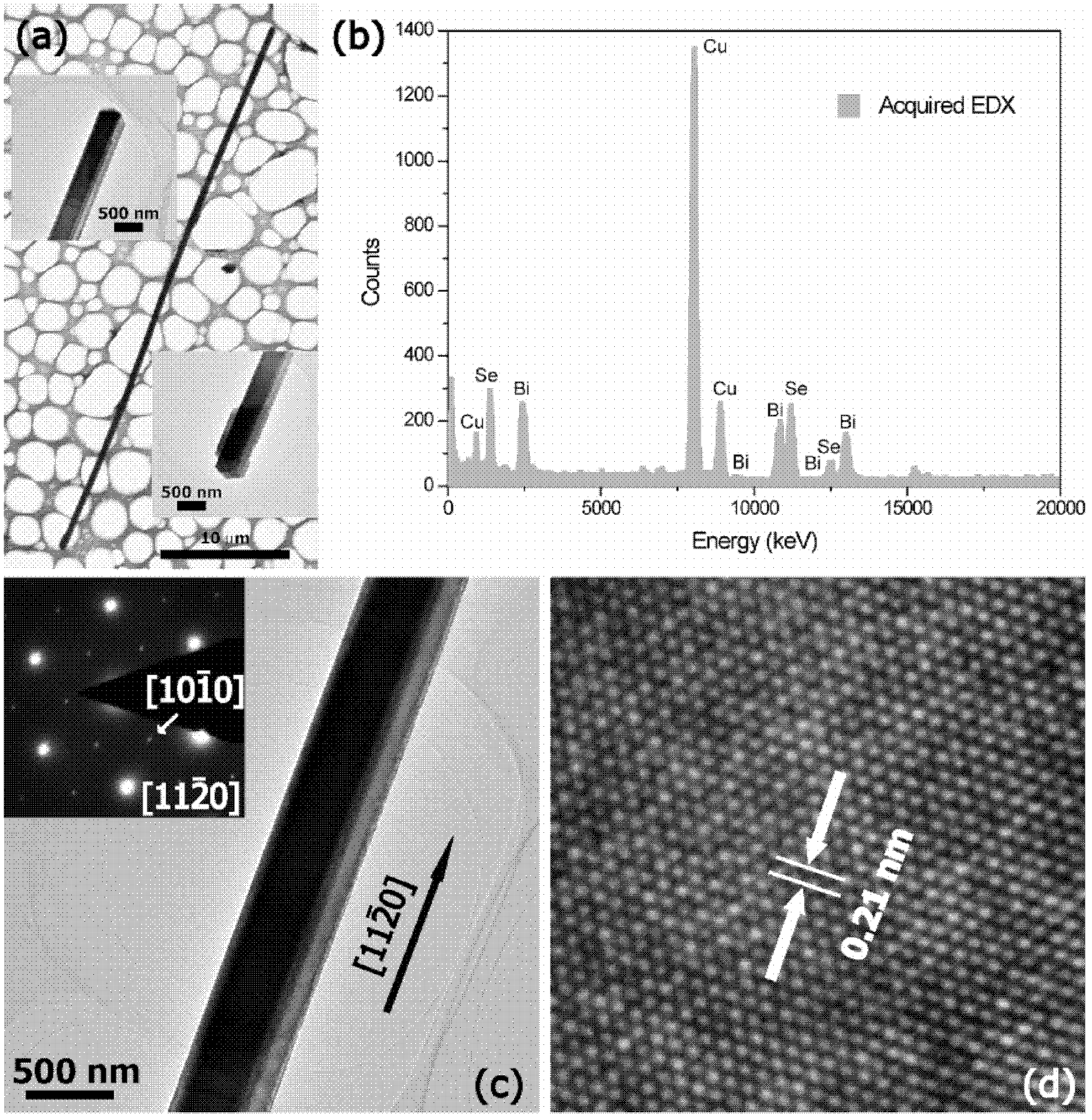

Method for preparing monocrystal Bi2Se3 nano structure

InactiveCN103046110AGood repeatabilityLow cost of preparationMaterial nanotechnologyPolycrystalline material growthNanometreSingle crystal

The invention provides a method for preparing a monocrystal Bi2Se3 nano structure. The Bi2Se3 nano structure comprises a nano belt and a nano sheet, wherein the width of the Bi2Se3 nano belt is 50nm to 4Mum, the length of the Bi2Se3 nano belt is 1-200Mum, and diameter of the Bi2Se3 nano sheet is 50nm to 20Mum. According to the method provided by the invention, high temperature thermal evaporation and gas phase transmission methods are adopted, Bi powder and Se powder or Bi2Se3 powder are taken as raw materials, thermal evaporation is carried out in a high temperature diffusion furnace, and the Bi2Se3 nano structure is obtained on a substrate. The Bi2Se3 nano structure obtained by the invention is a high-quality monocrystal material, no catalyst is used in a synthetic process, influence of introduced foreign impurity to material property is avoided, the method provided by the invention is simple and practicable, repeatability is good, raw materials and the substrate are available, and preparation cost is low.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

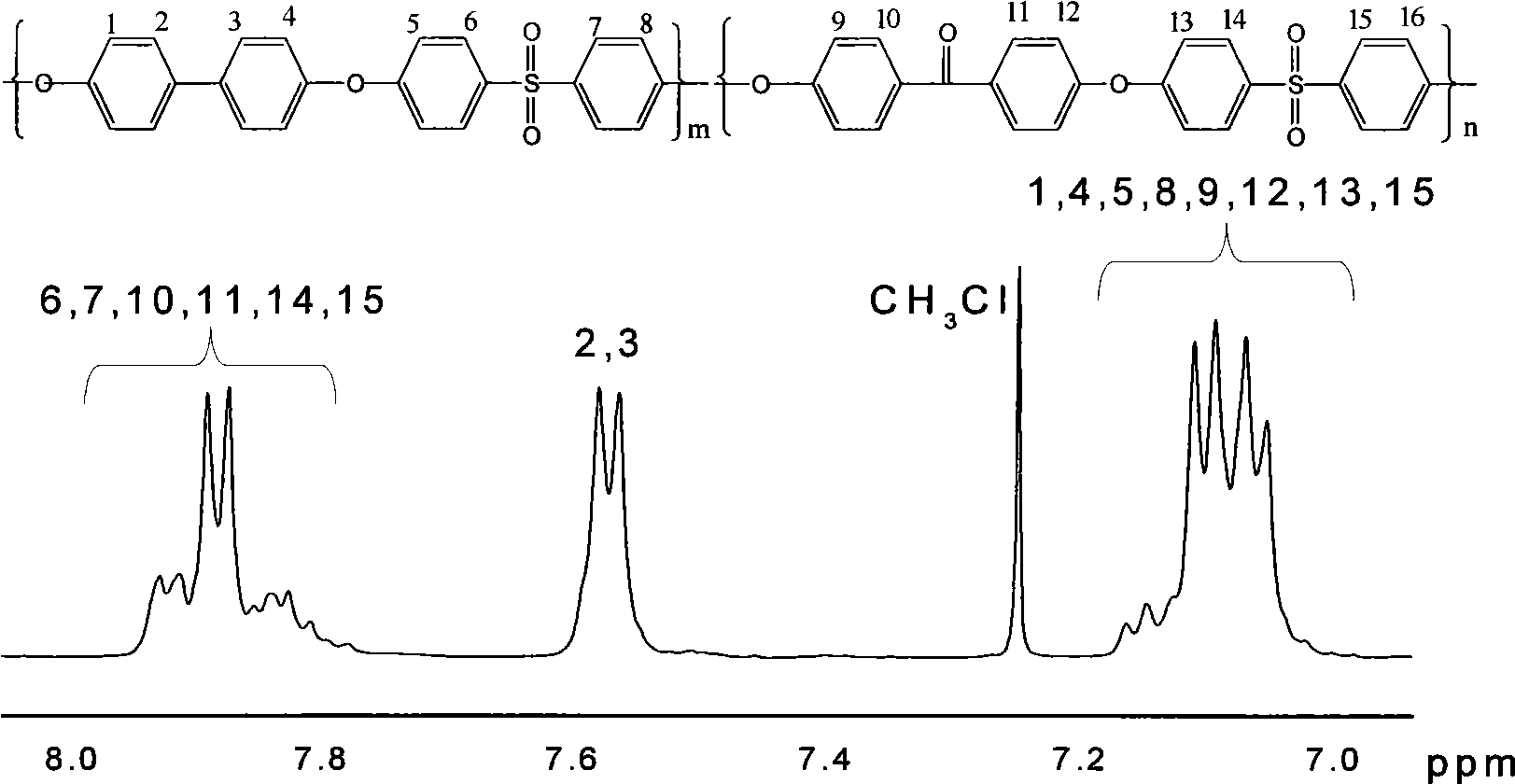

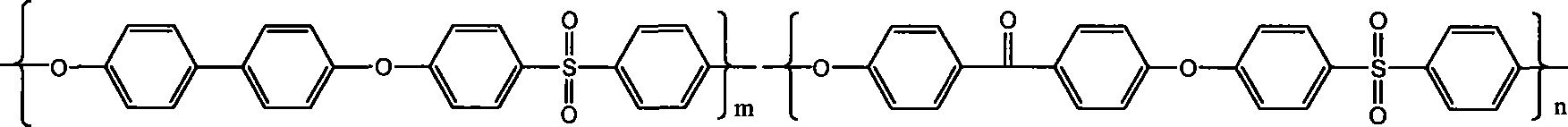

Random copolymer containing biphenyl structural polyether sulfone and polyether ketone sulfone and preparation method thereof

The invention relates to a random copolymer containing biphenyl structural polyether sulfone and polyether ketone sulfone and a preparation method thereof, and belongs to the field of high molecular materials. The preparation method comprises the following steps: using 4,4'-dichlorodiphenyl sulfone, 4,4'-dihydroxy biphenyl and 4,4'-dihydroxy diphenyl ketone as raw materials, anhydrous potassium carbonate as salt forming agent, N-methyl ketopyrrolidine or cyclobutyl sulfone as solvent, and methylbenzene or dimethyl benzene as water carrier; adding the raw materials, the salt forming agent, the solvent and the water carrier into a container provided with a mechanical stirrer and a thermometer, under the protection of nitrogen, heating the mixture to reflow with water, vaporizing redundant water carrier, and reacting the mixture for 4 hours at a temperature of between 160 and 240 DEG C to obtain a coarse product; and boiling the coarse product with ethanol or acetone, filtering the mixture, boiling the filtrate with distilled water, filtering the mixture, and drying the sediment to obtain a refined polymer product. The polymer has good compatibility for polyaryletherketone and polyarylethersulfone; and the preparation method is simple and convenient and has low cost.

Owner:JILIN UNIV

Preparation method of vinyl sulfate

InactiveCN109369609AReaction raw materials are readily availableLow cost of preparationOrganic chemistryWater contentDistillation

The invention relates to a preparation method of vinyl sulfate. The preparation method comprises the following steps: adding ethylene glycol into a reaction kettle A filled with a halohydrocarbon solvent, uniformly stirring, dropwise adding thionyl chloride to carry out a substitution reaction, removing hydrogen chloride by reduced-pressure distillation, then, washing a reaction solution to be neutral by using a saturated sodium bicarbonate solution, standing still, and skimming to obtain a glycol sulfite halohydrocarbon solution; adding the glycol sulfite halohydrocarbon solution into a reaction kettle B, adding monopotassium phosphate or sodium tungstate as a catalyst, regulating the pH by using a sodium bicarbonate aqueous solution, and adding a sodium hypochlorite aqueous solution to carry out an oxidation reaction; at the end of the reaction, skimming to obtain a vinyl sulfate halogenated alkane solution, carrying out concentration, then, adding n-hexane to carry out recrystallization, and carrying out filtration to obtain high-purity vinyl sulfate. By using the preparation method, raw materials are available, the price of the catalyst is low, the product is easy to purify, and the obtained product is low in acidity, low in water content, high in purity and suitable for large-scale production.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

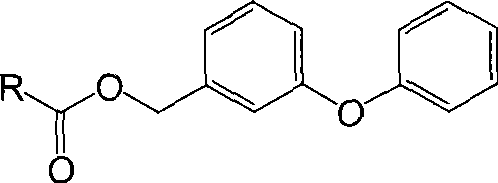

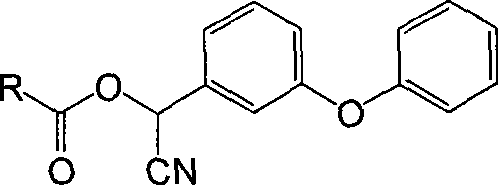

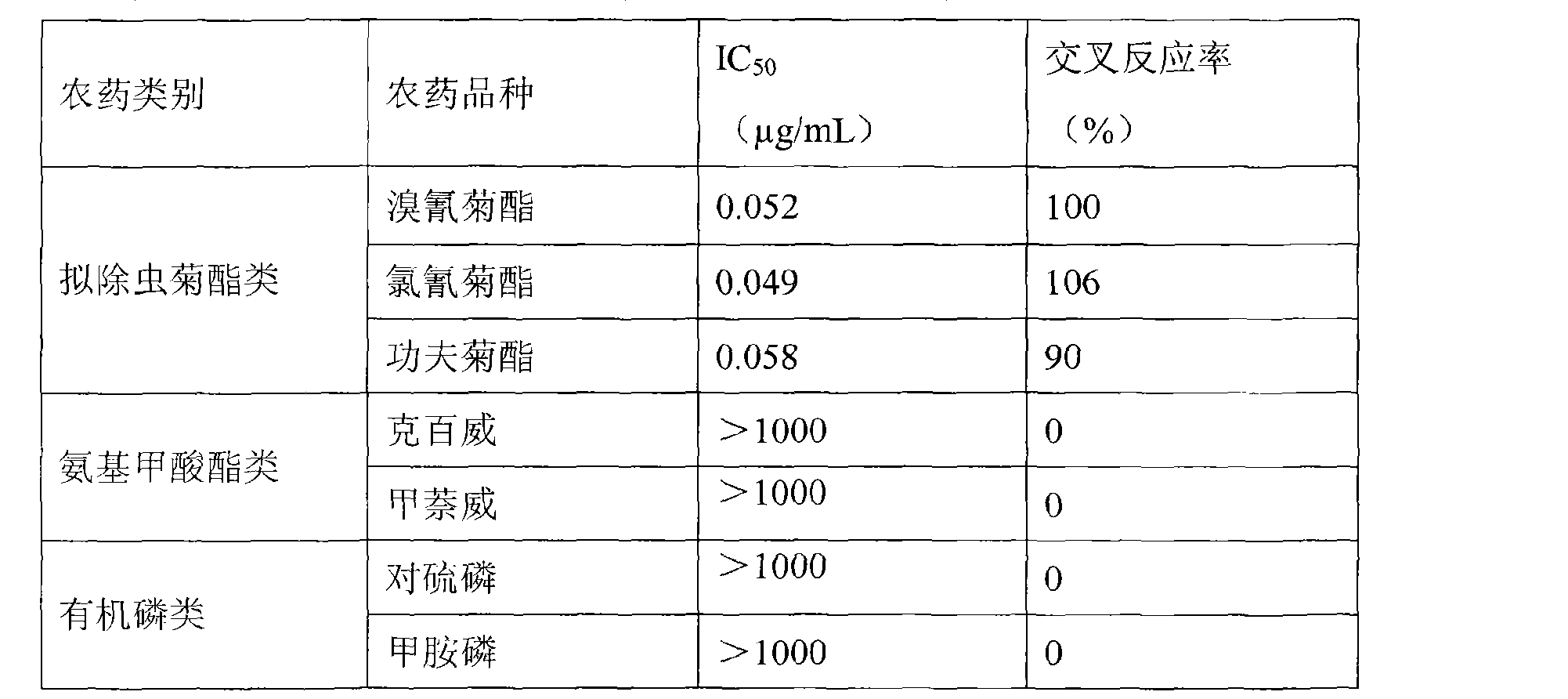

Pyrethroid pesticide artificial antigen, antibody and preparation thereof

InactiveCN101434652ALow cost of preparationHigh sensitivitySerum immunoglobulinsOvalbuminSpecific immunityPesticide

The invention relates to an artificial antigen and an antibody of a pyrethroid pesticide and a preparation method thereof. The artificial antigen is a chemical compound of an artificial antigen of the pyrethroid pesticide, and contains a majority of commonness configuration of the pyrethroid pesticide; the artificial antibody is a polyclonal immunoglobulin G which is prepared by the artificial antigen compound through the immune animal and can react with more than two pyrethroid pesticides for specific immune response. The method has the strengths of easy obtainment of a half antigen of the artificial antigen of the pyrethroid pesticide and environmental friendliness which lower the preparation cost of the artificial antigen; and in the prepared artificial antigen, the common ester bond configuration of the pyrethroid pesticide is retained simultaneously which facilitates the preparation of the high-quality antibody; the antibody has the advantages of high sensitivity and recognizing various pyrethroid pesticides. The antibody can be applied to develop the rapid analytical techniques, methods, and products of multi-residue immunity of the pyrethroid pesticide in the agricultural products and foods.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Method for preparing graphene reinforced aluminum matrix composite by using graphite micro pieces as raw materials

The invention relates to a method for preparing an aluminum matrix composite, in particular to a method for preparing a graphene reinforced aluminum matrix composite by using graphite micro pieces as raw materials to solve the problems that current graphene reinforced aluminum matrix composites are high in cost, composite castings are poor in performance, and opening of graphene piece layers is insufficient. The preparation method comprises the steps of weighing, graphite micro piece dispersion and precast block forming, aluminum metal vacuum permeation, large plastic deformation treatment and component homogenization treatment. According to the method, the low-cost graphite micro pieces are used as the raw materials, a graphite micro piece reinforced aluminum matrix composite is firstly prepared, and the prepared few-layer graphene reinforced aluminum matrix composite is excellent in comprehensive performance, over 90 GPa in elastic modulus, over 400 MPa in tensible strength and over 230 W / (m.K) in heat conductivity. The method is applicable to preparing the graphene reinforced aluminum matrix composite.

Owner:HARBIN INST OF TECH

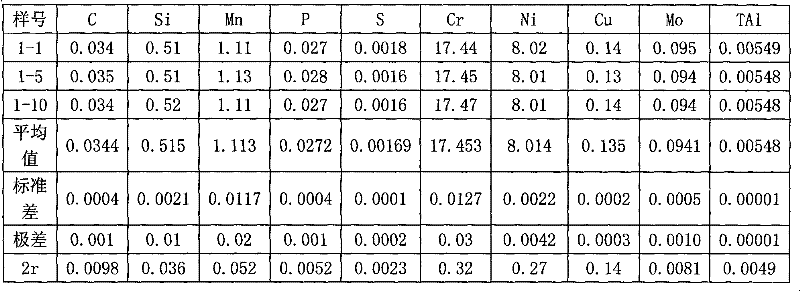

Preparation method of standard spectrum sample

ActiveCN102313661ALow cost of preparationIncrease the number of samplesPreparing sample for investigationStandard samplesSurface finishing

Belonging to the field of metallurgical sample detection, the invention relates to a preparation method of a standard spectrum sample. The method includes the processes of: component selection, preparation of a standard sample through a continuous casting middle ladle top pouring method, stability investigation and conclusion. The method is characterized in that the process of preparing the standard sample by the continuous casting middle ladle top pouring method comprises the steps of: model baking, sample model establishment, sample model pouring by the top pouring method, demolding, segmentation and surface treatment, physical property detection, surface treatment, chemical component uniformity test, and fixed value analysis. The standard sample prepared in the invention not only satisfies the standard sample requirements in terms of physical property, texture, component range and uniformity, but also has reduced preparation cost and increased sampling number. At least 200 pieces can be prepared every time, thus being over 20 times as many as a model casting sampling number. And the preparation number can satisfy the current production requirements. Thus, the standard sample preparation method of the invention boasts very high practical value.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Tissue engineering double-layered tubular support and preparation method thereof

The invention relates to a tissue engineering double-layered tubular support and a preparation method thereof. The support is composed of two polymer layers with different pore structures, the inner layer is a compact nanofiber structure, and the outer layer is of a porous nanofiber structure. The preparation method comprises the following steps of: dissolving a polymer material in a solvent, pouring in a mould, performing phase separation overnight, demoulding to obtain a polymer gel, performing solvent replacement, and freeze drying to obtain a nanofiber tubular support with a compact structure; sleeving the nanofiber tubular support on a mould stem to obtain a casting mould; and dissolving a polymer material in a solvent, casing the polymer solution in the casing mould by combing an electroporation technology, performing phase separation overnight, demoulding, performing solvent replacement, removing the solvent and / or porogen, and freeze drying to obtain the tissue engineering double-layered tubular support. The preparation method disclosed by the invention is simple in operation, free of complicated equipment, suitable for large-scale production and low in preparation cost; the whole mechanical property of the support is improved by introducing other polymers in the phase separation system.

Owner:DONGHUA UNIV

Marine organism fermentation fertilizer and preparation method thereof

InactiveCN104788227AWide variety of sourcesLow cost of preparationBio-organic fraction processingOrganic fertiliser preparationNutrientHumic acid

The invention discloses a marine organism fermentation fertilizer and a preparation method thereof. The marine organism fermentation fertilizer comprises the following components in parts by weight: 10-15 parts of a humic acid, 30-50 parts of shell powder, 20-40 parts of slit powder in a culture pond, 3-10 parts of a polypeptide amino acid, 12-14 parts of decaying manure, 5-10 parts of tea seed cakes subjected to tea saponin removing and degreasing, 0.5-1.5 parts of silicate bacteria, and 3-5 parts of strong brine. The marine organism fermentation fertilizer and the preparation method have the advantages that raw materials are wide in source, the preparation cost is low, and secondary pollution is avoided during the production process; the bioactivity is higher, the nutrient is more complete, and besides medium trace elements such as calcium, magnesium, zinc and silicon, the marine organism fermentation fertilizer is rich in natural organic nutrients such as nitrogen, phosphorus, potassium and the amino acid and the humic acid, is wide in use range, can be used as an acid soil conditioner, can also be used as a calcicolous and magniferous crop supplement trace element, and can be further used as a water quality improver and a fertilizer agent.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Method for preparing lithium silicate serving as high-temperature CO2 absorbing material

InactiveCN101696015ALow cost of preparationEnergy savingOther chemical processesCarbon compoundsIon exchangeSol-gel

The invention discloses a method for preparing lithium silicate material absorbing high-temperature CO2 by taking artificial zeolite as raw material, and provides a process for preparing lithium silicate material serving as high-temperature CO2 absorbent by use of artificial zeolite. Lithium silicate precursors are prepared from LiNO3 and artificial zeolite in different proportions by ion exchange and sol-gel methods, and the lithium silicate material is synthesized by roasting the lithium silicate precursors at a temperature between 600 and 900 DEG C for 2 to 8 hours. The lithium silicate material prepared absorbs CO2 in a thermogravimetric analyzer at a temperature between 400 and 700 DEG C in CO2 and N2 atmosphere in different proportions. Aiming at the problem of a great amount of high-temperature CO2 emitted from power plants and flue gas, the method recycles carbon resources and reduces CO2 emission. The method synthesizes the lithium silicate material by taking cheap artificial zeolite and LiNO3 as raw material and adopting the ion exchange and sol-gel methods. Compared with the prior art, the method has the advantages of cheap and readily available artificial zeolite used as the raw material, reduction in preparation cost of the lithium silicate material and easiness of realizing industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Method of repairing agricultural soil by calcium peroxide-charcoal

InactiveCN108393346ALow cost of preparationIncrease soil organic matterContaminated soil reclamationSoil-working methodsChemistryCalcium

The invention discloses a method of repairing agricultural soil by calcium peroxide-charcoal. The method of repairing the agricultural soil by the calcium peroxide-charcoal is characterized in that acharcoal raw material is washed to remove materials adhering on the surface and then dried naturally, and then broken; the broken charcoal is put in a pyrolyzing furnace for sealing and pyrolyzation;the charcoal after pyrolyzation is wrapped and formed by plastic mesh fabrics with pore diameters, and an active filler of charcoal is made and placed in the soil to be repaired; the calcium peroxideis dissolved in water, the pH value of the calcium peroxide is adjusted, leachate of the calcium peroxide is prepared to spray the soil to be repaired regularly, and the purpose of removing heavy metals and organic pollutants in the soil is finally achieved by combined treatment of the charcoal and the calcium peroxide. The method of repairing the agricultural soil by the calcium peroxide-charcoalis low in cost, the raw materials are easy to obtain, action time is long, the applicable pH range is wide, the heavy metals and the organic pollutants in the soil can be repaired, the soil fertilitycan be improved, and the method of repairing agricultural soil by calcium peroxide-charcoal is suitable for remediation of contaminated agricultural soil.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com