Patents

Literature

2884results about How to "Energy-saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

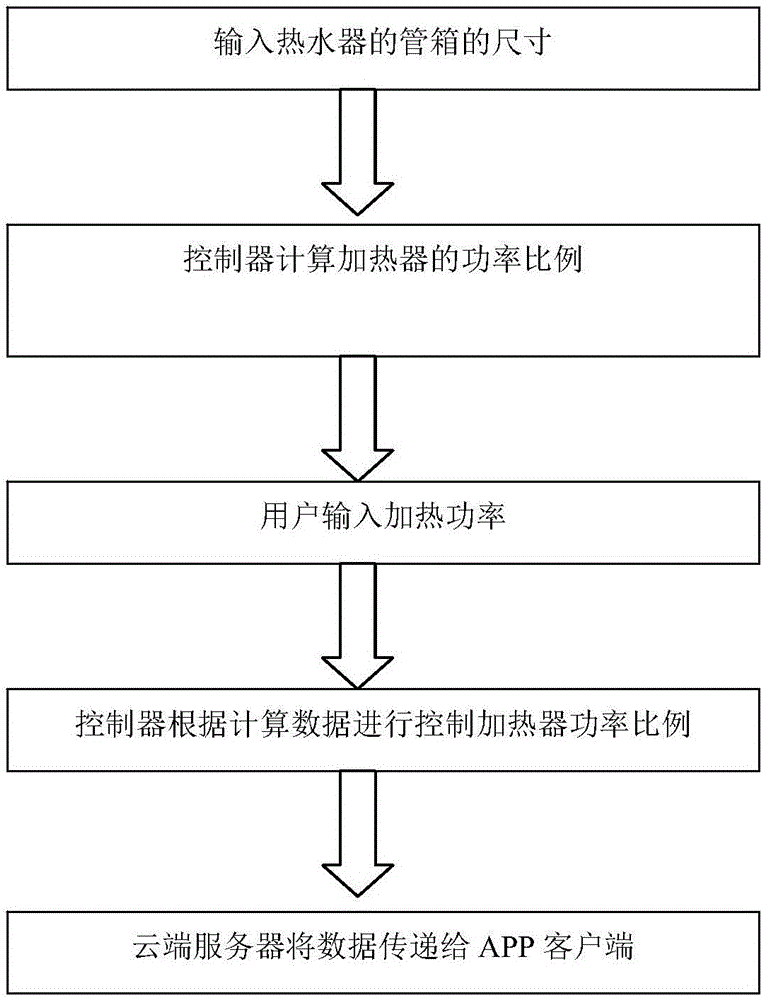

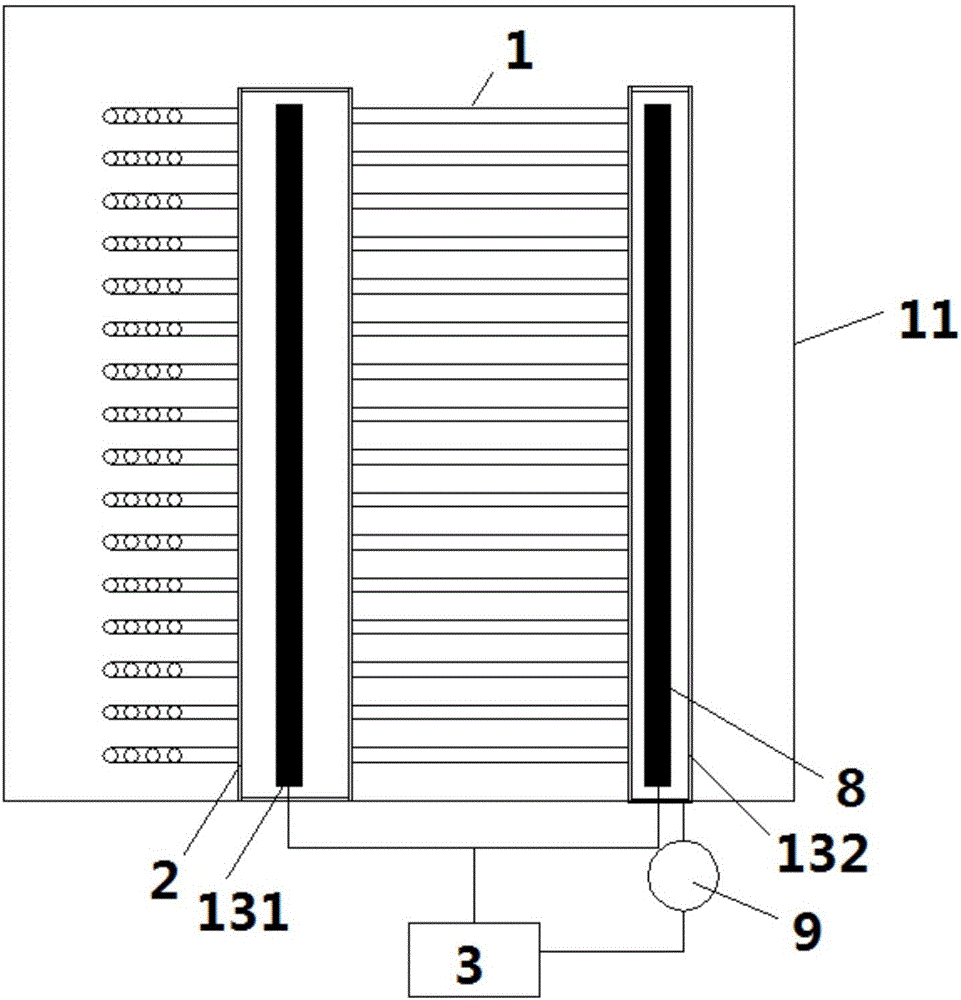

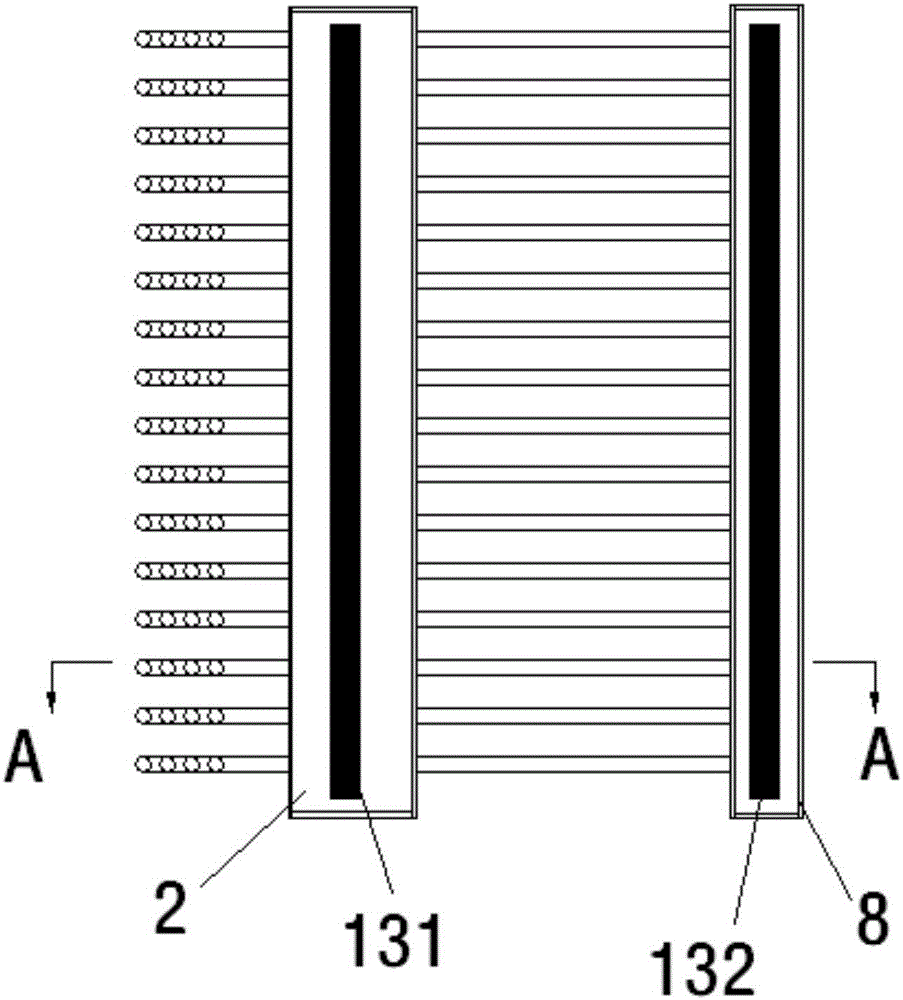

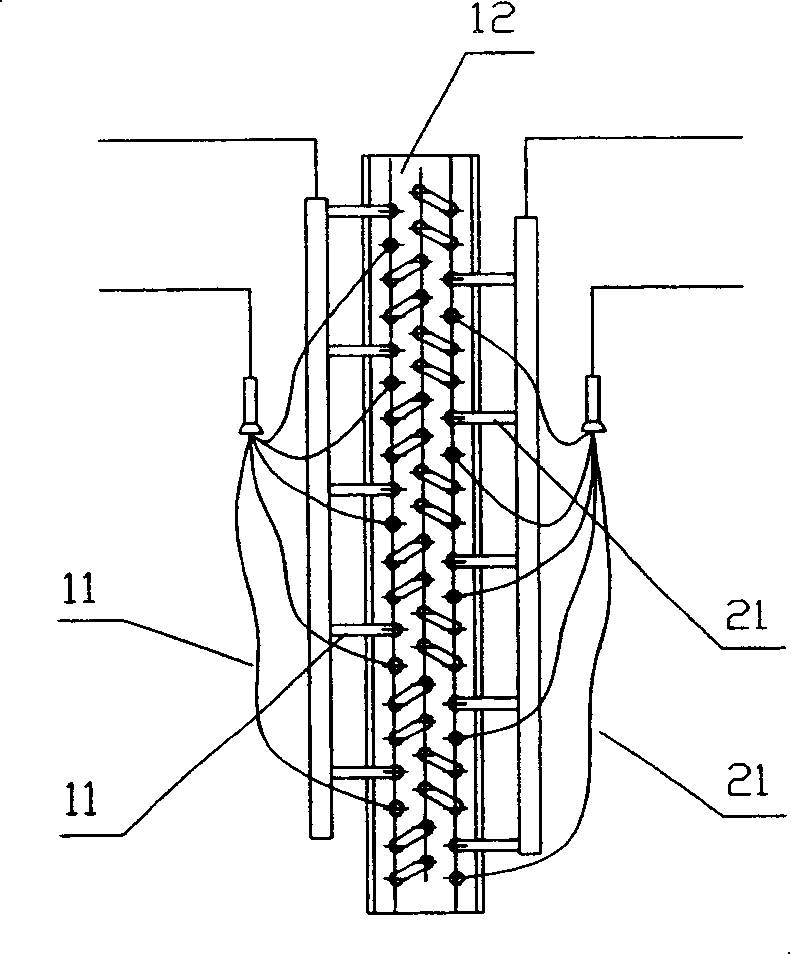

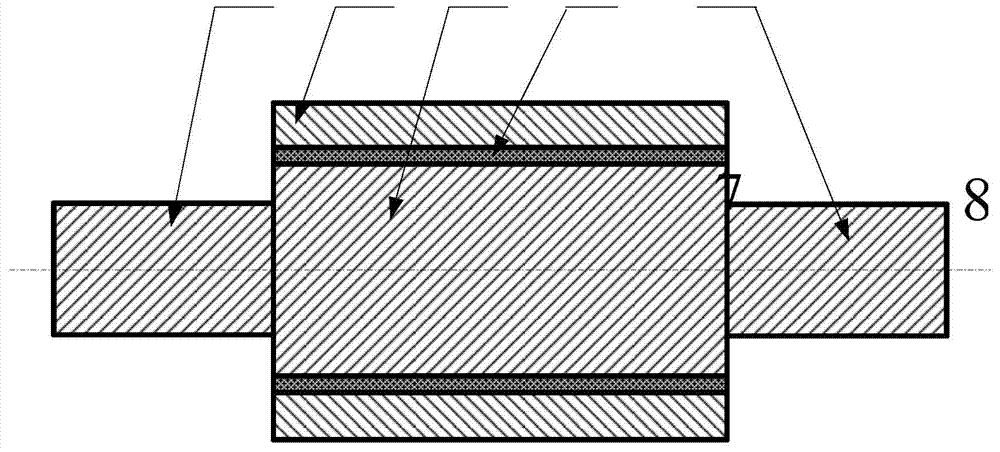

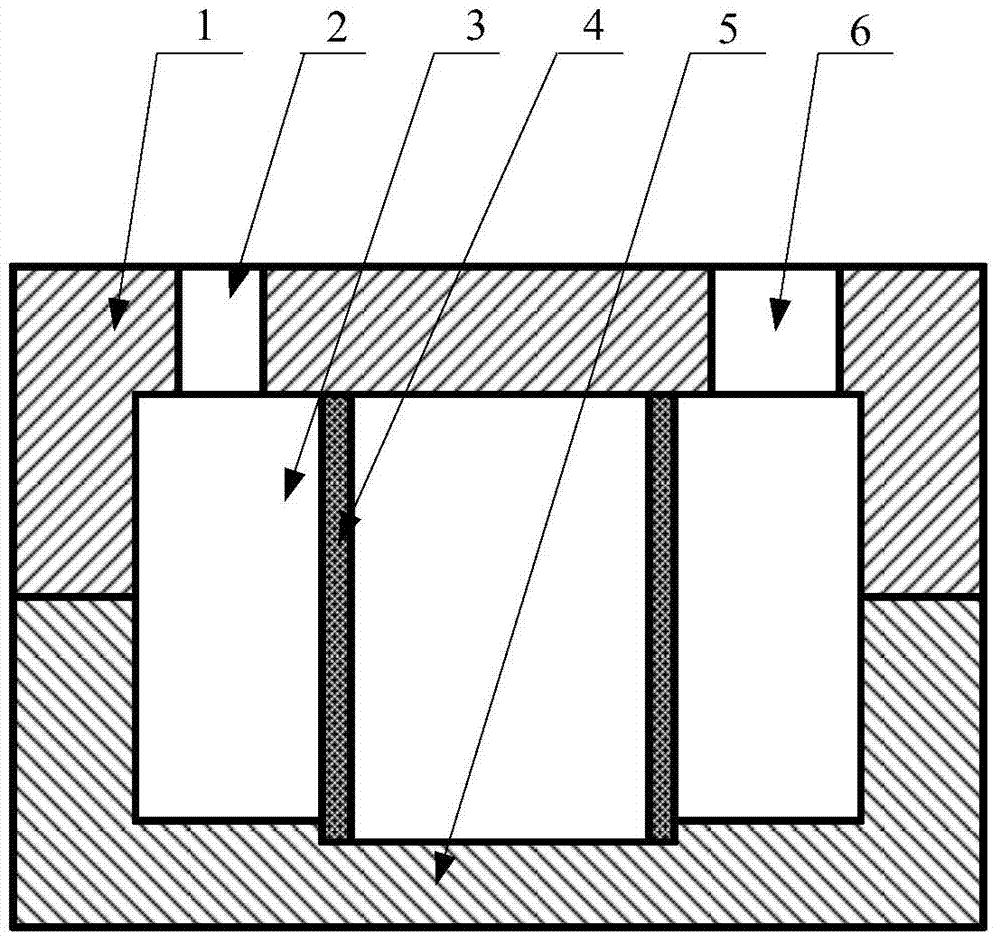

Electric water heater capable of intelligently distributing heating power

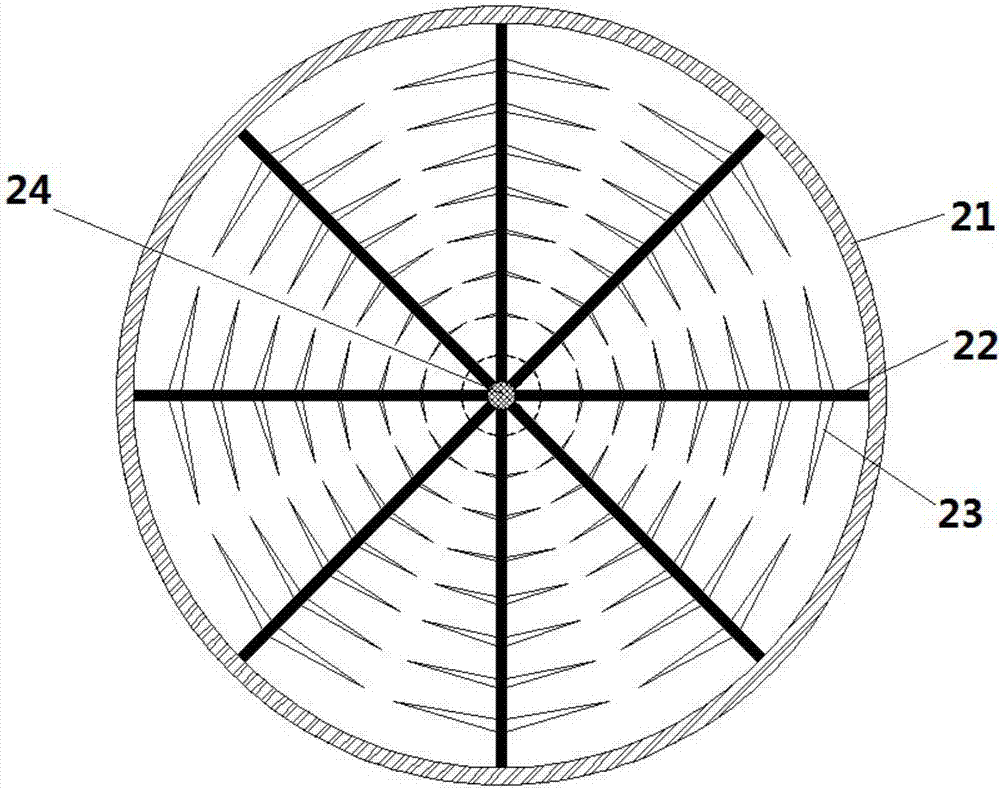

The invention provides an electric water heater. The electric water heater comprises a controller, an electric heating device and a water tank. The electric heating device is arranged in the water tank. The electric heating device comprises a left pipe box, a right pipe box and floating pipe coils. The floating pipe coils communicate with the left pipe box and the right pipe box to form sealed circulation of heating fluid. The left pipe box, the right pipe box and the floating pipe coils are filled with the heating fluid. One or more floating pipe coils are arranged. Each floating pipe coil comprises multiple arc-shaped pipe bundles. The center lines of the multiple pipe bundles are arcs of concentric circles. The end portions of the adjacent pipe bundles communicate so that the end portions of the pipe bundles can form free ends of the pipe bundles. The concentric circles are circles with the center of the left pipe box as the circle centers. The pipe diameter of the left pipe box is larger than the pipe diameter of the right pipe box. A first electric heater is arranged in the left pipe box. A second electric heater is arranged in the right pipe box. The first electric heater and the second electric heater are in data connection with the controller. The controller determines the ratio of the heating power of the first electric heater to the heating power of the second electric heater according to the pipe diameter of the left pipe box and the pipe diameter of the right pipe box. According to the electric water heater, automatic distribution of the heating power is achieved through the controller, energy is saved, and intellectualization of the water heater is improved.

Owner:QINGDAO UNIV OF SCI & TECH

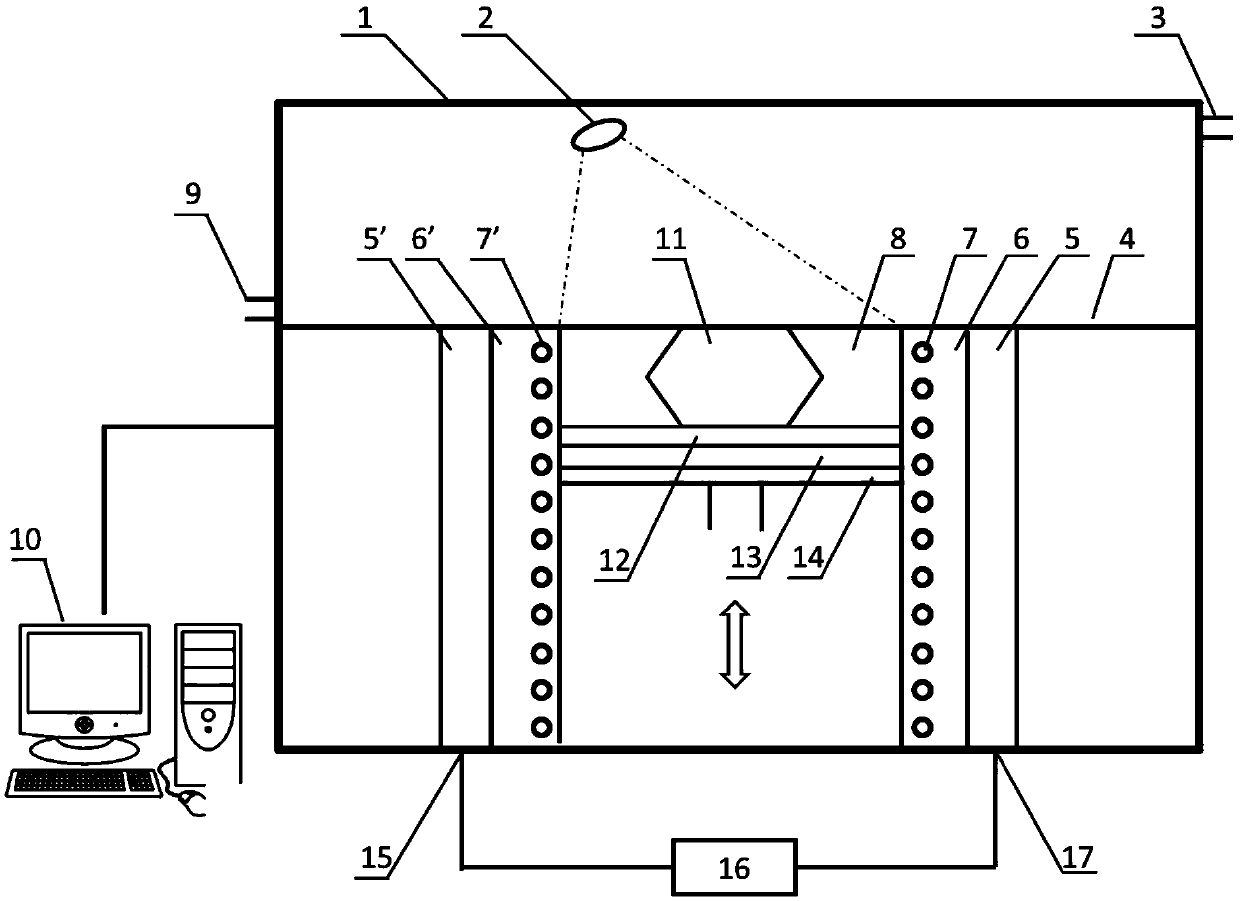

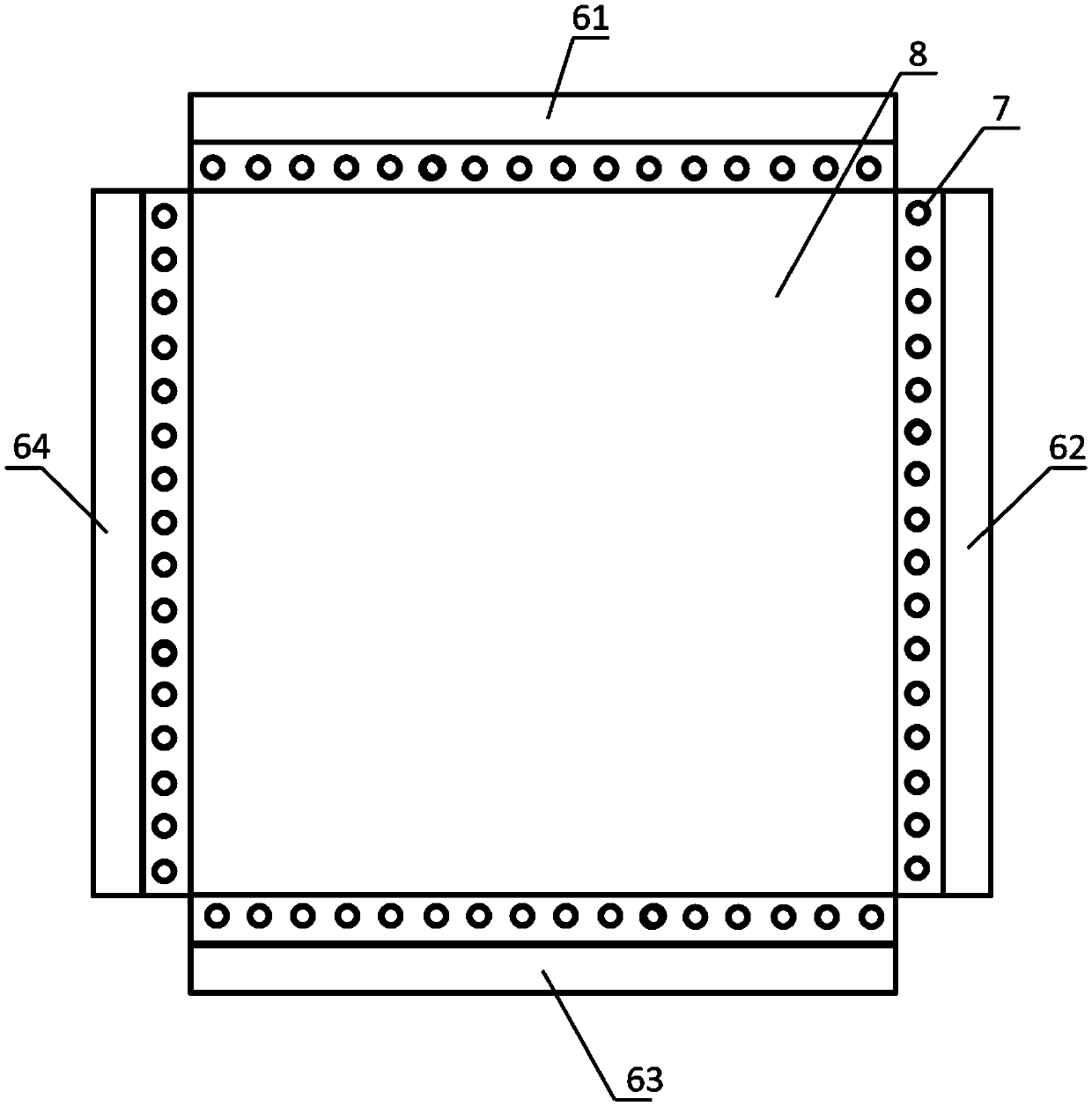

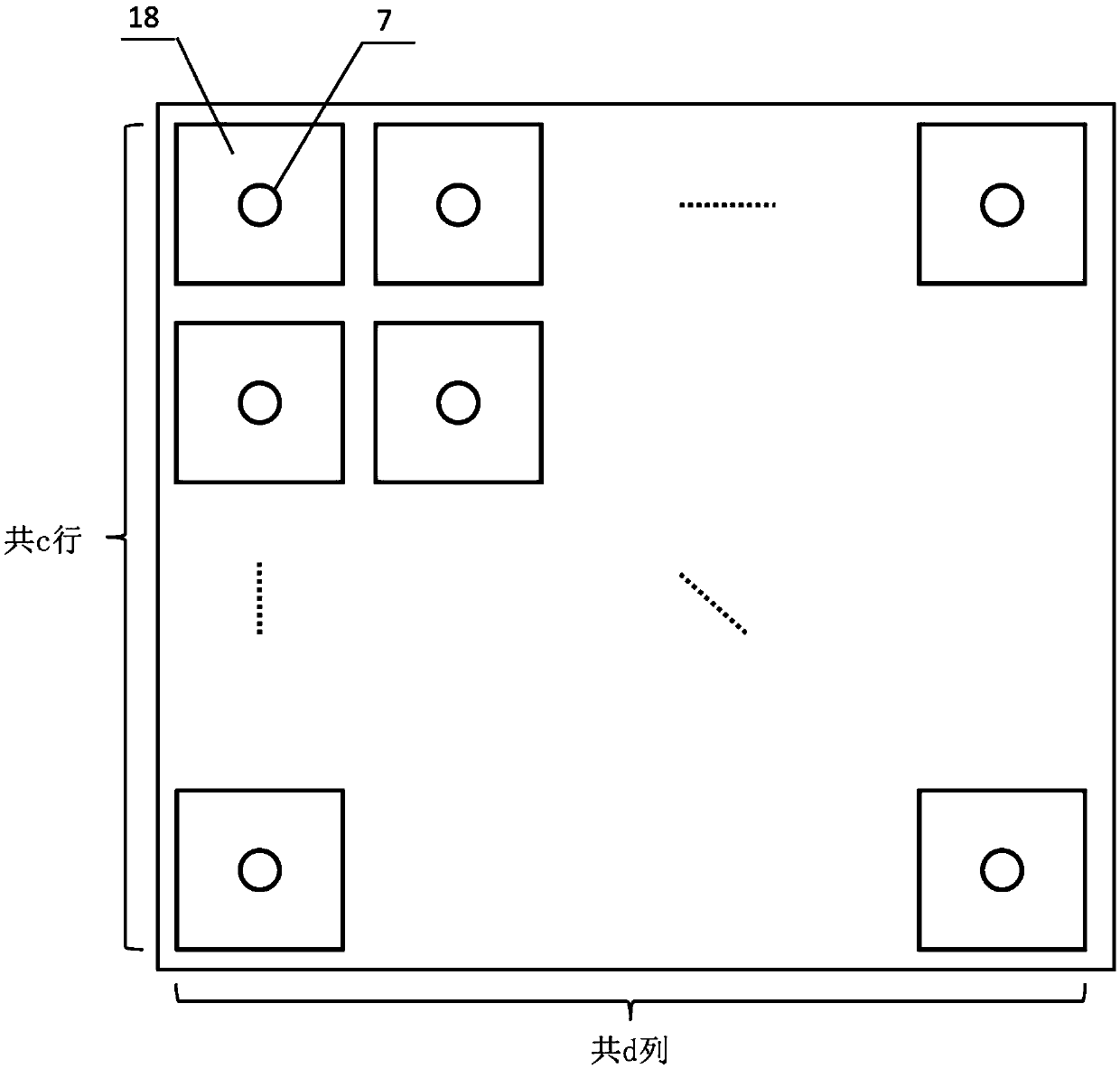

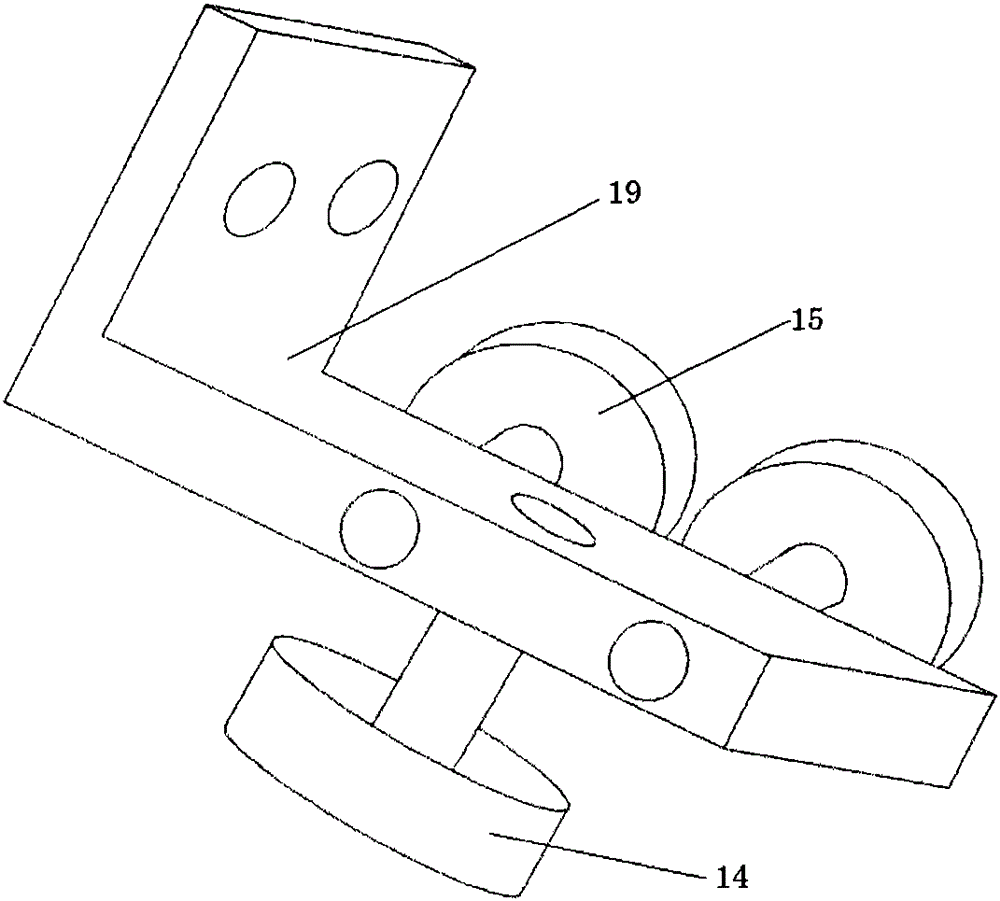

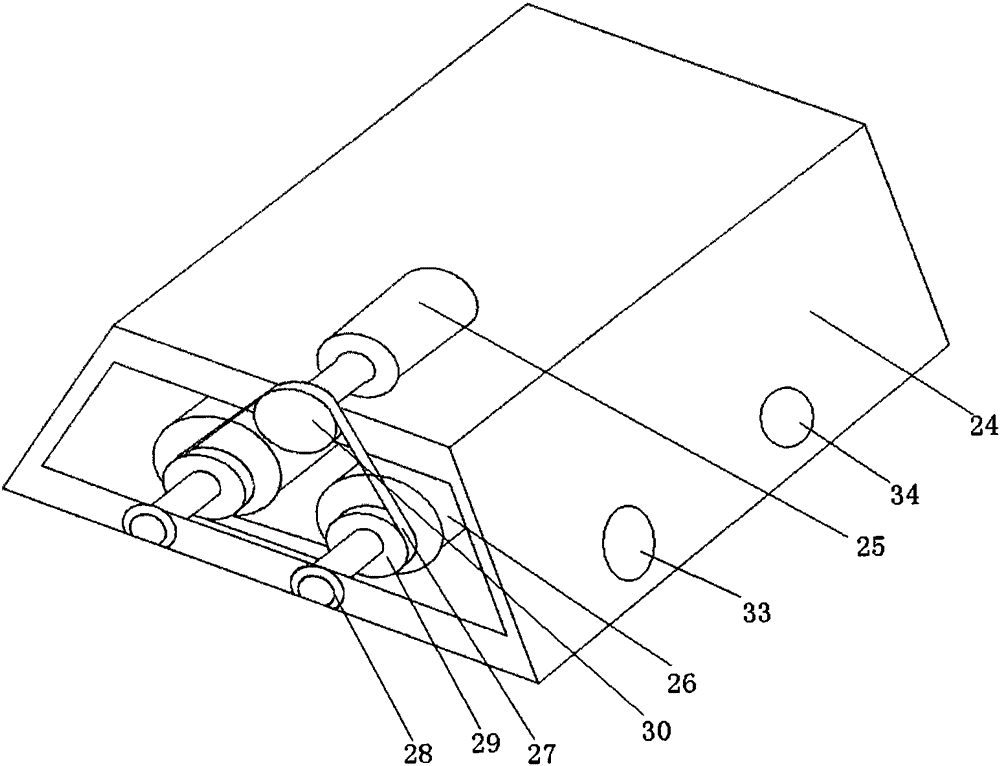

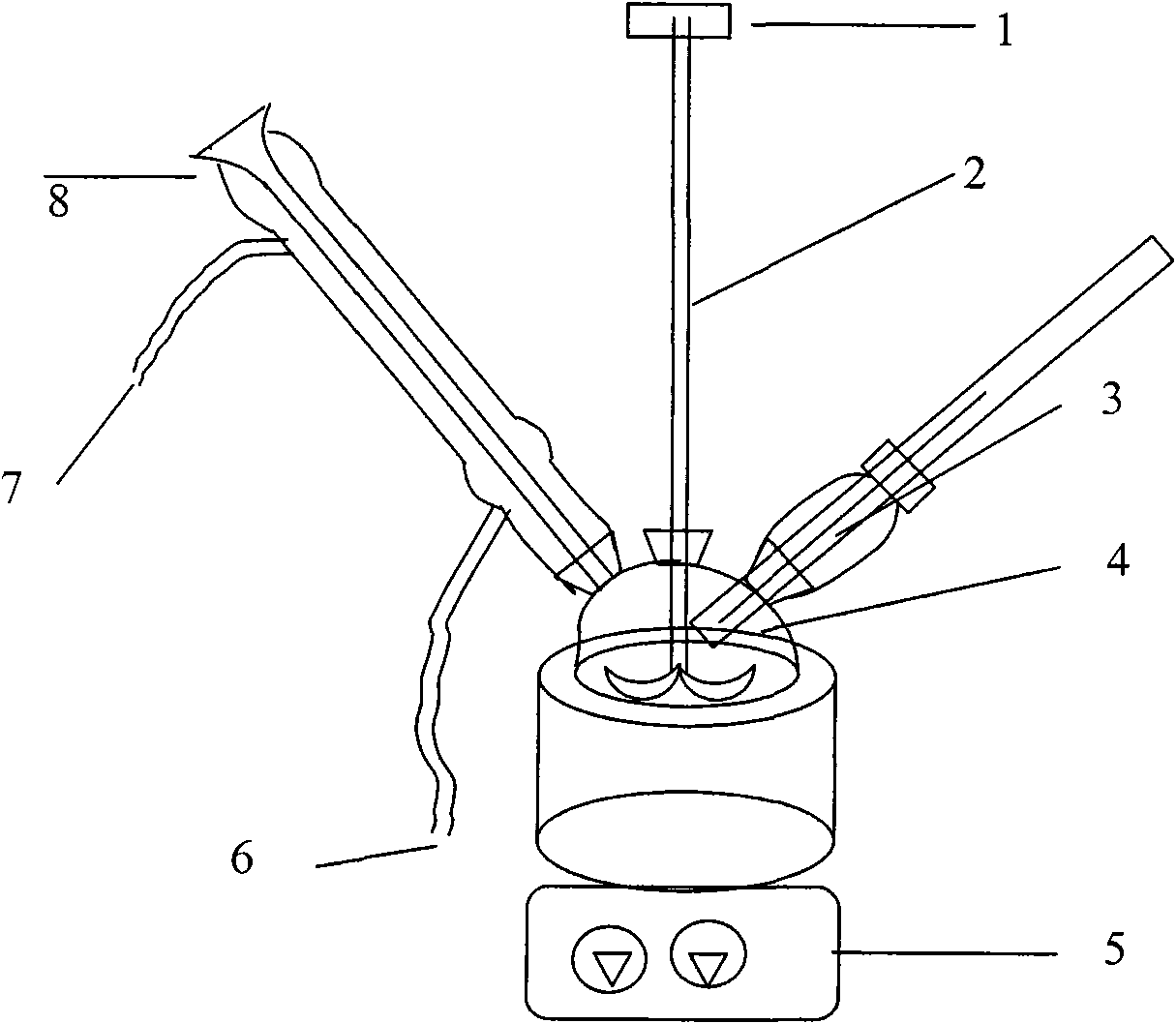

Active temperature field regulating and controlling system for manufacturing high-energy beam reinforced material and control method for active temperature field regulating and controlling system

ActiveCN105499569AShorten heat treatment cycleEnergy savingAdditive manufacturing apparatusIncreasing energy efficiencyHeating systemHolding time

The invention discloses an active gradient temperature field regulating and controlling system and a control method thereof. The system is composed of a temperature field monitoring system, a heating system and a control system, wherein the temperature field monitoring system is used for measuring temperature field information on an XOY plane and at the periphery of a forming region and feeding the temperature field information back to the control system after quantitatively processing the temperature field information; and the heating system is used for independently regulating subregions of a temperature field at the bottom and periphery of a forming tank in real time according to a command of the control system so as to keep the temperature field of the whole machining region constant in the machining process, keep a processed region and an unprocessed region in a reasonable temperature gradient and avoid structural member warping, deforming and cracking caused by thermal stresses. The system can also be used for directly carrying out stress relief annealing on a formed structural member or directly carrying out stress relief on the formed structural member while machining, so that the problems of warping, deforming, cracking and the like easily caused in the forming process are effectively solved, not only is the time shortened, but also energy sources are saved, meanwhile, the holding time of equipment can be effectively shortened, and the utilization ratio of the equipment can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

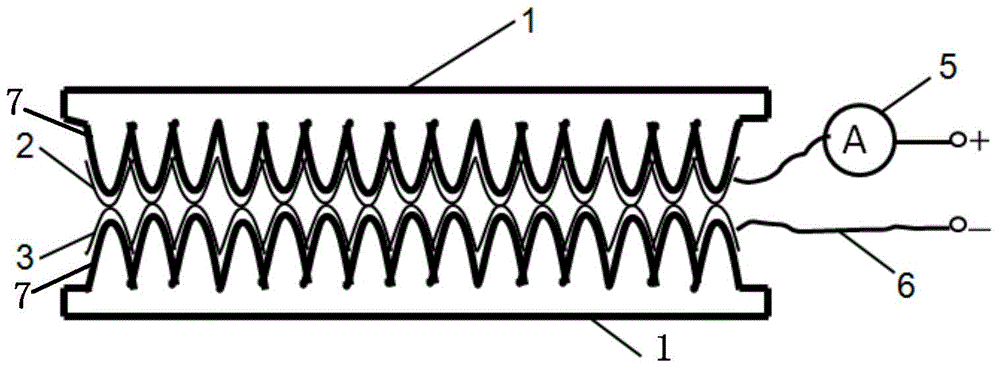

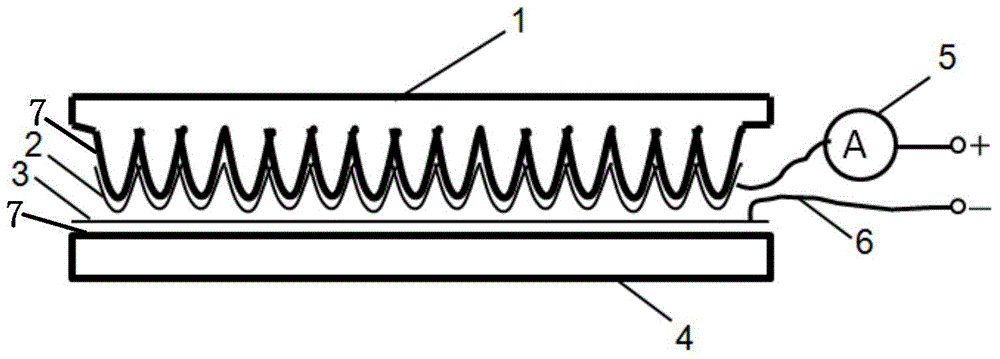

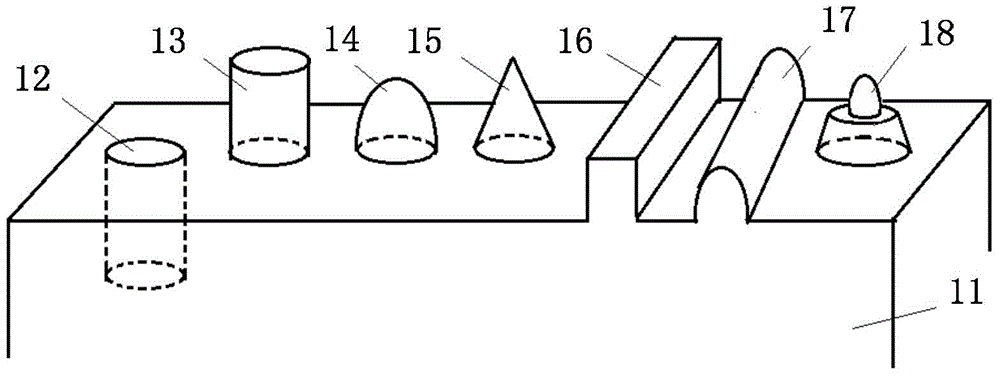

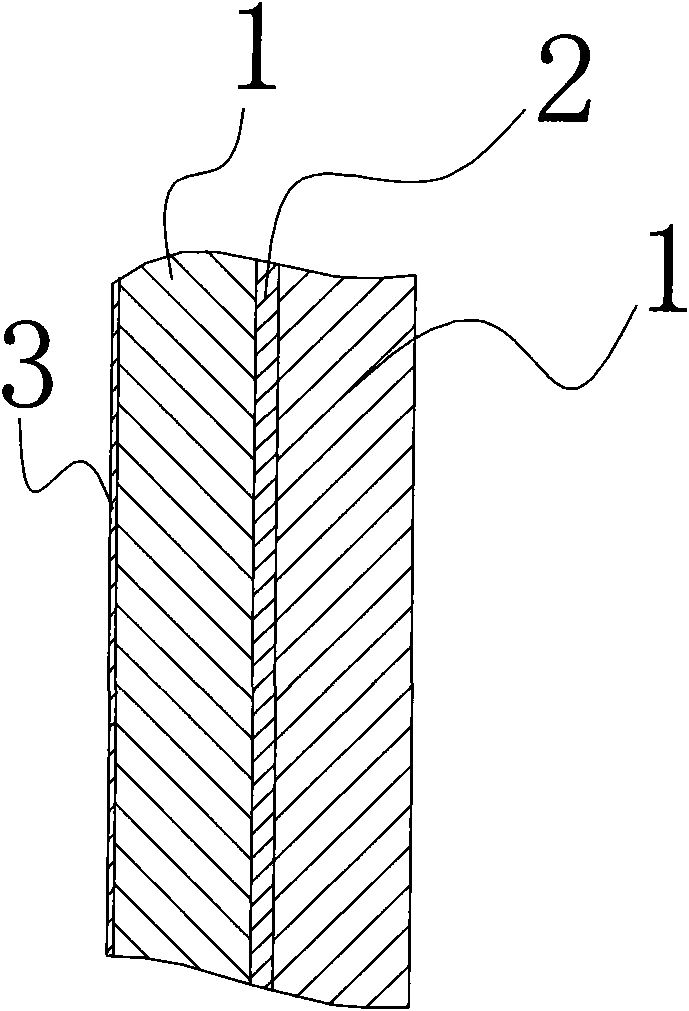

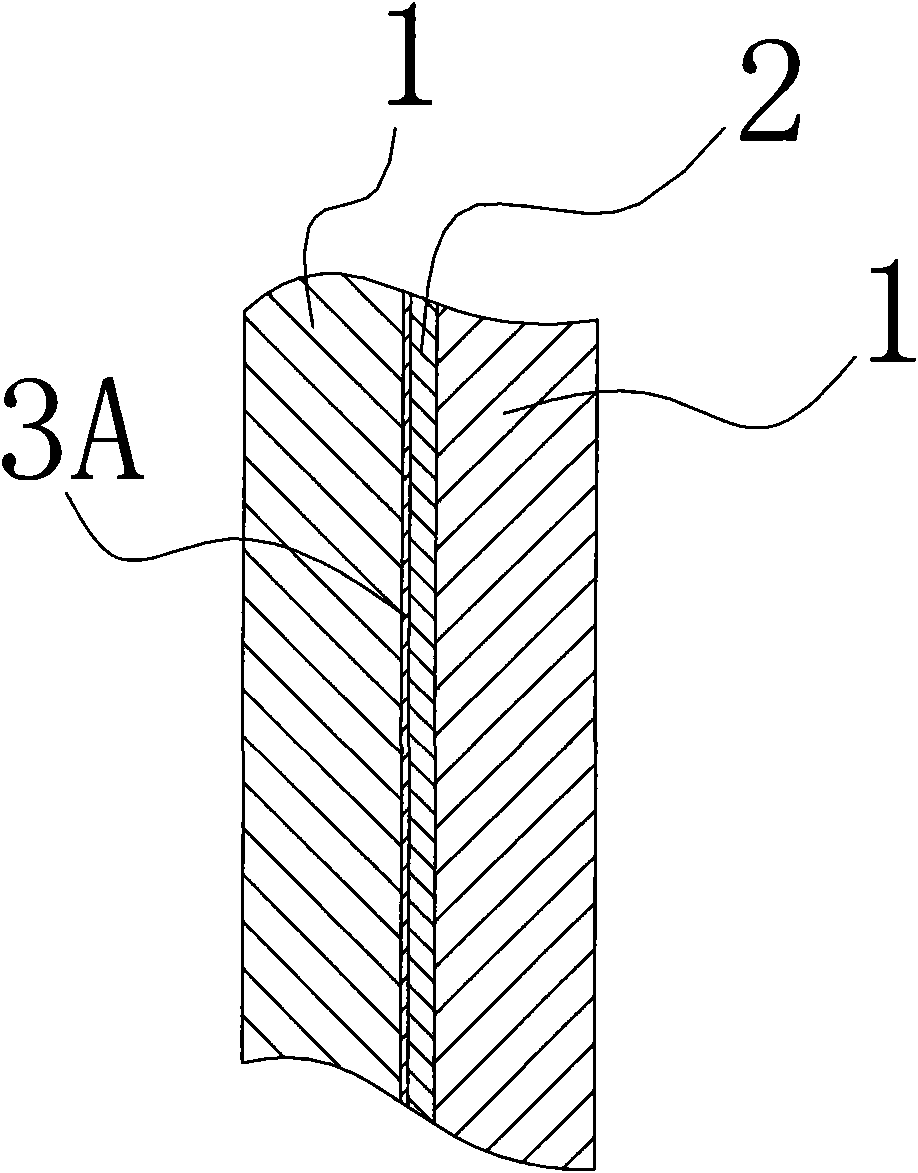

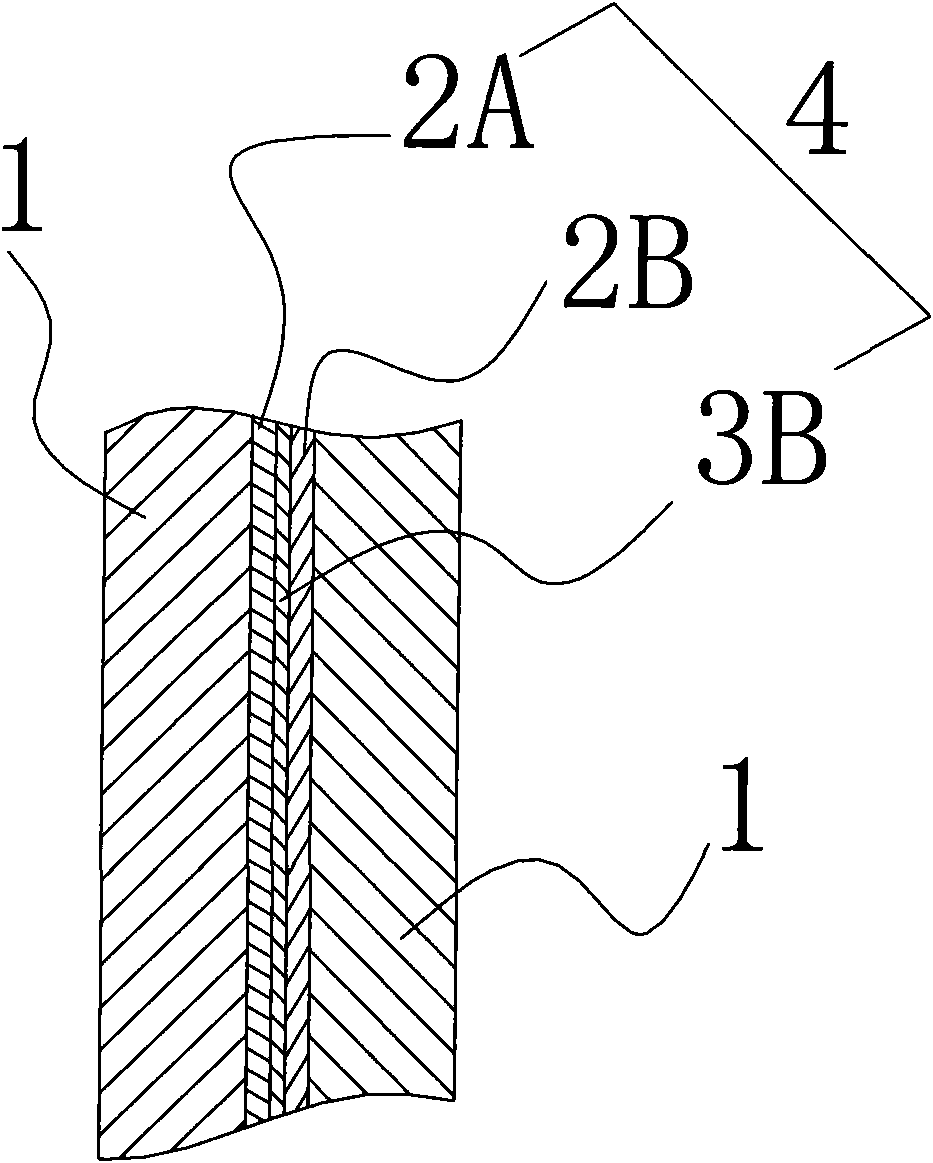

Electronic skin based on three-dimensional flexible substrate graphene and preparing method thereof

InactiveCN104359597AExcellent detection characteristicsUltra-light and ultra-thinForce measurementElectrical resistance and conductanceShape change

The invention relates to electronic skin based on three-dimensional flexible substrate graphene and a preparing method thereof. The graphene electronic skin comprises two flexible substrates and graphene films covering the inner surfaces of the flexible substrates. When the three-dimensional flexible substrates are subjected to external action force such as squeezing and stretching, the contact area of the upper graphene layer and the lower graphene layer is changed, so that change of the contact resistance between the two layers is caused directly, and then the shape change of the electronic skin under external force is reflected by reading a voltage or current signal. The electronic skin based on the three-dimensional flexible substrate graphene is transparent and has the advantages of being ultralight, ultrathin, capable of saving energy and the like. The graphene is environmentally friendly, poisonless and compatible with the human body and can be used on the human skin in a more healthy way.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

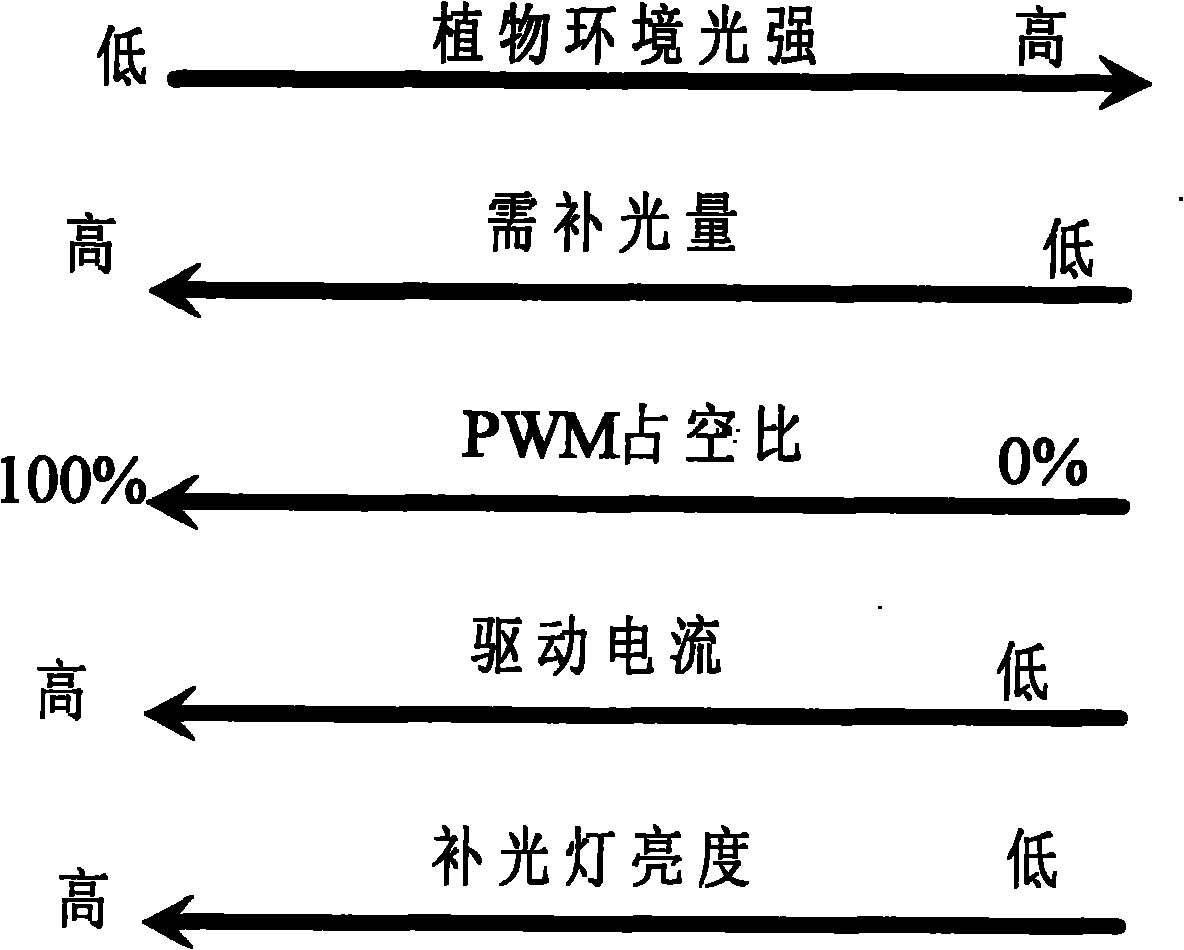

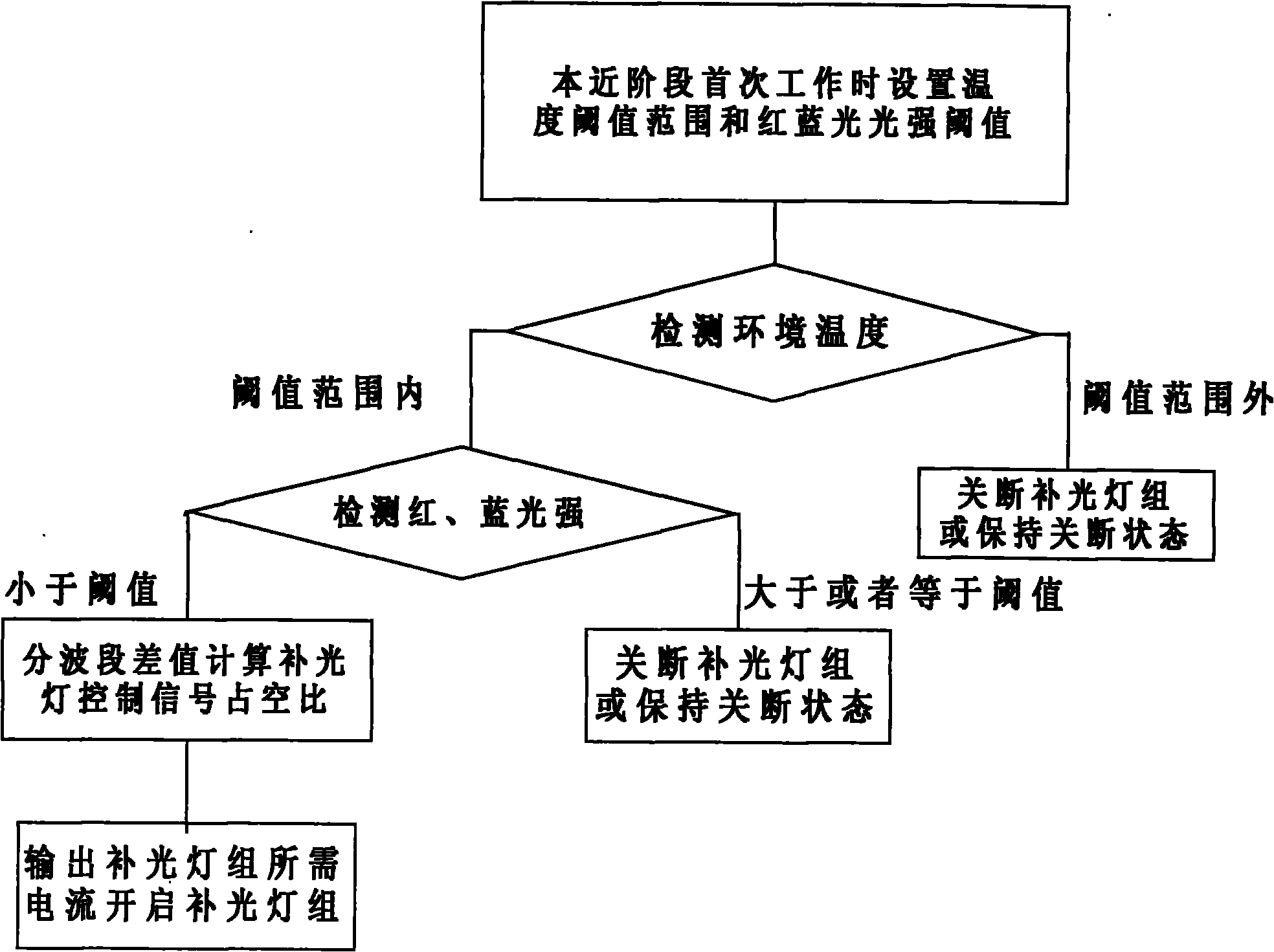

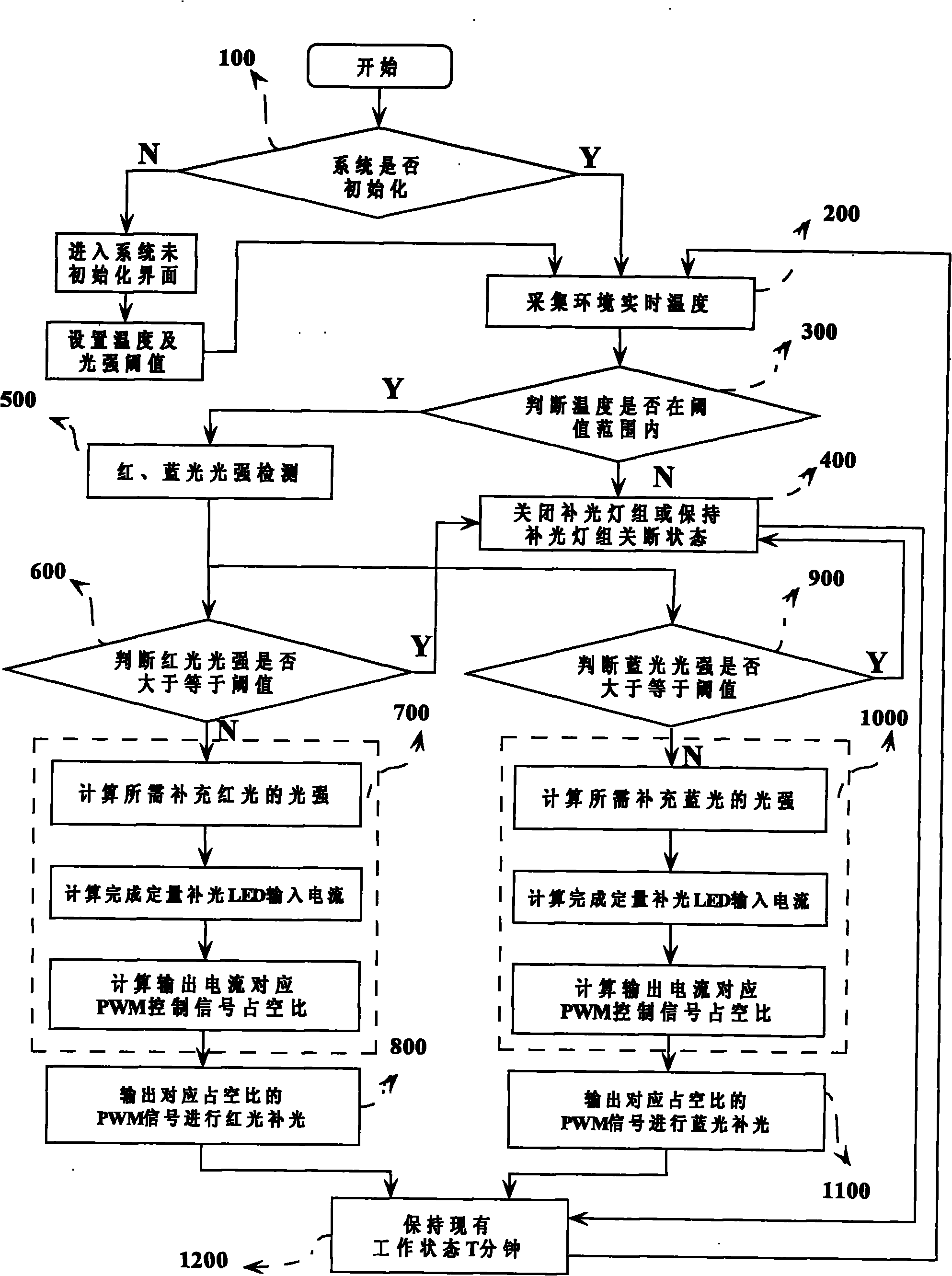

Intelligent plant supplementary lighting method and device

InactiveCN102077767AEnergy savingImprove light absorptionElectric light circuit arrangementGreenhouse cultivationPhysicsRed light

The invention relates to an intelligent plant supplementary lighting method. The method comprises the following steps: setting a red light threshold and a blue light threshold according to the demand of a plant on red light and blue light in each growth stage; detecting the intensities of the red light and the blue light in the growing environment of the plant; comparing the intensities with the corresponding red light threshold and blue light threshold to judge whether supplementary lighting is required and determine the accurate volume of the supplementary lighting; if the supplementary lighting is required, calculating the input current of a corresponding supplementary lighting set according to the volume of the supplementary lighting, so as to accurately control the intensity of the supplementary lighting set and realize intelligent and accurate supplementary lighting on demand, and if the supplementary lighting is not required, turning off the supplementary lighting set. The invention also provides a device realizing the method. By utilizing the supplementary lighting method and device in the invention, quantitative demand supplementary lighting by wavelength can be carried out on the plant according to the characteristics in different growth stage of the plant.

Owner:NORTHWEST A & F UNIV

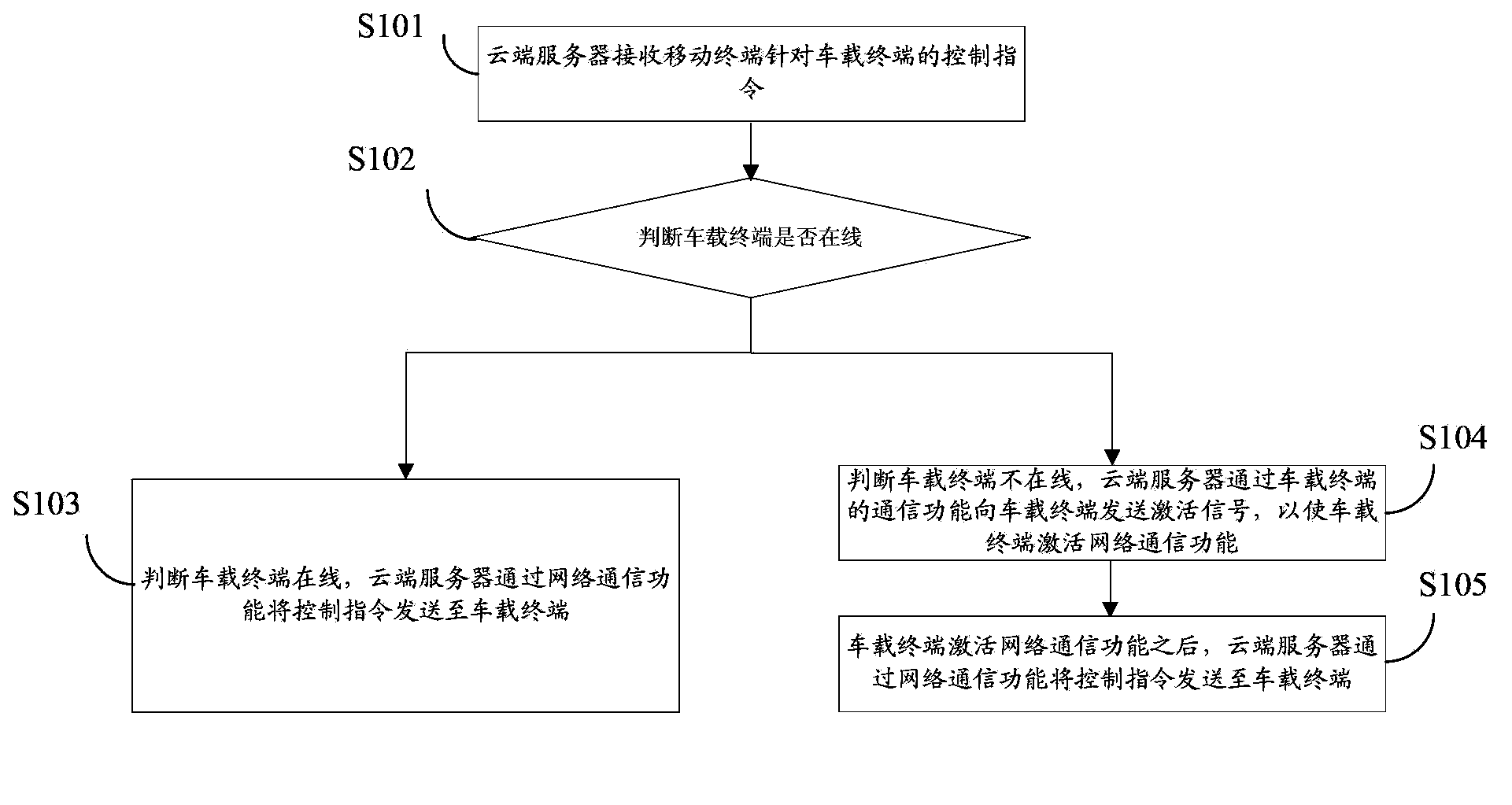

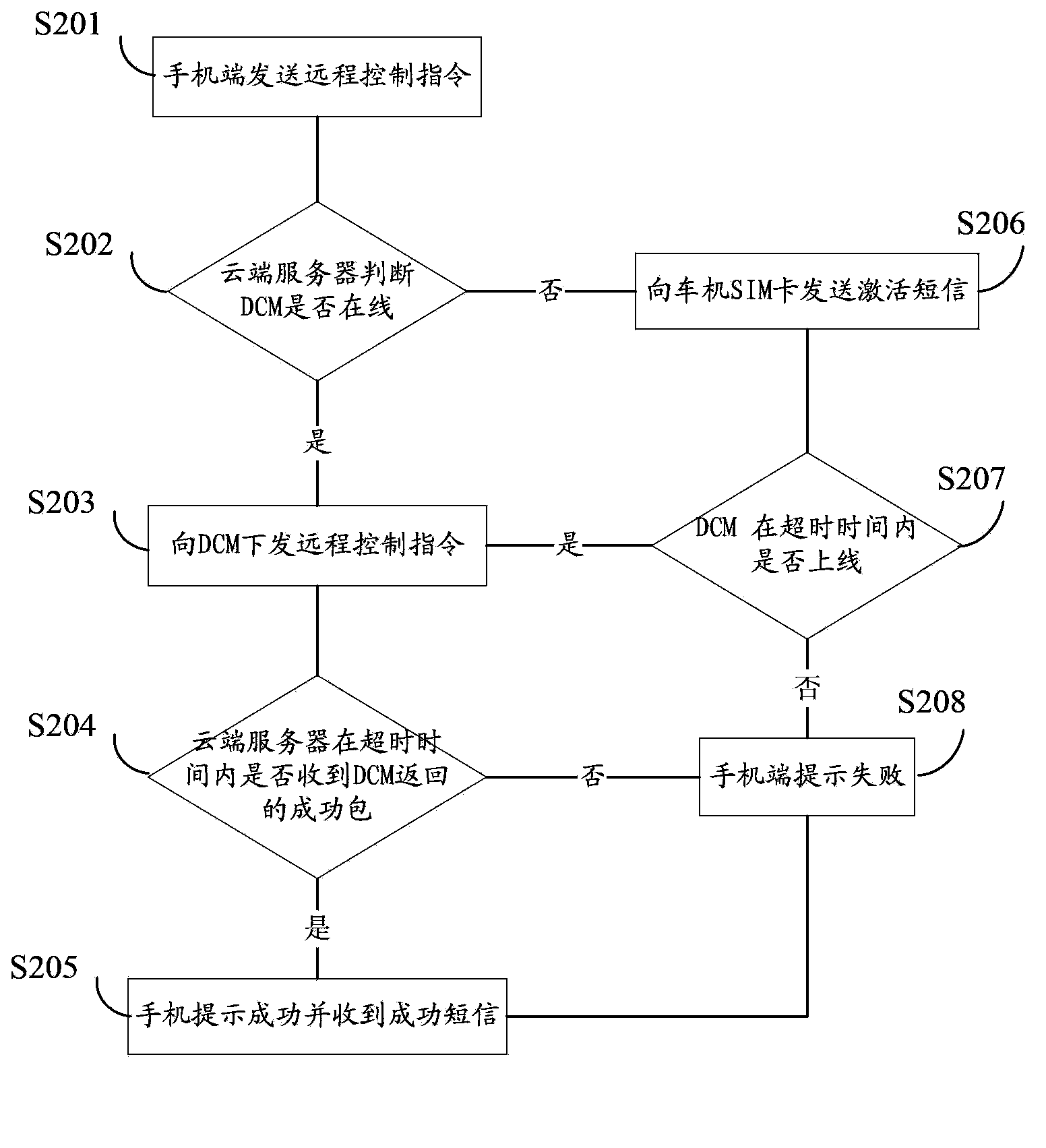

Vehicle-mounted terminal control method and system and cloud end server

ActiveCN103905520AEnergy savingRealize wireless communicationEnergy efficient ICTTelephonic communicationReal-time computingNetwork communication

The invention provides a vehicle-mounted terminal control method which comprises the steps that a cloud end server receives a control instruction on a vehicle-mounted terminal from a mobile terminal, whether the vehicle-mounted terminal is on line is judged, and if yes, the cloud server sends the control instruction to the vehicle-mounted terminal; and otherwise, the cloud server sends an activation signal to the vehicle-mounted terminal, the network communication function of the vehicle-mounted terminal is activated, and after the network communication function of the vehicle-mounted terminal is activated, the cloud end server sends the control instruction to the vehicle-mounted terminal through the network communication function. According to method, under the situation that energy is saved, long-distance vehicles can be controlled quickly at the same time, wireless communication is achieved, and easiness, high efficiency and applicability are achieved. The invention further discloses a vehicle-mounted terminal control system and the cloud end server.

Owner:BYD CO LTD

Zinc phosphating solution of aluminium and aluminium alloy

InactiveCN101812682ALower working temperatureEnergy savingMetallic material coating processesBuilding materialChromium

The invention belongs to the field of metal surface treatment, relating to a zinc phosphating solution of aluminium and aluminium alloy. The invention is mainly used for zinc phosphating treatment of the aluminium and aluminium alloy in the industries of home appliances, automobiles, hardware, building materials and railway locomotives. The zinc phosphating solution is composed of 8-25g / l of PO4<-3>, 6-16g / l of NO3<-1>, 1.6-8.0g / l of Zn<+2>, 0.12-0.38g / l of F<-1>, 0.6-8.0g / l of Fe<+2>, 0.01-1.5g / l of Ni<+2>, 0.0002-0.0006g / l of accelerating agent, 0.001-1.2g / l of organic complexing agent and the balance of water. When the phosphating solution of the invention is used for processing the aluminium and aluminium alloy, the obtained phosphating film has favourable matching capability with the coating, and the griding test of the paint film can reach 0 grade. The phosphating solution of the invention does not use toxic chromium, and the phosphating film does not contain chromium so as to solve the problems of environment pollution and toxic hazard on the human body when the chromium is used for processing the aluminium and aluminium alloy, and lower treatment cost.

Owner:中化化工科学技术研究总院有限公司

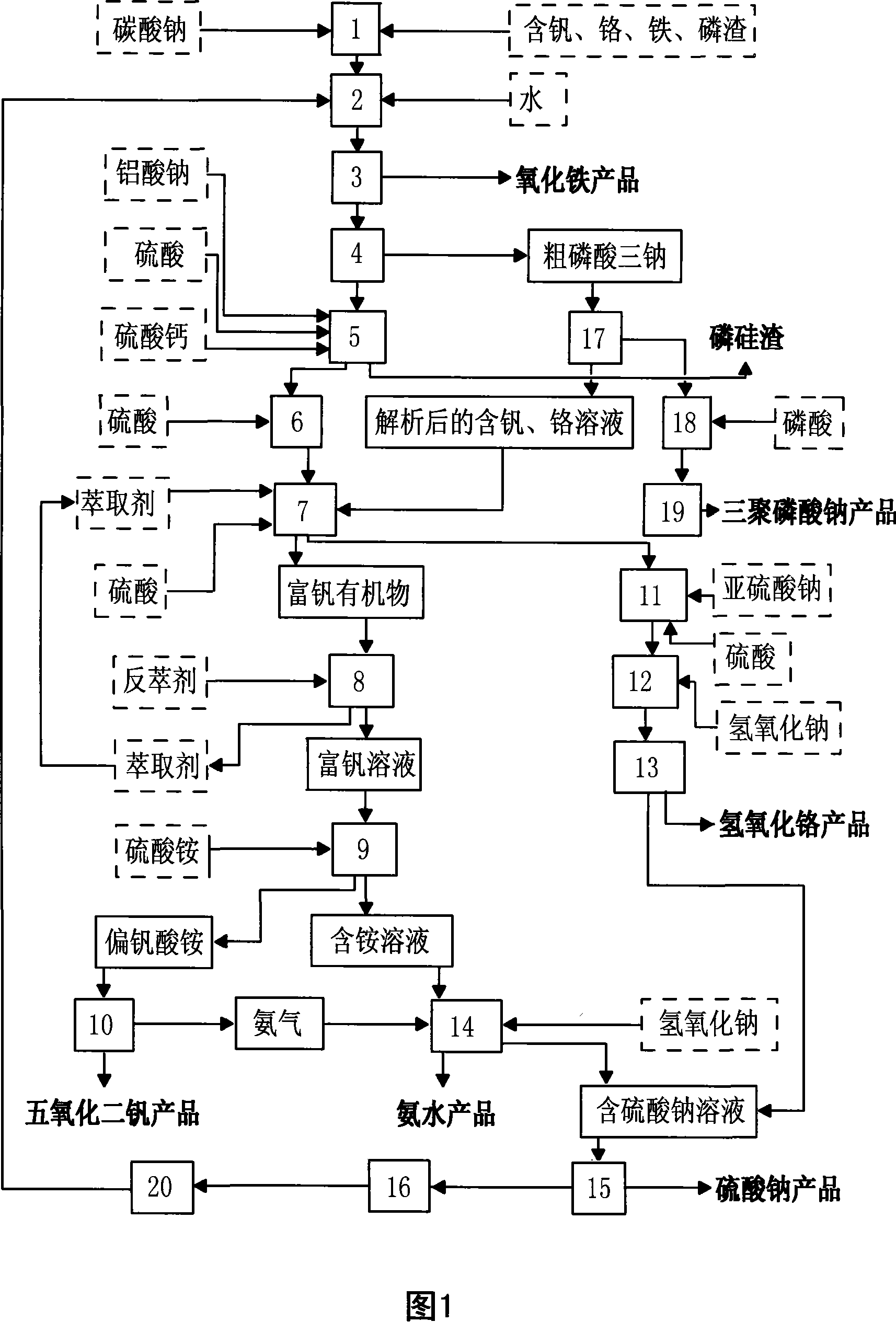

Method of reclaiming chemical industry products by using industrial slag containing vanadium, chromium, iron and phosphorous

ActiveCN101058853ATake advantage ofUsefulRaw phosphate material treatmentProcess efficiency improvementChemical industrySlag

The invention discloses a recovering chemical product method with a V, Cr, Fe and P industrial muck in the chemistry field, which comprises the following steps: roasting raw materials; heating and leaching the clinkers; separating ferric oxide from the solution containing V, Cr, Fe and P; crystallizing the solution in order to removing to P; removing P deeply; removing Si; adjusting the acidity of the solution containing V and Cr; extracting V; extracting V reversely; settling V; roasting metammonium vanadate; reducing Cr; settling chromic hydroxide; separating chromic hydroxide from sodium sulfate; removing NH3; getting sodium sulfate crystallization; purifying sodium sulfate mother liquor; adsorbing V, Cr, tertiary sodium phosphate solution with rough tertiary sodium phosphate refining resin and reacting with phosphoric acid; drying and roasting sodium tripolyphosphate; getting V, Cr, Fe and P from the industrial muck containing V, Cr, Fe and P and separating the secondary product of ammoniacal liquor and sodium sulfate in the heat exchange procedure. The invention saves the energy, which adapts to an industrial appliance.

Owner:辽宁虹京实业有限公司

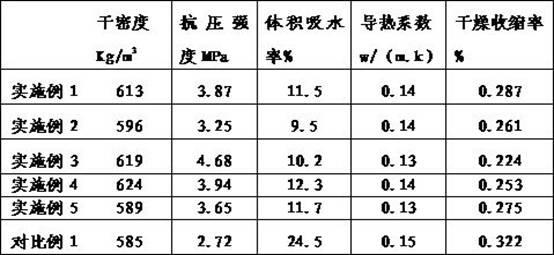

Method of preparing thermal insulating mortar from solid waste

This invention relates to a method for preparing heat-preservation mortar utilizing solid castoffs, in which, the raw material is composed of two groups: group A includes the following components and weight percentage: slag powder 20-40%, powdered coal ash 20-30%, Portland cement 30-40%, Ca reinforcing agent 5-15%, abandon polystyrene foams 3-8%, PP fiber 0.05-0.15%, re-dispersible latex powder 1-3%, water preservation agent 0.2-0.6%, water reducer 0.1-0.5%, defoamer 0.05-0.10%, and quartz sand is the raw material of group B, and the weight ratio of group A and B is 1:1. Raw materials of group A are weighed and matched then to be put into a sterring mill and mixed uniformly and then quartz sand of equal volume is added in it to be mixed continuously to get the heat preservation mortar, which can be used by adding suitable volume of water.

Owner:SHANGHAI UNIV

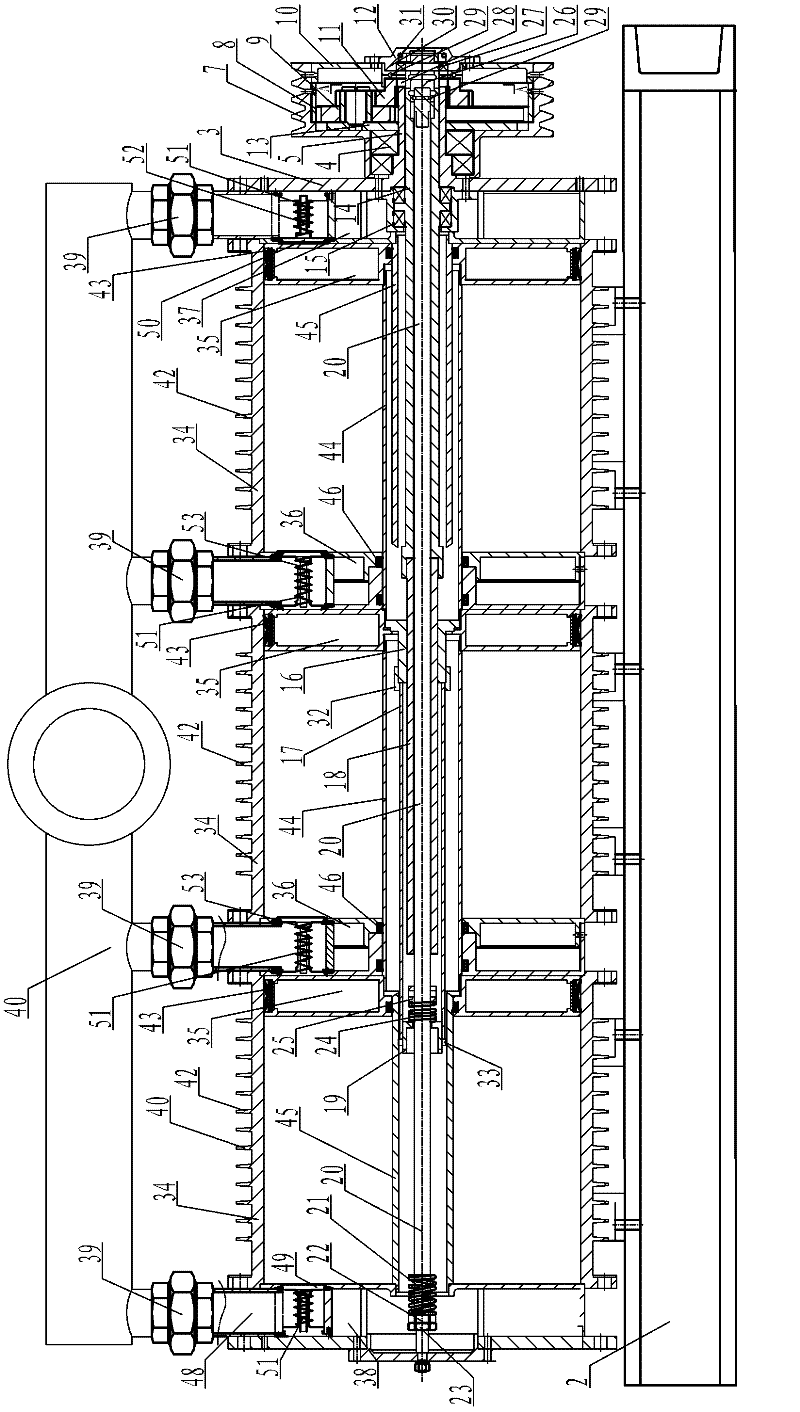

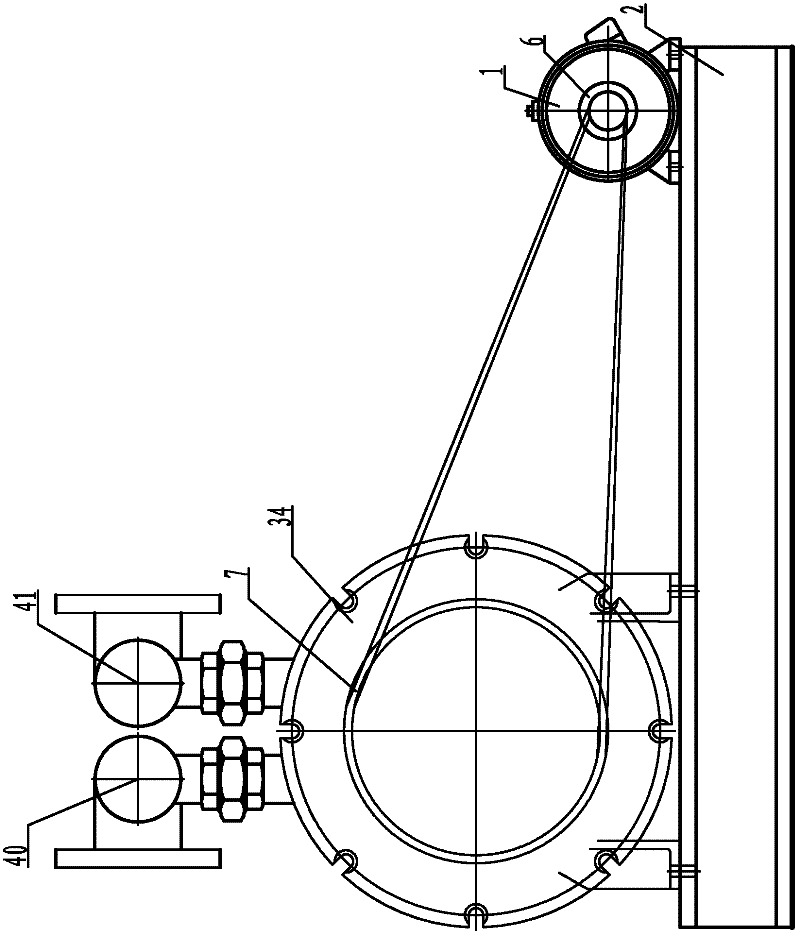

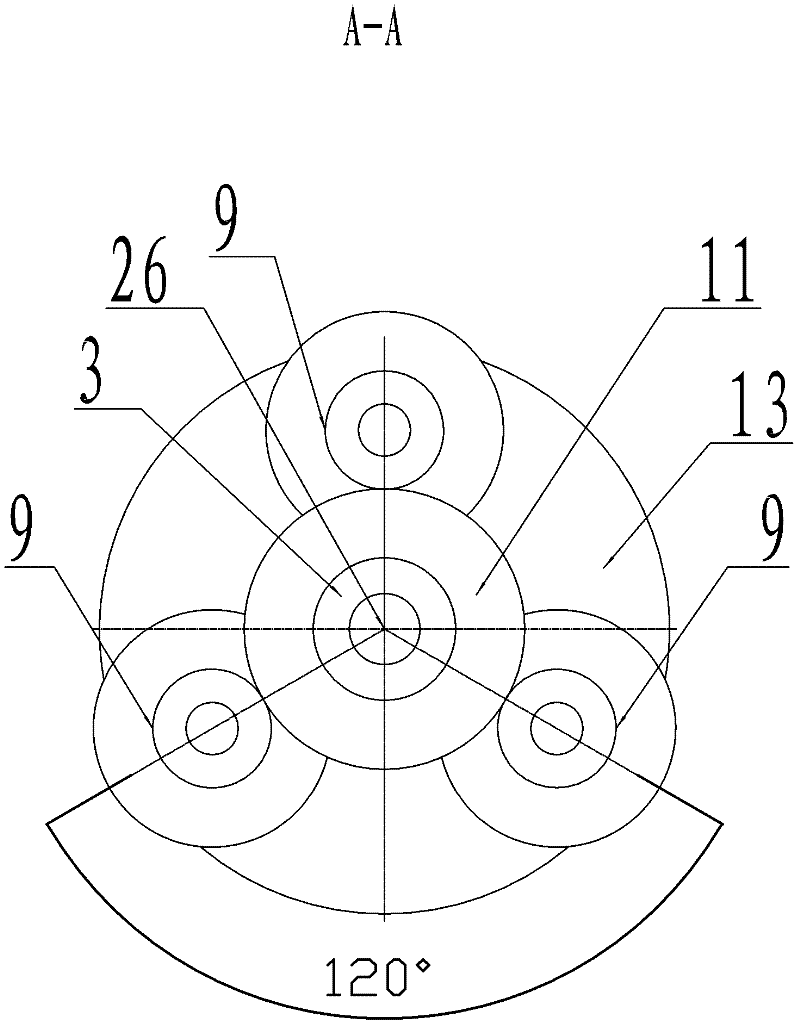

Reciprocating screw vacuum compressor

InactiveCN102226450ARealize forward and reverse commutation rotationReasonable designMechanical actuated clutchesPumpsExhaust valveDrive wheel

The invention relates to a reciprocating screw vacuum compressor. The compressor is characterized in that a driven wheel is provided with a reciprocating screw transmission mechanism formed by a driven wheel supporting shaft, a gear transmitting and reversing system, hollow shafts, bearing blocks, hollow screw rods, nuts, nut sleeves, connecting sleeves, reversing rods, a spring mechanism and a jaw clutch; tandem piston units in a vacuum compression device formed by cylinders, pistons, sealing connecting pipes, sealing elements A, intermediate separate cavities, sealing elements B, a front separate cavity, a rear separate cavity, three-way intake valves, three-way exhaust valves, intermediate three-way exhaust valves, intermediate three-way intake valves, a main exhaust pipe and a main intake pipe are driven by reversion of the reversing rods in the reciprocating screw transmission mechanism to continuously reciprocate in the cylinders, thus realizing the vacuumizing and compressing functions of the vacuum compressor. The vacuum compressor not only has reasonable design and compact structure, but also has the advantages of energy conservation, no vibration, no noises, conformity with the environmental protection requirement, stable operation, convenience in operation and use and the like.

Owner:DALIAN JINGGONG MACHINERY EQUIP

Light insulating brick prepared from fly ash, boiler slag, construction garbage and straw and preparation thereof

InactiveCN101298371ASimple preparation processEnergy savingSolid waste managementScrapAgricultural waste

The invention relates to a light-weight insulating brick produced by adopting pulverized fuel ash, furnace slag, building waste and stalk and a production method thereof. The materials of pulverized fuel ash, furnace slag, building waste, stalk, lime power, cement, gypsum, Na2SO4 and water are prepared according to the following mass ratio and are then mixed, molded and cured to product the light-weight insulating brick; the light-weight insulating brick comprises the following weight percentage of all ingredients of the raw materials: 36-55 parts of pulverized fuel ash, 6-20 parts of furnace slag, 26-35 parts of building waste, 3-15 parts of stalk, 12-15 parts of carbide slag, 8-14 parts of cement, 2-5 parts of gypsum, 1-3 parts of Na2SO4 and proper amounts of water. The method utilizes the industrial and agricultural wastes such as the pulverized fuel ash, furnace slag, building waste, stalk and so on to produce the light-weight insulating brick, and the brick is light in weight, heat-insulating, has high strength and meets the quality standard; furthermore, the production technique is simple and no wastewater, waste residue or exhaust gases is discharged, so the invention is energy-saving, pollution-free, low-cost and has good production condition.

Owner:李东升

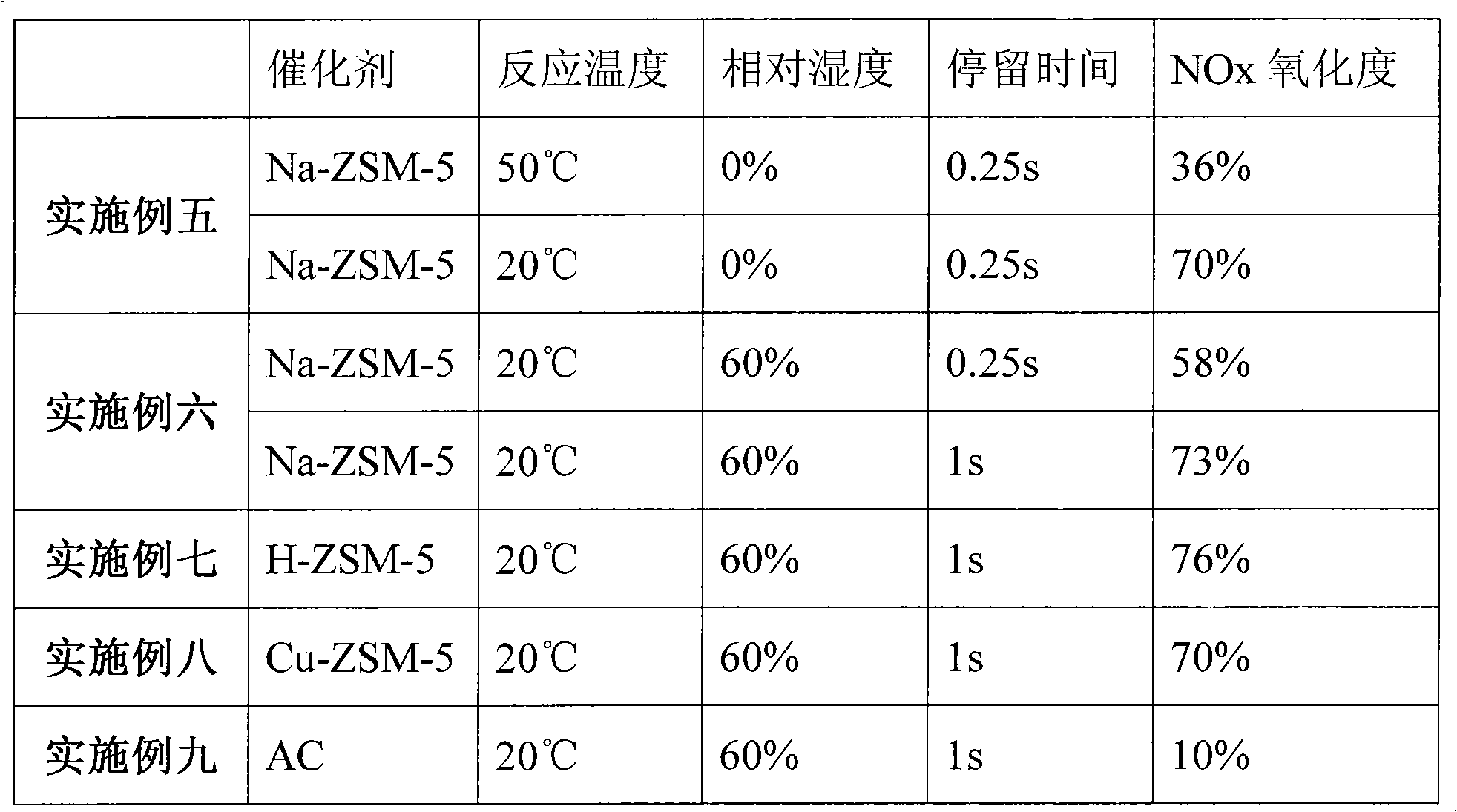

Method for catalytic oxidation NO with ZSM-5 type molecular sieve as catalyst

InactiveCN101259368AEnergy savingReduce consumption and costsMolecular sieve catalystsDispersed particle separationIonExhaust gas

The invention discloses a method for catalytic oxidizing NO with a ZSM-5 type molecular sieve as catalyst, which uses an H type, a Na type and the ZSM-5 type molecular sieve exchanged with, metallic ion as catalyst and uses the O2 in aerobic NOx exhaust gas as oxidant to oxidize the NO in the aerobic NOx exhaust gas into NO2 under the condition of 0-100 DEG C; the moisture content of the aerobic NOx exhaust gas is counted as 0 percent to 100 percent according to the relative humidity at ambient temperature. The Si / A1 rate of the ZSM-5 molecular sieve is no less than 30 to full silicon, which is provided with good low temperature catalytic activity and hydrophobicity and still can keep good catalytic activity when the relative humidity reaches 100 percent, thus solving the difficult problems of bad water-resistant performance and high activity temperature in traditional NO oxidation catalyst, which is especially suitable for NOx desorption of low temperature emission source of aerobic exhaust gas. At the same time, the method has the advantages of simple operation and low cost, which has good promotional value.

Owner:ZHEJIANG UNIV OF TECH

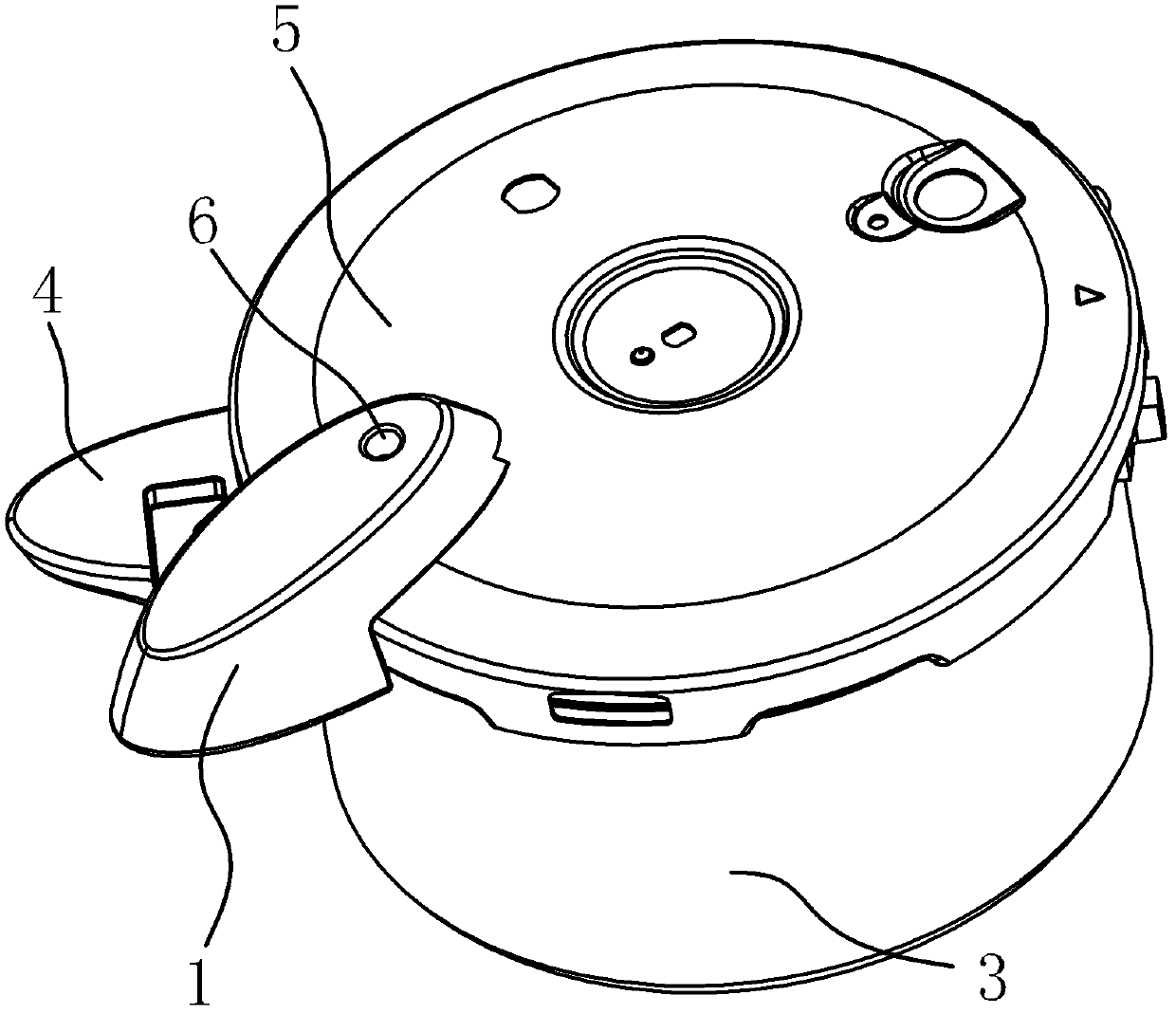

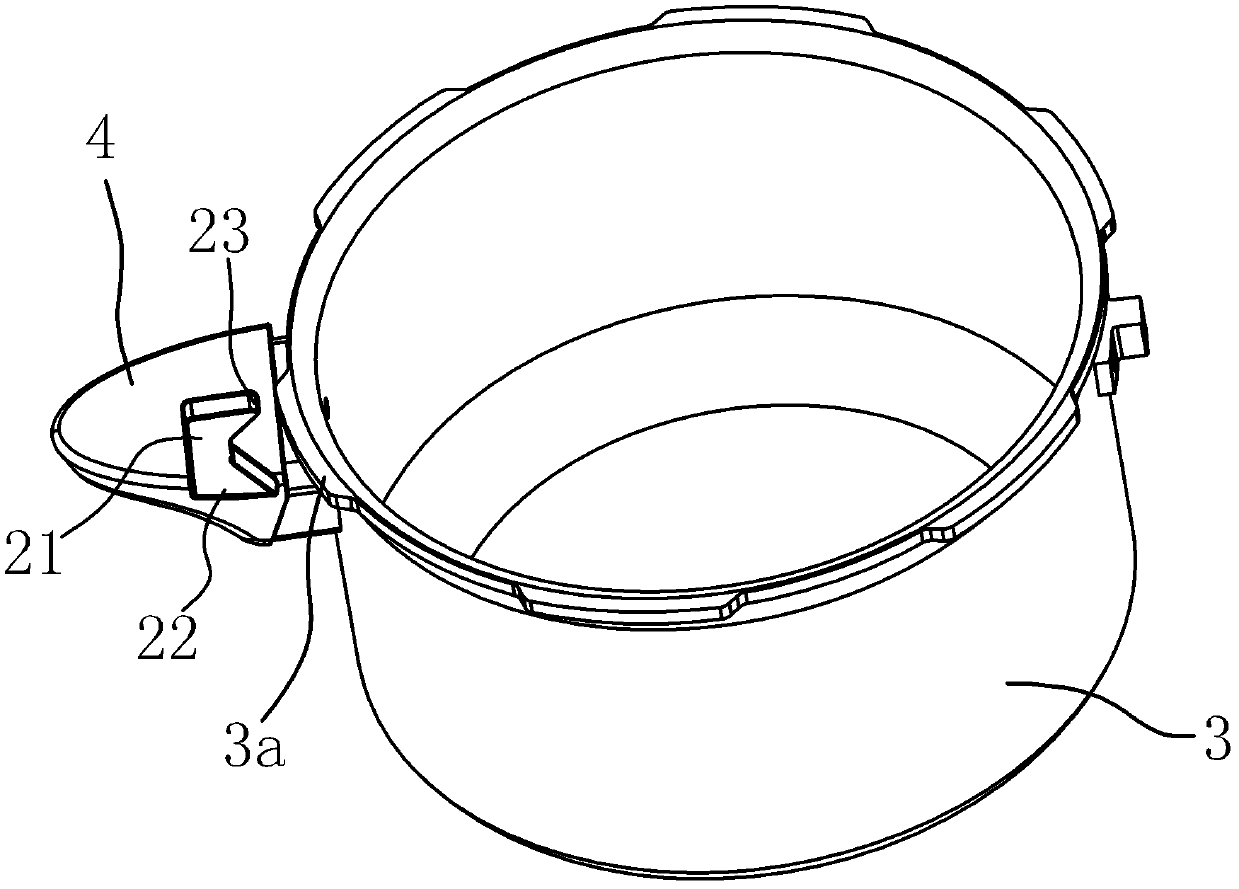

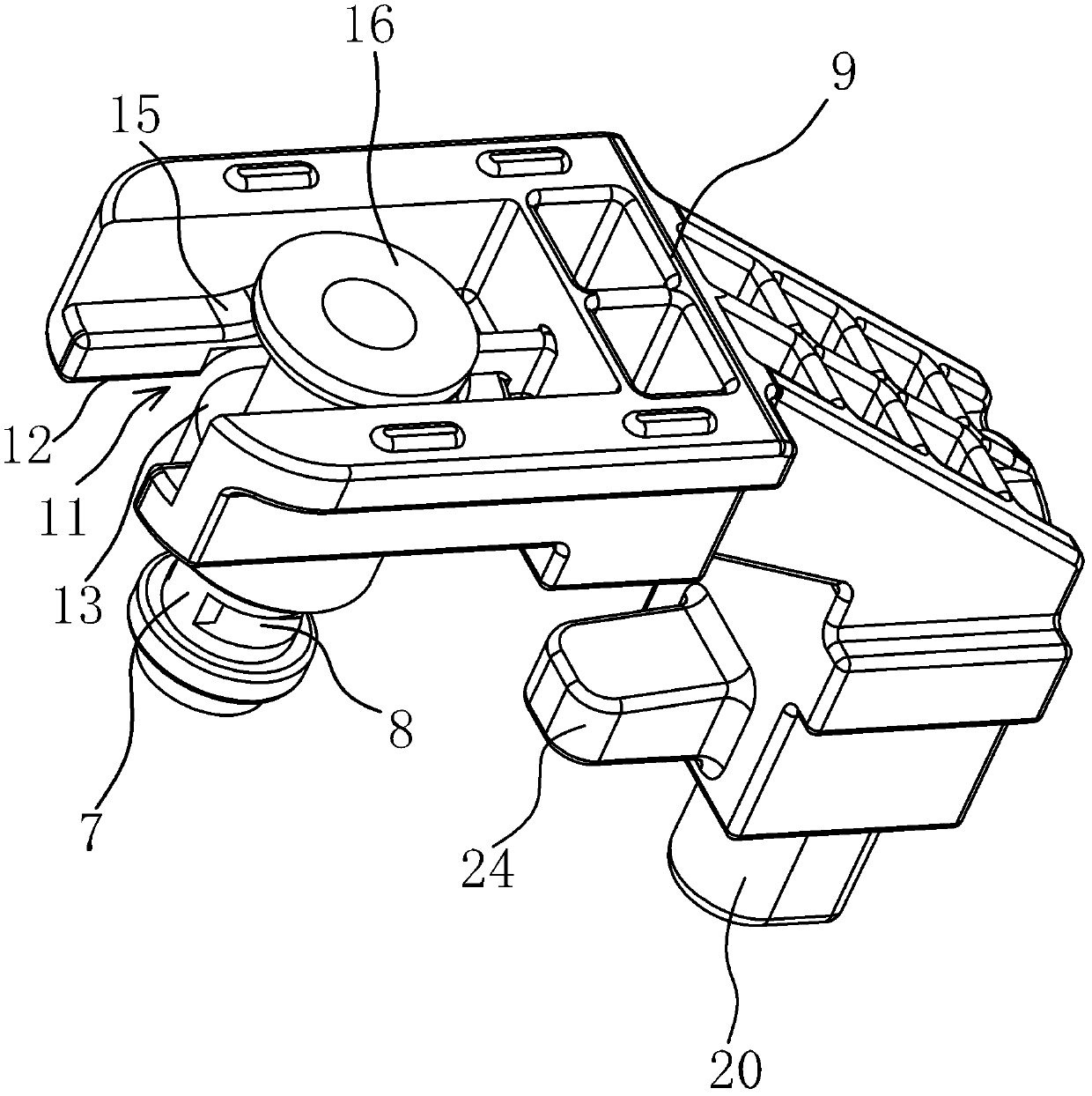

Cover opening and closing safety device of pressure cooker

ActiveCN102319018BEnsure safetyShorten the ascent strokePressure-cookersEngineeringMechanical engineering

The invention relates to a pressure cooking device comprising: - a vessel and a lid to form a cooking chamber, - a first port, - an opening safety means movable between a release position and a locking position, said opening safety means being designed to be in the locking position when the pressure inside the chamber is greater than or equal to a pre-determined value referred to as the rising pressure, characterised in that said opening safety means is designed to pass through a first intermediate position in which it releases said first port when it moves in either direction between said release and locking positions, , said device comprising an actuating means (13) for actuating the opening safety means, designed to allow the opening safety means to be moved into its first intermediate position. Pressure cooking devices.

Owner:ZHEJIANG SUPOR CO LTD

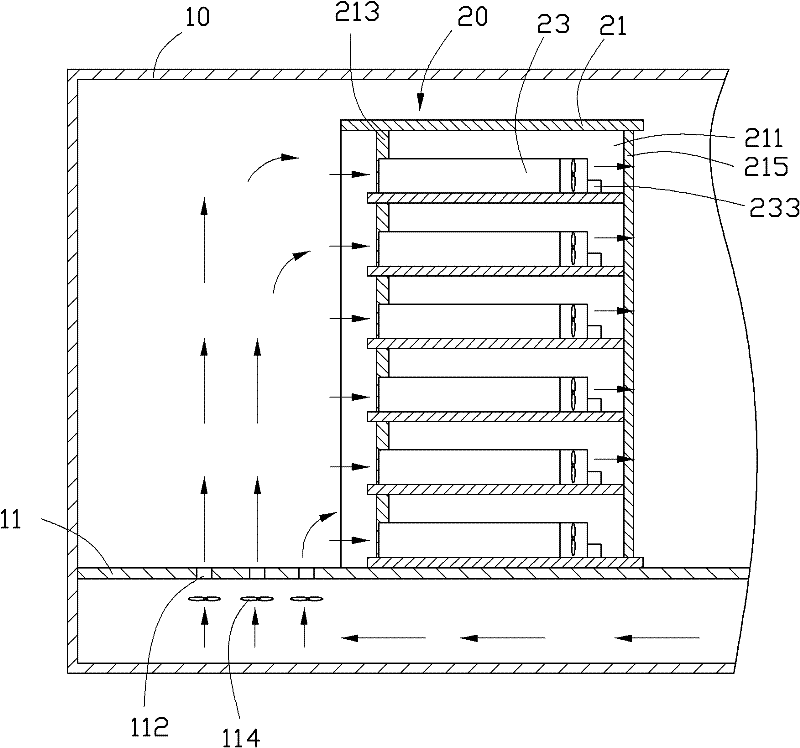

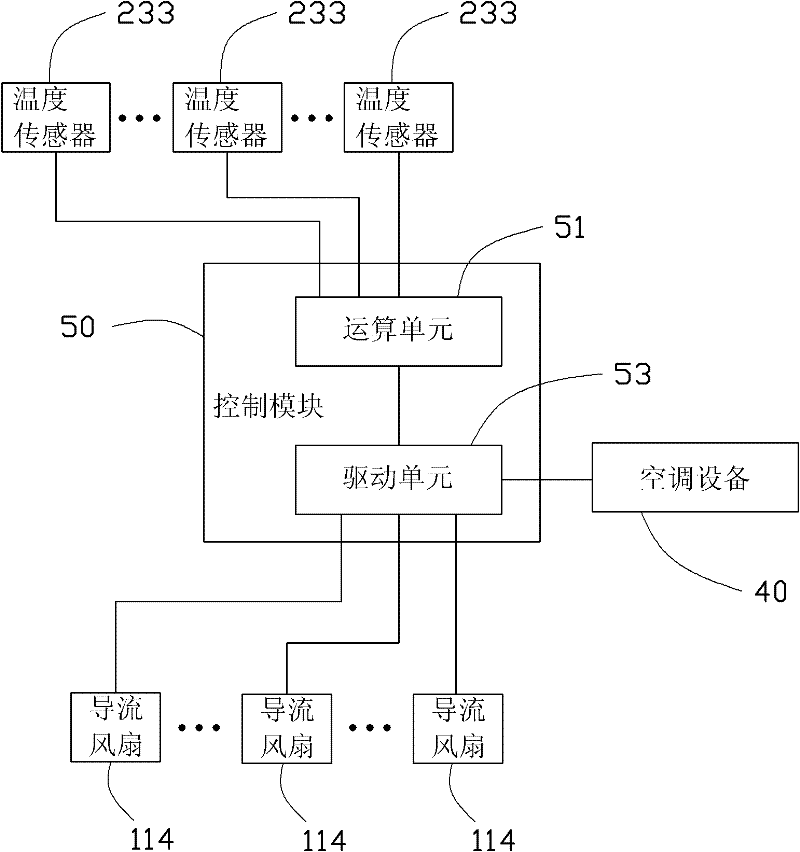

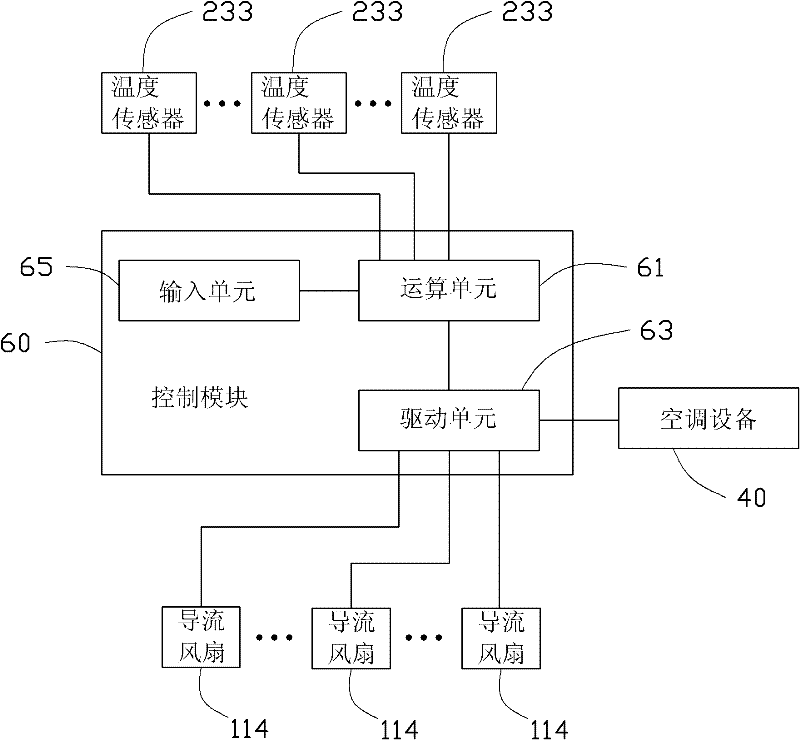

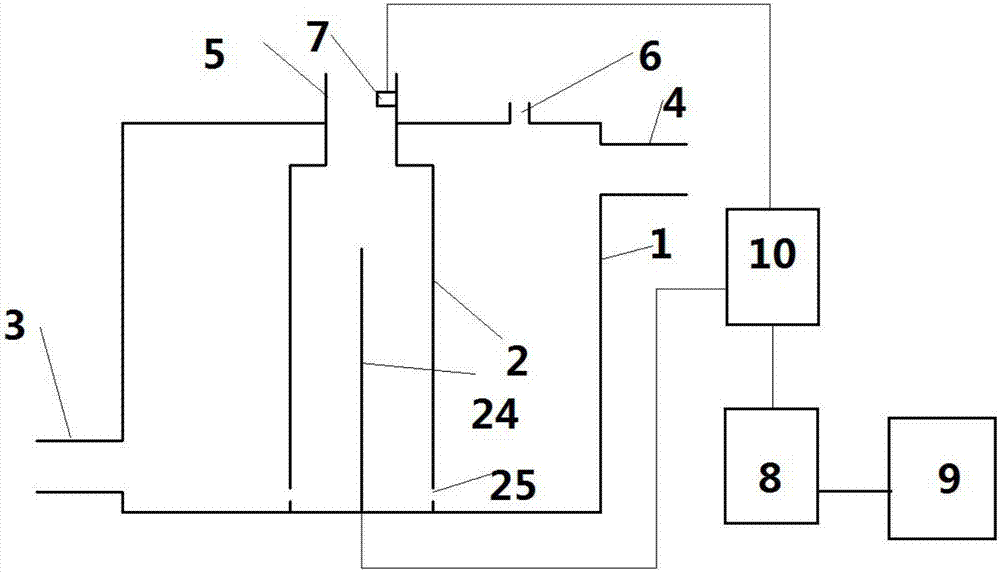

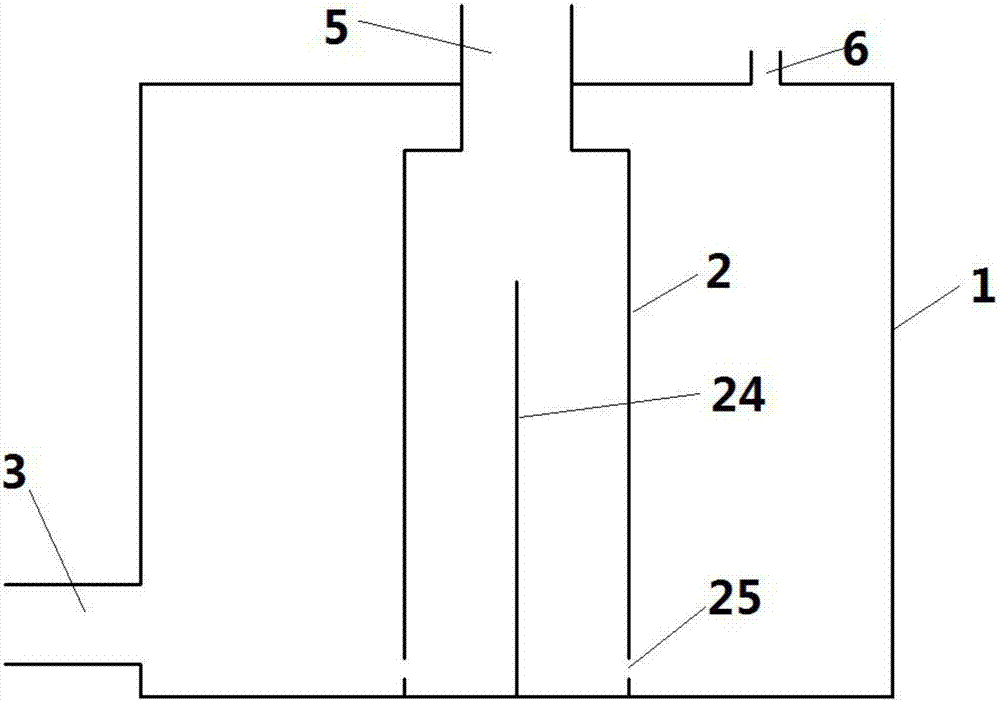

Data center and cooling system thereof

InactiveCN102458084AImprove cooling efficiencyEnergy savingTemperature control using electric meansCooling/ventilation/heating modificationsEngineeringServer system

The invention discloses a data center, comprising a cabinet and at least one server system, wherein the cabinet is provided with an elevated floor, and the at least one server system is arranged in the cabinet; the server system comprises multiple severs at different heights; and the elevated floor has a ventilating grate hole. The cooling system used for the data center comprises an air conditioner, multiple temperature sensors respectively arranged nearby the exhaust ends of the servers, a group of guide fans arranged nearby the ventilating grate hole of the elevated floor, and a control module electrically connected with the air conditioner, the temperature sensor and the guide fans, wherein the cool air from the air conditioner is injected below the elevated floor; the guide fans can drive the cool air to pass through the ventilating grate hole to flow upwards at an acceleration mode; and the control module adjusts the rotation speed of the guide fan based on the temperature value acquired by the temperature sensor, so as to enable the cool air to be uniformly distributed, and servers at different heights to uniformly cool. Compared with the prior art, the data center provided by the invention can improve the cooling efficiency, so as to save energy.

Owner:HONGFUJIN PRECISION ELECTRONICS (TIANJIN) CO LTD

Building silt soil non-sintered ceramic aggregate and preparation method thereof

ActiveCN102617107ASimple technical processEasy accessSolid waste managementSolid componentEnvironmental resistance

The invention discloses a building silt soil non-sintered ceramic aggregate, which is characterized by comprising solid components and water, wherein every kilogram of solid components comprise the following components in percentage by weight: 60-80 percent of building silt soil, 2-5 percent of cement, 2-5 percent of quick lime, 2-5 percent of desulfurized gypsum, 2-7 percent of perlite, 2-8 percent of fly ash and 5-10 percent of water glass; and the amount of the water accounts for 45-60 percent of the total mass of the solid components. The invention also discloses a preparation method of the ceramic aggregate. The ceramic aggregate and the preparation method thereof have the characteristics of simple pretreatment of building silt soil, simple preparation process and capabilities of eliminating industrial wastes such as fly ash and desulfurized gypsum without large-sized calcining equipment and expanding the utilization approach of the solid waste material; and by adopting a non-sintering process, the ceramic aggregate and the preparation method thereof have the advantages of environmental protection effects such as energy conservation and low carbon compared with a roasting process.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Vapor generator for intelligently controlling vapor temperature

ActiveCN107327821AEnergy savingImprove securitySteam generation heating methodsEnergy industryVapor generatorElectric heating

The invention provides a vapor generator for intelligently controlling vapor temperature. The vapor generator comprises a box, an electric heating pipe, a cold water inlet and a vapor outlet. The cold water inlet is formed in the side wall of the box. The upper portion of the box is provided with an exhausting opening. The electric heating pipe is arranged in the box and comprises an outer pipe and an electric heater arranged in the outer pipe. The electric heating pipe is arranged in the vertical direction. A water input channel is formed in the lower portion of the electric heating pipe to ensure that water in the box can enter the electric heating pipe to be heated. The upper portion of the electric heating pipe is connected with the vapor outlet. The vapor outlet is provided with a temperature sensor and used for measuring temperature of the vapor outlet. The temperature sensor, the electric heating device and a controller are in data connection. The vapor generator of the new structure is designed, vapor can be generated fast and efficiently, moreover, the vapor generator has the beneficial effects of carrying out heating fast, enabling temperature distribution to be uniform and being safe and reliable, and the heating efficiency is improved.

Owner:安徽省皖晨电子科技有限公司

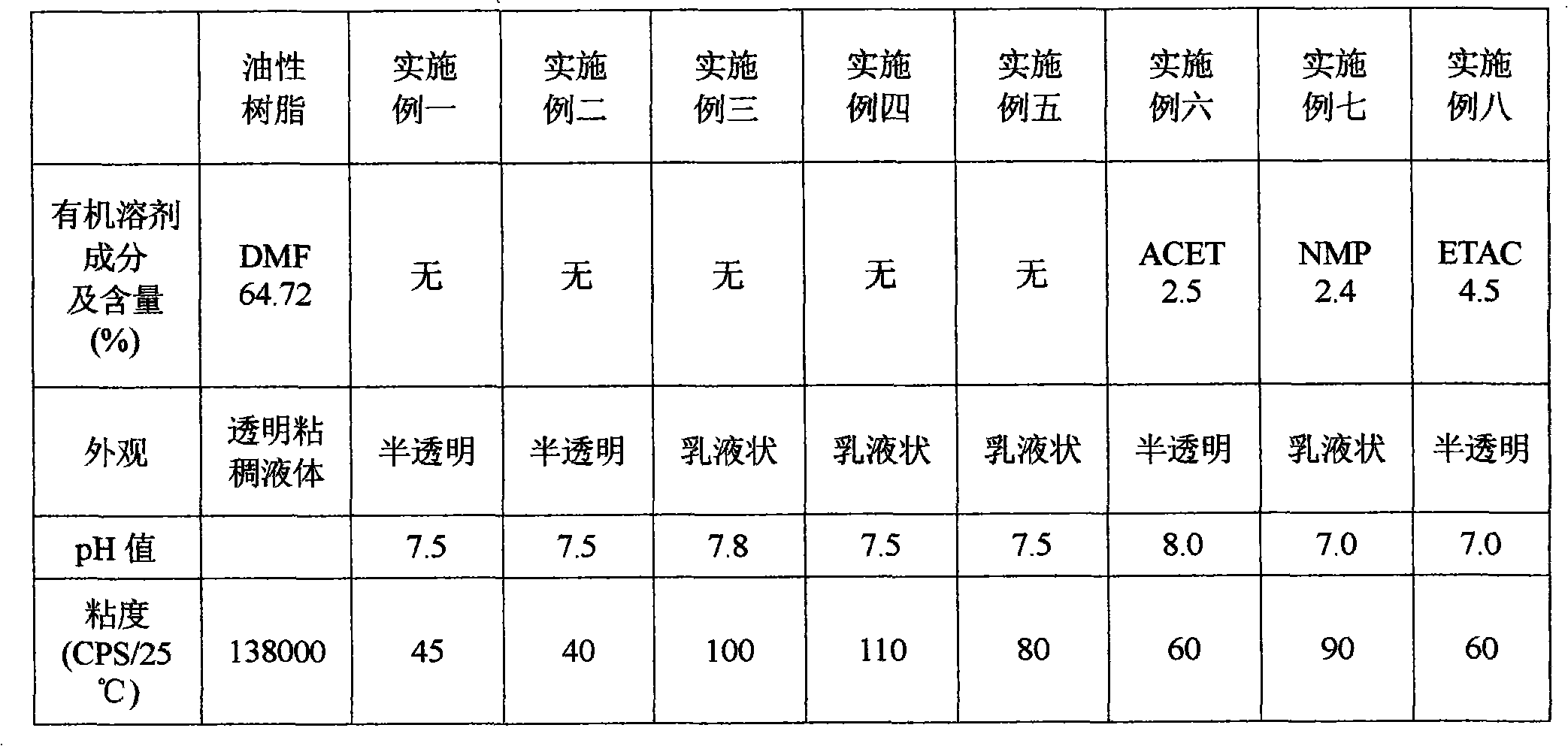

Preparation method of environmentally-friendly aqueous polyurethane adhesive

ActiveCN102102005AEasy to prepareEnergy savingPolyureas/polyurethane adhesivesIonPolyurethane adhesive

The invention discloses a preparation method of an environmentally-friendly aqueous polyurethane adhesive. The environmentally-friendly aqueous polyurethane adhesive is prepared from the following raw materials: polydiol with a number-average molecular weight between 500 and 5,000, a hydrophobic chain extender with a number-average molecular weight between 61 and 400, an inner-crosslinking agent,a hydrophilic chain extender, diisocyanate, a catalyst, an organic solvent, a neutralizing agent and deionized water. The preparation process comprises: heating the polydiol, the hydrophobic chain extender, the inner-crosslinking agent and the hydrophilic chain extender in a protective atmosphere of nitrogen, dewatering under vacuume and cooling; adding diisocyanate for reaction, cooling and adding a catalyst for a reaction; adding a proper amount of organic solvent for regulating viscosity; and adding aqueous solution of the neutralizing agent under the action of a high-speed shearing force to obtain the product. The product has the advantages of extremely low organic solvent content, high stability, insusceptibility to agglomeration and sedimentation, long storage period and low thermalactivation temperature, can be used for dry type combination and has the characteristics of high initial viscosity, high flexibility, high breathability, light odor and the like.

Owner:JIAXING HEXIN CHEM IND

Periclase-ferroalumina spinal brick and its making process

The present invention belongs to the field of refractory material technology, and is especially peiclase-ferroalumina spinel brick and its making process. The technological scheme is that the peiclase-ferroalumina spinel brick is made with magnesia 40-96 wt%, Al2O3 2-17 wt%, ferroalumina spinel or magnesia-alumina spinel 0-50 wt%, Fe 0.2-10 wt% and Fe2O3 0-10 wt%, and through mixing, adding sulfite pulp waste liquid in 2-8 wt%, mixing, forming, drying and in-site reaction sintering at 1000-2000 deg.c. The peiclase-ferroalumina spinel brick has simple making process, low power consumption, great bulk density and high strength.

Owner:WUHAN UNIV OF SCI & TECH

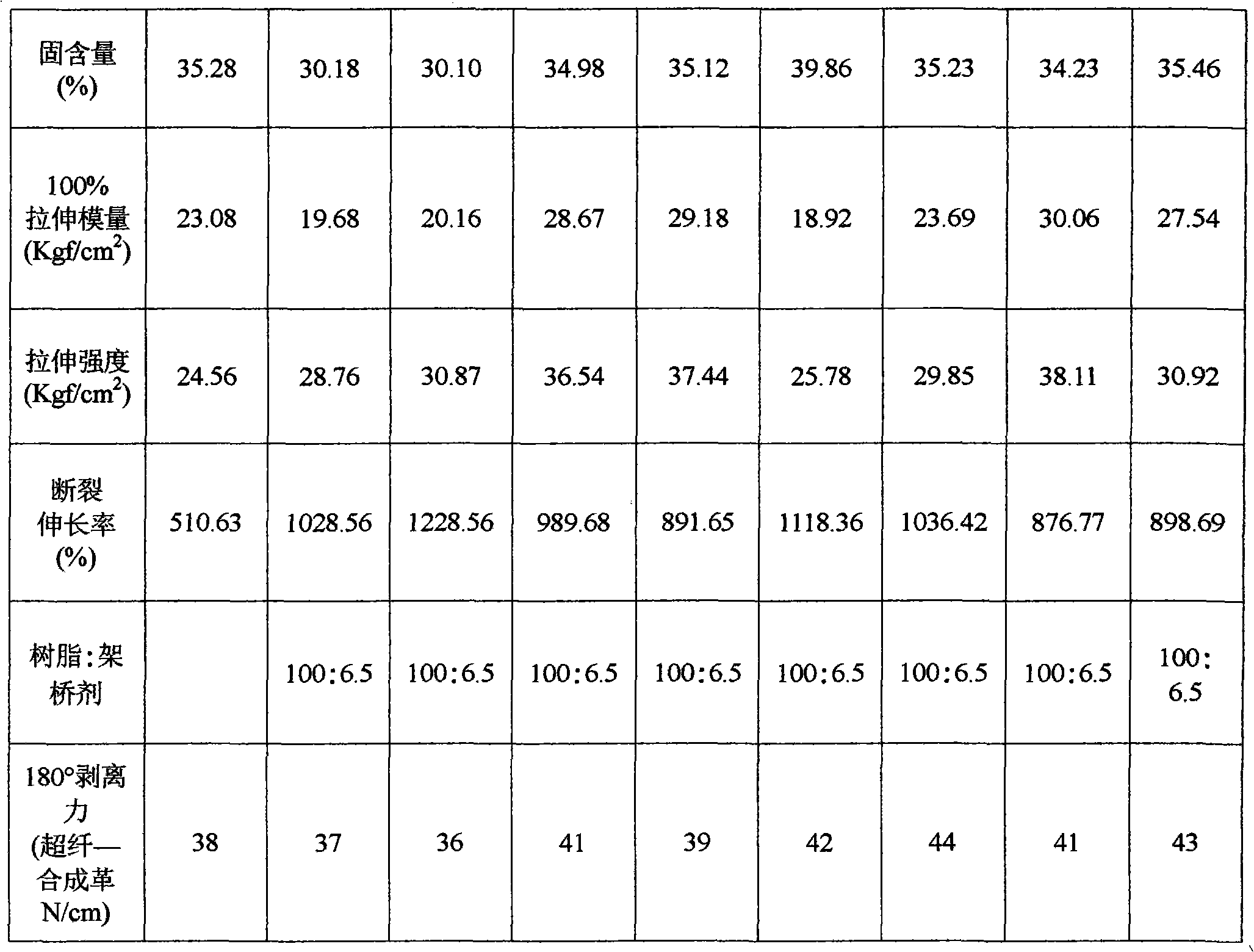

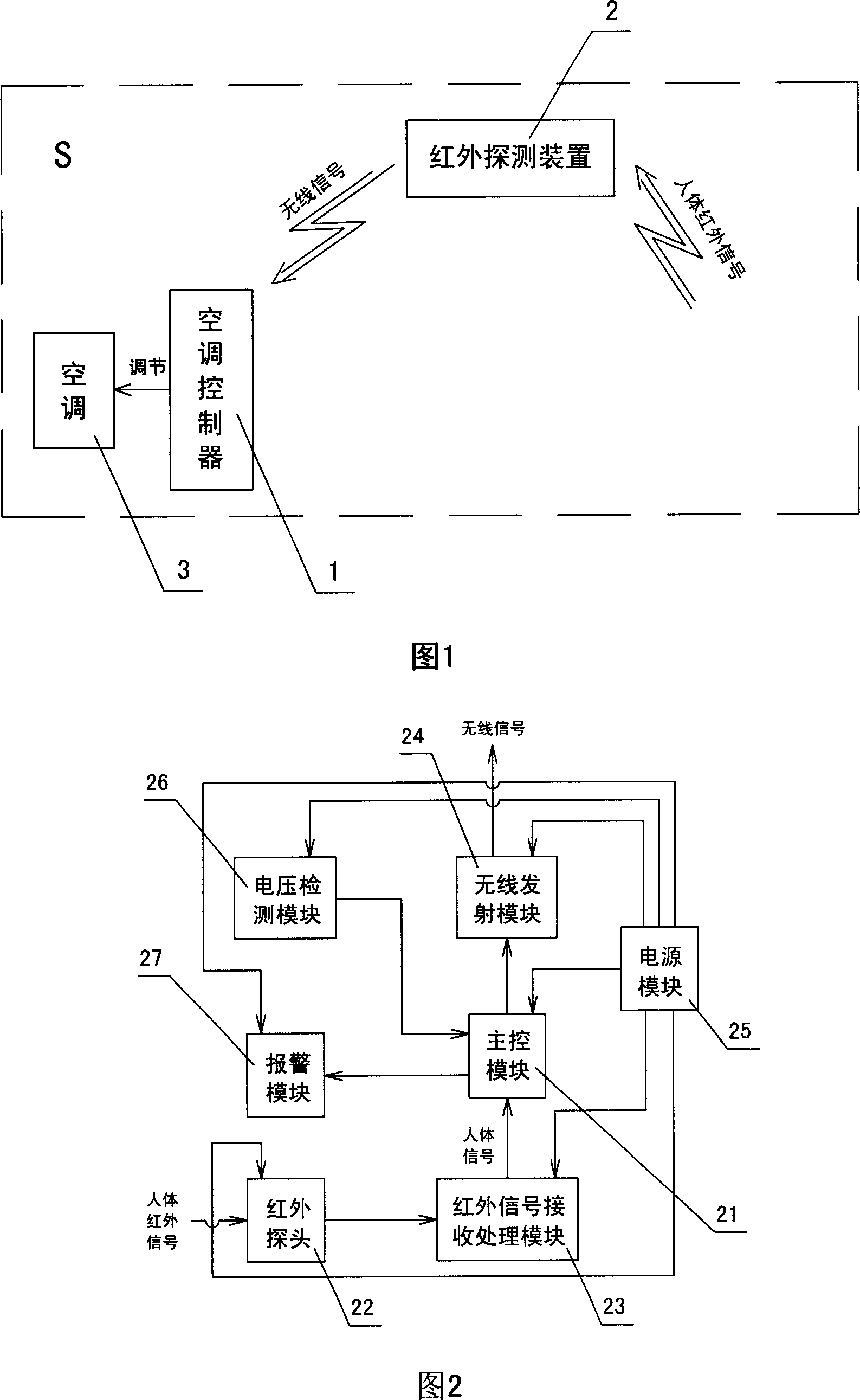

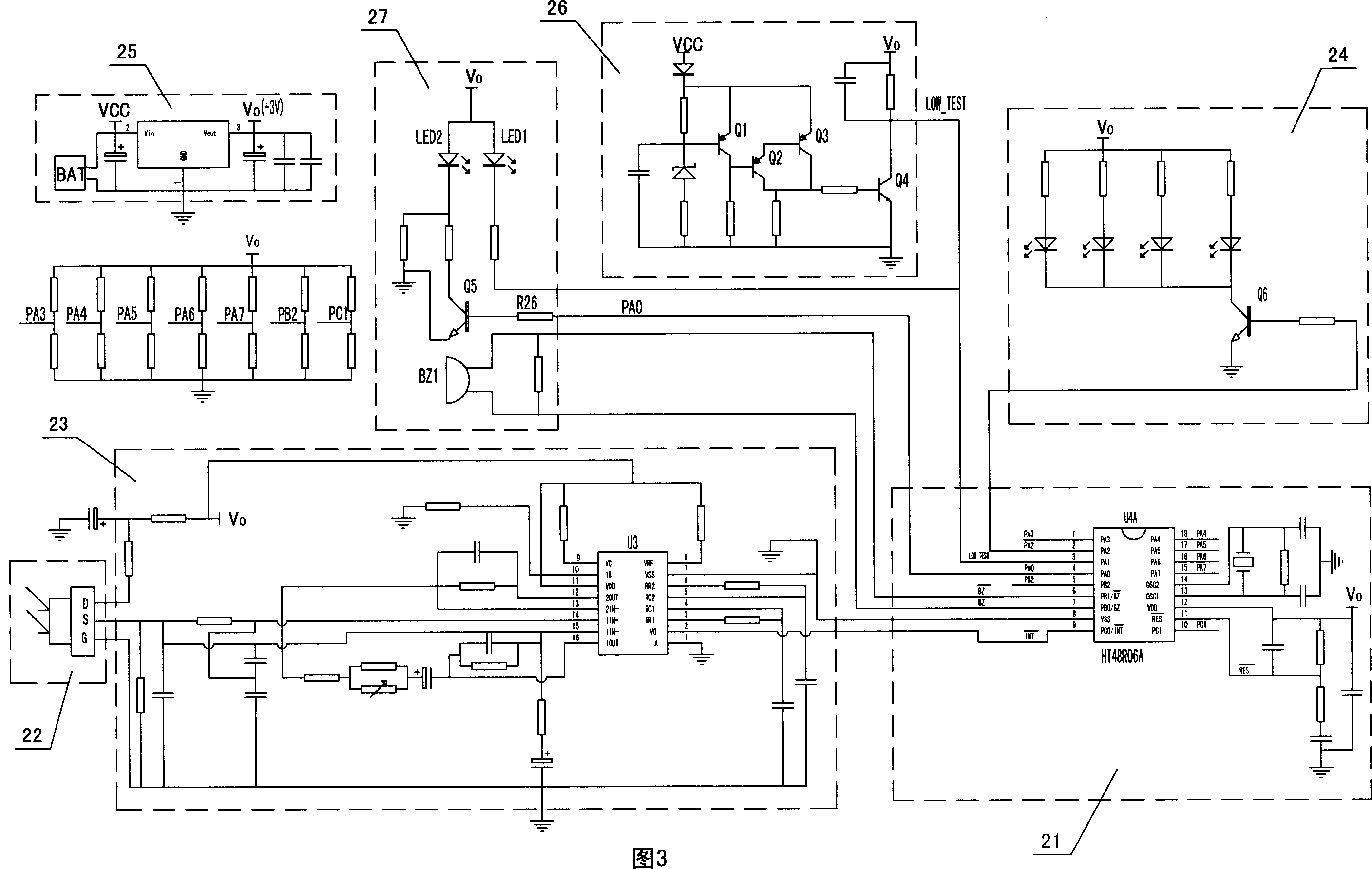

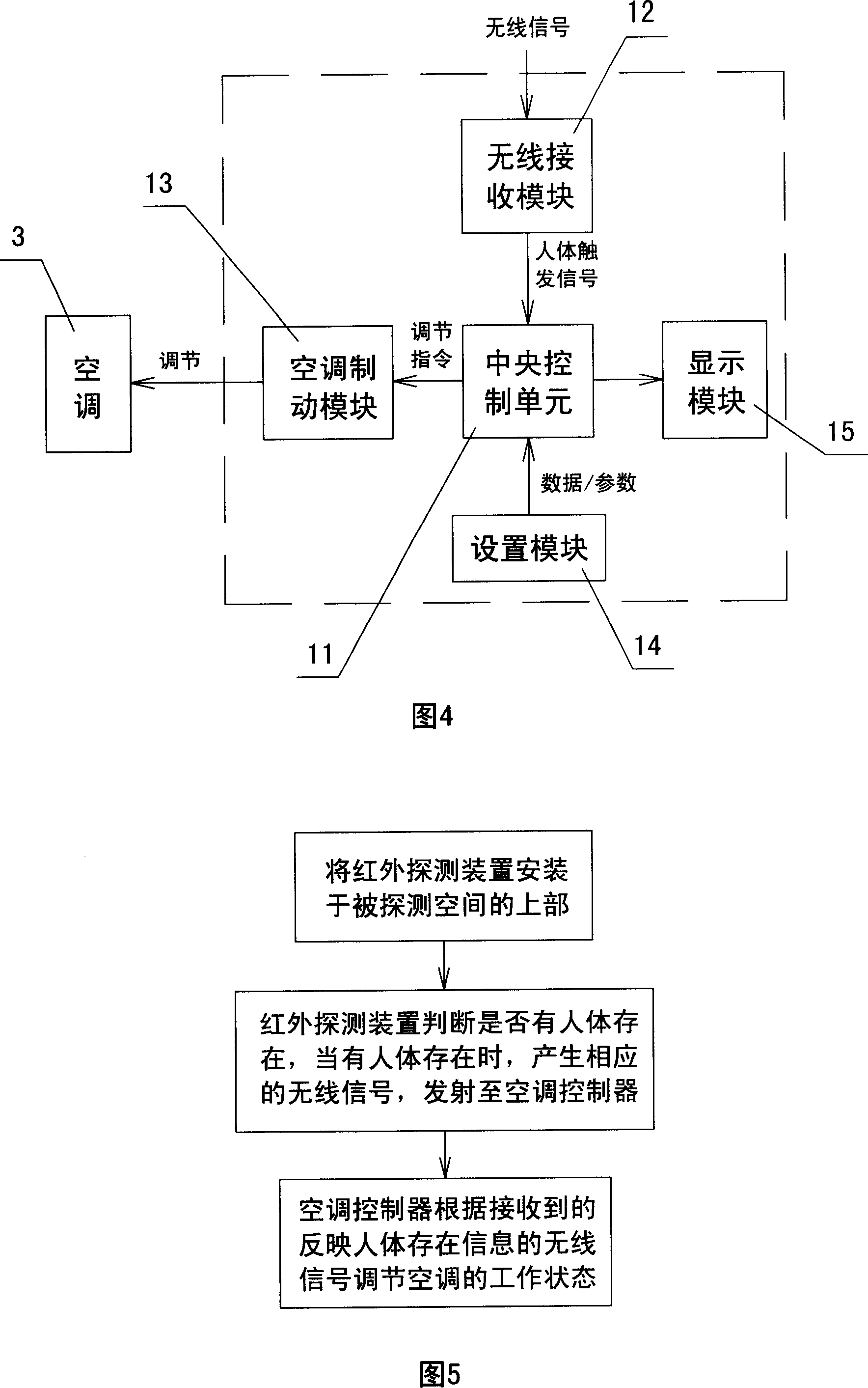

Intelligent air conditioner control method and system

InactiveCN101013522AGuaranteed detection accuracyEnergy savingNon-electrical signal transmission systemsSpace heating and ventilation safety systemsHuman bodyWireless signal

It involves an intelligent air condition control method and system, whose method is: A. infrared detection devices detect infrared signal of human body, and the presence information of human been detected is sent to air-conditioning controller through the wireless signal; B. the controller of air condition adjust the work state based wireless signal. Step A includes: A1. Infrared detection devices will be installed in the upper space to be detected, A2. Judging whether human existence, when human exists, produce the wireless signal to launch air conditioning controller; in A2 step, which further test the battery voltage, if the battery voltage is insufficient, a corresponding alarm signal is generated. The system includes air conditioning controller and also includes infrared detection devices to detect infrared signal, and the human presence information been detected is sent to the air condition controller through the wireless signal. The air condition controller adjusts its work state based on the wireless signal it received. The invention is of high accuracy, the easy implementation and more energy-saving.

Owner:SHENZHEN BITSOON ELECTRONICS TECH CO LTD

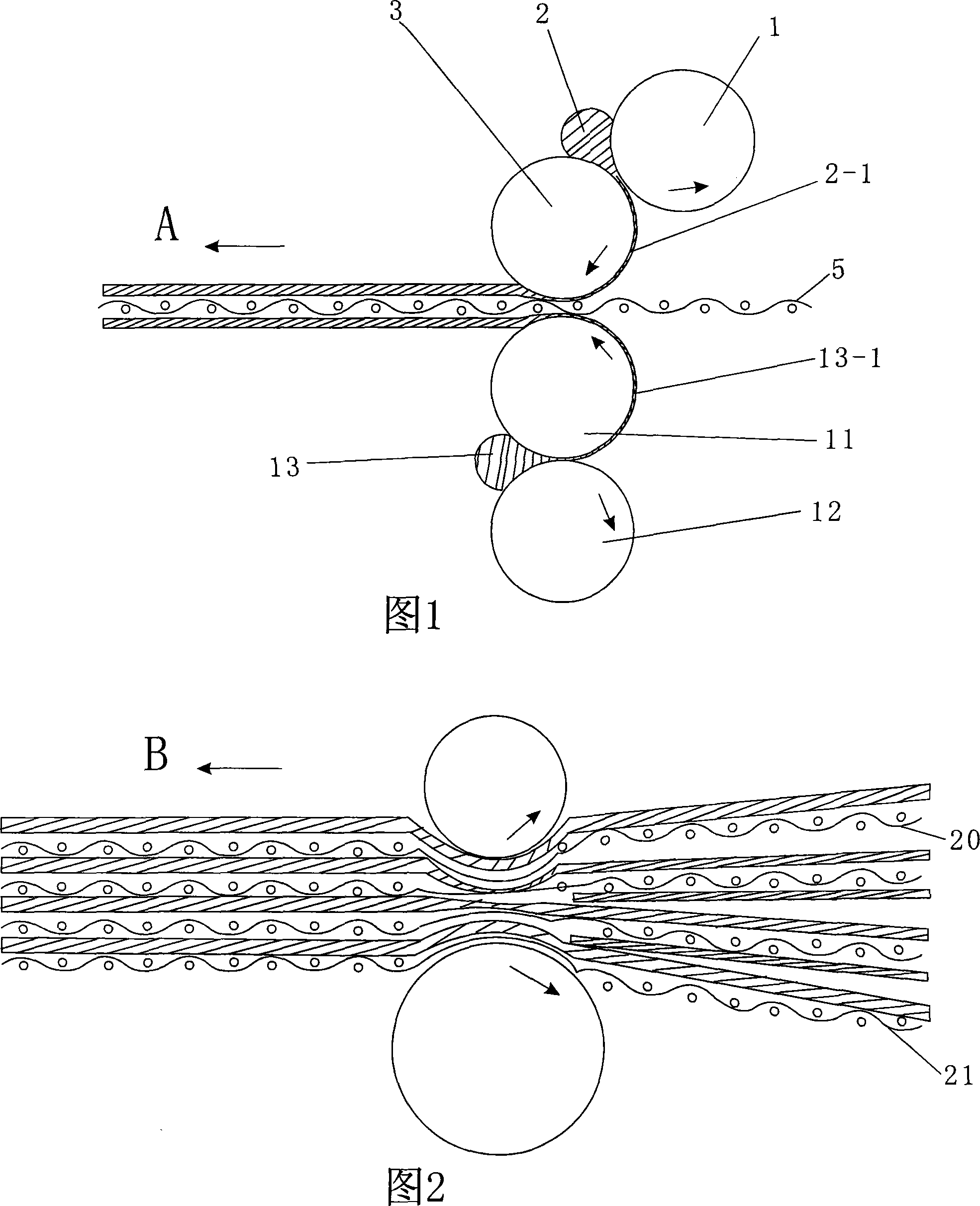

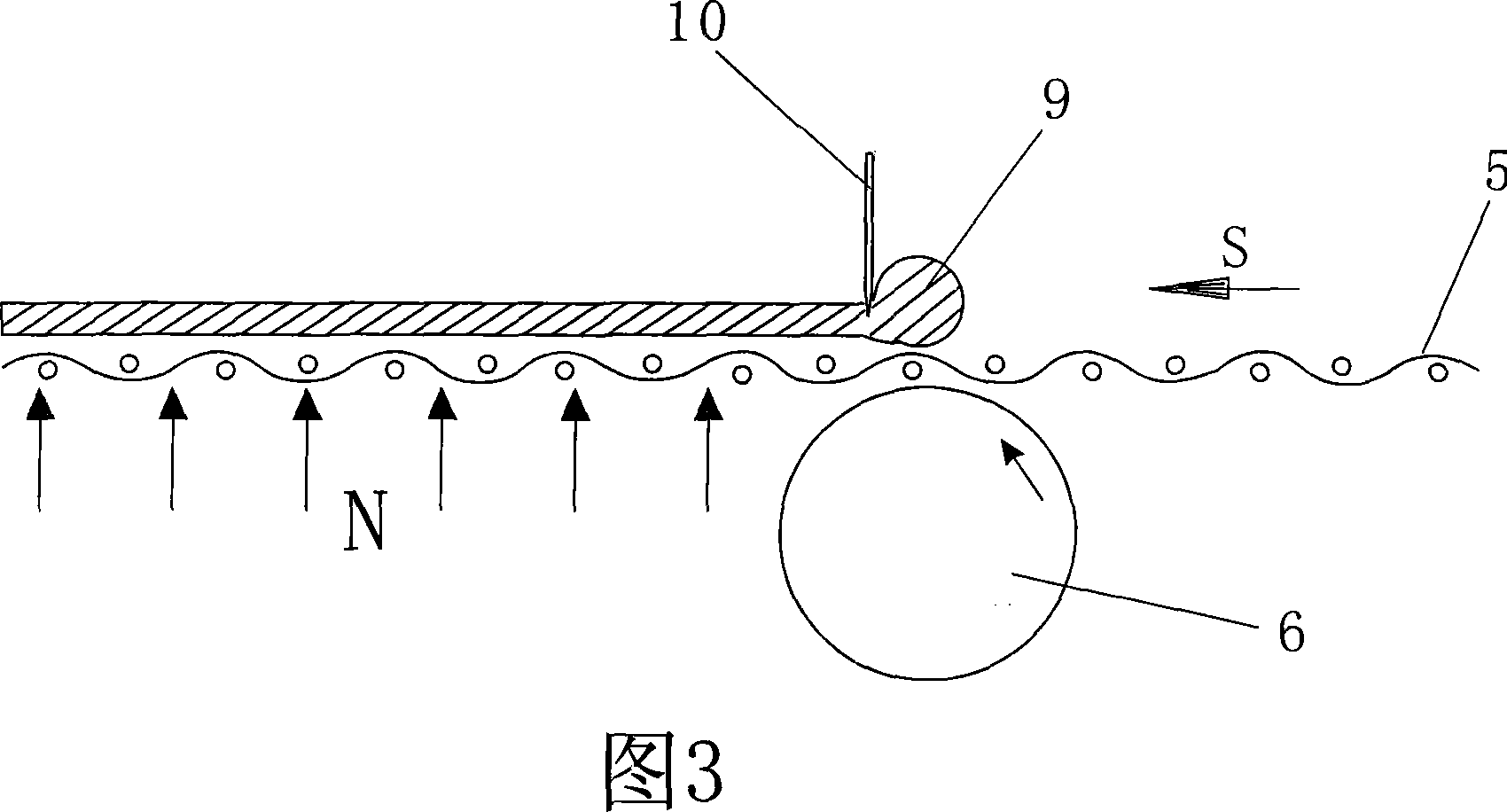

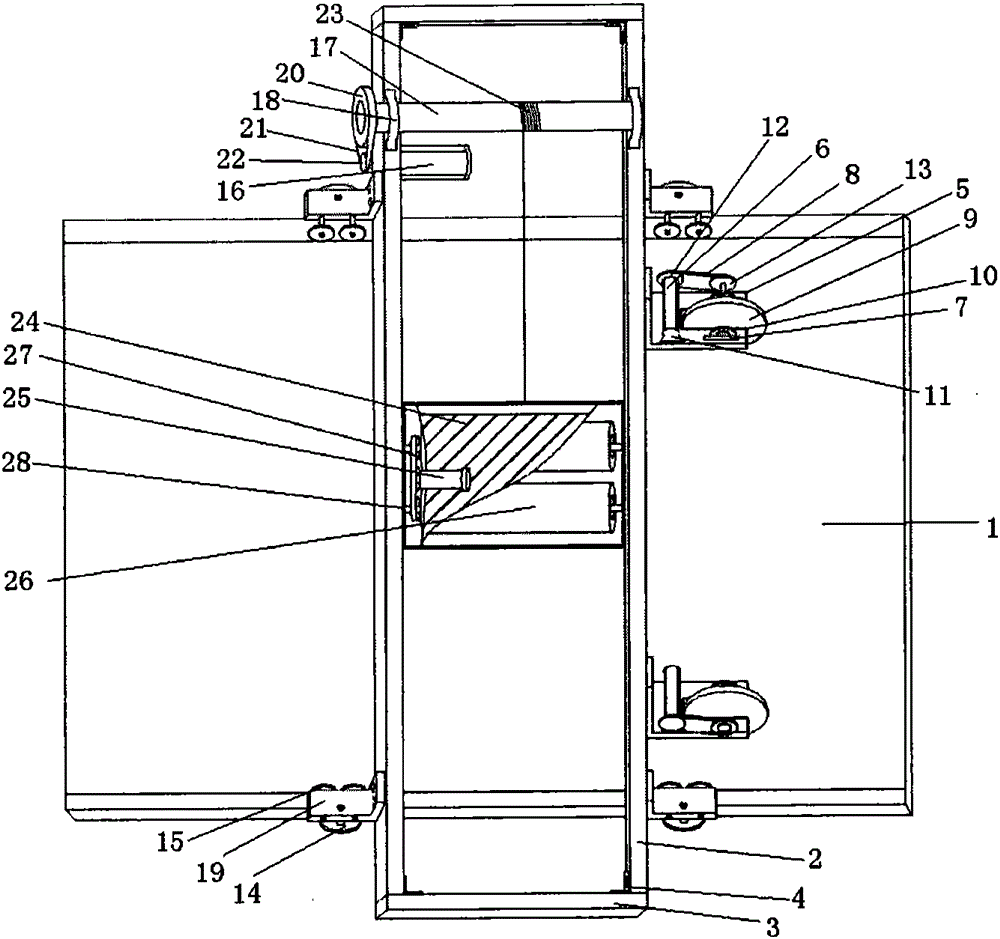

Technique for producing air cushion printing blanket

InactiveCN101177057AEnergy savingSave solvent and steam usageLamination ancillary operationsLaminationCotton clothHectograph

The invention relates to a manufacturing technology for an air cushion printing rubber blanket on a printing roller of a hectograph machine, which adopts the technical proposal that the manufacturing technology comprises a plurality of ordinal steps as followings: firstly, coating a rubber glue on single side of a cotton cloth of a surface layer and drying the glue, calendering a rubber sizing material simultaneously on the both side of the rest cotton cloth of a middle layer, and calendering the rubber sizing material on the single side of the cotton cloth of a bottom layer; secondly, folding the cotton cloths coated the rubber glue or calendered the rubber sizing material, and compounding the cloths on a dual-roller compound machine directly; thirdly, vulcanizing the compounded rubber blanket; fourthly, and grinding the vulcanized rubber blanket. The invention is characterized in that the calendering rubber sizing material on the single or both side of the cotton cloths is proceed on a four-roller calender, the running speed of the calender is 3 to 5 meters per minute and the calendering temperature is 70 to 100 DEG C.

Owner:HANGZHOU YUANYANG IND

Flame retardant heat-insulation foam concrete and preparation method thereof

The invention discloses flame retardant heat-insulation foam concrete which consists of the materials by mass as follows: 30-60 parts of cement; 30-70 parts of coal ash; 10-40 parts of mineral powder; 0.05-1. 0 part of water reducing agent; 0.02-0.2 part of cellulose ether; 0.05-1.0 part of water repellent; 1-10 parts of anhydrous anhydrite; 0.06-0.2 part of polypropylene fiber; 0.1-0.4 part of foaming agent; and 0.30-0.60 part of water. The advantages are as follows: the foam concrete has high strength, low shrinkage and good water repellent property; the heat insulation performance is good and can meet different heat-insulation requirements of buildings; the preparation technology is simple; and industrial wastes such as coal ash, mineral powder and the like are utilized fully, and the flame retardant heat-insulation foam concrete has excellent environment-protection effects of utilizing waste, saving energy and the like, as well as better economic benefit.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Vanadium slag treatment method capable of saving energy and reducing emission

InactiveCN102086487ARelieve the pressure of dephosphorizationEnergy savingProcess efficiency improvementWater solubleOxide

The invention belongs to the field of rare metal extraction, and particularly relates to a vanadium slag treatment method capable of saving energy and reducing emission. The method comprises the following concrete steps: first, placing high-temperature liquid vanadium slag with the temperature of higher than 1200 DEG C, which is separated from molten iron, in a slag tank; then, adding a sodium compound into the slag tank according to the grade of the vanadium slag; and supplying oxygen to the slag tank with a water-cooling supersonic speed or subsonic speed oxygen lance to produce a strong oxidizing atmosphere while realizing a stirring effect to promote quick generation of water-soluble sodium vanadate in the vanadium slag, wherein in order to ensure that the supplied oxygen is more than the oxygen required for totally oxidizing all components in the slag into the highest-valence oxides, FeO / T.Fe in the slag is taken as an index for checking the oxidation degree, V2O5 generated in the vanadium slag reacts with the added sodium compound to generate the water-soluble sodium vanadate, and finally the obtained slag containing the water-soluble sodium vanadate is treated to obtain V2O5. The method provided by the invention realizes vanadium extraction and steelmaking at the same time; and by adopting the method, tremendous economical and environmental benefits can be produced.

Owner:UNIV OF SCI & TECH BEIJING +1

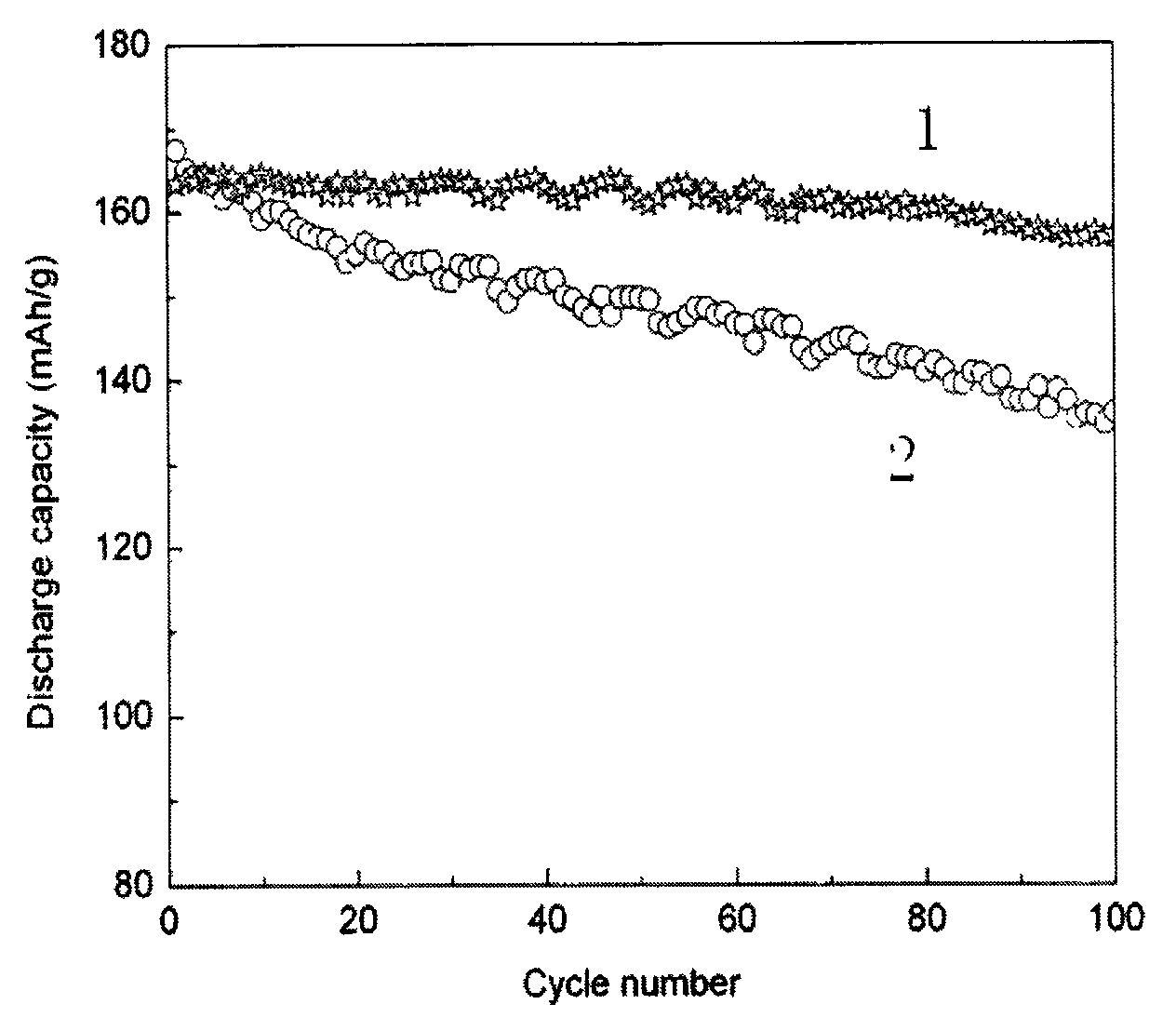

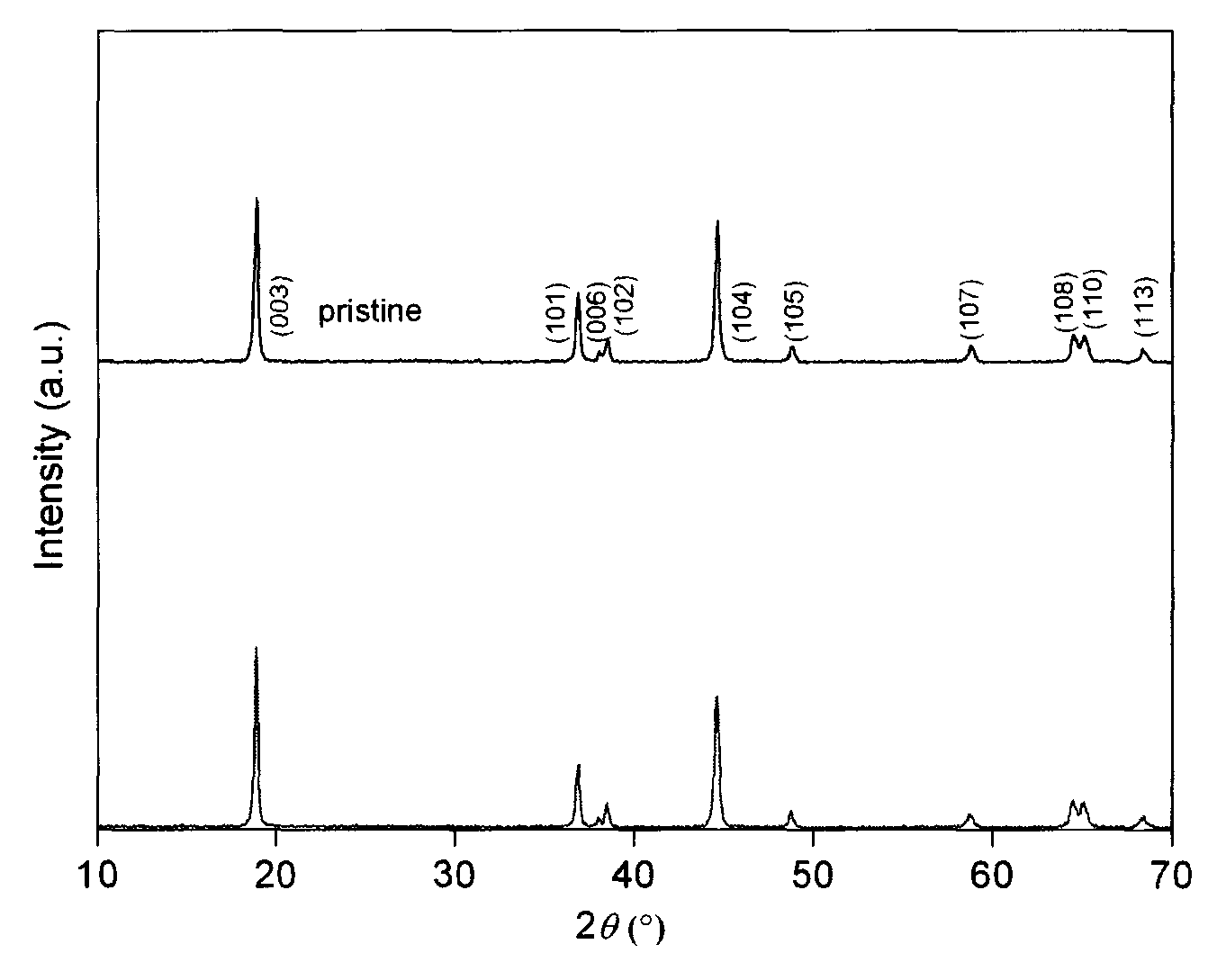

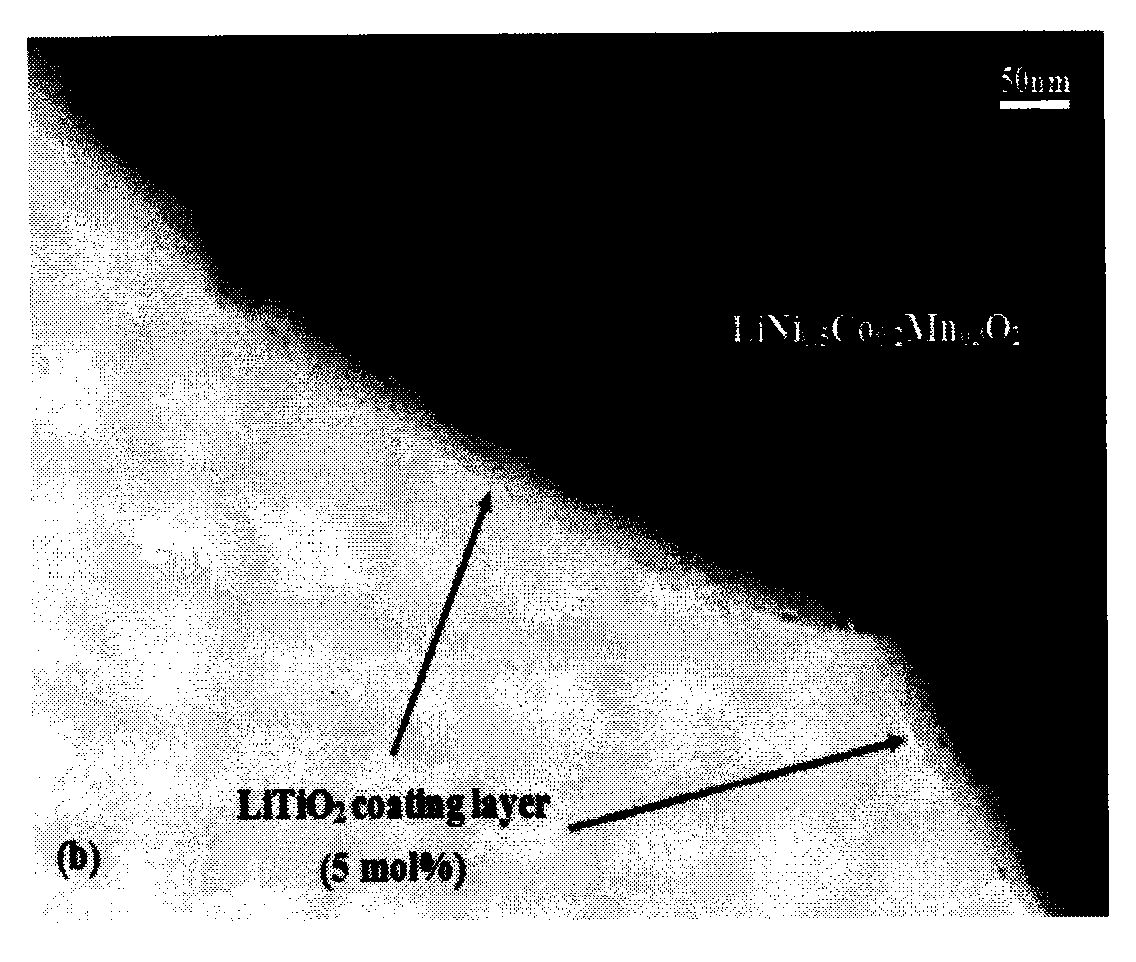

Composite multi-element lithium ion battery cathode material and preparation method thereof

ActiveCN103928673ASimple processEnergy savingCell electrodesSecondary cellsLayered structureLithium electrode

A nickel cobalt lithium manganate cathode material has a capability that lithium ions in structure can be removed continuously under high voltage, but the cycle performance of the material needs to be improved urgently along with the boost of a cut-off voltage. The invention provides a composite multi-element lithium ion battery cathode material and a preparation method thereof, the composite multi-element lithium ion battery cathode material has the chemical formula of Li1+zNi1-x-yCoxMnyMzO2+2z, wherein x is more than 0, y is less than 1, and z is more than 0 and less than 0.2; in the chemical formula, M is a composite metal or non-metal and comprises one or more out of Al, Si, Zn, Zr, Ti, Sn and Mg; the physical composition of the composite multi-element lithium ion battery cathode material adopts a layered LiNi1-x-yCoxMnyO2 as a core and is covered with a layer of LiMO2 with the same layered structure, and meanwhile, part of the LiMO2 penetrates to the structure of the LiNi1-x-yCoxMnyO2, and gradient adulteration from less to more is formed from inside to outside.

Owner:成都云津能源科技有限公司

Laminated glass with nanometer thermal insulation coating and product thereof

InactiveCN101602580AEnvironmentally friendlyEnergy savingWindowsWindscreensInfraredEnvironmental resistance

The invention discloses laminated glass with a nanometer thermal insulation coating, which comprises two or more layers of glass plates, a laminated layer arranged between the glass plates, and the nanometer thermal insulation coating consisting of nanometer painting. The laminated glass in the prior art is further innovated and designed by increasing the nanometer thermal insulation coating organically combined together with the laminated glass, so the product of the laminated glass with the nanometer thermal insulation coating has good strength, good thermal insulation effect and sound insulation effect of the laminated glass, can absorb 99 percent of ultraviolet rays, 75 percent of infrared rays and 15 to 20 percent of visible light, not only can maintain glass lighting and aesthetic needs, but also can directly block solar thermal radiation, achieves the aim of thermal insulation and energy saving, and has the characteristics of environmental protection and energy saving.

Owner:SHENZHEN DUONA TECH

Technique for producing deep-drawing cold-rolled plate based on CSP technique

ActiveCN101144113AIncrease productivityEnergy savingRoll mill control devicesFurnace typesHolding timeDeep drawing

The present invention discloses a CSP process-based manufacturing technique of a cup drawing stage cold-rolled steel sheet. The manufacturing technique comprises the working procedures of steel-making, continuous casting, heat soaking, hot continuous rolling, cooling, curling, pickling and cold rolling, annealing and flattening. The pickling and cold rolling working procedure is realized by that after decoiling, a hot rolled coil enters into a pickling tank with the pickling speed of 160-170 m / min, and then enters into a four-frame cold continuous rolling mill train. The present invention has the relative percent of reduction that STD1 is 30-37 percent, STD2 is 35-40 percent, STD3 is 30-35 percent and STD4 is 0.1-0.5 percent, and the curling is performed after the cold rolling. The annealing and the flattening working procedures are realized by that the cold rolled hard coil enters into a cover-type annealing furnace, the annealing temperature is 675-685 DEG C, the temperature holding time is 10-15 h, and the flattening elongation rate is 1.0-1.5 percent. Compared with the prior art, the performance of the cup drawing cold-rolled steel sheet produced with the present invention can achieve the European standard EN10130: 1999, at the same time, the production cost can be reduced, the energy is saved, and the consumption is reduced.

Owner:MAANSHAN IRON AND STEEL COMPANY

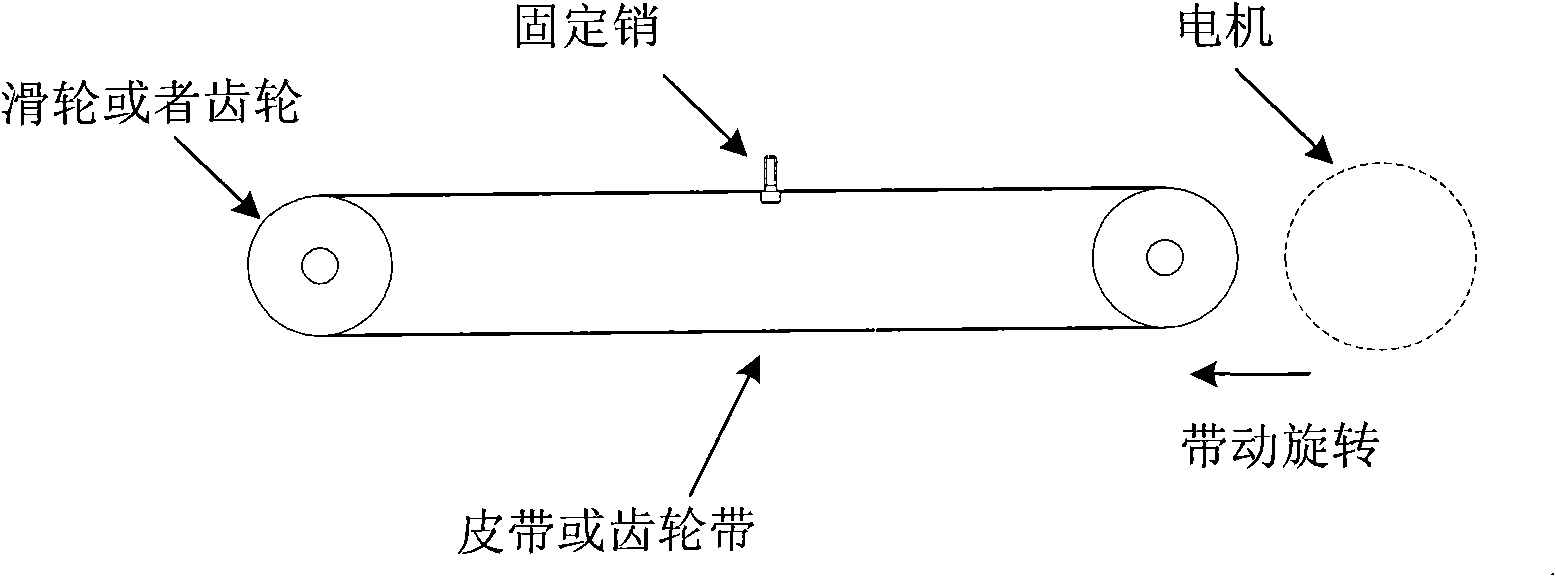

Photovoltaic cleaning robot

InactiveCN104984942AEnergy savingEasy to usePhotovoltaicsCleaning using toolsPhotovoltaic power stationMotor drive

The invention discloses a photovoltaic cleaning robot. The photovoltaic cleaning robot comprises a mobile platform mechanism, a driving mechanism, a walking mechanism, a cable collecting mechanism and a cleaning mechanism, wherein the mobile platform mechanism spans a photovoltaic module; the driving mechanism is positioned at one side of the mobile platform mechanism, and comprises a first motor; the first motor drives a driving wheel to walk on the surface of the photovoltaic module; the walking mechanism comprises liming wheels walking along the upper and lower side walls of the photovoltaic module, and walking wheels walking along the upper and lower edges of the photovoltaic module; the cable collecting mechanism comprises a second motor; the second motor drives a cable shaft to rotate; a cable on the cable shaft is wound up or payed off around the cable shaft; the cable is connected with the cleaning mechanism, and drives the cleaning mechanism to ascend or descend; the cleaning mechanism comprises a third motor; and the third motor drives a brush to rotate so as to clean ash on the photovoltaic module. The photovoltaic cleaning robot adopts a waterless cleaning mode, is simple in use, is directly placed on the photovoltaic module, widens application places of a photovoltaic power station, and reduces the product use cost.

Owner:上海联星股权投资管理有限公司

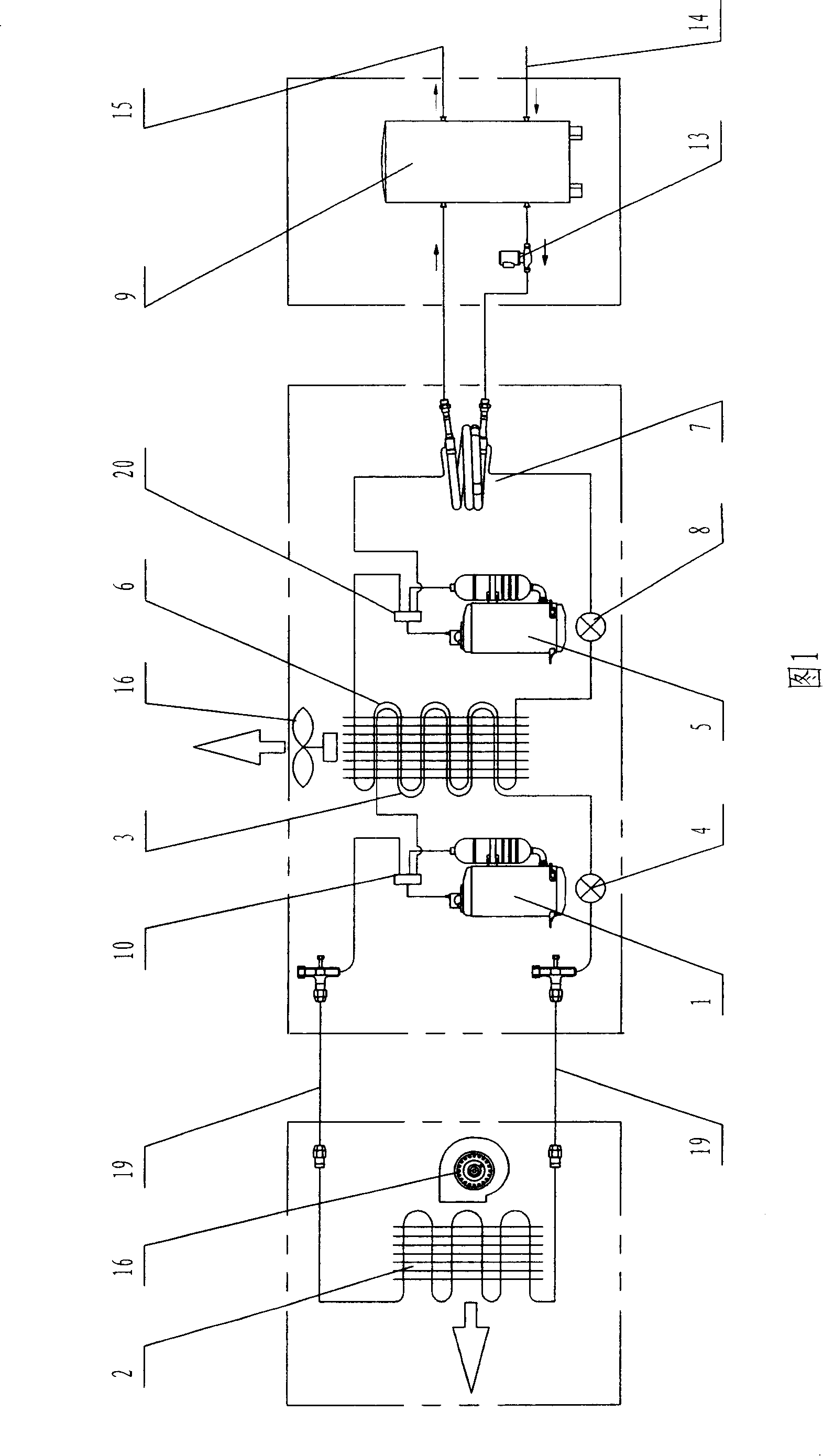

Air-conditioner hot-water composite machine

InactiveCN101210748AEnergy savingSimple structureCompression machines with cascade operationHeating and refrigeration combinationsProcess engineeringThrottle

The invention discloses an air-conditioning / water-heating compound machine which comrprises (1) a circulation loop for an air-conditioning system, consisting of a first compressor, a first heat exchanger, a second heat exchanger and a first throttle mechanism; and (2) a circulation loop for a water-heating system, consisting of a second compressor, a third heat exchanger, a fourth heat exchanger and a second throttle mechanism. The second heat exchanger and the third heat exchanger form a heat-transfer connection. The fourth heat exchanger and a hot-water pipeline form a water-passage connection. The hot-water pipeline is provided thereon with a water inlet and a water outlet. The invention can reduce energy consumption and has simple structure.

Owner:苏宇贵

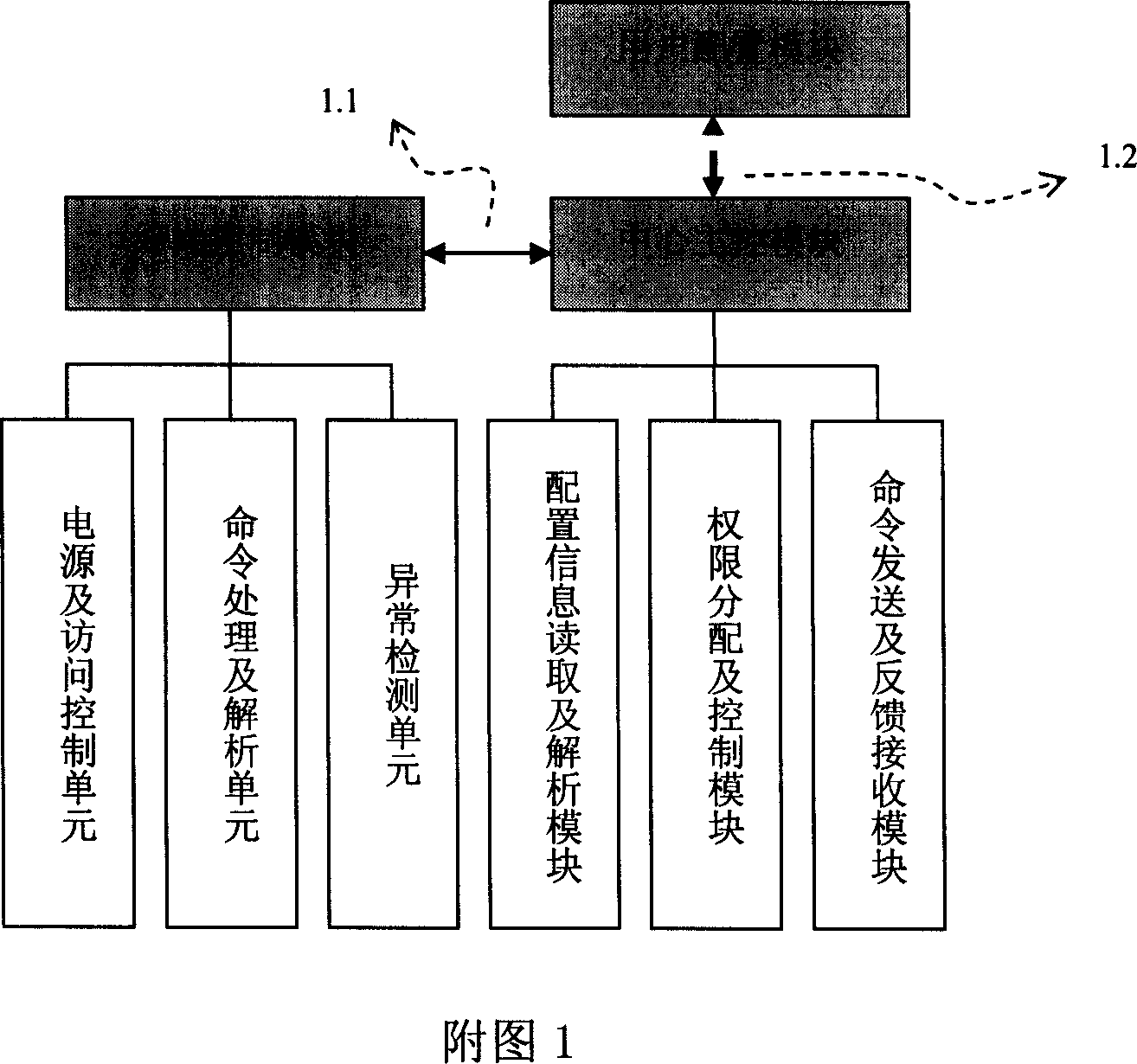

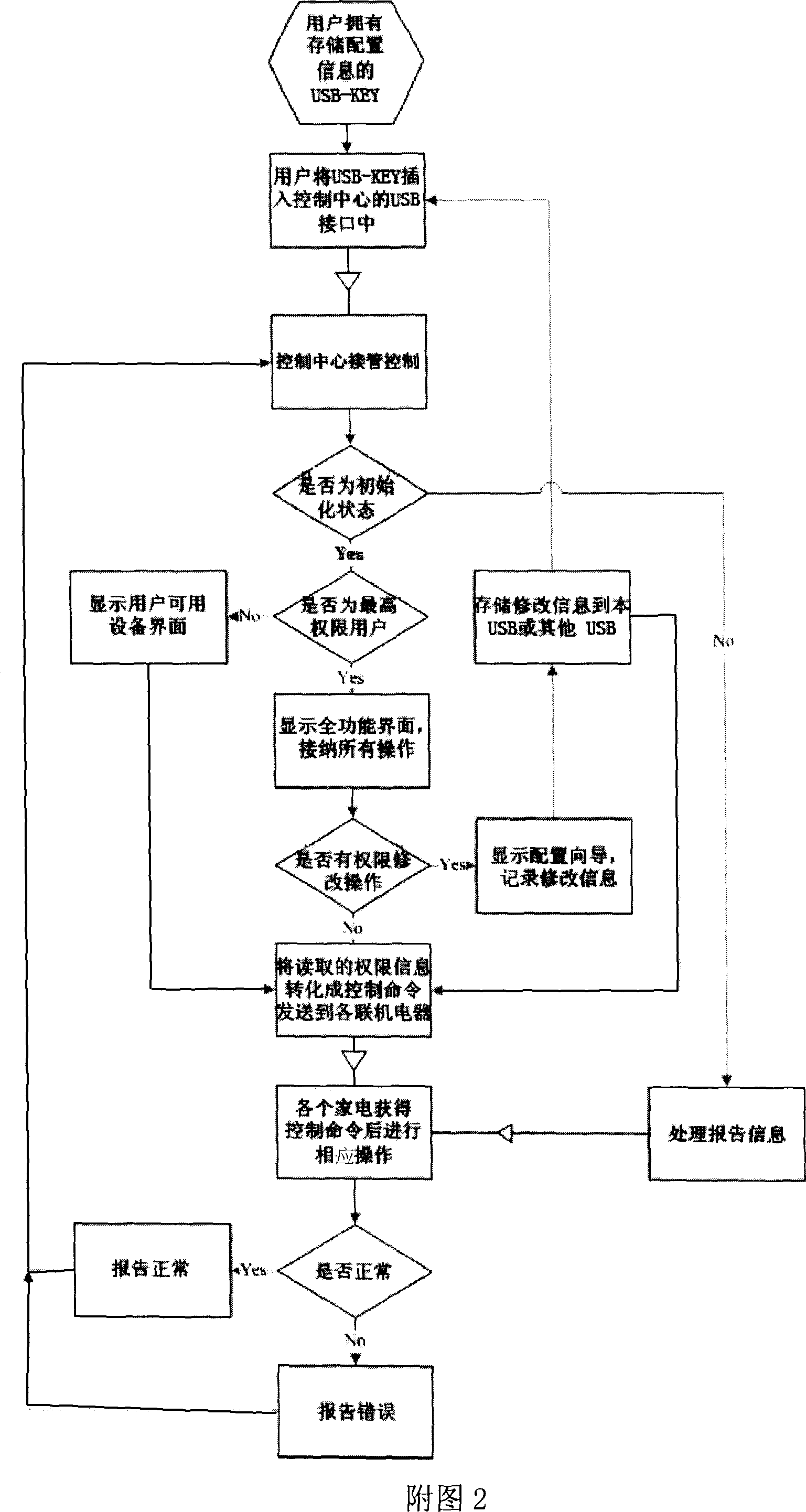

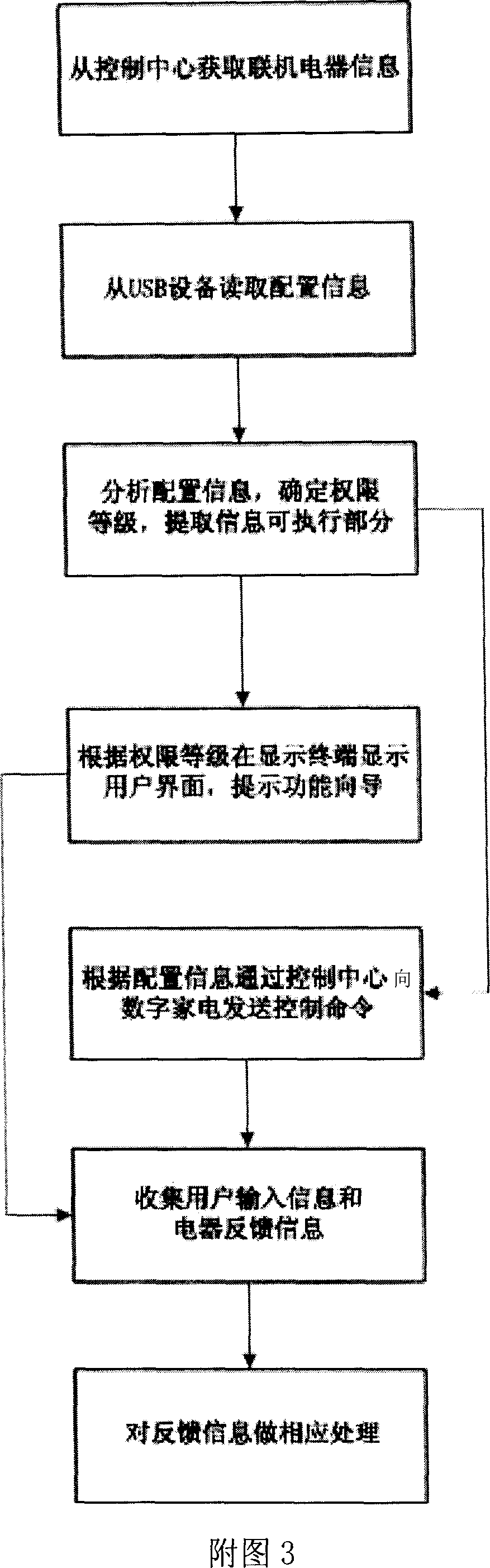

Apparatus and method for controlling digital household electrical appliance use authority by family members

InactiveCN101030885ASimplify user operationsEnergy savingData switching by path configurationEmbedded systemHome appliance

The apparatus comprises a central controller locating at the digital home control center, multi terminal controller locating at each digital home appliance, and multi users' configuration modules respectively kept by each home member. By the invention, user can set an access right for each user in order to prevent user from mis-operation.

Owner:SUN YAT SEN UNIV

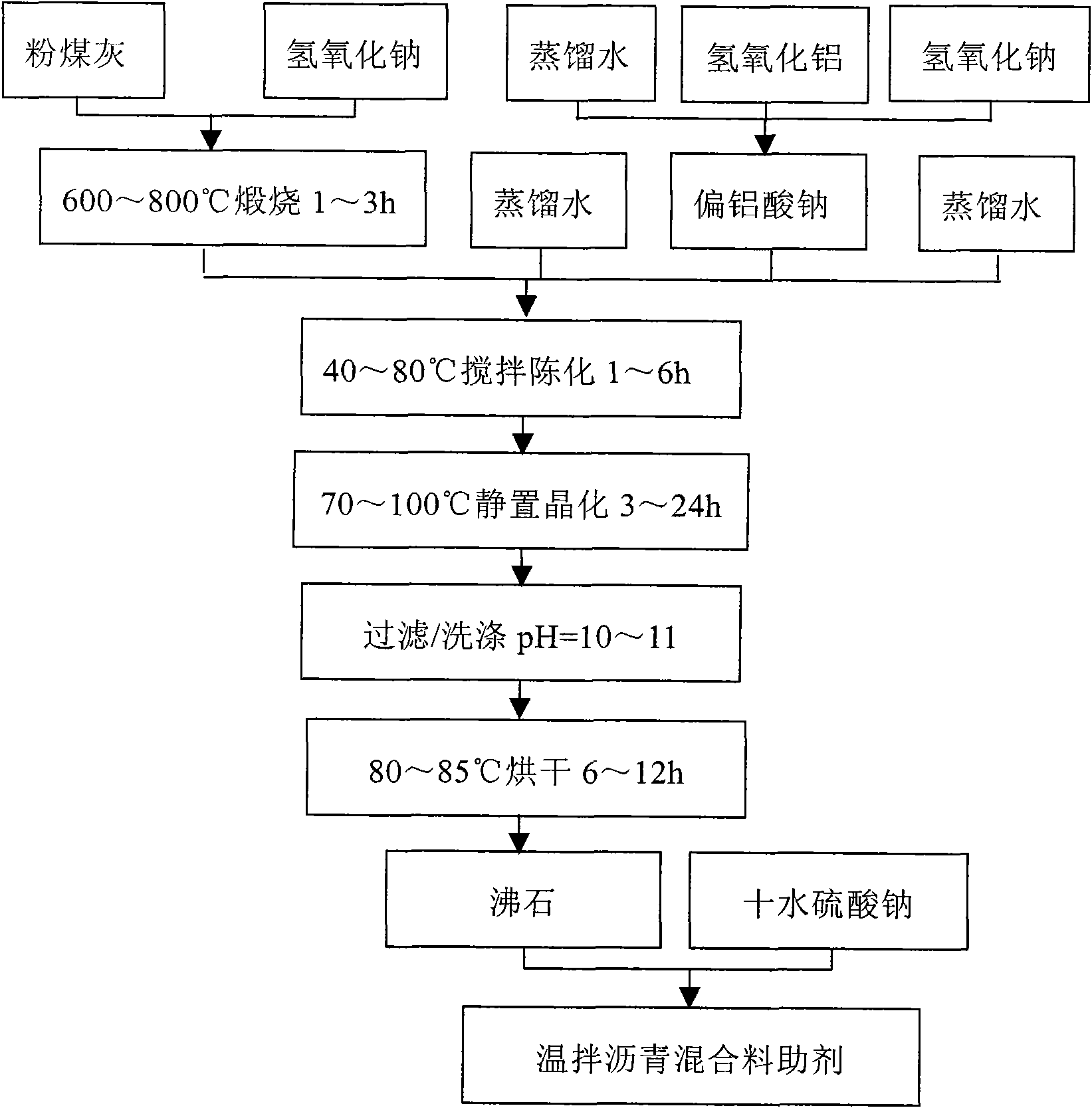

Warm-mixed auxiliary agent for asphalt mixture and preparation method thereof

ActiveCN101602583AEnergy savingReduce exhaust emissionsClimate change adaptationFilling materialsPitch blende

The invention relates to a warm-mixed auxiliary agent for asphalt mixture. The auxiliary agent is formed by uniformly mixing 93 to 97 percent of synthetic zeolite with 3 to 7 percent of granular sodium sulfate decahydrate by weight, wherein the synthetic zeolite includes 15 to 22 percent of crystal water, and the sodium sulfate decahydrate includes 55.9 percent of crystal water. Under normal temperature, the auxiliary agent is mixed with other raw materials according to the content of 0.3 to 0.5 percent of the total mass of the mixture, thereby preparing the product of the warm-mixed asphalt mixture; and other raw materials are 150 to 165 DEG C asphalt, 140 to 180 DEG C aggregate and mineral powder filling materials. During the blending of the mixture, the warm-mixed addition agent and the heated asphalt are added simultaneously, great amount of vapor generated by the moisture-containing auxiliary agent are released, which results in volumetric expansion of the asphalt, thereby forming foamed asphalt; meanwhile, the workability of the asphalt can be enhanced, the blending and mold temperature of the mixture can be reduced by 15 to 25 DEG C, exhaust emission can be effectively reduced, energy consumption is lowered, the aging of asphalt during blending is reduced, and the auxiliary agent has the advantages of simple preparation and low cost.

Owner:WUHAN UNIV OF TECH

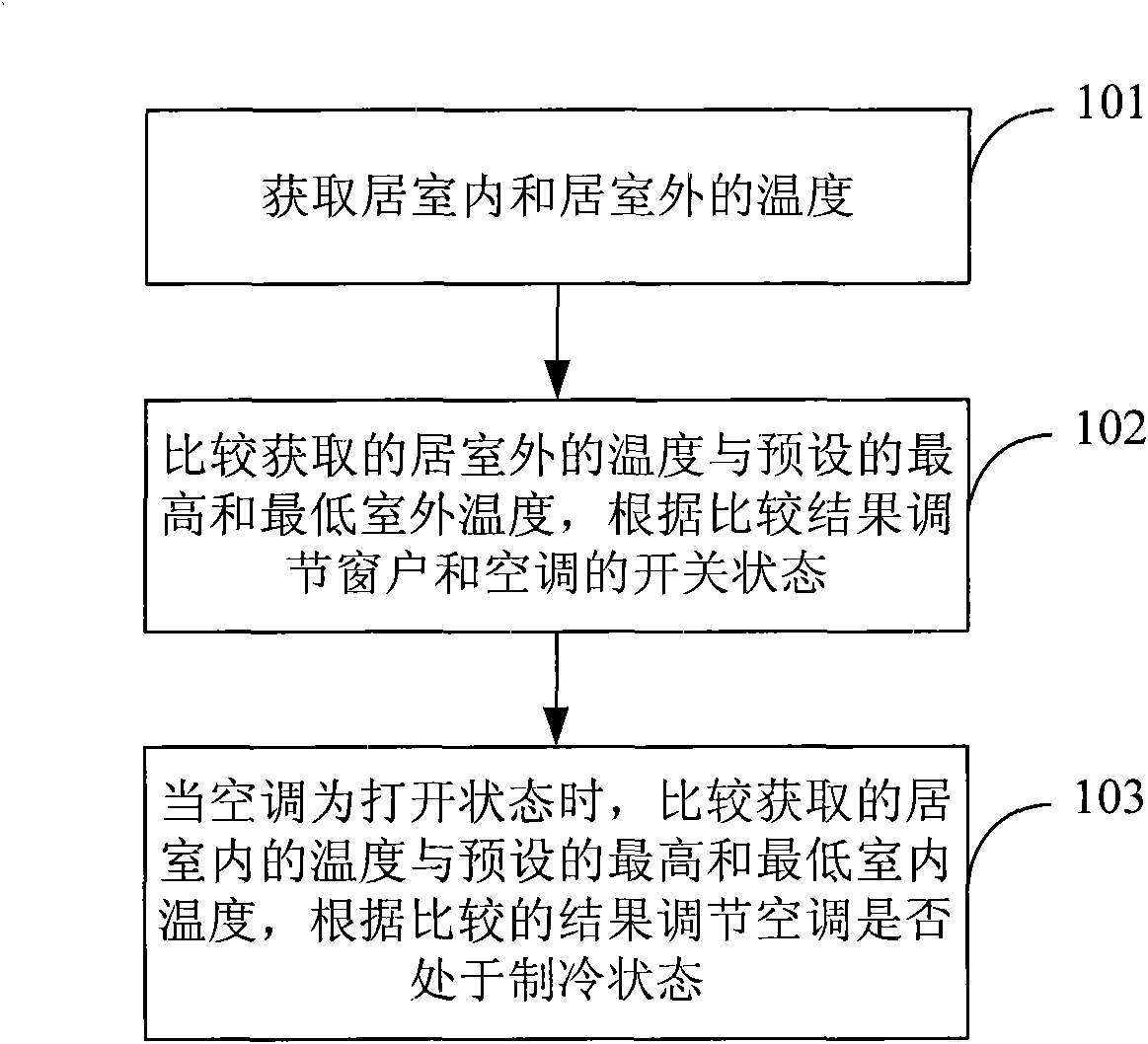

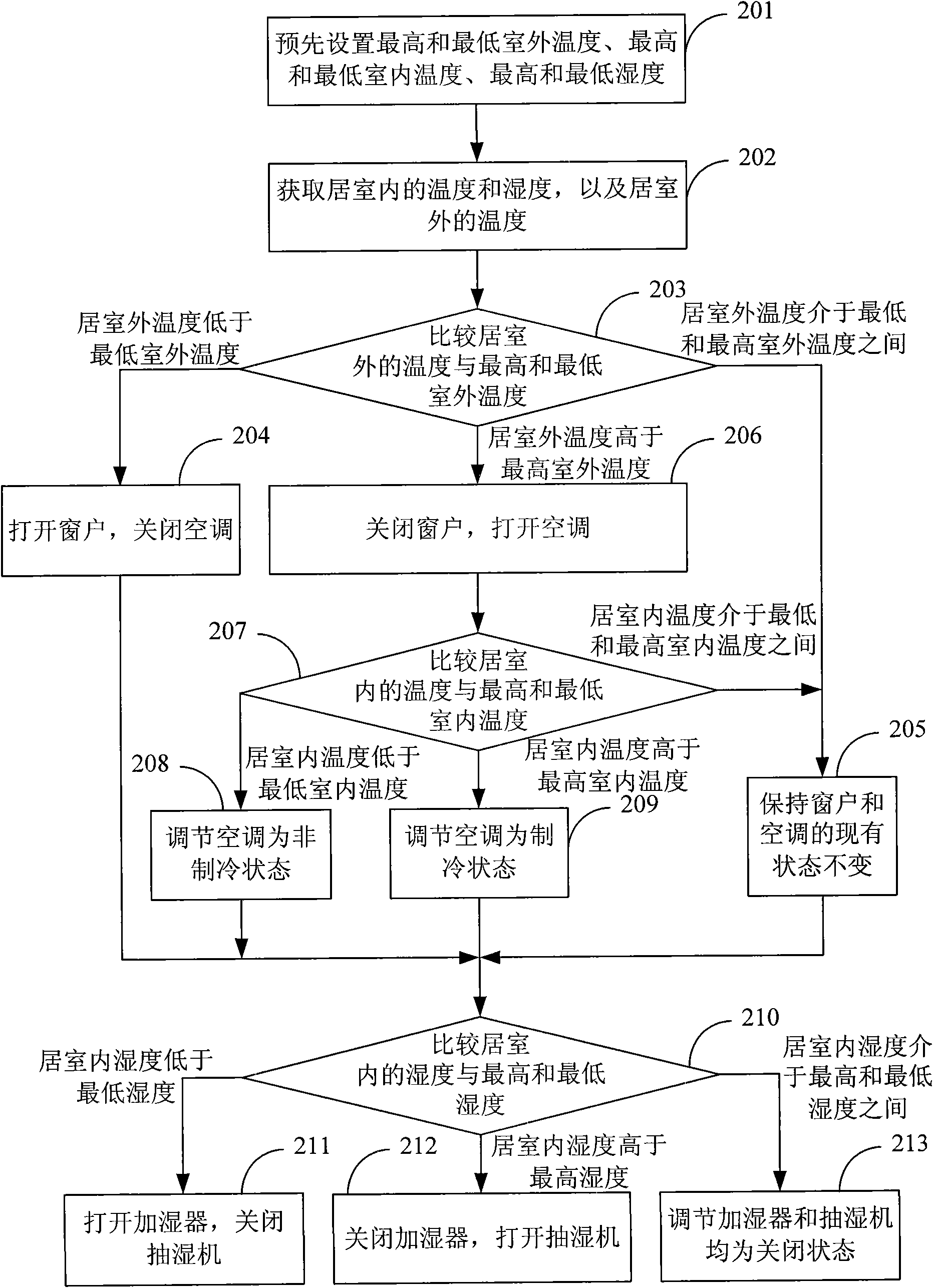

Method for adjusting indoor temperature and system

InactiveCN101581490AReduce usage timeEnergy savingSpace heating and ventilation safety systemsLighting and heating apparatusAutomatic controlIndoor air

The invention discloses a method for adjusting indoor temperature and a system, which belong to the automatic control field. The method comprises the steps of: obtaining indoor temperature and outdoor temperature; comparing the outdoor temperature with the highest and lowest preset outdoor temperature, and adjusting the opening and closing of an indoor window and the use state of an air conditioner according to the result of comparison; when the air conditioner is turned on, comparing the indoor temperature with the highest and lowest preset indoor temperature and adjusting whether the air conditioner is in cooling status according to the result of comparison. The system comprises the air conditioner, a collection module and a control module. The invention can adjust the indoor temperature automatically, control the opening and closing of window and the use state of the air conditioner as well as the cooling status of the air conditioner according to the indoor temperature and the outdoor temperature; when the outdoor temperature is lower, the window is opened to ventilate for cooling down instead of the air conditioner, thereby reducing use time of the air conditioner, saving energy and creating a healthy environment for people with improved quality of indoor air.

Owner:段一维

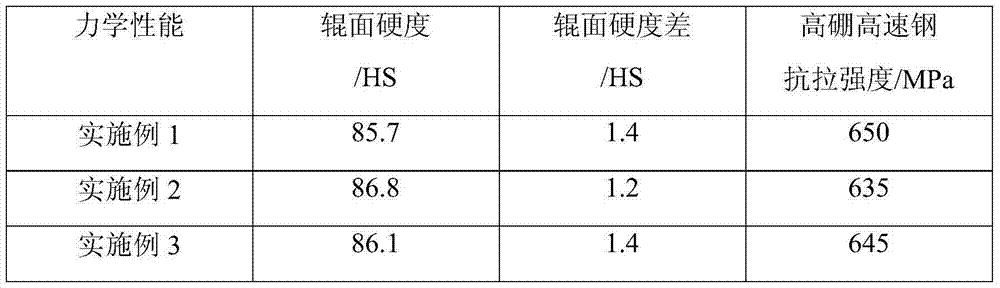

High-boron high-speed steel composite roller and manufacturing method thereof

ActiveCN103866200AEnergy savingHas the advantage of material savingRollsMetal rolling arrangementsAfter treatmentChemical composition

The invention discloses a high-boron high-speed steel composite roller and a manufacturing method thereof, belonging to the technical field of rollers. A roller shaft and a high-boron high-speed steel composite roller sleeve are combined together through hot charging; the outer layer of the composite roller sleeve is wear-resistant high-boron high-speed steel, and the inner layer is a steel pipe; the roller shaft is arranged in the steel pipe and coaxially penetrates through the steel pipe; the molten steel of the wear-resistant high-boron high-speed steel at the outer layer comprises the following chemical components in percentage by mass: 1.25-1.80% of C, 1.25-1.60% of B, 5.5-8.0% of Cr, 1.0-1.5% of W, 2.5-3.0% of Mo, 0.3-0.6% of V, 0.6-1.2% of Ni, 0.3-0.9% of Si, 0.30-0.55% of Mn, less than 0.04% of S, less than 0.05% of P and the balance of Fe and unavoidable impurities; the molten steel is prepared by casting and combination with the steel pipe after treatment outside the furnace. The composite roller disclosed by the invention has the advantages of high hardness, good wear resistance and low production cost, and brings good benefits in application.

Owner:娄底市巨能高新耐磨材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com