Method for preparing graphene reinforced aluminum matrix composite by using graphite micro pieces as raw materials

A technology of graphite microflakes and reinforced aluminum matrix, which is applied in the field of preparing aluminum matrix composite materials, can solve the problems of insufficient opening of graphene sheets, low ingot density, incomplete impregnation, etc., and achieves excellent flow properties and has Fluidity, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

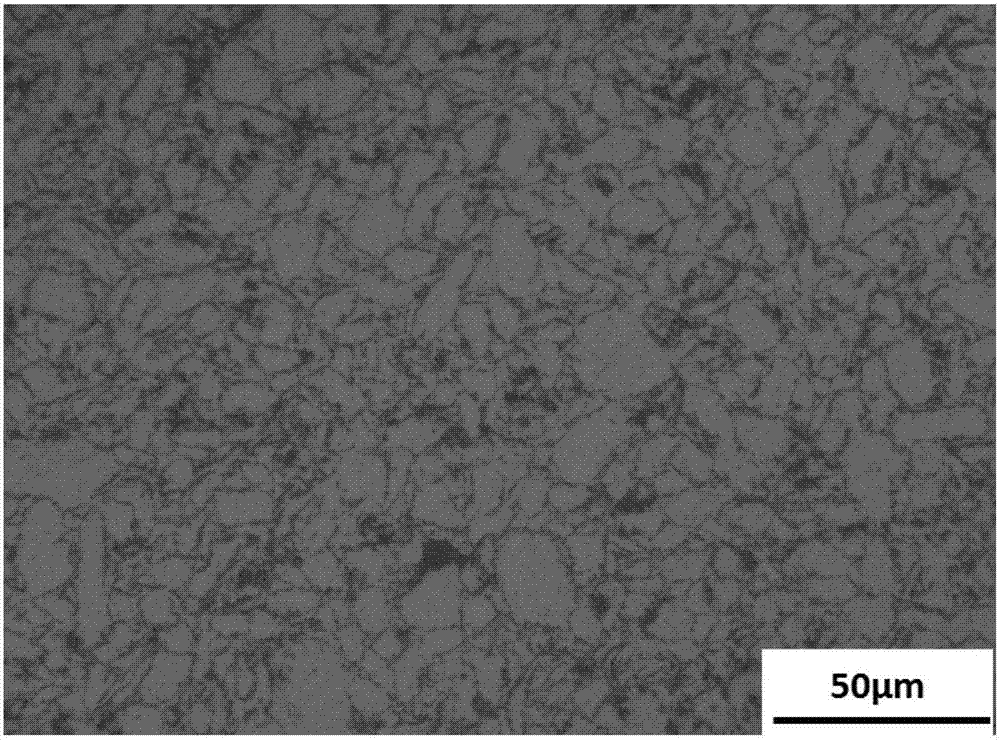

Image

Examples

specific Embodiment approach 1

[0037]Specific embodiment one: present embodiment is a kind of method that prepares graphene reinforced aluminum-based composite material with graphite microchip as raw material, and this method is carried out according to the following steps:

[0038] 1. Weighing

[0039] Take by weighing 0.5%~4% graphite flakes and 96%~99.5% aluminum metal powder by mass fraction, weigh industrial pure aluminum block, the weight ratio of industrial pure aluminum block and above-mentioned aluminum metal powder is (5~ 30): 1;

[0040] 2. Dispersion of graphite micro flakes and forming of prefabricated blocks

[0041] Put the graphite flakes and aluminum metal powder weighed in step 1 into a ball mill jar, ball mill the obtained mixed powder at a speed of 100-400rpm for 4-15 hours, and put the mixed powder obtained after ball milling into a cold-pressing mold for cold pressing Obtain graphite microchip prefabricated body; the specific steps of cold pressing are: pressurize the mixed powder to...

specific Embodiment approach 2

[0054] Embodiment 2: This embodiment differs from Embodiment 1 in that: the average diameter of the graphite microflakes in step 1 is 100 nm-10 μm, and the average thickness is 50-500 nm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0055] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the average particle size of the aluminum metal powder in Step 1 is 1-30 μm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com